Valve rod for high-temperature high-pressure stop valve and machining method of valve rod

A high-temperature, high-pressure, processing method technology, applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of small application range of valve stem heads, increased maintenance costs, poor adjustment performance, etc., and achieve good mechanical properties Requirements and product quality, material cost saving, and the effect of short opening and closing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

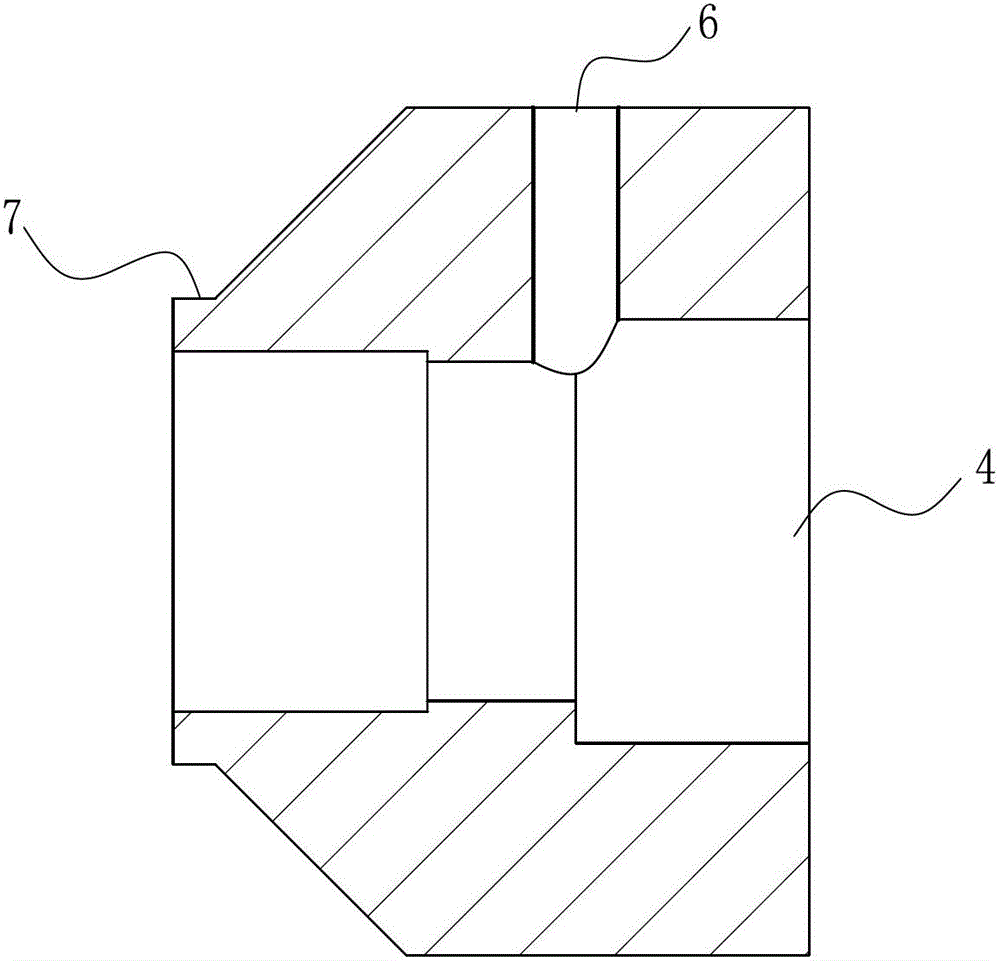

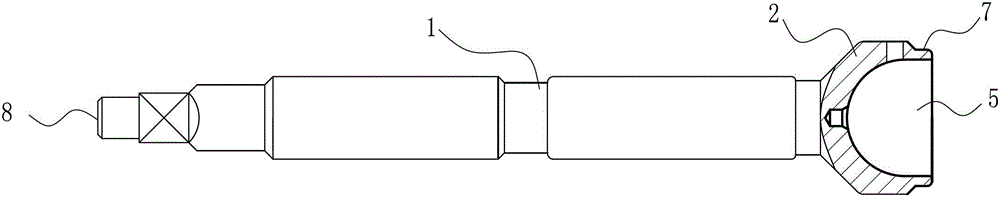

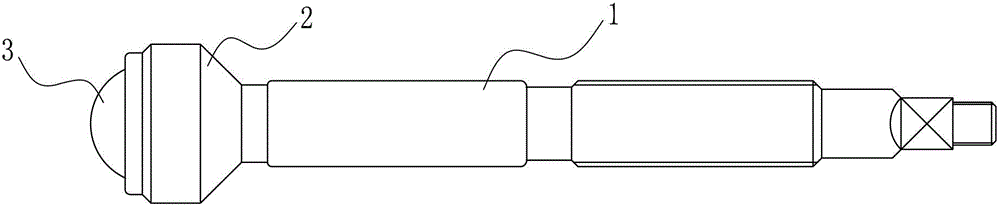

[0025] Embodiment one: see attached Figure 1-3 shown.

[0026] A valve stem for a high-temperature and high-pressure globe valve, which includes a valve stem main rod 1, a valve ball cap 2 fixedly arranged at one end of the valve stem main rod 1, a valve ball 3 freely rotatably arranged in the valve ball cap 2, and a valve ball 3 One end protrudes outside the valve ball cap 2, and the ball center of the valve ball 3 is located on the axis of the main rod 1 of the valve stem.

[0027] A method for processing a valve stem for a high-temperature, high-pressure globe valve, comprising the following steps:

[0028] Take the pipe material for solid solution treatment, the solution temperature is ≧1040°C, use the three-jaw chuck to find the coaxial clamping pipe material and ensure the clamping, and the two ends of the pipe material are smooth and flat, and the outer circle of the pipe material is φ20mm× 18mm, bore the inner hole of the valve ball cap 4φ10mm×5.5mm in the center of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com