Patents

Literature

133results about How to "Short work schedule" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

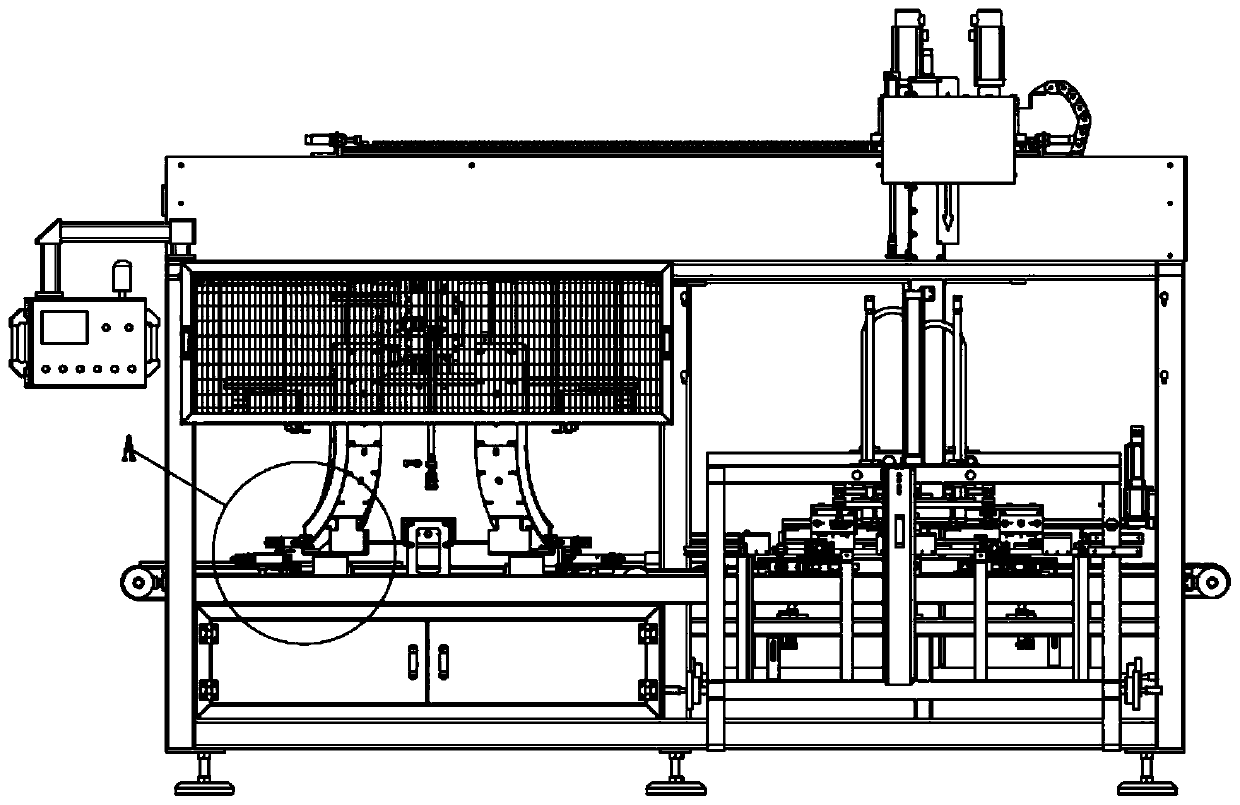

Machine for forming paper container

ActiveCN101073927AEffective protectionAvoid Ultrasonic RadiationPaper/cardboard wound articlesUltrasonic radiationMolding machine

The invention is concerned with the mechanical equipment for making and forming the paper container, includes the stander: sets the paper feeding equipment, the delivery plate, the sidewall preheating arrangement, the sidewall forming equipment, the sidewall bonding equipment, the hemline preheating arrangement, the hemline forming equipment, the hemline bonding equipment, the bottom paper conveying appliance, the bottom paper feed apparatus, and the hemline reinforcing equipment on the stander; sets the motor and drive gear in the stander. The invention can avoid ultrasonic radiation, improve the bonding speed, in order to improve the working efficiency. The invention uses the pneumatic control and air conveying to improve the yield; the complete machines shorts the power stroke farthest, improves the stability and processing speed of the equipment.

Owner:ZHEJIANG SEE MACHINERY

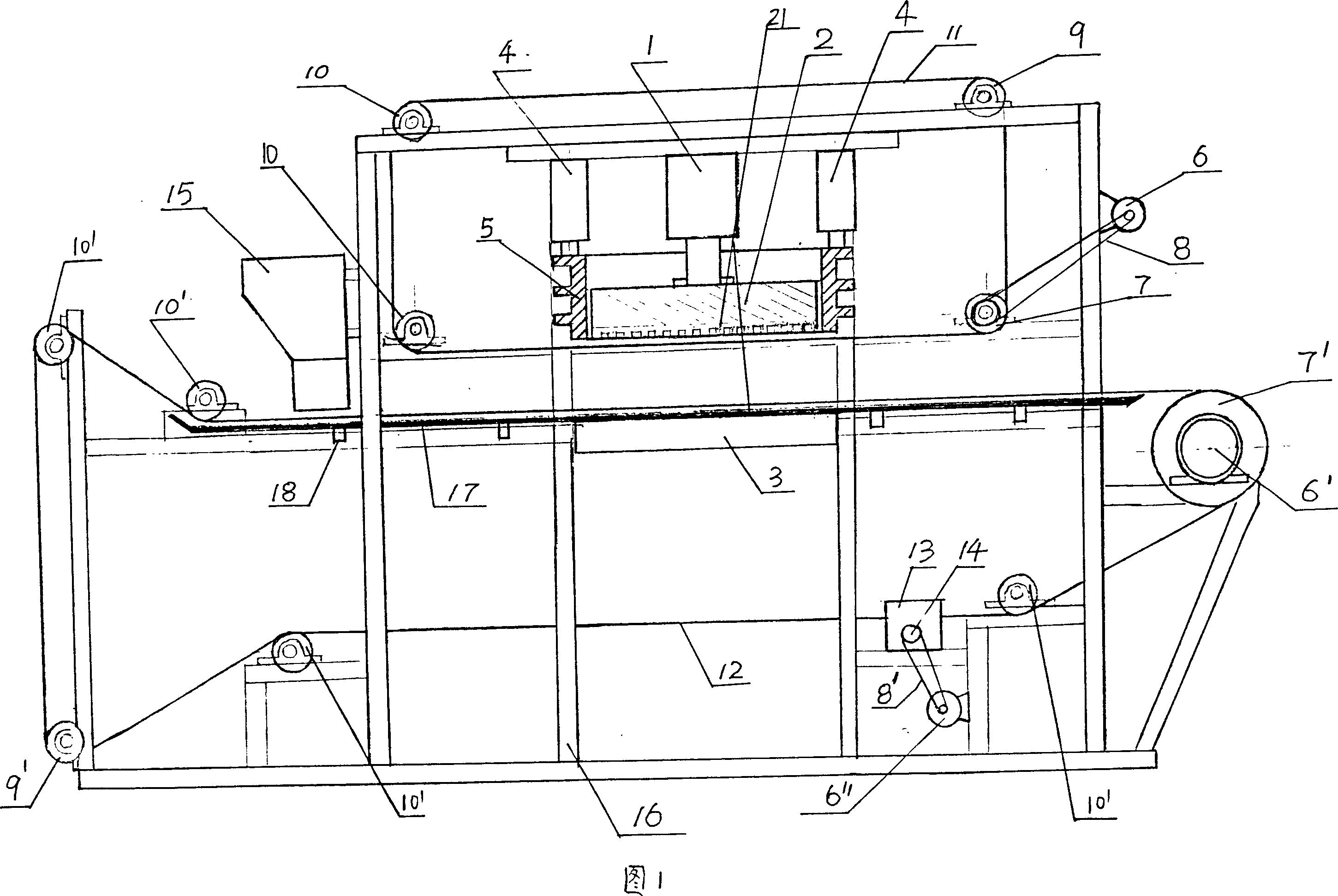

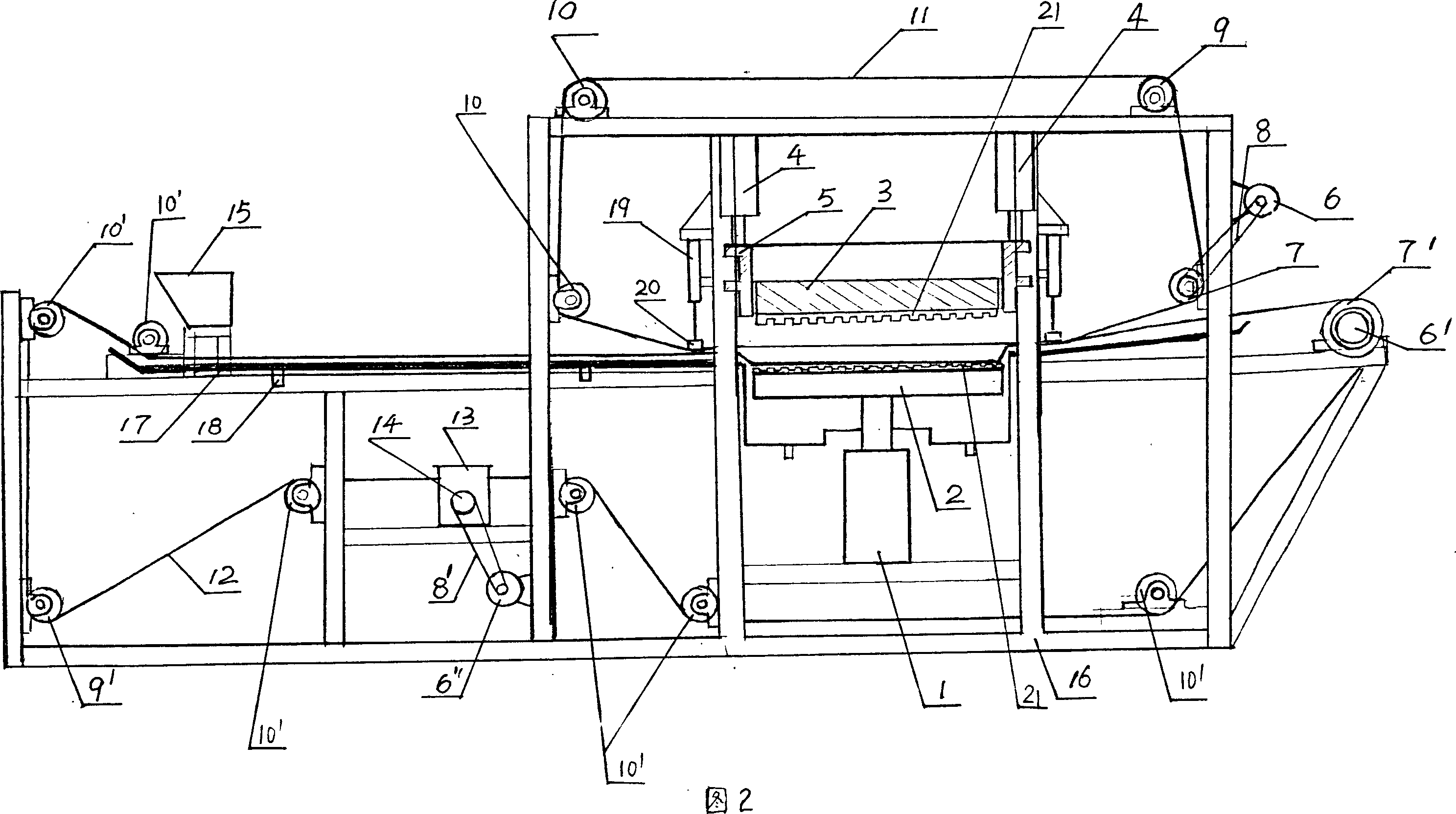

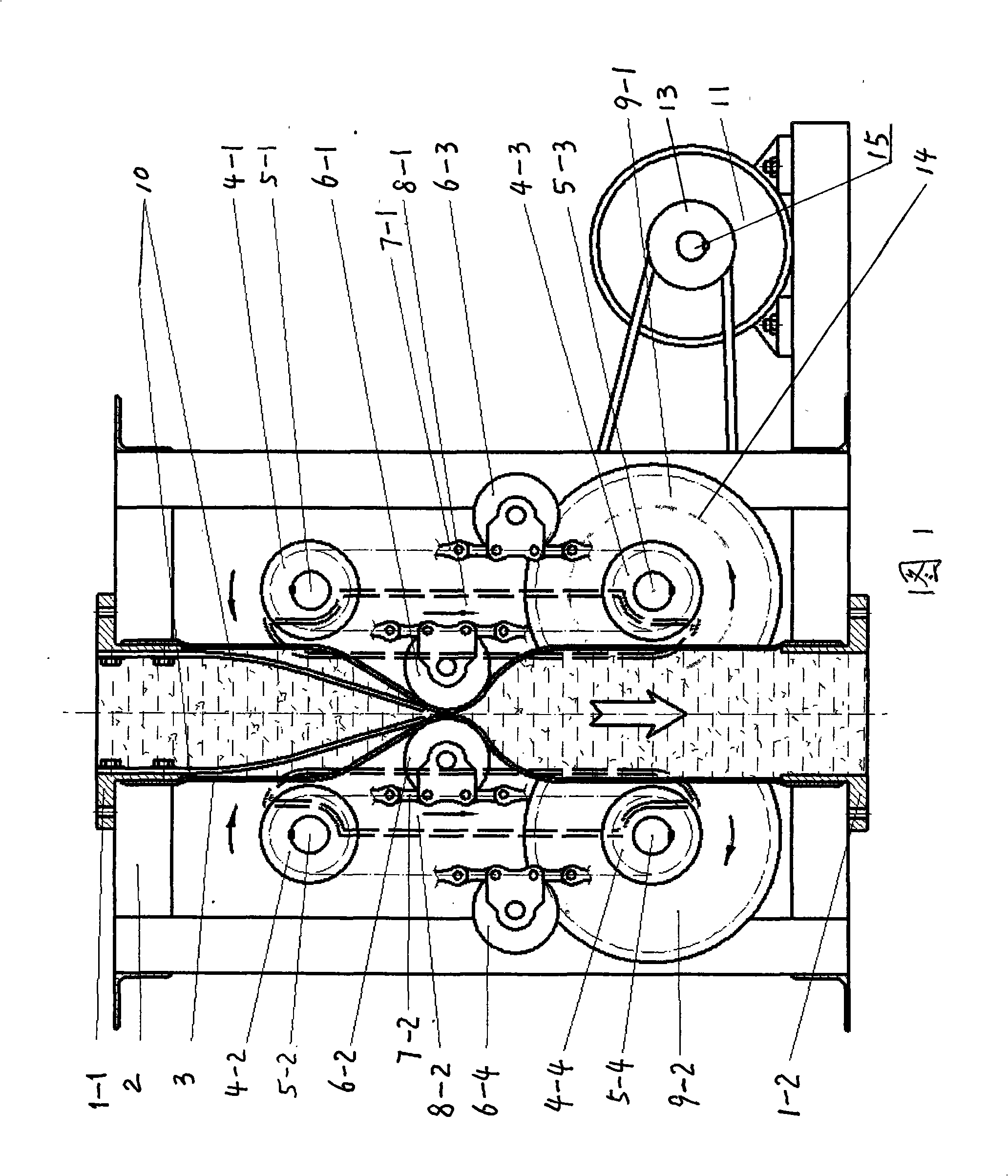

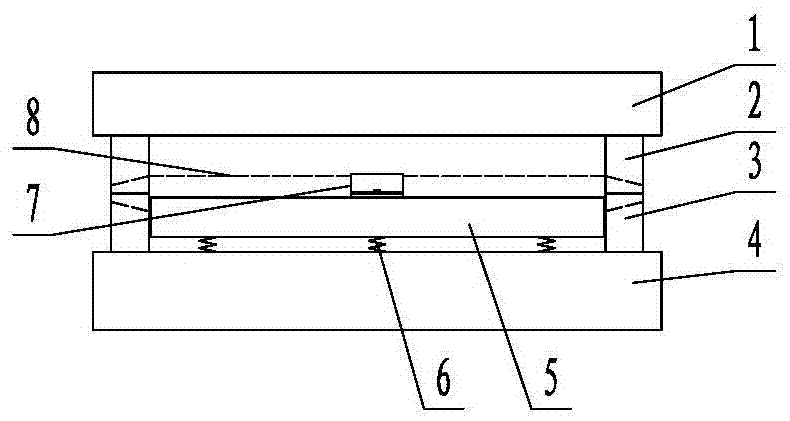

Continuous automatic belt type hydraulic squeezing press

InactiveCN101012997AStrong squeezeImprove applicabilityDrying solid materials without heatDrying machines with progressive movementsContinuous operationDevice form

The invention discloses a continuous automatic band-type hydraulic compressor, comprising a frame (16). The invention is characterized in that the frame (16) is arranged with upper and lower annular filter cloth devices formed by guide roller, expand roller, driving roller and connected upper and lower annular filter cloths and power device. The frame (16) is connected with a material compression sealing device formed by sealing box cylinder (4) and sealing box (5), and a hydraulic compressor formed by a compressing cylinder (1) and a compressing pushing plate (2). The frame (16) is connected with a stop plate (3) relative to the compressing pushing plate (2). The frame (16) is connected with a liquid disc (17) with liquid outlet (18) and a material distributor (15). The invention can realize automatic continuous operation and high compressing speed, with long service life and low cost.

Owner:李连乐

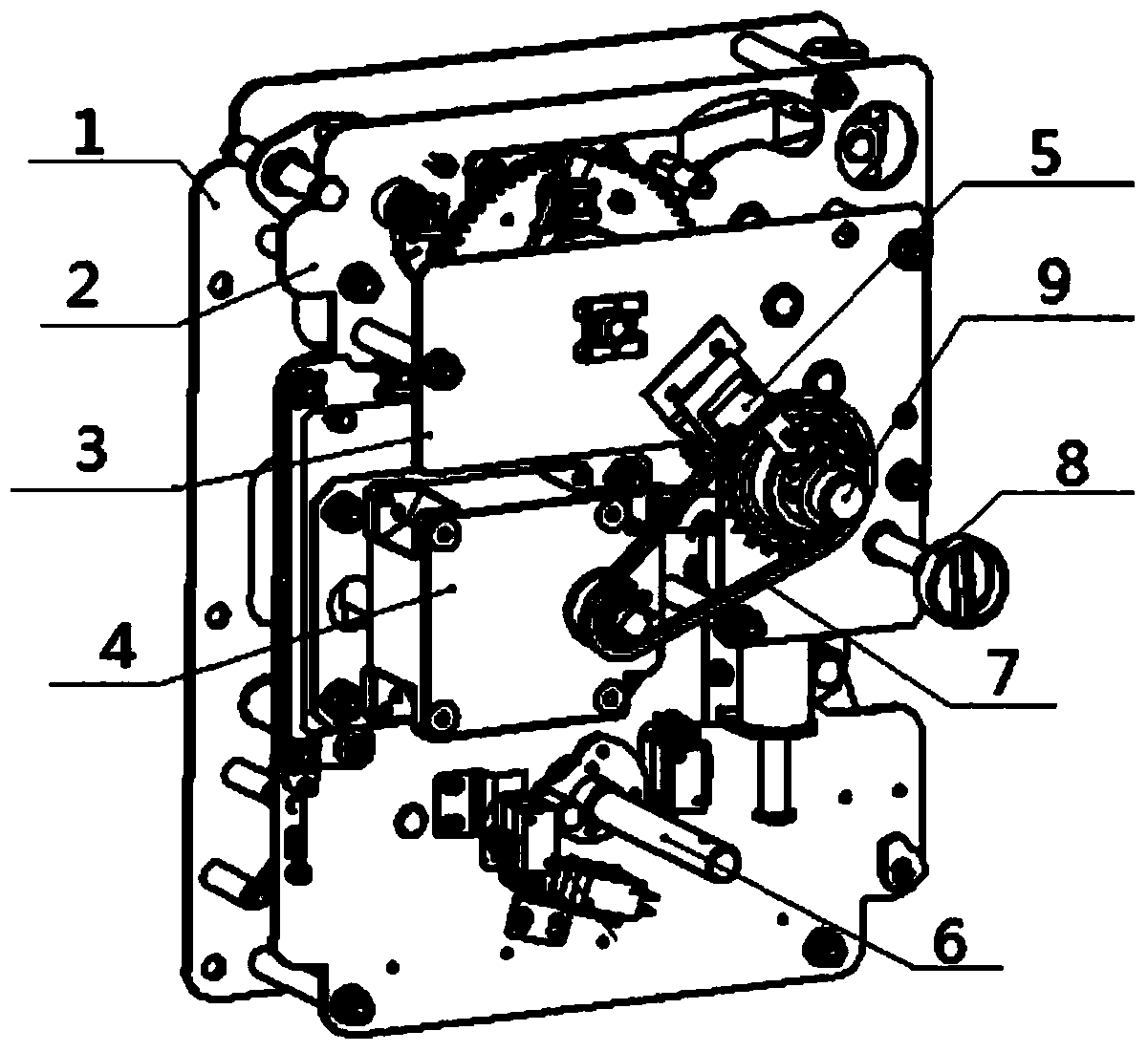

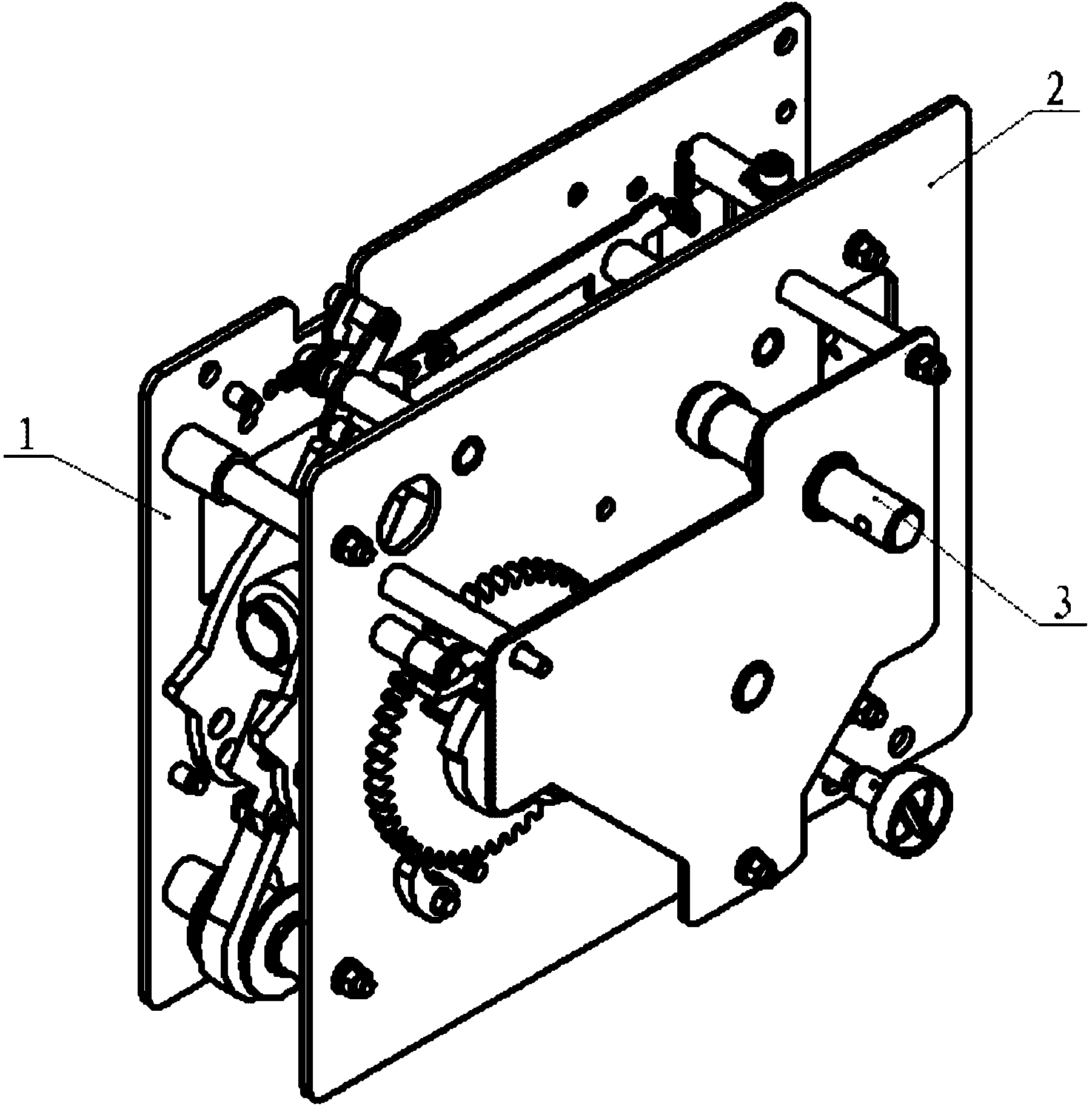

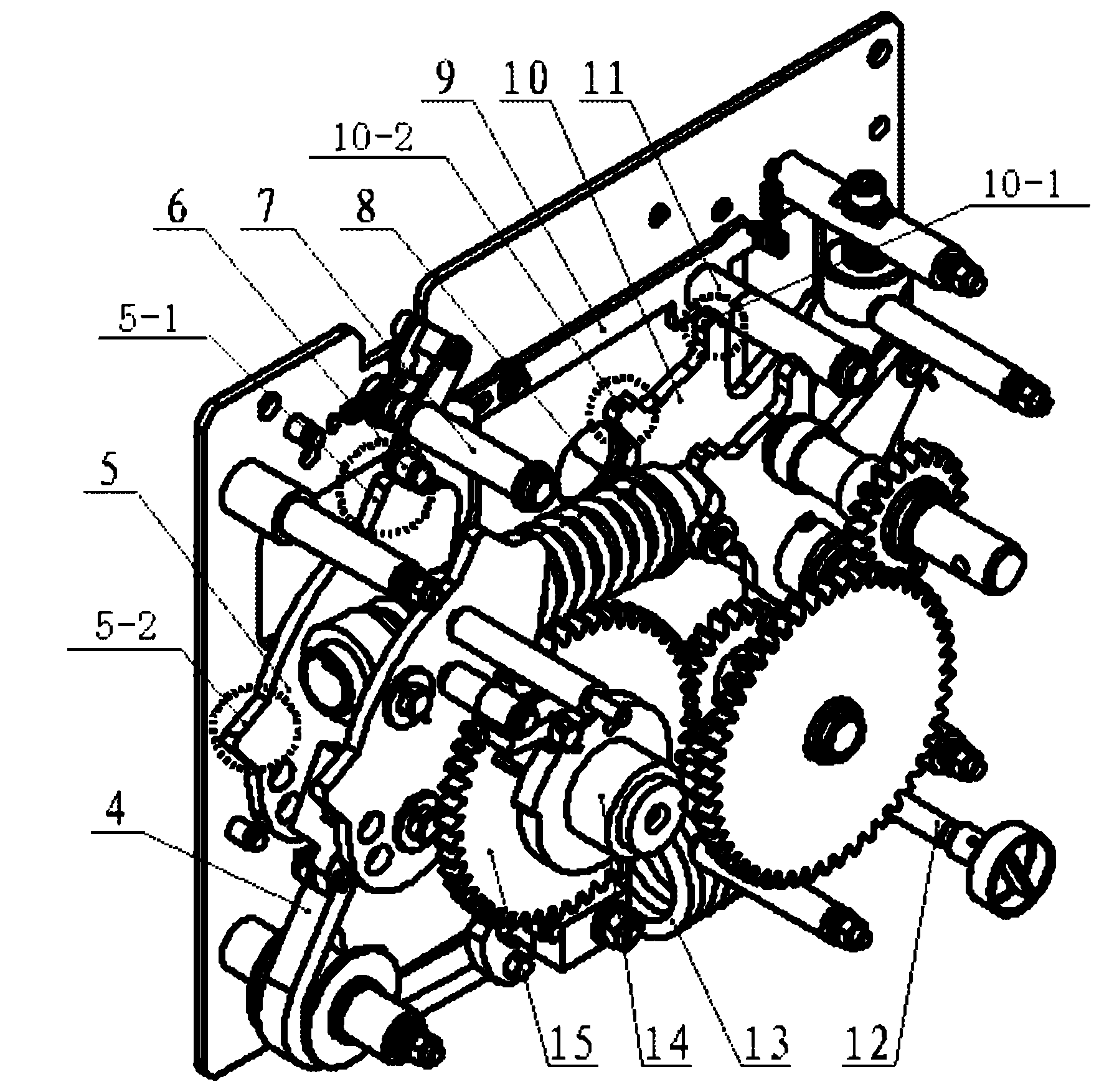

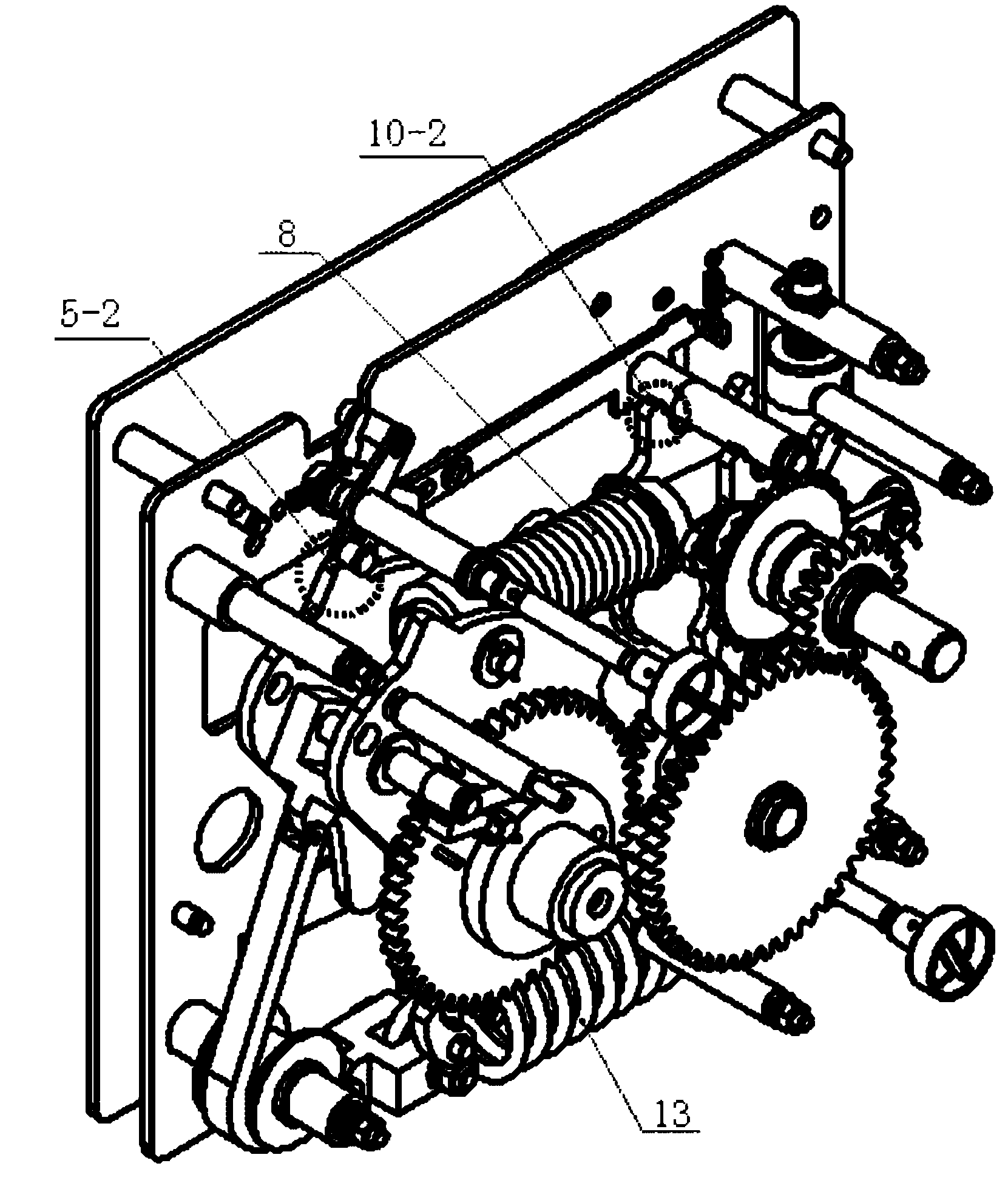

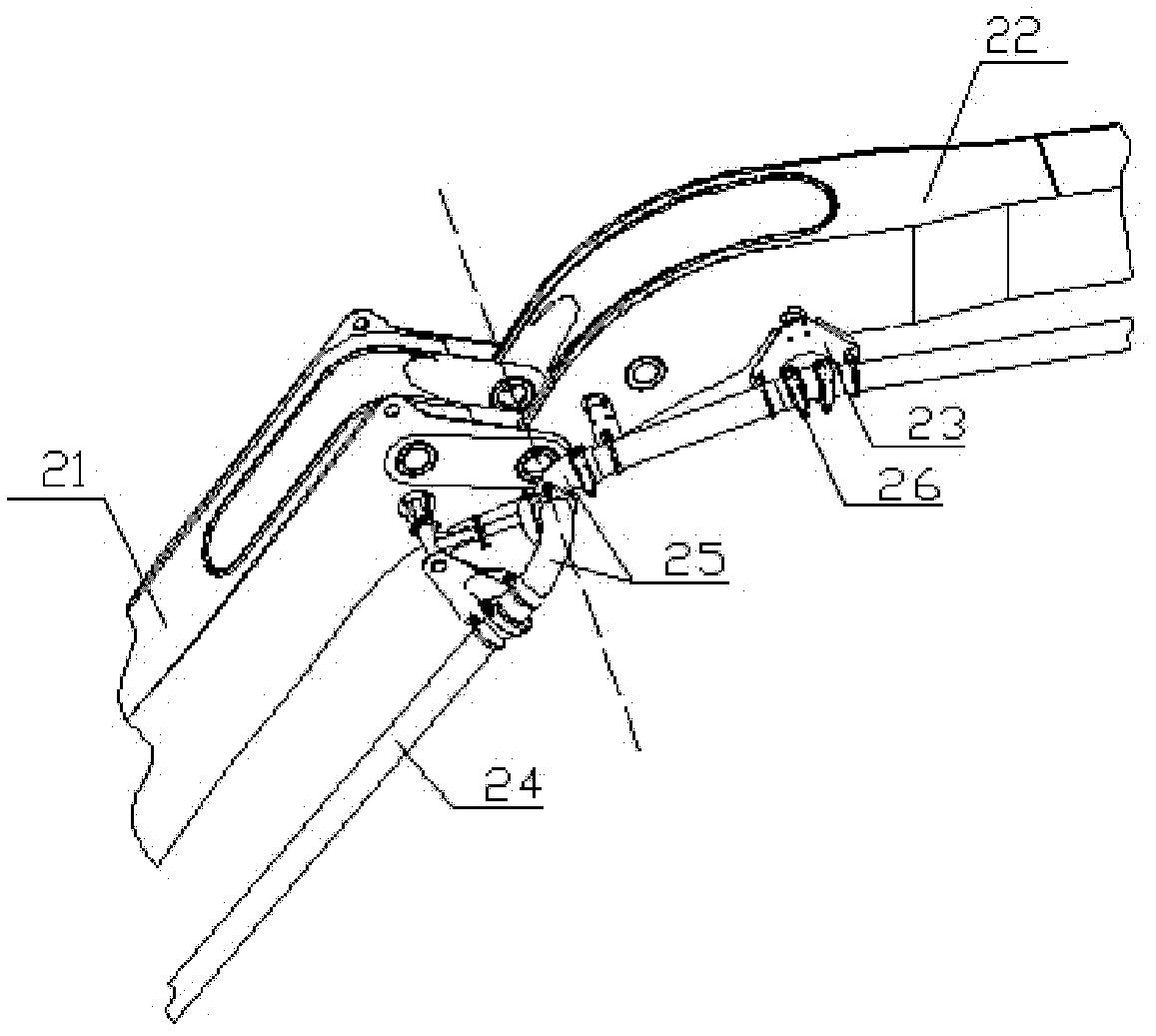

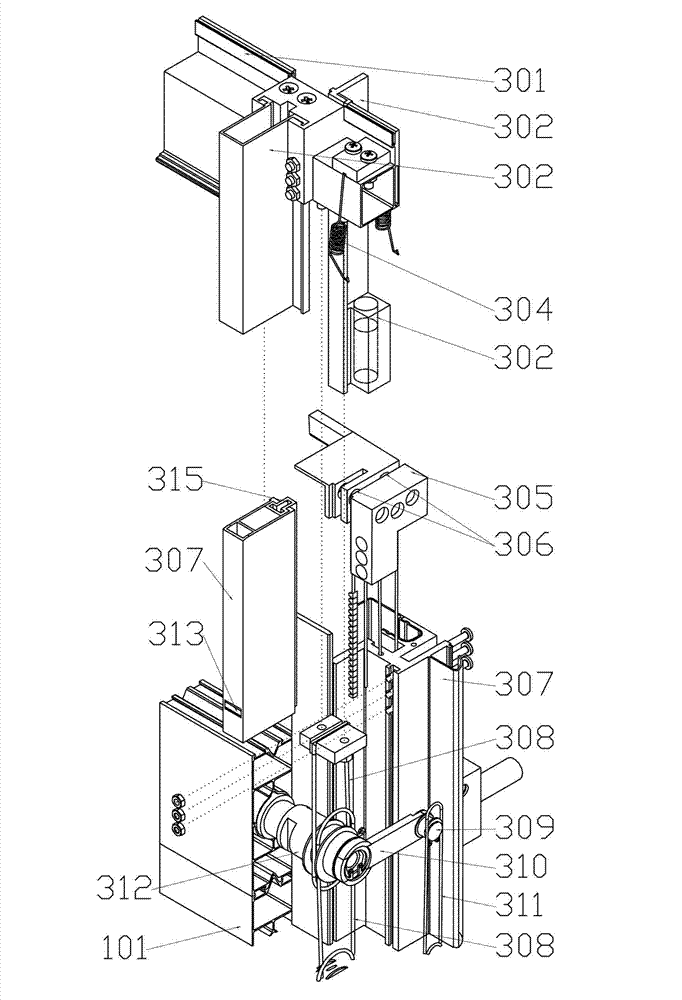

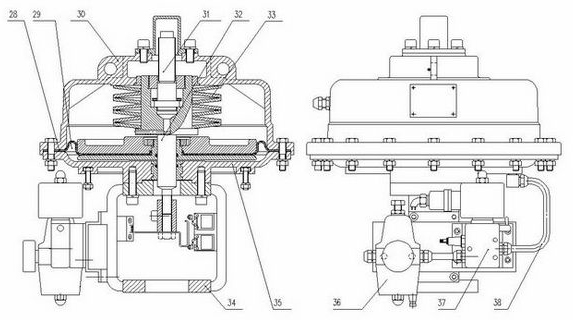

Sectional type load switch mechanism

ActiveCN103745872AHigh outputShort work scheduleHigh-tension/heavy-dress switchesAir-break switchesEngineeringSelf locking

The invention discloses a sectional type load switch mechanism. In the mechanism, an output shaft is provided with a first-stage limiting pin and a second-stage limiting pin, the segment motion mode of a main shaft is realized through cooperating with a switching-on interlocking device, a switching-on limiting device and a unidirectional limiting block disposed on the switching-on limiting device, and an elbow type power-assisted switching-on output connecting lever is utilized to enable the main shaft to provide a larger output force in a final switching-on process when a force is more needed in case of a closer switching-on finishing position; at the same time, when switching-on is put in place, the elbow type output connecting lever is distributed in the form of a horizontal connecting rod, and self-locking is formed; and a driving sector plate on one hand provides a release signal for two-stage motion of the output shaft, and on the other hand performs energy storage on a switching-off spring and enables the switching-off spring to maintain at a main shaft switching-on state through a connection plate, a switching-off interlocking plate, a switching-off limiting pin and a switching-off limiting device. The operation mechanism, through dividing a switching-on process into two segments to respectively cooperate with different motion requirements of an isolation knife and a vacuum bubble, reduces the working stroke of the spring, improves energy utilization rate, and saves cost.

Owner:SHANGHAI PINGGAO TIANLING SWITCHGEAR CO LTD +1

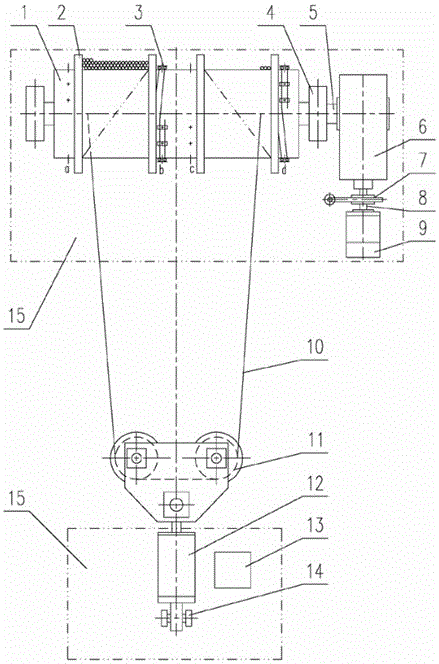

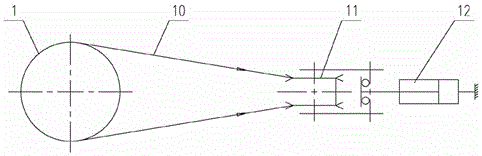

Drum stress test device and method thereof

ActiveCN105043885AReduce purchase quantityReduce test site requirementsMaterial strength using tensile/compressive forcesWinding mechanismsHydraulic pumpEnergy conservation

The invention discloses a drum stress test device and a method thereof and relates to the technical field of crane drum stress tests. The drum stress test device comprises a duplex-drum assembly, a steel wire rope (10), a drive assembly and a mounting rack (15). The duplex-drum assembly comprises a duplex drum (1). The test device further comprises a loading assembly. The loading assembly comprises a pulley set (11), a hydraulic oil cylinder (12) and a hydraulic pump station (13). According to the drum stress test device and the method, only one drive device set is needed, and the drive assembly and the loading assembly can be used as universal pieces to be suitable for different drums; the test cost is lowered, power consumption is lowered, and energy is saved.

Owner:SINOHYDRO JIAJIANG HYDRAULIC MACHINERY +1

Energy-saving high-efficiency closed-type pressurizing oil supply sectional material extruder

ActiveCN104624691AShort work scheduleReduce no-load travelPump assembliesPressesProduction rateMaster cylinder

The invention relates to an energy-saving high-efficiency closed-type pressurizing oil supply sectional material extruder which comprises a base, a mould, an ingot containing barrel, an auxiliary cylinder, a shearing device and an oil supply system, wherein the mould, the ingot containing barrel and the auxiliary cylinder are sequentially arranged on the base; the oil supply system comprises a main cylinder and an oil storage tank; the main cylinder is provided with a plunger; the extruder is a short-stroke extruder; the ingot containing barrel of the extruder is arranged on the top position of an extrusion rod, and the ingot containing barrel forms a feed space with the mould during displacement; the oil storage tank includes a closed oil return tank and a closed pressurizing oil cylinder; the oil return tank is connected with the main cylinder through a reflux oil way connected into the main cylinder, and the oil return tank is connected with the pressurizing oil cylinder through an oil supply pipeline; the pressurizing oil cylinder is provided with a piston which acts on the pressurizing oil supply pipeline to supply oil to the main cylinder, and oil inside the pressurizing oil cylinder is extruded into the main cylinder or oil inside the main cylinder is refluxed into the pressurizing oil cylinder through a circulating oil way through the reciprocating motion of the piston; and the oil supply system is controlled by a plurality of servo motor oil pump sets. The energy-saving high-efficiency closed-type pressurizing oil supply sectional material extruder disclosed by the invention can be used for effectively enhancing the production rate, reducing the manufacturing cost of an integral machine, saving the material and reducing the oil consumption.

Owner:FOSHAN NANHAI MINGSHENG MACHINE MFR

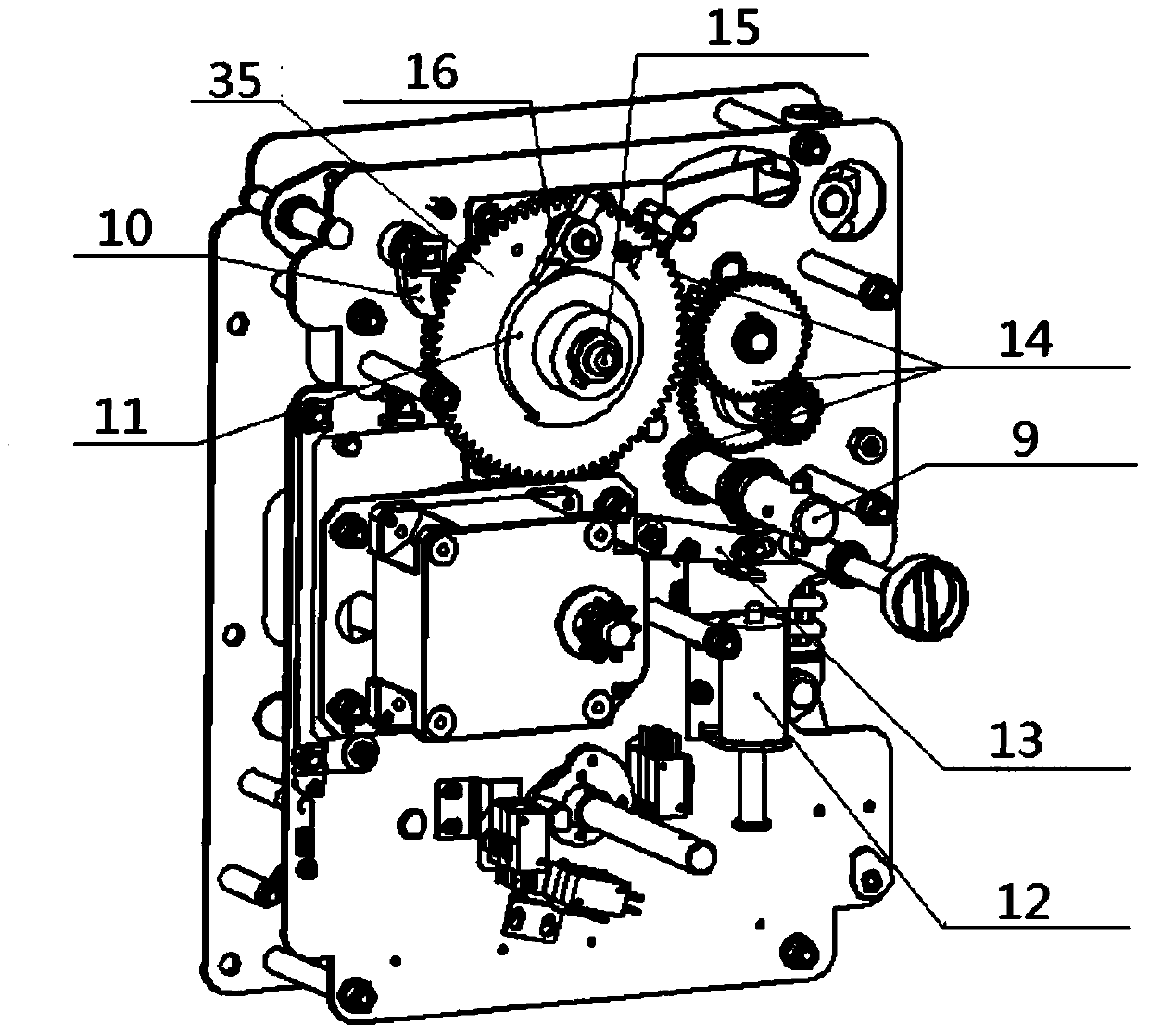

Stage-type load switch operation mechanism

InactiveCN102254717AReduce in quantityEasy to assembleSwitch power arrangementsEngineeringEnergy storage

The invention discloses a stage-type load switch operation mechanism. The stage-type load switch operation mechanism comprises a front support plate, a rear support plate, an operation shaft, a two-sectional switch-on output crank arm, a switch-on trip limiting shaft, a switch-on trip interlock crank arm, an interlock rotating shaft, an interlock plate, a switch-on trip position plate, a switch-off trip rotating shaft, a switch-off energy storage position rotating shaft, a gear set, a mechanism driving rotating shaft, a switch-on spring and a switch-off spring. The switch-on stroke is divided into two stages, in a first stage, the switch-on spring does not store energy, and a mechanism output shaft rotates along an operating shaft of an operation mechanism; in the second stage, the switch-on spring stores energy in compression, the mechanism output shaft does not rotate until the energy storage mechanism trips away, the switch-on spring releases energy to drive the mechanism output shaft to rotate in acceleration so as to drive the load switch to switch on. The stage-type load switch operation mechanism has fewer parts and is simple to assemble; the output capability of the switch-on spring of the operation mechanism is optimized through the stage-type operation.

Owner:SHANGHAI PINGGAO TIANLING SWITCHGEAR CO LTD +1

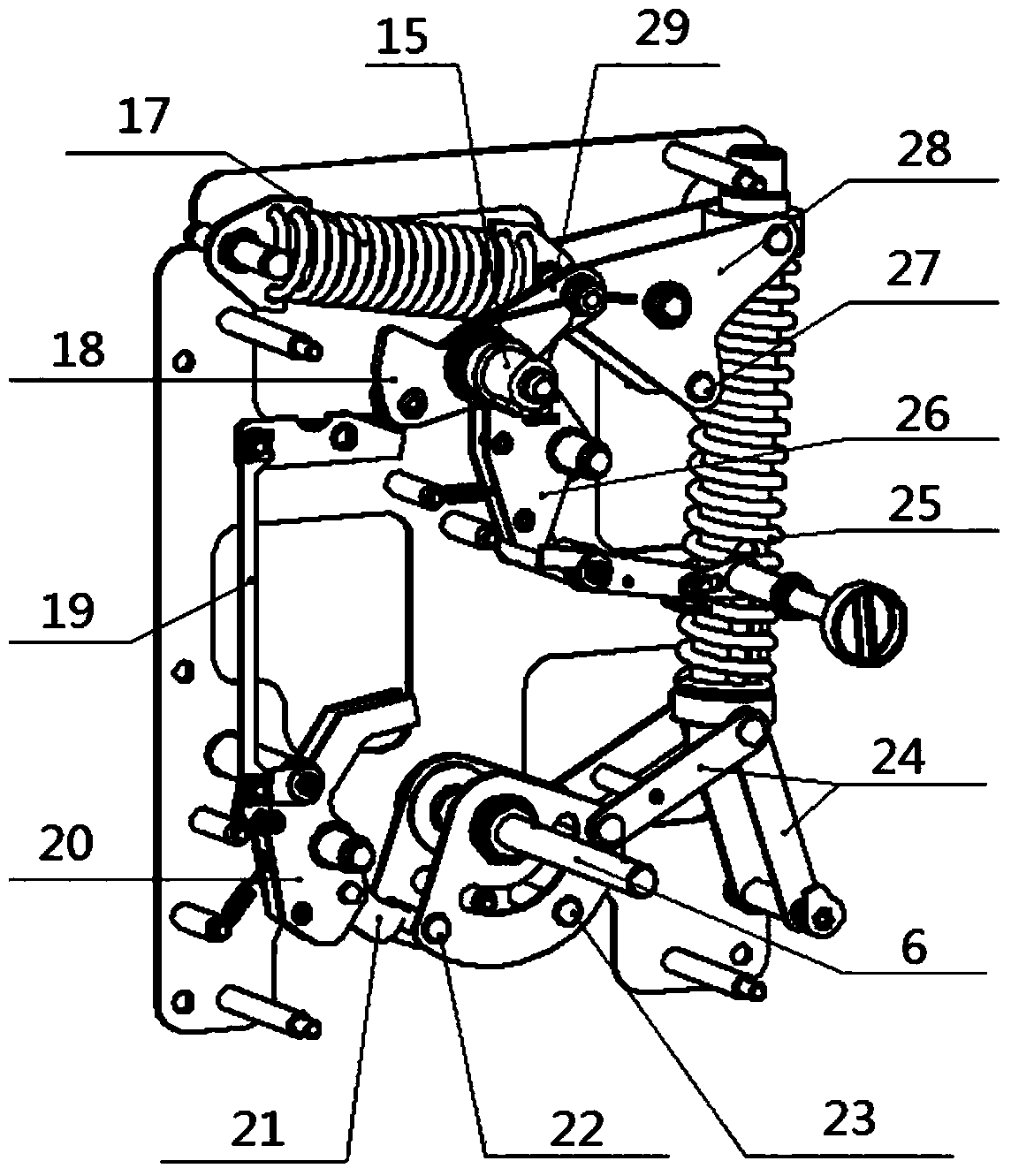

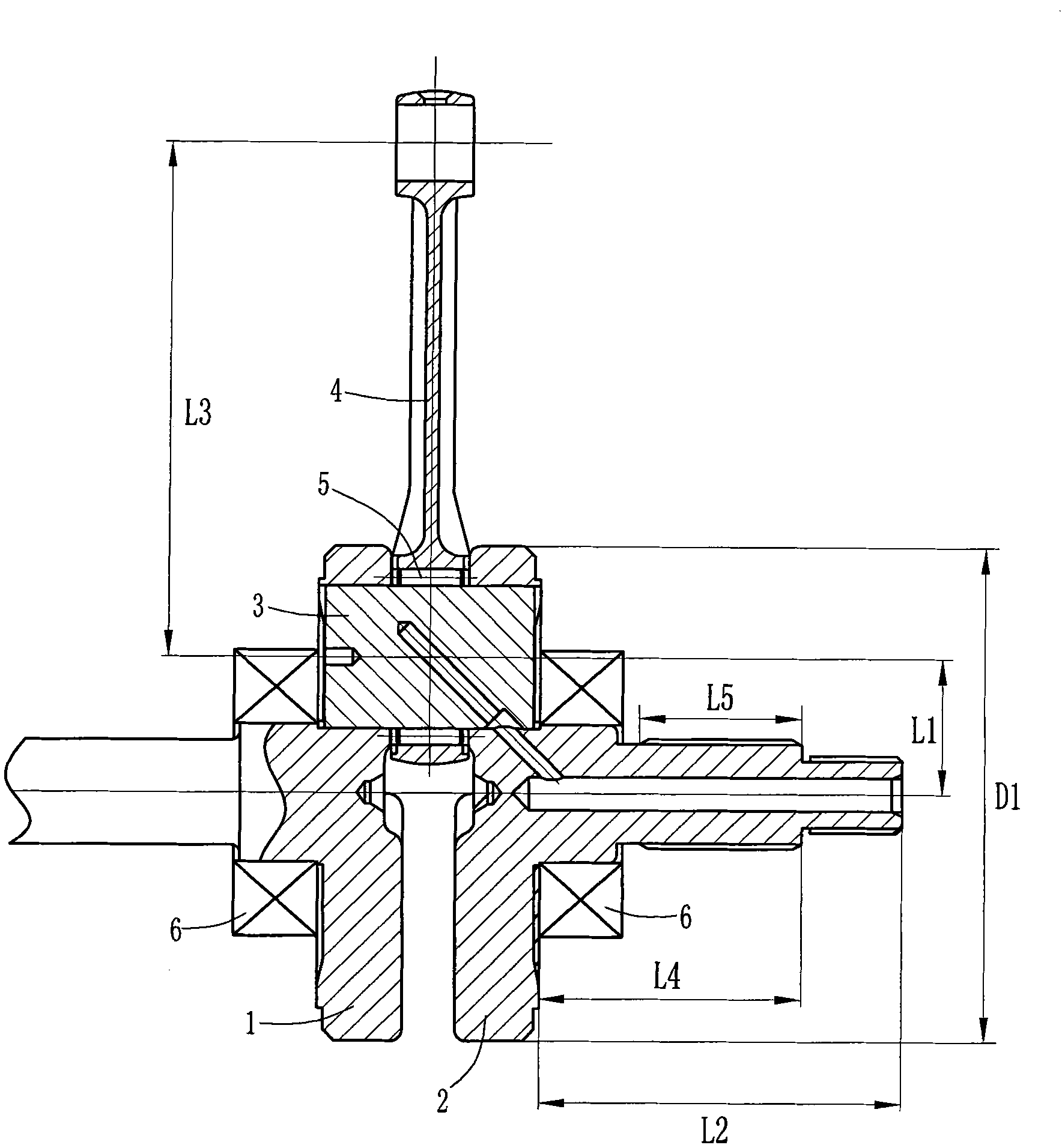

High-precision sulfur hexafluoride gas density relay

ActiveCN103456561ALight in massTo achieve temperature compensationElectric switchesSulfur hexafluorideElectrical performance

The invention discloses a high-precision sulfur hexafluoride gas density relay which is good in shock resistance, high in precision, good in electrical performance, and long in service life. The high-precision sulfur hexafluoride gas density relay comprises a signal control part and an indicating value displaying part which are arranged in a shell body, wherein the signal control part and the indicating value displaying part are relatively independent, the indicating value displaying part comprises a display bourdon tube, a display end base, a machine core and a pointer, one end of the display bourdon tube is welded on a base, the other end of the display bourdon tube is welded on the display end base, and the shell body is an airtight air chamber and is filled with sulfur hexafluoride gas used for temperature compensation; the signal control part comprises a control bourdon tube, the base, a control end base, a plurality of signal generators and a signal adjusting mechanism, one end of the control bourdon tube is fixed on the base, the other end of the control bourdon tube is fixed on the control end base, the signal adjusting mechanism is arranged on the control end base, and the signal generators are installed on the base and are triggered to move by the signal adjusting mechanism.

Owner:SHANGHAI ROYE ELECTRICAL CO LTD

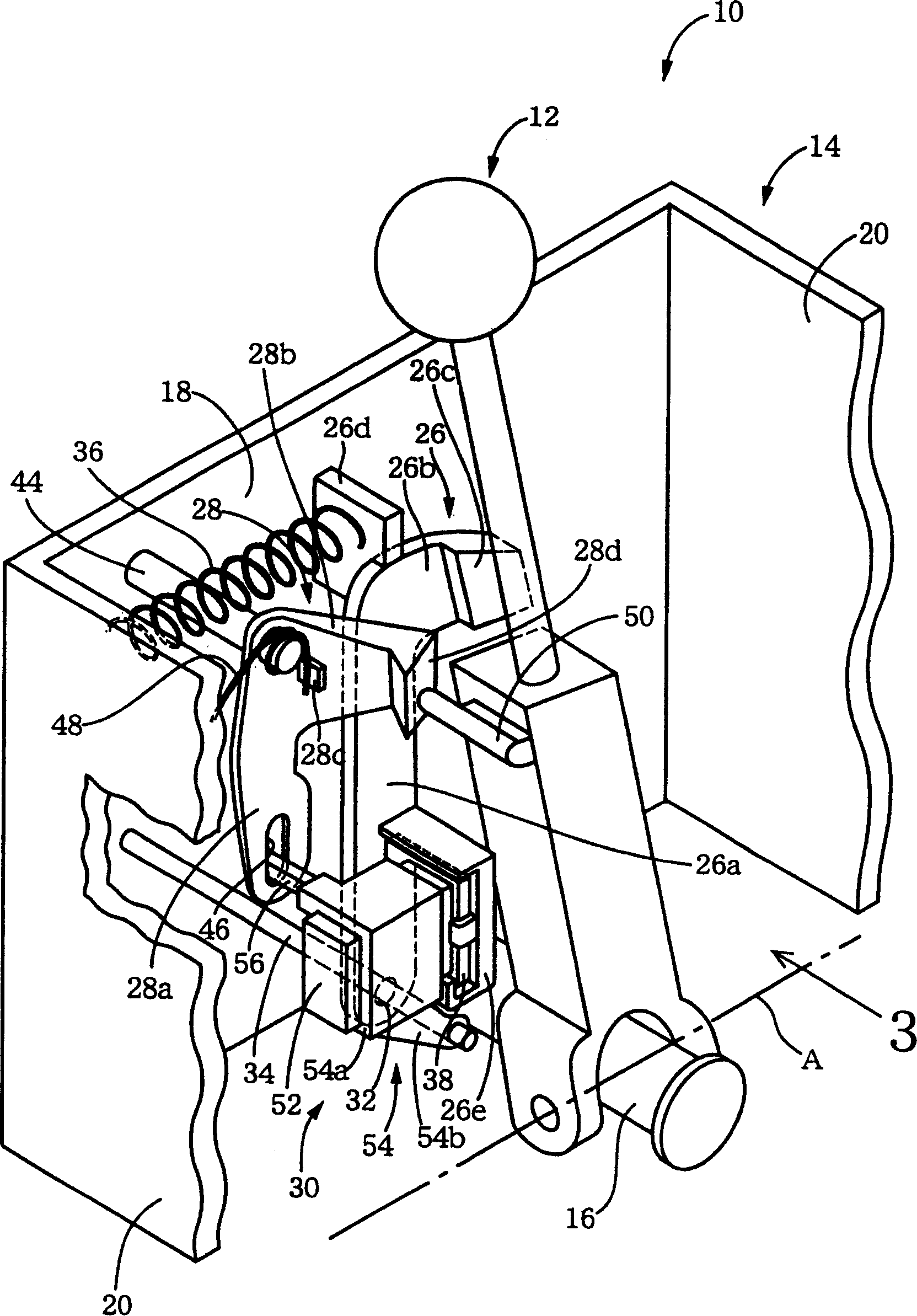

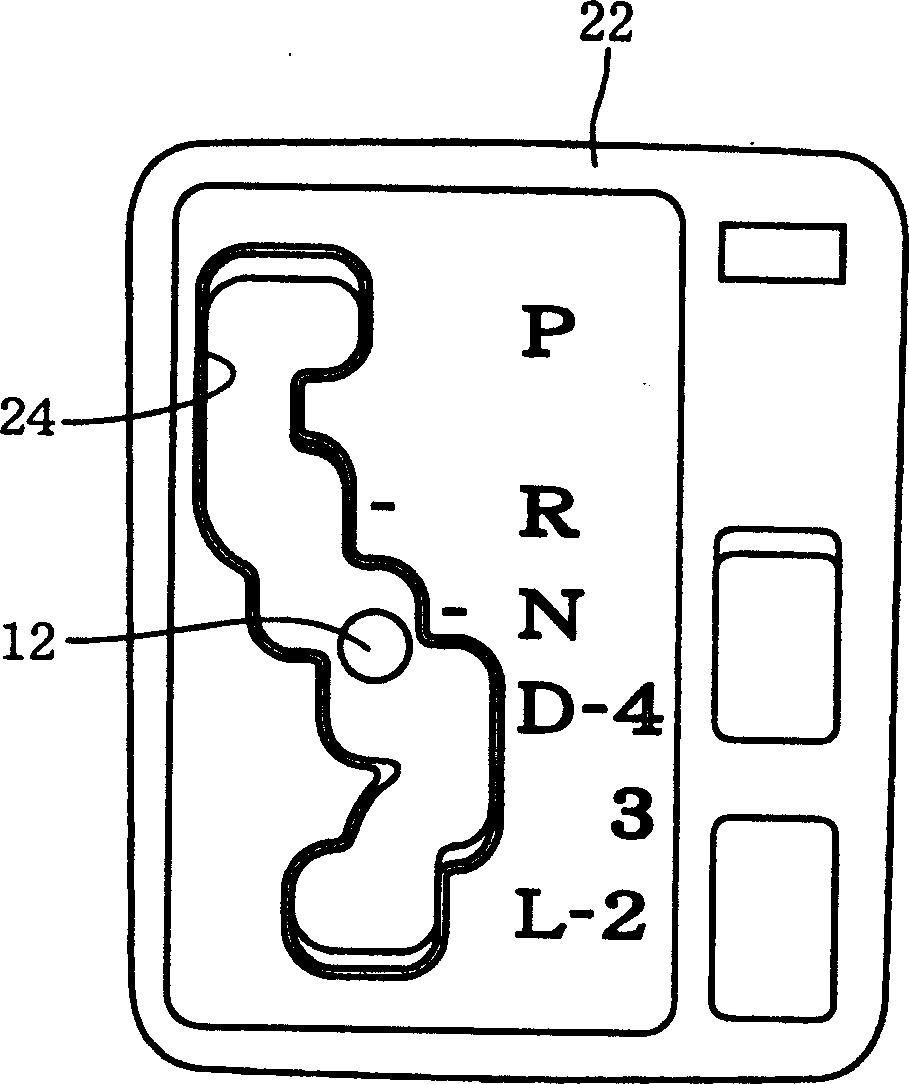

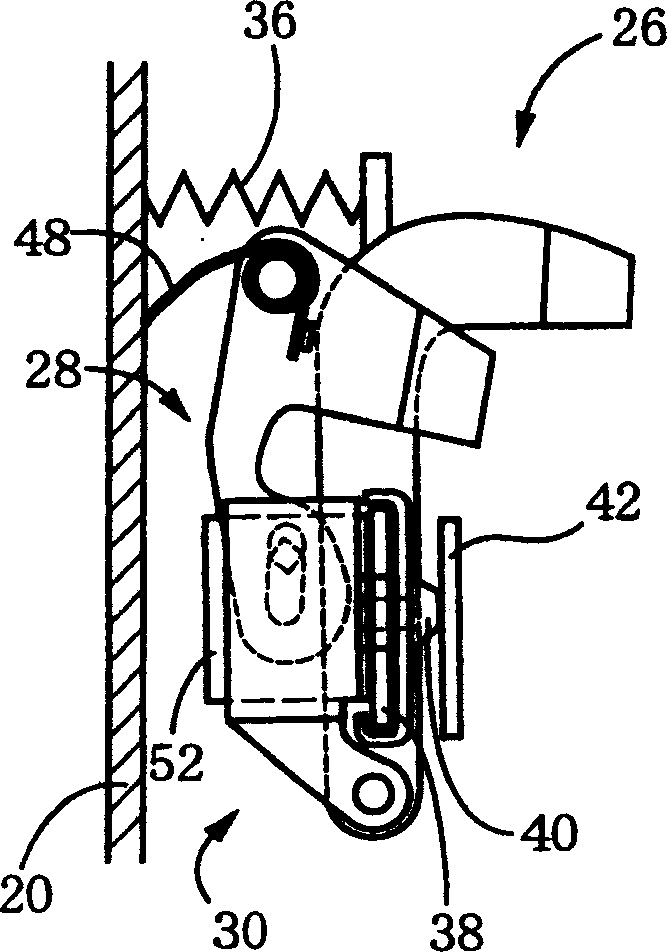

Vehicle gearshifting locking device with pivoted detent and connector

ActiveCN1739995AShort work scheduleGearing controlLimiting/preventing/returning movement of partsDetentElectrical and Electronics engineering

The present invention relates to a vehicle gearshifting locking device with pivoted detent and connector. A vehicular shift lock device for selectively inhibiting and permitting a movement of a shift lever, including (a) a stopper member pivotable about an axis between a stopping position and a non-stopping position for respectively preventing and permitting a movement of a manually operable member provided to place the shift lock device in its unlocking state, (b) a first biasing member biasing the stopper member toward the stopping position, (c) a first linkage device pivotable about an axis in a first direction by the movement of the manually operable member, (d) a second biasing member biasing the first linkage device in a second direction opposite to the first direction, and (e) a second linkage device pivotable about an axis to its operated position and having a connected state and a disconnected state in which the second linkage device is connected to and disconnected from the stopper member, respectively, wherein the second linkage device is operatively connected to the first linkage device such that the stopper member is pivoted to the non-stopping position when the second linkage device placed in the connected state is pivoted to the operated position by a pivotal movement of the first linkage device in the first direction.

Owner:TOYOTA JIDOSHA KK +4

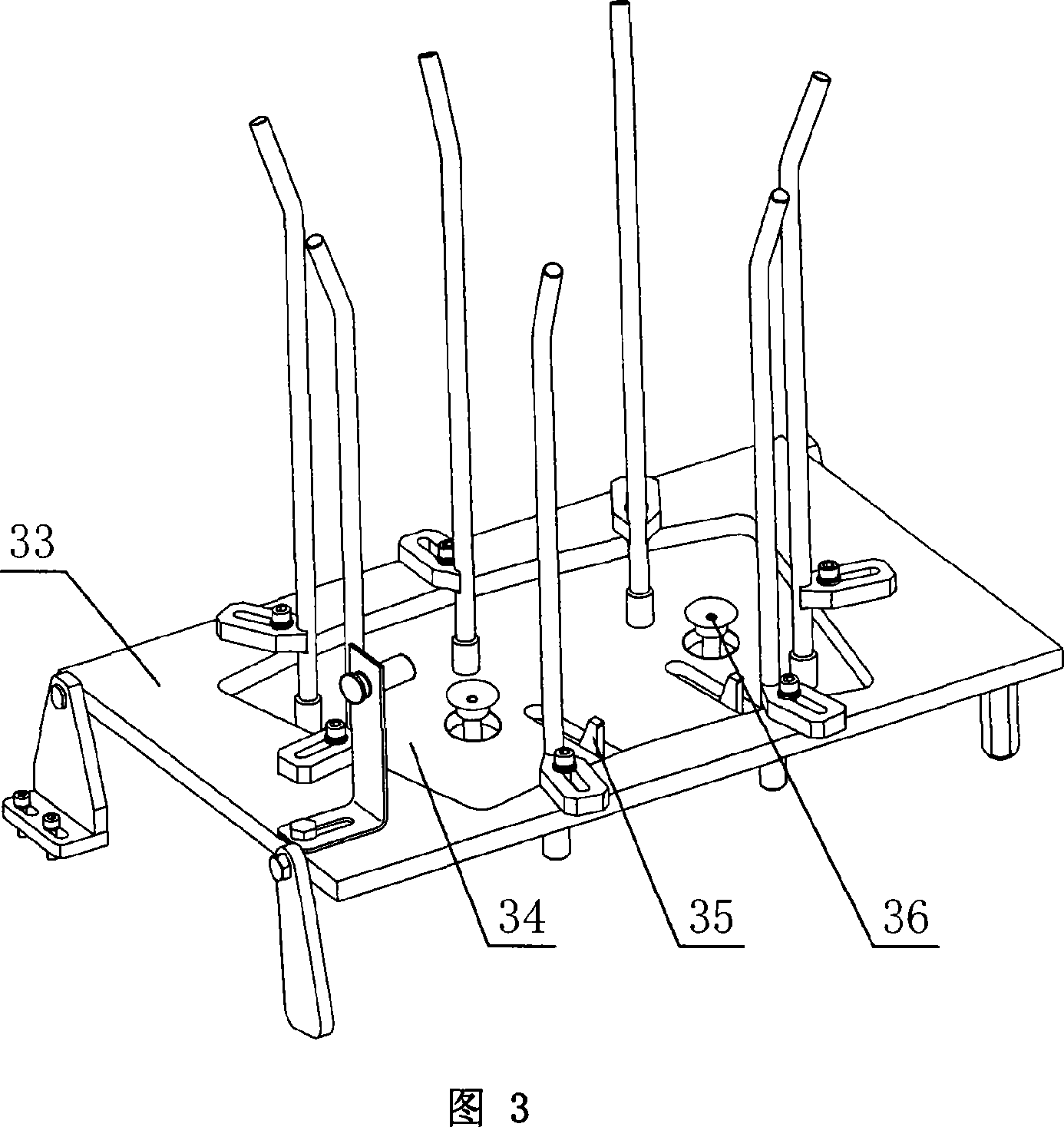

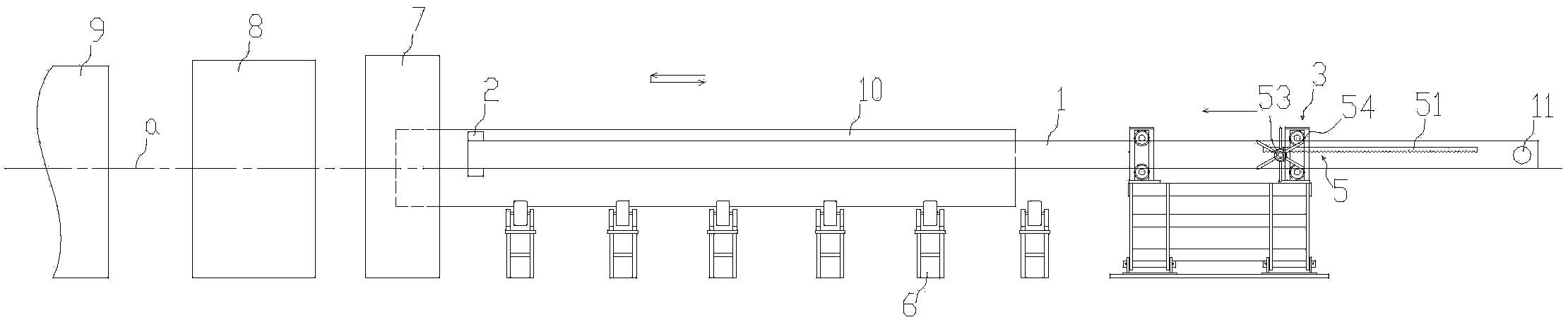

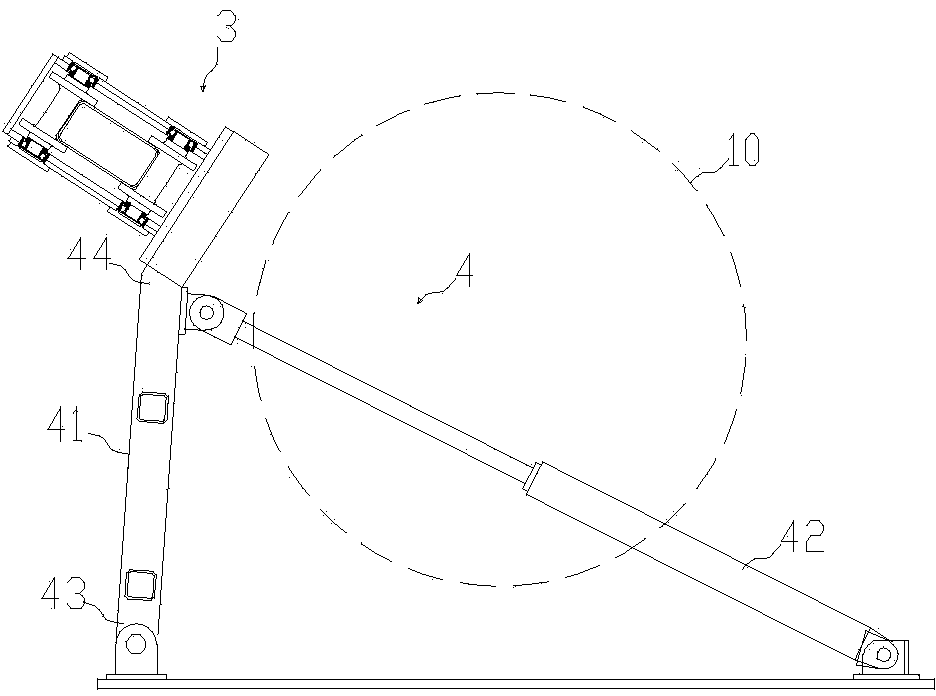

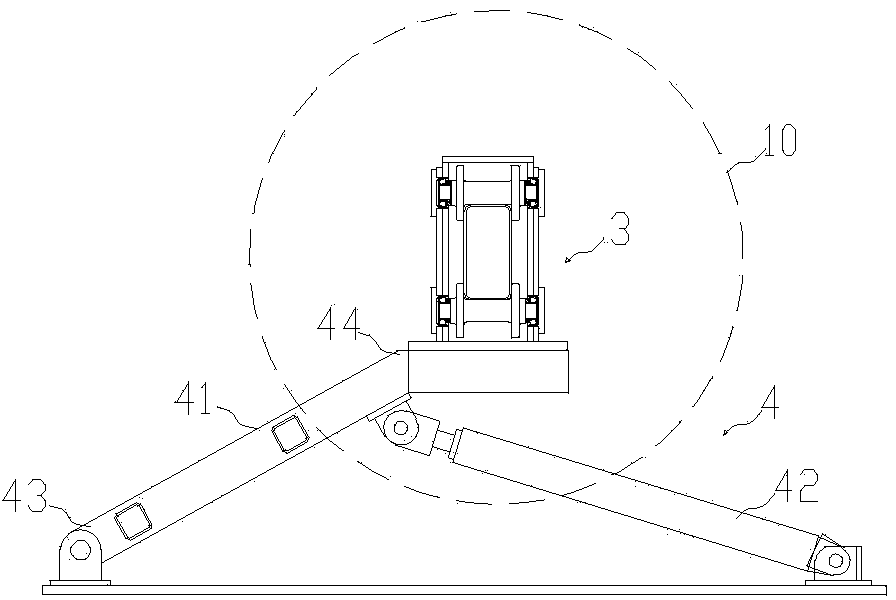

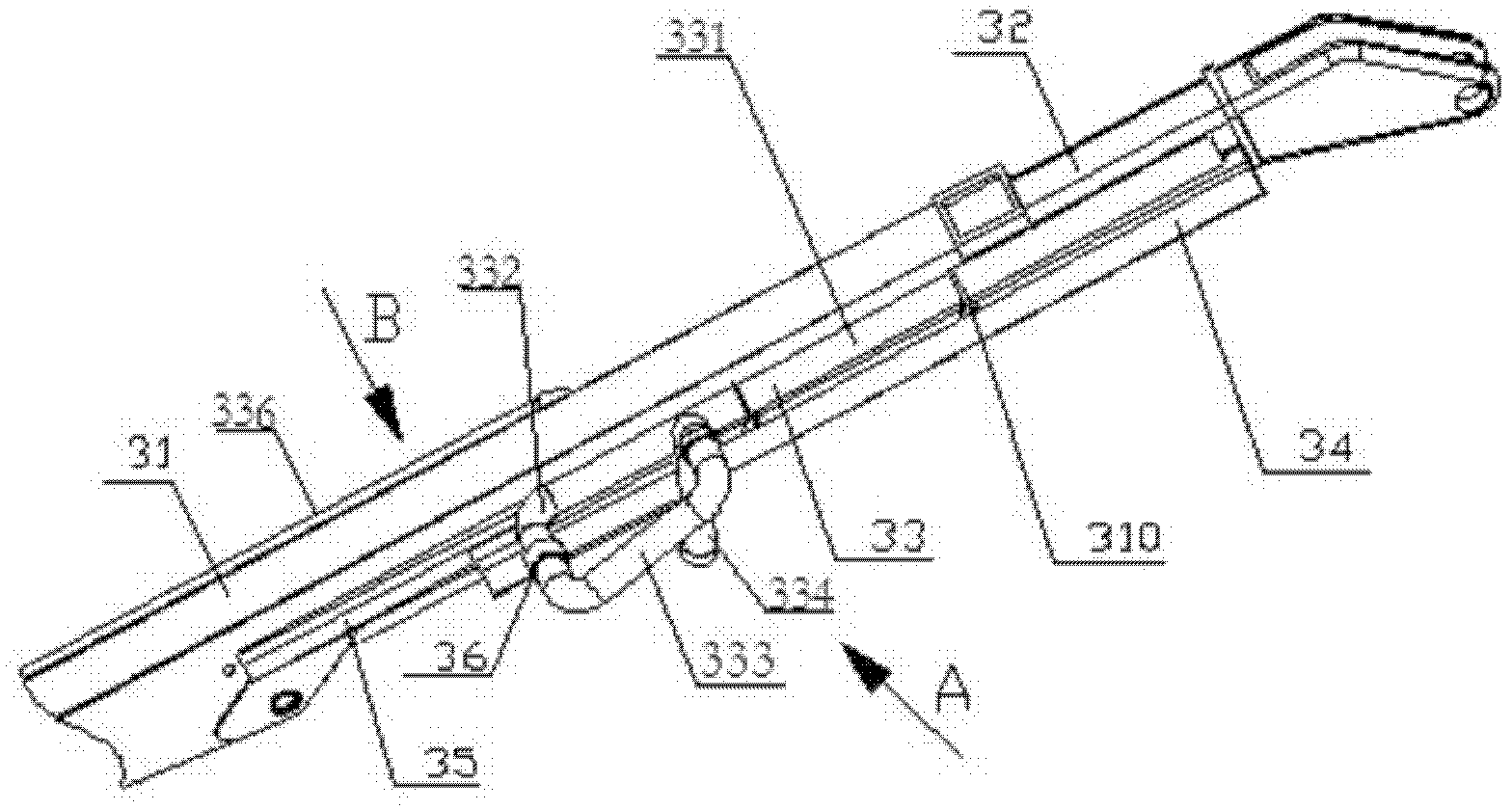

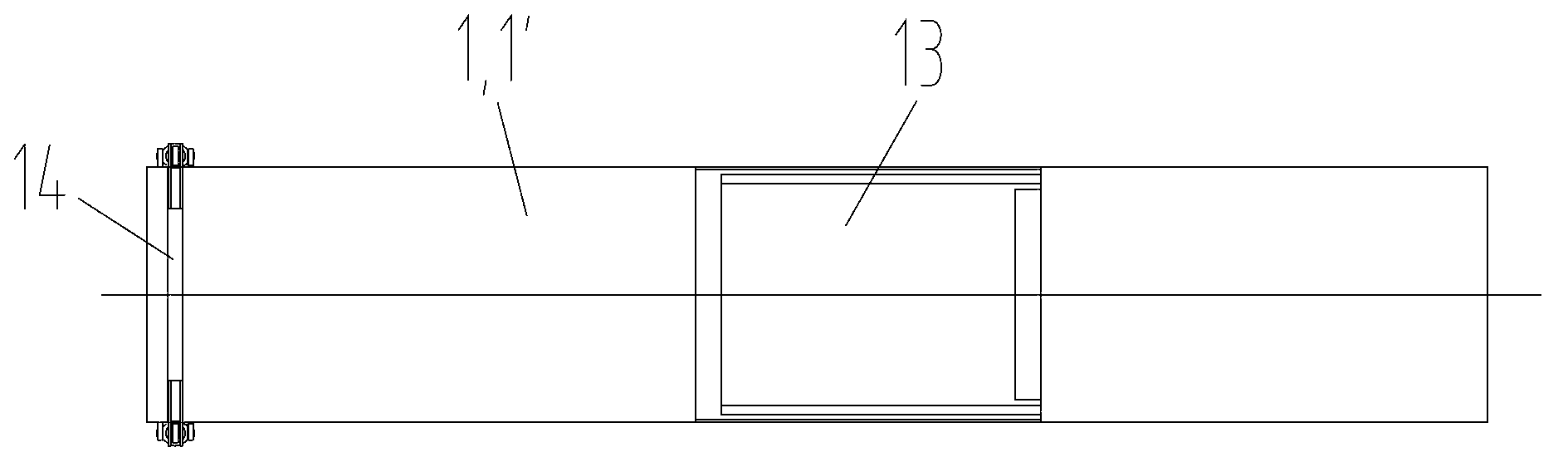

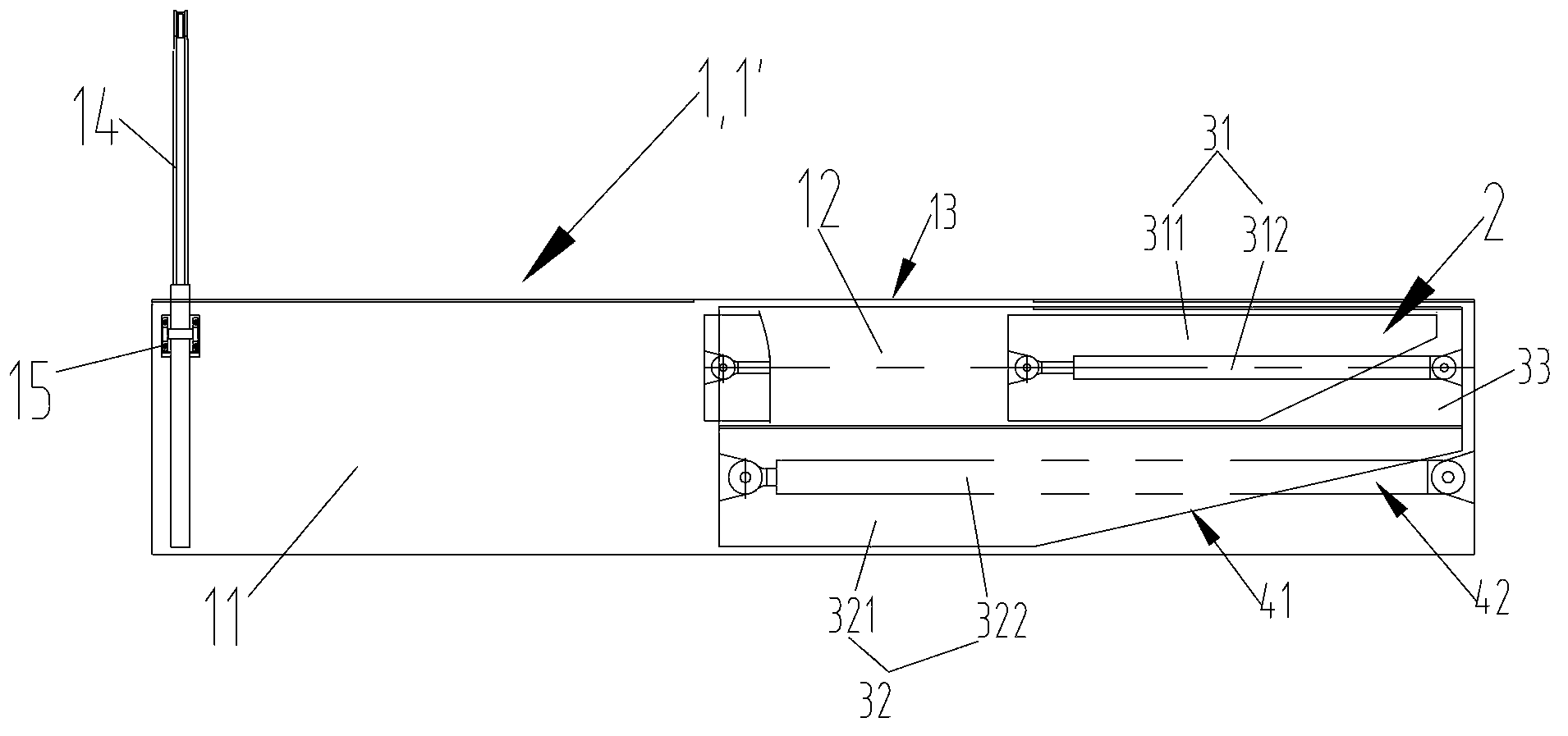

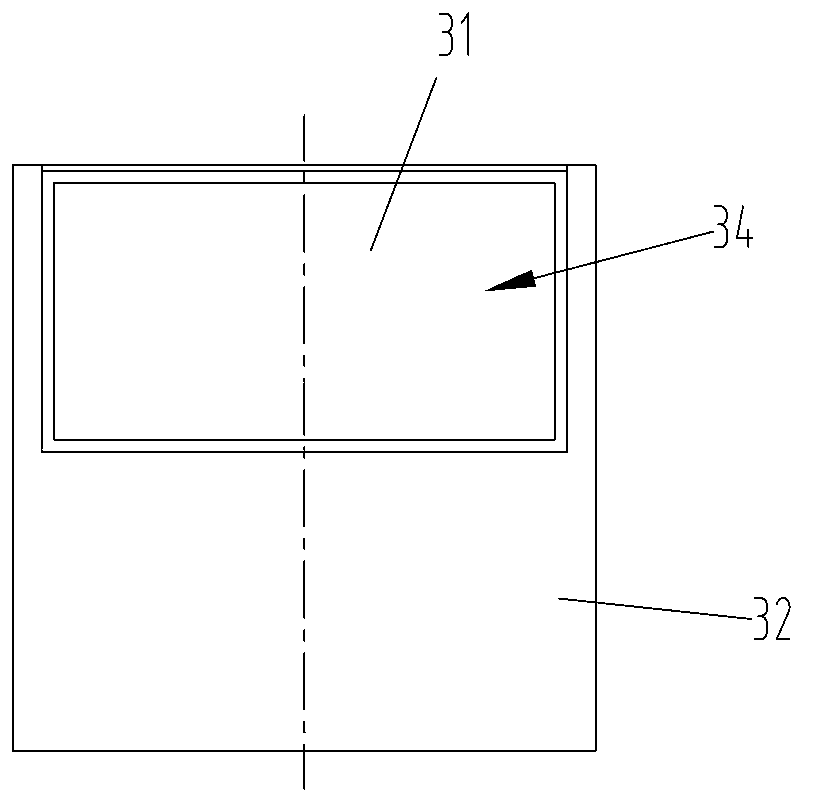

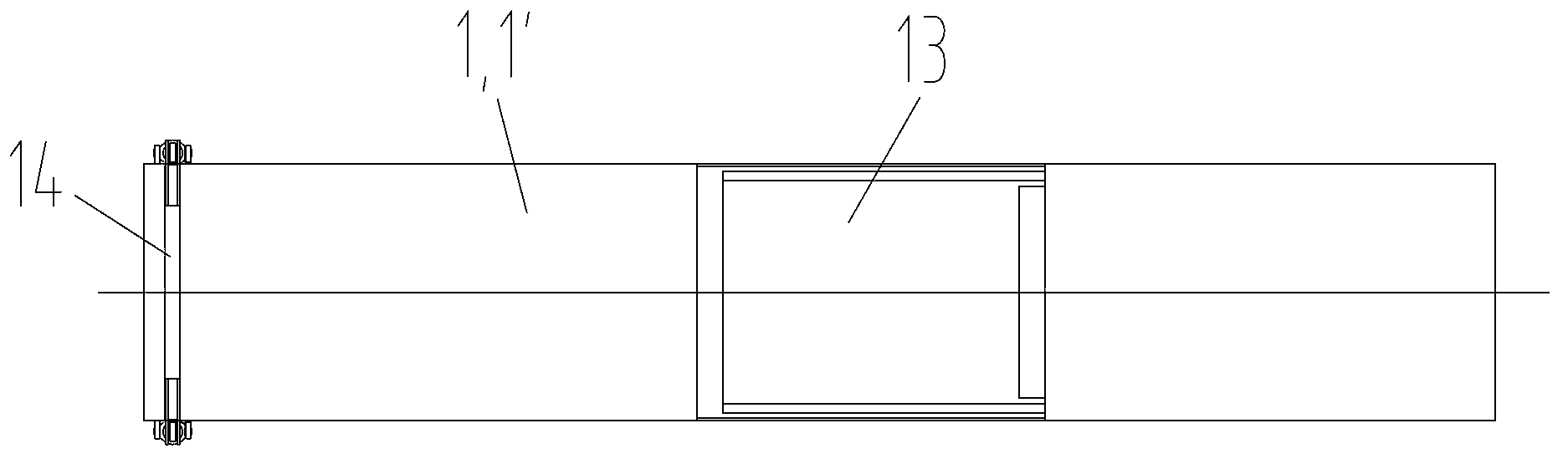

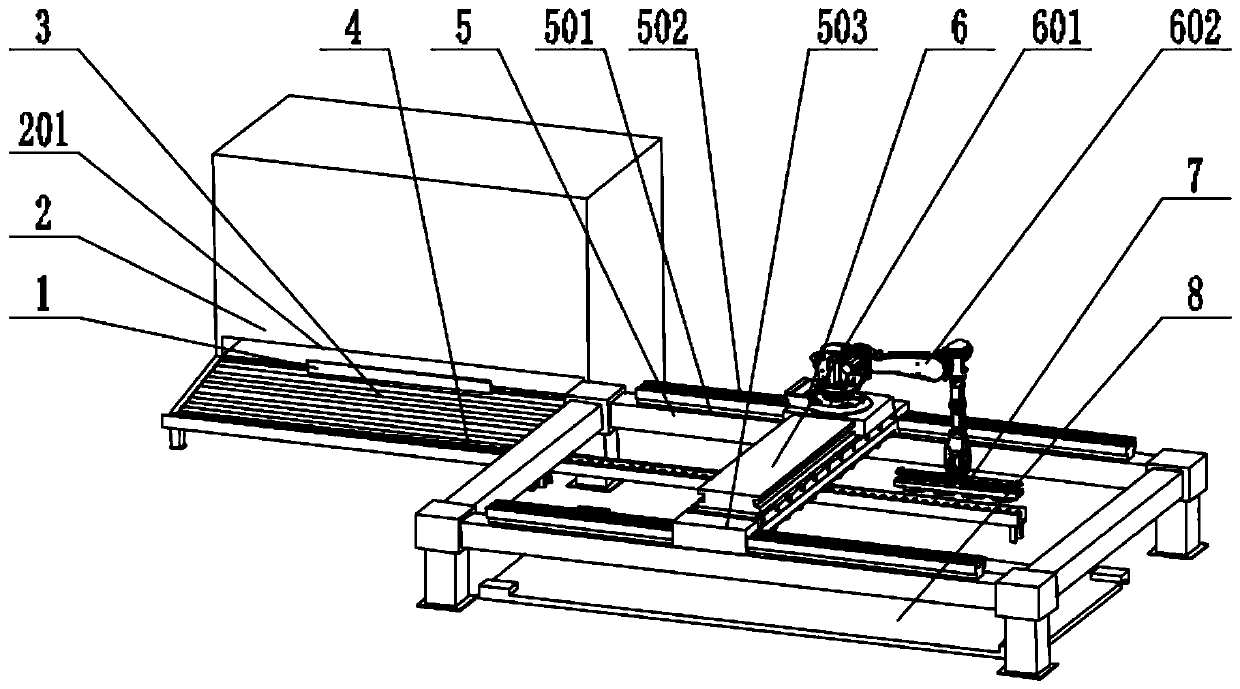

Side shifting type spraying mechanism and method for internal coating of anticorrosion steel pipe

ActiveCN103846193ASave space in the length directionAchieve the purpose of the inventionLiquid surface applicatorsCoatingsEngineeringSteel tube

The invention discloses a side shifting type spraying mechanism and method for an internal coating of an anticorrosion steel pipe, aiming at overcoming the defect that the whole length of an existing spraying mechanism is too long. According to the technical scheme, the side shifting type spraying mechanism comprises an internal spray rod capable of making straight line movement along a parallel axis, a spray gun component at the front end of the internal spray rod, a support component at the rear end of the internal spray rod, and a first shifting device enabling the internal spray rod to make lateral movement towards the axis on a precoating station parallel to the axis, wherein the first shifting device comprises a side shifting component and a driving component for driving the side shifting component; the support component is connected with the side shifting component; the driving component enables the side shifting component to control the internal spray rod to alternate in a reciprocating way between the position deviating from the axis and the position coincided with the axis; the side shifting component comprises at least one adjusting rod. The mechanism and the method have the advantages that the effect of saving the space along the length direction is achieved, the utilization rate of a factory is improved, the working process of a worker is reduced, and the operation is conveniently carried out.

Owner:NINGBO KEXIN CORROSION CONTROL ENG

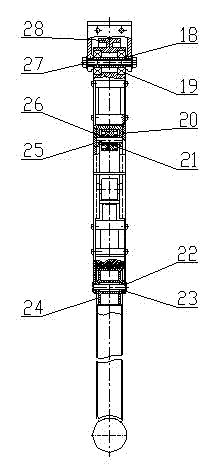

Telescopic distribution rod mechanism and concrete pump truck with same

InactiveCN103216096ARealize functionReduce weightBuilding material handlingPipe fittingArchitectural engineering

The invention discloses a telescopic distribution rod mechanism and a concrete pump truck, which relates to the technical field of engineering machinery, and solves the technical problems of the prior art that the structural occupation space and the unfolding space of a cantilever crane are large and the distribution is not flexible. The telescopic distribution rod mechanism comprises a telescopic arm, a fixed arm and a pipeline, wherein the telescopic arm is embedded inside the fixed arm, or the telescopic arm is sleeved outside the fixed arm; the length direction of the telescopic arm is overlapped or parallel to that of the fixed arm, and the end part of the telescopic arm in the length direction can stretch out or draw back along the length direction of the fixed arm; the pipeline is formed by movably connecting two or more pipe fittings, and two pipe fittings which are arranged in a pipeline material inlet and a material outlet are respectively fixedly connected with the fixed arm and the telescopic arm; or the pipeline is a flexible pipe fitting which is made of a telescopic material. The concrete pump truck comprises the telescopic distribution rod mechanism. The telescopic distribution rod mechanism and the concrete pump truck are used for reducing the size of the distribution rod mechanism.

Owner:XUZHOU XCMG CONSTR MACHINERY CO LTD BUILDING MACHINERY

Pushing mechanism

ActiveCN104249887AShort work scheduleImprove compactionRefuse transferringStorage devicesEngineeringMechanical engineering

The invention discloses a pushing mechanism. The pushing mechanism is arranged on a substrate, and comprises a first pushing head assembly and a second pushing head assembly which is at least partially arranged below the first pushing head assembly; the first pushing head assembly and the second pushing head assembly can extend and retract along forward and backward directions respectively; when the two pushing head assemblies retract to retraction states, the pushing end of the first pushing head assembly and the pushing end of the second pushing head assembly are spaced in the extending and retracting direction of the first pushing head assembly, thereby forming a feeding region above the second pushing head assembly to receive materials to be pushed. By adopting the pushing mechanism, pushing operation such as laminated compression of trash and continuous unloading of trash can be finished through respective extension and retraction of the pushing head assemblies, the feeding region is designed skillfully, and the working stroke of at least a single pushing head assembly can be reduced, so that compacting effect of trash and / or the unloading efficiency of trash can be improved or increased through small-specification pushing head assemblies, the structural arrangement of a corresponding substrate can be optimized, and the practicability and economical efficiency are improved and increased.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

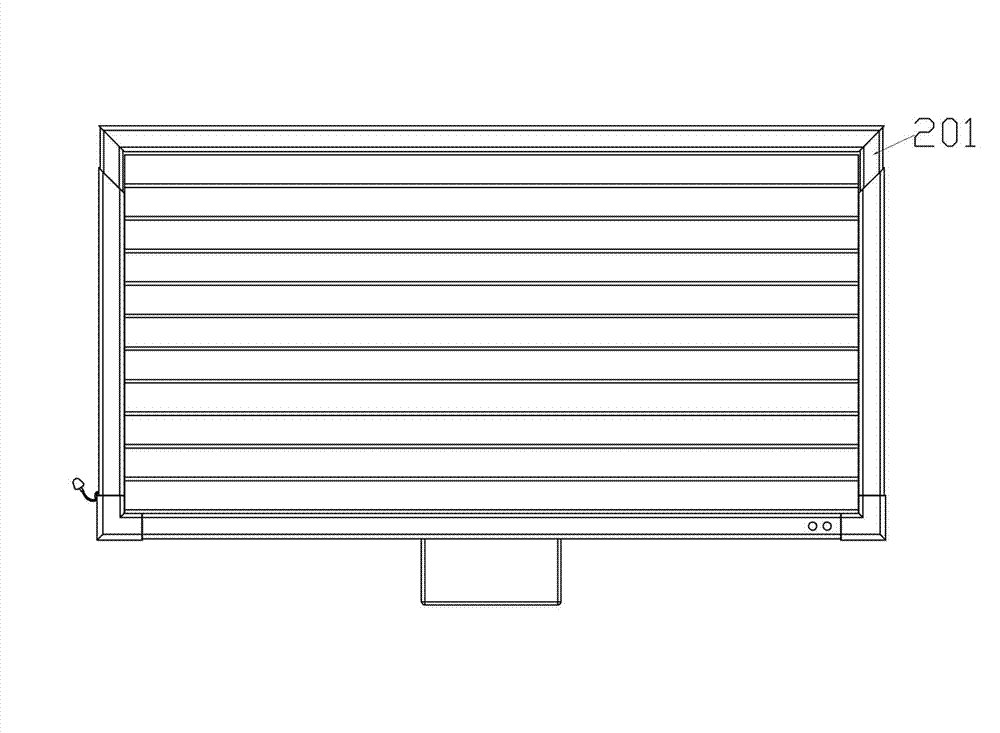

Batten type automatic overturning back cleaning blackboard

InactiveCN103192630AResolution timeEnough timeBoard cleaning devicesWriting boardsElectrical and Electronics engineering

The invention relates to a batten type automatic overturning back cleaning blackboard which is mainly composed of a board surface, a frame around the board surface and a power input mechanism. The board surface is composed of a plurality of horizontally arranged battens, mutually buckled protrusions or grooves are arranged at the positions of contact surfaces of the adjacent battens, and the frame is composed of a static frame, side frames and a movable frame. Board surface renewal mechanisms are arranged in two side frames respectively, sliding bodies are arranged at two ends of the movable frame, mandrels are arranged at two ends of the battens respectively, and the sliding bodies and the mandrels are respectively connected with the board surface renewal mechanisms. First driving bodies are arranged in the two side frames respectively, are driven by the power input mechanism and are connected with the board surface renewal mechanisms. By driving the movable frame and the plurality of horizontally arranged battens through the first driving bodies in the two side frames, separation of the movable frame, the battens and the static frame is achieved, then the battens are overturned for 180 degrees, integrated press fit is performed finally, cleaning of the back side is finished while normal teaching use of the visual board surface is achieved, and accordingly the problems which occur in blackboard use at present are solved.

Owner:王书廷

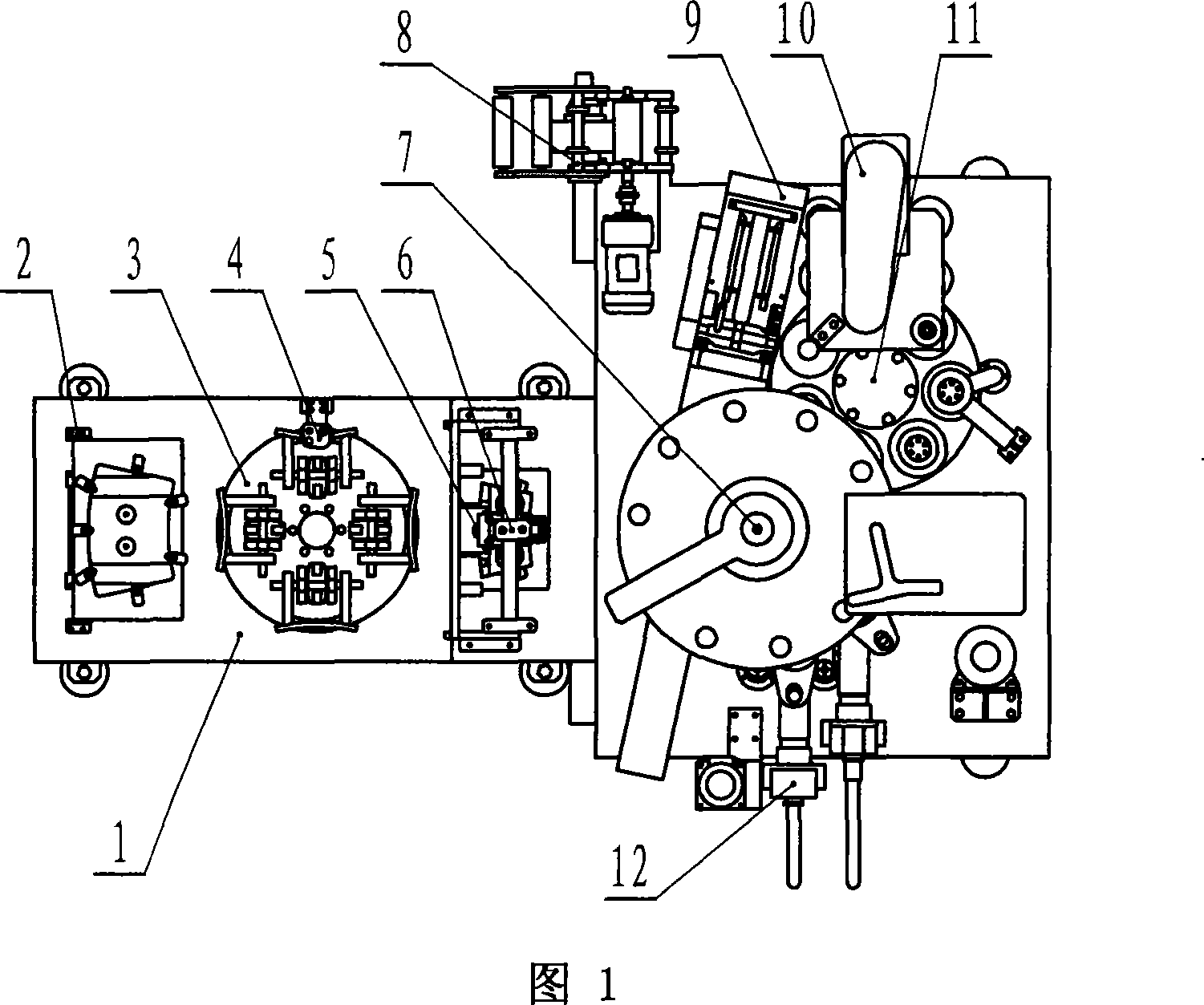

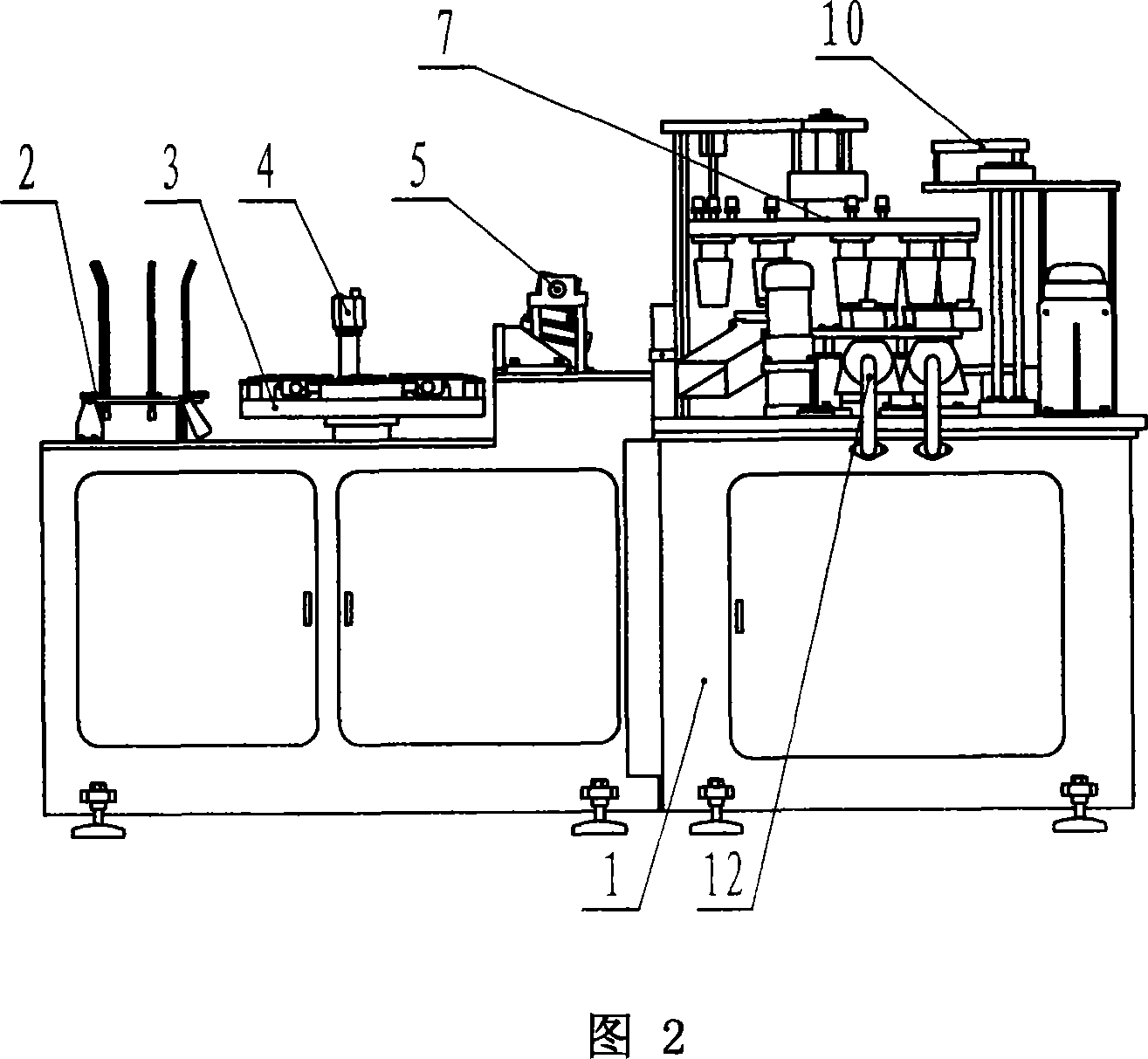

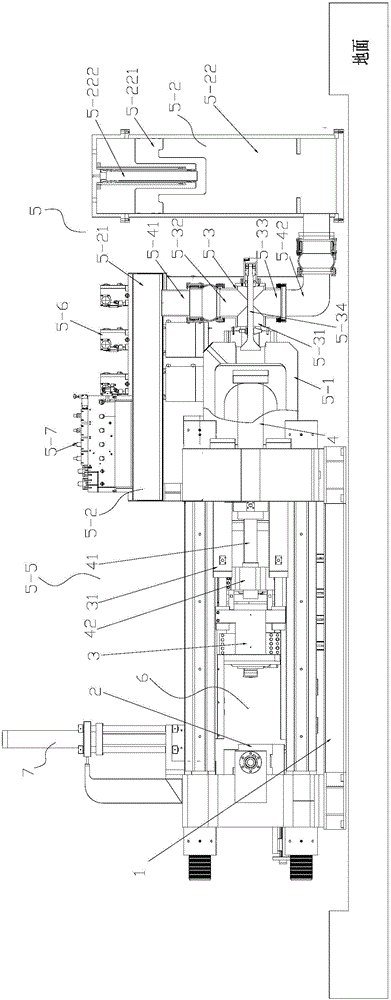

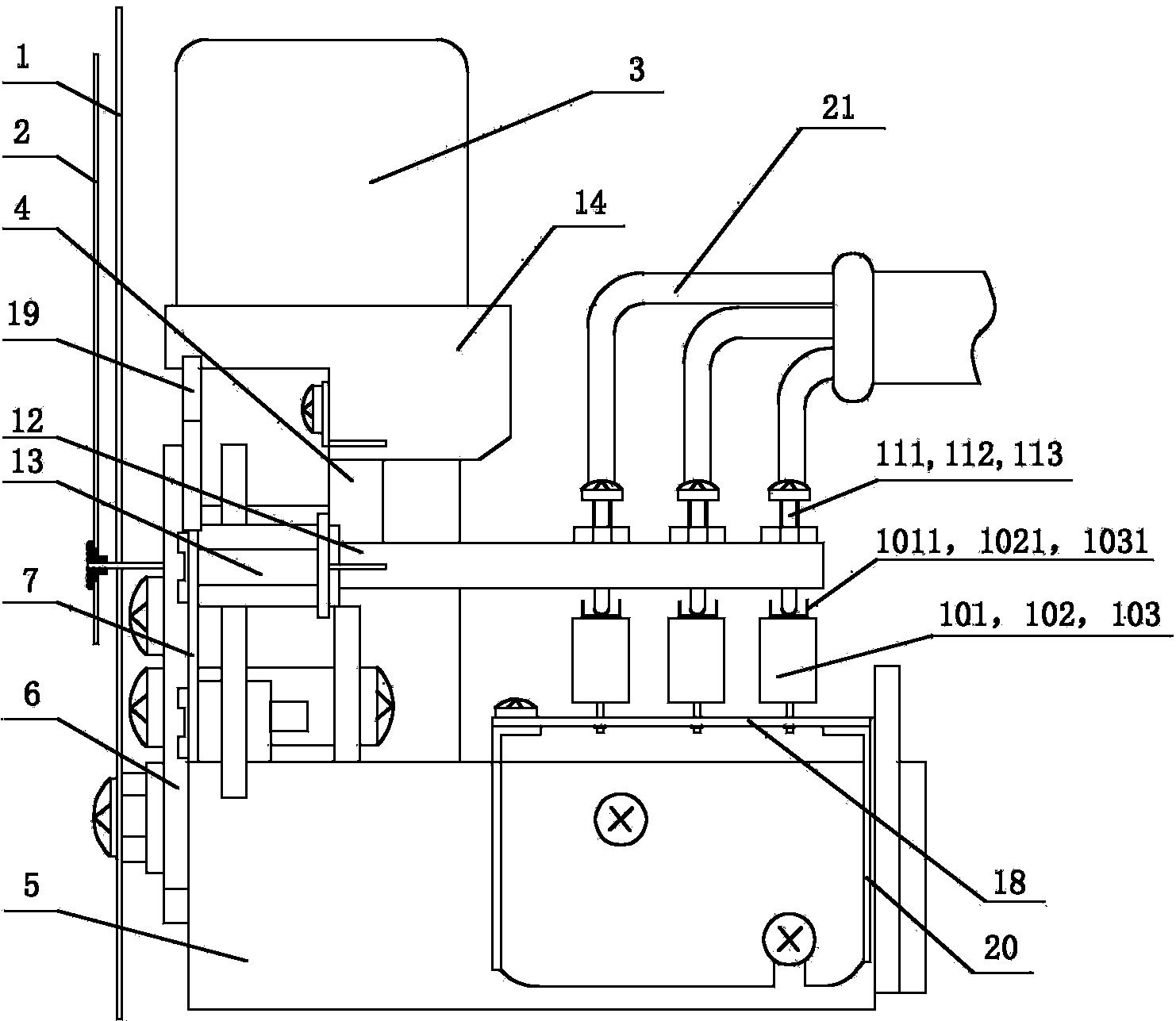

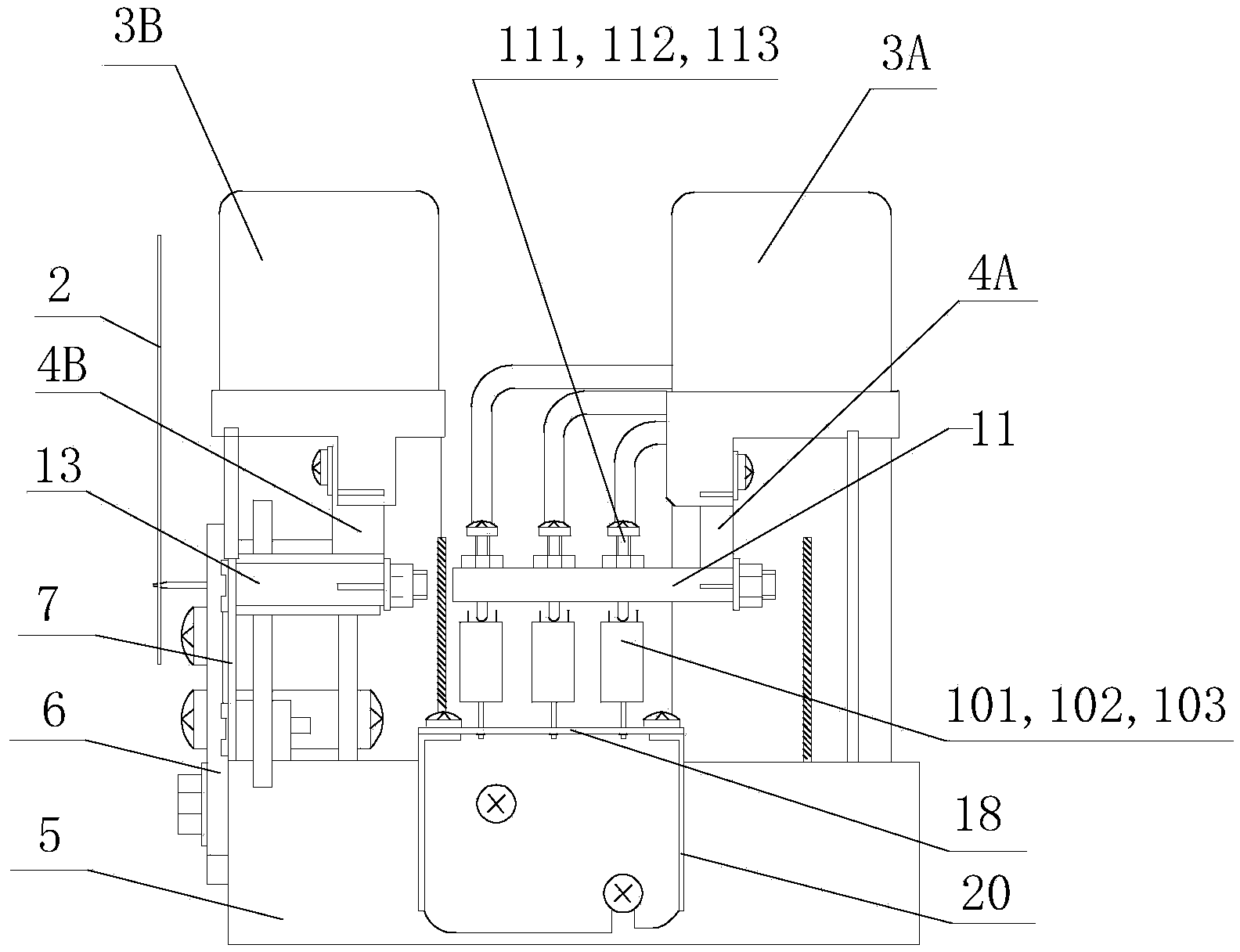

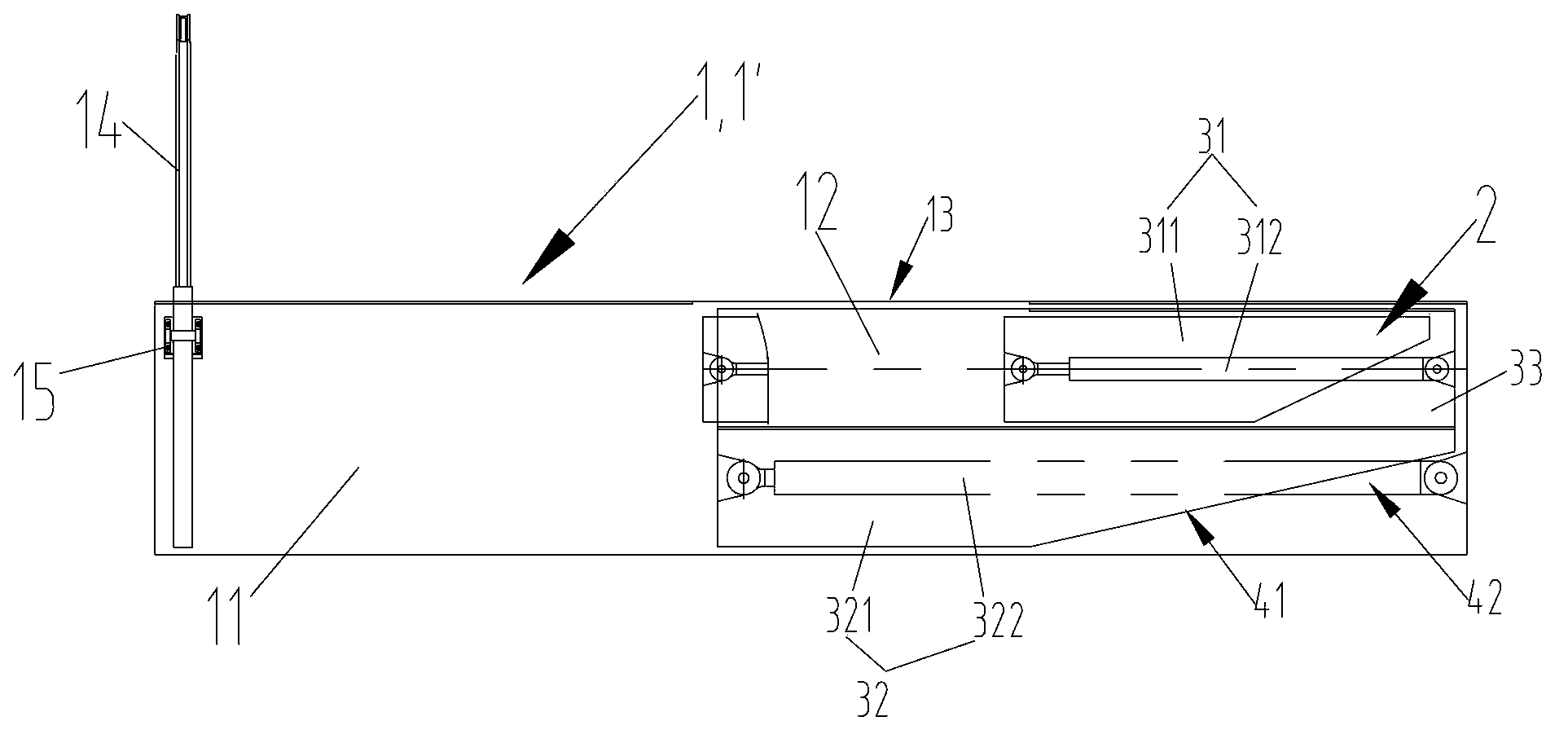

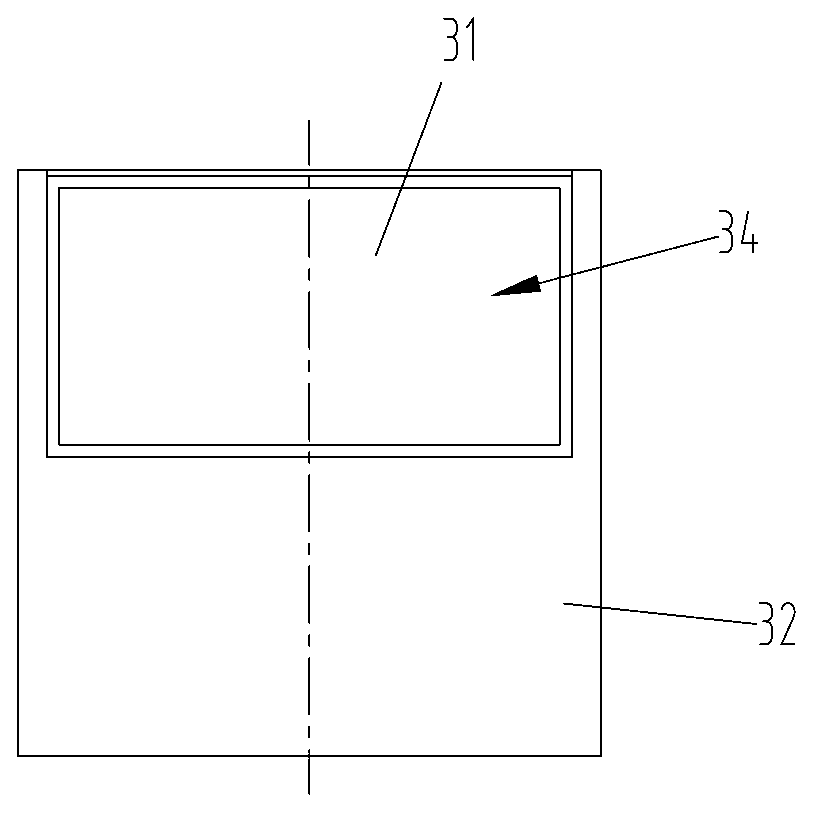

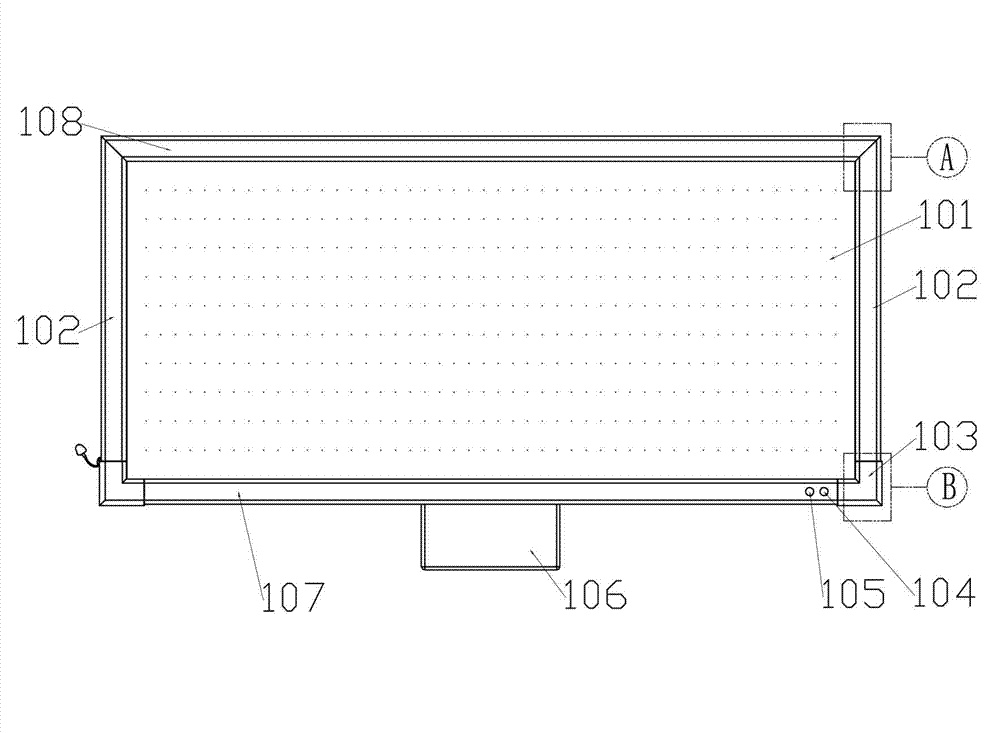

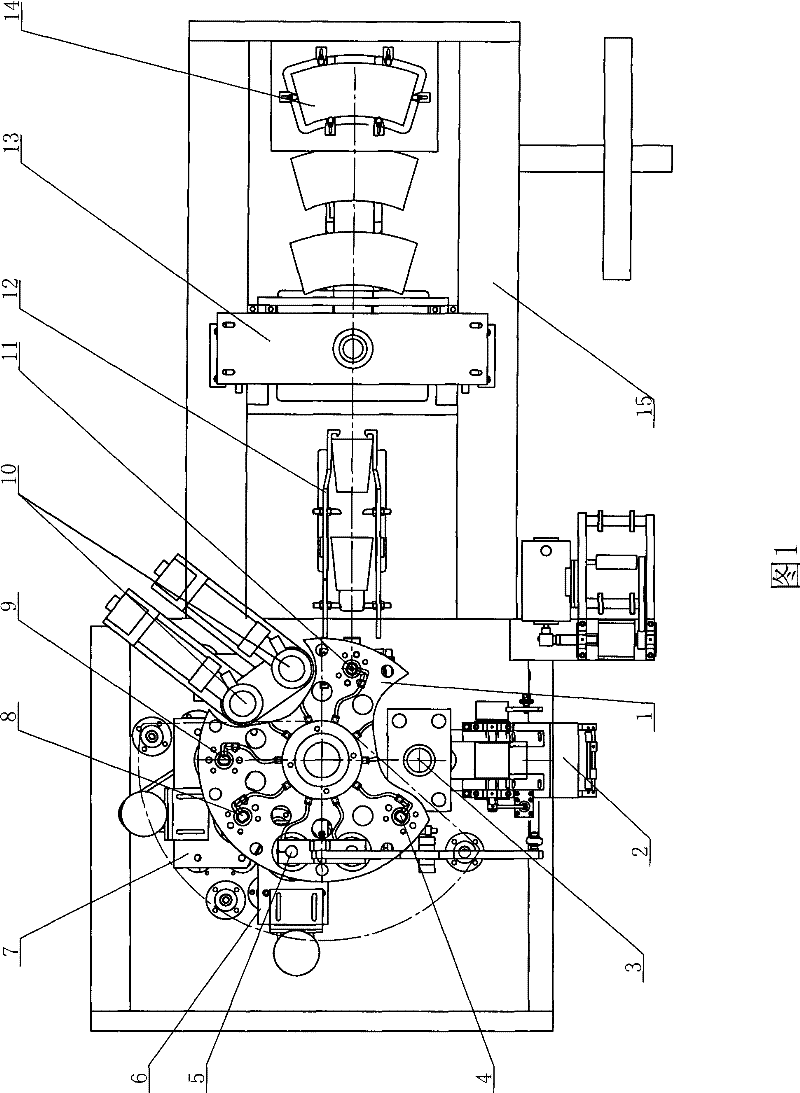

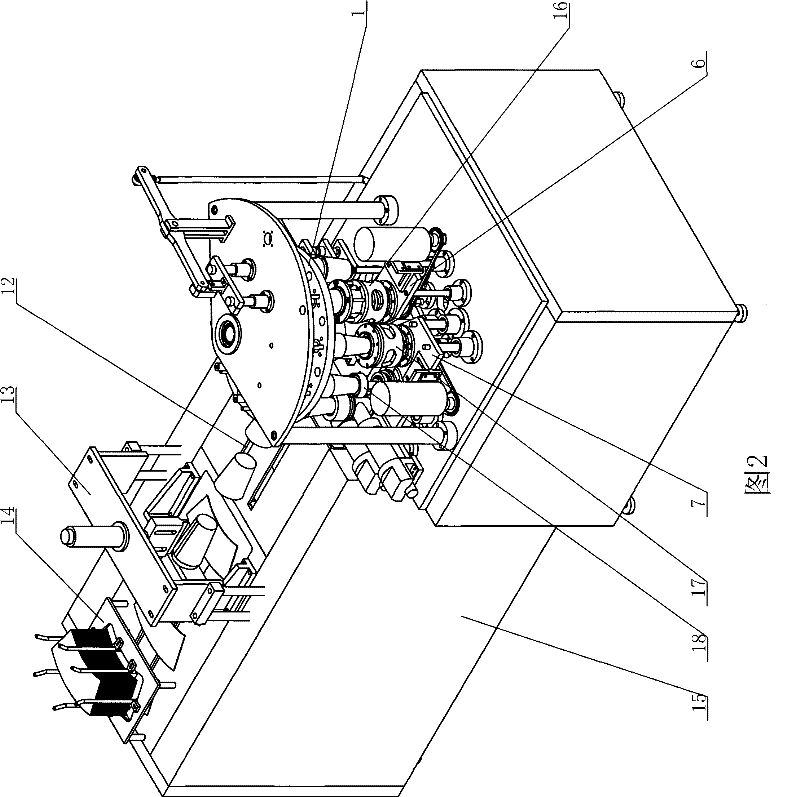

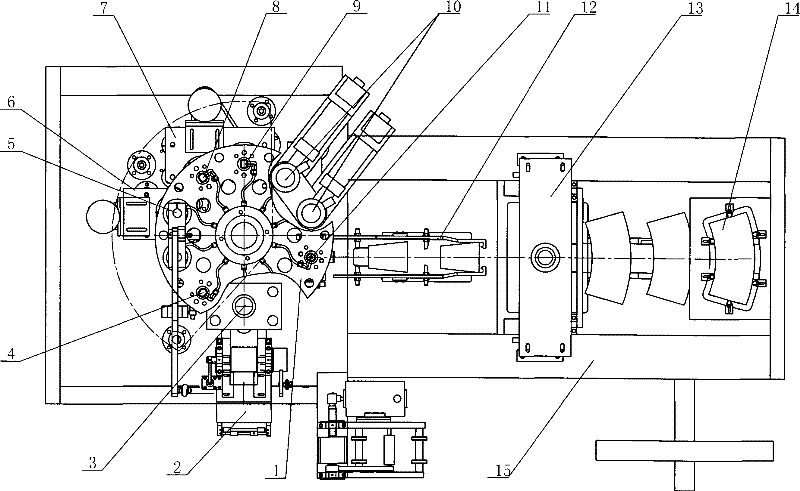

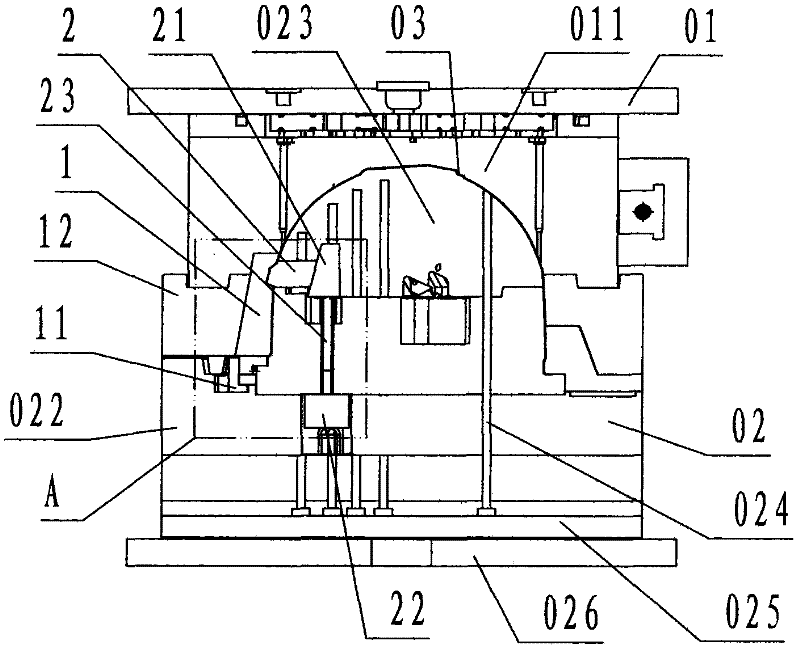

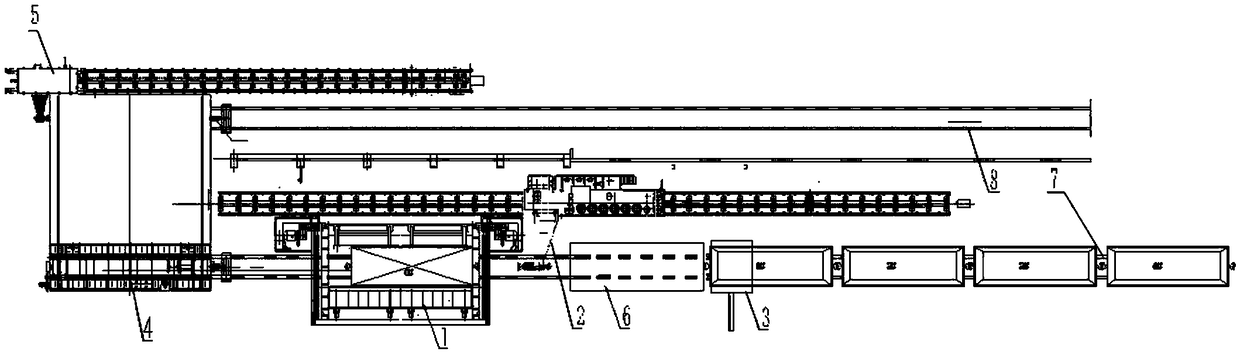

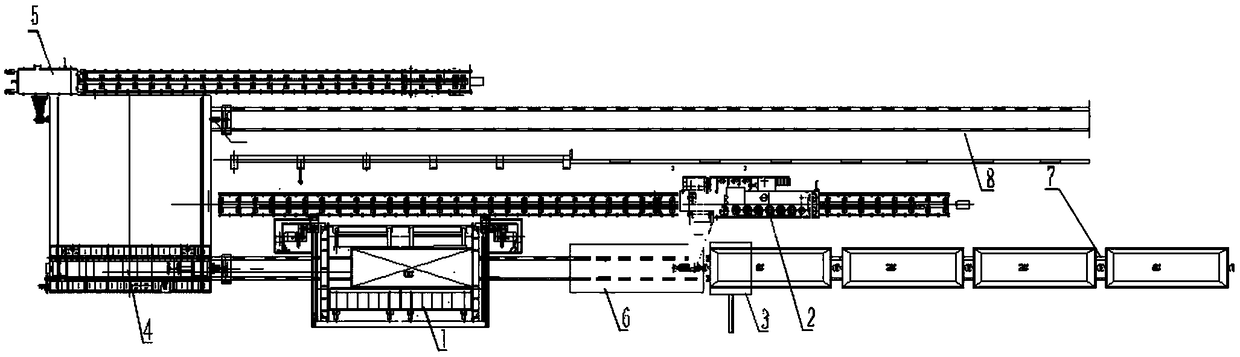

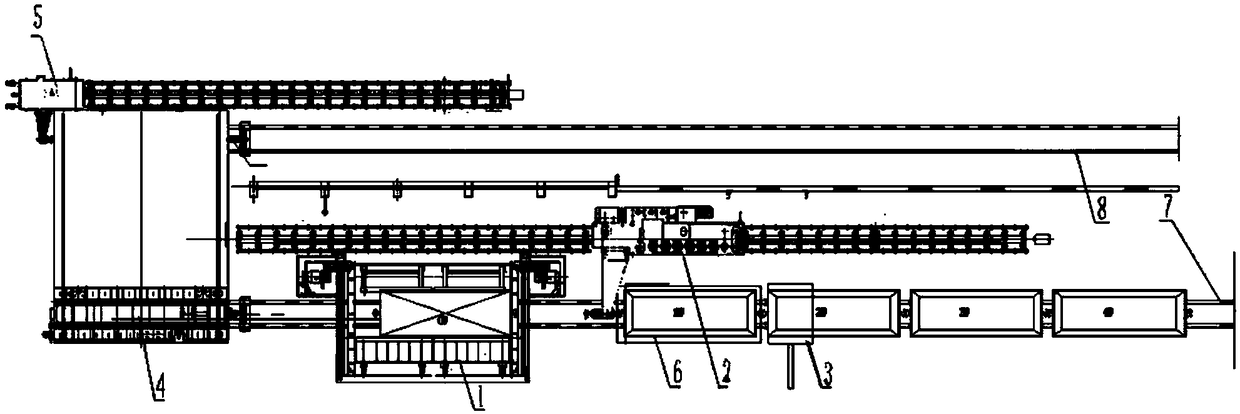

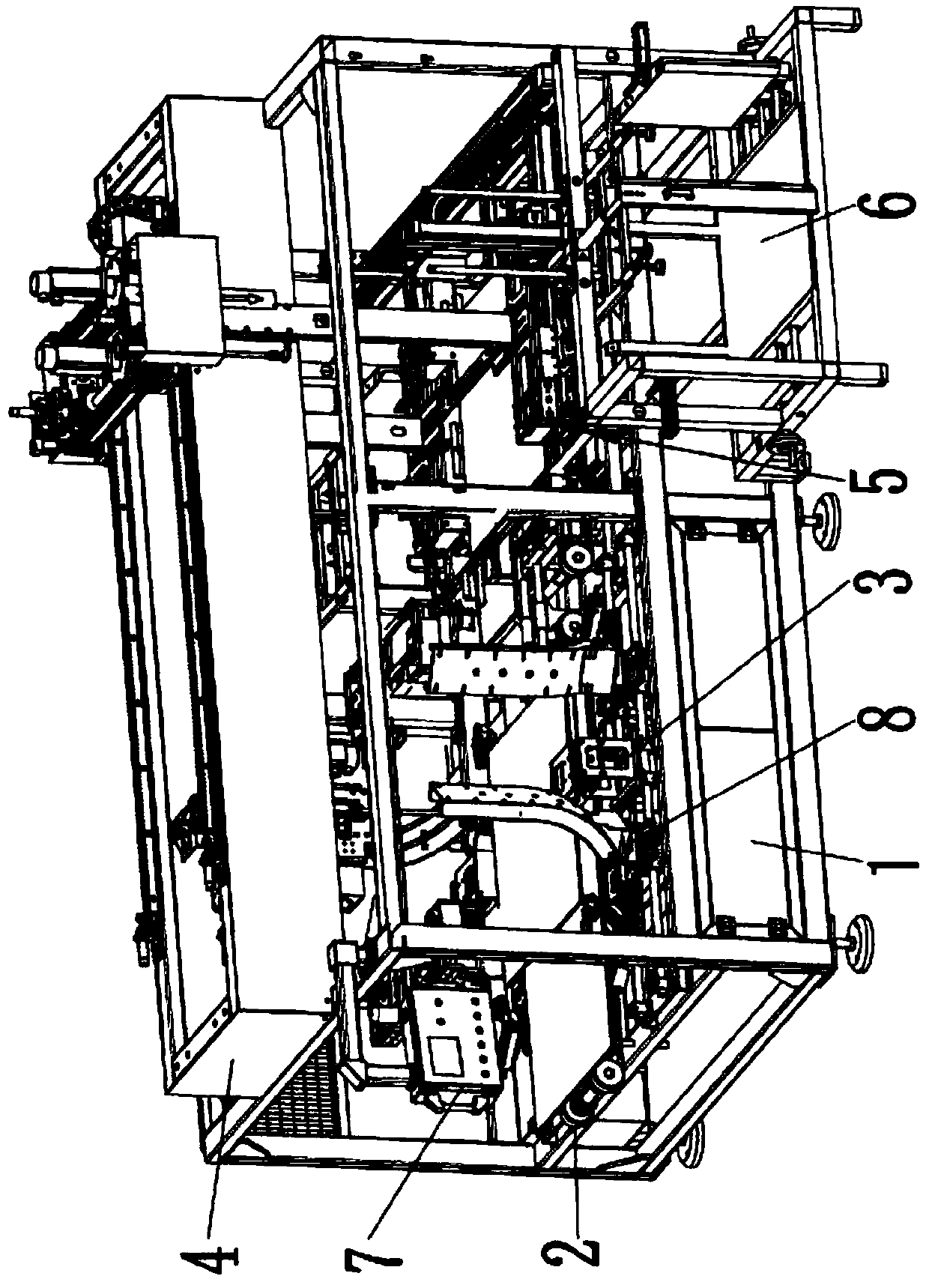

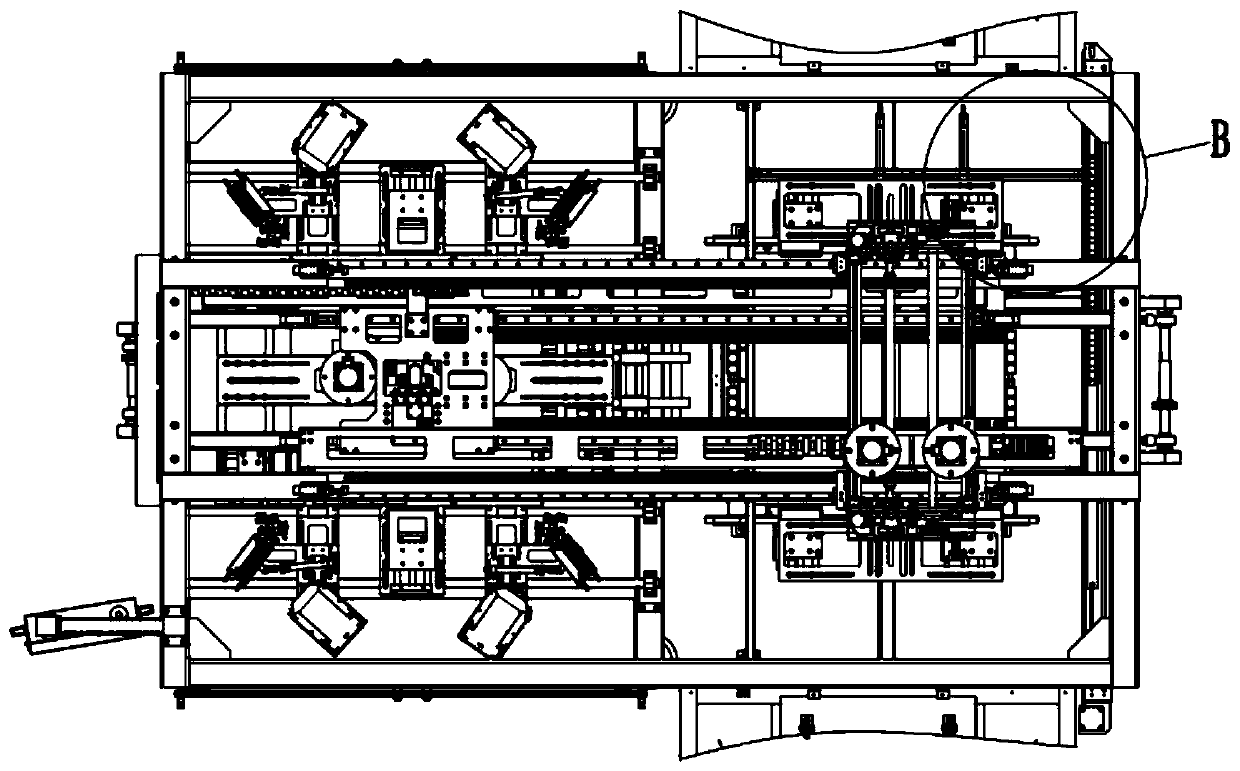

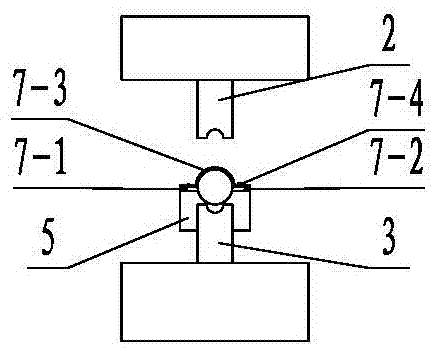

Paper cup making machine

ActiveCN101391493BReduce manufacturing costReduce use and maintenance costsPaper/cardboard wound articlesLow speedEngineering

The invention discloses a paper cup machine, comprising a frame (15), a cup body paper feeding mechanism (14), a cup cylinder forming mechanism (13), a cup cylinder feeding mechanism (12), an indexing turntable (1), a cup bottom paper feeding mechanism (2), a transmission mechanism, a bottom feeding working position (3), a cup receiving working position (11), a heating working position (10), a bottom folding working position (9), a bottom rolling working position (8), a mouth coiling working position (5) and a cup outgoing working position (4); all working positions are provided with corresponding working mechanisms; the paper cup machine is characterized in that the paper cup machine is only provided with an indexing turntable; the bottom feeding working position, the cup receiving working position, the heating working position, a bottom folding working position, a bottom rolling working position, a mouth rolling working position and a cup outgoing working position are all arranged on the indexing turntable. The paper cup machine has the advantages of simple structure, higher speed, stable running, has high speed mode and low speed mode, reduces the preparation cost of the die, shortens the preparation period of the die, reduces the equipment failure rate, reduces the maintenance difficulty and cost and leads the equipment to be easy to be operated.

Owner:ZHEJIANG RUIDA MACHINERY

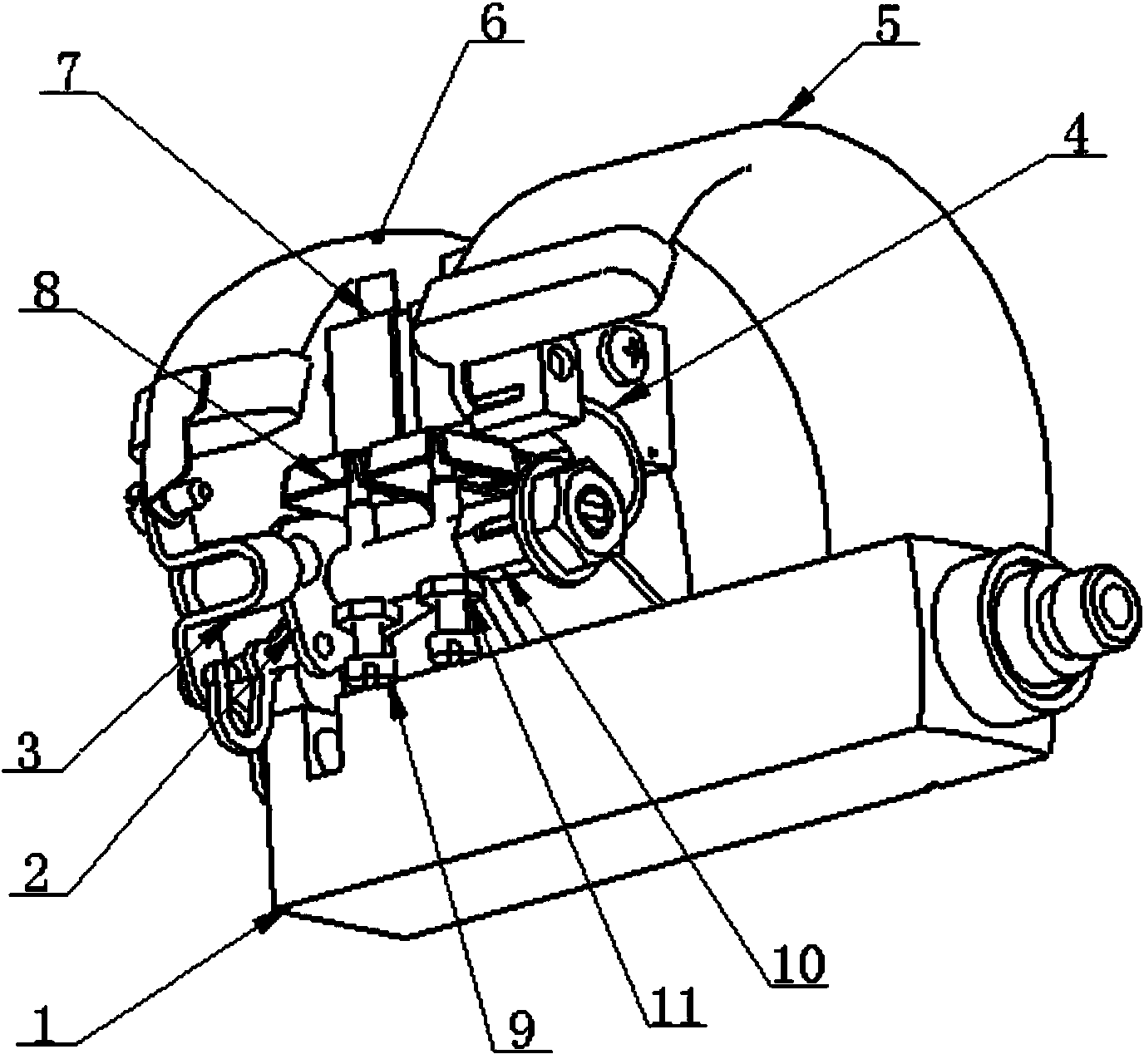

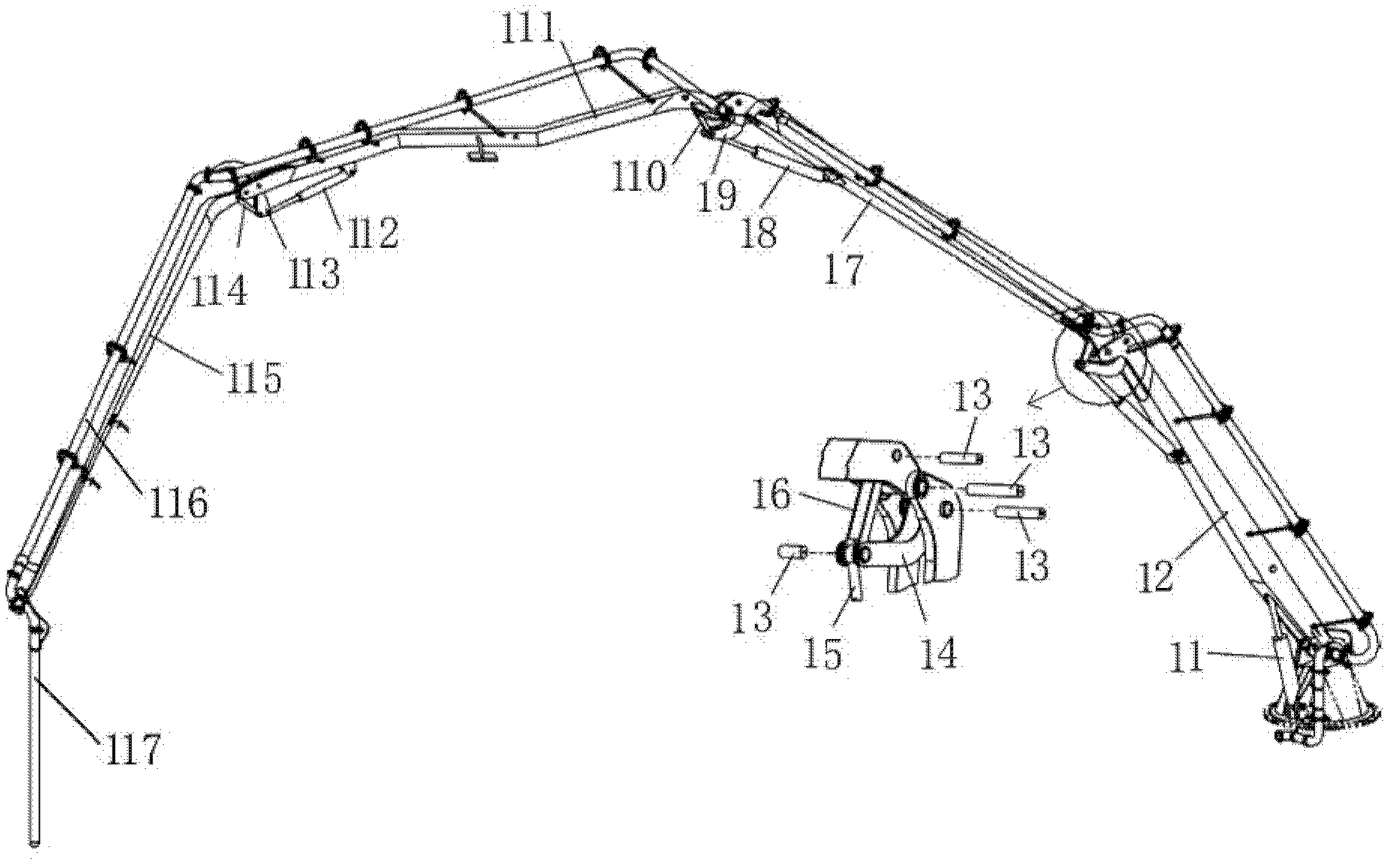

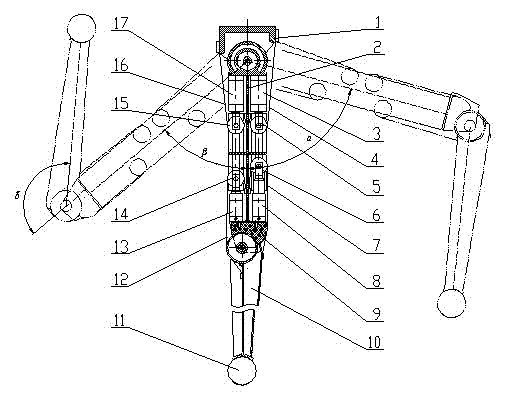

Driving leg mechanism for footed robot

The invention provides a driving leg mechanism for a footed robot, belonging to the technical field of footed robots. The driving leg mechanism comprises a leg support, a thighbone, a thigh forward swing cylinder, a thigh front stay cable, a thigh front pulley, a crus front pulley, a crus front stay cable, a crus forward swing cylinder, a joint mat, a focile, a ball-shaped foot, a crus rear stay cable, a crus backswing cylinder, a crus rear pulley, a thigh rear pulley, a thigh rear stay cable, a thigh backswing cylinder, a knee-joint pillar and a hip joint pillar, wherein the leg support is hinged with the hip joint pillar to form a hip joint, the upper end of the thighbone is fixedly connected with the hip joint pillar, the joint mat is arranged at the lower end of the thighbone and is hinged with the knee-joint pillar, a knee joint is composed of the thighbone, the joint mat and the knee-joint pillar, the upper end of the focile is fixedly connected with the knee-joint pillar, and the lower end of the focile is fixedly connected with the ball-shaped foot. The driving leg mechanism has the advantages of compact structure, light weight, low energy consumption, capability of realizing rapid joint movements, stable carrying capacity, large foot end movement space, good buffering performance and long service life.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

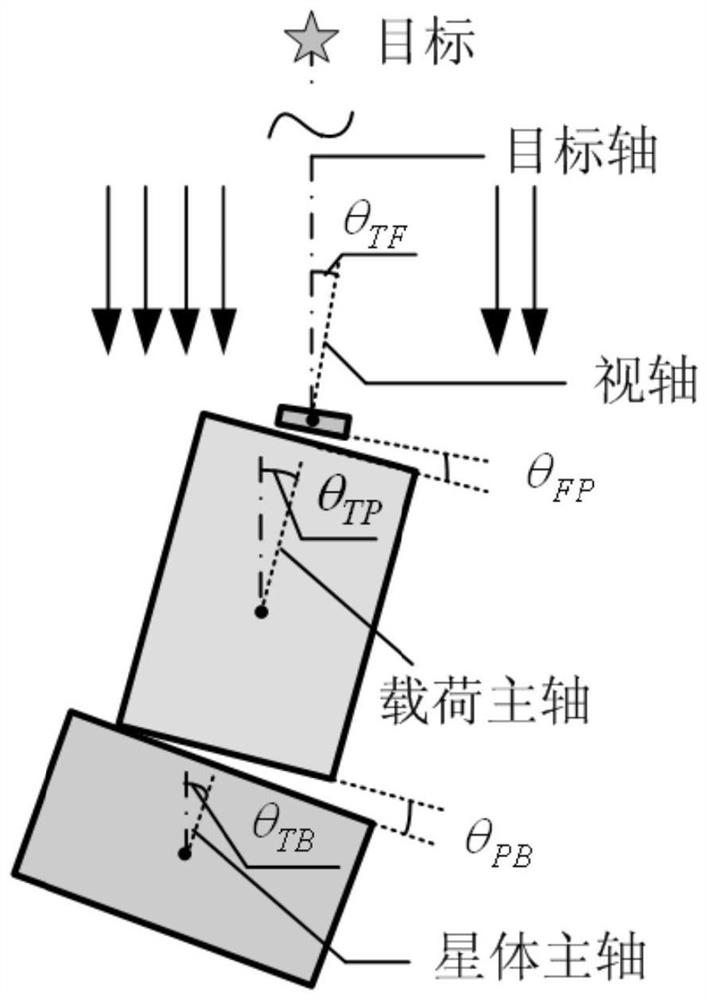

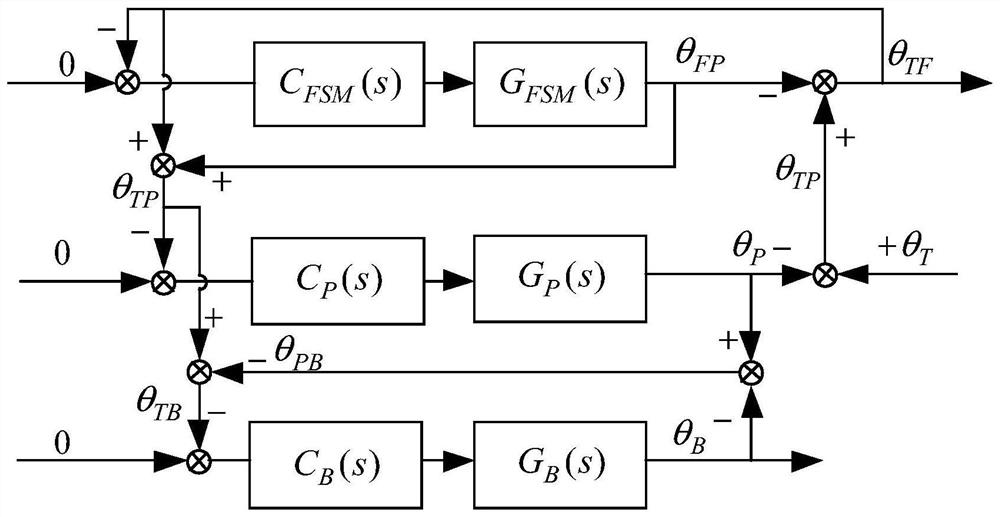

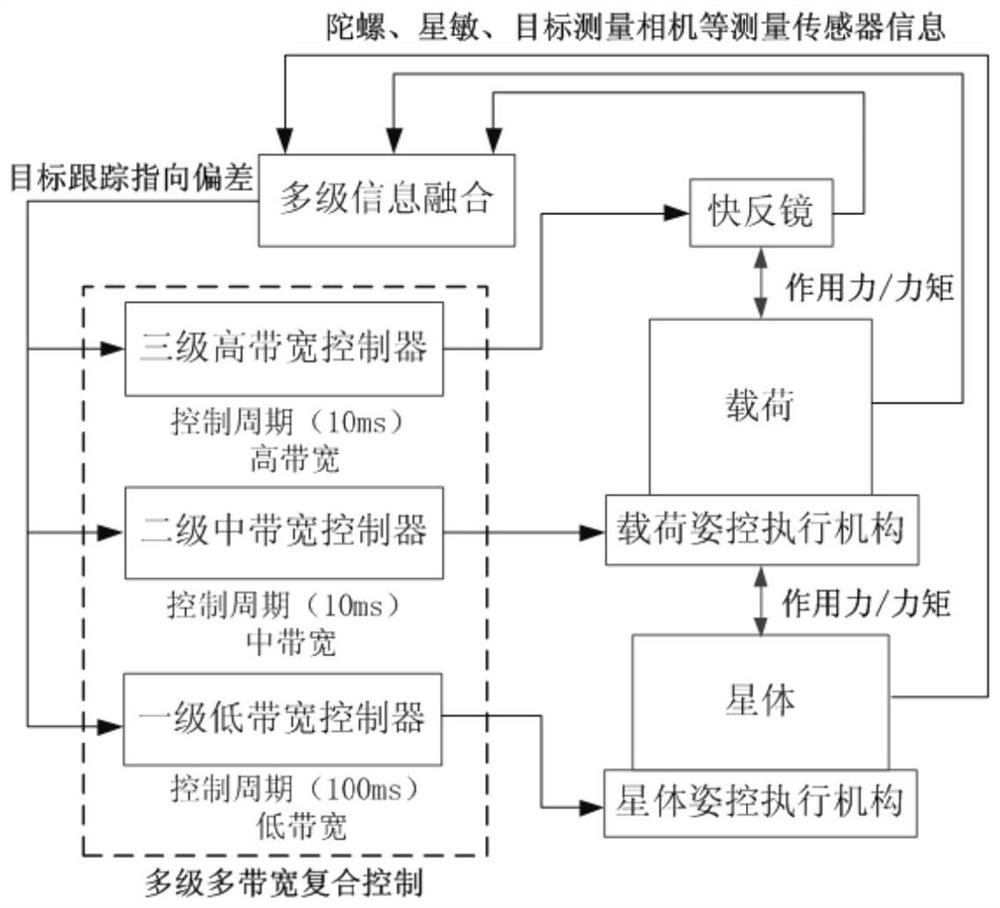

Multistage cooperative control method based on active pointing ultra-quiet platform

ActiveCN111619829AAvoid magnificationShort work scheduleCosmonautic vehiclesSpacecraft guiding apparatusAttitude control systemSpacecraft

The invention relates to a multistage cooperative control method based on an active pointing ultra-quiet platform, which is suitable for the fields of astronomical observation, high-resolution earth observation and the like with load ultra-high precision determination requirements. On the basis of a two-stage control system of a star attitude control system and a fast reflecting mirror, an ultra-static platform with a pointing function is installed between a spacecraft star and a load, and a three-stage control system composed of first-stage star attitude control, second-stage load attitude control and a third-stage fast swing mirror is formed. And high-precision control of an expected attitude is realized. Aiming at a novel spacecraft platform three-level composite system, the invention provides the multistage cooperative control method based on the active pointing ultra-quiet platform, and designs a star first-level system control law, a load second-level system control law and a fast reflecting mirror third-level system control law; and on the premise that a system response requirement is met, multi-stage multi-bandwidth composite control is achieved, and a cooperative control problem among a star body, a load and a fast reflecting mirror is solved.

Owner:BEIJING INST OF CONTROL ENG

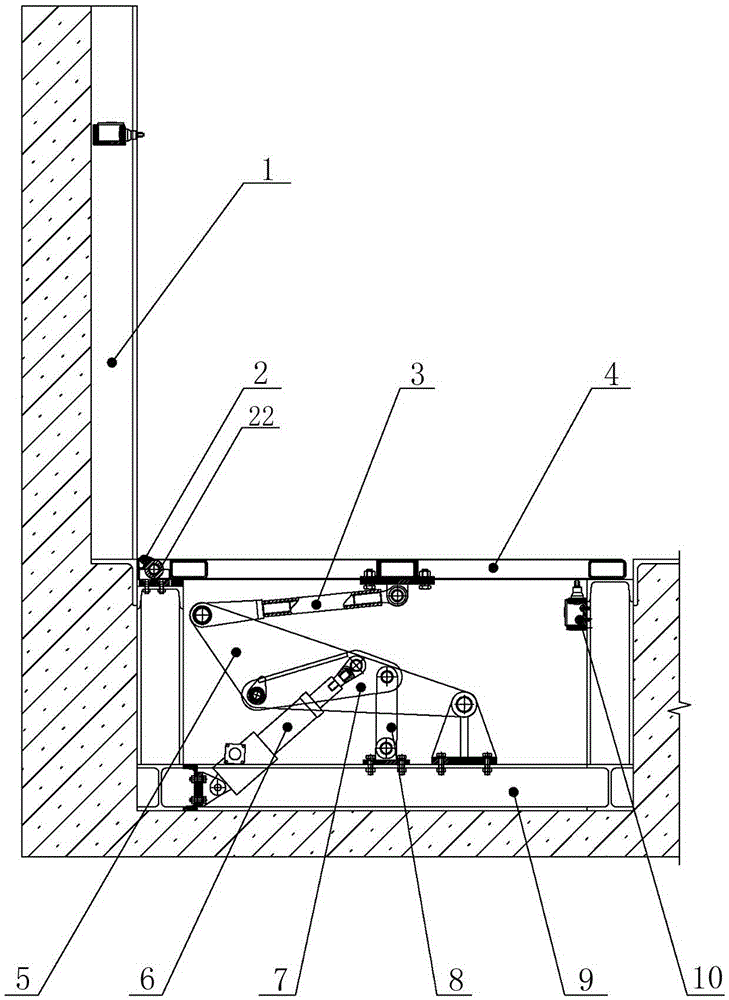

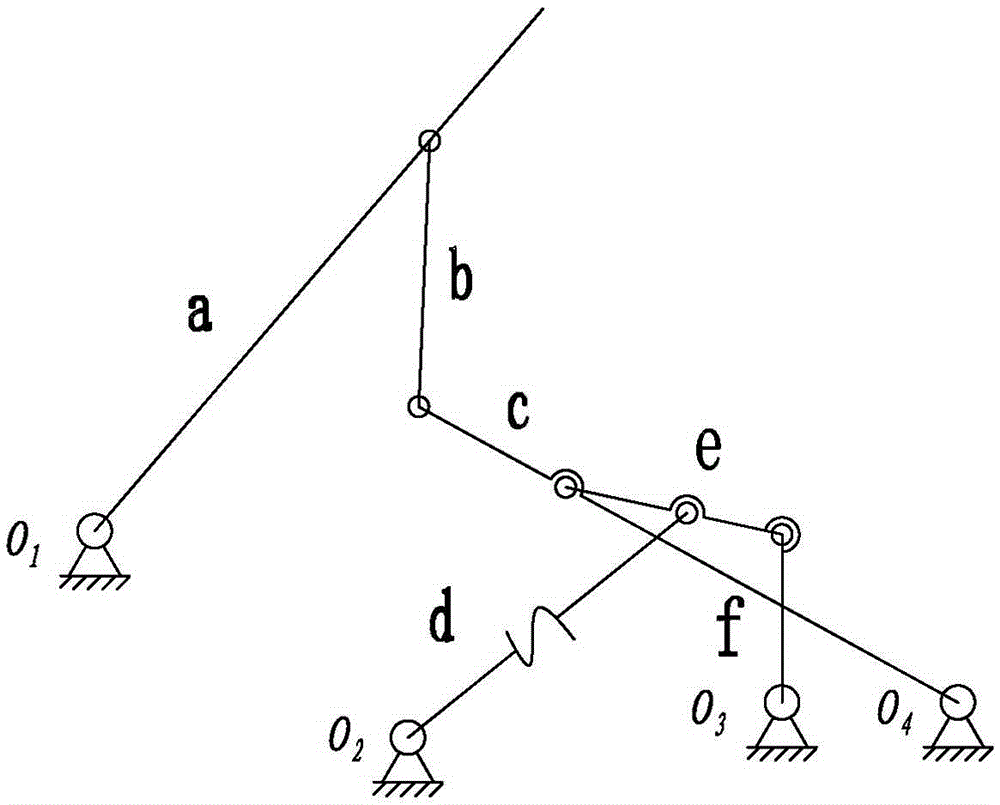

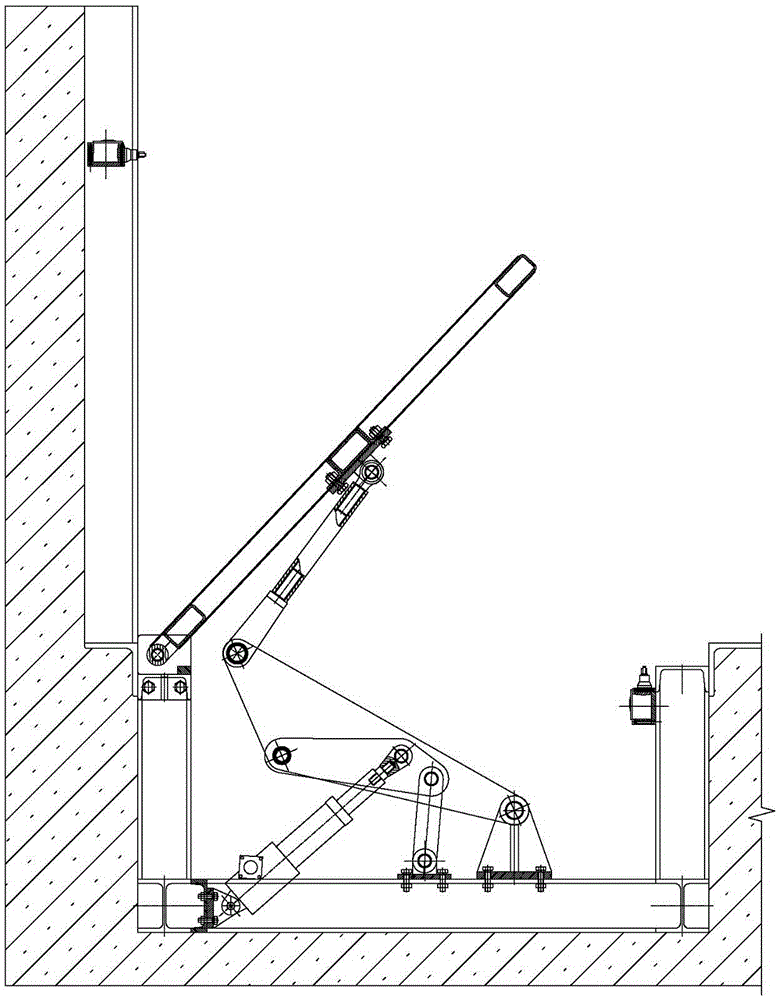

Buried turning plate type water stop gate

The invention provides a buried turning plate type water stop gate. The buried turning plate type water stop gate comprises a gate frame, a water stop gate plate, a power executing mechanism connected with the water stop gate plate, a power control system for controlling the power executing mechanism, and a sealing system and further comprises a bottom rack connected to the interior of buried space. The upper end of one side of the bottom rack is connected with a water stop gate plate door shaft. The height position of the water stop gate plate door shaft is matched with that of the upper edge of the buried space. The water stop gate plate is hinged to a door shaft seat fixed to the bottom rack through the water stop gate plate door shaft. The water stop gate plate is flush with the ground after being closed. The power executing mechanism comprises at least one set of folding type connecting rod structures connected between the water stop gate plate and the bottom rack and hidden in the buried space in a folded mode. The buried turning plate type water stop gate is good in water stop sealing performance, high in anti-hydraulic-pressure strength, reliable in structural performance, high in mechanical automation degree, high in adaptability, complete in function, convenient to maintain and small in buried depth size; the whole device is buried and hidden, so that space is saved, and labor cost is reduced.

Owner:CHINA INST OF BUILDING STANDARD DESIGN & RES

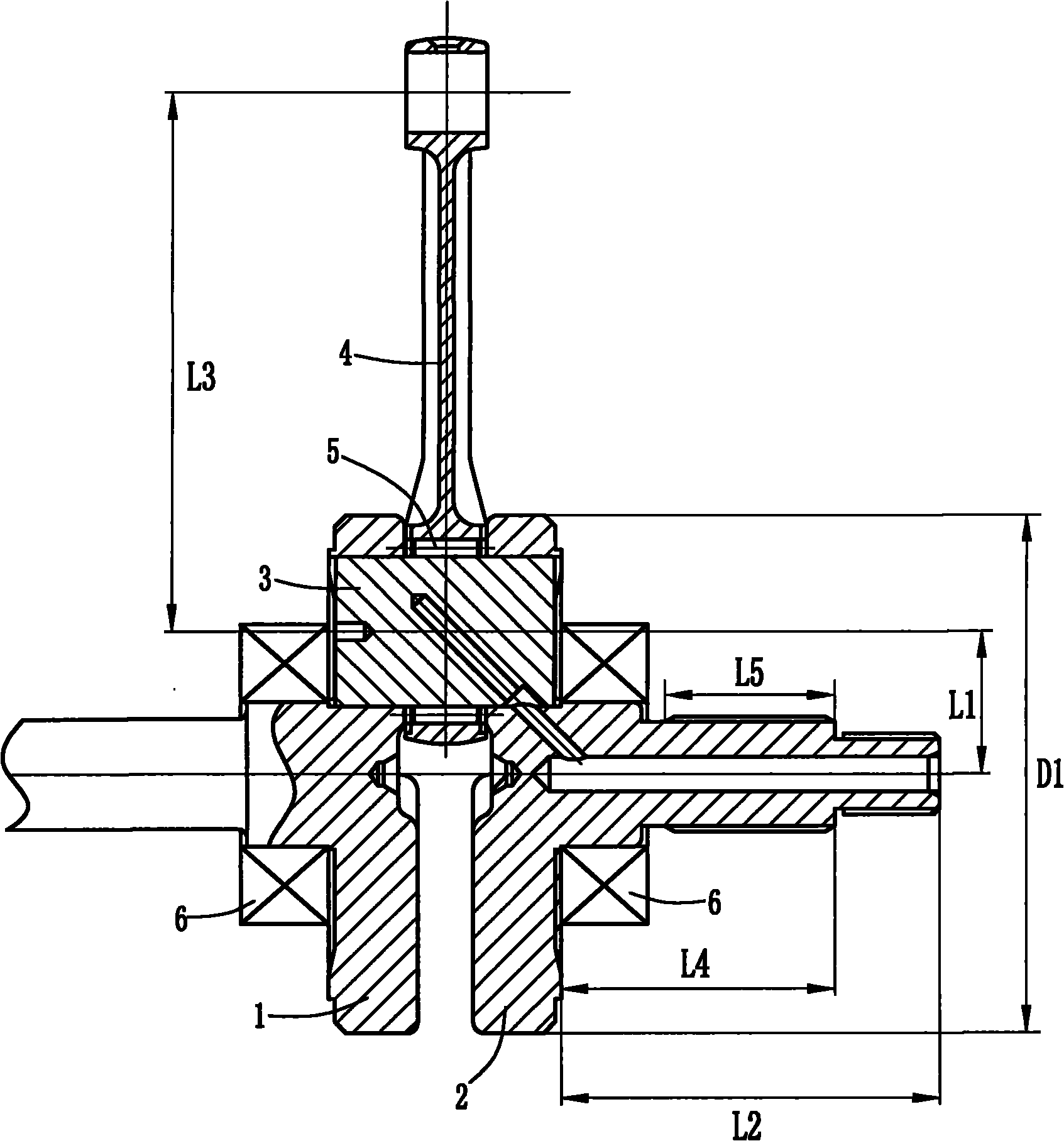

Crank-connecting rod mechanism for engine of miniature cross-country motorcycle

InactiveCN101798954AFast turning speedReduce weightReciprocating piston enginesEngineeringHigh torque

The invention discloses a crank-connecting rod mechanism for an engine of a miniature cross-country motorcycle. The crank-connecting rod mechanism comprises a left crank, a right crank, a crank pin and a connecting rod, wherein the big head end of the connecting rod is positioned between the left crank and the right crank; the big head end of the connecting rod, the left crank and the right crank are connected with each other through the crank pin; the axial lines of the left crank and the right crank are in the same line and are parallel to the axial line of the crank pin; the distance between the axial lines of the left crank and the right crank and the axial line of the crank pin is 28.5 to 30.5 mm; the diameter of the shaft part of the right crank is 95 to 97 mm; the axial length of the right crank is 64 to 66 mm; and the distance between the centre of an installing hole at the big head end of the connecting rod and the centre of the installing hole at the small head end of the connecting rod is 94.3 to 96.3 mm. By changing a plurality of key parameters of the crank-connecting rod mechanism, the crank-connecting rod mechanism for the engine of the miniature cross-country motorcycle meets the functional requirements on high raising speed, strong explosive power, high torque, high crank rotating speed of the engine of the miniature cross-country motorcycle, and has the characteristics of ingenious conception, simple structure, easy implementation and the like.

Owner:重庆动源摩托车配件销售有限公司

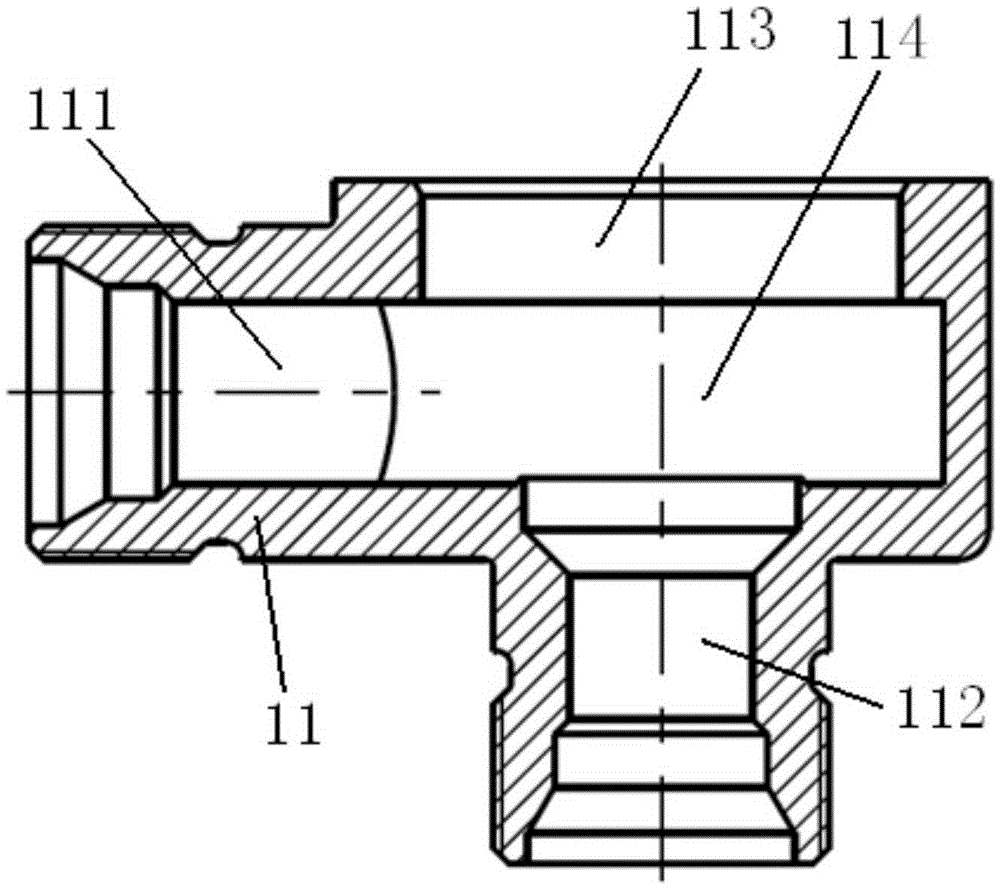

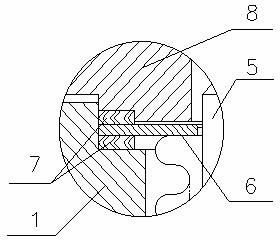

Step-by-step direct-action electromagnetic operating valve with wide working range

ActiveCN105387261AOverall small sizeSmall qualityOperating means/releasing devices for valvesLift valveTraffic volumeBatch production

The invention relates to a step-by-step direct-action electromagnetic operating valve with a wide working range. The step-by-step direct-action electromagnetic operating valve comprises a shell, a valve element assembly and a valve element driving assembly, wherein the valve element assembly comprises a guide valve element and a main valve element, and the guide valve element is sleeved with a first guide sleeve. According to the step-by-step direct-action electromagnetic operating valve, the characteristics of a direct-action electromagnetic valve structure and the characteristics of a pilot electromagnetic valve are combined; the step-by-step direct-action electromagnetic operating valve can drive the valve elements to operate directly through attraction force of an electromagnet like a direct-action electromagnetic valve, the structural characteristics of step-by-step actions of a pilot electromagnetic valve are also achieved, and the requirements of the wide working range of an engine are met through low weight and small size. Meanwhile, the product structure is simple, the machining manufacturability and assembly manufacturability are good, and the step-by-step direct-action electromagnetic operating valve is suitable for batch production. The electromagnetic operating valve is applicable to controlling over an engine fuel oil system which is wide in working pressure and working flow range and also applicable to the working conditions having large flow, mediate and low pressure, and high flow resistance requirements.

Owner:XIAN AEROSPACE PROPULSION INST

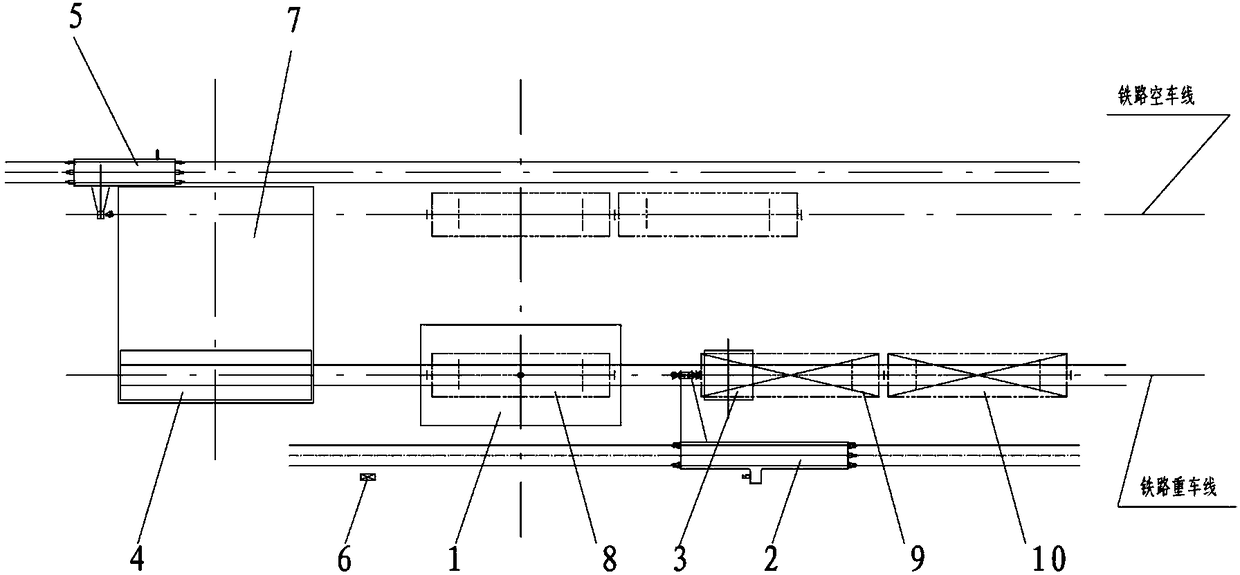

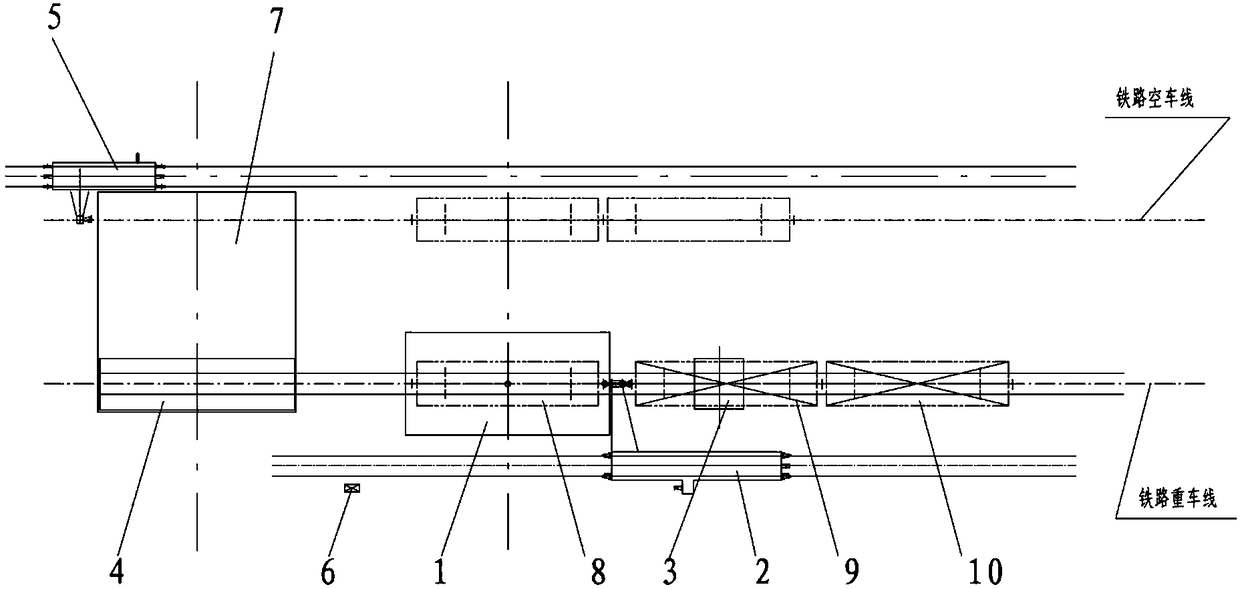

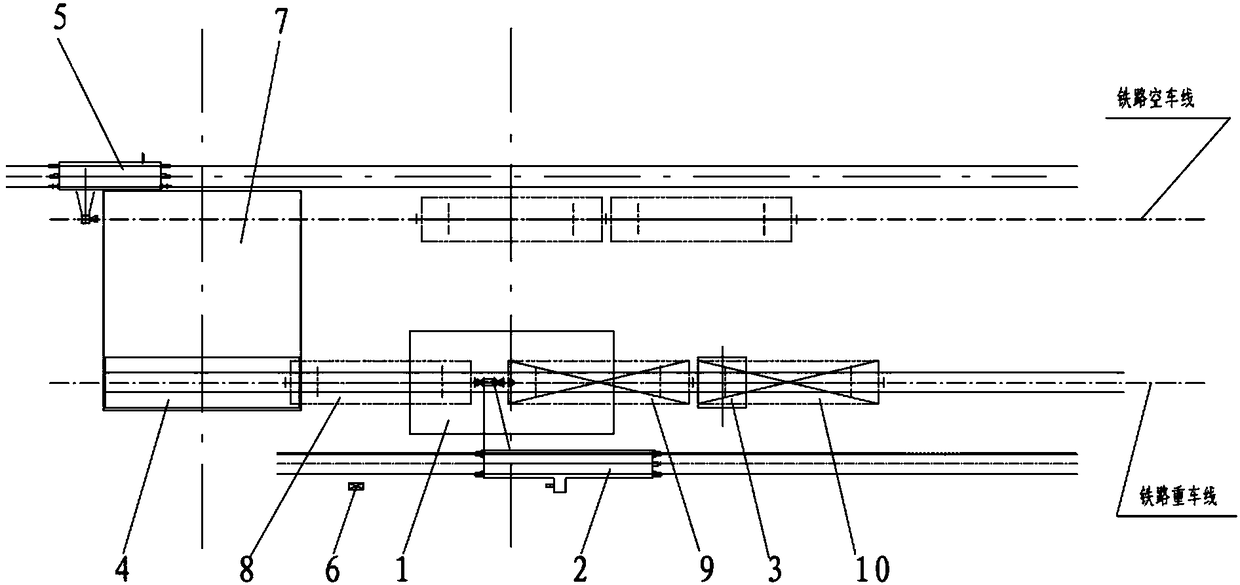

Efficient switch-back type car dumper unloading system

ActiveCN108438952AShort work scheduleImprove work efficiencyLoading/unloadingOperation timeAutomotive engineering

An efficient switch-back type car dumper unloading system comprises a car dumper, a car puller, a wheel gripper, a transfer platform, a car pusher and car stops and further comprises an auxiliary shunting locomotive. The auxiliary shunting locomotive is arranged at one end of the transfer platform on the car puller line. The car stops comprise a first moving car stop, a second moving car stop anda car puller travel stop. The first moving car stop and the second moving car stop can be raised and laid flat, when being raised, the first moving car stop and the second moving car stop are the carstopping station, and when being laid flat, the first moving car stop and the second moving car stop are the passage station, and the first moving car stop and the second moving car stop are arrangedbetween a transfer platform foundation pit and the car dumper. The car puller travel stop is arranged at the final end of the travel of the car puller and located at the position where a big arm of the car puller just moves out the car dumper. The efficient switch-back type car dumper unloading system has the beneficial effects that the work travel of the car puller is shortened, the operation time of the car puller and the operation time of the auxiliary shunting locomotive coincide, and the operation efficiency is improved; the auxiliary shunting locomotive smoothly conducts round-trip operation between the transfer platform and the car dumper, the auxiliary shunting locomotive can be effectively prevented from going beyond the planned position, and the efficient switch-back type car dumper unloading system is easy and convenient to use, efficient, low in investment, small in occupation area and capable of achieving automatic operation.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

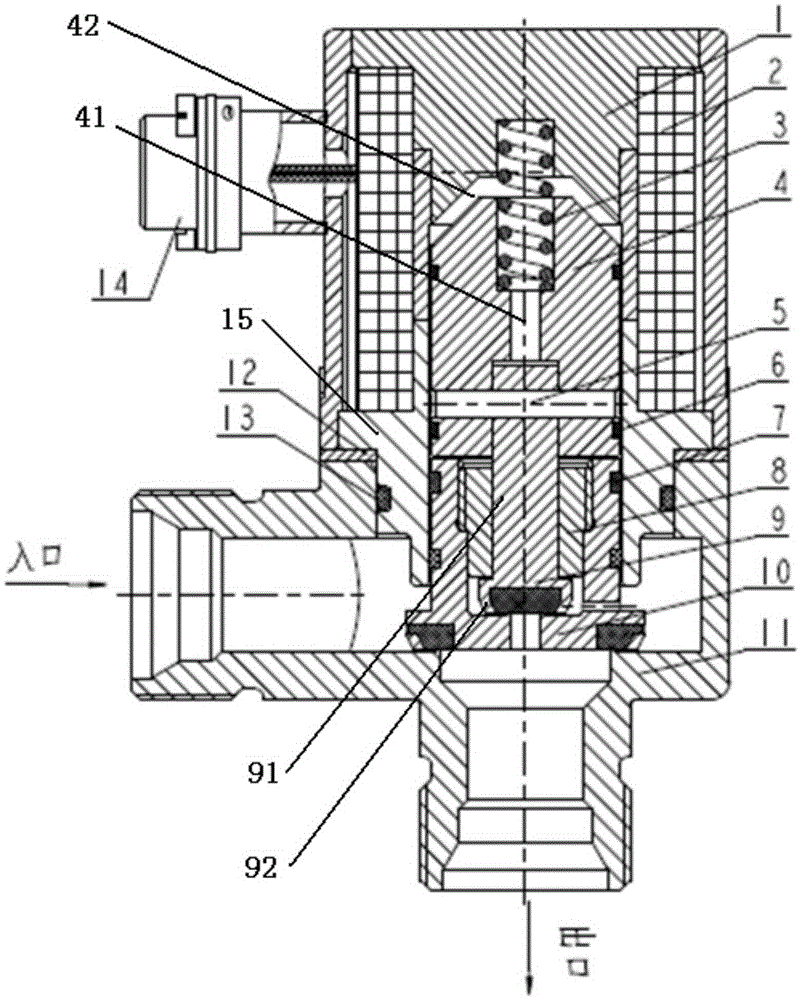

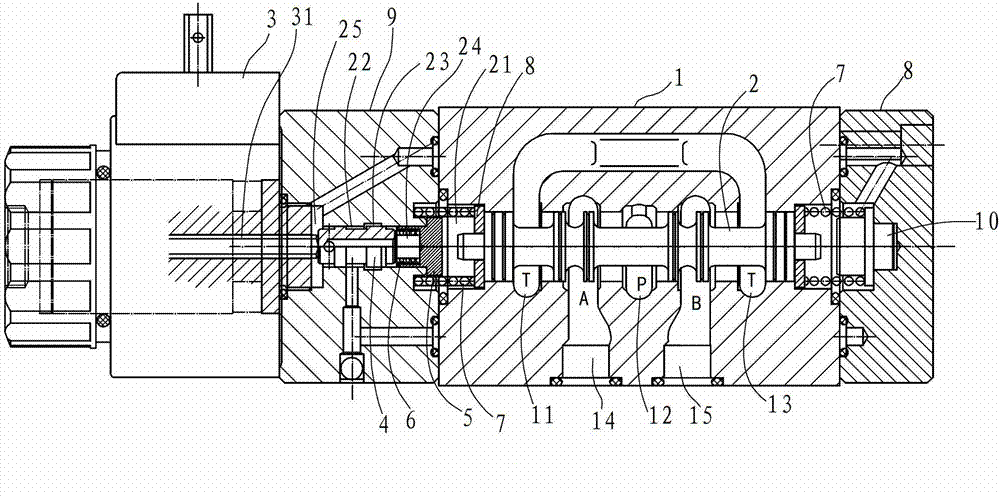

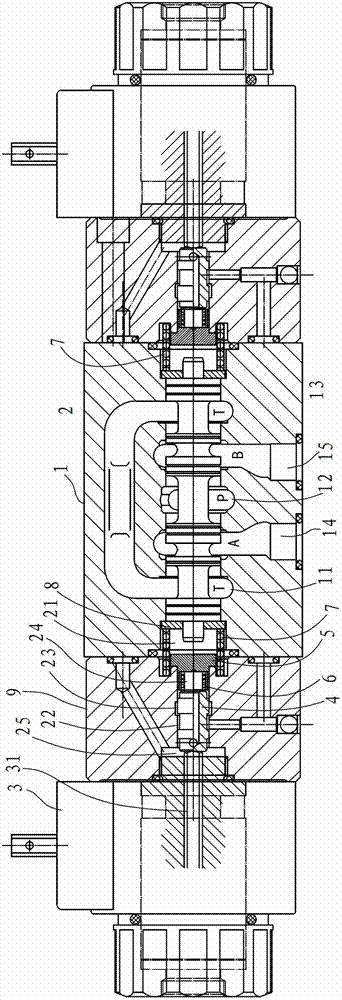

Electromagnetic directional valve

InactiveCN102829013ASmall reaction forcePower reduction requiredServomotor componentsMiniaturizationEngineering

The invention discloses an electromagnetic directional valve which comprises a valve body, a main valve core, an electromagnet and a main restoring spring, wherein the main valve core is positioned in the valve body and can move back and force along an axial channel of the valve body. The electromagnetic directional valve is characterized by also comprising a side cover, a pilot valve core and a pilot restoring spring, wherein the side cover is arranged on one side of the valve body; the pilot valve core can move back and force in an axial duct; the electromagnet is arranged on the other side of the side cover; and a push rod of the electromagnet pushes against the pilot valve core. Compared with the prior art, the electromagnetic directional valve provided by the invention has the advantages that with adoption of a hydraulic amplification principle and combination of a pilot control structure, an original working stroke is greatly shortened, and thus the miniaturization design on the electromagnetic directional valve is favorable; and meanwhile, the working stroke is shortened, and thus power can be greatly reduced.

Owner:NINGBO ZHENHAI HUALI HYDRAULIC ELECTROMECHANICAL CO LTD

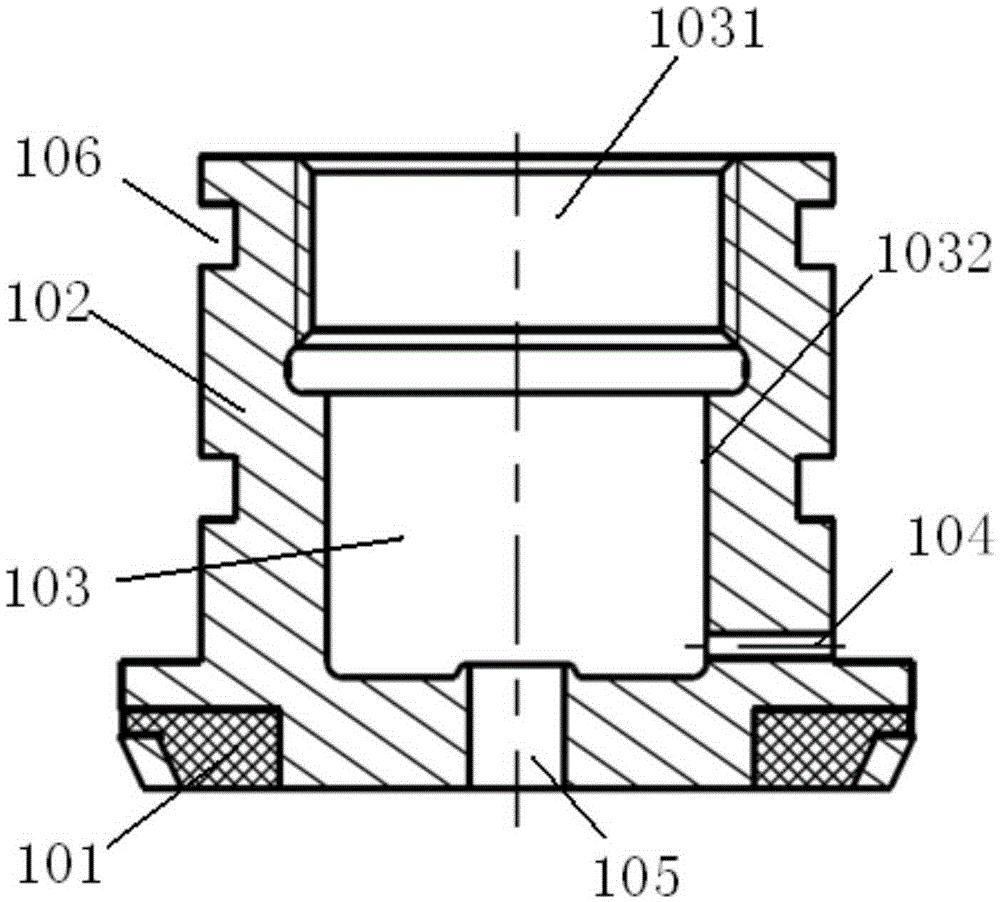

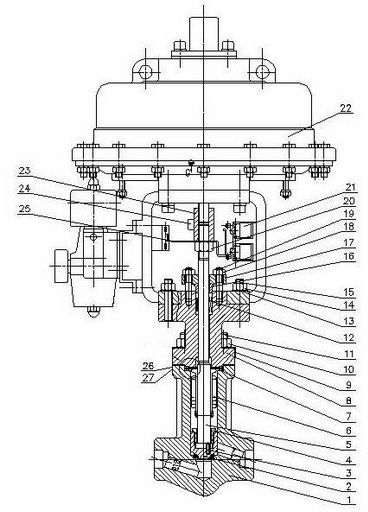

Nuclear class II film pneumatic bellows stop valve

InactiveCN102606748AHigh hardnessImprove sealingSpindle sealingsOperating means/releasing devices for valvesPressurized water reactorDiaphragm structure

A nuclear class II film pneumatic bellows stop valve belongs to the field of nuclear power valves used by large pressurized water reactor nuclear power station systems. Surfacing of hard alloy on both a valve seat and a valve clack enables sealing surfaces to be high in hardness, so that the valve is more wear-resistant and scour-resistant and is extremely resistant to corrosion. A Brinell hardness difference of 50 exists between the two sealing surfaces, so that excellent sealing property can be further guaranteed. A pneumatic device of a diaphragm structure is short in stroke, compact and flexible in structure, and a hand-operating mechanism can be mounted on the pneumatic device if needed. The pneumatic bellows stop valve is simple in structure, convenient in maintenance, short in opening and closing time by means of short operating stroke, and small in closing friction force, scour-resistant and reliable in sealing by means of conical surface sealing between the sealing surfaces of the valve clack and the valve seat.

Owner:DALIAN DAGAO VALVE

Garbage compaction complete equipment

ActiveCN104249886AShort work scheduleImprove practicalityRefuse transferringStorage devicesRisk strokeWaste management

The invention discloses garbage compaction complete equipment, which comprises garbage discharge equipment with a discharge opening, and a garbage compactor with a feed opening corresponding to the discharge opening, wherein the garbage discharge equipment and / or garbage compactor comprise / comprises a pushing mechanism, and the pushing mechanism comprises a plurality of pusher head assemblies which at least comprise a first pusher head assembly and a second pusher head assembly which is at least partially arranged below the first pusher head assembly; the two pusher head assemblies can respectively move back and forth along the length direction. Therefore, the layered compaction and / or continuous discharge of garbage are / is completed by respective telescoping of the pusher head assemblies, and the working stroke of a single pusher head assembly is at least reduced, so that the garbage compaction and / or discharge are / is completed by the pusher head assembly with smaller specification. The structural arrangement of the complete machine can be optimized to improve the practicality and economy of the garbage compaction complete equipment.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

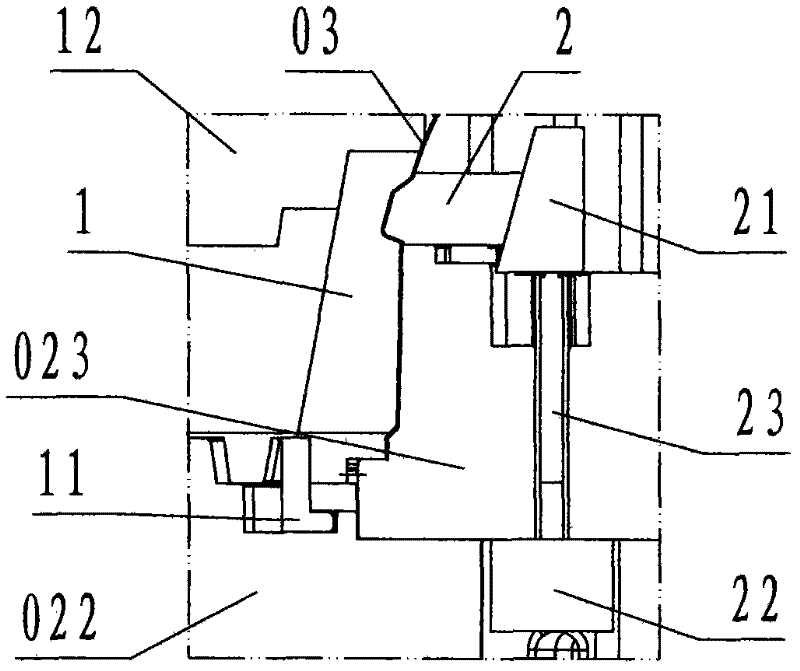

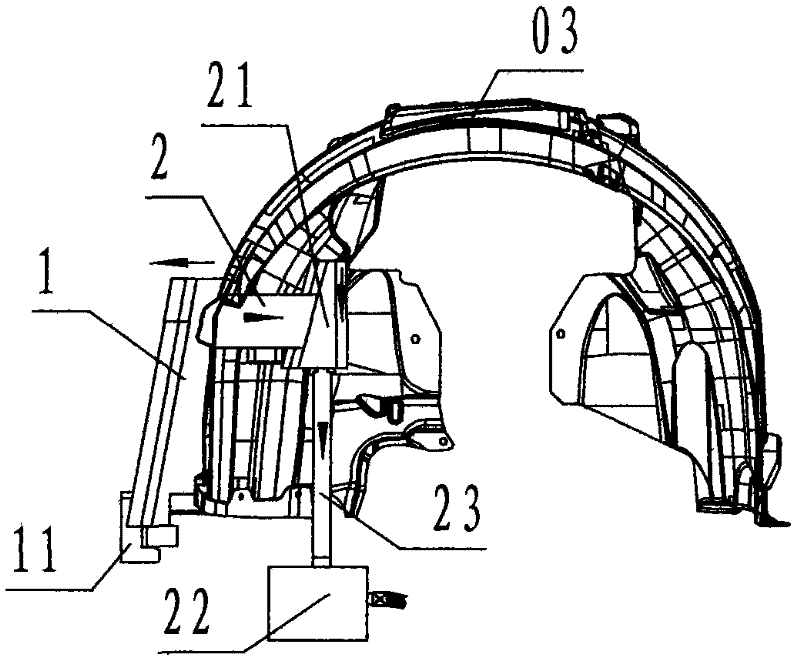

Synchronous core-pulling mechanism on the inner and outer sides of the injection mold for automobile wheel covers

Owner:宁波宇升模塑有限公司

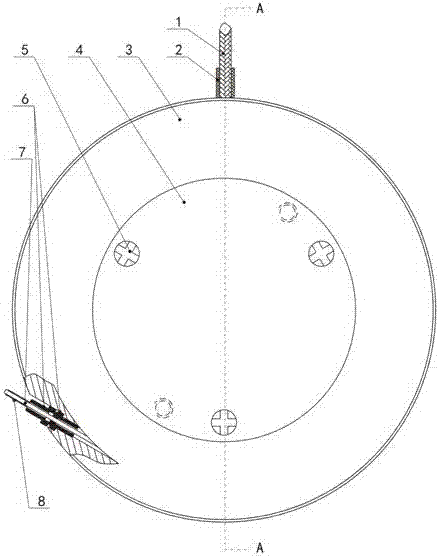

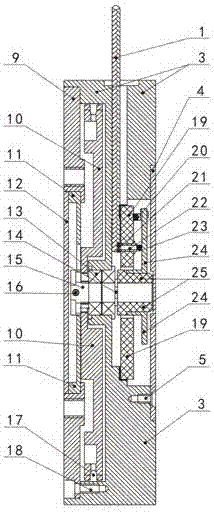

Sensor with large working stroke and small size

The invention discloses a sensor with a large working stroke and a small size. A rotating shaft is mounted in a shell through a bearing; a shaft disk is fixedly arranged on the rotating shaft and is coaxial with the rotating shaft; an annular groove is formed in the outer circumferential surface of the shaft disk; one end of a pull rope is fixed in the annular groove, and the other end of the pull rod is located outside the shell; an insulating sleeve is fixedly arranged on the rotating shaft in a sleeving manner; a circular resistor body is mounted inside the shell and is provided with a resistor body center hole; the insulating sleeve penetrates through the resistor body center hole and can freely rotate; a current collecting ring is fixedly arranged on the insulating sleeve in a sleeving manner. According to the sensor, by converting an angular displacement motion of an electric brush into a linear displacement motion of the pull rope, the aim of completing detection of relatively large linear displacement only through the relatively small size is fulfilled; the sensor is intrinsically a linear displacement sensor, but compared with the conventional linear displacement sensor, the sensor has an outstanding advantage of a decreased size, so that the sensor can meet an application environment of a relatively small installation space; meanwhile, the working stroke cannot be reduced due to the small installation space.

Owner:CHENGDU HONGMING ELECTRONICS CO LTD

Turning-back type car dumper unloading system with static scale

The invention relates to a turning-back type car dumper unloading system with a static scale. The turning-back type car dumper unloading system comprises a car dumper, a car puller, a wheel clamping device, a car transfer platform, a car pusher and the static scale; the car dumper and the static scale are arranged on a railway loaded car line; the static scale is arranged behind the car dumper; the wheel clamping device is arranged behind the static scale; a railway empty car line is arranged on one side of the railway loaded car line; the car puller is used for pulling a loaded car column tomove forward; the car transfer platform is located in front of the car dumper; the car transfer platform moves between the railway loaded car line and the railway empty car line and used for moving anempty car with materials being unloaded from the railway loaded car line to the railway empty car line; the car pusher is arranged on one side of the railway empty car line and used for pushing the empty car on the car transfer platform onto the railway empty car line to be gathered; and the wheel clamping device is arranged on the railway loaded car line, located behind the static scale and usedfor clamping car wheels of the loaded car to be turned over for unloading so as to prevent the car wheels from sliding. A car connection position of the car puller is changed to be located in front of, instead of behind, the static scale, so that the working stroke of the car puller is shortened, the turning unloading cycle time is shortened by about 50s, the working efficiency is increased by 20%, and the delay penalty of railway unloading is avoided.

Owner:威立雅(哈尔滨)热电有限公司

Efficient multiple color number packaging machine

InactiveCN109911283AShort work scheduleImprove transfer efficiencyWrapper folding/bending apparatusWrapper supporting apparatusBrickPaperboard

The invention discloses an efficient multiple color number packaging machine. The efficient multiple color number packaging machine comprises a transporting part, a brick moving part, a storing part,a paper folding part and a paper bin part, wherein the transporting part is used for transporting ceramic tiles to the position above the storing part; due to a beating aligning manner and an aligningmanner, the ceramic tiles are in good order, and a lifting table at the center of the storing part is used for jacking up the ceramic tiles; before the brick moving part is used for clamping and transporting the ceramic tiles to the paper folding work procedure position, the paper bin part is used for sucking a paperboard, and placing the paperboard over the paper folding part; and the brick moving part is used for placing the ceramic tiles over the paper folding part, and the paper folding part moves and completes the packaging work procedure. By implementing the efficient multiple color number packaging machine, the ceramic tile packaging efficiency can be improved, and distinguished packaging of the ceramic tiles in different levels is performed on the same equipment.

Owner:KEDA INDUSTRIAL GROUP CO LTD

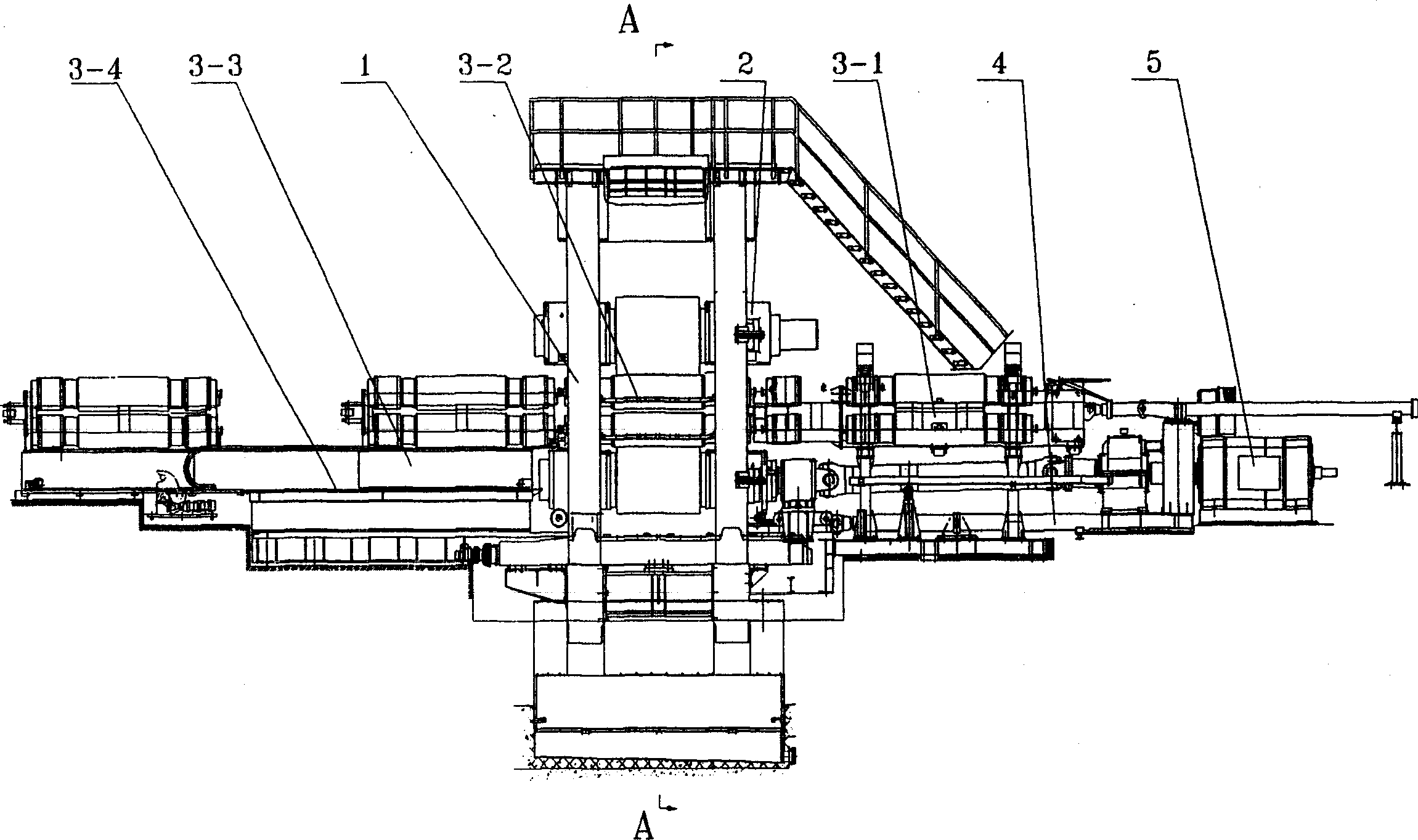

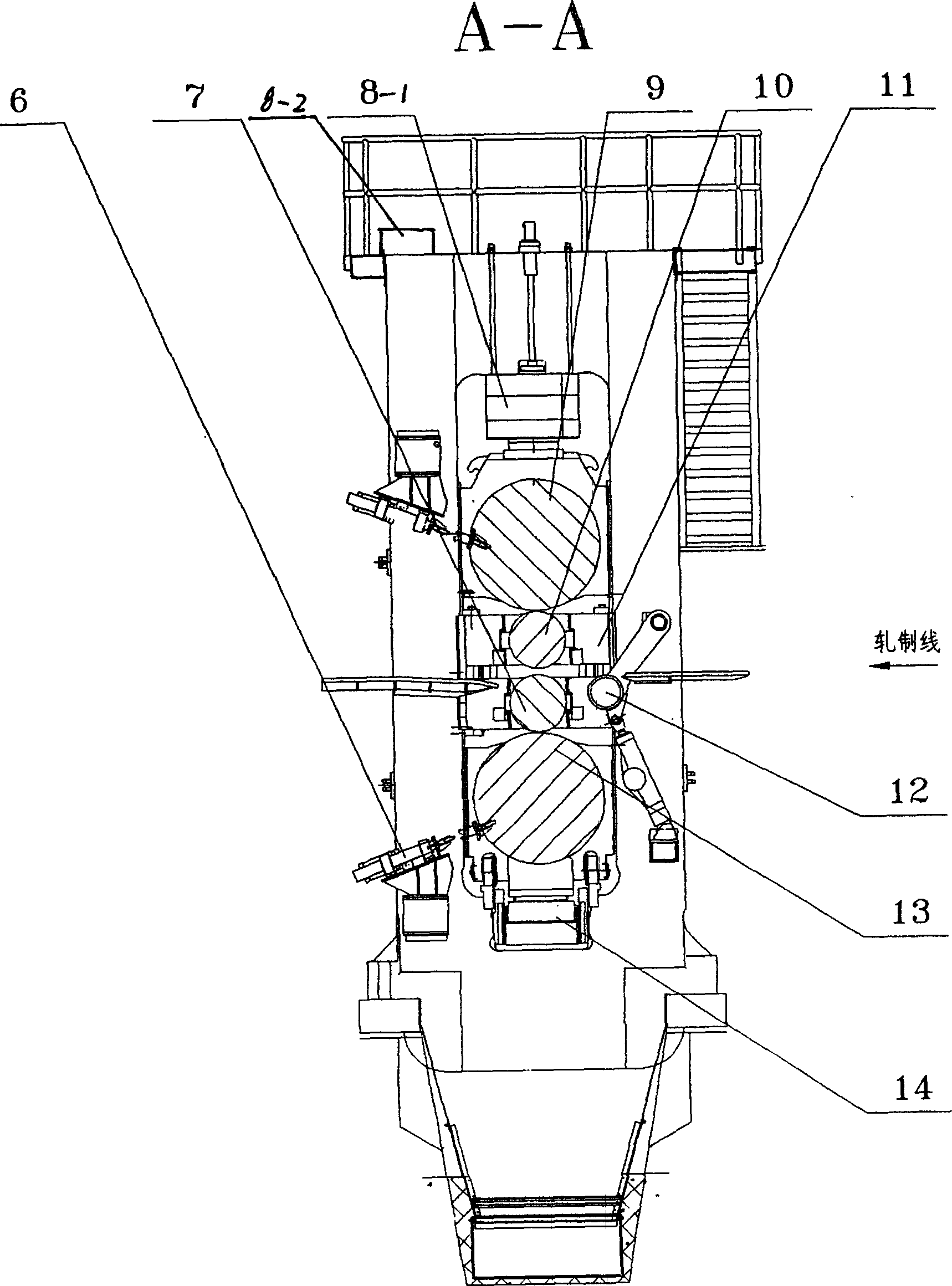

Leveling machine

ActiveCN1843645AShort work scheduleImprove working environmentMetal rolling stand detailsMetal rolling arrangementsResponse FrequencyStrip steel

The invention discloses a planisher, belonging to the molding technique, which can apply the belt steel planisher and the cold rolling finisher. It comprises an automatic thickness control cylinder and a table servo valve; wherein, the hydraulic elements as servo valve and the accumulator are mounted beside the automatic thickness control cylinder; the storing bracket of working roller beside the transmission is mounted on the base via bolt; the bolt and stop cut inside the framework used to change rolling rails are mounted on the bend roller; the roller changing vehicle of working roller besides operation is moiunted on the rail of roller changing vehicle of base. The invention can improve the response frequency of servo control system, simplify the design, and improve the service life with easy maintenance, short time for changing roller when the belt steel is between two working rollers, and improved working efficiency of planisher.

Owner:CISDI ENG CO LTD

Extrusion type conveying device for emulsion explosive and emulsion matrix

InactiveCN101289357AReliable actionShort work scheduleExplosive working-up apparatusEmulsion explosiveSprocket

The invention relates to a feedway in a production process for manufacturing emulsion explosive, in particular to a feedway of crushing type emulsion explosive and an emulsion matrix, which comprises a feeding hose that is arranged in a frame, wherein, the feed end and the discharge end of the feeding hose are respectively and fixedly connected with each connector and are also arranged on the frame; a chain transmission device is articulated with the frames which are positioned respectively at the two sides of the feeding hose; the two chains are oppositely articulated with at least one pair of press rolls that press the feeding hose; the frame is provided with a chain wheel driving mechanism; the frame at the position of the chain is fixedly connected with a guide that supports the press roll, and the feed end in the feeding hose is provided with a flexible pipe-expansion device; and in addition, the left side of the feeding hose can also be provided with a support plate while the right side can be provided with the chain transmission device, and the chain is articulated with the press roll that presses the feeding hose. Owing to the structure of pressing materials by applying an extrusion force to the external of the feeding hose and transporting materials in the feeding hose, the feedway has the advantages of reliable action, short working stroke, large over-current sectional area, high essential safety degree and long service life, etc.

Owner:蒙宝林

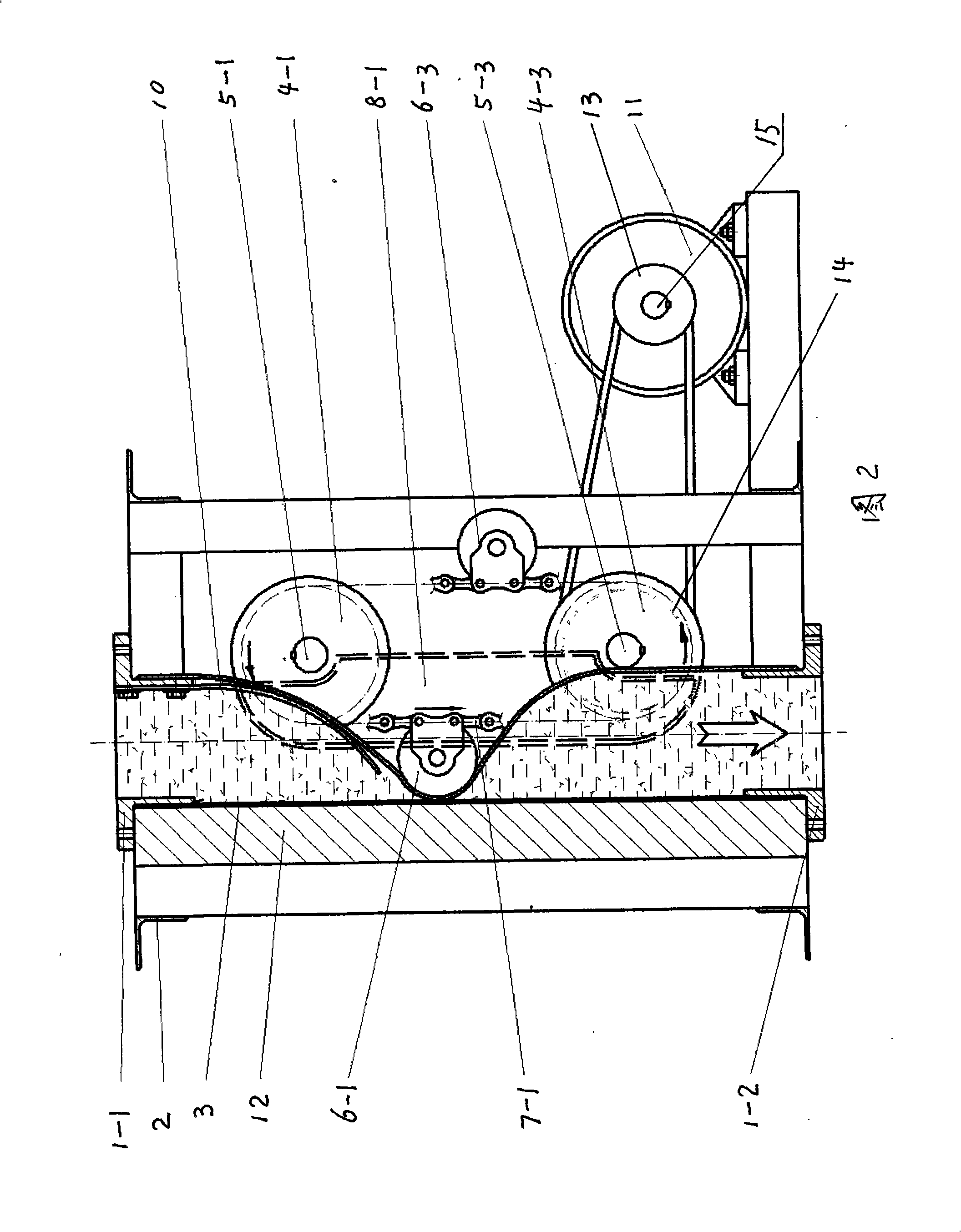

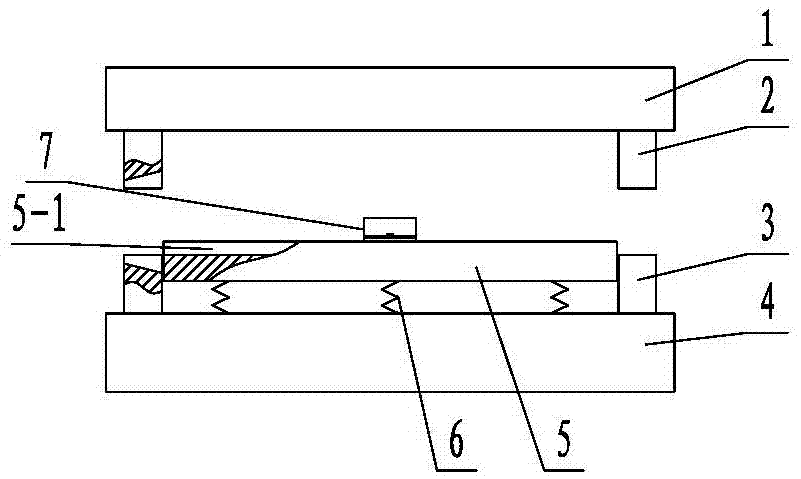

Stamping necking mold for pipe fittings

InactiveCN107096834AAvoid deformationShort work scheduleShaping toolsMetal-working feeding devicesPipe fittingEngineering

The invention discloses a stamping necking mold for pipe fittings and relates to the technical field of stamping molds. The stamping necking mold comprises two lower female mold bodies which are oppositely fixed to a lower mold seat. A support block is arranged between the two lower female mold bodies. The support block is supported above the lower mold seat through multiple springs. A limiting groove for horizontally containing the pipe fittings is formed in the upper end face of the support block. Two upper female mold bodies corresponding to the lower female mold bodies are fixedly arranged on an upper mold plate. A necking mold cavity is defined by the upper female mold bodies and the lower female mold bodies. The stamping necking mold for the pipe fittings solves the problems that by means of an existing necking mold for the pipe fittings, necked openings of overlong pipe fittings deform easily, and the working stroke is large.

Owner:柳州市御朗机械制造有限公司

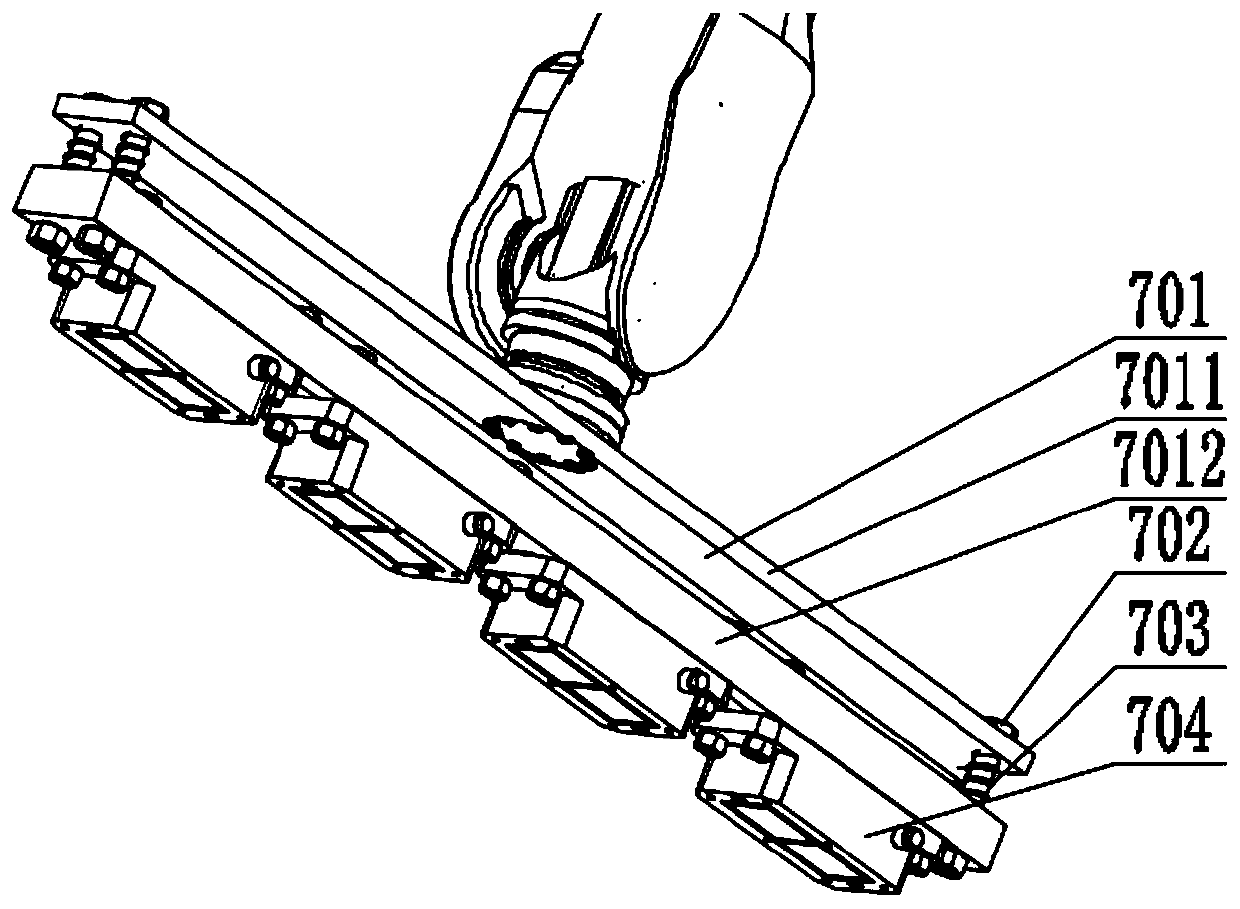

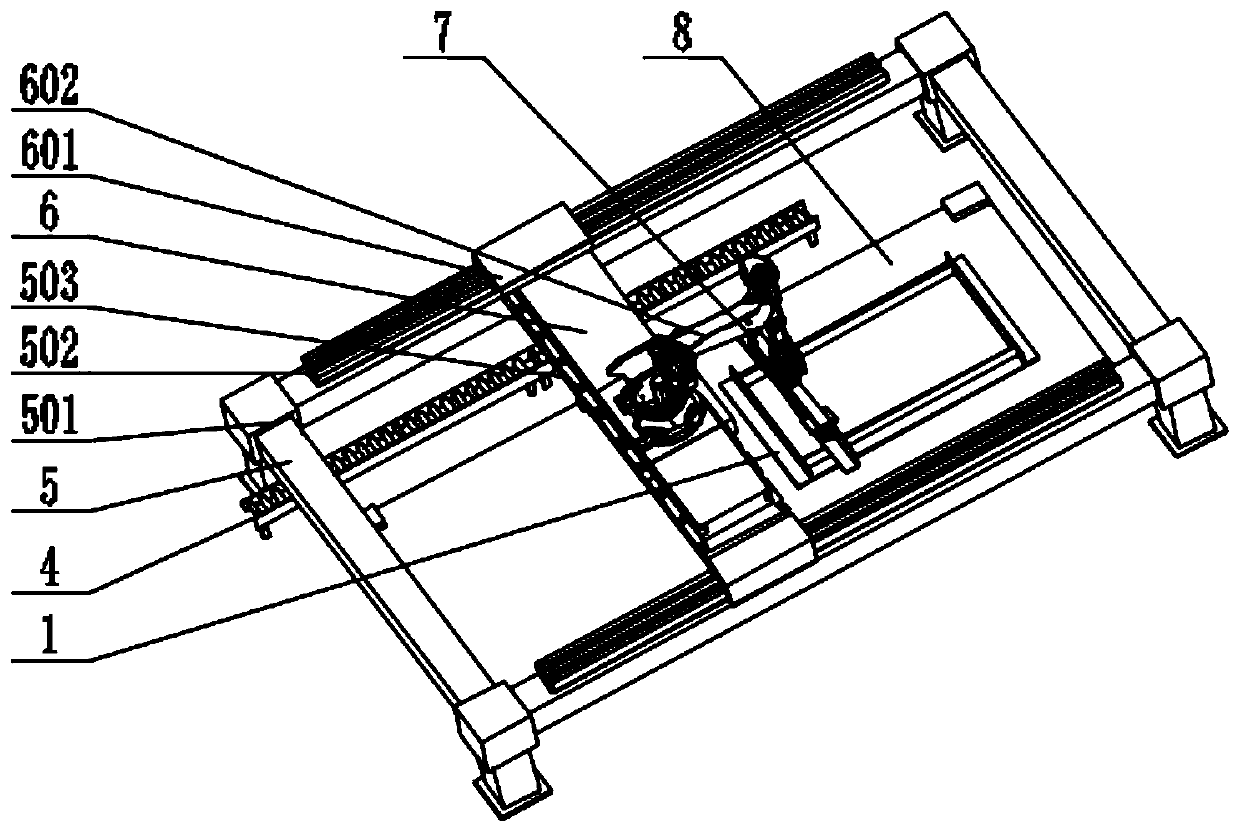

Side formwork arranging device for precast concrete component production line

InactiveCN111217147AAvoid consumptionAvoid timeAuxillary shaping apparatusConveyor partsProduction lineRobot hand

The invention discloses a side formwork arranging device for a precast concrete component production line, and belongs to the field of precast concrete component production equipment. The side formwork arranging device is composed of side formworks, a side formwork library, a bevel sliding table, a conveying rail, a truss, a formwork arranging robot, a tail end clamp and a formwork table. The formwork arranging robot is structurally divided into a walking shaft and a six-freedom-degree robot, the walking shaft is mounted on a cross beam, the six-freedom-degree robot is mounted on the walking shaft, and the tail end clamp is located at the tail end of a sixth shaft of the six-freedom-degree robot. The tail end clamp is structurally divided into bearing plates, bolts, buffering springs and electric permanent magnetic chucks, and the bearing plates are divided into an upper layer and a lower layer. When the device is used, for small components, after one component is arranged, the six-freedom-degree robot can rotate by 170 degrees, reverse formwork arrangement is carried out on the same formwork table, and the formwork arrangement process is identical with forward formwork arrangement; and compared with traditional truss type mechanical arm formwork arrangement, the linear movement stroke of the robot is reduced, and the work efficiency is improved.

Owner:SHANDONG JIANZHU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com