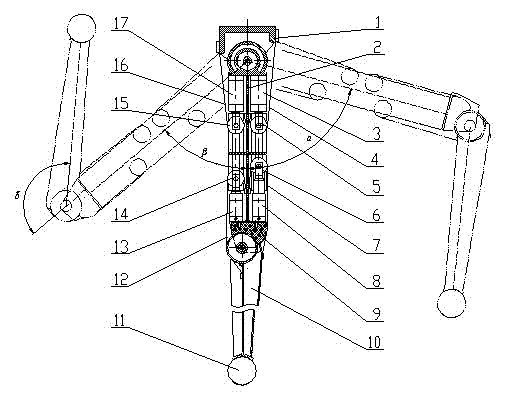

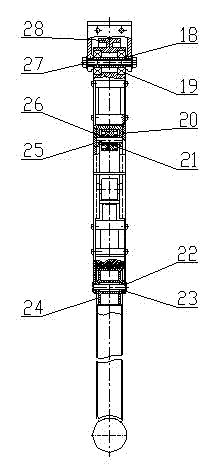

Driving leg mechanism for footed robot

A technology for driving legs and robots, which is applied in the fields of motor vehicles, transportation and packaging, etc. It can solve the problems of increasing thigh weight and structural space, complicated knee joint mechanism, and small working space at the end of the foot, and achieves light weight, compact structure, and high mobility. large space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

[0024] Hip joint column 28 is fixedly connected with femur 2, and its endoporus cooperates with the outer ring of bearing 19, and the inner ring of bearing 19 cooperates with hollow shaft 18, and the two ends of hollow shaft 18 are fixedly connected with leg support 1 with bolt 27, Forms the hip joint of the thigh. The upper end of the calf bone 10 is affixed to the knee joint column 24, and the joint pad 9 is fixed on the lower end of the femur 2 by screws, and is in contact with the cylindrical surface of the knee joint column 24 to bear the main load of the knee joint; meanwhile, the femur 2. The lug at the lower end is fixedly connected to the rivet 22, and the elastic sleeve 23 is fixedly installed in the through hole of the knee joint column 24. The rivet 22 and the elastic sleeve 23 cooperate with each other to form an auxiliary hinge between the femur 2 and the knee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com