Device and method for sealing metal and glass

A technology for sealing glass and metal, which is applied in the field of metal and glass sealing devices, and can solve problems such as difficult sealing, difficult glass sealing, and easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

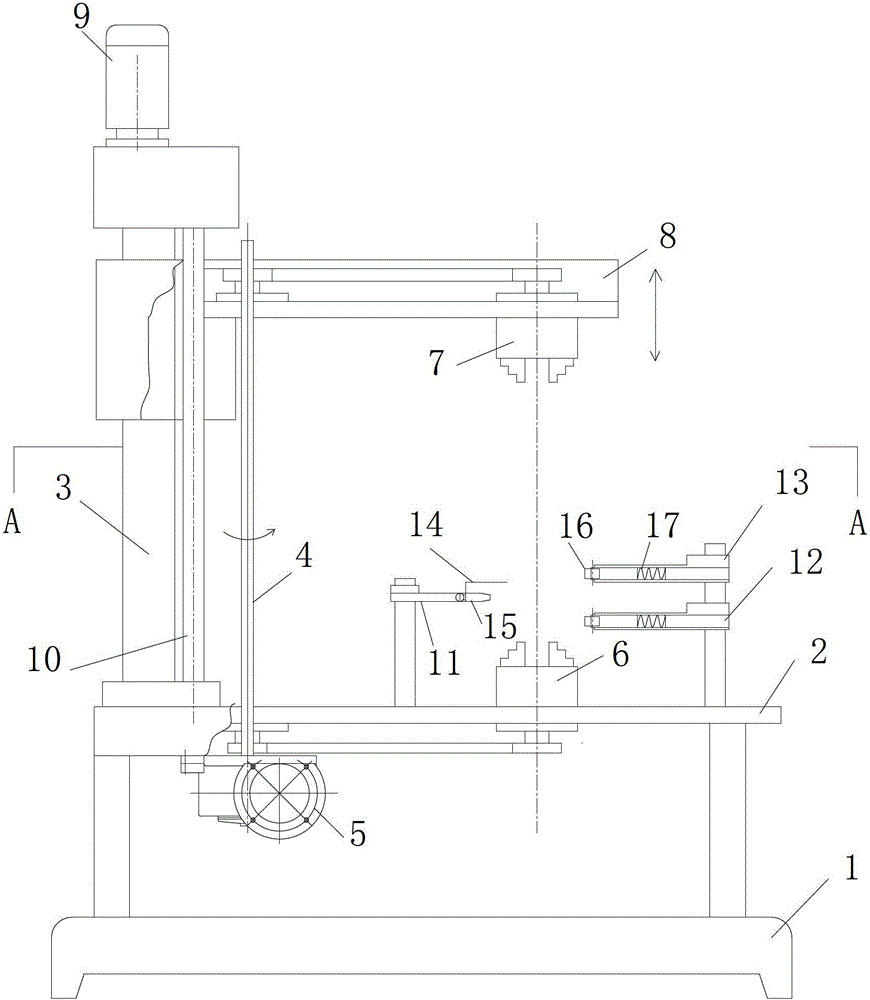

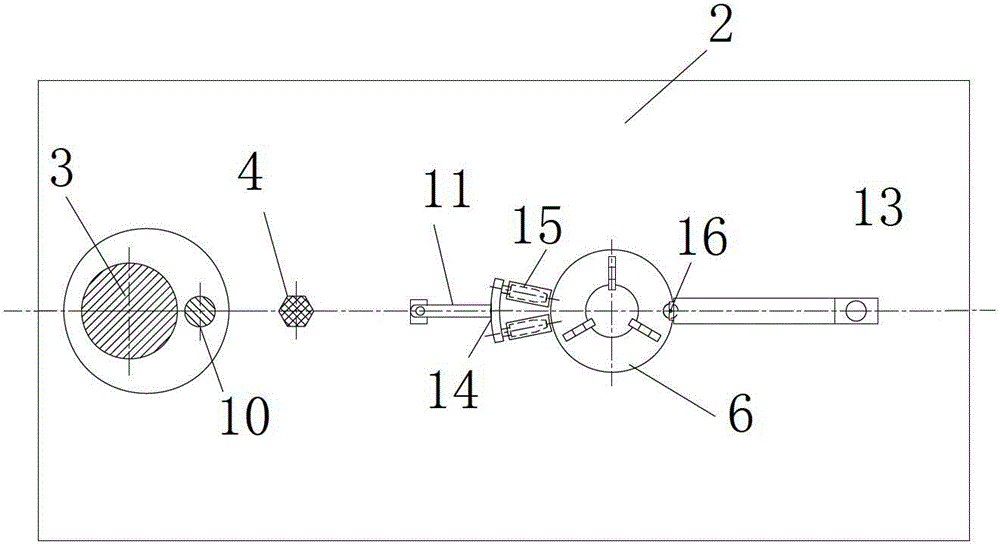

Embodiment 1

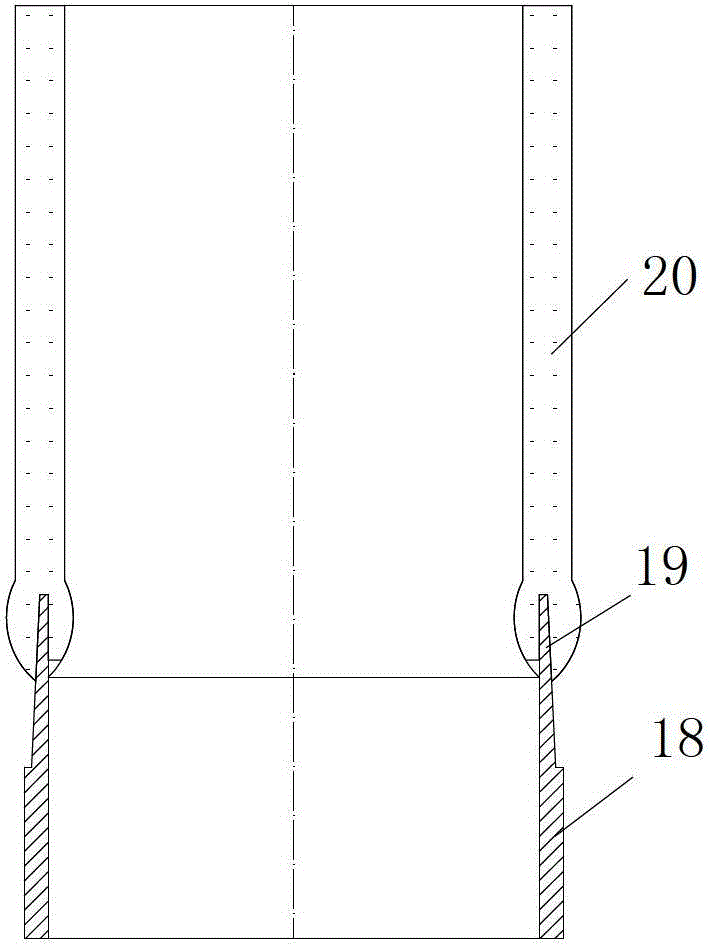

[0030] In this embodiment, the glass and metal sealing method is as follows: first, the sealing area of the metal ring 18 with an inner diameter of 116 mm and a wall thickness of 1 mm is pre-processed into a thin-walled knife edge 19 with a length of 15 mm, and the top wall thickness of the thin-walled knife edge 19 is 0.03. mm, with a taper of 1°, and then fix the metal ring 18 on the lower fixture 6. Fix the glass tube 20 with a diameter of 120 mm and a wall thickness of 3 mm on the upper fixture 7 . Turn on the upper motor drive device 9, and move the positioning device 8 through the screw 10 to move the glass tube 20 down along the column 3 to make contact with the metal ring 18; open the lower motor drive device 5 to synchronize the glass tube 20 with the metal ring 18 , Coaxial rotation, the speed is 20 rpm. Turn on the heating burner 11 with 6 nozzles 15 to start preheating, control the temperature of the glass tube 20 to 500°C, and adjust the distance between the up...

Embodiment 2

[0032] The sealing method between glass and metal in this embodiment is as follows: first, a metal ring 18 with an inner diameter of 96 mm and a wall thickness of 0.8 mm is fixed on the lower fixture 6; a glass tube 20 with an outer diameter of 100 mm and a wall thickness of 2.5 mm is fixed on the upper Fixture 7 on. Turn on the upper motor drive device 9, and move the positioning device 8 along the column 3 to move the glass tube 20 downwards to contact and align with the metal ring 18 through the screw 10. Open the lower motor driving device 5, and the glass tube 20 and the metal ring 18 are rotated synchronously and coaxially at a speed of 80 rpm. Turn on the heating torch 11 with two nozzles 15 to start preheating, control the temperature of the glass tube 20 to 300°C, and simultaneously adjust the distance between the upper coaxial positioning device 13 and the lower coaxial positioning device 12 to be controlled at 15mm, and the upper and lower coaxial The rotating whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com