Carbon-coated ternary positive electrode material and preparation method thereof

A positive electrode material, carbon coating technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of ineffective contact between conductive carbon and positive electrode materials, restricting material rate performance, and electrons cannot migrate smoothly, so as to increase the rate Performance and cycle stability, low cost, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

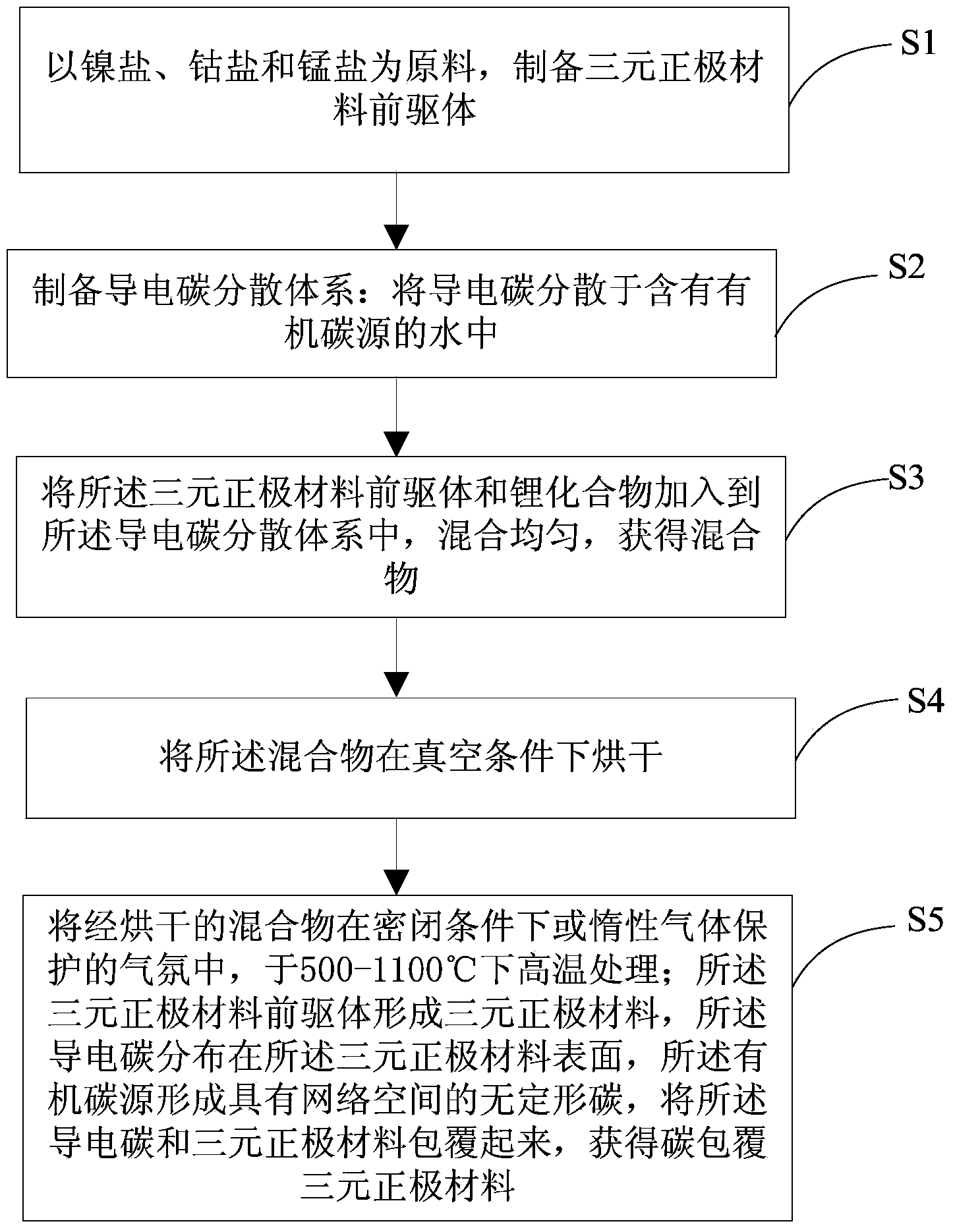

[0034] Such as figure 1 As shown, the preparation method of the carbon-coated ternary positive electrode material of the present invention comprises the following steps:

[0035] S1. Using nickel salt, cobalt salt and manganese salt as raw materials, prepare a precursor of ternary cathode material.

[0036] In this step S1, the nickel salt is a soluble salt such as nickel sulfate, nitrate or hydrochloride, the cobalt salt is a soluble salt such as cobalt sulfate, nitrate or hydrochloride, and the manganese salt is manganese sulfate, nitric acid Soluble salts such as salt or hydrochloride. The semi-liquid and semi-solid method is used to make the raw material into the precursor of the ternary positive electrode material; the semi-liquid and semi-solid method is to prepare a mixed solution of nickel salt, cobalt salt and manganese salt, and obtain nickel salt and cobalt salt by liquid phase precipitation method and a slurry-like mixture of manganese salt, and then adopt a low-...

Embodiment 1

[0050] S1. Prepare a mixed solution of 0.2mol / L nickel sulfate, cobalt sulfate and manganese sulfate according to the stoichiometric ratio, and prepare the precursor Ni of the ternary positive electrode material by the semi-liquid and semi-solid method 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 ;

[0051] S2. Disperse 5 grams of graphite in an aqueous solution of 500 grams of sucrose (10% by weight of sucrose) by mechanical stirring, and stir for 15 minutes to obtain a conductive carbon dispersion system;

[0052] S3, adding 125 grams of ternary positive electrode material precursor and 55 grams of lithium carbonate to the conductive carbon dispersion system, using mechanical stirring to make it evenly mixed to obtain a mixture;

[0053] S4. Dry the mixture obtained above at 50° C. under vacuum conditions for 10 hours;

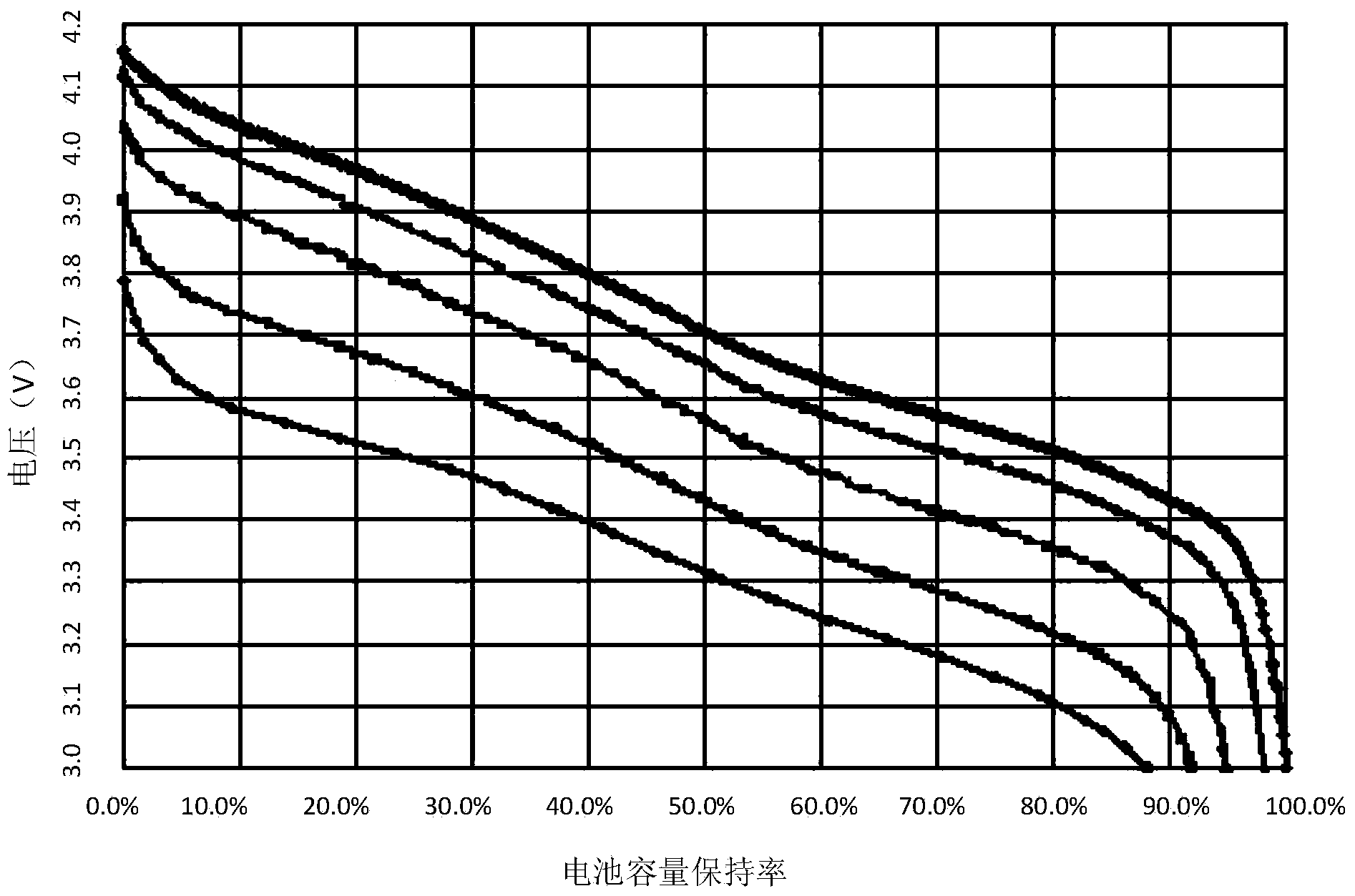

[0054] S5. Treat the dried mixture at a high temperature for 15 hours in a high-temperature furnace at 500° C. and a nitrogen flow rate of 0.2 L / min to obtain a carbon-coat...

Embodiment 2

[0056] S1. Prepare a mixed solution of 0.5mol / L nickel sulfate, cobalt sulfate and manganese sulfate according to the stoichiometric ratio, and prepare the precursor Ni of the ternary cathode material by the semi-liquid and semi-solid method 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 ;

[0057] S2, adopt mechanical stirring method to disperse 4 grams of acetylene carbon black in the aqueous solution of 300 grams of glucose (the weight percent composition of glucose is 30%), stirring time is 30 minutes;

[0058] S3, adding 76 grams of ternary positive electrode material precursor and 45 grams of lithium carbonate to the conductive carbon dispersion system, using mechanical stirring to make it evenly mixed to obtain a mixture;

[0059] S4. Dry the mixture obtained above at 60°C for 5 hours under vacuum conditions;

[0060] S5. Treat the dried mixture at 800° C. in a closed high-temperature furnace for 10 hours to obtain a carbon-coated ternary positive electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com