Patents

Literature

394results about "Electrolyte layer coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

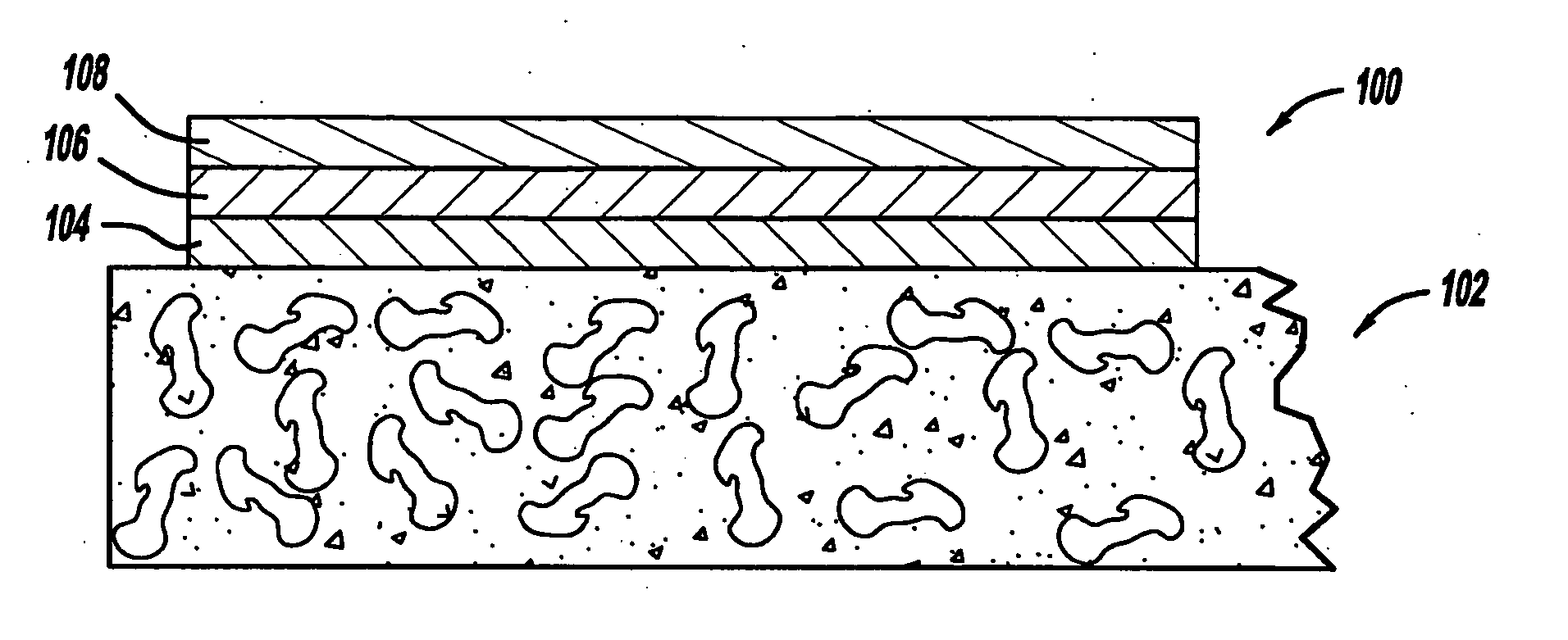

Ion conducting batteries with solid state electrolyte materials

ActiveUS20140287305A1Final product manufactureActive material electrodesSolid state electrolytePorous layer

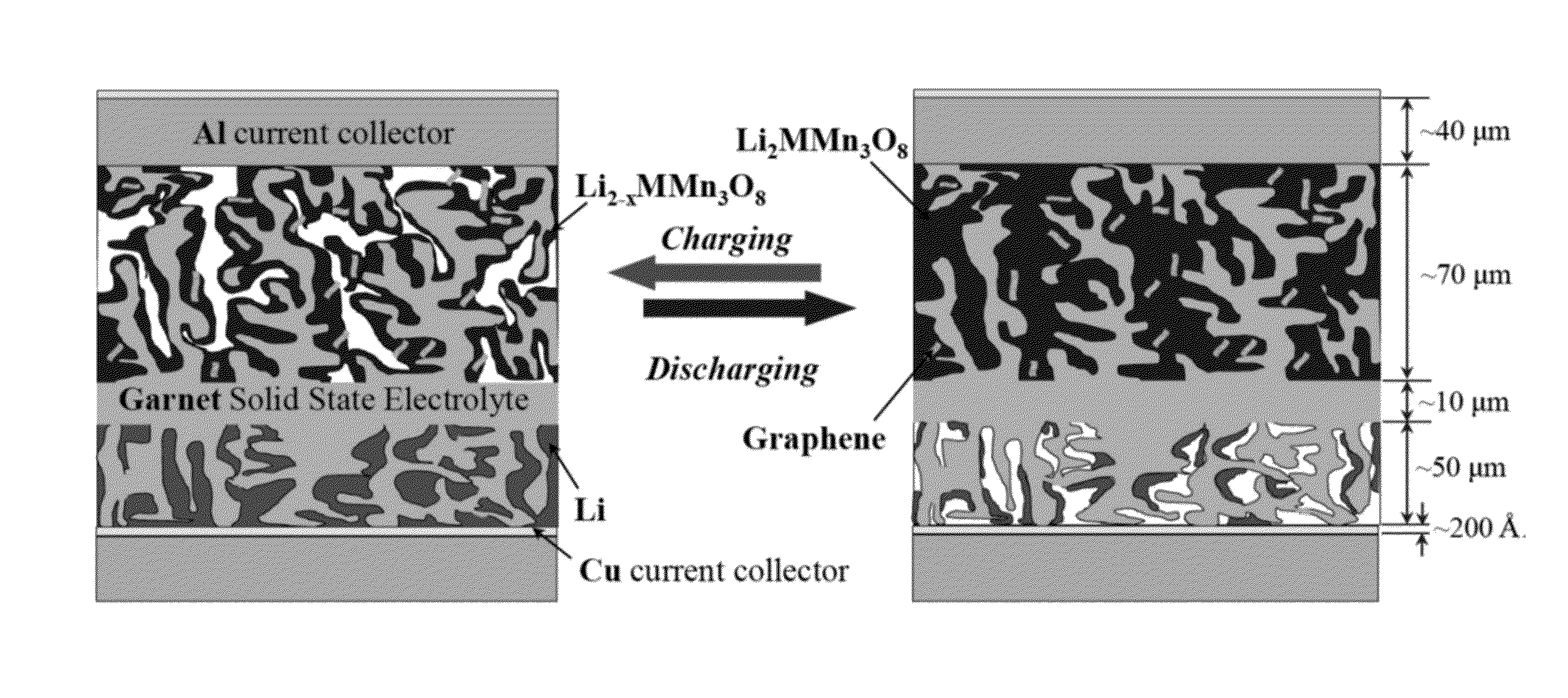

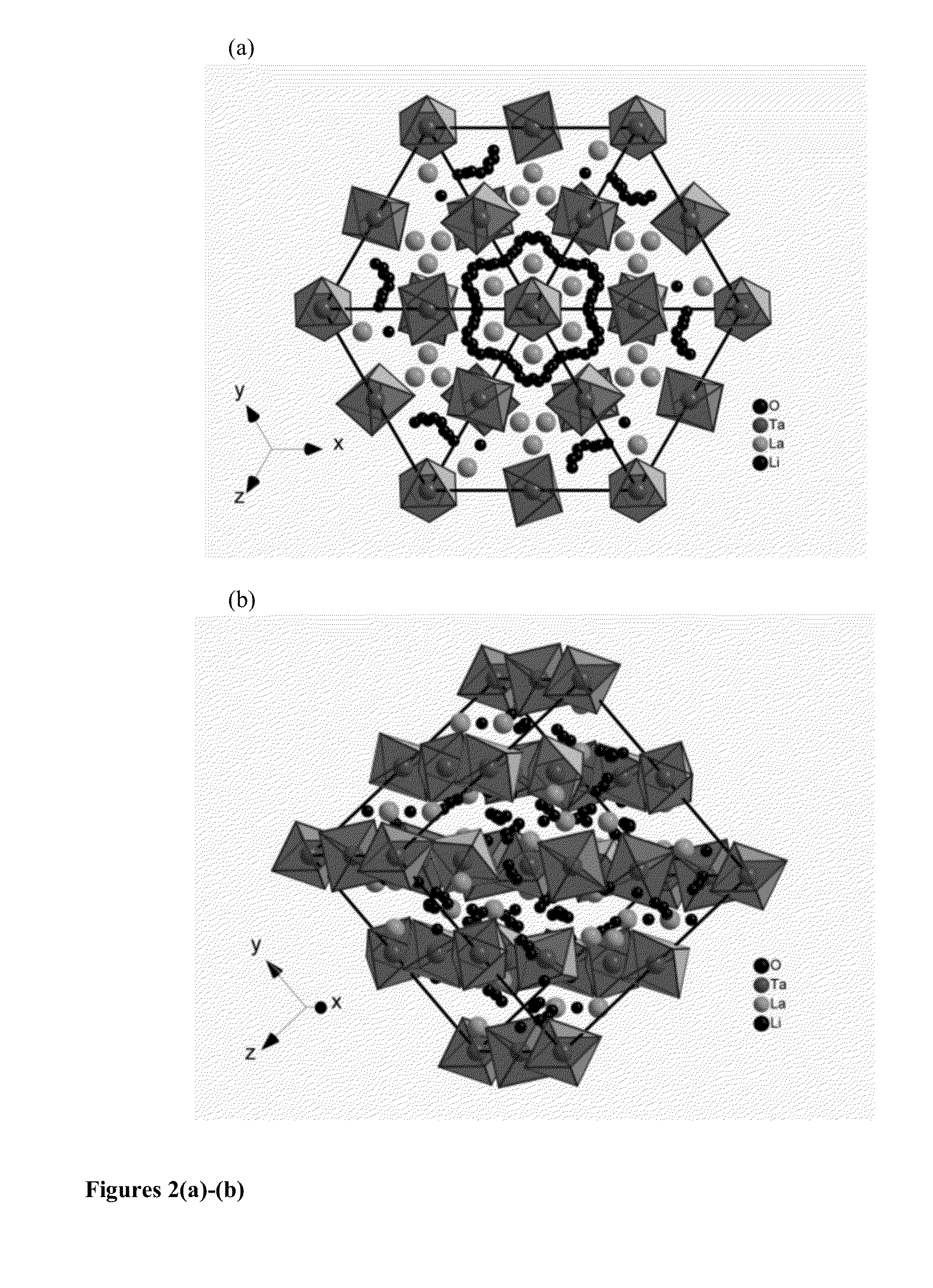

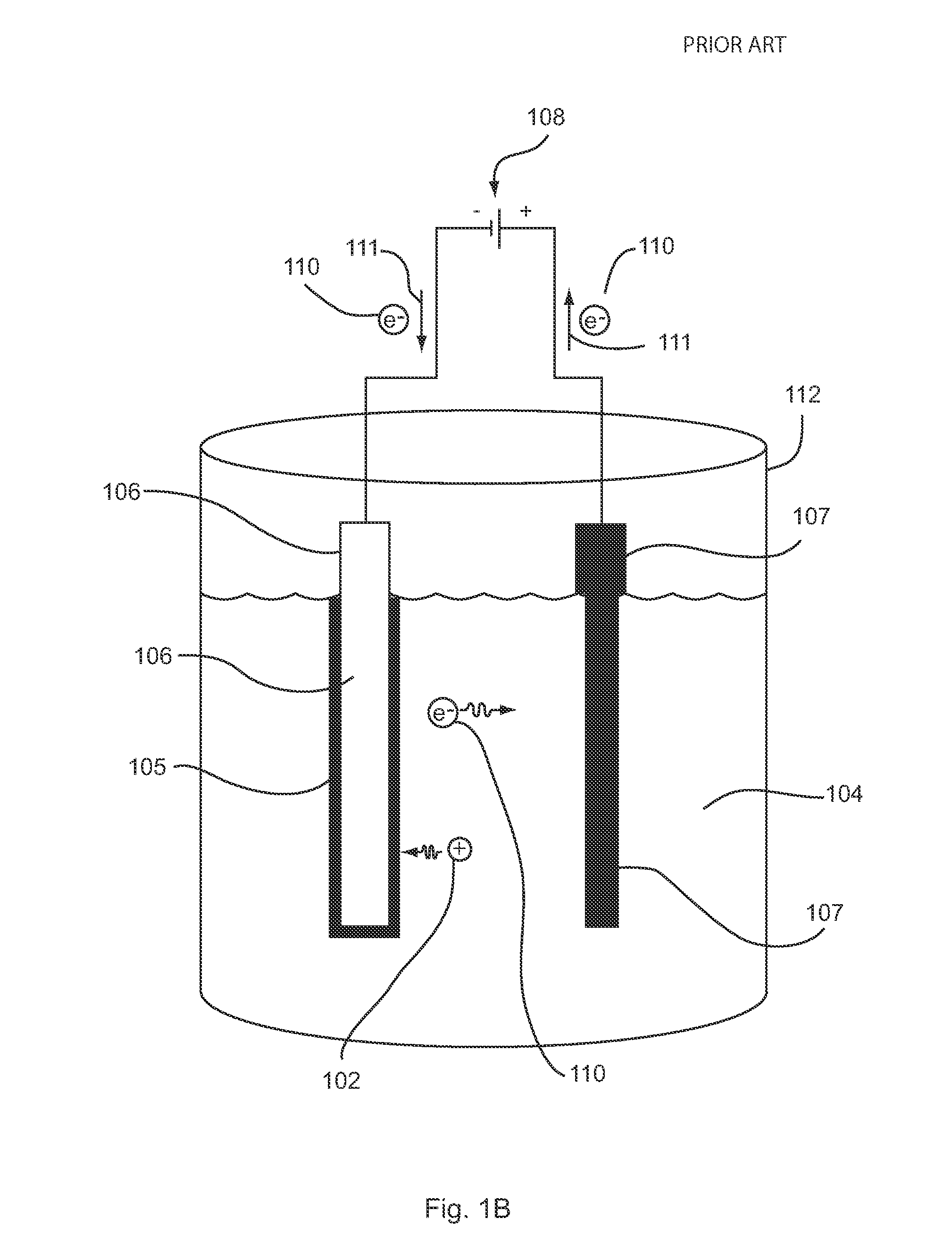

Solid-state, ion-conducting batteries with an ion-conducting, solid-state electrolyte. The solid-state electrolyte has at least one porous region (e.g., porous layer) and a dense region (e.g., dense layer). The batteries are, for example, lithium-ion, sodium-ion, or magnesium-ion conducting solid-state batteries. The ion-conducting, solid-state electrolyte is, for example, a lithium-garnet material.

Owner:UNIV OF MARYLAND

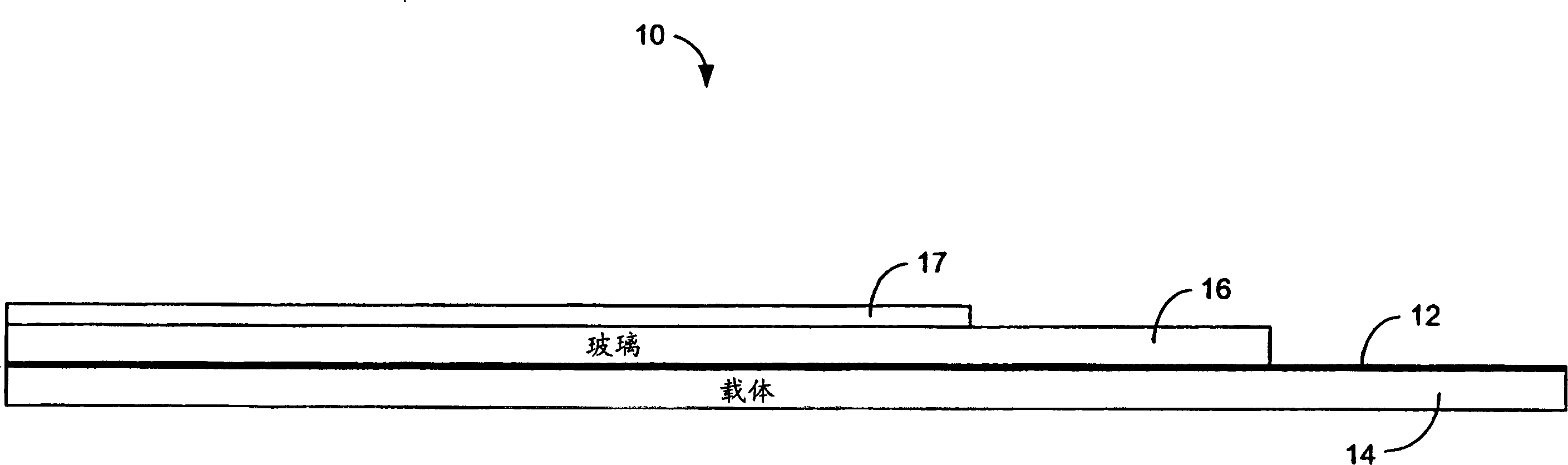

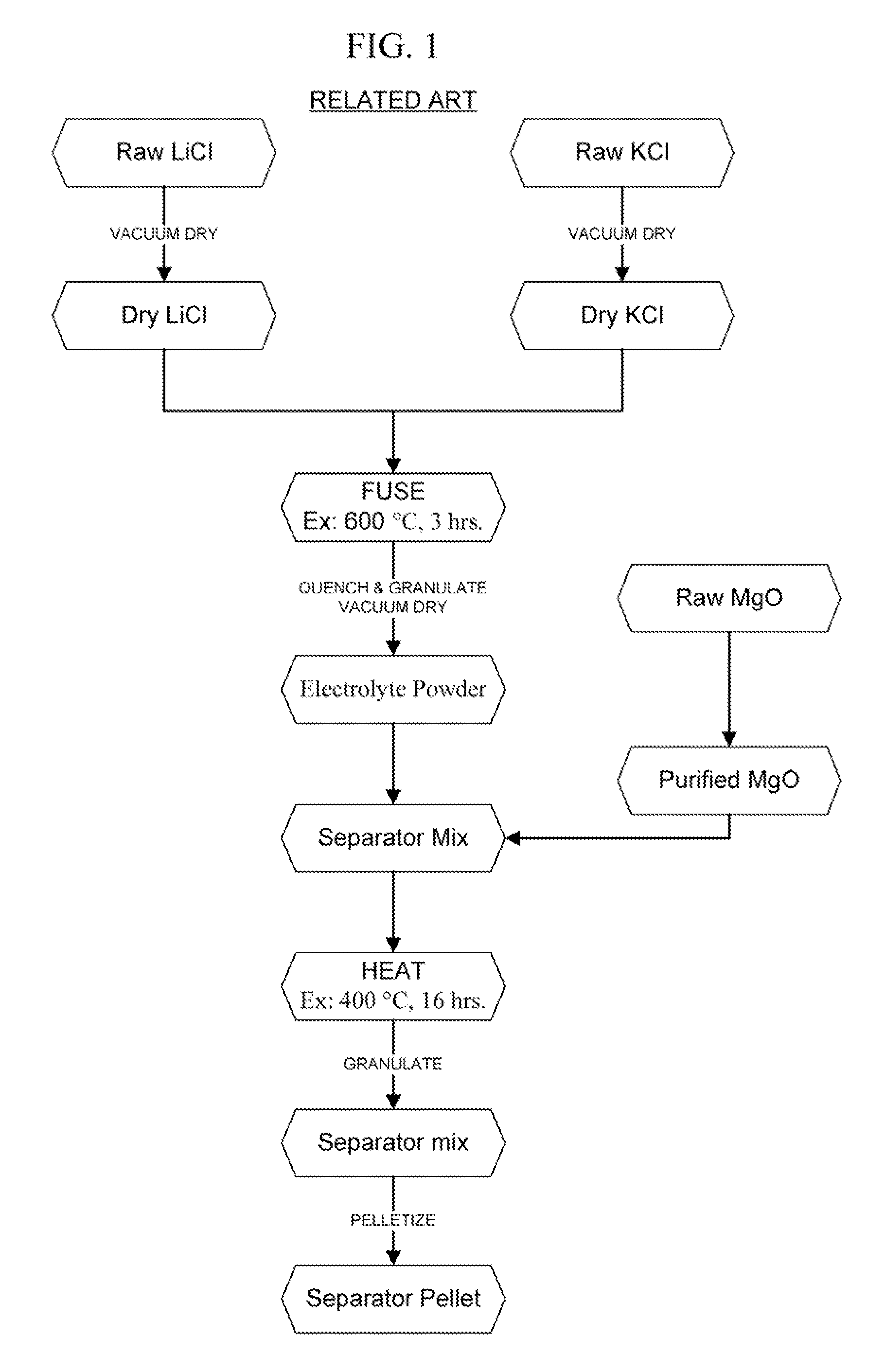

Methods of preparing electrochemical cells

InactiveUS7066971B1Electrode carriers/collectorsActive material electrodesLithium metalAnodic protection

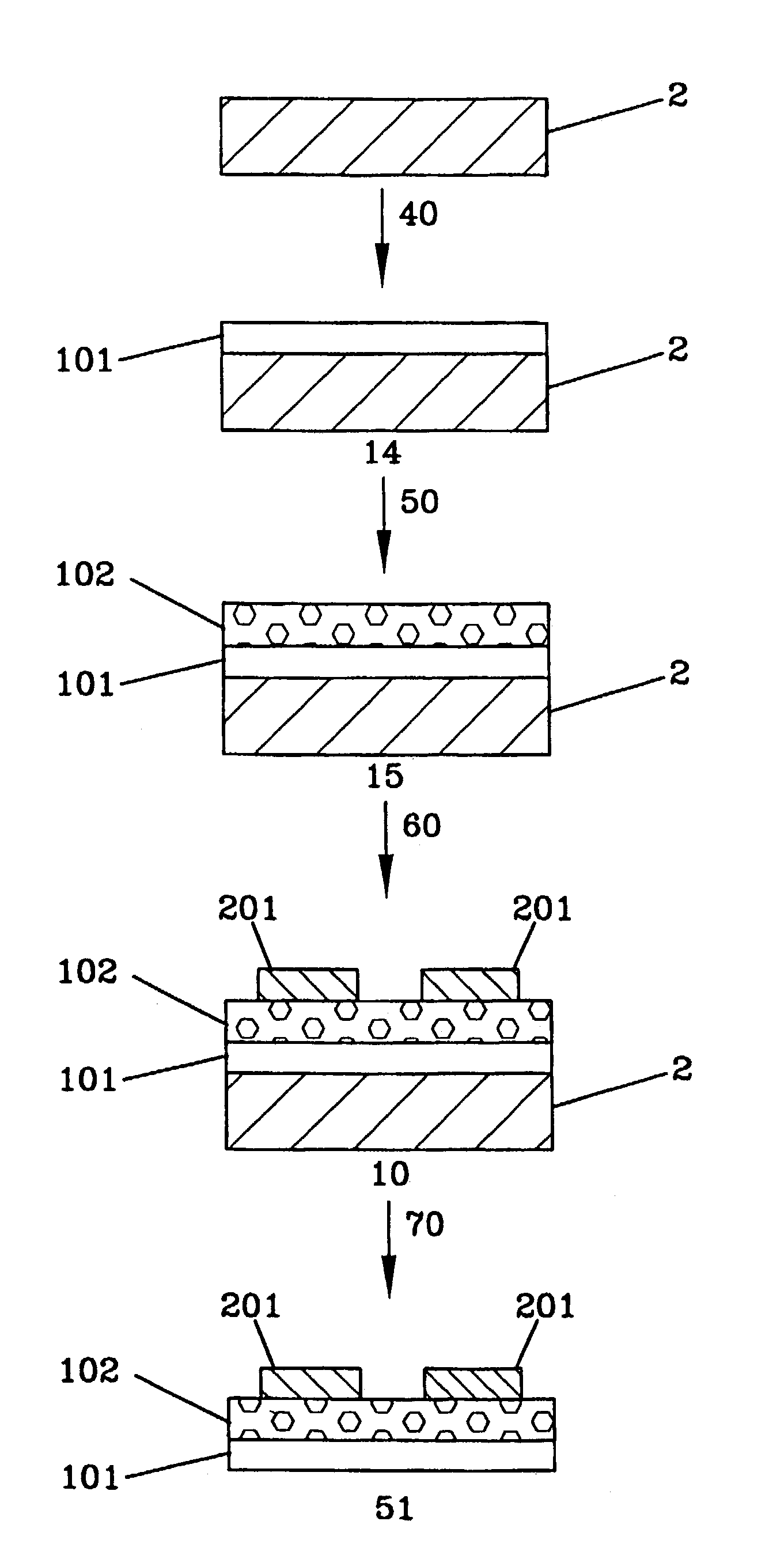

Methods of preparing a cathode / separator assembly for use in electrochemical cells in which a protective coating layer, such as a single ion conducting layer, is coated on a temporary carrier substrate, a microporous separator layer is then coated on the protective coating layer, and a cathode active layer is then coated on the separator layer, prior to removing the temporary carrier substrate from the protective coating layer. Additional layers, including an edge insulating layer, a cathode current collector layer, an electrode insulating layer, an anode current collector layer, an anode layer such as a lithium metal layer, and an anode protective layer, such as a single ion conducting layer, may be applied subsequent to the coating step of the microporous separator layer. Also, methods of preparing electrochemical cells utilizing cathode / separator assemblies prepared by such methods, and cathode / separator assemblies and electrochemical cells prepared by such methods.

Owner:OPTODOT CORP +1

Electrical Appliance

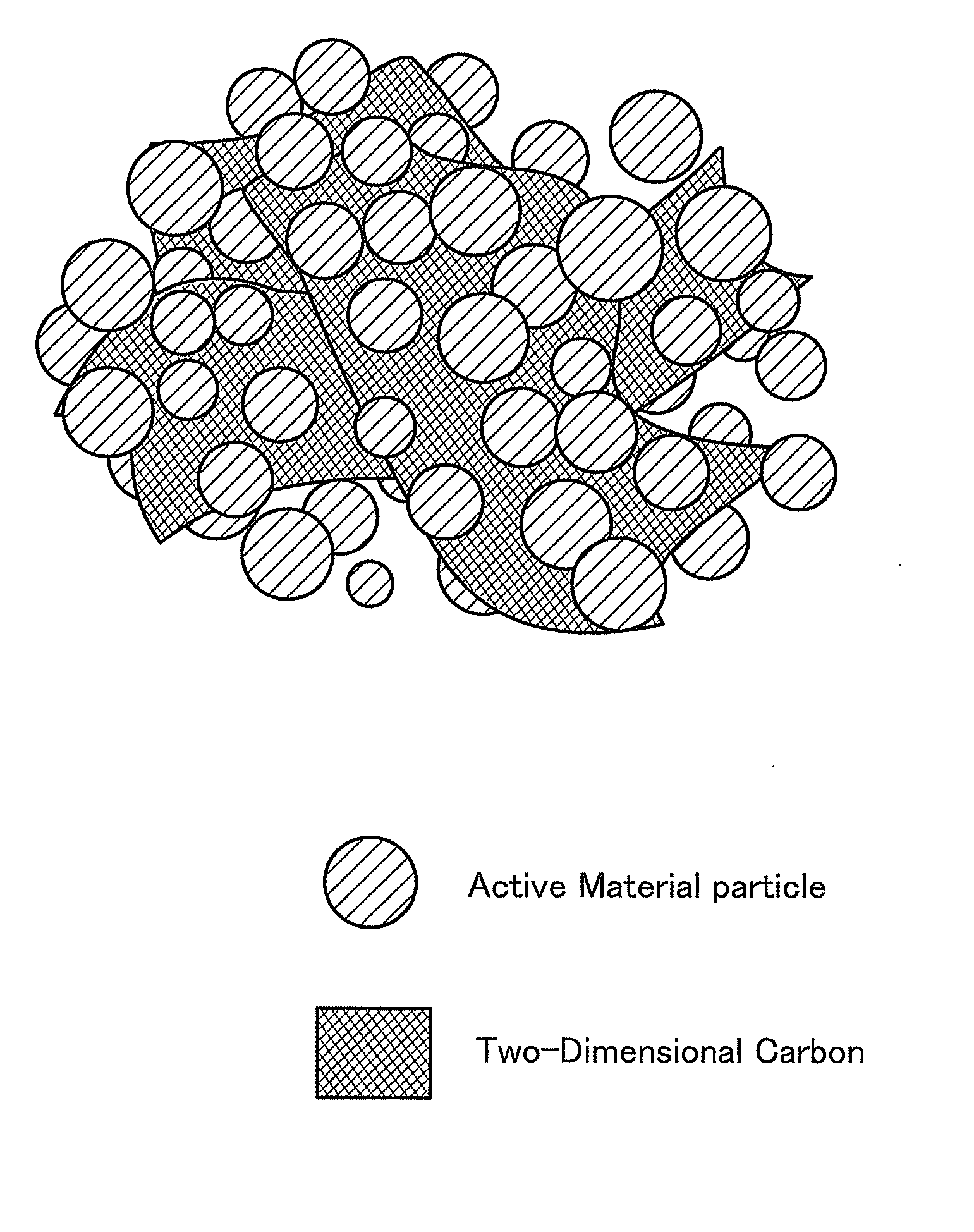

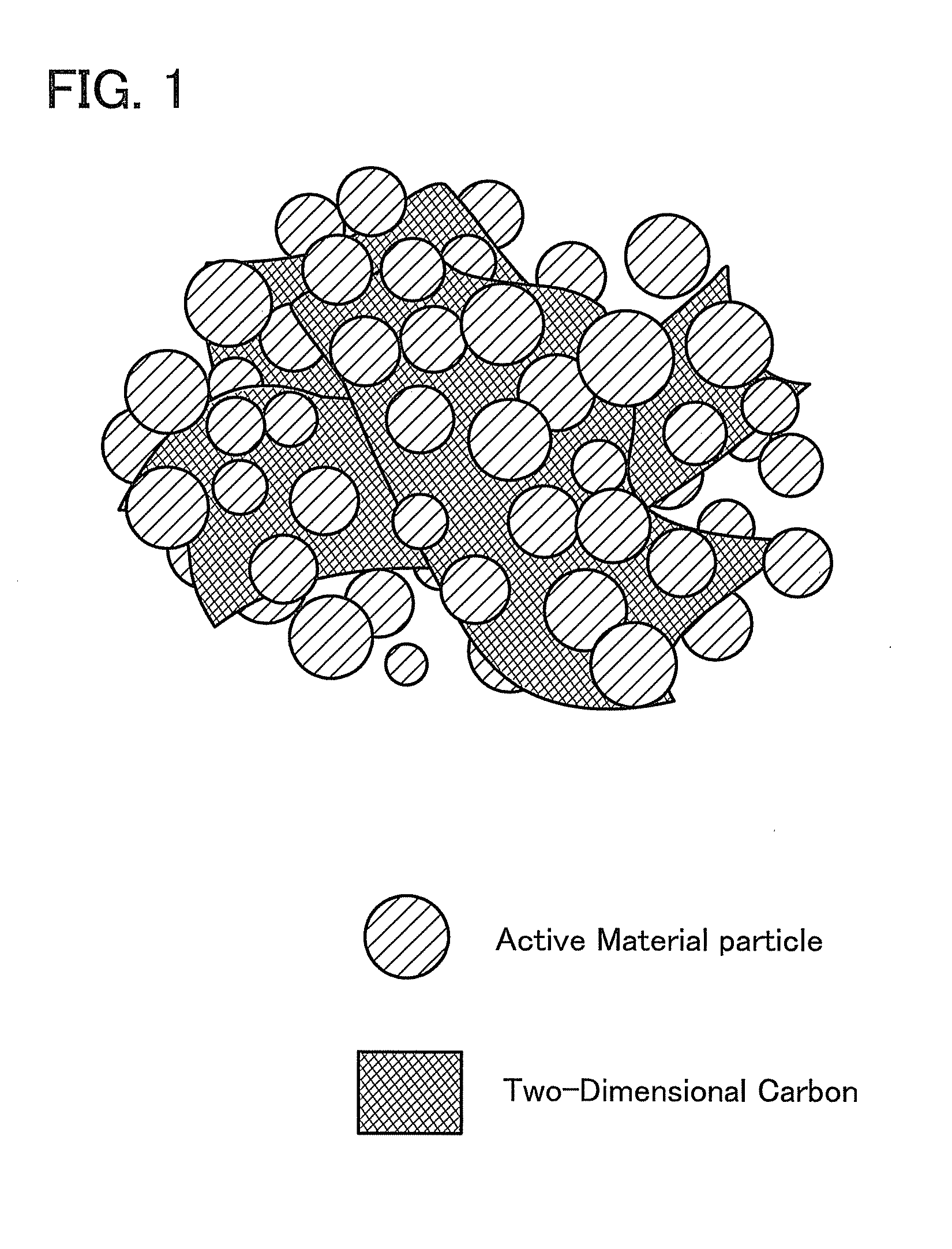

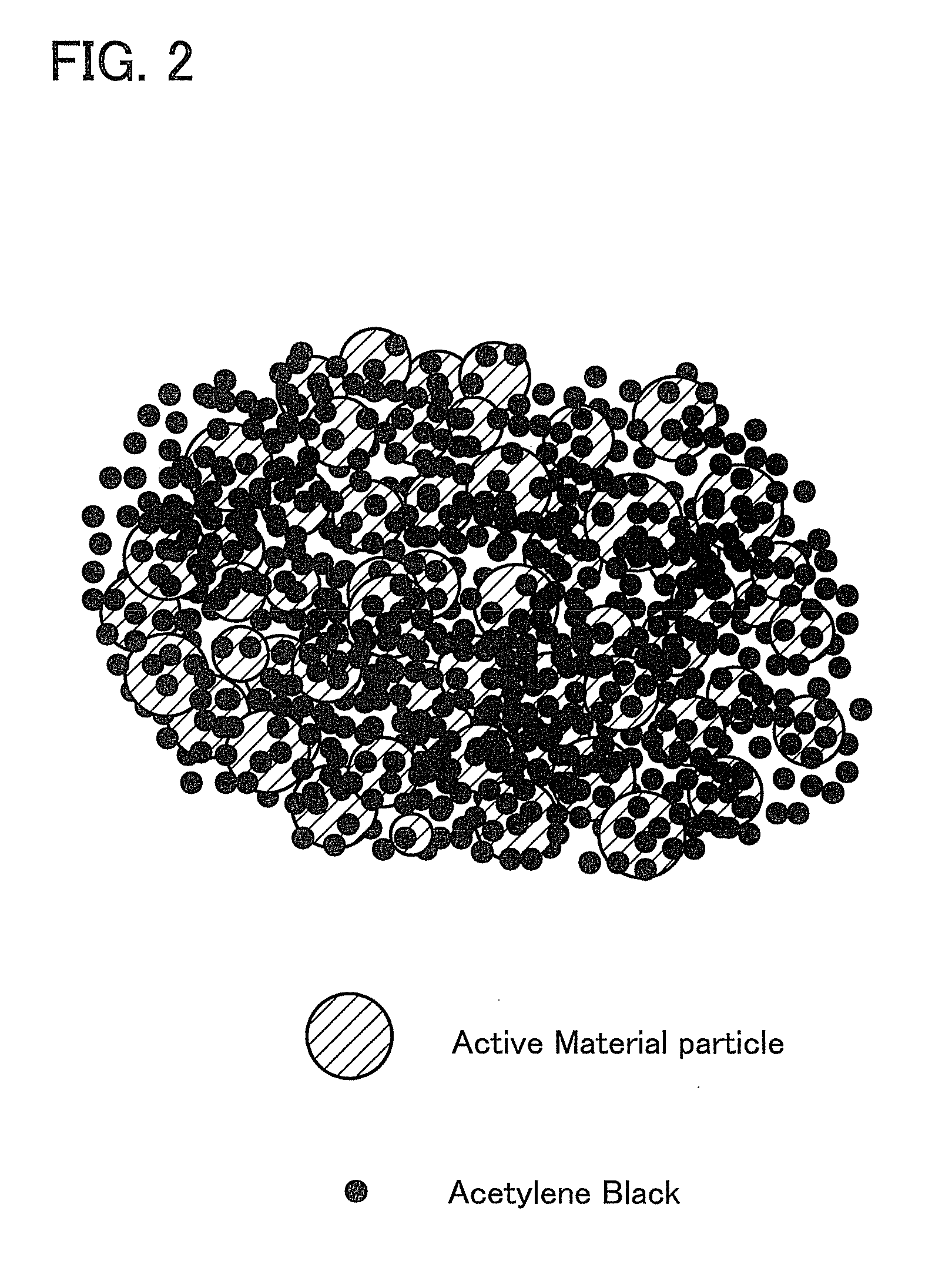

InactiveUS20120045692A1Improve conductivityLower the volumeActive material electrodesNon-aqueous electrolyte accumulator electrodesFiberCarbon fibers

An object is to increase the conductivity of an electrode including active material particles and the like, which is used for a battery. Two-dimensional carbon including 1 to 10 graphenes is used as a conduction auxiliary agent, instead of a conventionally used conduction auxiliary agent extending only one-dimensionally at most, such as graphite particles, acetylene black, or carbon fibers. A conduction auxiliary agent extending two-dimensionally has higher probability of being in contact with active material particles or other conduction auxiliary agents, so that the conductivity can be improved.

Owner:SEMICON ENERGY LAB CO LTD

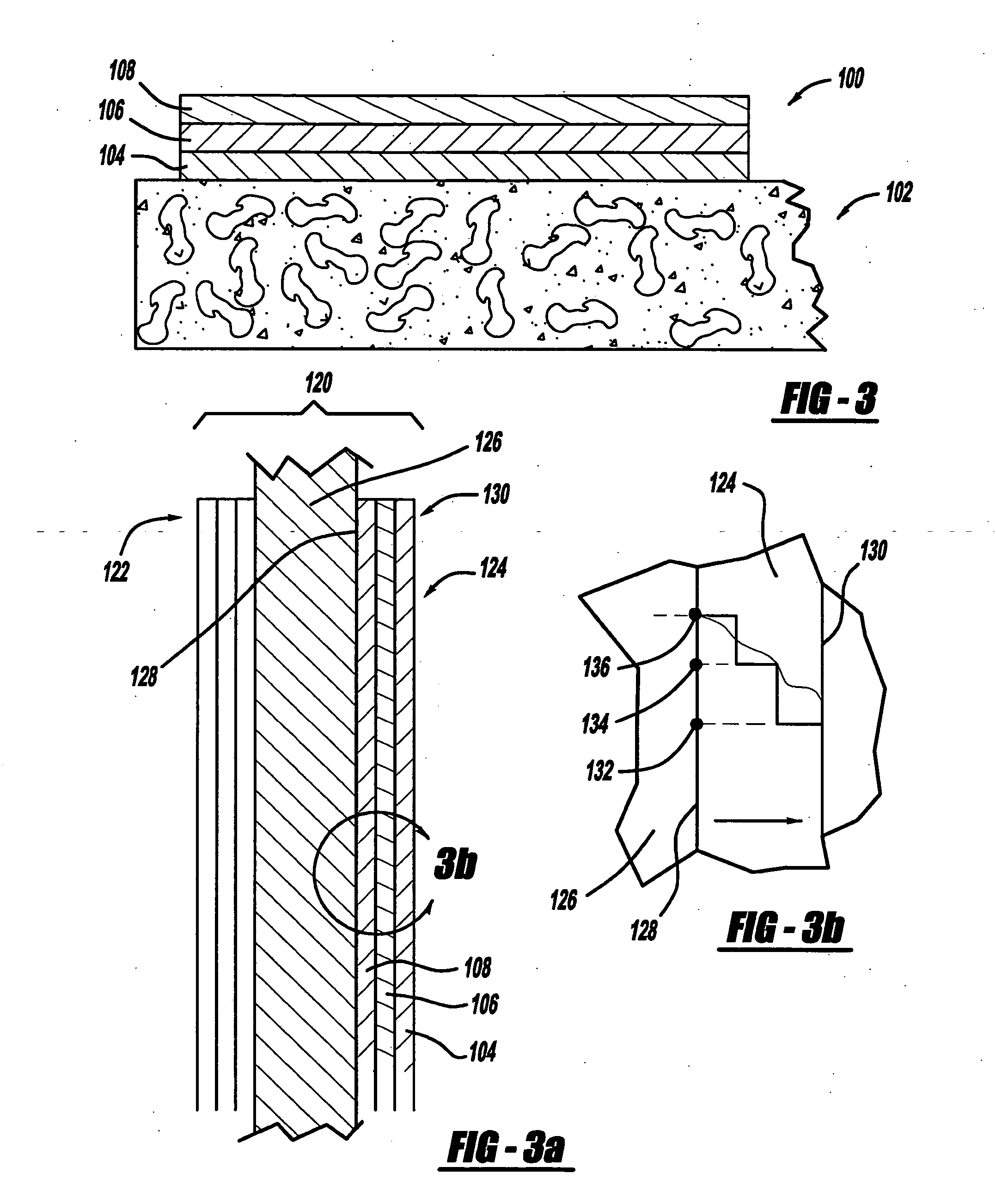

Electrochemical cell including functionally graded and architectured components and methods

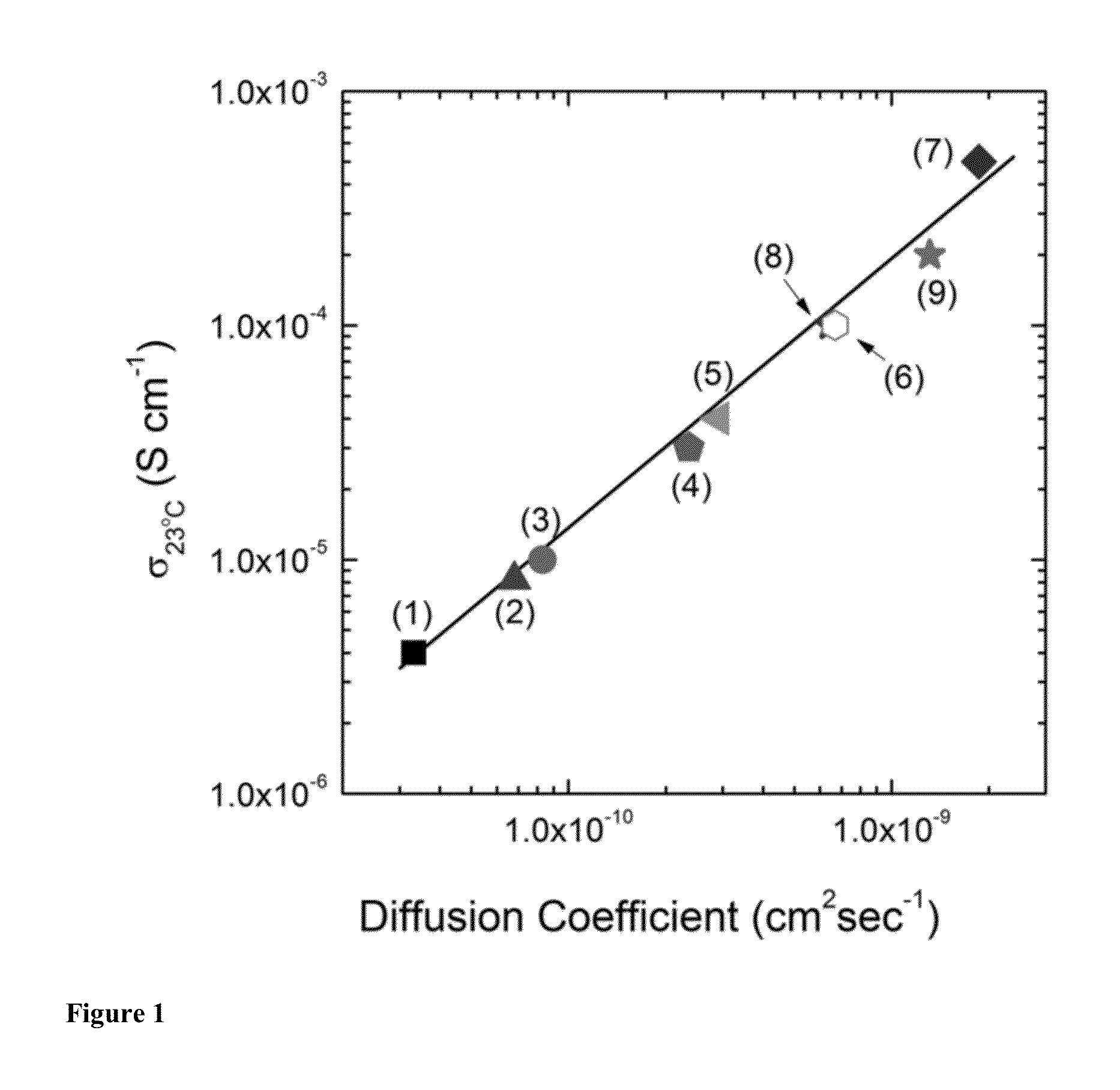

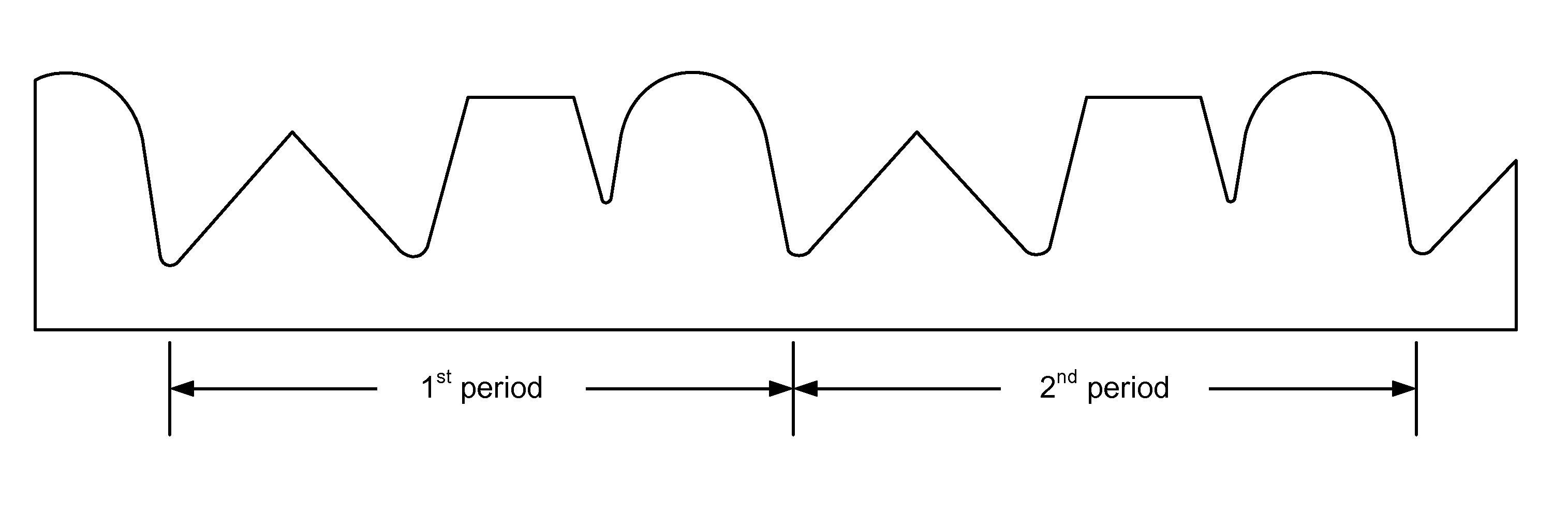

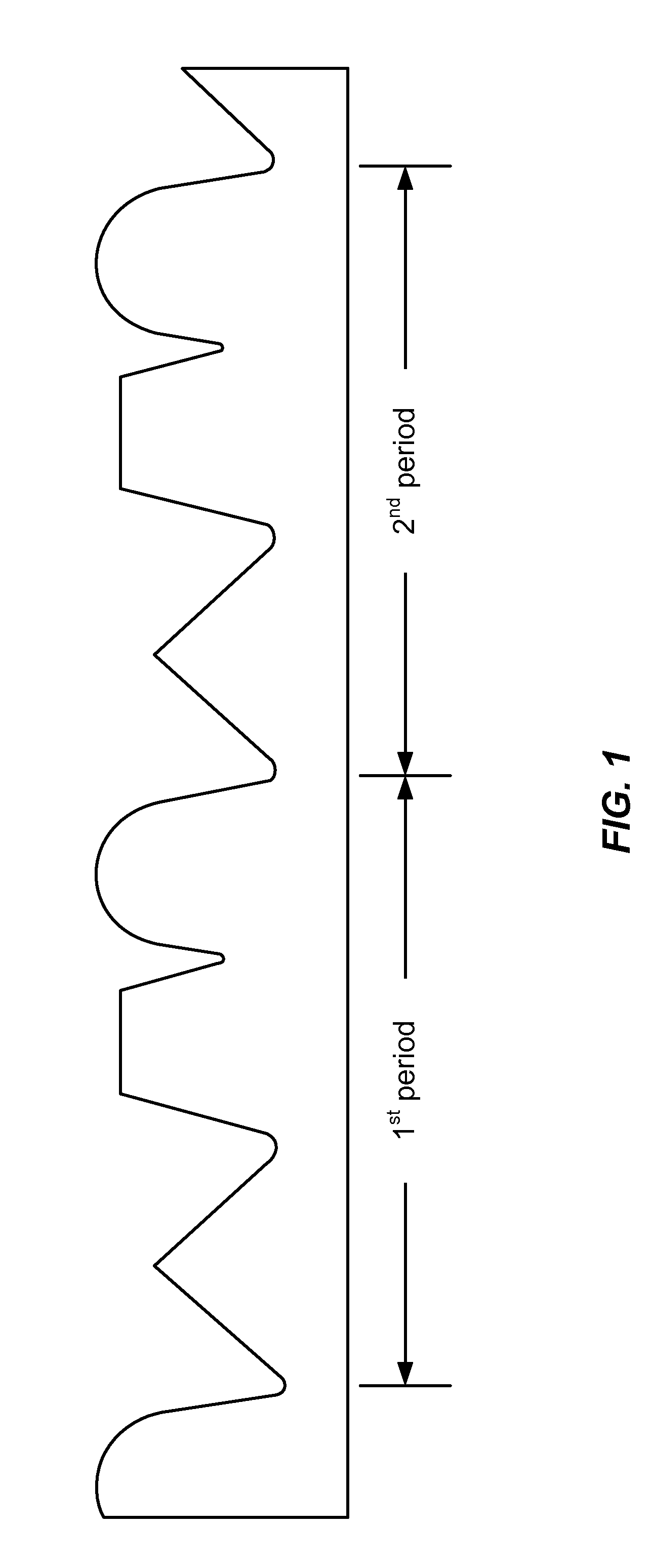

PendingUS20100035152A1Maintain good propertiesEliminate errorsMaterial nanotechnologyMolten spray coatingIonic diffusionHigh rate

Electrochemical cells or batteries featuring functional gradations, and having desirable, periodic configurations, and methods for making the same. One or more methods, in alone or in combination, are utilized to fabricate components of such electrochemical cells or batteries, which are designed to achieve certain thermal, mechanical, kinetic and spatial characteristics, and their effects, singly and in all possible combinations, on battery performance. The thermal characteristics relate to temperature distribution during charge and discharge processes. The kinetic characteristics relate to rate performance of the cells or batteries such as the ionic diffusion process and electron conduction. The mechanical characteristics relate to lifetime and efficiency of the cells or batteries such as the strength and moduli of the component materials. Finally, the spatial characteristics relate to the energy and power densities, stress and temperature mitigation mechanisms, and diffusion and conduction enhancements. The electrochemical cells or batteries constructed according to the methods presented in this invention are useful for all applications that require high rate performance, high energy / power density, good durability, high safety and long lifetime.

Owner:SAKTI3

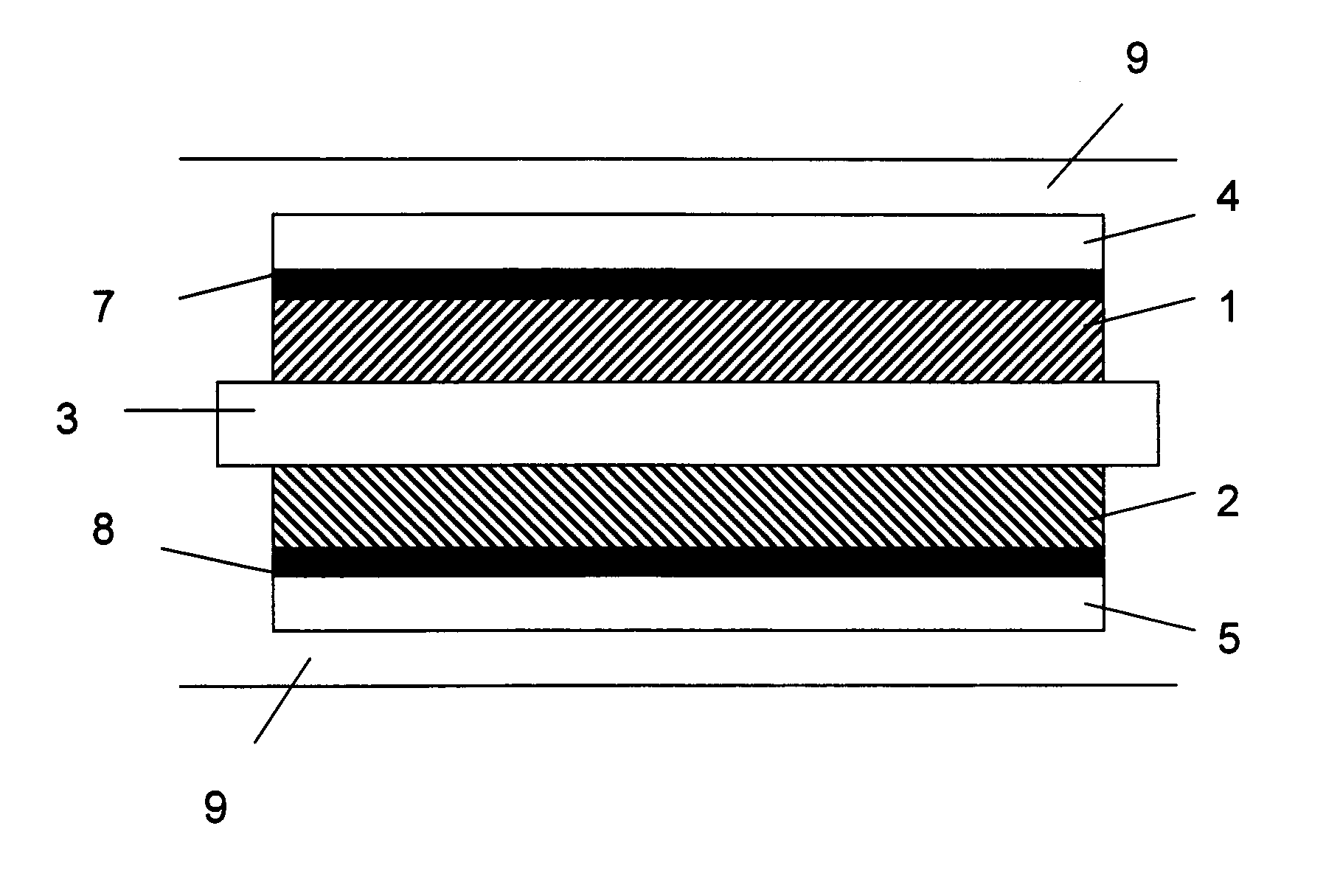

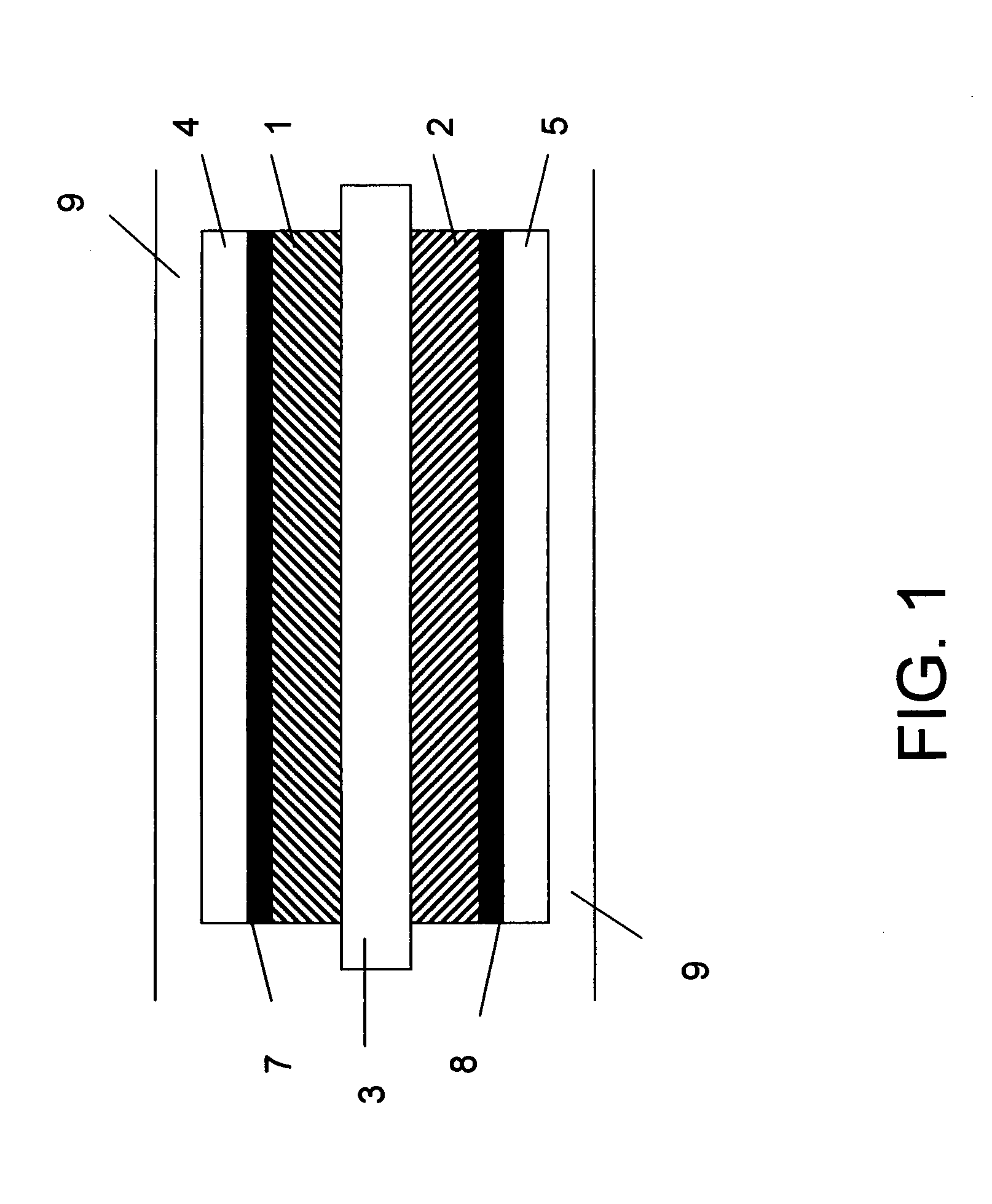

Layered arrangements of lithium cells

InactiveCN1415124ANon-aqueous electrolyte accumulatorsElectrode carriers/collectorsMetal electrodesMaterials science

A method employing a bonding layer is used to form active metal electrodes having barrier layers. Active metals such as lithium are highly reactive in ambient conditions. The method involves fabricating a lithium electrode or other active metal electrode without depositing the barrier layer on a layer of metal. Rather a smooth barrier layer is formed on a smooth substrate such as a web carrier or polymeric electrolyte. A bonding or alloying layer is formed on top of the barrier layer. Lithium or other active material is then attached to the bonding layer to form the active metal electrode. A current collector may also be attached to the lithium or active metal during the process.

Owner:POLYPLUS BATTERY CO INC

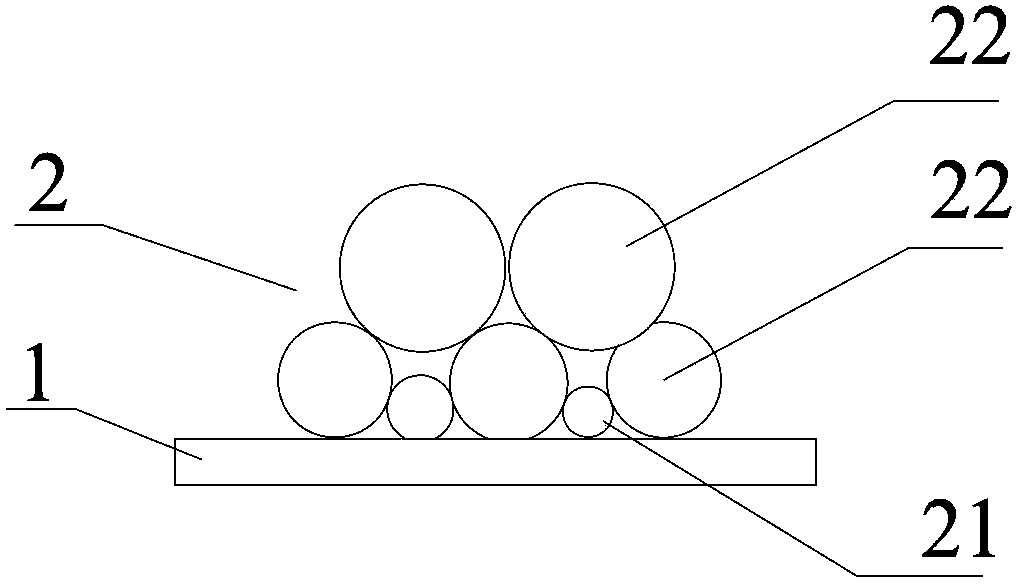

Combined electrode of battery and preparation method thereof

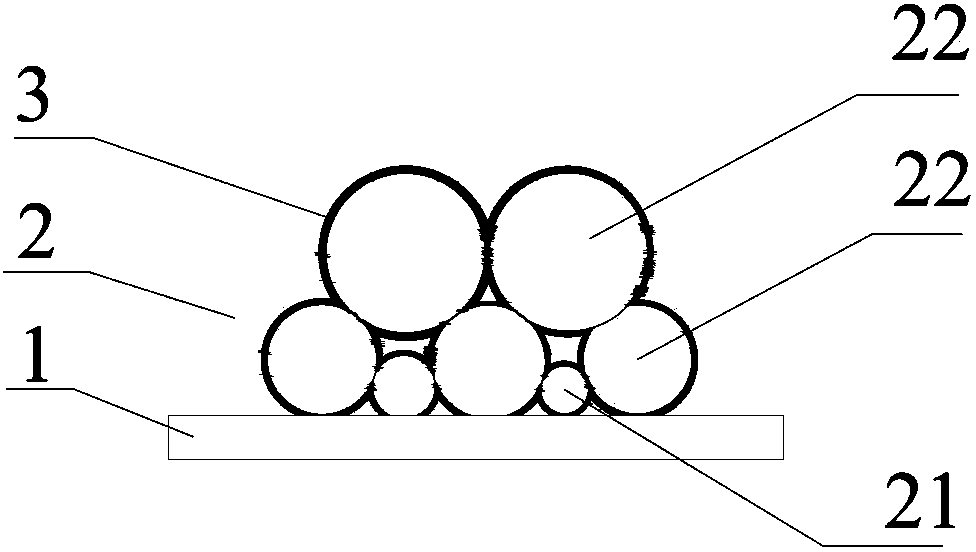

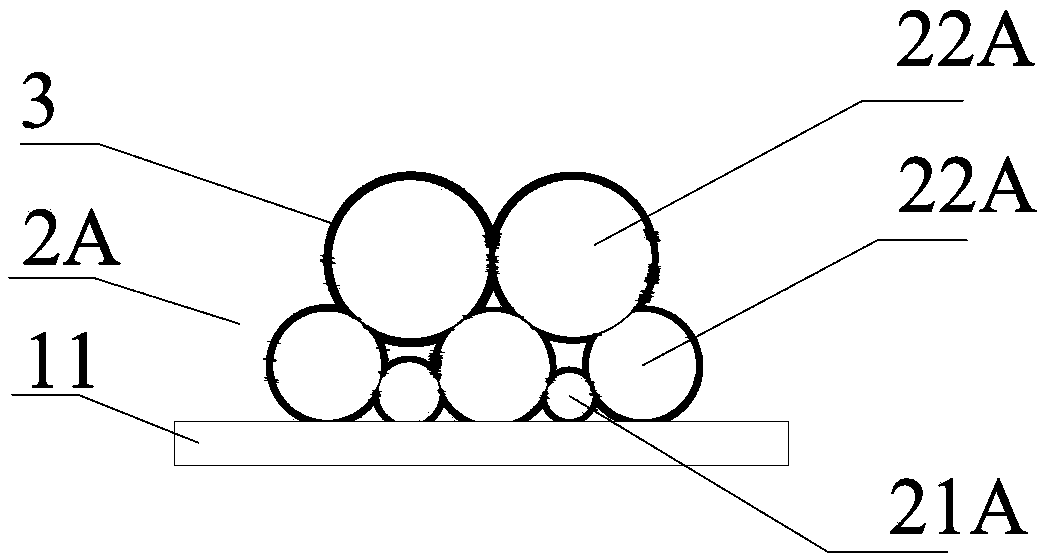

InactiveCN103730630AImprove electronic conductivityImprove ionic conductivityActive material electrodesElectrolyte layer coatingSolid state electrolyteElectrical battery

The application relates to the field of energy storage materials, and discloses a combined electrode with ultrahigh electron and ionic conductivity and a preparation method thereof. The combined electrode is formed in a manner that a battery active material is uniformly tied in a three-dimensional multi-hole network formed by carbon nano tubes which are connected in a crossing manner, and meshes and the surface of the active material are filled or coated with a solid electrolyte material. According to the combined electrode, the carbon nano tubes, which are communicated with one another, can form an ultrahigh electrical transmission network, on the one hand, a solid electrolyte can provide the ultrahigh lithium-ion transmission capacity while not influencing the connection of the carbon nano tubes and the conductive capacity of the electrode; on the other hand, the three-dimensional network formed by the carbon nano tubes is also fixed by virtue of the solid electrolyte, the formation of a solid electrolyte interface is controlled, and an active material is protected under the high charge-discharge voltage. The combined electrode has the high reversible capacity and the enhanced rate capability, and can meet the requirement of a power automobile or a mixed power automobile.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

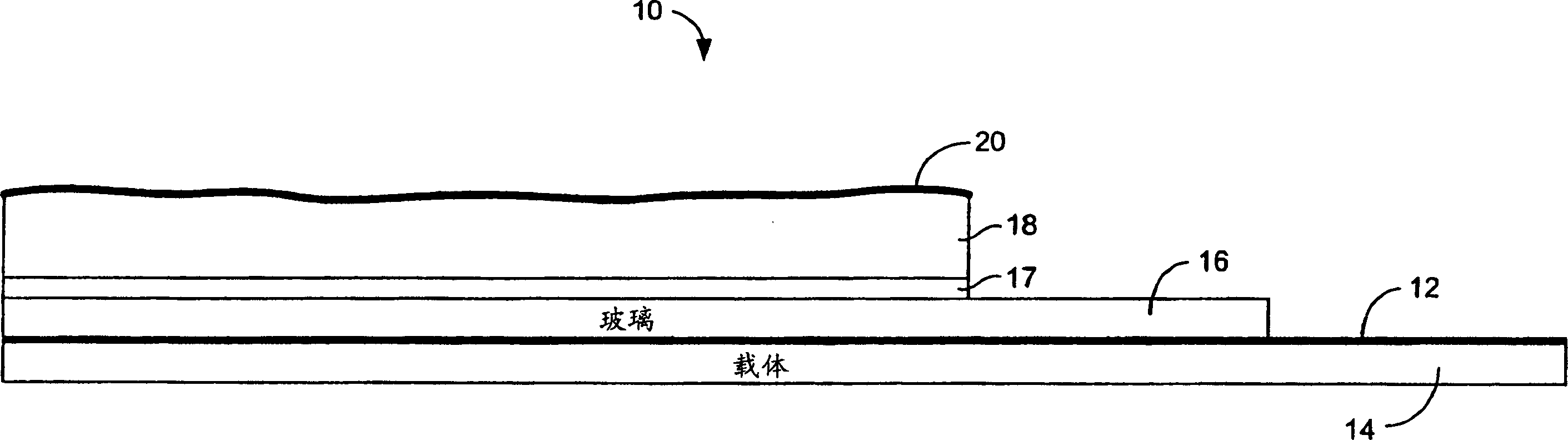

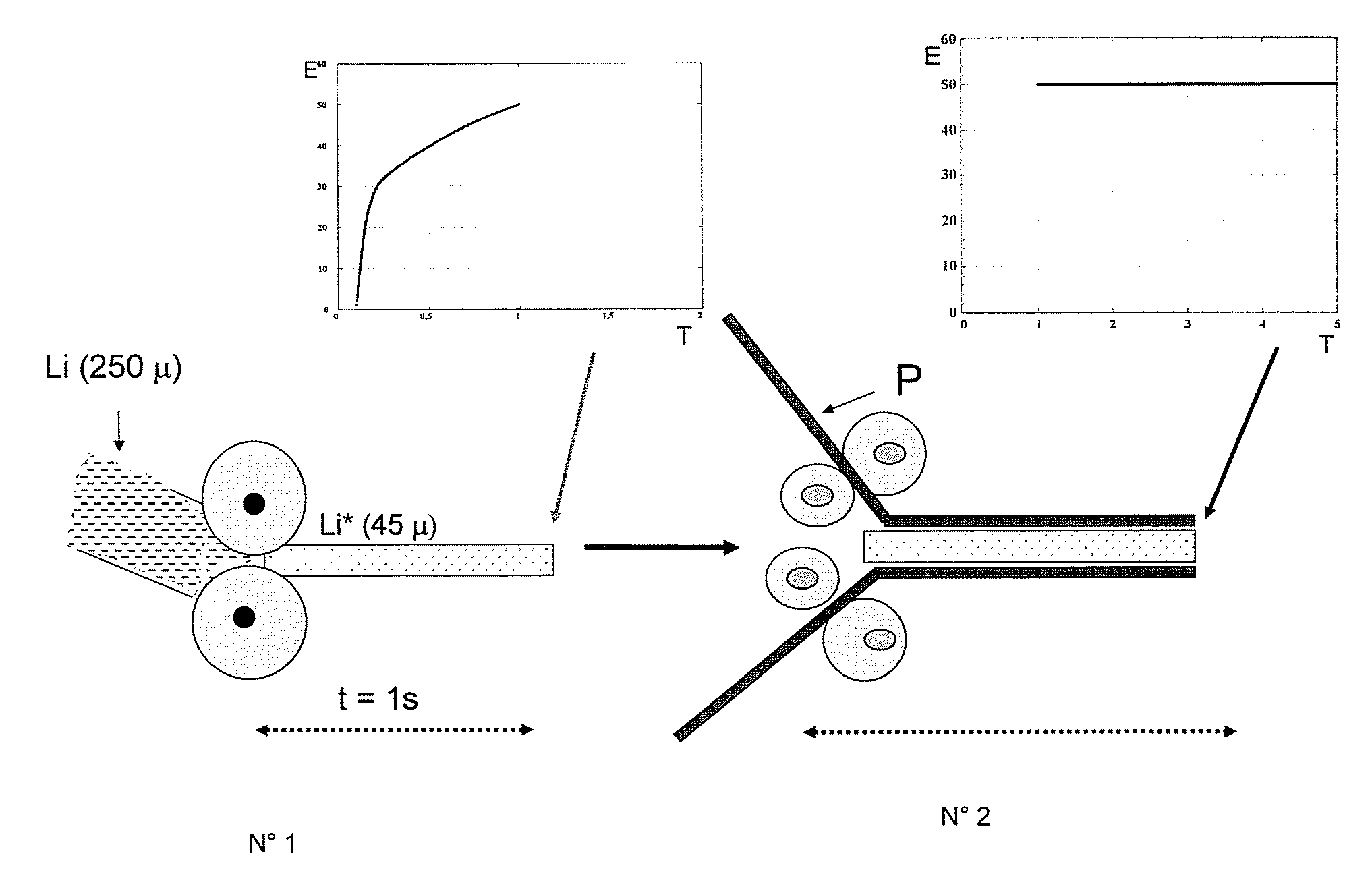

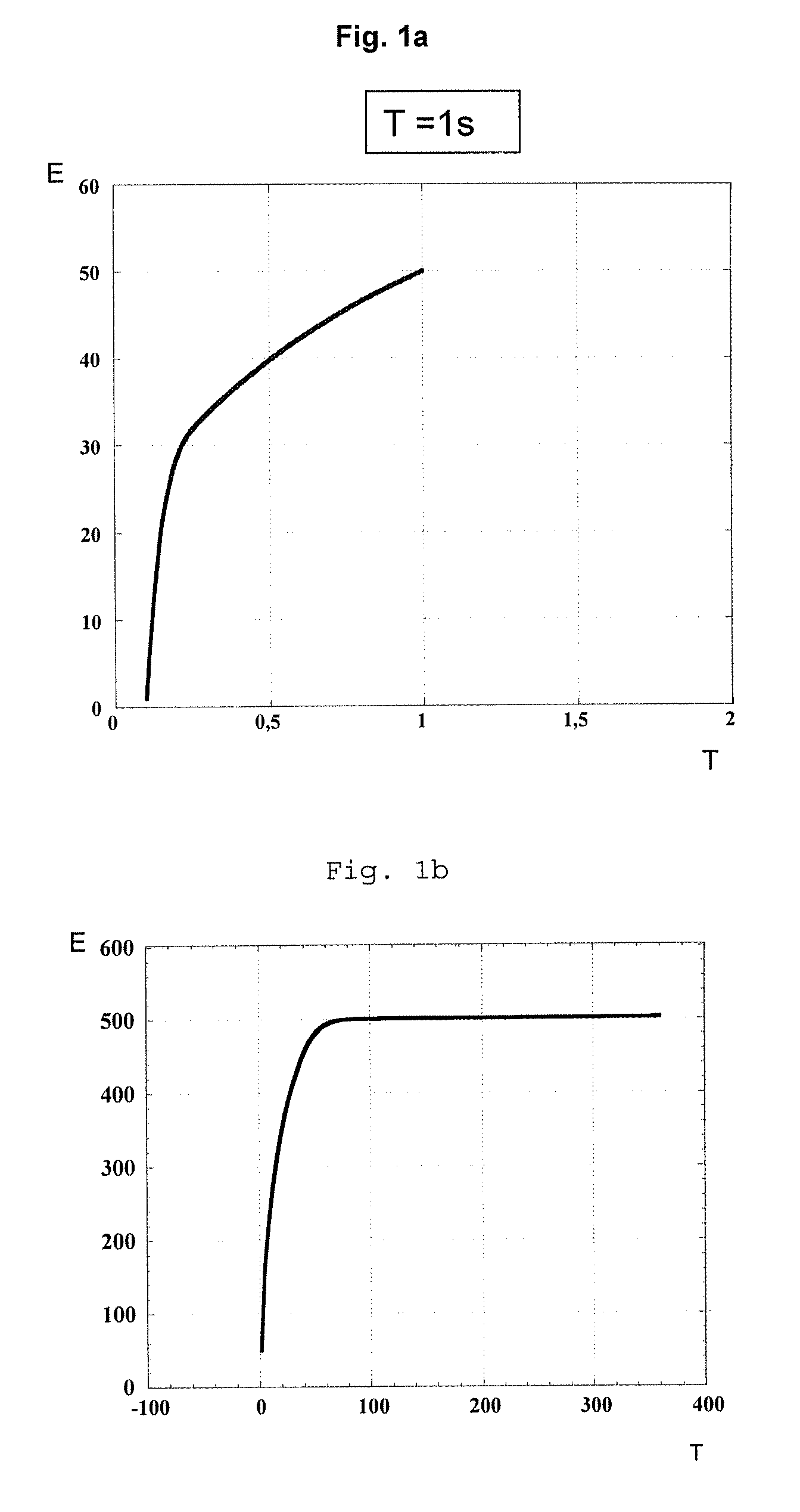

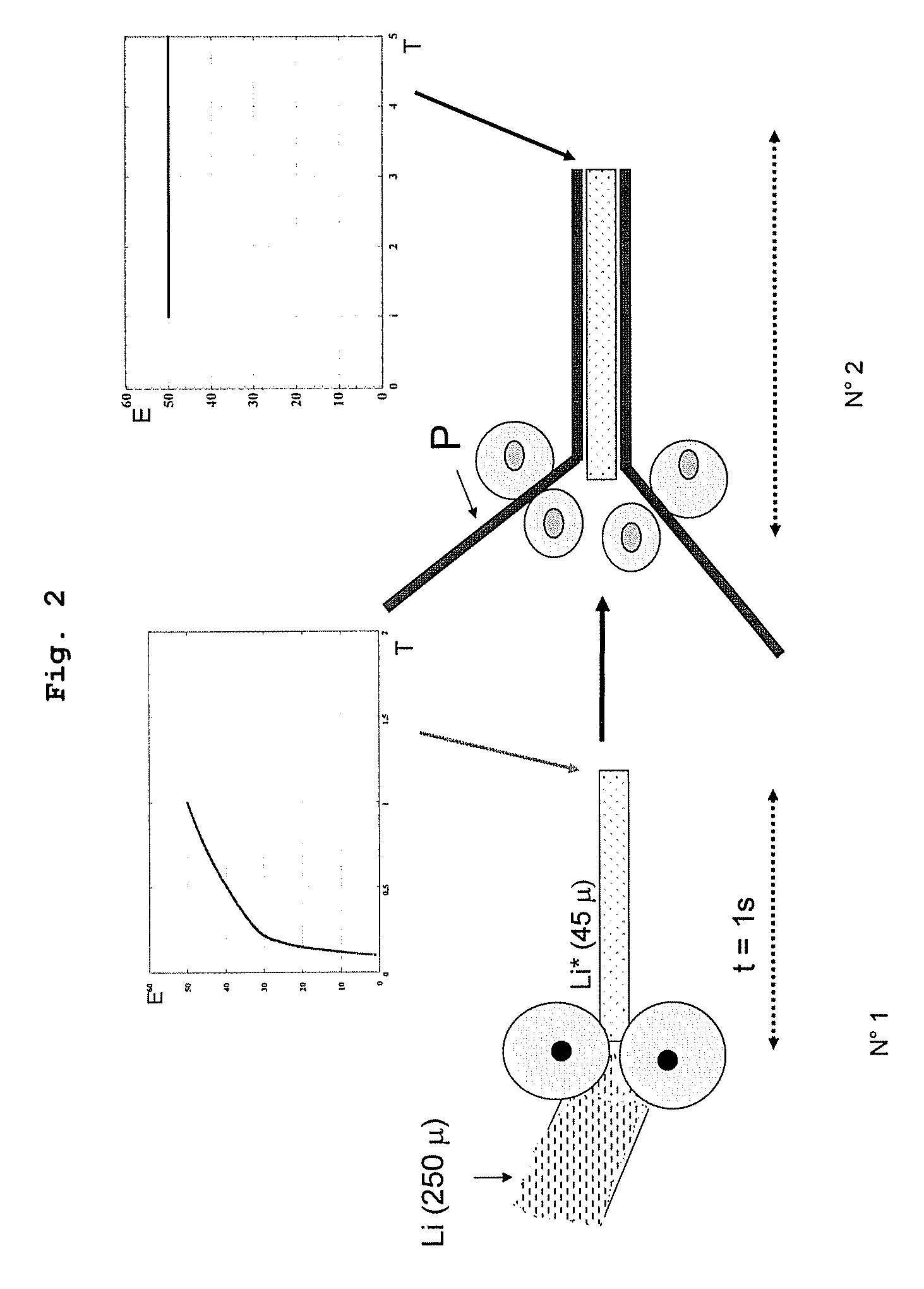

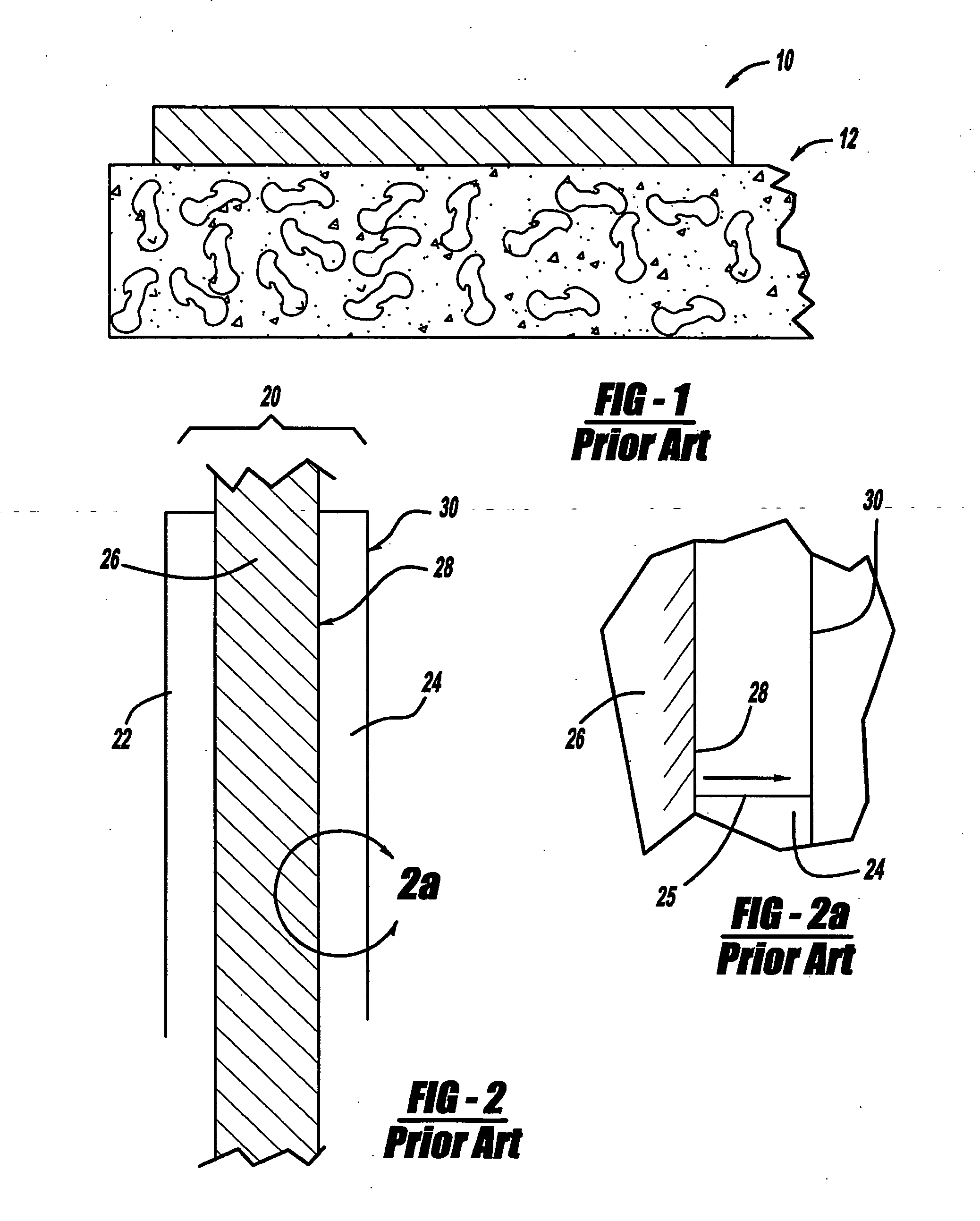

Multilayer material based on active lithium, method of preparation and applications in electrochemical generators

InactiveUS20090280410A1Improve adhesionExcellent impedance stabilityMolten spray coatingFinal product manufactureLithiumSufficient time

A method for preparing a multilayer material based on active lithium, by depositing a film of active lithium on a protective layer at a sufficient speed so that substantially no oxidation of the lithium occurs, and / or during a sufficient time for the adhesion of the lithium to develop after contact with the protective layer. The multilayer material, when incorporated in an electrochemical battery as an anode, has excellent impedance stability and no formation of dendrites during the cycling. Batteries where the anode is the multilayer material are particularly efficient in terms of their coulomb efficiency.

Owner:HYDRO QUEBEC CORP

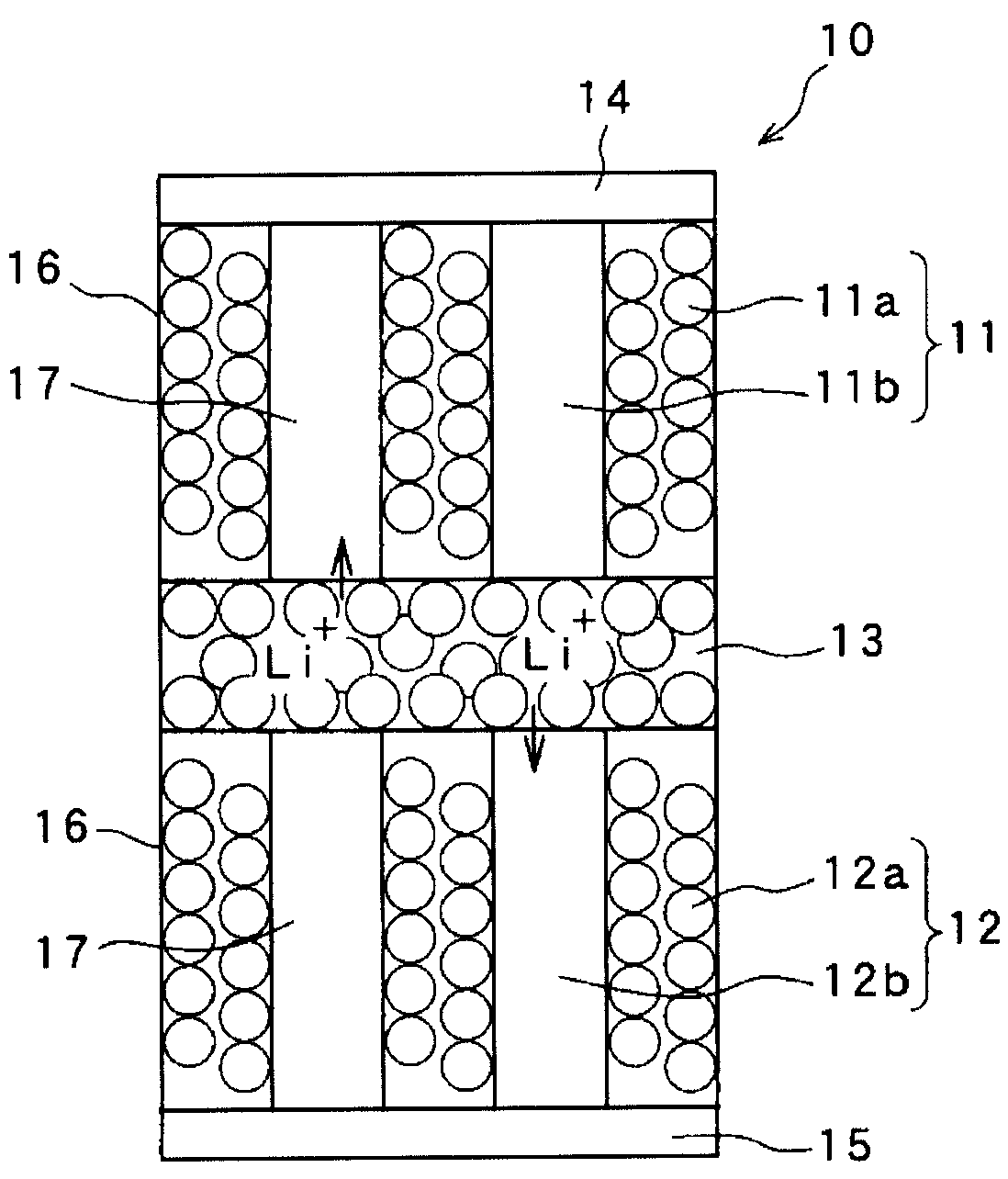

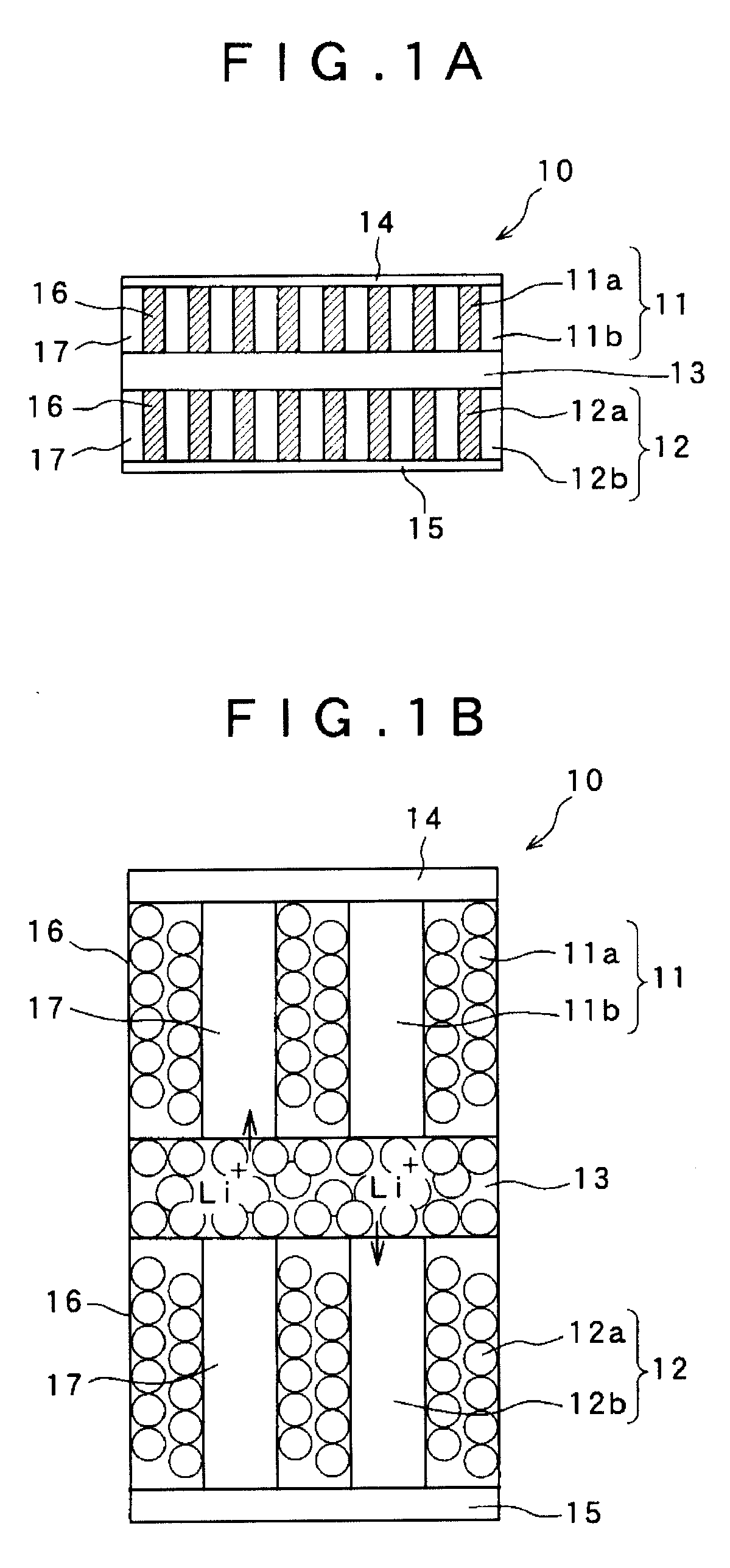

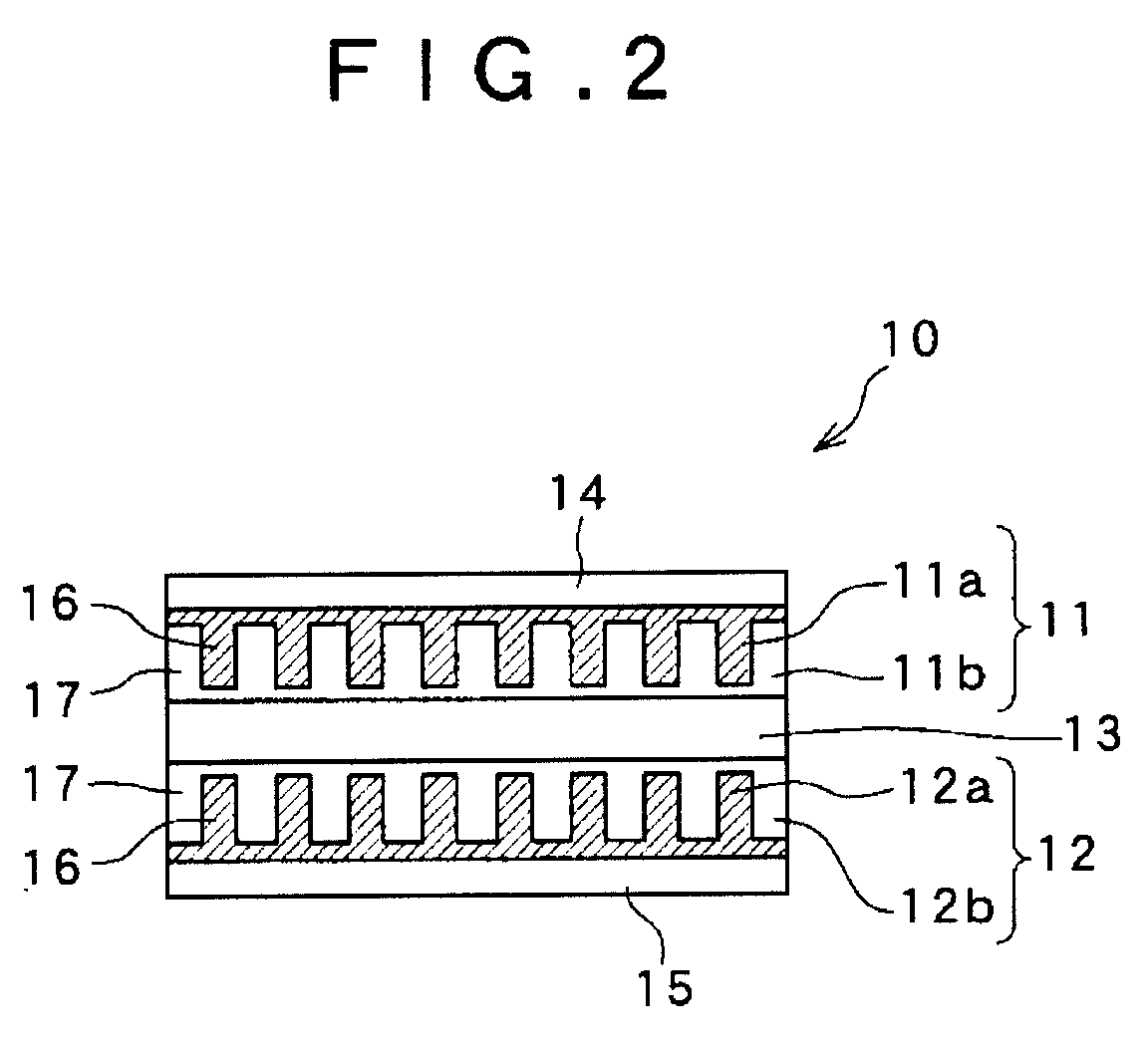

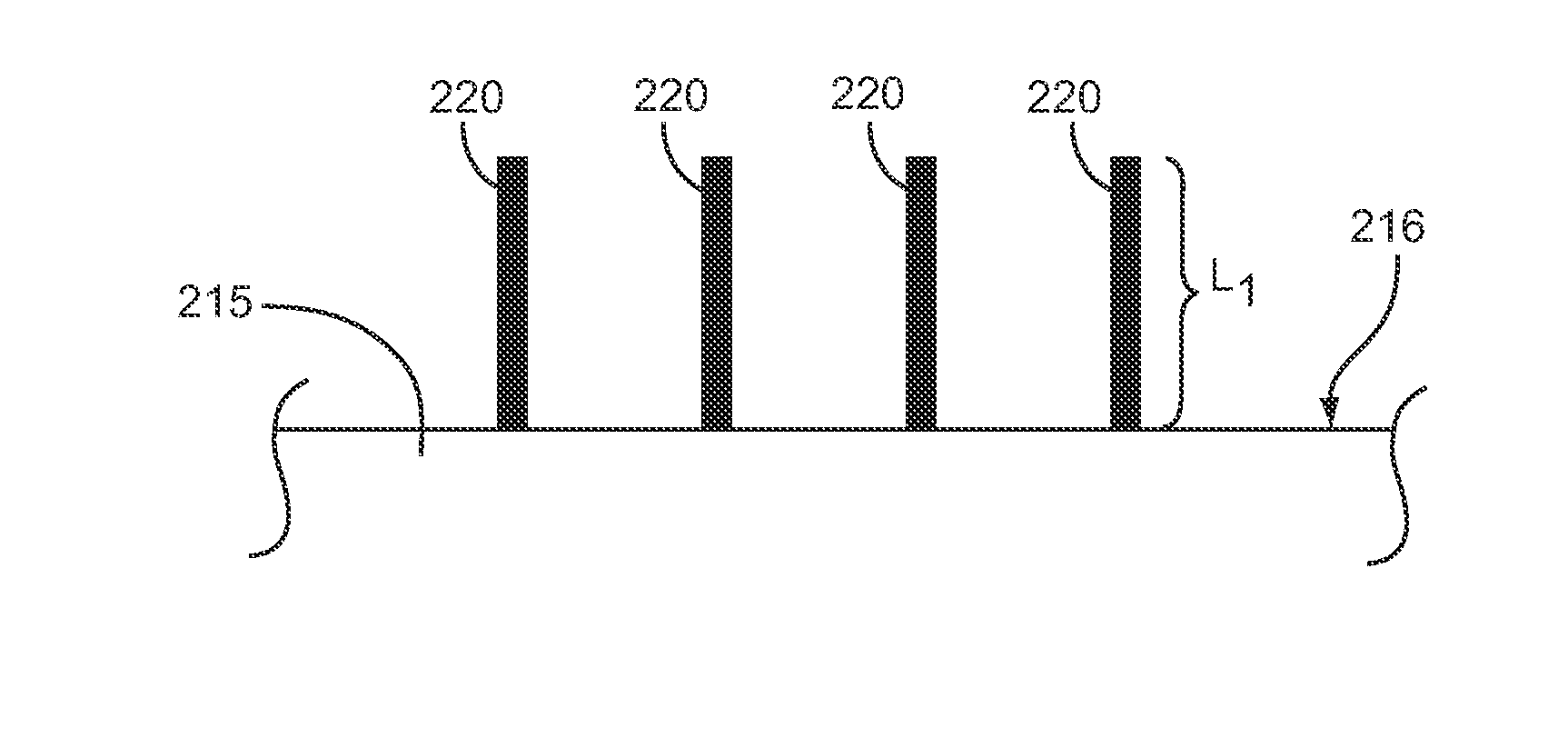

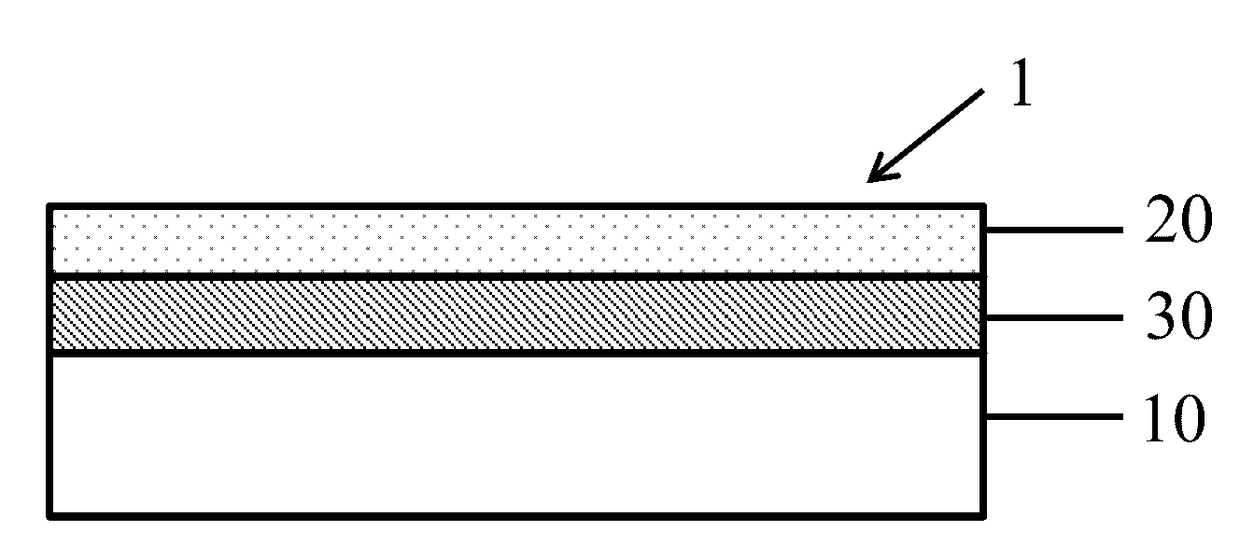

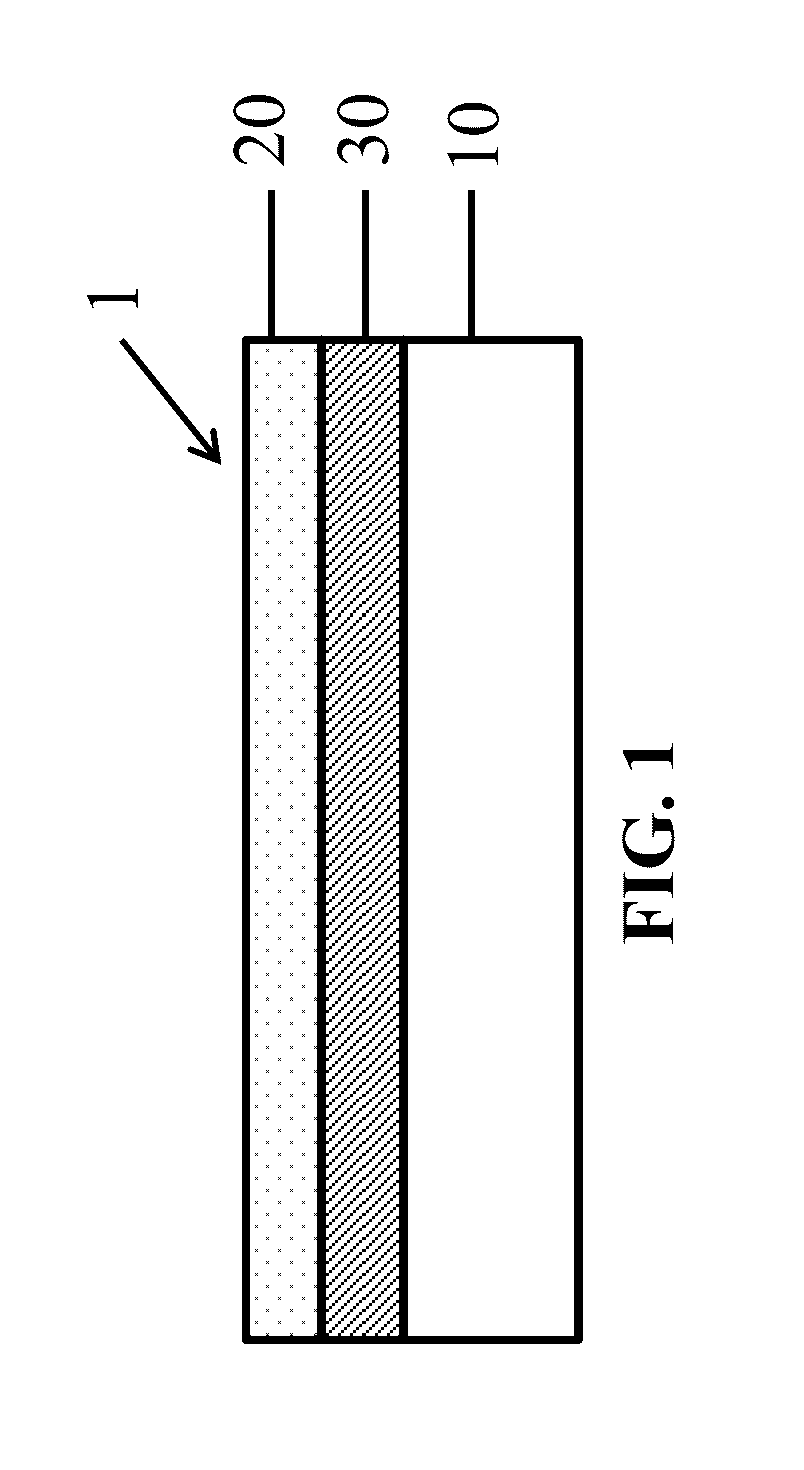

Solid battery and a method for manufacturing an electrode thereof

InactiveUS20090197183A1Reduce distanceContact member manufacturingFuel cells groupingEngineeringElectrolyte

A solid battery includes at least either one of a positive electrode and a negative electrode comprising bars of an active material of the electrode and bars of a solid electrolyte of the electrode arranged alternately in such a manner that each of the bars of the active material of the electrode is disposed adjacent to each of the bars of the solid electrolyte of the electrode, and a solid electrolyte constituting a separator and having a plane to which the bars of the active material and the bars of the solid electrolyte of the electrode are disposed in a crossing direction. There is also provided a method for manufacturing an electrode of such solid battery.

Owner:OHARA

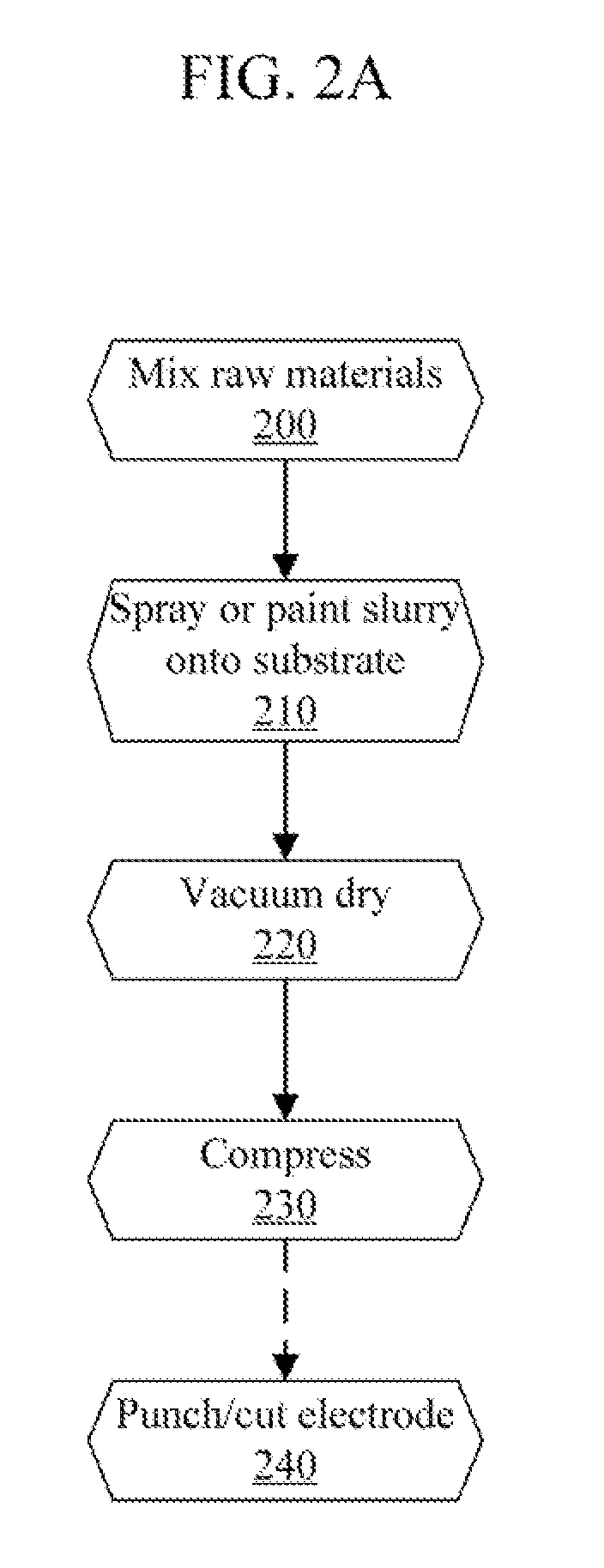

Electrode for a thermal battery and method of making the same

InactiveUS20080289676A1Deferred-action cellsElectrode collector coatingSlurryVolumetric Mass Density

An aqueous slurry can be used to paint thermal electrodes onto a current-collector substrate with a spray gun for thin electrodes or pasting with a thickened slurry. A feedstock aqueous slurry can include thermal electrode components, thermal electrolyte components, a binder or thickening agent, and water. This slurry can be sprayed or pasted onto a substrate and dried. To obtain different densities, the substrate can be compressed to a desired density. Thermal electrodes of a desired size and shape can be cut or punched from the sheet. Different binders and / or binder concentrations can be used to adjust the viscosity and / or thickness of the electrode.

Owner:ELECTRO ENERGY

Method for manufacturing a lithium ion secondary battery

InactiveUS20090194222A1Efficient preparationImprove electronic conductivityFinal product manufactureElectrode carriers/collectorsLithiumMaterials science

A method for manufacturing a lithium ion secondary battery includes a step of preparing a laminate comprising a solid electrolyte and a solid electrode or an electrode green sheet which is laminated on at least one surface of the solid electrolyte, and a step of providing a collector by laminating a collector material in the form of particles on the electrode or the electrode green sheet and sintering the collector material.

Owner:OHARA

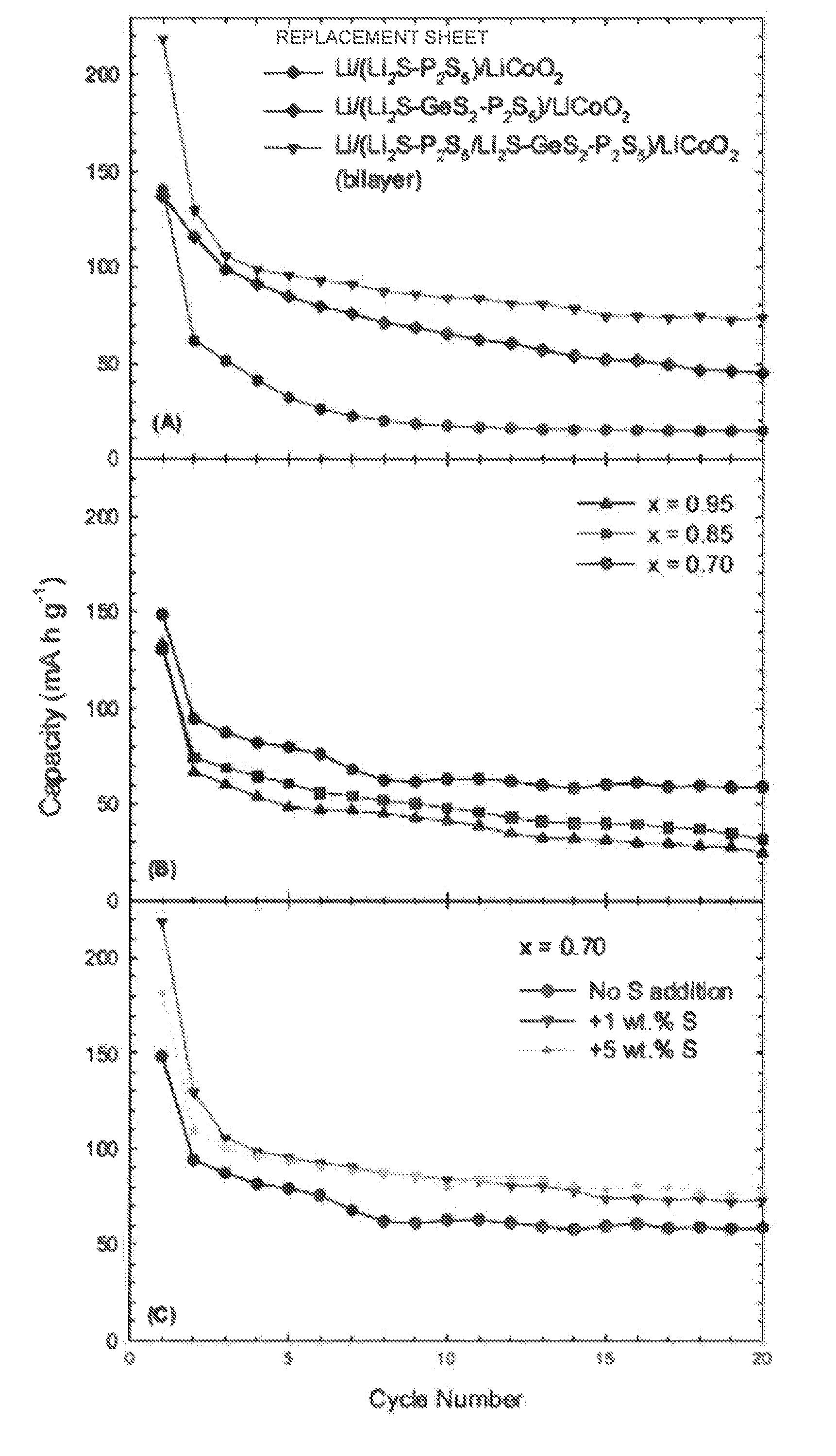

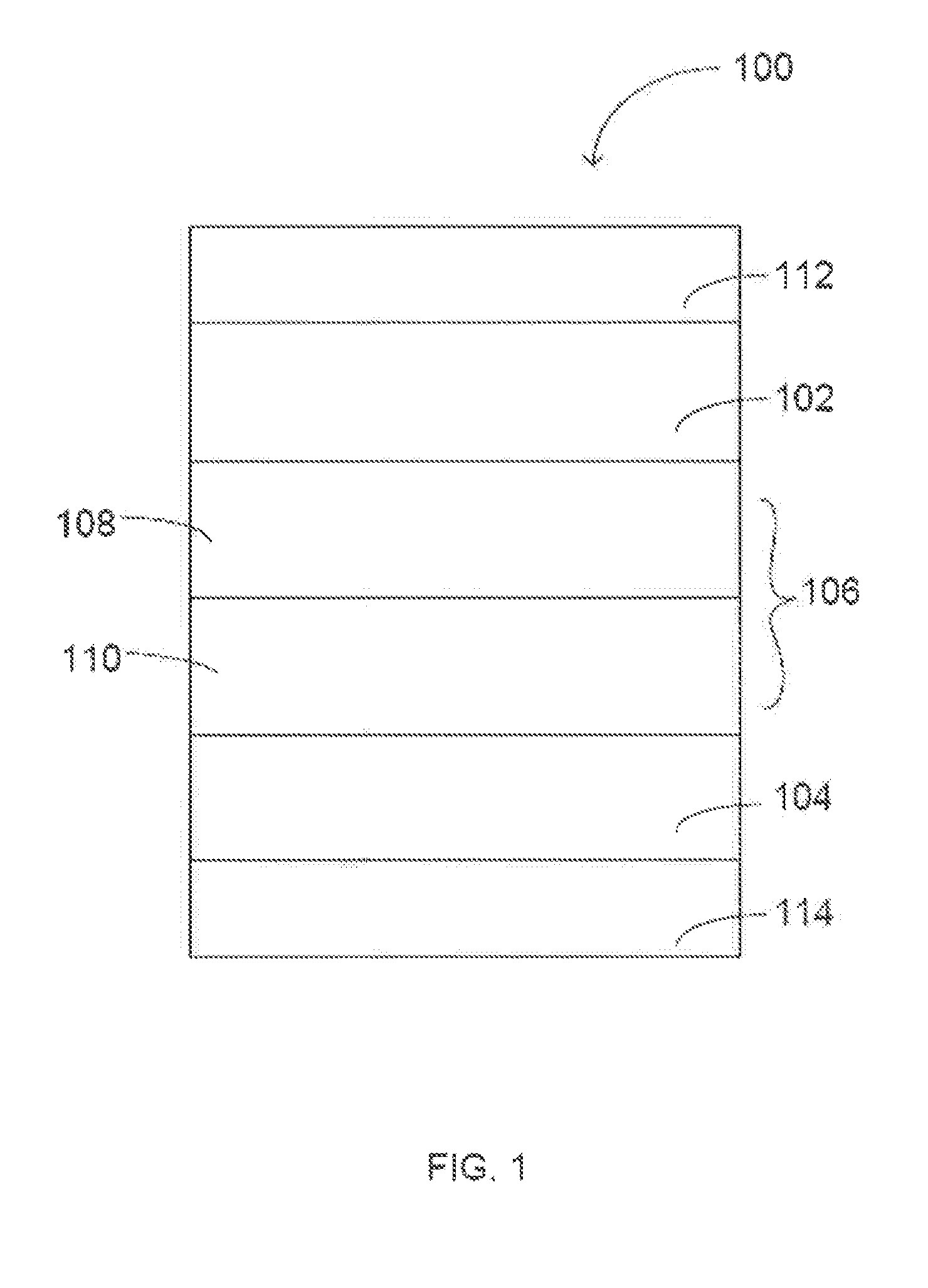

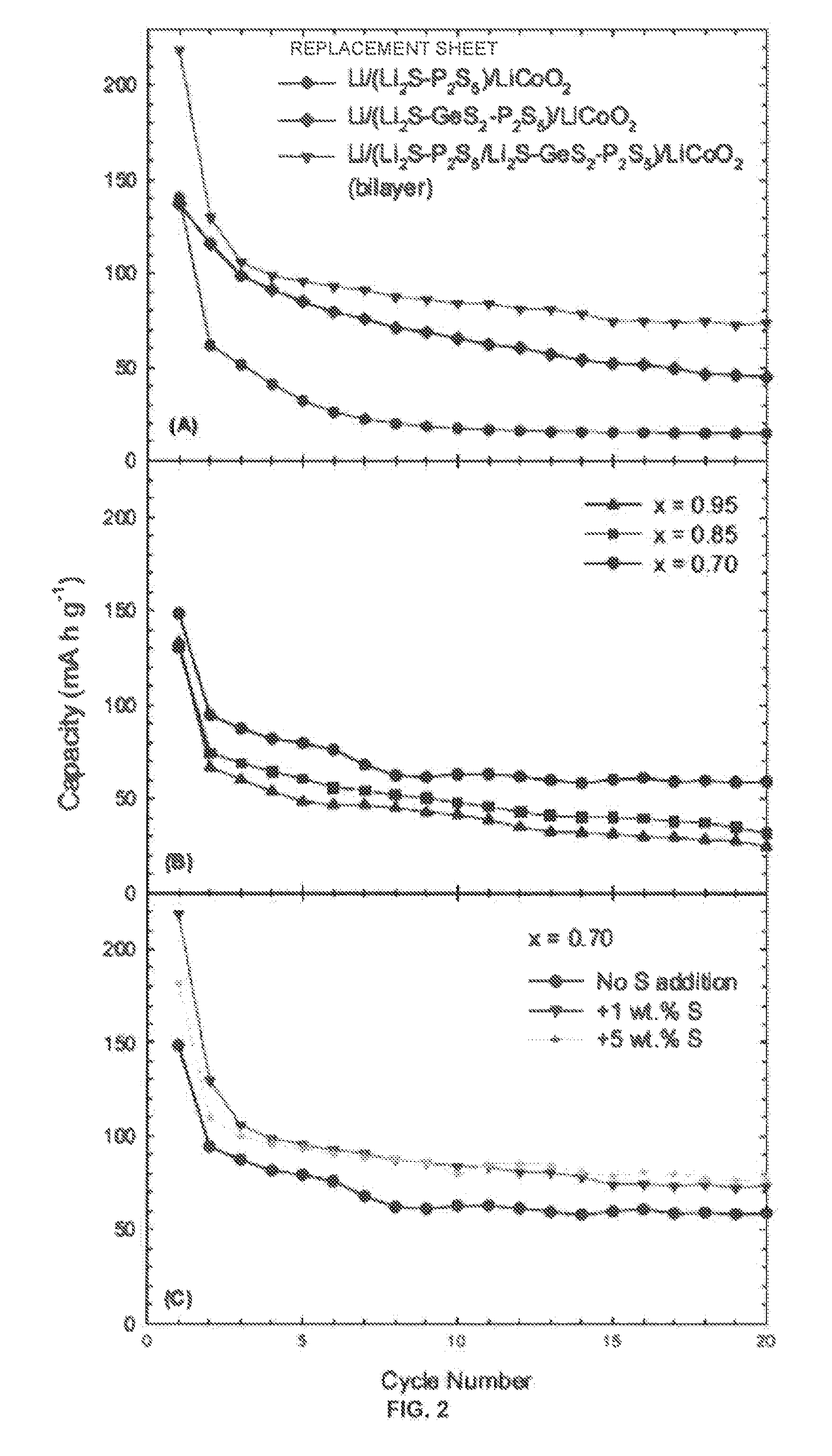

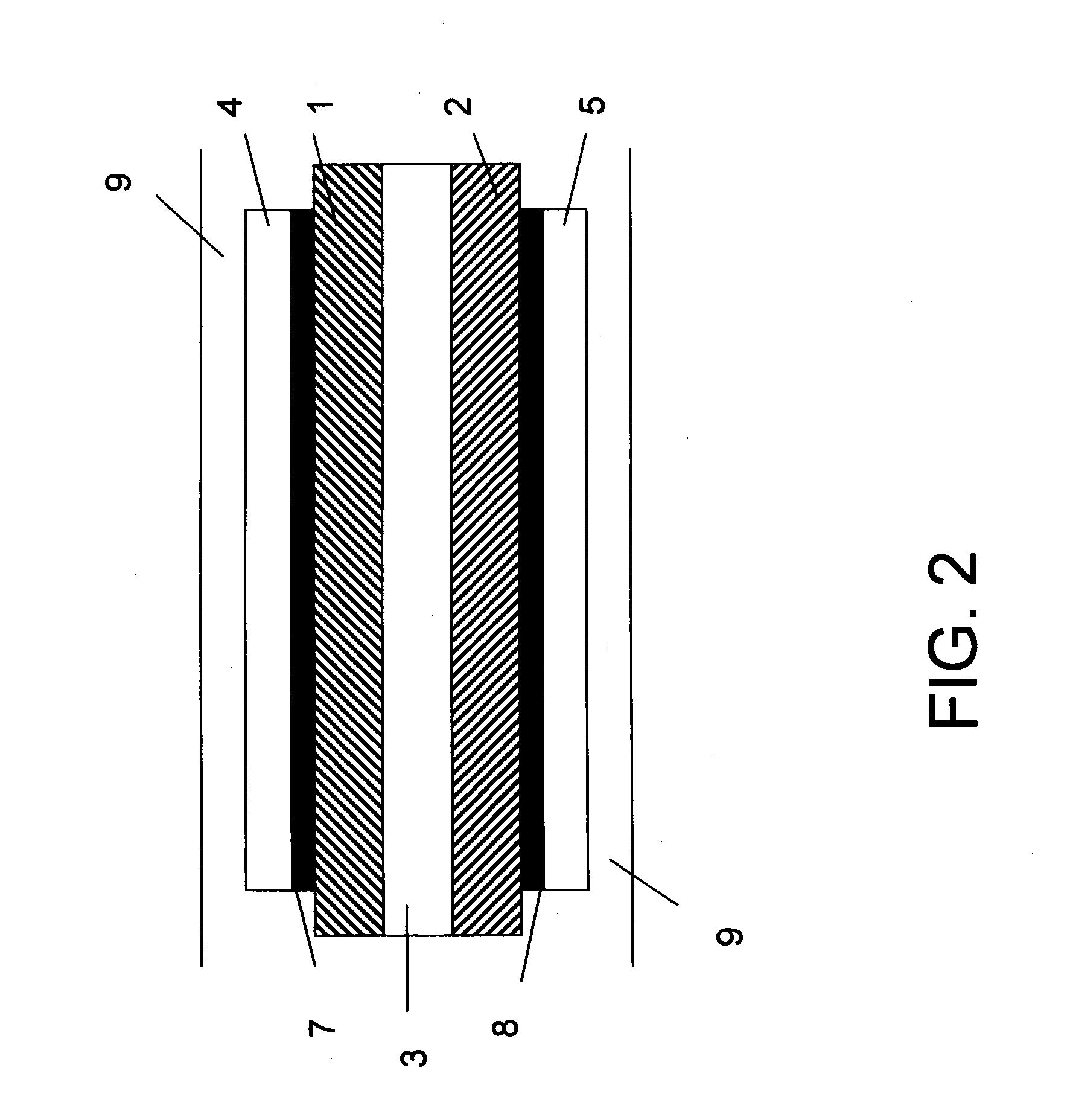

Solid-state multi-layer electrolyte, electrochemical cell and battery including the electrolyte, and method of forming same

InactiveUS20120301778A1Improve performanceReduce capacity lossFinal product manufactureSmall-sized cells cases/jacketsSolid state electrolyteEngineering

An electrochemical cell including a multi-layer solid-state electrolyte, a battery including the cell, and a method of forming the battery and cell are disclosed. The electrolyte includes a first layer that is compatible with the anode of the cell and a second layer that is compatible with the cathode of the cell. The cell exhibits improved performance compared to cells including a single-layer electrolyte.

Owner:UNIV OF COLORADO THE REGENTS OF

Silicon Nanostructure Active Materials for Lithium Ion Batteries and Processes, Compositions, Components and Devices Related Thereto

ActiveUS20140248543A1Highly controllableAvoid irreversibleElectrochemical processing of electrodesElectrode carriers/collectorsCopper electrodeGraphite particle

The present invention relates to nanostructured materials for use in rechargeable energy storage devices such as lithium batteries, particularly rechargeable secondary lithium batteries, or lithium-ion batteries (LIBs). The present invention includes materials, components, and devices, including nanostructured materials for use as battery active materials, and lithium ion battery (LIB) electrodes comprising such nanostructured materials, as well as manufacturing methods related thereto. Exemplary nanostructured materials include silicon-based nanostructures such as silicon nanowires and coated silicon nanowires, nanostructures disposed on substrates comprising active materials or current collectors such as silicon nanowires disposed on graphite particles or copper electrode plates, and LIB anode composites comprising high-capacity active material nanostructures formed on a porous copper and / or graphite powder substrate.

Owner:ONED MATERIAL INC

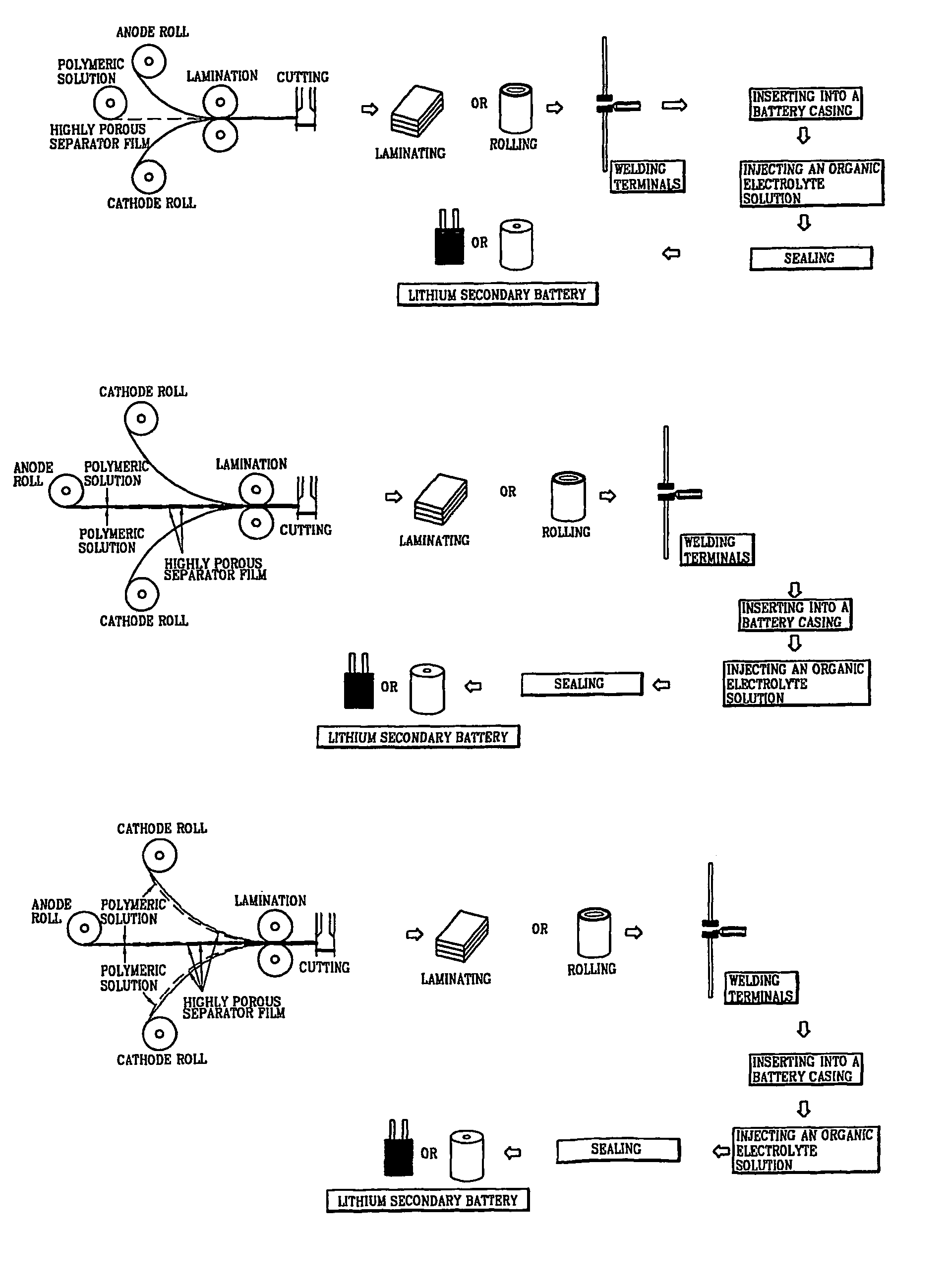

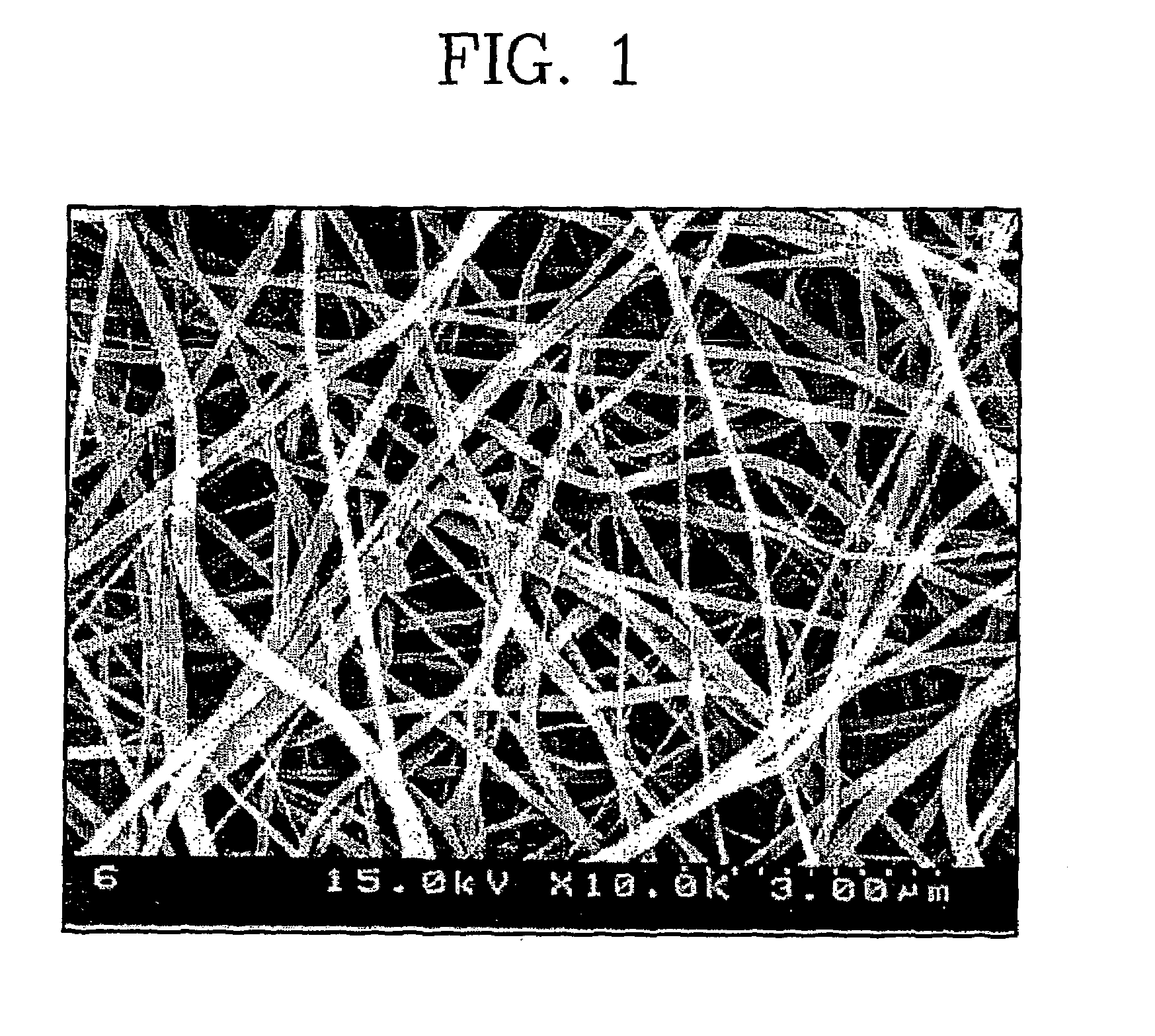

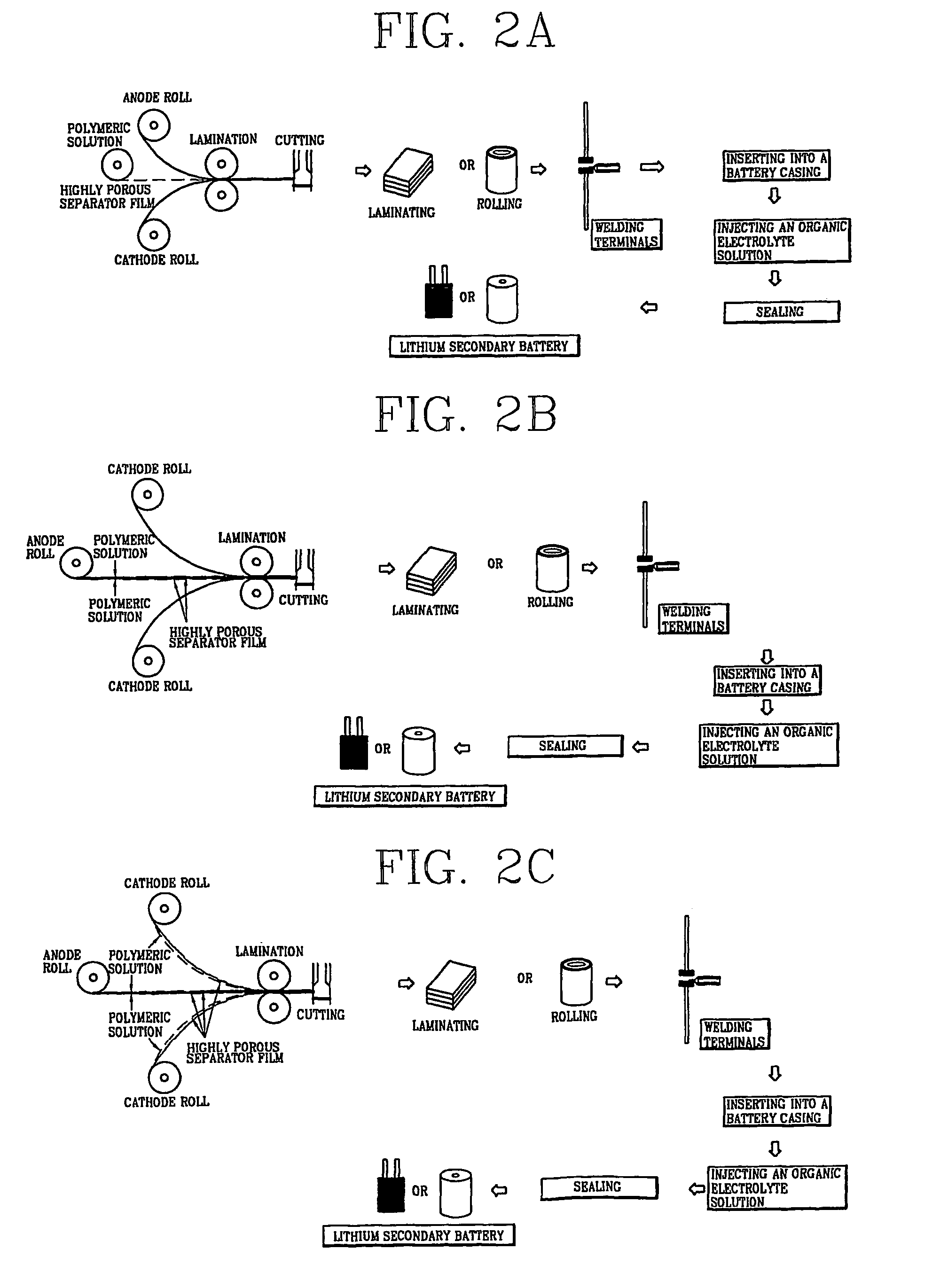

Lithium secondary battery comprising a super fine fibrous polymer separator film and its fabrication method

InactiveUS7279251B1Mechanical strengthReduce adhesionElectrode rolling/calenderingFinal product manufactureLithiumPolymer science

The present invention provides a lithium secondary battery and its fabrication method. More particularly, the present invention provides a lithium secondary battery comprising a super fine fibrous porous polymer separator film and its fabrication method, wherein the porous polymer separator film is fabricated by the following process: a) melting at least one polymer or dissolving at least one polymer with organic solvents to obtain at least one polymeric melt or at least one polymeric solution; b) adding the obtained polymeric melt or polymeric solution to barrels of an electrospinning machine; and c) discharging the polymeric melt or polymeric solution onto a substrate using a nozzle to form a porous separator film. The lithium secondary battery of the present invention has the advantages of better adhesion with electrodes, good mechanical strength, better performance at low and high temperatures, better compatibility with organic electrolyte solution of a lithium secondary battery.

Owner:KOREA INST OF SCI & TECH

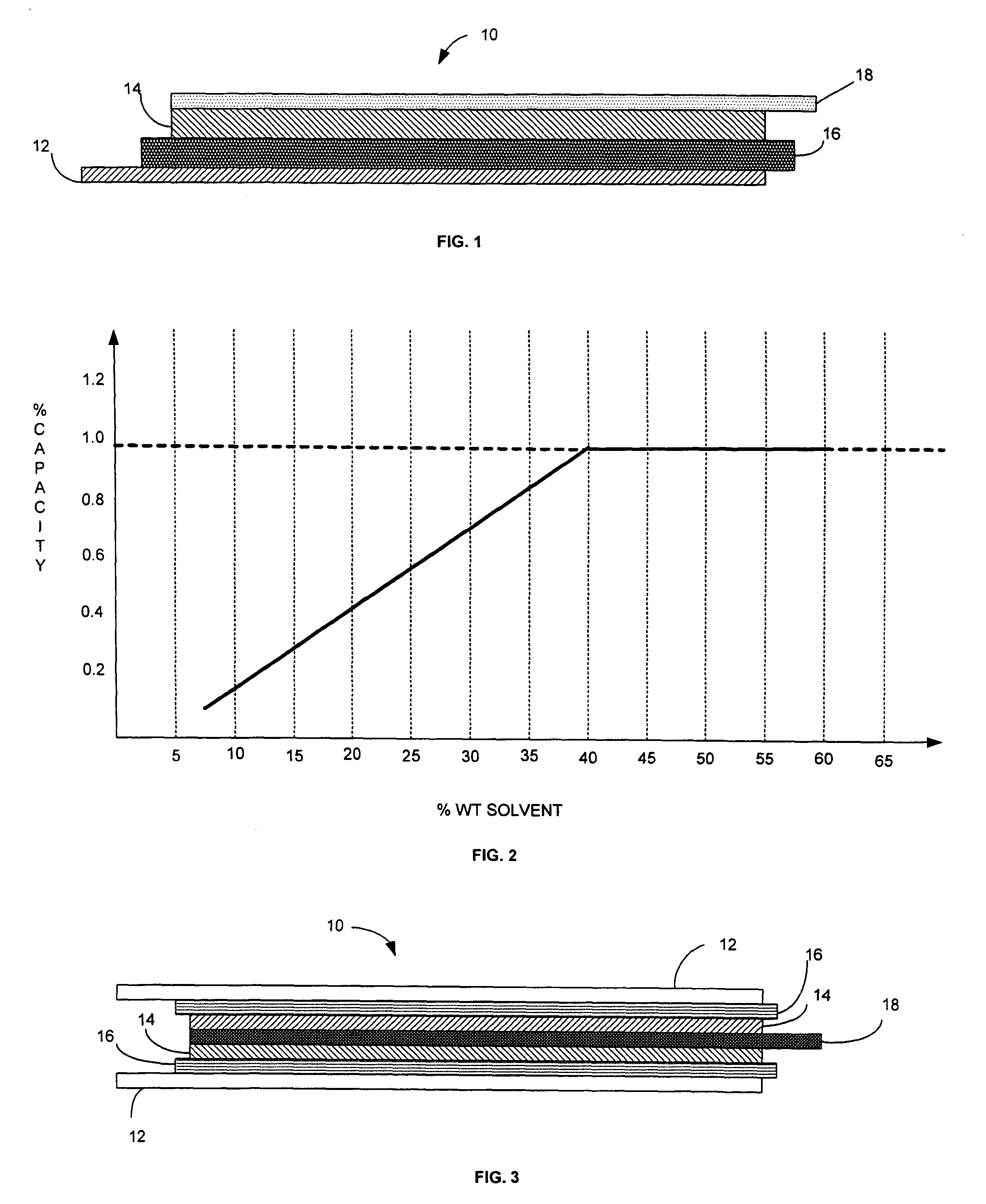

Polyimide-based lithium metal battery

ActiveUS20050153209A1Improve ionic conductivityGrowth inhibitionFinal product manufactureElectrode carriers/collectorsMetallic lithiumLithium metal

The present invention relates to Lithium Metal batteries. In particular, it is related to lithium metal batteries containing a polyimide-based electrolyte. The present invention concerns a new concept of polyimide-based electrolytic component having an electrolyte consisting of at least one solvent and at least one alkali metal salt, with specific amounts of solvents, to optimize the properties of conductivity of the polyimide-based electrolyte and the mechanical properties of the polyimide-based electrolyte separator towards metallic lithium anode to prevent dendrites growths.

Owner:BRIGHTVOLT INC

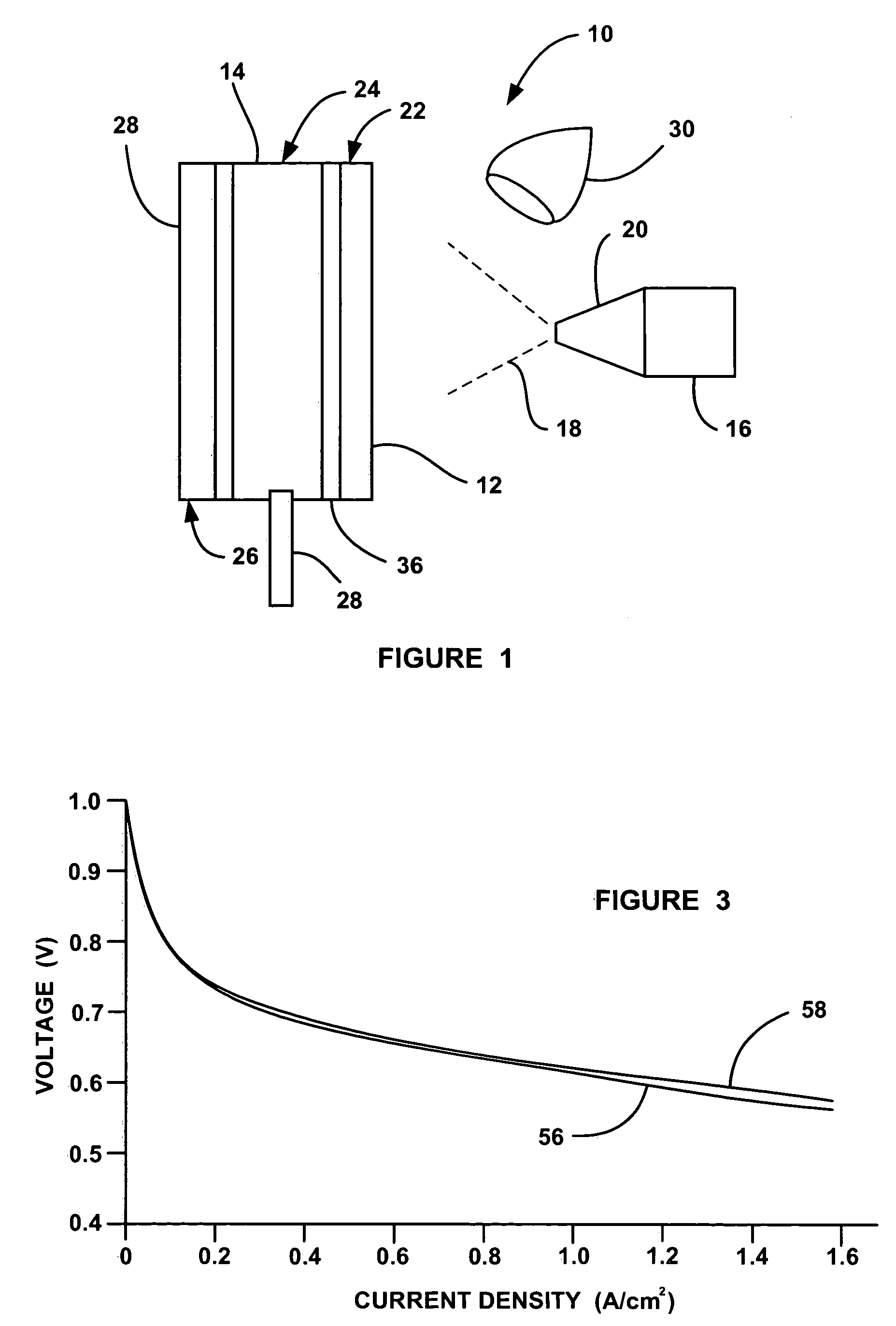

Control parameters for optimizing MEA performance

InactiveUS20060204831A1Increased and decreased concentrationActive material electrodesElectrolyte layer coatingIonomerFuel cells

A gradient of ionomeric material is generated, disposed, or otherwise provided in an electrode suitable for use in a fuel cell. The ionomer concentration, e.g., with respect to the carbon content of the catalyst layer (e.g., expressed as a ratio), is greatest in the area closest to the membrane, e.g., of the fuel cell (e.g., the membrane side), and is decreased in the area furthest from the membrane (e.g., the gas side). By way of another non-limiting example, the ionomer gradient can be formed such that the concentration (or the ratio if expressed in relation to the carbon content of the catalyst layer) can gradually, as opposed to rapidly, decrease as the distance away from the membrane increases.

Owner:GM GLOBAL TECH OPERATIONS LLC

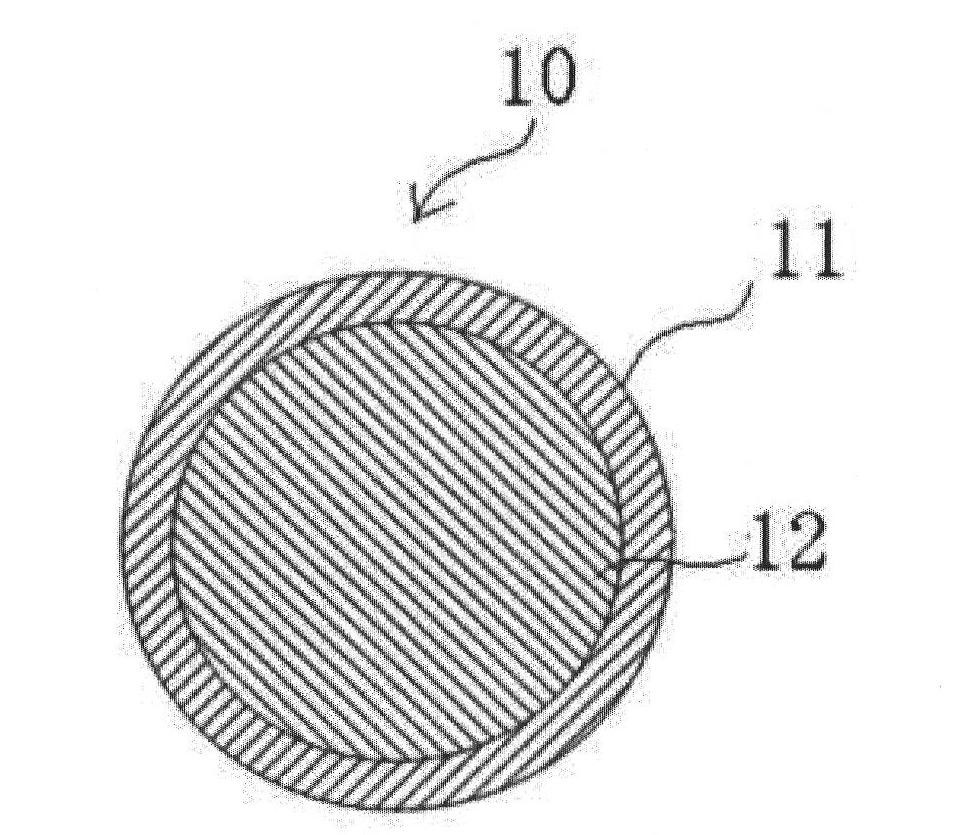

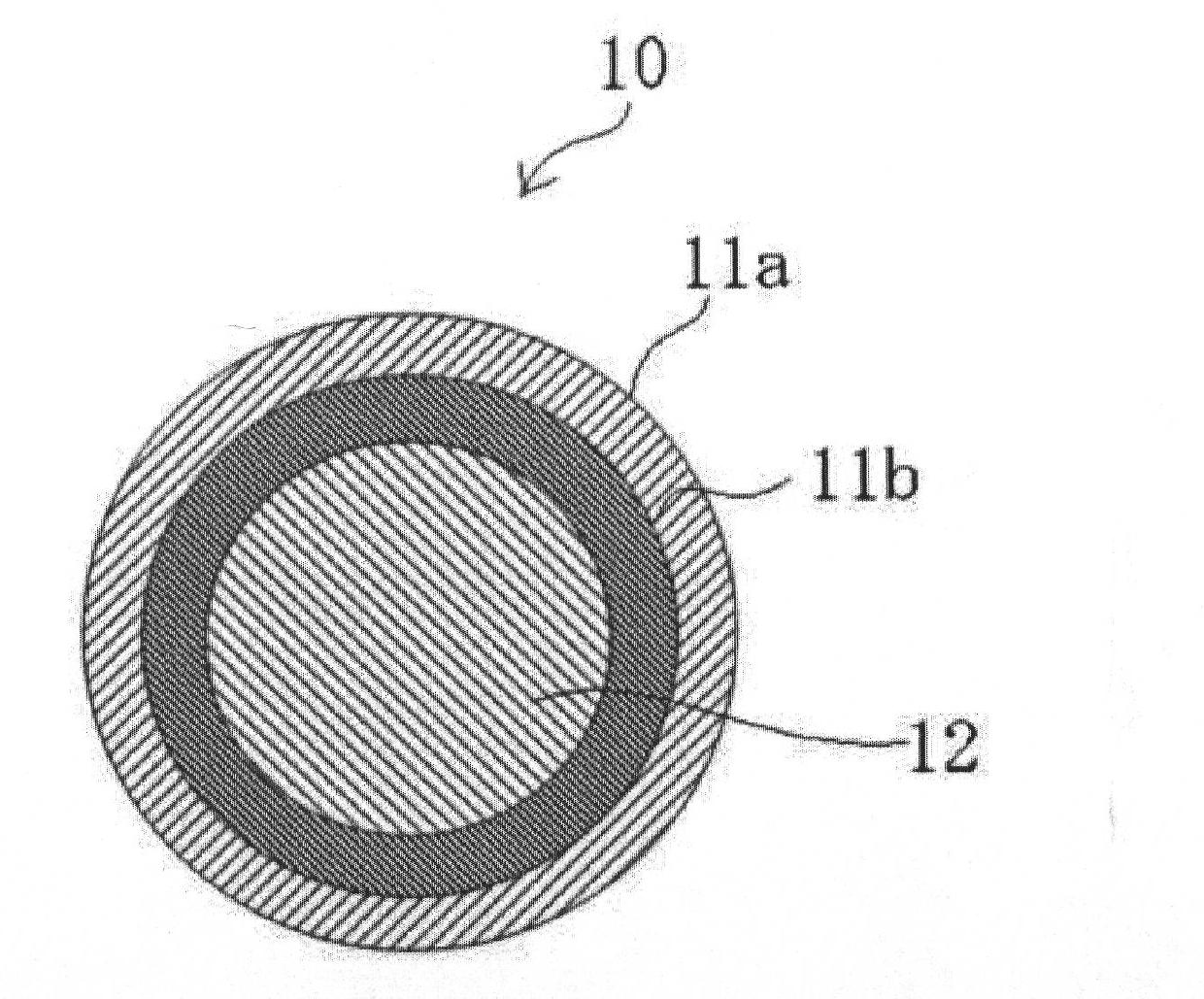

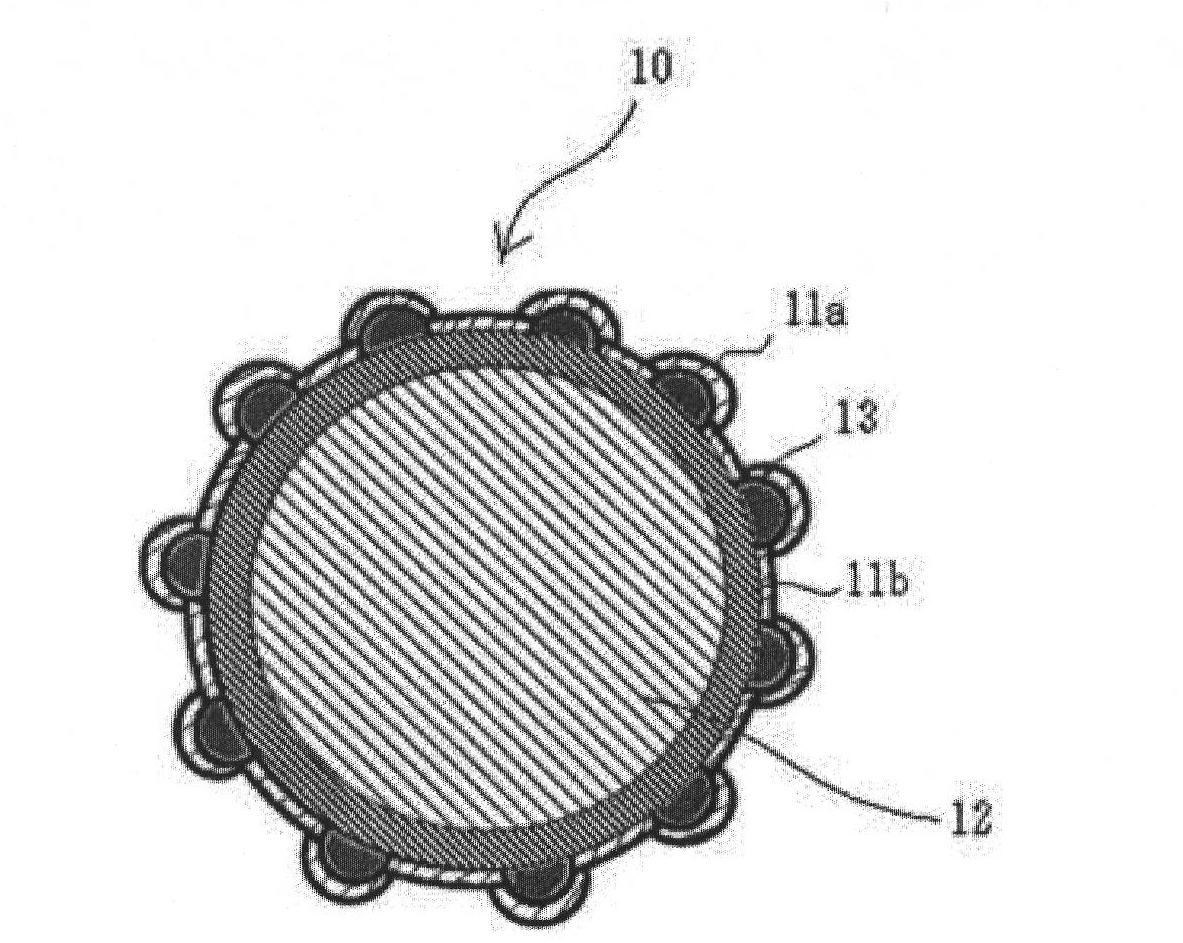

Conductive particle, anisotropic conductive film, joined body, and connecting method

ActiveCN102089832AGood spreadabilitySuppress stressPrinted circuit assemblingNon-insulated conductorsAnisotropic conductive filmElectrical connection

Disclosed are conductive particles wherein stress can be suppressed by improving spreadability while maintaining high hardness (cracks hardly occur even when the particles are crushed during the connection). The conductive particles assure sufficient electrical connection reliability not only for ITO substrates but also for IZO substrates. An anisotropic conductive film comprising the conductive particles, a joined body comprising the anisotropic conductive film, and a connecting method using the anisotropic conductive film are also disclosed. Each of the conductive particles comprises a polymer fine particle and a conductive layer formed on the surface of the polymer fine particle, and is characterized in that the outermost shell of the conductive layer is composed of a nickel-palladium alloy layer.

Owner:DEXERIALS CORP

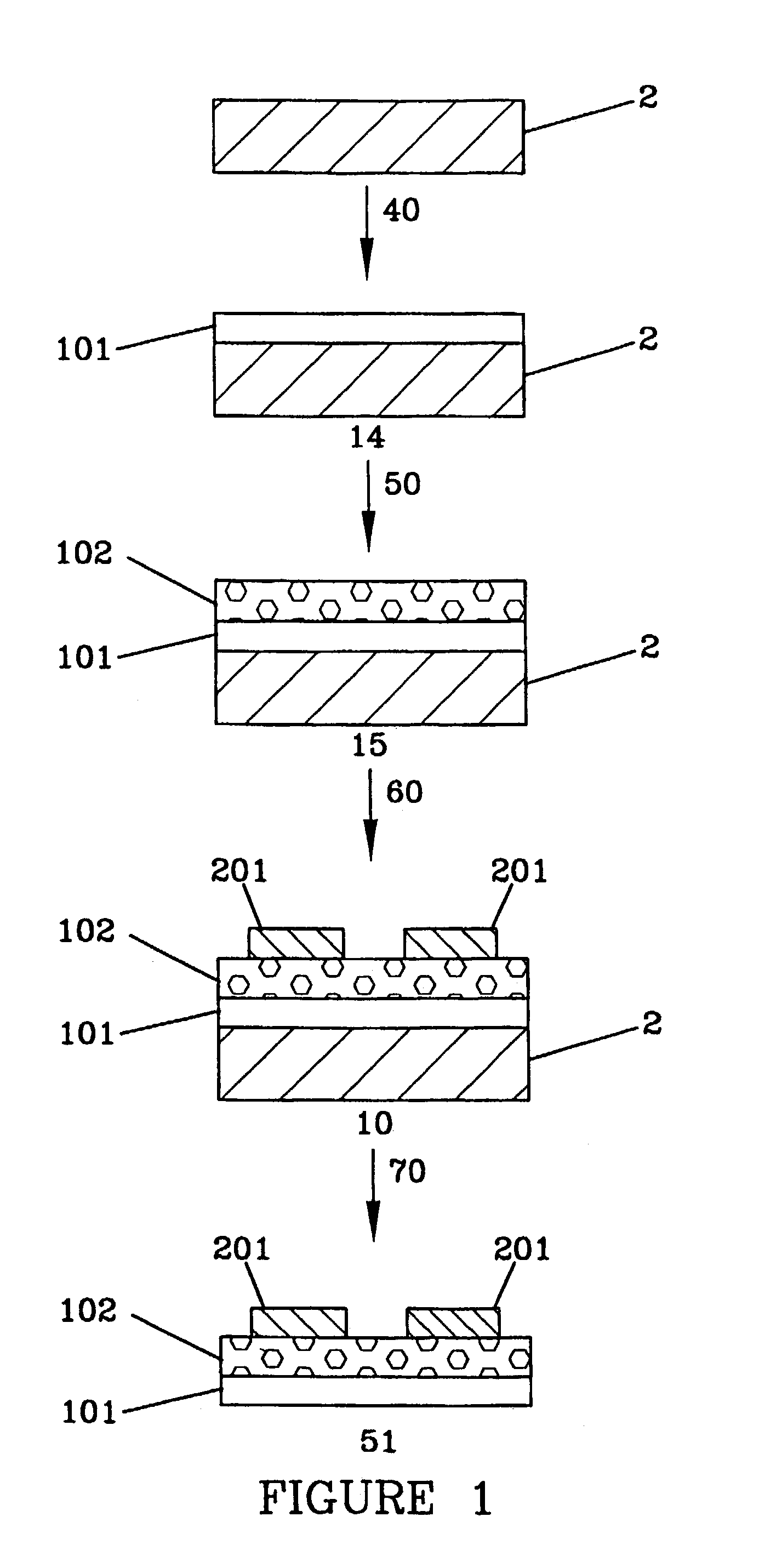

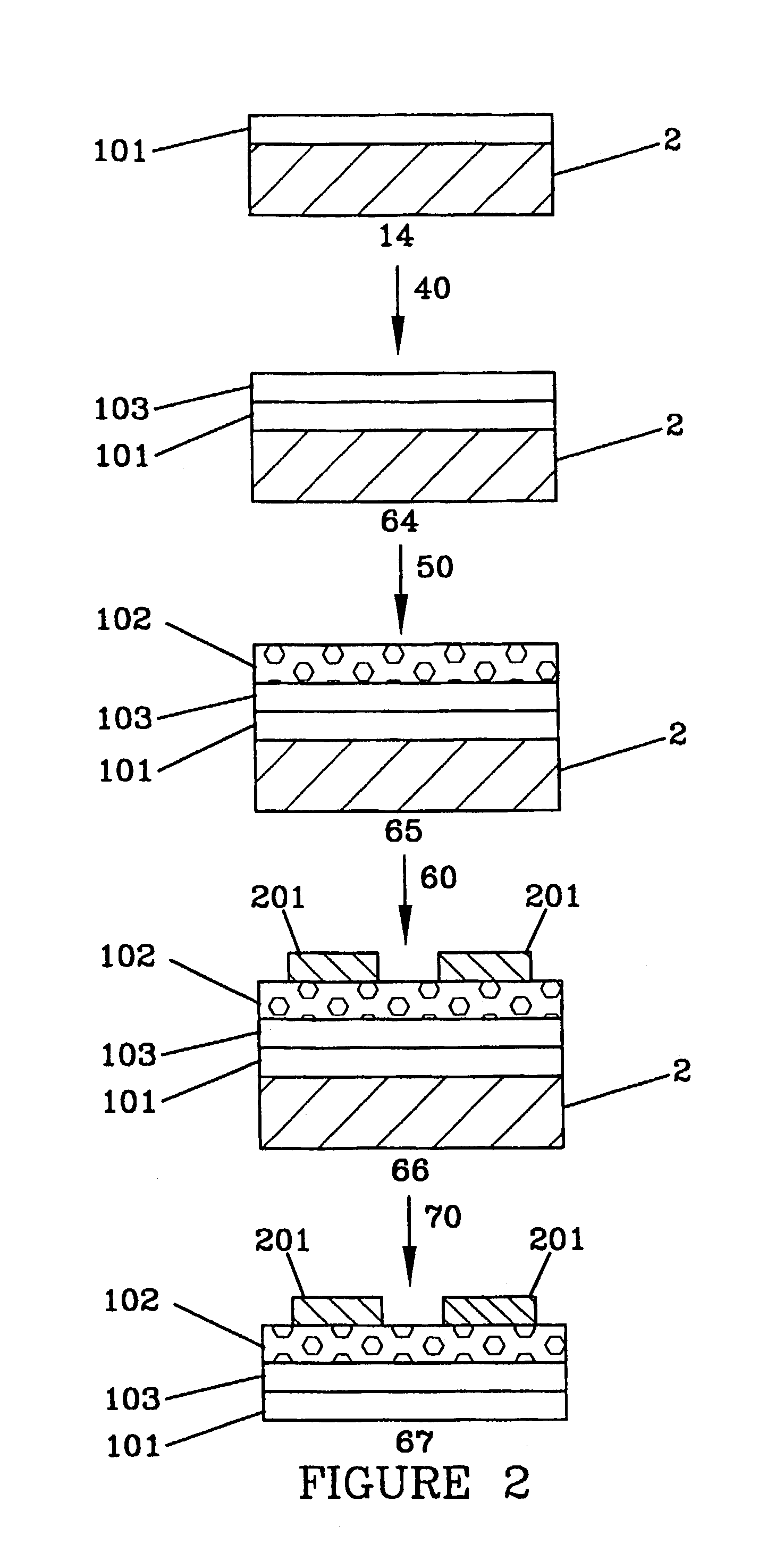

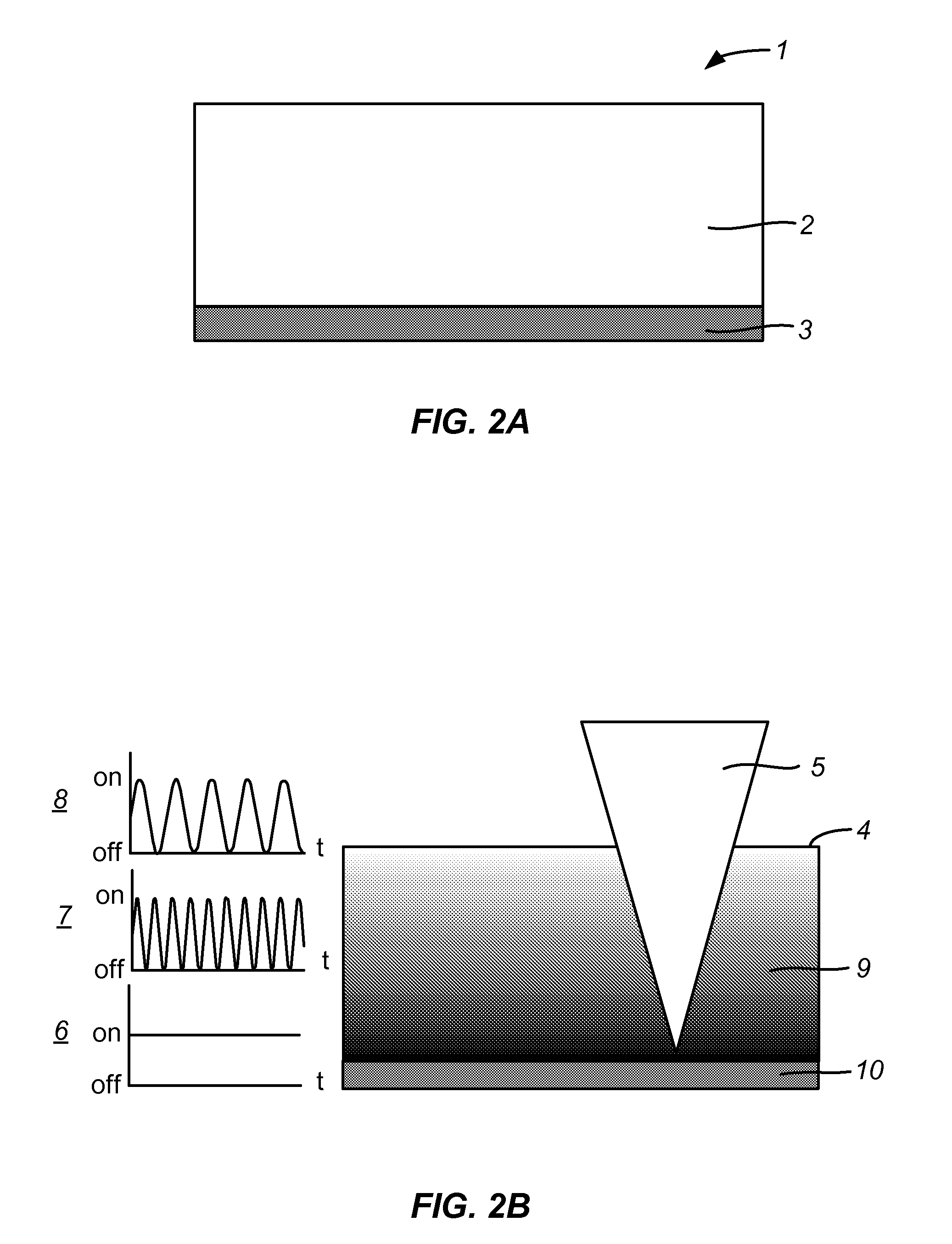

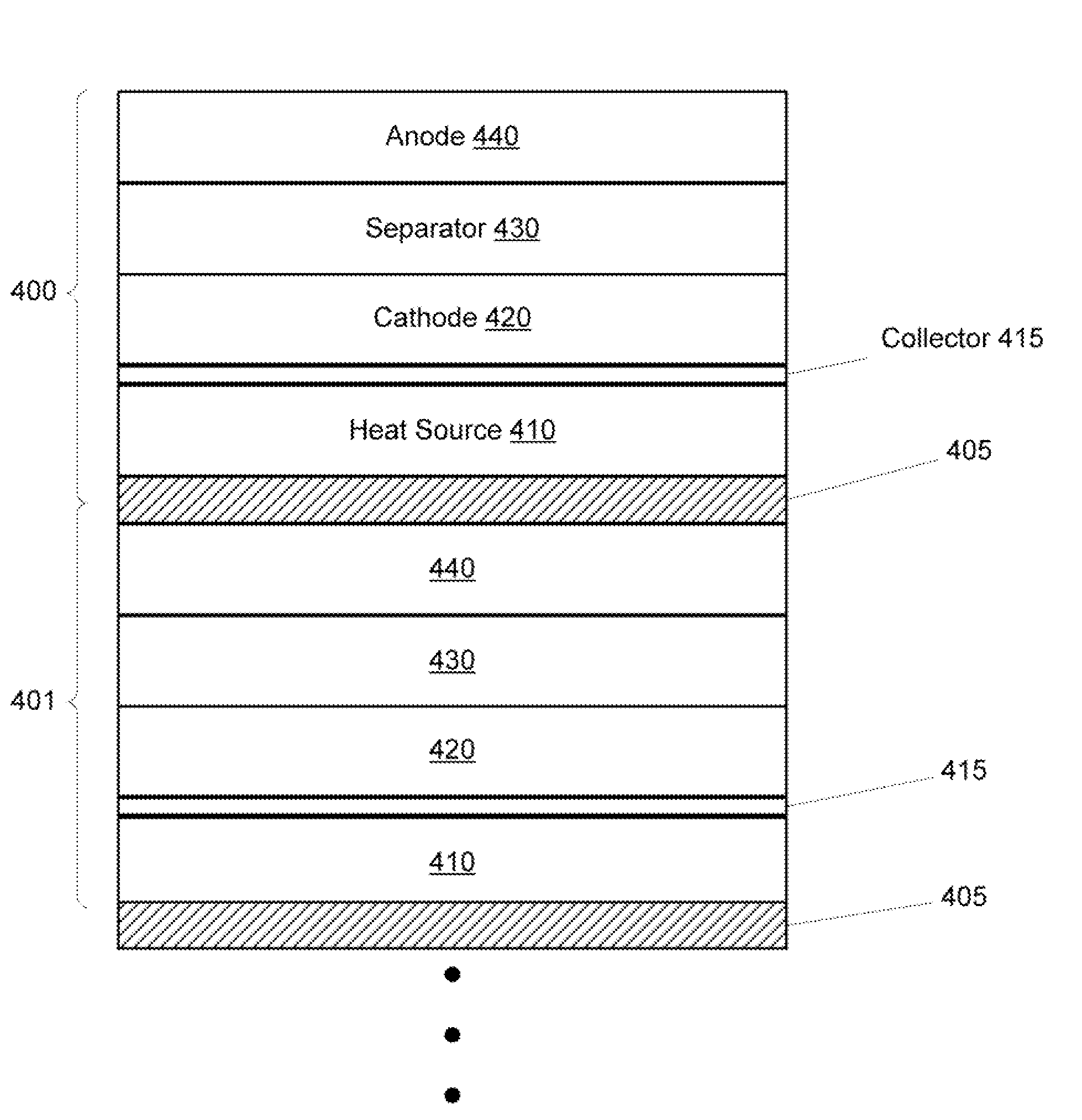

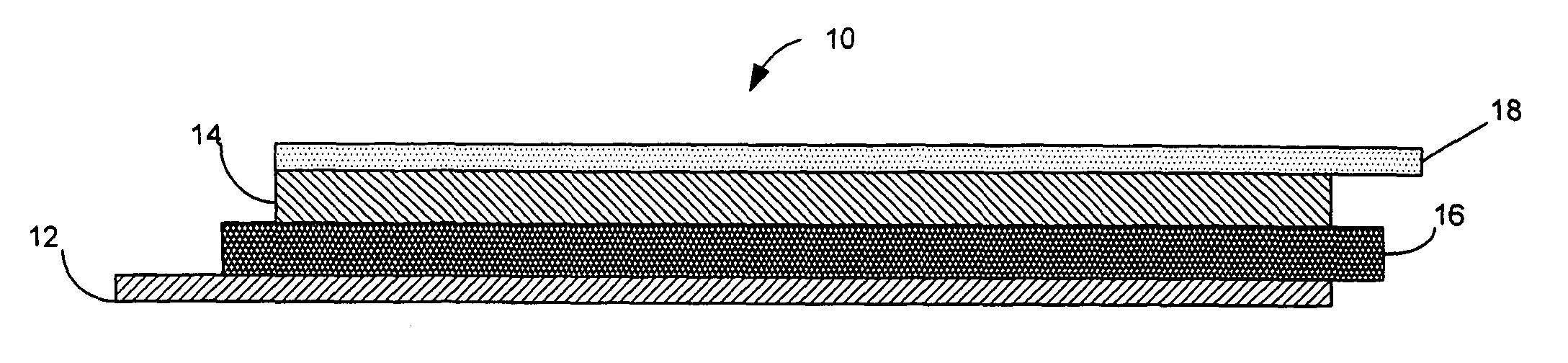

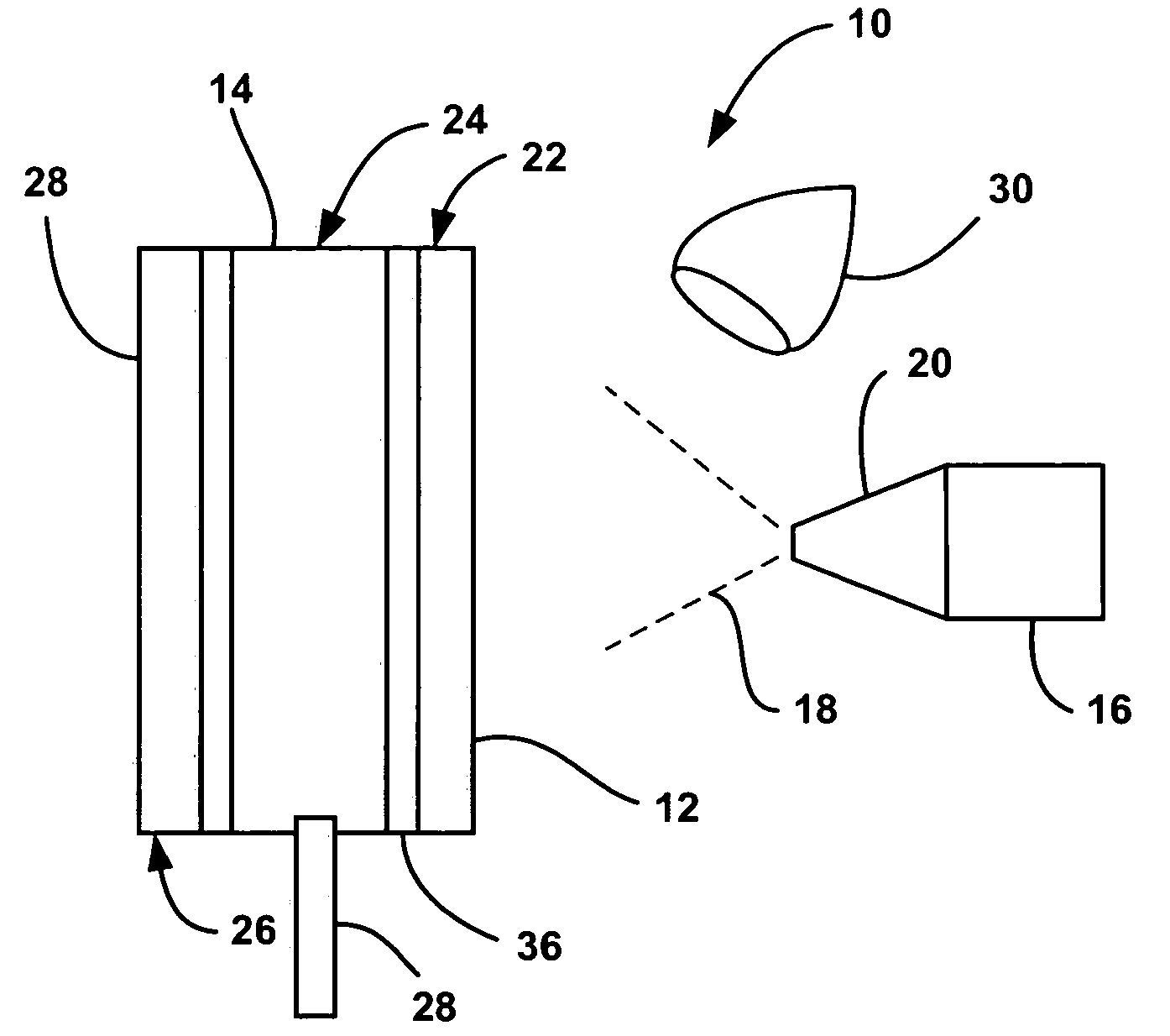

Coated stacks for batteries and related manufacturing methods

PendingUS20170098857A1Less complexIncrease speedFinal product manufactureElectrode carriers/collectorsOptoelectronicsMetal particle

Provided is a battery stack for use in an electric current producing cell, wherein the coated stack comprises a porous separator, an electrode layer adjacent the porous separator, and a current collector layer coated on the electrode layer, wherein the current collector layer comprises sintered metal particles. Also provided are methods of manufacturing such coated stacks.

Owner:META MATERIALS INC

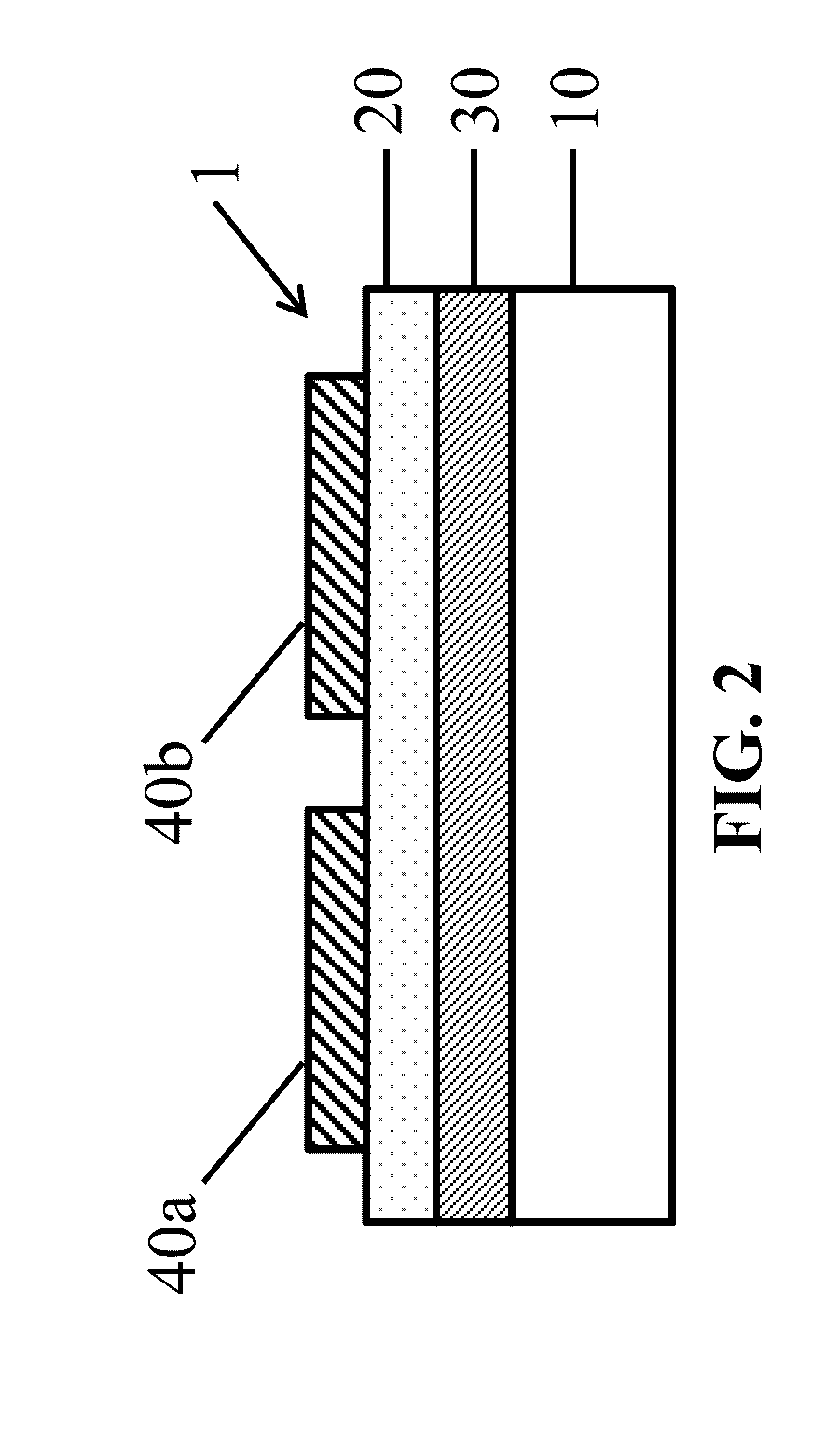

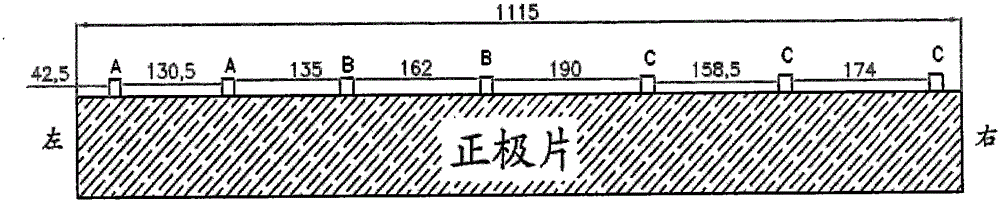

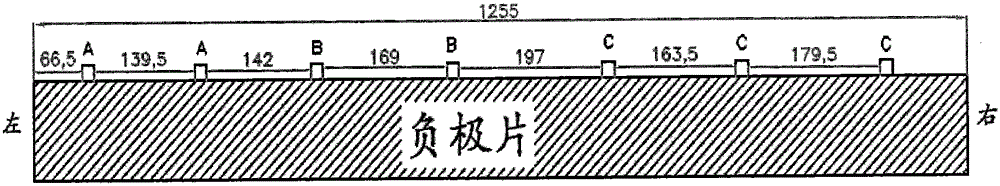

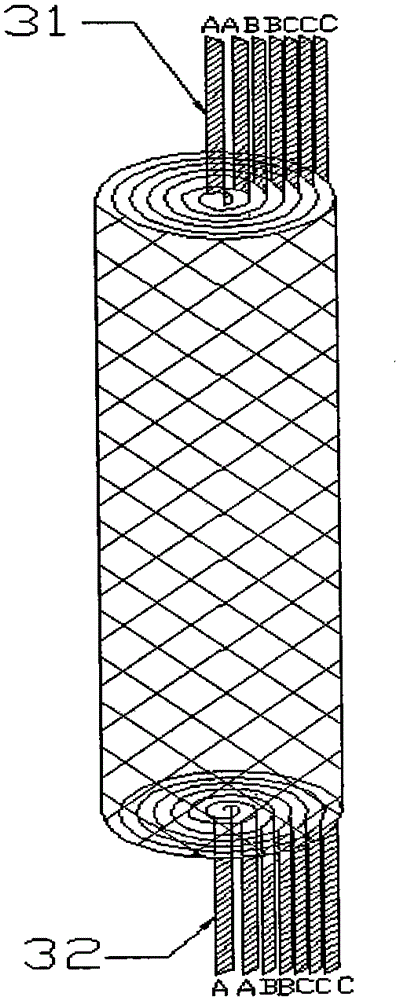

Multi-tab size-variable high magnification lithium ion battery

InactiveCN106257710ALower internal resistanceIncrease the number of tabsSecondary cellsElectrolyte layer coatingFirst pass yieldEngineering

The invention discloses a multi-tab size-variable high magnification lithium ion battery. The multi-tab size-variable high magnification lithium ion battery mainly comprises a positive pole piece, a negative pole piece, a diaphragm, an electrolyte and a housing. The battery is prepared from pole pieces with different sizes of multiple tabs through winding. A preparation method of the multi-tab lithium ion battery pole piece comprises fully stirring to mix active substances, a conductive agent and a binder according to a certain ratio to obtain slurry, uniformly coating a current collector with the slurry through a coating machine, wherein two sides of the current collector form blank zones, and preparing multiple tabs with different intervals and different widths, wherein the height values of the tabs are determined according to cell thickness and diameters. A winding method replaces a laminated soft package battery preparation process or a process of increasing the number of cylindrical form cell tabs so that a structure is simple, production efficiency is high and a first pass yield is high.

Owner:OPTIMUM BATTERY CO LTD

Electricity storage device and process for producing the same

InactiveUS20070117017A1Easy to produceWell formedHybrid capacitor electrolytesHybrid capacitor electrodesLithiumPolymer electrolytes

There are provided an electricity storage device, comprising a polymer electrolyte and polarizable electrodes, the polarizable electrodes each comprising an interface with the polymer electrolyte, the polarizable electrodes being metal electrodes, a negative electrode of the polarizable electrodes having, at its interface with the polymer electrolyte, a lithium alloy with a metal component contained in the negative electrode, the lithium alloy being capable of releasing lithium ions through a reversible electrochemical oxidation-reduction reaction; and a method for producing an electricity storage device, comprising: a structure forming step of obtaining an electrode-electrolyte structure where each of the polarizable electrodes is formed on a polymer electrolyte through an electroless plating method; and a layer forming step of applying voltage to the polarizable electrode while the electrode-electrolyte structure obtained by the structure forming step includes a solution containing lithium ions, to form a layer containing lithium and a metal component of the polarizable electrodes at the negative electrode of the polarizable electrodes.

Owner:EAMEX

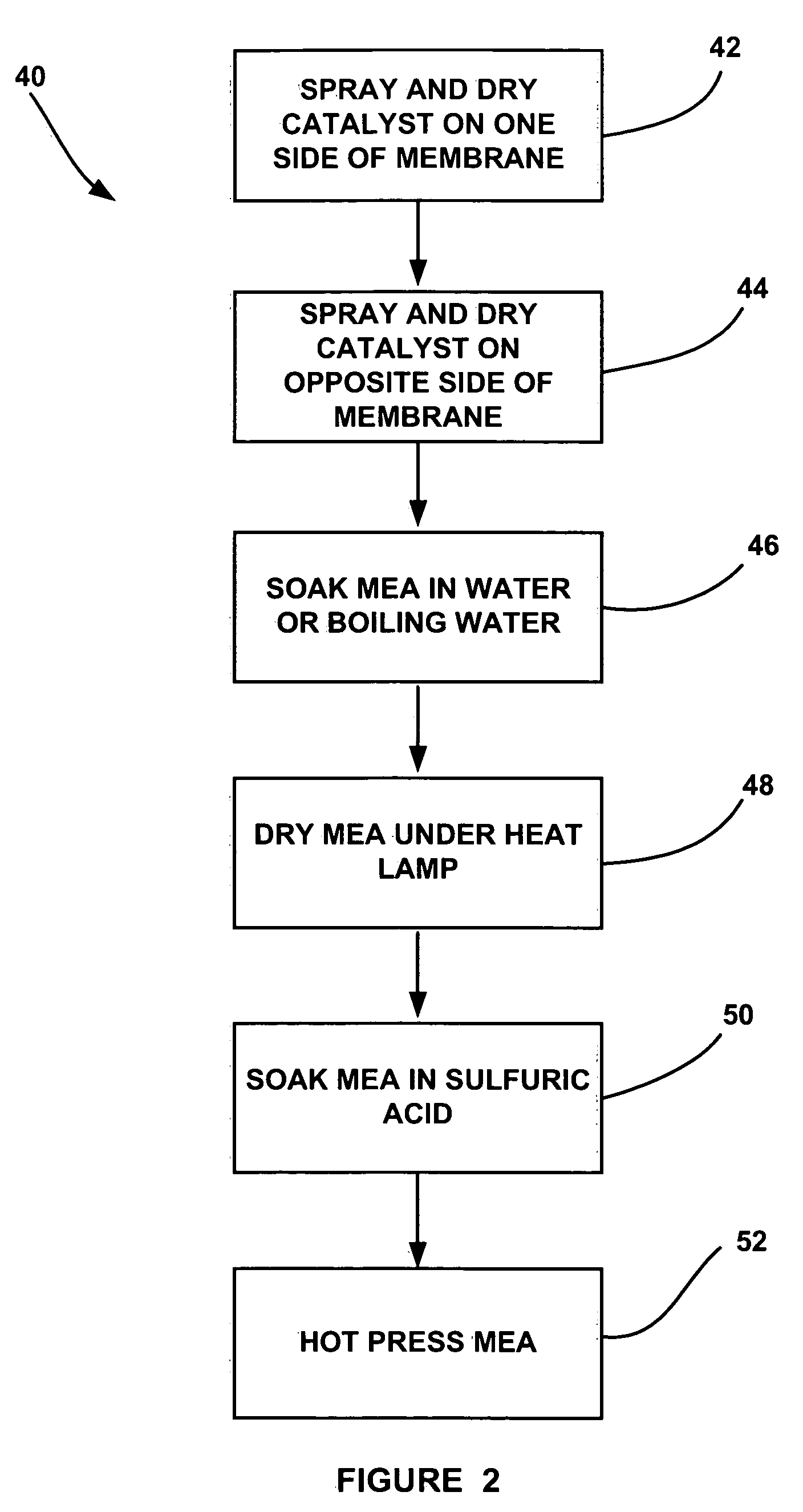

Membrane electrode assembly prepared by direct spray of catalyst to membrane

ActiveUS20050163920A1Improve MEA performanceEnhance layeringElectrolyte layer coatingSolid electrolyte fuel cellsIonomerPolymer electrolytes

Owner:GM GLOBAL TECH OPERATIONS LLC

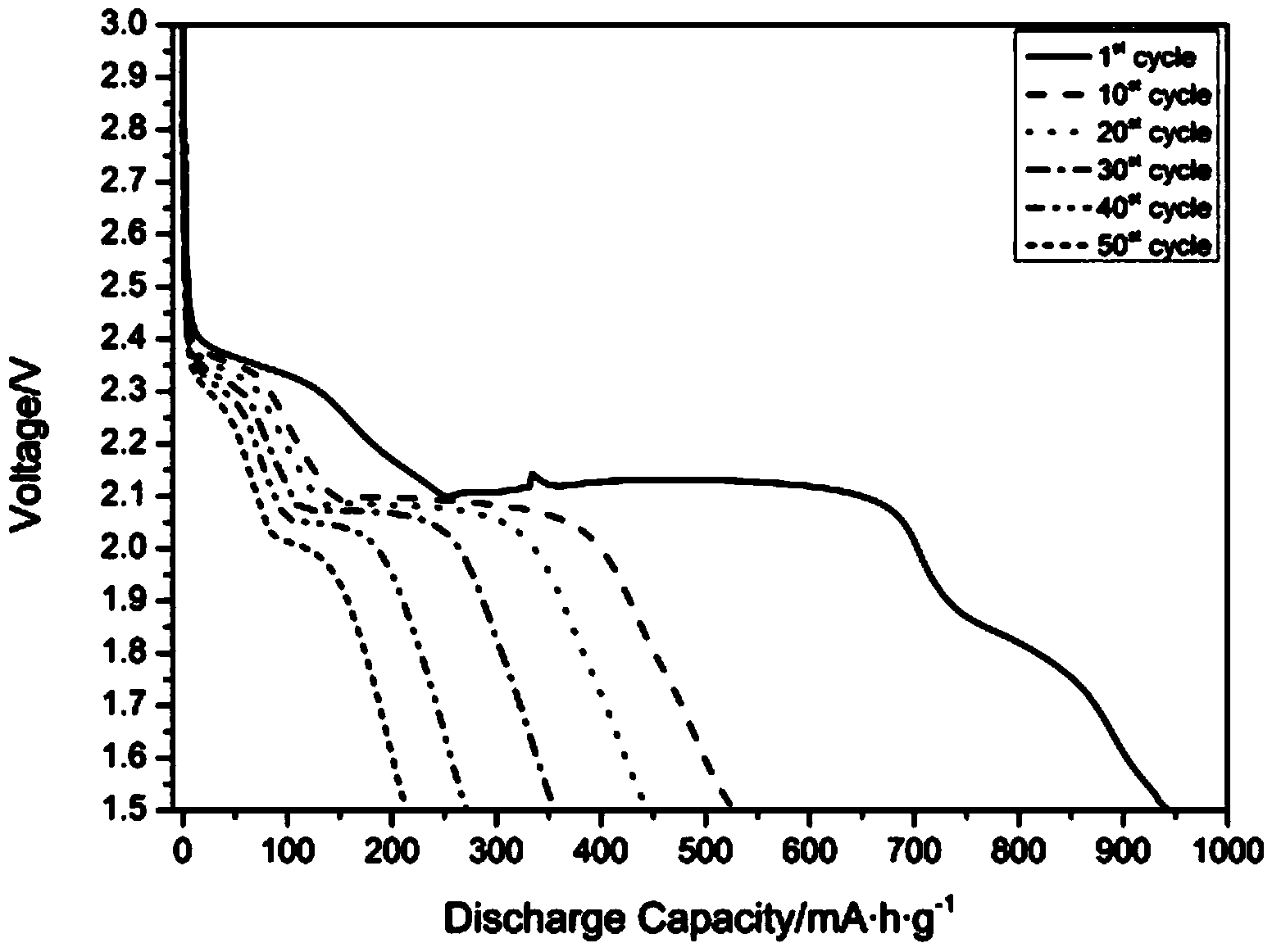

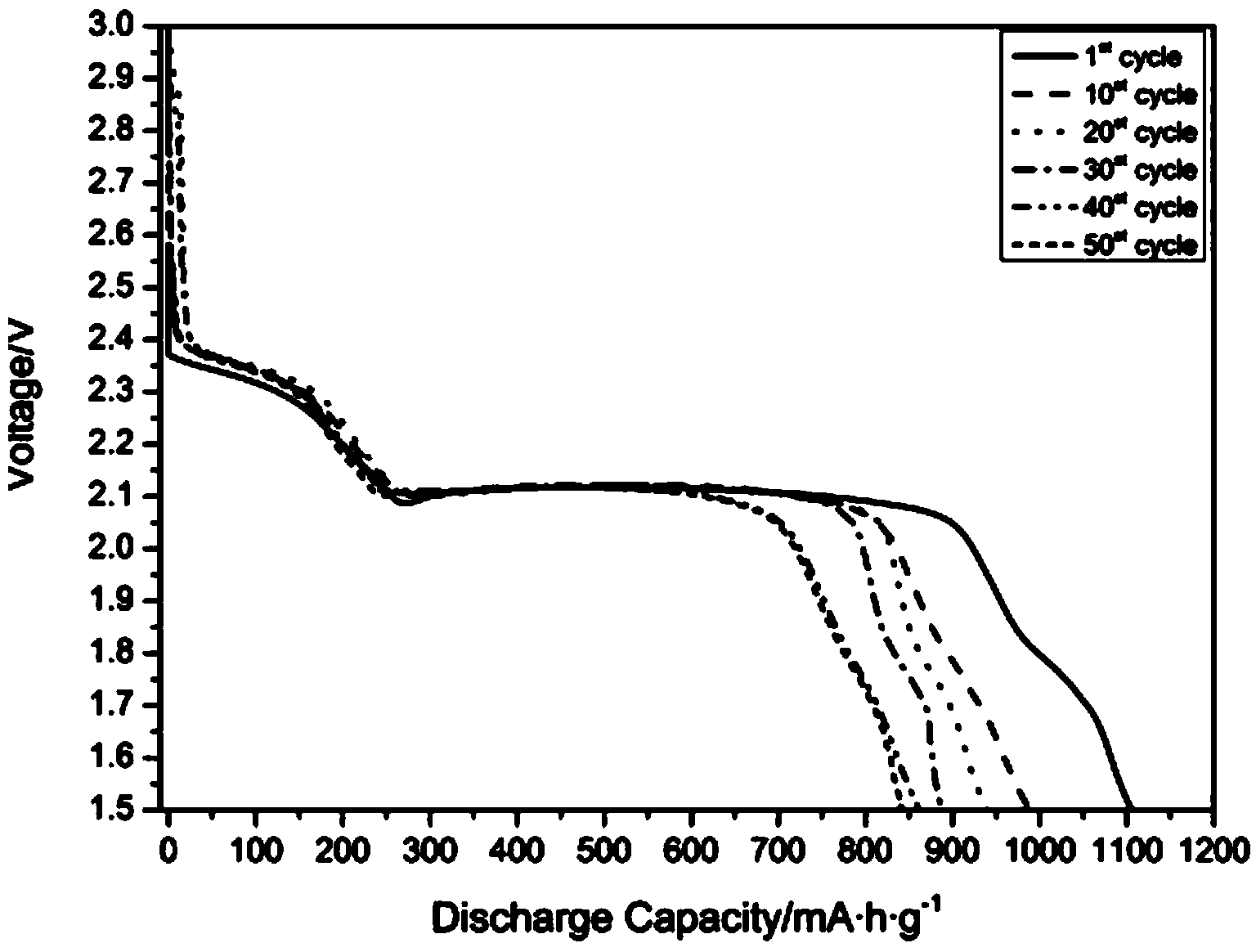

Additive for battery, cathode material containing same and preparation method for cathode material

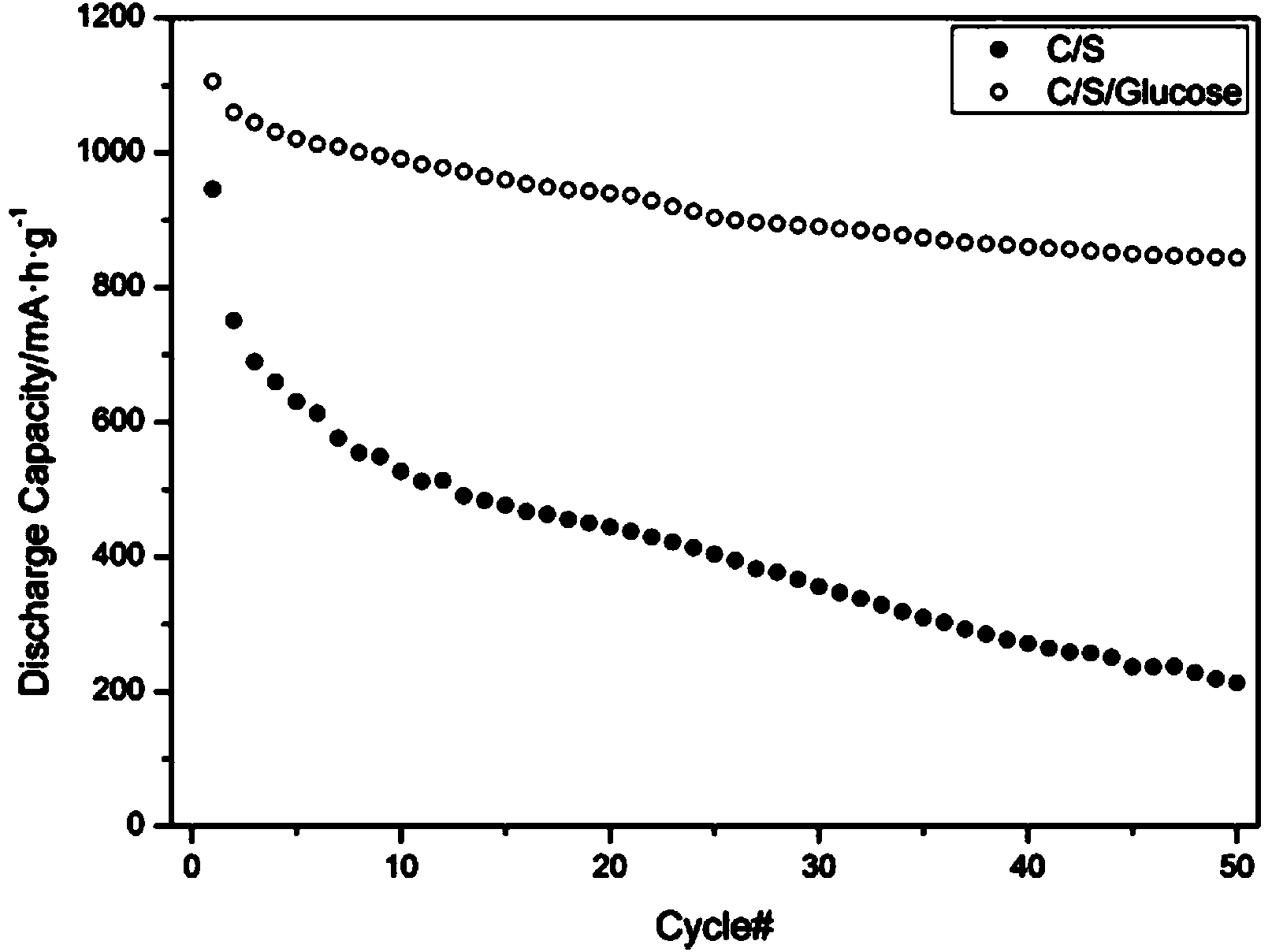

InactiveCN103515614AInhibition of dissolutionImprove cycle performanceElectrolyte layer coatingDissolutionElectron

The invention provides an additive for a lithium sulphur battery, a cathode material containing the same and a preparation method for the cathode material. The additive is a product formed by carbonizing and compounding a carbon material and monosaccharide or polysaccharide polymerized by monosaccharide, wherein the monosaccharide and the polysaccharide contain intensive arc pair electron groups. The intensive arc pair electron group is -C=O or -OH. The monosaccharide is selected from glucose, fructose, galactose, ribose, glycogen and ribodesose. The conductive carbon material in the cathode material has good adsorption capacity, large specific surface area, and high pore volume and adopts a porous structure, and the electrochemical active substance is sulphur. The additive is the substance containing the intensive arc pair electron group. Polysulfide lithium produced during the discharge process can perform interaction with the additive in a mode of coordination and the like, so that the dissolution of the polysulfide lithium in electrolyte is restrained, and the loss of the active substance and the lithium cathode corrosion, rapid capacity fading influence and the like can be effectively reduced.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

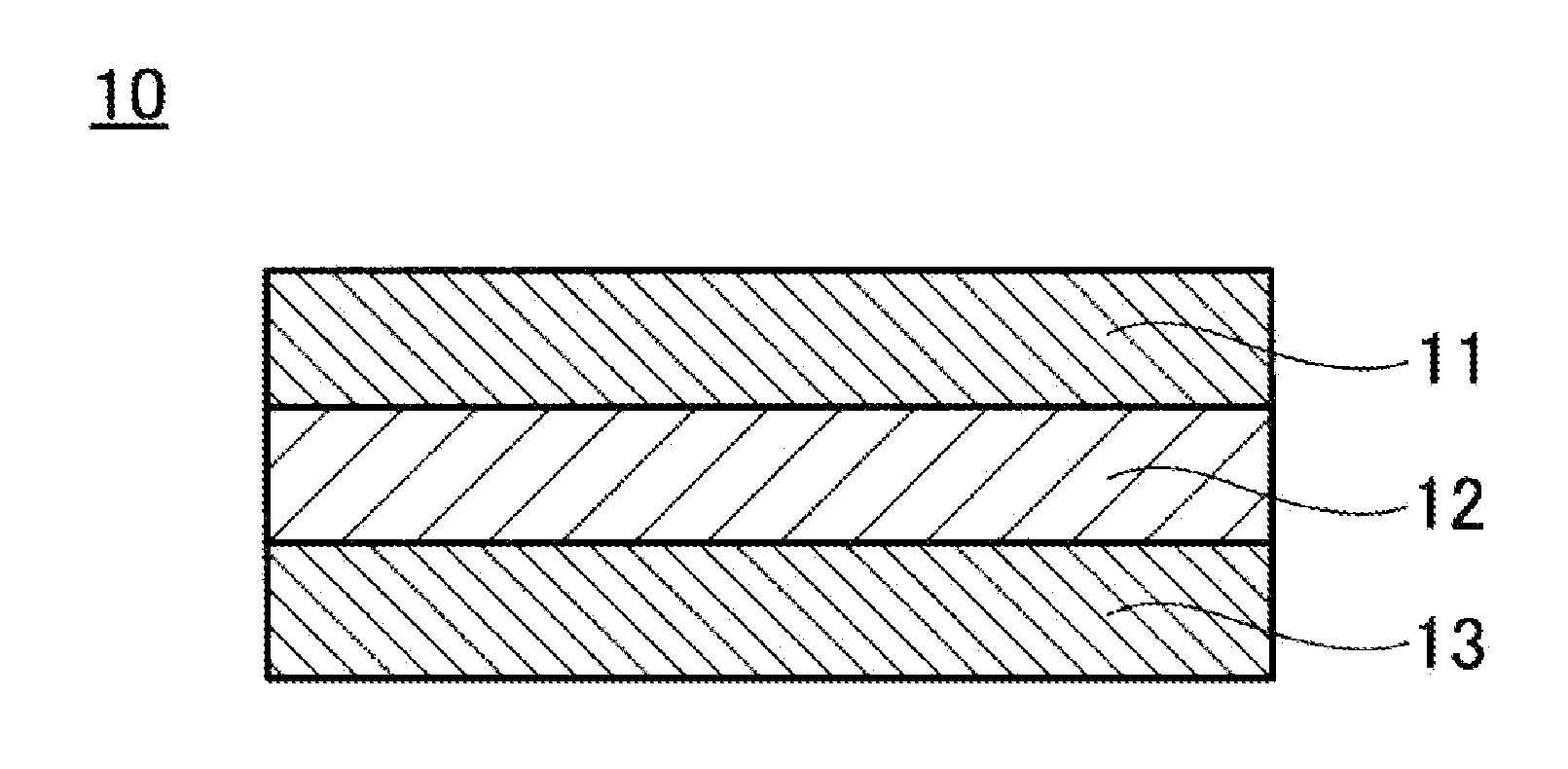

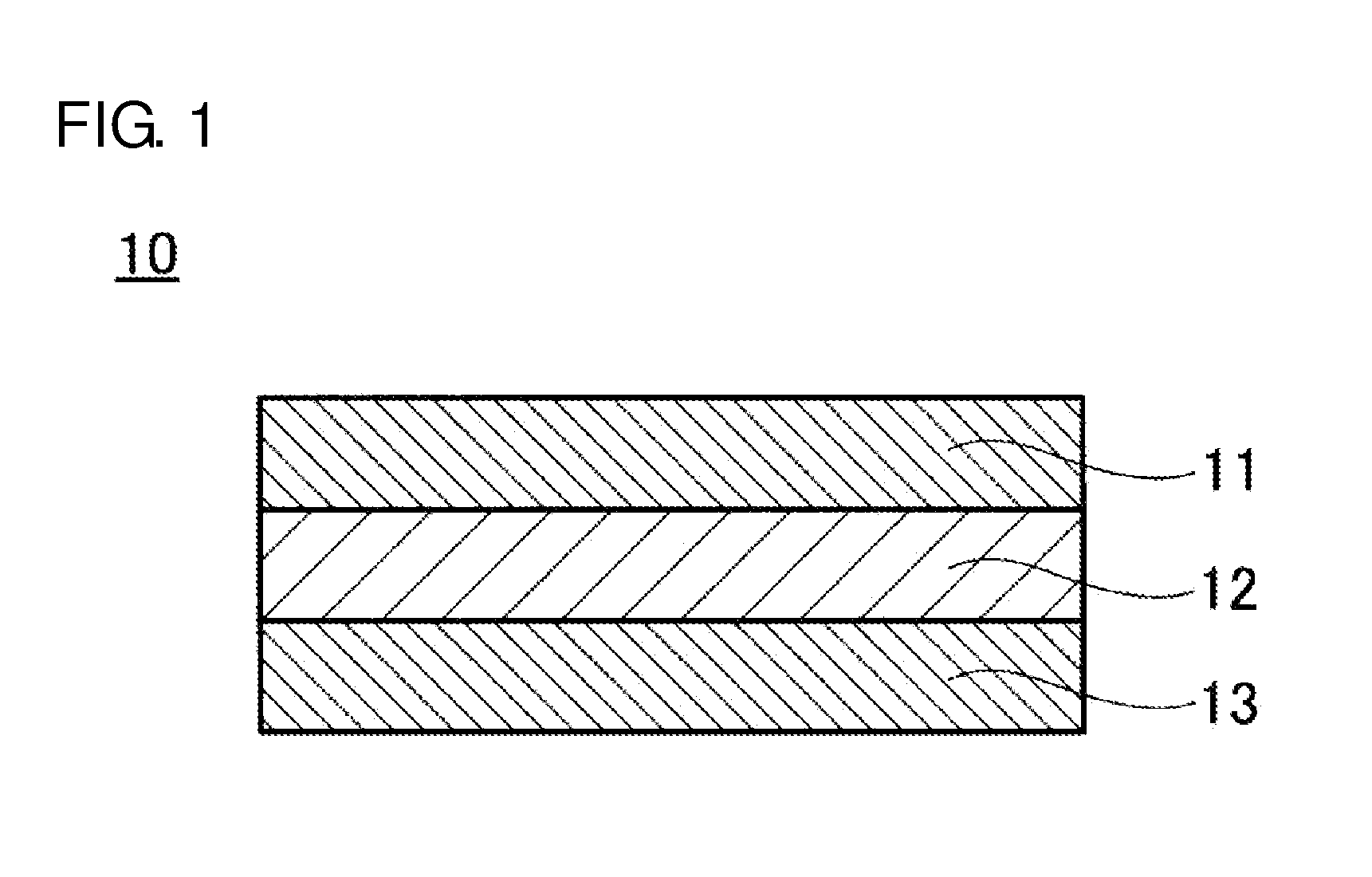

All solid state battery

InactiveUS20130273437A1Improve cycle stabilitySame level of dischargeElectrode thermal treatmentFinal product manufactureAll solid stateTitanium

Provided is an all solid state battery which has the same level of discharge capacity as in the case of using an electrolyte solution, and is able to improve the cycle stability. An all solid state battery includes a solid electrolyte layer, as well as a positive electrode layer and a negative electrode layer provided in positions opposed to each other with the solid electrolyte layer interposed therebetween. At least one of the positive electrode layer and the negative electrode layer is bonded to the solid electrolyte layer by firing. The negative electrode layer contains an electrode active material composed of a metal oxide containing no lithium, and a solid electrolyte containing no titanium.

Owner:MURATA MFG CO LTD

Aqueous lithium ion battery electrode, preparation method of electrode and aqueous lithium ion battery

InactiveCN103904291AAvoid direct contactAvoid redox reactionsSecondary cellsActive material electrodesAqueous electrolyteOxygen evolution

The invention discloses an aqueous lithium ion battery electrode, a preparation method of the electrode and an aqueous lithium ion battery. The aqueous lithium ion battery electrode comprises a positive electrode current collector or a negative electrode current collector, a positive electrode active material layer or a negative electrode active material layer and protective layers, wherein the positive electrode active material layer is combined on the surface of the positive electrode current collector; the negative electrode active material layer is combined on the surface of the negative electrode current collector; the protective layers are combined on the surface of the positive electrode active material layer or the negative electrode active material layer and hole walls in the positive electrode active material layer and the negative electrode active material layer. Materials adopted by the protective layers are polymers containing lithium ions. Through the aqueous lithium ion battery electrode, the direct contact between the positive electrode active material layer or the negative electrode active material layer and water of an aqueous electrolyte can be prevented, so that hydrogen evolution reaction and oxygen evolution reaction of the aqueous electrolyte can be prevented, thus side reaction between active substances and water can be prevented. The aqueous lithium ion battery comprises a positive aqueous lithium ion battery electrode and a negative aqueous lithium ion battery electrode, thus giving high voltage and energy density to the aqueous lithium ion battery.

Owner:INNER MONGOLIA RUISHENG GRAPHITE NEW MATERIAL CO LTD

Lithium-ion Battery Anode Including Preloaded Lithium

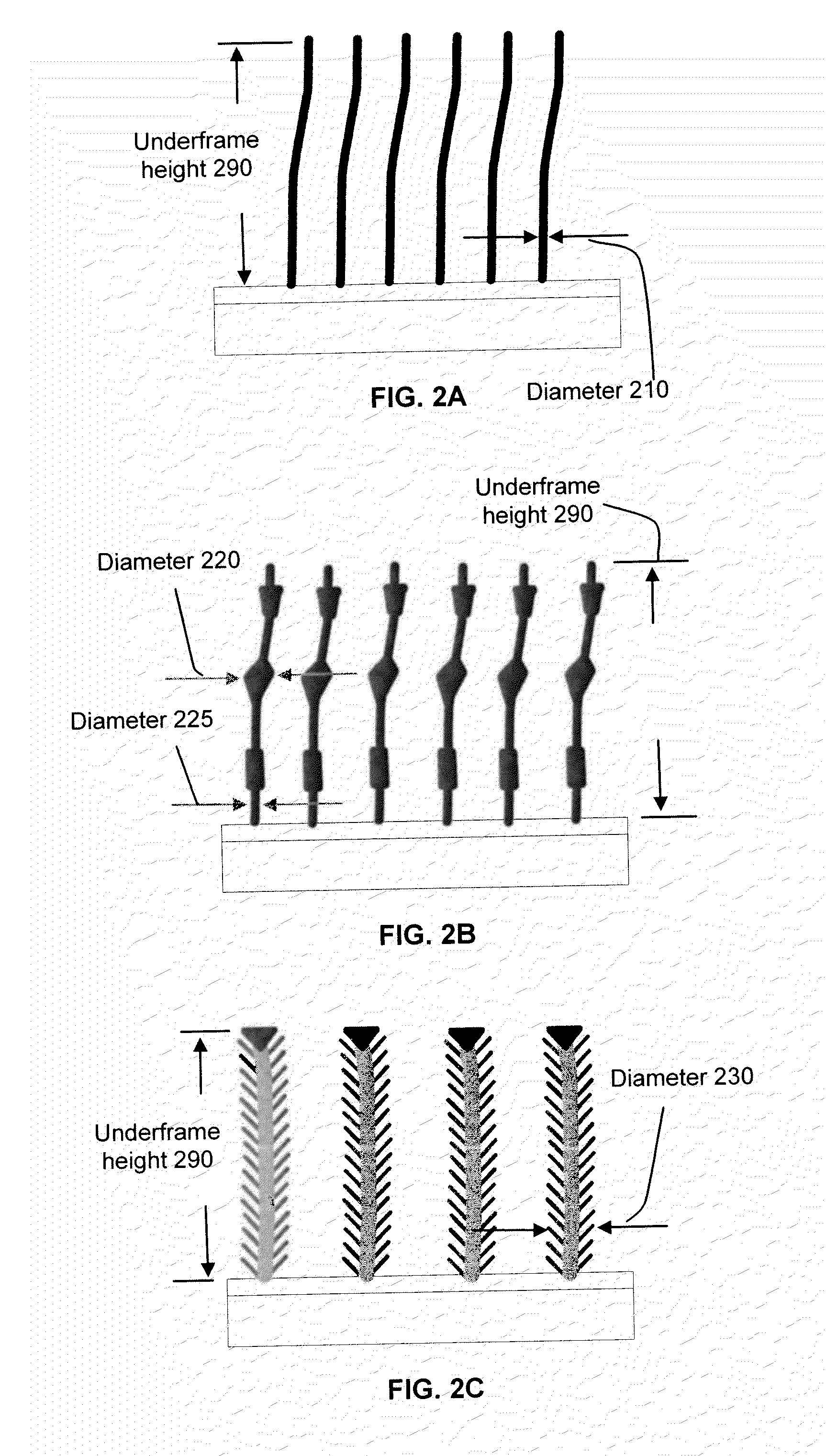

ActiveUS20150236342A1High energy storage densityFuel and secondary cellsElectrode carriers/collectorsLithiumEngineering

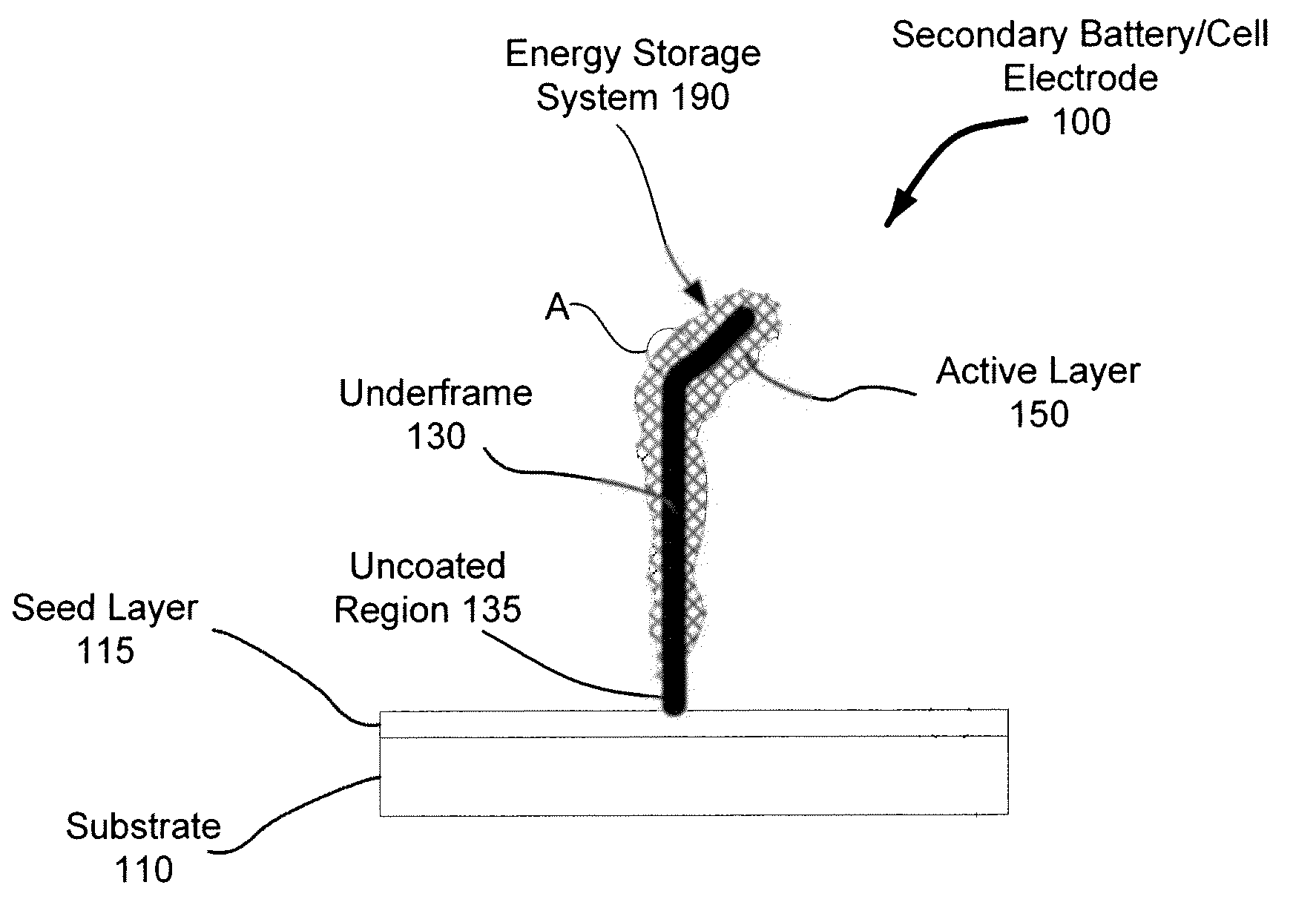

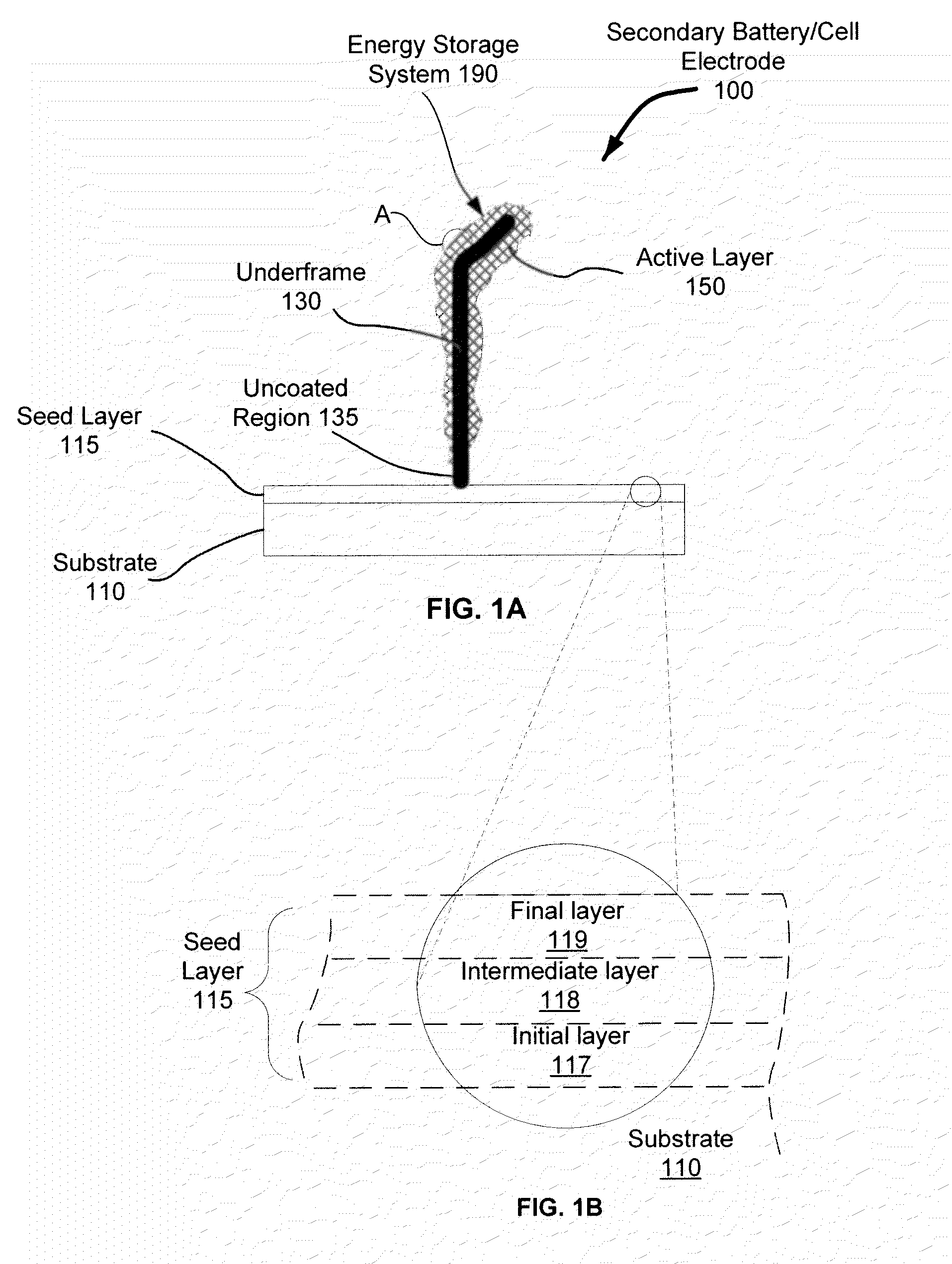

An energy storage device includes a nano-structured cathode. The cathode includes a conductive substrate, an underframe and an active layer. The underframe includes structures such as nano-filaments and / or aerogel. The active layer optionally includes a catalyst disposed within the active layer, the catalyst being configured to catalyze the dissociation of cathode active material.

Owner:CF TRAVERSE LLC

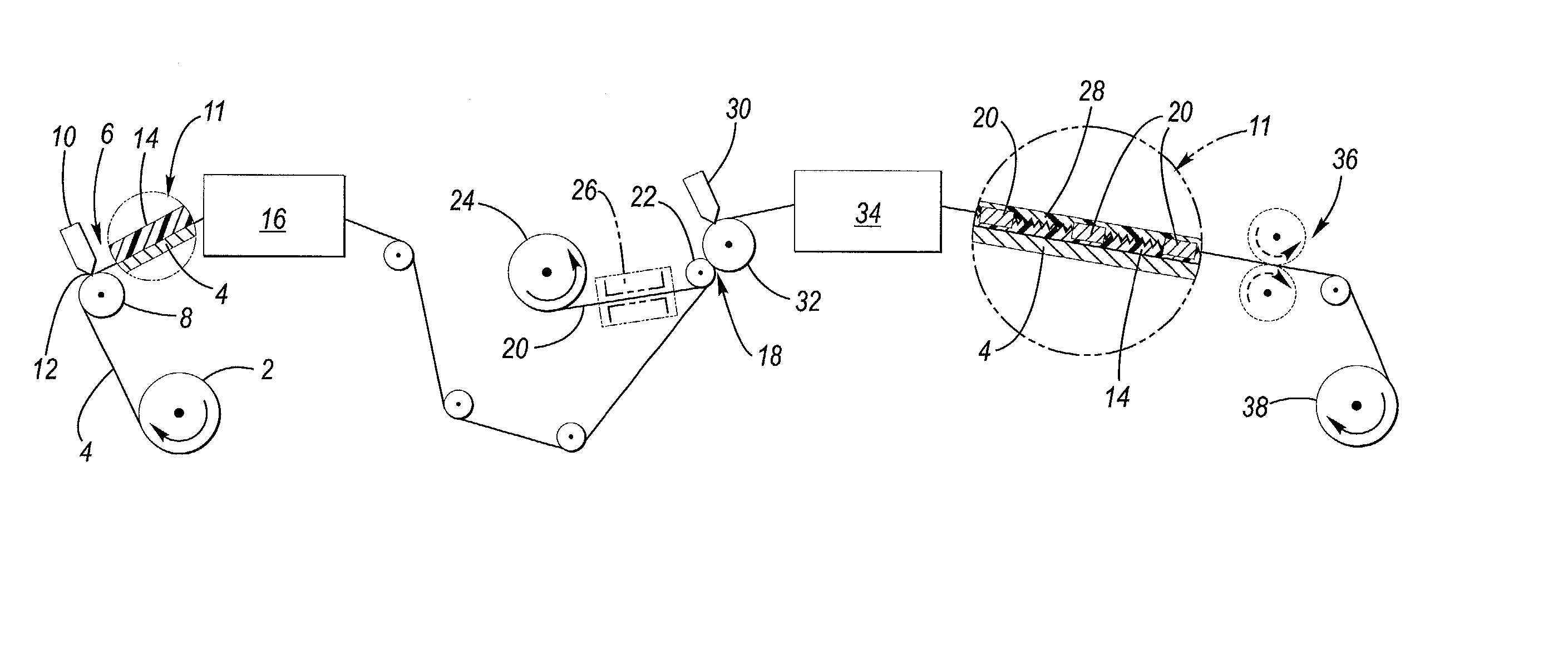

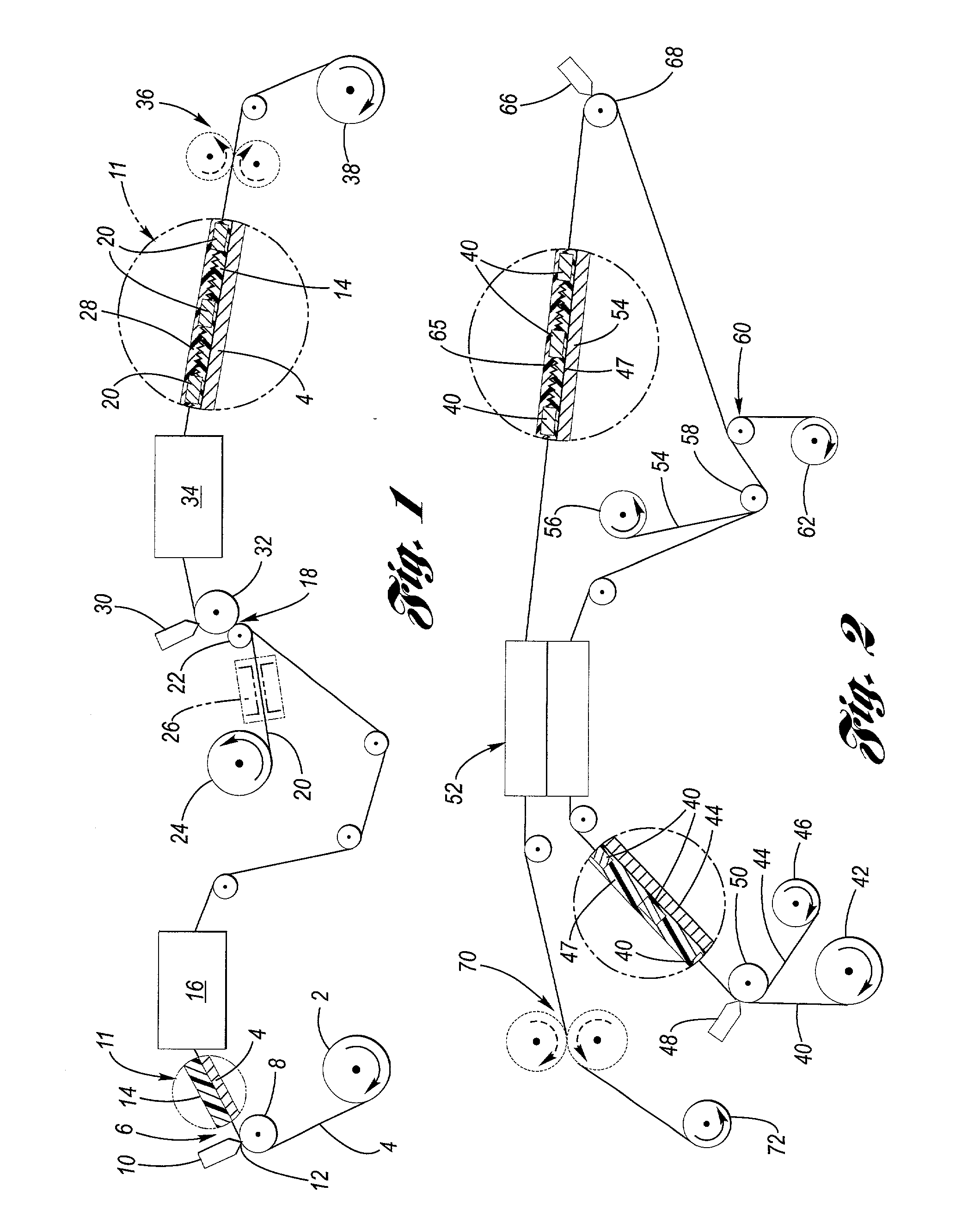

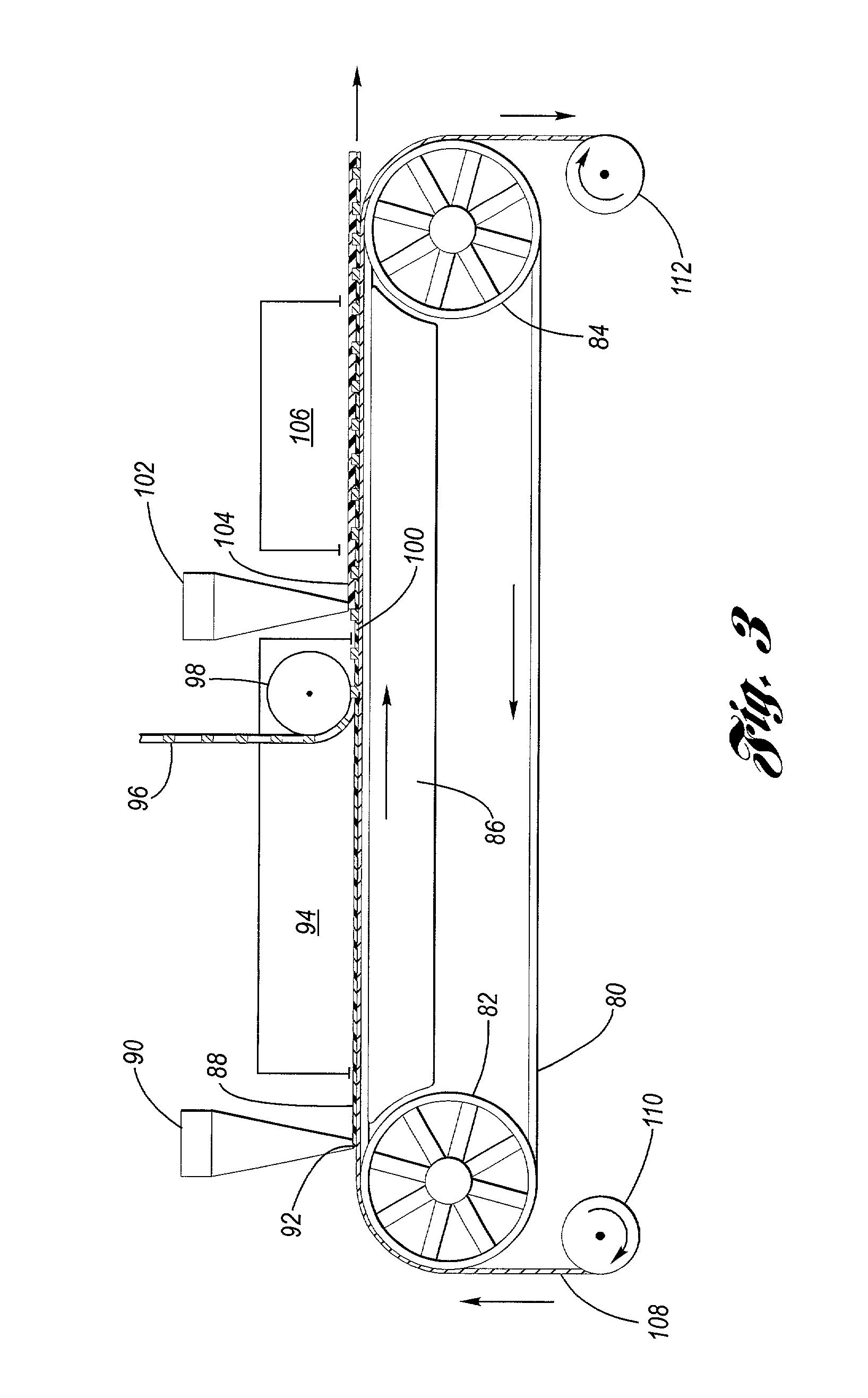

System and method for multilayer fabrication of lithium polymer batteries and cells using surface treated separators

InactiveUS20020170169A1Electrode thermal treatmentFinal product manufacturePlasticizerPhysical chemistry

Method of making Li-intercalateable electrodes for a lithium-ion battery by applying a first film onto a first face of an electrically conductive grid, which film comprises a plurality of Li-intercalateable particles dispersed throughout a mixture of a polymeric binder and a plasticizer for the binder. Thereafter, a film-forming slurry having the same composition as the first film, plus a solvent therefor, is applied to a second face of the grid opposing the first face so as to provide a second film and such that the solvent in the slurry dissolves at least a portion of the first film and promotes solvent bonding of the films with the grid embedded therein. A polymeric backing film treated with plasma and defining a separator is used as a manufacturing process aid, thereby eliminating the step of using a carrier film onto which the electrodes are fabricated and stripping off the carrier and discarding the same. Treating the separator with plasma enhances surface energy thereby improving the lamination process of the film-forming slurries to the separator and reducing degradation of the separator.

Owner:ENERDEL

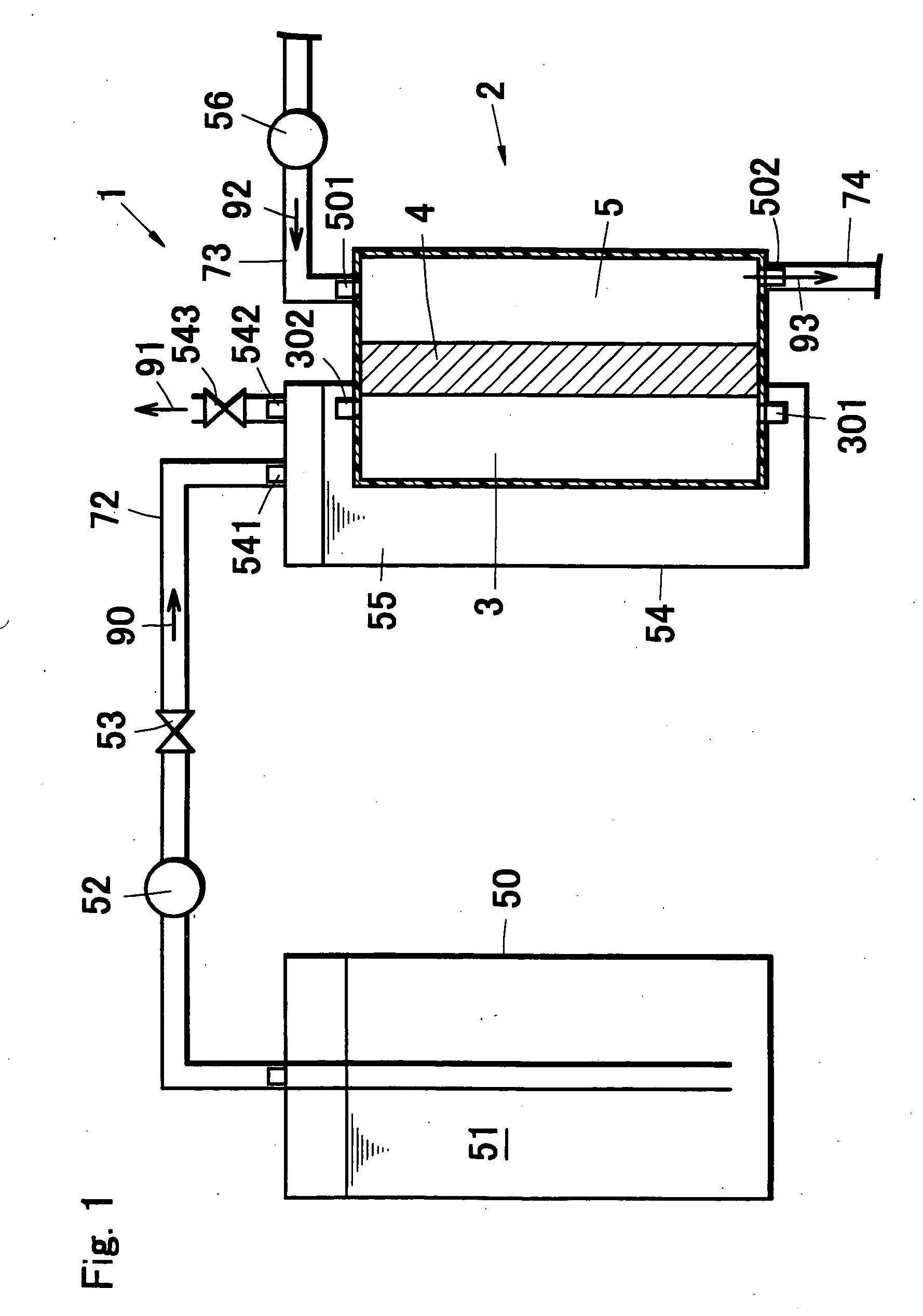

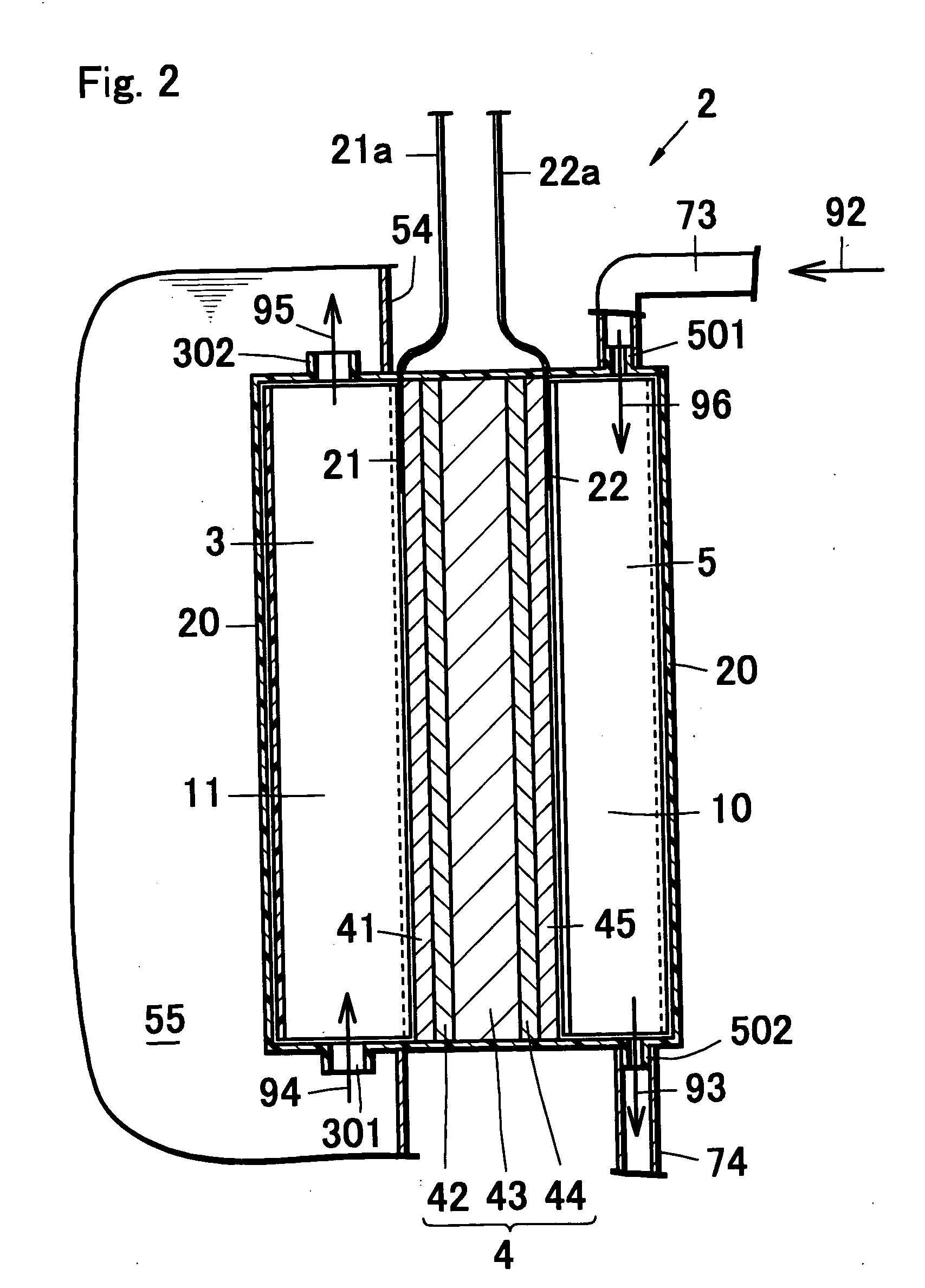

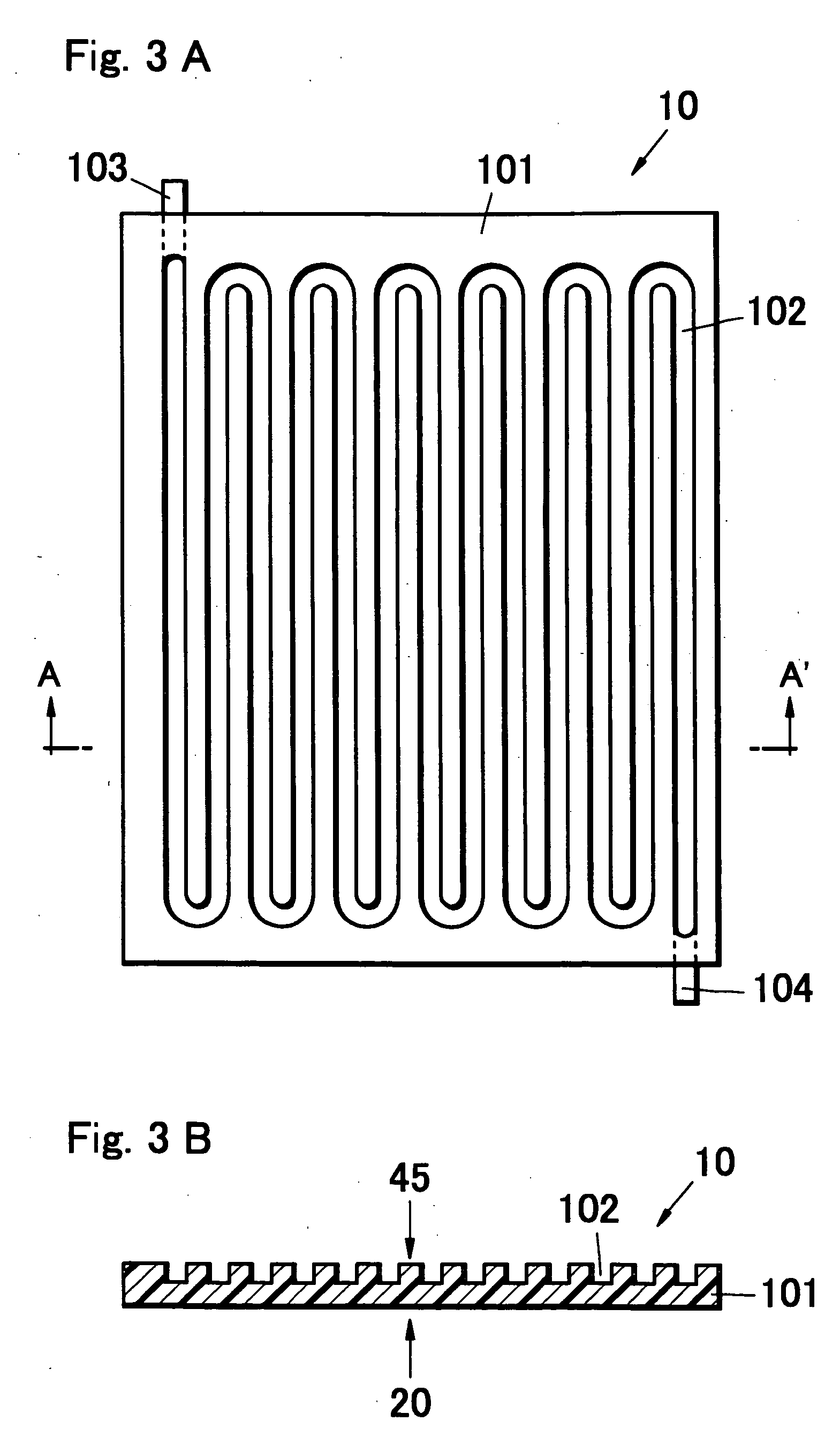

Fuel cell

InactiveUS20050026021A1Increase power generation outputReduce weightFuel cells groupingRegenerative fuel cellsFuel cellsEngineering

A fuel cell body has an anode having an anode-side separator with projections and depressions formed on its surface, a cathode, and a membrane electrode assembly disposed between the anode and the cathode, and the fuel cell body is disposed in a container for storing liquid fuel so that at least the anode side is immersed therein. Fuel passageways through which the liquid fuel flows are formed by regions surrounded by the projections and depressions on the surface of the separator and the membrane electrode assembly. By this, the downsized, simplified and lower power consuming structure of auxiliary equipment such as fuel feed system is achieved.

Owner:PANASONIC CORP

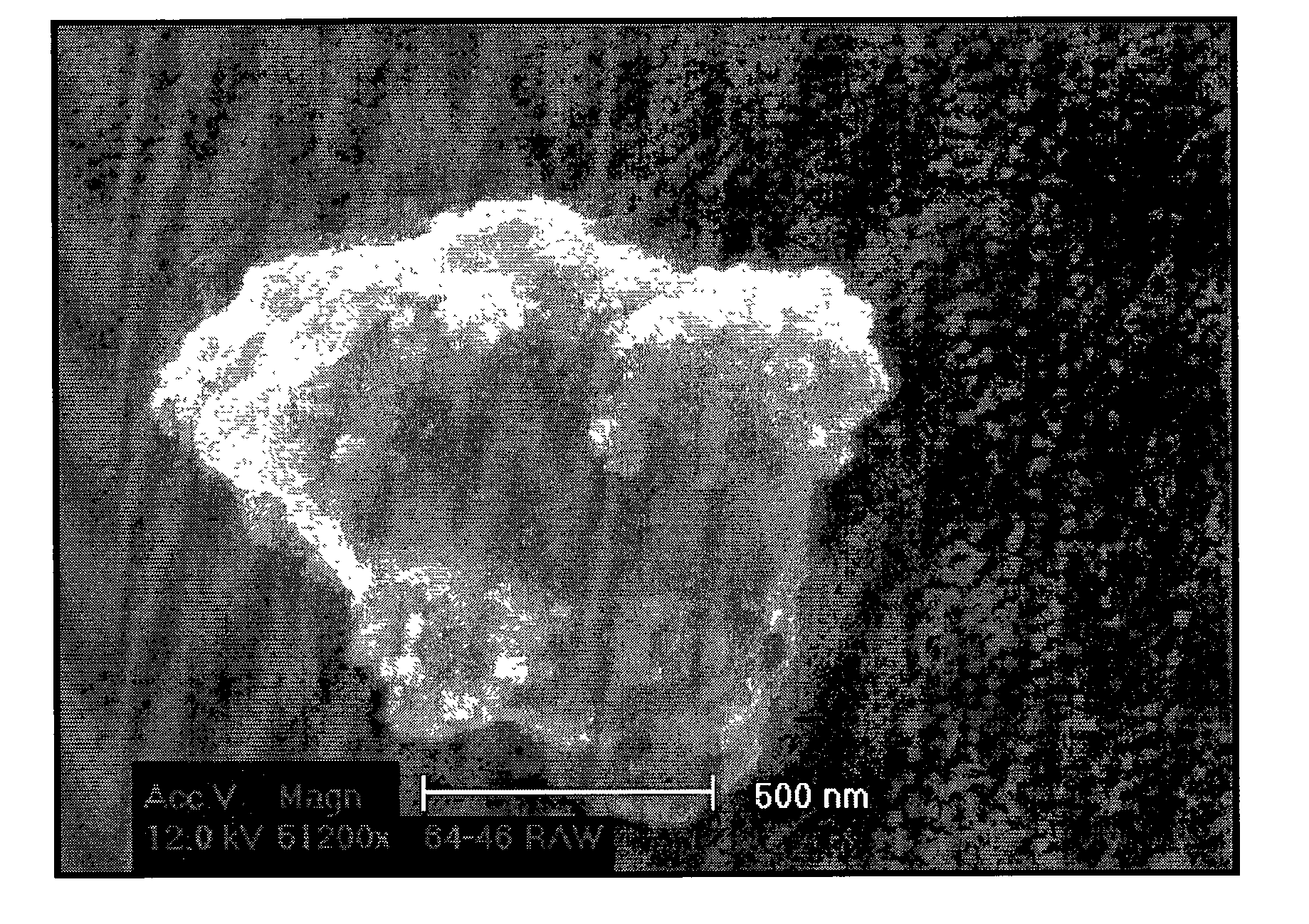

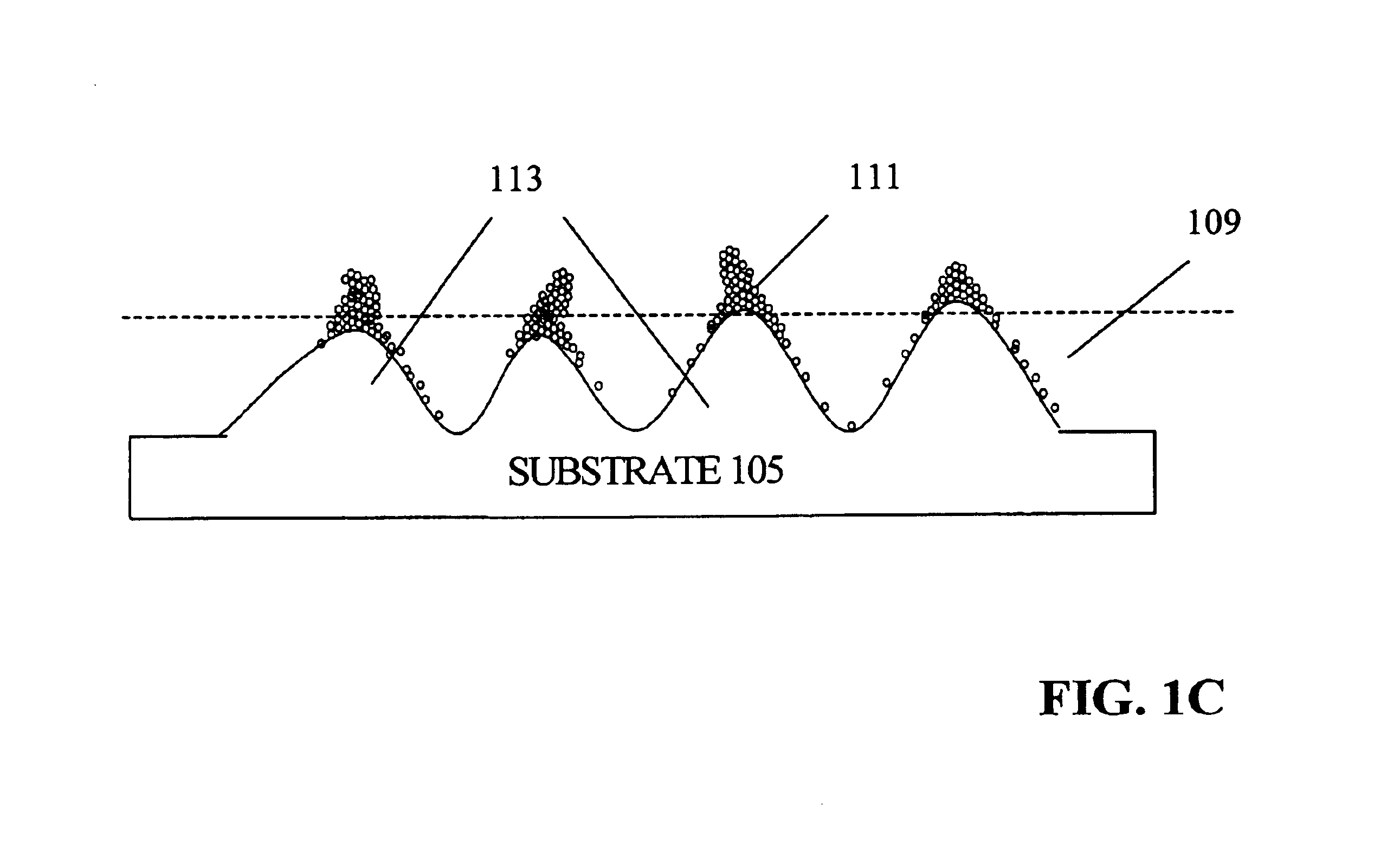

Nano-composite electrodes and method of making the same

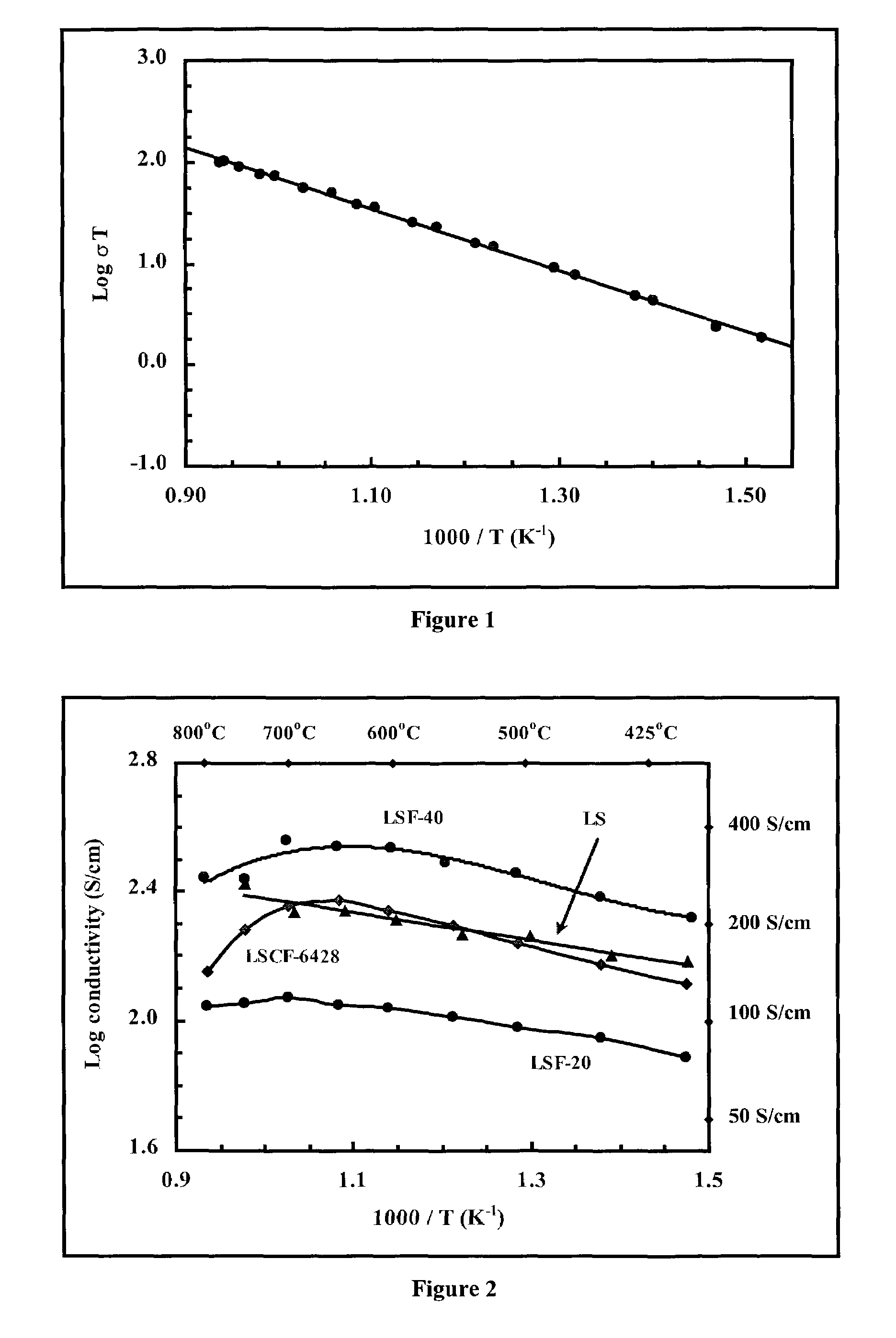

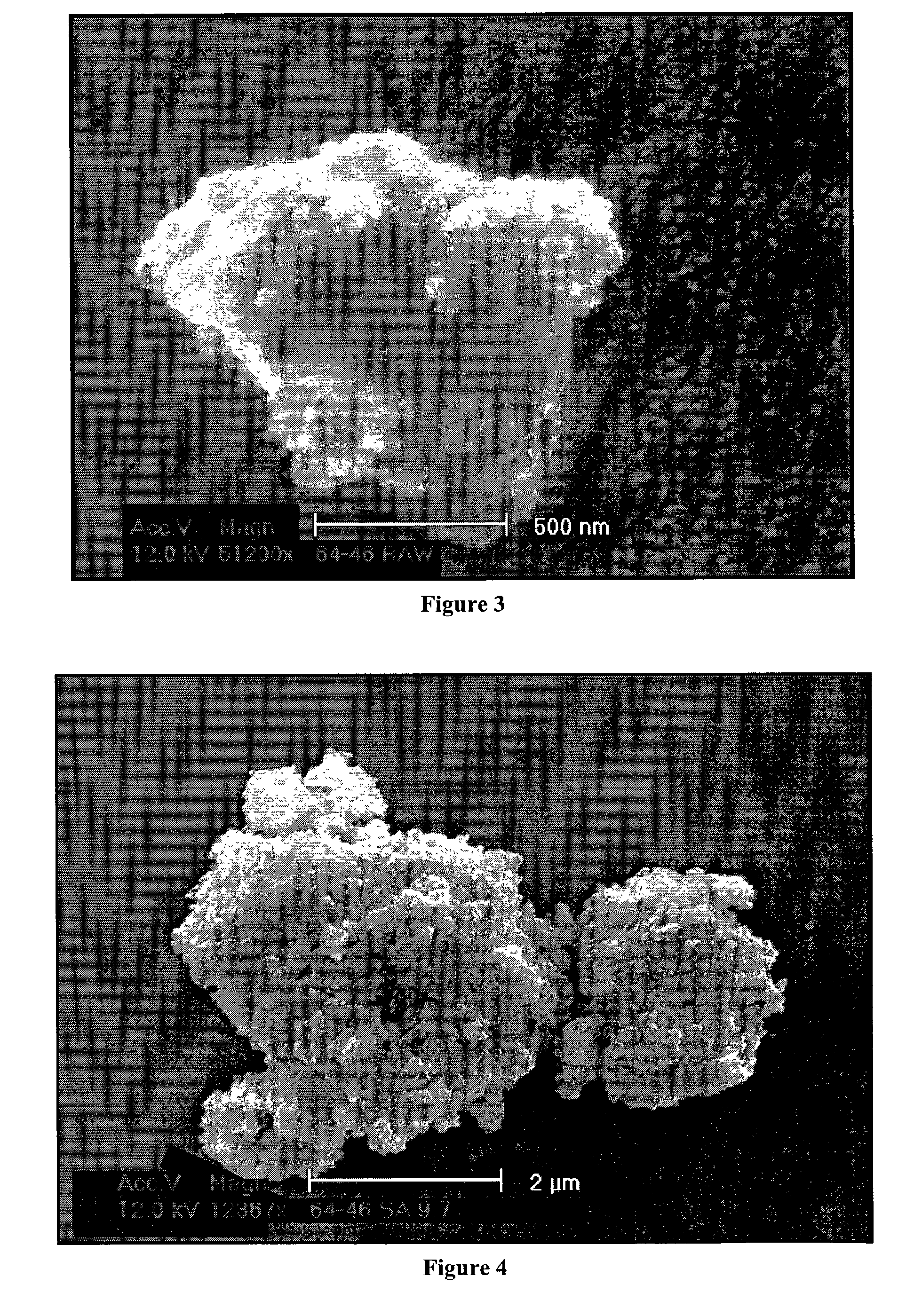

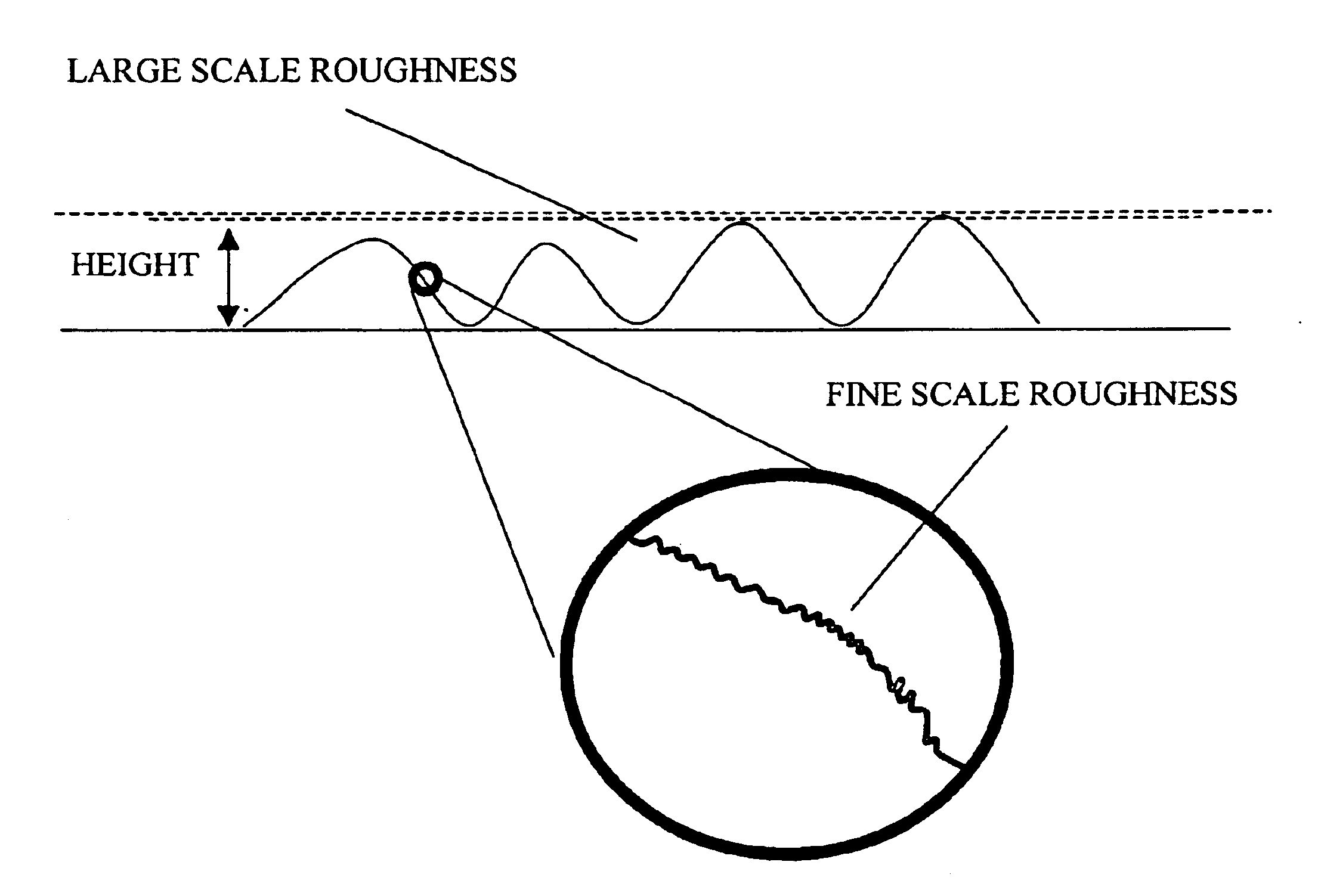

InactiveUS7595127B2Improve performanceLower operating temperatureElectrode thermal treatmentFinal product manufactureLanthanum strontium manganiteMetallic electrode

A method of making ceramic electrode materials comprising intimate mixtures of two or more components, including at least one nanoscale ionically conducting ceramic electrolyte material (e.g., yttrium-stabilized zirconia, gadolinium-doped ceria, samarium-doped ceria, etc.) and at least one powder of an electrode material, which may be an electrically conducting ceramic electrode material (e.g., lanthanum strontium manganite, praseodymium strontium manganese iron oxide, lanthanum strontium ferrite, lanthanum strontium cobalt ferrite, etc.) or a precursor of a metallic electrode material (e.g., nickel oxide, copper oxide, etc.). The invention also includes anode and cathode coatings and substrates for solid oxide fuel cells prepared by this method.

Owner:NEXTECH MATERIALS

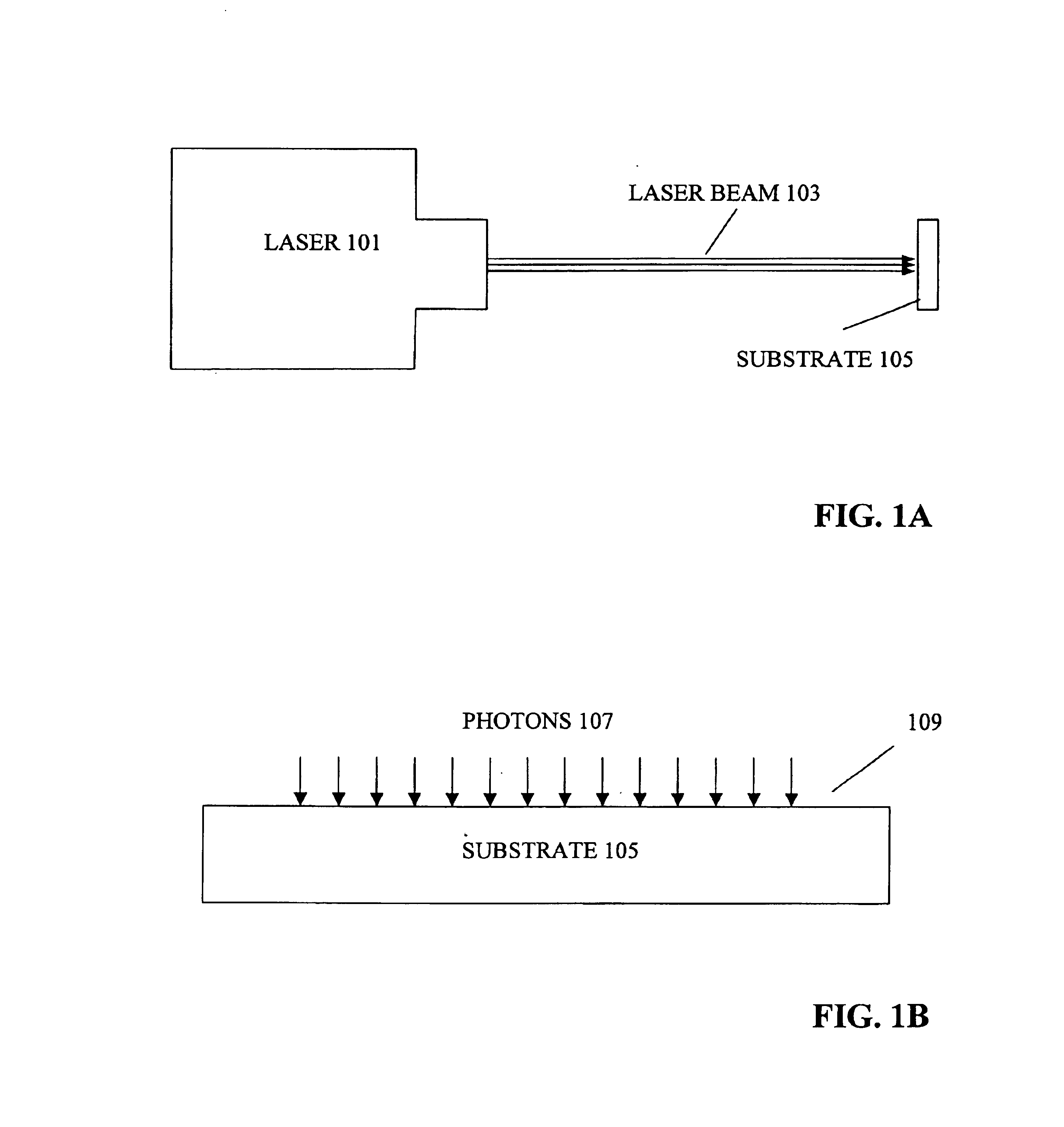

Ion exchange system structure with a microtextured surface, method of manufacture, and method of use thereof

InactiveUS6869712B2Reduce contaminationReduce the level of damageSolid electrolytesIon-exchanger regenerationIon exchangeHigh surface

A method for roughening a surface of an ion exchange system structure using laser interaction with a surface. The laser surface roughening process allows the use of a wide range of substrates such as metals, ceramics, silicates, polymers and the like, including varieties which can not be fabricated in a fine fibrous structure. The surface roughened ion exchange system structure may be used as an ion-exchange media in applications such as fuel cells, batteries, and other catalysis systems where a high surface exchange area is desirable.

Owner:INTELLIGENT ENERGY LTD

Thin battery and a method of manufacturing a thin battery

InactiveUS20100075215A1Easy to producePrevent short-circuitingElectrode rolling/calenderingCell seperators/membranes/diaphragms/spacersEngineeringElectrolyte

The thin battery of the invention comprises an anode material, a cathode material, two or more separator paper layers there between, and electrolyte. One of the outer separator paper layers has an anode material applied thereon, another separator paper layer being an outer layer on the opposite side having a cathode material applied thereon. The method of the invention for manufacturing such a thin battery is mainly characterized by the steps of wetting a separator paper with an electrolyte solution, applying an anode material on a first separator paper and applying a cathode material on a second separator paper. The separator papers are then combined by pressing them together so that the anode and cathode materials are outmost, respectively in order to form a layered structure. The combined layers are then cut in desired sizes.

Owner:ENFUCELL

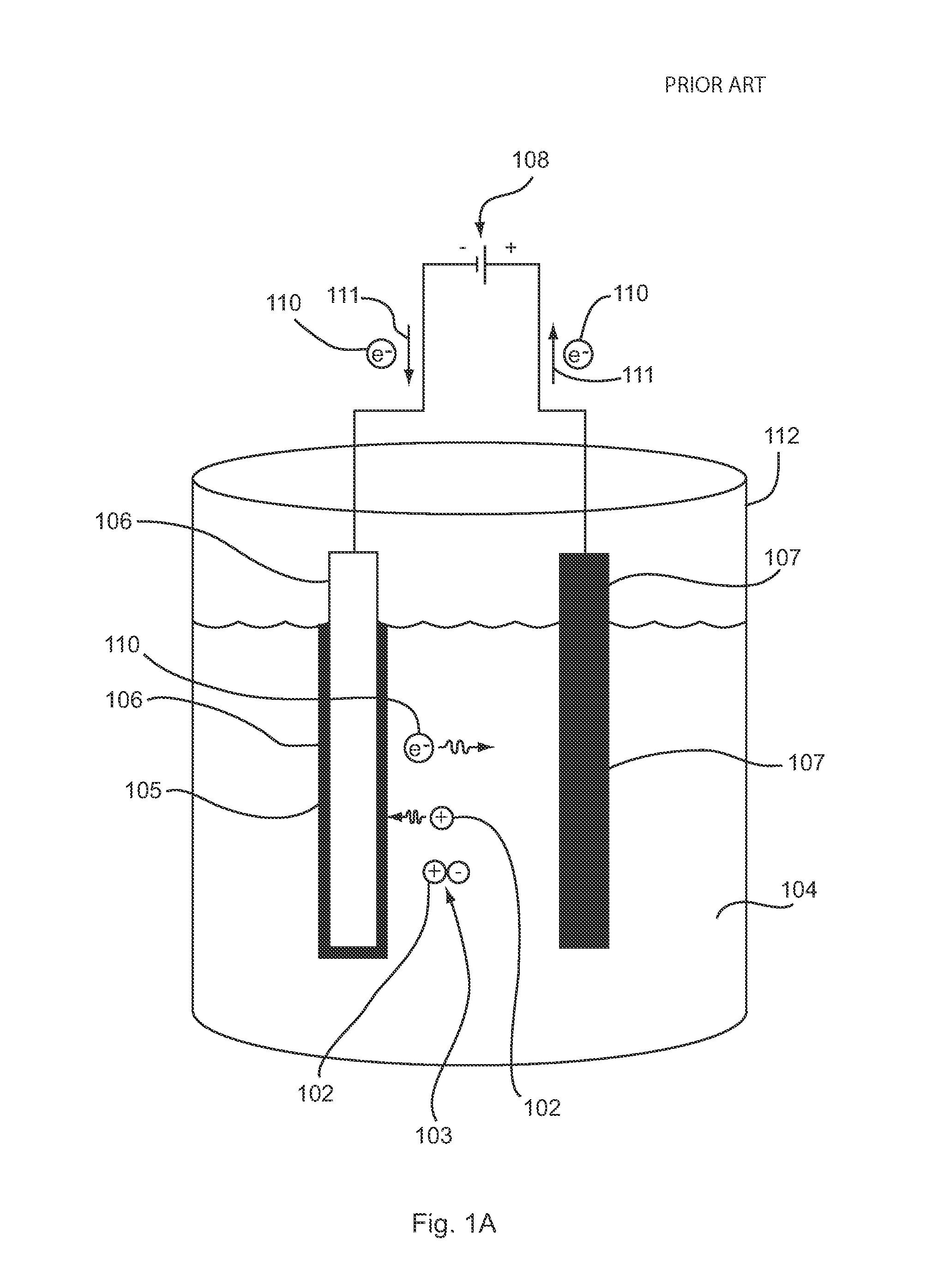

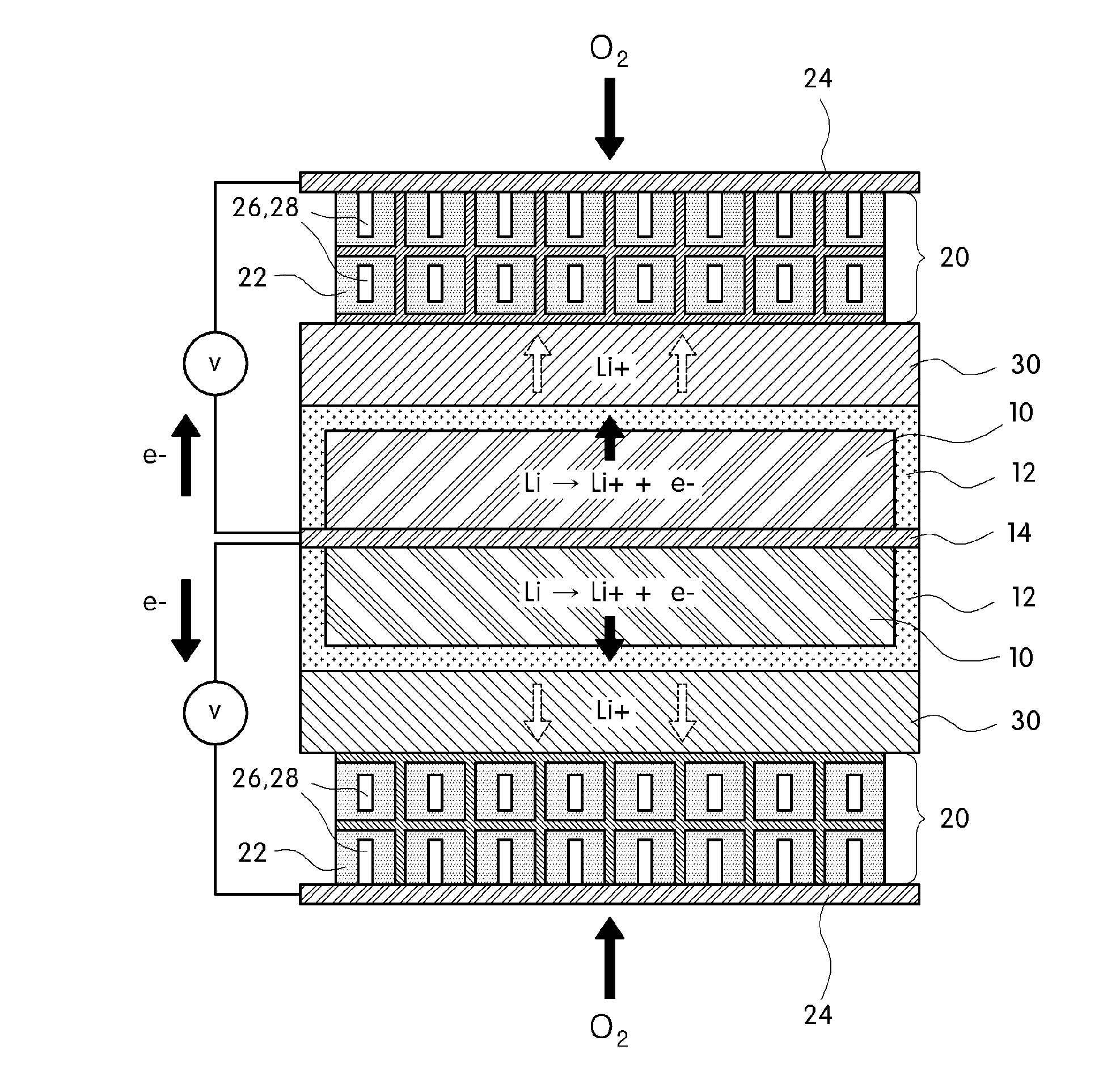

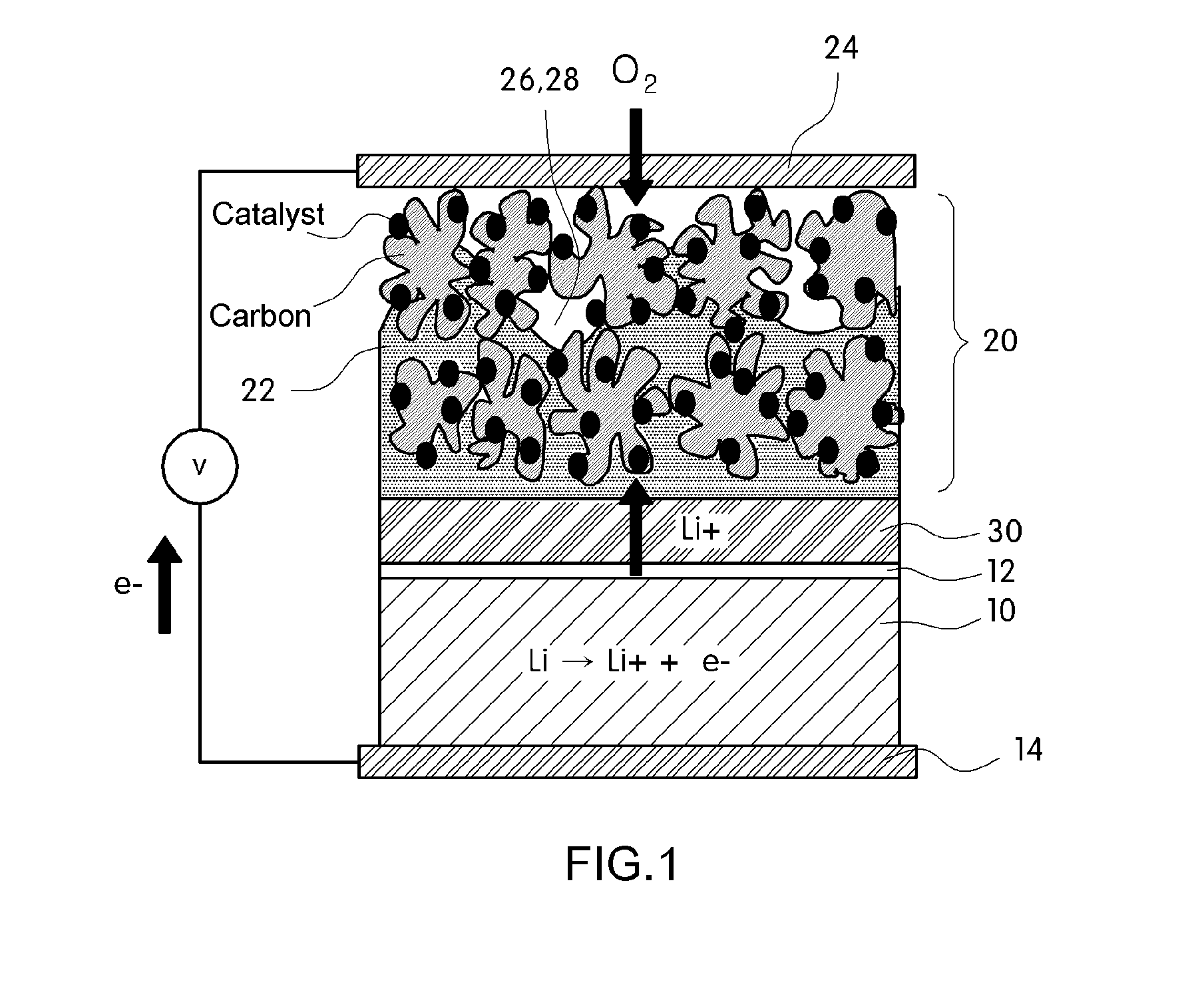

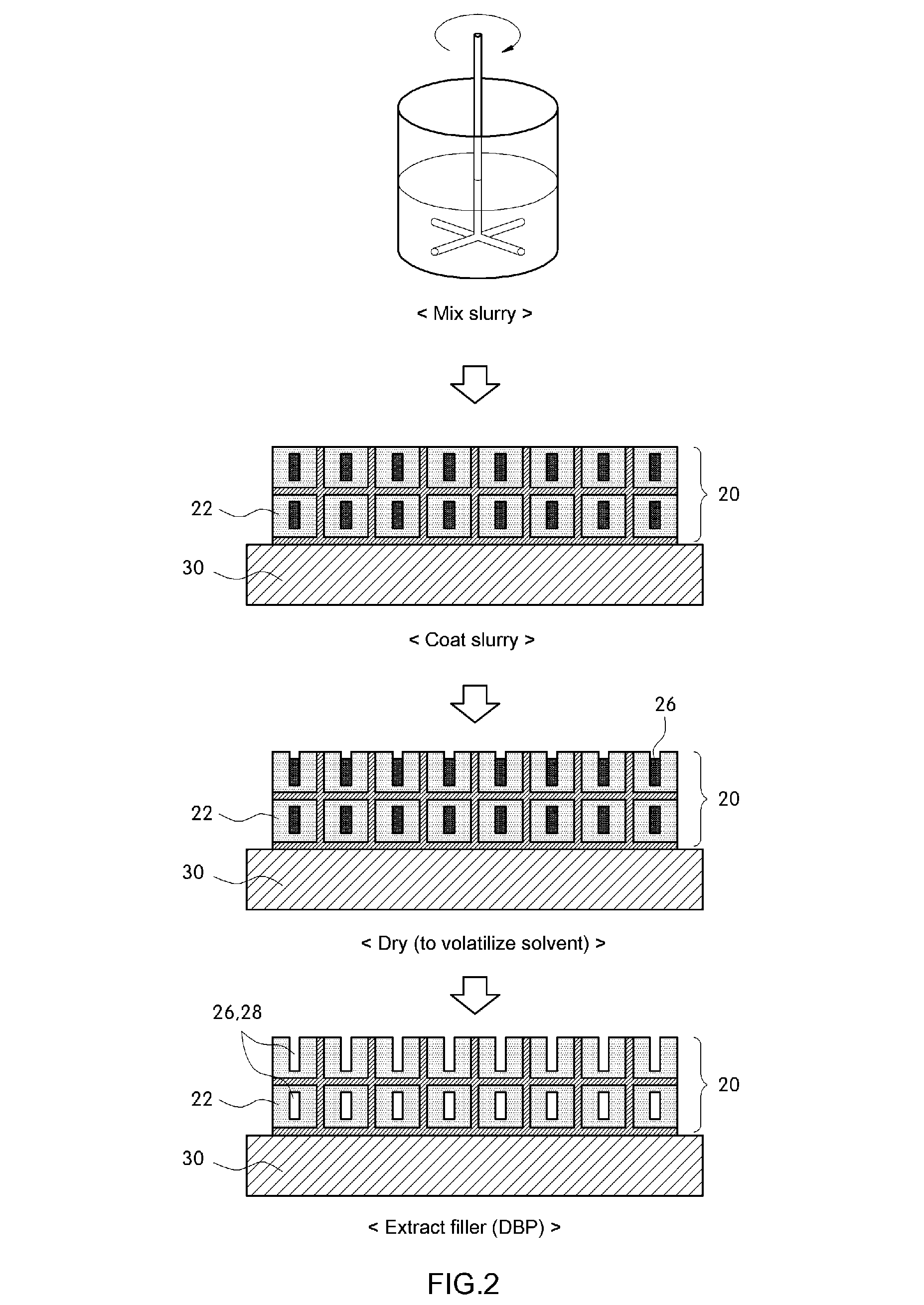

Li-air hybrid battery and method for manufacturing the same

The present invention provides a lithium-air hybrid battery and a method for manufacturing the same, which has a structure in which a liquid electrolyte electrode and a solid electrolyte electrode are stacked on both sides of an ion conductive glass ceramic. That is, disclosed is a lithium-air hybrid battery and a method for manufacturing the same, which has a structure in which a lithium metal negative electrode includes a liquid electrolyte and a porous air positive electrode comprising a carbon, a catalyst, a binder and a solid electrolyte are separately stacked on both sides of an impermeable ion conductive glass ceramic, and the liquid electrolyte is present only in the lithium metal negative electrode.

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com