Patents

Literature

290results about "Primary cell details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

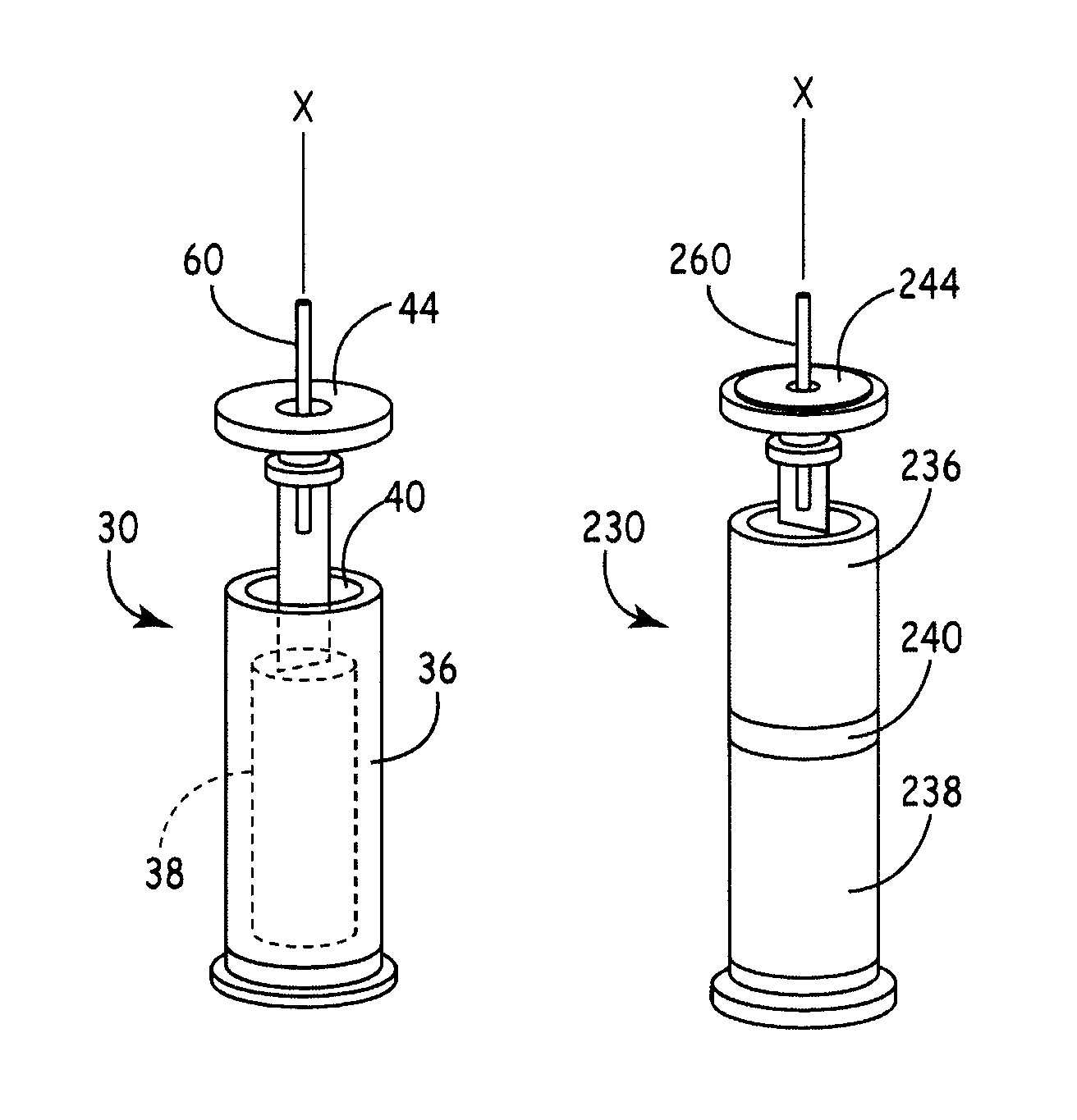

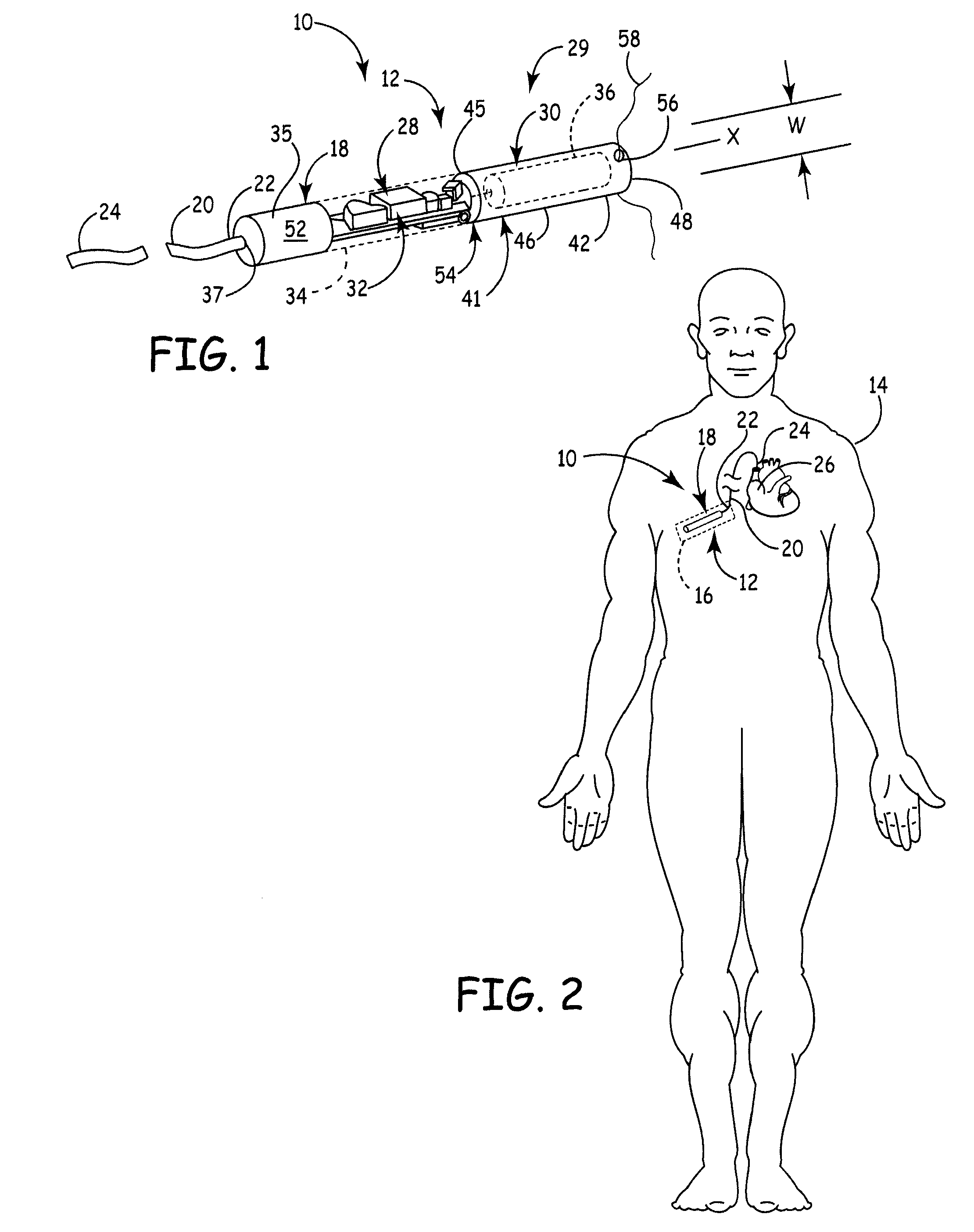

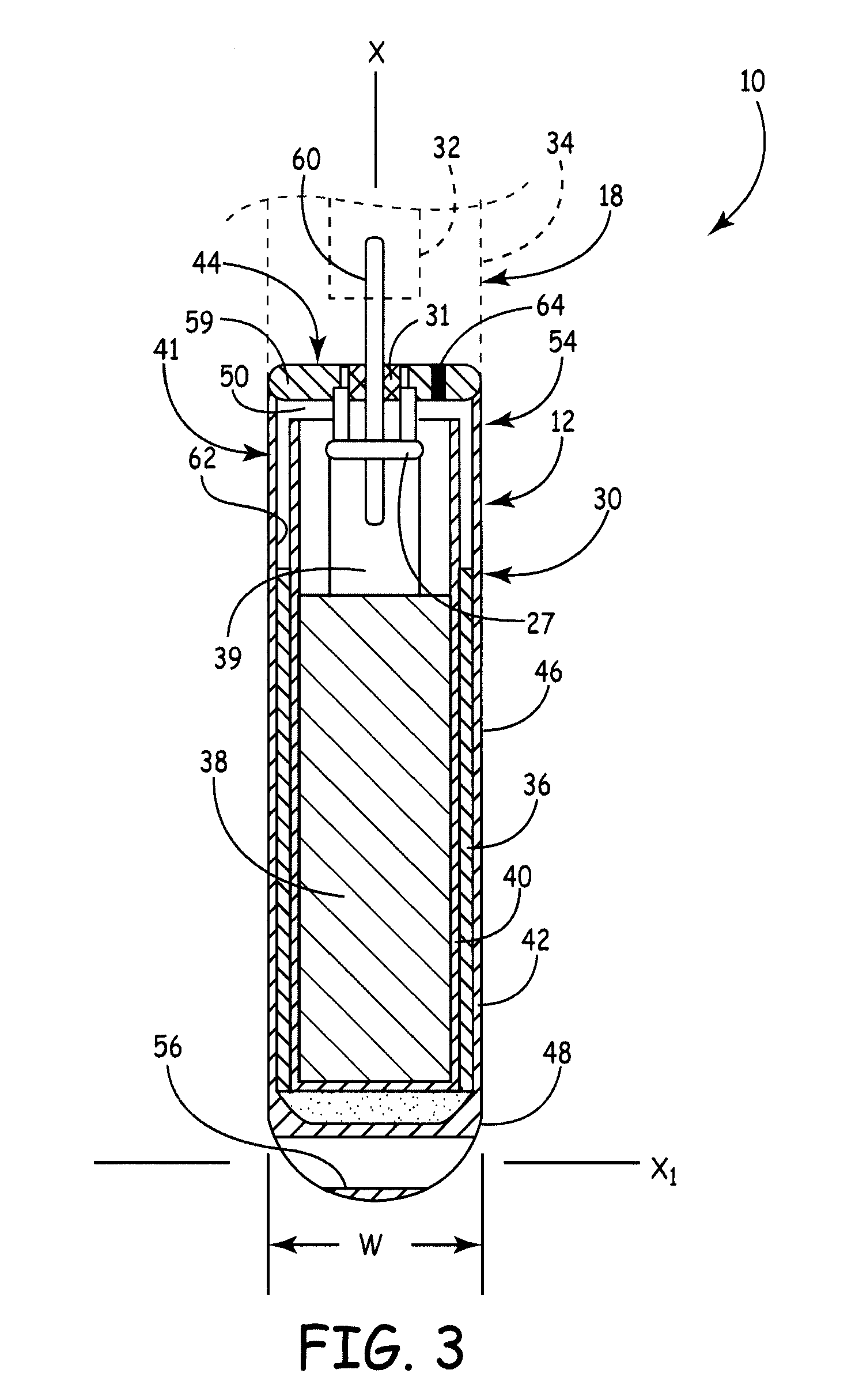

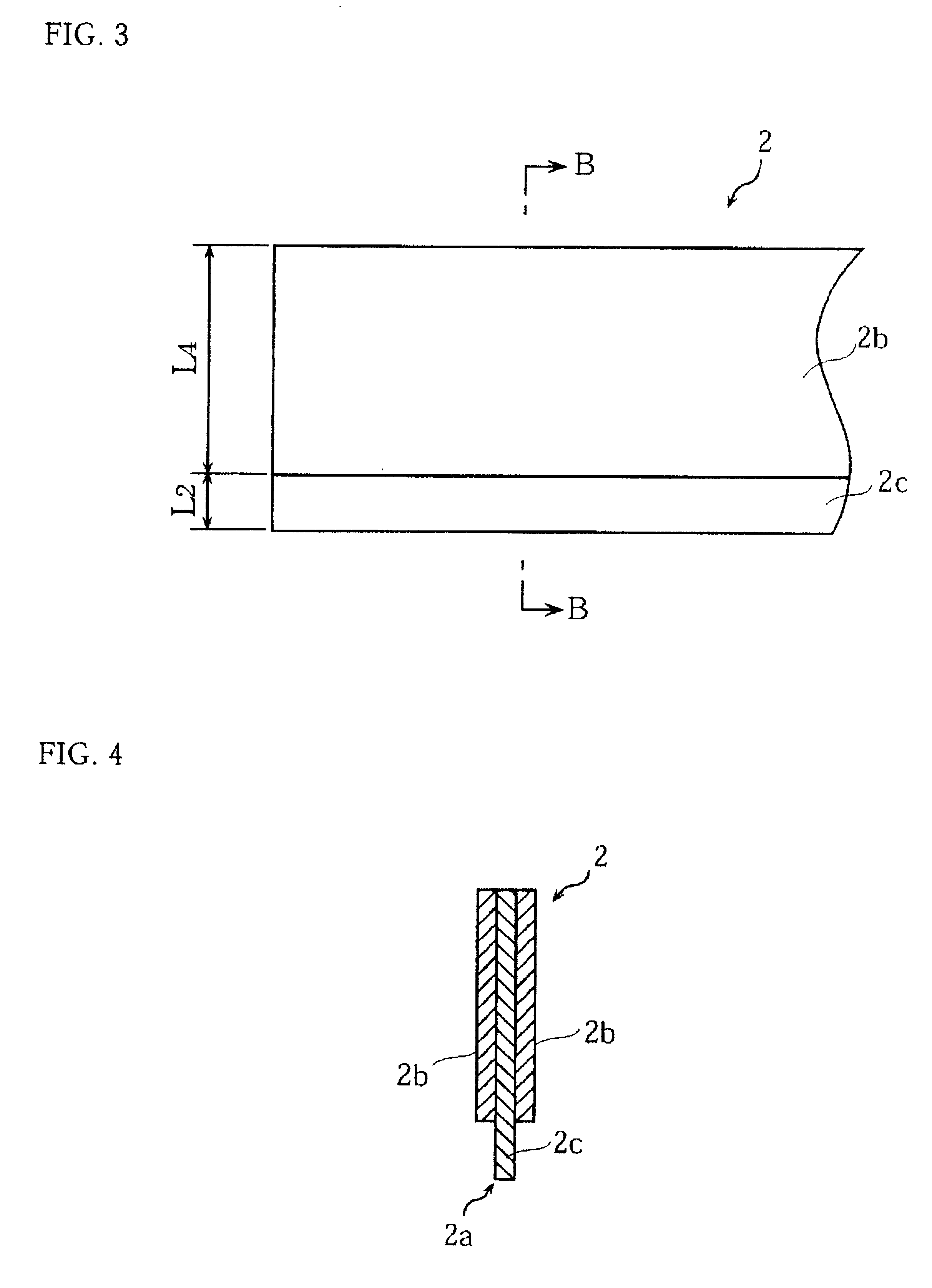

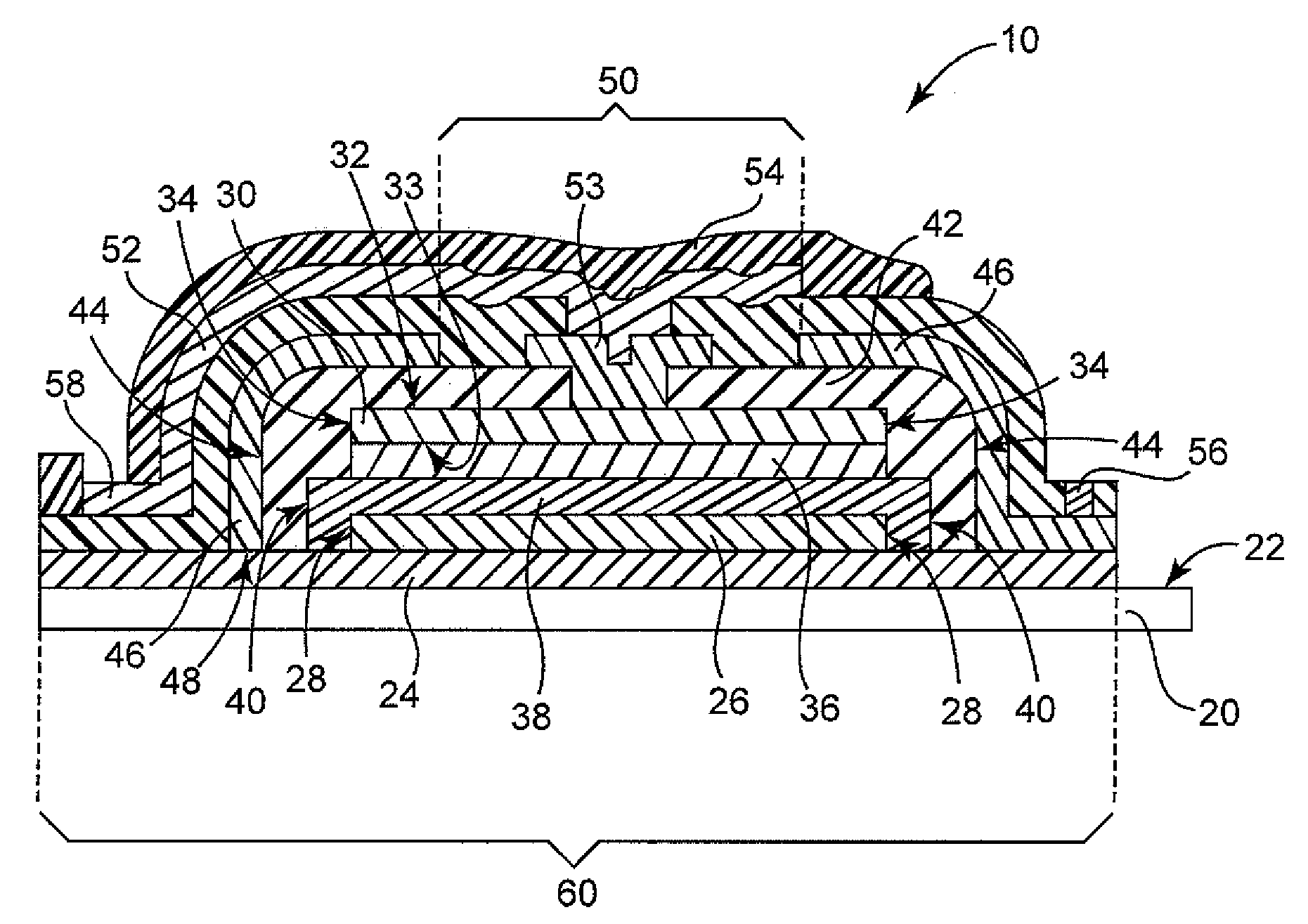

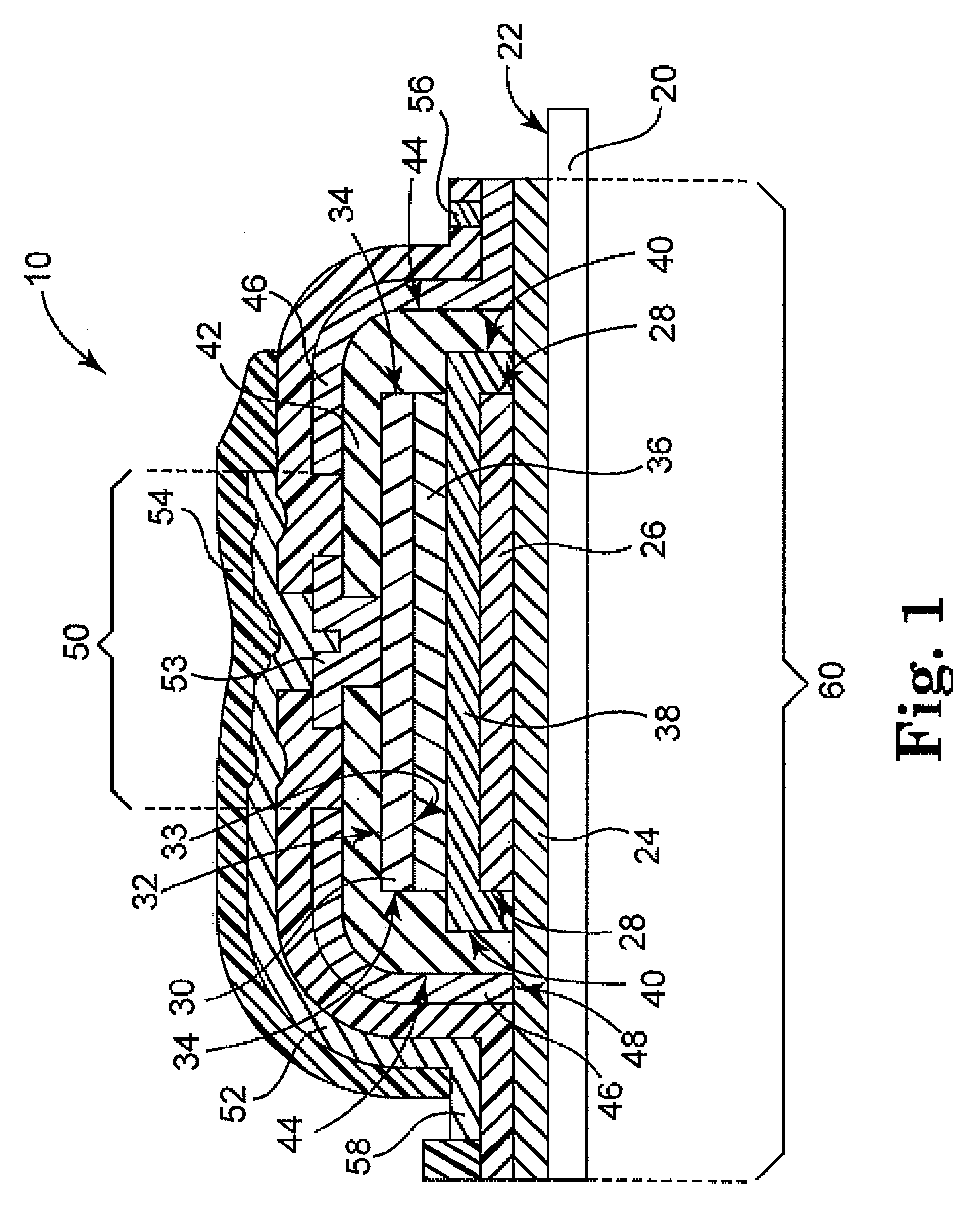

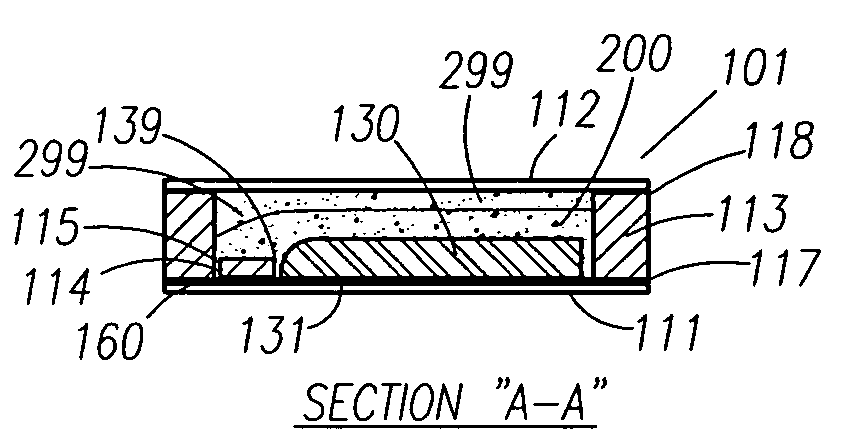

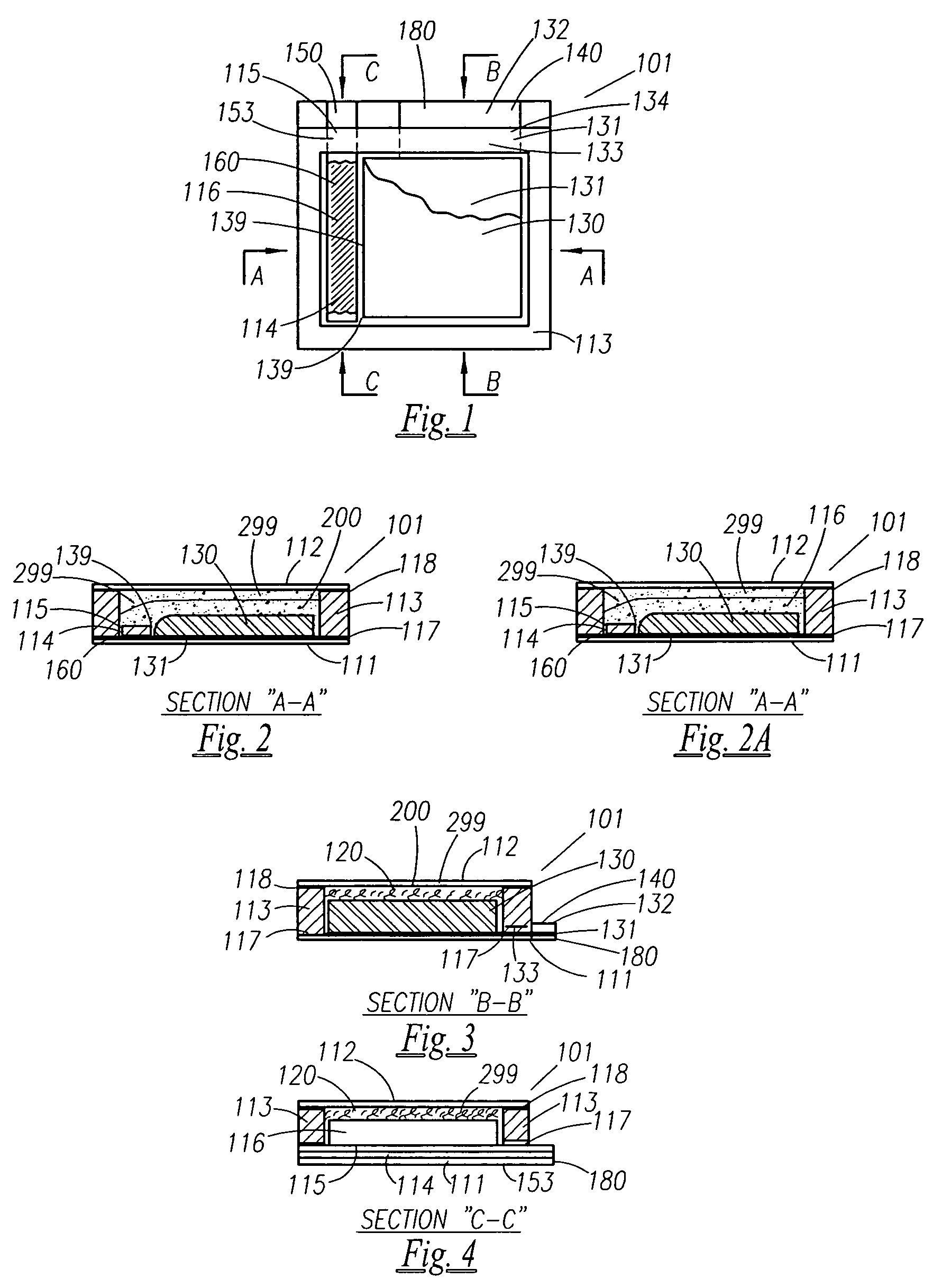

Elongate battery for implantable medical device

A battery assembly for a medical device includes an elongate cathode, an elongate anode, an electrolyte, and an elongate housing assembly encapsulating the cathode, the anode, and the electrolyte. The battery assembly also includes a first electrode that is exposed from and electrically insulated from the housing assembly. One of the anode and the cathode is electrically coupled to the first electrode, and the other of the anode and the cathode is electrically coupled to the housing assembly. One of the cathode and the anode includes a first portion and a second portion disposed in spaced relationship from the first portion. The other of the cathode and the anode is disposed between the first and second portions.

Owner:MEDTRONIC INC

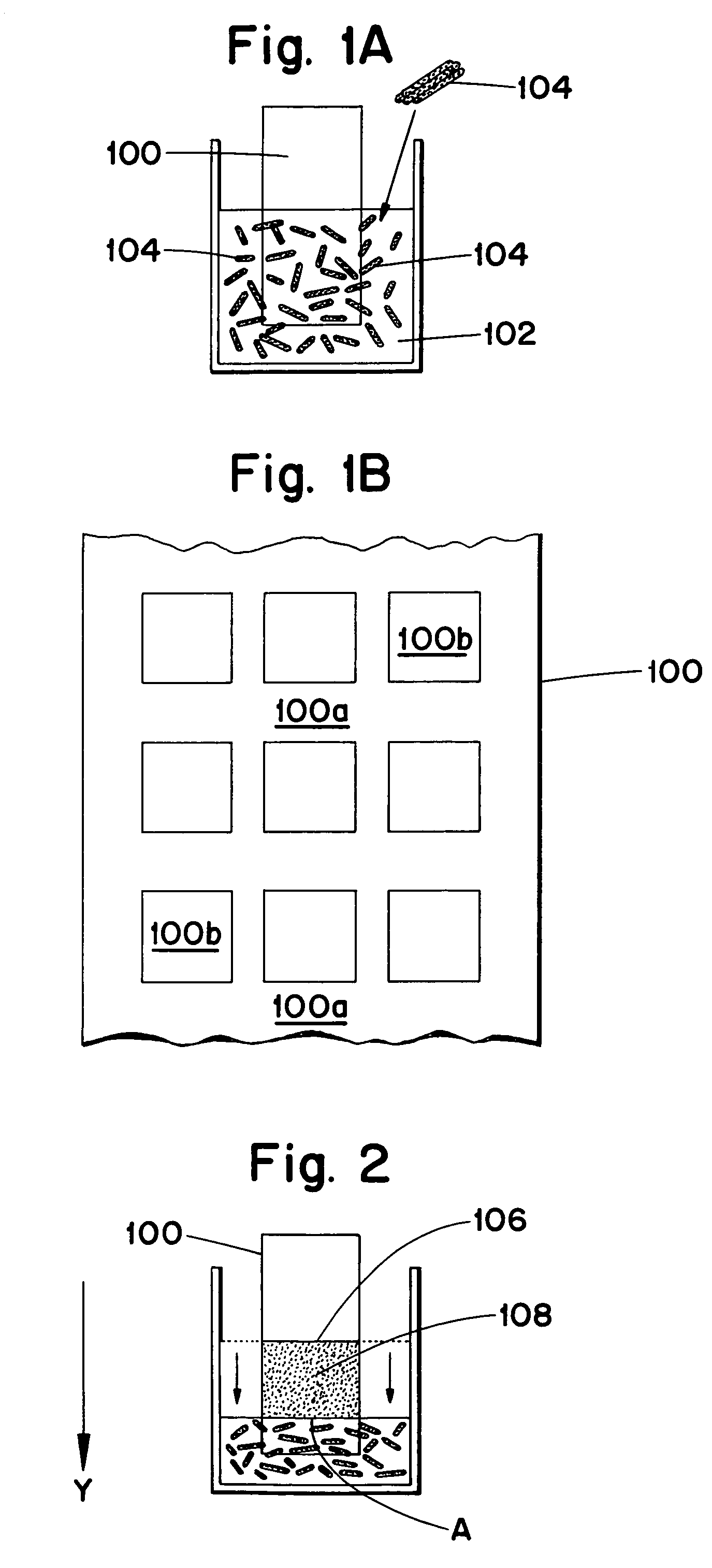

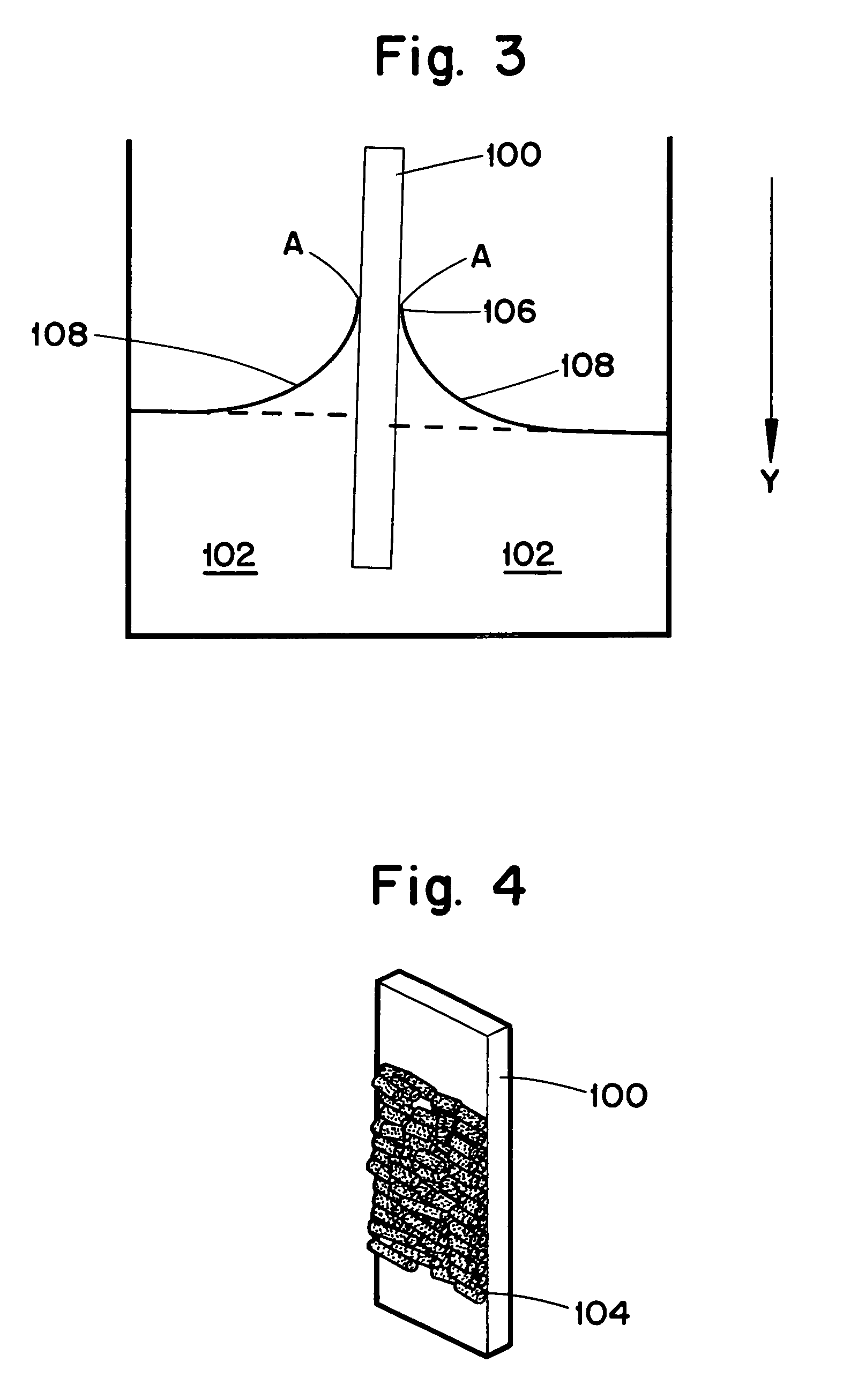

Method for assembling nano objects

InactiveUS7147894B2Orientation can be controlledEfficient assemblyMaterial nanotechnologyNanostructure manufactureEvaporationSolvent

A method for the self assembly of a macroscopic structure with a pre-formed nano object is provided. The method includes processing a nano object to a desired aspect ratio and chemical functionality and mixing the processed nano object with a solvent to form a suspension. Upon formation of the suspension, a substrate is inserted into the suspension. By either evaporation of the solvent, changing the pH value of the suspension, or changing the temperature of the suspension, the nano objects within the suspension deposit onto the substrate in an orientational order. In addition, a seed crystal may be used in place of the substrate thereby forming single-crystals and free-standing membranes of the nano-objects.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

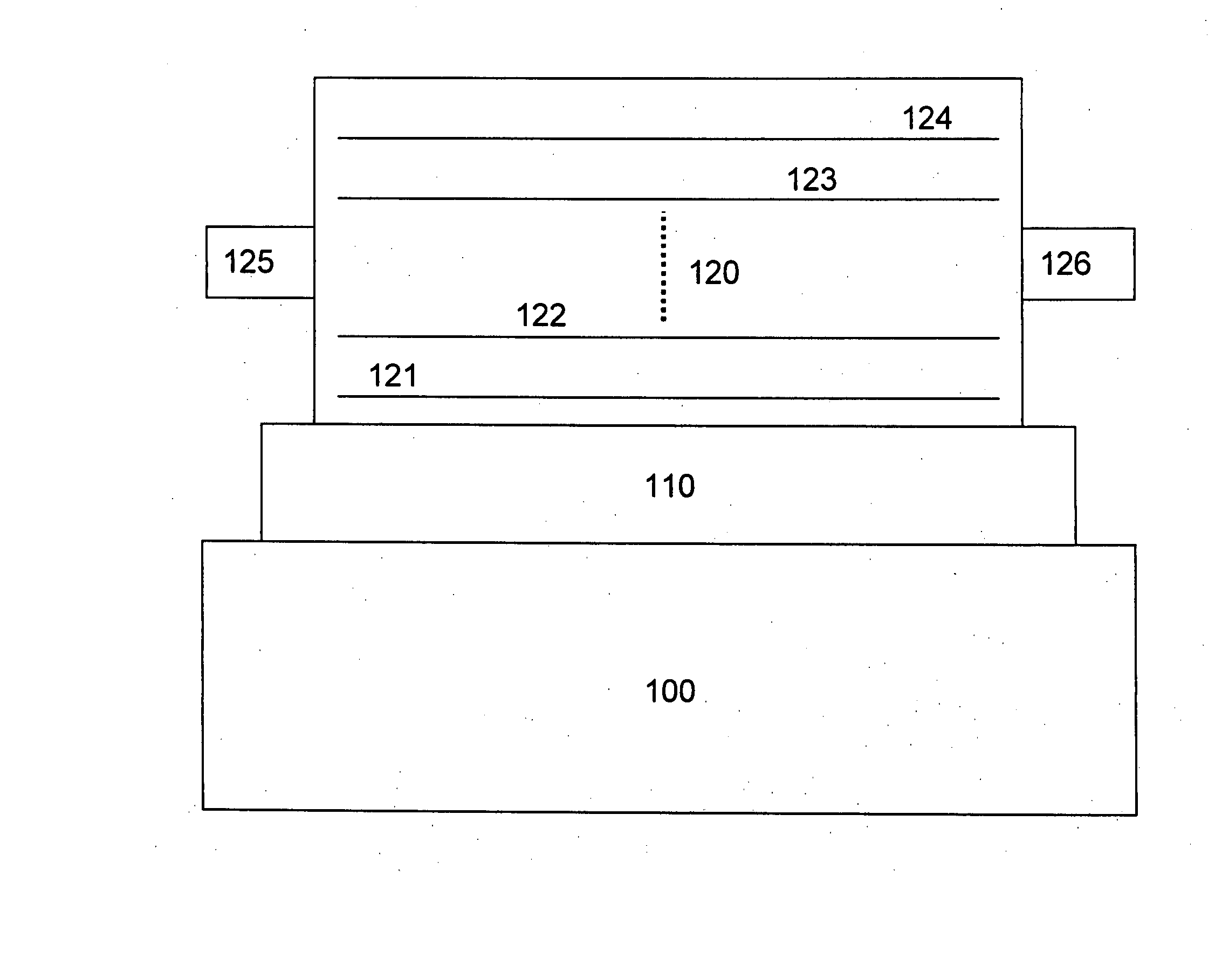

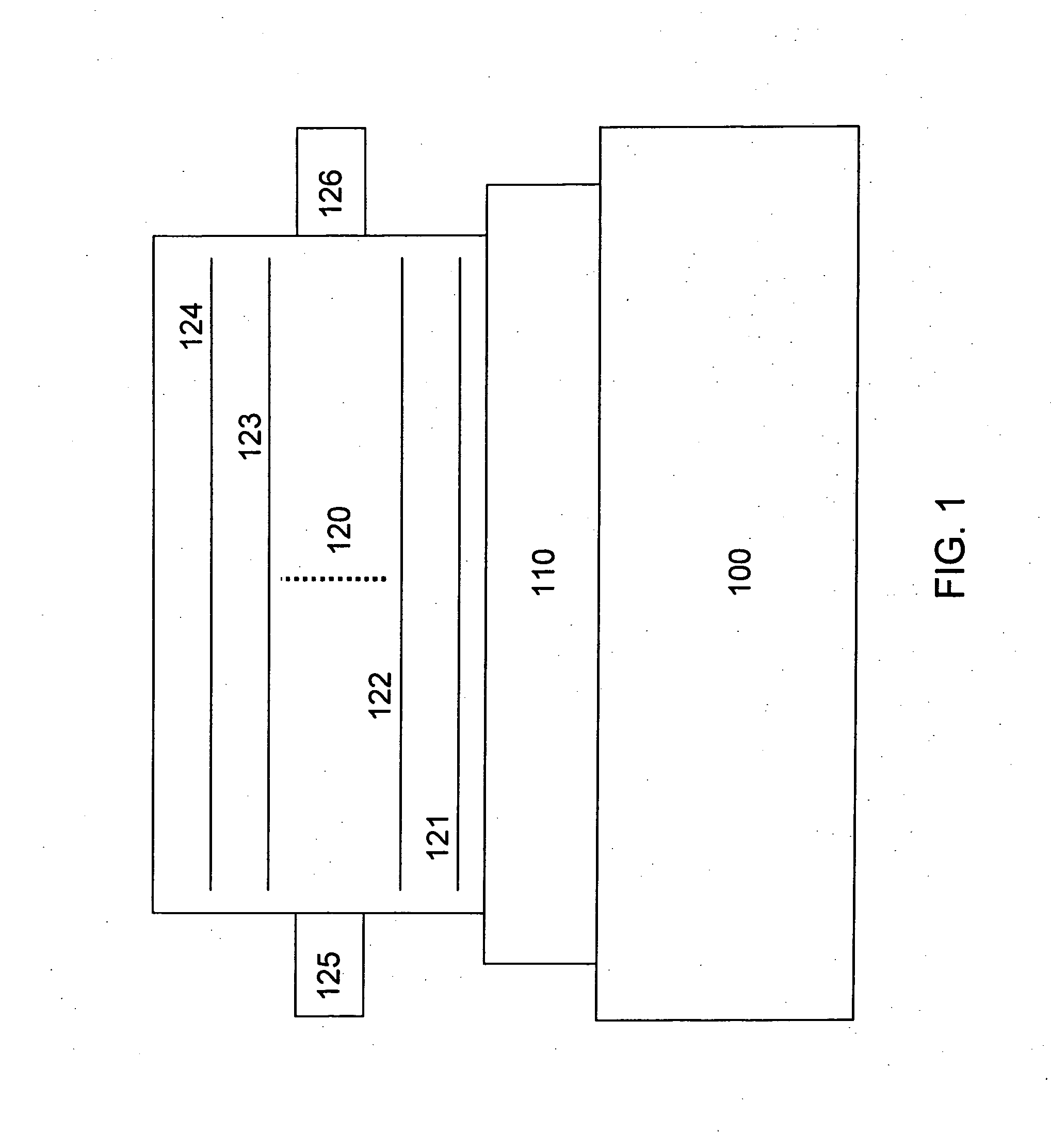

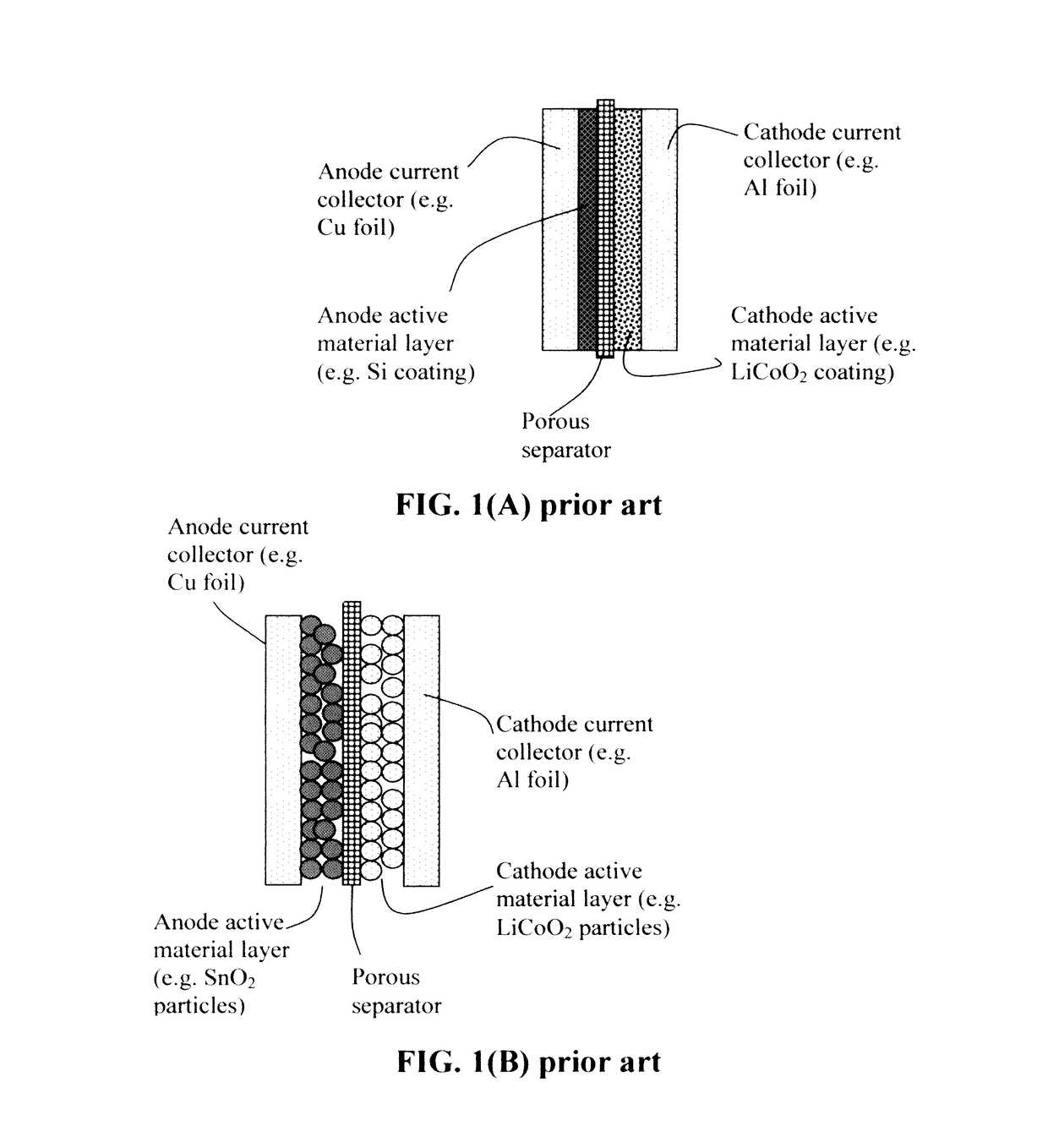

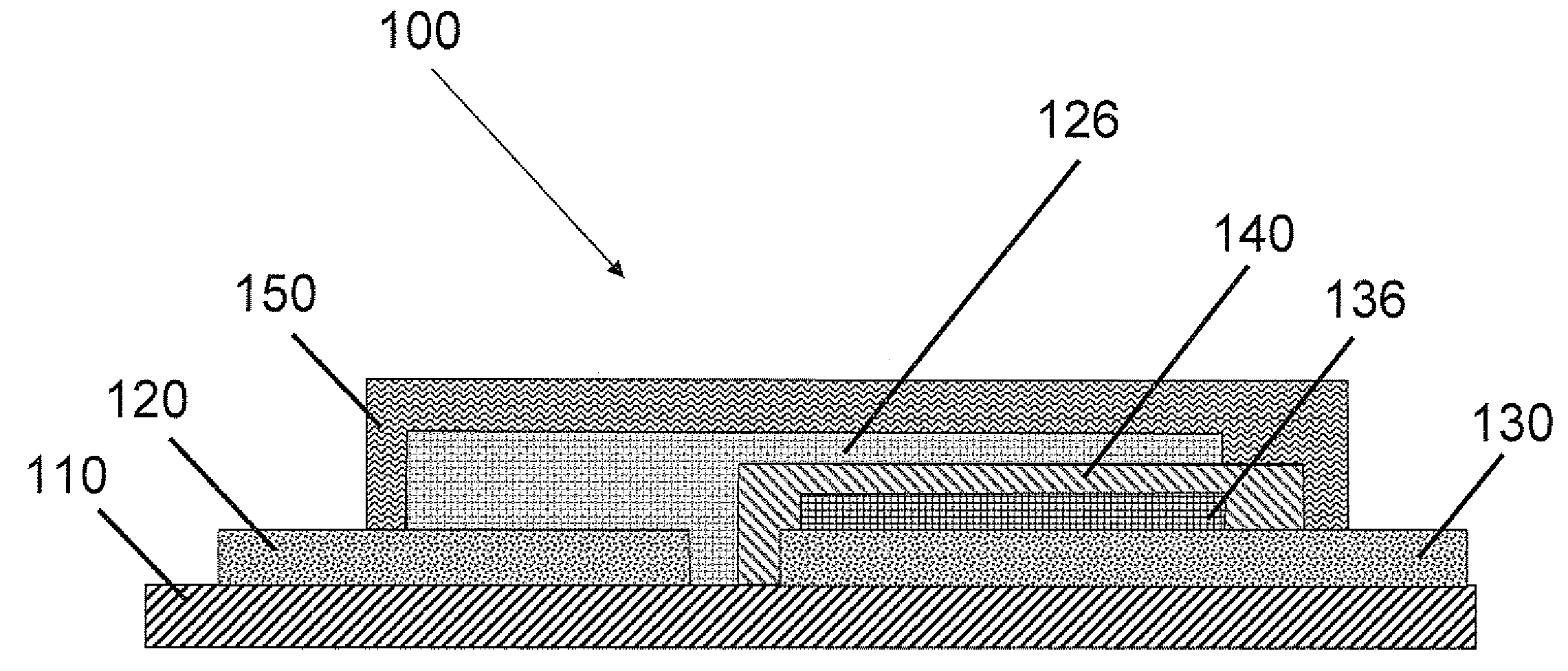

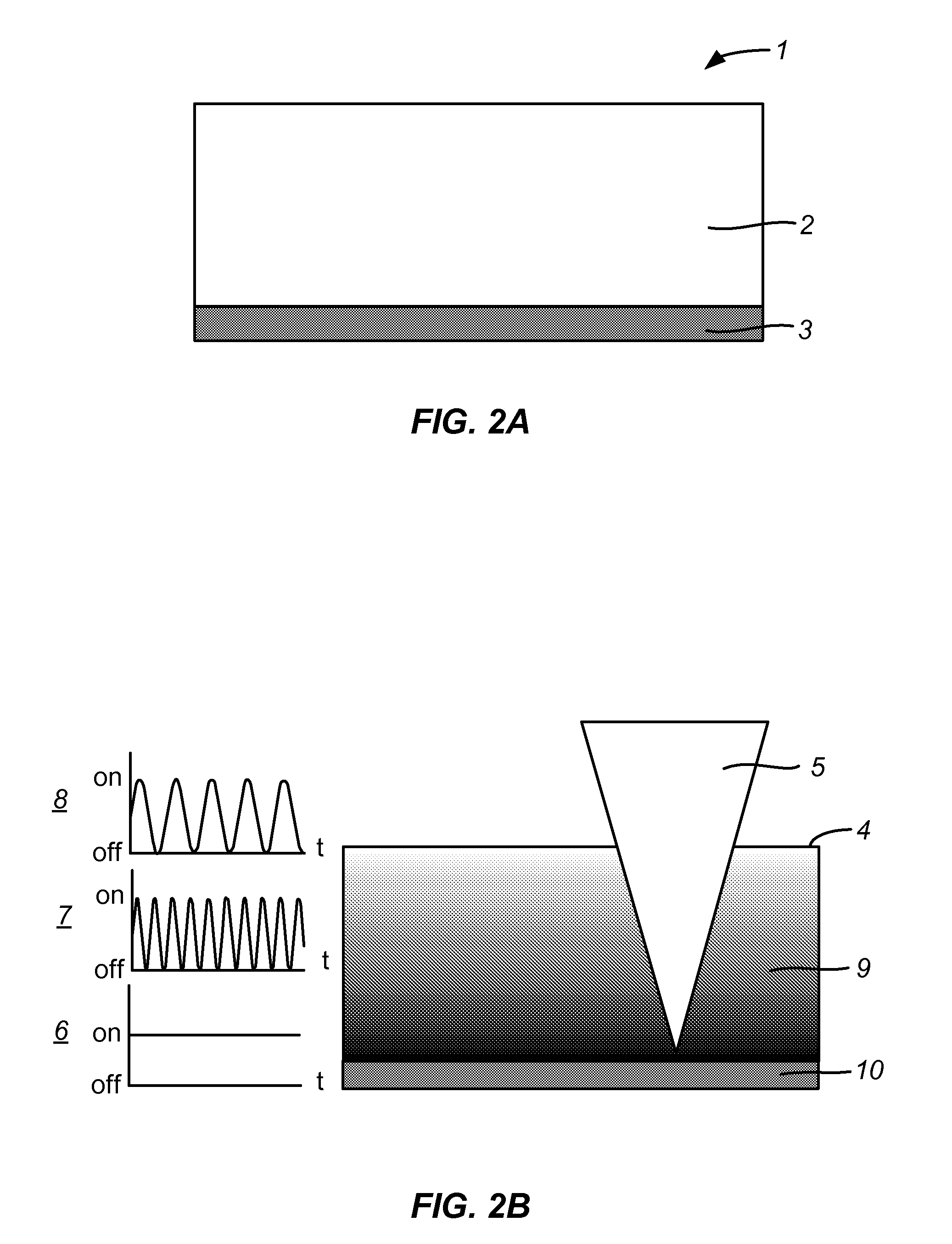

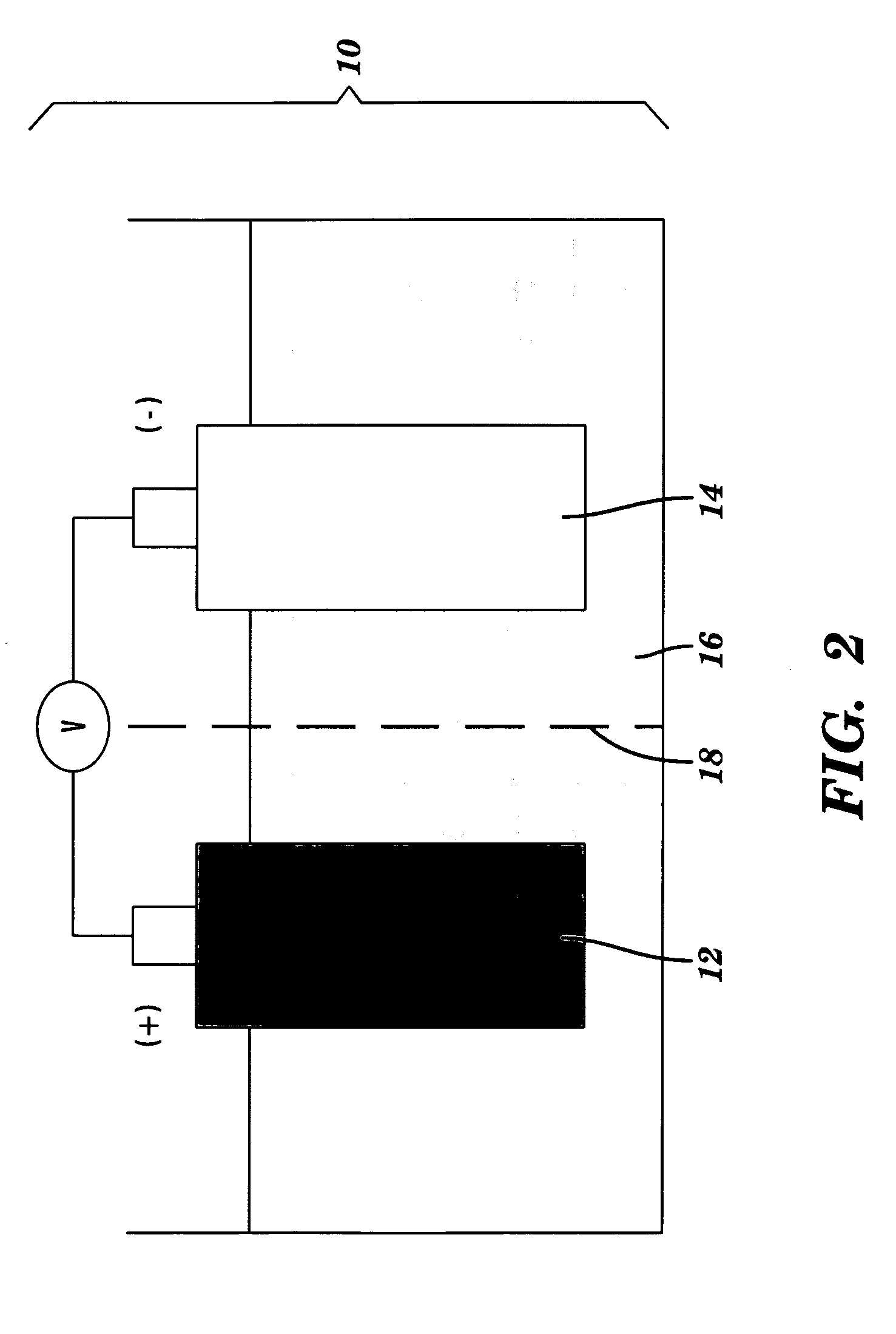

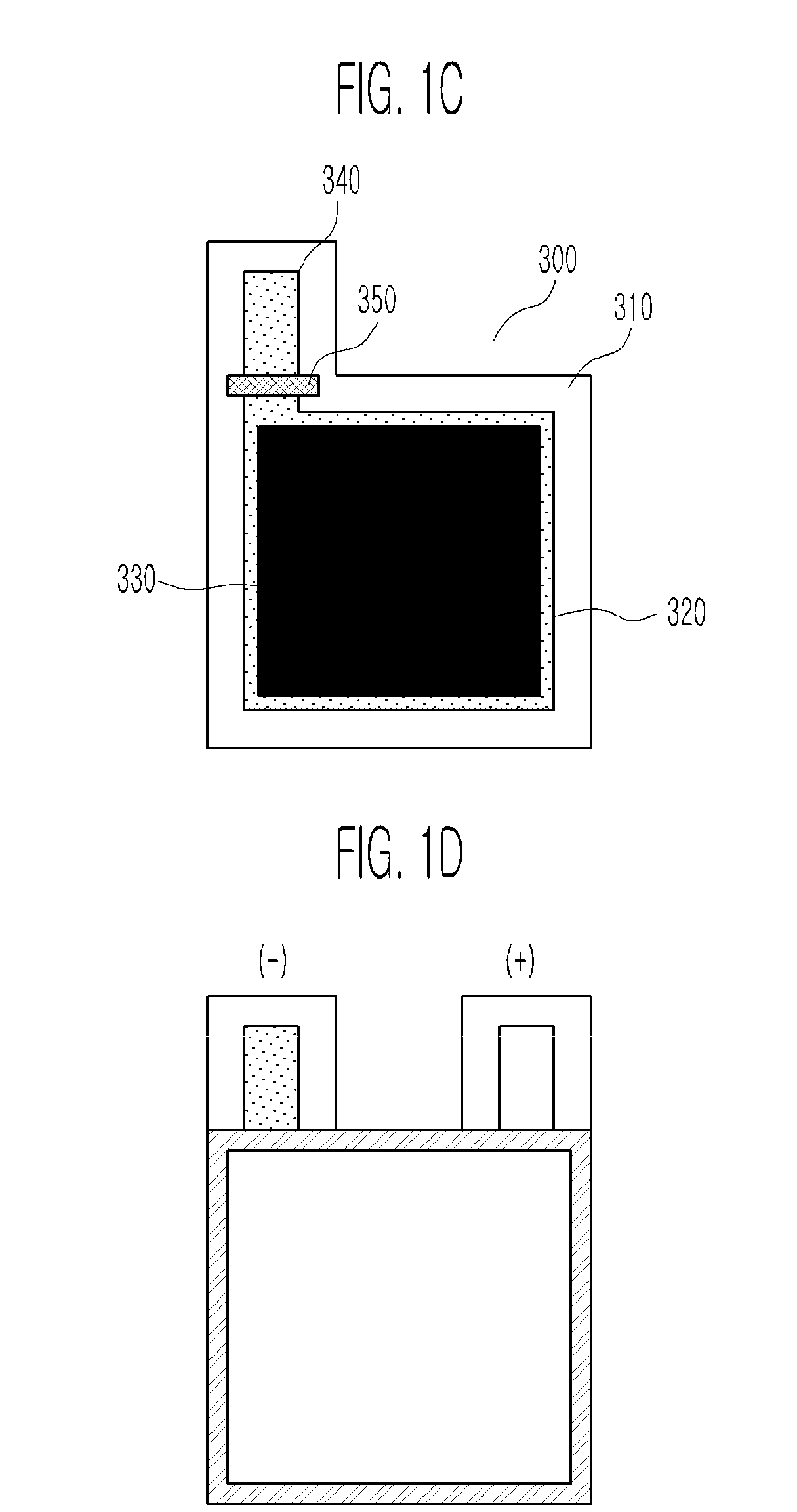

Electrochemical apparatus with barrier layer protected substrate

InactiveUS20080003496A1High crystallinityMore flexibleCell electrodesBattery isolationDiffusion barrierElectrochemistry

The present invention relates generally to fabricating well performing thin-film batteries onto metallic substrates, polymeric substrates, and doped and undoped silicon substrates. More specifically, the invention may include fabricating an appropriate diffusion barrier layer between the substrate and the battery part of the present invention that separates said two parts chemically during the entire battery fabrication process and the operation and storage conditions of the electrochemical apparatus during its entire lifetime. In one embodiment of the present invention, thin-film batteries fabricated onto a thin, flexible, stainless steel foil substrate using an appropriate diffusion layer show uncompromised electrochemical performance compared to thin-film batteries fabricated onto ceramic substrates when using a 700° C. post-deposition anneal process for the LiCoO2 positive cathode.

Owner:SAPURAST RES

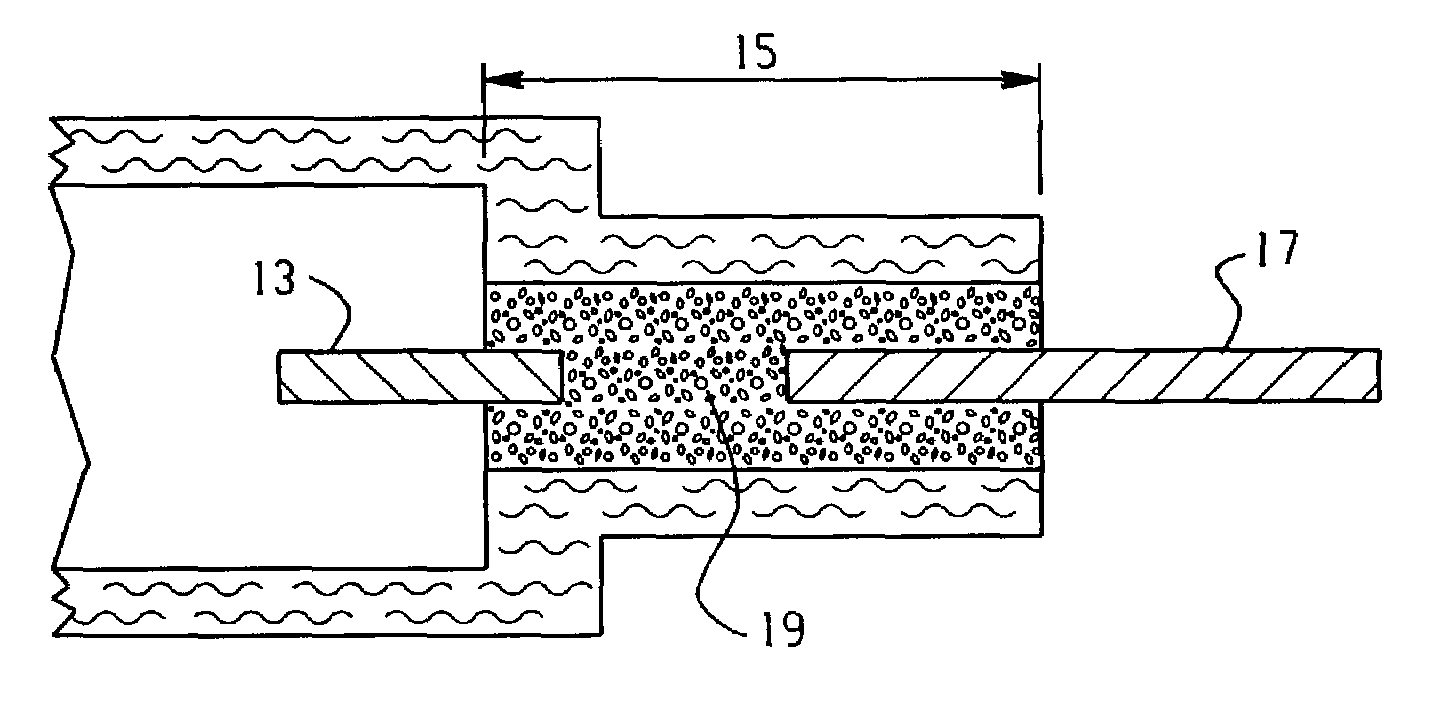

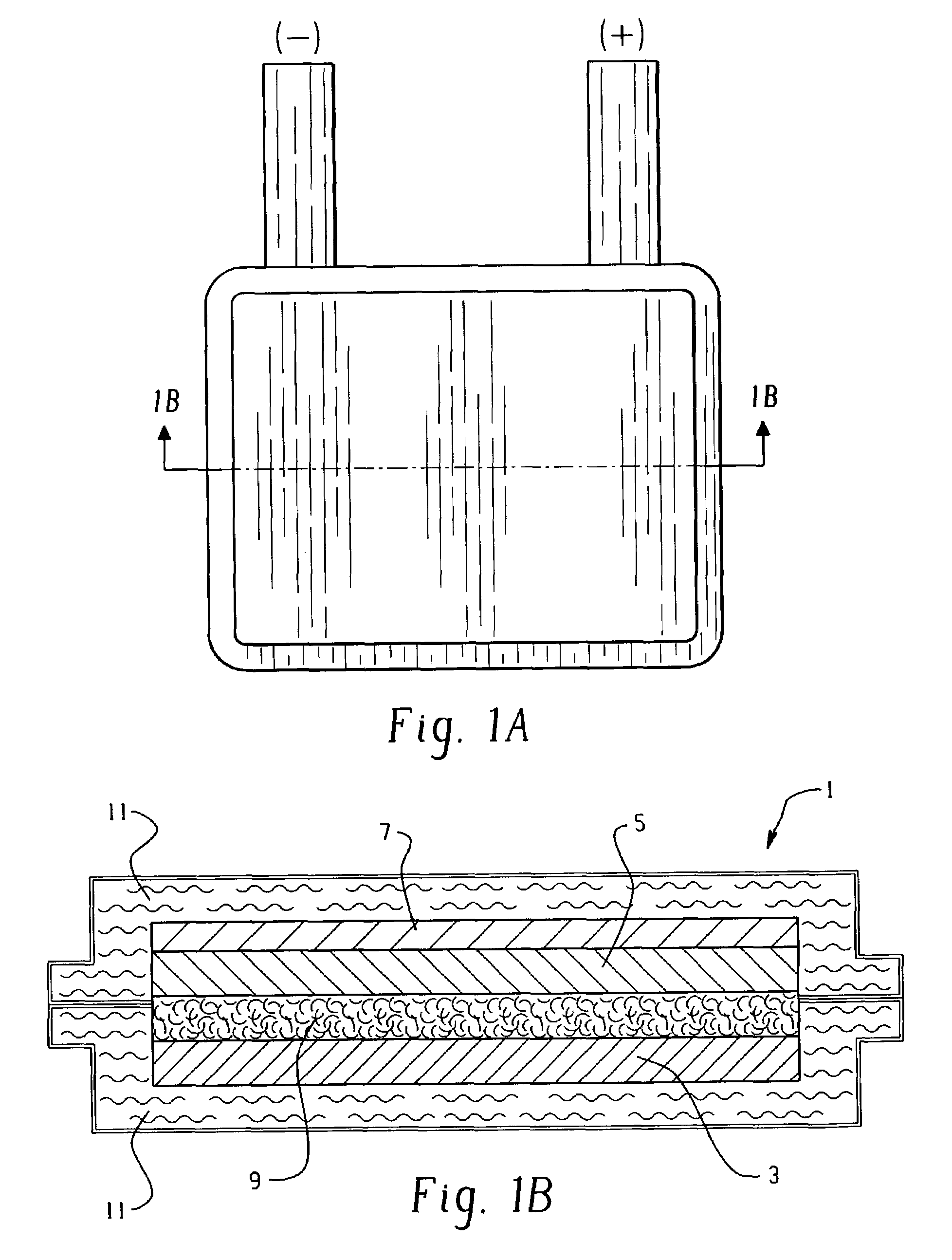

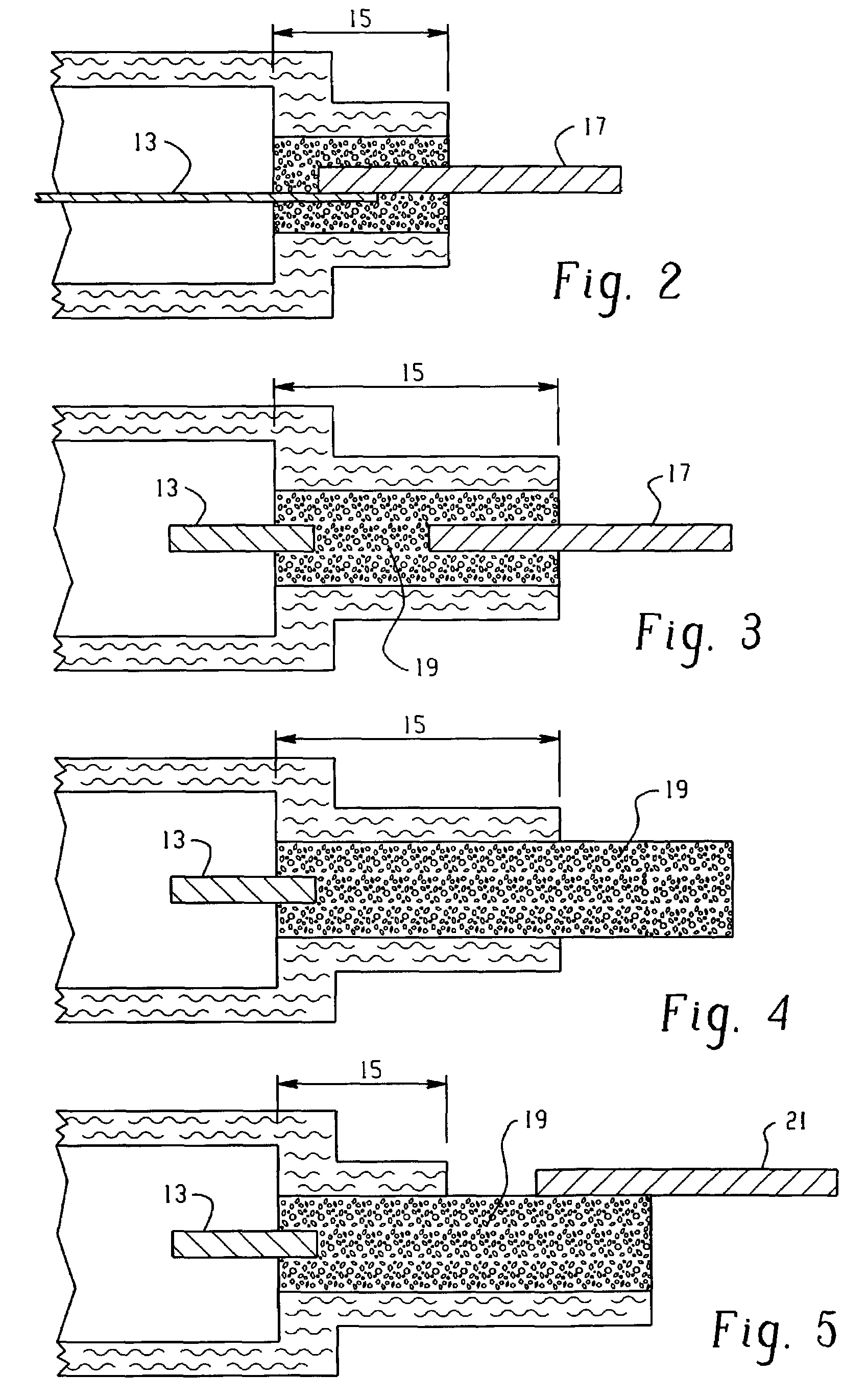

Process for producing lithium batteries having an ultra-high energy density

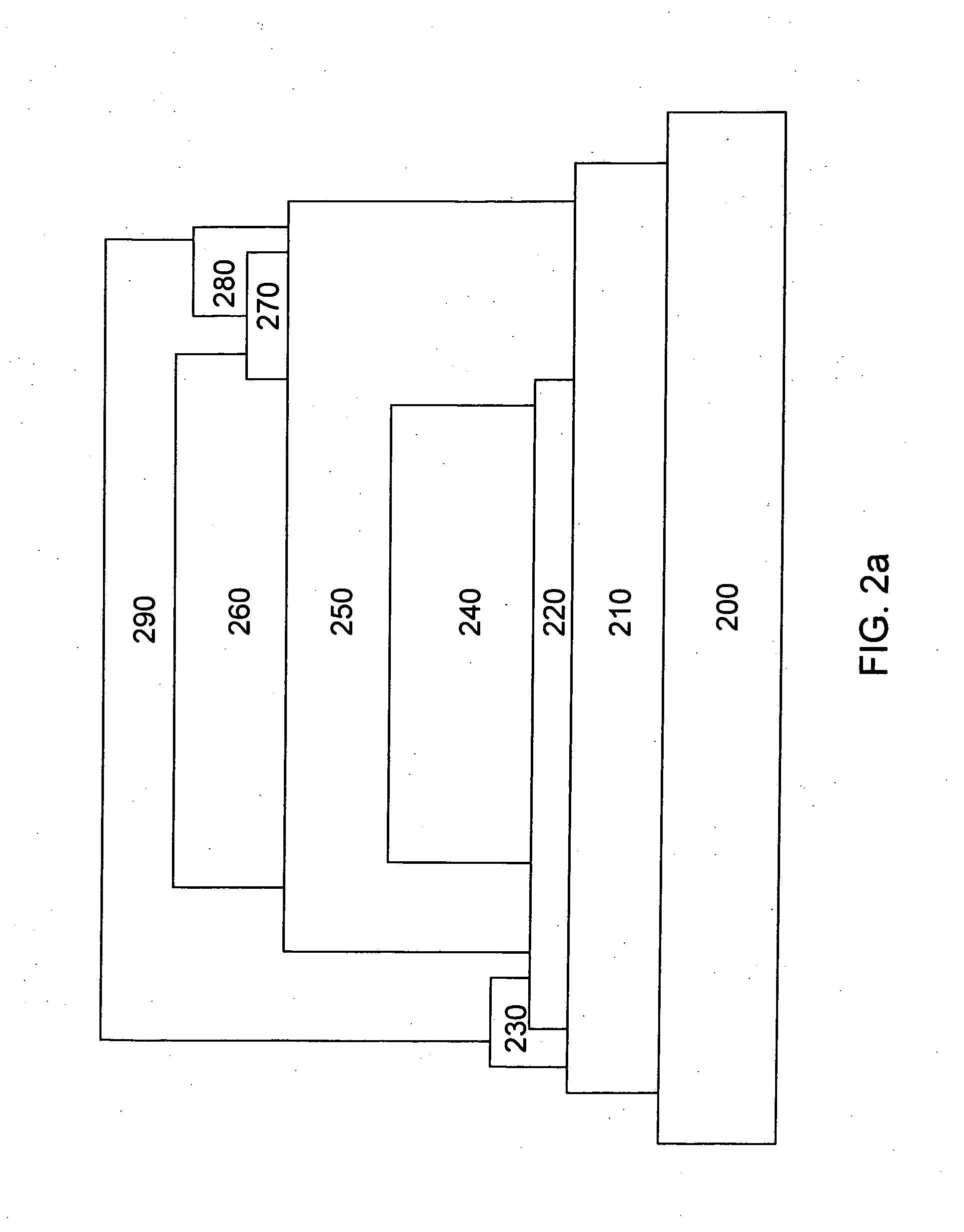

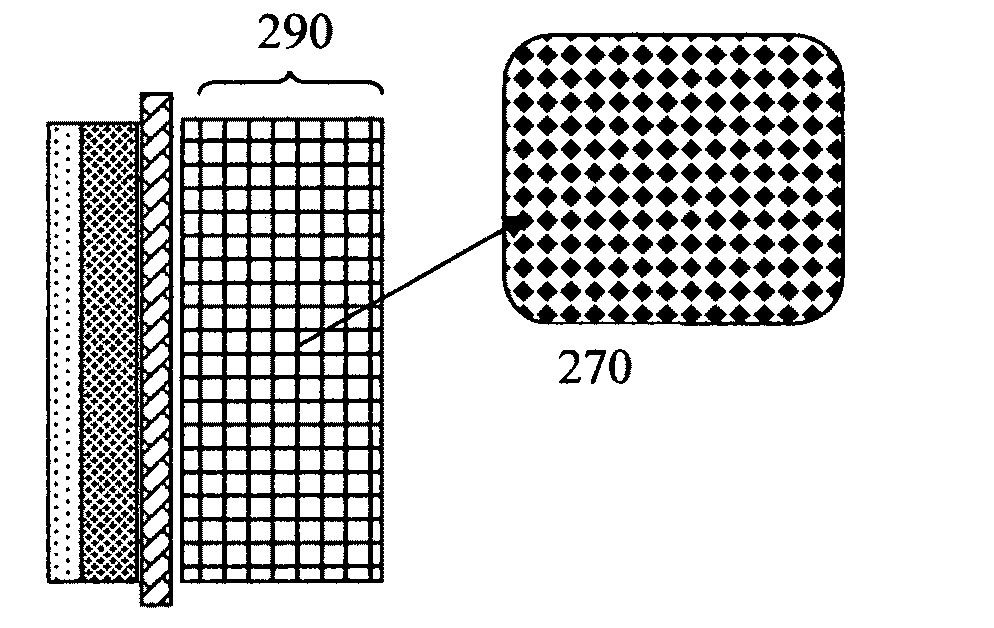

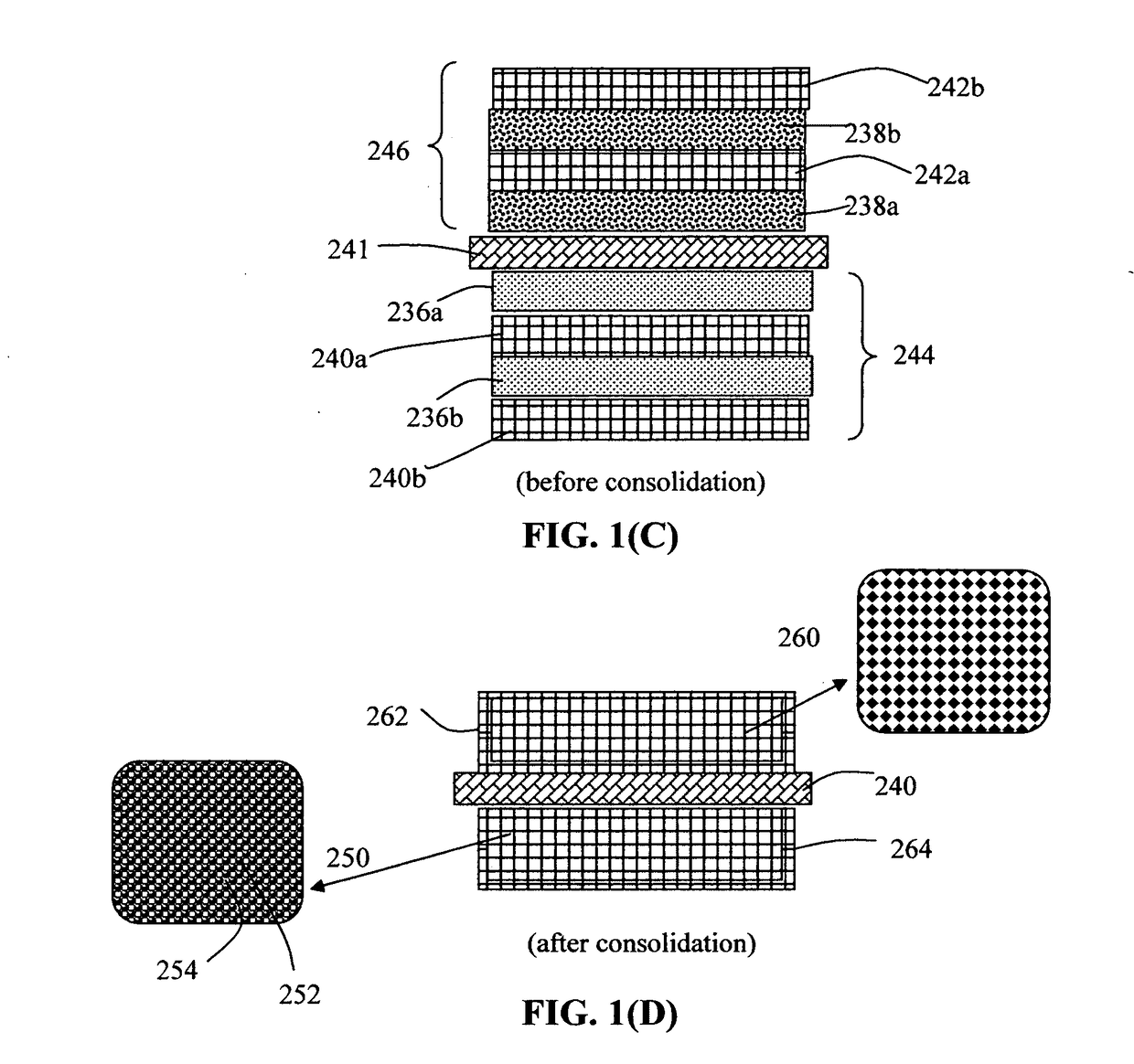

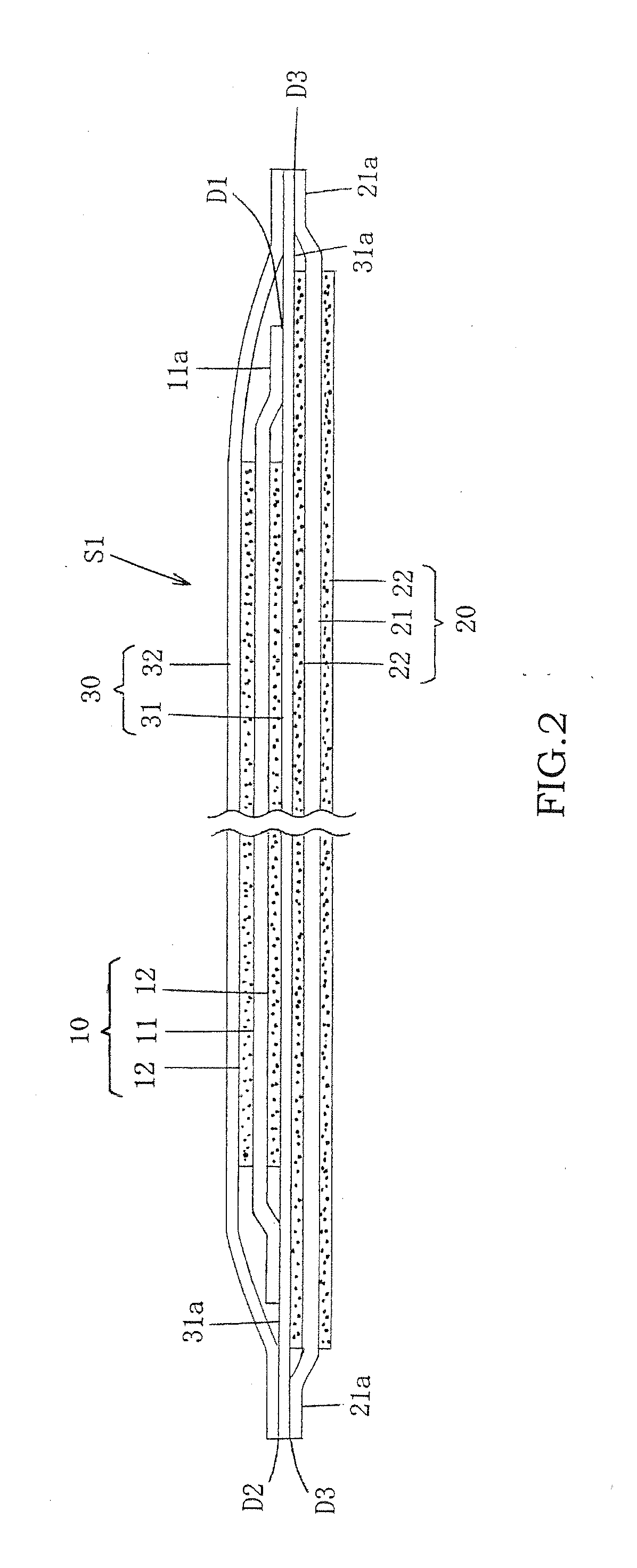

ActiveUS20170098856A1Increase energy densityImprove power densityFinal product manufactureNon-aqueous electrolyte cellsPorous layerHigh energy

A process for producing a lithium battery, comprising: (A) Preparing a plurality of conductive porous layers, wet anode layers, and wet cathode layers; (B) Stacking a desired number of porous layers and wet anode layers in an alternating manner to form an anode electrode having a thickness no less than 100 μm; (C) Placing a porous separator layer in contact with the anode electrode; (D) Stacking a desired number of porous layers wet cathode layers in an alternating manner to form a cathode electrode in contact with the porous separator, wherein the cathode electrode has a thickness no less than 100 μm; and (F) Assembling and sealing the anode electrode, separator, and cathode electrode in a housing to produce the lithium battery. The consolidated anode or cathode layer is preferably thicker than 300 more preferably thicker than 400 μm, and further more preferably greater than 500 μm.

Owner:GLOBAL GRAPHENE GRP INC

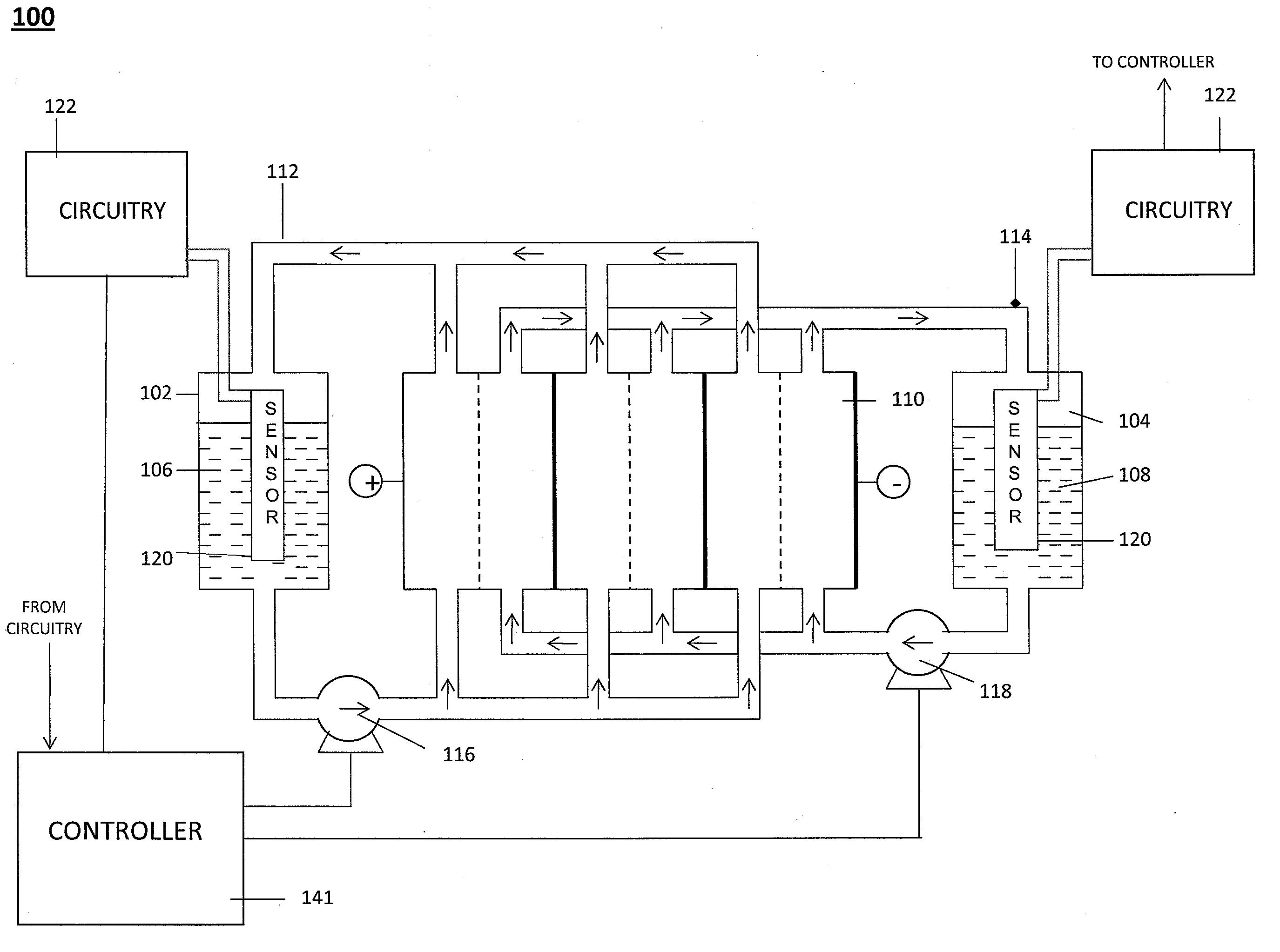

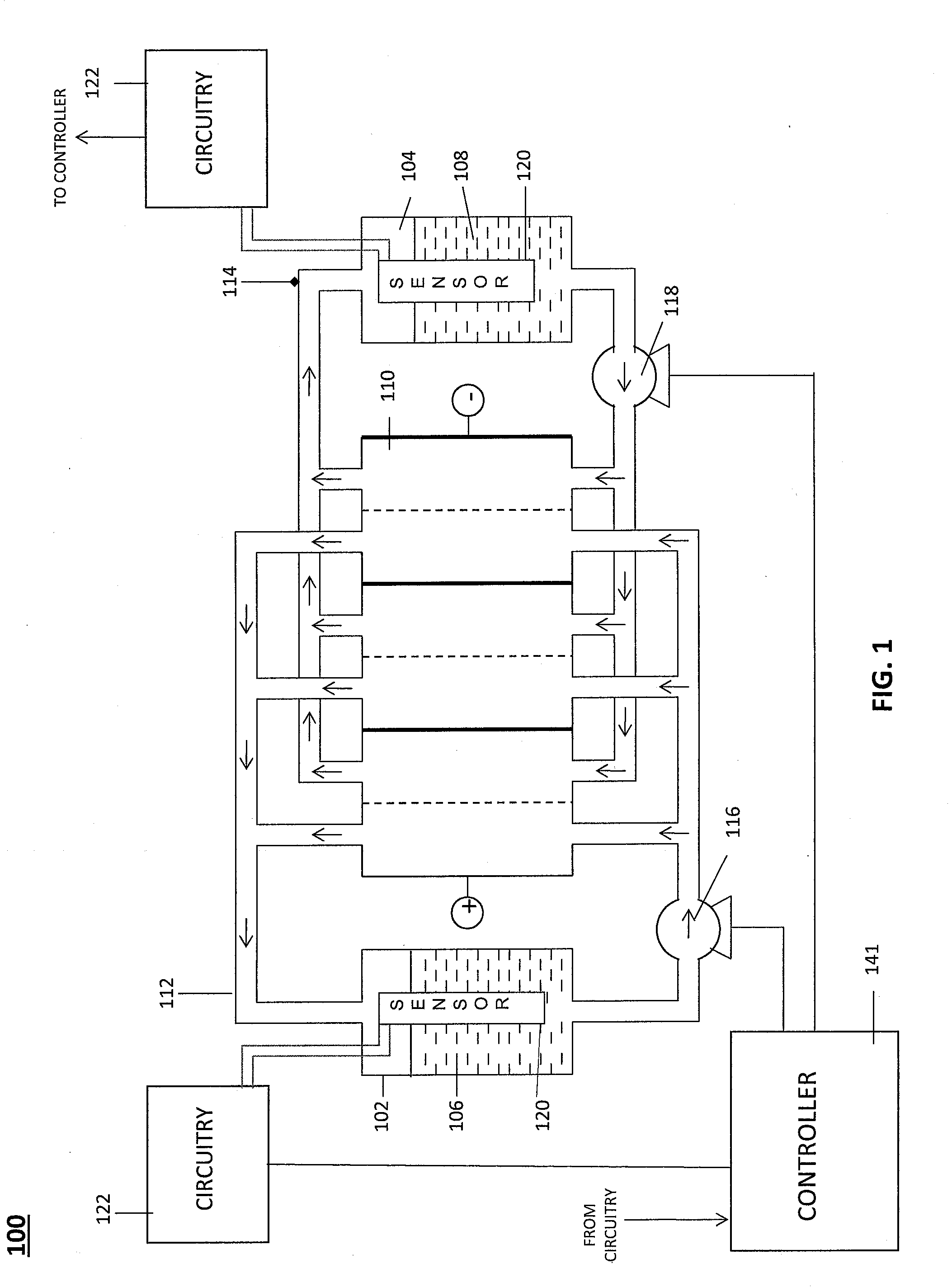

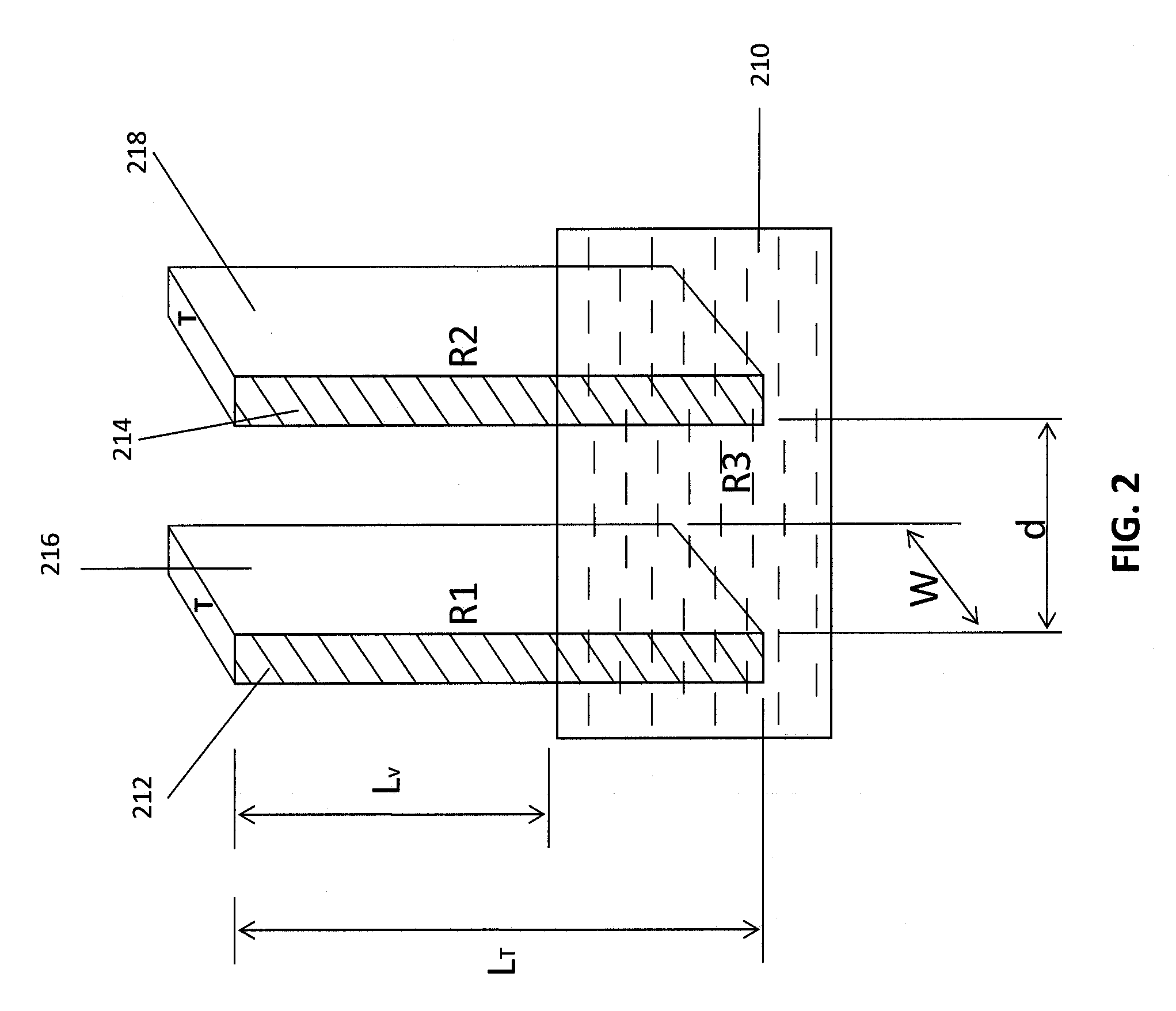

Level Sensor for Conductive Liquids

A sensor for measuring a level of a conductive liquid, is provided. The sensor includes at least two electrodes that can be positioned in a holding tank so as to be partially submerged in the conductive liquid, sensor leads coupled to the at least two electrodes, and circuitry and a controller for determining the properties of the electrolyte, the circuitry being coupled to the at least two electrodes via the sensor leads, and the controller being coupled to the circuitry. The sensor may be used as an electrolyte level sensor in a flow battery system.

Owner:IMERGY POWER SYST

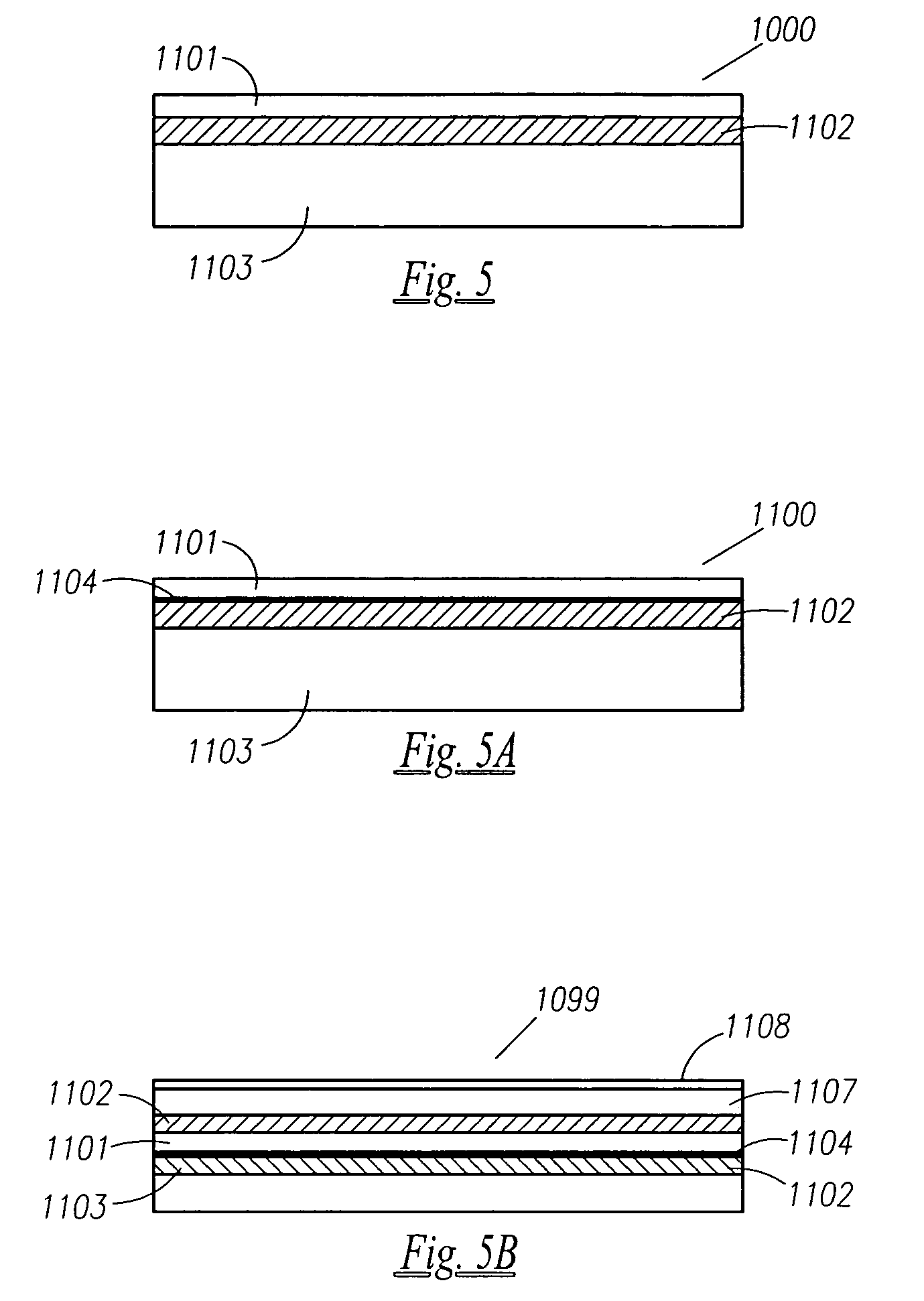

Barrier layer for thin film battery

InactiveUS20100190051A1Improve efficiencyExtend lifetime of battery packFinal product manufactureElectrode carriers/collectorsPhosphateChalcogenide glass

A thin film battery comprises a substrate, anode and cathode current collector layers formed over the substrate, anode and cathode layers formed over and in electrical contact with respective ones of the current collector layers, and an electrolyte layer formed between the anode and cathode layers. The thin film battery further comprises a barrier layer formed from a material such as tin oxide, tin phosphate, tin fluorophosphate, chalcogenide glass, tellurite glass or borate glass. The barrier layer is configured to encapsulate the thin film battery layers and substantially inhibit or prevent exposure of the thin film battery layers to air or moisture.

Owner:CORNING INC

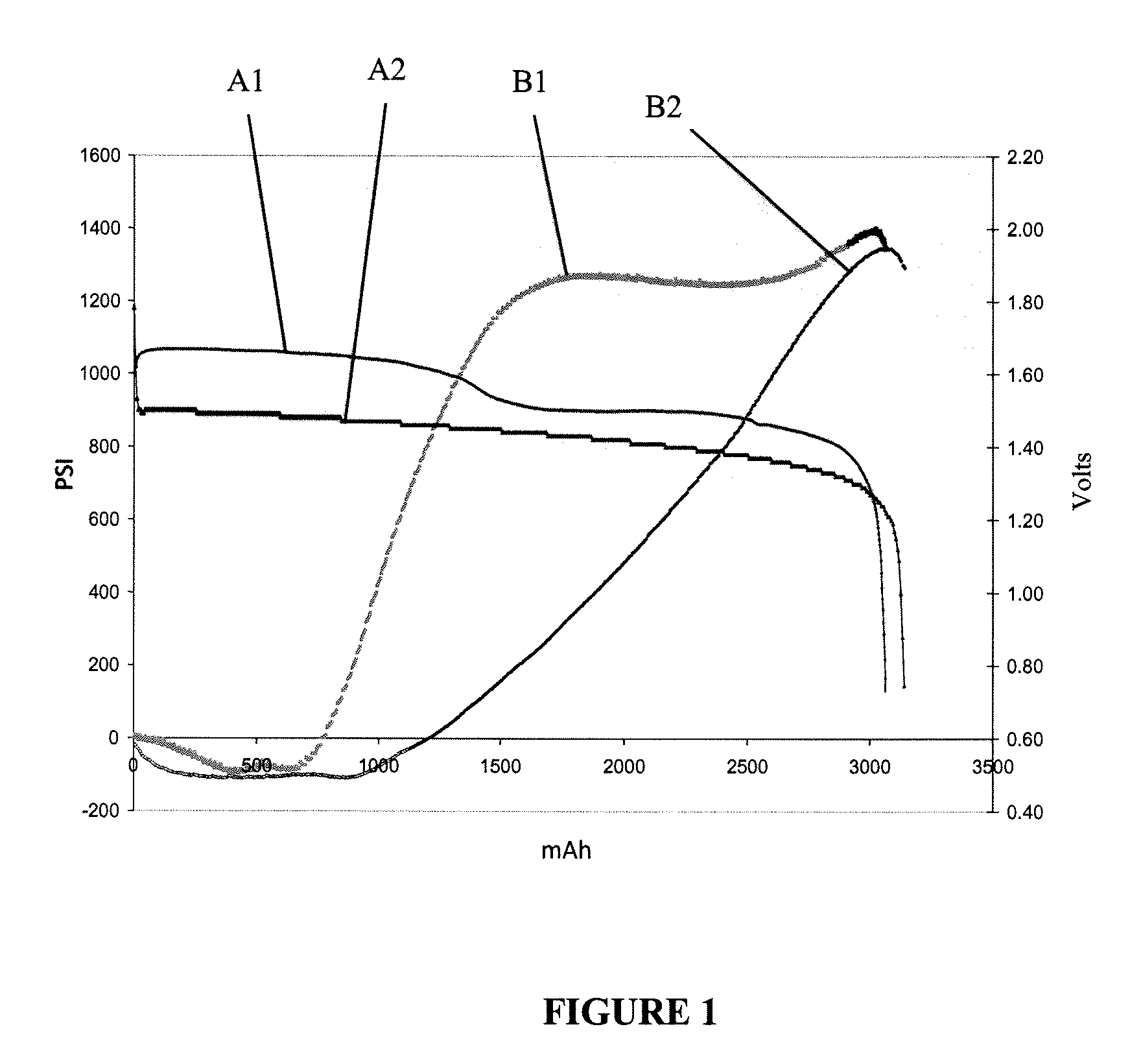

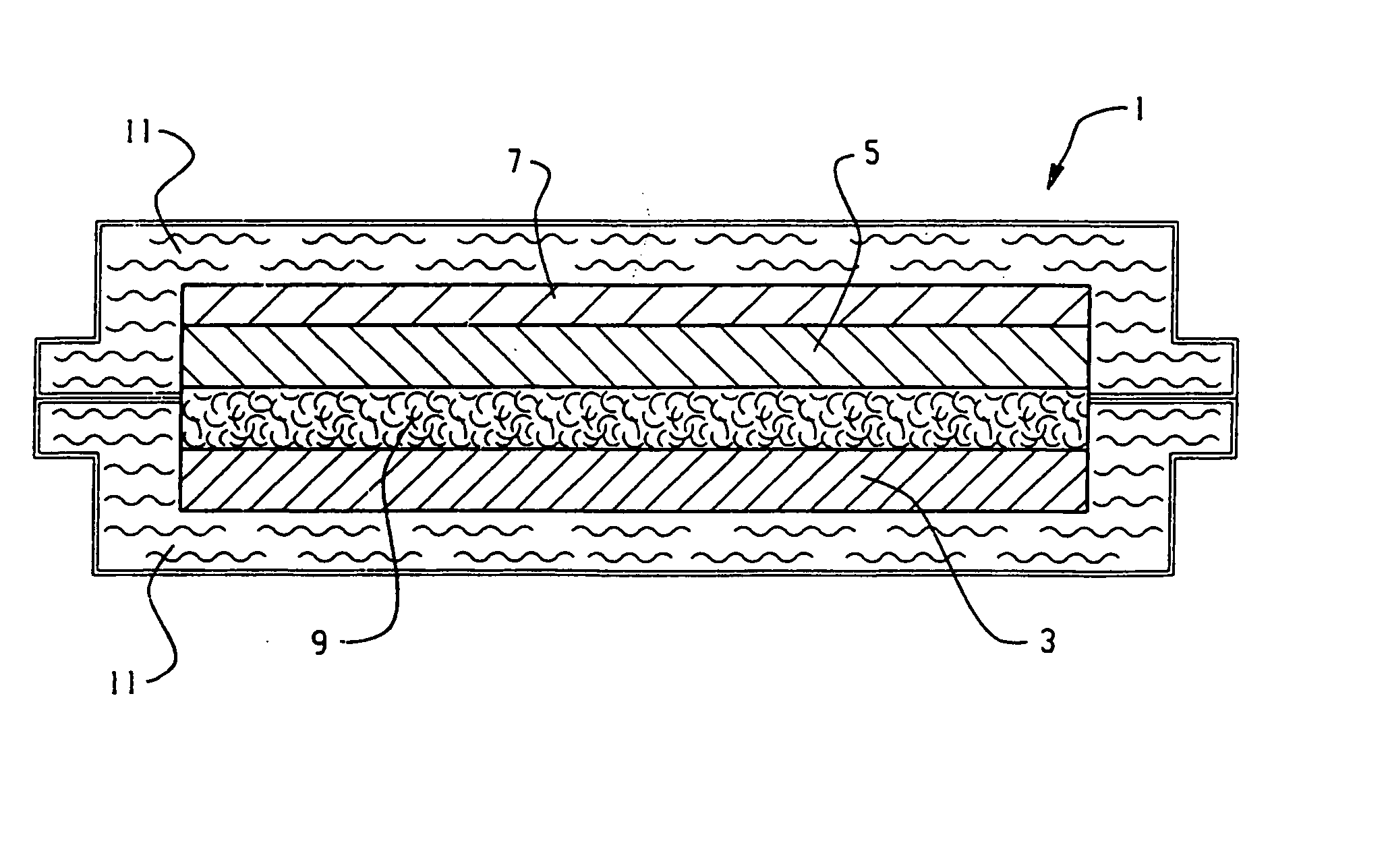

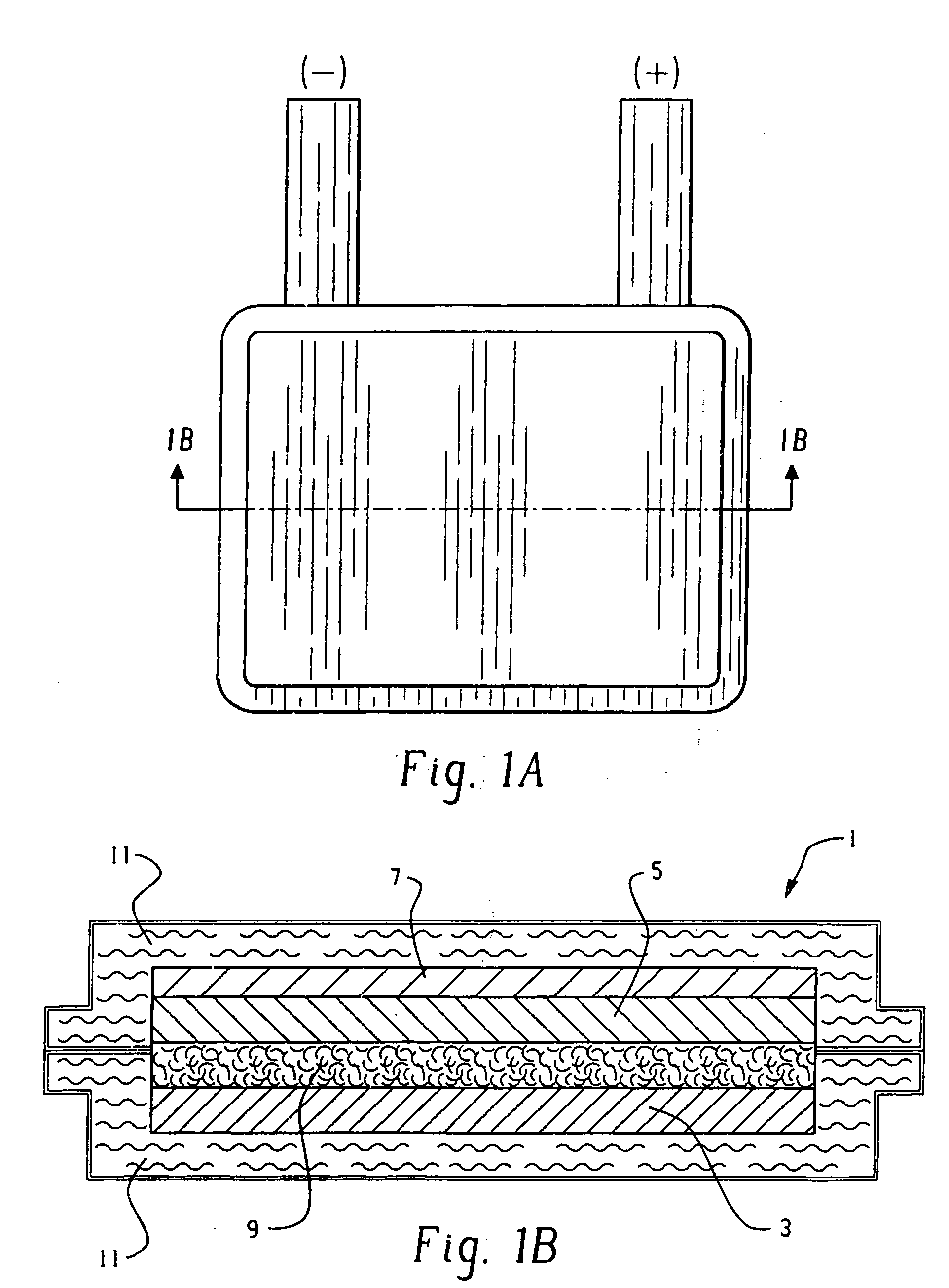

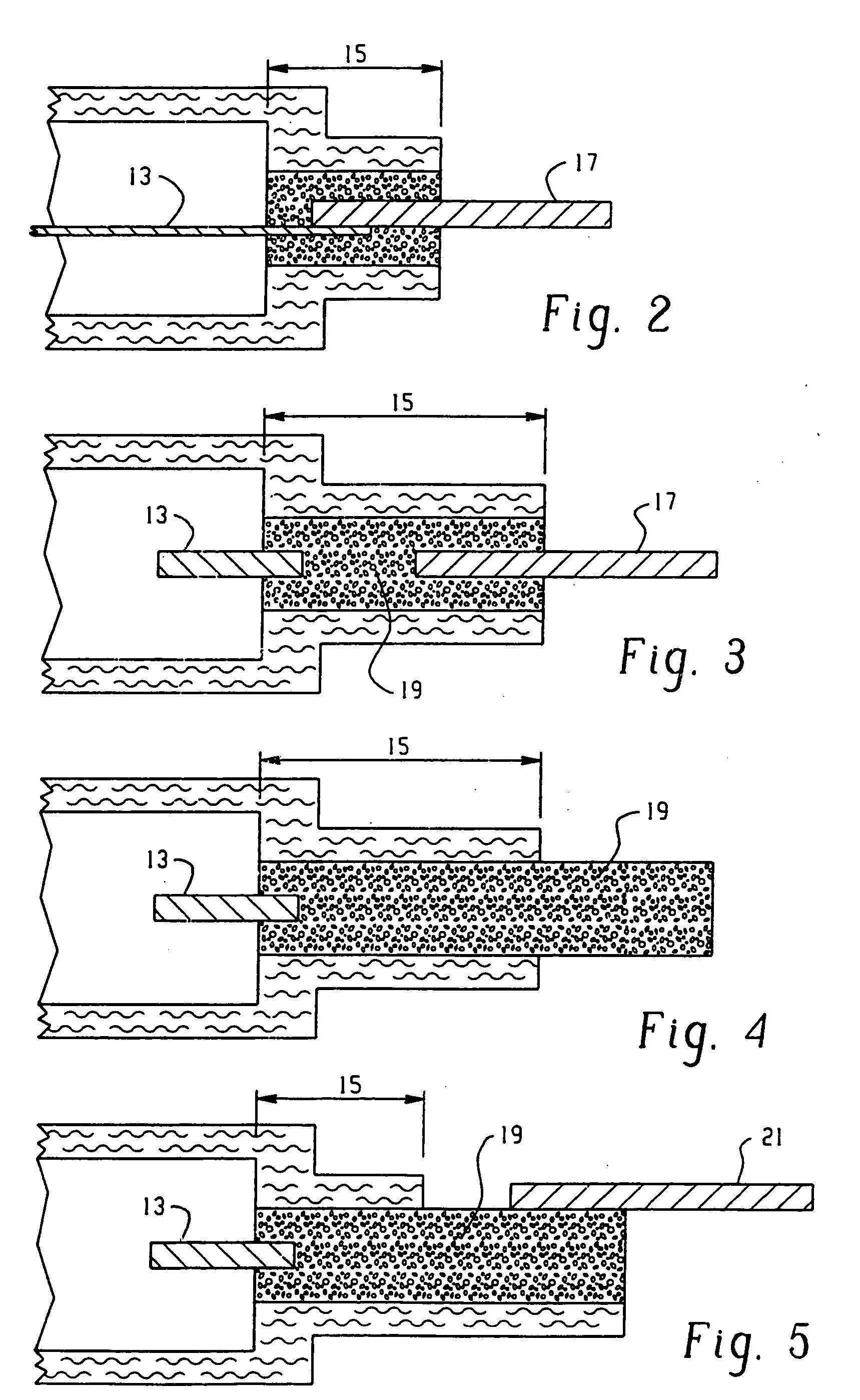

Lithium-Iron Disulfide Cell Design

ActiveUS20090104520A1Large capacityIncrease capacityCell seperators/membranes/diaphragms/spacersSmall-sized cells cases/jacketsCell designEngineering

Owner:ENERGIZER BRANDS

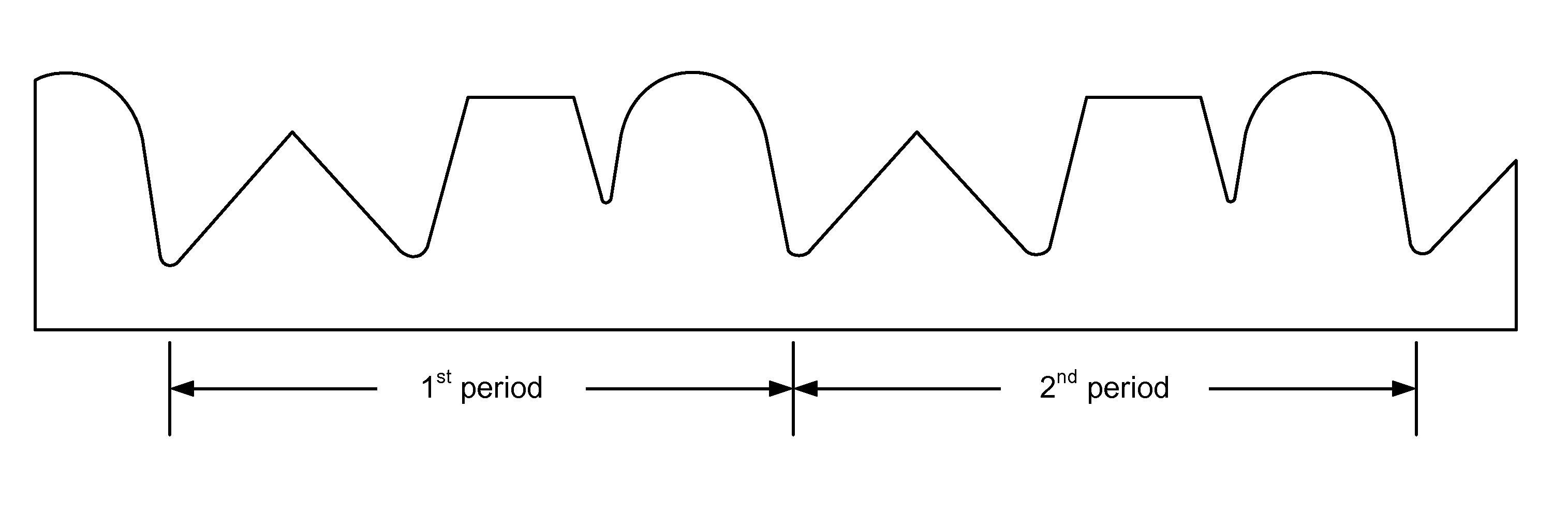

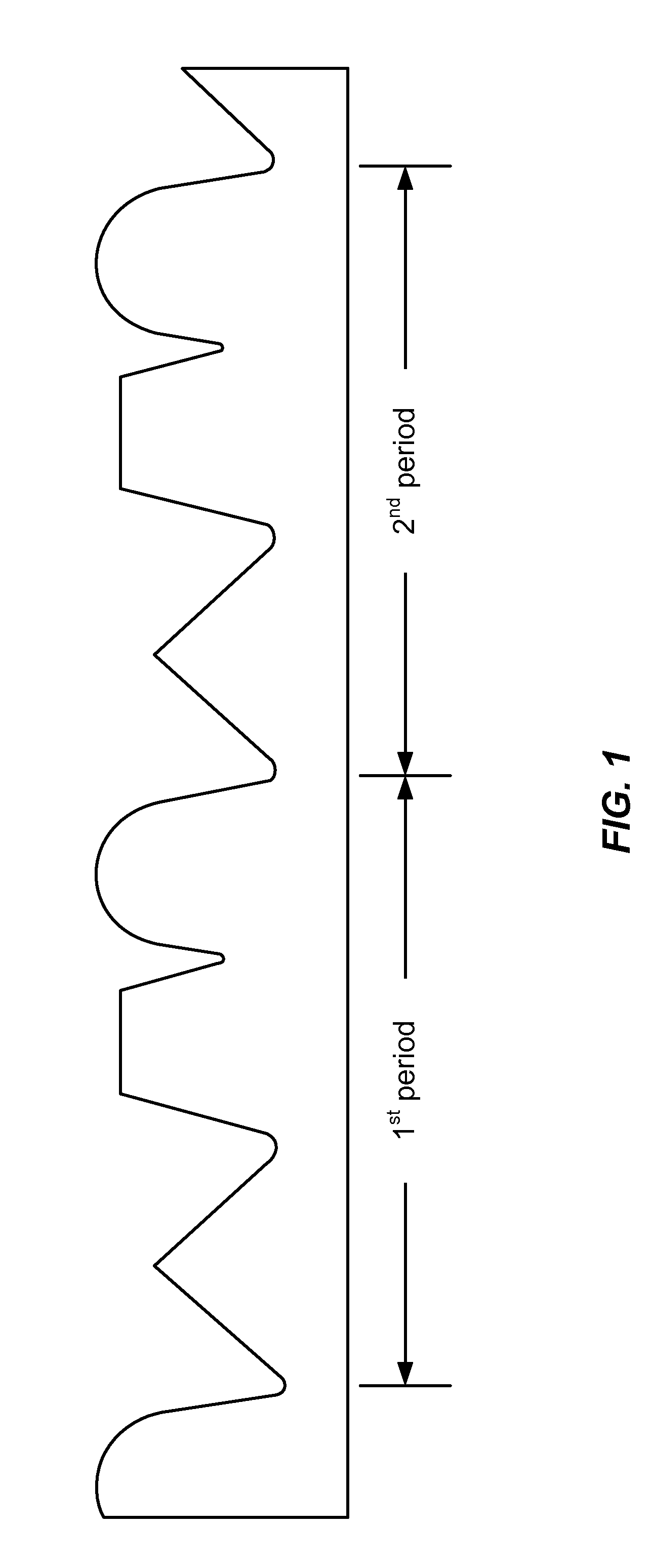

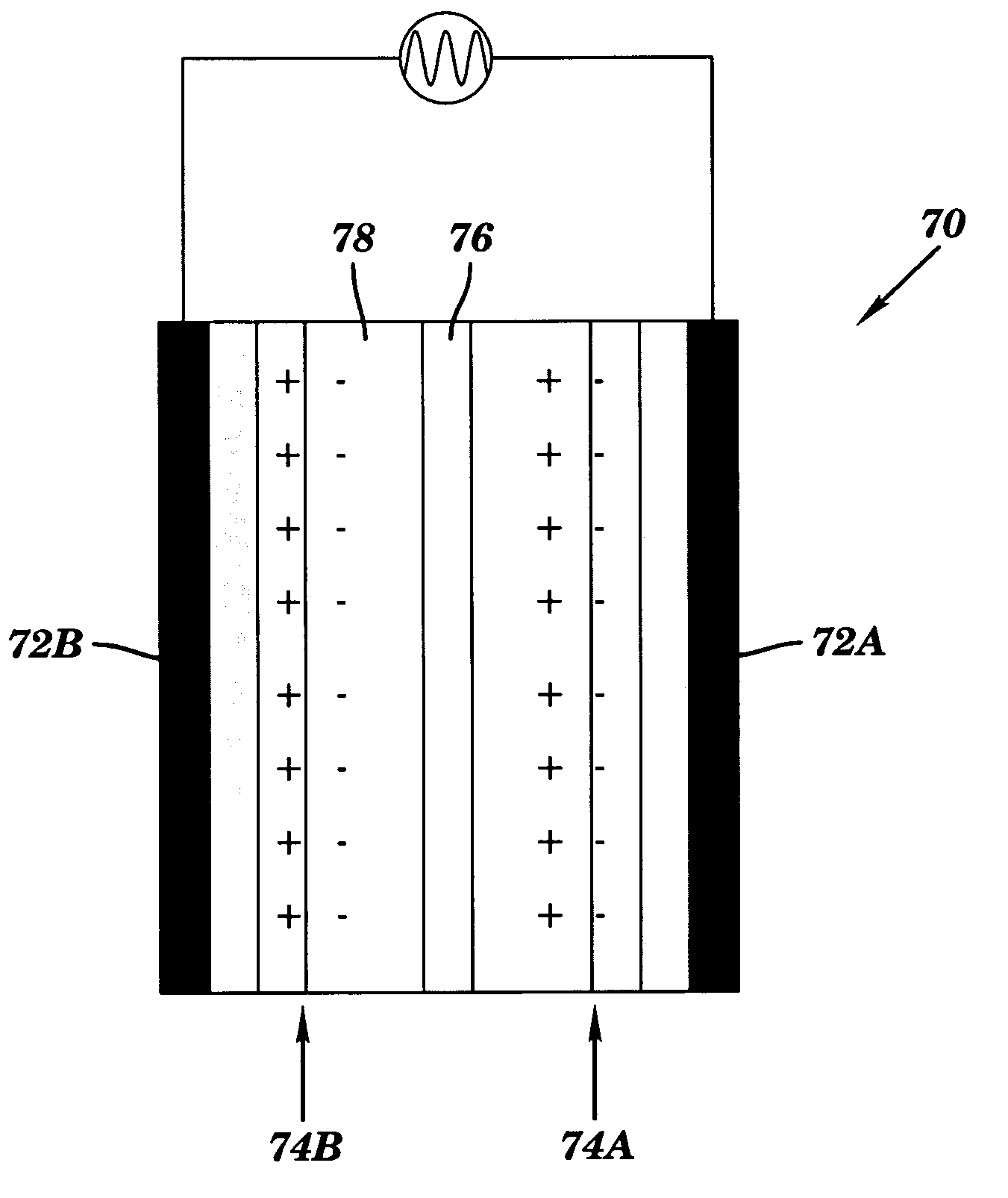

Electrochemical cell including functionally graded and architectured components and methods

PendingUS20100035152A1Maintain good propertiesEliminate errorsMaterial nanotechnologyMolten spray coatingIonic diffusionHigh rate

Electrochemical cells or batteries featuring functional gradations, and having desirable, periodic configurations, and methods for making the same. One or more methods, in alone or in combination, are utilized to fabricate components of such electrochemical cells or batteries, which are designed to achieve certain thermal, mechanical, kinetic and spatial characteristics, and their effects, singly and in all possible combinations, on battery performance. The thermal characteristics relate to temperature distribution during charge and discharge processes. The kinetic characteristics relate to rate performance of the cells or batteries such as the ionic diffusion process and electron conduction. The mechanical characteristics relate to lifetime and efficiency of the cells or batteries such as the strength and moduli of the component materials. Finally, the spatial characteristics relate to the energy and power densities, stress and temperature mitigation mechanisms, and diffusion and conduction enhancements. The electrochemical cells or batteries constructed according to the methods presented in this invention are useful for all applications that require high rate performance, high energy / power density, good durability, high safety and long lifetime.

Owner:SAKTI3

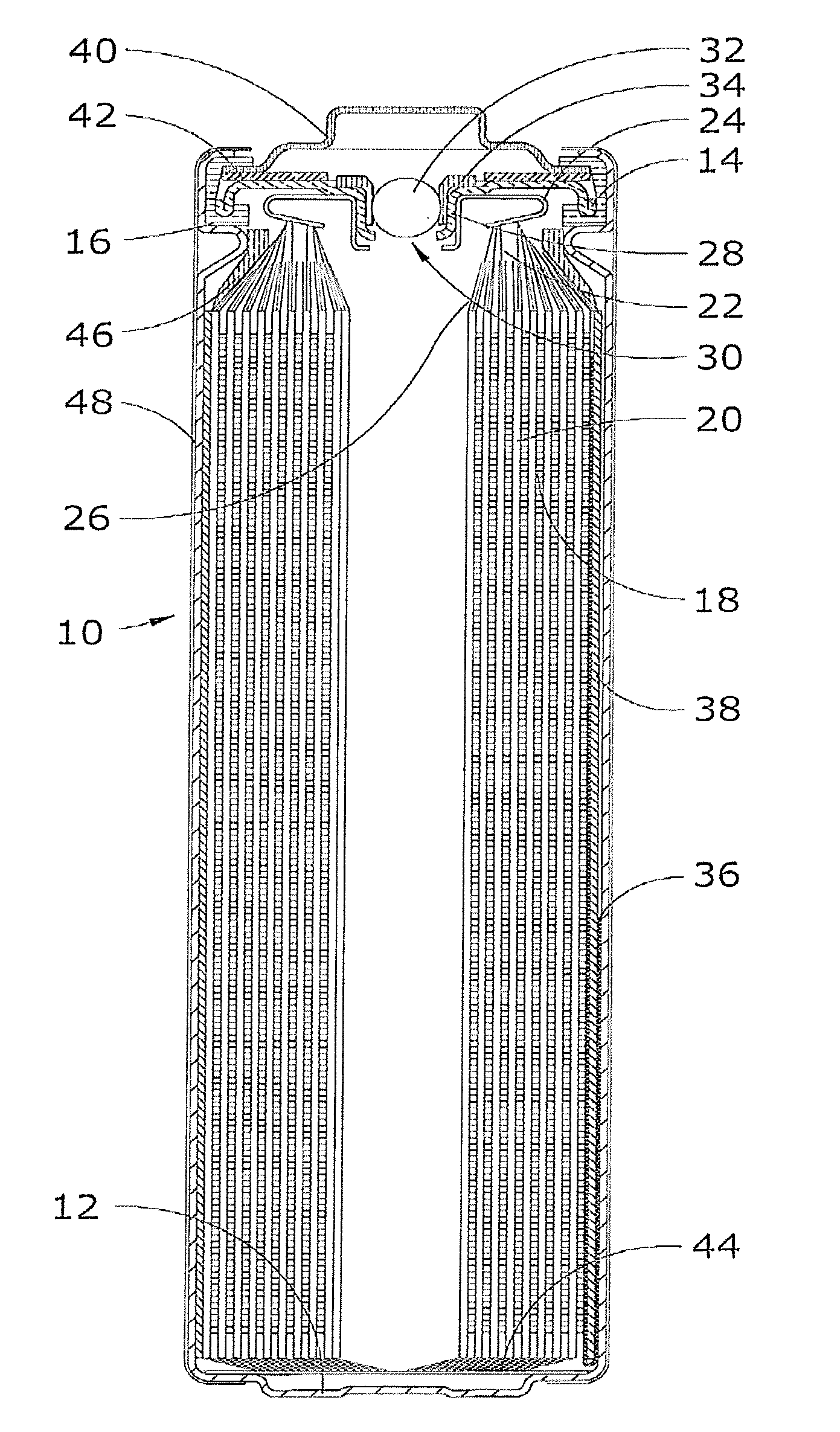

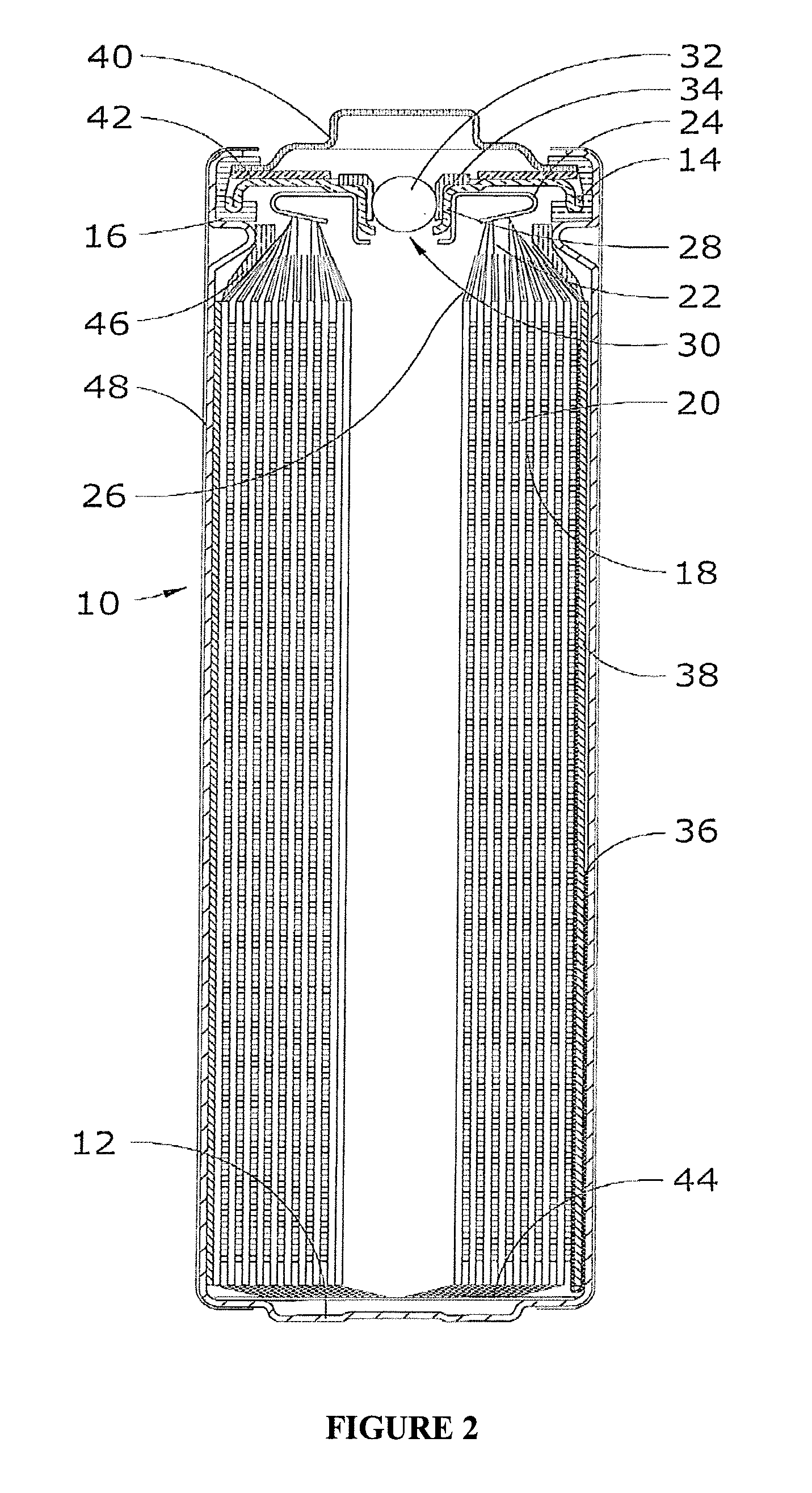

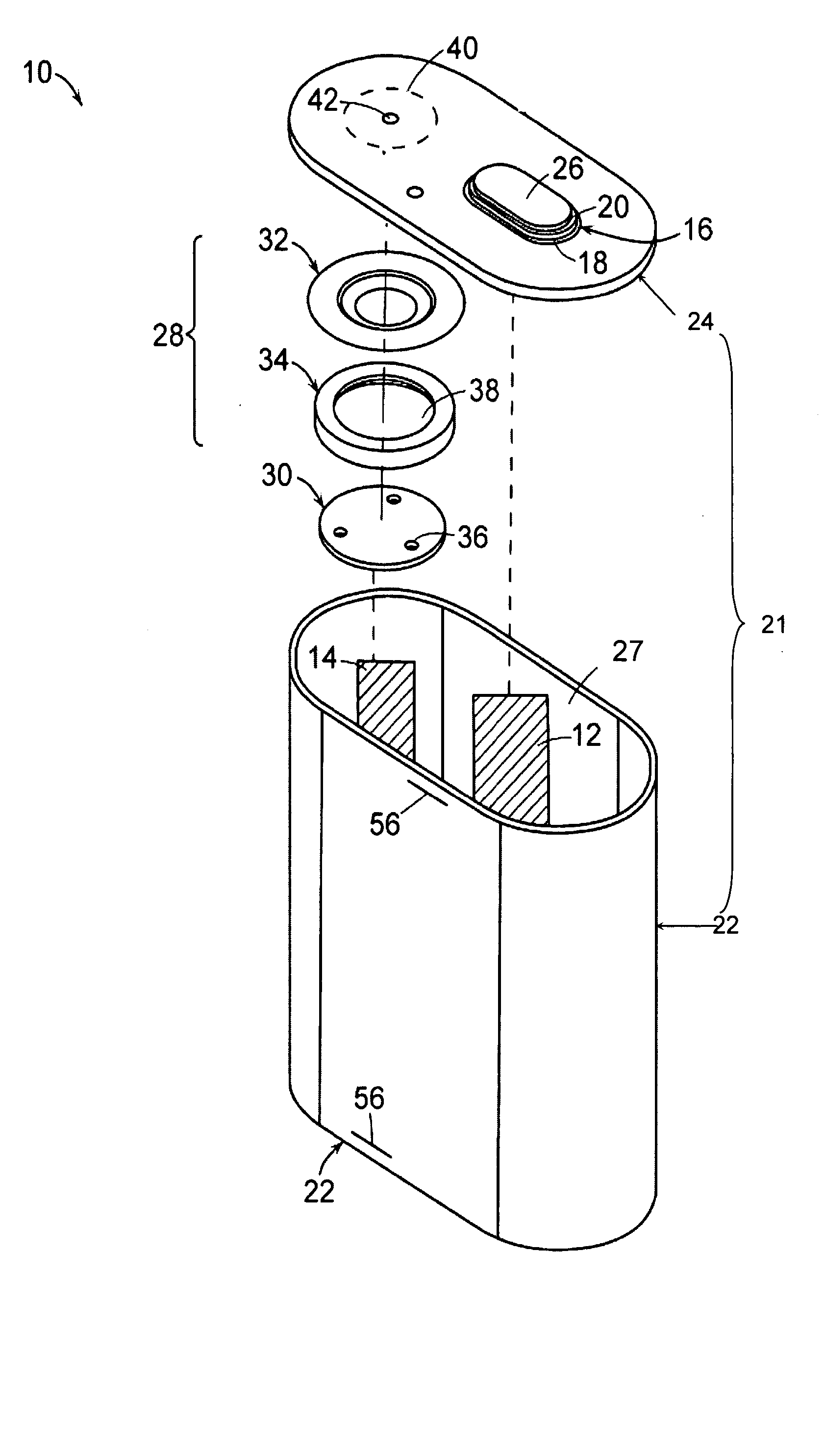

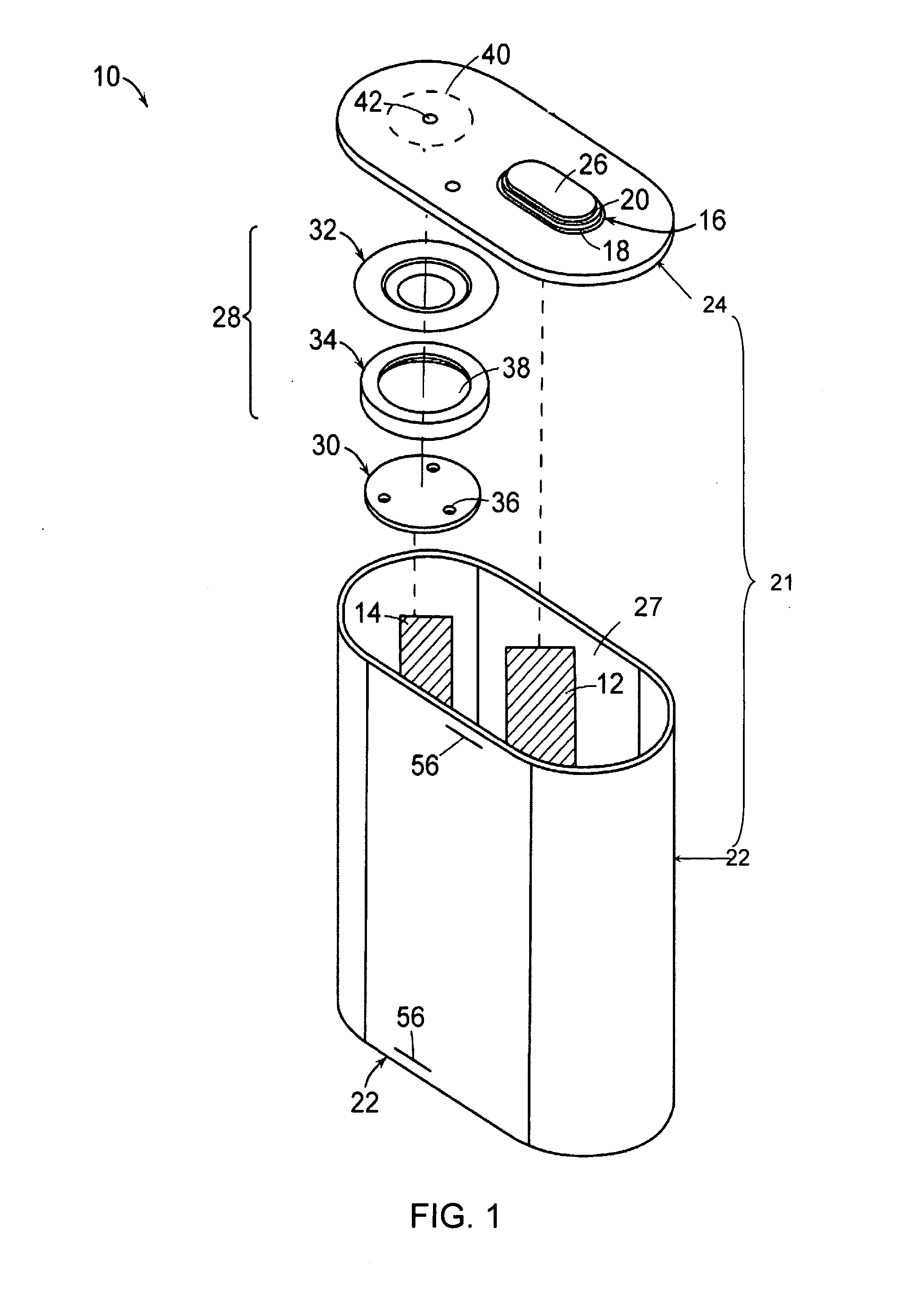

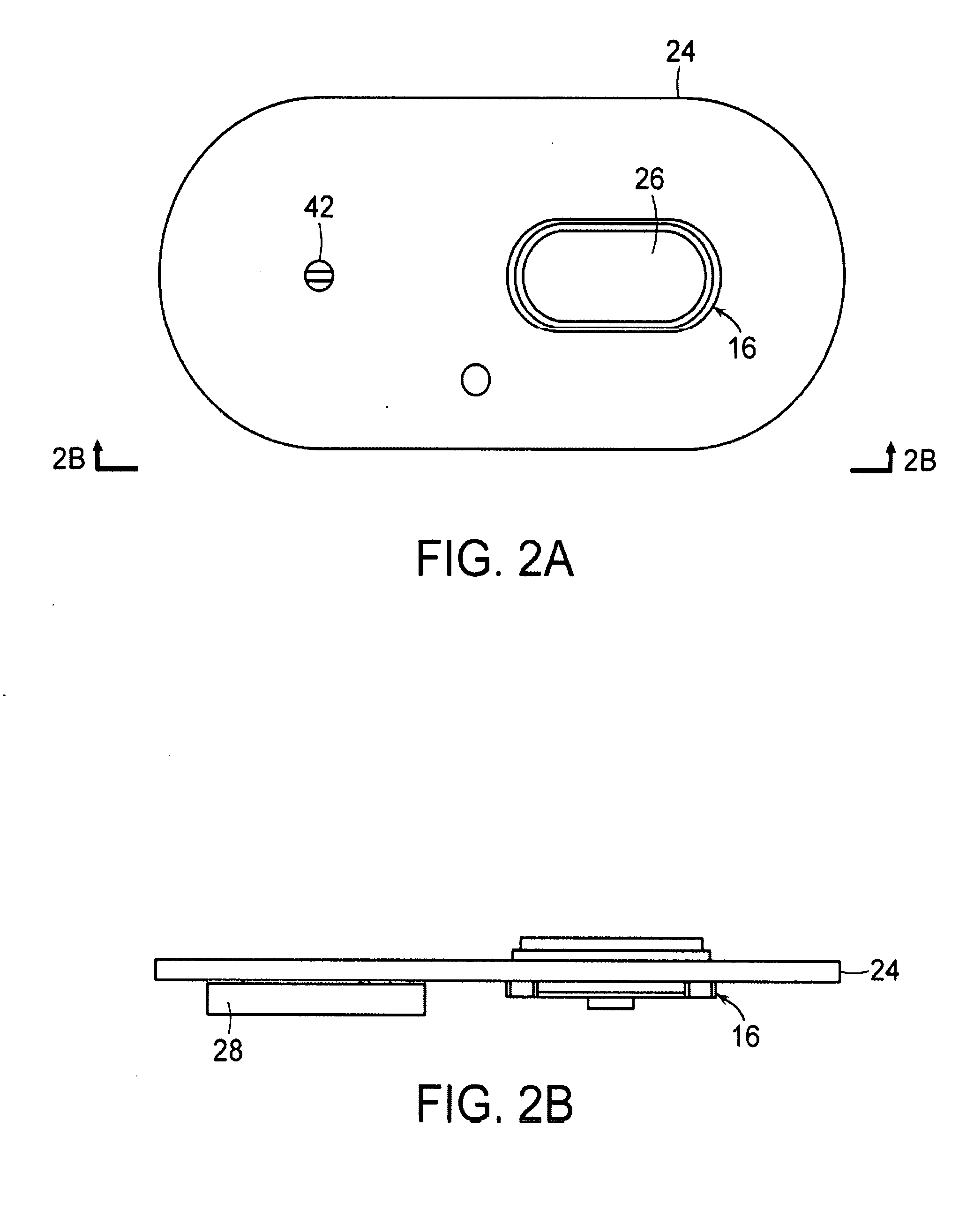

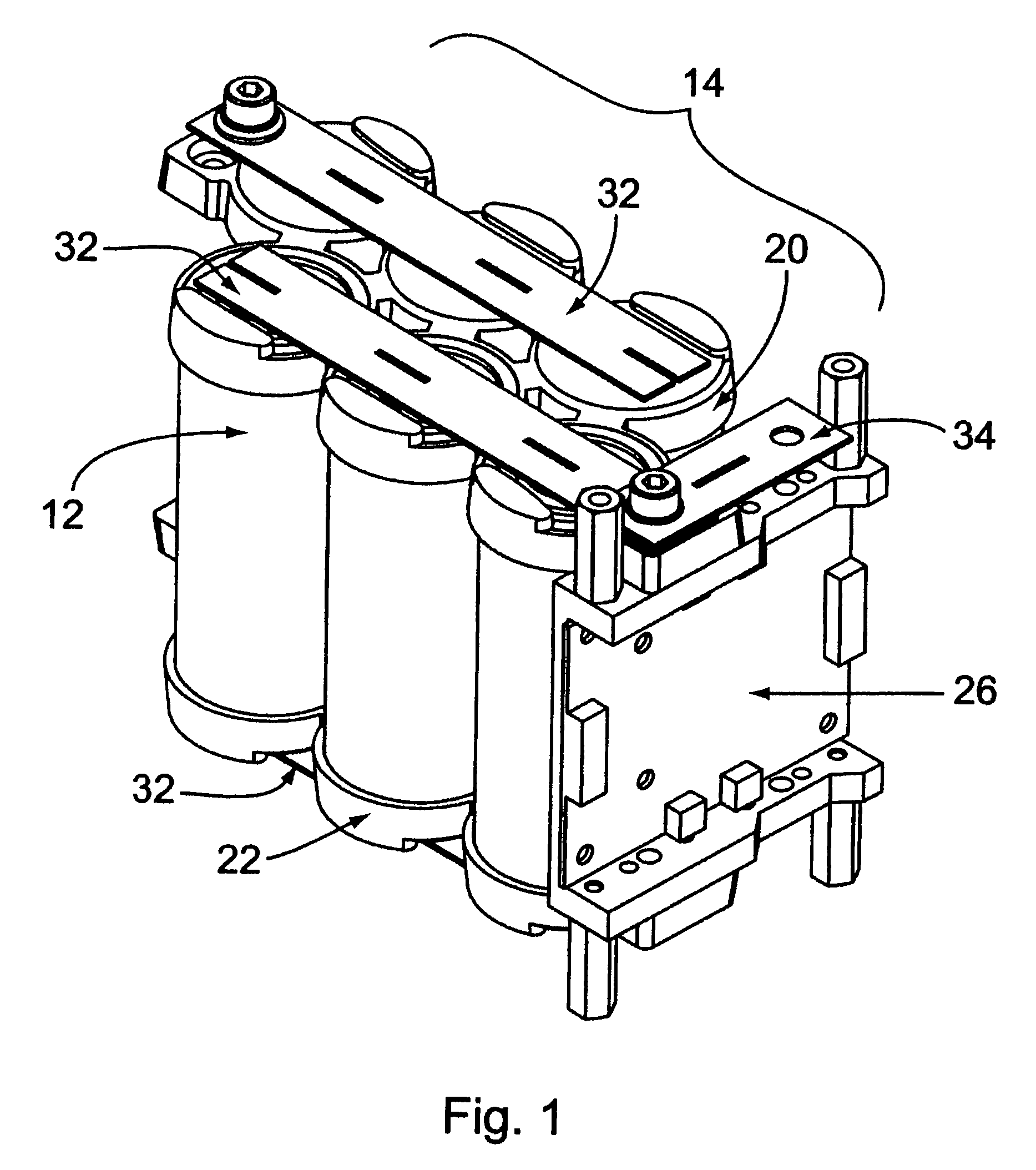

Integrated current-interrupt device for lithium-ion cells

InactiveUS20080008928A1Minimum footprintIncrease battery capacityPrimary cell to battery groupingFinal product manufactureElectricityEngineering

A battery comprises a first terminal in electrical communication with a first electrode of the battery, a second terminal in electrical communication with a second electrode of the battery, a battery can electrically insulated from the first terminal, and at least one current interrupt device in electrical communication with the battery can. The battery can includes a cell casing and a lid which are in electrical communication with each other. At least a portion of the battery can is at least a component of the second terminal, or is electrically connected to the second terminal. The current interrupt device includes a first conductive plate in electrical communication with the second electrode, and a second conductive plate in electrical communication with the first conductive plate. The second conductive plate separates from the first conductive plate when pressure inside the battery is greater than a predetermined value, whereby a current flow between the second electrode and the second terminal is interrupted.

Owner:BOSTON POWER INC

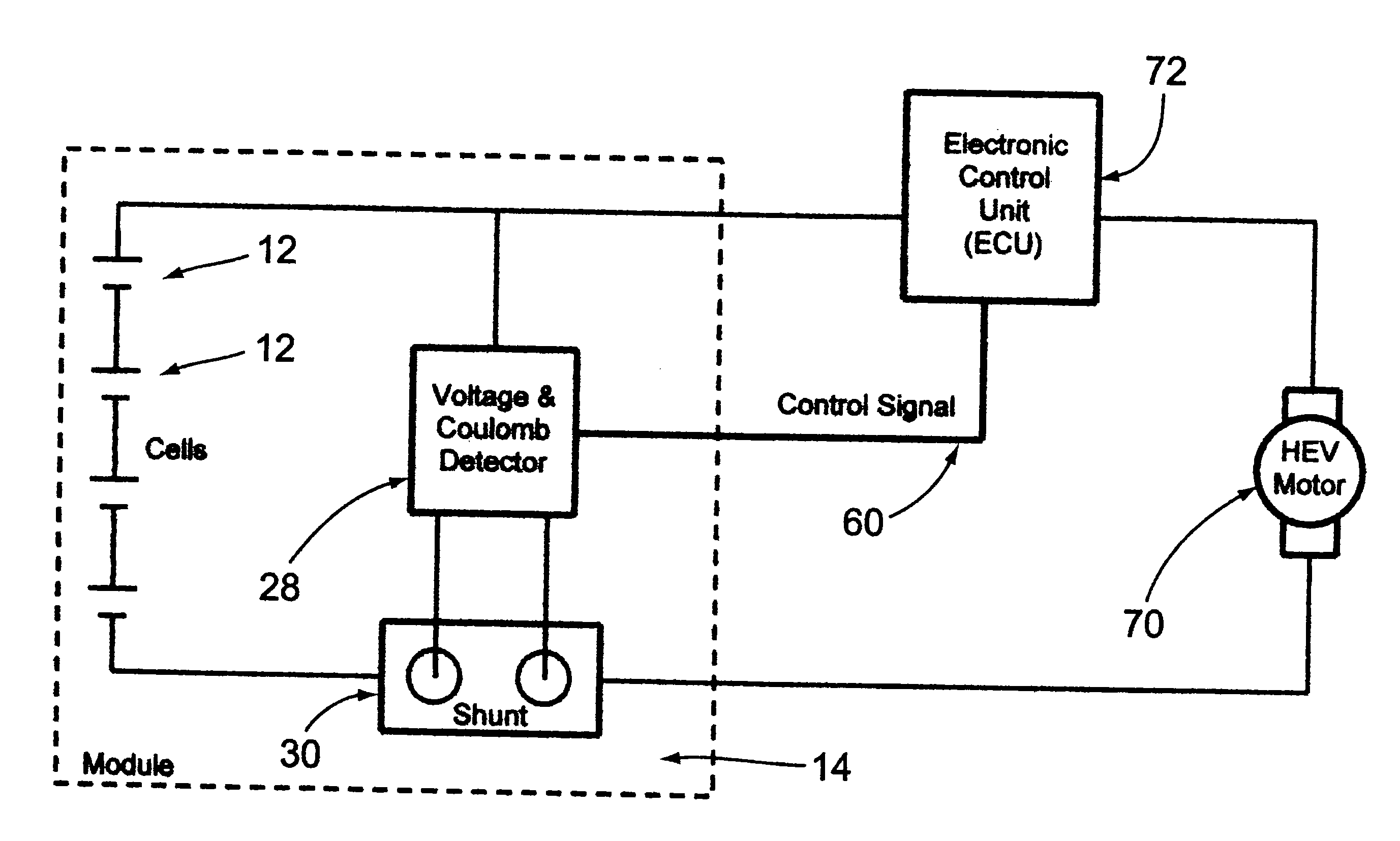

Battery management system

Disclosed herein is a battery management system for lithium ion batteries capable of determining a battery pack's state of capacity; determining a battery pack's state of charge limits; adjusting for voltage drops and power losses over a battery's internal and / or connector impedances; adjusting the upper and lower voltage limits of a battery pack; and of actively balancing the cells making up the battery pack. In order to achieve this functionality, the battery pack management system includes an electronic control unit, which unit is coupled to module and cell-level circuitry that is designed to measure operating conditions of the battery such as voltage and current at any given time.

Owner:ADVANCED LITHIUM POWER

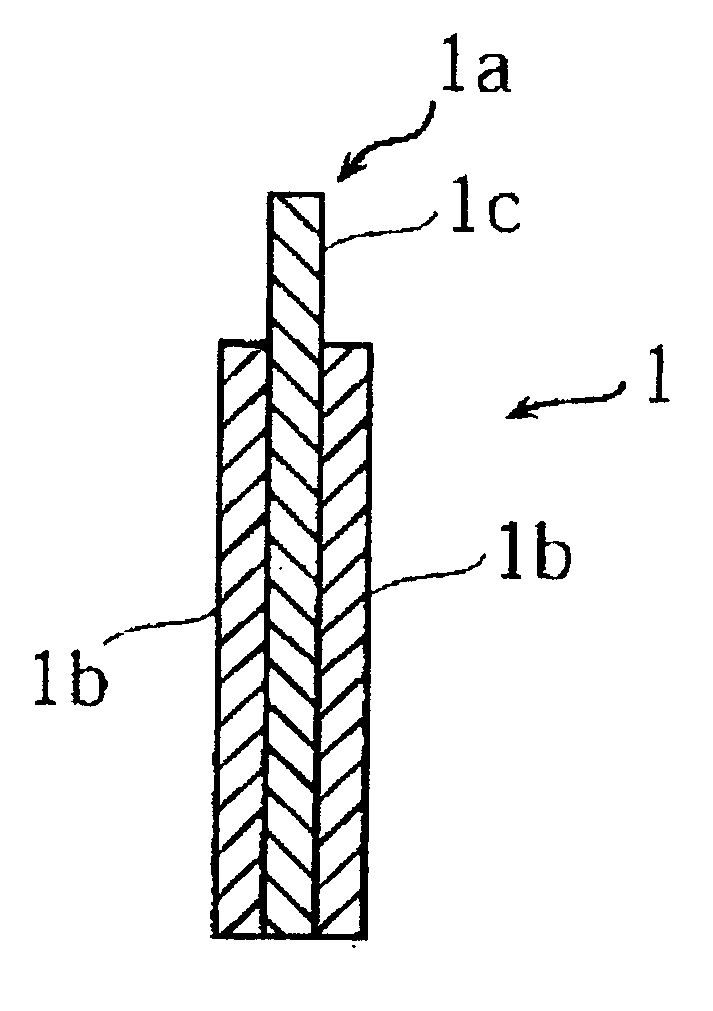

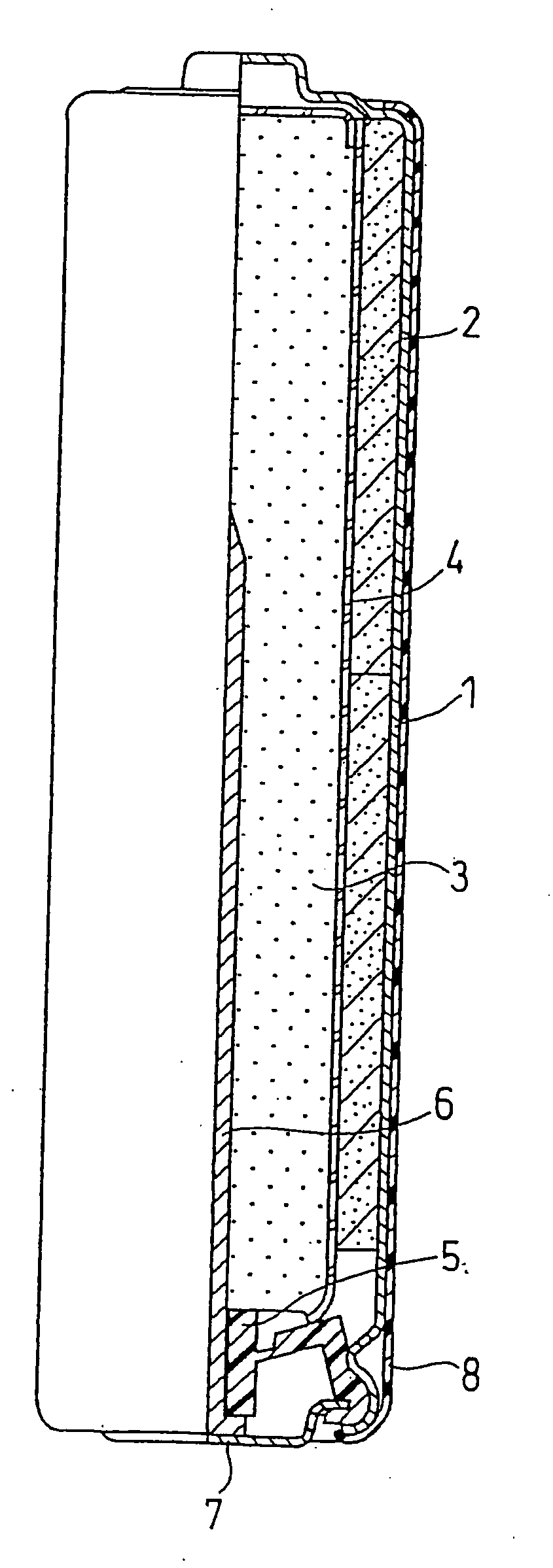

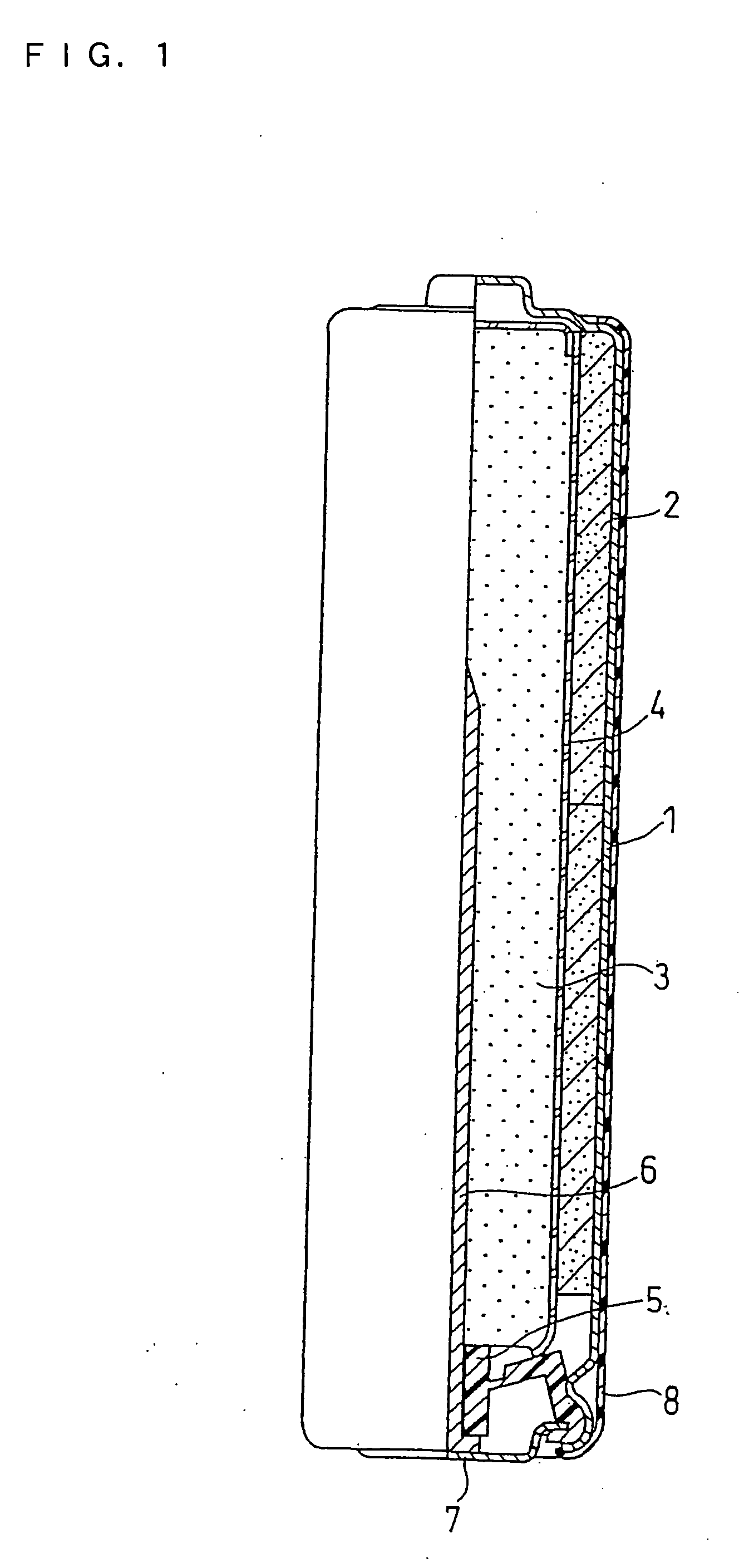

Method of manufacturing cylindrical non-aqueous electrolyte secondary cell

InactiveUS6193765B1Improve power densityReduce resistanceFinal product manufactureElectrode carriers/collectorsEngineeringLaser beams

Owner:SANYO ELECTRIC CO LTD

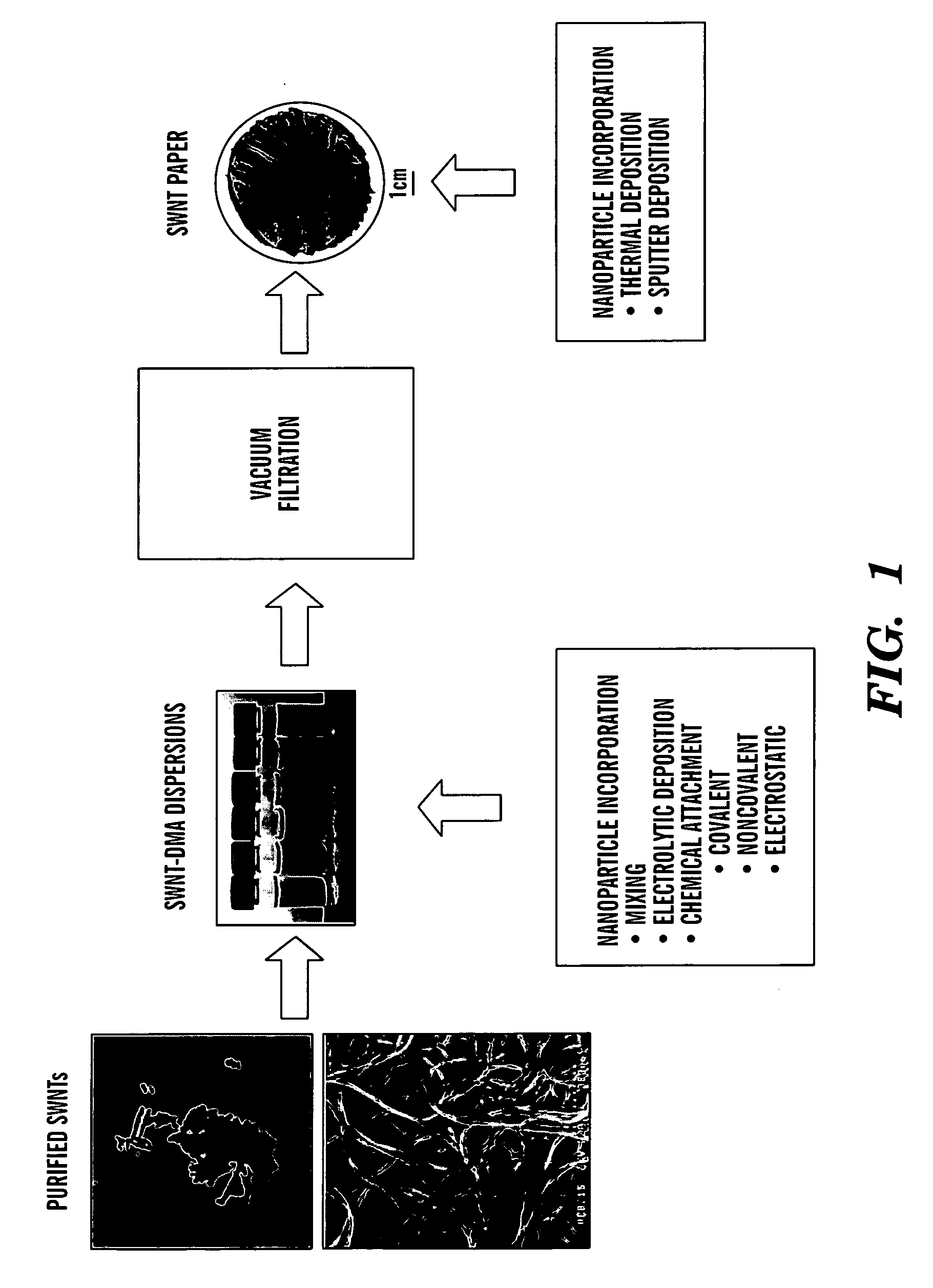

Nano-composite structures, methods of making, and use thereof

ActiveUS20080254362A1Improve electronicImprove ionic transportMaterial nanotechnologyCell electrodesCrystallographyFuel cells

The present invention relates to a nano-composite structure containing nanostructured carbon and nanoparticles. Also disclosed are methods of making the nano-composite structures. The present invention also relates to a lithium ion battery, a capacitor, a supercapacitor, a battery / capacitor, or a fuel cell containing the nano-composite structures of the present invention.

Owner:ROCHESTER INSTITUTE OF TECHNOLOGY

Flexible thin printed battery and device and method of manufacturing same

ActiveUS7348096B2Eliminate needFinal product manufactureElectrode carriers/collectorsElectrical batteryEngineering

A flat, flexible electrochemical cell is provided. The within invention describes various aspects of the flat, flexible electrochemical cell. A printed anode is provided that obviates the need for a discrete anode current collector, thereby reducing the size of the battery. An advantageous electrolyte is provided that enables the use of a metallic cathode current collector, thereby improving the performance of the battery. Printable gelled electrolytes and separators are provided, enabling the construction of both co-facial and co-planar batteries. Cell contacts are provided that reduce the potential for electrolyte creepage in the flat, flexible electrochemical cells of the within invention.

Owner:ENERGIZER BRANDS

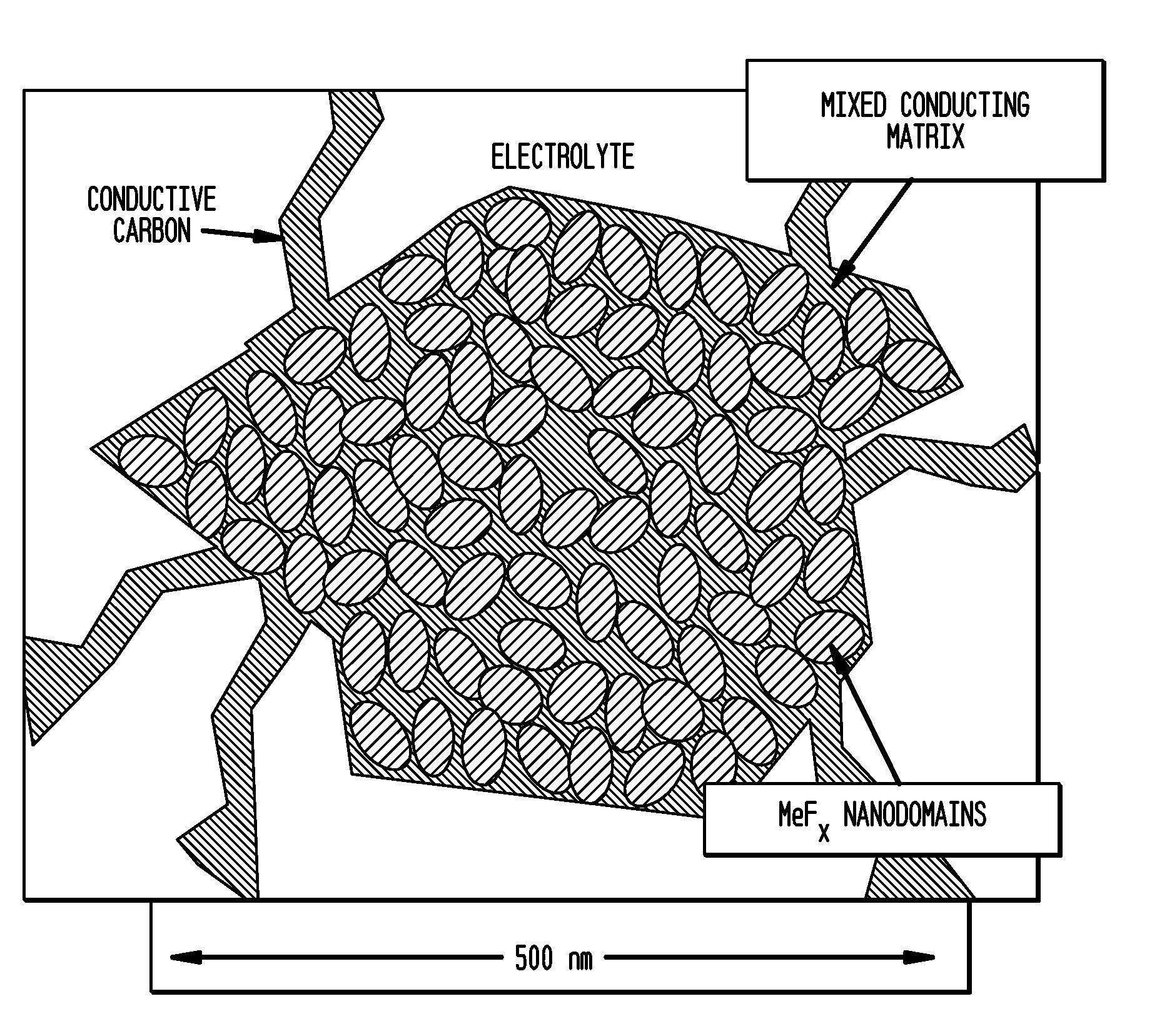

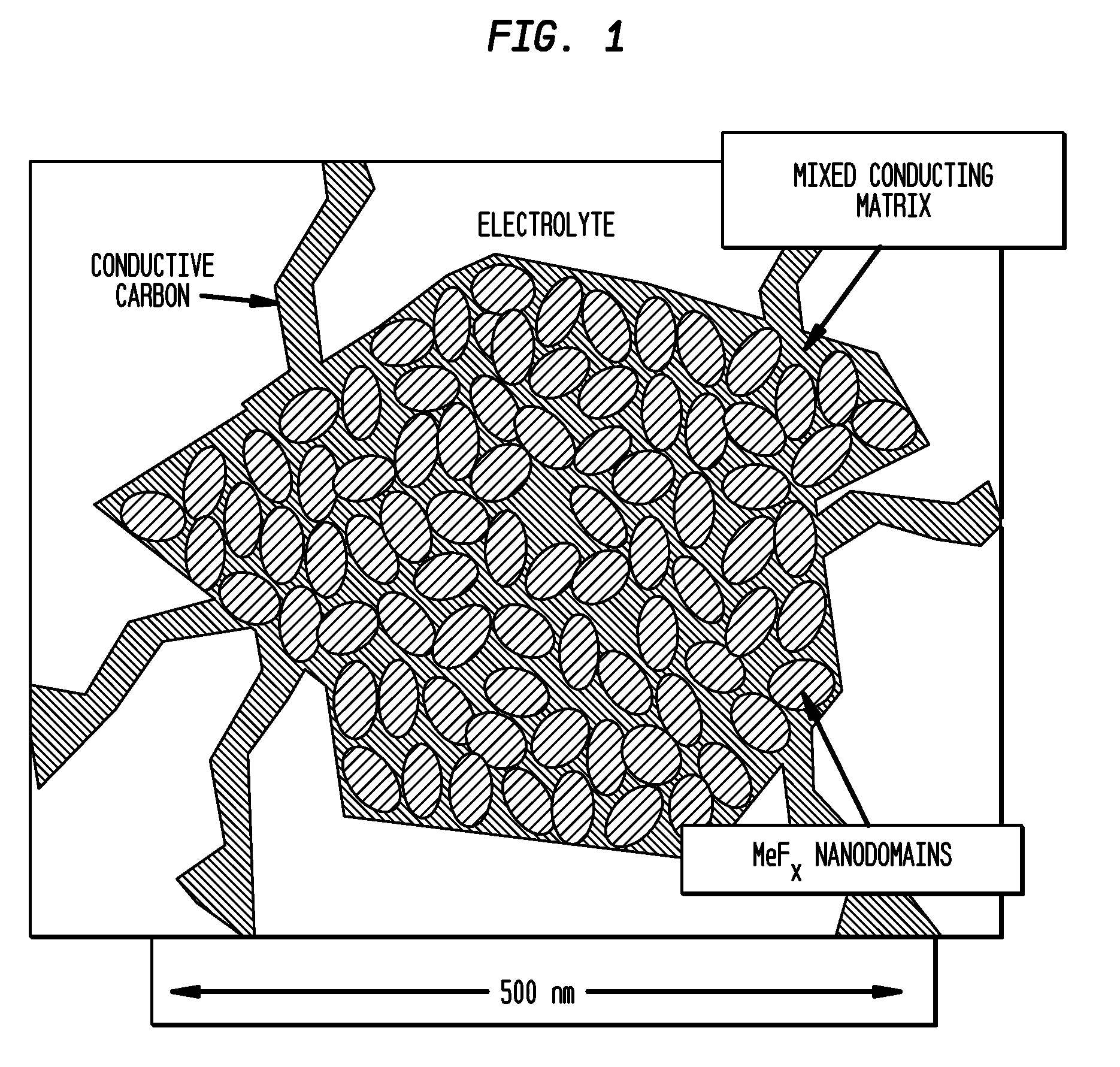

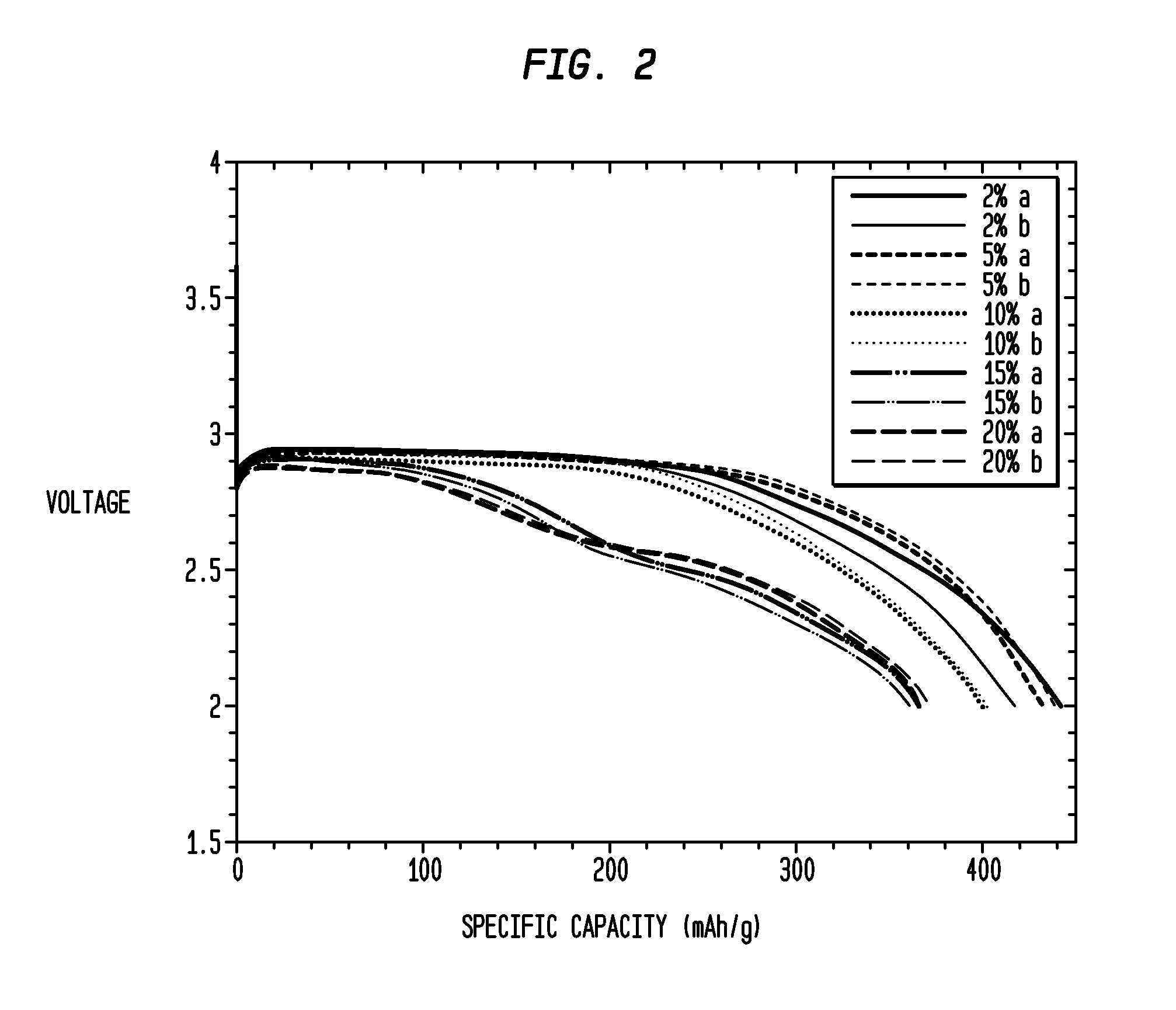

Metal Fluoride And Phosphate Nanocomposites As Electrode Materials

ActiveUS20080199772A1High specific capacityHigh discharge rateSilver accumulatorsElectrode manufacturing processesPhosphatePhysical chemistry

The present invention relates to primary and secondary electrochemical energy storage systems. More particularly, the present invention relates to such systems as battery cells, especially battery cells utilizing metal fluorides with the presence of phosphates or fluorophosphates, which use materials that take up and release ions as a means of storing and supplying electrical energy.

Owner:RUTGERS THE STATE UNIV

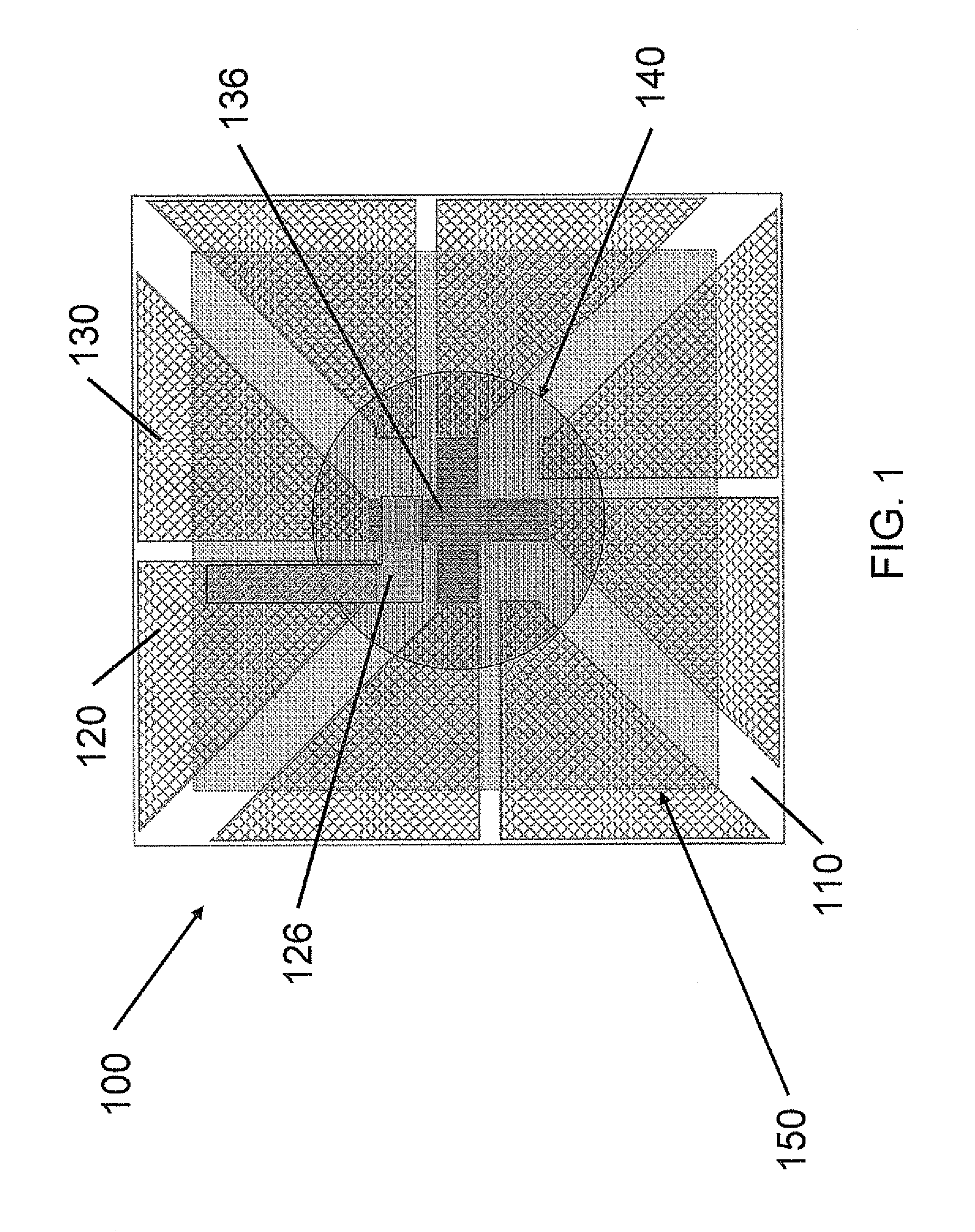

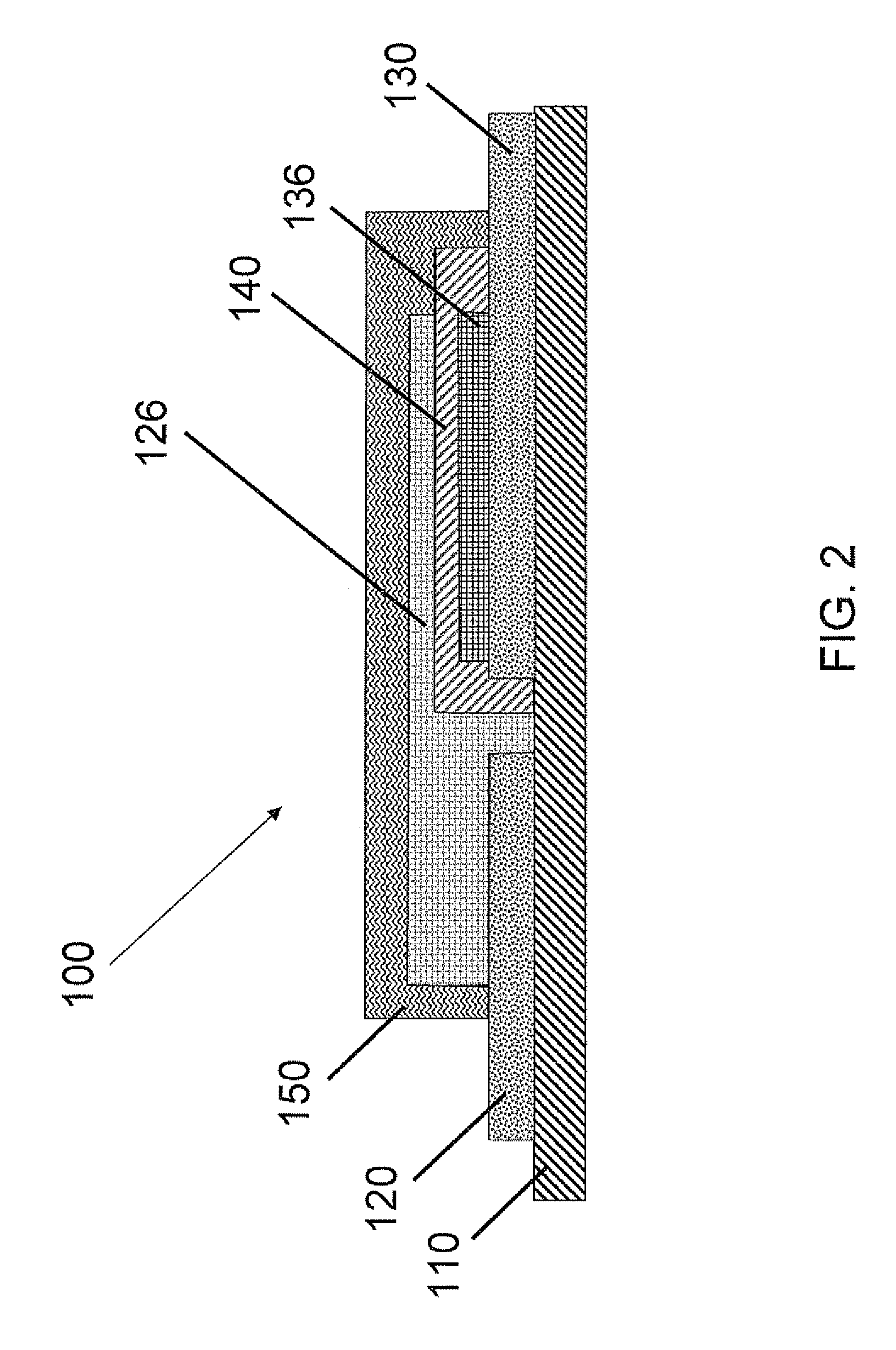

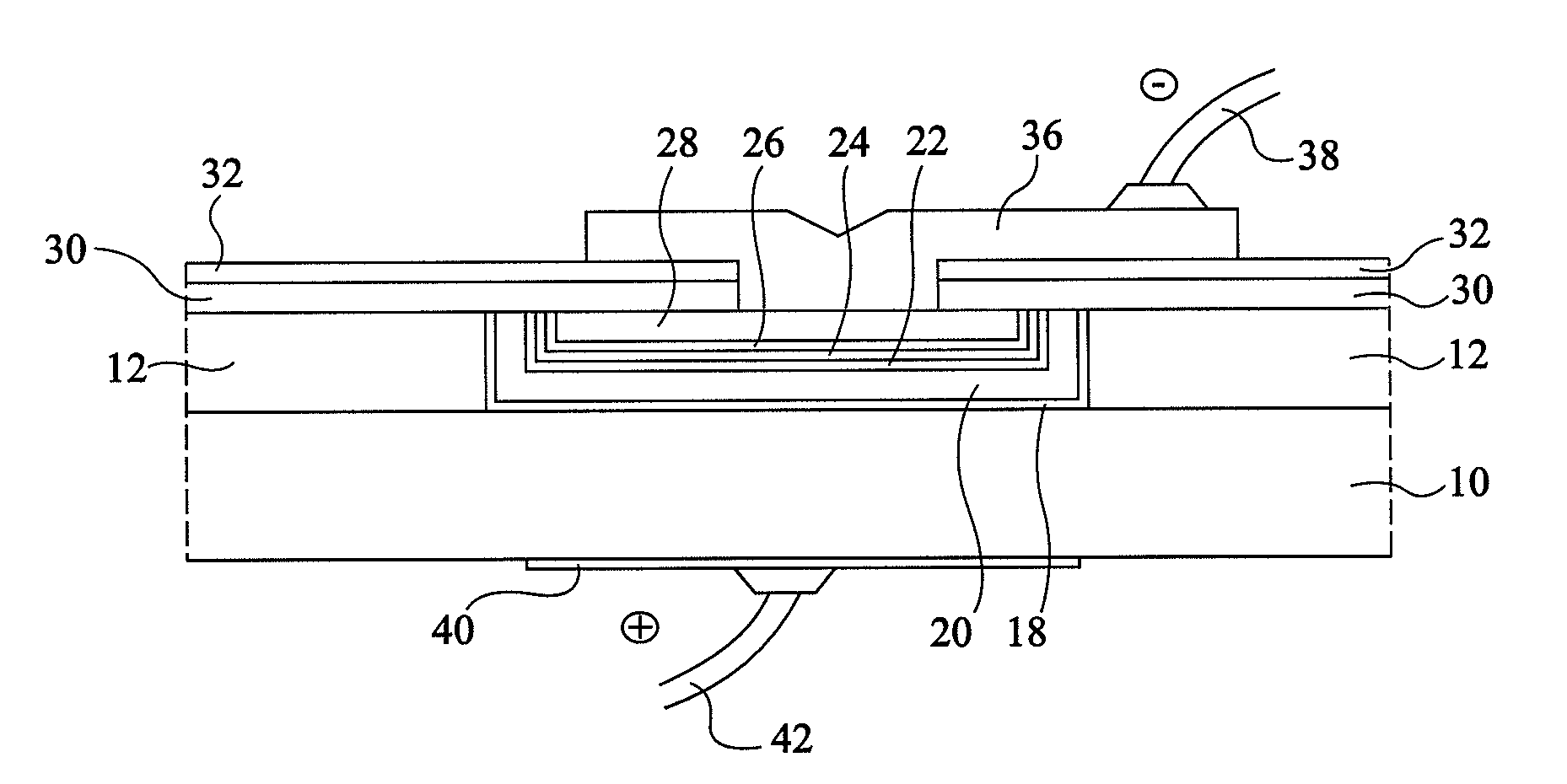

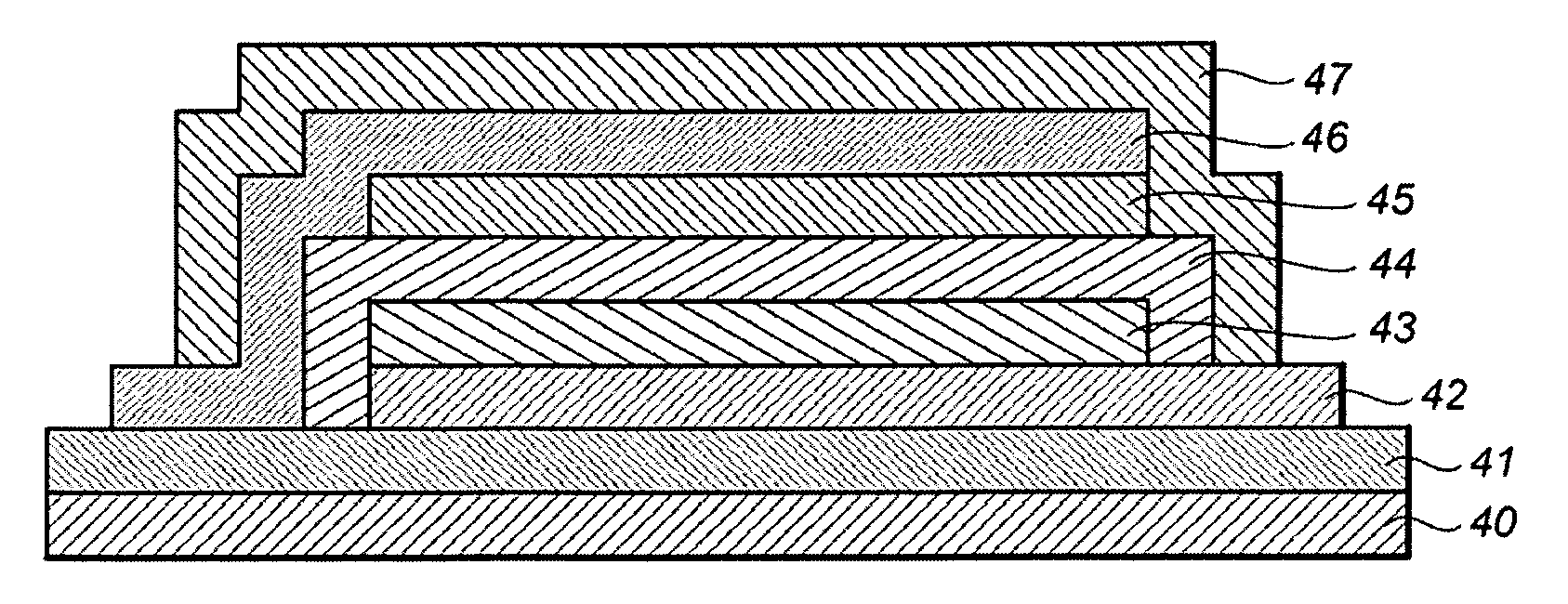

Battery layout incorporating full metal edge seal

ActiveUS20090214899A1Exceptional coverageExceptional protectionSolid electrolytesFinal product manufactureInsulation layerMetal

A first current collector on the first surface of the substrate and a second current collector having a first surface and a perimeter. One of the first and second current collector is an anode current collector and the other is a cathode current collector. The battery also comprises a cathode material having a perimeter, the cathode material being located on the cathode current collector; an electrolyte layer having a perimeter, the electrolyte separating the cathode material from the anode current collector; an insulation layer having a perimeter, the insulation layer together with the electrolyte layer separating the anode current collector from the cathode material and the cathode current collector. A first passivation layer generally overlies at least the perimeter of the cathode material, the perimeter of the electrolyte, and the perimeter of the insulation layer, the first passivation layer being electrically coupled to the first current collector and forming a continuous metal to metal seal around a defined area of the first current collector. The first passivation layer has a via opening. A second passivation layer is electrically coupled to the second current collector through the via opening of the first passivation layer.

Owner:CYMBET CORP

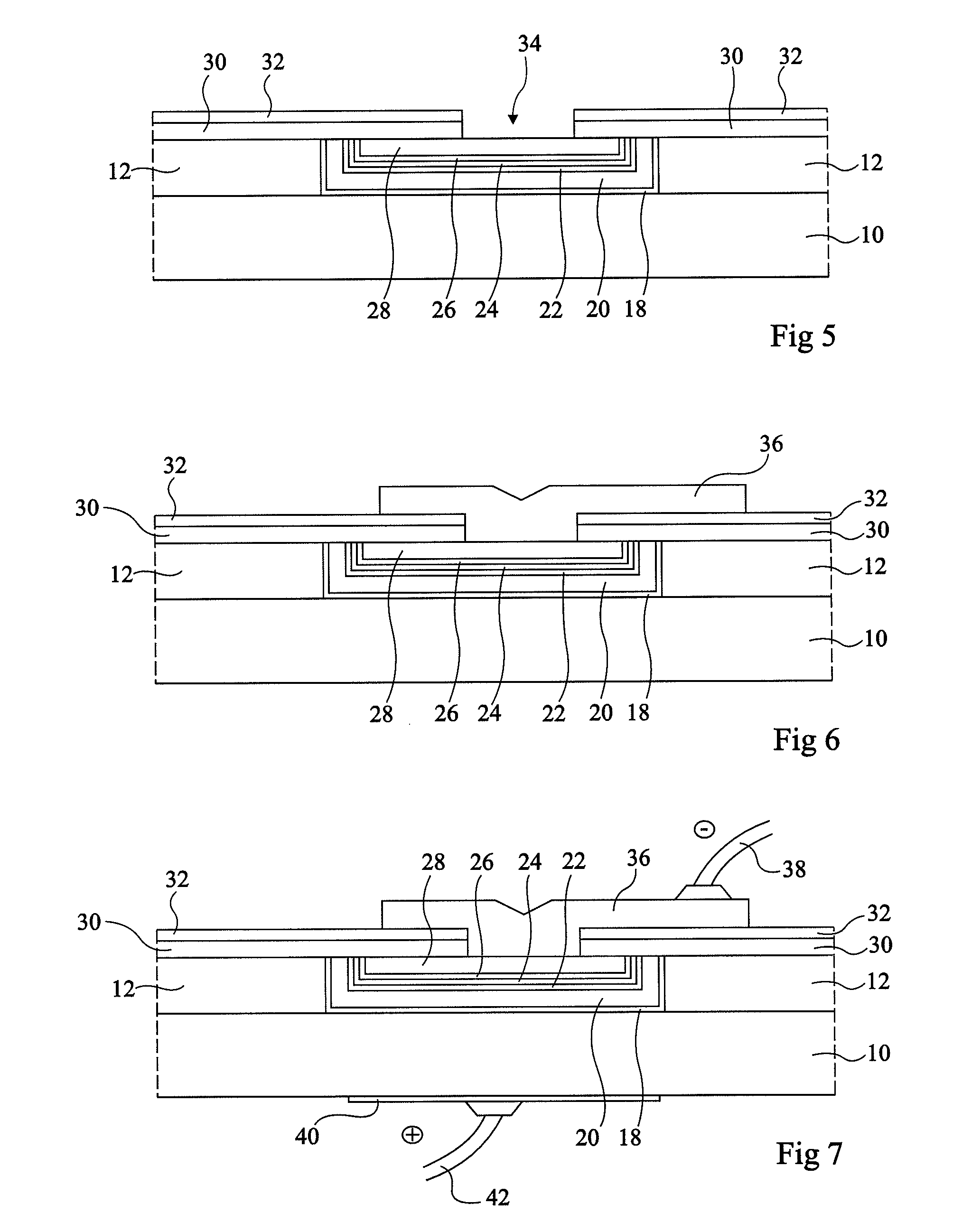

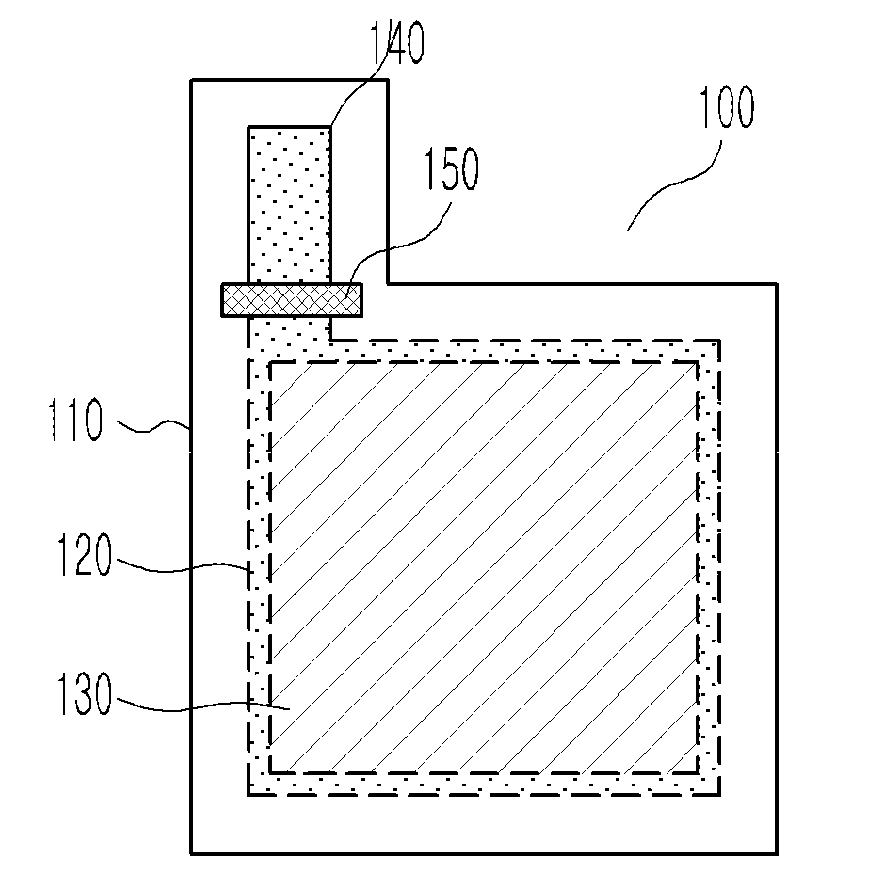

Thin printable electrochemical cell utilizing a “picture frame” and methods of making the same

Owner:BLUE SPARK INNOVATIONS LLC

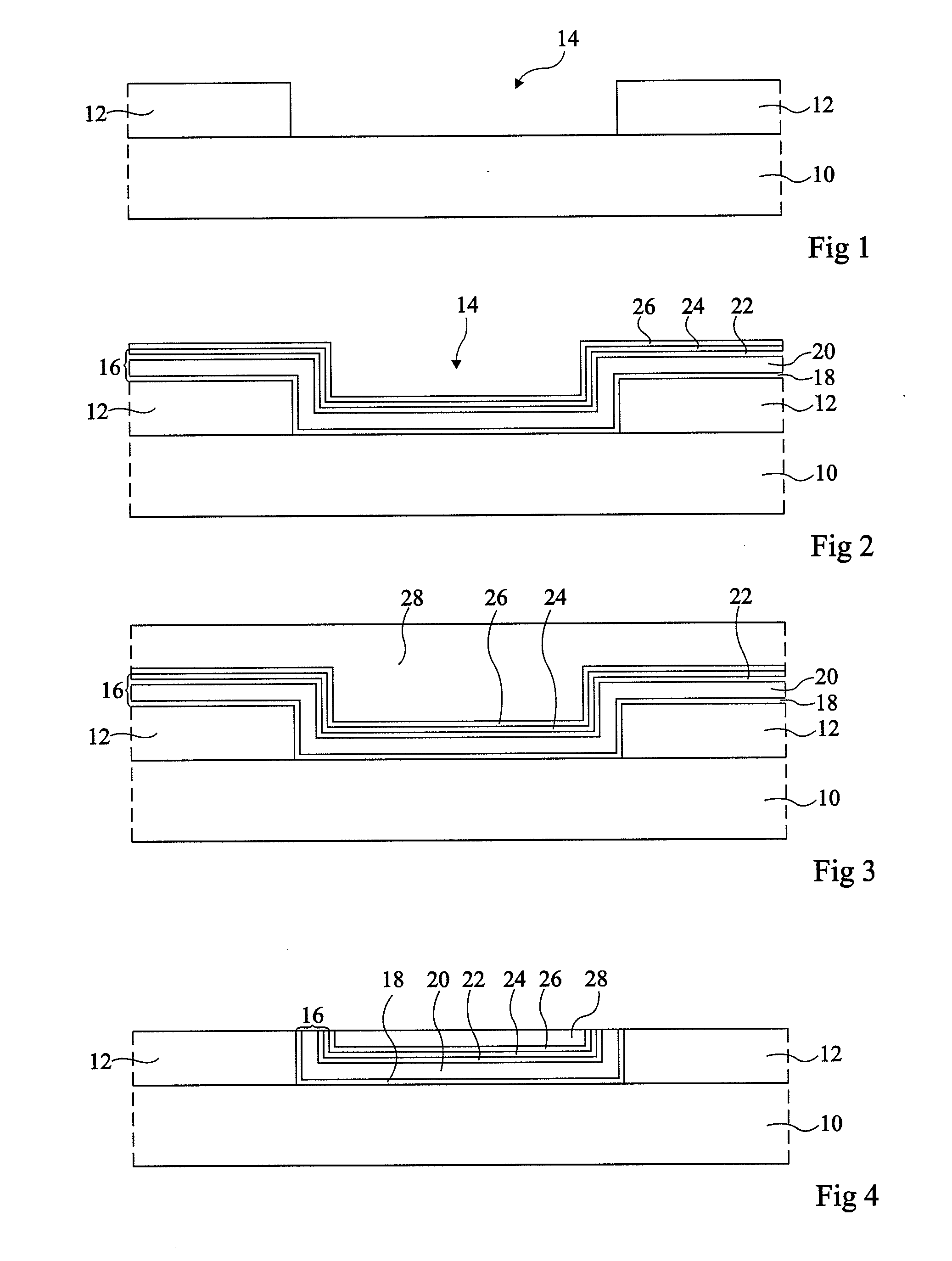

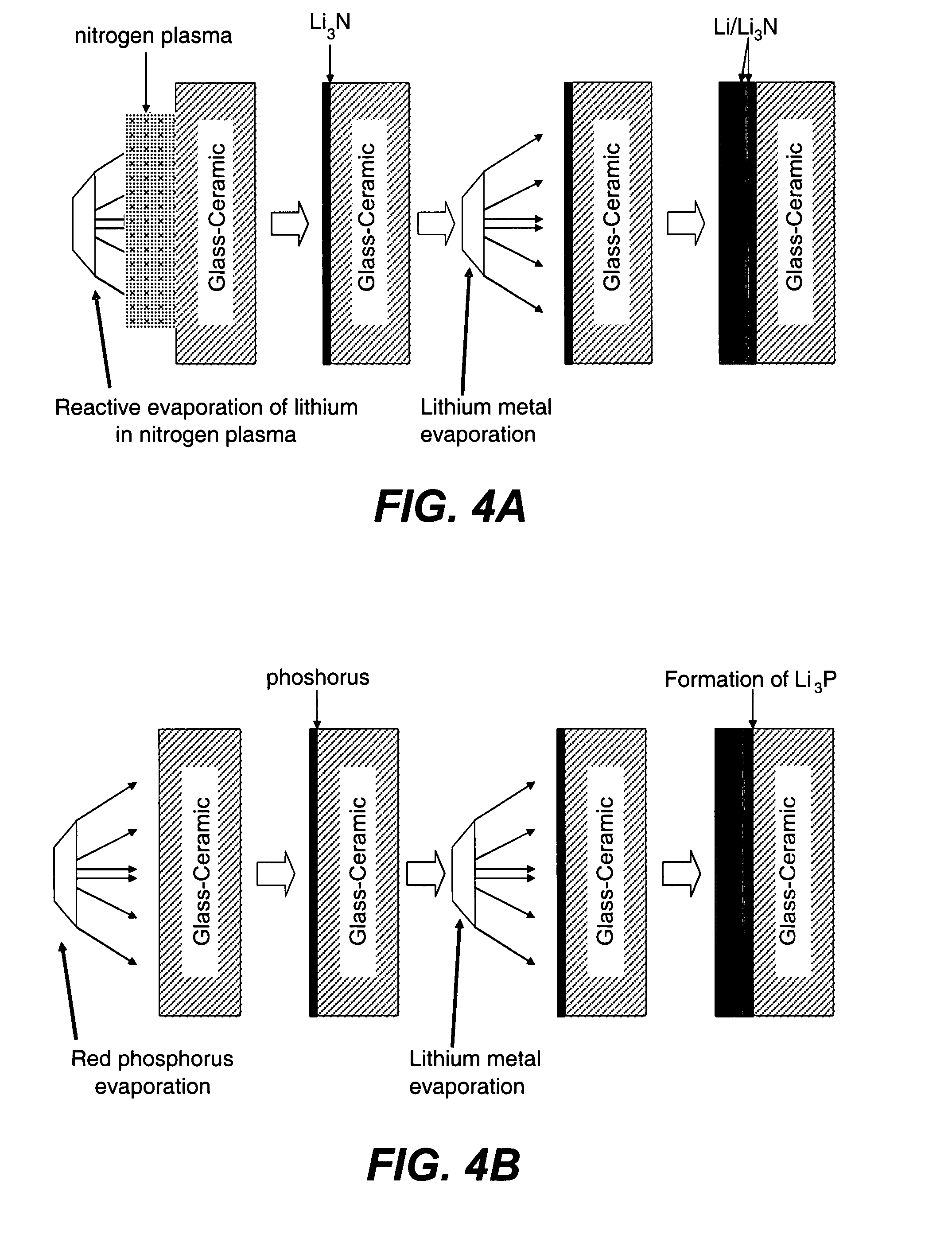

Method for forming a thin-film lithium-ion battery

InactiveUS20110076567A1Low costFinal product manufactureVacuum evaporation coatingLithiumOptoelectronics

A method for forming a lithium-ion type battery including the steps of forming, over an at least locally conductive substrate, an insulating layer having a through opening; successively and conformally depositing a stack comprising a cathode collector layer, a cathode layer, an electrolyte layer, and an anode layer, this stack having a thickness smaller than the thickness of the insulating layer; forming, over the structure, an anode collector layer filling the space remaining in the opening; and planarizing the structure to expose the upper surface of the insulating layer.

Owner:STMICROELECTRONICS (TOURS) SAS

Vacuum-sealing-type flexible-film primary battery and method of manufacturing the same

ActiveUS20110045337A1Improve corrosion resistanceElectrode carriers/collectorsPrinted batteriesCarbon layerScreen printing

Provided are a vacuum-sealing-type flexible-film primary battery and a method of manufacturing the same. The primary battery includes a battery assembly comprising a positive electrode plate including a positive electrode collector having a first conductive carbon layer disposed on a surface-treated inner surface of a first pouch and a positive electrode layer disposed on the first conductive carbon layer of the positive electrode collector, a negative electrode plate including a negative electrode collector having a second conductive carbon layer disposed on a surface-treated inner surface of a second pouch and a negative electrode layer disposed on the second conductive carbon layer of the negative electrode collector, and an adhesion / post-injection polymer electrolyte layer interposed between the positive electrode plate and the negative electrode plate, wherein the battery assembly is completely sealed. The flexible-film primary battery may employ the pouch as a collector film to improve flexibility. Also, the flexible-film primary battery may be completely sealed using the pouch to improve a retention period and cell performance. Furthermore, the flexible-film primary battery may be manufactured using a screen printing technique, thereby facilitating a roll-to-roll sequential process.

Owner:ELECTRONICS & TELECOMM RES INST

All solid state electrolyte and preparing method and application of the same

InactiveCN101183727AAct as an electrolytePlays double role as a diaphragmCell electrodesOrganic electrolyte cellsPolyethylene oxideUltra fine

The invention relates to an all-solid-state electrolyte, the preparation method and the application, which solves the problems that the liquid state electrolytet in the prior lithium ion secondary battery is easy to volatilize and has the leakage potential safety hazard, or the gel polymer electrolyte has a bad mechanical property and molding difficulty. The invention comprises lithium salt, polyethylene oxide, ultra fine powder packing. The invention prepares the all-solid-state electrolyte through the method that: firstly, the lithium salt and the solvent are mixed evenly and then the PEO powder is scattered in and mixed evenly; secondly, the ultra fine powder packing is added into the solvent and mixed evenly, and the mixture is stood; thirdly, the mixed liquids of the first step and the second step are mixed evenly, molded after being cast and dried, and then demoulded to form the product. The invention has the advantages that the all-solid-state electrolyte is used as the electrolyte of the all-solid-state secondary lithium battery and matches with the cathode of the metal lithium; thus the potential safety hazard of the liquid state electrolyte leakage is avoided, the mechanical property is good and the molding is easy.

Owner:HARBIN INST OF TECH

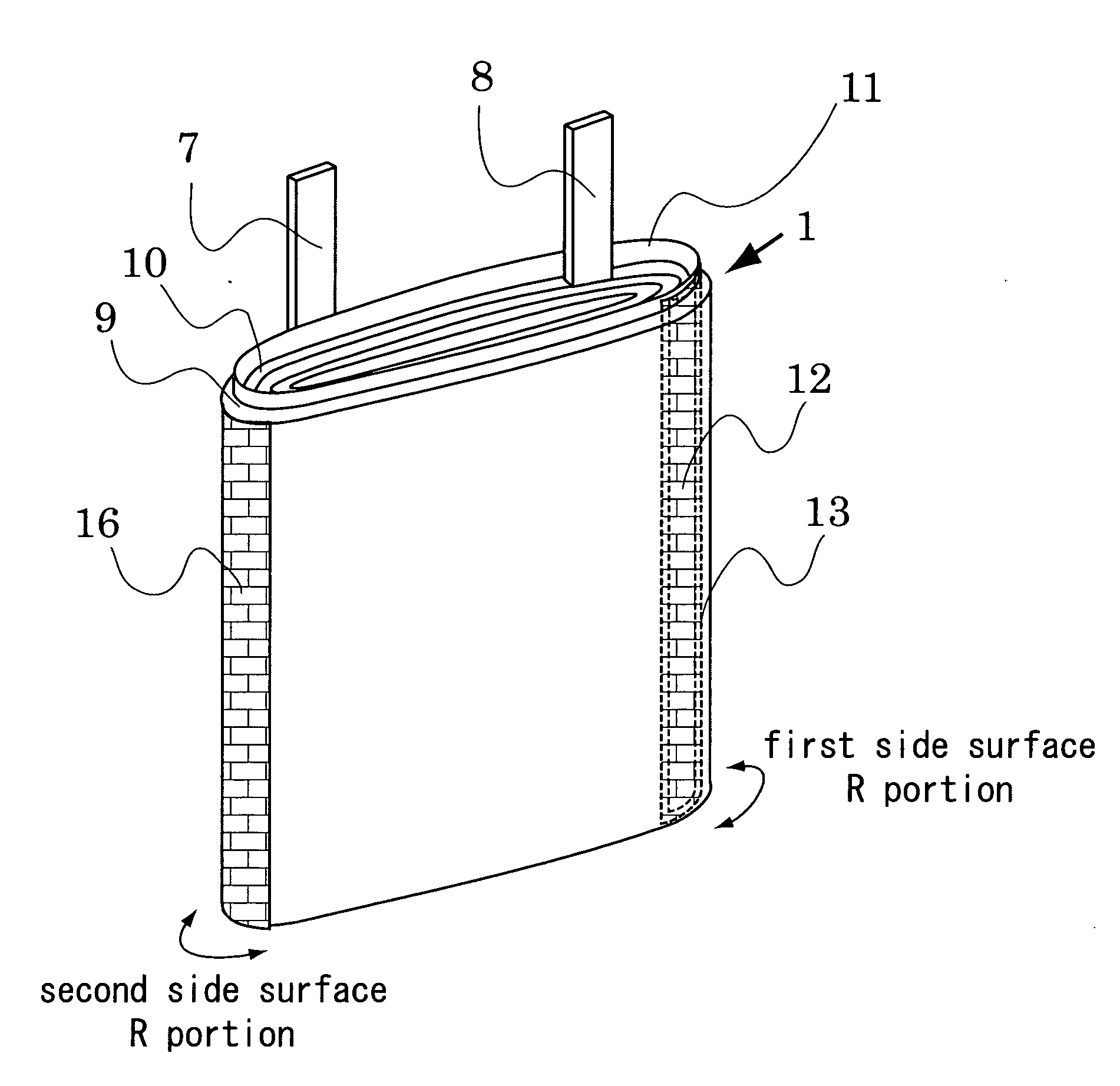

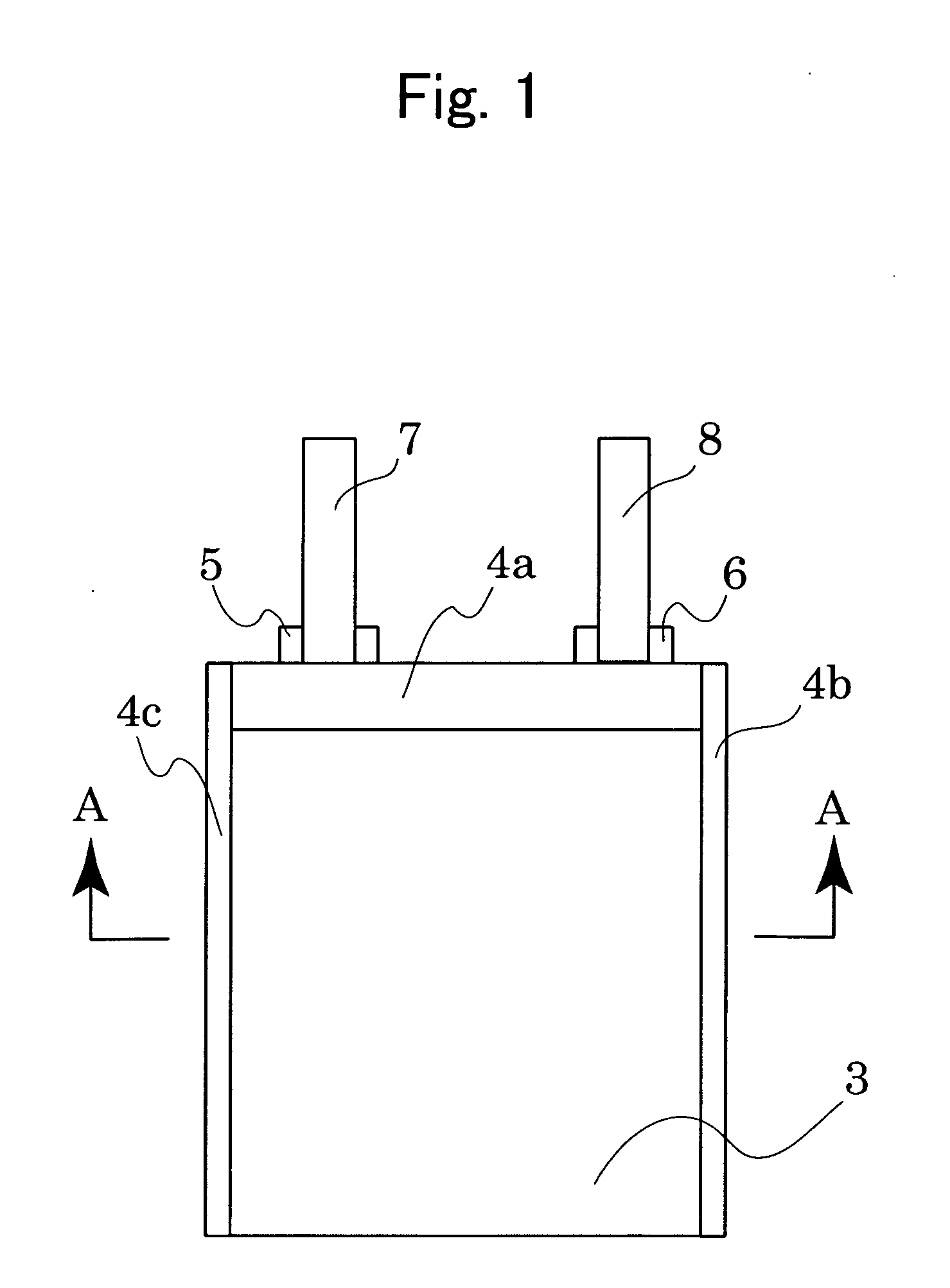

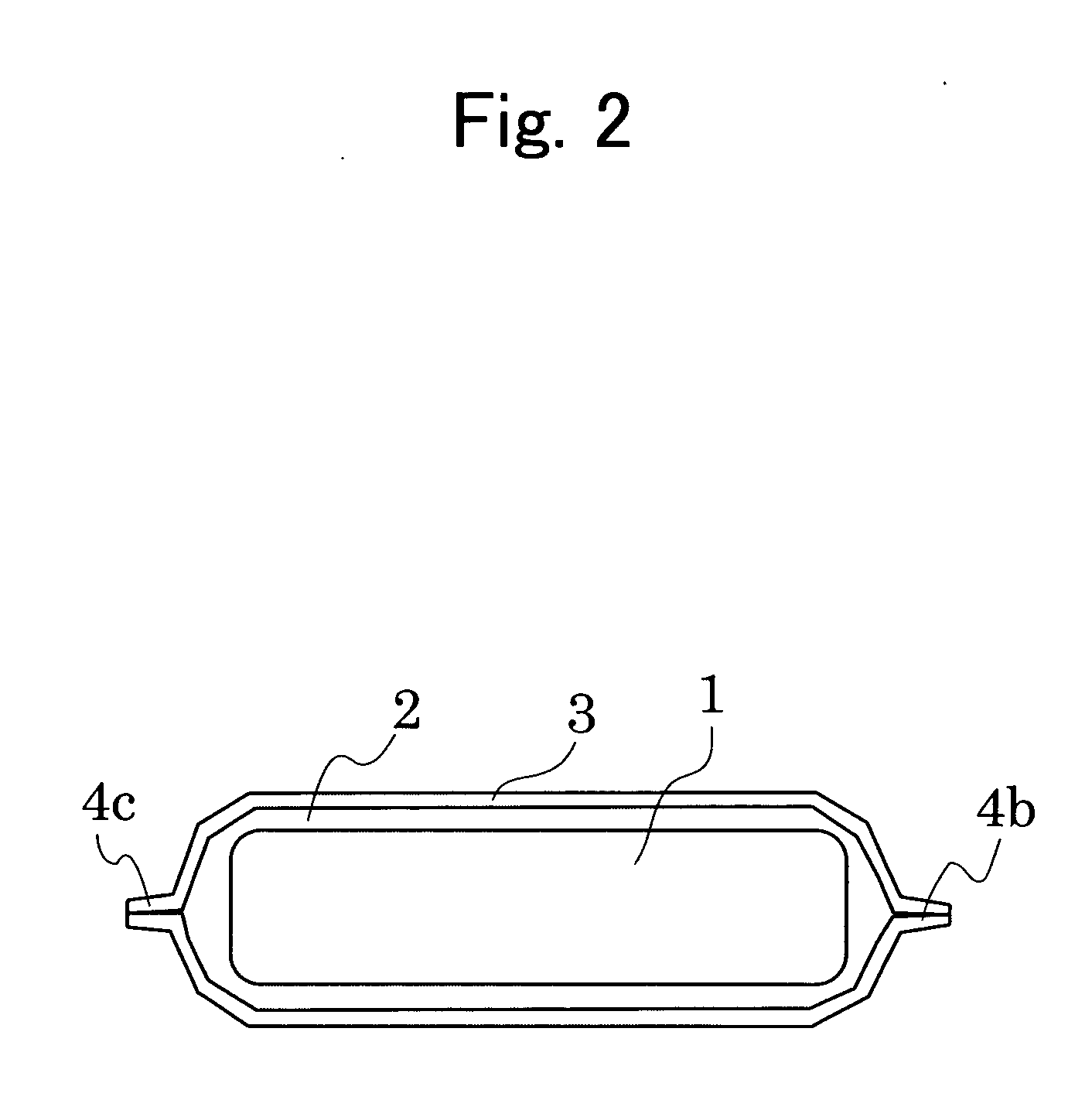

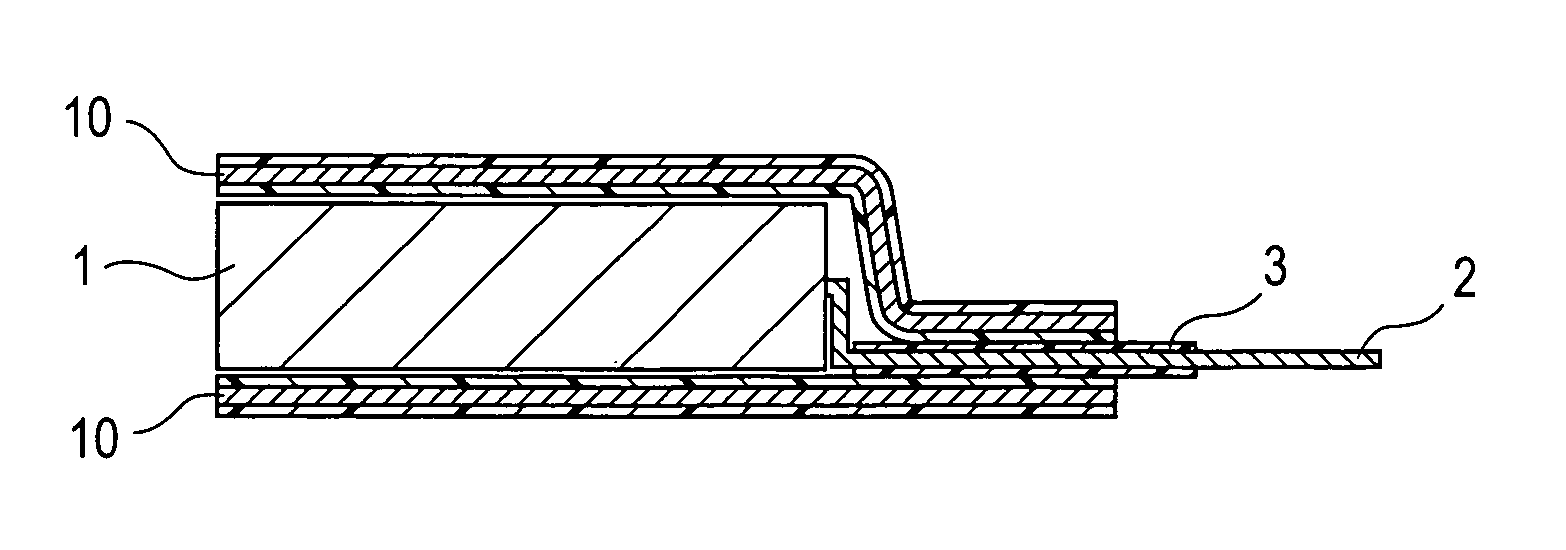

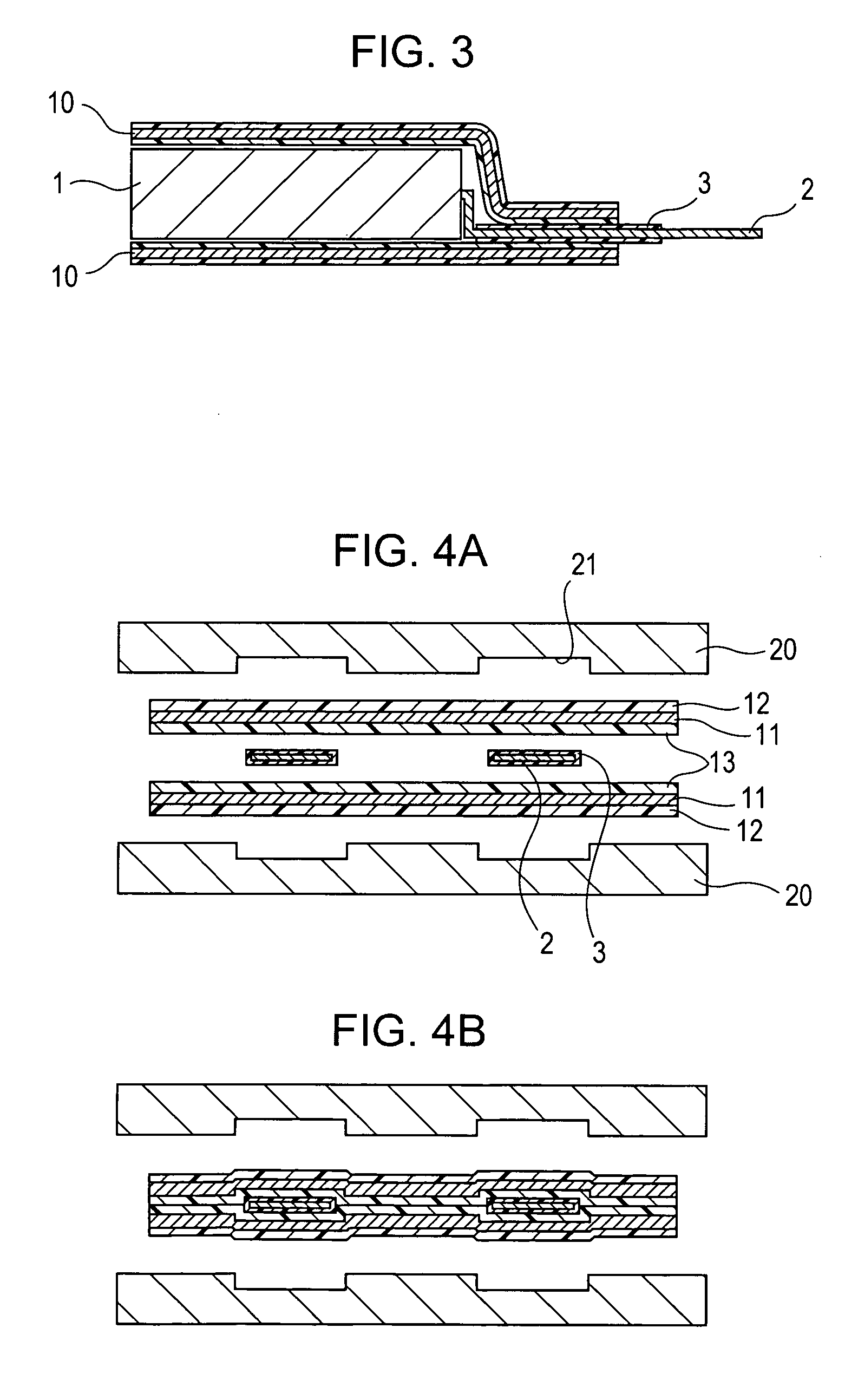

Sealed cell using film outer casing body

InactiveUS20050069764A1Increase credibilityEasy to transformNon-aqueous electrolyte accumulatorsFinal product manufactureDrop impactBiomedical engineering

The present invention prevents a cell with a film outer casing body from suffering internal short-circuiting caused by dropping impacts. This is accomplished by a sealed cell with a film outer casing body having a flat electrode body. The flat electrode body has first and second electrodes and a separator therebetween, which are wound into a flat shape having first and second flat side surface R portions. The first electrode is the outermost surface of the electrode body. An insulation member is provided on the electrode body to completely cover the lower edge and / or upper edge of the first flat side surface R portion. Specifically, the insulation film is provided between the outermost portion of the first electrode and a portion of the second electrode immediately inside the outermost portion, and between the portion of the second electrode and another portion of the first electrode immediately inside the portion of the second electrode.

Owner:SANYO ELECTRIC CO LTD

Alkaline battery

InactiveUS20080096108A1Improve leak-proof effectAlkaline accumulatorsNegative electrodesMethacrylatePolymer science

An alkaline battery of this invention includes: a positive electrode including at least one selected from the group consisting of a manganese dioxide powder and a nickel oxyhydroxide powder; a gelled negative electrode including a zinc alloy powder, a gelling agent, and an alkaline electrolyte; and a separator interposed between the positive electrode and the gelled negative electrode. The gelling agent comprises a polymer that is obtained by polymerizing a polymerizable monomer including at least an acrylic monomer, and part of the acrylic monomer remains in the gelling agent without being polymerized. The acrylic monomer includes at least one selected from the group consisting of acrylic acid, methacrylic acid, an acrylate, and a methacrylate. The weight ratio of the remaining acrylic monomer to the total weight of the polymer and the remaining acrylic monomer is 5000 ppm or less.

Owner:PANASONIC CORP

Active metal/aqueous electrochemical cells and systems

ActiveUS20080052898A1Degree of flexibilityWithout performanceFuel and primary cellsElectrode manufacturing processesTectorial membraneManufacturing technology

Alkali (or other active) metal battery and other electrochemical cells incorporating active metal anodes together with aqueous cathode / electrolyte systems. The battery cells have a highly ionically conductive protective membrane adjacent to the alkali metal anode that effectively isolates (de-couples) the alkali metal electrode from solvent, electrolyte processing and / or cathode environments, and at the same time allows ion transport in and out of these environments. Isolation of the anode from other components of a battery cell or other electrochemical cell in this way allows the use of virtually any solvent, electrolyte and / or cathode material in conjunction with the anode. Also, optimization of electrolytes or cathode-side solvent systems may be done without impacting anode stability or performance. In particular, Li / water, Li / air and Li / metal hydride cells, components, configurations and fabrication techniques are provided.

Owner:POLYPLUS BATTERY CO INC

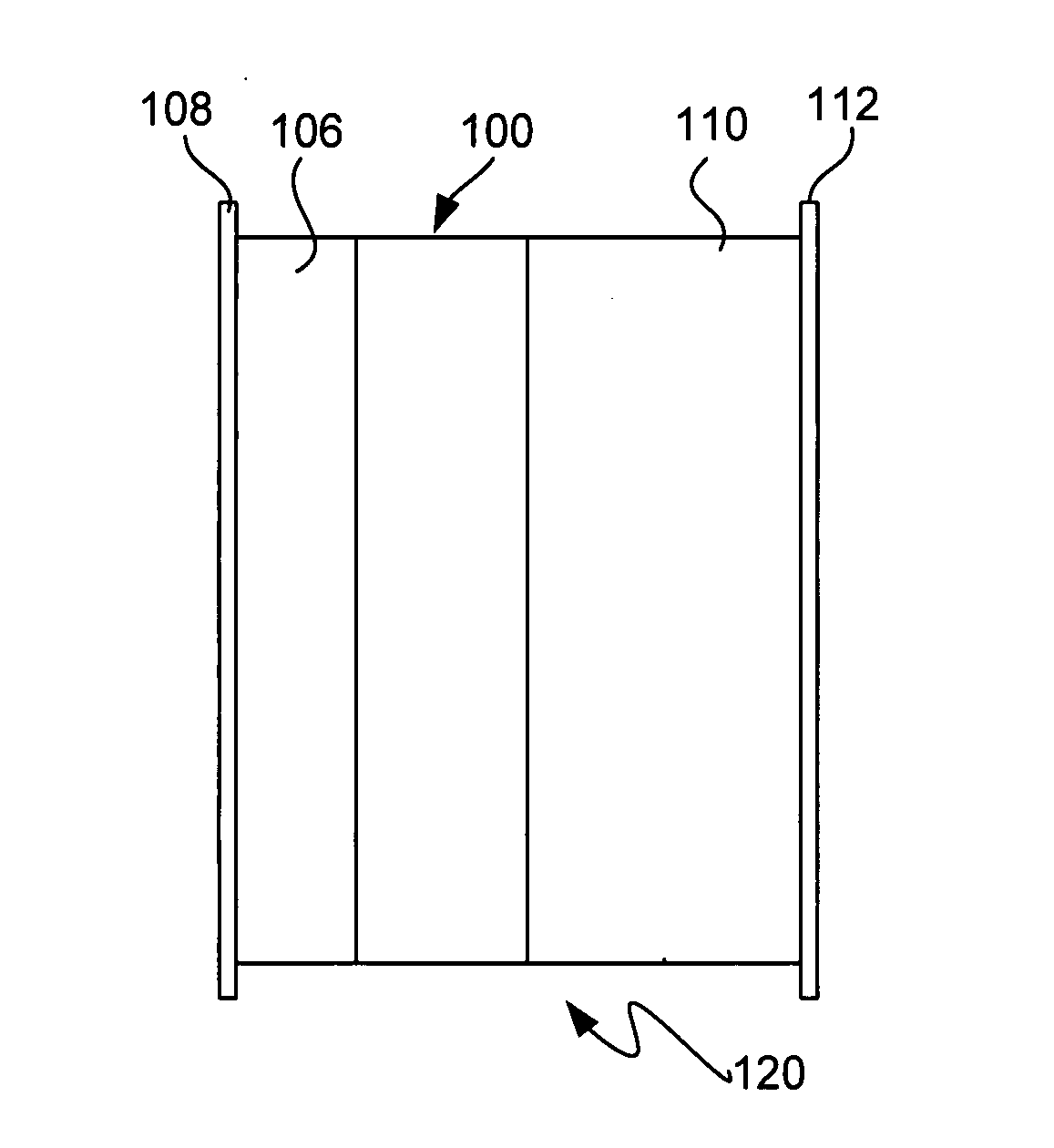

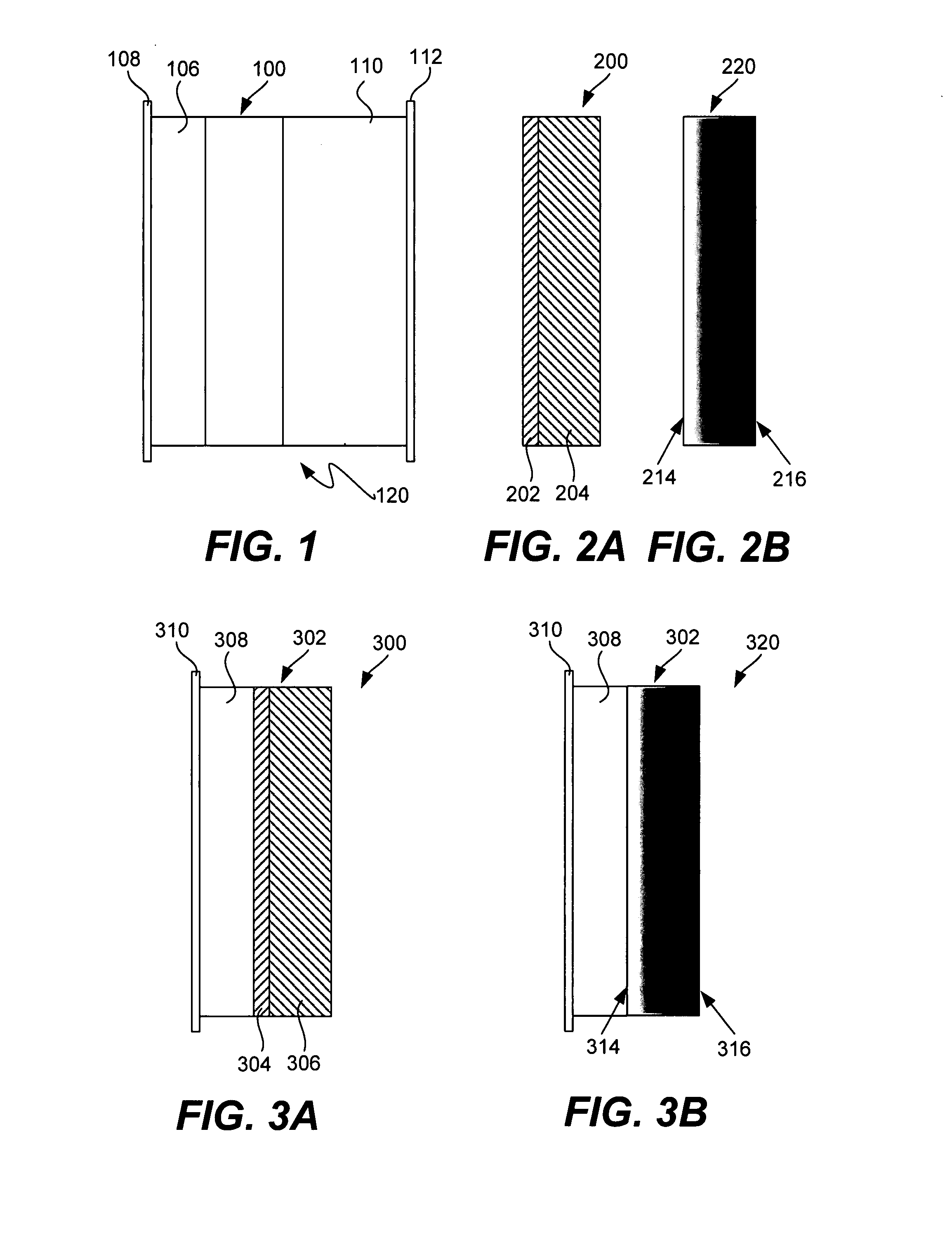

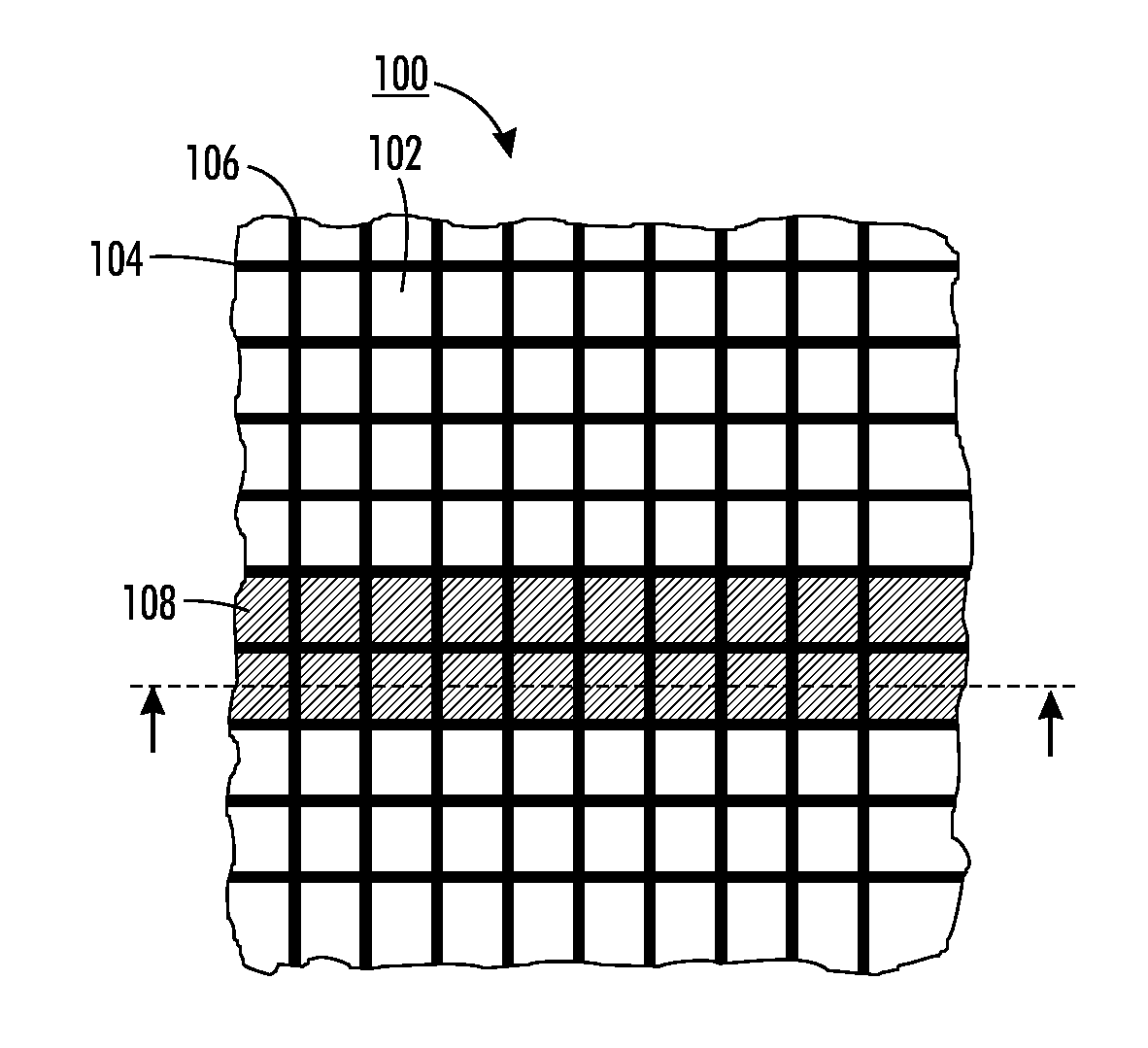

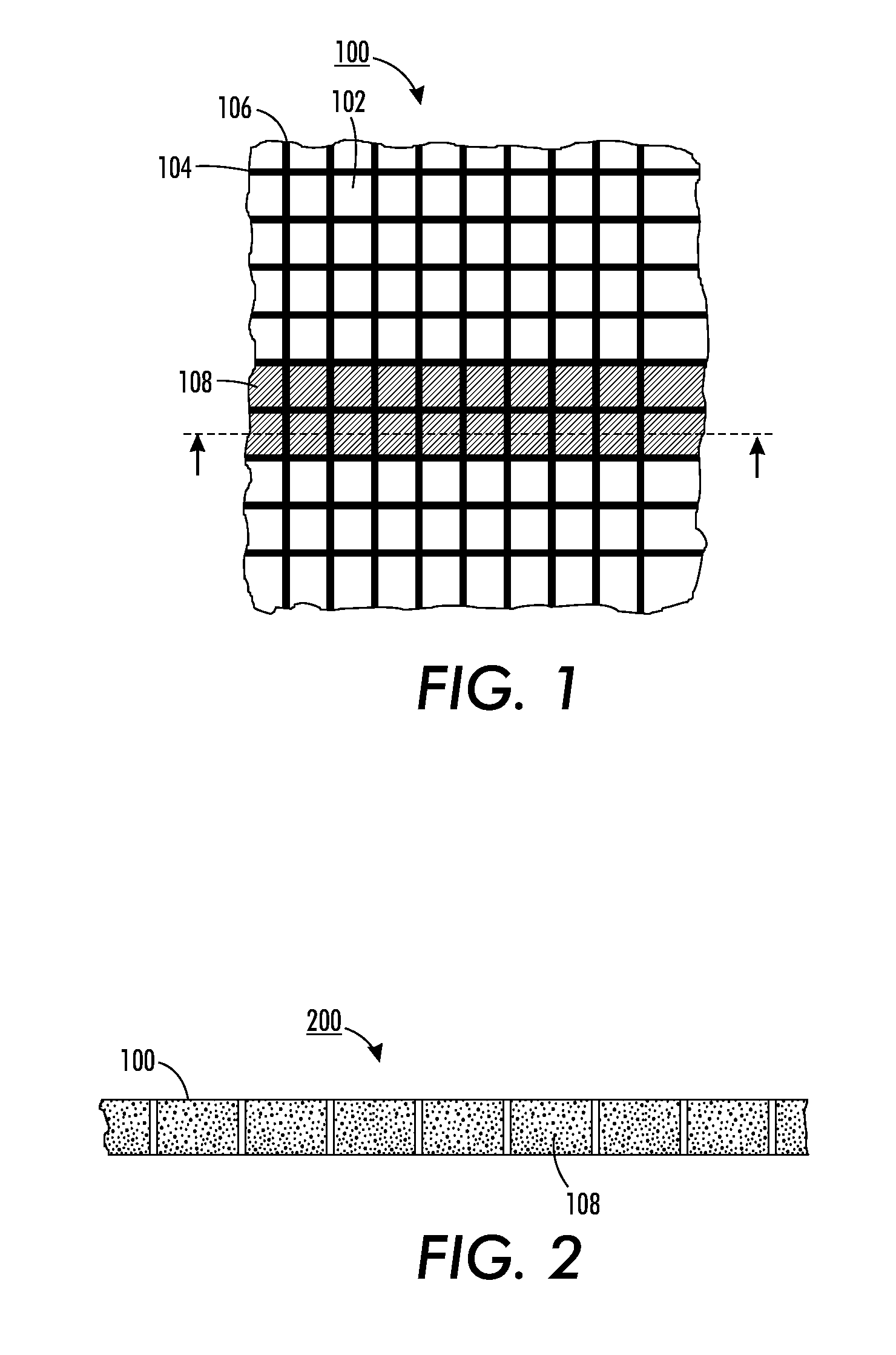

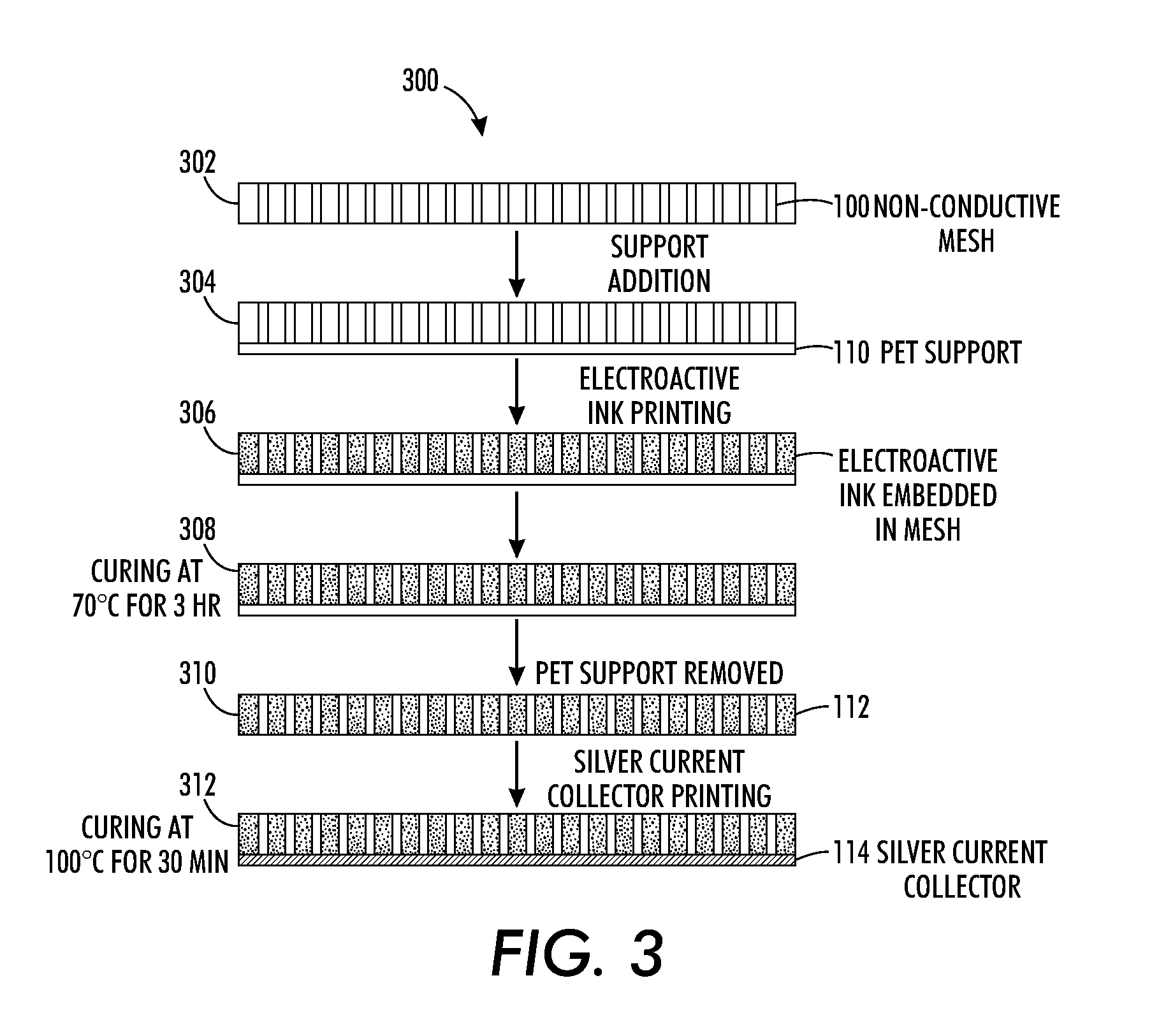

Highly flexible printed alkaline batteries based on mesh embedded electrodes

InactiveUS20120276434A1Final product manufactureElectrode carriers/collectorsMetallurgyFlexible battery

A flexible battery and a method to form the flexible battery include forming an anode by embedding an anode type electro-active material within a mesh material and associating an anode current collector with the anode. Similarly a cathode is formed by embedding a cathode type electro-active material within a mesh material and a cathode current collector is associated with the cathode. An electrolyte is located between the anode and cathode, and the arrangement is sealed.

Owner:PALO ALTO RES CENT INC

Flexible thin printed battery and device and method of manufacturing same

InactiveUS20060115717A1Sufficiently conductiveEliminate needFinal product manufactureElectrode carriers/collectorsElectrical batteryEngineering

A flat, flexible electrochemical cell is provided. The within invention describes various aspects of the flat, flexible electrochemical cell. A printed anode is provided that obviates the need for a discrete anode current collector, thereby reducing the size of the battery. An advantageous electrolyte is provided that enables the use of a metallic cathode current collector, thereby improving the performance of the battery. Printable gelled electrolytes and separators are provided, enabling the construction of both co-facial and co-planar batteries. Cell contacts are provided that reduce the potential for electrolyte creepage in the flat, flexible electrochemical cells of the within invention.

Owner:ENERGIZER BRANDS

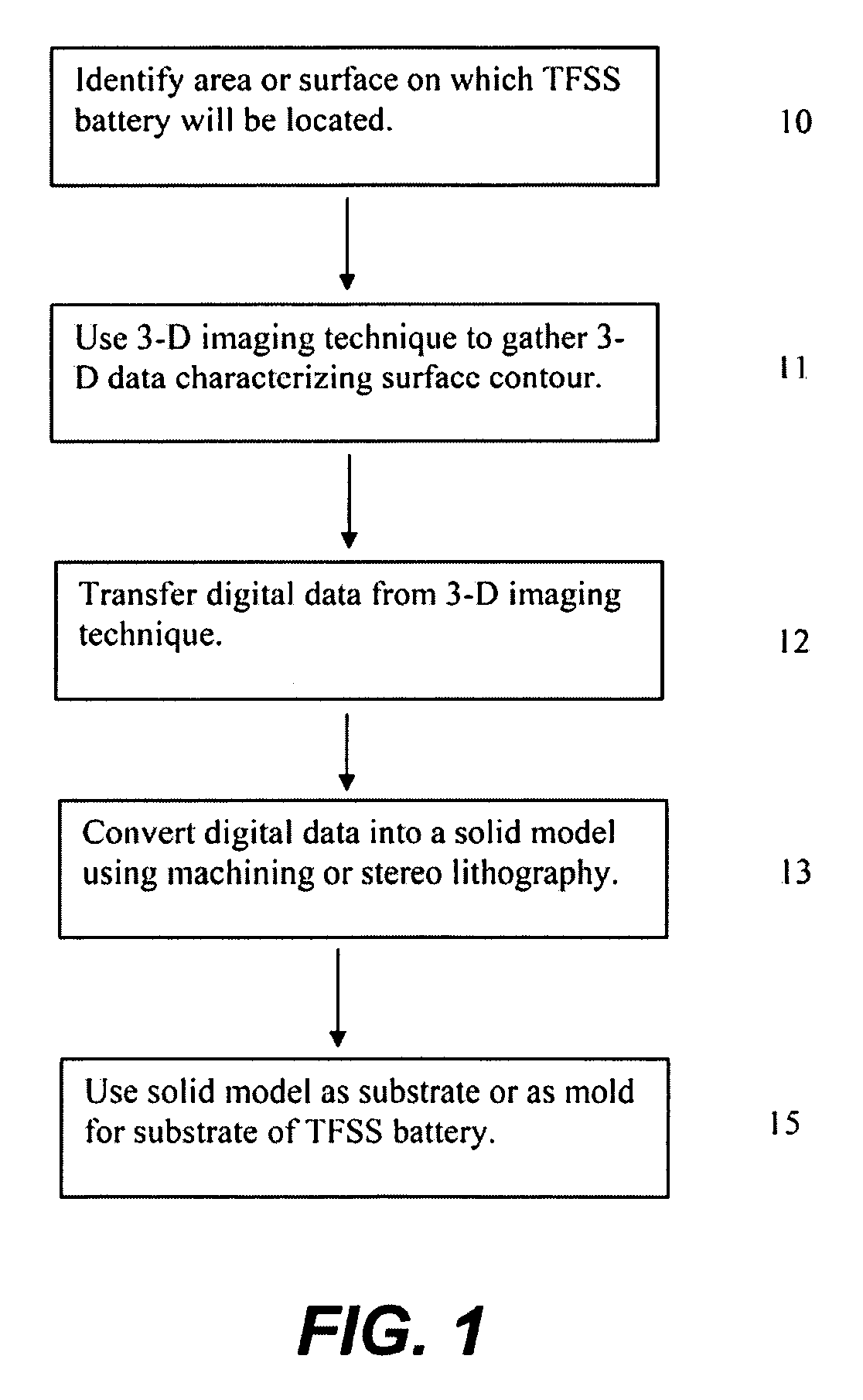

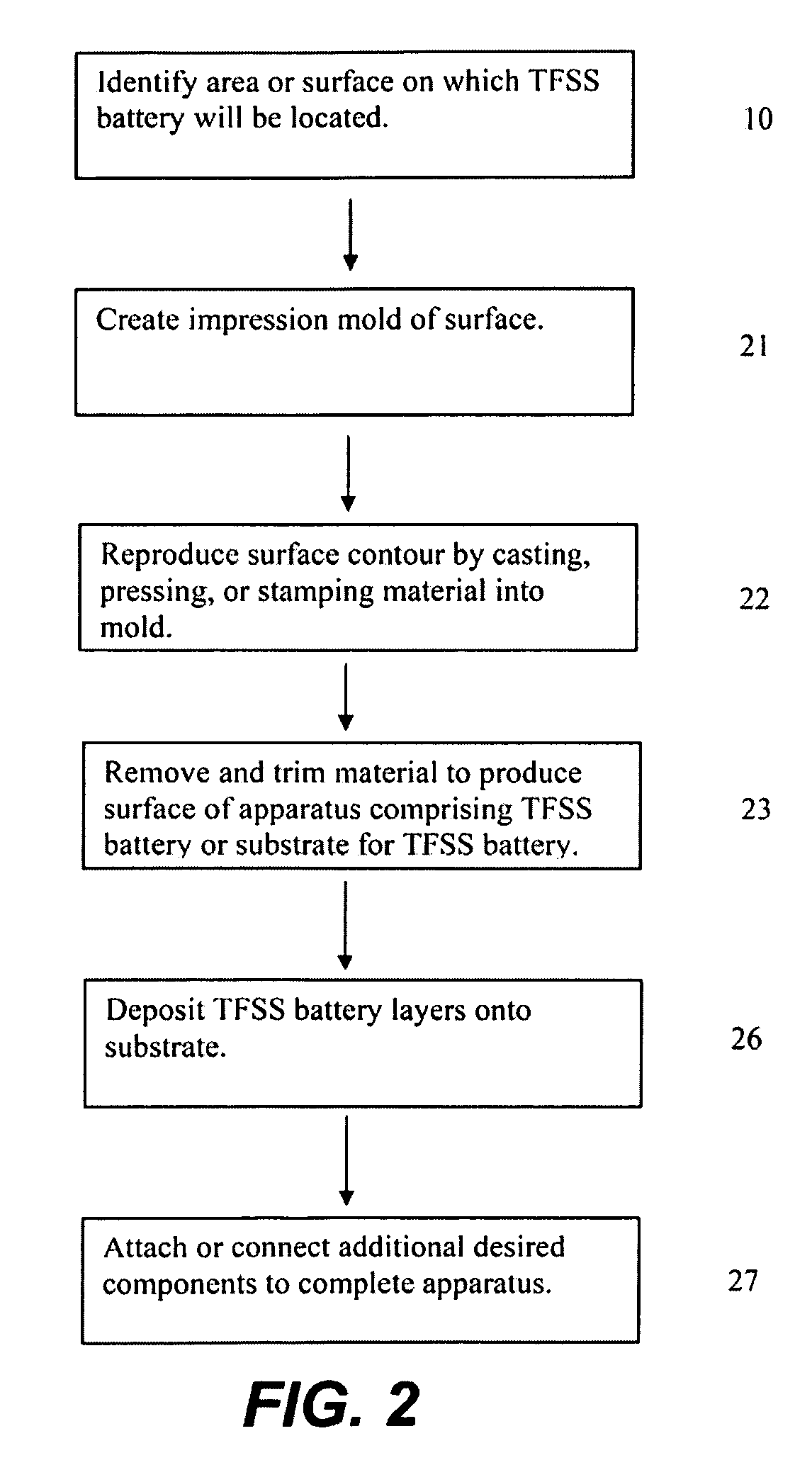

Electrical apparatus with integral thin film solid state battery and methods of manufacture

InactiveUS20090202899A1ElectrotherapyFinal product manufactureElectrical devicesThree dimensional shape

The invention provides a thin film solid state (TFSS) battery that can conform to the surface of an apparatus having a complex, three-dimensional surface. The invention also provides methods for constructing the thin film solid state battery by forming components directly onto a substrate of a complex three-dimensional shape. The resulting thin film solid state battery can be used to power electronics associated with a variety of devices such as medical devices.

Owner:GENESEE NORTHERN RES

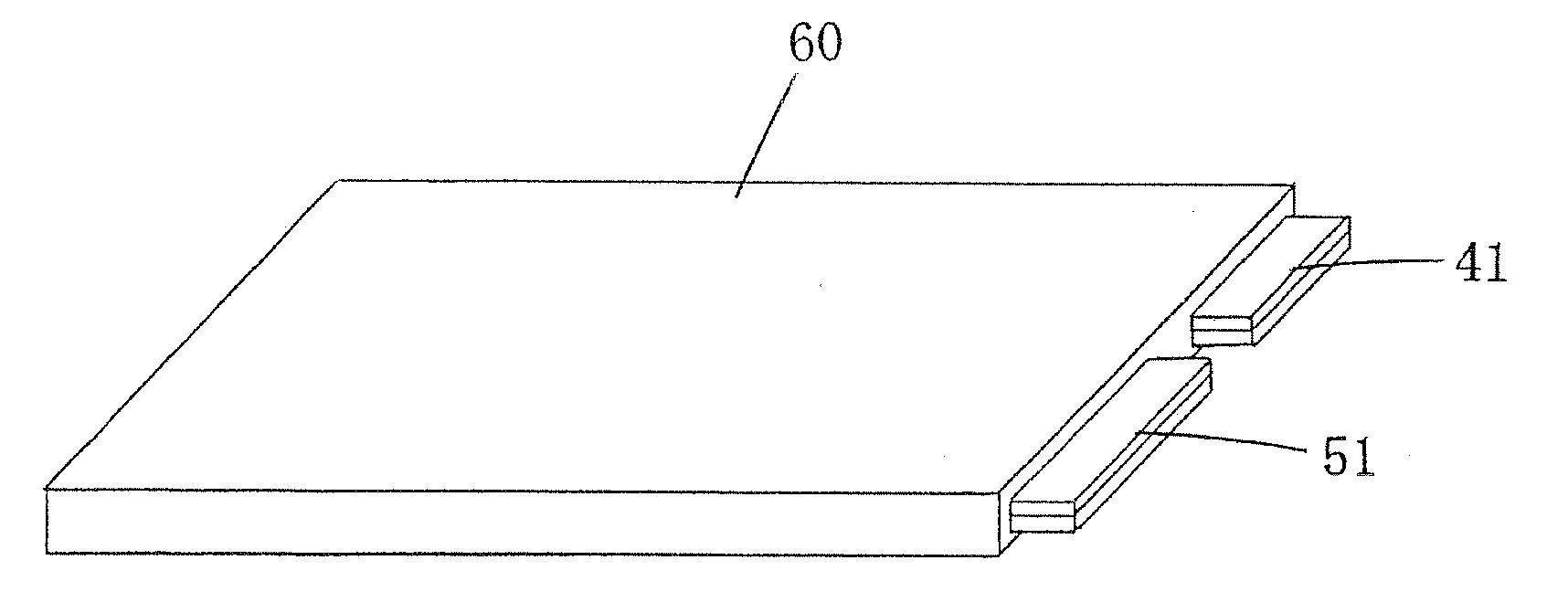

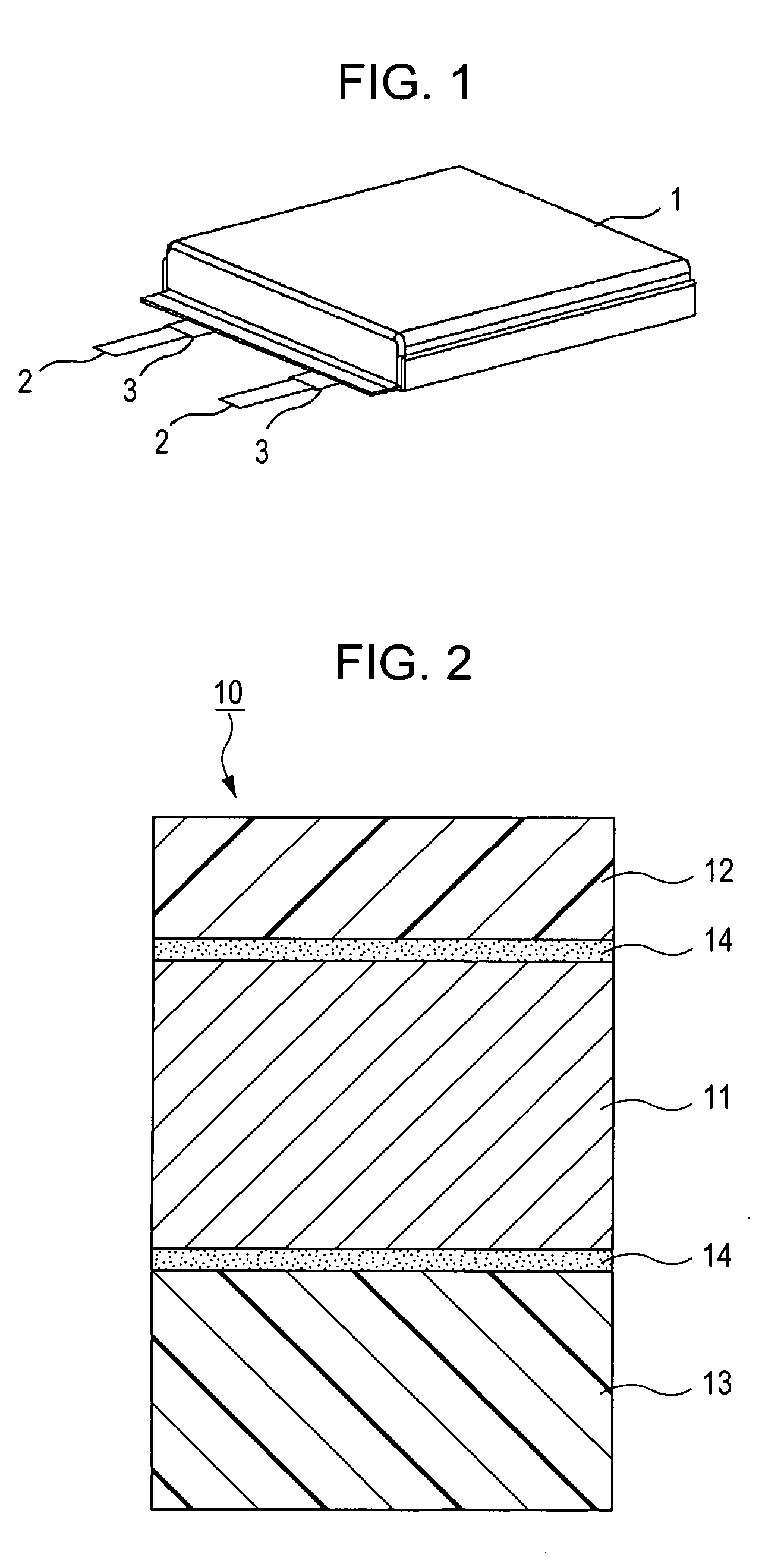

Flat secondary battery and method of manufacturing the same

InactiveUS20110129722A1Improve impact resistanceFinal product manufactureElectrode carriers/collectorsEngineeringElectrical and Electronics engineering

A flat secondary battery comprising: a positive electrode plate; a negative electrode plate opposed to the positive electrode plate; an electrolytic solution being present between the electrode plates; a separator interposed between the electrode plates; and a covering material for sealing the electrolytic solution, whereinthe positive electrode plate includes: a positive-electrode current-collector sheet whose peripheral area has a bonding area bonded to a peripheral area of the separator; and a positive-electrode active-material layer laminated on a non-bonding area of one surface or both surfaces of the positive-electrode current-collector sheet,the negative-electrode plate includes: a negative-electrode current-collector sheet whose peripheral area has a bonding area bonded to the peripheral area of the separator; and a negative-electrode active-material layer laminated on a non-bonding area of one surface or both surfaces of the negative-electrode current-collector sheet and having a sufficient size to cover the positive-electrode active-material layer, andthe peripheral areas of both surfaces of the separator are bonded to the bonding areas of the positive-electrode current-collector sheet and the negative-electrode current-collector sheet to maintain a state in which an area of the negative-electrode active-material layer entirely covers an area of the positive-electrode active-material layer so that a battery module is formed.

Owner:SHARP KK

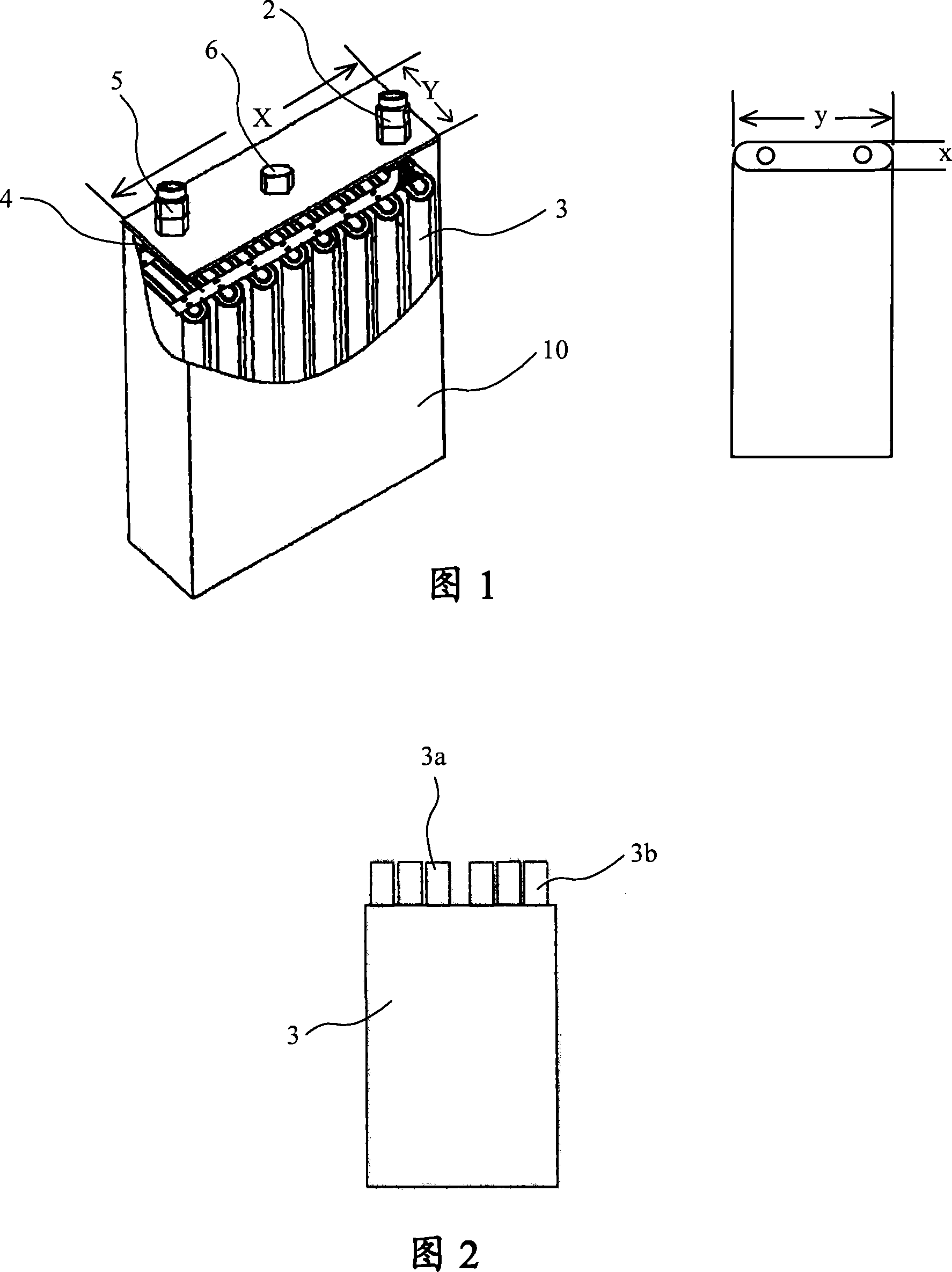

Highly secure lithium ion dynamic battery and its assembly method

InactiveCN101106185AAvoid the danger of exothermic reactionsReduced risk of exothermic reactionsPrimary cell to battery groupingCell electrodesElectricityElectrical battery

The invention provides a method for assembling power lithium-ion battery, including the sequence-free steps as following: a) unit batteries are provided according to the needed number; b) the unit batteries are placed in a housing; c) the electrical connection is accomplished between the unit batteries; d) flame retardant or heat transfer medium is filled into the housing; and e) the unit batteries are electrically connected with the housing and the encapsulation is completed. The invention also relates to a power lithium-ion battery made by using the method. The power lithium-ion battery assembled by using the method in the invention has an enhanced security.

Owner:北京中润恒动电池有限公司

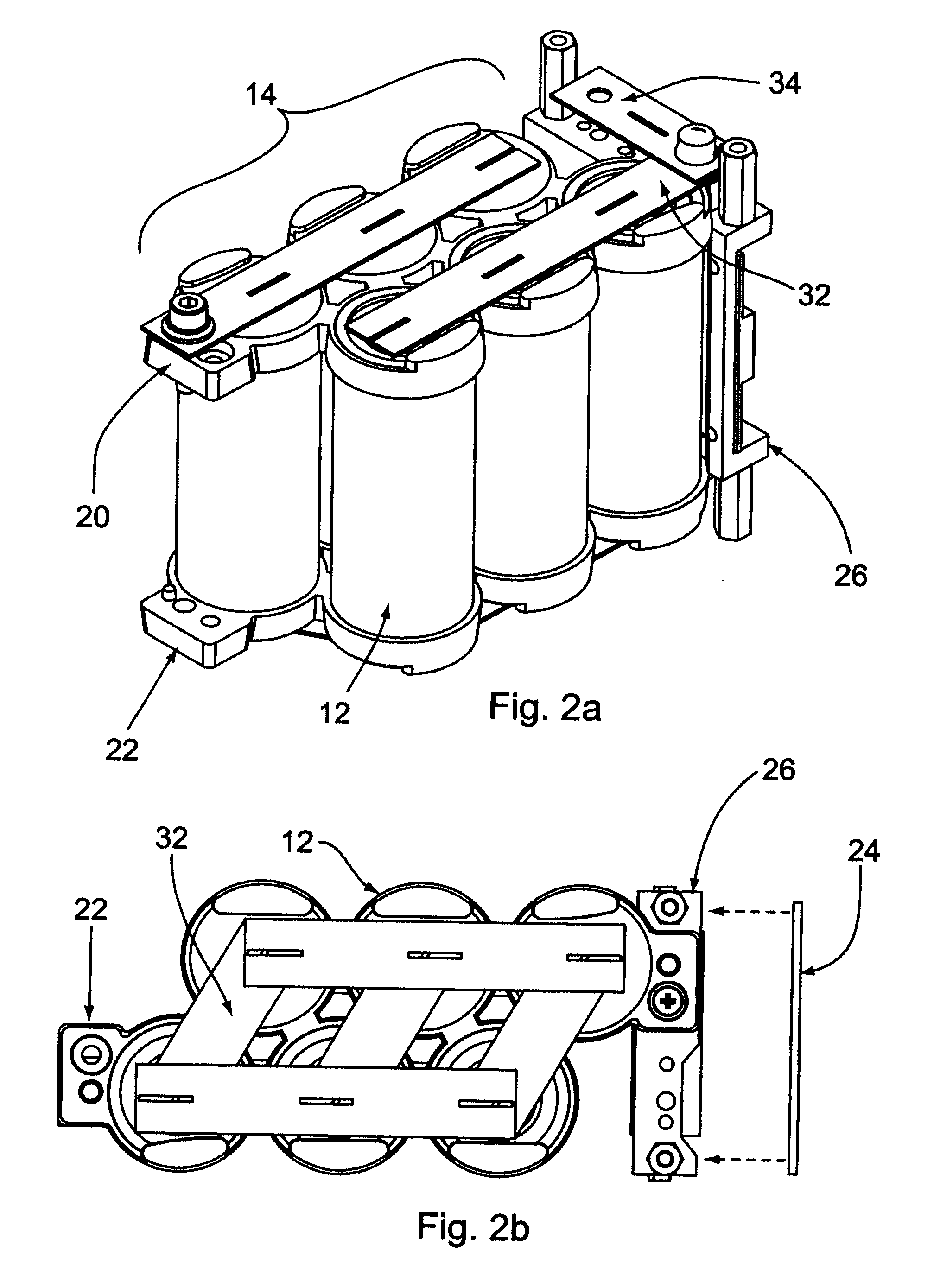

Cell

ActiveUS20060127760A1Increase battery capacityImprove performanceFinal product manufacturePrimary cell electrodesEngineeringElectrode

A highly safety cell is provided in which short-circuiting is unlikely to occur. In order to prevent short-circuiting, for example, burrs generated when a laminate film used as an exterior packaging material is cut are prevented from penetrating an interior resin layer of the laminate film. When an electrode terminal extension side of the laminate film is thermal welded, heating and compression are performed by a heater head on a part of the laminate film apart from the edge portion thereof so that the thickness of the above edge portion is larger than that of a thermal welded portion. In addition, thermal welding is performed so that the thickness of a thermal welded portion including an electrode terminal is larger than that of a thermal welded portion including no electrode terminal, and as a result, short-circuiting can be more effectively prevented.

Owner:MURATA MFG CO LTD

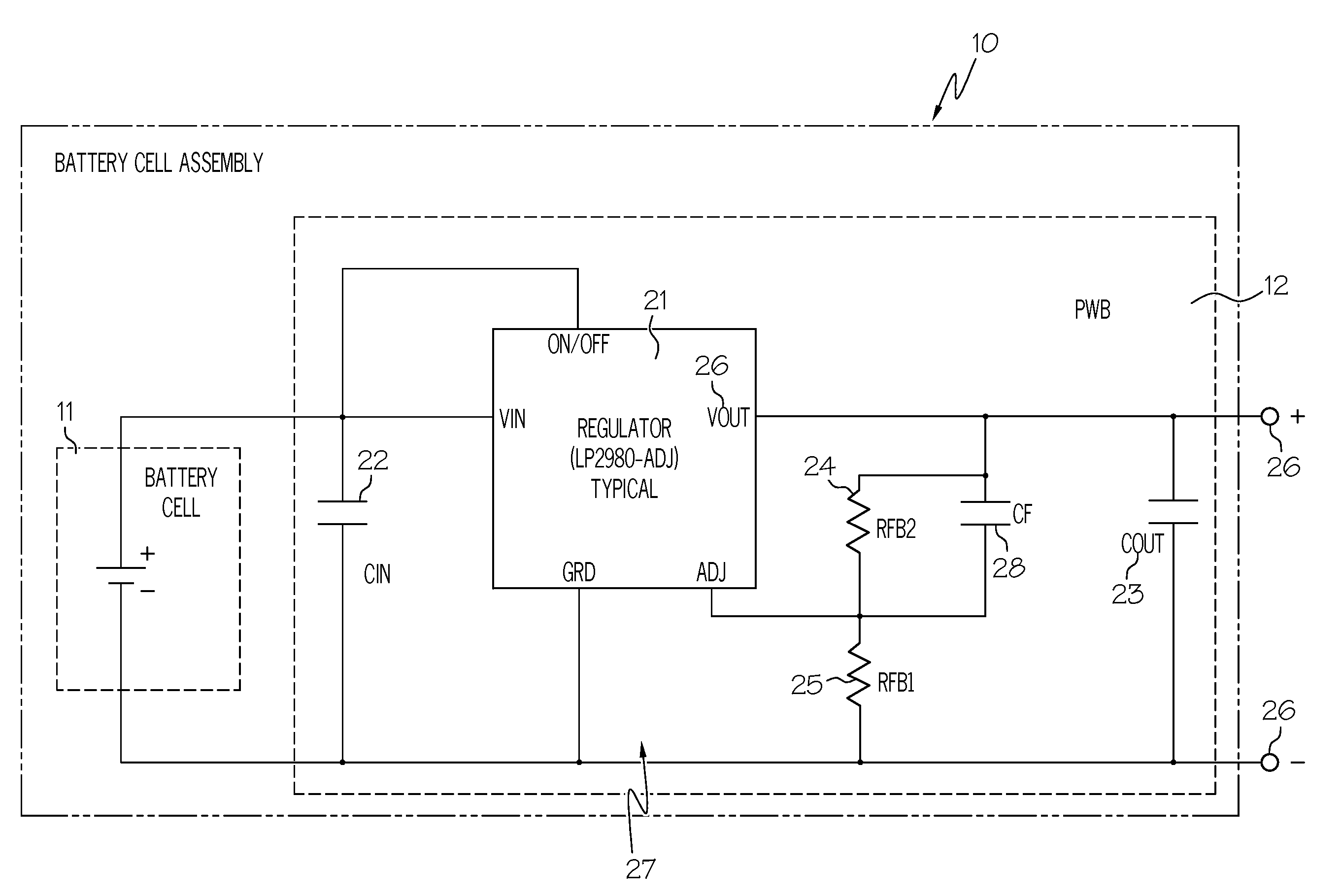

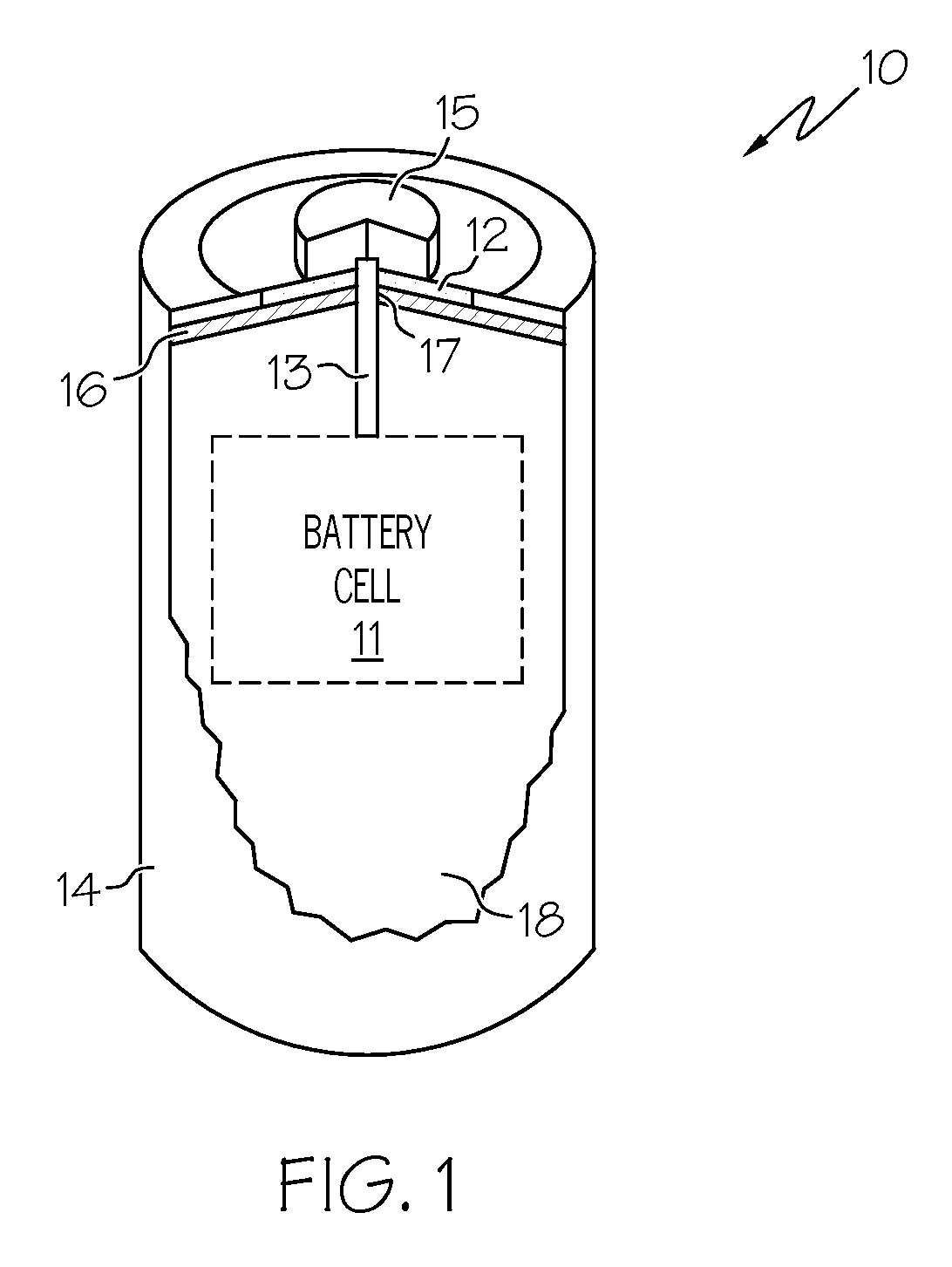

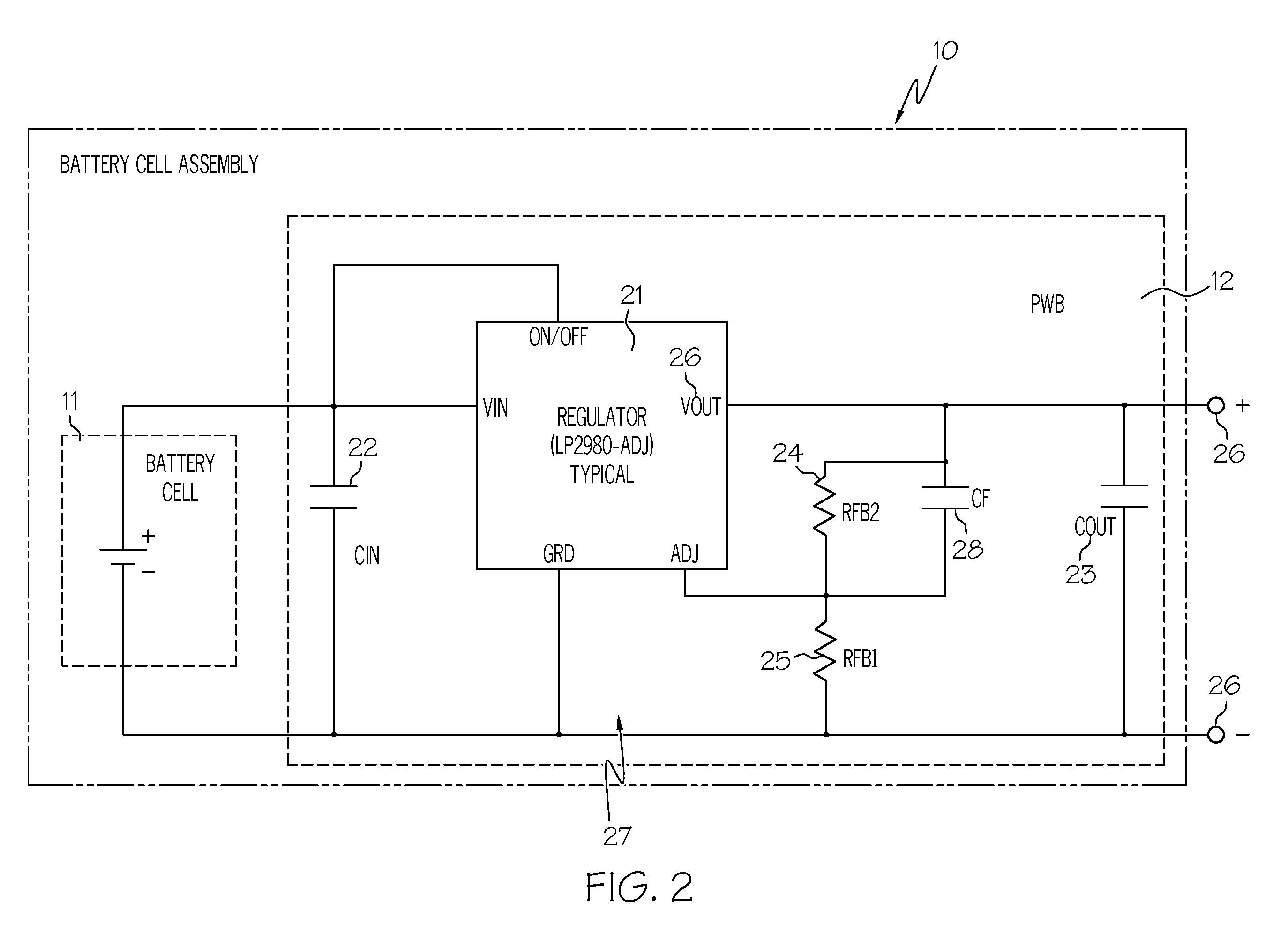

Primary battery with internal voltage regulator

A battery cell assembly includes a standard size primary high energy density battery cell assembly and a voltage regulator integrated within the battery cell assembly. A method for providing a standard size primary high energy density battery cell assembly includes integrating a voltage regulator circuit into a standard size primary high energy density battery assembly and regulating an output voltage of the high energy density battery cell assembly to match an output voltage of a standard primary battery. Embodiments of the present invention may integrate a voltage regulator into a commercially available primary high energy density battery cell. The voltage regulator as in one embodiment of the present invention may be used to downscale the output voltage of the high energy density battery cell. The high density battery assembly as in embodiments of the present invention may be used in existing equipment currently powered by standard primary batteries.

Owner:HONEYWELL INT INC

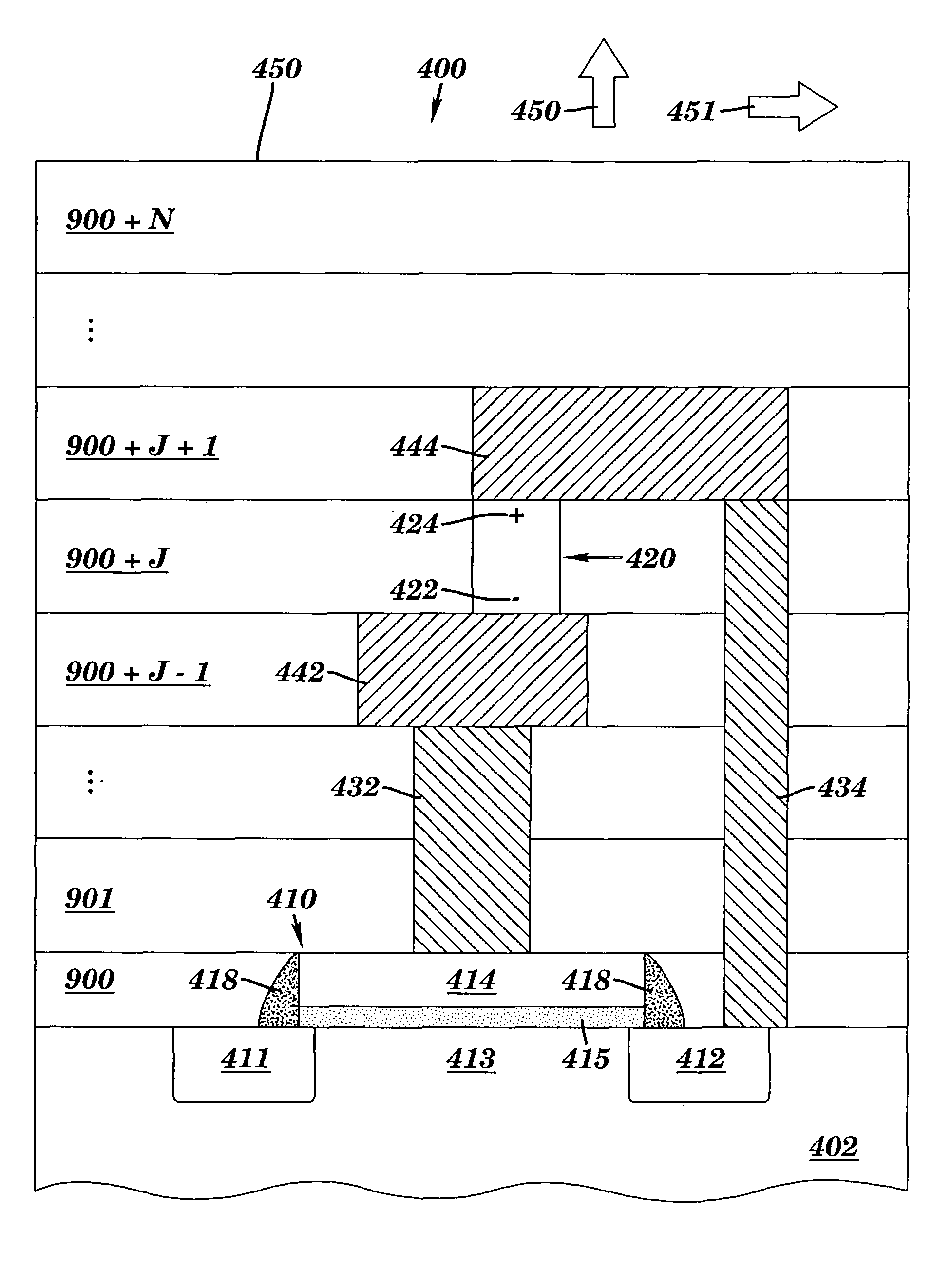

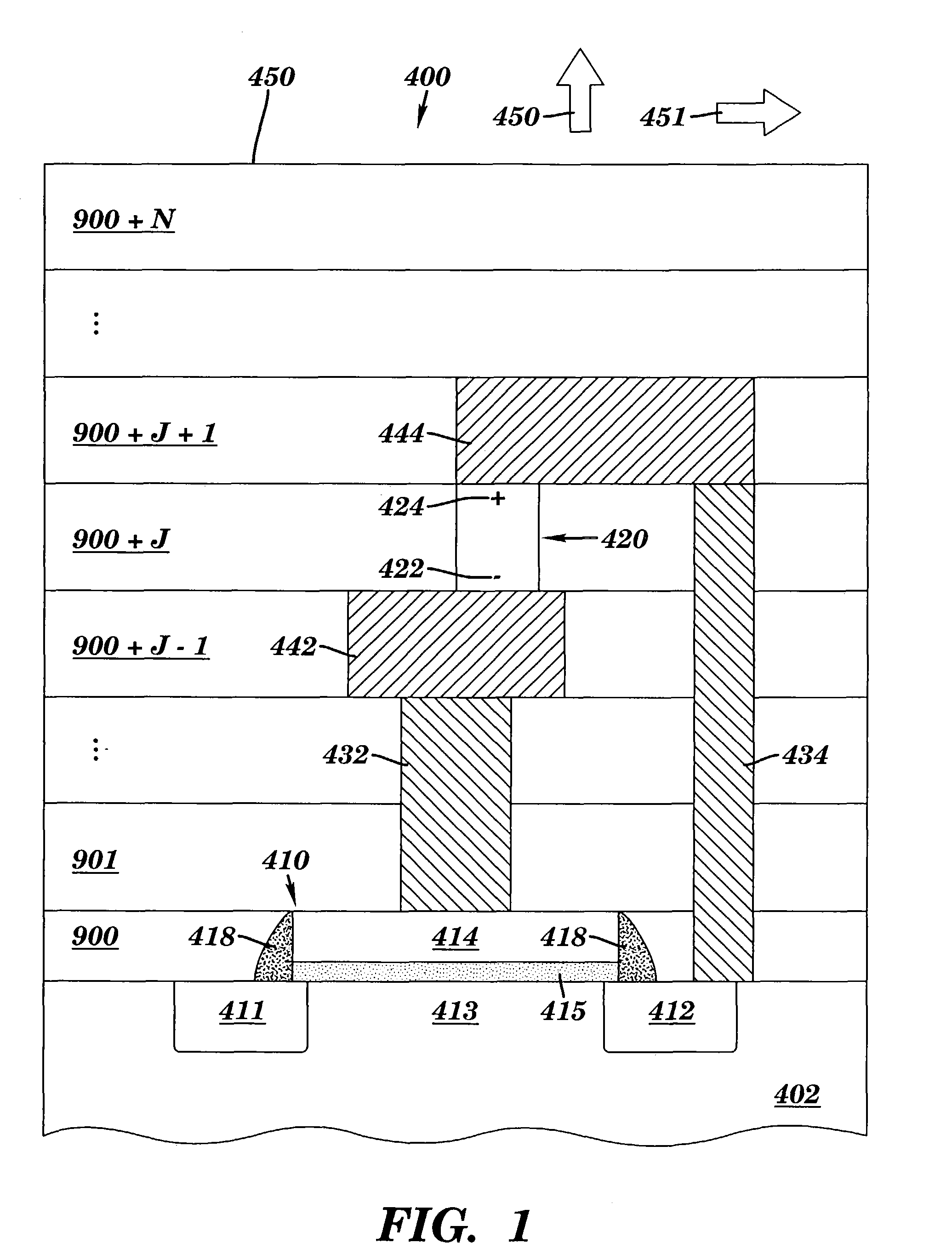

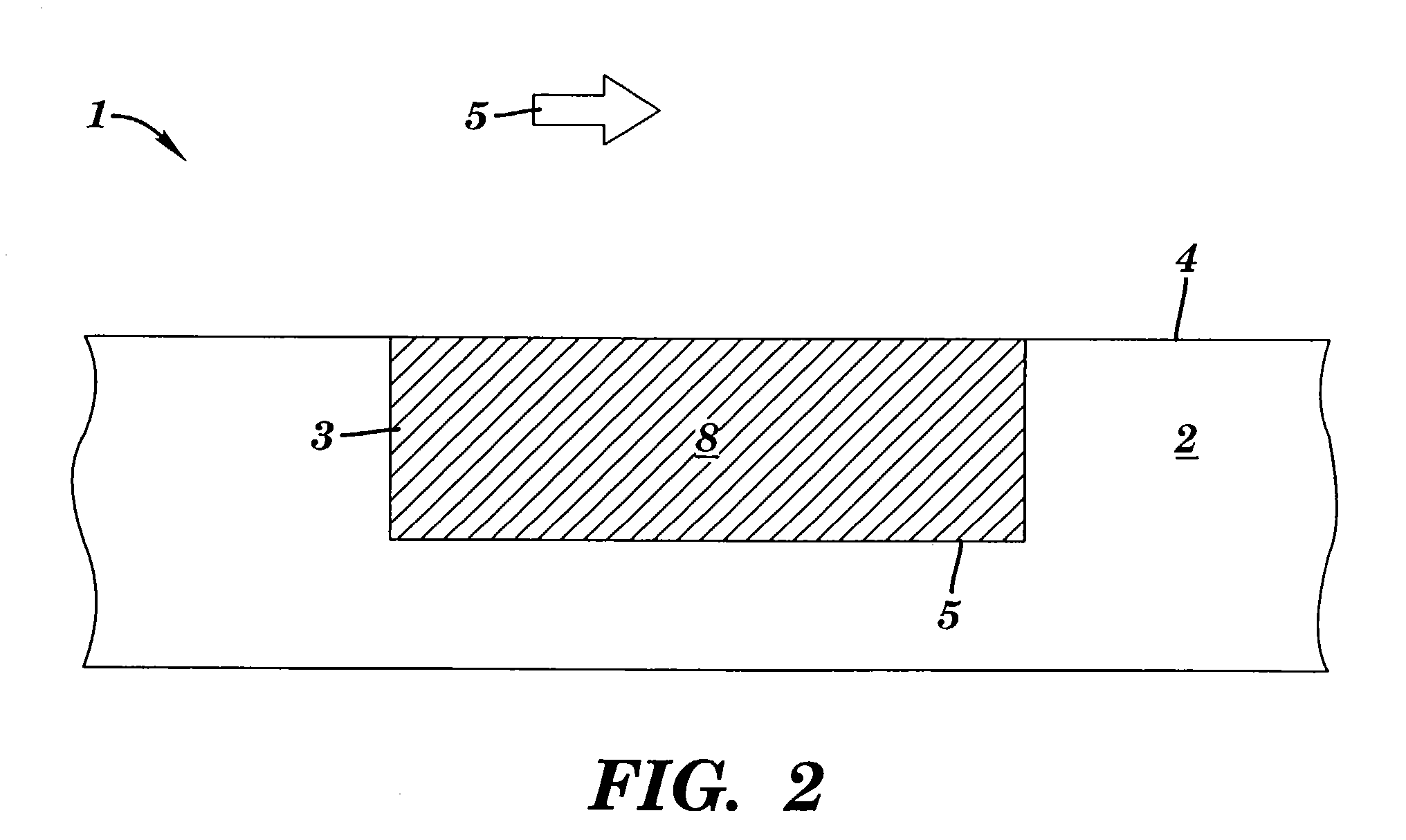

Apparatus and method for forming a battery in an integrated circuit

InactiveUS7045372B2More wiring levelSmall sizePrimary cell to battery groupingCell electrodesFront end of lineEngineering

A method and structure that provides a battery within an integrated circuit for providing voltage to low-current electronic devices that exist within the integrated circuit. The method includes Front-End-Of-Line (FEOL) processing for generating a layer of electronic devices on a semiconductor wafer, followed by Back-End-Of-Line (BEOL) integration for wires connecting the electronic devices together to form completed electrical circuits of the integrated circuit. The BEOL integration includes forming a multilayered structure of wiring levels on the layer of electronic devices. Each wiring level includes conductive metallization (e.g., metal-plated vias, conductive wiring lines, etc.) embedded in insulative material. The battery is formed during BEOL integration within one or more wiring levels, and the conductive metallization conductively couples positive and negative terminals of the battery to the electronic devices. The battery may have several different topologies relative to the structural and geometrical relationships among the battery electrodes and electrolyte. Multiple batteries may be formed within one or more wiring levels, and may be conductively coupled to the electronic devices. The multiple batteries may be connected in series or in parallel.

Owner:GLOBALFOUNDRIES US INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com