Patents

Literature

378results about How to "Improve leak-proof effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

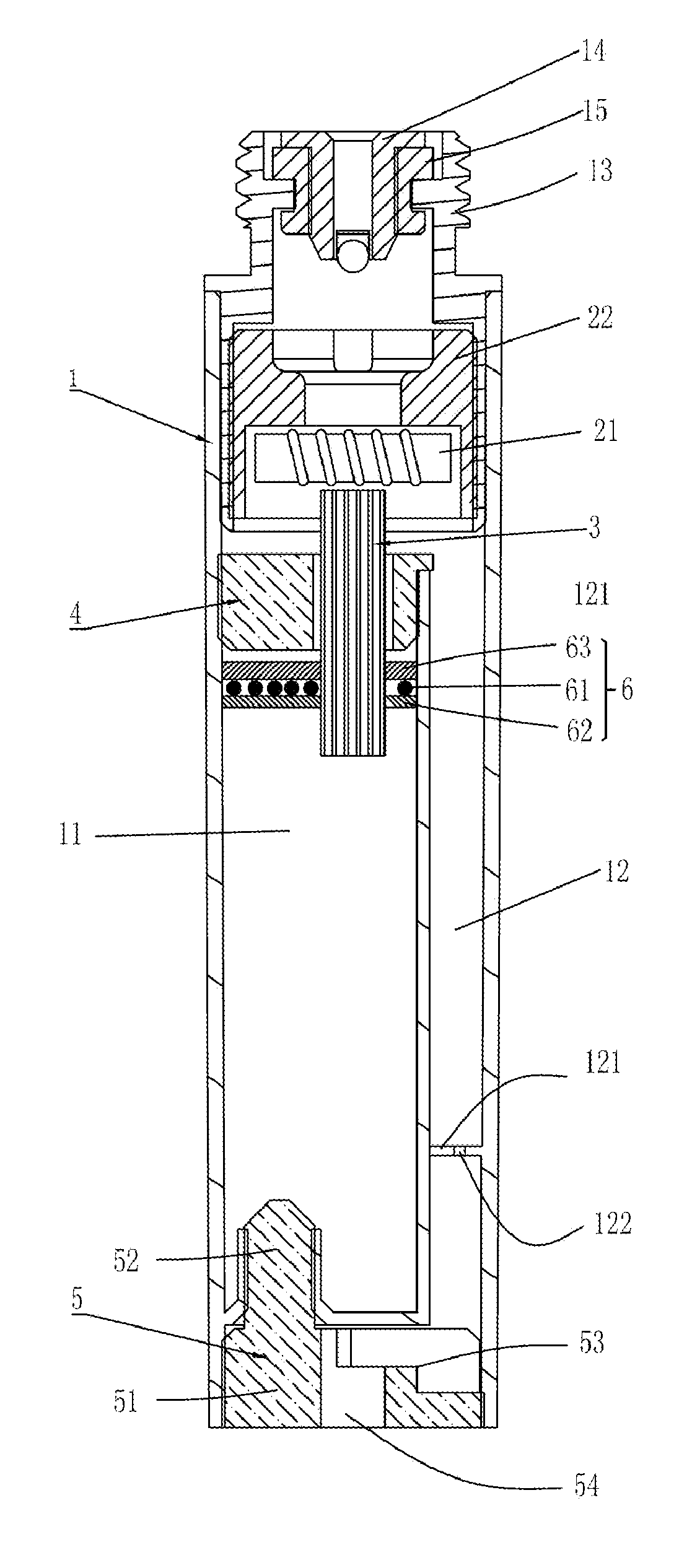

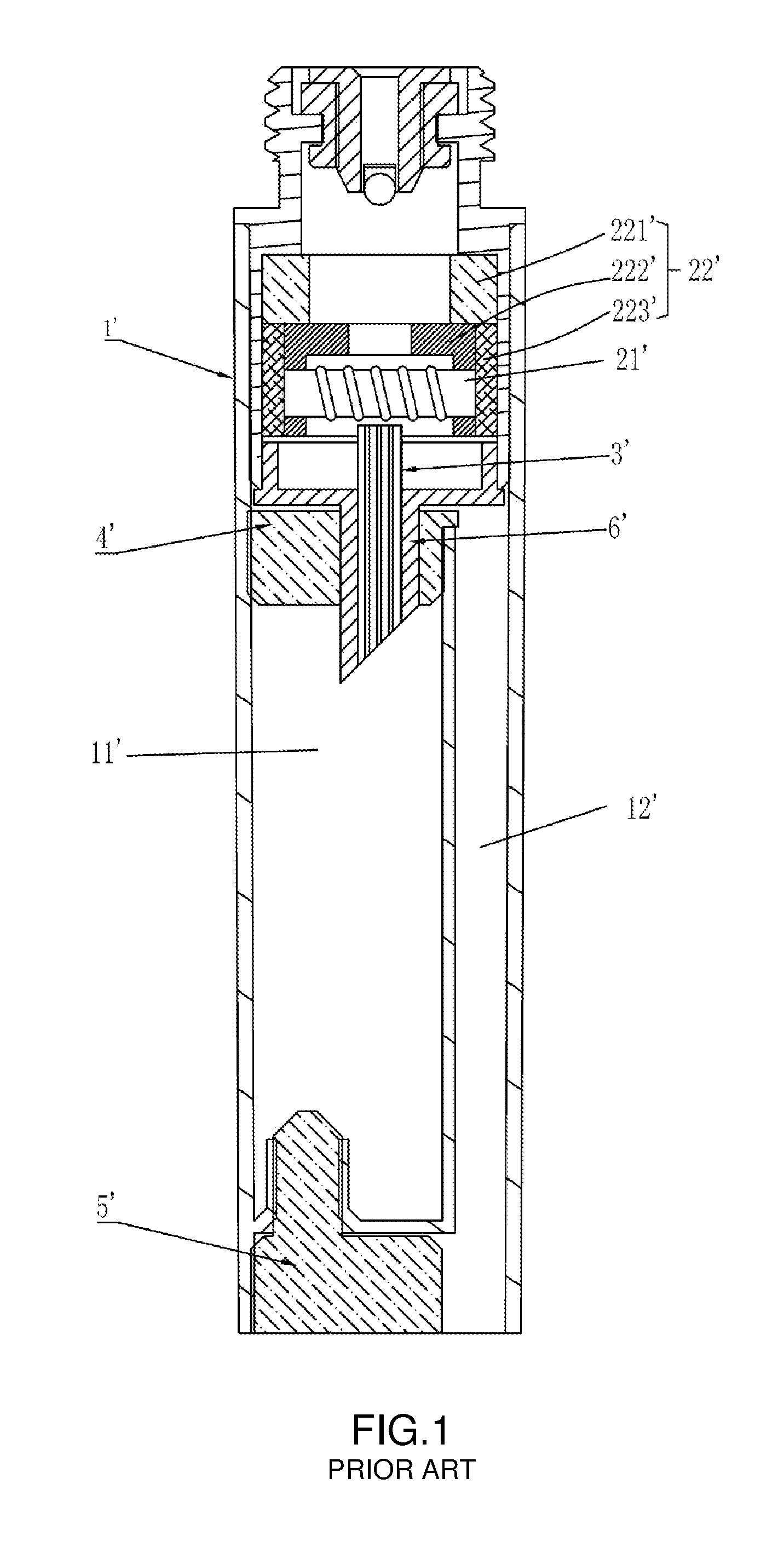

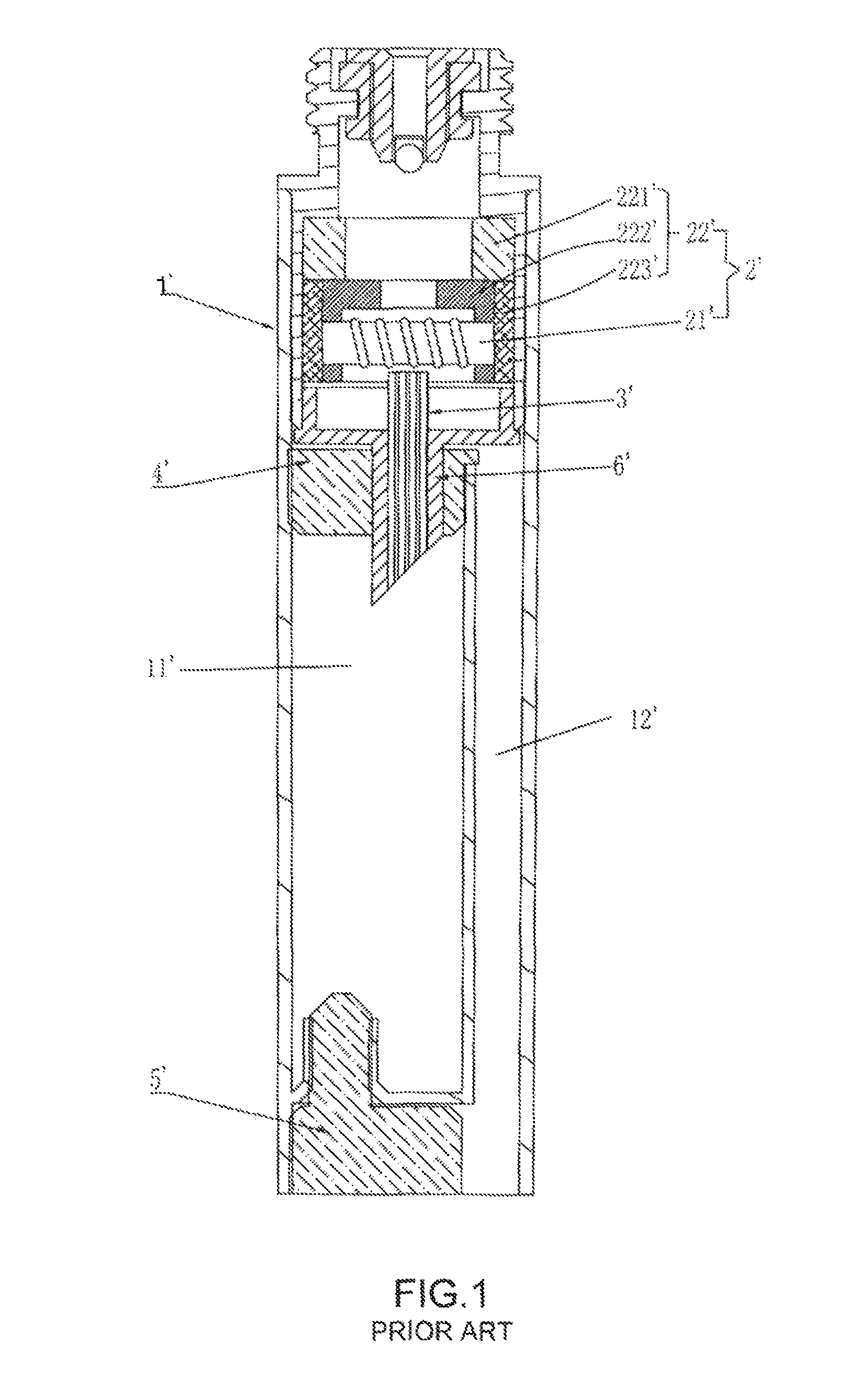

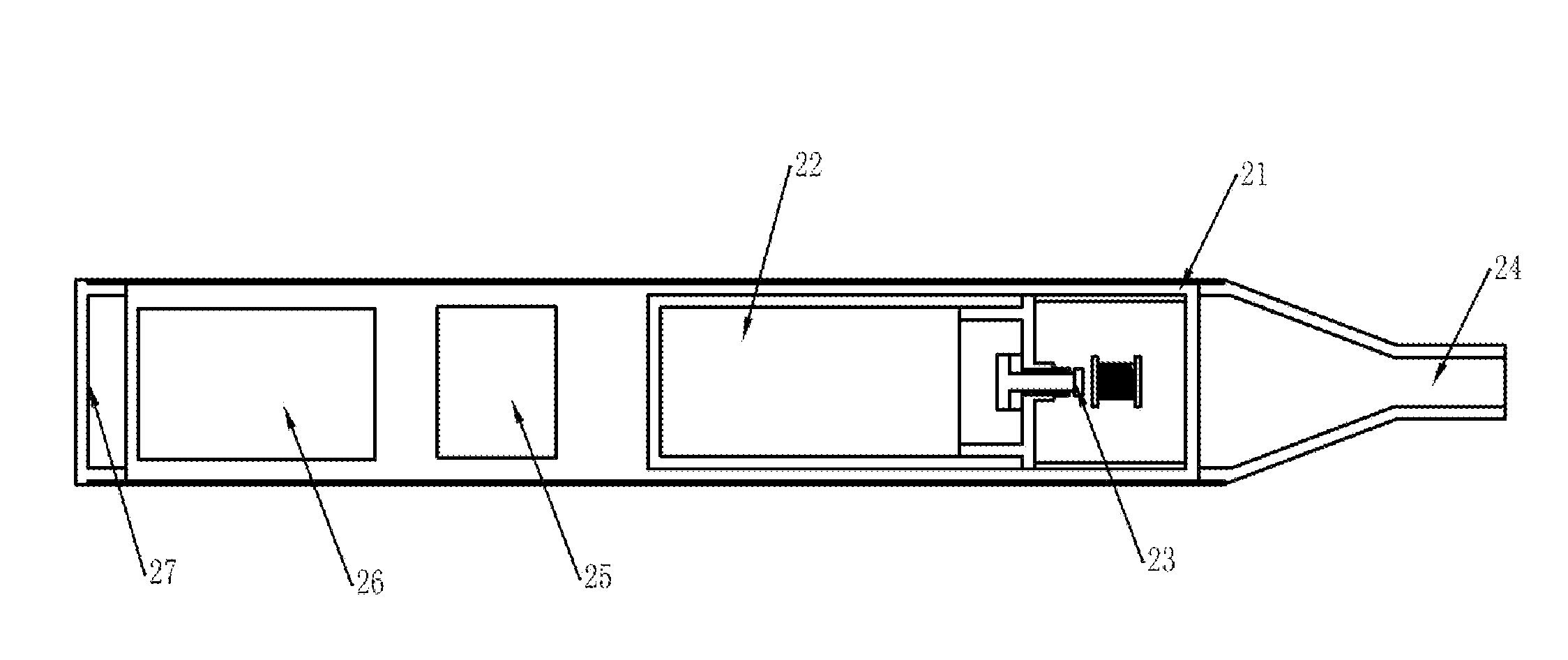

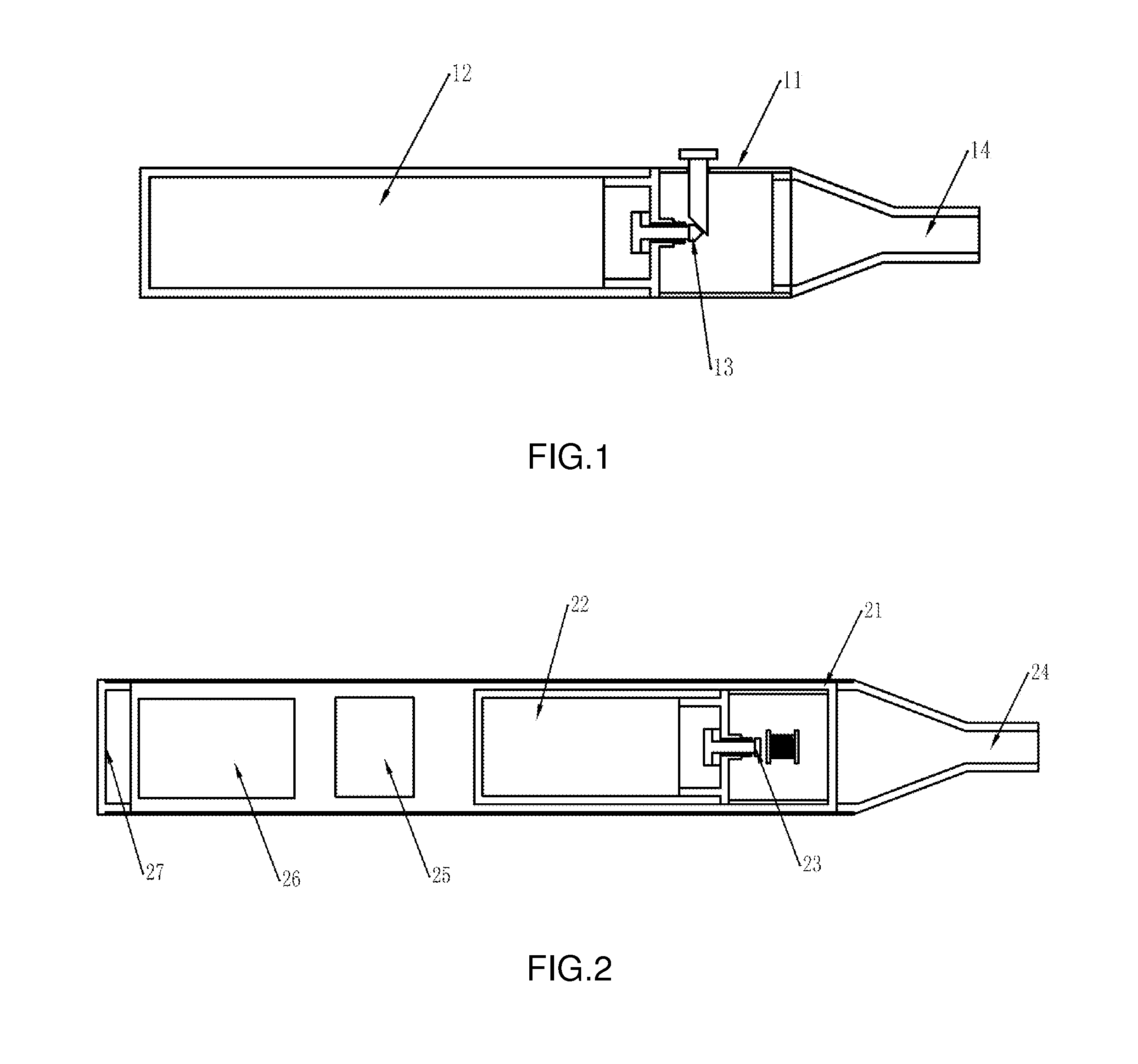

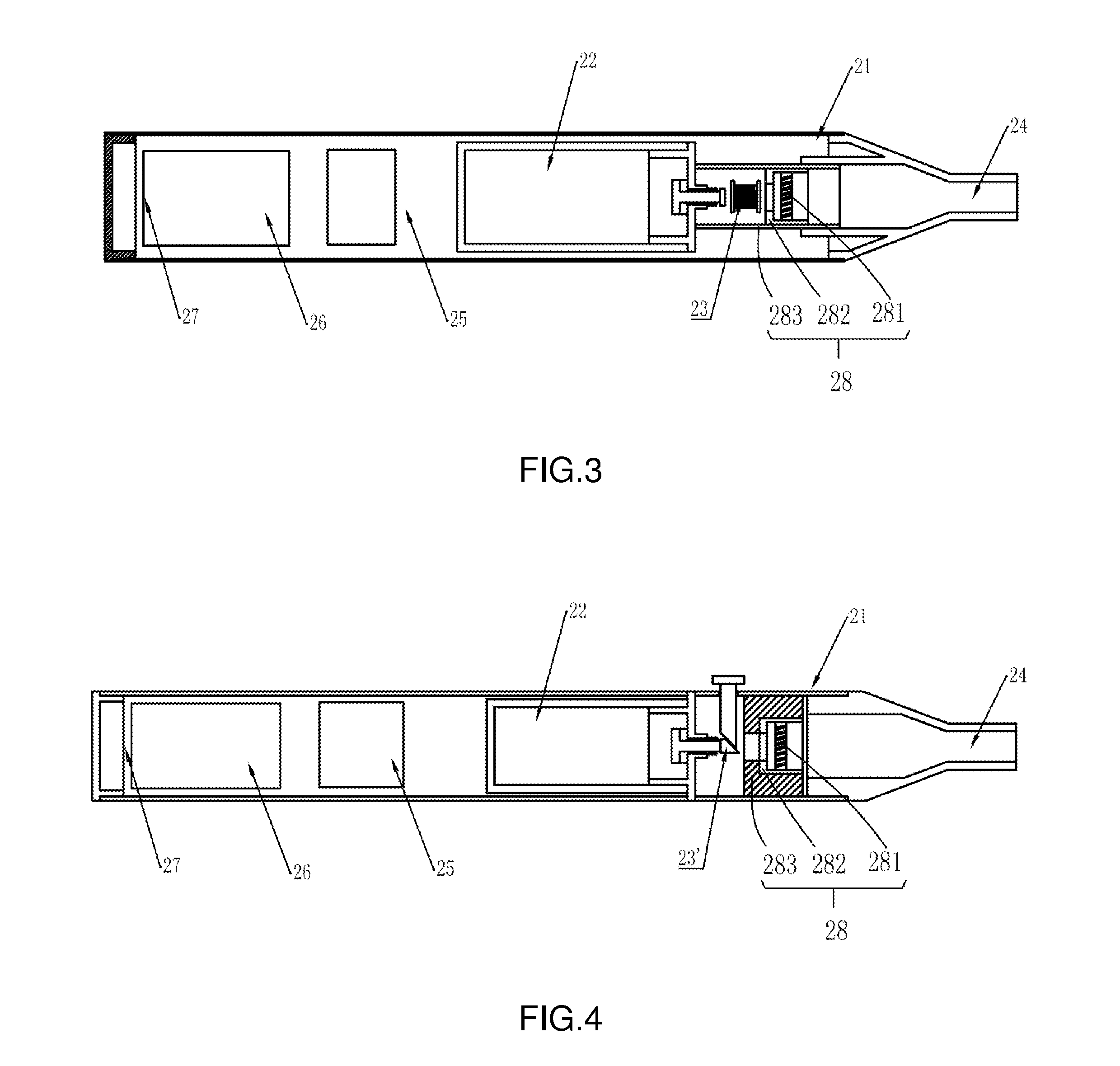

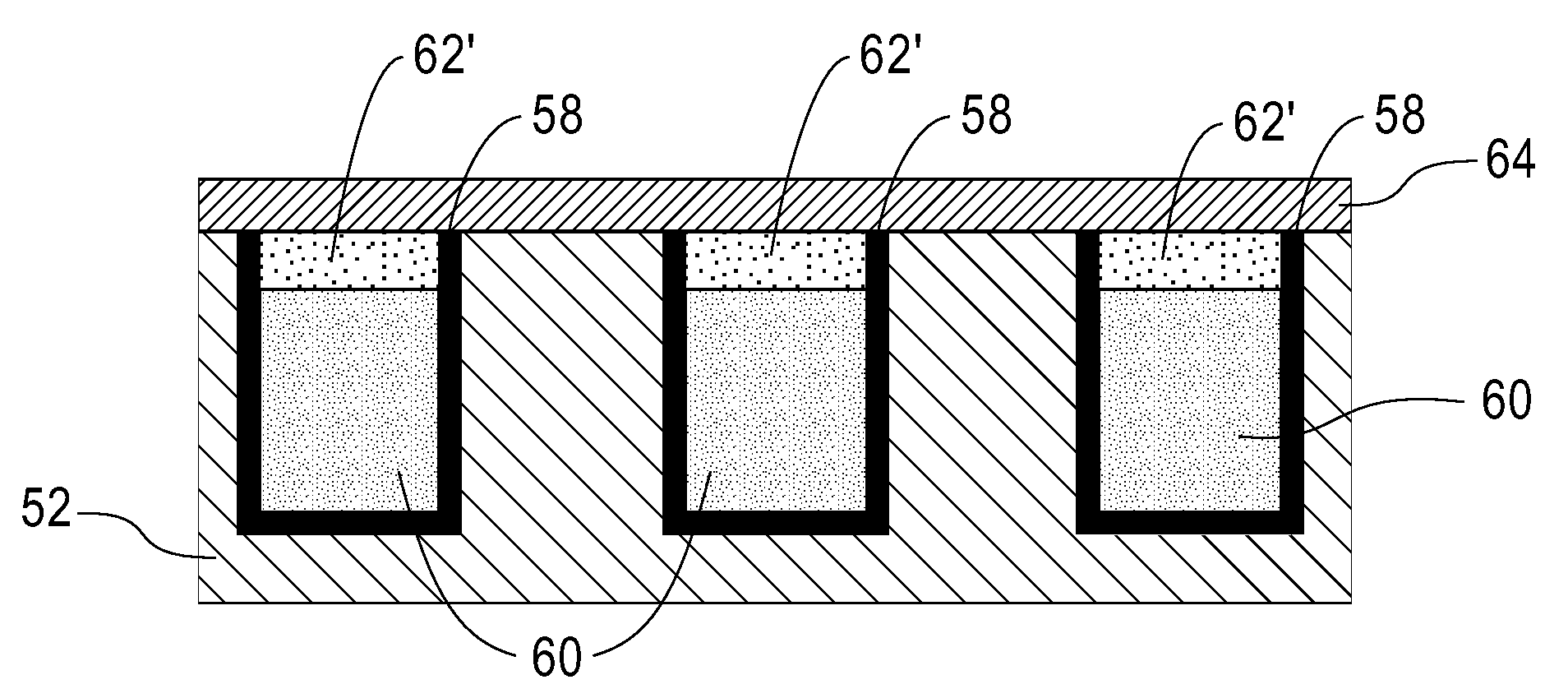

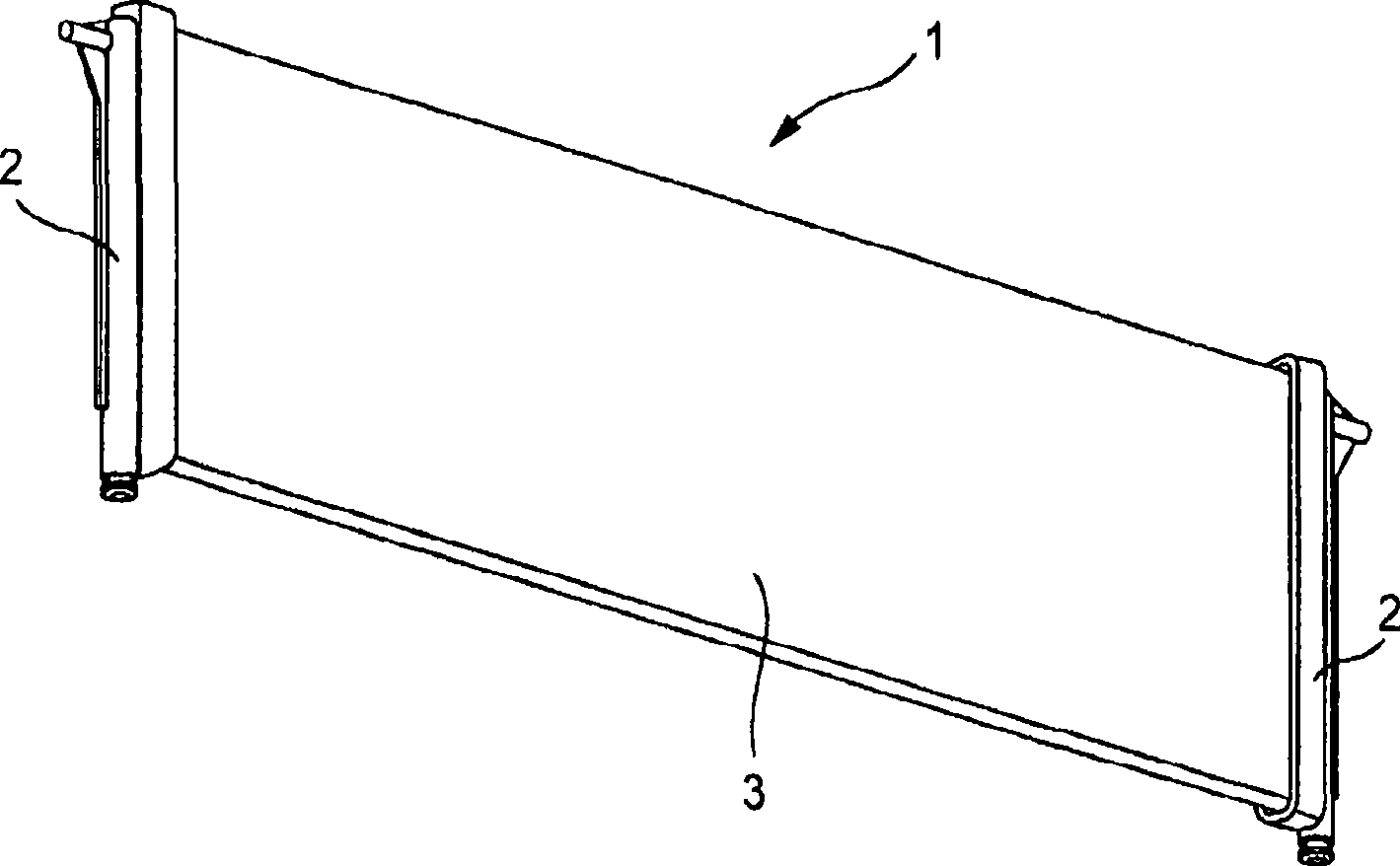

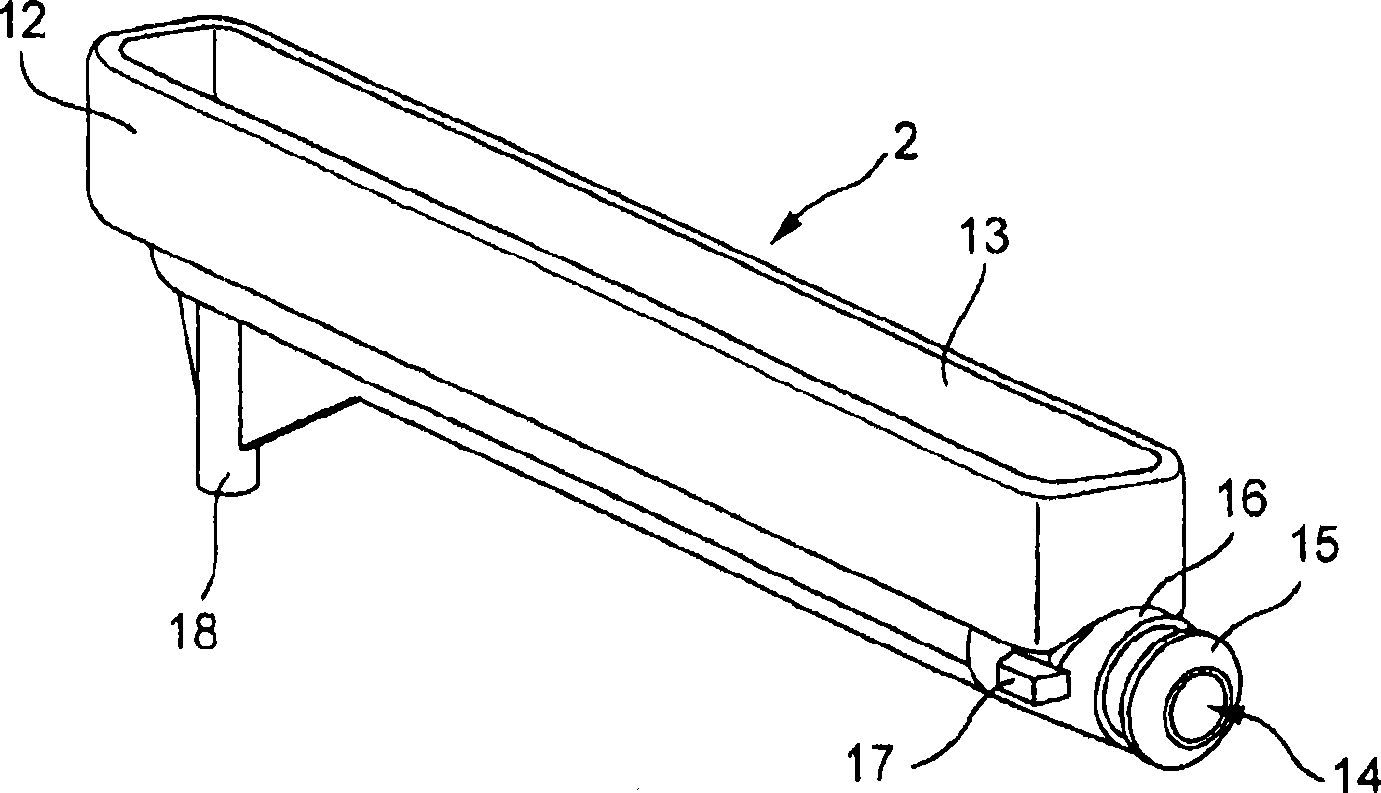

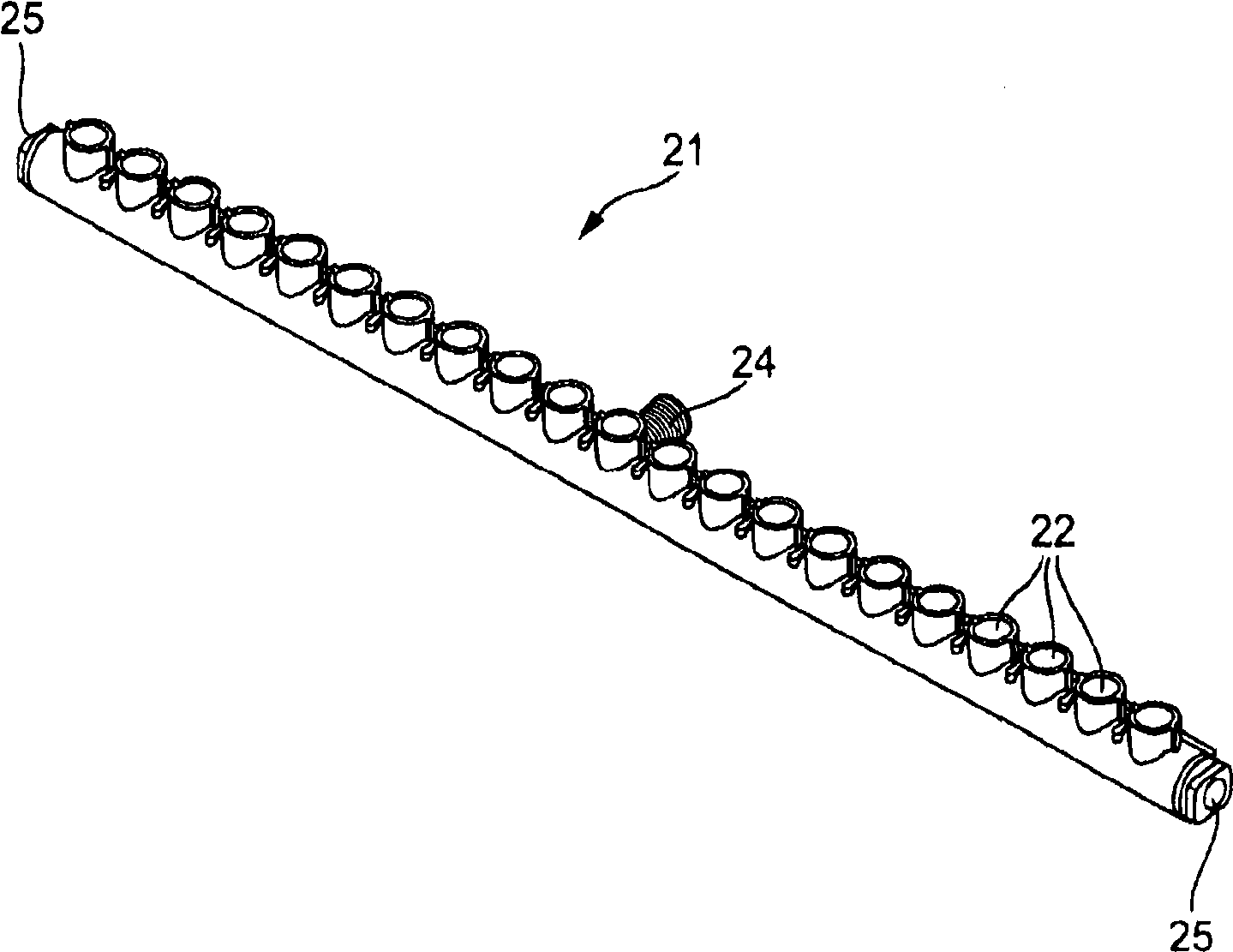

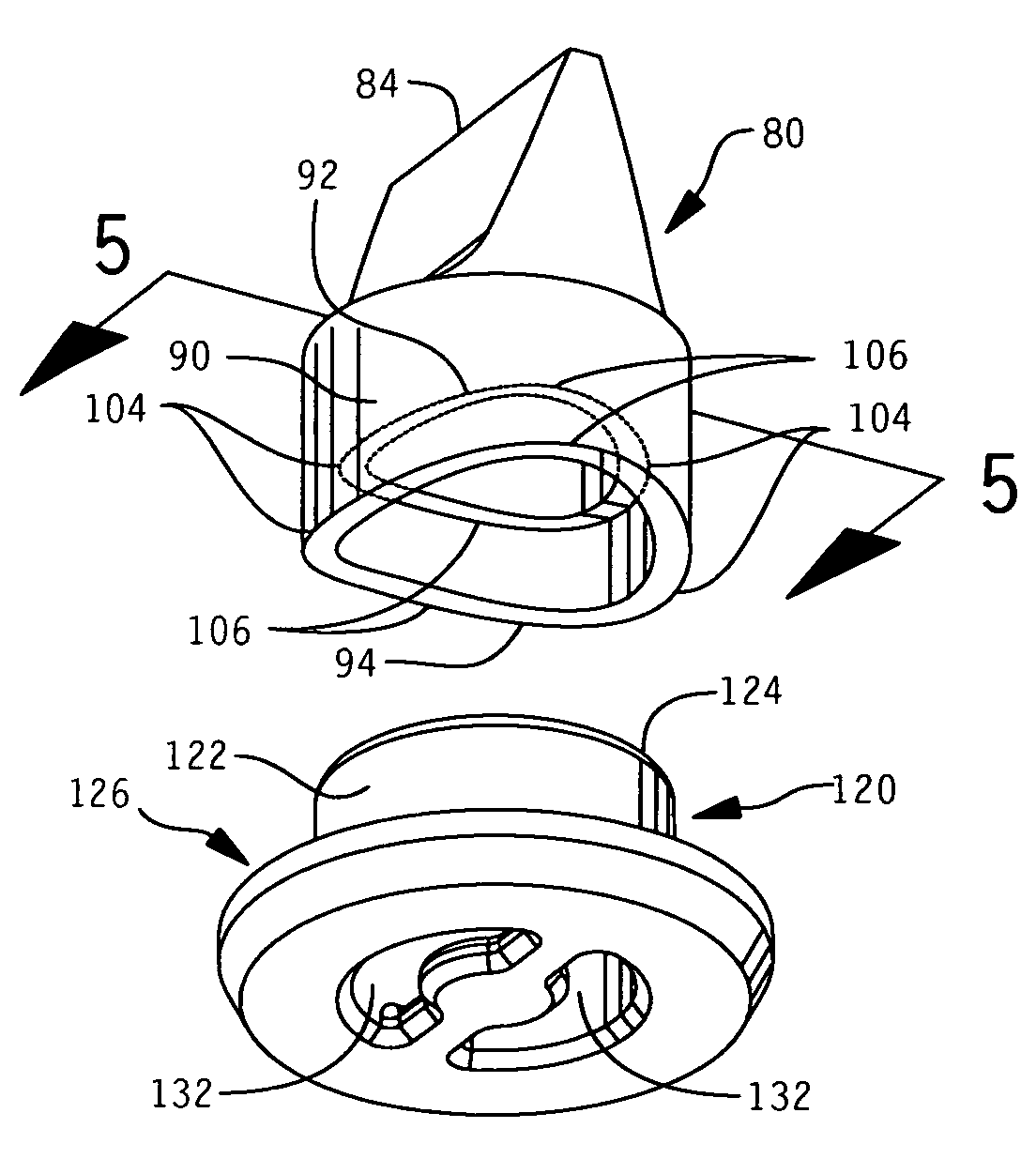

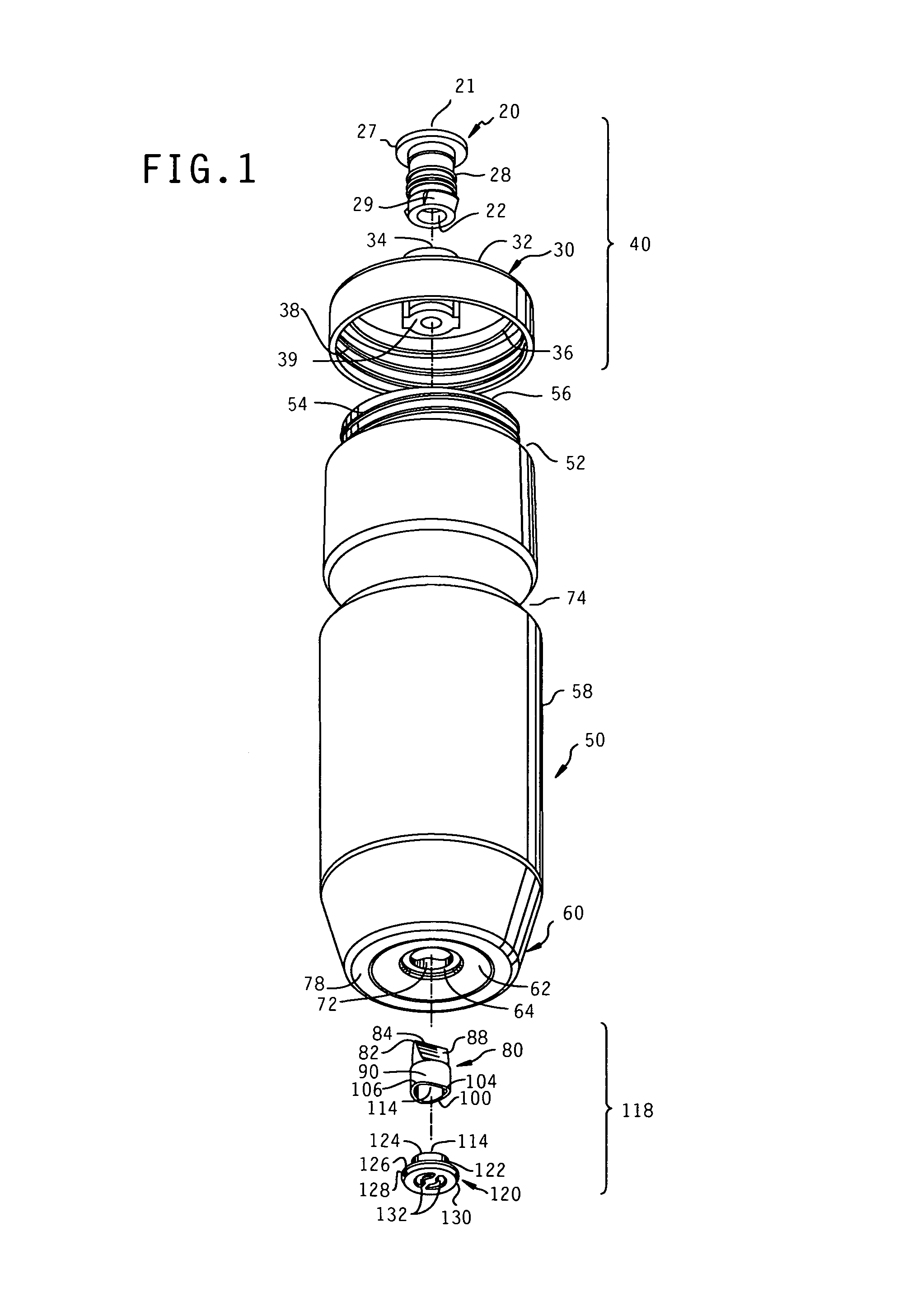

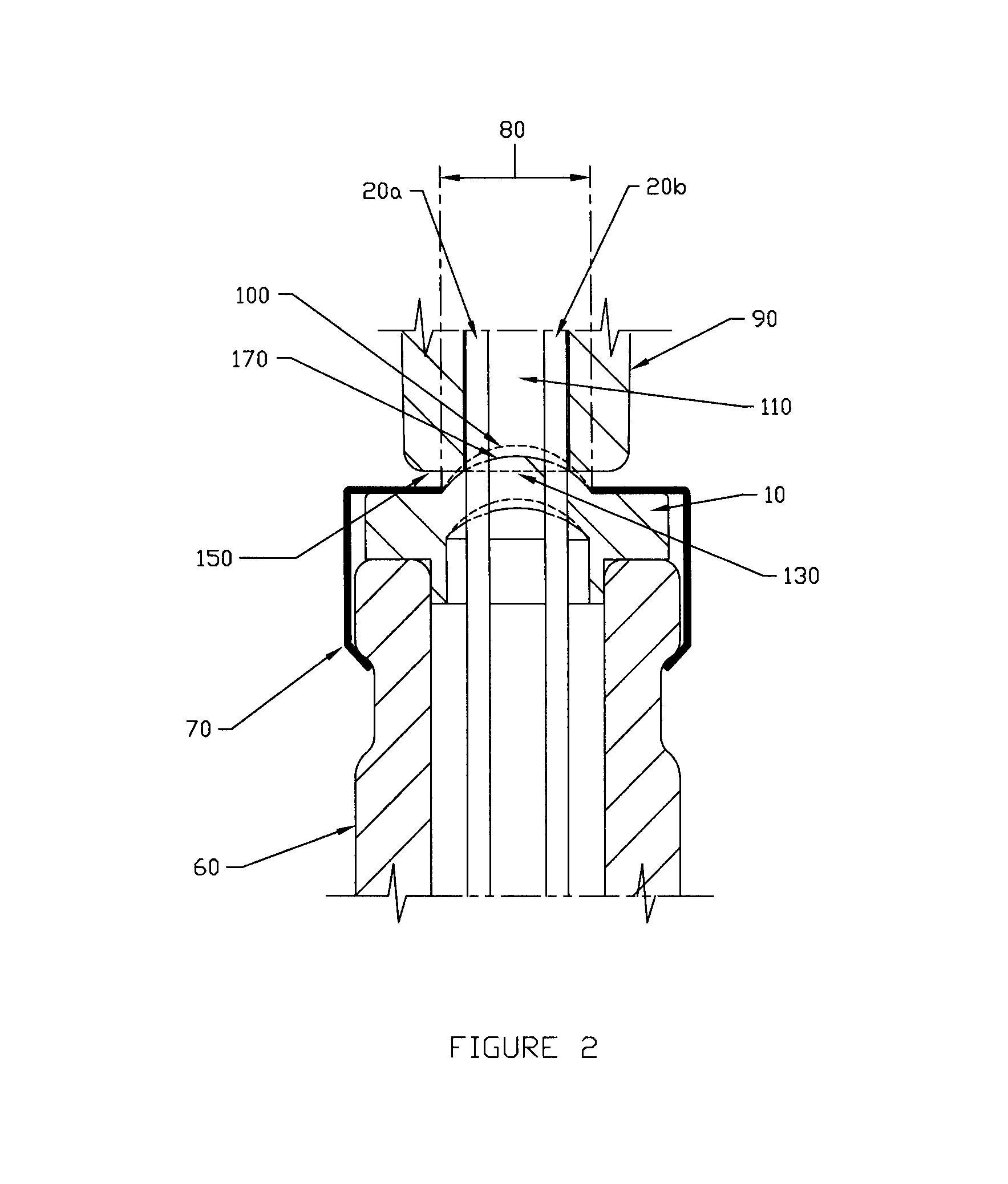

Mouthpiece device of electronic cigarette

InactiveUS20130160765A1Improve leak-proof effectEasy to manufactureTobacco treatmentTobacco smoke filtersElectronic cigaretteEngineering

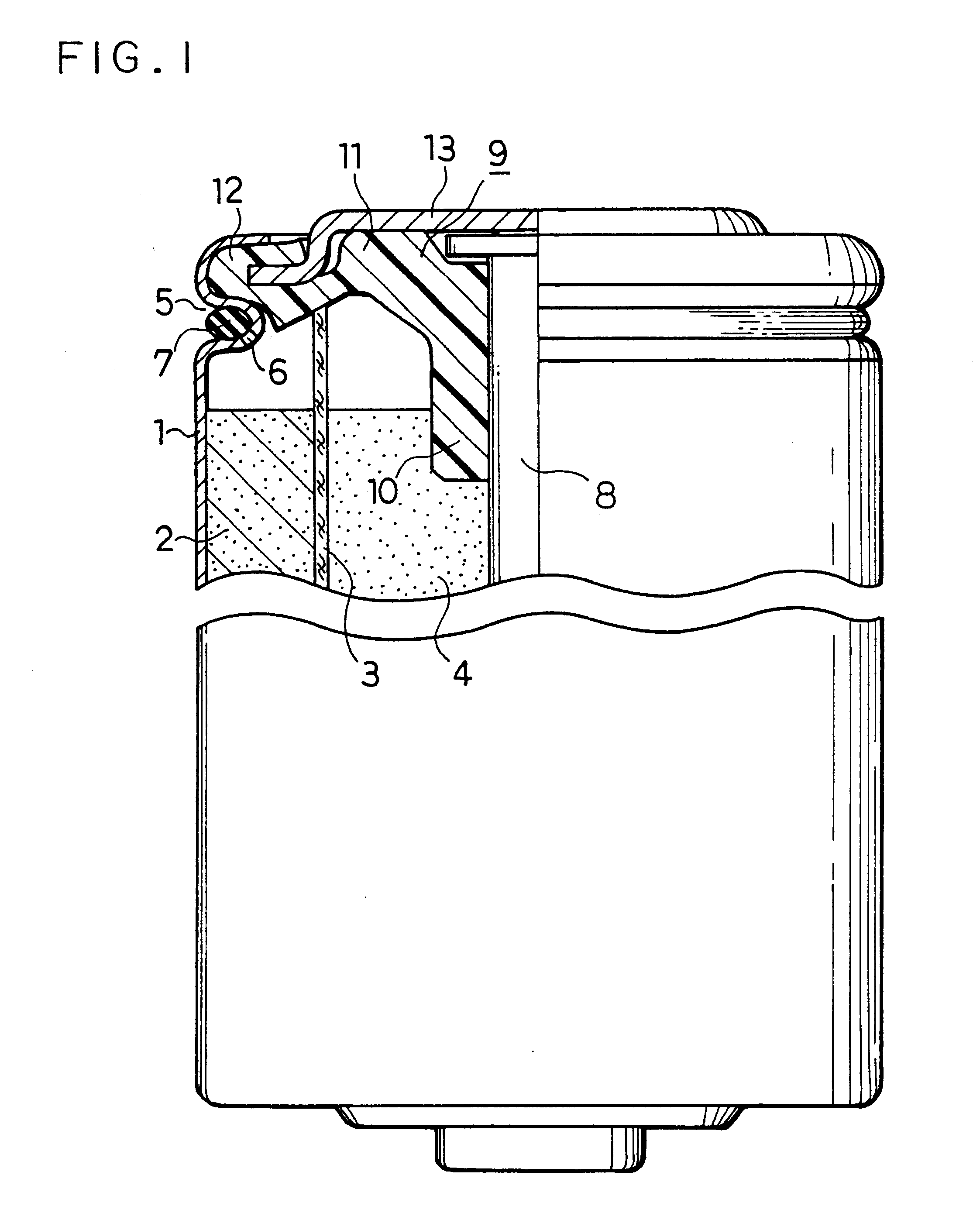

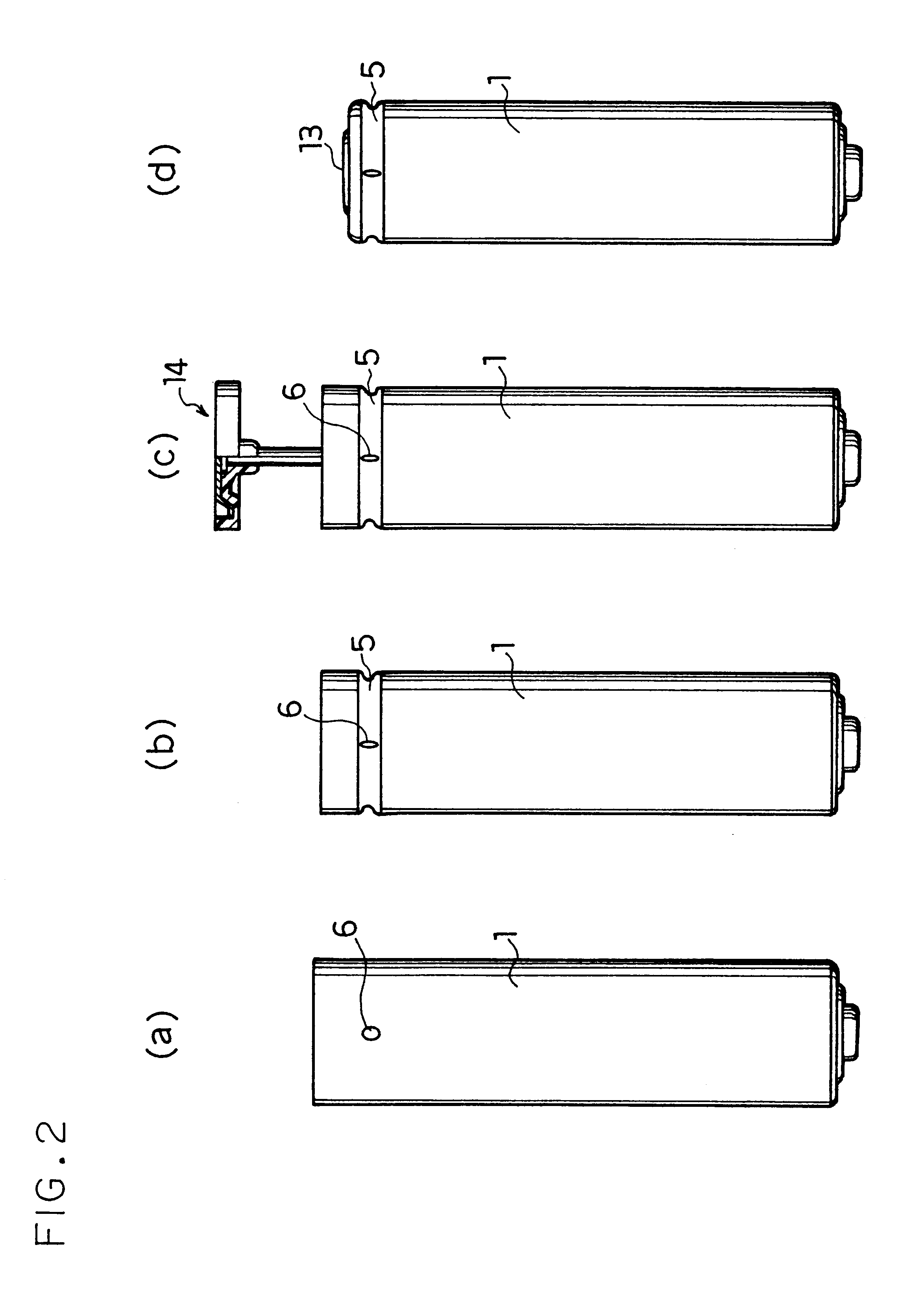

The present invention relates to a mouthpiece device of electronic cigarette, includes an atomizing device for vaporizing tobacco substance into aerosol, a reservoir for storing tobacco substance and a guiding tube for guiding tobacco substance from the reservoir to the atomizing device, which are set in an shell. The guiding tube has one end inserted in the reservoir and the other end communicated with atomizing device. The mouthpiece device further includes a preheat device for heat solid tobacco substance in the reservoir to generate liquid. The preheat device is set in the end of the reservoir near the guiding tube, and seals solid tobacco substance in the reservoir. The present invention solves existing problems such as fluid leakage, complicate manufacturing, high cost, bad heat insulation and filtering aerosol; and obtains perfect leakage proof, simple manufacturing, lower cost, good heat insulation and well filtering aerosol.

Owner:HUIZHOU KIMREE TECH

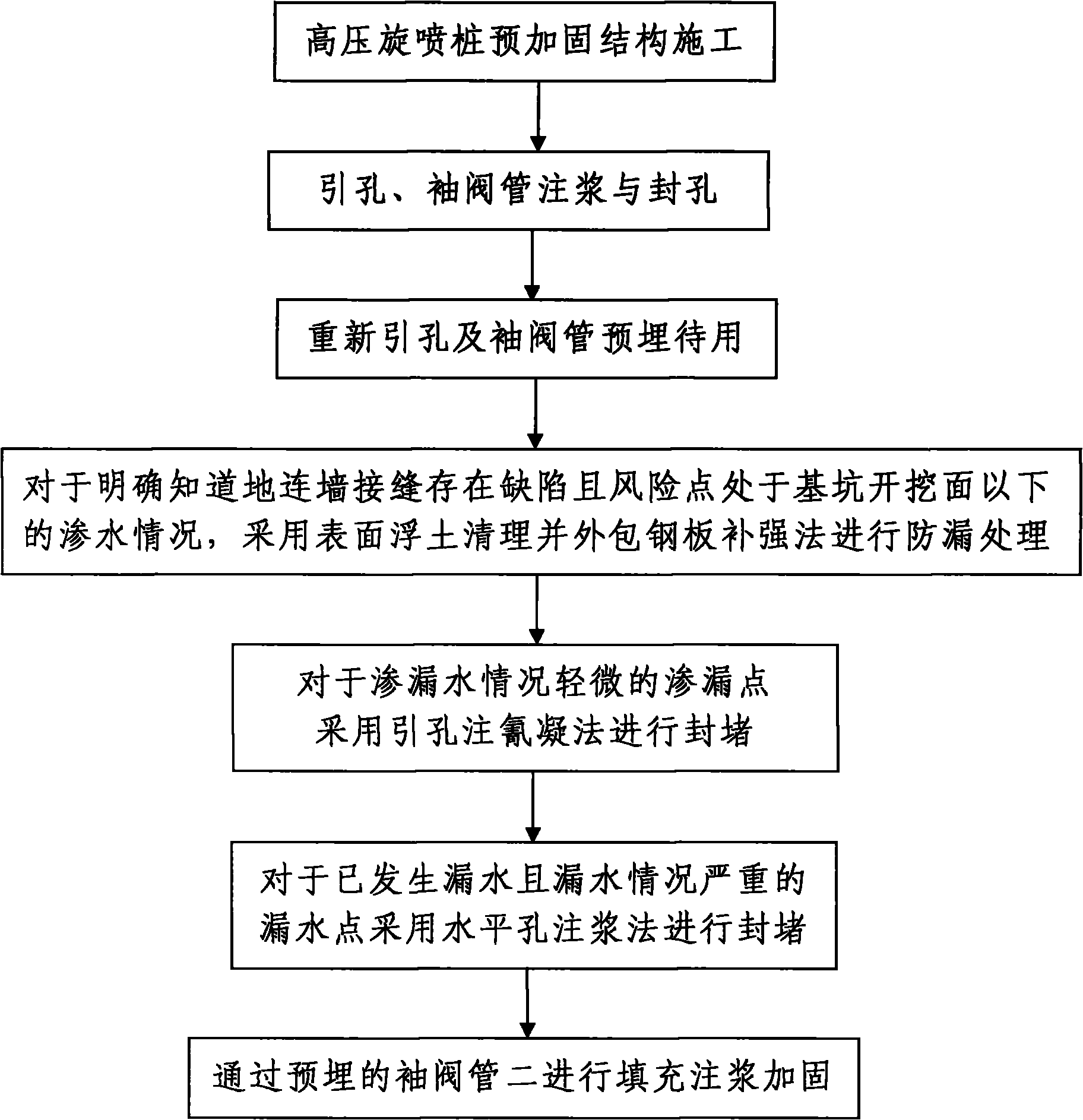

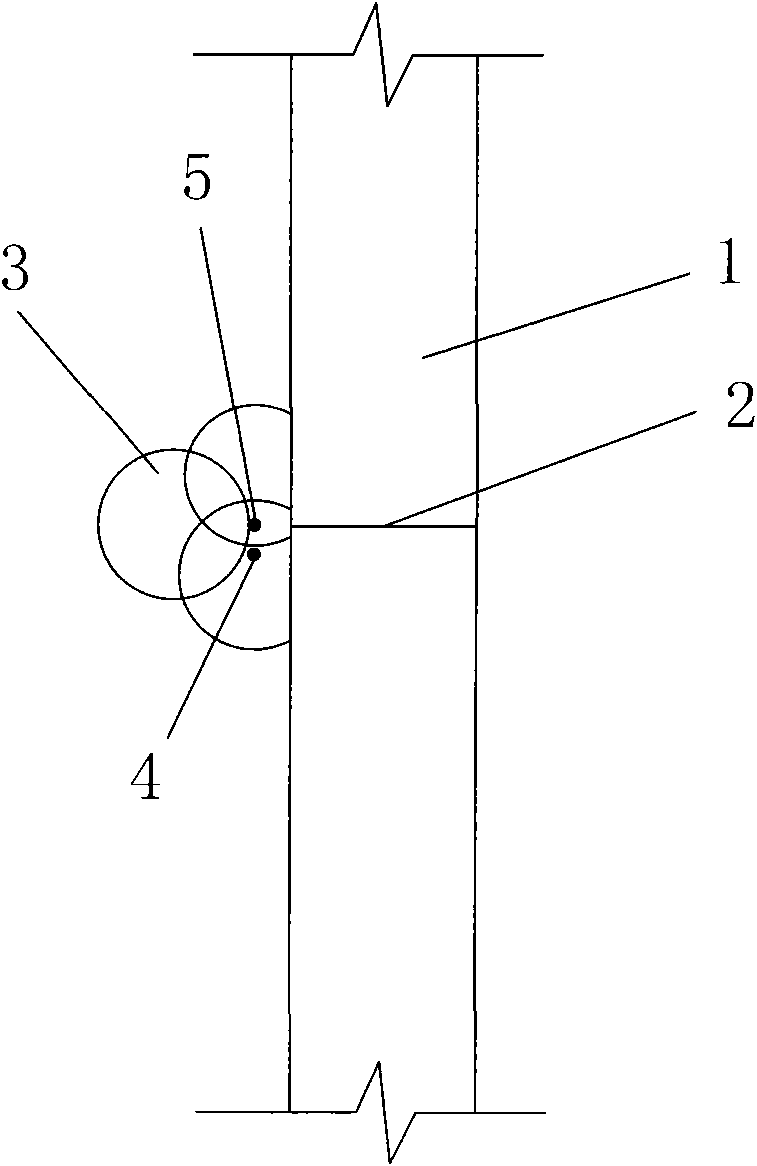

Anti-seepage and leak-blocking construction method for excavation of subway foundation pit in soft soil area

The invention discloses an anti-seepage and leak-blocking construction method for excavation of a subway foundation pit in a soft soil area, which comprises the following steps: 1) joint pre-reinforcement construction of an underground continuous wall: constructing a pre-reinforcement structure of a high-pressure rotary jet grouting pile, guiding holes, grouting by a sleeve valve pipe, sealing the holes, guiding the holes again and pre-burying the sleeve valve pipe for standby; and 2) the excavation of the foundation pit and the anti-seepage and leak-blocking construction: using surface floating earth for clearing and using the encased steel plate reinforcement method for anti-leak treatment for the situations that joints of the underground continuous wall have defects definitely and risk points are positioned below the excavation surface of the foundation pit, adopting the hole-guiding cyanogen injection condensing method for blocking of leak points with slight water leakage situation, adopting the horizontal hole grouting method for blocking for the water leak points with serious water leakage situation, and carrying out filling, grouting and reinforcement through the pre-buried sleeve valve pipe after completing the blocking. The method has reasonable design, convenient construction, comprehensive consideration, good anti-leak and leak-blocking effect, fast leak-blocking speed and can solve the problems of pipe blocking, poor anti-leak and leak-blocking effect, slow construction progress and the like in the existing anti-leak and leak-blocking construction.

Owner:TIANJIN CONSTR ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

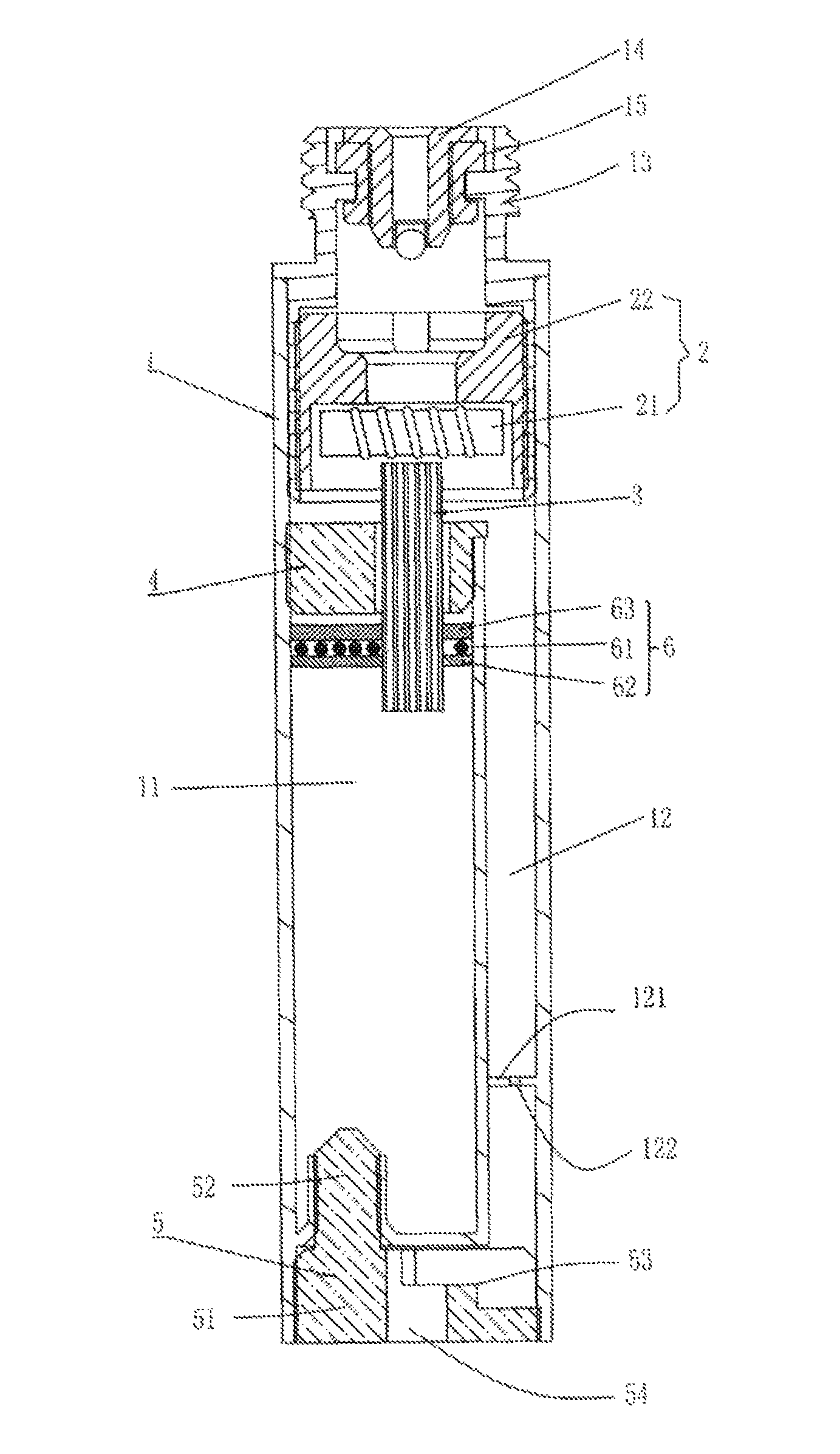

Mouthpiece device of electronic cigarette

InactiveUS9072322B2Improve leak-proof effectEasy to manufactureTobacco treatmentTobacco smoke filtersMouth pieceElectronic cigarette

The present invention relates to a mouthpiece device of an electronic cigarette, includes an atomizing device for vaporizing tobacco substance into aerosol, a reservoir for storing tobacco substance and a guiding tube for guiding tobacco substance from the reservoir to the atomizing device, which are all set in a shell. The guiding tube has one end inserted in the reservoir and the other end communicated with atomizing device. The mouthpiece device further includes a preheating device for heating solid tobacco substance in the reservoir to generate liquid. The preheating device is set in the end of the reservoir near the guiding tube, and seals solid tobacco substance in the reservoir. The present invention solves existing problems such as fluid leakage, complicate manufacturing, high cost, bad heat insulation and filtering aerosol; and obtains perfect leakage proof, simple manufacturing, lower cost, good heat insulation and well filtering aerosol.

Owner:HUIZHOU KIMREE TECH

Electrochemical Cell With A Catalytic Electrode And Process For Making The Electrode And The Cell

InactiveUS20080155813A1Easy and economical and safe mannerEliminate useMaterial nanotechnologyFuel and primary cellsNano catalystLiquid medium

A process for making a catalytic electrode containing a transition metal nano-catalyst without using spray or thermal decomposition, and a process for making an electrochemical cell with a catalytic electrode. The nano-catalyst is a particulate material that includes particles that are at least partially oxidized, preferably to include at least oxide shells, before mixing with an activated carbon and binder in a liquid medium to adhere particles of the nano-catalyst to internal and external surfaces of the particles of activated carbon. Oxidation of the nano-catalyst particles allows the mixing of the nano-catalyst, activated carbon and binder in air rather than an inert gas atmosphere and can avoid the use of potentially dangerous liquid media such as highly volatile alcohols.

Owner:EVEREADY BATTERY CO INC

Simulated cigarette

InactiveUS20160135501A1Improve leak-proof effectSteam generation heating methodsTobacco pipesFlavorProcess engineering

The present invention relates to a simulated cigarette, which includes a gas tank set in a shell for storing gas of cigarette-smoking flavor in a liquefied-gas phase. The gas tank has a valve device set thereto for controlling the gas of cigarette-smoking flavor in and out. The simulated cigarette further includes a heat device for heating up the gas of cigarette-smoking flavor emitted from the gas tank, and accordingly a controlling unit and a power source set in the shell. The shell of the simulated cigarette has an integrated or parted structure. The gas tank is detachably set in the shell. The present invention mainly resolves fluid-leaking problem in the prior art. The simulated cigarette of the present invention has good leakage-proof performance. The simulated cigarette emits out gas tasted as cigarette-smoking flavor so that it can be used right after switched on.

Owner:HUIZHOU KIMREE TECH

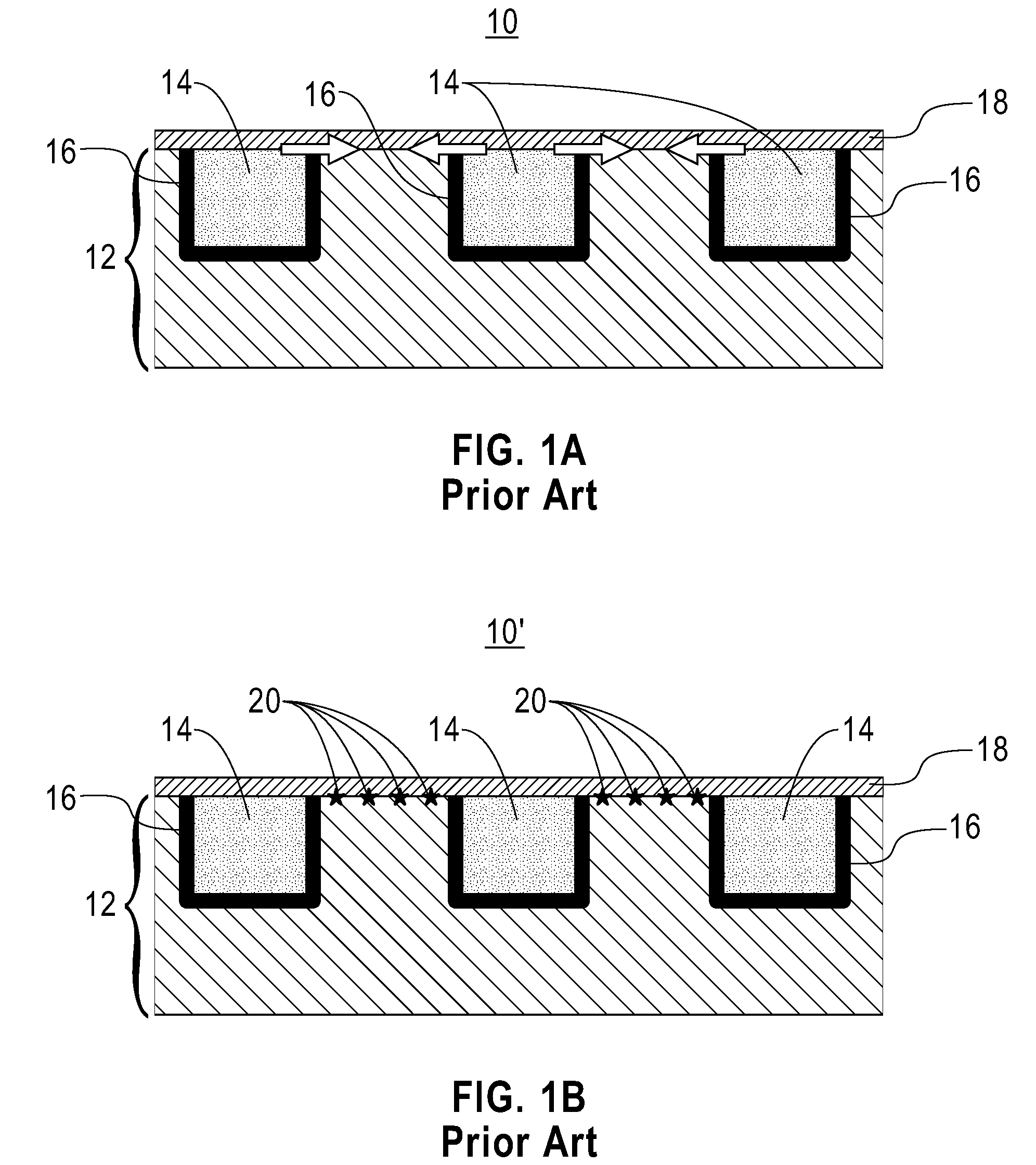

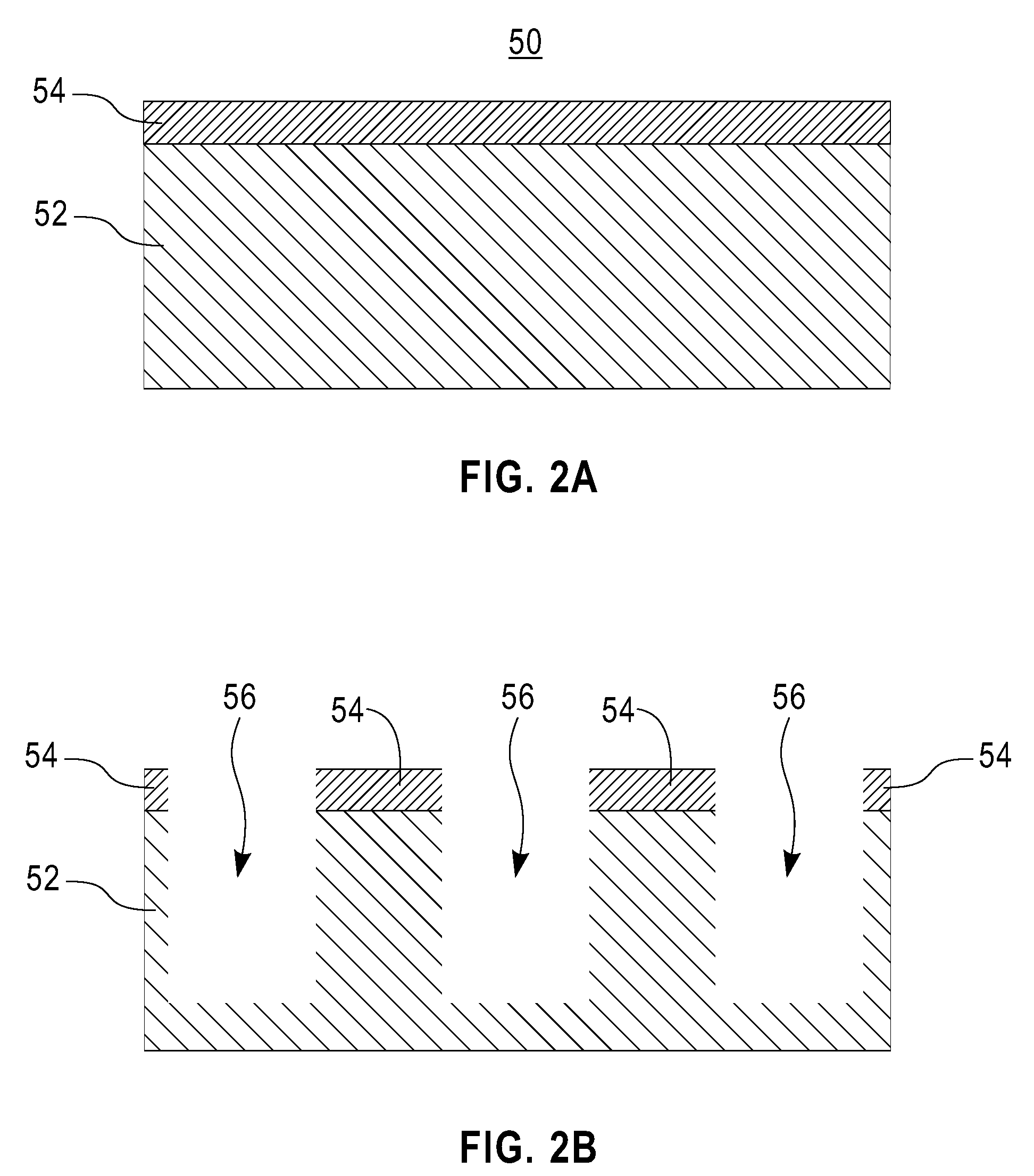

Interconnect structure with high leakage resistance

InactiveUS20090200668A1High leak resistanceImprove leak-proof effectSemiconductor/solid-state device detailsSolid-state devicesConductive materialsMaterials science

An interconnect structure is provided in which the conductive feature (i.e., conductive material) is not coplanar with the upper surface of the dielectric material, but instead the conductive material is recessed below an upper surface of the dielectric material. In addition to being recessed below the upper surface of the dielectric material, the conductive material of the interconnect structure is surrounded on all sides (i.e., sidewall surfaces, upper surface and bottom surface) by a diffusion barrier material. Unlike prior art interconnect structures, the barrier material located on the upper surface of the recessed conductive material is located with an opening including the recessed conductive material.

Owner:IBM CORP

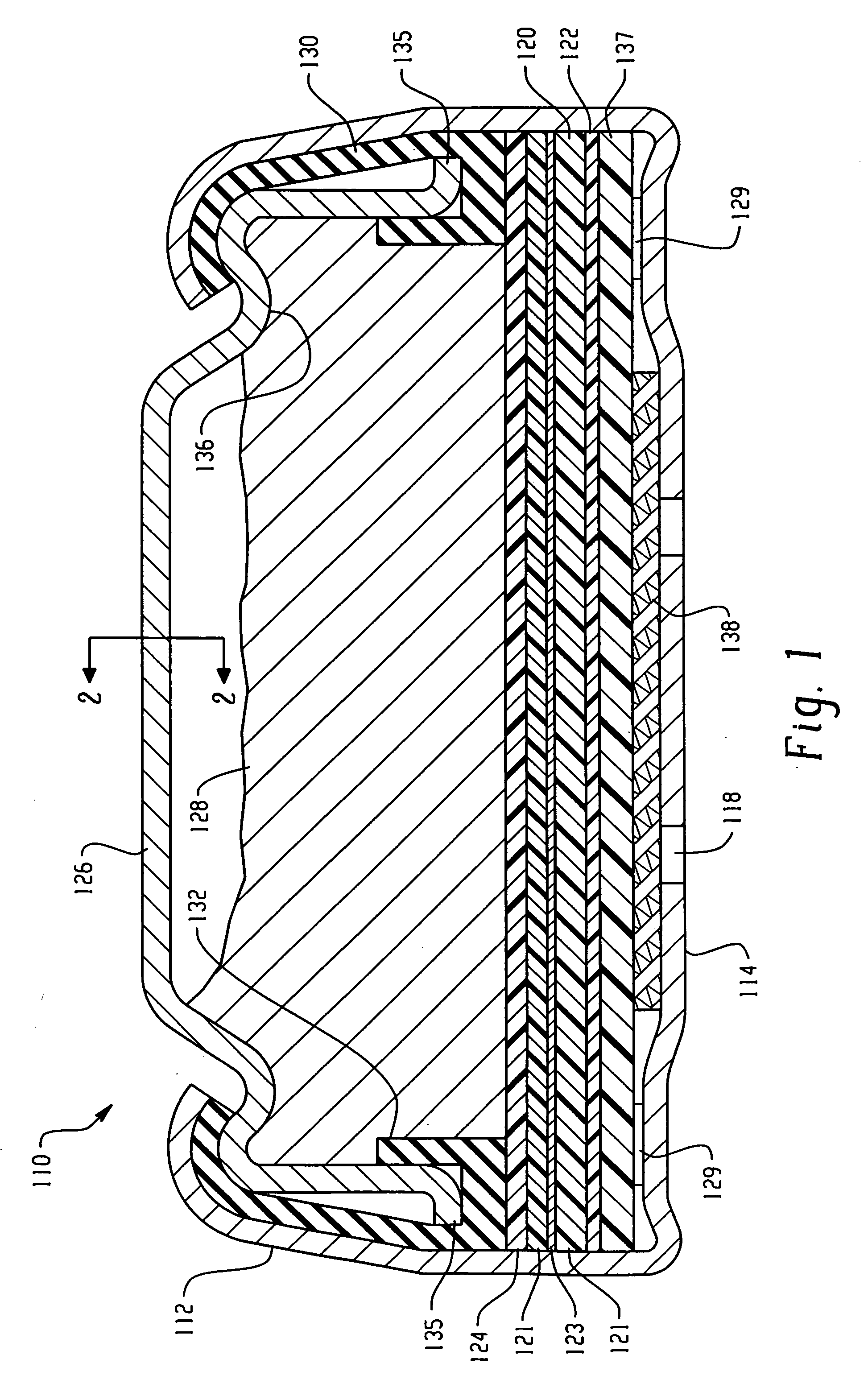

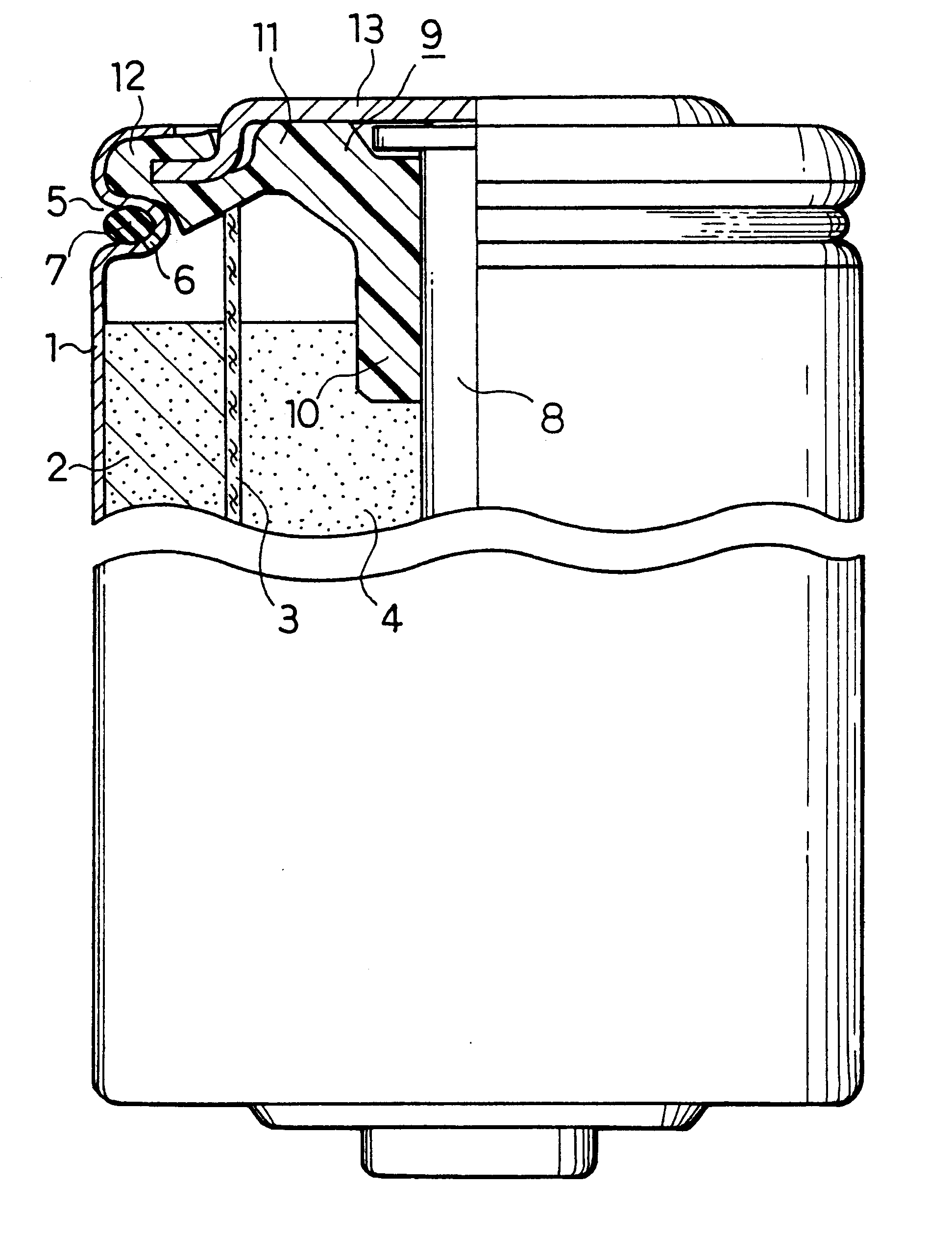

Alkaline battery

InactiveUS20080096108A1Improve leak-proof effectAlkaline accumulatorsNegative electrodesMethacrylatePolymer science

An alkaline battery of this invention includes: a positive electrode including at least one selected from the group consisting of a manganese dioxide powder and a nickel oxyhydroxide powder; a gelled negative electrode including a zinc alloy powder, a gelling agent, and an alkaline electrolyte; and a separator interposed between the positive electrode and the gelled negative electrode. The gelling agent comprises a polymer that is obtained by polymerizing a polymerizable monomer including at least an acrylic monomer, and part of the acrylic monomer remains in the gelling agent without being polymerized. The acrylic monomer includes at least one selected from the group consisting of acrylic acid, methacrylic acid, an acrylate, and a methacrylate. The weight ratio of the remaining acrylic monomer to the total weight of the polymer and the remaining acrylic monomer is 5000 ppm or less.

Owner:PANASONIC CORP

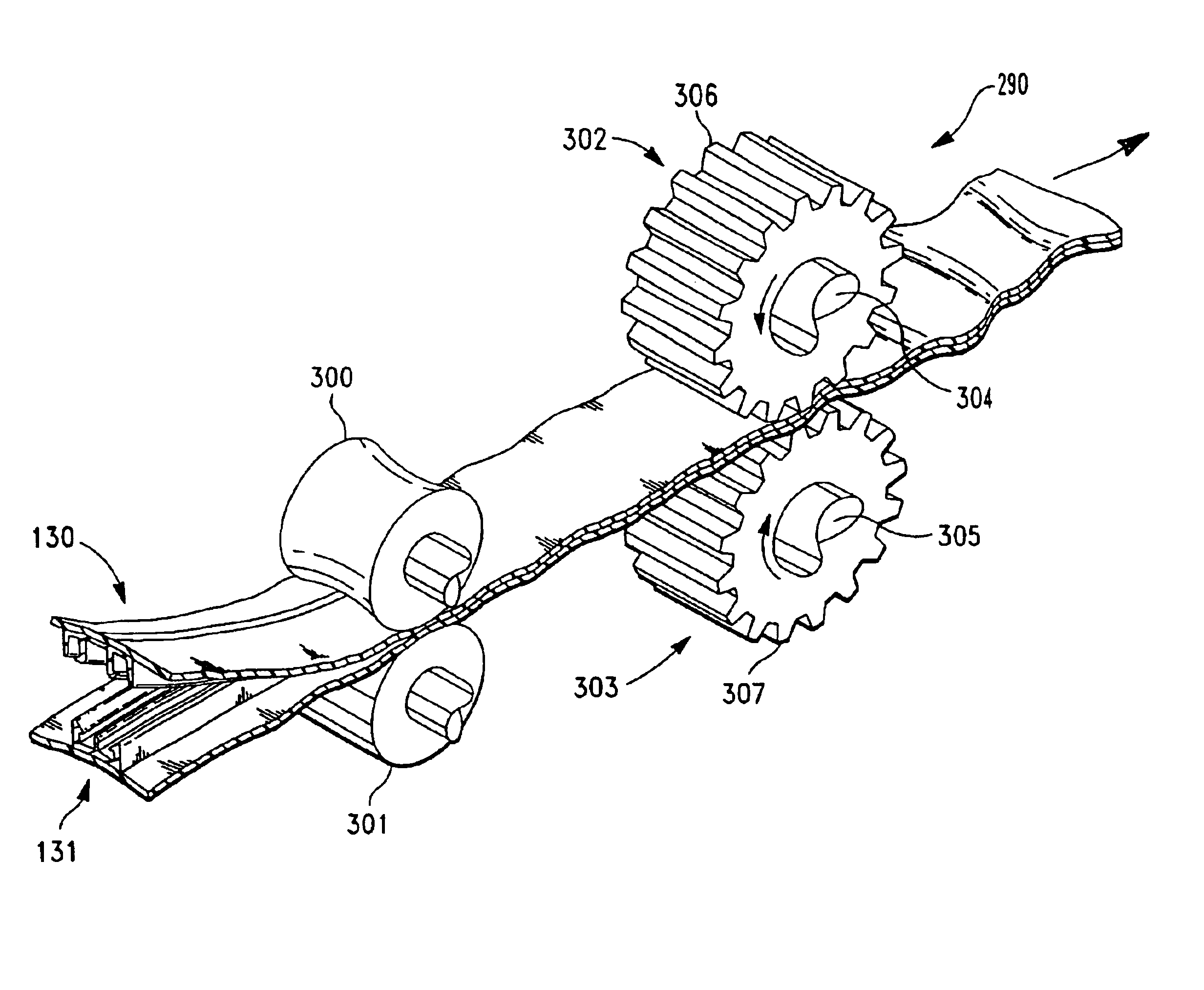

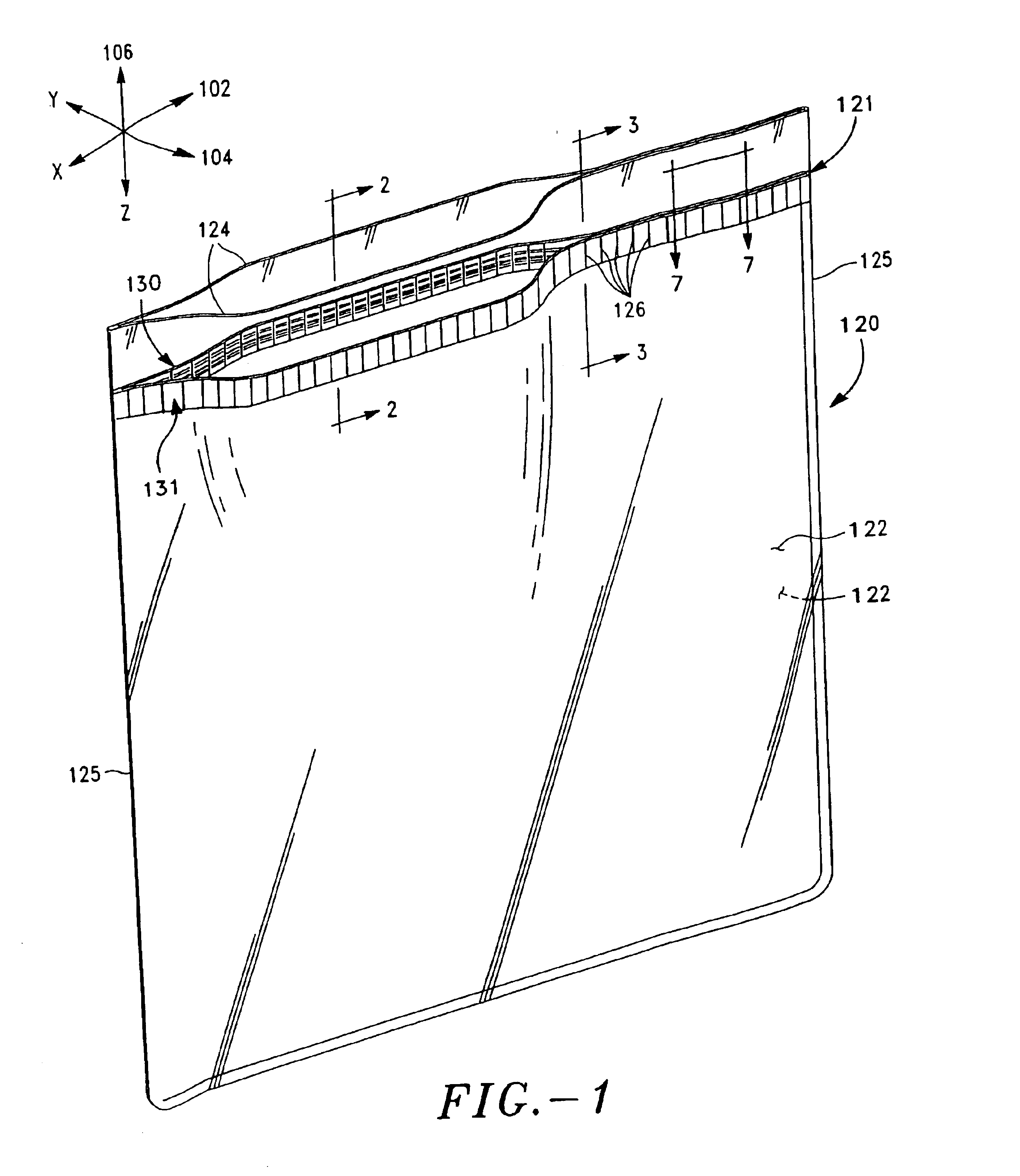

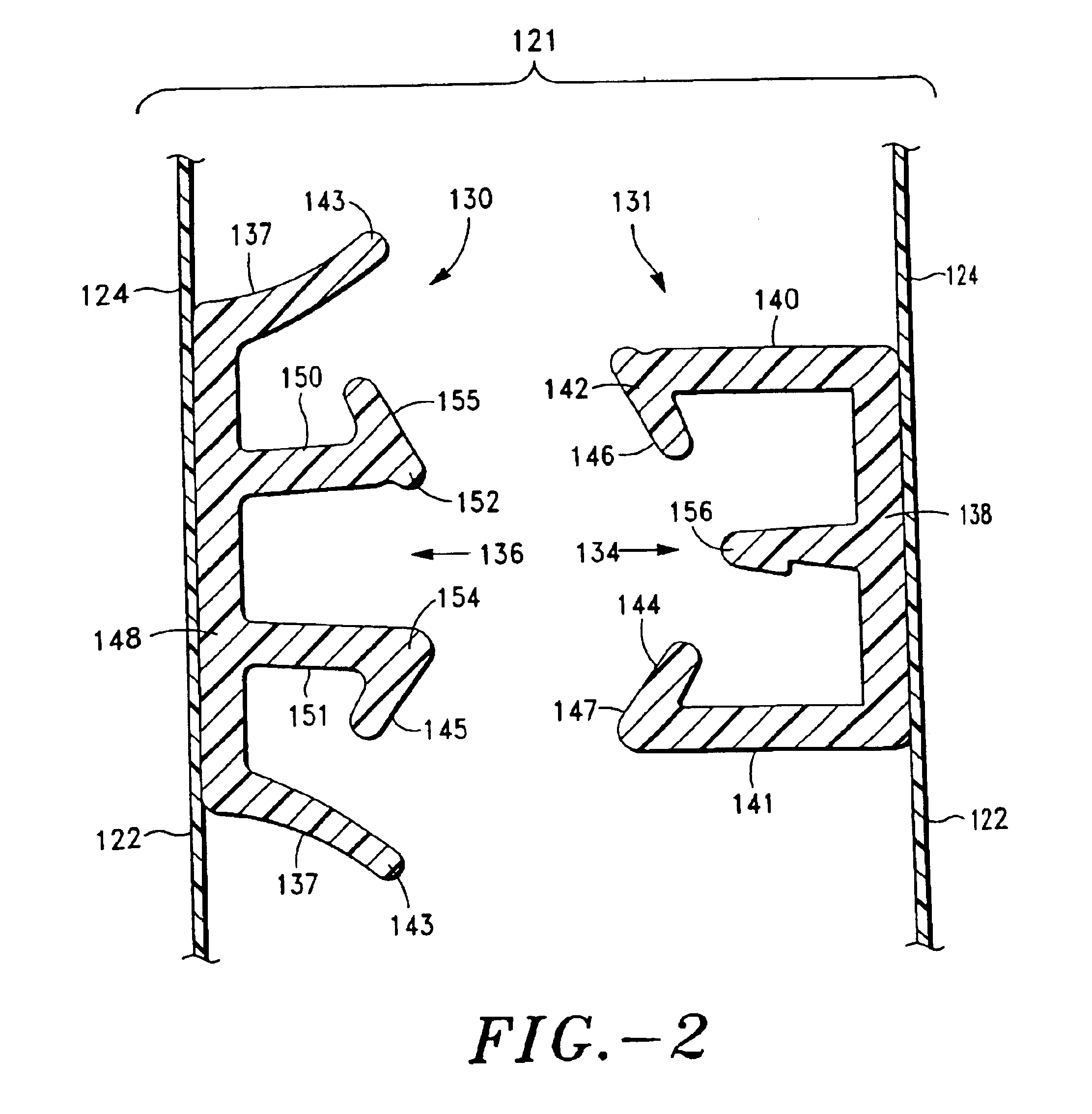

Interlocking closure device

InactiveUS6953542B2Improve leak-proof effectDesired audible and/or tactile effectsSnap fastenersMechanical working/deformationThermoplasticCold formed

A closure device for a thermoplastic bag which includes two opposing, longitudinally extending interlockable male and female fastening strips having respective male and female closure elements or profiles that are deformed to interdigitate and produce an audible clicking sound and or tactile effect that is perceptible to the touch as the closure device is opened and closed. Interdigitation of the two profiles is achieved by cold forming the profiles while interlocked. The shape of the cold form is a stepped deflection of both profiles so that their shapes are generally congruent. The stepped deflections provide a change in the occlusion and peel force of the interlocking closure device thereby resulting in an audible clicking or popping sound as the closure device is opened and closed and a tactile effect that is perceptible to the touch as the closure device is closed.

Owner:WATER KINETICS LTD

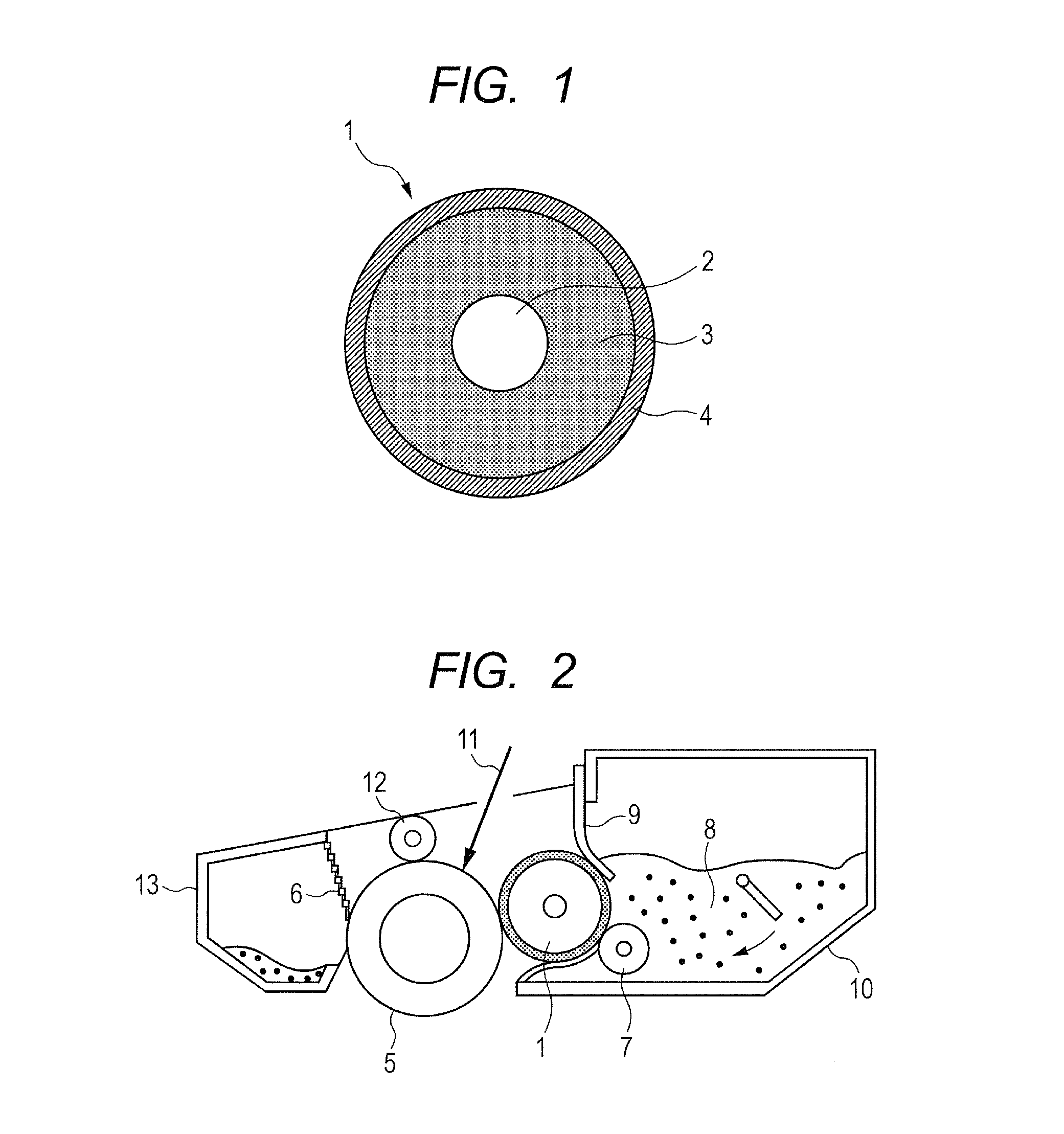

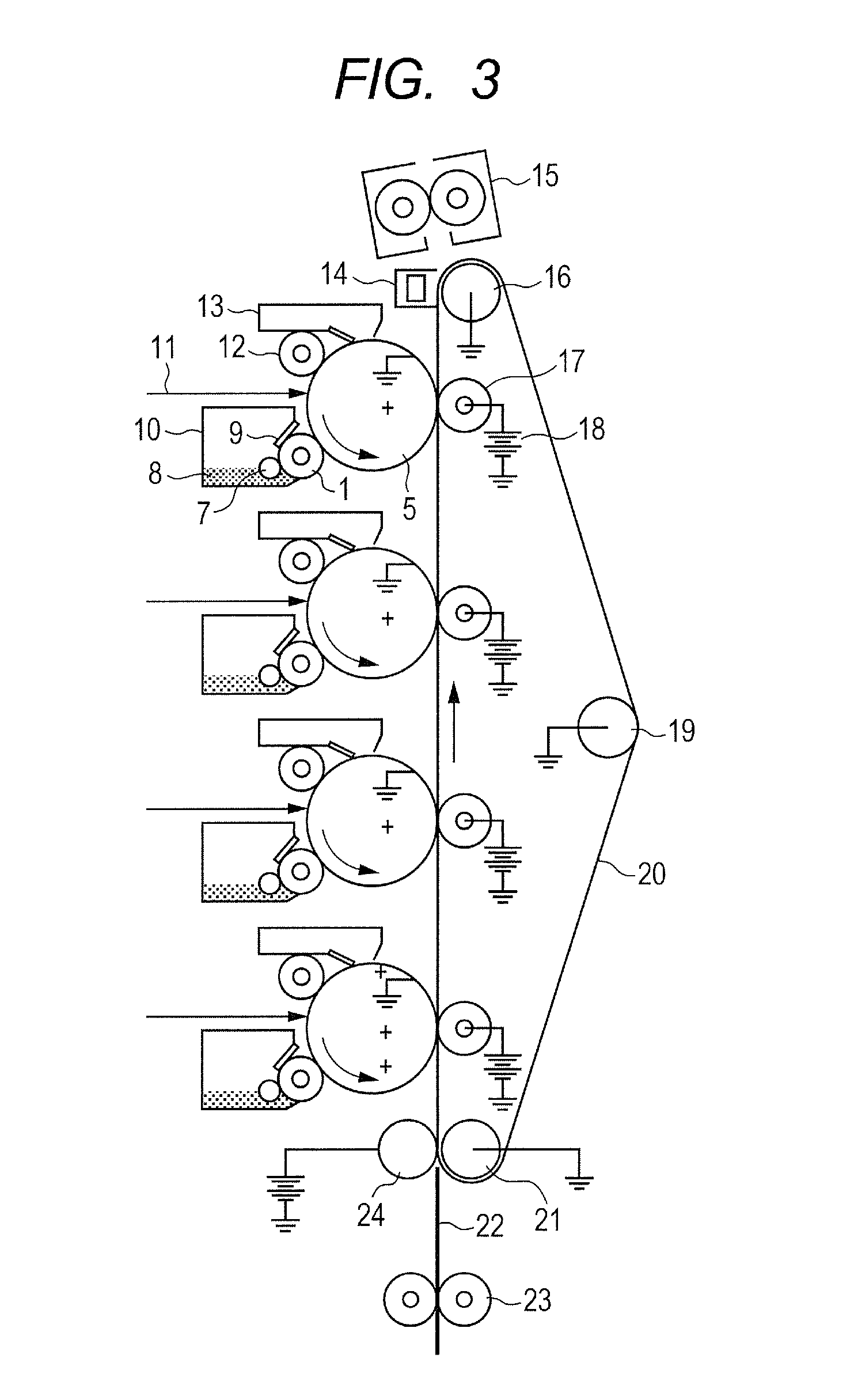

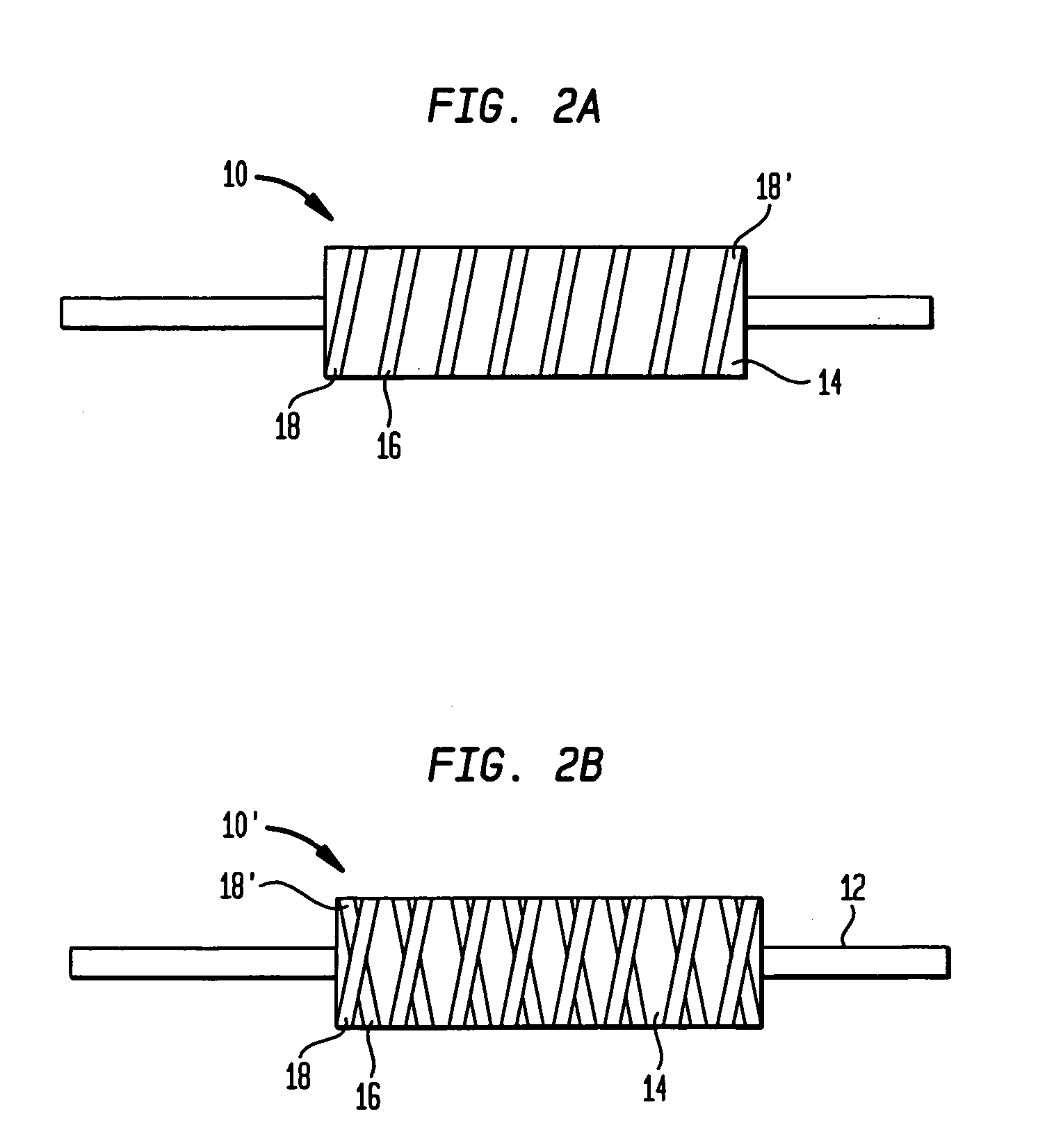

Developing member, process cartridge, and electrophotographic apparatus

ActiveUS8798508B2Quality improvementImprove leak-proof effectSynthetic resin layered productsSpecial tyresSurface layerEngineering

A high-quality developing member which excels in filming resistance and excels in leak resistance despite high electroconductivity is provided. The developing member includes an electroconductive substrate, an elastic layer formed on the substrate, and a surface layer which covers a surface of the elastic layer. The surface layer includes a first resin which has, between two adjacent urethane linkages, a structure represented by the structural formula (1) and one or both of structures selected from the group consisting of a structure represented by the structural formula (2) and a structure represented by the structural formula (3), a second resin which has a structure represented by the structural formula (4) and one or both of structures selected from the group consisting of a structure represented by the structural formula (5) and a structure represented by the structural formula (6), and an electronically conductive filler.

Owner:CANON KK

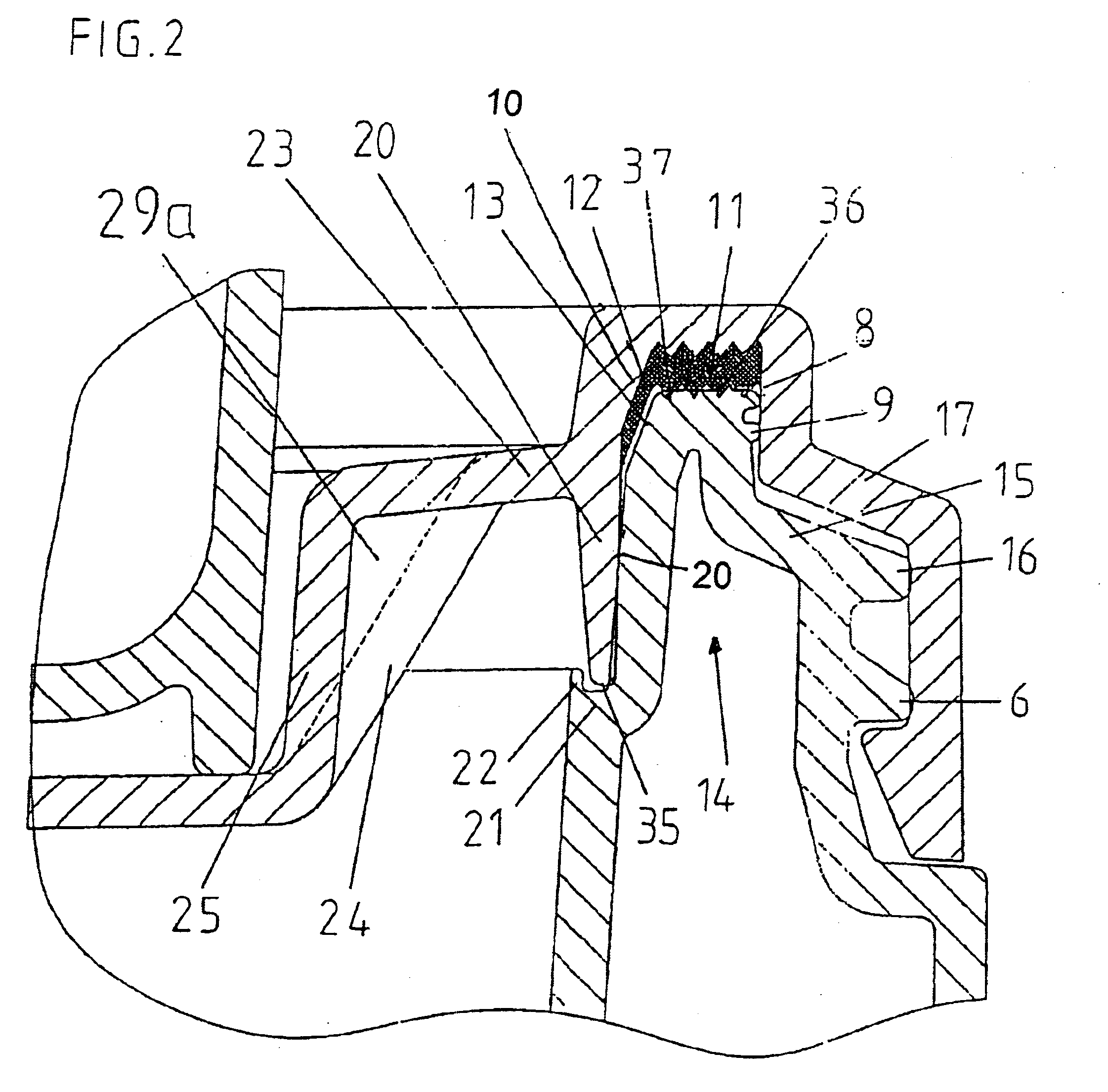

Plastic container with snap lid and a sealing web located on the inside of the container

InactiveUS6845877B2Improve leak-proof effectImprove accuracyCapsClosure using stoppersEngineeringHigh load

A plastic container with a snap lid and with a snap element is provided on the upper edge region of the container for the lid to snap onto, where the lid has a circumferential sealing web projecting downwards that contacts the inside of the container, where at least one projection that extends in an essentially radial and essentially vertical direction is provided on the lid radially inside the sealing web. To provide a plastic container with snap lid, which fulfils the special demands imposed on leak-proofness, while simultaneously providing high load-bearing capacity, the vertical extension of the area of the projection adjacent to the sealing web is small relative to the total vertical extension of the projection. The inward-facing projection can be located on an inside circumferential edge integrally molded on the sealing web. In addition to the sealing web, another circumferential seal is provided in the region of the top edge of the container.

Owner:JOKEY PLASTIK GUMMERSBACH

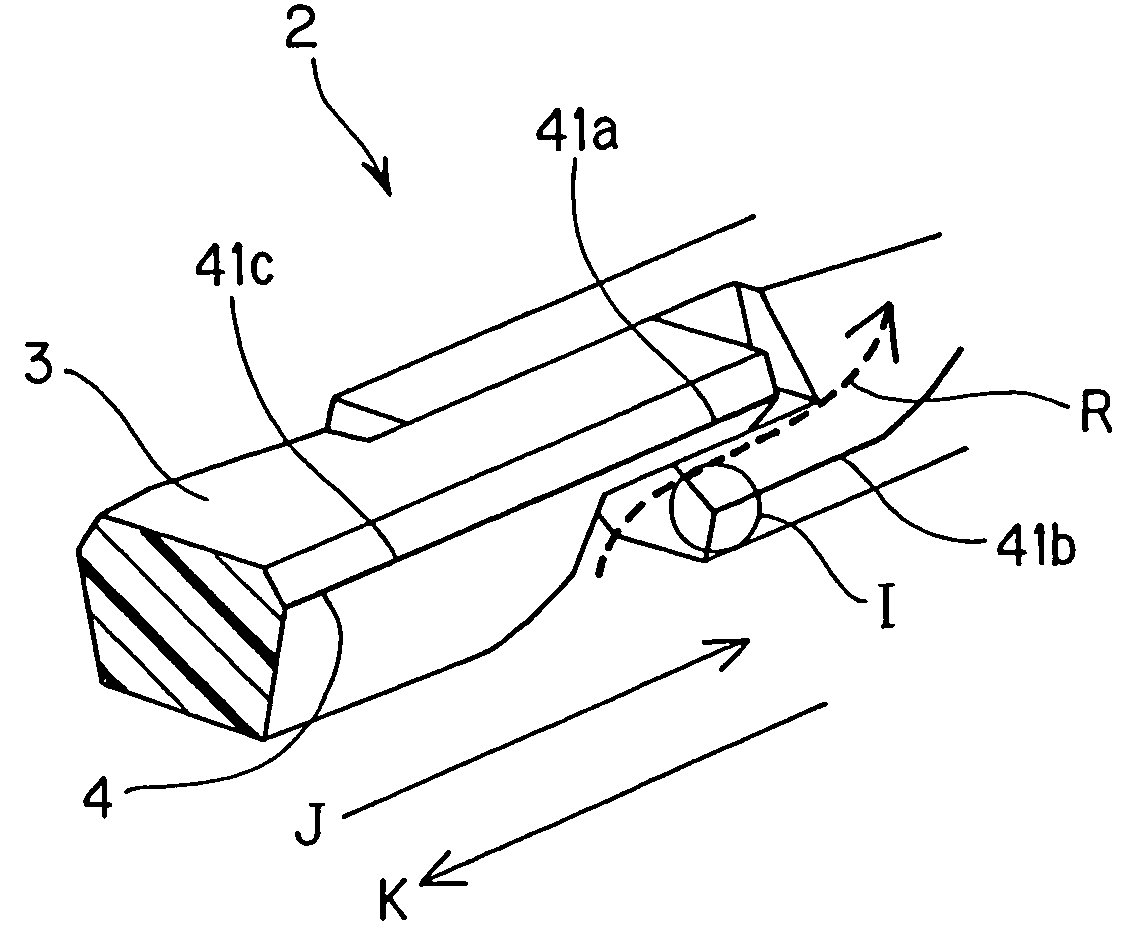

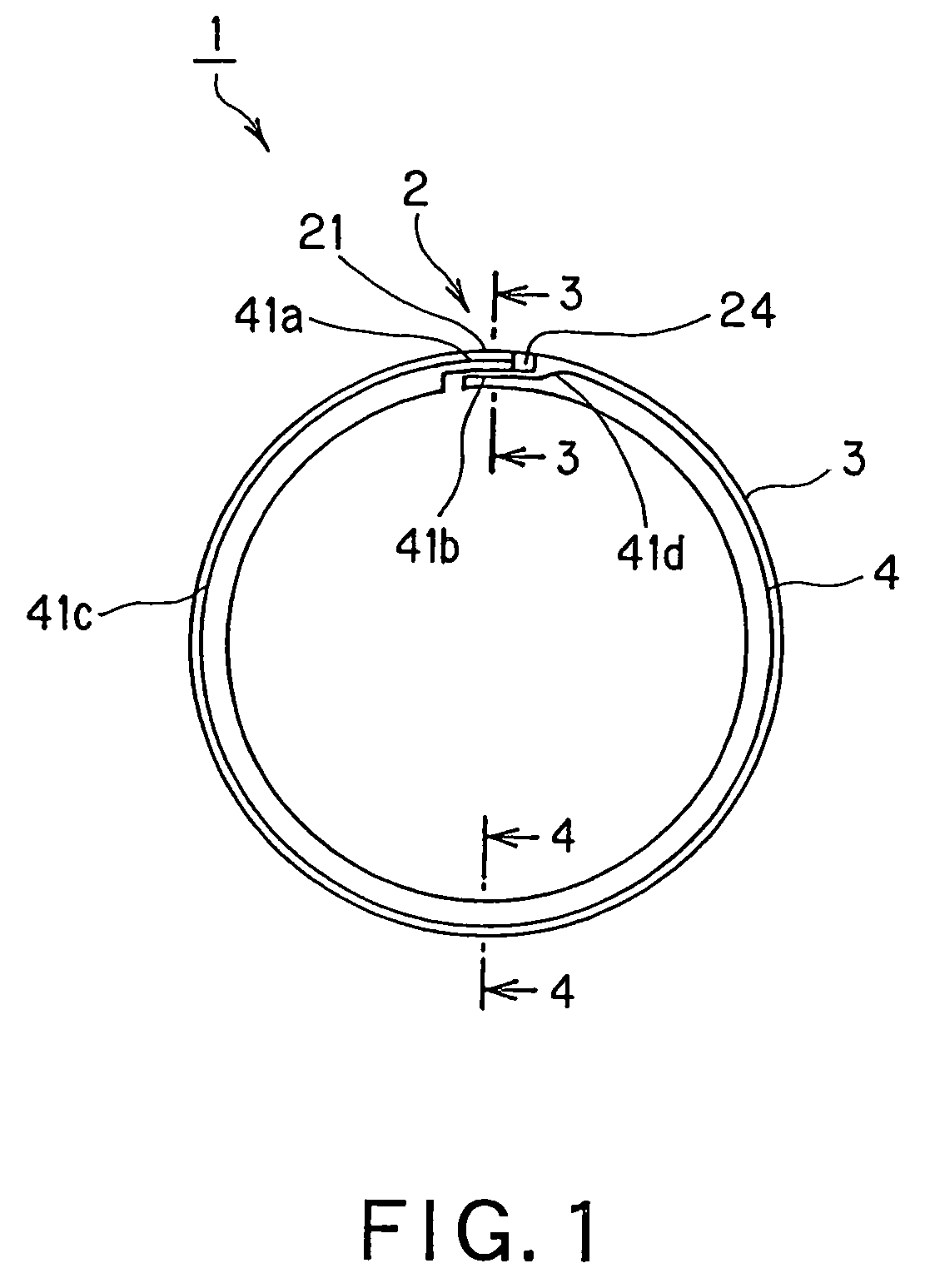

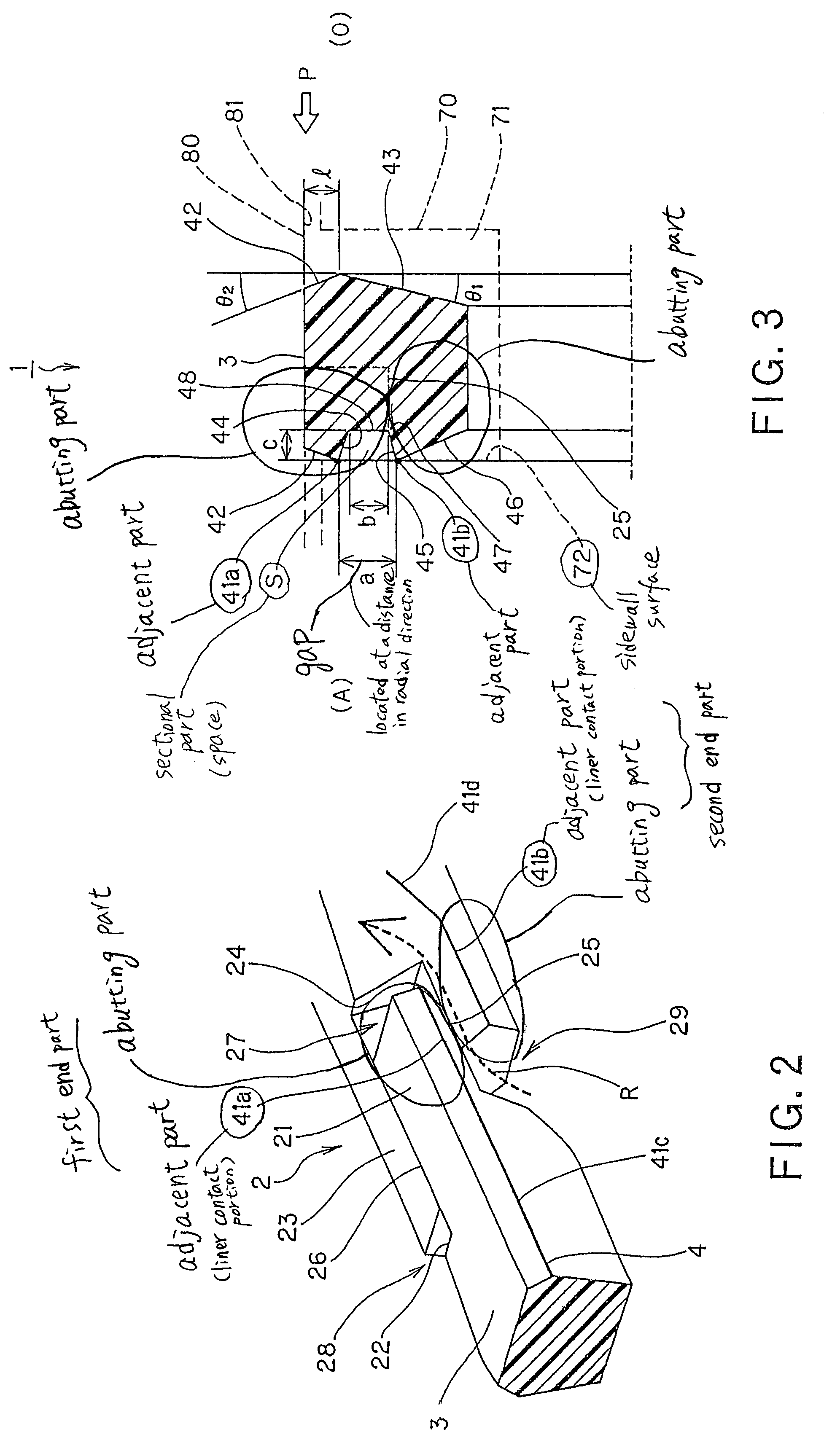

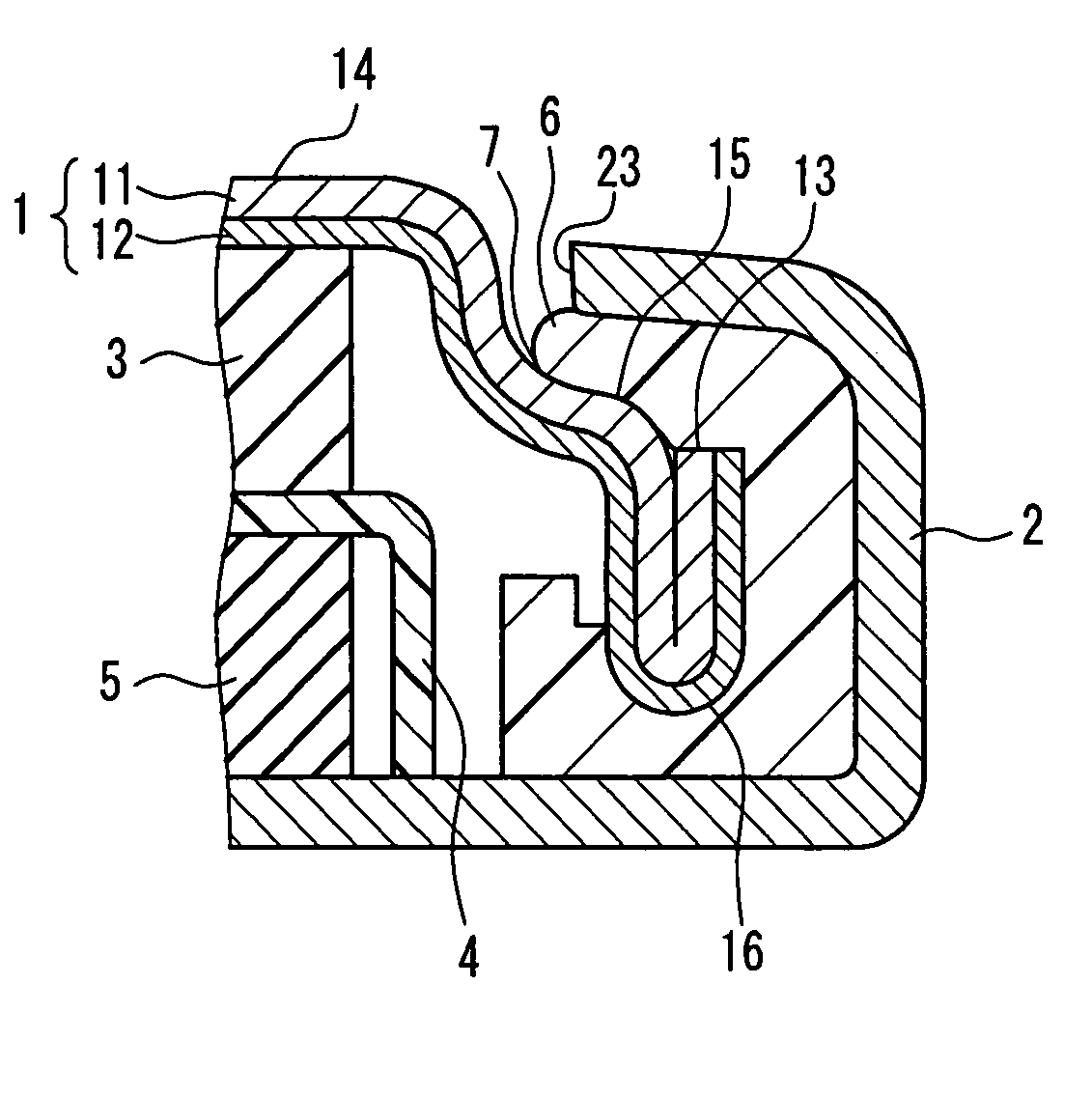

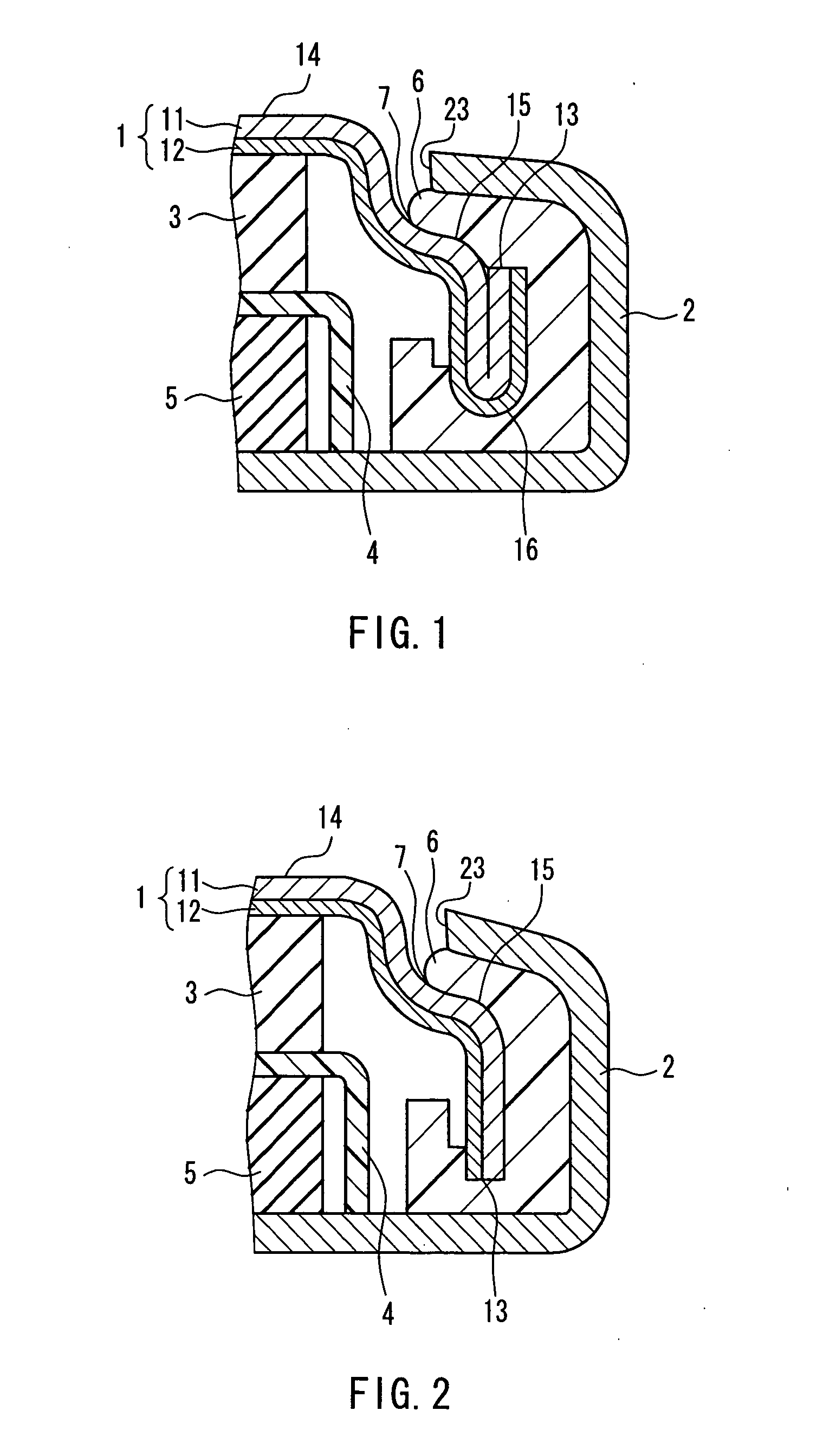

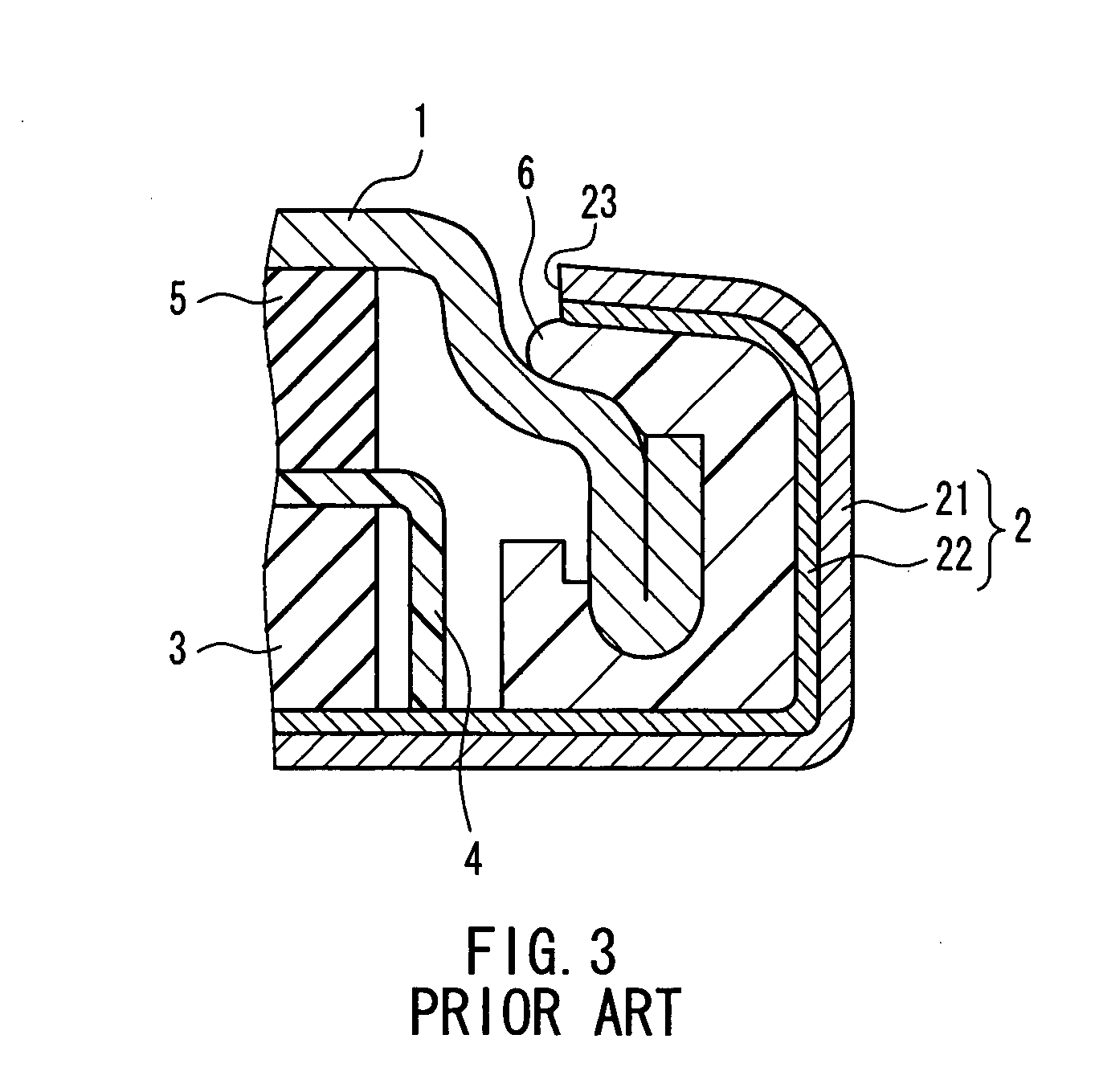

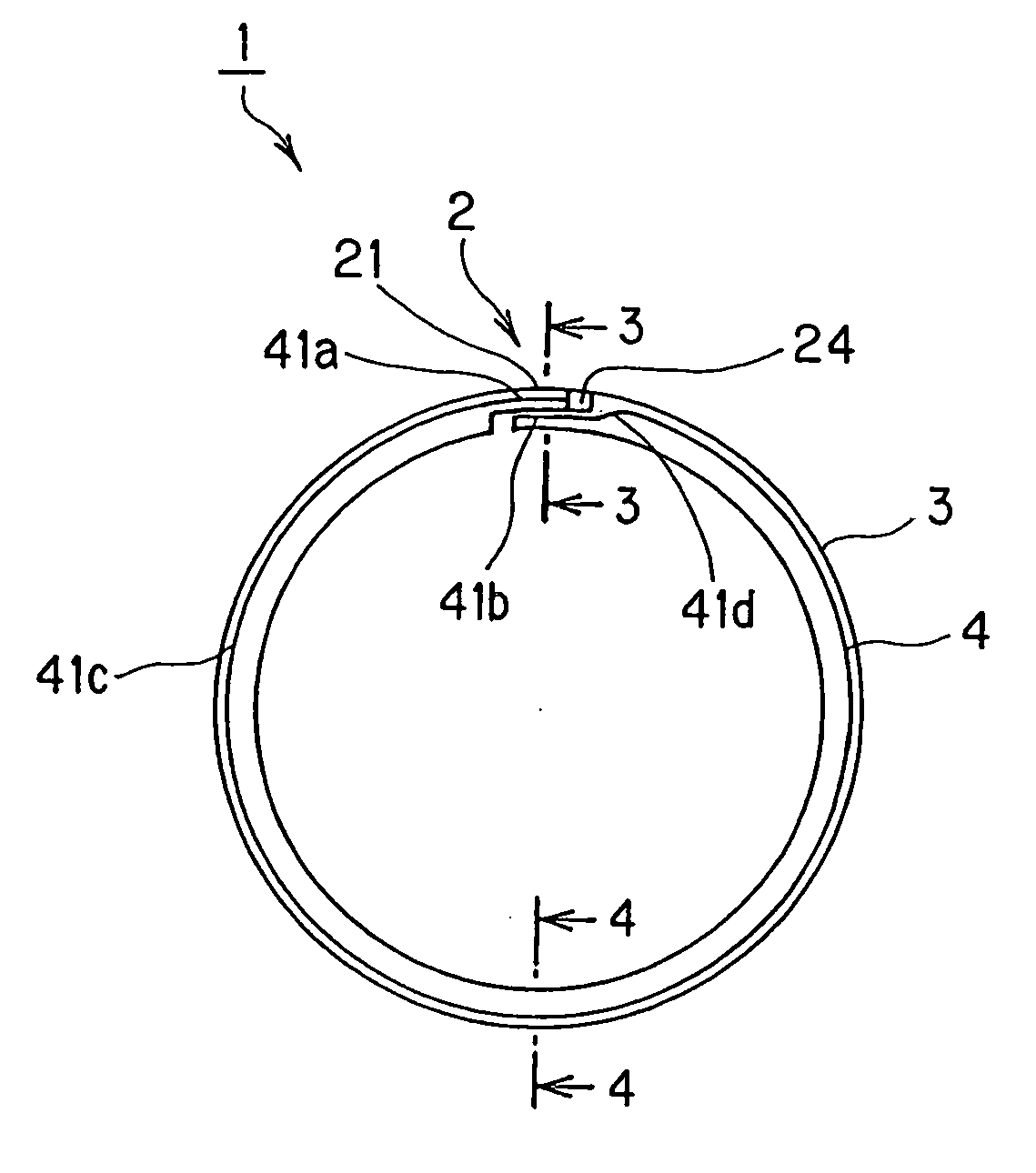

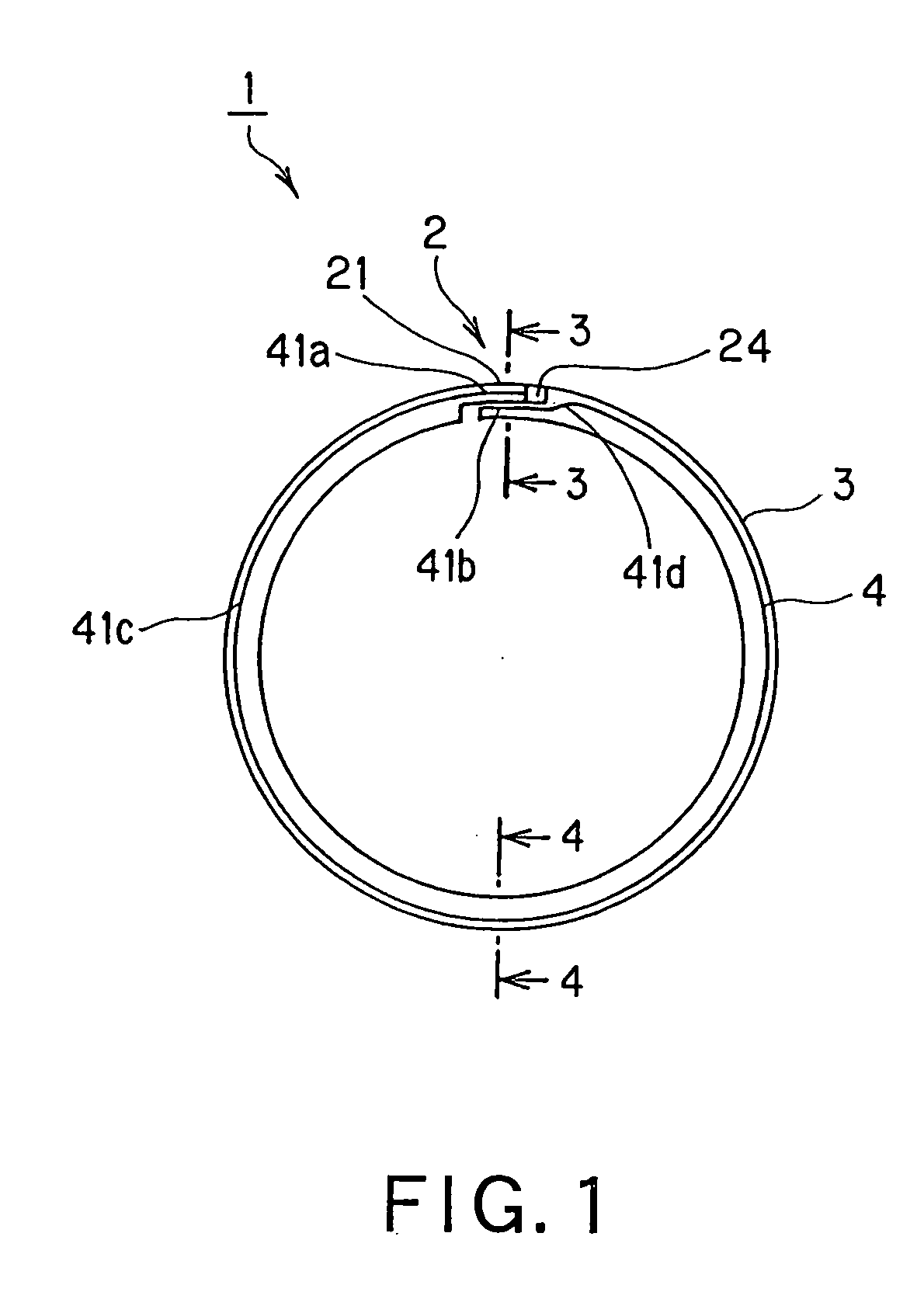

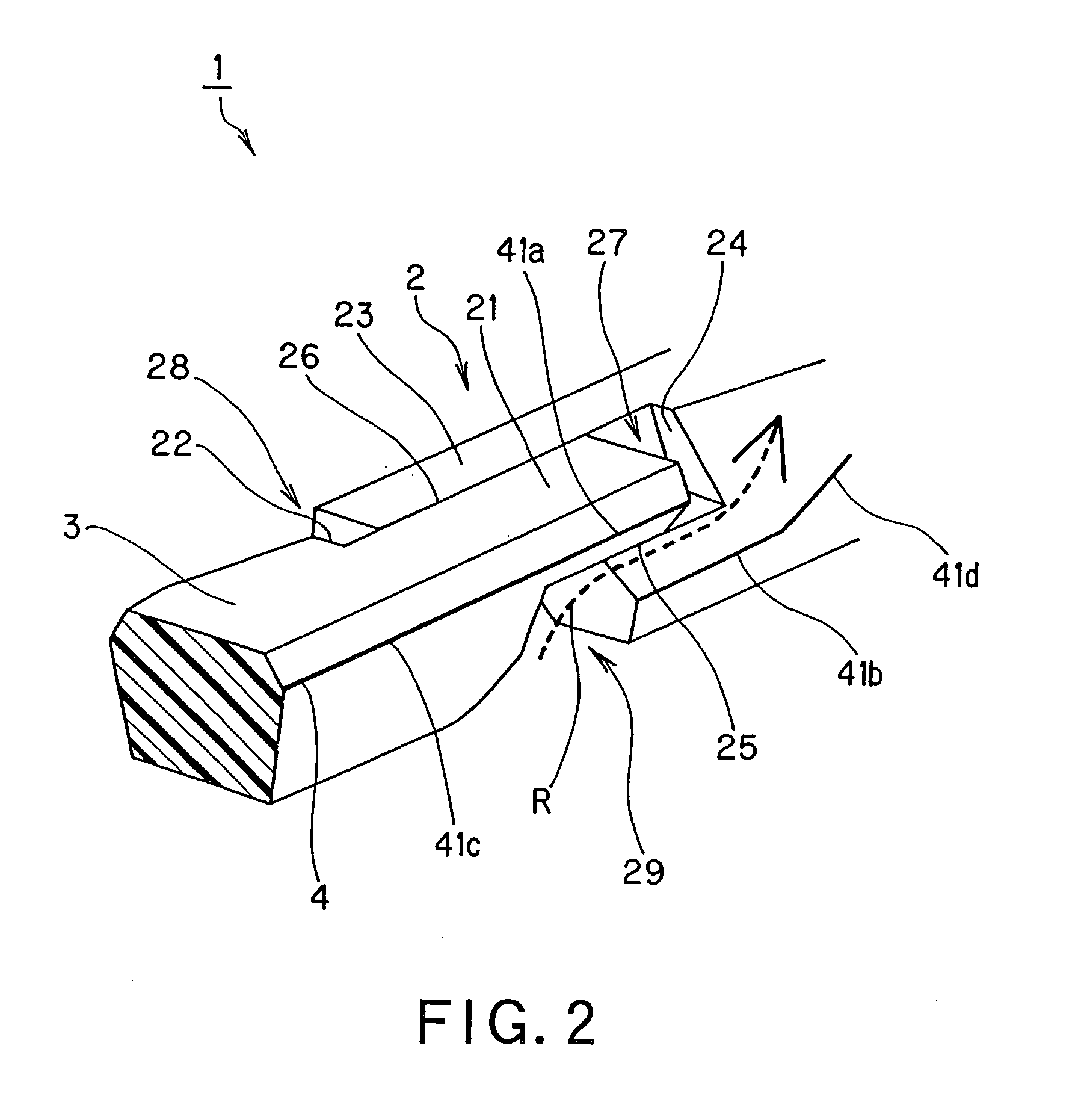

Seal ring

InactiveUS7341256B2Easily vomitedReduce pressureEngine sealsPiston ringsEngineeringMechanical engineering

Owner:NOK CORP

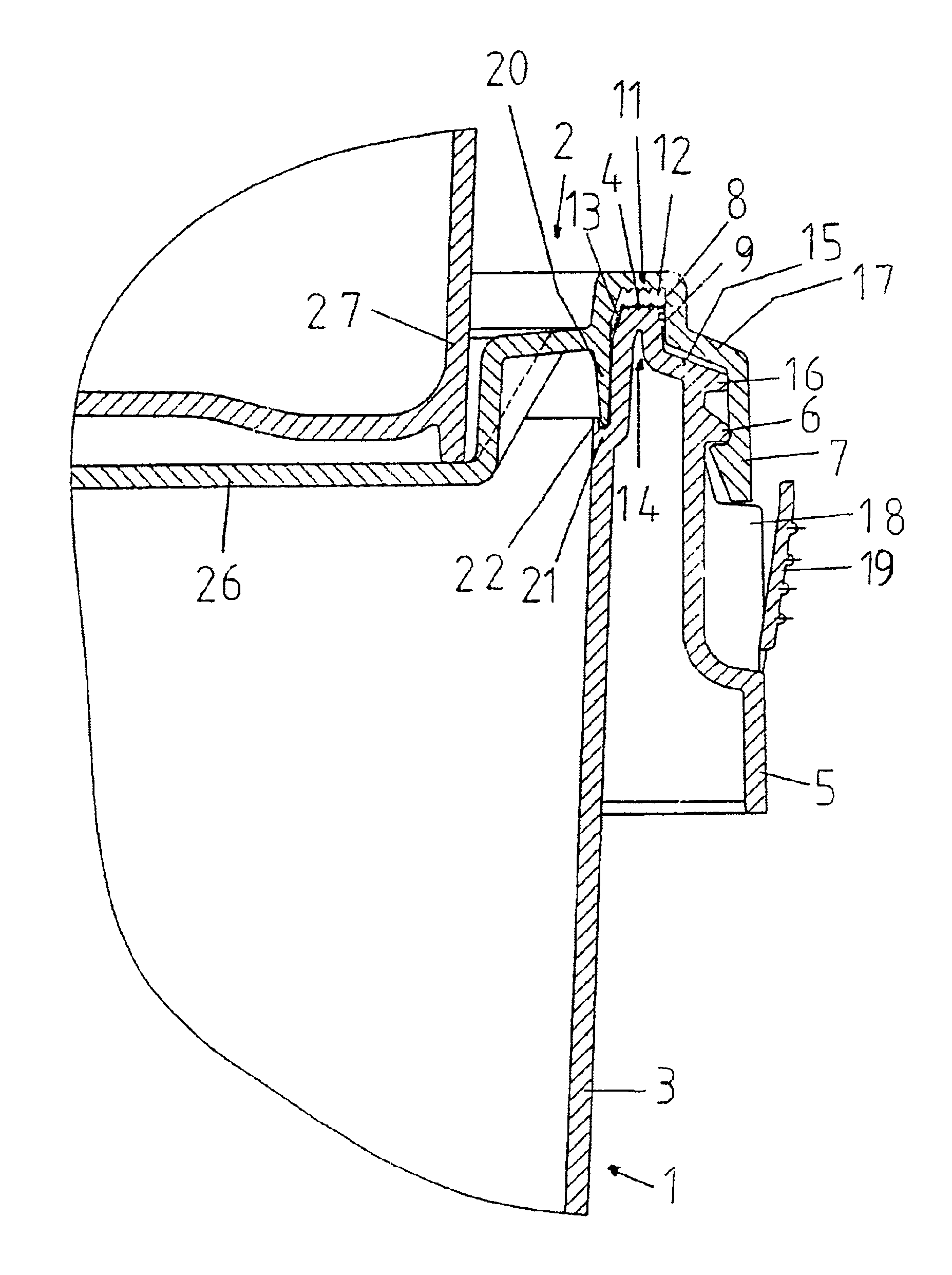

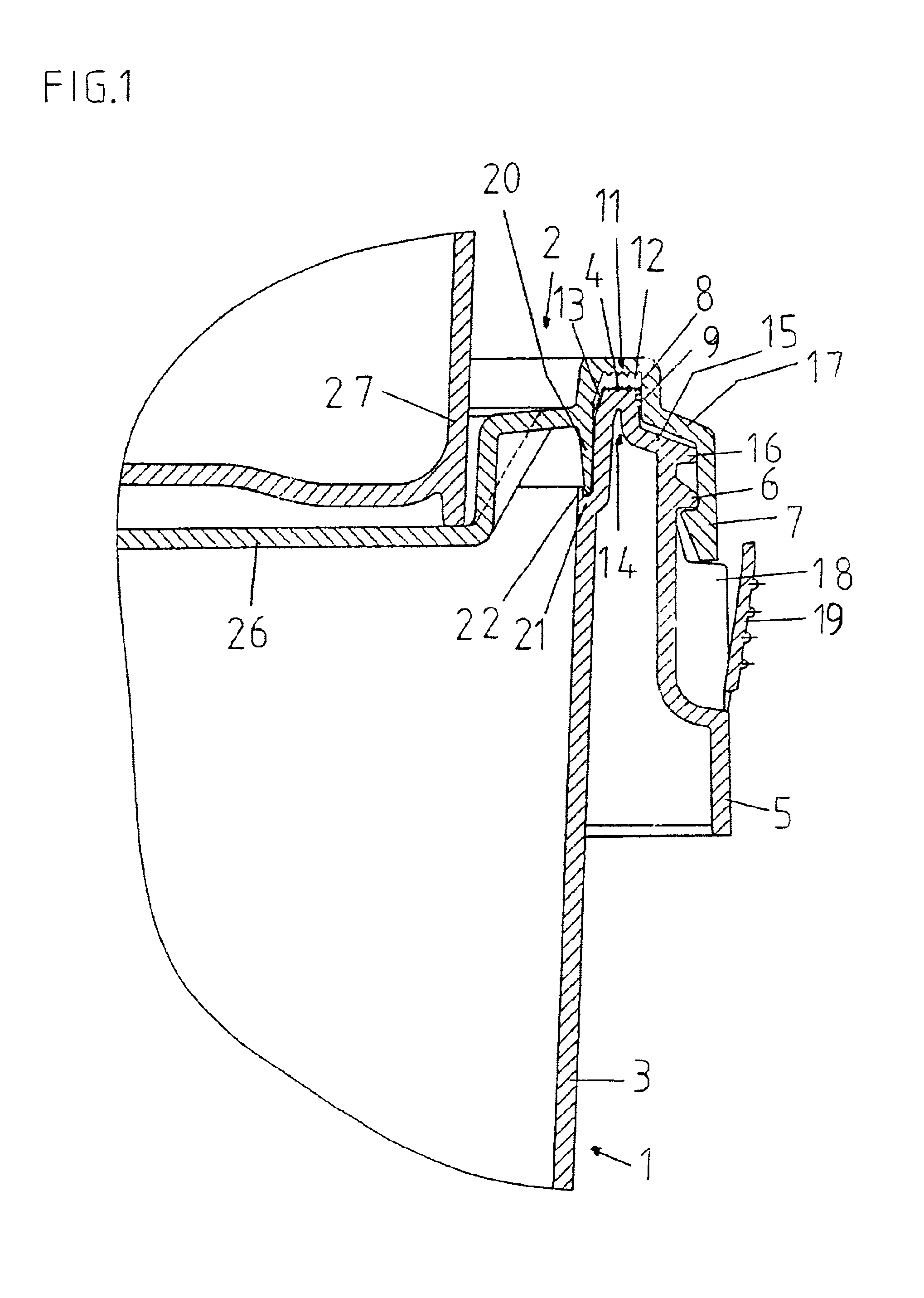

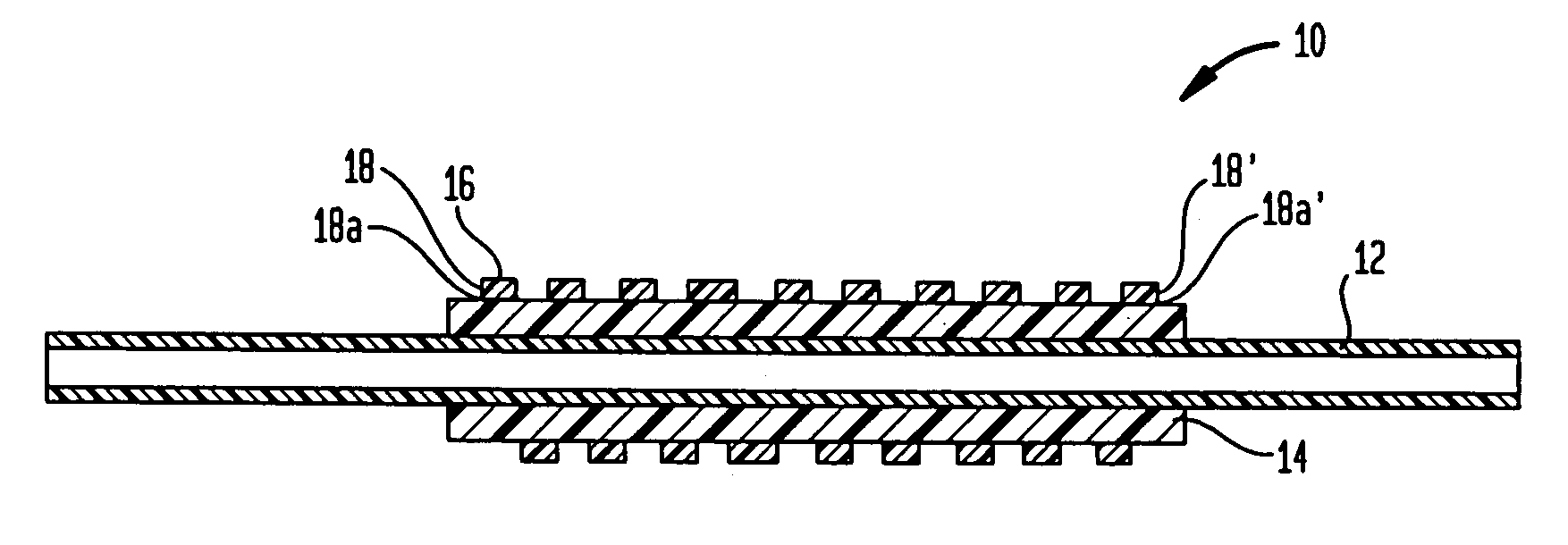

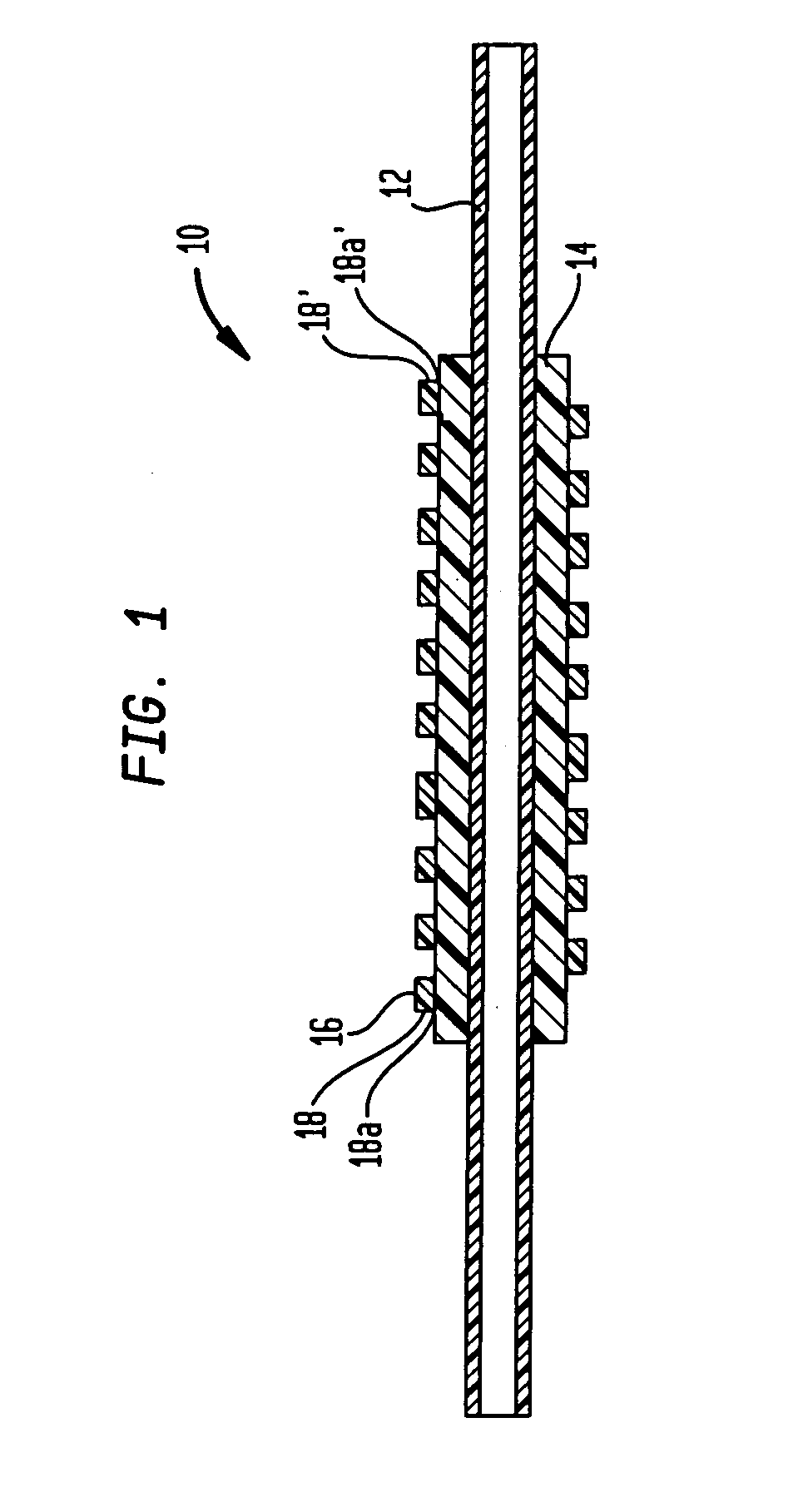

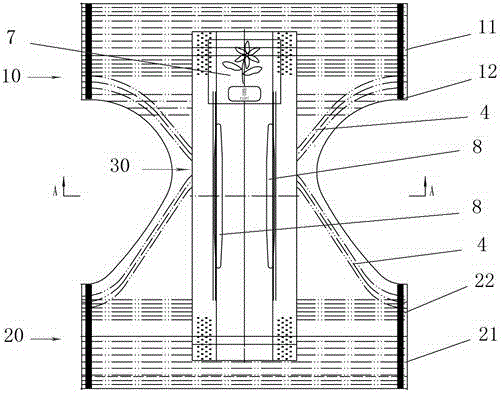

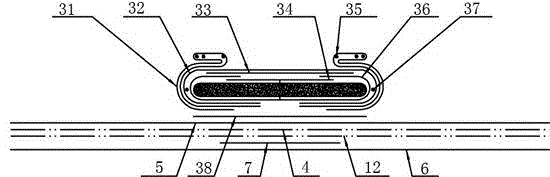

Filter unit for wastewater treatment and production of drinking water

InactiveCN101489653AIncrease productionHigh filter actionMembranesUltrafiltrationFilter systemRetrofitting

A filter unit for sewage treatment and drinking water provision and components which are suitable for the production and the use of such filter units are described. The filter unit has at least one ceramic filter(3) and at least one holder for liquid-tight fixing of the filter in the holder(2), the filter being fixed in the holder by adhesive bonding with the aid of an adhesive. At the same time, the holder is adjusted to the design of the filter, especially to its design as a flat filter. A separate filtrate collecting channel (21)and a holding device (18)for the filter units or other components allow the provision of a finished filter system which is also suitable for retrofitting of already existing plants.

Owner:ITN NANOVATION AG

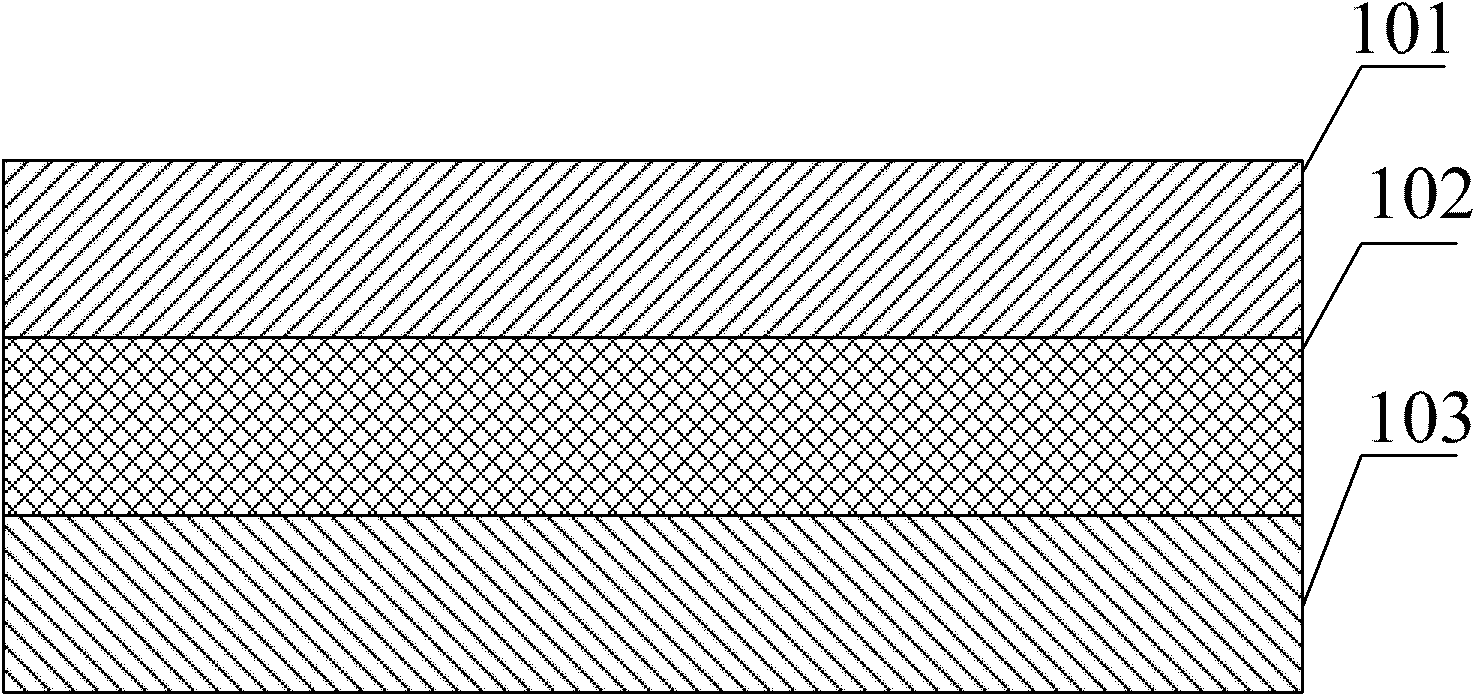

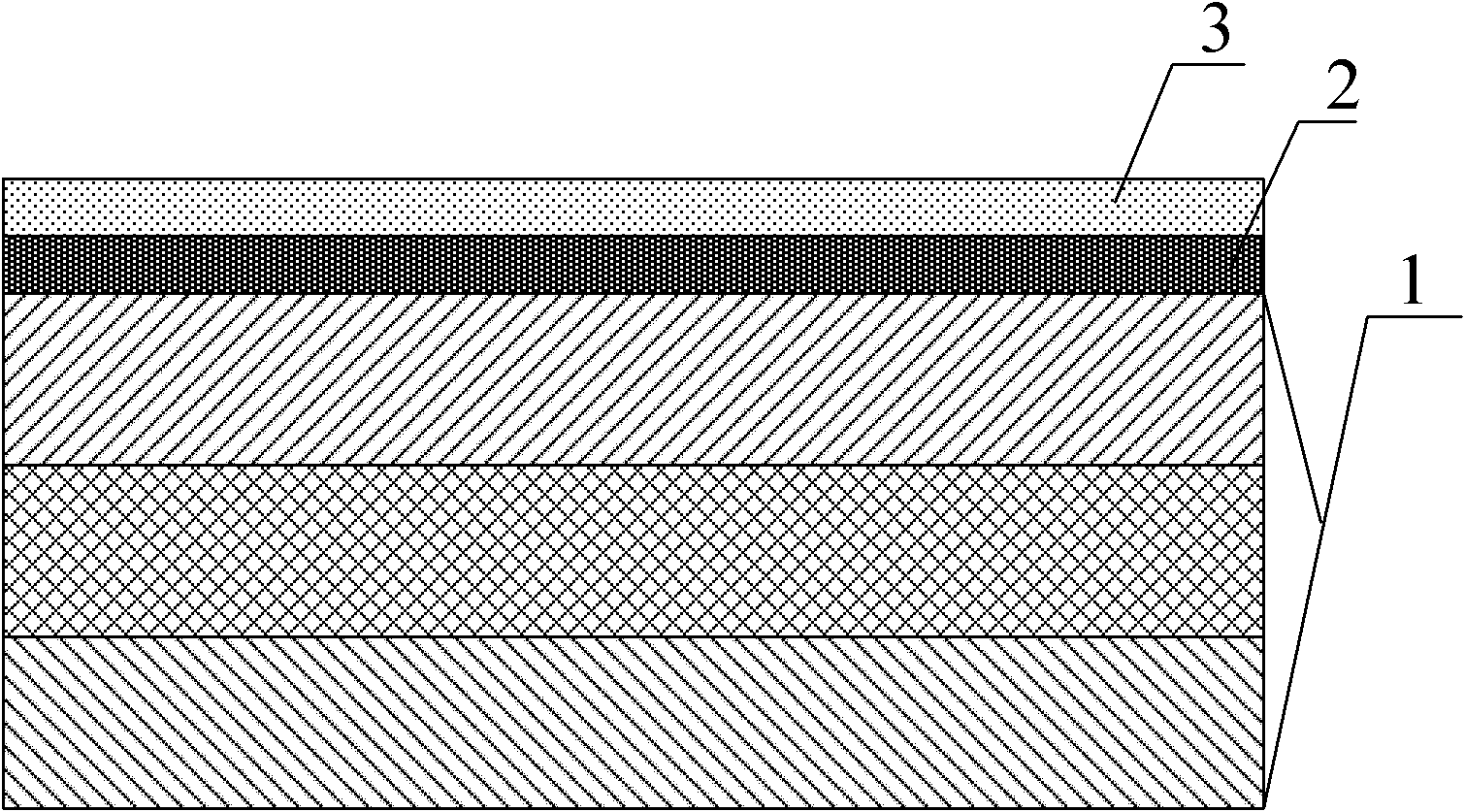

Polyethylene (PE) film and preparation method thereof

ActiveCN102179985AImprove mechanical propertiesGood solvent resistanceFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a polyethylene (PE) film and a preparation method thereof. The PE film sequentially comprises a composite layer, an intermediate layer and a heat-seal layer, wherein the composite layer comprises 25 to 40 weight percent of low-density PE, 25 to 40 weight percent of linear low-density PE and 33 to 45 weight percent of modified metallocene linear low-density PE; the intermediate layer comprises 25 to 50 weight percent of the low-density PE and 50 to 75 weight percent of the linear low-density PE; and the heat-seal layer comprises 28 to 35 weight percent of the low-density PE and 65 to 72 weight percent of the linear low-density PE. The invention also provides a cleaning solution packaging composite film and a cleaning solution packaging bag, wherein the cleaning solution packaging composite film is prepared from the PE film. Correspondingly, the invention also provides a preparation method of the cleaning solution packaging composite film which is prepared from the PE film. A product is packaged by the PE film provided by the invention, so the packaging bag has certain solvent resistance and excellent heat-seal performance, the relatively high sealing property and tensile strength of a material subjected to heat sealing are guaranteed, and the leakage resistance and falling resistance of the composite film which is prepared by the material are further improved.

Owner:HUANGSHAN NOVEL

Self-sealing vascular graft

ActiveUS20070123968A1Improve leak-proof effectAvoid insufficient compressionMedical devicesBlood vesselsVascular graftBlood vessel

Owner:VASCULAR DEVICES

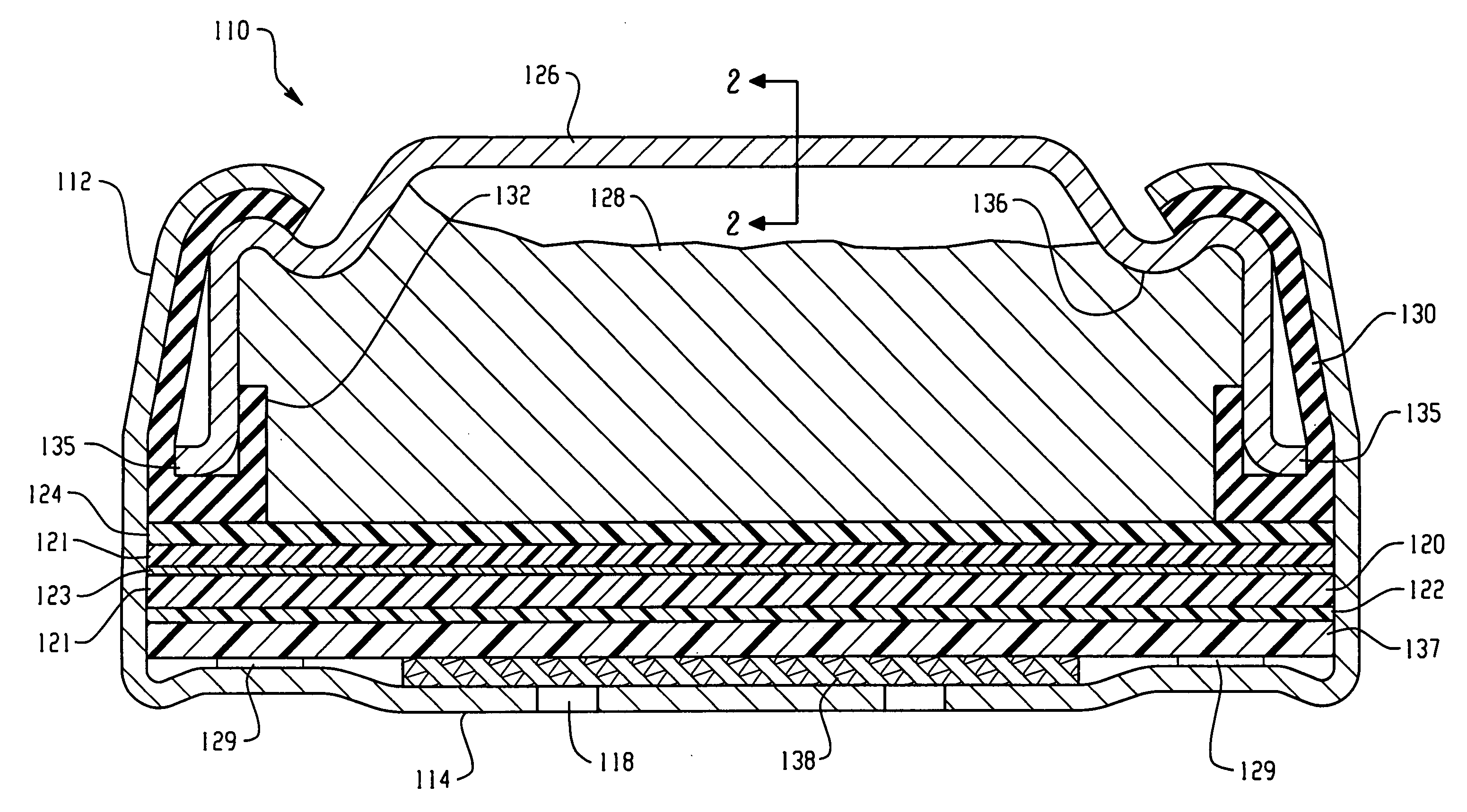

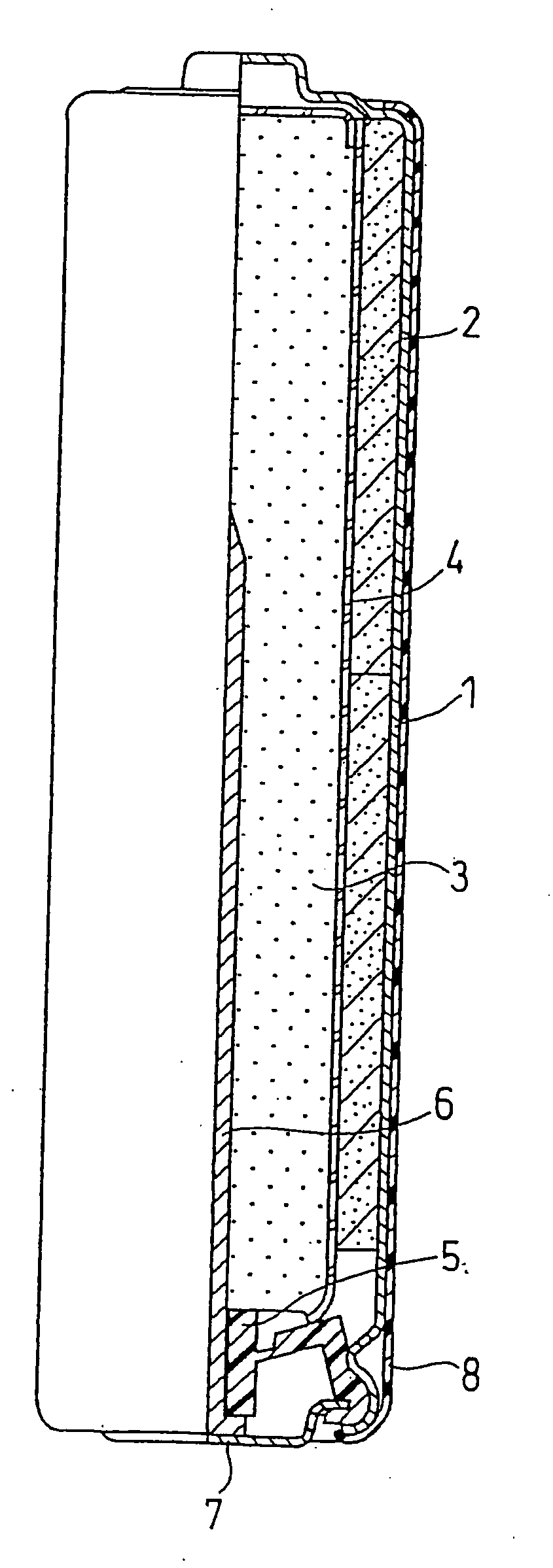

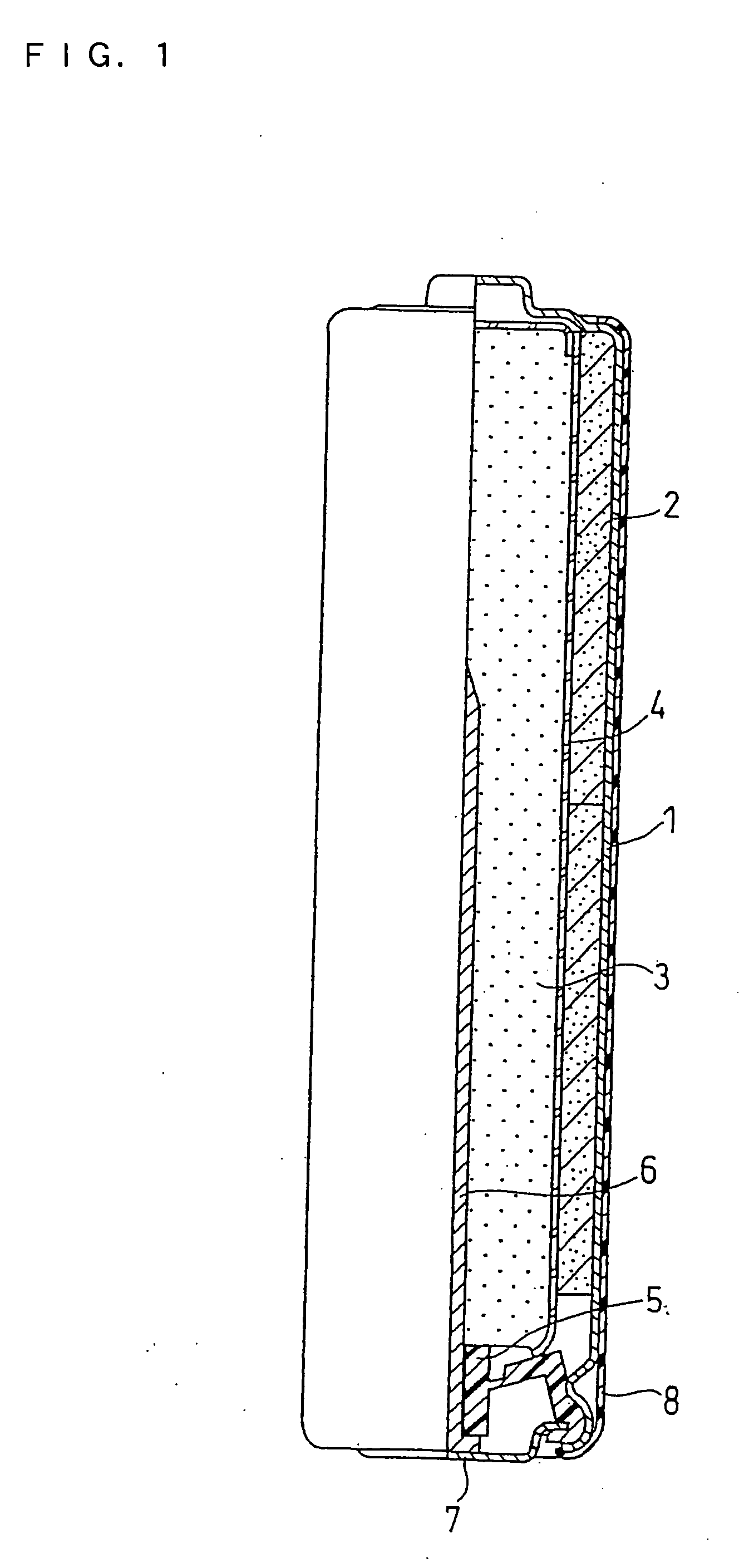

Flat-shaped non-aqueous electrolyte secondary battery

InactiveUS20080070109A1Improve leak-proof effectFinal product manufactureJackets/cases materialsSurface layerEngineering

A flat-shaped non-aqueous electrolyte secondary battery of the present invention includes: an electrode body formed by opposing a positive electrode and a negative electrode while interposing a separator therebetween; an outer case for housing the electrode body; and a sealing plate for sealing an opening of the outer case, and an end part of the sealing plate is positioned inside the outer case. Besides, the sealing plate functions as a positive electrode terminal, the outer case functions as a negative electrode terminal, and a surface layer of the sealing plate in contact with the positive electrode is formed with a metal layer made of aluminum or aluminum alloy.

Owner:HITACHT MAXELL LTD

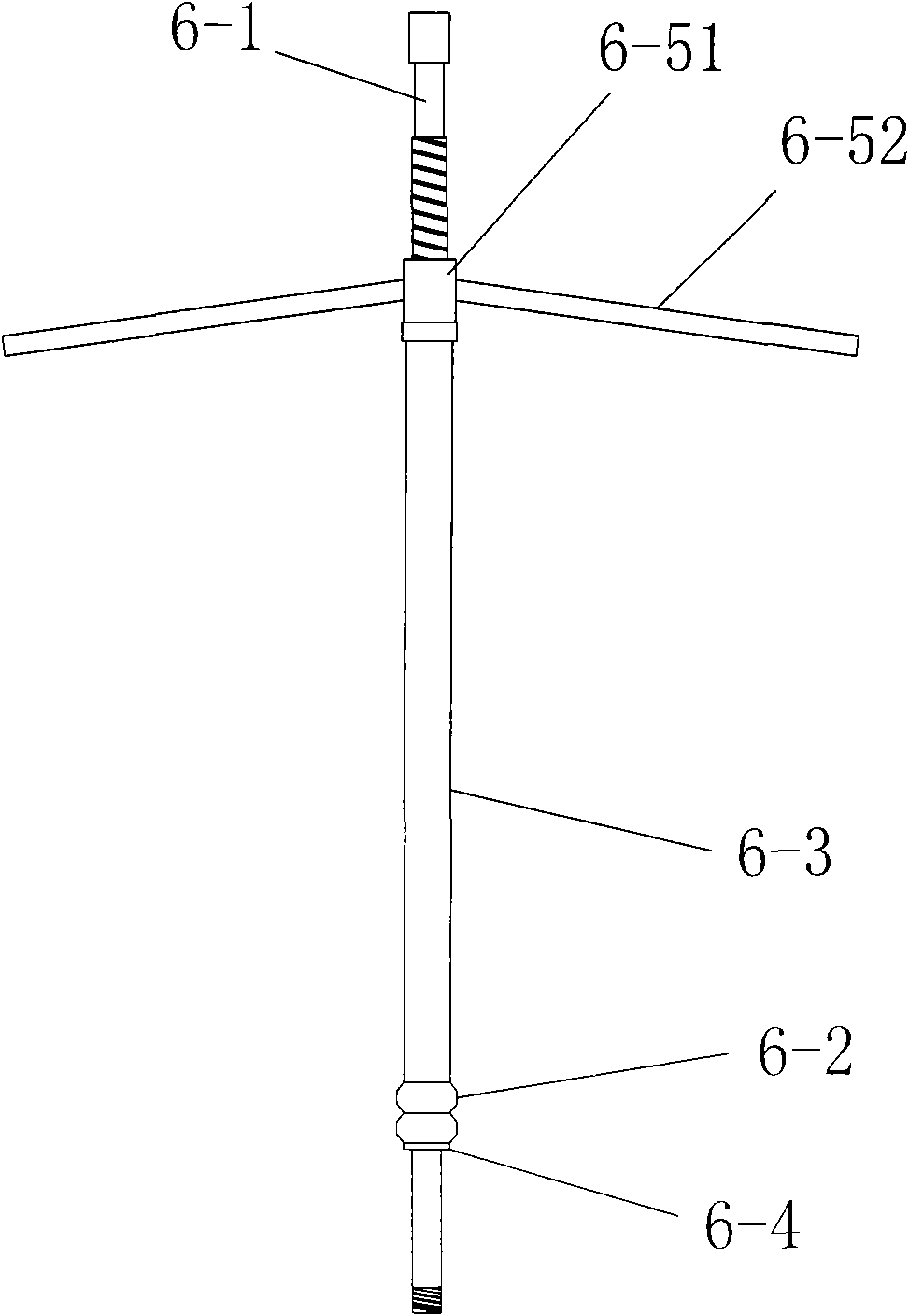

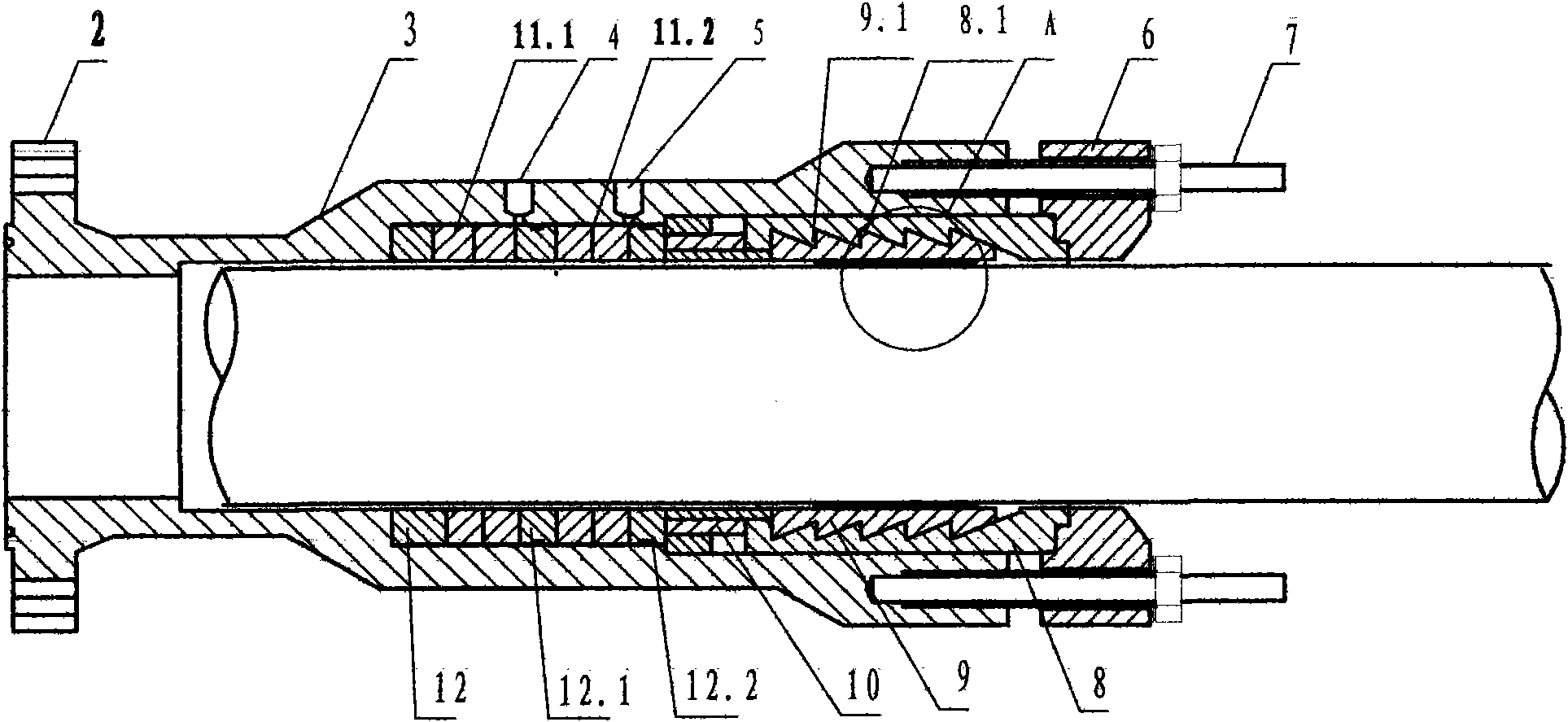

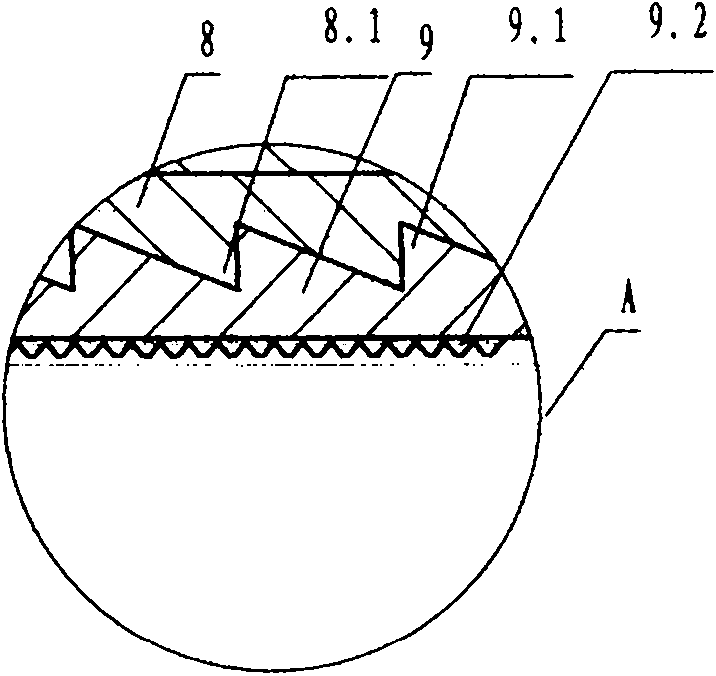

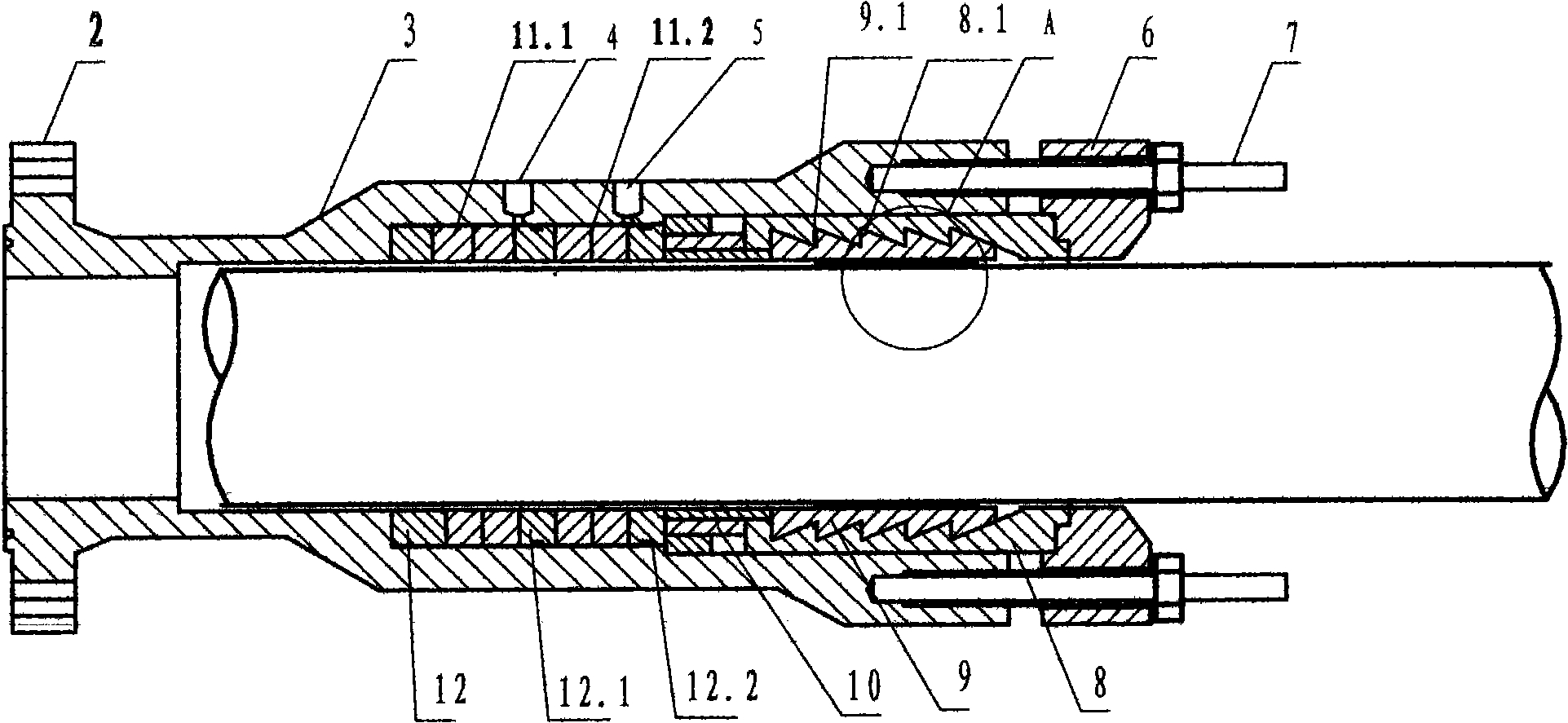

Pipeline connector

The invention relates to a pipeline connector. The pipeline connector is characterized in that a tubular connection body (3) is arranged, the front end of the tubular connection body is provided with a flange connection tray (2) while the rear end is provided with a flange pressure plate (6), the inner chamber of the connection body is internally provided with a sealing element that and a clasping element, wherein the sealing element consists of sealing rings (11.1, 11.2) and sealing ring retainer rings (12, 12.1, 12.2) arranged in parallel or at intervals, and the clasping element consists of a tubular slip (9) and a slip sleeve (8), the slip sleeve is sheathed outside the slip, the outer wall of the slip and the inner wall of the slip sleeve are respectively provided with chucking teeth (9.1, 8.1) matched with each other, the rear end of the slip sleeve is tightly pressed by the flange pressure plate, and the flange pressure plate and the rear end of the connection body are fixed by an axial bolt (7). The invention has advantages of simple and smart structure, quick and convenient operation and good leakage-proof effect; and particularly, by adopting the invention, broken pipelines can be removed flexibly, available pipelines can be reserved to the largest extent, the restoration work is simple and convenient, the materials can be saved, and the restoration cost can be reduced greatly.

Owner:周庆涛

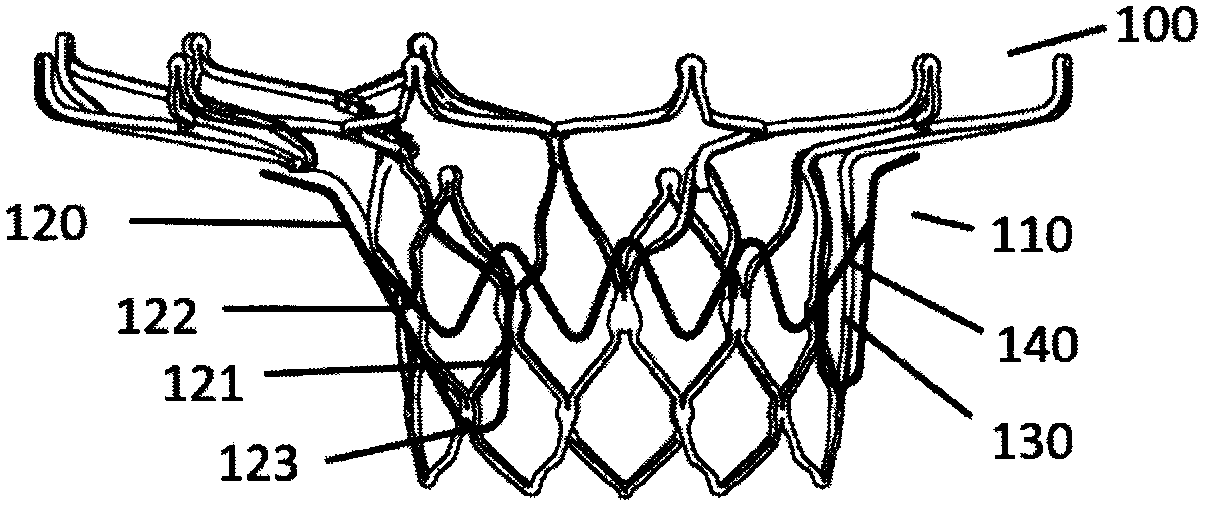

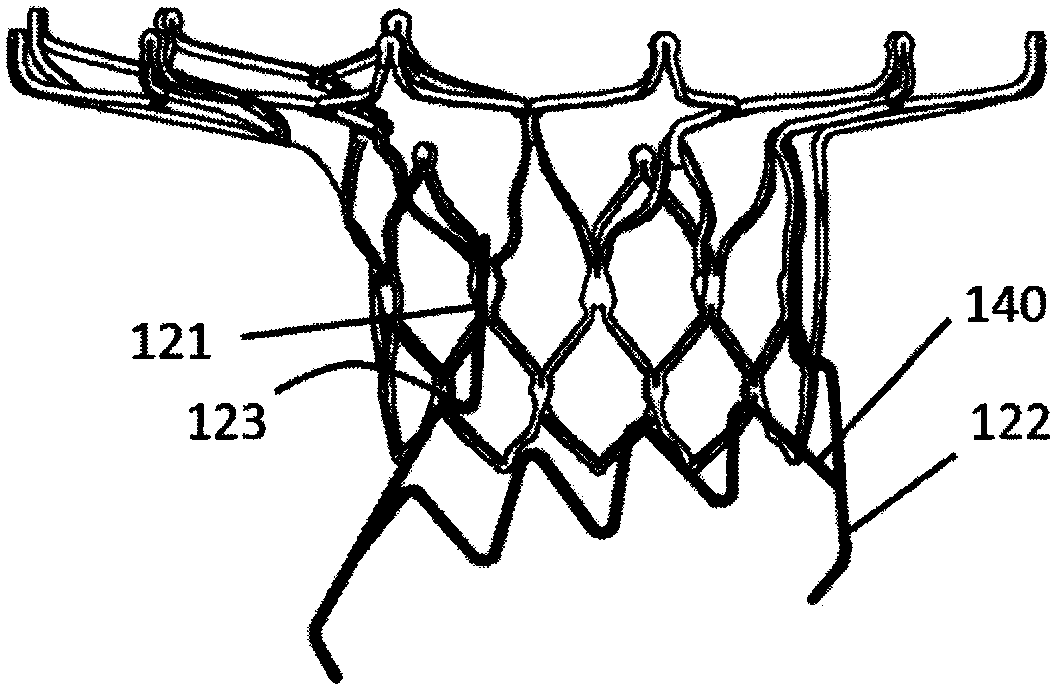

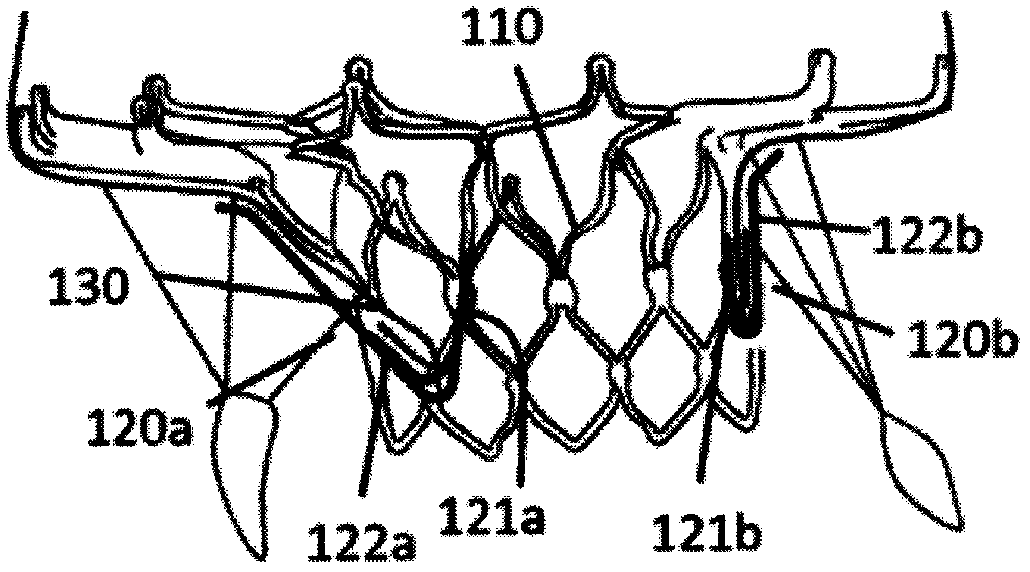

A prosthetic valve prosthesis with an anchor

The present application relates to a prosthetic valve prosthesis with an anchor, includes a bracket body having a passage for supplying blood flow and at least one fixing member, the fixing member isconnected with the bracket body, the fixing member includes a lower extension section and an upper extension section, one end of the lower extension section is connected with the bracket body as a fixed end, the other end of the lower extension extends proximally along the axis of the bracket body, extending distally in the opposite direction after passing through the bent region and connected tothe upper extension. The upper extension section is located on the outer side of the lower extension section, and a leaf receiving cavity is formed between the lower extension section and the upper extension section. The fixing member is further provided with a lamination device, and when the fixing member is completely released, the self-body leaf is stacked in the leaf receiving cavity. The clamping force of the fixation part of the prosthetic valve prosthesis is not influenced by the space between the stent body and the fixation part, and the influence on the blood outflow channel after thestent body is released is greatly reduced.

Owner:NINGBO JENSCARE BIOTECHNOLOGY CO LTD

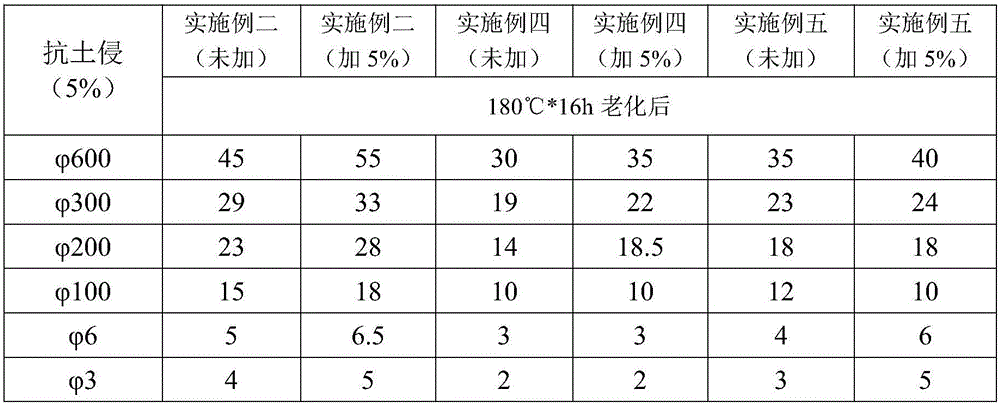

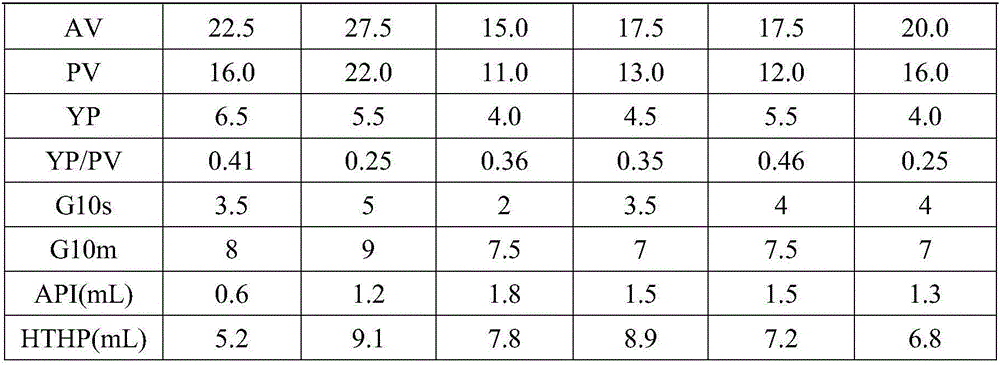

Ultralow-density oil-base drilling fluid and preparation method thereof

The invention relates to an ultralow-density oil-base drilling fluid. The invention is characterized in that the ultralow-density oil-base drilling fluid is prepared from the following raw materials: base oil, a density reducer, a suspension stabilizer, an emulsifier, a tackifier, a fluid loss additive, a flow pattern regulator, an alkalinity regulator and a calcium chloride water solution. The base mixed oil is prepared by the following steps: mixing 3# white oil, 5# white oil and natural gas prepared oil, adding a flash point enhancer while stirring, and standing for 0.5-1 hour; and stirring at low speed at the temperature of 30-40 DEG C, and slowly adding oil-soluble nano fumed silica while stirring, wherein the addition process is controlled at 2-3 hours. The ultralow-density oil-base drilling fluid has the advantages of favorable emulsifying stability, favorable rheological properties, high inhibition property for mud shale, high emulsion-breaking voltage, low filter loss, low density (0.75-0.90 g / cm<3>), and high sand carrying and pressure bearing capacities, is beneficial to cleaning the borehole and enhancing the mechanical drilling speed, solves the problem of severe lost circulation in the low-pressure formation and long-section shatter zone formation, and is especially suitable for low-pressure oil gas pools and depletion water-sensitive formations.

Owner:成都西油华巍科技有限公司 +1

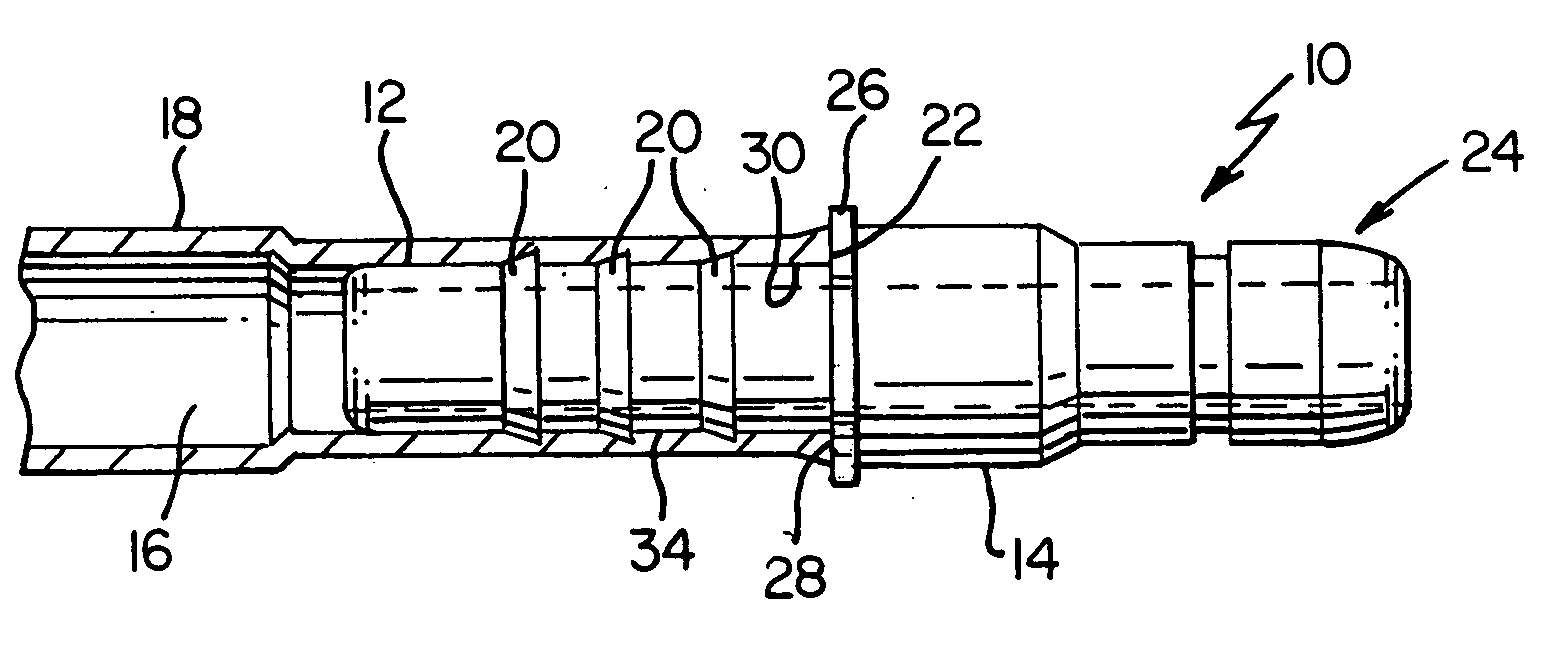

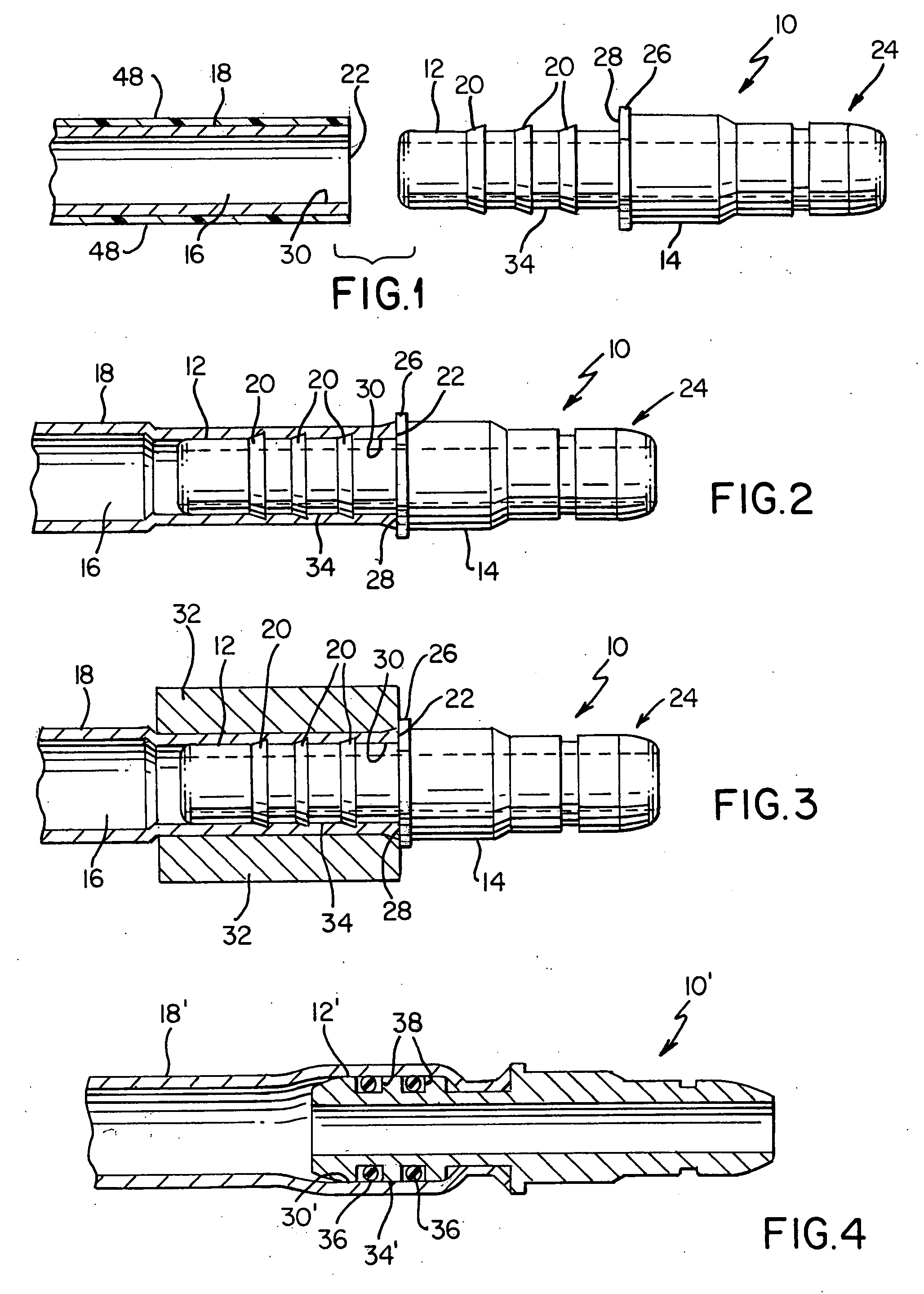

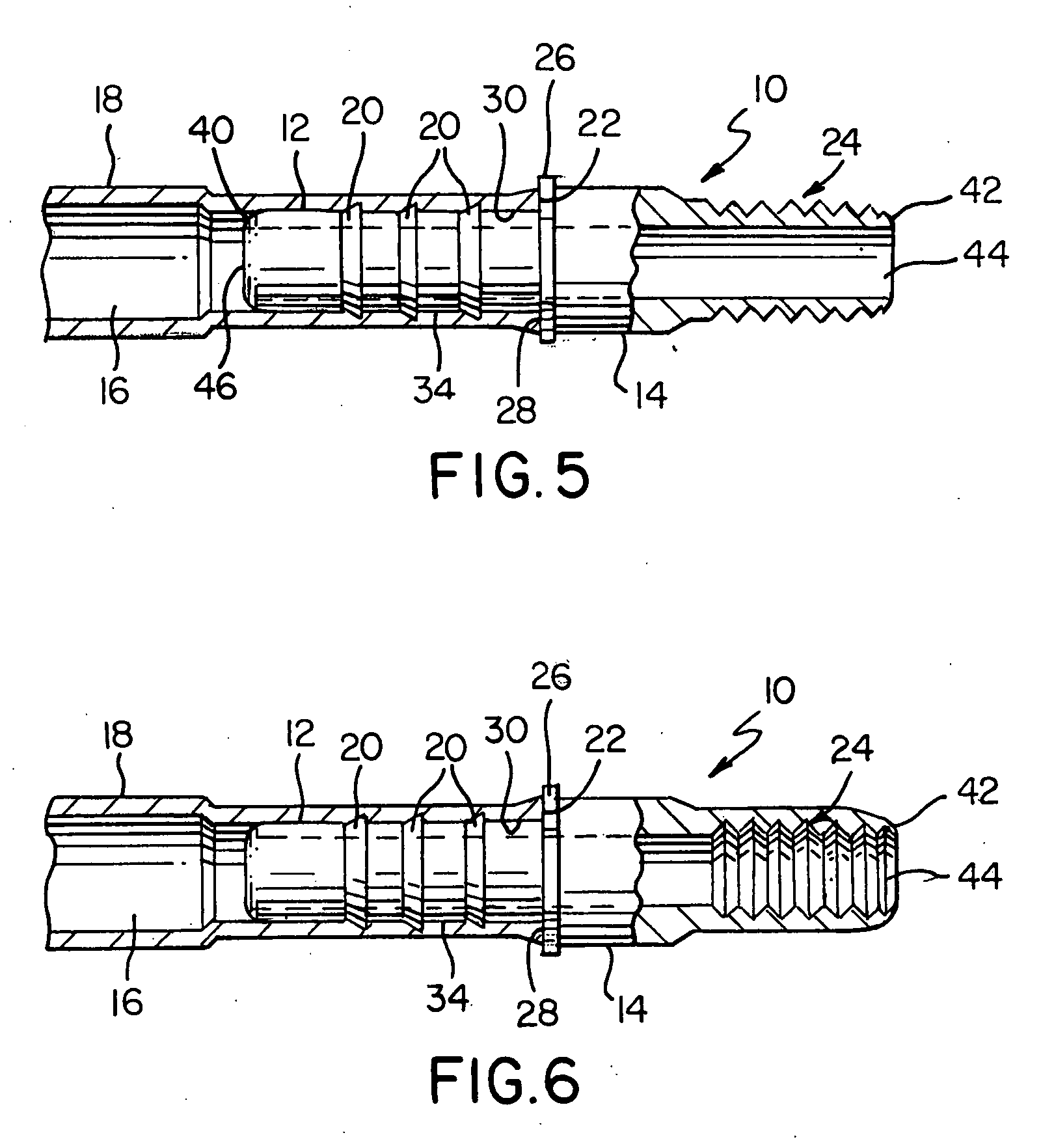

Brazeless connector for fluid transfer assemblies

InactiveUS20070152442A1Improve leak-proof effectImprove sealingHose connectionsPipe connection arrangementsFluid transportEngineering

A metal end fitting connector having an axial bore through which a fluid is conveyed; comprises a metal stem portion which includes a first metal tubular body having a first annular rim disposed at a distal end of the first metal tubular body, wherein the distal end is adapted to be inserted into an inner channel of a metal fluid transport tube. The metal stem portion includes at least one annular sealing member extending circumferentially outward from an outer surface of the first metal tubular body; and a metal connector portion opposite the distal end of the first metal tubular body. The metal connector portion includes a second metal tubular body having a second annular rim disposed at a distal end of the second metal tubular body, wherein the distal end of the second metal tubular body is adapted to be coupled with another fluid conveying structure.

Owner:FLUID ROUTING SOLUTIONS

Cylindrical battery and method for manufacturing the same

InactiveUS6703157B1Good effectImprove leak-proof effectAlkaline accumulatorsFinal product manufactureInternal pressureLarge capacity

The present invention provides a high-capacity cylindrical battery, wherein a burst-proof mechanism, which functions to discharge a gas outside when the internal pressure of the battery abnormally increases, does not sacrifice the space for power generating elements but increases the total capacity for power generating elements. The cylindrical battery of the present invention has a circular groove formed in the vicinity of an opening of a battery case, in which power generating elements are accommodated, the circular groove having a bottom that is bent inward the battery case and has at least one gas discharge aperture, which is sealed with a seal element. The seal element is an elastic ring to be set in the groove and seal the gas discharge aperture. This arrangement enables the gas discharge aperture to be sealed again even after the burst-proof mechanism functions, thereby ensuring a continuous use of the battery.

Owner:PANASONIC CORP

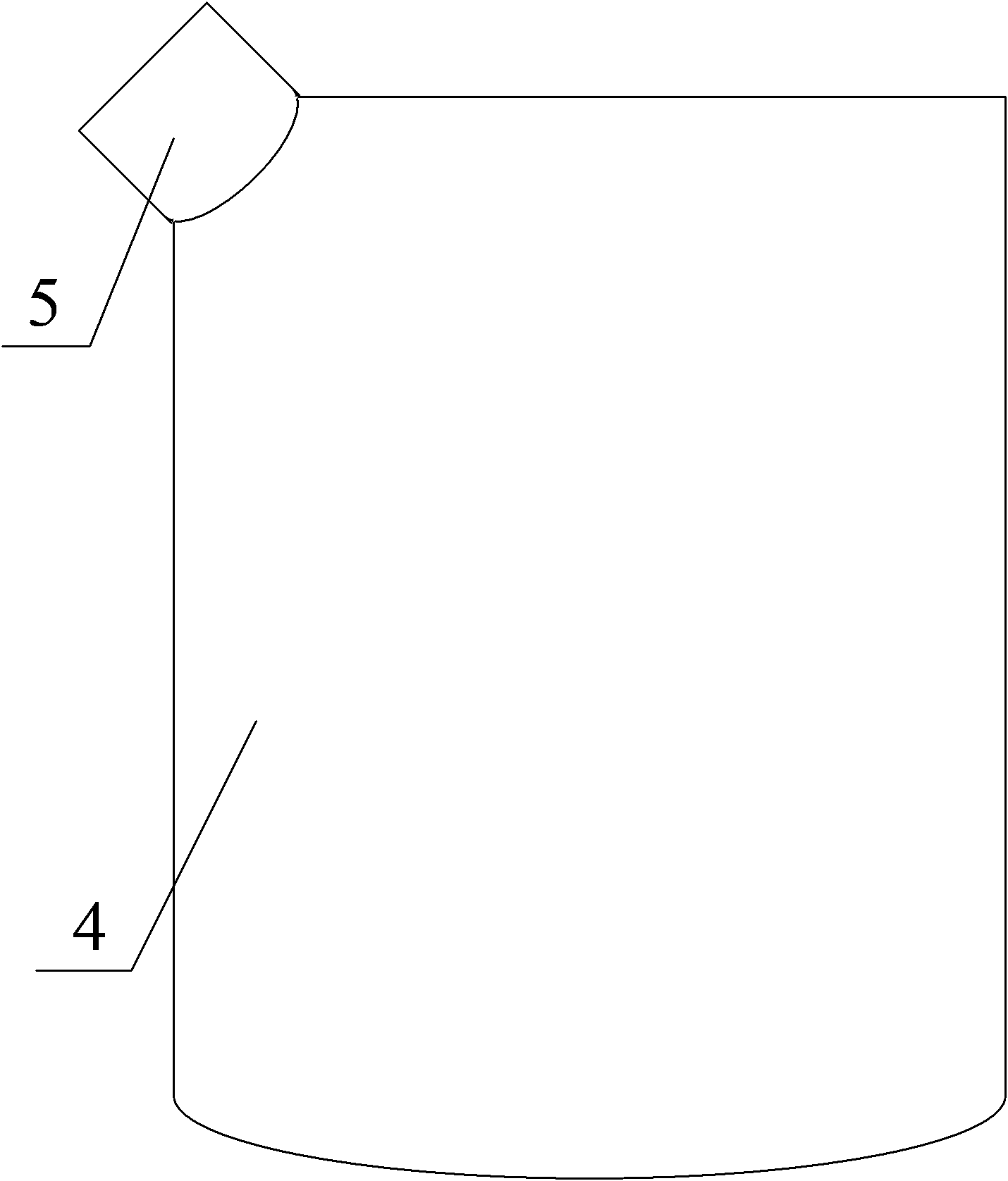

Novel pull-up pants

InactiveCN104970925AFit to wearImprove leak-proof effectAbsorbent padsBandagesEngineeringRubber band

The present invention provides novel pull-up pants. The novel pull-up pants comprise a front waist portion, a rear waist portion and a compound diaper; the compound diaper is disposed at a crotch position between the front waist portion and the rear waist portion; the front waist portion and the rear waist portion are both provided with waistline rubber bands; the waistline rubber bands are arranged with intervals; the waistline rubber bands of the front waist portion comprise first outer waistline rubber bands and first inner waistline rubber bands; the number of the first outer waistline rubber bands is 10-20; the number of the first inner waistline rubber bands is 3-8, and the first inner waistline rubber bands are close to the crotch position; the waistline rubber bands of the rear waist portion comprise second outer waistline rubber bands and second inner waistline rubber bands; the number of the second outer waistline rubber bands is 8-12; and the number of the second inner waistline rubber bands is 4-10, and the second inner waistline rubber bands are close to the crotch position. Configuration arrangement of the waistline rubber bands is more suitable for infant wearing, according to usual body actions of infants, the rubber bands of the front waist portion are tight outside and loosening inside, the novel pull-up pants are comfortable and air-permeable, the rubber bands of the rear waist portion are loosening outside and tight inside, so that the novel pull-up pants are attached to the waist portion with good leakproof effect.

Owner:JINJIANG SHUNCHANG MACHINE MFG

Seal ring

ActiveUS20060038355A1Inhibit wearEasily vomitedEngine sealsPiston ringsEngineeringMechanical engineering

Owner:NOK CORP

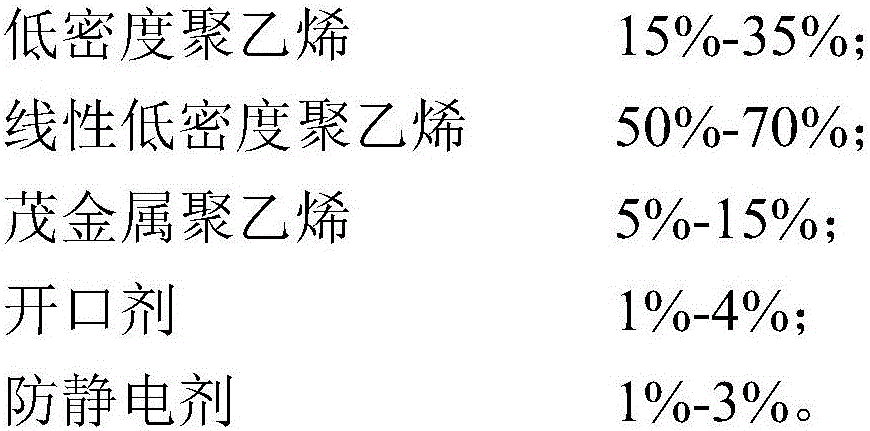

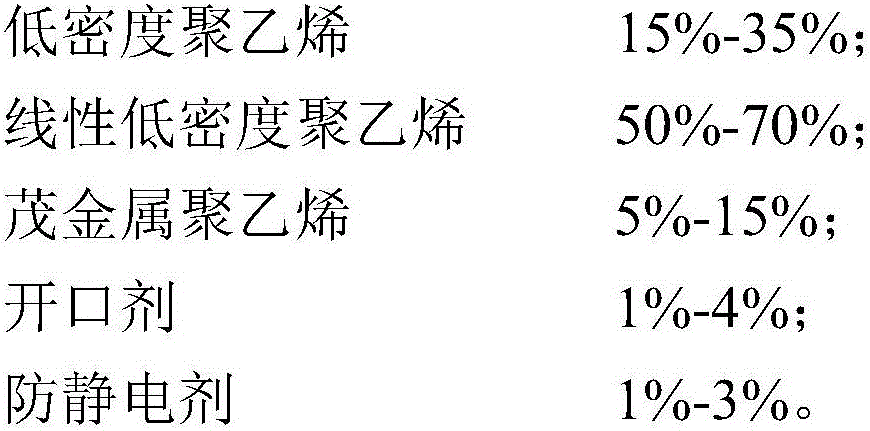

High-strength antistatic polyethylene film as well as preparation method and application thereof

InactiveCN106432888AImprove mechanical propertiesEasy to stretchBag making operationsPaper-makingLow-density polyethyleneBlow molding

The invention discloses a high-strength antistatic polyethylene film. The polyethylene film contains the following components in percentage by weight: 15-35% of low-density polyethylene, 50-70% of linear low-density polyethylene, 5-15% of metallocene polyethylene, 1-4% of an anti-blocking agent, and 1-3% of an antistatic agent. Besides, the invention also discloses a preparation method and application of the high-strength antistatic polyethylene film. The high-strength antistatic polyethylene film provided by the invention is prepared by the steps of taking the low-density polyethylene (LDPE) as a base material, adding the linear low-density polyethylene (LLDPE) and the metallocene polyethylene (MLLPE) and performing blending extrusion, granulation and blow molding, so that the polyethylene film has relatively good tensile strength and antistatic property; and a packaging bag prepared from the high-strength antistatic polyethylene film has the characteristics of good economical efficiency and mechanical property, lasting antistatic property and convenience in use.

Owner:东莞市中为包装制品有限公司

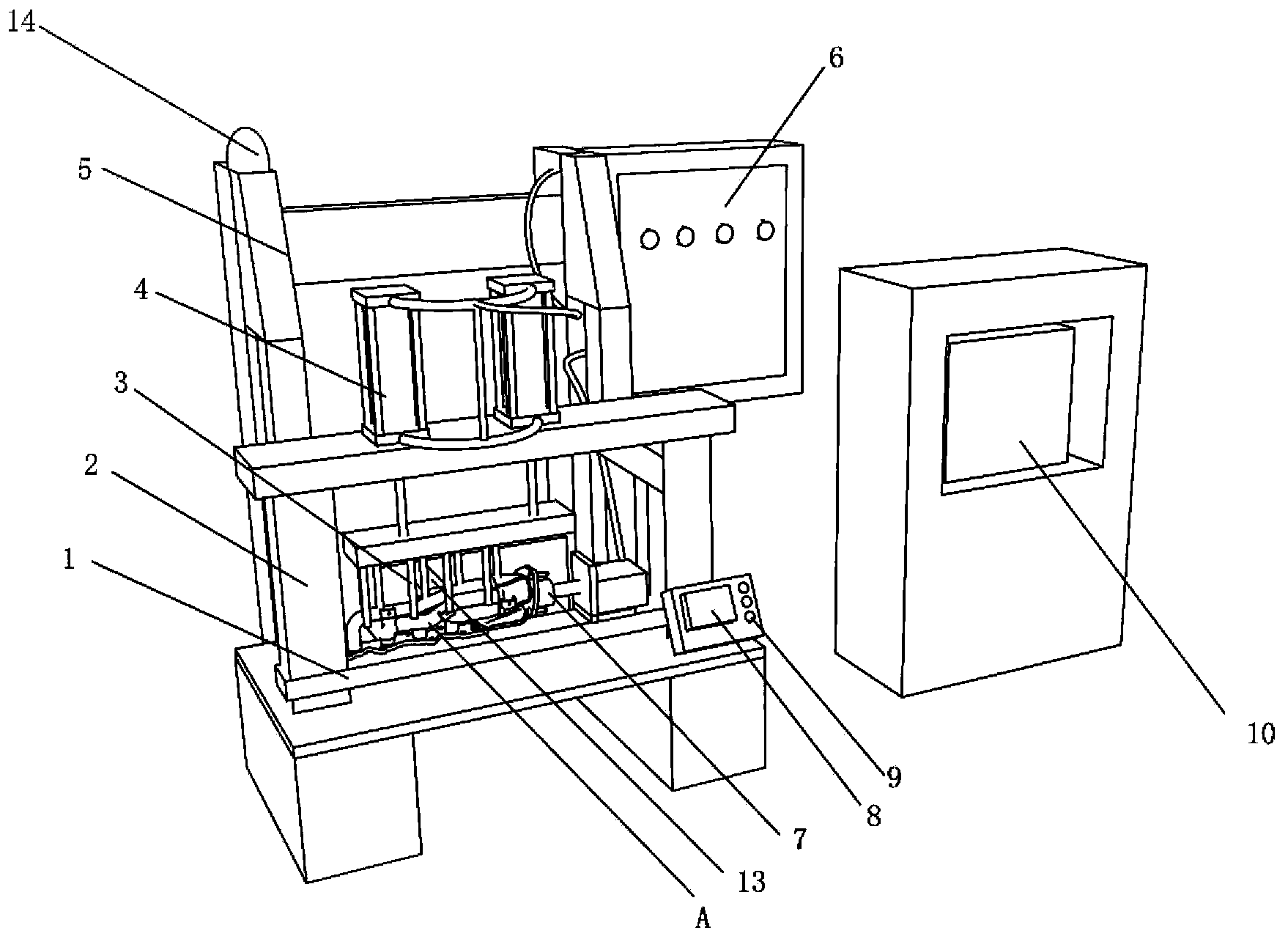

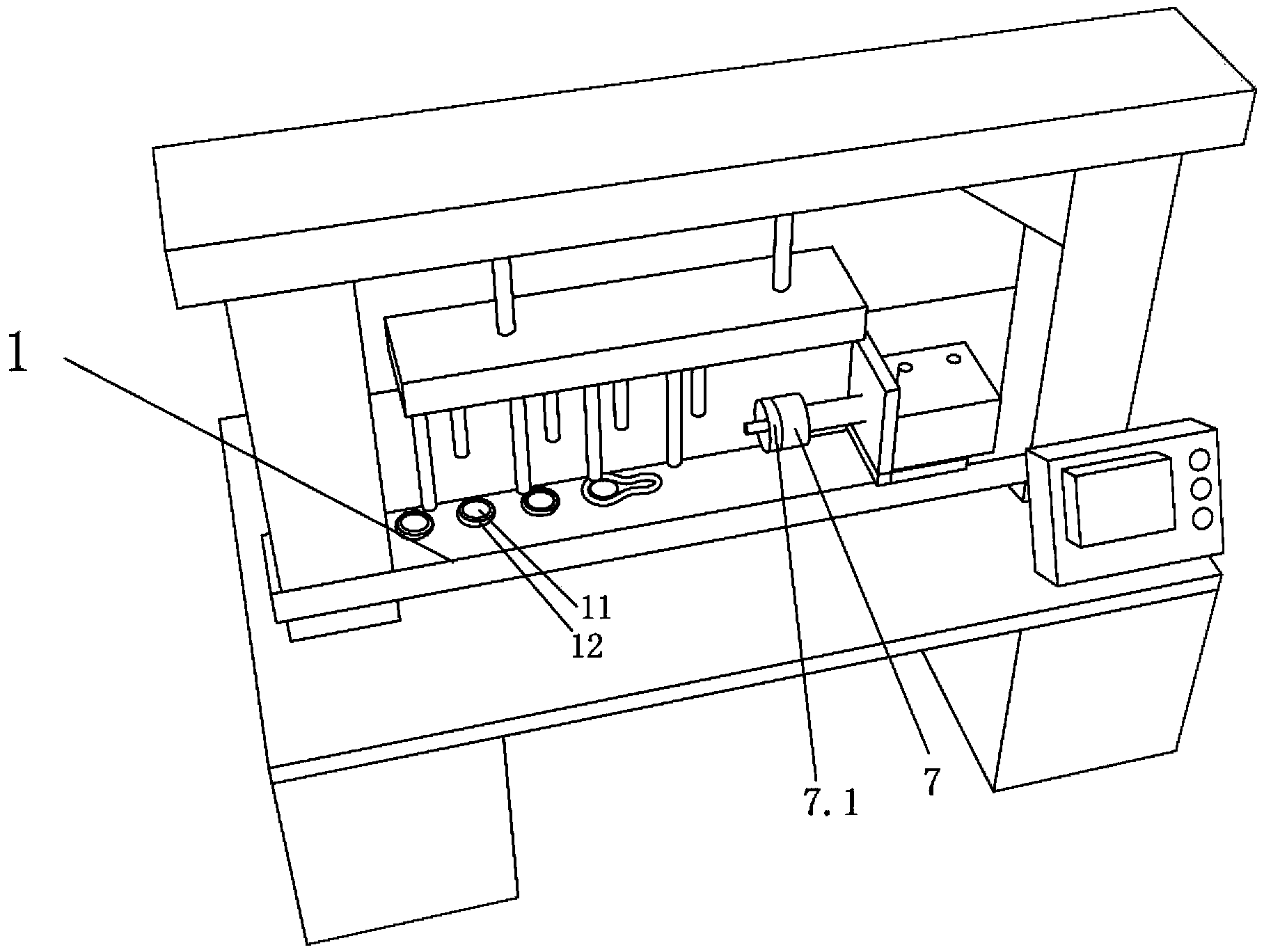

Exhaust manifold gas detection machine and detection method thereof

InactiveCN103868666AQuality improvementExtended service lifeMeasurement of fluid loss/gain rateCompression deviceDisplay device

The invention discloses an exhaust manifold gas detection machine and a detection method thereof. The exhaust manifold gas detection machine comprises a detection platform for placing an exhaust manifold; a compression device for compressing the exhaust manifold is arranged on the detection platform; the exhaust manifold gas detection machine is characterized in that an inflating valve capable of sliding in the detection platform is arranged at the side part of the detection platform; the inflating volume and time of the inflating valve are controlled by a control computer and a control display panel; the inflating valve is also provided with pressure sensor equipment capable of feeding gas pressure data back to a control display device. The detection method is reliable, and the anti-leakage property is improved by more than 40% compared with that of the existing product.

Owner:柳州恒耀汽车零部件有限公司

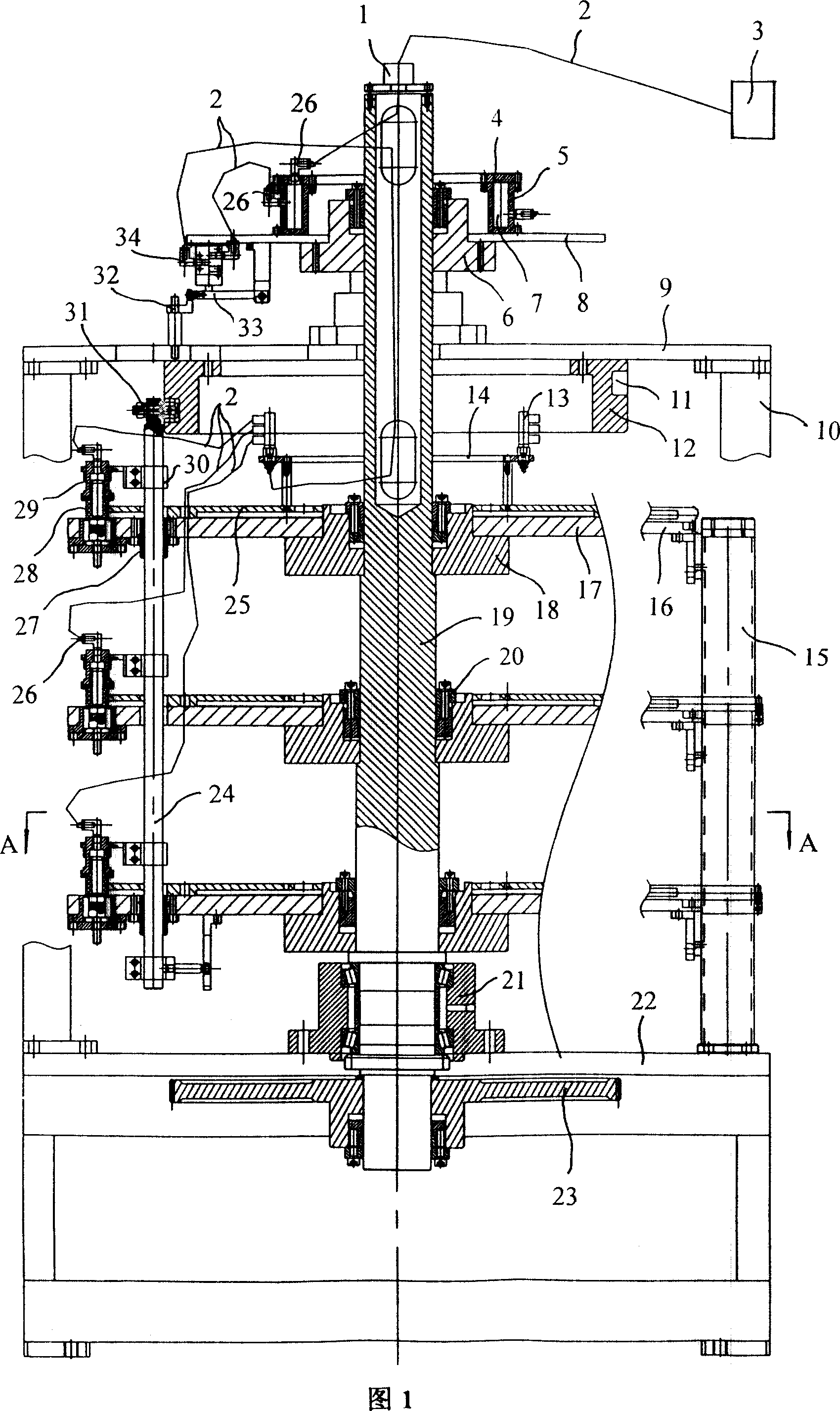

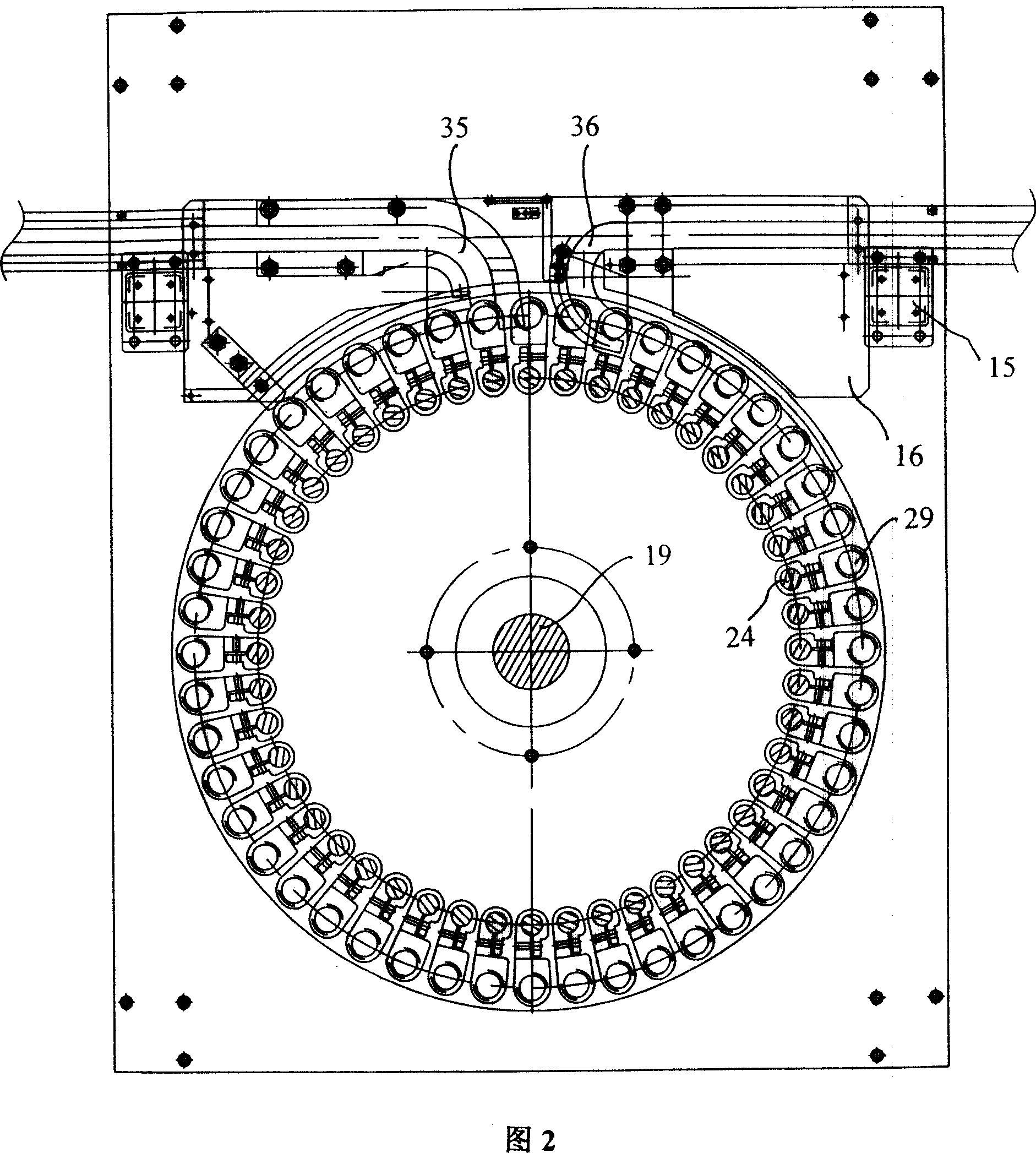

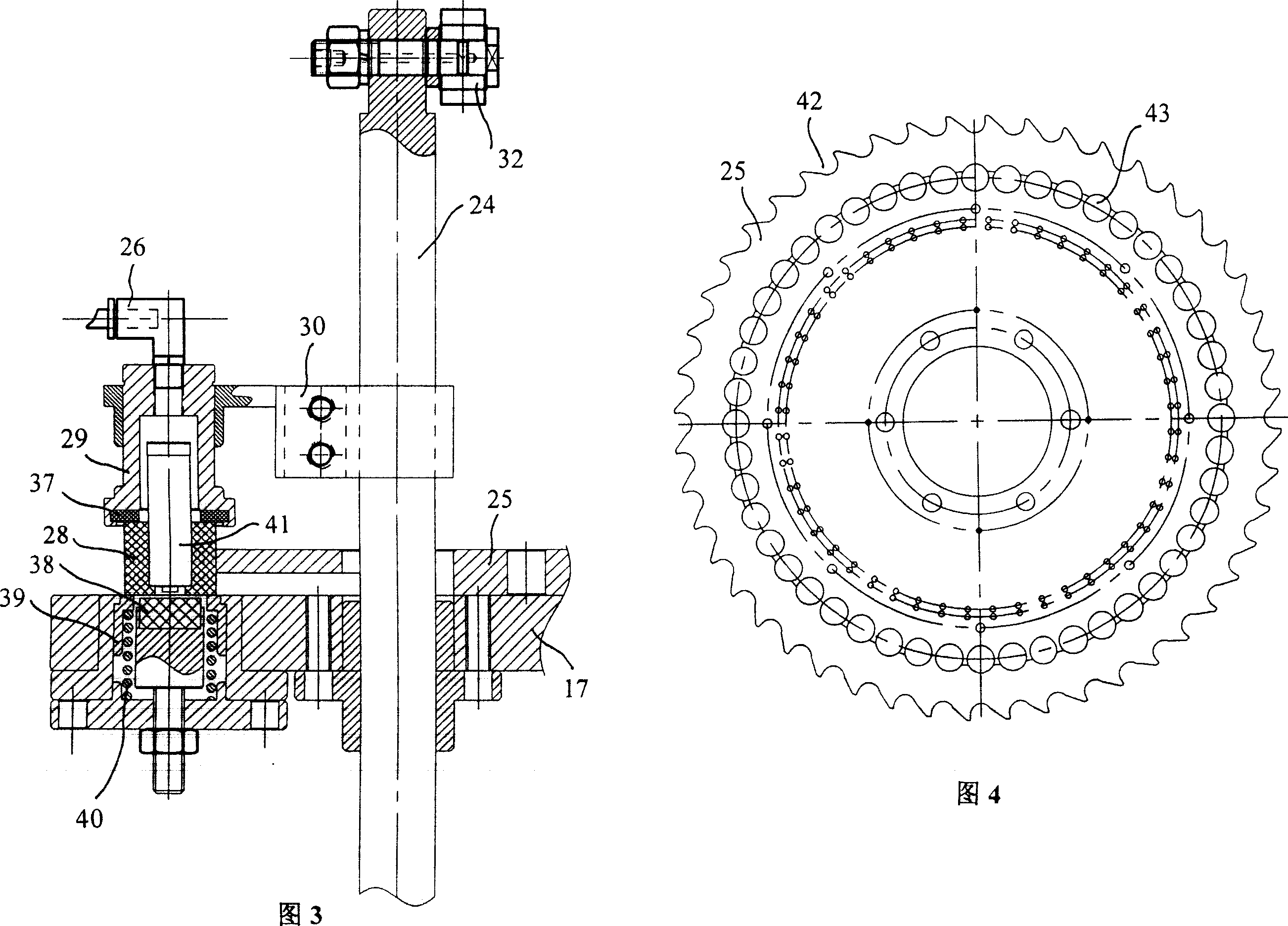

Alkaline dry battery electrolyte vacuum absorption device

InactiveCN101017889APrevent splashIngenious ideaElectrolyte moving arrangementsPrimary cell maintainance/servicingInternal resistanceEngineering

The disclosed vacuum absorption device for electrolyte in alkali dry cell comprises: a base, a column, a top plate, a main shaft set on the base and plate to drive the rotation by frequency- changing motor and gear, multilayer synchronous rotating support-cup rotative mechanisms every with multiple support-cup positions for assembling cell roundly and transferring the cups, a cell set in the room sealed by the cover cup and support cup, a gas-pipe member connected with a vacuum pump and controlled by a vacuum valve. this invention is smart and simple, fit to fast complete the absorption process, avoids liquid splashing, and overcomes defects in prior art.

Owner:NINGBO BODAWUTONG BATTERY TECH

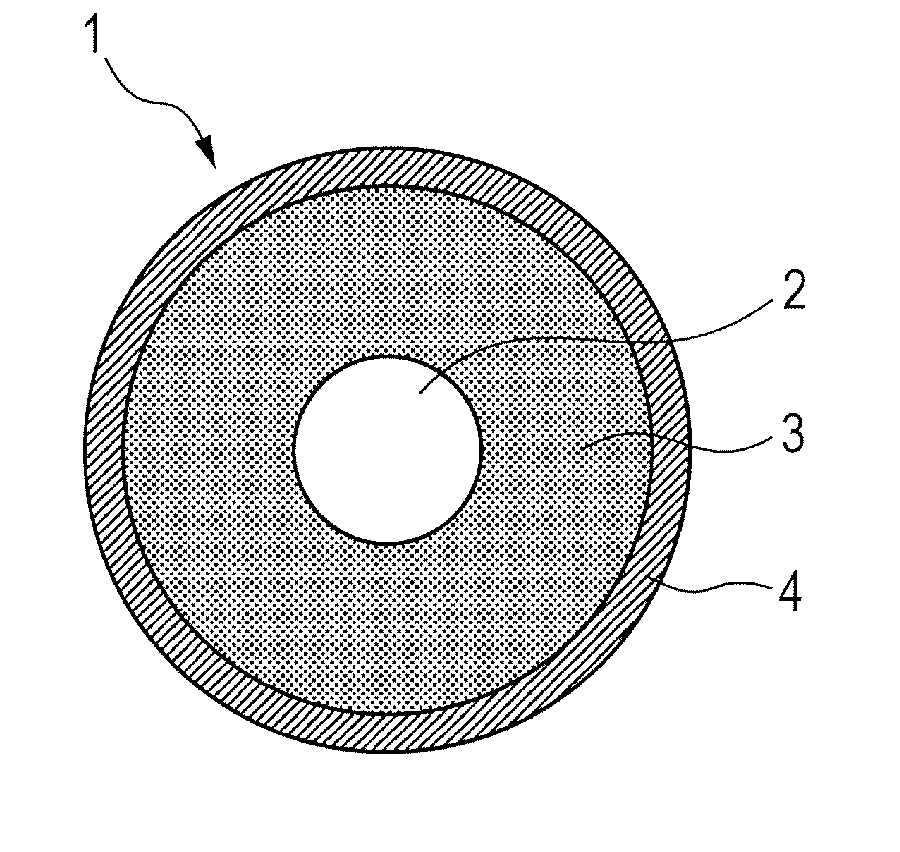

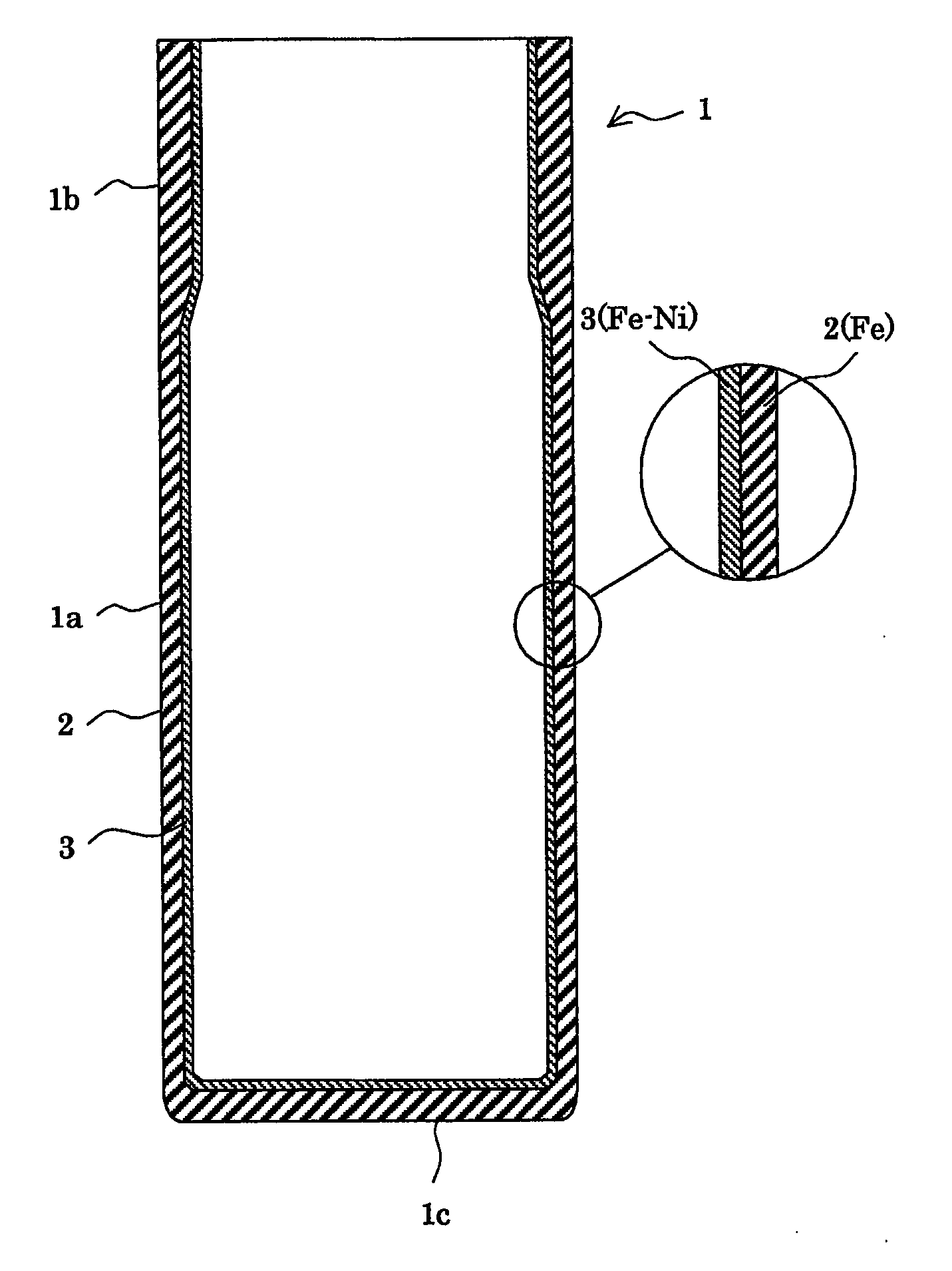

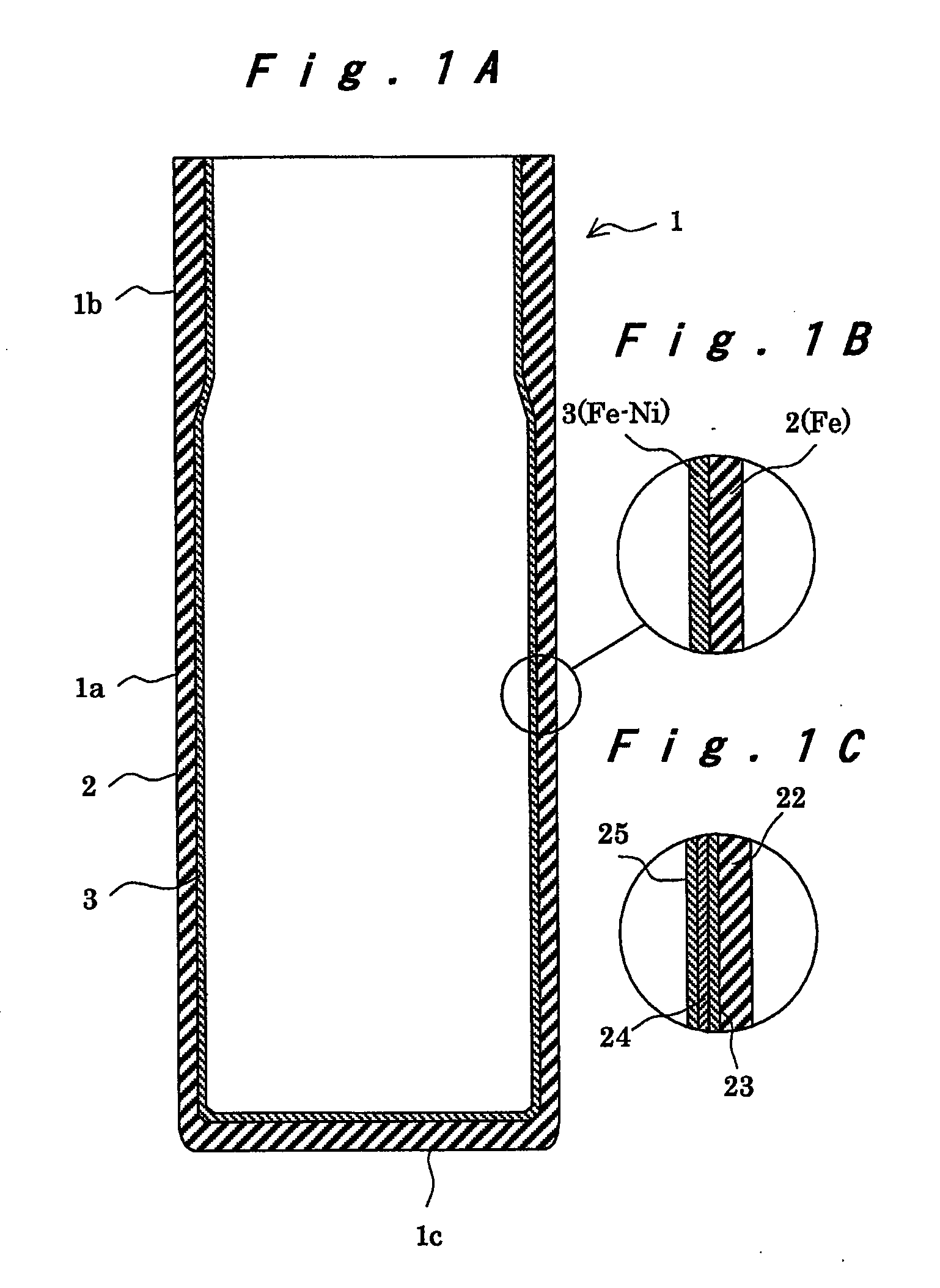

Battery case and battery using the same

InactiveUS20090311595A1Lower battery costsIncrease volumeFinal product manufactureJackets/cases materialsEngineeringDiffusion layer

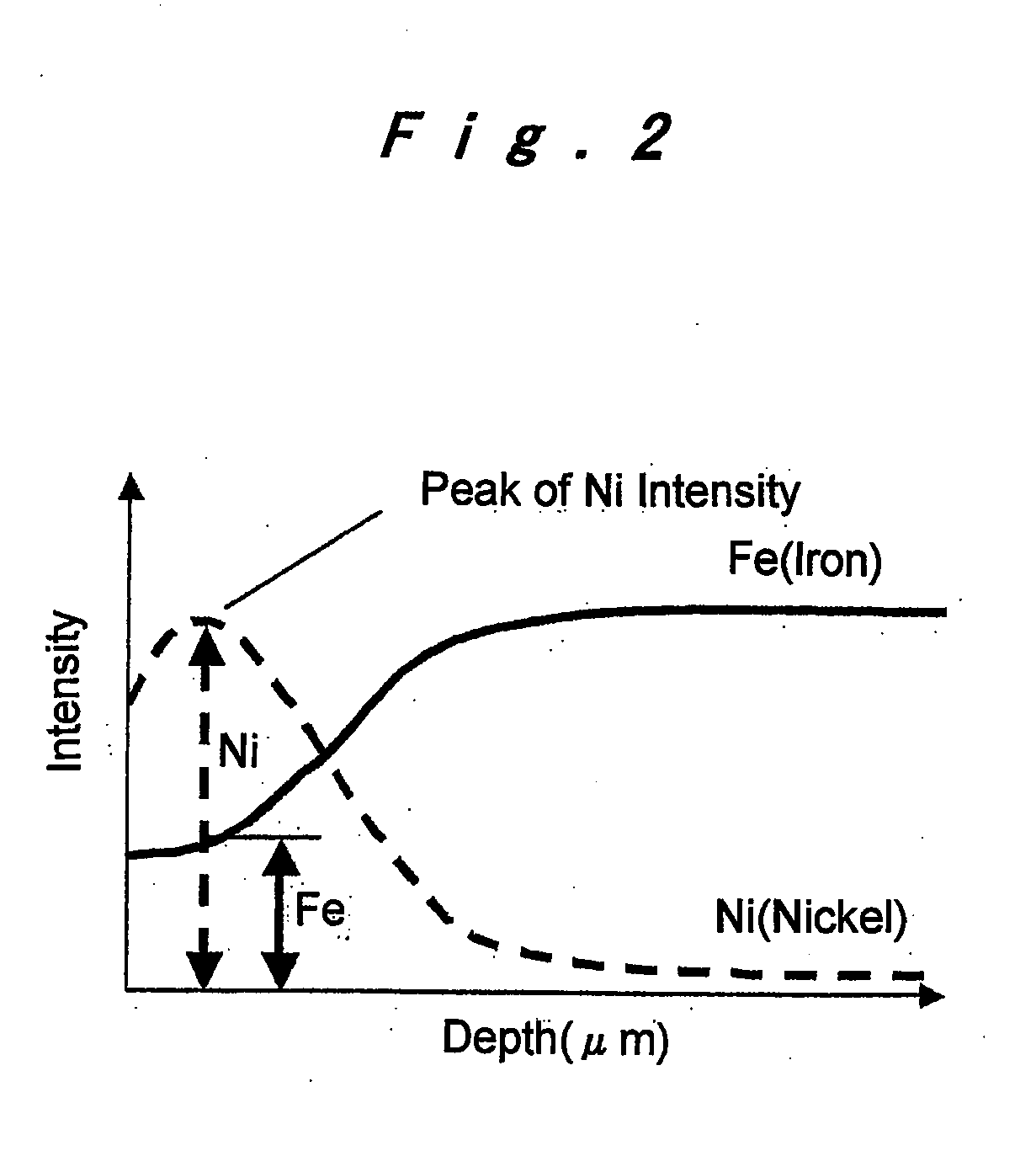

An Fe—Ni diffusion layer (3) is formed on the surface of a steel plate (2) containing Fe in an amount of 98 percent by weight or more, and the Fe / Ni ratio is adjusted within the range of 0.1 to 2.5. The steel plate (2) is shaped into a battery case (1) having a predetermined shape with predetermined dimensions such that the Fe—Ni diffusion layer (3) serves as the inner surface of the battery case (1). When a battery is produced using the battery case (1), corrosion due to over-discharge is suppressed even when the amount of Ni used is small. Therefore, the produced battery is excellent in leakage resistance.

Owner:PANASONIC CORP

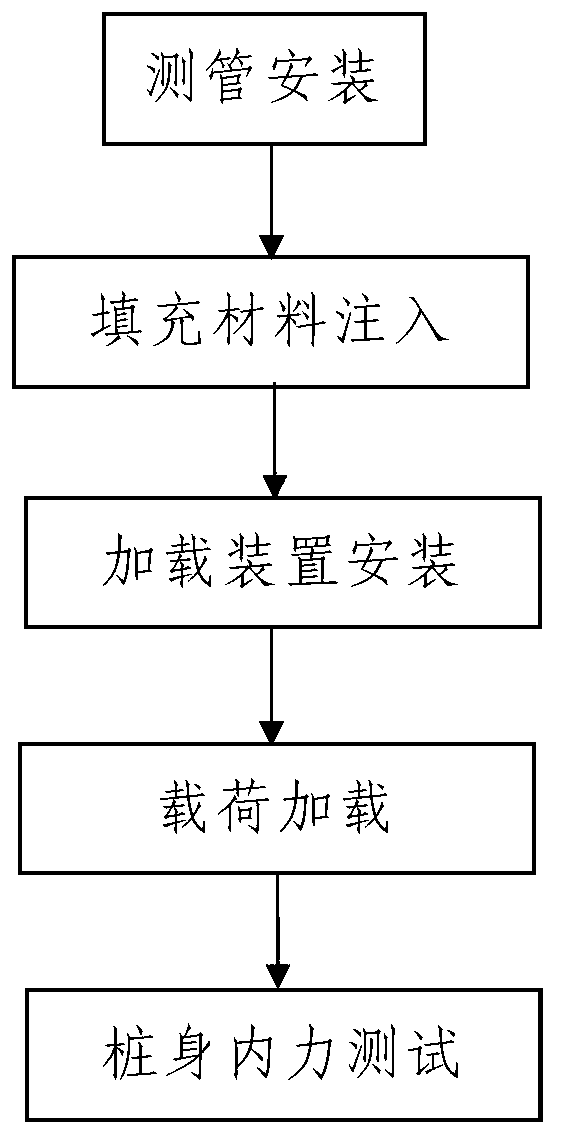

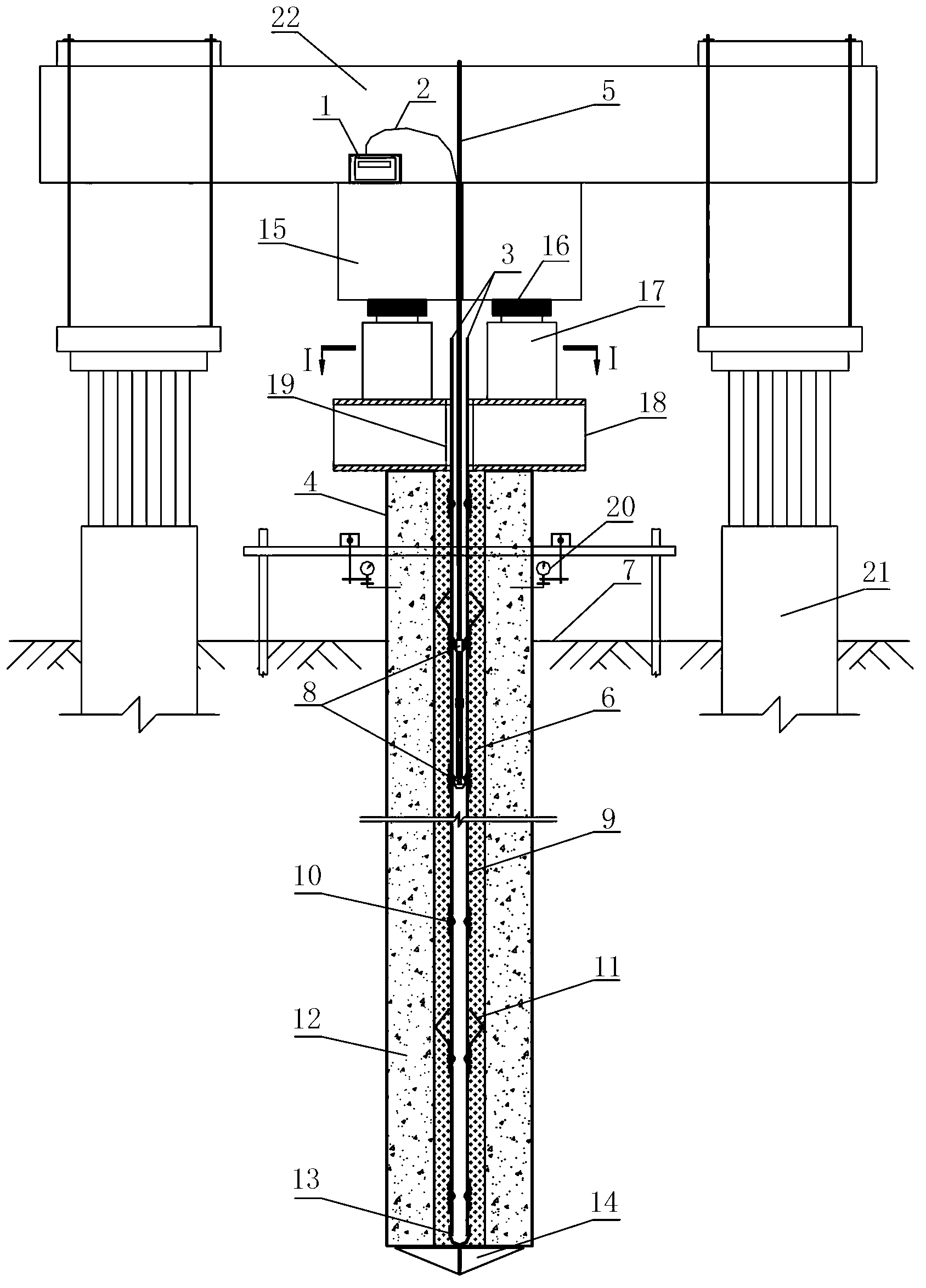

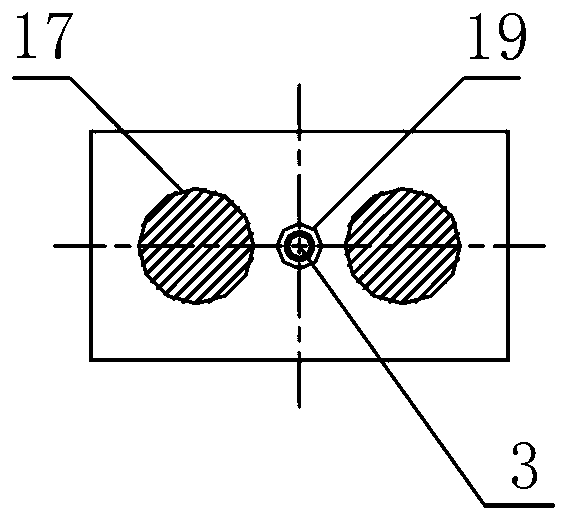

Internal force testing method for load test of pre-stress tubular pile

ActiveCN102797269AReasonable designSimple and fast operationFoundation testingMicrometerFilling materials

The invention discloses an internal force testing method for a load test of a pre-stress tubular pile. The method comprises the following steps: 1, installing a testing tube: the testing tube of a slide micrometer is installed in a constructed pre-stress tubular pile, and the testing tube is arranged in the middle of the pile core of the pre-stress tubular pile in the vertical direction; the bottom of the testing tube is sealed through a sealing cap and the testing tube is full of water; 2, injecting a filling material: the filling material is injected into the cavity between the tubular pile core of the pre-stress tubular pile and the testing tube from bottom to top by adopting grout injecting equipment, and comprises water, cement and bentonite; 3, loading an installation device; 4, loading a load; and 5, testing the internal force of a pile body: after the load is loaded and the pre-stress pile is settled and stabilized, the internal force of the pile body of the pre-stress tubular pile is tested by adopting the slide micrometer. According to the invention, the measuring method has simple steps and is convenient to implement while having high test precision and low investment, so as to obtain the internal force test result of the pre-stress tubular pile simply, conveniently, rapidly and accurately.

Owner:CHINA JK INST OF ENG INVESTIGATION & DESIGN

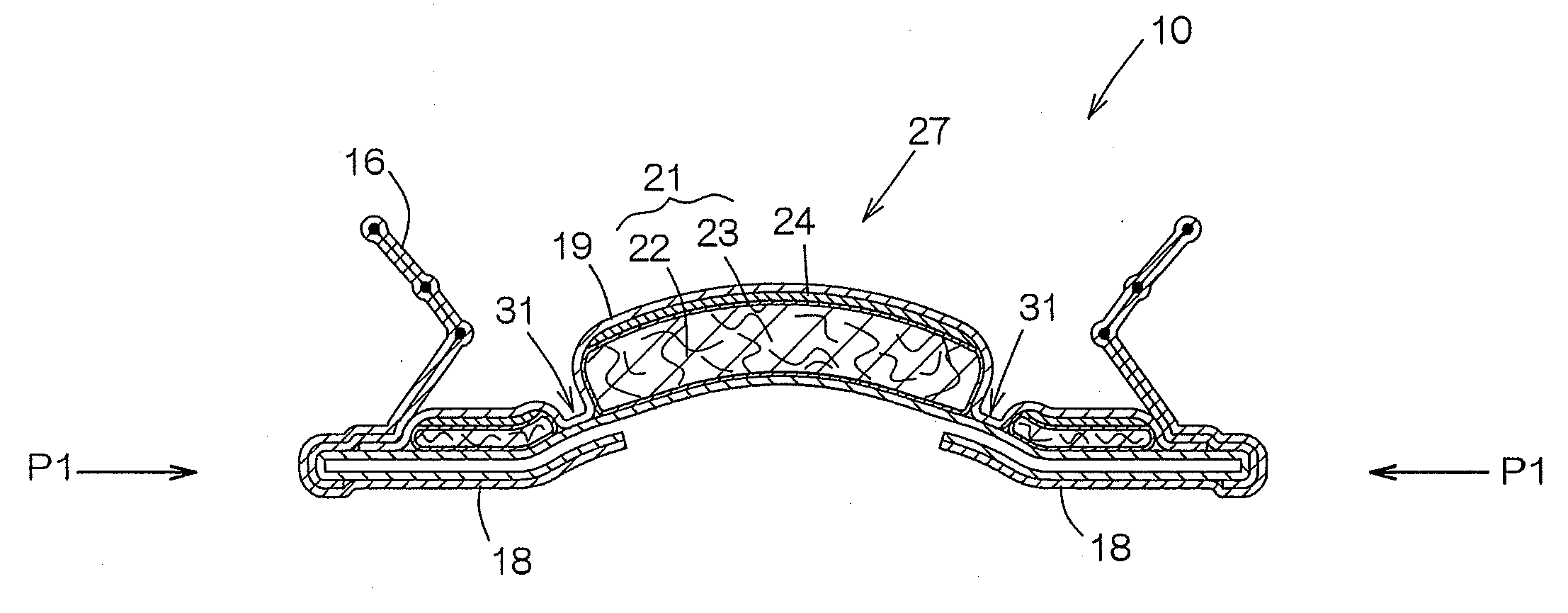

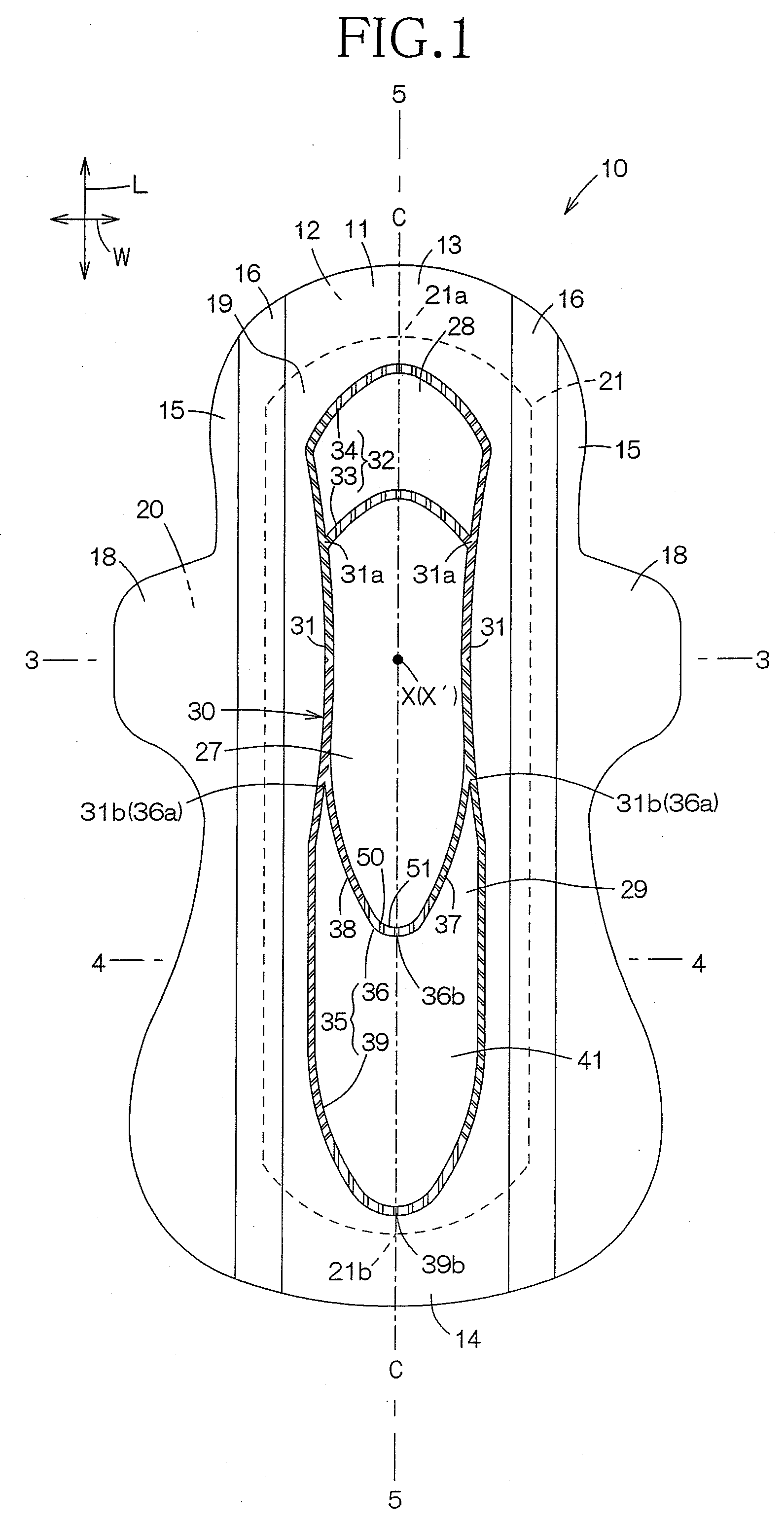

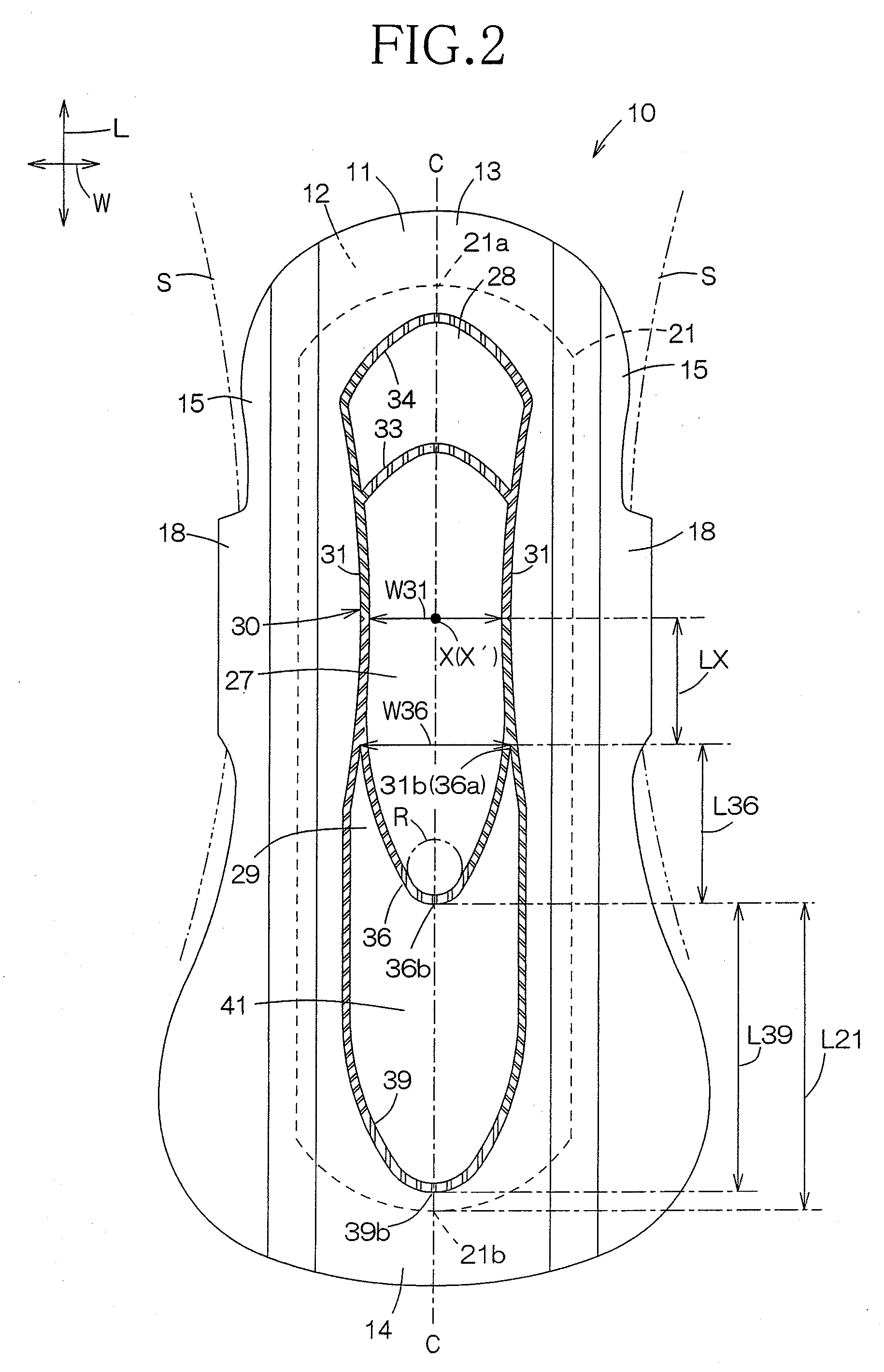

Absorbent Article

InactiveUS20070005036A1Enhance physical fitnessImprove leak-proof effectSanitary towelsBaby linensEngineeringMechanical engineering

An absorbent article includes a compressed groove provided on a body-side surface of a sanitary napkin includes a pair of lateral groove segments extending substantially in the longitudinal direction symmetrically about a longitudinal center line and a pair of rear groove segments converging rearward from respective rear ends of the pair of lateral groove segments so that the compressed groove as a whole presents an elongated shape which is angular rearward. The rear side groove segment has a curve conforming, in the vicinity of its rear end, with an arc of a circle having a predetermined radius and inscribed to the rear side groove segment. A bottom covering region extending rearward from the rear end of the rear groove segment has a predetermined thickness and is adapted to be folded along the longitudinal center line so that the bottom covering region can become convex on the side of the body-side surface. A distance between a pair of proximal ends of the rear side groove segment as measured in the transverse direction is in a predetermined range and a distance from the pair of proximal ends to the rear end of the rear groove segment as measured in the longitudinal direction is in a predetermined range.

Owner:UNI CHARM CORP

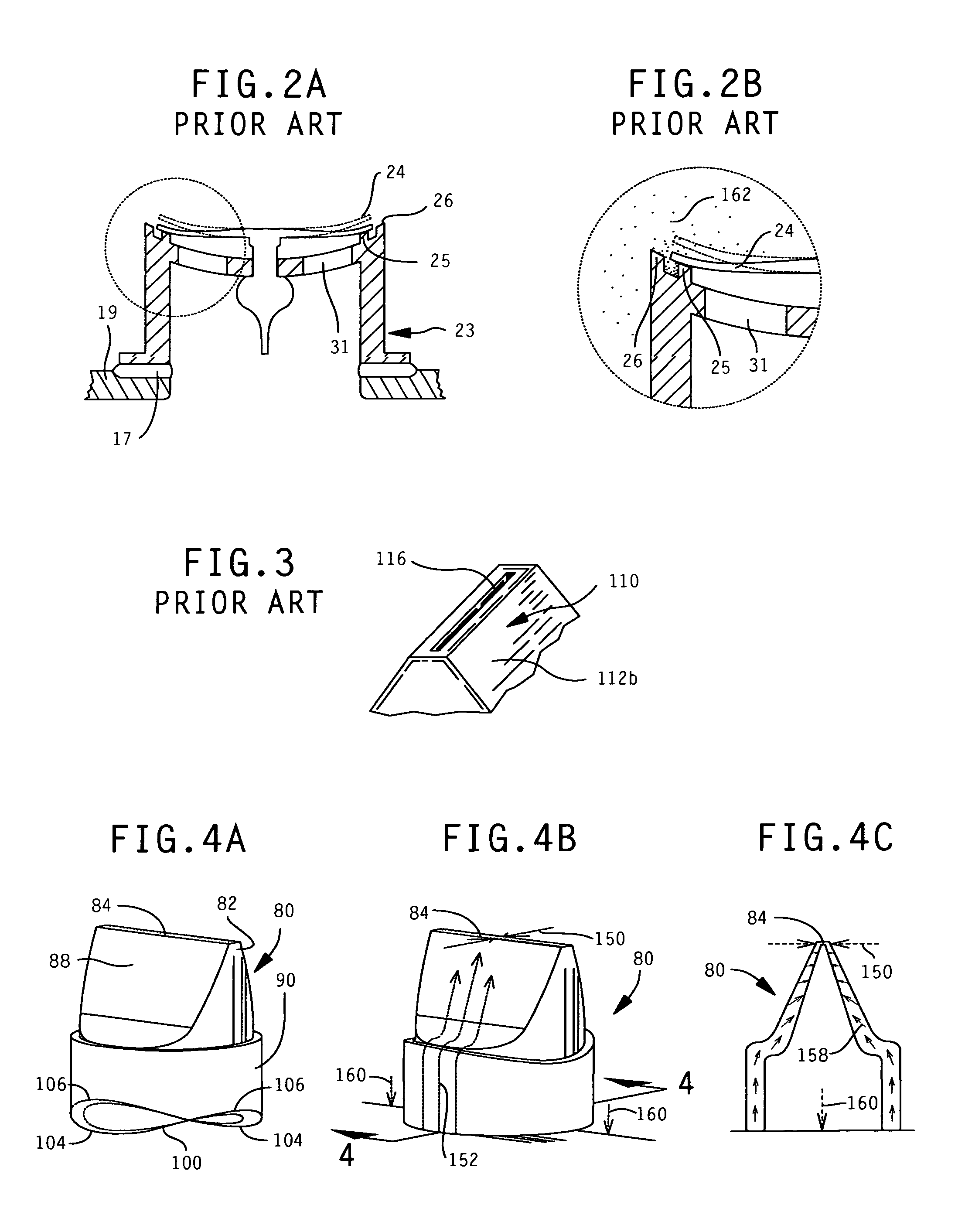

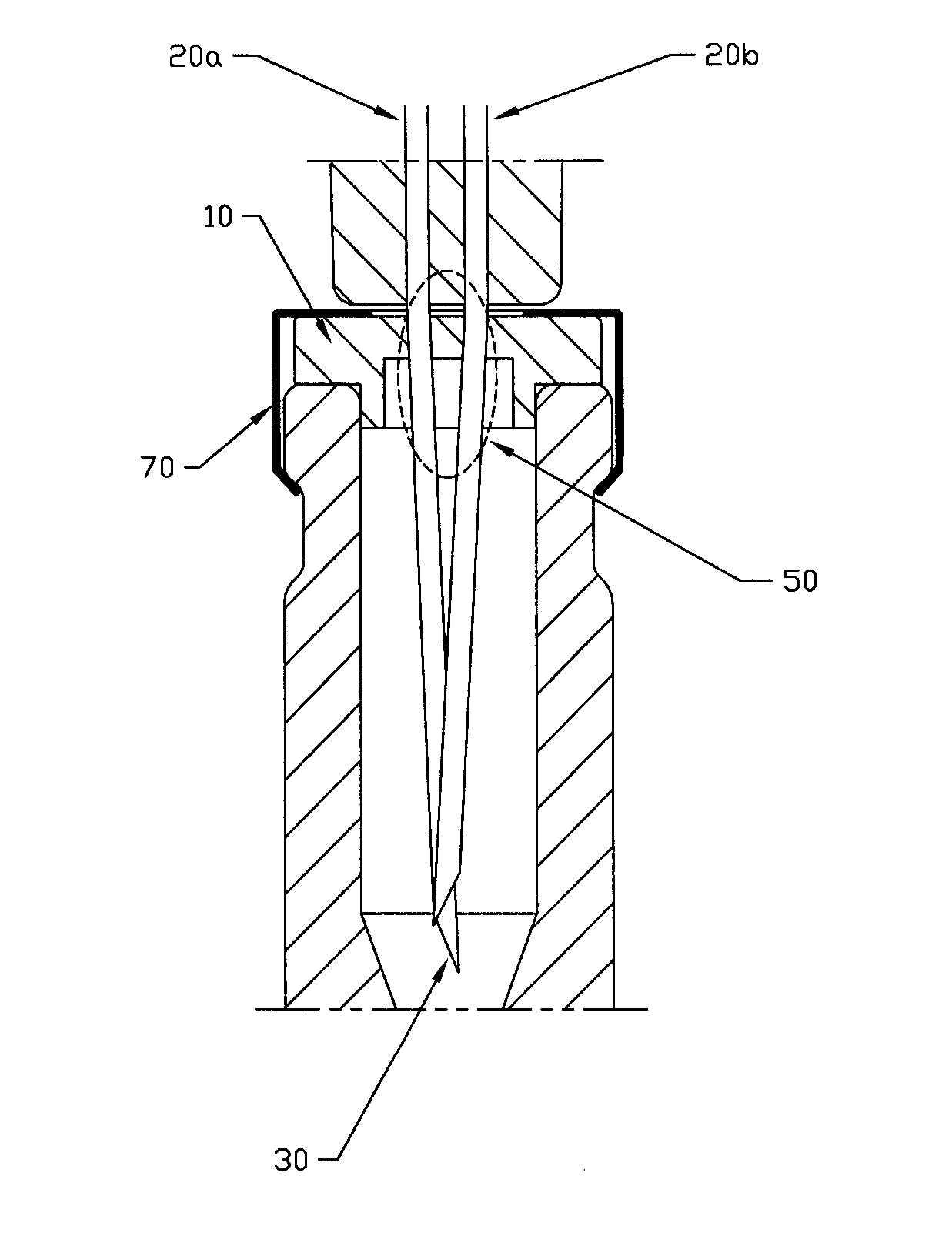

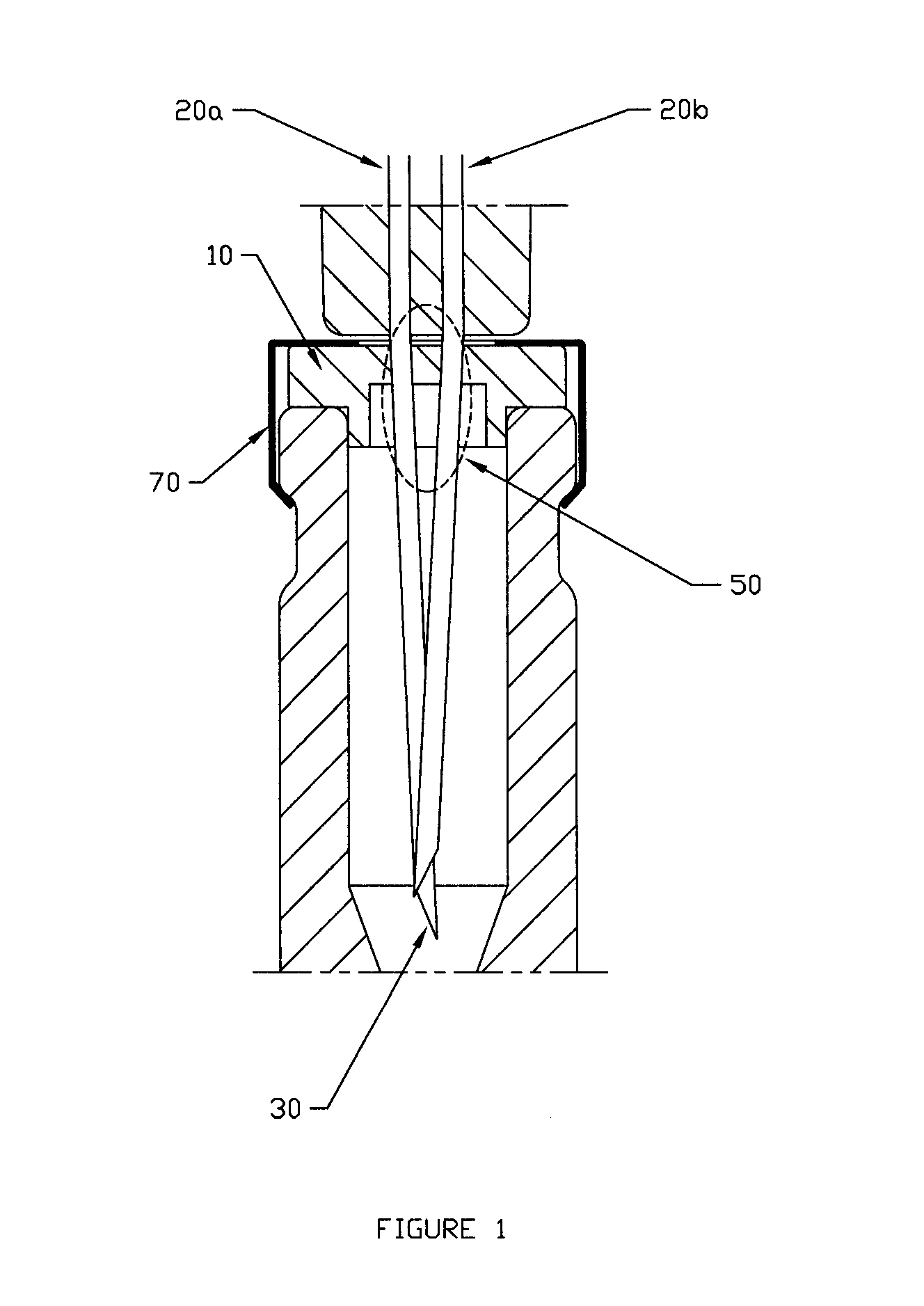

Sports bottle with preloaded valve and methods

InactiveUS8561851B1Particular resistanceResistant to leakageCheck valvesEqualizing valvesEngineeringWater bottle

A beverage bottle for storing and dispensing water and impure sports beverages having a container and a dispensing opening on a top wall movable between an open position and a closed position and a unitary valve disposed within the container bottom wall having a vertically sinuous contour, and laterally opposed, laterally actuating, compliant slit faces and a substantially rigid annular flat surface. As the vertically sinuous contour is flattened upon the annular flat surface, the slit faces are laterally urged together establishing a preloaded seal, for leak resistant valve operation, and reduced restriction dispensing of water and impure sports beverages.

Owner:LEONOFF CHRISTOPHER A

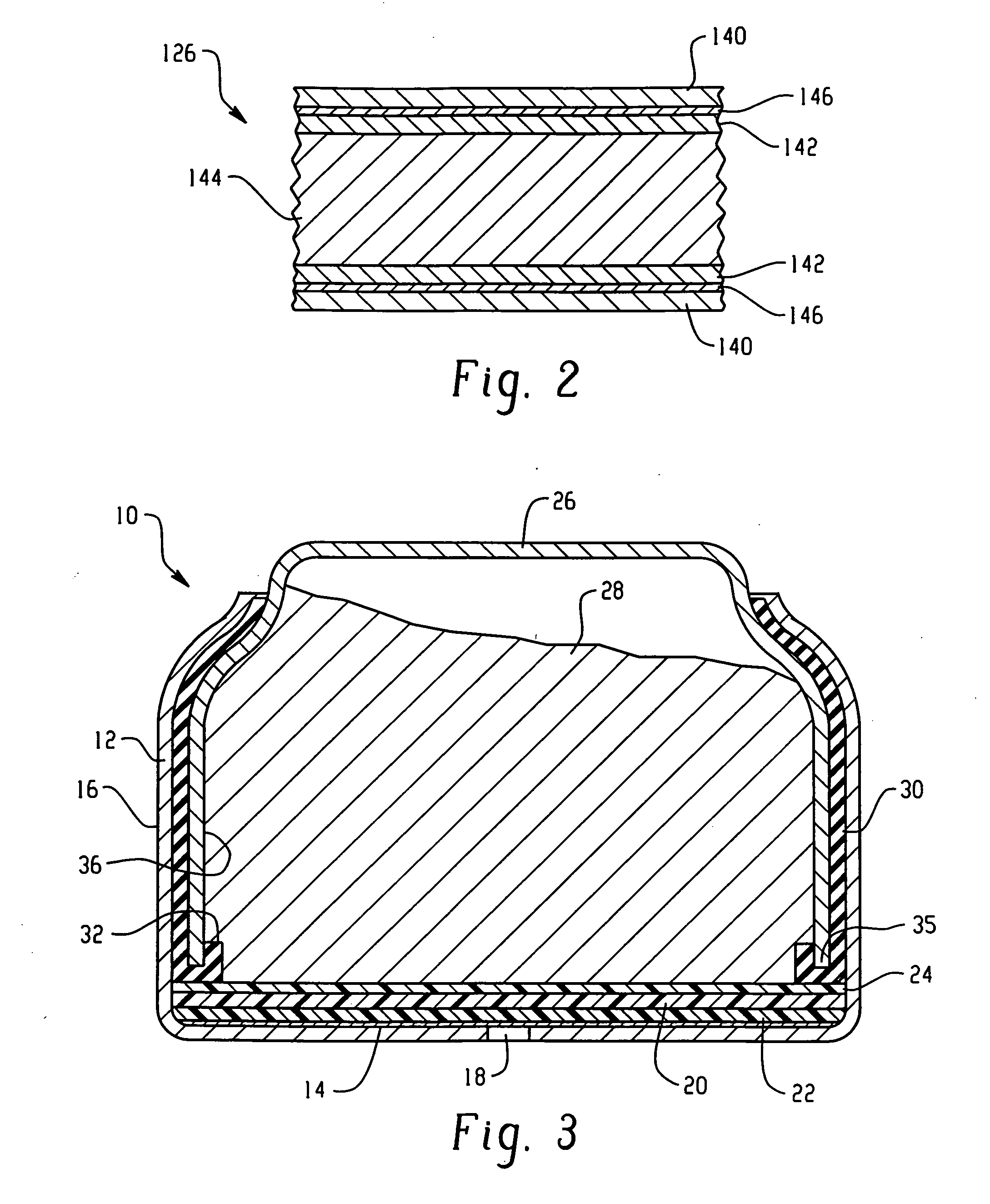

Method for increasing the leakage resistance in a closed, pressurized system comprising a septum-sealed container

ActiveUS20120053554A1Improve leak-proof effectSmall sizeClosuresDiagnosticsStructural engineeringDiaphragm seal

The present invention relates to a method for increasing leakage resistance in a closed, pressurized system. The method involves providing a closed system including a container sealed with a septum having a top surface with an exposed section, which is maintained under a positive pressure of at least about 5 psig. A contact surface of a hard component is fixedly placed adjacent to or in contact with at least a portion of a border section or a central section of the exposed section of the septum, or both, to reduce the size of any bulge or deformation formed in the exposed section of the septum. The present invention also relates to a kit for increasing leakage resistance in a closed, pressurized system, which includes the hard component.

Owner:BIOCOMPATIBLES UK LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com