Anti-seepage and leak-blocking construction method for excavation of subway foundation pit in soft soil area

A construction method and regional technology, applied in excavation, infrastructure engineering, construction, etc., can solve the problems of slow construction progress, easy pipe plugging, poor leak prevention and plugging effect, etc., and achieve fast plugging speed and short construction time , easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

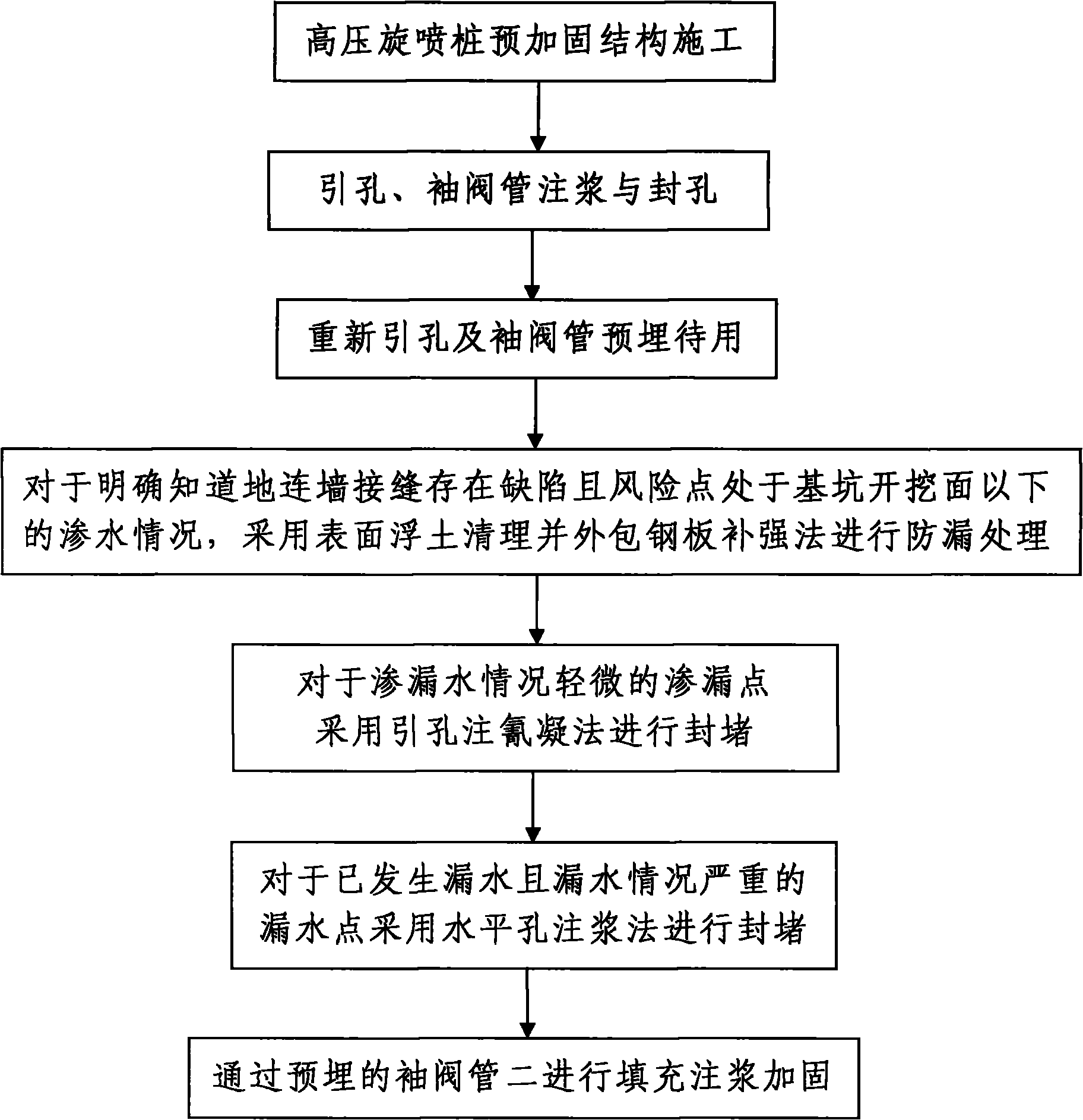

[0056] Such as figure 1 A kind of anti-seepage and plugging construction method for subway foundation pit excavation in soft soil area shown comprises the following steps:

[0057] Step 1. The pre-reinforcement construction of the ground connection wall joints, the construction process is as follows:

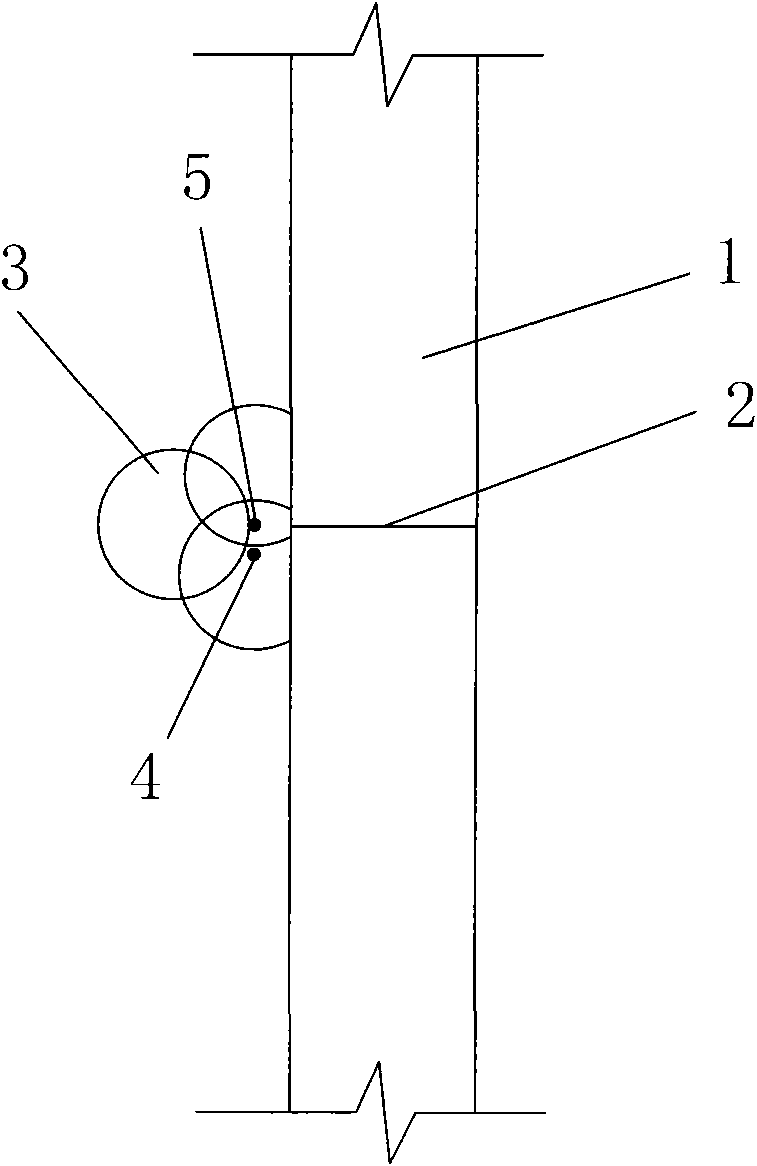

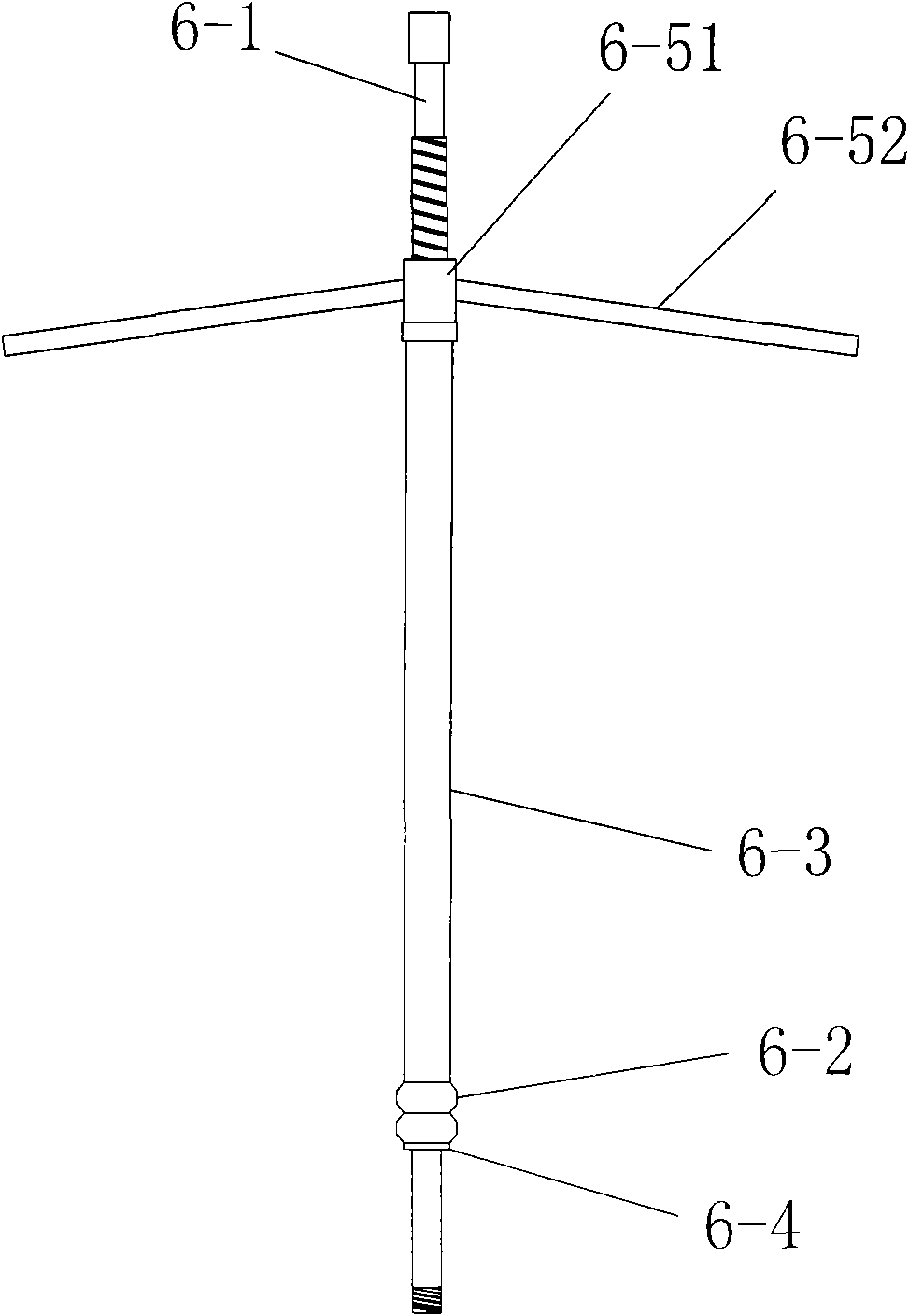

[0058] 101. Pre-reinforcement structure construction of high-pressure rotary grouting piles: After the construction of the ground connection wall 1 of the subway under construction is completed and before the excavation of the foundation pit, all the ground connection wall joints existing on the completed ground connection wall 1 2 is marked, and the high-pressure rotary grouting pile pre-reinforcement structure 3 is used to reinforce all the marked ground-wall joints 2 respectively, and the high-pressure rotary grouting pile pre-reinforcement structure 3 is formed by rotary spraying machine, and the The high-pressure rotary grouting pile pre-reinforcement structure 3 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com