Patents

Literature

509 results about "Sleeve valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The sleeve valve is a type of valve mechanism for piston engines, distinct from the usual poppet valve. Sleeve valve engines saw use in a number of pre-World War II luxury cars and in the United States in the Willys-Knight car and light truck. They subsequently fell from use due to advances in poppet-valve technology, including sodium cooling, and the Knight system double sleeve engine's tendency to burn a lot of lubricating oil or to seize due to lack of it. The Scottish Argyll company used its own, much simpler and more efficient, single sleeve system (Burt-McCollum) in its cars, a system which, after extensive development, saw substantial use in British aircraft engines of the 1940s, such as the Napier Sabre, Bristol Hercules, Centaurus, and the promising but never mass-produced Rolls-Royce Crecy, only to be supplanted by the jet engines.

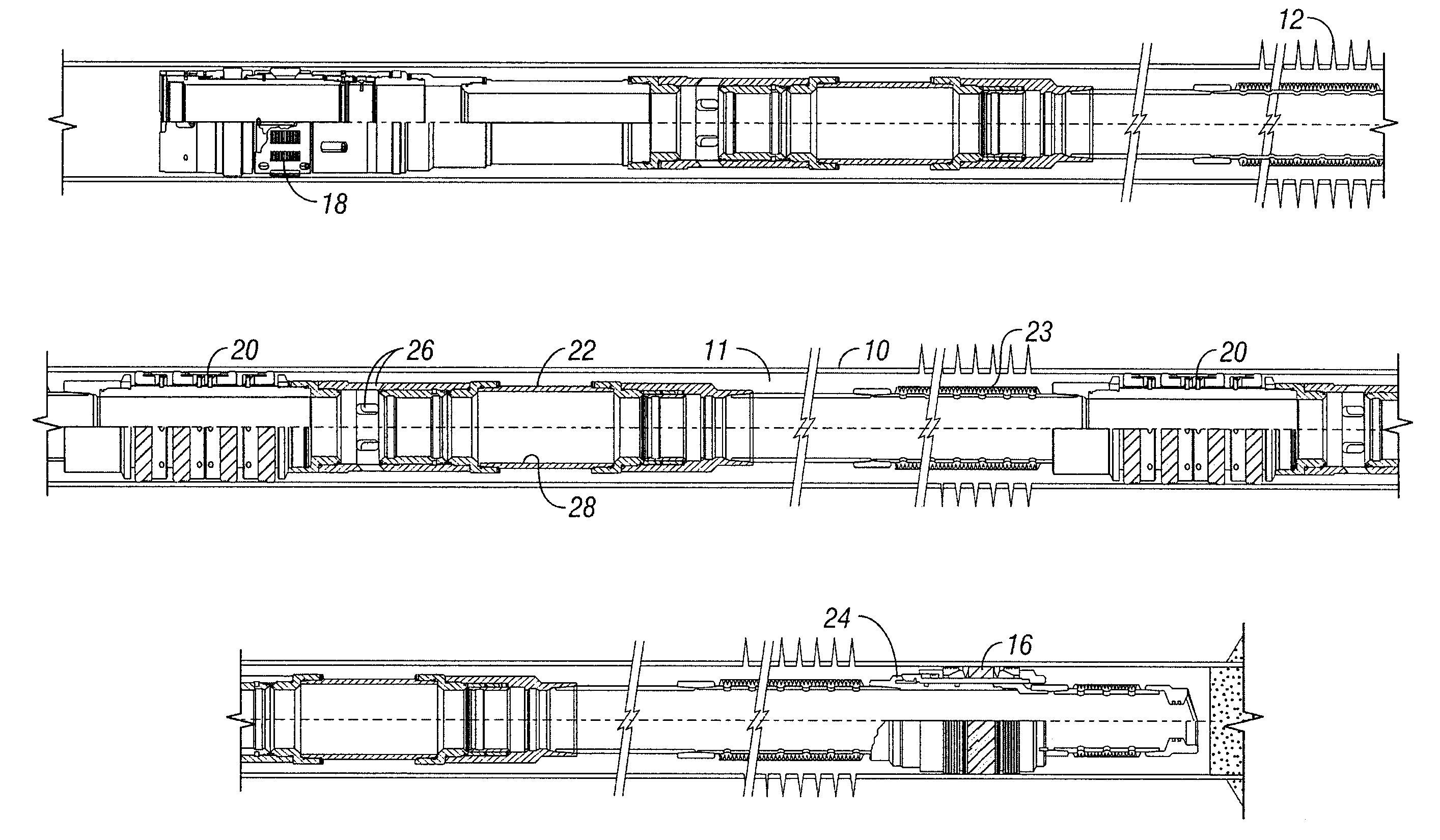

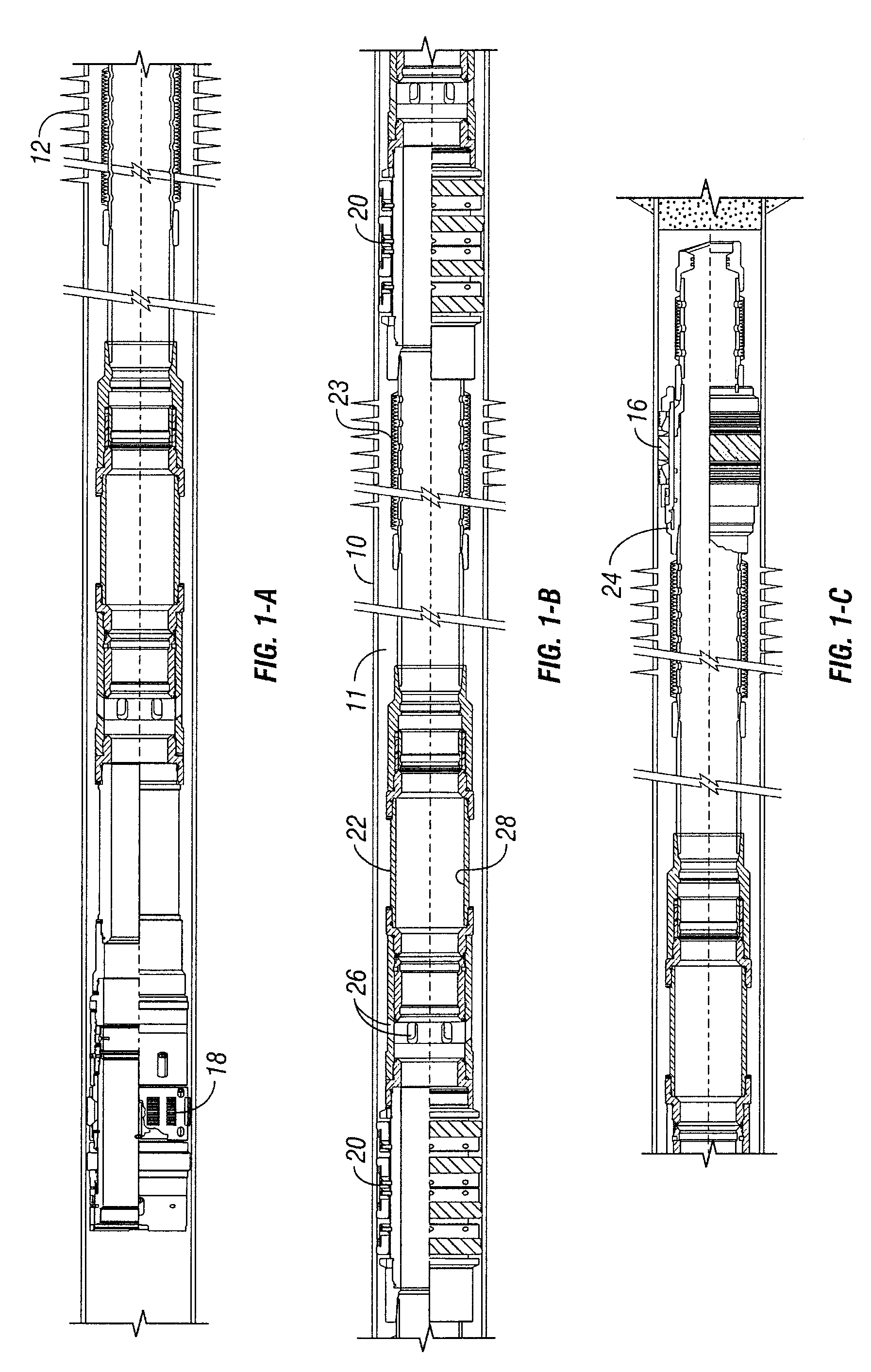

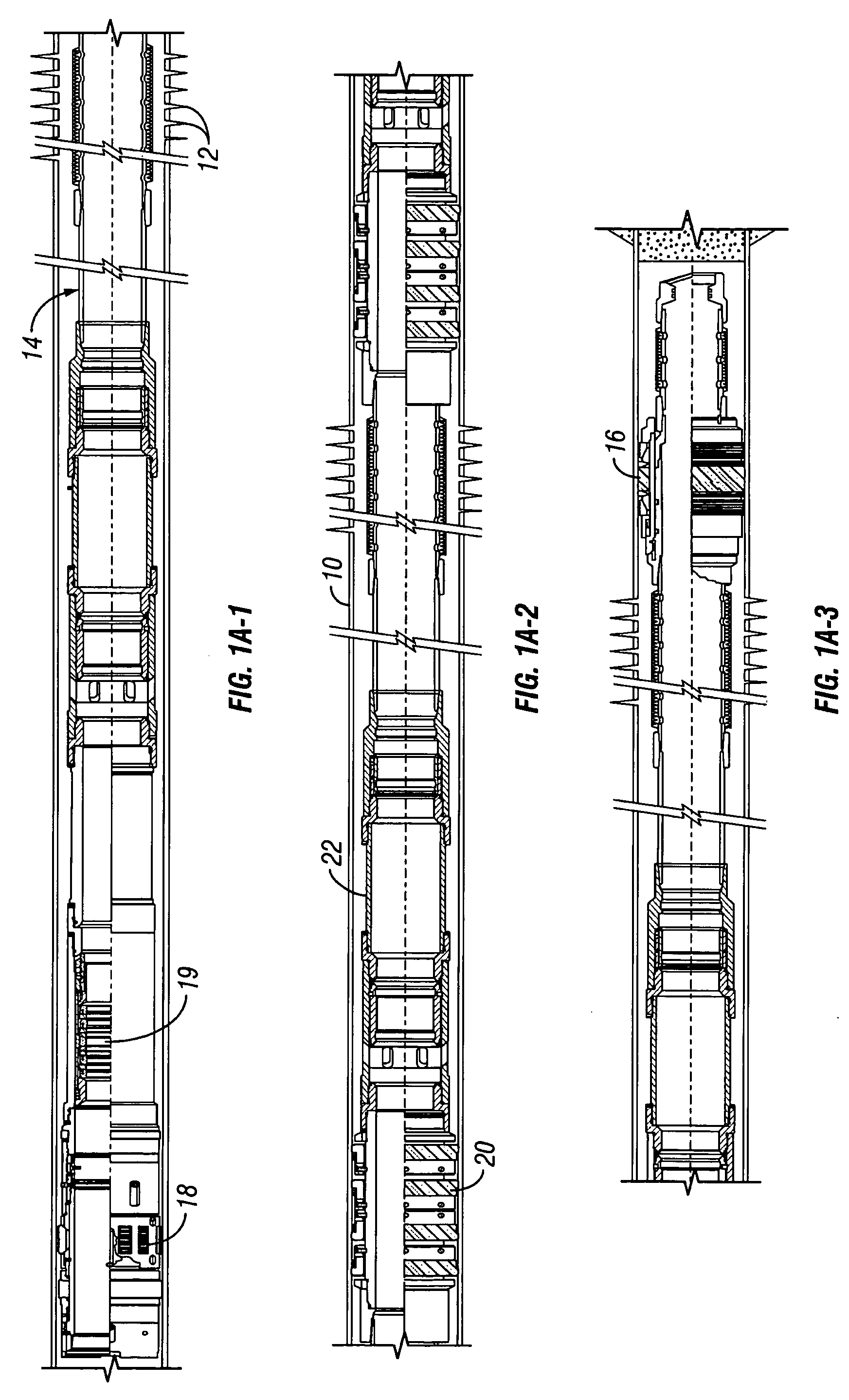

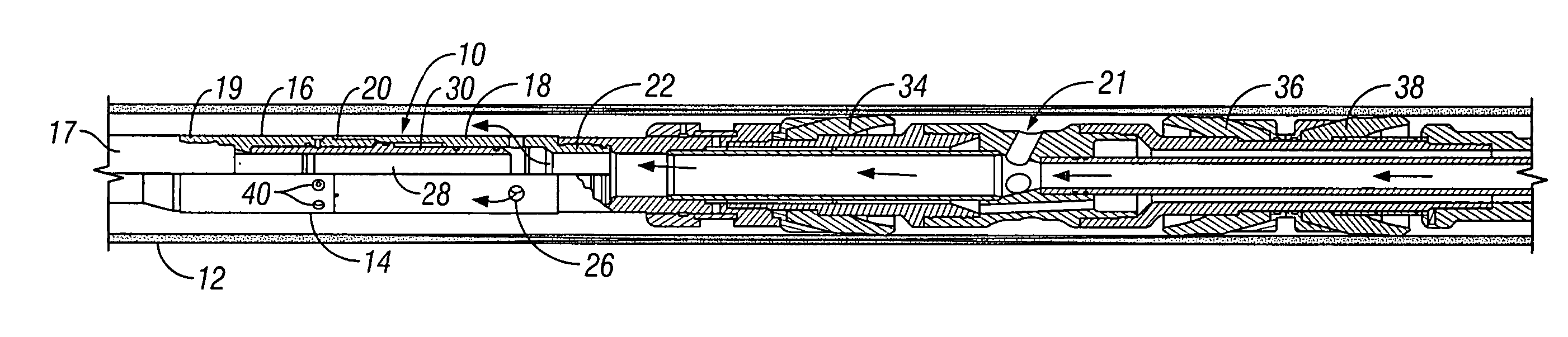

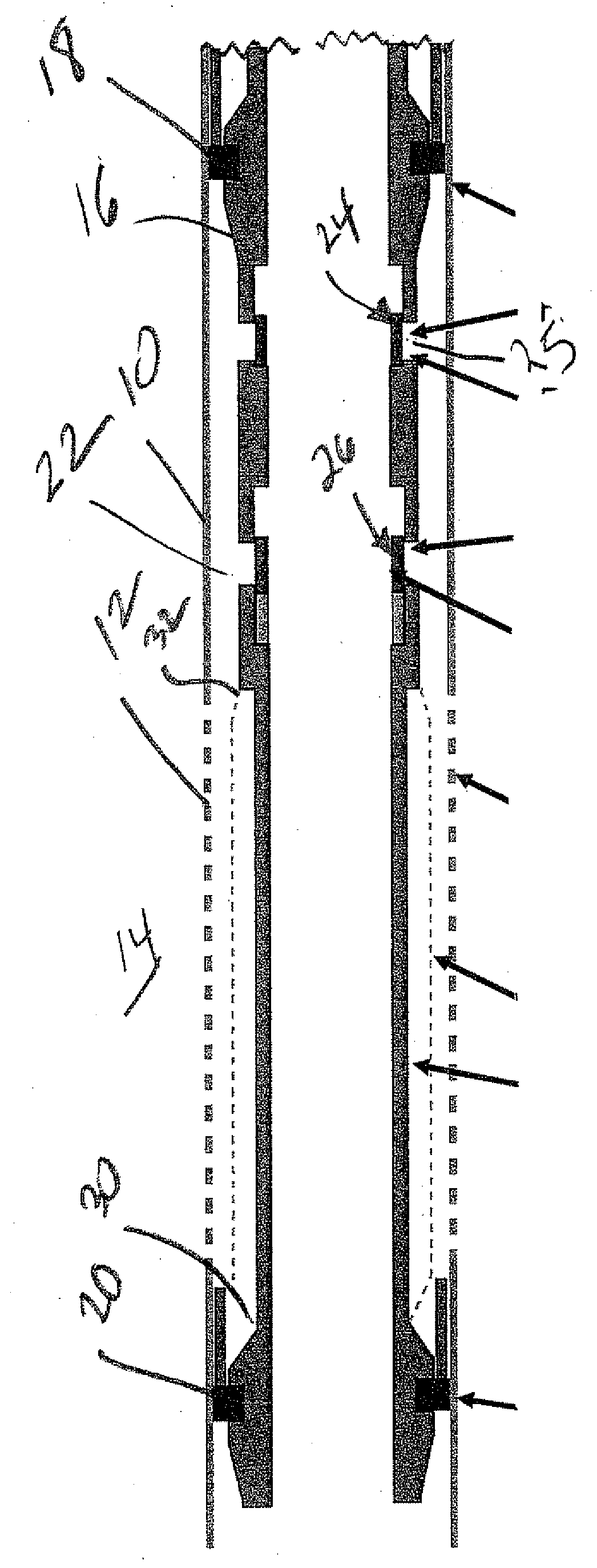

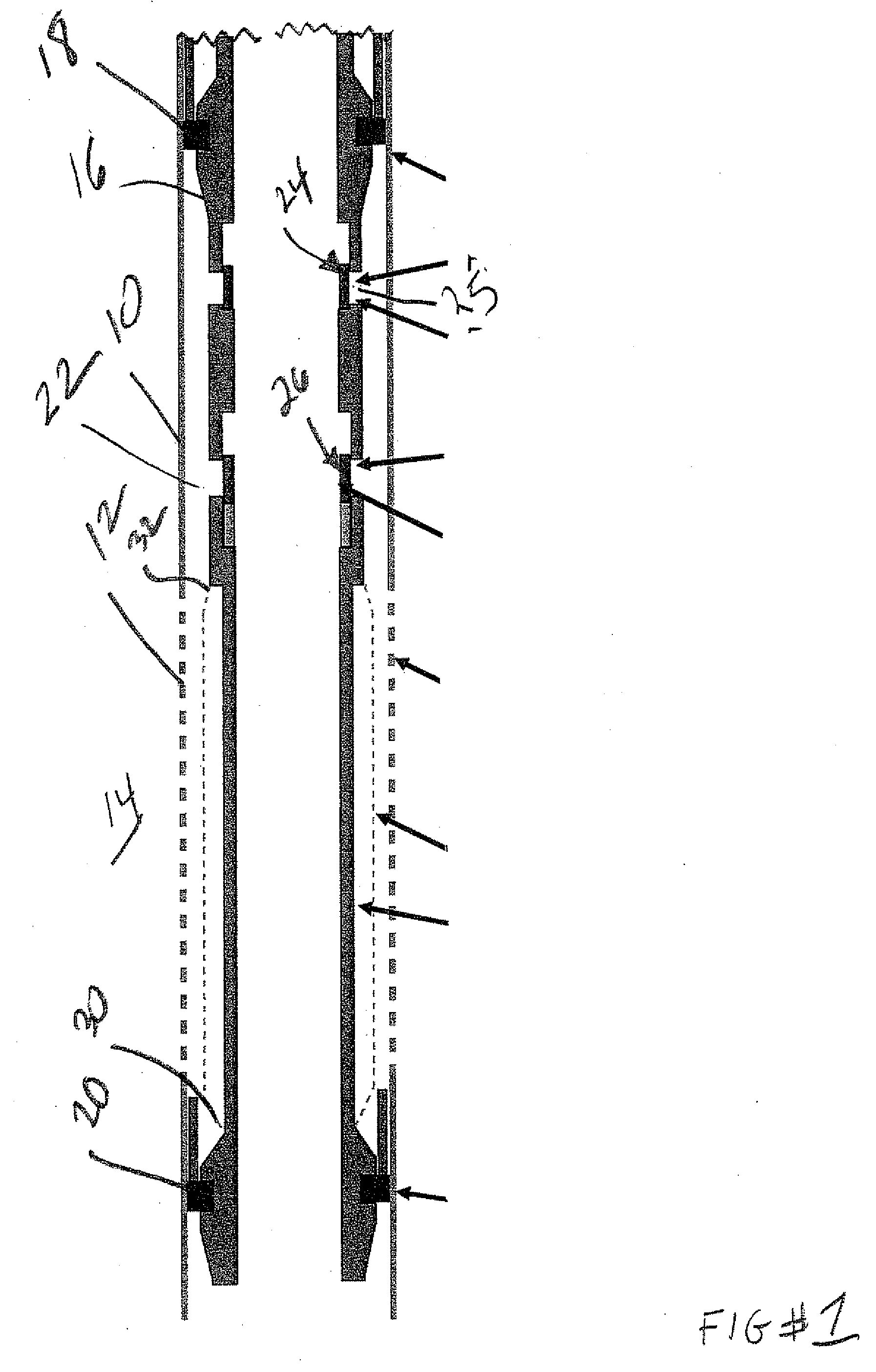

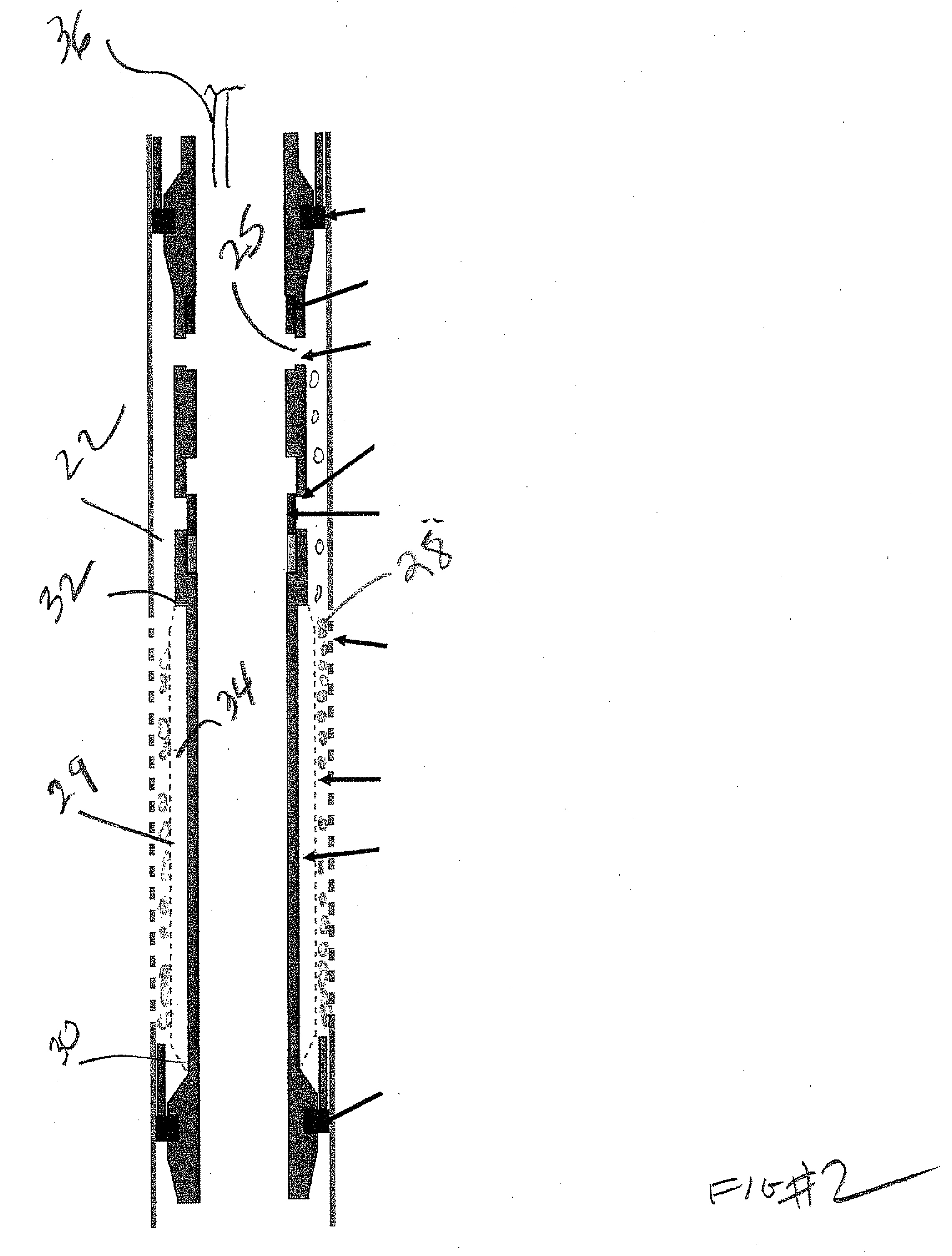

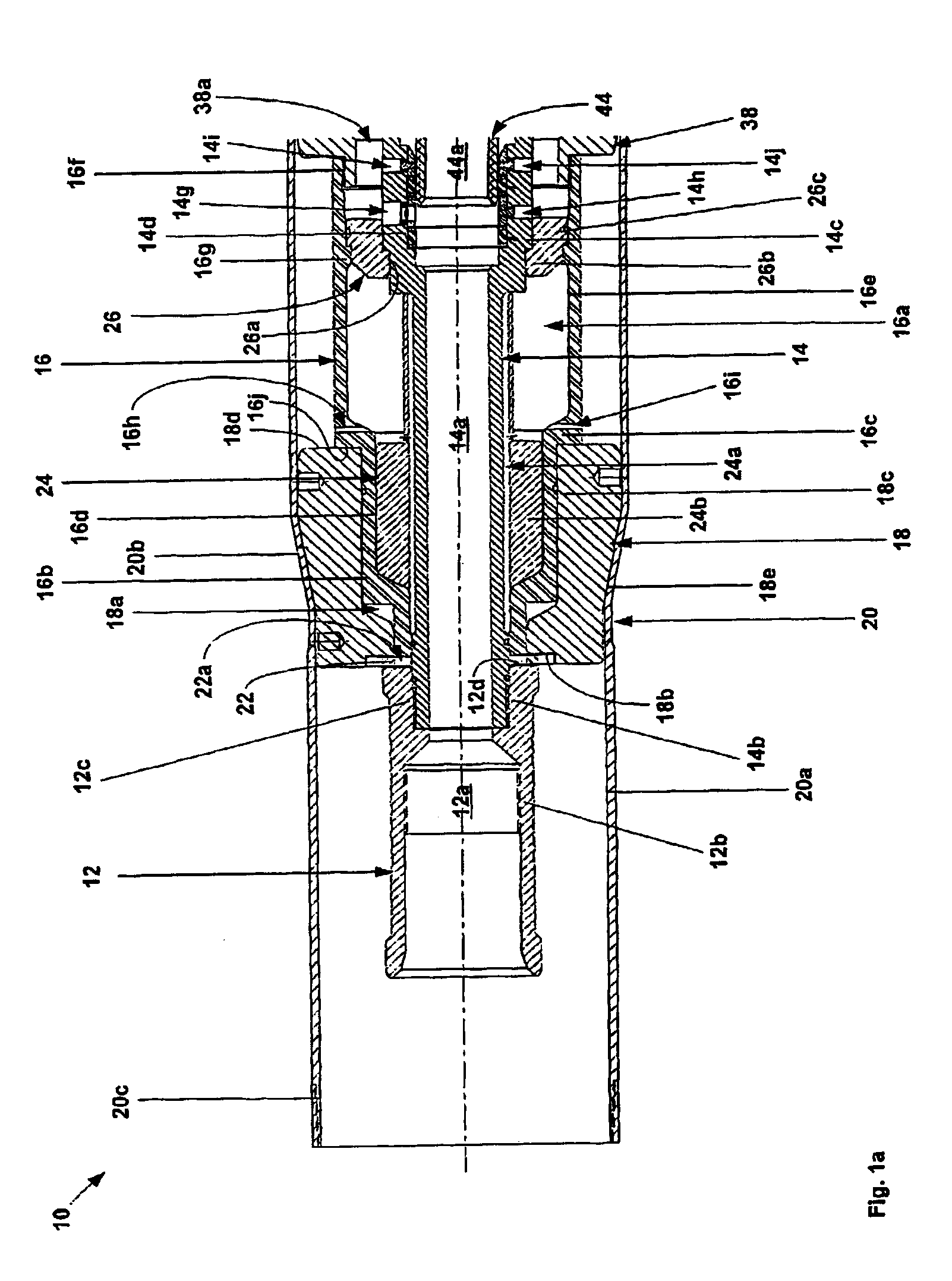

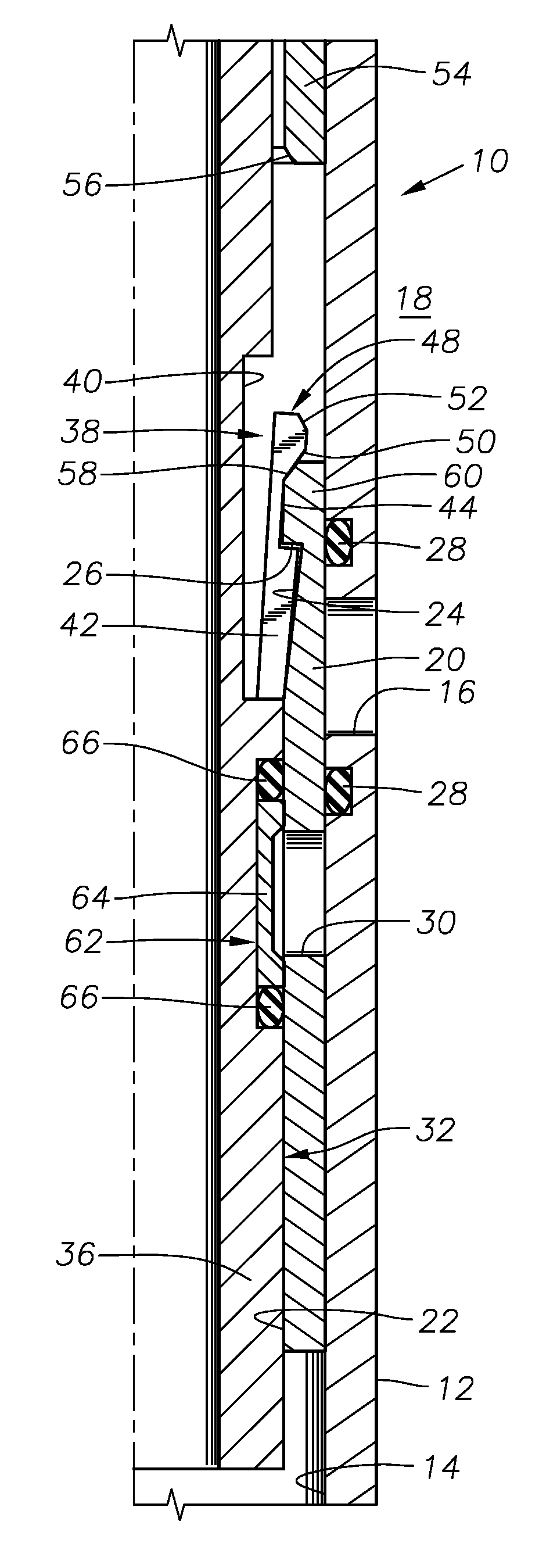

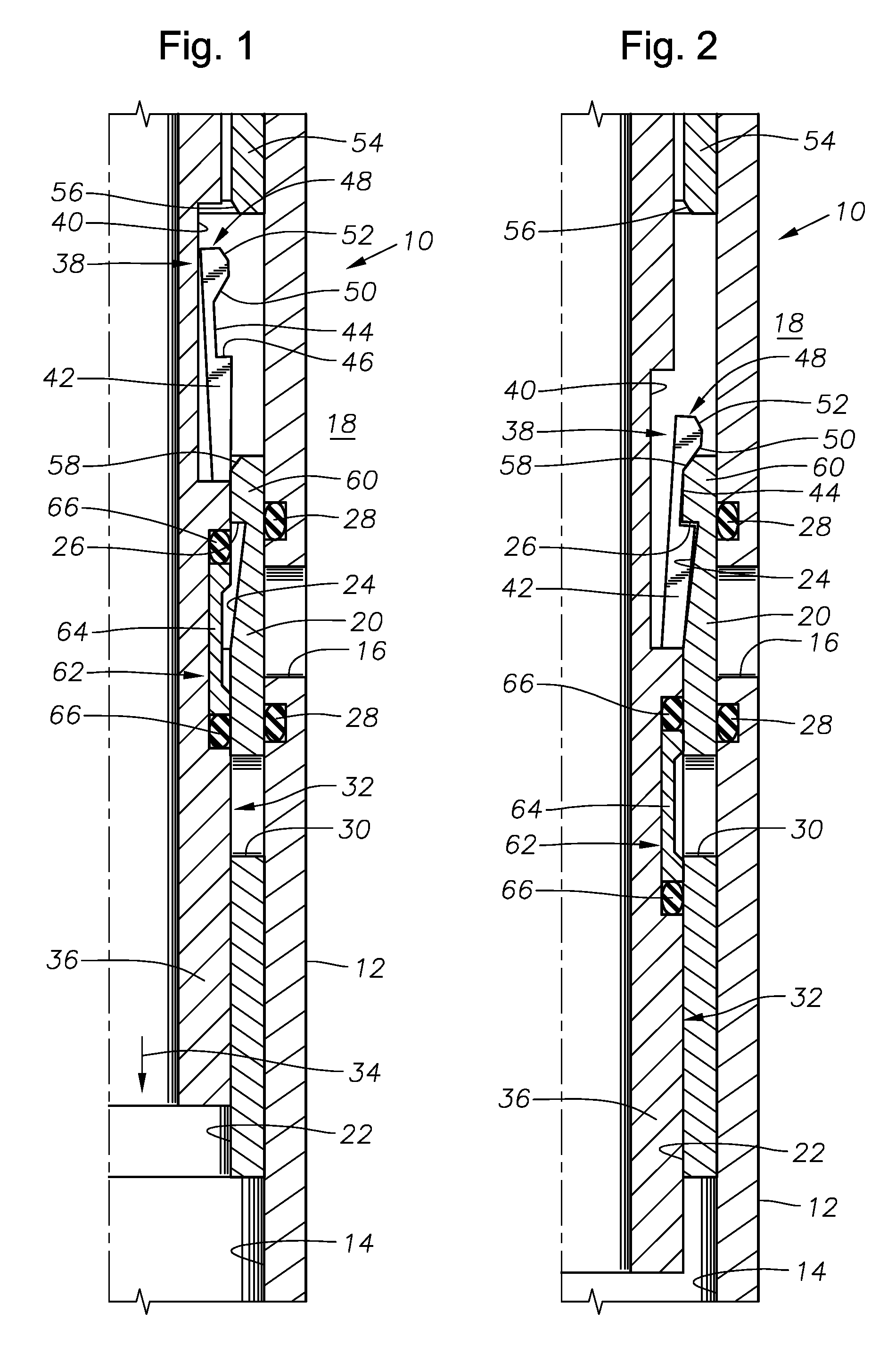

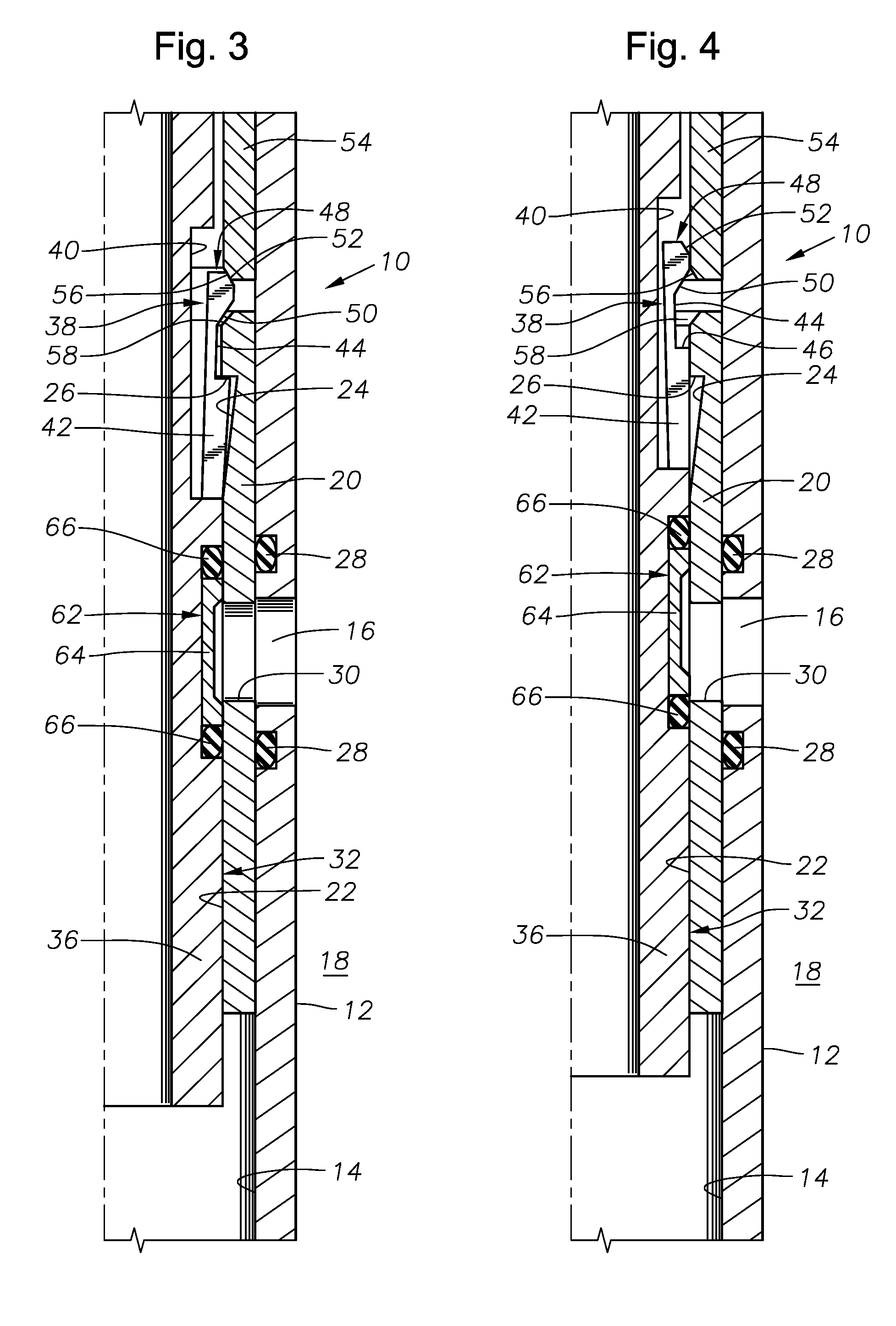

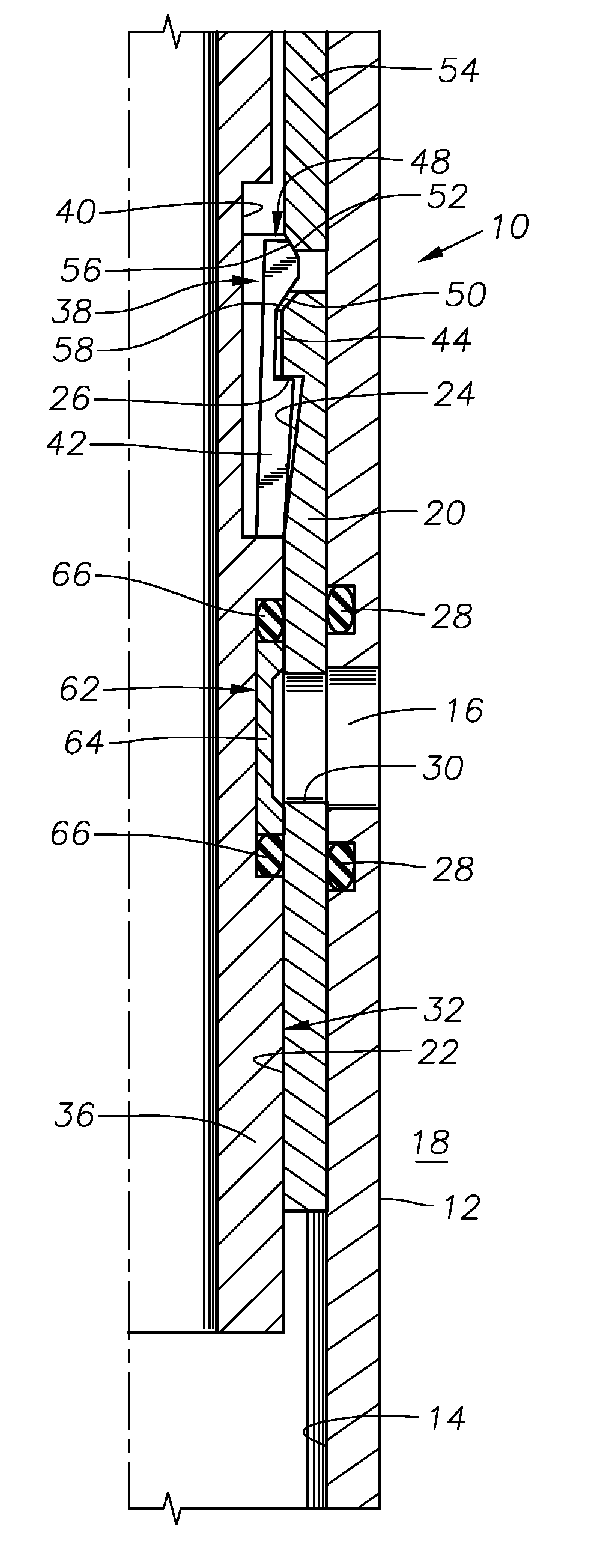

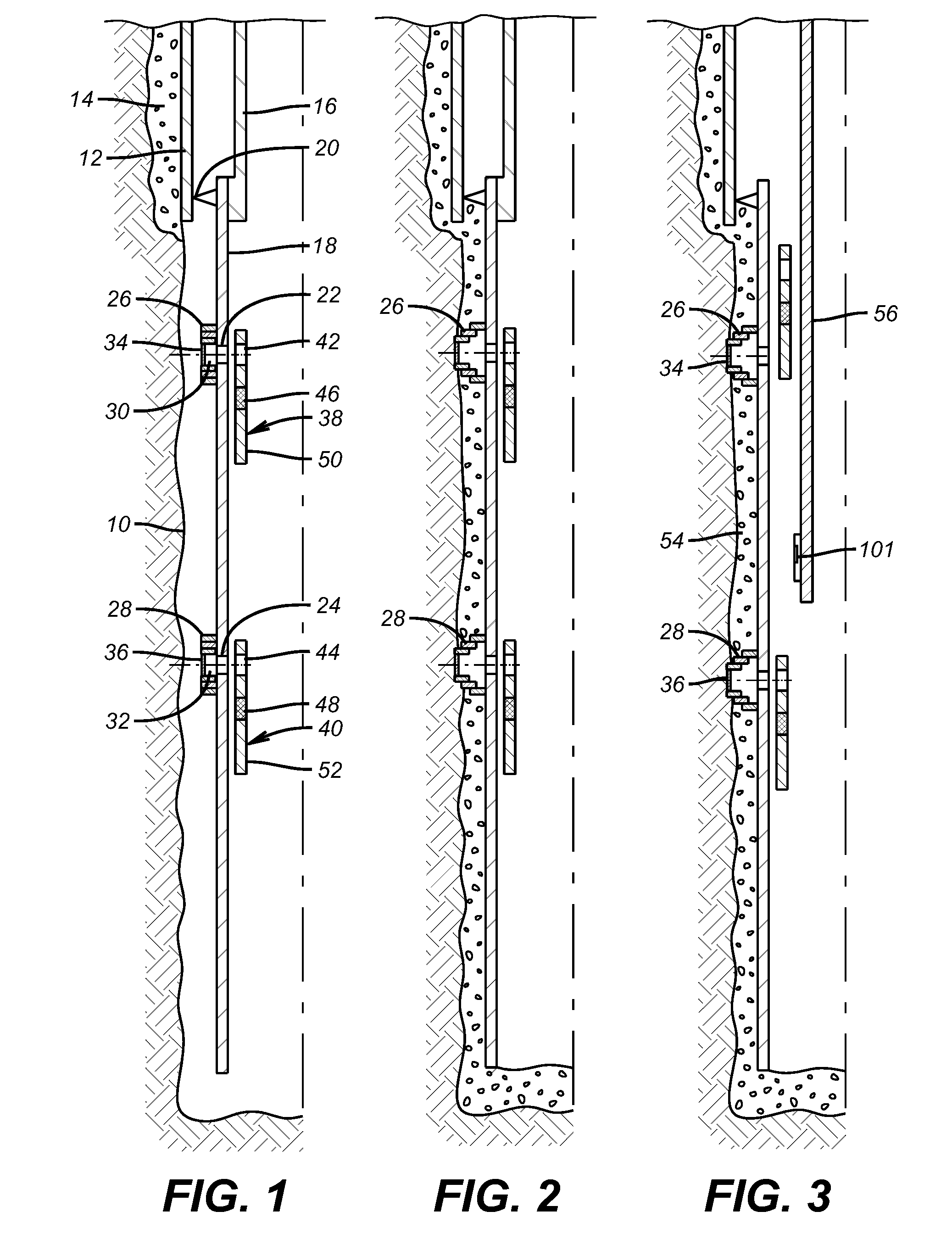

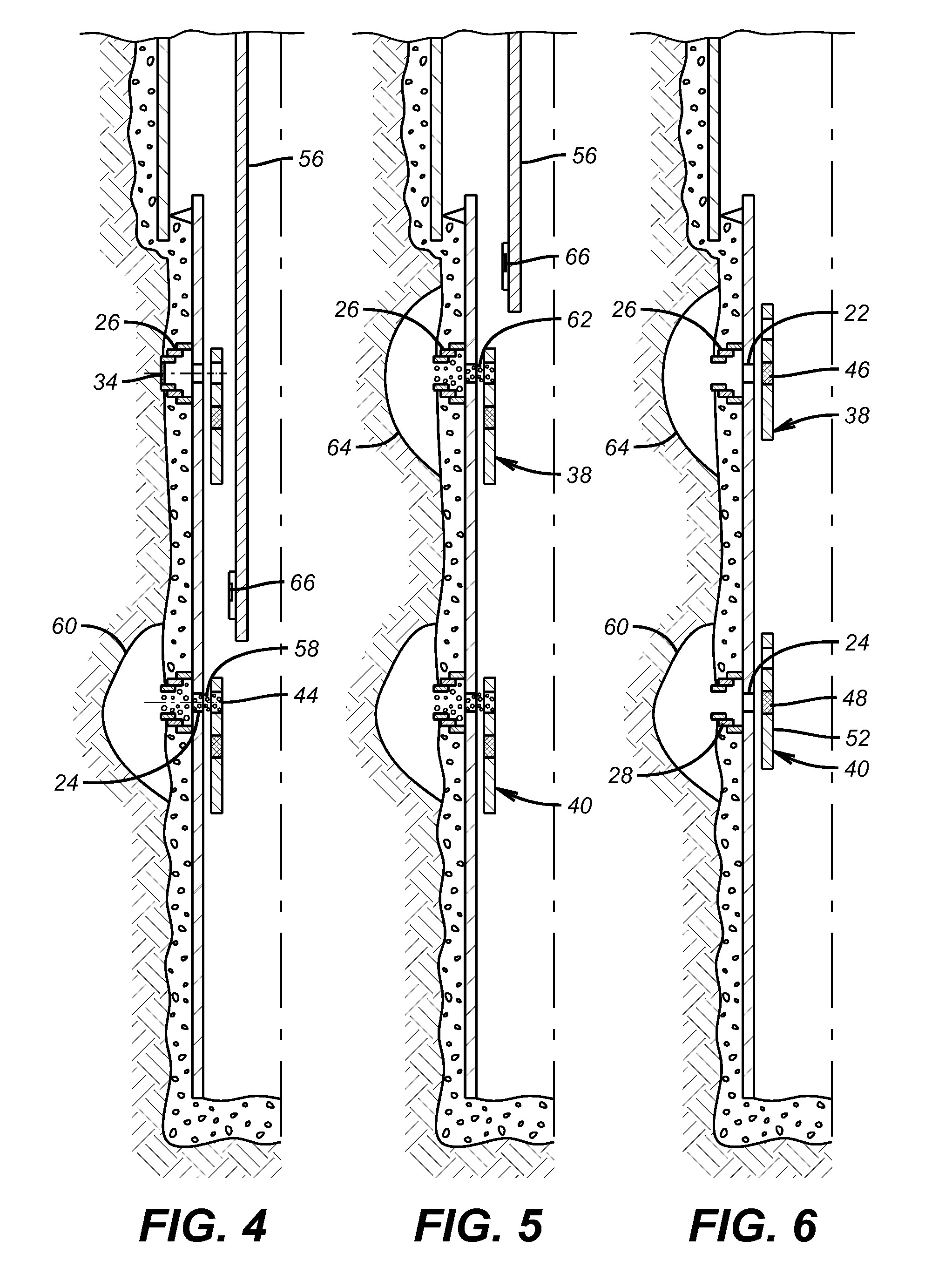

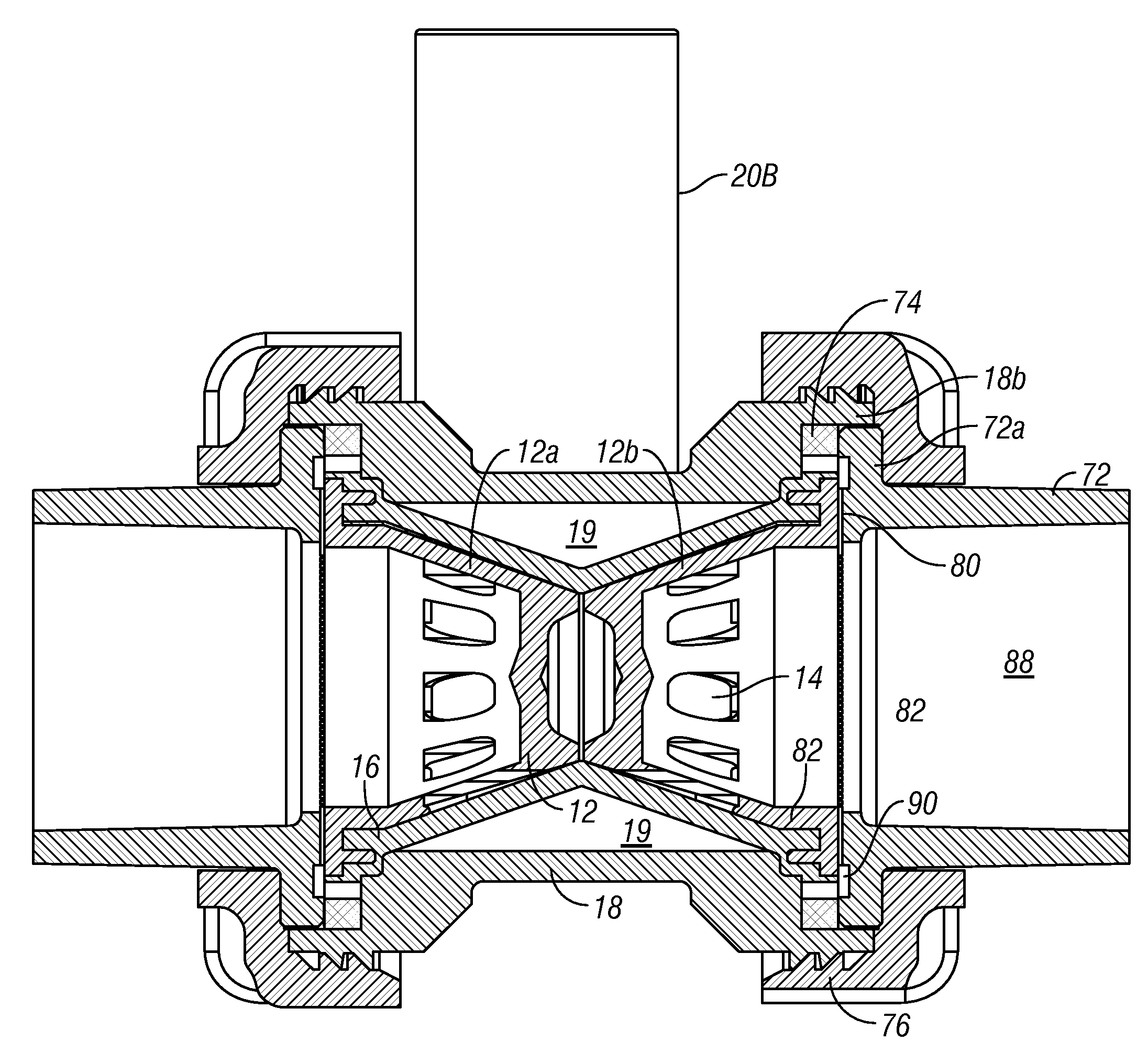

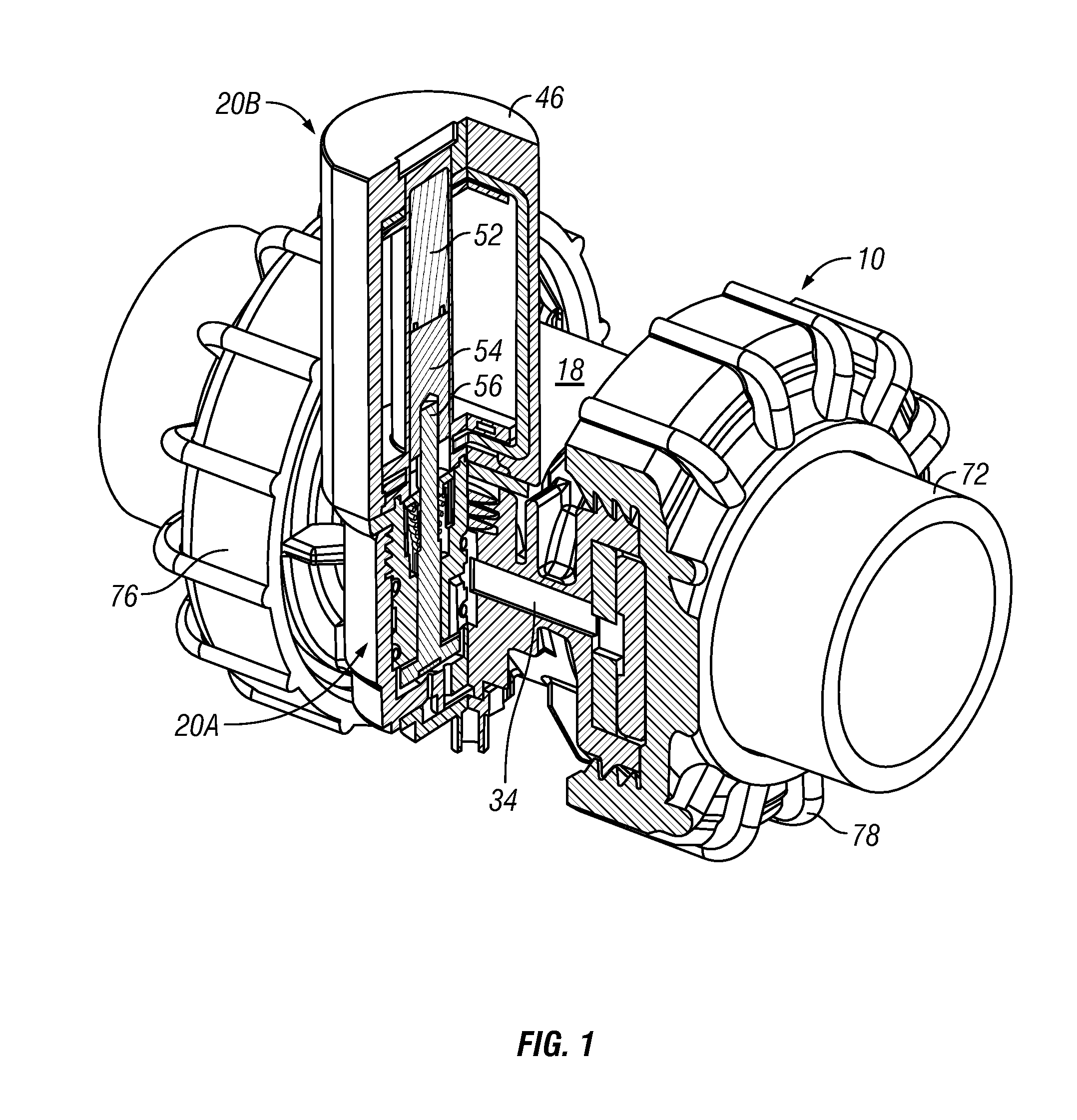

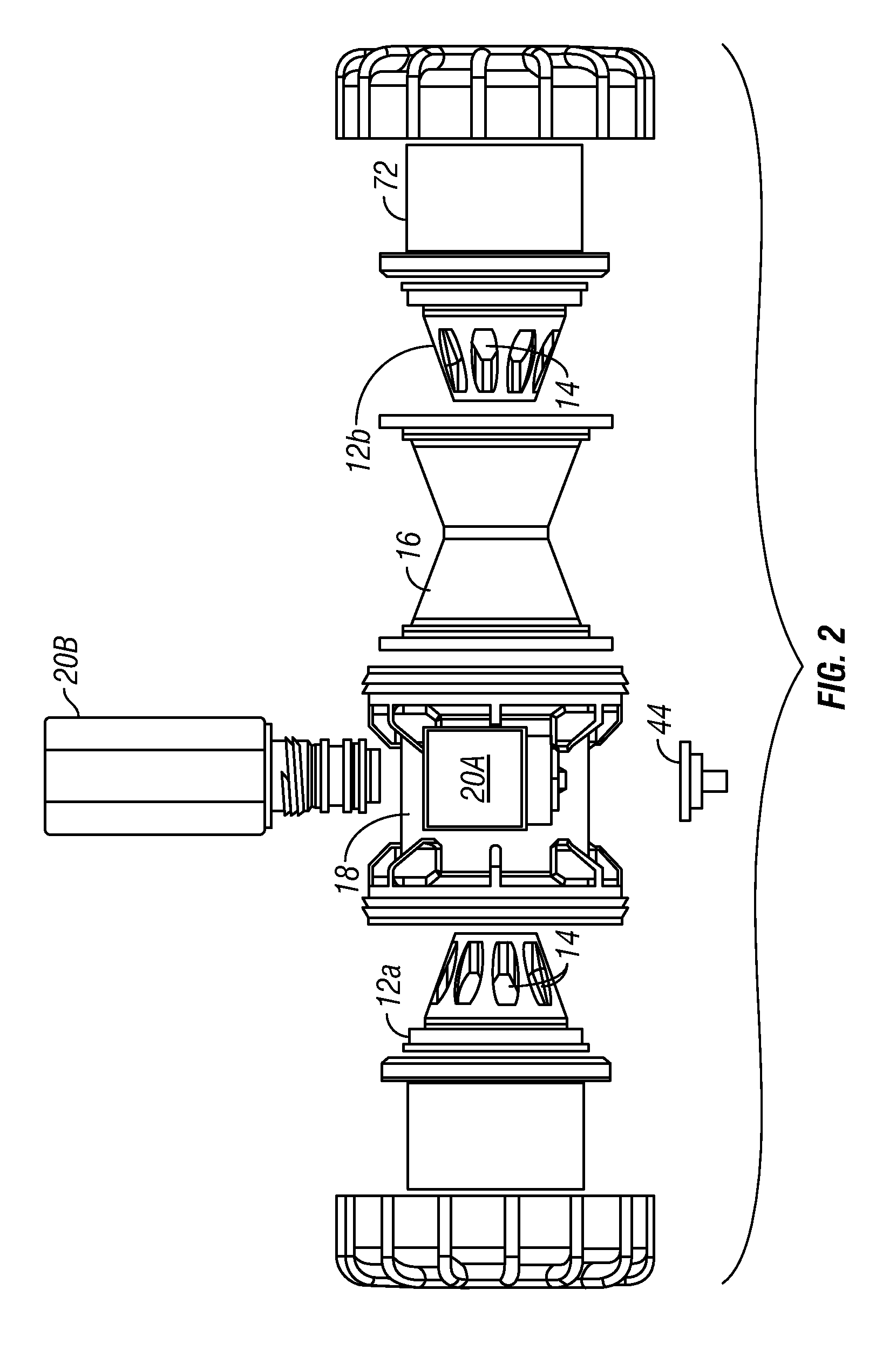

Multi-Position Valve for Fracturing and Sand Control and Associated Completion Methods

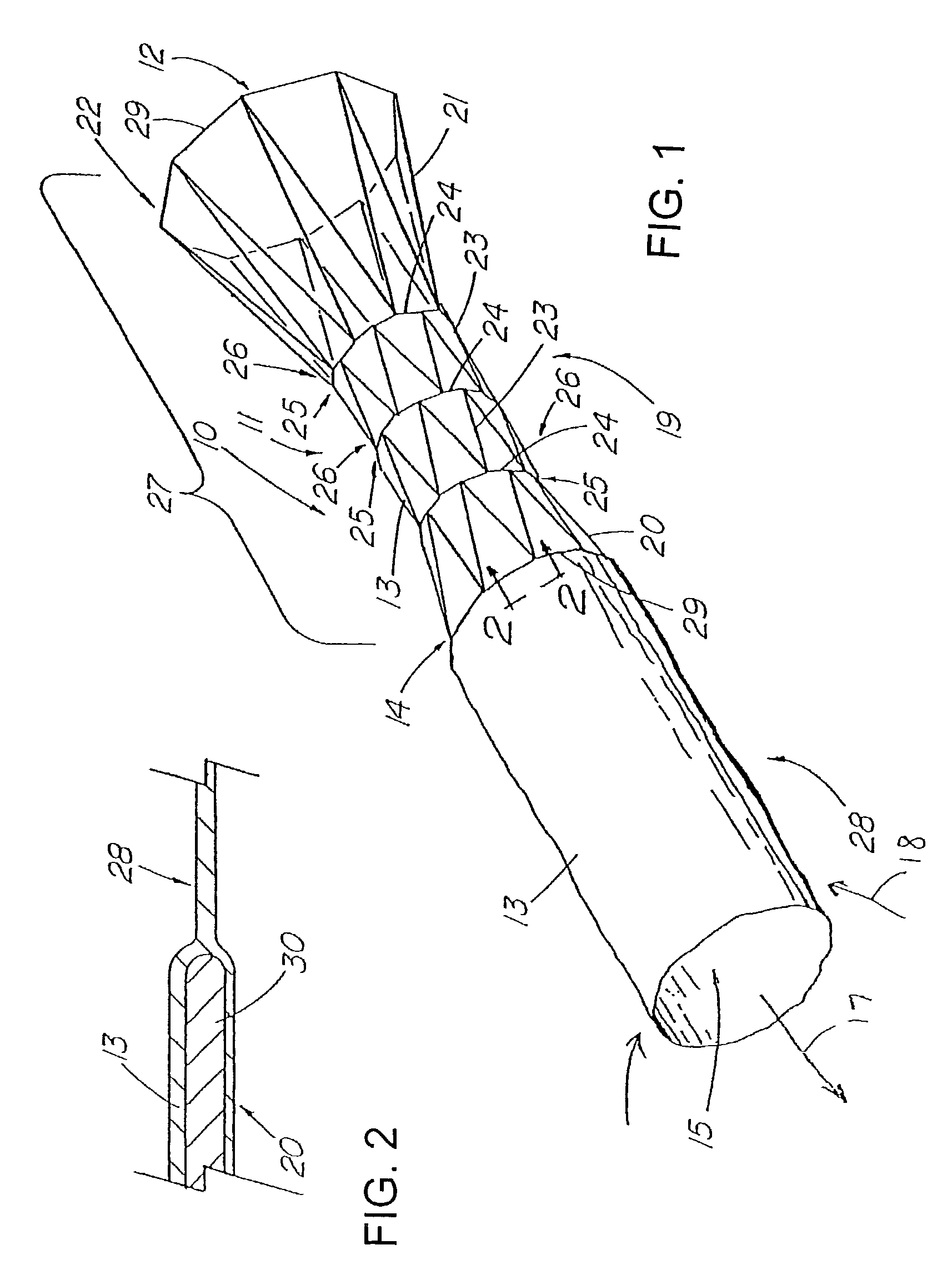

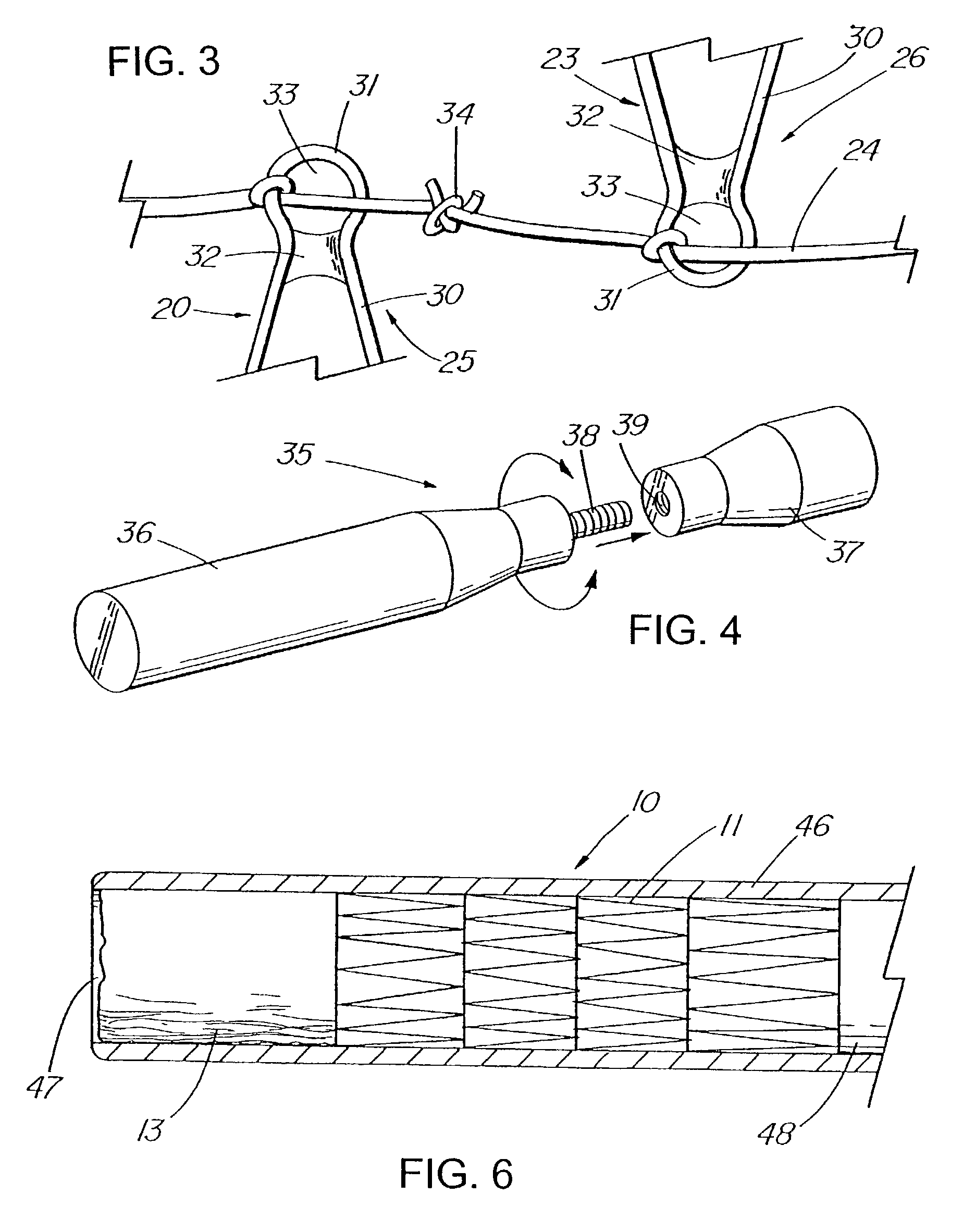

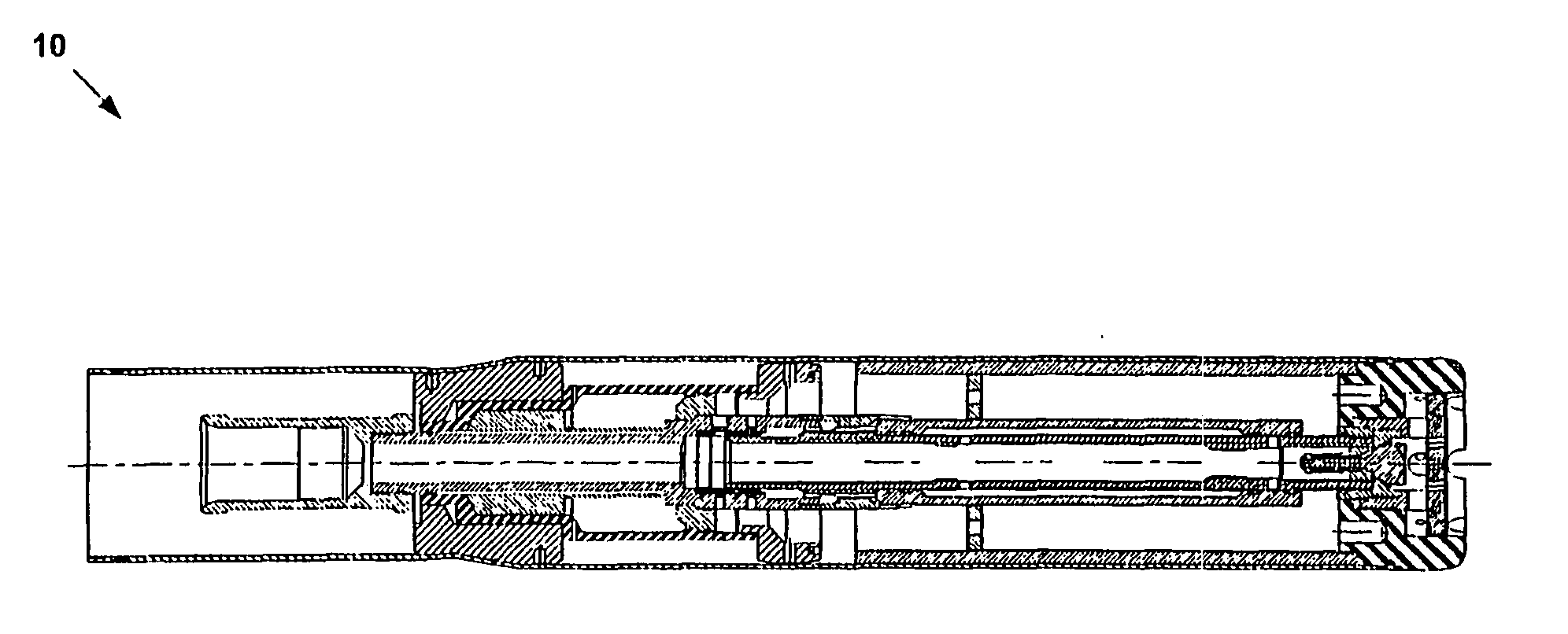

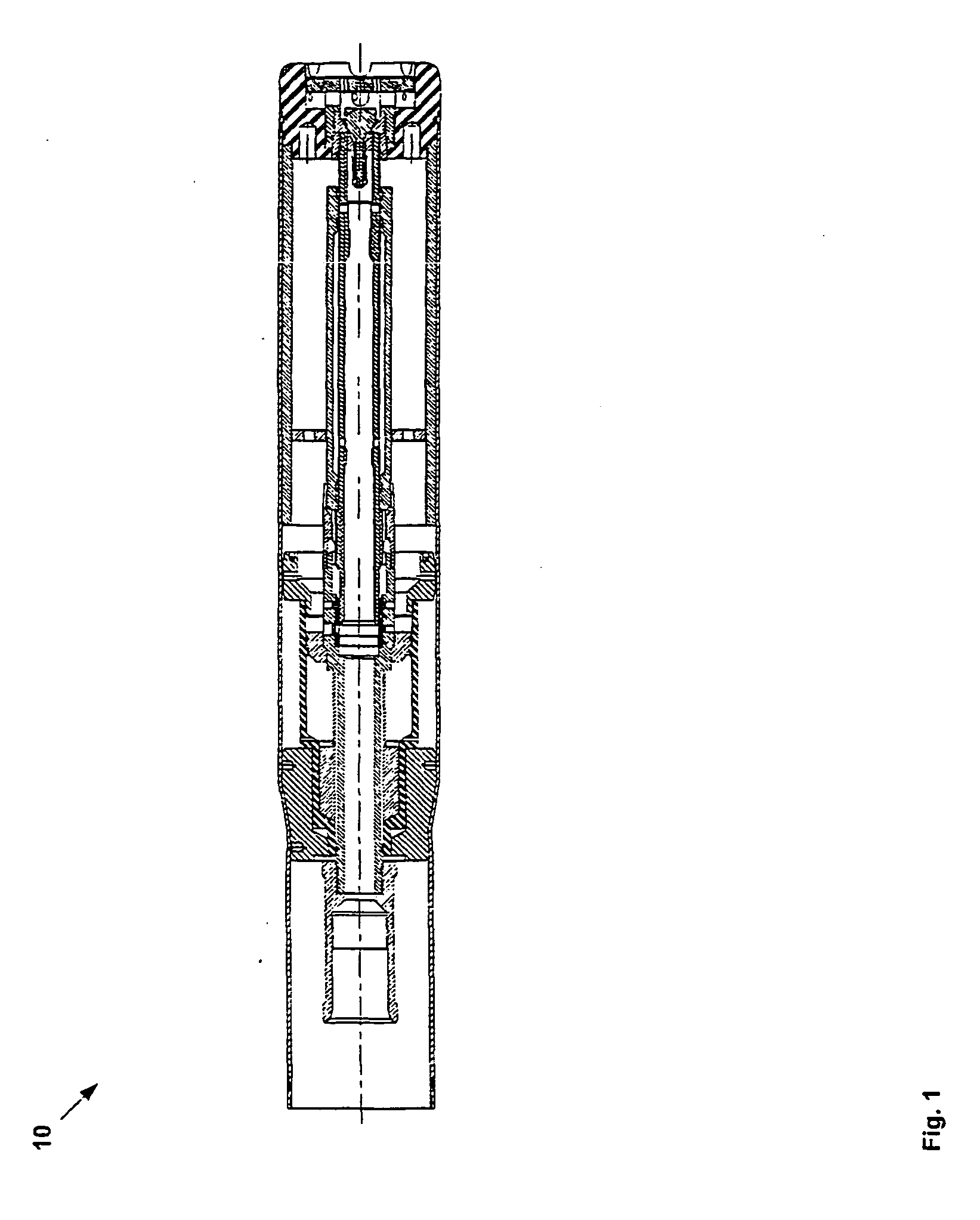

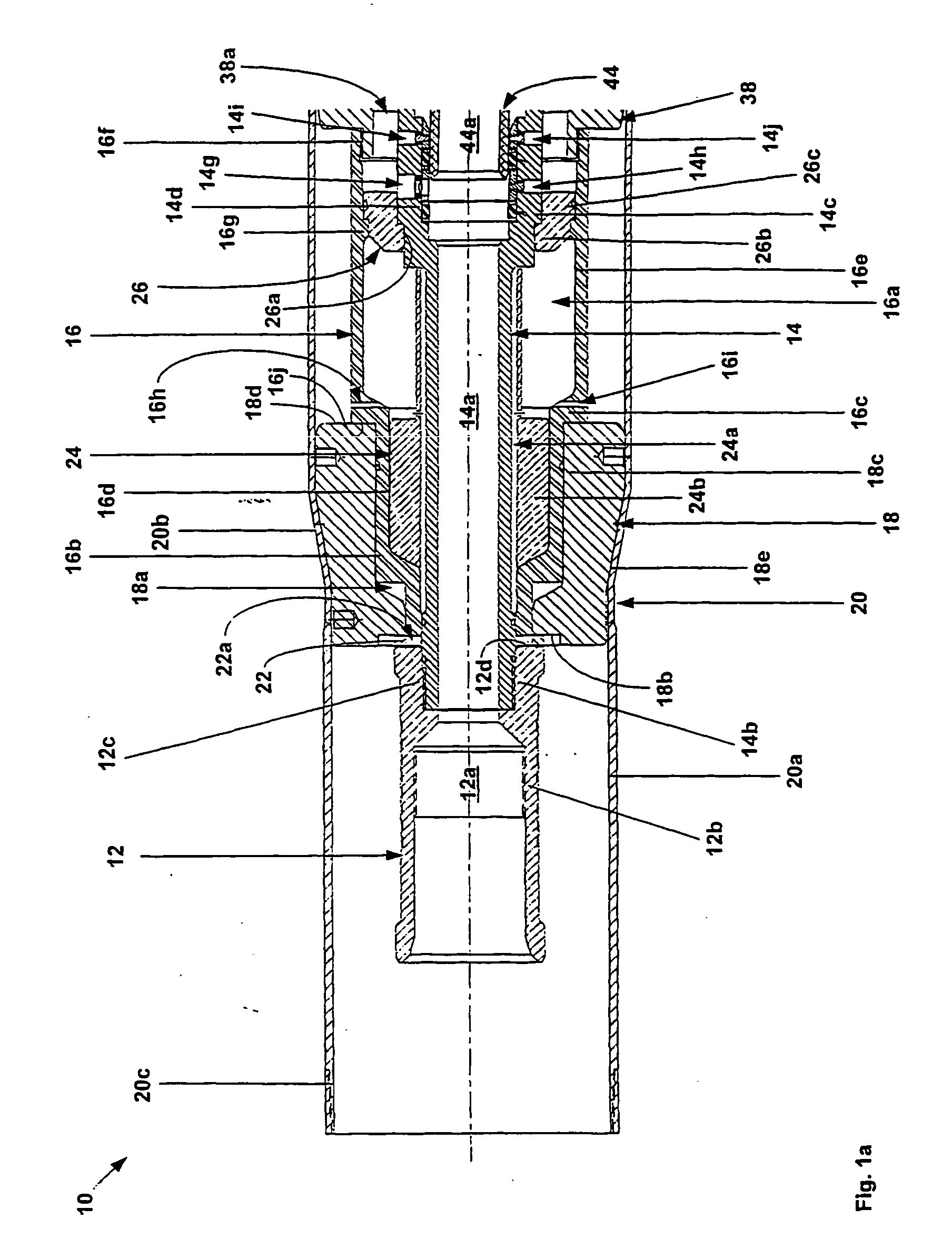

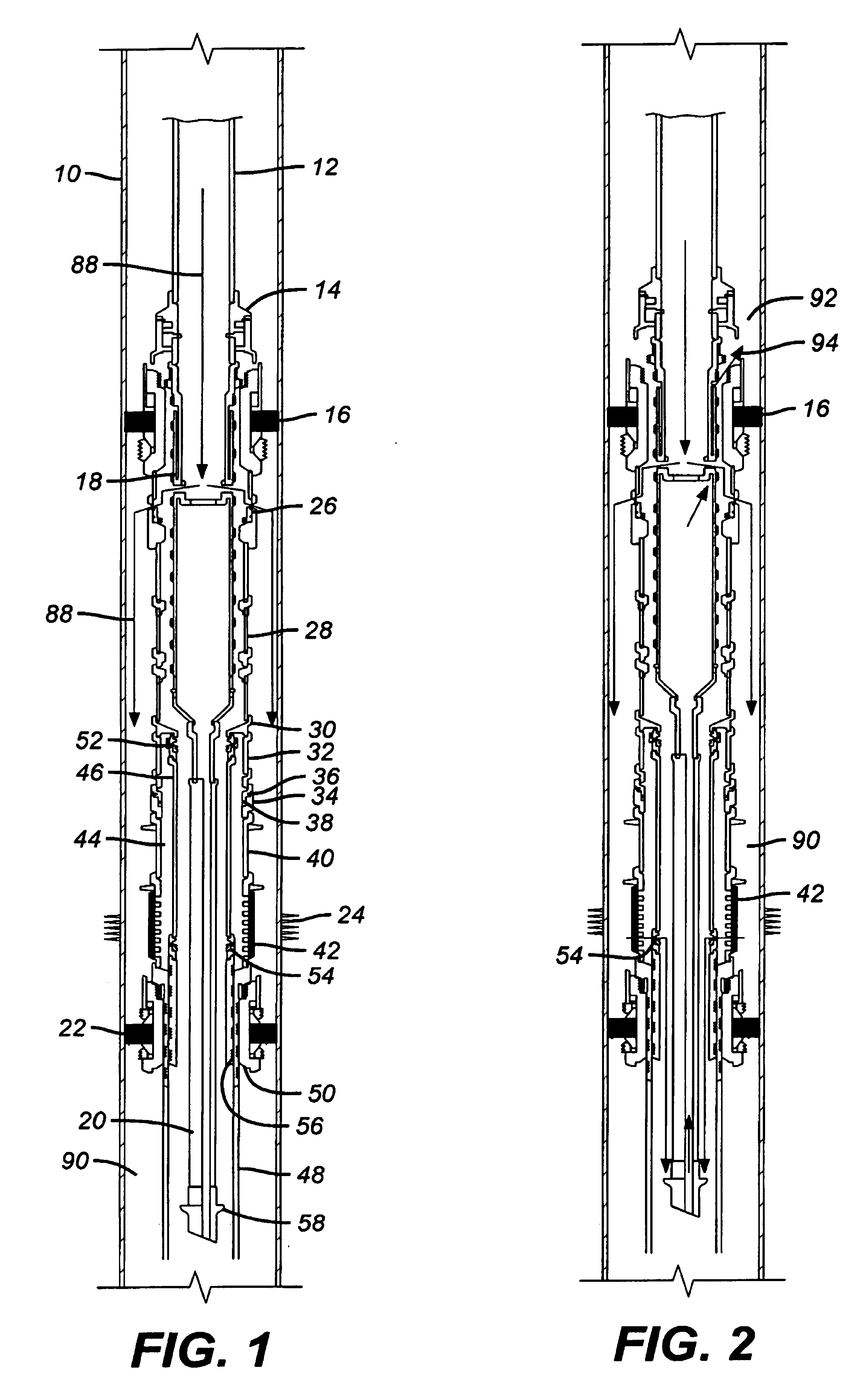

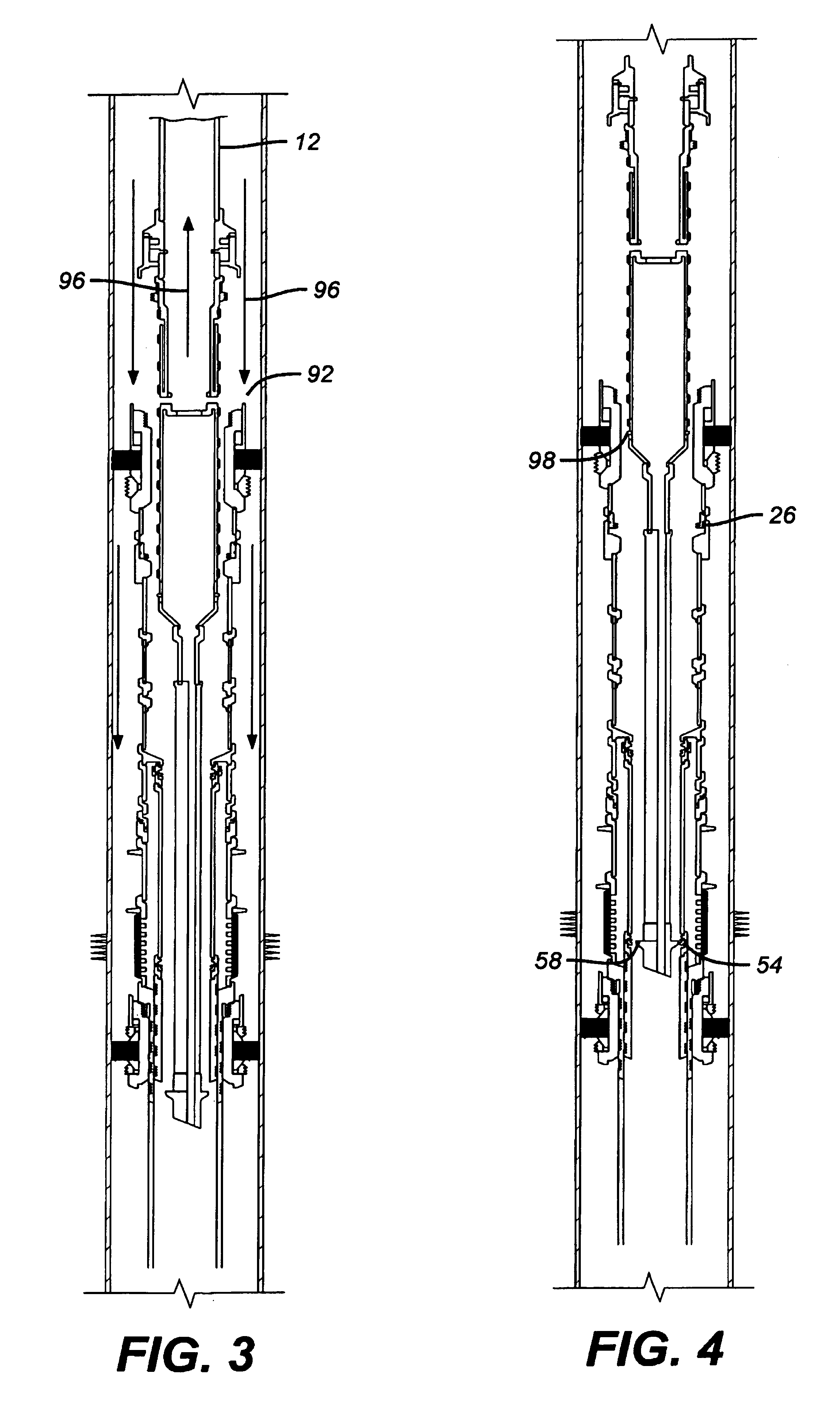

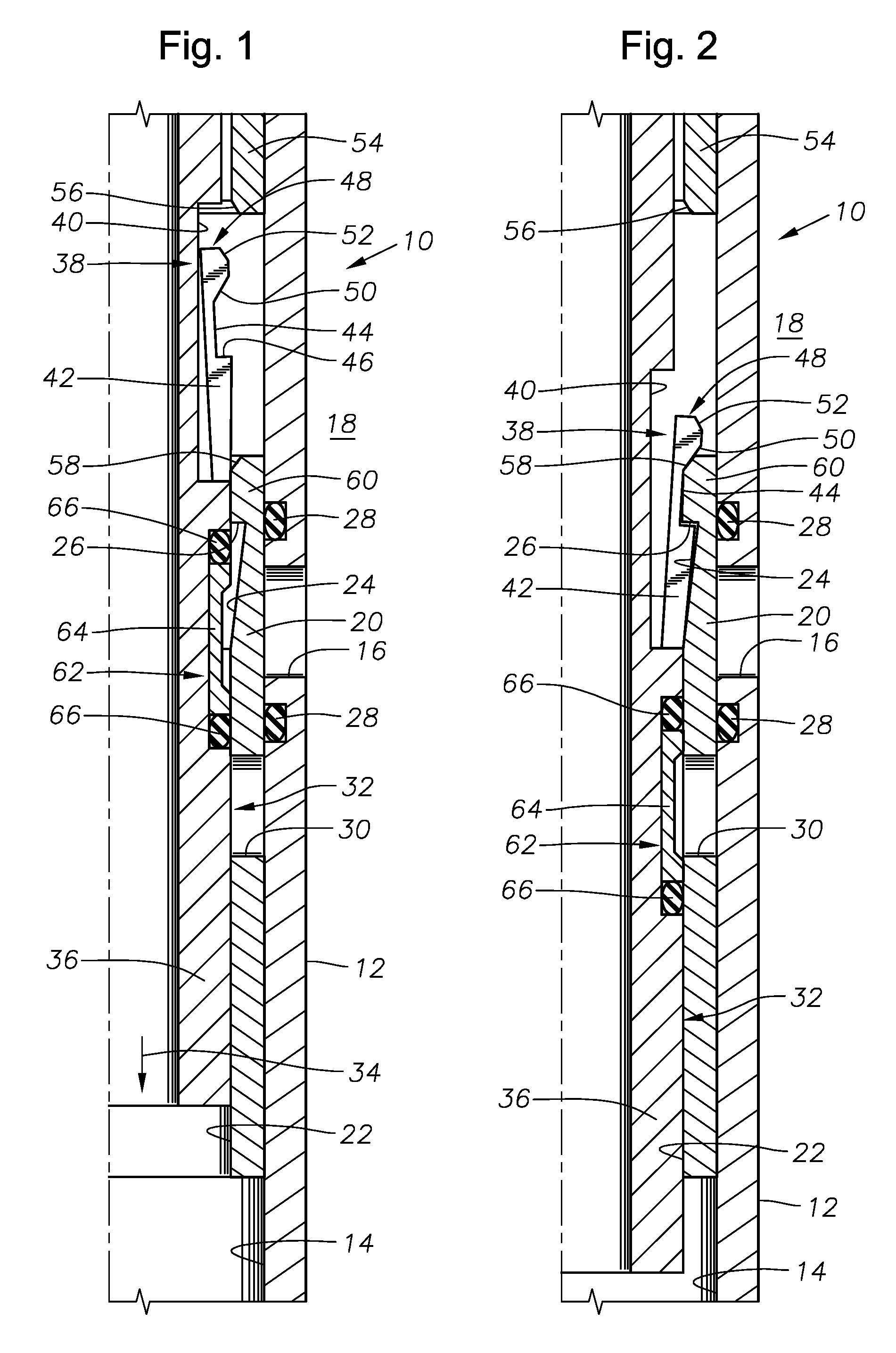

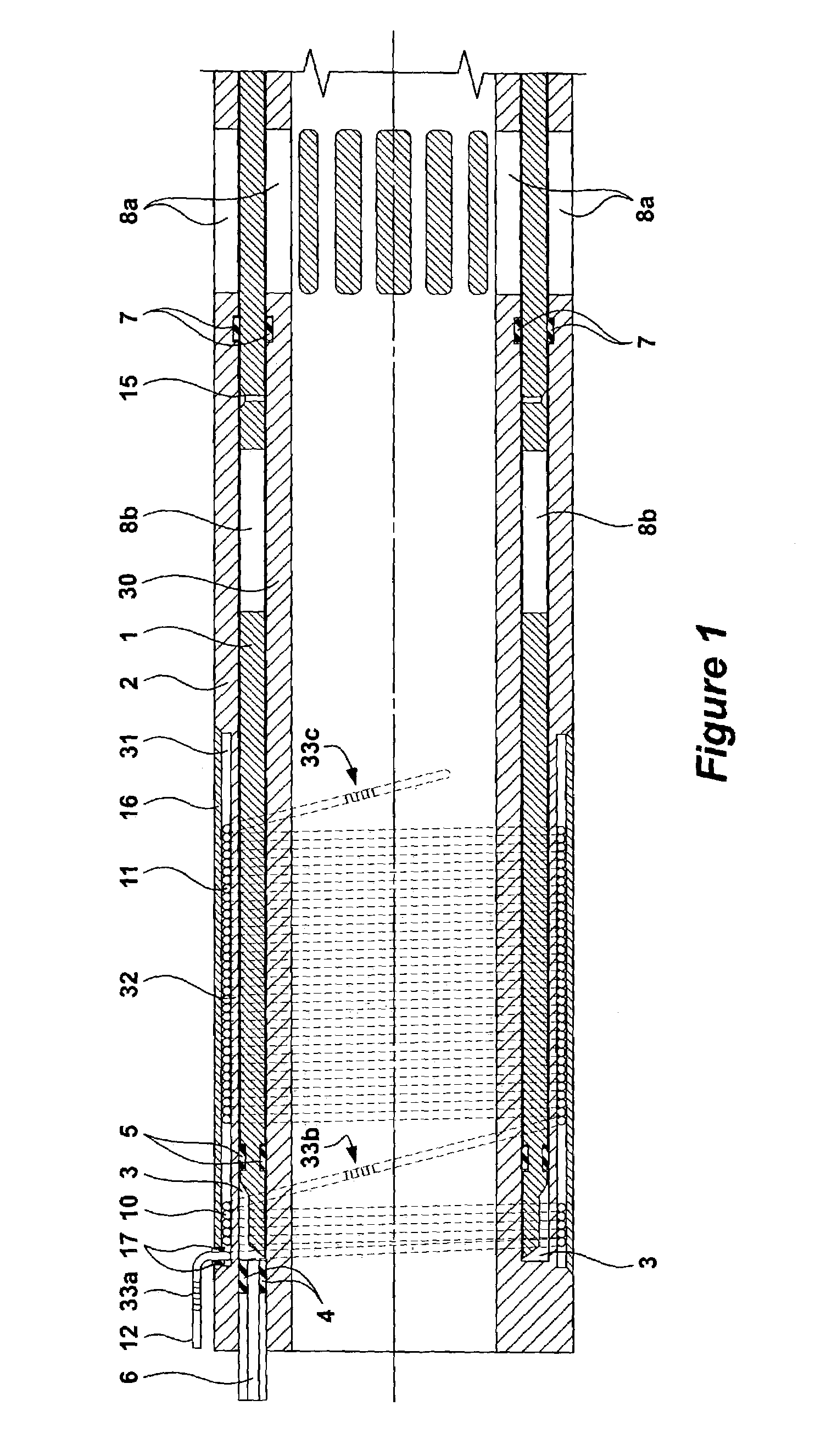

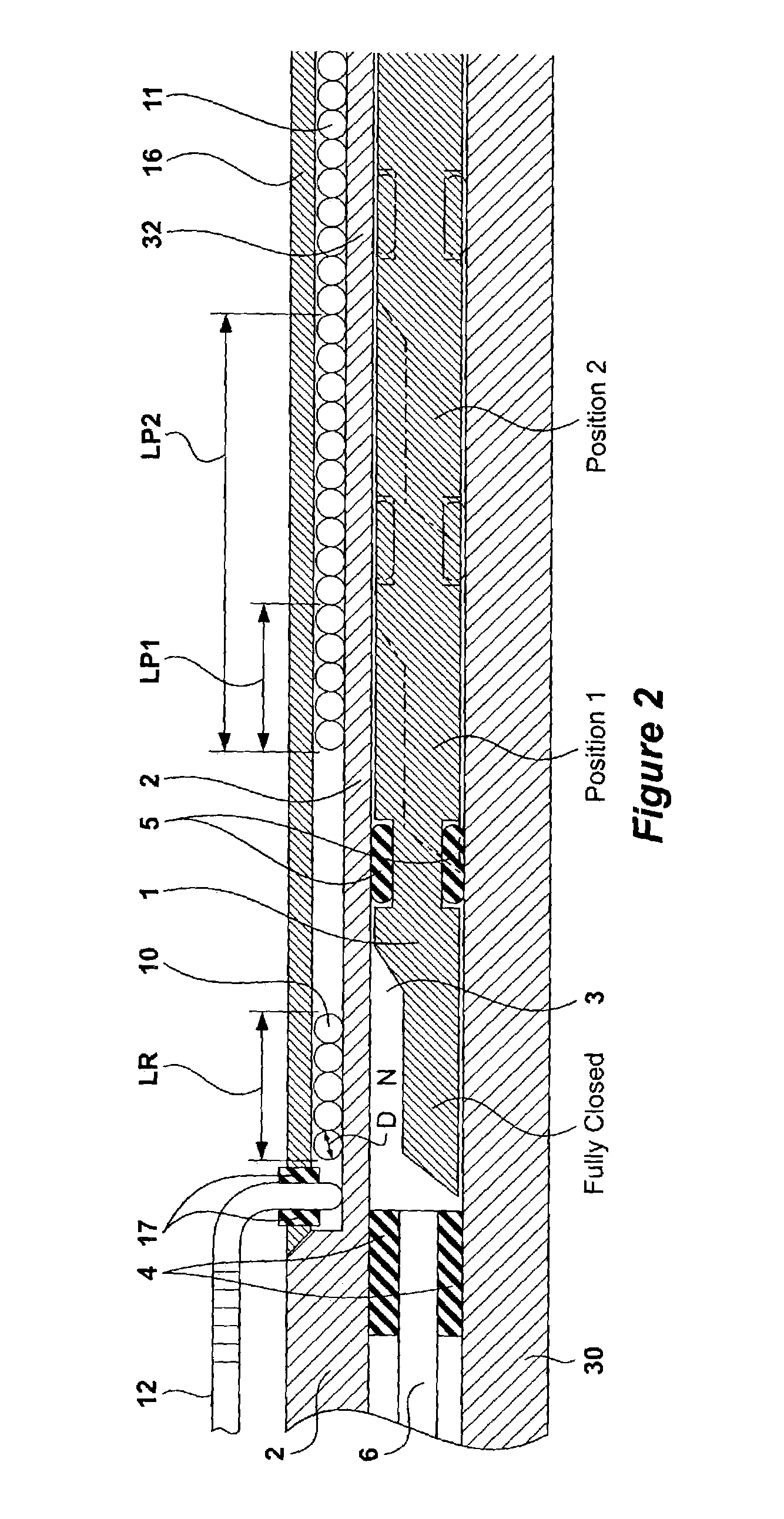

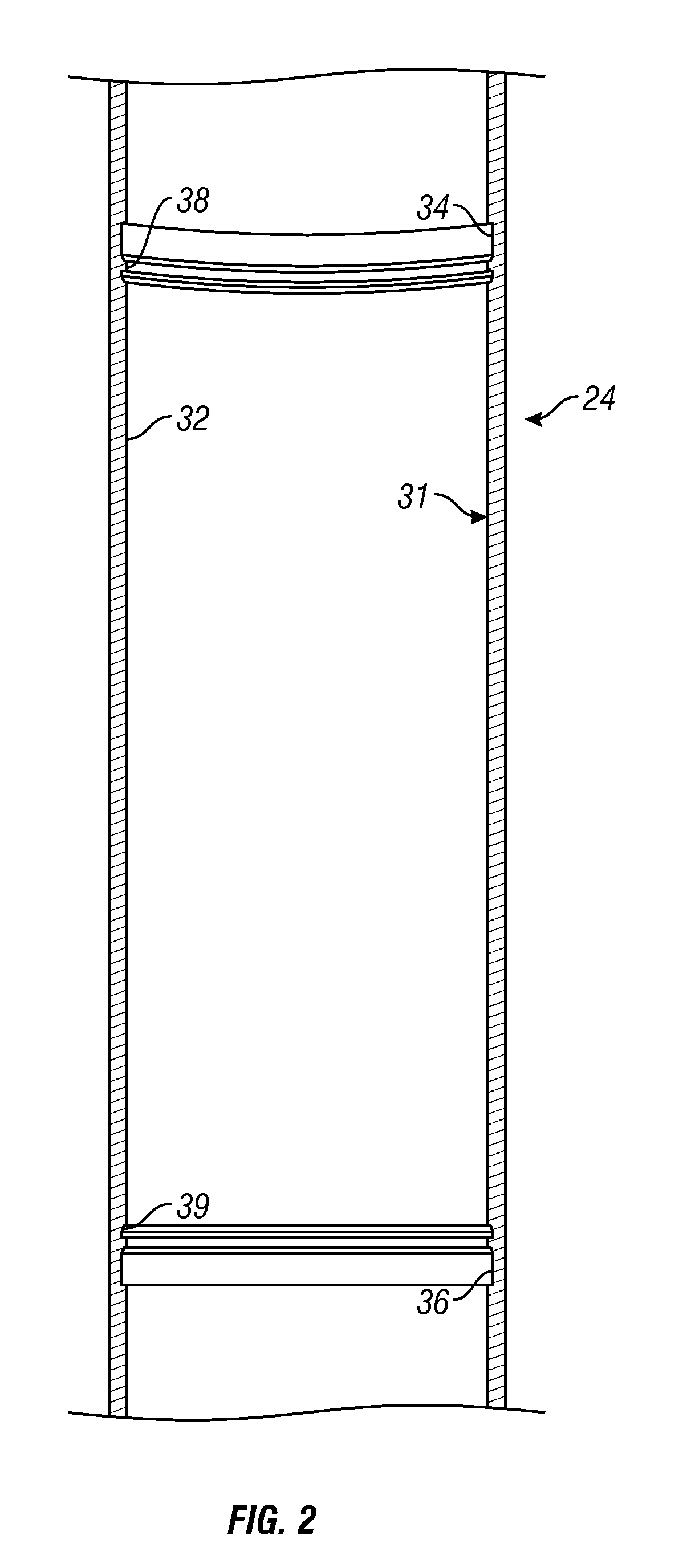

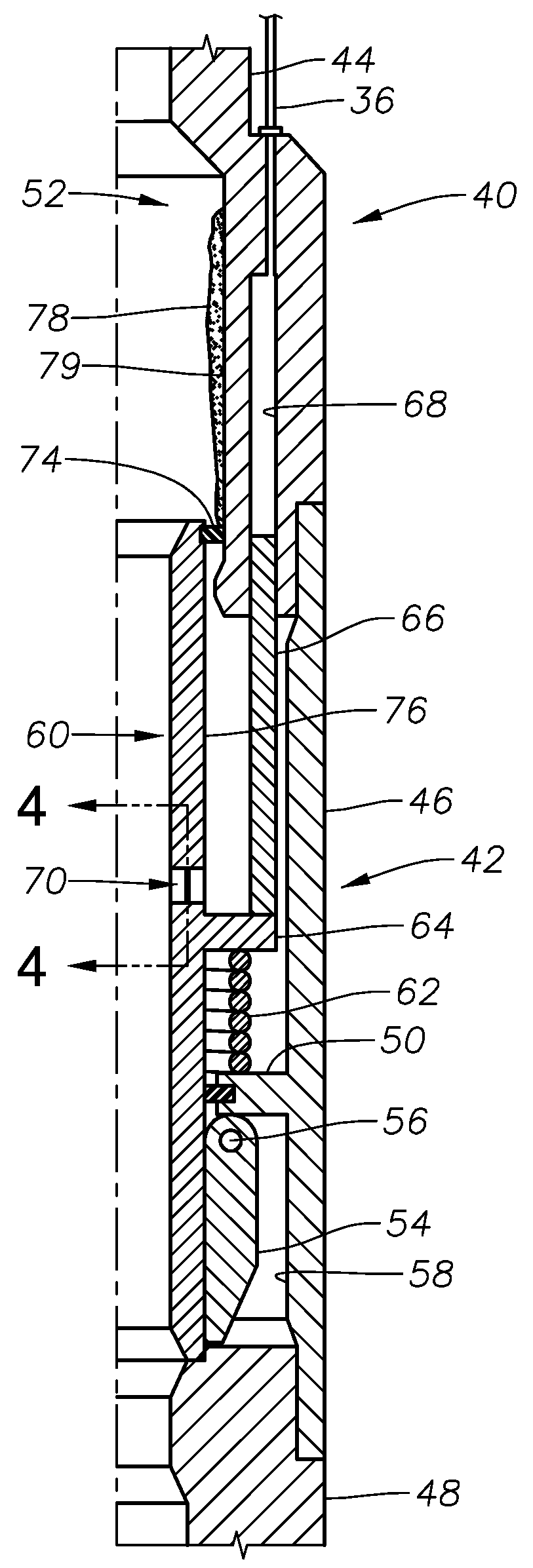

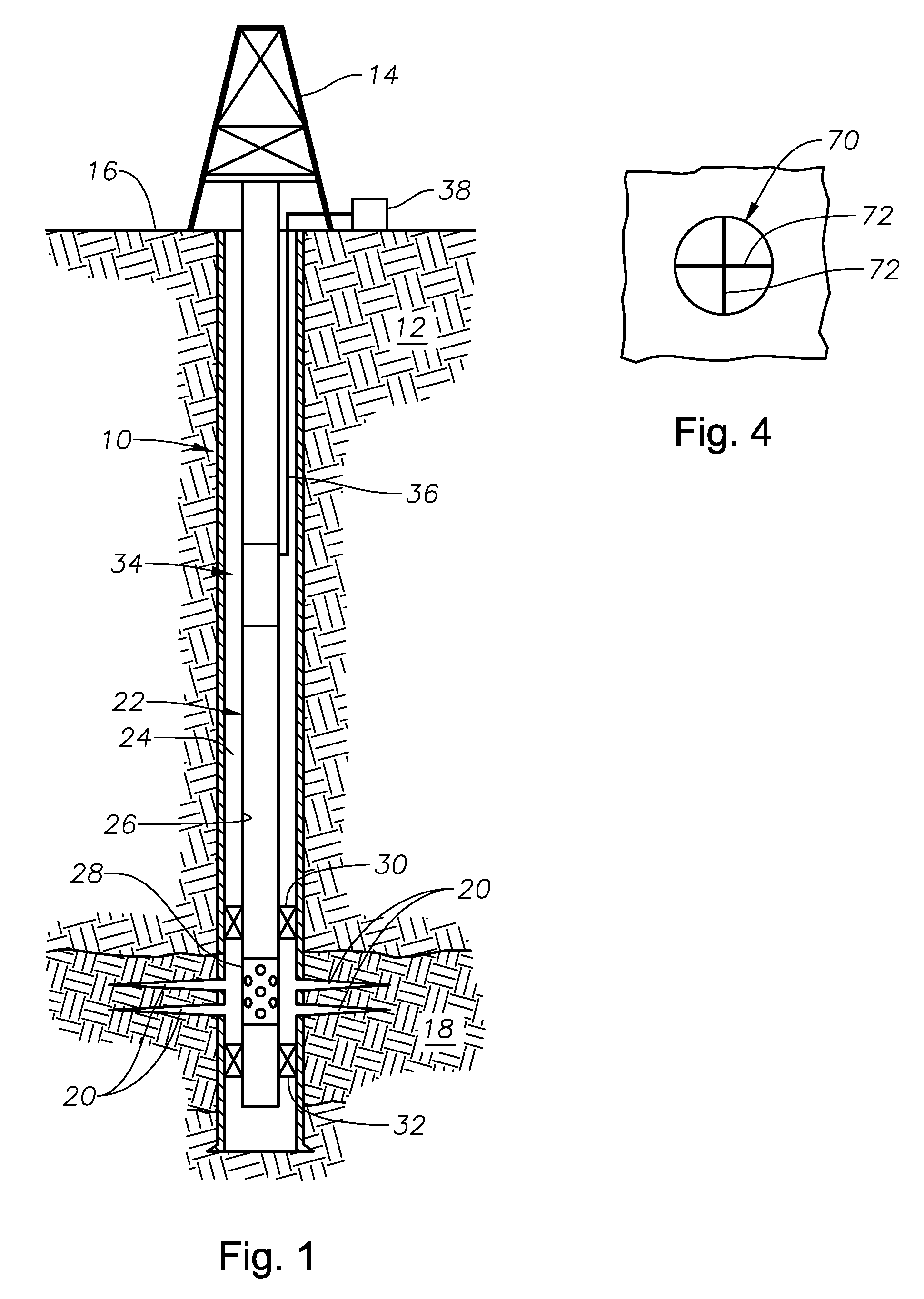

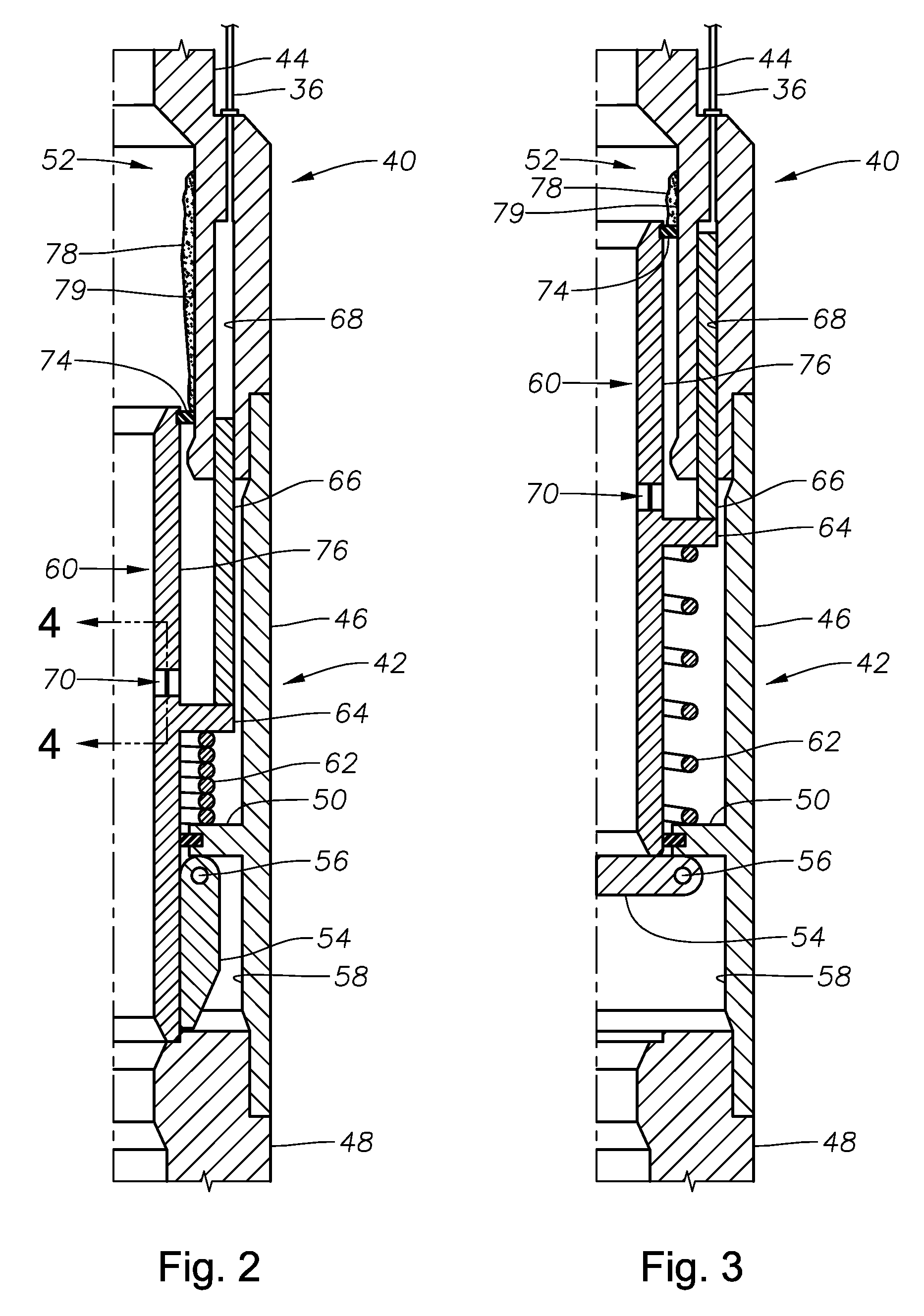

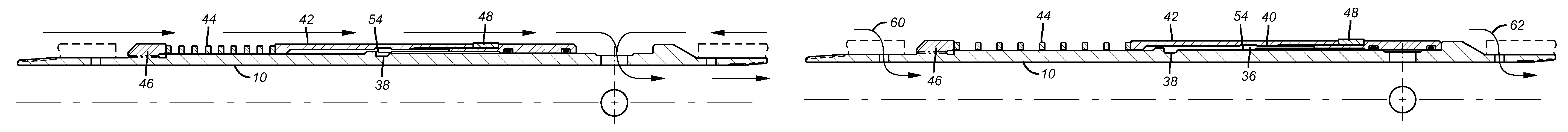

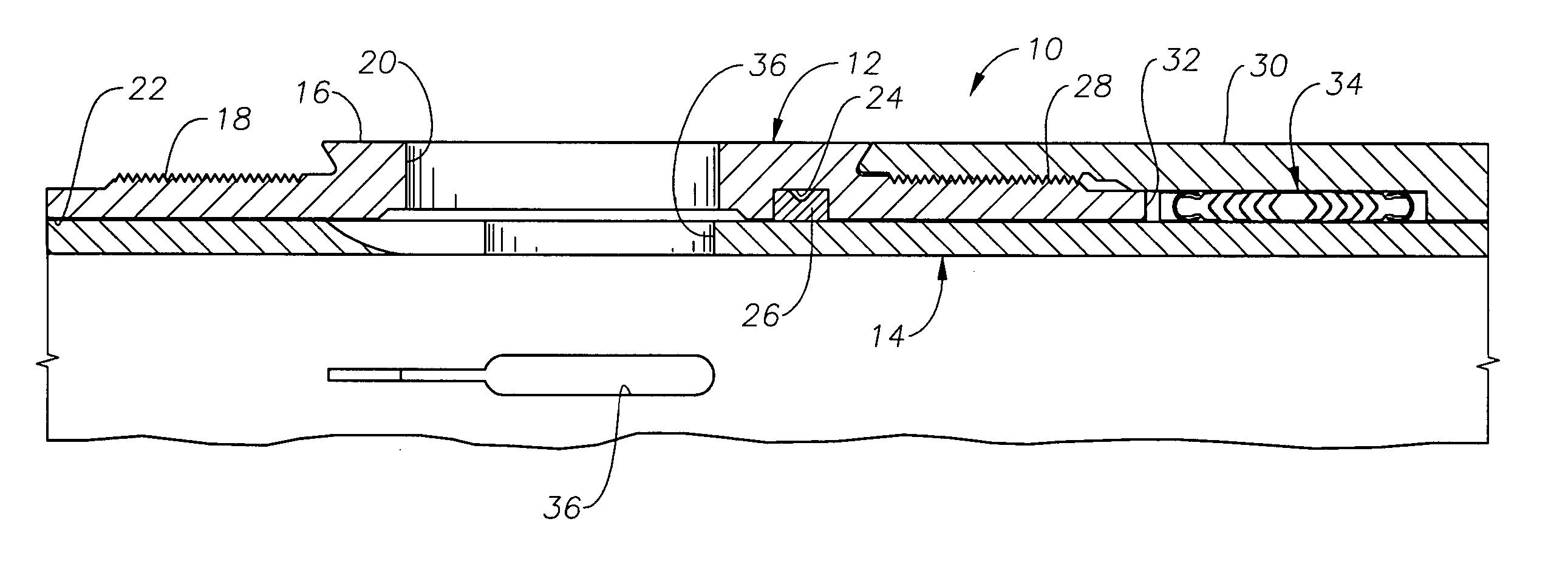

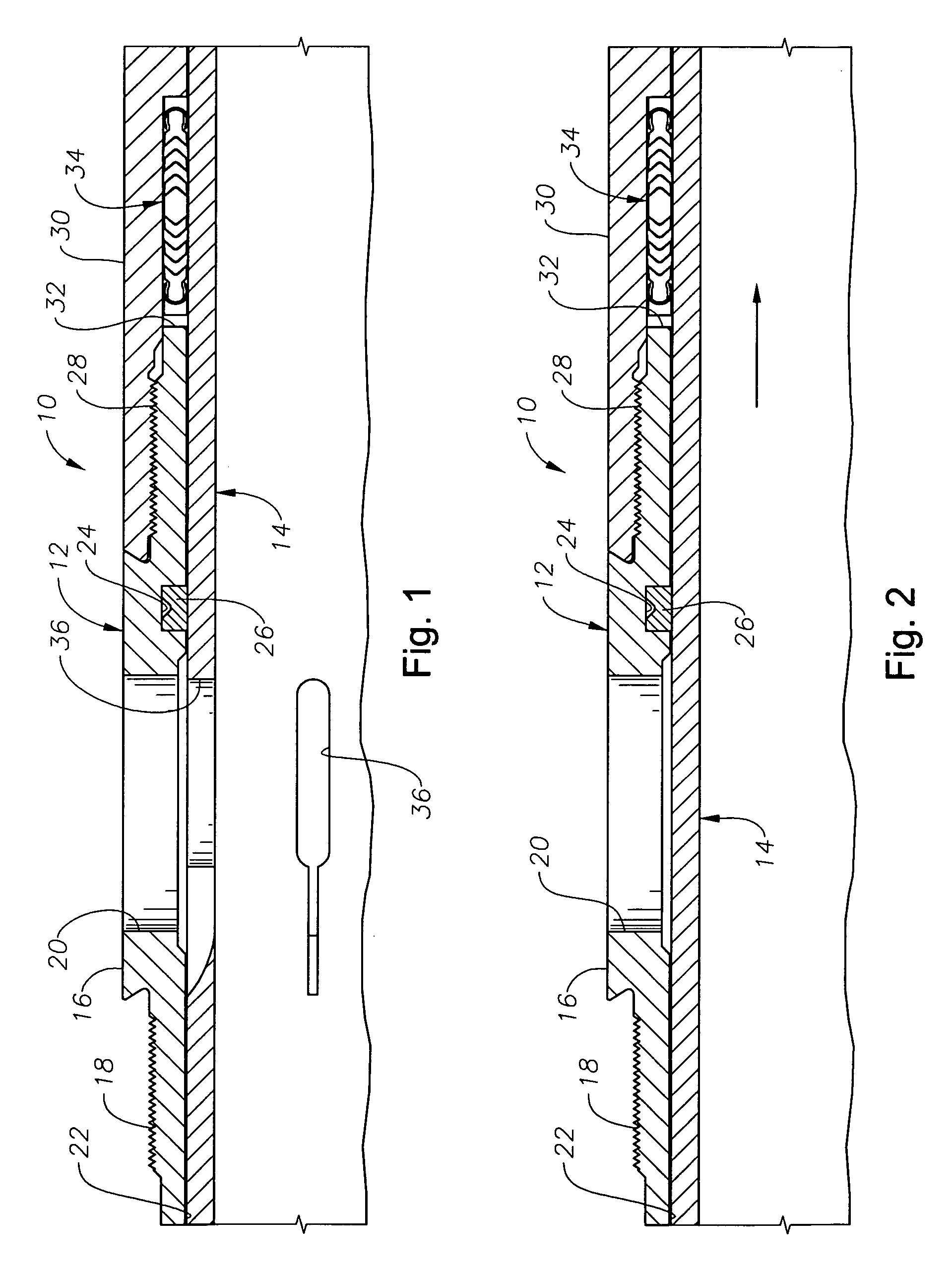

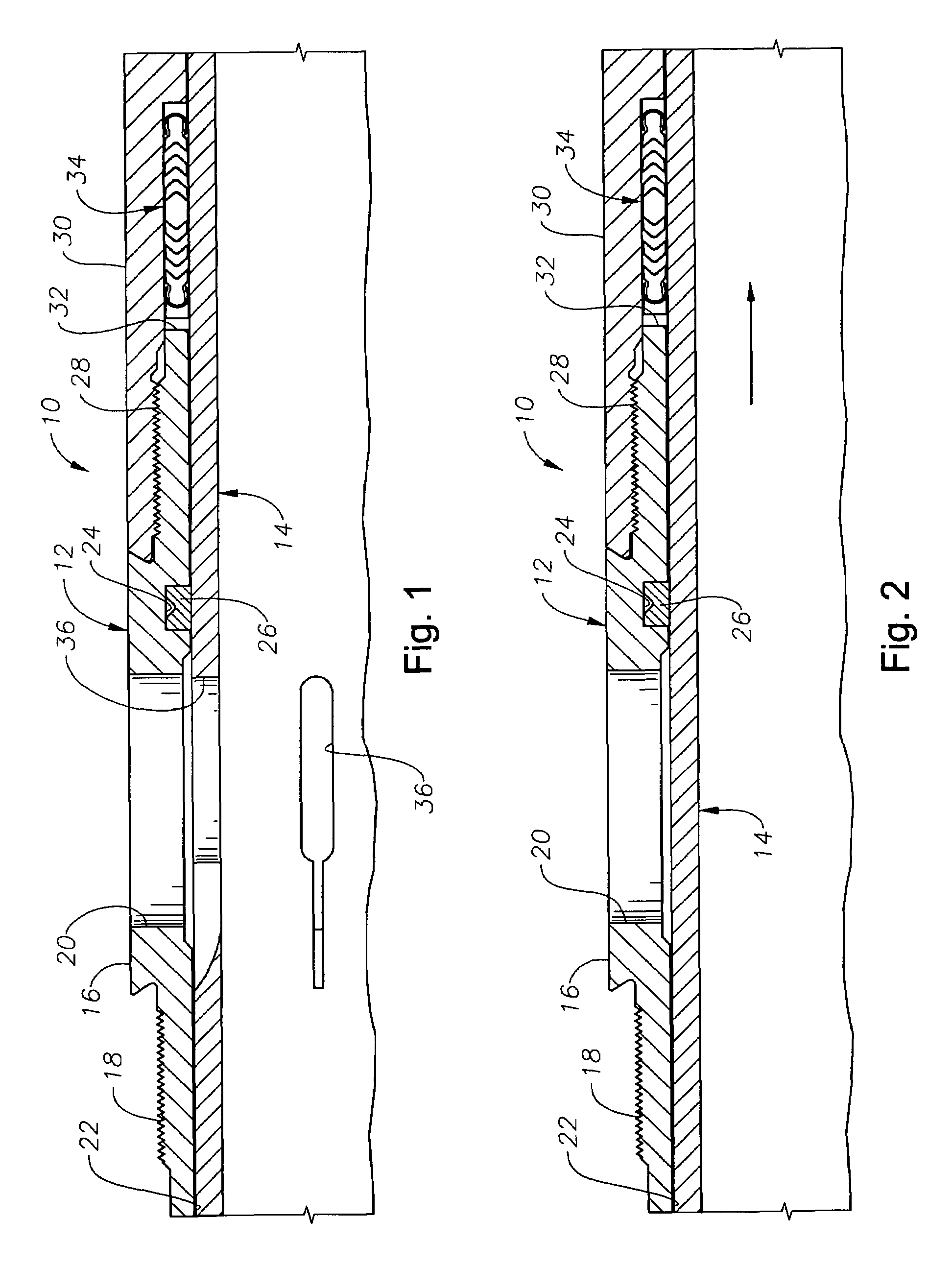

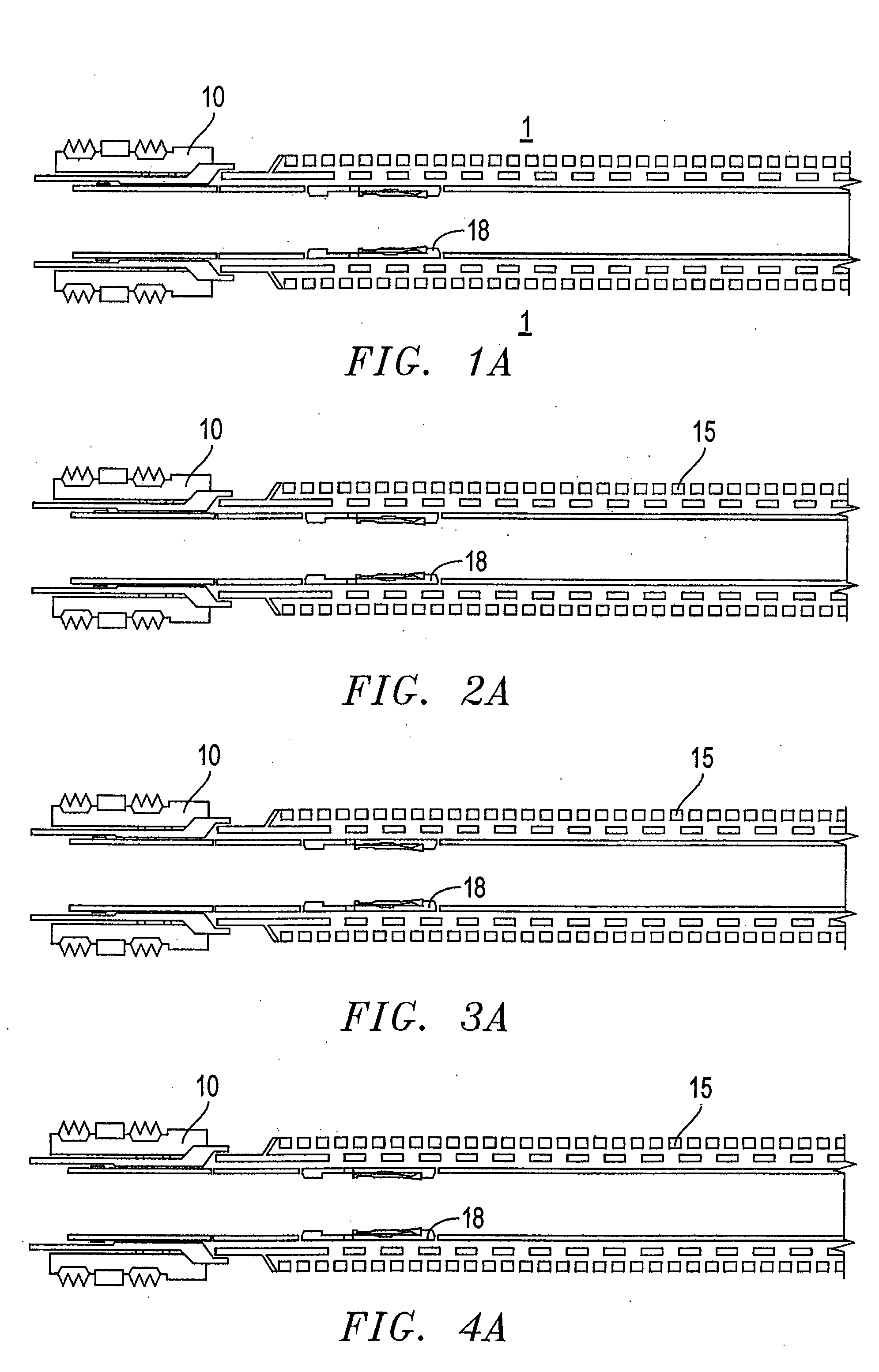

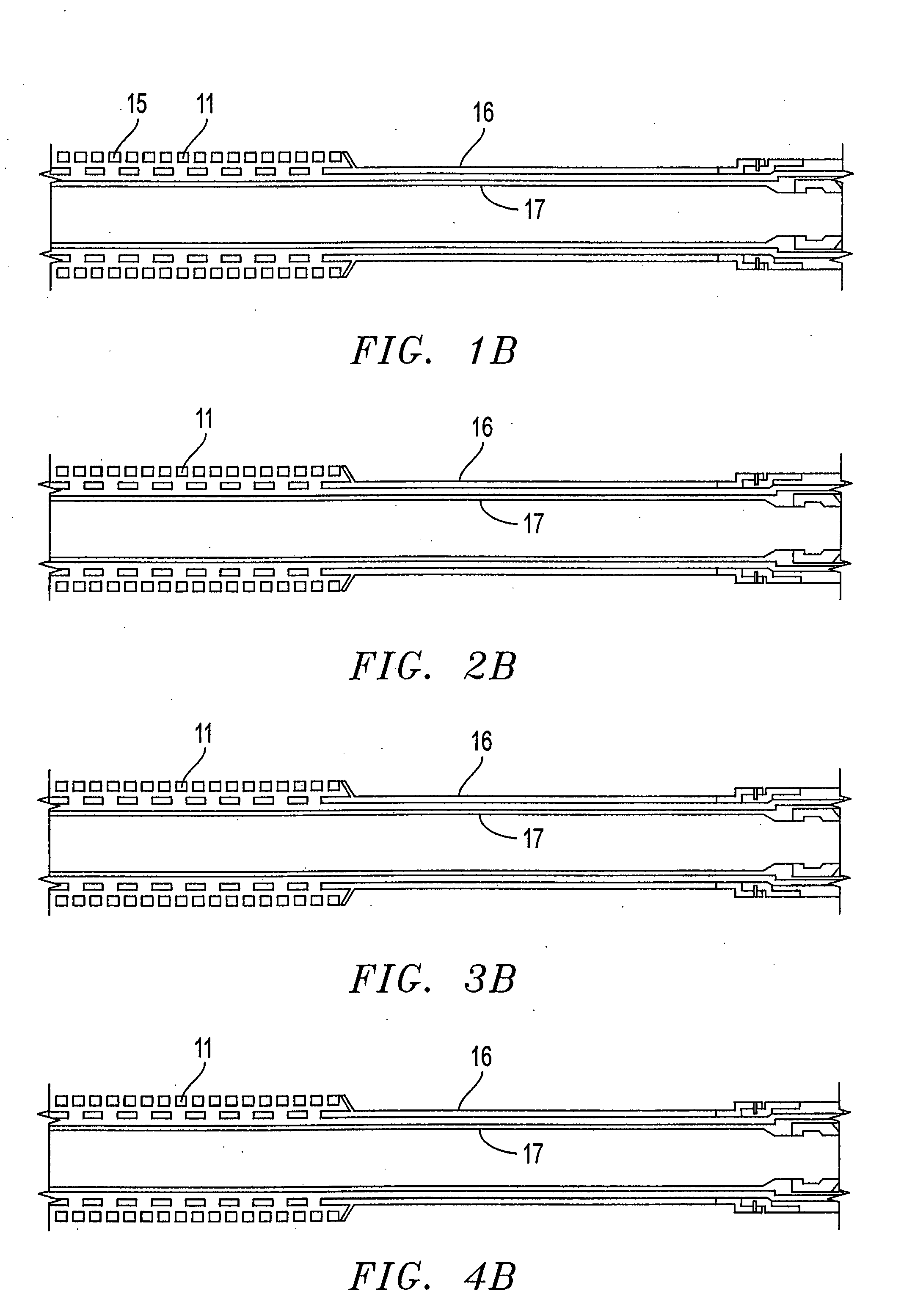

A completion tubular is placed in position adjacent the zone or zones to be fractured and produced. It features preferably sliding sleeve valves that can assume at least two configurations: wide open and open with a screen material juxtaposed in the flow passage. In a preferred embodiment the valve assembly has three positions, adding a fully closed position to the other two mentioned. After run in, the valves can be put in the wide open position in any order desired to fracture. After fracturing, the valves can be closed or selectively be put in filtration position for production from the fractured zones in any desired order. Various ways are described to actuate the valves. The tubular can have telescoping pistons through which the fracturing can take place if the application calls for a cemented tubular. Alternatively, the tubular can be in open hole and simply have openings for passage of fracture fluid and external isolators to allow fracturing in any desired order.

Owner:BAKER HUGHES INC

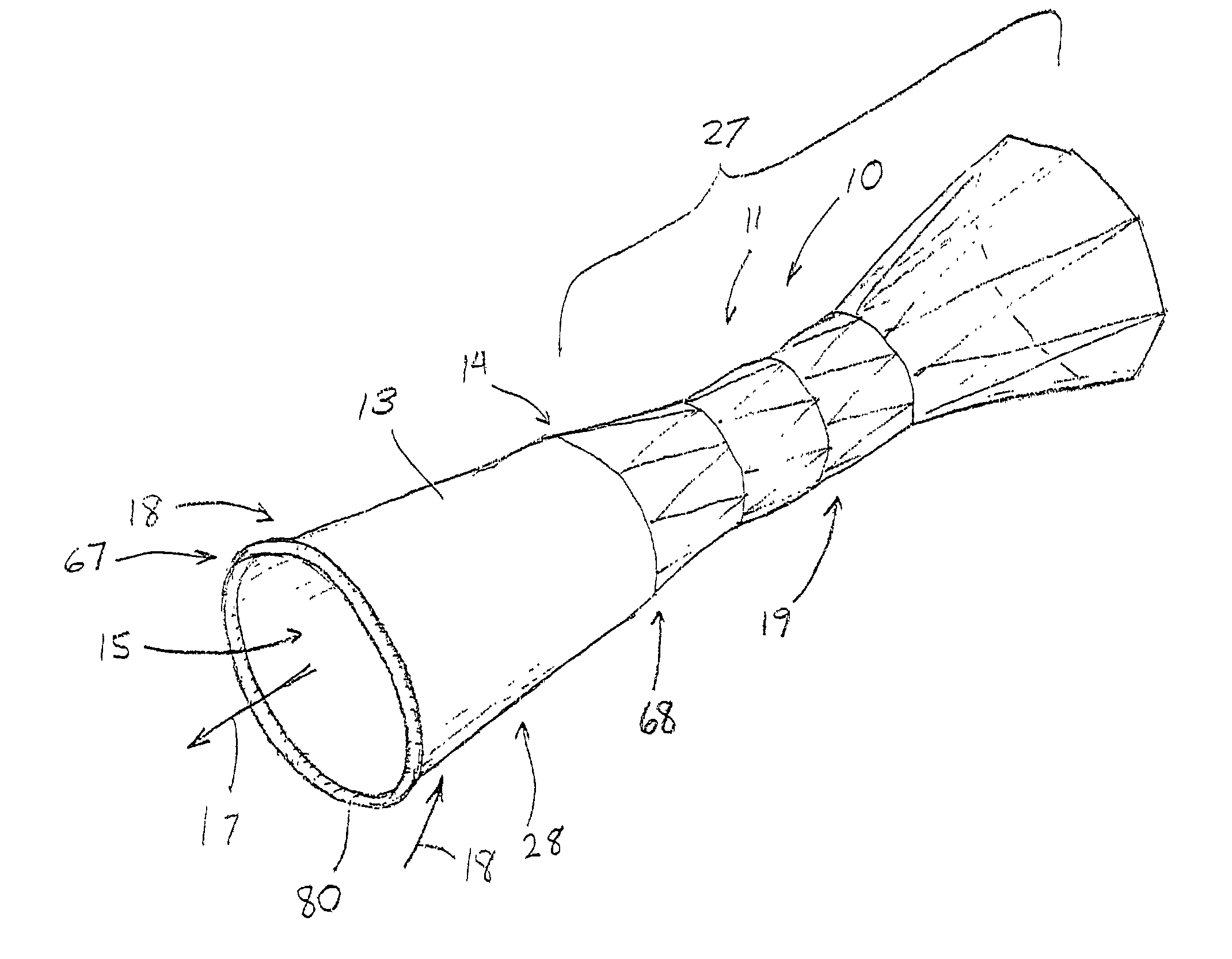

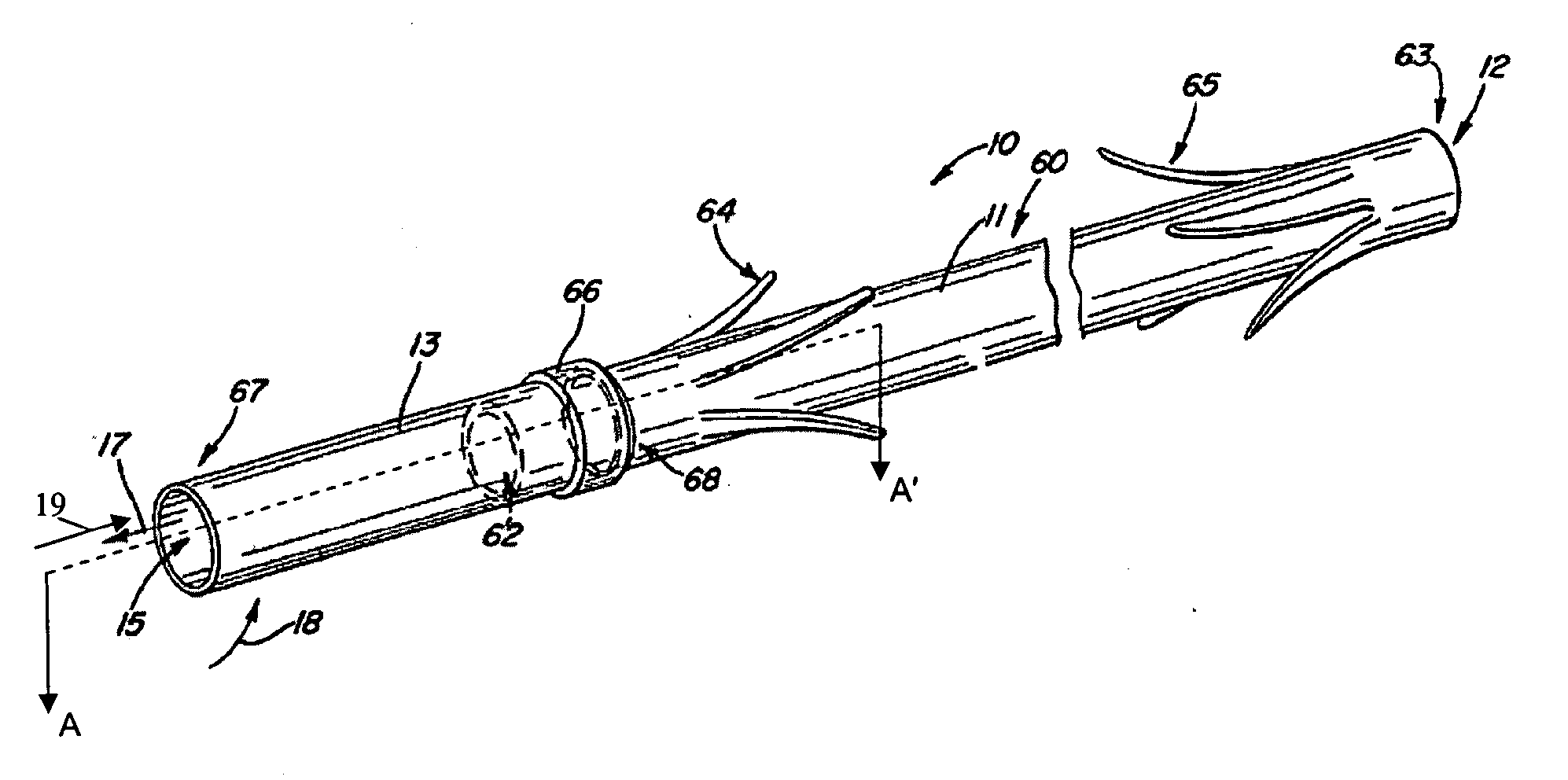

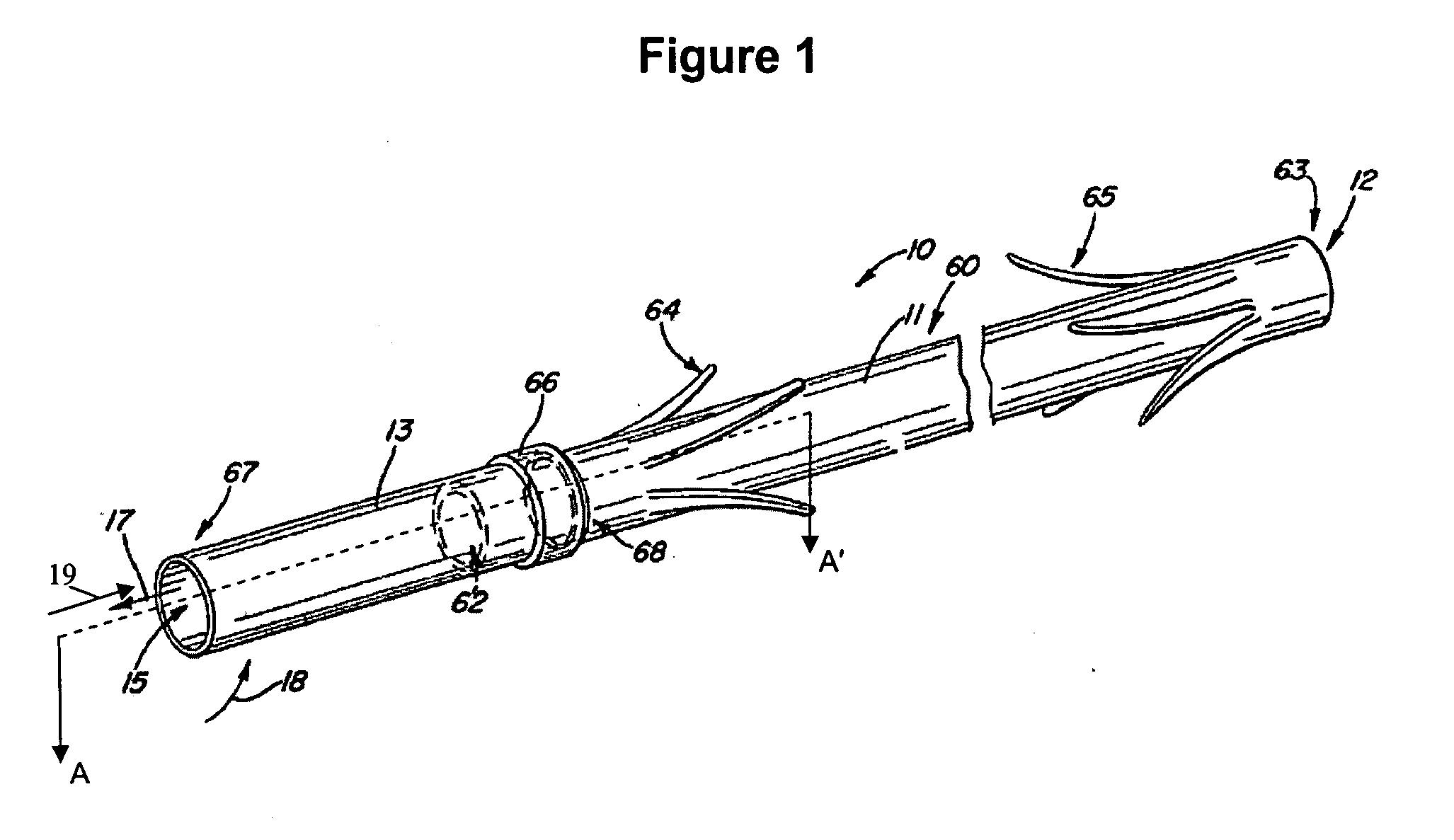

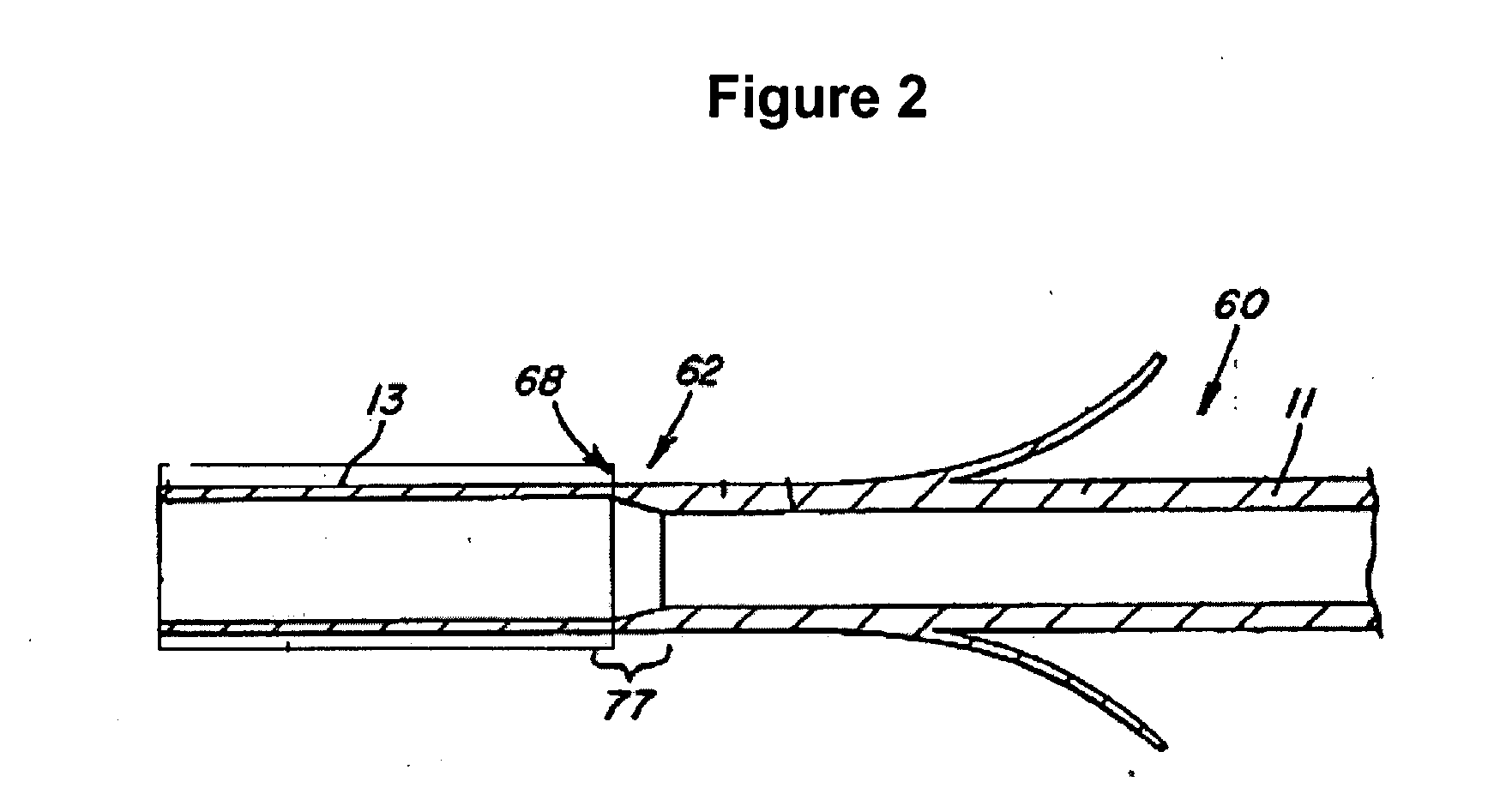

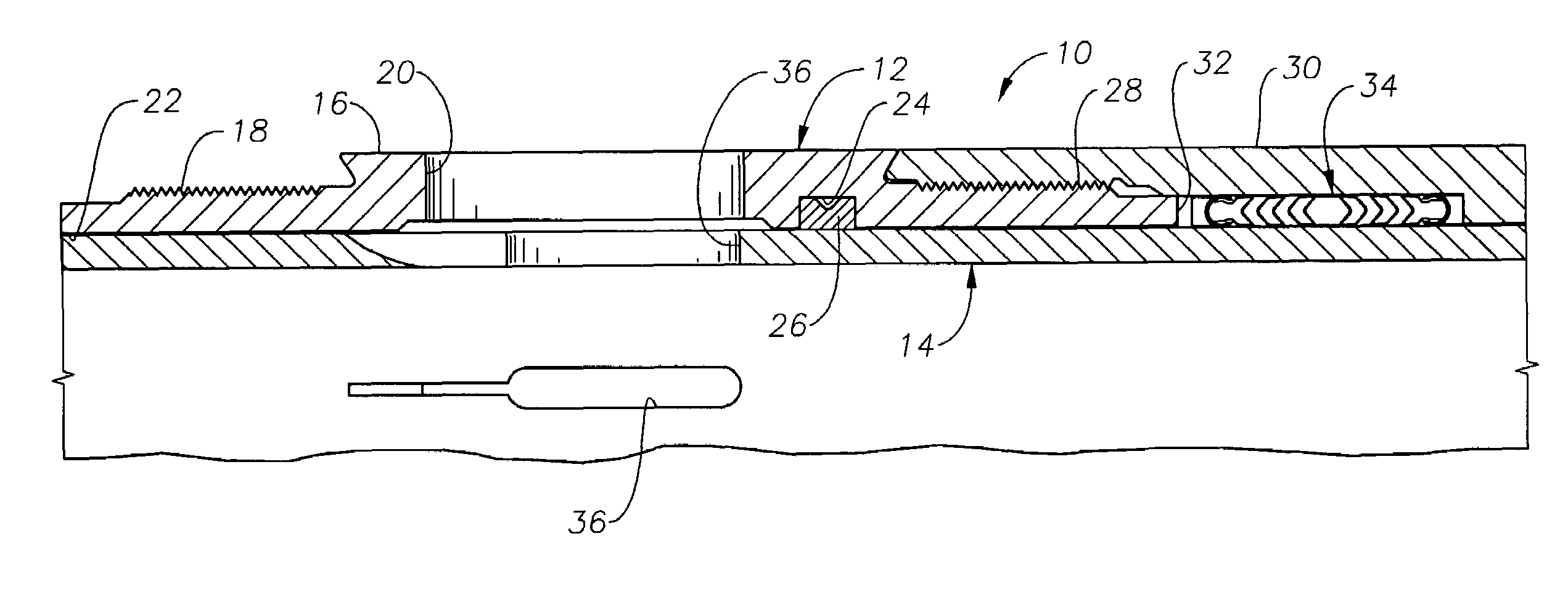

Prosthesis having a sleeve valve

Disclosed is a pressure sensitive prosthesis that includes a tubular member having a passageway extending therethrough and a sleeve attached about one end of the tubular member. The sleeve functions as a one-way valve to permit fluid flowing through the sleeve lumen in a first direction and under a first pressure, while collapsing in response to fluid flowing in a second direction when the pressure thereof exceeds that of the first direction or pressure. One aspect of the invention includes an esophageal anti-reflux expandable prosthesis wherein the sleeve is adapted to invert back through the tubular stent frame to permit belching or vomiting (fluid or materials under a third, significantly higher pressure). Another aspect of the invention includes a tubular drainage stent, such as a biliary or urethral stent in which the sleeve opens to permit passage of fluids, then collapses to prevent retrograde flow.

Owner:COOK MEDICAL TECH LLC

Medical device having a sleeve valve with bioactive agent

InactiveUS20080086214A1Inhibitory contentInhibition formationStentsBile ductsActive agentSleeve valve

Medical devices for implantation in a body vessel are provided. A medical device can be configured as a drainage stent adapted for placement in a bodily passageway. The drainage stent preferably includes a drainage lumen extending longitudinally through the drainage stent, and a sleeve defining a collapsible lumen in fluid flow communication with the drainage lumen. The sleeve may function as a one-way valve and preferably includes a biodeposition-reducing bioactive agent, such as an antibiotic or antimicrobial agent. The medical device may be configured as a biliary or pancreatic stent.

Owner:WILSONCOOK MEDICAL

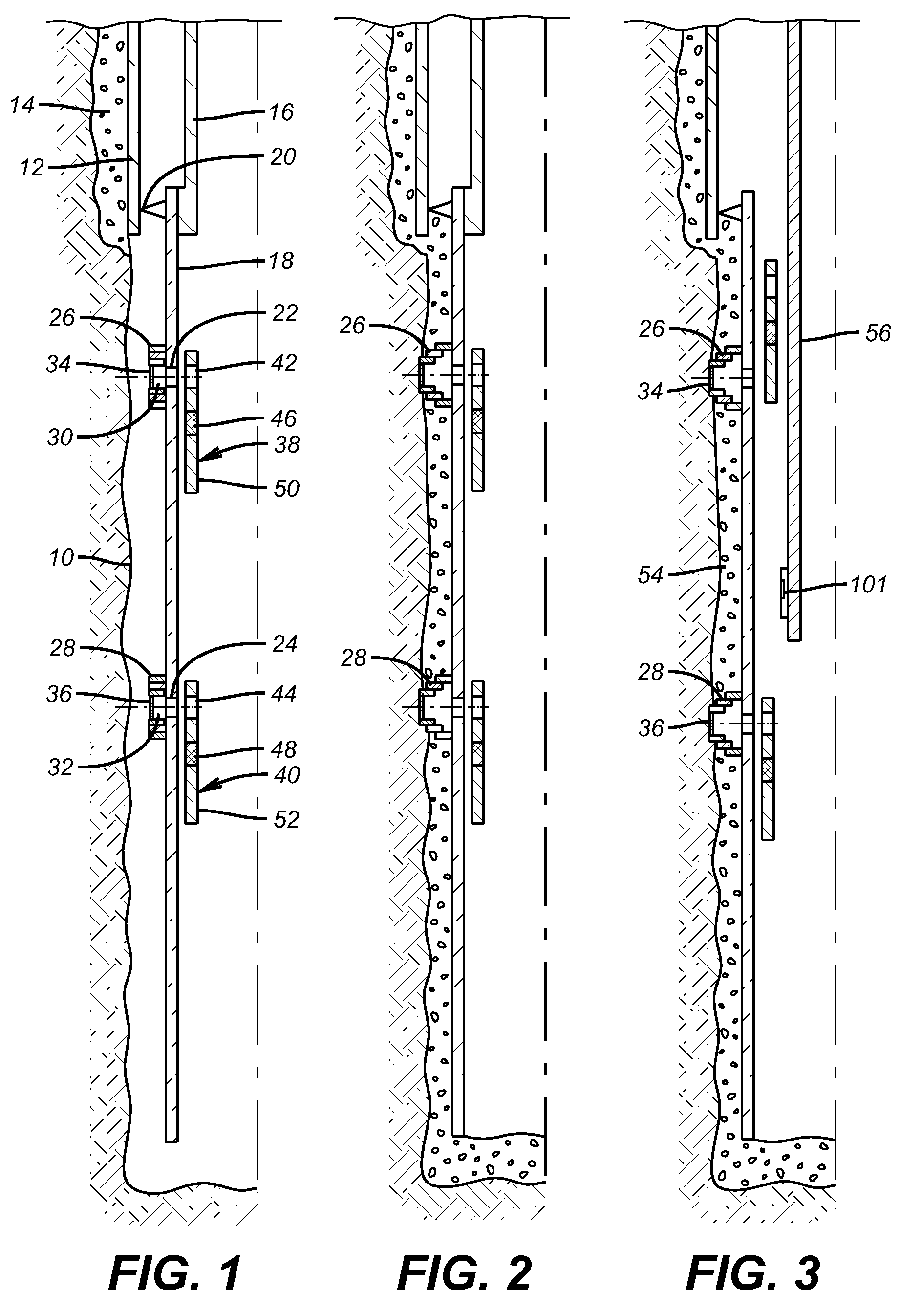

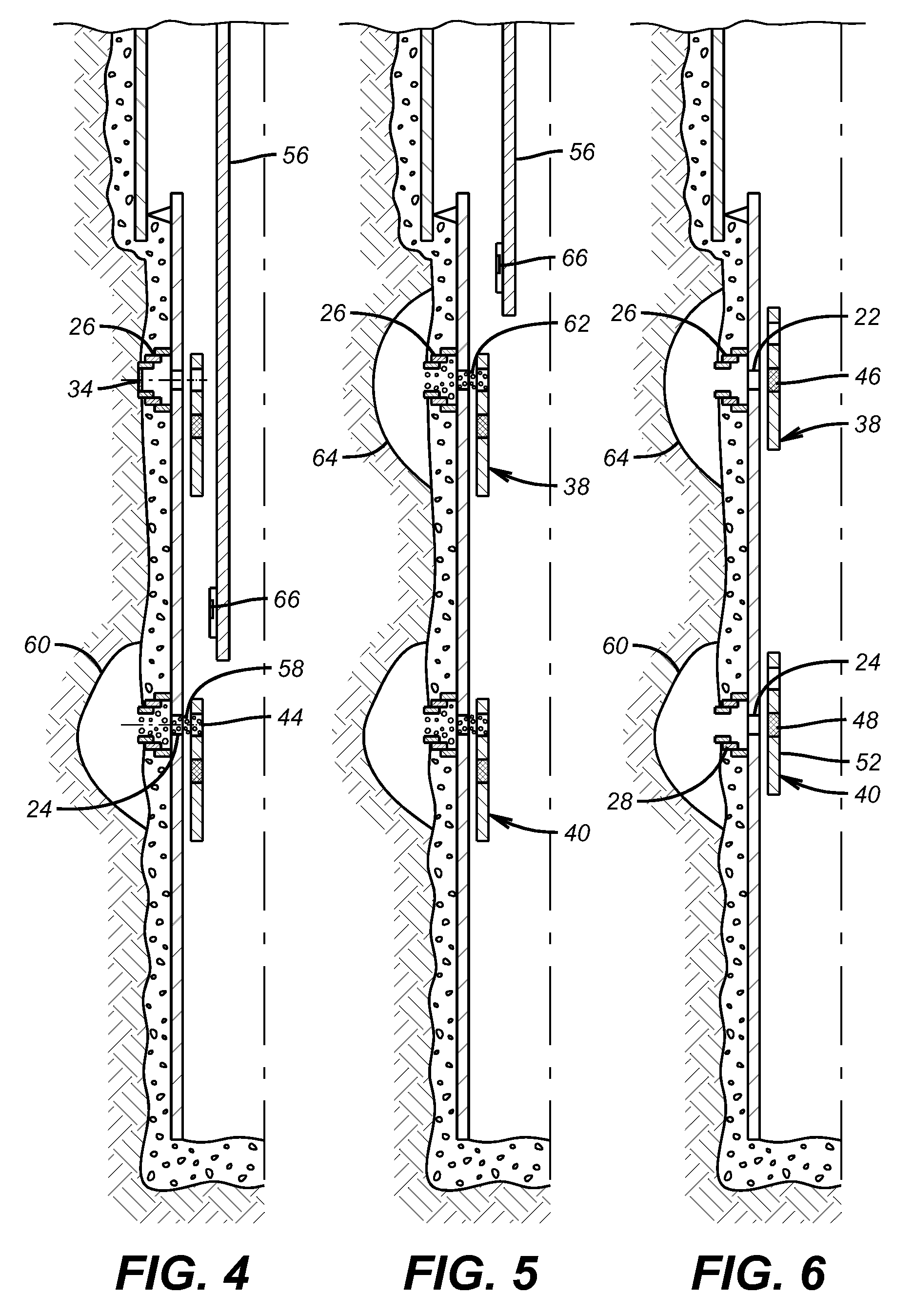

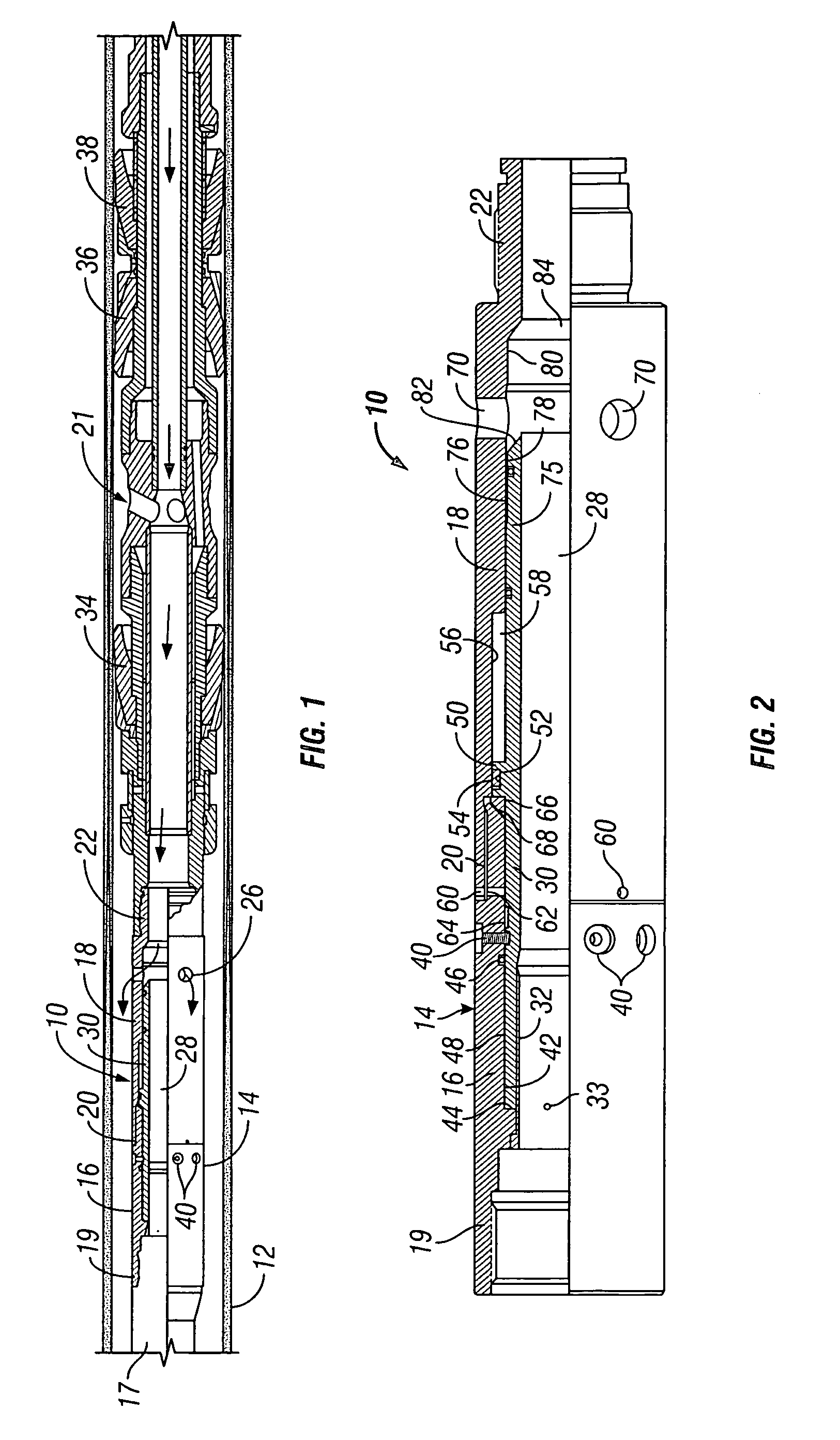

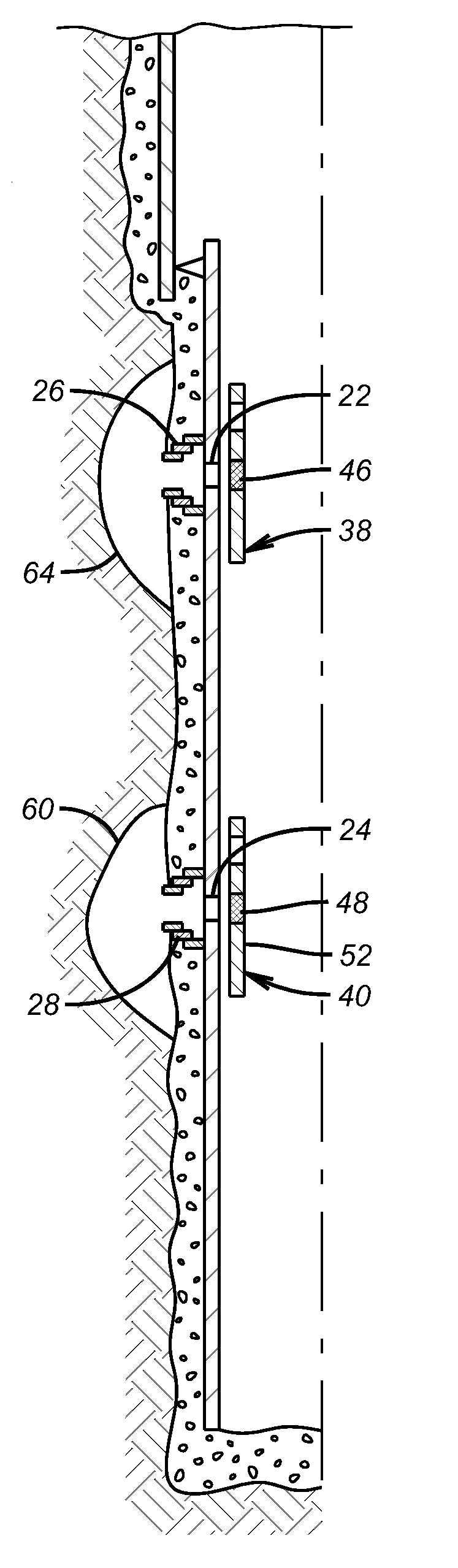

Method and apparatus for treating a subterranean formation

InactiveUS7066264B2Precise positioningMaintain positionFluid removalVibration devicesSleeve valveEngineering

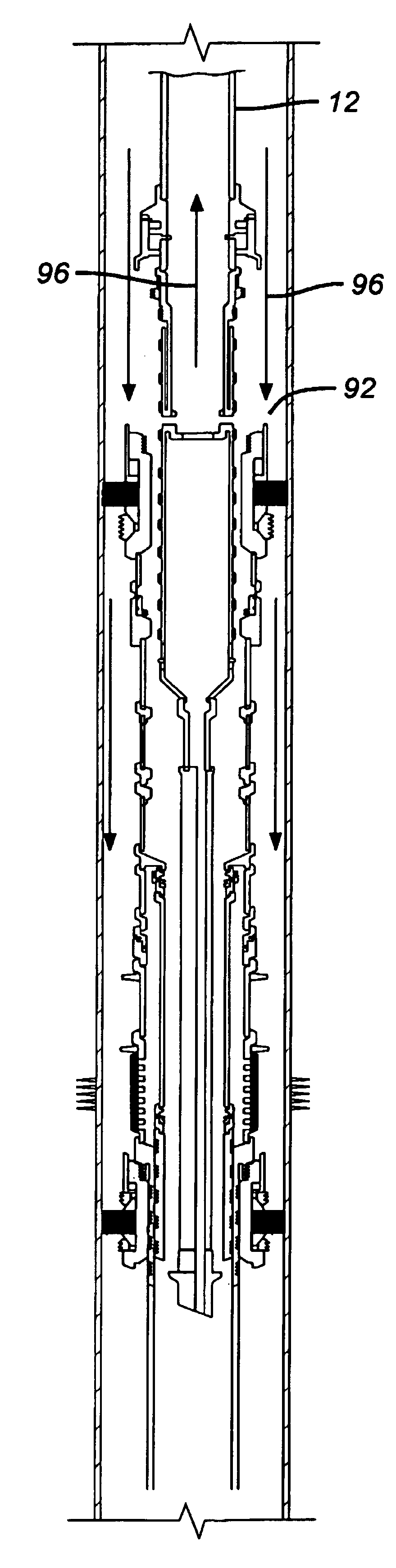

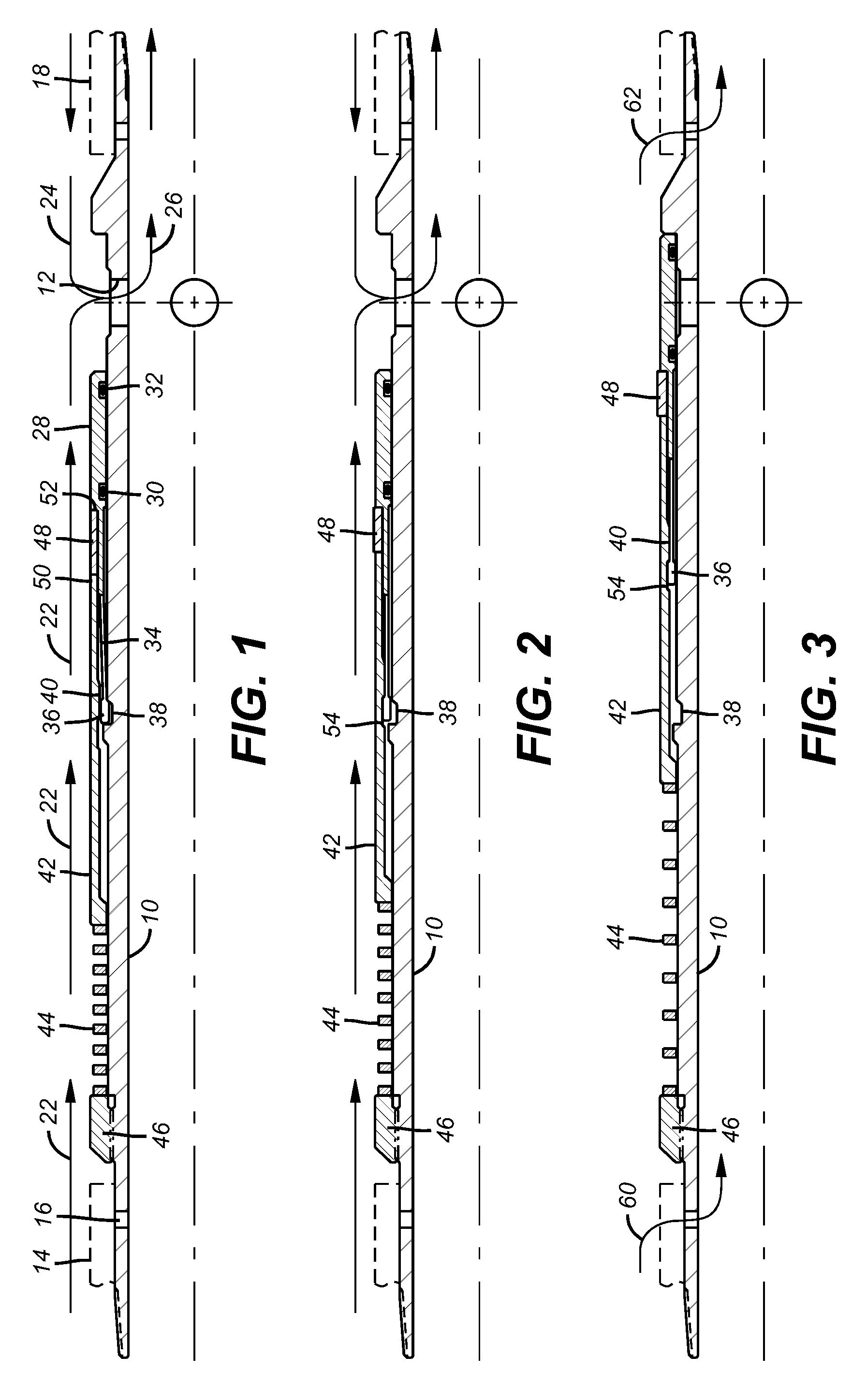

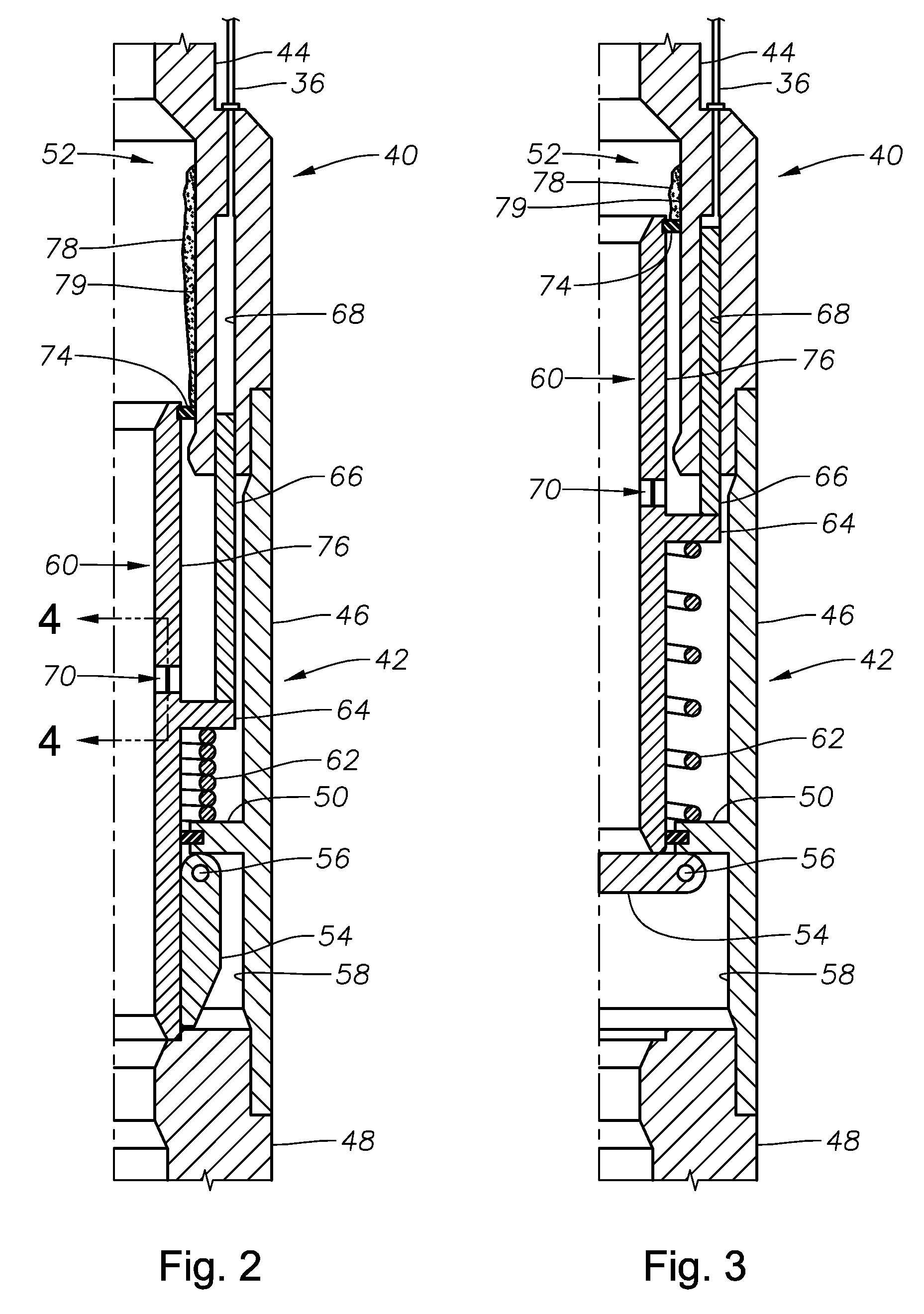

A service / completion liner having a plurality of downhole selectable indicating tools and being used in sand control (gravel pack) placement systems in conjunction with a straddle packer service tools or with conventional crossover type service tools. Each indicating collar has a downhole selectable indicating collar providing a robust, landing profile for precisely locating and maintaining service tool position during well treatment operations. The landing collars accommodate hydraulic and / or thermal effects commonly referred to as tubing move effects which are the principle cause of tool position error and excessive seal wear. The landing collar is downhole convertible between a pass through (Go) and non pass through (No-go) condition by simple upward and downward cycling via the tool running and treatment fluid tubing and a shifting tool, which may also be referred to as a set down collet. The shifting / set down collet is also used to open and close a downhole sliding sleeve valve and may be an integral part of an injection tool or a tool for gravel or fracture packing. A sliding sleeve valve design and a straddle packer configuration that protects the primary PBRs in the gravel pack system and also protects the sliding sleeve while sand is placed in the screen casing annulus.

Owner:SCHLUMBERGER TECH CORP

Liner hanger with sliding sleeve valve

An apparatus and method for forming or repairing a wellbore casing, a pipeline, or a structural support. An expandable tubular member is radially expanded and plastically deformed by an expansion cone that is displaced by hydraulic pressure. Before or after the radial expansion of the expandable tubular member, a sliding sleeve valve within the apparatus permit a hardenable fluidic sealing material to be injected into an annulus between the expandable tubular member and a preexisting structure.

Owner:ENVENTURE GLOBAL TECH LLC

Downhole zone isolation system

A gravel packing system featuring pressure actuated sliding sleeve valves mounted to an exterior annulus around a blanking pipe for screen sections is disclosed. An internal sliding sleeve valve is provided for subsequent closure of access through the screens. The presence of the annulus between the blanking pipe and the screen permits a backup access through perforating the blanking pipe while not damaging the screen. The sliding sleeve valves that are mounted internally and externally on the blanking pipe are removable apart from the screen section that already has gravel packed around it, if they fail to operate and need repair.

Owner:BAKER HUGHES INC

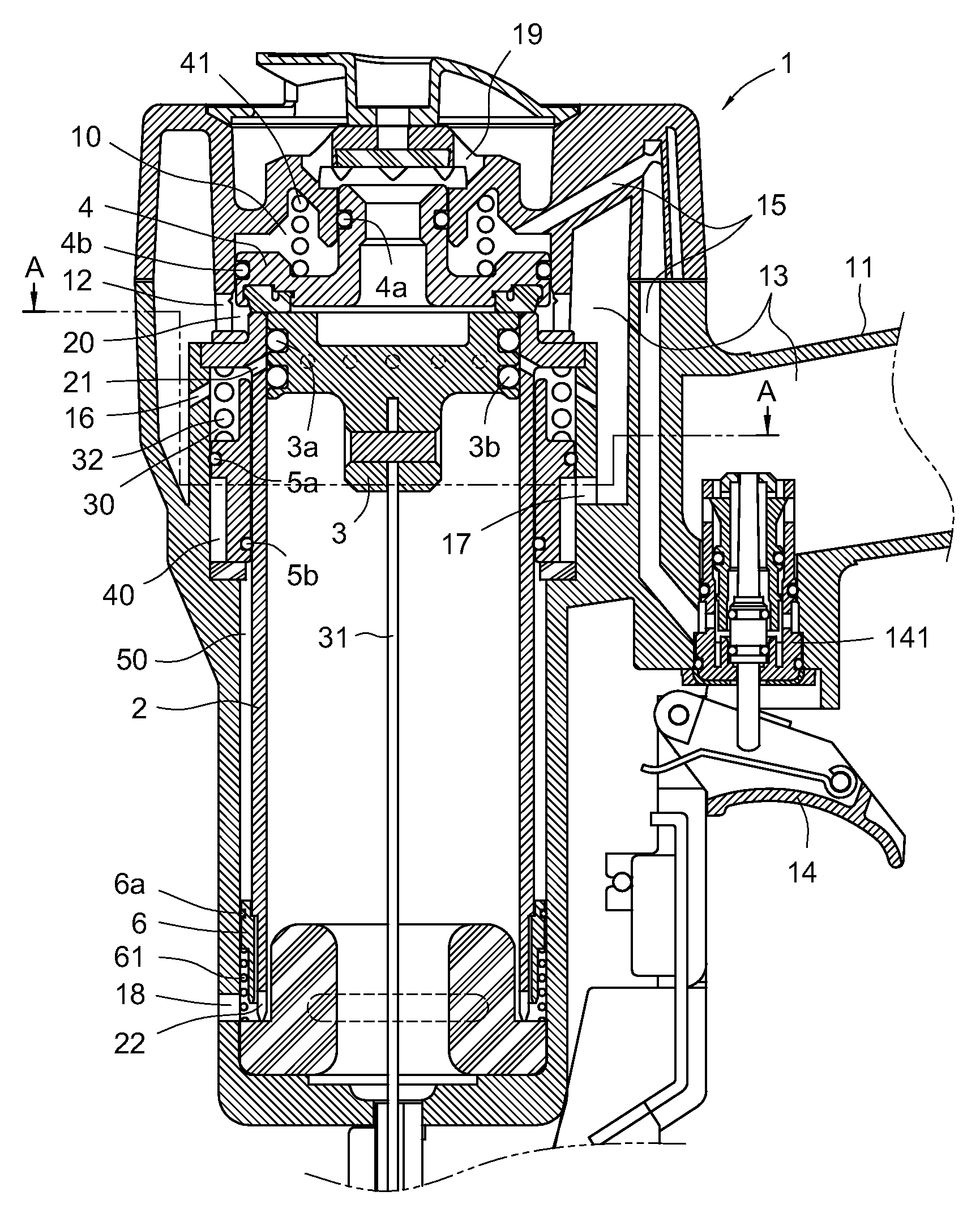

Internal combustion engine

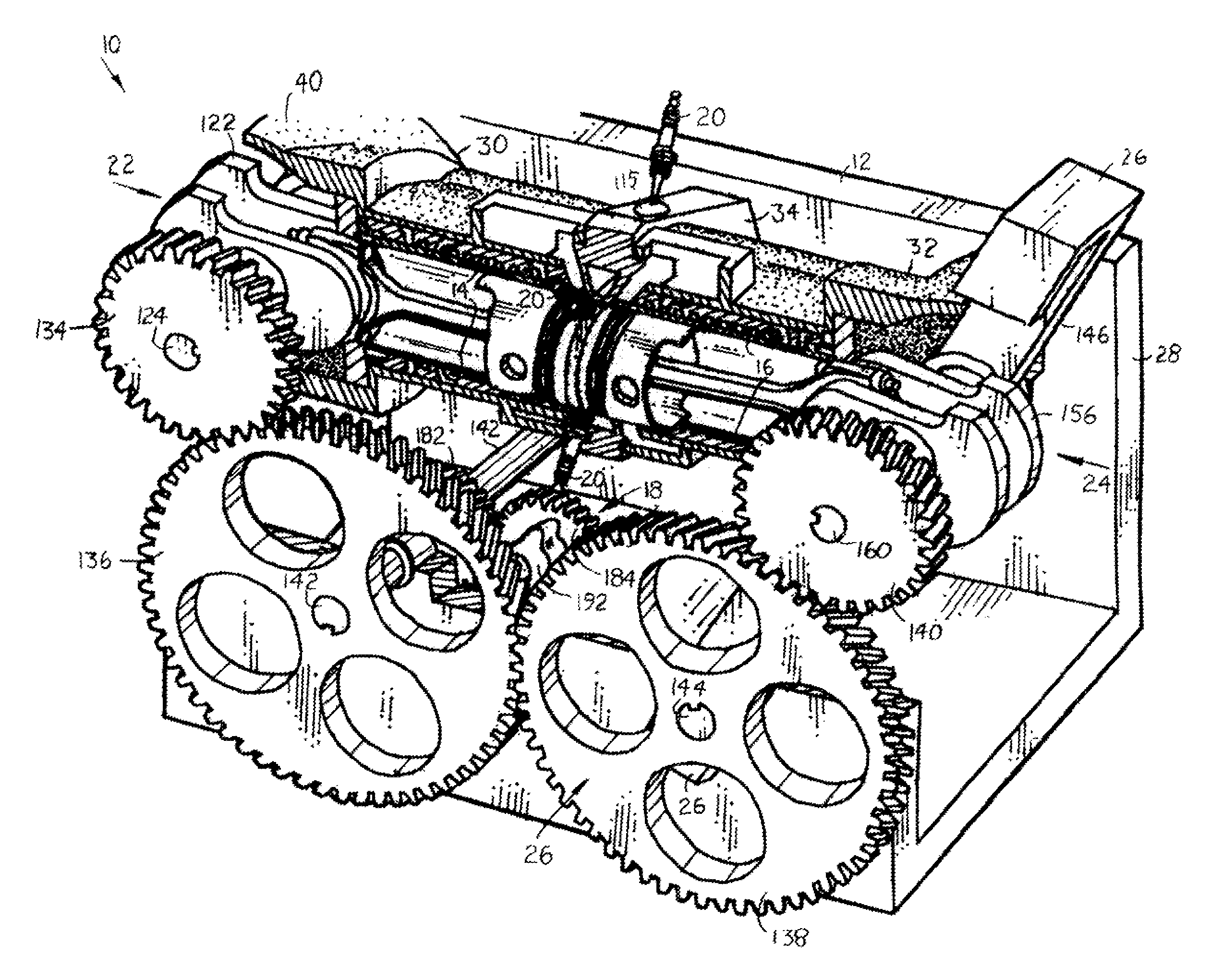

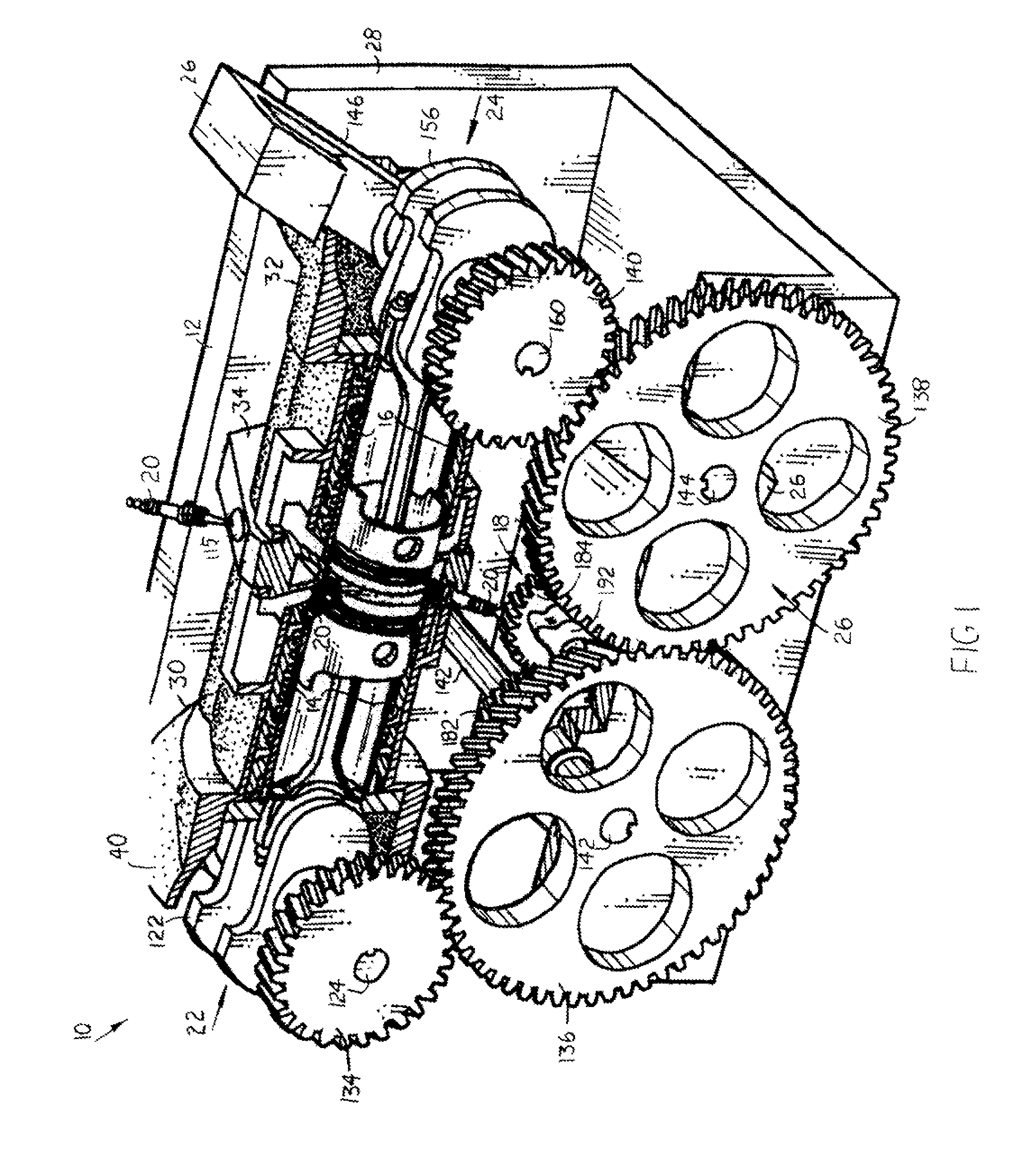

InactiveUS7559298B2Assist in containment of heat energyReduce energy lossLiquid coolingInternal combustion piston enginesCombustion chamberCylinder head

An internal combustion engine is provided. Facing pistons eliminate a cylinder head, thereby reducing heat losses through a cylinder head. Facing pistons also halve the stroke that would be required for one piston to provide the same compression ratio, and the engine can thus be run at higher revolutions per minute and produce more power. An internal sleeve valve is provided for space and other considerations. A combustion chamber size-varying mechanism allows for adjustment of the minimum size of an internal volume to increase efficiency at partial-power operation. Variable intake valve operation is used to control engine power.

Owner:CLEEVES ENGINES

By-pass valve mechanism and method of use hereof

InactiveUS20040159447A1Minimize potentialMinimizes pressure surgeFluid removalWell/borehole valve arrangementsSleeve valveControl system

A by-pass valve mechanism for a well treatment tool having at least one flow sensitive element, permitting by-pass of well fluid past the flow sensitive element of the well treatment tool during conveyance of the well treatment tool to treatment depth within a well. A valve housing adapted for connection with a well tool defines an internal flow passage and has at least one by-pass port communicating well fluid between the flow passage of the service tool and the annulus between the well casing and the service tool. A sliding sleeve valve element is normally secured at its open position by shear elements permitting flow of well fluid through the and is moveable between an open position diverting fluid flow from within the service tool to the annulus and a closed position blocking the flow of well fluid through the by-pass port. The sleeve valve element is released and automatically closed by predetermined hydrostatic tubing or casing pressure or pump pressure. The by-pass valve mechanism may have a test pressure control system permitting pressure testing of a well without causing release and closure of the sleeve valve.

Owner:SCHLUMBERGER TECH CORP

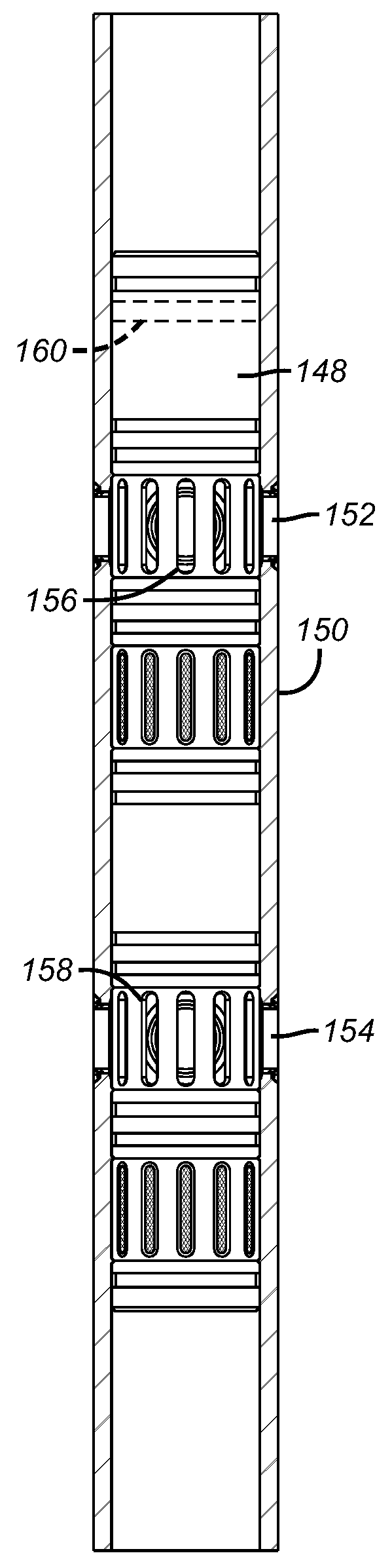

Multi-Position Valves for Fracturing and Sand Control and Associated Completion Methods

ActiveUS20090139717A1Easy to moveFluid removalWell/borehole valve arrangementsSleeve valveFracture zone

Owner:BAKER HUGHES INC

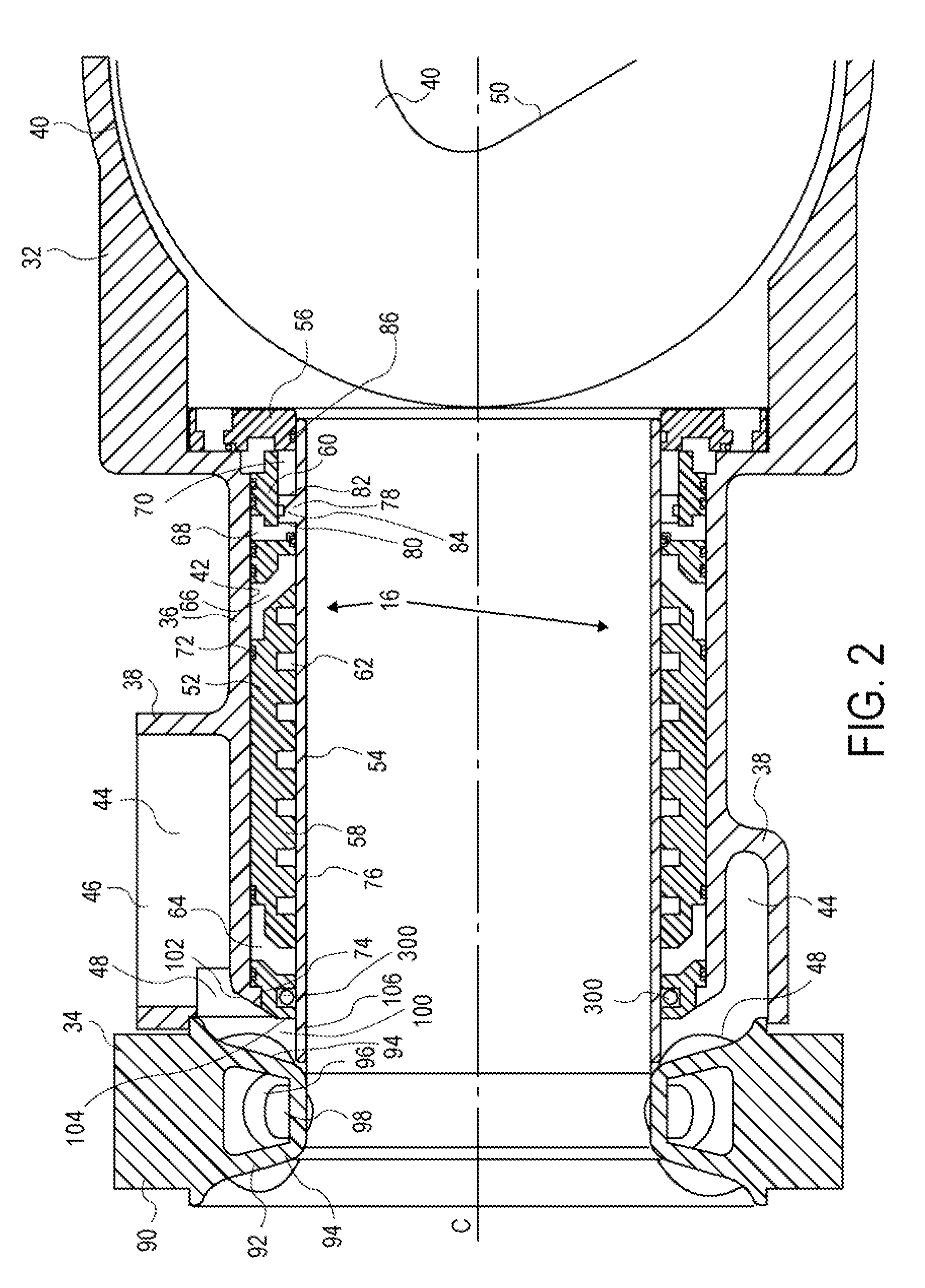

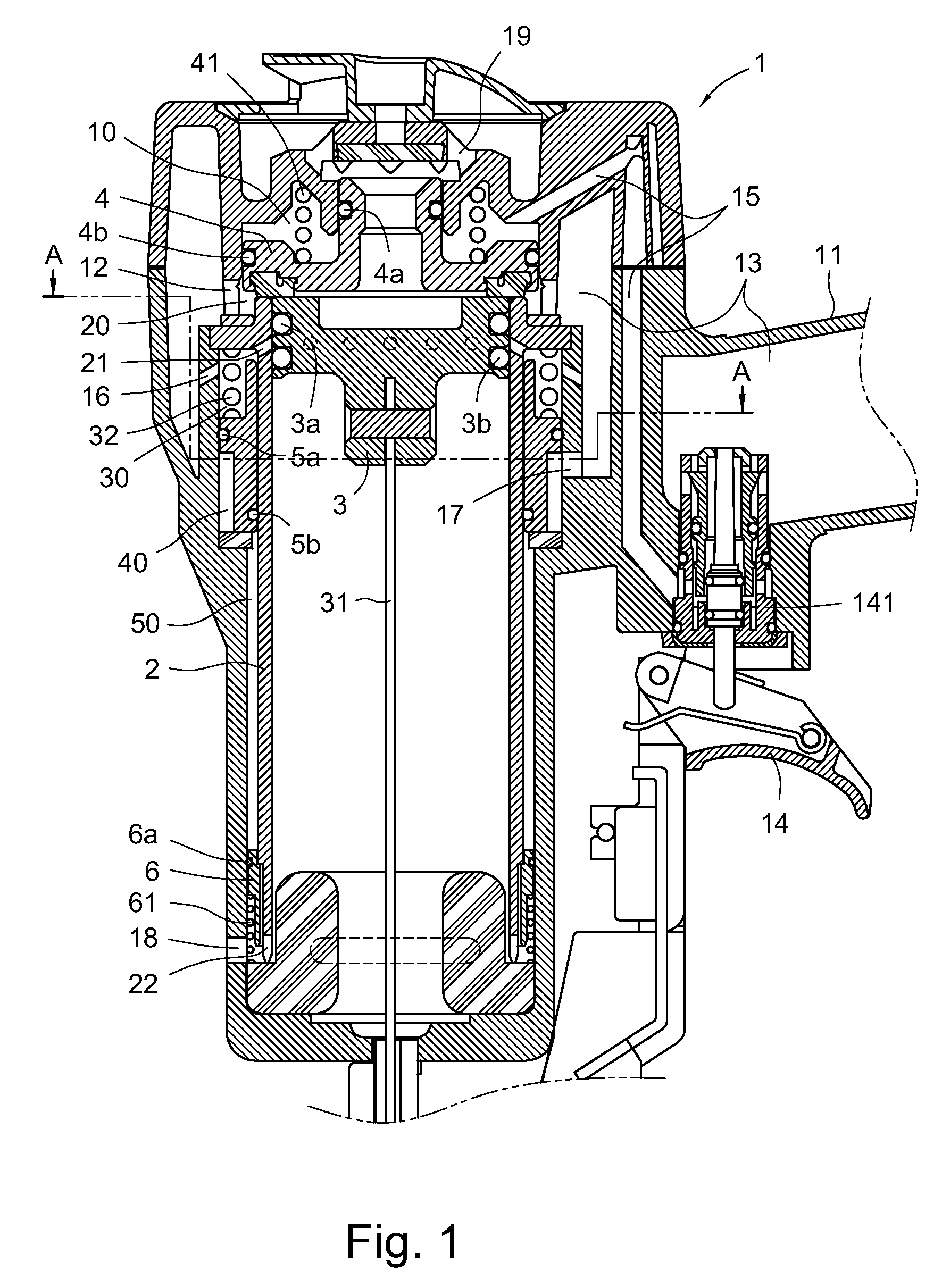

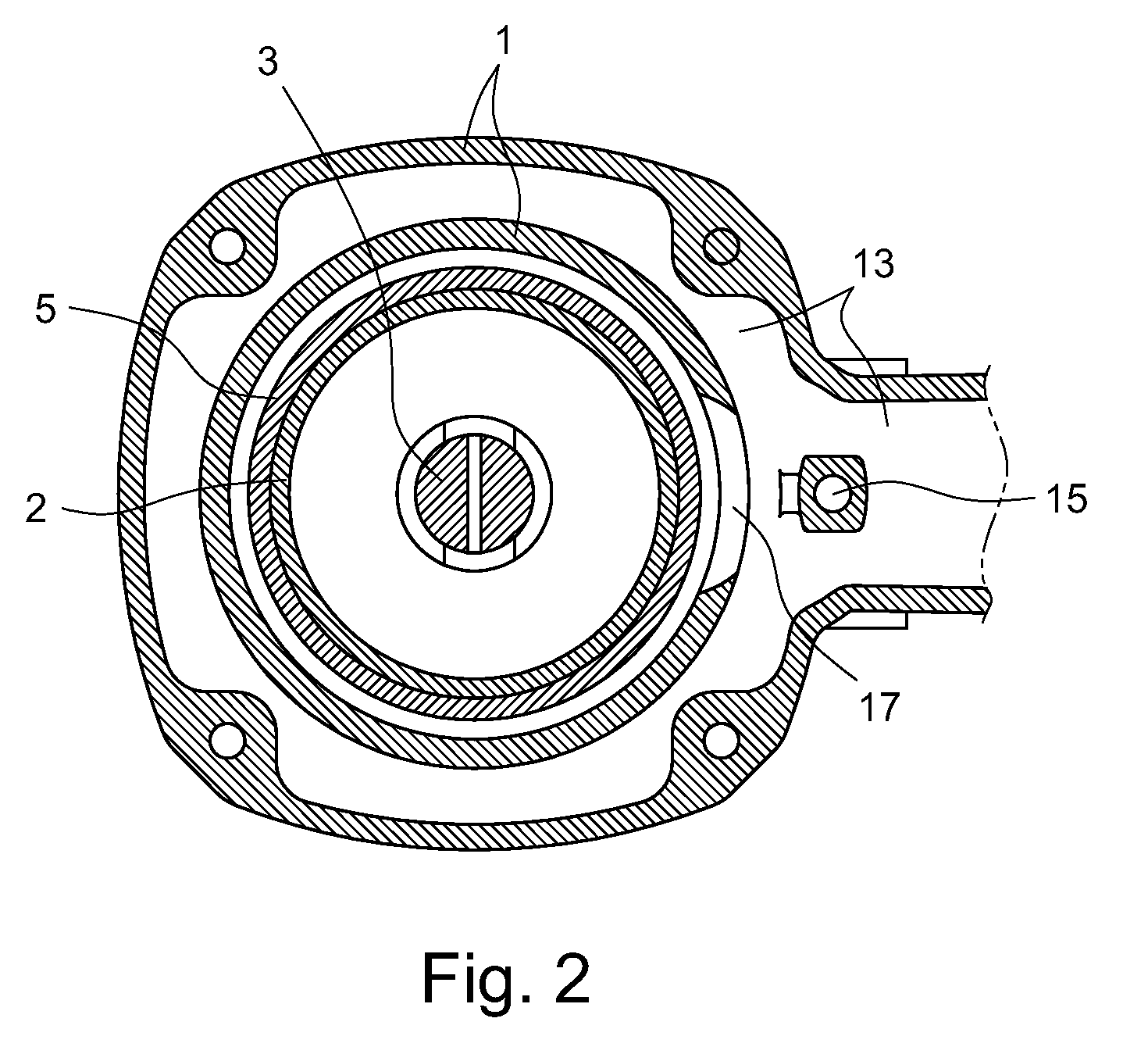

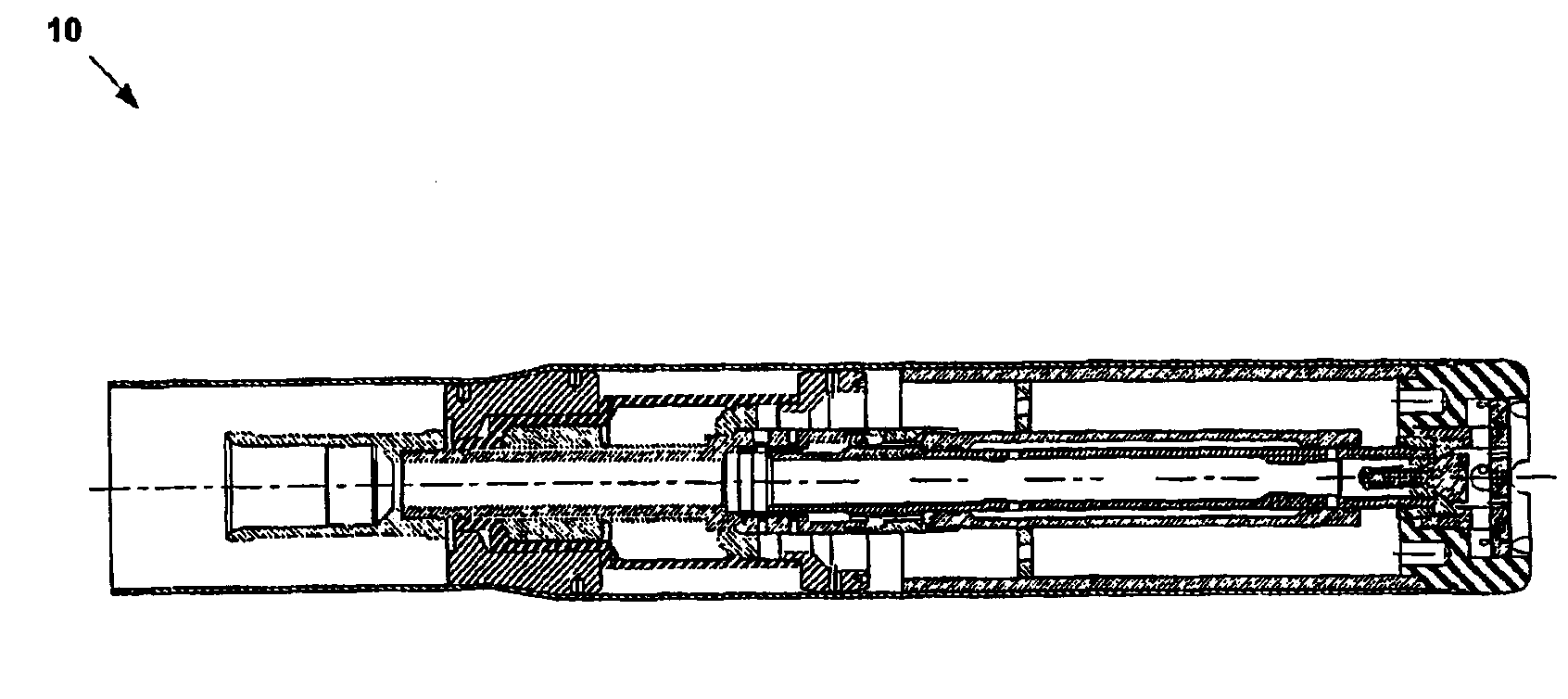

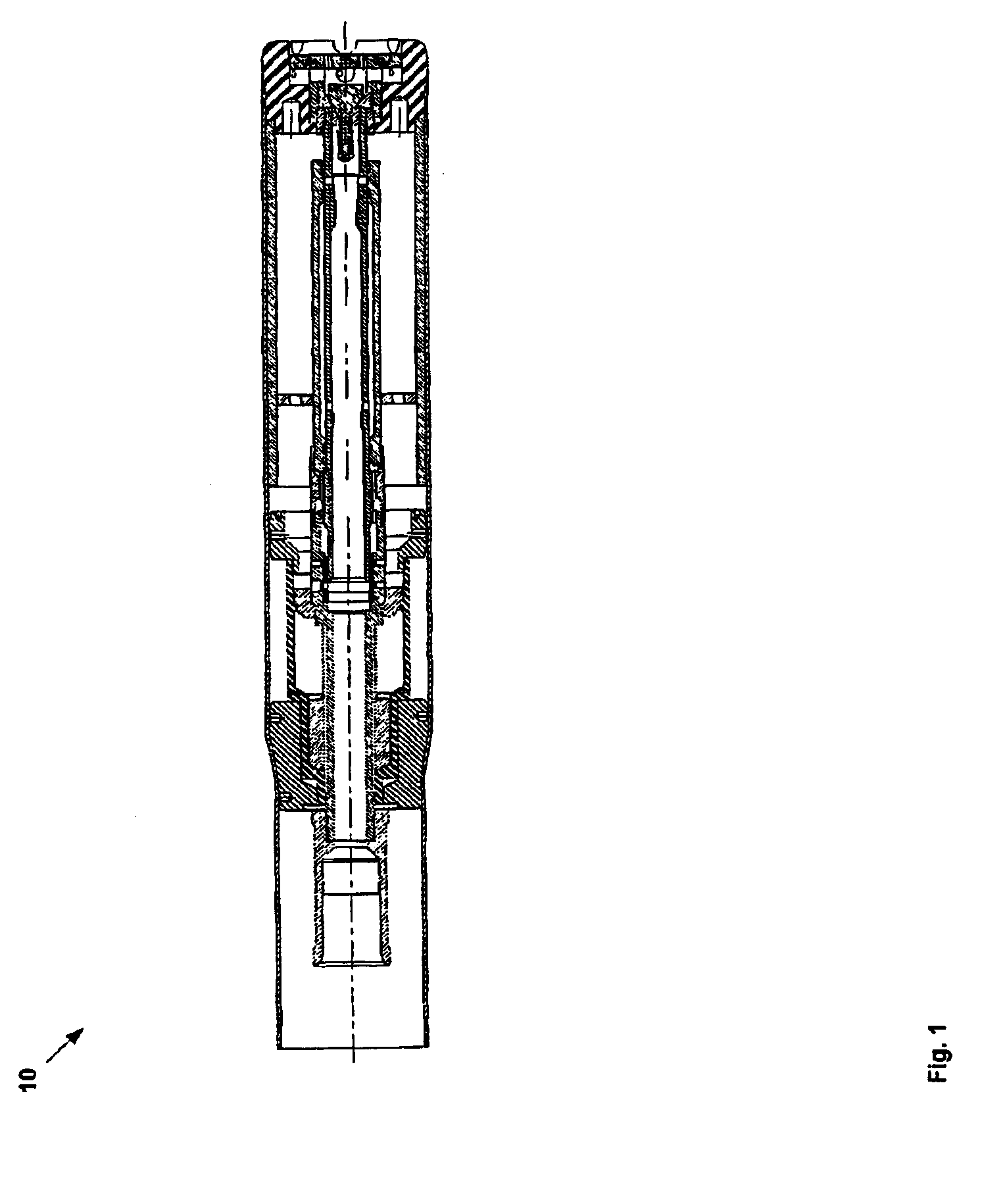

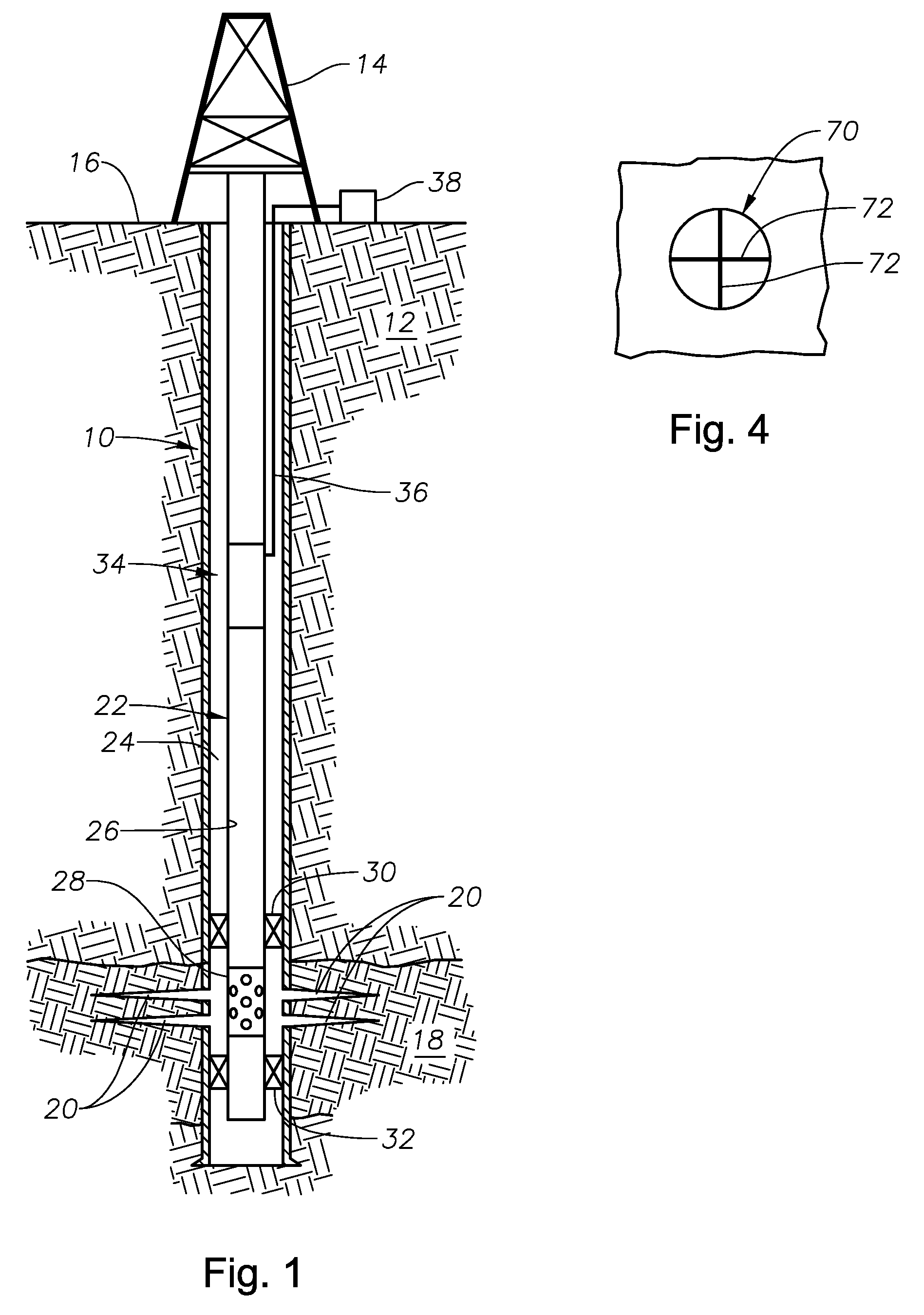

Pneumatic nail gun

A pneumatic nail gun has a gun body having a main air housing; a cylinder fixed in the main air housing; a hitting piston slidably movable in the cylinder; a dish-shaped piston disposed at a top end portion of the cylinder; an upper slidable sleeve valve disposed at a top portion of an out peripheral surface of the cylinder, which is driven to move upward by the high pressure air in the main air housing; and a lower slidable sleeve valve disposed at a lower portion of an outer peripheral surface of the cylinder, which is driven to move downward for guiding the high pressure air into the cylinder for upward deposition of the hitting piston when the upper slidable sleeve valve moves upward, and is driven to upward reposite when the hitting piston moves to its upper dead center.

Owner:DE POAN PNEUMATIC

Liner hanger with sliding sleeve valve

An apparatus and method for forming or repairing a wellbore casing, a pipeline, or a structural support. An expandable tubular member is radially expanded and plastically deformed by an expansion cone that is displaced by hydraulic pressure. Before or after the radial expansion of the expandable tubular member, a sliding sleeve valve within the apparatus permit a hardenable fluidic sealing material to be injected into an annulus between the expandable tubular member and a preexisting structure.

Owner:ENVENTURE GLOBAL TECH LLC

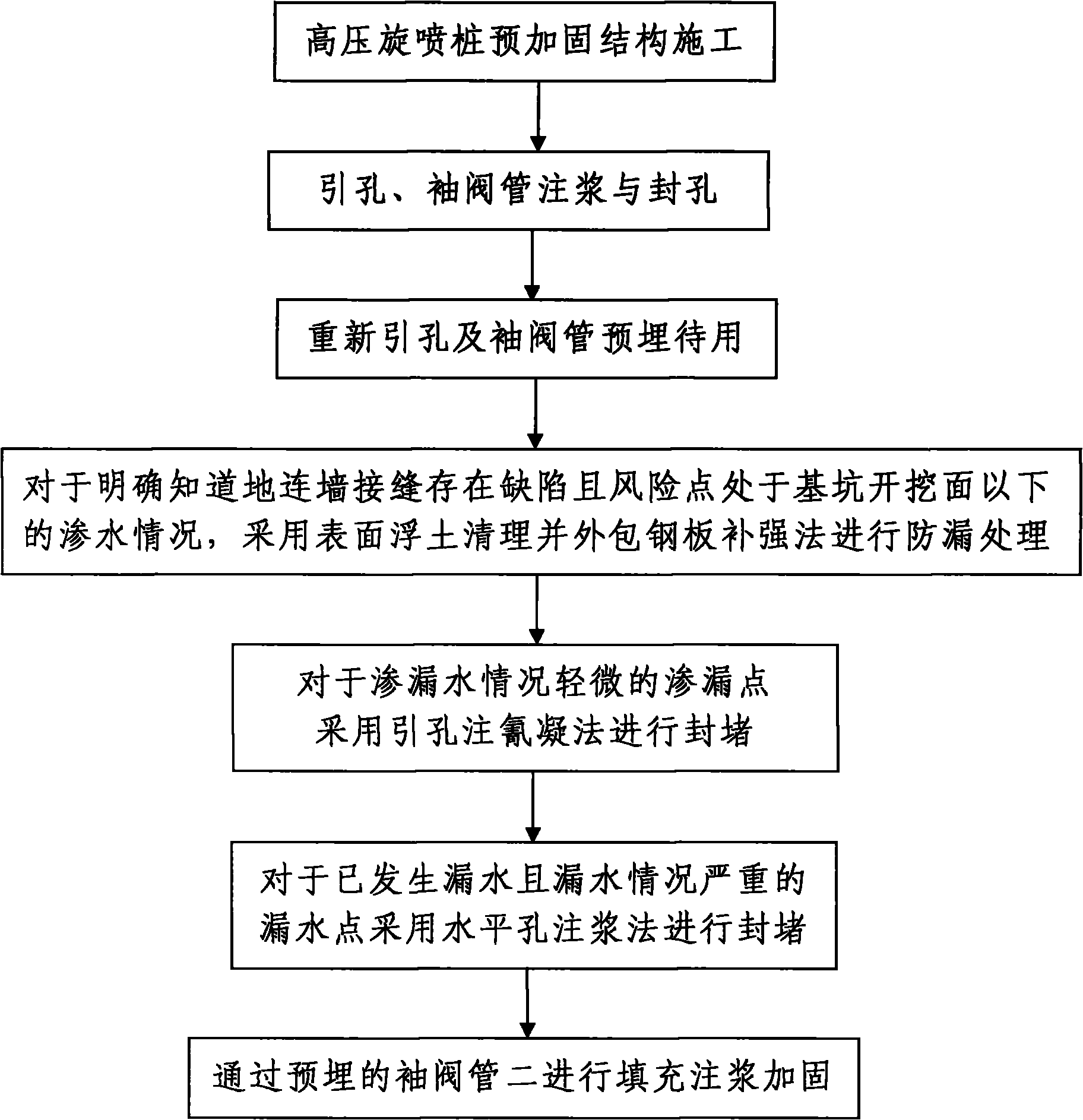

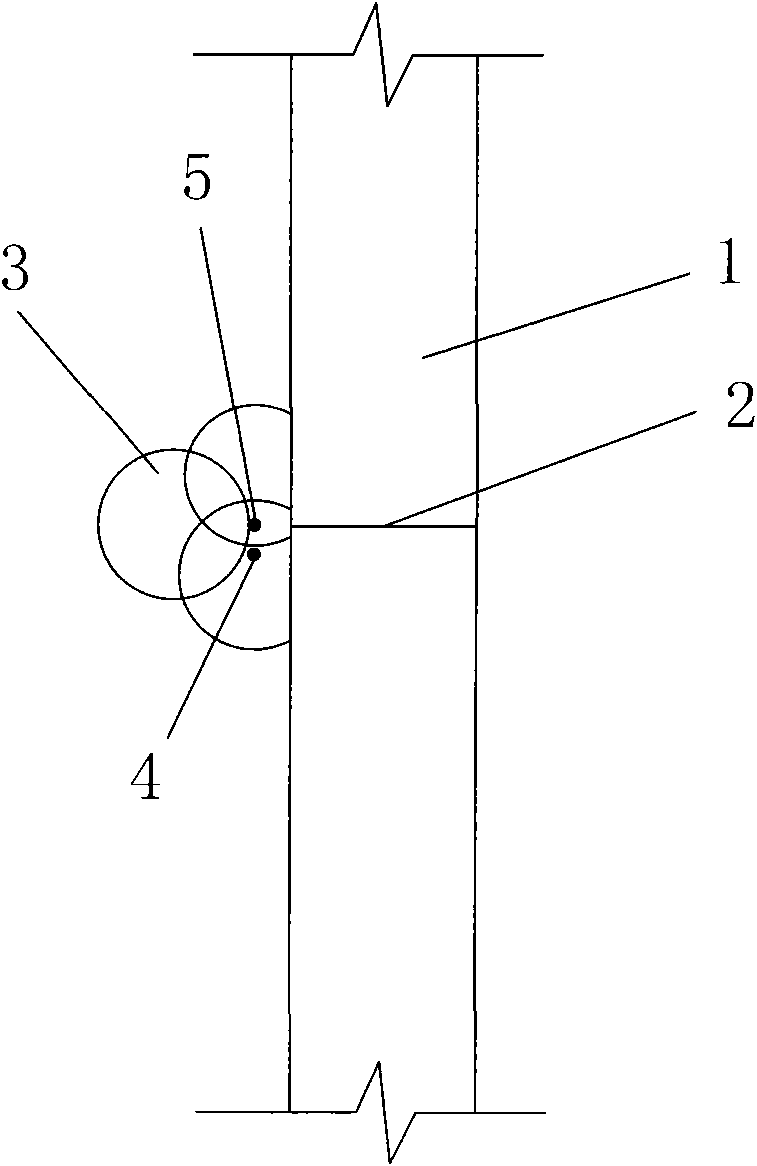

Anti-seepage and leak-blocking construction method for excavation of subway foundation pit in soft soil area

The invention discloses an anti-seepage and leak-blocking construction method for excavation of a subway foundation pit in a soft soil area, which comprises the following steps: 1) joint pre-reinforcement construction of an underground continuous wall: constructing a pre-reinforcement structure of a high-pressure rotary jet grouting pile, guiding holes, grouting by a sleeve valve pipe, sealing the holes, guiding the holes again and pre-burying the sleeve valve pipe for standby; and 2) the excavation of the foundation pit and the anti-seepage and leak-blocking construction: using surface floating earth for clearing and using the encased steel plate reinforcement method for anti-leak treatment for the situations that joints of the underground continuous wall have defects definitely and risk points are positioned below the excavation surface of the foundation pit, adopting the hole-guiding cyanogen injection condensing method for blocking of leak points with slight water leakage situation, adopting the horizontal hole grouting method for blocking for the water leak points with serious water leakage situation, and carrying out filling, grouting and reinforcement through the pre-buried sleeve valve pipe after completing the blocking. The method has reasonable design, convenient construction, comprehensive consideration, good anti-leak and leak-blocking effect, fast leak-blocking speed and can solve the problems of pipe blocking, poor anti-leak and leak-blocking effect, slow construction progress and the like in the existing anti-leak and leak-blocking construction.

Owner:TIANJIN CONSTR ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

High differential shifting tool

ActiveUS7556102B2Prevent significant stress upon and damageFluid removalWell/borehole valve arrangementsSleeve valveEngineering

Owner:BAKER HUGHES INC

High Differential Shifting Tool

ActiveUS20090139726A1Prevent significant stress uponAvoid damageFluid removalWell/borehole valve arrangementsSleeve valveEngineering

Owner:BAKER HUGHES INC

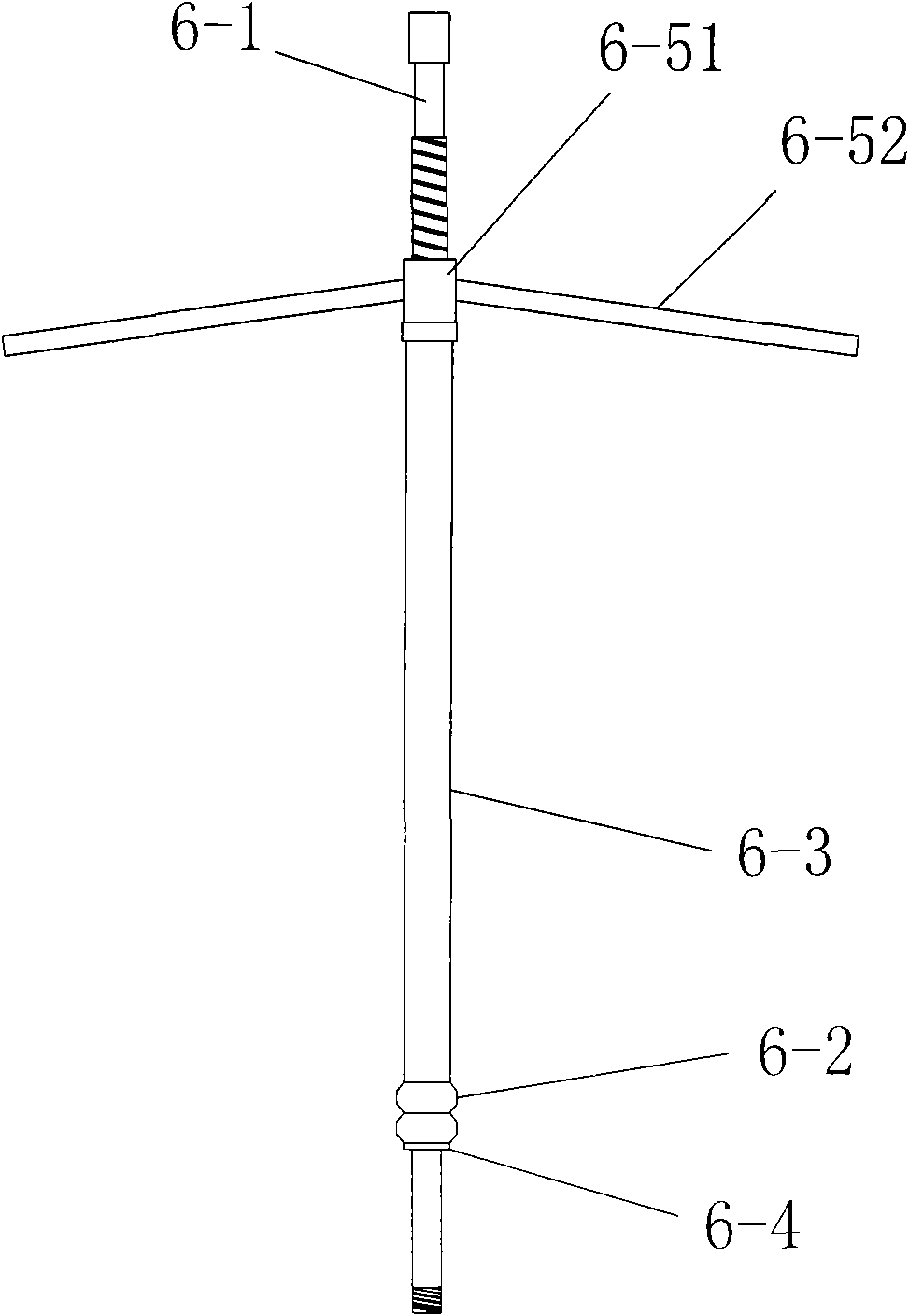

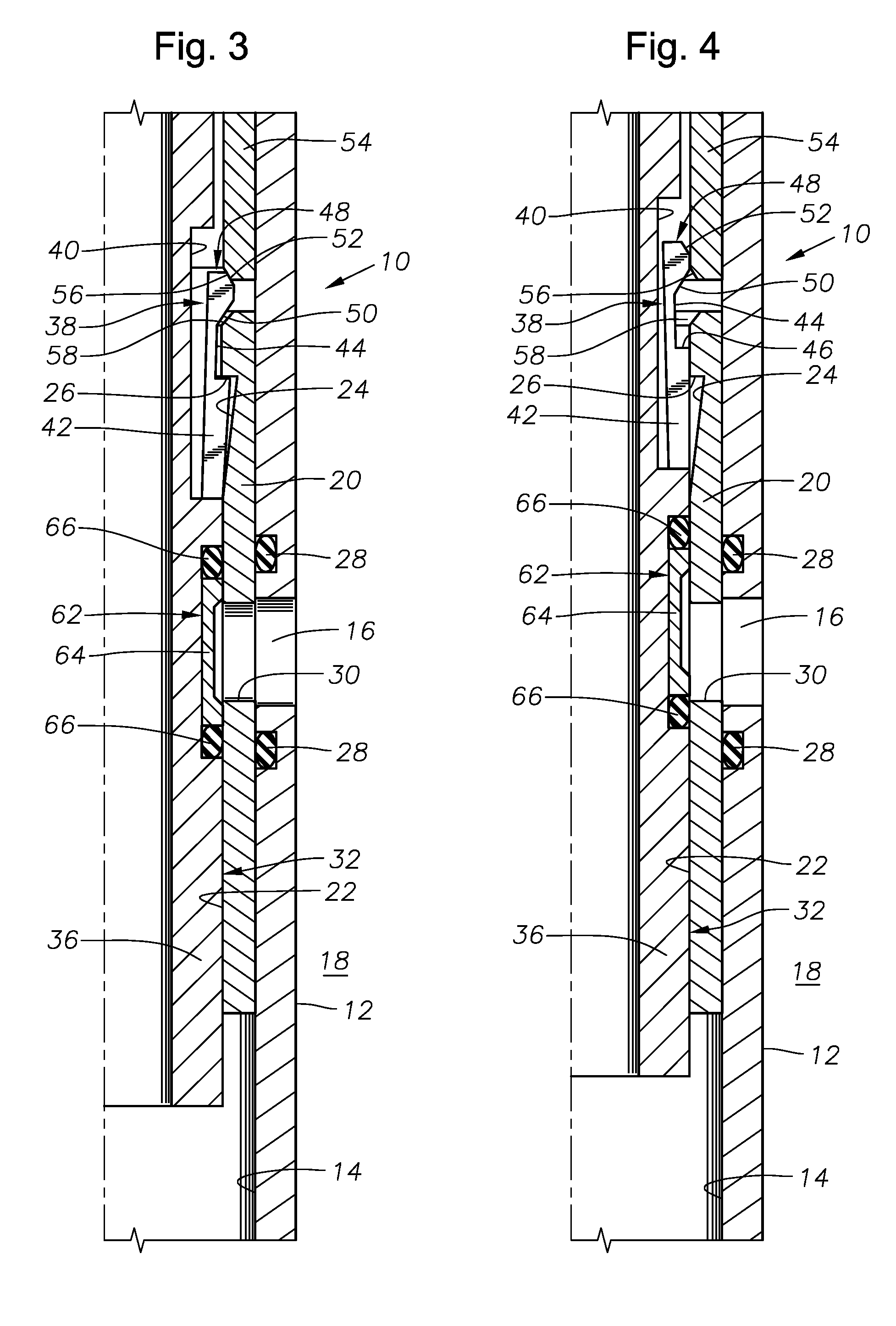

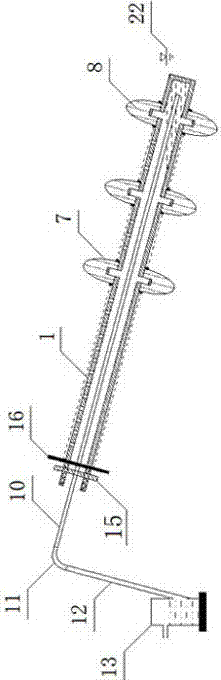

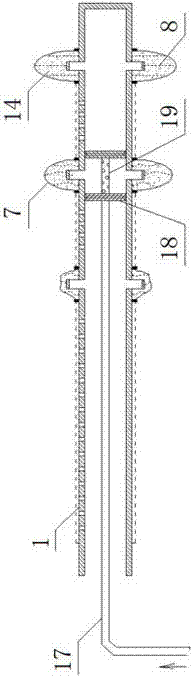

Slope self-drainage anchor rod and construction method

The invention relates to a slope self-drainage anchor rod and a construction method. The self-drainage anchor rod comprises a hollow anchor pipe, an anchorage device, a cushion plate and a siphon, wherein one end of the hollow anchor pipe is open, the other end of the hollow anchor pipe is closed, the hollow anchor pipe is wrapped in a filter screen, threads are arranged at the open end of the hollow anchor pipe, water-pervious holes are formed in the rear middle of the hollow anchor pipe, the rear segment of the hollow anchor pipe and a slurry outlet pipe are perpendicularly connected, the end of the slurry outlet pipe is sleeved with a sleeve valve and a geotextile bag, and on the two sides of the slurry outlet pipe, the geotextile bag is clamped and fixed to the hollow anchor pipe through hoops; the lower side of the hollow anchor pipe is obliquely placed in a slope, the relative height difference between the pipe opening of the hollow anchor pipe and the pipe bottom of the hollow anchor pipe is kept smaller than 7 m, pulp solidifies in the geotextile bag and is anchored in stable soil, and the front segment of the hollow anchor pipe is anchored to the cushion plate through the anchorage device; a water suction pipe of the siphon is inserted in the hollow anchor pipe and stretches to the bottom, the water suction pipe is connected with a drainage pipe and a balance water outlet device through connector bent pipes on the slope, and a water inlet of the water suction pipe is as high as a water outlet of the balance water outlet device. The slope self-drainage anchor rod is simple in structure, can achieve anchoring and draining at the same time and is good in drainage effect, easy and convenient to construct and low in manufacturing cost.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Multi-Position Valve for Fracturing and Sand Control and Associated Completion Methods

A completion tubular is placed in position adjacent the zone or zones to be fractured and produced. It features preferably sliding sleeve valves that can assume at least two configurations: wide open and open with a screen material juxtaposed in the flow passage. In a preferred embodiment the valve assembly has three positions, adding a fully closed position to the other two mentioned. After run in, the valves can be put in the wide open position in any order desired to fracture. After fracturing, the valves can be closed or selectively be put in filtration position for production from the fractured zones in any desired order. Various ways are described to actuate the valves. The tubular can have telescoping pistons through which the fracturing can take place if the application calls for a cemented tubular. Alternatively, the tubular can be in open hole and simply have openings for passage of fracture fluid and external isolators to allow fracturing in any desired order.

Owner:BAKER HUGHES INC

Sleeve valve for residential and commercial irrigation systems

ActiveUS7665713B1Diaphragm valvesOperating means/releasing devices for valvesSleeve valveEngineering

A sleeve valve includes a rigid mandrel with a plurality of openings and a generally cylindrical elastomeric sleeve that surrounds the mandrel. A generally cylindrical rigid sleeve valve housing surrounds the elastomeric sleeve and defines a control chamber between the elastomeric sleeve and the sleeve valve housing. A pilot valve is mounted to the sleeve valve housing for supplying pressurized liquid to, and venting pressurized liquid from, the control chamber through a first passage formed in the sleeve valve housing. A filter screens debris from pressurized liquid entering an inlet end of the sleeve valve housing before it enters a second passage that communicates with the pilot valve.

Owner:HUNTER INDUSTRIES

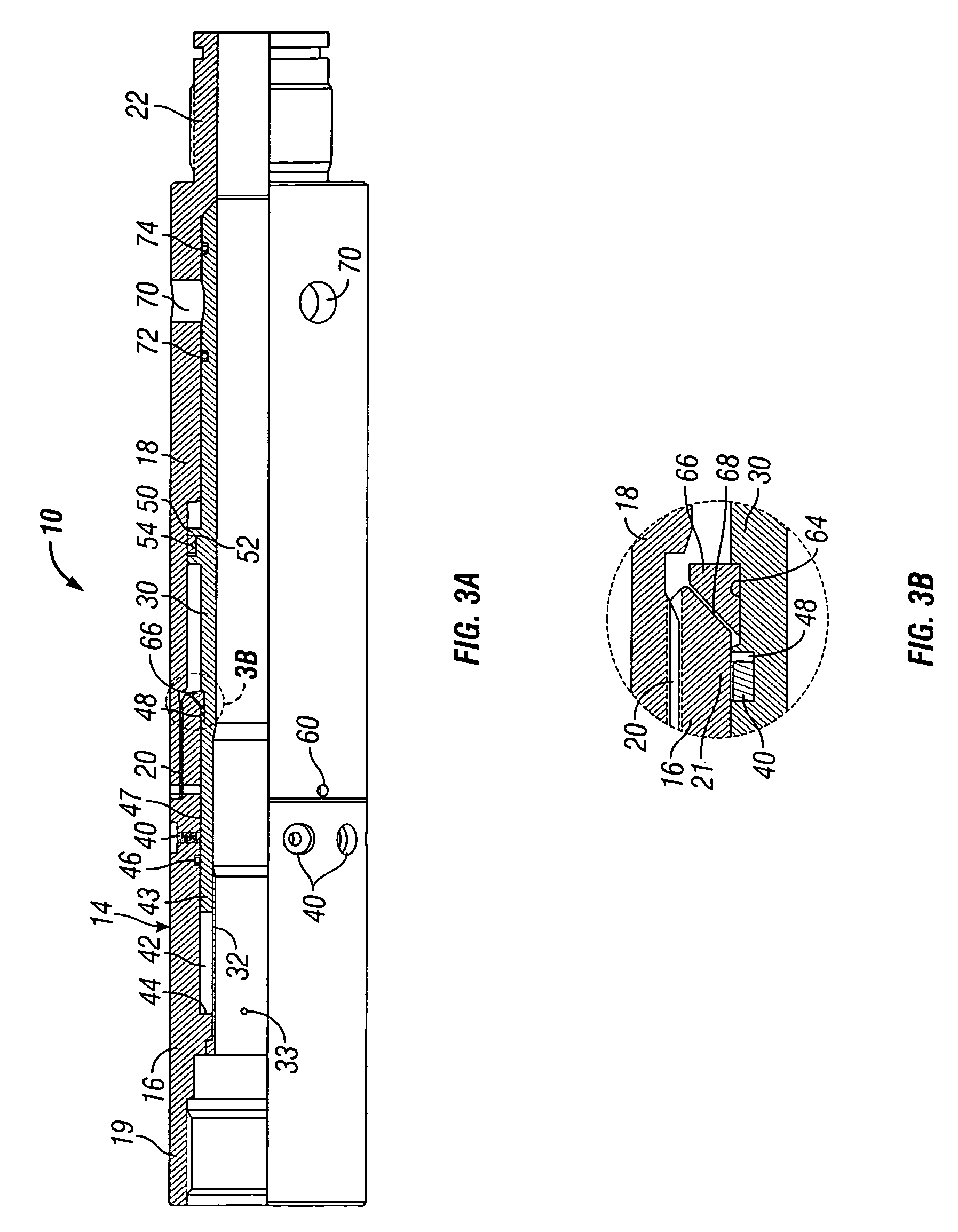

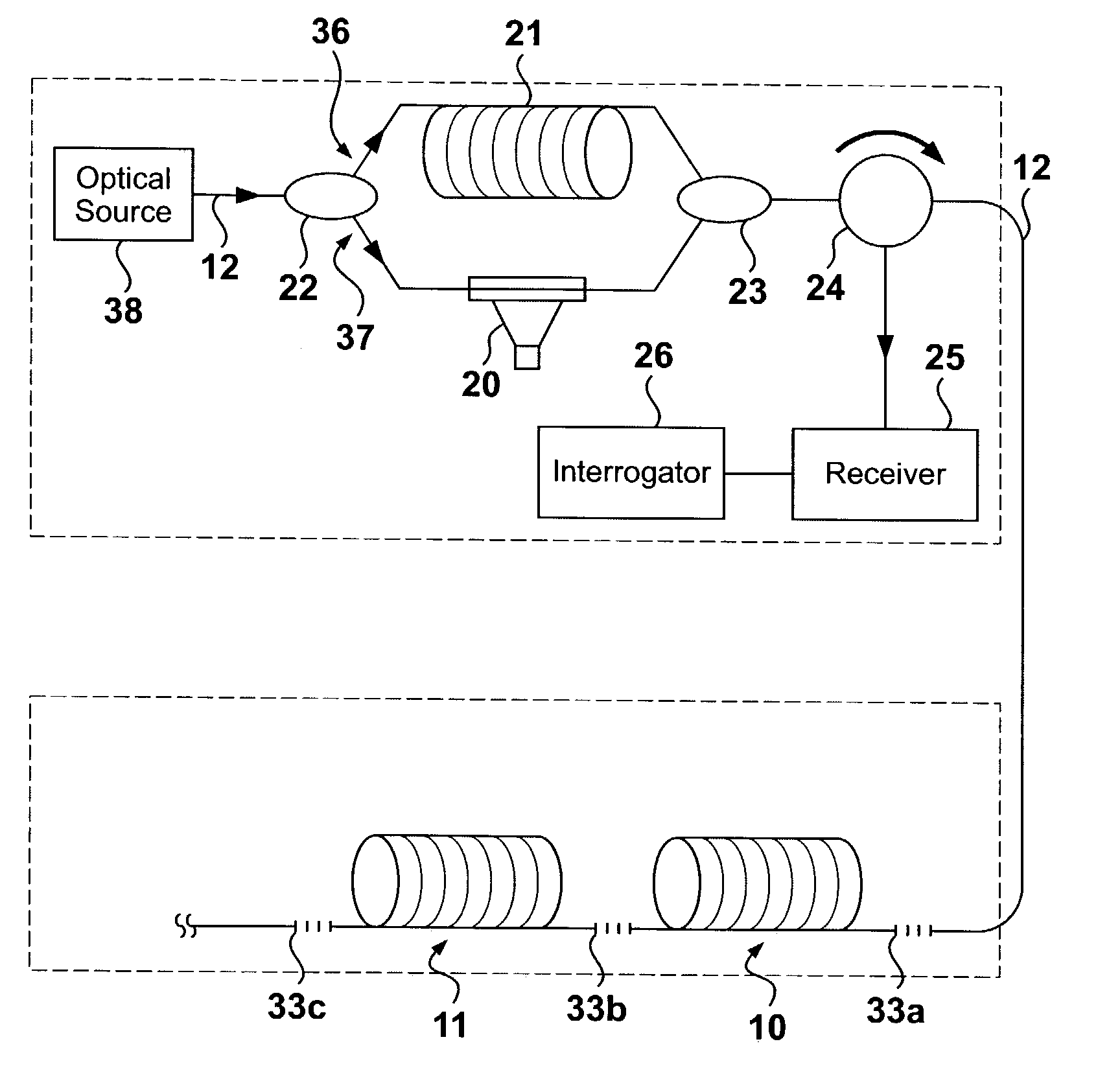

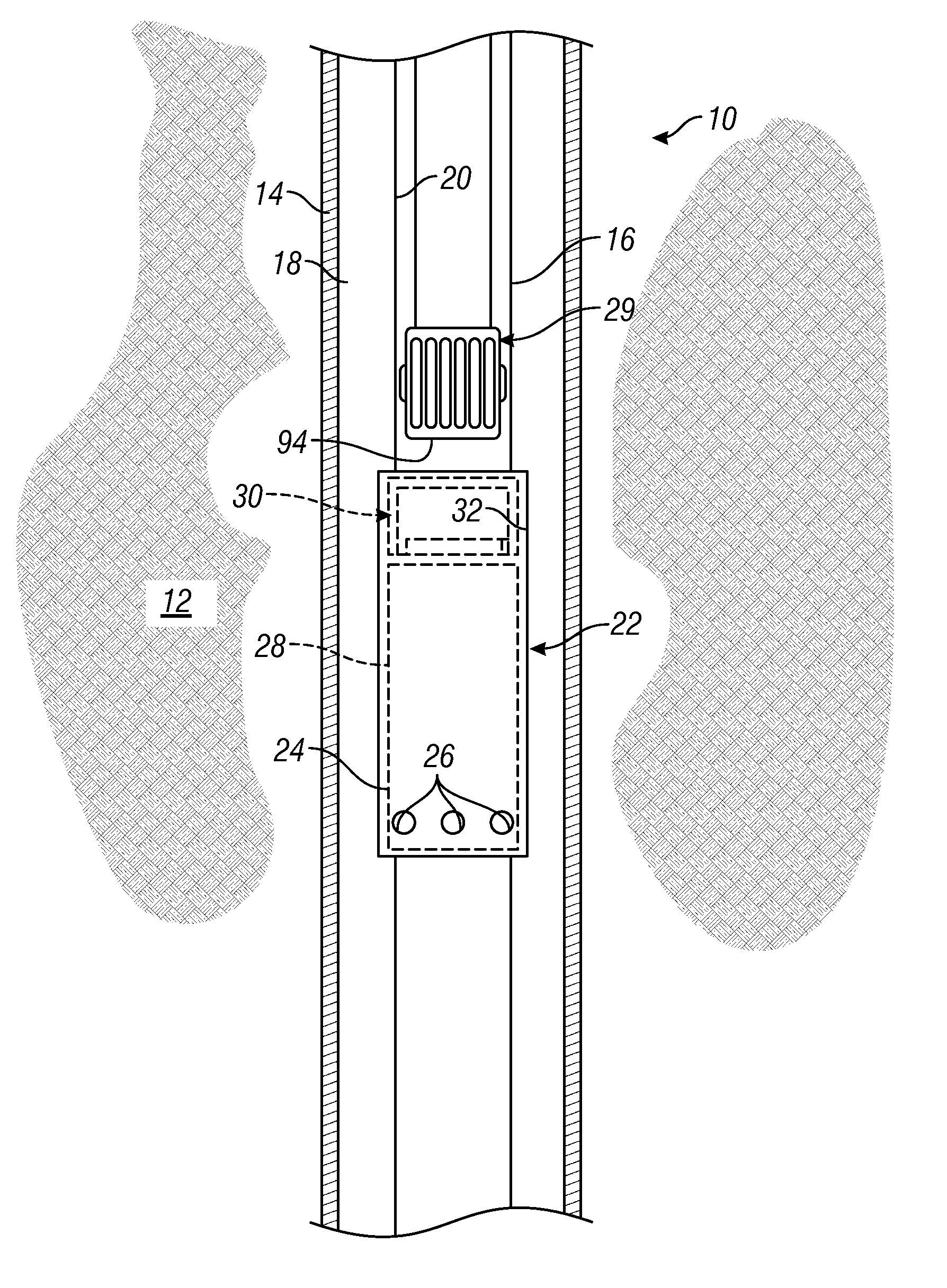

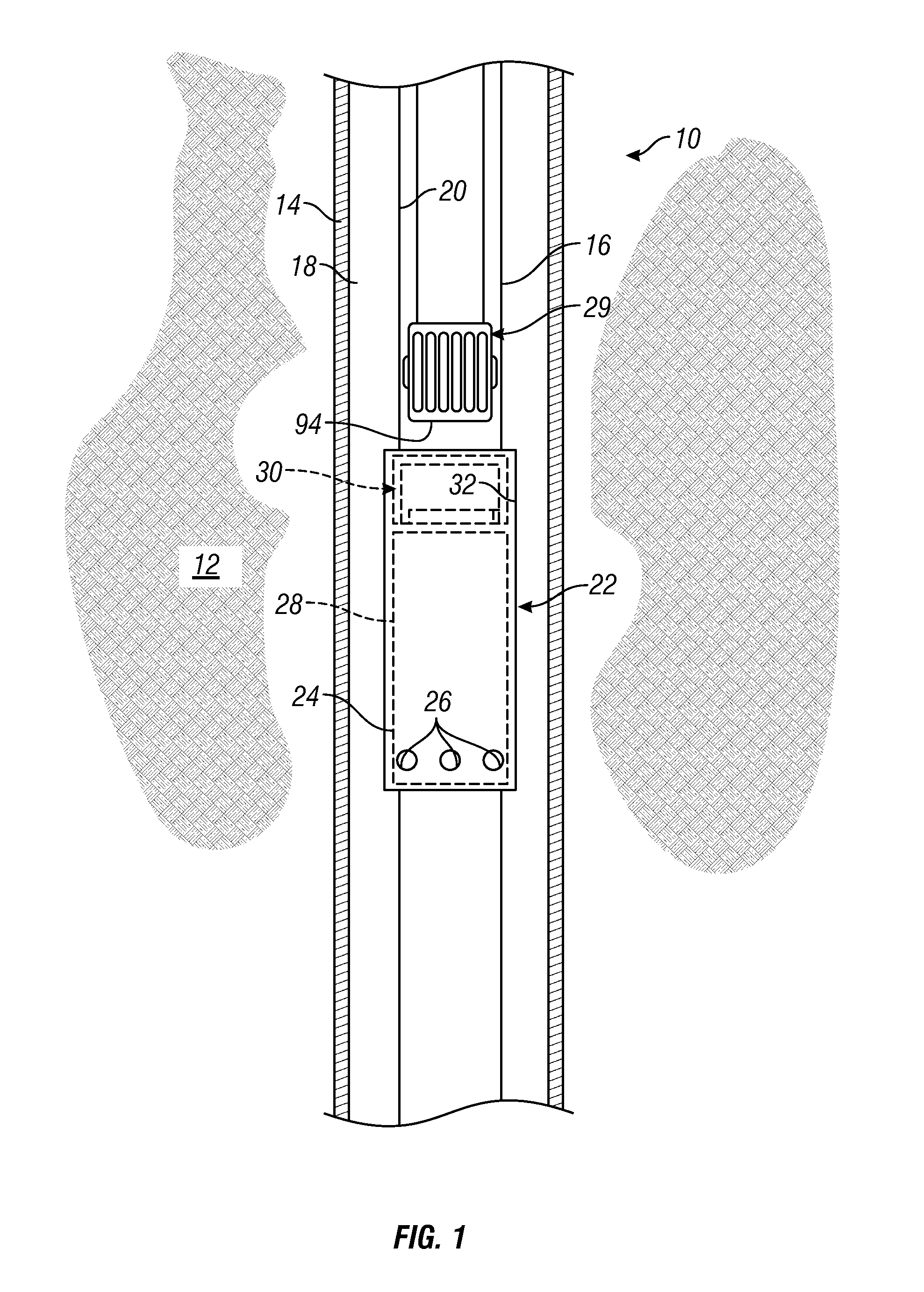

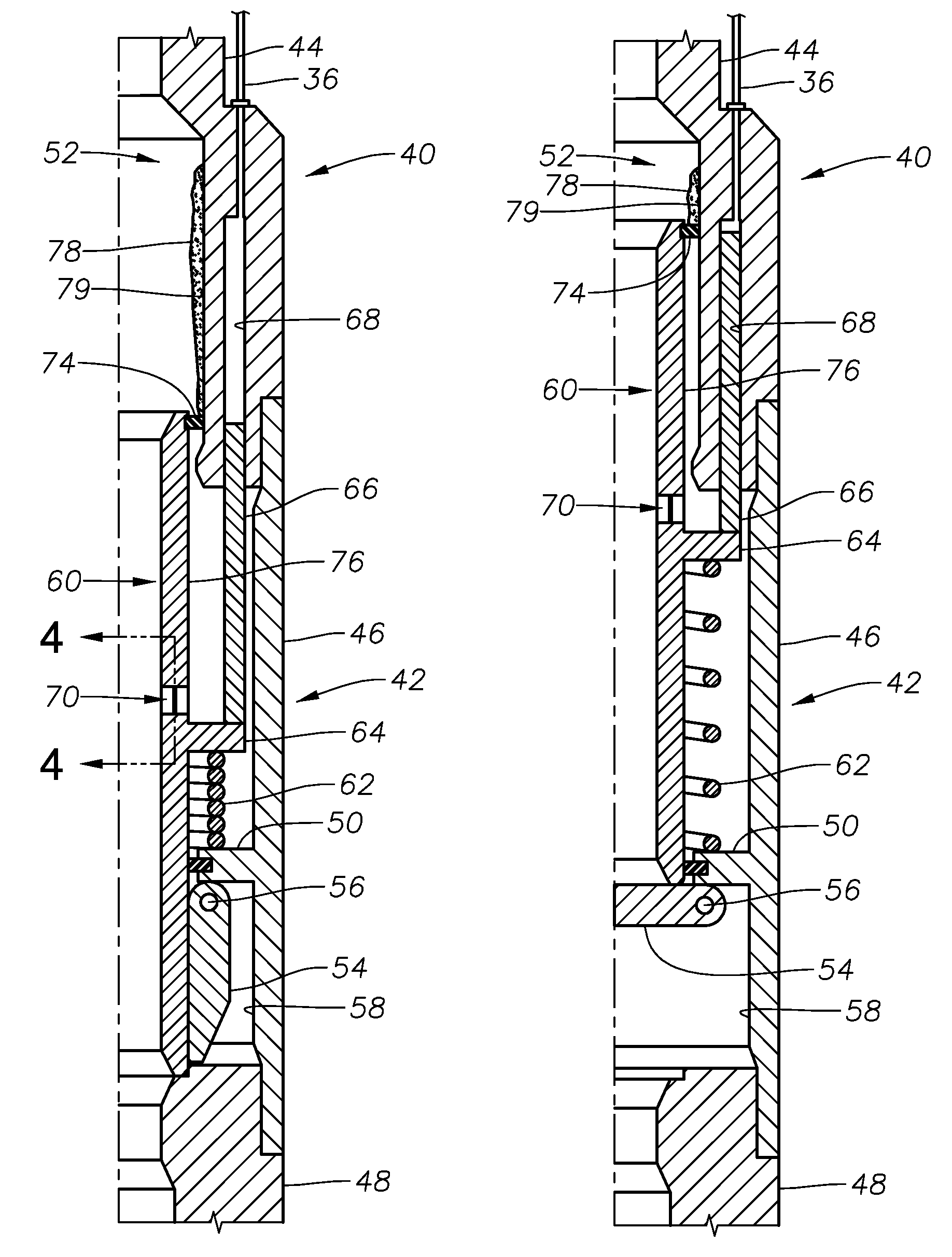

Fiber optic based method and system for determining and controlling position of a sliding sleeve valve

InactiveUS6995352B2Improve accuracy and reliabilityPhotometry using reference valueSurveyFiberSleeve valve

An apparatus and method for determining the position of a hydraulically actuated sliding sleeve valve in real time is disclosed. The apparatus comprises, in a preferred embodiment, a reference sensor and a position sensor, both of which constitute fiber optic windings wound around the hydraulic fluid cavity used to activate the sleeve. The sensors measure the pressure exerted by the hydraulic fluid in the cavity, with the reference sensor circumferentially lengthening to create an optical time delay indicative of the base line pressure of the hydraulic fluid. As the sleeve moves, the position sensor becomes increasingly exposed to the hydraulic fluid pressure and also begins to experience a time delay, which can be compared to the reference sensor's time delay to determine sleeve position.

Owner:WEATHERFORD TECH HLDG LLC

Karst grouting reinforcement water-stop constructing method

The invention discloses a karst grouting reinforcement water-stop constructing method, which is to construct according to sizes of karst caves by adopting a principle of from big to small regarding a certain area, construct by adopting a principle of from outside to inside for the karst caves with the same size, and construct by adopting a principle of from the bottom to the top in a vertical direction. On the basis of the construction principles, the method comprises the following steps of: (1) forming grouting holes by adopting a core drill; (2) forming construction exhaust and drainage pressure relief holes; (3) inserting grouting pipes into the grouting holes, wherein the grouting pipes comprise steel pipes, grouting shock pipes and sleeve valve pipes; (4) cleaning the holes, wherein when the step (3) is completed, the grouting pipes are cleaned with clean water; (5) grouting; and (6) drawing out the grouting pipes after the grouting is completed, and blocking the grouting holes with cement mortar or concrete. By adopting the constructing method, the pertinence to karst caves is strong, the grouting quantity is small, the engineering work amount is small, the cost is low, and the effect of filling and reinforcing is good.

Owner:GUANGZHOU URBAN PLANNING & DESIGN SURVEY RES INST

Sliding Sleeve Locking Mechanisms

Systems and methods for locking a sliding sleeve valve in an open position and / or a closed position to prevent inadvertent operation of the sleeve valve during other operations.

Owner:BAKER HUGHES INC

Methods for Preventing Mineral Scale Buildup in Subsurface Safety Valves

ActiveUS20100230109A1Prevent scalingRemove scale buildupConstructionsCleaning apparatusSleeve valveSafety valve

Methods and devices for negating scale buildups on interior surfaces of a sliding sleeve valve housing above the flow tube. In some aspects, a wiper member provides additional clearance between the flow tube and housing to compensate for scale buildup. In other aspects, the interior surface of the valve housing is provided with a sleeve that is disposed between the interior surface of the valve housing and the general flowbore passing through the valve housing to protect the interior surface against scale buildup.

Owner:BAKER HUGHES INC

Production actuated mud flow back valve

A material that reacts to produced hydrocarbons acts as a latch to retain a stored potential energy force. In a specific application, a sliding sleeve valve is held away from a circulating port to allow drilling mud to be circulated out. Later, when the well is put on production, the lock that holds collets in a groove releases as exposure to produced hydrocarbons at a retaining sleeve makes it get soft. This, in turn, allows a spring force to run the collets out of their groove and straddle the circulation port between two o-rings on the shifting sleeve to close the port. The closure of the port directs produced hydrocarbons to screens that had been bypassed when mud was circulated out due to ports being the path of least resistance.

Owner:BAKER HUGHES INC

Methods and apparatus for negating mineral scale buildup in flapper valves

ActiveUS7896082B2Prevent scalingEliminate buildupConstructionsCleaning apparatusSleeve valveEngineering

Methods and devices for negating scale buildups on interior surfaces of a sliding sleeve valve housing above the flow tube. In some aspects, a wiper member provides additional clearance between the flow tube and housing to compensate for scale buildup. In other aspects, the interior surface of the valve housing is provided with a sleeve that is disposed between the interior surface of the valve housing and the general flowbore passing through the valve housing to protect the interior surface against scale buildup.

Owner:BAKER HUGHES INC

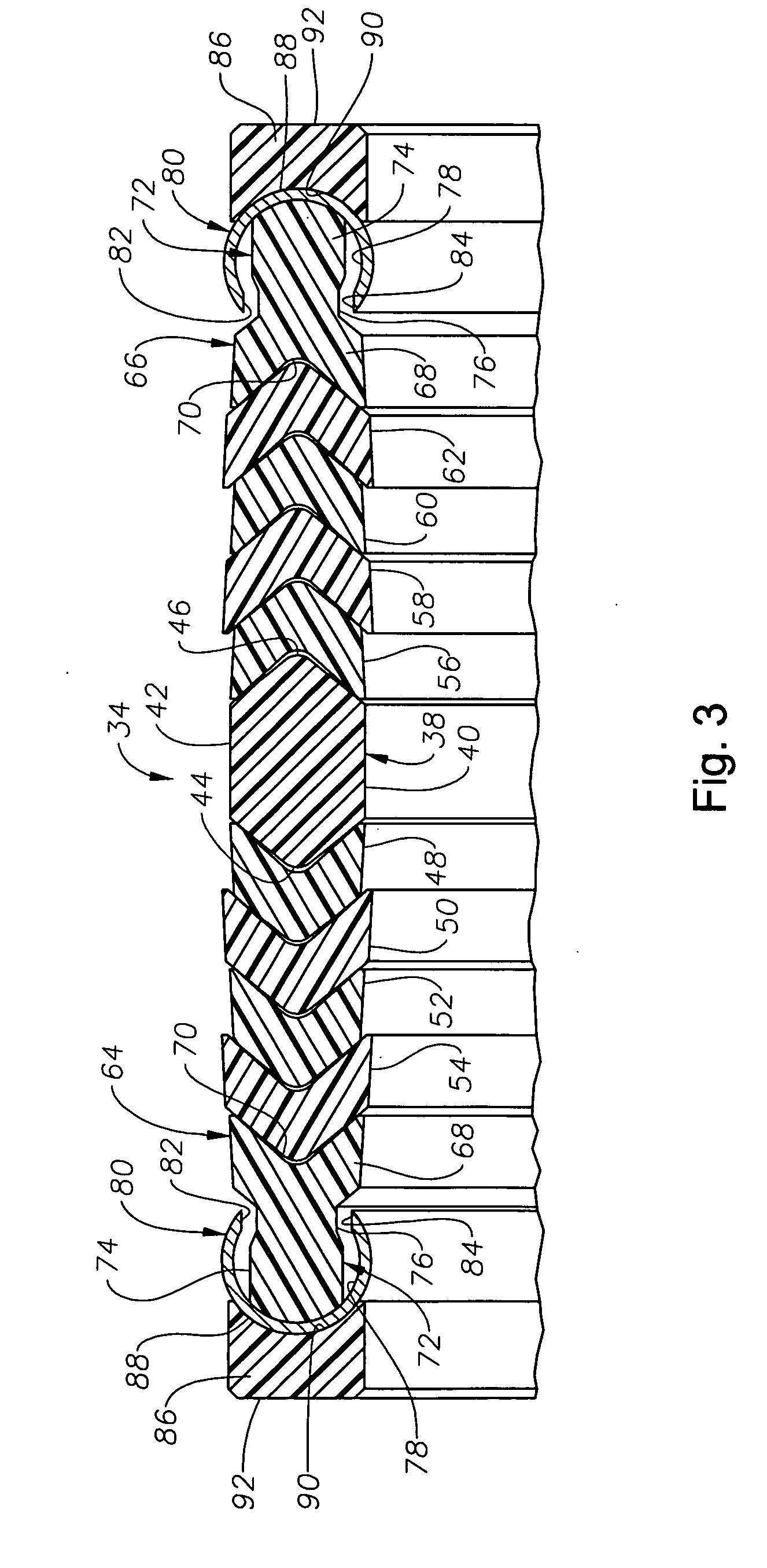

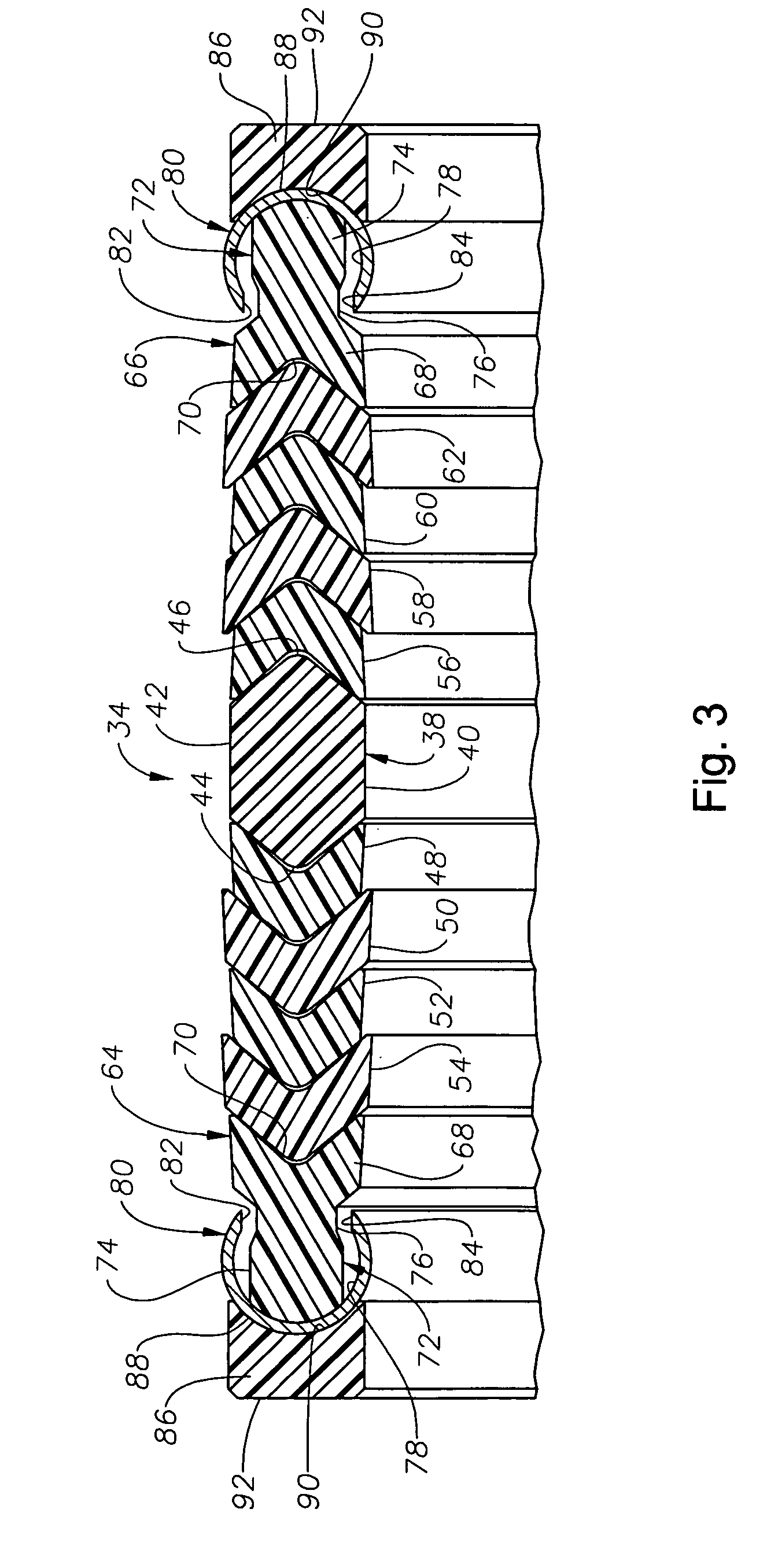

Metal-to-metal non-elastomeric seal stack

ActiveUS20070089887A1Increase pressureIncrease temperatureEngine sealsConstructionsSleeve valveAxial compression

An improved seal assembly for use in sliding sleeve valves. The seal assembly incorporates a number of annular, chevron-shaped seal elements that are in a stacked configuration and preferably formed of a thermoplastic material to provide a fluid seal between the outer housing and the inner sleeve member of the sliding sleeve valve. In addition, the seal assembly preferably includes a pair of annular metallic seal members that have a C-ring cross-section (a “C-seal”). On opposite axial sides of each metallic C-seal are a C-seal support ring and an end adapter that are shaped and sized to assist the metallic C-seals to be axially compressed and uncompressed to resiliently seal against both the inner sleeve member and the outer housing.

Owner:BAKER HUGHES INC

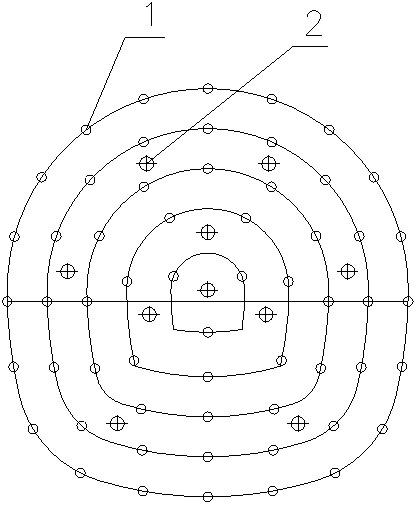

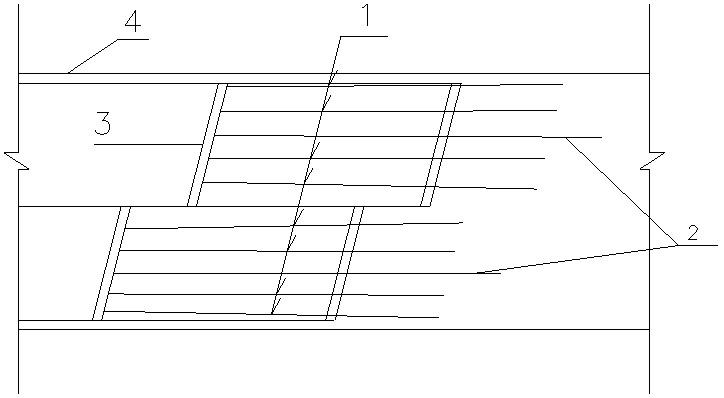

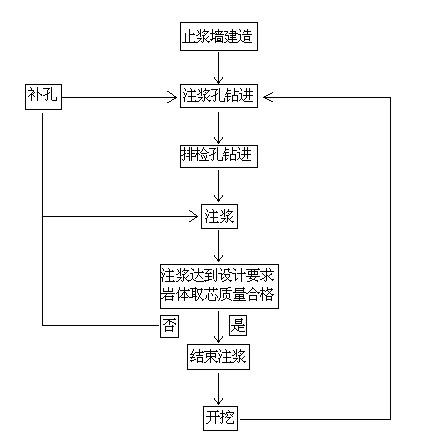

Full-section sealing extrusion grouting method

InactiveCN102182470AKeep abreast of the reinforcement effectReduce pore water pressureUnderground chambersTunnel liningSleeve valveSlurry

The invention relates to an auxiliary method for tunnel excavation construction, namely, a full-section sealing extrusion grouting method for tunnel excavation, comprising a working surface slurry stop wall, grouting holes and discharge checking holes, wherein the slurry stop wall can improve the drilling precision of the grouting hole and the discharge checking hole, and also can prevent the phenomenon of grout oozing out of the working surface due to overhigh grouting pressure. The grouting holes are uniformly distributed in a working surface in the annular direction and the radial direction, and the discharge checking holes and the grouting holes are arranged at intervals and both incline by a certain angle during drilling. The discharge checking holes are arranged between endless belts of the grouting holes, so as to be beneficial to the smooth discharge of clearance water in a soft soil layer when the clearance water is extruded during grouting, and be convenient for coring of rock soil body after grouting so as to check the grouting effect of the working surface. A sleeve valve pipe (namely a splitting grouting pipe) is adopted as the grouting pipe, and a retreating type splitting grouting method is adopted to conduct grouting sequentially from the periphery to the inner ring of of the working surface. According to the design, the stability of the working surface during the excavation of the tunnel in the soft soil layer can be ensured, and sediment quantity caused by the tunnel excavation can be reduced.

Owner:TONGJI UNIV

Metal-to-metal non-elastomeric seal stack

An improved seal assembly for use in sliding sleeve valves. The seal assembly incorporates a number of annular, chevron-shaped seal elements that are in a stacked configuration and preferably formed of a thermoplastic material to provide a fluid seal between the outer housing and the inner sleeve member of the sliding sleeve valve. In addition, the seal assembly preferably includes a pair of annular metallic seal members that have a C-ring cross-section (a “C-seal”). On opposite axial sides of each metallic C-seal are a C-seal support ring and an end adapter that are shaped and sized to assist the metallic C-seals to be axially compressed and uncompressed to resiliently seal against both the inner sleeve member and the outer housing.

Owner:BAKER HUGHES INC

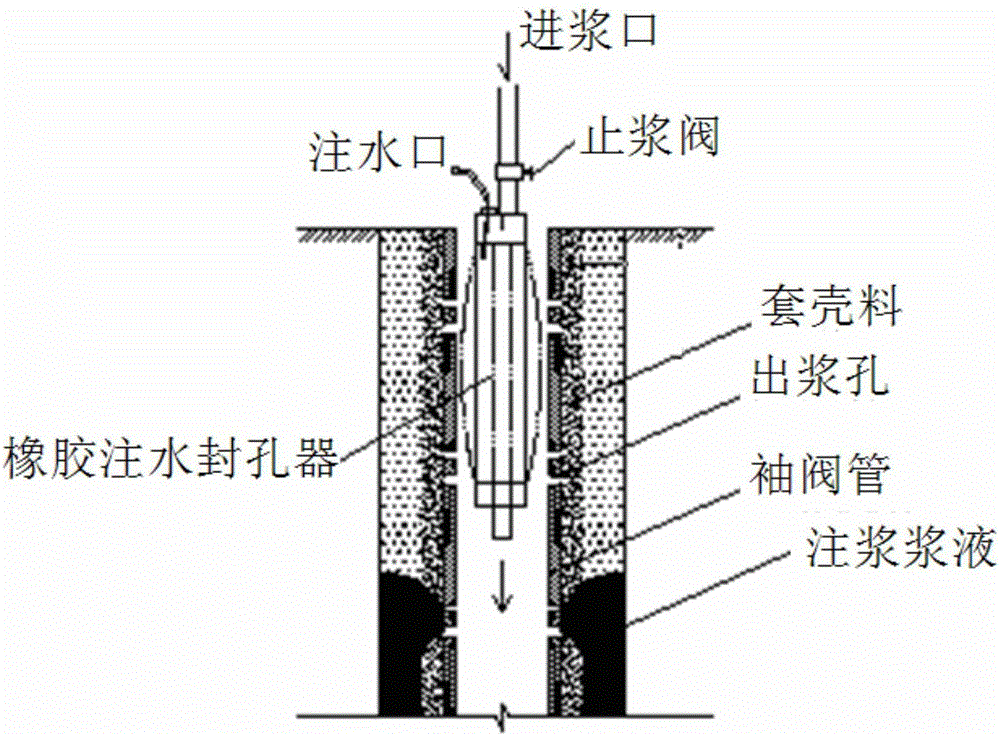

Tunnel ground deep-hole sleeve valve tube grouting construction method

InactiveCN105714764AHigh strengthReduce distortionUnderground chambersTunnel liningSleeve valveUltimate tensile strength

A tunnel ground deep-hole sleeve valve tube grouting construction method is used for treating an operating tunnel and is characterized in that first a construction joint in the tunnel is treated and a polyurethane waterproof material is adopted; then a bore with a certain depth is constructed at an angle in strata, a sleeve valve tube is arranged, a casing material is pre-poured, the sleeve valve tube stays in soil permanently, grout outlet holes are reserved in the grouted sleeve valve tube at intervals, a water-injection rubber hole packer is placed in the sleeve valve tube, and a stop valve is additionally arranged at a grout inlet; during grouting, water is injected into the water-injection rubber hole packer to block a grouting tube, and a to-be-grouted part is grouted by a retreating grouting method; and finally, the grouting effect is checked, and grouting is performed repeatedly if the effect is bad. The tunnel ground deep-hole sleeve valve tube grouting construction method has the advantages as follows: the working efficiency is increased; and the method is implemented in combination with in-tunnel grouting blockage, thus improving and radically changing the physical and mechanical properties of a foundation and a load-bearing action mechanism, increasing soil strength, reducing deformation and achieving the purposes of reinforcing soil and blocking water gaps.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

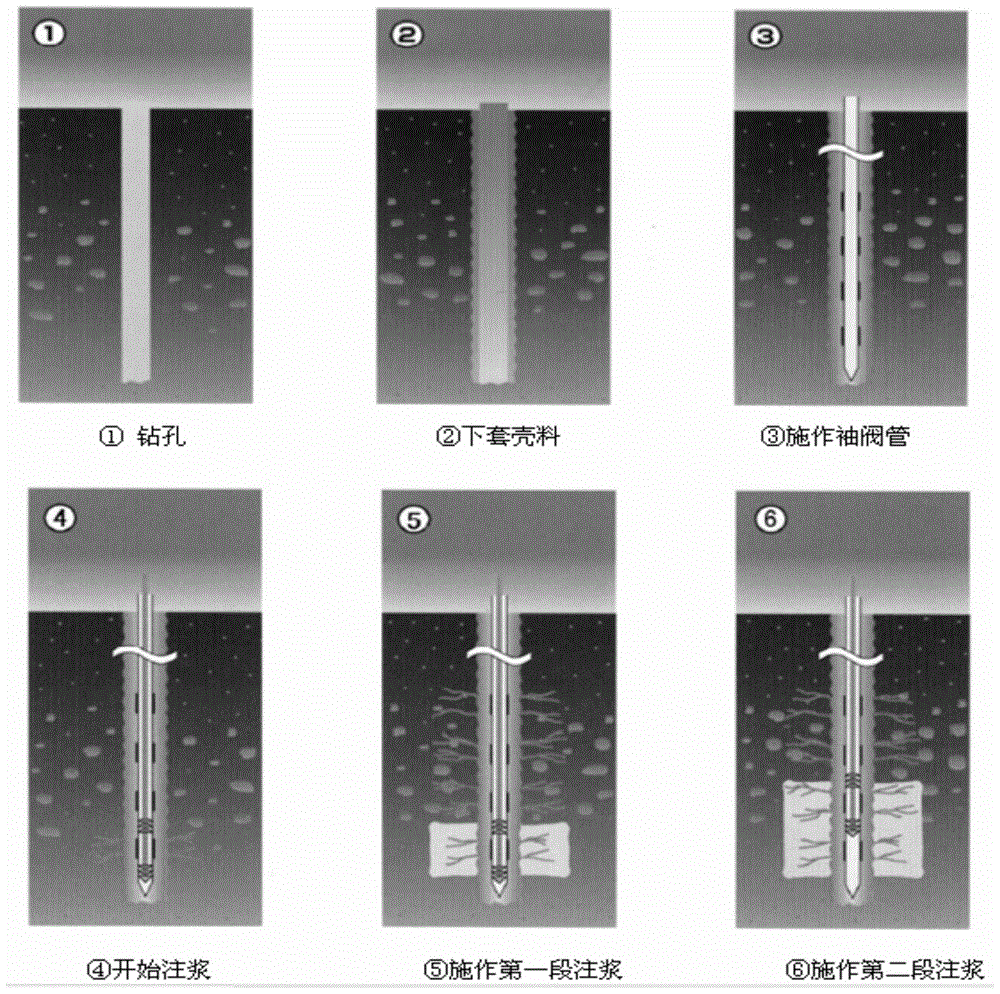

Construction method for grouting reinforcement of sleeve valve pipe

InactiveCN102444118ATo achieve the purpose of segmented groutingImprove work efficiencyBulkheads/pilesSoil preservationSleeve valveSlurry

The invention discloses a construction method for the grouting reinforcement of a sleeve valve pipe, comprising the following steps of: firstly, drilling a hole; secondly, inserting a grouting pipe B into the grouting drilled hole; thirdly, inserting a grouting pipe A into the grouting pipe B; fourthly, sealing the hole; and fifthly, performing grouting. The grouting pipe B is inserted into the grouting drilled hole down to the bottom of the hole with the top exceeding the ground. In the step of inserting the grouting pipe A into the grouting pipe B, a lower blank cap is added to the bottom of the connected grouting pipe A, and the grouting pipe A and the lower blank cap are slowly inserted into the grouting pipe B section by section. After the grouting pipe A is inserted to the bottom of the grouting pipe B, hole sealing slurry is fully injected between the gap between the grouting pipe B and the soil body; after the hole sealing slurry is injected, water is fully injected in the grouting pipes; the grouting pipe B may not float under the action of gravity; and then the pipe A is pulled out slowly; and finally, an upper blank cap is arranged to cover the upper part of the grouting pipe B. Furthermore, reinforcement slurry is injected in 48 hours after the hole sealing slurry is injected; grouting is performed in a sectional injection manner; and the step distance of grouting is 0.6-1 m.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

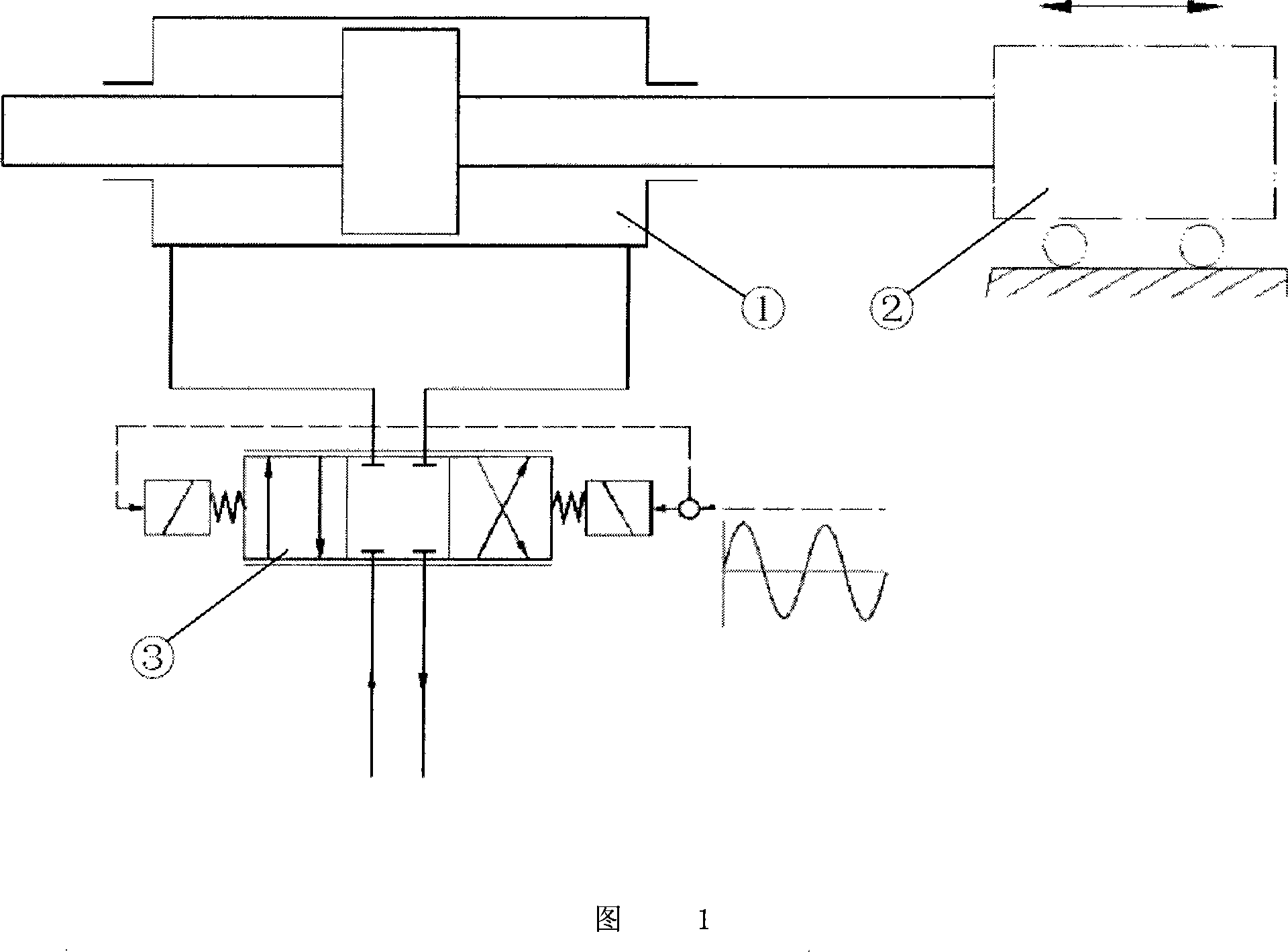

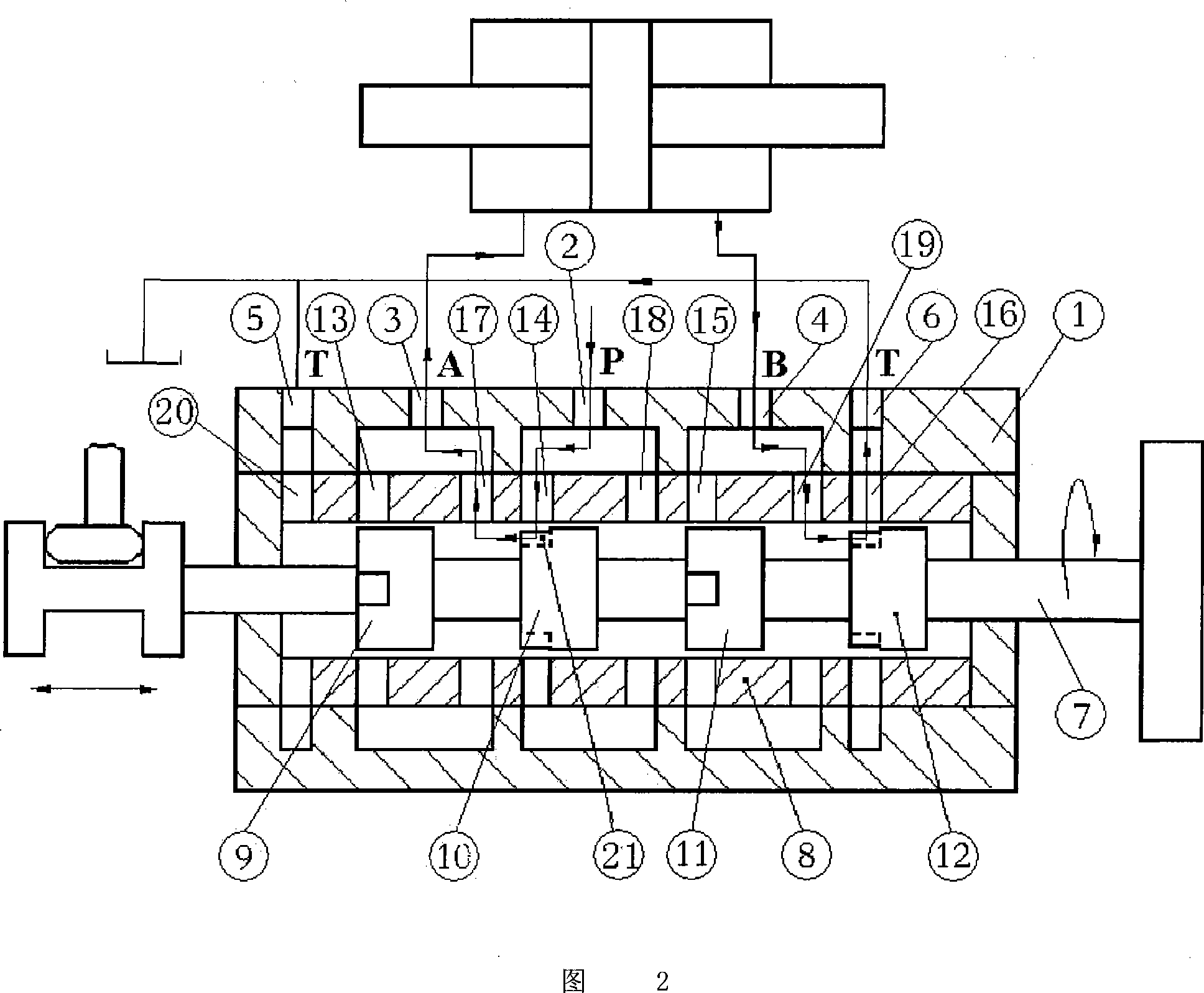

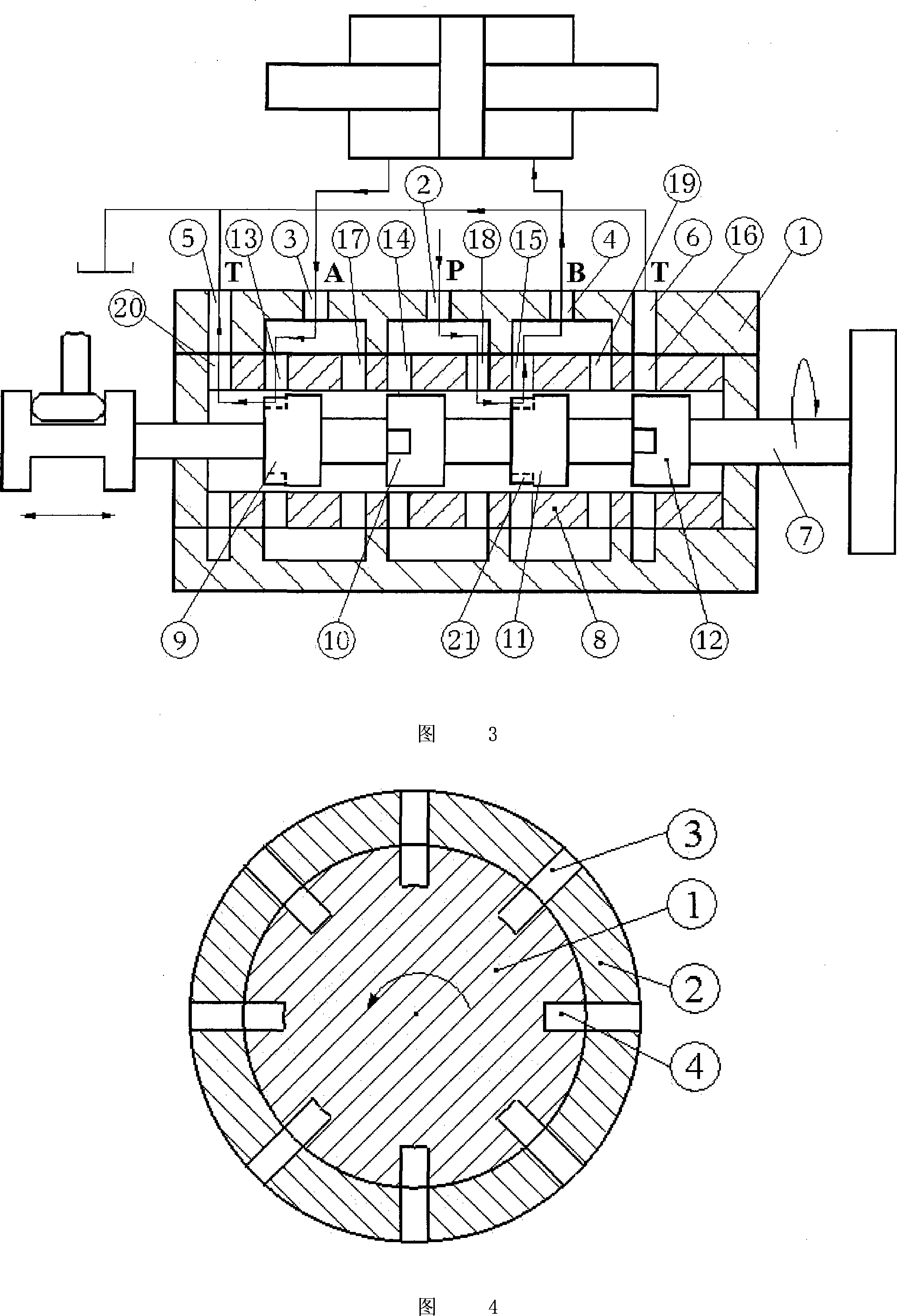

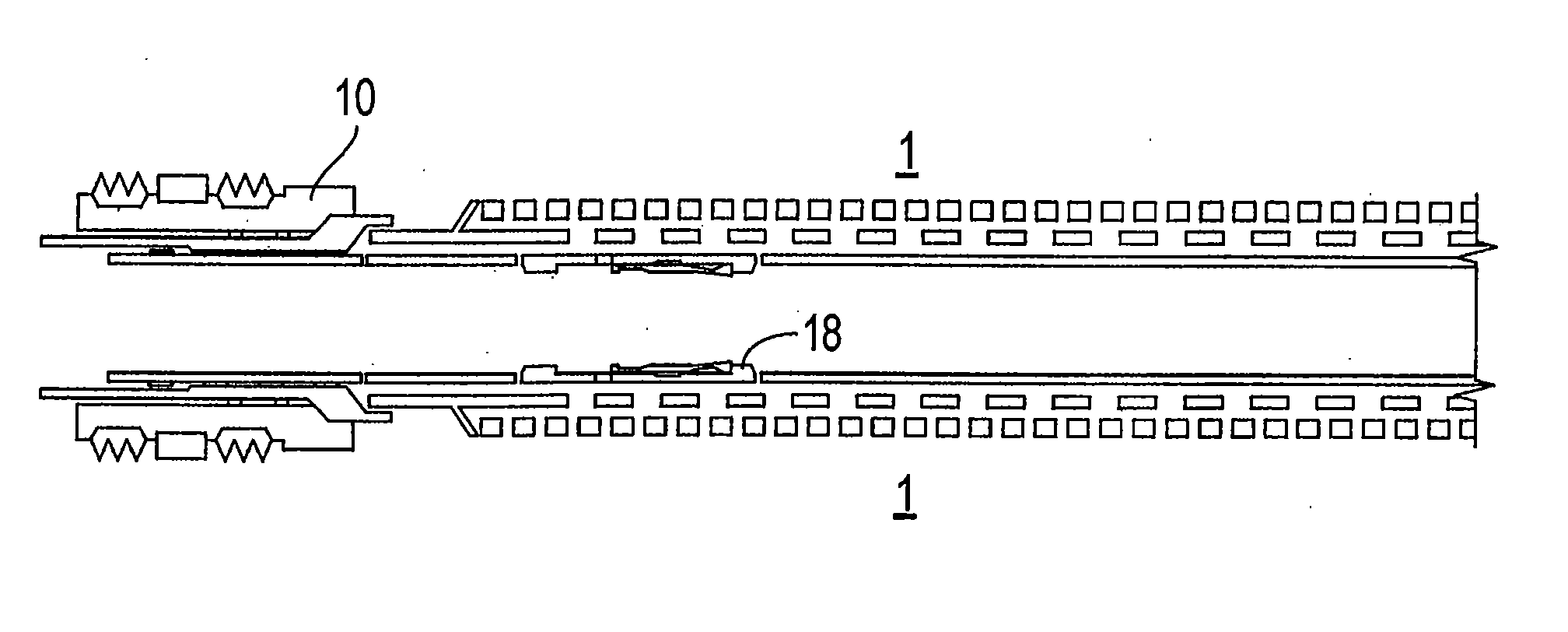

Electrohydraulic excitation controlling valve

InactiveCN101183038AIncrease the excitation frequencyServomotor componentsVibration testingHydraulic cylinderSleeve valve

An electro-hydraulic excitation control valve, comprising a valve body, the valve body is provided with an oil inlet connected to a high-pressure oil tank, a first oil inlet and outlet connected to a hydraulic cylinder, a second oil inlet and an outlet, and an oil return port. The first oil outlet and the second oil outlet connected to the oil tank. The electro-hydraulic vibration control valve also includes a valve core and a valve sleeve. The valve sleeve is nested in the inner wall of the valve body, and the valve core passes through the The valve sleeve, the spool is connected to the first servo motor and the second servo motor; at least four shoulders are equidistantly arranged on the spool, and at least two grooves are uniformly opened in the circumferential direction of each shoulder, The grooves on the front and rear adjacent shoulders are misaligned; a ring of valve sleeve windows matching each shoulder is uniformly opened in the circumferential direction of the valve sleeve, and the valve sleeve windows are at least four circles. The valve sleeve between the windows is provided with an auxiliary window, and an additional window is provided at the end of the valve sleeve close to the first valve sleeve window. The invention can greatly increase the electro-hydraulic excitation frequency.

Owner:ZHEJIANG UNIV OF TECH +1

System and method for downhole operation using pressure activated and sleeve valve assembly

Owner:SUPERIOR ENERGY SERVICES LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com