Full-section sealing extrusion grouting method

A full-section, grouting technology, which is applied in the shaft lining, tunnel lining, underground chamber, etc., can solve the problems that it is difficult to ensure the stability of the tunnel face, the surface settlement is not easy to control, and the porosity is low, so as to increase the effective soil mass. Stress, reduce soil pore water pressure, the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The design features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through the embodiments, so as to facilitate the understanding of those skilled in the art:

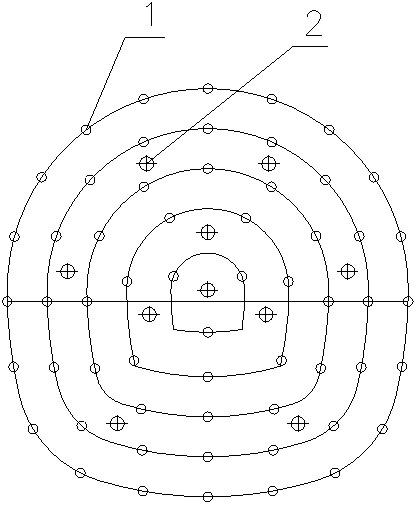

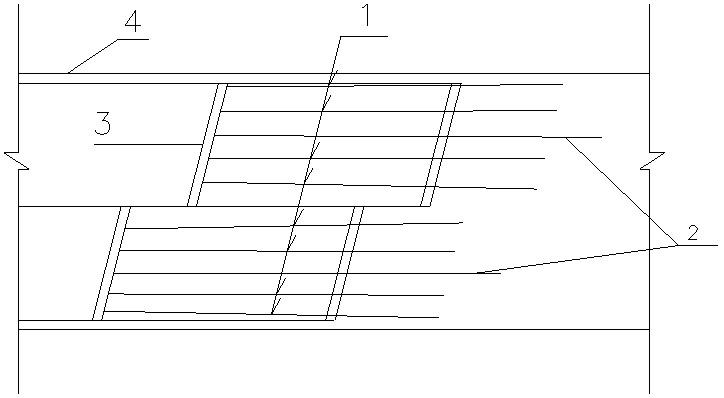

[0017] attached Figure 1-2 The marks 1-4 represent the grouting hole 1, the inspection hole 2, the grout stop wall 3, and the primary support 4.

[0018] attached figure 1 For the present invention, the layout diagram of the hole location of the full-section closed extrusion grouting method is designed. Depend on figure 1 It can be seen that the full-section extrusion grouting method is composed of a grouting hole 1 and a row inspection hole 2. It also has the functions of drainage and inspection. Under the reinforcement of the surrounding rock of the tunnel by the initial support 4 of the tunnel, the grout in the grouting hole 1 is injected into the weak stratum of the face, which plays a role in changing the loose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com