Patents

Literature

639 results about "Internal friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Internal friction is the force resisting motion between the elements making up a solid material while it undergoes deformation. When surfaces in contact move relative to each other, the friction between the two surfaces converts kinetic energy into thermal energy (that is, it converts work to heat ).

Friction generator

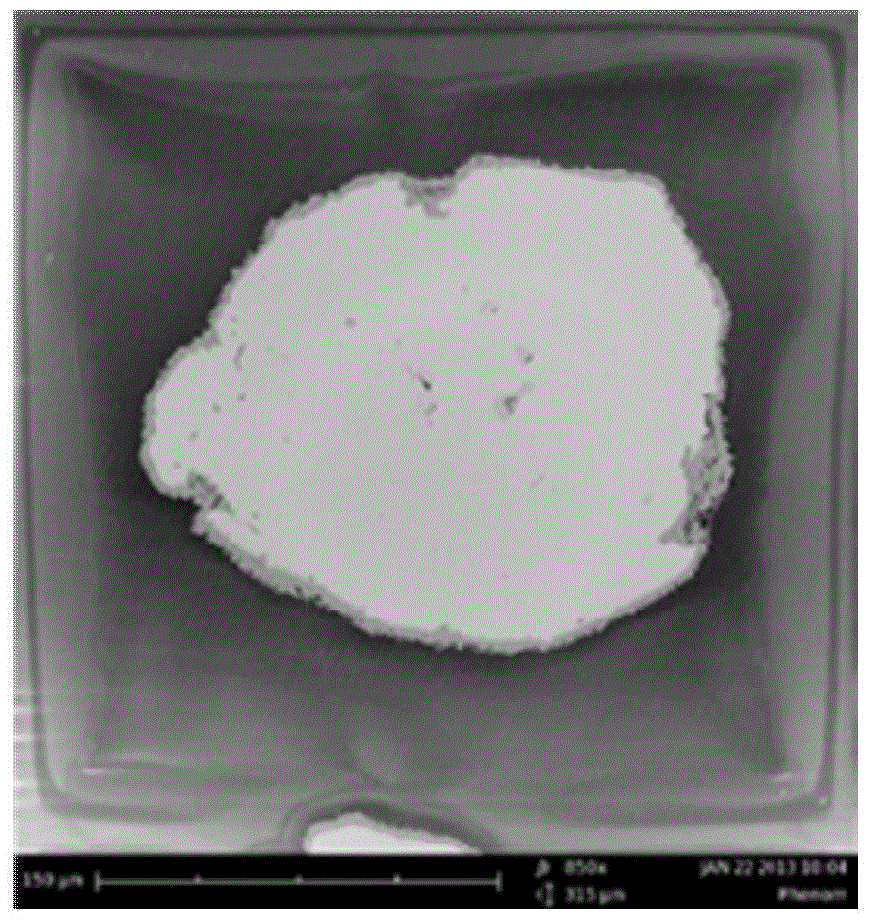

ActiveCN102710166AExtended service lifeLow costFriction generatorsMetal layered productsMicro nanoConvex structure

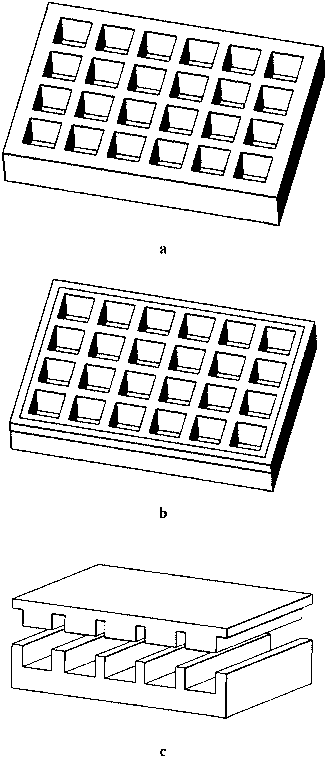

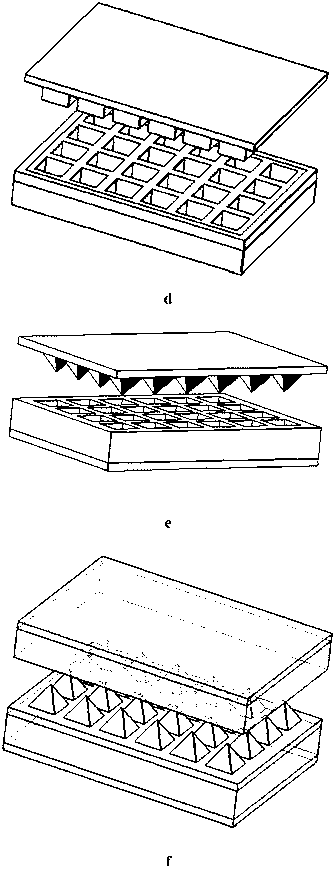

The invention provides a friction generator, which comprises a first electrode, a second electrode and an intermediate film, wherein the first electrode comprises a first macromoleclar polymer insulation layer of which one side surface is provided with a conductive film; the second electrode comprises a second macromoleclar polymer insulation layer of which one side surface is provided with a conductive film; the intermediate film is fixed on the other side surface of the second macromoleclar polymer insulation layer; the non-fixed surface of the intermediate film is provided with a micro-nano concave-convex structure; the surface of the micro-nano concave-convex structure of the intermediate film on the second electrode and the surface without the conductive film of the first electrode are oppositely fit and are mutually fixedly connected; and the conductive film of the first macromoleclar polymer insulation layer and the conductive film of the second macromoleclar polymer insulation layer are both the voltage and current output electrodes of the friction generator. The invention provides an innovated and effective method by the friction action, and electricity energy is generated by the variation of internal friction electrification electric potential and the induction effect of metal pole plates on two sides. The method is simple and efficient and has low cost.

Owner:NEWNAGY TANGSHAN

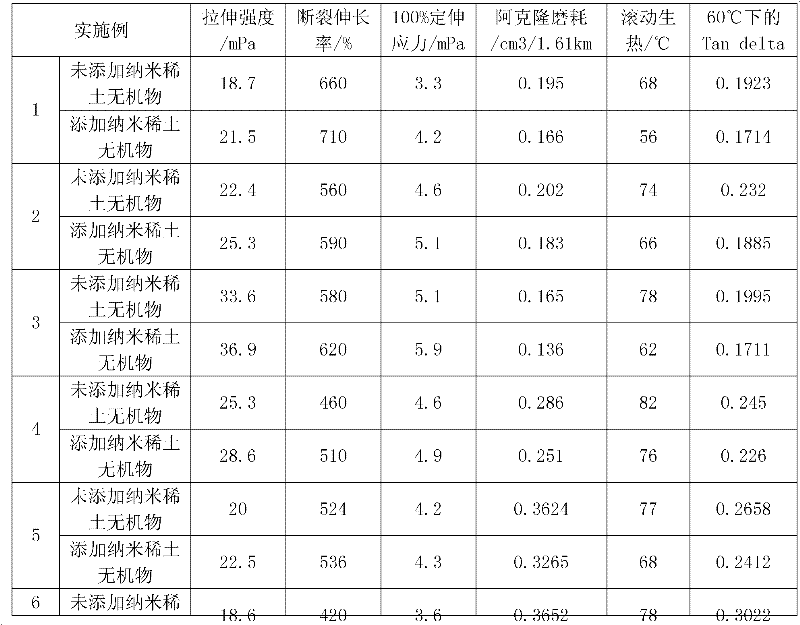

Nanometer rare earth inorganic substance/ rubber composite with high wear resistant and excellent dynamic property

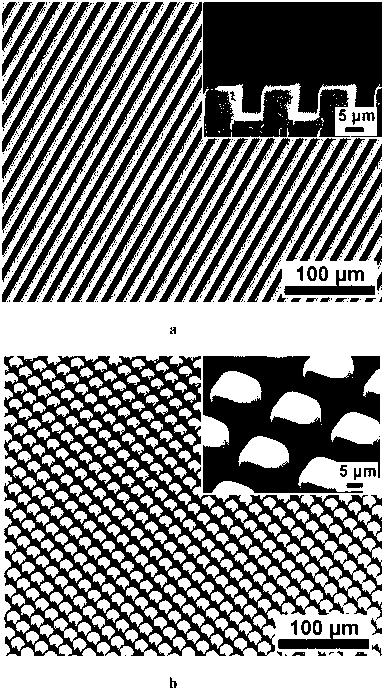

The invention prepares a nanometer rare earth inorganic substance / rubber composite with high wear resistant and excellent dynamic property. The invention adopts a mechanical blending method to prepare the nanometer rare earth inorganic substance and rubber composite. After the nanometer rare earth inorganic substance and the rubber are composited, higher modulus can be provided, the mechanical property of the rubber composite is improved, the abrasion stripes are blocked up to achieve the aim of dispersing stress through the high strength of the nanometer rare earth inorganic substance so as to improve wear-resisting property, and the internal friction of the composite is improved by utilizing the specific characteristic of smooth surface of the rare earth material so as to achieve the aim of reducing internal friction and resistance to rolling. According to the material prepared by the invention, the modulus can be improved, the mechanical property is improved, the abrasion is greatly reduced simultaneously, the internal friction and the resistance to rolling are reduced, and the composite can be widely applied to materials such as tyres, conveyer belts, sealing elements, piston rings, soles and the like.

Owner:江苏绿源橡胶资源循环利用创新中心有限公司

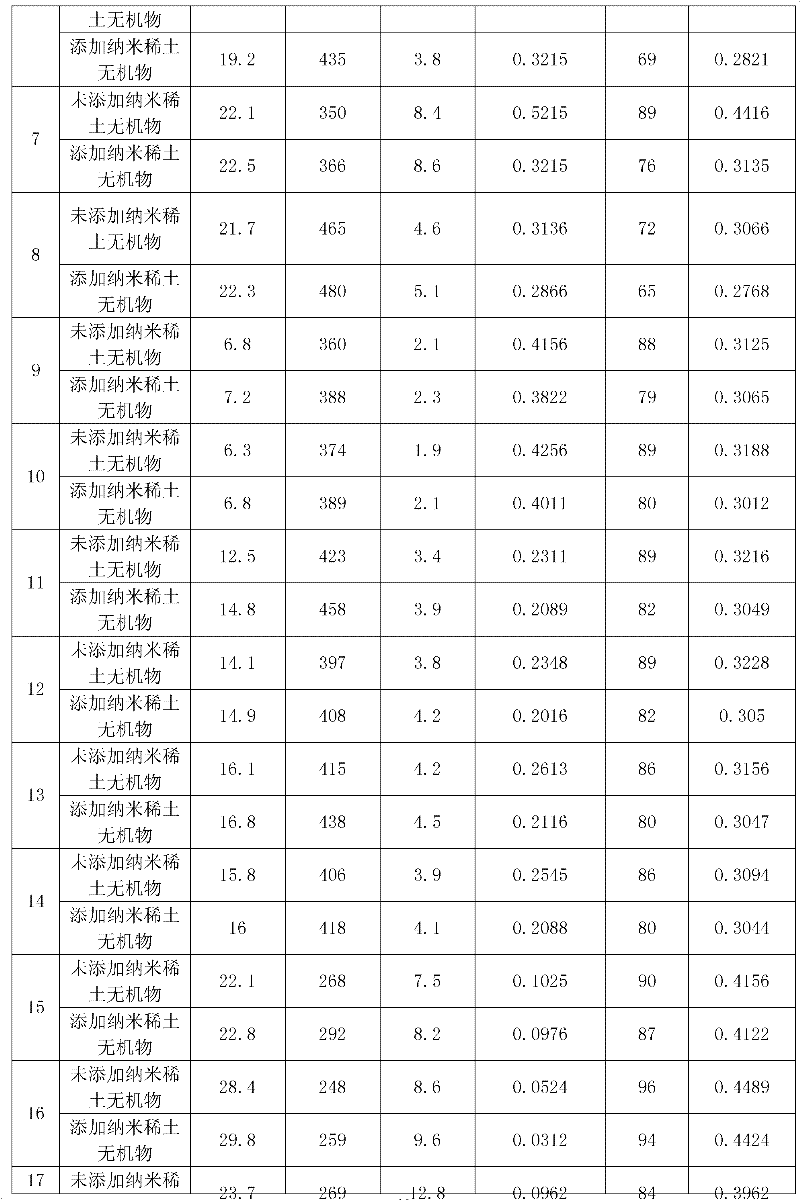

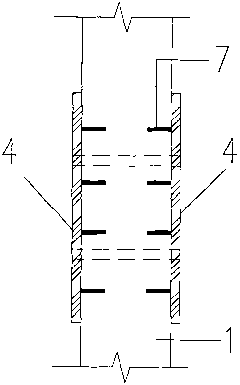

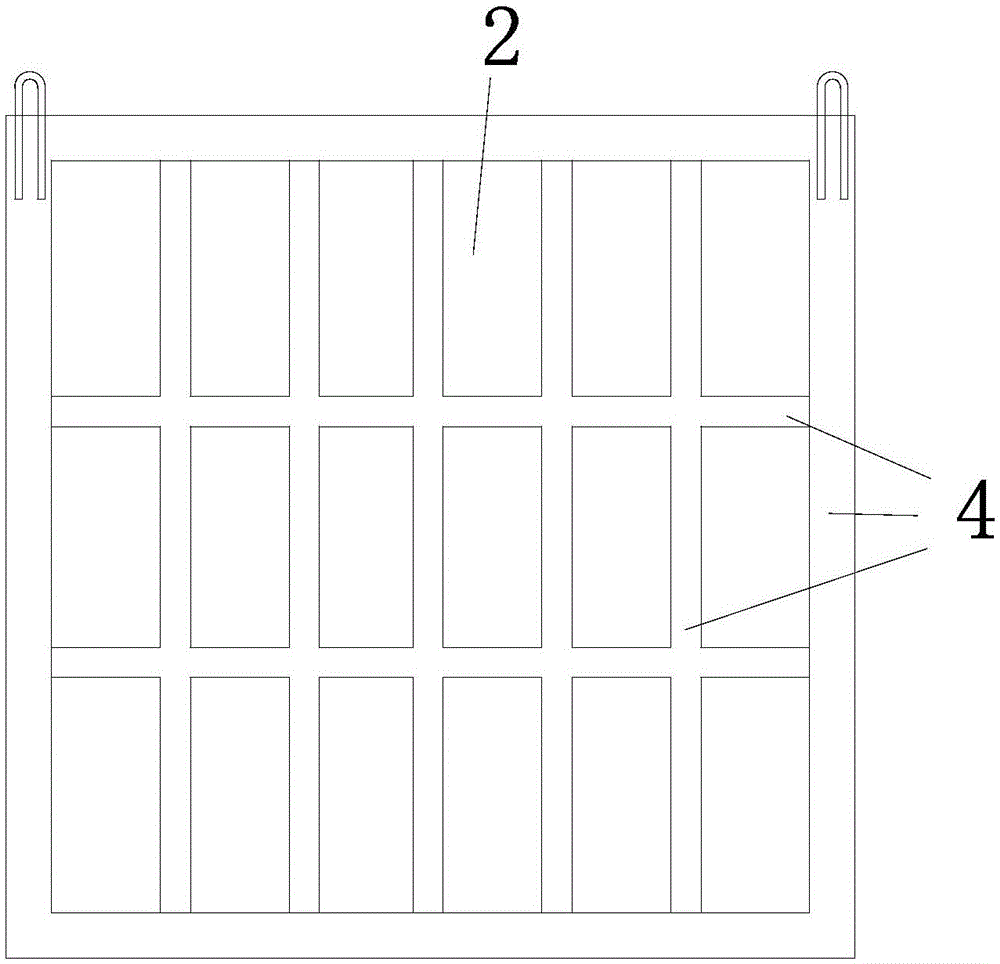

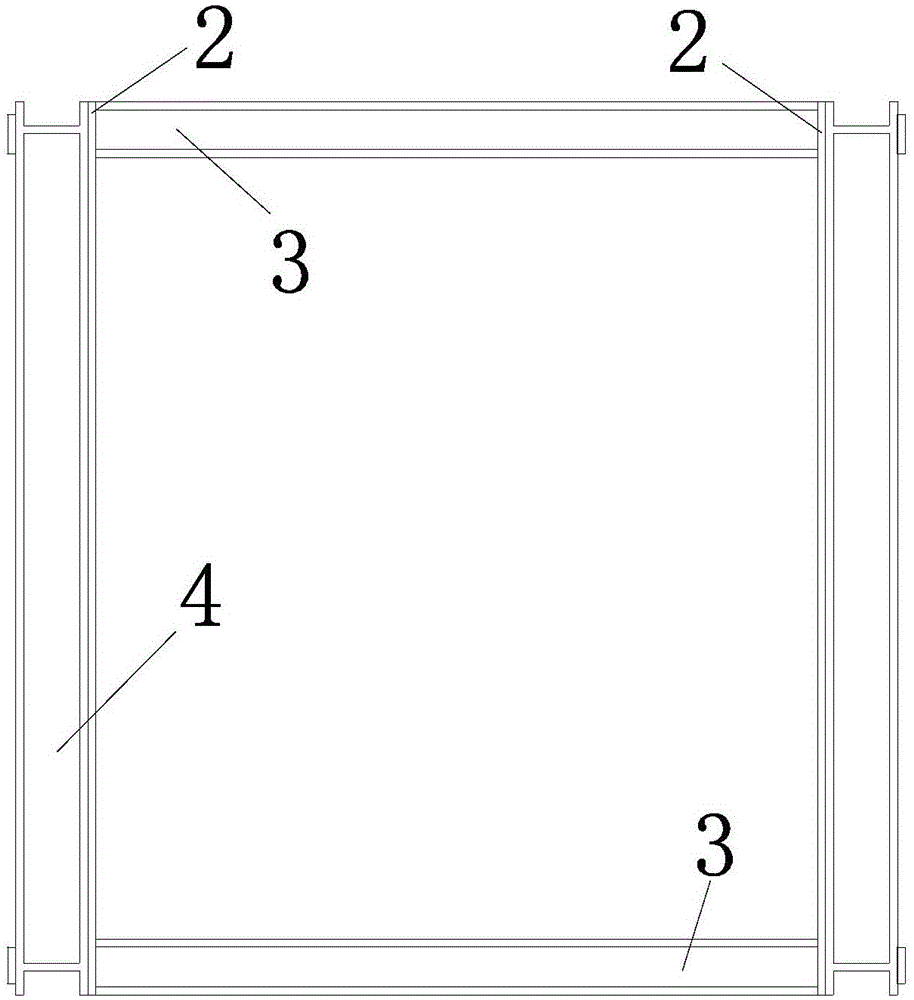

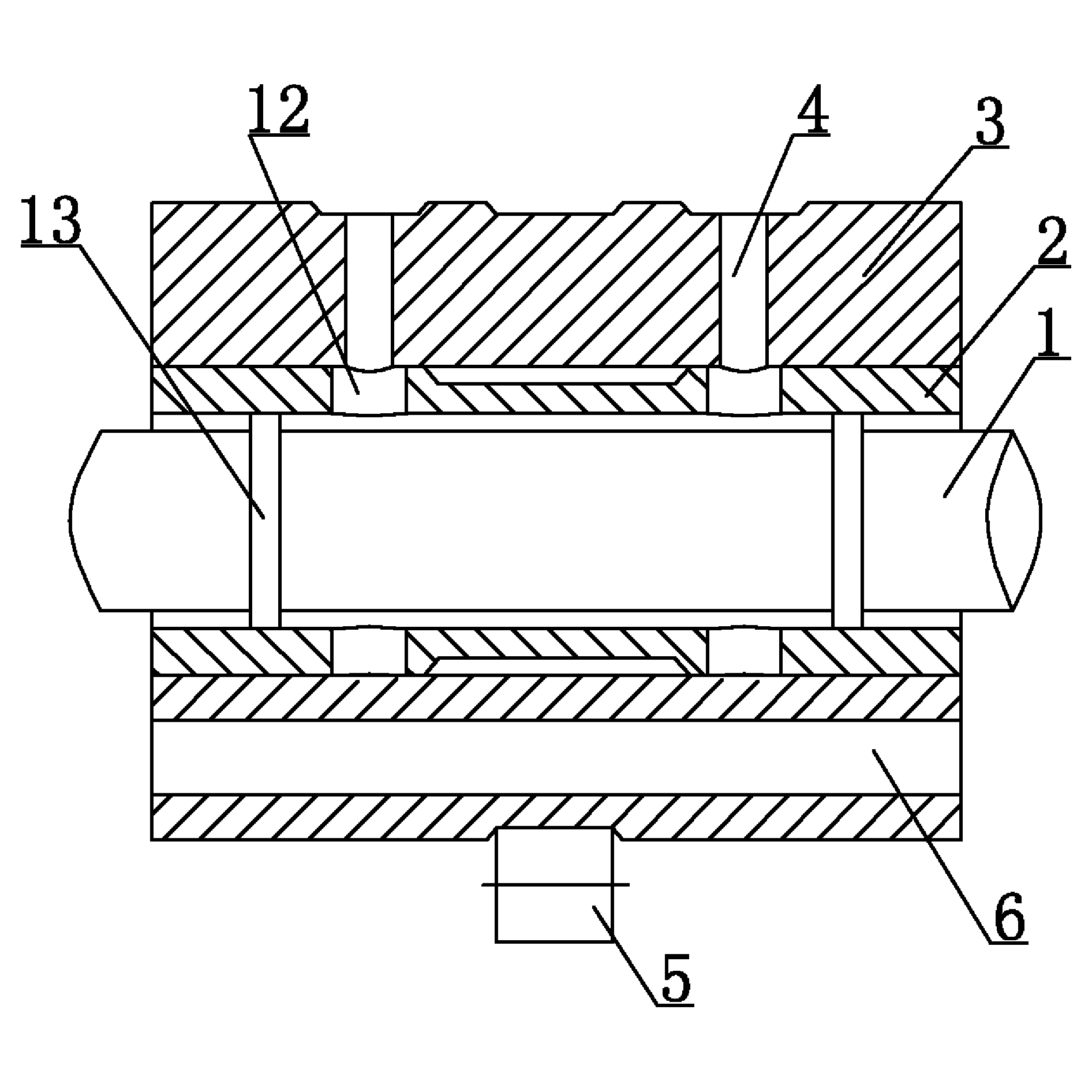

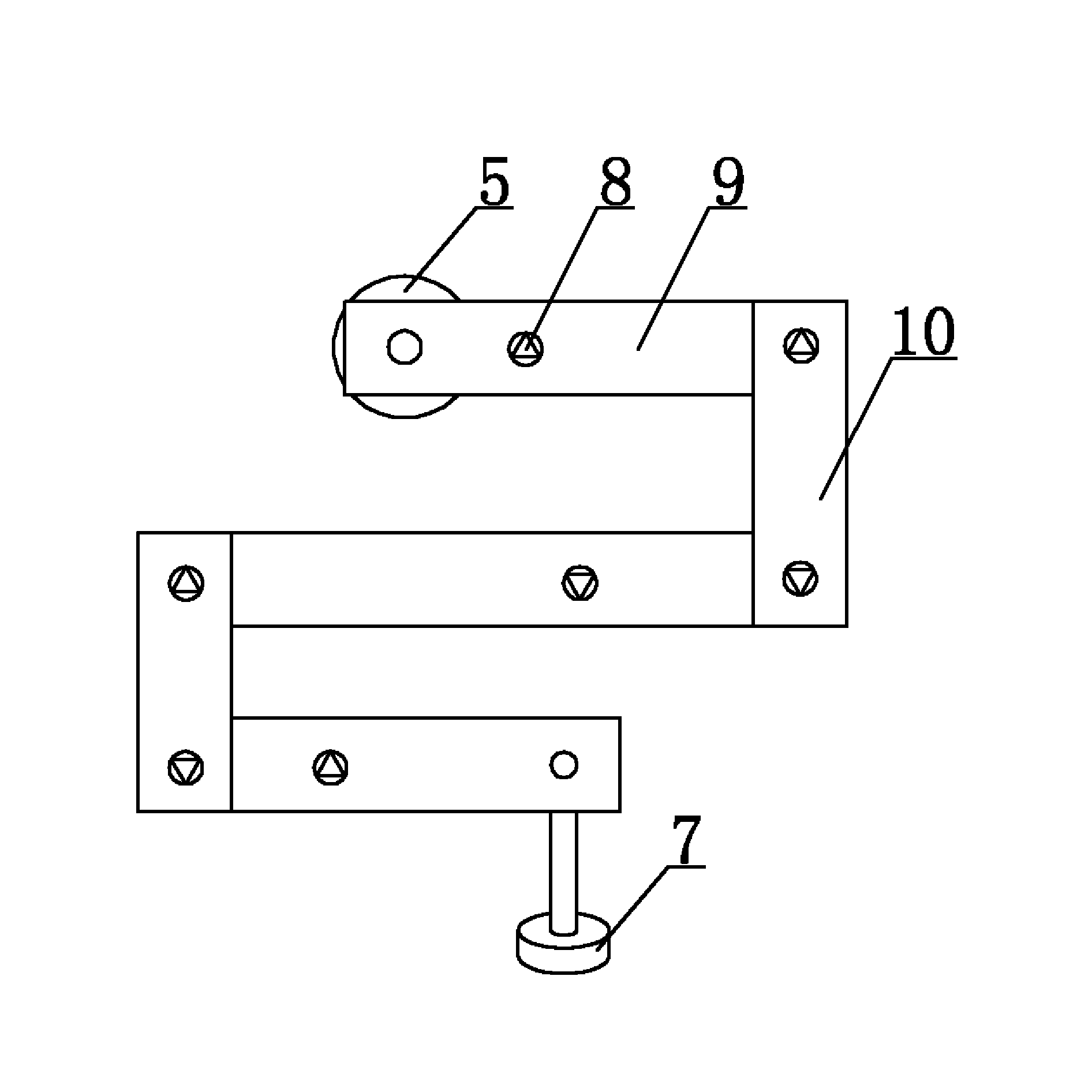

Node connection device for self-centering prestressed concrete frame

InactiveCN101798849ASolve local pressure problemsEliminate or reduce residual deformationShock proofingResidual deformationWhole body

The invention relates to a node connection device for a self-centering prestressed concrete frame. The node connection device is a device used for the connection between the beam and the column of a prefabricated reinforced concrete frame, and aims at improving energy consumption of a frame structure under seismic action and eliminating or reducing the residual deformation and damage of the frame structure. The connection device is characterized in that combined steel parts form an energy consuming device, two external friction steel plates (3) are arranged in the energy consuming device, are respectively and symmetrically arranged on the two sides of a column end reinforcing steel plate (4) and are connected with the column end reinforcing steel plate (4) into a whole body, two internal friction steel plates (8) are arranged between the two external friction steel plates (3), the upper end and the lower end of each internal friction steel plate (8) are respectively provided with a bean end reinforcing steel plate (5), friction discs (15) are respectively arranged between the two internal friction steel plates (8) and the two external friction steel plates (3), and friction-type high-strength bolts (12) penetrate through the external friction steel plates (3), the friction discs (15), the internal friction steel plates (8) and a prefabricated concrete beam (2) and connect all parts together.

Owner:SOUTHEAST UNIV

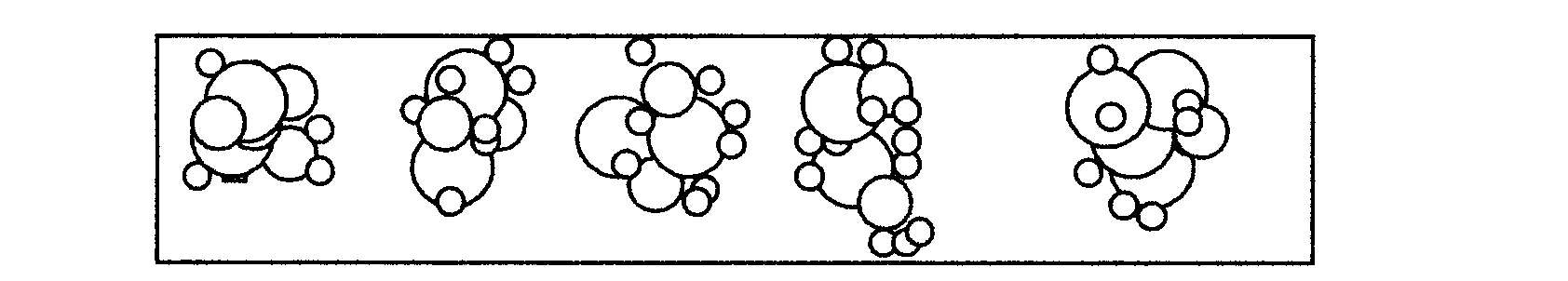

Low cost and high efficient soundproof material and manufacturing method thereof

InactiveCN103897262AImprove heat and aging resistanceExcellent ozone resistanceSound producing devicesRelaxation effectFilling materials

The invention relates to a low cost and high efficient soundproof material and a manufacturing method thereof, relates to the field of soundproof materials, solves the problems that in the prior art, soundproof materials do not have a prominent soundproofing effect, generate harmful gas, which can harm the human health, and have a high cost; and provides a low cost and high efficient soundproof material. The soundproof material comprises thermoplastic resin and an inorganic filling material, wherein the surface of the inorganic filling material has been processed by a coupling agent processing liquid, the inorganic filling material accounts for 15 to 80 wt% of the total weight of the soundproof material, and the balance being thermoplastic resin. In the soundproof material, the connections among the particles are abnormal, thus the internal friction of the incident sound waves is increased by the structure of the soundproof material, and a relaxation effect is generated to absorb the sound waves. Filling materials with different particle sizes are corresponding to waves in different wavelengths or frequencies, so the soundproof material can reduce sounds in different frequencies. Moreover the soundproof material has a good soundproof effect and is suitable for being promoted and used.

Owner:浙江艾迪雅科技有限责任公司

Multimode organic filler/polymer composite damping material and manufacturing method thereof

InactiveCN103897287AImprove shock absorptionImprove heat and aging resistanceSound energyRelaxation effect

The invention relates to a multimode organic filter / polymer composite damping material and a manufacturing method thereof, relates to the field of soundproof materials, aims to solve the problems that in the prior art high efficient soundproof materials do not have a prominent effect, and generate harmful gas, which harms the human health; and provides a multimode inorganic filler / polymer composite damping material. The damping material comprises the following materials: thermoplastic resin and an inorganic filler, which has been subjected to a surface treatment with a coupling agent processing fluid; wherein the inorganic filter accounts for 15 to 80 wt% of the total weight of the damping material, and the balance being thermoplastic resin. In the damping material, the binding between each particle is abnormal, thus the internal friction between incident sound waves in this structure is effectively increased, thus a relaxation effect is generated, and the sound is absorbed. Fillers with different particle sizes are corresponding to sound waves in different bandwidths or frequencies, so sounds in different frequencies can all be absorbed by the damping material, and moreover the damping material has a good soundproof effect, and is suitable for promotion and application.

Owner:浙江艾迪雅科技有限责任公司

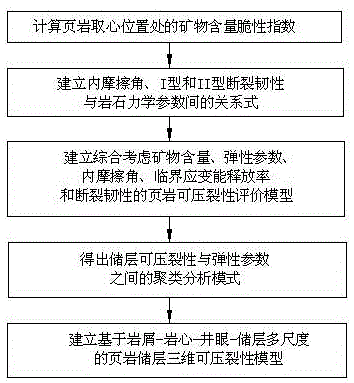

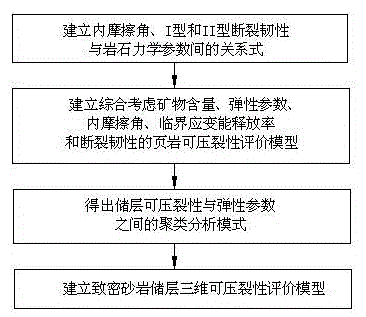

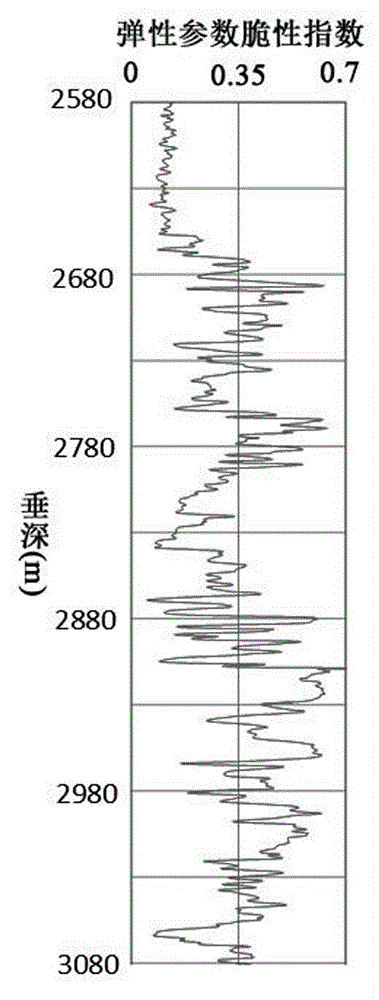

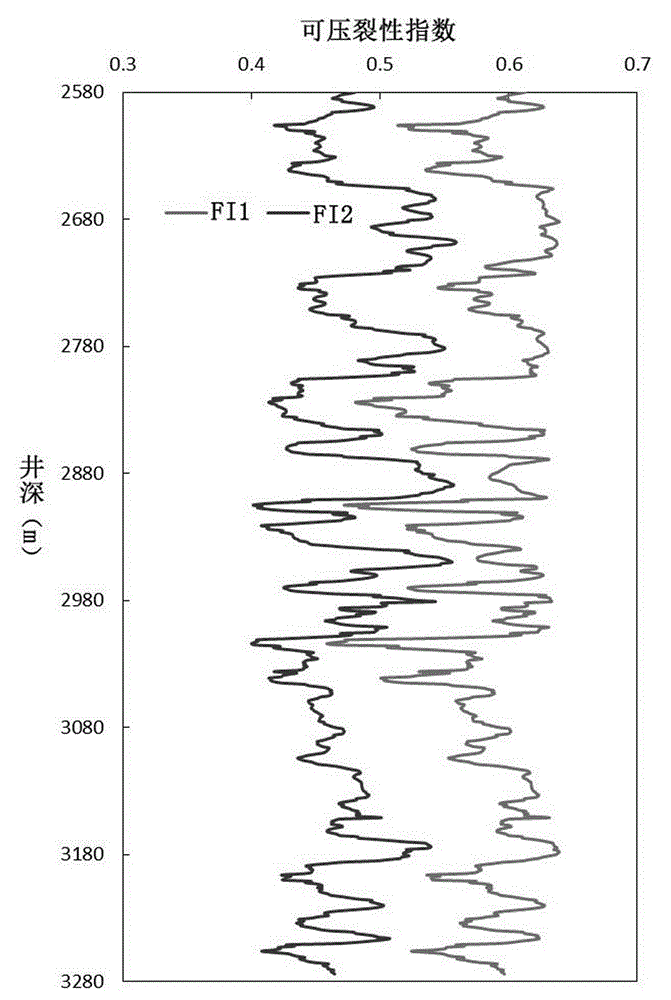

Debris-core-borehole-reservoir multiscale shale reservoir three-dimensional fracturing evaluation method

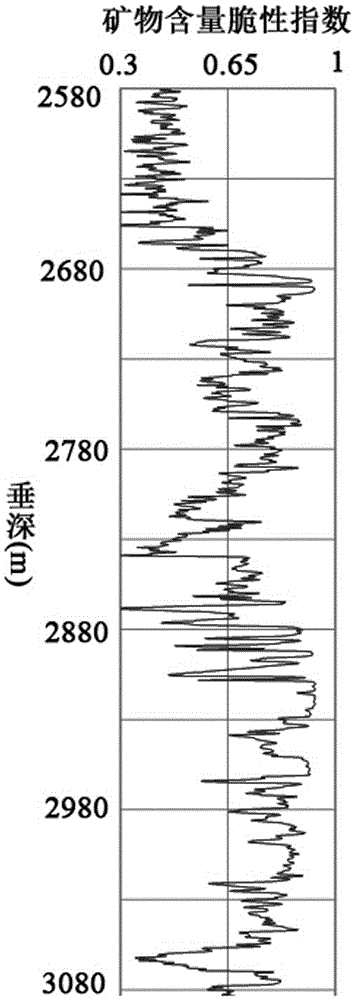

ActiveCN105156103ALarge capacityQuantification of fracabilityBorehole/well accessoriesType fractureWell placement

The invention relates to a debris-core-borehole-reservoir multiscale shale reservoir three-dimensional fracturing evaluation method. The method comprises the steps of: (S1) calculating mineral content brittleness indexes in a shale coring position; (S2) building relations among an internal friction angle, I type and II type fracture toughness and rock mechanical parameters; (S3) building shale fracturing evaluation models comprehensively considering a mineral content, elastic parameters, the internal friction angle, a critical strain energy release rate and the rapture toughness; (S4) applying a support vector machine algorithm to obtain a cluster analysis mode between a reservoir fracturing performance and the elastic parameters; and (S5) applying the cluster analysis mode and a reservoir three-dimensional elastic parameter data body to obtain a debris-core-borehole-reservoir multiscale shale reservoir three-dimensional fracturing model. The method can be applied to obtain the fracturing performance of any space position in a shale reservoir, so that the well position selection blindness is prevented, and the fracturing modification effect and the after-pressing yield are improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

Low loss ultrasound transducers

InactiveUS20070080609A1Minimize attenuationPiezoelectric/electrostriction/magnetostriction machinesMechanical vibrations separationUltrasonic sensorAlloy

An ultrasound transducer is constructed to be under damped at higher overtone frequencies by reducing losses through one or more of the following: even pressure shaped surfaces on masses, reversed drive to at least one piezoelectric ceramic, an ultrasonically formed metallic bond between the transducer's front mass and the radiating surface, high current carrying strain relieved electrodes, fine grain structure masses, low internal friction masses and radiating materials, and zero bias stress change due to temperature variations. Improved methods and construction details for bonding the higher overtone frequency transducer to quartz are disclosed and include: front masses with cross-hatched or concentric circle patterns and invar front masses or an invar transition mass that is bonded to the quartz.

Owner:CLEANING TECH GROUP

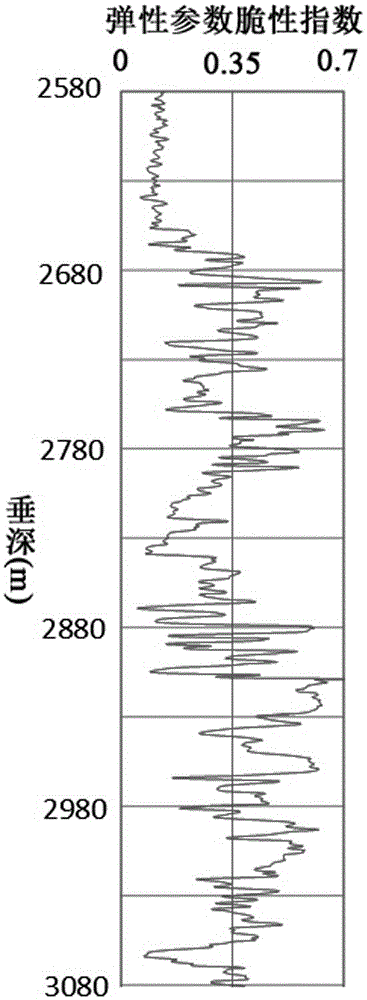

Modeling method for compact sandstone reservoir three-dimensional fracability model

ActiveCN105134156AImproving the effectiveness of volumetric fracturingShorter payback timeFluid removalSpecial data processing applicationsModel methodWell placement

The invention relates to a modeling method for a compact sandstone reservoir three-dimensional fracability model. The method comprises the following steps: S1, establishing a relation formula among an internal friction angle, I type and II type crack fracture toughness and the parameter of sandstone mechanical characteristics; S2, establishing a shale fracability evaluation model which comprehensively considers an elastic parameter, the internal friction angle, the critical strain energy release rate and fracture toughness; S3, adopting a support vector machine algorithm to obtain a cluster analysis mode between the reservoir fracability and the elastic parameter; S4, adopting the cluster analysis mode to obtain a reservoir three-dimensional elastic parameter data body, and establishing the multi-scale compact sandstone reservoir three-dimensional fracability evaluation model based on the core, the borehole and the reservoir of multiple scales. According to the method, the fracability of an arbitrary space position in the compact sandstone reservoir can be obtained, a sweet spot with high fracability can always be drilled when drilling a compact sandstone gas well, blindness of well location selection is avoided, and the fracture modification effect and the yield after fracture are improved.

Owner:SOUTHWEST PETROLEUM UNIV

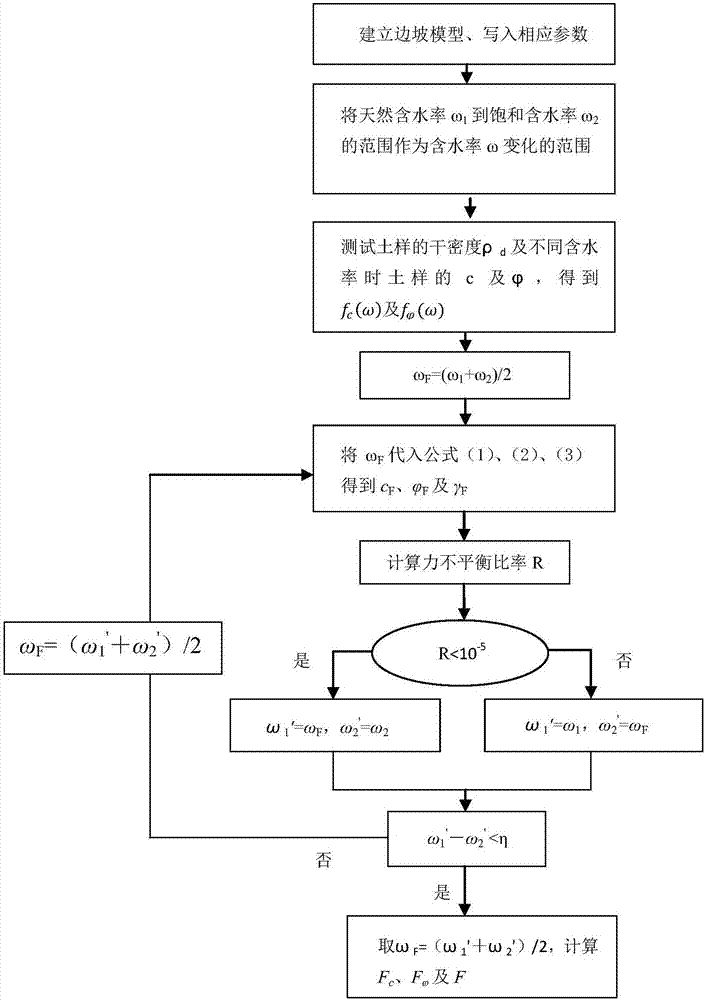

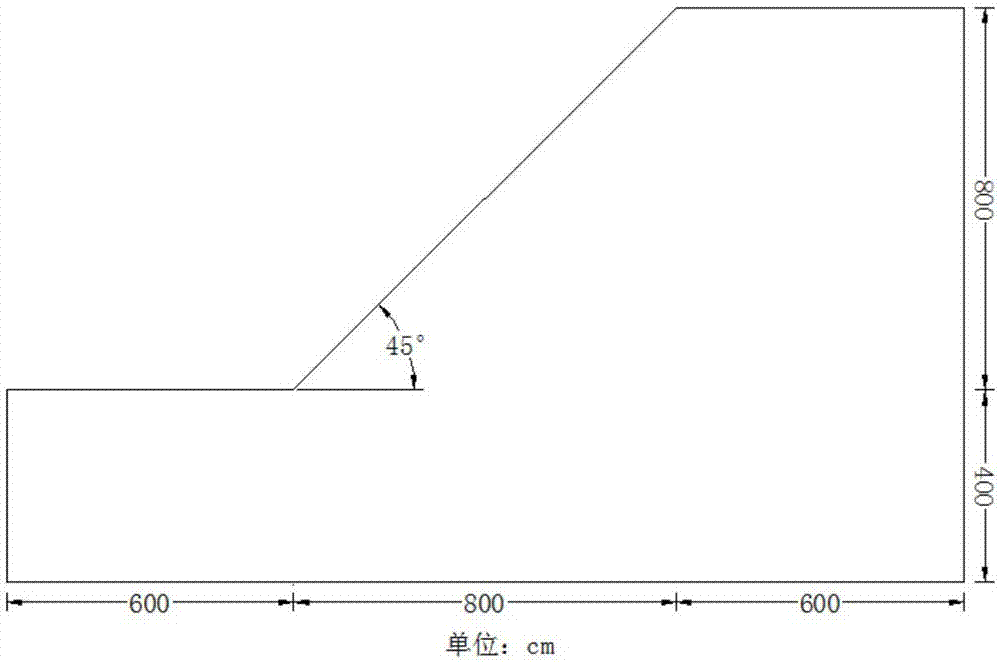

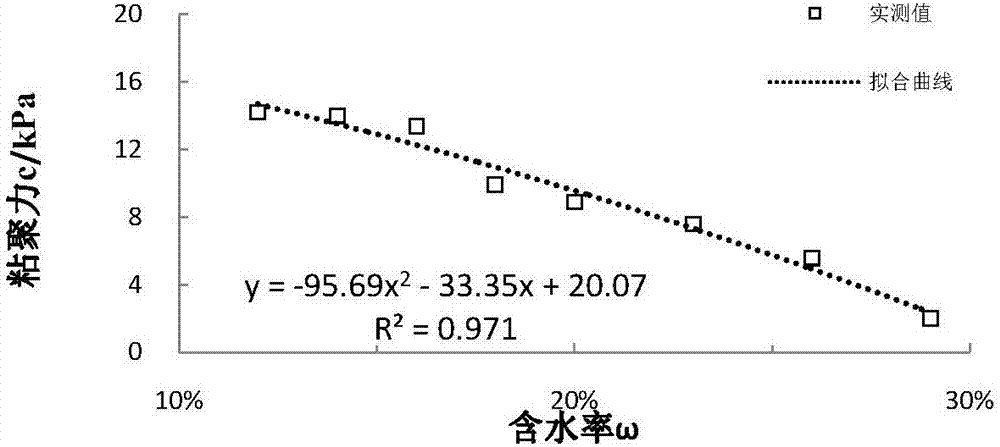

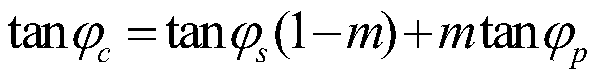

Method for calculating slope stability safety coefficient based on strength reduction of humidifying condition

InactiveCN107330182AOvercome the shortcomings of the unclear mechanical concept of the strength reduction methodLow shear strengthDesign optimisation/simulationSpecial data processing applicationsWeight changeUltimate tensile strength

The invention discloses a method for calculating the slope stability safety coefficient based on strength reduction of a humidifying condition. The method comprises the steps of testing the dry density rhod, the natural moisture content omega1, and the percentage of saturated moisture content omega2 of a slope soil body sample, testing the cohesive force c and internal friction angles of samples with different moisture contents, and calculating the volume weight gamma of the samples, wherein the formula of internal friction angles is shown in the description; drawing the relation curves of the cohesive force c and the internal friction angles respectively with the moisture content omega, and obtaining a mathematic formula of a fitting relation curve; adopting a dichotomy approximation method and considering the volume weight change, and calculating the moisture content omegaF when the slope is in critical failure; calculating the slope stability safety coefficient F. According to the method for calculating the slope stability safety coefficient based on the strength reduction of the humidifying condition, anti-shearing strength of the slope soil body is reduced based on the humidifying condition, the method better conforms to the engineering practice that the moisture content of the soil body is increased, and thus the strength is lowered due to rainfall infiltration or irrigation or the like, and the shortcoming that a prior strength reduction method is not clear in mechanical concept is overcome. When strength reduction is conducted, the adverse influence of the increase of the volume weight of the soil body on the slope stability is further considered. Therefore, the method for calculating the slope stability safety coefficient based on the strength reduction of the humidifying condition is more scientific and safer.

Owner:NORTHWEST A & F UNIV

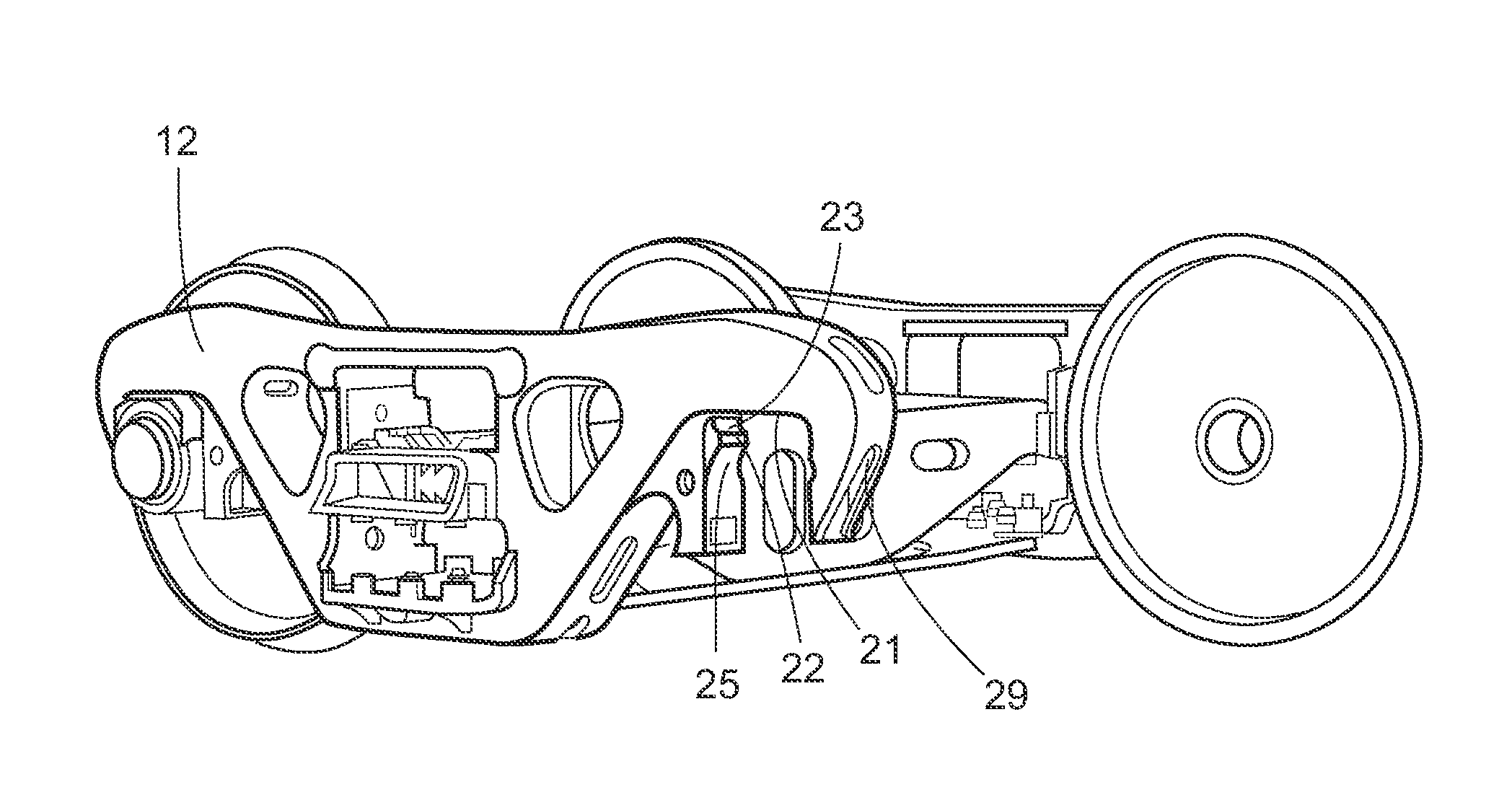

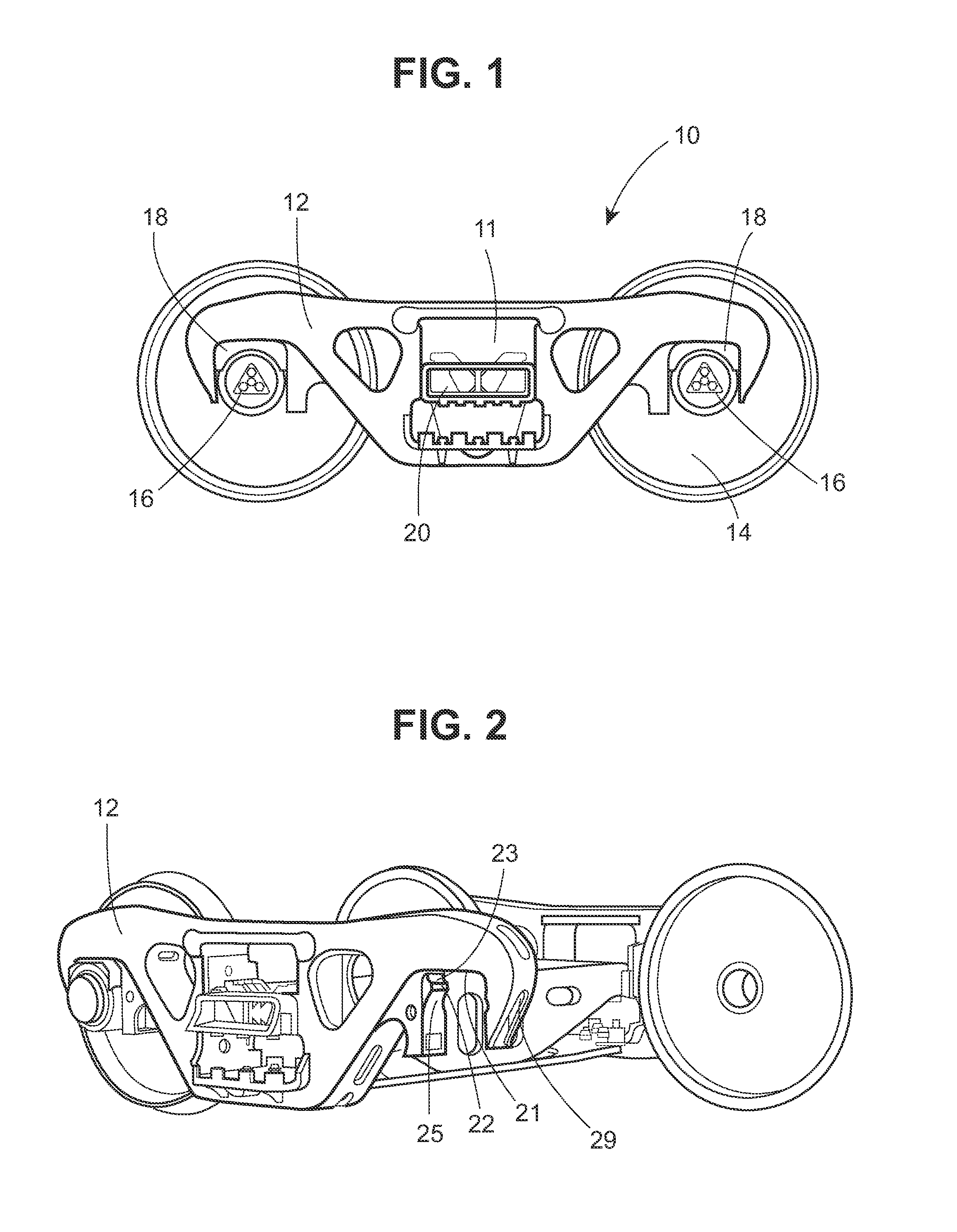

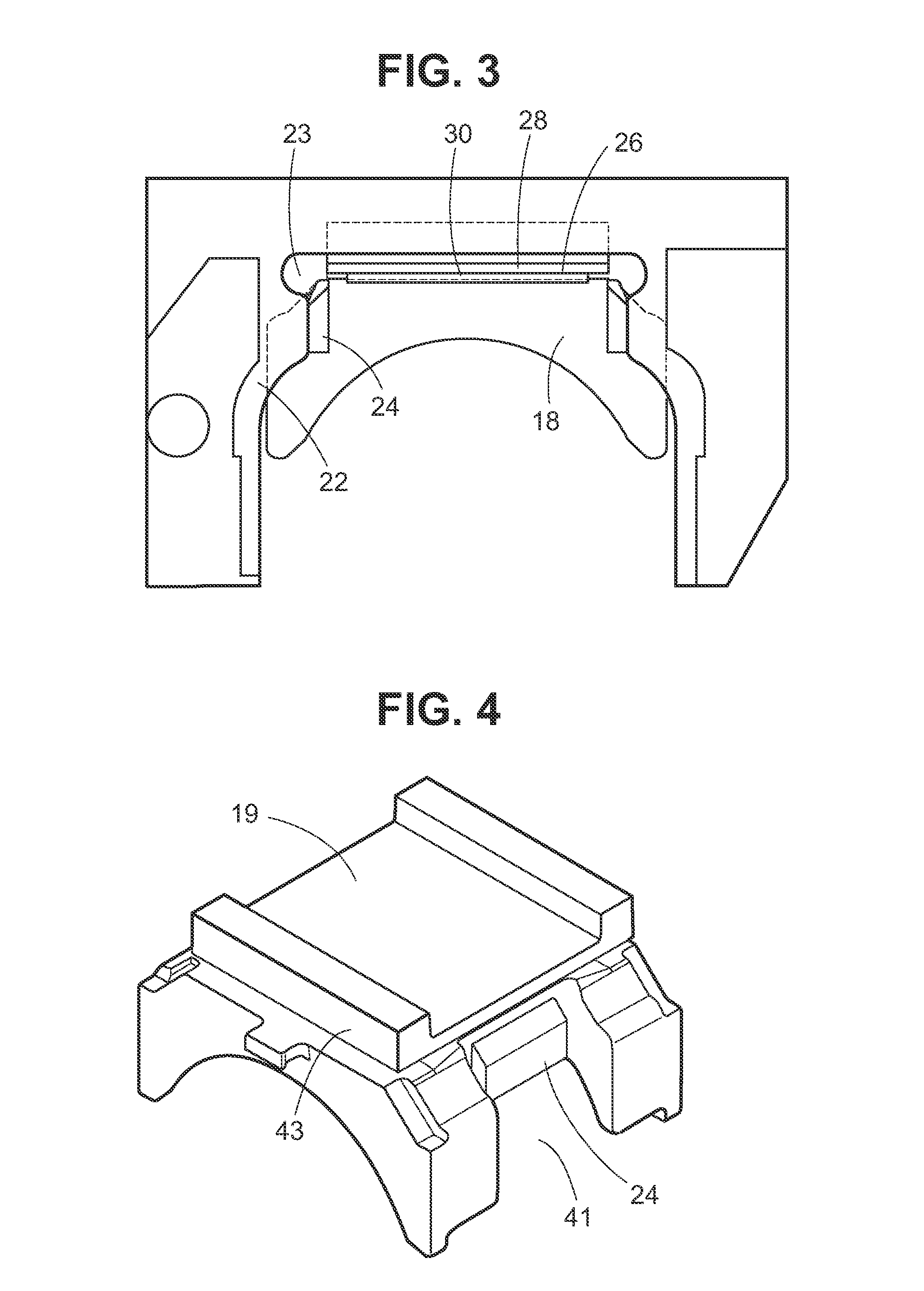

Wheelset to side frame interconnection for a railway car truck

InactiveUS20140060380A1Increase the spring rateReduce the spring rateAxle-boxesBogiesHysteresisEngineering

The invention relates to a railway car truck incorporating a novel interconnection between the side frame and bearing adapter characterized by a low lateral spring constant relative to the longitudinal spring constant. The interconnection provides a proportional restoring force with minimal internal friction and hysteresis. In embodiments, the interconnection comprises compressed elastomeric members positioned between the thrust lug of the side frame and the bearing adapter in the longitudinal direction and a low friction interface between the roof of the pedestal jaw and the top of the bearing adapter.

Owner:STRATO AG

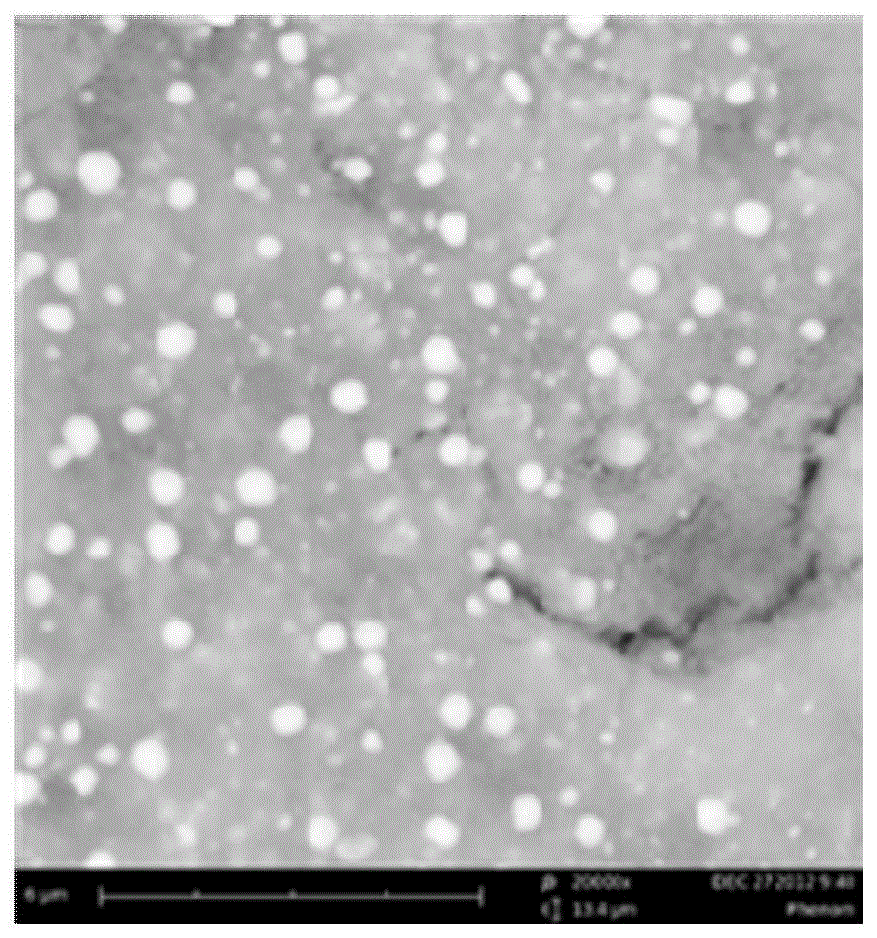

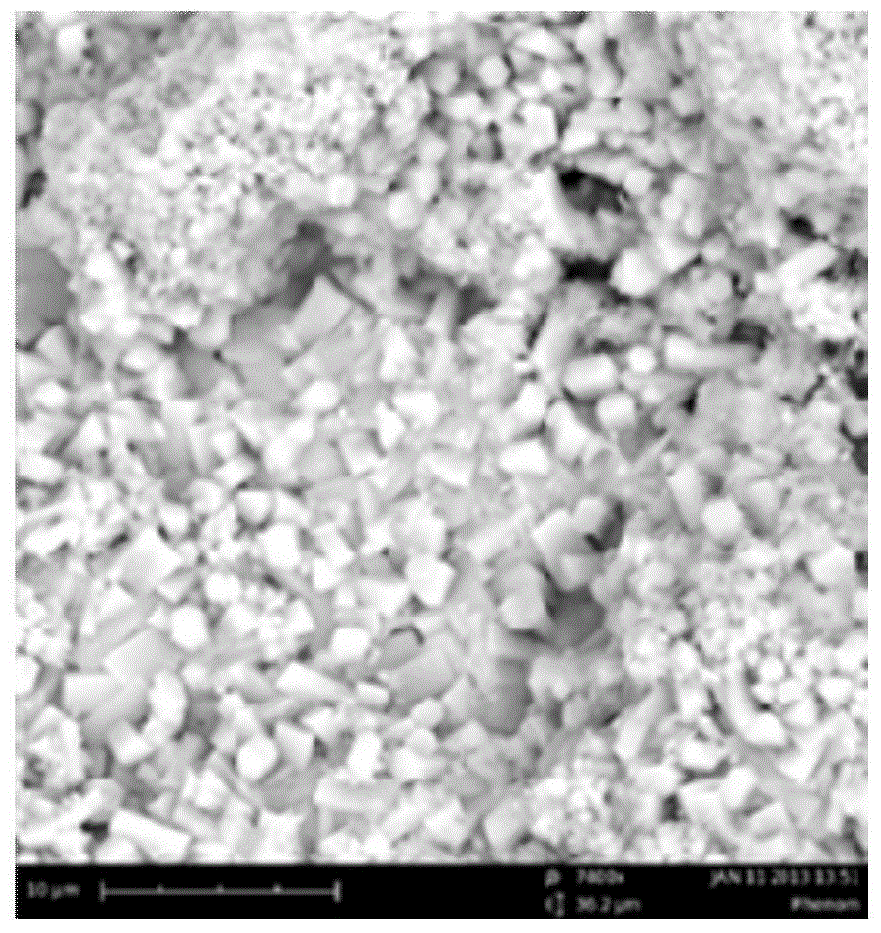

Iron-based soft magnetic composite and preparation method thereof

ActiveCN104425093AHigh compressibilityIncrease green densityInorganic material magnetismCompressibilityMelting point

The invention discloses an iron-based soft magnetic composite. The iron-based soft magnetic composite comprises atomized iron-based powder, ultra-fine high melting point inorganics and lubricant, wherein phosphate and an organic silicone resin insulating layer cover the surface of the atomized iron-based powder. A preparation method of the iron-based soft magnetic composite comprises the following steps that the atomized iron-based powder and the ultra-fine high melting point inorganics are fully mixed to obtain a mixture, high-temperature heating treatment is conducted on the mixture in a non-oxidizing atmosphere, heat preservation is conducted on the mixture for above 30min, the mixture is cooled to enable the temperature of the mixture to be the room temperature, surface phosphating treatment and organic silicon resin covering are conducted on obtained iron powder isolated through the inorganics, and then pressing annealing is carried out. Due to the fact that the iron powder is isolated through the ultra-fine high melting point inorganics, annealing can be conducted on the iron powder at a high temperature of about 1000 DEG C, sintering cannot happen, and the iron powder has high compressibility; an insulating layer covers the surface of the iron powder after phosphating treatment is conducted on the iron powder, phosphide has a lubricating effect on the iron powder, internal friction is reduced in the pressing process, and the compaction density of the powder is improved; due to the fact that organic silicon resin is added, distribution of the insulating layer on the surface of the iron powder is improved, and the soft magnetic property is optimized after forming sintering is conducted on the powder.

Owner:NBTM NEW MATERIALS GRP

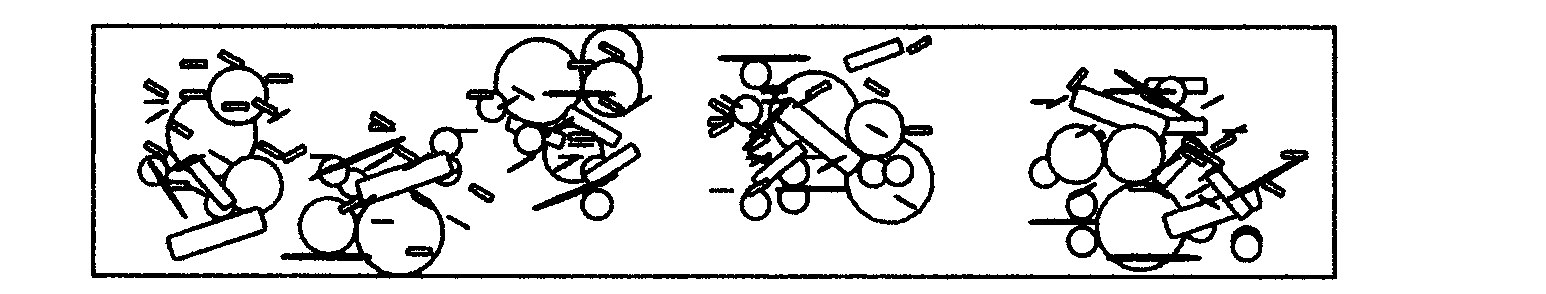

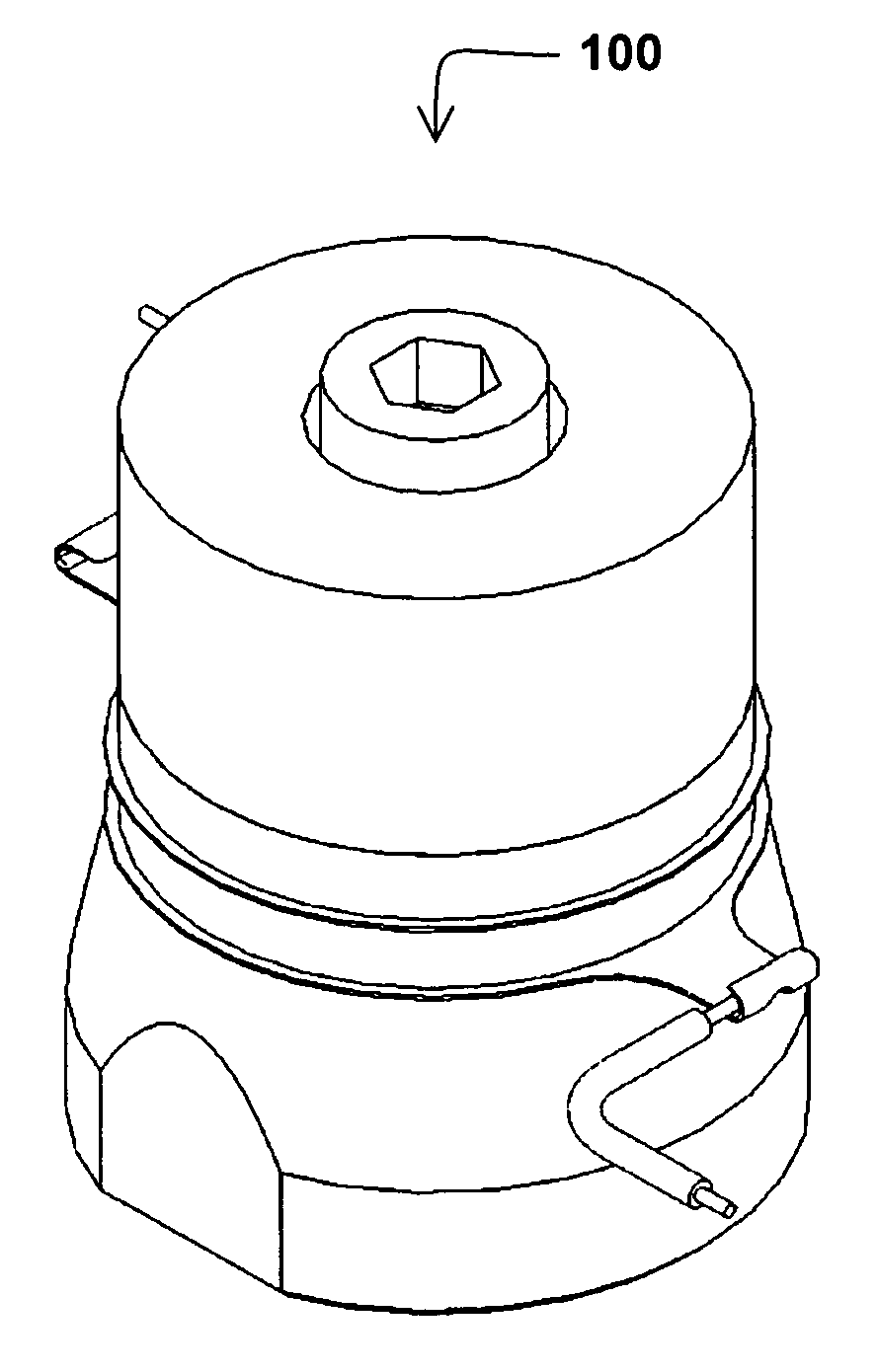

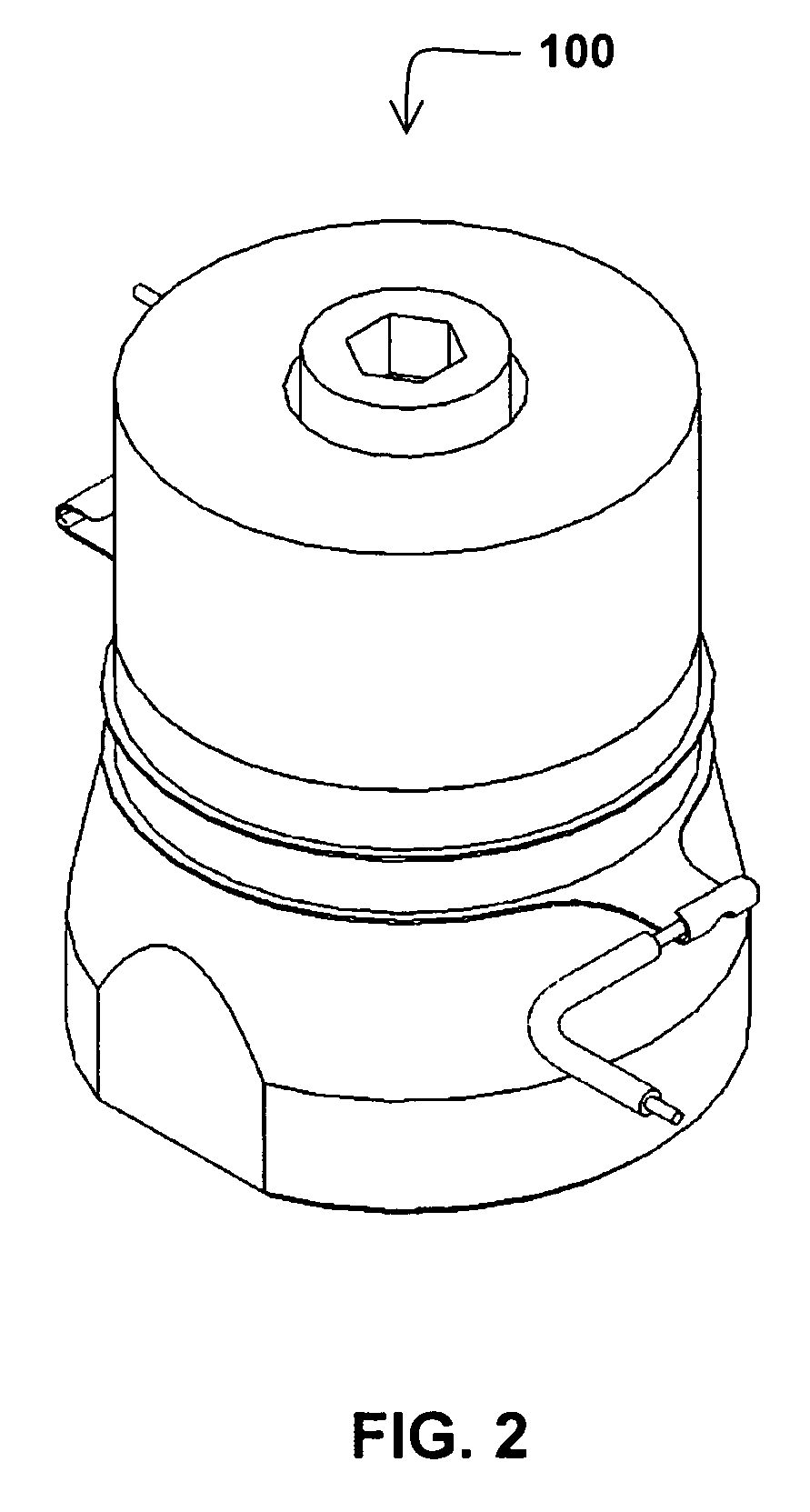

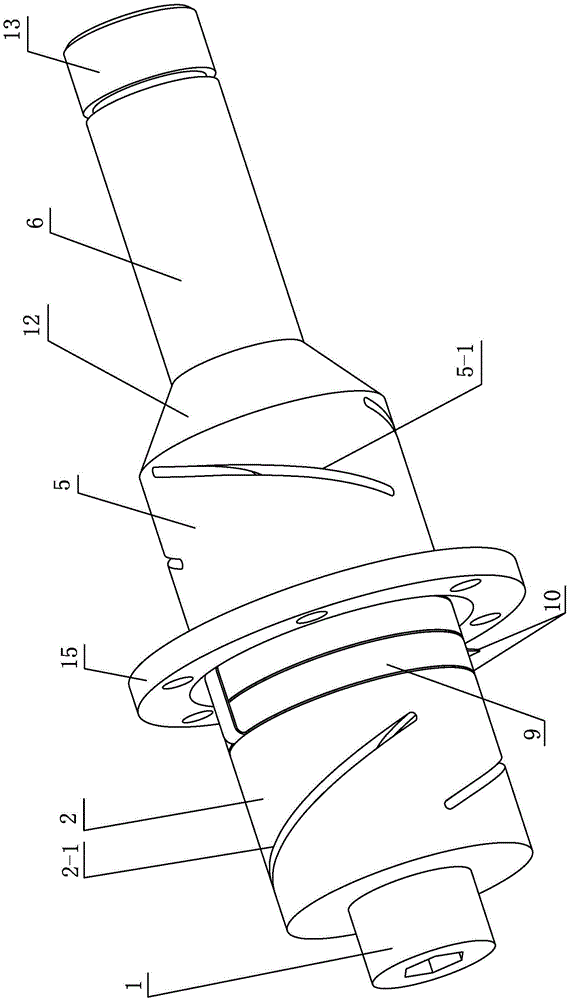

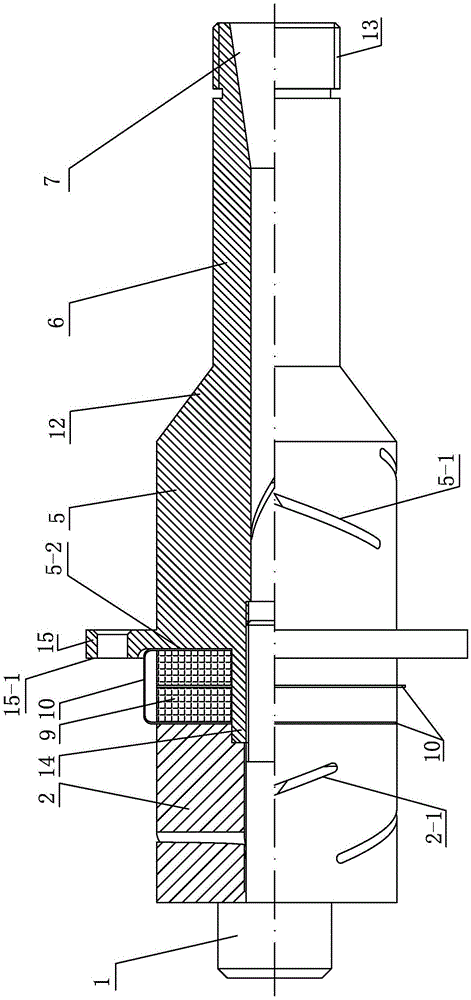

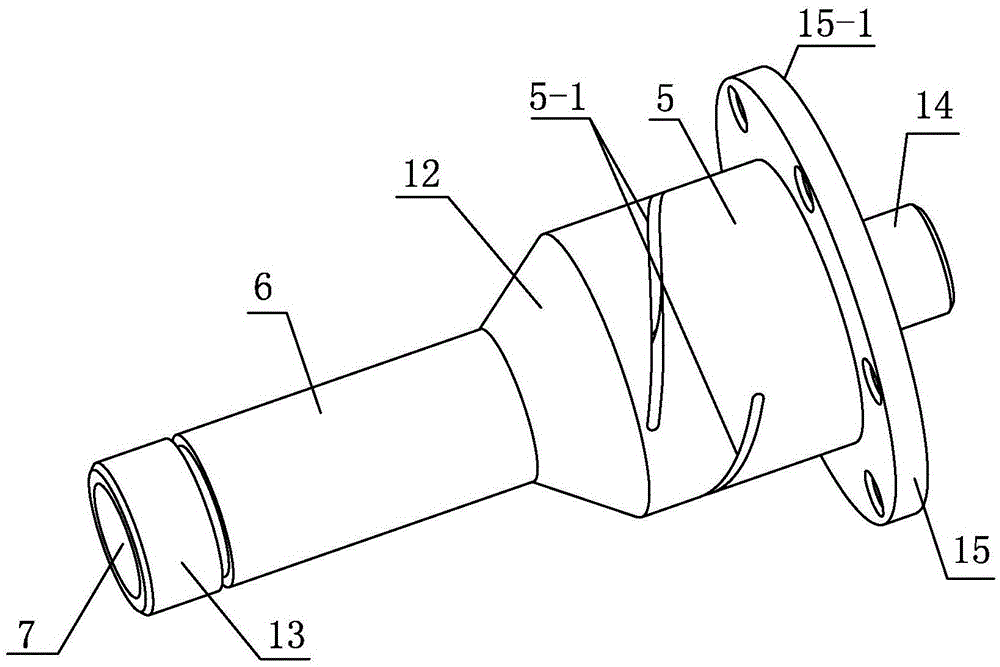

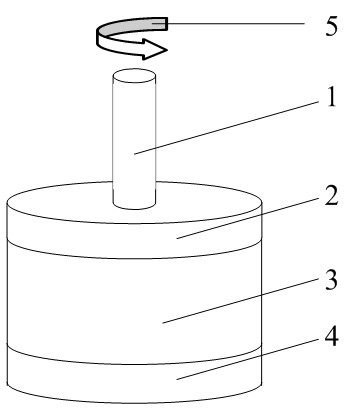

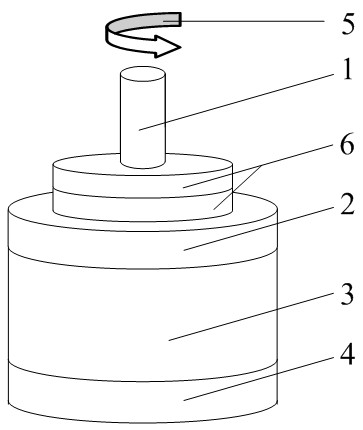

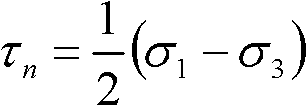

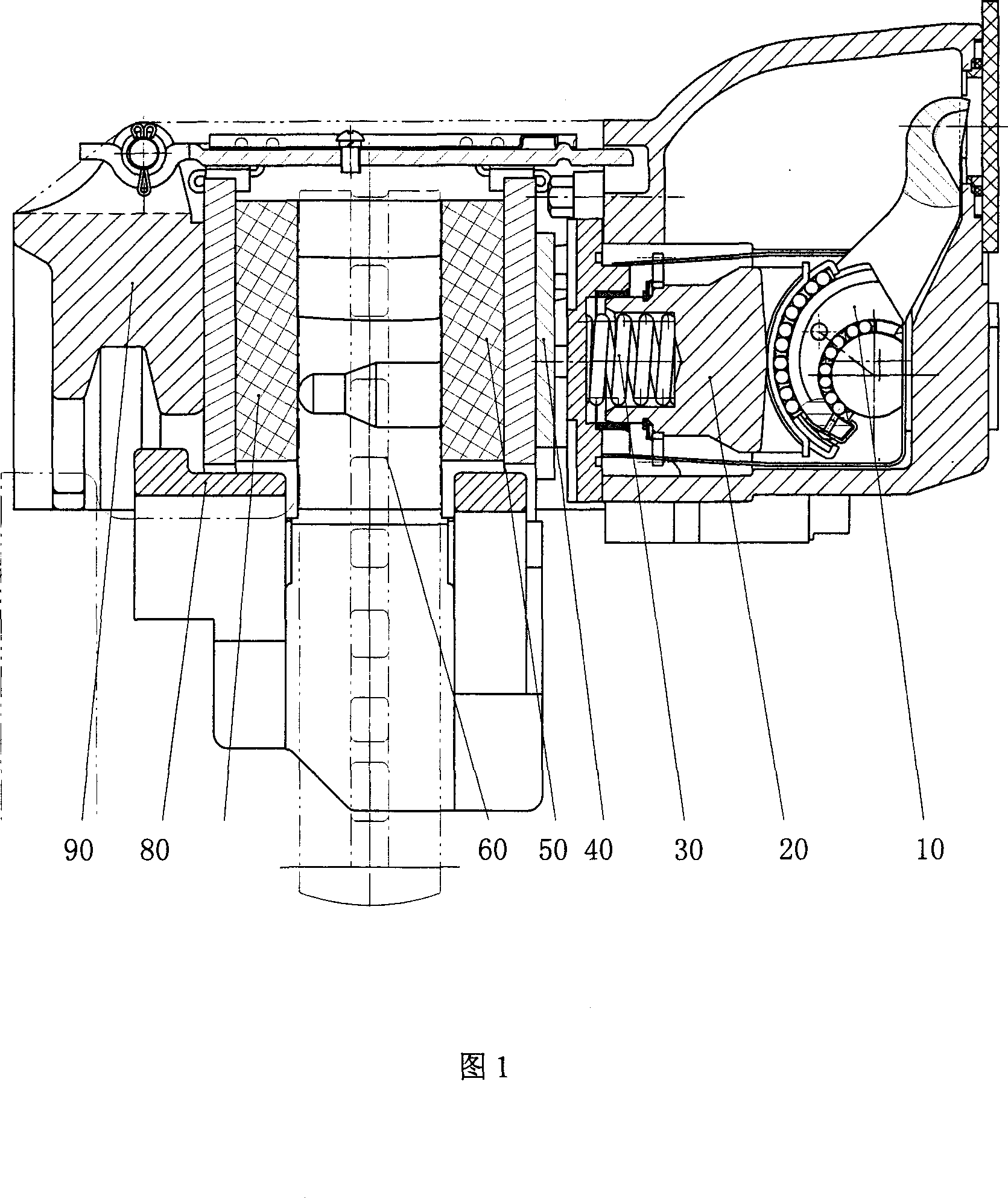

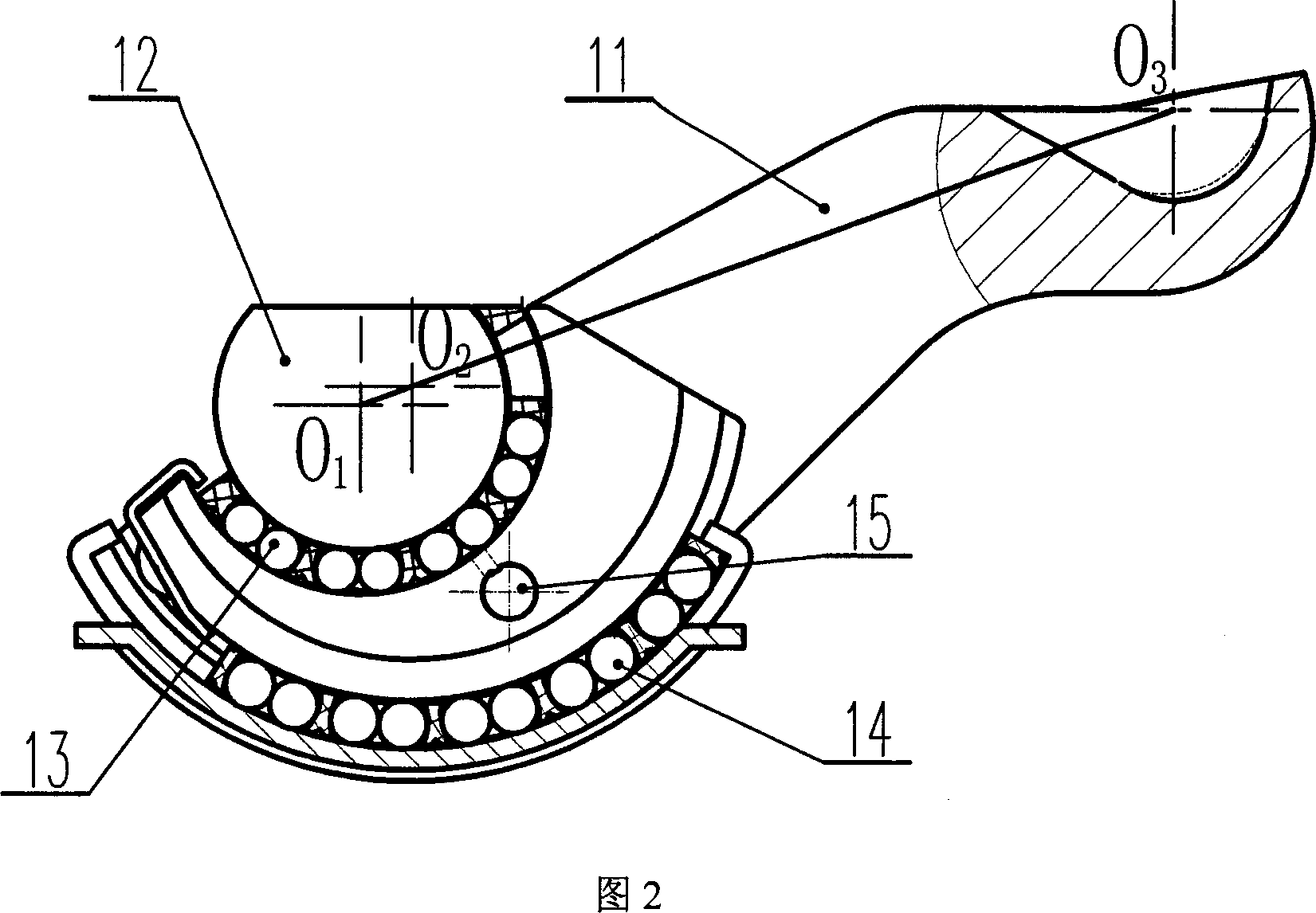

Longitudinal-torsional resonance ultrasonic vibration device

InactiveCN105478332ASimple form of vibrationComposite vibration in vibration form, simple power supply formMechanical vibrations separationElectricityEngineering

The invention discloses a longitudinal-torsional resonance ultrasonic vibration device, and relates to the field of ultrasonic processing and precise cutting. The problems that when an existing torsional vibration device applied to milling machining carries out torsional vibration, internal friction of a material loses most energy, and consequently, the torsional amplitude is small, and the energy utilization efficiency is low are solved. The device comprises a ladder type hollow cylinder cone composite body, a longitudinal-torsional conversion hollow cylinder, a pre-tightening bolt, the even number of piezoelectric ceramic pieces and a plurality of electrode pieces; the ladder type hollow cylinder cone composite body is mainly composed of an axial locating shaft, a cylindrical longitudinal-torsional conversion body, a conical torsional vibration amplifying body and a cylindrical longitudinal vibration amplifying body which are coaxially and sequentially arranged and are manufactured into a whole; and the ladder type hollow cone composite body, the longitudinal-torsional conversion hollow cylinder body, the even number of piezoelectric ceramic pieces and the electrode pieces are connected together through the pretightening bolt. The longitudinal-torsional resonance ultrasonic vibration device is used for ultrasonic vibration machining.

Owner:HARBIN INST OF TECH

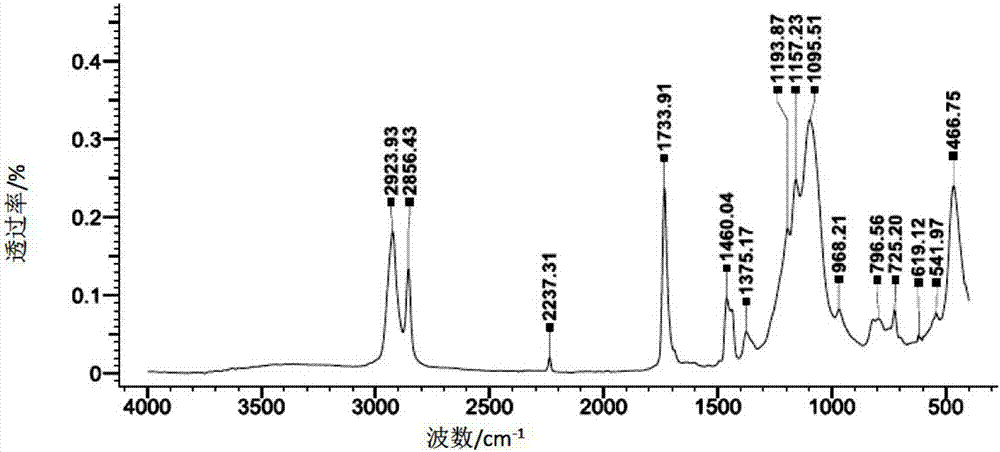

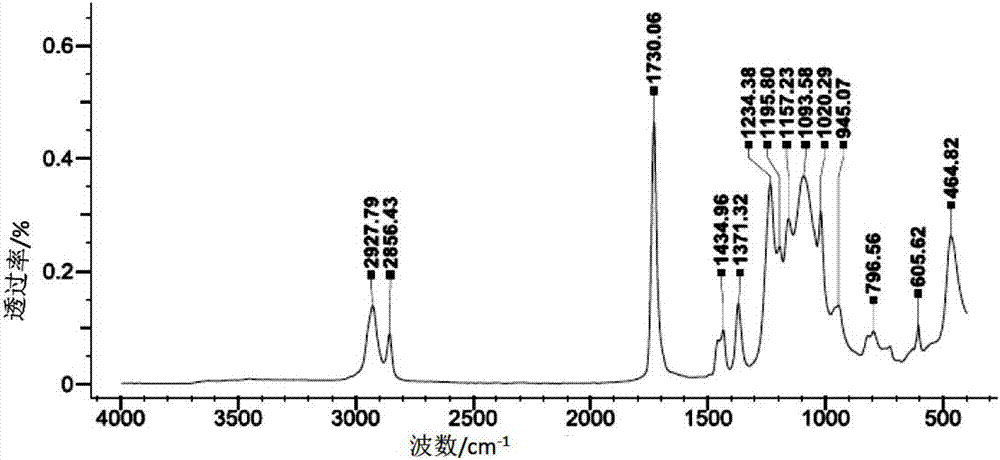

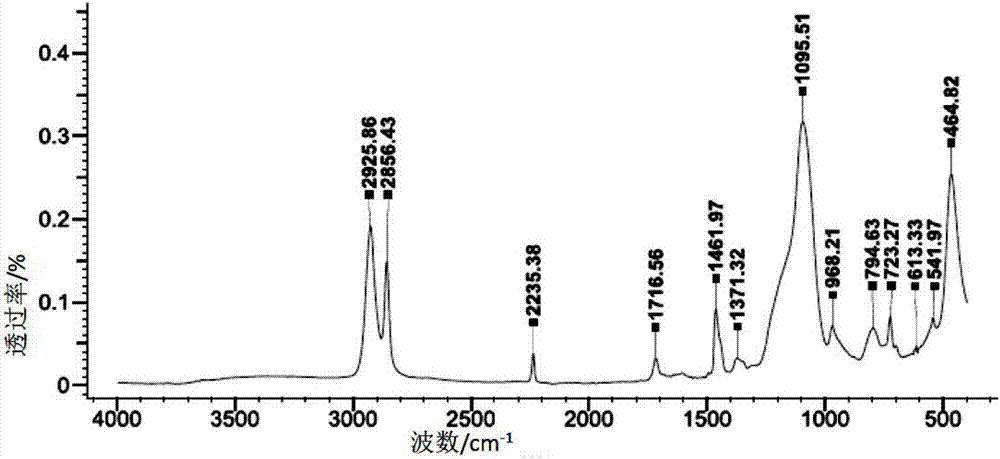

Vibrating diaphragm for electro-acoustic system and preparation method of vibrating diaphragm

The invention belongs to the technical field of acoustic materials and discloses a vibrating diaphragm for an electro-acoustic system. The vibrating diaphragm is prepared from a rubber mixed compound, wherein the rubber mixed compound is prepared by mixing raw rubber, a filling and an additive; the vibrating diaphragm is prepared from the rubber mixed compound through vulcanization; the rubber mixed compound is prepared by mixing raw rubber, the filling and the additive; the raw rubber contains nitrile groups and / or ester groups; the filling contains Si-O-Si groups; the additive contains a vulcanizing agent. The invention simultaneously provides a preparation method of the vibrating diaphragm. According to the preparation method, a rubber material is utilized for replacing a multi-layer resin composite film raw material to prepare the vibrating diaphragm, and distortion can be reduced by virtue of internal friction of the rubber, so that the nature of sound can be well restored by the prepared vibrating diaphragm; and besides, the material cost is low, the processing process is simple, the forming consistency is good, and the production efficiency can be substantially improved.

Owner:AAC TECH PTE LTD

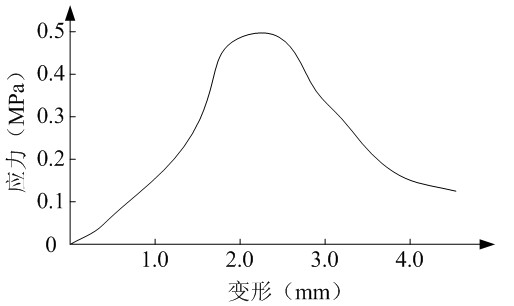

Fast test method of shearing resistance of bituminous mixture

InactiveCN102109442AEasy to testShear Properties StudyMaterial strength using steady shearing forcesStructural engineeringFriction angle

The invention discloses a fast test method of the shearing resistance of an bituminous mixture, and provides a new method for testing the shearing performance of a bituminous mixture which bears torsional shearing in the horizontal direction and constant pressure stress in the vertical direction on the basis of borrowing the conventional shearing performance test theory and according to the practical significance of coulomb law and shearing strength. The method provided by the invention not only is applicable to the bituminous mixture newly stirred in a laboratory, but also can be used for estimating the shearing resistance of the bituminous mixture in an actual road surface; and by utilizing the fast test method, not only can the shearing resistance of the bituminous mixture be tested, but also the cohesion and an internal friction angle which play a role in determining the shearing strength of the bituminous mixture can be obtained, so that the content of the shearing damage of the bituminous mixture can be deeply understood and accurately mastered conveniently, and a test analyzing means is provided for the optimum design of the bituminous mixture based on the shearing resistance.

Owner:NANTONG ZHONGRUN CONCRETE +1

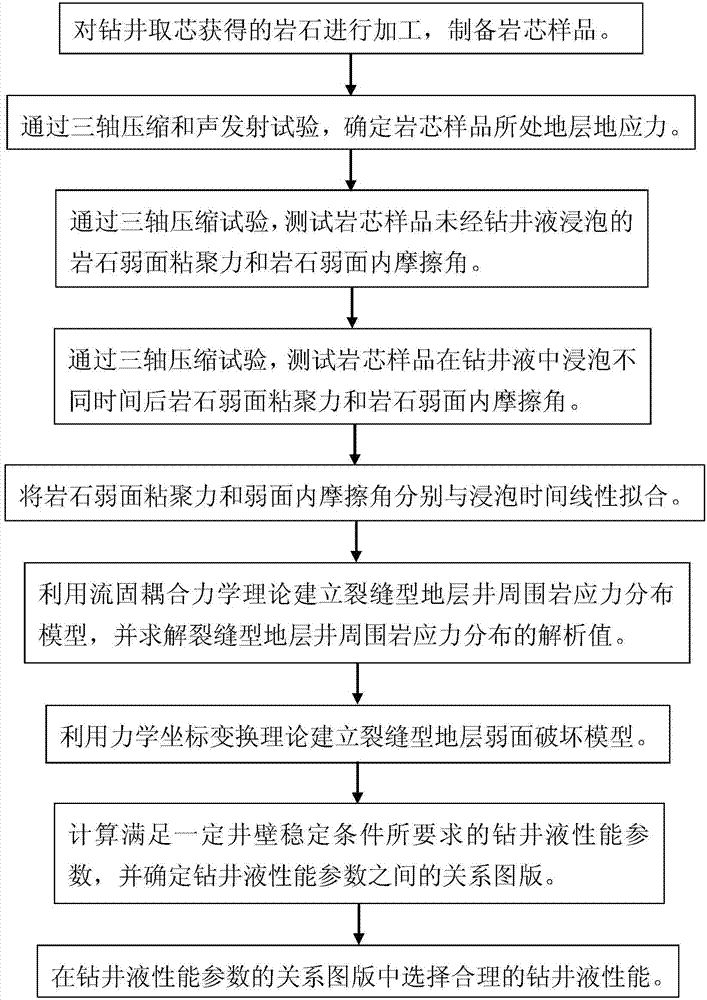

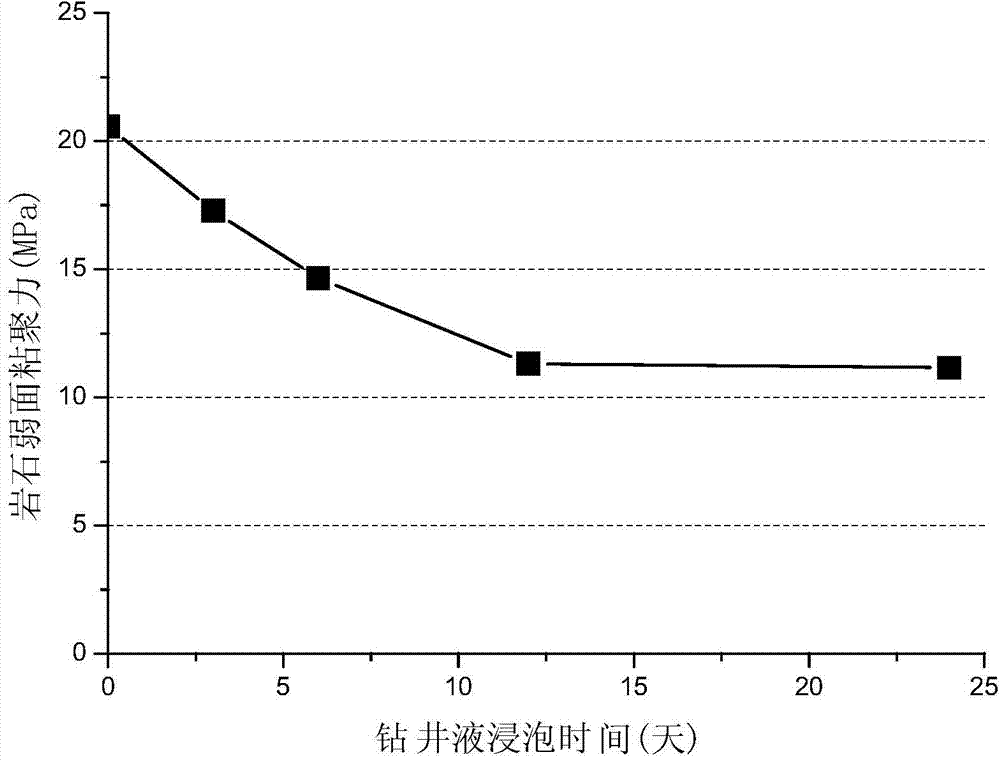

Design method for property parameters of anti-collapse drilling fluid for fractured formations

ActiveCN104778303AAchieving Stability RequirementsApp performance is stableSpecial data processing applicationsStress distributionAcoustic emission

The invention discloses a design method for property parameters of anti-collapse drilling fluid for fractured formations. According to sequence, the design method includes the following steps: core samples are prepared; four of the core samples are chosen for a triaxial compression test and an acoustic emission test, and the crustal stress of a formation owning the core samples is determined; two of the core samples are chosen for the triaxial compression test, and the cohesion and internal friction angle of the weak planes of the rocks are tested; eight of the core samples are chosen to be put into the drilling fluid, the triaxial compression test is carried out after the core samples are soaked for different times, and the cohesion and internal friction angle of the weak planes of the rocks are tested; the cohesion and internal friction angle of the weak planes of the rocks are respectively linearly fitted to soaking times; the fluid-solid coupling theory is utilized to create a fractured formation well surrounding rock stress distribution model; the elastic mechanics coordinate transformation theory is utilized to create a fractured formation weak plane destruction model; a relation chart between the property parameters of the drilling fluid is determined. The design method disclosed by the invention can quantitatively optimize the key property parameters of the drilling fluid according the requirement of a site for well wall stability.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for website operator to directly achieve intra-city same-day delivery

InactiveCN105160503AReduce internal frictionReduce the chance of wrong ordersLogisticsWorld Wide WebAutomatic processing

The invention discloses a method for a website operator to directly achieve an intra-city same-day delivery. The method comprises the following steps that an intra-city same-day delivery function is started for merchants; (2) an intra-city same-day delivery means is selected when a user orders; (3) a delivery management terminal set by the website operator divides a delivery range according to a delivery address and performs automatic scheduling management; (4) identifying code verification is performed when a delivery man delivers goods to the home of the user. By means of a transparent ordering procedure, the website operator performs automatic processing on its own. The mistaken order probability is lowered. The internal friction during a website delivering link can be alleviated. Meanwhile, different delivery operation schemes can be realized through cooperation with the merchants. The website operator achieves intra-city same-day delivery demands through operations of its own.

Owner:SHAOXING YUETAO NETWORK TECH

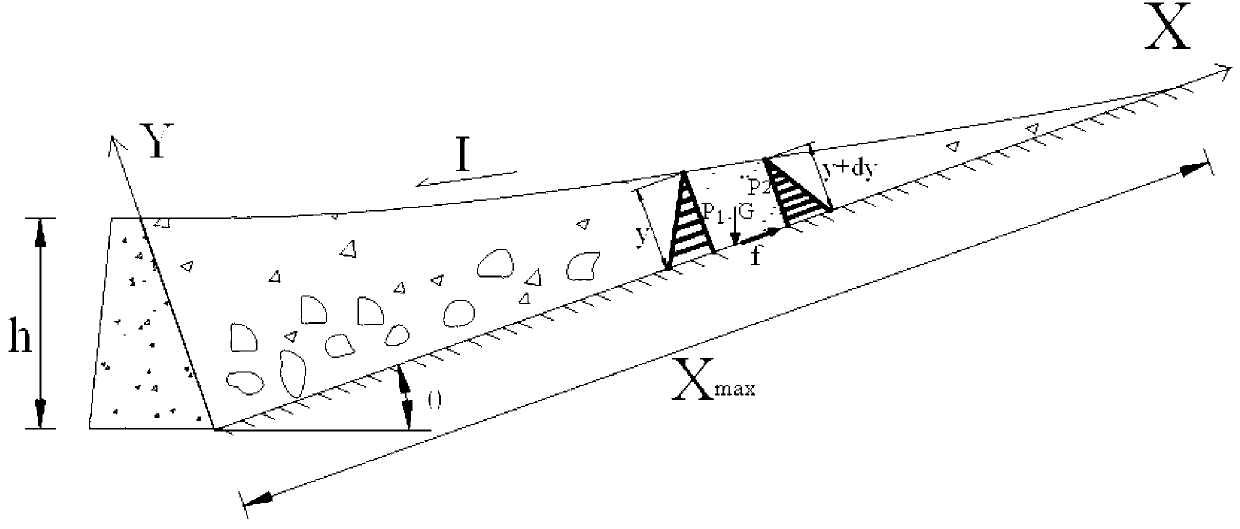

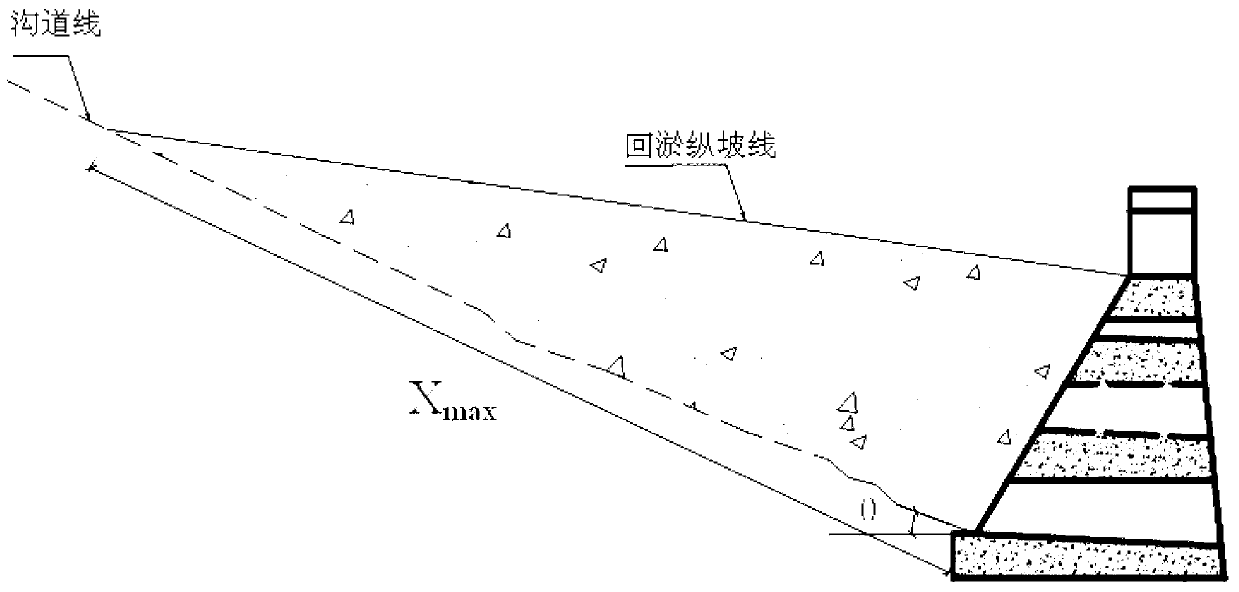

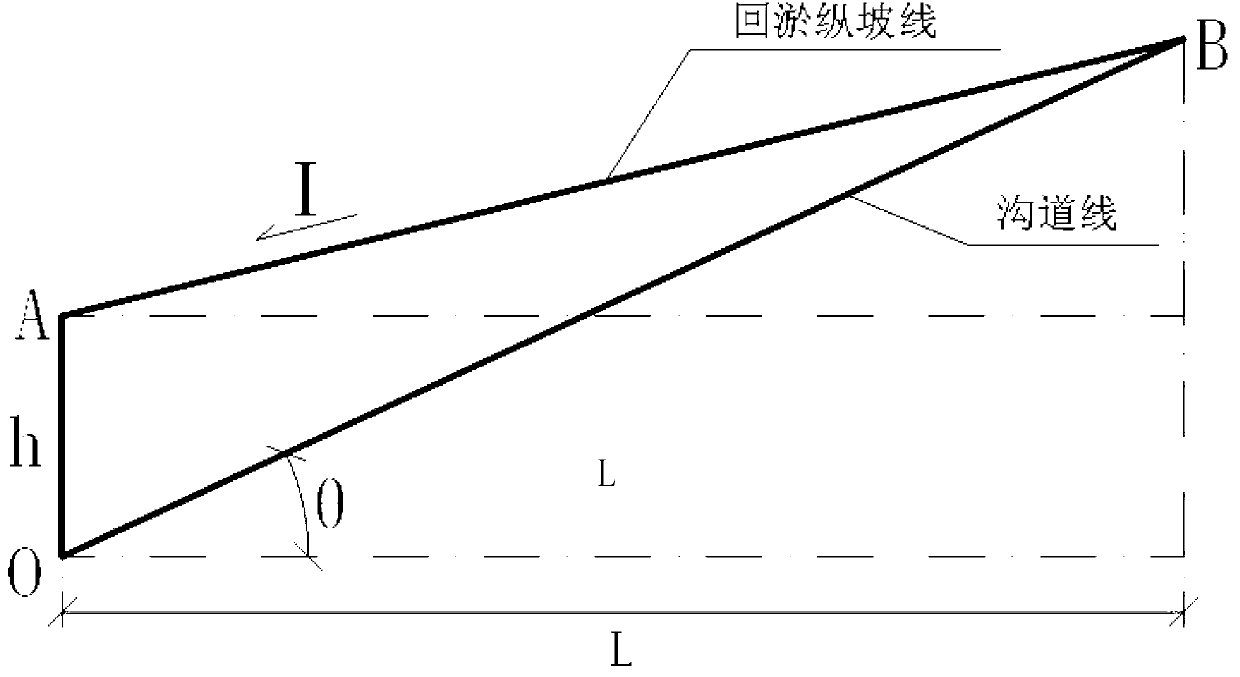

Calculating method and calculating application of forms of debris flow siltation behind silt arresters

InactiveCN103276687AReasonable determination of back silt thicknessReasonably determine the maximum back-silting lengthHydraulic engineering apparatusEffective lengthTopographic map

The invention discloses a calculating method and calculating application of forms of debris flow siltation behind silt arresters. The method includes: using methods such as site measuring, indoor geotechnical tests, and large-scale topographic map calculating to determine internal friction angles of debris flows and gully slopes of debris flow gullies; putting obtained parameters into a formula of the forms of the debris flow siltation behind the silt arresters, namely reasonably determining debris flow siltation thickness at different positions in a reservoir; and further determining maximum siltation length and siltation longitudinal slopes of the debris flows behind the silt arresters, and effective length of each silt arrester in the presence of limited silt burying points. Compared with the prior art, gully conditions and self-properties of the debris flows are considered comprehensively, an equation of forms of the debris flow siltation behind the silt arresters is obtained through theoretical derivation, engineering parameters such as the maximum siltation length, the siltation slopes and the permitted maximum arrester height can be determined reasonably, and scientific evidence can be provided for debris flow prevention engineering.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

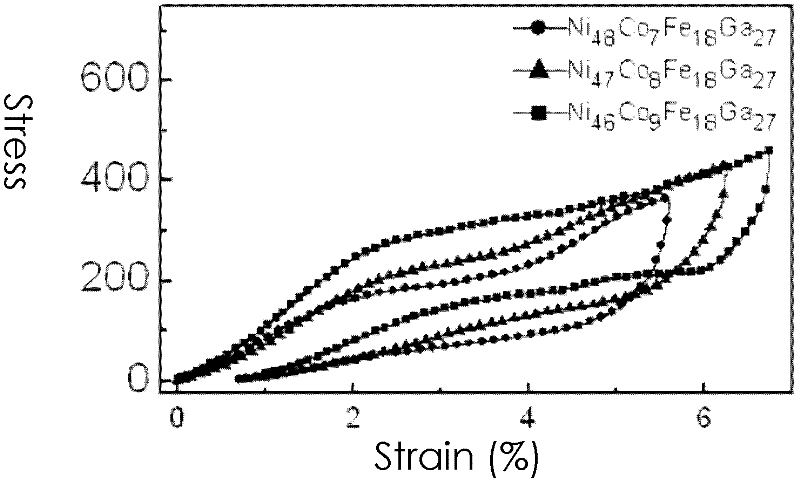

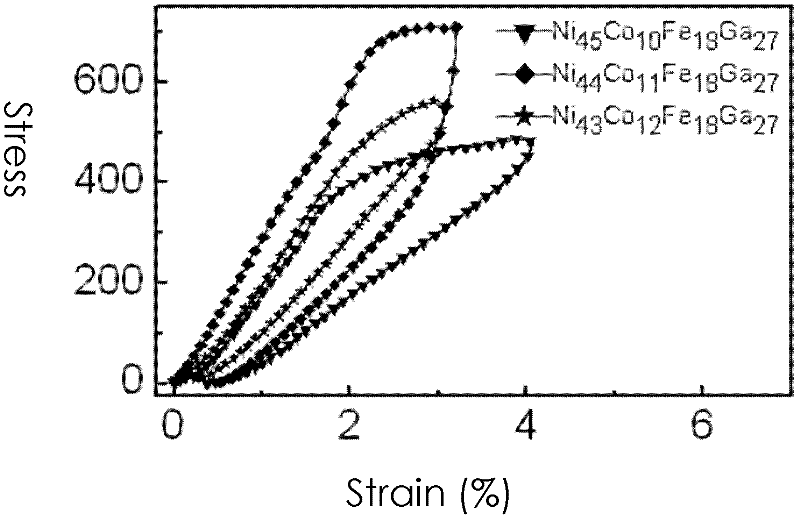

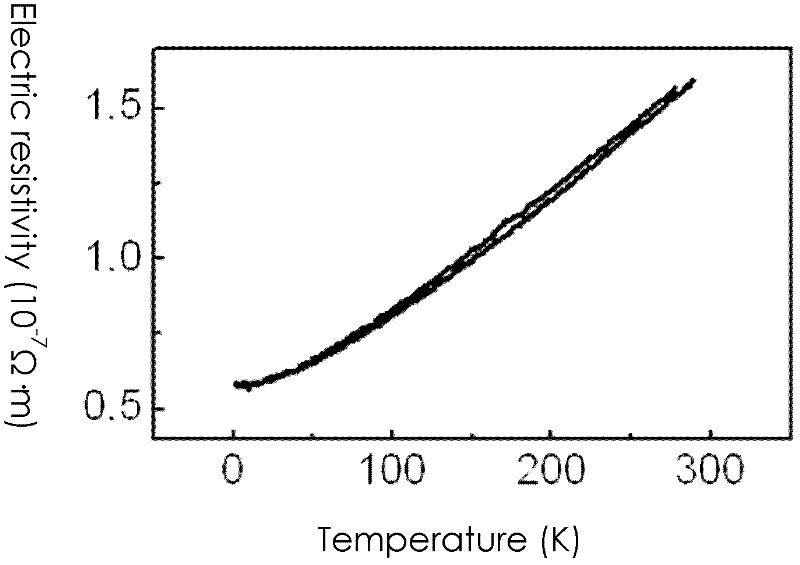

Nickel-cobalt-iron-gallium hyperelastic alloy material and preparation method thereof

The invention relates to a nickel-cobalt-iron-gallium hyperelastic alloy material and a preparation method thereof, belonging to the technical field of alloy. The alloy material is a Ni55-xCoxFe18Ga27 hyperelastic material, wherein when x ranges from 7 to 12, the alloy material comprises hyperelastic actions at room temperature; when x ranges from 10 to 12, the alloy material comprises narrow-hysteresis hyperelastic actions at room temperature; and the alloy material comprises no martensitic phase transformation actions at the temperature ranging from 0K to 298K. The alloy material is obtained through smelting, suction casting and annealing treatment in sequence. The alloy material disclosed by the invention has lower cost in comparison with NiTi series of hyperelastic alloy, so that low price and popularization of hyperelastic alloy for daily use are hopefully achieved; the alloy material has the advantages of narrow-hysteresis hyperelastic actions, low internal friction and capability of being widely applied to industrial production; and moreover, the alloy material is simple in preparation method and low in cost.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

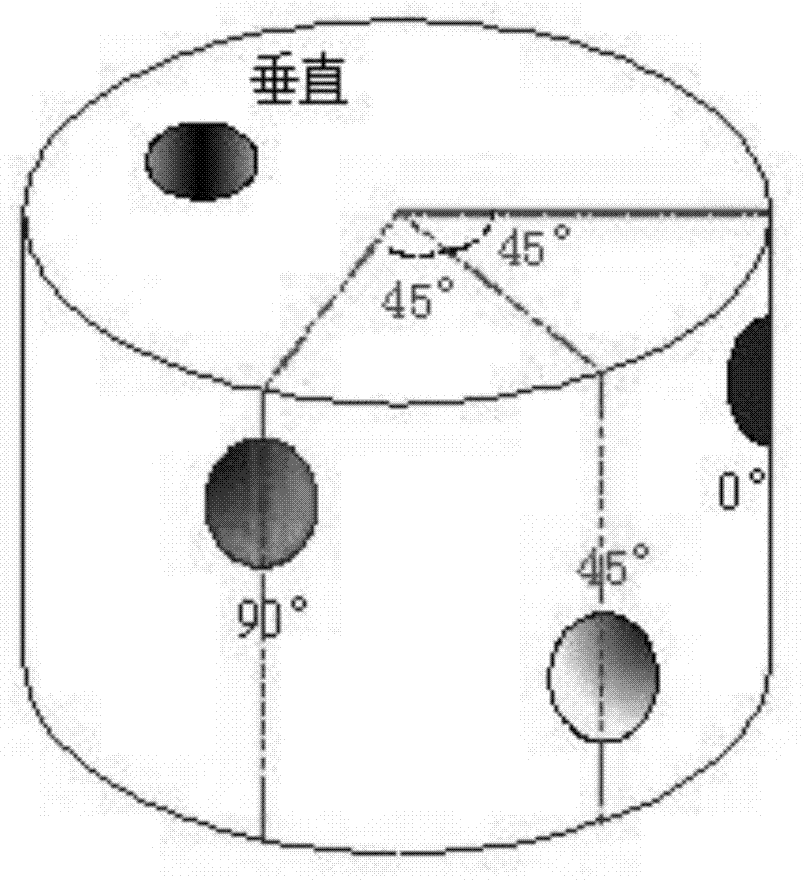

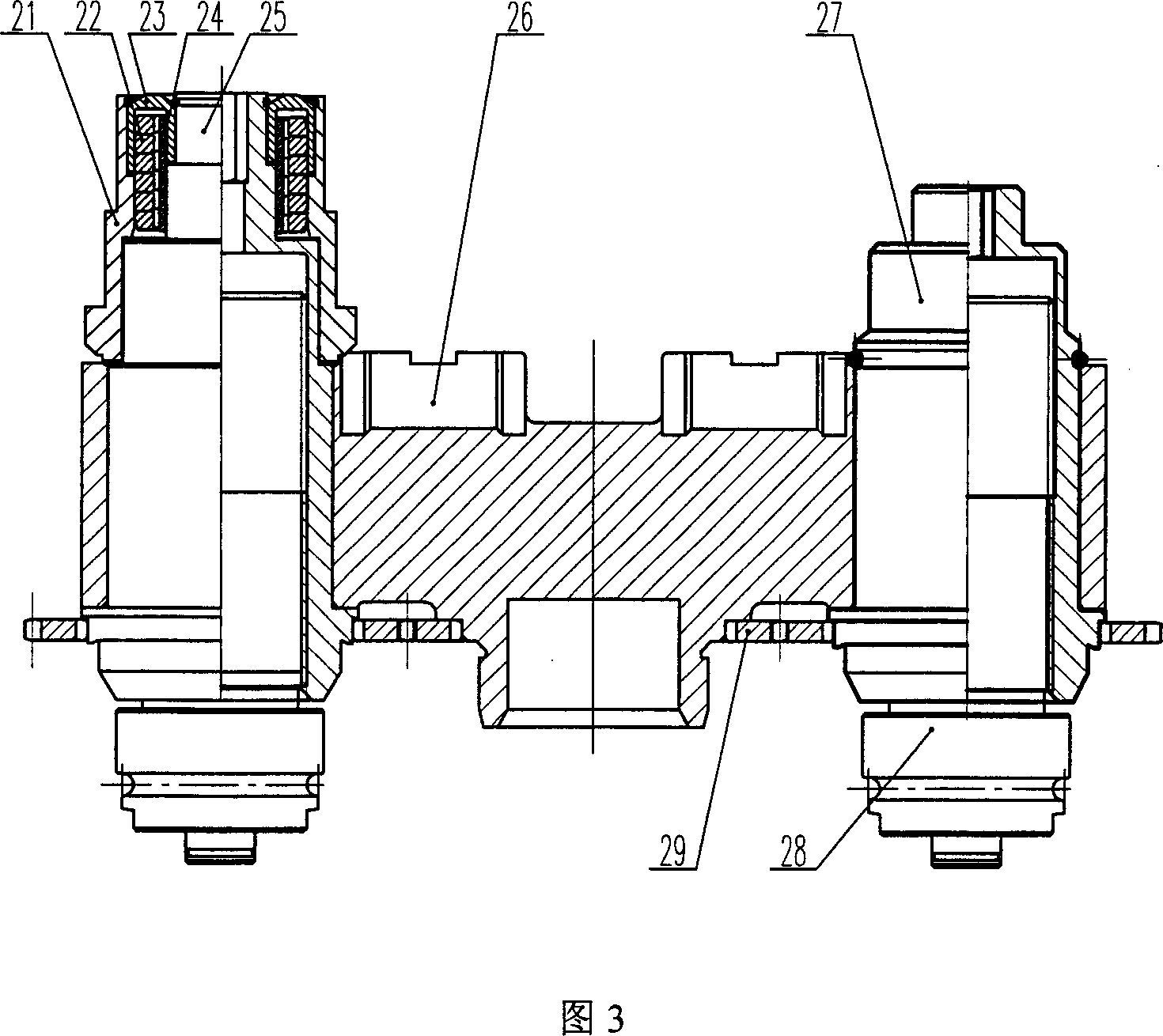

Triaxial test method for shear strength property of weak layer

ActiveCN101986130ACalculation and analysis is simple and clearNo problem of uneven shear deformationPreparing sample for investigationMaterial strength using steady shearing forcesSpecific testAmbient pressure

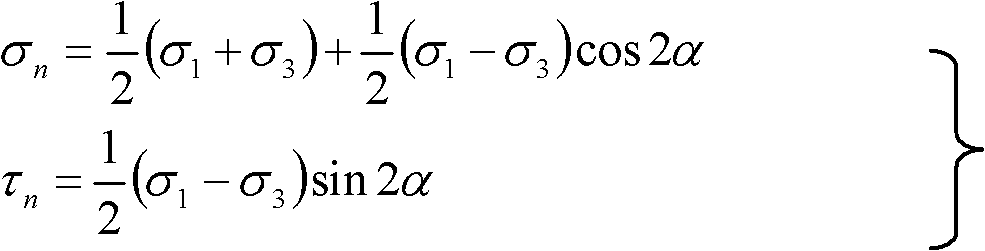

The invention relates to a triaxial test method for shear strength property of a weak layer, a test device adopts a triaxial shear instrument, and test purposes are realized through the specific test sample preparation method: (1) test sample preparation-1: cutting a soil column on an undisturbed soil sample containing the weak layer along an included angle of 45 degrees in the vertical direction; (2) test sample preparation-2: cutting the soil column into the stipulated diameter; (3) taking out of a test sample: leveling two ends by cutting according to the stipulated height and weighing; and taking remaining oil for determining water content; (4) test sample saturation; (5) testing; and (6) data analysis: taking normal stress sigma as horizontal coordinate, and taking shear stress tau as vertical coordinate; taking an inclination angle of a connected straight line of positive stress sigma n and failure shear stress tau n () obtained under different ambient pressure conditions as an internal friction angle phi, and taking intercept on a longitudinal axial on the straight line as cohesive strength C; and obtaining the test result. By adopting the special soil sample preparation method and the analysis method, the uniformity of the shear stress and strain on the weak layer can be ensured and the main problems during testing of a direct shear apparatus can be effectively solved.

Owner:NANJING HYDRAULIC RES INST

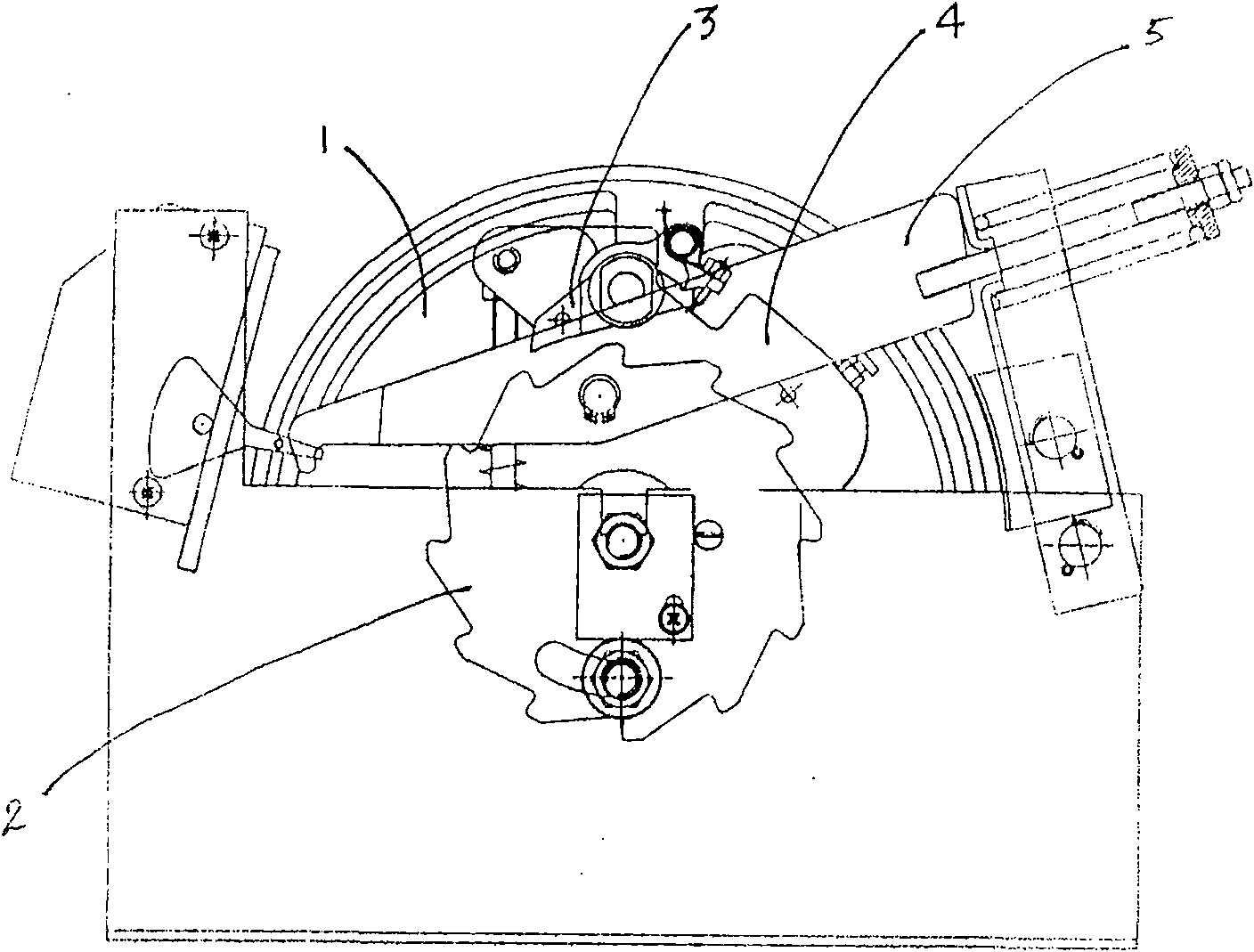

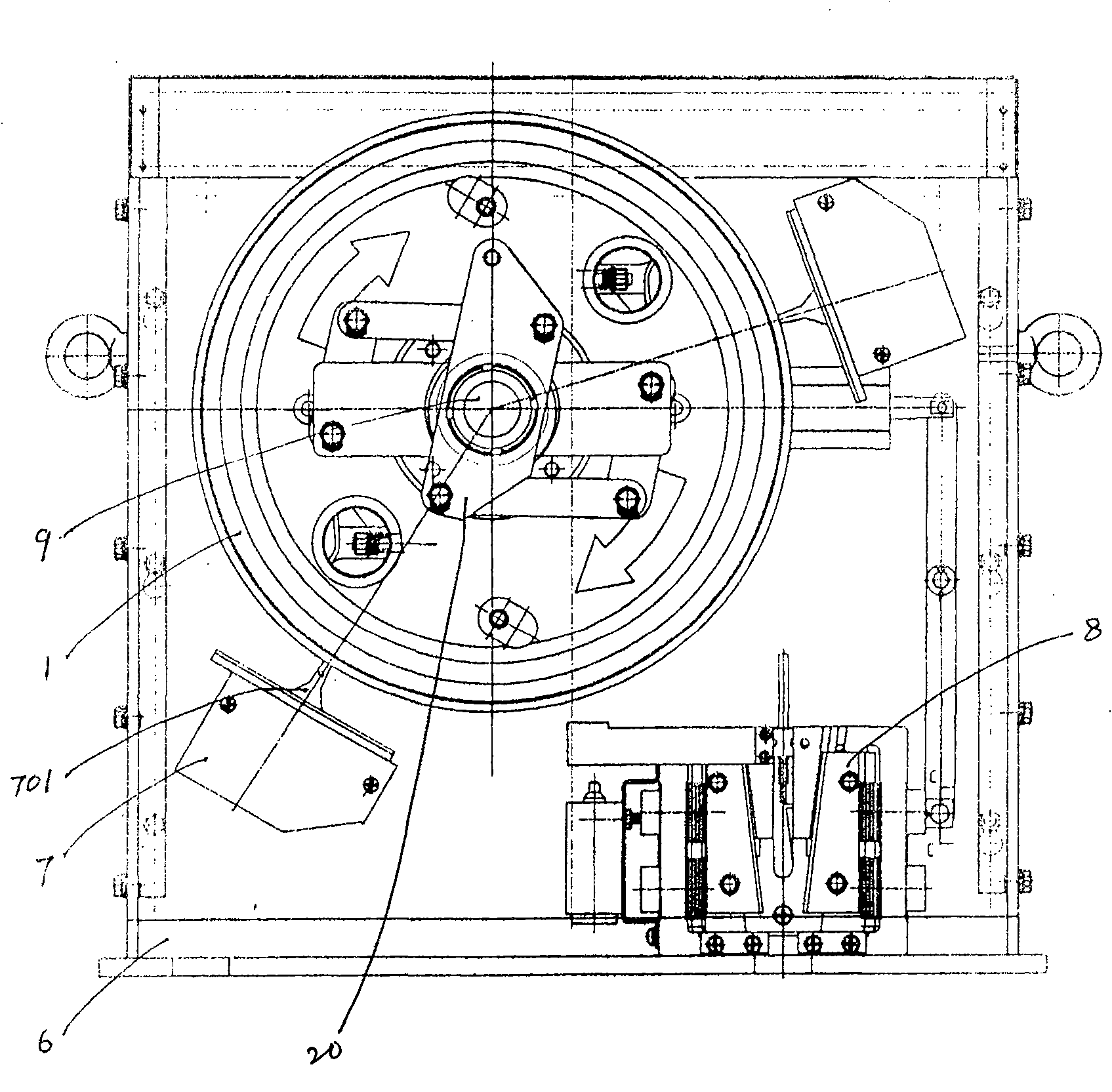

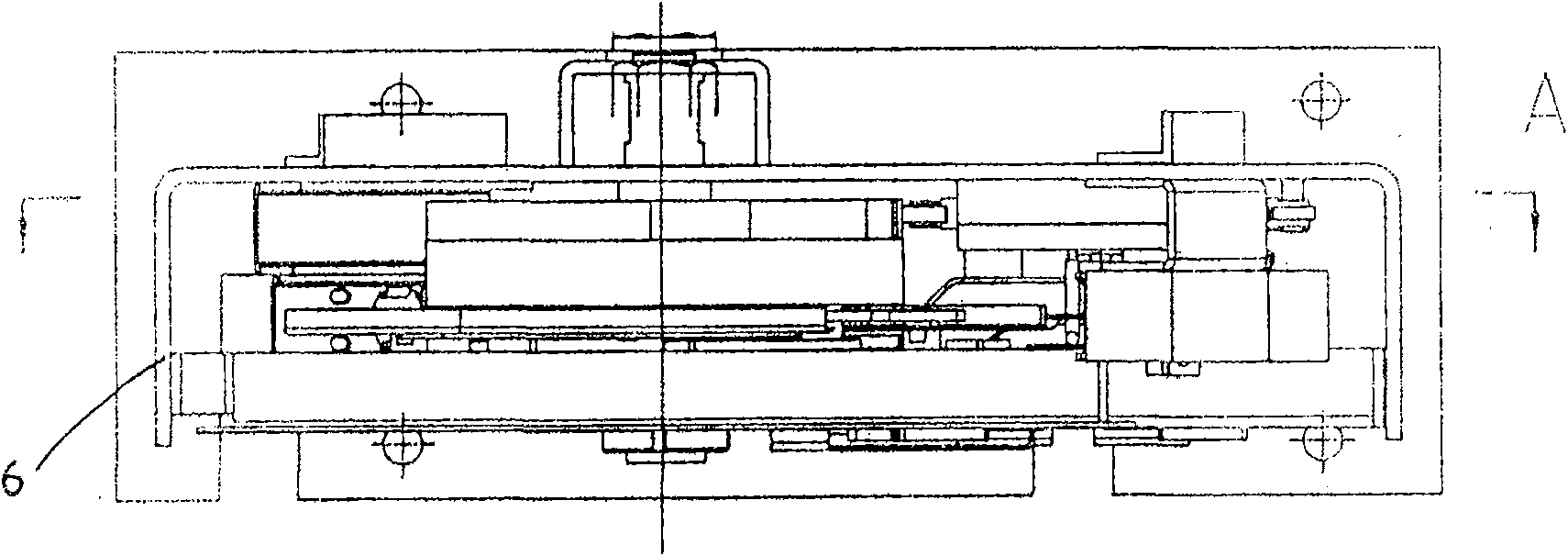

Floating tong type bipushing rod pneumatic disk brake based on rectangular torsional spring single dicrection clutch

ActiveCN1948778ALarge braking torqueConstant braking force ratioAxially engaging brakesBrake actuating mechanismsCalipersDisc brake

The invention comprises a pressure arm unit, a rotation shaft unit, a return spring, a push pedal, an internal friction plate, a brake, an external friction plate, a support and a caliper body arranged in order from right to left. Because of using the rectangular section torsional spring function, in a specific environment the invention can realize a one-way transmission of the torque and also can realize an overload protection effectively. The reasonable design of the pressure arm unit can supply the stable brake moment.

Owner:WUHAN YOUFIN AUTOPARTS

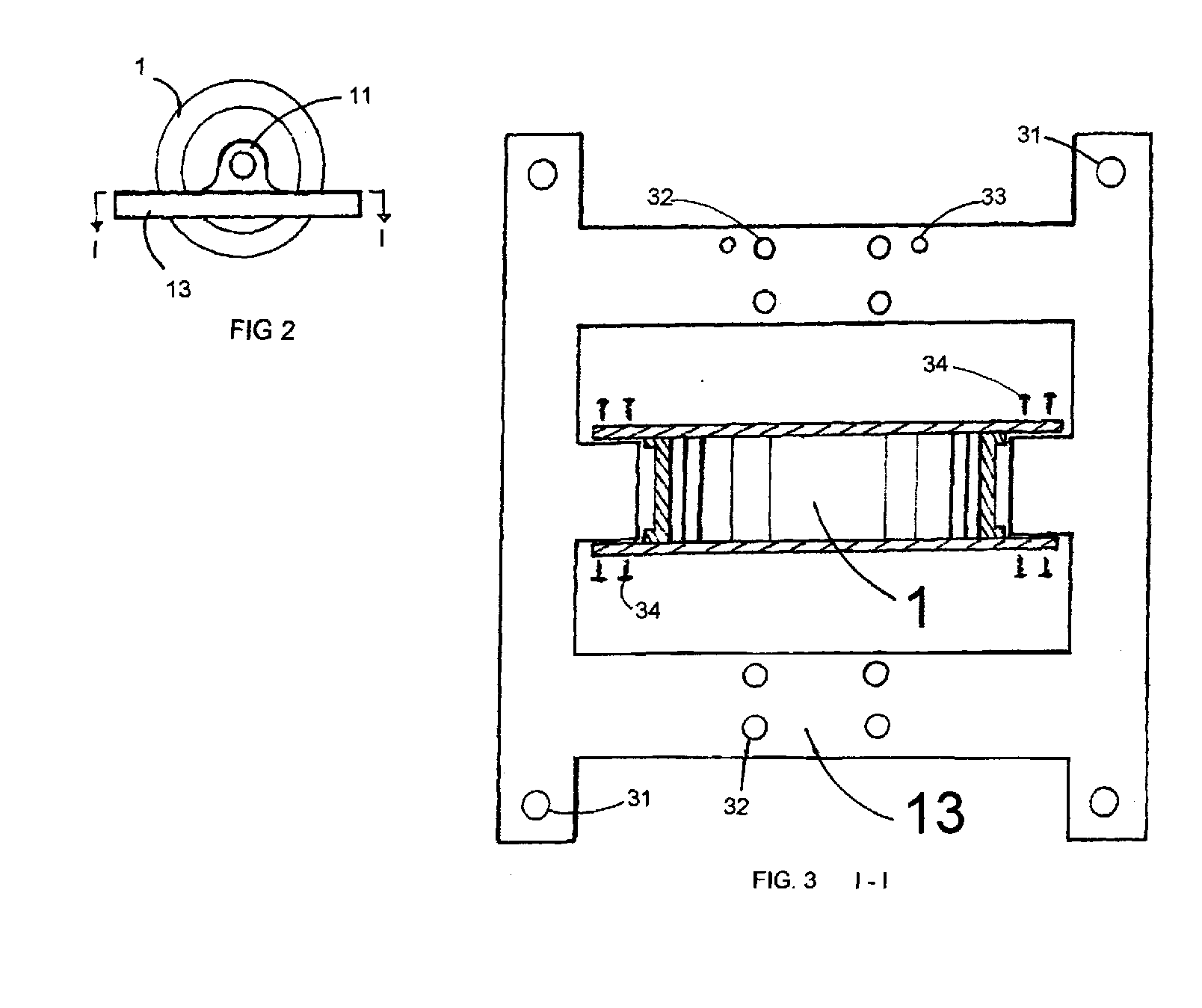

Vibration attenuating spring and damper mechanism using the same spring

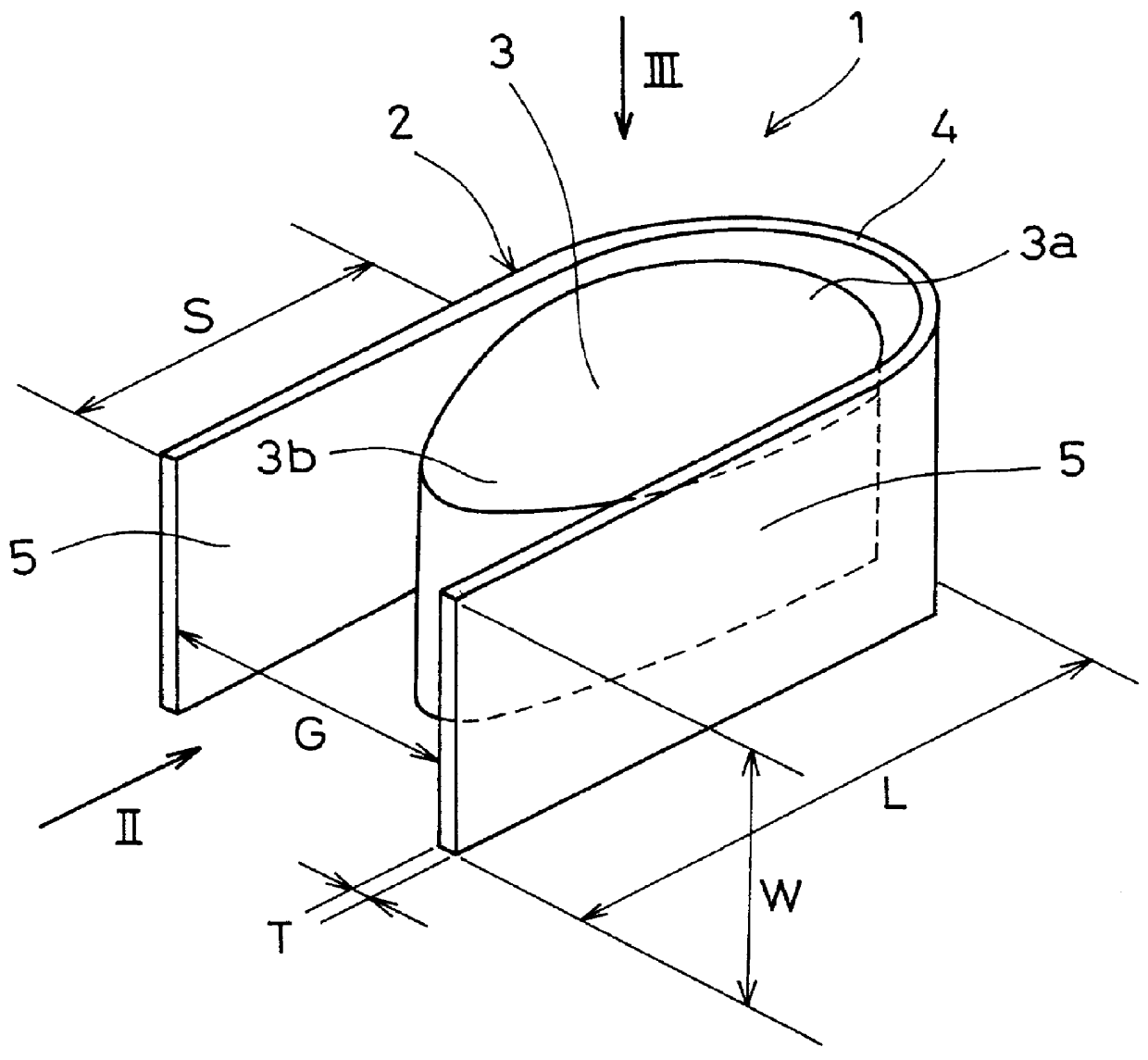

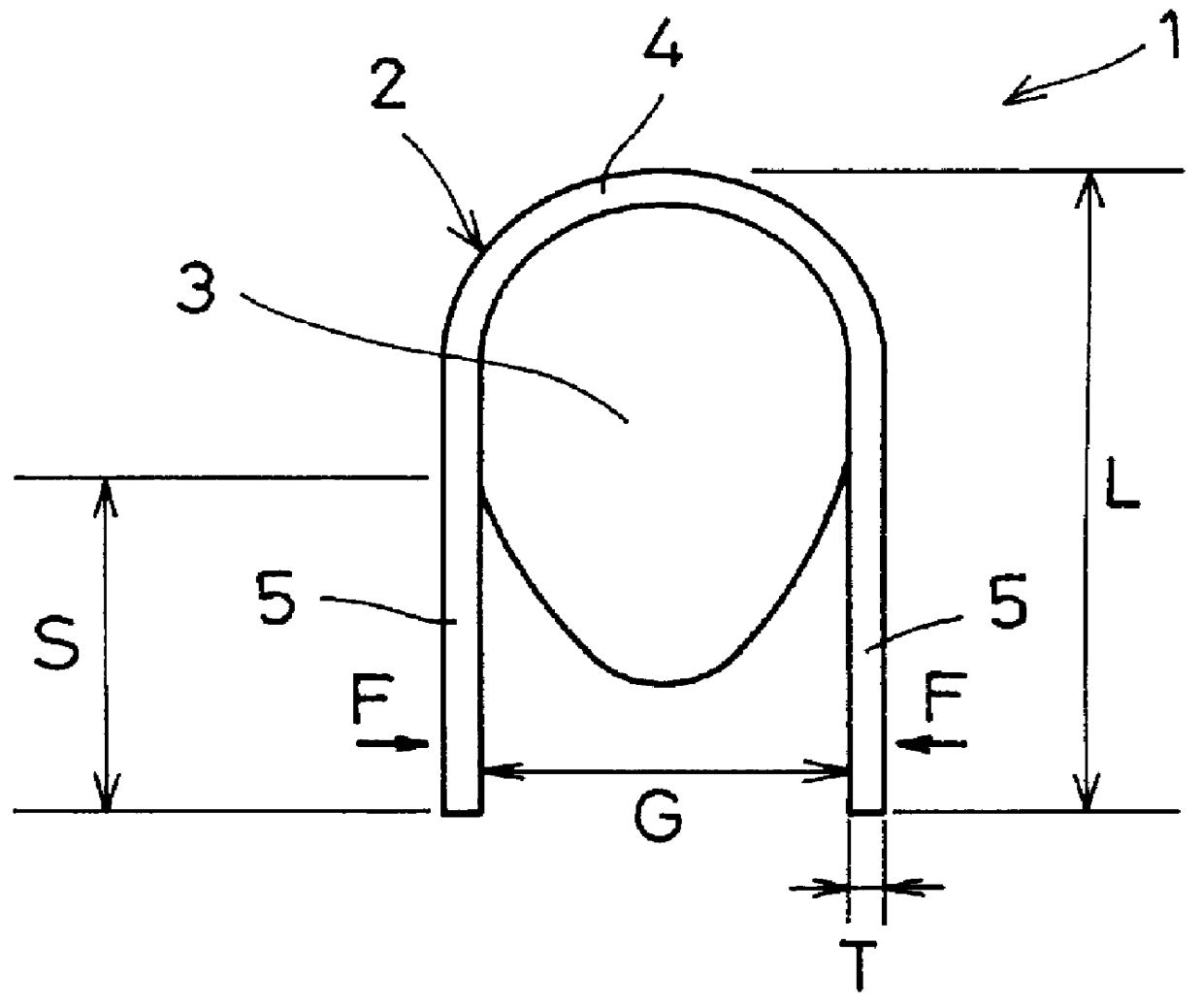

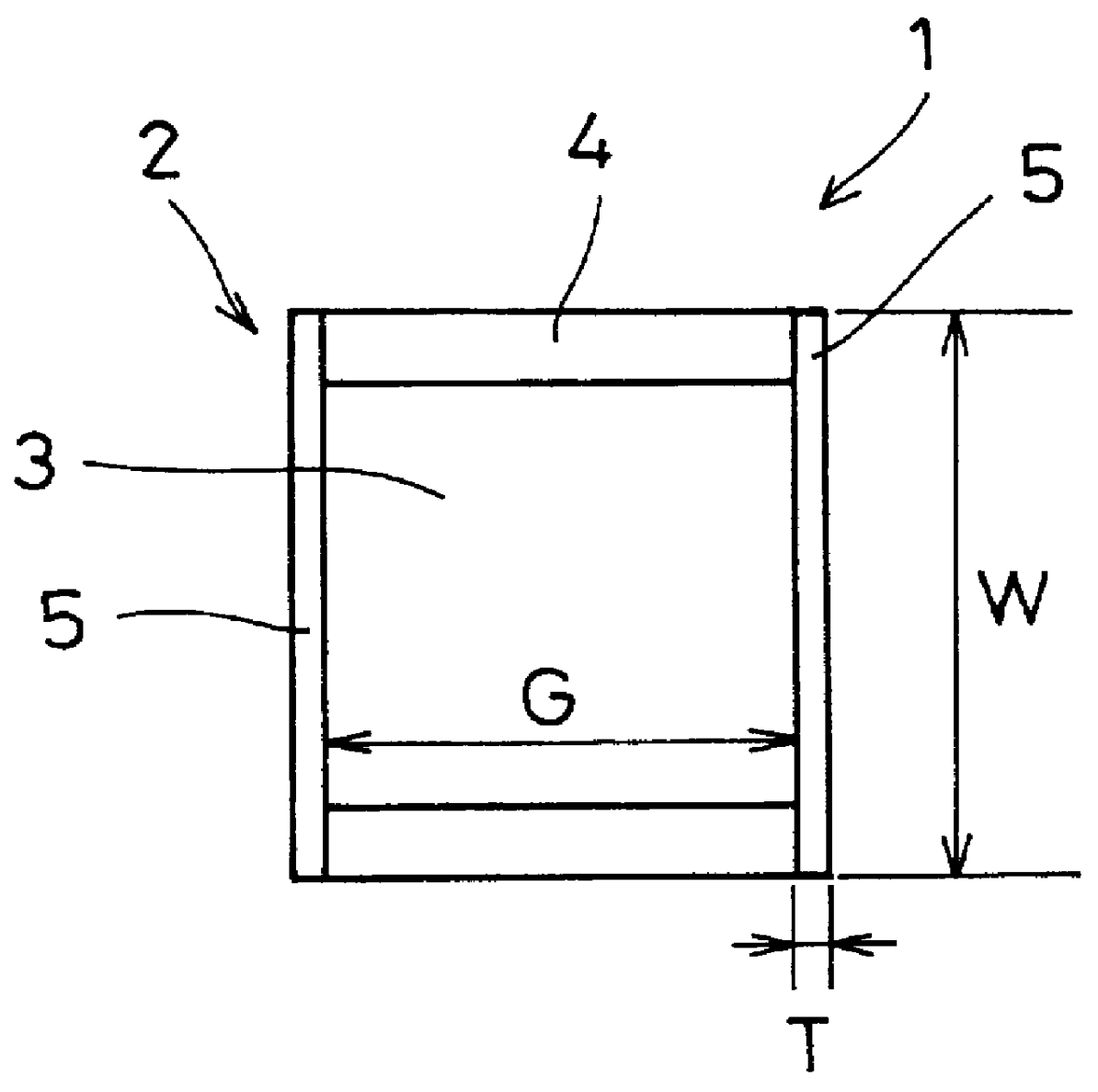

InactiveUS6062548AHighly desirable dampening characteristicHigh strengthPlungersLeaf springsEngineeringLeaf spring

A damper mechanism for attenuating vibrations having a vibration attenuating spring element (1) which includes: a leaf spring (2) having a bent portion (4) and a pair of lever portions (5) extending from both ends of the bent portion (4); and an elastic member (3) disposed between the lever portions (5). When the leaf spring (2) is subjected to compressive forces, the lever portions (5) and the elastic member (3) are elastically deformed. Internal friction is generated in the elastic member (5). The functions typically provided by a conventional elastic member and a conventional resistance generating mechanism are realized by utilizing a simple spring element composed of the leaf spring (2) and the elastic member (3).

Owner:EXEDY CORP

Reinforced earth retaining wall model test apparatus and method

ActiveCN105113555AMeasure the forceMeasured characteristicsFoundation testingFilling materialsVolumetric Mass Density

The invention discloses a reinforced earth retaining wall model test apparatus and method. The apparatus includes: a model case (1), a retaining wall panel (5), filling materials (7), a vertical load loading system (10) and a testing system. The filling materials (7) are put inside the model case (1). The retaining wall panel (5) is arranged in front of the model case (1). The vertical load loading system (10) is arranged above the model case (1) and applies vertical pressure to a model. According to the invention, the filling materials (7) are made of mixed cast-steel shots which have a density between 5.2g / cm<3> to 7.0g / cm<3> and an internal friction angle between 28 DEG to 35 DEG. The density of the mixed cast-steel shots is 3-4 times greater than that of ordinary sand filling materials, and the internal friction angle of the mixed cast-steel shots is similar to that of ordinary sands. A stress field is made equivalent by increasing the density of the filling materials, so that the stress state of the filling materials of a retaining wall is made to be equivalent, and the stress and deformation characteristics of the model can be measured effectively. The filling materials can be used repeatedly for many times, which significantly reduces the cost of the testing.

Owner:HUNAN UNIV

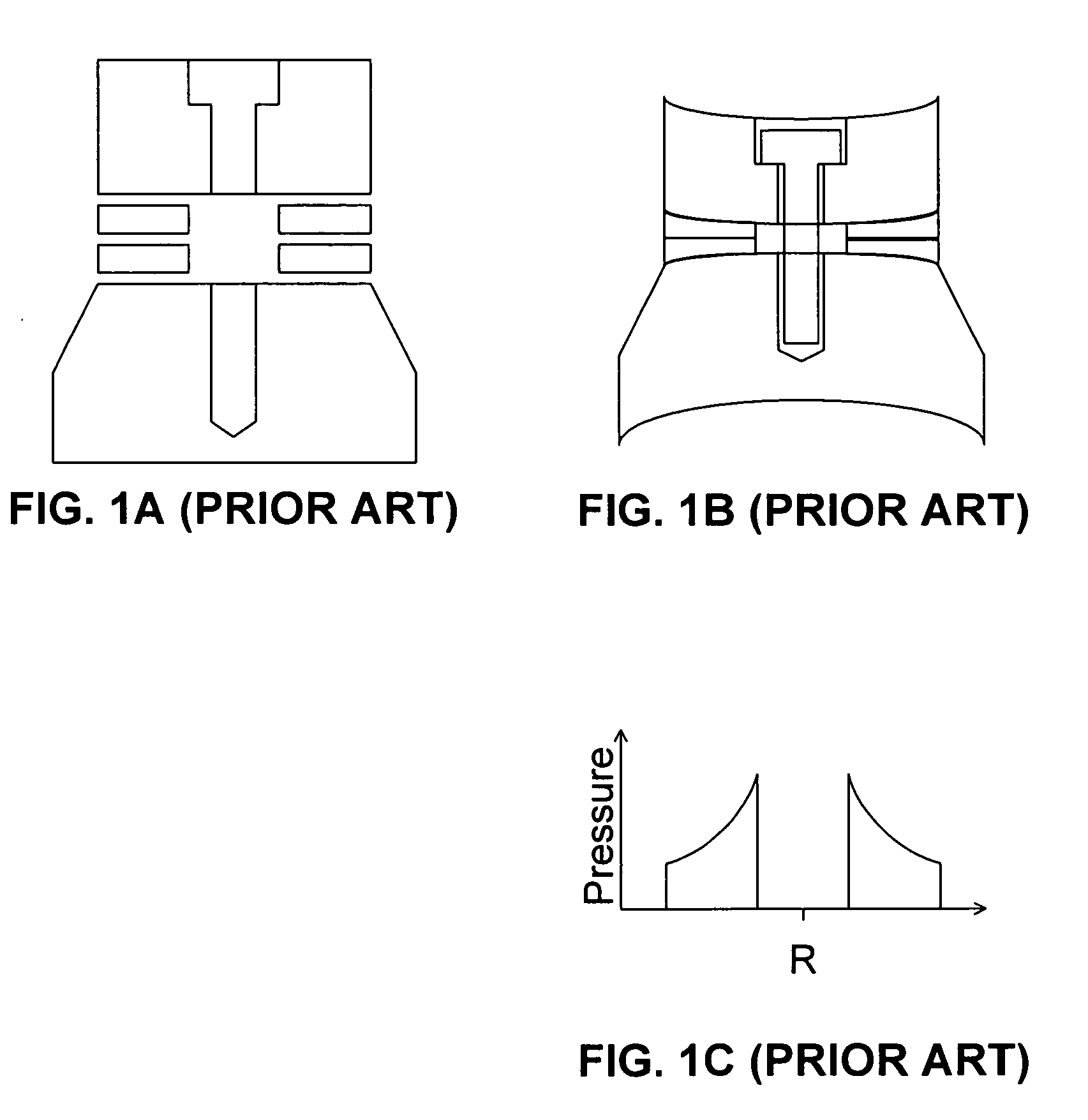

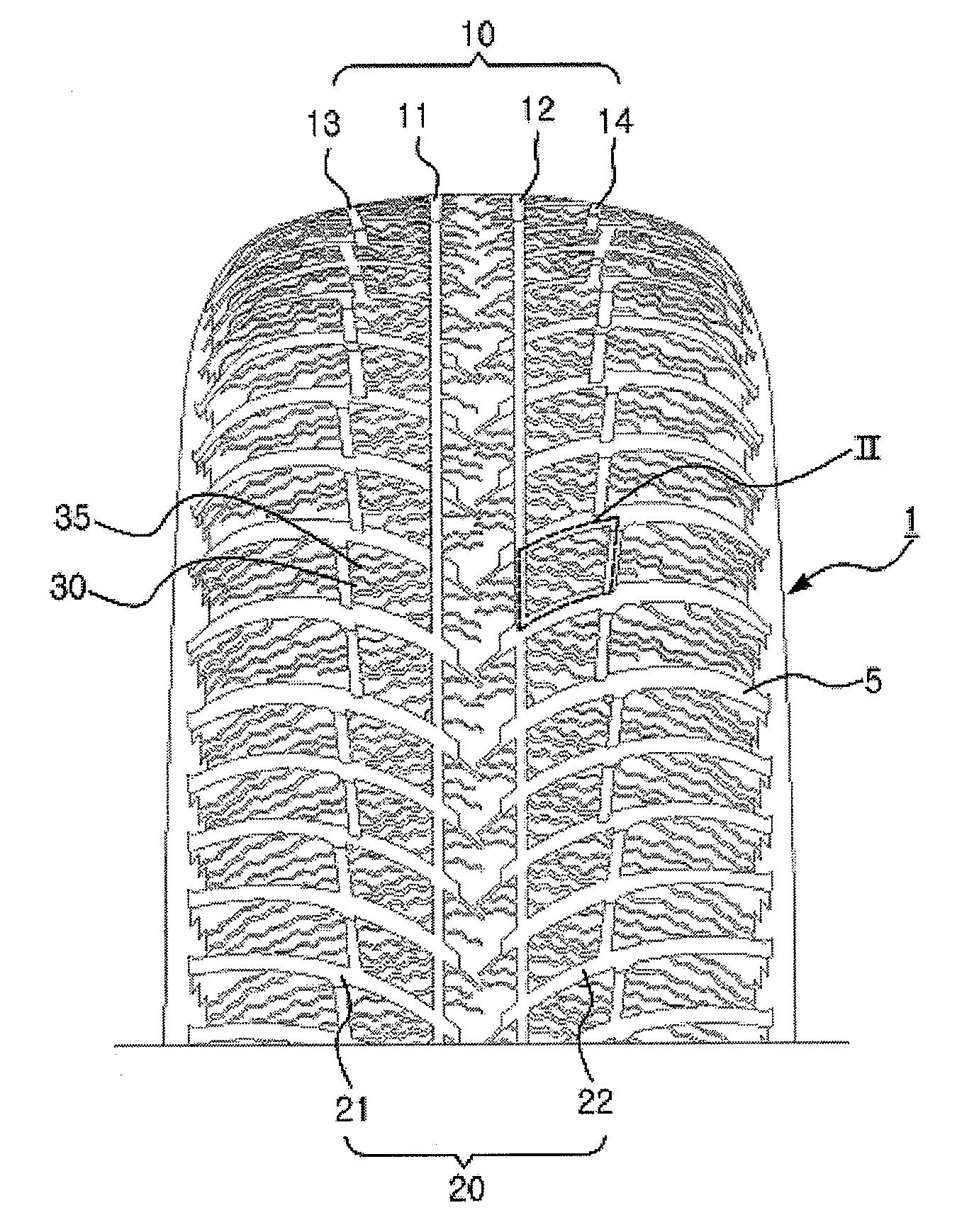

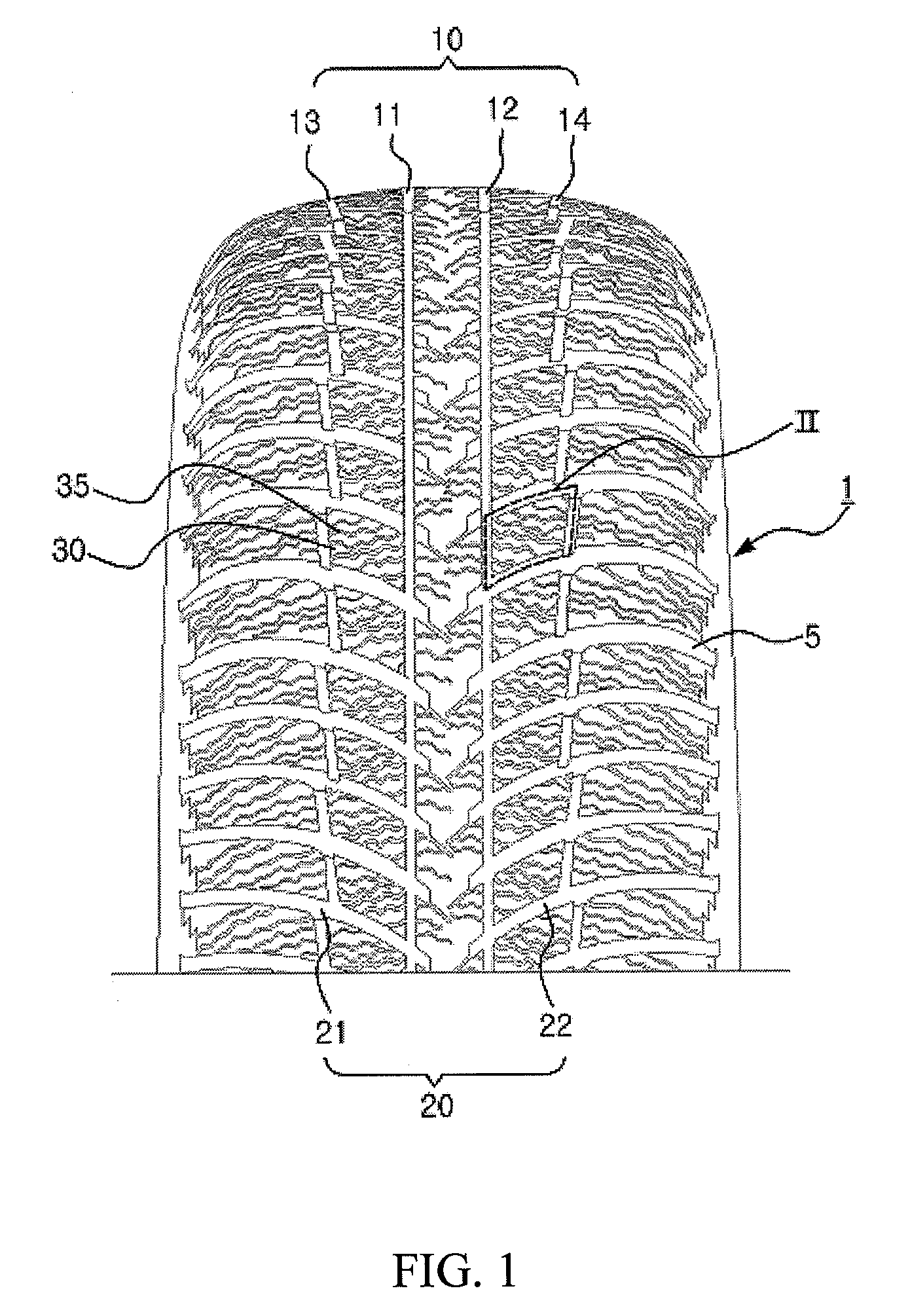

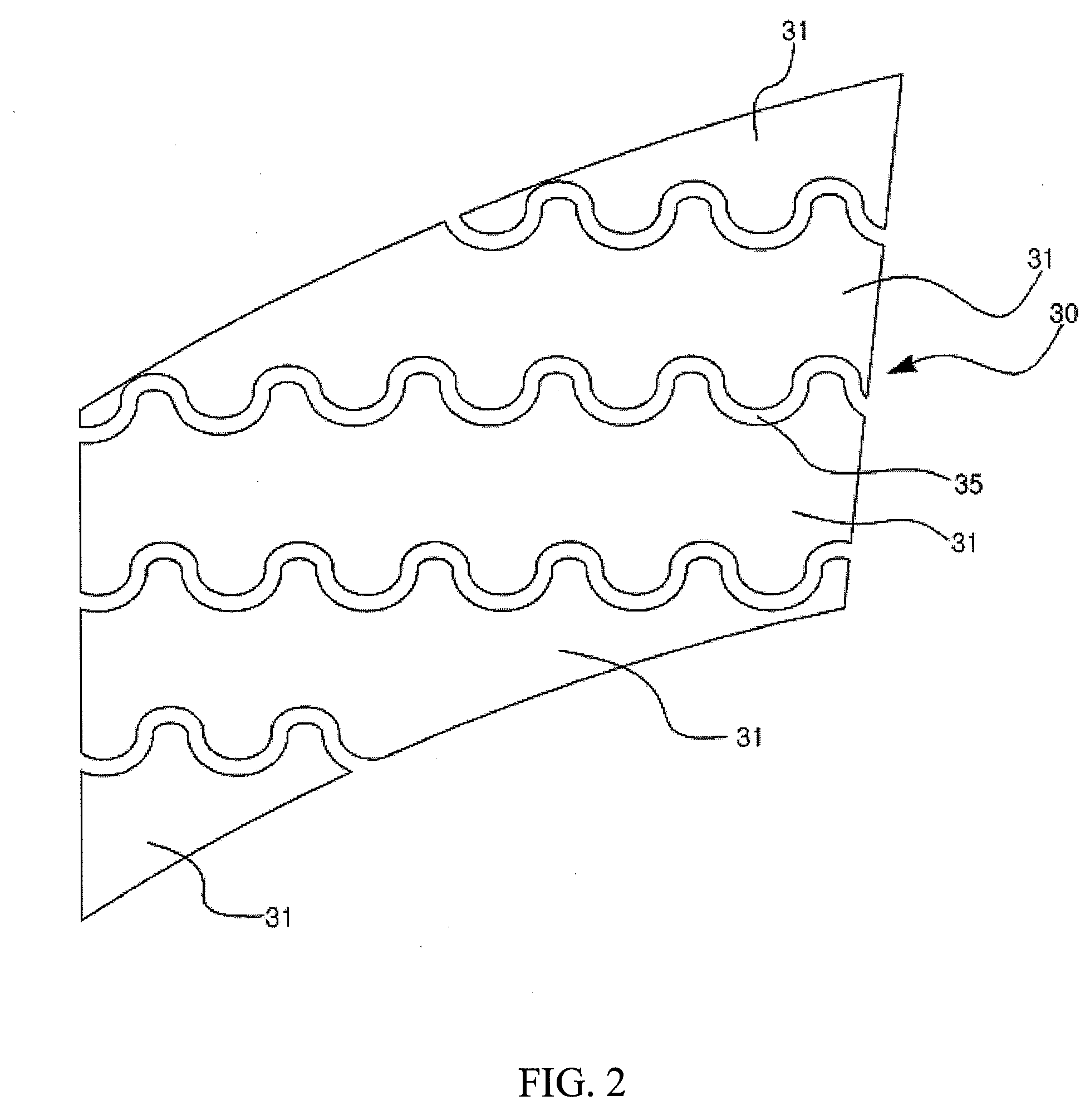

Snow tire

InactiveUS20090283189A1Improve steering performanceImprove braking performanceTyre tread bands/patternsNon-skid devicesTransverse grooveEngineering

The present invention discloses a snow tire for improving steering performance and braking performance while running on a general road surface. The snow tire of the present invention comprises a plurality of tread blocks 30 subdivided by a plurality of longitudinal grooves 10 which are longitudinally formed on a tread rubber layer consisting of the tread, and a plurality of transverse grooves 20 which are formed widthwise of the tire in cross relation with the longitudinal grooves 10; a plurality of sipes 35 which are formed in the plurality of tread blocks 30 in parallel each other in one direction to subdivide the tread blocks into a plurality of subblocks 31; and at least one protruded portion 33 which is formed on the side surface of the subblock 31 subdivided by the plurality of sipes 35 of the tread blocks 30. The present invention can improve steering performance and braking performance when running on a road surface besides a snowy road or icy road by reinforcing the lowered rigidity of the tread block by forming sipes through internal friction between subblocks by protruded portions.

Owner:KUMHO TIRE CO INC

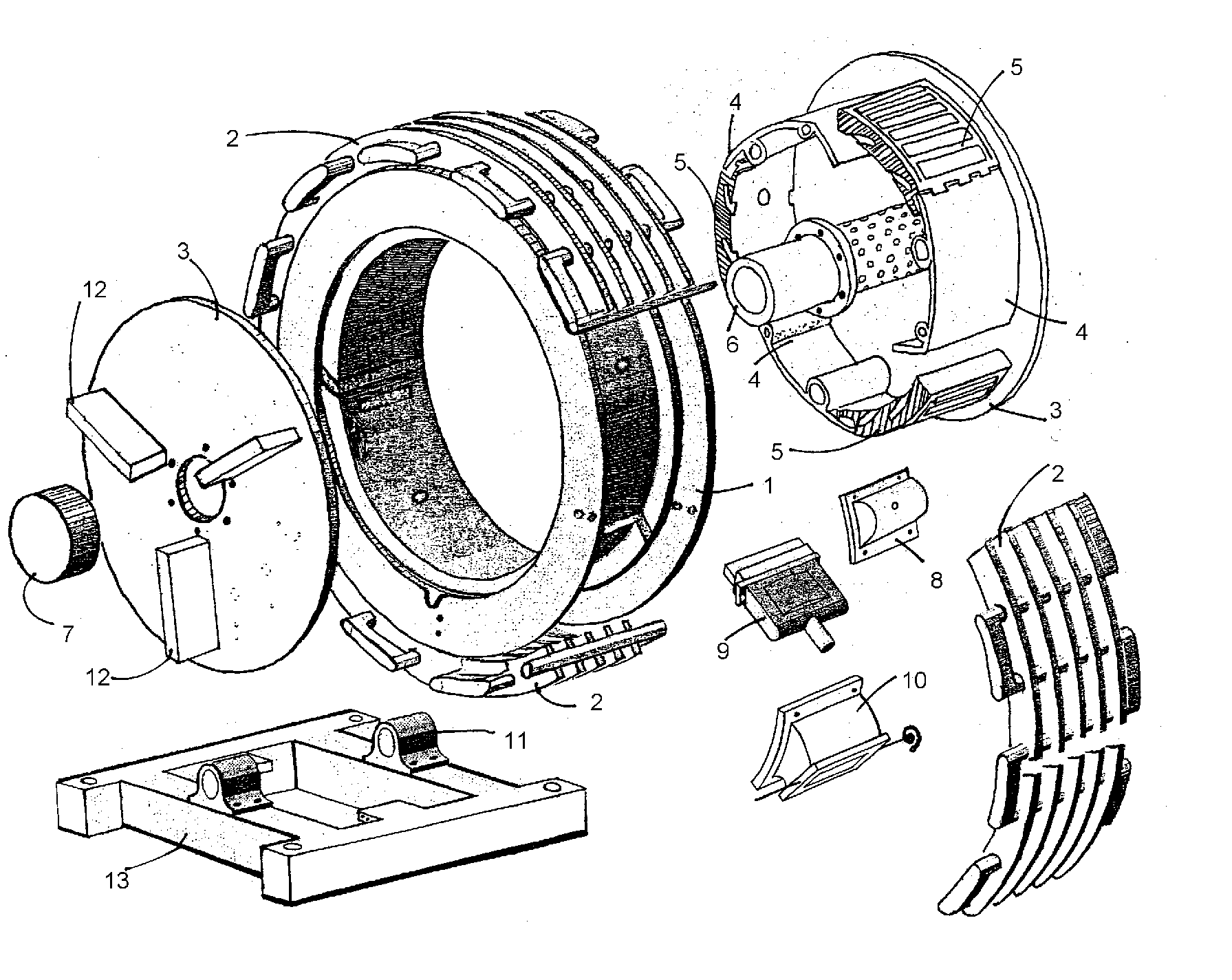

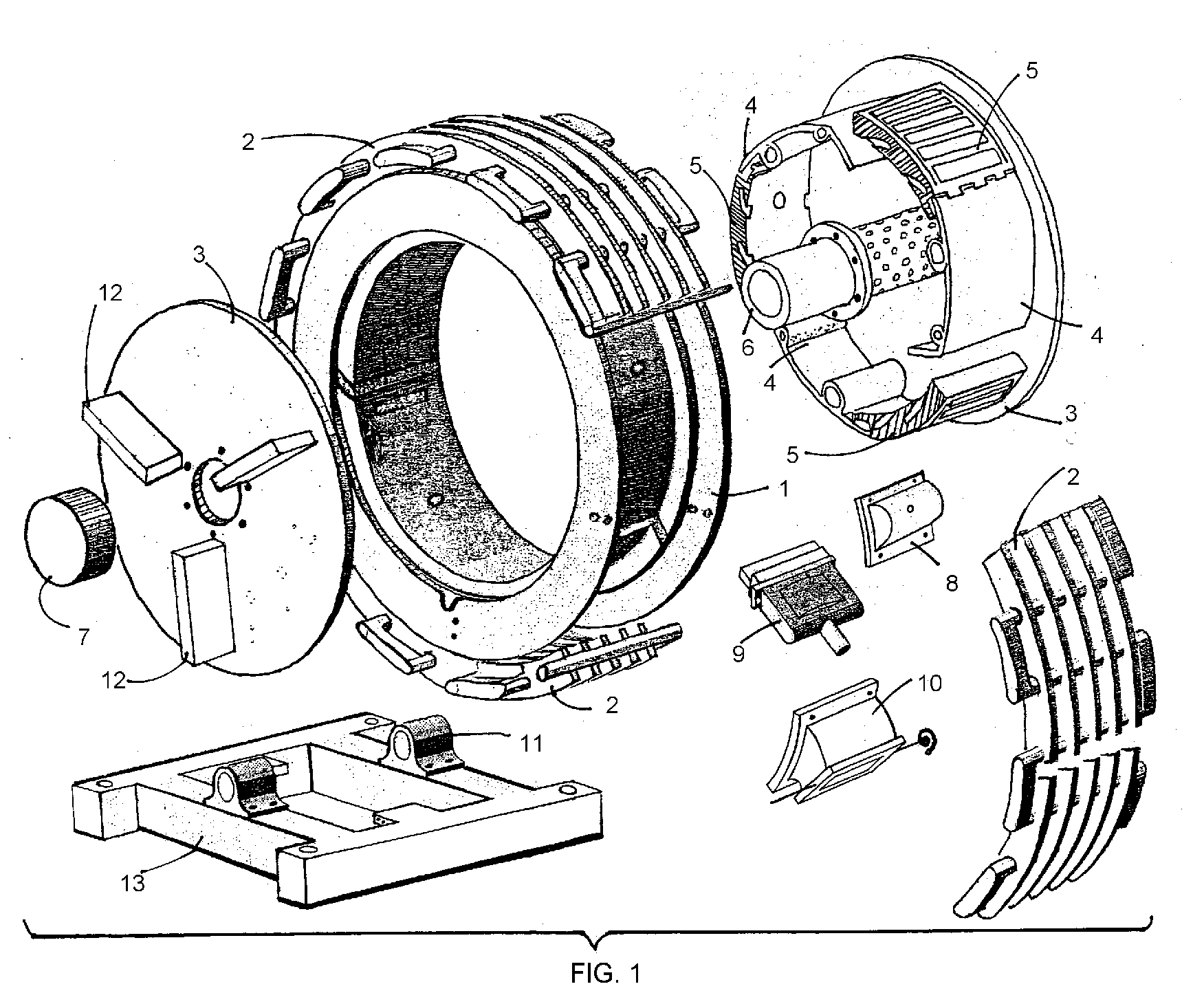

Modular Rotary Engine

InactiveUS20070084434A1Low reciprocating massReduce distanceInternal combustion piston enginesOscillating piston enginesExternal energyEngineering

An internal combustion rotary engine, self cooled, totally concentric and symmetric, dynamically variable compression ratio, capable of developing multiple Otto cycles in each rotation, by means using modules, composed mainly by a solenoid gate valve and three chambers operating at the rotor periphery, producing at low RPM, torsion of value near close at theoretical limit. High power / weight ratio, which increases substantially when number of modules increase, without drive shaft length increase; plus reduced internal friction, is a truly saver fuel machine; with volumetric asymmetry ratio between expansion and compression chambers, and that compression chambers working at beginning of the cycle at normal atmospheric pressure, it gives a fast rise pressure peak, because of the almost wedged form of that chambers. Proper for many types of combustion and class of fuels, including hydrogen, liquefied propane gas and efficient use of air compressed as external energy supply. Excels in aircraft use.

Owner:LEON ENRIQUE HALUY

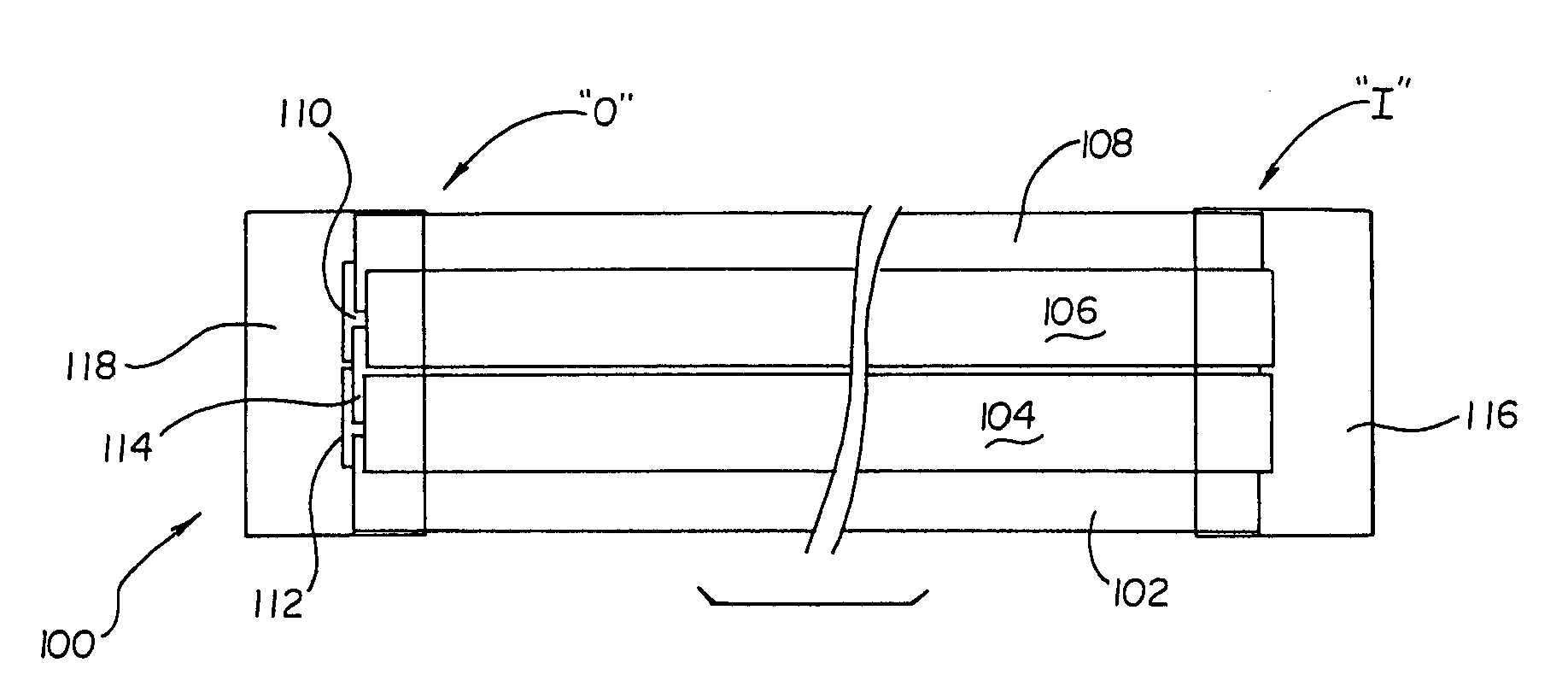

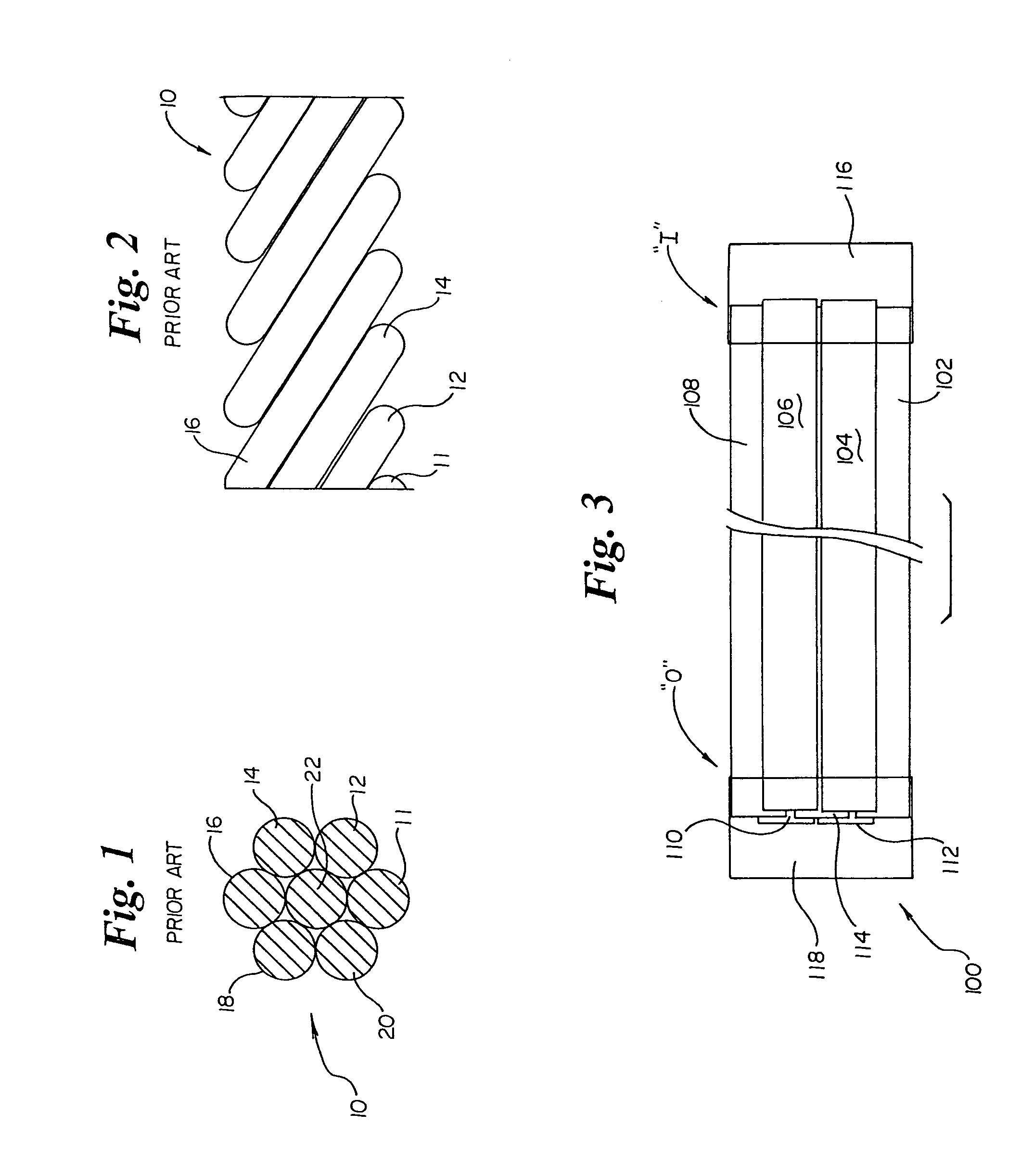

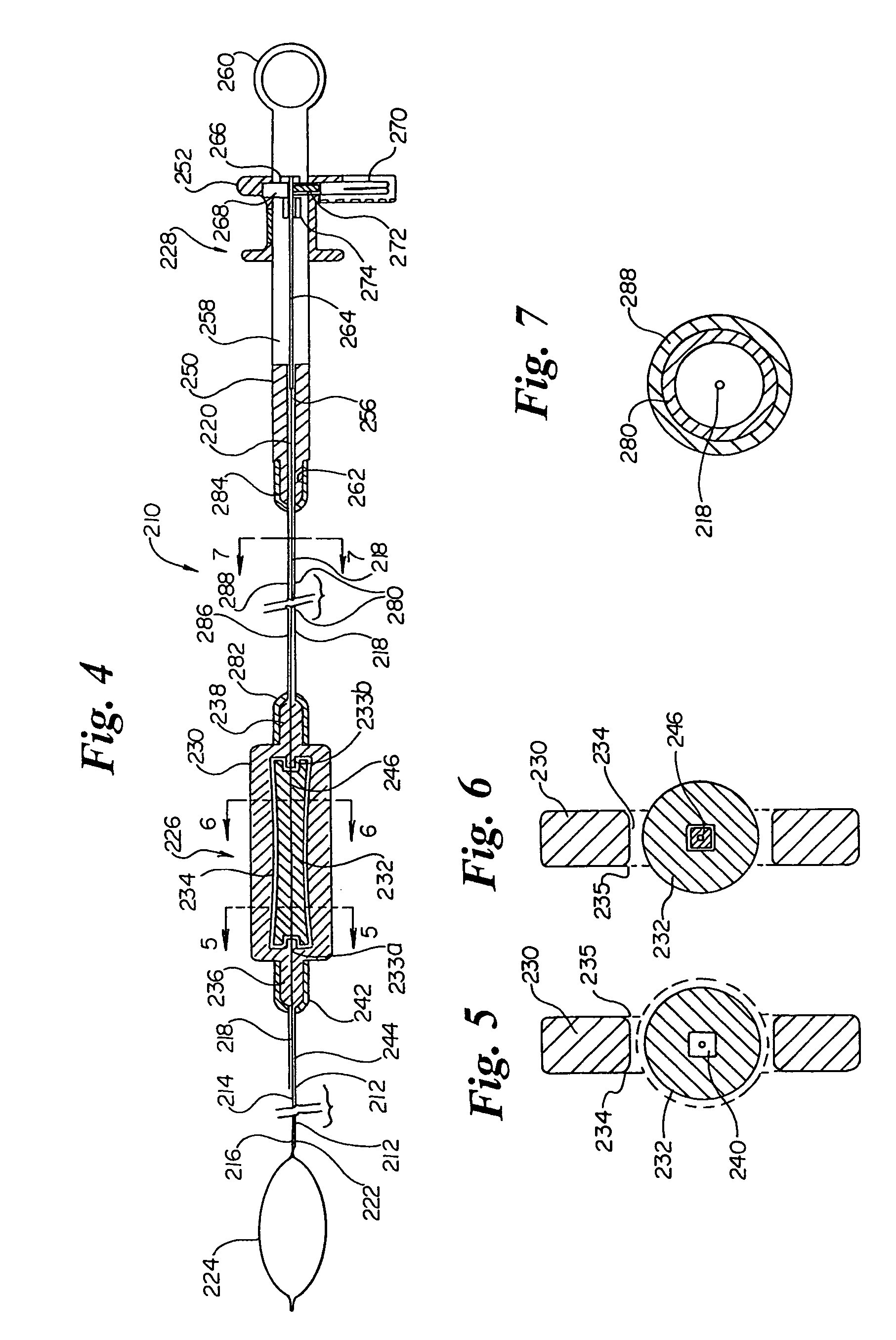

Multifilar flexible rotary shaft and medical instruments incorporating the same

InactiveUS7276067B2Reduce hysteresisGood torque transmissionCatheterExcision instrumentsHysteresisEngineering

A multifilar flexible rotary shaft includes a plurality of individual filaments which are not wound around each other or around a central core, a loose ensemble of filaments. The input ends of each filament are coupled to each other and the output ends of each filament are coupled to each other. Preferably all of the filaments are identical. A loose ensemble of N filaments can transmit N times the torque of a single filament, and will have N times the torsional stiffness of a single filament, while retaining the minimum radius of operation of a single filament. Since a loose ensemble of filaments does not have any appreciable contact forces among the filaments (because they are not forcibly twisted together), there is no appreciable internal friction or hysteresis. In order to appreciably eliminate all the hysteresis in such an ensemble of filaments, the filaments should be no more than loosely twisted together, if at all. The only reason for loosely twisting the wires together is to allow the ensemble to be easily handled and to insure that the individual wire filaments follow the same general curved path from one end to the other. Several practical applications of the invention are also disclosed.

Owner:BOSTON SCI SCIMED INC

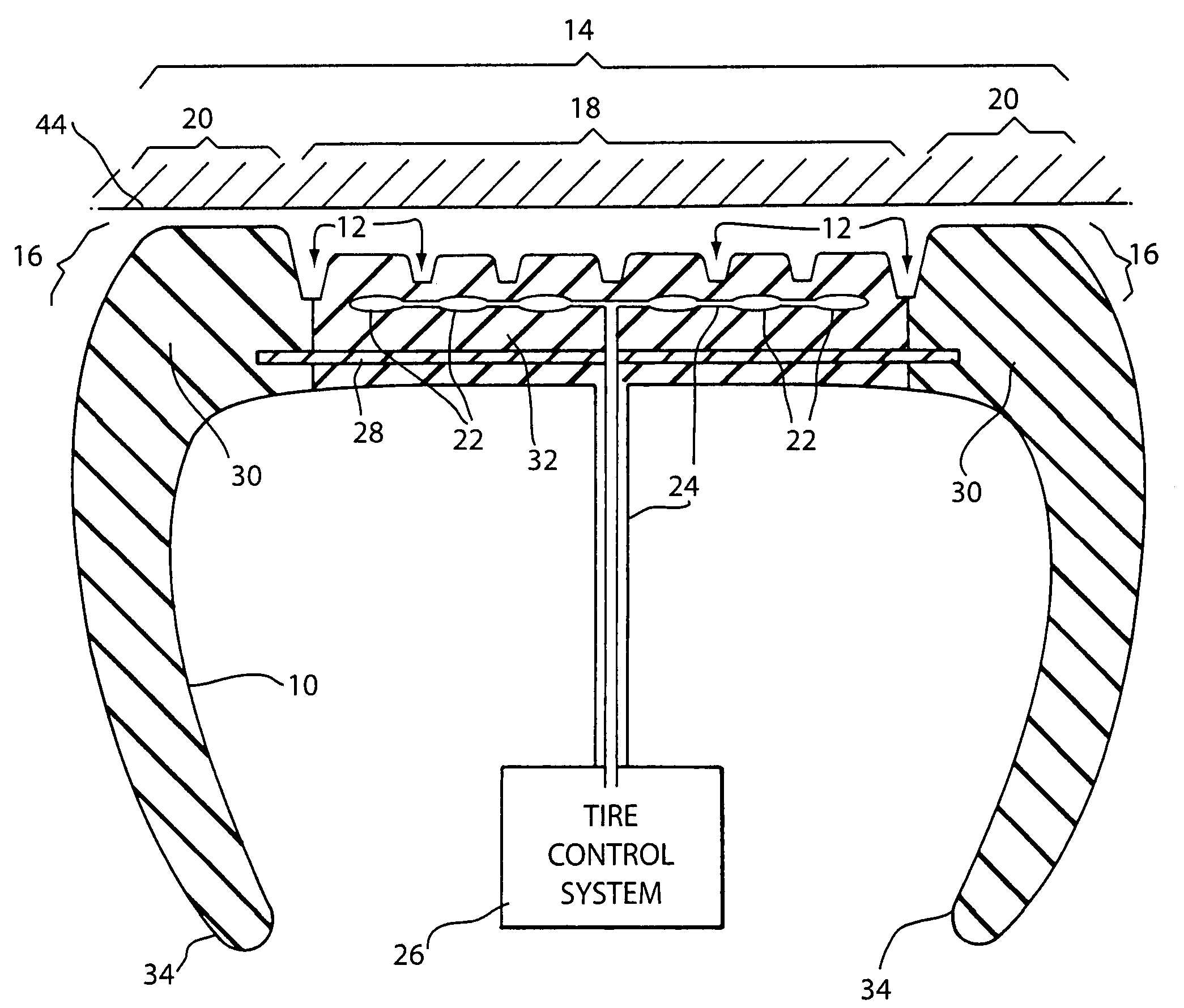

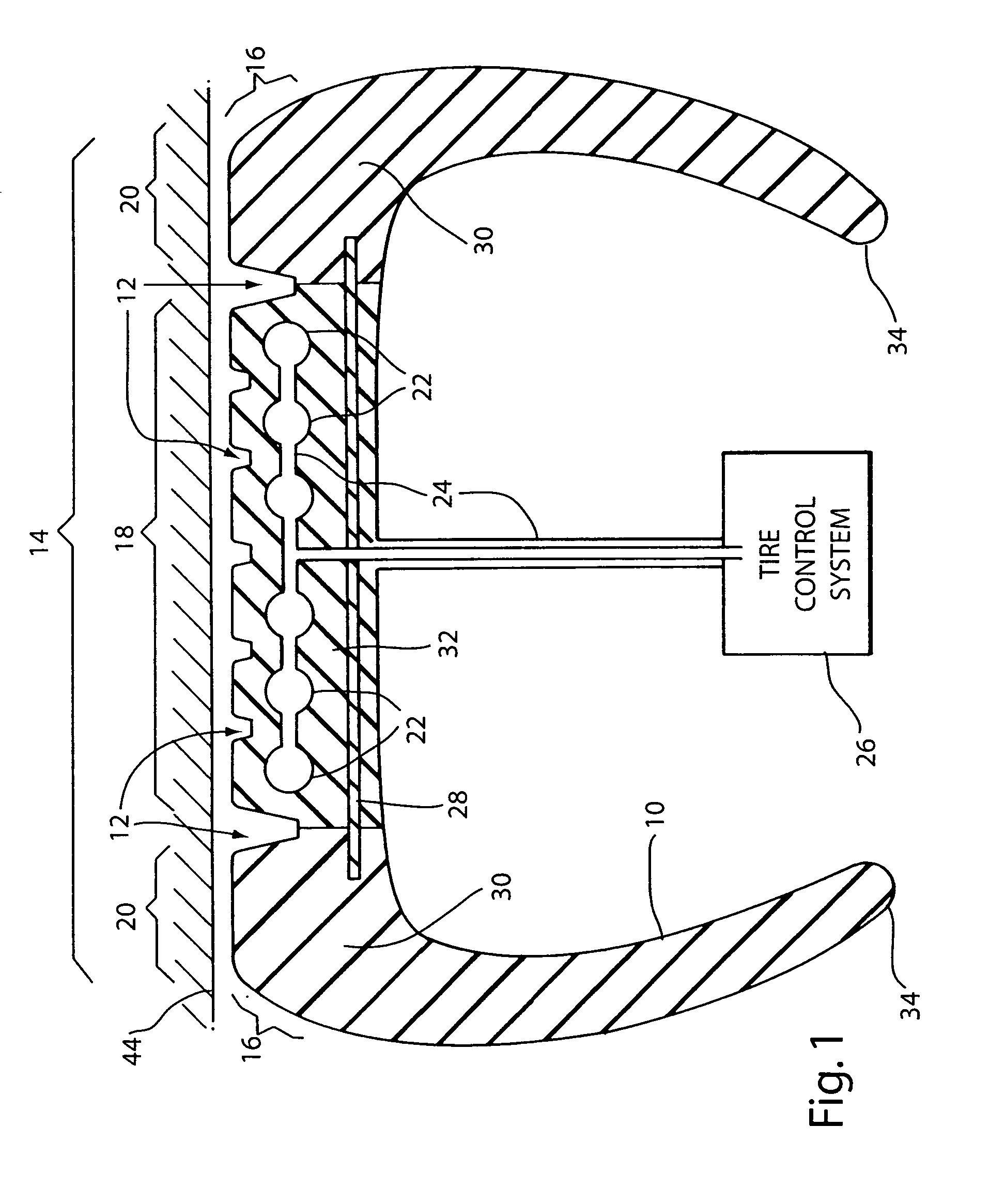

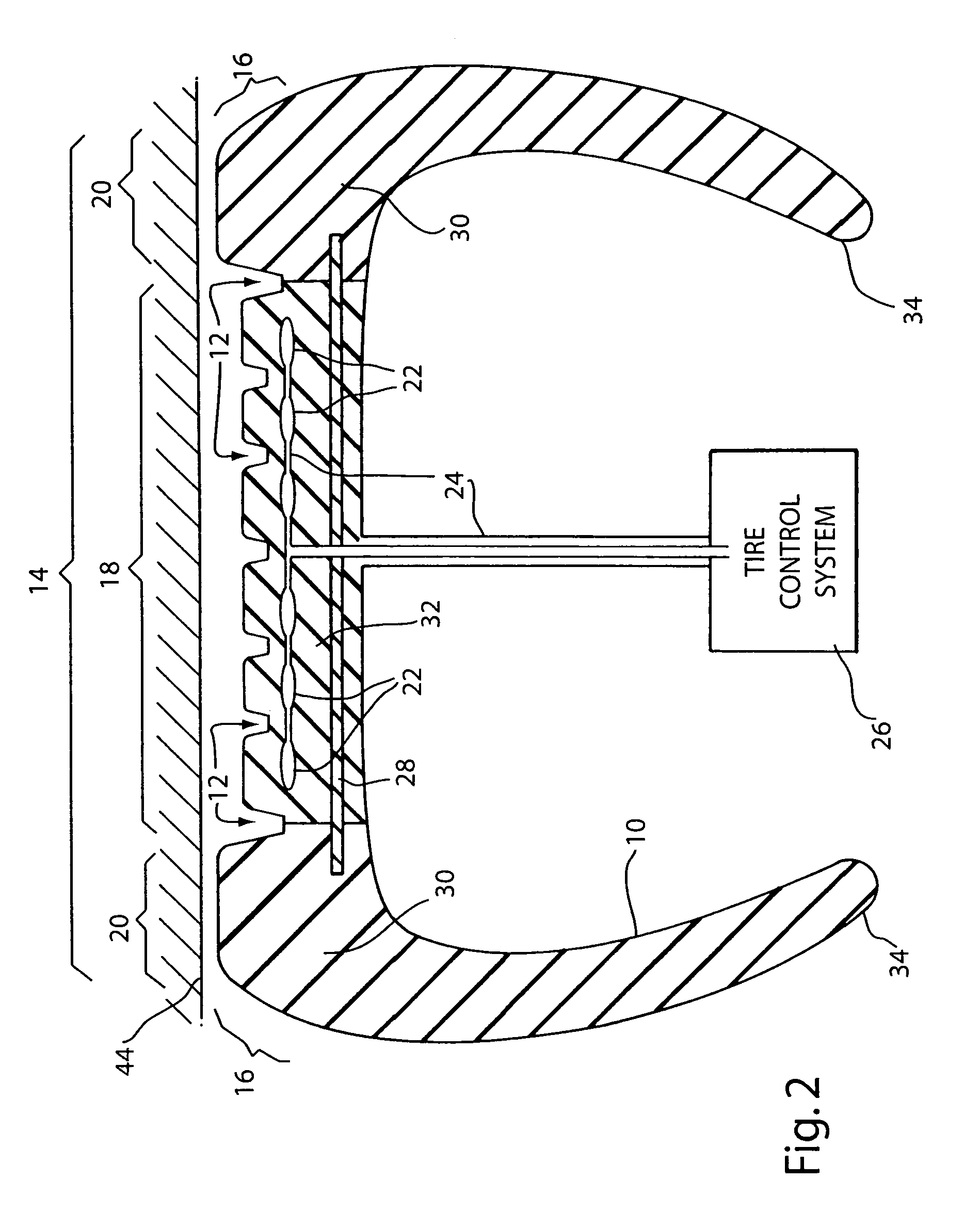

Fuel efficient vehicle tire having a variable footprint and low rolling resistance

InactiveUS7066226B1Low gas consumptionEffective dry tractionSpecial tyresTyre tread bands/patternsGround contactMicrocomputer

A tire for vehicles offering low rolling resistance wherein the ground-contact surface area is variable as a portion of the tread part can be retracted and / or extended using pneumatic, mechanical or hydraulic force to withdraw from, or come into contact with the road surface before, during or after operation permitting more efficient operation wherein the material used within the tread part that retains contact with the road may generally have a smaller internal friction loss than the material used in conventional tires and the rolling resistance is thereby reduced when the retractable portion of the tread is selectively withdrawn from contact with the road surface furthermore achieving a smaller ground-contact patch footprint. The achieved object of a tire with a lower rolling resistance yields improved fuel consumption efficiency. Improvements in exterior and interior noise levels and a reduced tendency to exhibit hydroplaning action are also attained with a variable groove volume to tread surface-contact ratio. Within one embodiment of the present invention, an automated microcomputer-based tire control system is disclosed useable to command the motion of the moveable tread portion of the said tire in response to various operational scenarios.

Owner:FIORE ROBERT ANGELO

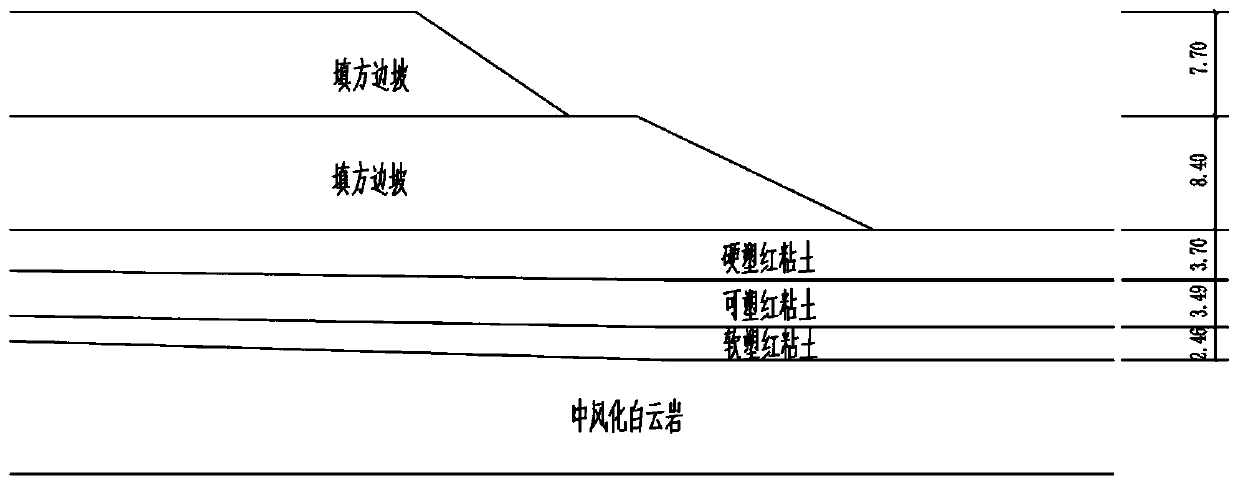

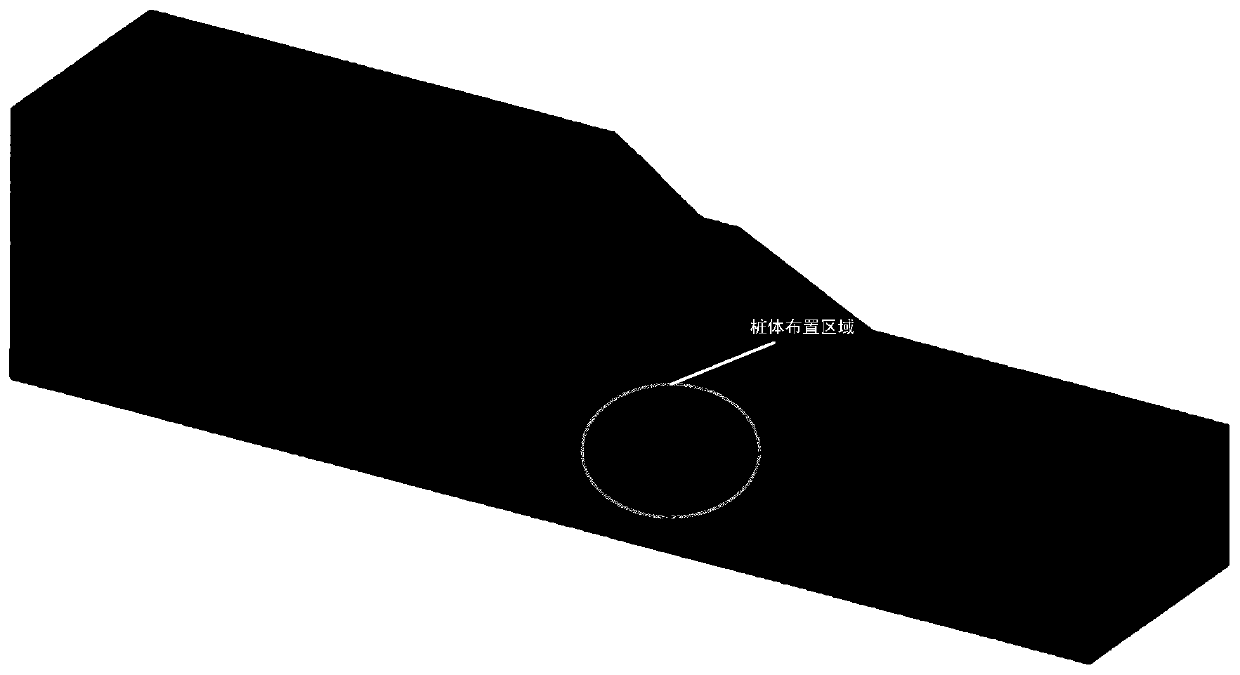

Finite element stability calculation method for filling slope of composite foundation

The invention discloses a finite element stability calculation method for a filling slope of a composite foundation. The method comprises the following steps that firstly, rock-soil physical and mechanical parameters of all materials are determined through a field test or an indoor test; 2, determining the arrangement form, the arrangement interval and the pile body diameter of the pile body; and3, calculating the cohesion Cc of the composite foundation, the internal friction angle phic of the composite foundation, the elasticity modulus Ec of the composite foundation and the volume weight gammac of the composite foundation within the pile body arrangement range according to the following formula; 4, establishing a filling slope finite element model with a composite foundation, calculating soil parameters of a composite foundation area through the calculation result in the step 3, and calculating the slope stability safety factor FOS through a strength reduction method. Compared withthe prior art, the method has the advantages that compared with a finite element model for establishing a complete pile body, the calculation precision of the method does not exceed 3%; 2, the calculation time of the method only needs to establish 1 / 10-1 / 8 of the finite element model calculation time of the complete pile body;

Owner:ZHENGYE ENG & INVESTMENT INC

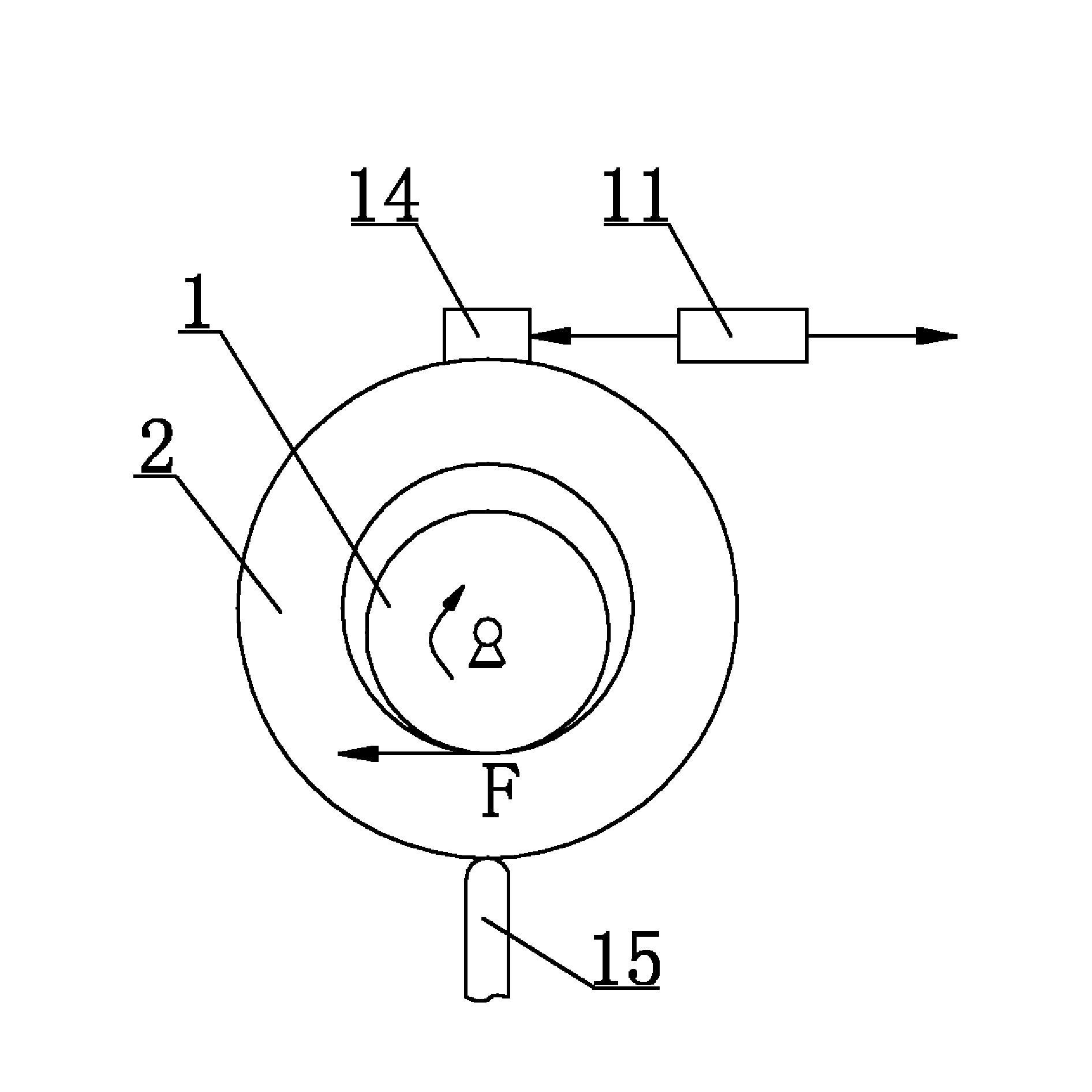

Speed limiter of elevator

ActiveCN100575234CGuaranteed uptimeAchieve speed continuous captureElevatorsFreewheel clutchesInstabilityEngineering

The invention relates to a novel elevator overspeed governor applicable to the protection of ascending overspeed or descending overspeed or bidirectional overspeed of the ascending and the descending. The elevator overspeed governor comprises a frame, a rope pulley, a rope pulley shaft, an overspeed switch and a roller-type overrunning clutch; wherein, the roller-type overrunning clutch consists of a set of internal friction pulley and external friction pulley coaxially arranged with the rope pulley, a friction roller between the internal friction pulley and the external friction pulley, and a centrifugal quadrilateral component; wherein, the centrifugal quadrilateral component consists of two centrifugal sheets, two balancing springs and two connecting rods. By adopting the roller-type overrunning clutch instead of the conventional centrifugal ratchet wheel typed clutch structure, the overspeed governor solves the discontinuity and the instability of the action of the overspeed governor and the delay of the action of an electrical switch, thereby enabling the elevator overspeed governor to act instantaneously when overspeed occurs, realizing the continuous speed capture of the overspeed governor, stabilizing the drawing force of the steel wire rope and the rope pulley and resulting in safer and more reliable operation of the elevator.

Owner:宁波申菱机电科技股份有限公司

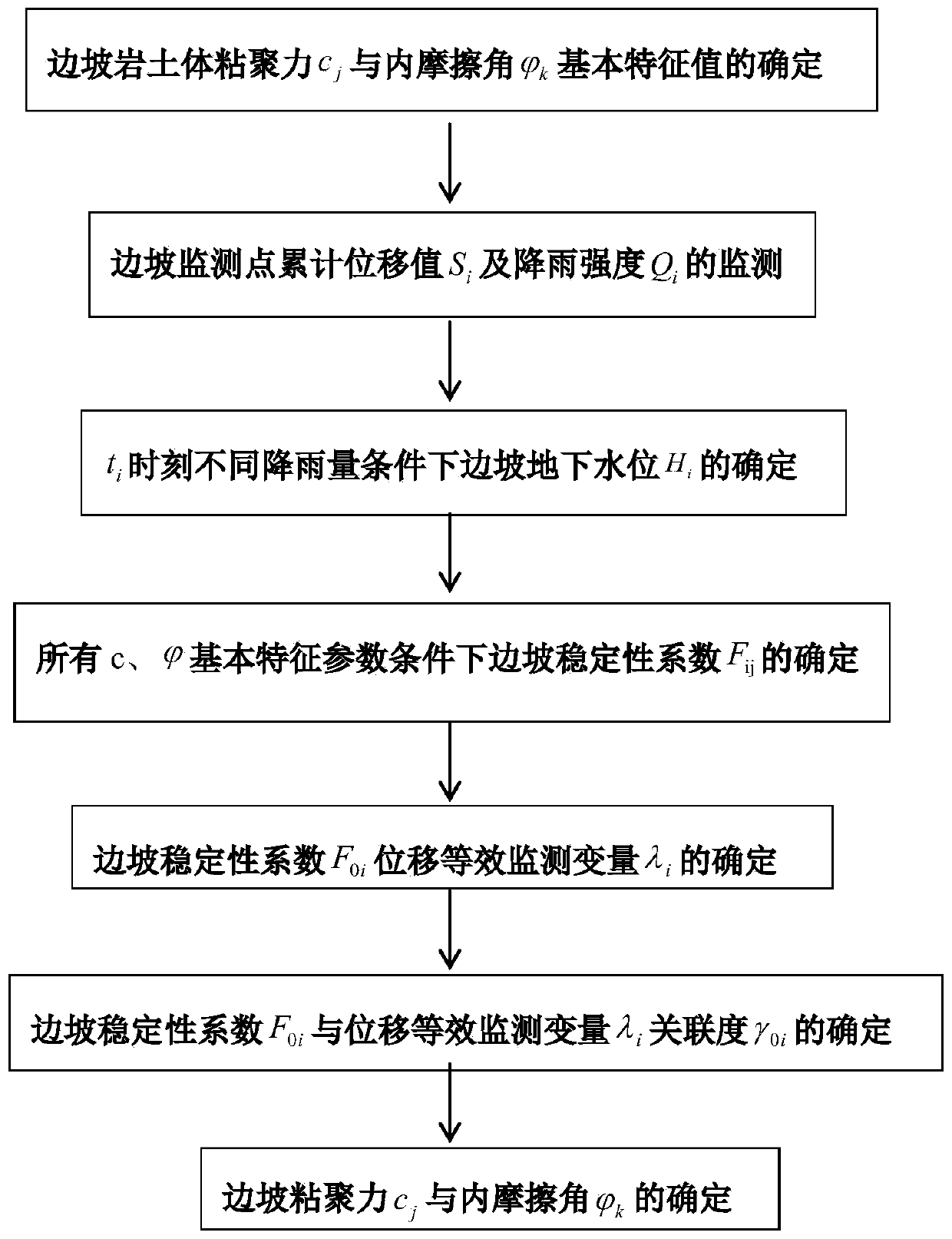

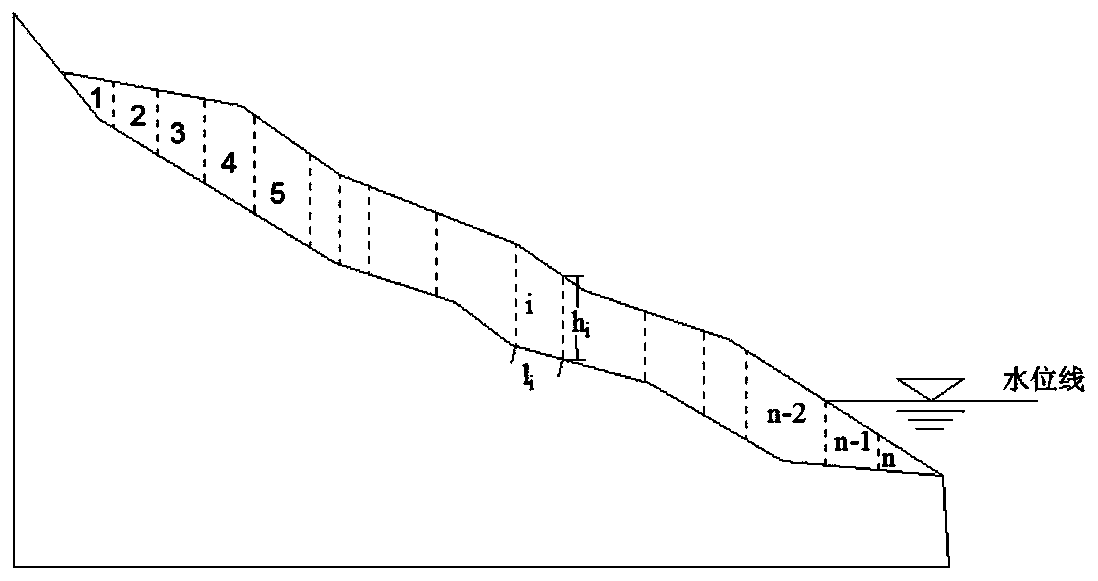

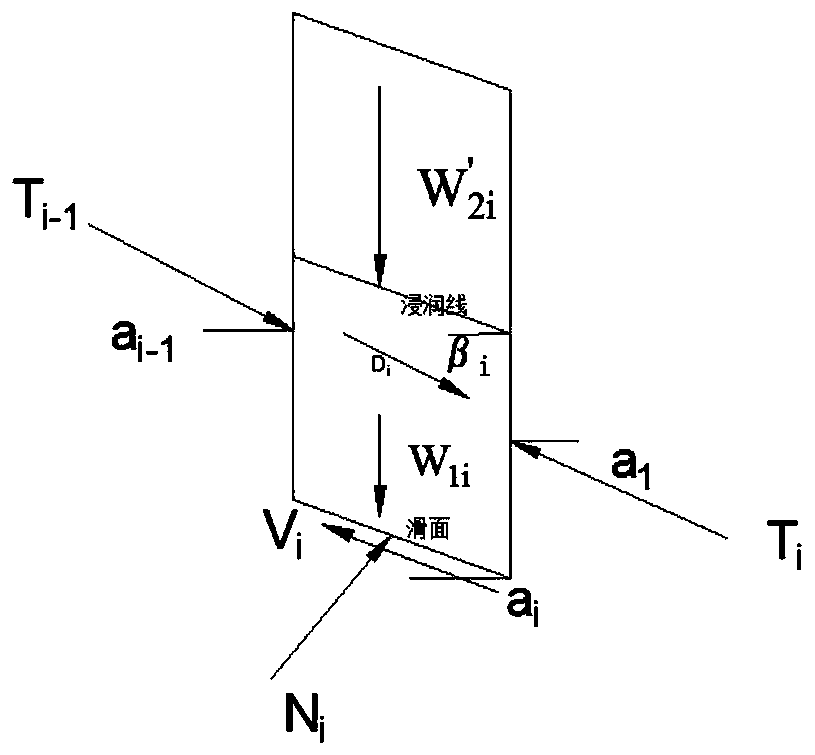

An inversion determination method of rainfall type landslide shear strength parameters

InactiveCN109726444AEasy to operateReduce computing costSpecial data processing applicationsSlope monitoringLandslide

The invention relates to an inversion determination method for rainfall type landslide shear strength parameters, and belongs to the technical field of slope engineering stability evaluation. The method comprises the following steps that 1, the basic characteristic value of the cohesive force cj and the internal friction angle (shown in the specification) of the side slope rock-soil body is determined; 2, the basic characteristic value of the side slope rock-soil body is obtained, 2, monitoring a slope monitoring point cumulative displacement value Si and rainfall intensity Qi; Step 3, determining the side slope underground water level Hi under different rainfall conditions at the ti moment; Step 4, determining a slope stability coefficient Fij under the basic characteristic parameter condition of all the c,(shown in the specification); 5, determining a slope stability coefficient F0i displacement equivalent monitoring variable Lambda i; 6, determining the correlation degree Lambda 0ibetween the slope stability coefficient F0i and the displacement equivalent monitoring variable Lambda i; And 7, determining the cohesive force cj and the internal friction angle (shown in the specification) of the side slope according to the grey correlation degree. According to the method, the calculation result is accurate, and the overall shear strength of the side slope can be better reflected. and moreover, the operation steps are easy to implement, and the calculation cost is lower than that of other determination methods.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Test device of frictional characteristic of sliding bearing under middle and heavy radial load

InactiveCN101995310AReduce contact surfaceSmall sizeMachine bearings testingWork measurementRolling-element bearingEngineering

The invention relates to a test device of a frictional characteristic of a sliding bearing under a middle and heavy radial load, comprising a simulative sliding bearing, wherein the simulative sliding bearing comprises a shaft and a shaft sleeve, a radial loading device is arranged on the outer peripheral surface of the shaft sleeve, and two raised ring surfaces which have the same structure and are matched with the inner peripheral surface of the shaft sleeve in a sliding mode are symmetrically arranged on the outer peripheral surfaces of shafts arranged on both sides of loading points supported by the loading end and the outer peripheral surface of the shaft sleeve. In the invention, two raised ring surfaces are arranged on the outer peripheral surface of the shaft along an axial direction at intervals, the inner peripheral surface of the shaft sleeve is in contact with two ring projections, thus, the contact surface of the shaft sleeve and the shaft is smaller, the dimensions of related parts can be reduced in the same proportion, the working state of the sliding bearing can be simulated in reality, the internal friction force of the sliding bearing can be accurately measured in an experiment condition, and meanwhile, the two raised ring surfaces are symmetrically arranged corresponding to the loading points to ensure two even contact loads.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com