Longitudinal-torsional resonance ultrasonic vibration device

A technology of ultrasonic vibration and longitudinal vibration, applied in the direction of fluid using vibration, can solve the problems of small torsional amplitude and low energy utilization efficiency, and achieve the effects of large amplitude, simple power supply form, and easy and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

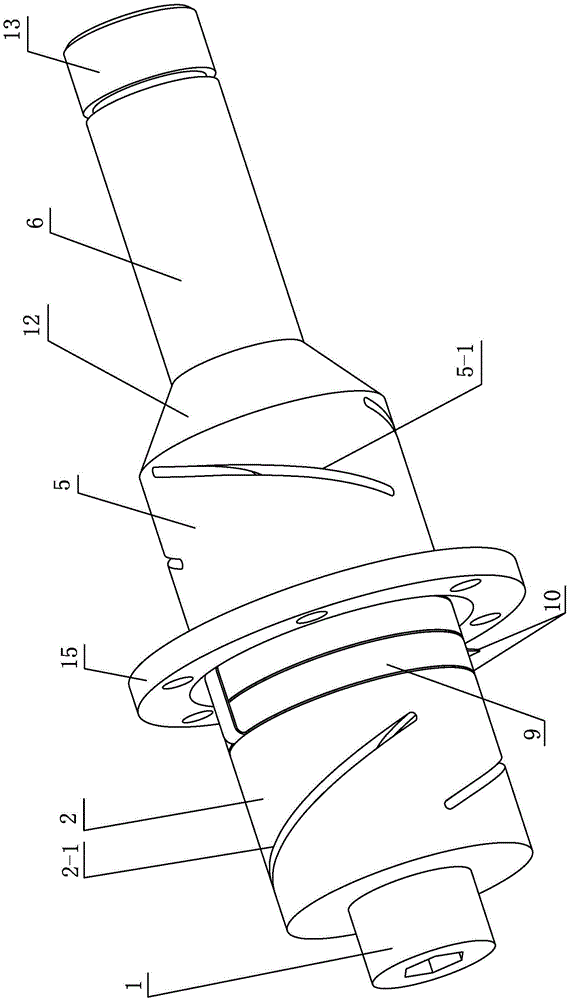

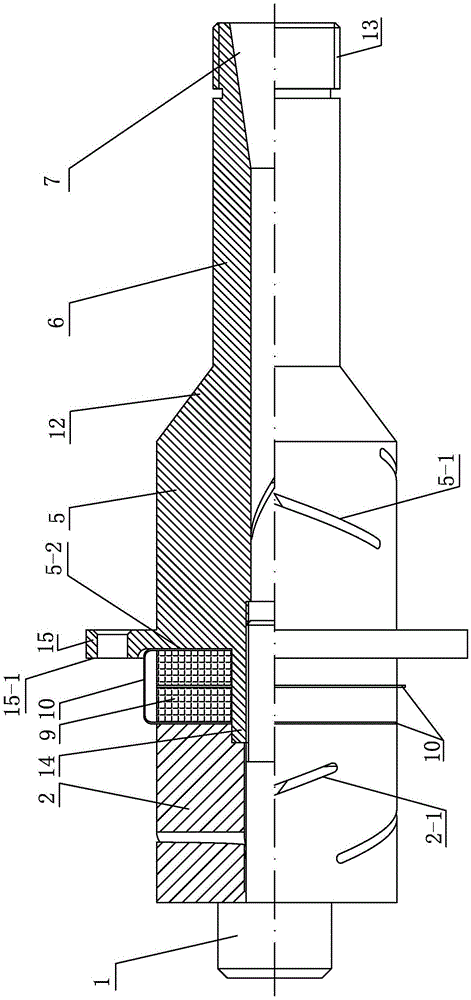

[0014] Specific implementation mode one: combine Figure 1-Figure 4 Explain that the longitudinal-torsional resonance ultrasonic vibration device of this embodiment includes a stepped hollow cylindrical cone complex, a longitudinal-torsion conversion hollow cylinder 2, a pre-tightening bolt 1, an even number of piezoelectric ceramic sheets 9 and a plurality of electrode sheets 10; The stepped hollow cone complex is mainly composed of an axial positioning shaft 14, a cylindrical longitudinal and torsional conversion body 5, a conical torsional vibration amplifier 12 and a cylindrical longitudinal vibration amplifier 6, which are coaxially arranged in sequence and integrated;

[0015] The large-diameter end of the conical torsional vibration amplifying body 12 is connected with the cylindrical longitudinal-torsion conversion body 5, and the small-diameter end of the conical torsional vibration amplifying body 12 is connected with the cylindrical longitudinal vibration amplifying ...

specific Embodiment approach 2

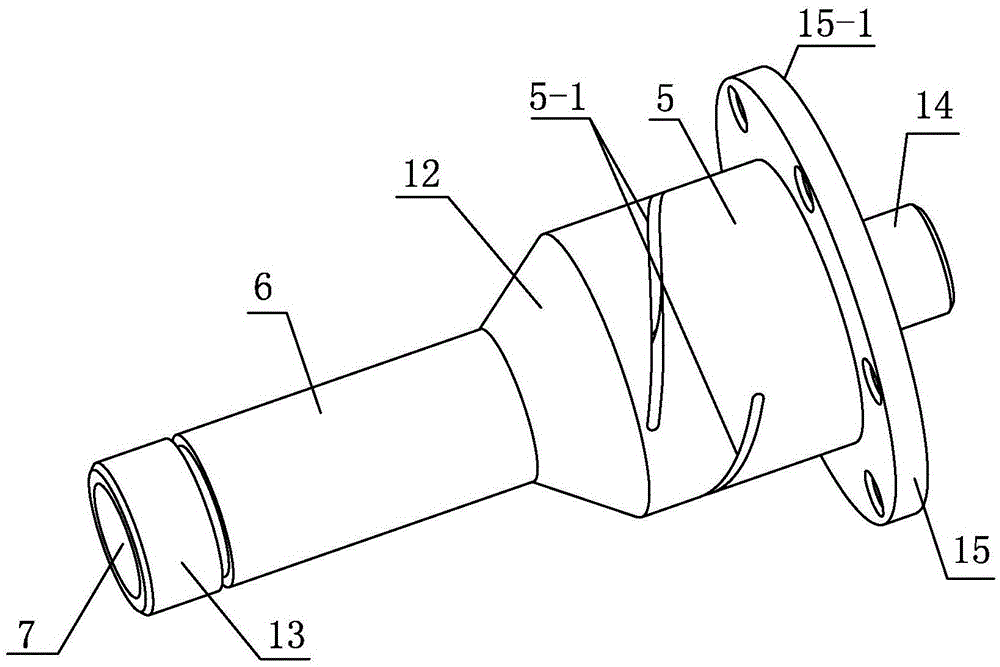

[0019] Specific implementation mode two: combination figure 1 and image 3 Note that the sum of the central angles corresponding to the plurality of first helical grooves 5 - 1 in this embodiment is 360°. Such setting maximizes the conversion efficiency of longitudinal torsion, makes the nodal surface of torsional vibration coincide with the nodal surface of longitudinal vibration, and balances the torsional momentum of the stepped hollow cylinder-cone complex and the hollow cylinder for longitudinal torsion conversion; it is installed at the end nodal surface, The torsional vibration of the structure does not affect the installation structure (such as the spindle of the machine tool); it is installed at the end section surface, so that the installation method will not affect the torsional vibration of the structure, and the torsional vibration mode of the structure can be used more efficiently. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination figure 1 and Figure 4 Note that the sum of the central angles corresponding to the plurality of second helical grooves 2 - 1 in this embodiment is 360°. Such setting maximizes the conversion efficiency of longitudinal torsion, makes the nodal surface of torsional vibration coincide with the nodal surface of longitudinal vibration, and balances the torsional momentum of the stepped hollow cylinder-cone complex and the hollow cylinder for longitudinal torsion conversion; it is installed at the end nodal surface, The torsional vibration of the structure does not affect the installation structure (such as the spindle of the machine tool); it is installed at the end section surface, so that the installation method will not affect the torsional vibration of the structure, and the torsional vibration mode of the structure can be used more efficiently. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com