Patents

Literature

48 results about "Torsional resonance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

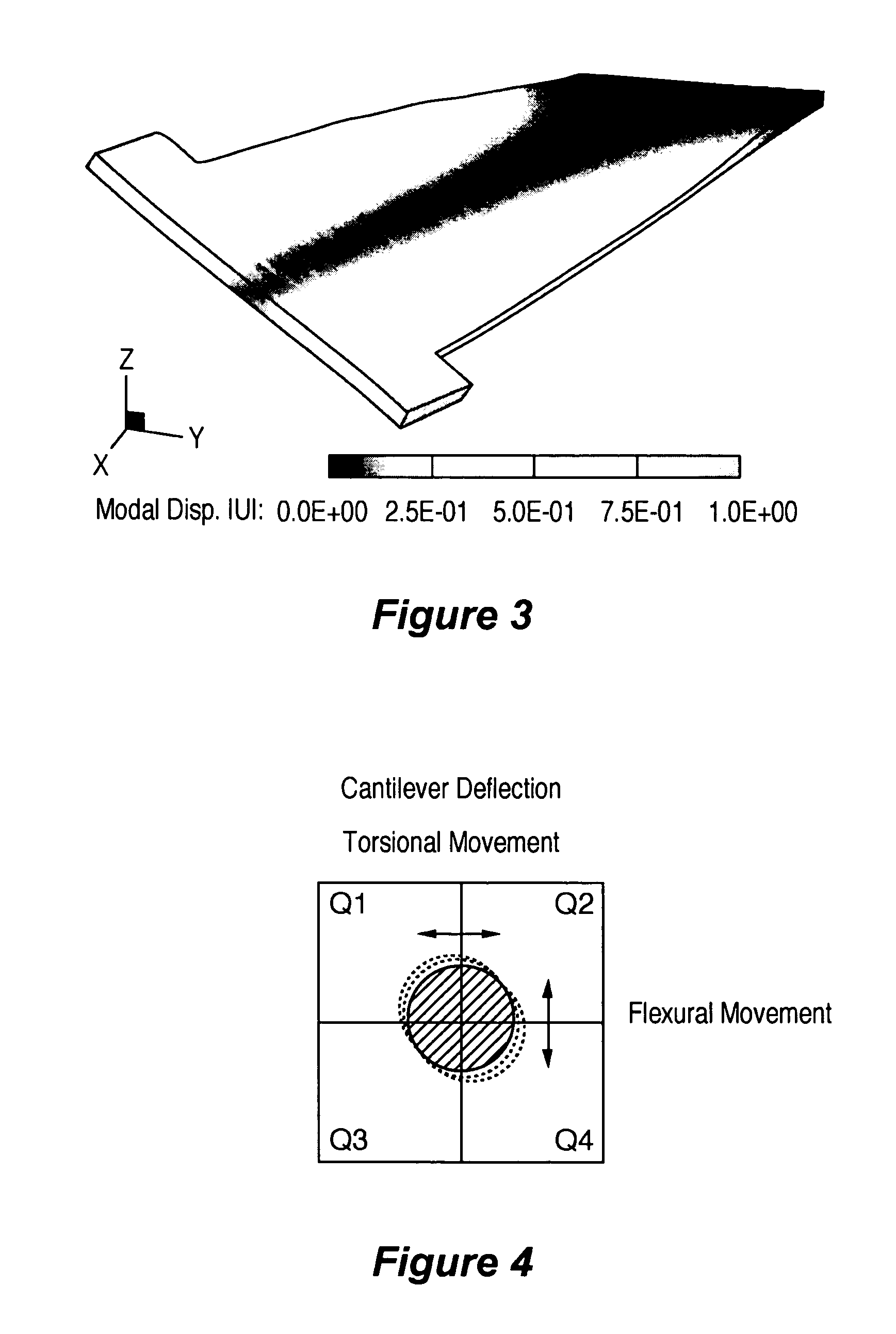

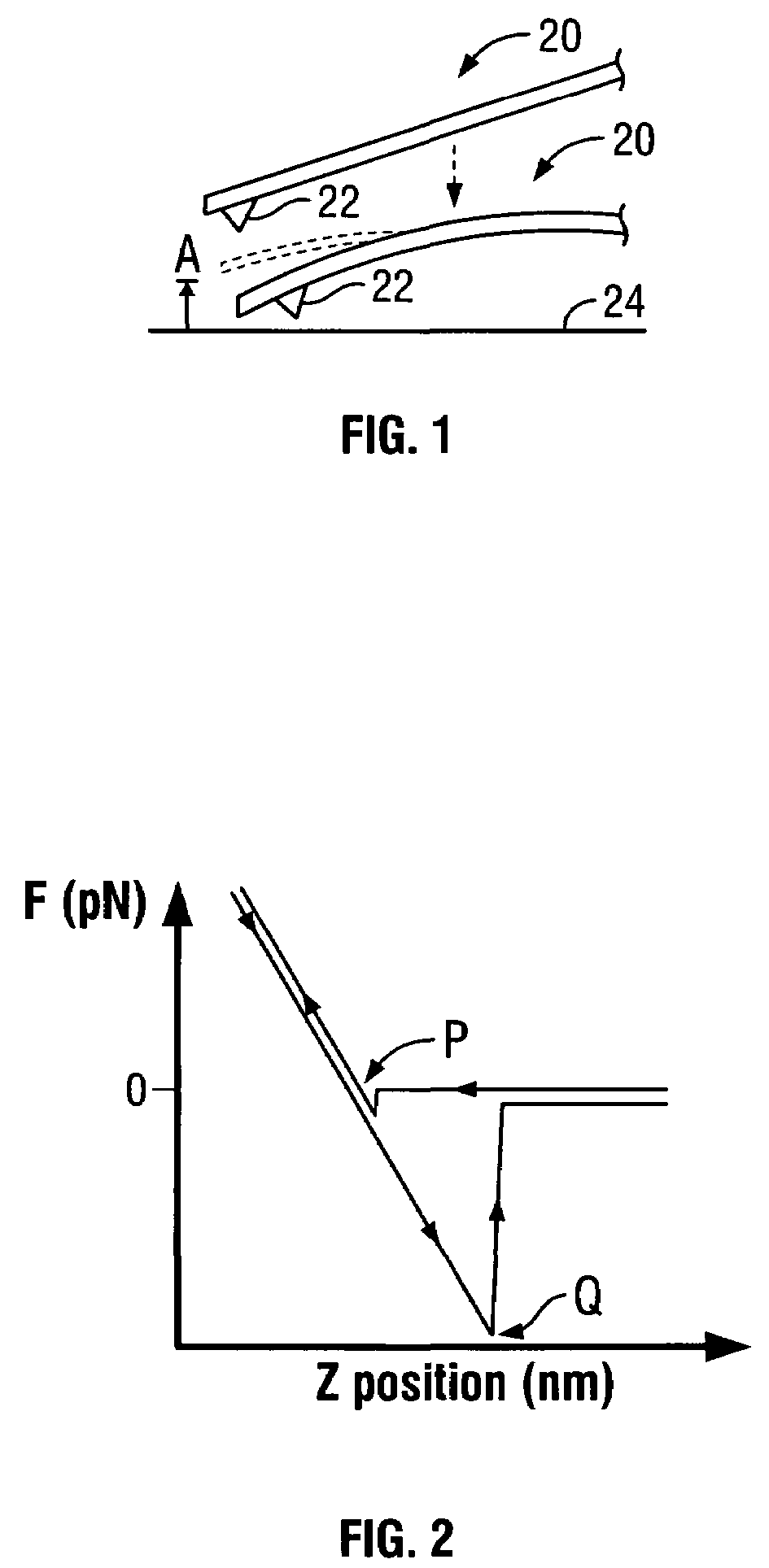

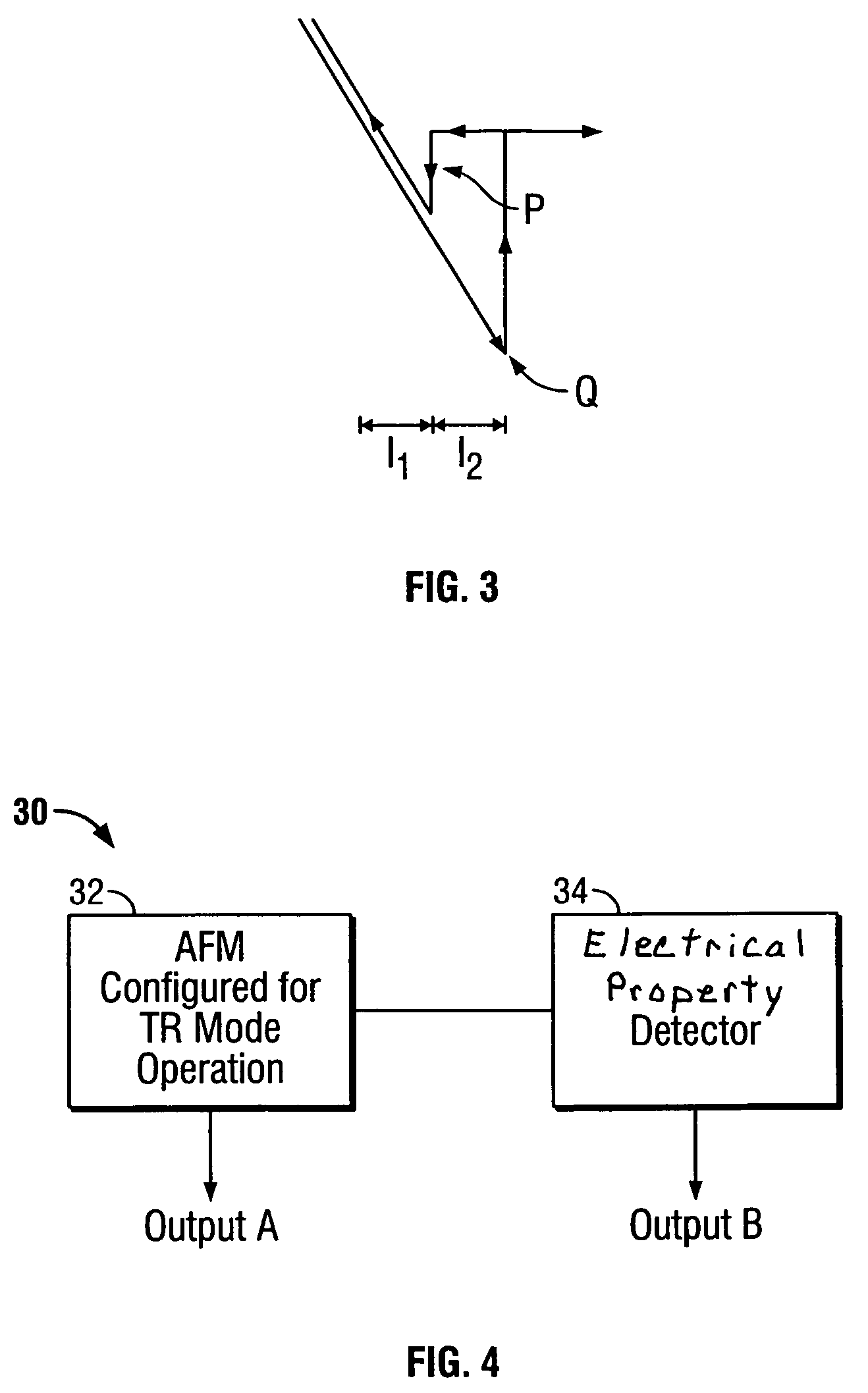

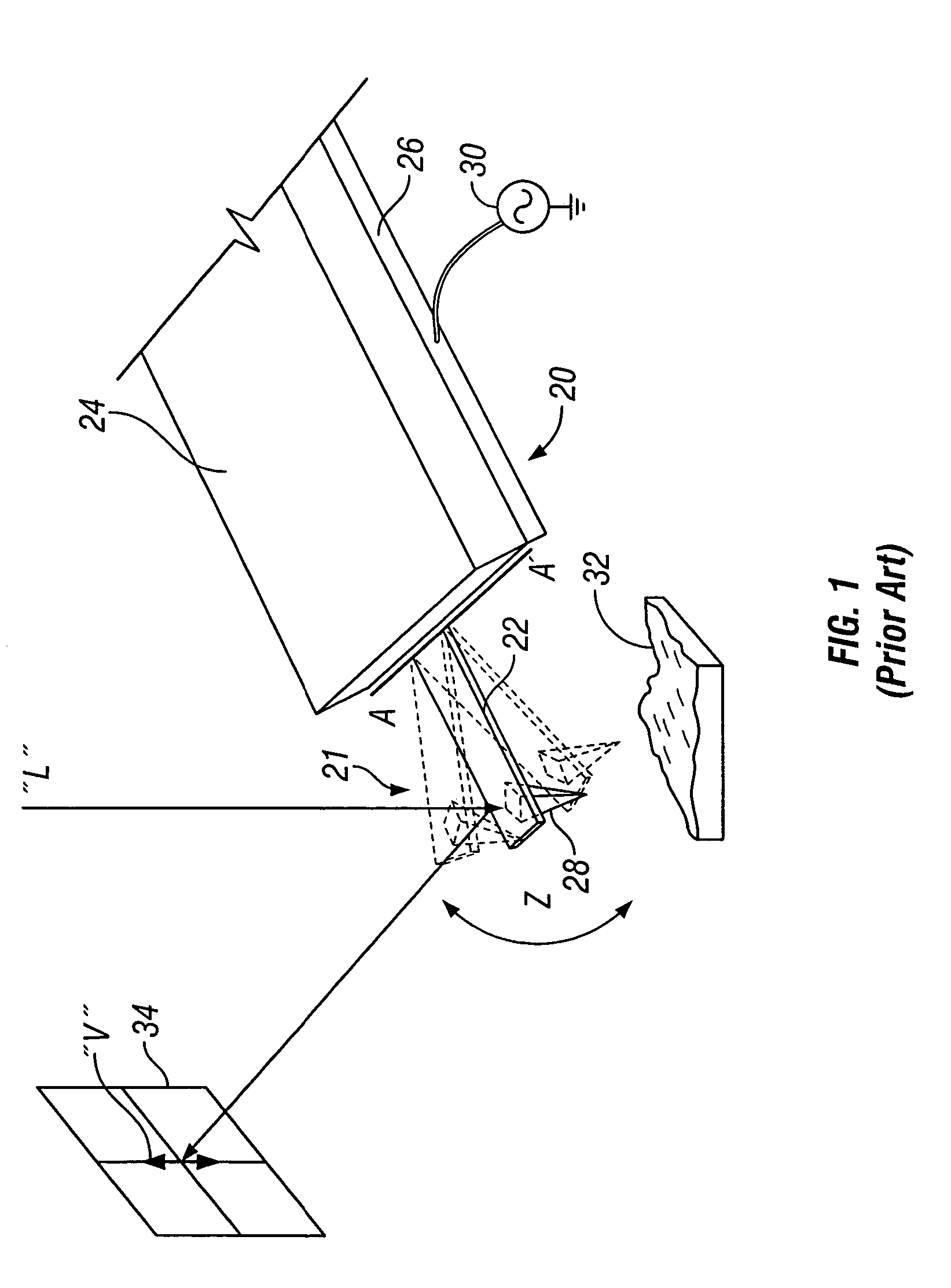

Torsional harmonic cantilevers for detection of high frequency force components in atomic force microscopy

InactiveUS7089787B2Fast response timeQuick checkForce measurement by measuring frquency variationsSurface/boundary effectAtomic force microscopyHarmonic

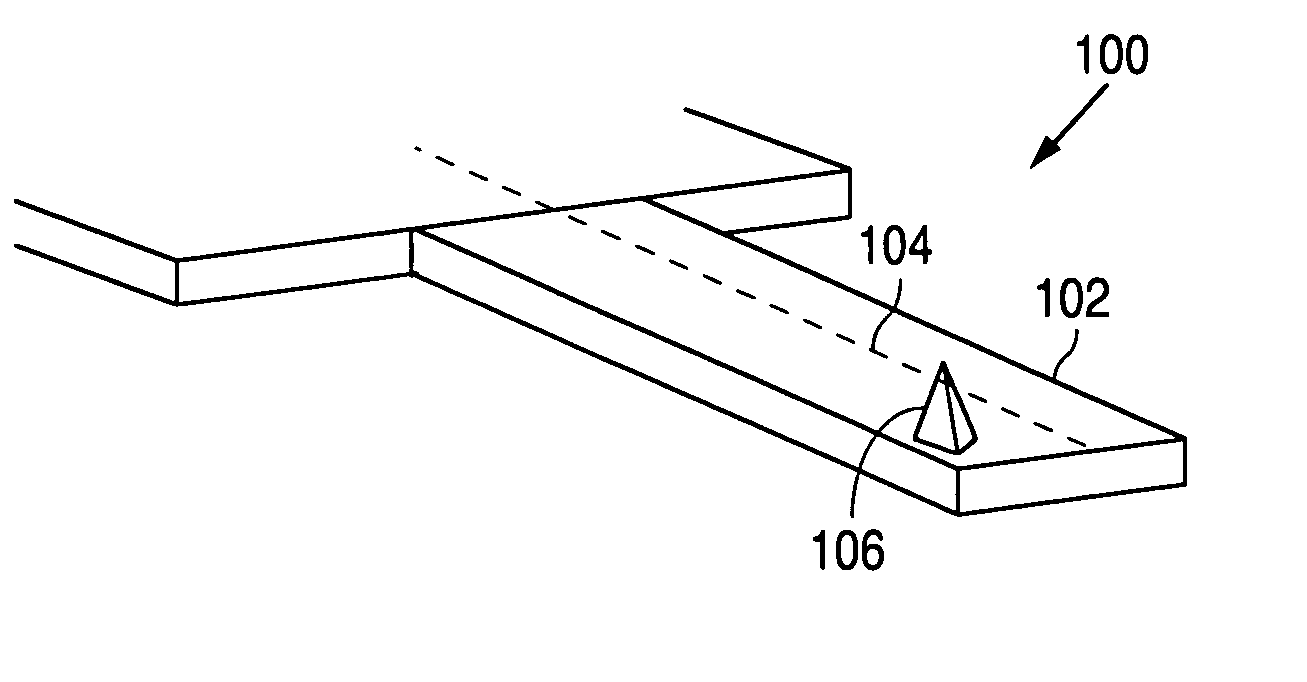

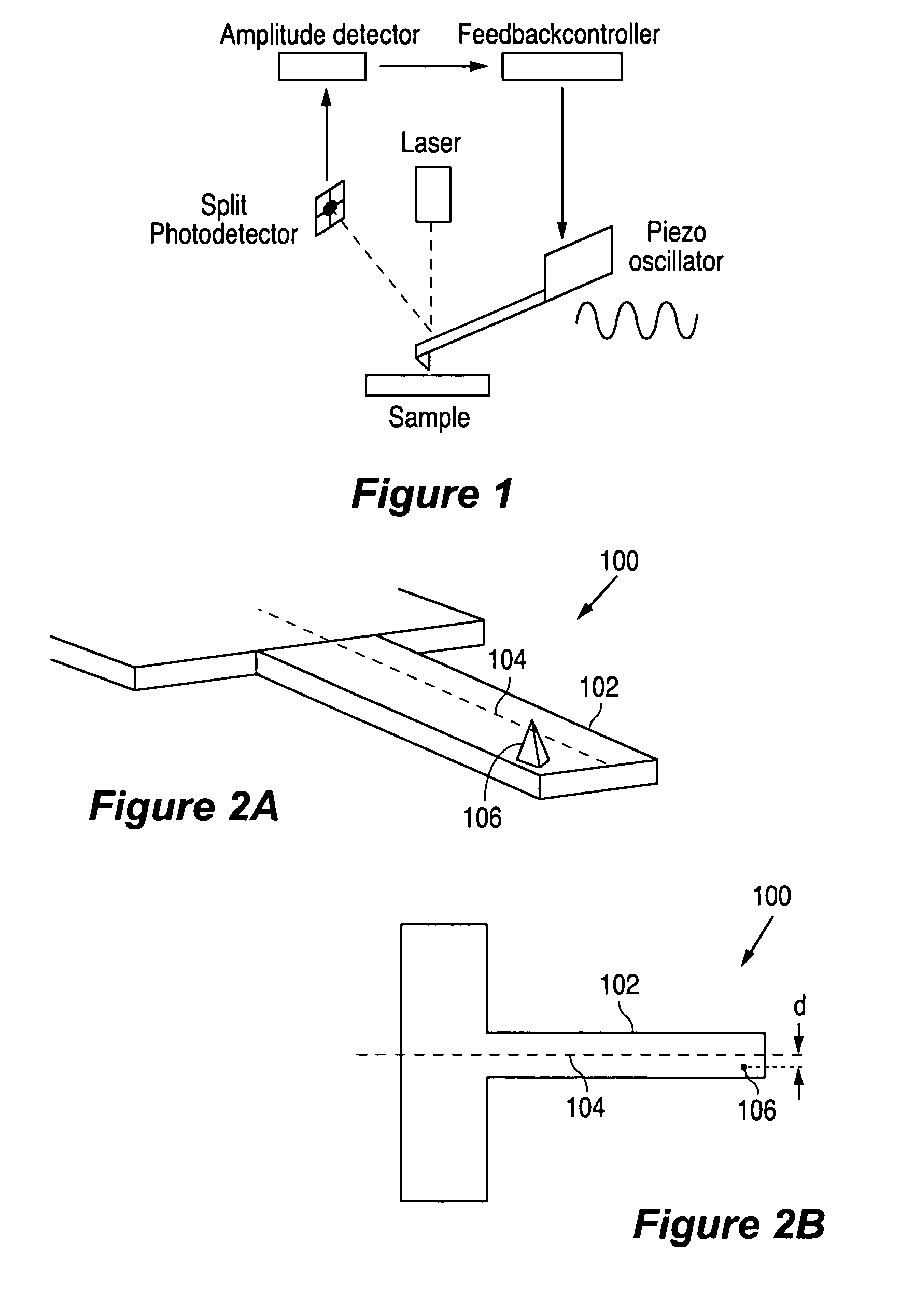

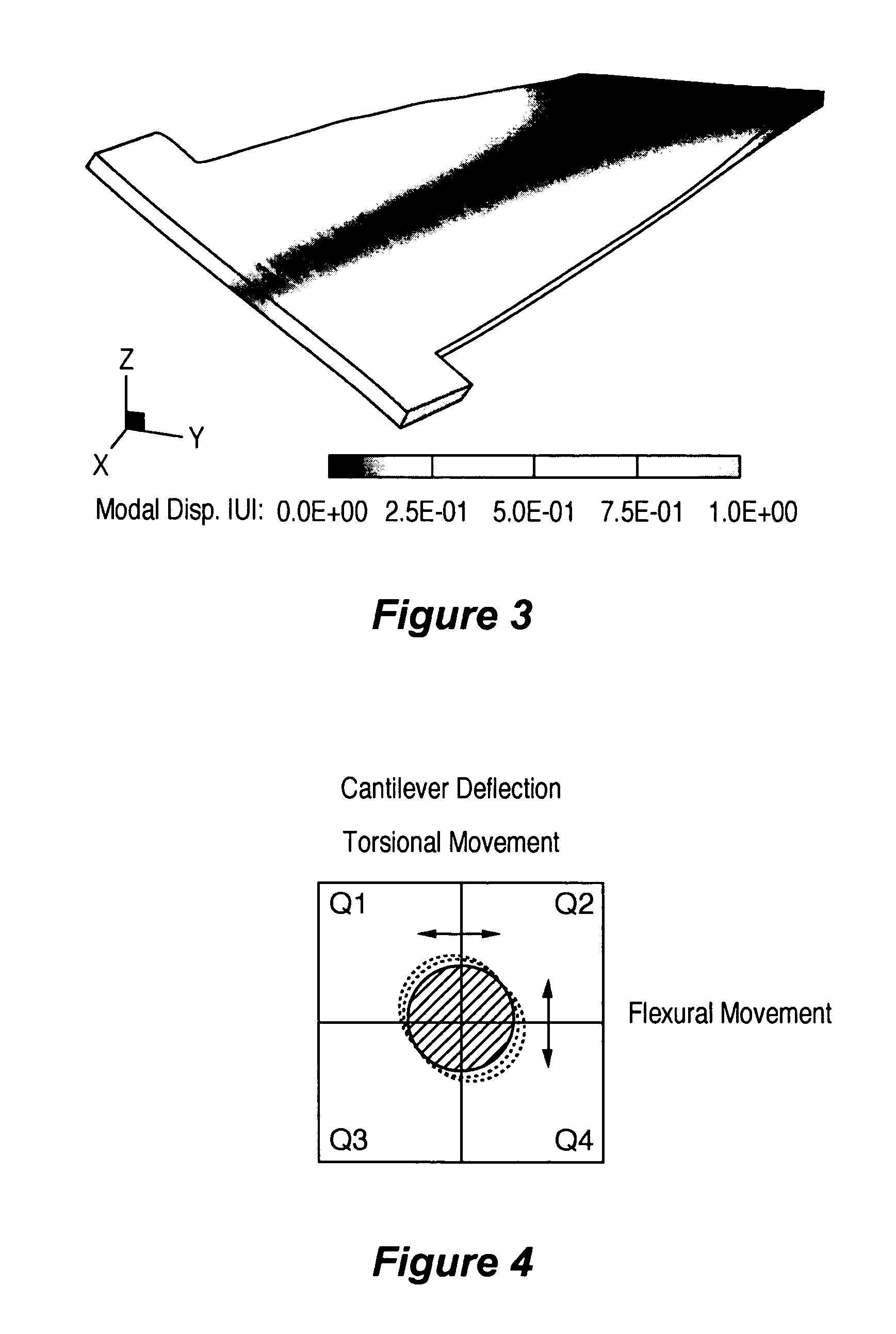

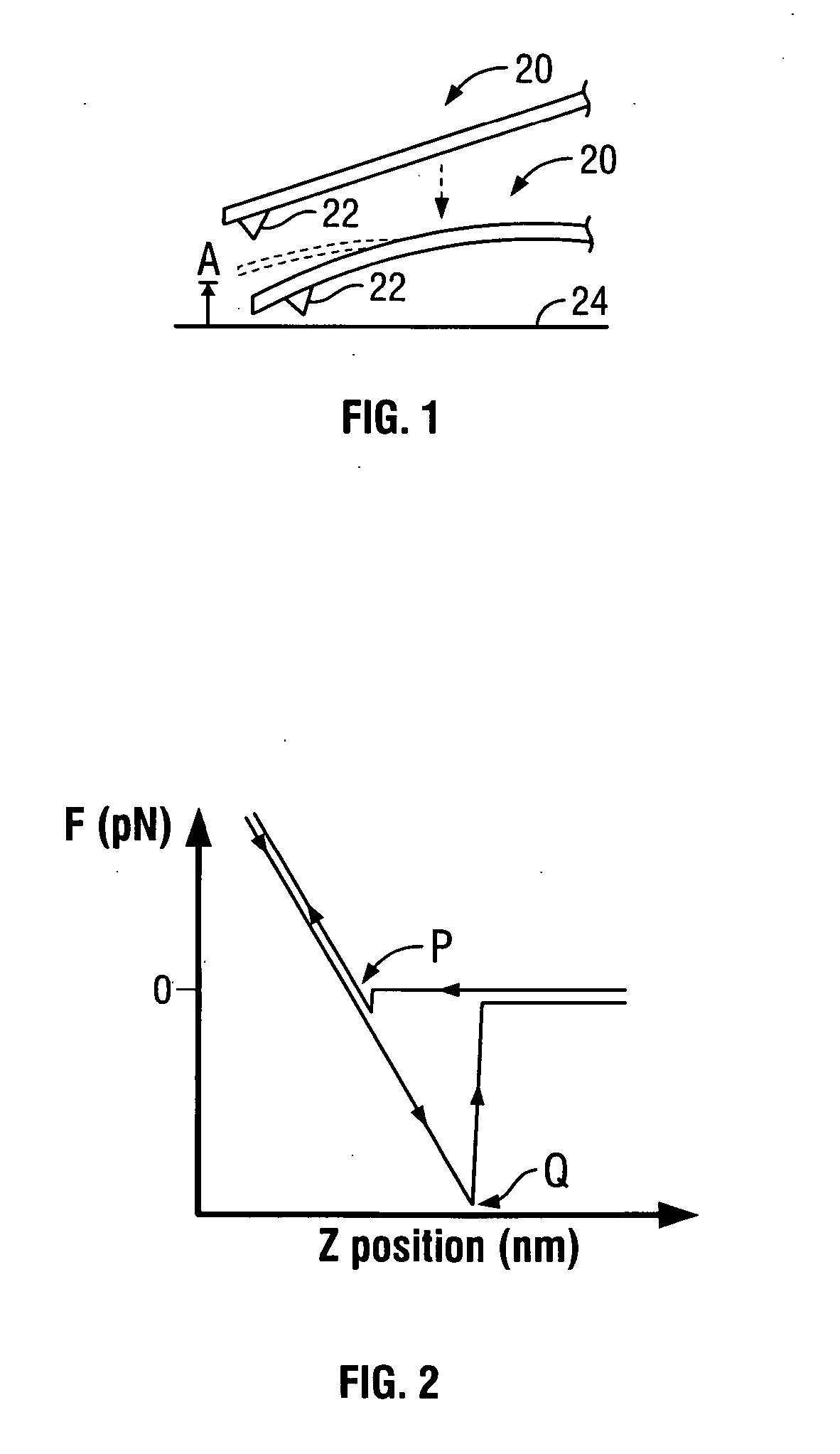

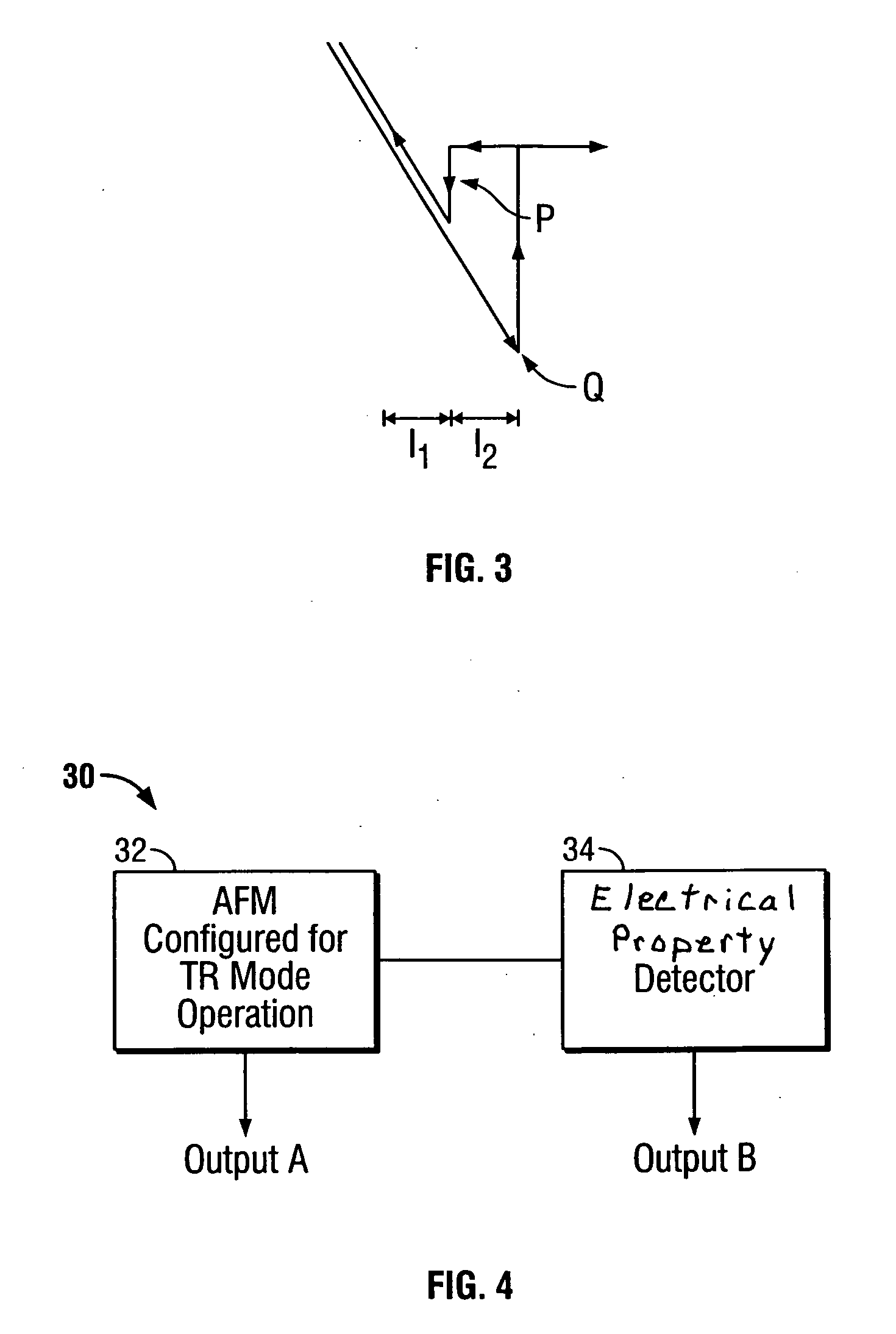

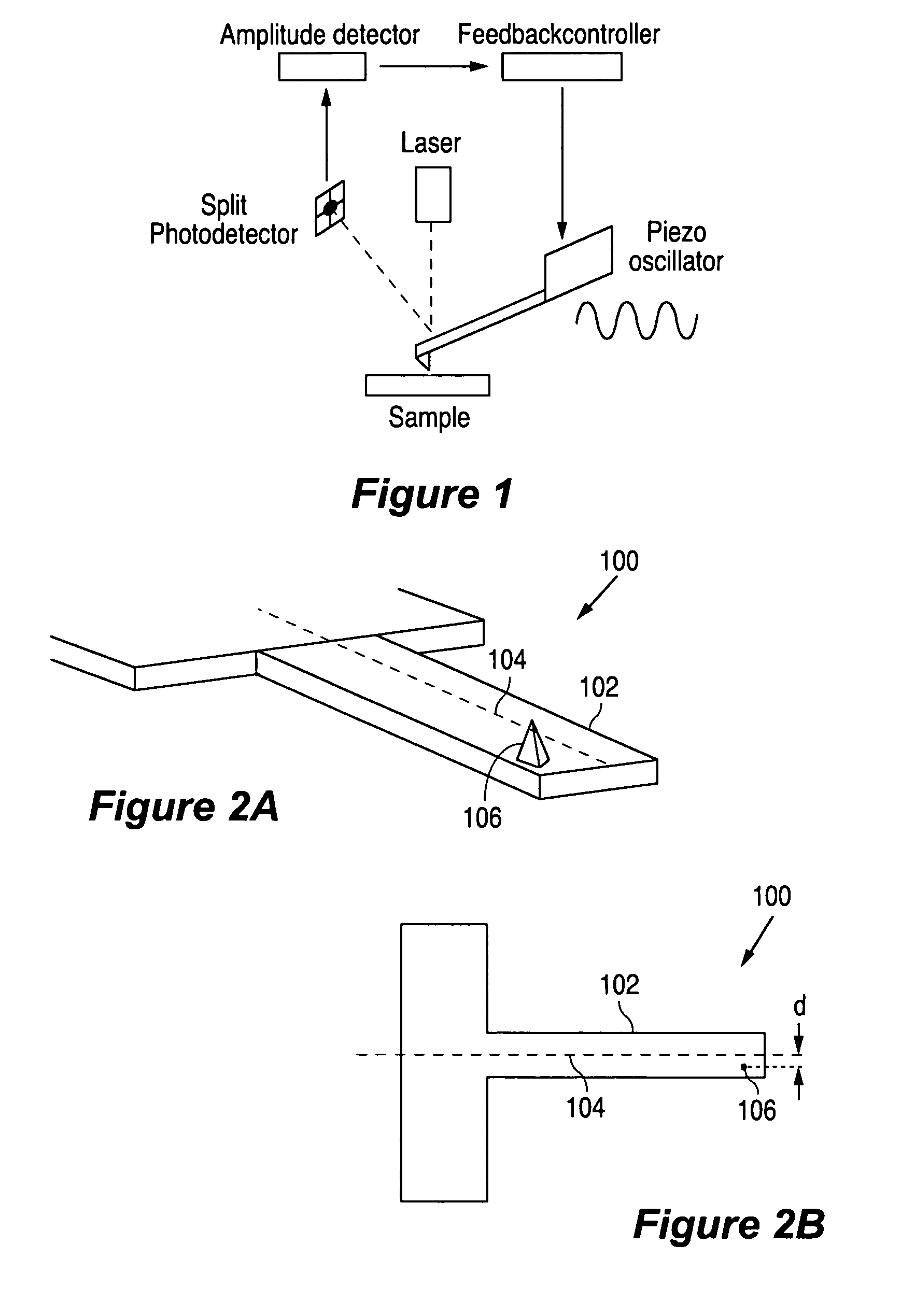

A cantilever for the use in atomic force microscopy includes a cantilever arm having a fixed end being attached to a base member and a free end where the cantilever arm has a first shape and an axis of torsion associated with the first shape, and a probe tip projecting from the cantilever arm near the free end where the probe tip is positioned in an offset displacement from the axis of torsion. Alternately, the cantilever arm has a first shape selected to tune a torsional resonance frequency of a selected torsional mode or the fundamental flexural resonance frequency of the fundamental mode so that the torsional resonance frequency and the fundamental flexural resonance frequency has an integer ratio. In this manner, the torsional motion of the torsional harmonic cantilever at that harmonic frequency will be largely enhanced by the corresponding torsional resonance.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

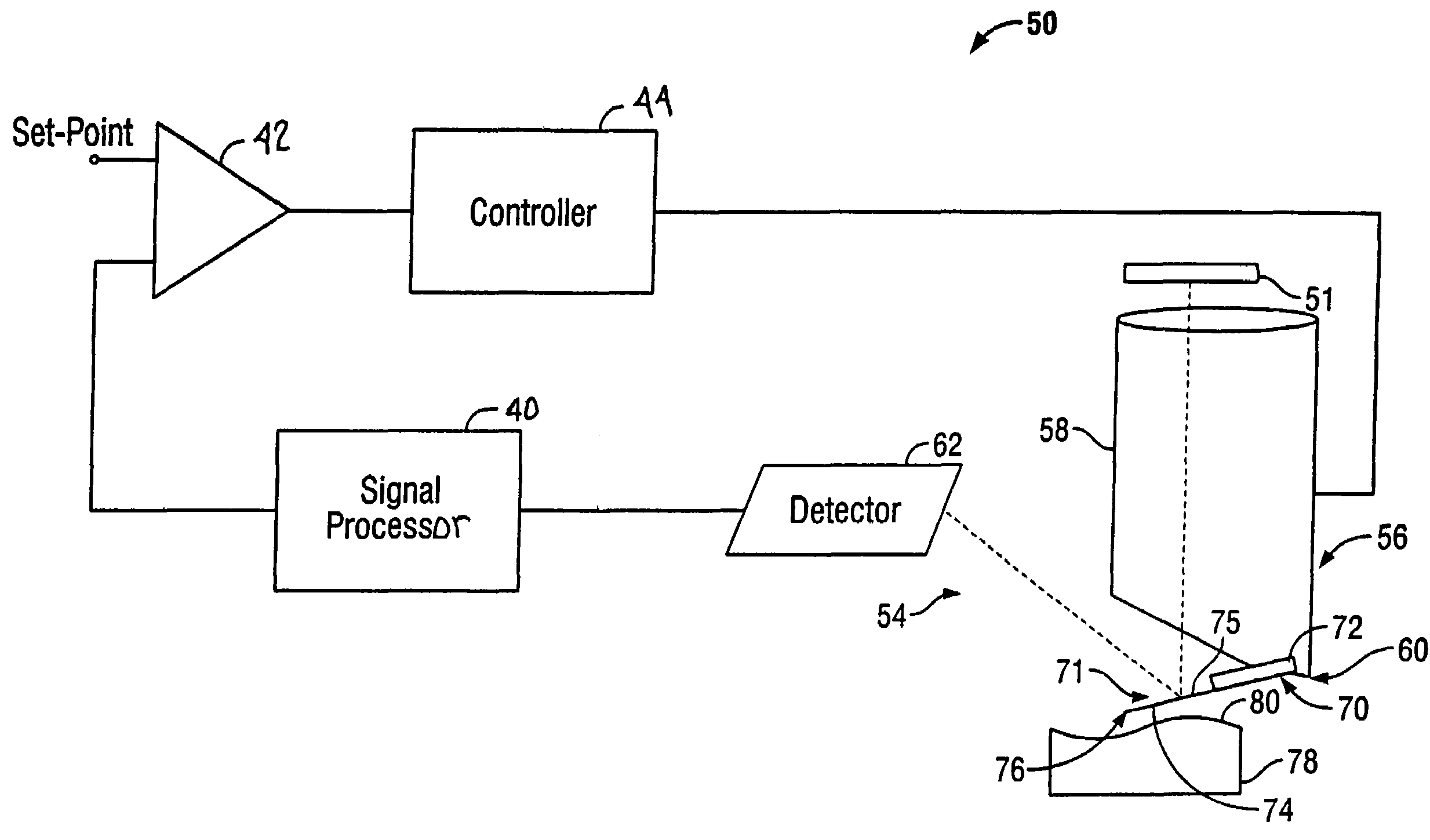

Method and apparatus for measuring electrical properties in torsional resonance mode

InactiveUS20050212529A1Soft and delicate materialAccurate measurementResistance/reactance/impedenceNanotechnologyCapacitanceElectricity

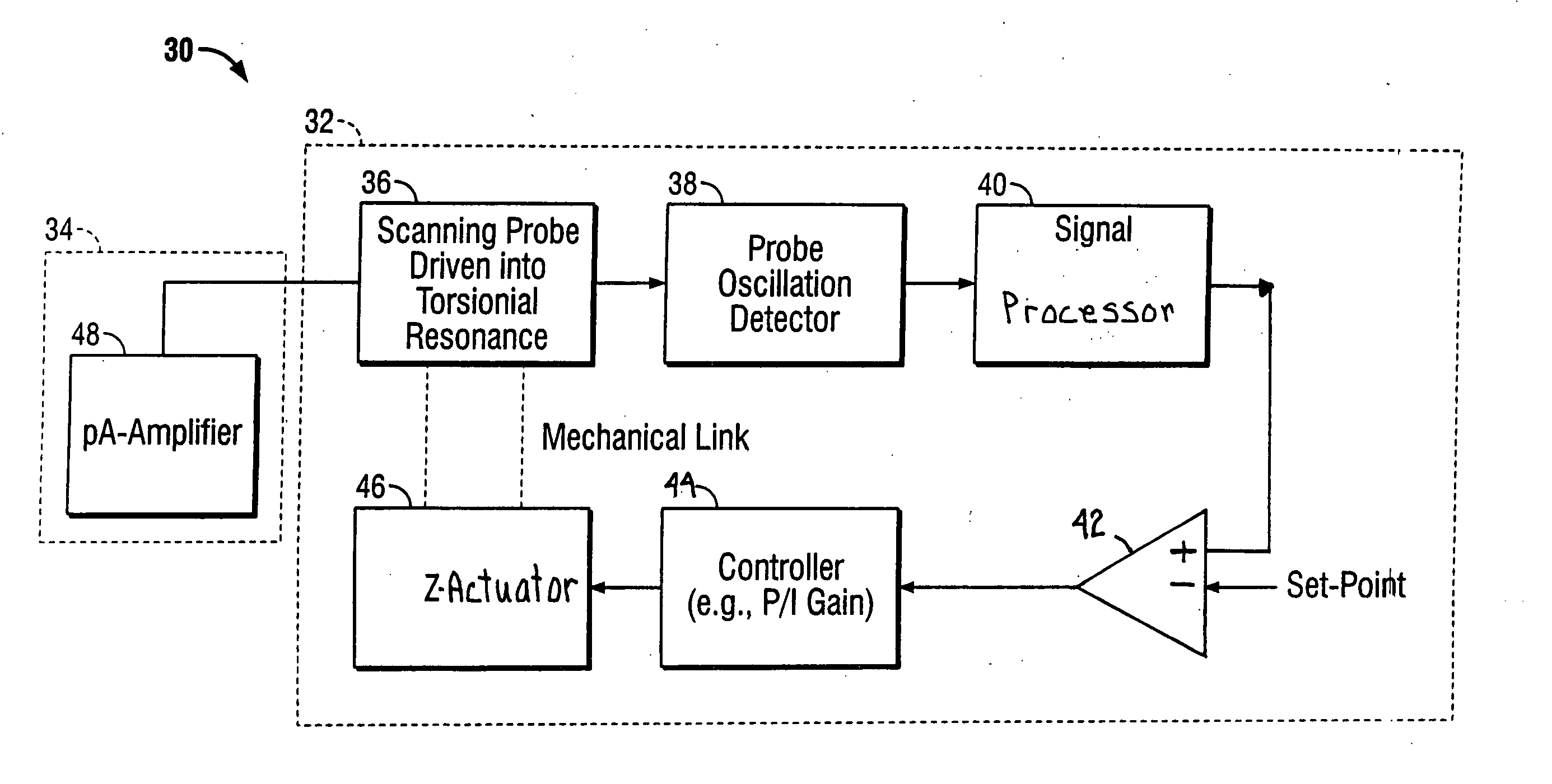

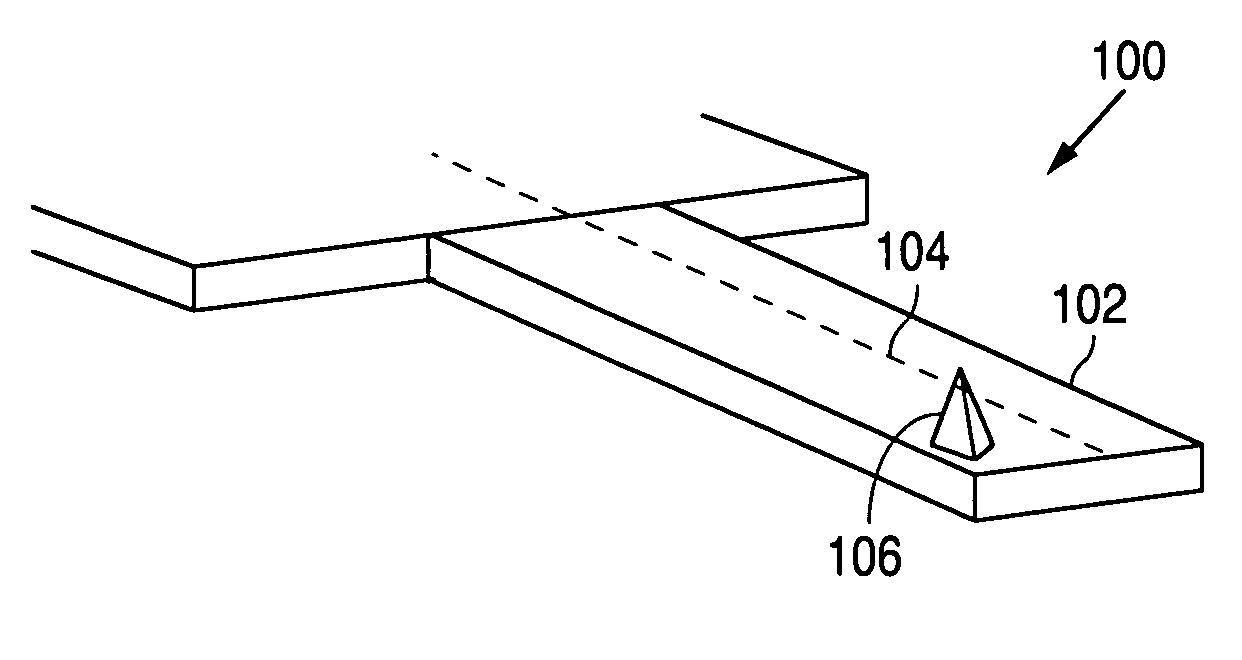

The preferred embodiments are directed to a method and apparatus of operating a scanning probe microscope (SPM) including oscillating a probe of the SPM at a torsional resonance of the probe, and generally simultaneously measuring an electrical property, e.g., a current, capacitance, impedance, etc., between a probe of the SPM and a sample at a separation controlled by the torsional resonance mode. Preferably, the measuring step is performed while using torsional resonance feedback to maintain a set-point of SPM operation.

Owner:BRUKER NANO INC

Torsional harmonic cantilevers for detection of high frequency force components in atomic force microscopy

InactiveUS20060005614A1Fast response timeQuick checkForce measurement by measuring frquency variationsSurface/boundary effectAtomic force microscopyHarmonic

A cantilever for the use in atomic force microscopy includes a cantilever arm having a fixed end being attached to a base member and a free end where the cantilever arm has a first shape and an axis of torsion associated with the first shape, and a probe tip projecting from the cantilever arm near the free end where the probe tip is positioned in an offset displacement from the axis of torsion. Alternately, the cantilever arm has a first shape selected to tune a torsional resonance frequency of a selected torsional mode or the fundamental flexural resonance frequency of the fundamental mode so that the torsional resonance frequency and the fundamental flexural resonance frequency has an integer ratio. In this manner, the torsional motion of the torsional harmonic cantilever at that harmonic frequency will be largely enhanced by the corresponding torsional resonance.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

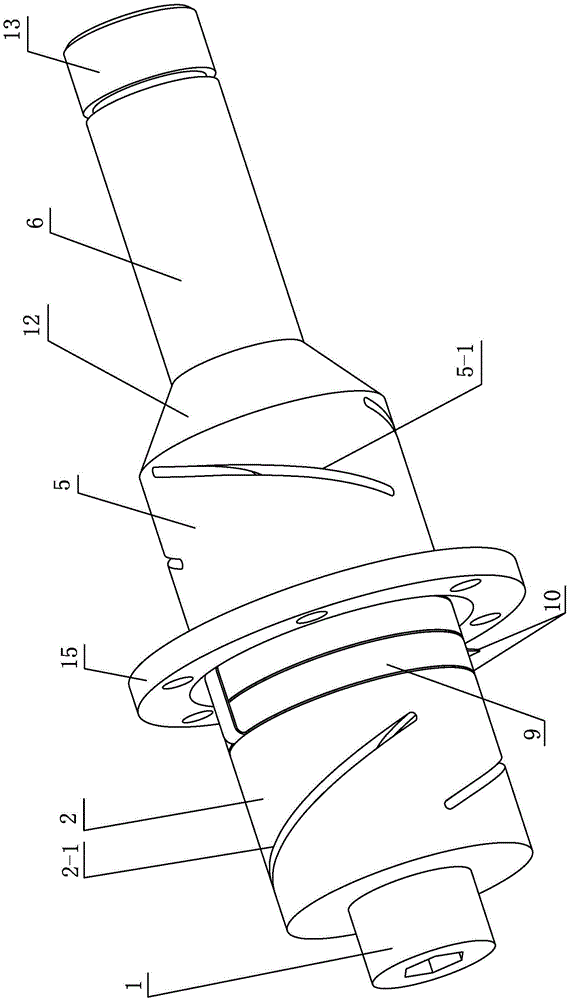

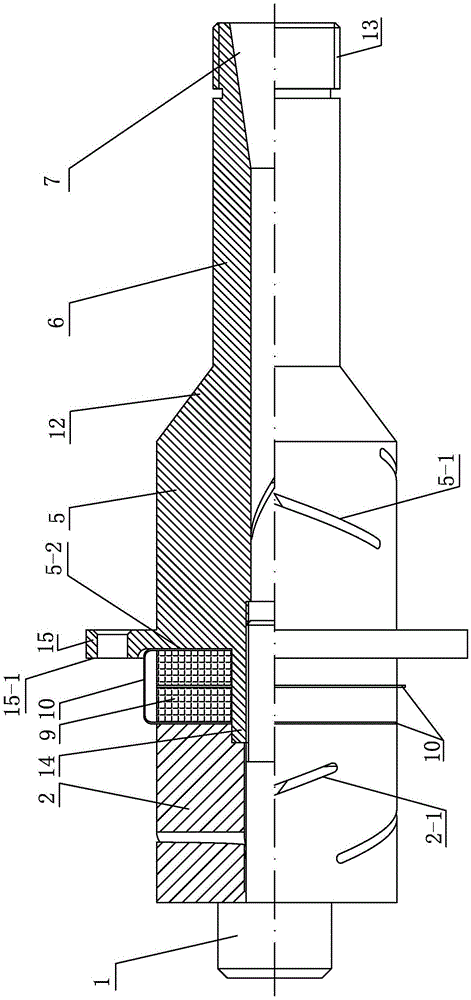

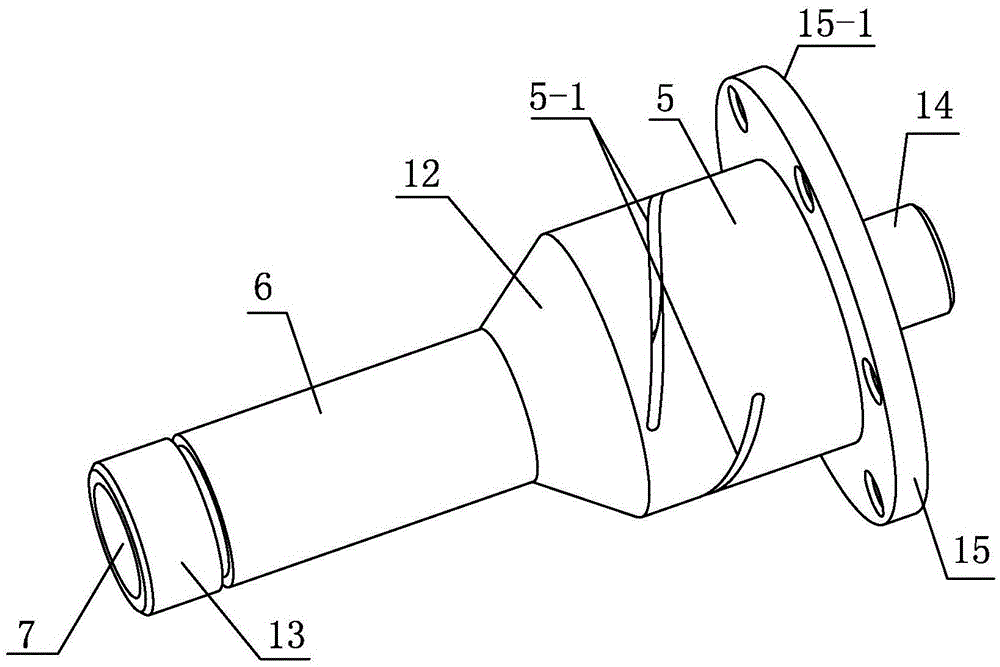

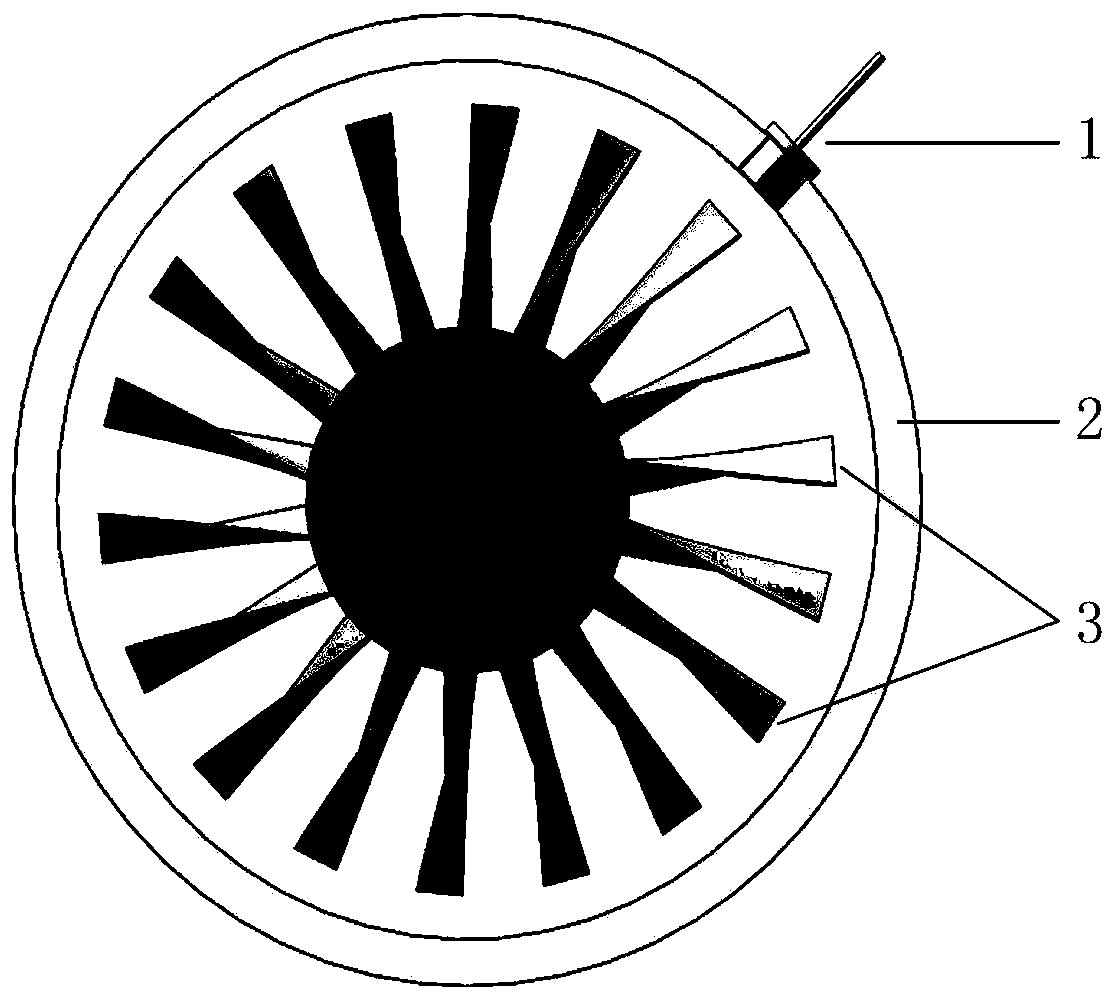

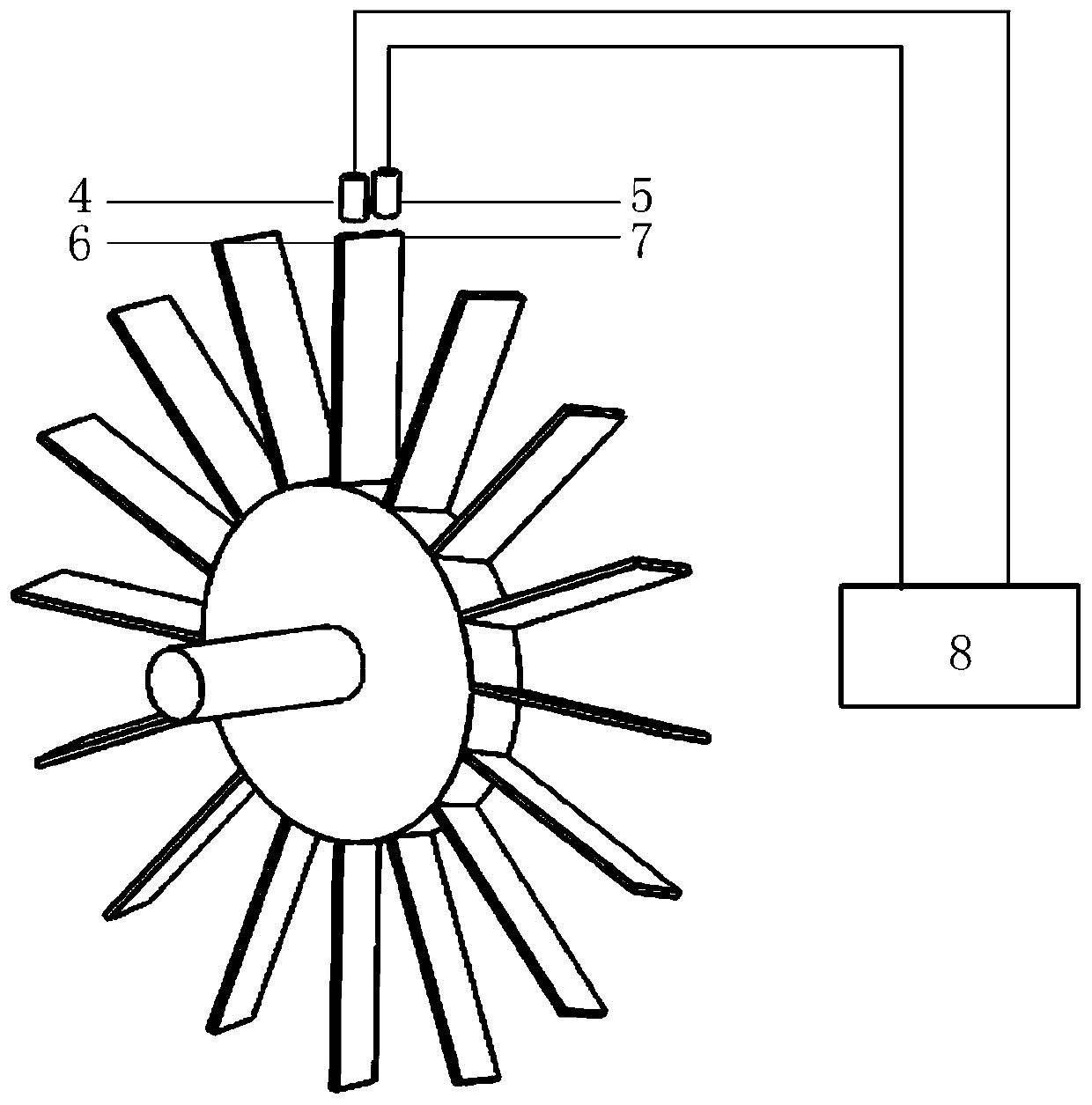

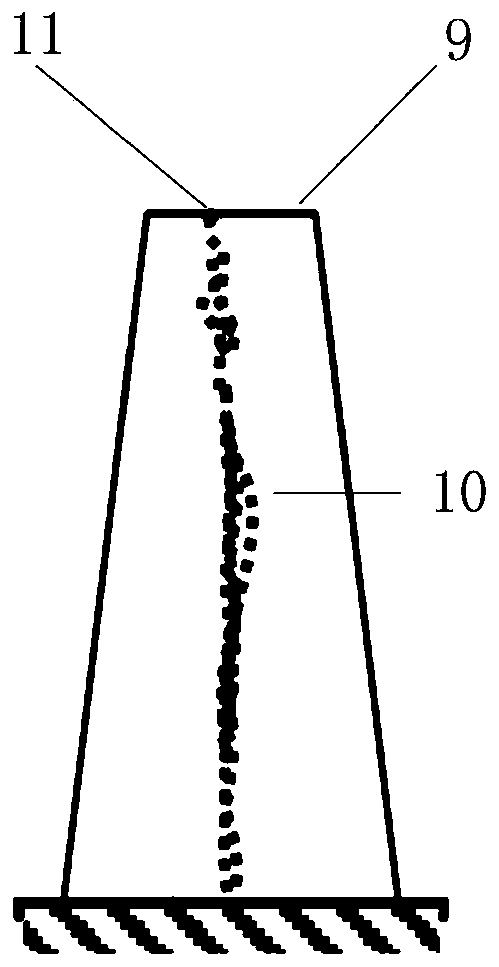

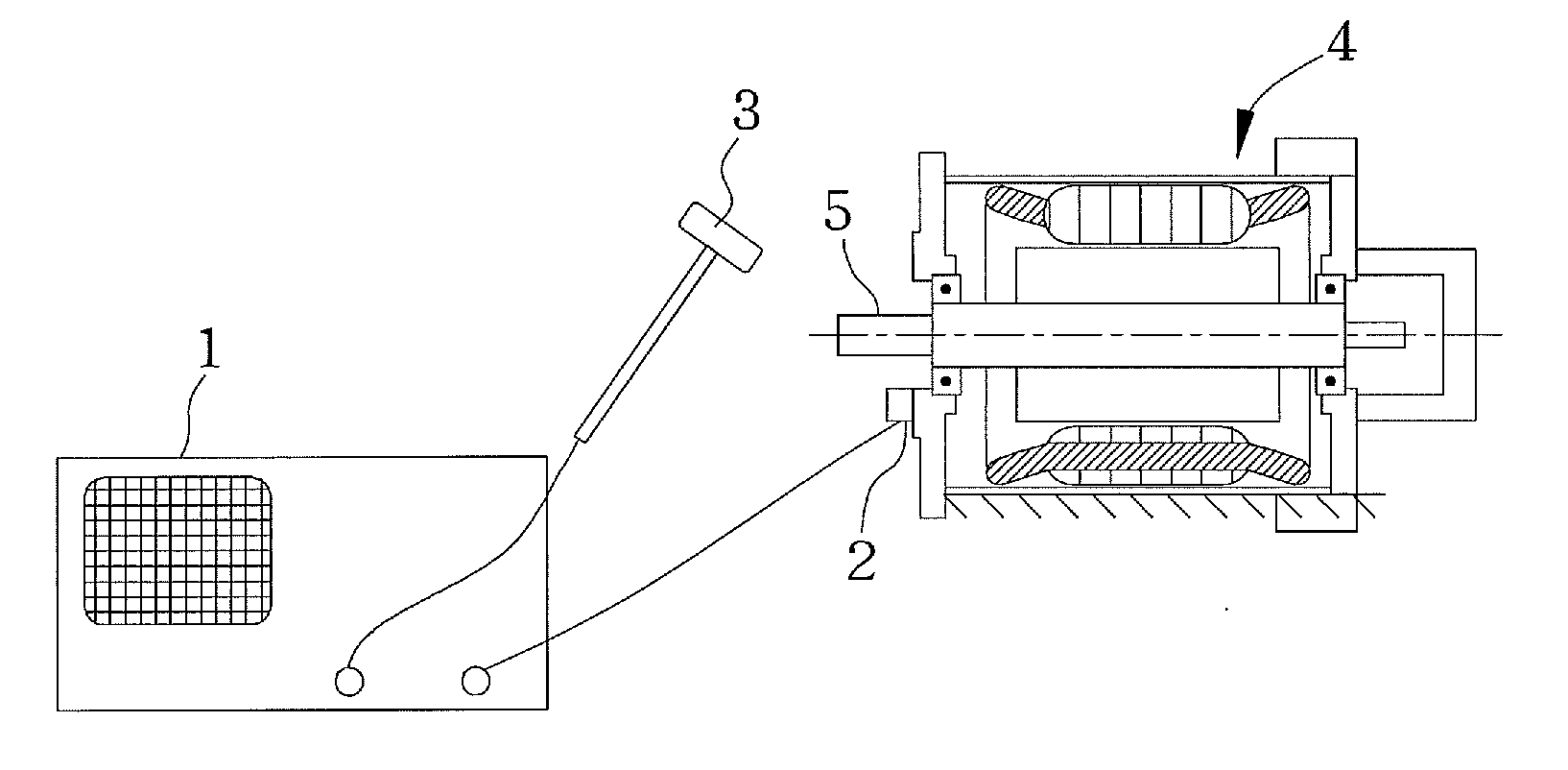

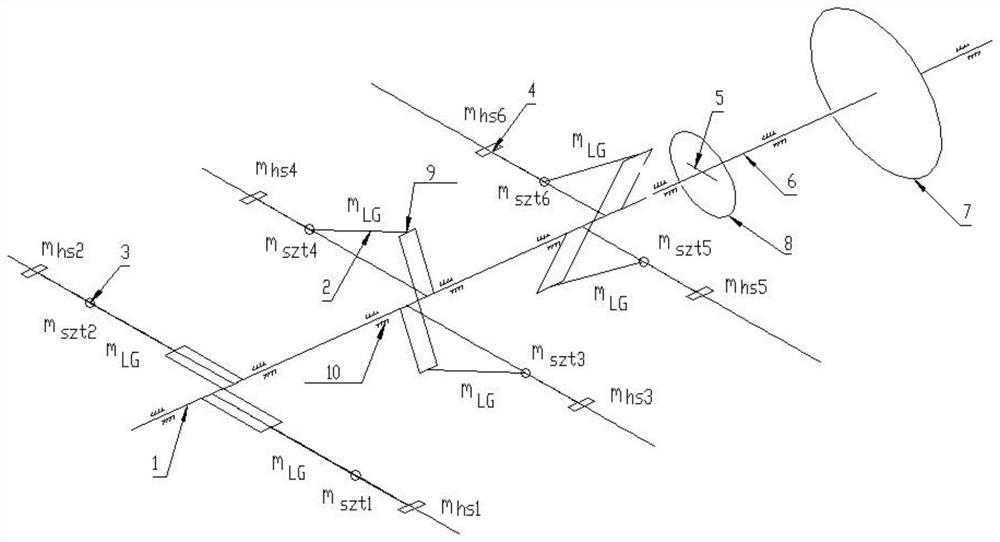

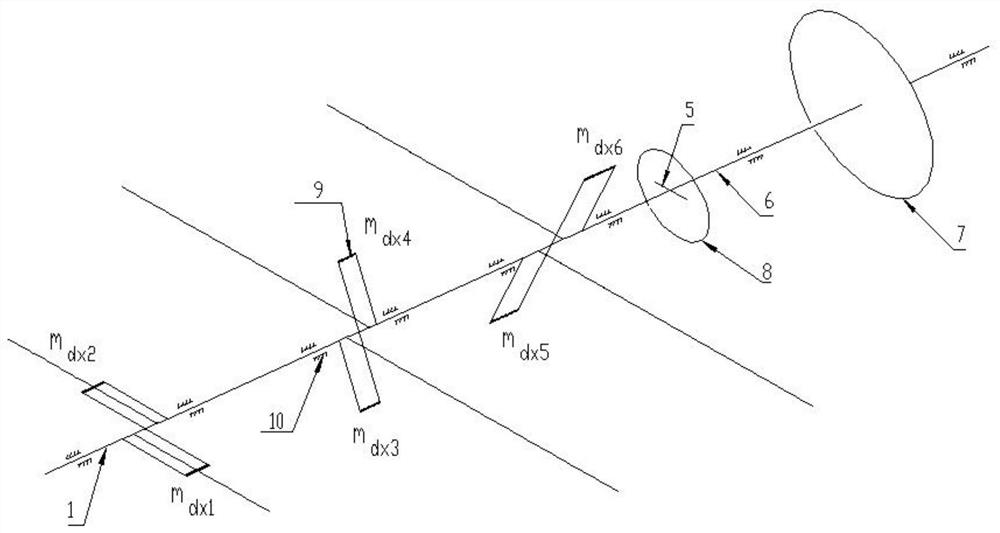

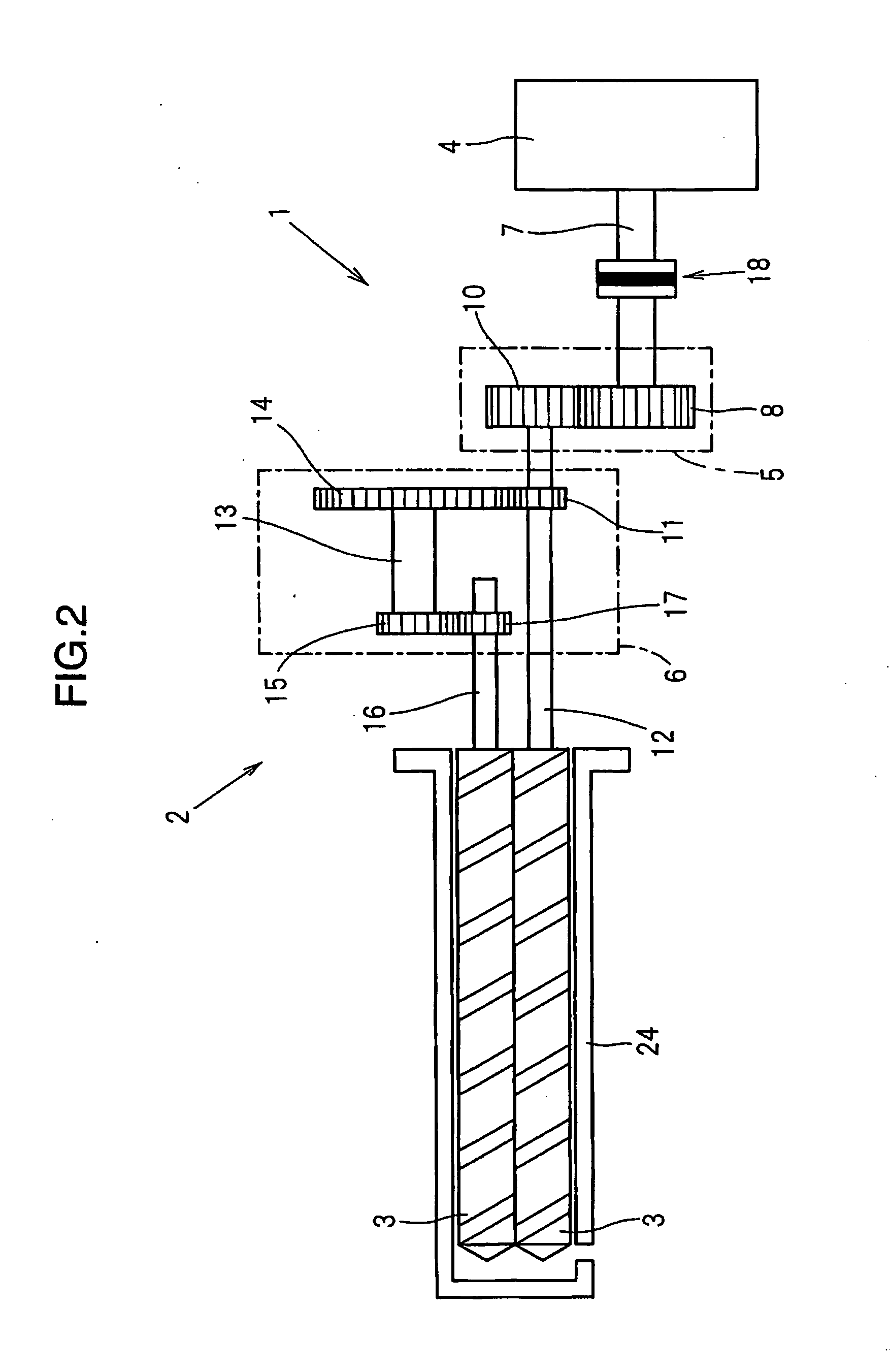

Longitudinal-torsional resonance ultrasonic vibration device

InactiveCN105478332ASimple form of vibrationComposite vibration in vibration form, simple power supply formMechanical vibrations separationElectricityEngineering

The invention discloses a longitudinal-torsional resonance ultrasonic vibration device, and relates to the field of ultrasonic processing and precise cutting. The problems that when an existing torsional vibration device applied to milling machining carries out torsional vibration, internal friction of a material loses most energy, and consequently, the torsional amplitude is small, and the energy utilization efficiency is low are solved. The device comprises a ladder type hollow cylinder cone composite body, a longitudinal-torsional conversion hollow cylinder, a pre-tightening bolt, the even number of piezoelectric ceramic pieces and a plurality of electrode pieces; the ladder type hollow cylinder cone composite body is mainly composed of an axial locating shaft, a cylindrical longitudinal-torsional conversion body, a conical torsional vibration amplifying body and a cylindrical longitudinal vibration amplifying body which are coaxially and sequentially arranged and are manufactured into a whole; and the ladder type hollow cone composite body, the longitudinal-torsional conversion hollow cylinder body, the even number of piezoelectric ceramic pieces and the electrode pieces are connected together through the pretightening bolt. The longitudinal-torsional resonance ultrasonic vibration device is used for ultrasonic vibration machining.

Owner:HARBIN INST OF TECH

Method and apparatus for measuring electrical properties in torsional resonance mode

InactiveUS7155964B2Soft and delicate materialAccurate measurementResistance/reactance/impedenceNanotechnologyCapacitanceElectricity

The preferred embodiments are directed to a method and apparatus of operating a scanning probe microscope (SPM) including oscillating a probe of the SPM at a torsional resonance of the probe, and generally simultaneously measuring an electrical property, e.g., a current, capacitance, impedance, etc., between a probe of the SPM and a sample at a separation controlled by the torsional resonance mode. Preferably, the measuring step is performed while using torsional resonance feedback to maintain a set-point of SPM operation.

Owner:BRUKER NANO INC

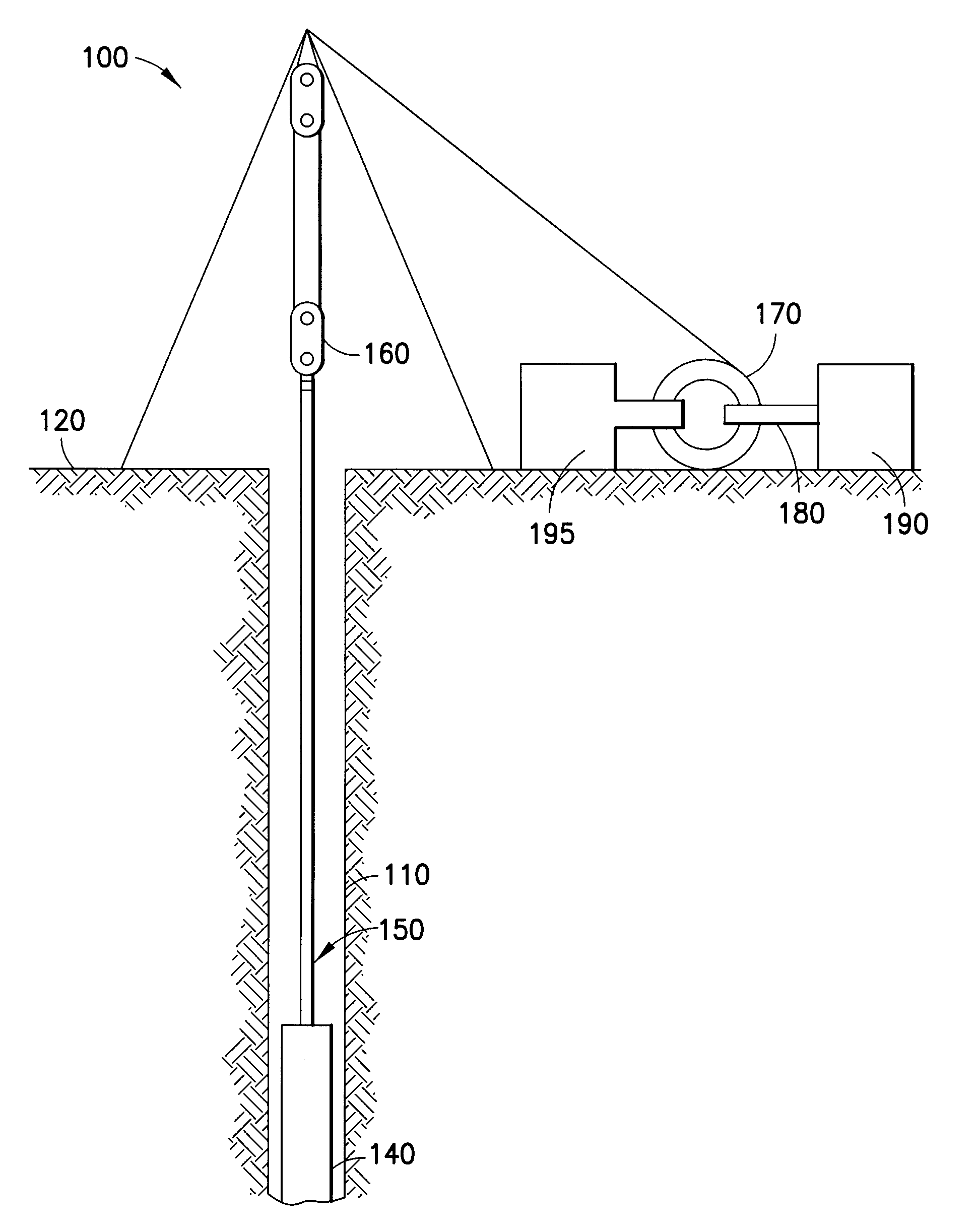

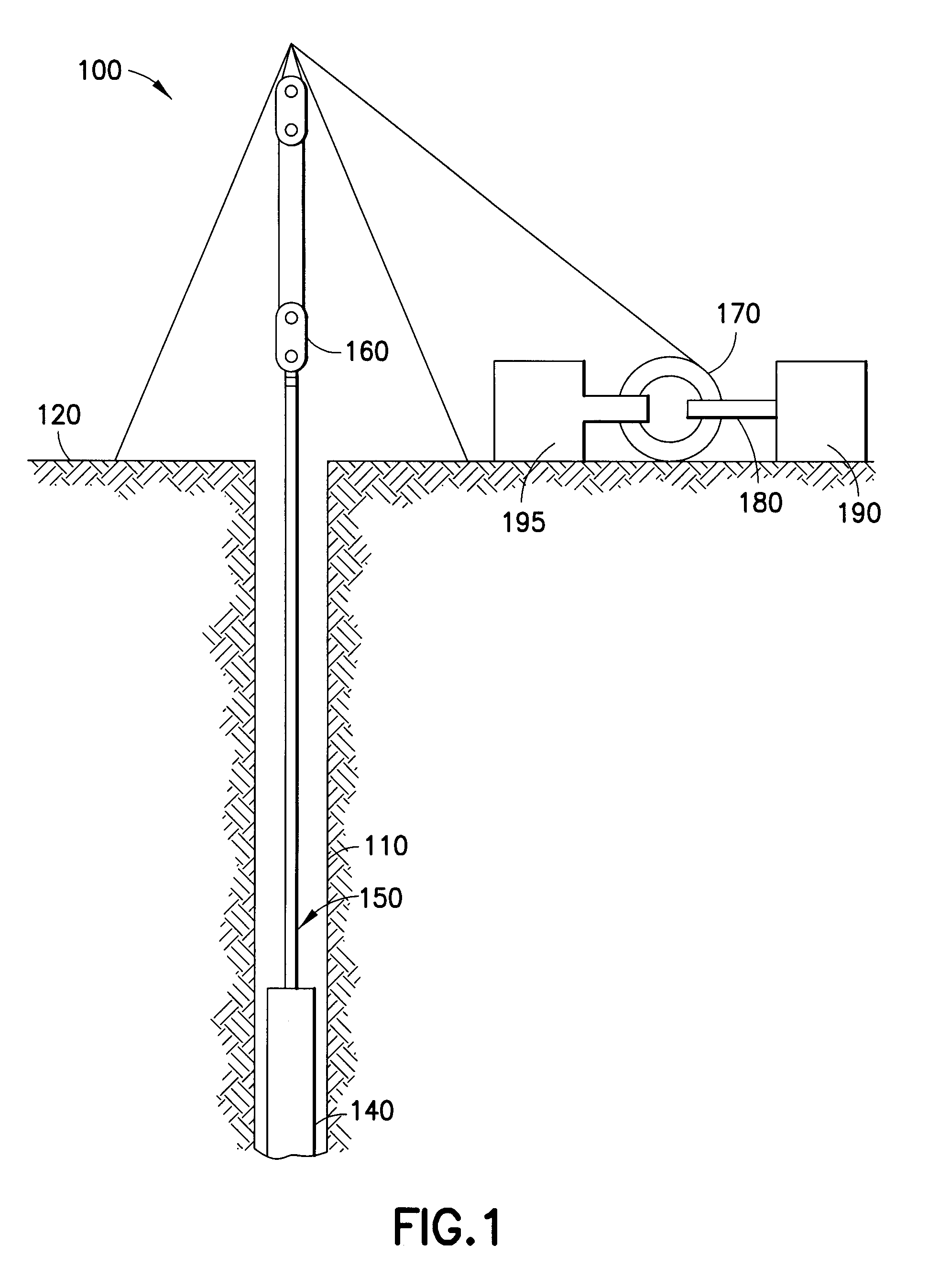

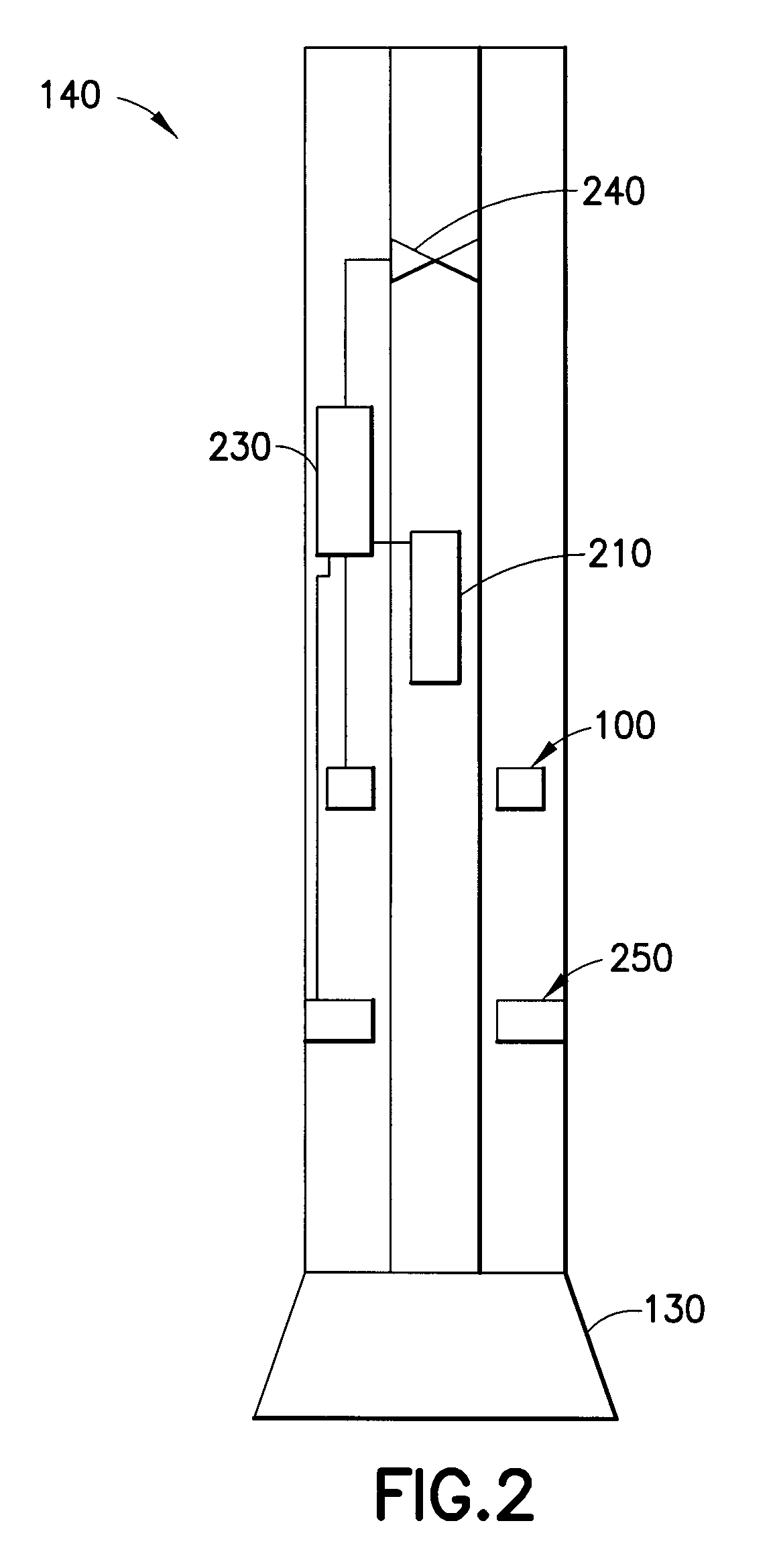

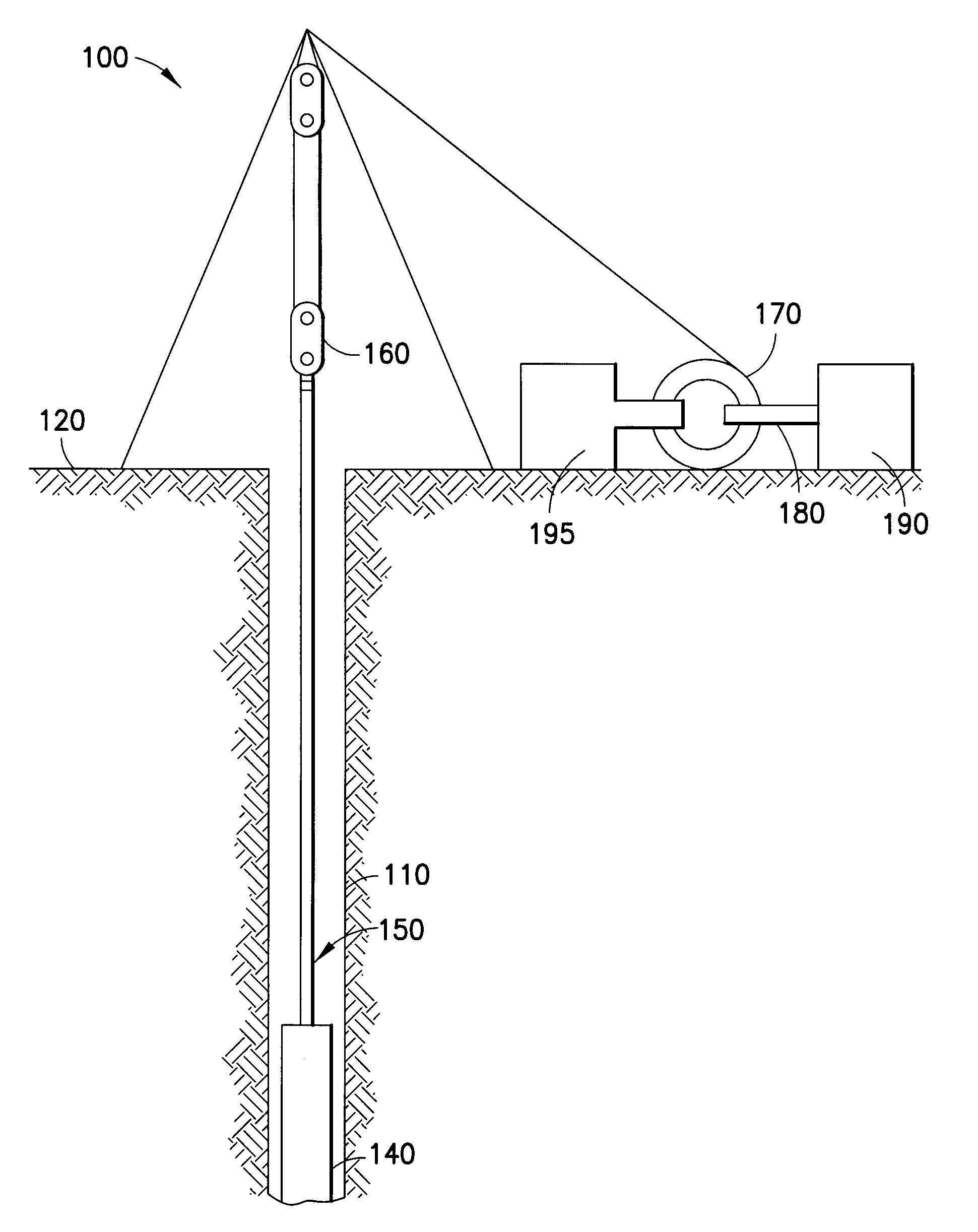

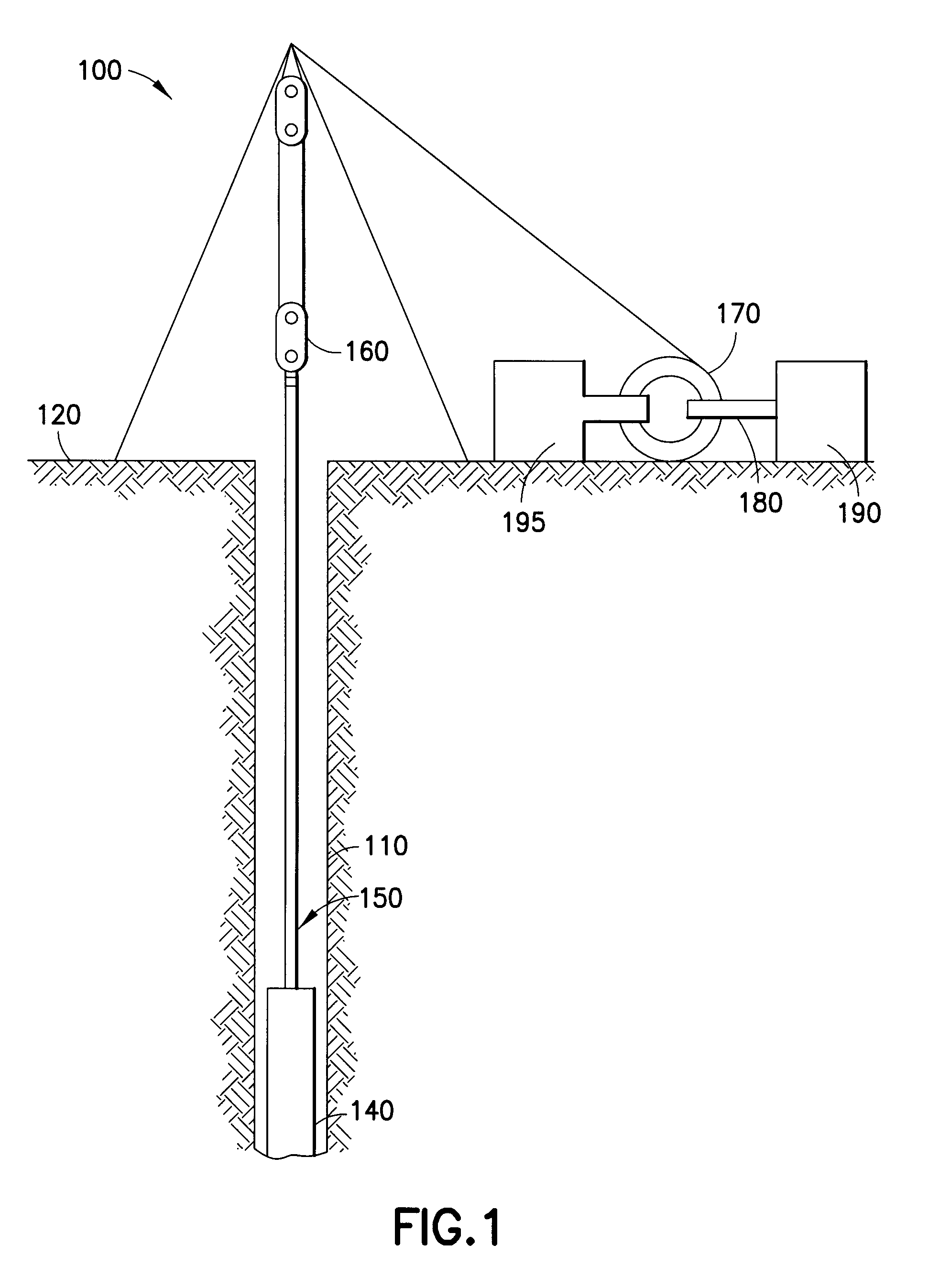

Torsional resonance prevention

According to the invention, a system for drilling a cavity in a medium is disclosed. The system may include a drill bit, a processor, and a controller. The drill bit may be configured to rotate in the medium and remove at least a portion of the medium. The processor may be configured to receive a first set of data representative of a variable rotational speed of the drill bit during a length of time in the medium, and determine, based at least in part on the first set of data, a first resonant frequency of the variable rotational speed of the drill bit. The controller may be configured to receive a second set of data representative of the first resonant frequency of the variable rotational speed of the drill bit, and vary the force applied to the drill bit based at least in part on the second set of data.

Owner:SCHLUMBERGER TECH CORP

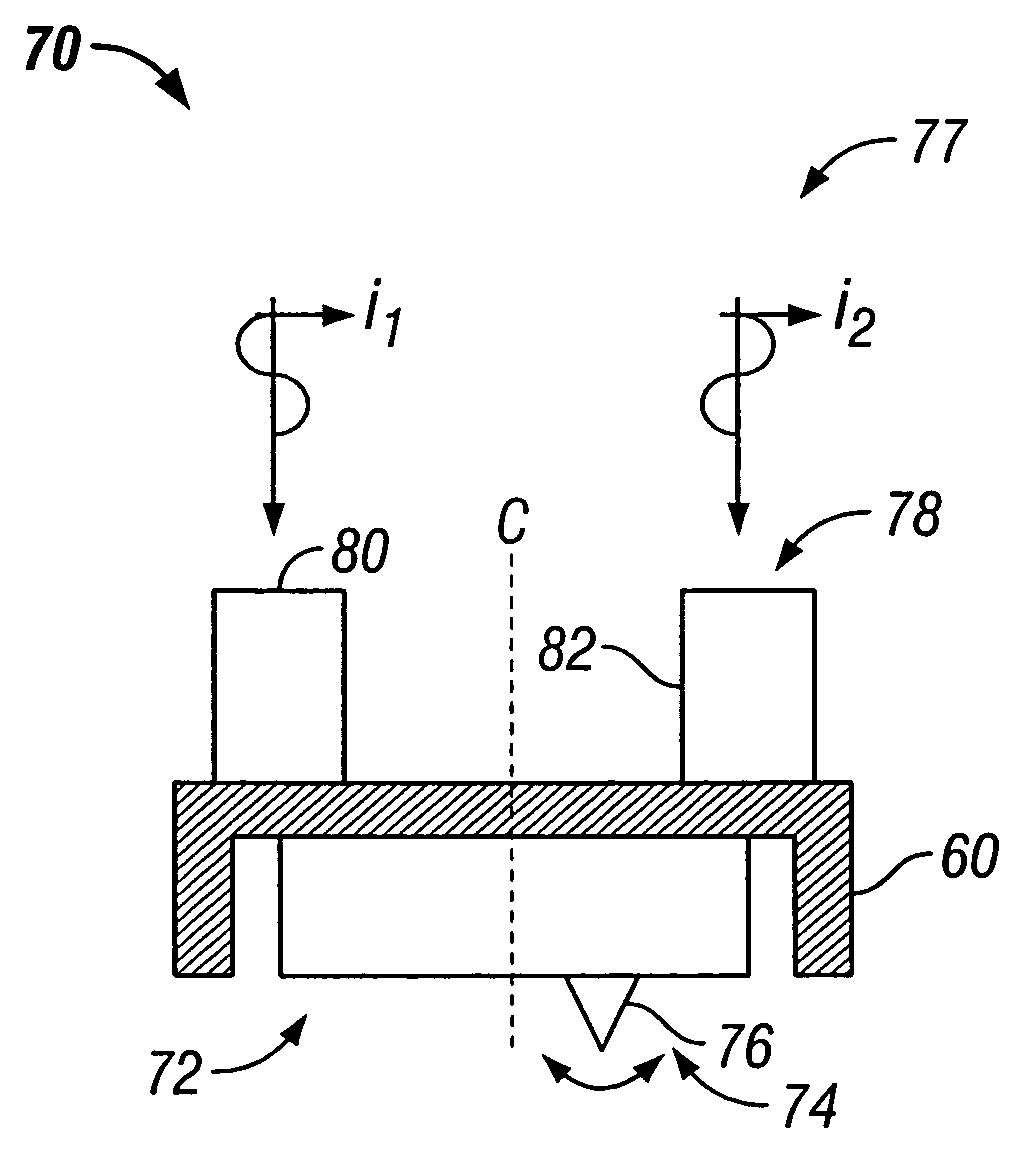

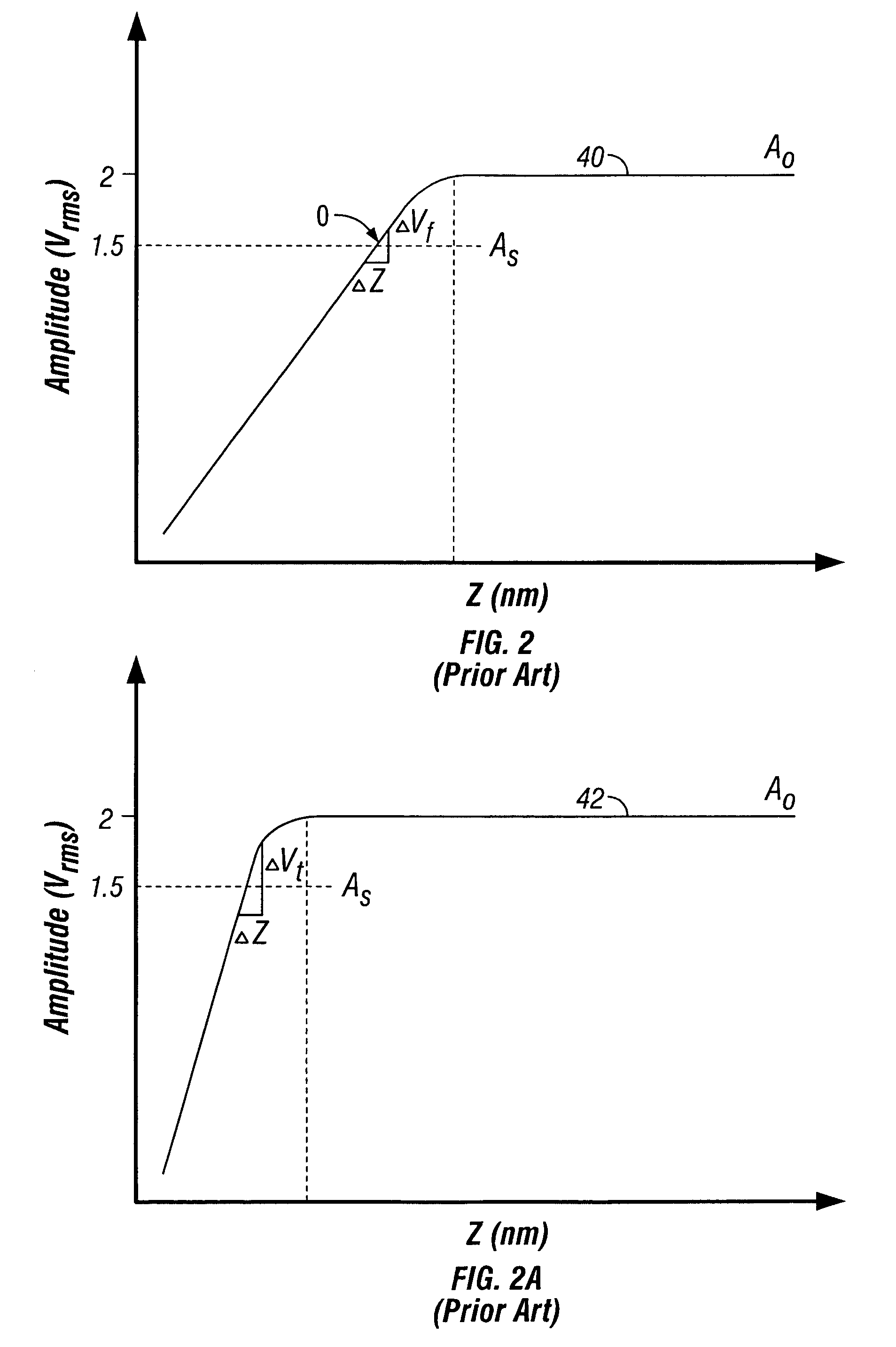

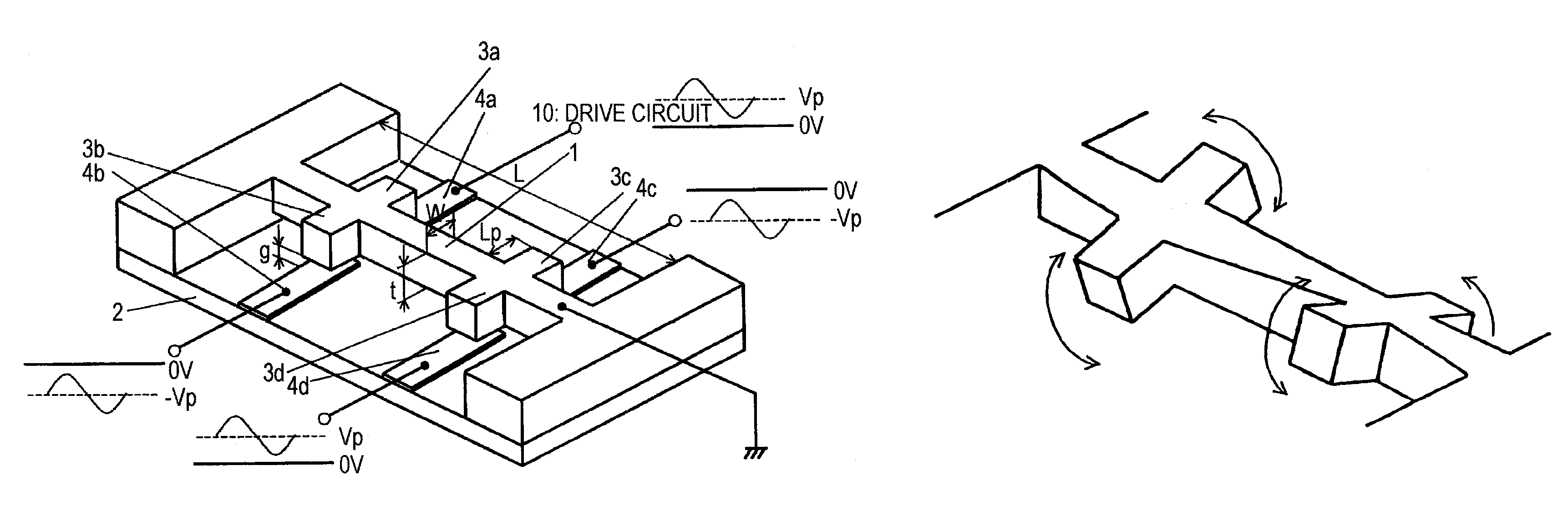

Method and apparatus of driving torsional resonance mode of a probe-based instrument

InactiveUS7168301B2Improve abilitiesMaximising amplitudeNanotechnologyScanning probe microscopyTorsional oscillationsEngineering

A method of operating a scanning probe microscope includes using a probe having a cantilever, and oscillating the probe at a torsional resonance frequency thereof. In addition, the method includes substantially increasing torsional drive efficiency with dual actuators disposed on the probe or the probe base. First and second actuators may be driven by corresponding first and second drive signals, the first and second drive signals being about 180° out of phase. The maximizing step includes altering at least one of the amplitudes of the first and second drive signals to maximize torsional oscillation. Torsional and flexural oscillation of the cantilever probe can be excited concurrently, sequentially or independently by adjusting the phase of the corresponding drive signals. A pair of cantilever components can be used to form a nanotweezer by rotating the respective arms having corresponding tip portions at the distal ends.

Owner:BRUKER NANO INC

Blade torsional vibration displacement measurement method based on blade tip timing principle

PendingCN110319922AAchieve optimal positioningSubsonic/sonic/ultrasonic wave measurementRest positionResonance

The invention relates to a blade torsional vibration displacement measurement method based on a blade tip timing principle. At the same circumferential position on a case of a rotary machine, two blade tip timing sensors in one group are arranged along the axial direction of a rotor, respectively called as an air inlet side blade tip timing sensor and an air outlet side blade tip timing sensor andused for measuring time of arriving at the blade tip timing sensors by an air inlet side and an air outlet side at the blade tip of the same blade in the same circle; the two blade tip timing sensorsare arranged at a projection point of a maximum displacement position of a torsional resonance blade tip on a blade tip rest position horizontal line, which is called as a torsional resonance projection process, and by combining torsional resonance parameters of the blade, optimal location of the blade tip timing sensors is realized by utilizing the torsional resonance projection process, so as to guarantee that the two blade tip timing sensors can sample a blade tip arrival time signal respectively and accurately under the condition that torsional resonance and torsional non-resonance of theblade occur; and blade torsional vibration displacement measurement is realized.

Owner:TIANJIN UNIV

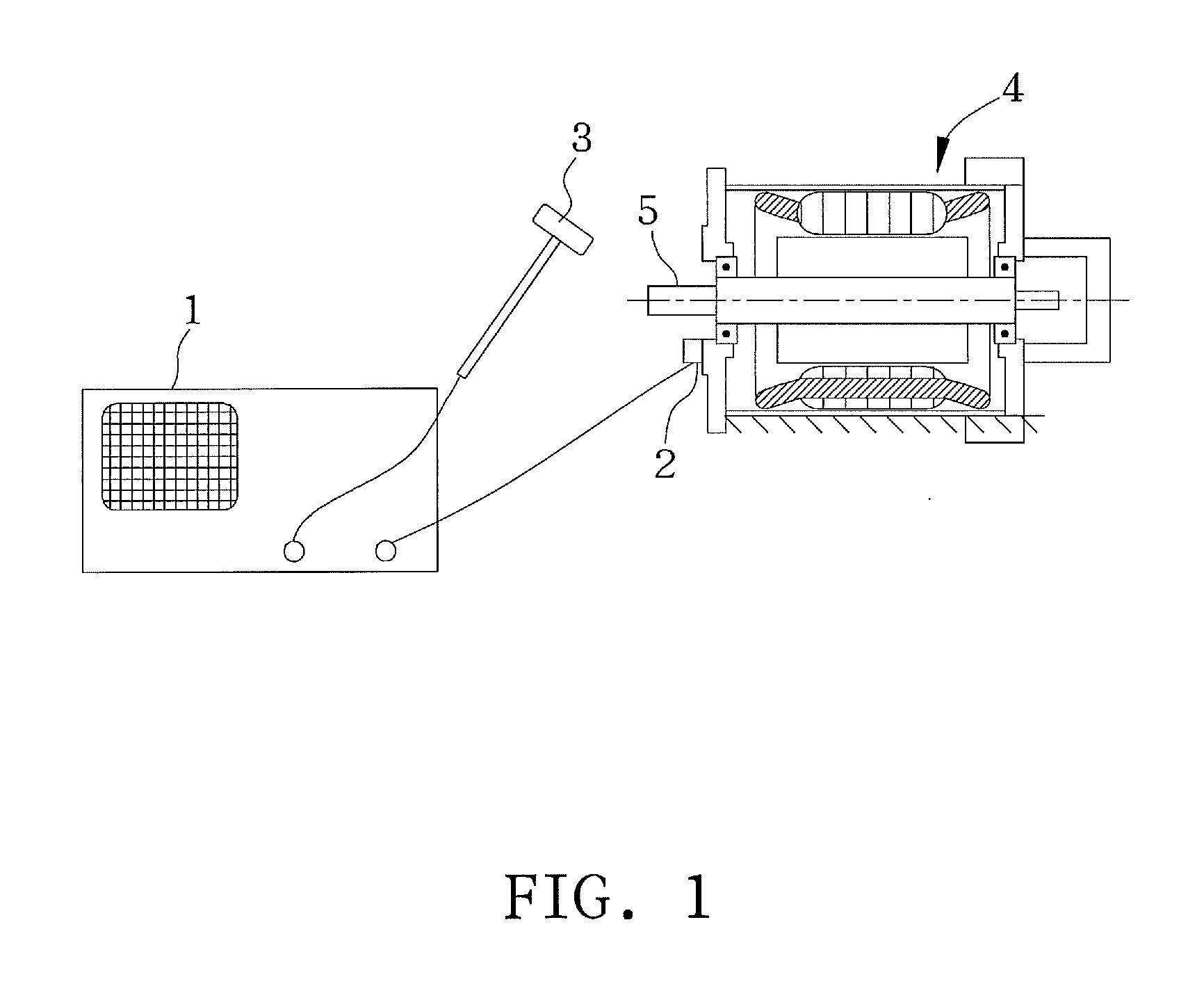

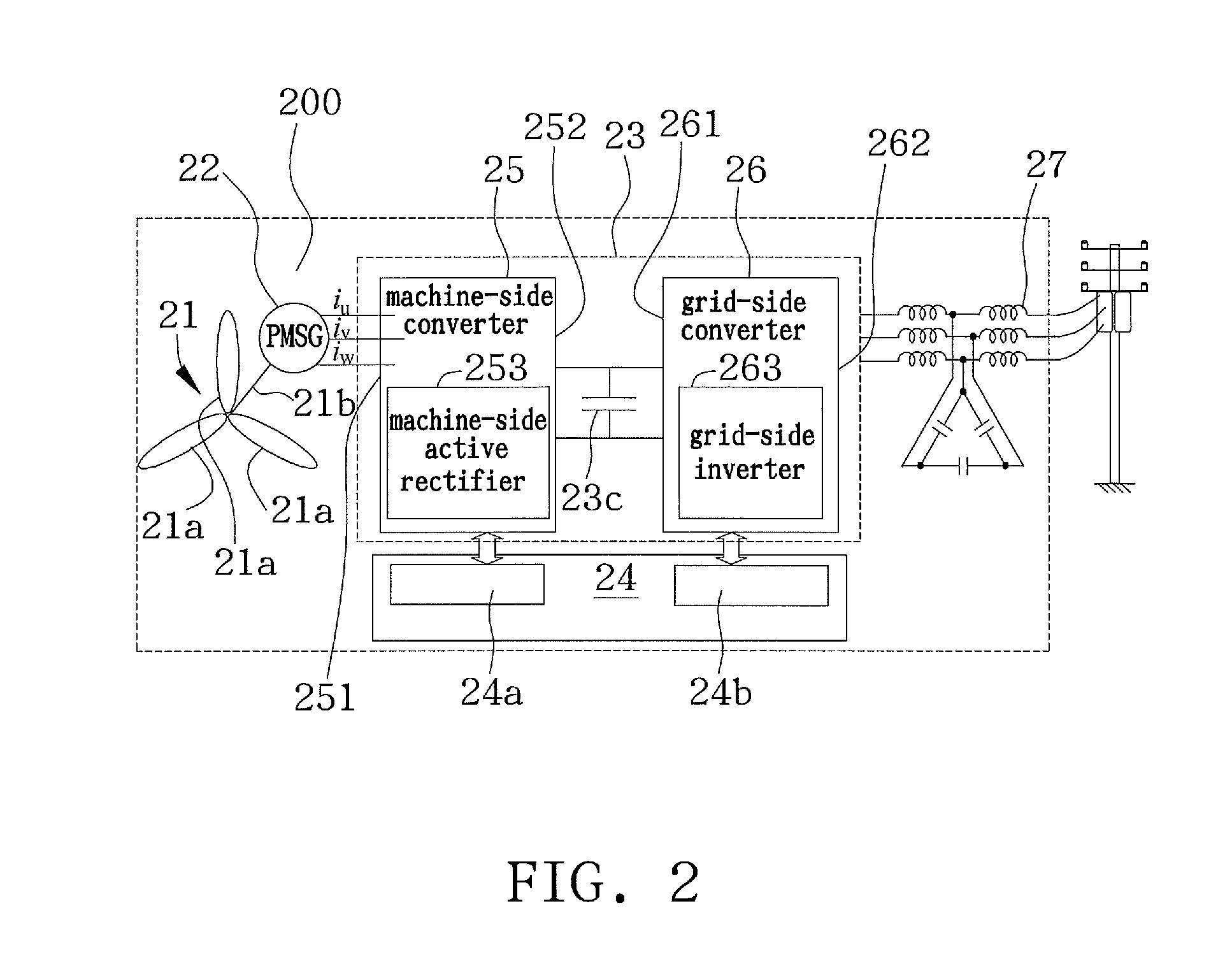

Torsional resonance frequency measuring device and method

ActiveUS20110144929A1Shorten the timeLow costVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesFrequency spectrumMeasurement device

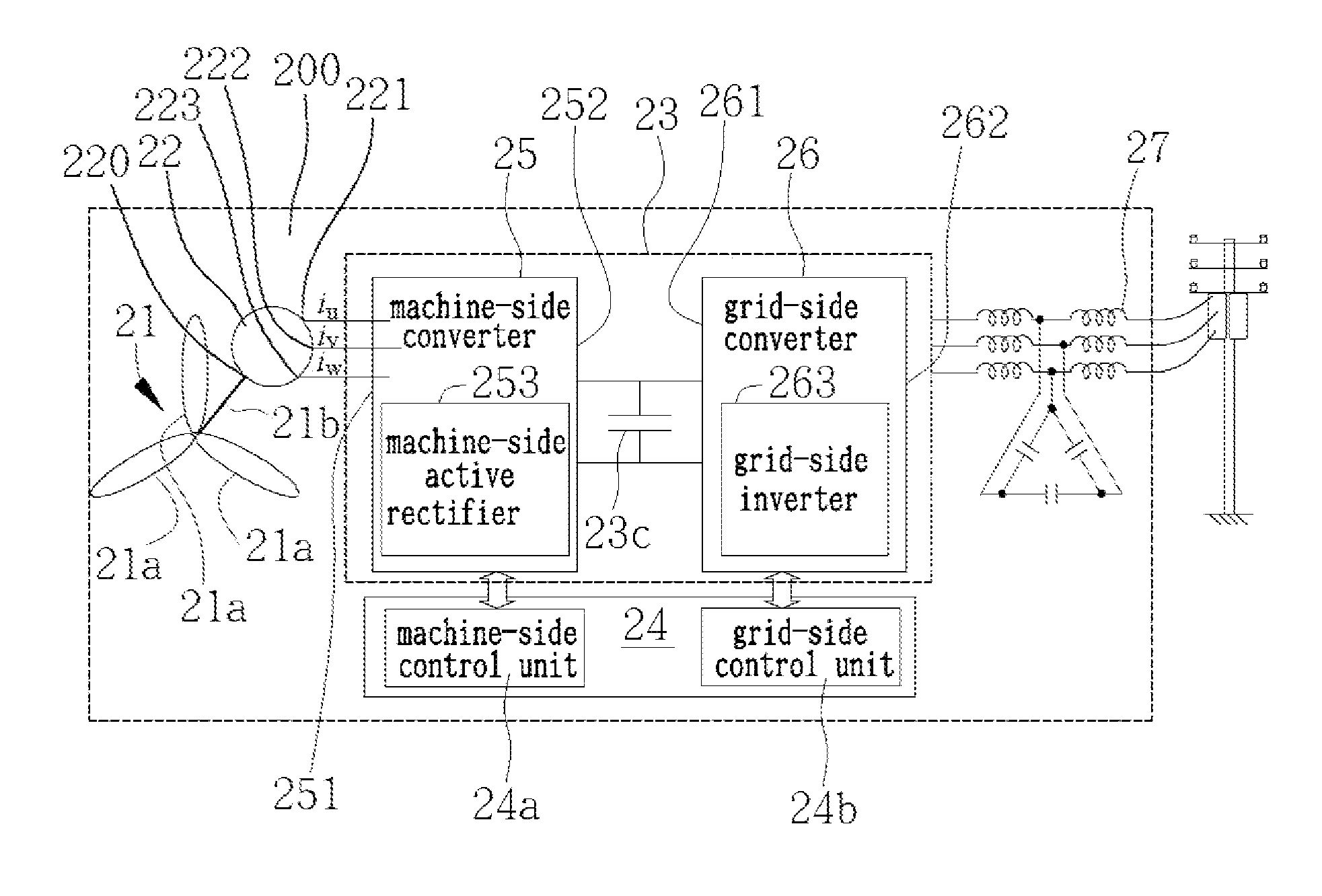

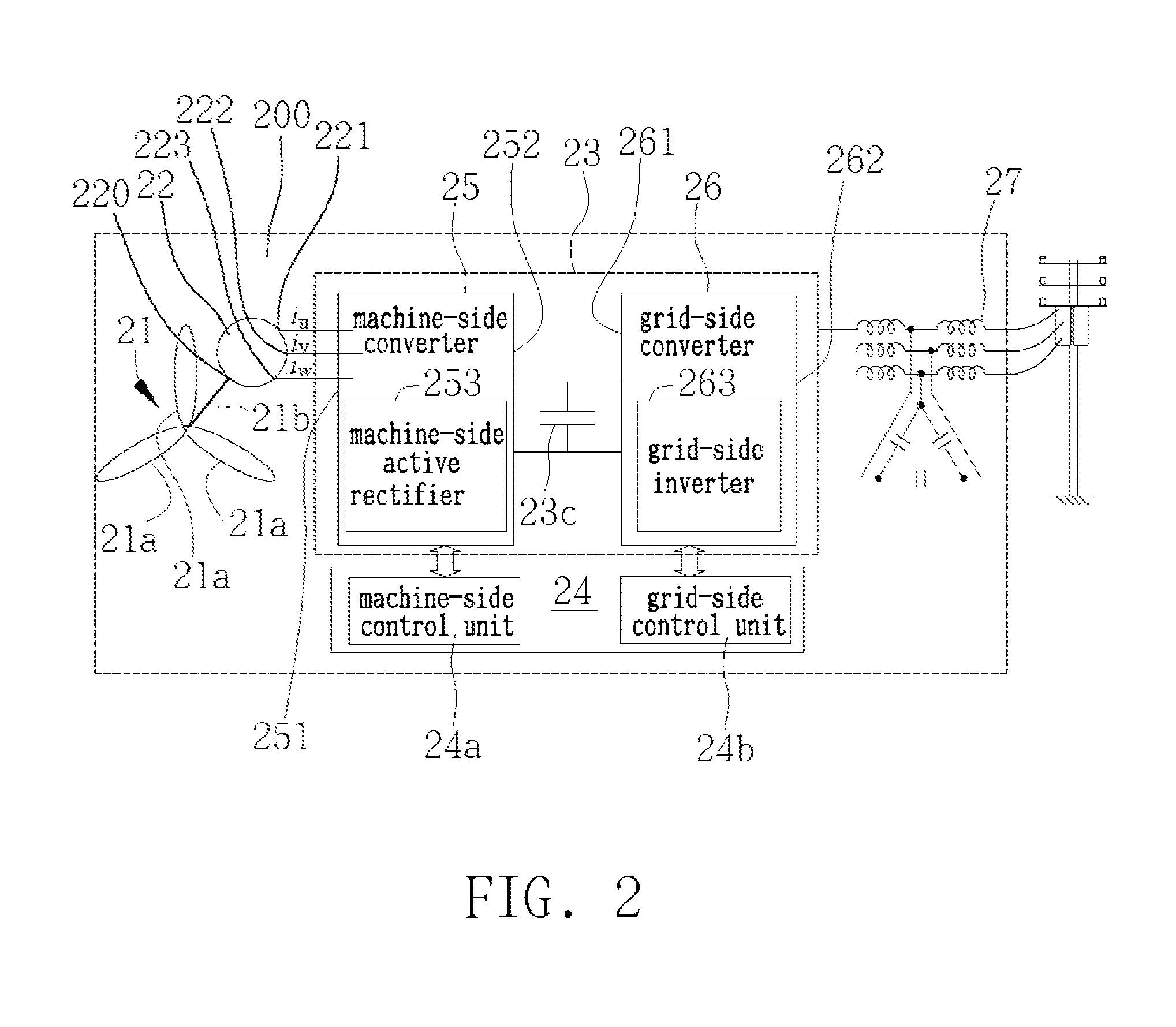

The invention provides a torsional resonance frequency measuring device and method applicable to a large-scale power generating equipment or a traction motor equipment with a rotating shaft, such as a large power grid-tied wind turbine. The invention is characterized by employing a machine-side converter existing in the grid-tied wind turbine to output direct currents to a three-phase PMSG (permanent magnet synchronous generator), such that a pulse torque is generated to mechanically excite a rotor of the three-phase PMSG. Afterwards, a control circuit of the machine-side converter acquires back electromotive force generated by the mechanically excited rotor so as to calculate the torsional resonance frequency of the overall drive-chain system according to the frequency spectrum of the back electromotive force.

Owner:IND TECH RES INST

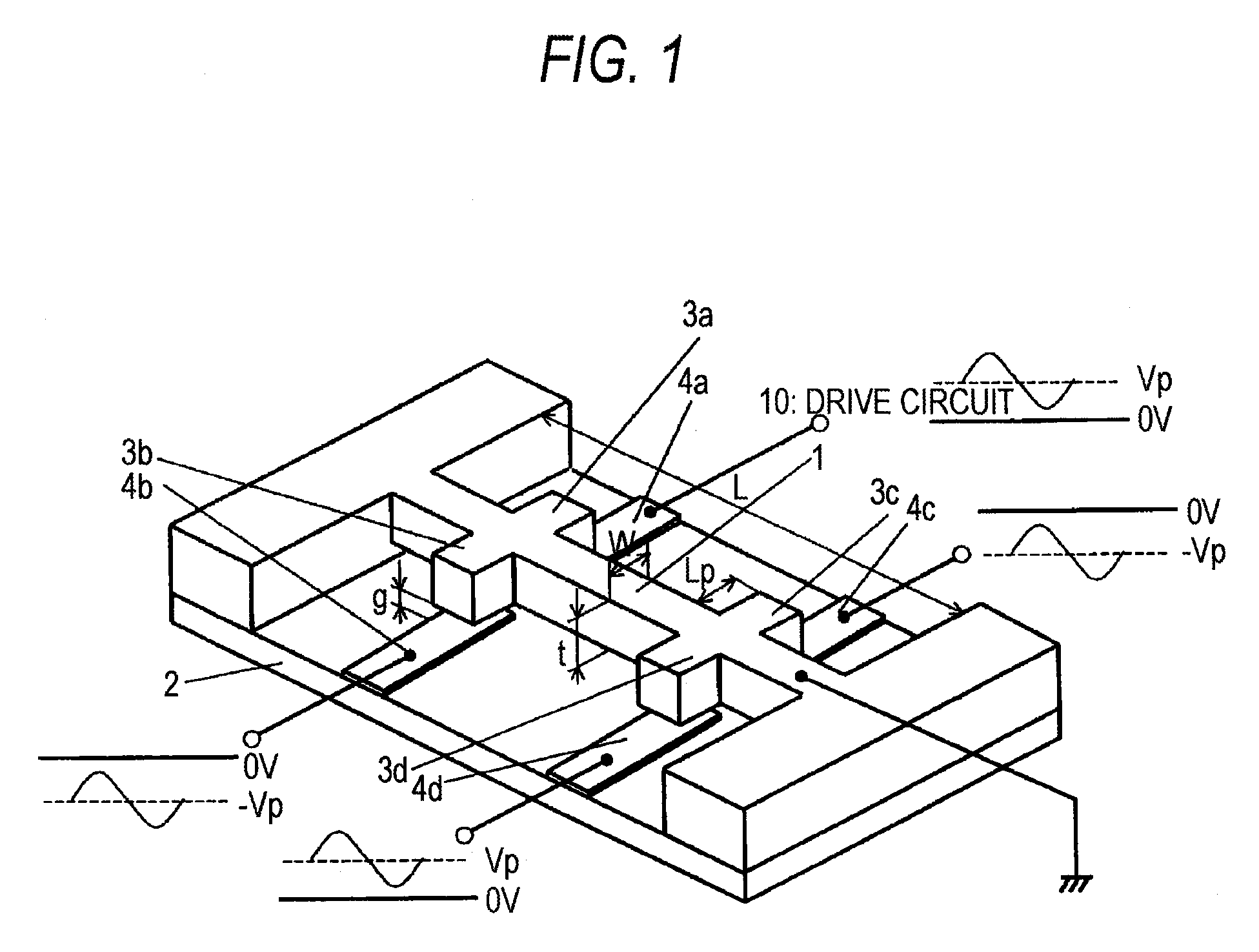

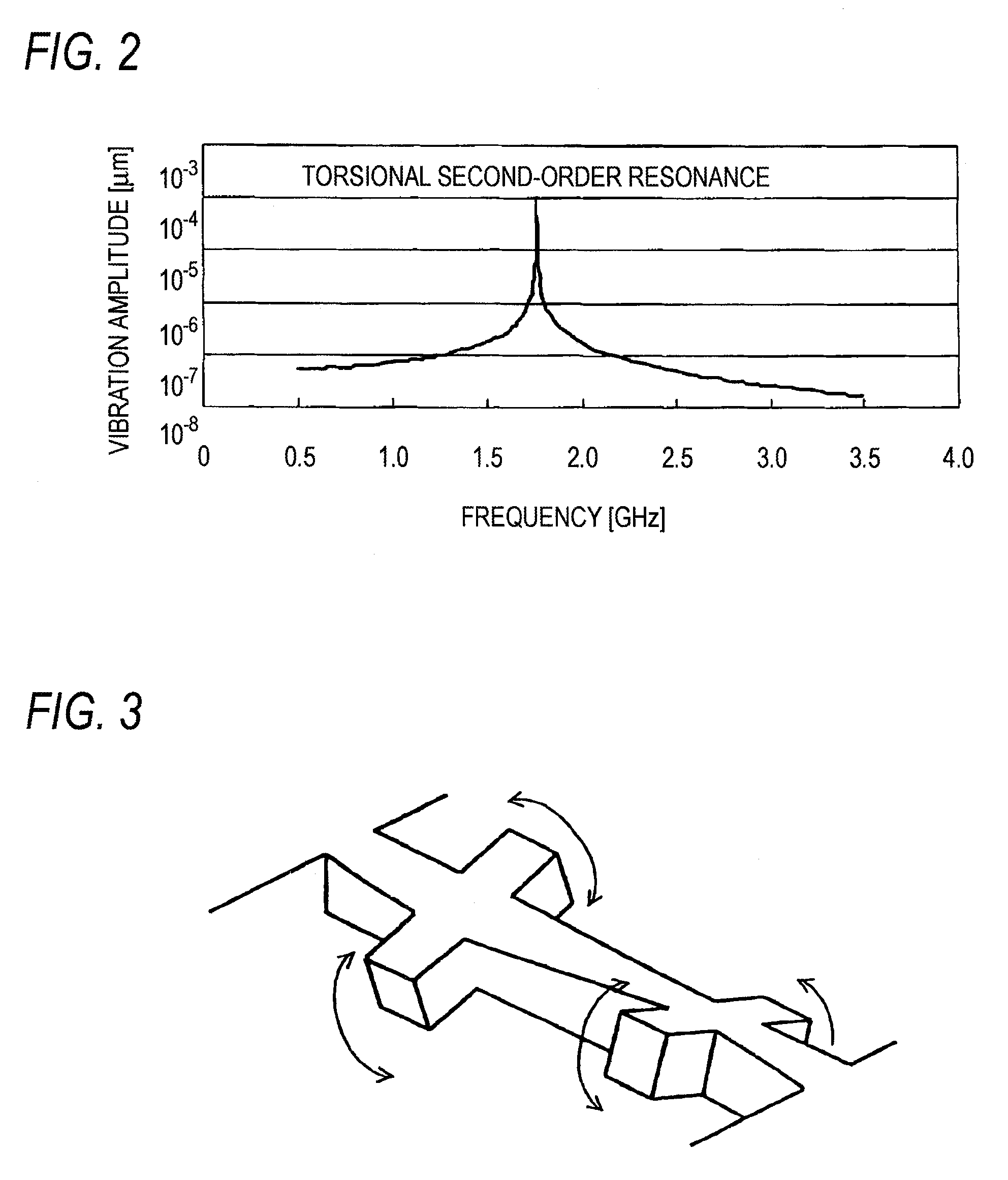

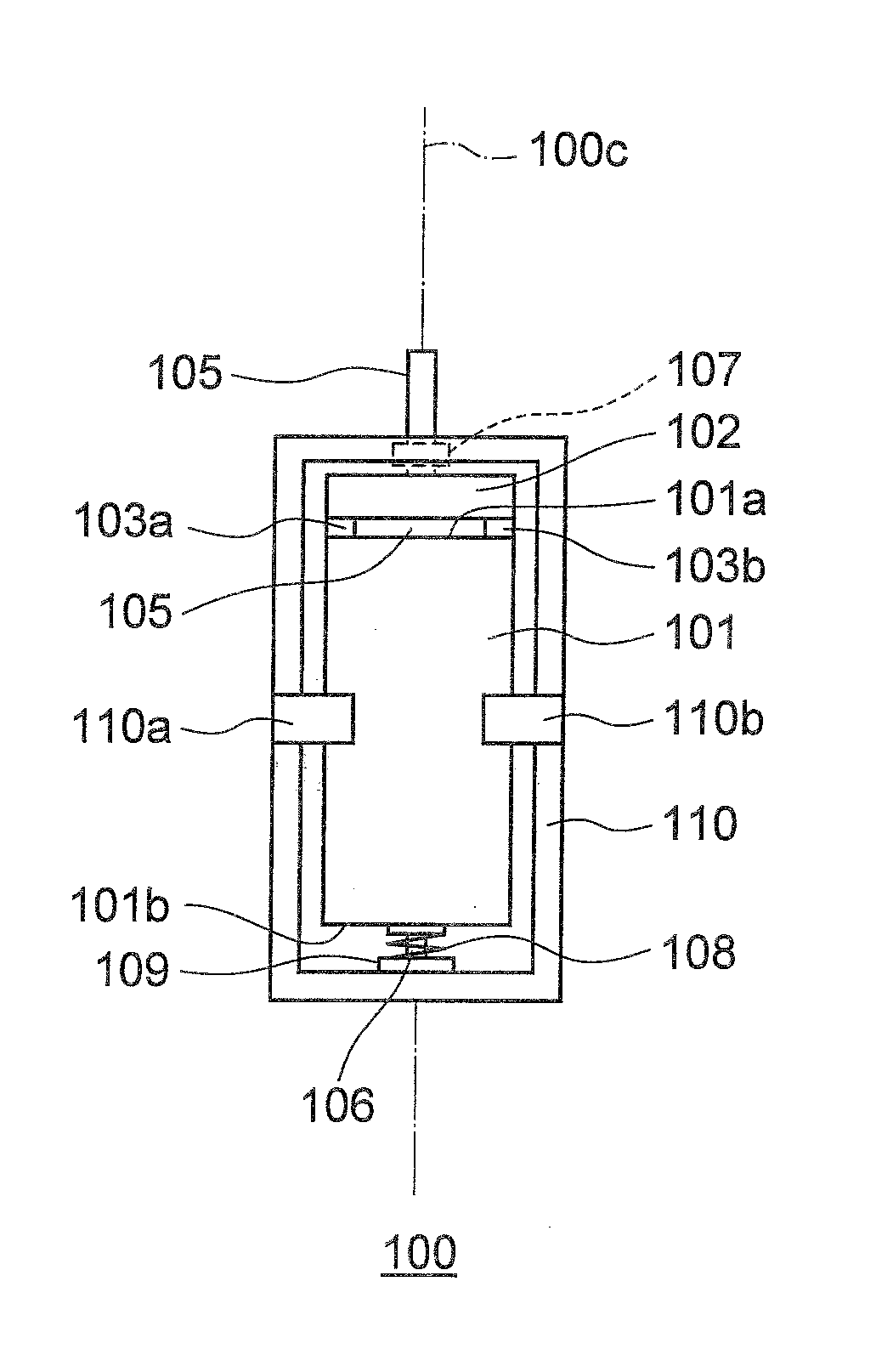

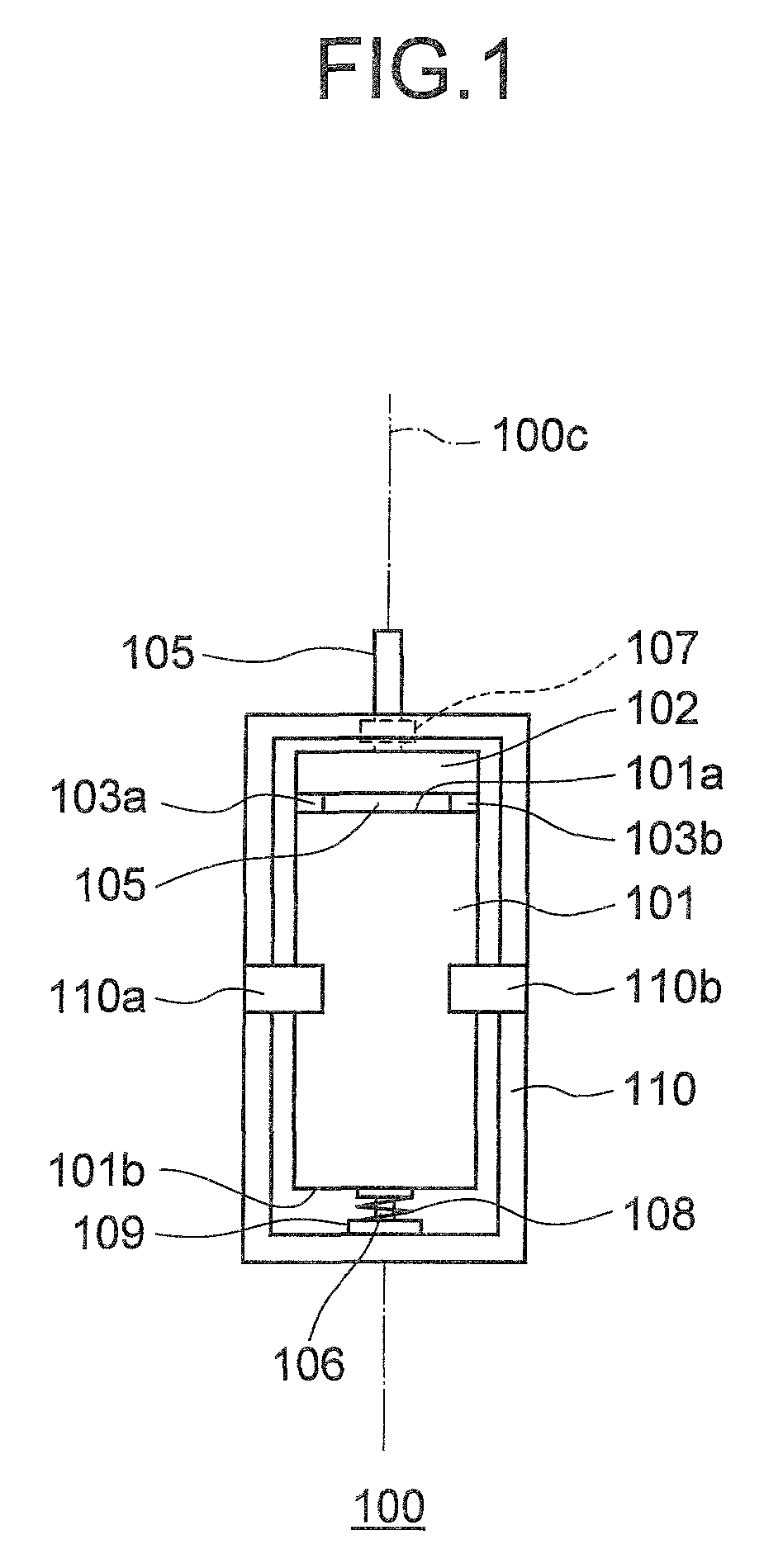

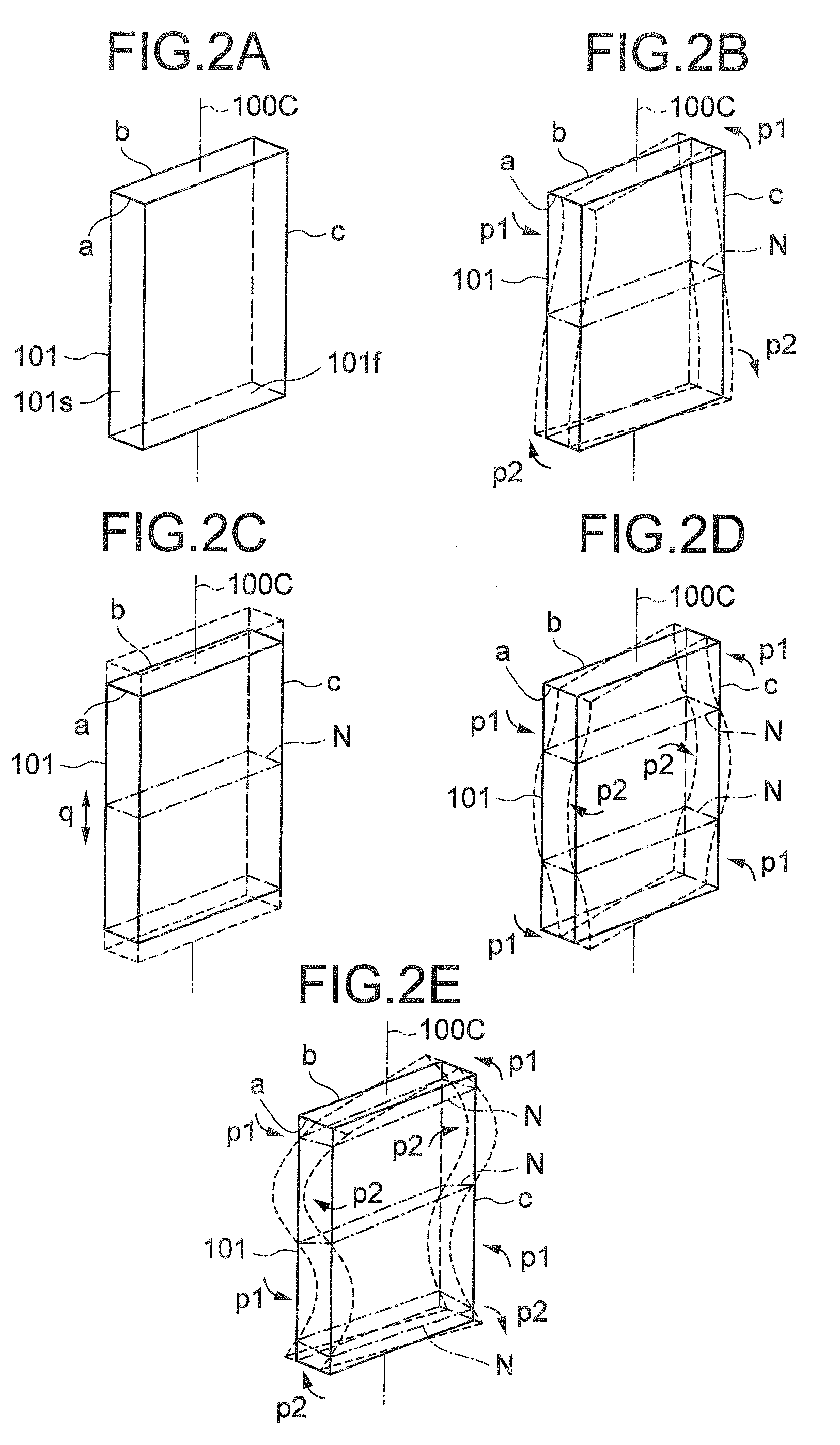

Torsional resonator and filter using this

ActiveUS7741932B2Increase valueImpedence networksElectrostatic generators/motorsPotential differenceElectrical polarity

A torsional resonator for suppressing unnecessary flexural vibration and providing excellent resonance characteristic is provided. A vibrator is a beam structure or a paddle-like projection structure added onto a beam structure and an electrostatic force produced due to the potential difference between an electrode and the vibrator adds a moment with the axis of the beam of the vibrator as the center axis, but does not add a force for producing flexure to the beam. As one method, the same AC signal and DC bias voltages different in polarity are applied to an electrode pair of the electrode brought away from the vibrator and the electrode brought close to the vibrator with torsional vibration of the vibrator, so that only torsional vibration can be excited.

Owner:PANASONIC CORP +1

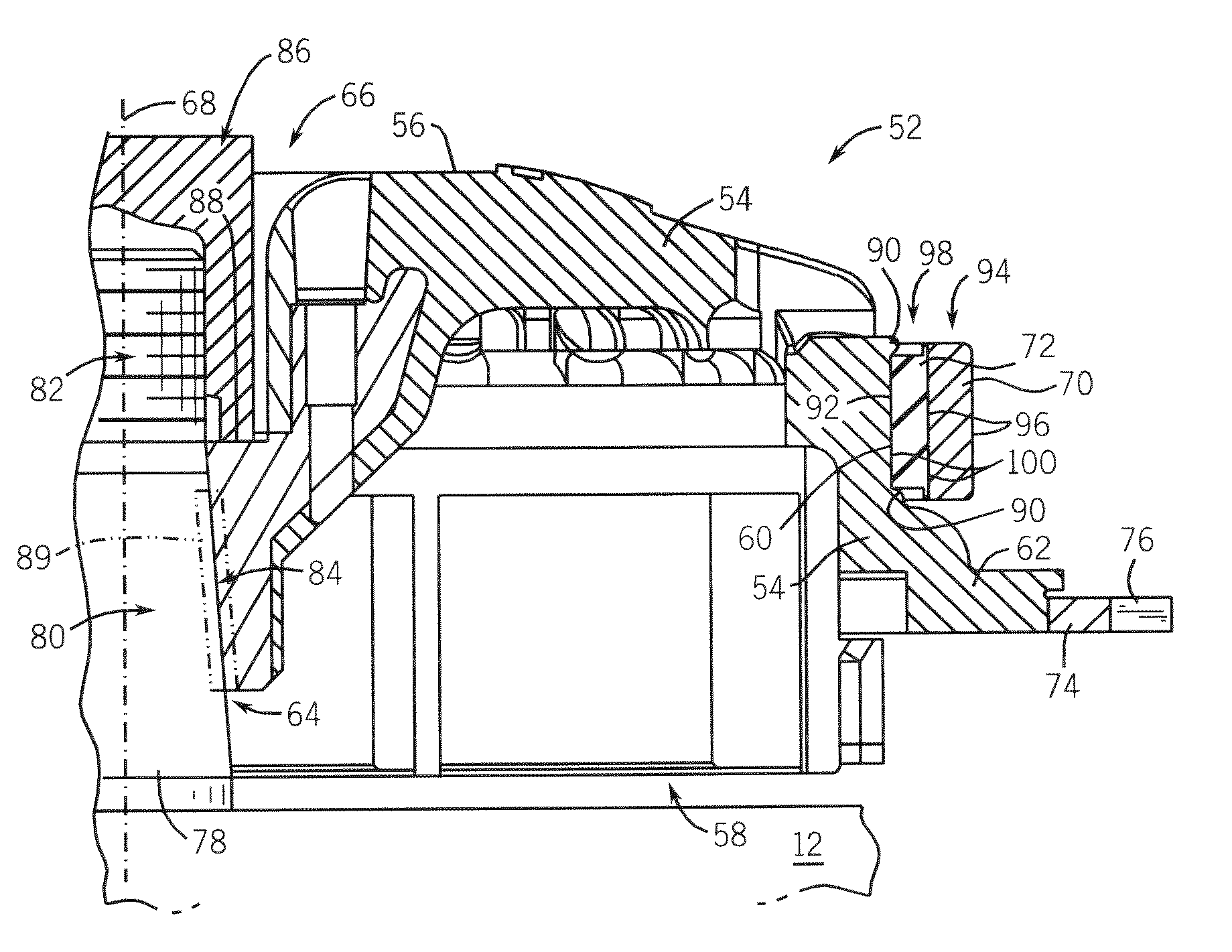

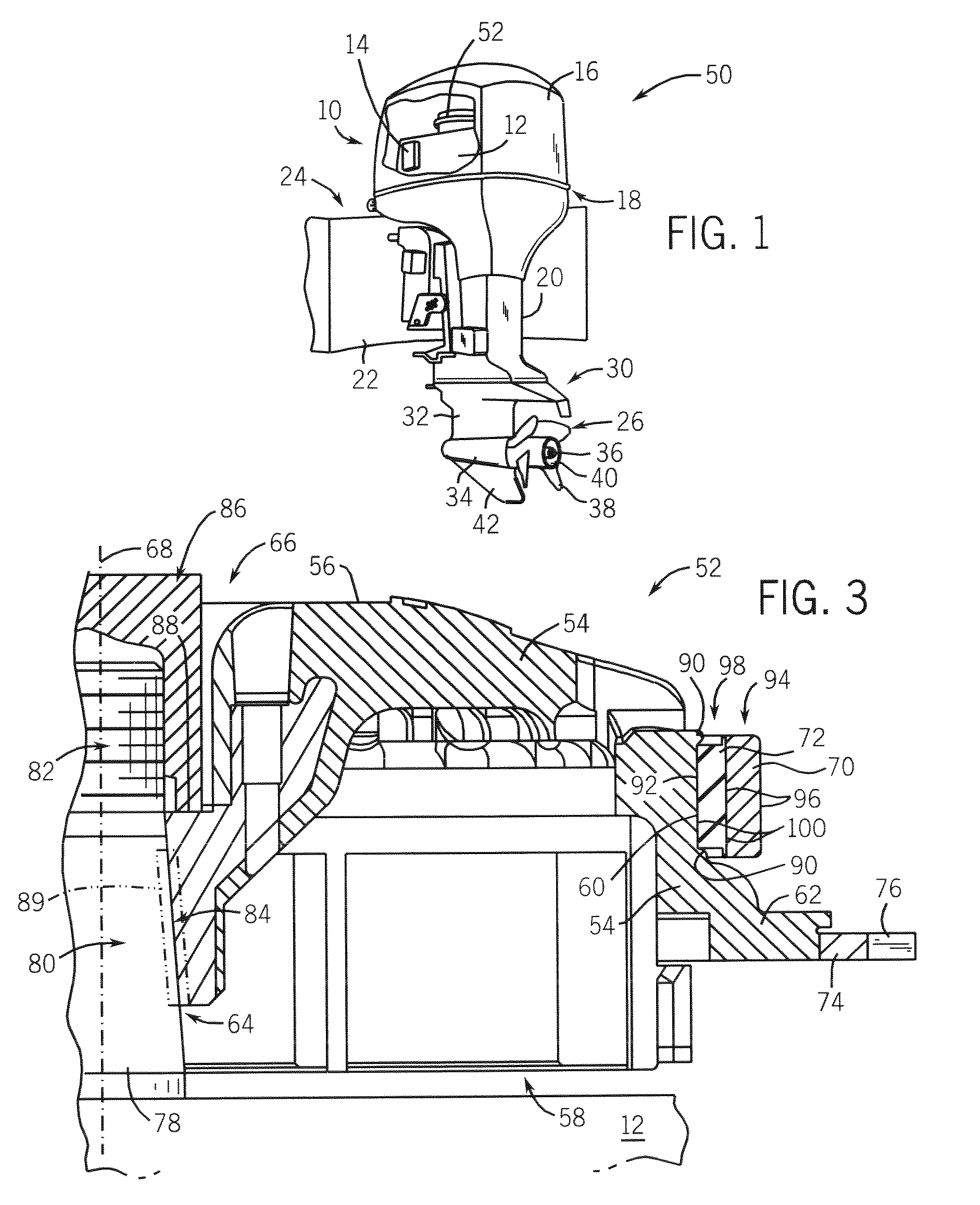

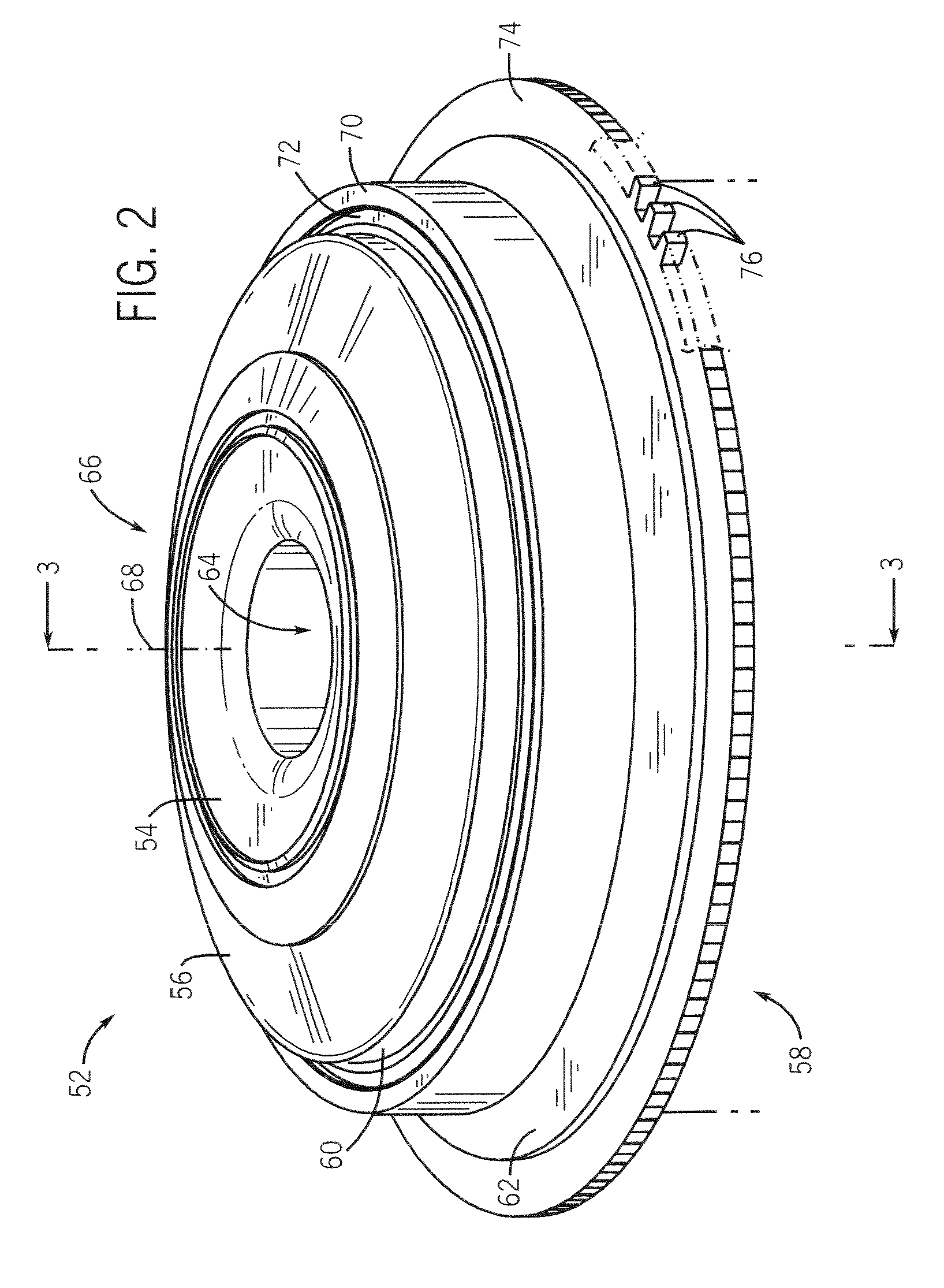

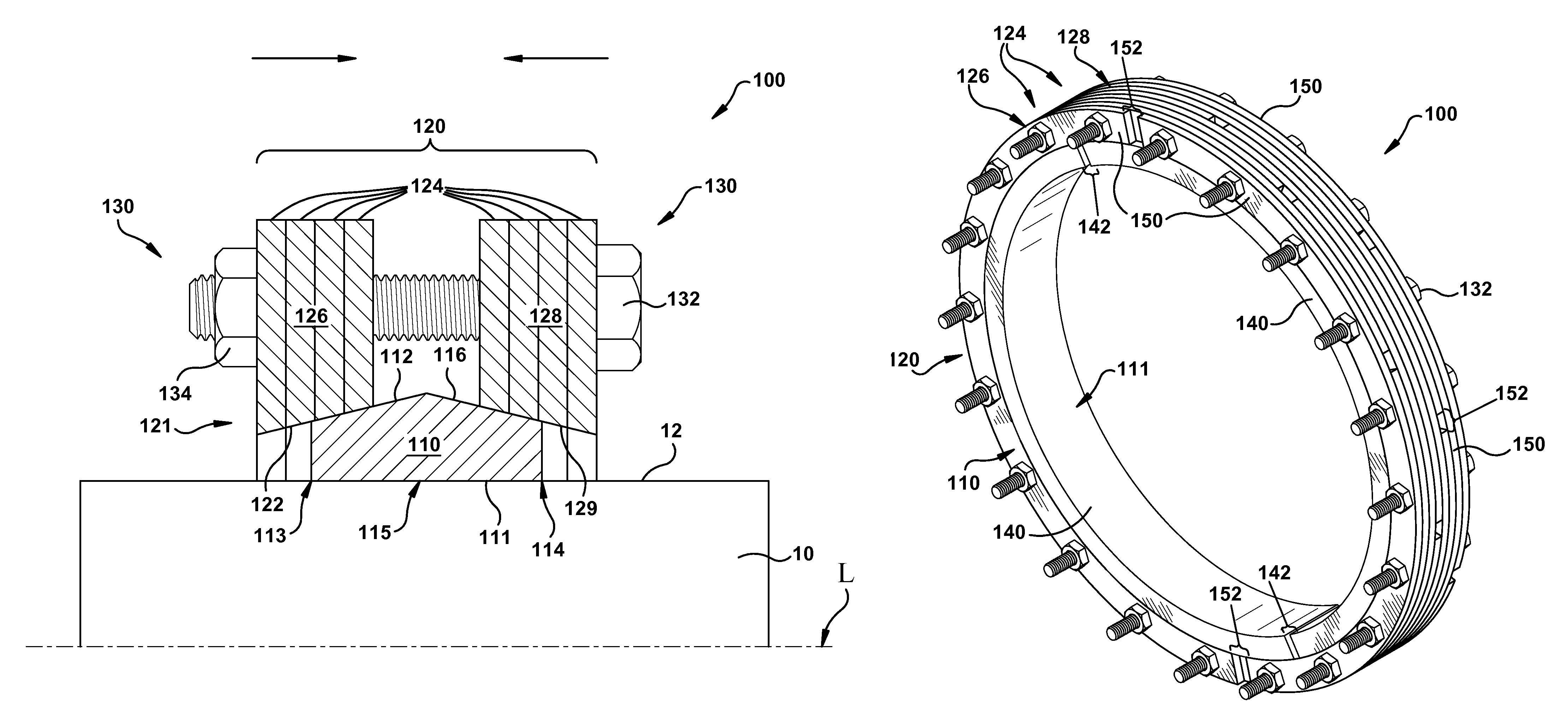

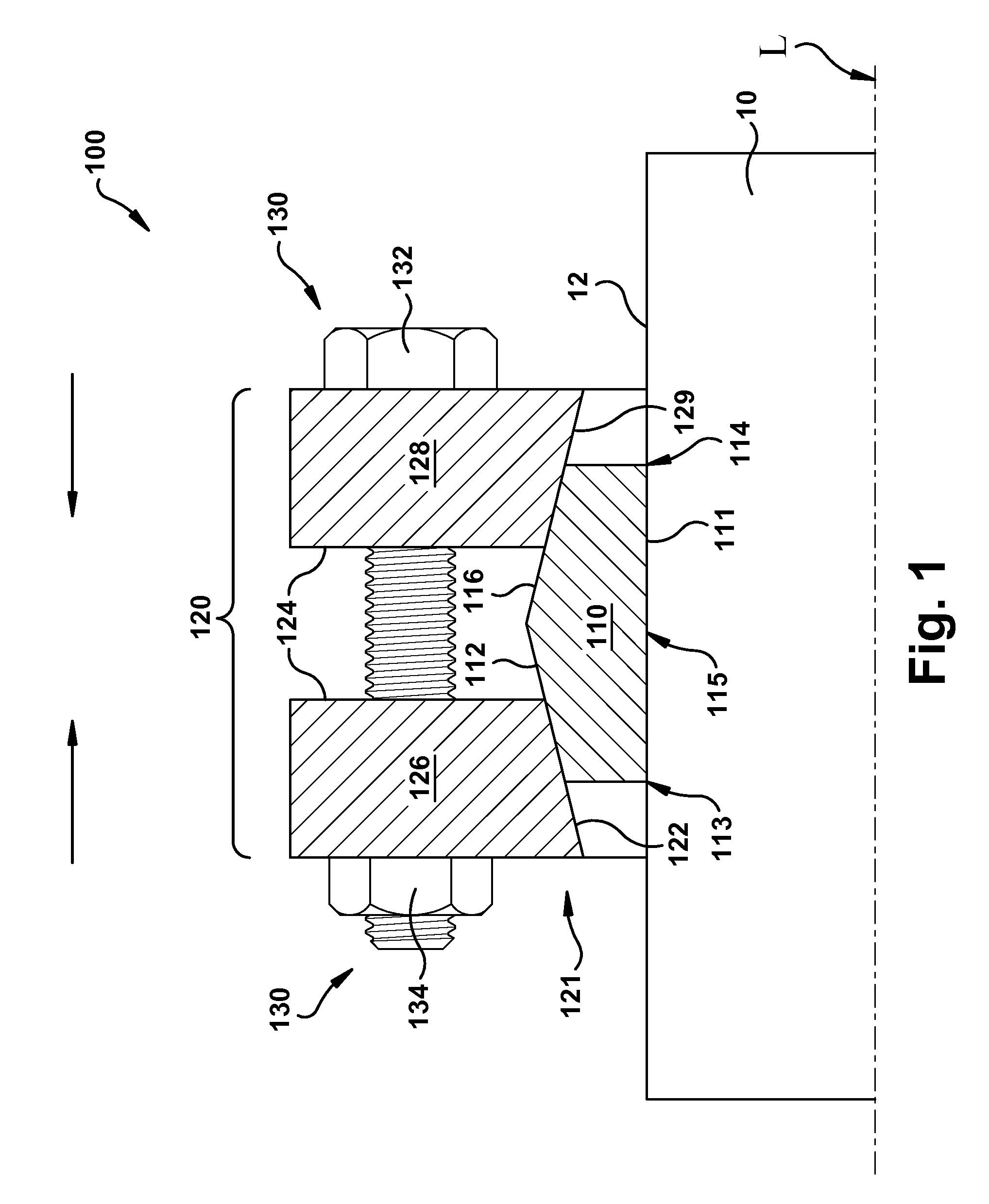

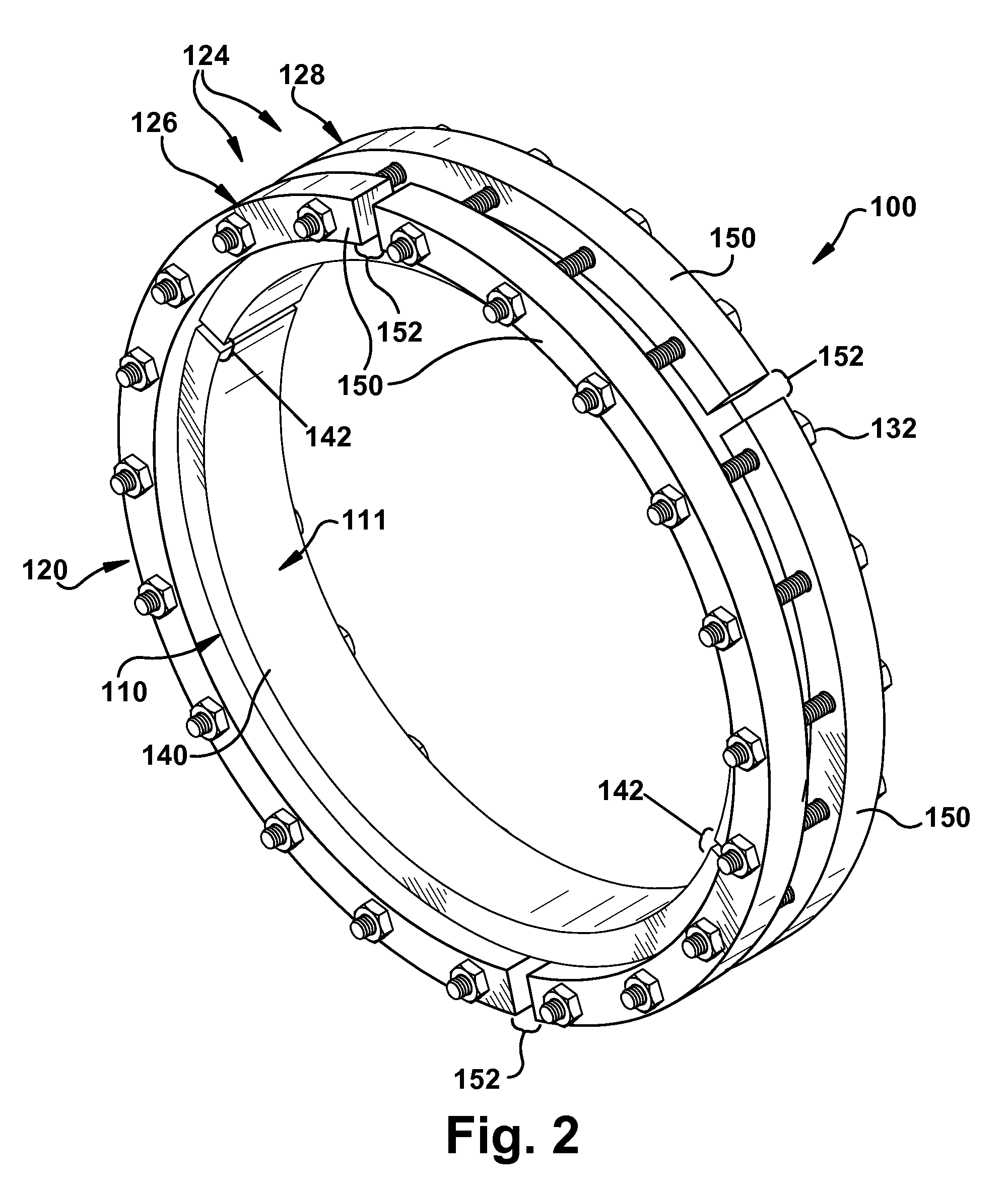

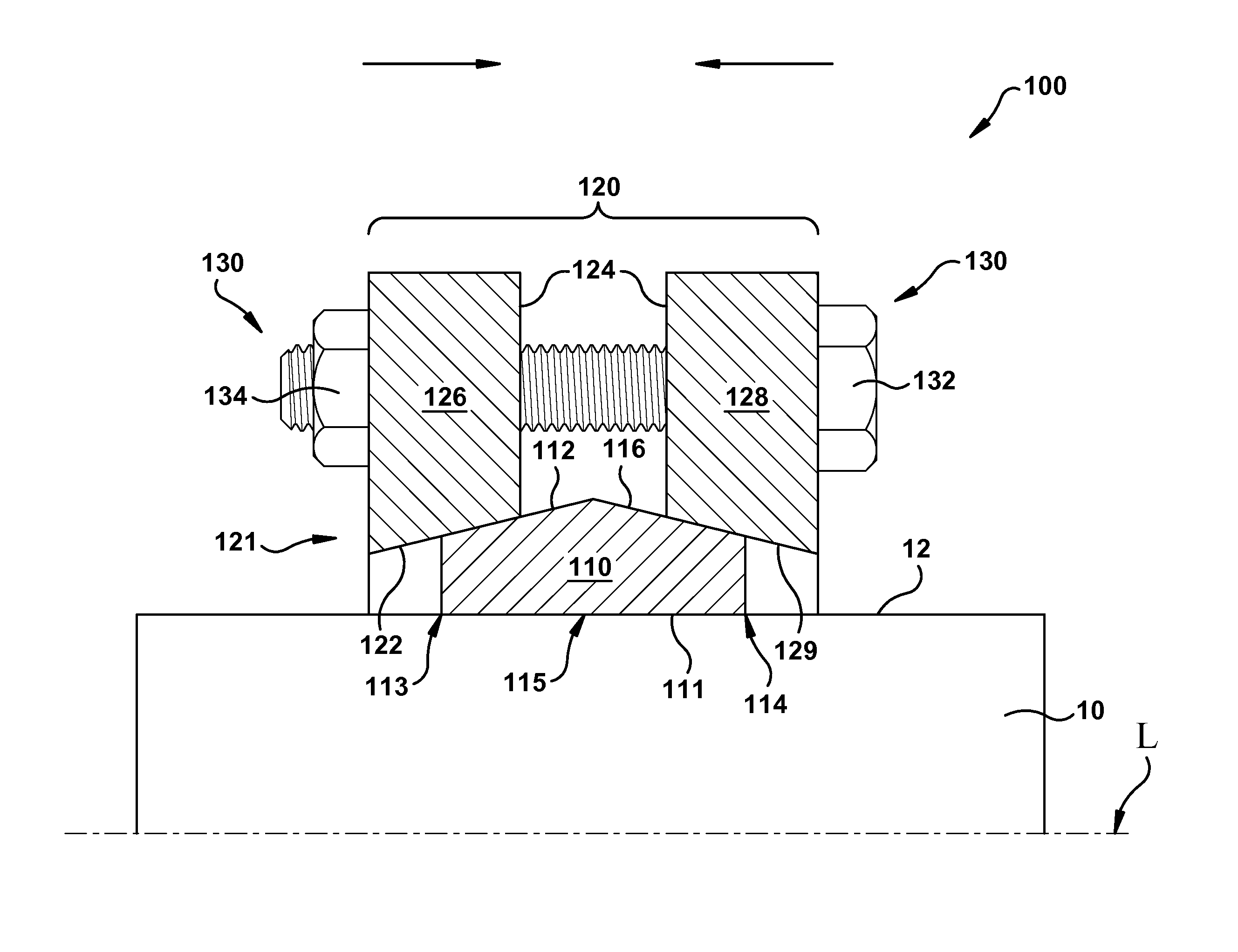

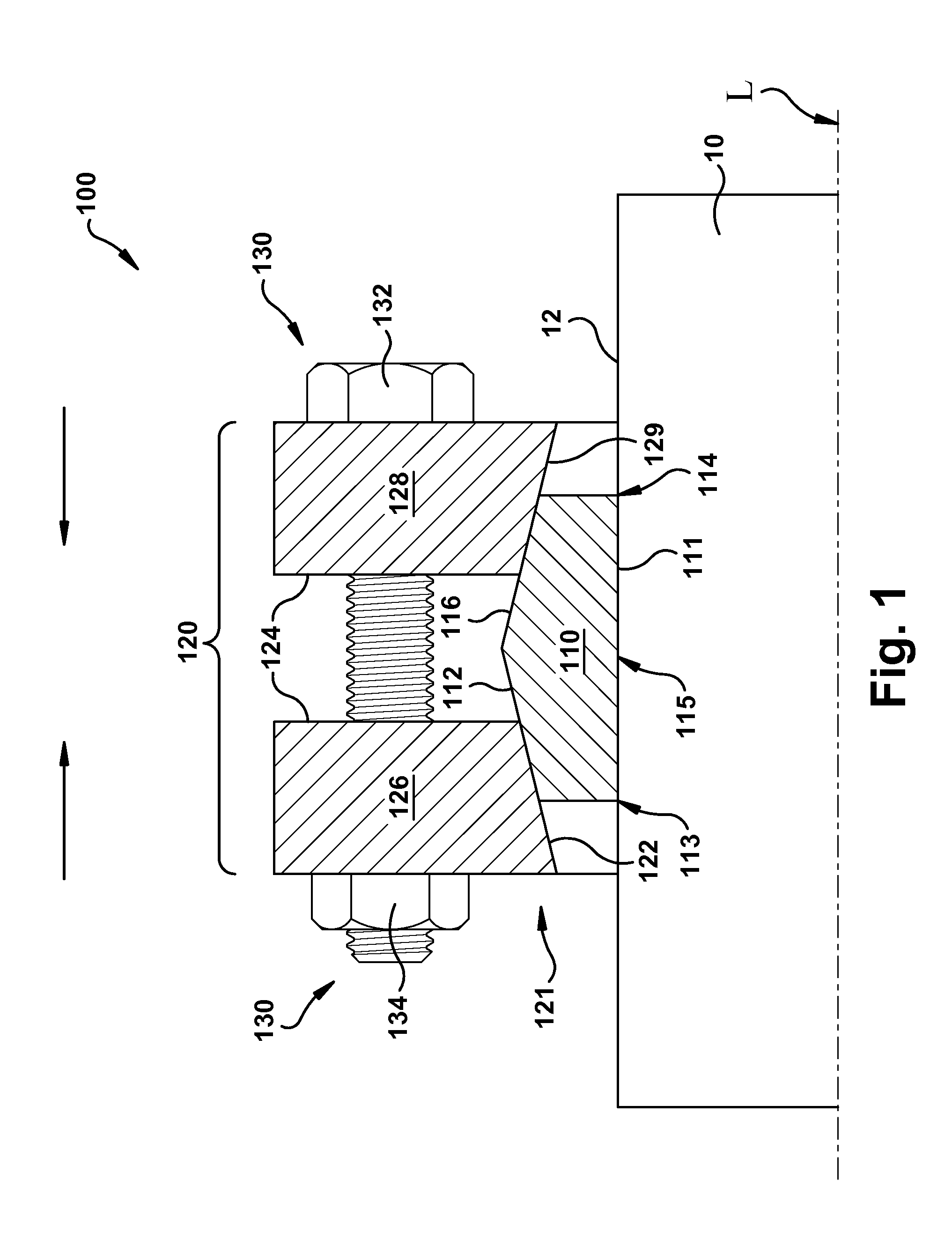

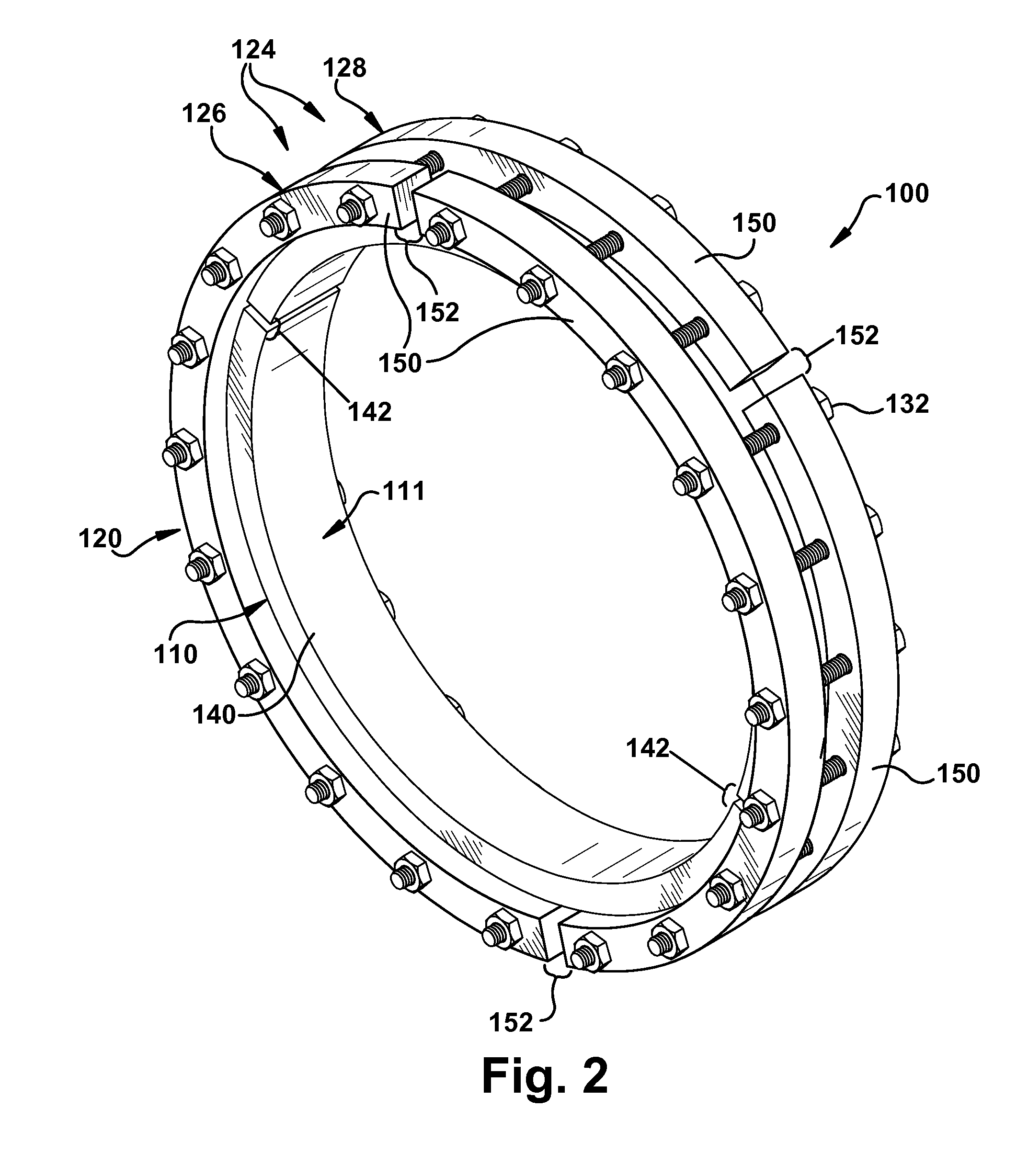

Flywheel with torsional dampening ring

An apparatus and method for constructing a flywheel assembly is disclosed. The flywheel assembly includes a flywheel hub that is constructed to engage a crankshaft of an internal combustion engine. A ferrous ring is attached to the flywheel hub with an elastomer ring positioned therebetween. The elastomer ring isolates the ferrous ring from the flywheel hub such that the ferrous ring resonates at a frequency that substantially reduces the amplitude of the resonance of the crankshaft and flywheel. Such a construction effectively dampens the torsional resonance of the engine and provides for smoother operation.

Owner:BRP US

Torsional resonance prevention

Owner:SCHLUMBERGER TECH CORP

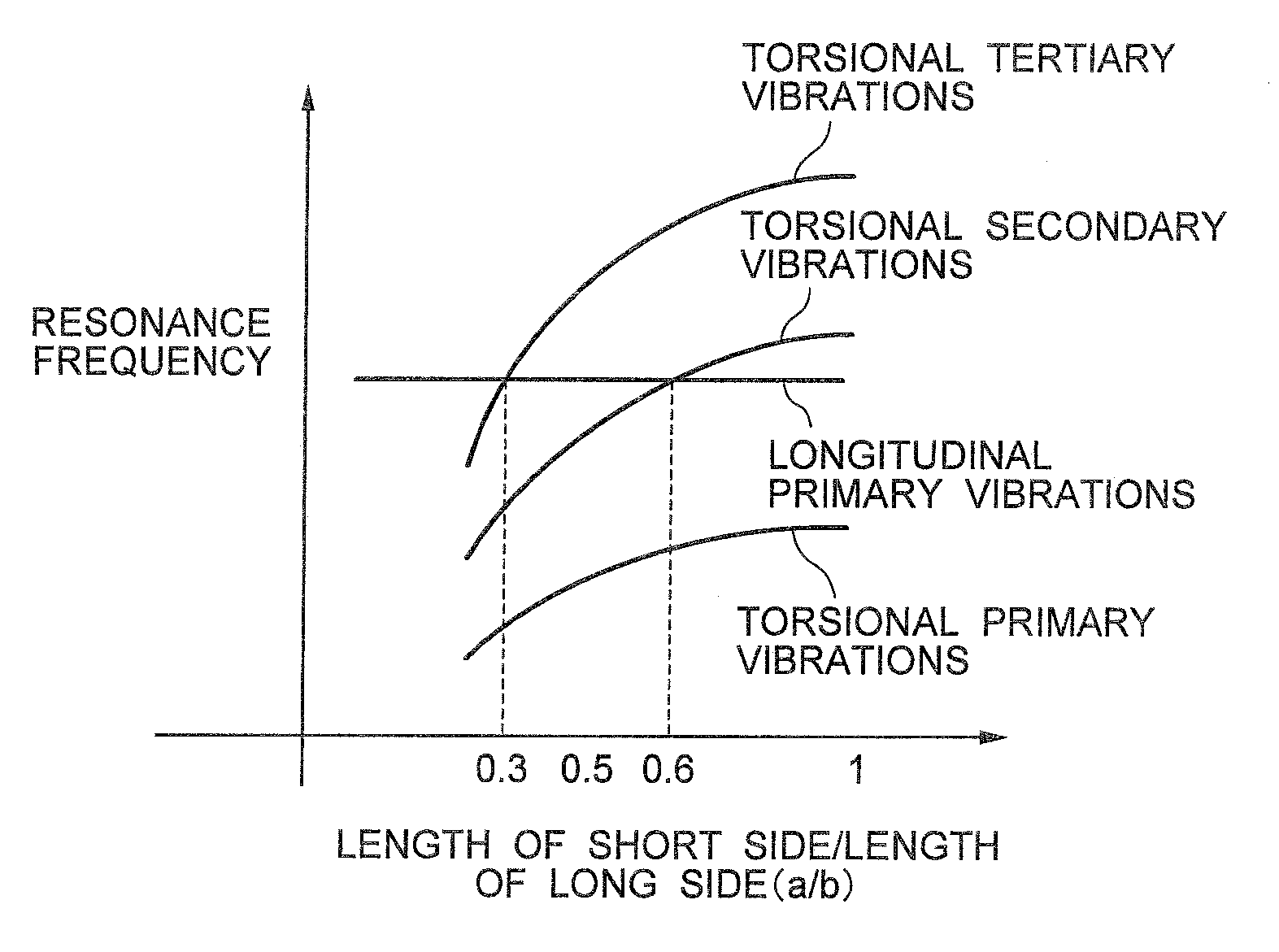

Ultrasonic motor

ActiveUS20110204748A1Simple structureReduce the numberPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesAcousticsVibration detection

An elliptical vibration is generated by combining a longitudinal primary resonance vibration of the vibrator resulting from an expansion and a contraction of the vibrator in a direction of the central axis and a torsional resonance vibration resulting from twisting of the vibrator around the central axis as a torsional axis. The dimension ratio of the rectangle of the vibrator is chosen such that a resonance frequency of the longitudinal primary resonance vibration resulting from the expansion and the contraction of the vibrator in the direction of the central axis and a resonance frequency of the torsional resonance vibrations resulting from twisting of the vibrator around the central axis as the torsional axis match. The ultrasonic motor further includes a vibration detecting electrode layer.

Owner:OLYMPUS CORP

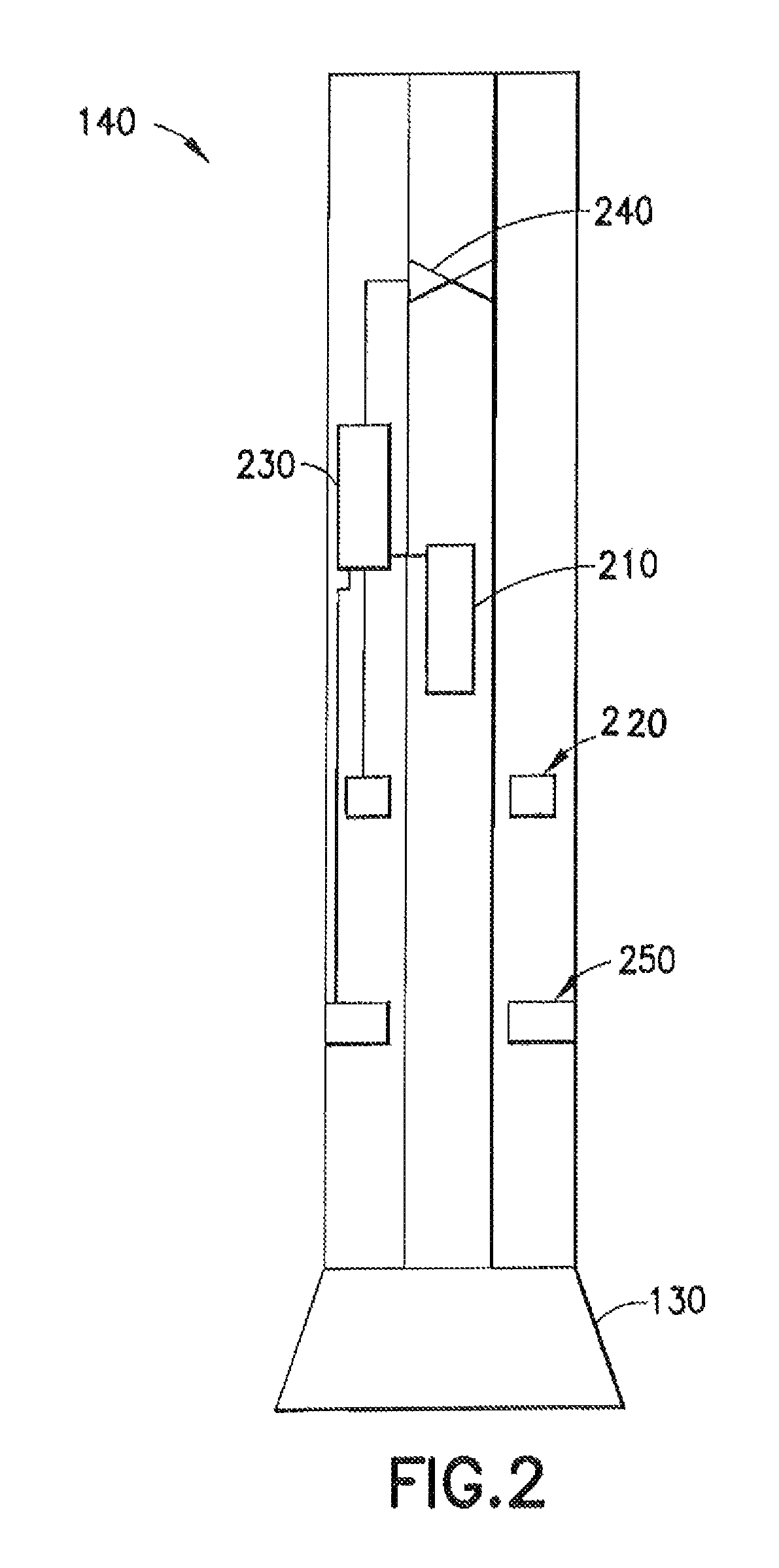

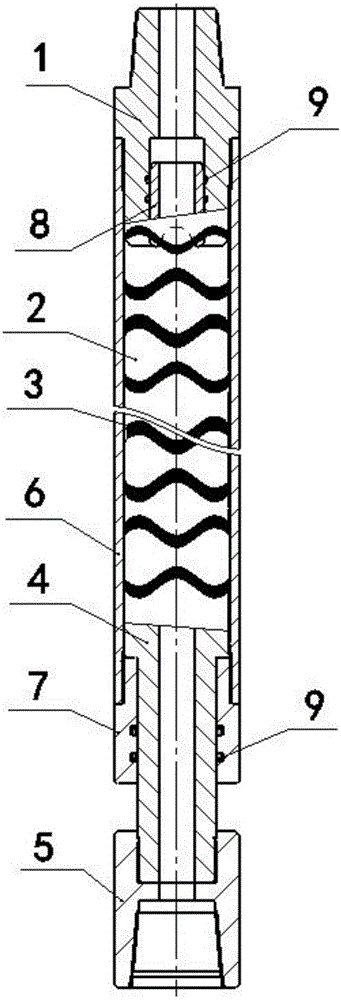

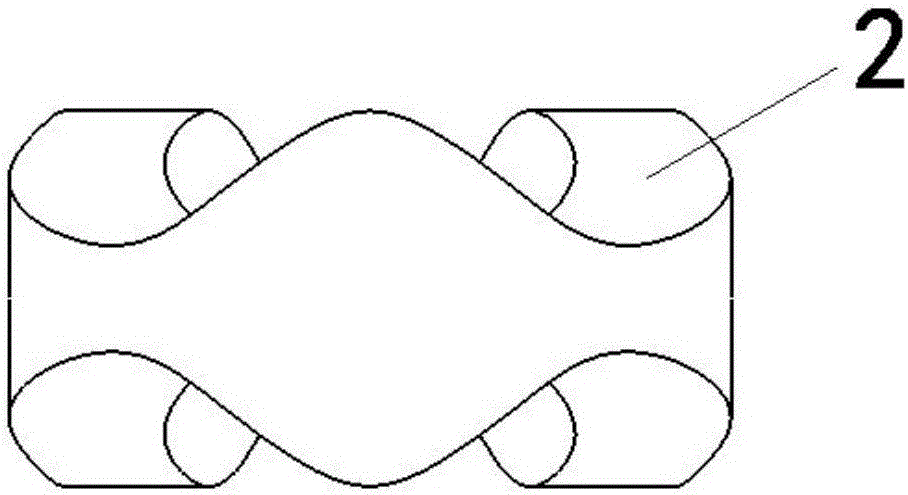

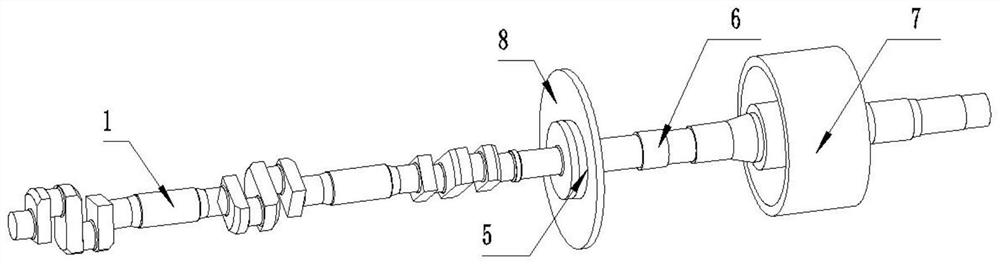

Method for preventing drill column from generating torsional resonance and flexible torque shock absorber

InactiveCN106089118AAvoid torsional resonance phenomenonImprove job stabilityDrilling rodsDrilling casingsDrive shaftWave shape

The invention discloses a method for preventing a drill column from generating torsional resonance and a flexible torque shock absorber. According to the flexible torque shock absorber, more than two flexible torque transmission short joints are arranged between an upper driving connector and a lower driving shaft in a cylinder, the two end faces of each flexible torque transmission short joint are provided with sinusoidal-wave-shaped meshing teeth, every two adjacent flexible torque transmission short joints are mutually meshed together through the corresponding sinusoidal-wave-shaped meshing teeth to transmit torque, and elastic elements matched with the sinusoidal-wave-shaped meshing teeth are arranged between the meshing faces of every two adjacent sinusoidal-wave-shaped meshing teeth. According to the flexible torque shock absorber, torque shock loads generated on the drill column are buffered step by step through the flexible torque transmission short joints; meanwhile, torque peak values are dispersed and decreased through the elastic elements among the flexible torque transmission short joints, so that the severe torque shock loads are decreased until the torque shock loads disappear; therefore, the phenomenon that the drill column generates torsional resonance is avoided, the working stability of the drill column is improved, the drilling speed is increased, the well bore quality is improved, and the drilling cost is reduced.

Owner:GUIZHOU GAOFENG GASOLINEEUM MACHINERY

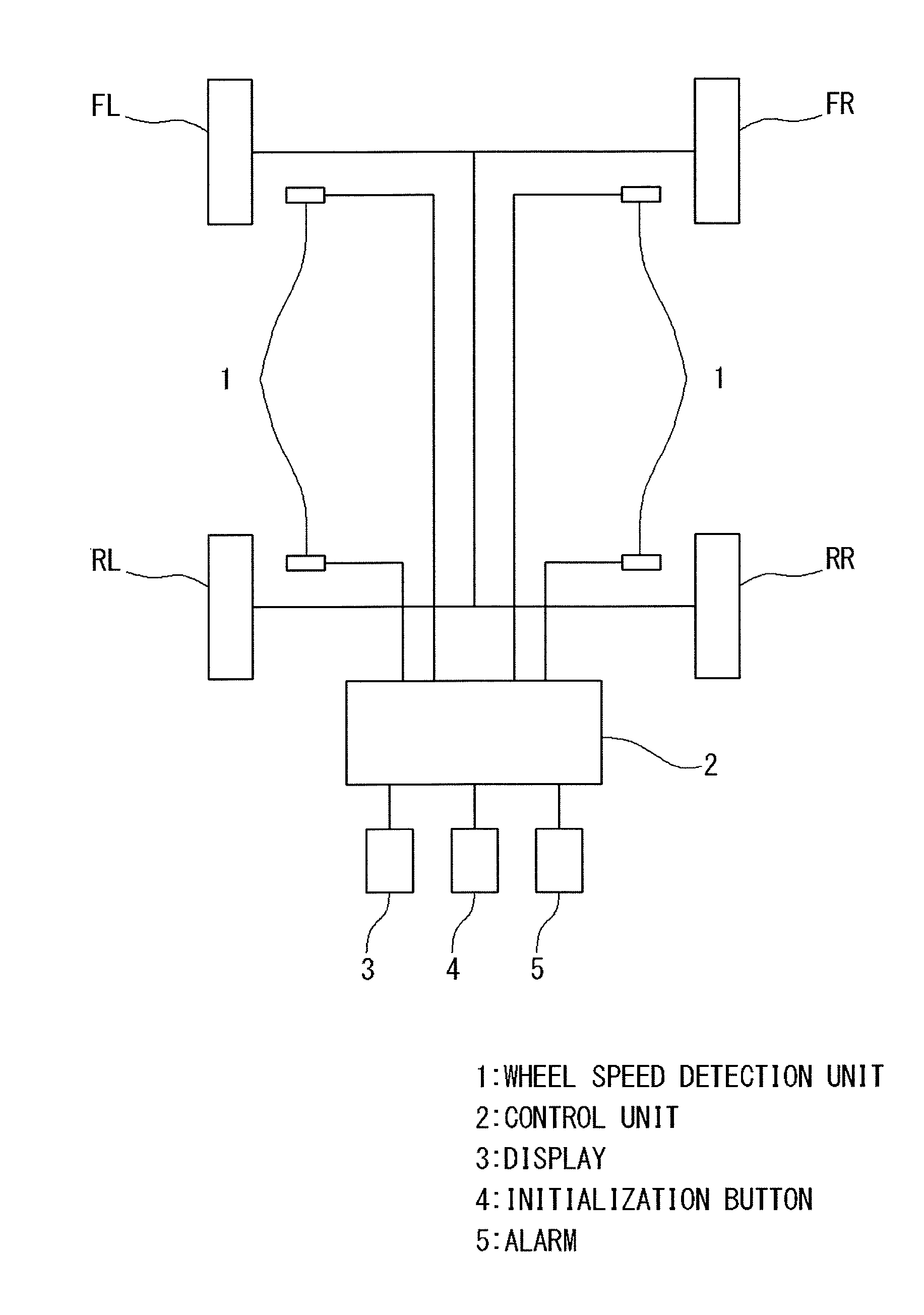

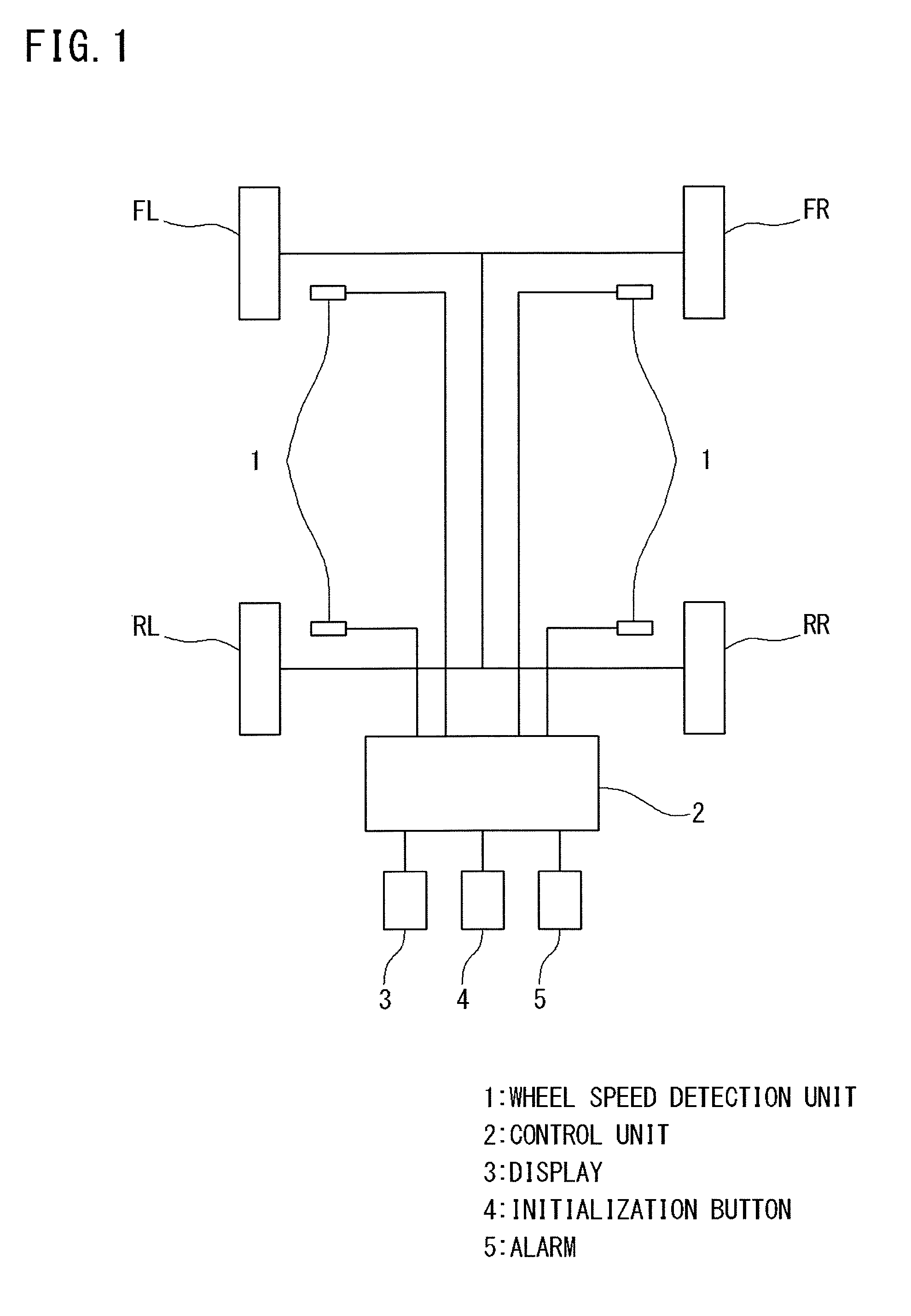

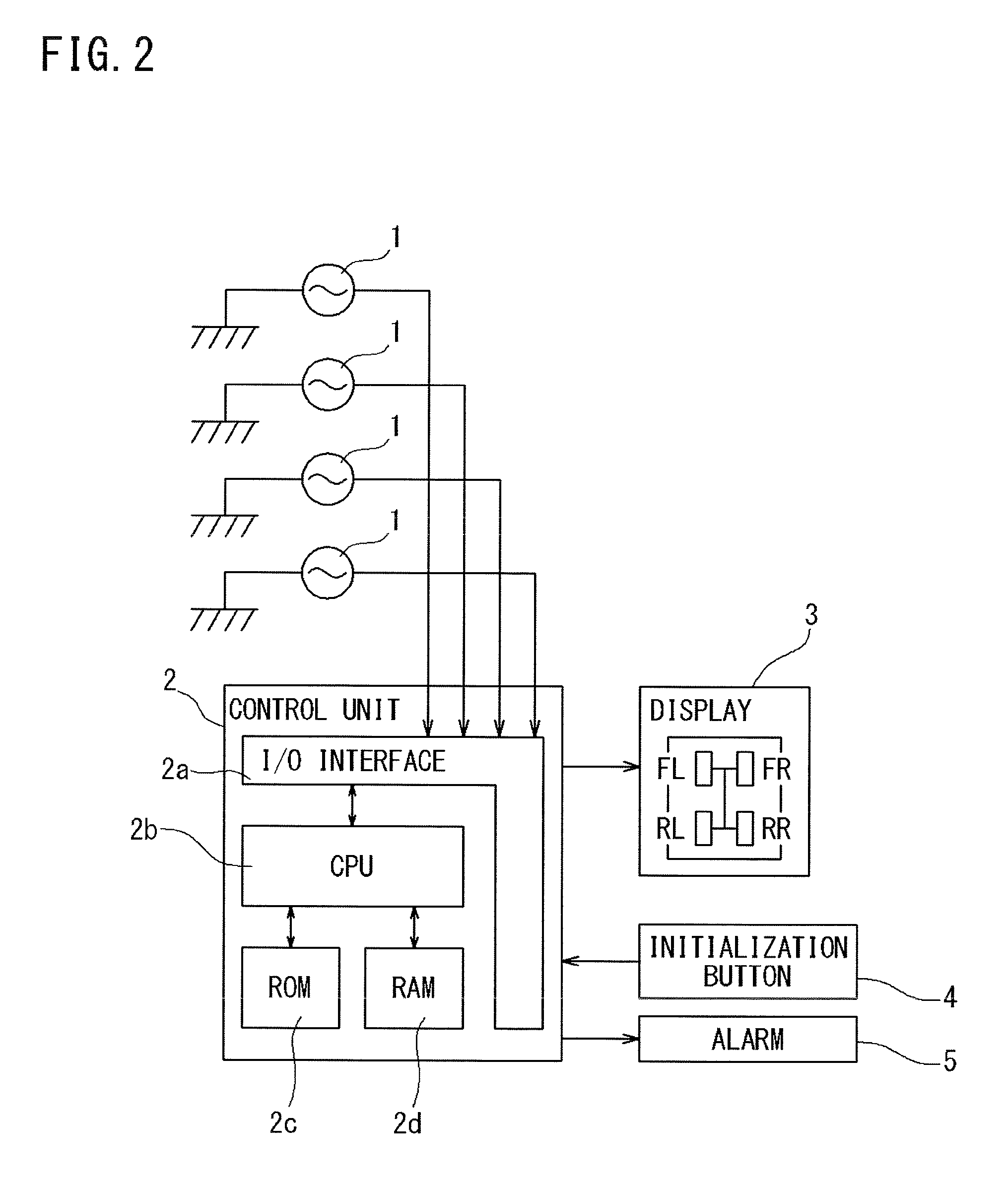

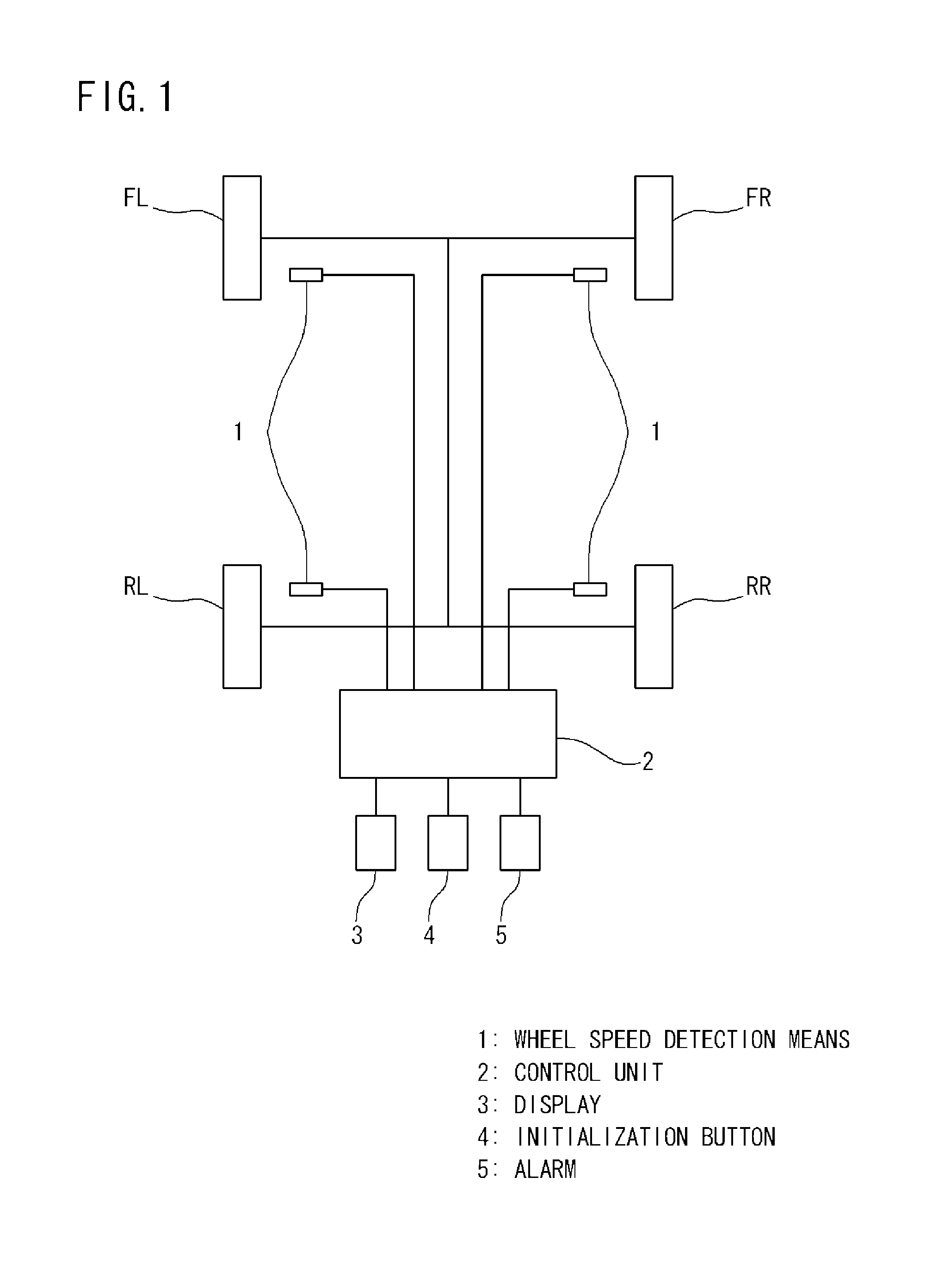

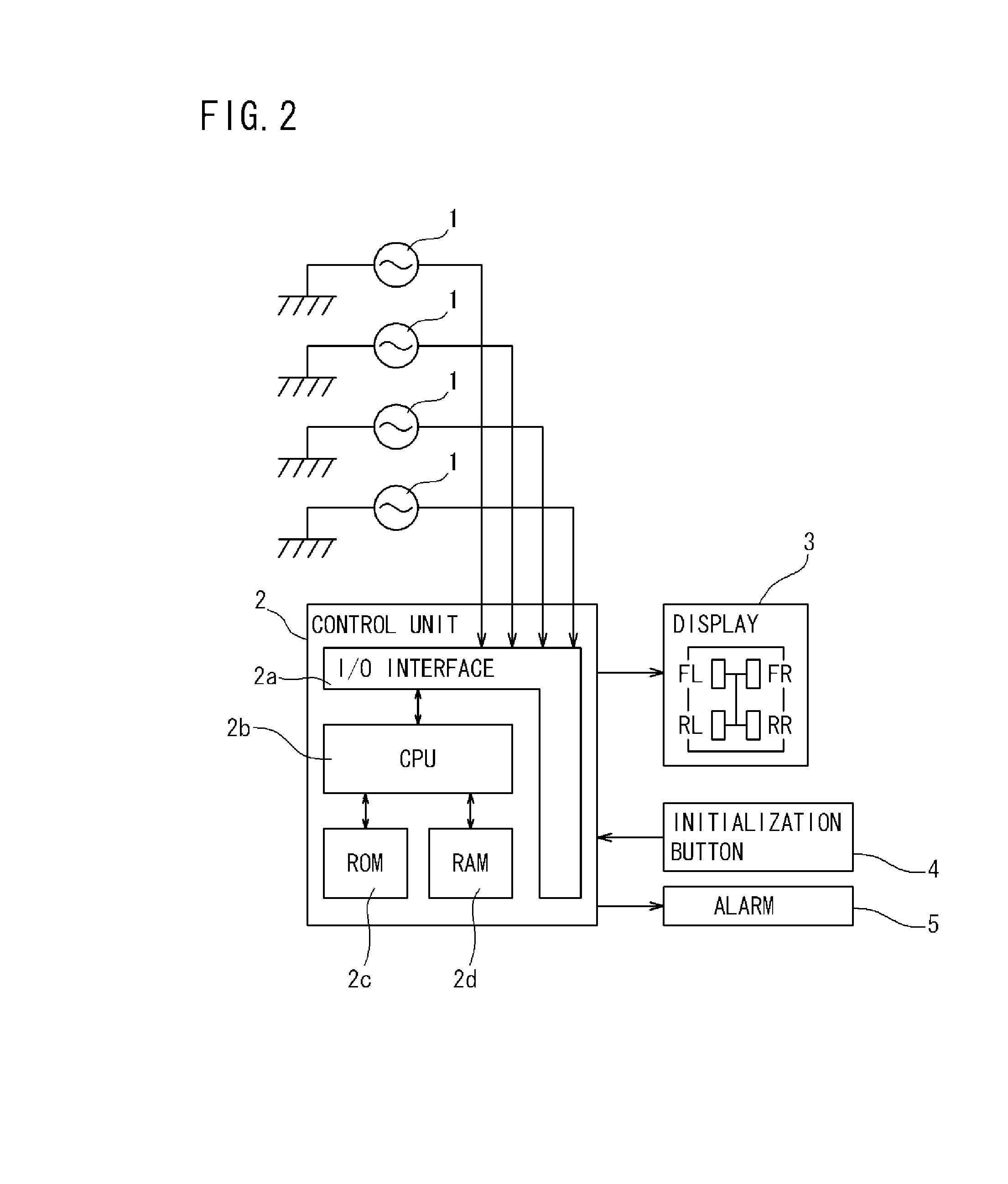

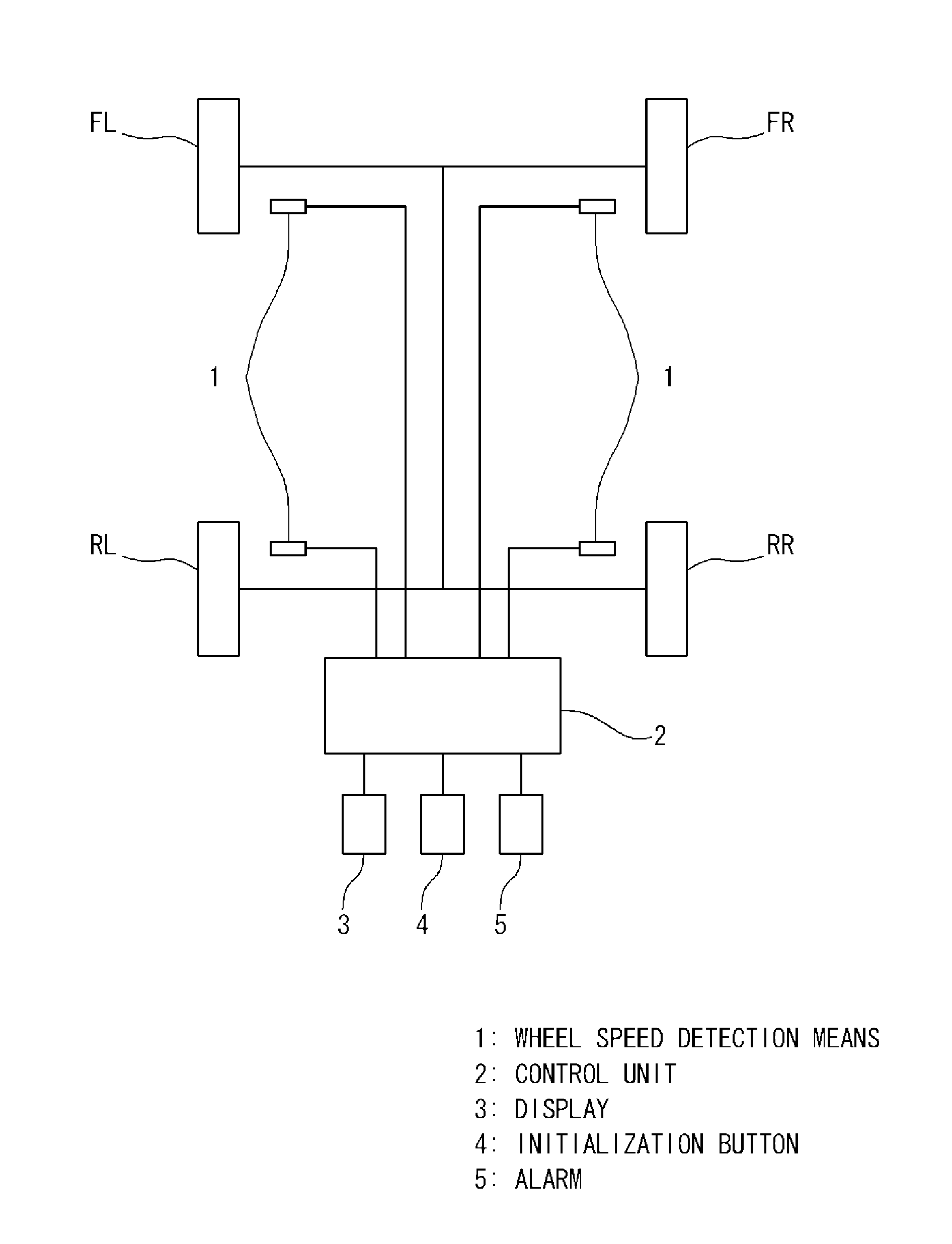

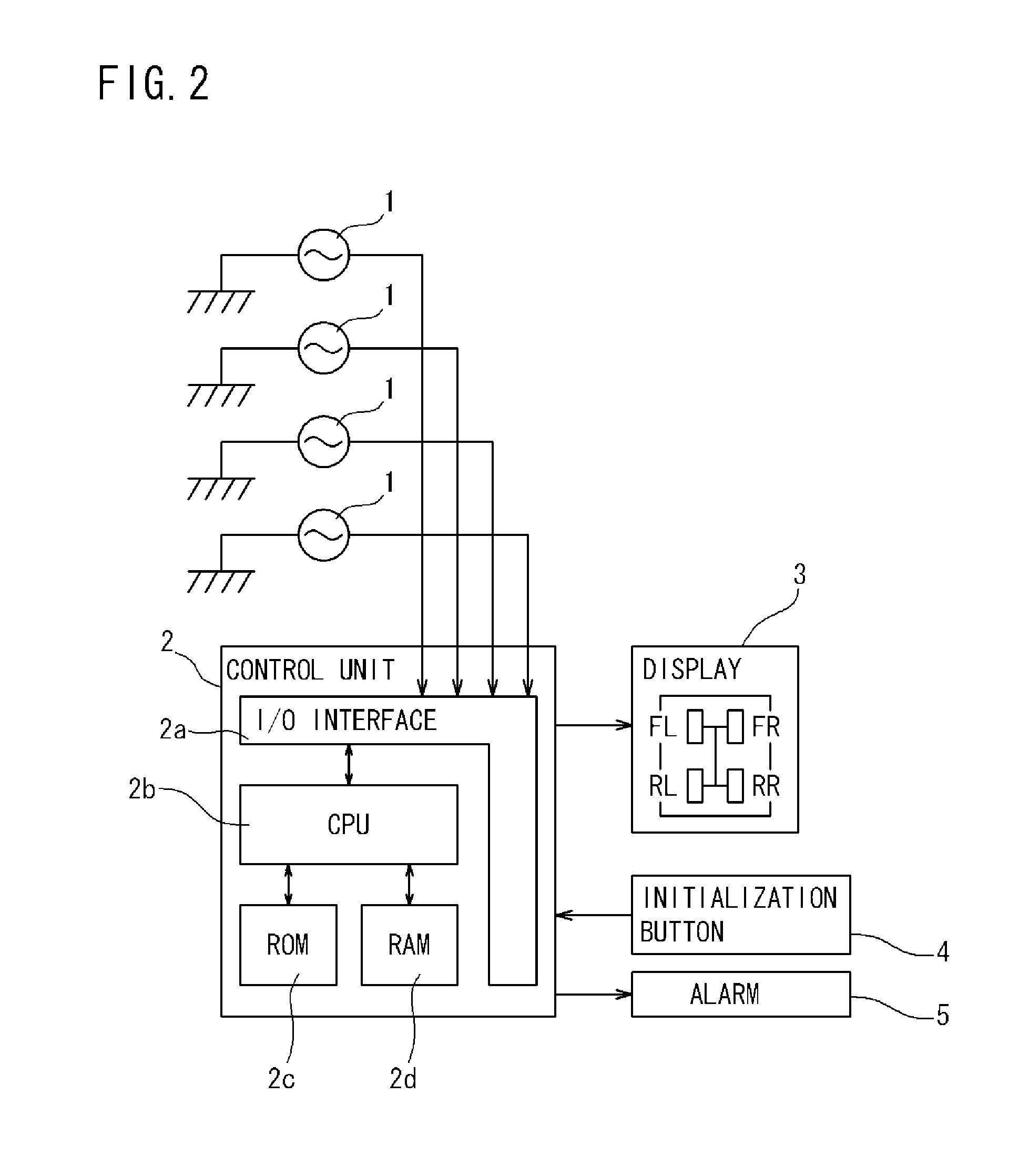

Tire pressure decrease detection apparatus, method, and program

ActiveUS20160131547A1Exclude influenceEstimation precision can be improvedInflated body pressure measurementFlow propertiesResonanceNoise removal

A tire pressure decrease detection apparatus comprising a rotation speed information detection unit for detecting rotation speed information of wheels of a vehicle, a resonance frequency estimate unit for time-series estimating a torsional resonance frequency of the rotation speed information from the rotation speed information obtained by the rotation speed information detection unit, and a judgment unit for judging a decrease in pressure of tires installed in the wheels based on the estimated torsional resonance frequency. The resonance frequency estimate unit includes a noise removal unit for removing a noise superimposed on a wheel speed signal serving as the rotation speed information for each of the wheels with using an active noise control technology.

Owner:SUMITOMO RUBBER IND LTD

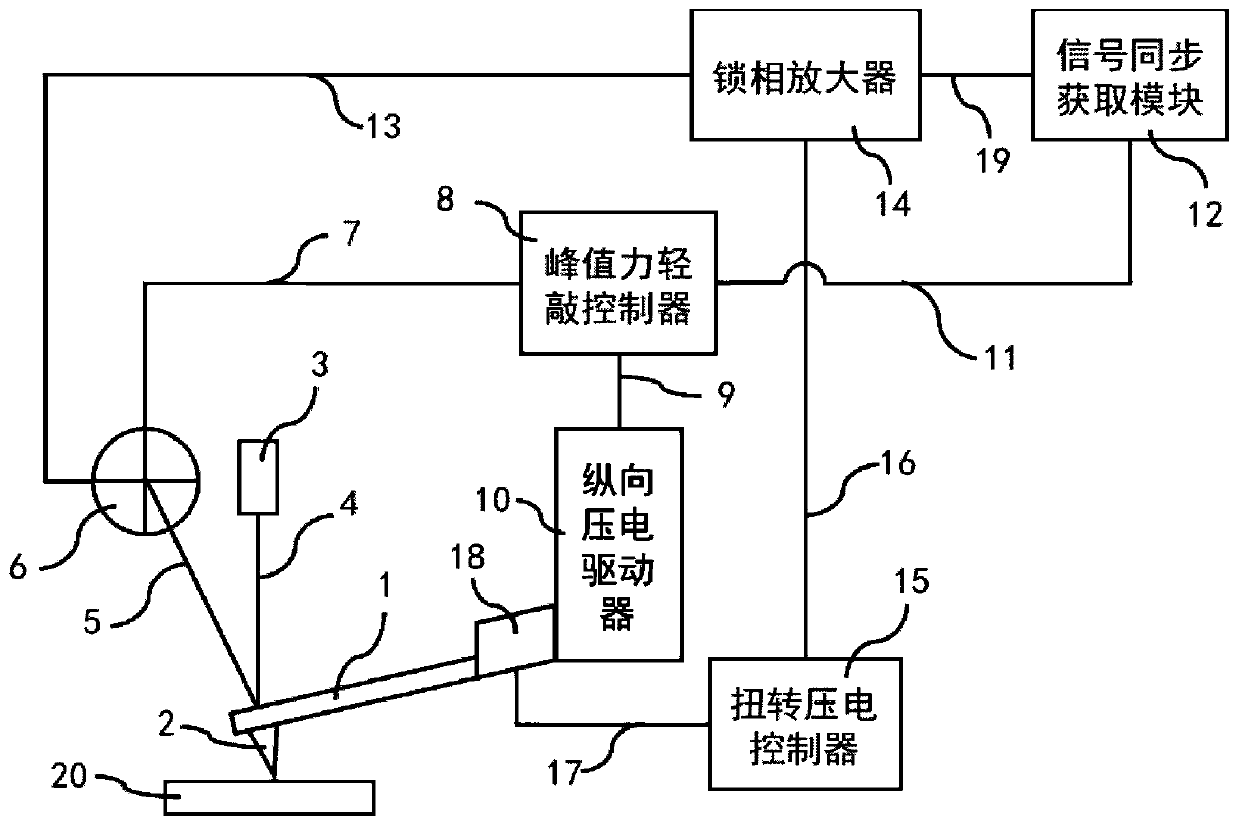

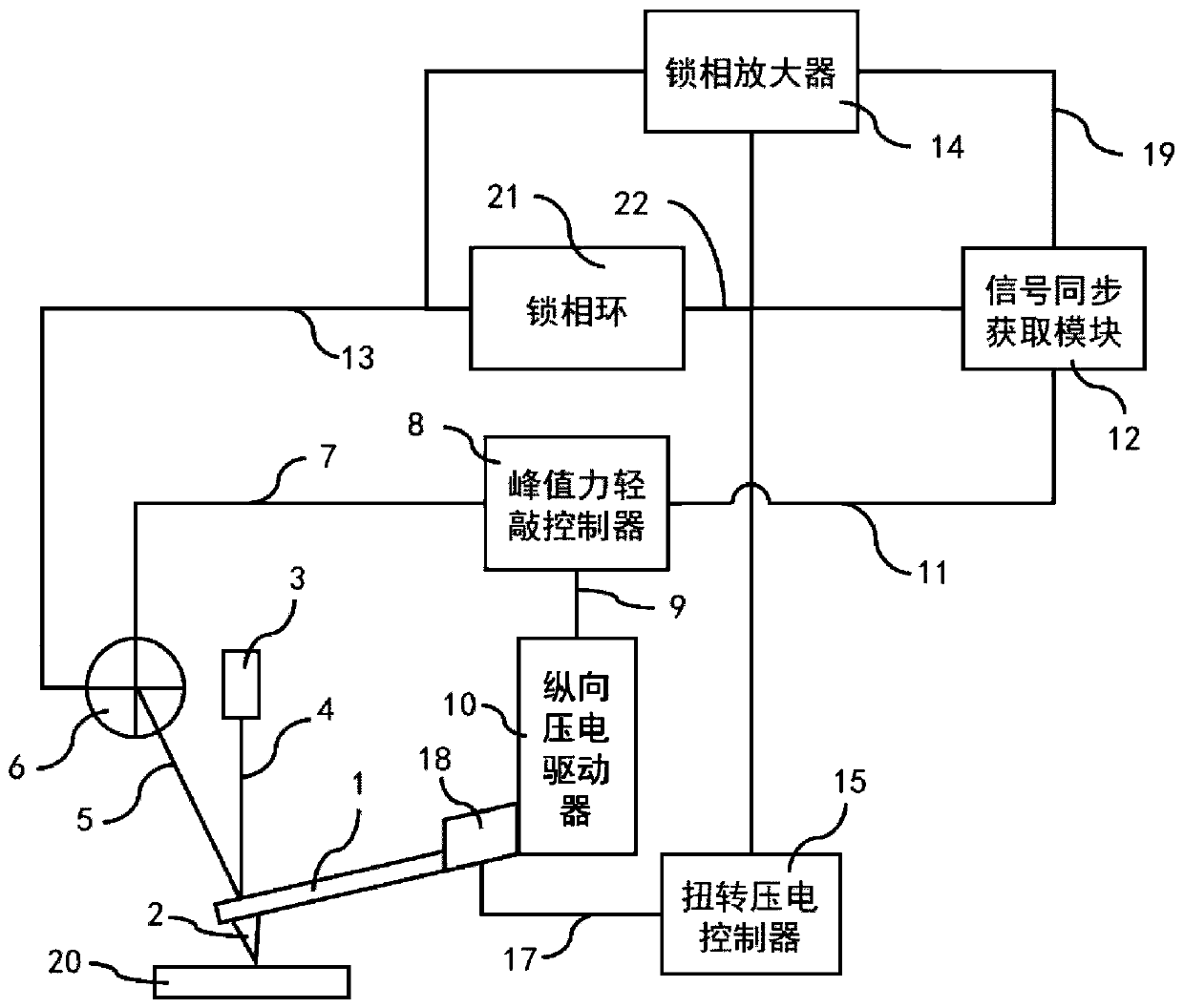

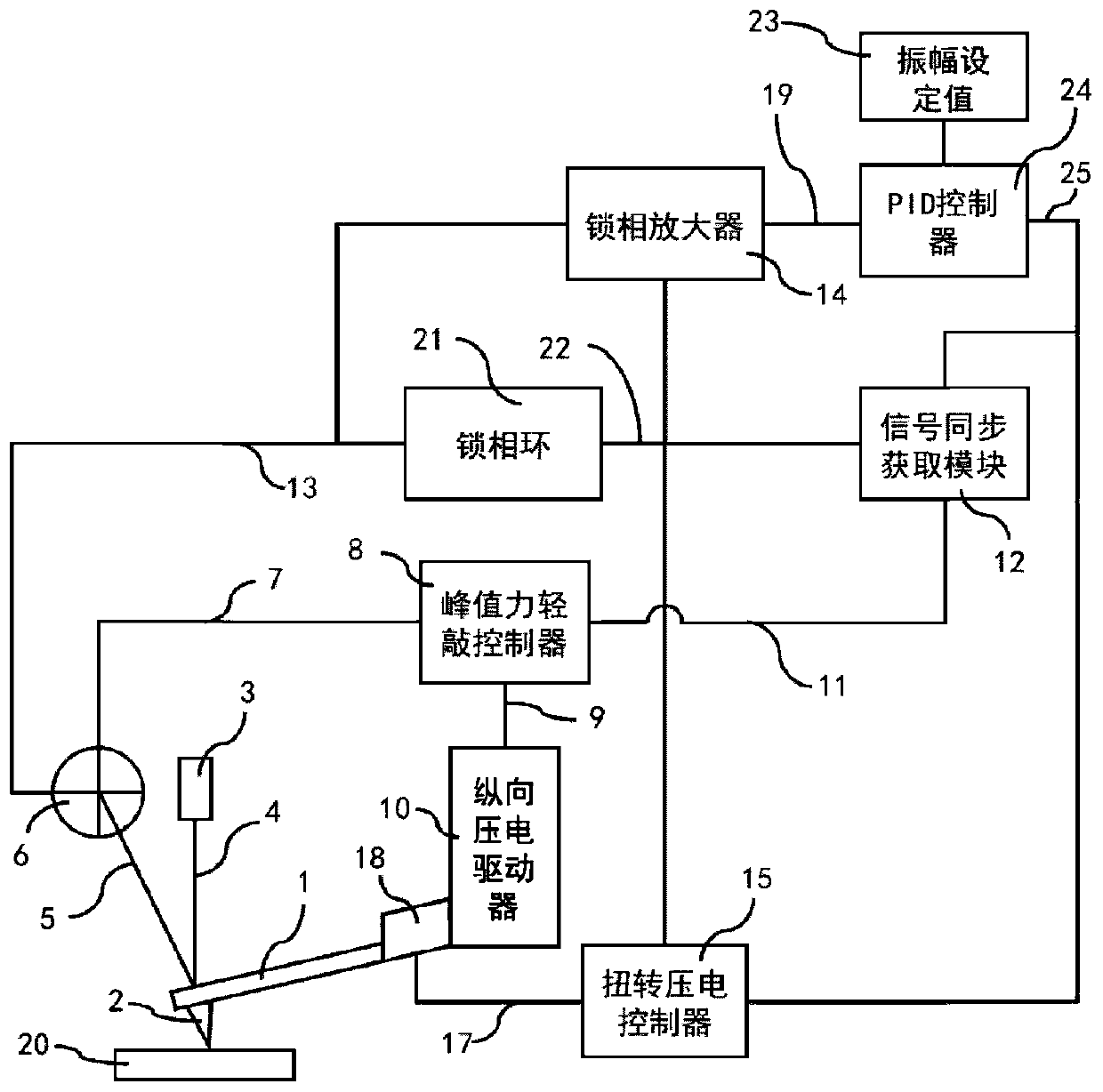

Peak force tapping and torsional resonance combination method based on atomic force microscope technology

ActiveCN110763873ASmall contact forceConvenient time controlScanning probe microscopyAfm atomic force microscopyParticle physics

The invention relates to a peak force tapping and twisting resonance combination method based on an atomic force microscope technology. According to the method, a combined mode of a peak force tappingmode and a torsional resonance mode is used for performing imaging and sample physical property measurement and representation, the peak force tapping mode is utilized to control the interaction between a tip and a sample, and the torsional resonance mode is utilized to measure transverse physical properties of the sample while the peak force tapping mode works. Through the method, the defect that the torsional resonance mode has a special requirement on the sample is overcome, and the problem that the vertical interaction force between the tip and the sample is large in the torsional resonance mode is solved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

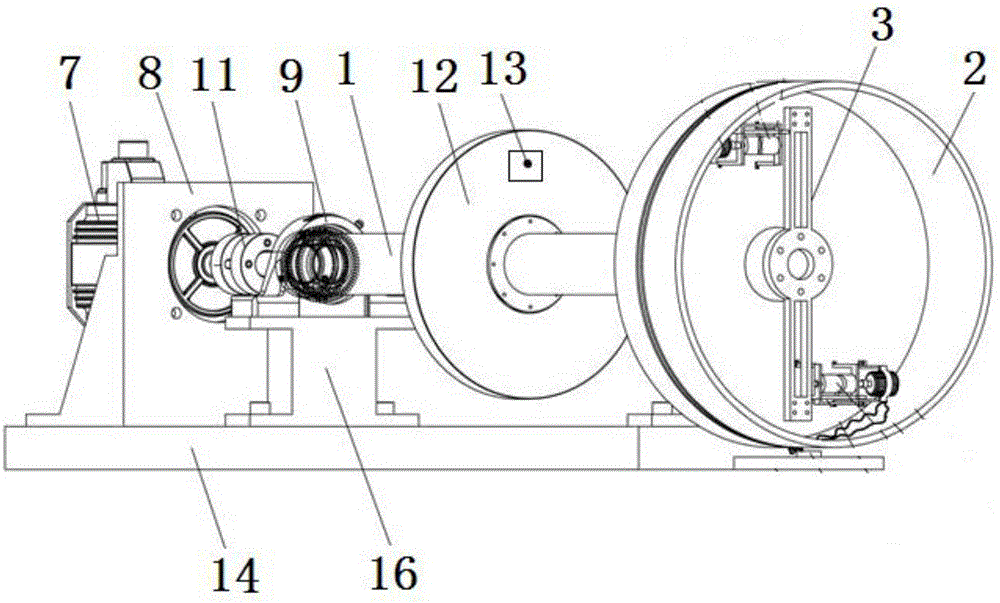

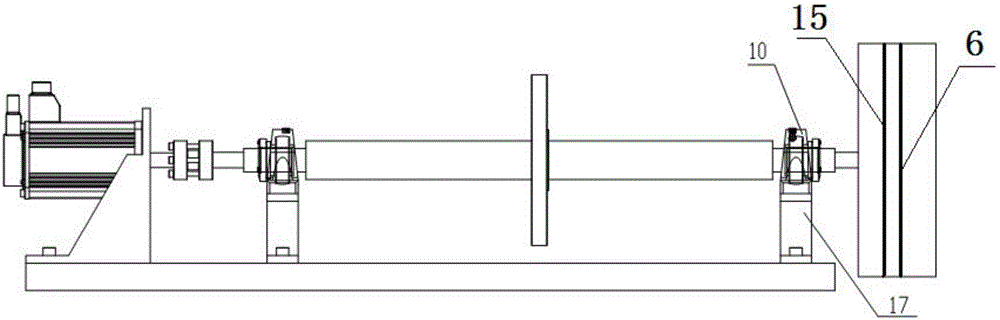

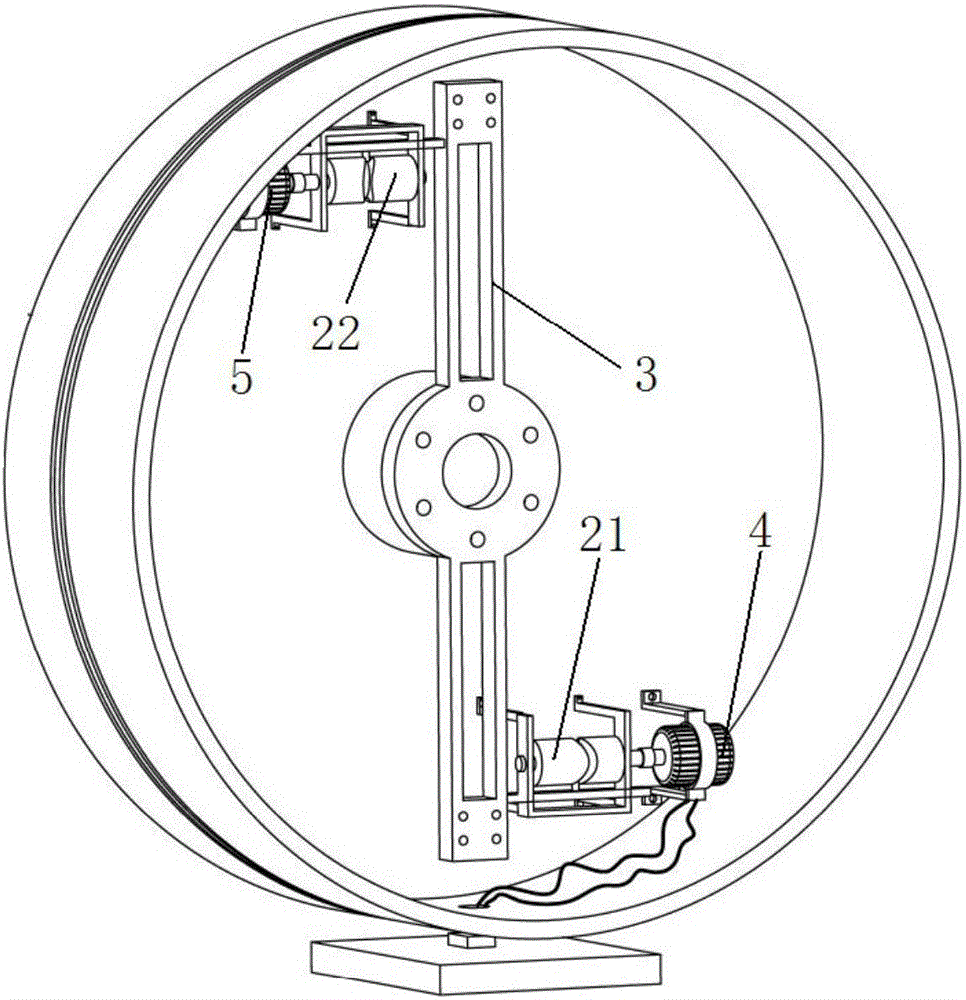

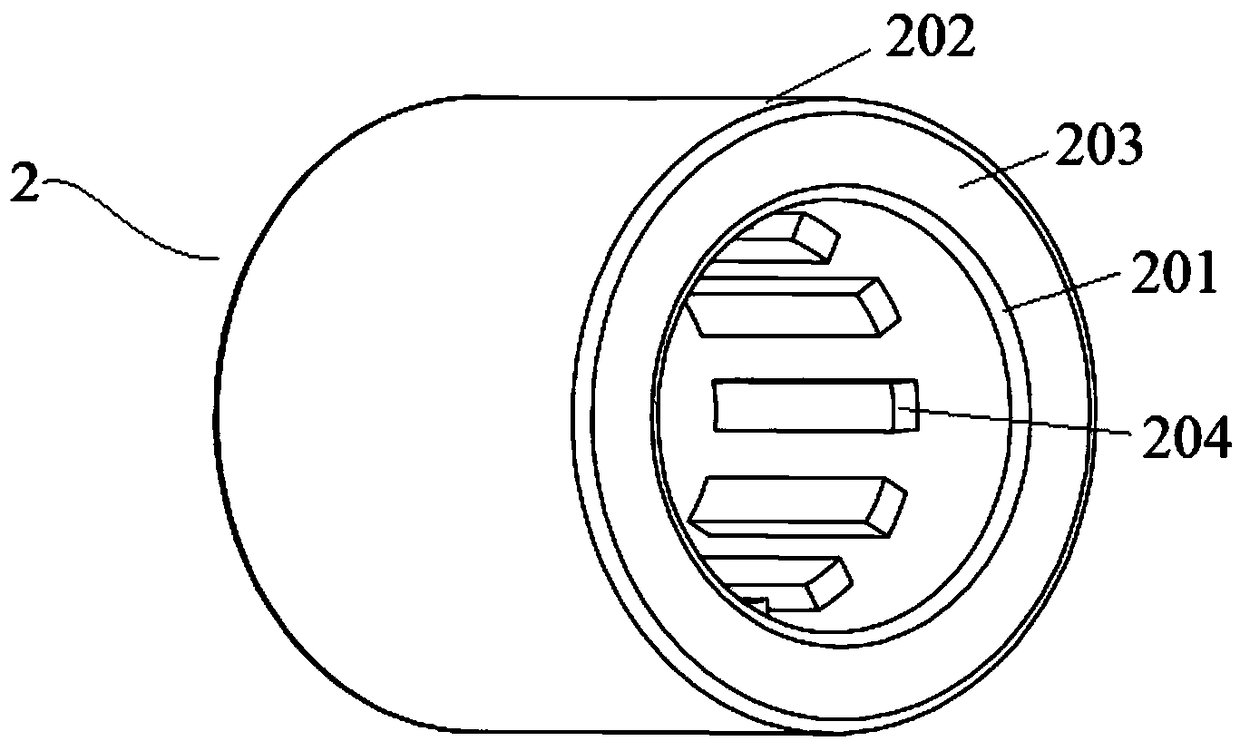

Cylindrical cam excitation driven bending-torsional coupling resonance type residual stress relieving device

ActiveCN106702136AHigh transmission precisionReduce shockProcess efficiency improvementCouplingEngineering

The invention discloses a cylindrical cam excitation driven bending-torsional coupling resonance type residual stress relieving device, and relates to a cylindrical cam transmission type alternated force moment bending-torsional coupling resonance type vibratory stress relief method. Torsional vibration output by a cylindrical cam transmission type alternated force moment torsional vibration exciter is applied to a high-rigidity rotary shaft, when the rotating frequency of the rotary shaft is equal to the difference of the natural bending frequency and the natural torsion frequency, based on the bending-torsional coupling resonance theory, namely, torsional vibration excitation with the frequency equal to the natural torsion frequency can excite bending resonance, meanwhile, the bending resonance and the torsional resonance are mutually strengthened, and enough dynamic stress is generated to eliminate the residual stress of the high-rigidity rotary shaft. According to the residual stress relieving device, the problem that bending-torsional coupling resonance vibratory stress relief is limited by a torsional vibration excitation source is solved, the residual stress of the high-rigidity rotary shaft is eliminated through cylindrical cam transmission type alternated force moment bending-torsional coupling resonance, the efficiency is improve, and the safety and reliability of production are improved.

Owner:GUANGXI UNIV

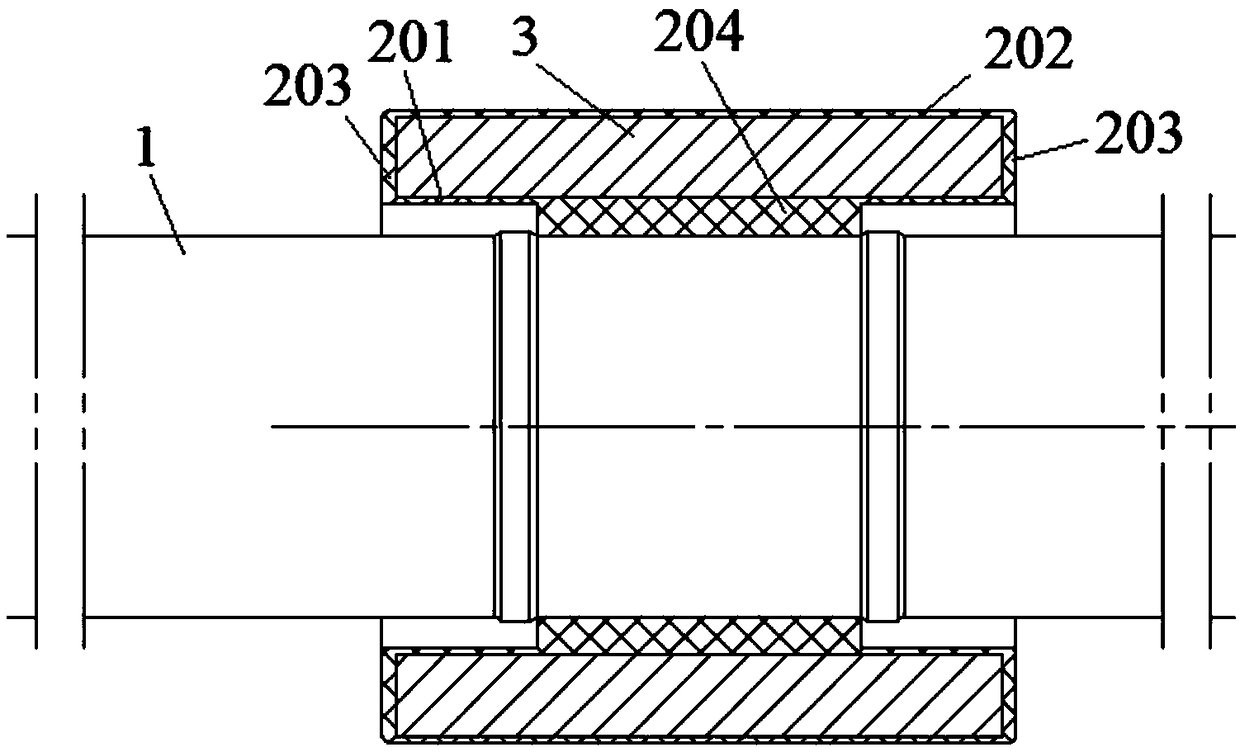

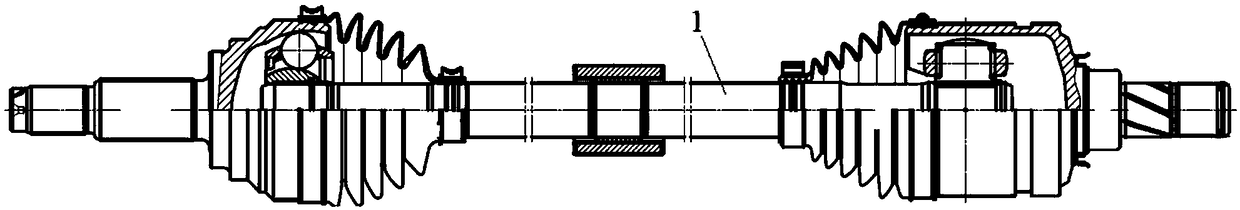

Vehicle driving shaft torsional vibration damper

InactiveCN108644310ASuppression of torsional amplitudeImprove ride comfortRotating vibration suppressionDrive shaftMotion space

The invention discloses a vehicle driving shaft torsional vibration damper. The vehicle driving shaft torsional vibration damper comprises an elastic energy storage body with elasticity and used for sleeving a driving shaft, and an inertia mass block arranged in the elastic energy storage body; the elastic energy storage body comprises convex blocks contacted with the driving shaft; multiple convex blocks are provided; and all the convex blocks are peripherally distributed on the outer side of the driving shaft. In the vehicle driving shaft torsional vibration damper, the elastic energy storage body and the inertia mass block are provided for cooperation; and as a gap with a certain width is formed between the convex blocks on the peripheral surface in the elastic energy storage body and the driving shaft, the inertia mass block can obtain wider torsional motion space relative to the elastic energy storage body, the torsional vibration amplitude of a vehicle transmission system can beinhibited, the damping effect is improved, the effect of reducing torsional resonance and noise is achieved, and the overall vehicle driving smoothness and sitting comfort and the service life of parts are improved.

Owner:CHERY AUTOMOBILE CO LTD

Ultrasonic motor

ActiveUS8304962B2Simple structureReduce the numberPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesResonance vibrationPrimary resonance

Owner:OLYMPUS CORP

Torsional resonance frequency adjustor

Owner:GE INFRASTRUCTURE TECH INT LLC

Design method for torsional vibration of reciprocating compressor rotor system

PendingCN112270050AImprove calculation accuracyExtended functional scopeGeometric CADDesign optimisation/simulationFlywheelControl theory

The invention discloses a design method for torsional vibration of a reciprocating compressor rotor system, and the method comprises the steps of carrying out the mass equivalent calculation on a moving part of a reciprocating compressor, and providing data for the model conversion of a torsional vibration system of the reciprocating compressor rotor system, wherein the reciprocating compressor moving part for mass equivalent calculation comprises a connecting rod, a crosshead and a piston; and according to the principle that the rotational inertia of the structure is equal, carrying out equivalent processing on a coupler structure, a flywheel and a motor rotor structure of the rotor system, thereby completing the geometric model construction of the reciprocating compressor rotor system comprising a crankshaft, the equivalent coupler, the equivalent flywheel, a motor shaft and a equivalent motor rotor; and using the general ANSYS finite element calculation software for replacing the original special analysis software, so that the calculation precision and the working efficiency of the torsional resonance of the reciprocating compressor rotor system are improved, and the method is not limited by the proprietary technical attribution of reciprocating compressor series products and can be widely applied in the industry.

Owner:SHENYANG POLYTECHNIC UNIV

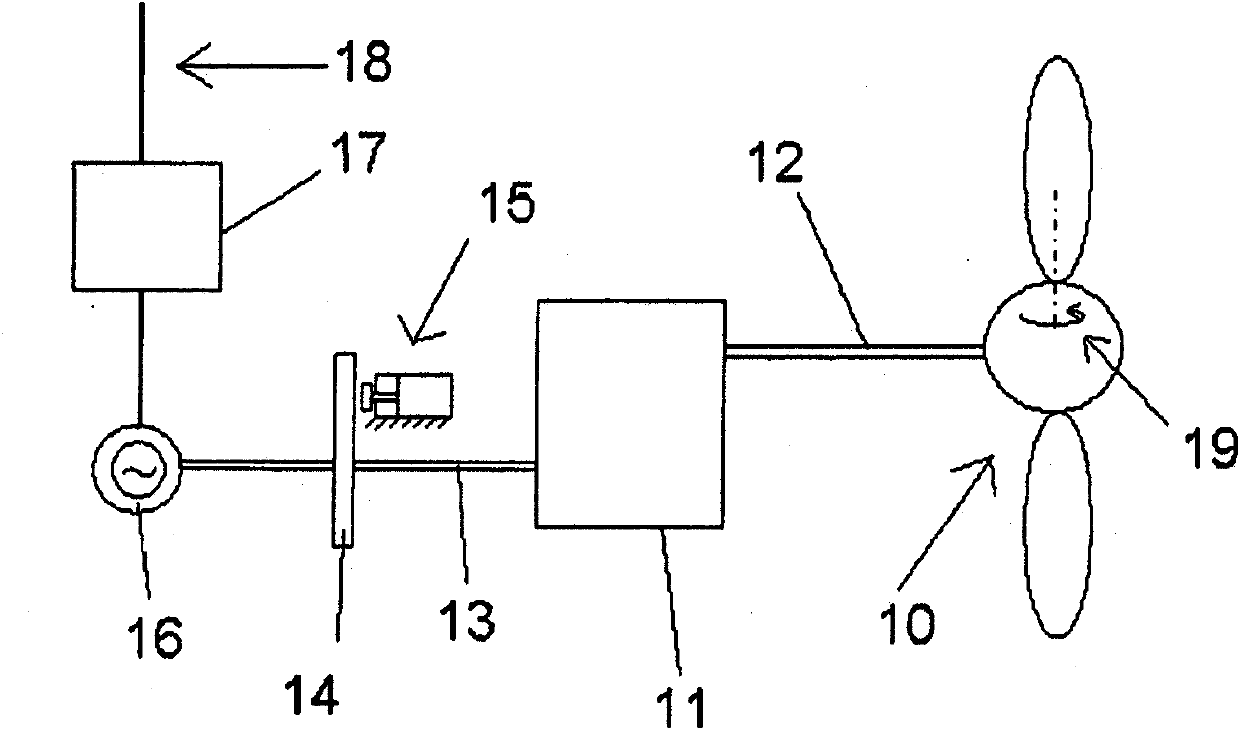

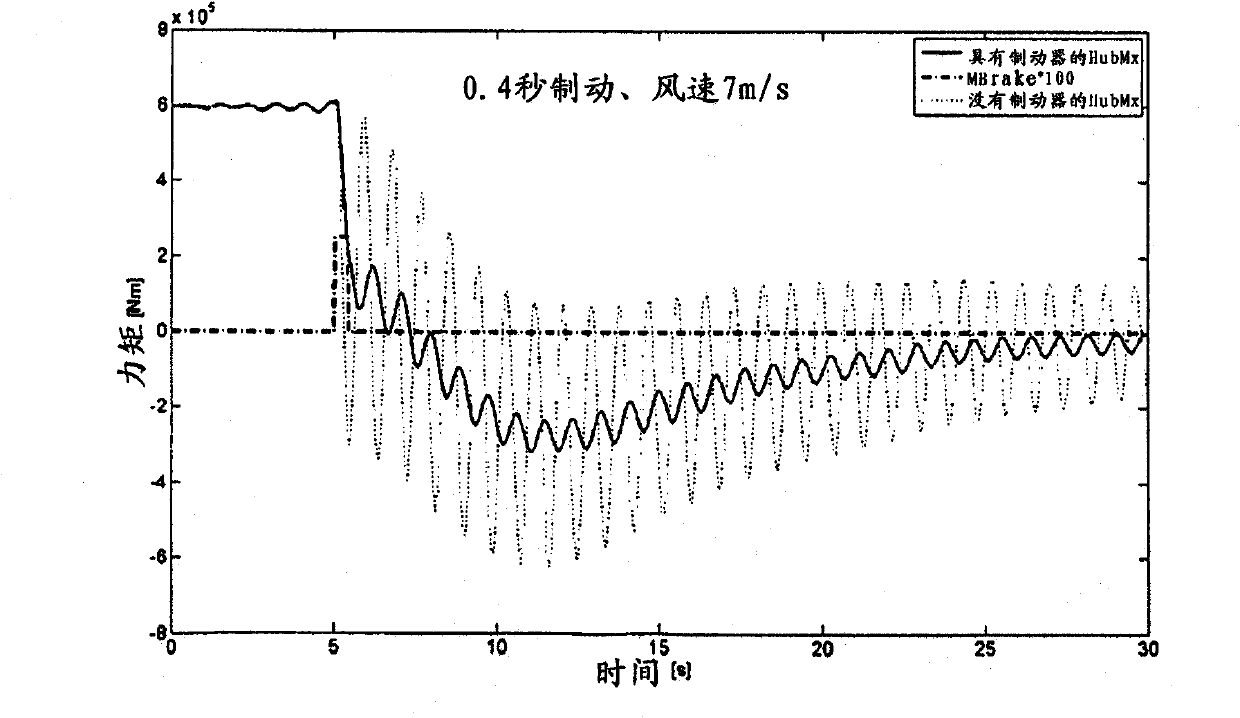

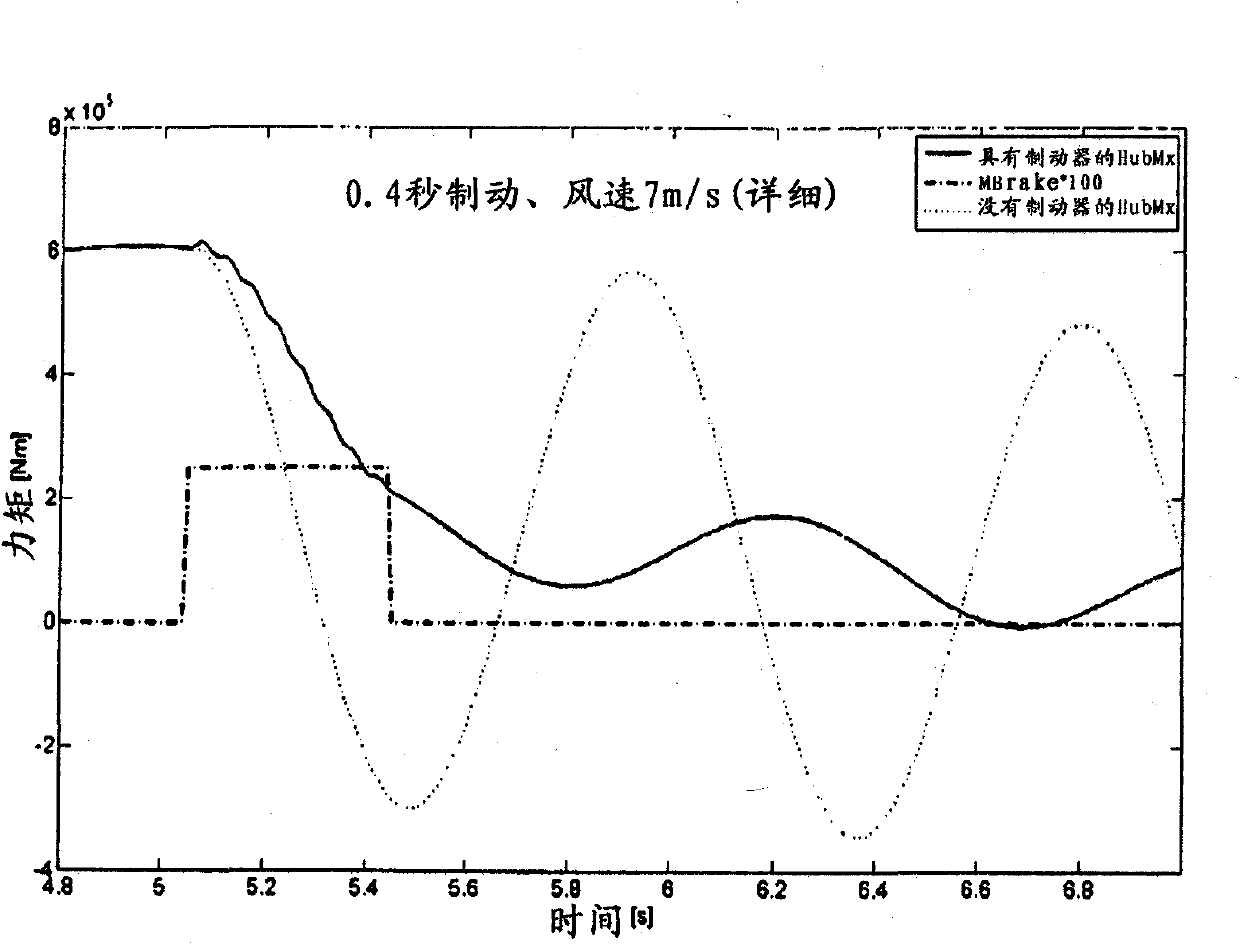

Method of reducing torsional oscillations in the power train of a wind turbine

The present invention refers to a method of reducing torsional oscillations in the power train of a wind turbine in the event of grid loss. According to the method, after the grid loss, a braking torque is applied to the power train during a period of time and said period of time is determined as a function of the torsional resonance frequency of the power train.

Owner:阿尔斯通风力有限个人公司

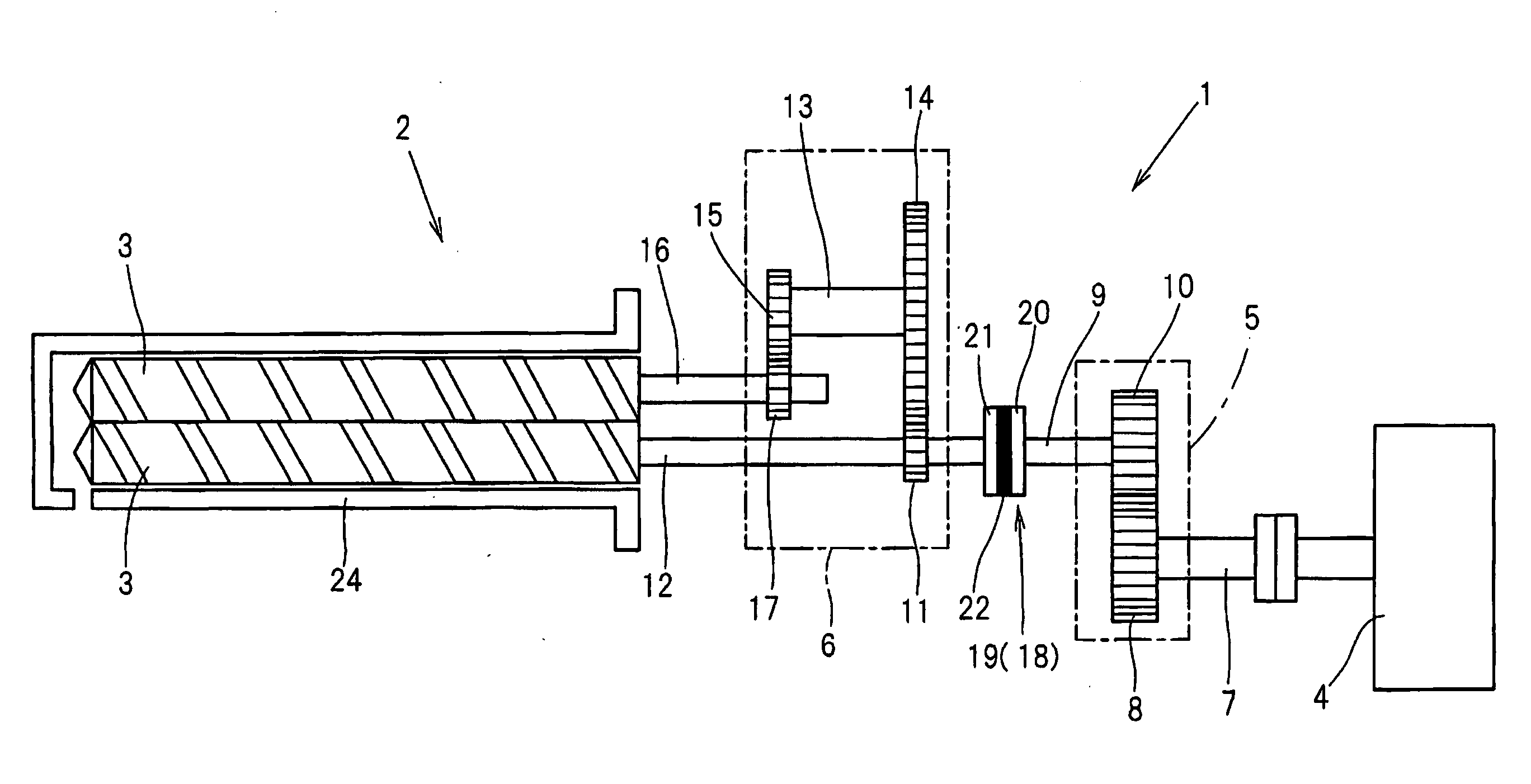

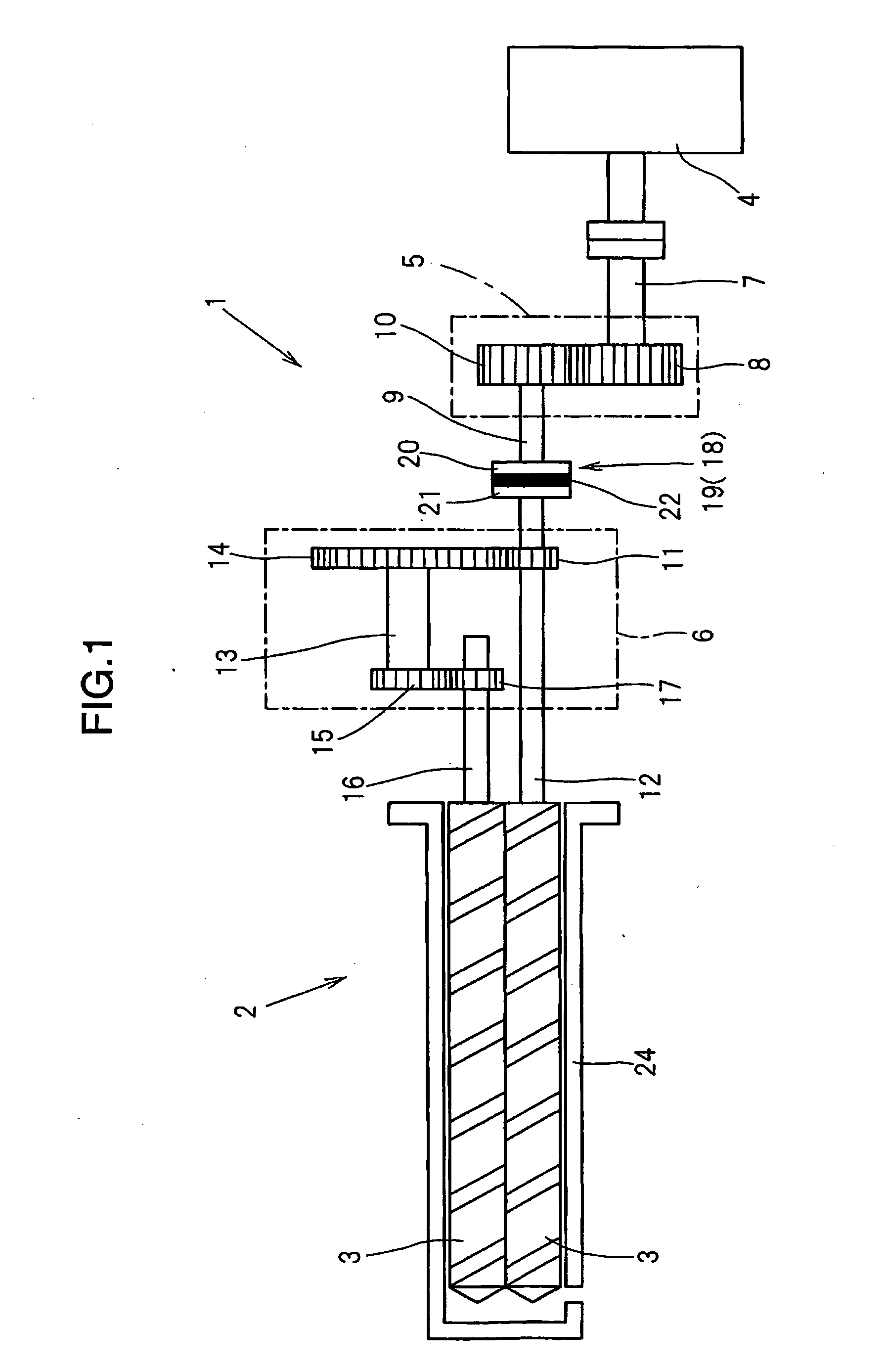

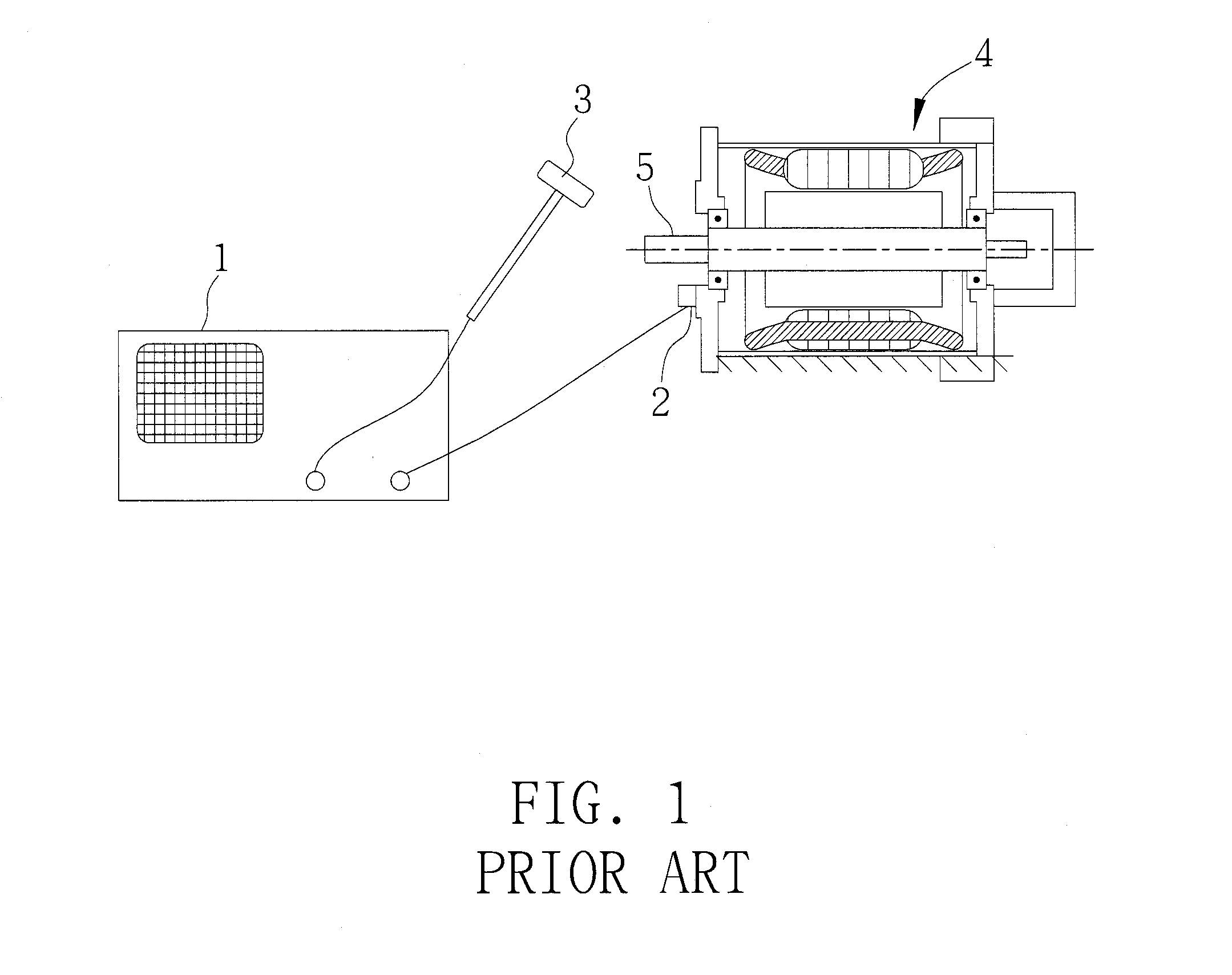

Kneading extruder

InactiveUS20110002189A1Avoid breakingRotary stirring mixersClay mixing apparatusResponse factorResonance

It is intended to provide a kneading extruder which makes it possible to prevent breakage due to resonance regardless of the rotating speed of kneading screws. The kneading extruder comprises a driving motor, kneading screws for kneading a material, each of the kneading screws having a screw shaft, a motive power transmitting path including a first speed regulator for varying a rotating speed produced by motive power output from the driving motor, the motive power transmitting path serving to transmit the motive power which produces a rotating speed varied by the first speed regulator to the screw shafts of the kneading screws, and a resonance suppressor for suppressing torsional resonance of the kneading screws caused by fluctuations in load exerted on the kneading screws, the resonance suppressor serving to reduce a resonance response factor which is the ratio of an output amplitude of the kneading screw amplified by resonance response to an input amplitude of the kneading screw caused by the fluctuations in load to suppress the torsional resonance.

Owner:KOBE STEEL LTD

Torsional resonance frequency measuring device and method

ActiveUS8990031B2Low costImprove efficiencyVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesFrequency spectrumEngineering

The invention provides a torsional resonance frequency measuring device and method applicable to a large-scale power generating equipment or a traction motor equipment with a rotating shaft, such as a large power grid-tied wind turbine. The invention is characterized by employing a machine-side converter existing in the grid-tied wind turbine to output direct currents to a three-phase PMSG (permanent magnet synchronous generator), such that a pulse torque is generated to mechanically excite a rotor of the three-phase PMSG. Afterwards, a control circuit of the machine-side converter acquires back electromotive force generated by the mechanically excited rotor so as to calculate the torsional resonance frequency of the overall drive-chain system according to the frequency spectrum of the back electromotive force.

Owner:IND TECH RES INST

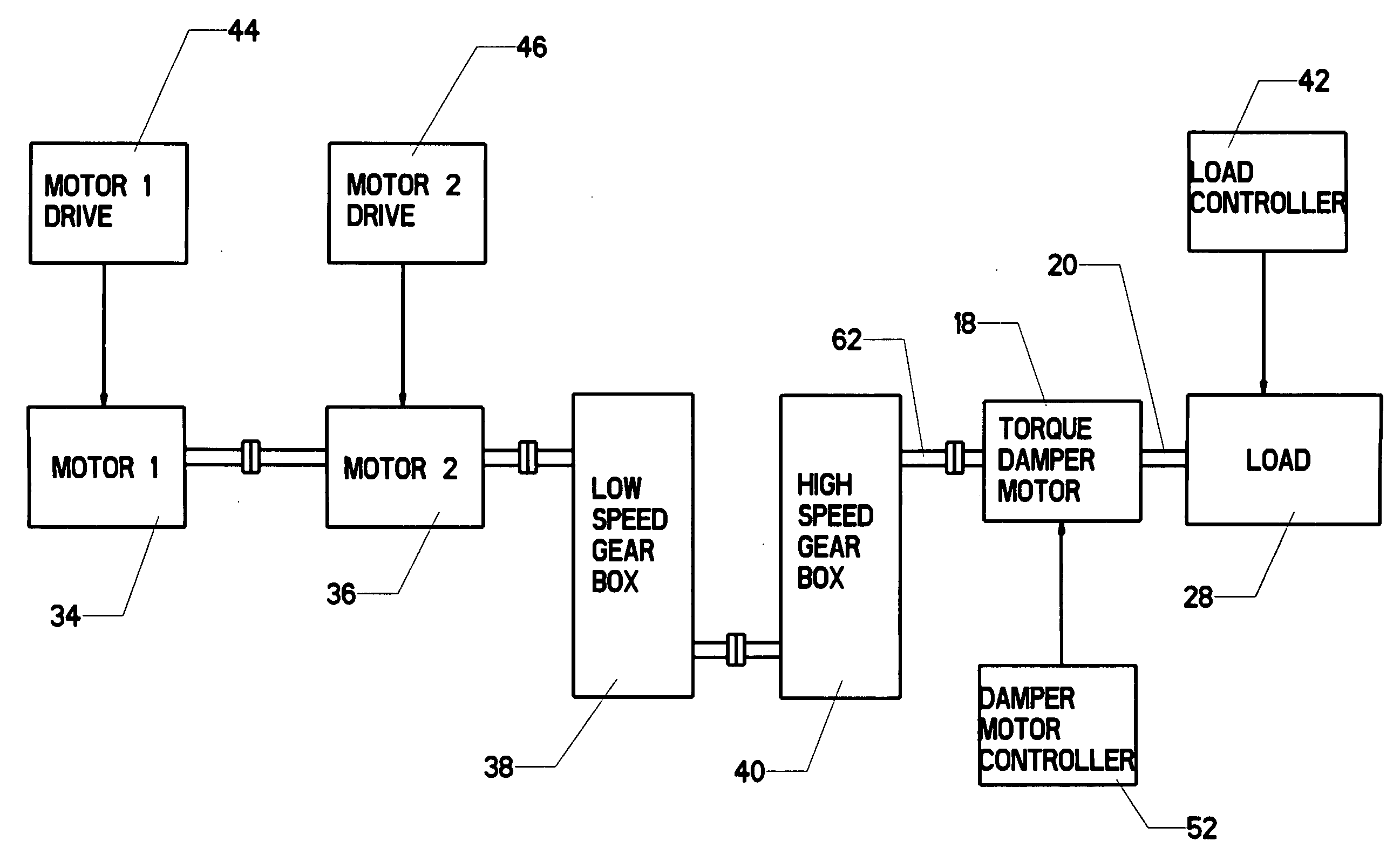

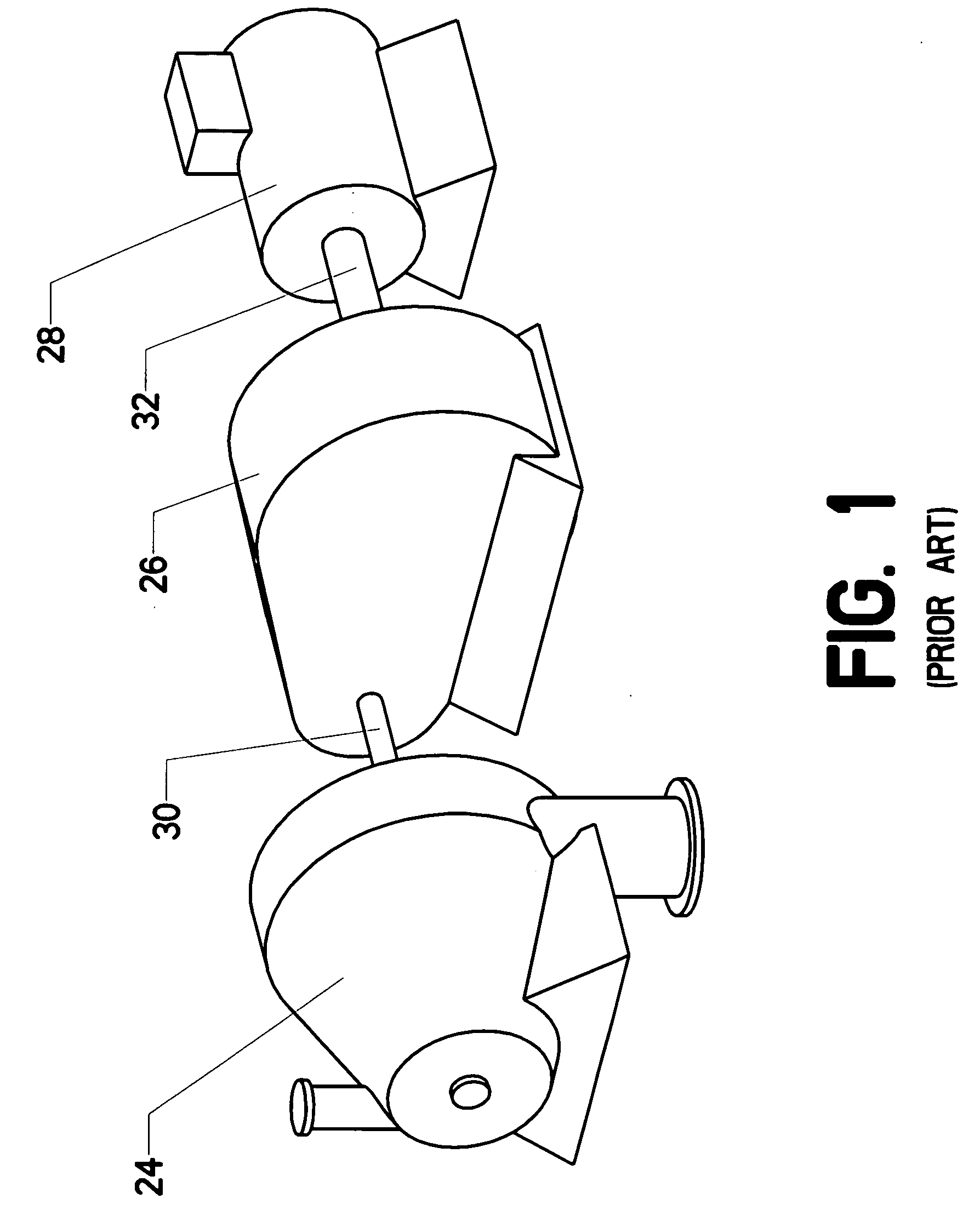

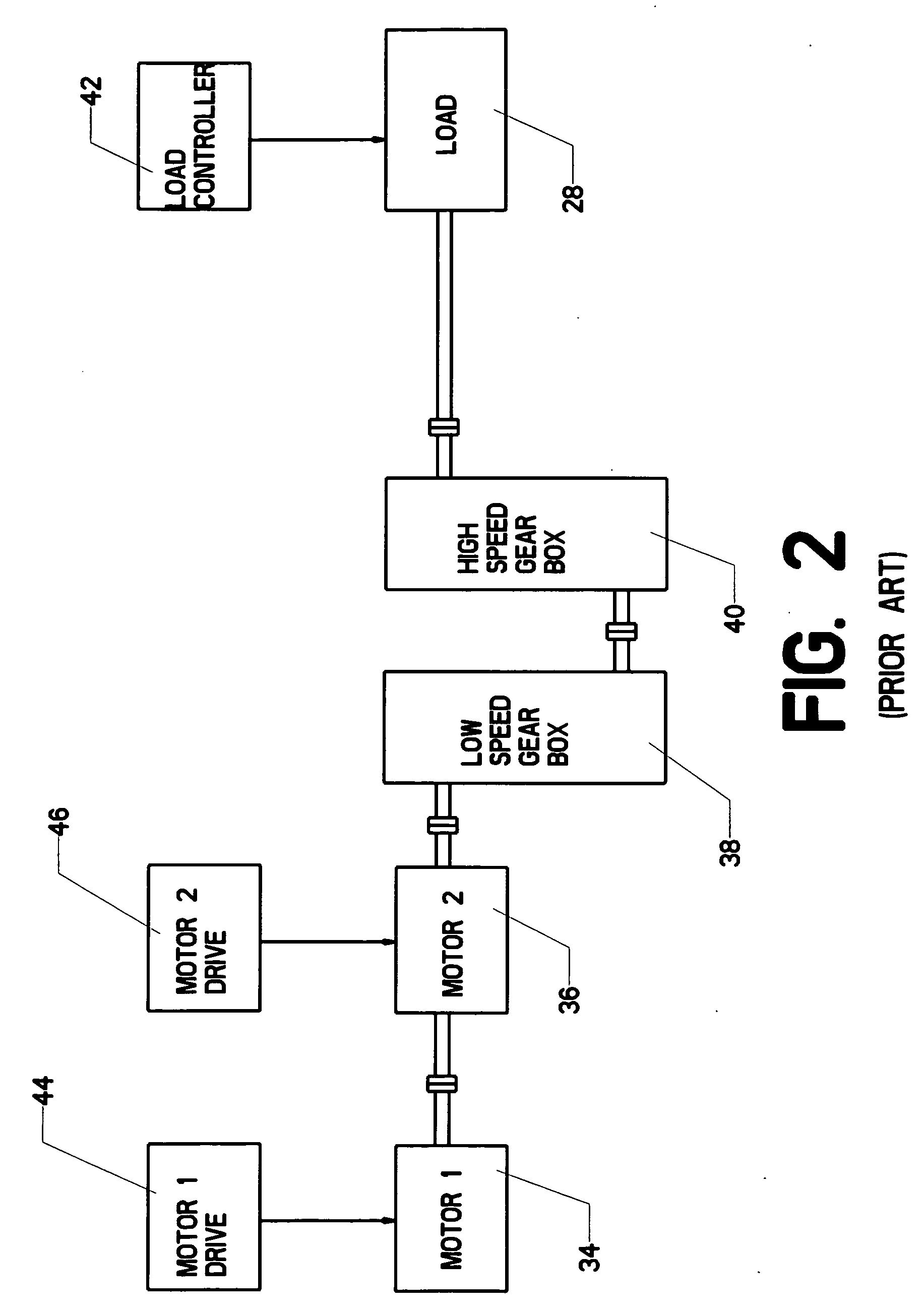

Damping motor and control approach for mitigating torsional backlash, damping critical geartrain speeds, and providing improved torque control in mechanical gears

ActiveUS20090049941A1Less powerReduce decreaseHybrid vehiclesRotating vibration suppressionControl systemGear wheel

A torque damper motor connected to the output side of a mechanical gear system. The damper motor, along with its associated control system, mitigates backlash problems, reduced torsional resonance, and provides improved output torque control. In the preferred embodiment, the damper motor is powered by a power electronics—based variable speed drive. The damper motor can be significantly less powerful than the overall rating of the gear system (typically 5-10% of the overall rating) while still providing the enhanced performance.

Owner:FLORIDA STATE UNIV RES FOUND INC

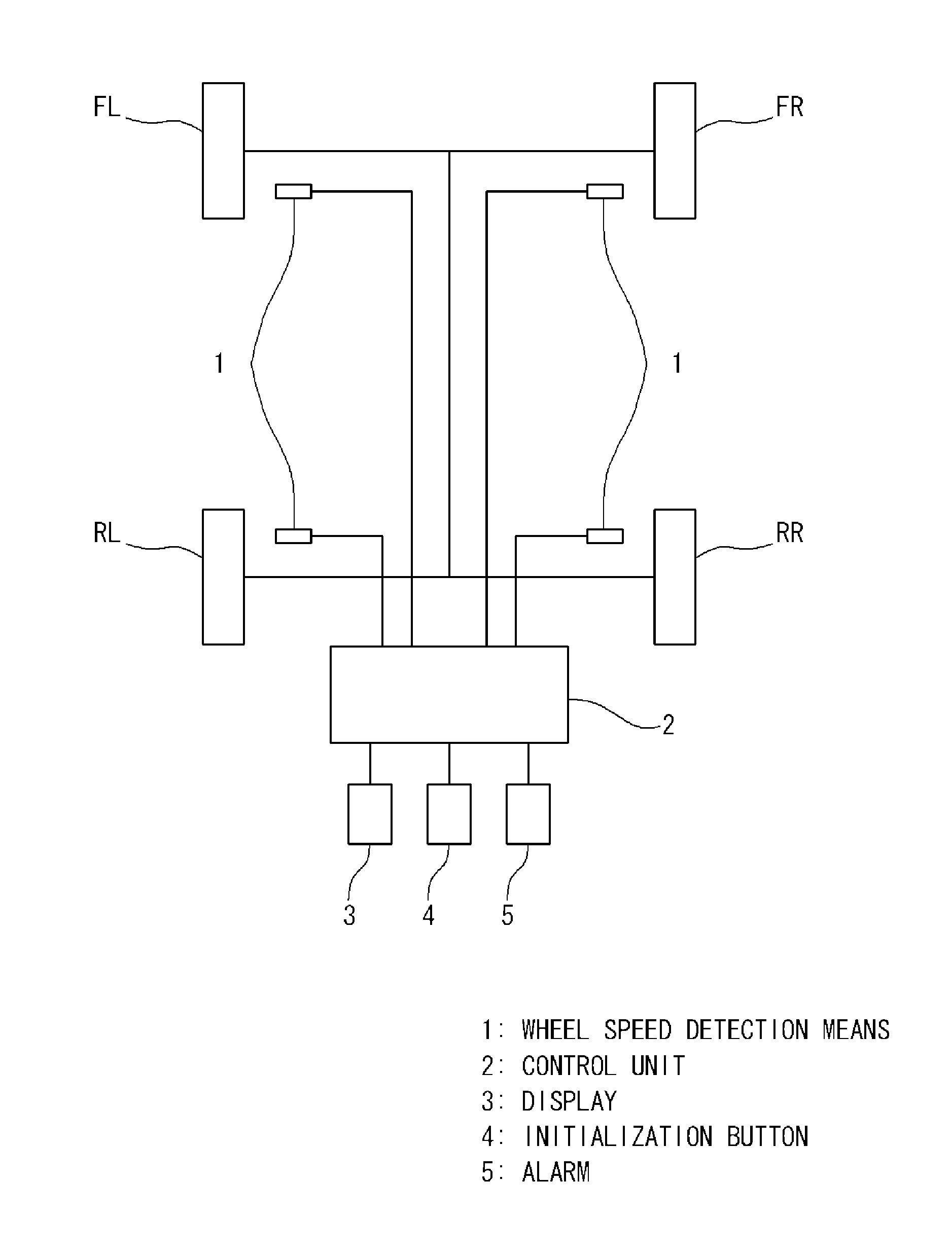

Tire pressure decrease detection apparatus and method, and computer readable medium therefor

ActiveUS20140053625A1Eliminate erroneous alarmReduce pressureFluid pressure measurementTyre measurementsResonanceEngineering

A tire pressure decrease detection apparatus comprising: rotation speed information detection means, rotation acceleration information calculation means, resonance frequency estimate means for time-series estimating a torsional resonance frequency of the rotation speed information, correlation calculation means for, regarding front and rear right wheels and front and rear left wheels, respectively calculating time series correlations of the rotation acceleration information, and judgment means for judging a decrease in pressure of the tires based on the estimated torsional resonance frequency. In a case where the correlations exceed predetermined threshold values, the resonance frequency estimate means takes that a periodic noise from a road surface is generated in the vicinity of the torsional resonance frequency and stops estimating the torsional resonance frequency of the front and rear wheels of the side exceeding the threshold value.

Owner:SUMITOMO RUBBER IND LTD

Tire pressure decrease detection apparatus and method, and computer readable medium therefor

ActiveUS9134194B2Eliminate erroneous alarmReduce pressureFluid pressure measurementTyre measurementsResonanceRoad surface

A tire pressure decrease detection apparatus comprising: rotation speed information detection means, rotation acceleration information calculation means, resonance frequency estimate means for time-series estimating a torsional resonance frequency of the rotation speed information, correlation calculation means for, regarding front and rear right wheels and front and rear left wheels, respectively calculating time series correlations of the rotation acceleration information, and judgment means for judging a decrease in pressure of the tires based on the estimated torsional resonance frequency. In a case where the correlations exceed predetermined threshold values, the resonance frequency estimate means takes that a periodic noise from a road surface is generated in the vicinity of the torsional resonance frequency and stops estimating the torsional resonance frequency of the front and rear wheels of the side exceeding the threshold value.

Owner:SUMITOMO RUBBER IND LTD

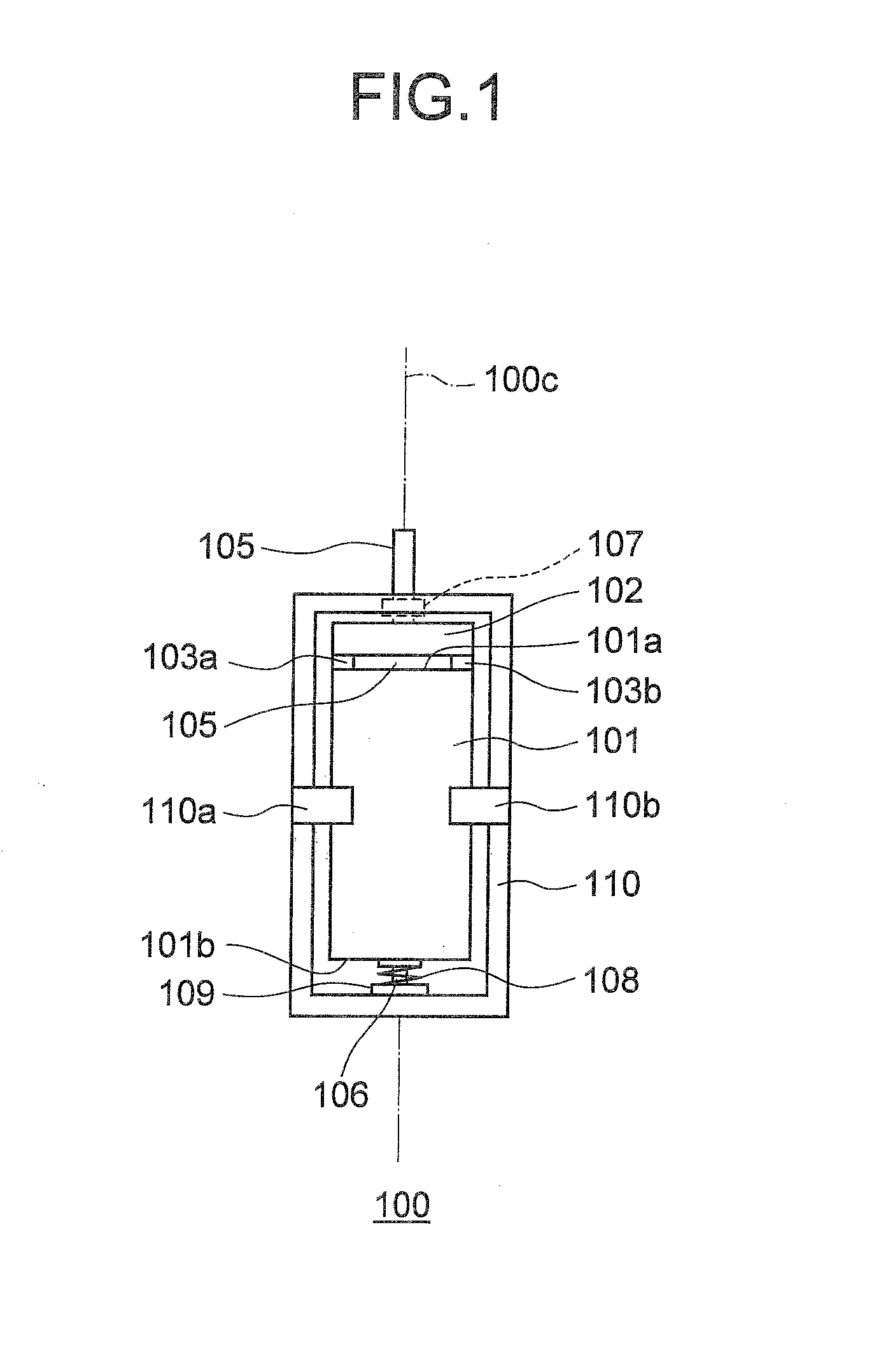

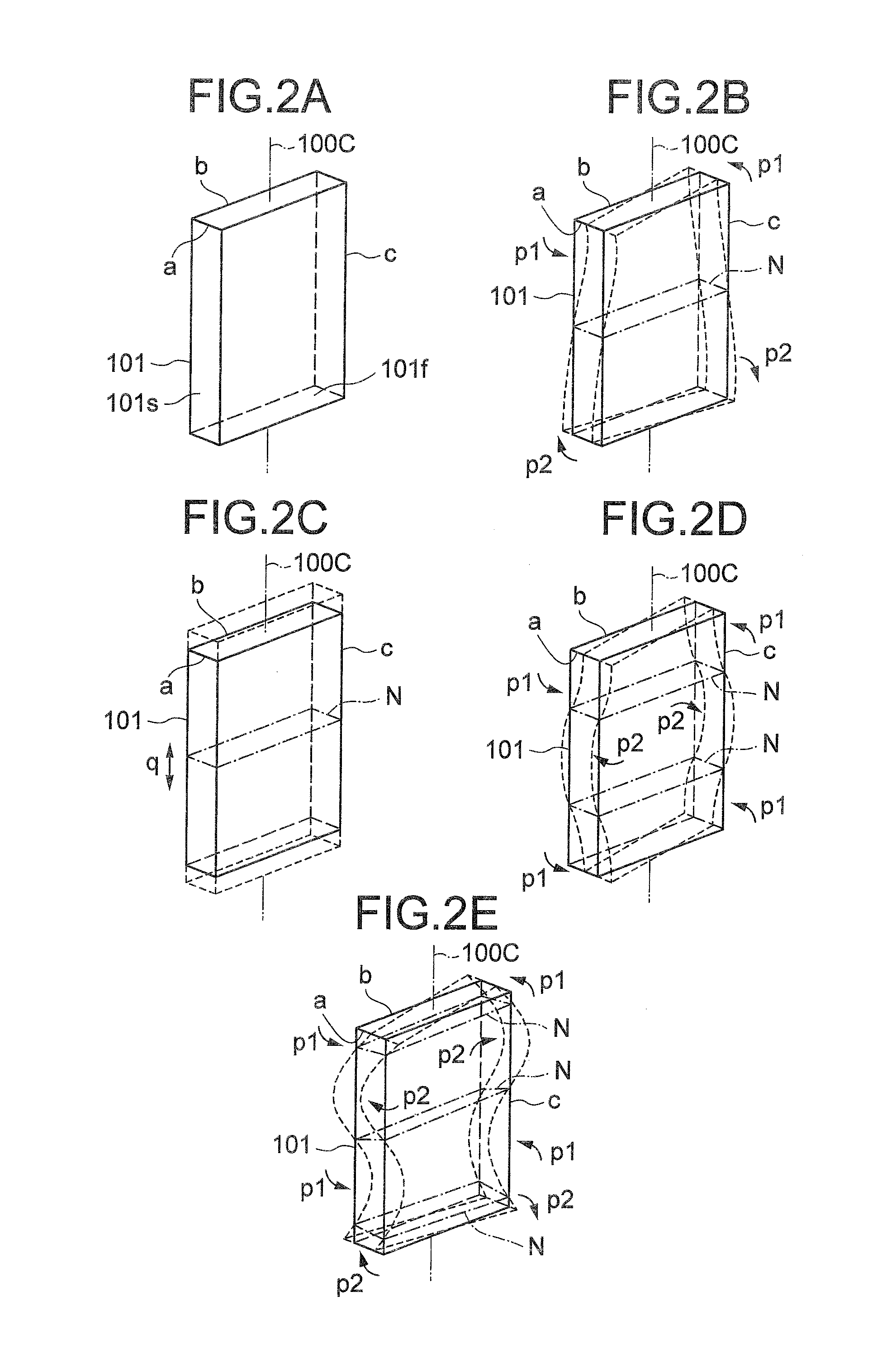

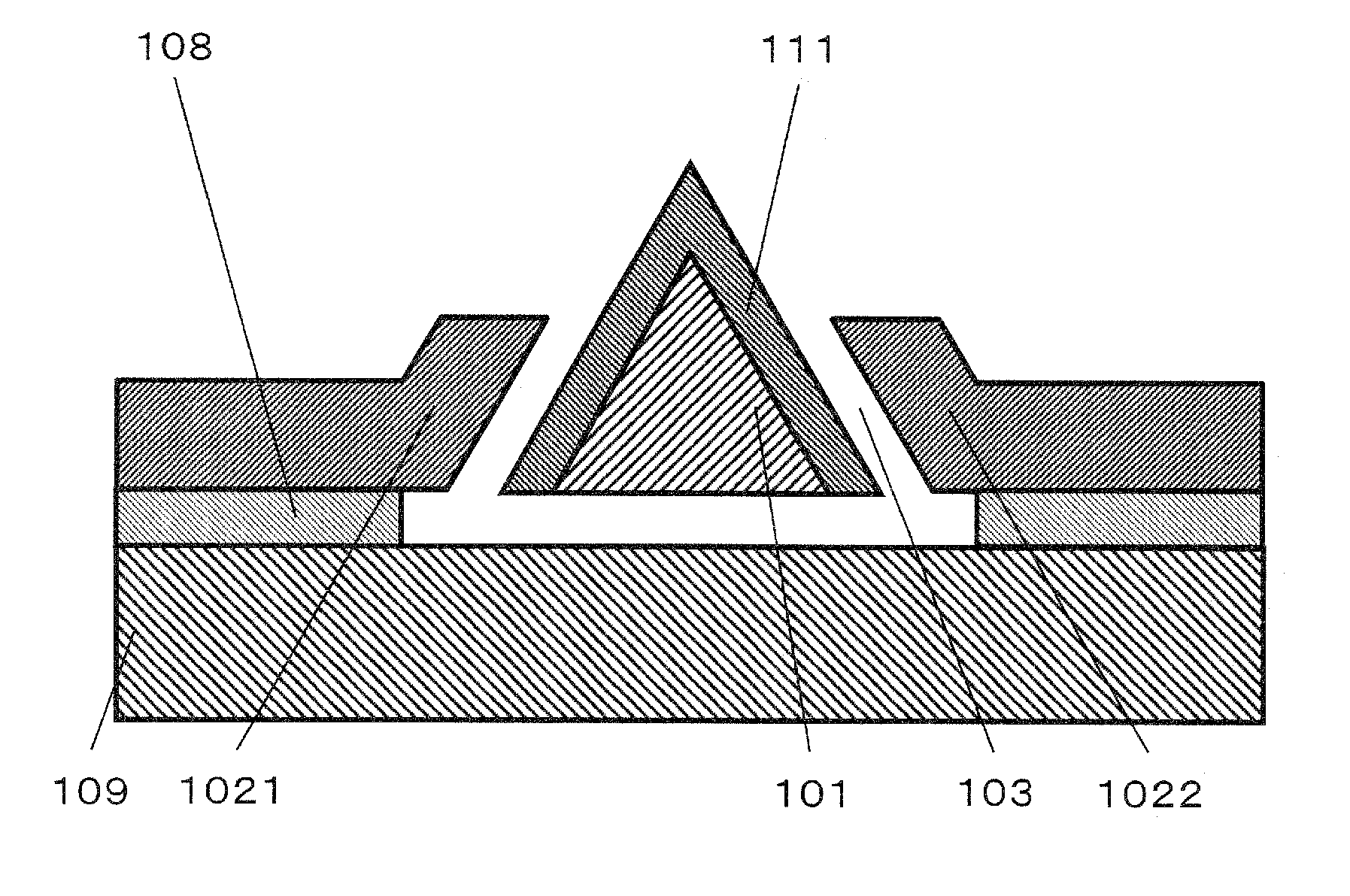

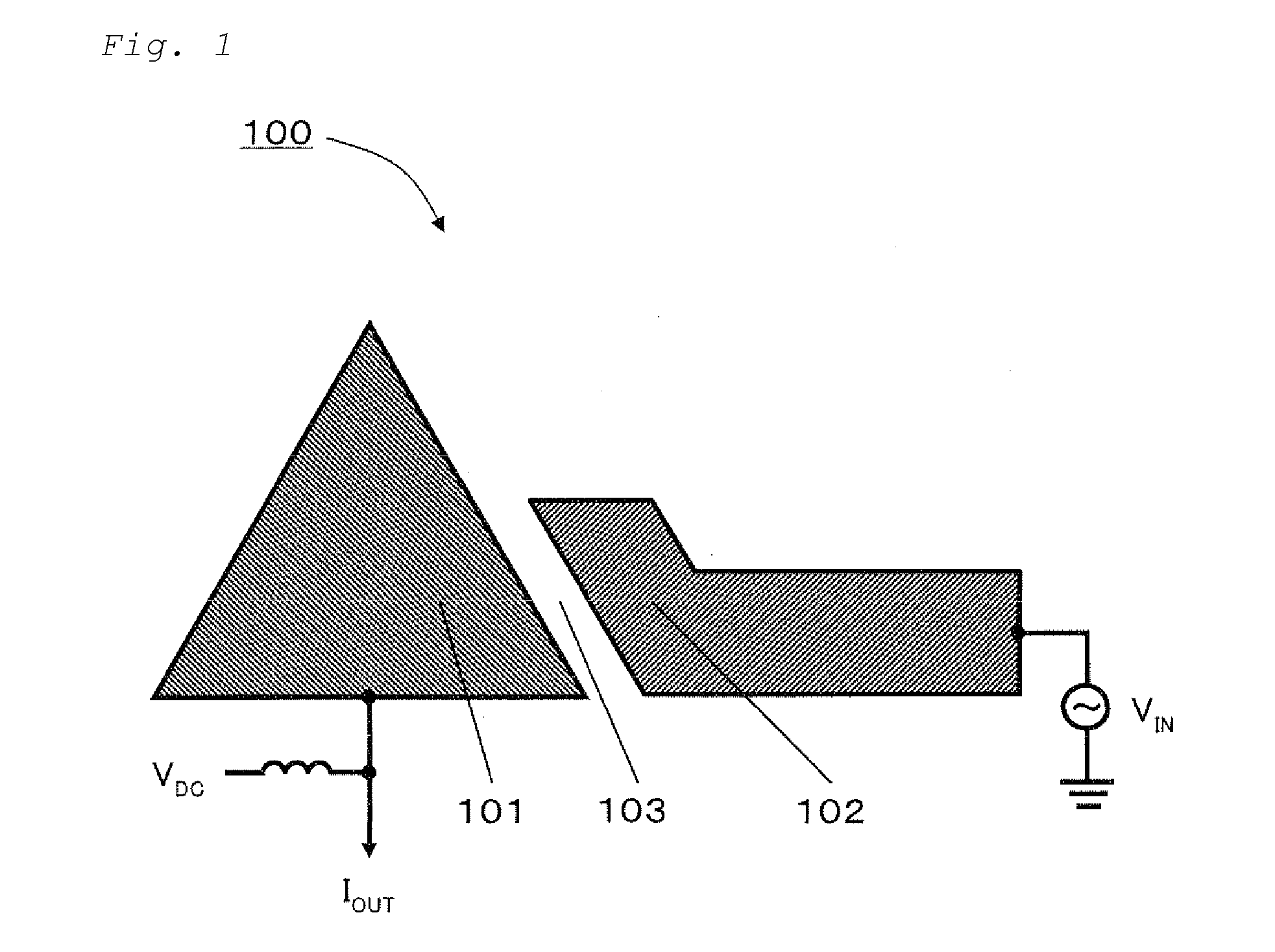

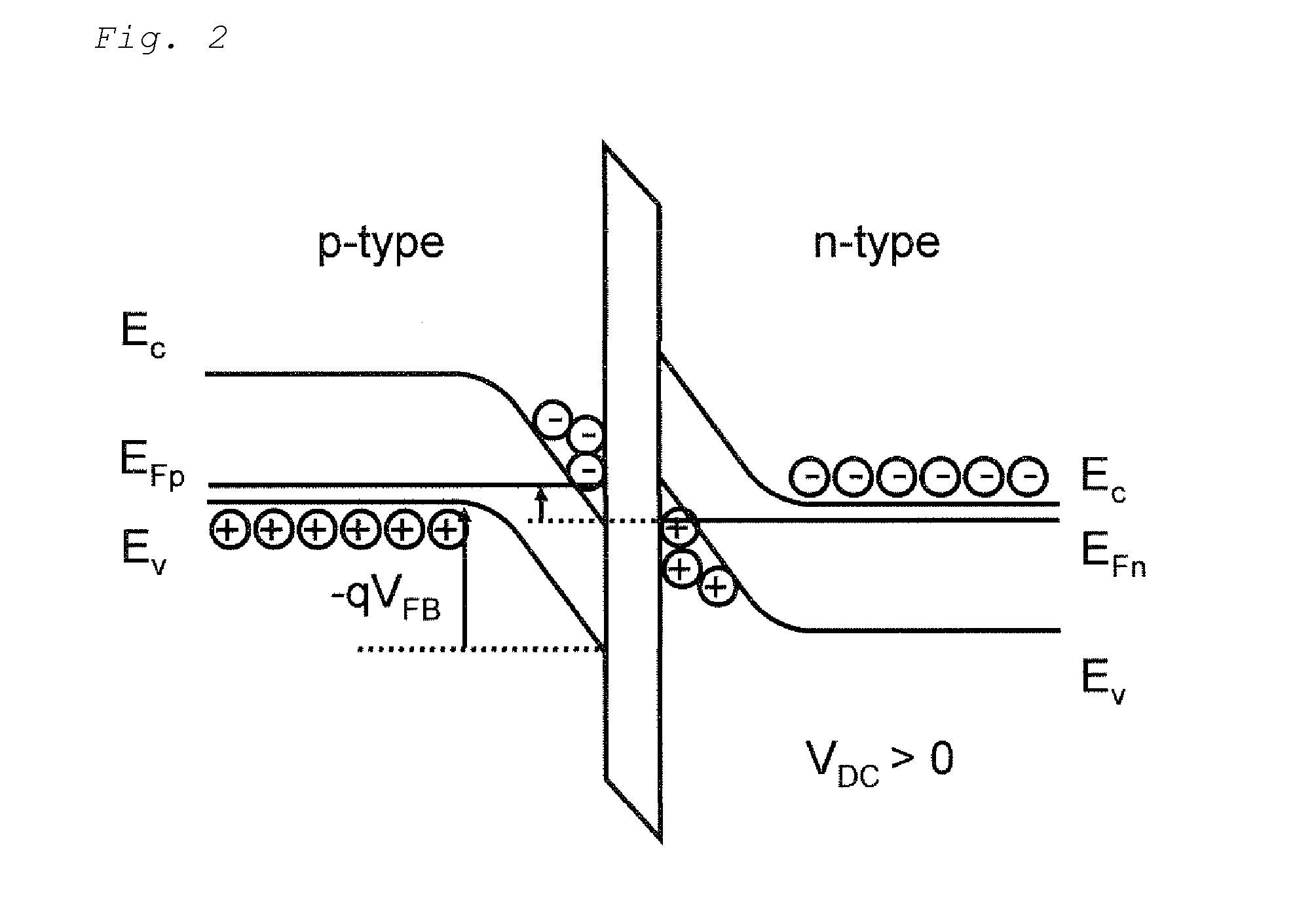

MEMS resonator and electrical device using the same

ActiveUS20130033334A1Increasing sizeIncreasing costMultiple-port networksOscillations generatorsPower flowHigh density

A MEMS resonator 200 includes: a beam oscillator 101 that oscillates mechanically when an electrostatic force is applied; a supporter that oscillatably supports the oscillator 101; and at least one electrode 102 that includes an opposing face to the oscillator 101 across a gap 103, wherein an electric current generated by the oscillation of the oscillator 101 is output through an output terminal connected with the oscillator 101 or electrode 102, the oscillator 101 oscillates in a torsional resonance mode with a center being a longitudinal axis of the oscillator 101, an opposing faces of the oscillator 101 and the electrode 102 are made of semiconductors of which conductive types are different from each other, and a surface part 111 of the oscillator 101 including the opposing face is doped with an impurity at a higher density than other part of the oscillator 101.

Owner:PANASONIC CORP

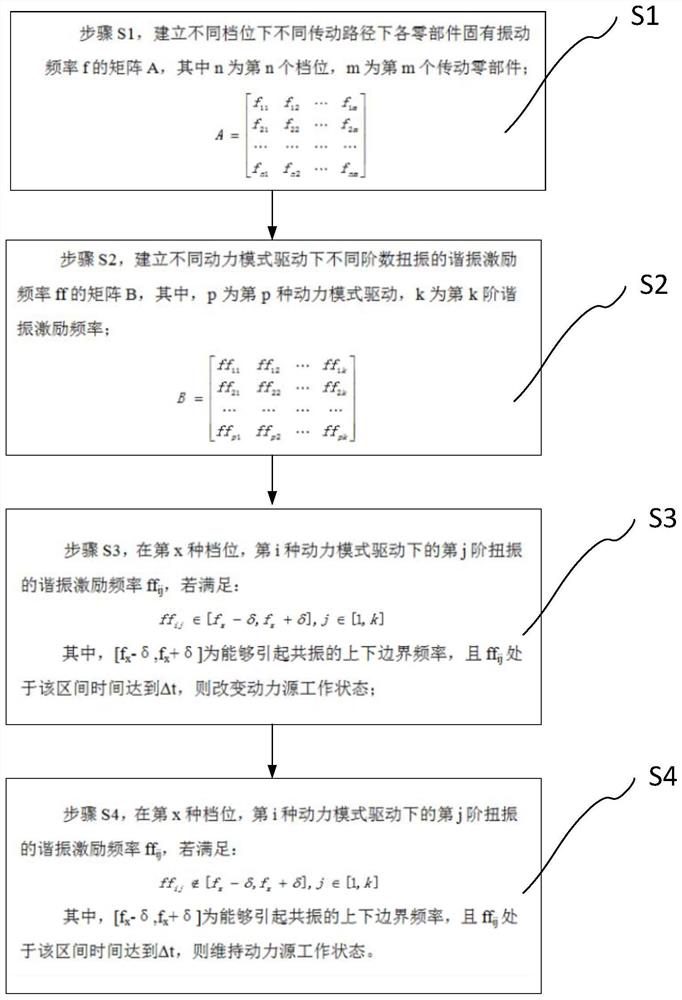

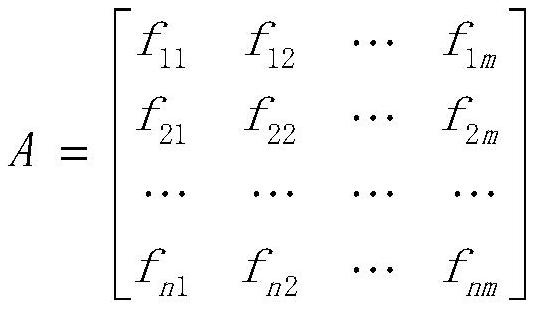

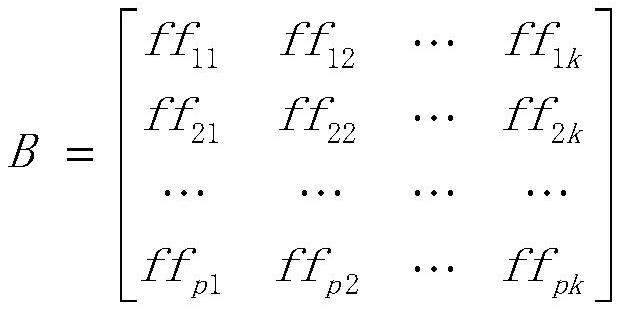

Torsional resonance control method for vehicle multi-power source coupling transmission system

The invention relates to the field of torsional vibration control methods, and provides a vehicle multi-power source coupled transmission system torsional resonance control method. The torsional resonance control method includes the following steps that 1, a matrix A of natural vibration frequency f of each part under different gears and different transmission paths is established; 2, a matrix B of resonance excitation frequency f f of torsional vibration of different orders driven by different dynamic modes is established; and S 3, if the resonance excitation frequency f f i j of torsional vibration of the j order driven by a power mode i at an x gear meets the requirement that the resonance excitation frequency of the torsional vibration of the j order is close to the natural vibration frequency of each component under a transmission path under the working state, the working state of a power source is changed. The vehicle multi-power source coupled transmission system torsional resonance control method is not only simple and easy to operate and control, the resonance noise can be effectively reduced, and the reliability of the system is improved.

Owner:南通京翔科技有限公司

Torsional resonance frequency adjustor

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com