Patents

Literature

48 results about "Vibratory stress relief" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vibratory Stress Relief, often abbreviated VSR, is a non-thermal stress relief method used by the metal working industry to enhance the dimensional stability and mechanical integrity of castings, forgings, and welded components, chiefly for two categories of these metal workpieces...

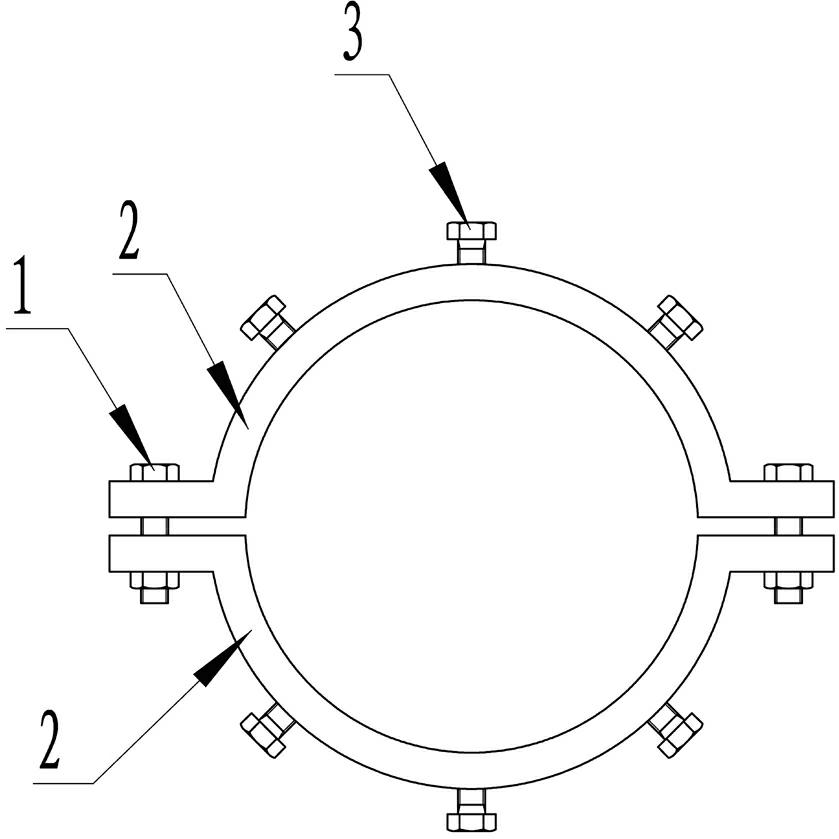

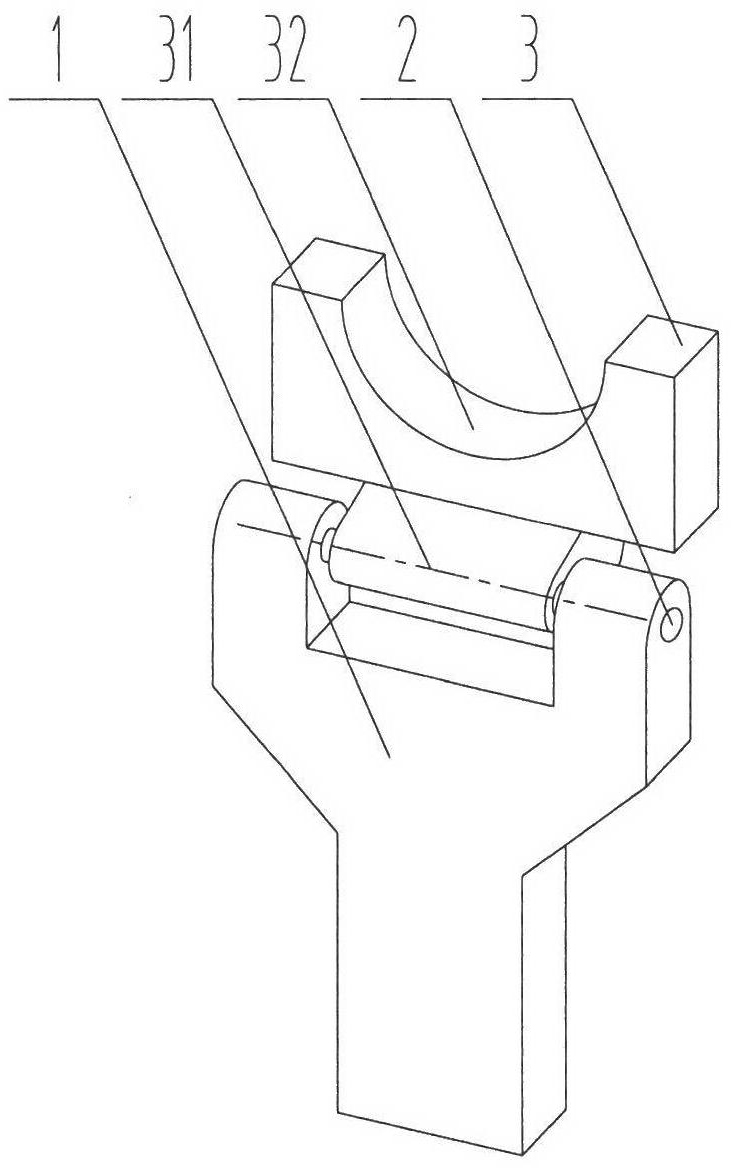

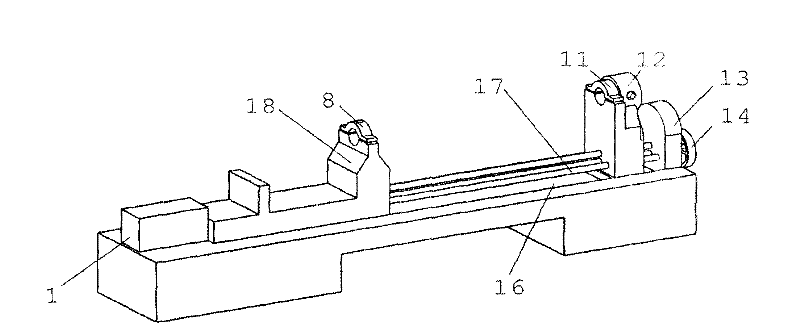

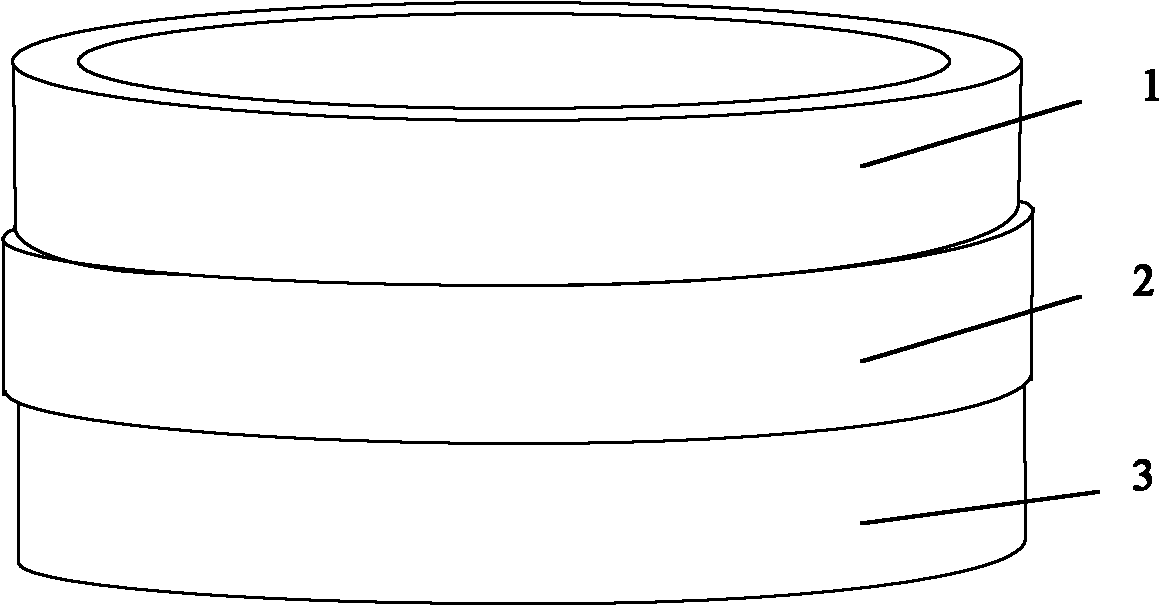

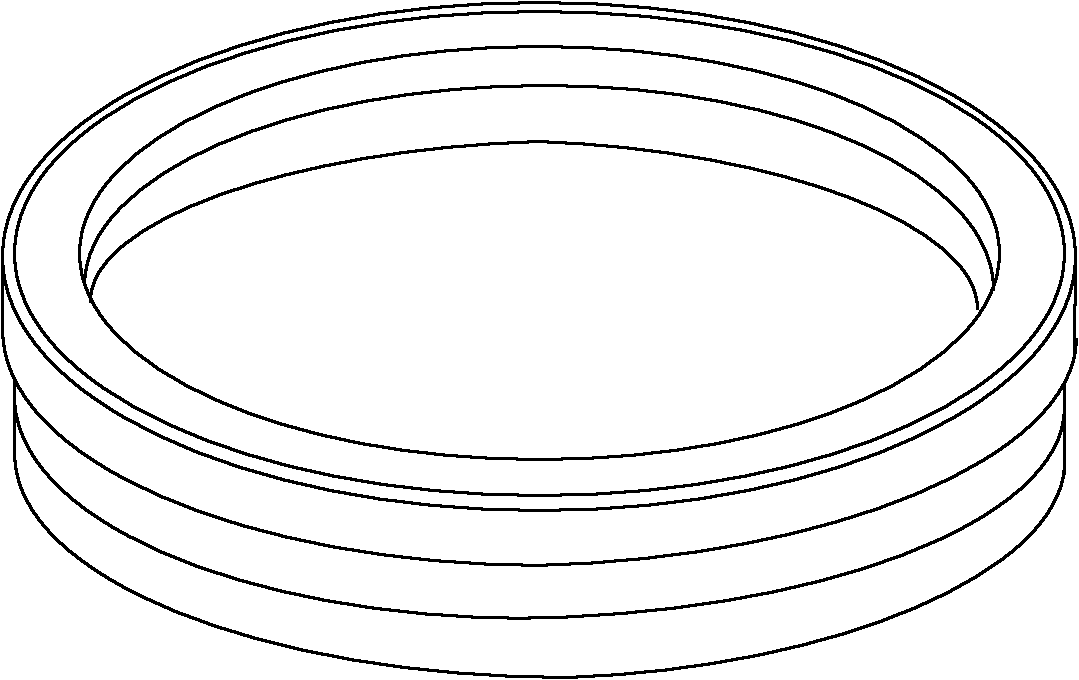

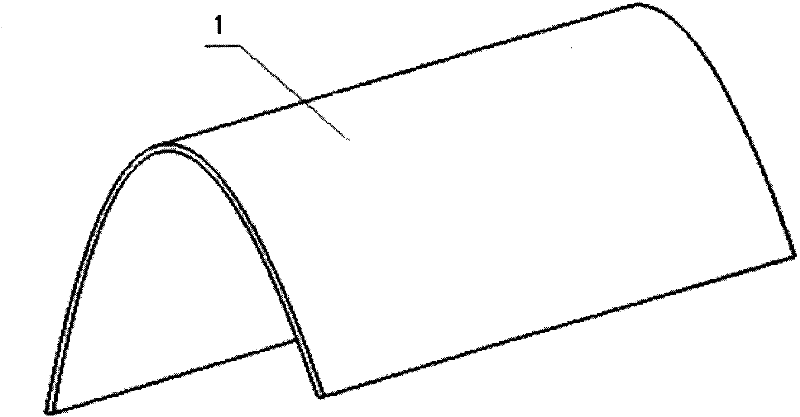

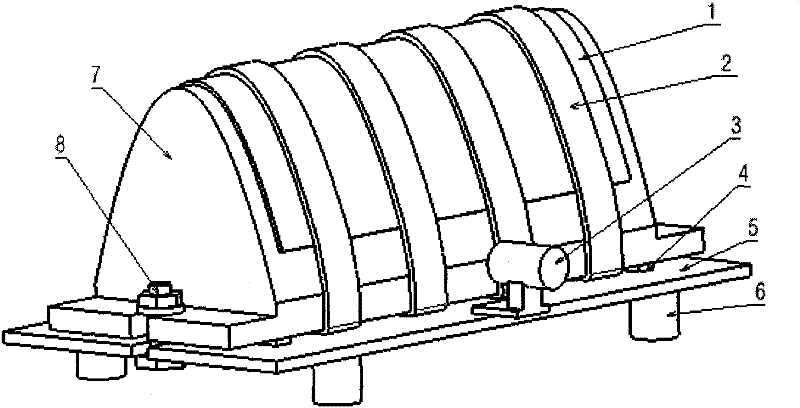

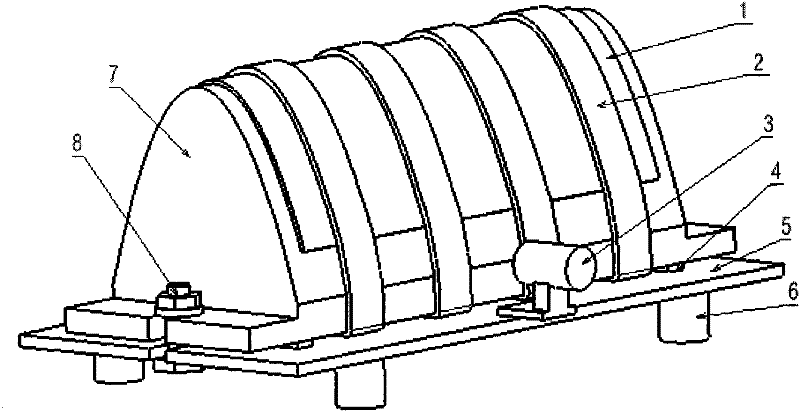

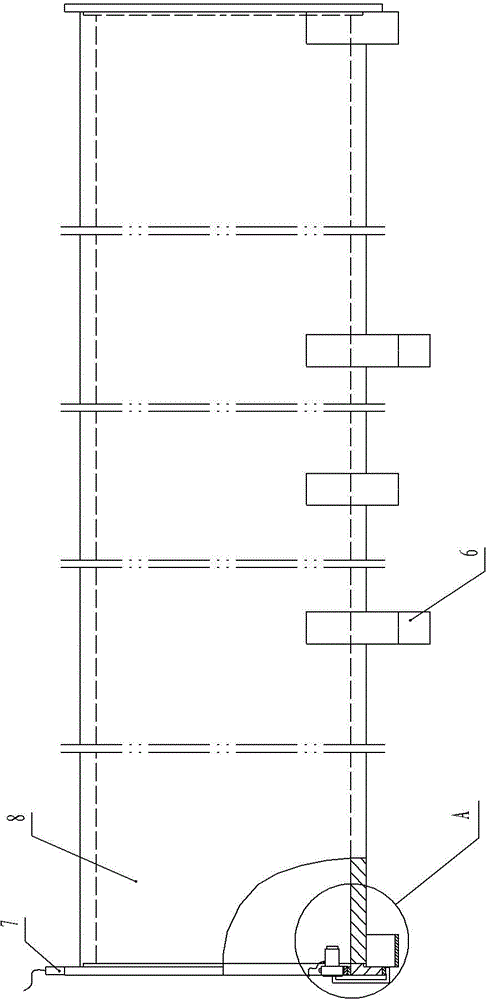

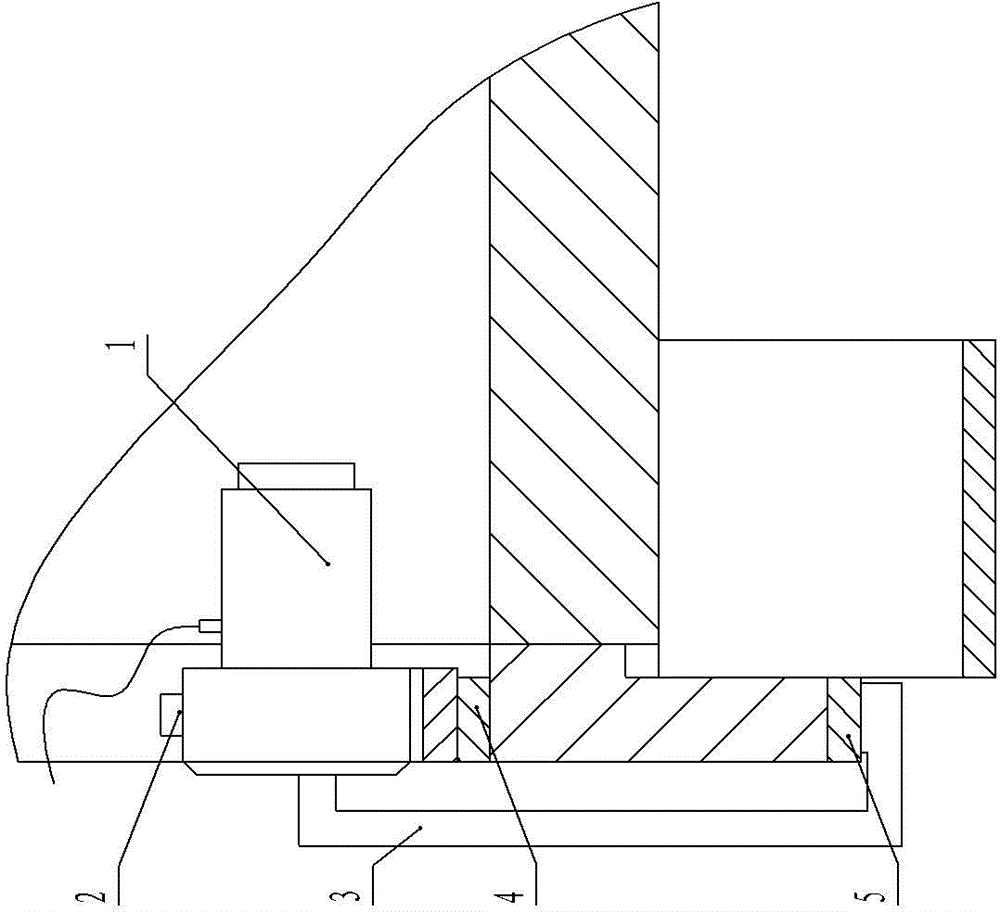

Vibration aging correction method for deformation of cylindrical parts and anti-deformation restraint fixture

ActiveCN102277475AEliminate internal stressLong-term stable dimensional errorEngineeringProcessing cost

The invention provides a vibratory stress relief corrected cylindrical part deforming method in order to solve the problem that a part deforms once again because internal stress can not be relieved during the deformation correction of the traditional cylindrical part. The method comprises the following steps of: firstly, installing the cylindrical part in such a way that the inherent frequency ofresonant frequency of the cylindrical part is within the operating range of a vibration exciter as vibratory stress relief equipment, wherein the installation methods comprise simply support installation, cantilever installation and segment-connected installation; then, carrying out anti-deformation restriction at the deformed position of the deformed part by using the fixture; and finally, carrying out vibratory stress relief on the cylindrical part. The anti-deformation restricting fixture used for realizing the method comprises two semicircular hoop type anti-deformation restricting fixture bodies tightened by anti-deformation restricting fixture bolts, and anti-deformation adjusting screws are arranged on the cambered surfaces of the semicircular hoops. Through the method provided by the invention, the dimension and shape errors of the processed part can be ensured to be stable for long term, materials and processing cost are saved, and the processing efficiency and the processingsuccess rate are high.

Owner:SHANXI PINGYANG IND MACHINERY

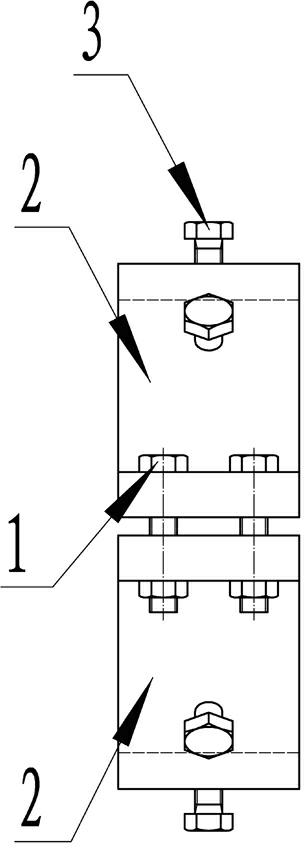

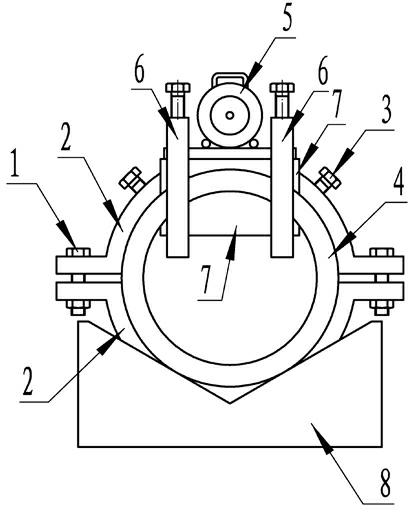

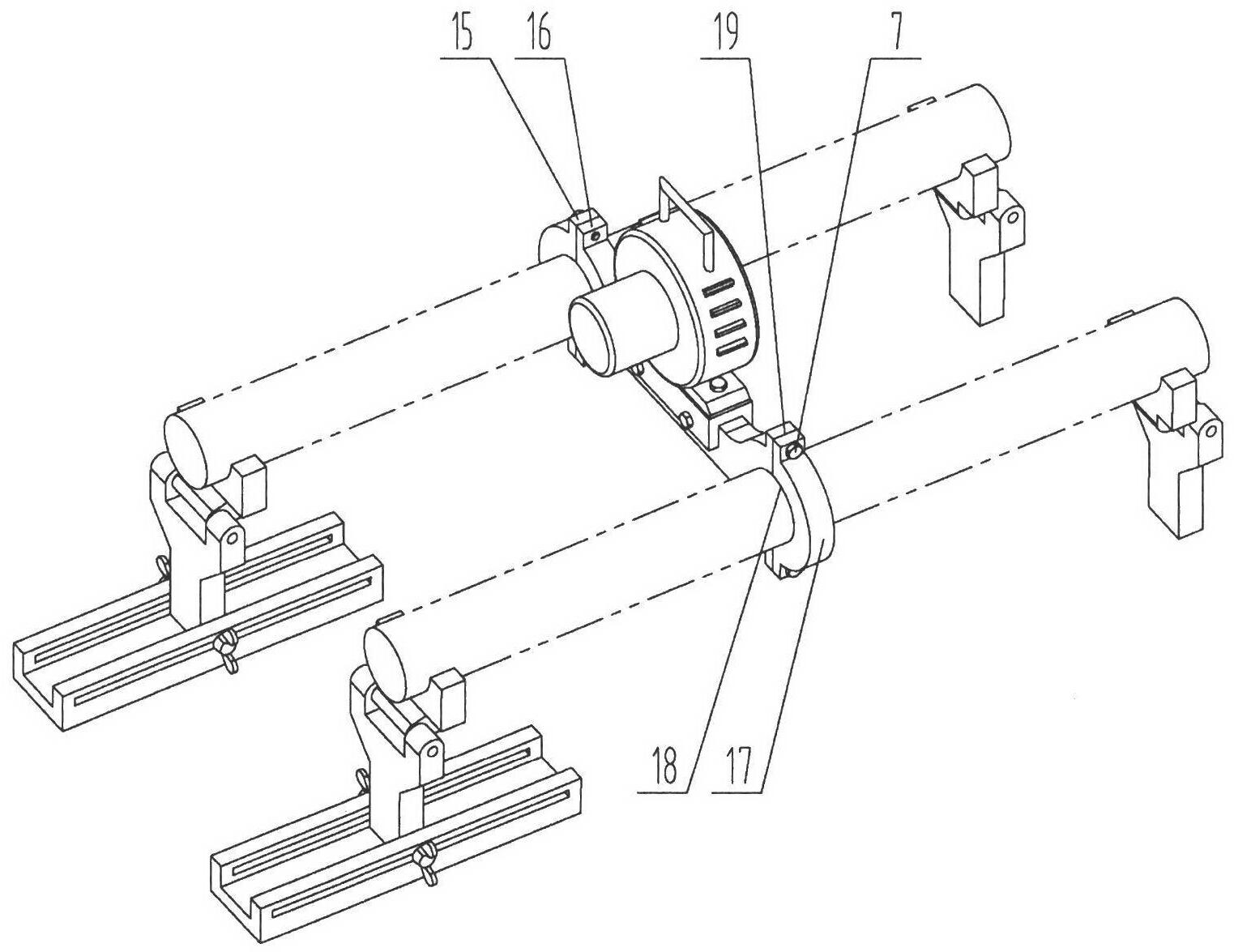

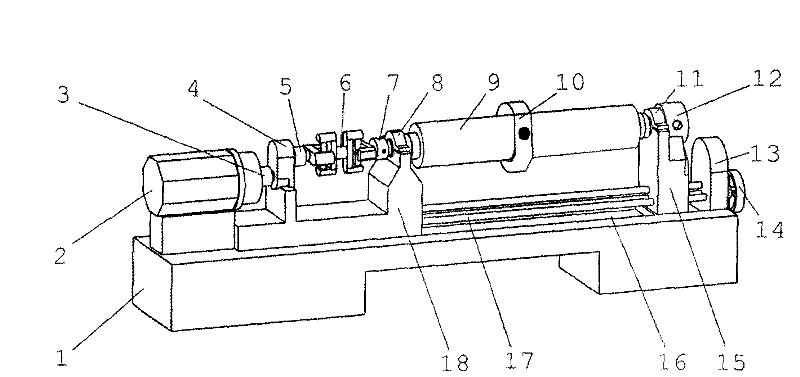

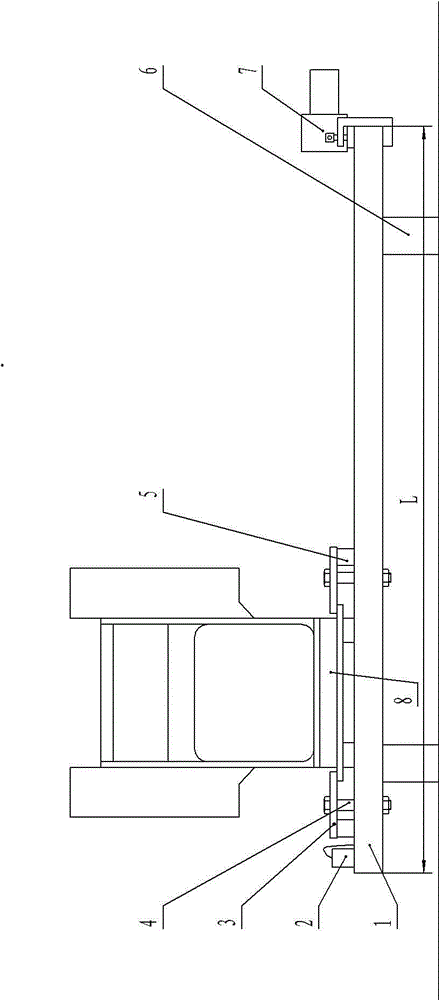

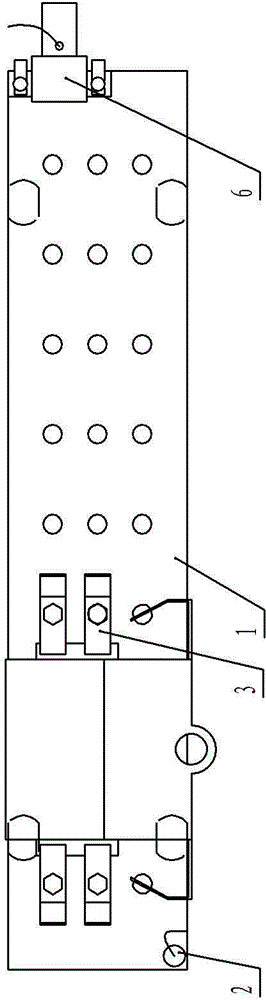

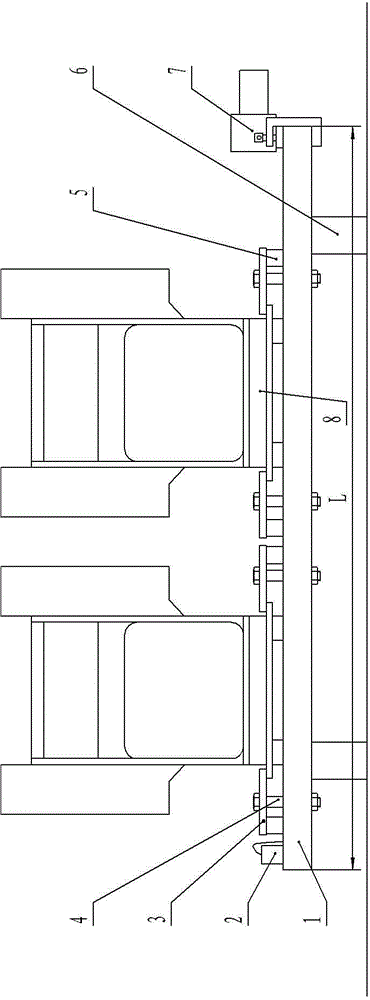

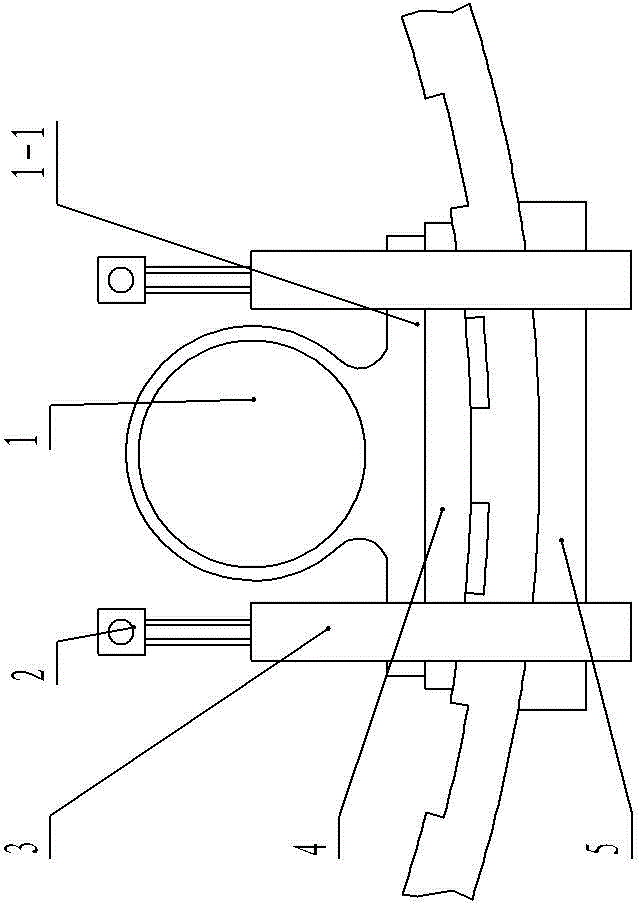

Vibratory stress relief apparatus for medium frequency and low frequency shaft type parts, and use method thereof

InactiveCN102321793AAddress effectivenessAddress stressFurnace typesHeat treatment furnacesMedium frequencyEngineering

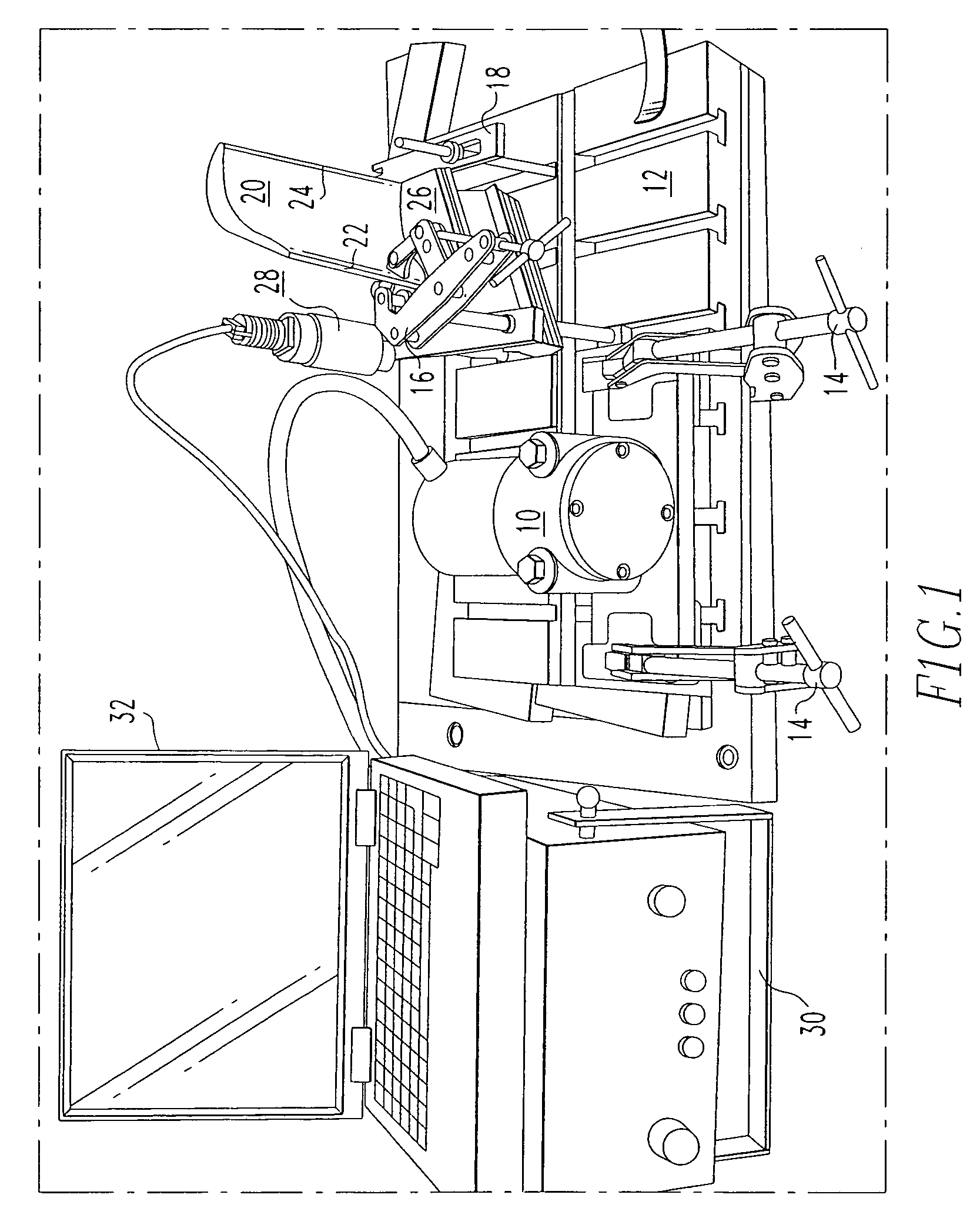

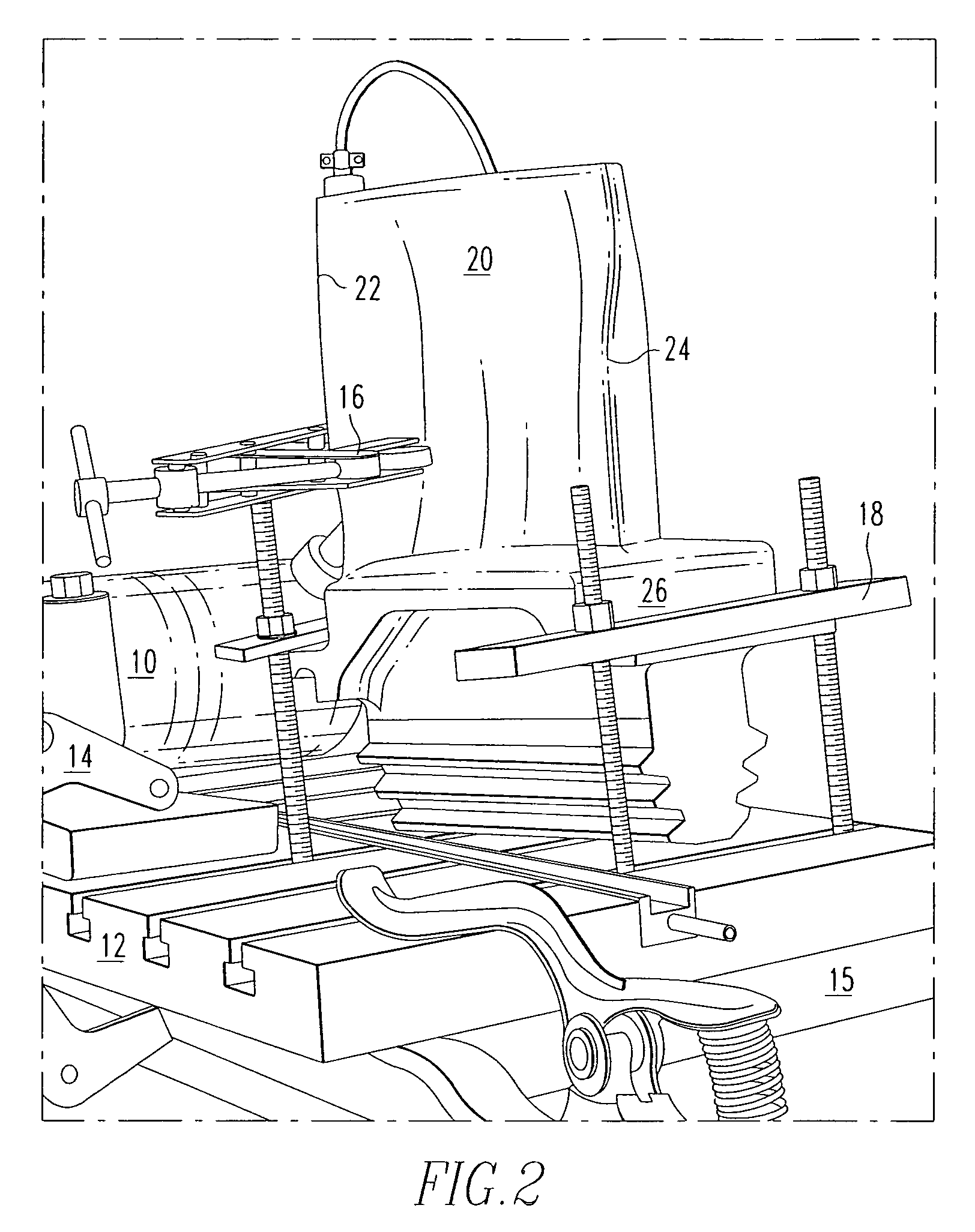

The invention relates to a vibratory stress relief apparatus for medium frequency and low frequency shaft type parts, and a use method thereof. The apparatus comprises a vibration exciter, a support block for clamping and supporting a workpiece, and a support mechanism connected with the support block. The support mechanism comprises a pair of support frames comprising a left support frame and a right support frame, and a support seat for installing the left support frame and the right support frame, wherein the left support frame and the right support frame right are arranged relatively. Thesupport block respectively forms rotatable connections with the left support frame of the support mechanism and the right support frame of the support mechanism. The apparatus further comprises a vibration exciter base for installing the vibration exciter, wherein the vibration exciter base is arranged on the middle portion of the workpiece, the vibration exciter, the vibration exciter base and the workpiece synchronously vibrate during vibratory stress relief. According to the present invention, a simply supported beam form is adopted, the flexural vibration type primary resonance is generated by the shaft type parts under the excitation of the vibration exciter at the natural frequency adopted for shaft flexural vibration; in the prior art, the dynamic stress generated by the apparatus does not reach the requirement of residual stress decreasing, with the apparatus provided by the present invention, the problem in the prior art is solved; the deformation amounts on both ends of the shaft are substantially improved; the dynamic stress distribution of the shaft is uniform so as to effectively reduce the residual stress of the shaft part.

Owner:GUANGXI UNIV

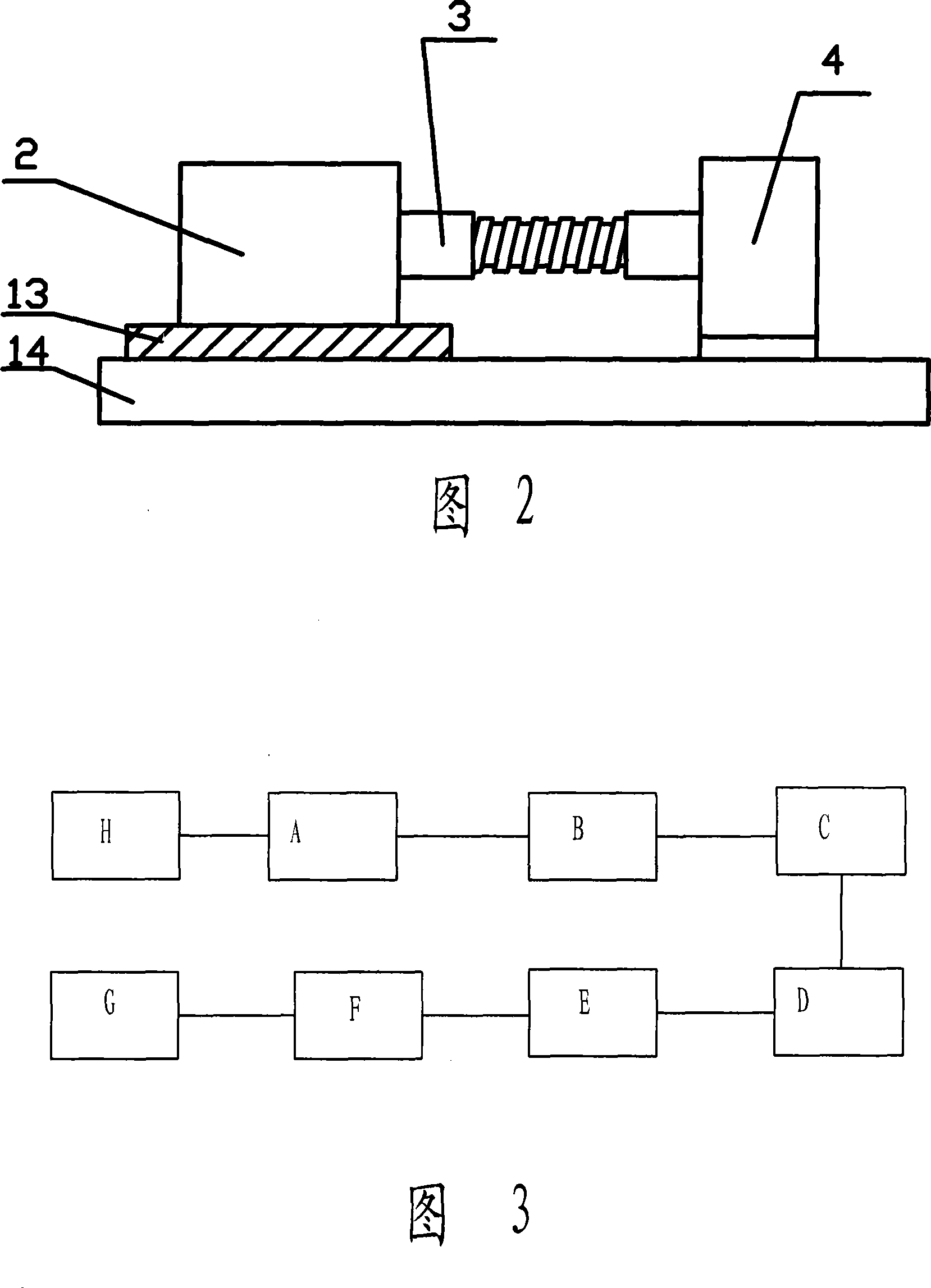

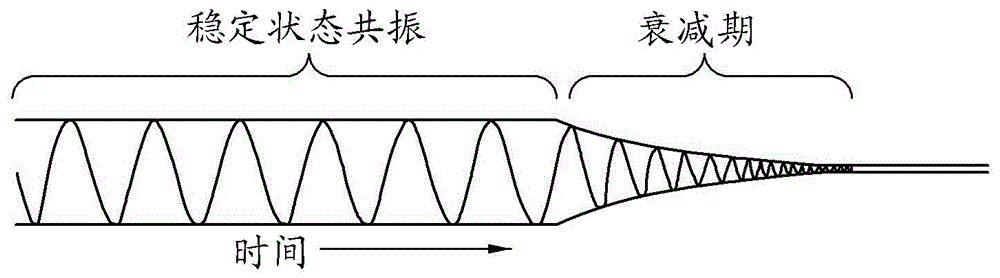

Frequency self-adaptive oscillation time-effect method and device

The invention provides a vibratory stress relief (VSR) method and device with adaptive frequency, wherein, an acceleration sensor collects information on acceleration change and inputs that into a controller, which outputs controlling signals so that the vibratory frequency of a vibration exciter changes, till the optimal resonance frequency is obtained. The invention comprises an acceleration sensor, an electric charge converting circuit, an amplifying circuit, a low-pass filter circuit, a voltage amplifying circuit, a detection circuit, a controller, a speed-regulating circuit and a vibration exciter. The invention is of a simple process method, is easy to operate, with simple and reasonable structure, can efficiently improve the VSR efficiency, track just in time the change in resonance frequency, improve effectively VSR effect, can substitute prior VSR method, and is especially suitable for relieving inner stress of thick sheets, and is suitable for industrialized application.

Owner:CENT SOUTH UNIV

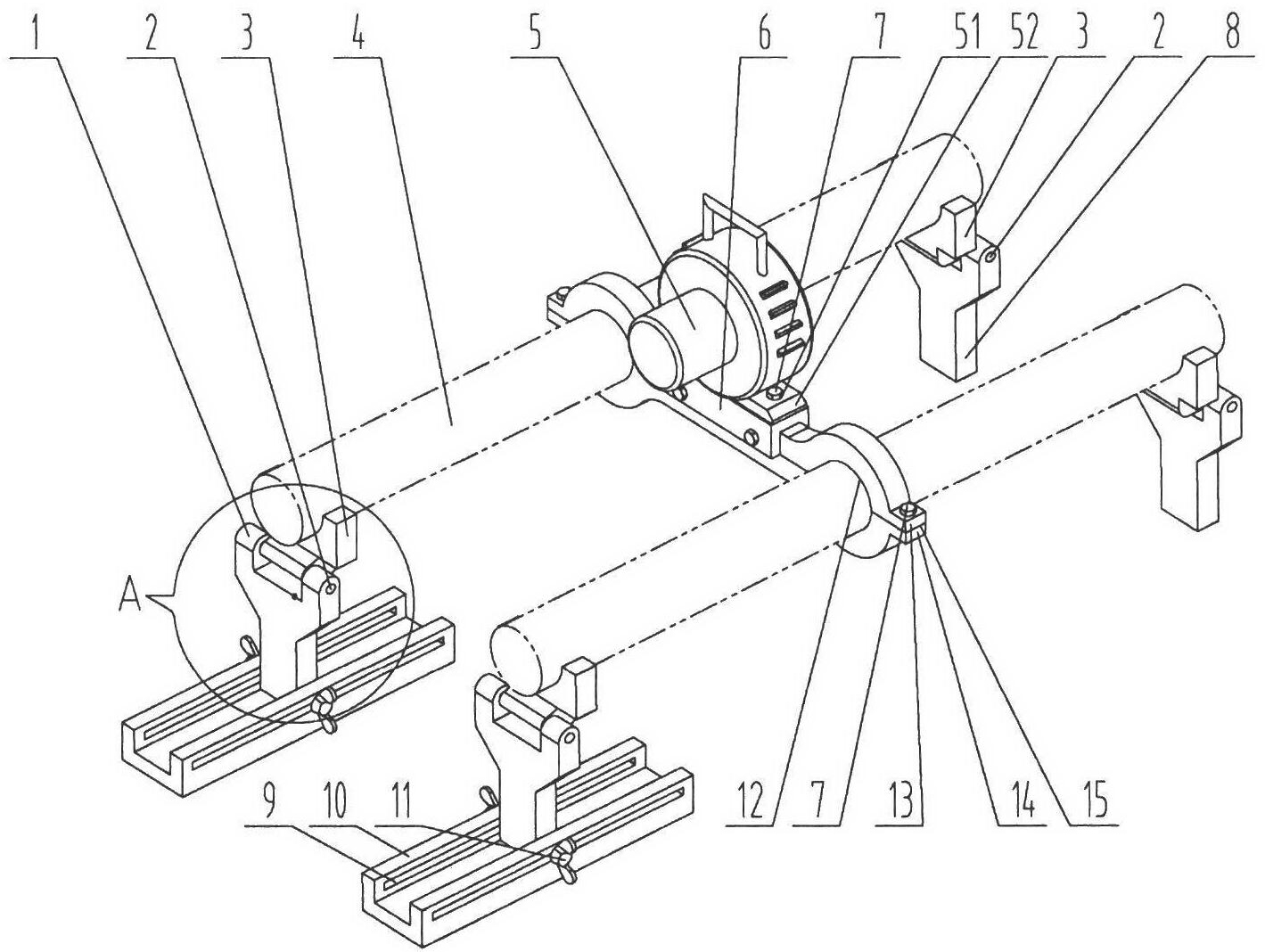

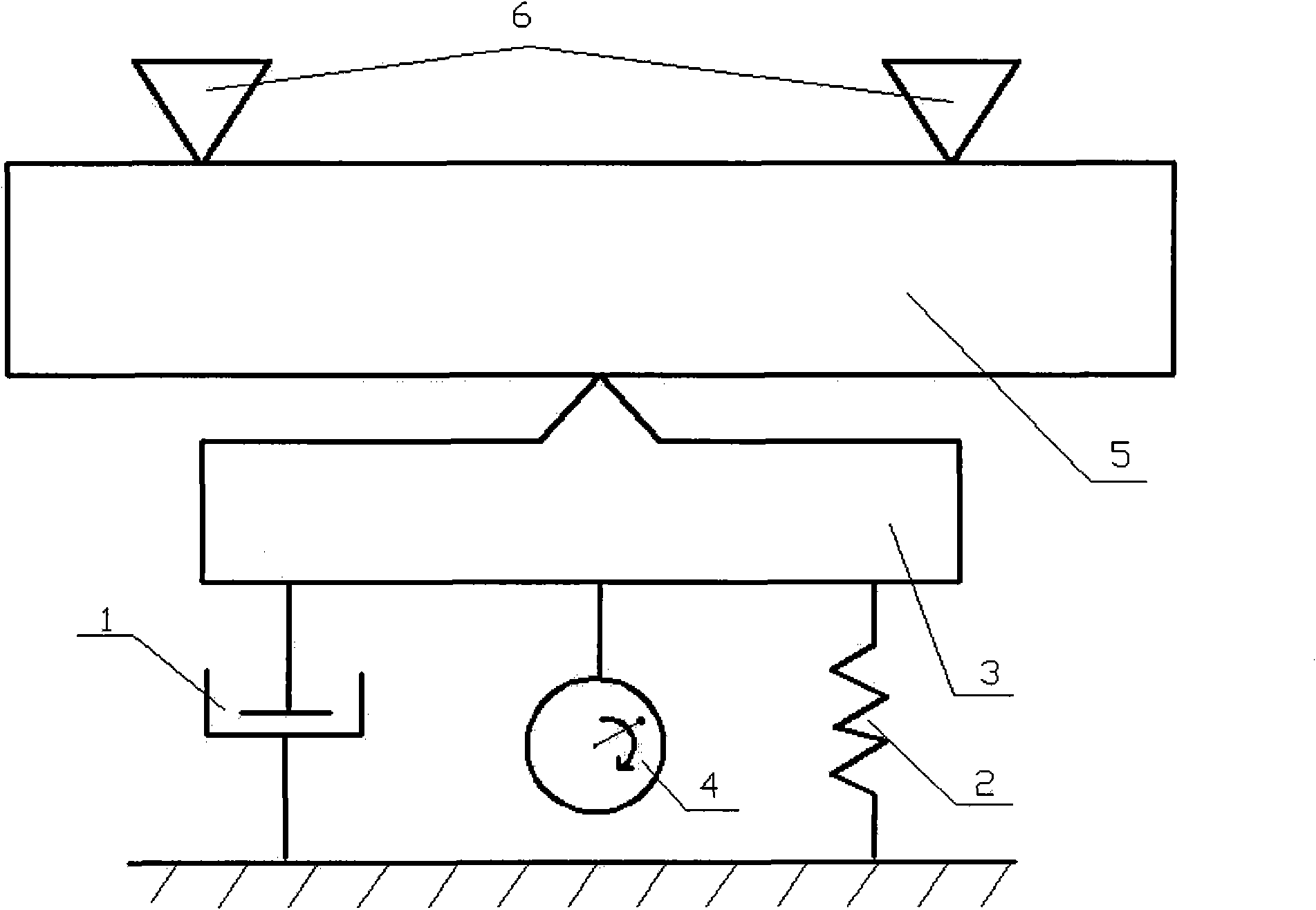

Flexural coupling resonance type vibratory stress relief device and implementation method thereof

InactiveCN102212672ACan eliminate residual stressSolve problems such as vibration aging cannot be handledResonanceCoupling

The invention relates to a flexural coupling resonance type vibratory stress relief device and an implementation method thereof. A fixed support table of a workbench of the flexural coupling resonance type vibratory stress relief device is fixed on a base and is provided with a fixed support sliding bearing; a sliding stand is installed on a sliding rail; a sliding stand support bearing is arranged on the sliding stand; one end of a screw rod is connected with the fixed support table, and the other end is connected with a base baffle after penetrating through the sliding stand; the base baffle is provided with a sliding stand setting dial; a motor of the speed-adjustable main transmission system is installed on the base and connected with a reducer through a motor coupling; the output endof the reducer is connected with a universal coupling through a main coupling; the other end of the universal coupling is connected with a workpiece holder; the workpiece holder locks a workpiece; the eccentric weight is installed on the workpiece; and a torsion increasing device is fixed on the sliding stand. The invention can effectively solve the problem that a large-size high-rigidity workpiece can not be easily subjected to vibratory stress relief treatment.

Owner:GUANGXI UNIV

Vibration stress relief of superalloy components

A method of conditioning and stress relief for superalloy components includes vibrating the component during welding at a subharmonic frequency. The proper frequency is selected to be below a harmonic frequency, and to produce an amplitude in the range of ⅓ to ½ the amplitude produced by a harmonic frequency. The component to be repaired is vibrated during and after welding at this frequency.

Owner:SIEMENS ENERGY INC

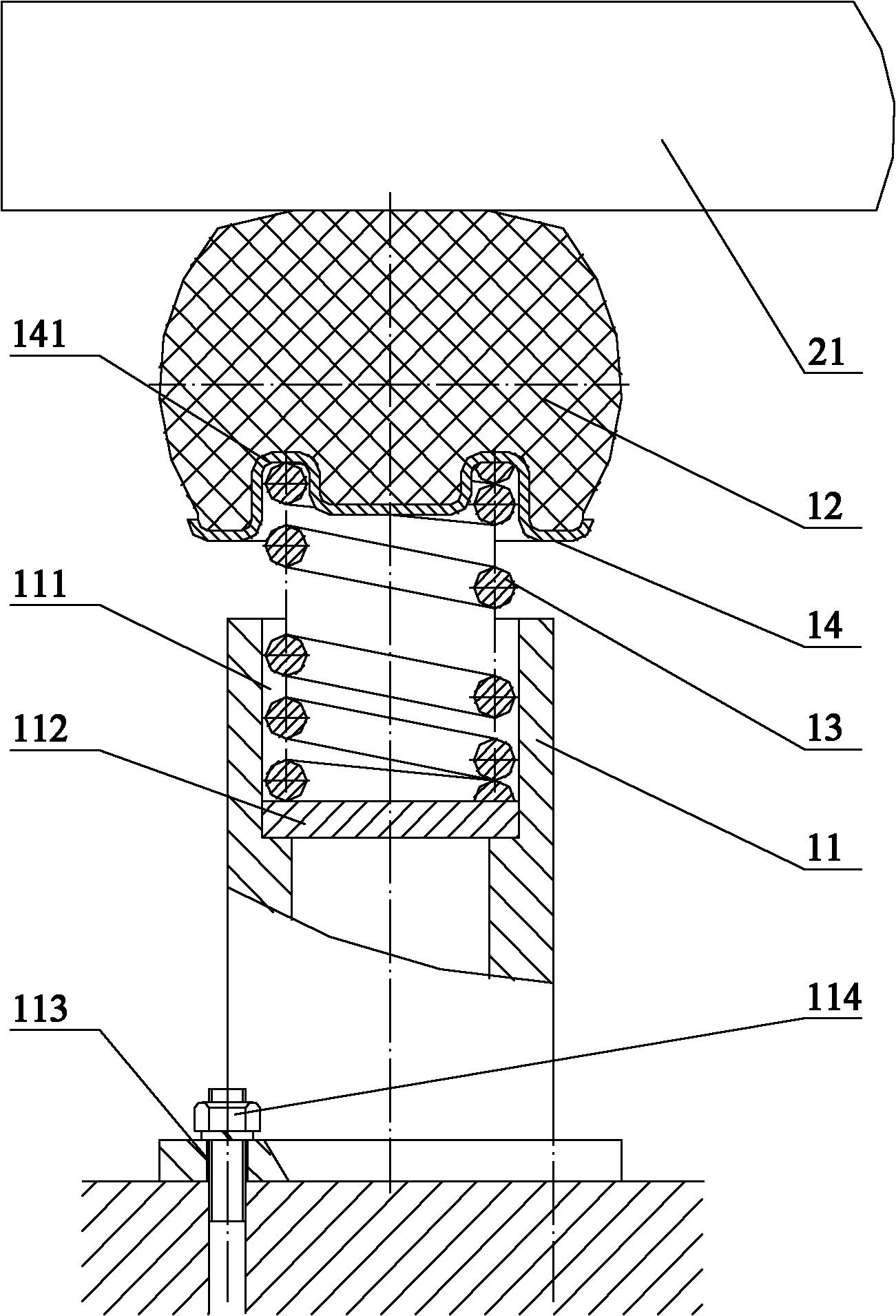

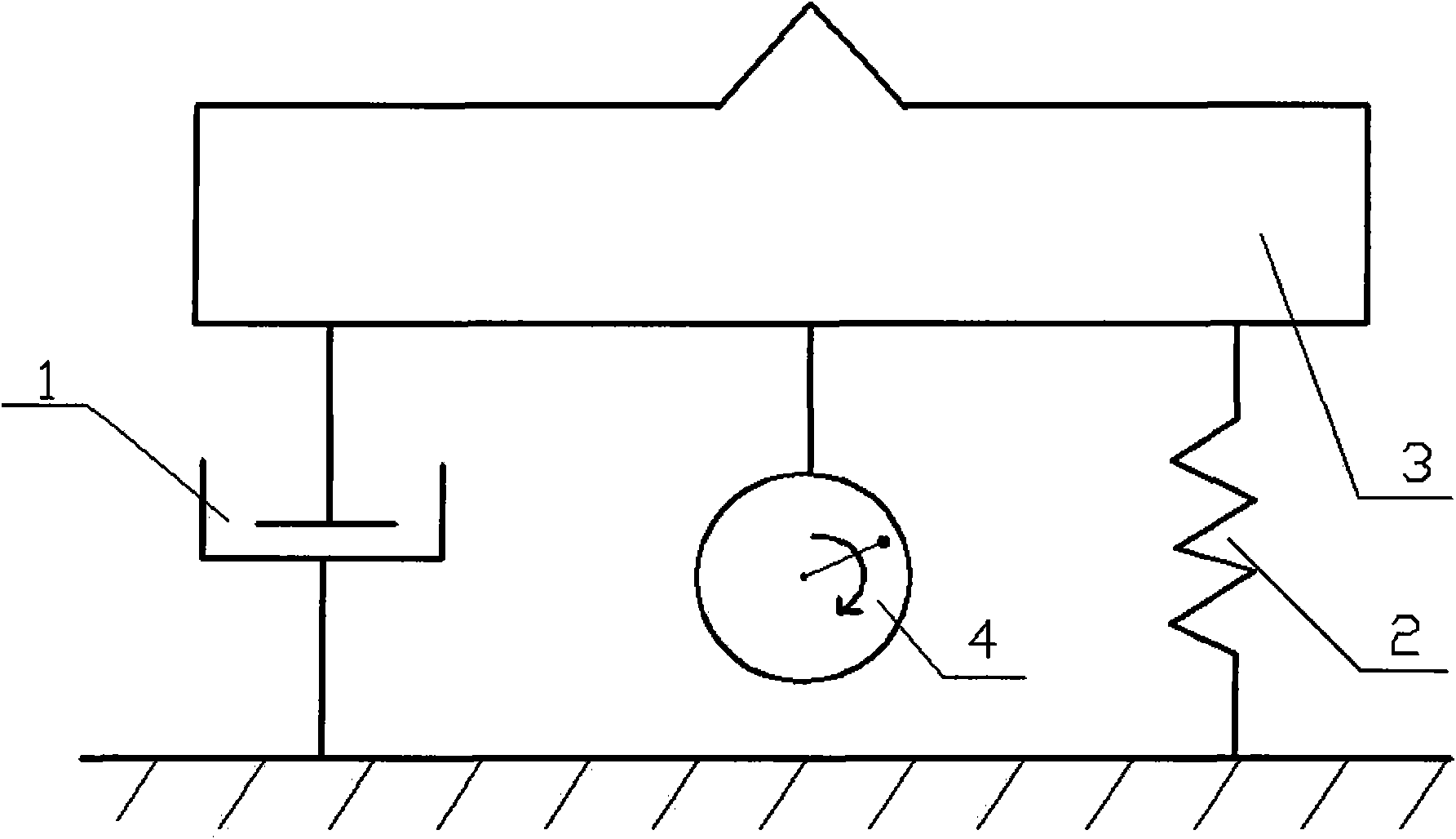

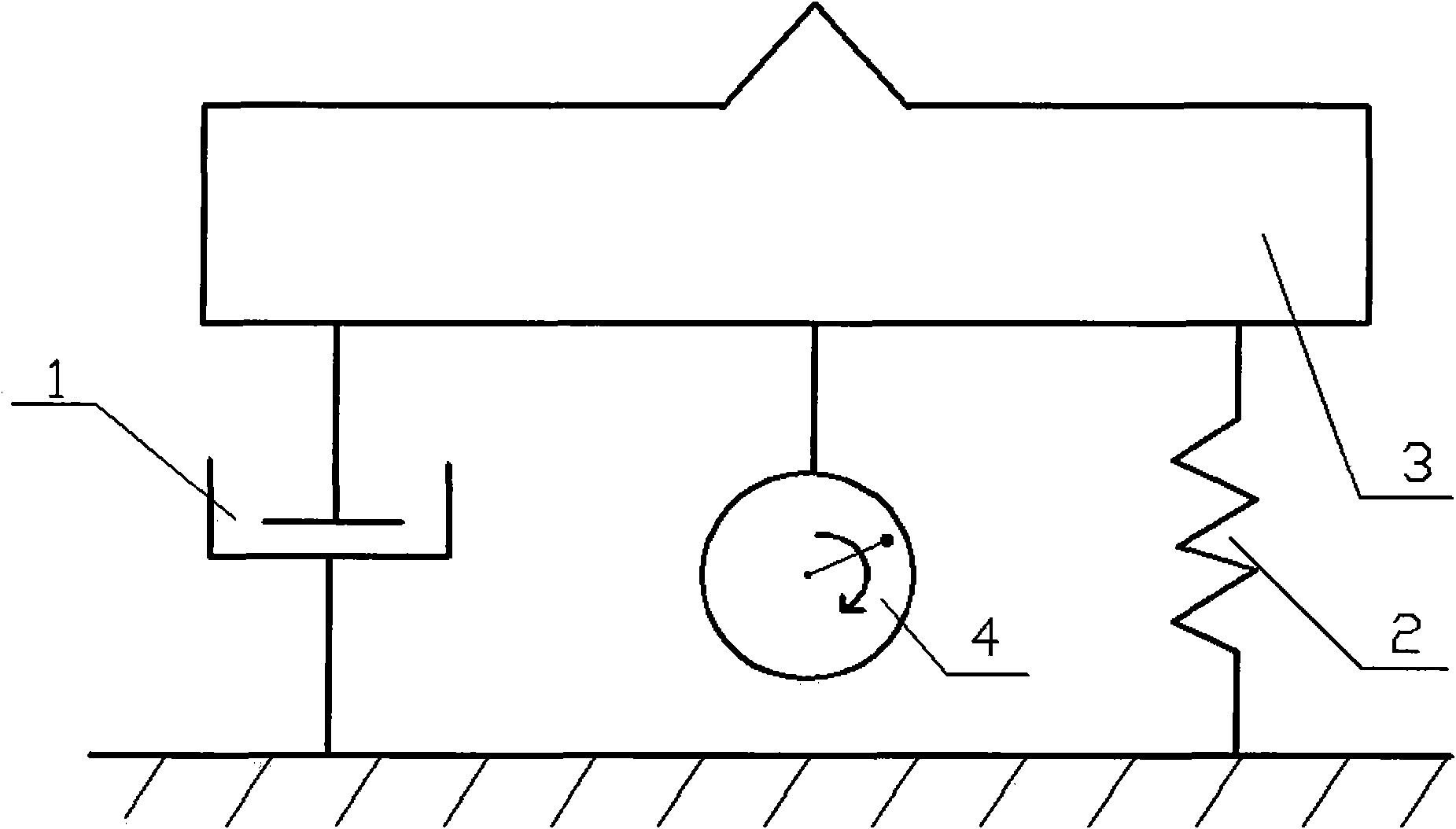

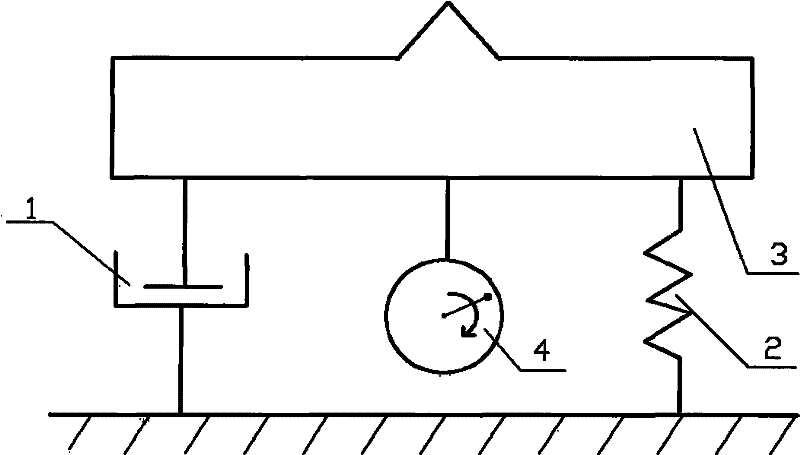

Vibratory stress relief equipment and vibration reduction bearing device thereof

InactiveCN102116359AImprove vibration damping effectHigh damping efficiencySpringsNon-rotating vibration suppressionCushioningDouble stage

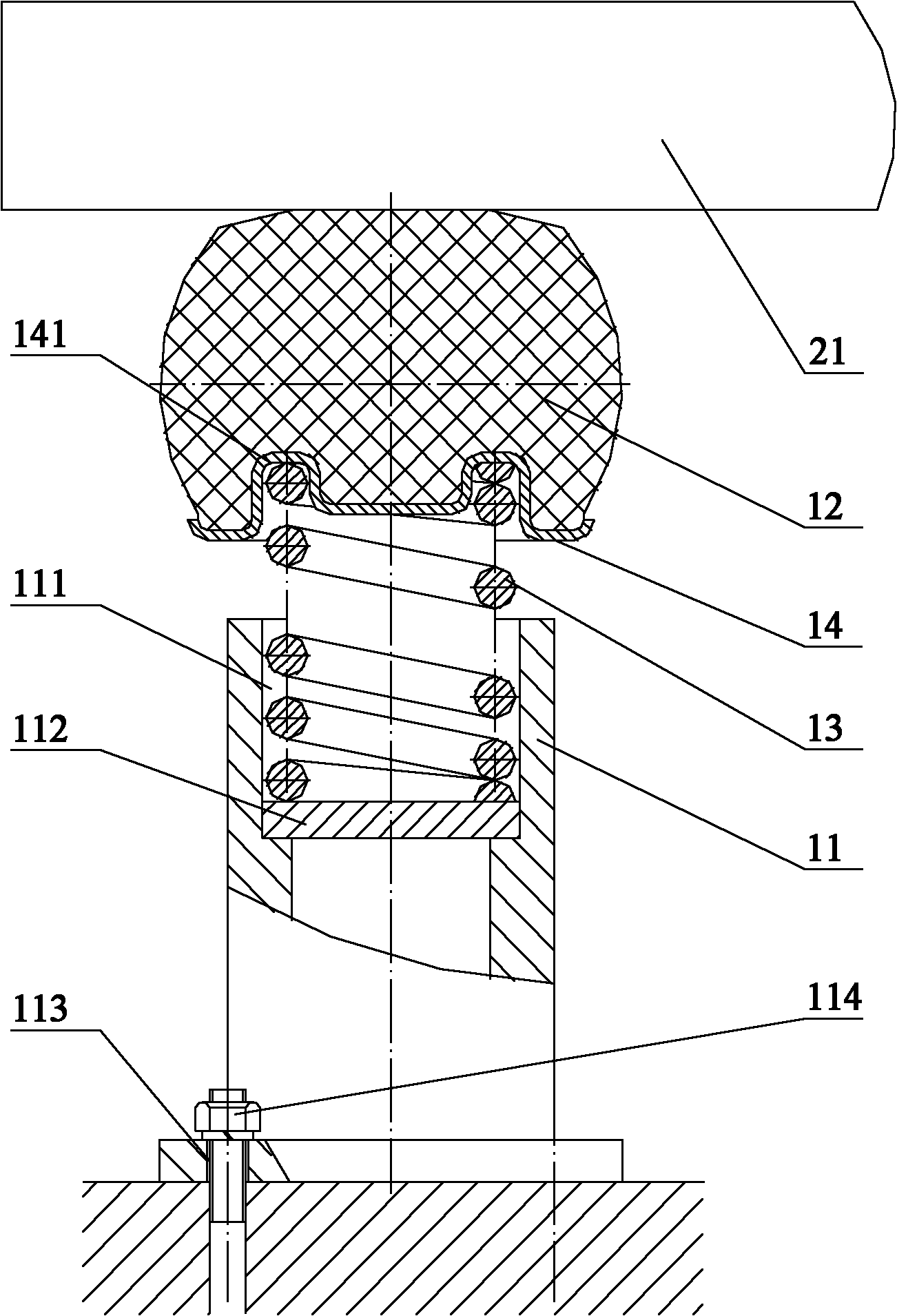

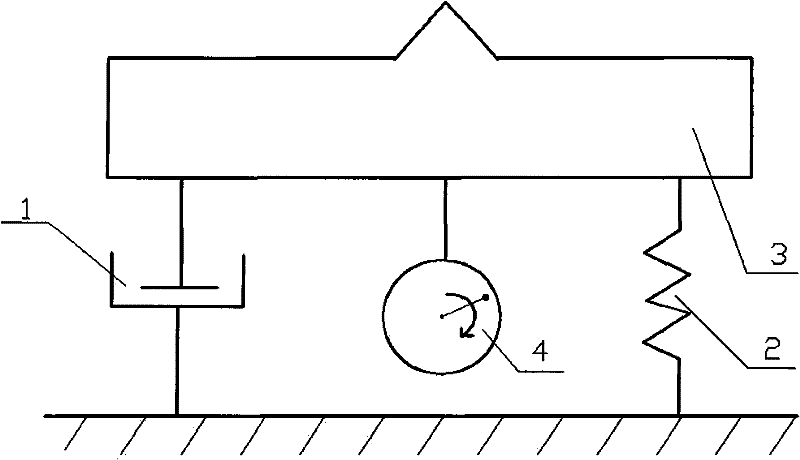

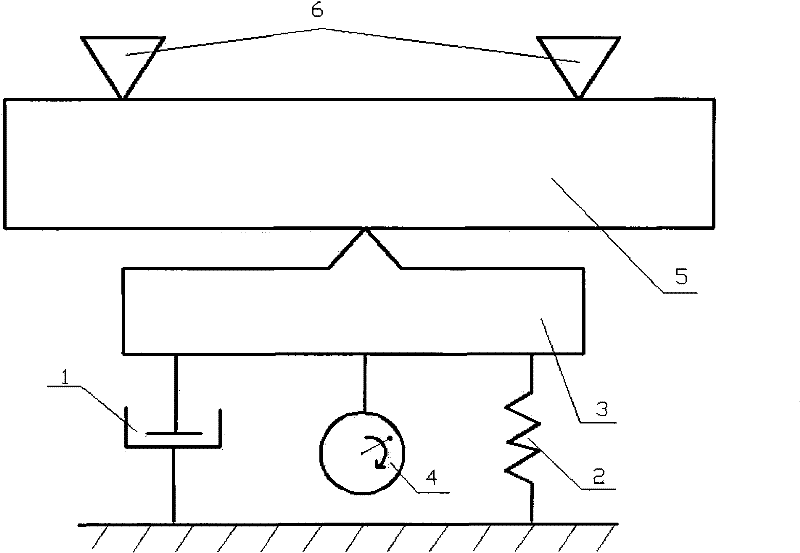

The invention discloses a vibration reduction bearing device. The vibration reduction bearing device comprises a bearing seat fixed on the ground; a rubber gasket and a spring matched with the rubber gasket are arranged on the top of the bearing seat from top to bottom sequentially, and the stretching and retracting direction of the spring is consistent with the vertical direction. The rubber gasket and the spring can be matched mutually to form a double-stage vibration reduction structure, so that the vibration reduction capacity of the vibration reduction bearing device is greatly enhanced, and the vibration reduction efficiency of the vibration reduction bearing device is greatly improved; and the stretching and retracting direction of the spring is consistent with the vertical direction to ensure that the cushioning and vibration reduction effect generated by the stretching and retraction of the spring during stressing is maximized, so that the vibration reduction efficiency of the vibration reduction bearing device is further improved. The invention also discloses vibratory stress relief equipment applying the vibration reduction bearing device. Little vibration and noise generated by the vibratory stress relief equipment is spread, and the working process of the vibratory stress relief equipment is more environmental-friendly and efficient.

Owner:CHONGQING TECH & BUSINESS UNIV

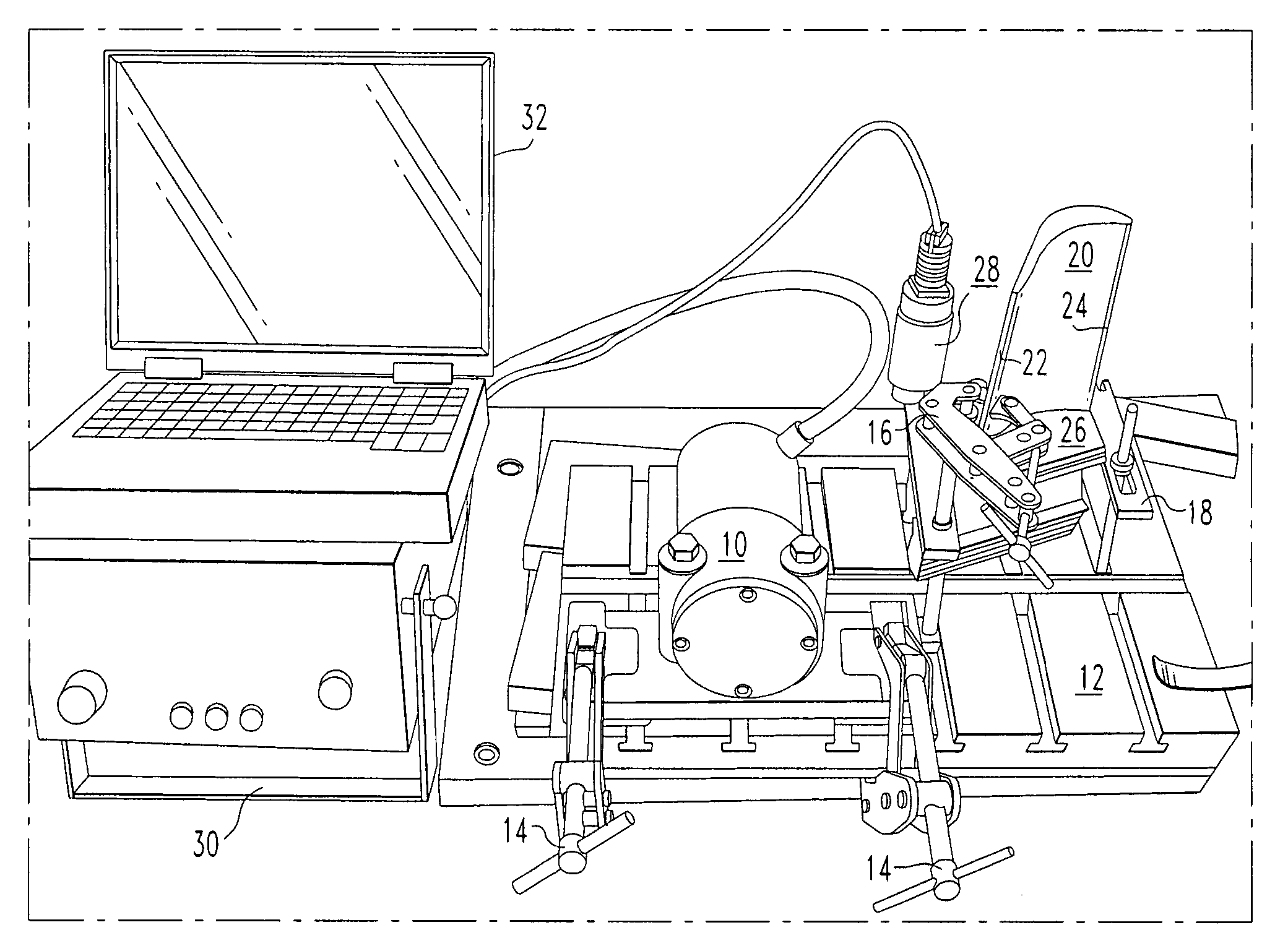

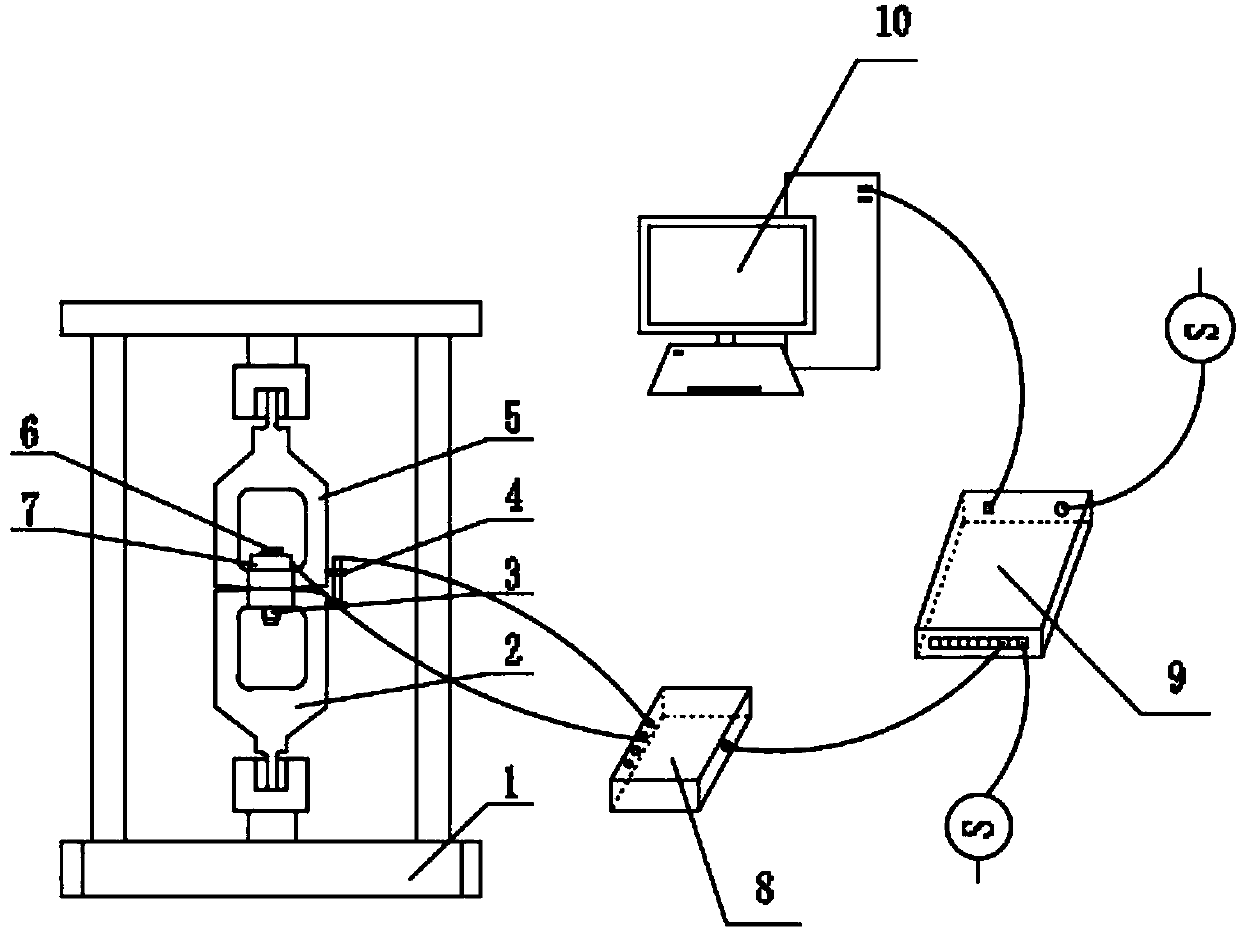

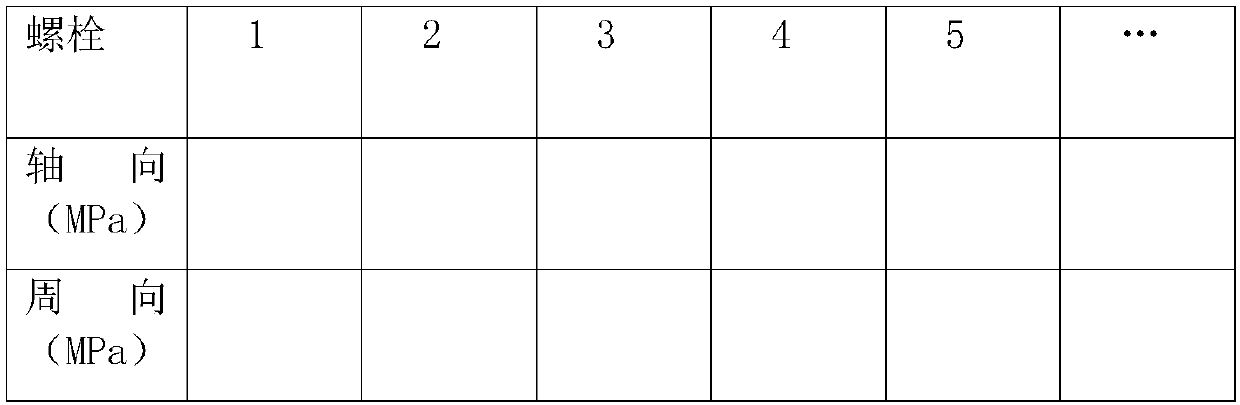

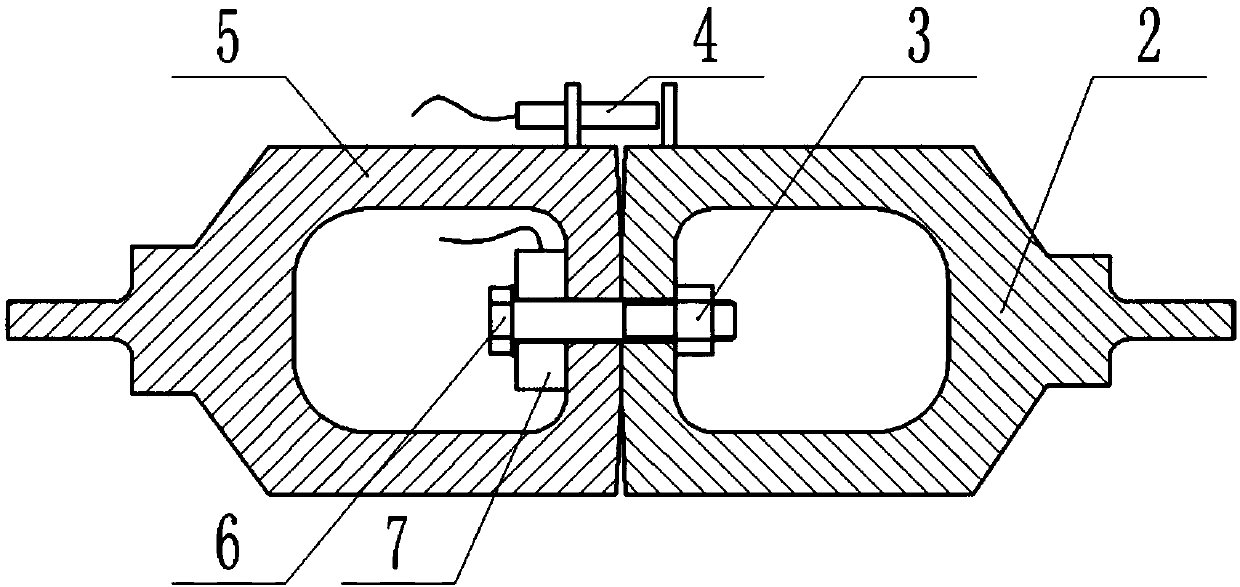

Measurement method for influence of residual stress on bolt connection structure clamping force attenuation

InactiveCN107607398AEasy to operateHigh precisionMaterial strength using tensile/compressive forcesApparatus for force/torque/work measurementData acquisitionX-ray

The invention discloses a measurement method for the influence of residual stress on bolt connection structure clamping force attenuation. A device for realizing the method includes: a tensile testingmachine, a lower connecting piece, a nut, an eddy current displacement sensor, an upper connecting piece, a bolt, a pressure sensor, and a corresponding sensor data acquisition system and a computer,a 3D surface morphology measurement instrument, a digital display torque wrench, a vibration table, and an X ray residual stress tester. The 3D surface morphology measurement instrument is employed to acquire the three-dimensional morphology of a contact surface, vibratory stress relief process and the X ray residual stress tester are employed to acquire bolts that are made of a same material andhave different levels of residual stress, the tensile testing machine, the pressure sensor and the displacement sensor are combined to collect the data under the circumstances of a same pretighteningforce and specific amplitude circulating alternating load. The method can achieve quantitative analysis of the relationship between the two structures, provides the experimental basis for further study of the influence of residual stress on bolt connection structure clamping force attenuation, and has the characteristics of simple and quick operation and accurate measurement.

Owner:BEIJING UNIV OF TECH

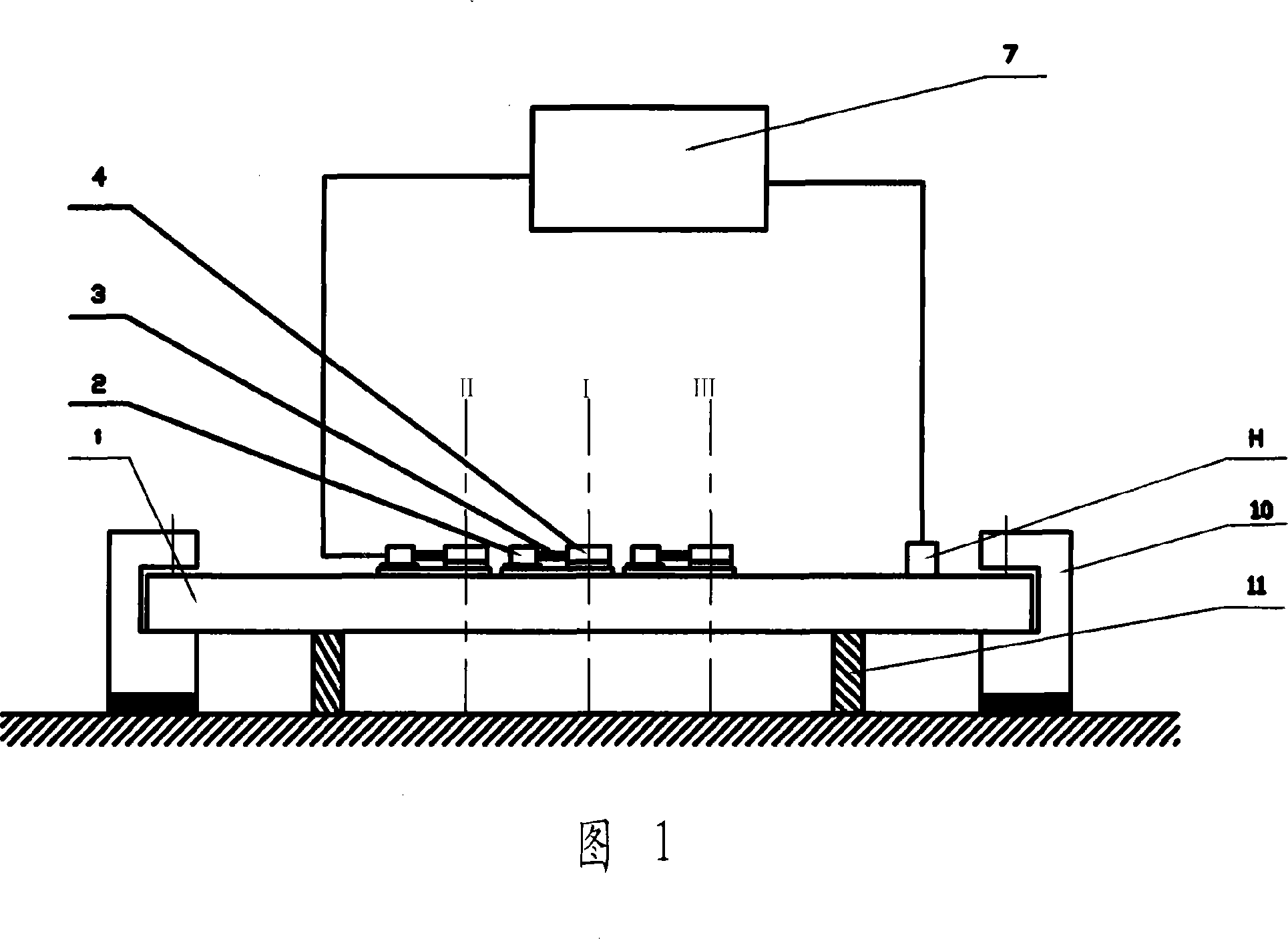

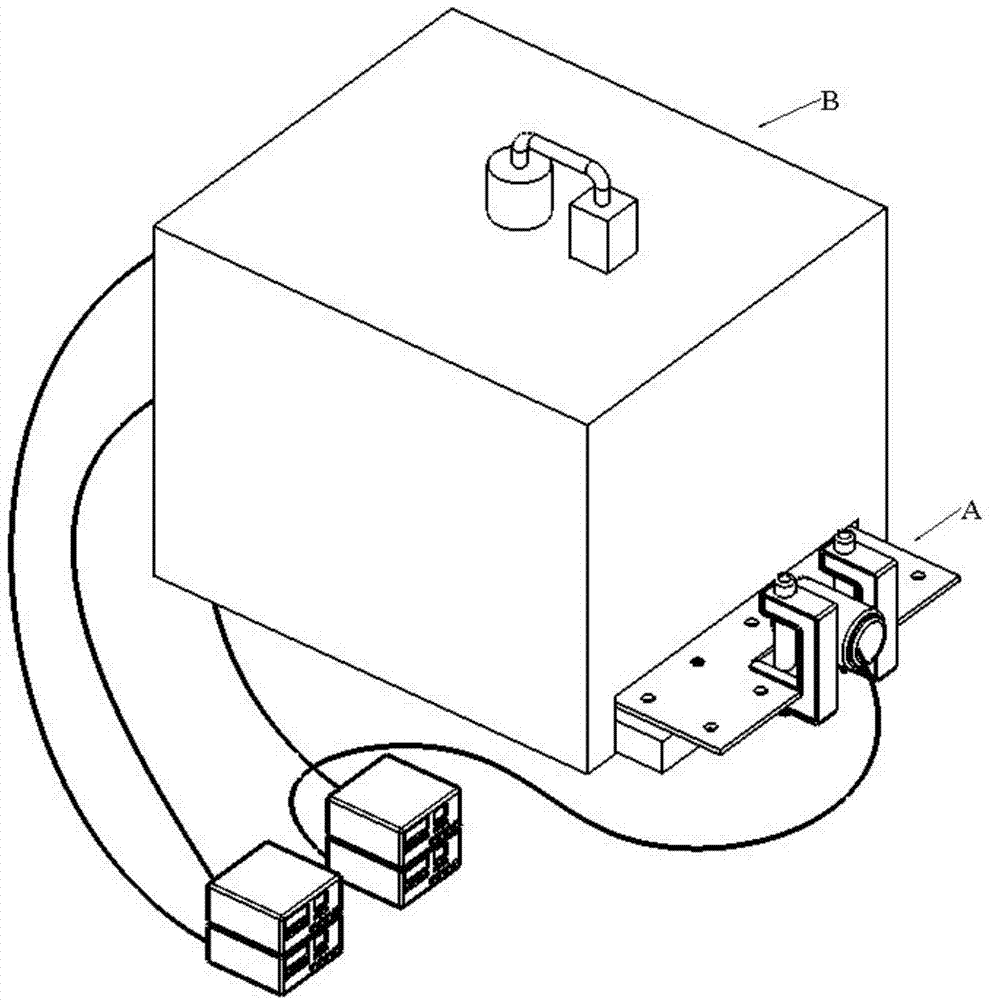

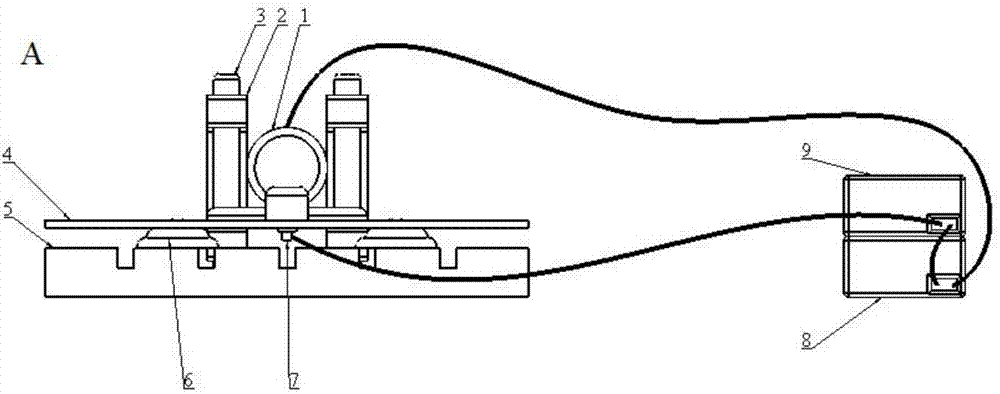

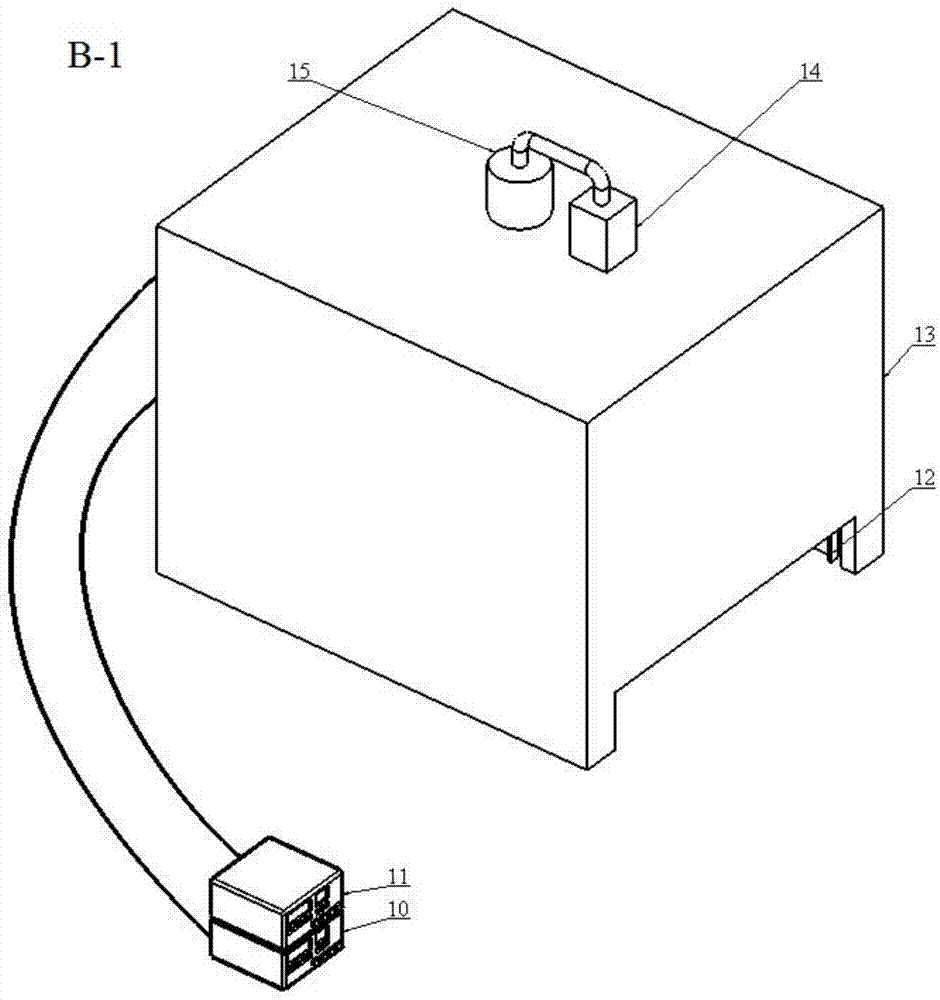

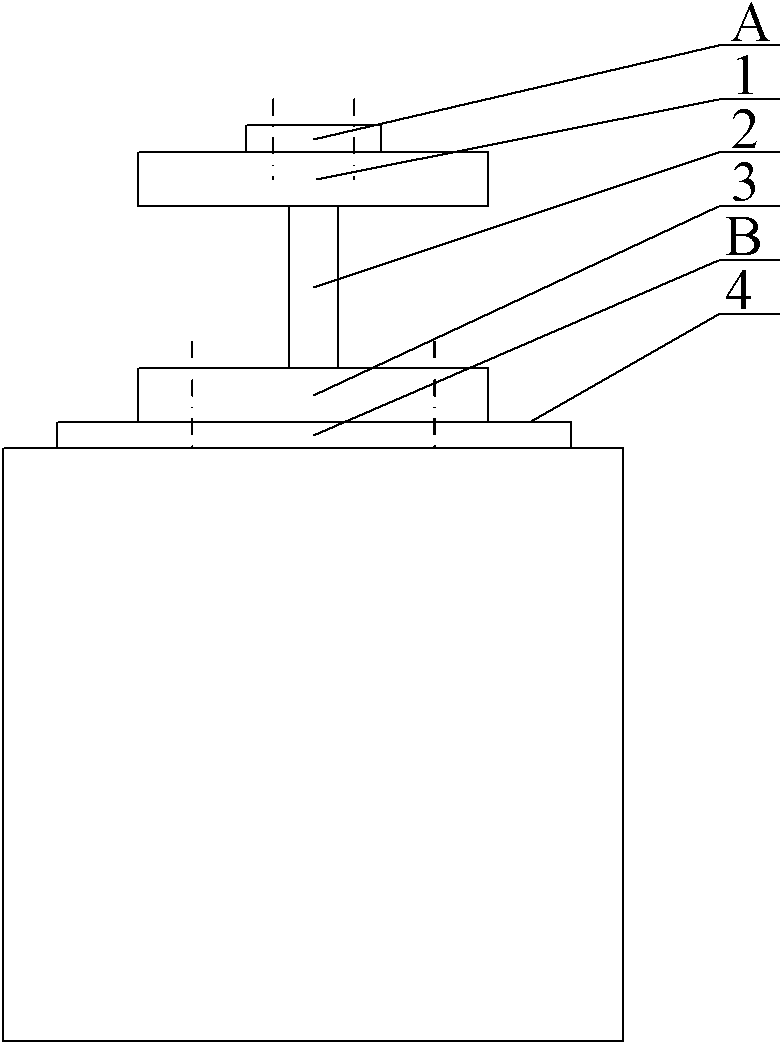

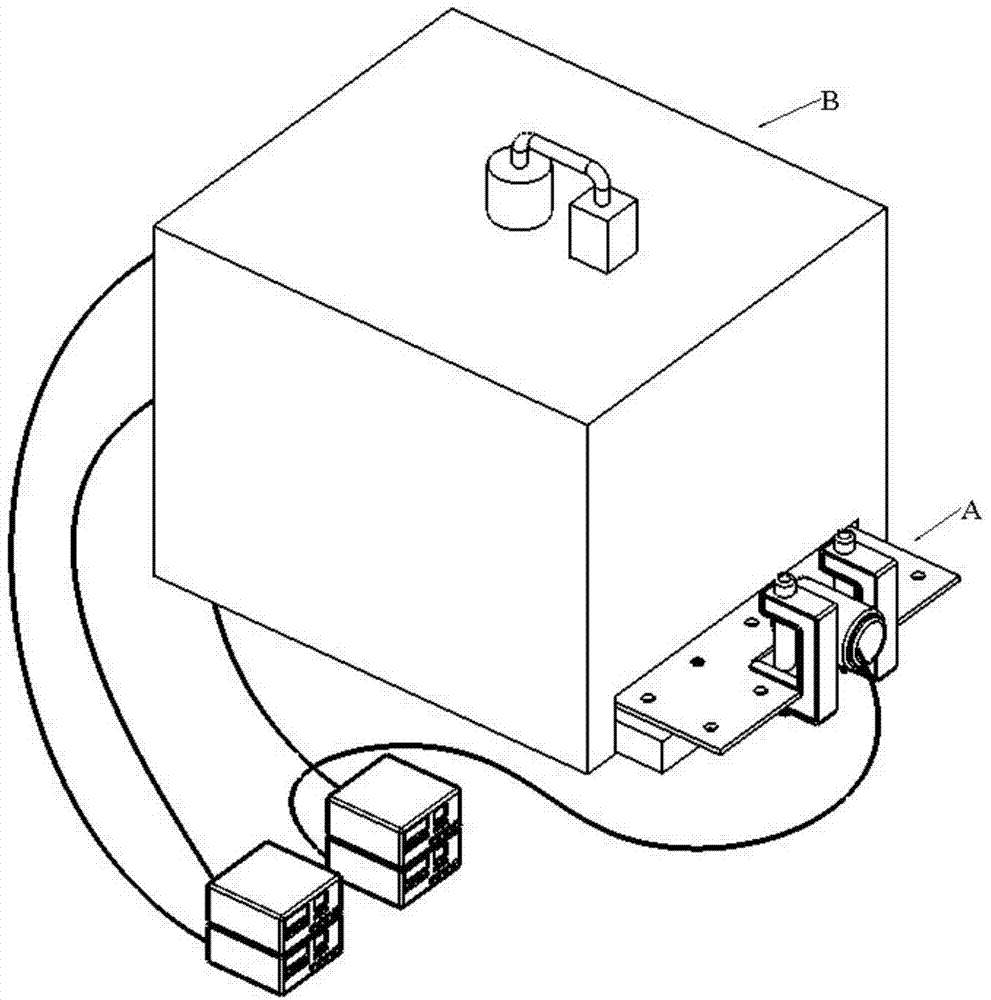

Thermal/vibratory combined stress homogenizing device

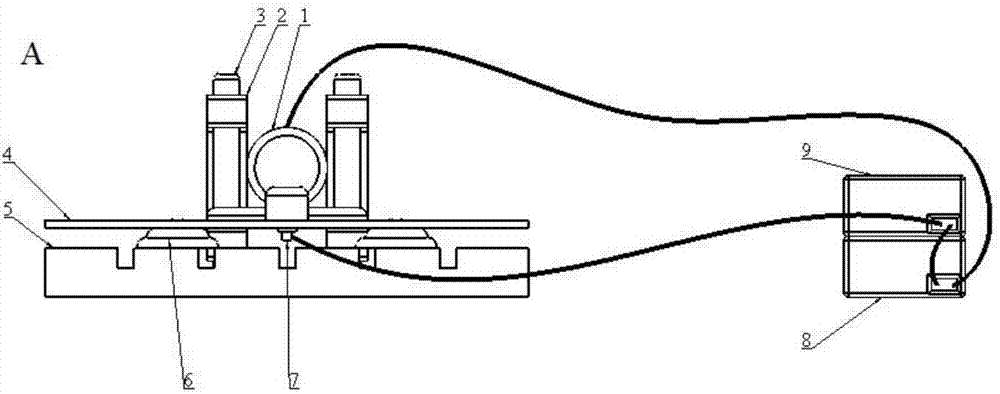

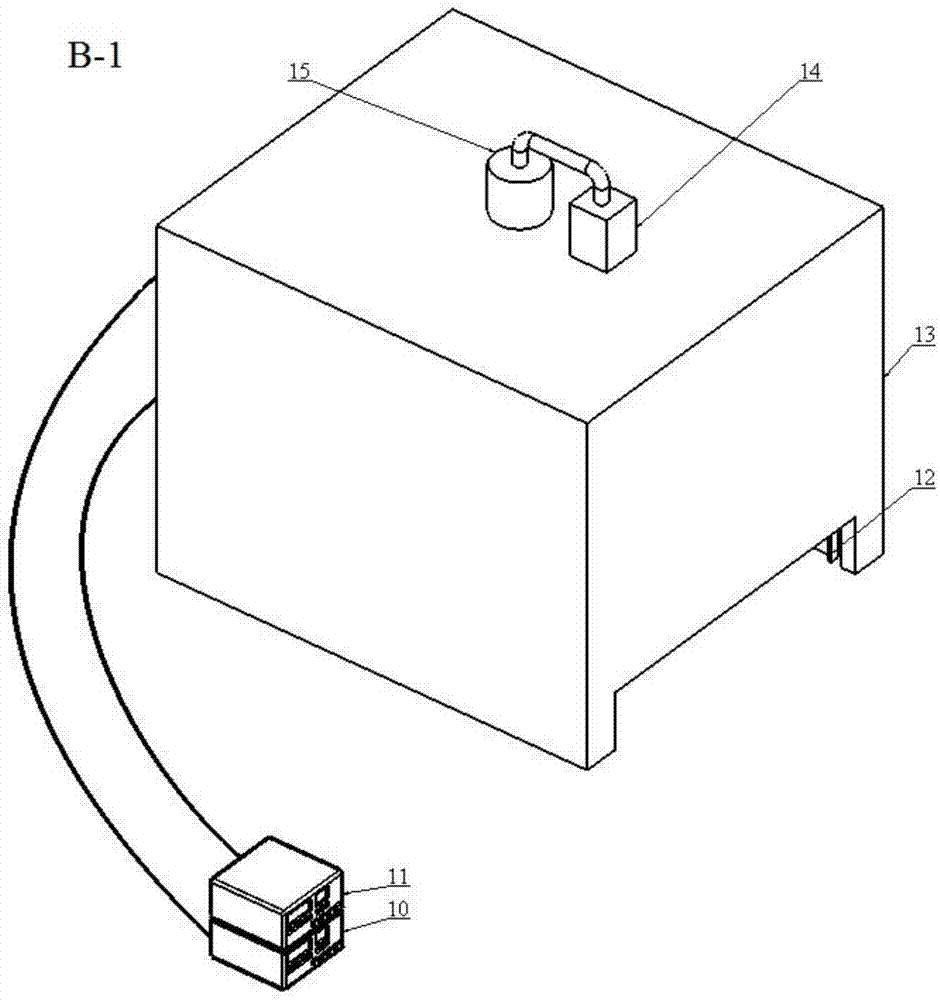

The invention relates to a thermal / vibratory combined stress homogenizing device which is composed of a vibratory stress relief system (A) and a thermal stress relief system (B), wherein most of the vibratory stress relief system (A) is contained in an outer cover (13) of the thermal stress relief system (B); an internal bladder (12) of the thermal stress relief system (B) is covered on a vibratory platform (4) of the vibratory stress relief system (A); the bottom of the internal bladder (12) is in contact with the ground; and the relative positions of the internal bladder (12) and the vibratory platform (4) are positioned by regulating three internal walls among four side walls until the distances between the three internal walls and the contour of the vibratory platform (4) are equal. Traditional natural stress relief prolongs the production cycle of spare parts and also influences the quality of the product. According to the invention, the production efficiency can be effectively improved, the research and development cycle of the product can be shortened, and the quality of the product can be enhanced. Thus, the thermal / vibratory combined stress homogenizing device plays a very important role in actual industrial production.

Owner:BEIHANG UNIV

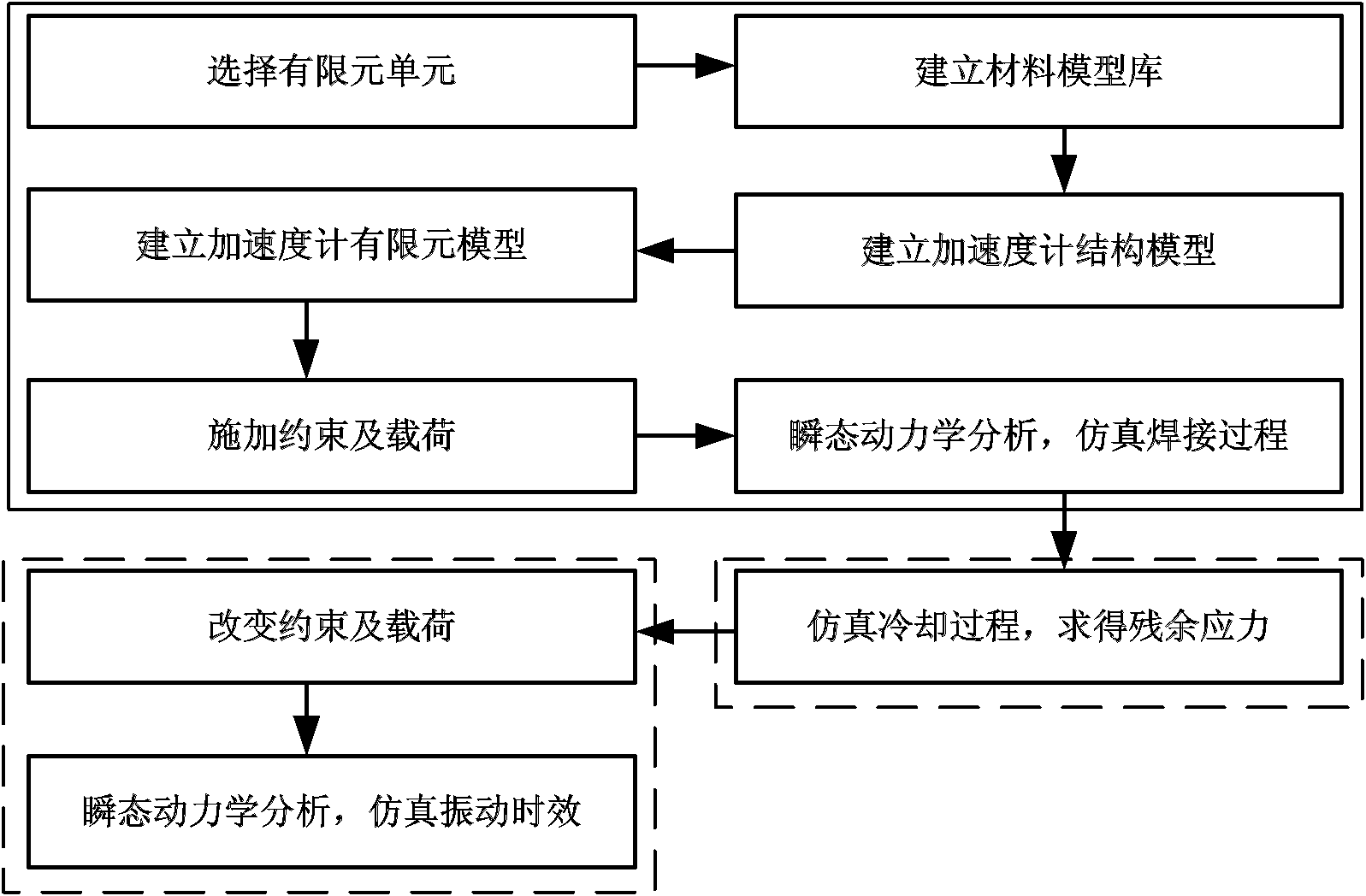

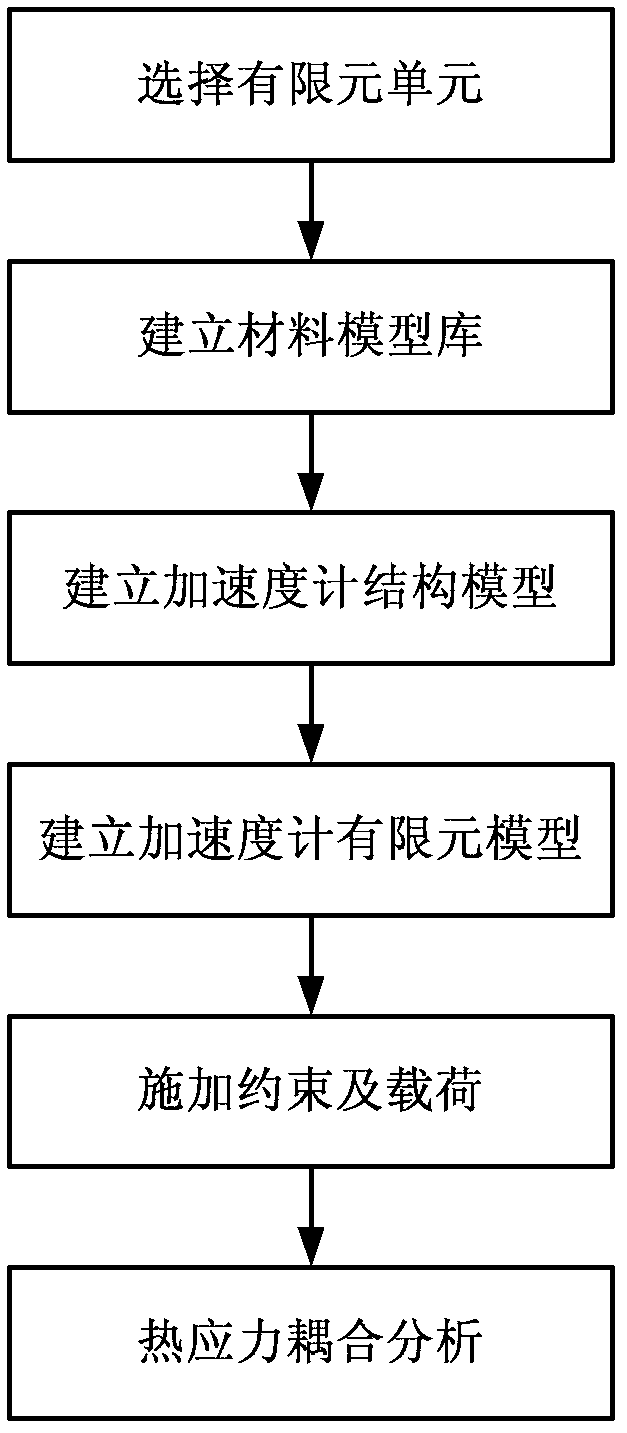

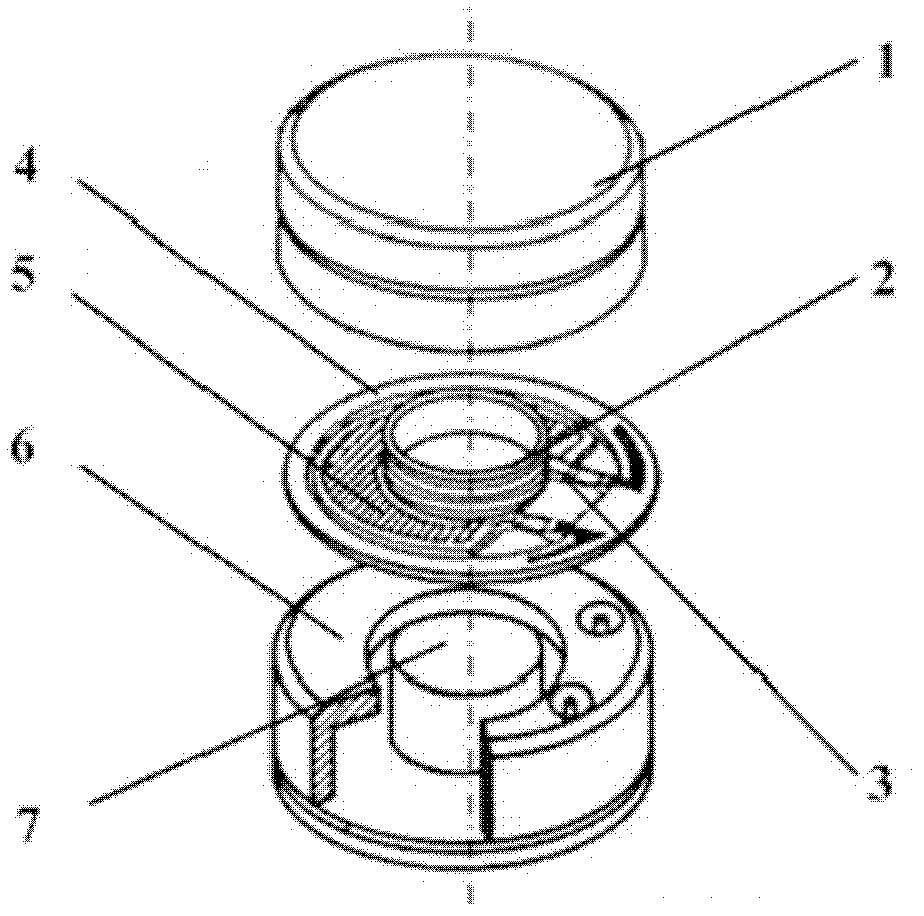

Multi-field coupling based vibratory stress relief simulating method for accelerometers

ActiveCN102542117AAvoid human errorEasy to compareSpecial data processing applicationsHeat fluxAccelerometer

A multi-field coupling based vibratory stress relief simulating method for accelerometers includes three steps: the first step, simulating laser welding process; the second step, cooling naturally, reserving residual stress, keeping a model constant, removing heat flux density load, simulating natural cooling process and coupling transient state of a heat structure; and the third step, applying vibration stress and simulating time domain dynamics. By finite element coupling simulation of multiple physical fields of heat, structures and vibration and the like, distribution states of the residual stress after VSR (vibratory stress relief) are acquired. On one hand, the multi-field coupling based vibratory stress relief simulating method is used for evaluating removing effect of the residualstress of the VSR, on the other hand, by comparing affections on residual stress removal from different vibration stress, the optimum VSR vibration section is found, and accordingly stability and navigation accuracy of the accelerometers are improved. Besides, the multi-field coupling based vibratory stress relief simulating method can be applied in the technical fields of aeronautics and astronautics and finite element simulation and has excellent application prospect.

Owner:厦门蓝威可靠性系统工程研究院有限公司

Sheet metal part vibratory stress relief method and device

ActiveCN102251096AOvercome the defect that it is not easy to fix the shapeSolve the practical problem of inability to vibrate and agingControl systemVibration exciter

The invention provides a sheet metal part vibratory stress relief method and device. A machined sheet metal part and a model tire are together fixed on a vibratory stress relief platform, a vibration exciter is rigidly fixed with the vibratory stress relief platform, and a control system is used for starting the vibration exciter, so that the vibratory stress relief platform, and the model tire and the sheet metal part fixed with the vibratory stress relief platform can vibrate simultaneously, thereby eliminating and homogenizing the internal stress of the sheet metal part.

Owner:XIAN AIRCRAFT IND GROUP

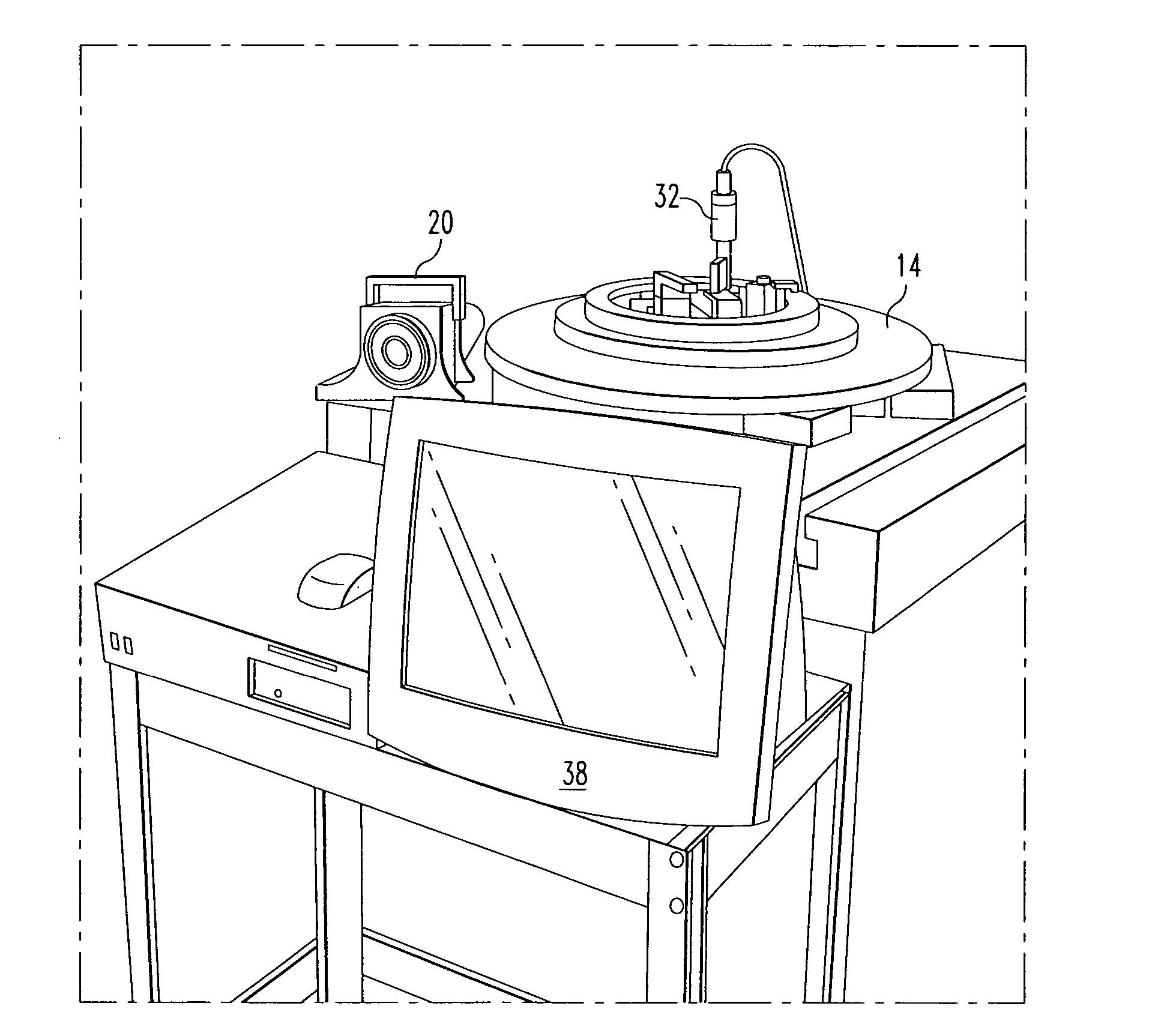

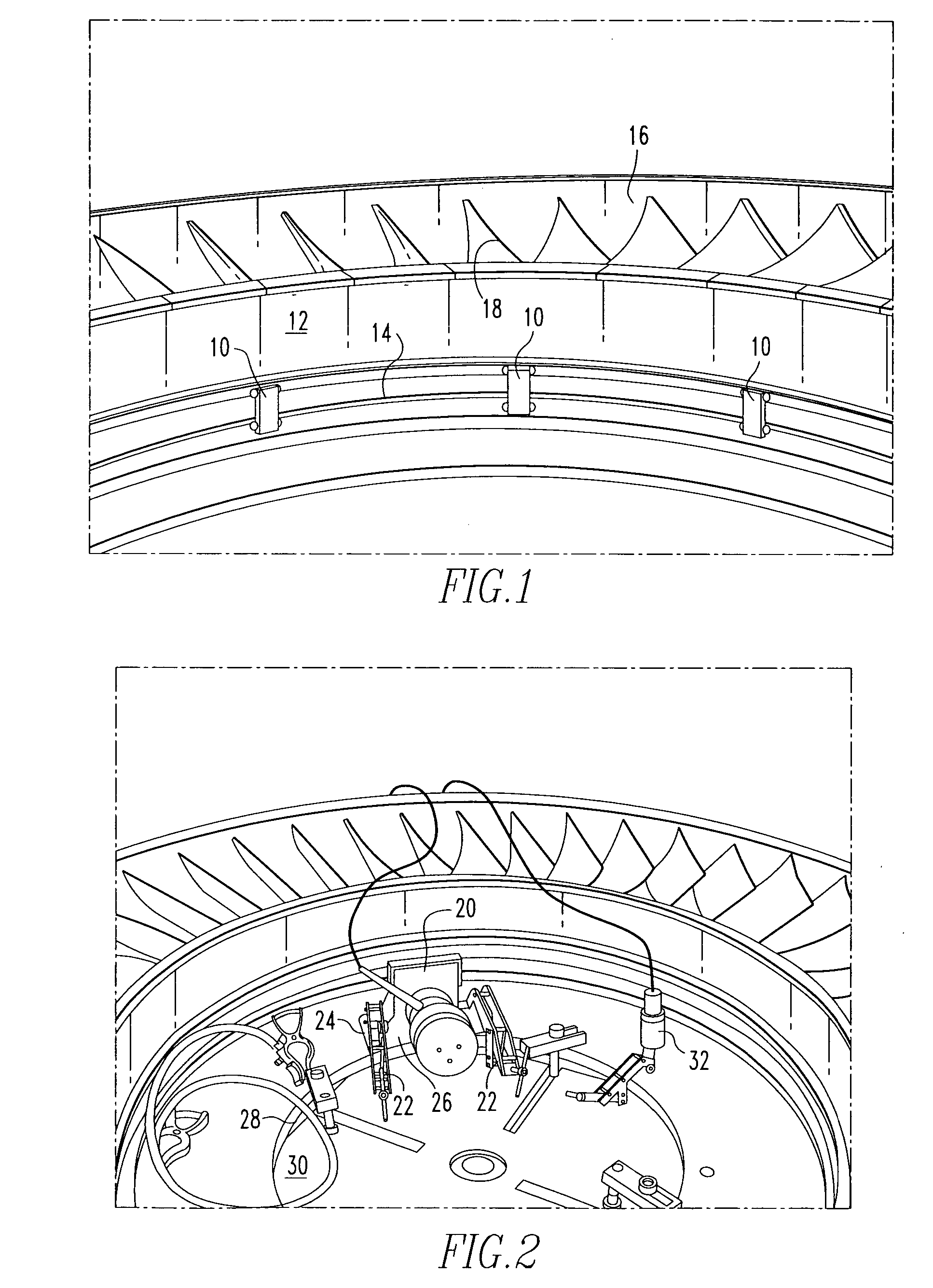

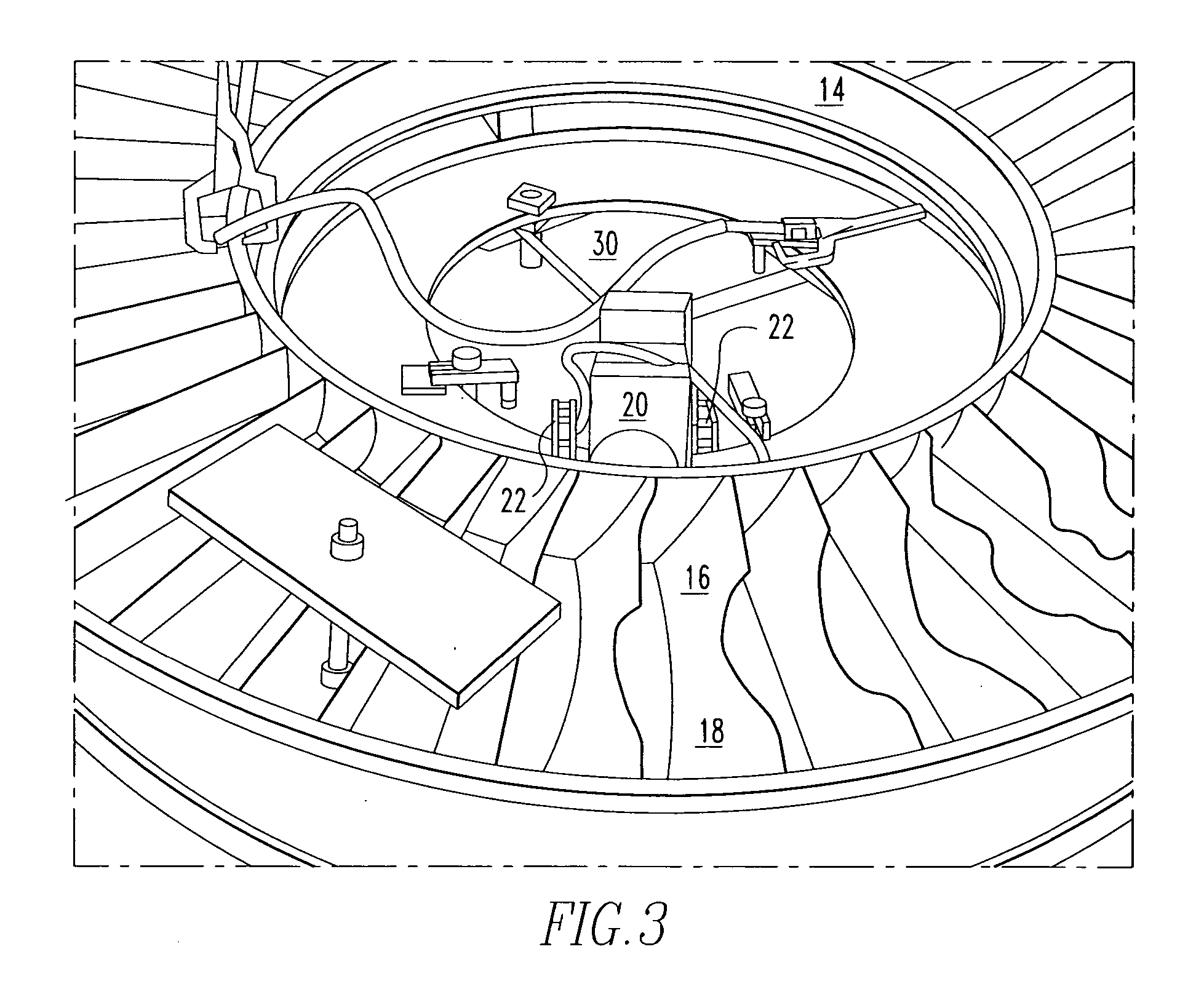

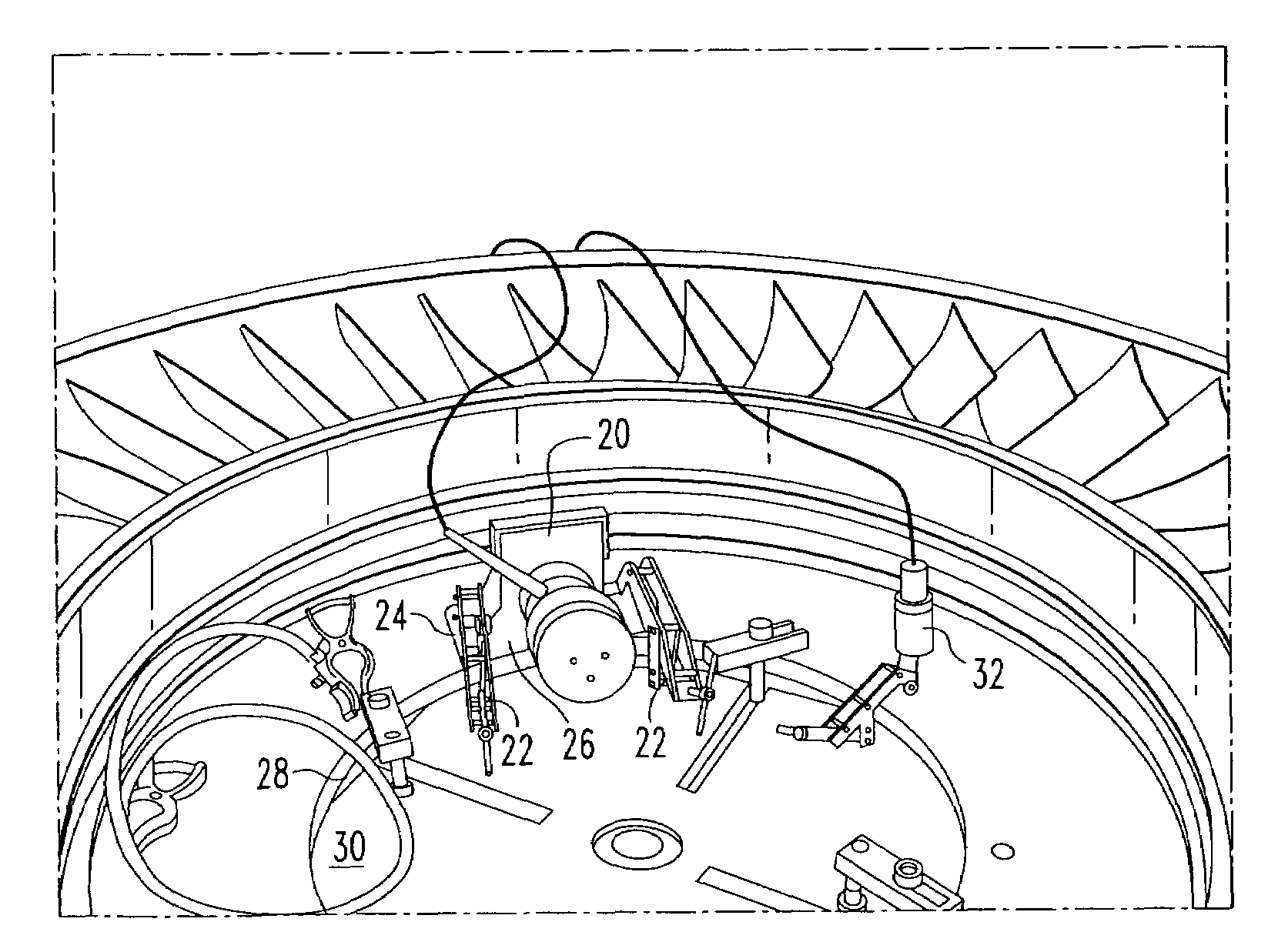

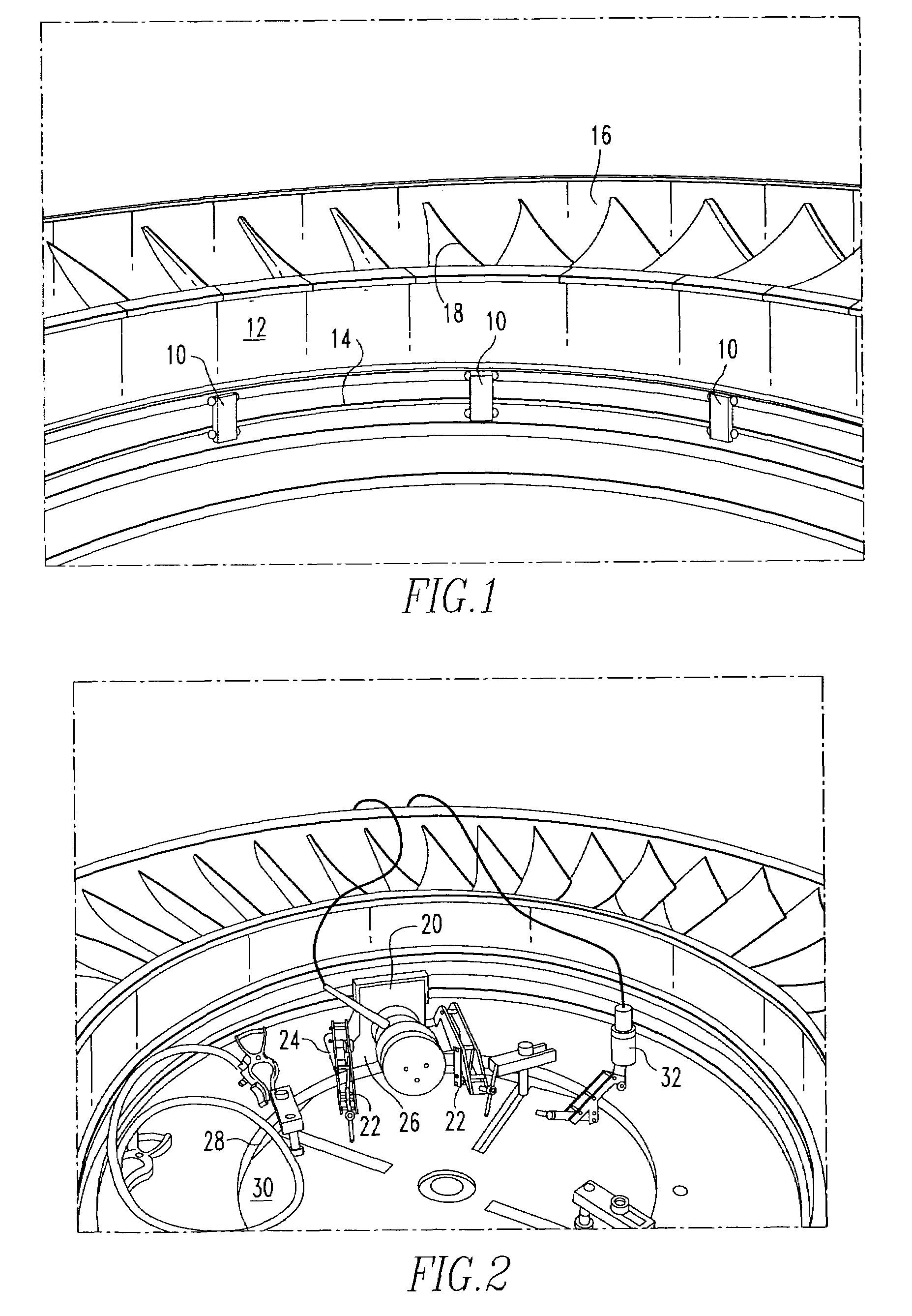

Vibration stress relief of weldments

ActiveUS20070040005A1Reduce distortion problemsVibration measurement in solidsTurbinesHarmonicEngineering

A method of stress relief for stainless steel combustion turbine components includes vibrating the components during welding at a subharmonic frequency. The proper frequency is selected to be below a harmonic frequency, and to produce an amplitude in the range of ¼ to ½ the amplitude produced by a harmonic frequency. The component to be repaired is vibrated during and after welding at this frequency.

Owner:SIEMENS ENERGY INC

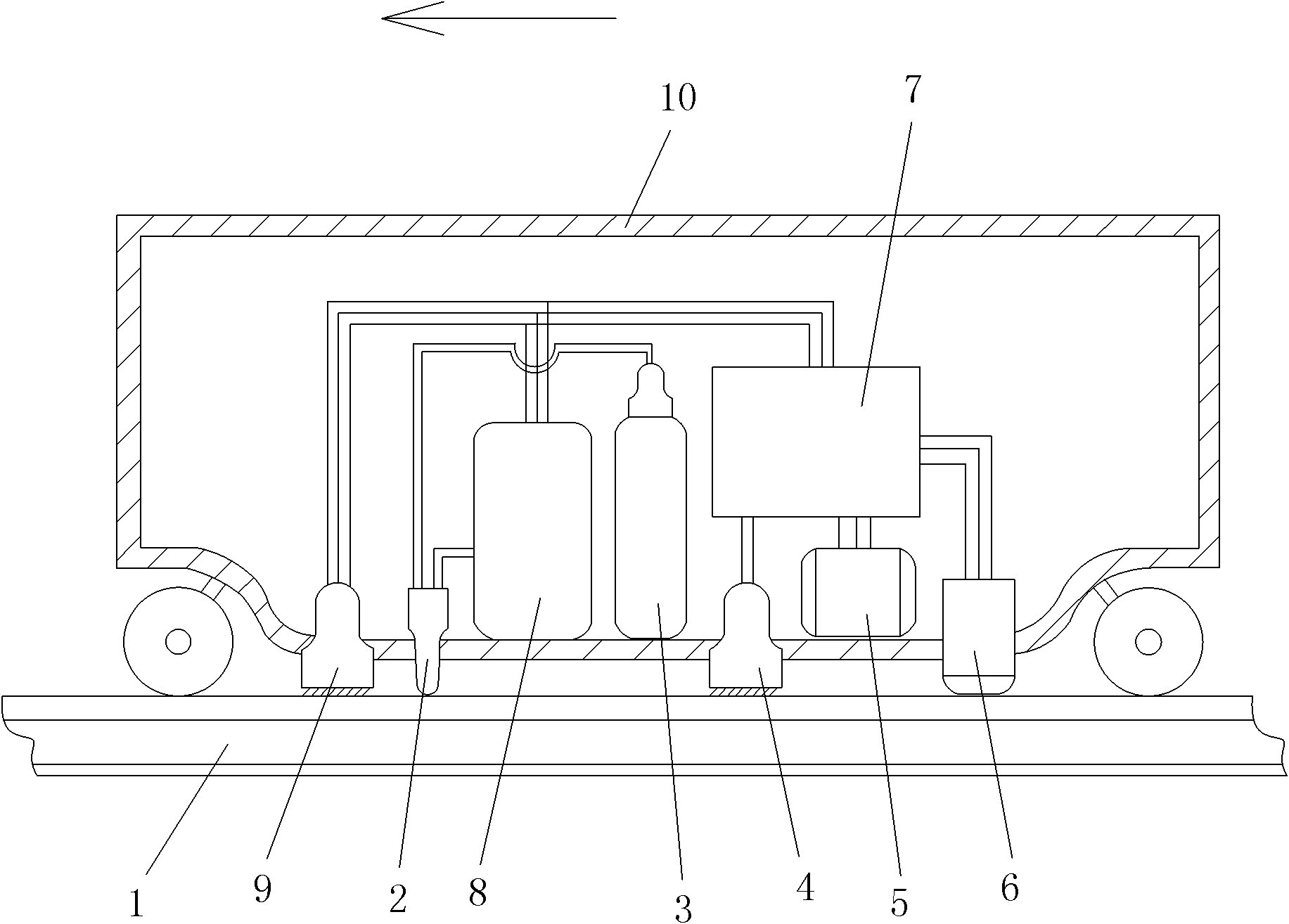

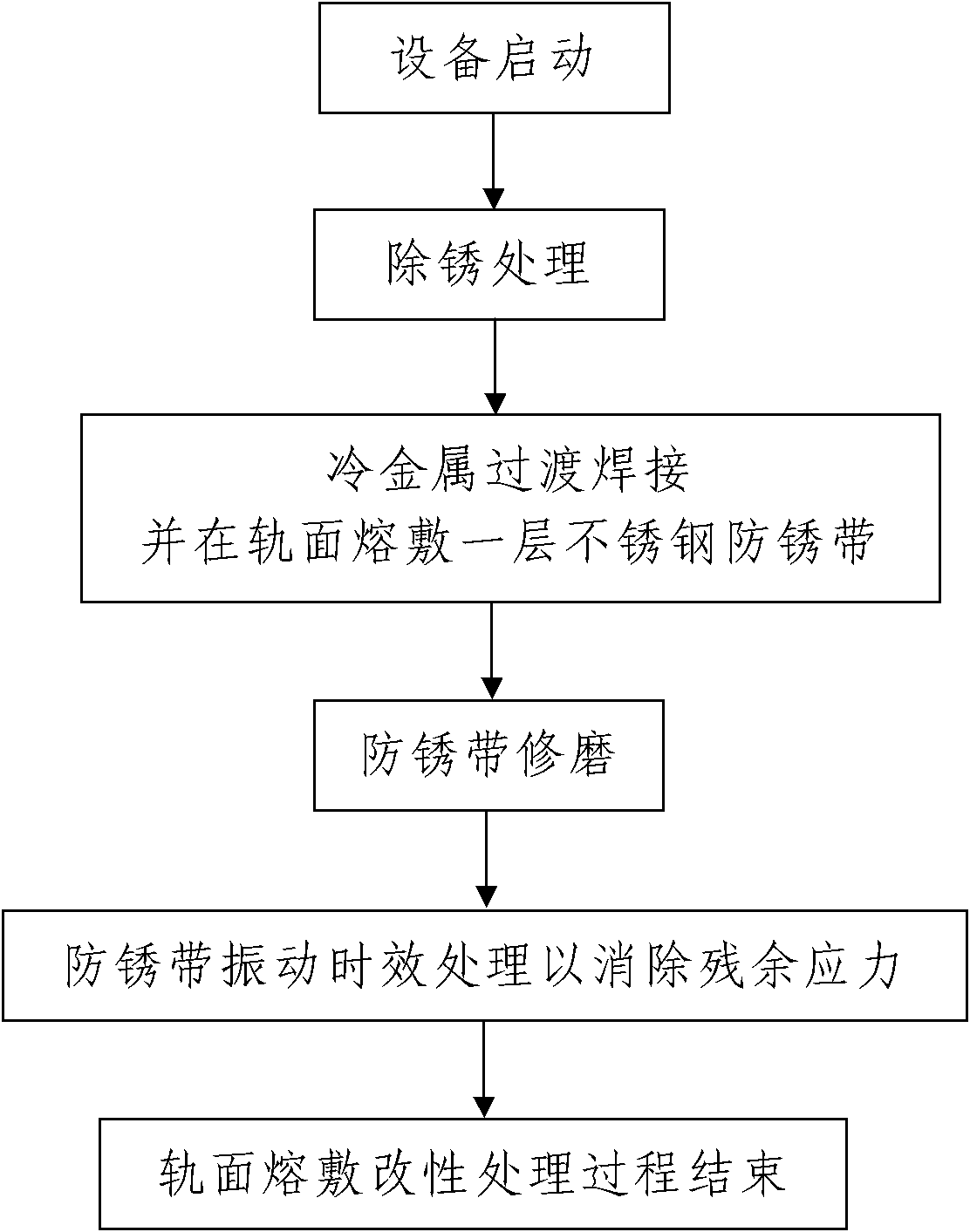

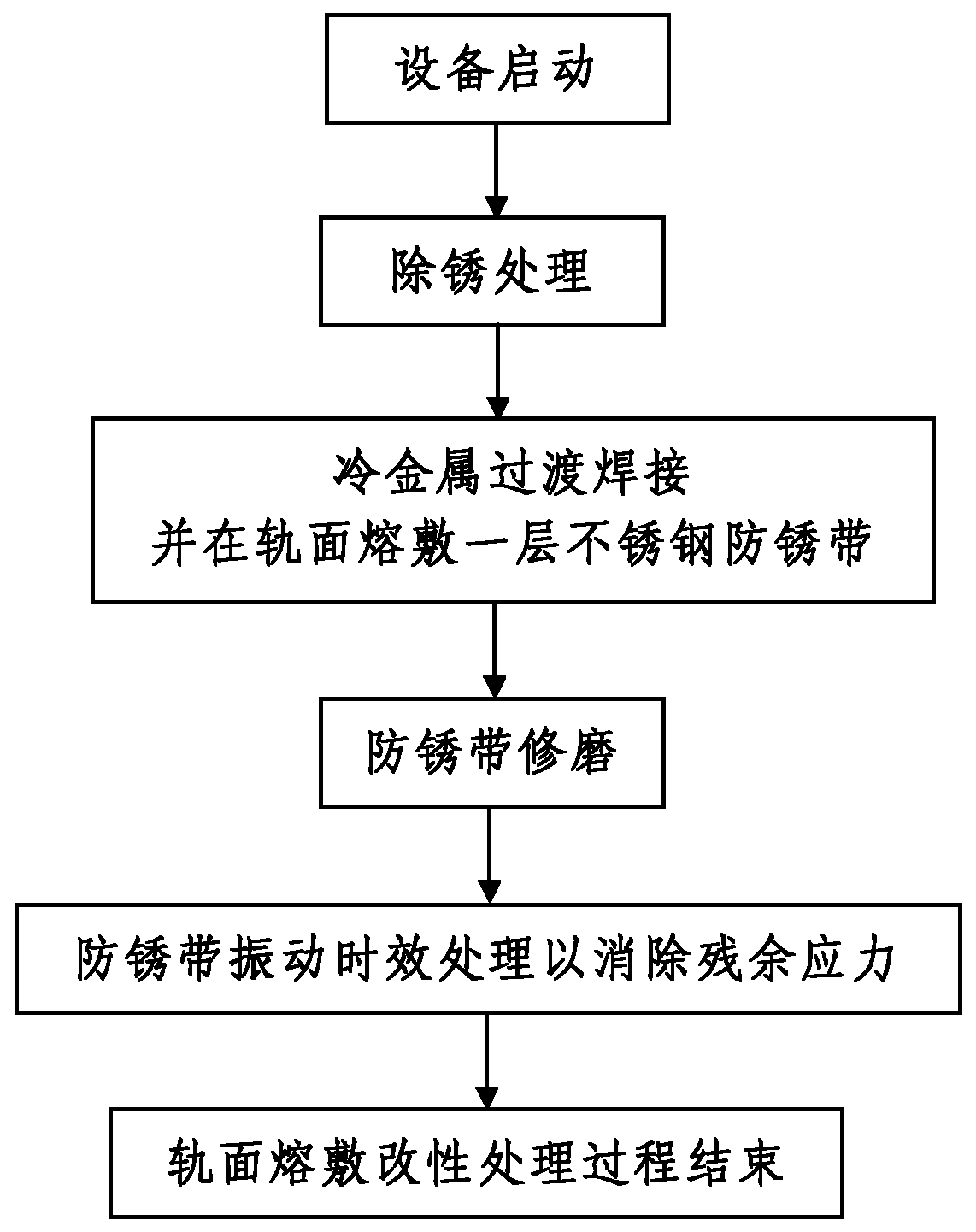

Steel rail surface modification antirust welding device and rail surface fusing modification method

ActiveCN102133677ASimple structureEasy installation and layoutArc welding apparatusEngineeringVibratory stress relief

The invention discloses a steel rail surface modification antirust welding device and a rail surface fusing modification method. The welding device comprises a railcar, an electric rust removal machine tool, a cold metal transition welding machine, an electric sharpening machine, a vibratory stress relief device and a power supply system, wherein the cold metal transition welding machine is arranged in the railcar, and a welding gun of the cold metal transition welding machine extends out from the bottom of the railcar; and the welding gun, a rust removal mechanism of the electric rust removal machine tool, a grinding head of the electric sharpening machine and a vibratory mechanism of the vibratory stress relief device are all arranged right above a treated steel rail. The rail surface fusing modification method comprises the following steps of: 1, equipment start; and 2, rail surface fusing modification treatment: rust removal treatment, cold metal transition welding, fusion of a layer of stainless steel antirust belt on the rail surface, antirust belt grinding and antirust belt vibratory stress relief treatment for eliminating residual stress. The design is reasonable, the operation is simple and convenient, the effect is high, the antirust modification effect is good, and the problem of poor railway track circuit shunt caused by oxidative corrosion on the surface of the steel rail can be solved.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

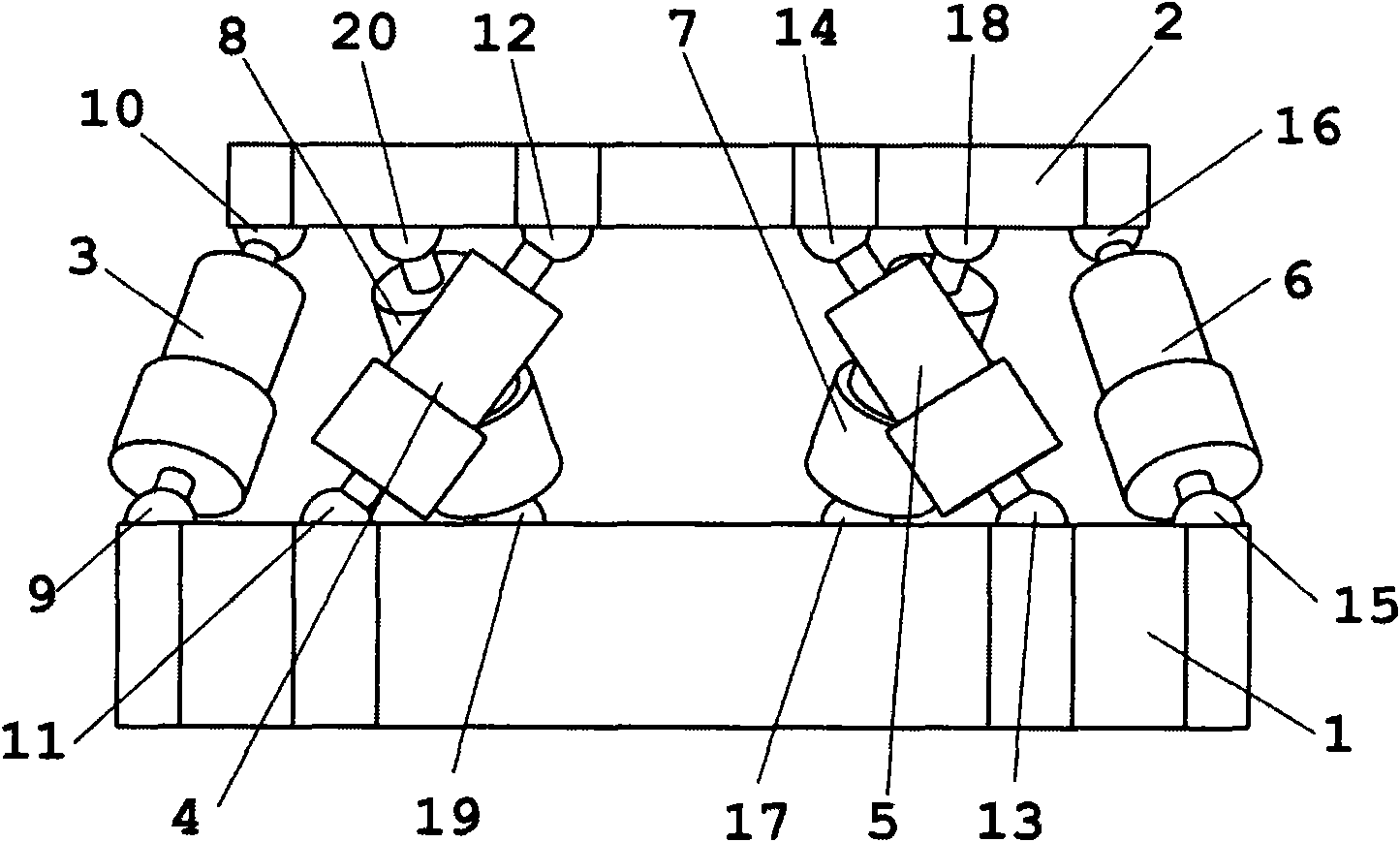

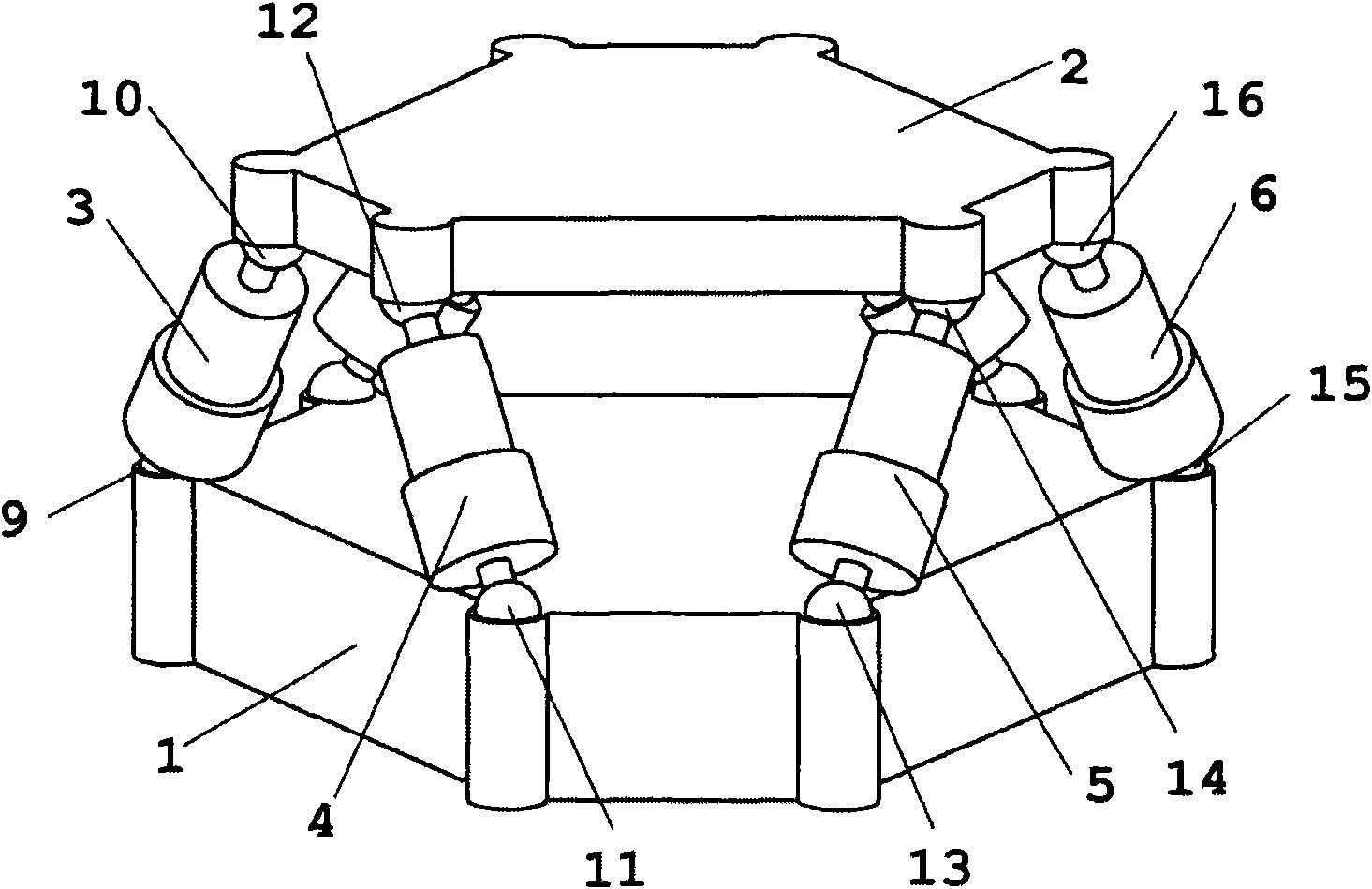

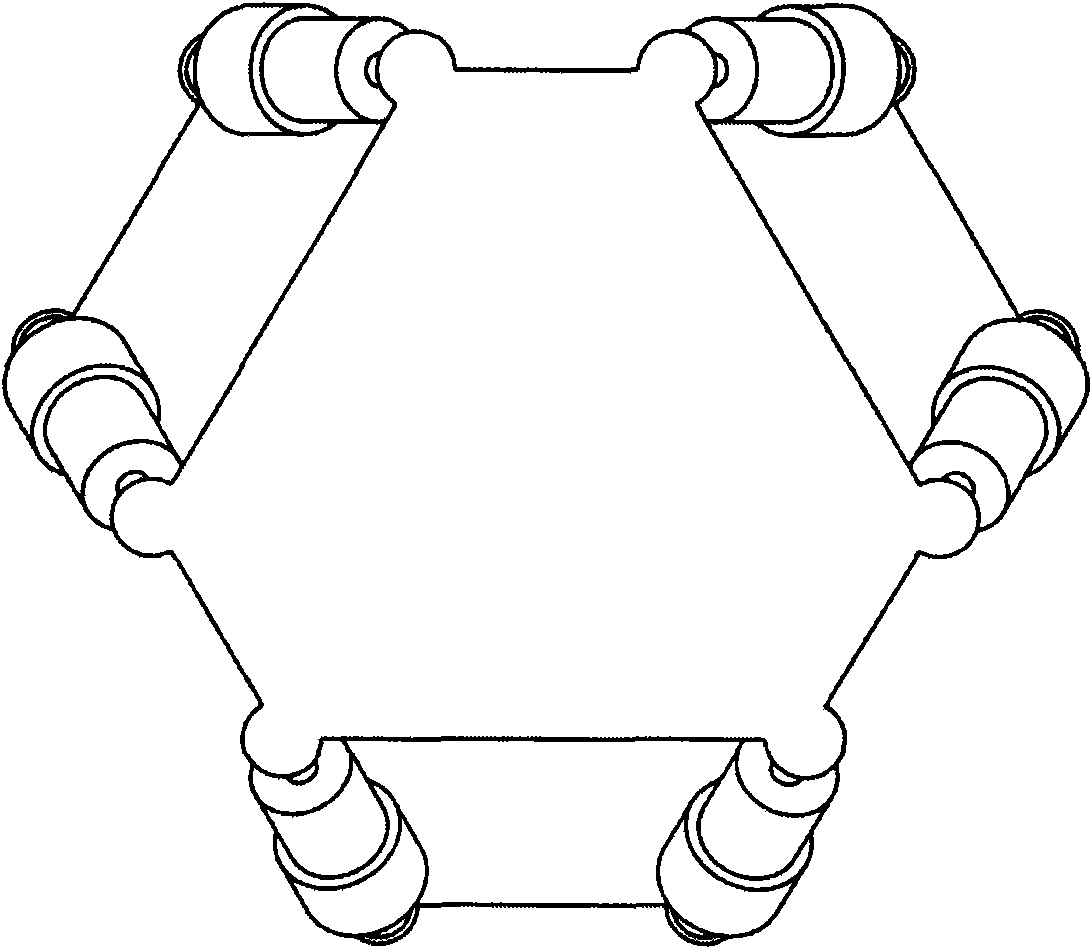

Six-degree-of-freedom vibratory stress relief device

InactiveCN102071309AReduce residual stressEnough stress strainMechanical vibrations separationDegrees of freedomMultiple resonance

The invention relates to a six-degree-of-freedom vibratory stress relief device. The device comprises six exciting branch chains, a movable platform and a stand, wherein the upper ends of the six exciting branch chains are connected with the movable platform through a second spherical pair, a fourth spherical pair, a sixth spherical pair, an eighth spherical pair, a tenth spherical pair and a twelfth spherical pair respectively, and the lower ends of the six exciting branch chains are connected with the stand through a first spherical pair, a third spherical pair, a fifth spherical pair, a seventh spherical pair, a ninth spherical pair and an eleventh spherical pair respectively; and the movable platform is used for mounting various workpieces for vibratory stress relief treatment. Through joint excitation of six exciters, the movable platform can produce spatial six-degree-of-freedom vibration, so that the workpieces can be excited to produce resonance of various frequencies and vibration modes, which comprises non-linear vibration such as combined resonance, subharmonic resonance, multiple resonance and the like; thus sufficient stress strain can be produced at each position inside the workpieces to effectively eliminate residual stress of the workpieces and obviously improve the vibratory stress relief effect.

Owner:GUANGXI UNIV

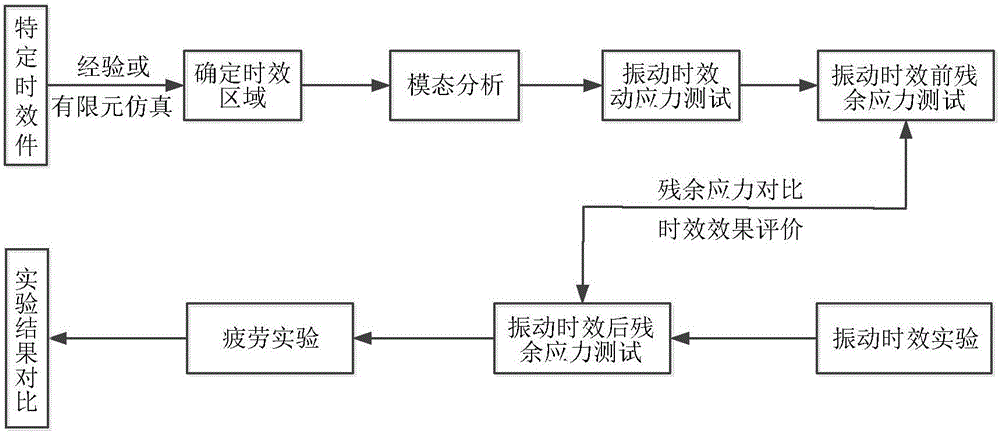

Method for controlling fatigue life of stress relief piece through positioning vibratory stress relief

InactiveCN106197915AAvoid blindnessImprove targetingMachine part testingVibration testingStress reliefEngineering

The invention relates to a method for controlling the fatigue life of a stress relief piece through positioning vibratory stress relief. The method includes the following steps that: the stress relief region of the stress relief piece is determined; (2) modal analysis is carried out on the stress relief piece, a vibration mode is selected optimally, so that the stress relief region can be consistent with a fatigue region; (3) a card mounting mode and an excitation frequency are determined according to the selected vibration mode; (4) the magnitude of an excitation force is changed, dynamic stress testing is performed on the stress relief region; (5) pre-vibration residual stress testing is performed on the stress relief region; (6) different excitation forces are selected to carry out vibratory stress relief according to the step (4); (7) post-vibration residual stress testing is performed on the stress relief region, and testing results are compared with testing results obtained in the step (5); and (8) a fatigue test is carried out, so that the fatigue life of the stress relief piece after the vibratory stress relief of different excitation forces under a fixed vibration mode and a fixed excitation frequency. According to the method of the invention, the dynamic stress of the vibration vibratory stress relief is tested, and therefore, the blindness of the vibratory stress relief can be avoided. The method is high in universality and high in research result reliability.

Owner:BEIHANG UNIV

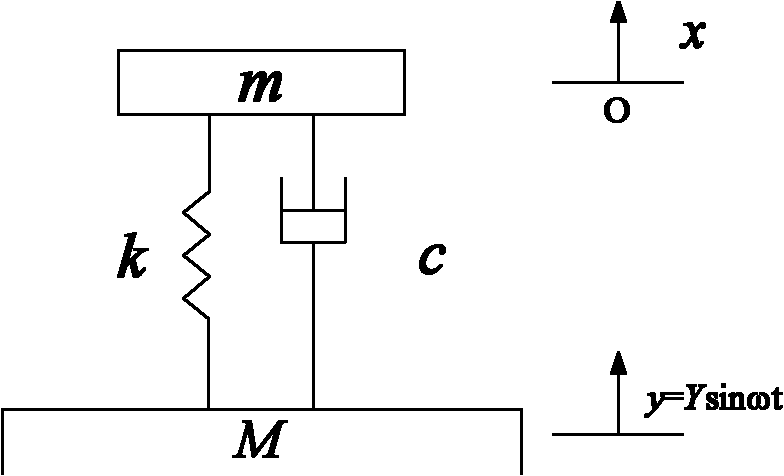

Ultraharmonic-resonance vibratory stress relief device for high-natural-frequency workpiece

InactiveCN102181625AThe excitation frequency is adjustableThe vibration frequency of the excitation frequency is adjustableResonanceVibration exciter

The invention relates to an ultraharmonic-resonance vibratory stress relief device for a high-natural-frequency workpiece, which comprises a vibration exciter, a vibration excitation block, an adjustable damping and an adjustable nonlinear spring, wherein the vibration exciter is connected with the vibration excitation block, and the adjustable damping, adjustable nonlinear spring and vibration excitation block constitute a nonlinear vibration system. The vibration exciter acts on the nonlinear vibration system, so that the nonlinear vibration system generates ultraharmonic resonance at a frequency which is far higher than the original exciting frequency of the vibration exciter; and the vibration excitation block acts on the workpiece at an ultraharmonic resonance frequency approximate to the natural frequency of the high-rigidity workpiece, so that the workpiece generates main resonance and corresponding dynamic stress to reduce the residual stress of the workpiece. The invention can solve the problem that the high-rigidity workpiece can not be subjected to vibratory stress relief treatment.

Owner:GUANGXI UNIV

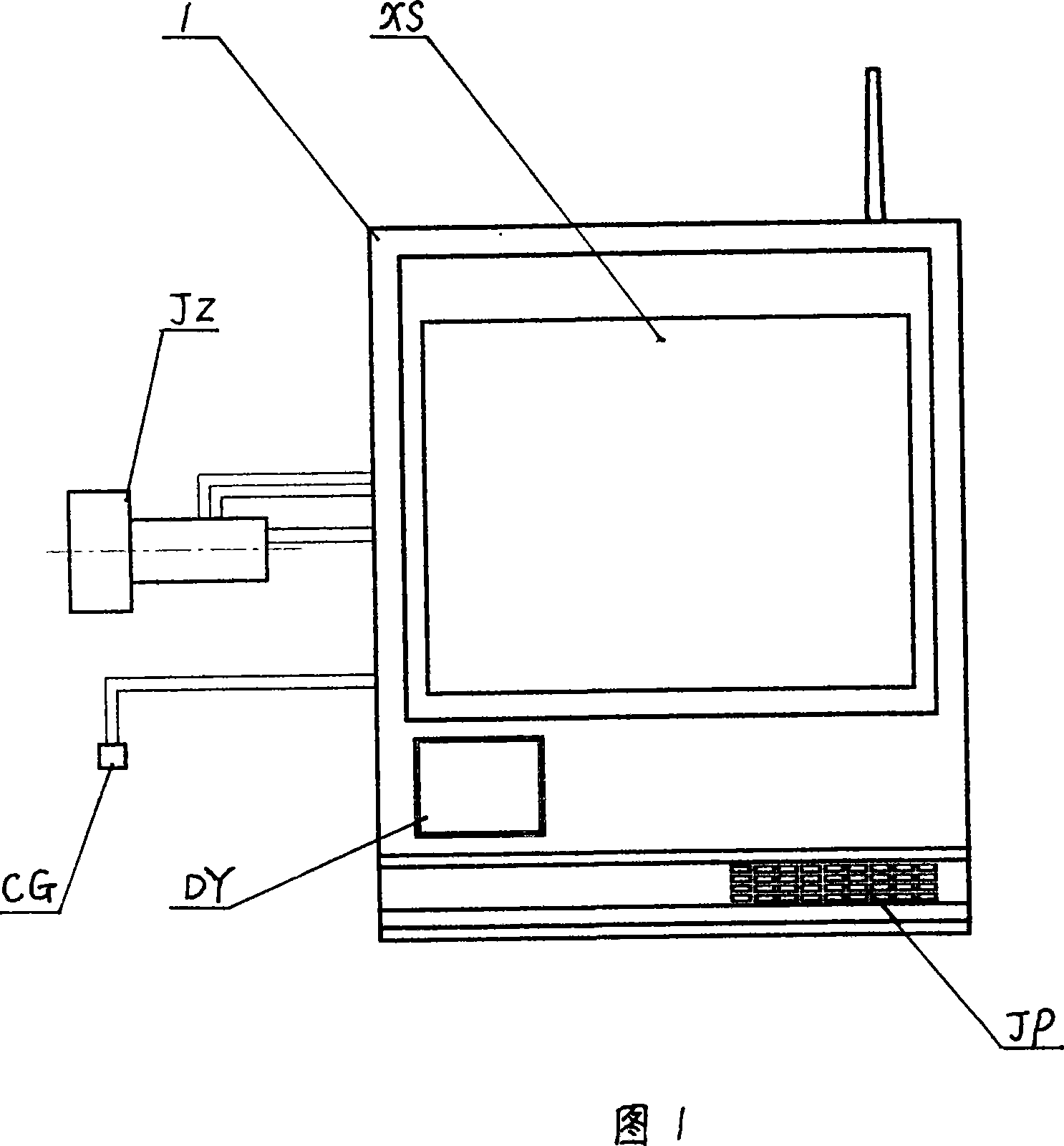

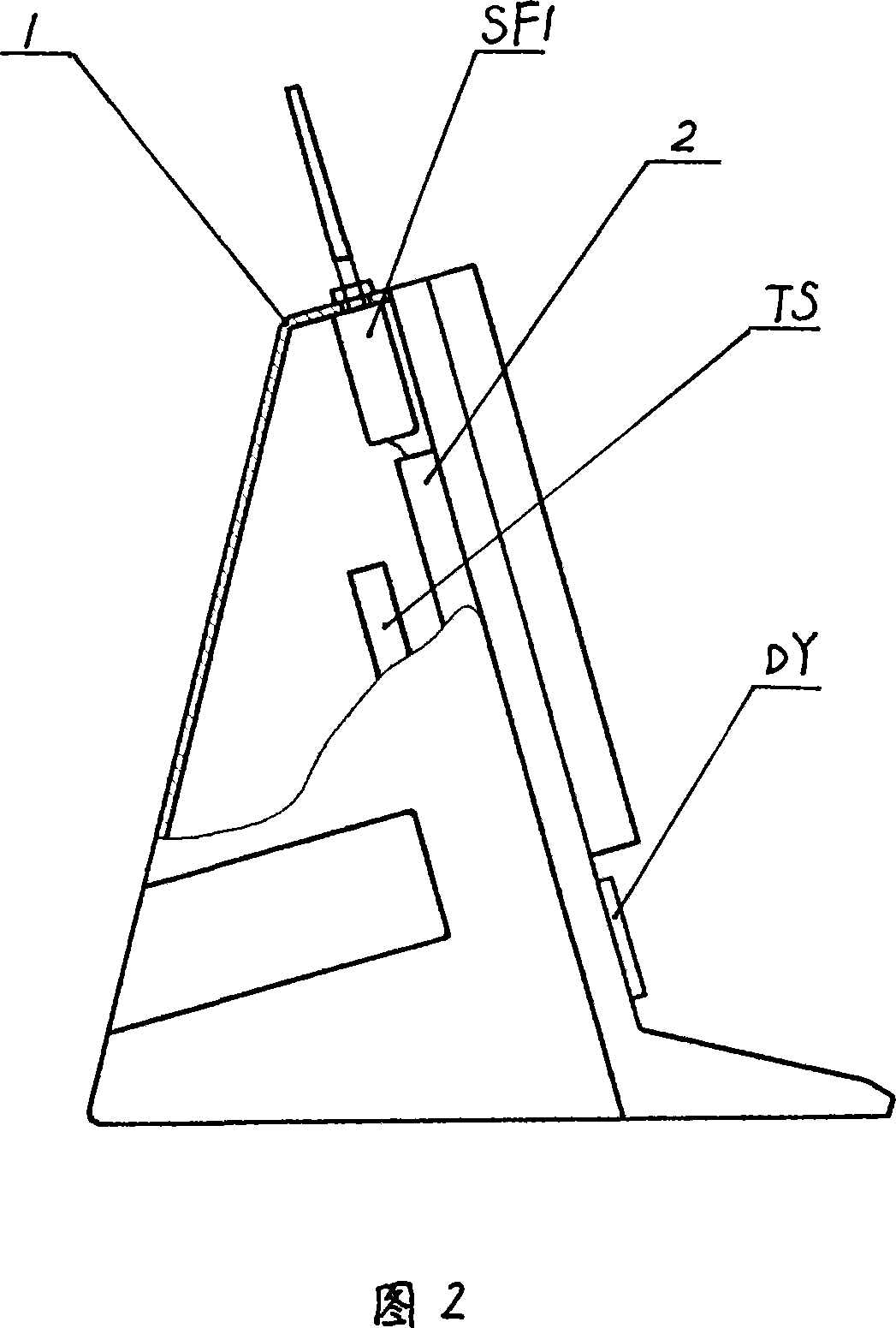

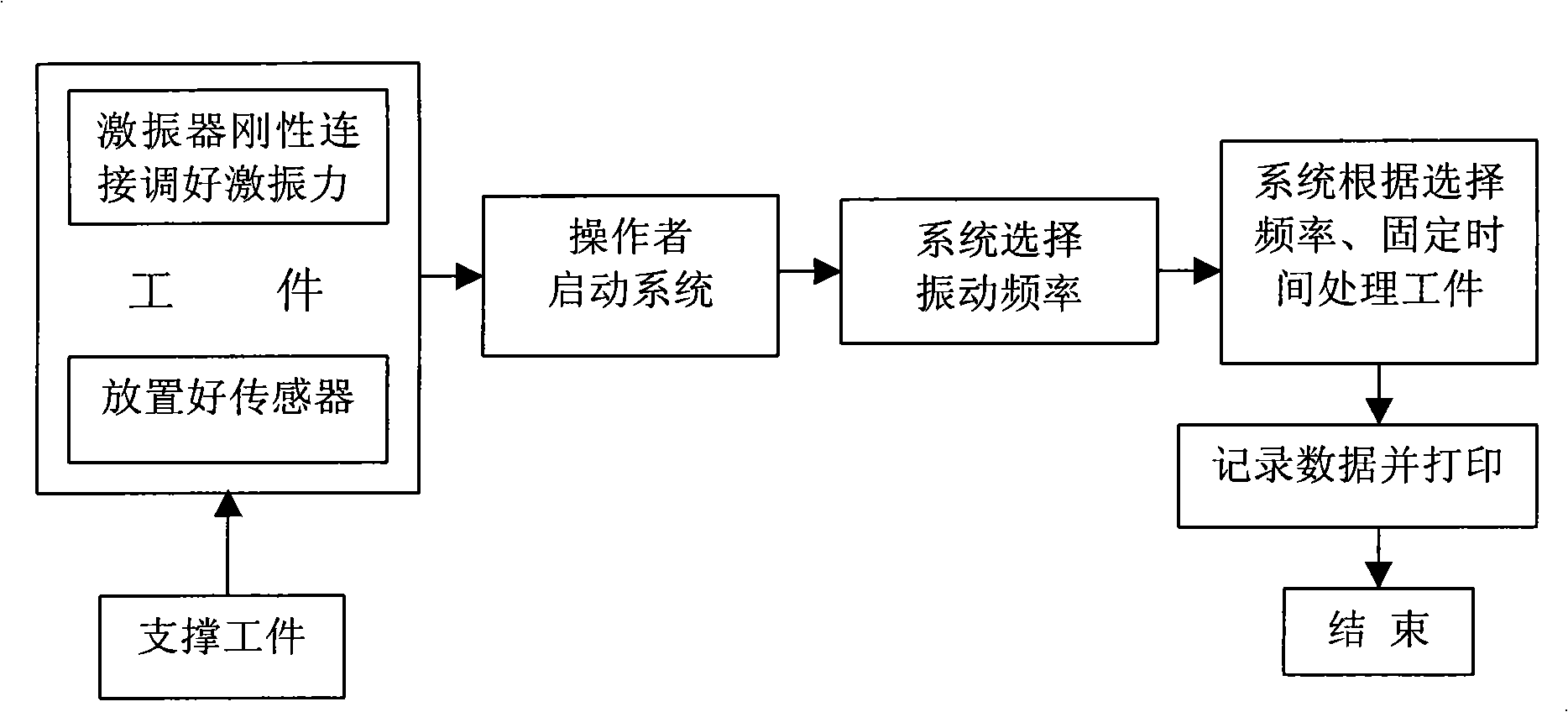

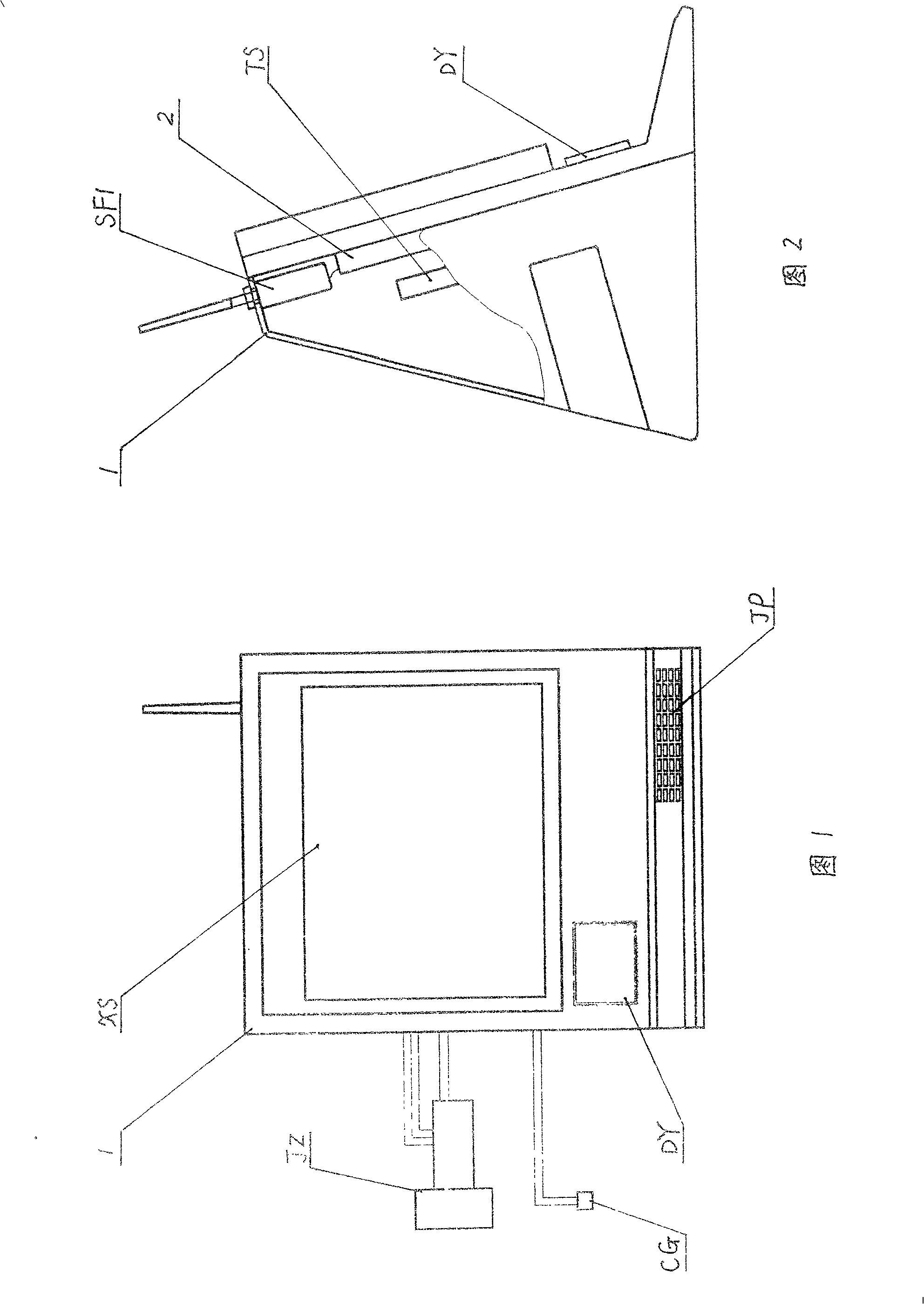

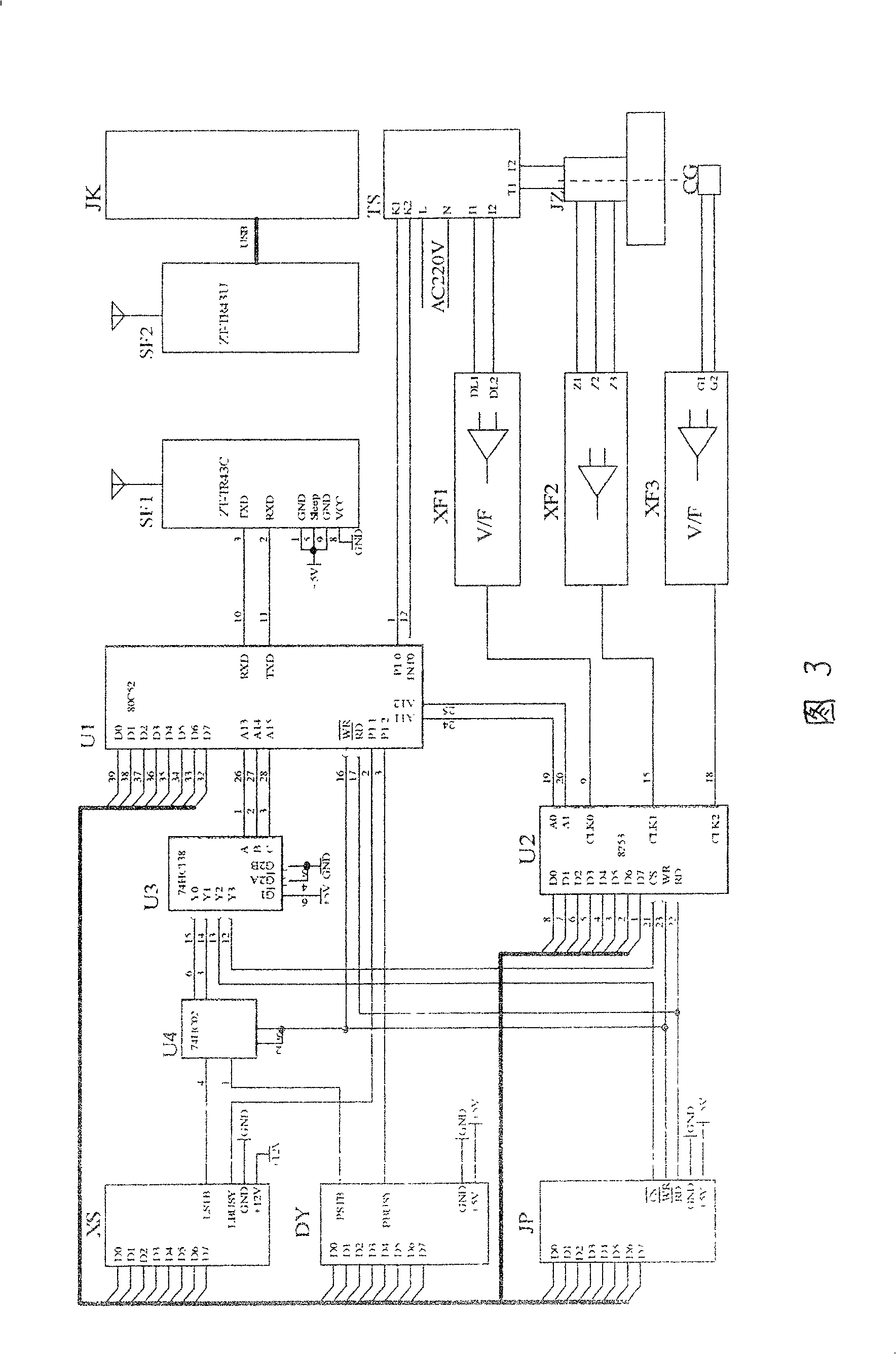

Method and device capable of remotely real-time monitoring vibratory stress relief process

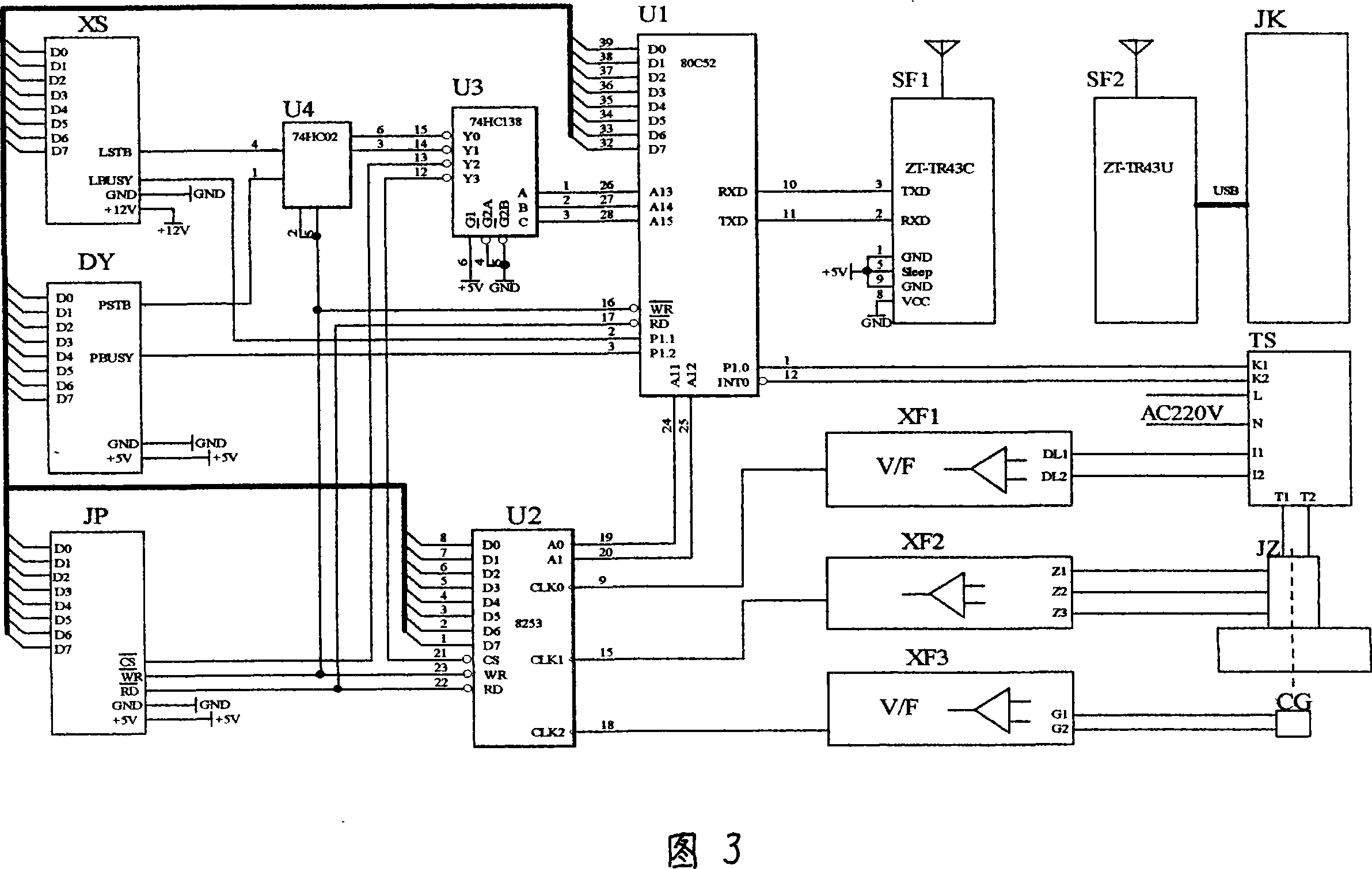

InactiveCN101078924AQuality assuranceGuaranteed uptimeComputer controlSimulator controlEngineeringVibratory stress relief

The invention discloses a method to remote real time monitoring vibration time-effect craft course and device, which is characterized by the following: comprising vibration time-effect device; assembling digital wireless emitting receiver on the vibration time-effect device; corresponding with the vibration time-effect device as remote monitoring device; assembling the digital wireless receiving emitting device on the remote monitoring device; corresponding with the digital wireless emitting receiver; treating host machine controlled parameter, work piece under test dynamics parameter and operating course parameter with the vibration time-effect device; launching to the remote monitoring device; treating the signal; displaying; recording; controlling the work of the host machine controlled parameter through the remote monitoring device. This invention can resolve the problems of the existing technique.

Owner:济南西格马科技有限公司

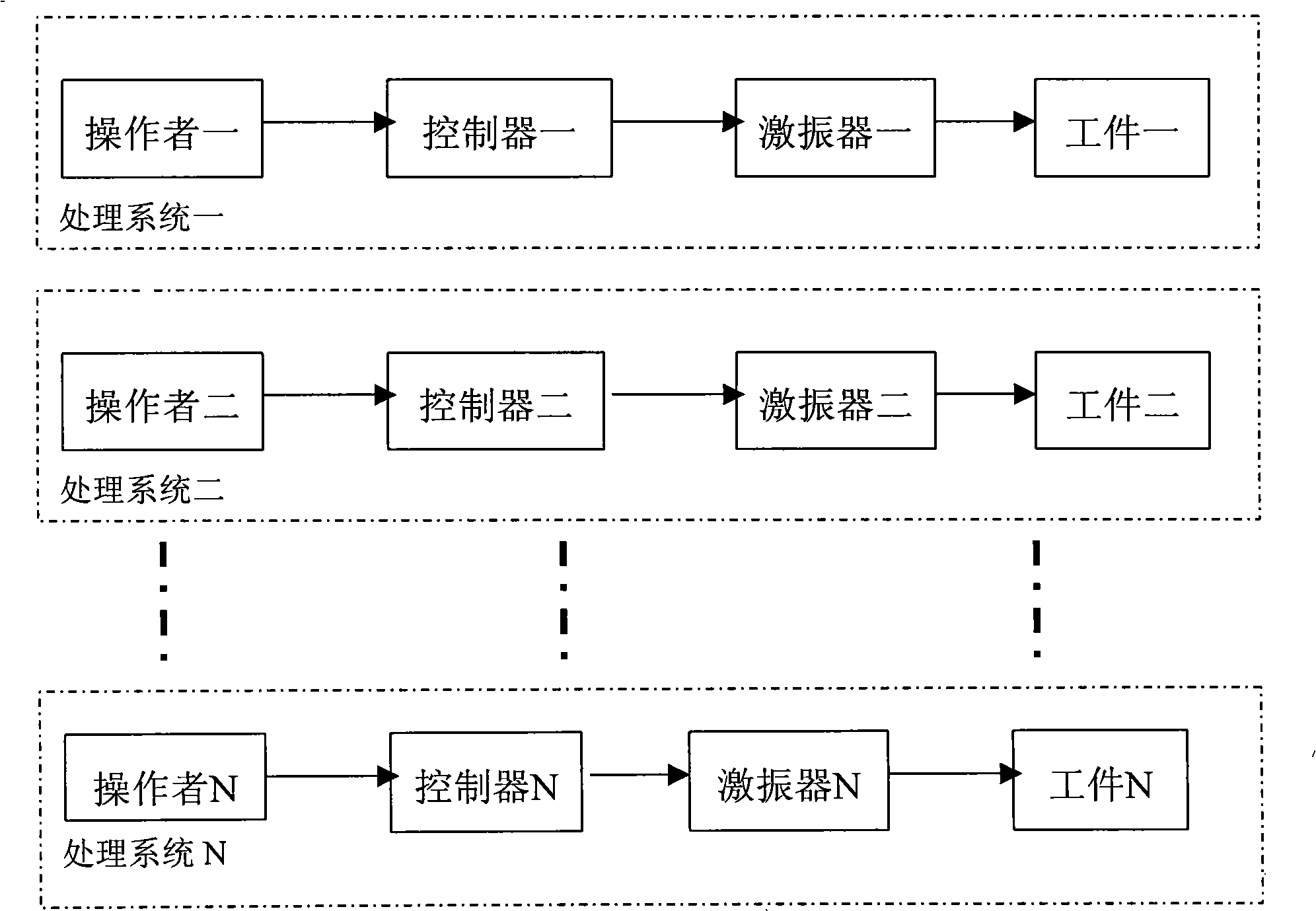

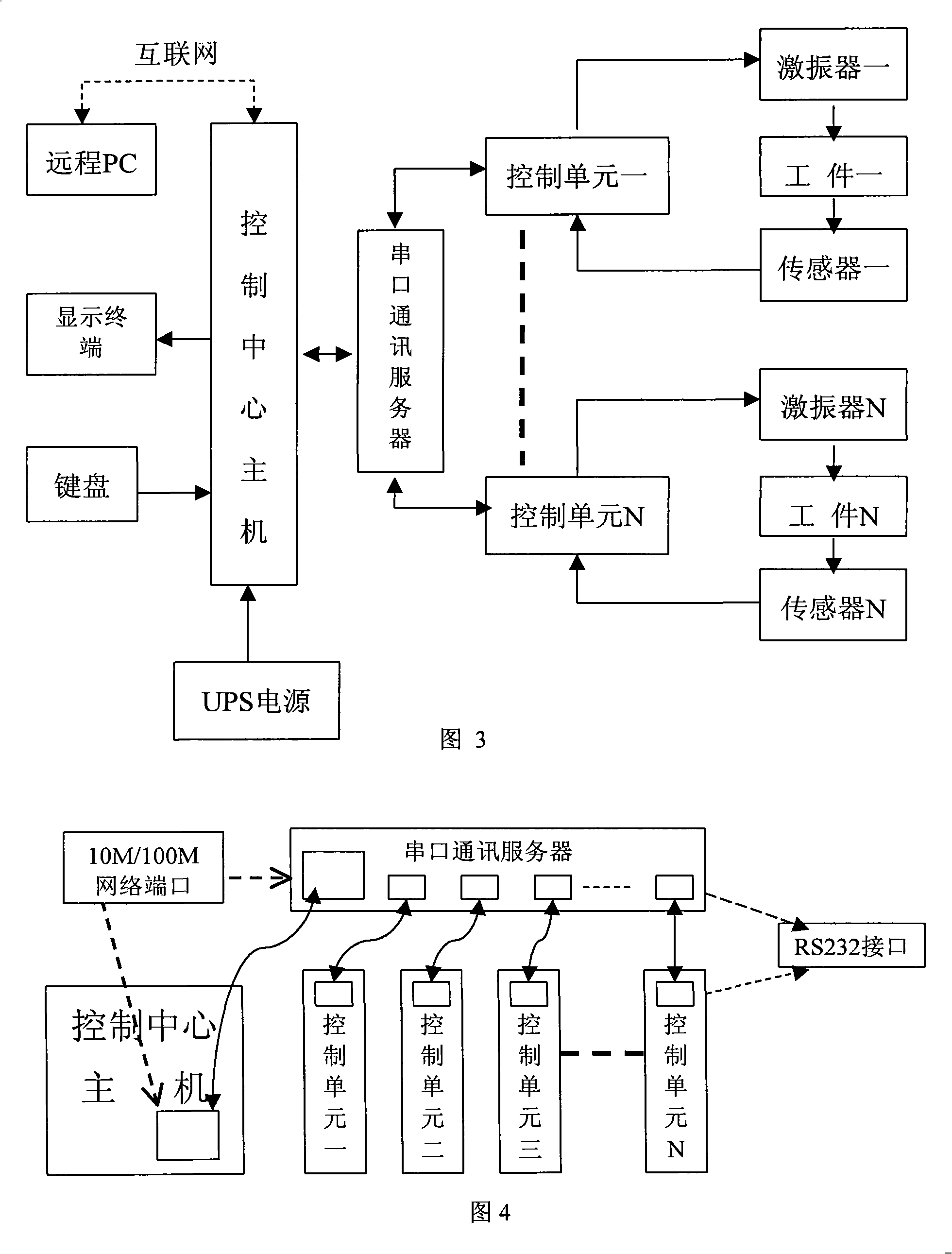

Vibratory stress relief multitask control system

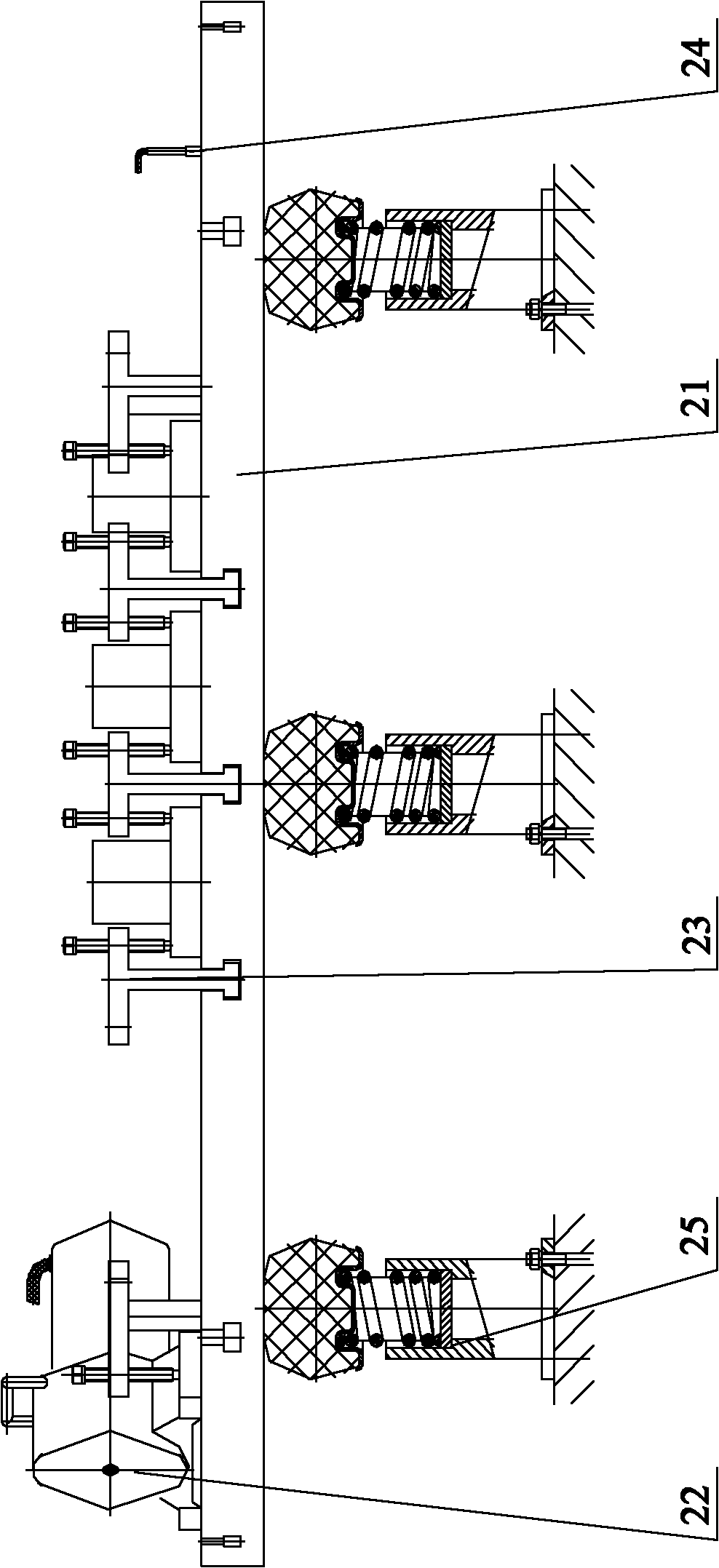

The invention relates to a multitask control system for removing stress by vibration. The multitask control system comprises vibration generators, sensors, control units, a control centre mainframe and a serial port communication server. The vibration generators, the sensors and the control units have a plurality of sets; each set of the sensors is respectively connected with the set of the control units; each set of the control units is respectively connected with the set of the vibration generators; and each set of the control units is respectively connected with the control centre mainframe by the serial port communication server. The control centre mainframe stores a sequence of a programe which simultaneously controls N vibration generators to carry out process treatment and monitoring, wherein, N is more than or equal to 2; the control units can simultaneously and separately work; under the condition that a workpiece handling capacity is unchanged, the multitask control system greatly reduces equipment and operators and improves production efficiencies and economical benefits, thereby reducing cost. The control centre mainframe is connected with a remote PC computer by Internet; a manager can monitor the filed workpiece handling state and data in a long distance, contribute to the remote customer training and guiding by a manufacturer and system upgrading and maintenance and improve service efficiency.

Owner:BEIJING SEMBOO SCI & TECH CO LTD

Method and device capable of remotely real-time monitoring vibratory stress relief process

InactiveCN100478817CQuality assuranceGuaranteed uptimeComputer controlSimulator controlEngineeringVibratory stress relief

The invention discloses a method to remote real time monitoring vibration time-effect craft course and device, which is characterized by the following: comprising vibration time-effect device; assembling digital wireless emitting receiver on the vibration time-effect device; corresponding with the vibration time-effect device as remote monitoring device; assembling the digital wireless receiving emitting device on the remote monitoring device; corresponding with the digital wireless emitting receiver; treating host machine controlled parameter, work piece under test dynamics parameter and operating course parameter with the vibration time-effect device; launching to the remote monitoring device; treating the signal; displaying; recording; controlling the work of the host machine controlled parameter through the remote monitoring device. This invention can resolve the problems of the existing technique.

Owner:济南西格马科技有限公司

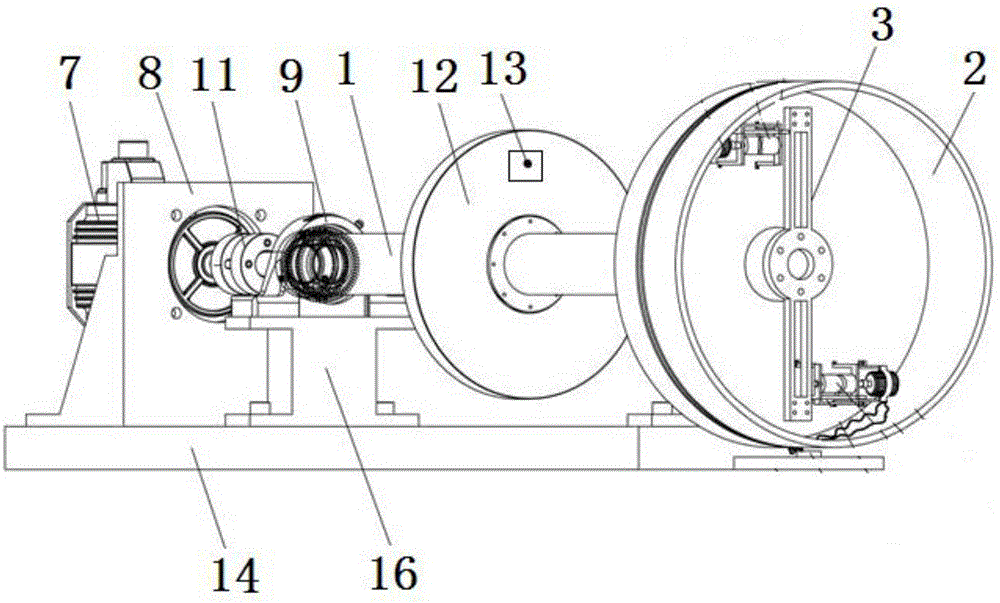

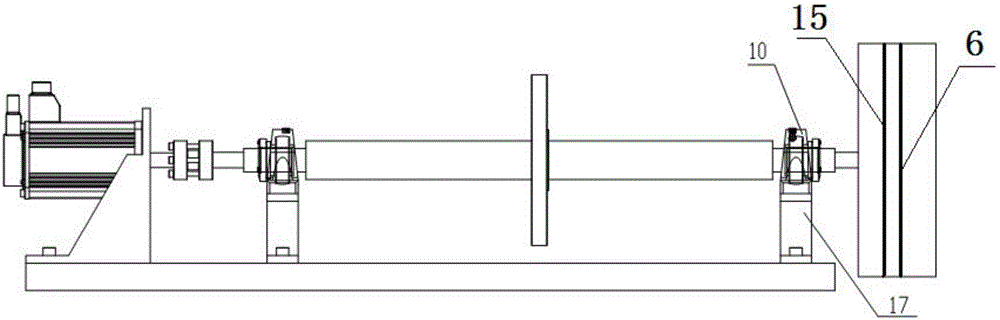

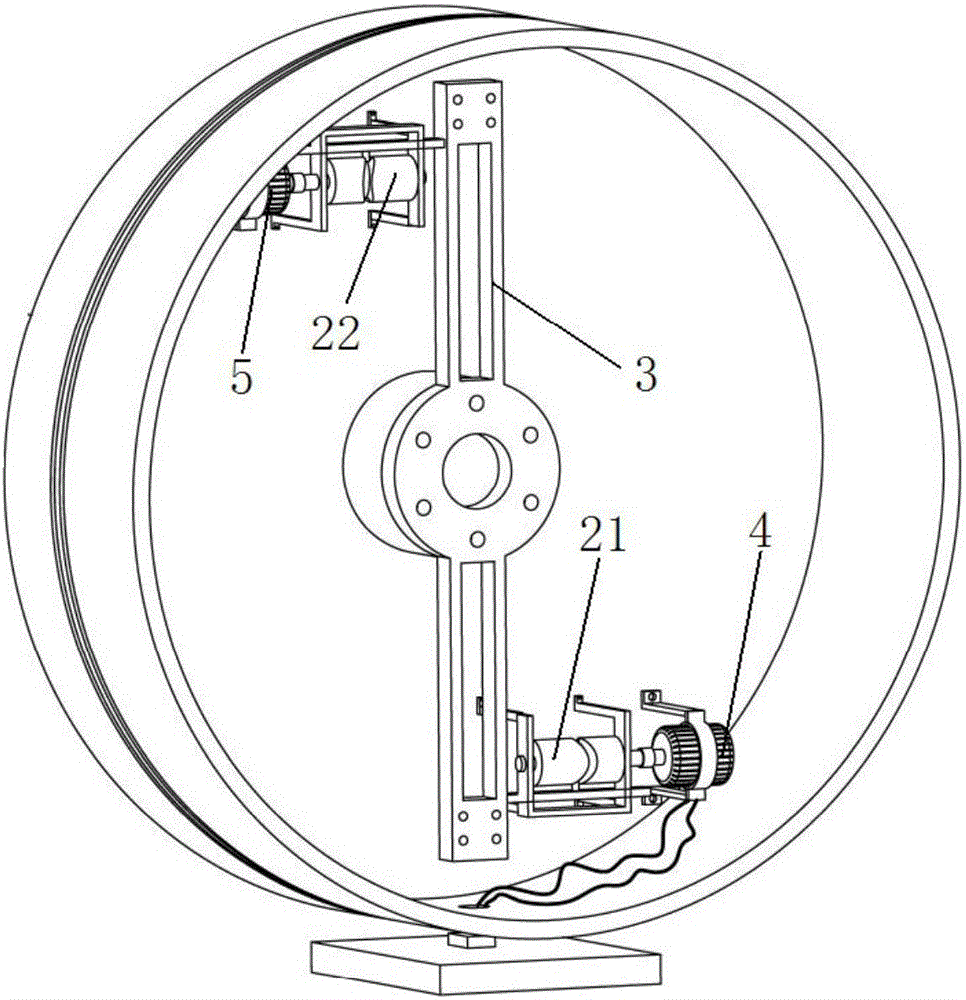

Cylindrical cam excitation driven bending-torsional coupling resonance type residual stress relieving device

ActiveCN106702136AHigh transmission precisionReduce shockProcess efficiency improvementCouplingEngineering

The invention discloses a cylindrical cam excitation driven bending-torsional coupling resonance type residual stress relieving device, and relates to a cylindrical cam transmission type alternated force moment bending-torsional coupling resonance type vibratory stress relief method. Torsional vibration output by a cylindrical cam transmission type alternated force moment torsional vibration exciter is applied to a high-rigidity rotary shaft, when the rotating frequency of the rotary shaft is equal to the difference of the natural bending frequency and the natural torsion frequency, based on the bending-torsional coupling resonance theory, namely, torsional vibration excitation with the frequency equal to the natural torsion frequency can excite bending resonance, meanwhile, the bending resonance and the torsional resonance are mutually strengthened, and enough dynamic stress is generated to eliminate the residual stress of the high-rigidity rotary shaft. According to the residual stress relieving device, the problem that bending-torsional coupling resonance vibratory stress relief is limited by a torsional vibration excitation source is solved, the residual stress of the high-rigidity rotary shaft is eliminated through cylindrical cam transmission type alternated force moment bending-torsional coupling resonance, the efficiency is improve, and the safety and reliability of production are improved.

Owner:GUANGXI UNIV

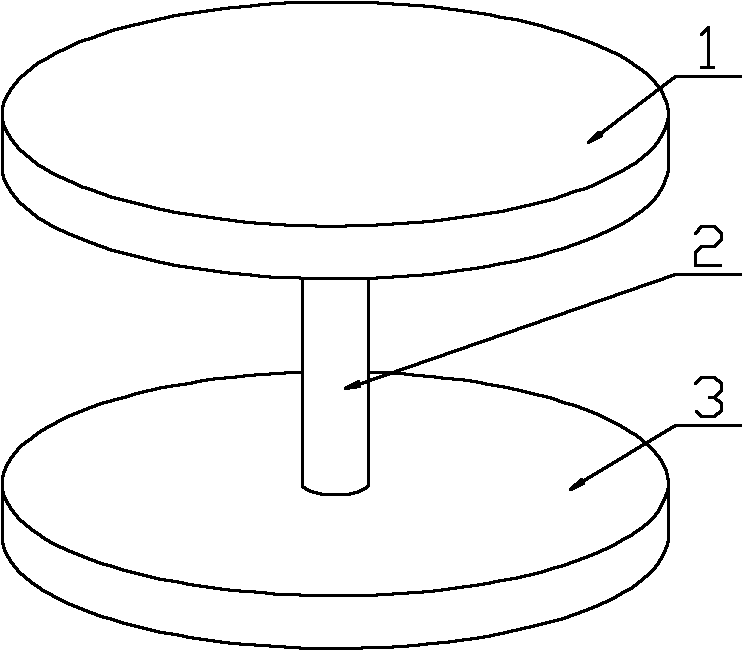

Vibratory stress relief vibration level amplifying device

InactiveCN102304616AThe effect of eliminating residual stressSimple structureMechanical vibrations separationResonanceVibratory stress relief

The invention relates to a vibratory stress relief vibration level amplifying device which consists of an upper supporting table, a lower base plate fixed and a connecting rod, wherein the upper supporting table is used for installing a workpiece; the lower base plate is fixed on an exciting vibration table top of a vibration table; the connecting rod is used for connecting the upper supporting table and the lower base plate; and the cross-sectional area of the connecting rod not only is smaller than that of the upper supporting table, but also is smaller than that of the lower base plate. The vibratory stress relief vibration level amplifying device has the beneficial effects that in the resonance, the vibration level of the exciting vibration table top of the vibration table can be remarkably amplified, the effects of improving the vibratory stress relief and eliminating the residual stress can be realized, the structure is simple and practical, and the operation is convenient.

Owner:ZHEJIANG UNIV

Method for relieving vibratory stress of loader front frame

The invention discloses a method for relieving vibratory stress of a loader front frame and relates to the technical field of stress relief of metal components, wherein a vibratory stress relief device for the loader front frame is used. The method comprises the operation steps of horizontally placing the platform top of the vibratory stress relief device for the loader front frame; placing a rubber pad between a platform and the ground, wherein the outer edge of the rubber pad is close to two side edges of the platform and the distance between the center of the rubber pad and a platform top end is 2 / 9*L mm; fixing the loader front frame on the platform top; and starting a vibration exciter for vibrating for 15-30min under the vibratory stress relief frequency. Compared with the prior art, the method has the advantages of fast and effectively eliminating the welding residual stress of the loader front frame and solving the problem of high noise in the existing vibratory stress relief treatment of the loader front frame.

Owner:NANNING SHENHUA VSR TECH RES INST

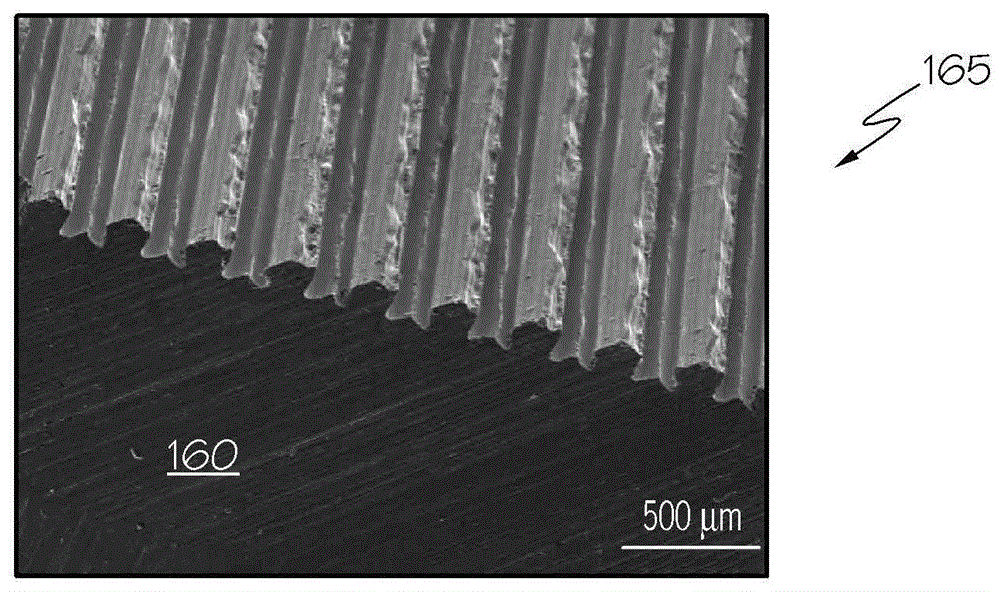

Stress relief of mechanically roughened cylinder bores for reduced cracking tendency

The invention discloses stress relief of mechanically roughened cylinder bores for reduced cracking tendency. A method of treating the surface of an aluminum-based engine block cylinder bore that has been mechanically roughened is disclosed. In one form, this method includes using vibratory stress relief, elevated temperature stress relief or cryogenic stress relief so that residual stresses imparted to the surface by the roughening process are reduced. In this way, a protective coating that is also applied to the bore surface will exhibit better adhesion and lower incidence of stress-induced or fatigue-induced cracking.

Owner:GM GLOBAL TECH OPERATIONS LLC

Vibration stress relief of weldments

ActiveUS7431193B2Reduce distortion problemsVibration measurement in solidsTurbinesCombustionHarmonic

A method of stress relief for stainless steel combustion turbine components includes vibrating the components during welding at a subharmonic frequency. The proper frequency is selected to be below a harmonic frequency, and to produce an amplitude in the range of ¼ to ½ the amplitude produced by a harmonic frequency. The component to be repaired is vibrated during and after welding at this frequency.

Owner:SIEMENS ENERGY INC

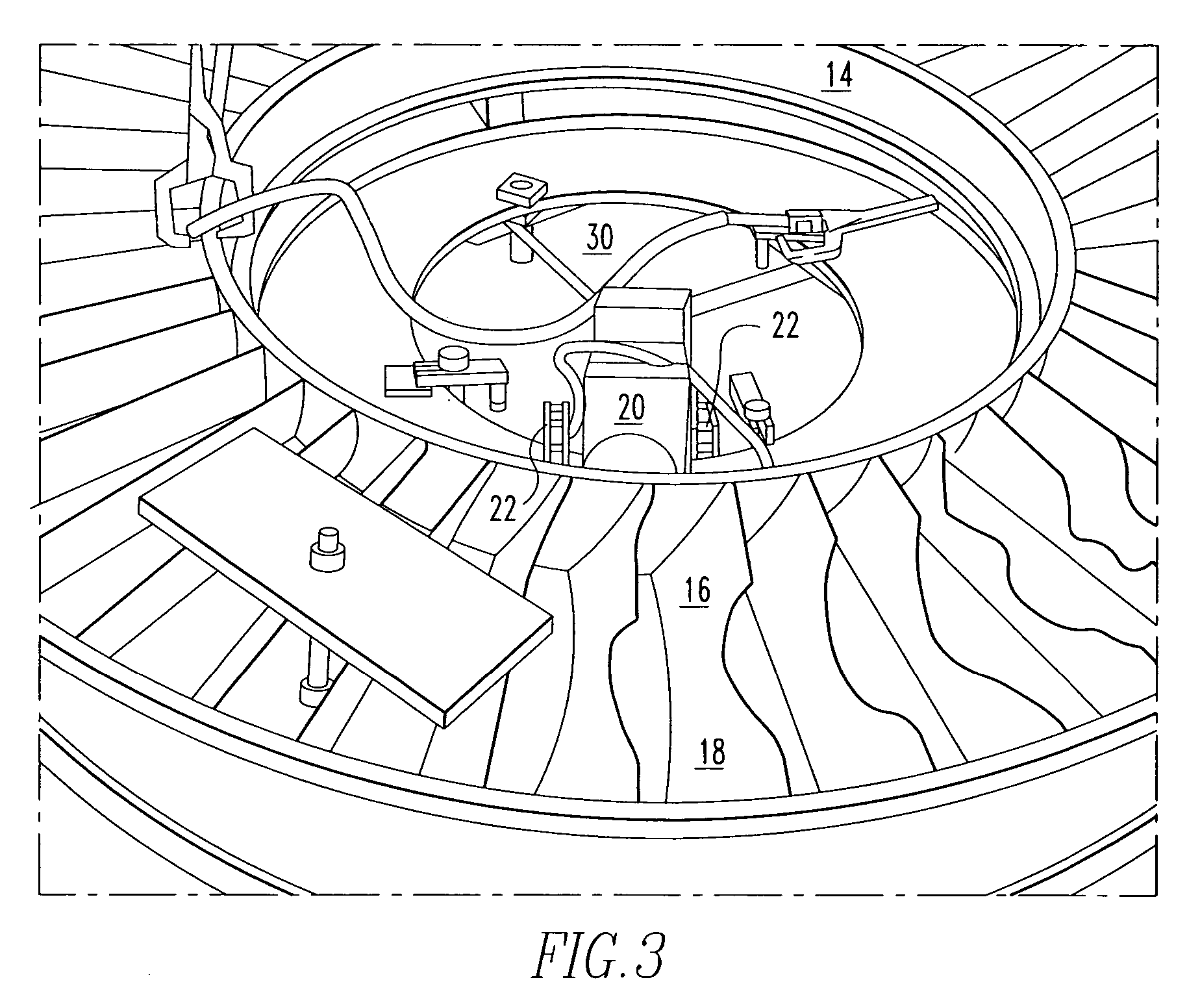

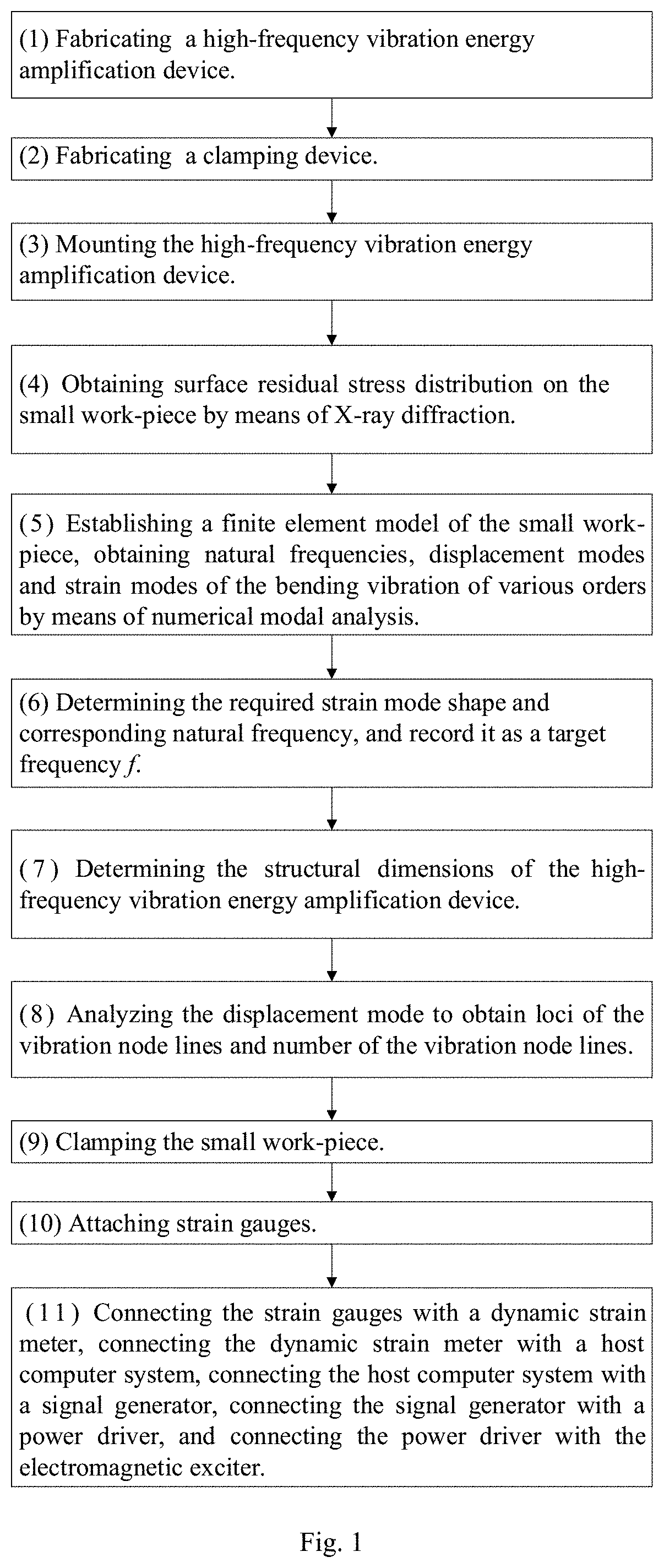

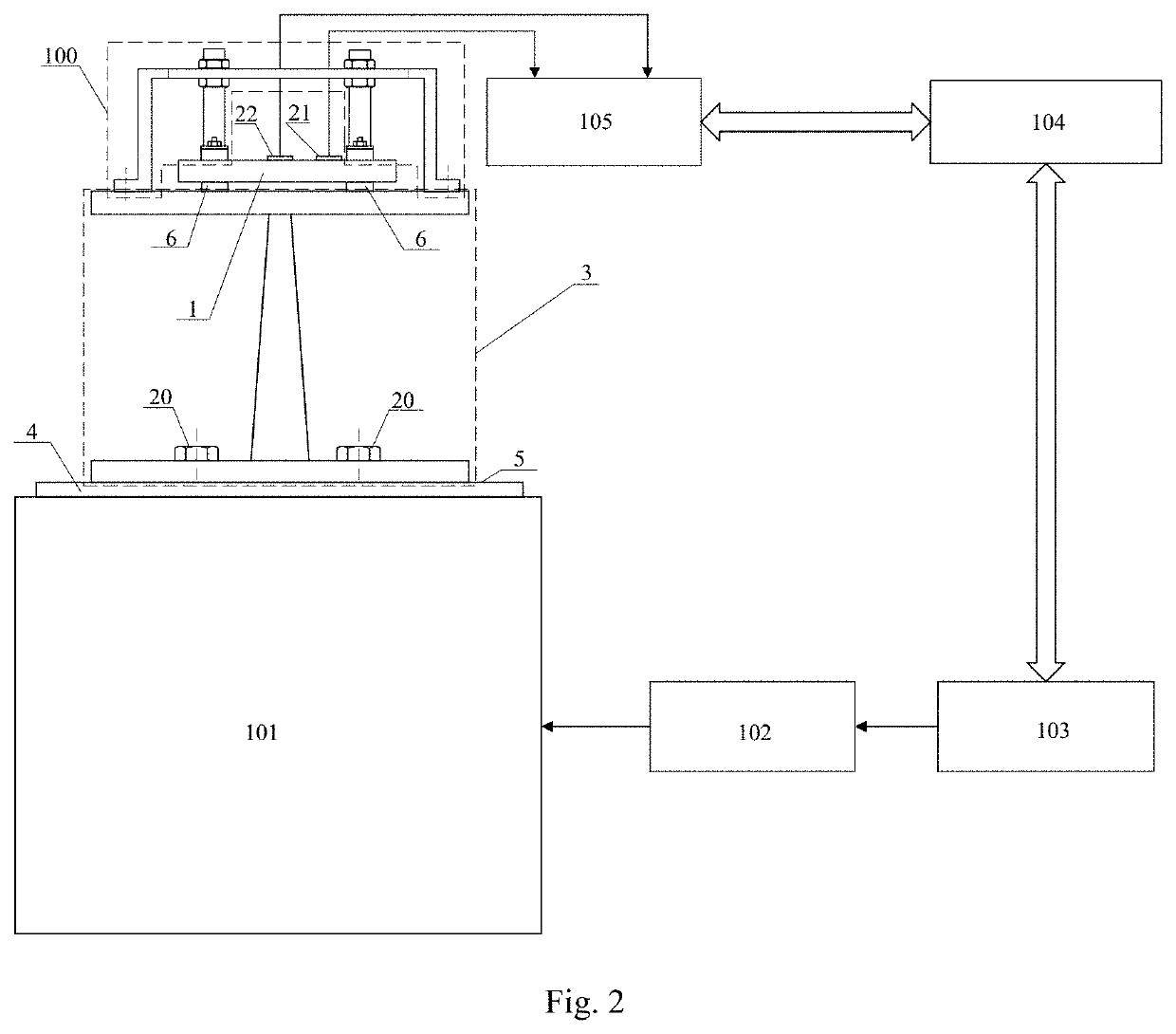

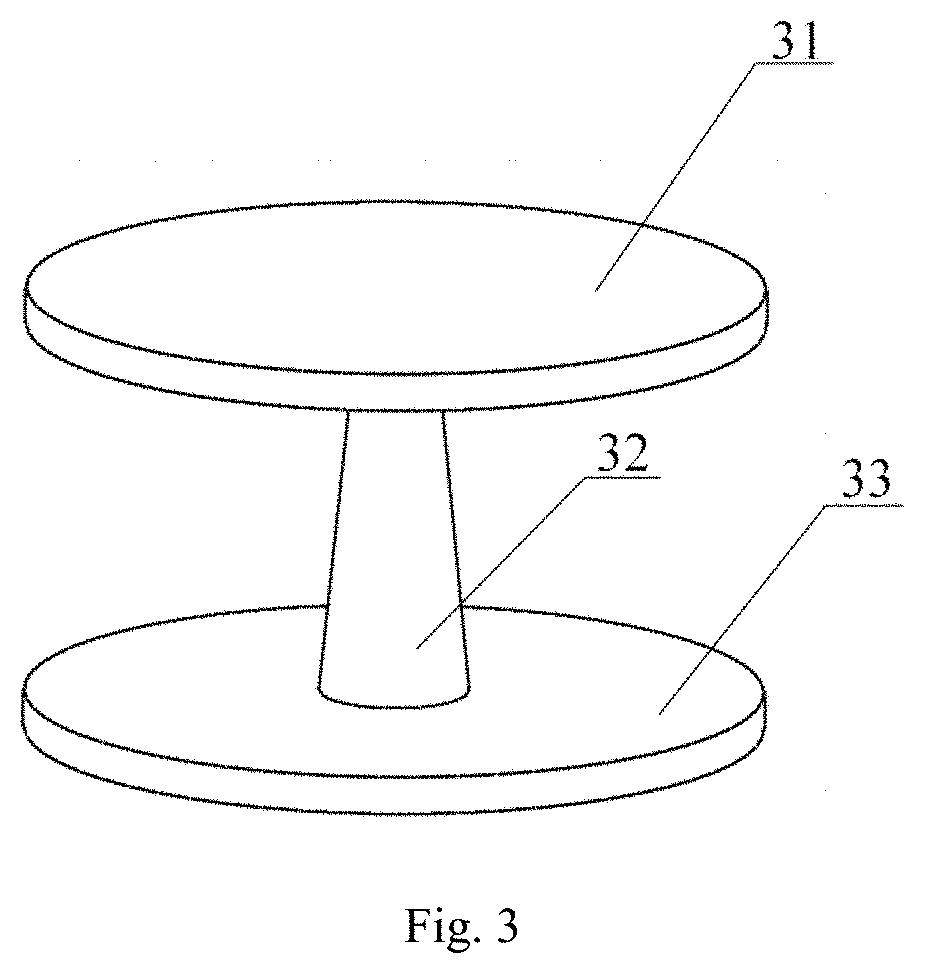

Method of Constructing High-frequency Vibratory Stress Relief Device for Eliminating Residual Stress of Small Work-piece

PendingUS20210162548A1Eliminate the effects ofReduce residual stressThread cutting machinesDesign optimisation/simulationElement modelEngineering

The present invention discloses a method of constructing a high-frequency vibratory stress relief device for eliminating residual stress of a small work-piece. The method comprises the following steps: (1) fabricating a high-frequency vibration energy amplification device; (2) fabricating a clamping device; (3) mounting the high-frequency vibration energy amplification device; (4) obtaining surface residual stress distribution on the small work-piece by means of X-ray diffraction; (5) establishing a finite element model of the small work-piece, obtaining natural frequencies, displacement modes and strain modes of the bending vibration of various orders by means of numerical modal analysis; (6) determining the required strain mode shape and corresponding natural frequency, and record it as a target frequency f; (7) determining the structural dimensions of the high-frequency vibration energy amplification device; (8) analyzing the displacement mode to obtain loci of the vibration node lines and number of the vibration node lines; (9) clamping the small work-piece; (10) attaching strain gauges; (11) connecting the strain gauges with a dynamic strain meter, connecting the dynamic strain meter with a host computer system, connecting the host computer system with a signal generator, connecting the signal generator with a power driver, and connecting the power driver with the electromagnetic exciter. The present invention has the advantage of being able to increase the vibration energy acting on the small work-piece to achieve a better effect of high-frequency vibratory stress relief.

Owner:SHANGHAI MARITIME UNIVERSITY

Force-measuring sensing elastic composite material and preparation method thereof

The invention discloses a force-measuring sensing elastic composite material and a preparation method thereof. The method comprises the following steps of: putting 0.15 percent of raw material A, 99.3 percent of raw material B and 0.55 percent of raw material C into a heating container, stirring and mixing solution, heating to the temperature of 360 DEG C, transferring to a closed injection molding container cavity, and keeping temperature and pressure to obtain a dislocation-free superfine crystalline liquid mixed solution body, wherein the molded product has high strength and plasticity; and opening an injection outlet of the molding container cavity, injecting into a cylindrical cavity under pressure for extrusion molding, and processing the required force sensor body product by a liquid nitrogen aging treatment and time vibration stress eliminating process.

Owner:QUANZHOU HENGJIN KEBO MEASUREMENT & CONTROL TECH

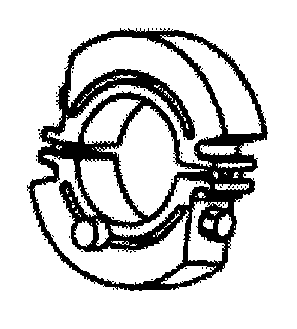

Vibratory stress relief device for autoclave body

InactiveCN102978374BEliminate welding residual stressStable speedManufacturing technologyStress relief

The invention discloses a vibratory stress relief device for an autoclave body, and relates to the technical field of machining equipment manufacturing. The vibratory stress relief device comprises a vibration exciter, wherein the lower end of the vibration exciter is provided with two lug plates extending sideways; each of the two lug plates of the vibration exciter is provided with an arc-shaped clamp body; the upper end of the clamp body is provided with a screw rod through a thread; and an upper backing plate and a lower backing plate are arranged between the bottom surface where the lug plates are arranged and the clamping surface of the clamp bodies. Compared with the prior art, the invention can solve the problems of high investment of stress relief equipment, high stress relief cost and difficulty in performing thermal stress relief treatment on equipment installation site in the existing autoclave body thermal stress relief; the thermal stress relief cost of the autoclave body is reduced by 98%, and the investment of the stress relief equipment is lowered by 80%; and two-year follow-up inspection shows that none of 100 autoclave bodies subjected to vibratory stress relief treatment has quality problems of deformation and cracking.

Owner:NANNING SHENHUA VSR TECH RES INST

Thermal/vibratory combined stress homogenizing device

The invention relates to a thermal / vibratory combined stress homogenizing device which is composed of a vibratory stress relief system (A) and a thermal stress relief system (B), wherein most of the vibratory stress relief system (A) is contained in an outer cover (13) of the thermal stress relief system (B); an internal bladder (12) of the thermal stress relief system (B) is covered on a vibratory platform (4) of the vibratory stress relief system (A); the bottom of the internal bladder (12) is in contact with the ground; and the relative positions of the internal bladder (12) and the vibratory platform (4) are positioned by regulating three internal walls among four side walls until the distances between the three internal walls and the contour of the vibratory platform (4) are equal. Traditional natural stress relief prolongs the production cycle of spare parts and also influences the quality of the product. According to the invention, the production efficiency can be effectively improved, the research and development cycle of the product can be shortened, and the quality of the product can be enhanced. Thus, the thermal / vibratory combined stress homogenizing device plays a very important role in actual industrial production.

Owner:BEIHANG UNIV

Force-measuring sensing elastic composite material and preparation method thereof

The invention discloses a force-measuring sensing elastic composite material and a preparation method thereof. The method comprises the following steps of: putting 0.15 percent of raw material A, 99.3 percent of raw material B and 0.55 percent of raw material C into a heating container, stirring and mixing solution, heating to the temperature of 360 DEG C, transferring to a closed injection molding container cavity, and keeping temperature and pressure to obtain a dislocation-free superfine crystalline liquid mixed solution body, wherein the molded product has high strength and plasticity; and opening an injection outlet of the molding container cavity, injecting into a cylindrical cavity under pressure for extrusion molding, and processing the required force sensor body product by a liquid nitrogen aging treatment and time vibration stress eliminating process.

Owner:QUANZHOU HENGJIN KEBO MEASUREMENT & CONTROL TECH

Ultraharmonic-resonance vibratory stress relief device for high-natural-frequency workpiece

InactiveCN102181625BThe excitation frequency is adjustableThe vibration frequency of the excitation frequency is adjustableResonanceAcoustics

The invention relates to an ultraharmonic-resonance vibratory stress relief device for a high-natural-frequency workpiece, which comprises a vibration exciter, a vibration excitation block, an adjustable damping and an adjustable nonlinear spring, wherein the vibration exciter is connected with the vibration excitation block, and the adjustable damping, adjustable nonlinear spring and vibration excitation block constitute a nonlinear vibration system. The vibration exciter acts on the nonlinear vibration system, so that the nonlinear vibration system generates ultraharmonic resonance at a frequency which is far higher than the original exciting frequency of the vibration exciter; and the vibration excitation block acts on the workpiece at an ultraharmonic resonance frequency approximate to the natural frequency of the high-rigidity workpiece, so that the workpiece generates main resonance and corresponding dynamic stress to reduce the residual stress of the workpiece. The invention can solve the problem that the high-rigidity workpiece can not be subjected to vibratory stress relief treatment.

Owner:GUANGXI UNIV

Simulation method for welding residual stress of quartz flexible accelerometer

ActiveCN102592019BEasy to modifyAvoid human errorSpecial data processing applicationsHeat flowElement model

Disclosed is a simulation method for welding residual stress of a quartz flexible accelerometer. The simulation method includes the following steps: selecting a finite element unit combining with generation mechanism of welding residual stress; constructing a material model base; constructing a structural model of an accelerometer; constructing a finite element model of the accelerometer; exerting constraint and load; performing direct thermal stress coupling simulation; cooling naturally, retaining the residual stress, remaining the model the same, deleting heat-flow density load, simulatinga natural cooling process, still performing direct thermal stress coupling transient simulation, and working out variations of temperature and stresses during the cooling process. The invention provides a transient direct thermal stress coupling simulation method based on the finite element model of the quartz flexible accelerometer. By means of the simulation method, distribution of residual stress of weld points can be obtained, simulation results can be used as inputs of the simulation process of vibratory residual stress relief, and foundations are laid for further study on vibratory stress relief.

Owner:厦门蓝威可靠性系统工程研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com