Vibratory stress relief vibration level amplifying device

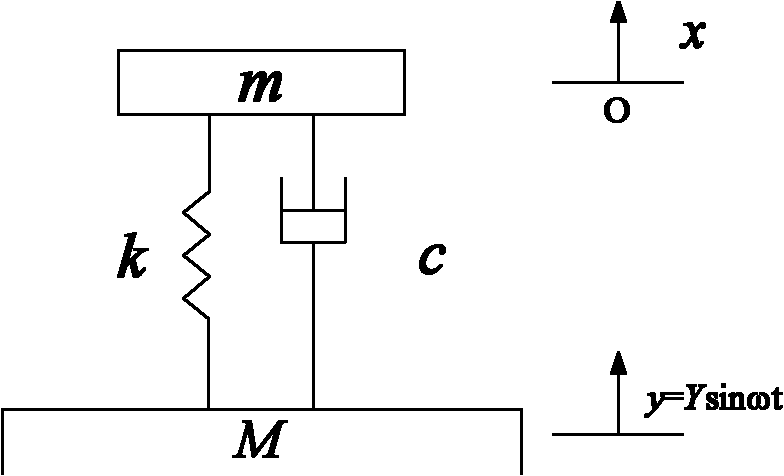

A technology of vibration aging and amplifying device, which is applied in the direction of fluid using vibration, can solve the problems of providing enough dynamic stress and small vibration level for difficult workpieces, and achieves the effect of simple and practical structure, improved elimination and improvement of residual stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

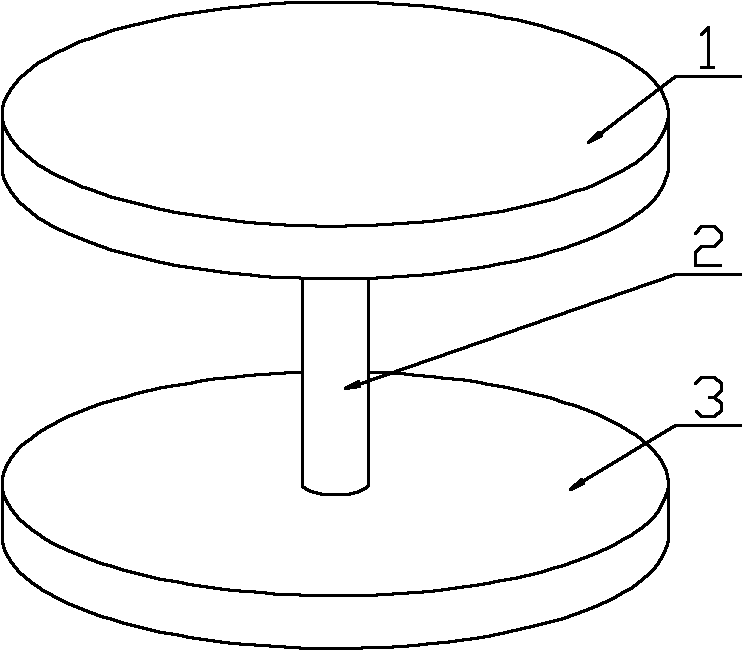

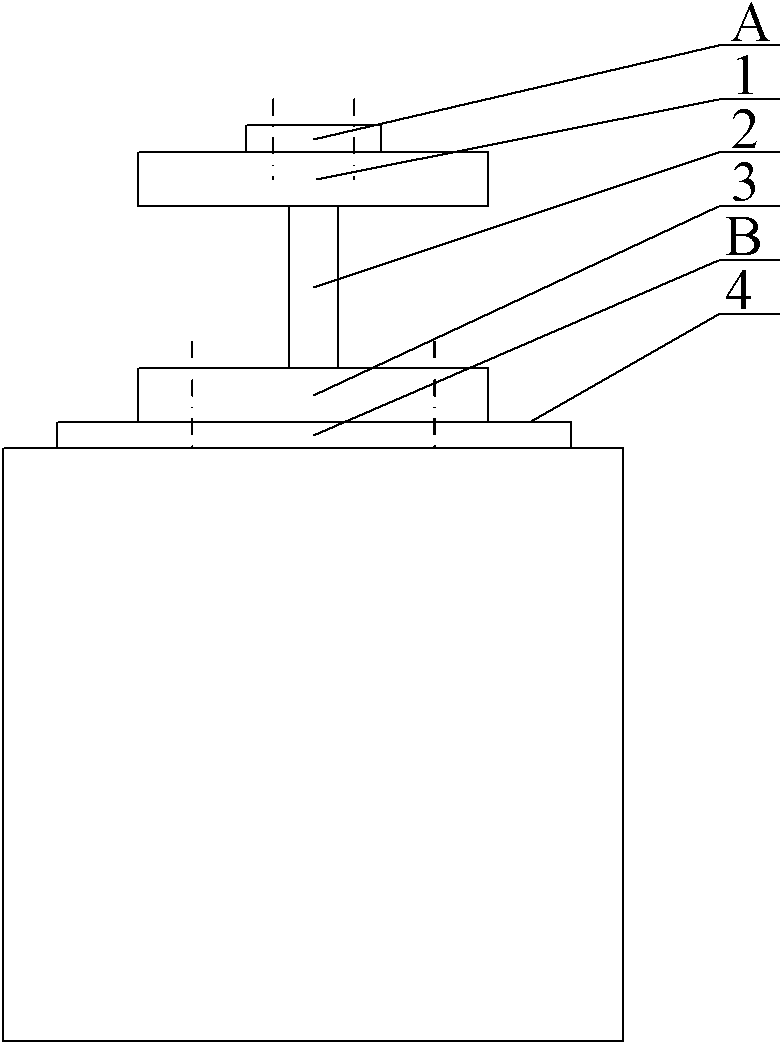

[0029] refer to Figure 1-4

[0030] The vibration time-effect vibration level amplifying device is composed of an upper supporting platform 1 for installing workpieces, a lower chassis 3 fixed on the vibrating table surface 4 of the vibrating table, and a connecting rod 2 connecting the upper supporting platform 1 and the lower chassis 3. The upper end of the rod 2 is affixed to the upper pallet 1, and the lower end is affixed to the lower chassis 3. The cross-sectional area of the connecting rod 2 is smaller than the cross-sectional area of the upper pallet 1, and the cross-sectional area of the connecting rod 2 The area is smaller than the cross-sectional area of the lower chassis 3 described above.

[0031] The upper pallet 1, the connecting rod 2 and the lower chassis 3 are integrally formed.

[0032] The upper pallet 1 and the lower chassis 3 are both symmetrical figures, the centroids of the upper pallet 1 and the lower chassis 3 coincide with the symmetrical ...

Embodiment 2

[0051]The difference between this embodiment and the first embodiment is that the connecting rod 2 is fixedly connected to the upper pallet 1 and the lower chassis 3 respectively through fasteners. The rest are the same.

[0052] The connecting rod, the upper support platform and the lower chassis are connected by fasteners, and the three parts can be processed separately, which is convenient for processing and low in processing cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com