Patents

Literature

371 results about "Exciter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An exciter (also called a harmonic exciter or aural exciter) is an audio signal processing technique used to enhance a signal by dynamic equalization, phase manipulation, harmonic synthesis of (usually) high frequency signals, and through the addition of subtle harmonic distortion. Dynamic equalization involves variation of the equalizer characteristics in the time domain as a function of the input. Due to the varying nature, noise is reduced compared to static equalizers. Harmonic synthesis involves the creation of higher order harmonics from the fundamental frequency signals present in the recording. As noise is usually more prevalent at higher frequencies, the harmonics are derived from a purer frequency band resulting in clearer highs. Exciters are also used to synthesize harmonics of low frequency signals to simulate deep bass in smaller speakers.

Method and system for enhancing audio signals

InactiveUS6606388B1Facilitates separate modificationFacilitates enhancementElectrophonic musical instrumentsGain controlHarmonicComputer module

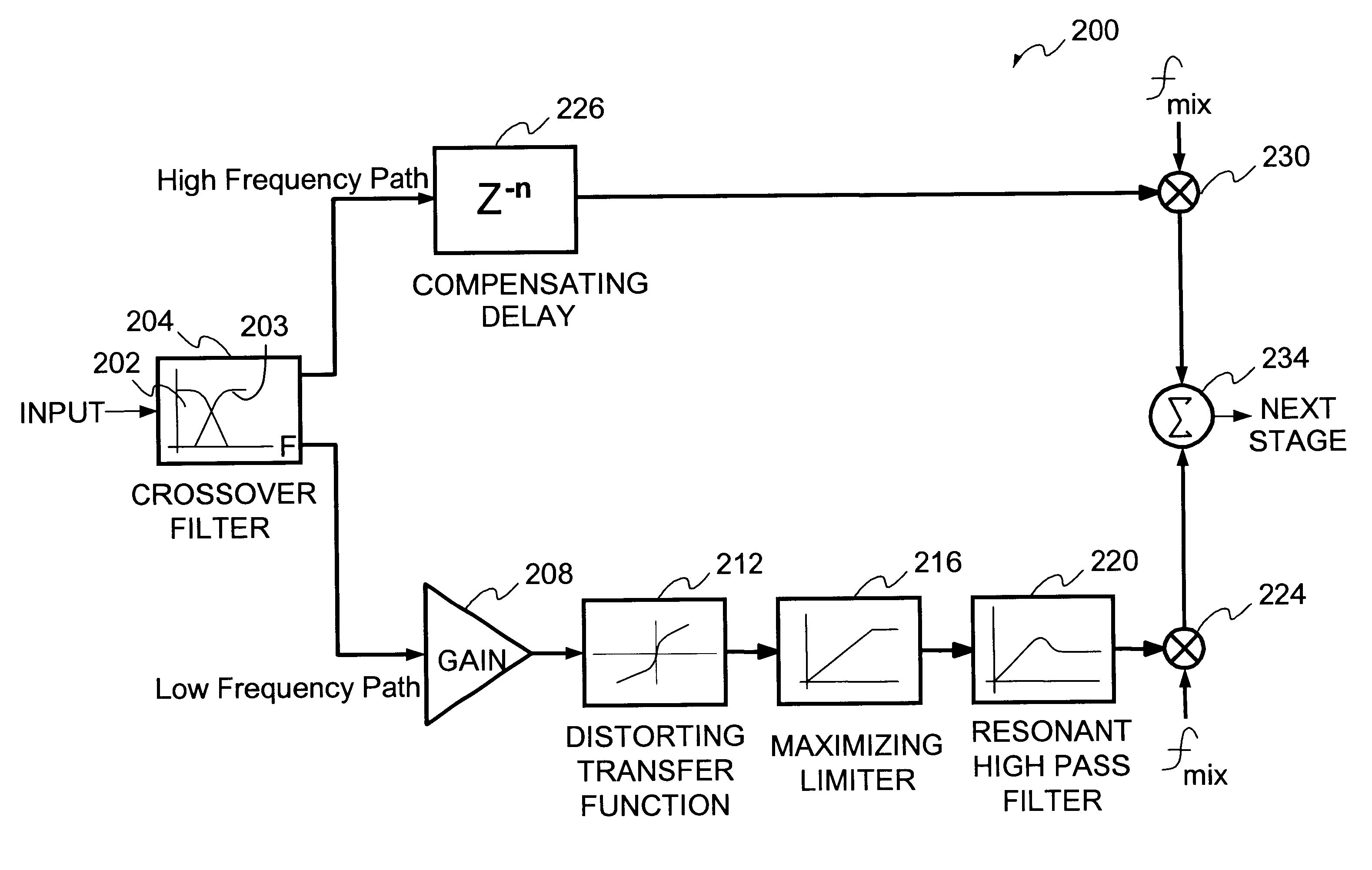

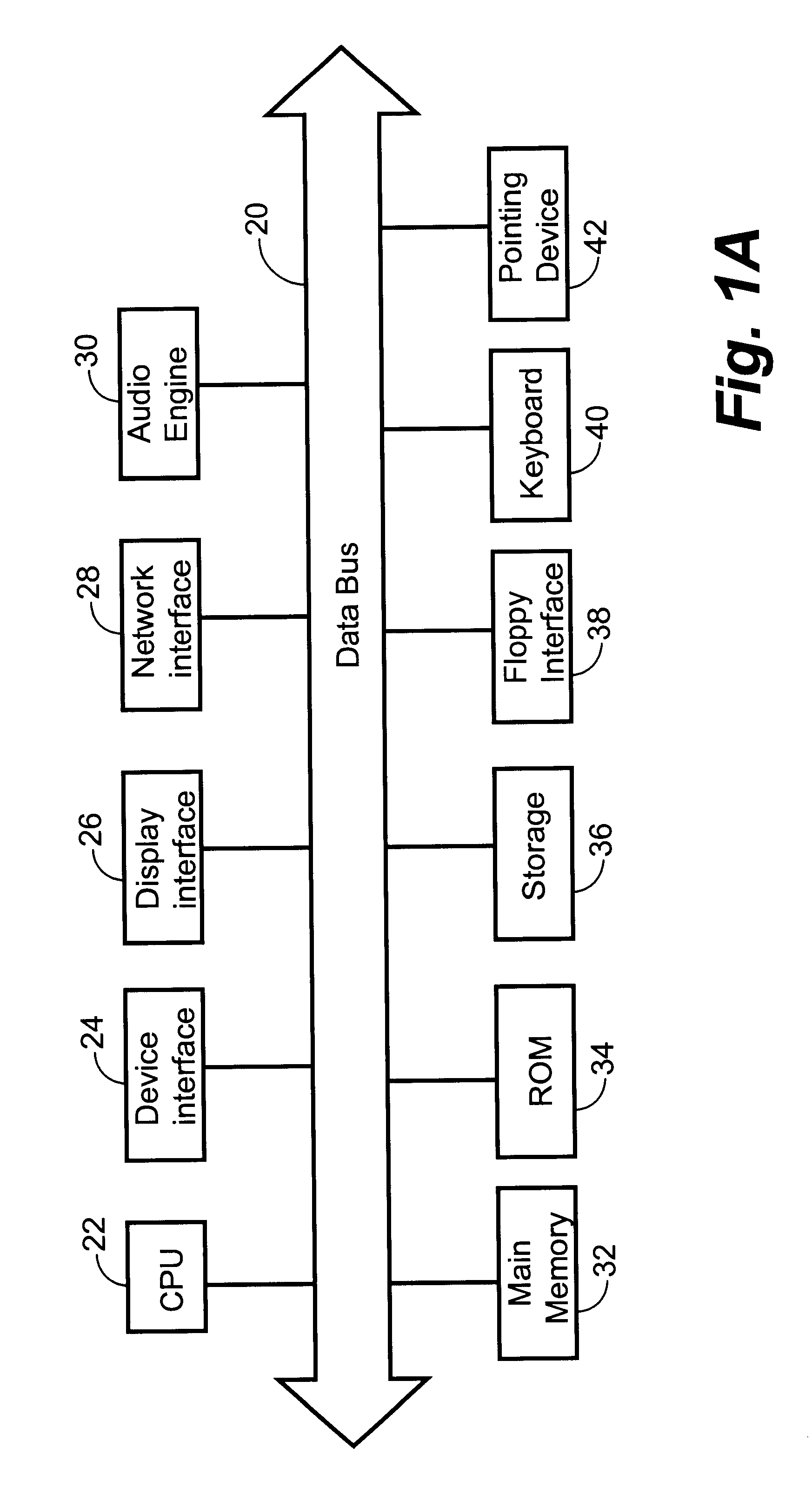

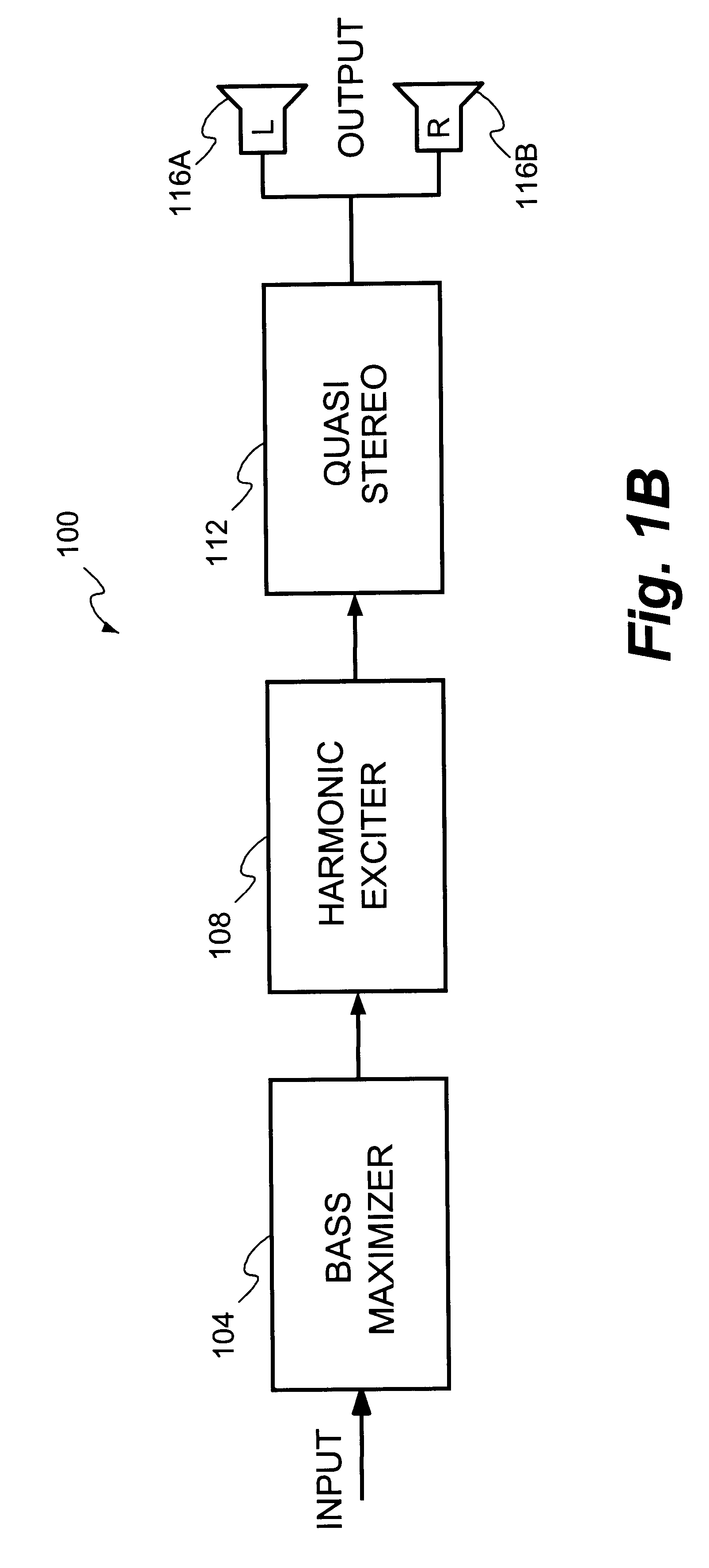

A technique for enhancing audio signals generated from compressed digital audio files is described. The technique uses a Bass Maximizer module, a Harmonic Exciter module and a Quasi Stereo module. The Bass Exciter module enhances the intensity, depth and punch of the bass audio content by creating harmonic sequences from low frequency components contained in the original input signal. The Harmonic Exciter module adds to the treble audio content of the original input signal by generating harmonic series from the high frequency components contained in the input signal. The Quasi Stereo Module creates a stereo image of the enhanced input signal by adding and subtracting delayed and filtered versions of the enhanced input signal with itself to create left and right channeled stereo-like outputs. The technique provides a useful tool to regenerate from an audio signal more pleasant and joyful sounds.

Owner:ARBORETUM SYST

Efficient Combined Harmonic Transposition

ActiveUS20120065983A1Reduce complexityComplex designElectrophonic musical instrumentsSpeech analysisEngineeringFilter bank

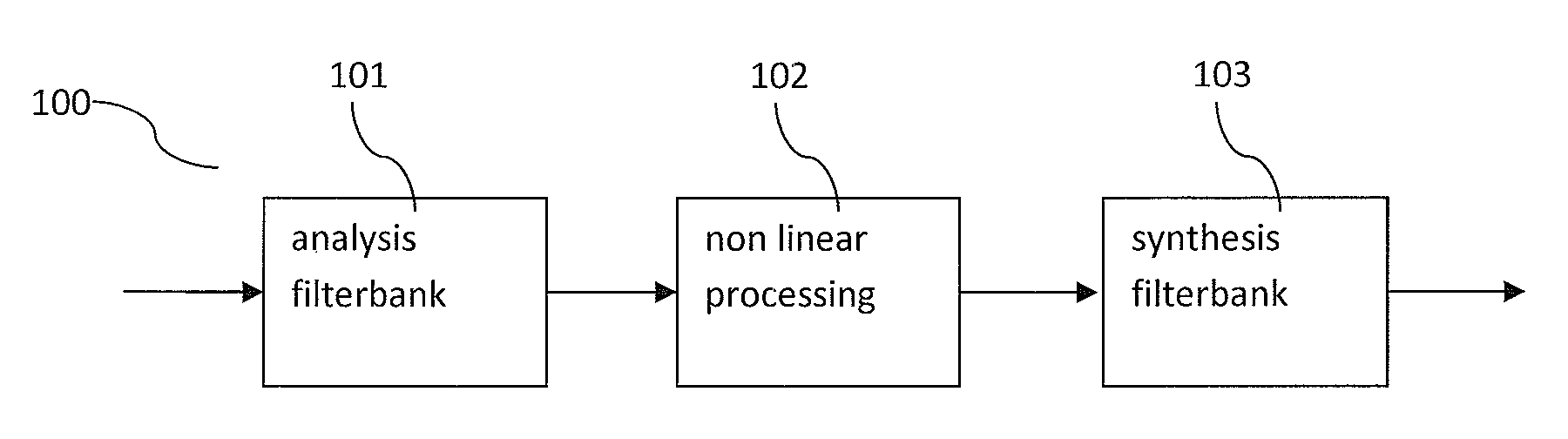

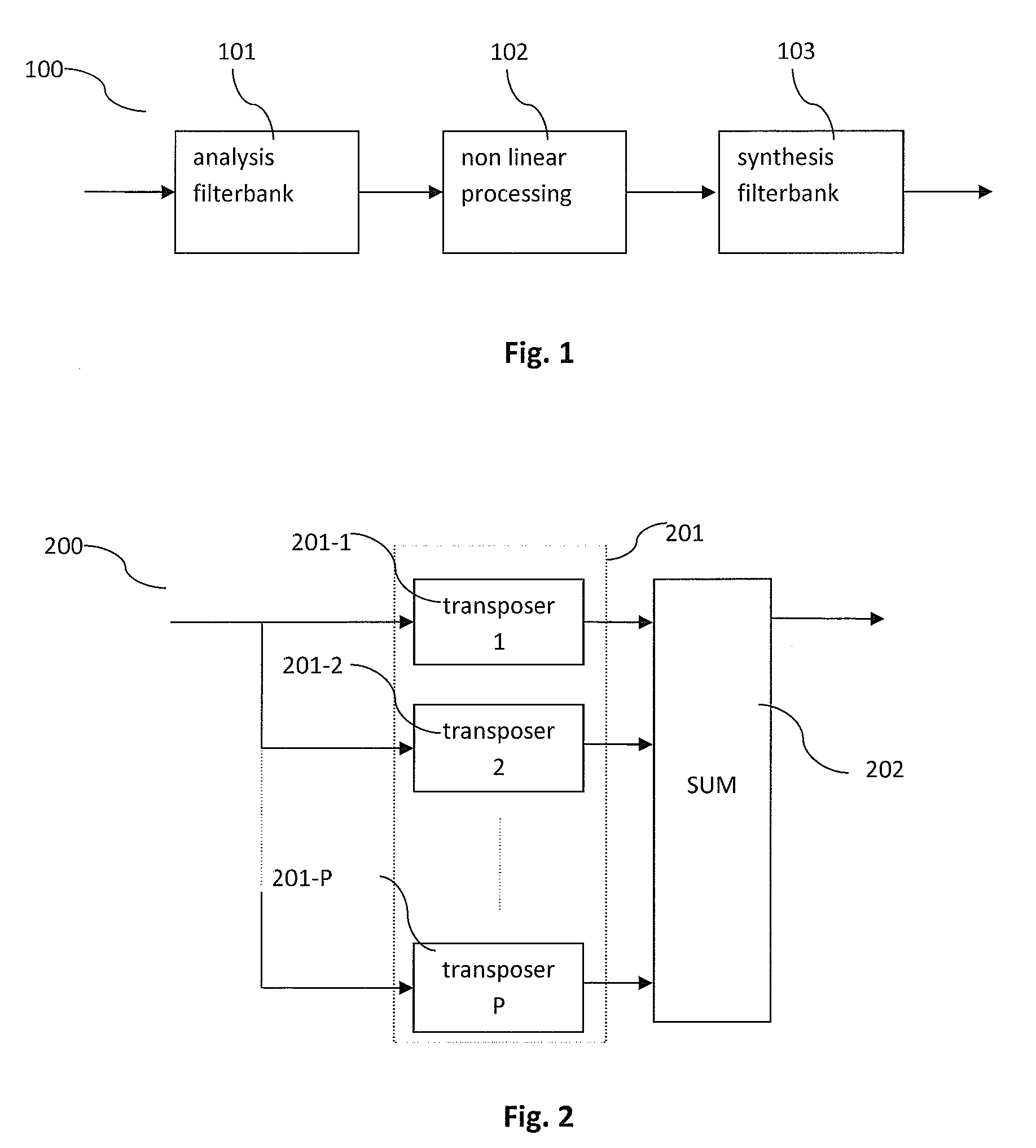

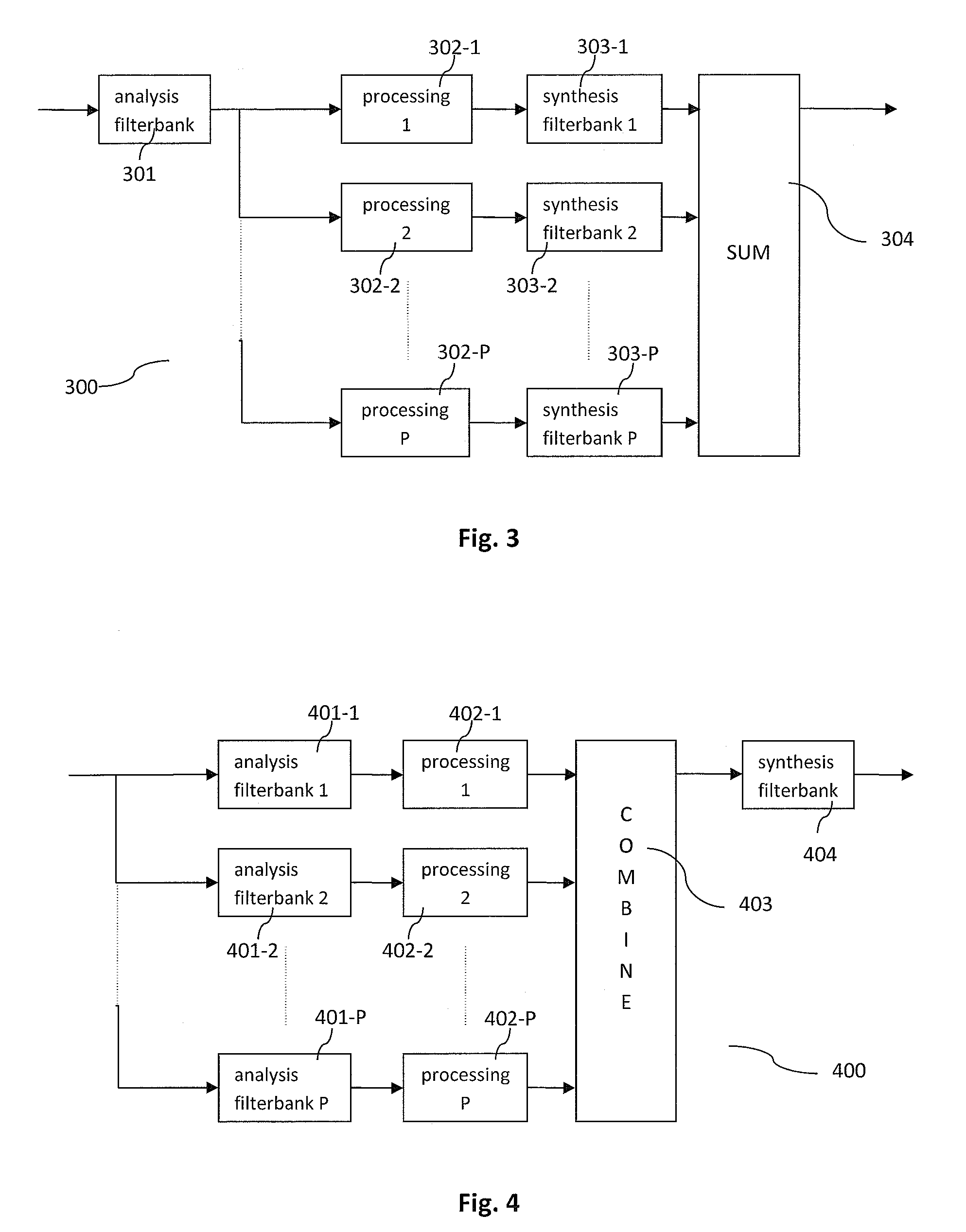

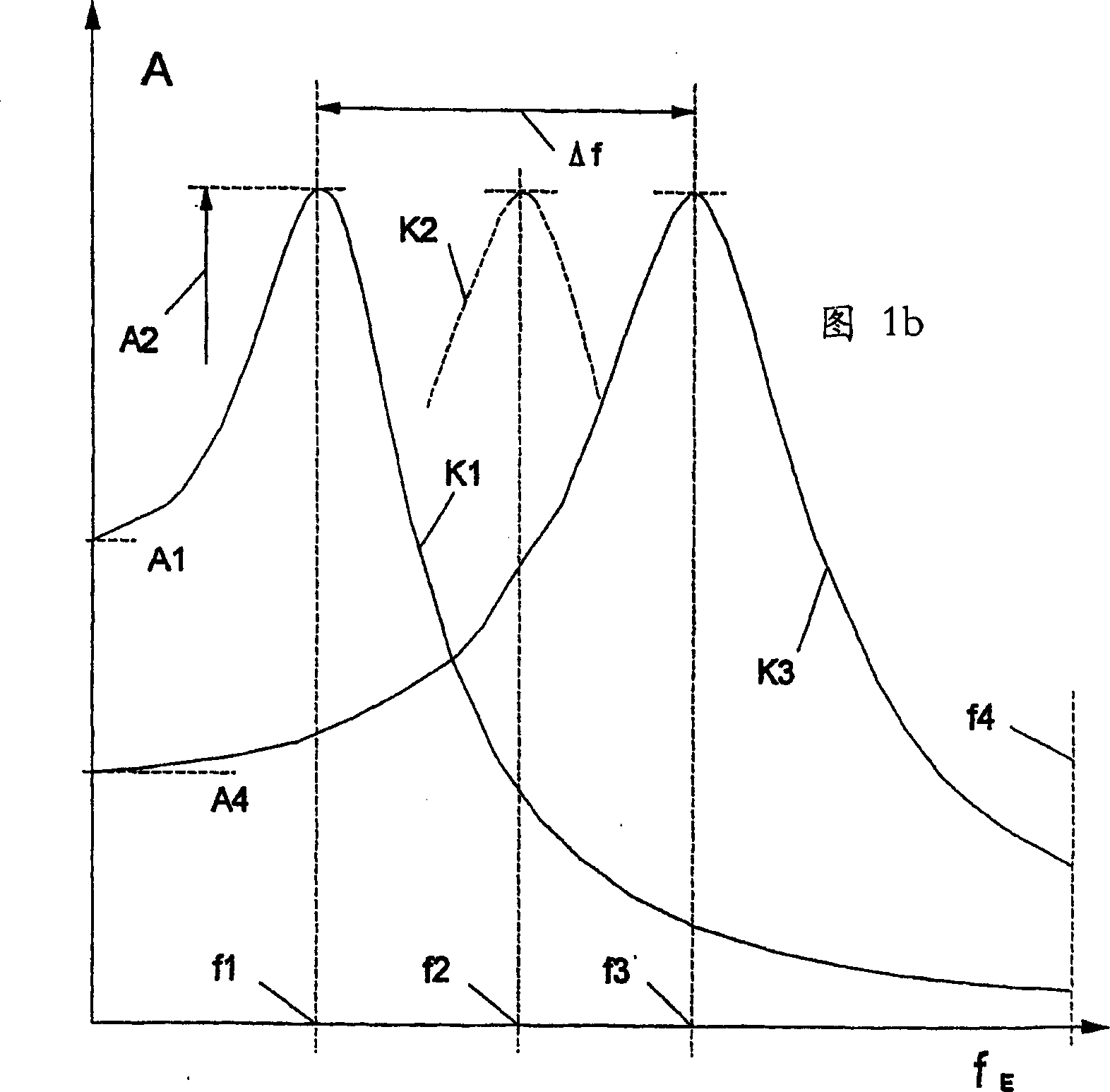

The present document relates to audio coding systems which make use of a harmonic transposition method for high frequency reconstruction (HFR), and to digital effect processors, e.g. so-called exciters, where generation of harmonic distortion adds brightness to the processed signal. In particular; a system configured to generate a high frequency component of a signal from a low frequency component of the signal is described, The system may comprise an analysis filter bank (501) configured to provide a set of analysis subband signals from the low frequency component of the signal; wherein the set of analysis subband signals comprises at least two analysis subband signals; wherein the analysis filter bank (501) has a frequency resolution of Δf, The system further comprises a nonlinear processing unit (502) configured to determine a set of synthesis subband signals from the set of analysis subband signals using a transposition order P; wherein the set of synthesis subband signals comprises a portion of the set of analysis subband signals phase shifted by an amount derived from the transposition order P; and a synthesis filter bank (504) configured to generate the high frequency component of the signal from the set of synthesis subband signals; wherein the synthesis filter bank (504) has a frequency resolution of FΔf; with F being a resolution factor, with F≧1; wherein the transposition order P is different from the resolution factor F.

Owner:DOLBY INT AB

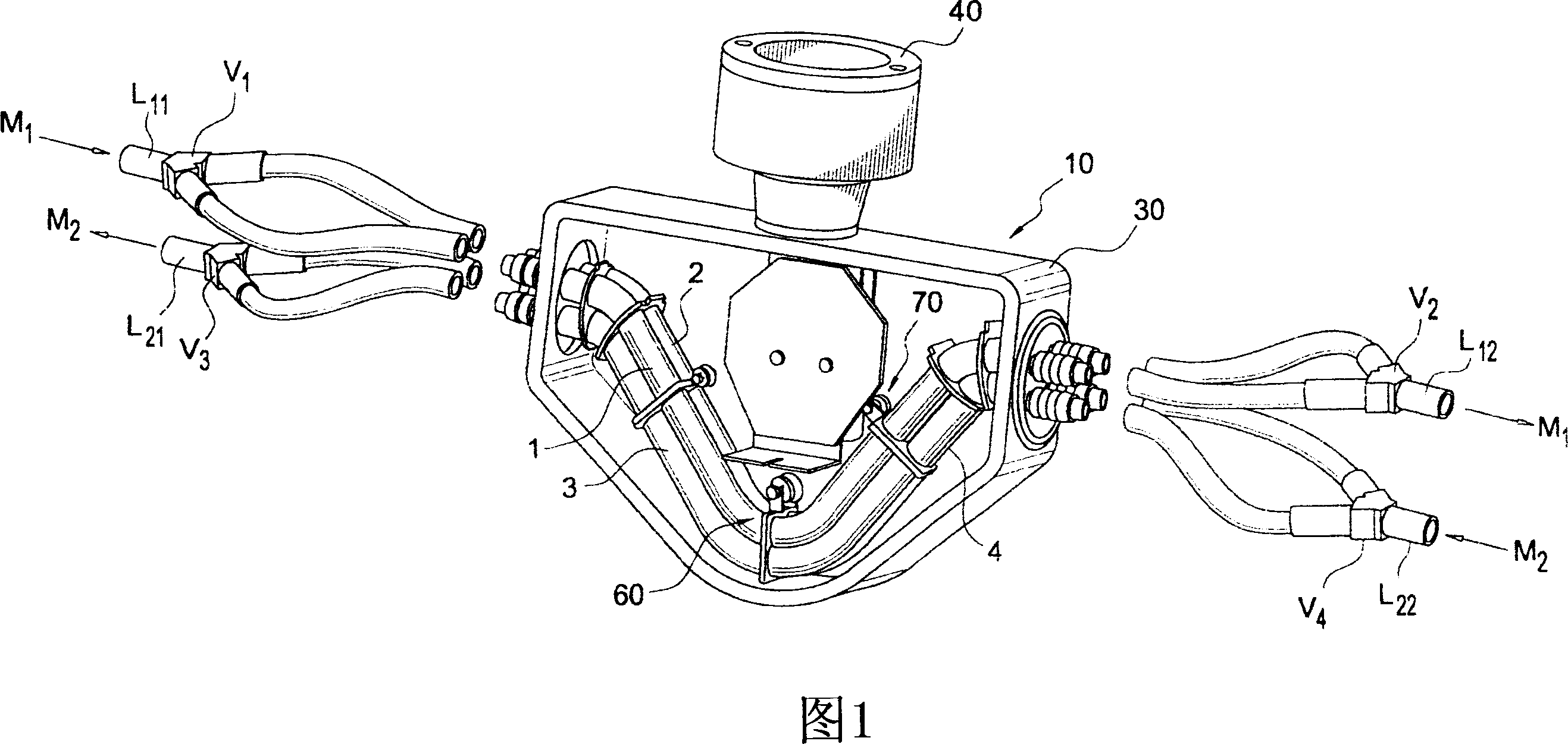

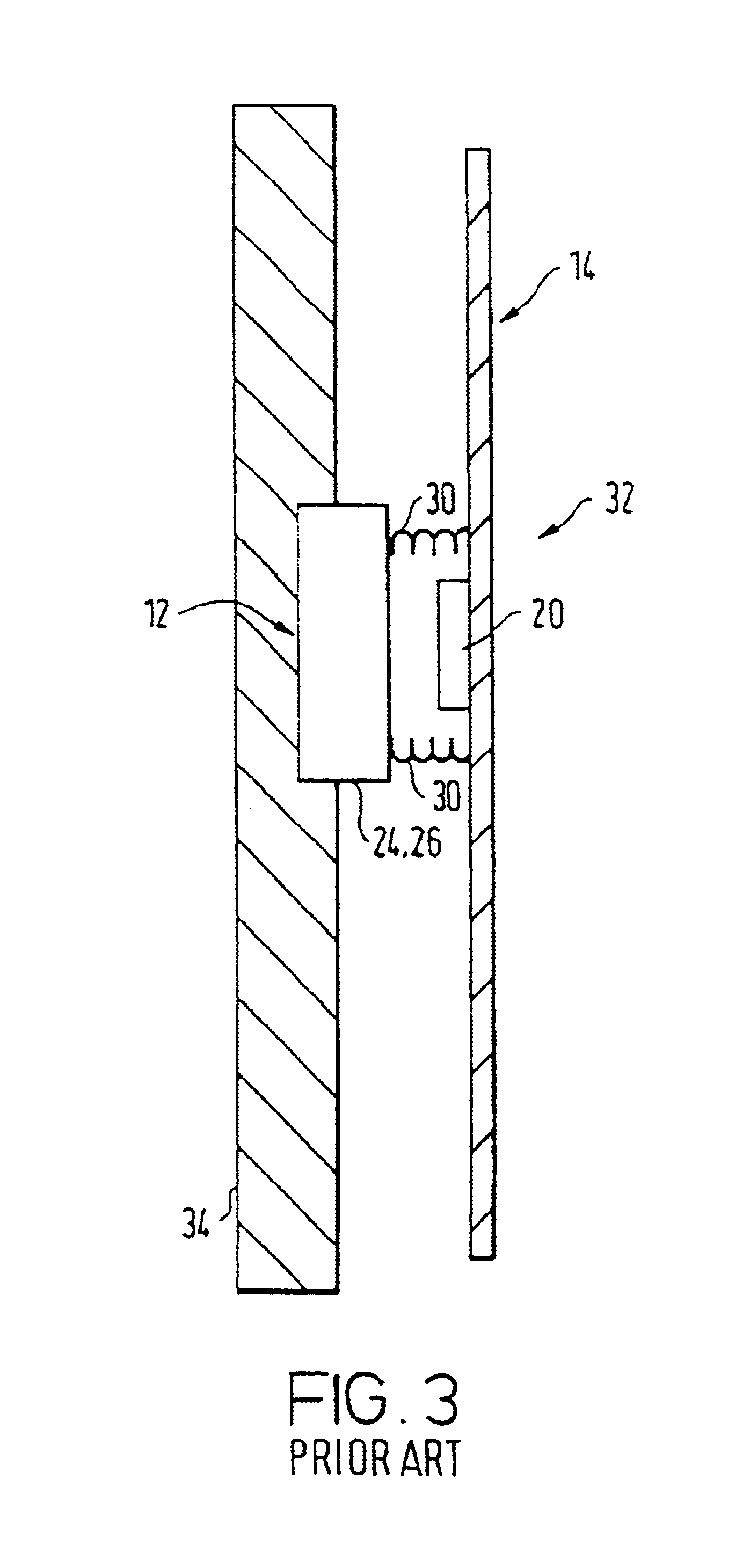

Sound reproduction system

InactiveUS6959096B2Easy to installExtension of timeGain controlPseudo-stereo systemsWave field synthesisTransducer

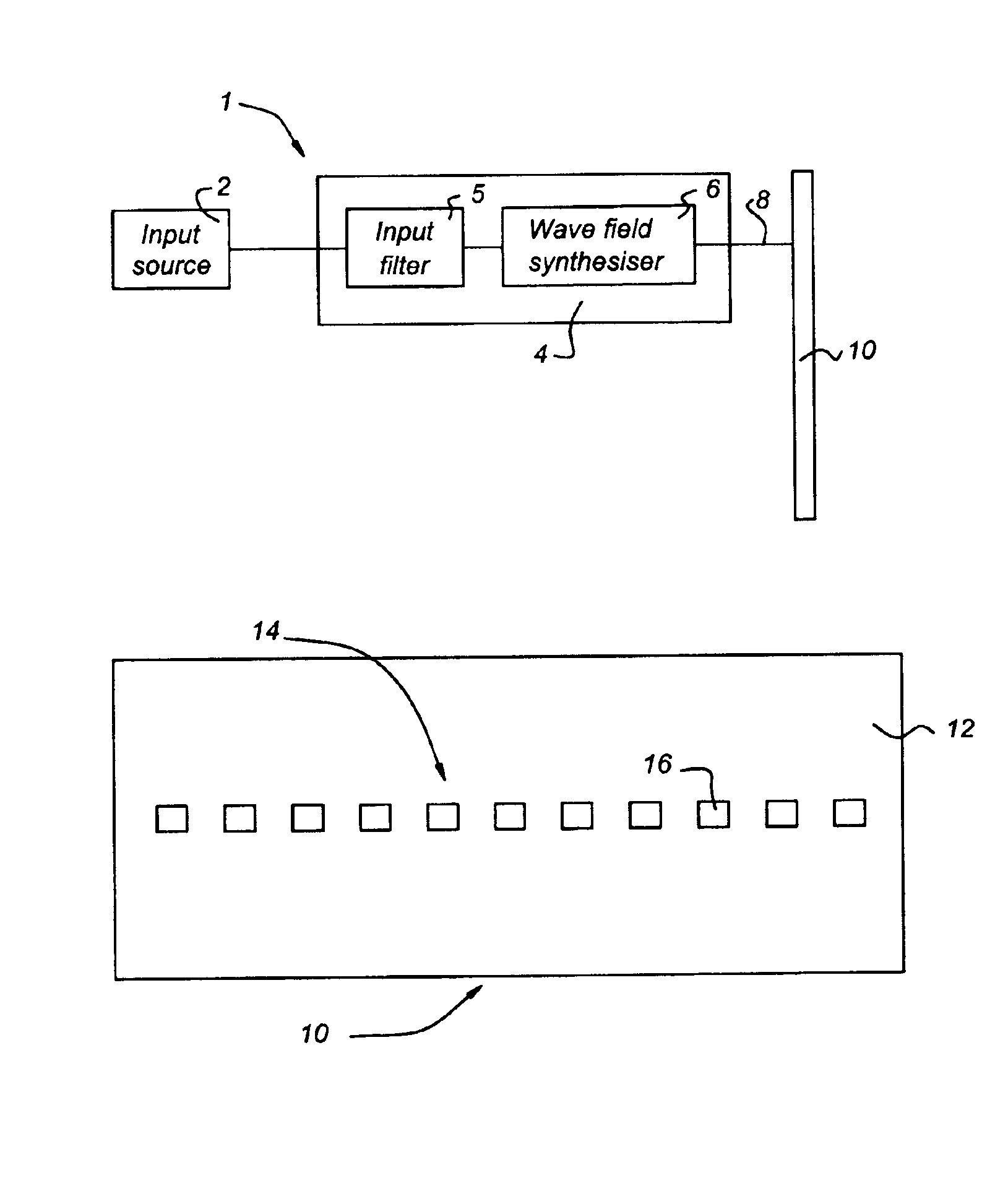

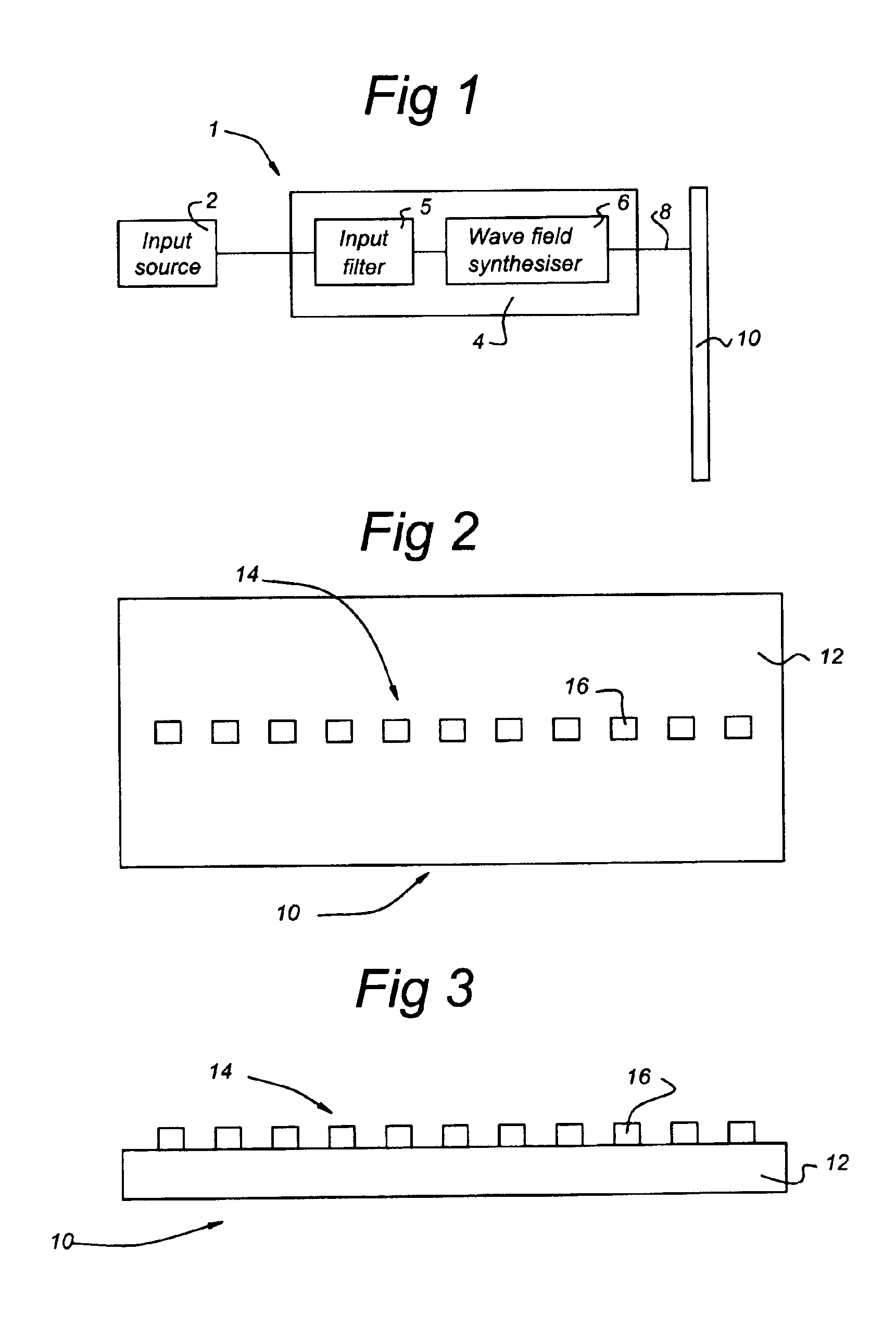

Arrangement of a sound reproduction system (1), including at least one input (2), a sound field generator (4), a loudspeaker panel (10); the at least one input (2) connected to the sound field generator (4), and the sound field generator (4) connected to the loudspeaker panel (10); the at least one input (2) arranged for generating an audio signal; the sound field generator (4) including a wave field synthesizer (6) arranged for generating a spatially perceptible sound field for the audio signal and for outputting the spatially perceptible sound field to the loudspeaker panel (10), the loudspeaker panel (10) being a multi-exciter Distributed Mode Loudspeaker panel (10) consisting of a plate (12) and a plurality of transducers (16), arranged within an array (14) on the large plate (12) for reproducing the spatially perceptible sound field from the wave field synthesizer (6) by exciting bending waves in the plate (12).

Owner:TECH UNIV DELFT

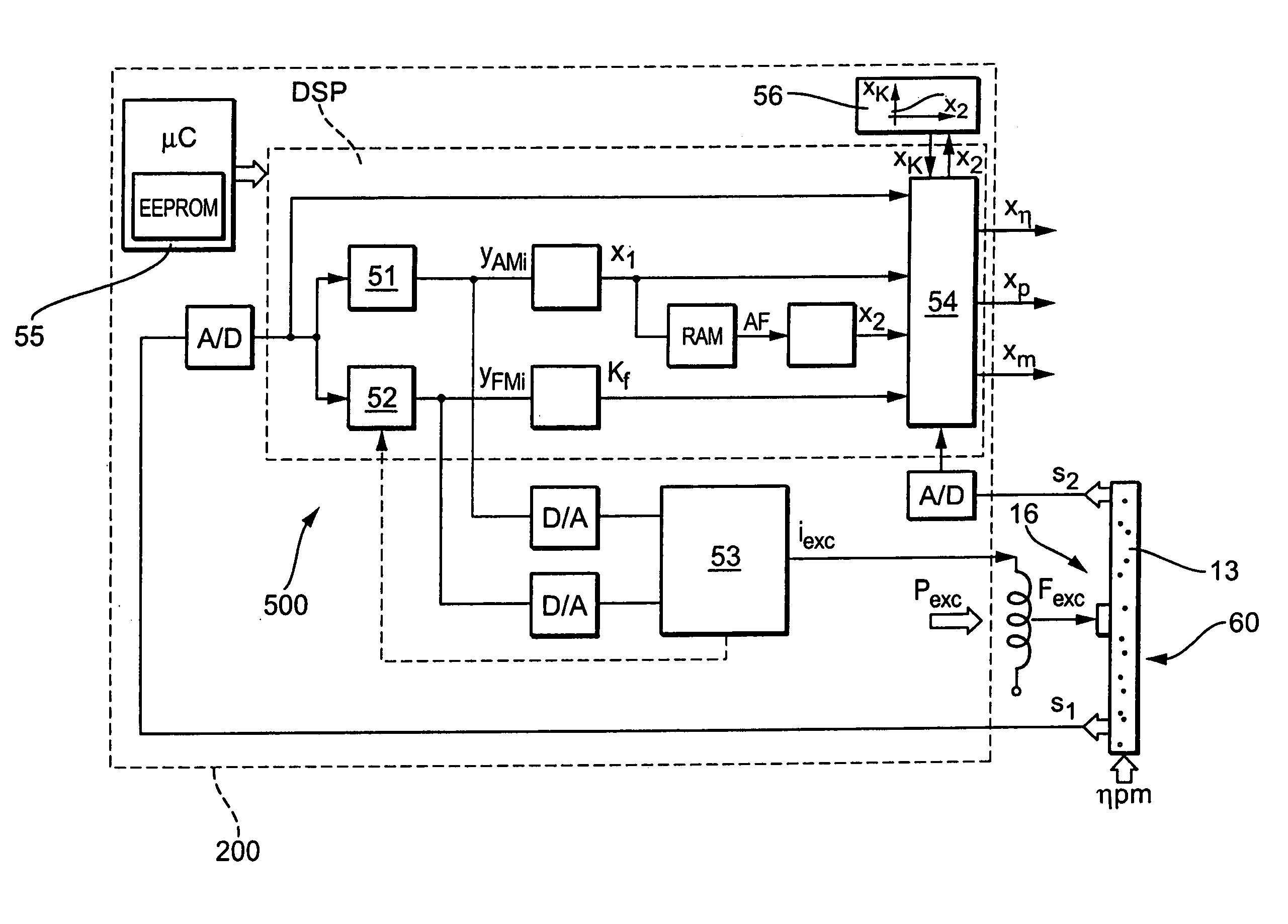

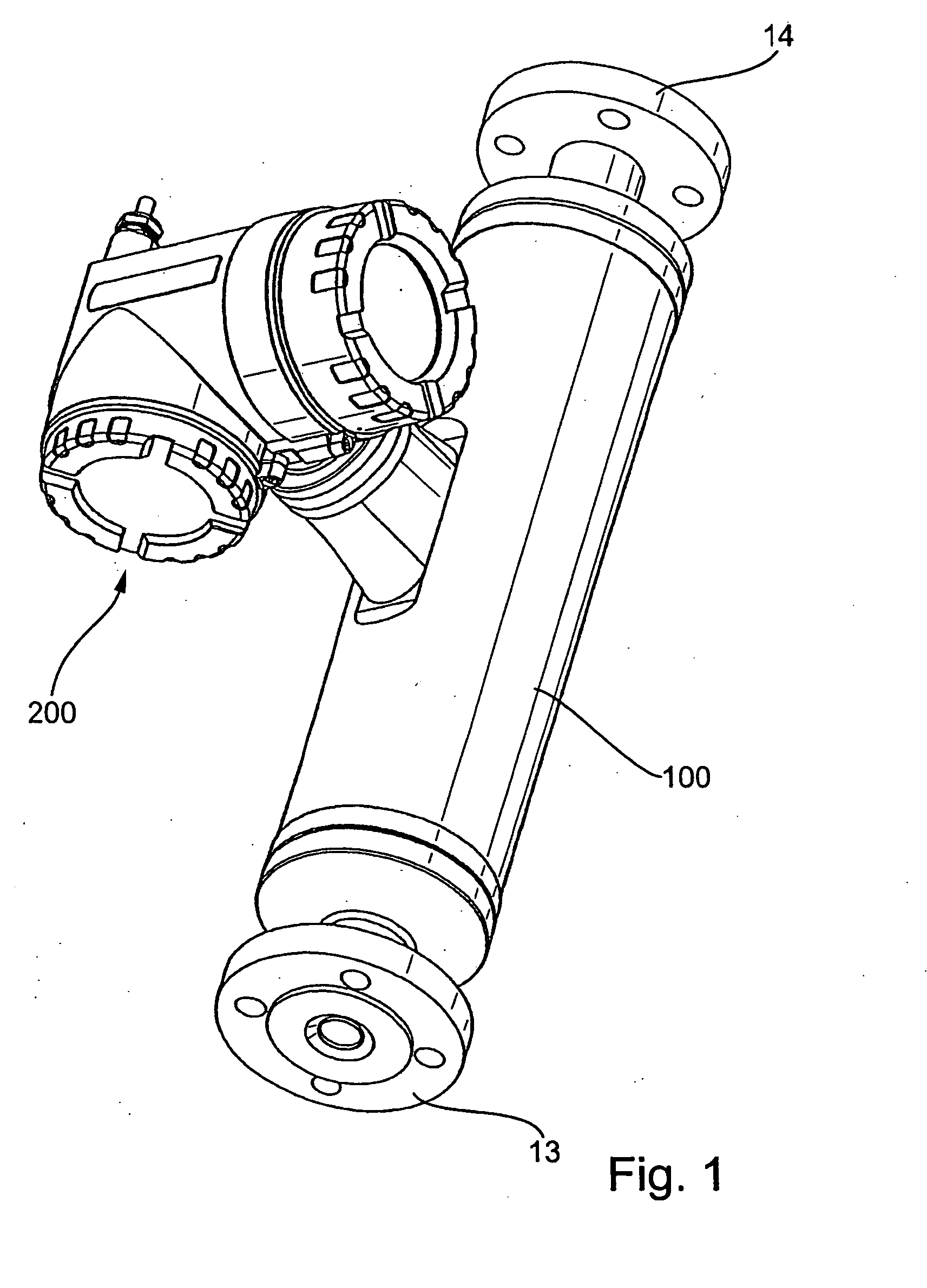

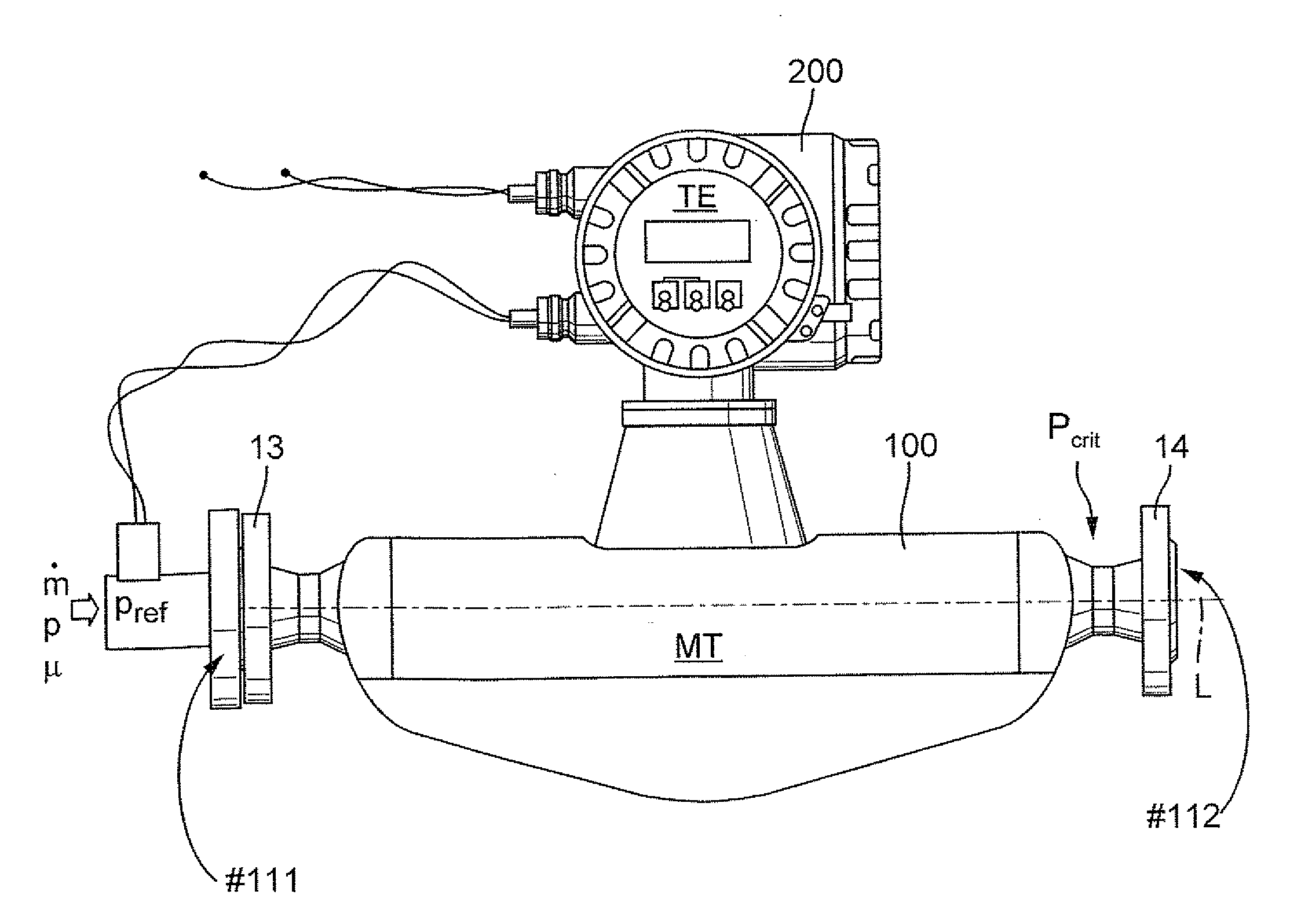

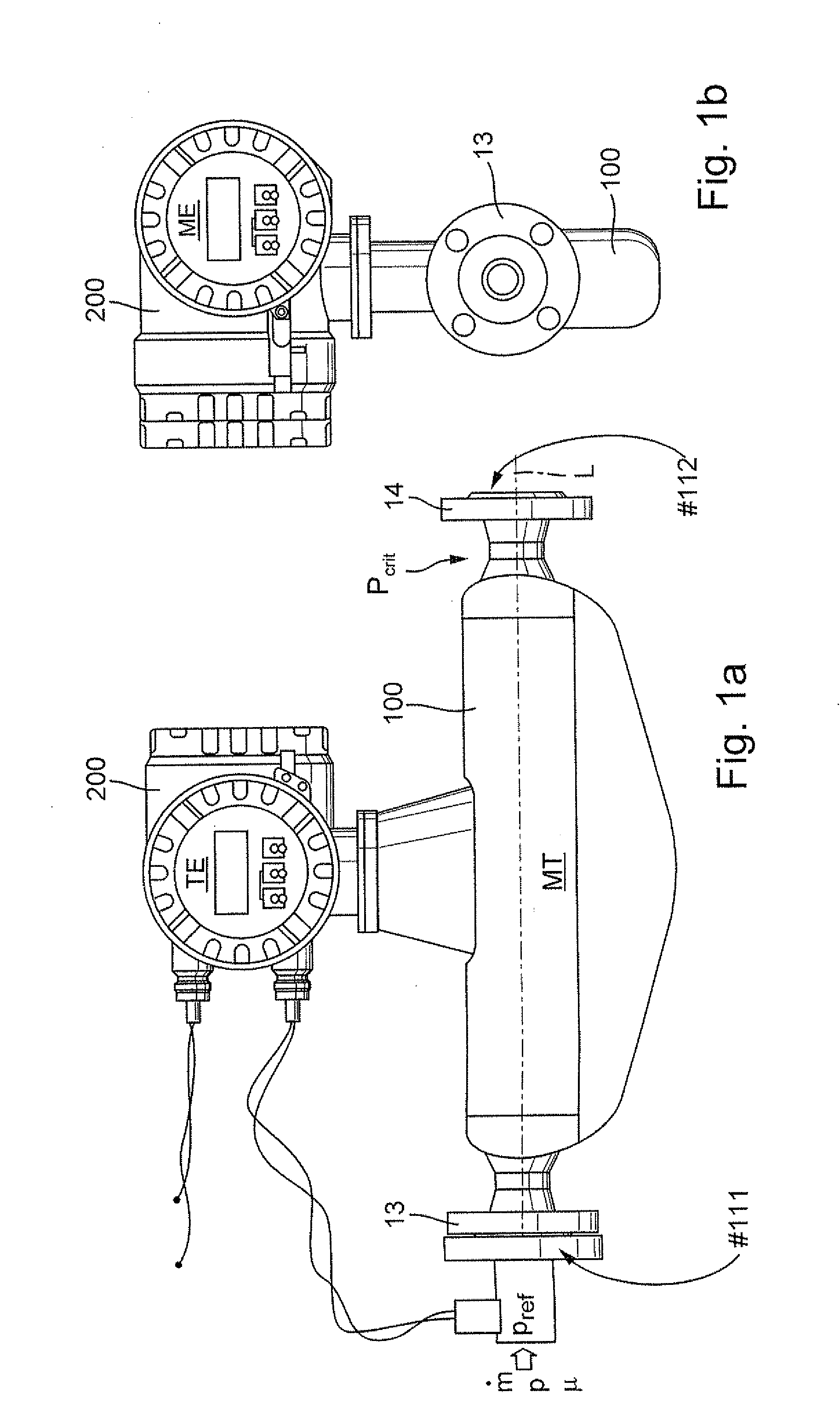

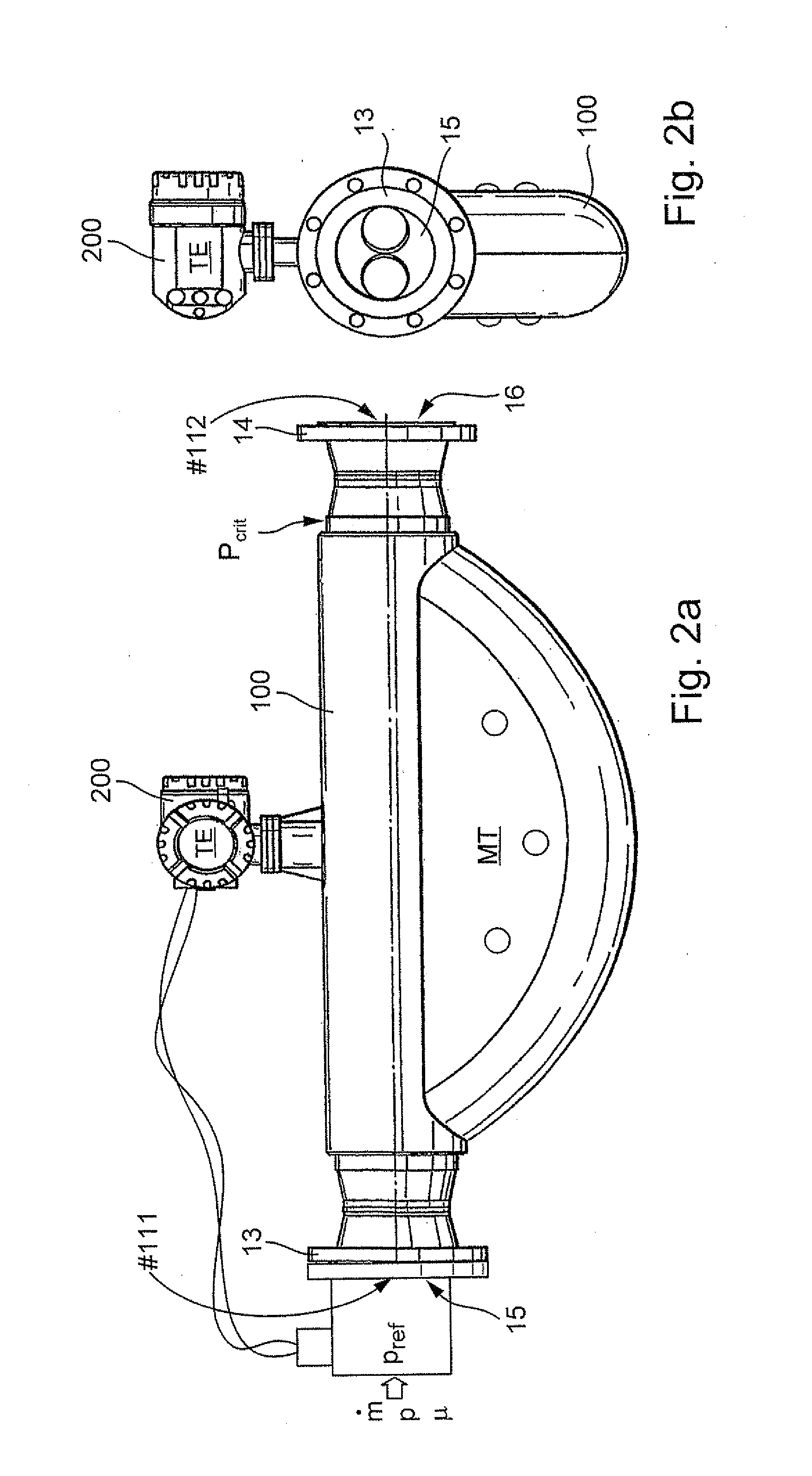

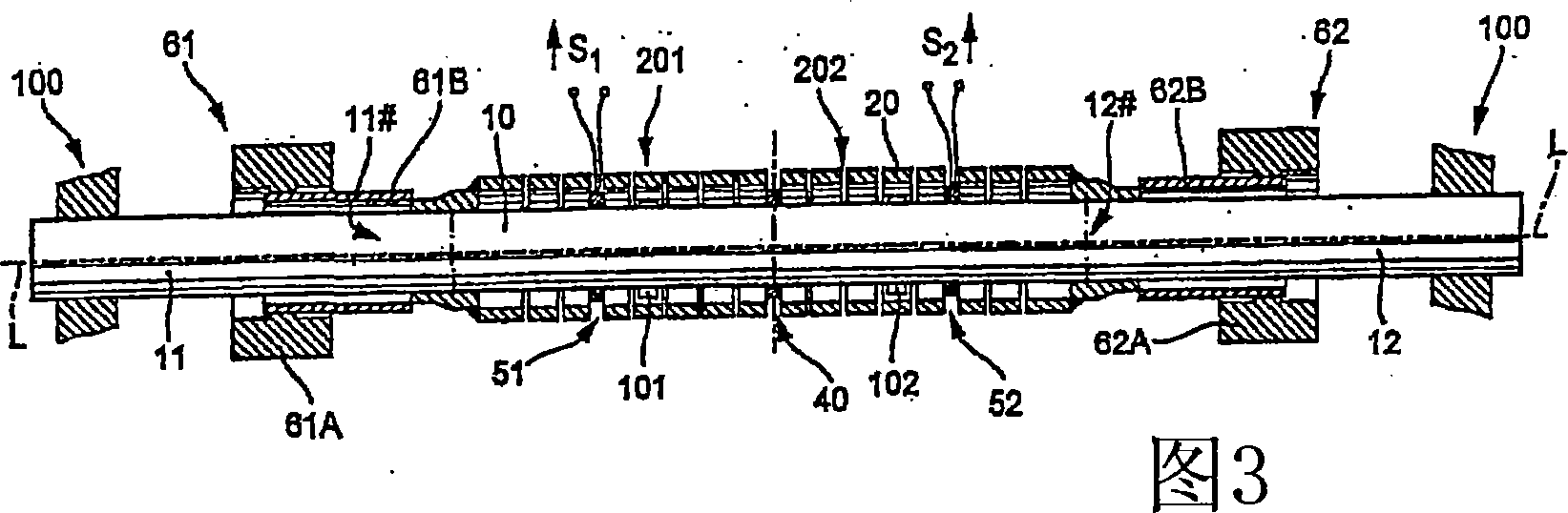

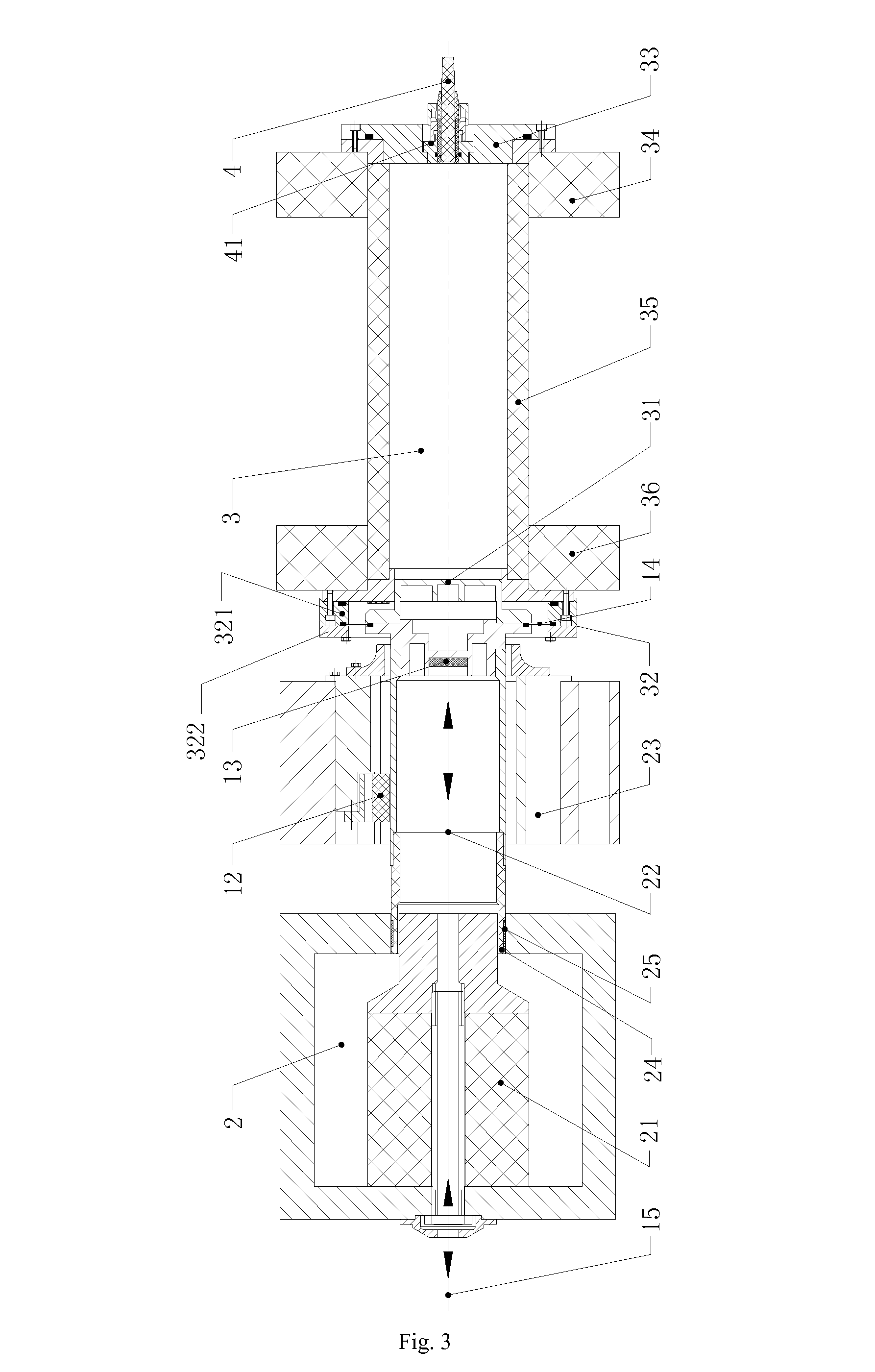

In-Line measuring devices and method for compensation measurement errors in in-line measuring devices

ActiveUS20070186686A1Little effortVolume meteringDirect mass flowmetersElectricityMeasurement device

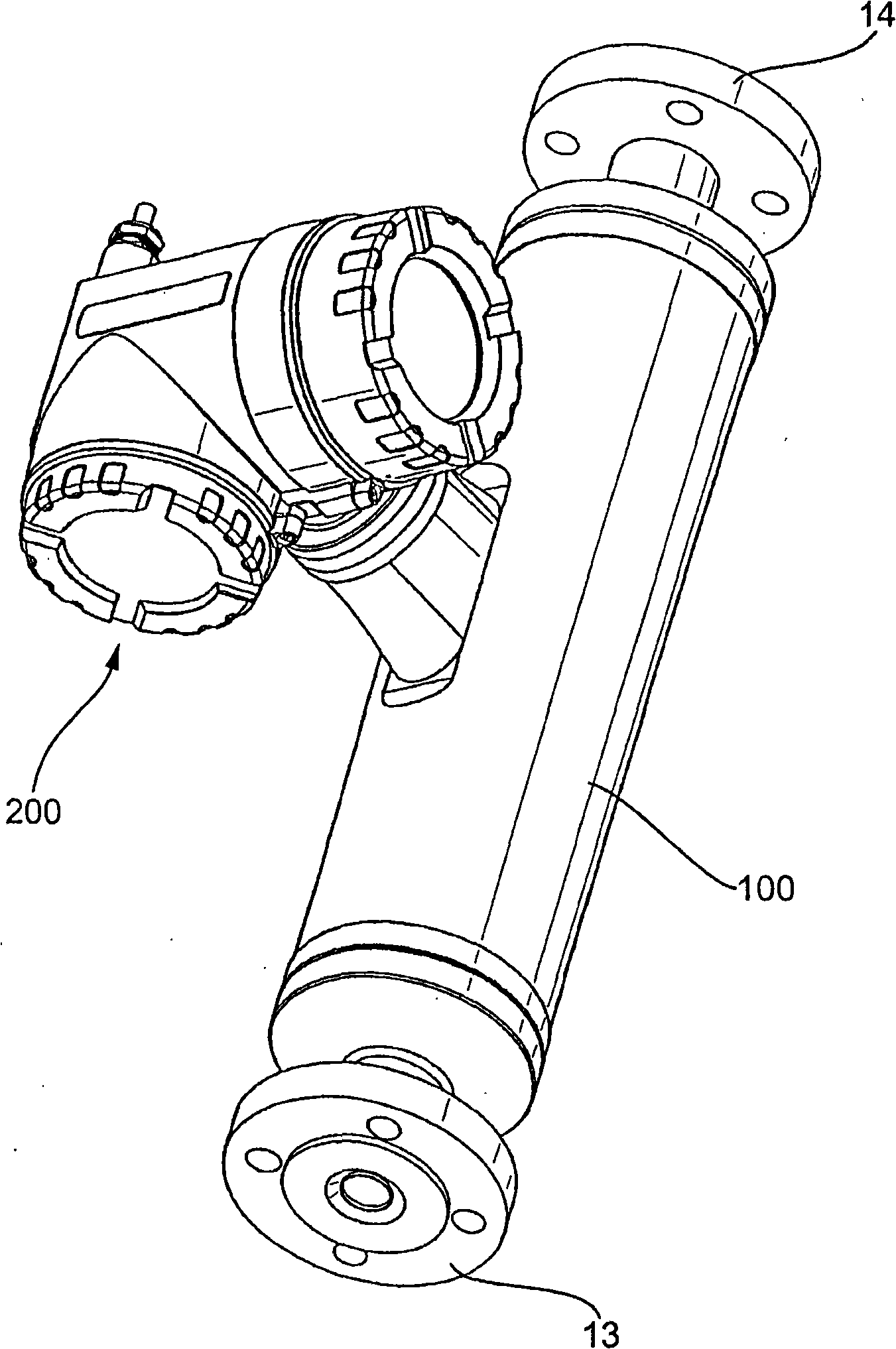

The measuring device comprises, for measuring multi phase mixture, a vibratory-type transducer and a measuring device electronics electrically coupled with the vibratory-type transducer. The transducer includes at least one measuring tube inserted into the course of the pipeline. An exciter arrangement acts on the measuring tube for causing the at least one measuring tube to vibrate. A sensor arrangement senses vibrations of the at least one measuring tube and delivers at least one oscillation measurement signal representing oscillations of the measuring tube. Further, the measuring device electronics delivers an excitation current driving the exciter arrangement. The measuring device is adapted to compensating measurement errors, induced due to the presence of multi phase mixture, based on a movin resonator model (MRM).

Owner:ENDRESS HAUSER FLOWTEC AG

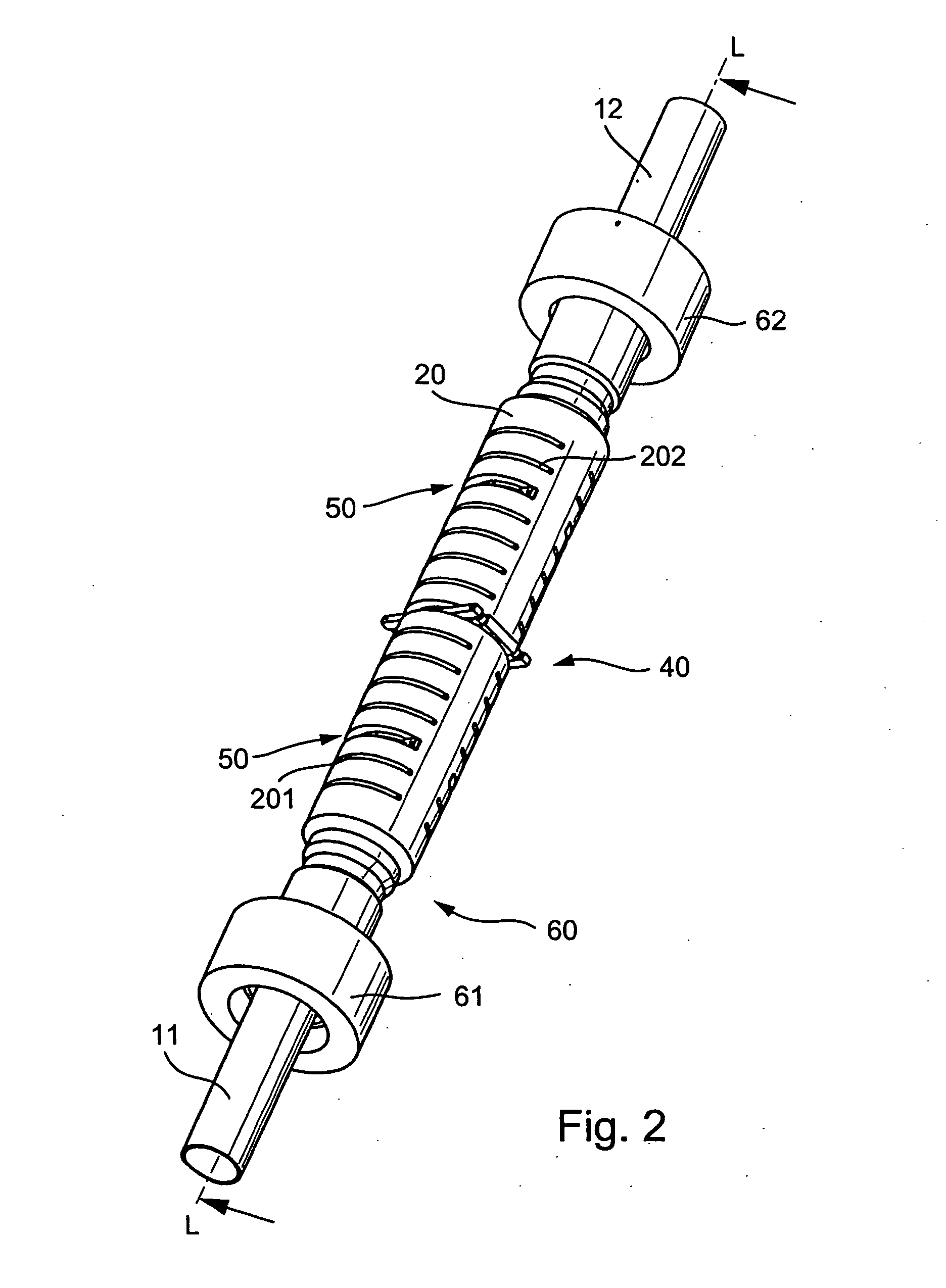

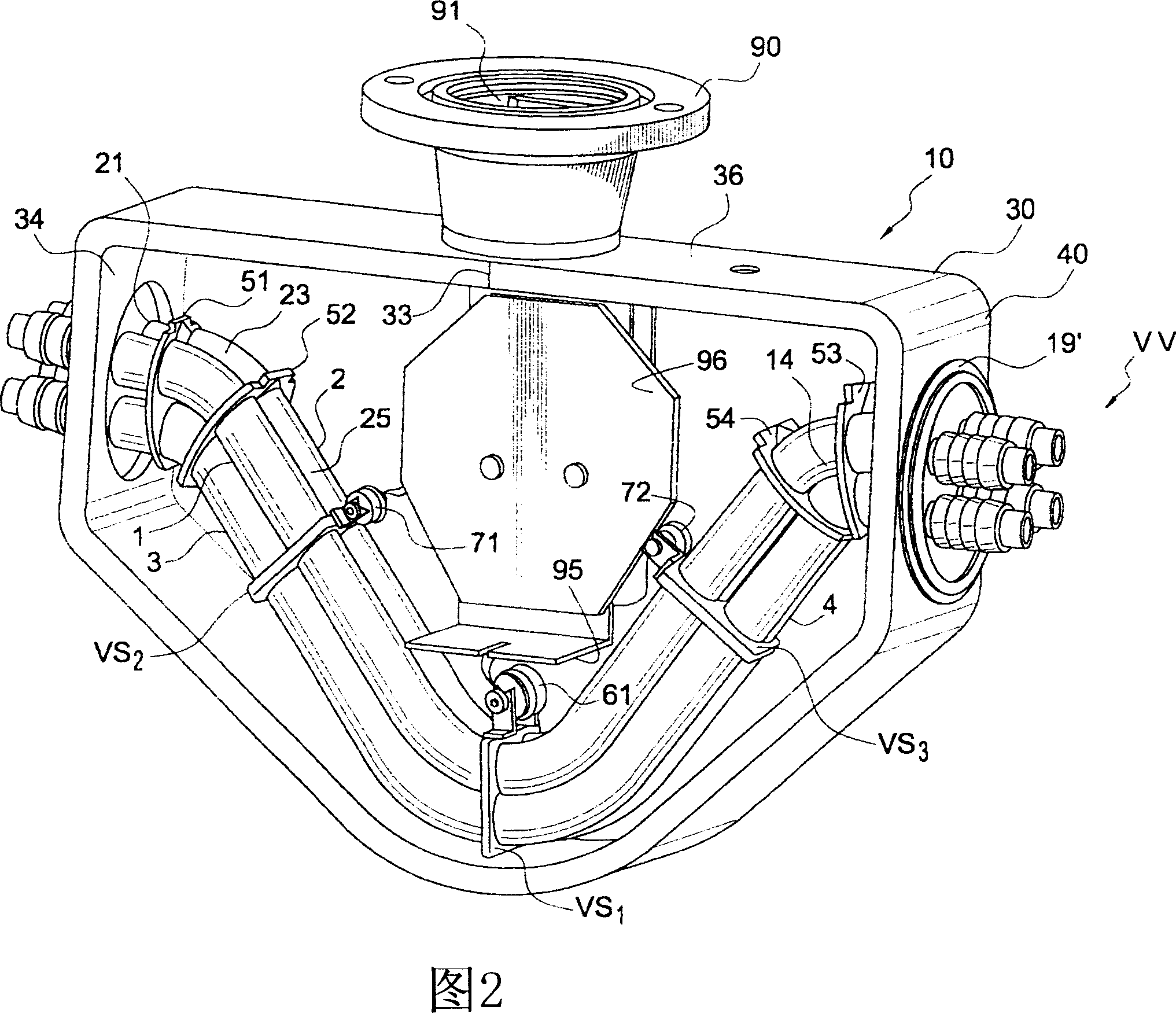

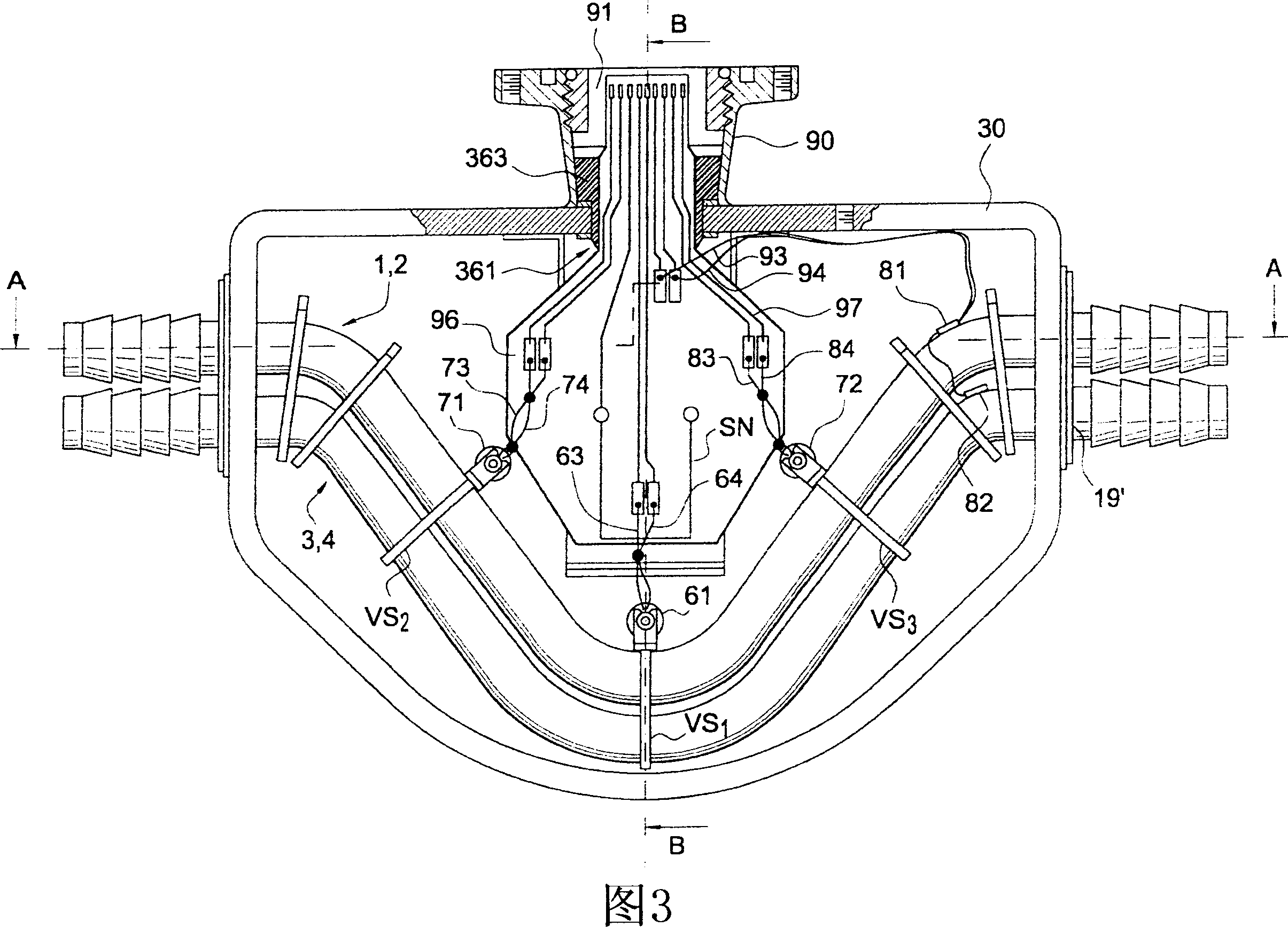

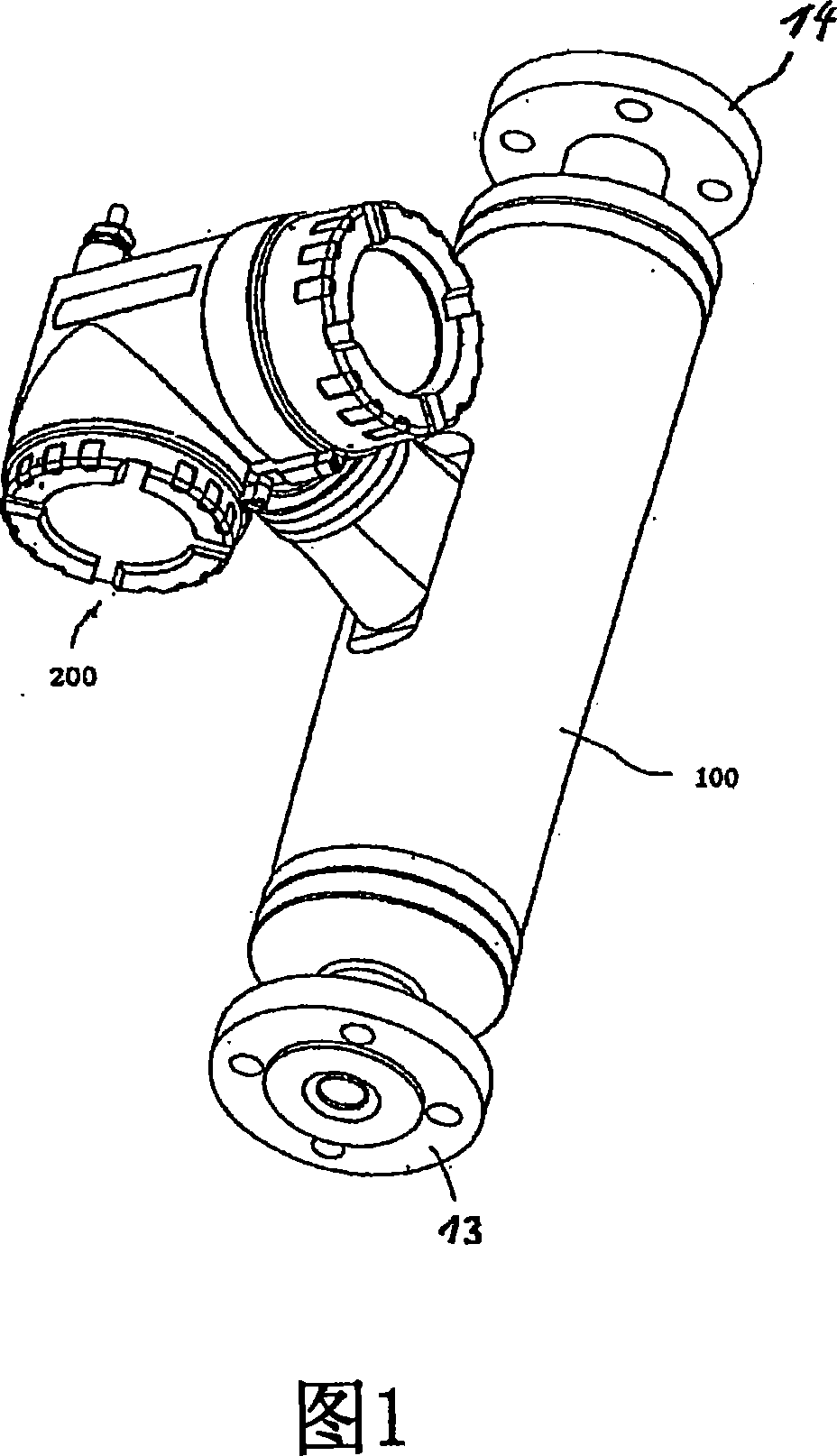

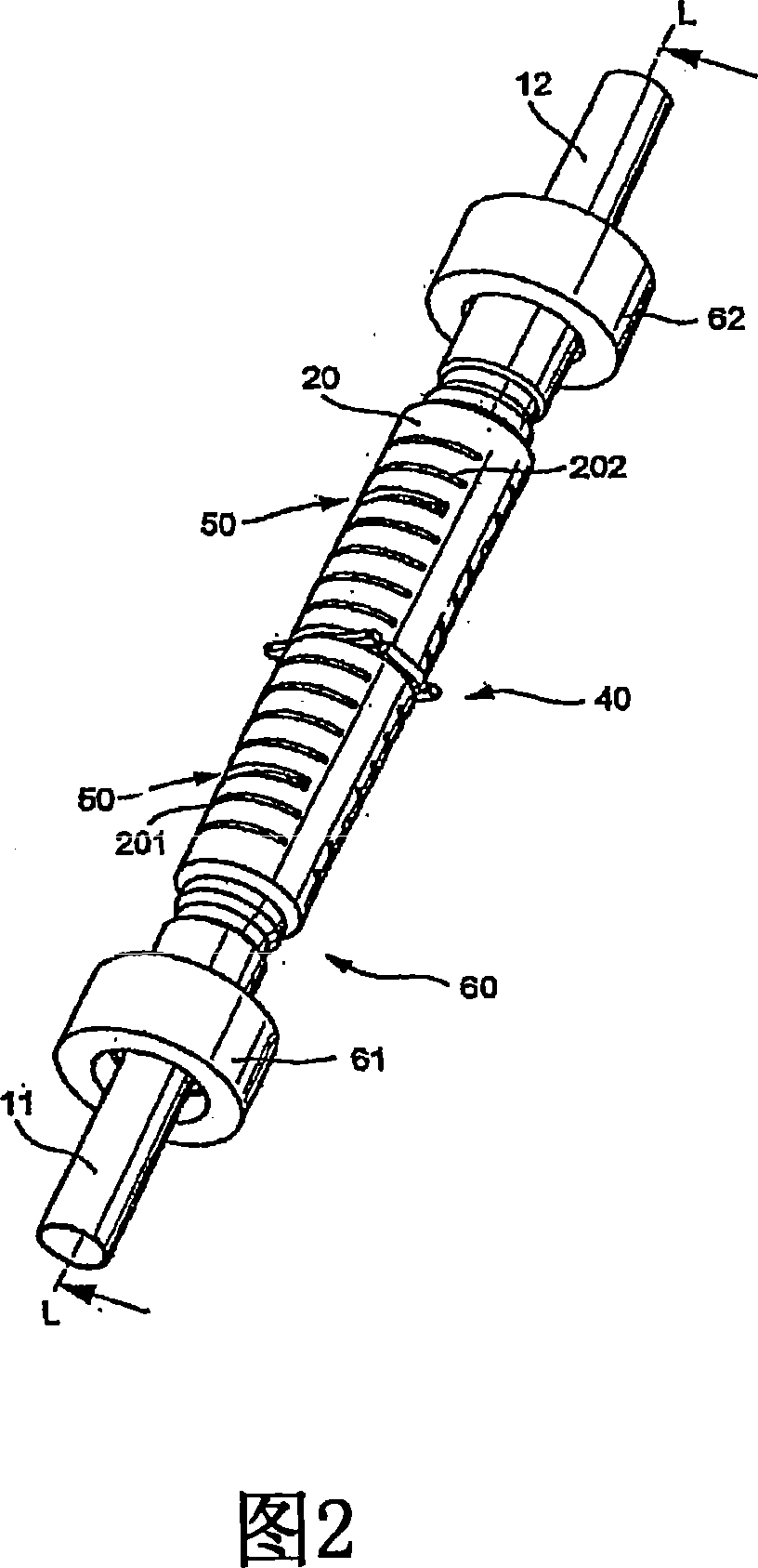

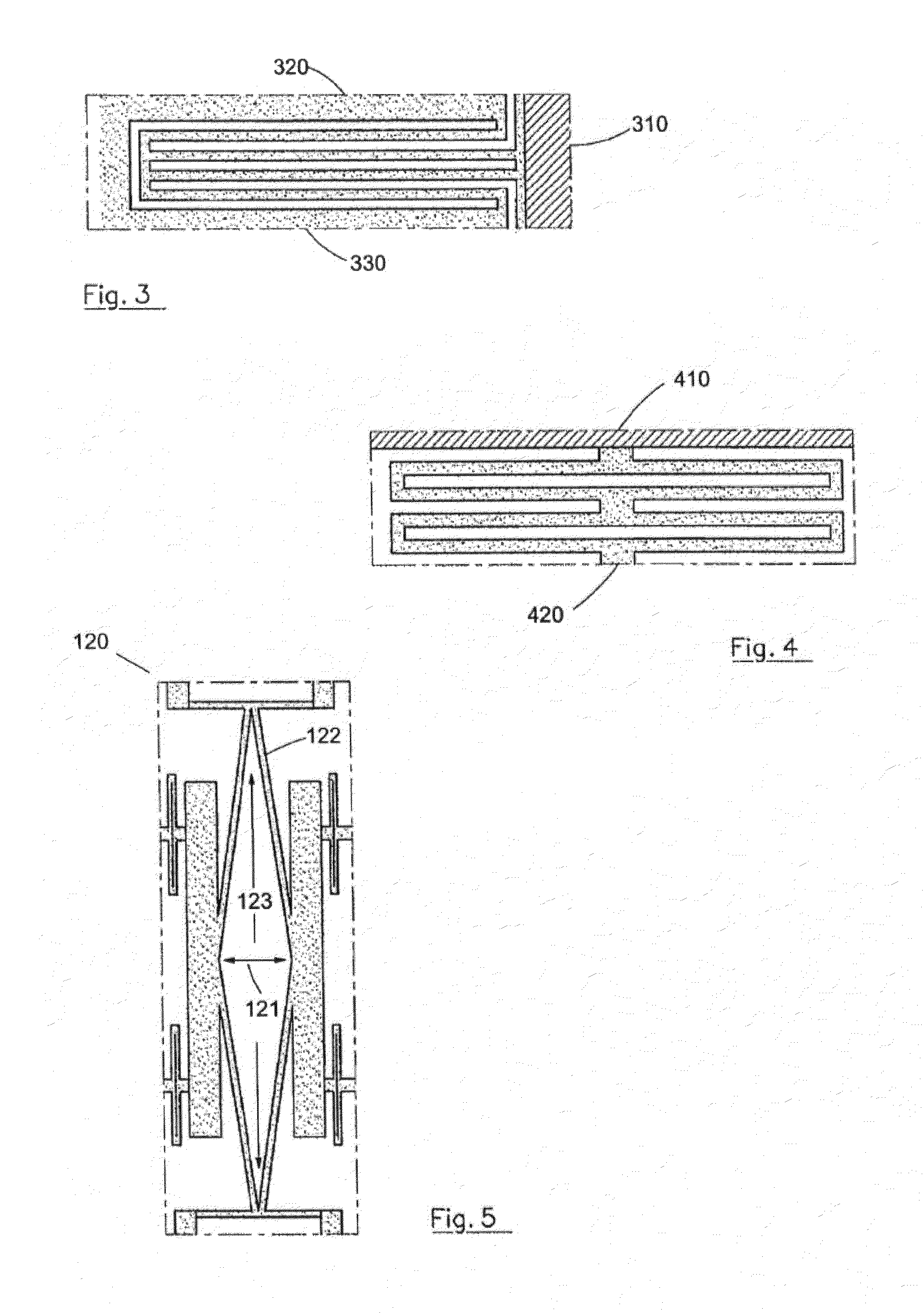

Vibration-type measuring sensor for conduction measurements in media flowing inside two medium lines, and in-line measuring device equipped with a measuring sensor of this type

InactiveCN101019008ACheap manufacturingHigh measurement accuracyFlow propertiesDirect mass flowmetersMedium densityEngineering

A measurement pickup includes at least four measuring tubes for conveying media to be measured. Each measuring tube has a first in- / outlet end and a second in- / outlet end. During operation, the measuring tubes vibrate, at least at times, especially simultaneously. The measurement pickup further includes an electromechanical exciter mechanism causing the measuring tube to vibrate, as well as a sensor arrangement reacting at least to local vibrations of the measuring tubes for producing at least one measurement signal influenced by vibrations of the measuring tubes. Of the at least four measuring tubes, two measuring tubes are, at least at times, inserted into the course of a first medium-line such that each of these two measuring tubes simultaneously conveys, in each case, a partial volume of a medium flowing through the first medium line, and two other measuring tubes of the at least four measuring tubes are, at least at times, inserted into the course of a second medium line such that each of these two measuring tubes simultaneous conveys, in each case, a partial volume of a second medium flowing through the second medium line. The measurement pickup can thus, on the one hand, have two media flowing through it, which differ measurably from one another in at least one physical property, for example mass flow rate, medium density and / or medium temperature, while having, on the other hand, despite the different media, a good zero-point stability.

Owner:ENDRESS HAUSER FLOWTEC AG

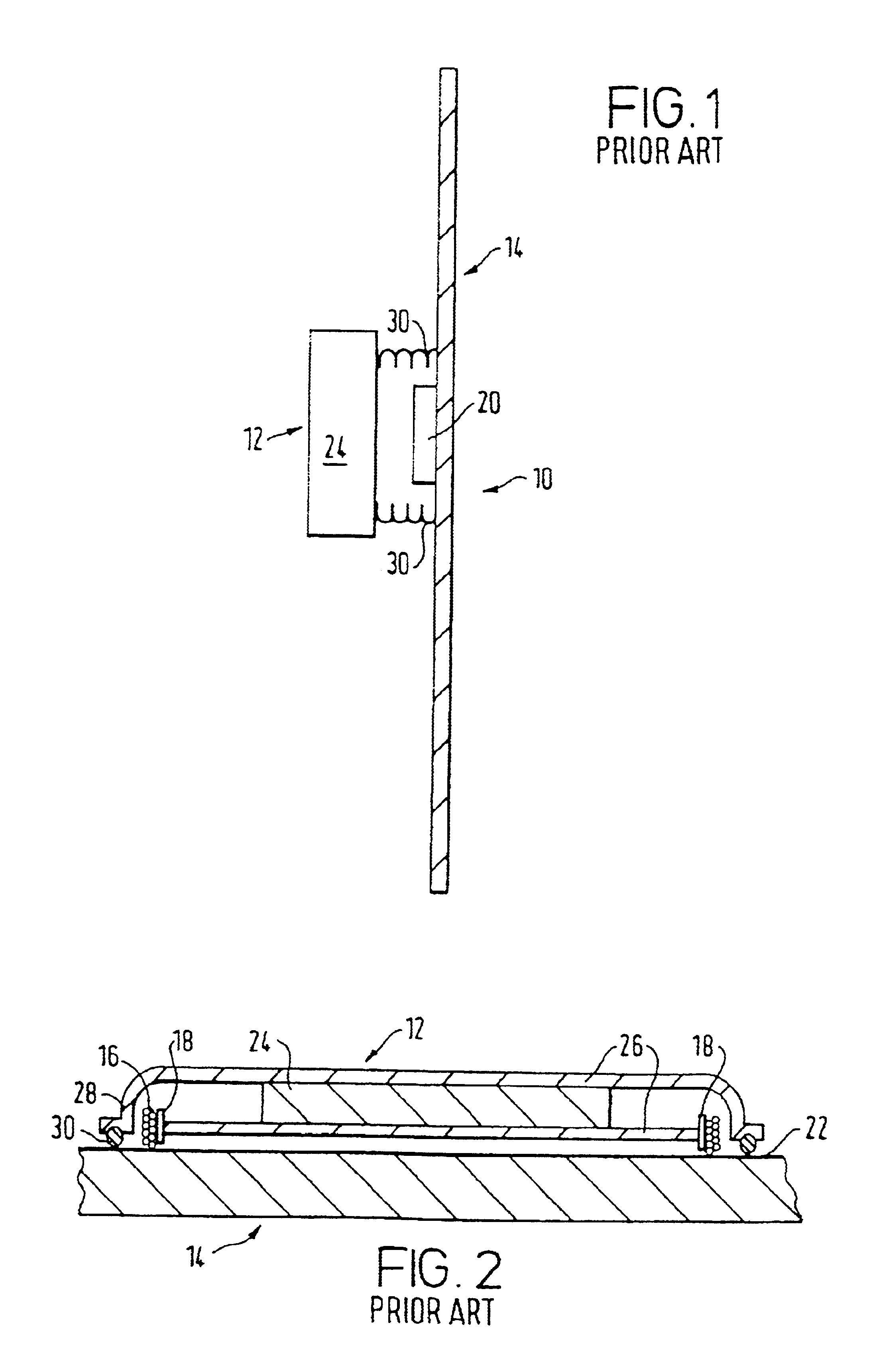

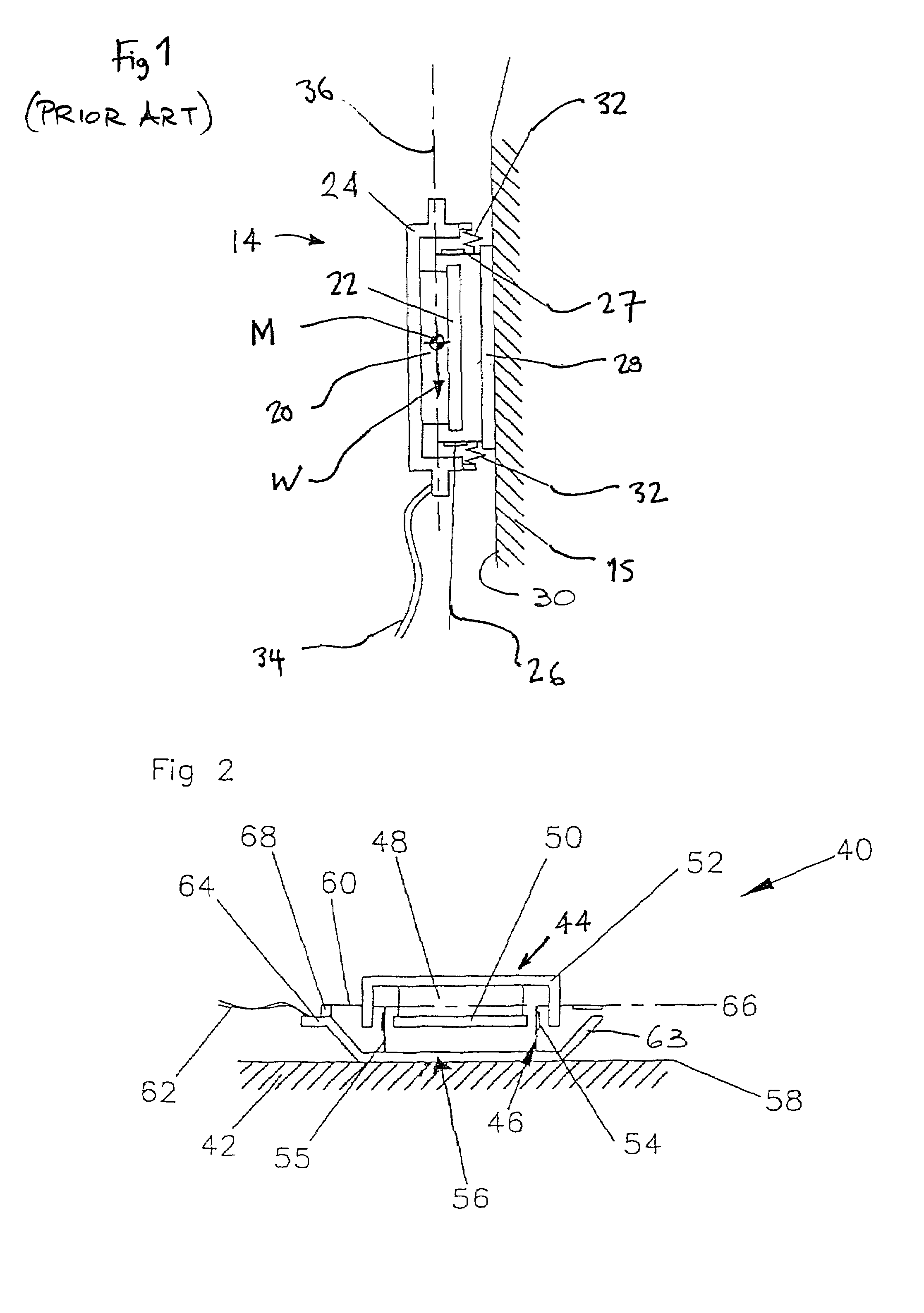

Loudspeakers

InactiveUS6956957B1Prevent radial movementLower Level RequirementsSound producing devicesPlane diaphragmsEngineeringLoudspeaker

A loudspeaker drive unit comprising a resonant acoustic radiator, an exciter on the radiator to apply bending wave energy to the radiator to cause it to resonate, a support for the loudspeaker drive unit, and means resiliently coupling the exciter to the support.

Owner:GOOGLE LLC

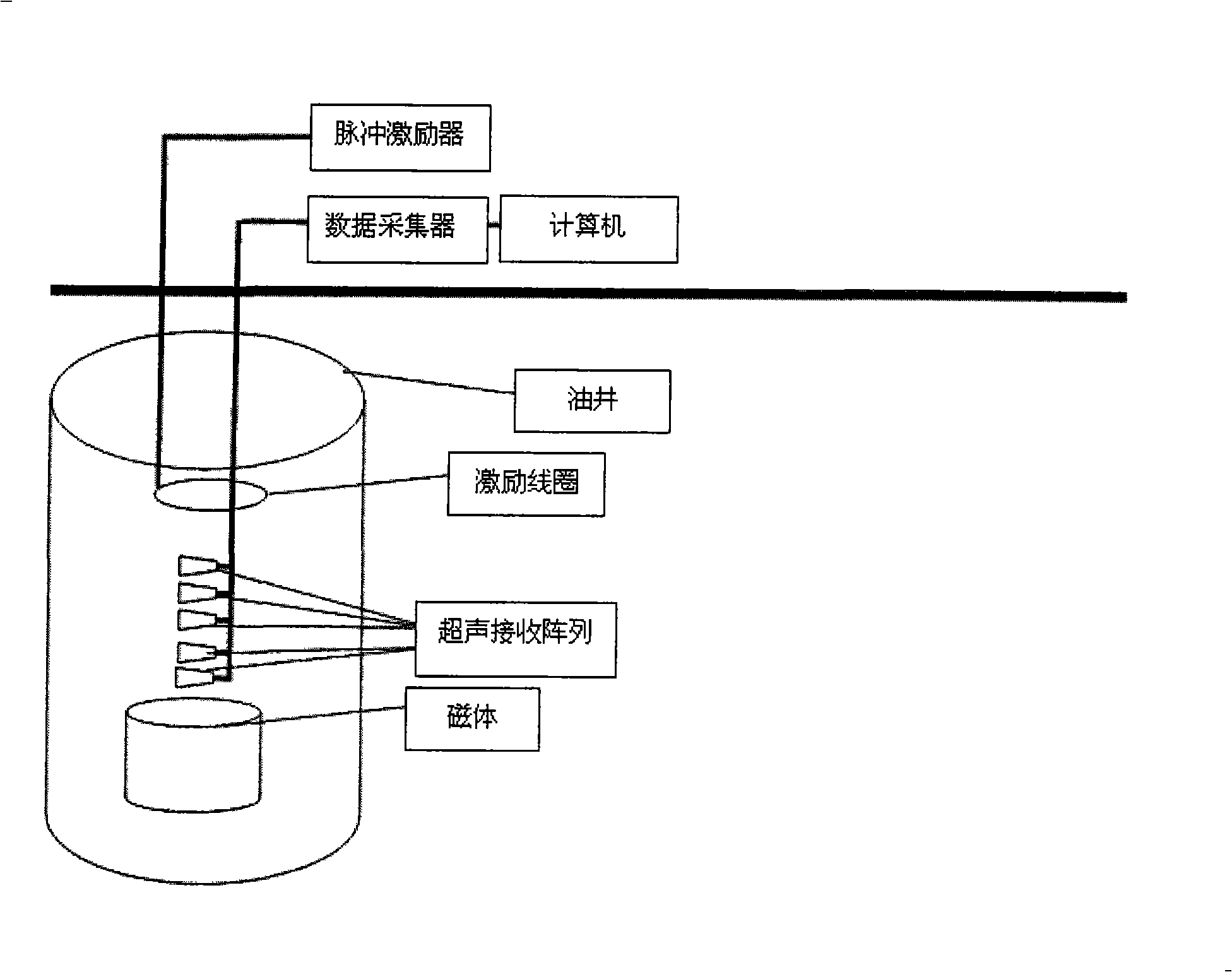

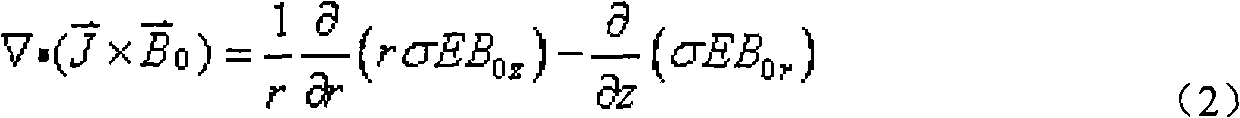

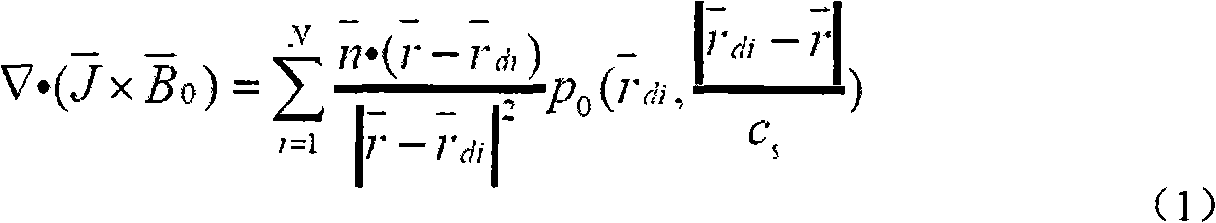

Array magnetic-acoustic electro-conductibility imaging logging method and apparatus

The invention relates to an array magnetic sound electrical conductivity imaging logging method. The array magnetic sound electrical conductivity imaging logging method is characterized in that a static magnetic field is generated by magnets distributed in the well in the stratum around the well, an impulse exciter connected with an exciting coil ensures the exciting coil to generate transient current, induction current is generated in the stratum around the well, and Lorentz force is generated by the induction current under the effect of the static magnetic field, thereby exciting supersonic signals; the supersonic signals which are transmitted in the well through the stratum are received and measured, and according to the nonlinear relationship between the sound pressure and the electrical conductivity, an image of the electrical conductivity around the well is obtained through the image reconstruction. In the devices applying the array magnetic sound electrical conductivity imaging logging method, the magnets, the exciting coil and a supersonic receiving array are positioned in the oil well, and the impulse exciter, a data collector and a computer are positioned on the ground around the oil well. The supersonic receiving array is positioned between the magnets and the exciting coil, and the magnets and the exciting coil are distributed up and down. The impulse exciter is connected with the exciting coil through a cable; and the supersonic receiving array, the data collector and the computer are mutually connected sequentially.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Measuring system having a measuring transducer of vibration-type

ActiveUS20110154912A1High measurement accuracyVolume/mass flow by dynamic fluid flow effectElectricityTransducer

The measuring system comprises: A measuring transducer of vibration-type, through which medium flows during operation and which produces primary signals corresponding to parameters of the flowing medium; as well as a transmitter electronics electrically coupled with the measuring transducer for activating the measuring transducer and for evaluating primary signals delivered by the measuring transducer. The measuring transducer includes: At least one measuring tube for conveying flowing medium; at least one electro-mechanical, oscillation exciter for exciting and / or maintaining vibrations of the at least one measuring tube; as well as at least a first oscillation sensor for registering vibrations at least of the at least one measuring tube and for producing a first primary signal of the measuring transducer representing vibrations at least of the at least one measuring tube. The transmitter electronics, in turn, delivers at least one driver signal for the exciter mechanism for effecting vibrations of the at least one measuring tube and generates, by means of the first primary signal, as well as with application of a damping, measured value, which represents an excitation power required for maintaining vibrations of the at least one measuring tube, and, respectively, a damping of vibrations of the at least one measuring tube as a result of inner friction in the medium flowing in the measuring transducer, a pressure difference, measured value, which represents a pressure difference occurring between two predetermined reference points in the flowing medium.

Owner:ENDRESS HAUSER FLOWTEC AG

Coriolis mass flowmeter

ActiveCN1934425AAccurate measurementFlow propertiesVolume meteringApparent viscosityClassical mechanics

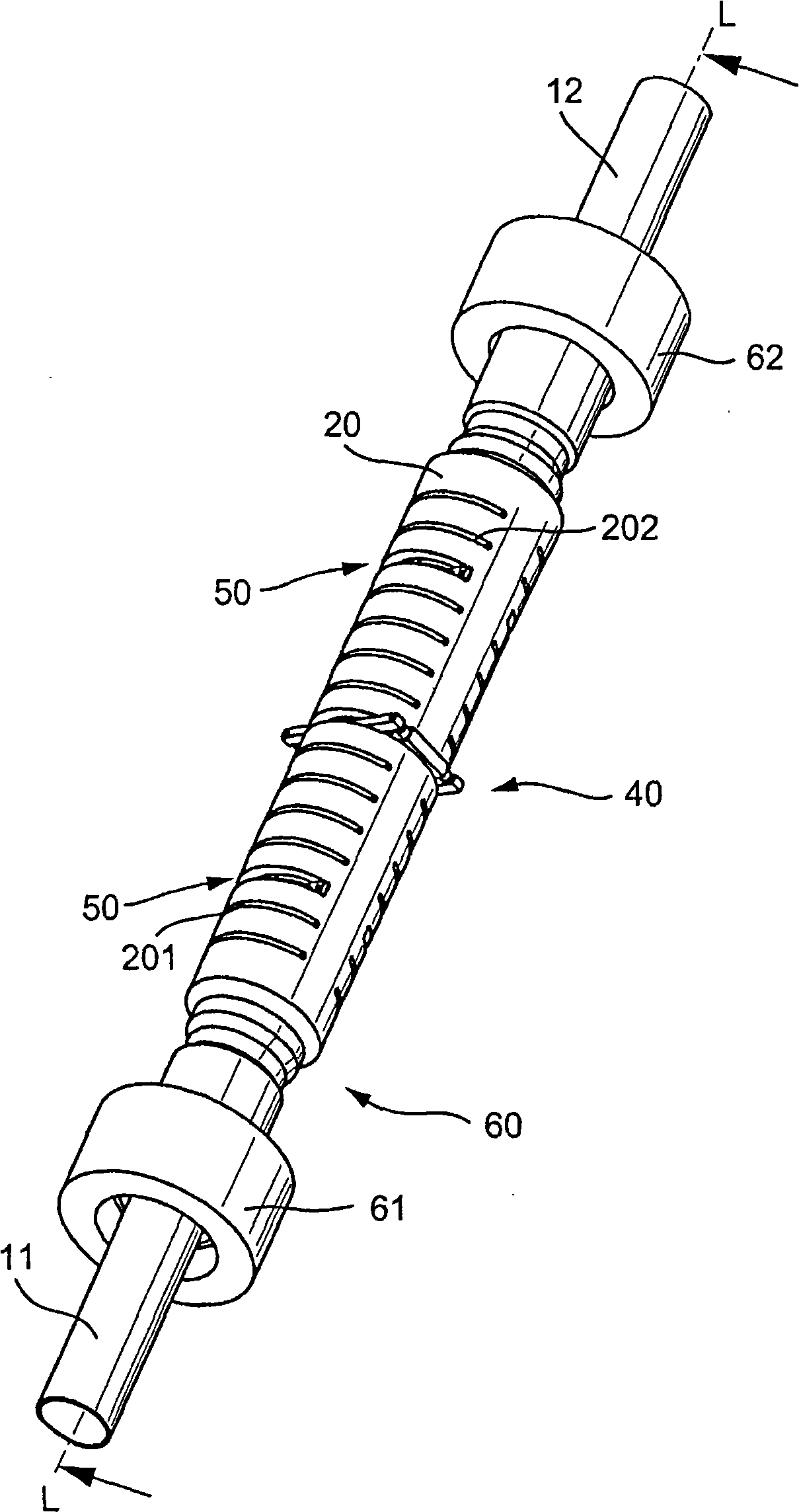

The invention relates to a Coriolis mass flowmeter comprising a vibration-type measuring sensor (1) comprising at least one measuring tube (10) through which a medium can flow during operation. During operation, the measuring tube moves by mechanical vibrations, especially bending vibrations, by means of an exciter arrangement (40). The Coriolis mass flowmeter also comprises a sensor arrangement (50) for generating vibration measuring signals (sl, s2) representing inlet-side and outlet-side vibrations of the measuring tube (10). Flowmeter electronics (2) controlling the exciter arrangement generate an intermediate value (X'm) which is derived from the vibration measuring signals (s1, s2) and represents an uncorrected mass flow, and an exciter current (iexc) driving the exciter arrangement. An intermediate value (X2) is derived from the exciter current and / or from part of the exciter current (iexc), said value corresponding to a dampening of the vibrations of the measuring tube (11), dependent on an apparent viscosity and / or a viscosity-density product of the medium guided in the measuring tube (11). Furthermore, a correction value (XK) for the intermediate value (X'm) is generated using the intermediate value (X2) and a viscosity measuring value (Xeta) that is determined previously or during operation and corresponds to a viscosity of the medium guided in the measuring tube and / or a pre-determined reference viscosity. On the basis of the intermediate value (X'm) and the correction value (XK), the flowmeter electronics can then generate an accurate mass flow measuring value (Xm).

Owner:ENDRESS HAUSER FLOWTEC AG

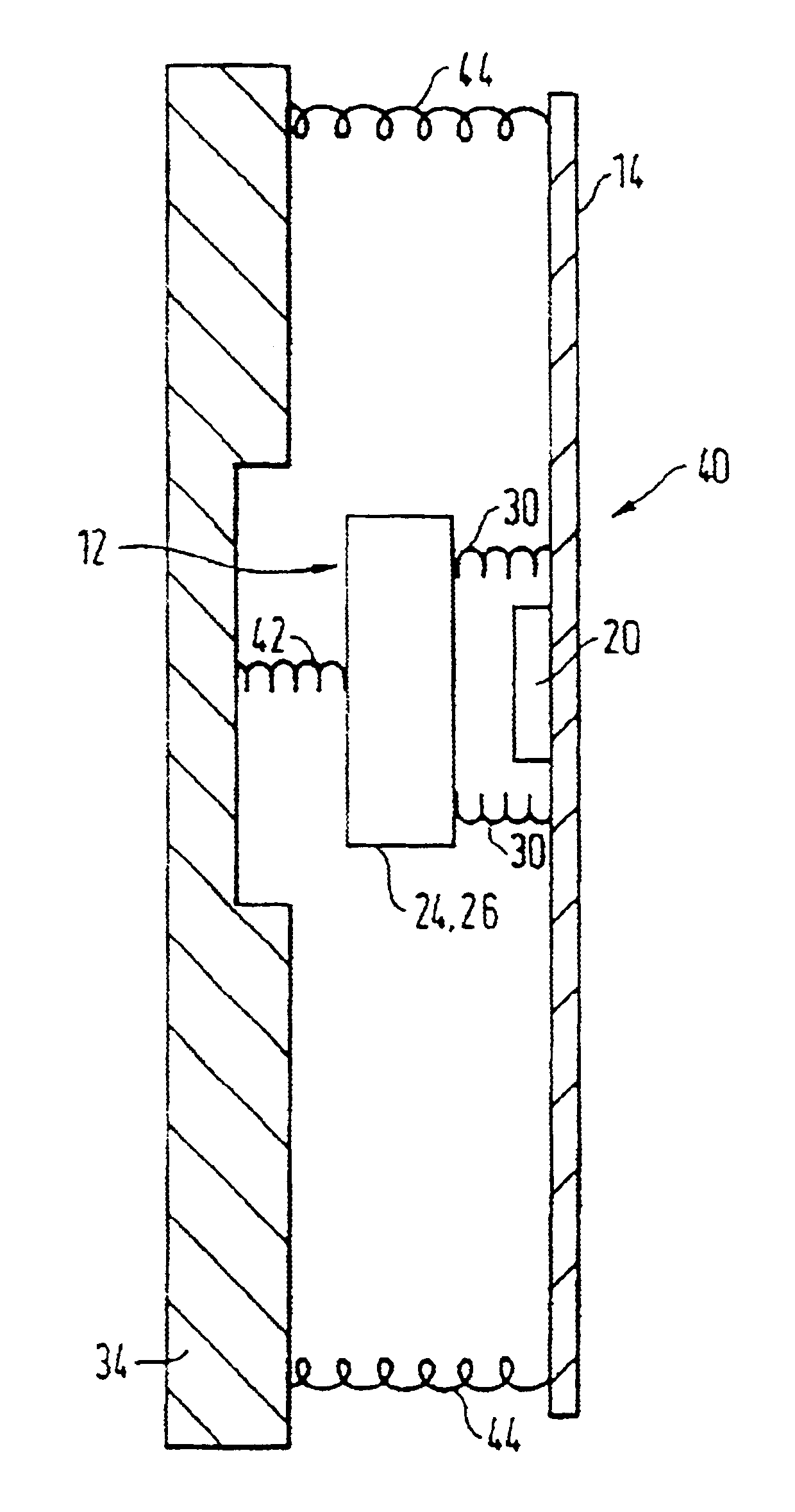

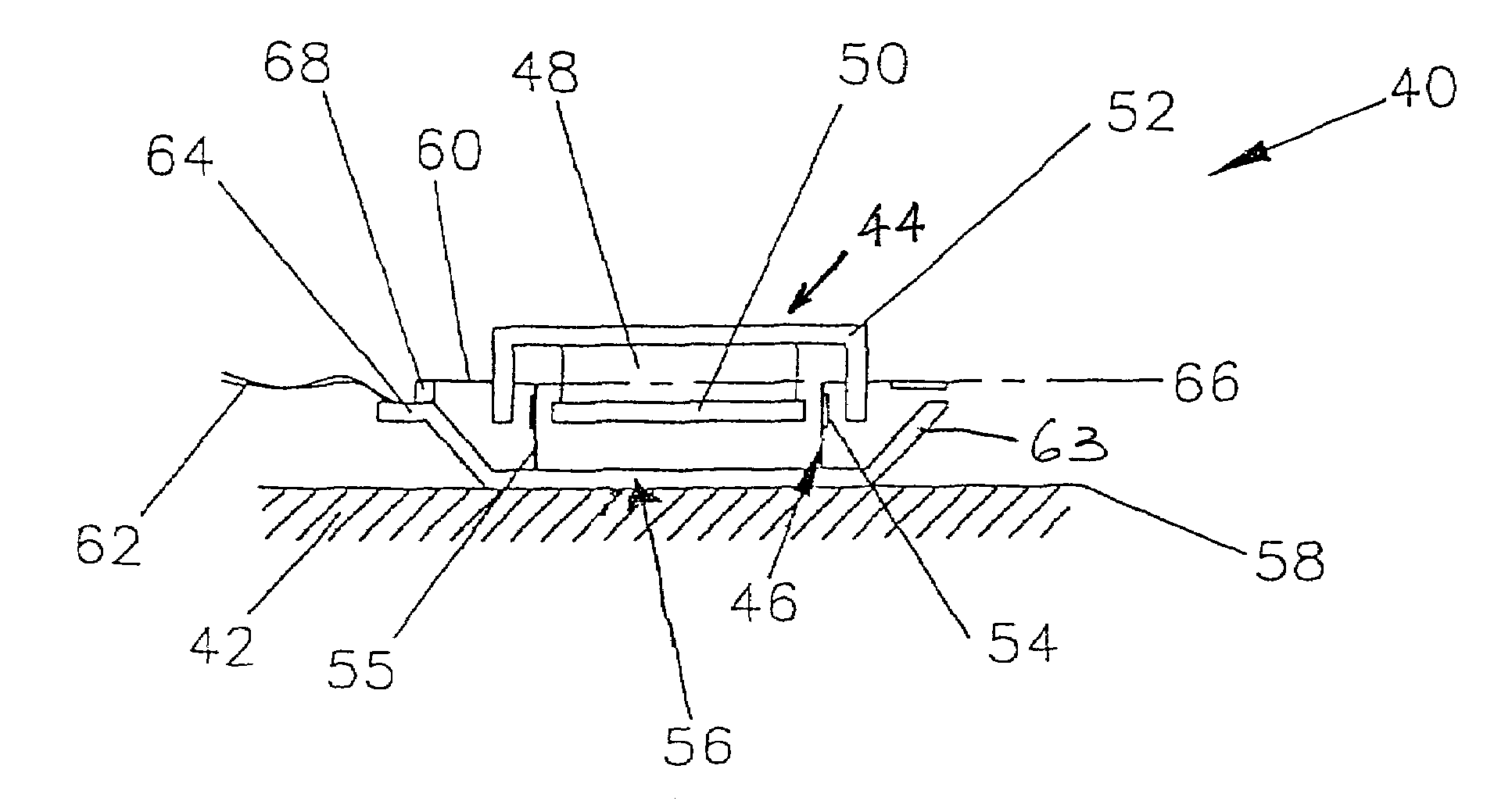

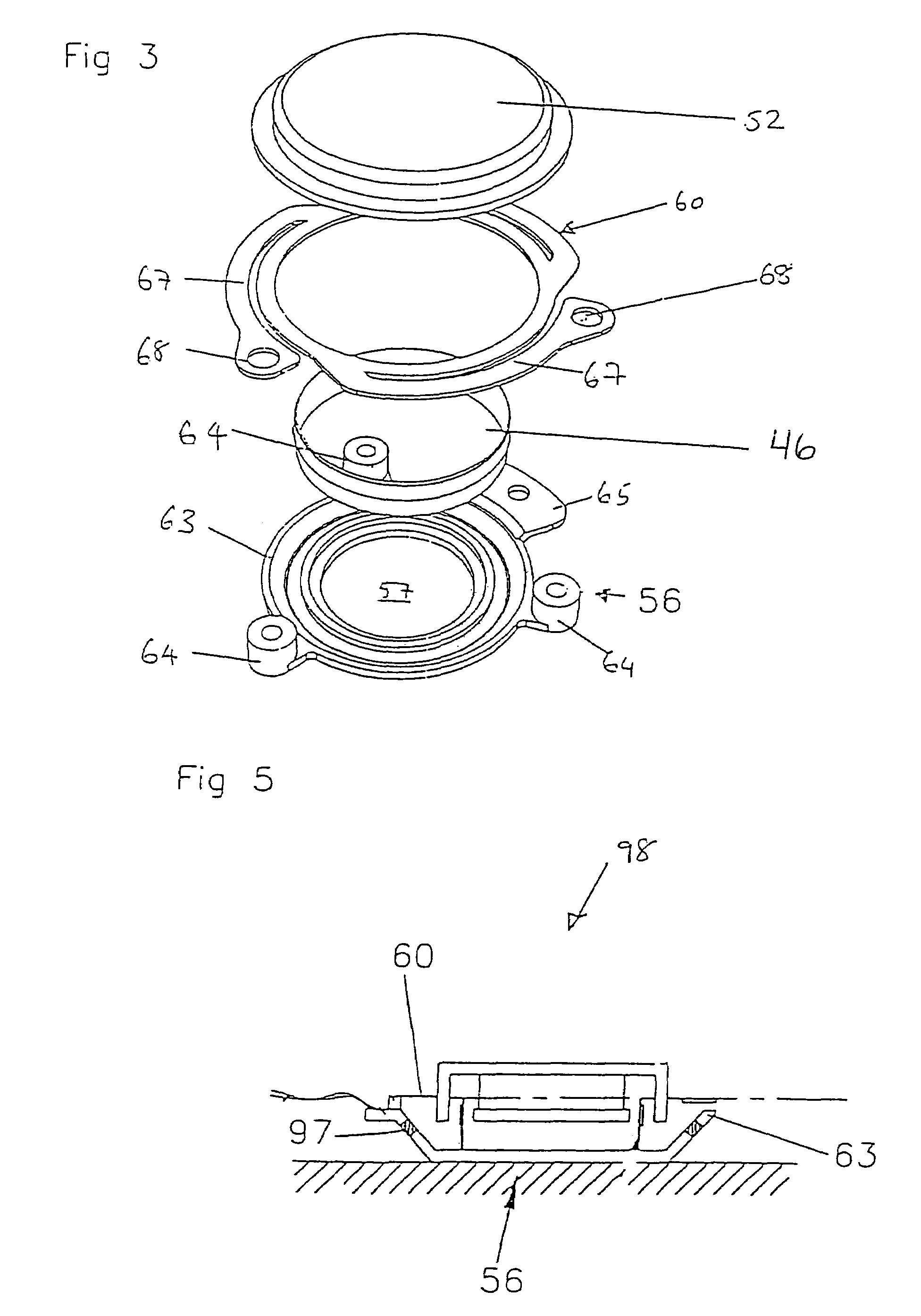

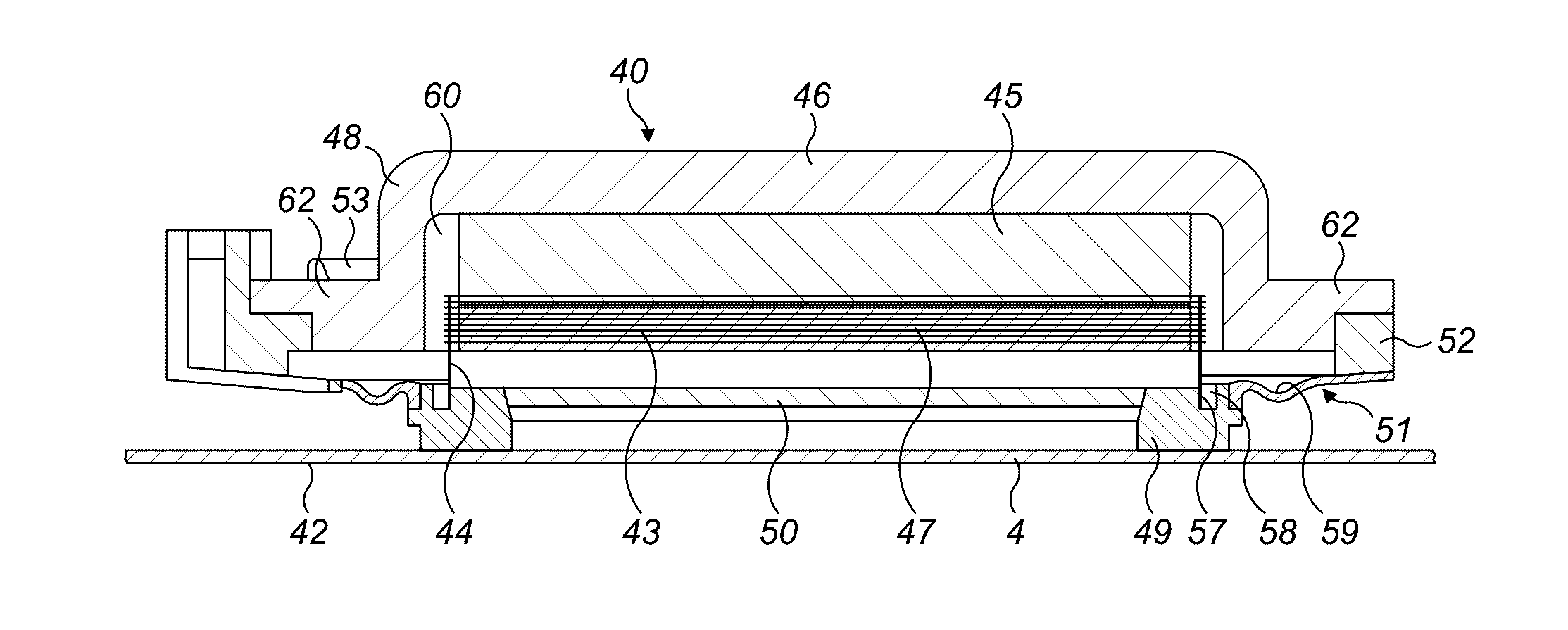

Loudspeaker driver

ActiveUS7372968B2Reducing any moment actingPlane diaphragmsTransducer casings/cabinets/supportsRelative motionLoudspeaker

An inertial exciter (40) for an acoustic radiator (42), and a loudspeaker incorporating an acoustic radiator and such an exciter. The exciter has a massive member (44); a coupler (56) adapted for attachment to the acoustic radiator (42) and adapted for relative movement with respect to the massive member (44); a motor for effecting relative movement of the coupler with respect to the massive member; and a suspension (60) for supporting the massive member relative to the coupler. The suspension (60) acts in a plane generally passing through the center of mass of the massive member, thereby reducing any moment acting on the suspension.Also disclosed is a loudspeaker exciter assembly (70) that has a base plate (86) for attachment to an acoustic radiator in a non-repeatedly engageable manner, and an exciter (40) attached to the base plate (86) in a repeatedly engageable manner; and a loudspeaker incorporating such an exciter assembly.

Owner:GOOGLE LLC

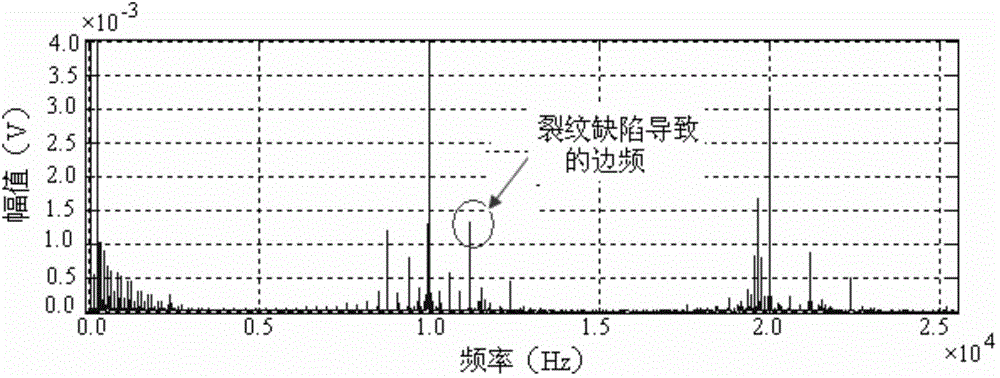

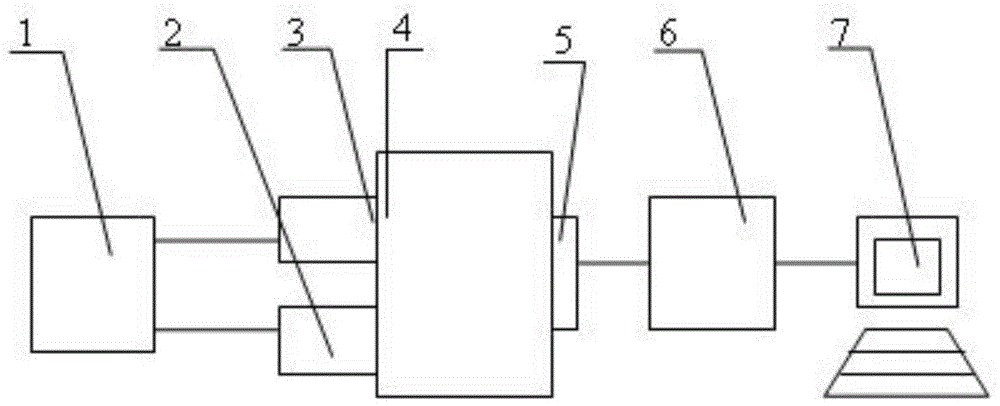

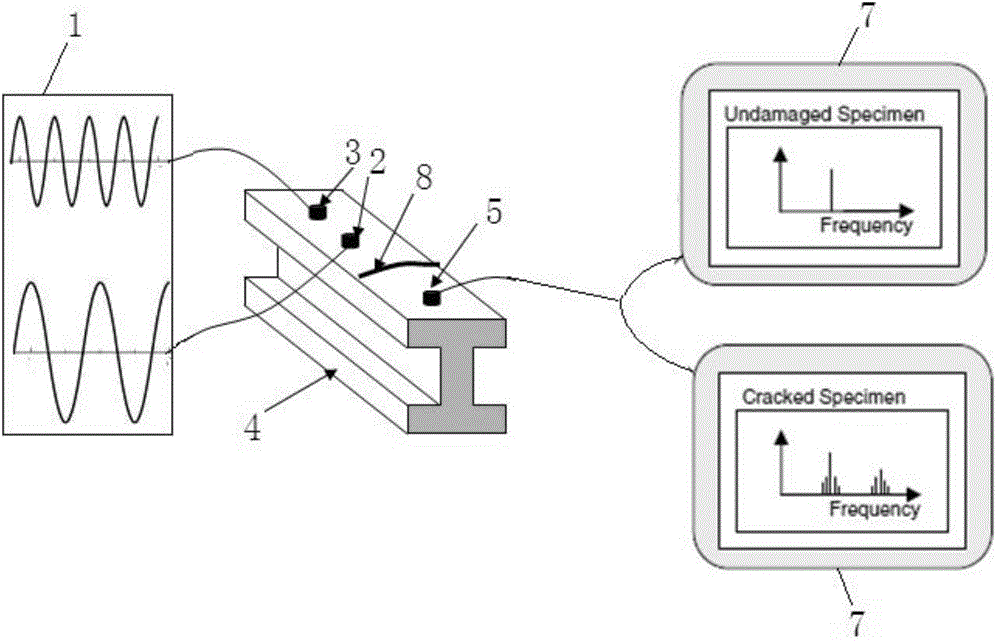

Micro-crack nondestructive detection system and detection method thereof

ActiveCN104407049AOvercoming insensitivityHigh sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesAdhesiveResponse spectrum

The invention discloses a micro-crack nondestructive detection system and a detection method thereof. The micro-crack nondestructive detection system comprises a signal generator, a low frequency vibration exciter, a high frequency exciter, a detected member, a piezoelectric sensor, a preamplifier and a signal acquisition and analysis system; the signal generator is electrically connected with the detected member through the low frequency vibration exciter and the high frequency exciter, the piezoelectric sensor is fixed on the detected member through an adhesive, and the signal acquisition and analysis system is electrically connected with the piezoelectric sensor through the preamplifier; and the signal-generator can simultaneously output two paths of simple harmonic excitation signals with different frequencies. Defect detection is carried out by using the non-linear modulation effect of a crack structure under multi-frequency excitation, and whether the existence or not of the micro-crack and the micro-crack damage of the detected member are directly determined according to the quantity and amplitude of side frequencies in a response spectrum without complex signal processing, so the system and the method have the advantages of use convenience, sensitive detection and high detection efficiency.

Owner:HUNAN INSTITUTE OF ENGINEERING

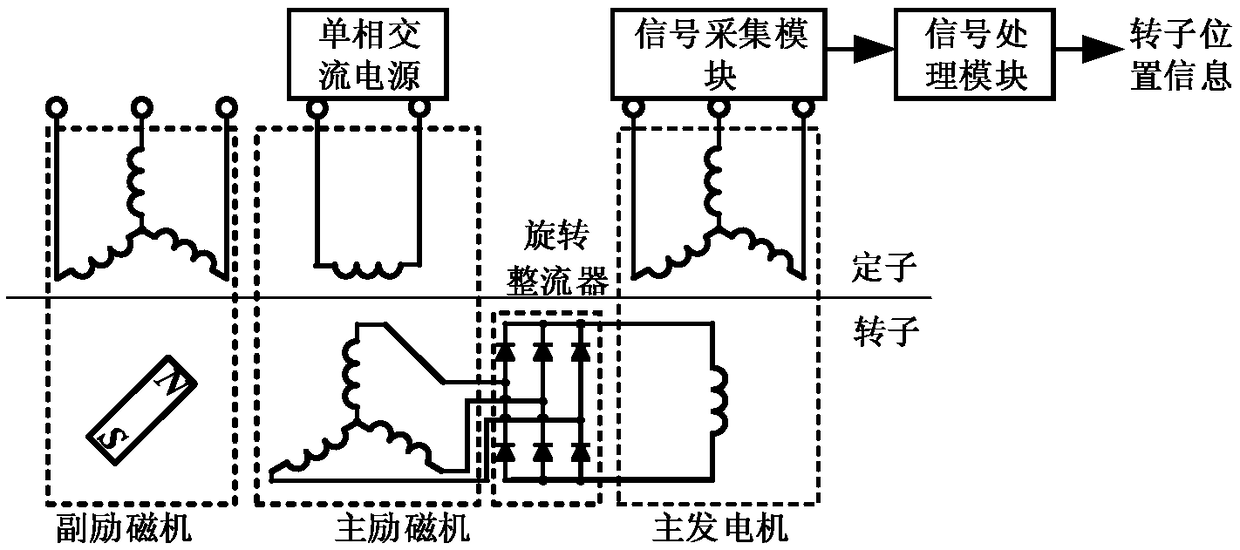

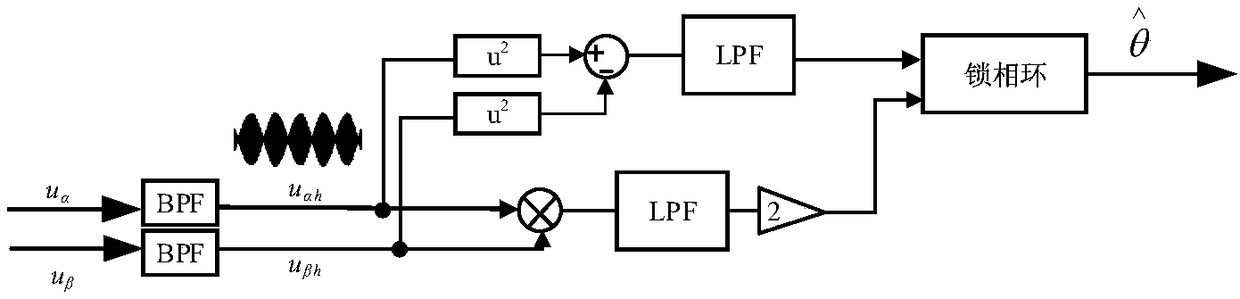

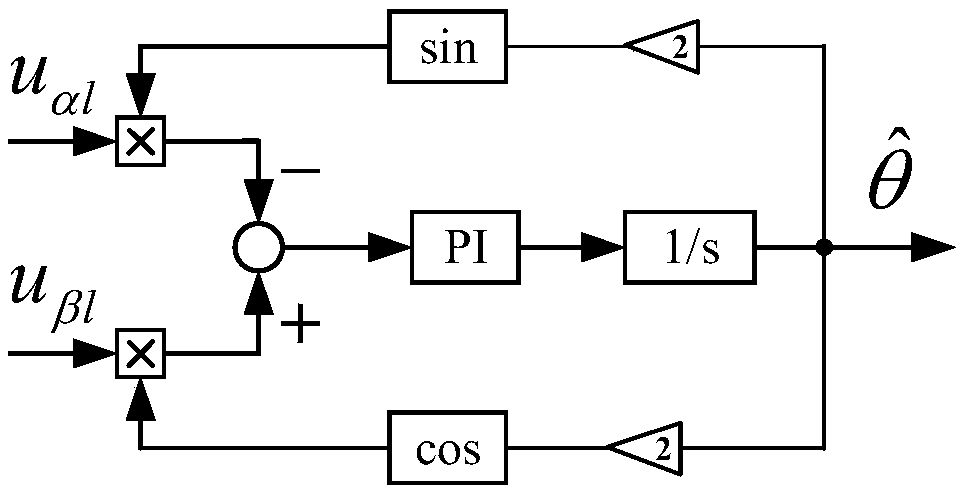

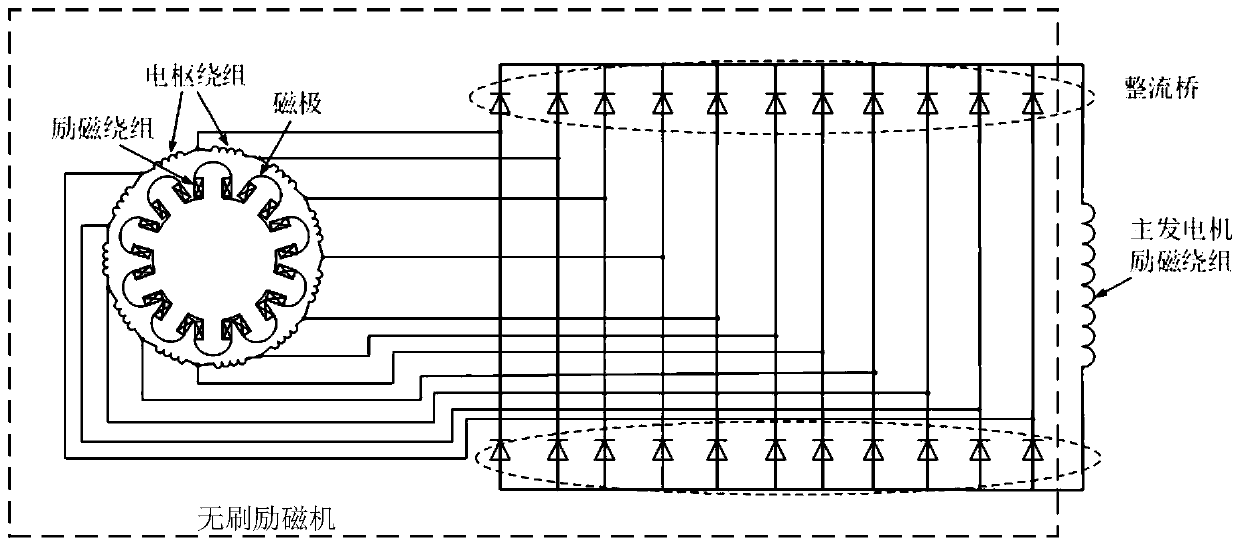

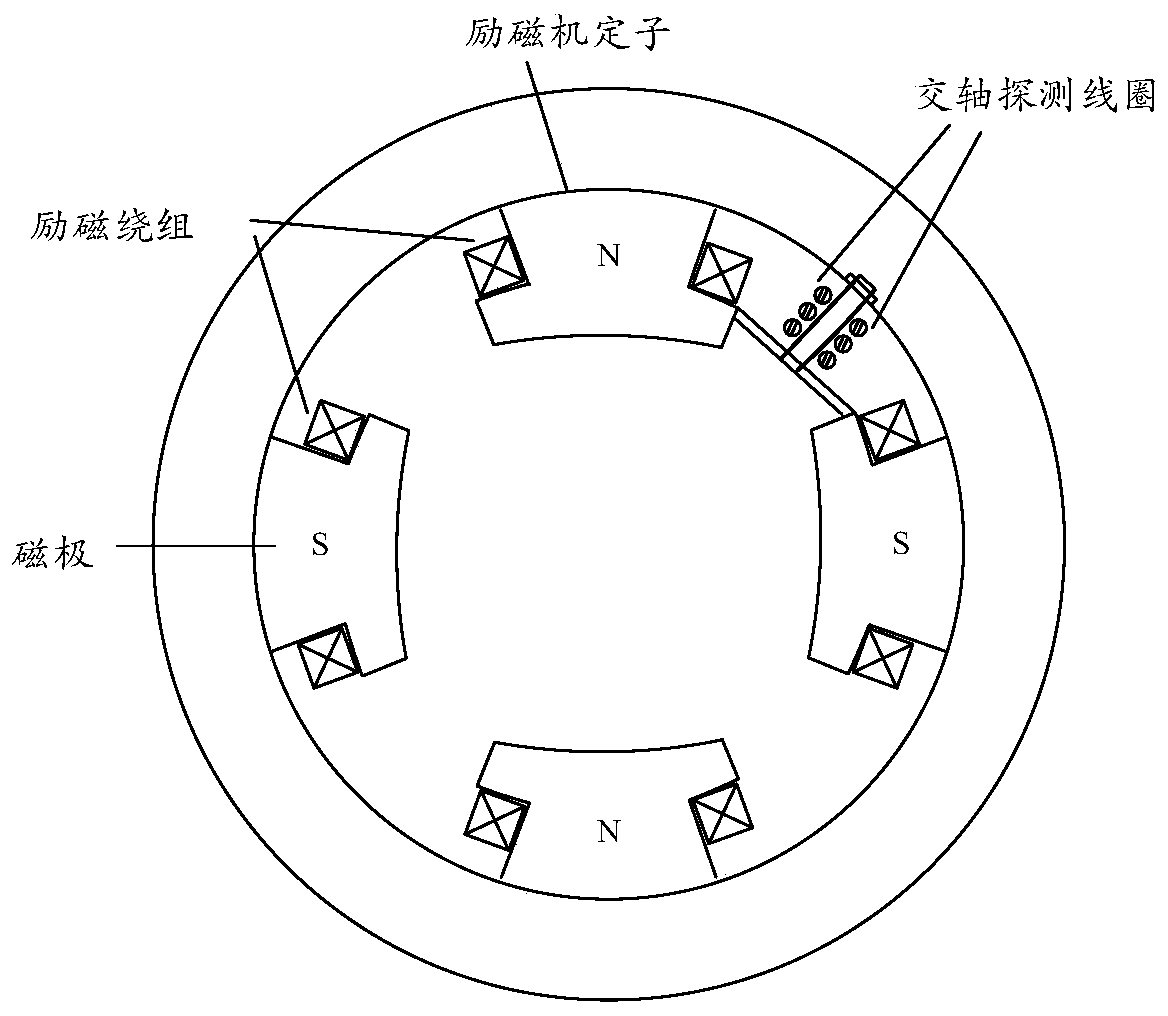

Three-stage synchronous machine rotor position estimation system and estimation method

ActiveCN109150028AReduce complexityReduce volumeTorque ripple controlElectric motor controlSynchronous motorEngineering

The invention discloses a three-stage synchronous motor rotor position estimation system and an estimation method. The system comprises a three-stage synchronous motor, a single-phase AC power supply,a signal acquisition module and a signal processing module. The three-stage synchronous motor comprises a main exciter, a rotary rectifier and a main generator coaxially arranged. The single-phase alternating current power supply leads the excitation winding of the main exciter into the single-phase alternating current to generate pulsating magnetic field, A three-phase alternating current is induced in the armature winding of the main exciter, After pssing the rotary rectifier, the excitation winding of the main generator is supplied with power, and a high-frequency signal containing rotor position information is induced in the armature winding of the main generator. The signal acquisition module extracts the high-frequency signal containing rotor position information, and then the rotorposition angle is estimated through the signal processing module. As that invention does not require additional injection of other signals, the output torque fluctuation of the motor introduce by thetraditional high-frequency signal injection method is avoided, and the invention has good robustness and stability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

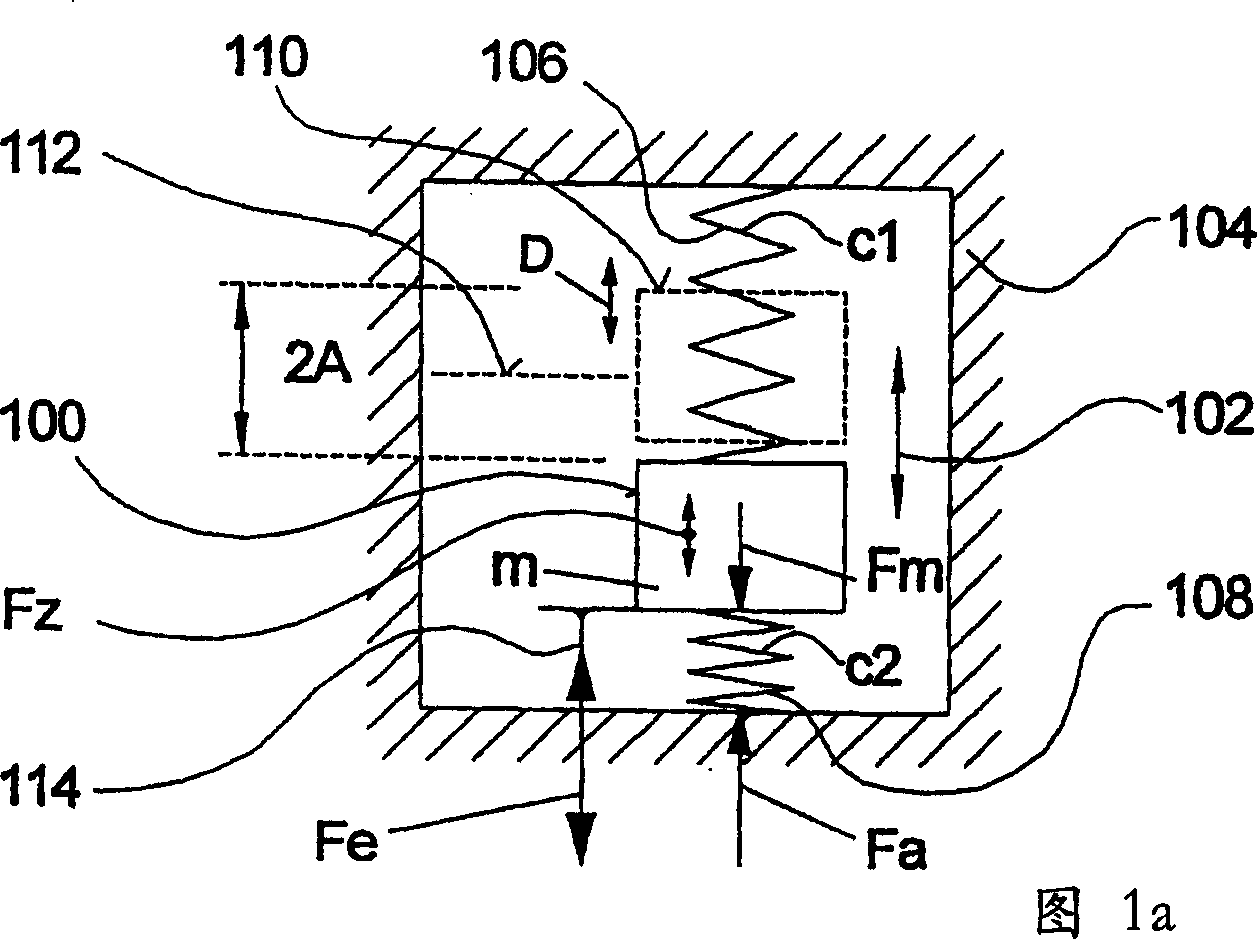

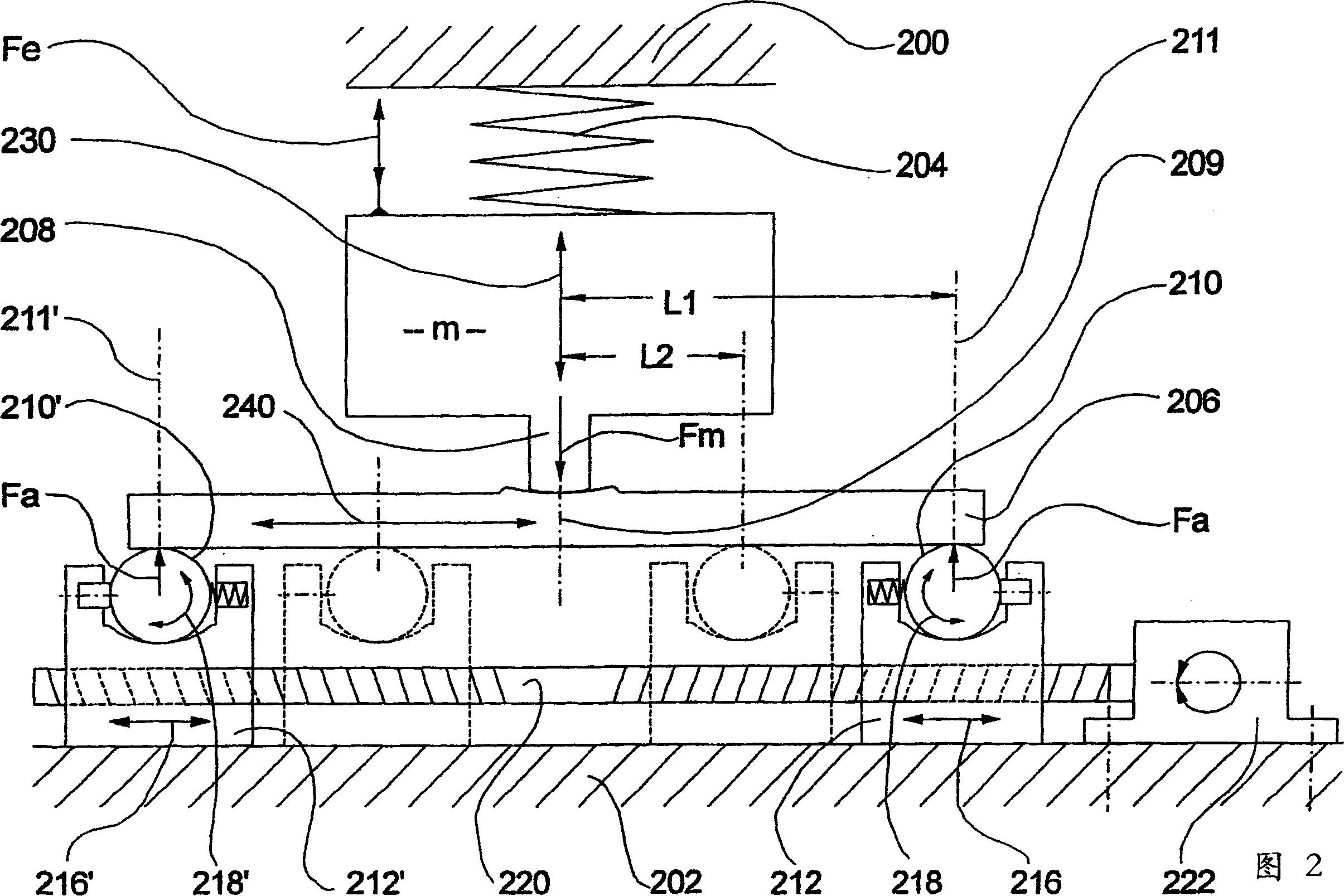

Method and device for compressing granular materials

InactiveCN1476376AReduce vibration amplitudeDetermine the costCeramic shaping apparatusMechanical vibrations separationForced oscillationLinear vibration

The invention relates to a method and device for the compression of granular materials. On compressing granular material to give prepared products e.g. concrete paving slabs, a resonance vibrator with an oscillating mass-spring system is applied, which may be energised by a controllable energiser to produce forced oscillation of a given frequency and oscillatory amplitude. The resonant effect, making use of the proximity of the inherent resonance frequency and the exciter frequency permits a reduction in the size of the exciter force. According to the invention, along with an adjustment of the exciter frequency the resonant frequency is also simultaneously co-adjusted by means of a suitable adjuster, in order to be able to g make use of the resonance effect throughout the whole spectrum of the exciter frequencies to be carried out.

Owner:吉迪布工程局和革新指导处有限责任公司

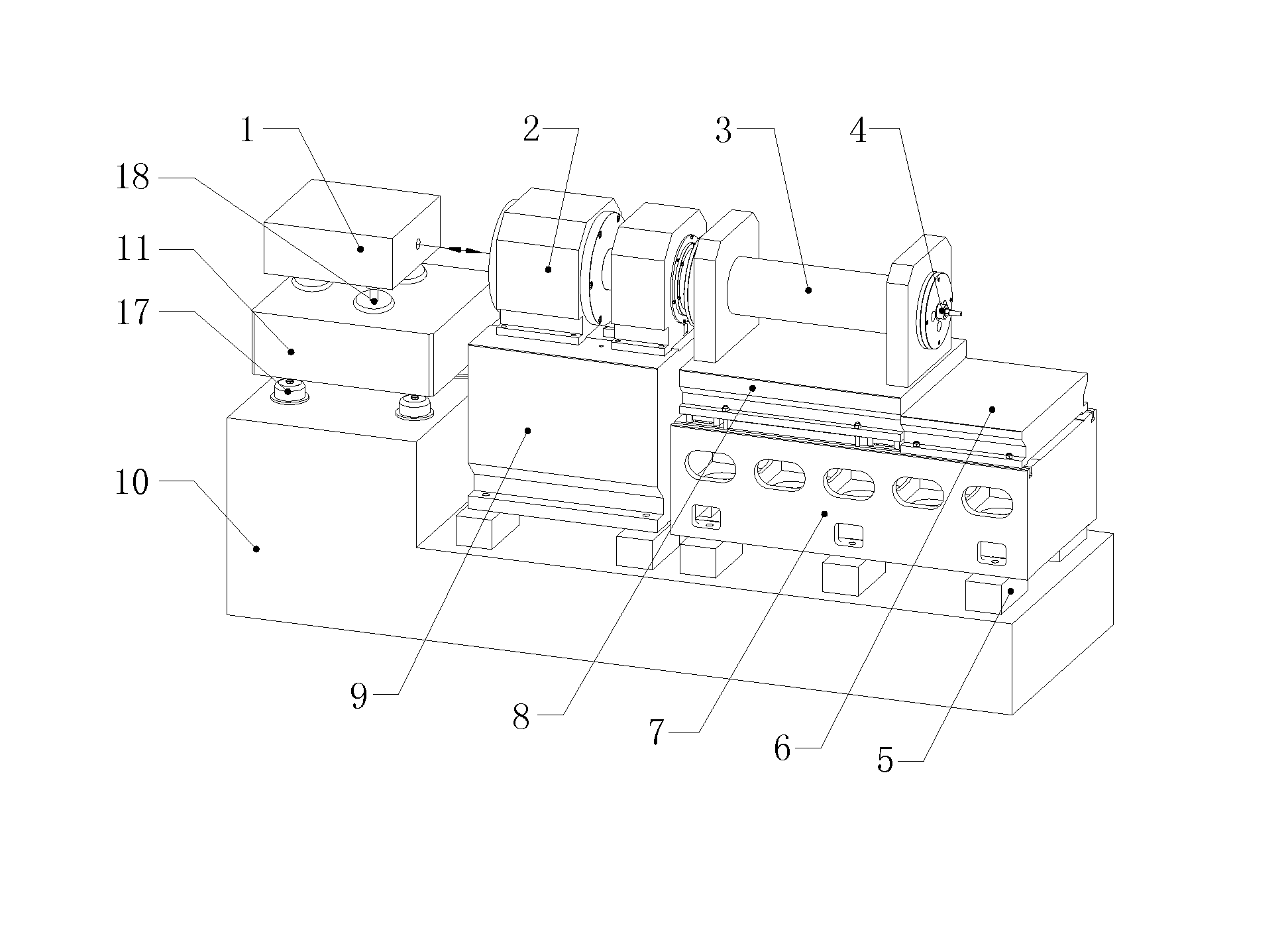

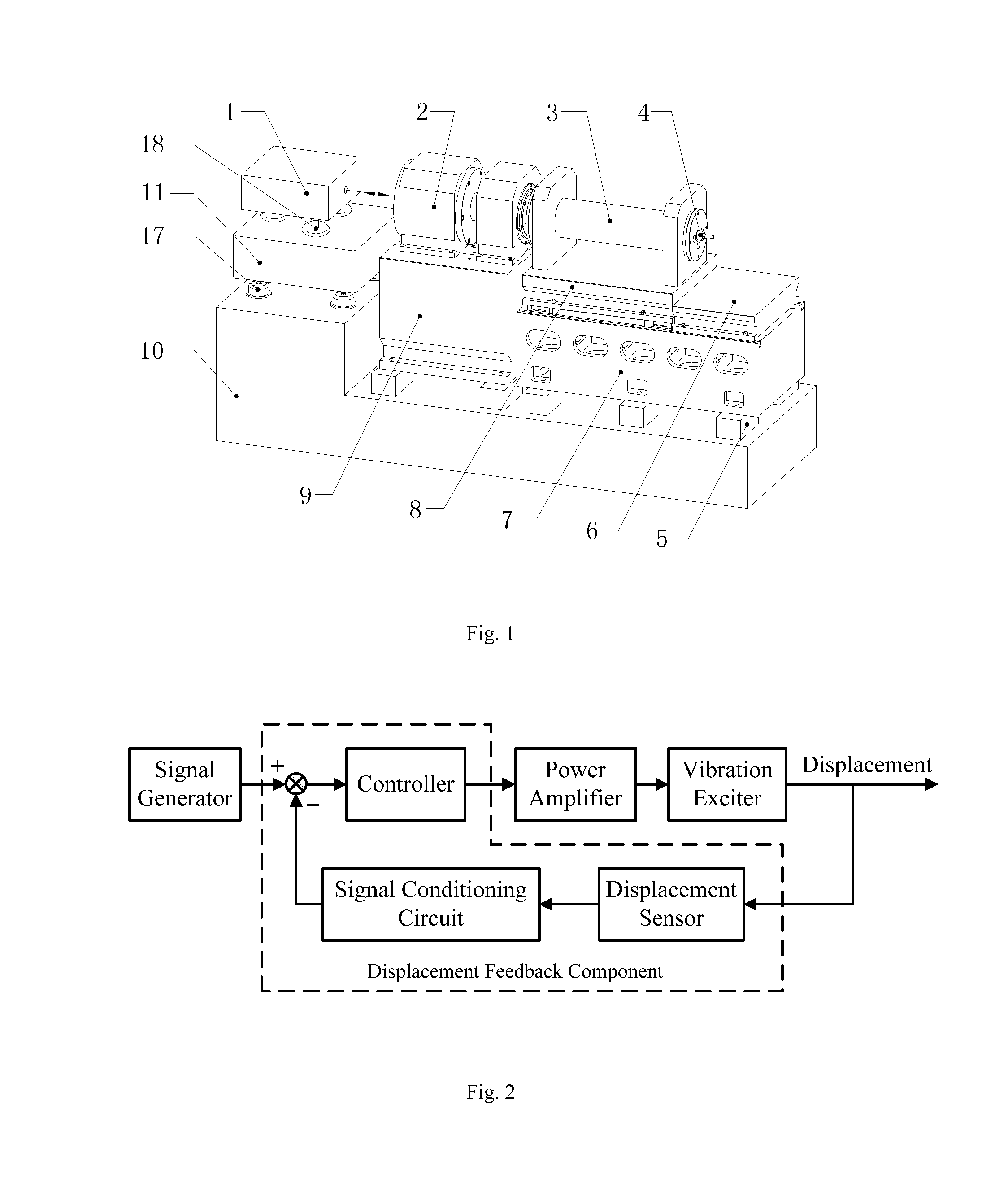

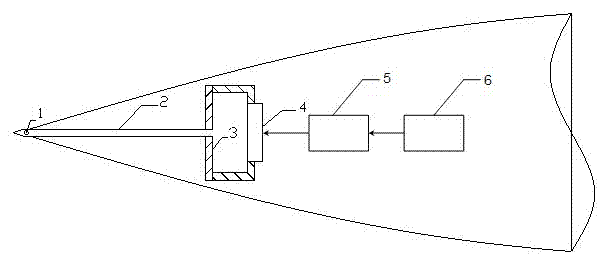

Infrasound generating device based on a displacement-feedback type vibration exciter

ActiveUS20140140179A1Reduce Harmonic DistortionHigh feasibilityVibration measurement in fluidSeismic energy generationHarmonicLaser vibrometry

The infrasound generating device based on a displacement-feedback type vibration exciter comprises a displacement-feedback type vibration exciter system, an infrasound generating chamber (3) and a laser vibrometer (1); the displacement feedback mechanism is adopted in the vibration exciter (2). The piston (31) is driven by the vibration exciter to move in a sinusoidal manner in the cavity (35) of the airtight infrasound generating chamber (3) and the standard infrasonic pressure signal with low harmonic distortion can be achieved. The displacement of the moving part (22) of the vibration exciter (2) can be measured by the laser vibrometer (1) through the measurement beam (15) injecting into the vibration exciter (2) through the optical channel running through the vibration exciter and the standard infrasonic pressure can also be obtained. The value of the standard sound pressure produced by the infrasound generating chamber is calculated. Such value is used as the calibration reference for the infrasound sensors (4) to be calibrated in order to achieve the primary calibration of the infrasound sensors. The standard infrasonic sensor can be installed inside the infrasound generating chamber (3) and the output of the standard infrasonic sensor can be used as the reference for the infrasonic sensor (4) to be calibrated in order to achieve the secondary calibration of the infrasound sensors. This invention has the advantages of technical maturity, high feasibility, easy to realize, high calibration accuracy and so on.

Owner:ZHEJIANG UNIV +1

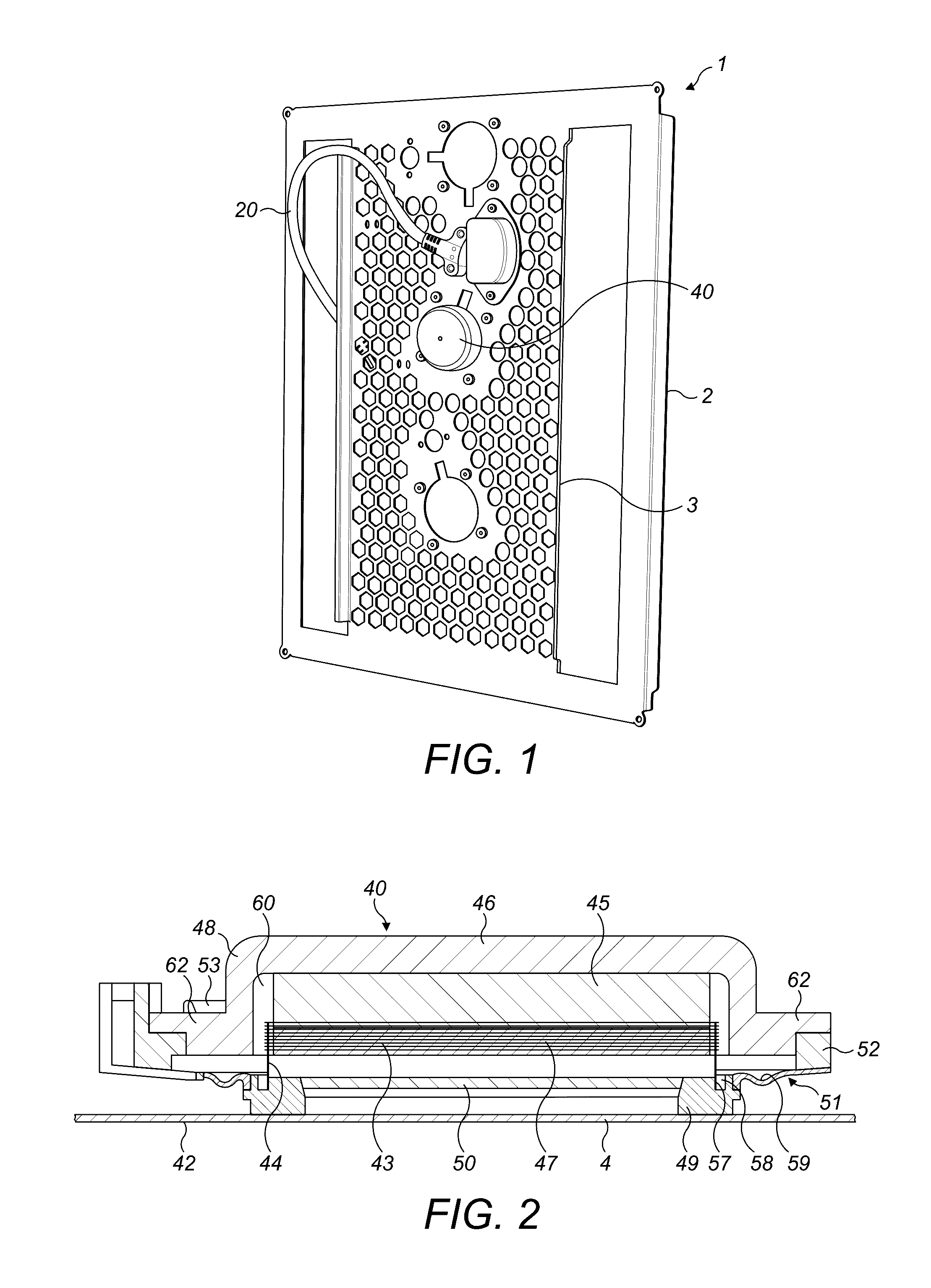

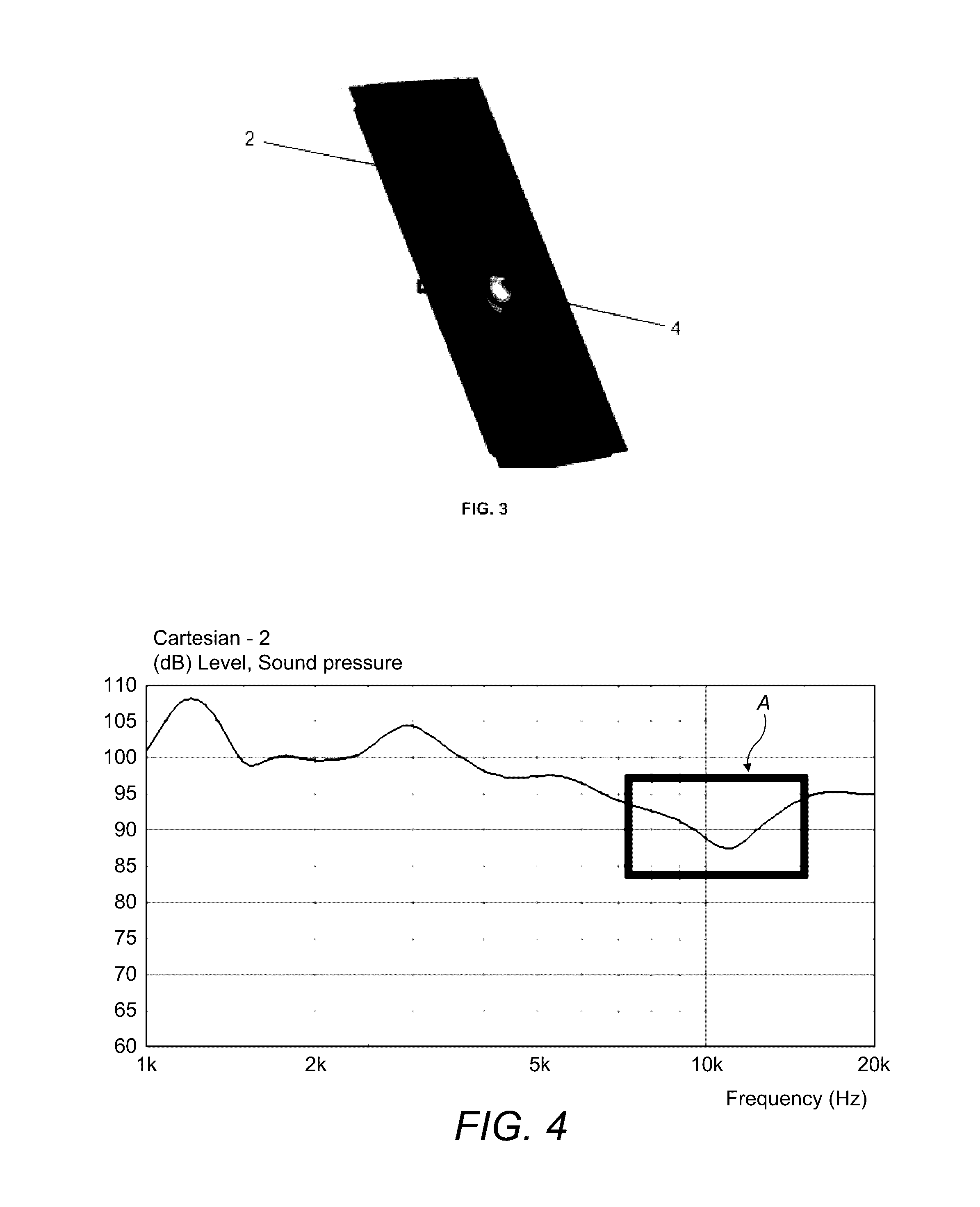

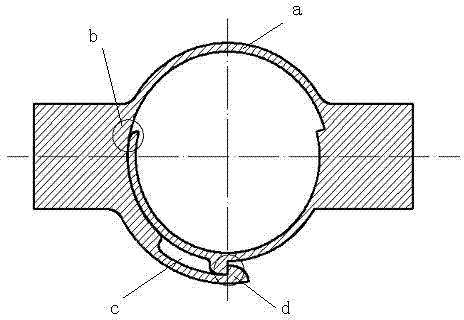

Distributed mode louspeaker damping oscillations within exciter feet

ActiveUS20160360313A1Improve performanceIncrease amplitudeBending wave transducersDiaphragm dampingEngineeringLoudspeaker

There is provided a flat panel loudspeaker comprising a resonant panel, an exciter comprising a foot generally cylindrical in shape, coupled to the resonant panel and defining an inner region of the resonant panel. The exciter is drivable to vibrate the resonant panel via the foot, whereby to produce a sound. A stiffness of the resonant panel in the inner region is greater than a stiffness of the resonant panel in a region of the resonant panel outside the inner region. Additionally or alternatively, the flat panel loudspeaker further comprises a damping member in contact with the inner region of the resonant panel and arranged inside the foot to generally brace against the vibration of the resonant panel so as to damp a response of the resonant panel in the inner region to a vibration from the exciter.

Owner:AMINA TECH

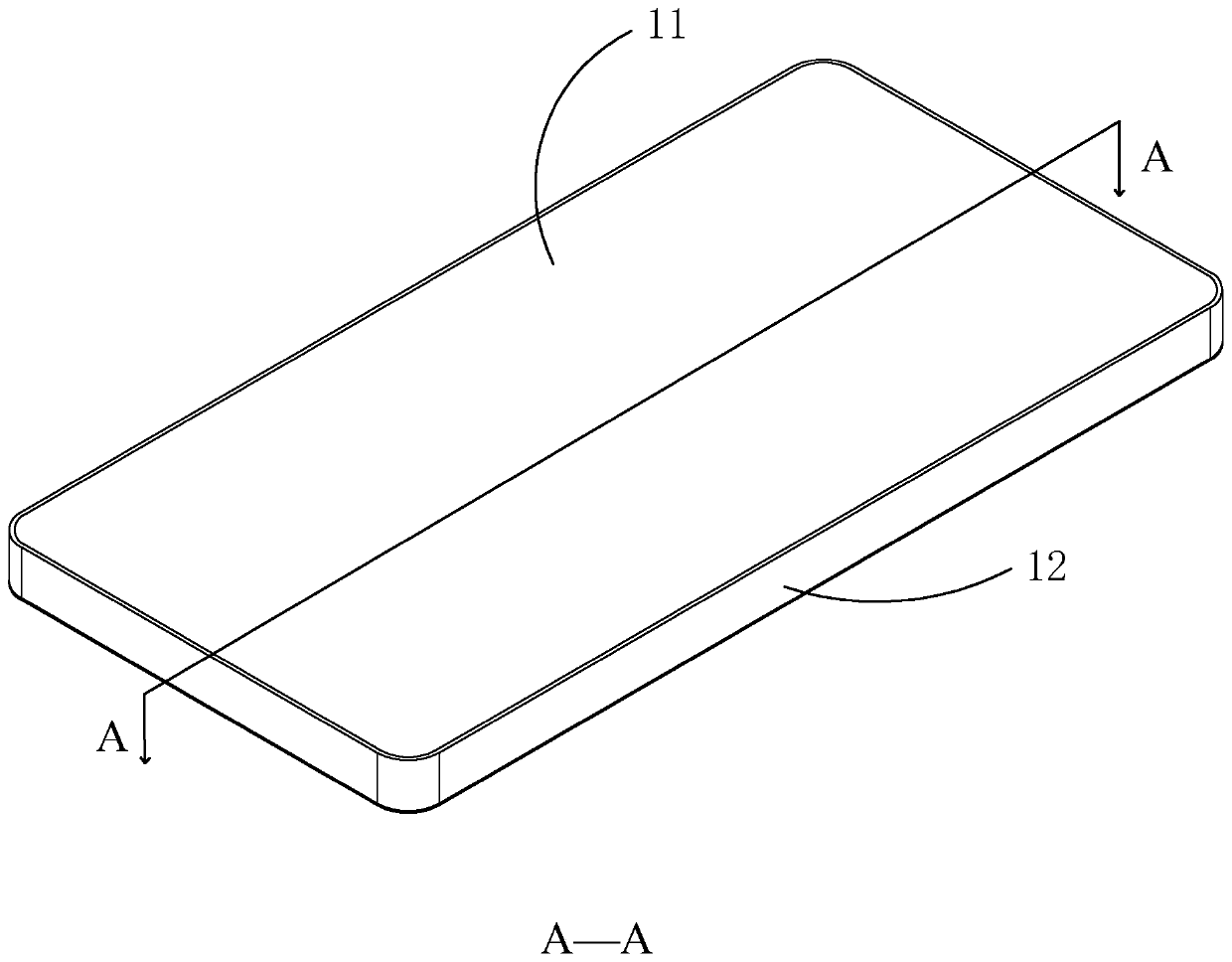

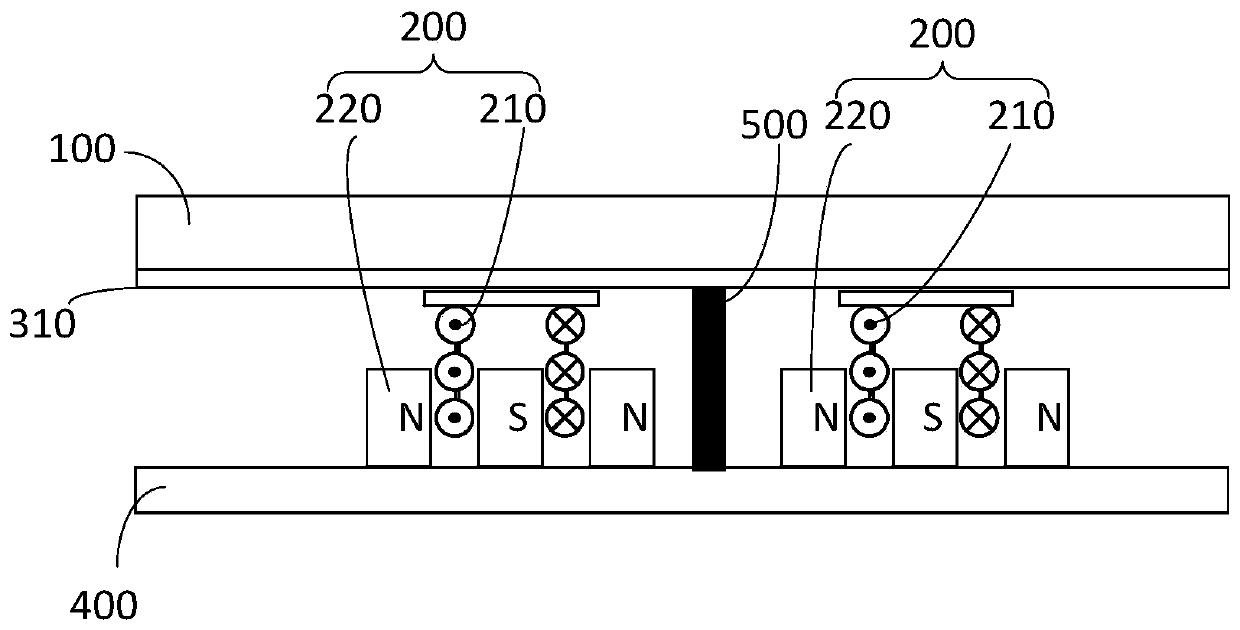

Display panel and display device

InactiveCN111491242ASmall footprintVocal realizationPlane diaphragmsLoudspeaker signals distributionVibrating membraneDisplay device

The invention provides a display panel and a display device, and belongs to the technical field of display. The invention provides a display panel. The display panel comprises a panel body and a plurality of sound production units. The panel body comprises a substrate and a plurality of pixel units arranged on the substrate. Each sound production unit comprises a vibrating diaphragm, an exciter and a supporting structure, and the supporting structure is arranged on one side of the vibrating diaphragm and provided with a cavity. The exciter comprises a movable part and a driving part, the driving part is arranged in the cavity, the movable part makes contact with the vibrating diaphragm, and the driving part drives the movable part to vibrate so as to drive the vibrating diaphragm to vibrate. The substrate and the vibrating diaphragm share a structure, and the plurality of pixel units are arranged on one side, deviating from the supporting structure, of the vibrating diaphragm. The vibrating diaphragm of the sound production unit is shared with the substrate of the panel, that is, the vibrating diaphragm is used as the substrate of the panel, and the plurality of pixel units are arranged on the vibrating diaphragm, so that the sound production unit and the panel can be integrated, the space occupied by the sound production unit is reduced, and the display panel can realize screen sound production.

Owner:BOE TECH GRP CO LTD

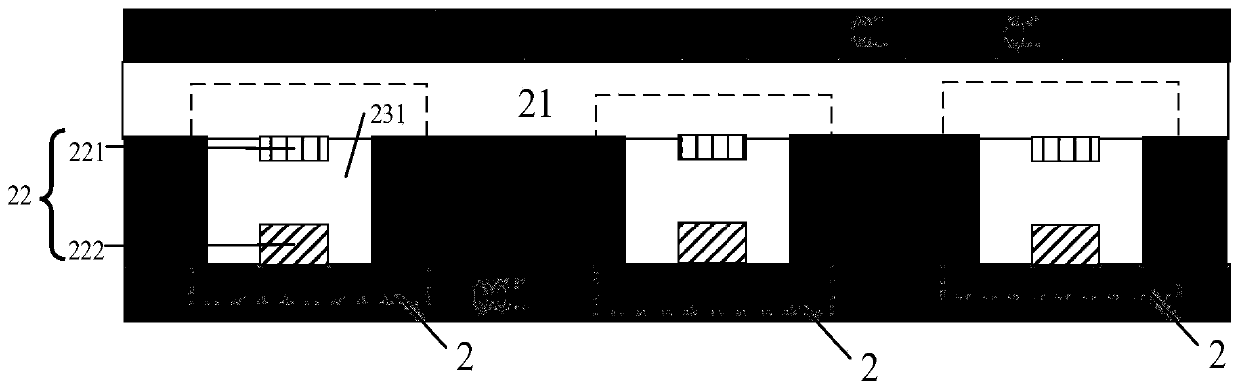

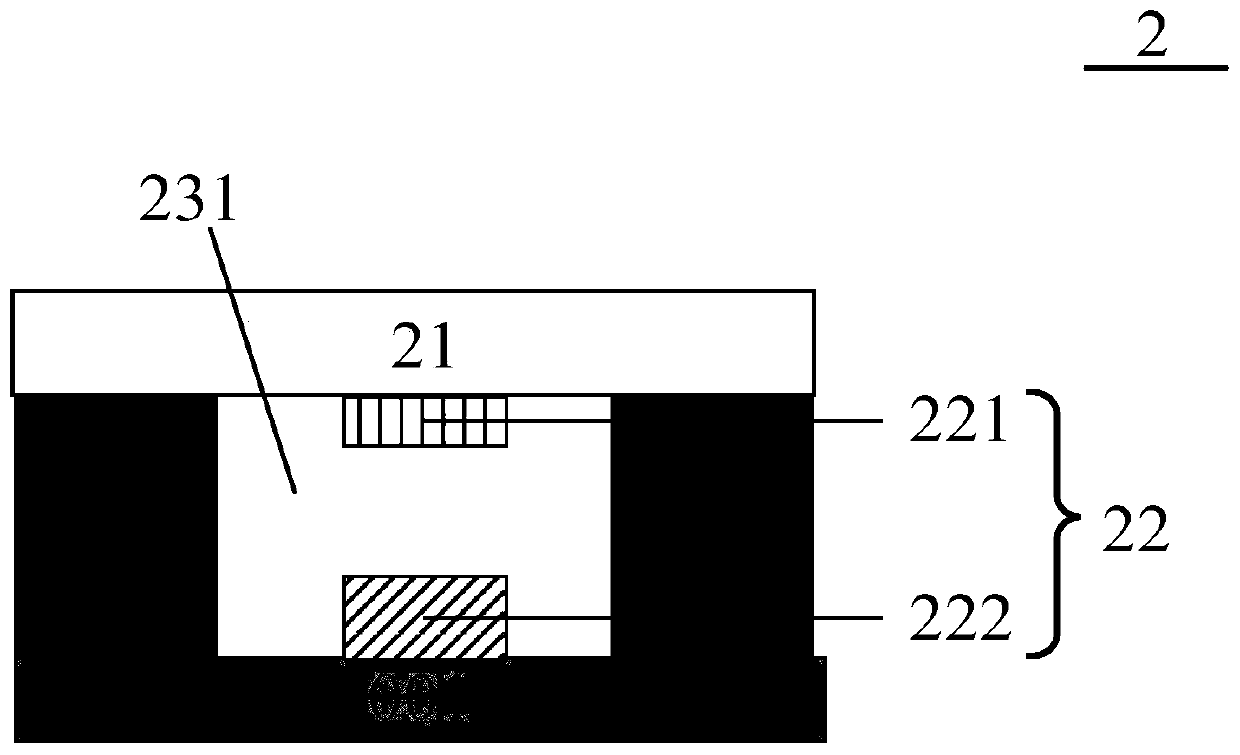

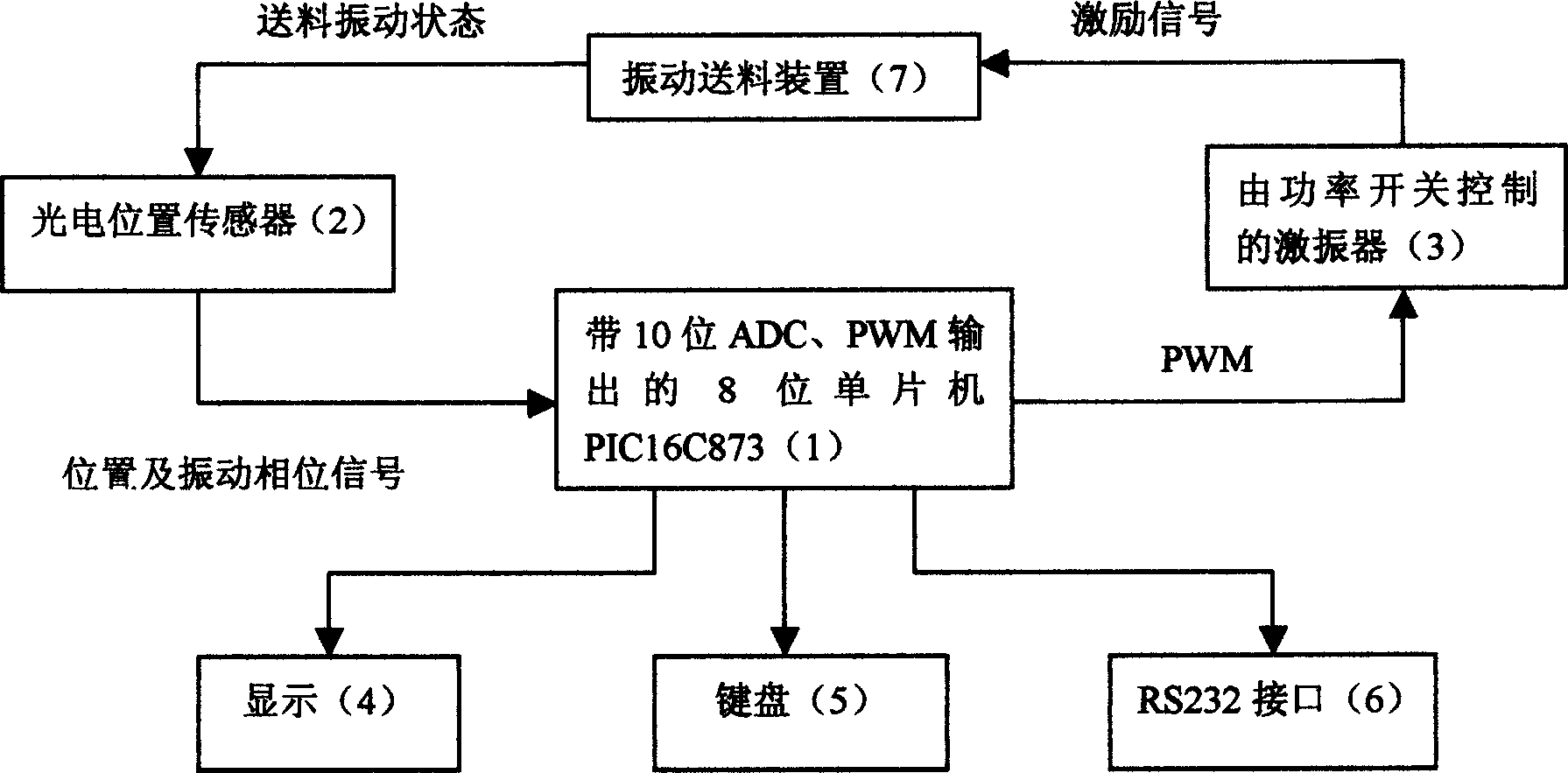

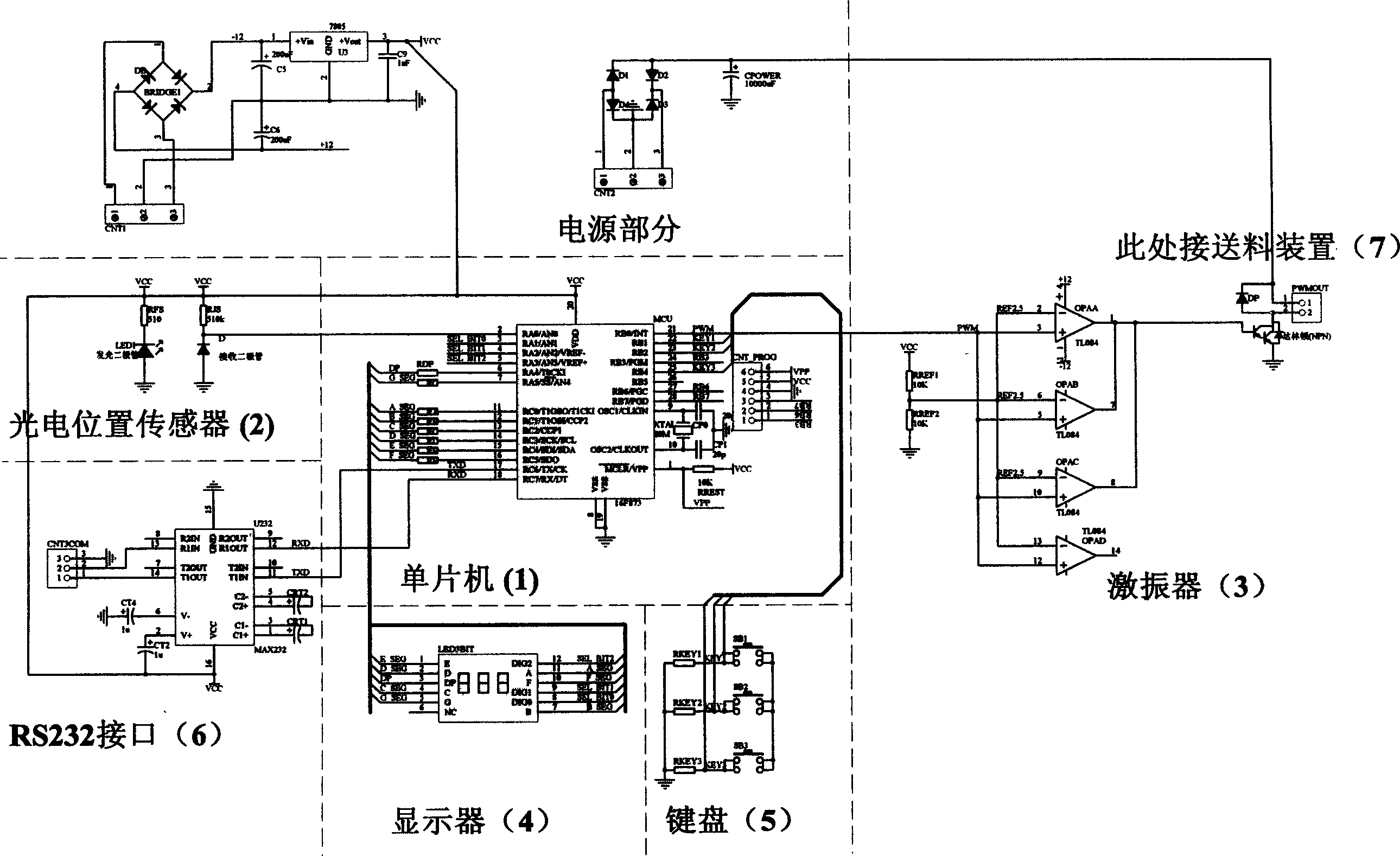

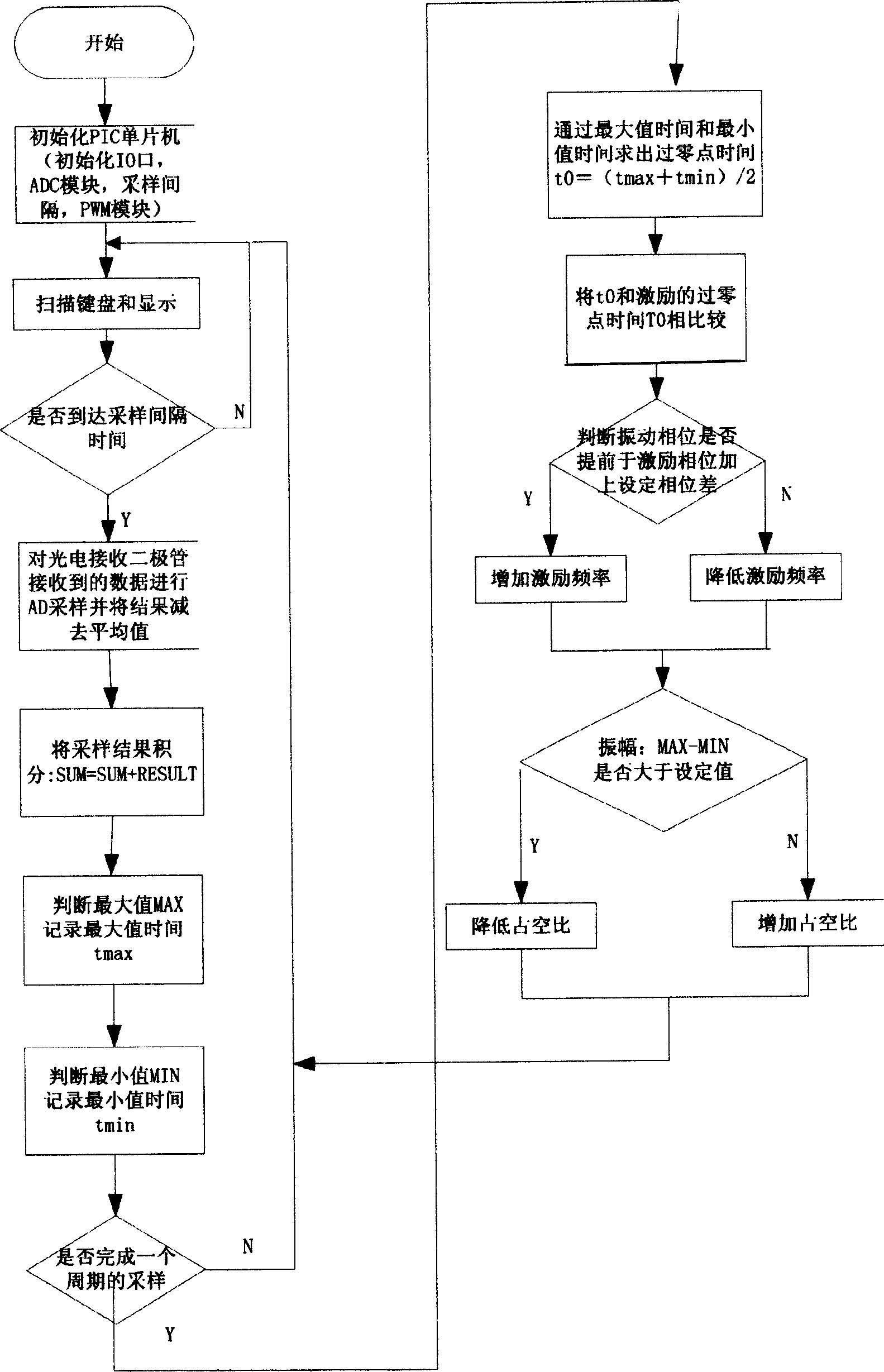

Vibration material feeding controller with self-adapting frequency self maintaining amplitude and its control method

ActiveCN1597471AAmplitude stableStable feeding speedComputer controlControl devices for conveyorsMicrocontrollerAmplitude control

This ivnention relates to a method and a cotnroller for vibration feeder with self-frequency adaptation and self-amplitude control. The controller consists of a monolithic computer, a photoelectric position sensor, an exciter, a display, a keyboard, an RS232 interface. The control emthod is based on phase feedback, and carried out by using a photoelectric position sensor to collect position and phase signals of the vibration feeder, using a computer to process the signals, sending them to the display and RS232 interface and the exciter, and actuating the feeder.

Owner:SOUTHEAST UNIV

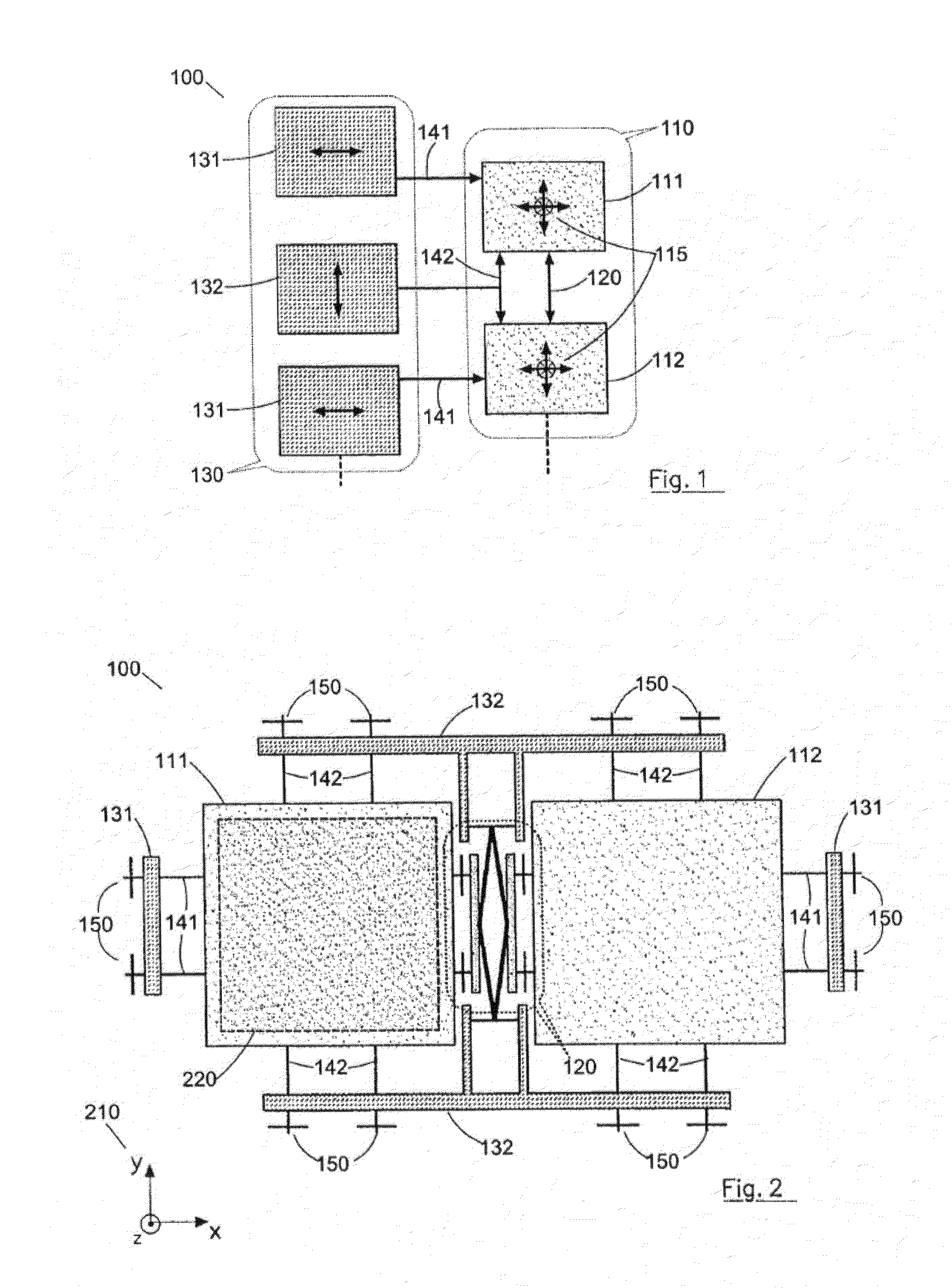

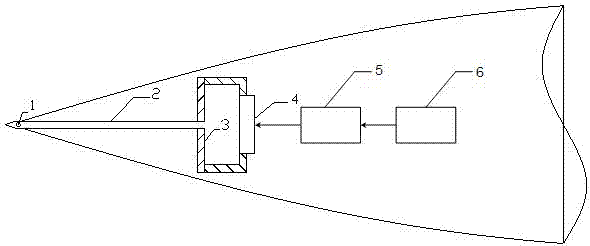

Inertial micro-sensor of angular displacements

ActiveUS20130205897A1Acceleration measurement using interia forcesSpeed measurement using gyroscopic effectsInertial massCoriolis force

The present invention relates to an inertial micro-sensor of angular displacements comprising at least one inertial mass (112, 1210) movable in space (x, y, z); an exciter (131) configured to generate a first vibratory movement of the inertial mass along a first direction (X) included in the plane (x, y), so as to generate a first Coriolis force induced by an angular displacement of the inertial mass (112, 1210) around a second direction (Y) included in the plane (x, y) and perpendicular to the first direction (X); an exciter (131) configured to generate a second vibratory movement of the inertial mass along the second direction (Y), so as to generate a second Coriolis force induced by an angular displacement of the inertial mass (112, 1210) around the first direction (X), and means for detecting the first Coriolis force and the second Coriolis force, characterized by the fact that the detection means comprise a common detector for the first Coriolis force and the second Coriolis force and configured to produce an electrical signal processed by a processing circuit so as to distinguish a first component of the electrical signal corresponding to the first Coriolis force and a second component of the electrical signal corresponding to the second Coriolis force.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Unsteady small-perturbation control device for synthetic jet of asymmetric vortices at high attack angle

The invention discloses an unsteady small-perturbation control device for a synthetic jet of asymmetric vortices at high attack angle. The unsteady small-perturbation control device comprises a synthetic jet outlet, a needle tube type hollow structure, a synthetic jet exciter cavity body, a speaker diaphragm, a power amplifier and a signal generator, wherein the output end of the signal generator is connected with the input end of the power amplifier, an output end driving signal of the power amplifier is connected with the synthetic jet exciter cavity body and the speaker diaphragm, the speaker diaphragm is fixedly mounted at the synthetic jet exciter cavity body, the needle tube type hollow structure is connected with the opening of the synthetic jet exciter cavity body, and the synthetic jet outlet is arranged at the other end of the needle tube type hollow structure. The control device can regulate and control parameters, such as perturbation control frequency of the synthetic jet, and the like according to actual needs, so as to achieve the aim of controlling the asymmetric vortices at high attack angle and proportionally controlling a lateral force by low energy consumption.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

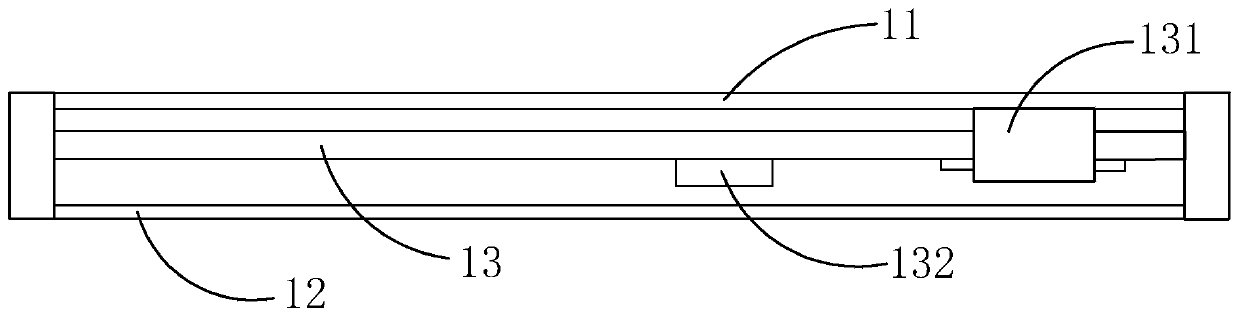

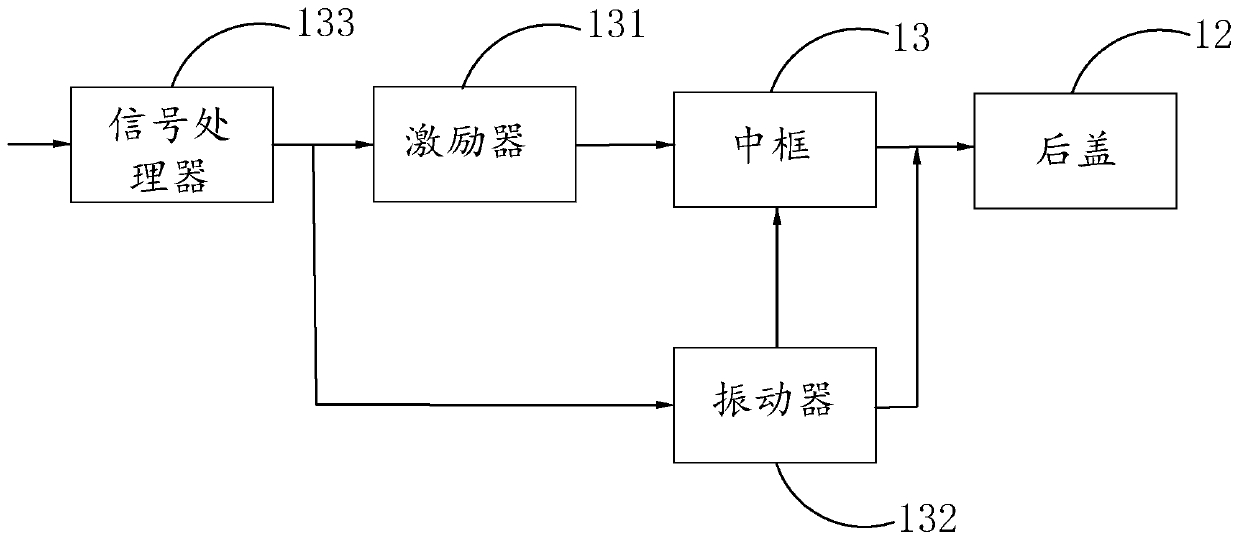

Screen sounding equipment and screen sounding method

InactiveCN111131975AReduce vibration effectsReduce deliveryElectrical transducersEngineeringSignal processing

The invention is applicable to the technical field of acoustic equipment, and provides screen sounding equipment and a screen sounding method. The equipment comprises a screen, a rear cover and a middle frame arranged between the screen and the rear cover, and the screen and the rear cover are respectively fixed at two sides of the middle frame to form a cavity; the middle frame is provided with an exciter fixed on the screen, the middle frame is also fixedly provided with a vibrator and a signal processor electrically connected with the vibrator, and the vibrator is arranged between the middle frame and the rear cover; and when the exciter vibrates to cause the screen to vibrate and produce sound, the signal processor processes a driving signal in the vibrator, so that the vibrator and the exciter vibrate synchronously and reversely to counteract the vibration of the middle frame and / or the rear cover. Redundant vibration caused by vibration of the rear cover can be reduced, and the comfort of holding a mobile terminal for a long time by a user is improved.

Owner:AAC TECH PTE LTD

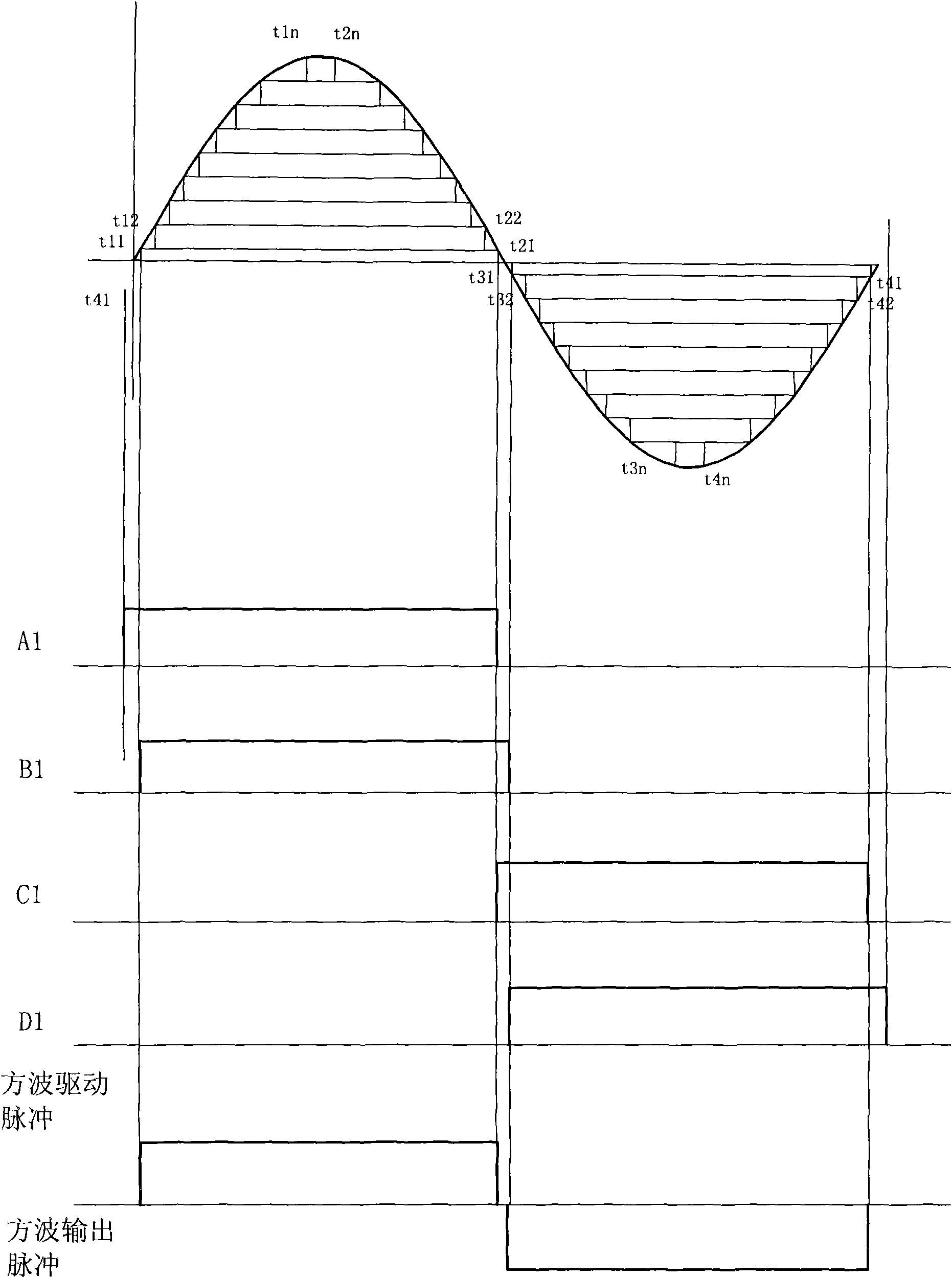

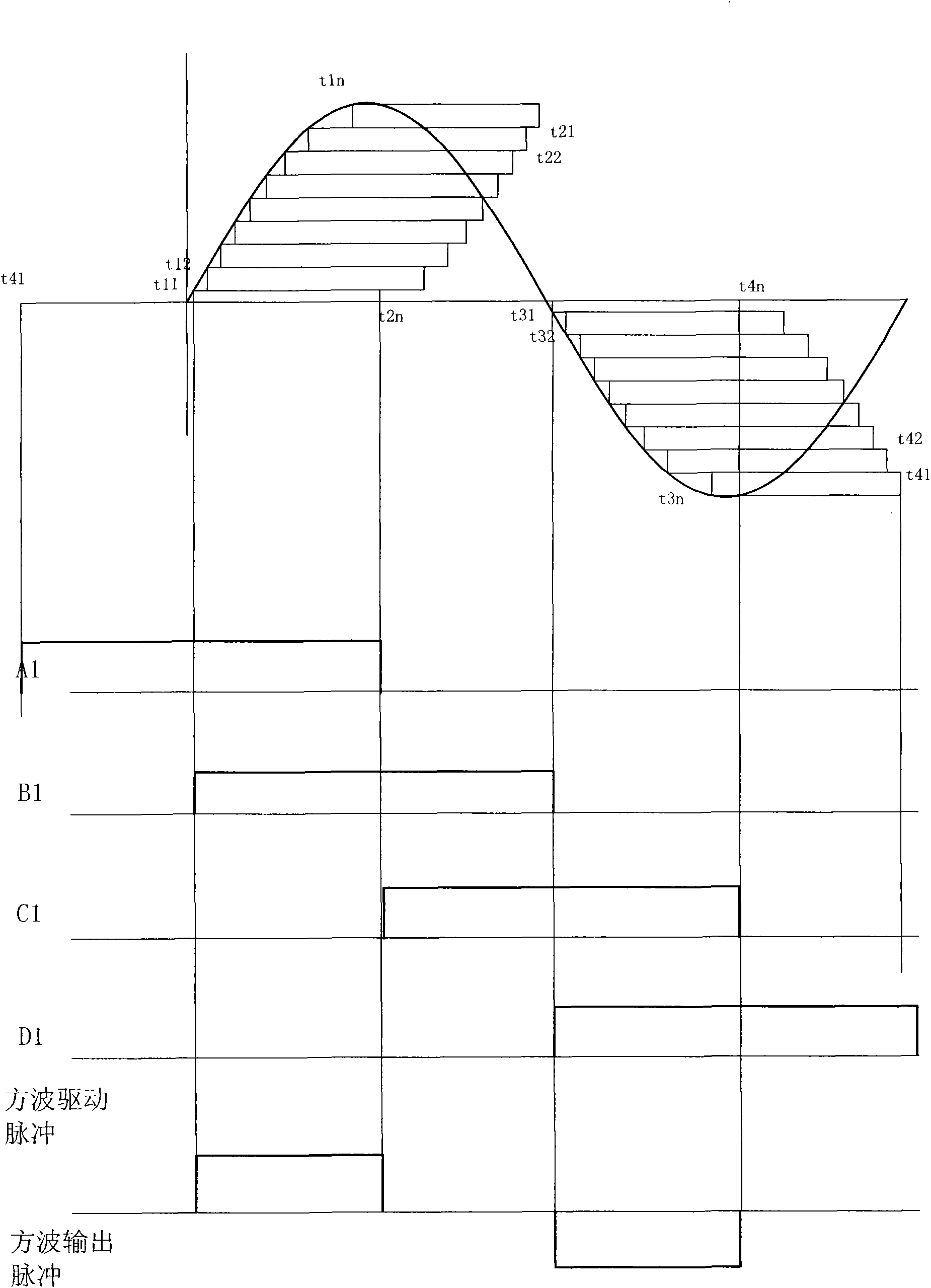

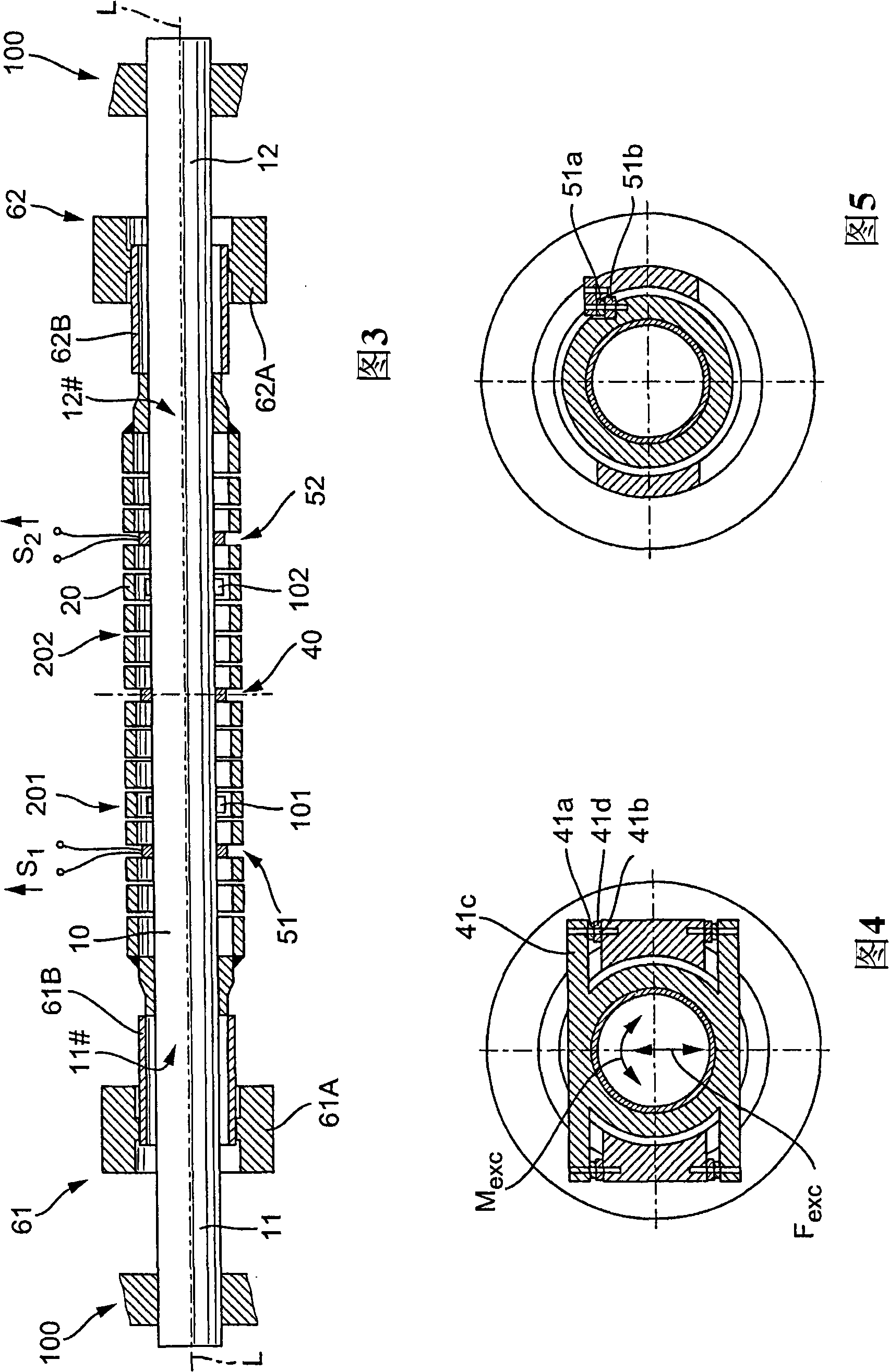

Method for processing signals between analog exciter and power amplifier and interface circuit

ActiveCN101847983AFix not workingSimple structureContinuous to patterned pulse manipulationTransmissionEngineeringFront edge

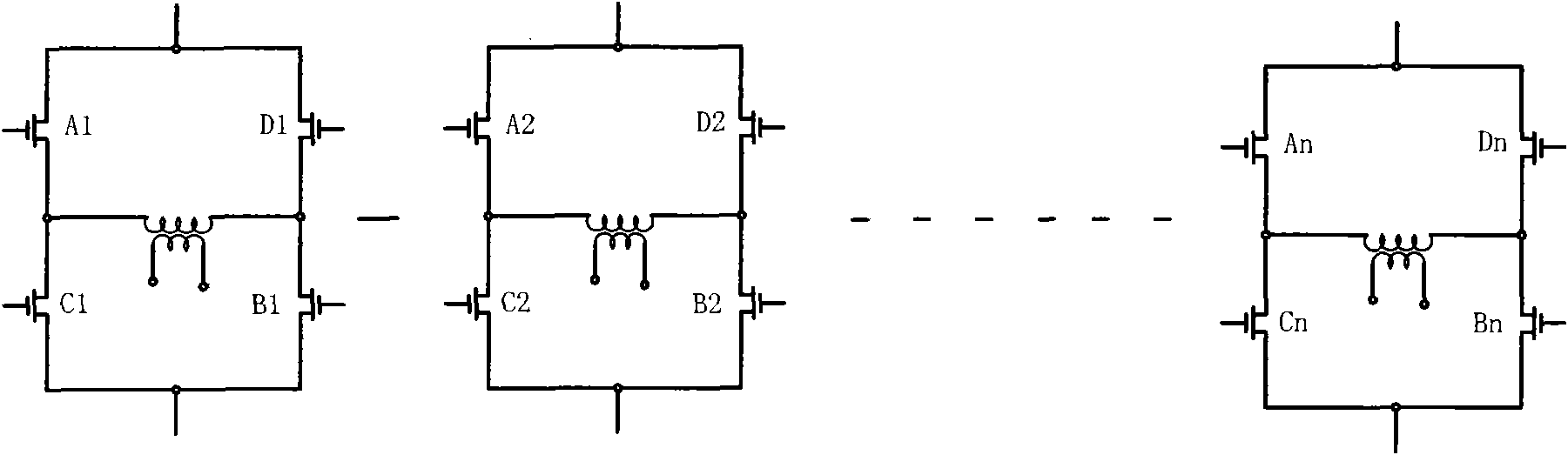

The invention relates to a transmitter, in particular relating to a method for processing signals between an analog exciter and a power amplifier used for a long wave / super long wave transmitter and an interface circuit thereof. The method comprises the following steps: dividing sine voltage signals of the analog exciter into 2n numbered constant amplitude square-wave voltage, successively performing differential operation to obtain a series of front edge pulses arranged in order, acquiring pulse delay time of quasi-monspaced square-wave superposition closure time by calculating, delaying the front edge pulses, feeding the front edge pulses and the delayed front end pulses in a drive pulse generator to start up and shut down driving voltages of n numbered step square-wave inverters, and conducting the n numbered square-wave inverters to obtain sinusoid with different amplitudes. The invention solves the problems of pulse loss and incapability of normal work of a system when an inverted rear edge pulse sequence method is used.

Owner:BEIJING BBEF SCI & TECH

In-line measuring devices and method for compensating measurement errors in in-line measuring devices

The measuring device for measuring multi phase mixture, which comprises a vibratory-type transducer and a measuring device electronics electrically coupled with the vibratory- type transducer. The transducer includes at least one measuring tube inserted into the course of the pipeline. An exciter arrangement acts on the measuring tube for causing the at least one measuring tube to vibrate . A sensor arrangement senses vibrations of the at least one measuring tube and delivers at least one oscillation measurement signal representing oscillations of the measuring tube. Further, the measuring device electronics delivers an excitation current driving the exciter arrangement. The measuring device is adapted to compensating measurement errors, induced due to the presence of multi phase mixture, based on a moving resonator model (MRM).

Owner:ENDRESS HAUSER FLOWTEC AG

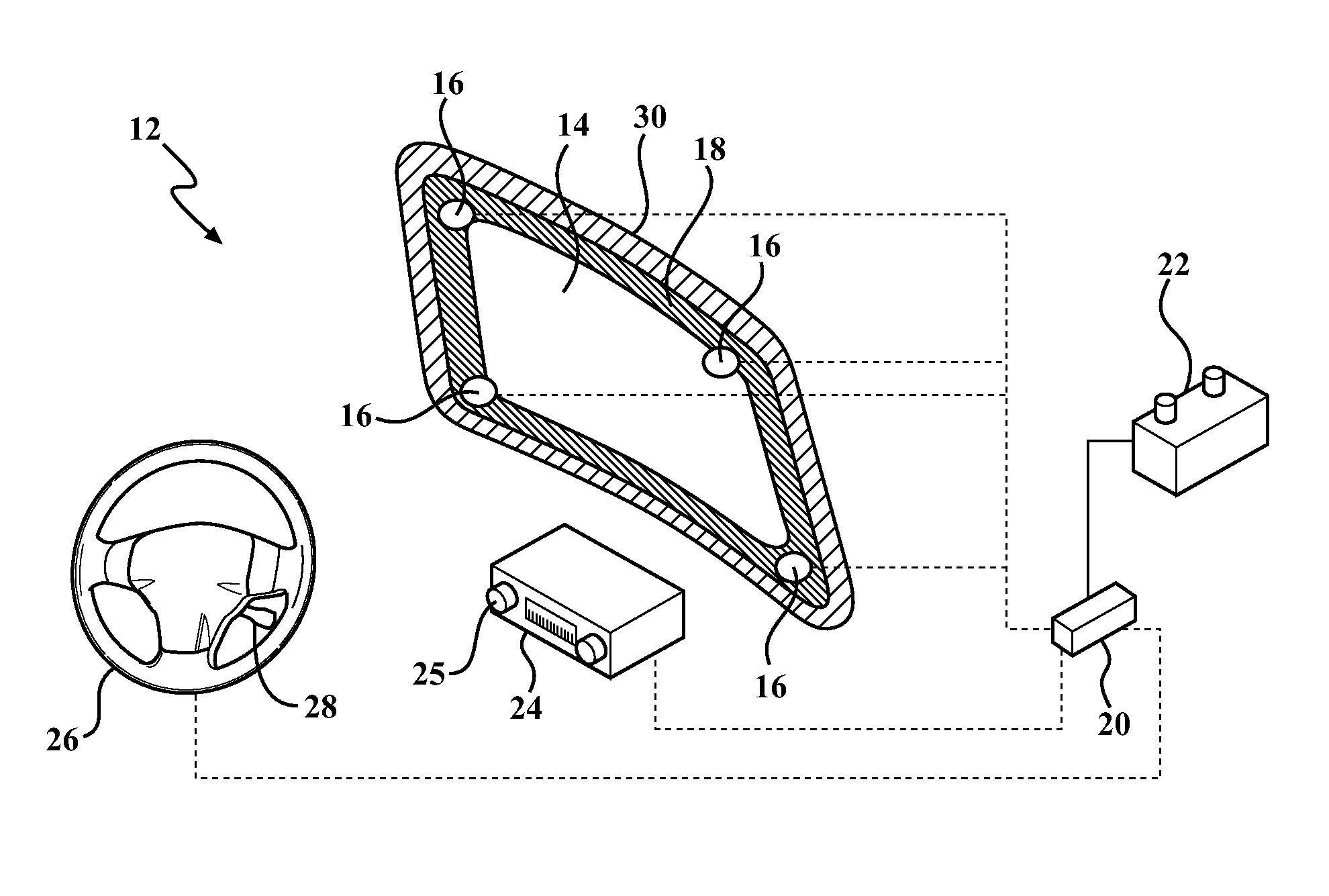

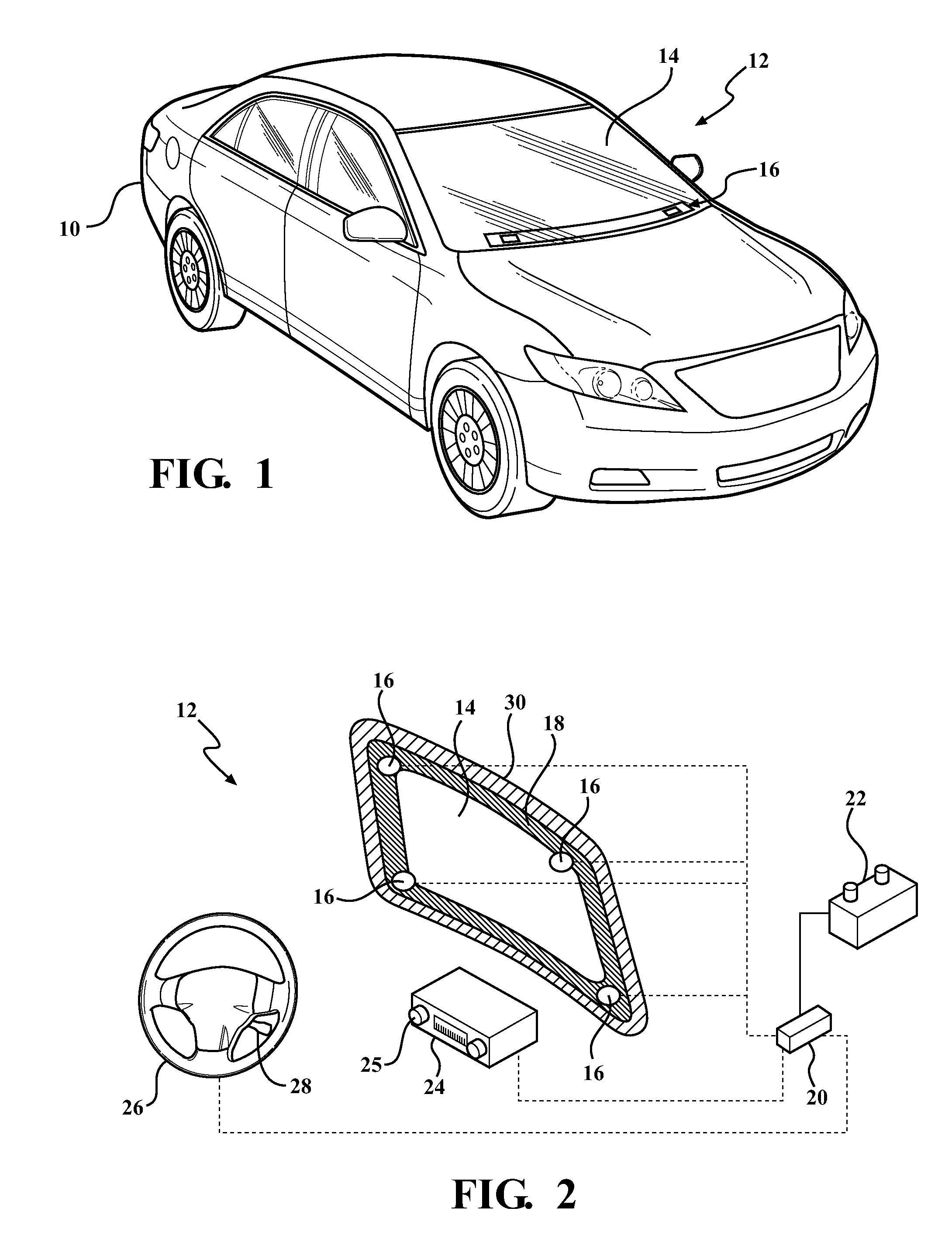

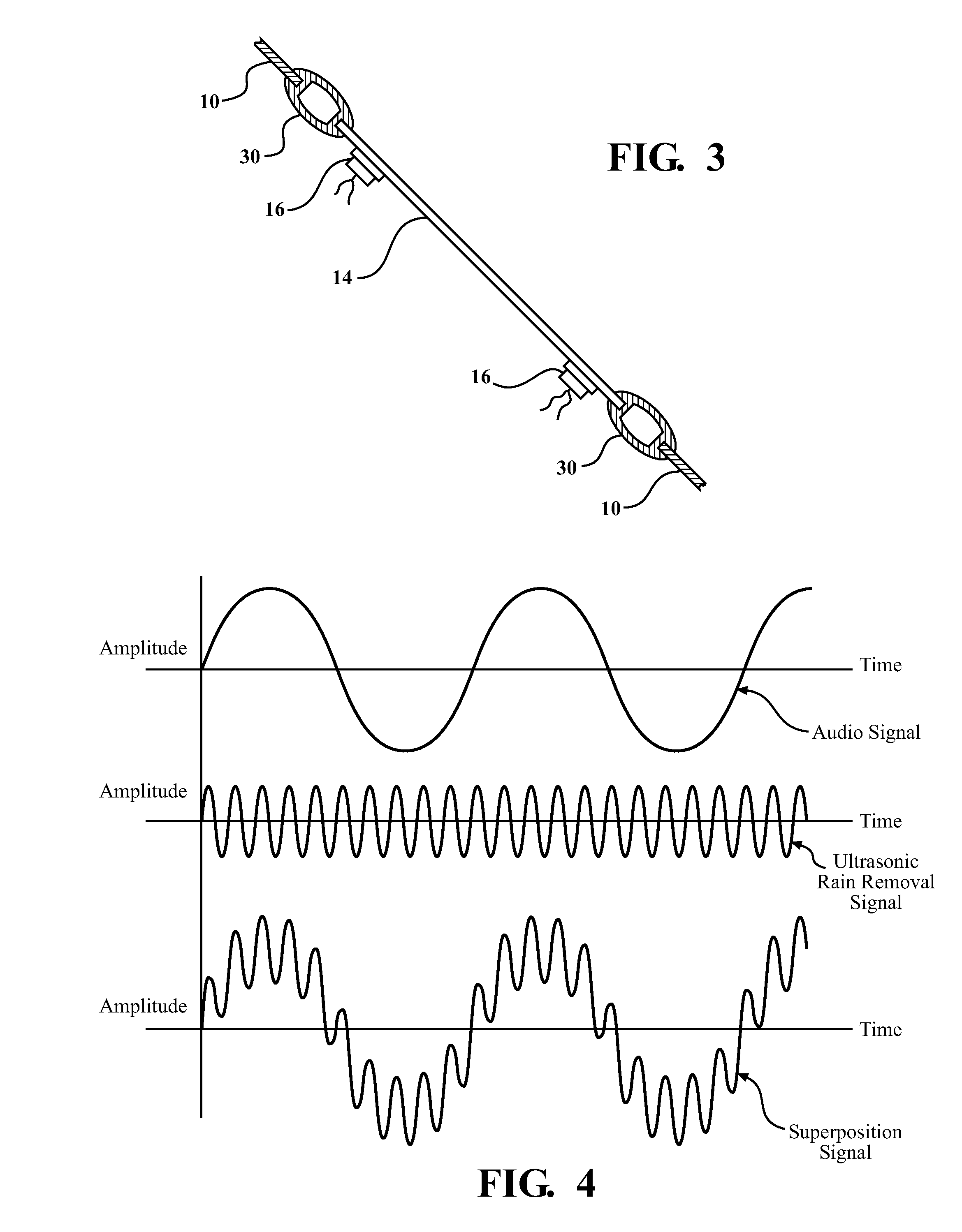

Acoustical and rain clearing window assembly for a vehicle

An acoustical and rain clearing window assembly for a vehicle includes a window panel mounted to the vehicle and at least one exciter attached to the window panel. An exciter control unit is connected to the at least one exciter and is configured to generate a superposition wave form for communication to the at least one exciter to simultaneously produce audio sound within the vehicle and clear water from the window panel. The exciter control unit is electrically connected to a first mode switch for receiving a first input signal to initiate the production of audio sound within the vehicle and a second mode switch for receiving a second input signal to initiate the clearing of water from the window panel. The exciter control unit is configured to receive the first and second input signals and combine the first and second input signals into the superposition wave form.

Owner:MAGNA INTERNATIONAL INC

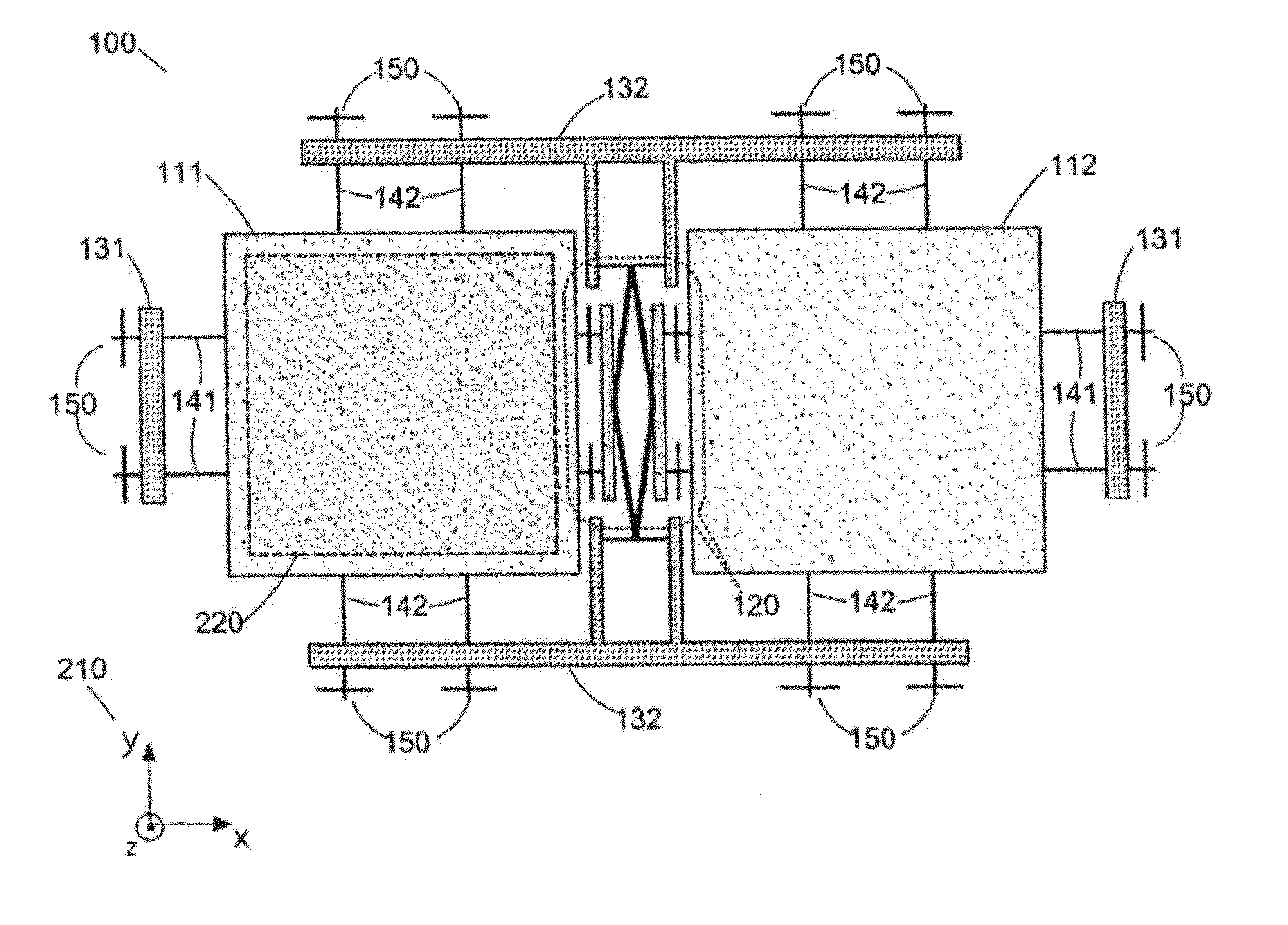

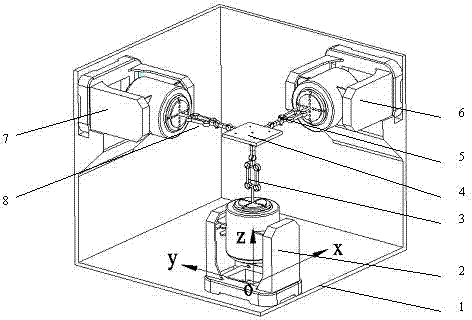

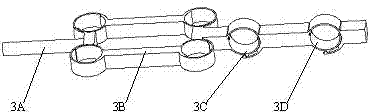

Parallel workbench for realizing space three-translation high-frequency excitation

InactiveCN102445319ASymmetrical arrangementImprove mechanical performanceVibration testingKinematic pairEngineering

The invention discloses a parallel workbench for realizing space three-translation high-frequency excitation in which a flexible kinematic pair is combined with a parallel mechanism, wherein a static platform is composed of three panels orthogonal with each other; a single-dimensional exciter is vertically and fixedly arranged on each panel; three parallel branch chains are connected between a movable platform and the single-dimensional exciters; the tail ends of three branch chains in orthogonal distribution are connected to the corresponding single-dimensional exciters through movable pairs, respectively; and the top ends of the three branch chains in orthogonal distribution are all vertically connected to the movable platform through rotating pairs; the single branch chain is formed by orderly connecting the movable pair 3A, 4R structure 3B, the rotating pair 3c and the rotating pair 3D in series according to the vertical and parallel position relations of the axes of the movable pairs; and the movable pair is a continuous integrated body and is provided with a surface contact compression-resisting structure and a surface contact tensile structure. The parallel workbench is good in stress performance, compact in structure and relatively high in structural rigidity.

Owner:JIANGSU UNIV

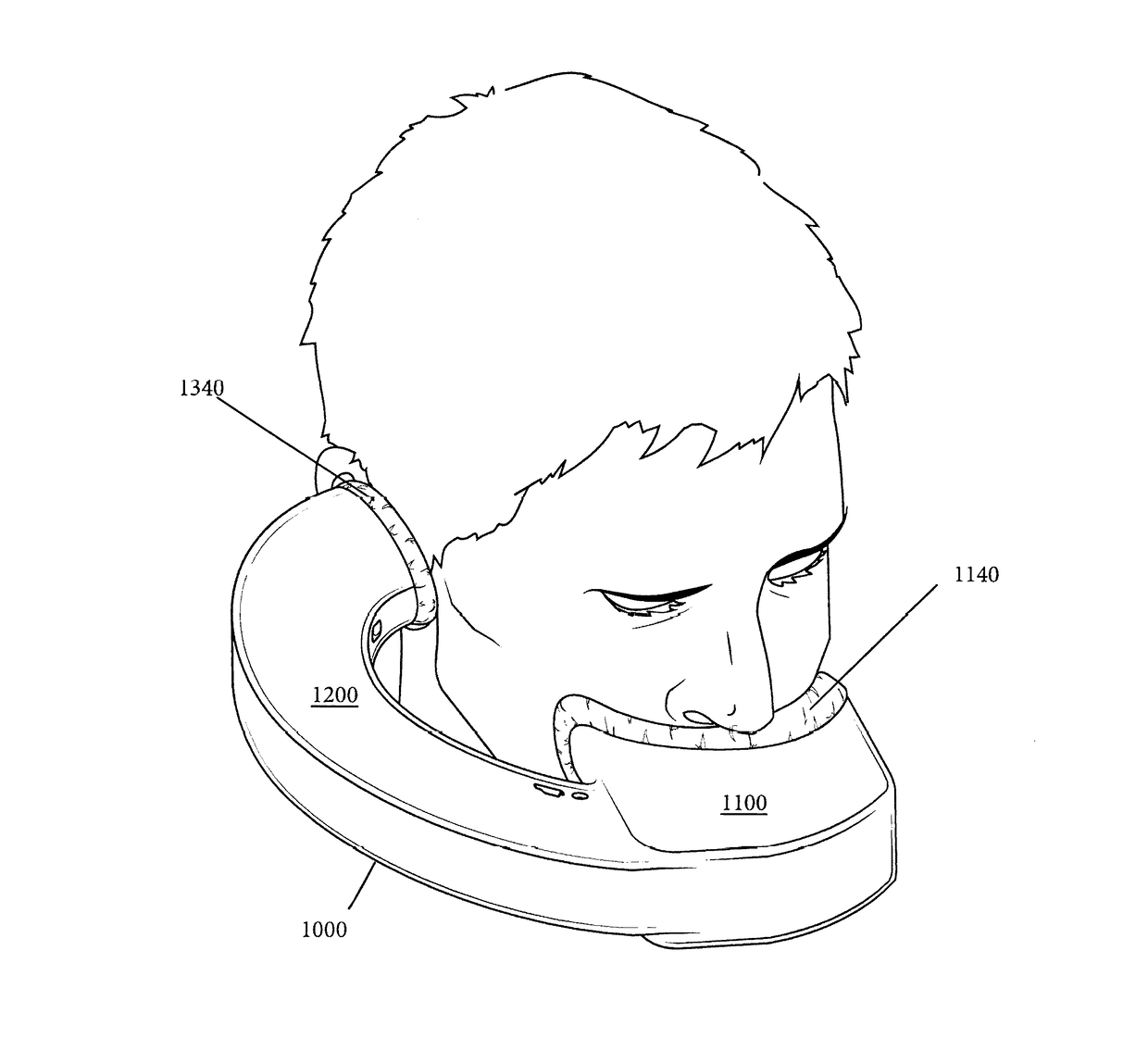

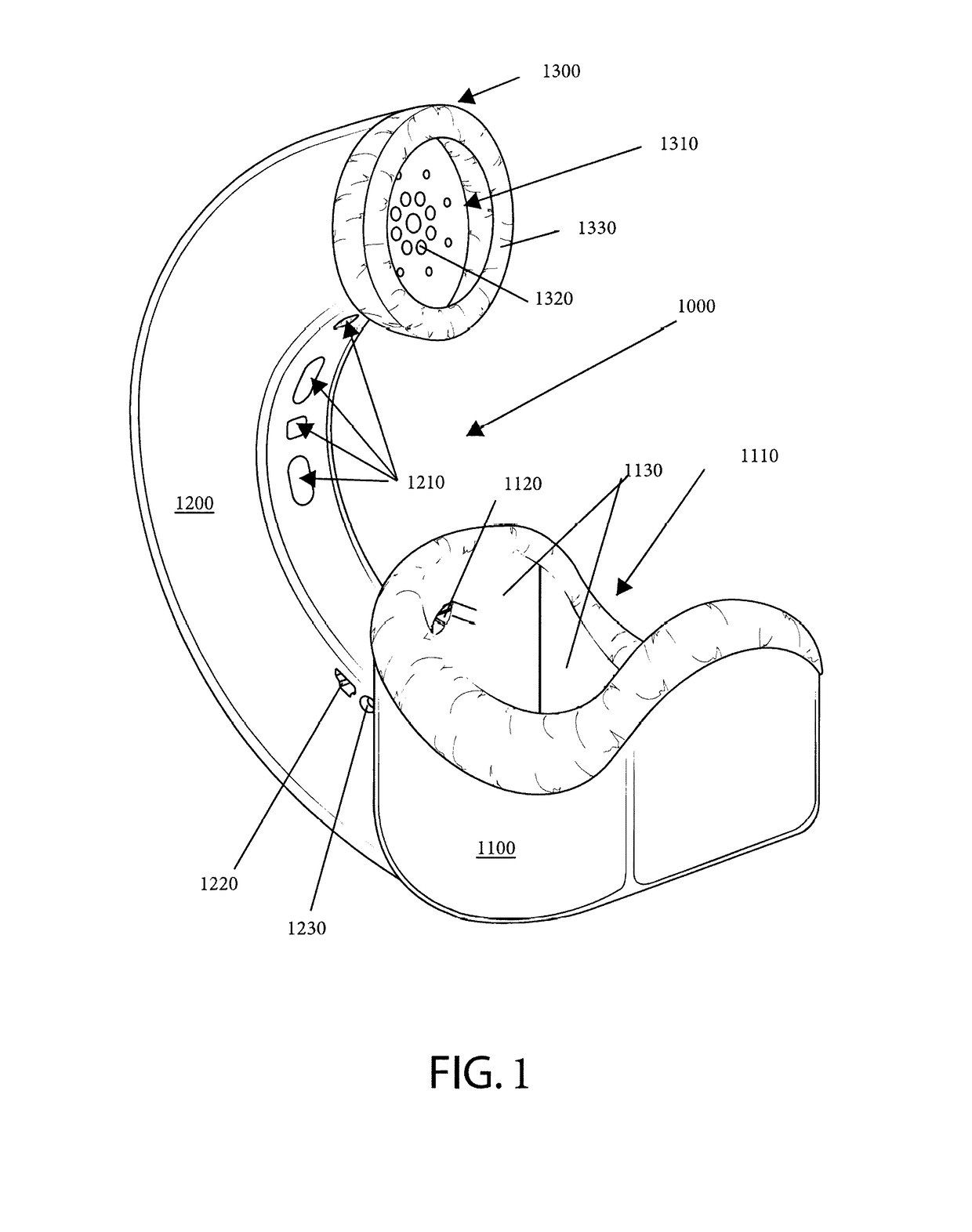

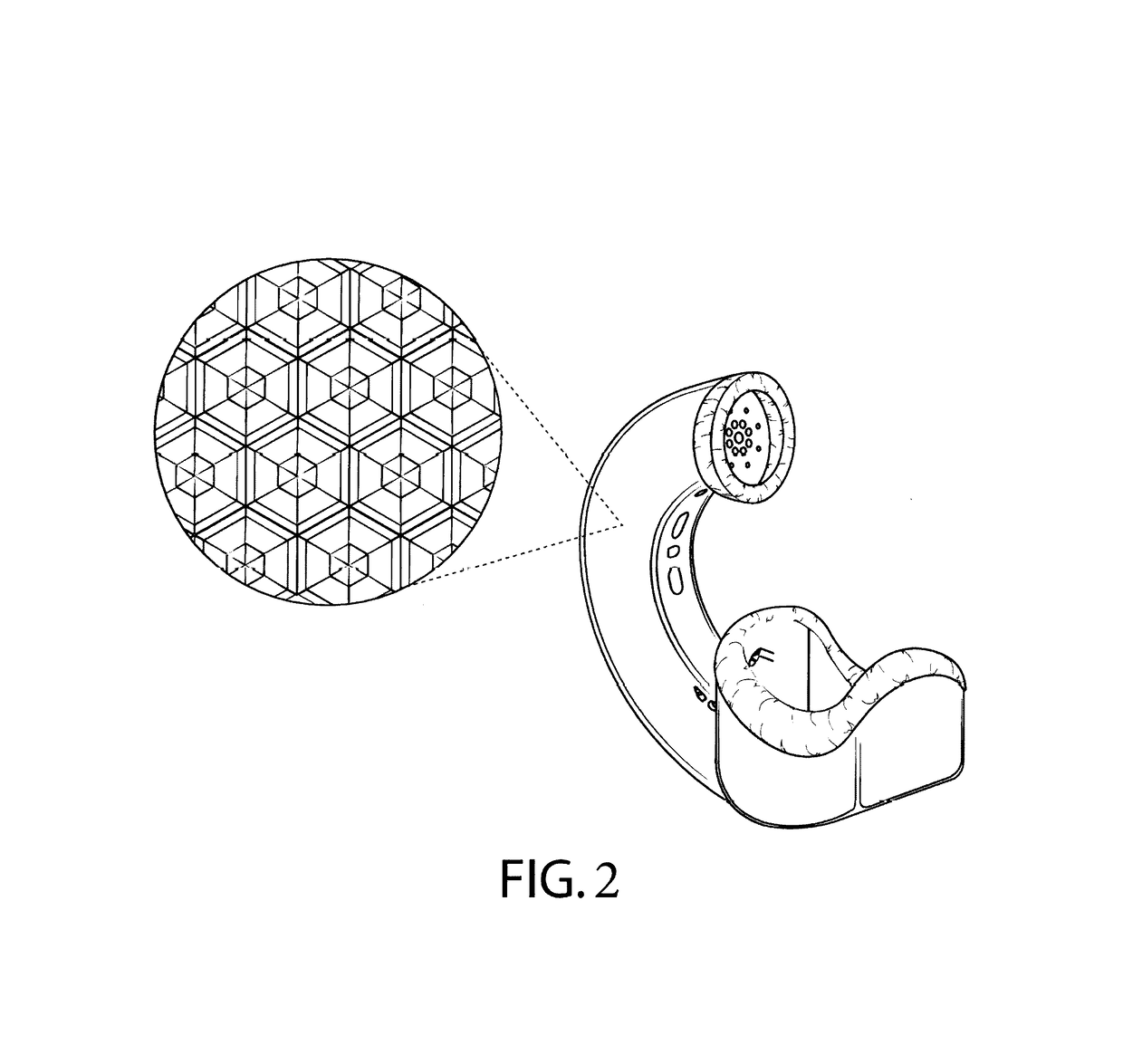

Anechoic cup or secondary anechoic chamber comprising metallic flake mixed with sound attenuating or absorbing materials for use with a communication device and related methods

ActiveUS20170149943A1Improve privacyImprove clarityMicrophonesLoudspeakersEngineeringAnechoic chamber

Disclosed is a telephone headset that features an antiphase / anti-noise speaker within an anechoic chamber so that noises provided therein can be combatted with antiphase noises. In some embodiment, the antiphase / anti-noise speaker can be an exciter. In some embodiments, the headset is designed to include passive and active noise cancelation of a use's voice. Suitably, the headset can be adjusted to fit an inclusive range of head dimensions comfortably, the headsets may connect wirelessly to the user's phone to ensure cable free operation and communication.

Owner:QUIET

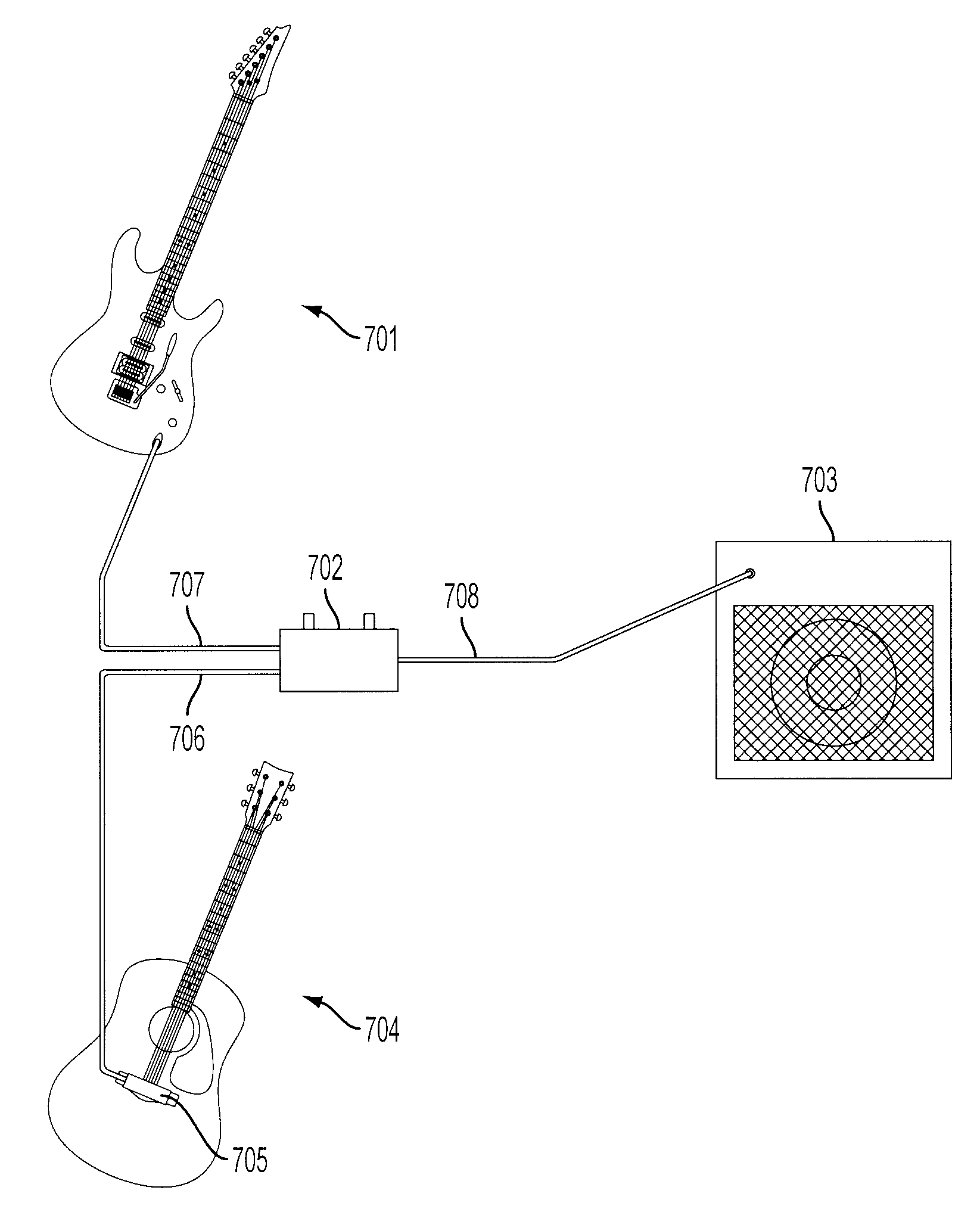

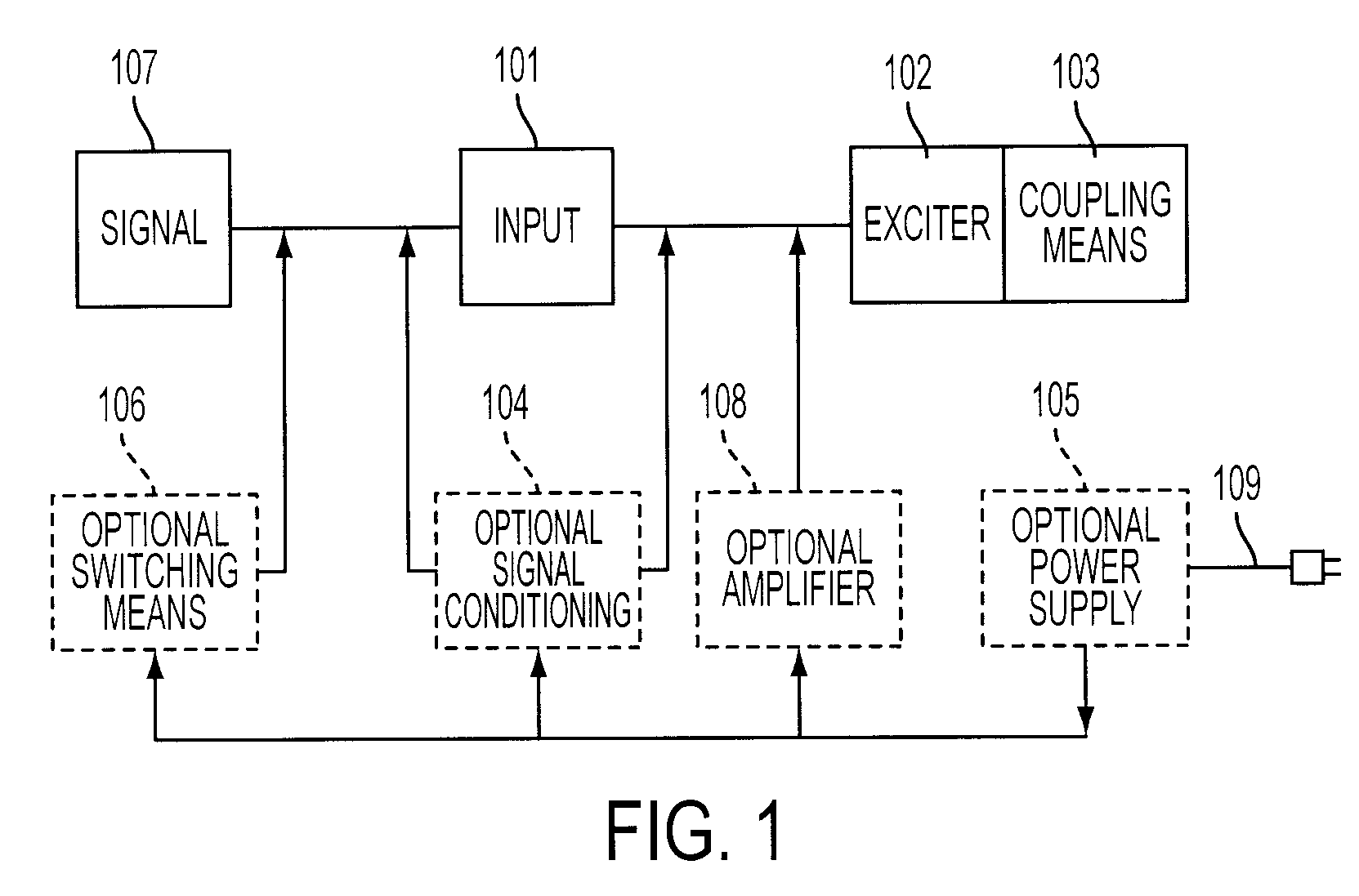

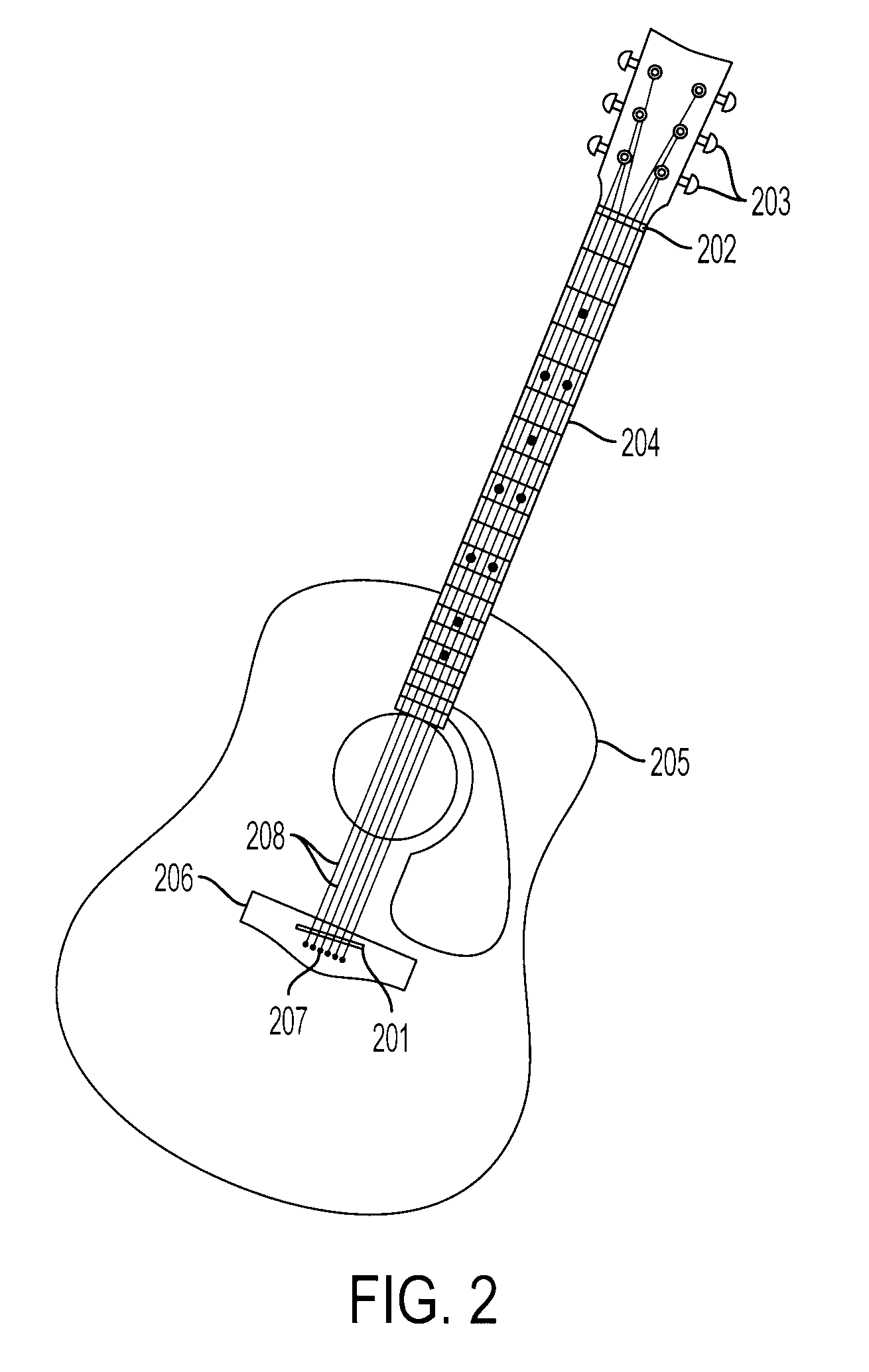

System and method for remotely generating sound from a musical instrument

A system and method for remotely generating sound from a musical instrument. In one embodiment, the system includes an input configured to receive a signal representative of the sound of a first musical instrument, an exciter for converting the signal to mechanical vibrations, and a coupling interface for coupling the mechanical vibrations into a second musical instrument. The method for remotely generating sound includes the steps of generating a signal representative of the sound of a first musical instrument, transmitting the signal, receiving the signal at an input, converting the signal to mechanical vibrations, and coupling the mechanical vibrations to a second musical instrument capable of producing sound waves.

Owner:LANGBERG ERIC AARON

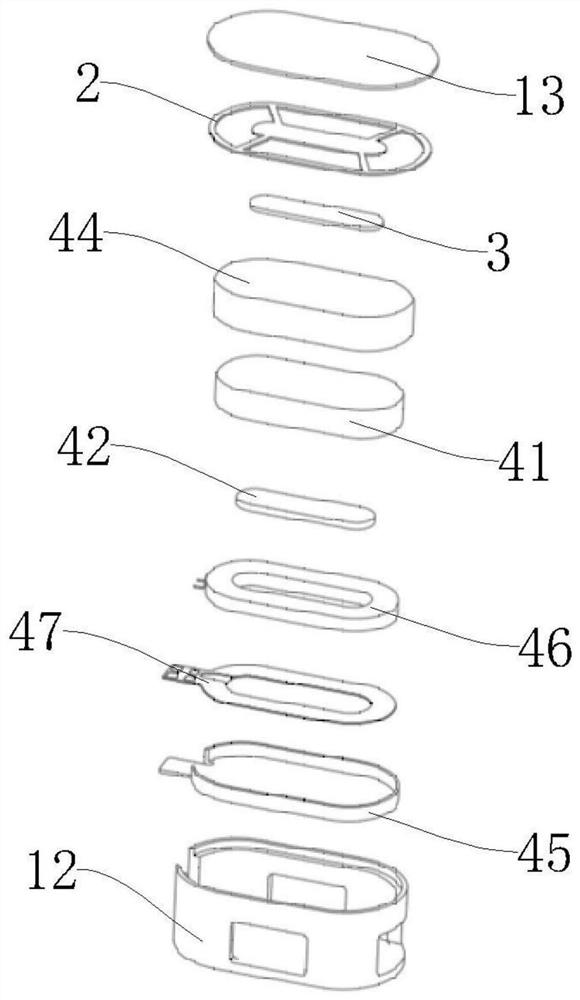

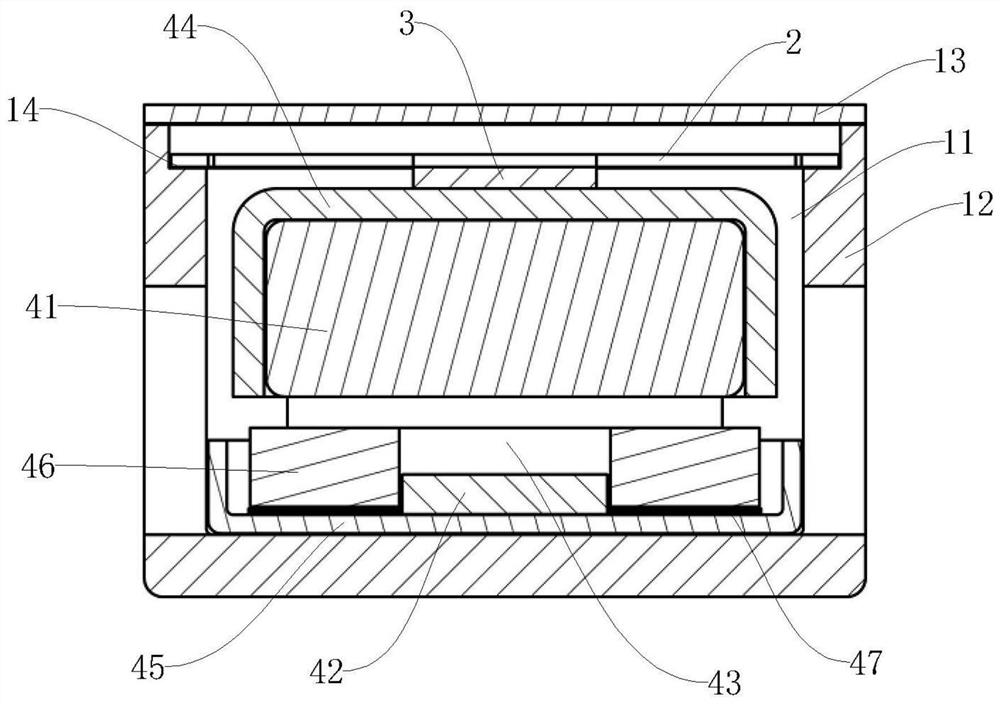

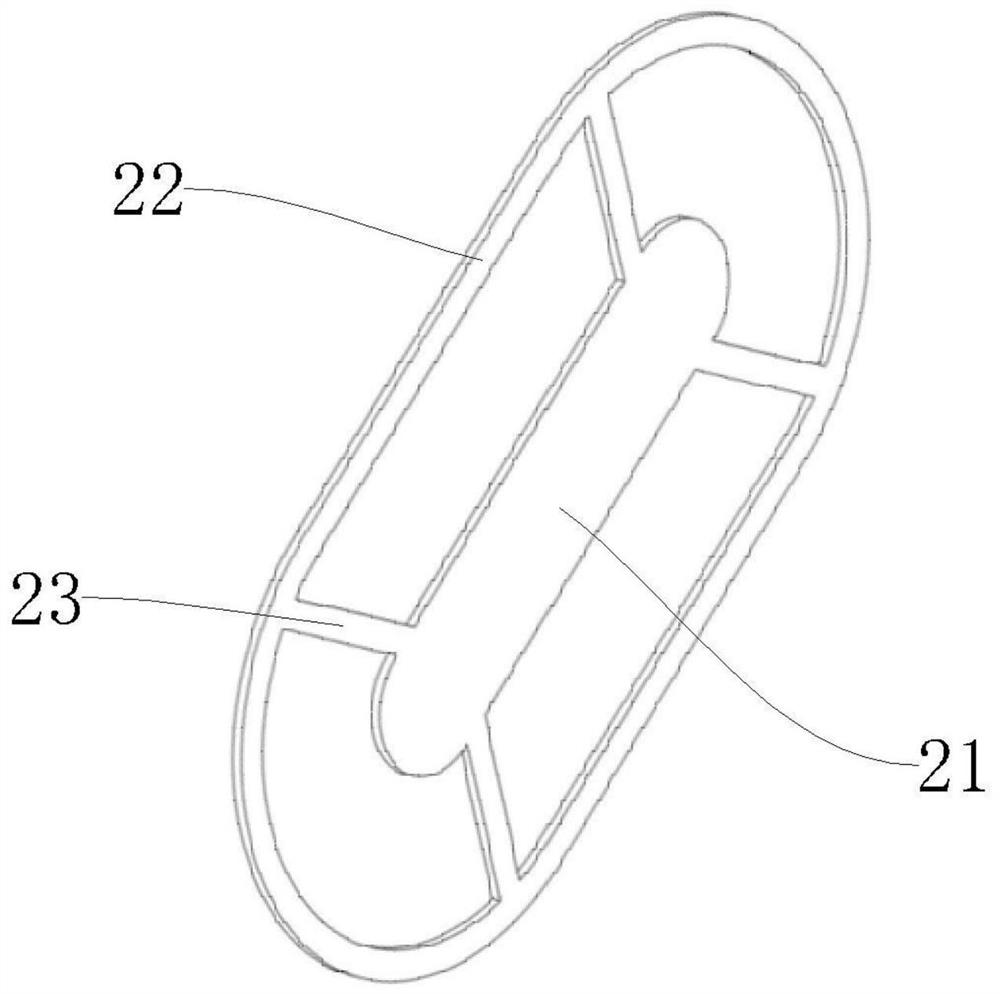

Bone conduction sound production device and wearable equipment

PendingCN112887870AImprove experienceModerate rangeBone conduction transducer hearing devicesFrequency/directions obtaining arrangementsVibration amplitudeTransmission amplitude

The invention discloses a bone conduction sound production device and wearable equipment, wherein the bone conduction sound production device comprises an external packaging structure, the external packaging structure is internally provided with a hollow cavity, and the hollow cavity is internally provided with: a hollow elastic sheet; an exciter, which comprises an upper magnetic piece and a lower magnetic piece, wherein the upper magnetic piece and the lower magnetic piece are oppositely arranged in parallel in the Z-axis direction, and a gap exists between the upper magnetic piece and the lower magnetic piece to form an isolation area; a space low-frequency adjusting plate, which is arranged between the hollowed-out elastic piece and the exciter, wherein the space low-frequency adjusting plate is used for adjusting the framework stacking of the hollowed-out elastic piece and the exciter in the Z-axis direction and adjusting the gap of the isolation area; the hollowed-out elastic piece is matched with the space low-frequency adjusting plate to adjust the effective vibration area of the hollowed-out elastic piece so as to adjust the resonant frequency point of the device. The wearable equipment provided with the bone conduction sound production device can transmit low-frequency signals, wherein the transmission amplitude is moderate, the whole sound frequency band is balanced, the good acoustic effect is achieved, and the user experience and the product sound quality are remarkably improved.

Owner:SUZHOU THOR ELECTRONIC TECH CO LTD

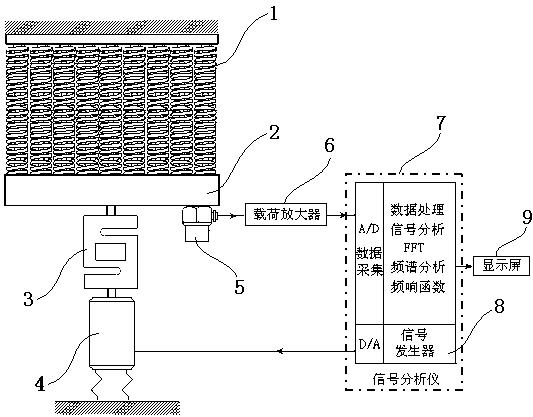

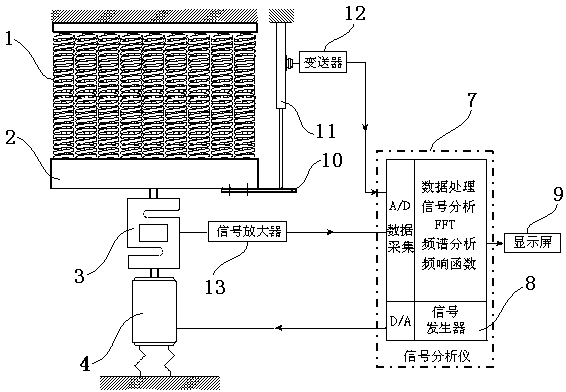

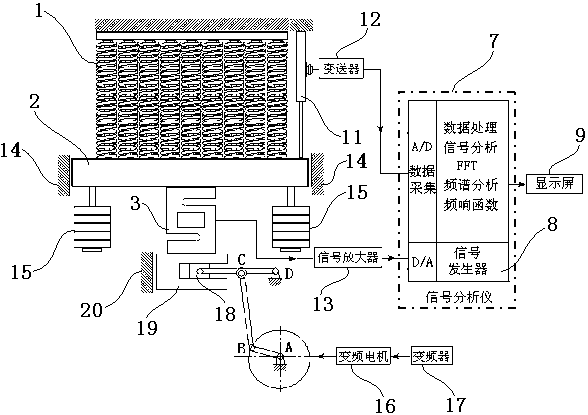

Device and method for measuring dynamic stiffness frequency-dependent characteristics of return springs

The invention discloses a device and a method for measuring dynamic stiffness frequency-dependent characteristics of return springs. The device comprises a return spring set, a force sensor, a signal analyzer, an acceleration sensor and a displacement sensor. The upper end of the return spring set is fixedly grounded. The lower end of the return spring set is fixedly connected to a spring base plate. The spring base plate is connected with an exciter or a six-connecting rod mechanism through the force sensor to drive the return spring to vibrate or reciprocate. The acceleration sensor or the displacement sensor is disposed on the spring base plate. The return spring set vibrates or reciprocates to allow the acceleration sensor or the displacement sensor to output response signals to the signal analyzer, and the signal analyzer acquires dynamic stiffness frequency-dependent characteristics of the return springs through data processing and FFT (fast Fourier transform) analysis. By researching the dynamic stiffness of the return springs, the highest operation speed of a passive shedding mechanism can be explored, and basis is provided for improvement of the passive shedding mechanism.

Owner:WUJIANG WANGONG ELECTROMECHANICAL EQUIP

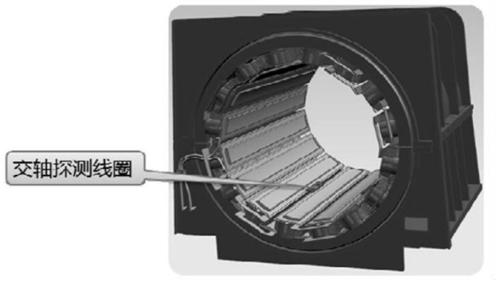

Method and system for detecting electrical fault of brushless exciter and storage medium

ActiveCN111308345AHigh sensitivityImprove reliabilityDynamo-electric machine testingElectrical malfunctionMagnetic poles

The embodiment of the invention provides a method and a system for detecting an electrical fault of a brushless exciter and a storage medium. The method comprises the following steps: winding a sub-detection coil on each of at least two uniformly distributed magnetic poles of the brushless exciter; connecting the at least two wound sub-detection coils in series to obtain a series-connected magnetic pole detection coil, wherein a port of the magnetic pole detection coil is kept in an open-circuit state; detecting the port voltage of the magnetic pole detection coil; and determining whether thebrushless exciter has an electrical fault based on the harmonic component of the port voltage. According to the method and the system for detecting the electrical fault of the brushless exciter and the storage medium, the sensitivity and reliability of fault protection and monitoring of a multi-phase annular winding brushless excitation system can be effectively improved, and the method and the system have great application prospects in the aspect of fault detection.

Owner:TSINGHUA UNIV

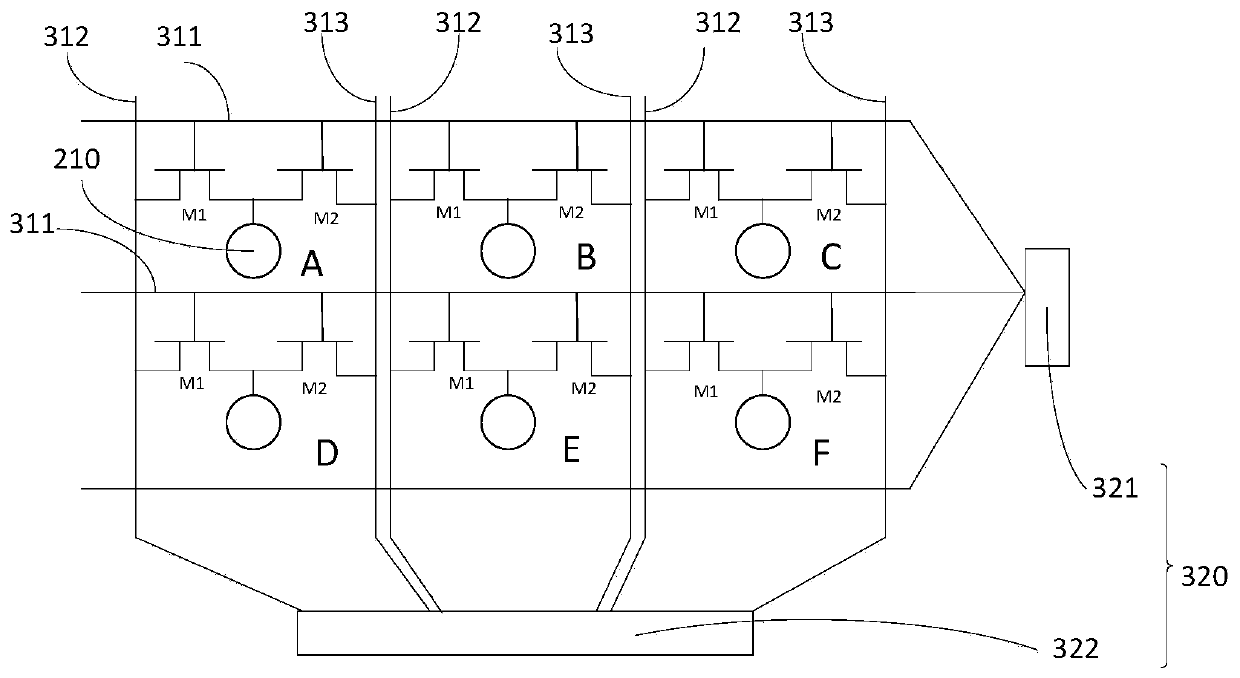

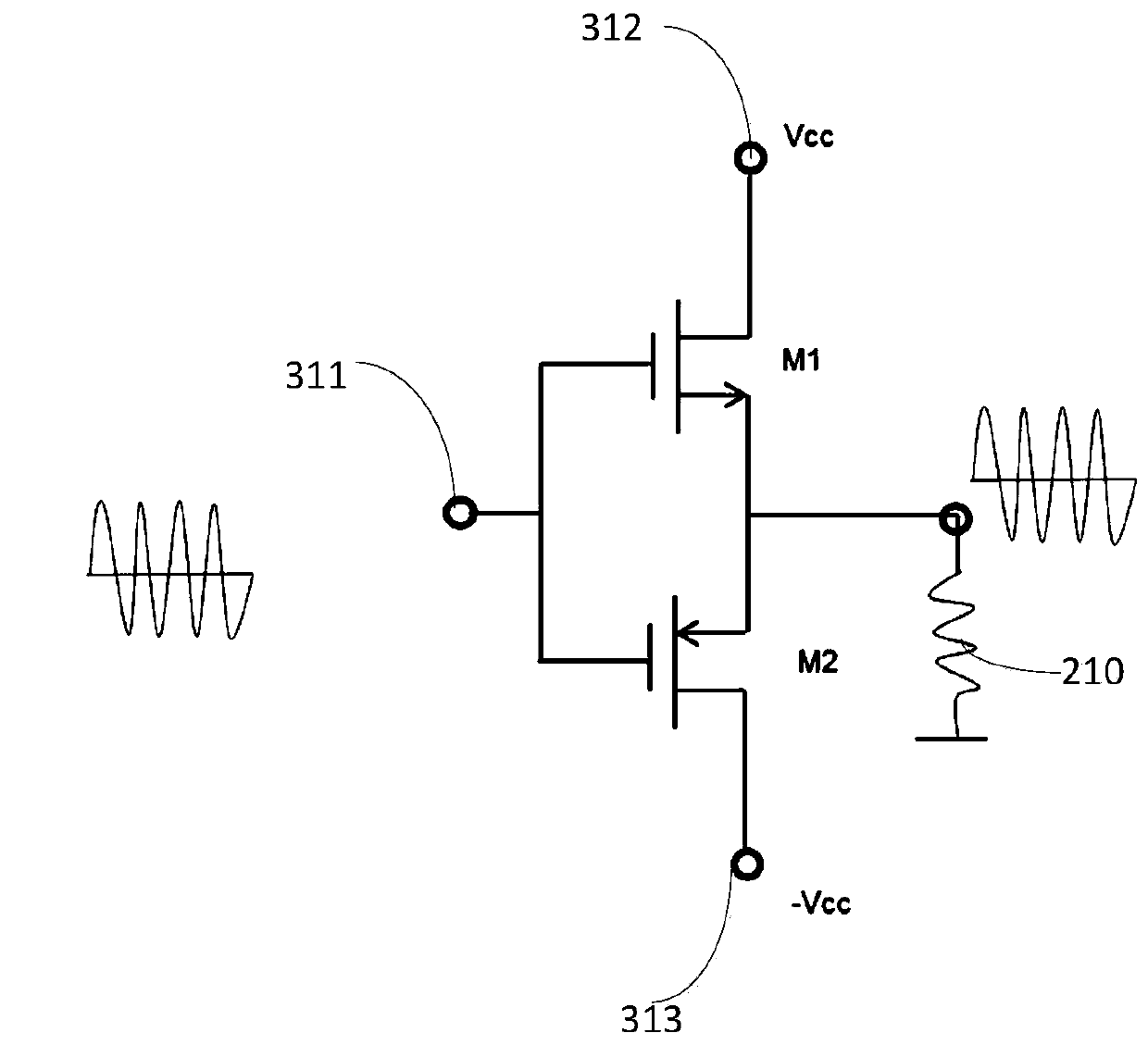

Screen sounding unit, manufacturing method thereof and display device

The invention provides a screen sounding unit, a manufacturing method thereof and a display device. The screen sounding unit comprises a display panel, a plurality of exciters and a driving unit. Eachexciter is arranged on one side of the non-display surface of the display panel, each exciter comprises magnets and a voice coil, the magnets in the exciters are configured to generate magnetic fieldforce between the magnets with opposite magnetisms, and voice coils are driven to vibrate in the direction perpendicular to the display panel; the driving unit comprises a wiring layer and an audio control circuit; audio control lines are distributed on the wiring layer; the wiring layer is integrated on the non-display surface of the display panel; the screen sound production unit comprises a plurality of sound production areas, at least one exciter is arranged in each sound production area, the exciter in each sound production area is correspondingly connected with the audio control line inthe sound production area, and the exciters in different sound production areas apply audio signals independently. According to the screen sounding unit, the manufacturing method thereof and the display device, regional sound production is achieved, the structure is compact, and more integrated and miniaturized design is achieved.

Owner:BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com