Vibration material feeding controller with self-adapting frequency self maintaining amplitude and its control method

A frequency self-adaptive, vibrating feeding technology, applied in vibrating conveyors, conveyor control devices, computer control and other directions, can solve the problems of unstable transmission speed, unstable working state, unstable device amplitude, etc., to achieve low cost, The effect of stable amplitude and stable feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

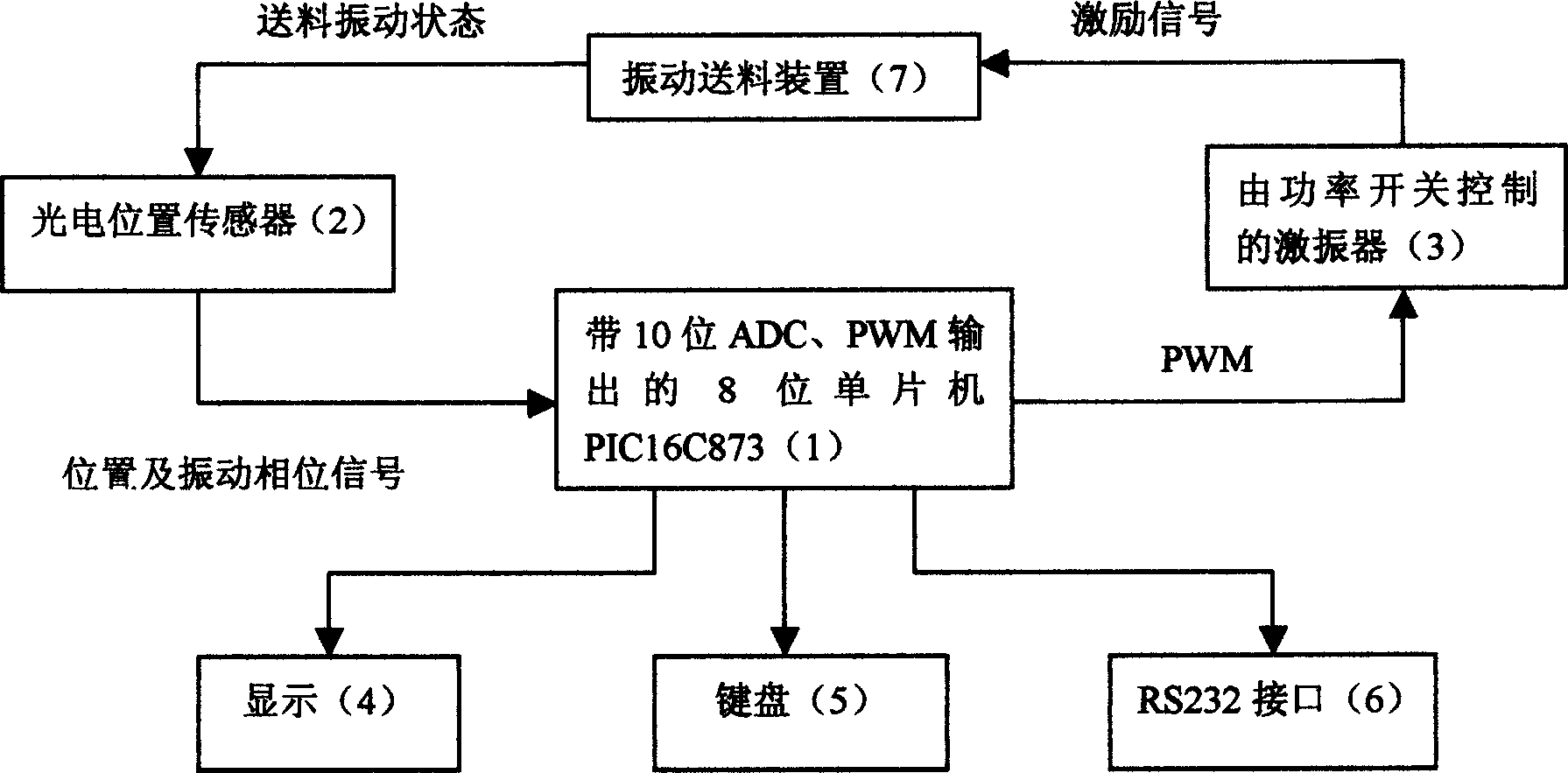

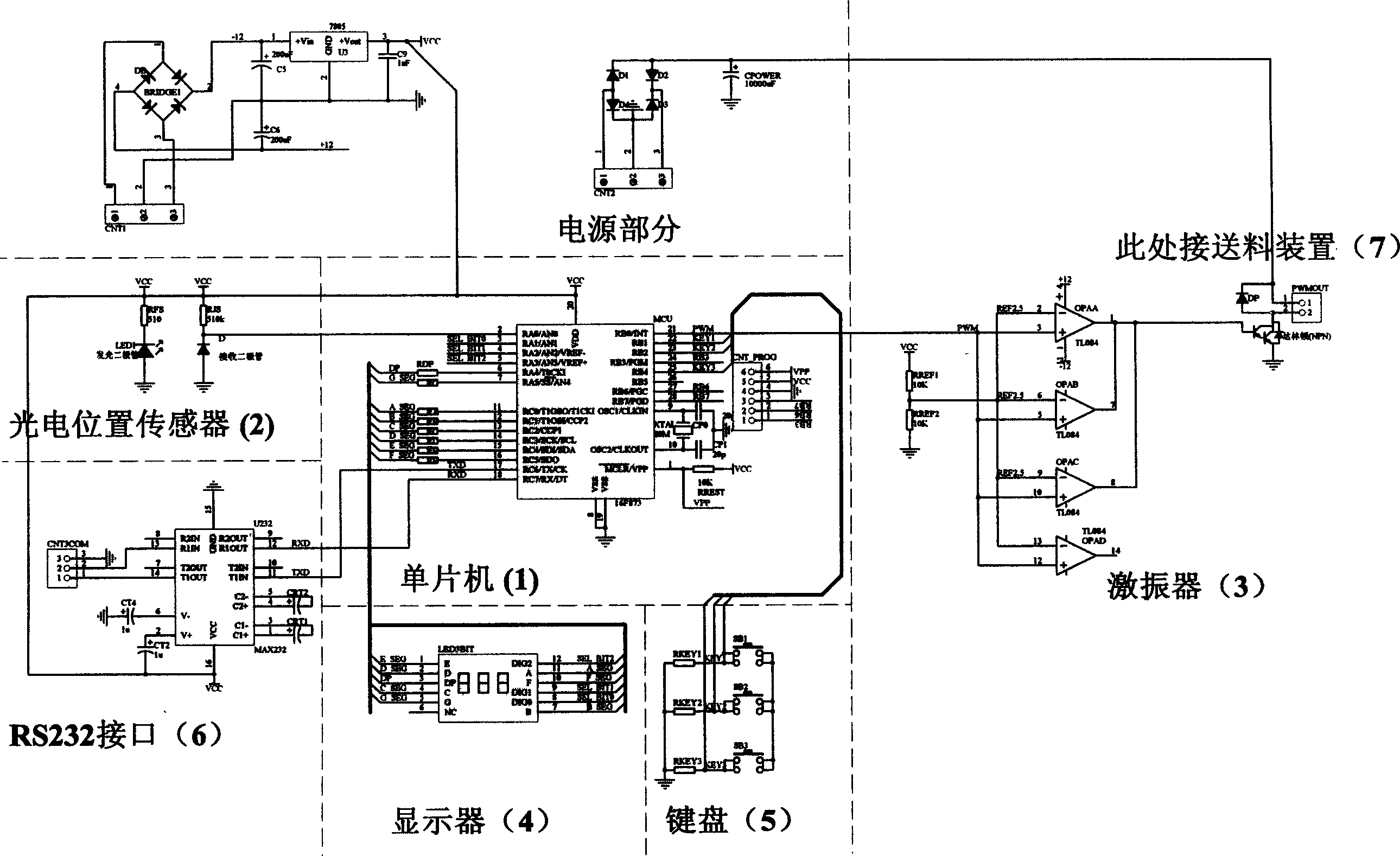

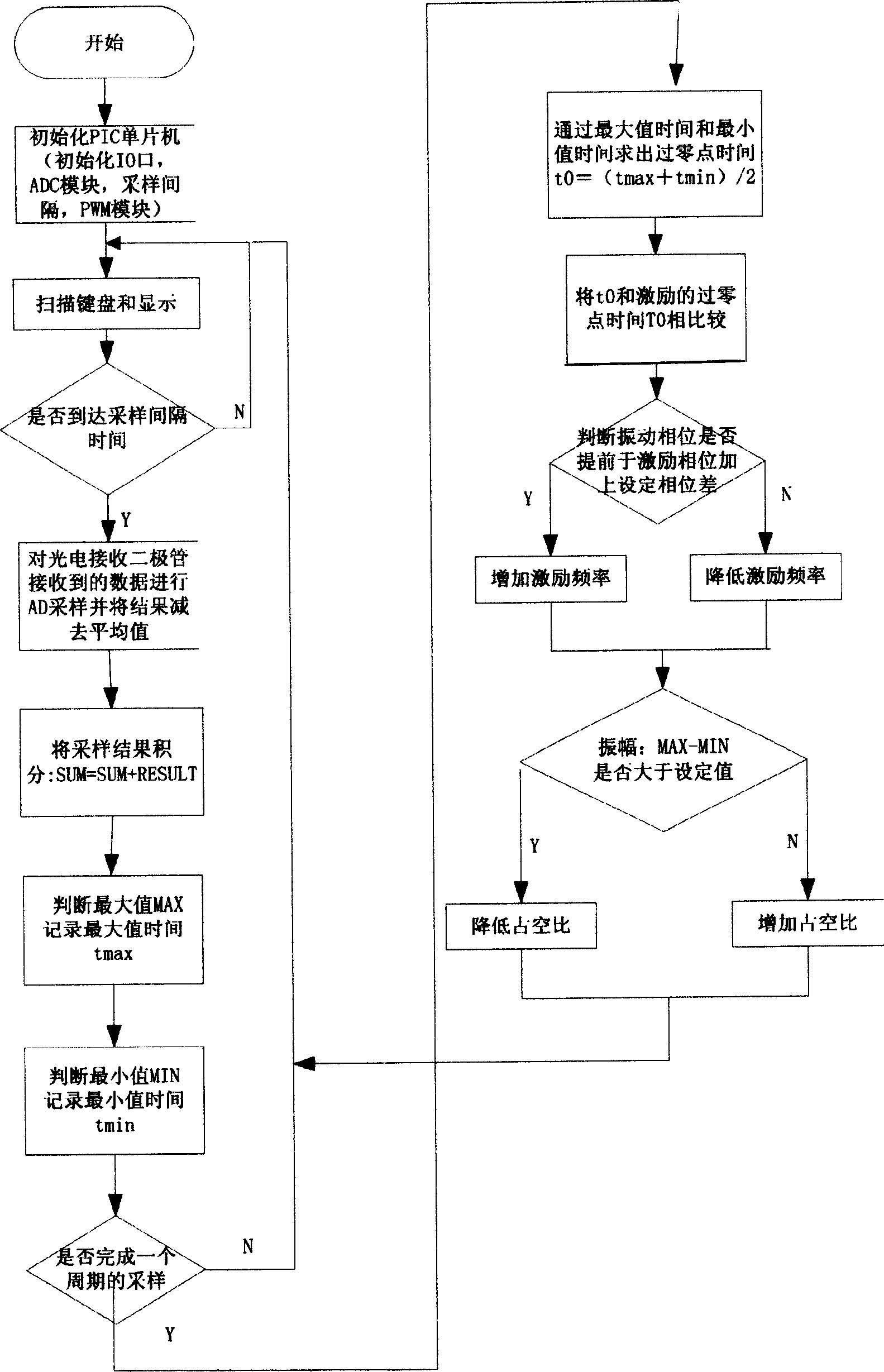

[0045] The frequency self-adaptive, amplitude self-maintaining vibration feeding controller of the present invention comprises single-chip microcomputer 1, photoelectric position sensor 2, exciter 3, display 4, keyboard 5, RS232 interface 6, vibration feeding device 7; Wherein, photoelectric position sensor 2 The input is connected to the vibration feeding device 7, the output terminal of the photoelectric position sensor 2 is connected to the input terminal of the single-chip microcomputer 1, and the output terminal of the single-chip microcomputer 1 is respectively connected to the exciter 3, the display 4, the keyboard 5, the RS232 interface 6, and the output of the exciter 3 Connect the vibration feeding device 7.

[0046] The hardware composition of the present invention includes: eight-bit single-chip microcomputer 1 with ten-bit ADC and PWM output, the model is "PIC16C873", and its crystal oscillator adopts 20MHz; FG471068U; PWM output operational amplifier adopts TL082...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com