Patents

Literature

40results about How to "Stable feeding speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

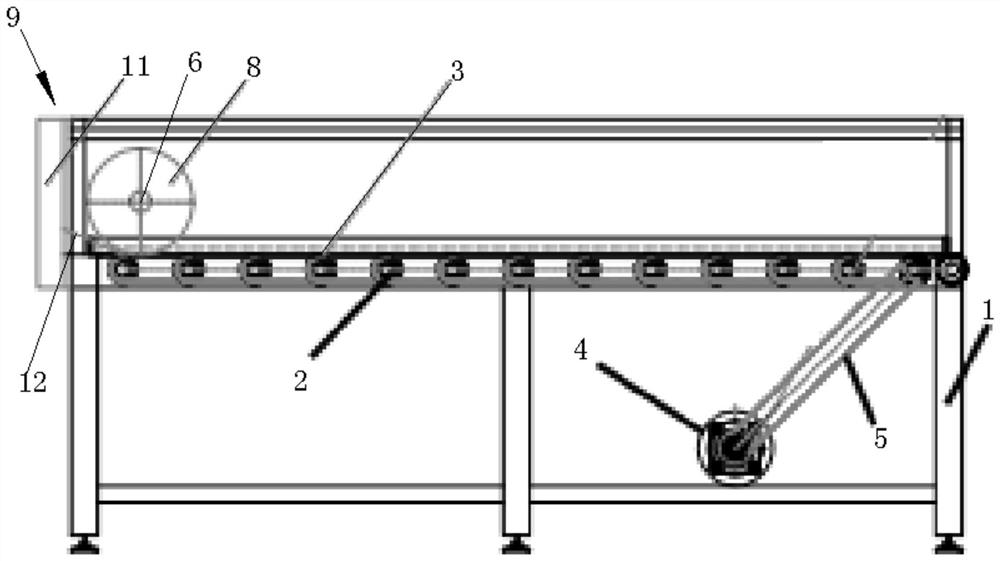

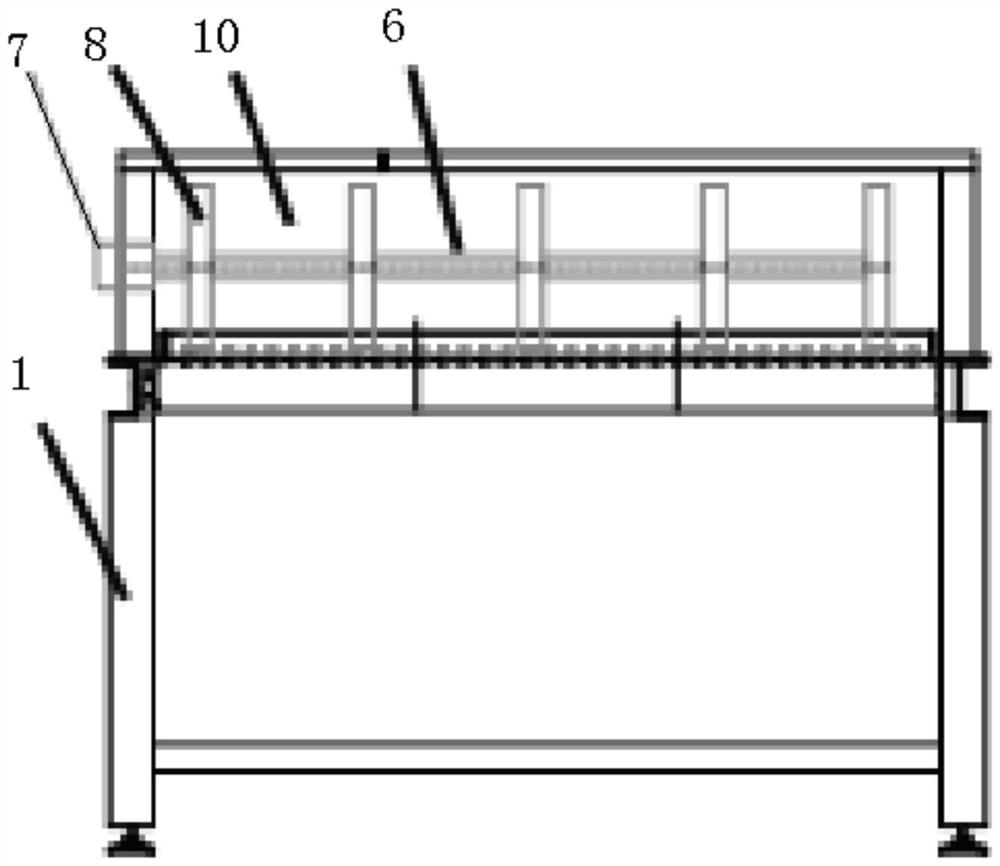

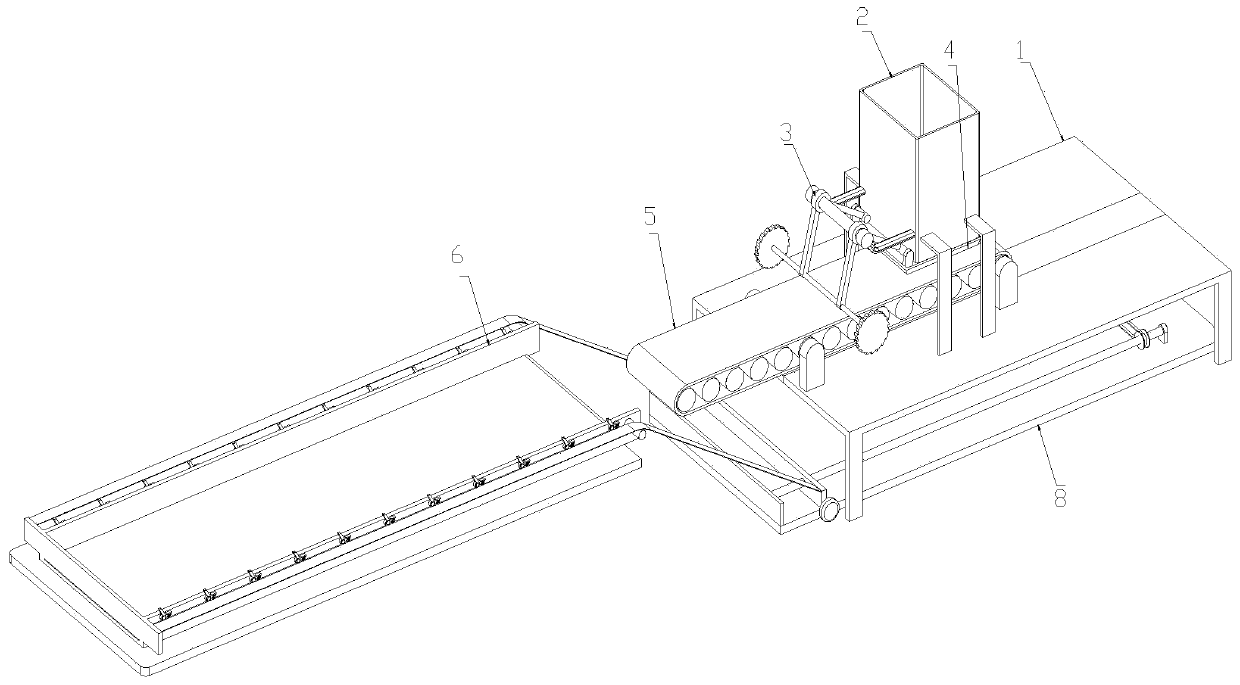

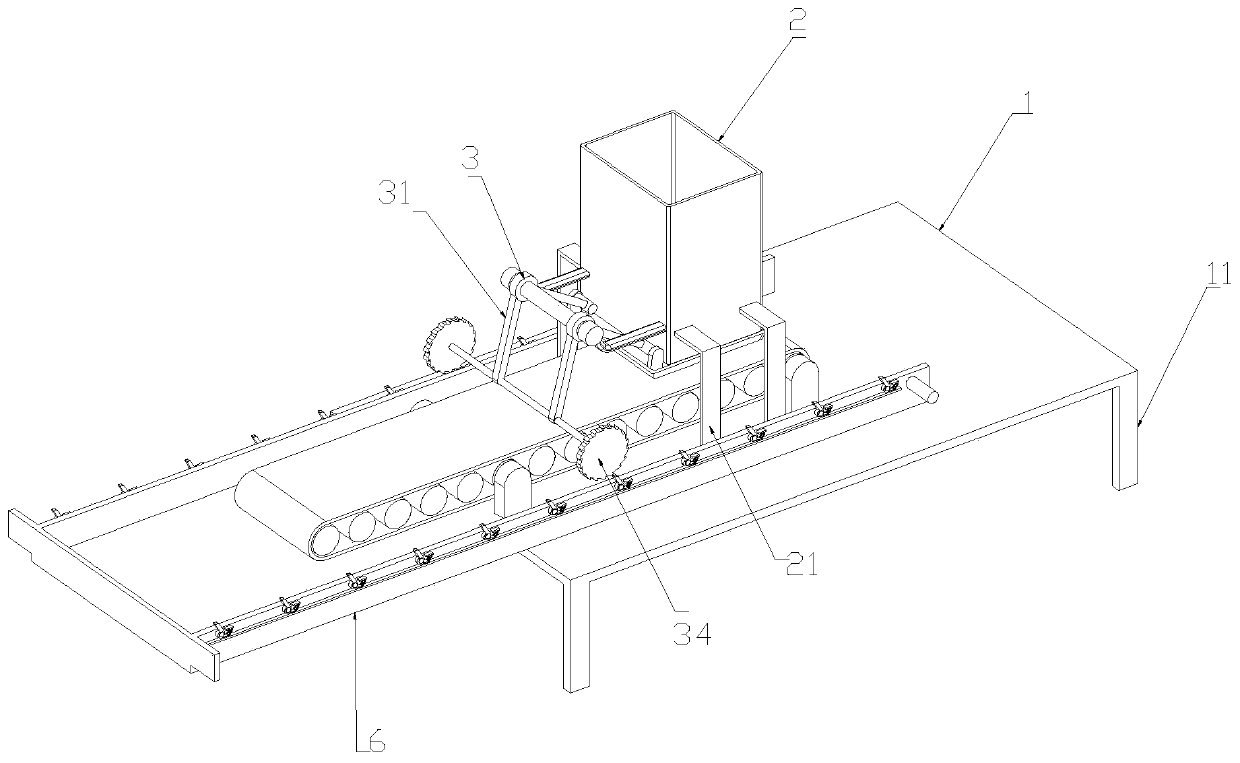

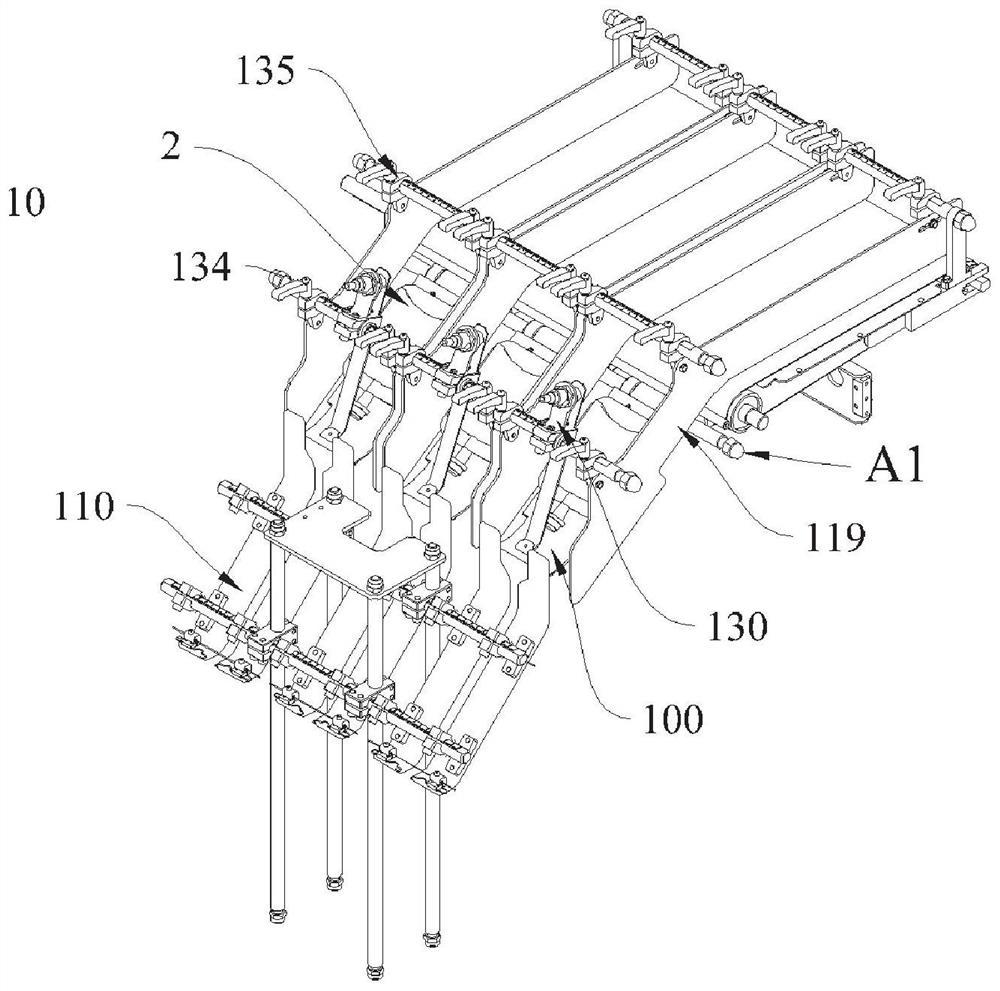

Automatic single-color mosaic-particle lay-up device and lay-up method thereof

ActiveCN104085241AImprove laying efficiencyHigh speedOrnamental structuresConveyor partsEngineeringAutomatic testing

The invention provides an automatic single-color mosaic-particle lay-up device and a lay-up method of the automatic single-color mosaic-particle lay-up device. The automatic single-color mosaic-particle lay-up device comprises a stander, a mosaic forming die which is arranged on the stander, at least one automatic mosaic-particle single-track lay-up unit, a loading device and a controller, wherein each automatic mosaic-particle single-track lay-up unit is used for gradually collecting mosaic particles one by one after transporting the mosaic particles one by one, arranging the mosaic particles into rows / columns according to a preset rule and then driving the entire row / column of mosaic particles to enter a loading procedure; the loading device is connected with the stander and used for sequentially transporting and loading the well-arranged entire row / column of mosaic particles in each automatic mosaic-particle single-track lay-up unit into the mosaic forming die; the controller is respectively connected with each automatic mosaic-particle single-track lay-up unit and the feeding device by signals. The automatic single-color mosaic-particle lay-up device is high in lay-up stability, high in lay-up speed and capable of effectively improving the lay-up efficiency and lay-up accuracy of the mosaic particles. The automatic lay-up method is used for substituting the traditional manual lay-up process, so that the problems that the current mosaic industry is low in automation degree and low in production efficiency can be solved.

Owner:FOSHAN UNIVERSITY

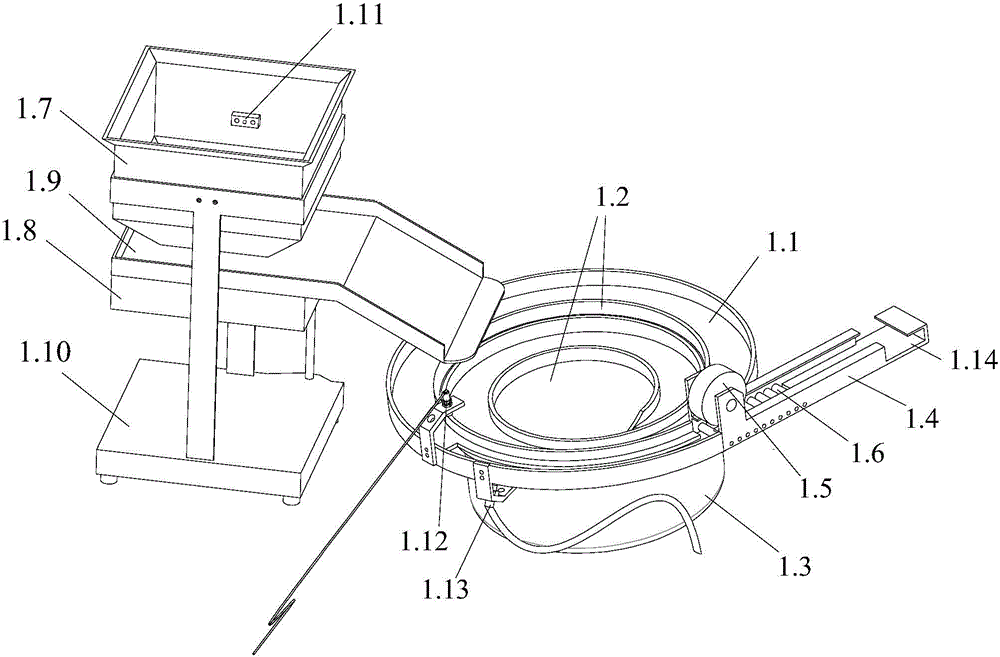

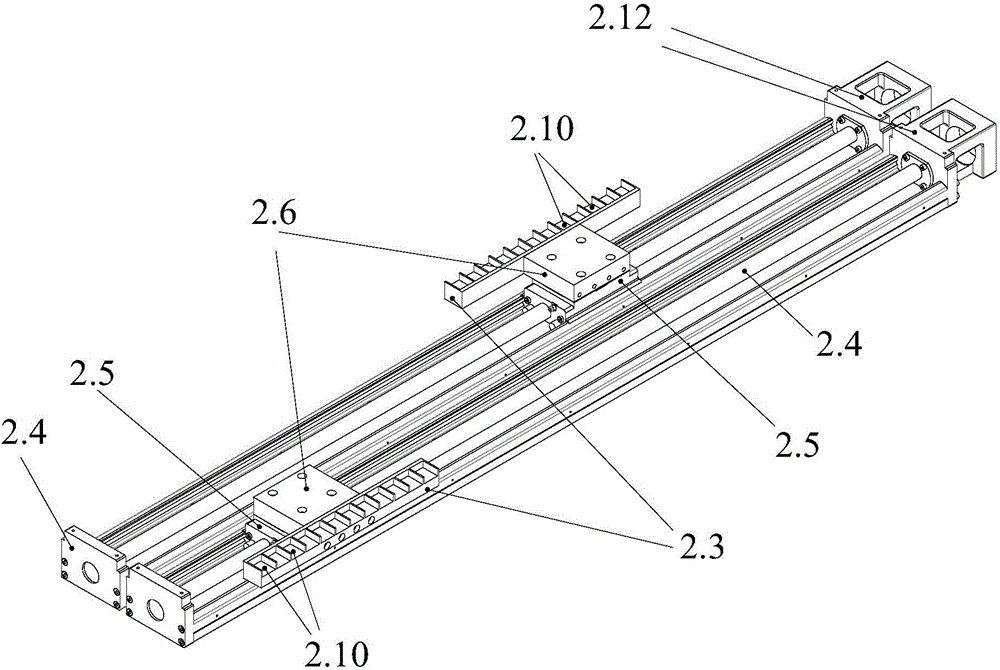

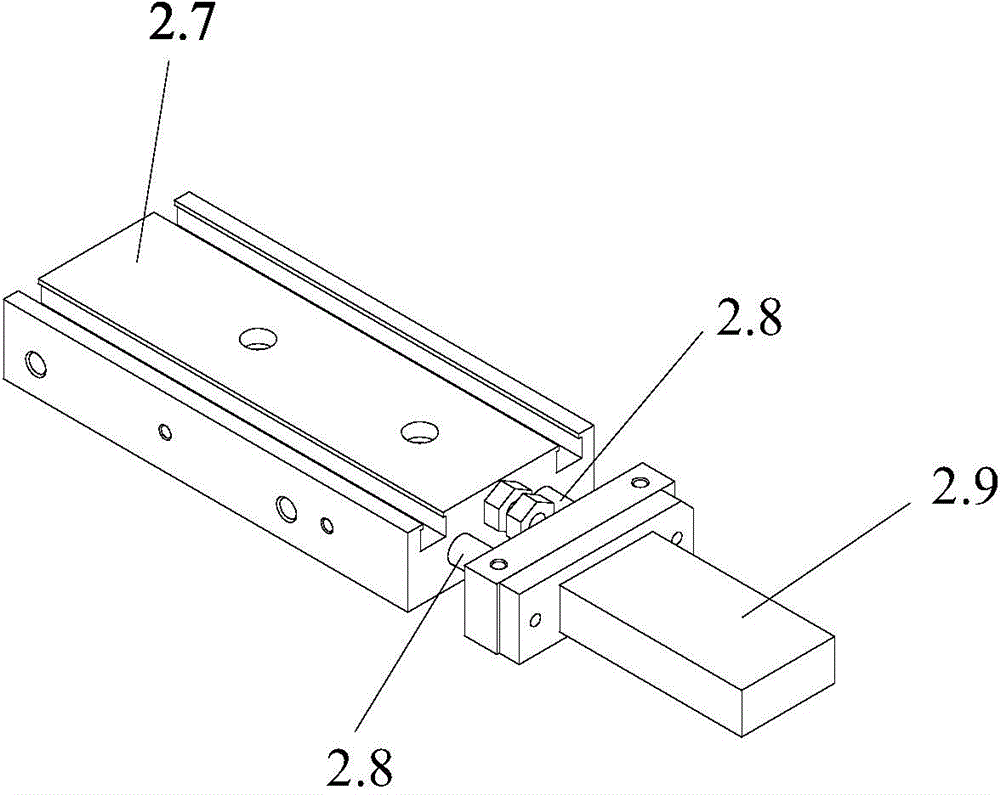

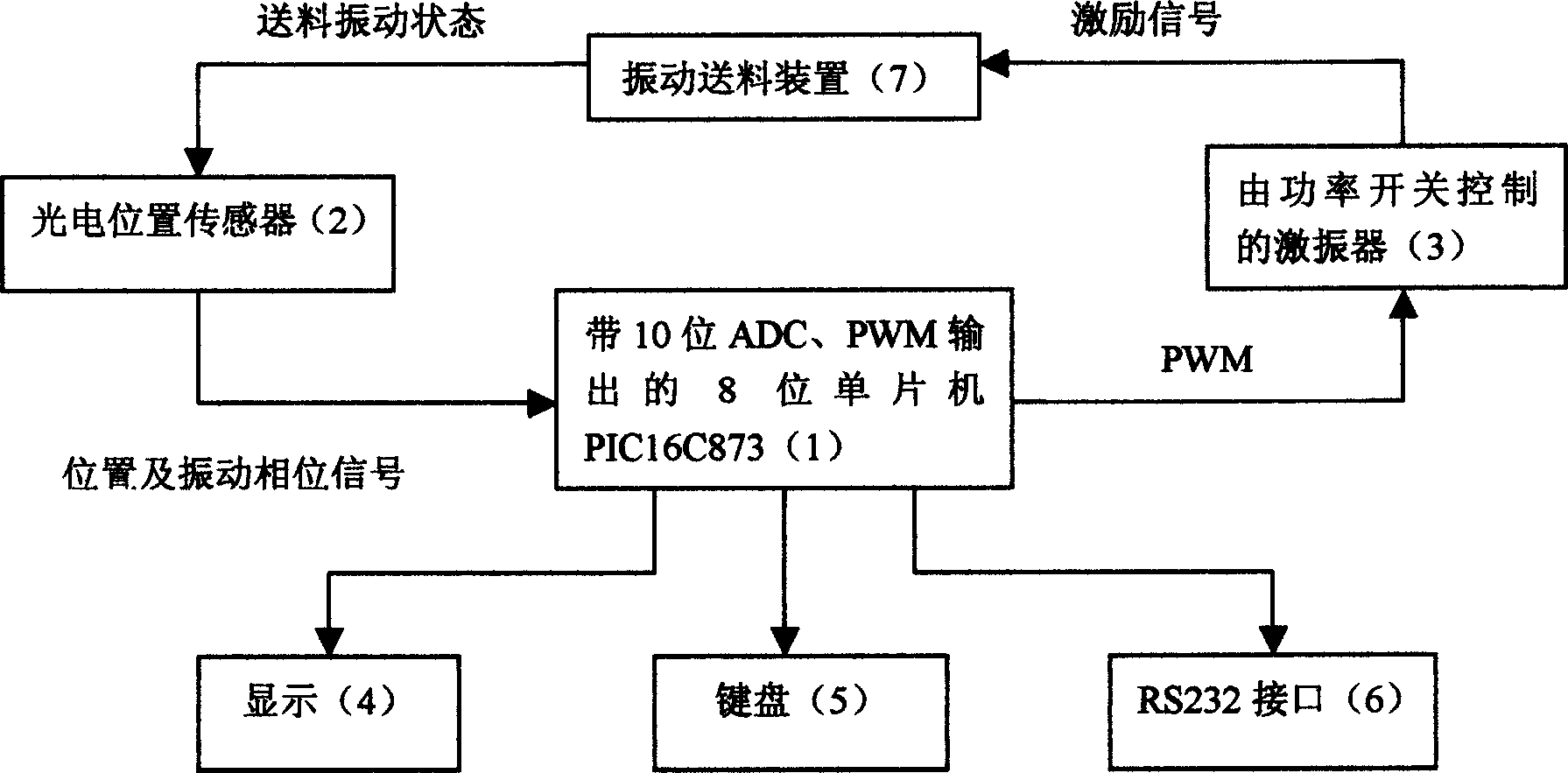

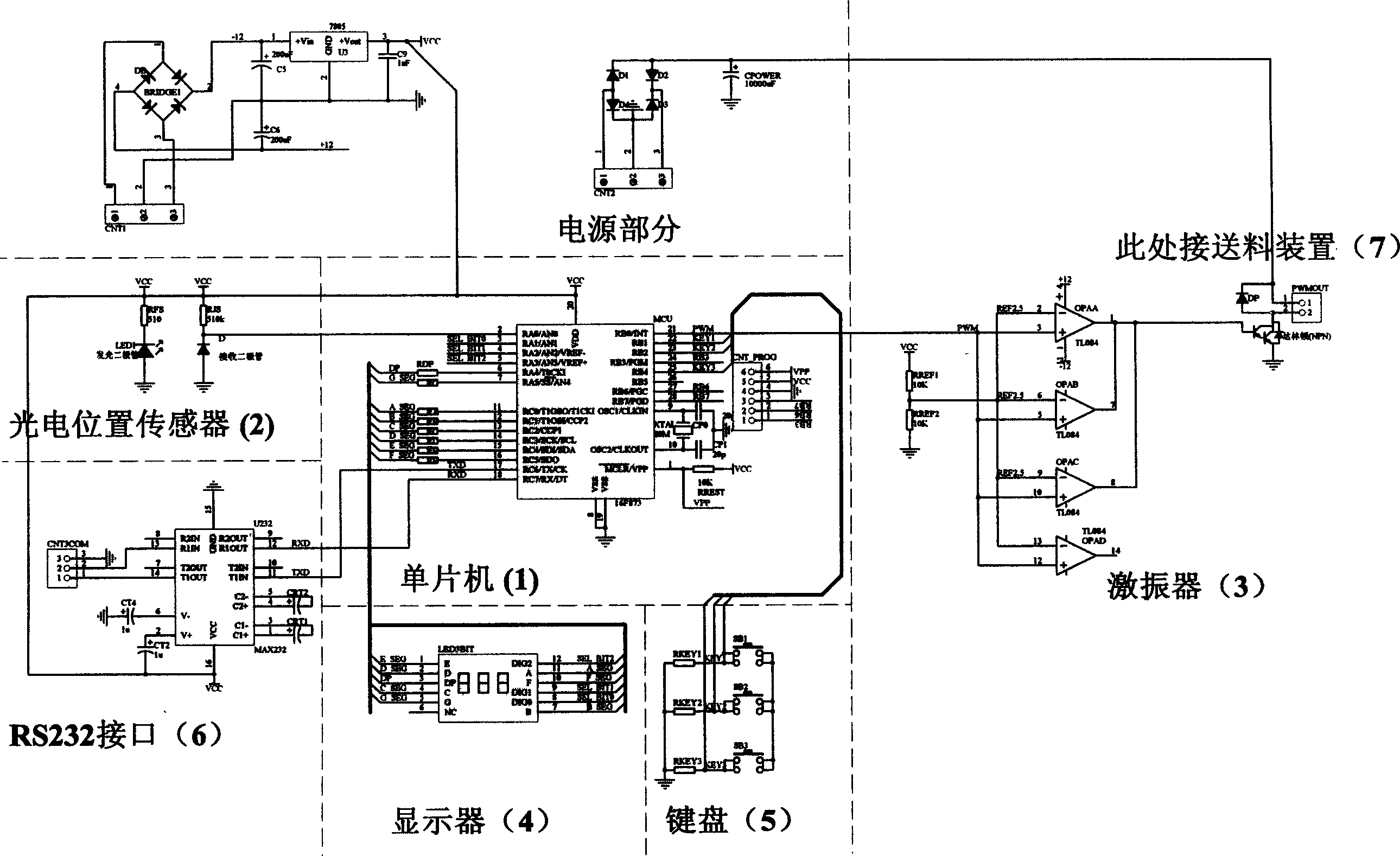

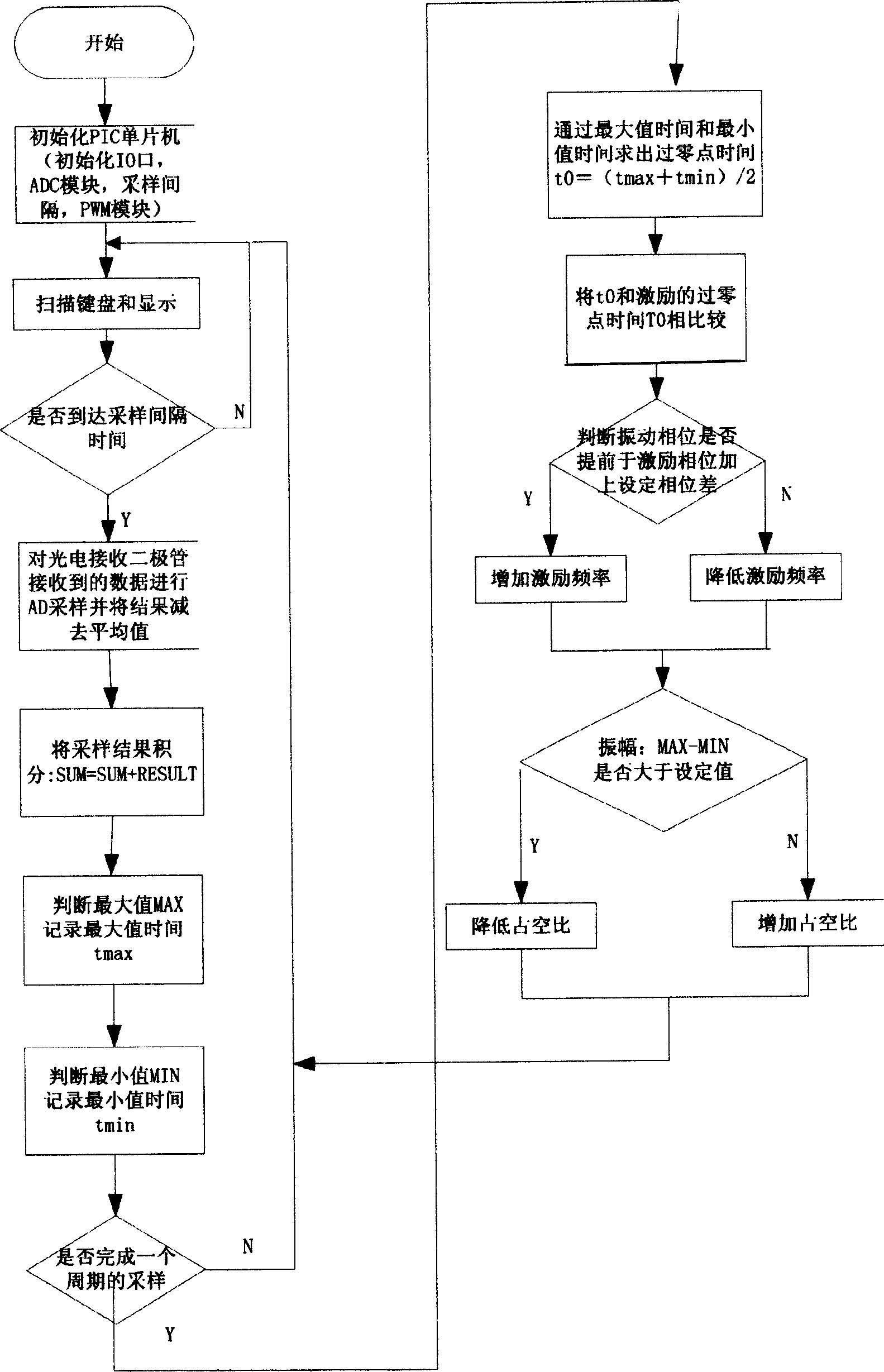

Vibration material feeding controller with self-adapting frequency self maintaining amplitude and its control method

ActiveCN1597471AAmplitude stableStable feeding speedComputer controlControl devices for conveyorsMicrocontrollerAmplitude control

This ivnention relates to a method and a cotnroller for vibration feeder with self-frequency adaptation and self-amplitude control. The controller consists of a monolithic computer, a photoelectric position sensor, an exciter, a display, a keyboard, an RS232 interface. The control emthod is based on phase feedback, and carried out by using a photoelectric position sensor to collect position and phase signals of the vibration feeder, using a computer to process the signals, sending them to the display and RS232 interface and the exciter, and actuating the feeder.

Owner:SOUTHEAST UNIV

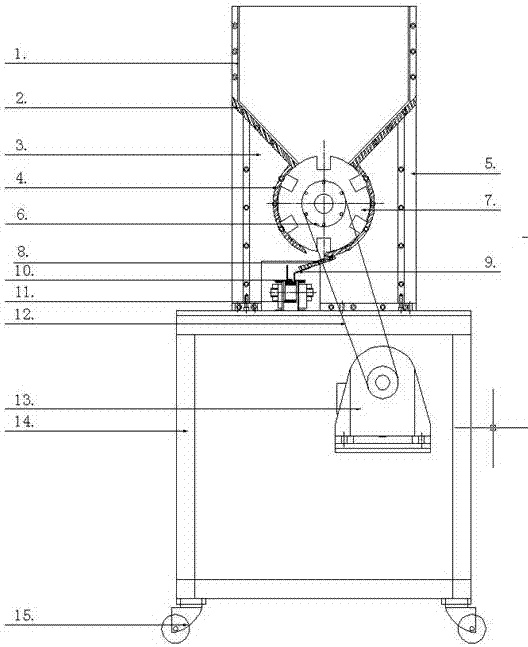

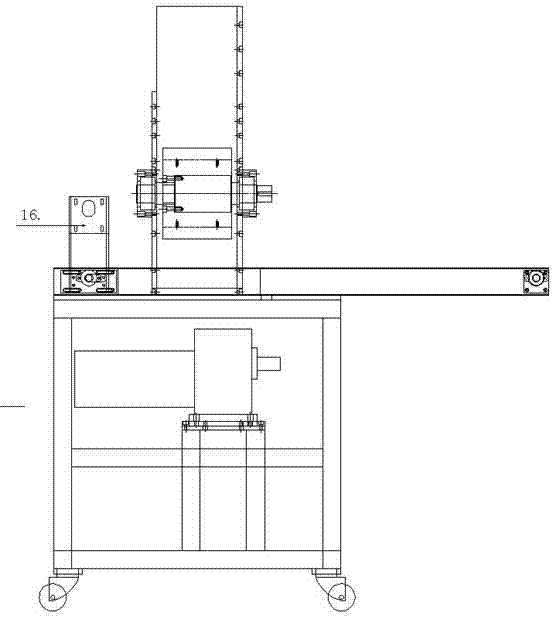

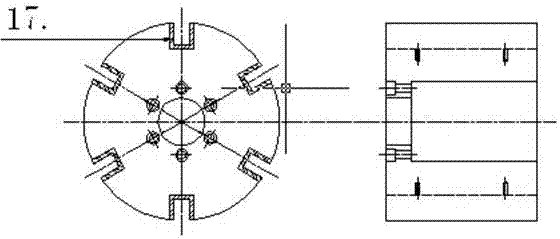

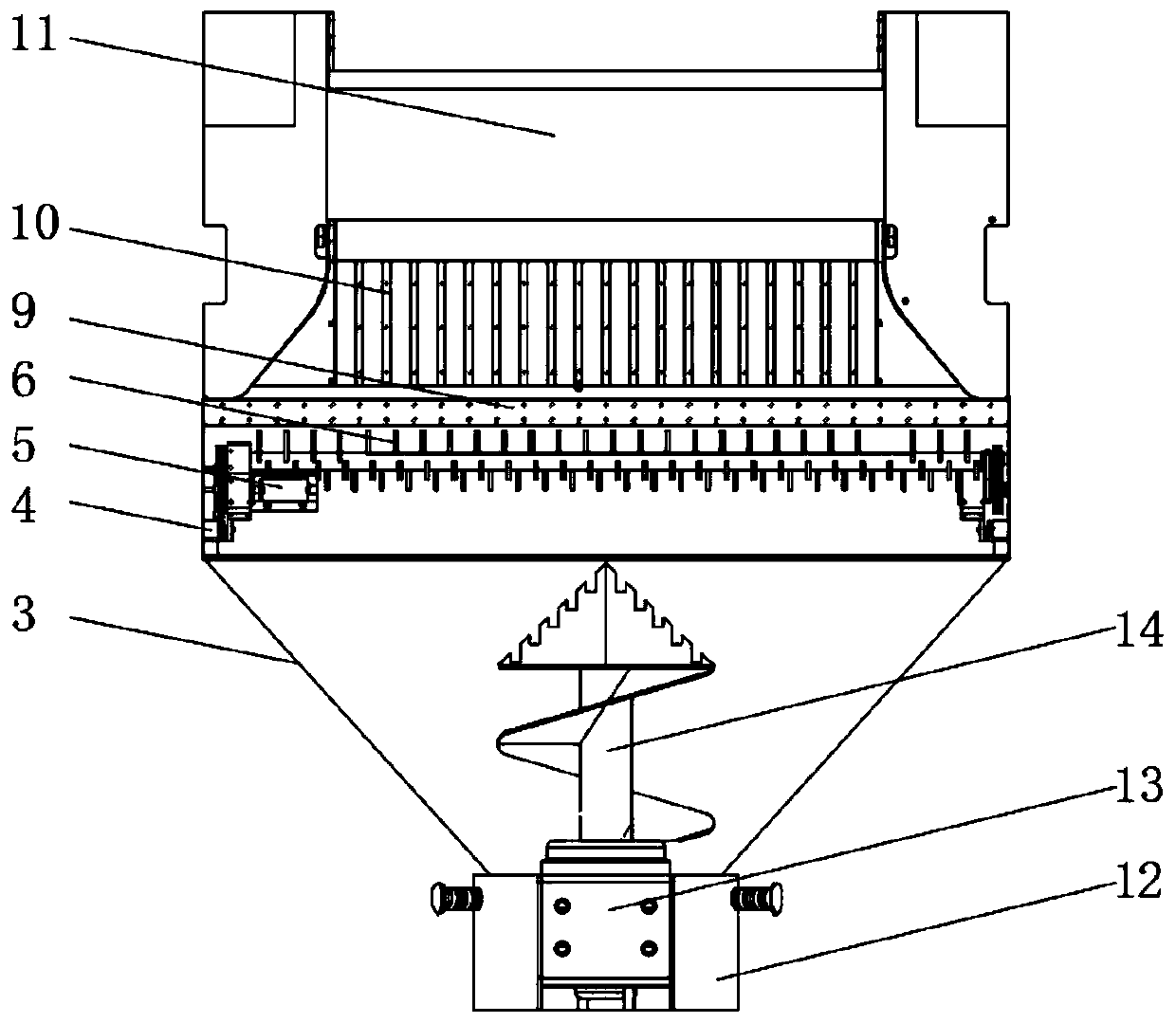

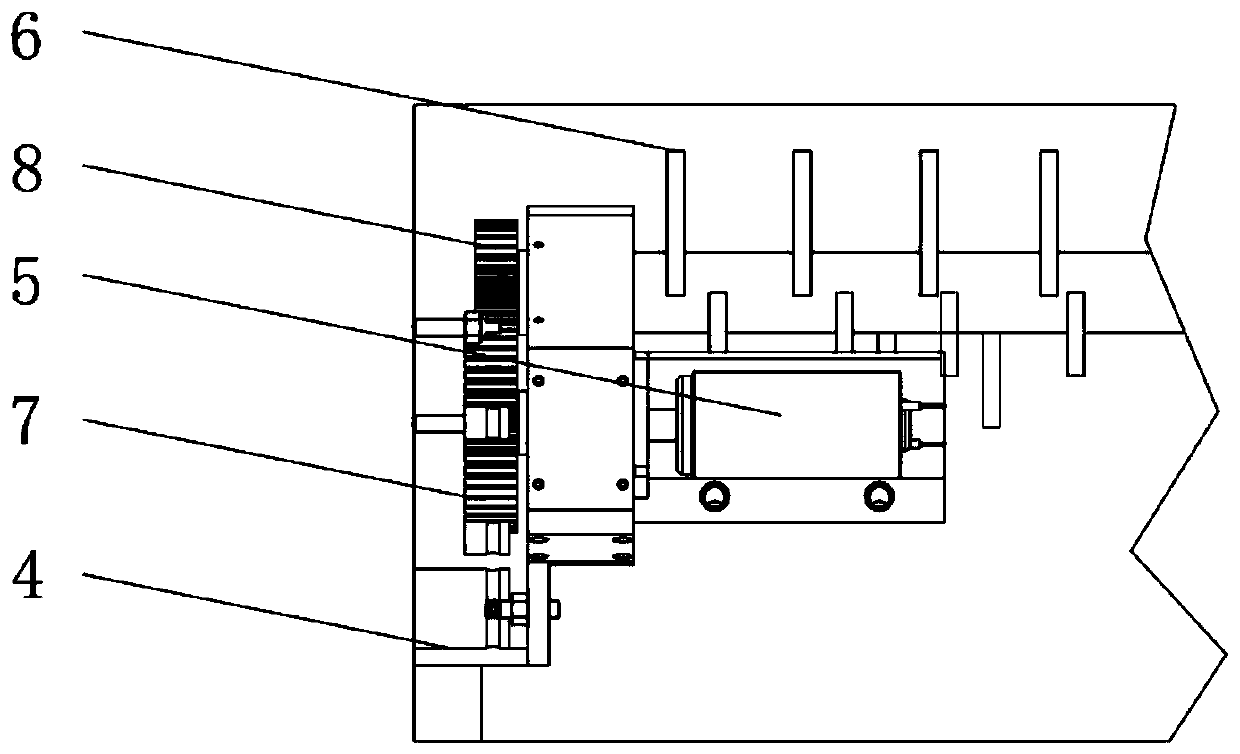

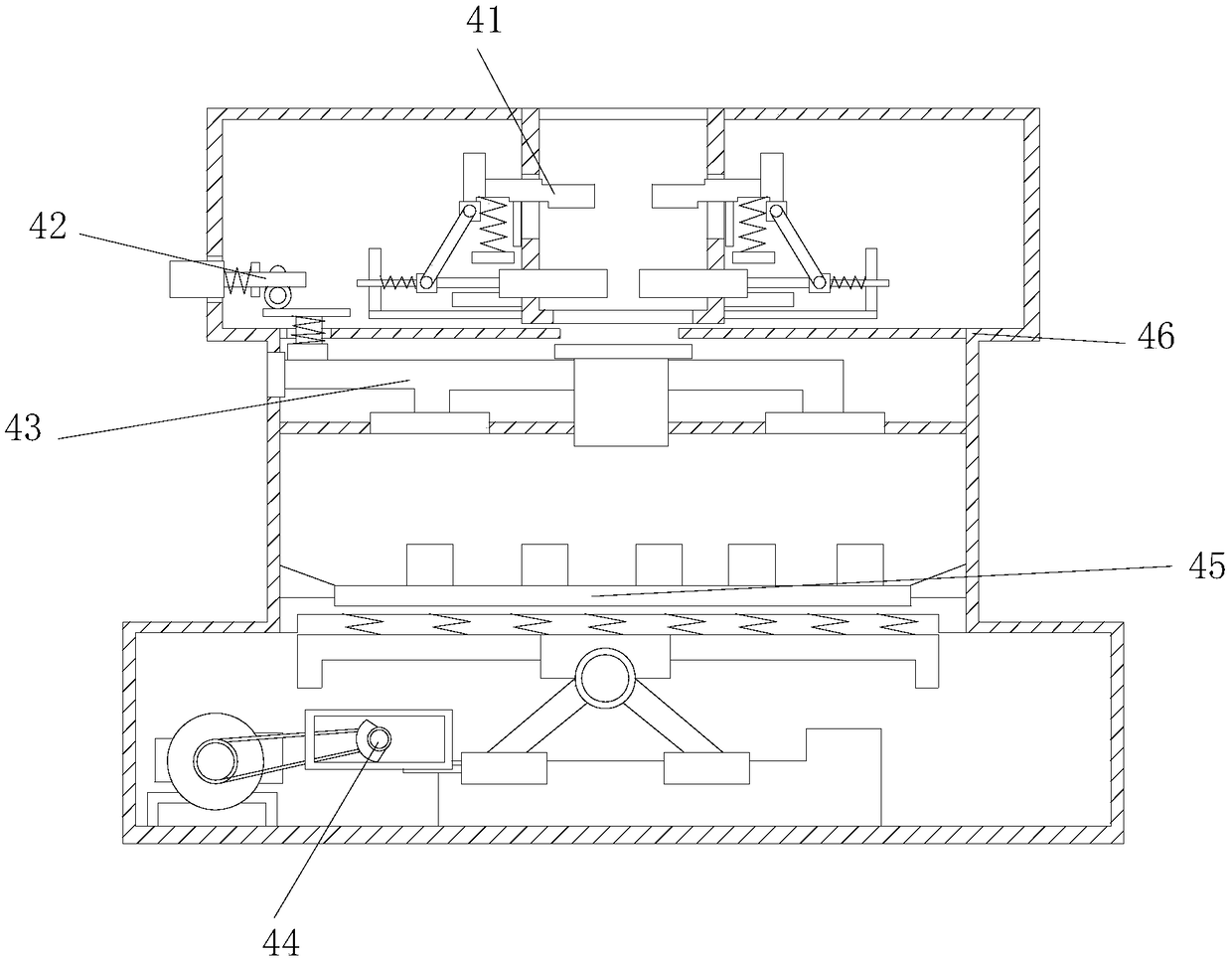

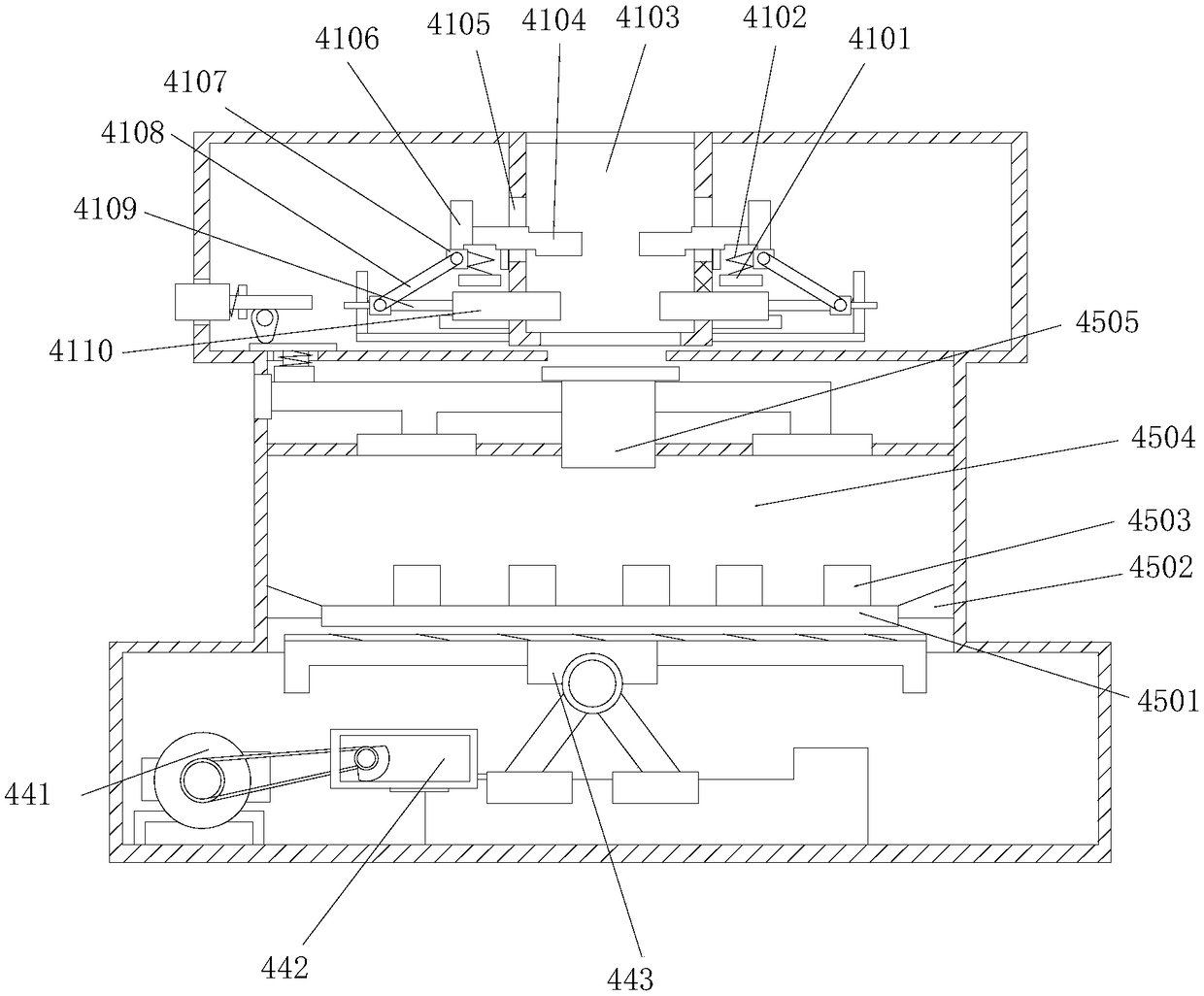

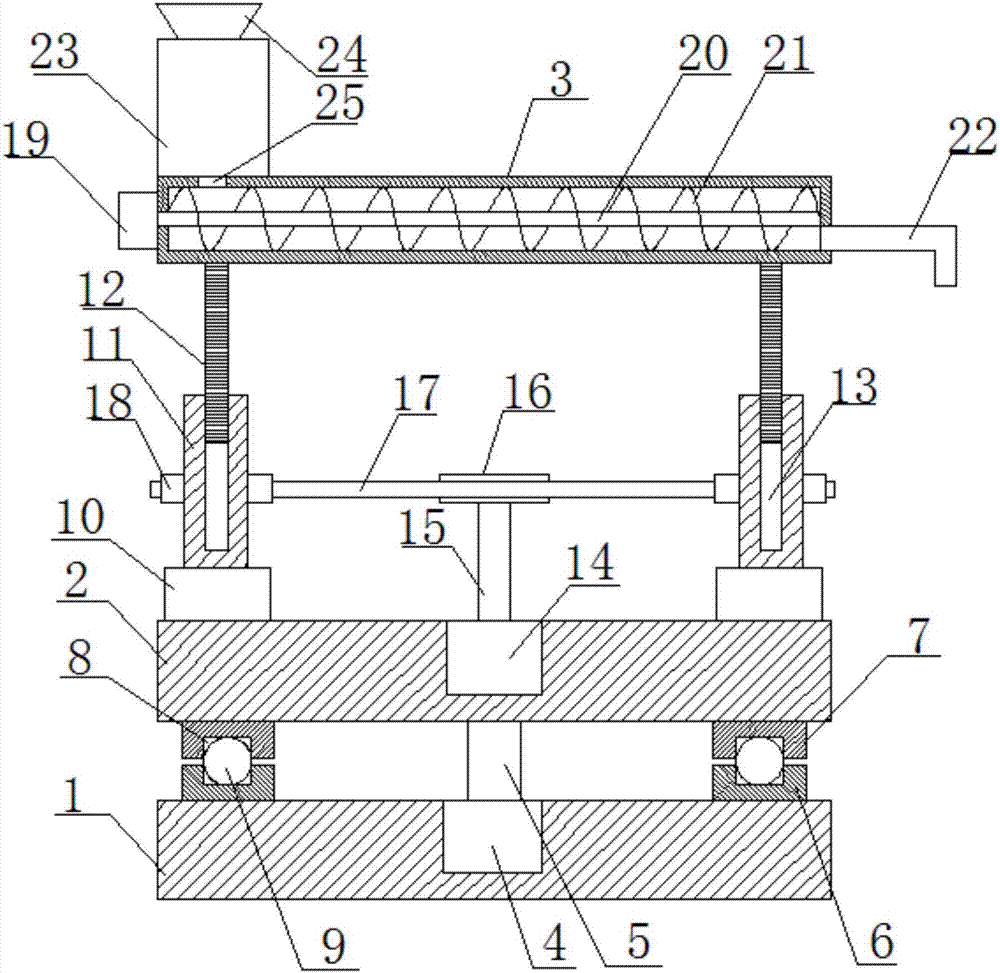

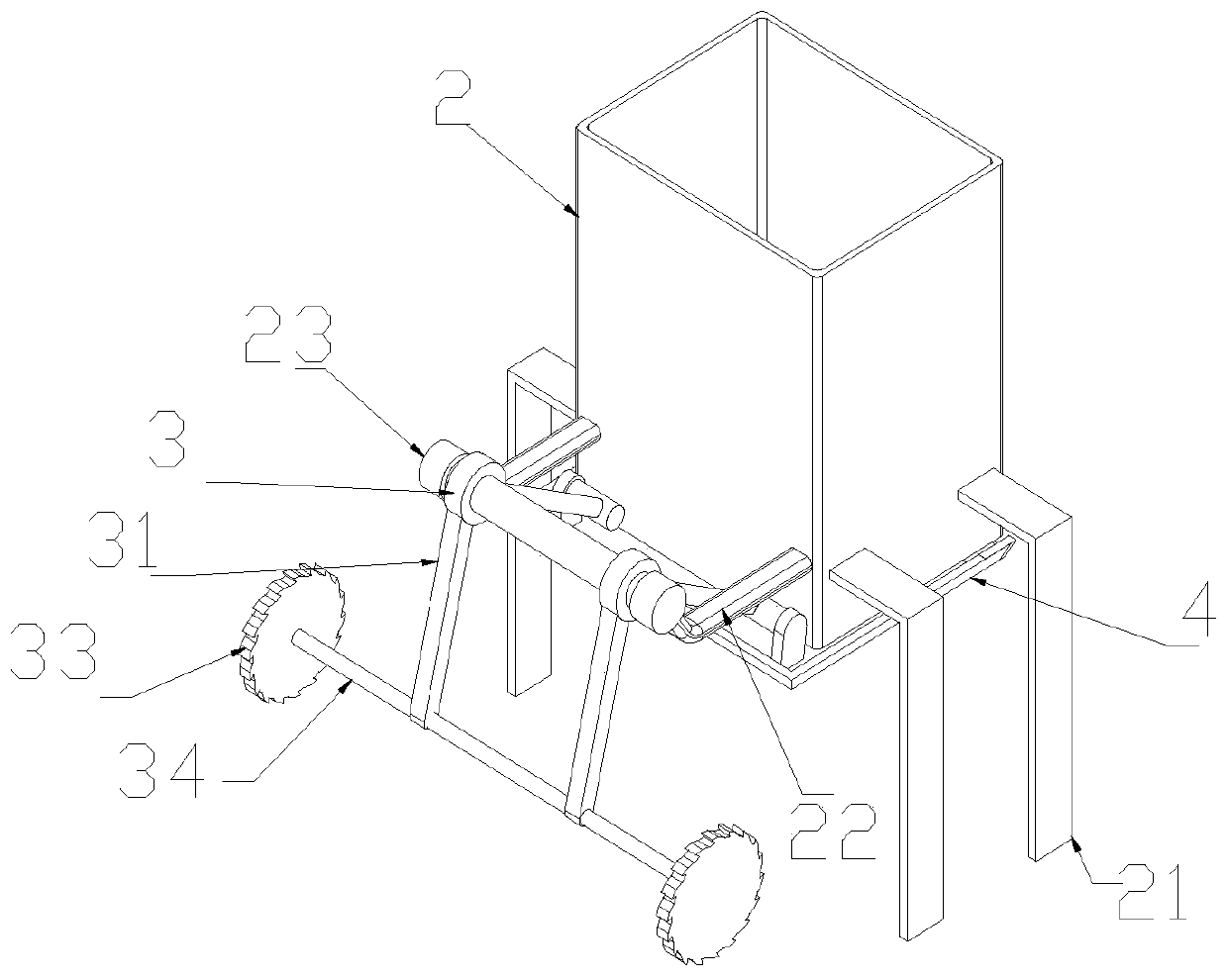

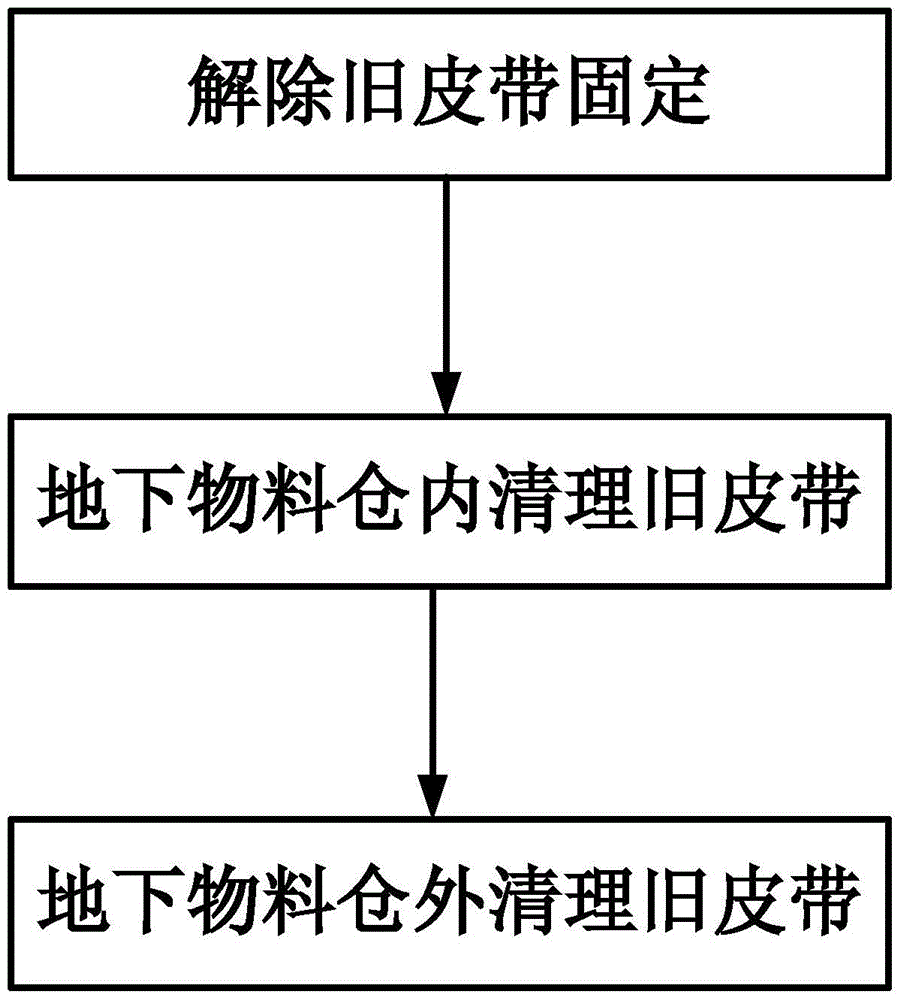

Grooved wheel type bar separating and automatic feeding device

InactiveCN107984378AStable feeding speedNo secondary gapGrinding feedersFailure rateElectric machinery

The invention relates to a grooved wheel type bar separating and automatic feeding device. A box body is divided into an upper part and a lower part by a separation partition, a V-shaped storage box is arranged in the upper part, and a grooved wheel rotating space is formed in the lower part; a grooved wheel is arranged on the lower part of the box body, a main shaft and an electric fixture are arranged on the grooved wheel, and the main shaft is fastened by virtue of a fastening bolt, so that the grooved wheel forms an integral rotating structure; both ends of the main shaft are installed onfront and back support plates on which bearings are arranged, the electric fixture is fixed to the grooved wheel by virtue of a fastening bolt, a guide plate is fixed to an arc-shaped baffle, and a gap is formed between the arc-shaped baffle and the grooved wheel; the quantity of grooves which are circumferentially and uniformly distributed in the grooved wheel is designed according to the specification and feeding speed of bars; the outer contour of the electric fixture is matched with the grooves in the grooved wheel; and the main shaft and the grooved wheel are driven to do a rotary motionby a main motor through a driving belt. The grooved wheel type bar separating and automatic feeding device has the advantages of stable feeding speed, simple structure and low failure rate, second gaps are not generated, the feeding speed is more than 6 m / min, and the grooved wheel type bar separating and automatic feeding device is especially suitable for efficient centerless grinding productionof hard alloy bars.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

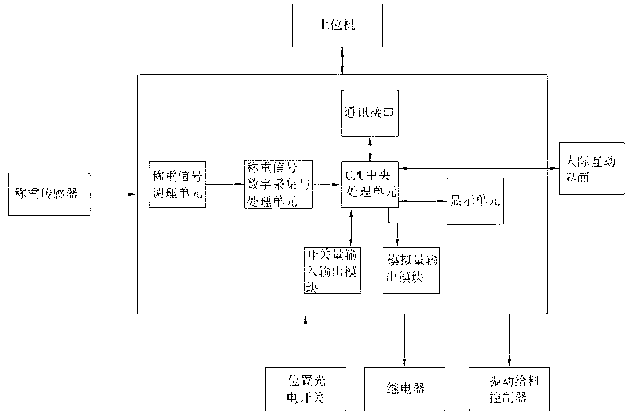

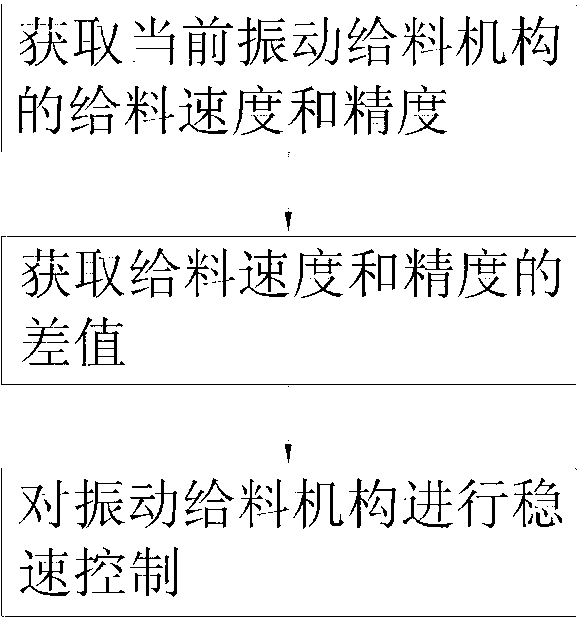

System and method for controlling vibration feeding in speed stabilizing mode

ActiveCN103253405ASmooth vibrationReduce labor intensityPackaging automatic controlSolid materialCommunication interfaceSignal conditioning

The invention discloses a system for controlling vibration feeding in a speed stabilizing mode and a control method of the system, wherein the control system and the control method have stable feeding speed and stable feeding precision, the automation degree of the control system and the control method can be greatly improved, labor intensity of workers is reduced, and cost is relatively reduced. The system for controlling the vibration feeding in the speed stabilizing mode comprises a vibration feeding mechanism and a weighing mechanism, and further comprises a weighing sensor, a weighing signal conditioning unit, a weighing signal digital acquisition and processing unit, a CPU, an on-off input and output module, a communication interface, a displaying unit and an analog quantity output module. The control method of the control system comprises the controlling steps of obtaining feeding speed and feeding precision of the vibration feeding mechanism at present, obtaining a difference value between the feeding speed and the feeding precision, and controlling the stable speed of the vibration feeding mechanism. The system for controlling the vibration feeding in the speed stabilizing mode can be applied to the field of feeding control.

Owner:合肥长陆工业科技有限公司

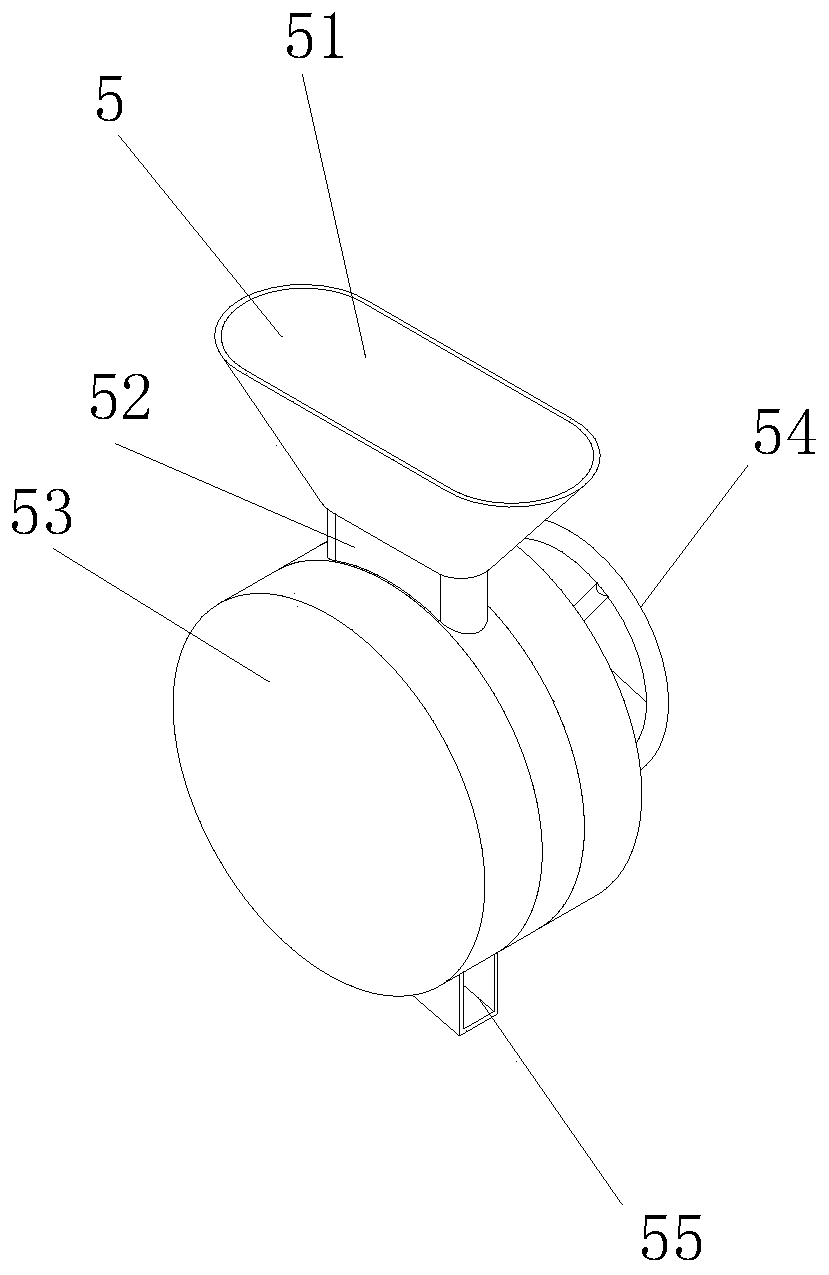

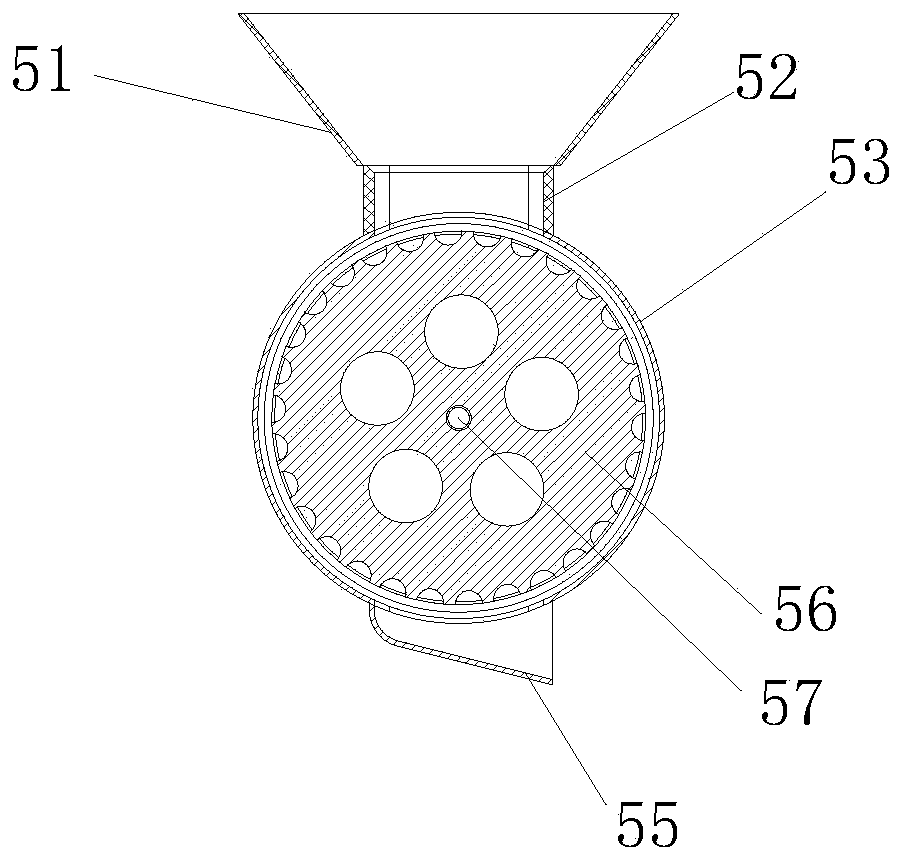

Batching structure of quantitative proportioning type feed stirrer for livestock raising

InactiveCN111514810ASmooth dischargeStable feeding speedFeeding-stuffTransportation and packagingAnimal scienceCrop livestock

The invention discloses a batching structure of quantitative proportioning type feed stirrer for livestock raising. The batching structure comprises a top cover, a quantifying device is installed in the middle of the front end of the top cover, stable, accurate and quantitative discharging can be achieved through the quantifying device, a user only needs to inject feed into a storage bin, during discharging, the discharging amount is equal every time, and the quantifying effect is good; a rotating cylinder is installed in the quantifying device and controlled by a bottom driving mechanism to rotate, when the rotating cylinder rotates, an internal fan-shaped notch moves leftwards to a notch of a fixed disc to receive feed, the fan-shaped notch can be reset to a notch in the right end of a bottom shell to be discharged after being filled, the efficient and stable quantitative discharging effect is achieved, and manual calculation and intervention are not needed; a intermittent motion mechanism is installed in the driving mechanism and can be driven under the control of the motor, the gap rotation angle of the intermittent motion mechanism is matched with the notch angle of the rotating cylinder, and efficient and stable discharging is achieved through cooperation.

Owner:福建九州宇圣科技有限公司

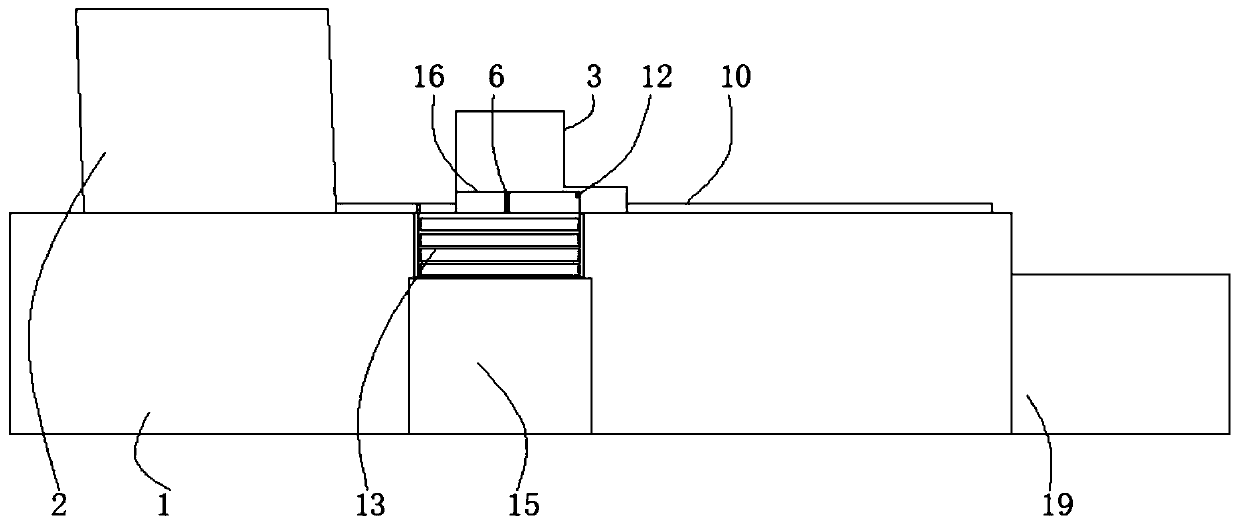

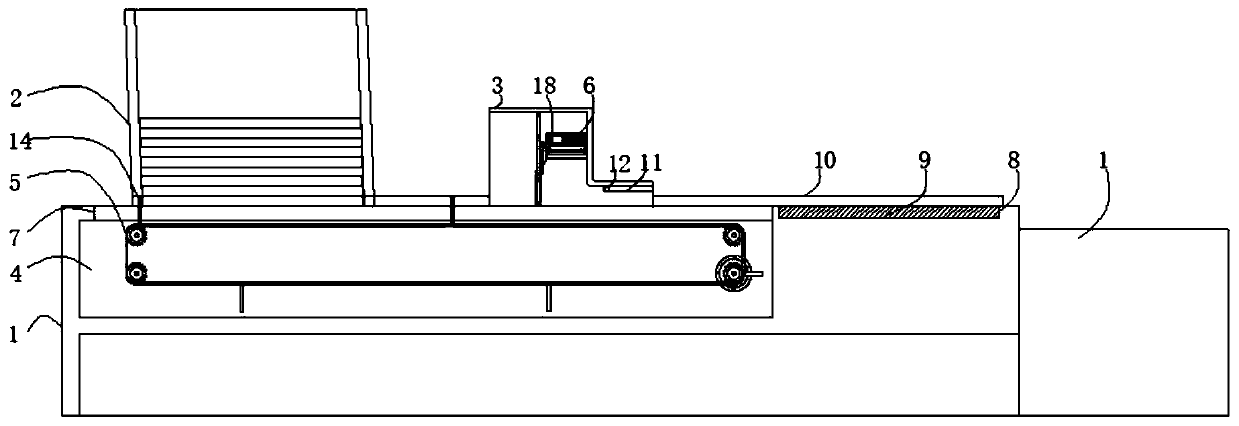

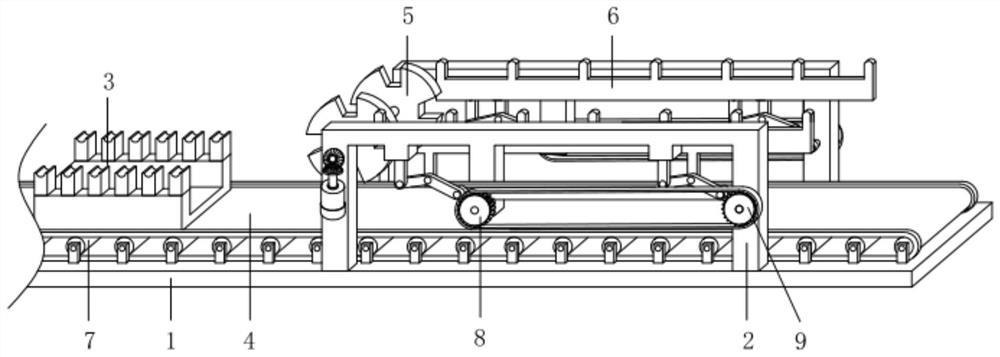

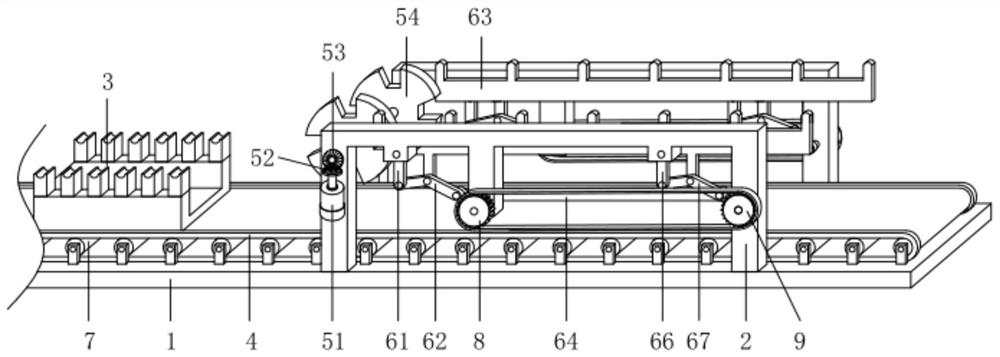

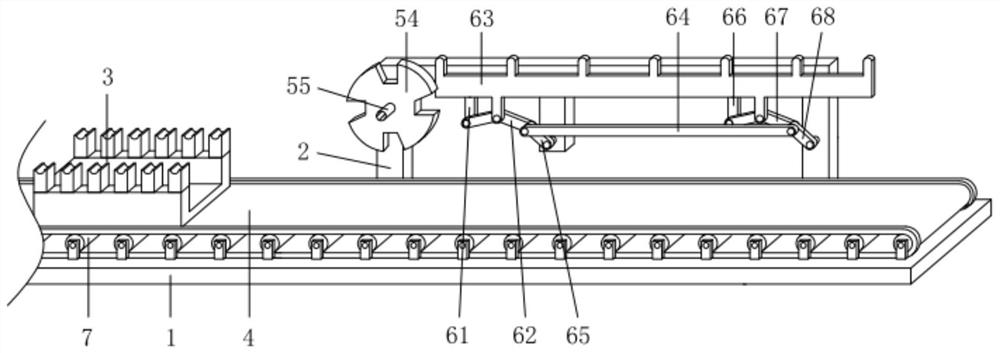

Injection molding automatic quality testing production line for plastic products

InactiveCN111037867ARealize automatic feeding detectionStable feeding speedSortingProcess engineeringManual handling

The invention provides an injection molding automatic quality testing production line for plastic products. The injection molding automatic quality testing production line comprises an operation tableand a containing box fixed to the left side of the top of the operation table. According to the injection molding automatic quality testing production line for the plastic products, a feeding assembly is arranged and cooperates with the containing box, to-be-detected plastic plates are automatically fed and detected, a detection box can remove plastic plates with unqualified quality for the firstround, and automatic removal is gradually achieved through removal; a sliding way is used in cooperation to automatically convey unqualified plastic plates into a first collection box; meanwhile, pushing strips arranged at equal distance cooperate with a second trigger switch to control the fee speed, so that the feed speed is more stable, and the detection rate is increased; meanwhile, the plastic plates are detected again through an electronic scale; and in the detection process, manual operation is simple, detection quality is improved through two times of detection, the automation degreeis high, the detection rate is high, meanwhile, the structure is simple, cost is low, and use is convenient.

Owner:巢湖市荣达塑业有限公司

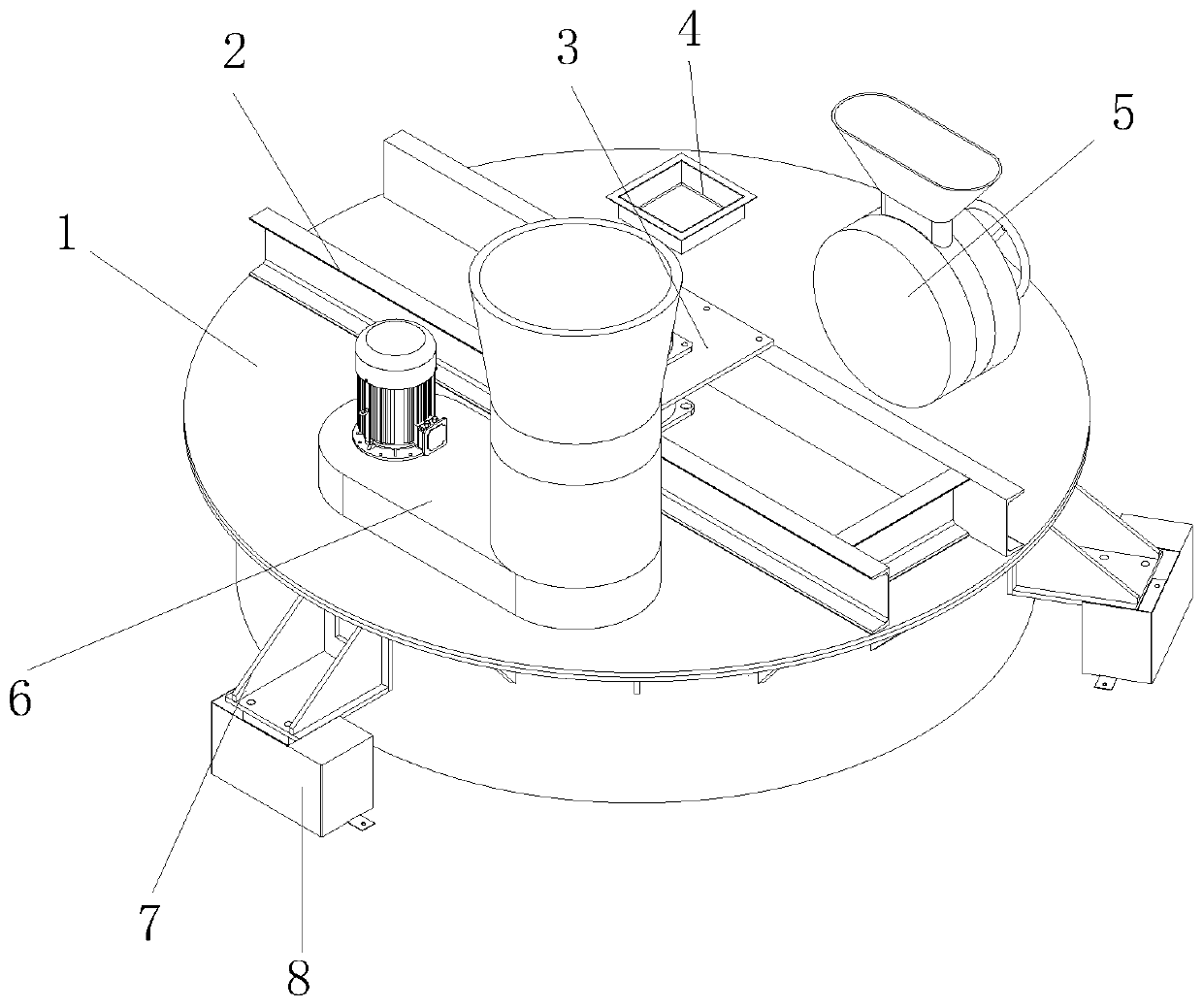

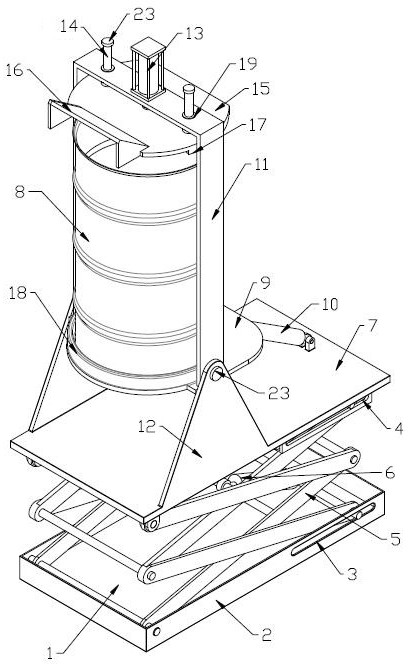

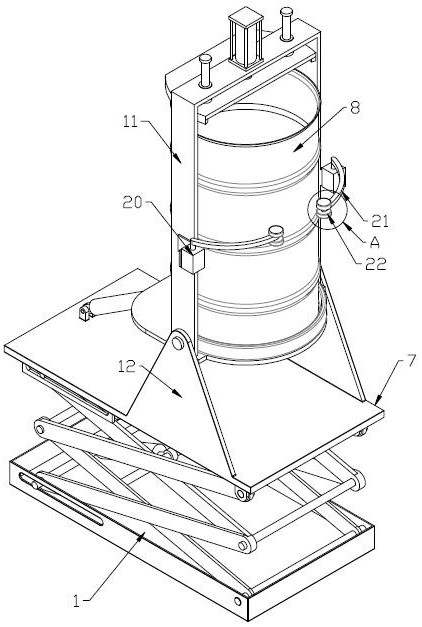

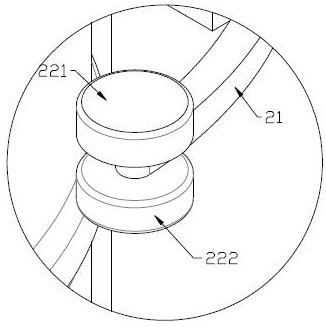

Automatic feeding equipment for molecular sieve ion exchange

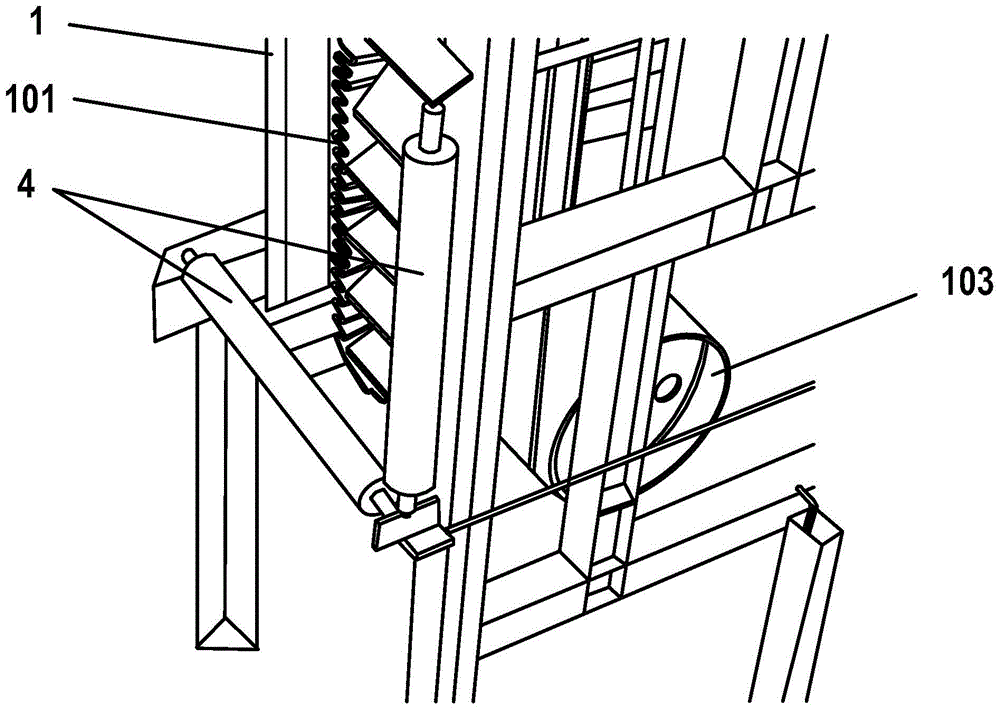

PendingCN113460721AImprove work efficiencyReduce physical exertionLifting framesBottle emptyingMolecular sieveIon exchange

The invention provides automatic feeding equipment for molecular sieve ion exchange. The automatic feeding equipment comprises a lifting table plate, a turnover plate and a pressing plate, wherein a lifting mechanism for driving the lifting table plate to ascend or descend is arranged at the bottom of the lifting table plate; the two sides of the turnover plate are rotationally arranged above the lifting table plate, and a turnover device for driving the turnover plate to turn over or reset is arranged at one end of the turnover plate; and the pressing plate is erected above the turnover plate, and a barrel pressing mechanism for driving the pressing plate to descend or ascend so as to press or release the upper portion of the turnover plate is arranged on the pressing plate. According to the automatic feeding equipment, the lifting and pouring actions of a barrel can be automatically completed instead of manual work, the physical consumption is reduced, the labor expenditure is reduced, the feeding speed is stable, and the working efficiency can be remarkably improved; and automatic feeding of the molecular sieve ion exchange is realized, an operator is prevented from carrying the barrel at a high position, and the safety is improved.

Owner:LUOYANG TIANPING MOLECULAR SIEVE

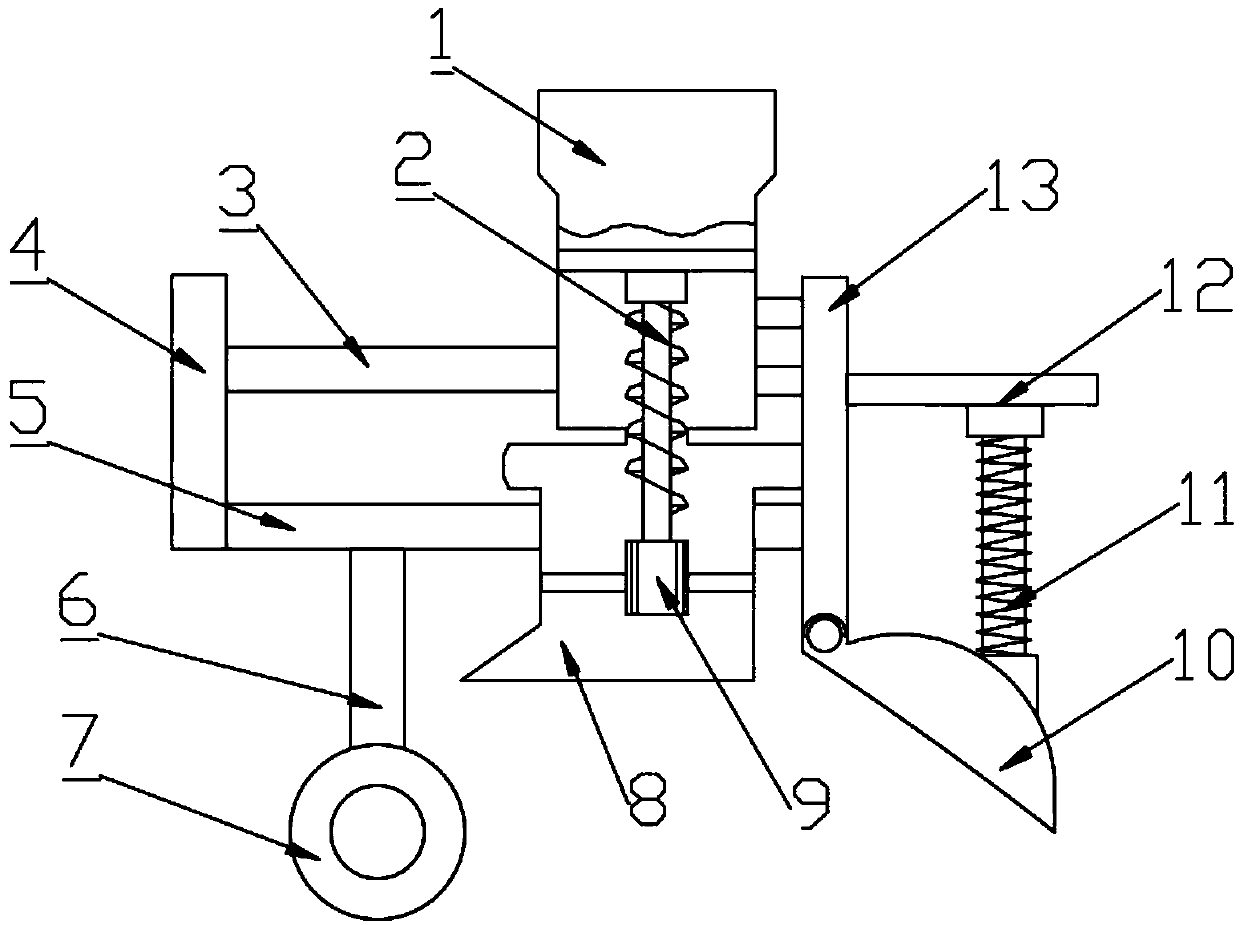

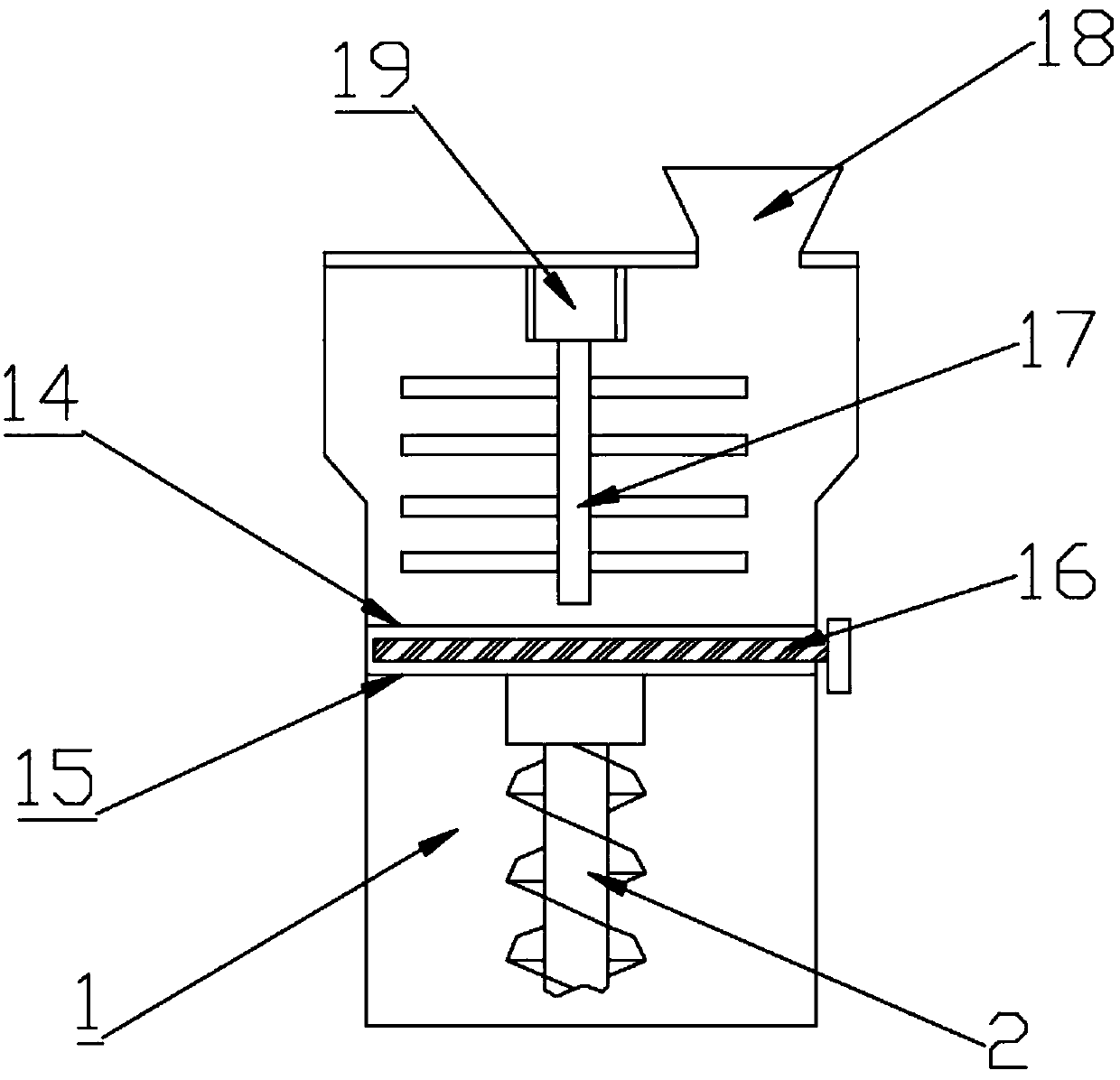

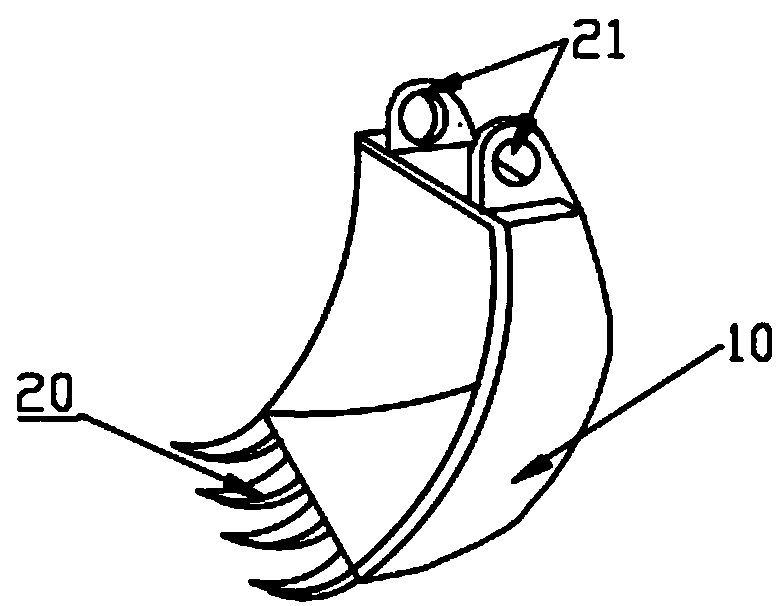

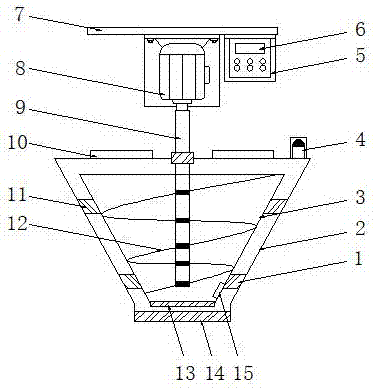

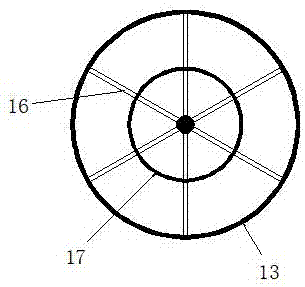

Fertilization mechanism for rotary cultivator

InactiveCN107836148AHas the effect of mixed fertilizerImprove uniformitySpadesPloughsAgricultural engineeringDrive motor

The invention discloses a fertilizing mechanism for a rotary tiller, which comprises a fertilizer bin, a fixing seat and a lower feeding bin, the fixing seat is fixedly installed with the rotary tiller, and the top of the inner chamber of the fertilizer bin is equipped with a detachable Stirrer, the bottom of the stirrer is provided with an upper filter screen and a lower filter screen in sequence, and a screw feeder is installed at the bottom of the lower filter screen, and the lower end of the screw feeder extends to the lower feeder, and the lower feeder A drive motor is installed inside, and a baffle is installed with bolts on the other side of the fertilizer bin, and a soil return device that can move up and down is connected to the lower end of the baffle. The device installs a detachable stirrer in the fertilizer bin, so that the fertilizer bin of the fertilization mechanism has the function of mixing fertilizers, and the screw feeder drives the stirred fertilizer to be fed in a spiral, so that the feeding speed is more stable; the soil returning device The falling fertilizer can be covered in time to prevent the fertilizer from becoming invalid under the sun exposure or being washed away by rainwater, reducing manpower and material resources.

Owner:湖南一田农业机械有限公司

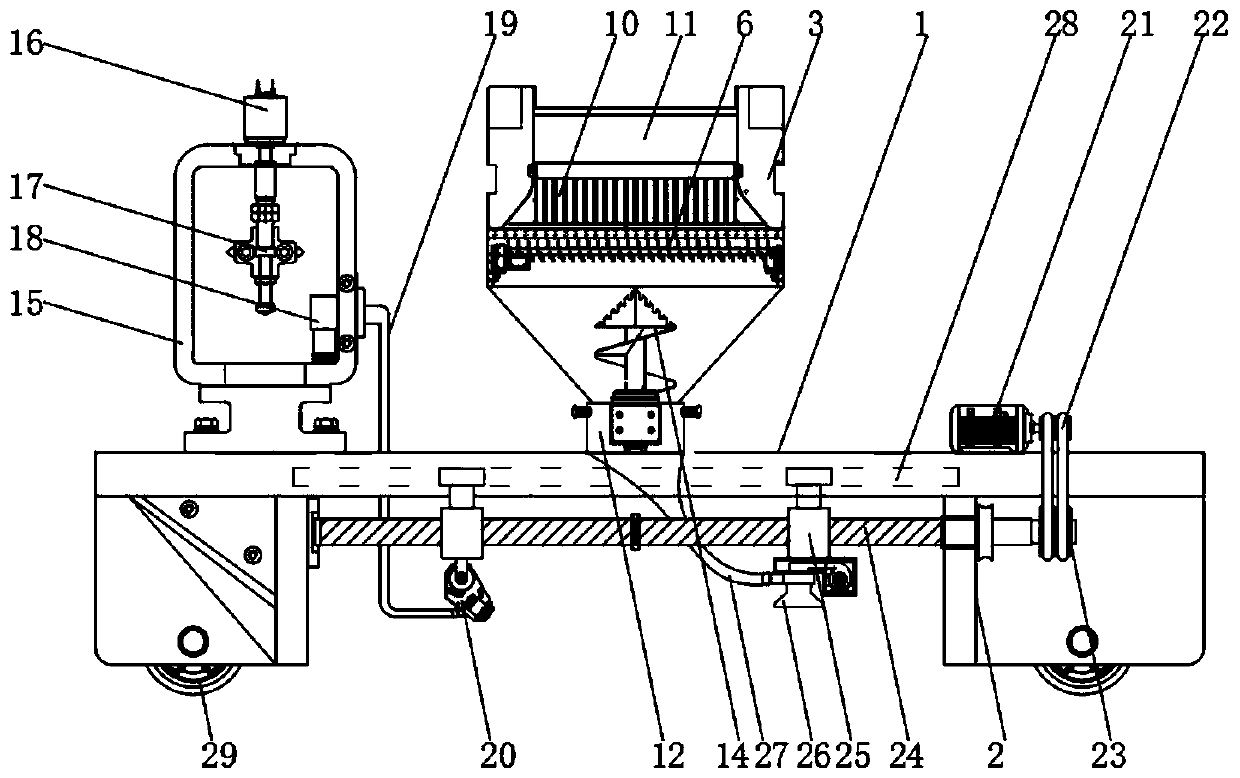

Biological fertilizer spreader

ActiveCN109757179AReduce wasteAchieve the purpose of mixingFertiliser distributersPressurised distribution of liquid fertiliserAgricultural engineeringFertilizer

The invention discloses a biological fertilizer spreader. The biological fertilizer spreader comprises a spreading frame. A biological solid fertilizer loading box is fixedly connected to the middle of the top of the spreading frame; a biological liquid fertilizer loading tank is fixedly connected to the left side of the top of the spreading frame; a supporting frame is fixedly connected to the bottom of the spreading frame, and a fertilizer treatment frame is arranged inside the biological solid fertilizer loading box; an agitating motor is fixedly connected to the inner side of the fertilizer treatment frame; a stirring tooth rack shaft is mounted above the fertilizer treatment frame; driven gears are mounted at two ends of the stirring tooth rack shaft; and the lower portion of each driven gear is connected with a connecting gear in an engaged manner. The invention relates to the technical field of biological fertilizers. According to the biological fertilizer spreader, a purpose ofmixing, discharging and spreading solid fertilizers is achieved, the solid fertilizers can be mixed stably, a fertilizer opening cannot be blocked, waste of the fertilizers is reduced, the angle of the adjustable liquid fertilizer spreader can be adjusted in a working process, and thus, the biological fertilizer spreader is suitable for spraying the fertilizers to various crops.

Owner:清原满族自治县宏运有机肥有限公司

Discharging device for zinc oxide particle production

InactiveCN108002011AUniform feedingSmooth feedingConveyorsControl devices for conveyorsEngineeringSingle chip

The invention discloses a discharging device for zinc oxide particle production. The discharging device comprises an outer shell and a rotating roller; an inner shell is arranged on the inner side ofthe outer shell through a lower bearing and an upper bearing; a spiral plate is fixed inside the inner shell; the interior of the spiral plate is fixedly connected to the rotating roller; a feed portis formed in the upper end of the outer shell; an alarm lamp arranged at the upper end of the outer shell is arranged on one side of the feed port; a mounting plate is arranged right above the outer shell; a motor is fixed to the right lower end of the mounting plate; and the output end of the motor is in meshing connection with the upper end of the rotating roller. The discharging device has theadvantages that the outer shell, the inner shell, the alarm lamp, a single-chip microcomputer, a display screen, the motor, the rotating roller, the spiral plate, a first discharge port, a second discharge port and a gravity sensor are arranged, and therefore the problems that the discharging speed of an existing discharging device is not uniform and stable enough, an intelligent detection mechanism is lacked, and the amount of zinc oxide particles in the discharging device cannot be checked and known in time can be solved.

Owner:XINGHUA SANYUAN ZINC

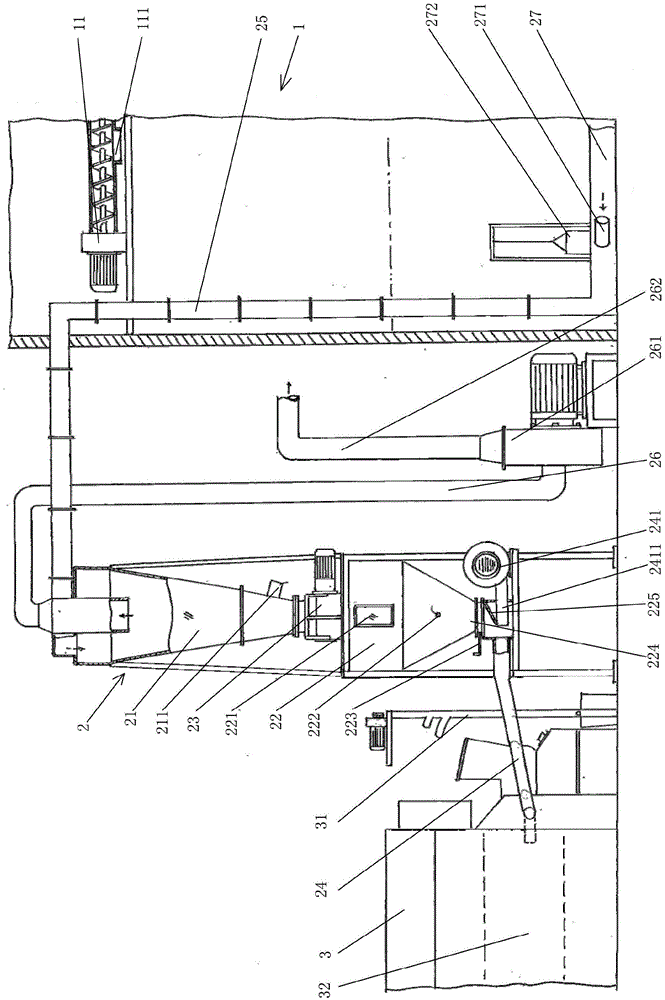

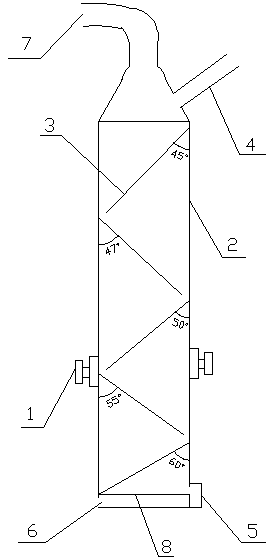

Rice husk conveying device for coal-fired boiler

InactiveCN105650664AThe conveying speed is continuously stableStable conveying speedFuel feeding arrangementsLump/pulverulent fuel feeder/distributionAssistive device/technologyHusk

The invention discloses a rice husk conveying device for a coal-fired boiler and belongs to the technical field of auxiliary equipment for boiler feeding. The rice husk conveying device comprises a conveying tower connected with a rice husk room and the coal-fired boiler through pipelines. The conveying tower comprises a negative-pressure suction hopper and a bin. The negative-pressure suction hopper communicates with the bin through an air lock. A feeding guide pipe is arranged on the side, close to the lower portion of a discharging opening, at the bottom of the bin, and a fan is mounted on the other side of the bin. An air outlet of the fan carries out intermittent air supply towards the feeding guide pipe. The upper portion of the negative-pressure suction hopper communicates with one end of a conveying pipe and one end of an air suction pipe. The other end of the conveying pipe stretches into the rice husk room and communicates with a suction main pipe. The other end of the air suction pipe communicates with an induced draft fan. An exhaust pipe is arranged on the induced draft fan. The conveying speed of rice husks is continuous and stable, and conveying cost is reduced. Feeding speed can be controlled, the stable fuel quantity can be provided for the coal-fired boiler, and the feeding guide pipe can be prevented from being blocked. Coal resources are saved, the use cost is reduced, and environment friendliness is achieved.

Owner:CHANGSHU YUSHENG AGRI PROD SPECIALIZED COOP

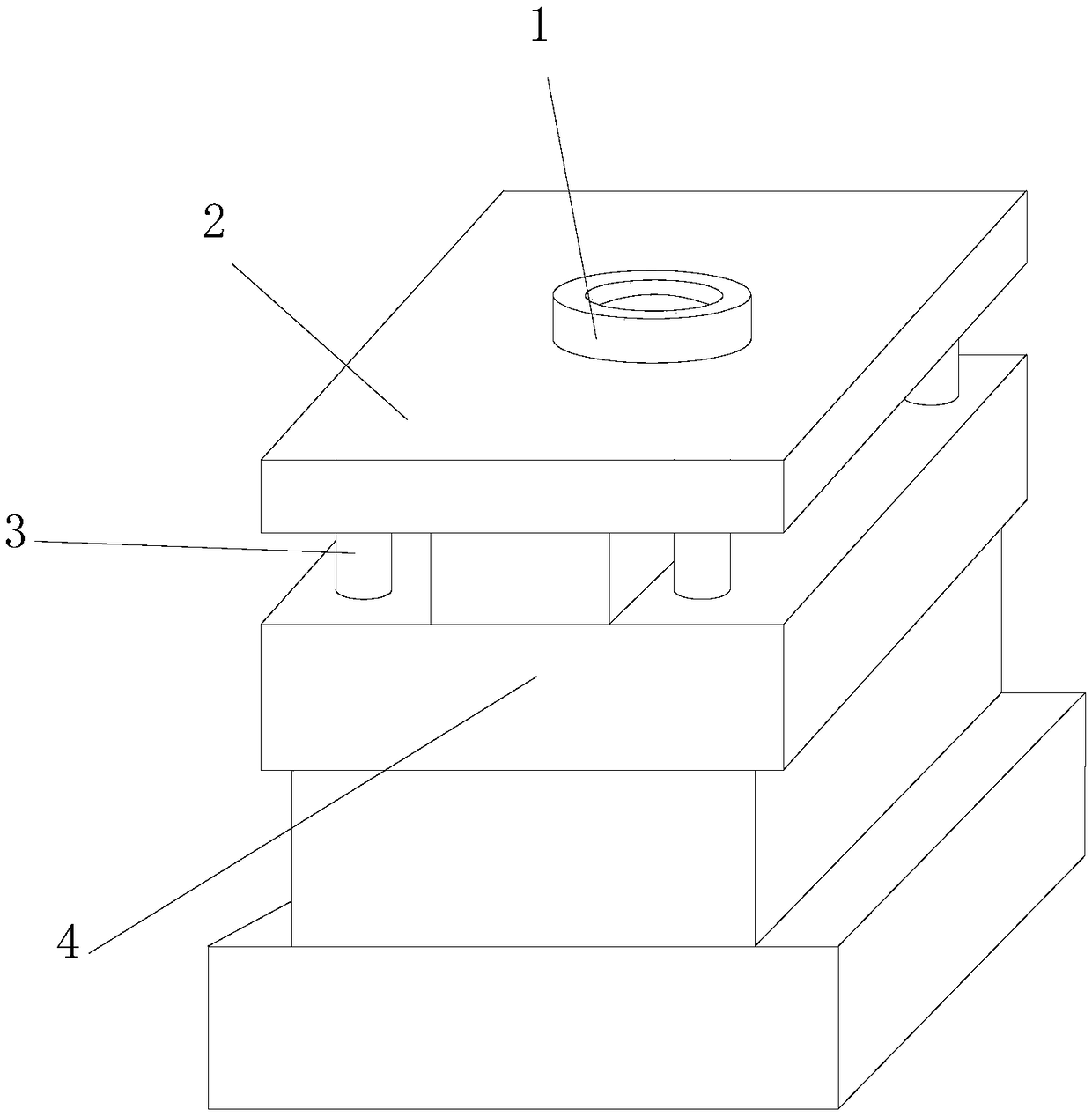

Powder metallurgy self-cleaning mold

The invention discloses a powder metallurgy self-cleaning mold. The powder metallurgy self-cleaning mold structurally comprises an injection molding hole, an upper top cover, a fixing rod and a machine body, wherein the bottom end of the injection molding hole is welded with the top end of the upper top cover, the upper top cover is located above the machine body, the top end of the fixing rod isvertically embedded into the bottom end of the upper top cover, and the bottom end of the fixing rod is vertically embedded into the top end of the machine body; and the machine body comprises a flowspeed control mechanism, a powder collection driving device, a dust collection mechanism and a demolding mechanism. By improving an internal structure, the size of an injection molding hole can be automatically changed according to the circulation speed of an injection molding device in the injection molding process of the raw materials, and the injection molding circulation speed is steadily controlled, so that the situation that air holes are formed in the surface of a formed workpiece due to the overhigh flow speed is avoided; and meanwhile, the bottom of the mold can be uniformly vibratedduring the mold stripping so as to drive the workpiece to fall, so that the surface abrasion of the workpiece during the prying is avoided.

Owner:彭勤英

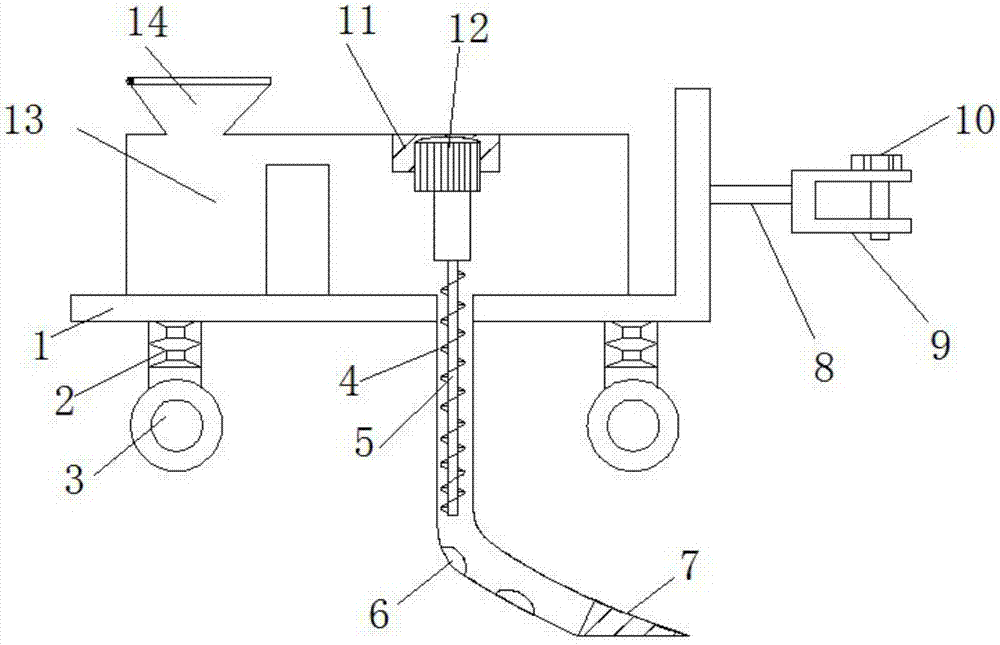

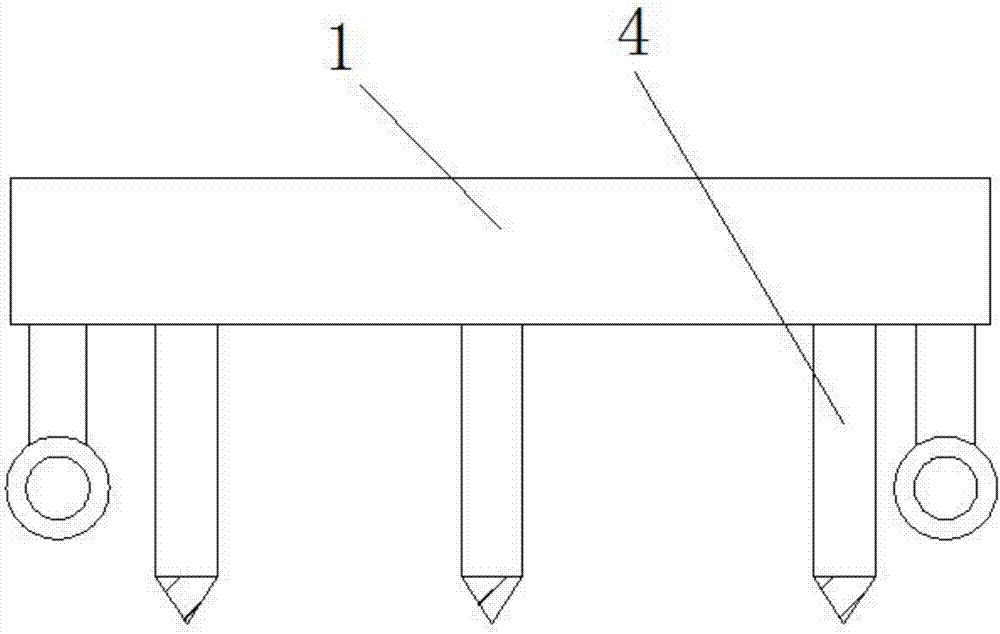

Soil deep fertilizing device capable of preventing fertilizer loss

InactiveCN107155481AWon't clogImprove stabilityPlantingFertiliser distributersAgricultural engineeringReducer

The invention discloses a soil deep fertilizing device capable of preventing fertilizer loss. The soil deep fertilizing device capable of preventing fertilizer loss comprises a bottom plate and a discharging bent tube at the bottom of the bottom plate, wherein a triangular block is welded to the bottom end of the discharging bent tube; a circular hole is formed in a bent position of the discharging bent tube; a spiral conveying rod is arranged in the discharging bent tube; a discharging motor is fixed on a top plate in a fertilizer box through a fixing rack; and the discharging motor is in transmission connection with a bolt conveying rod through a speed reducer. By the discharging bent tube at the bottom of the bottom plate, the discharging bent tube can be inserted into soil through a triangular block when moving through a roller on the bottom plate, then a fertilizer is applied into the soil through the circular hole formed in the discharging bent tube, and fertilizer loss is prevented effectively; and furthermore, by the bolt conveying rod in the discharging bent tube, the fertilizer is conveyed by the spiral conveying rod, the discharging speed is stable, the discharging bent tube cannot be blocked, and therefore, stability of the soil deep fertilizing device is improved effectively.

Owner:CHENGDU YANXINGGUO TECH CO LTD

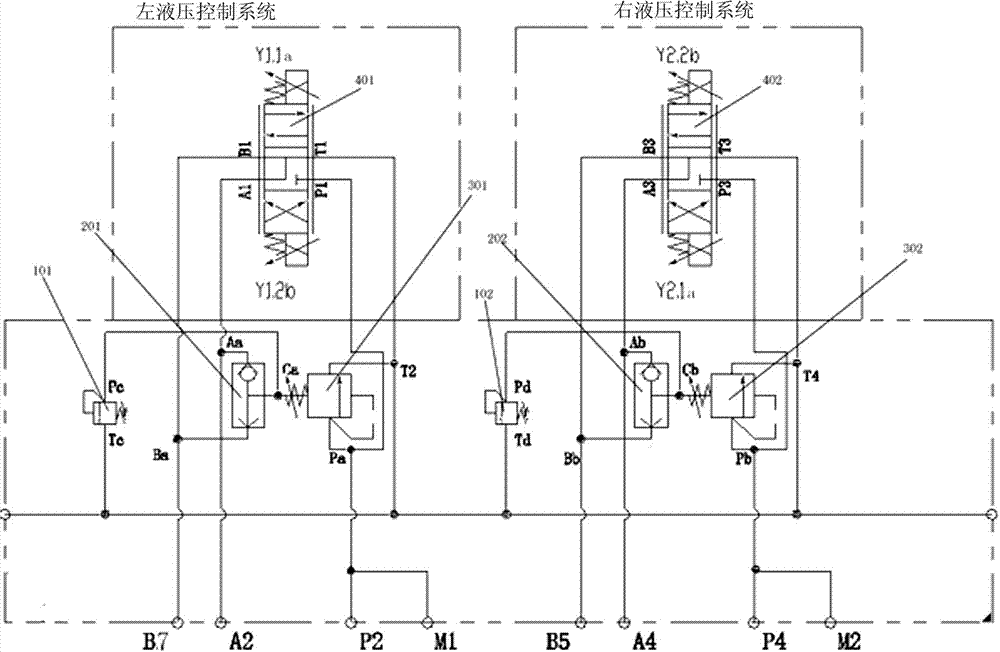

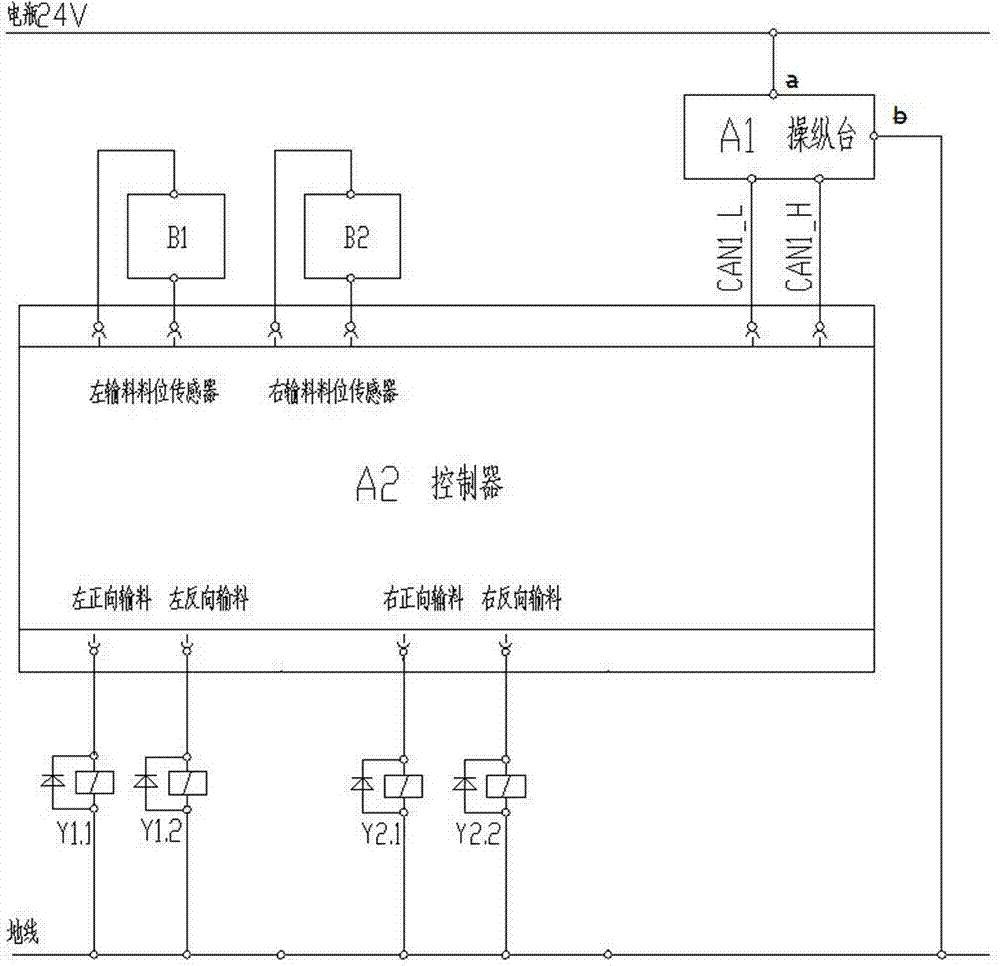

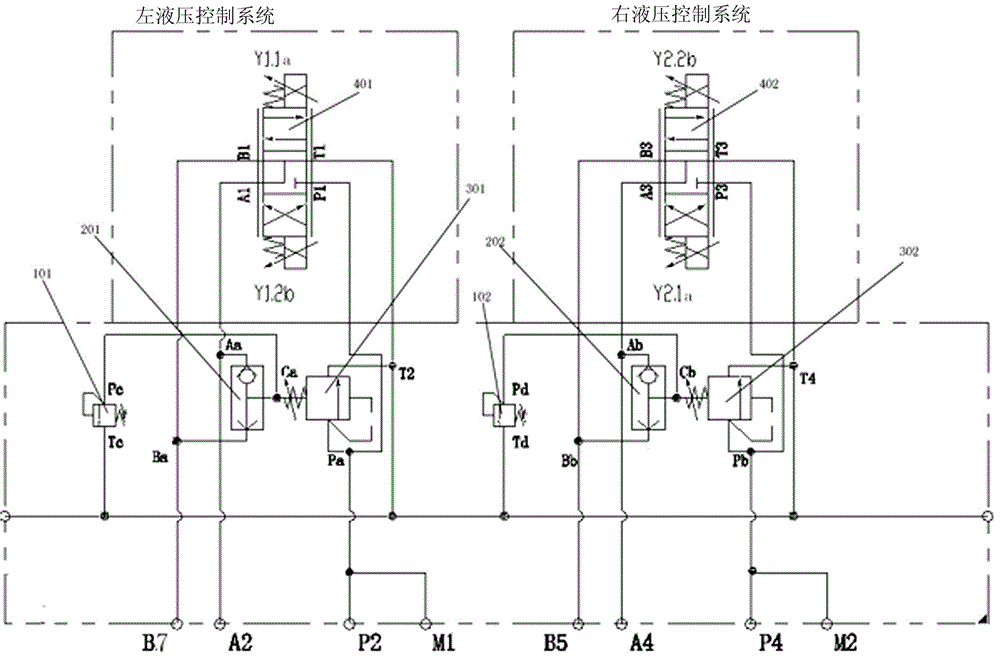

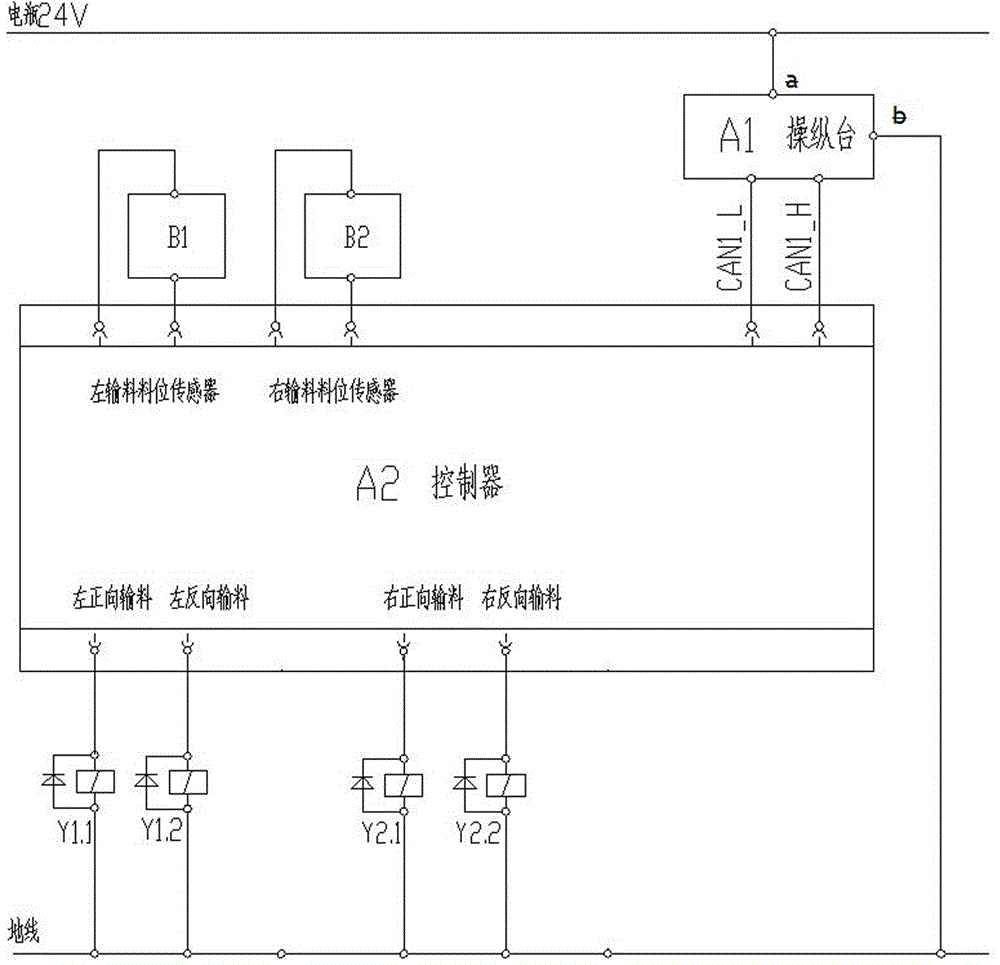

Paver material conveying system with multiple working condition adaptation modes

ActiveCN104776070AReduced service lifeExtended service lifeOperating means/releasing devices for valvesServomotorsSolenoid valveControl system

The invention discloses a paver material conveying system with multiple working condition adaptation modes. The paver material conveying system comprises a left material conveying hydraulic control system, a right material conveying hydraulic control system and an electric control system, wherein the first proportional electromagnetic reversing valve (401) of the left hydraulic control system is respectively connected with a first logic control valve (201) and a first pressure compensation valve (301); a first overflow valve (101) is connected with the first pressure compensation valve (301); the second proportional electromagnetic reversing valve (402) of the right material conveying hydraulic control system is respectively connected with a second logic control valve (202) and a second pressure compensation valve (302); a second overflow valve (102) is connected with the second pressure compensation valve (302); the electric control system comprises a control console A1 connected with a controller A2, a left material conveying material level sensor B1, a right material conveying material level sensor B2, a left material conveying solenoid valve and a right material conveying solenoid valve. The paver material conveying system has the advantages of simplicity and convenience in control implementation and easiness in operation.

Owner:XCMG CONSTR MACHINERY

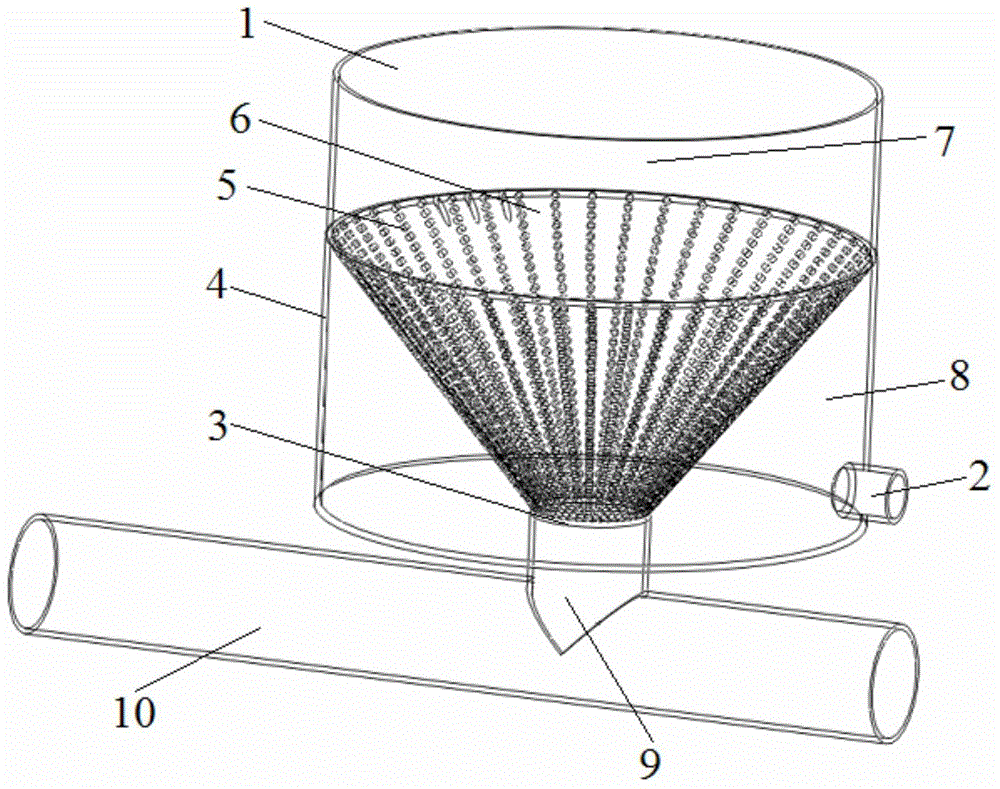

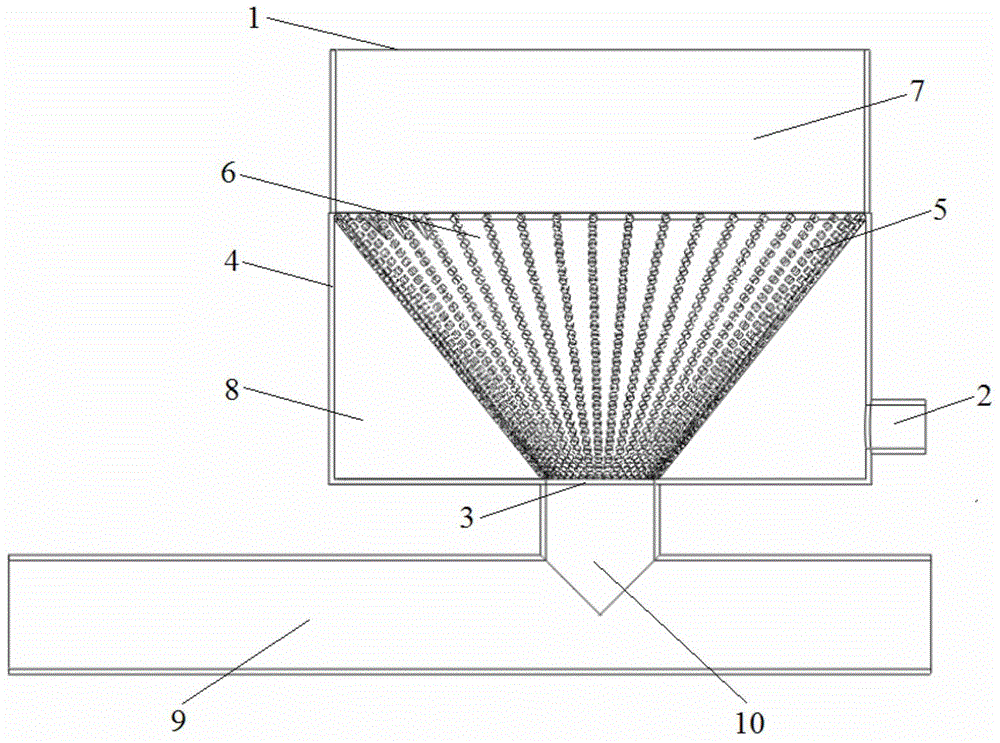

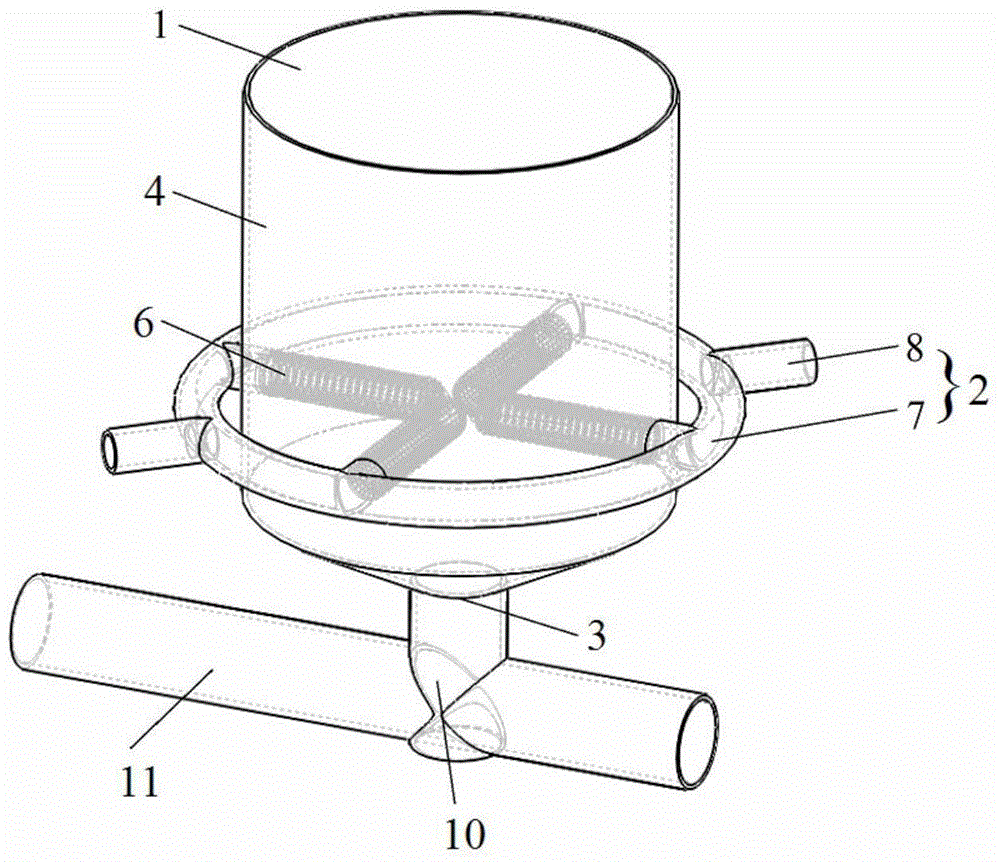

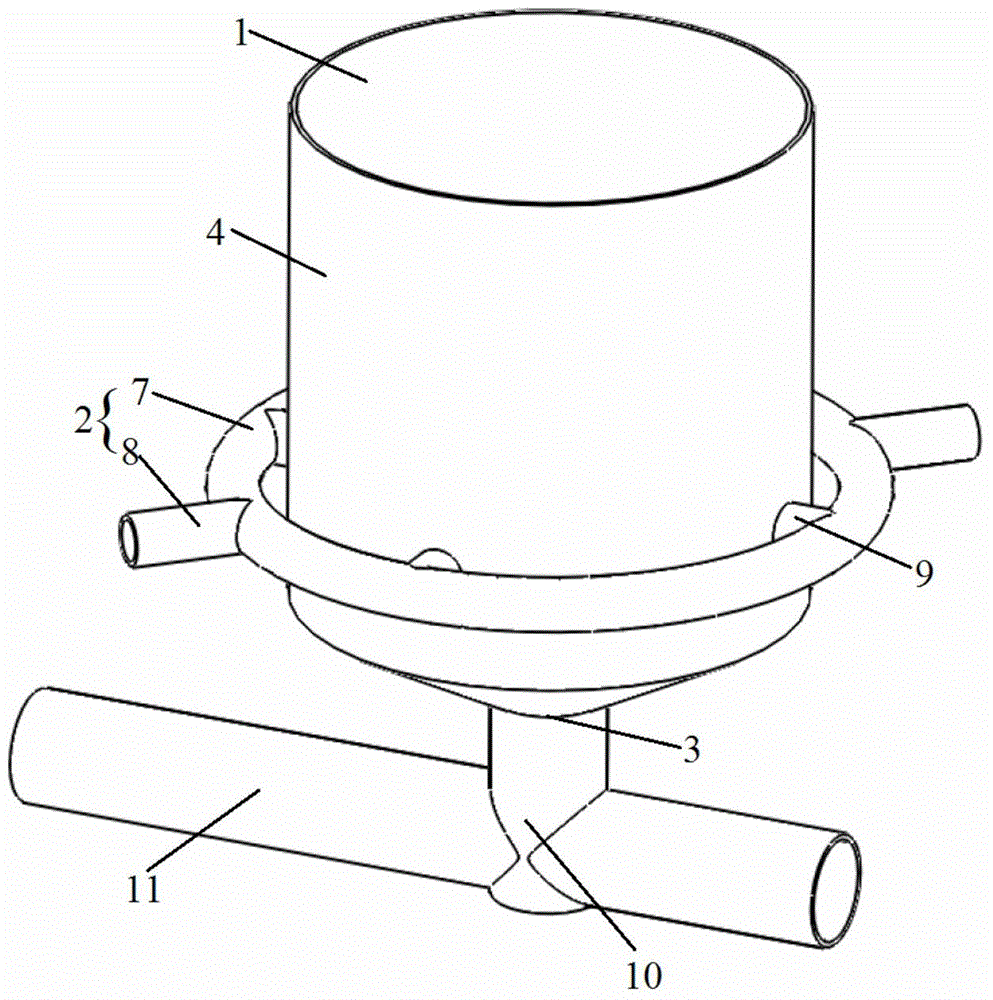

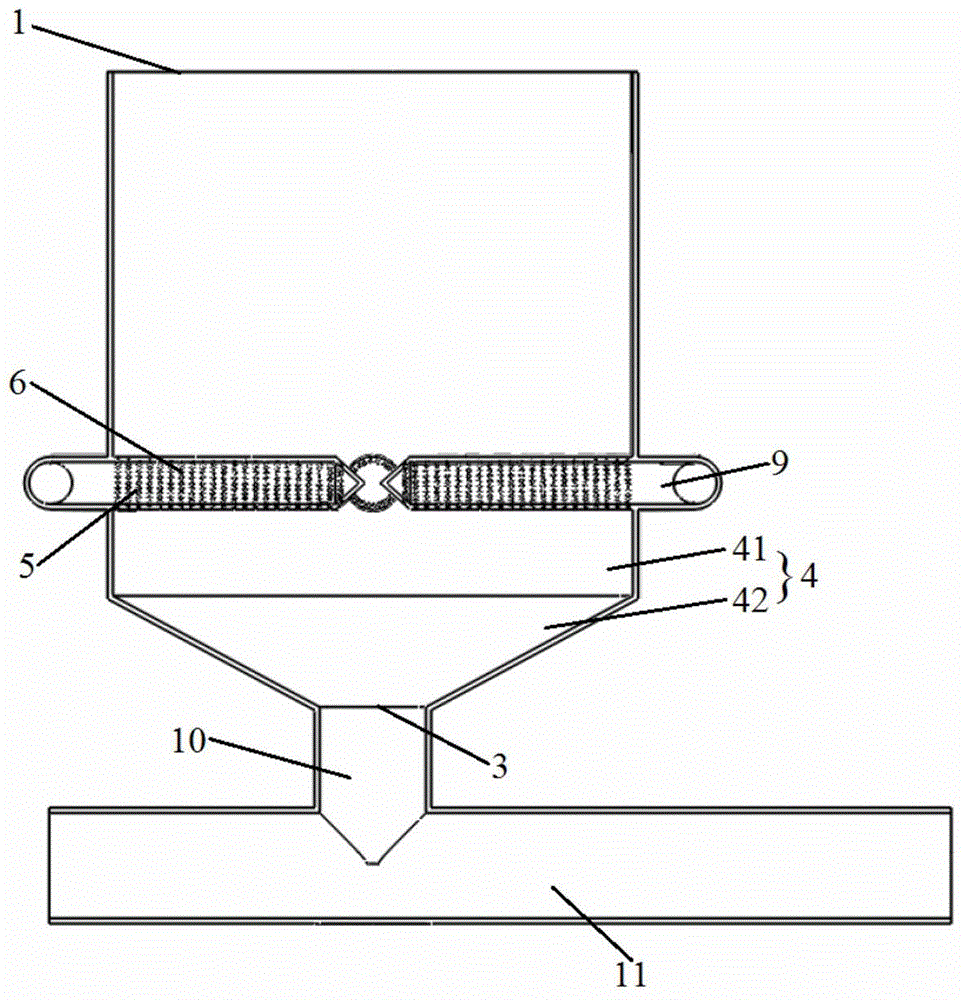

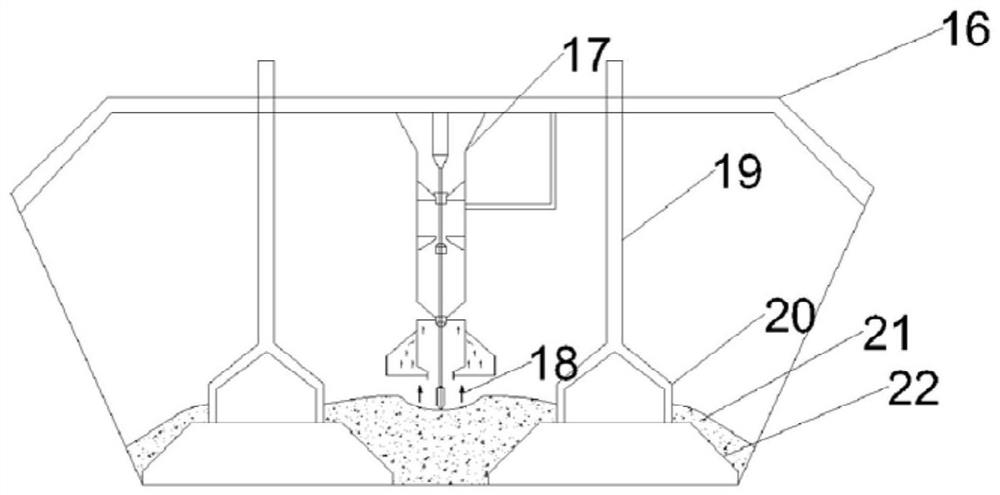

Blowing desulfurization fluidized chamber

InactiveCN104419797AStable feeding speedReduce processing timeCharge manipulationGas supplyProcess time

The invention discloses a blowing desulfurization fluidized chamber. The blowing desulfurization fluidized chamber comprises a shell (4) which comprises a desulfurizer inlet (1) and a desulfurizer outlet (3) formed in the height direction, an air supply duct (2) and an air distributing plate (6) provided with a plurality of air outlet holes (5) densely, wherein the upper edge of the air distributing plate (6) is attached to the inner wall of the shell (4) and the lower edge is connected with the desulfurizer outlet (3) so as to divide the shell (4) into a fluidized chamber (7) above the air distributing plate (6) and an air inlet chamber (8) below the air distributing plate (6); the air supply duct (2) is communicated with the air inlet chamber (8); and gas supplied from the air inlet chamber (8) enters into the air inlet chamber (8) and is sprayed into the fluidized chamber (7) through the plurality of air outlet holes (5) of the air distributing plate (6). According to the blowing desulfurization fluidized chamber disclosed by the invention, the desulfurizer is uniformly fluidized in the process of discharging the desulfurizer with a relatively good fluidizing effect, so that the desulfurizer is stable in discharging speed, the blowing process time is shortened, the spattering is reduced, and the iron loss is reduced.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Feeder convenient to adjust

InactiveCN106966134AHeight adjustableEasy alignmentSupporting framesArchitectural engineeringEngineering

The invention discloses a conveniently adjustable feeder, which comprises a base, a support base and a feeding pipeline. A first motor is arranged in the middle of the upper side of the base, and a first rotating shaft is arranged at the output end of the first motor. The upper end of the first rotating shaft It is connected with the lower side of the support seat in the middle, the upper side of the base is provided with a lower annular seat, the lower side of the support seat is provided with an upper annular seat, and the upper side of the lower annular seat and the lower side of the upper annular seat are symmetrically provided with annular chute , a number of balls are arranged in the annular chute, support rods are symmetrically arranged on the upper side of the support seat, a threaded rod is arranged on the upper end of the support rod, a second motor is arranged in the middle of the upper side of the support seat, and the output end of the second motor is arranged There is a second rotating shaft, the upper end of the second rotating shaft is provided with a driving wheel, the outer side of the supporting rod is provided with a driven wheel, the driving wheel and the driven wheel are connected by a belt, and the feeding pipe is arranged at the upper end of the threaded rod. The invention has the advantages of simple structure, convenient use, height adjustment, rotation alignment and stable feeding.

Owner:TONGLING SANNUO ELECTRONICS

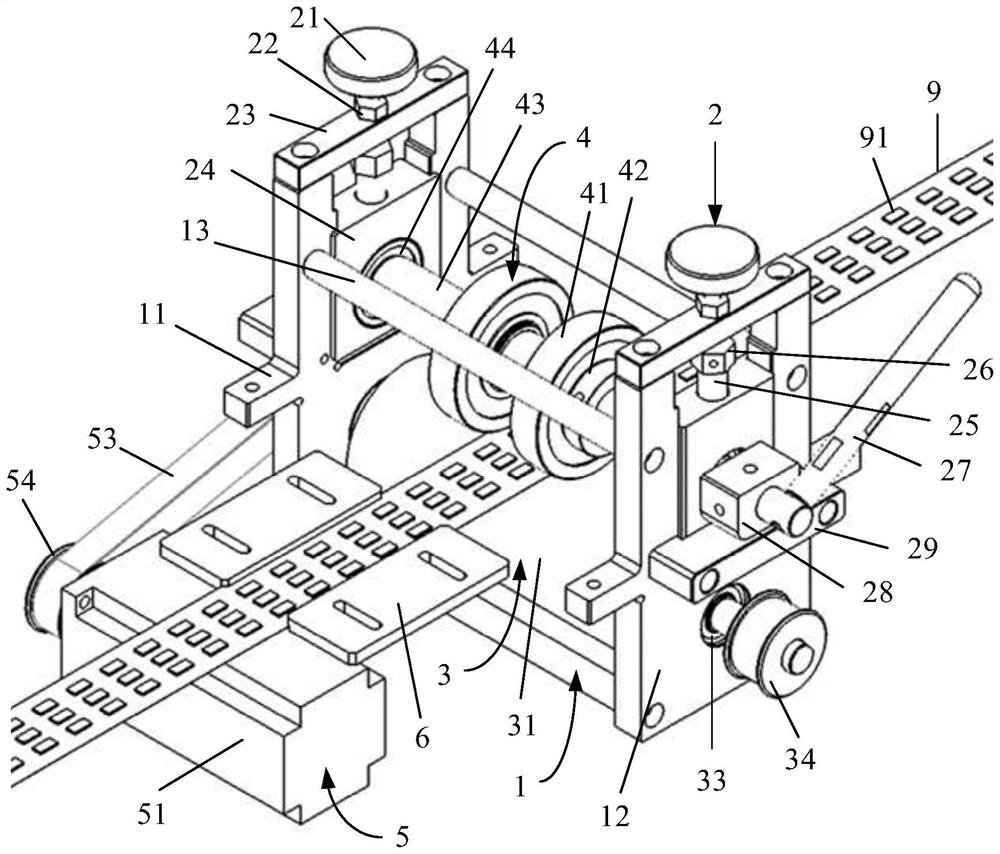

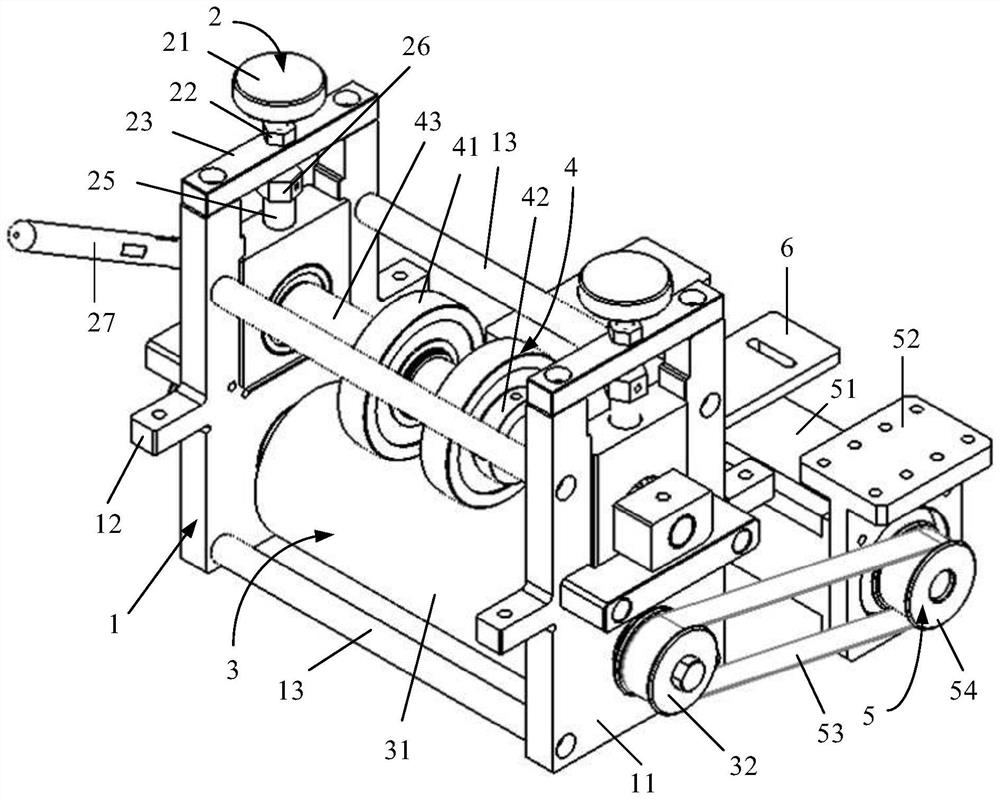

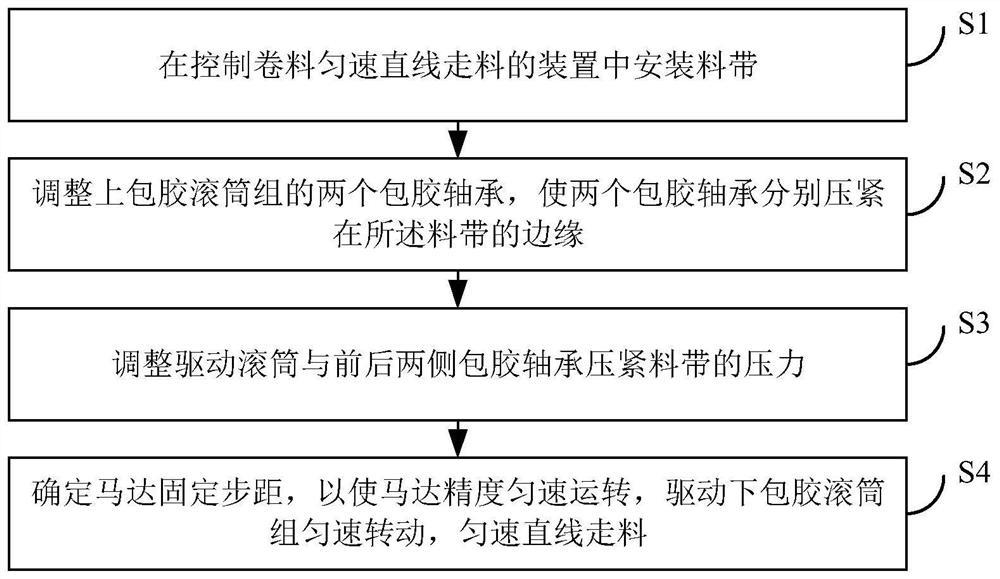

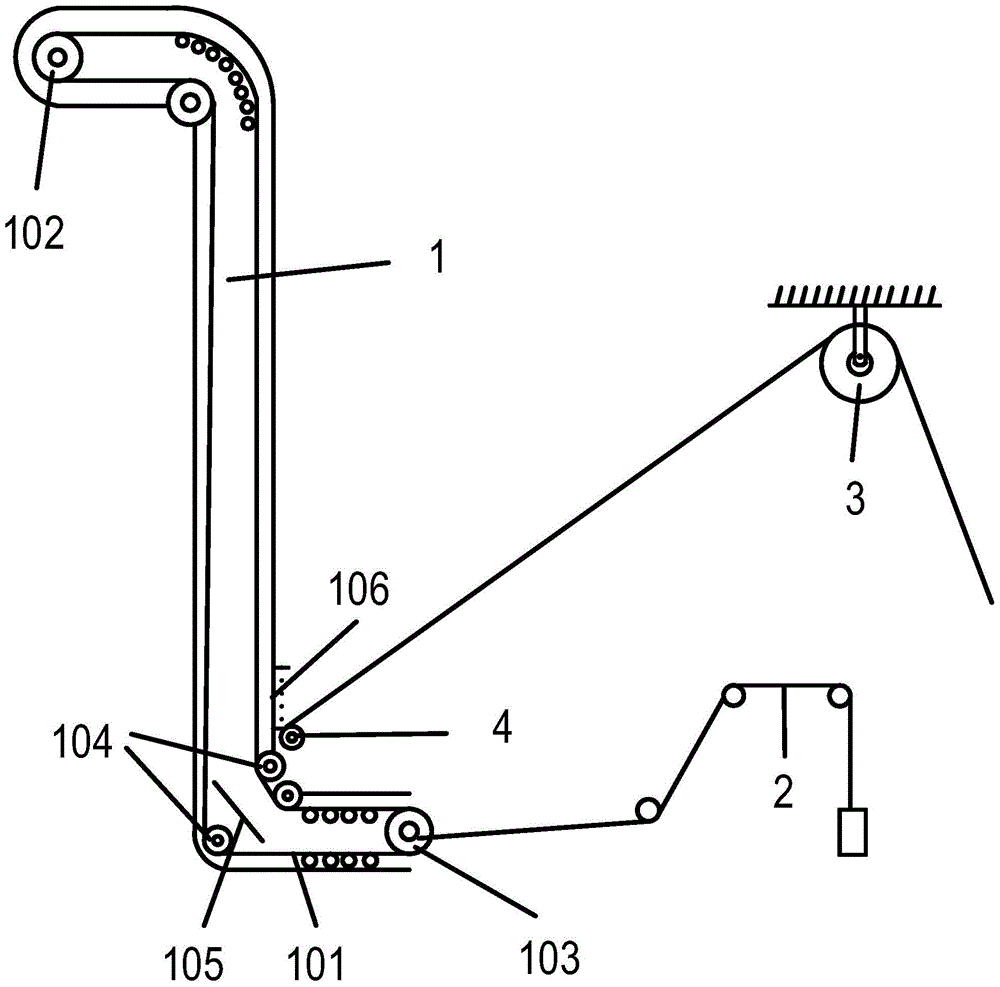

Device and method for controlling constant-speed linear feeding of coil stock

The invention discloses a device and method for controlling constant-speed linear feeding of coil stock, and relates to the technical field of coil stock feeding. The device comprises a frame mechanism, a material pressing adjusting mechanism, a lower rubber-coated roller group, an upper rubber-coated roller group and a transmission mechanism. The frame mechanism is used for fixedly mounting the material pressing adjusting mechanism, the lower rubber-coated roller group and the upper rubber-coated roller group. The material pressing adjusting mechanism is used for adjusting the upper rubber-coated roller set to ascend and descend so as to enable a material belt to penetrate through the upper rubber-coated roller set, and adjusting the pressure for pressing the material belt. The lower rubber-coated roller group is used for linearly conveying a material belt at a constant speed. The upper rubber-coated roller group comprises two rubber-coated bearings with adjustable widths, and the two rubber-coated bearings are respectively pressed on the edge of the material belt. The transmission mechanism is linked with the lower rubber coating roller group to drive the lower rubber-coated roller group to rotate at a constant speed, so that the lower rubber-coated roller group moves materials linearly at a constant speed. According to the embodiment of the invention, only the edge of the bottom film of the material belt instead of a product is pressed, so that the straightness of coil stock feeding is improved, and the feeding speed is stable.

Owner:易视智瞳科技(深圳)有限公司

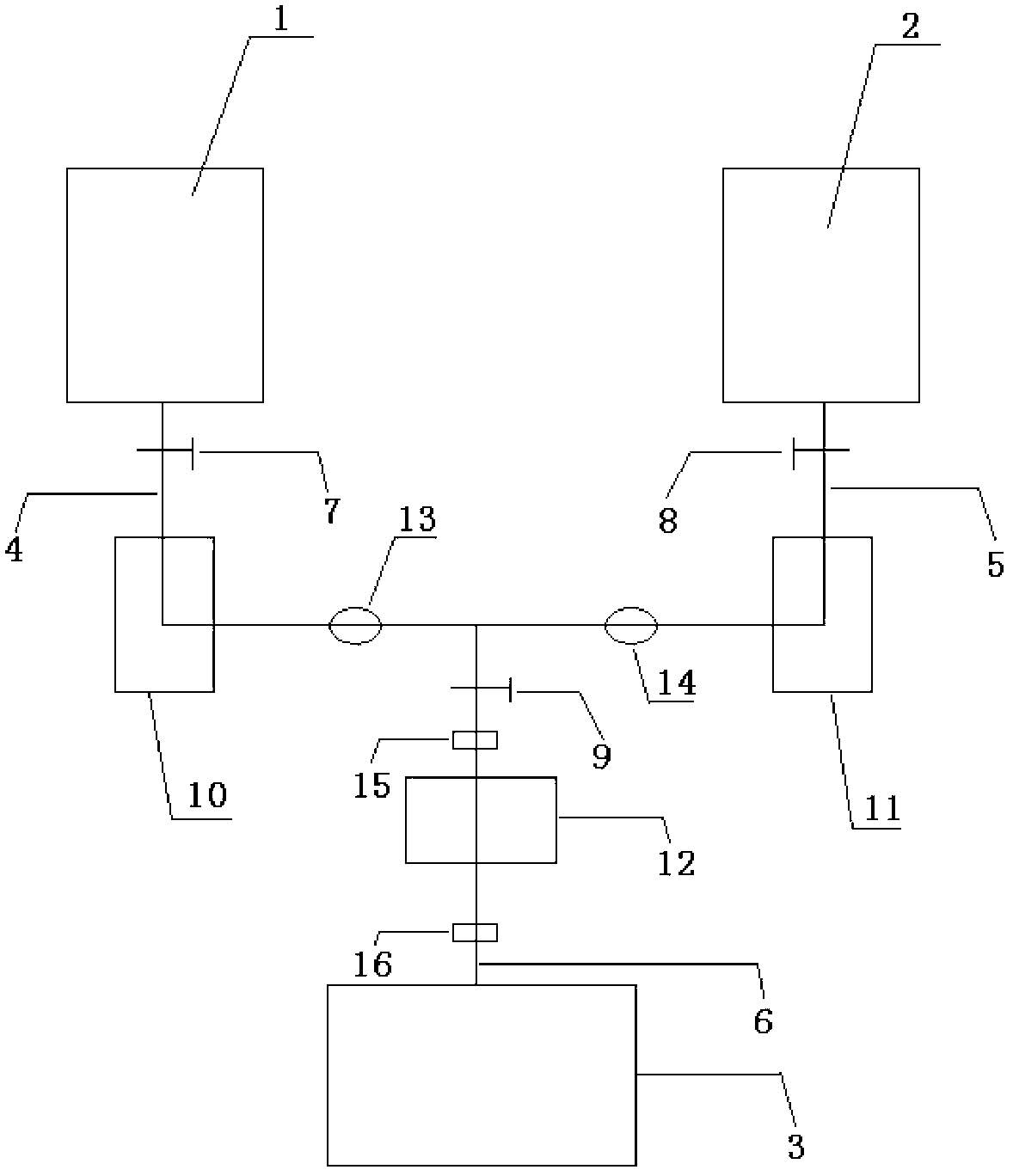

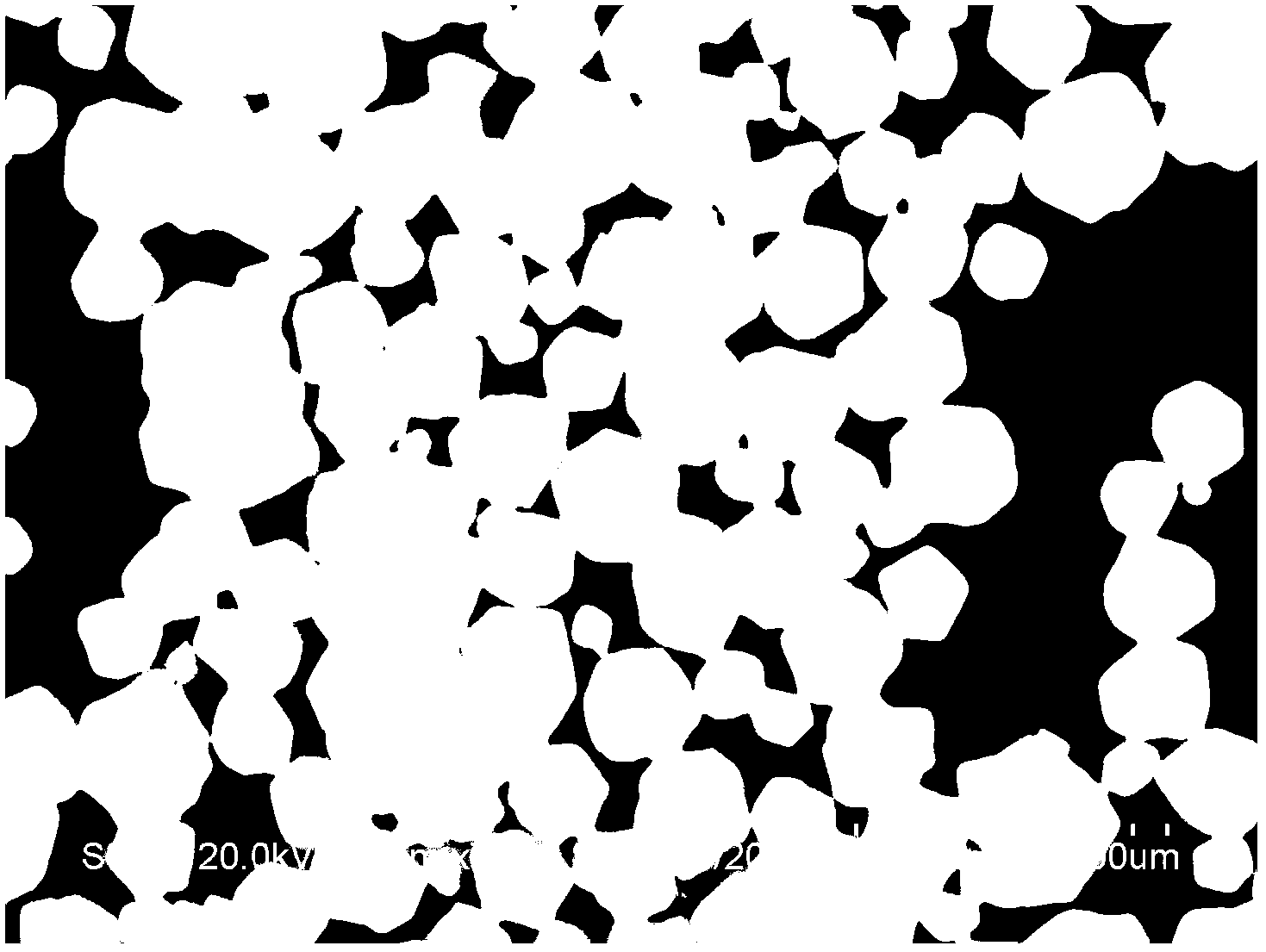

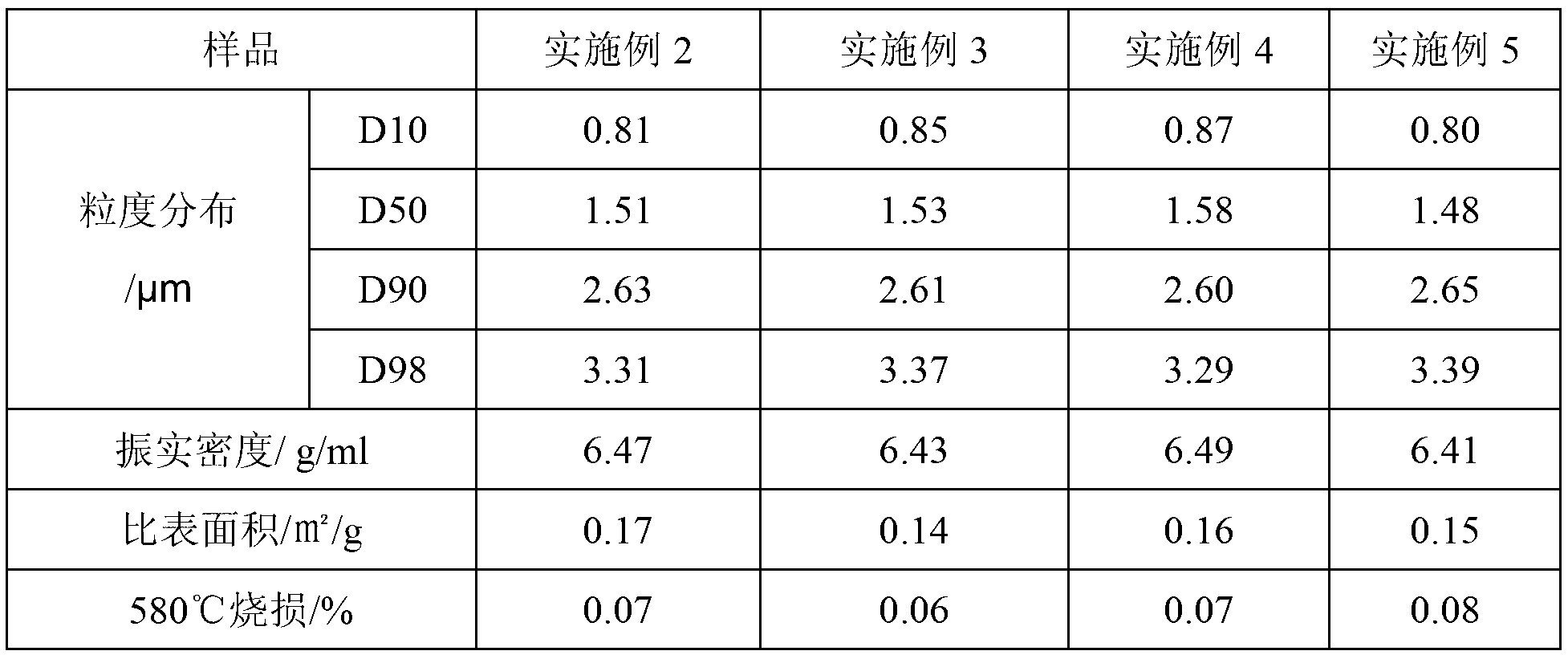

Device and method for continuously producing silver powder for solar energy

The invention provides a device for continuously producing silver powder for solar energy. The device comprises a first liquid dispensing tank, a second liquid dispensing tank and a container, wherein a liquid outlet of the first liquid dispensing tank is connected to one end of a first pipeline; a liquid outlet of the second liquid dispensing tank is connected to one end of a second pipeline; a liquid inlet of the container is connected to one end of a third pipeline; the other ends of the first pipeline, the second pipeline and the third pipeline are connected; a first electromagnetic valve, a first water bath device and a first flowmeter are arranged on the first pipeline; a second electromagnetic valve, a second water bath device and a second flowmeter are arranged on the second pipeline; and a third electromagnetic valve and a third water bath device are arranged on the third pipeline sequentially. The device is simple in structure, low in cost and convenient to operate, so that the silver powder with stable quality, high purity degree, high dispersibility and tap density and low specific surface area can be obtained.

Owner:SUZHOU HAILI METAL POWDER MATERIAL

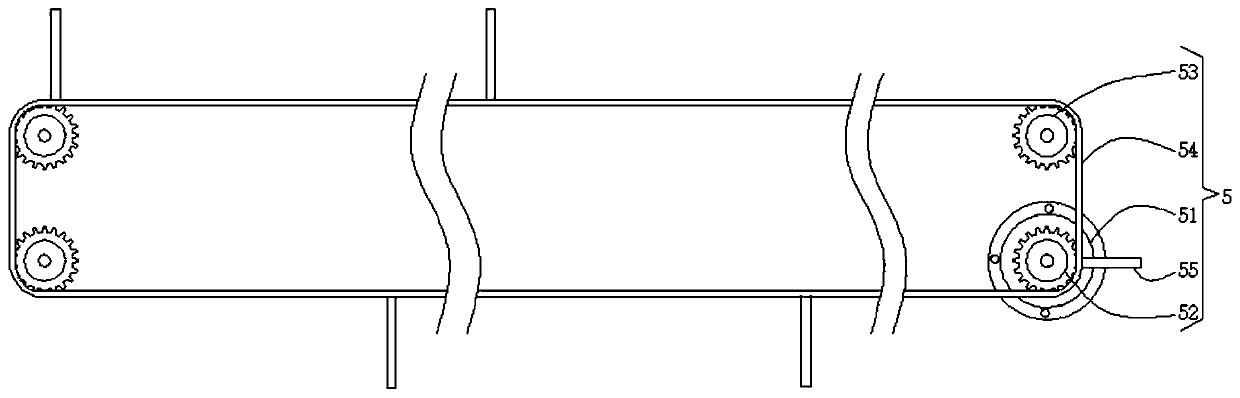

Automatic feeding machine

InactiveCN111977266AStable feeding speedImprove performanceConveyorsTransmission beltElectric machinery

The invention discloses an automatic feeding machine. The automatic feeding machine comprises a rack, conveying rollers mounted on the rack, a conveying belt winding across the conveying rollers, a transmission motor used for driving the conveying rollers to rotate, and a belt wheel assembly connected between the transmission motor and one of the conveying rollers. The automatic feeding machine further comprises a guide shaft rotationally connected to the rack, and a plurality of guide wheels fixed to the guide shaft, wherein a guide channel is formed between every two adjacent guide wheels; and materials are divided into multiple columns in order when passing through the guide channels. According to the automatic feeding machine, the materials to be welded enter surface pretreatment equipment in order through the guide wheels, and it can be ensured that the feeding speed is stable and the materials are not prone to being damaged.

Owner:盐城市瑞华涂装设备有限公司

Air drying machine for pre-processing raw materials in rice oil preparation

InactiveCN103234337AConsistent feeding speedAccelerate evaporationDrying chambers/containersDrying solid materialsAgricultural engineeringPre treatment

The invention relates to an air drying machine for pre-processing raw materials in rice oil preparation. The air drying machine is characterized by mainly comprising an air outlet drum, an air drying drum, vibrating devices and a screen. The top end of the air drying drum is connected with the air outlet drum, a feeding port is arranged at the edge of the air outlet drum, a discharging port and an upright air inlet are arranged at the bottom of the air drying drum, the screen is arranged in a drum body of the air drying drum, and two bilaterally symmetrical vibrating devices are arranged on an outer wall of the middle section of the air drying drum. The air drying machine is arranged behind a granulator, air dries rice bran grains, can reduce moisture content in the rice bran grains, can guarantee that rice oil in rice bran is not inactivated, can improve quality of finally obtained rice oil, and is simple and reasonable in structural design and easy to popularize and apply.

Owner:SHANDONG YANGXIN HUIYUAN GREASE

Injection desulfurization fluidization unit

The invention discloses a blowing desulfurization fluidization device. The blowing desulfurization fluidization device comprises a housing (4), a gas supply passage (2) and an air distribution pipe (6), wherein a desulfurizer inlet (1) and a desulfurizer outlet (3) are formed in the housing (4) along the height direction of the housing, a plurality of air outlet holes (5) are densely distributed in the air distribution pipe (6), a fluidization chamber is formed inside the housing (4), the air distribution pipe (6) is arranged inside the fluidization chamber and located between the desulfurizer inlet (1) and the desulfurizer outlet (3), the gas supply passage (2) is communicated with the air distribution pipe (6) and the gas supplied by virtue of the gas supply passage (2) is blown into the fluidization chamber by virtue of the plurality of air outlet holes (5) formed in the air distribution pipe (6). By the blowing desulfurization fluidization device, the desulfurizer can be uniformly fluidized during the charging of the desulfurizer, good fluidization effect is achieved so that the charging speed of the desulfurizer is stable, the blowing process time is shortened, the spattering is reduced and the amount of iron loss is decreased.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

A Paver Conveyor System with Adaptive Modes for Multiple Working Conditions

ActiveCN104776070BReduced service lifeExtended service lifeOperating means/releasing devices for valvesServomotorsSolenoid valveControl system

The invention discloses a paver material conveying system with multiple working condition adaptation modes. The paver material conveying system comprises a left material conveying hydraulic control system, a right material conveying hydraulic control system and an electric control system, wherein the first proportional electromagnetic reversing valve (401) of the left hydraulic control system is respectively connected with a first logic control valve (201) and a first pressure compensation valve (301); a first overflow valve (101) is connected with the first pressure compensation valve (301); the second proportional electromagnetic reversing valve (402) of the right material conveying hydraulic control system is respectively connected with a second logic control valve (202) and a second pressure compensation valve (302); a second overflow valve (102) is connected with the second pressure compensation valve (302); the electric control system comprises a control console A1 connected with a controller A2, a left material conveying material level sensor B1, a right material conveying material level sensor B2, a left material conveying solenoid valve and a right material conveying solenoid valve. The paver material conveying system has the advantages of simplicity and convenience in control implementation and easiness in operation.

Owner:XCMG CONSTR MACHINERY

Tobacco drying and transferring device based on rapid transportation

InactiveCN111528512ATo achieve the purpose of automatic feedingNo need for manual cuttingTobacco preparationLoading/unloadingAgricultural engineeringRapid transit

The invention discloses a tobacco drying and transferring device based on rapid transportation. The device comprises a spreading unit and a transporting unit, the spreading unit comprises a processingframe and a conveying frame used for spreading tobaccos, the conveying unit comprises a movable frame, second supporting legs and a conveying belt are arranged on the upper surface of the processingframe, a discharging frame is arranged at the upper ends of the second supporting legs, the conveying belt is located below the discharging frame, and the conveying belt can be used for conveying tobaccos; tobacco in the discharging frame falls off from a discharging plate and is conveyed by the conveying belt, the purpose of automatic discharging is achieved, manual discharging is not needed in the whole process, the discharging speed is stable, and excessive coverage of the tobacco cannot be caused. Tobacco can slide onto the conveying belt from the discharging frame, in the whole process, the conveying frame can certainly drive the tobacco to automatically fall onto the winding belt, the linkage effect is achieved, manual operation is not needed, and efficiency is improved.

Owner:HEFEI ANLUYI TECH CO LTD

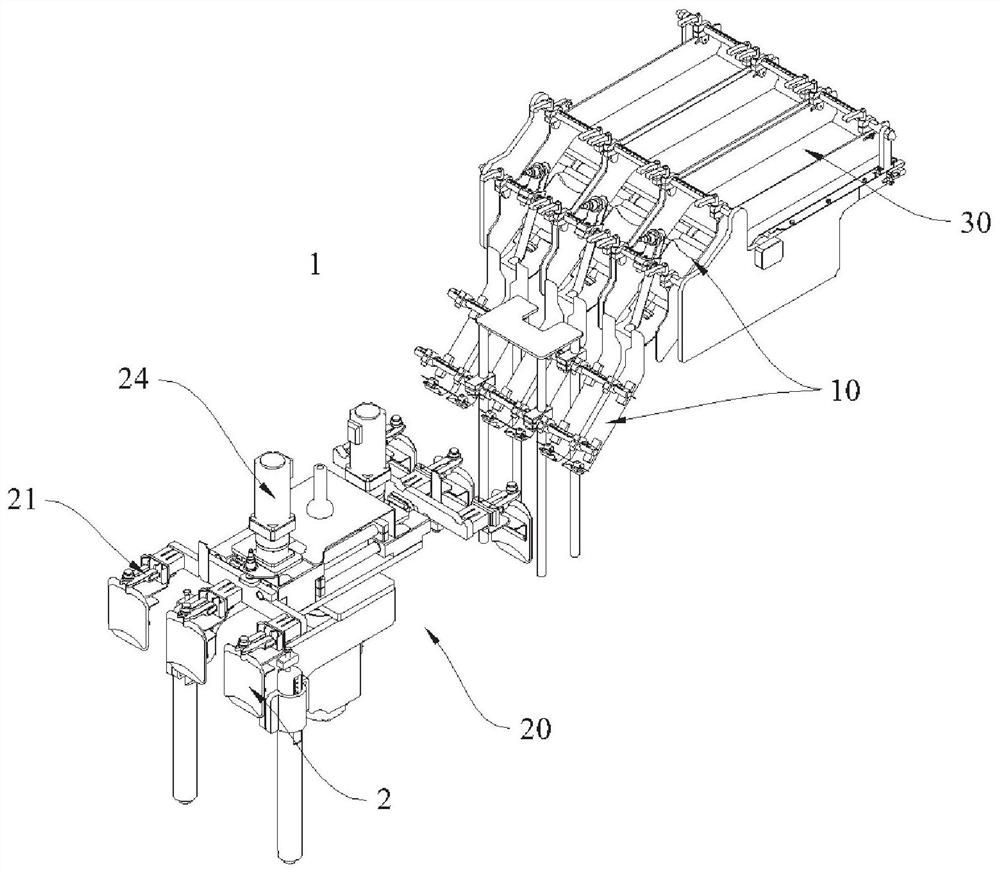

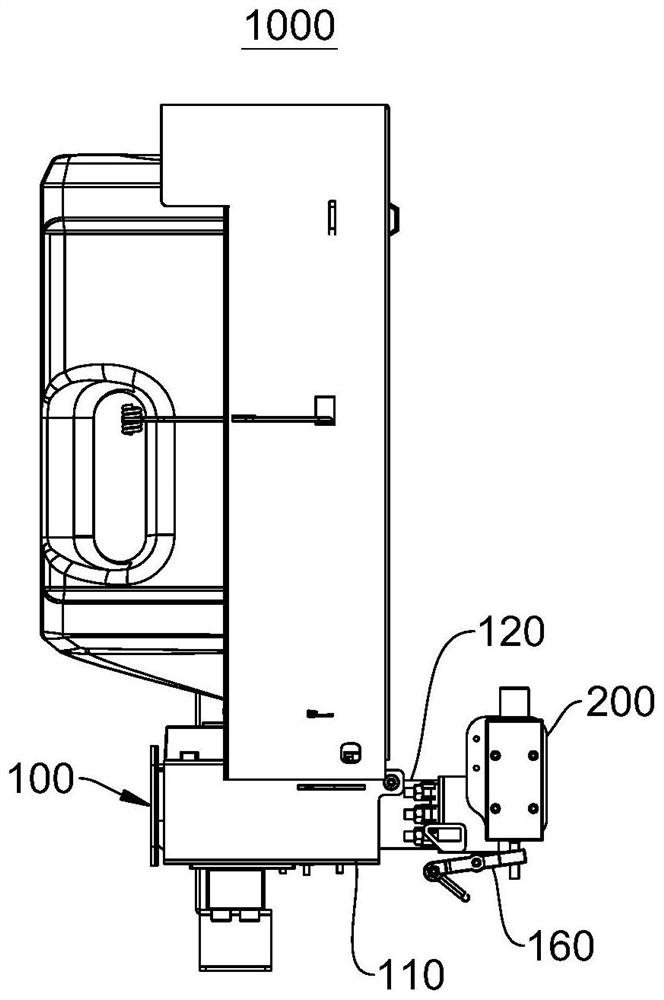

Soft bag feeding device and lamp inspection machine

PendingCN114132742AImprove versatilityImprove accuracyOptically investigating flaws/contaminationConveyor partsEngineeringMechanical engineering

Owner:CHENGDU HONGRUI TECH

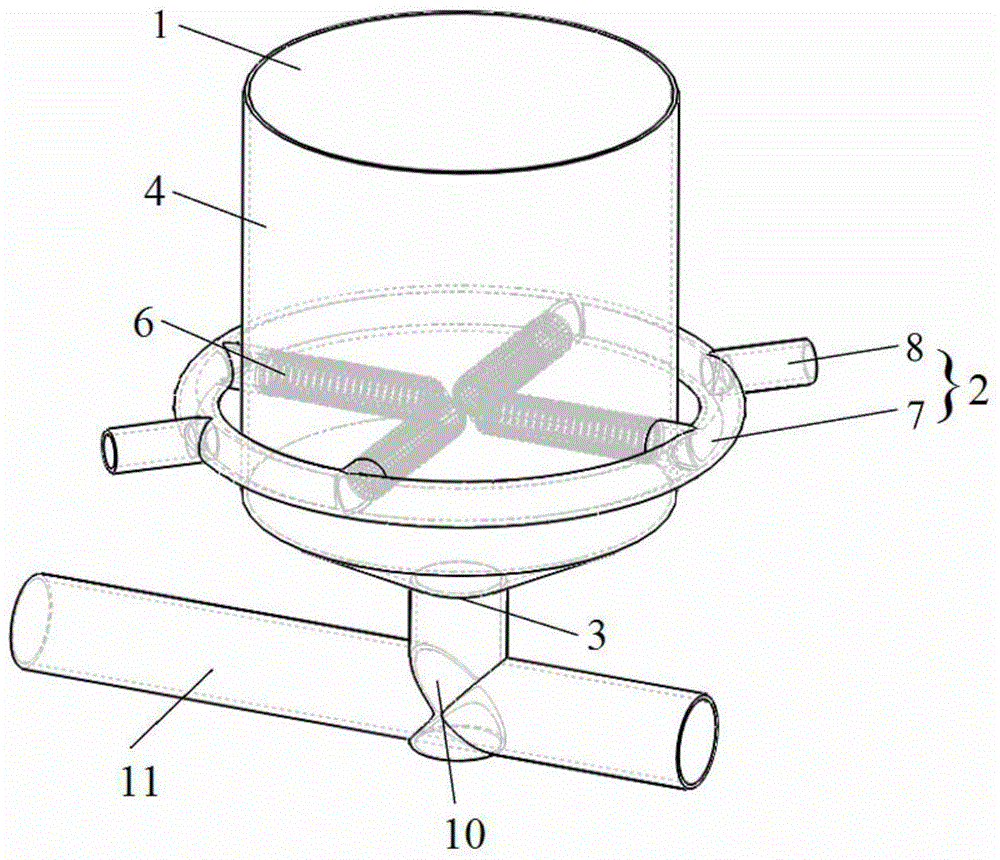

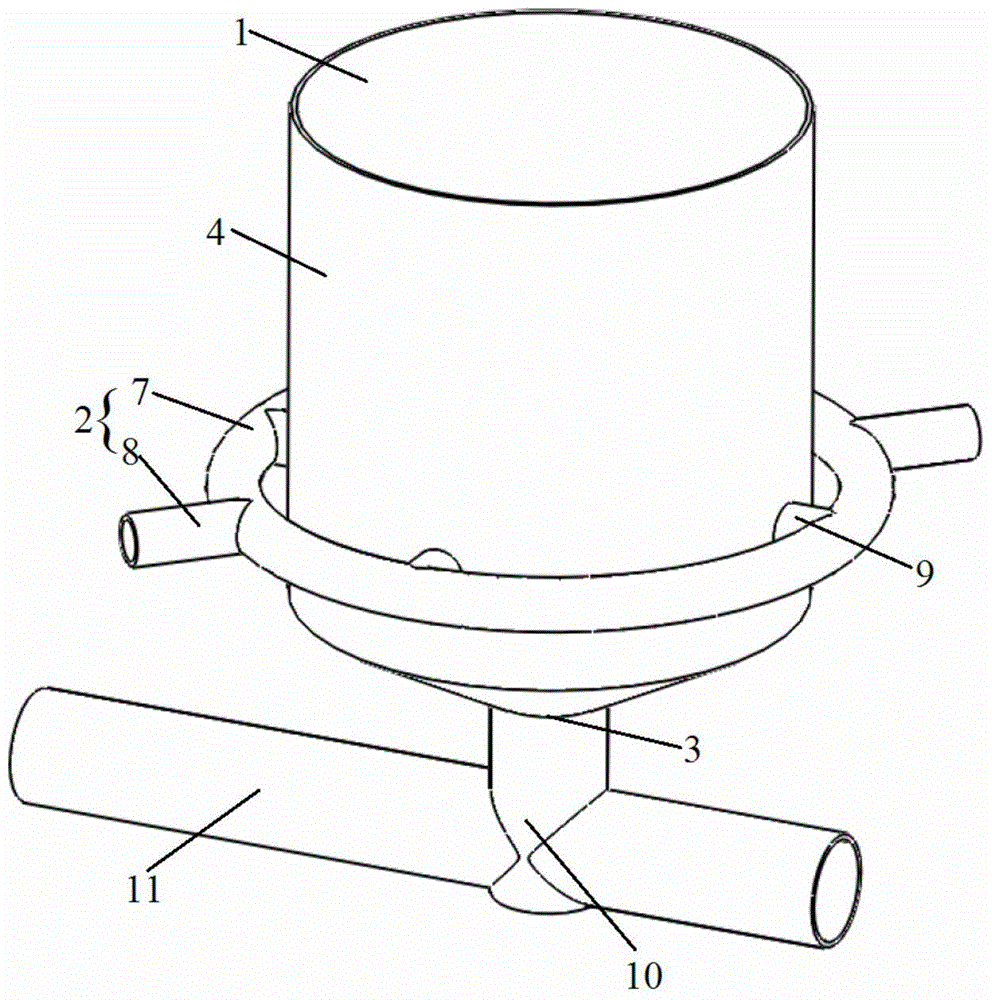

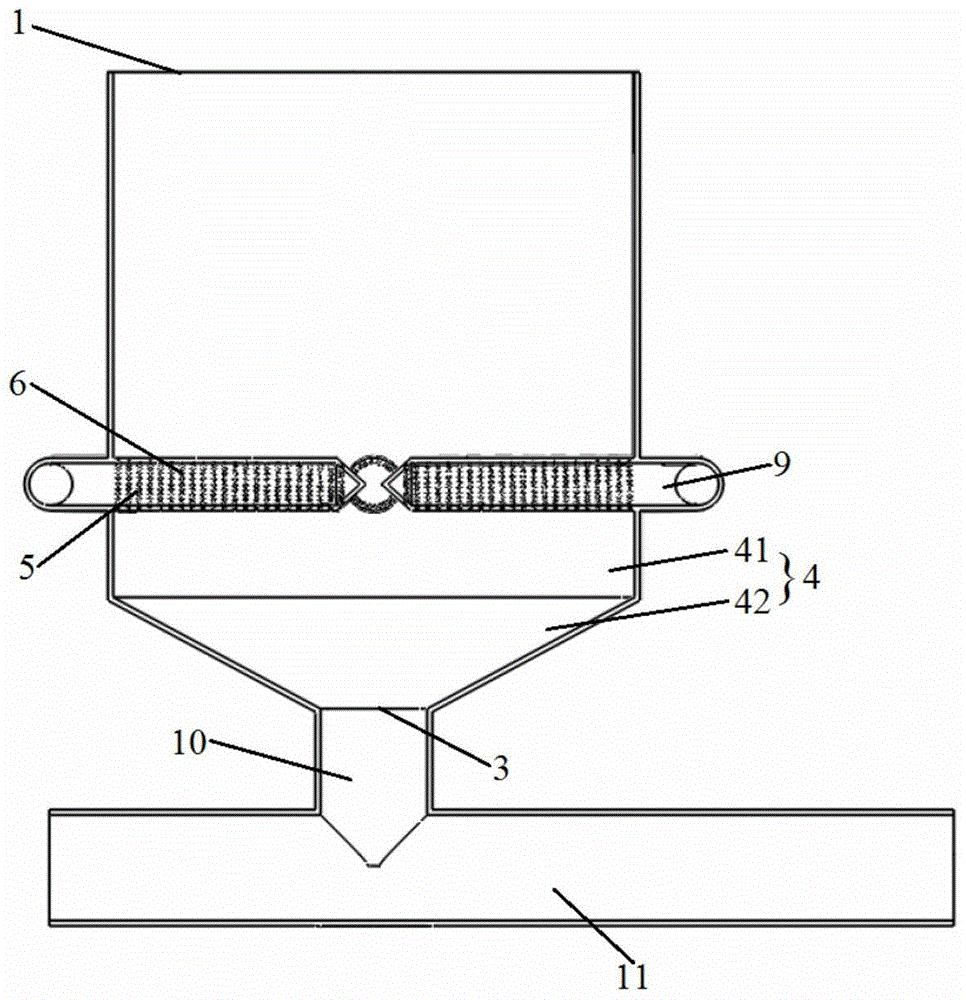

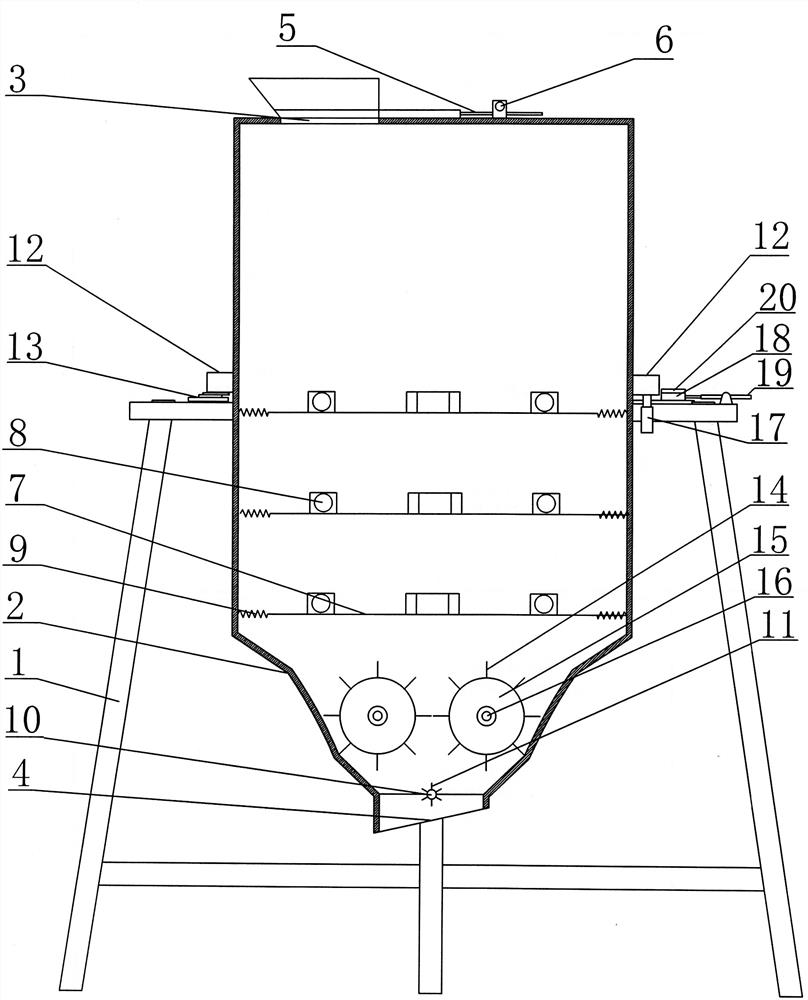

Large-moisture desulfurization gypsum stable feeding and metering system

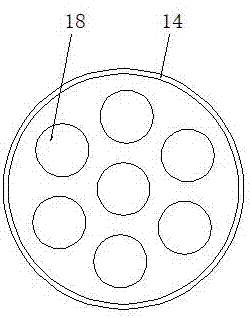

PendingCN114194637AGuarantee feed stabilityReduce sensitivityLarge containersLoading/unloadingElectric machineryLoad cell

The invention discloses a moisture desulfurization gypsum stable discharging and metering system which comprises a support, a material storage barrel is arranged on the support, the material storage barrel is provided with a feeding port and a discharging port, the material storage barrel is provided with at least one layer of vibration disc, the vibration disc comprises a grating disc, more than one vibrator is arranged on the grating disc, a vibration spring is arranged between the grating disc and the inner wall of the material storage barrel, and the vibration spring is connected with the vibration disc. A ring beam is arranged outside the storage barrel, a weighing sensor is arranged on the support below the ring beam, at least two discharging wheels are arranged above the discharging port, each discharging wheel comprises a wheel shaft, blades are arranged on the wheel shafts, a discharging driving motor is arranged on the wheel shafts, a discharging detection device is arranged at the discharging port and comprises a rotating shaft, and more than six detection blades are arranged on the rotating shaft. And a speed measurement sensor is arranged on the rotating shaft. The problem that in the prior art, a storage barrel cannot conduct stable discharging is solved.

Owner:HENAN QIUSHI AUTOMATION ENG CO LTD

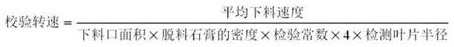

Disassembly and cleaning method of the old belt of the transfer tower bucket elevator

ActiveCN104816937BStable feeding speedEasy to adjust and control the pulling speedConveyorsCleaningEngineeringTower

The invention discloses a method for dismounting and cleaning an old belt of a transfer tower bucket elevator. The method comprises the three steps of releasing the fixation of the old belt, cleaning the old belt in an underground material bin and cleaning the old belt outside the underground material bin. The method has the advantages that overall dismounting and overall cleaning of the old belt can be achieved, the stability of structural components of the bucket elevator is guaranteed, the cleaning difficulty of the old belt can also be lowered, the cleaning efficiency is improved, and time is gained for the overall remounting of a subsequent new bucket belt.

Owner:CHINA 19TH METALLURGICAL CORP

An assembly line loading and unloading structure

The invention discloses a material loading and unloading structure on an assembly line, which includes a base and a bracket. The brackets are two. The left side of the inner wall is provided with connecting blocks and rollers along the up and down directions. Several of the rollers are arranged on the upper surface of the base in sequence along the left and right directions, and the front and rear ends of the rollers are connected with the upper surface connecting seats of the base through pin shafts. , the conveyor belt, the conveyor belt is arranged on the upper and lower sides of the outer wall of the rotating roller, the material tray, the material tray is arranged on the upper surface of the conveyor belt, the first gear, and there are two first gears. The assembly line loading and unloading structure can stably take out the workpieces, and can feed the workpieces to the processing equipment one by one, realizing mechanical loading and unloading and stacking instead of manual loading and unloading, saving labor and ensuring the speed of feeding. It is stable, reduces the production cost, and is conducive to popularization.

Owner:嵊州市法克机械有限公司

Blowing desulfurization fluidization device

The invention discloses a blowing desulfurization fluidization device. The blowing desulfurization fluidization device comprises a housing (4), a gas supply passage (2) and an air distribution pipe (6), wherein a desulfurizer inlet (1) and a desulfurizer outlet (3) are formed in the housing (4) along the height direction of the housing, a plurality of air outlet holes (5) are densely distributed in the air distribution pipe (6), a fluidization chamber is formed inside the housing (4), the air distribution pipe (6) is arranged inside the fluidization chamber and located between the desulfurizer inlet (1) and the desulfurizer outlet (3), the gas supply passage (2) is communicated with the air distribution pipe (6) and the gas supplied by virtue of the gas supply passage (2) is blown into the fluidization chamber by virtue of the plurality of air outlet holes (5) formed in the air distribution pipe (6). By the blowing desulfurization fluidization device, the desulfurizer can be uniformly fluidized during the charging of the desulfurizer, good fluidization effect is achieved so that the charging speed of the desulfurizer is stable, the blowing process time is shortened, the spattering is reduced and the amount of iron loss is decreased.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

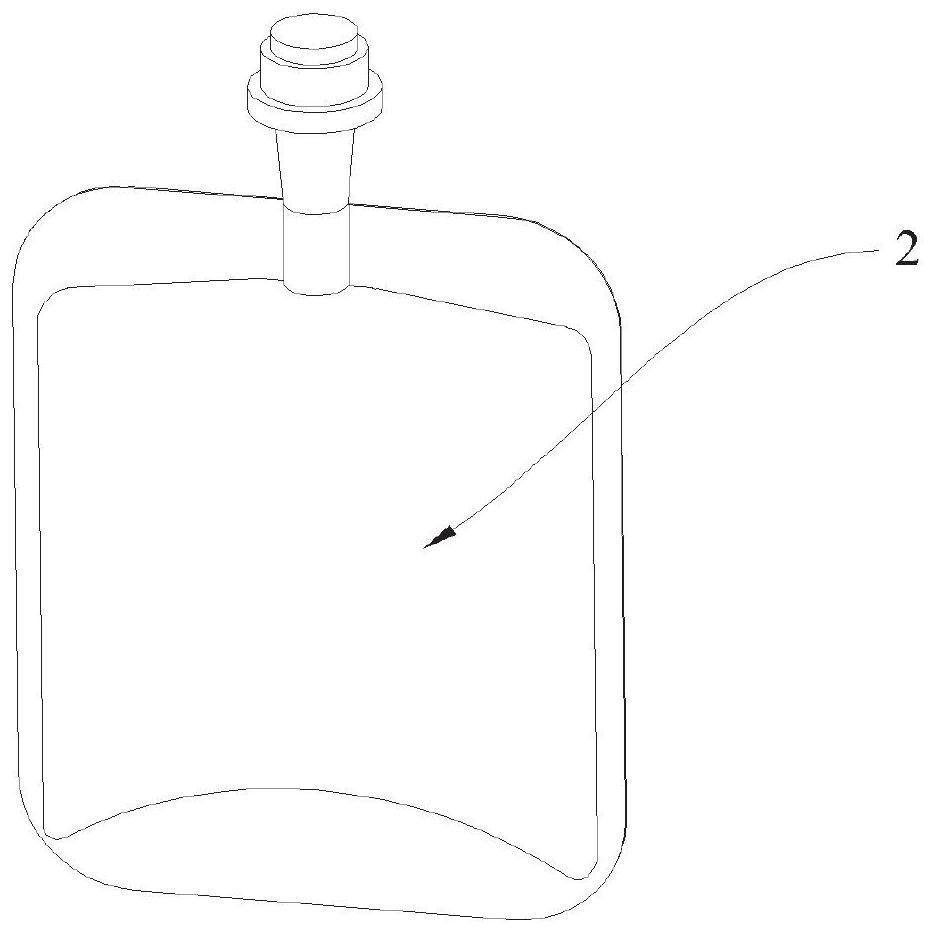

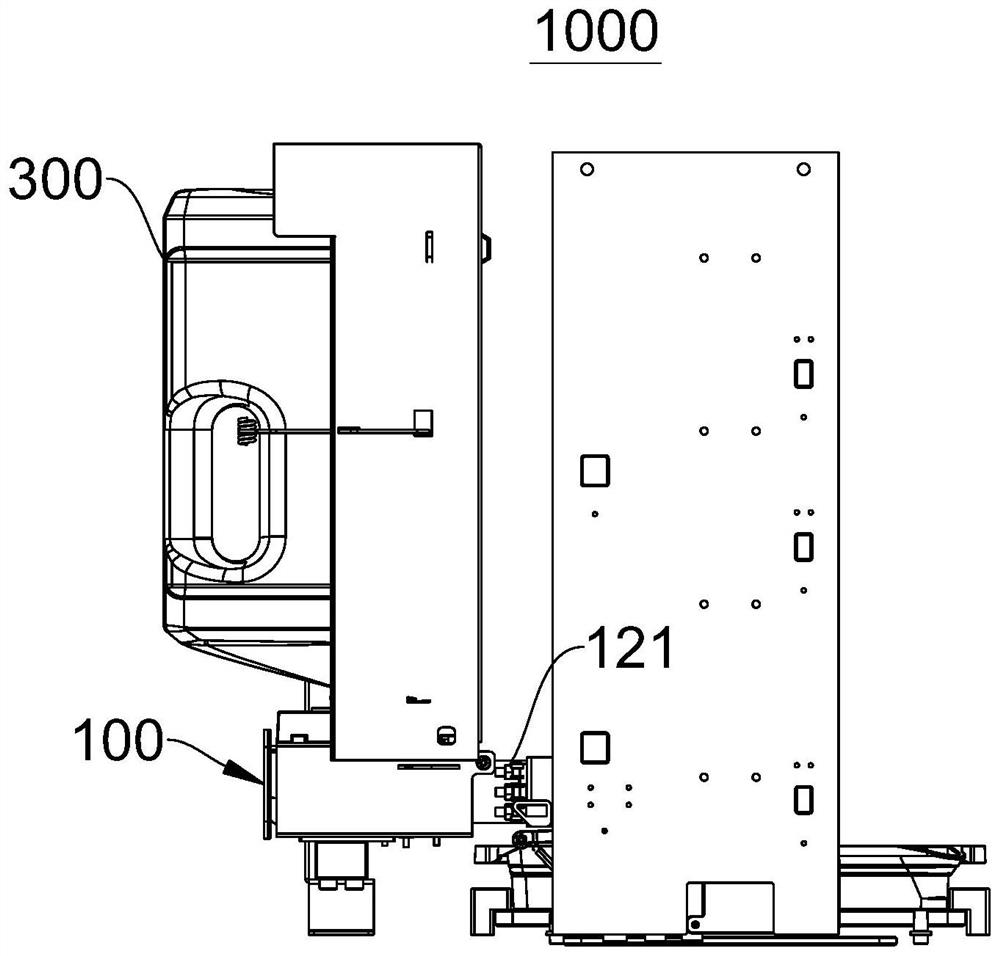

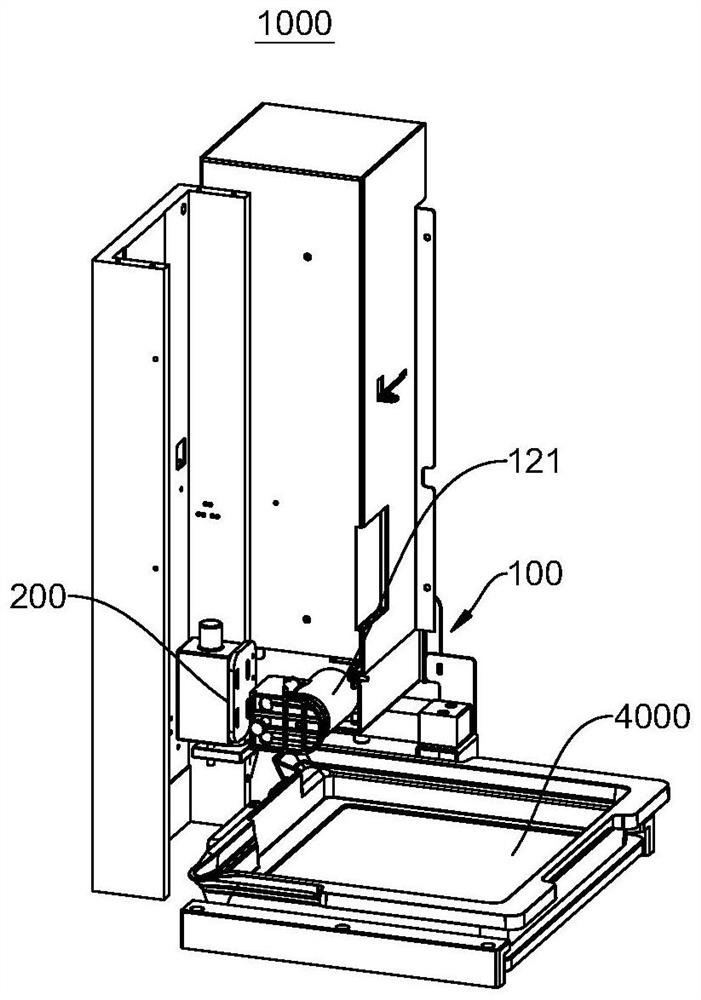

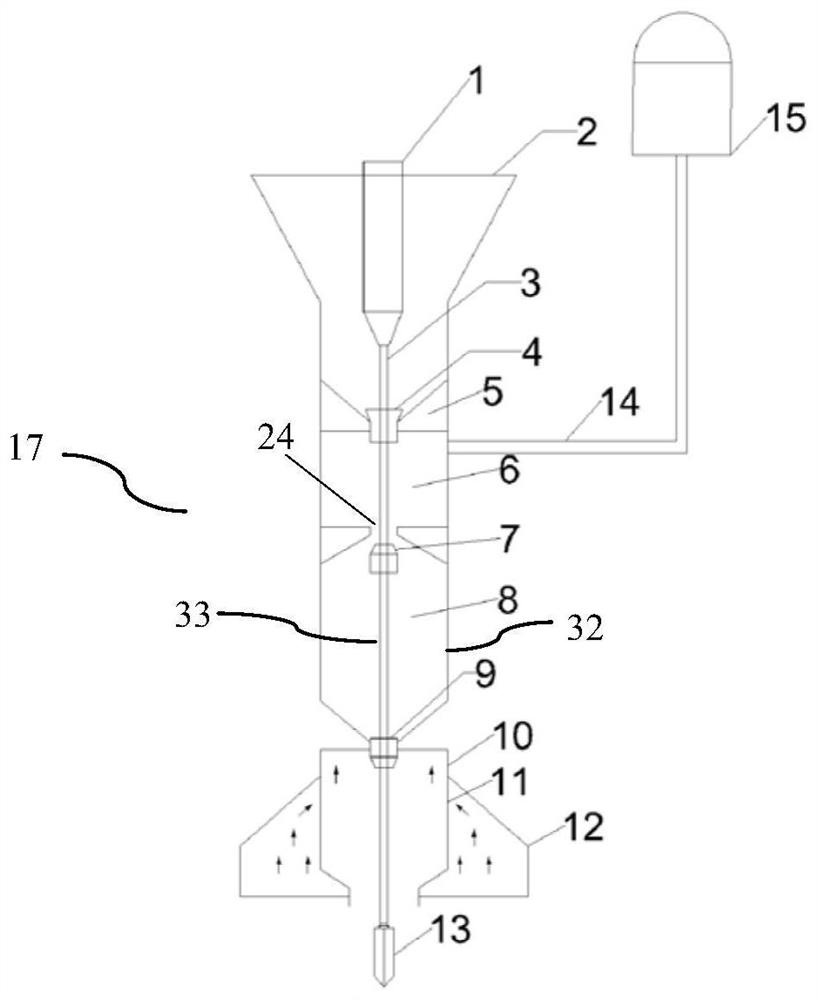

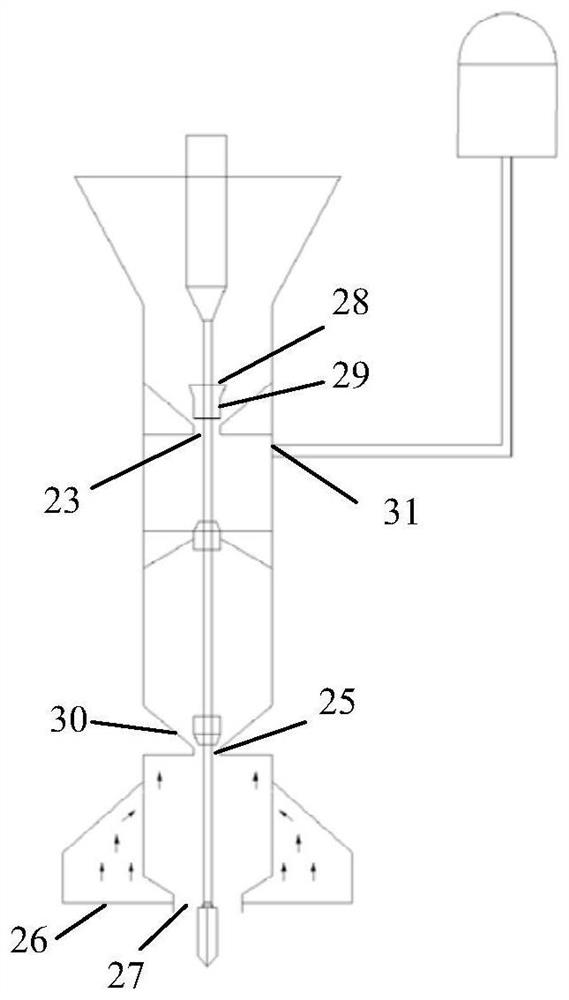

Transfer liquid adding device, automatic liquid adding device, 3D printer and liquid adding method

PendingCN114734637AStable feeding speedEasy to controlAdditive manufacturing apparatus3D object support structuresComputer printingEngineering

The invention provides a transfer liquid adding device, an automatic liquid adding device, a 3D printer and a liquid adding method, and relates to the technical field of 3D printing. The 3D printer comprises the automatic liquid adding device, the liquid adding method is applied to the 3D printer, the automatic liquid adding device comprises a transfer liquid adding device and a driving device, a printing material is firstly added into a feeding box of the transfer liquid adding device through a material storage device, and then the printing material is led to a material disc through a liquid outlet part; it can be guaranteed that the feeding speed of the feeding box into the charging tray is in a stable state, and then the feeding speed is controlled to be stable.

Owner:GUANGZHOU HEIGE ZHIZAO INFORMATION TECH CO LTD

An integrated device and method for acid-process alumina shelling and cutting and flue gas separation

The invention provides a device and method for integrating crust breaking and blanking of alumina produced by an acid process with flue gas separation. The inner cavity of an blanking cylinder of thedevice is divided into at least two blanking cavities, and the bottom of each blanking cavity is provided with a blanking hole; a material box is arranged on the upper portion of the blanking cylinder, a blanking chamber is formed in the lower portion of the blanking cylinder, the blanking cavity adjacent to the blanking chamber is communicated with the blanking chamber through the corresponding blanking hole, and the bottom of the blanking chamber is provided with a feeding hole; a transmission mechanism can move up and down relative to the blanking cylinder and close or open each blanking hole; a crust-breaking head is installed on the bottom of the transmission mechanism, a gas-collecting hood is arranged on the periphery of the blanking chamber, and the side wall of the blanking chamber is provided with a flue gas inlet of the gas-collecting hood; the upper portion of the blanking cavity adjacent to the material box is provided with a flue gas outlet, and a flue gas chamber is communicated with the flue gas outlet. The device integrates crust breaking and blanking of alumina produced by the aid process with flue gas separation, the equipment structure is simplified, and moreover, the device is conductive to uniform and stable blanking and flue gas purification.

Owner:SHENHUA ZHUNNENG RESOURCE COMPREHENSIVE DEV COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com