Grooved wheel type bar separating and automatic feeding device

An automatic feeding and sheave technology, which is applied in the direction of grinding feed motion, grinding machine parts, metal processing equipment, etc., can solve the problem of difficult to achieve feeding speed, troublesome and time-consuming to replace bar specifications, and failure of the feeder. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

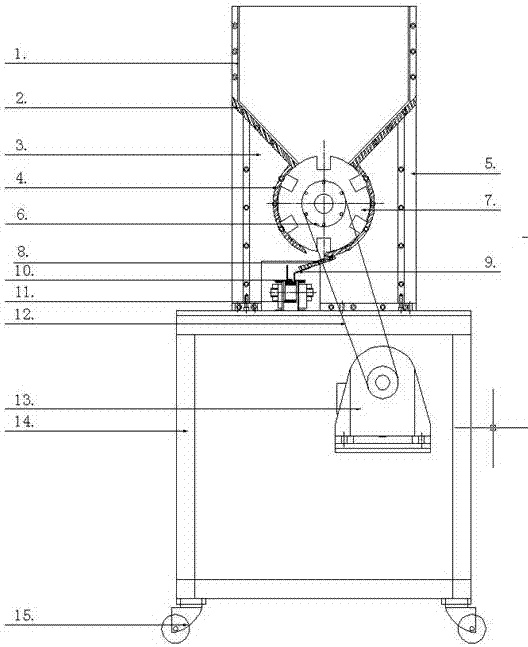

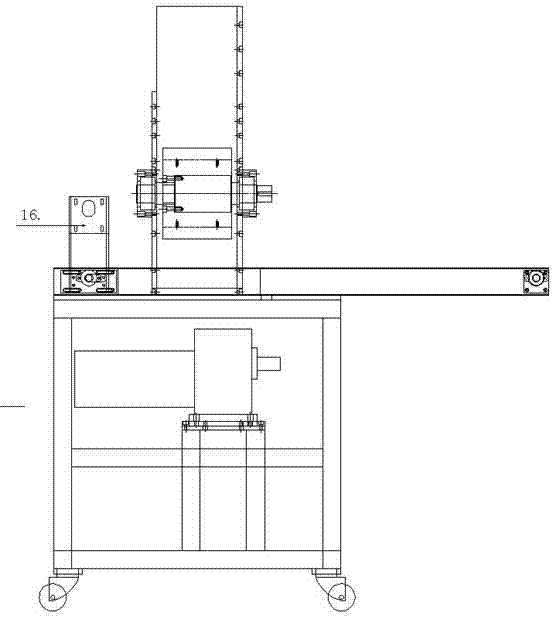

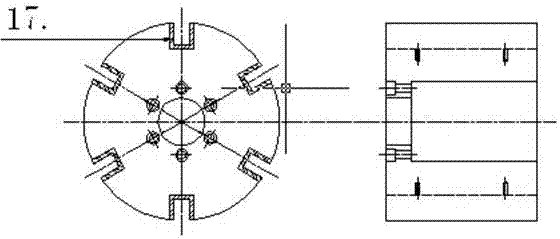

[0019] A sheave-type automatic feeding device for bar separation, including a rubber pad 1, a separation plate 2, a front and rear support plate 3, an arc-shaped baffle plate 4, a left and right support plate 5, a main shaft 6, a sheave 7, a material guide plate 8, Feeding baffle 9, fastening bolt 10, feeding belt 11, transmission belt 12, main motor 13, frame 14, universal wheel 15, feeding motor 16 and elastic clamp 17,

[0020] The front and rear support plates 3 and the left and right support plates) are combined into a box structure through several fastening bolts 10, and the box is fixed on the frame 14 through several fastening bolts 10, and universal wheels 15 are installed under the frame 14. The front and rear support plates 3 are correspondingly provided with bearings;

[0021] The separating partition 2 separates the box body into upper and lower parts, the upper part is a V-shaped storage box, and the lower part is the rotation space of the sheave 7;

[0022] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com