An integrated device and method for acid-process alumina shelling and cutting and flue gas separation

A technology of shelling and blanking, alumina, applied in the field of aluminum electrolysis, can solve problems such as environmental and personnel hazards, and achieve the effect of purifying flue gas, enhancing fluidity, and improving smoothness and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the technical solution of the present invention, the content of the present invention will be further described below in conjunction with the examples, but the content of the present invention is not limited only to the following examples.

[0036] Where words such as "up", "down", "top", "bottom", "above" and "below" appear in the text, they are based on the orientation of the attached drawings.

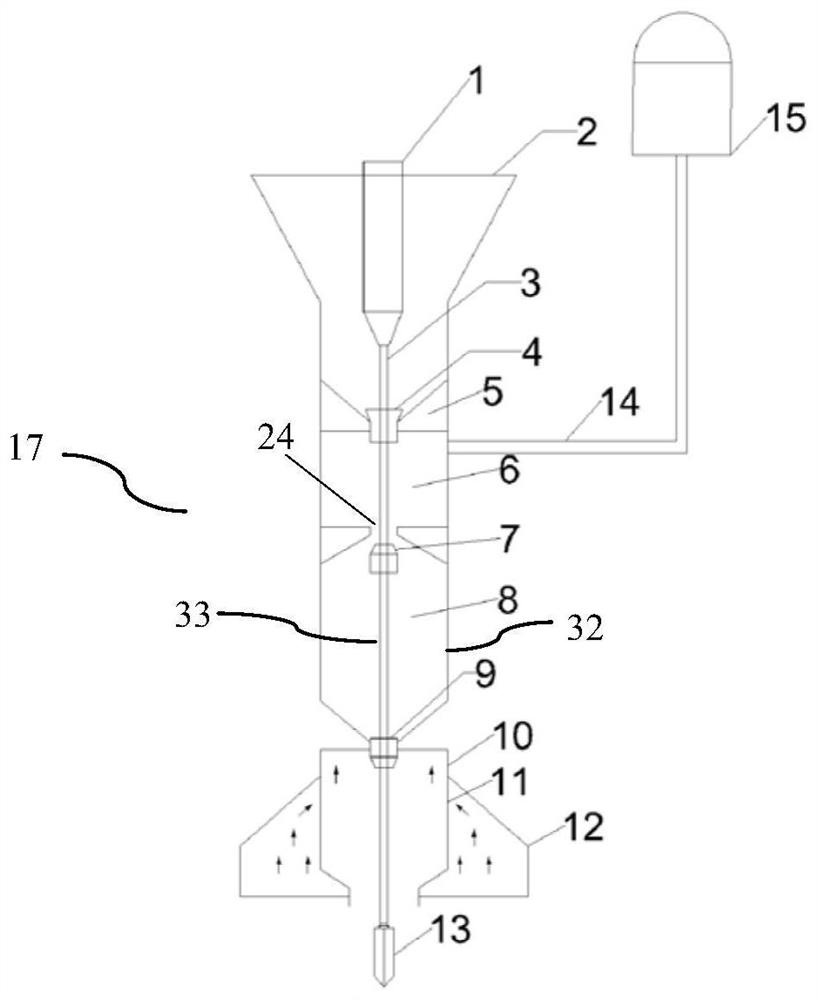

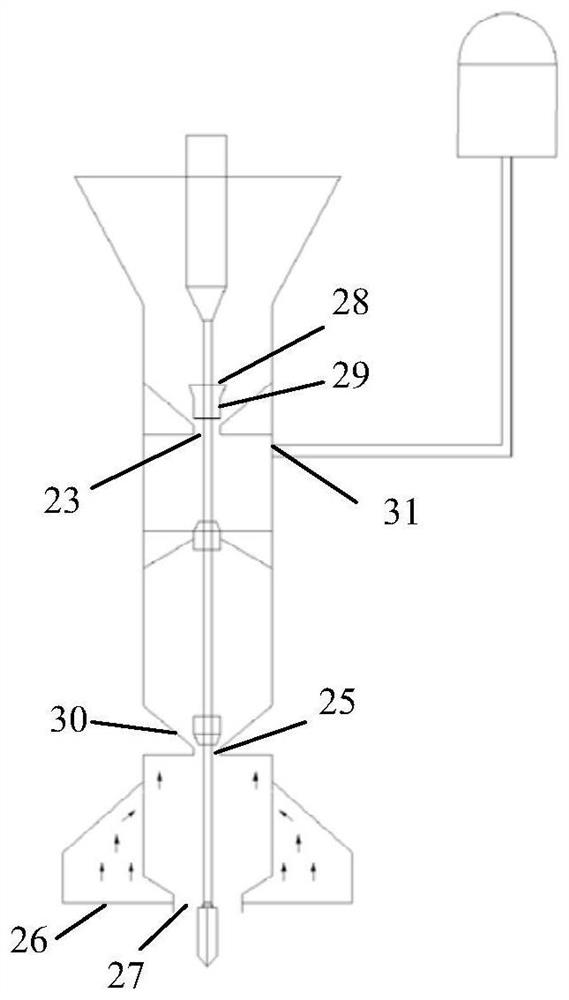

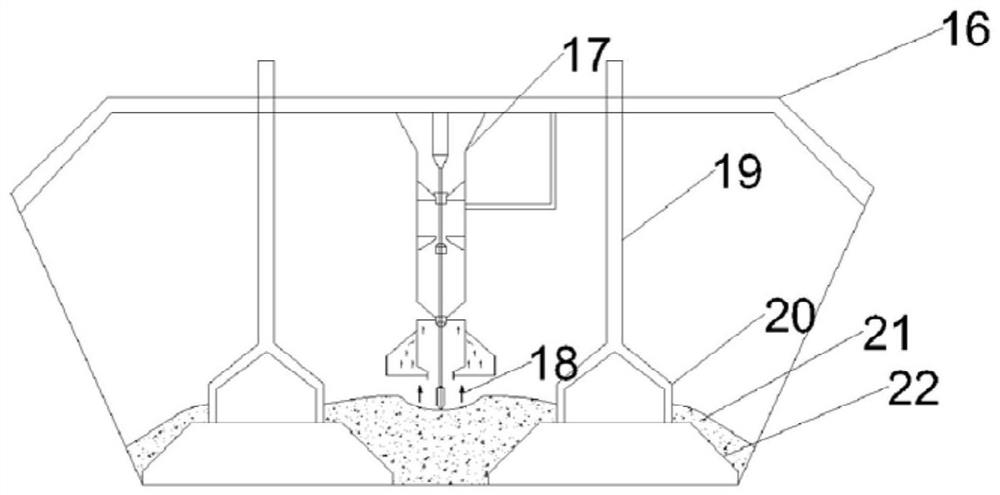

[0037] The integrated device for shelling and cutting and flue gas separation of acid-processed alumina provided by the present invention, see the attached Figure 1-2 , mainly including material box 2, feeding cylinder 32, feeding chamber 10, gas collecting hood 12, smoke chamber 15, transmission mechanism 33, power mechanism 1 and shelling head 13.

[0038] The inner cavity of the feeding cylinder 32 is divided into at least two feeding chambers (such as feeding chambers 6, 8) successively from top to bottom, such as two feeding chambers, three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com