Patents

Literature

4255results about How to "Easy to unload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

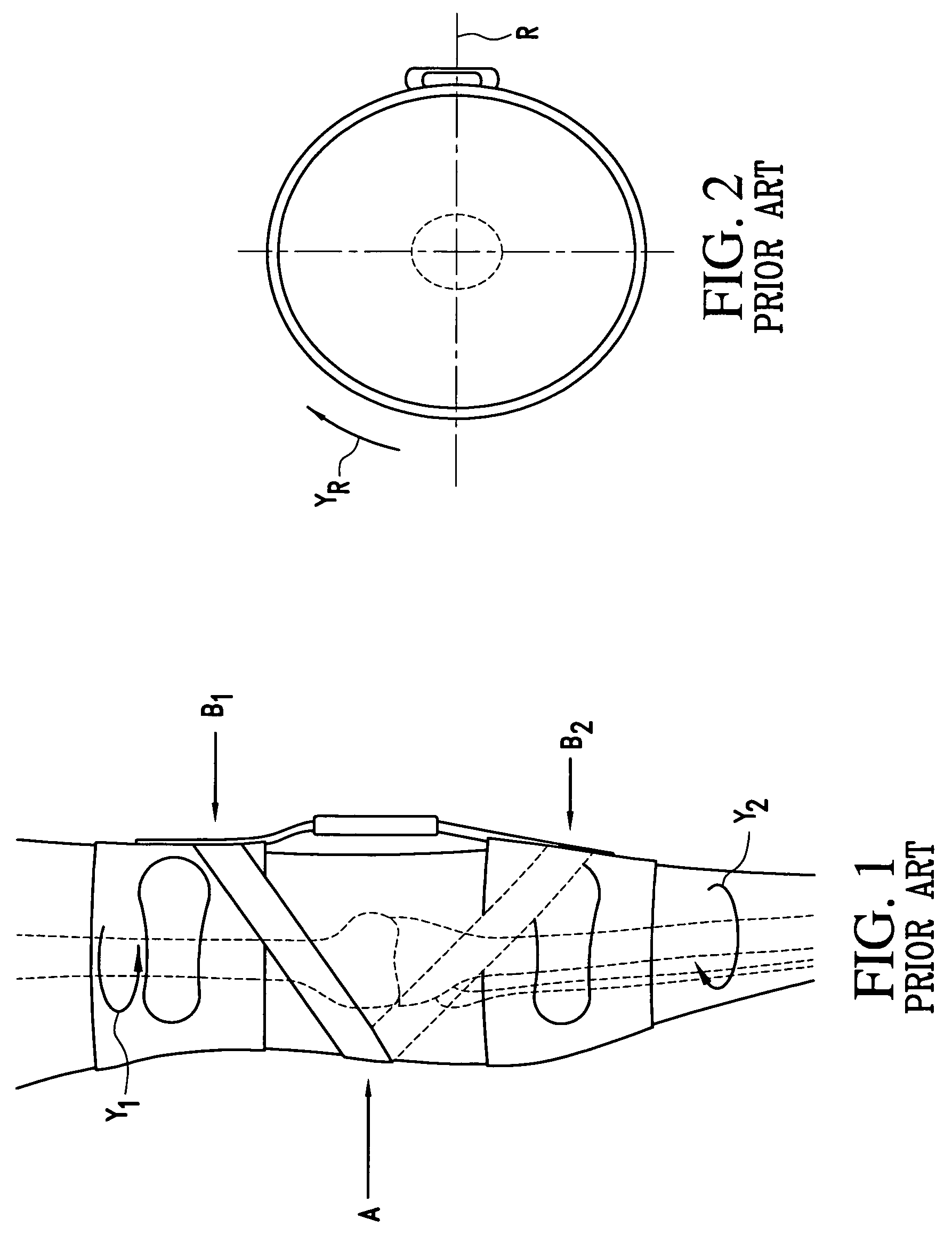

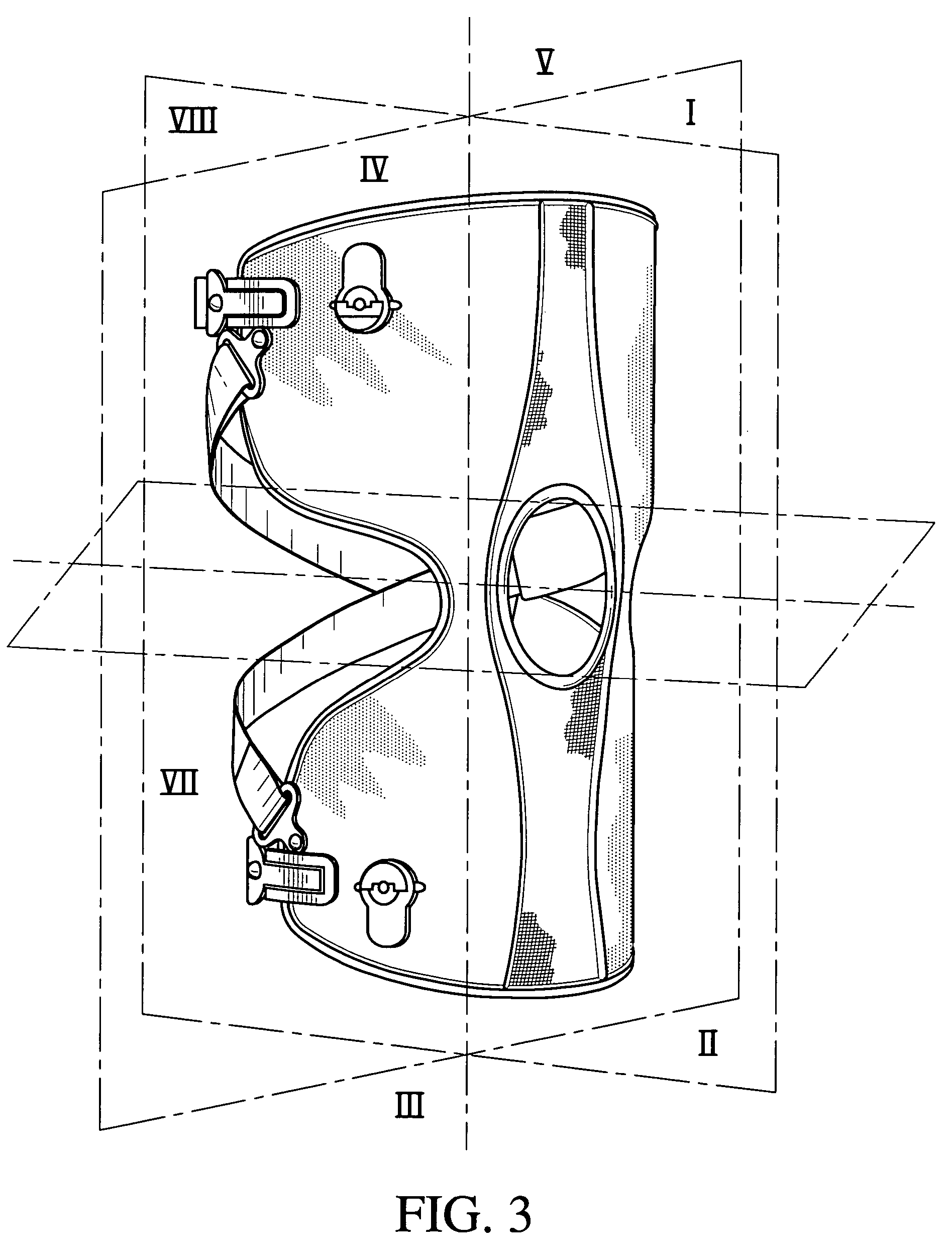

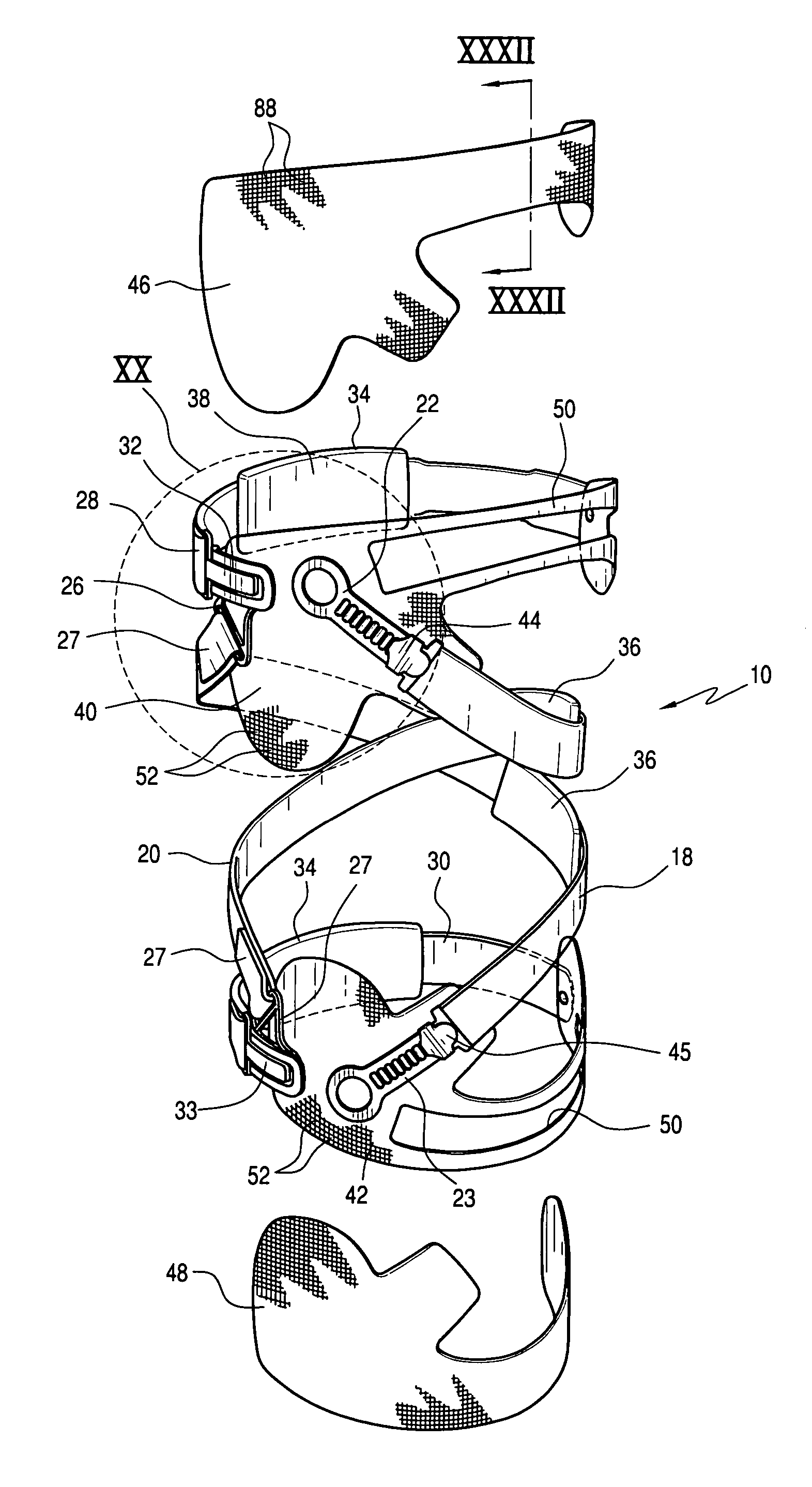

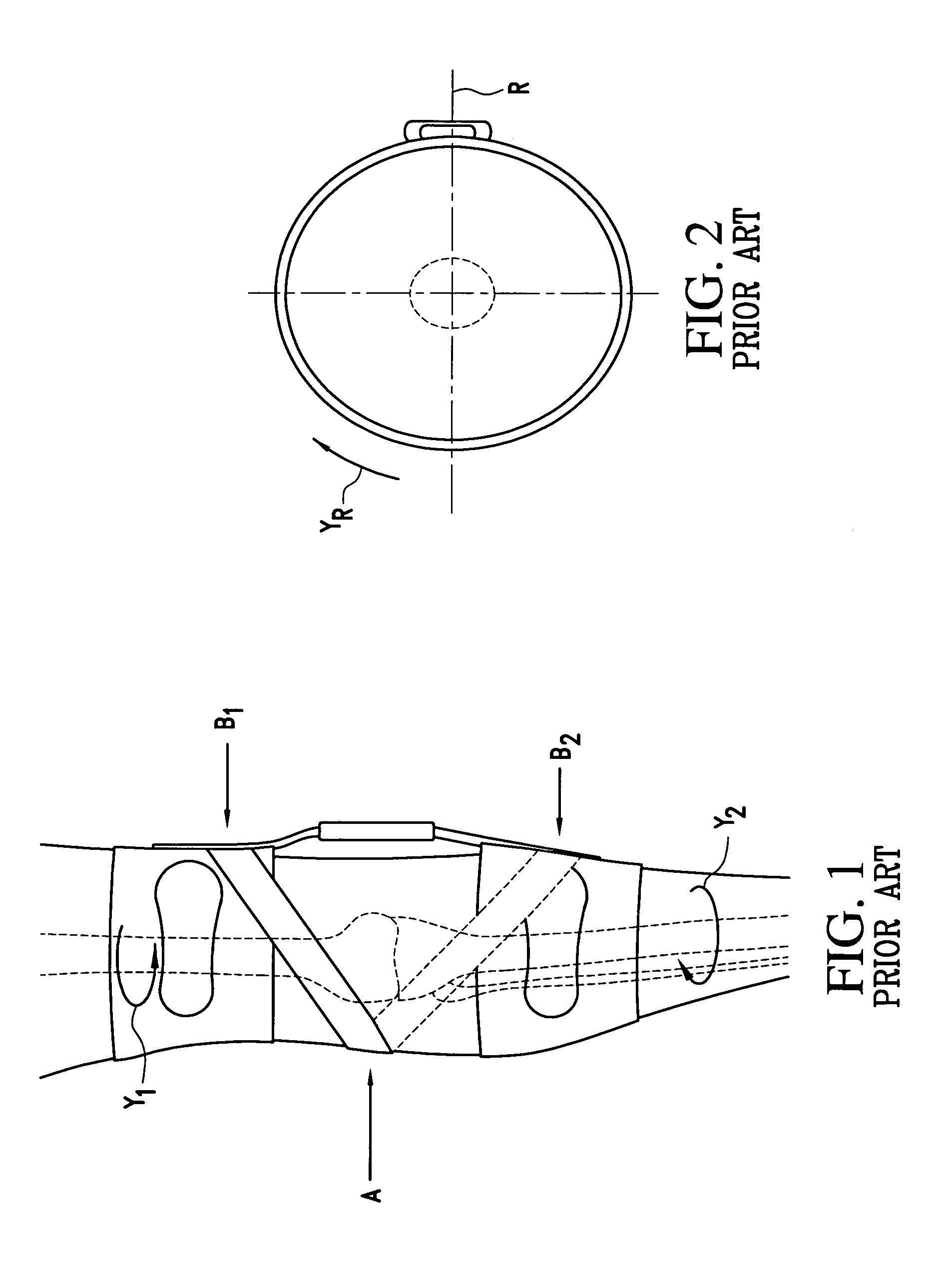

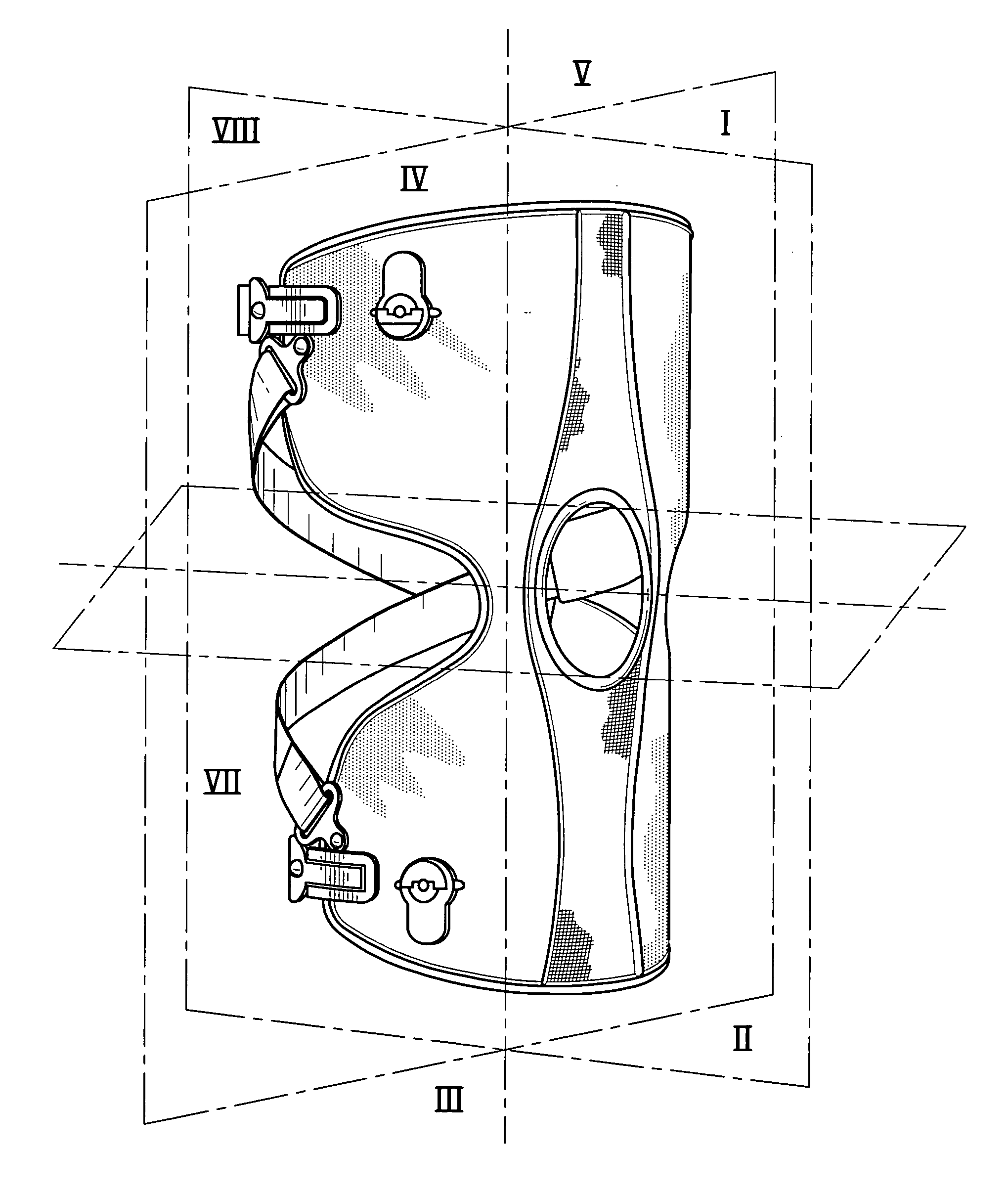

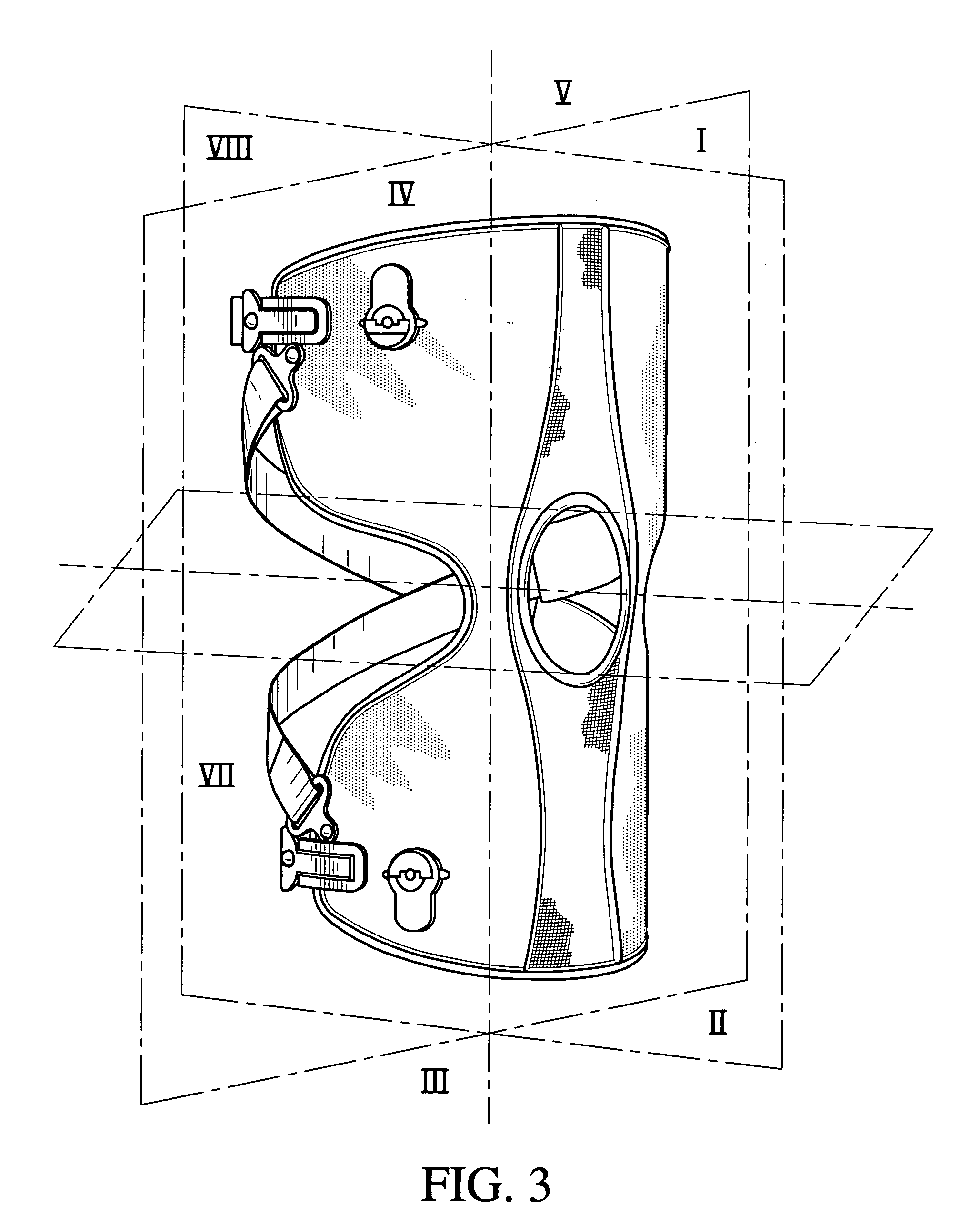

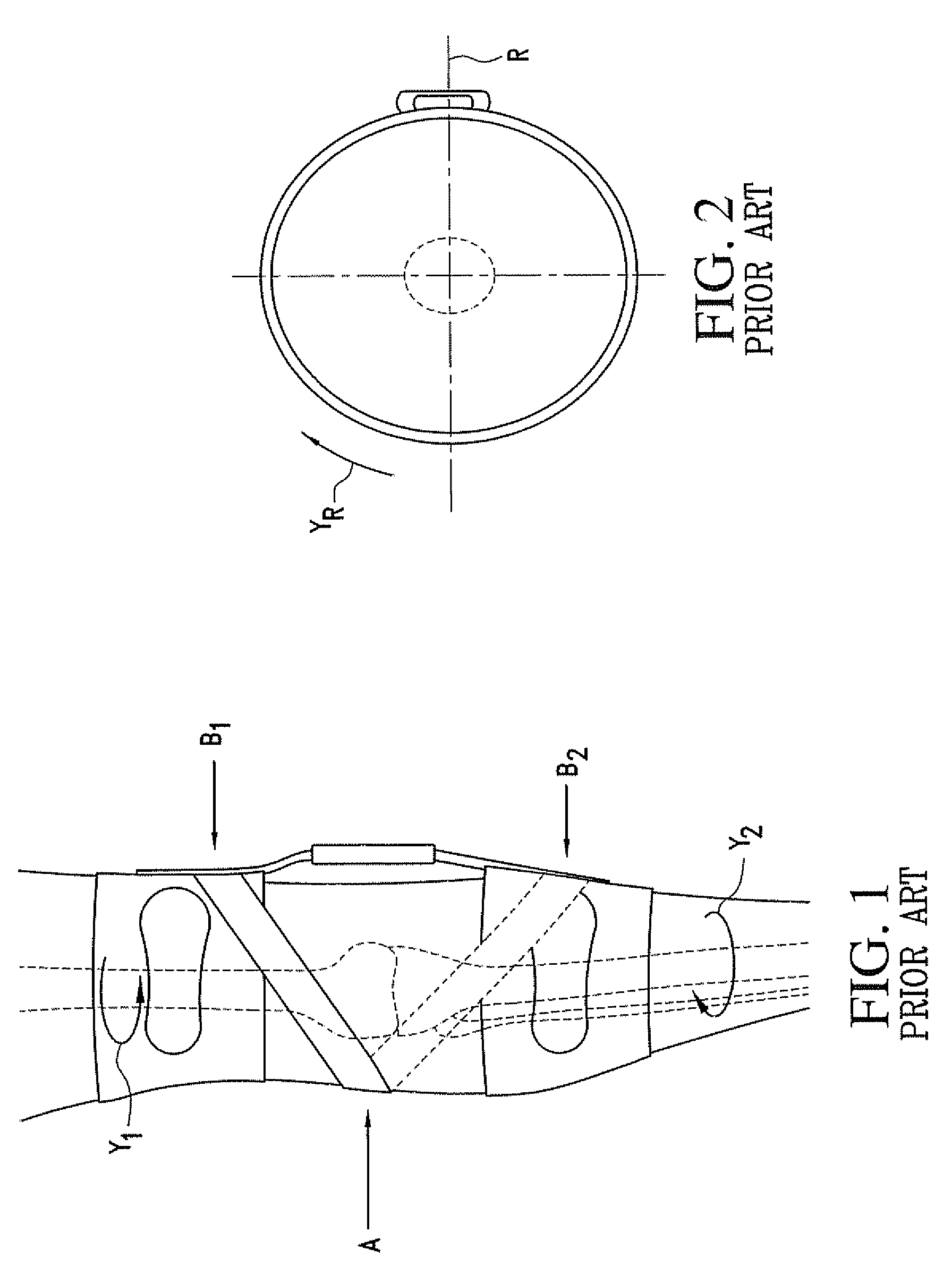

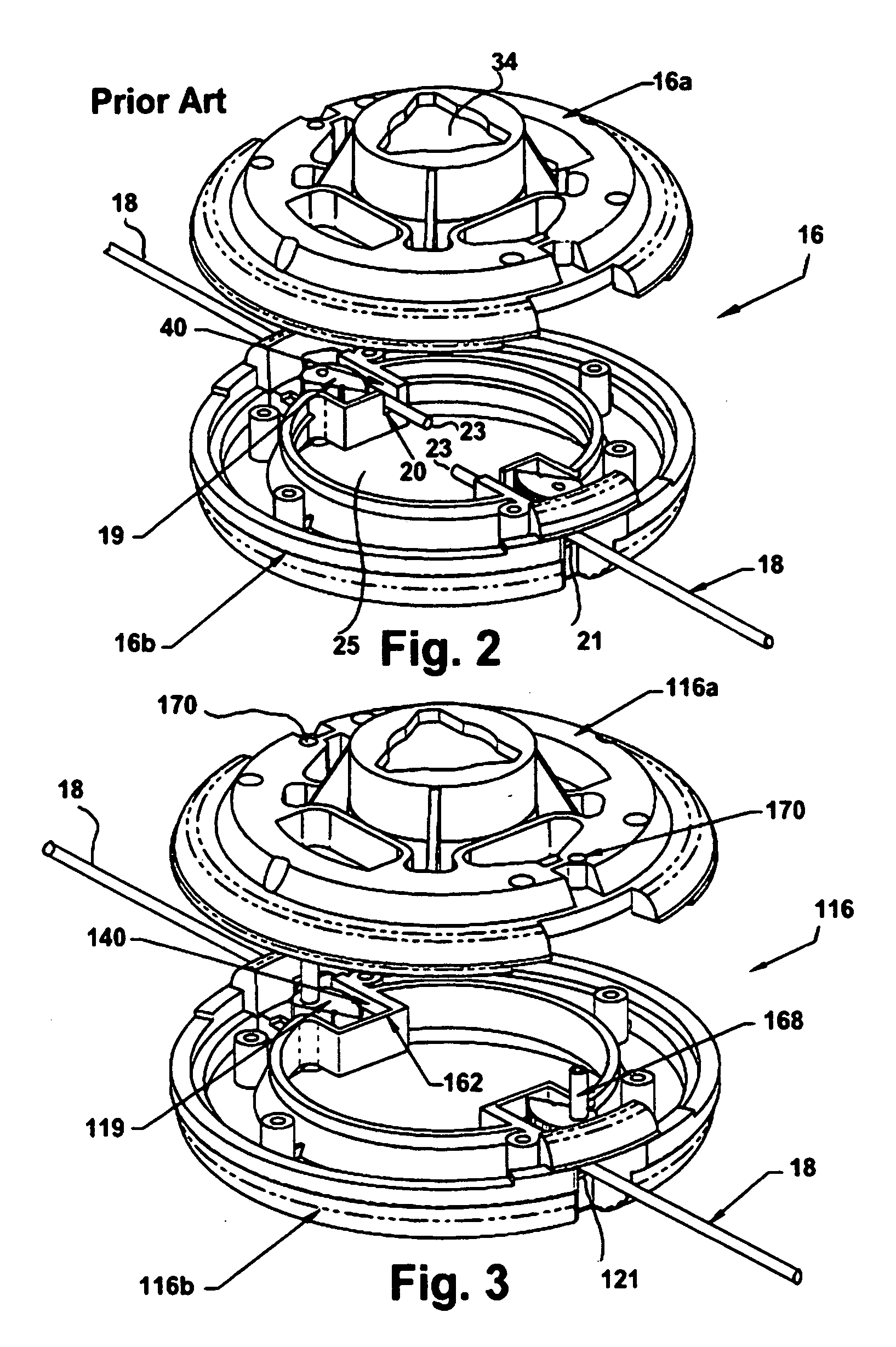

Knee brace and method for securing the same

ActiveUS7198610B2Reduce impactMinimizing rotational forceNon-surgical orthopedic devicesMedicineKnee braces

Owner:OSSUR HF

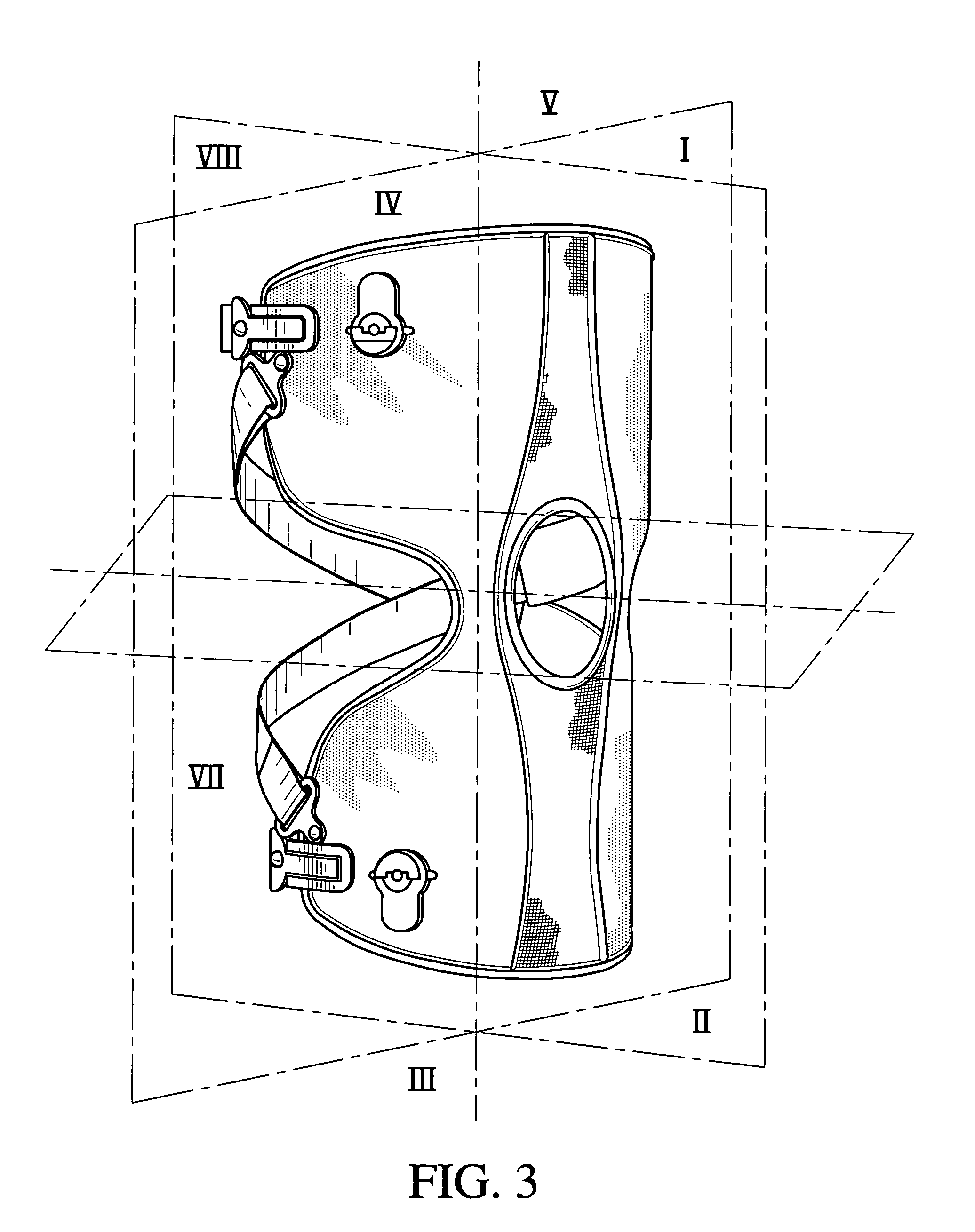

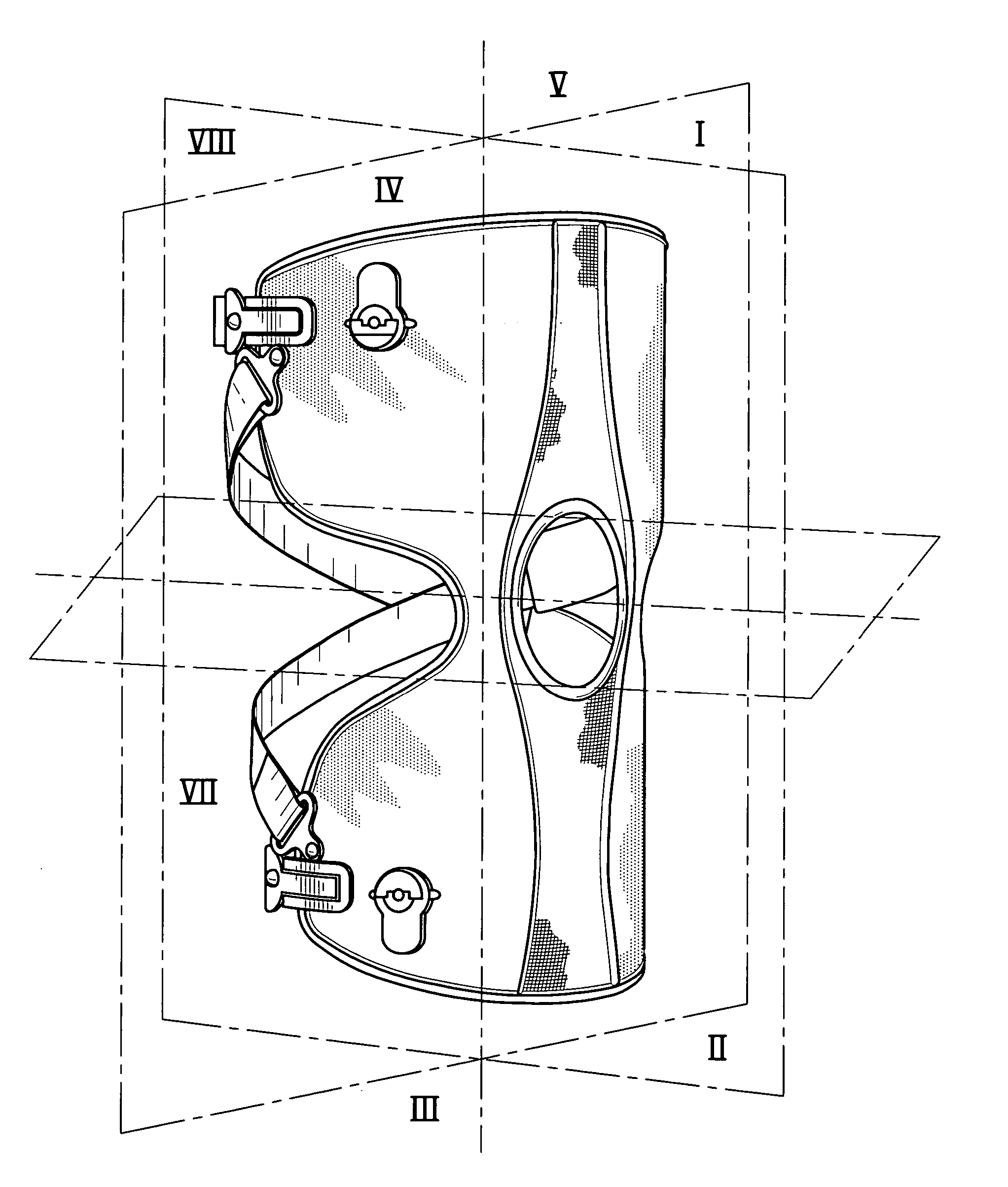

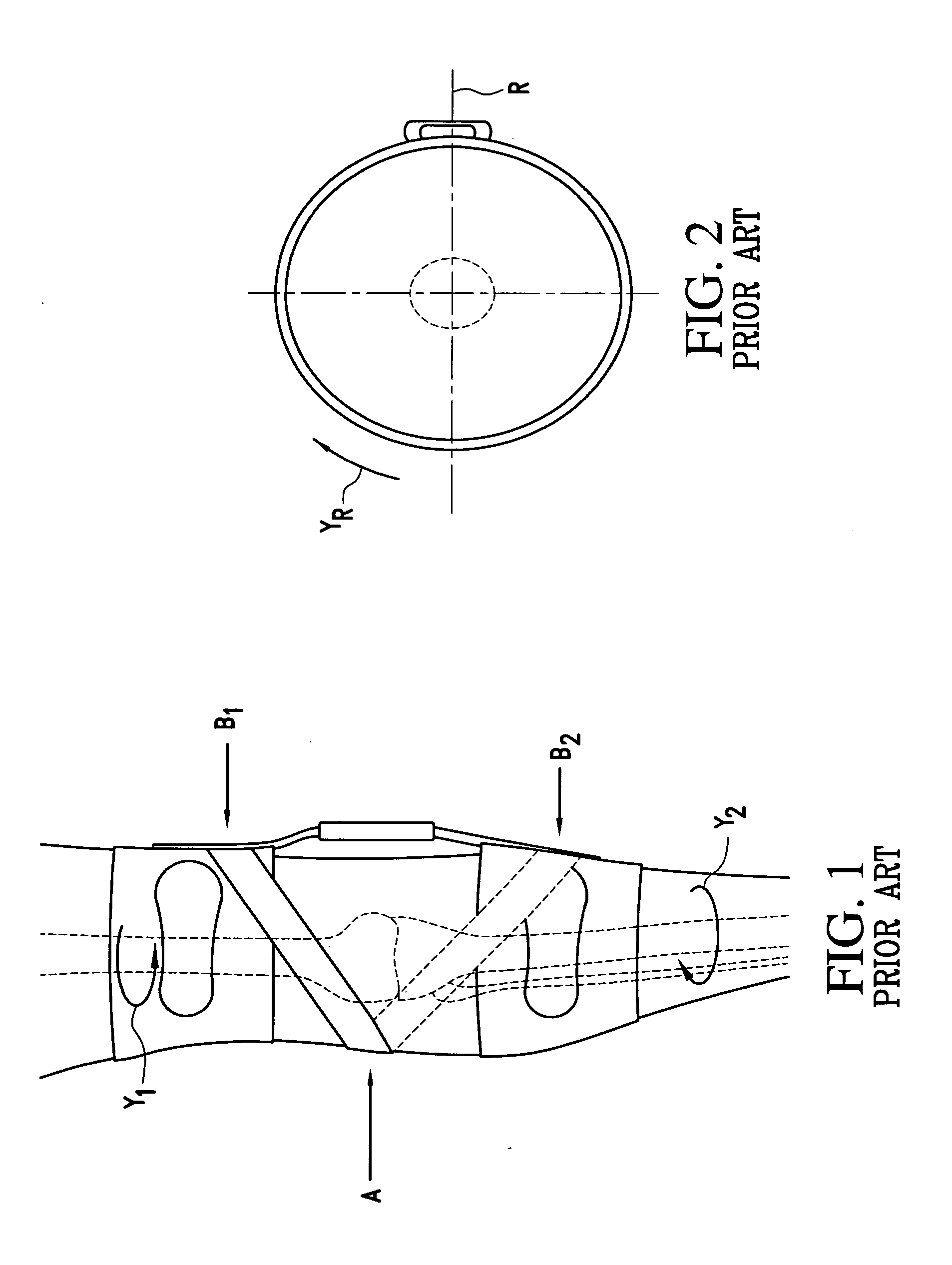

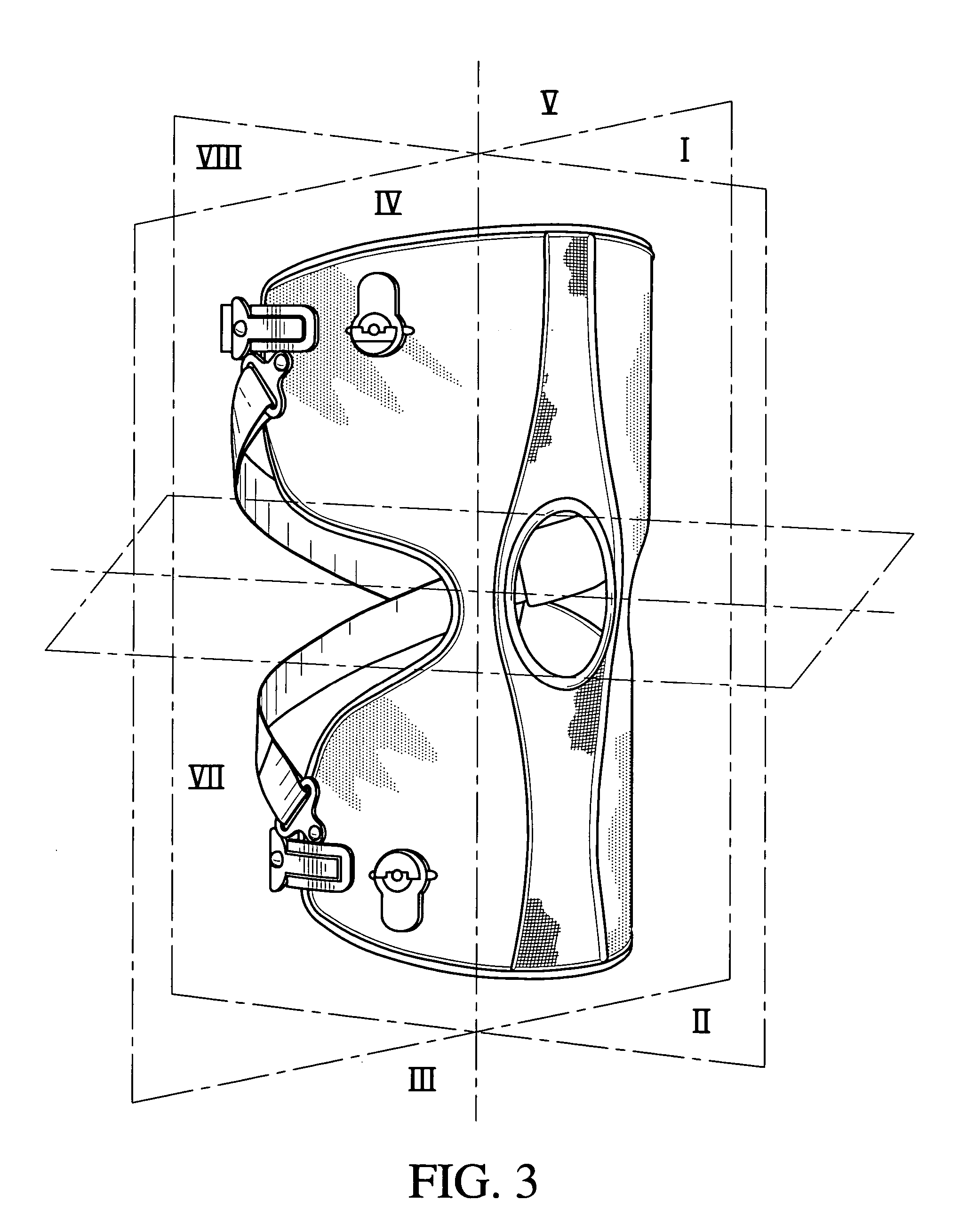

Knee brace and method for securing the same

ActiveUS7597675B2Reduce impactMinimizing rotational forceNon-surgical orthopedic devicesPhysical medicine and rehabilitationKnee braces

Owner:KAUPTHING BANK

Knee brace and method for securing the same

ActiveUS7896827B2Reduce impactMinimizing rotational forceFeet bandagesNon-surgical orthopedic devicesDistal portionPhysical therapy

Owner:KAUPTHING BANK

Knee brace and method for securing the same

ActiveUS20060135902A1Reduce impactMinimizing rotational forceFeet bandagesNon-surgical orthopedic devicesMedicineDistal portion

Owner:KAUPTHING BANK

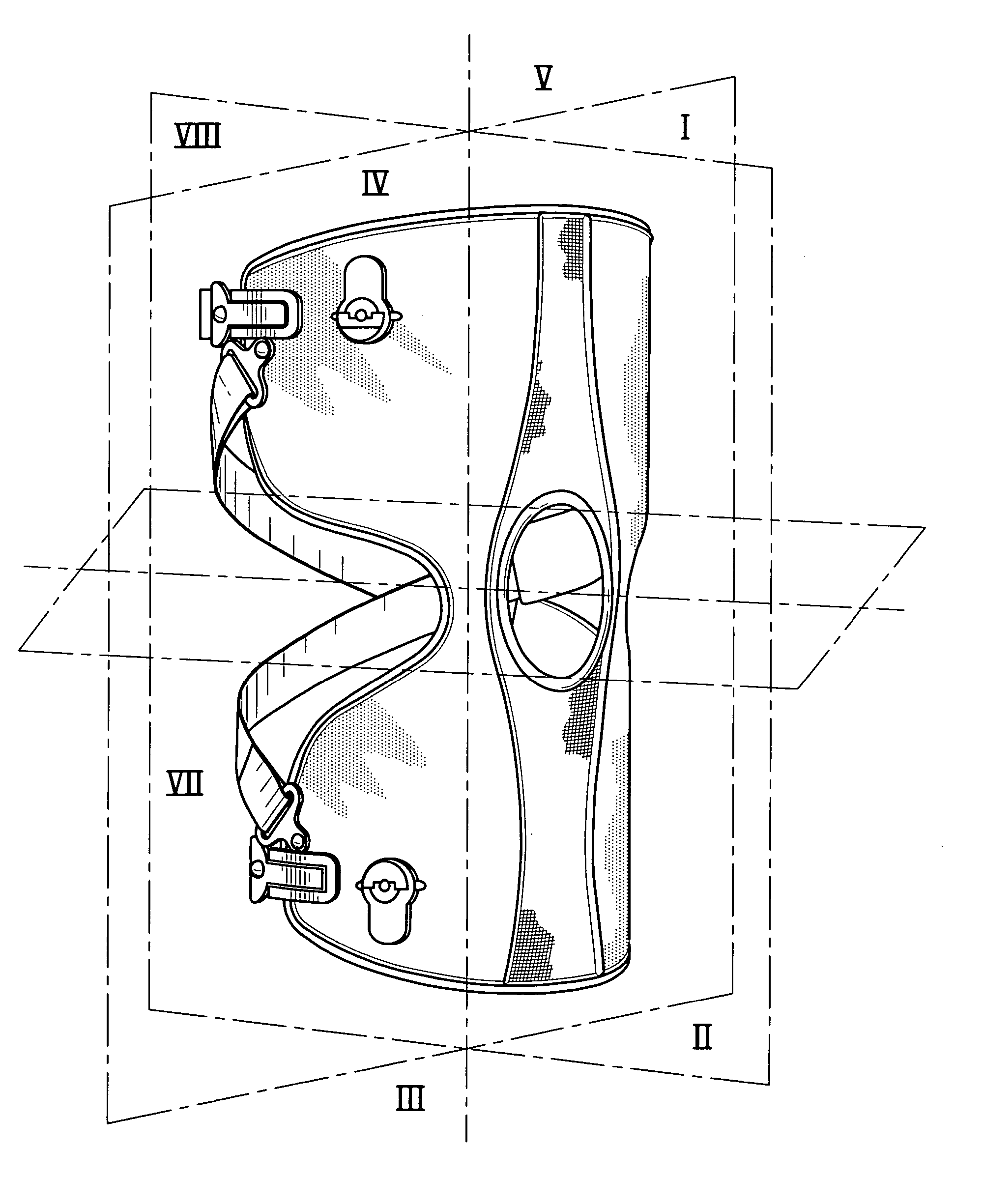

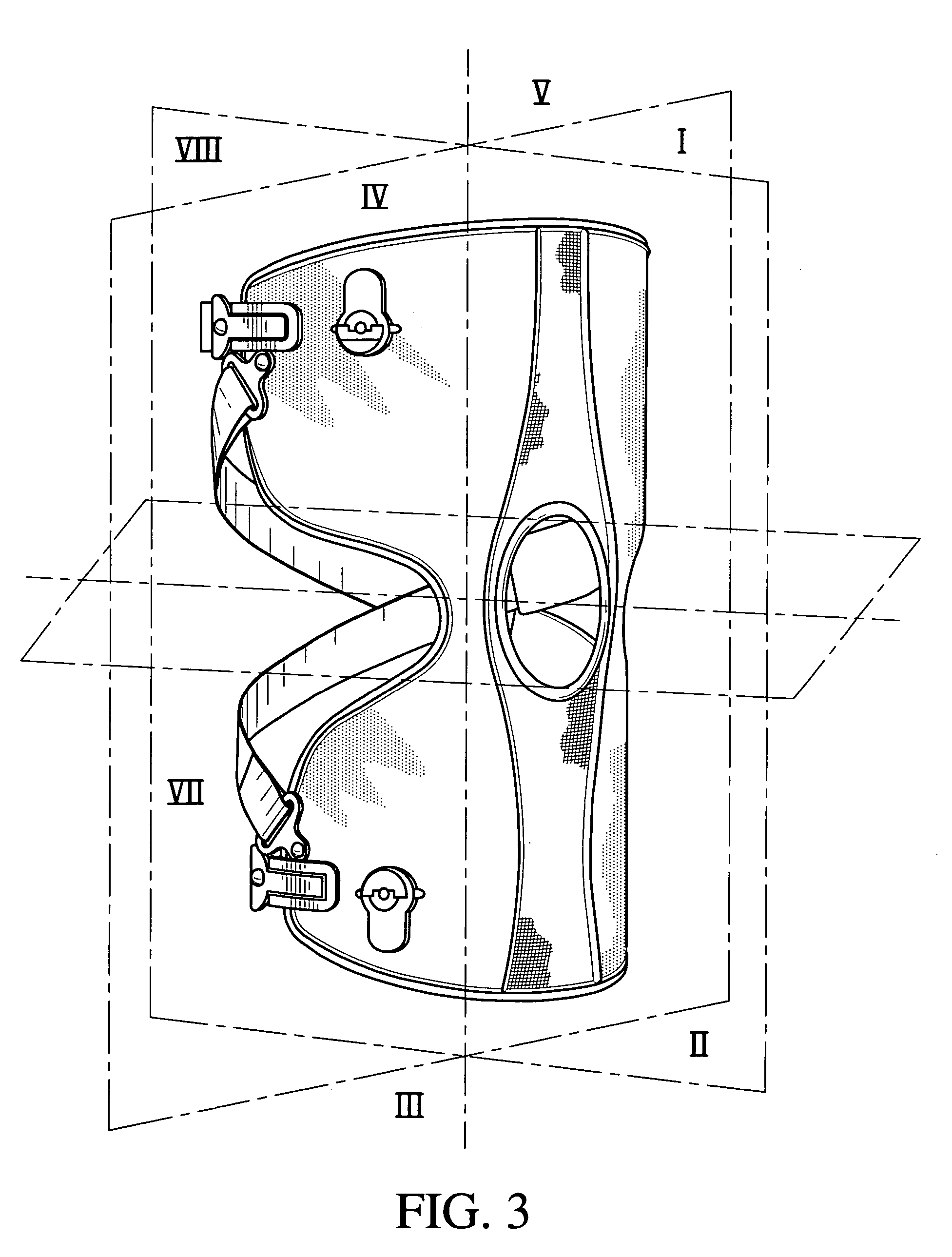

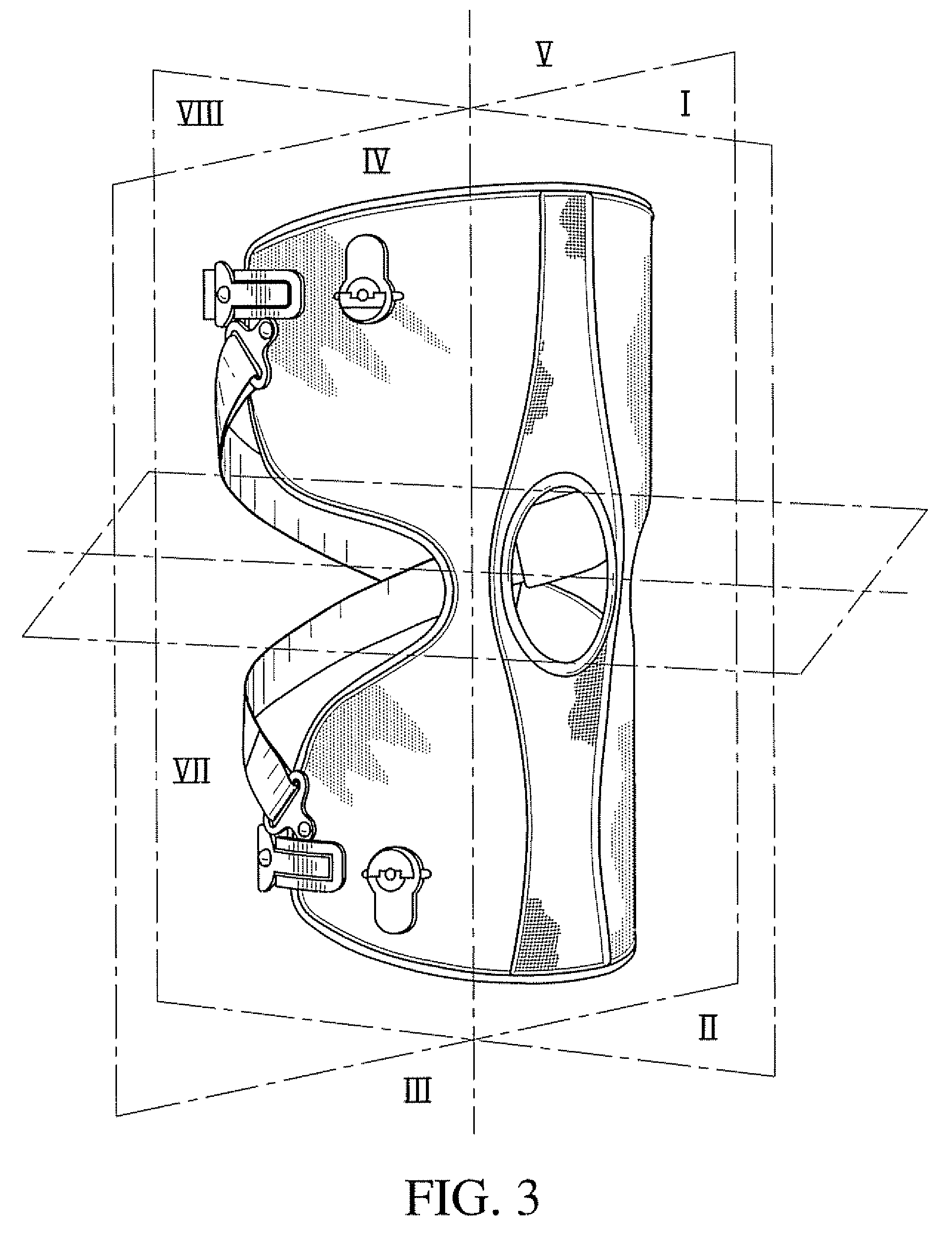

Knee brace and method for securing the same

ActiveUS20060135901A1Reduce the impactMinimizing rotational forceNon-surgical orthopedic devicesMedian planeKnee braces

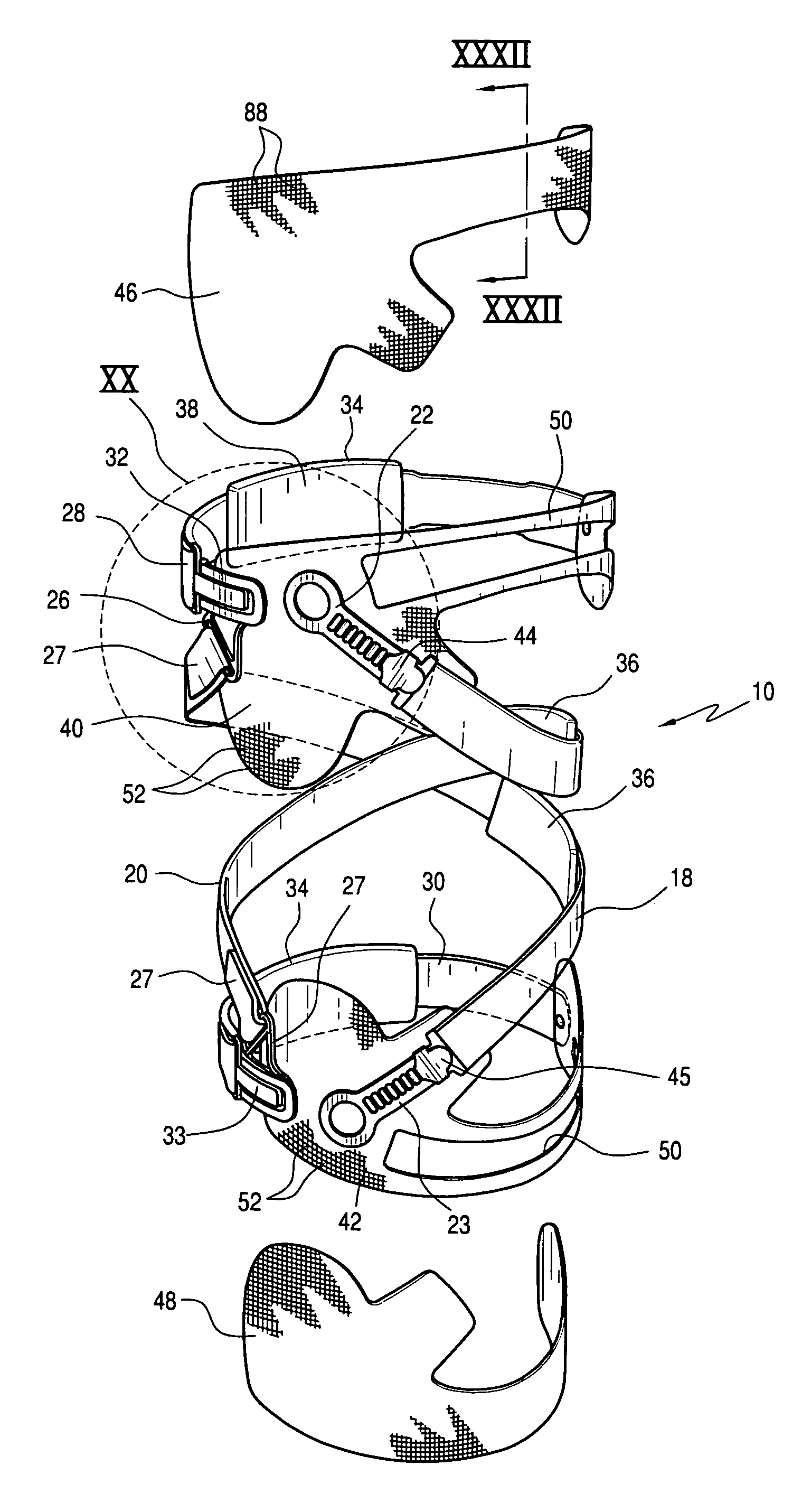

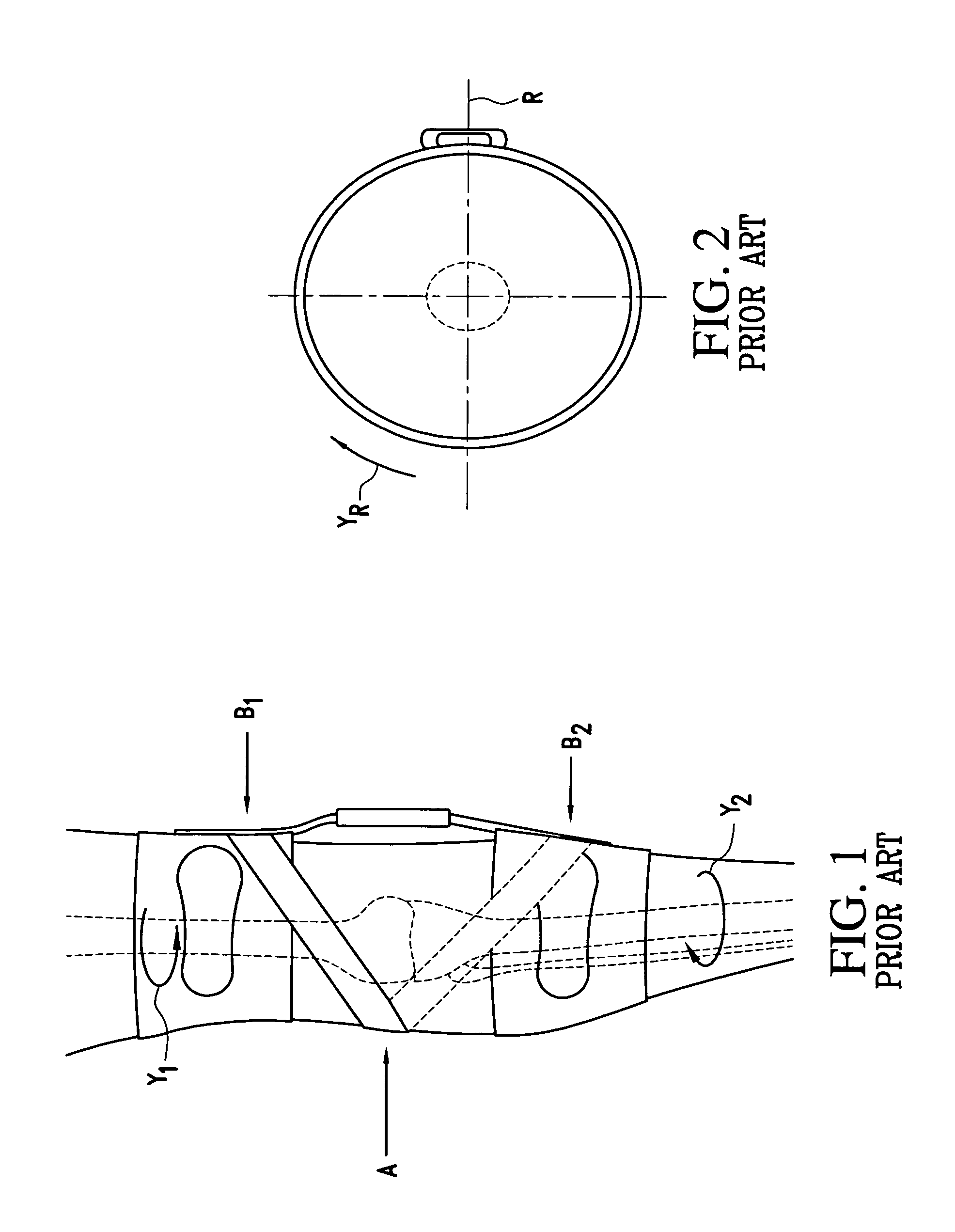

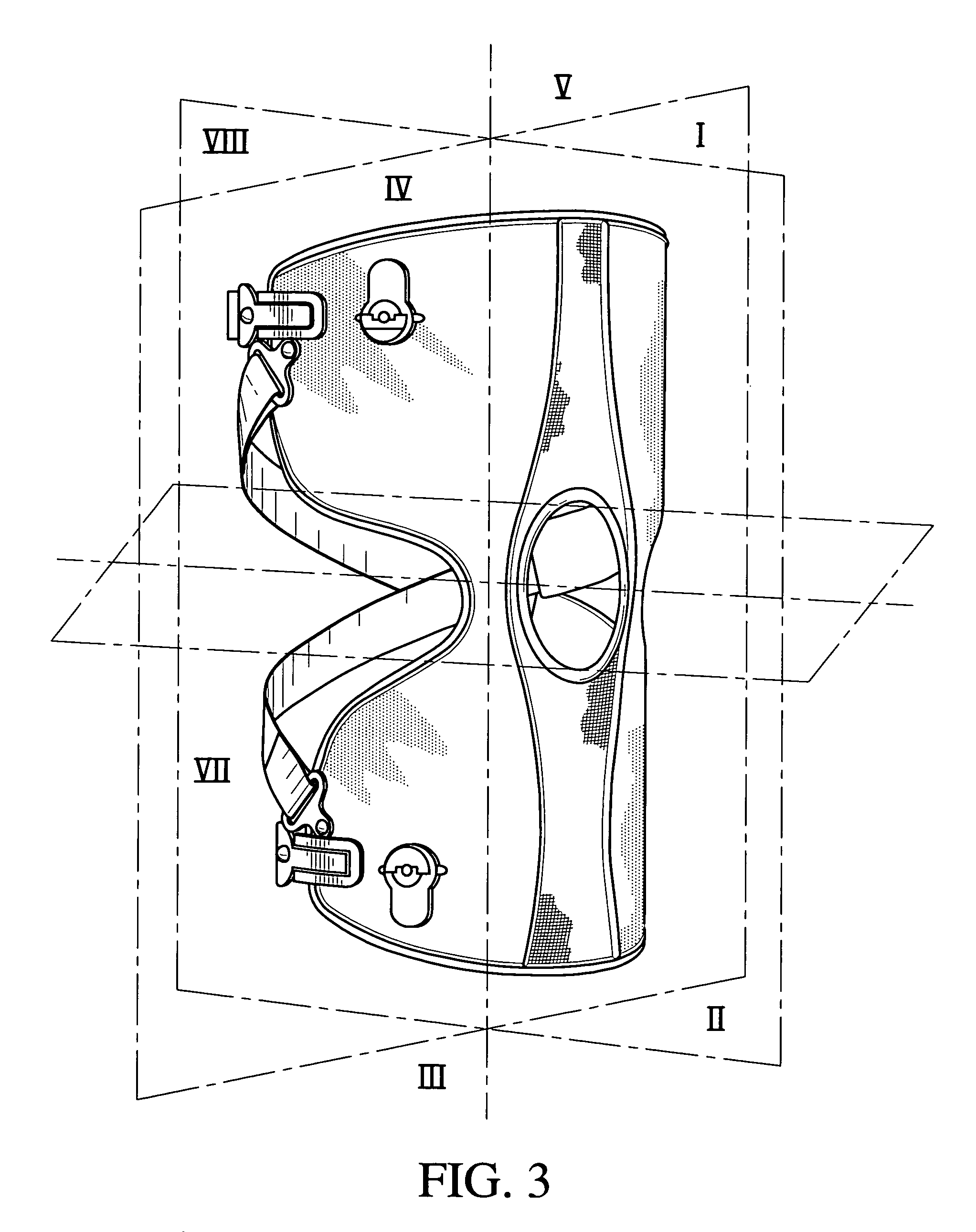

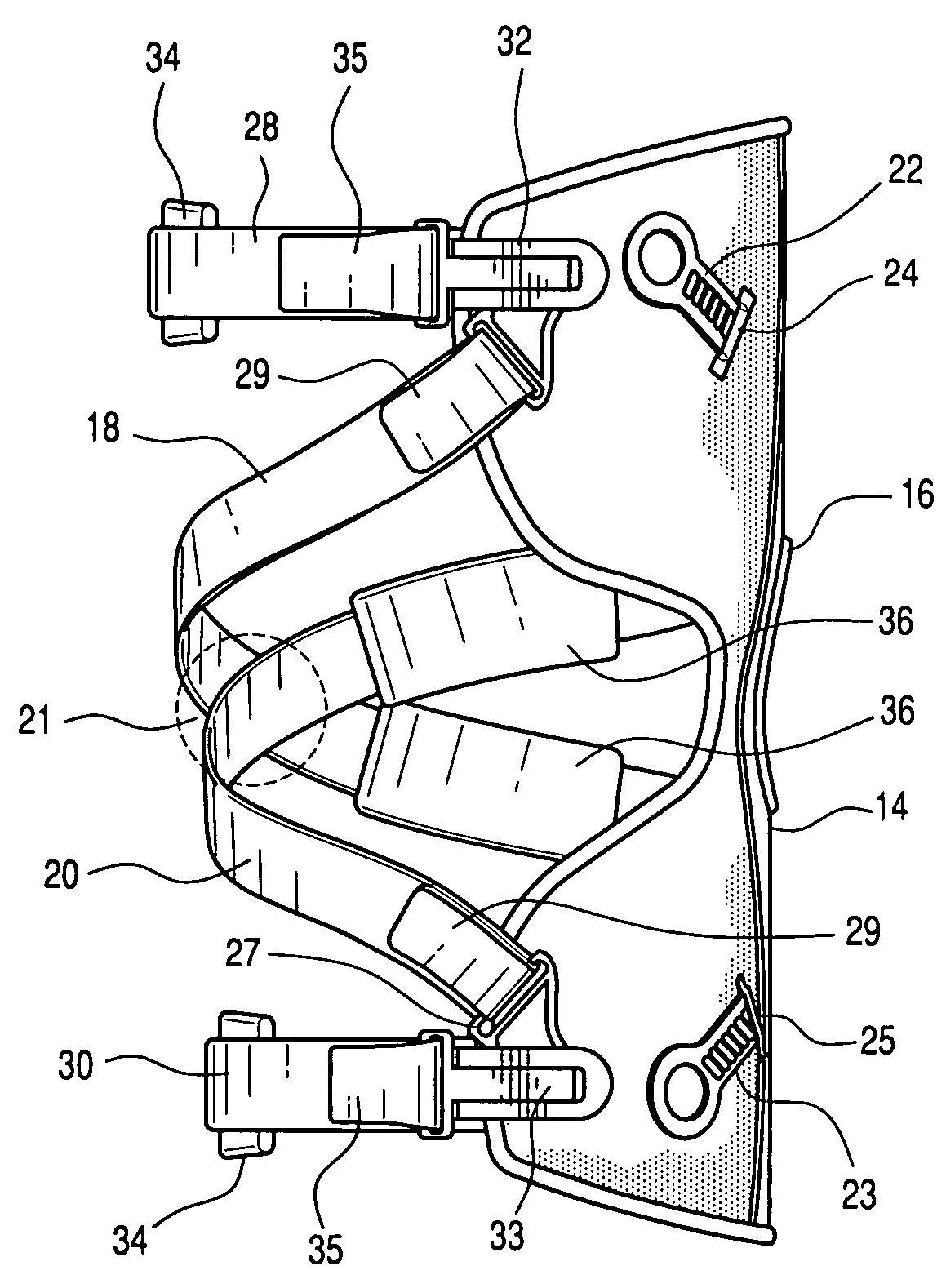

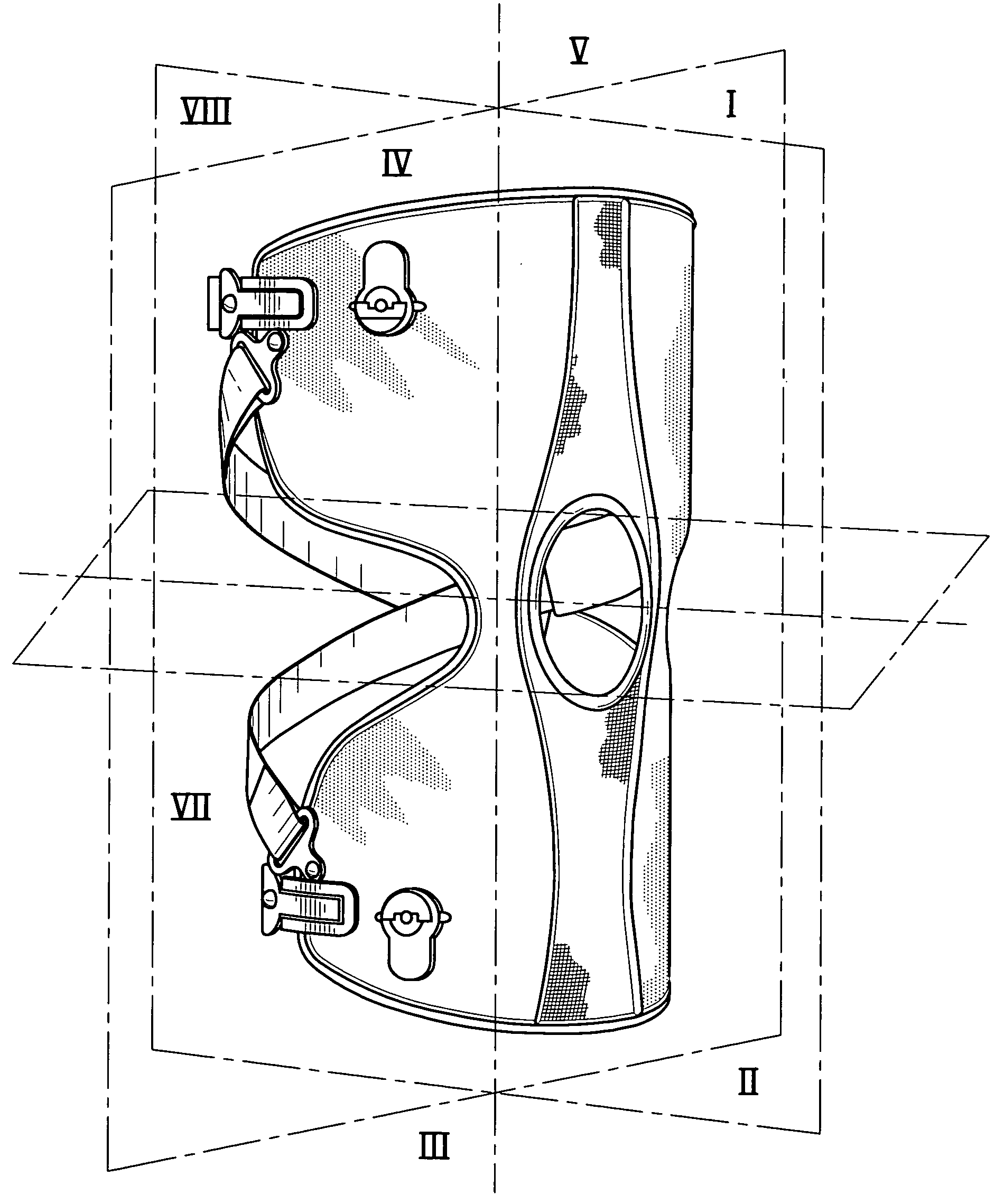

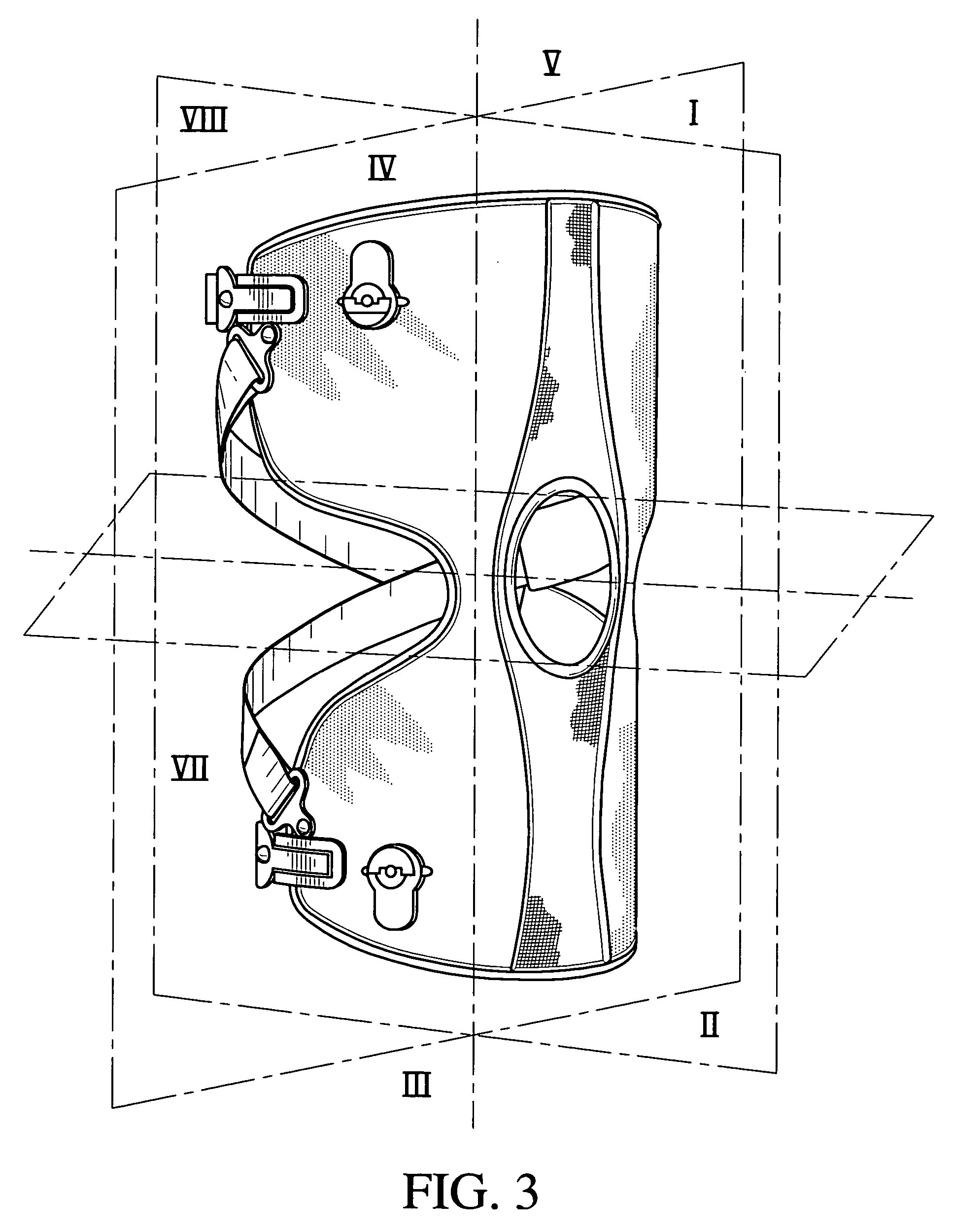

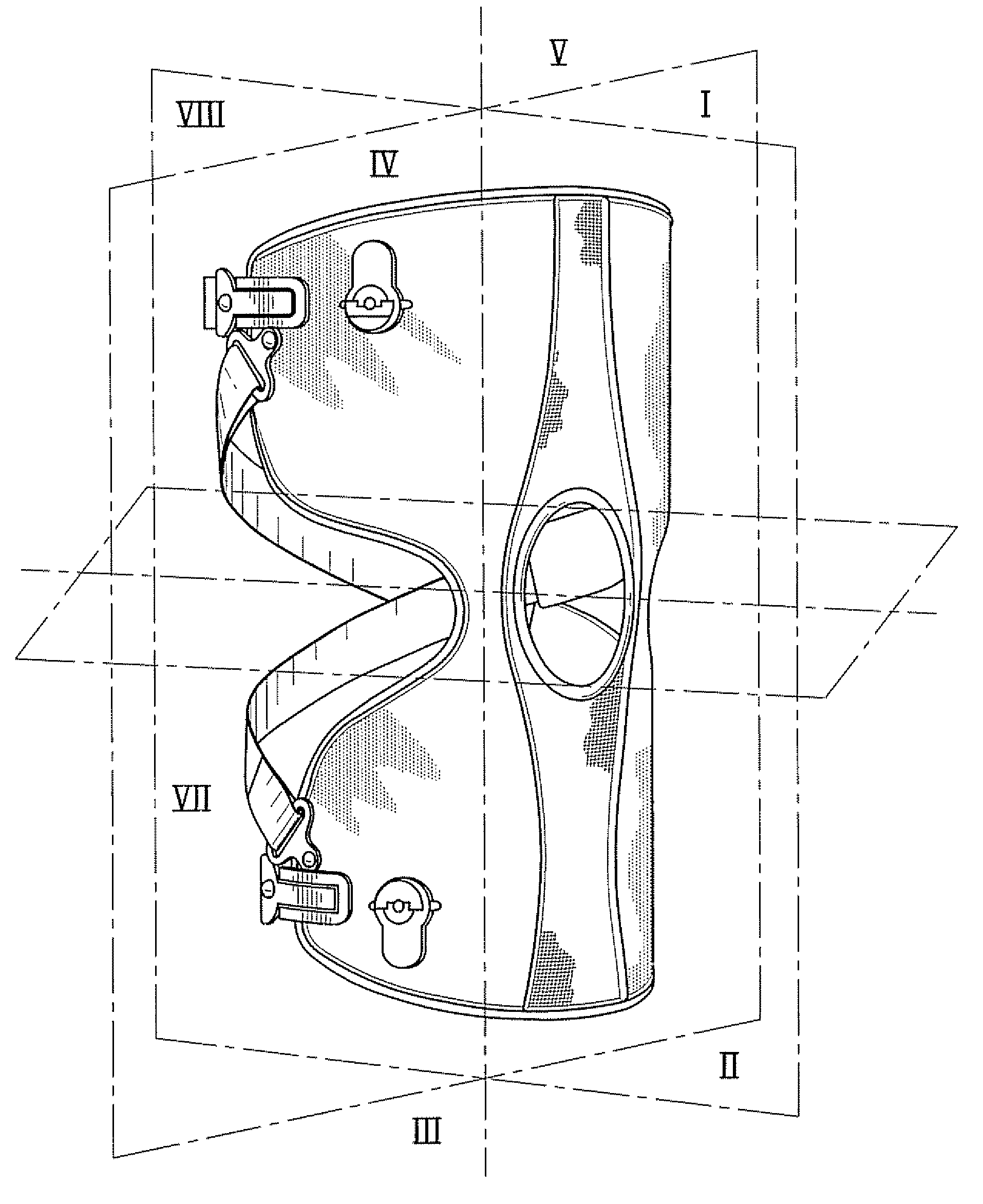

A knee brace divided into anterior and posterior sides by a frontal plane, and having first and second sides divided by a median plane. The knee brace having a frame, and at least one cross strap that is connected to the frame and extends across over at least a portion of the first and second brace sides. The at least one cross strap is arranged obliquely relative to the median plane. The brace also includes a tightening mechanism that is connected to the frame and is configured to incrementally tension the at least one cross strap at predefined settings and to release tension on the at least one cross strap. A first end of the at least one cross strap engages the tightening mechanism. A dosage meter is connected to the frame, and includes an indication feature representing tension settings of the at least one cross strap.

Owner:KAUPTHING BANK

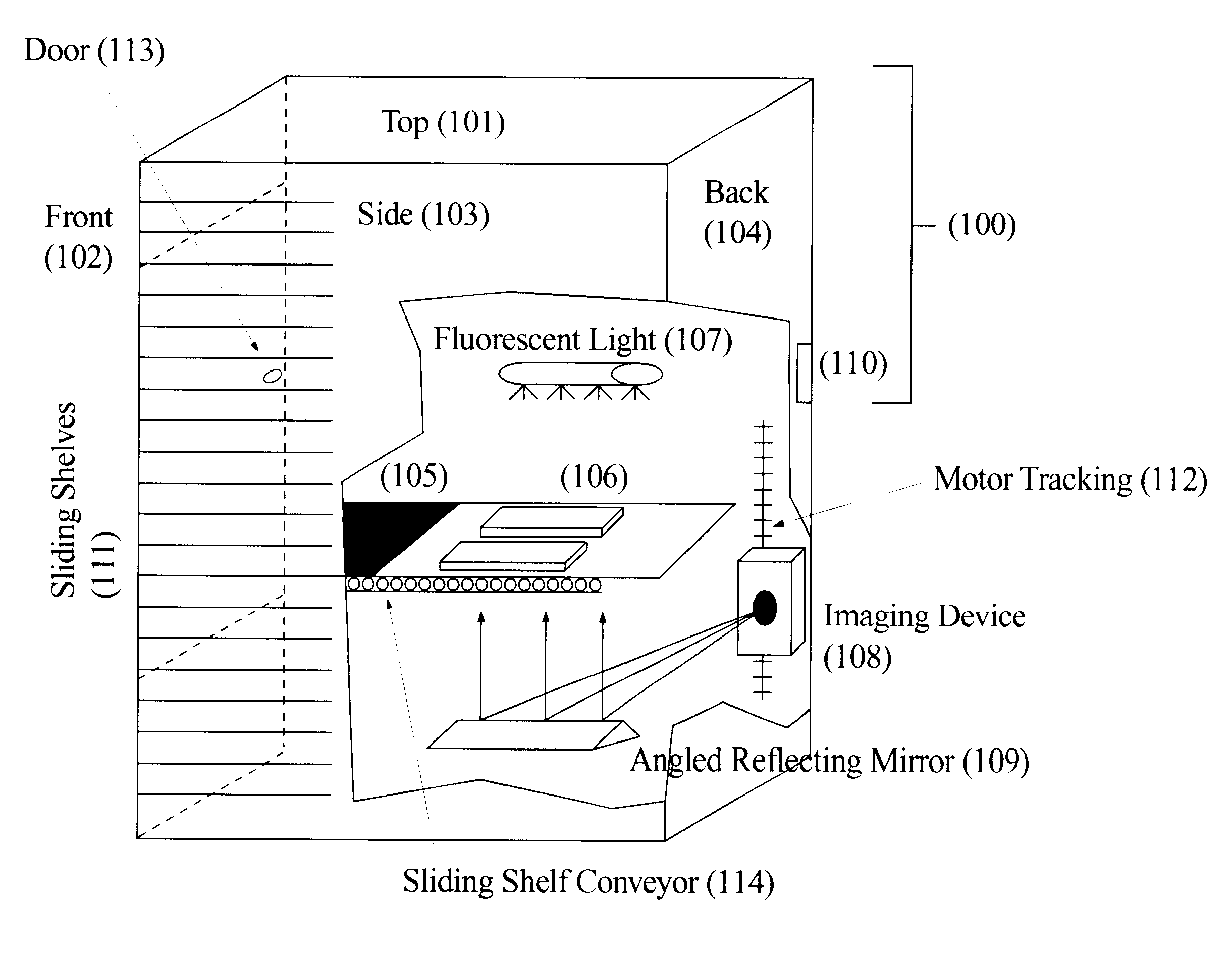

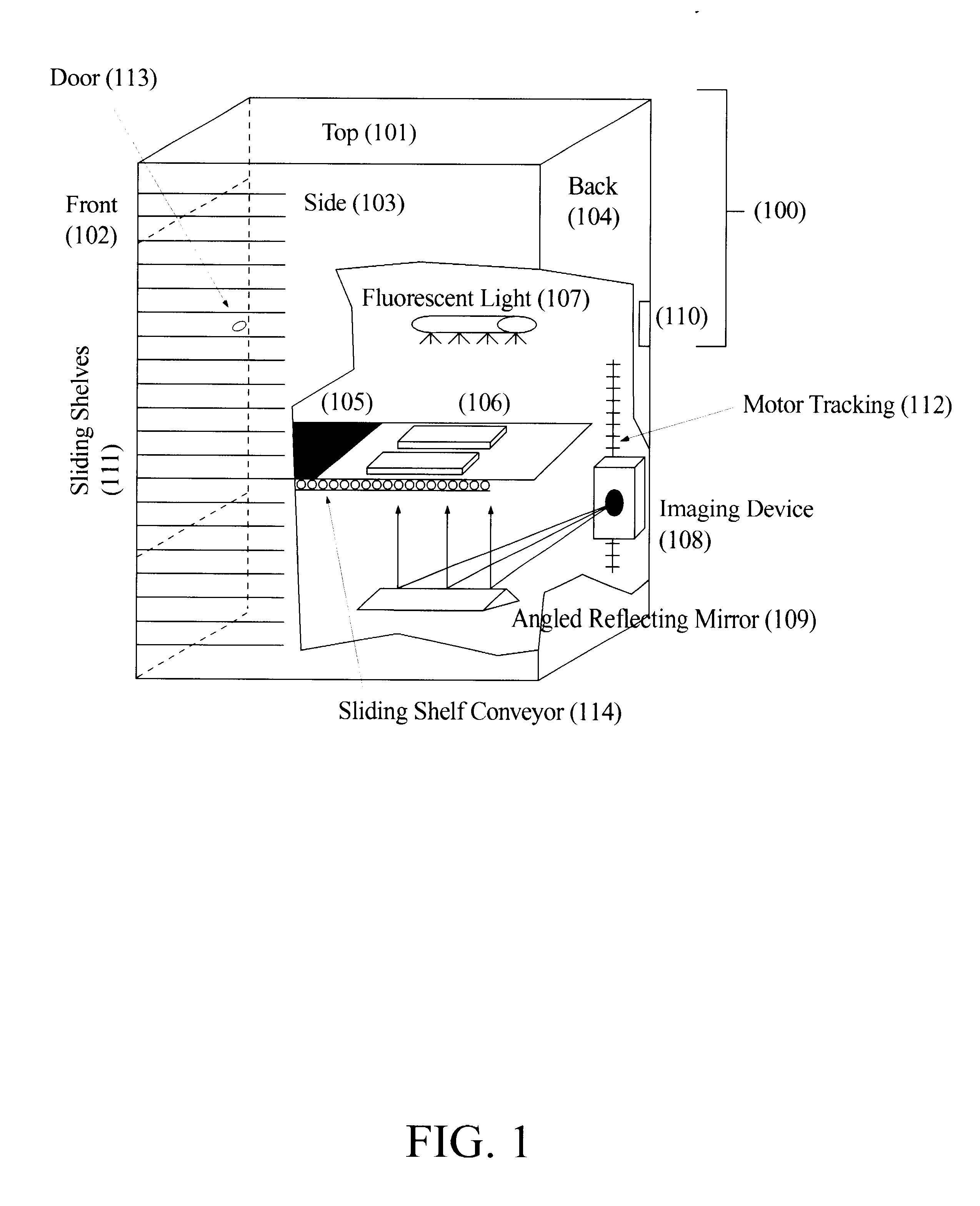

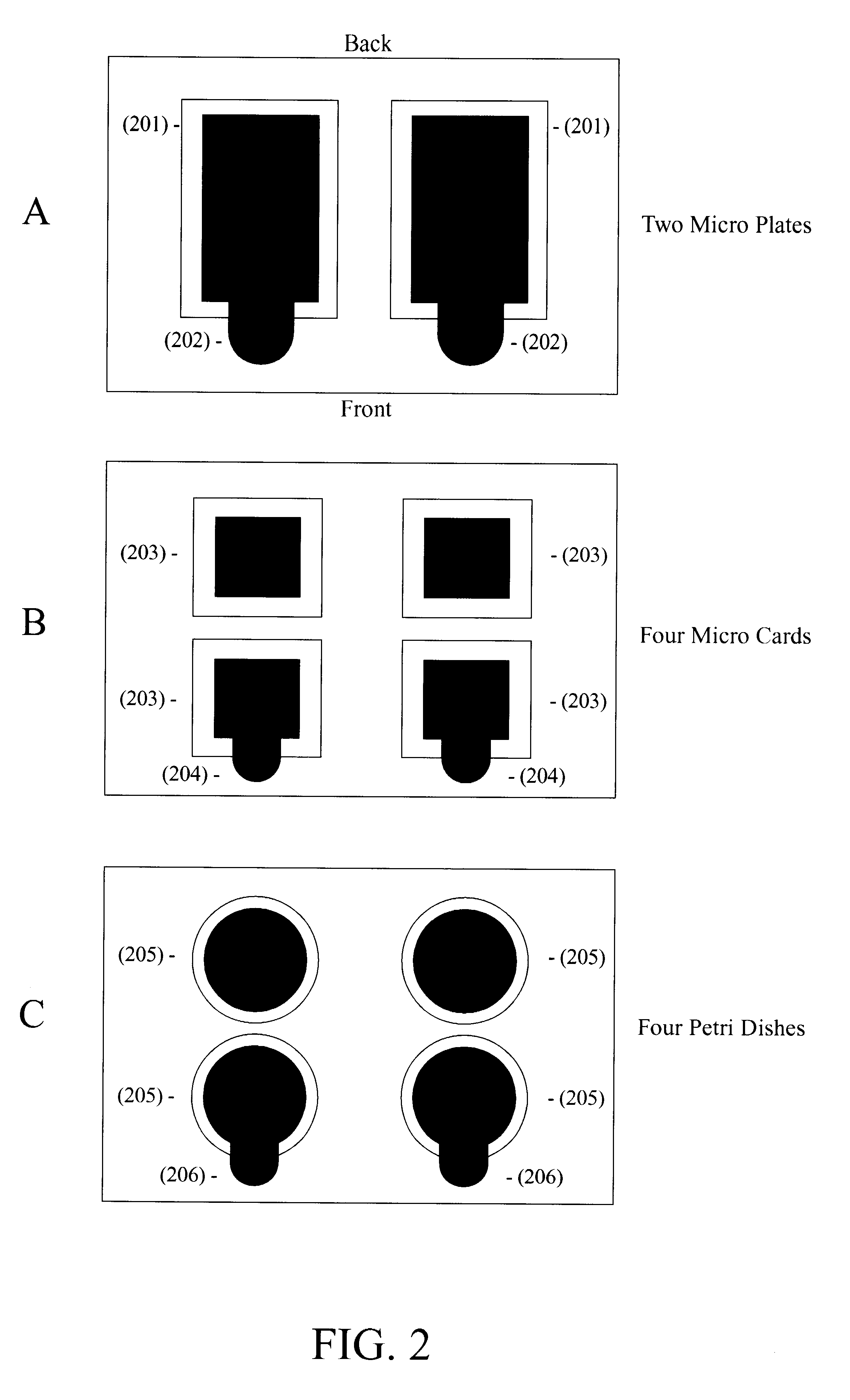

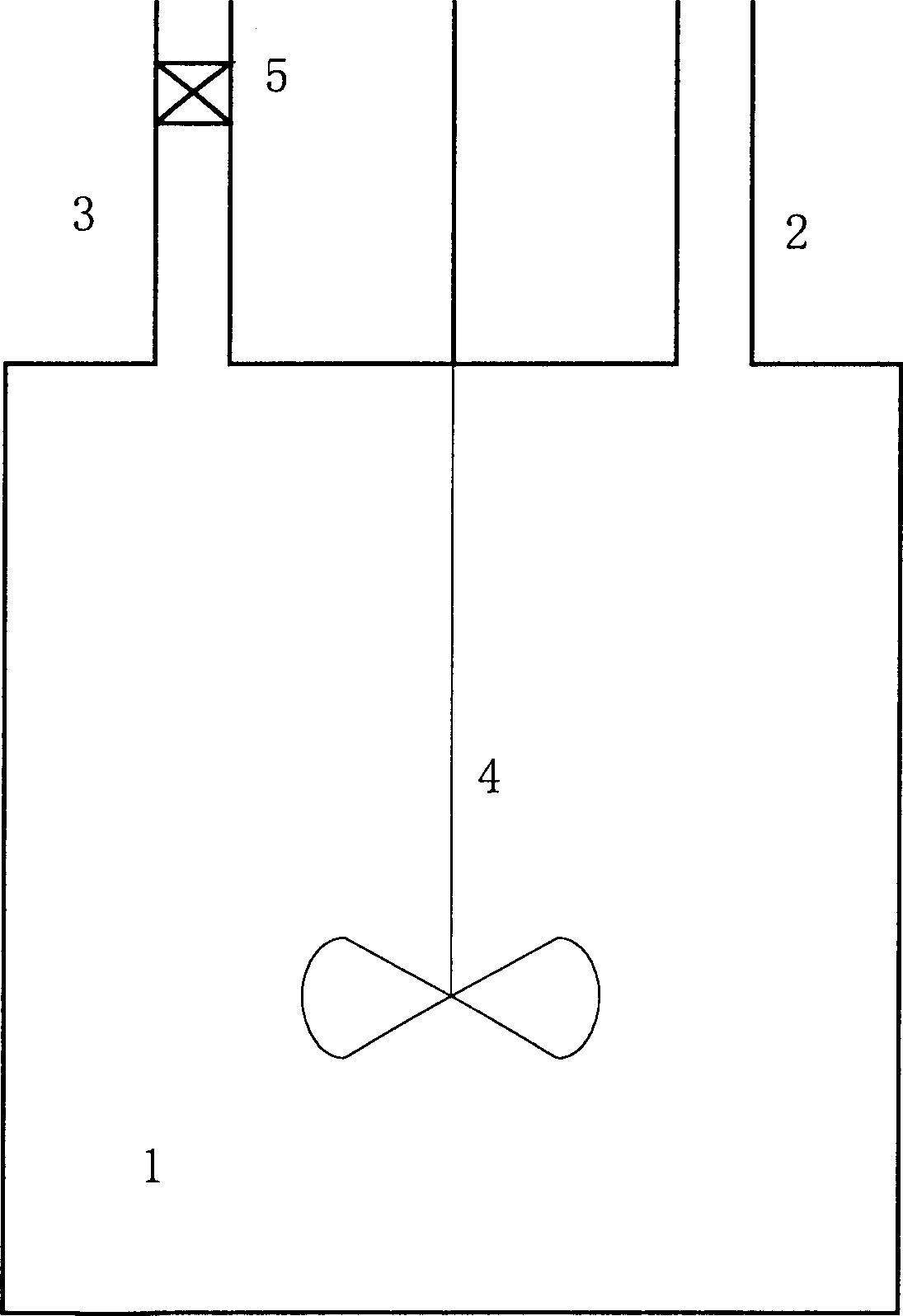

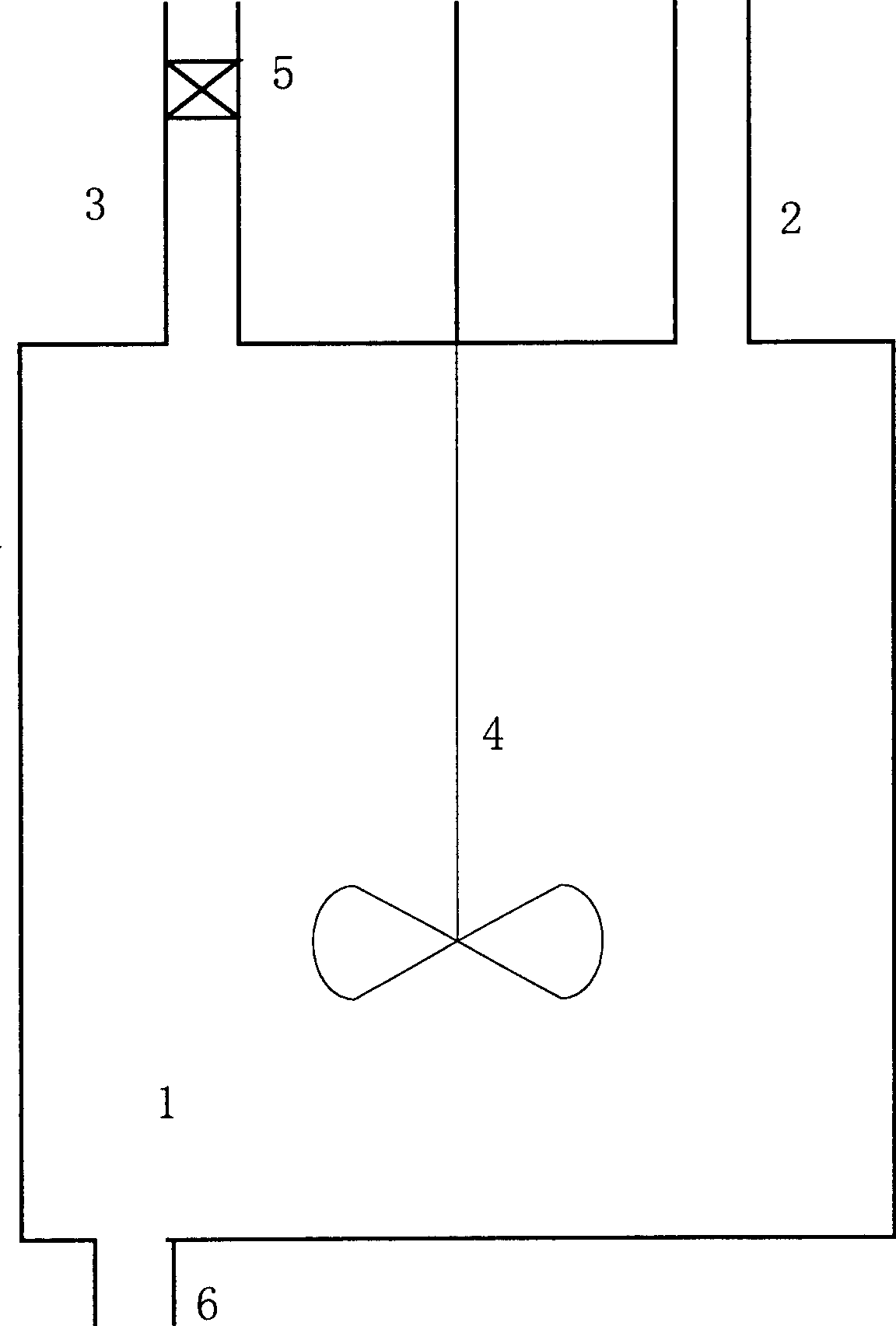

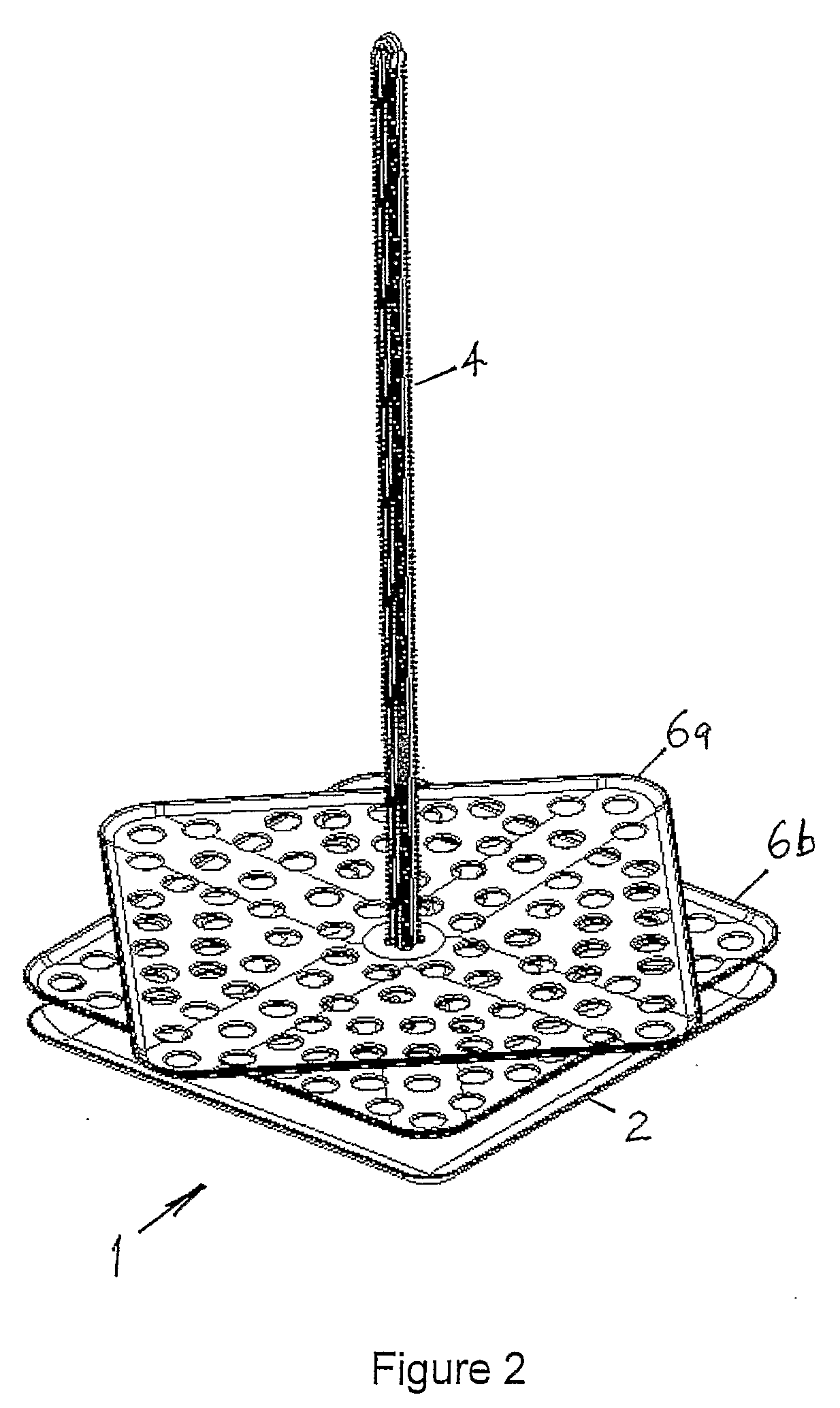

Device for incubating and monitoring multiwell assays

InactiveUS6271022B1Easy to unloadBioreactor/fermenter combinationsBiological substance pretreatmentsMicrotiter plateEngineering

Owner:BIOLOG

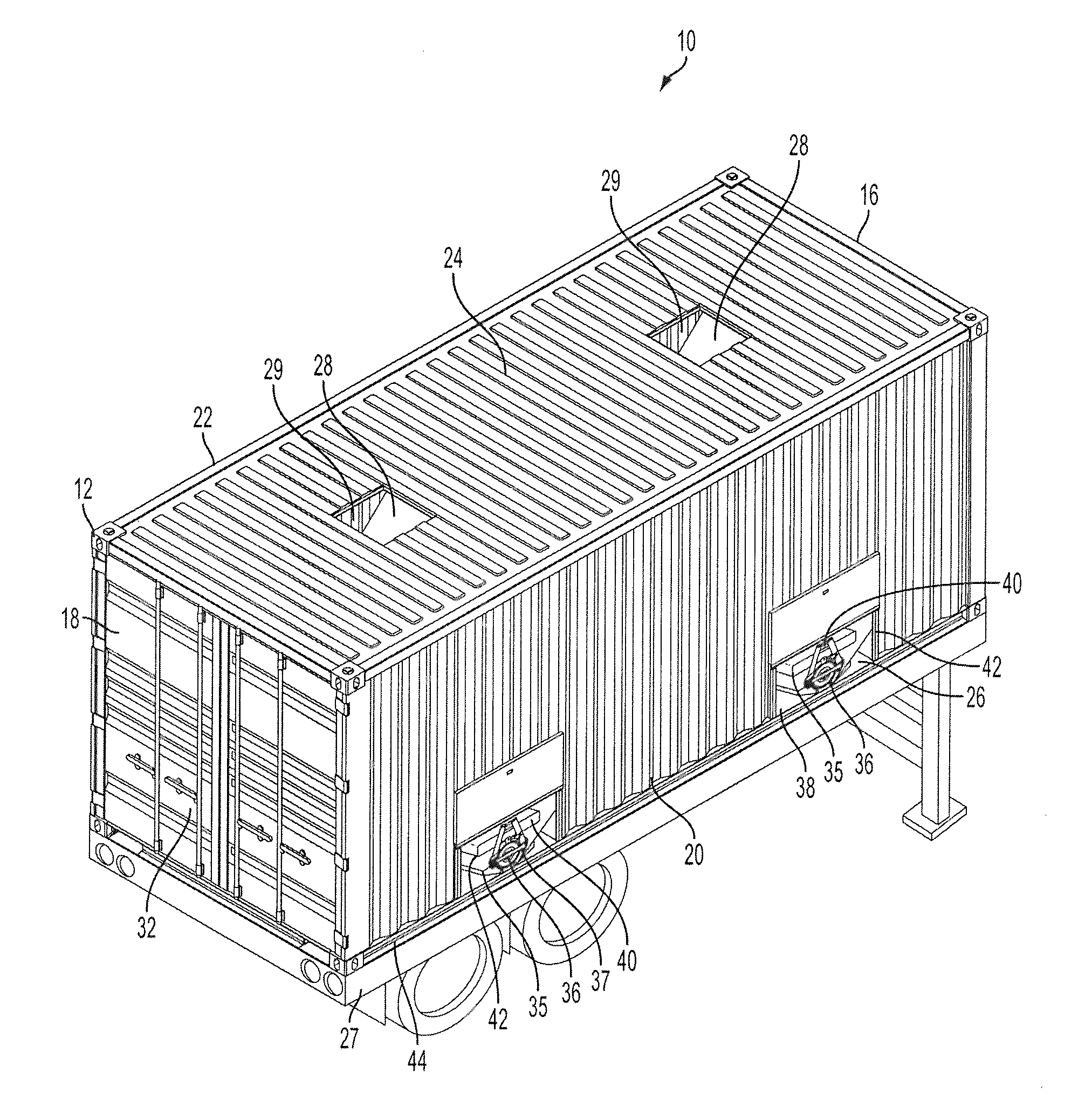

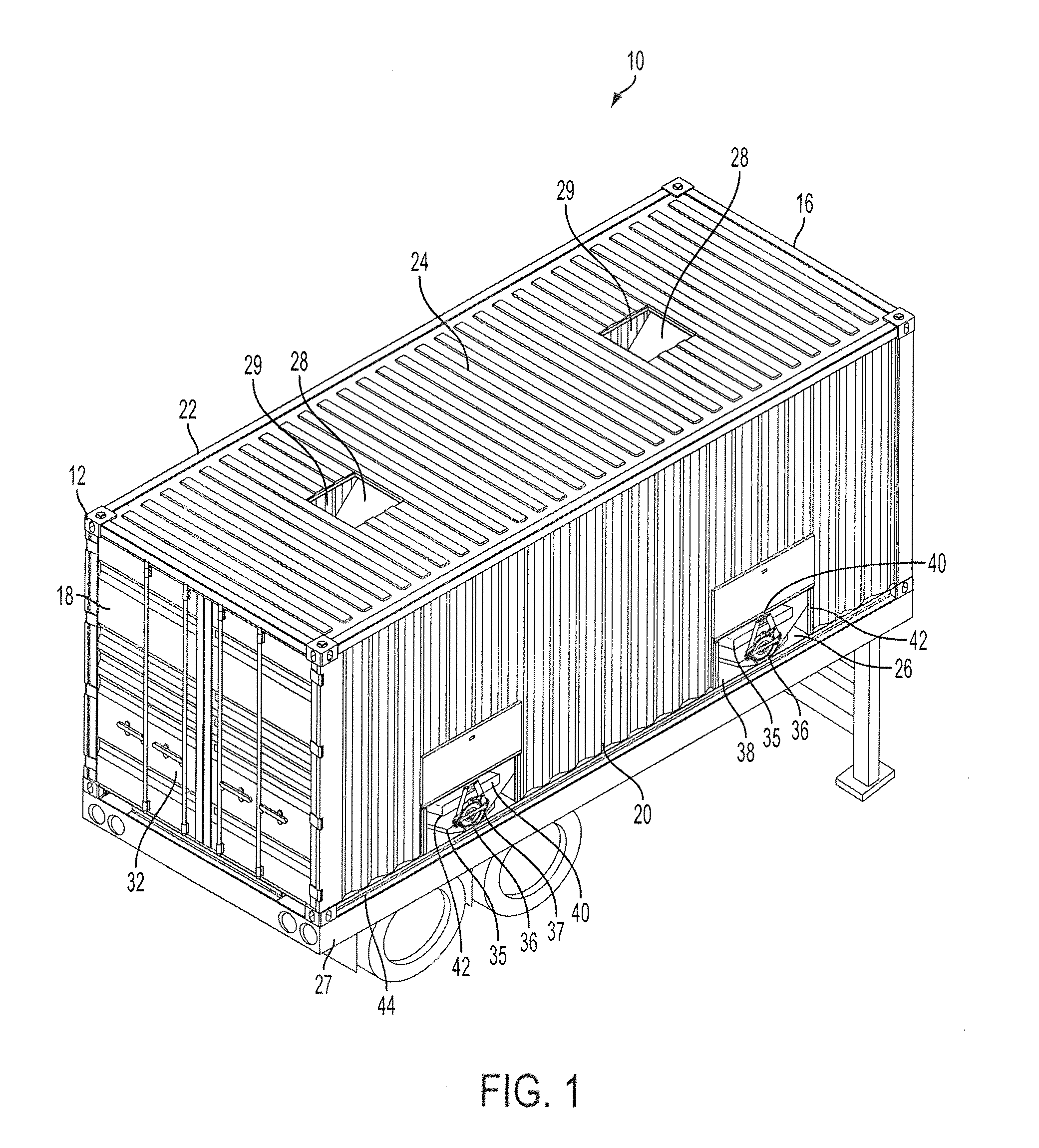

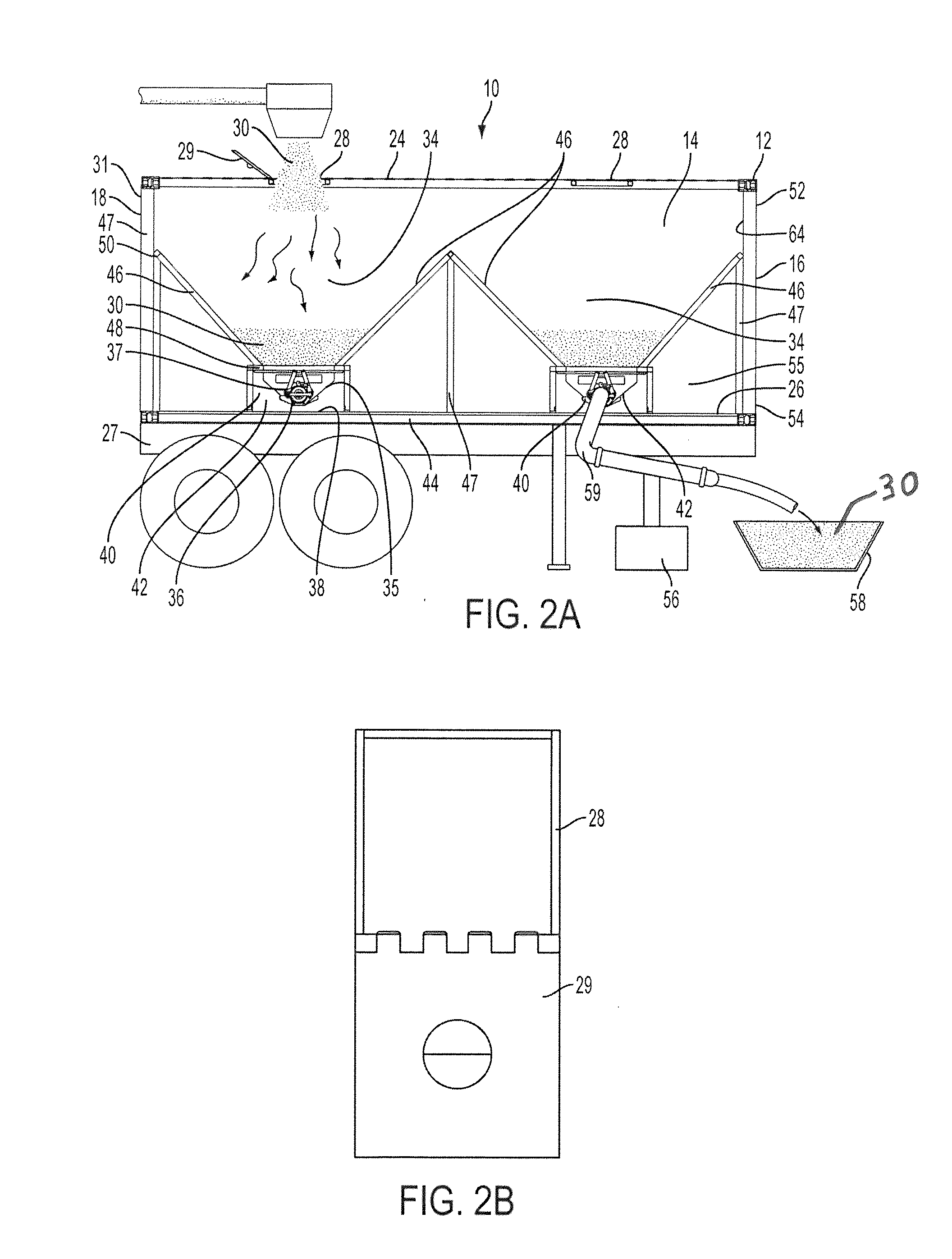

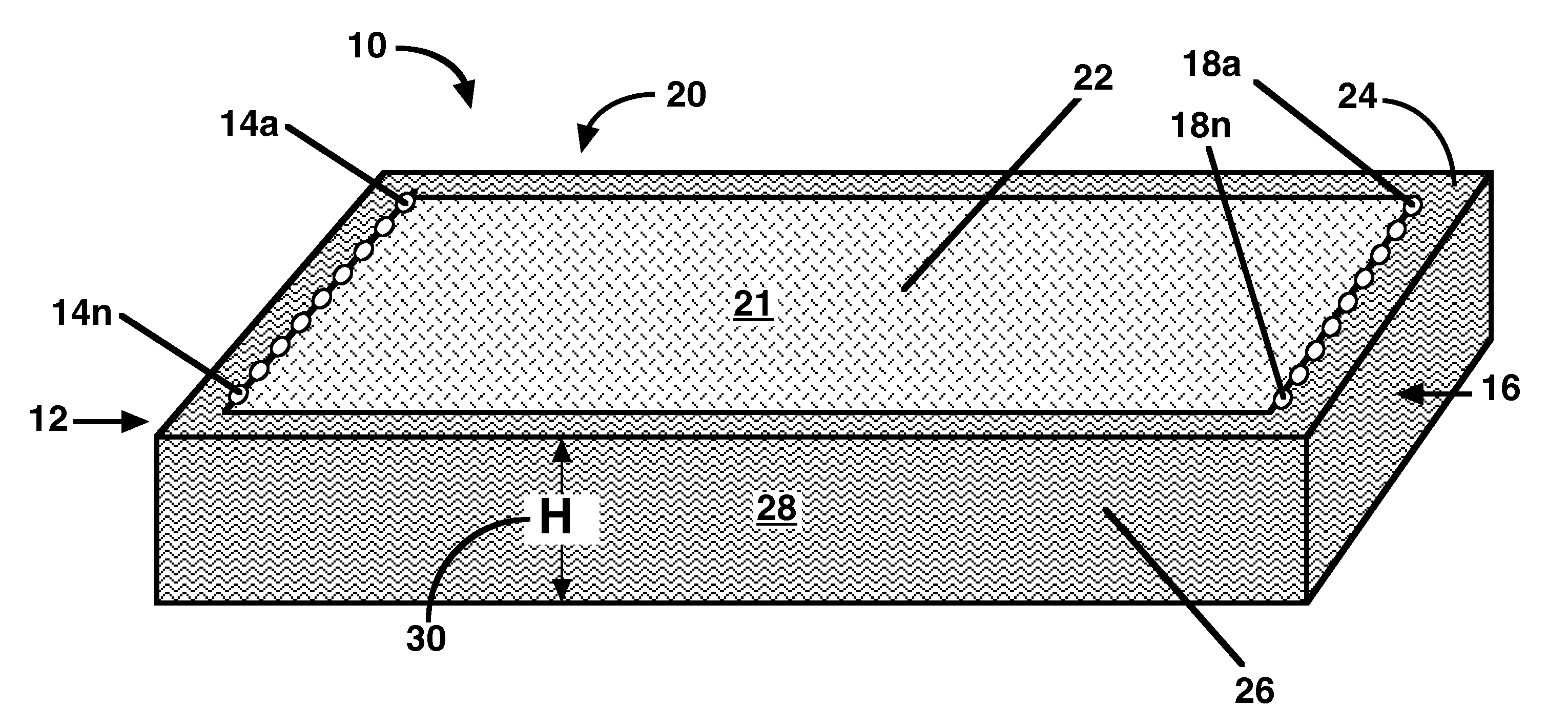

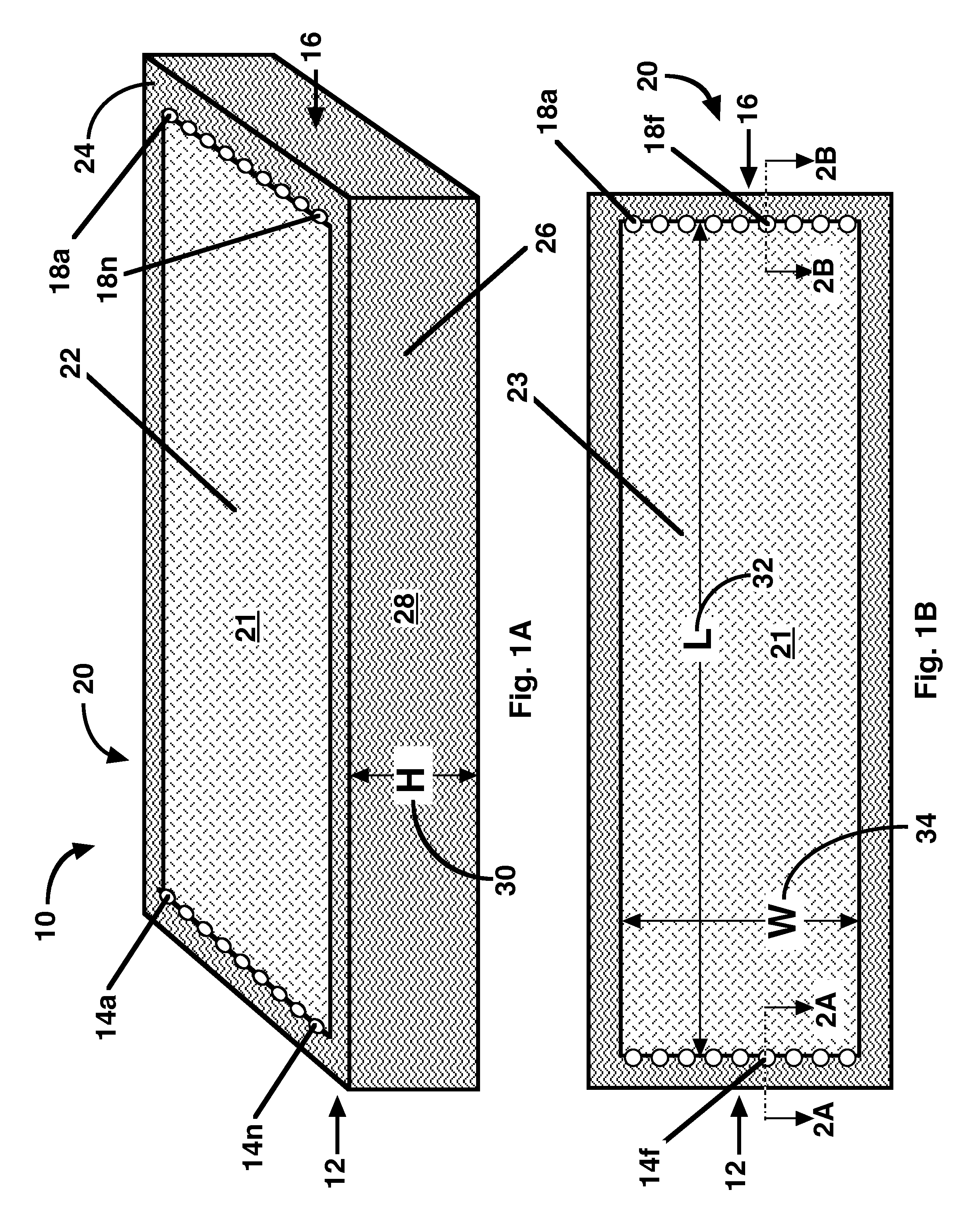

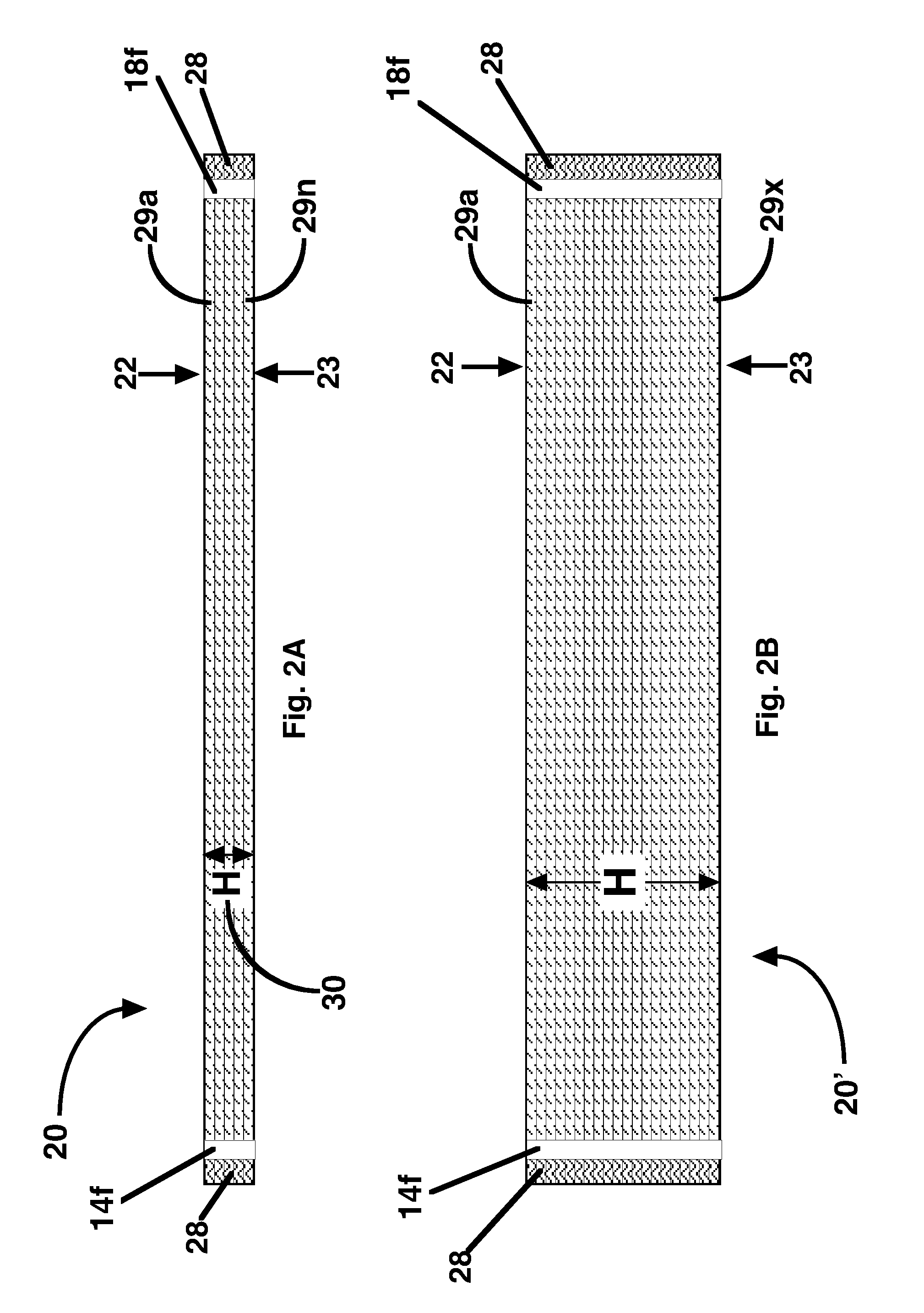

Storage container

A self-contained container for storing and transporting particulate material is provided, the container including a frame, a storage cavity defined by opposing front and back walls, opposing side walls, a top wall, and a floor, each of the front and back walls, side walls, top wall and floor connected to the frame, at least one loading port in the top wall, and at least one discharge region including at least one discharge port and one sloped wall configured for removing material from the container. The discharge region and discharge port being positioned within the frame.

Owner:FRONTIER LOGISTICS

Knee brace and method for securing the same

ActiveUS20060135900A1Reduce impactMinimizing rotational forceNon-surgical orthopedic devicesKnee bracesMedian plane

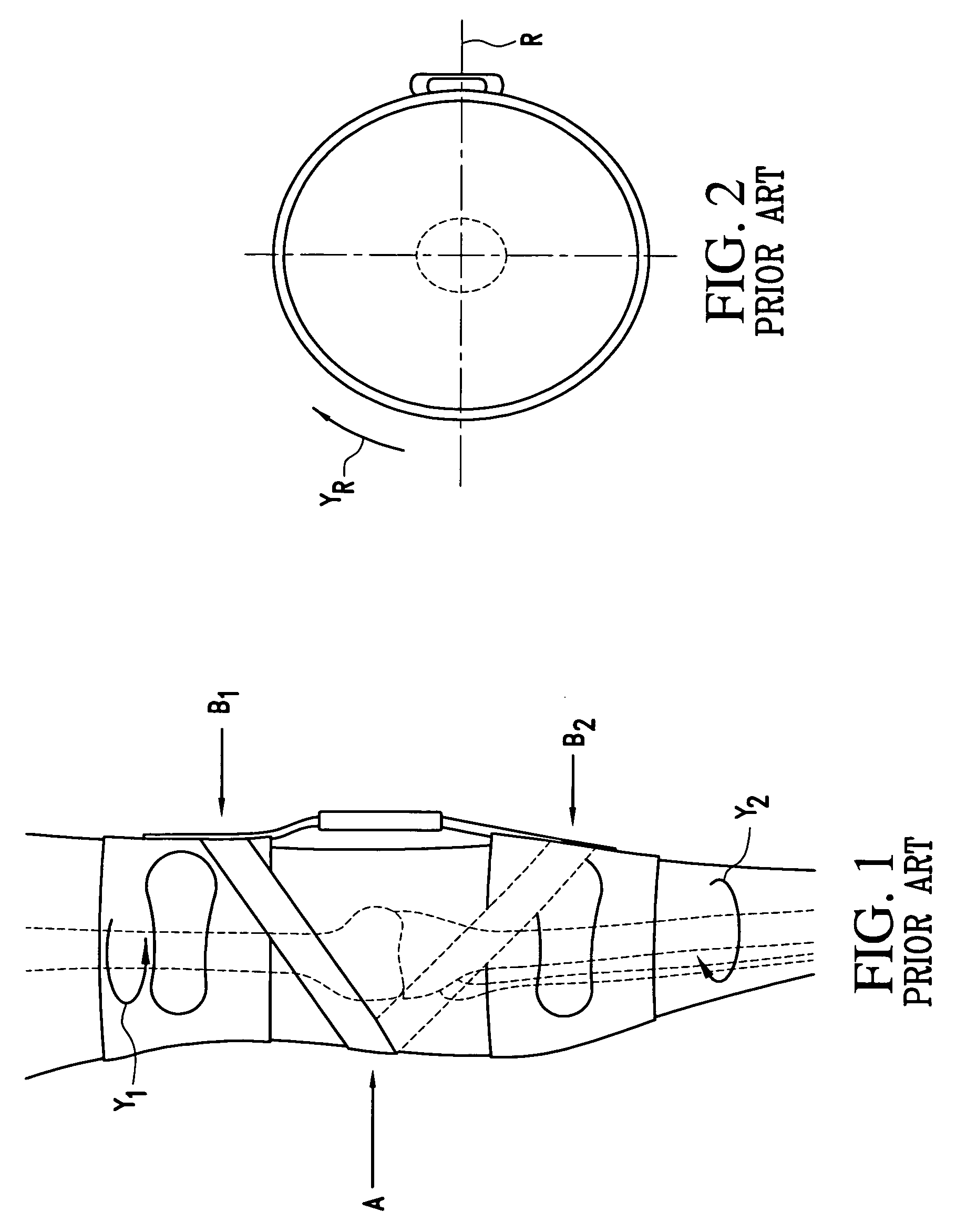

A knee brace that is divided into anterior and posterior sides by a frontal plane, and having first and second sides divided by a median plane. The knee brace includes a ventilated, flexible proximal shell generally extending between the first and second sides on the anterior side of the brace, and a flexible distal shell connected to the proximal shell and generally extending across the first and second sides on the anterior side of the brace. The distal shell has an extension segment extending from one of the first and second sides to the posterior side of the brace. The proximal and distal shells include suitable openings and slots for attaching brackets and mechanical devices. The proximal and distal shells each include a body portion and a compliant edge. The compliant edges are formed from flexible resilient material that is configured to extend beyond the outer perimeter of the body portion of each the proximal and distal shells.

Owner:KAUPTHING BANK

Knee brace and method for securing the same

ActiveUS20060135903A1Reduce impactMinimizing rotational forceNon-surgical orthopedic devicesMedicineKnee braces

Owner:OSSUR HF

Knee brace and method for securing the same

ActiveUS20090124948A1Reduce impactMinimizing rotational forceFeet bandagesNon-surgical orthopedic devicesPhysical medicine and rehabilitationDistal portion

A knee brace divided into anterior and posterior sides by a frontal plane, and having first and second sides divided by a median plane. The knee brace including a frame having proximal and distal portions, a stability strap having first and second ends respectively connected to first and second sides on the proximal frame portion along the posterior side thereof, and a cross strap having a first end connected to the first side of the proximal and a second end connected to the distal frame portions. A bracket assembly having a buckle connects the stability and cross straps to the frame. A sleeve is provided which covers the frame and upon which the bracket assembly rests.

Owner:OSSUR HF

High silicon Y-type zeolite containing rare-earth and its preparing method

ActiveCN1281493CThe initial unit cell constant is smallThe equilibrium cell constant is largeFaujasite aluminosilicate zeoliteGasolineRare earth

A rare-earth-containing high-silicon Y-type zeolite, the zeolite contains rare earths, is characterized in that the silicon-aluminum ratio of the zeolite is 5-30, the initial unit cell constant is 2.430-2.465 nanometers, and the balance unit cell constant and the initial unit cell constant The ratio is at least 0.985. The zeolite has the characteristics of small initial unit cell constant and large equilibrium unit cell constant. It has high structural stability and hydrothermal stability. The cracking catalyst containing this zeolite is not easy to deactivate. The choice of gasoline, diesel oil, dry gas and coke Good sex.

Owner:CHINA PETROLEUM & CHEM CORP +1

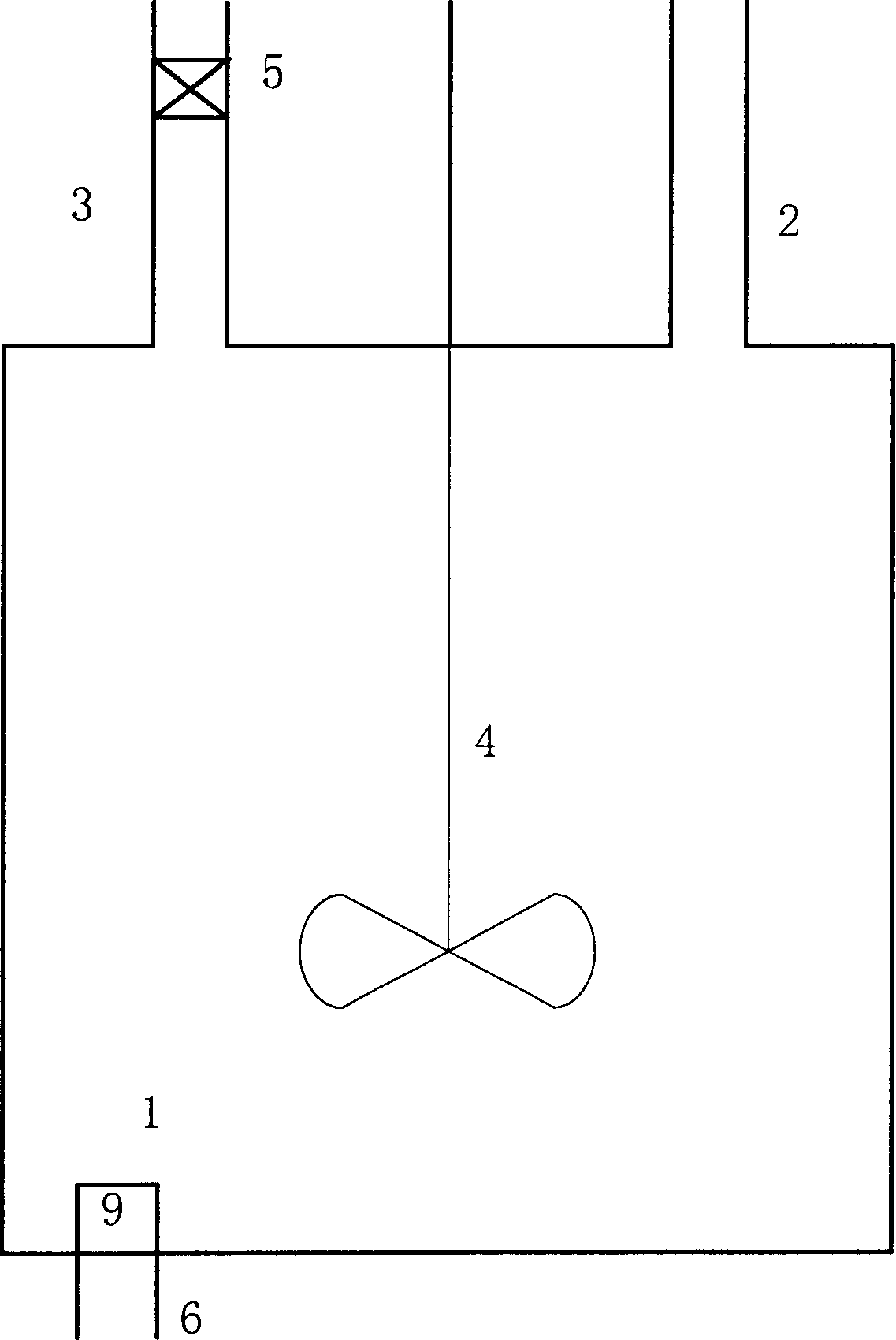

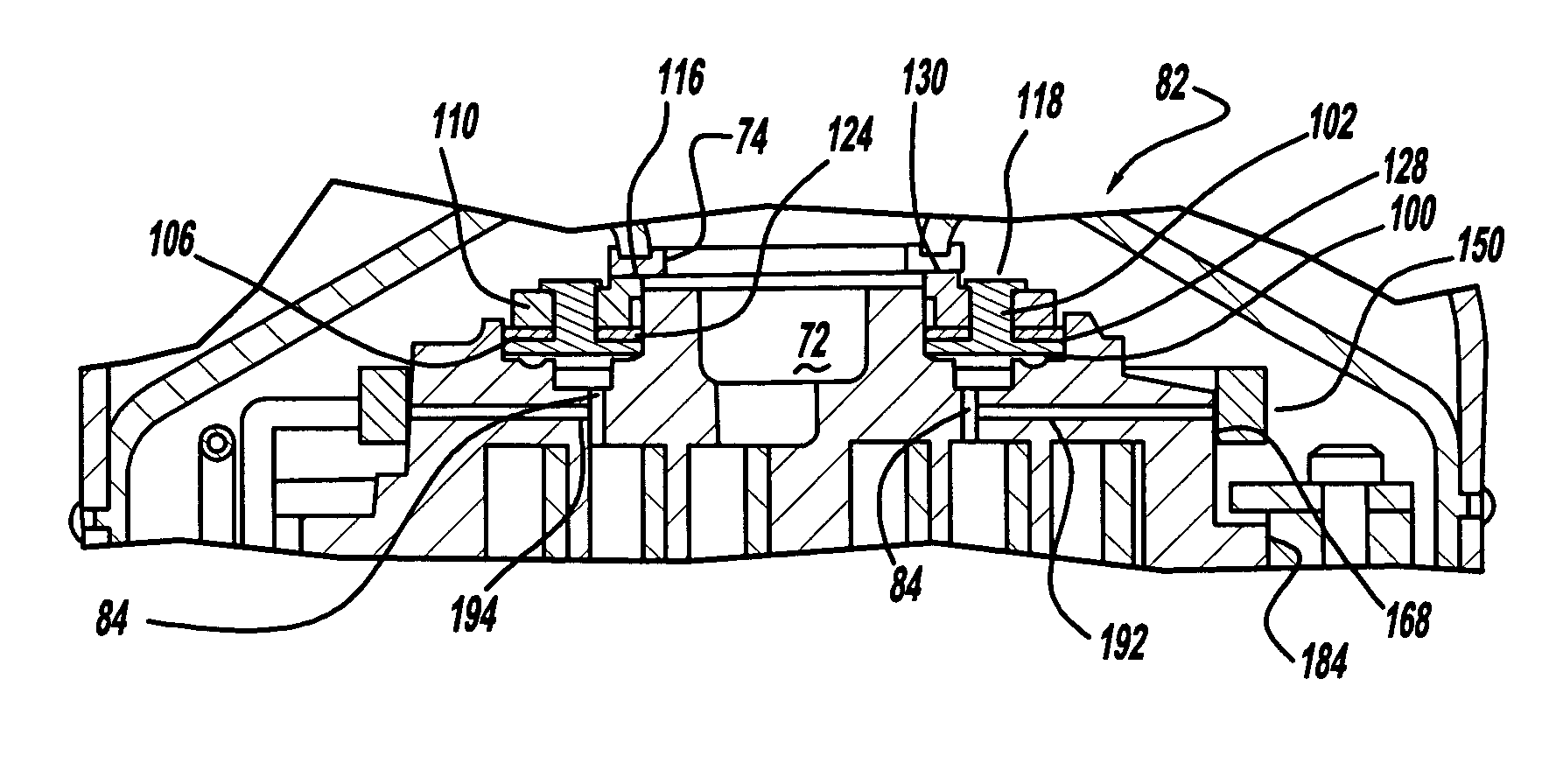

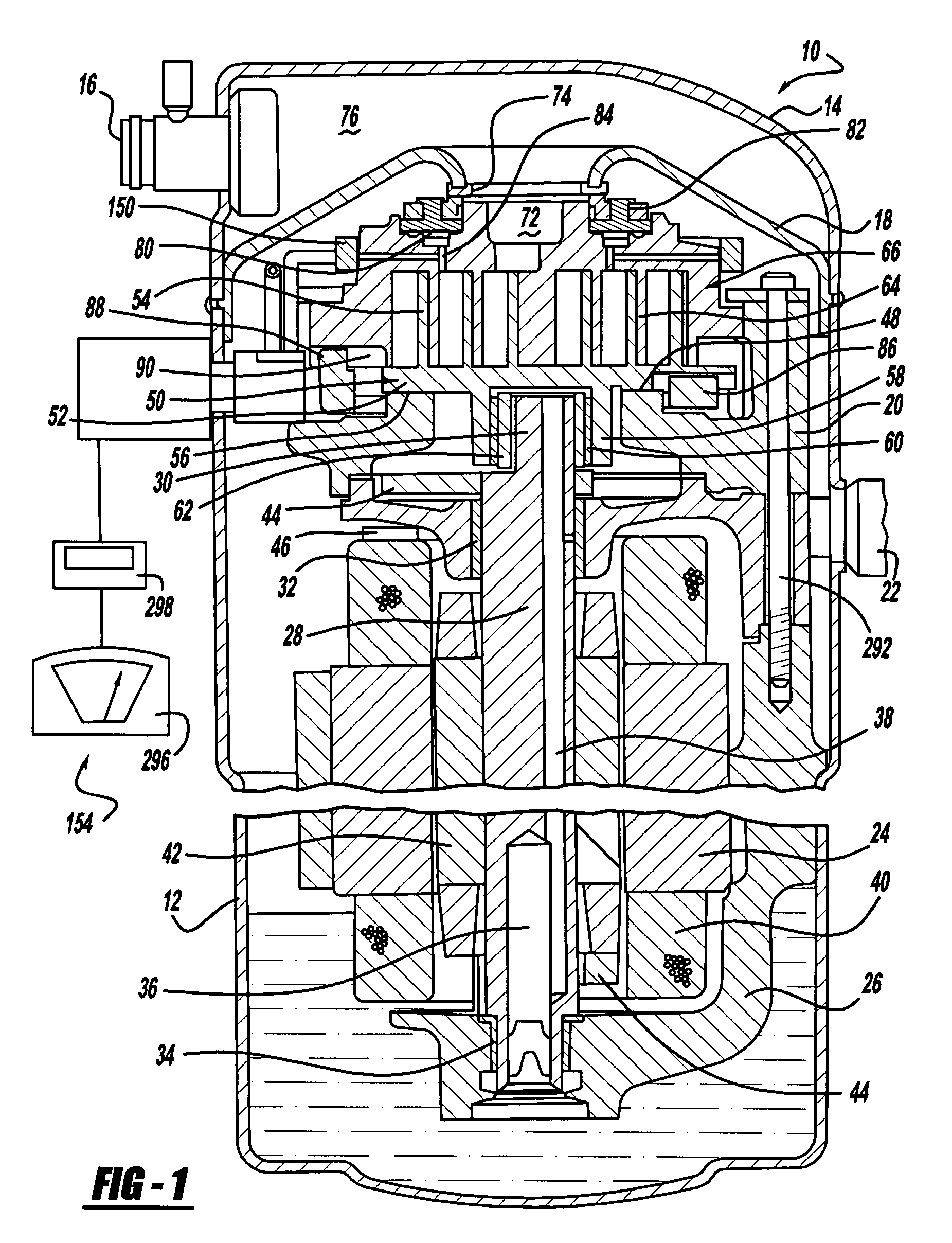

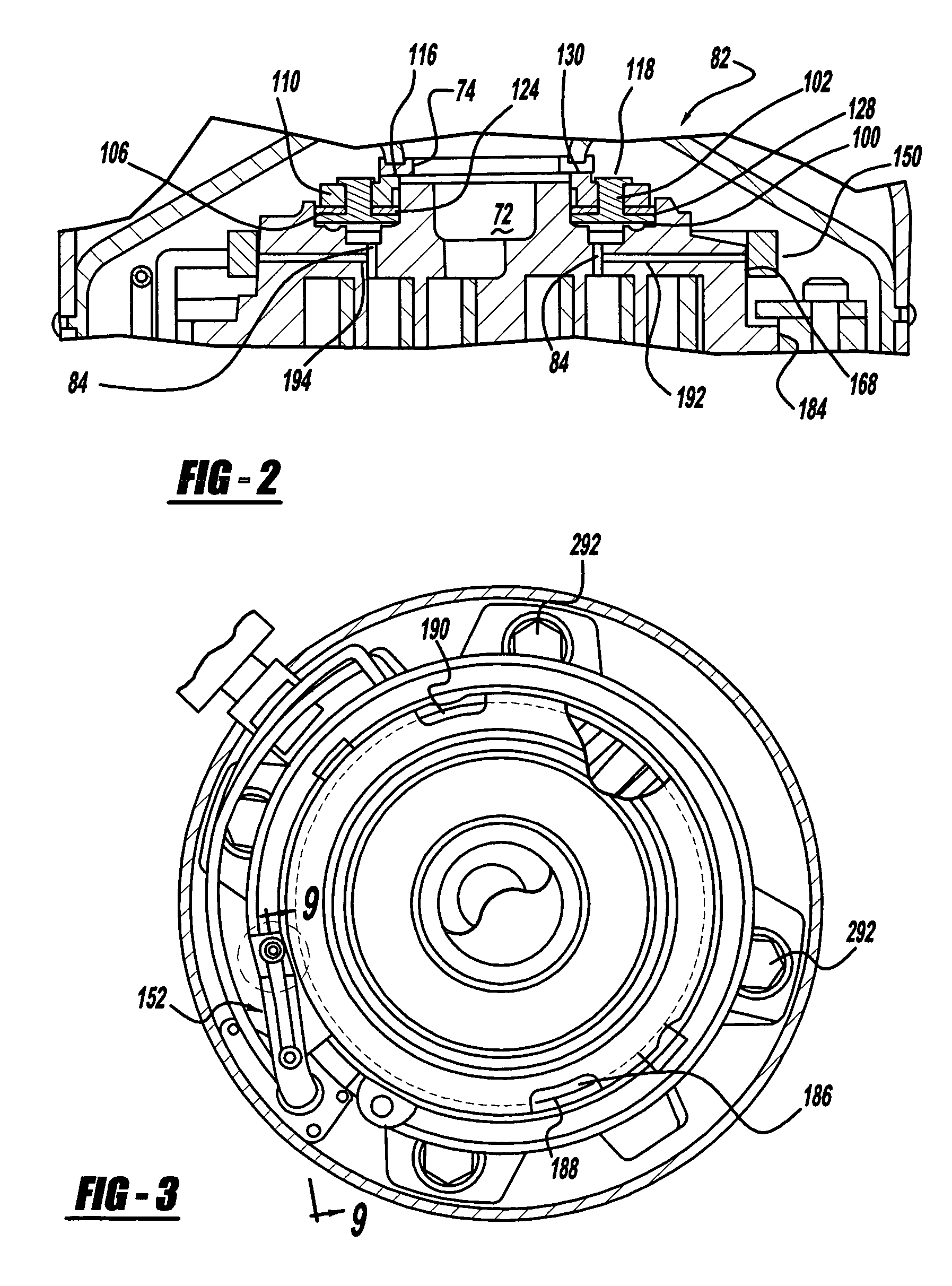

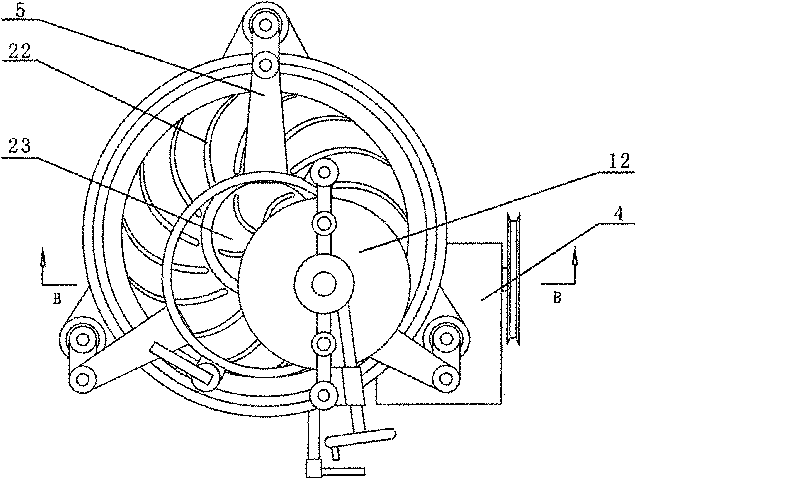

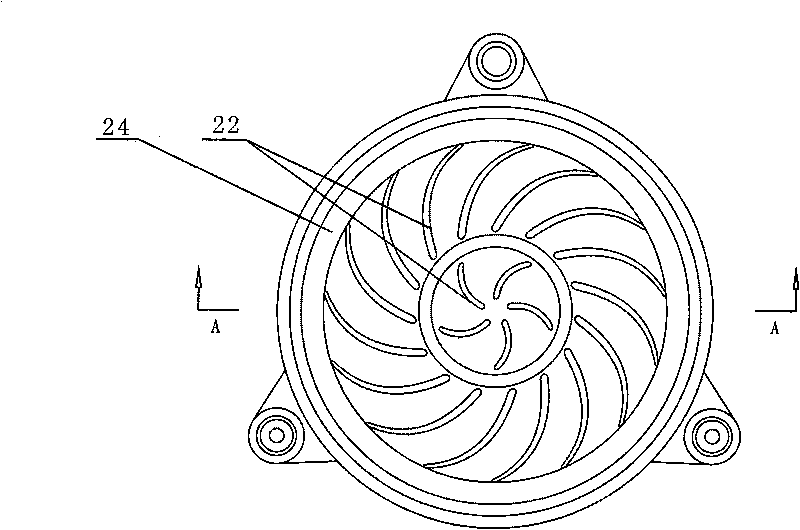

Capacity modulated scroll compressor

InactiveUS20070036661A1Reduce compressionCapacity modulationRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsElectrical and Electronics engineeringScroll compressor

A scroll compressor has a biasing chamber which contains a pressurized fluid. The pressurized fluid within the chamber biases the two scroll members together. A rotatable ring is attached to one of the scroll members to open and close a passage leading to this biasing chamber. When the ring opens the passage in one embodiment, this releases the pressurized fluid to remove the load, biasing the two scroll members together. When the biasing load is removed, the two scroll members separate, creating a leakage path between discharge and suction to reduce the capacity of the scroll compressor. When the ring opens the passage in another embodiment, a delayed suction passage is opened to reduce the capacity of the compressor.

Owner:EMERSON CLIMATE TECH INC

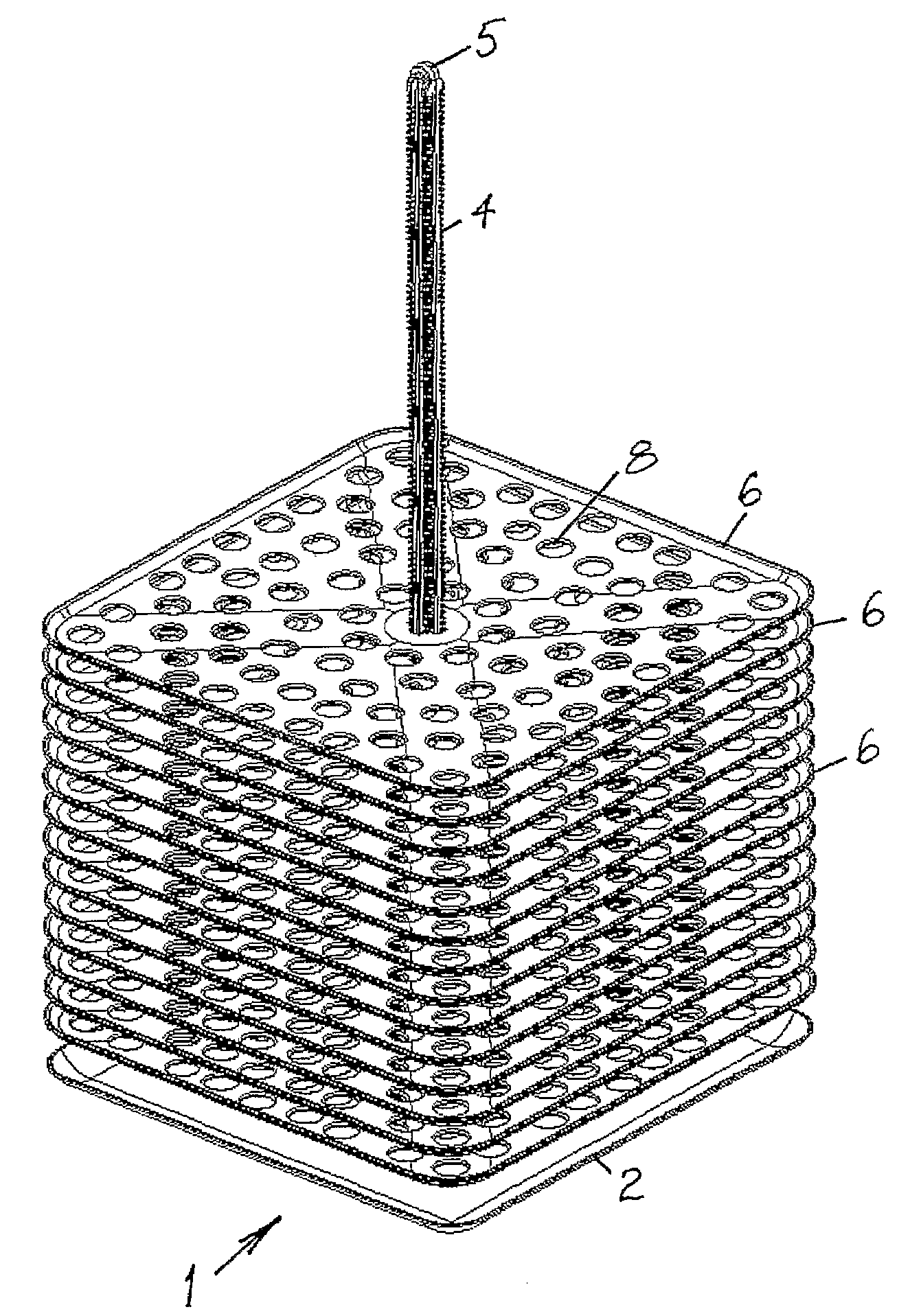

Stackable planar adsorptive devices

ActiveUS8506802B1Easy to unloadLarge dynamic rangeIon-exchange process apparatusComponent separationElectrical and Electronics engineering

Stackable planar adsorption devices include a plurality of layers of adsorptive media provided in a web format. The layers are stacked in contiguous fashion, sealed and include fluid passageways to provide a range of scalable chromatography devices suitable for large scale manufacturing applications.

Owner:SPF TECH

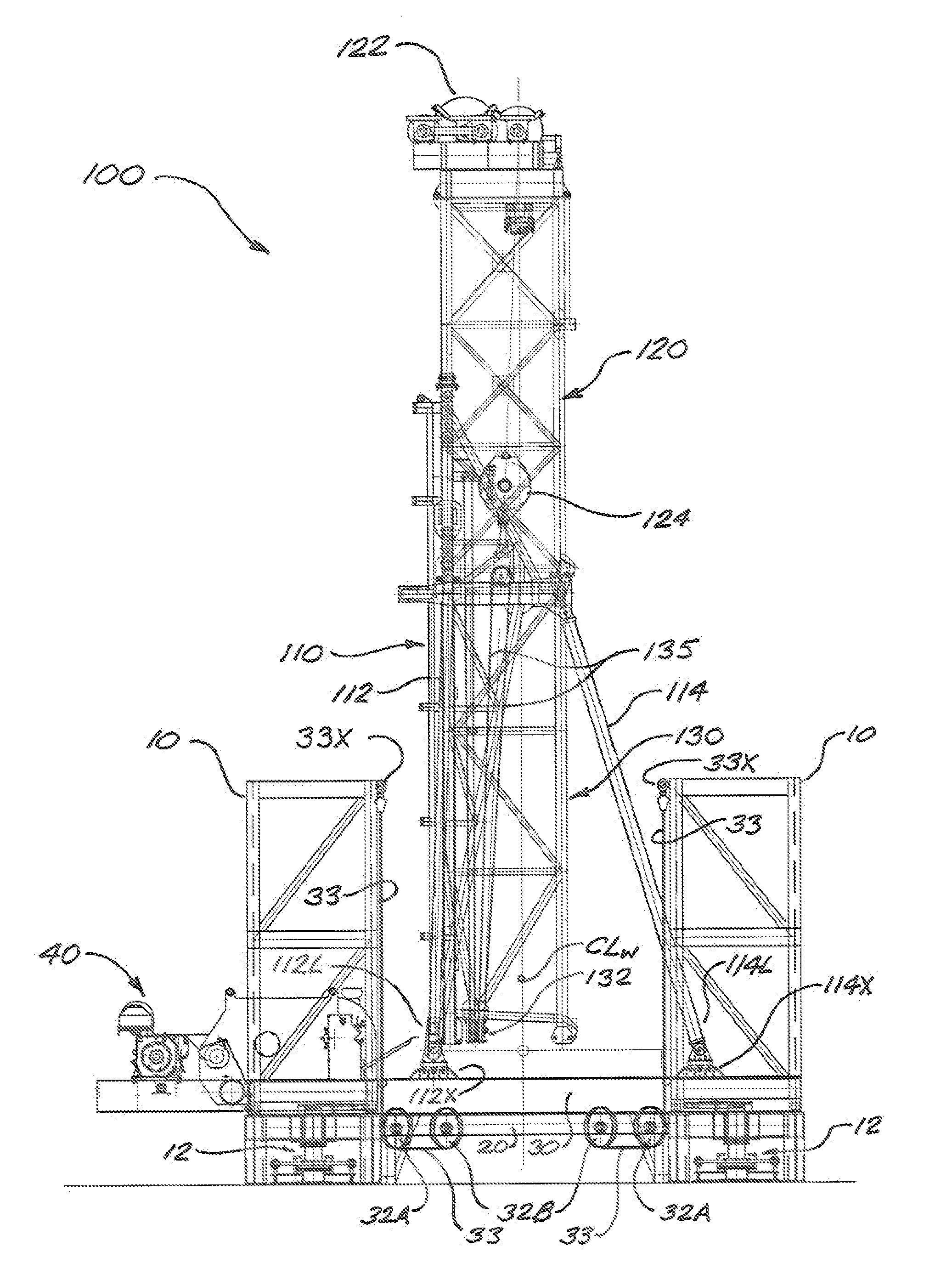

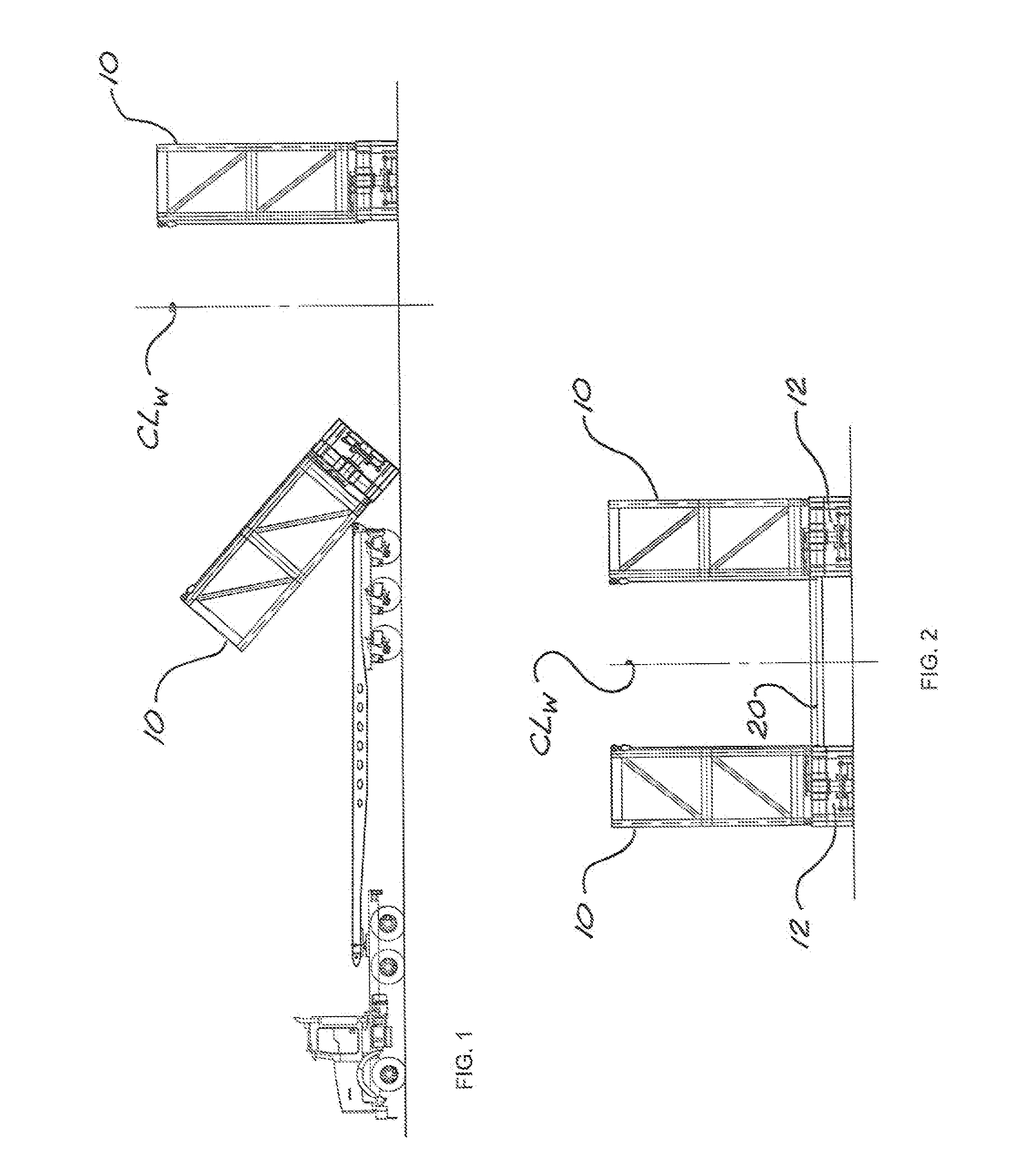

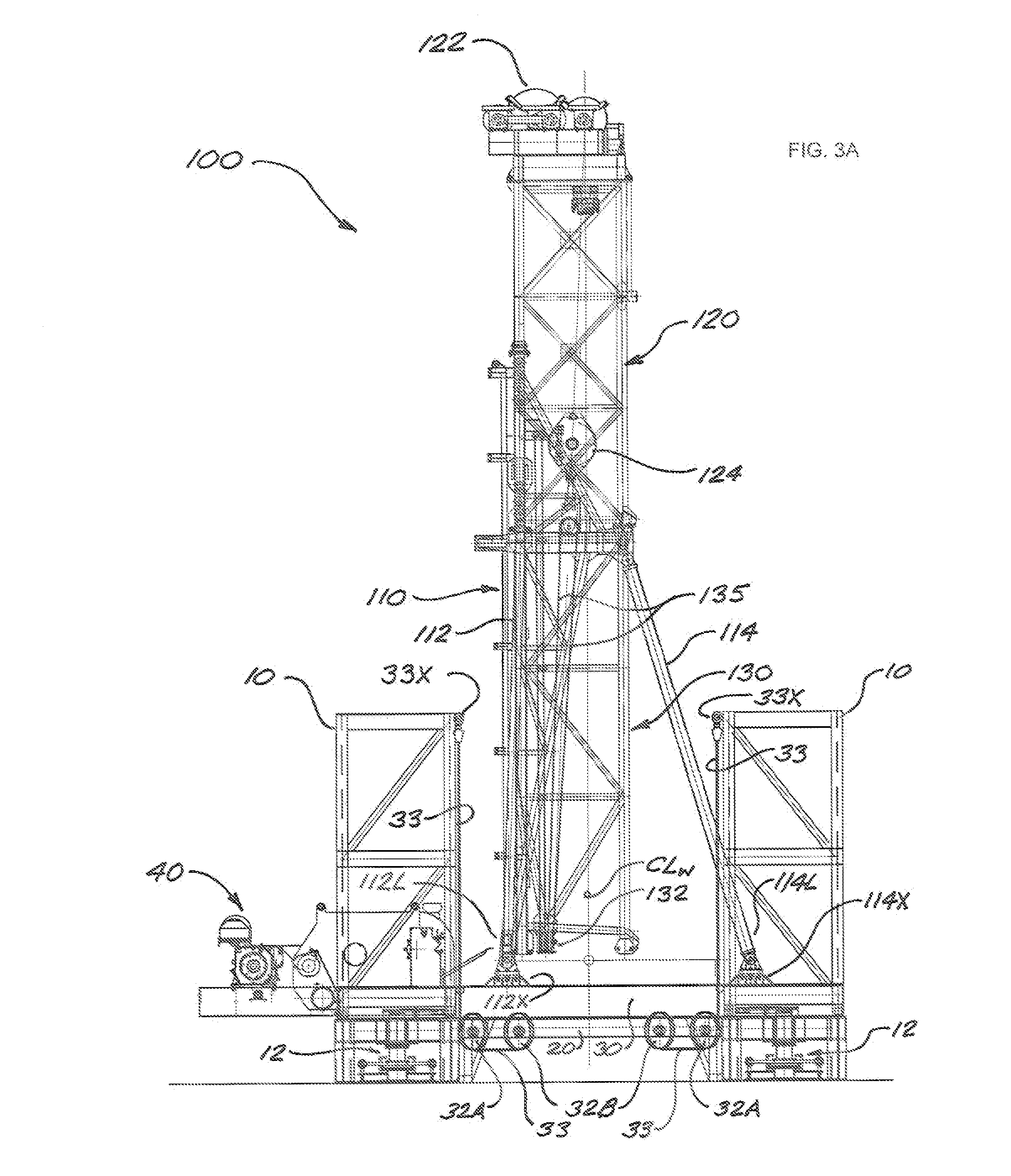

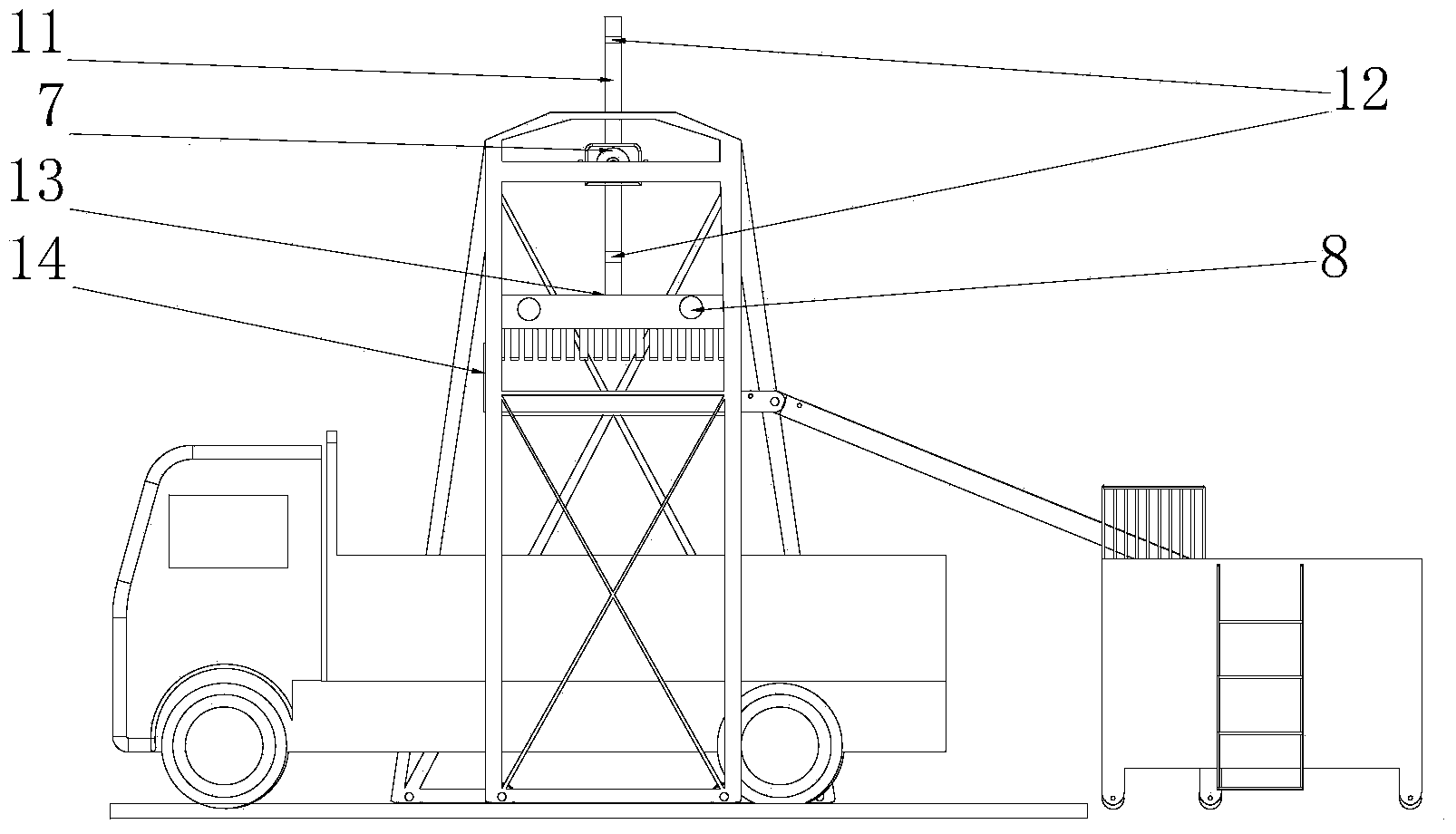

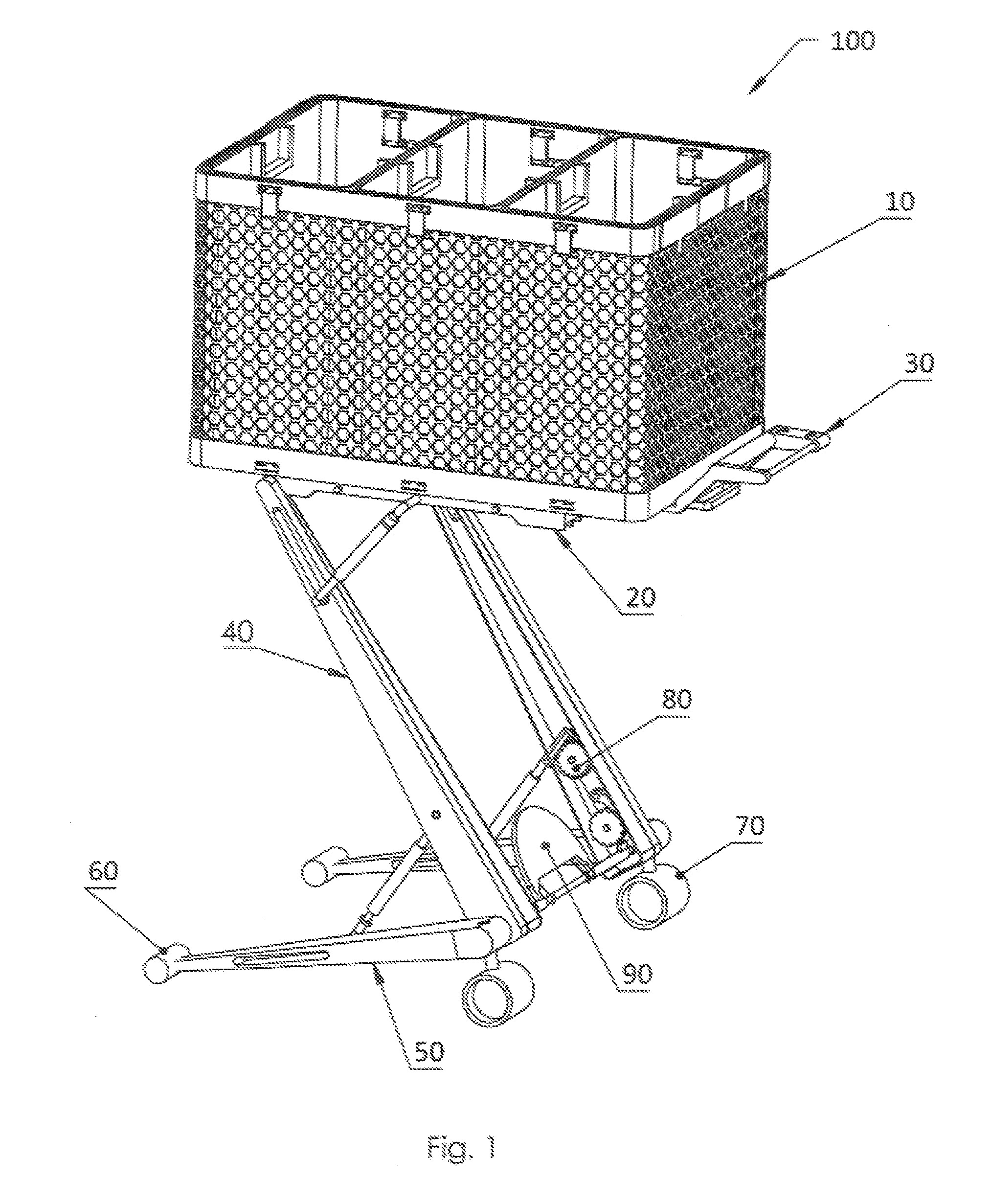

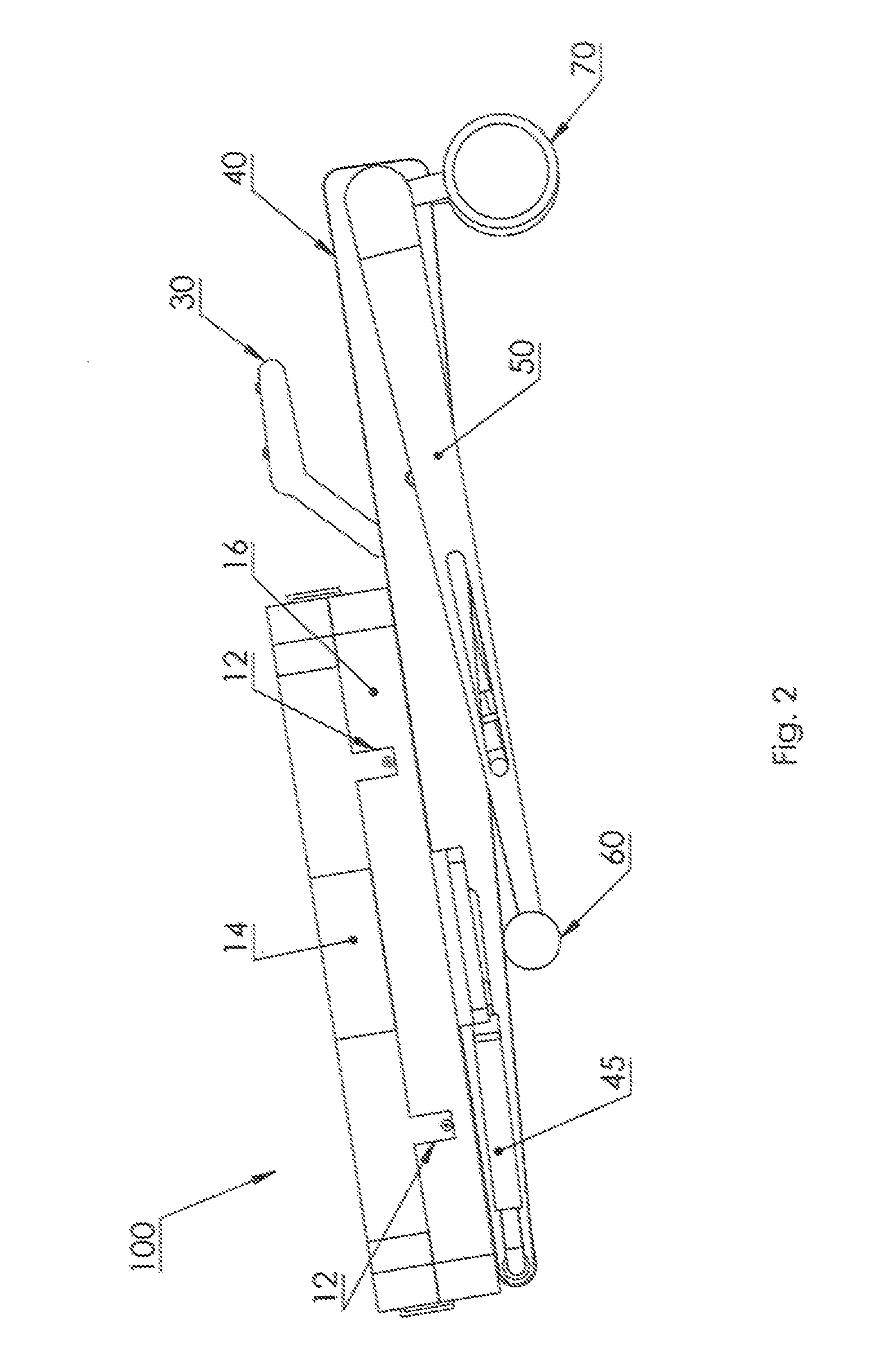

Drilling rig system with self-elevating drill floor

InactiveUS20120304553A1Improve the level ofFor lateral movementCeilingsDerricks/mastsTowerTraveling block

A transportable drilling rig having a self-elevating drill floor includes a base structure comprising multiple base towers that can be transported to a wellsite and positioned around an intended wellbore location. A horizontal base frame is installed between lower regions of the towers to form a stable rig base structure, and a drill floor can then be constructed over the base frame and between the base towers. A suitable rig mast can then be erected on the drill floor. Floor-lifting cables are anchored to upper regions of the base towers and disposable around corresponding sheave assemblies associated with the drill floor. The free ends of the floor-lifting cables can be engaged by the traveling block in the rig mast, whereupon the rig's drawworks can be actuated to elevate the drill floor and mast as required and then locked to the base towers.

Owner:NAT OILWELL VARCO LP

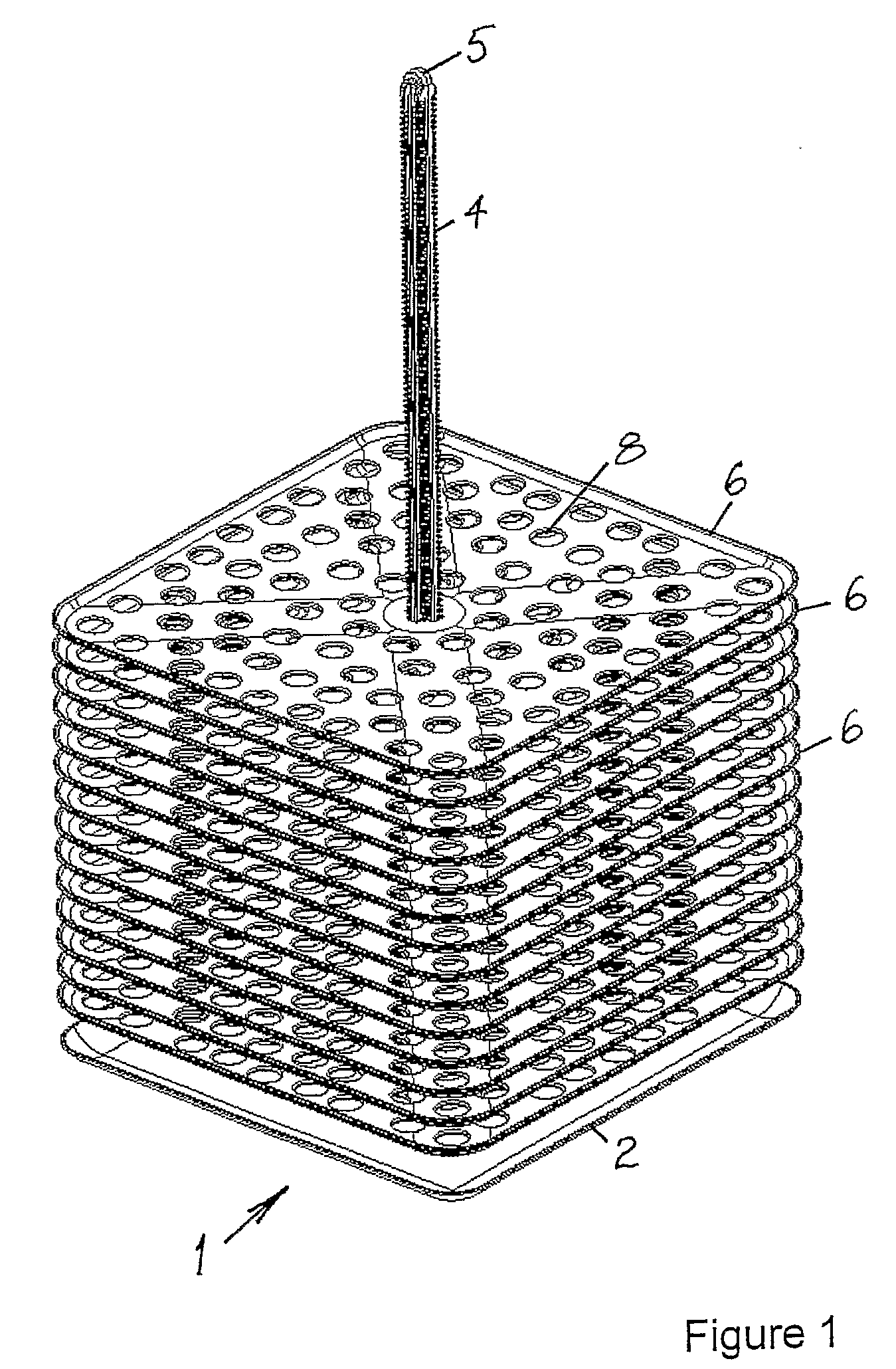

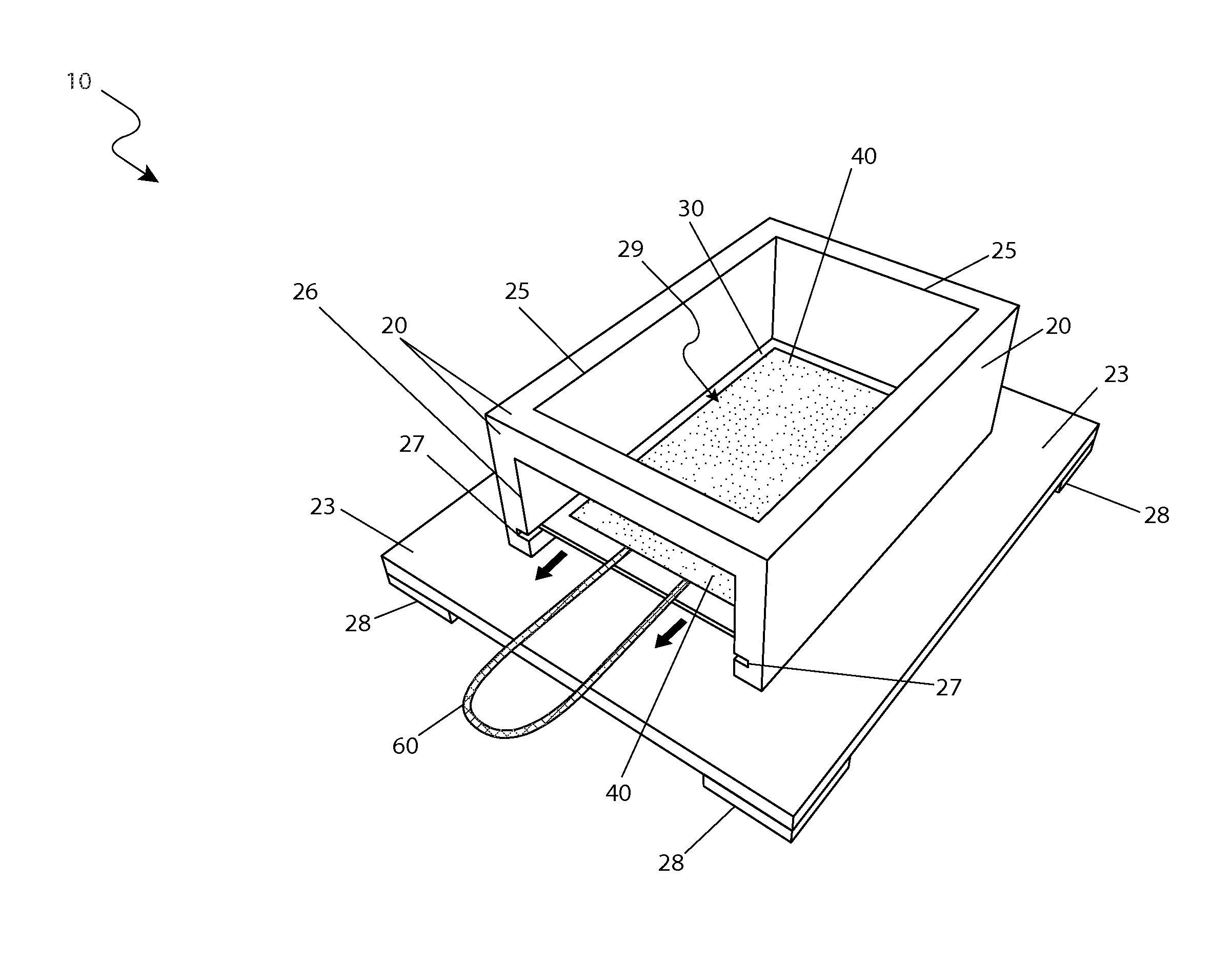

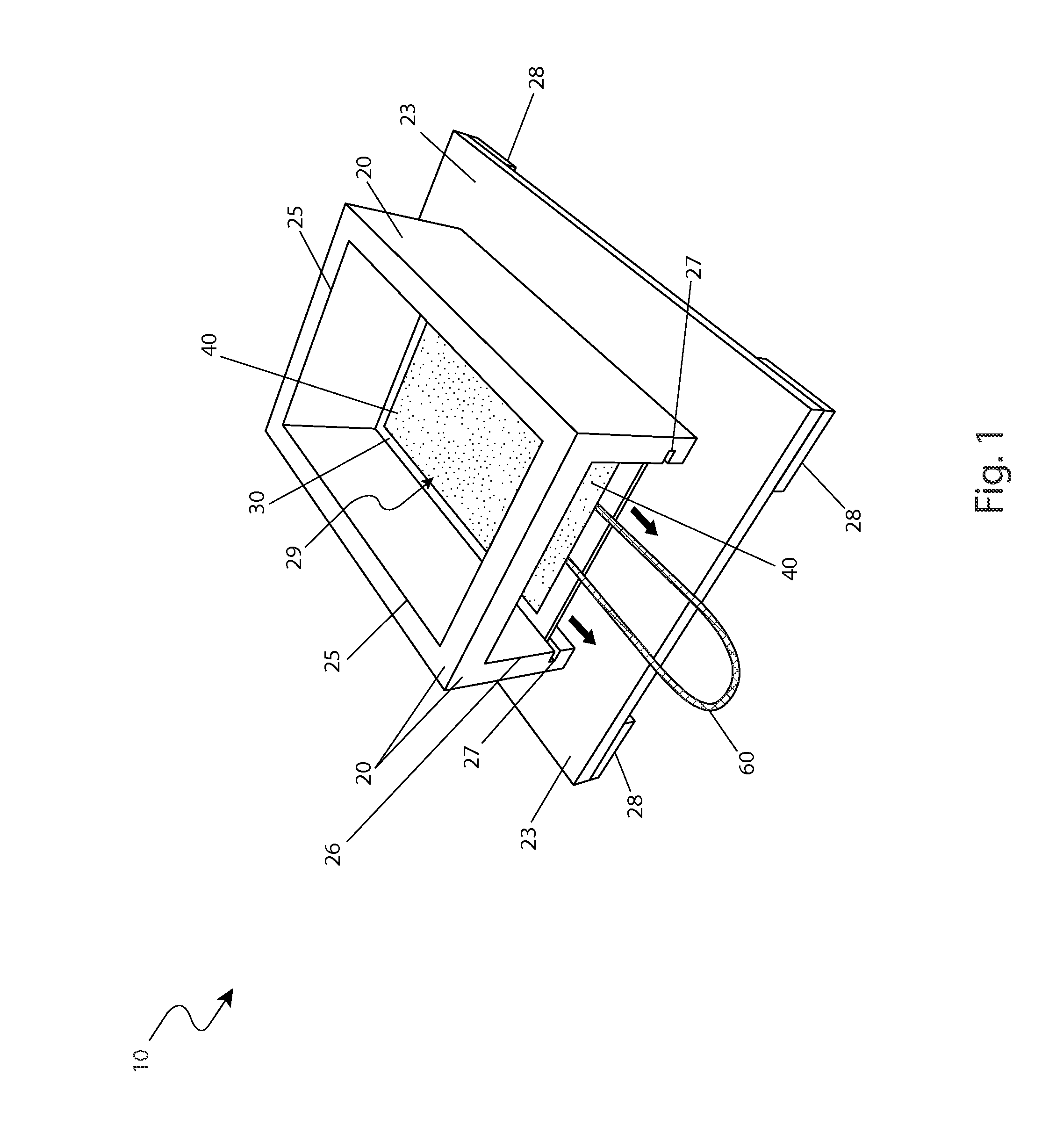

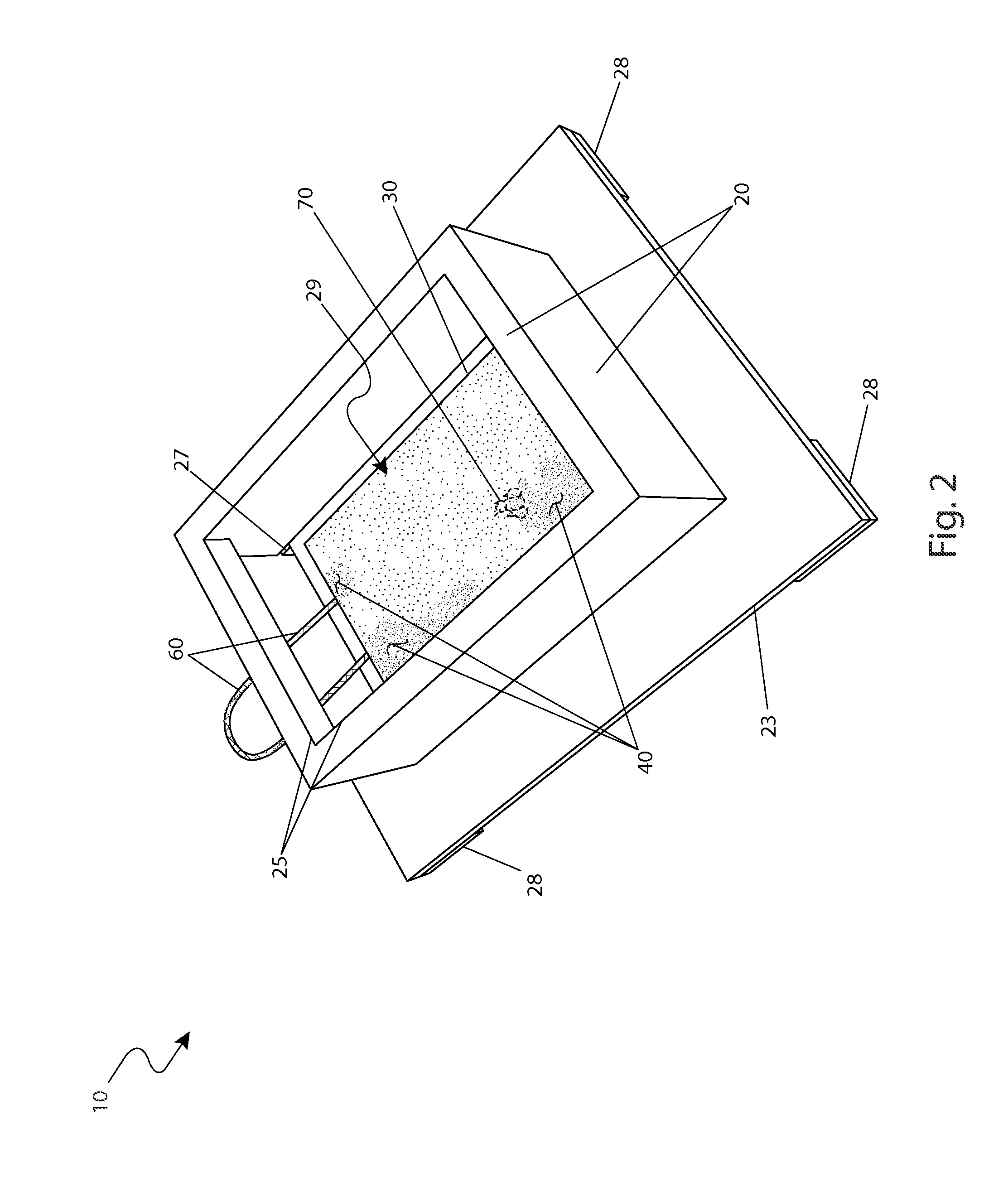

Product Distribution Methods and Apparatus

InactiveUS20090063166A1Easy to unloadEasy loadingShow cabinetsReservationsAssignment methodsMechanical engineering

Products (30) are distributed to retail outlets in containers (20). The products (30) are loaded onto the tray assembly (1) that is placed in a container (20) at a production or storage facility and transported to the retail outlet. Information as to a sequence in which the products (30) will be placed on retail shelving (32) at the retail outlet is used to determine a loading order of the products (30) on the tray assembly (1) so that the products (30) may be removed from the carrying device in the order required for placement on the retail shelves (32). The tray assembly (1) is removable from the container, and the trays (6) are moveable relative to each other to facilitate loading and unloading.

Owner:FOODCAP INT

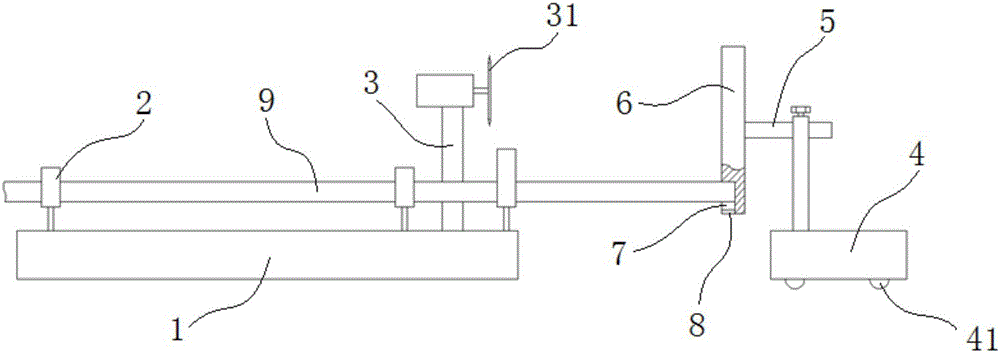

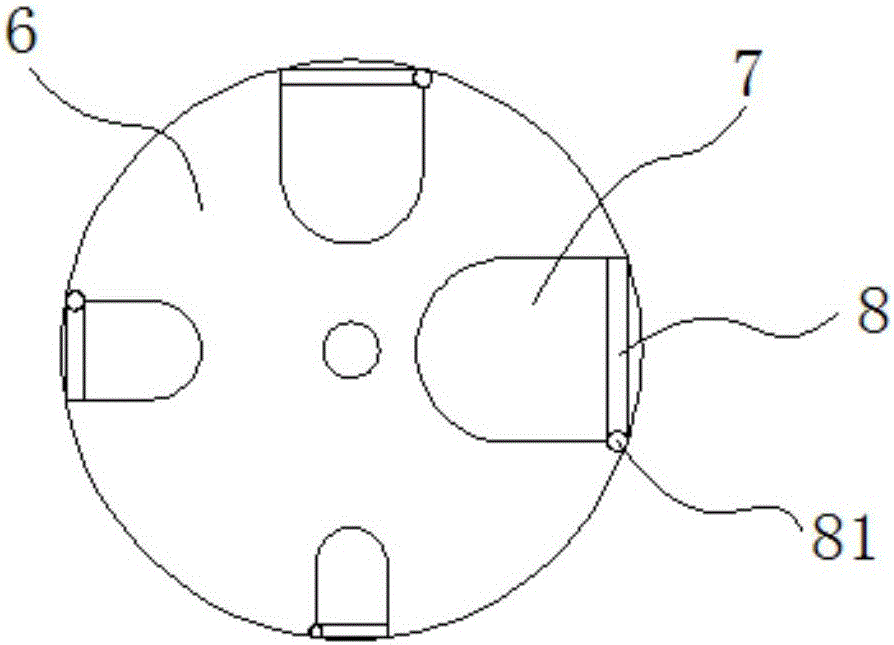

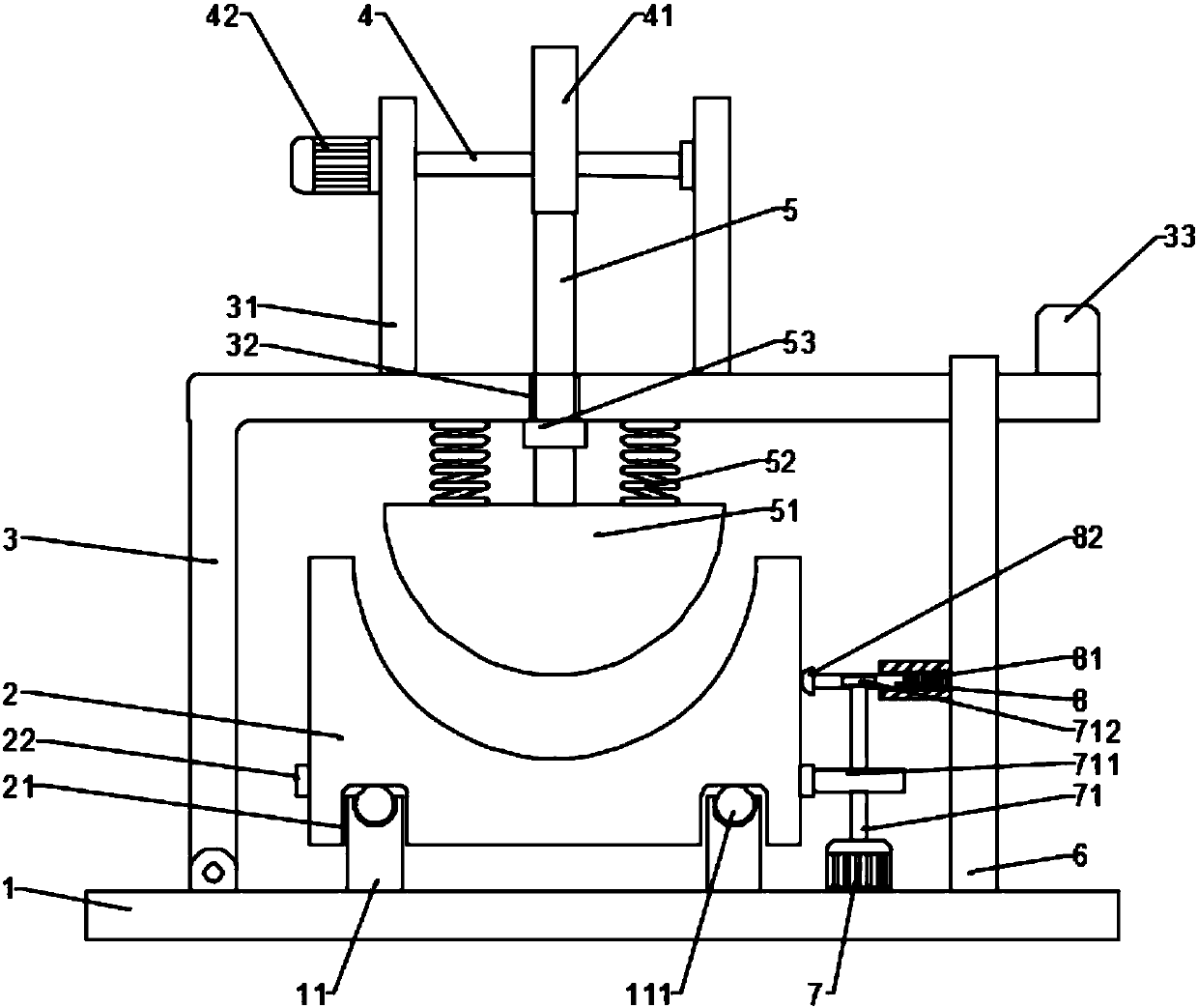

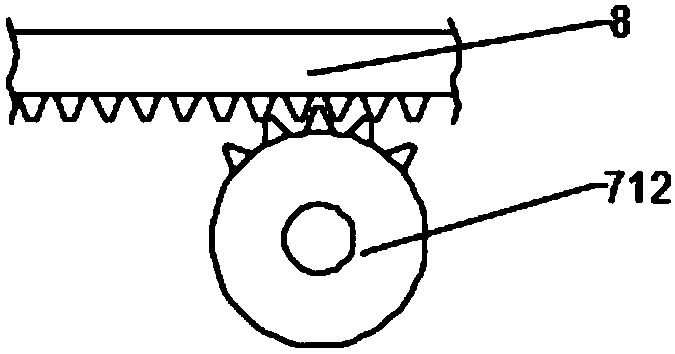

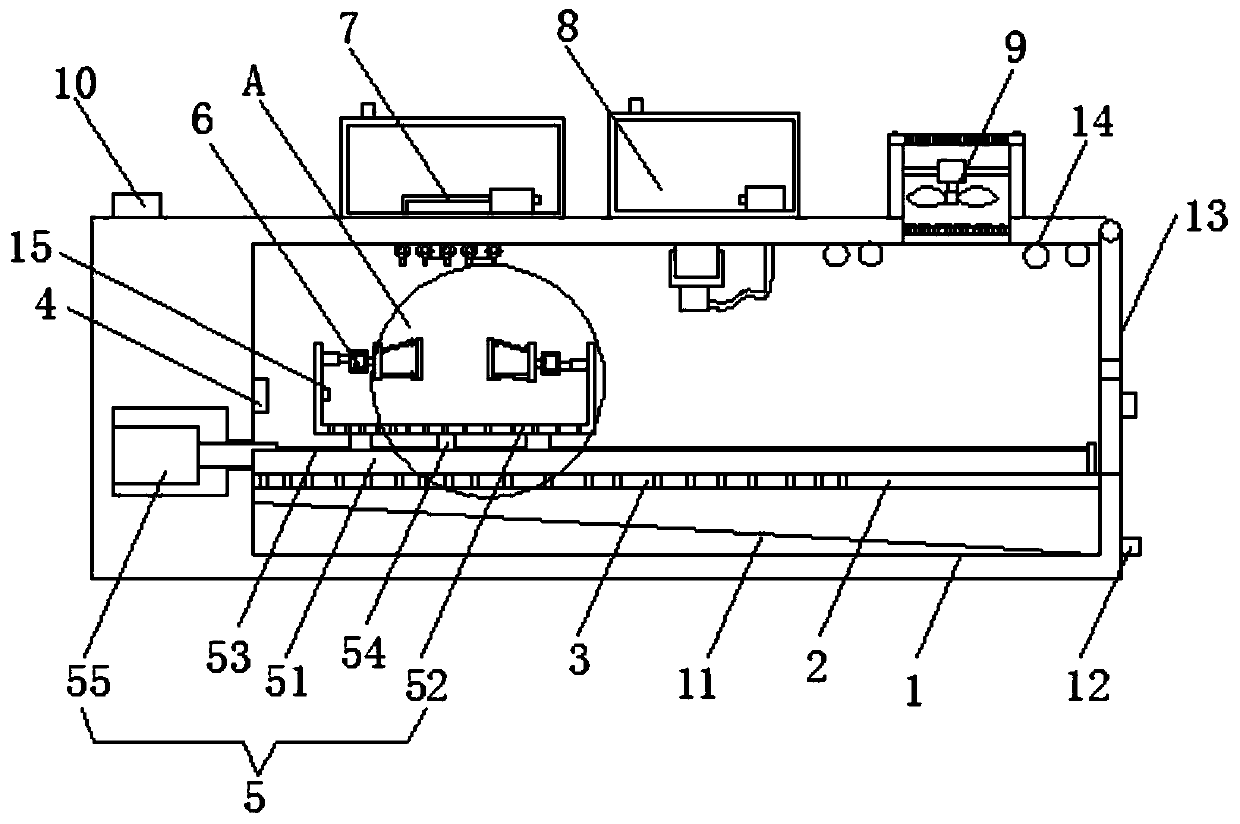

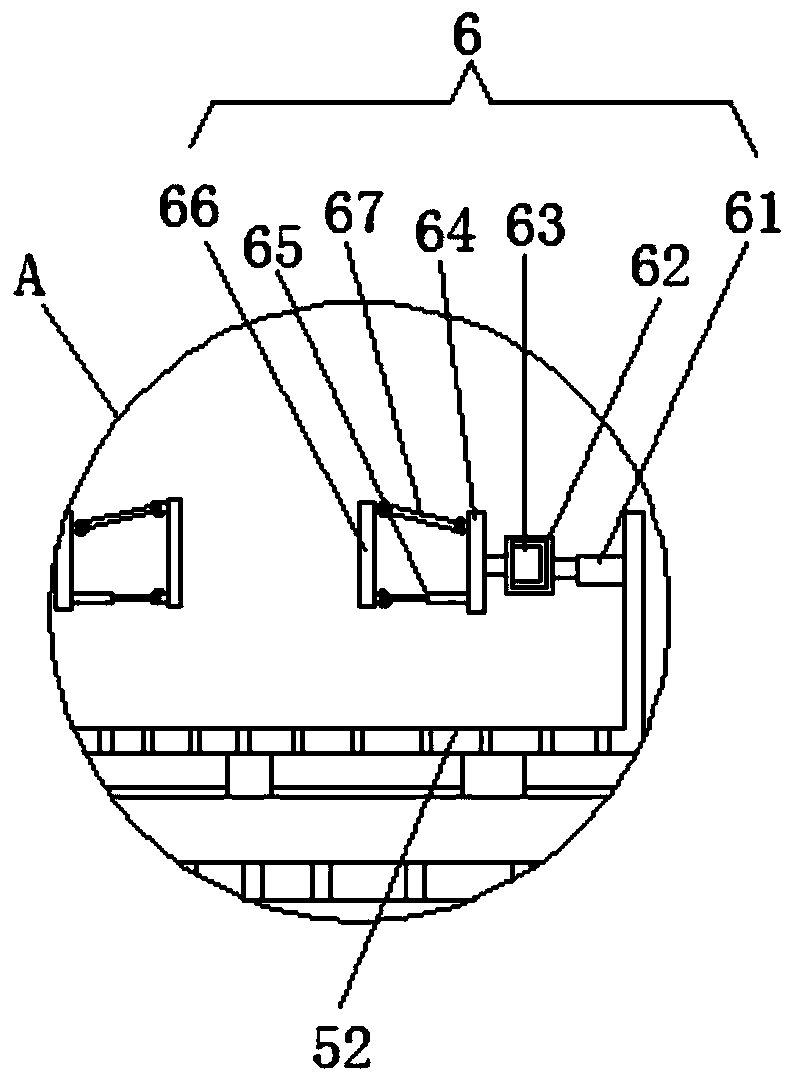

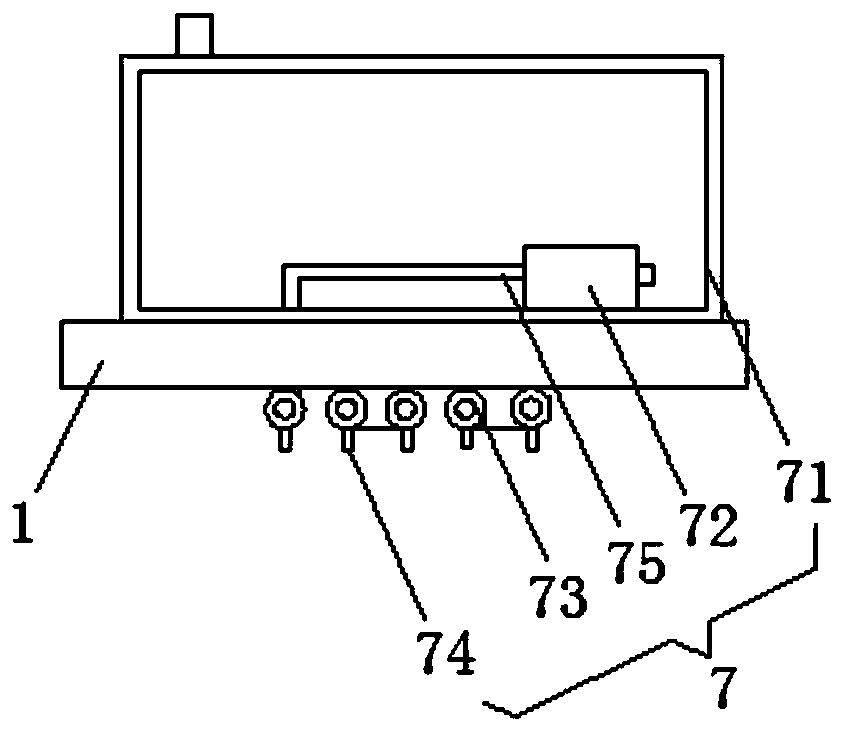

Fixed-length cutting device for tubes

ActiveCN105689788AEasy to cut to lengthImprove securityTube shearing machinesMetal working apparatusEngineeringMechanical engineering

The invention discloses a fixed-length cutting device for tubes. The fixed-length cutting device comprises a cutting table, a cutting device, support elements, a location table, a support shaft, a location disc and baffles, wherein the cutting device is arranged at the front end of the cutting table; the plurality of support elements are arranged on the cutting table along the same straight line, wherein the support element at the forefront is located in front of the cutting device; the location table is arranged in front of the cutting table; the support shaft is erected on the location table in a manner of being capable of sliding forwards and backwards; the location disc is rotatably arranged at the rear end of the support shaft in a sleeving manner, a plurality of U-shaped grooves are arranged in the rear end surface of the location disc in a sinking manner along a peripheral direction, and the opening of each U-shaped groove penetrates through the sidewall of the location disc; one baffle is arranged at the opening of each U-shaped groove in a covering manner; and one end of each baffle is hinged at one side of the opening of the corresponding U-shaped groove through a pin shaft, and a torsional spring is arranged on each pin shaft in a sleeving manner. The fixed-length cutting device disclosed by the invention is capable of conveniently carrying out fixed-length cutting on the tubes, safe and efficient in cutting process, and low in cost.

Owner:海宁经开产业园区开发建设有限公司

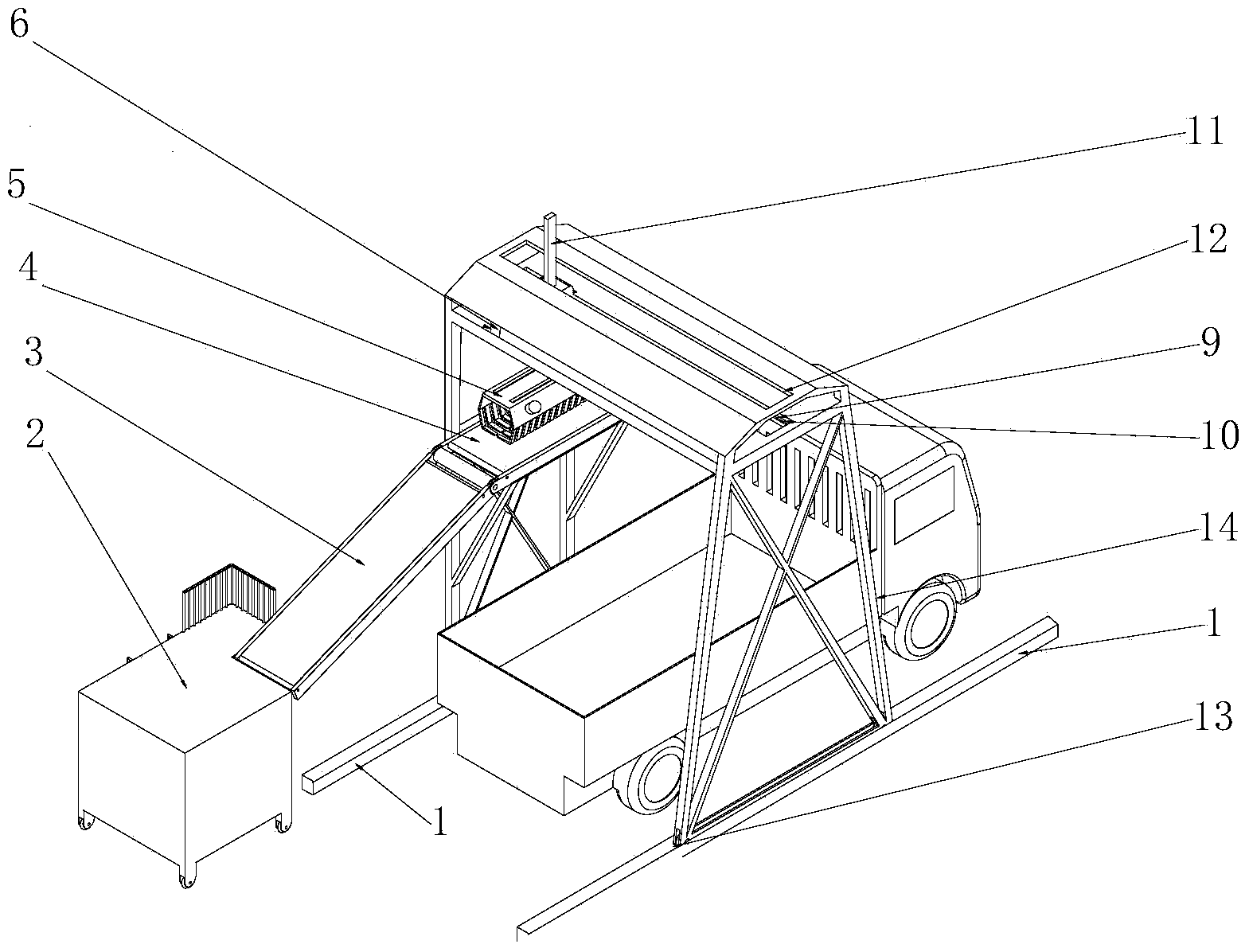

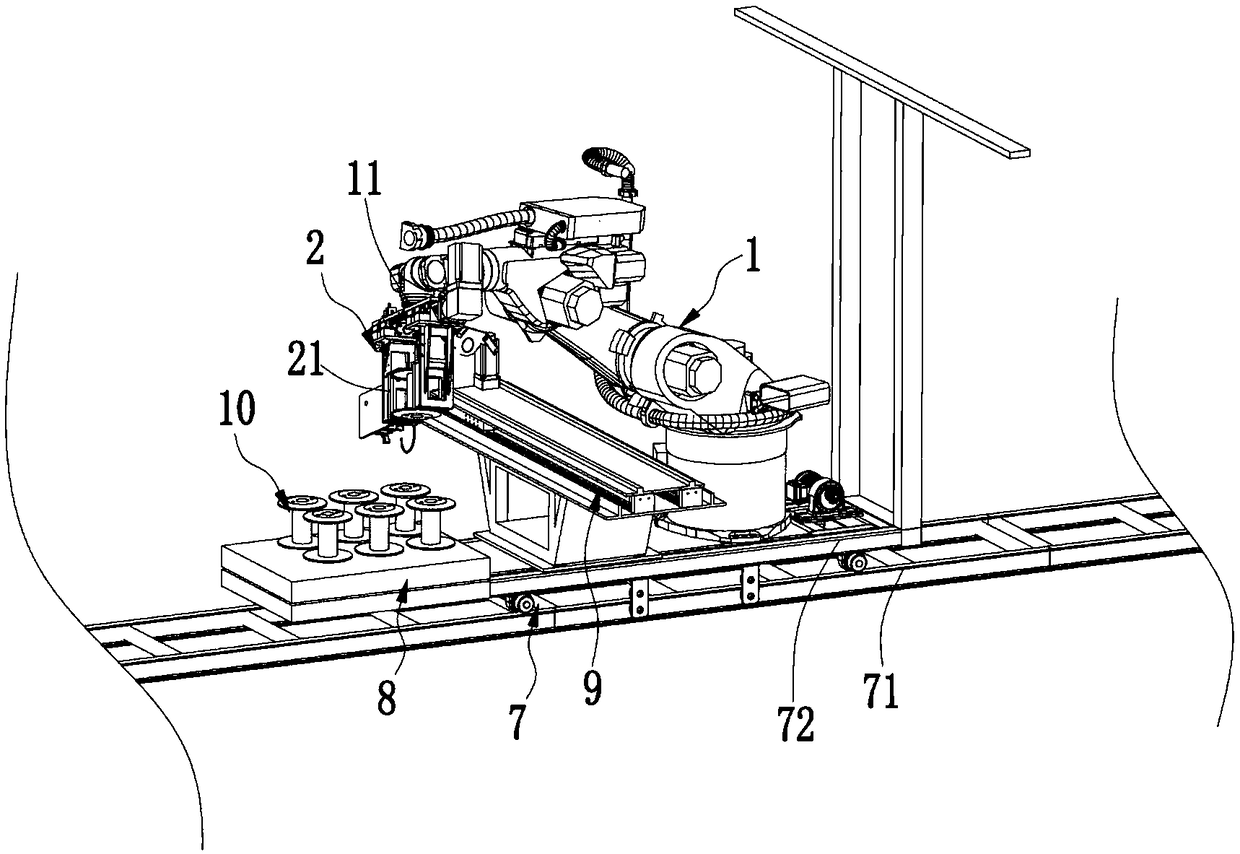

Loading robot

ActiveCN103964224ARealize unmannedFully automaticLoading/unloadingConveyor partsManipulatorPosition sensor

The invention discloses a loading robot. The loading robot is characterized by comprising a main framework, a manipulator, a vertical moving mechanism, a horizontal moving mechanism, a power unit and a sensing control device, the main framework is used for fixing all the mechanisms and other parts; the manipulator is used for rotating and grabbing goods; the vertical moving mechanism is connected with the upper end of the manipulator and used for driving the manipulator to vertically move; the horizontal moving mechanism is installed at the upper end of the main framework, is connected to the vertical moving mechanism through a sliding block and is used for driving the manipulator to horizontally move; the power unit comprises a rotary servo motor for controlling the manipulator to rotate, a vertical moving servo motor for controlling the vertical moving mechanism to move, and a horizontal servo motor for controlling the horizontal moving mechanism to move; the sensing control device comprises a goods position sensor, a goods falling sensor and a vehicle position sensor all of which are installed at different positions of the main framework and used for controlling the manipulator to operate. The loading robot achieves unmanned loading, thereby saving labor, improving the loading efficiency greatly and enabling loading to be standard and orderly.

Owner:青岛德和丰科贸有限公司

Insect capturing apparatus

An apparatus designed to catch flies and other flying insects comprises an aesthetically pleasing rectangular housing with a top opening which allows an insect to fly or crawl onto an internal tacky sheet to be trapped. The housing may be placed upon any flat surface or be wall-mounted, thereby minimizing an occurrence of observing the trapped dead insects. A side surface of the housing provides loading and unloading of a slide-in tacky sheet. The tacky sheet attracts and traps flying or crawling insects such as flies through the top opening of the housing, thereby partially blocking a view of the trapped insects inside.

Owner:RODRIGUEZ JOHN

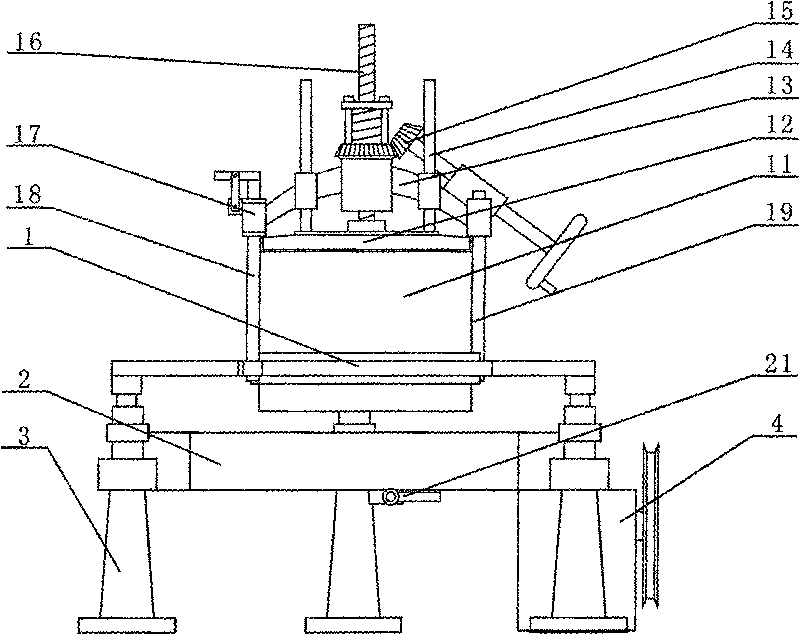

Mechanical medicine pounding device

The invention discloses a mechanical medicine pounding device. The device comprises a base, a medicine bowl and an L-shaped plate, wherein the medicine bowl is arranged above the base and detachably and rotationally connected with the base; the L-shaped plate covers the medicine bowl inside, the short edge of the L-shaped plate is hinged with the left side of the top of the base, and a support plate is fixed on the right side of the top of the base; support frames are symmetrically fixed at the top of the long edge of the L-shaped plate, a first rotating shaft is arranged between the tops of the support frames on two sides, a cam is fixed on the periphery of a shaft body of the first rotating shaft, a moving rod is arranged below the cam, and a medicine pounding hammer is fixed at the bottom of the moving rod and extends into the medicine bowl; a second motor driving the medicine bowl to rotate is mounted at the top of the base and located on the right side of the medicine bowl. The medicine pounding device can efficiently pound medicinal materials, has a good medicine pounding effect, can conveniently and thoroughly discharge the medicinal materials and also is compact in structure and convenient to operate.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

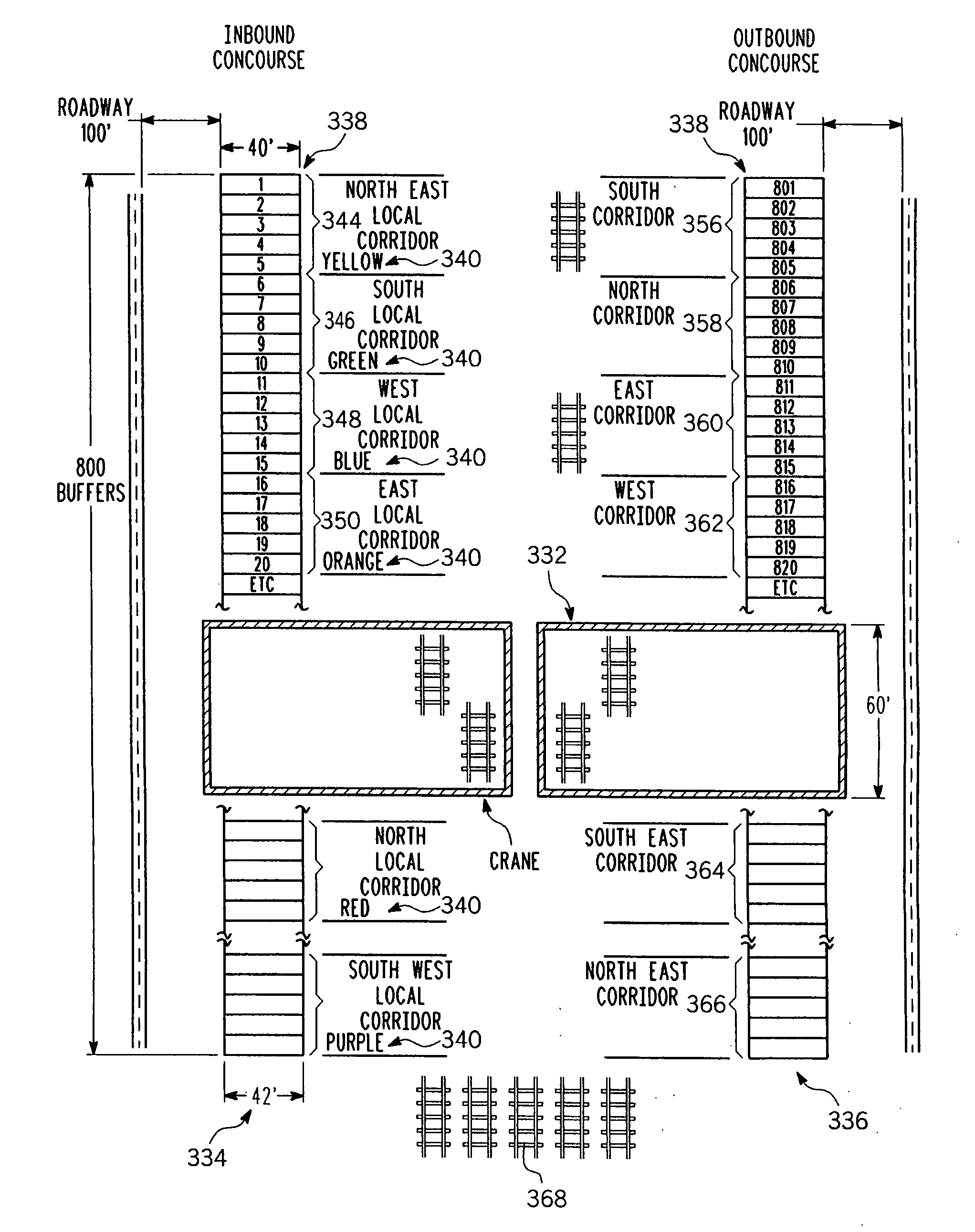

Inline terminal, hub and distribution system

ActiveUS20080219827A1Improve productivityTruck, buffer and crane utilization and efficiencyStacking articlesLoading/unloadingDistribution systemComputer terminal

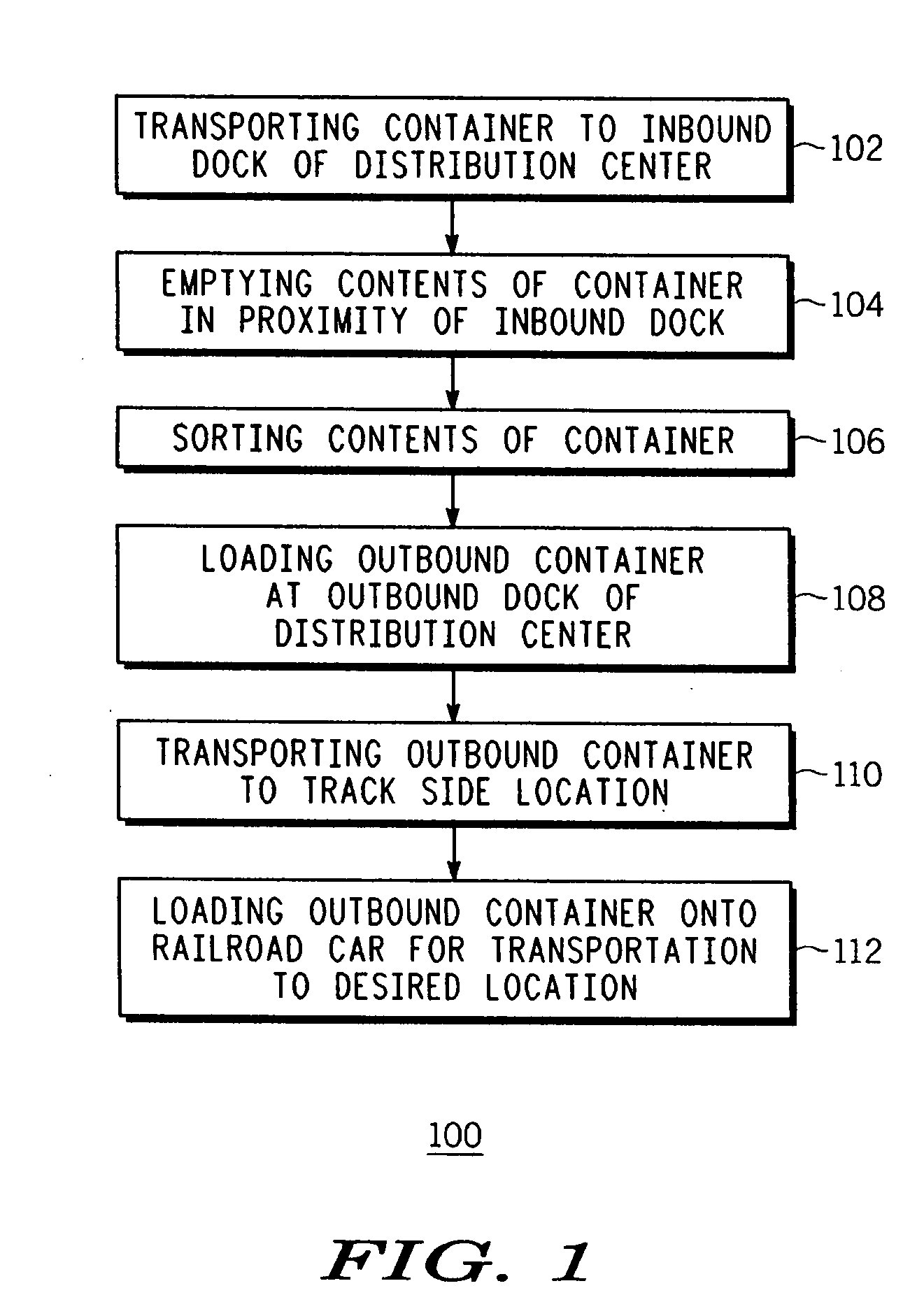

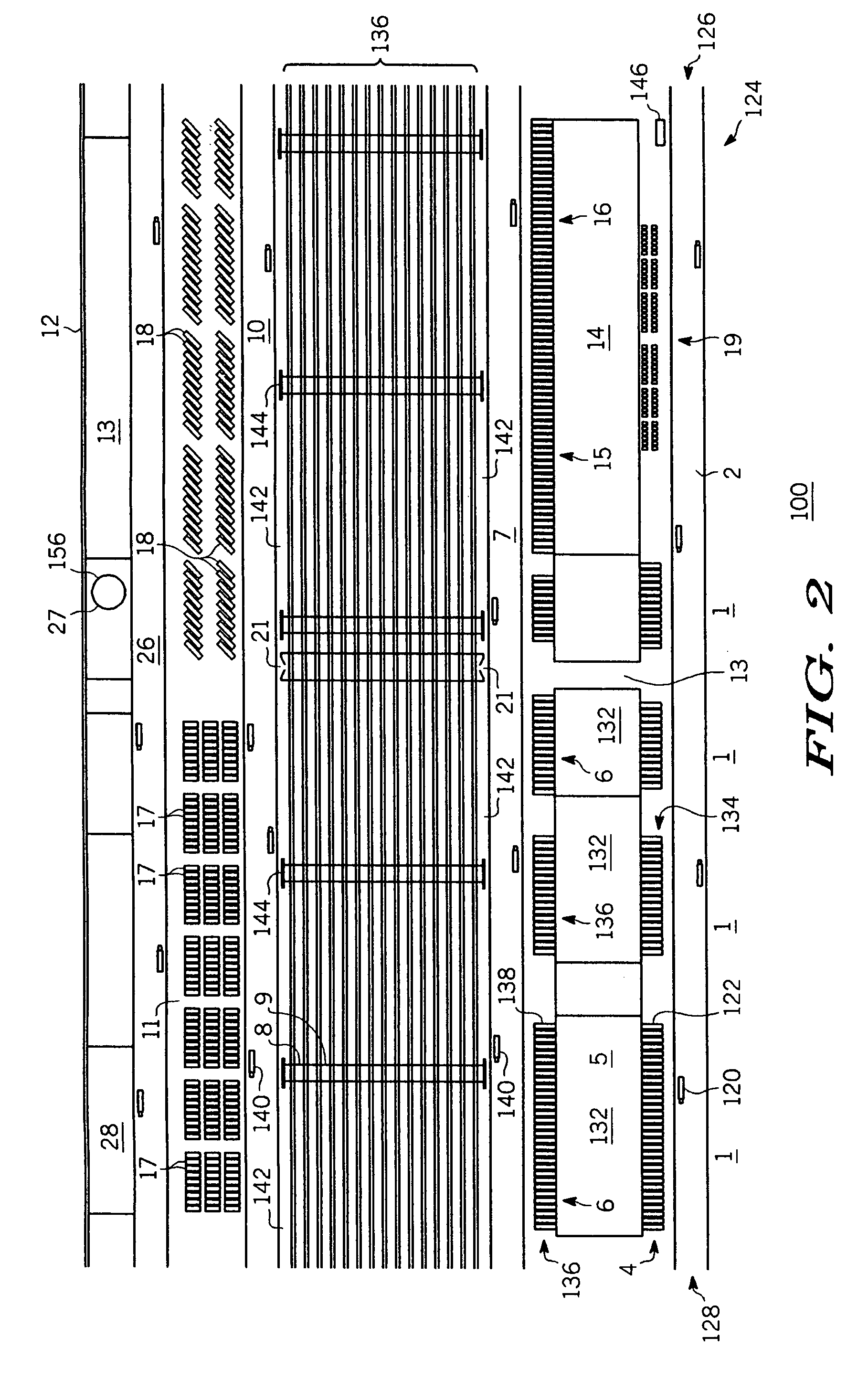

An inline terminal system (300), which includes the steps of: (i) transporting (302) a first container with a cargo via an inbound railroad car to a terminal having a plurality of train rails; (ii) picking and placing (304) the first container from the railroad car to a track side location having at least one buffer in proximity to the plurality of train rails, including: (a) rotating the first container at an angle of at least ten or more degrees with respect to the train rails; and (b) positioning the at least one buffer substantially adjacent to the train rails, at the track side location, at an angle of at least ten or more degrees with respect to the train rails; and (iii) moving (306) the first container via a tractor truck to a desired location for unloading. This system provides a simple, robust and efficient method to load, and in the reverse unload, a container on a chassis or rail car, respectively.

Owner:MI JACK PRODS

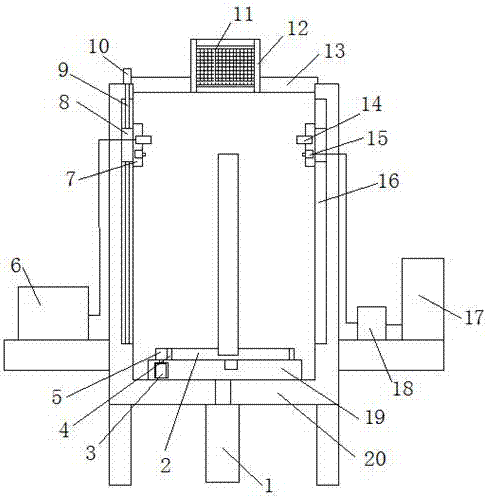

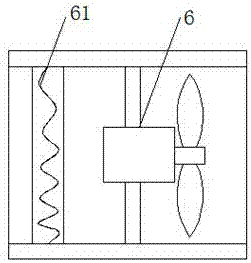

Cleaning and disinfection device for laboratory equipment

InactiveCN111299230AGuaranteed stability and suitabilityPrecise positioningDrying gas arrangementsLavatory sanitoryEquipments laboratoryMechanical engineering

The invention discloses a cleaning and disinfection device for laboratory equipment. The cleaning and disinfection device comprises a box body, a conveying structure, a clamping and overturning structure, a spraying and cleaning structure, a washing structure and a drying structure; a supporting plate is arranged at the lower end in the box body; uniformly distributed water leakage holes are formed in the left side of a wall body of the supporting plate; the upper side of the right end of the box body is provided with an opening; the conveying structure is arranged laterally at the upper end of the supporting plate; the clamping and overturning structure is arranged at the upper end of the conveying structure; the spraying and cleaning structure is arranged on the left side of the upper end of the box body; and the cleaning and disinfection device for the laboratory equipment is simple to operate, moderately holds fixes the equipment, can realize the overturning operation of the equipment during cleaning and disinfection, ensures the completeness of cleaning, washing and drying, and stably and accurately position and convey the equipment to a working area to form a complete set ofcomplete disinfectant spray disinfection, pure water showering cleaning and drying operations, ensures the quality of cleaning and disinfection, and reduces the workload of personnel.

Owner:李桂芳

Automatic paint spraying device for metal castings

PendingCN107214035AEasy to installEasy to unloadLiquid surface applicatorsLiquid spraying apparatusPiston rodSpray painting

The invention discloses an automatic paint spraying device for metal castings. The automatic paint spraying device comprises a paint spraying barrel with an opening in the top end. Support columns are correspondingly mounted on the four corners of the bottom end of the paint spraying barrel. An air cylinder vertically arranged is fixedly arranged on the side wall of the bottom end of the paint spraying barrel through bolts. A movable plate is welded to a piston rod of the air cylinder. The movable plate is located on the inner wall of the bottom end of the paint spraying barrel. The top end of the movable plate is rotationally connected with a mounting plate horizontally arranged. A first electric motor is embedded into the movable plate. An output shaft of the first electric motor is connected with a gear. The gear is located on one side of the mounting plate. Tooth mouths distributed in an array manner are mounted on the side walls of the periphery of the mounting plate. The tooth mouths are engaged with the gear. A fixing ring is slidably connected into the paint spraying barrel. An annular air outlet pipe and a liquid spraying pipe are mounted on the inner wall of the fixing ring. The air outlet pipe is located above the liquid spraying pipe. By the adoption of the automatic paint spraying device, the multi-angle paint spraying of the metal castings can be achieved, the paint spraying effect is good, the quick mounting and discharging of the metal castings are achieved, and the air pollution is reduced.

Owner:JIANGSU SUGAO FLUID MACHINERY

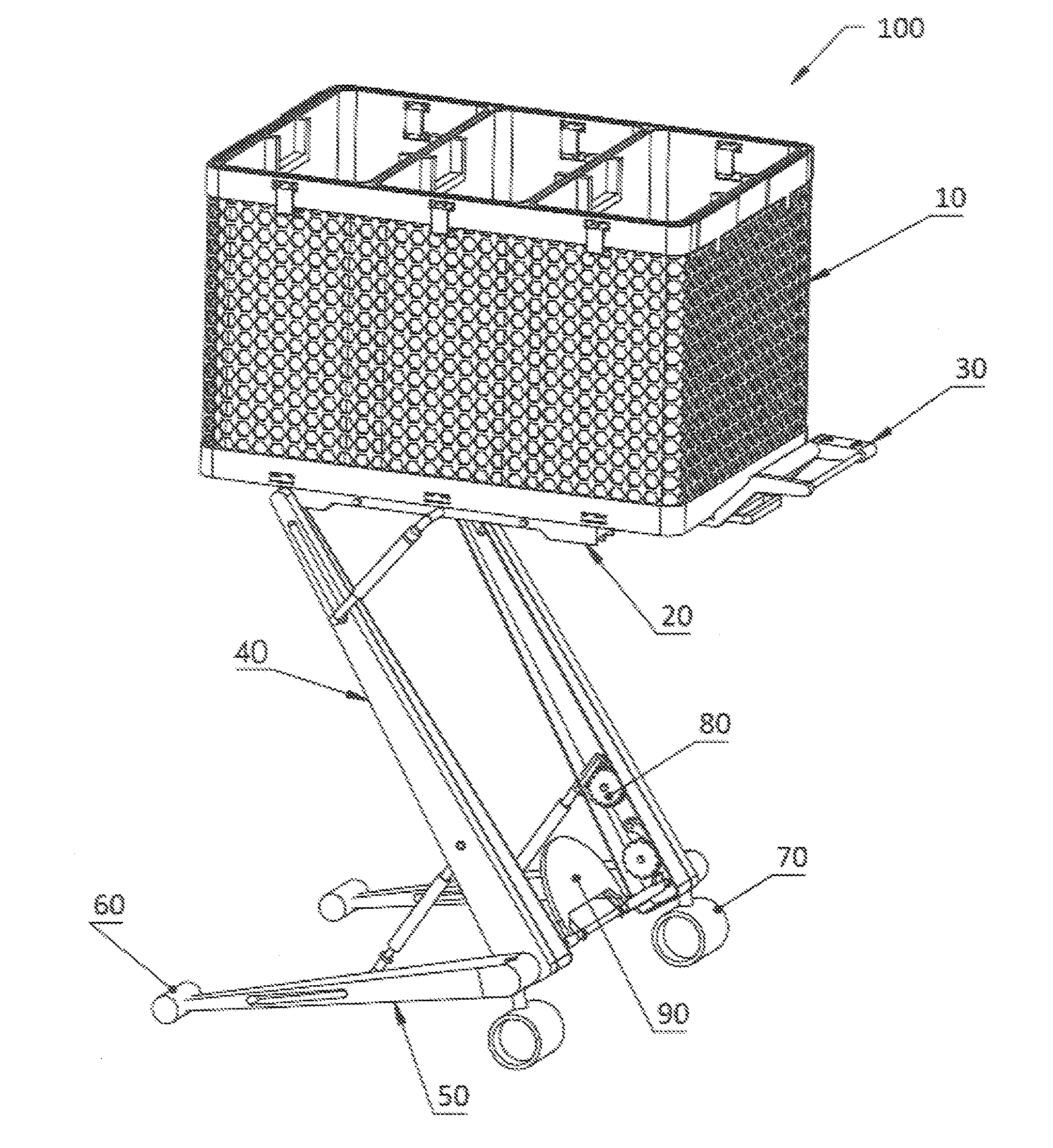

Shopping cart

ActiveUS8979115B1Short heightEasy loadingCarriage/perambulator accessoriesCarriage/perambulator with multiple axesShopping basketEngineering

The shopping cart has a foot pedal mechanism to adjust the height of the shopping basket to accommodate different sized users and can lower the cart height automatically with just the push of a button. The shopping basket includes separate detachable smaller bags used for bringing in items from the car. The cart is also designed to be fully collapsible to a height of only six inches and can be easily loaded into the rear trunk space of a car or SUV. The entire basket is also both collapsible and expandable in size and can also be detached from the cart easily and includes at least two carrying handles.

Owner:BARON BRETT

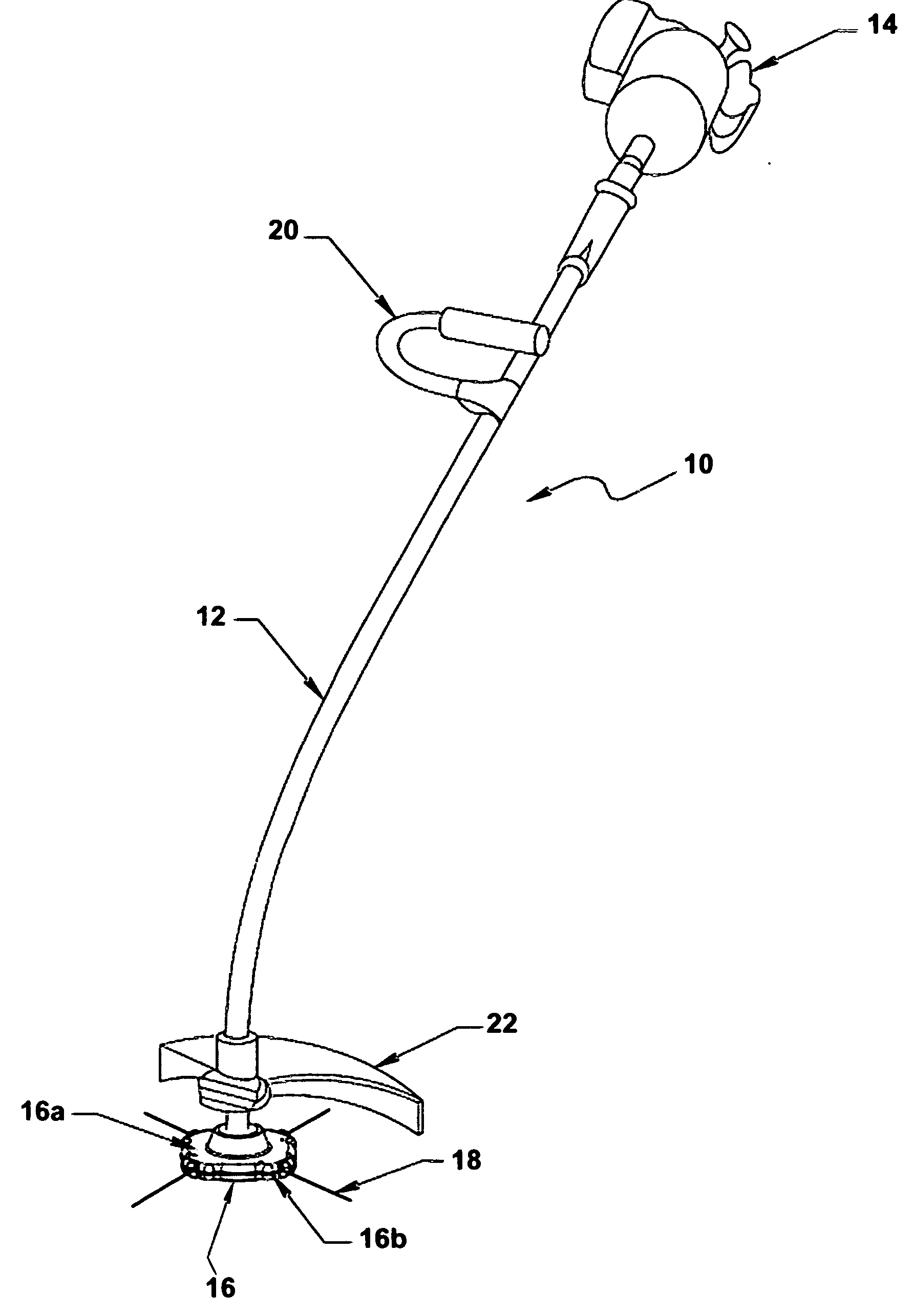

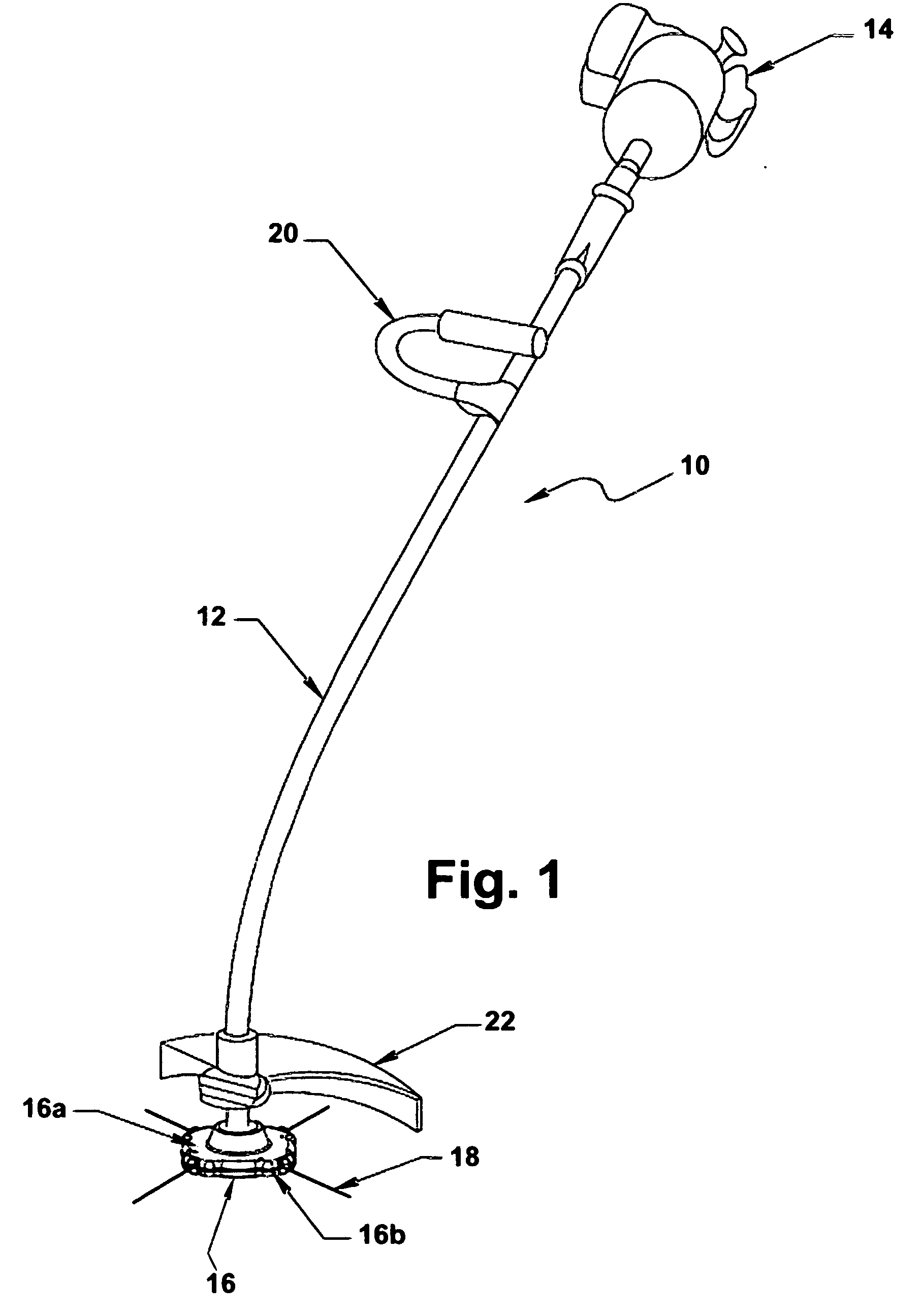

Vegetation trimmer apparatus

InactiveUS20060026846A1Easy to unloadReduce the possibilityMowersMetal working apparatusVegetationEngineering

A motorized vegetation trimmer apparatus comprising an elongate main handle to which is connected a motor that rotatably drives a trimmer head located at a distal end of the handle. The trimmer head carries one or more radially outwardly projecting cutting members which cut vegetation as the trimmer head rotates. Each cutting member comprises a finite length of flexible strand. The cutting member is releasably gripped in a substantially enclosed chamber by a gripping mechanism including a movable gripping member and a spring that biases the gripping member into gripping contact with the strand. A release member cooperates with the gripping member to urge the gripping member against the biasing force of the spring to permit removal of a cutting member from the trimmer head.

Owner:SPECIALTY COATED PROD +1

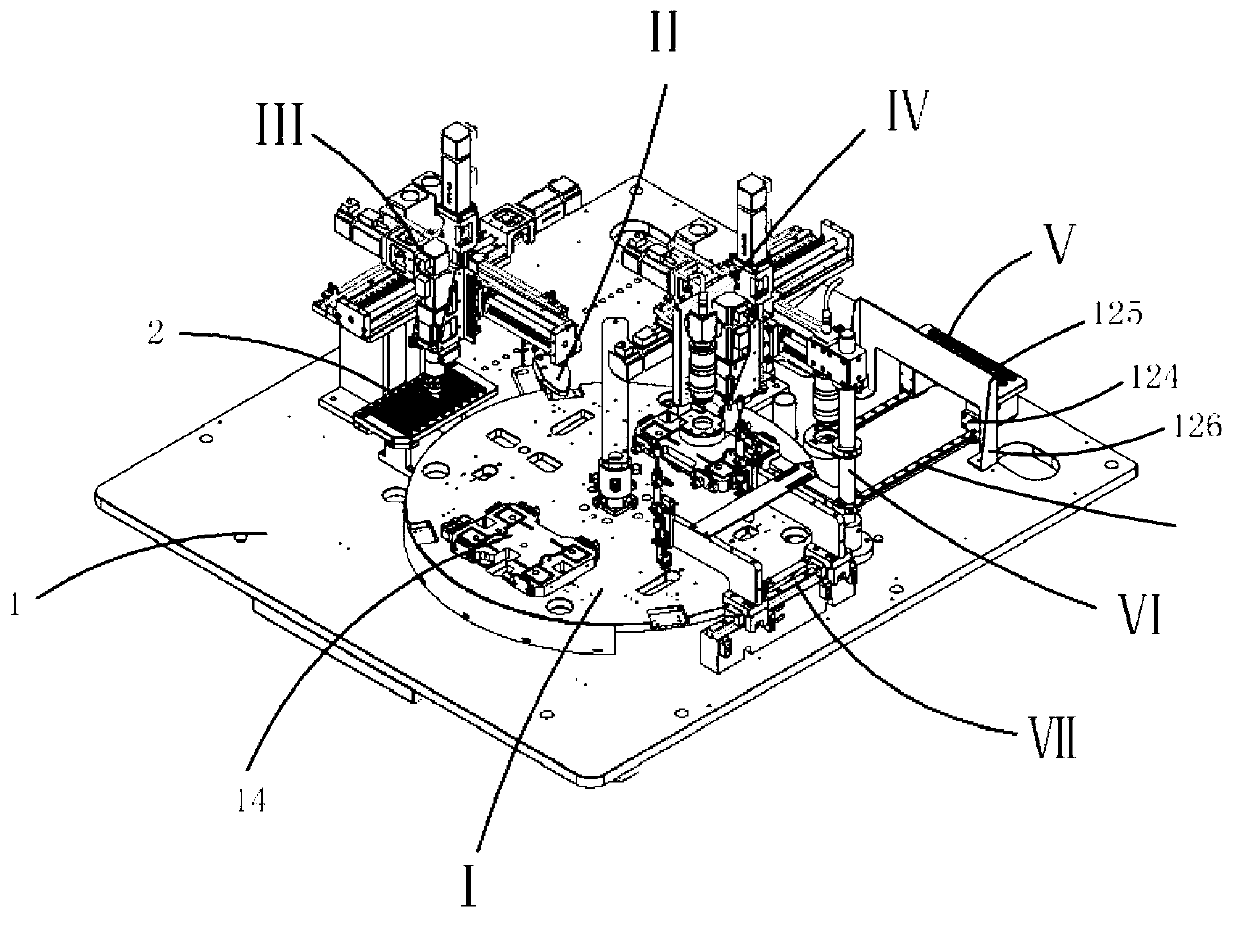

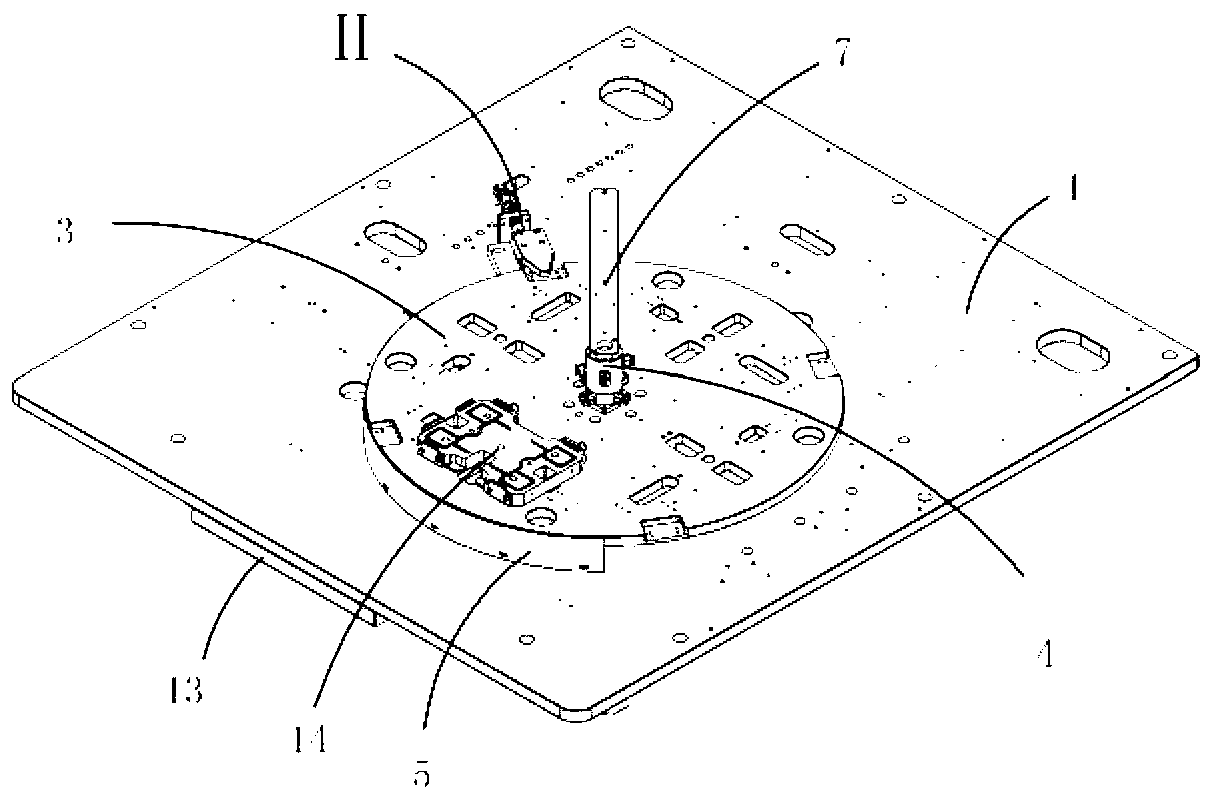

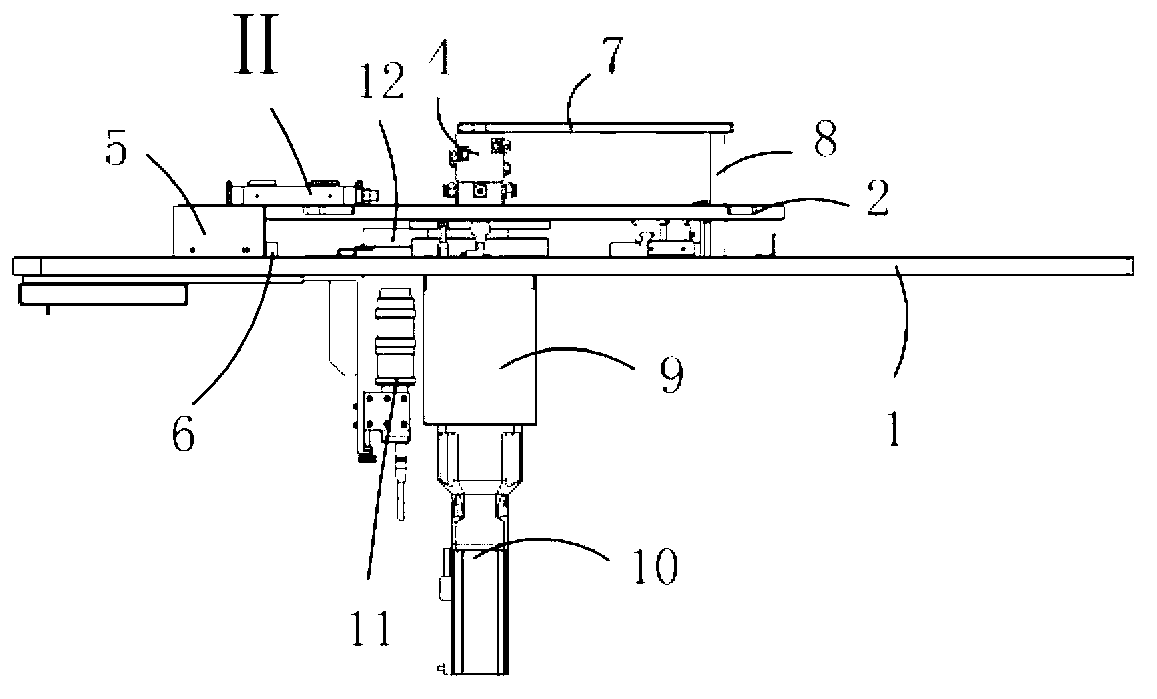

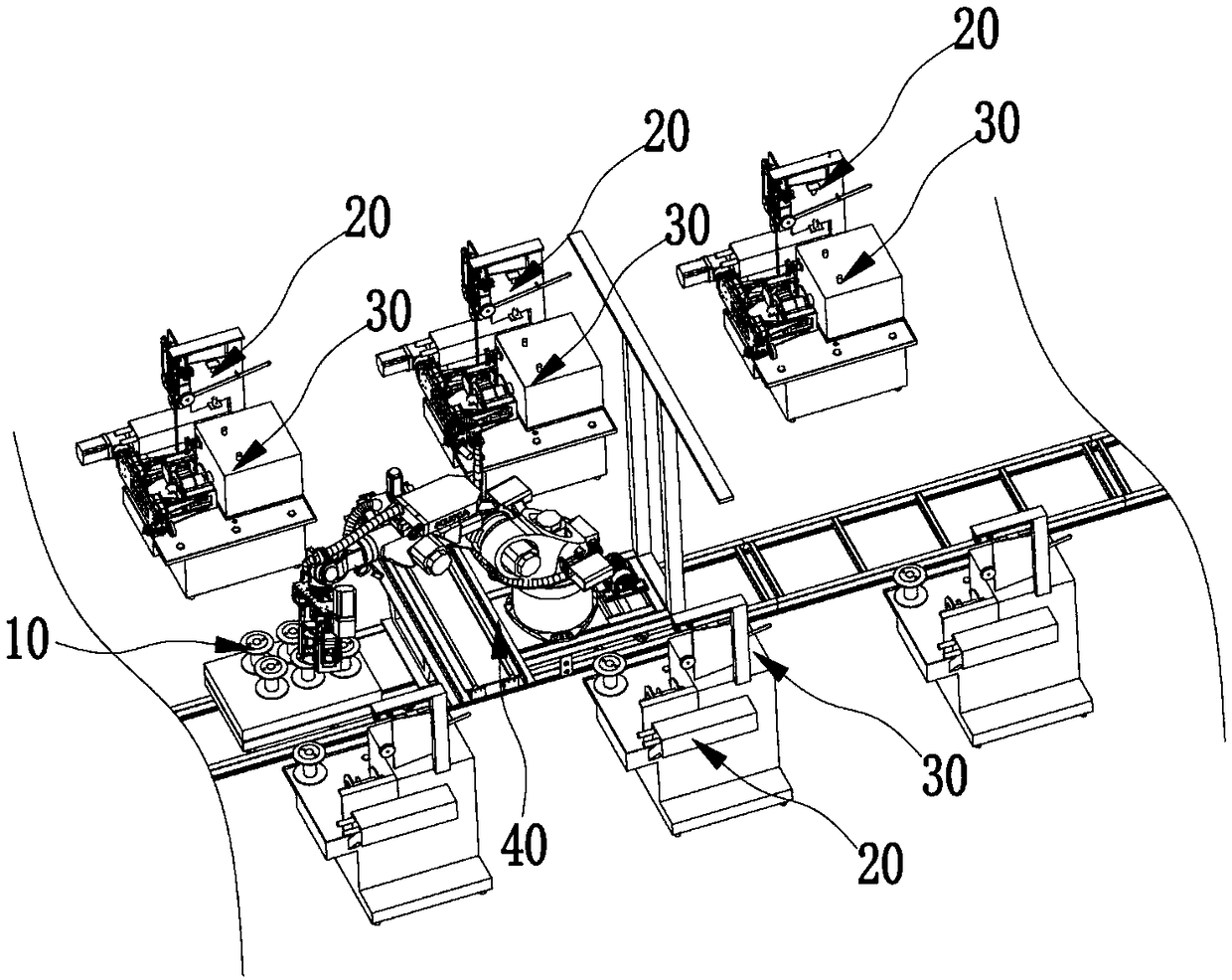

Part assembling machine

ActiveCN102990357AAccurate suctionMobile location is accurateAssembly machinesLarge buttonEngineering

The invention relates to a part assembling machine. The part assembling machine comprises a bottom plate, a turnplate mechanism, a turnplate locating mechanism, a button assembling mechanism, a fixing sheet assembling mechanism, a large button charging tray, a large fixing sheet charging tray component, a CCD (Charge Coupled Device) position correcting mechanism and a pressure maintaining mechanism, wherein the turnplate mechanism is arranged on the bottom plate; the button assembling mechanism is arranged at the left side of the turnplate mechanism; the large button charging tray is arranged on the bottom plate and is positioned below the button assembling mechanism; the turnplate locating mechanism is arranged above the left side of the bottom plate; the fixing sheet assembling mechanism is arranged at the upper end of the bottom plate, and the large fixing sheet charging tray component is arranged at the right side of the fixing sheet assembling mechanism; the CCD position correcting mechanism is arranged at the right upper side of the bottom plate; and the pressure maintaining mechanism is arranged at the right side of the bottom plate. The part assembling machine has the advantages that the turnplate is driven to rotate by a servo motor, parts can be assembled on standard operation positions by correction of the CCD position correcting mechanism and the turnplate locating mechanism, and the high automation of part assembling is completed through the coordination of all the mechanisms.

Owner:BOZHON PRECISION IND TECH CO LTD

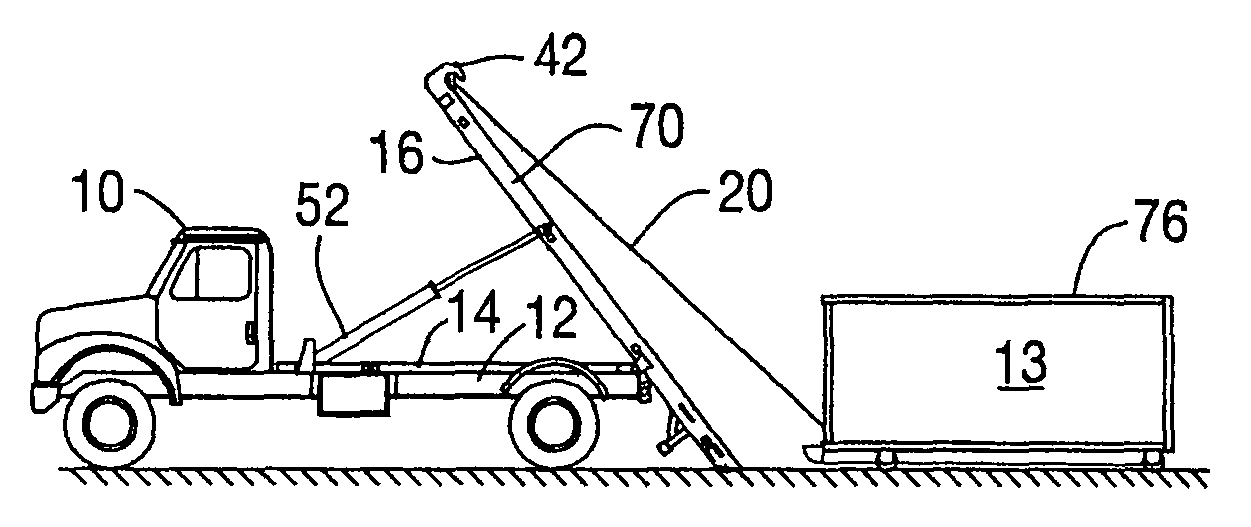

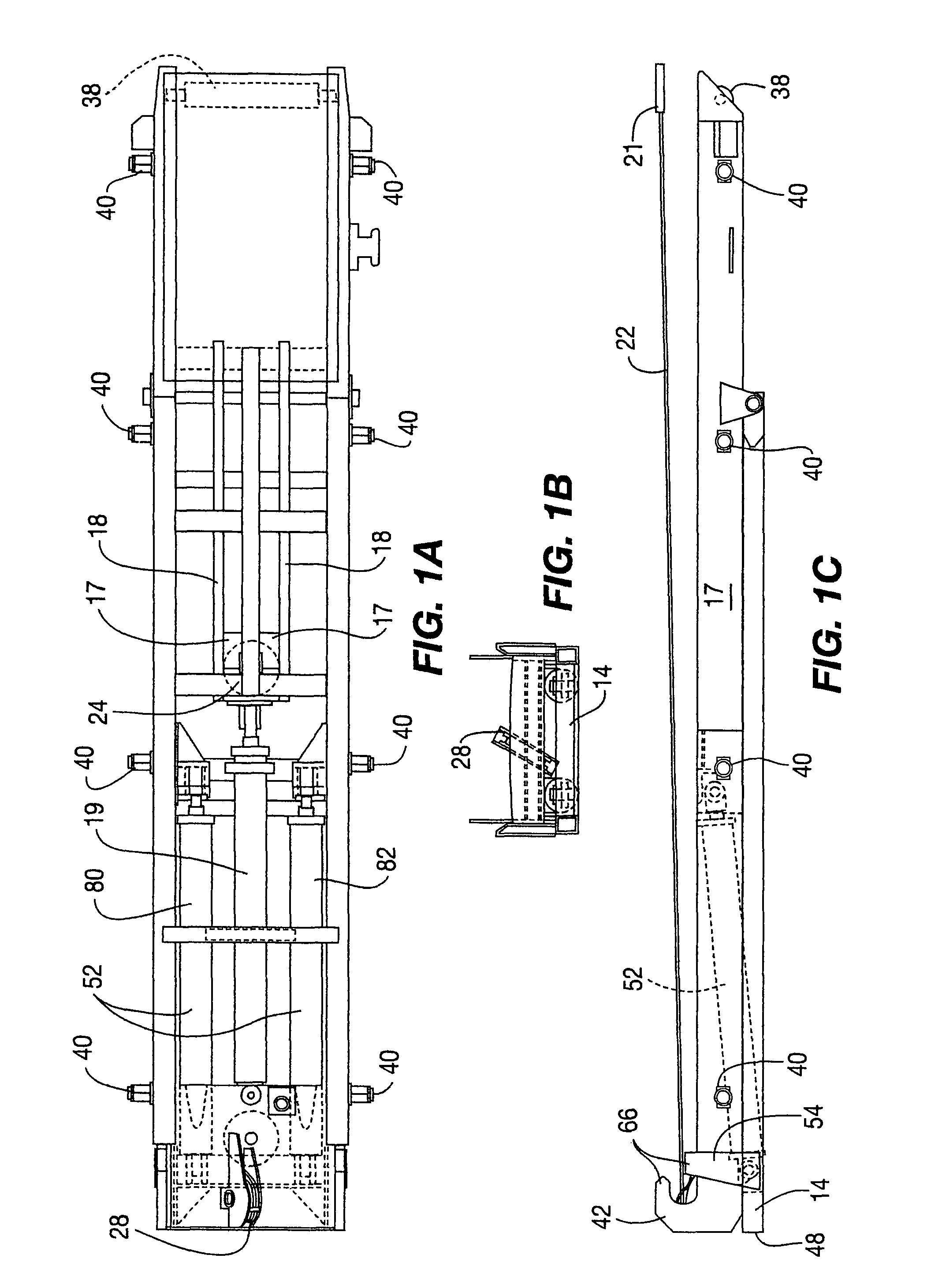

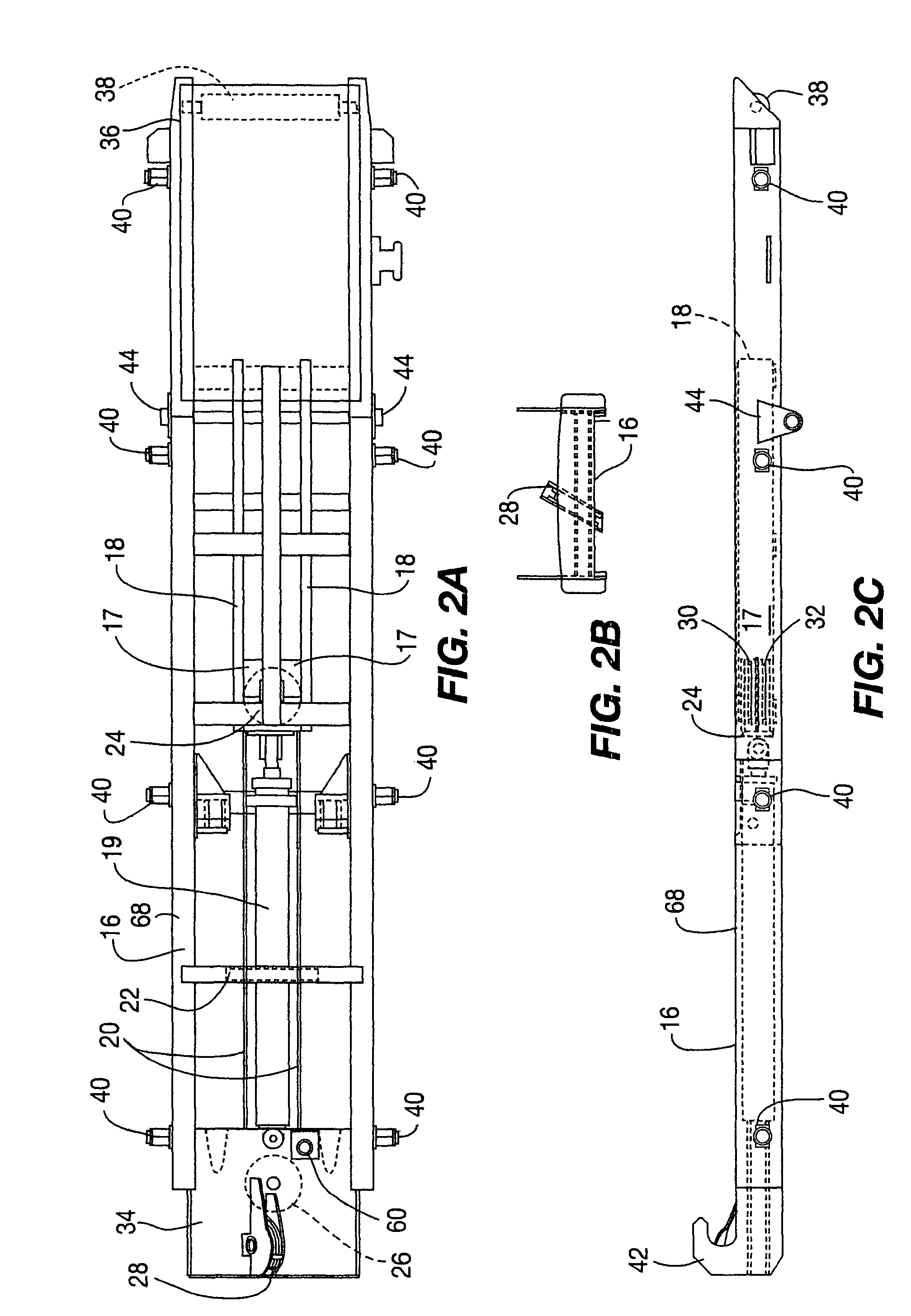

Cable hoisting apparatus

ActiveUS8029228B2Easy loading and unloadingEasy loadingArticle unpackingRefuse receptaclesVehicle frameElectric cables

A cable hoisting apparatus for loading and unloading of containers with respect to vehicles including a modular assembly allowing the apparatus to be easily attached or detached with respect to the vehicle. This modular assembly includes a subframe directly attachable detachably to the vehicle which includes a reeve cylinder and a lifting cylinder mounted therewithin. A top frame is included which is pivotally movably mounted to the subframe. The lifting cylinder powers pivotal movement of the top frame. Loading and unloading of the container is powered by the reeve cylinder. The reeve cylinder moves a shoe within a shoe track which extends or contracts a cable attached to a container which is positioned about a plurality of sheaves one of which is attached to the slideable shoe. A positively engaging locking construction is included defined between the subframe and the top frame for positively retaining the container.

Owner:OMAHA STANDARD

Novel tea knead entwist machine

The invention discloses a novel tea knead entwist machine and relates to tea processing machineries. The circular movement of the knead entwist device above the knead entwist plate can be realized by connecting the knead entwist device with a crank rocker mechanism; and the tailor-made knead entwist plate matches with the screw cover in the knead entwist device. The stripping tea rate of the tea is high, broken tea is little, and the broken tea generated in production can be separated from the mature tea automatically, thus improving tea grade and increasing production efficiency.

Owner:WUFENG TIANCHI TEA MACHINERY

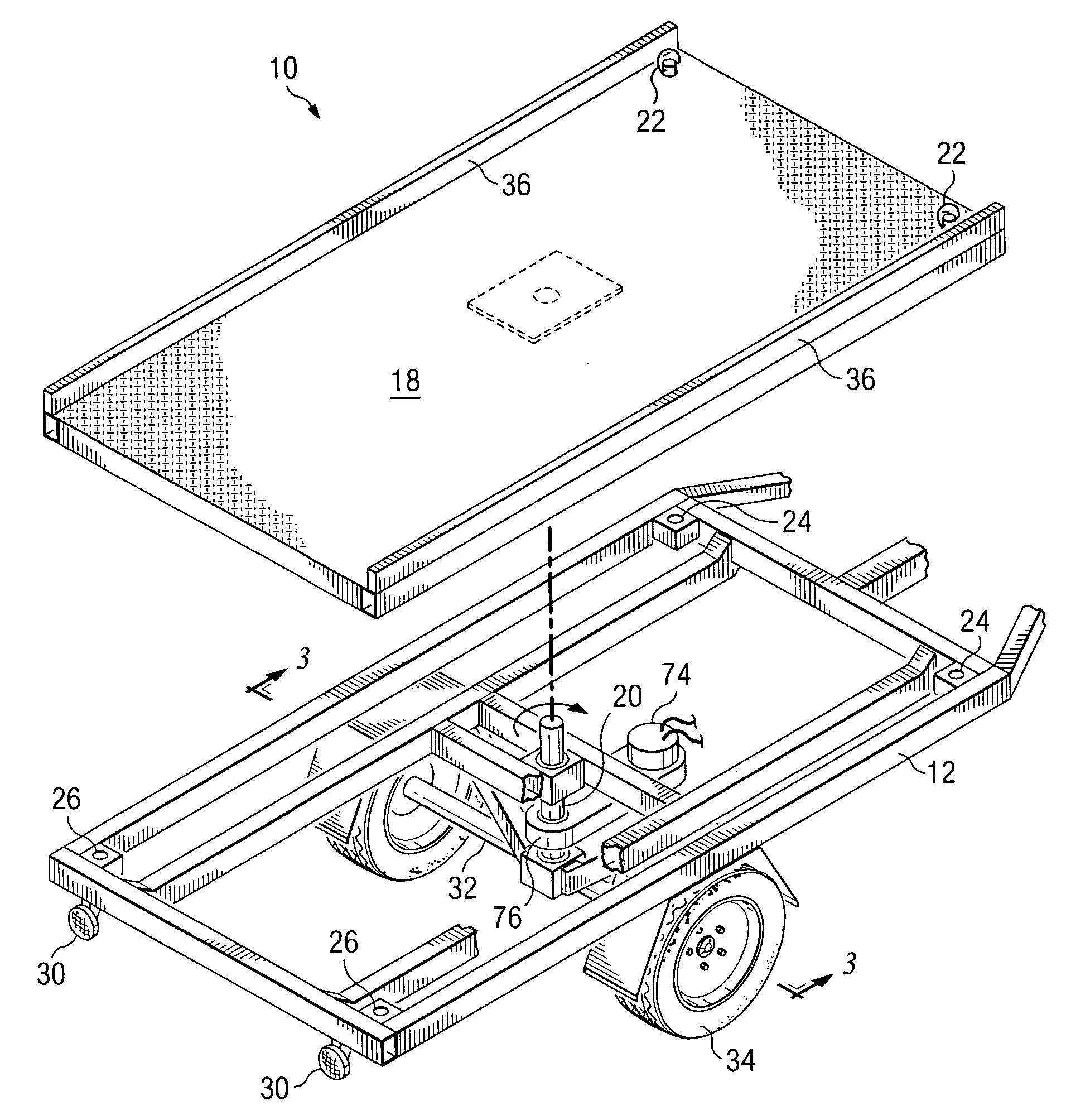

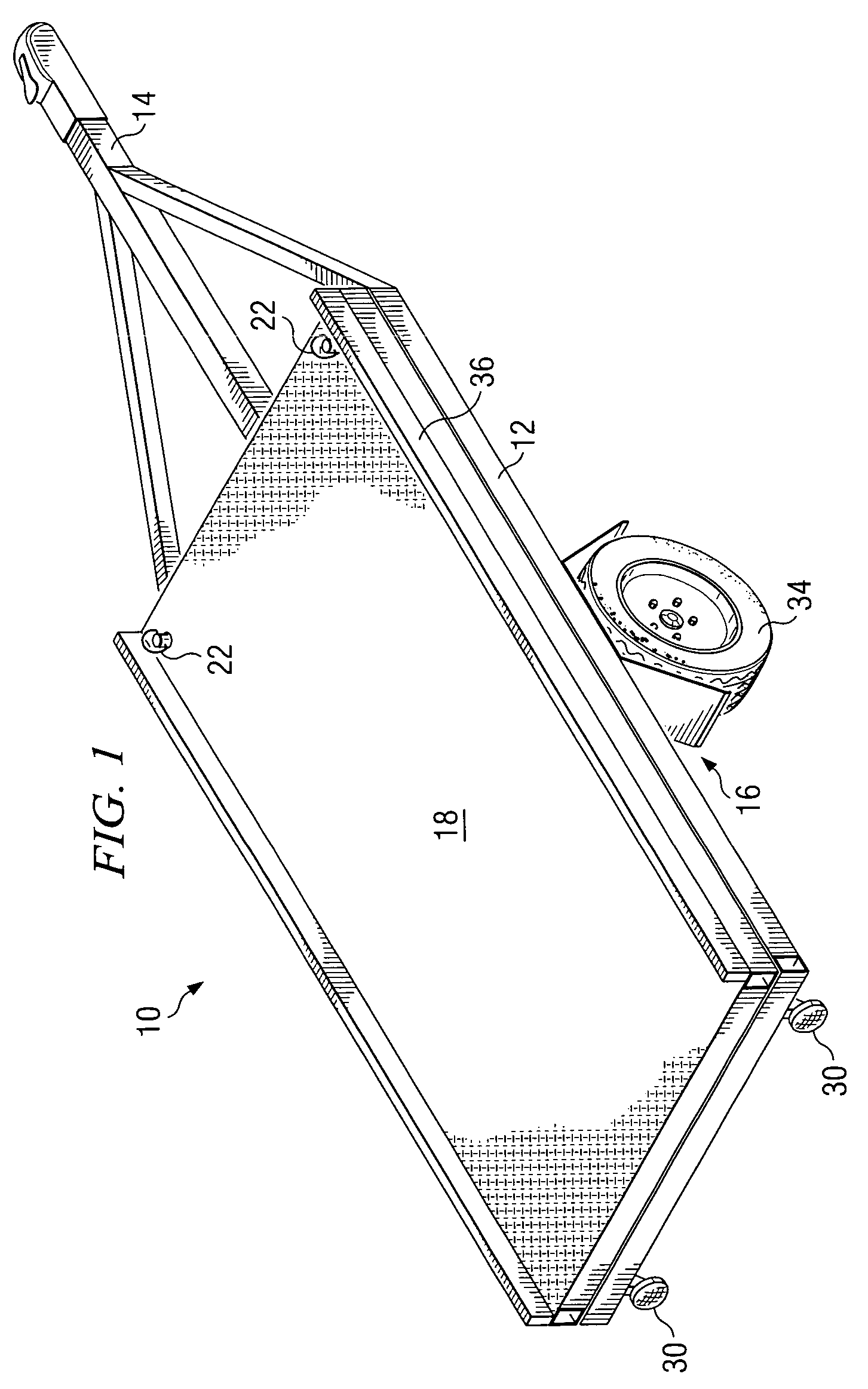

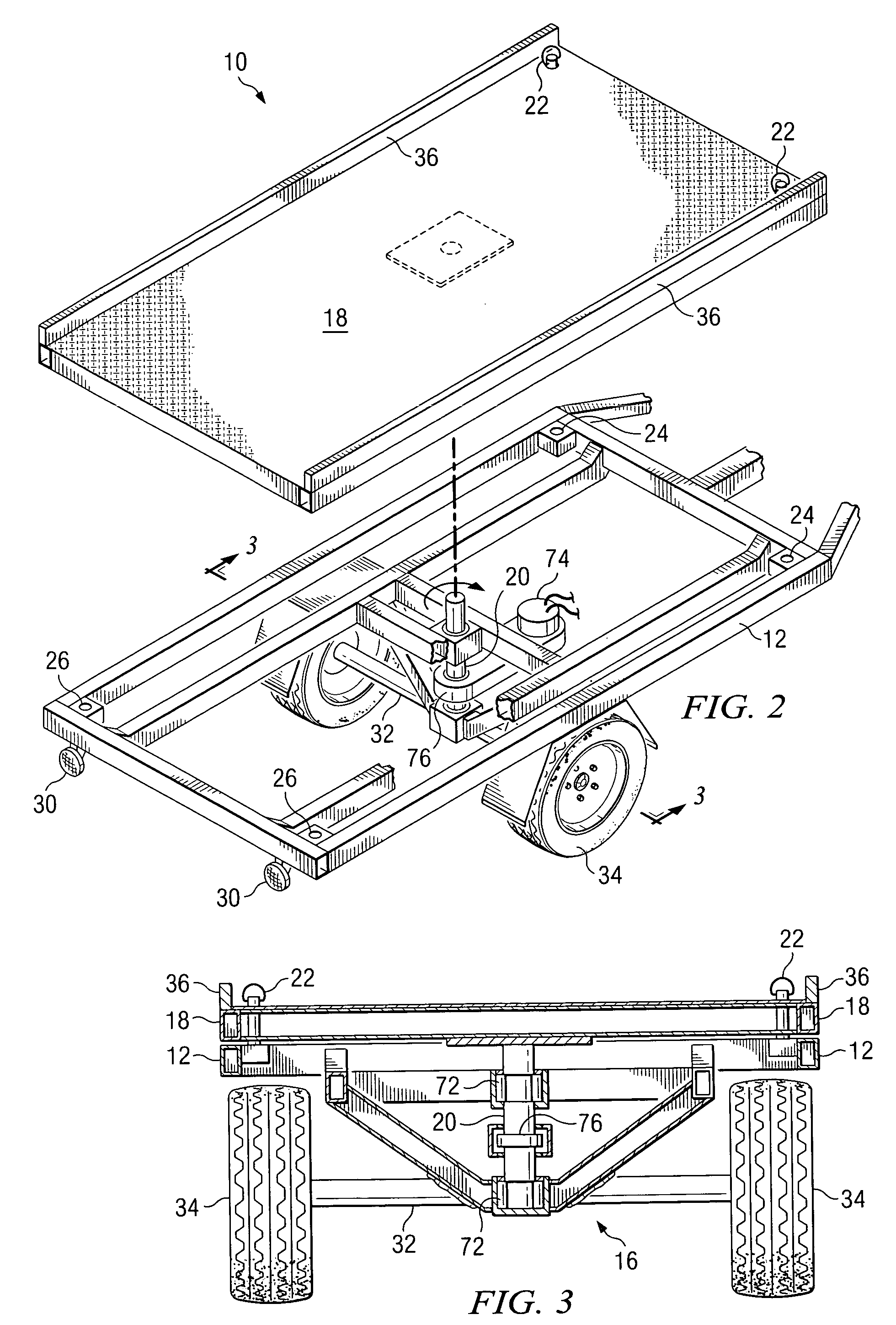

Reversible transport trailer

InactiveUS7427183B2Easy to unloadOvercome difficultiesHand carts with one axisItem transportation vehiclesEngineeringSupport surface

A transport trailer comprises a support surface mounted for rotation relative to an underlying frame to facilitate the loading of vehicles and other articles by forward movement thereof and the unloading of the vehicles and other articles also by forward movement thereof.

Owner:STABENO GARY L

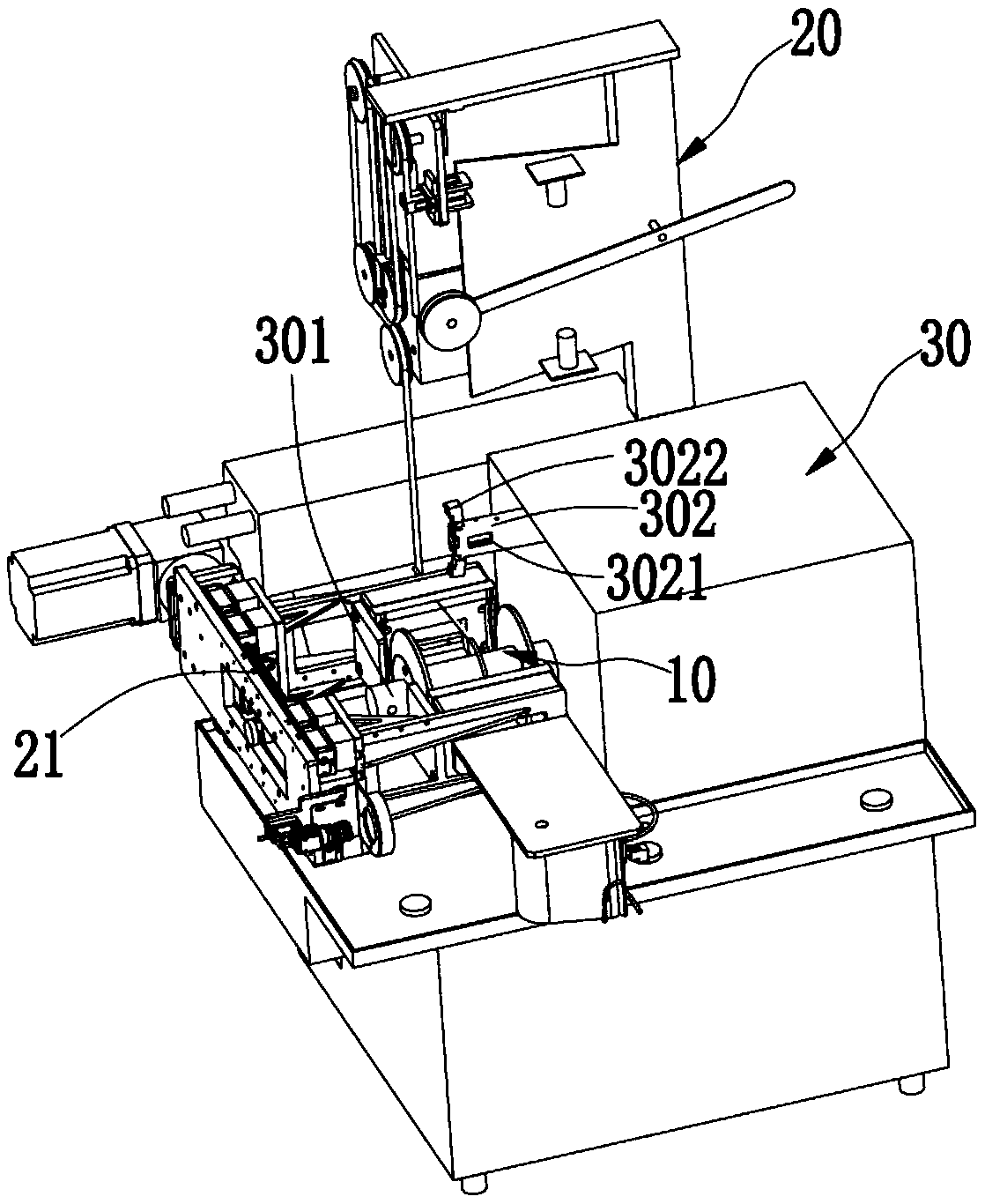

Full-automatic winding production line and processing method thereof

PendingCN109436951ASimple structureIncrease flexibilityFilament handlingProduction lineWinding machine

The invention discloses a full-automatic winding production line and a processing method thereof. The full-automatic winding production line comprises at least one automatic feeding machine, at leastone winding machine and an automatic winding disc feeding and discharging robot, wherein the automatic feeding machine is used for supplying a filament-shaped body; the winding machine is used for fixing a winding disc and driving the winding disc to rotate; and the automatic winding disc feeding and discharging machine can move the winding disc onto the winding machine and taking the winding discdown from the winding machine, and the position of the filament-shaped body can be determined visually when the filament-shaped body is grabbed and cut off. According to the scheme, the automatic winding disc feeding and discharging robot cooperates with the automatic feeding machine and the winding machine, so that the whole process of feeding, winding and discharging is achieved automatically,and the novel full-automatic winding production line which is simple in structure and capable of controlling the winding process easily is provided; in addition, the visual positioning technique can effectively and accurately determine the position of the filament-shaped body, so that automatic grabbing and shearing are made possible; and the visual positioning technique is good in flexibility andhigh in accuracy and efficiency, so that the winding efficiency is improved.

Owner:WUXI MINGONG TECH

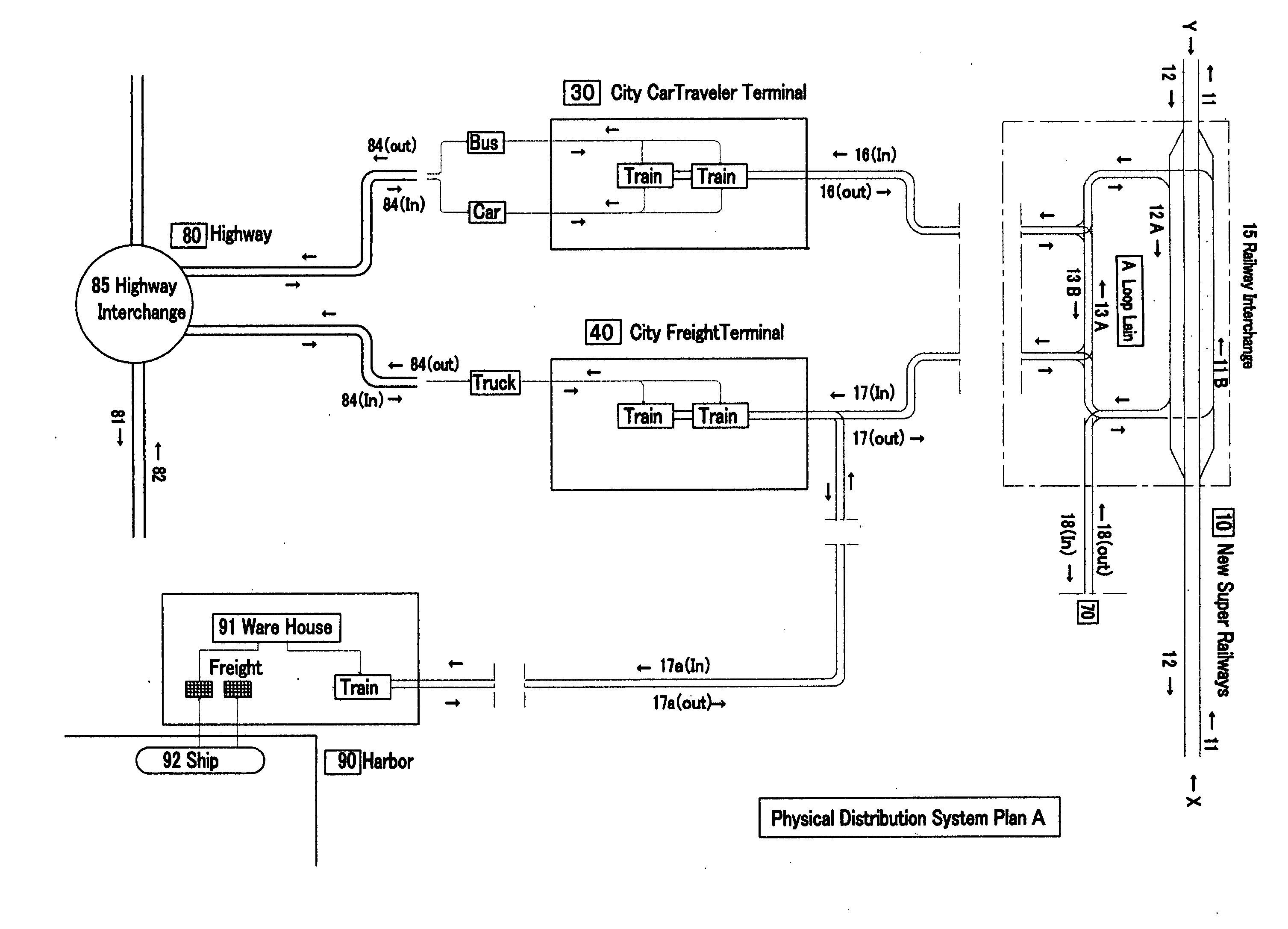

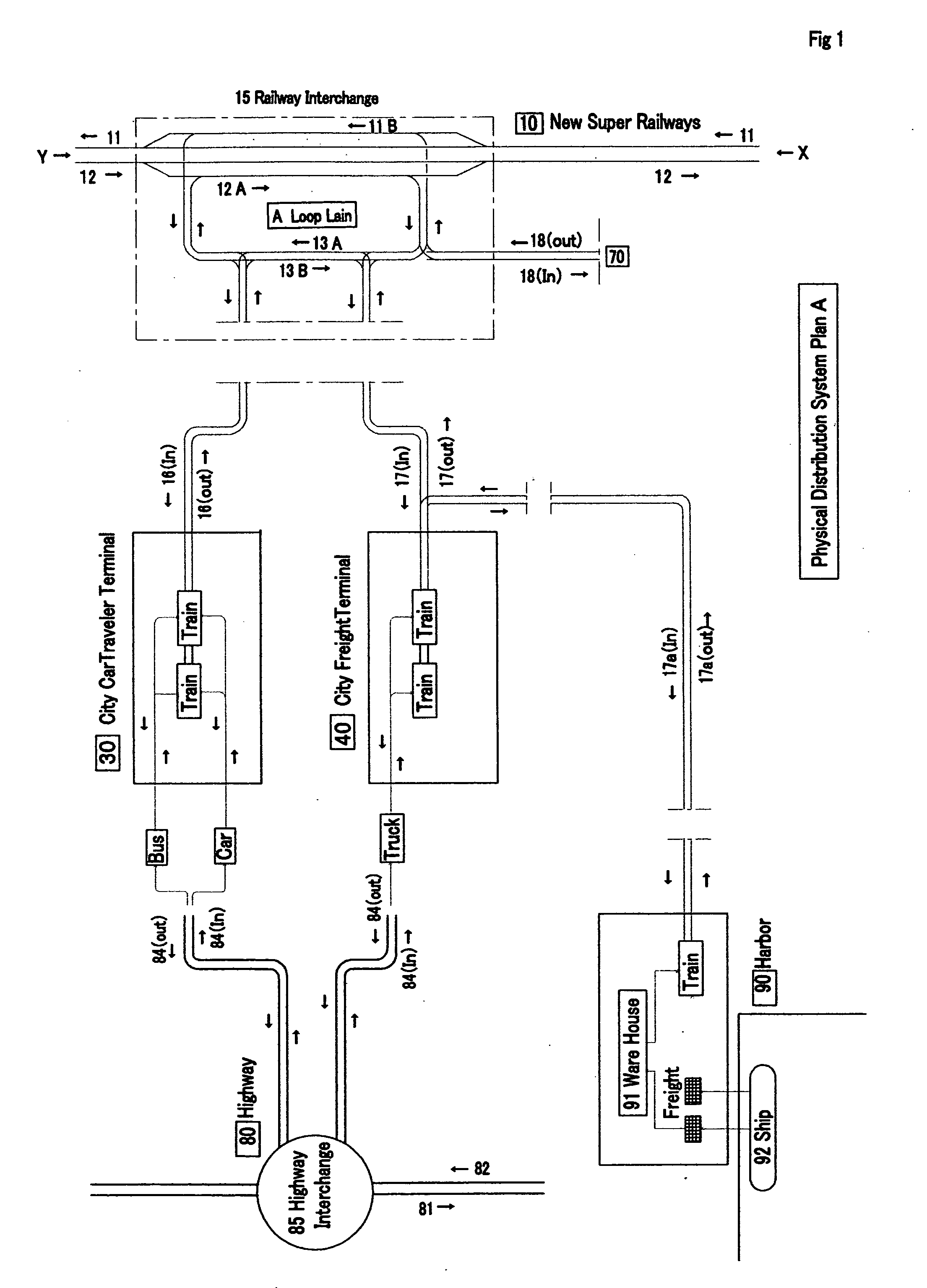

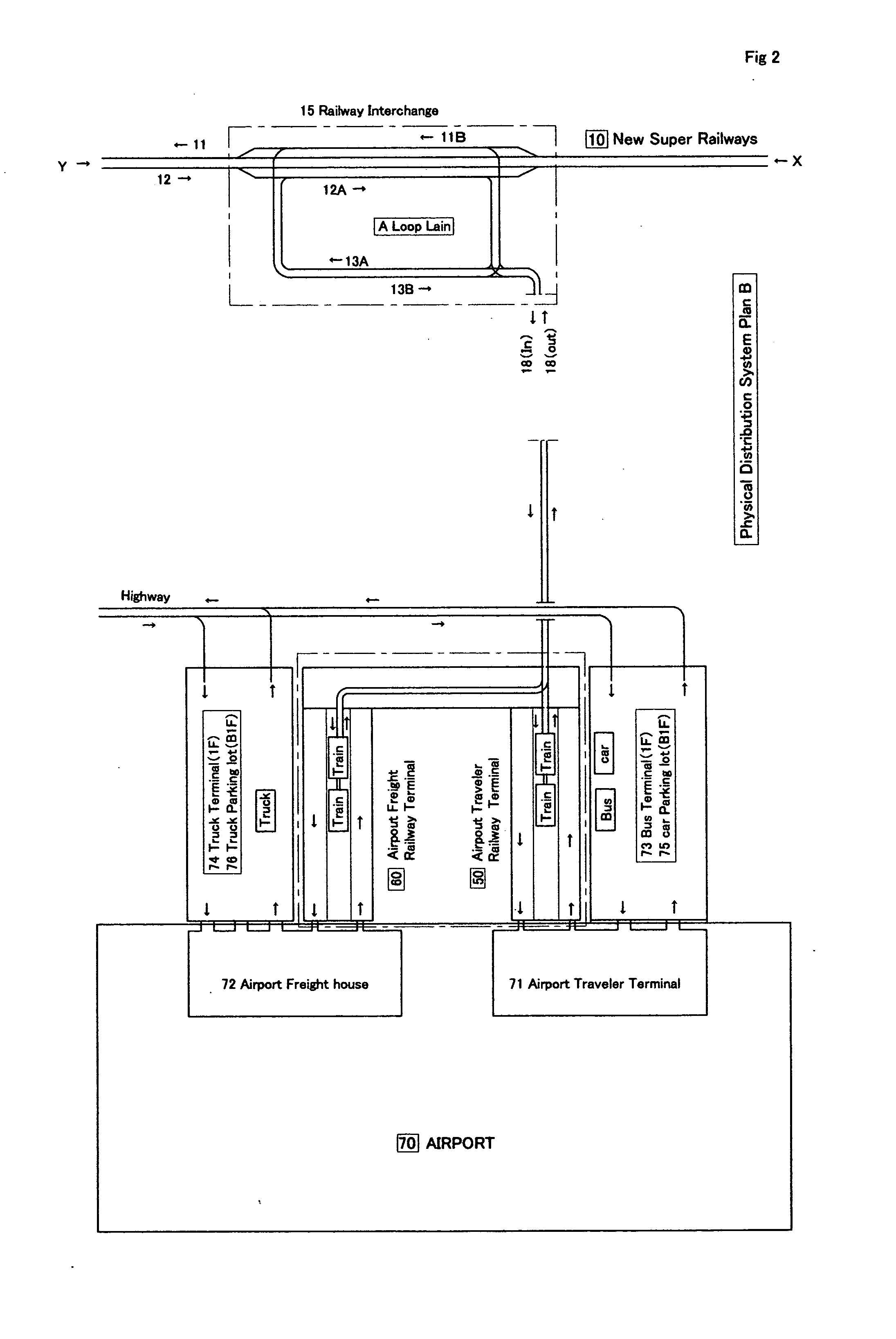

Super railway for USA

InactiveUS20060027133A1Easy to unloadSuppress construction costRefuge islandsRailway componentsPetroleumAir pollution

[OBJECT]To greatly reduce the passenger and freight traffic on highways and greatly reduce the consumption of petroleum due to short-distance domestic air traffic by the use of railway, so as to contribute to energy saving and mitigation of air pollution, and reduce the transportation costs through high speed and efficient transportation of people and goods. [SOLUTION MEANS]Railroad are constructed in uninhabited areas to connect a plurality of cities, with no stations constructed on the main tracks and railway interchanges are constructed instead that are provided with side tracks branching out from the main tracks or leading to the main tracks, so that a train bound to a particular town is directed through the railway interchange to a terminal constructed outside the town.

Owner:SUEMATSU TOSHIO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com