Drilling rig system with self-elevating drill floor

a drilling rig and floor technology, applied in the direction of ceilings, cranes, building repairs, etc., can solve the problems of increasing the set-up, take-down and operational costs of the rig, the wellbore is not sufficiently productive to warrant completion and operation of the well, and the equipment and labor costs can be incurred for each end of the set-up and take-down operation. to achieve the effect of facilitating the lateral movement of the completed rig base structure and facilitating the leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

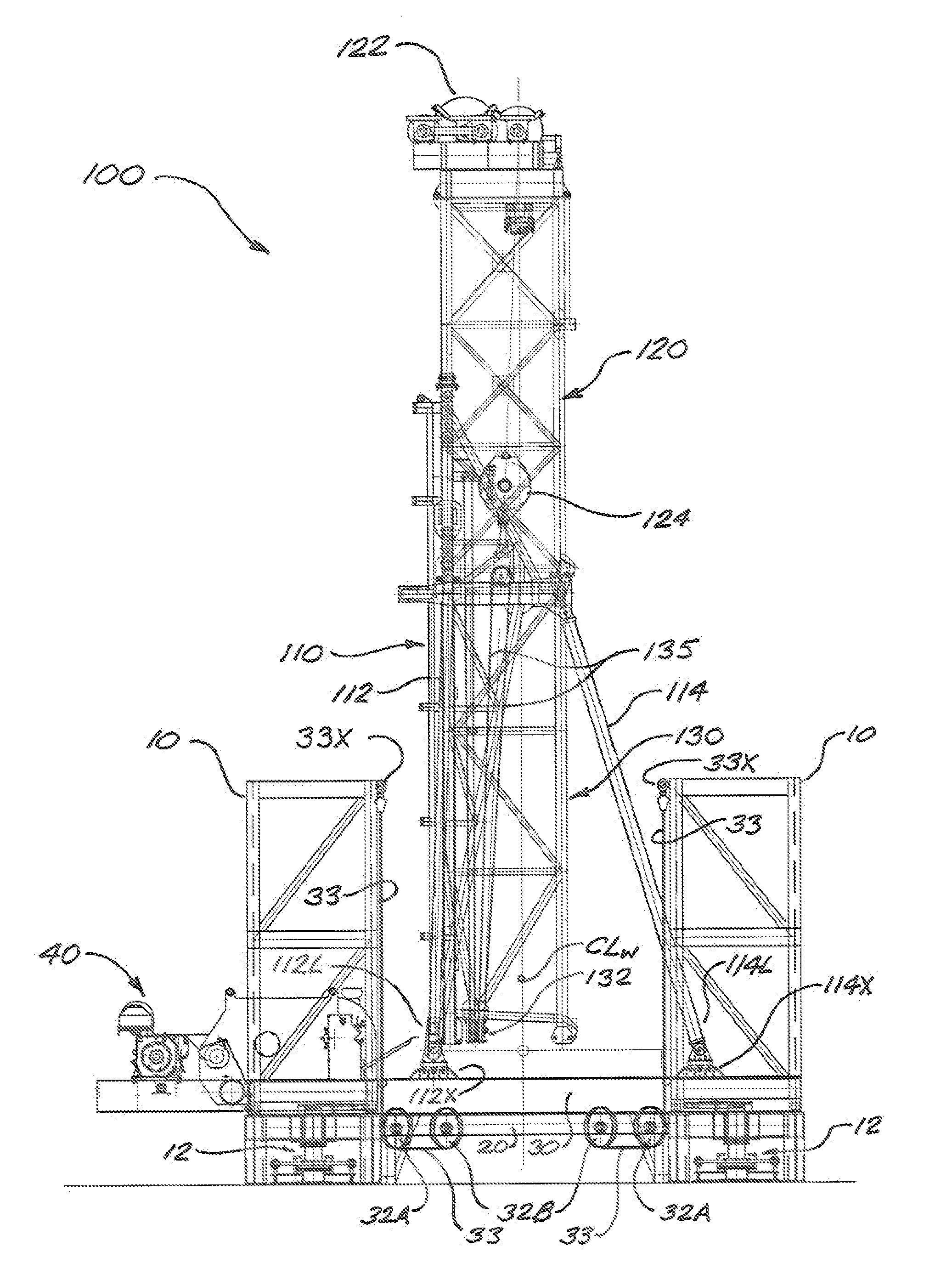

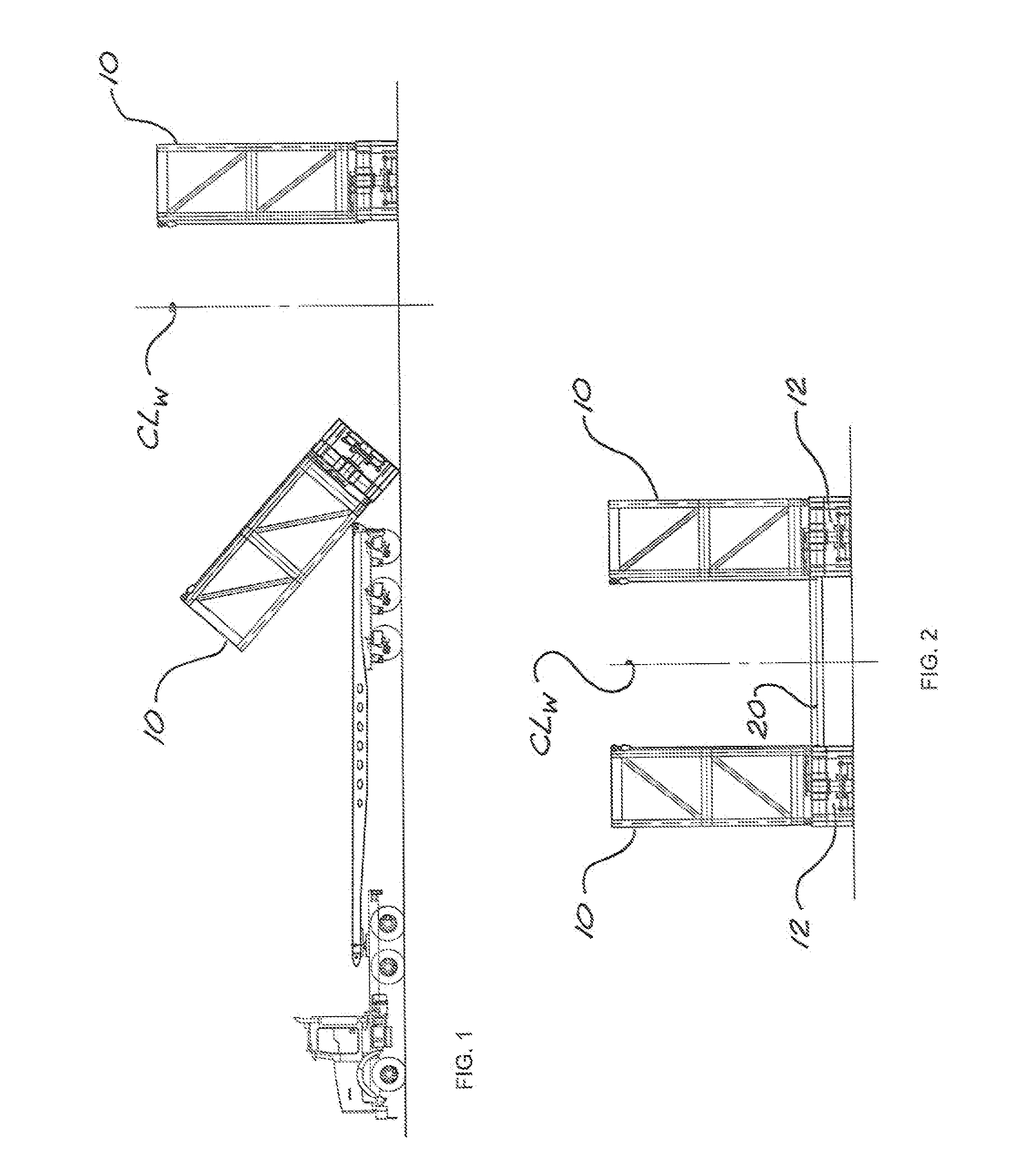

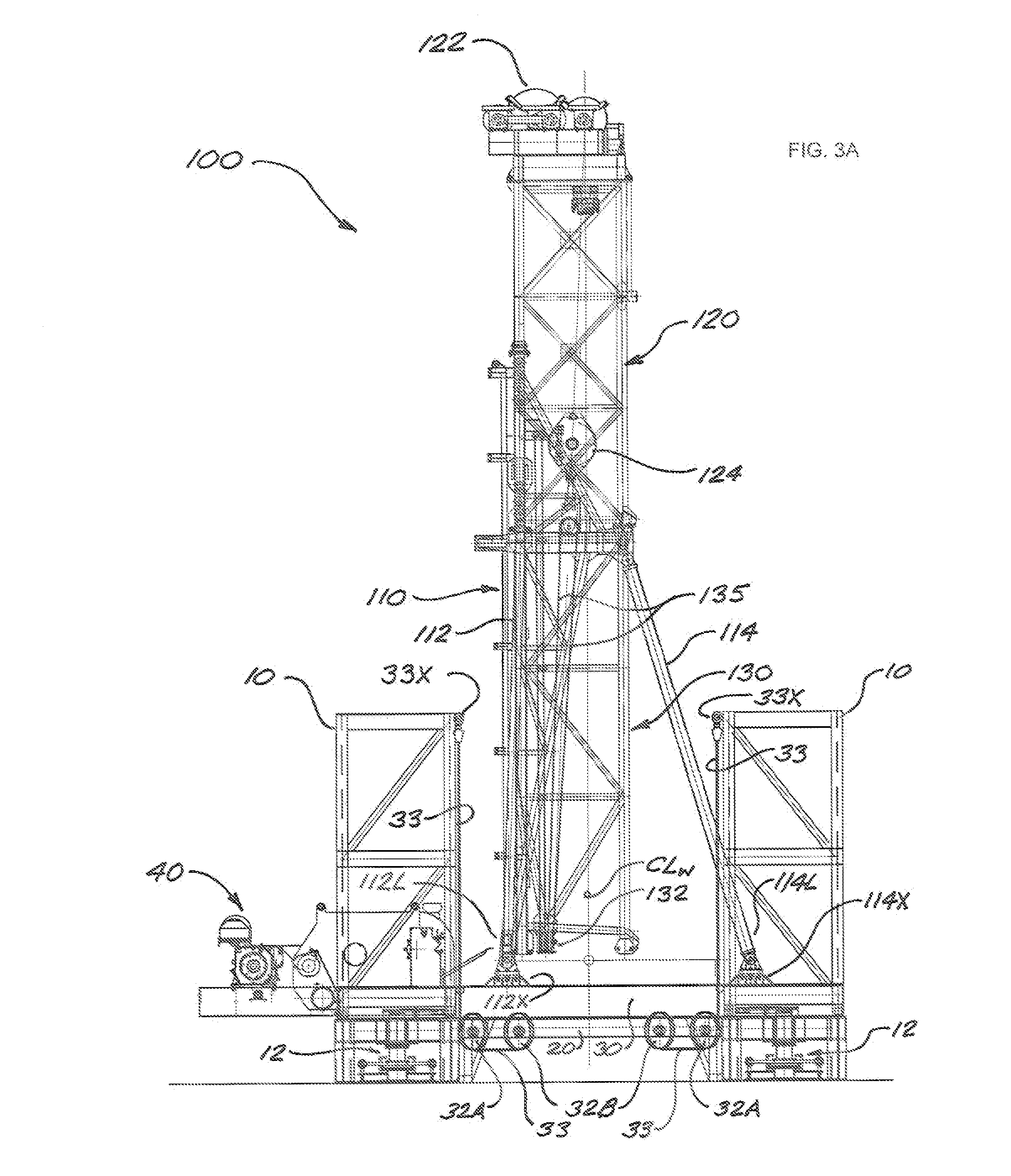

[0027]FIGS. 1 through 5B progressively illustrate the steps involved in assembling one embodiment of a transportable drilling rig in accordance with present disclosure. FIGS. 1 and 2 depict the delivery and positioning of a plurality of base towers 10 at a drill site. Preferably (but not necessarily), towers 10 will be provided with adjustment means 12 for adjusting their height, lateral position, and vertical alignment. Persons skilled in the art will know that such means can be provided in a variety of ways using known technologies, and such means do not constitute components of the broadest embodiments of drilling rigs in accordance with this disclosure.

[0028]After the required number of towers 10 are in their required positions relative to the centerline CLW of a wellbore to be drilled using the rig being constructed, a base frame 20 is constructed or installed as shown in FIG. 2, interconnecting the base towers 10. Base frame 20 can be of any suitable layout and structural conf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com