Patents

Literature

324results about How to "Fast exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

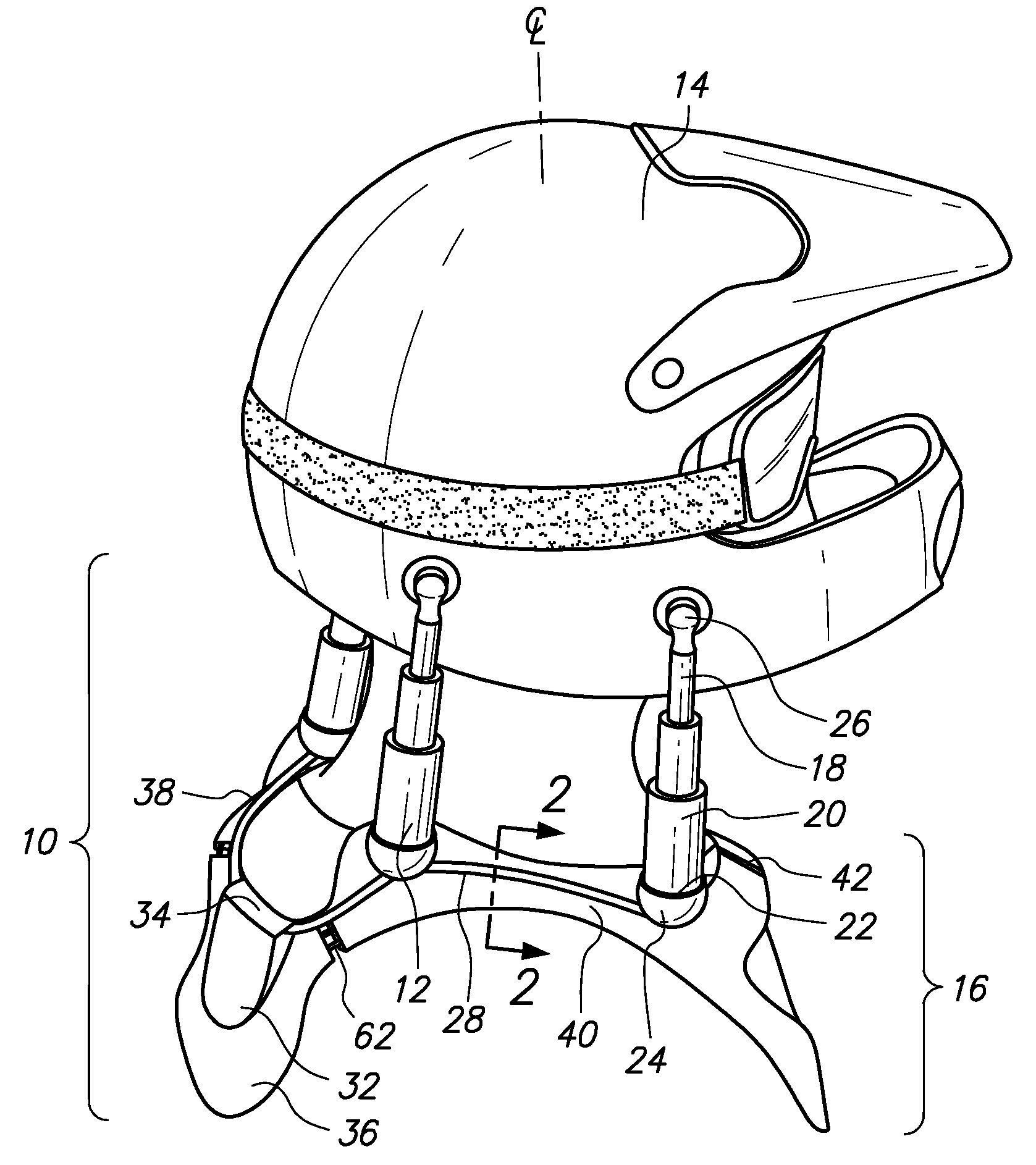

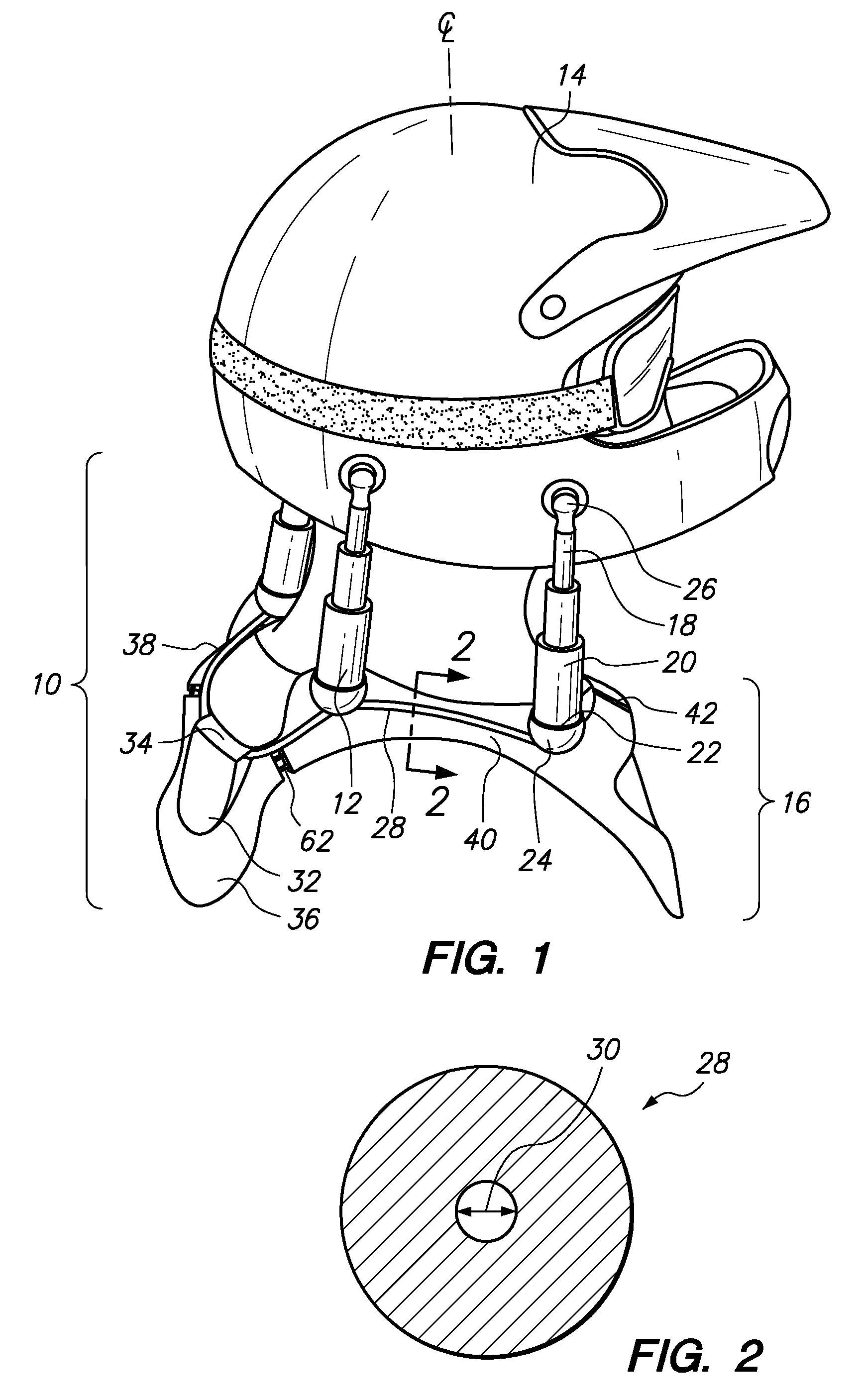

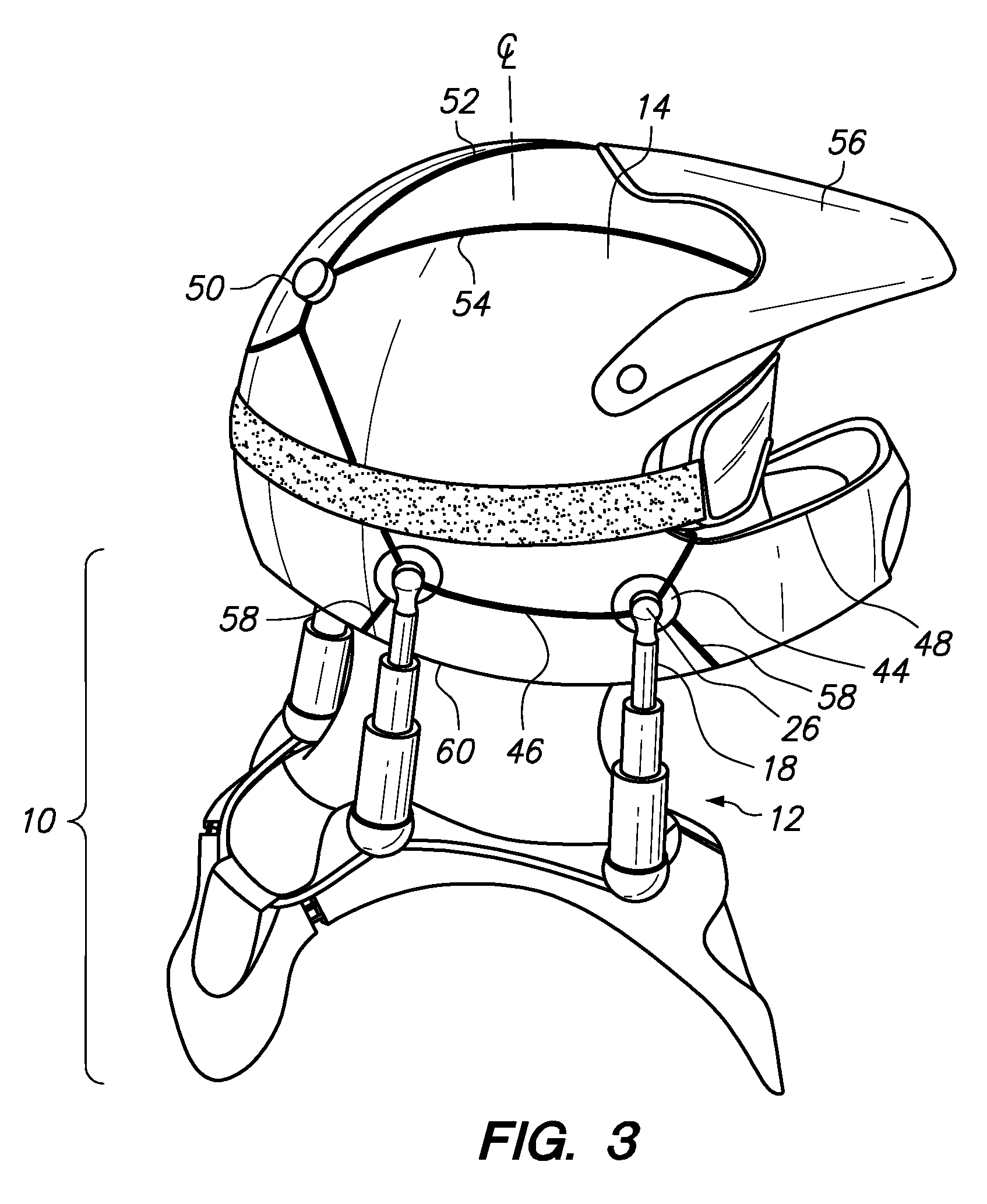

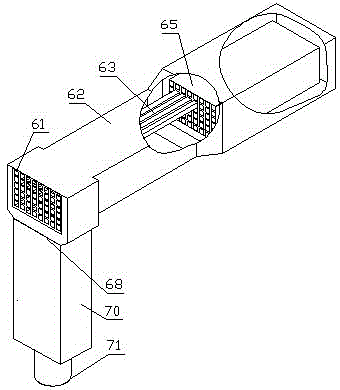

Helmet suspension system

A head protection system is disclosed herein. The system may comprise a helmet having a rigid exterior shell and a padded interior. A shoulder cuff may be disposable over left and right shoulders of the wearer. A plurality of pistons may be attached to the helmet and the shoulder cuff. Each of the pistons may be fluidly connected to each other through a tube and ultimately to a reservoir. The tube may have a small inner diameter to provide resistance to movement of the pistons during rapid deceleration or acceleration of the helmet with respect to the wearer's body.

Owner:JDC RES & DEV CORP

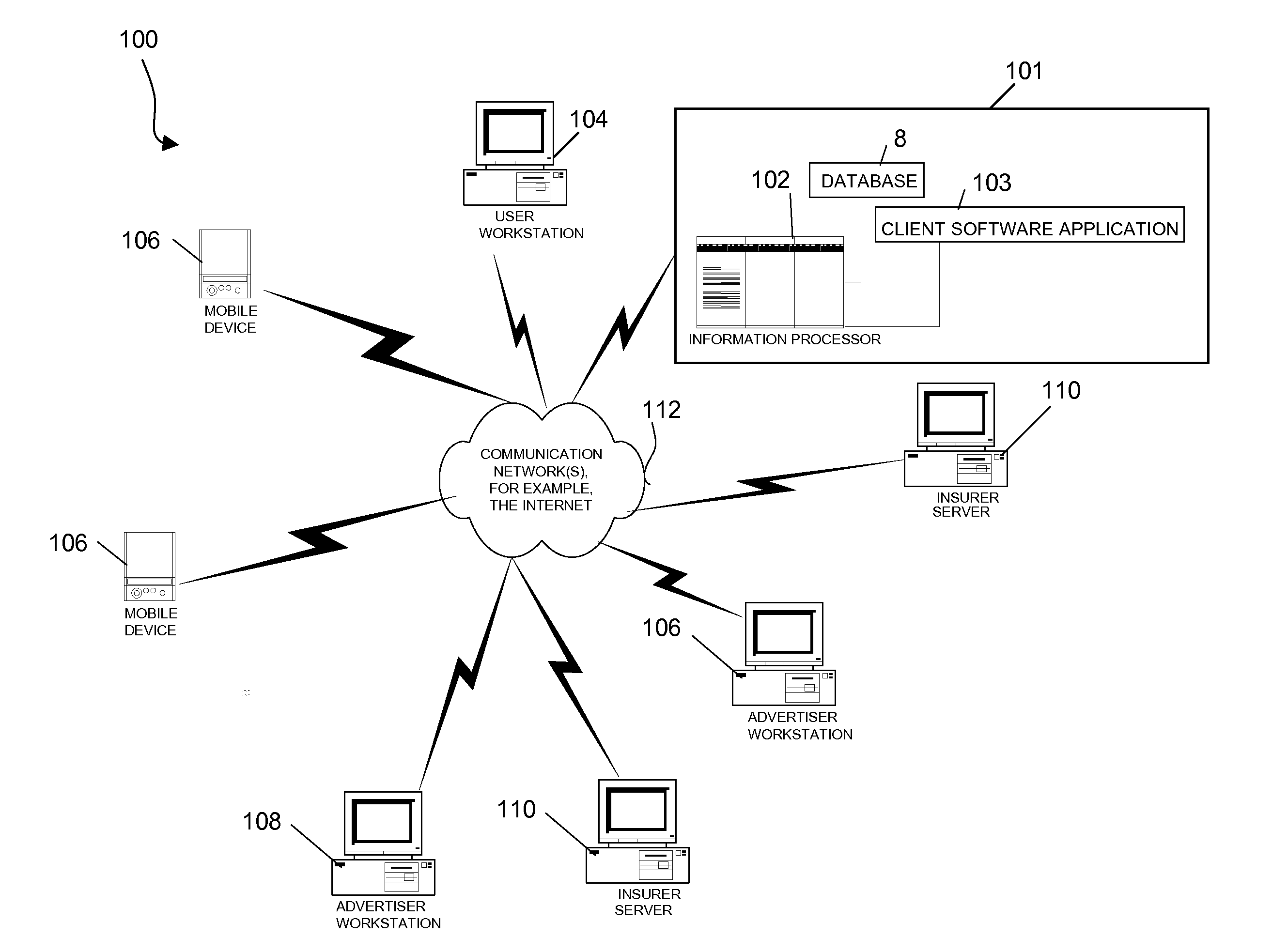

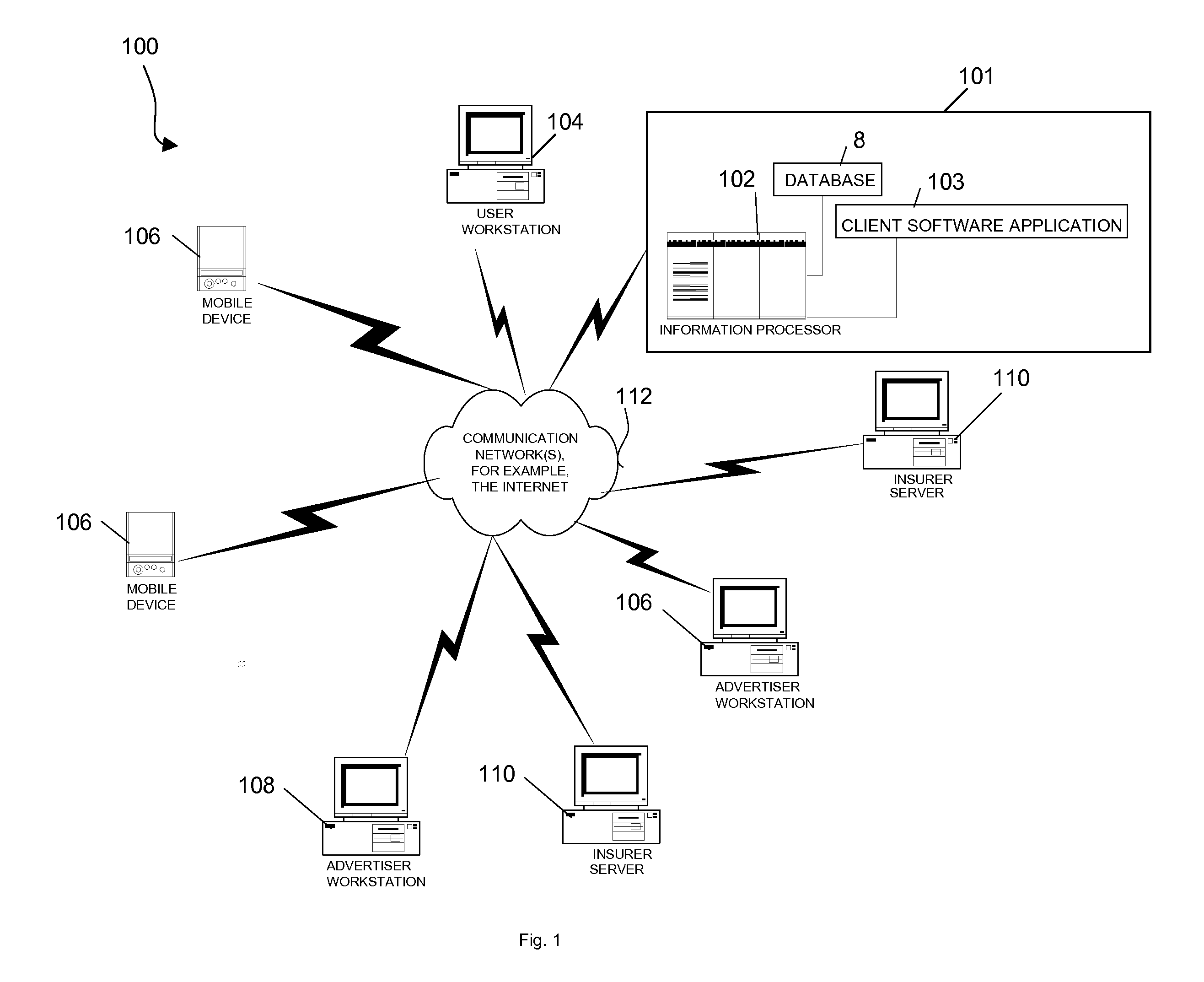

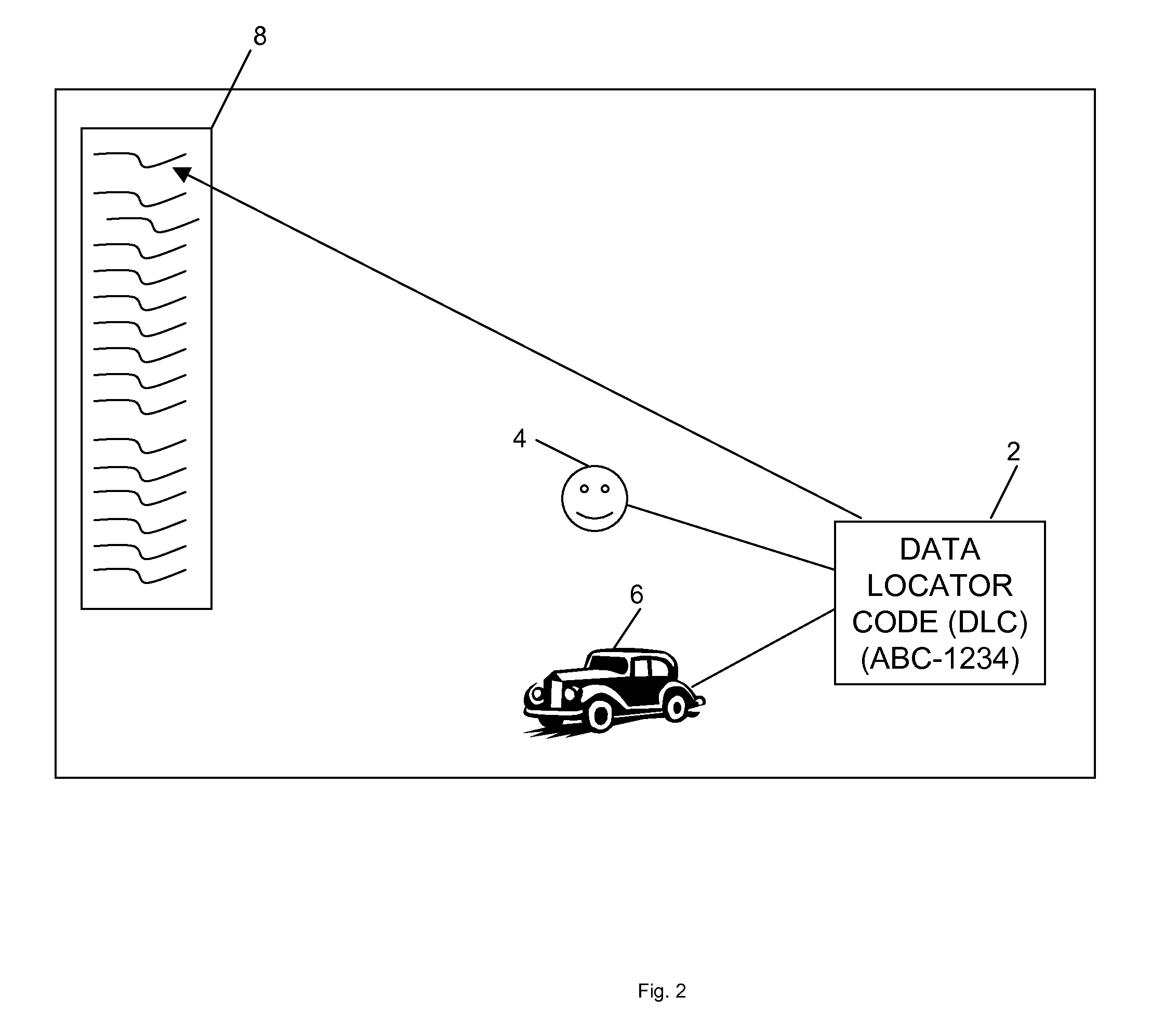

System and method for rapid exchange of accident scene data

InactiveUS20120109690A1Fast exchangeFast gatheringFinanceMultiple digital computer combinationsDriver/operatorCare personnel

A system and method are disclosed for rapidly exchange accident related information. Data locator codes representing people and respective vehicles the people are insured to drive are generated and stored by central server. Software is installed on mobile devices that interface with the central server, and the software is configured with at least one of the data locator codes. A notification regarding an accident event involving two parties is received via the software. The central server receives accident information, which may include a data locator code the other driver, as well as images, voice messages or text information representing the accident. The central server uses the information to contact respective insurers of the parties, processes the data, and the parties can depart the scene without a need for police or other emergency care personnel.

Owner:WEINRAUCH NISSIM +1

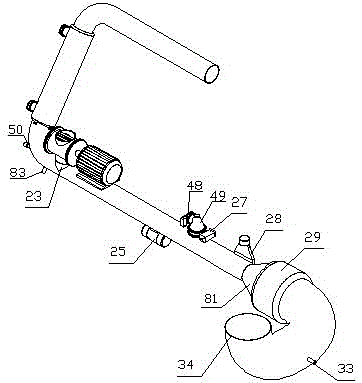

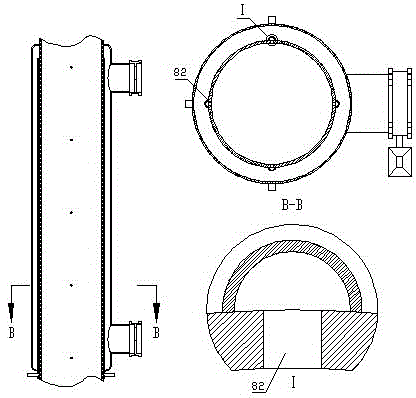

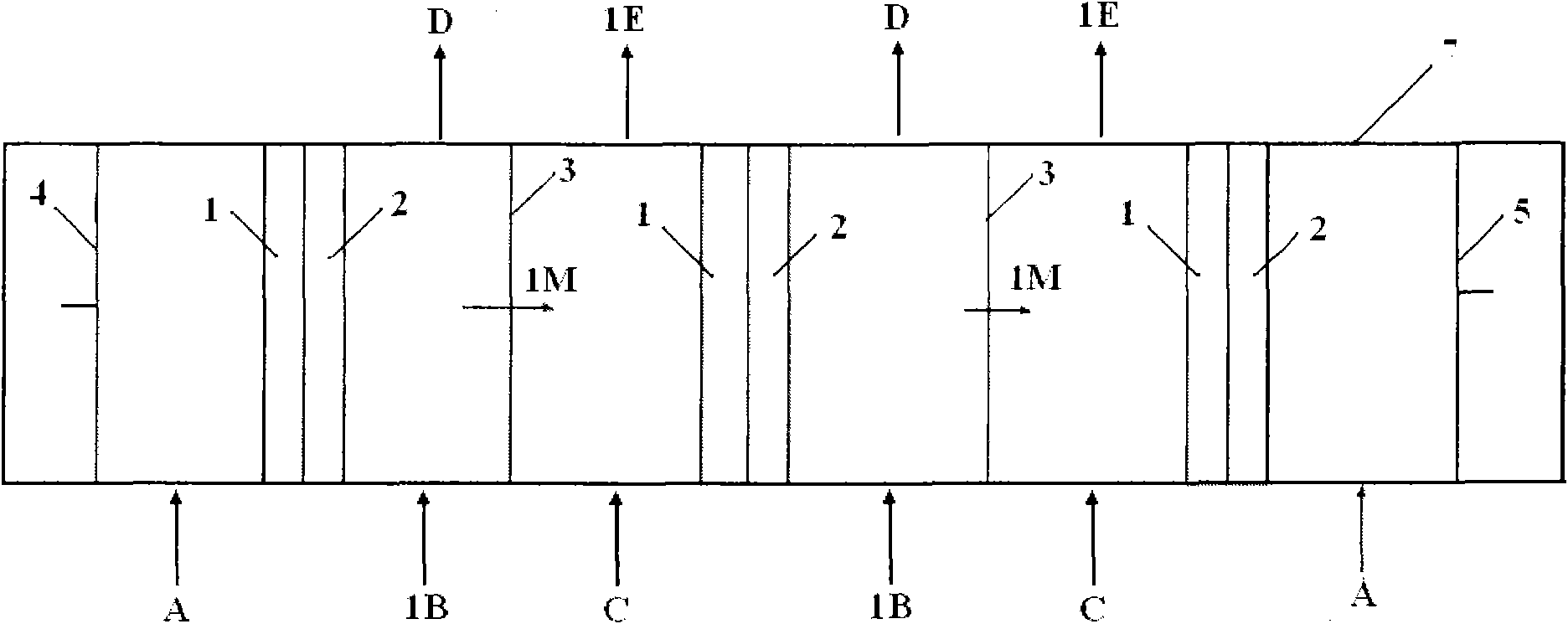

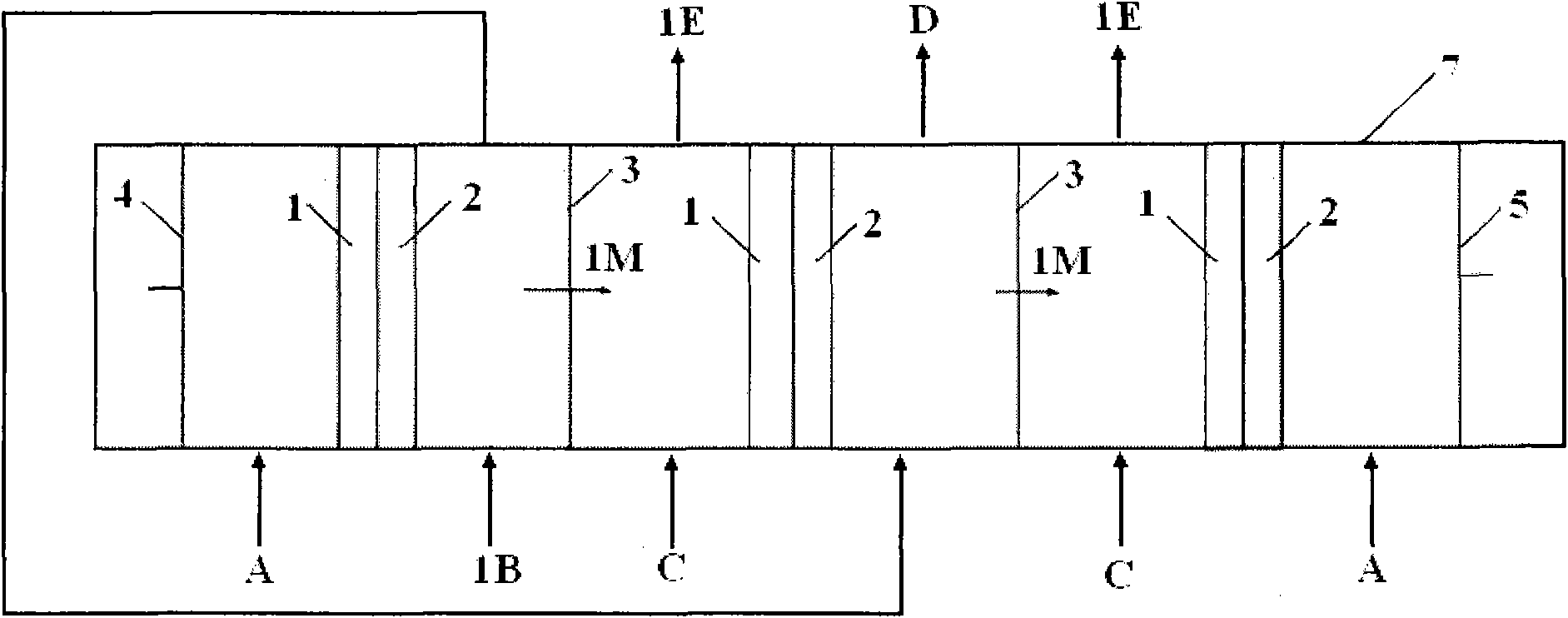

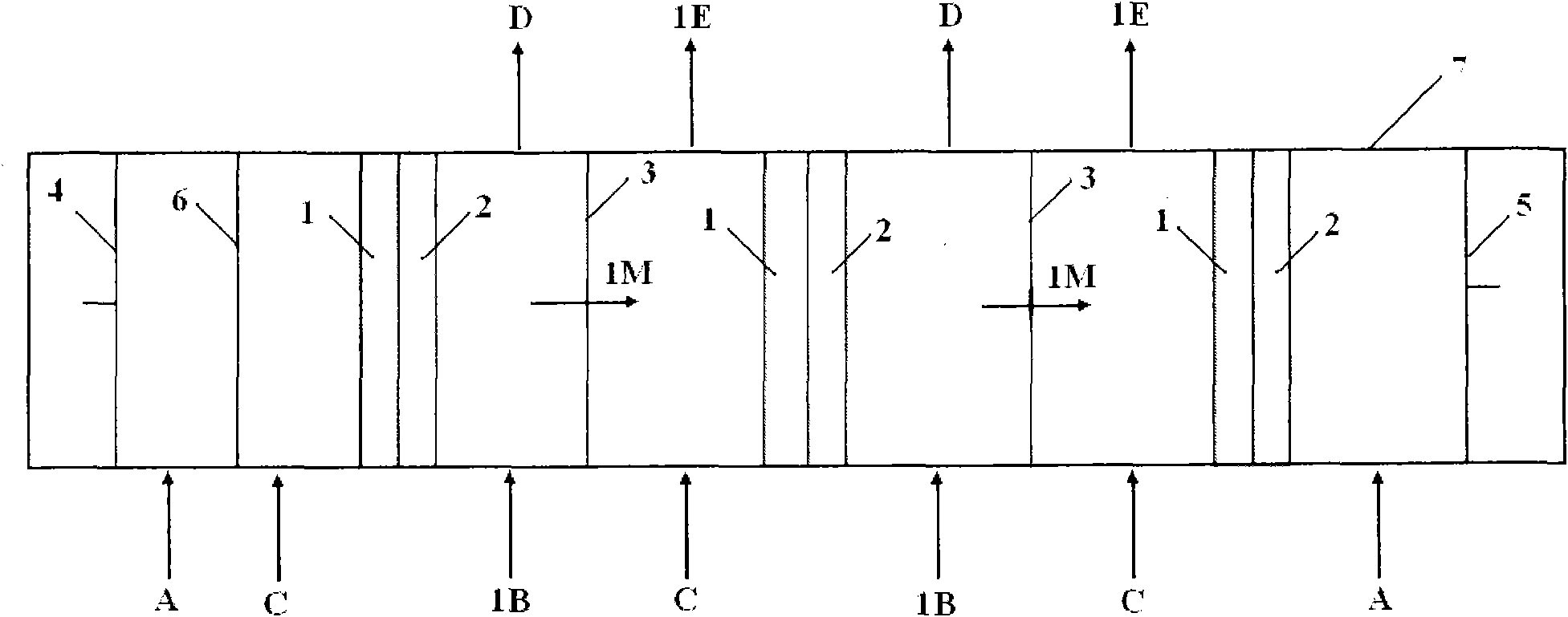

Entire closed-loop circulating fluidized bed as well as usage and application method thereof

ActiveCN105641961AImprove utilizationFast exchangeDrying solid materials with heatDrying gas arrangementsDistillationHigh energy

The invention provides an entire closed-loop circulating fluidized bed as well as usage and an application method thereof. Third generation circulating fluidized bed equipment is improved, the problems of high energy consumption and high processing cost and the like caused by moisture and slow heat exchange speed between materials and working mediums in prior process methods, such as drying, crushing, evaporation, distillation, condensation, gasification, liquefaction, and other operations are solved; entire closed circulation work and rapid normal temperature work of scaled materials are economically realized, and an economically feasible solution scheme is provided for developing works, such as improvements of output and quality of foodstuff, medicine, chemical products and other basic raw material products, as well as energy saving and consumption reduction, cleaning production, etc.

Owner:KUNMING TEKANG TECH CO LTD

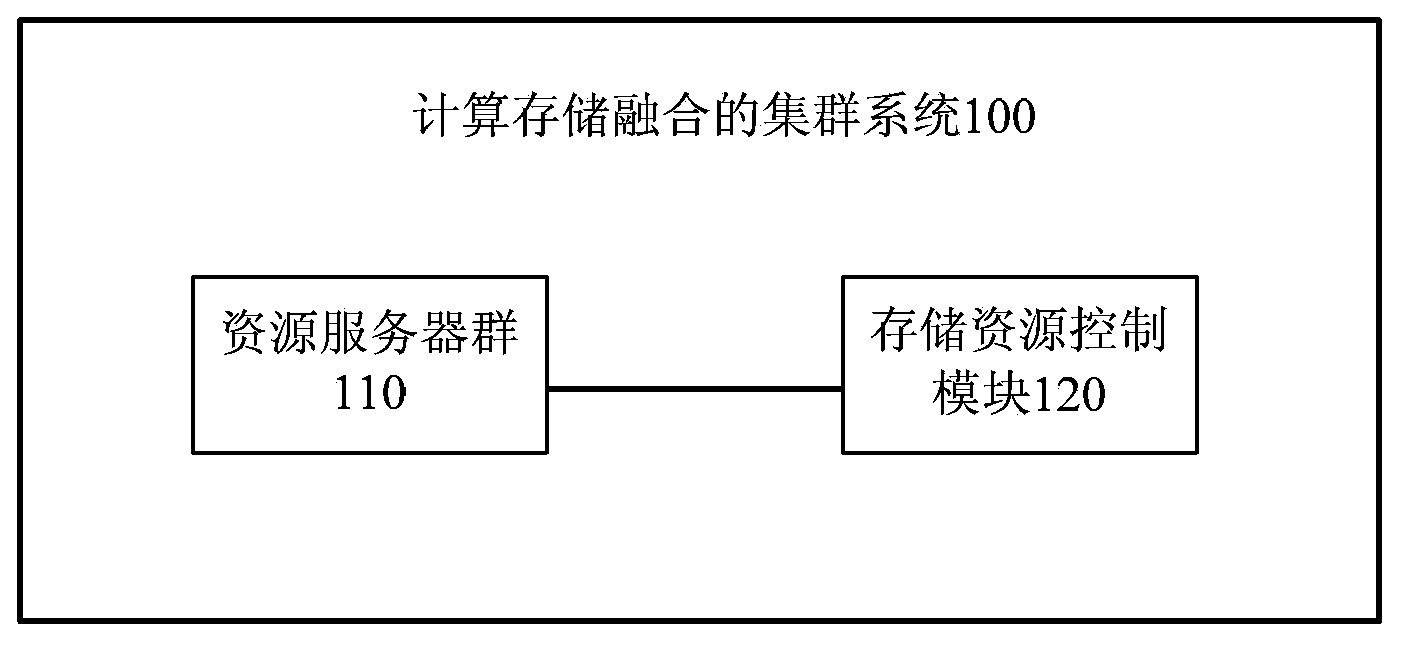

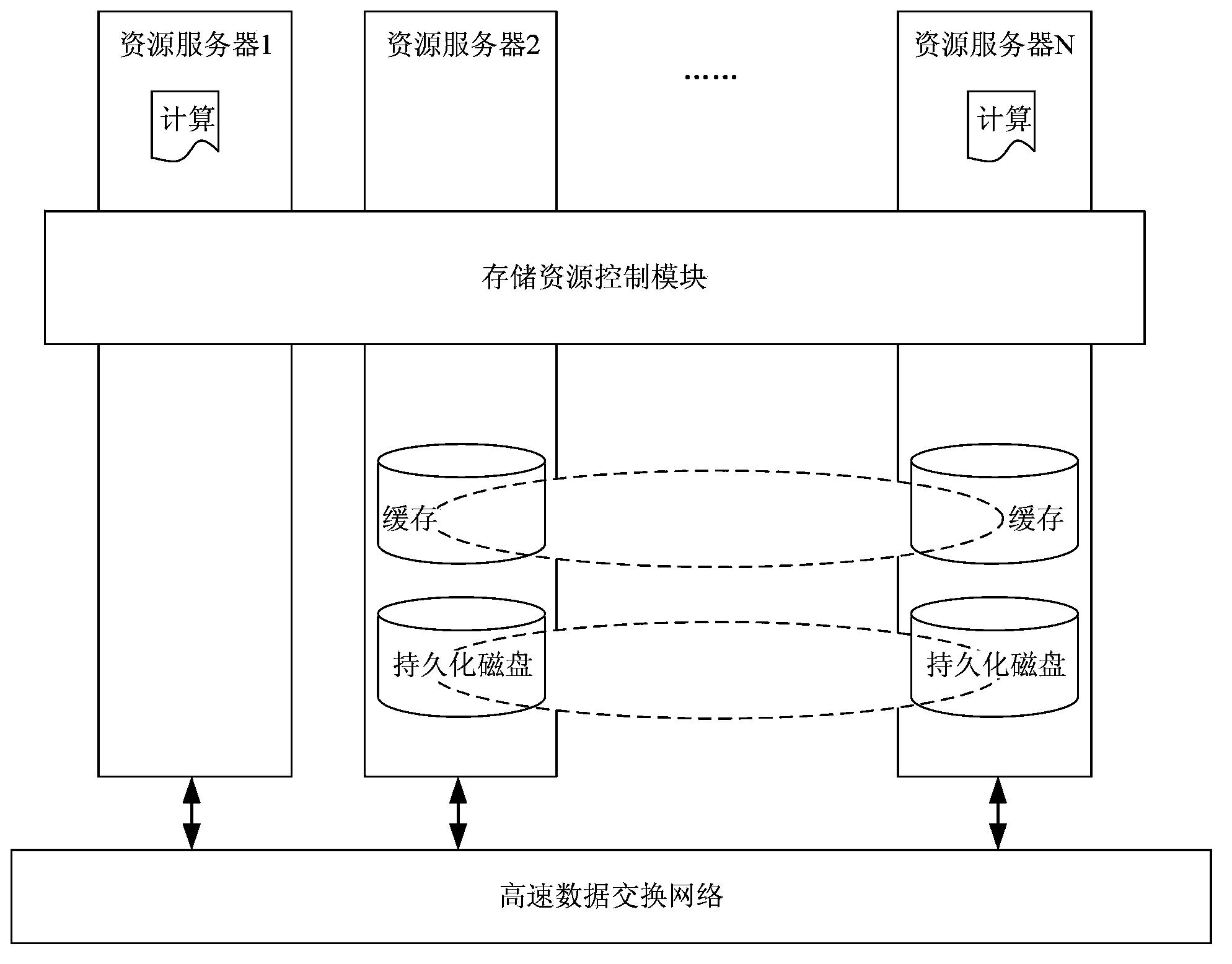

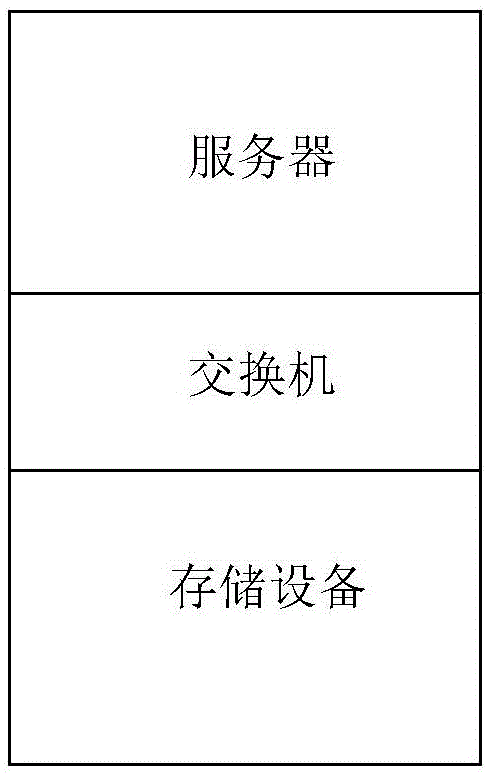

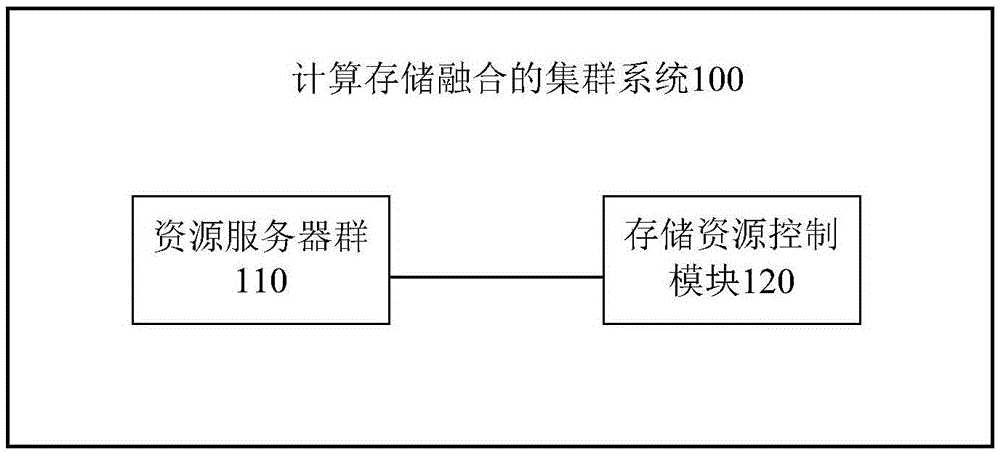

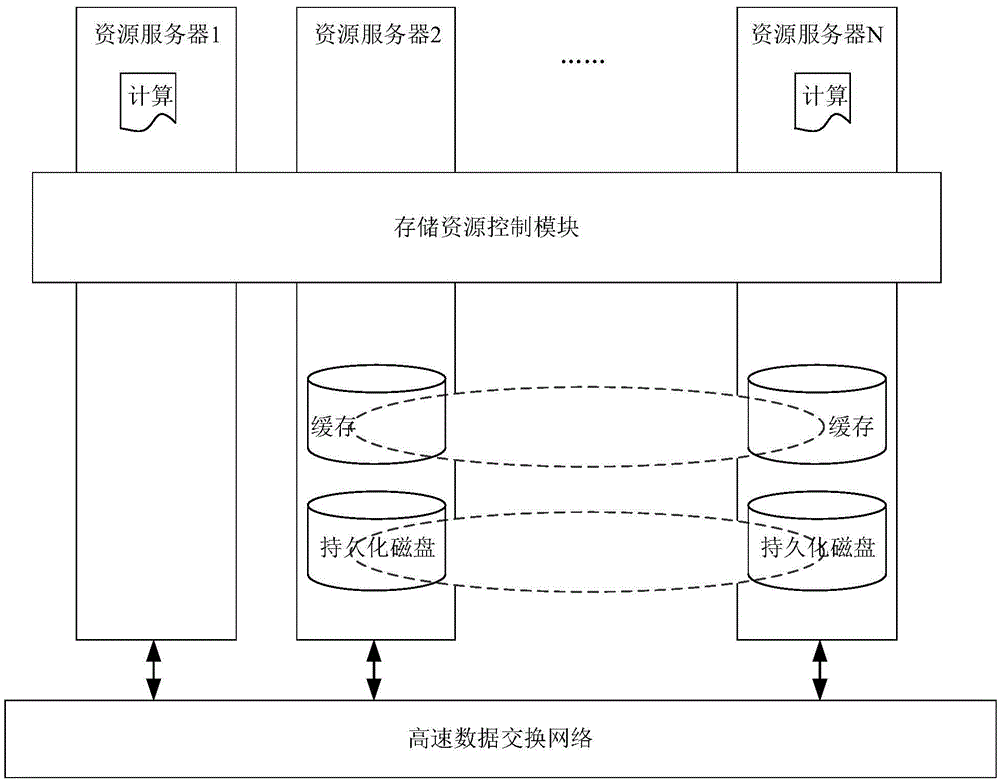

Computing storage integration cluster system

ActiveCN103503414AImprove acceleration performanceFast exchangeInput/output to record carriersTransmissionResource poolCluster systems

Embodiment of the invention provides a computing storage integration cluster system comprising a resource server cluster. The resource server cluster comprises at least two resource servers, each resource server of the resource server cluster at least has one of a computing resource and a storage resource, and at least one resource server of the resource server cluster has the computing resource and the storage resource, the storage resource includes a persistent disk and cache corresponding to the persistent disk. The cluster system also comprises a storage resource control module for constructing a shared storage resource pool by adopting the storage resource of the resource server cluster so as to provide a storage service, wherein the storage resource included in each storage resource pool the resources of the server is from at least two resource servers of the resource server cluster.

Owner:HUAWEI CLOUD COMPUTING TECH CO LTD

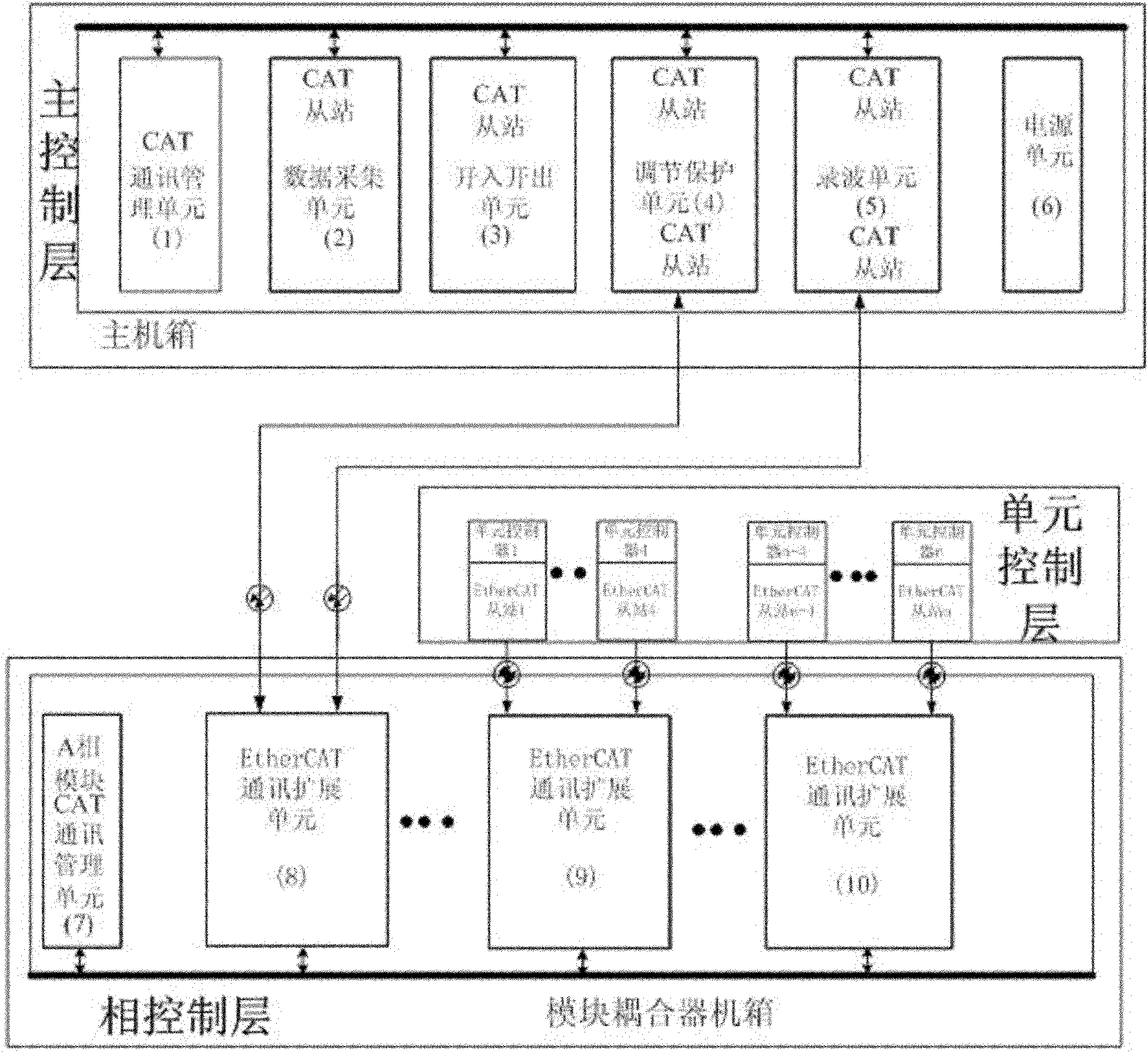

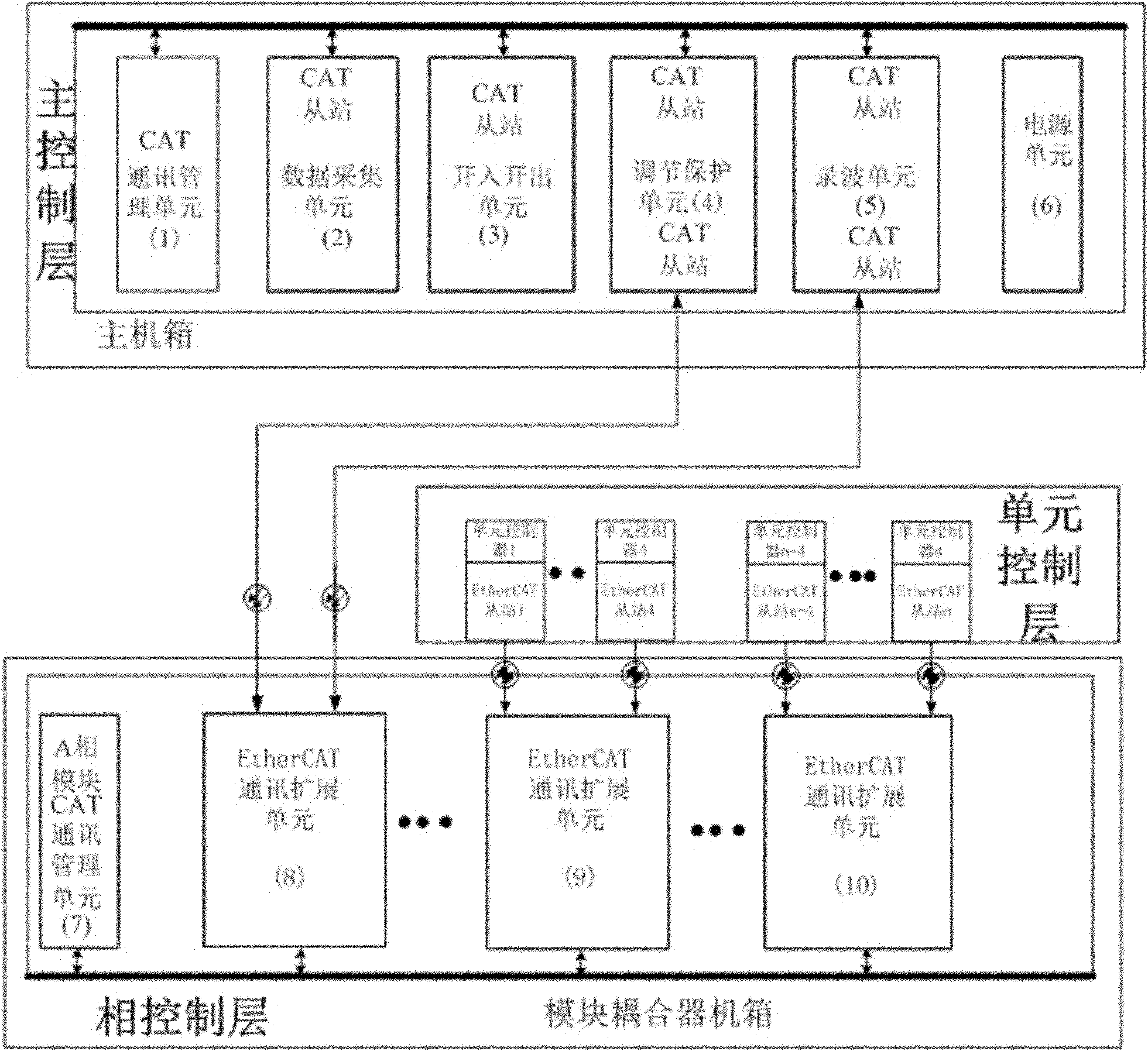

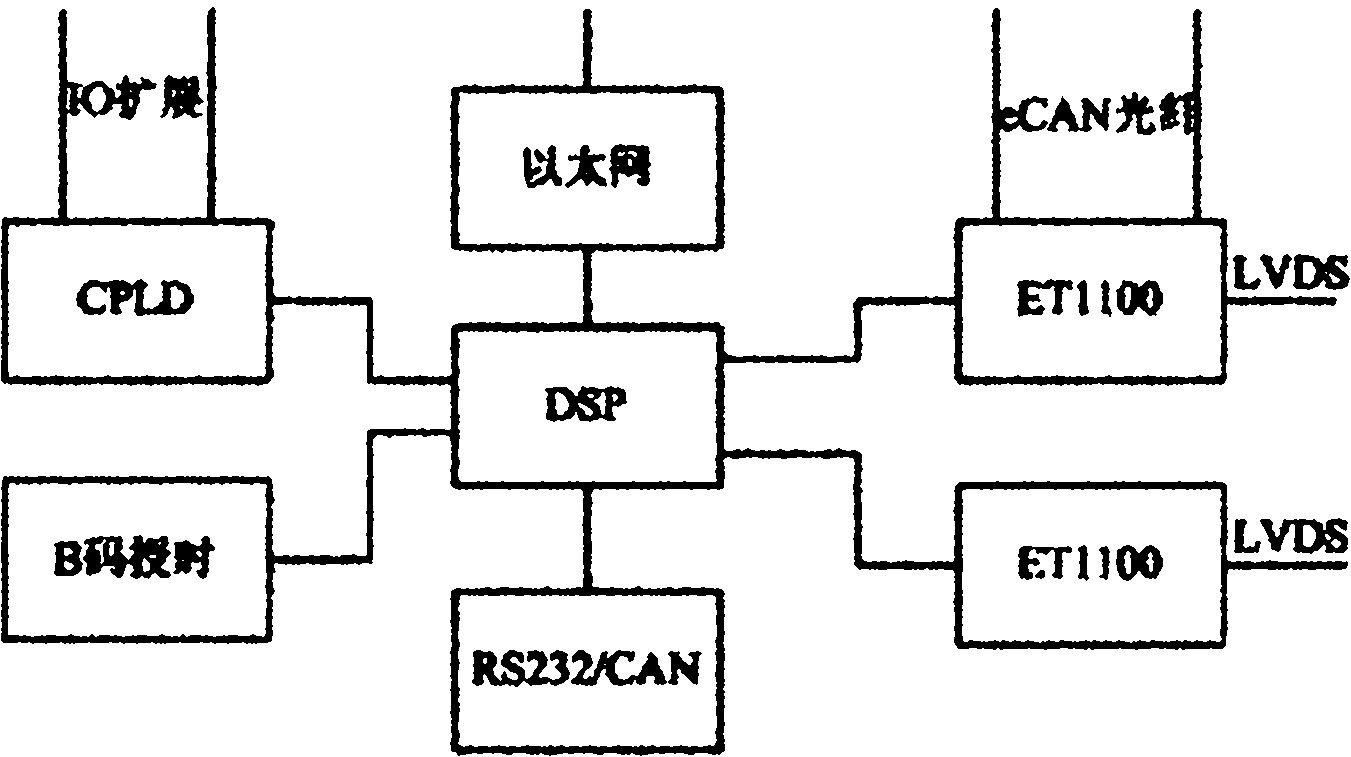

Chain type STATCOM control system based on EtherCA technology

ActiveCN102096407AData transfer speed is fastGuaranteed reliabilityFlexible AC transmissionReactive power adjustment/elimination/compensationIndustrial EthernetControl layer

The invention provides a chain type STATCOM (Static Synchronous Compensator) control system based on EtherCA technology, wherein the chain type STATCOM control system uses real-time industrial Ethernet EtherCA as a channel of data transferring, and the control system uses a layered distribution topology structure. The layered distribution topology structure of the STATCOM control system comprises a main control layer, a phase control layer and a unit control layer. The main control layer comprises a main control case and the like functional cases, the phase control layer is composed of a phase coupler case, and the unit control unit is composed of a unit controller. The communication between the main case and the phase coupler case is carried out by means of firewire connected EtherCA. The chain type STATCOM control system based on EtherCA technology provided by the invention has the advantages that the data transferring speed is high, the number of the cable is less, the exchange speed is fast, the expansion is convenient, the accurate synchronism and the diagnosis ability are strong and the configuration is flexible.

Owner:CHINA EPRI SCIENCE & TECHNOLOGY CO LTD +2

Method for rapid preparation of SiO2 aerogel micro-balloons

The utility model relates to a rapid preparation method of SiO2 aerogel sphere, belonging to a field of inorganic metallic materials, in particular to a method of rapidly preparing SiO2 aerogel sphere. Water glass is used as raw material that performs ion exchange to obtain the silicic acid PH=2-3, after added with alkaline catalyst, the silicic acid is added into the hydrophobic oil, and then is mixed to cut into micro liquid drops that are spherically suspended in the oil under the action of surface tension, the silicic acid is mixed until aerogel sphere is generated, afterwards, the oil and the sphere perform solid-liquid separation, and then are cleaned with water to obtain aerogel sphere, the aerogel sphere is soaked by the ethanol and absolute alcohol in sequence to perform solvent exchange to obtain alcohol gel sphere, after dried, aerogel sphere with micrometer or millimeter grade particles can be otained. The invention has low cost, easy and controllable process, mass production, good product quality and wide application prospect in the heat isolation and catalysis fields.

Owner:UNIV OF SCI & TECH BEIJING

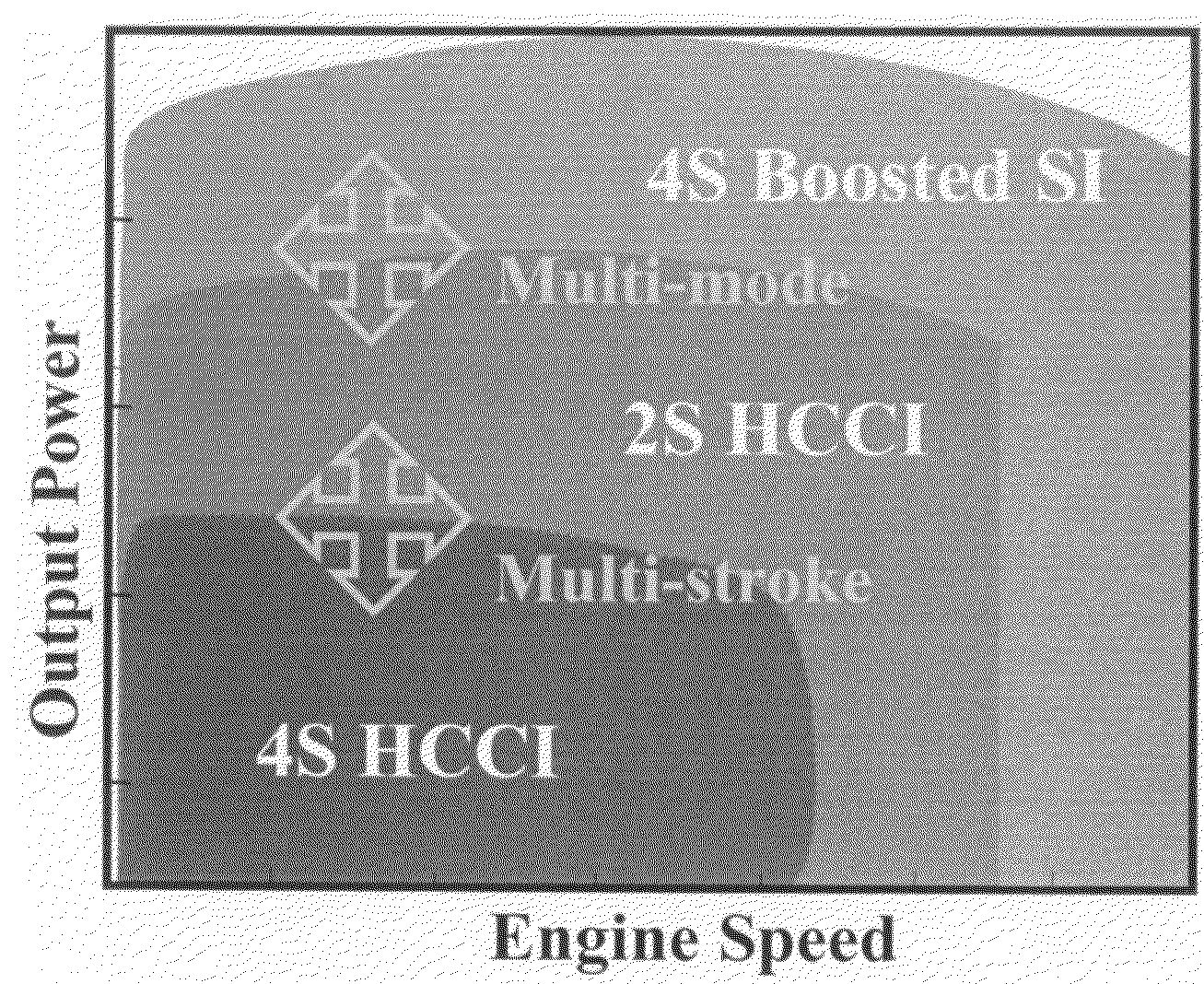

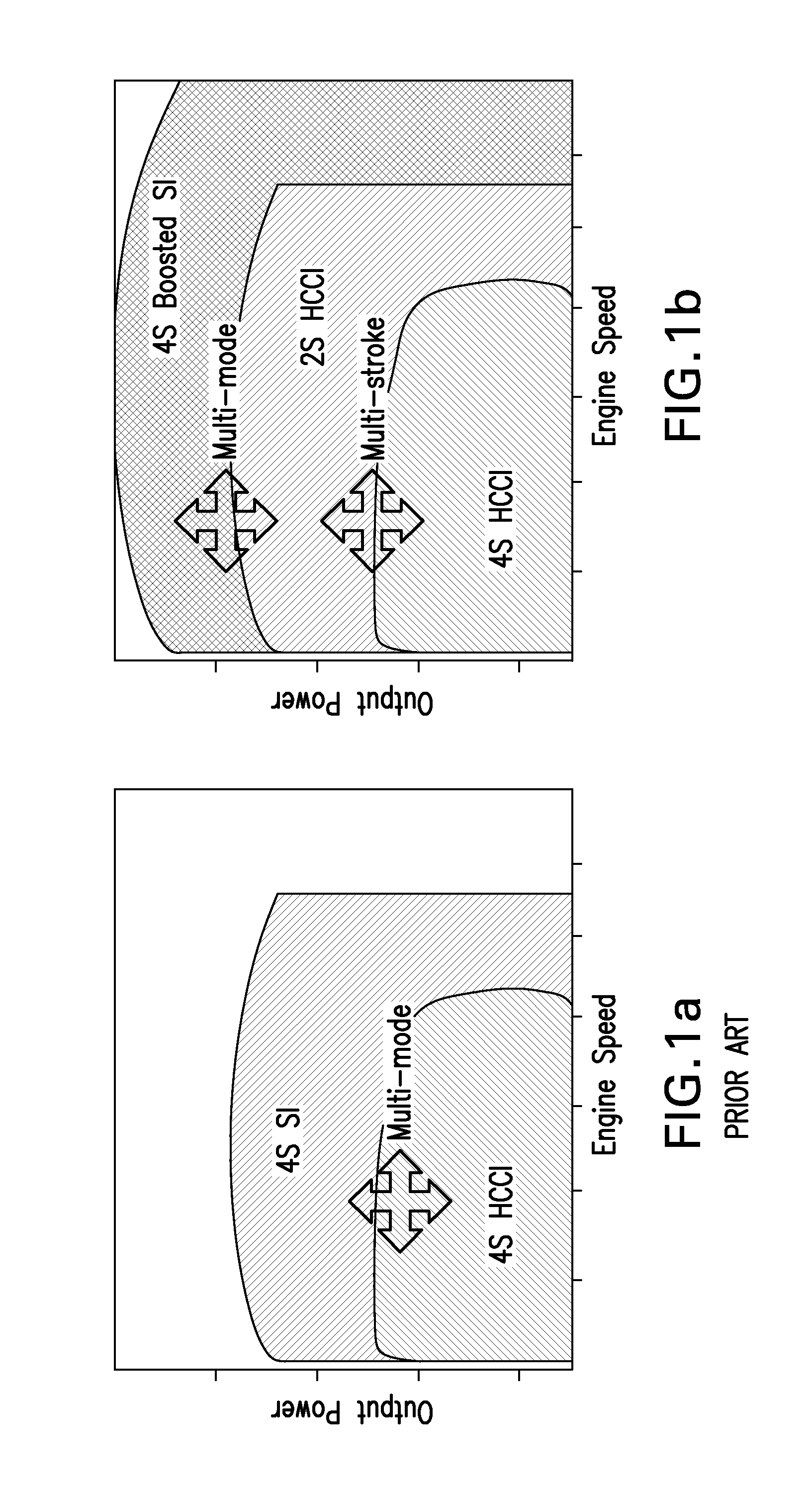

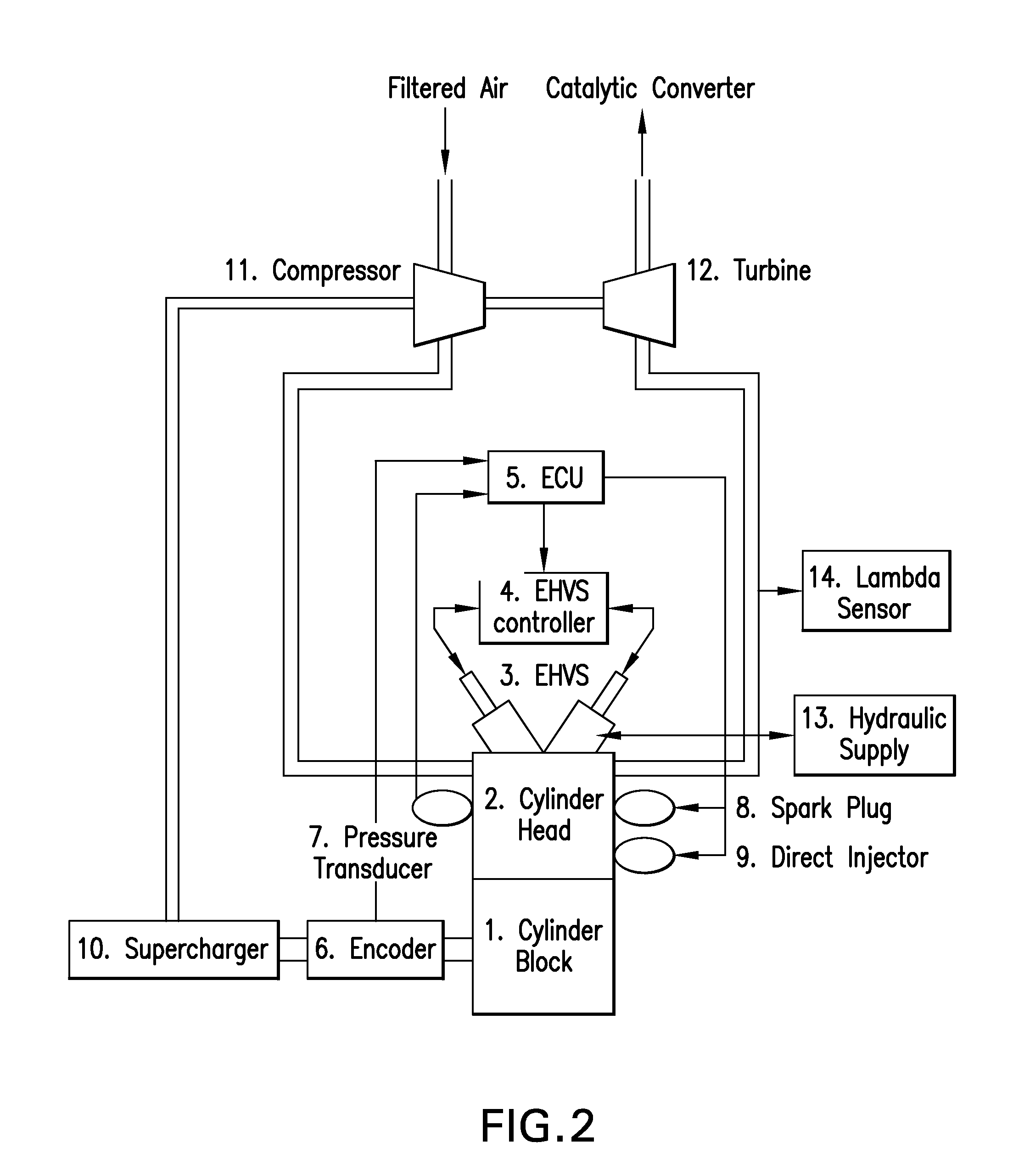

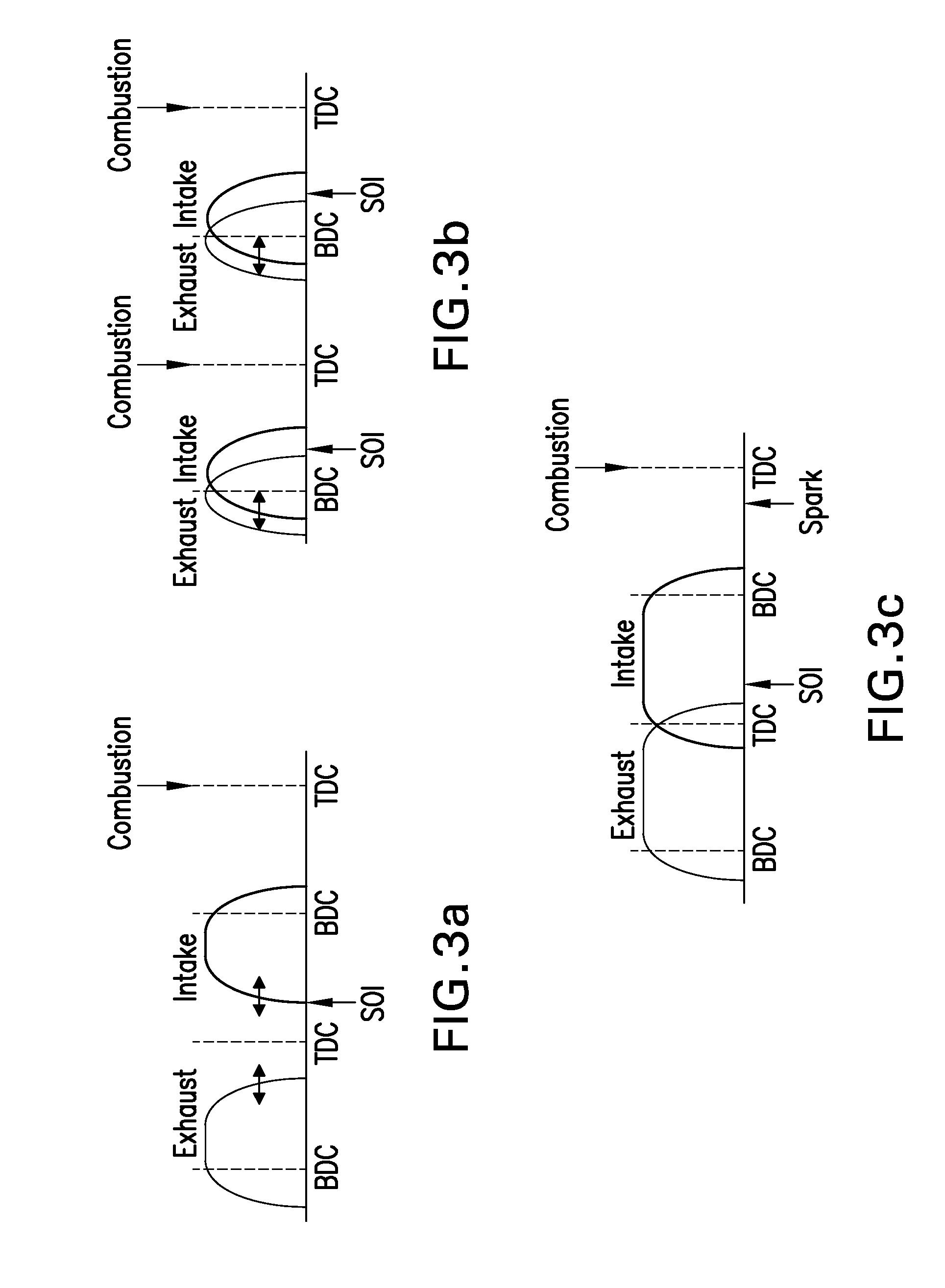

Multi-mode 2-stroke/4-stroke internal combustion engine

ActiveUS7481185B1Wide load rangeSacrificing efficiencyAnalogue computers for vehiclesElectrical controlCombustionInternal combustion engine

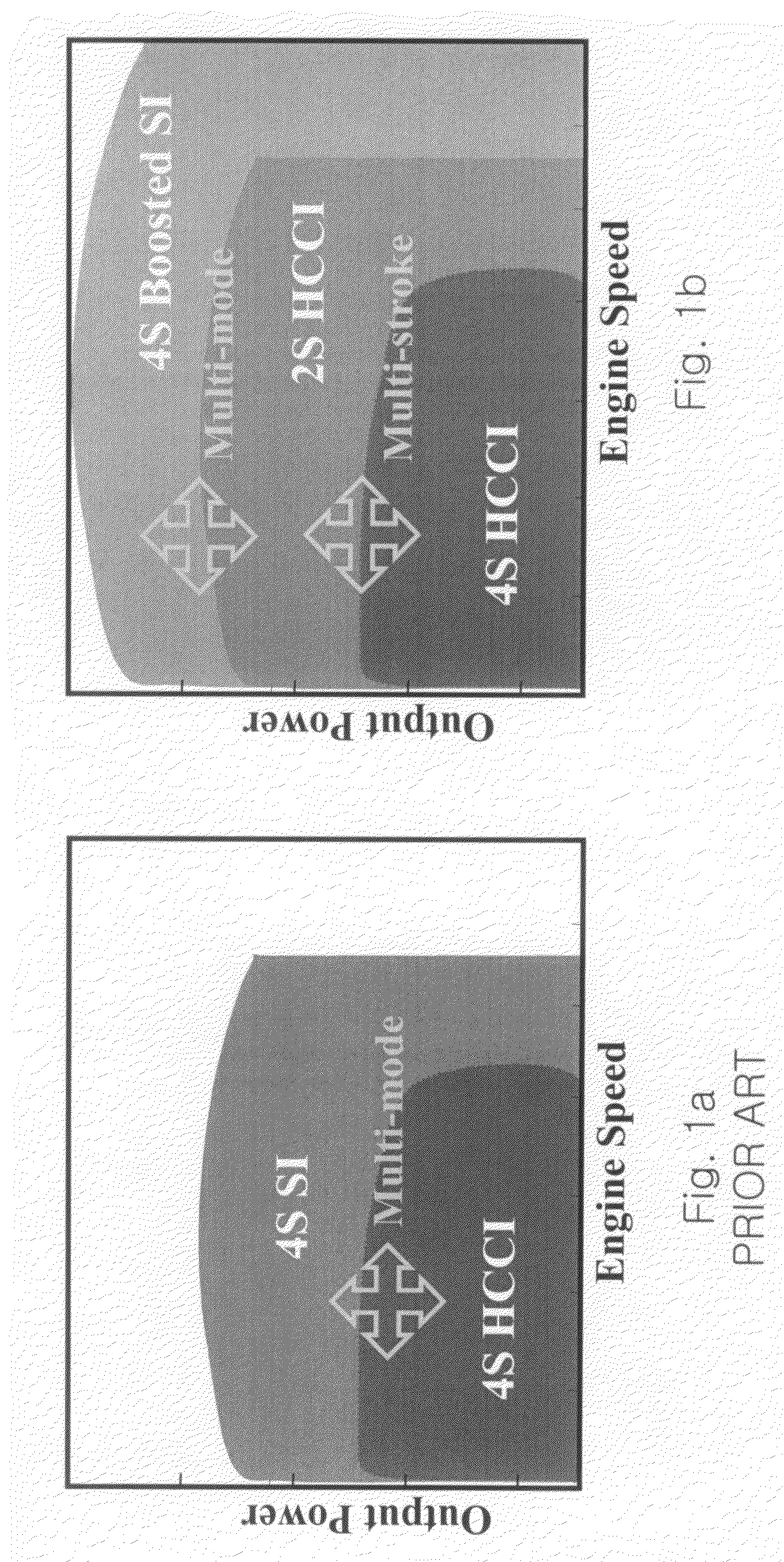

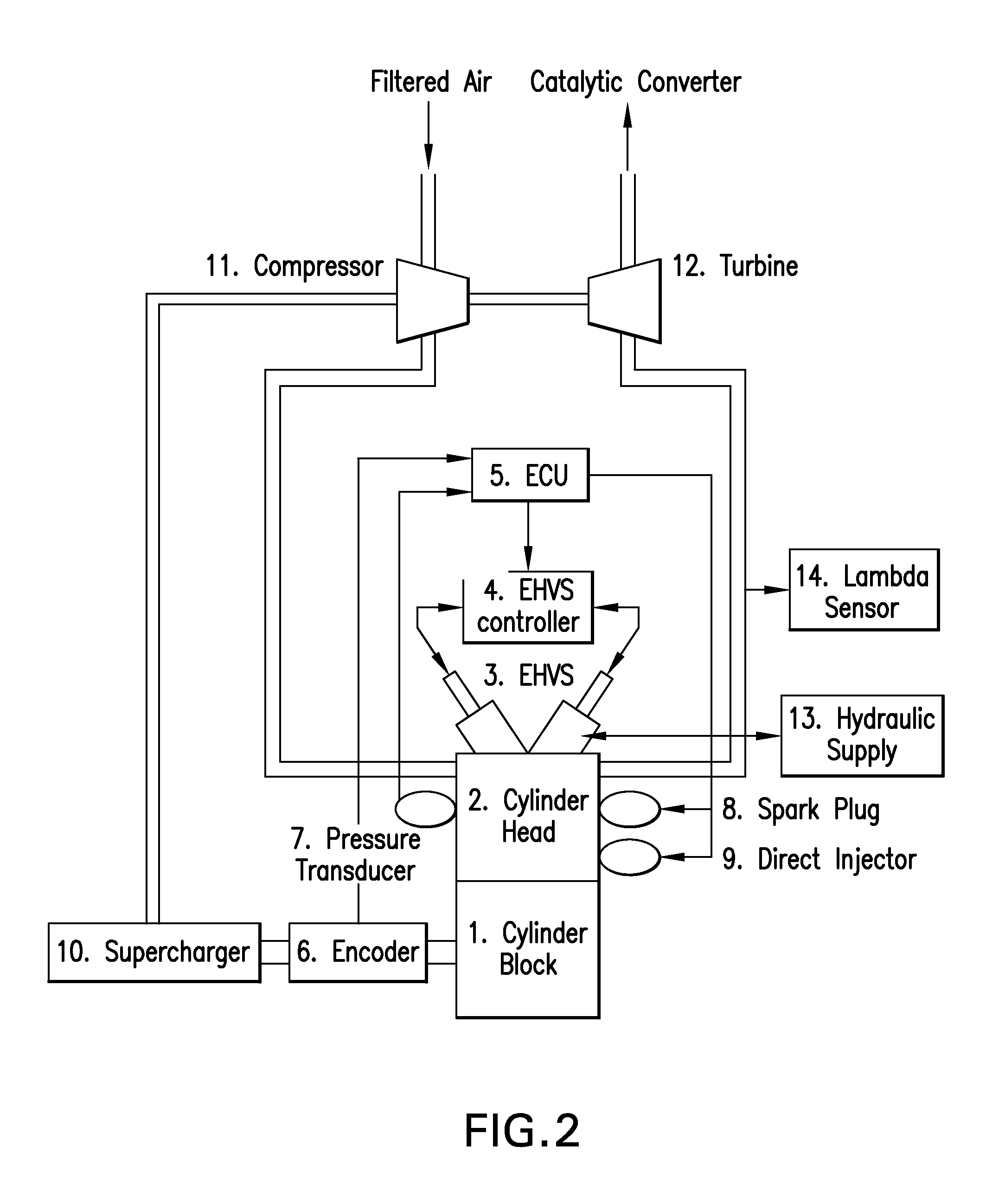

In a multi-mode, 2-stroke / 4-stroke internal combustion engine operation, by switching the engine stroke from 4-stroke operation to 2-stroke operation so that the combustion frequency is doubled, doubling of the engine power is achieved even at the same work output per cycle. In order to meet the demand of extremely high power, the engine operates in 4-stroke boosted SI operation transitioned from 2-stroke HCCI operation at pre-set level of power and crank speed requirements. By combining the multi-stroke (2-stroke HCCI and 4-stroke HCCI) and multi-mode operation (2-stroke HCCI and 4-stroke boosted SI operation), full load range and overall high efficiency with minimal NOx emission are achieved.

Owner:ROBERT BOSCH GMBH

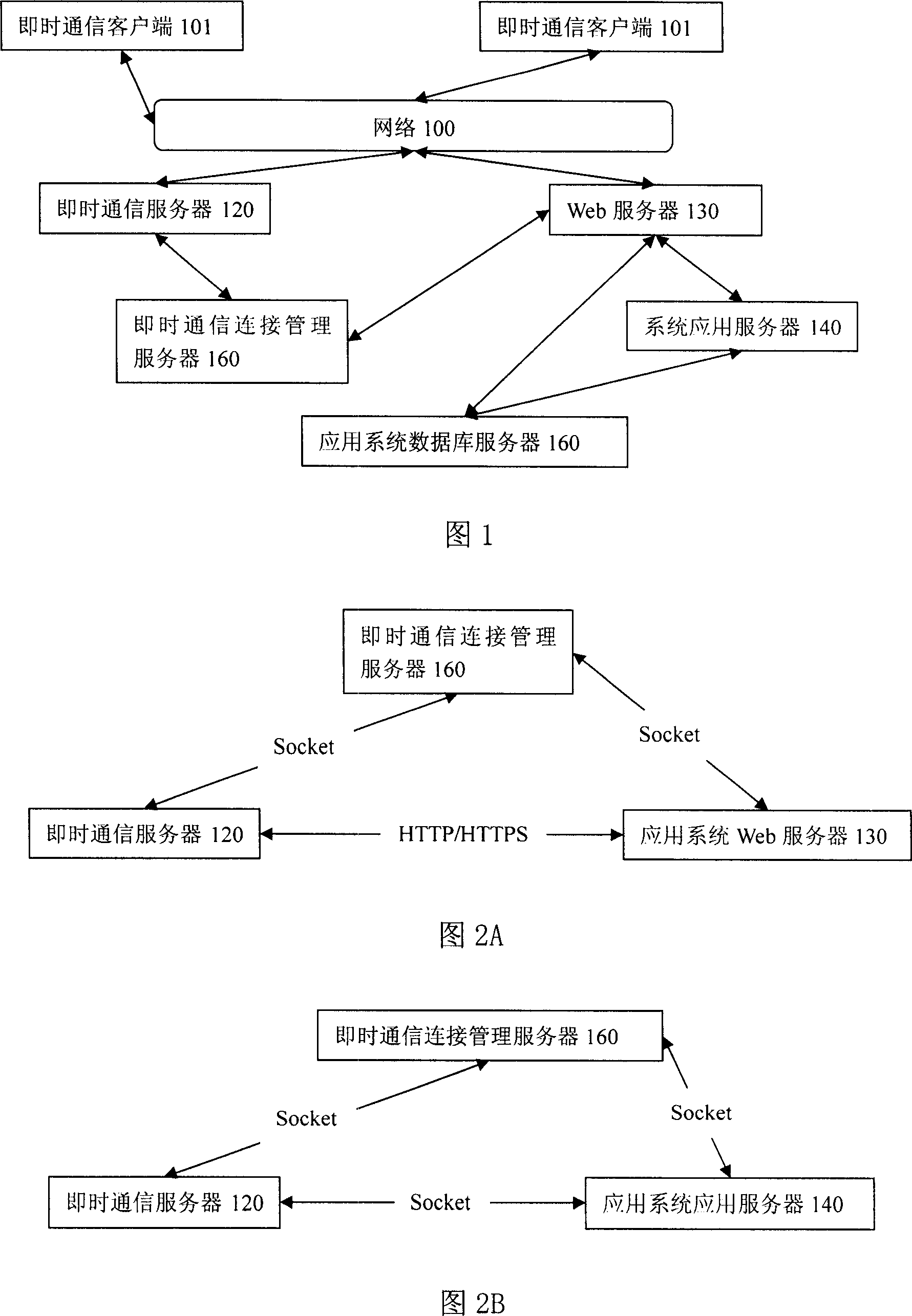

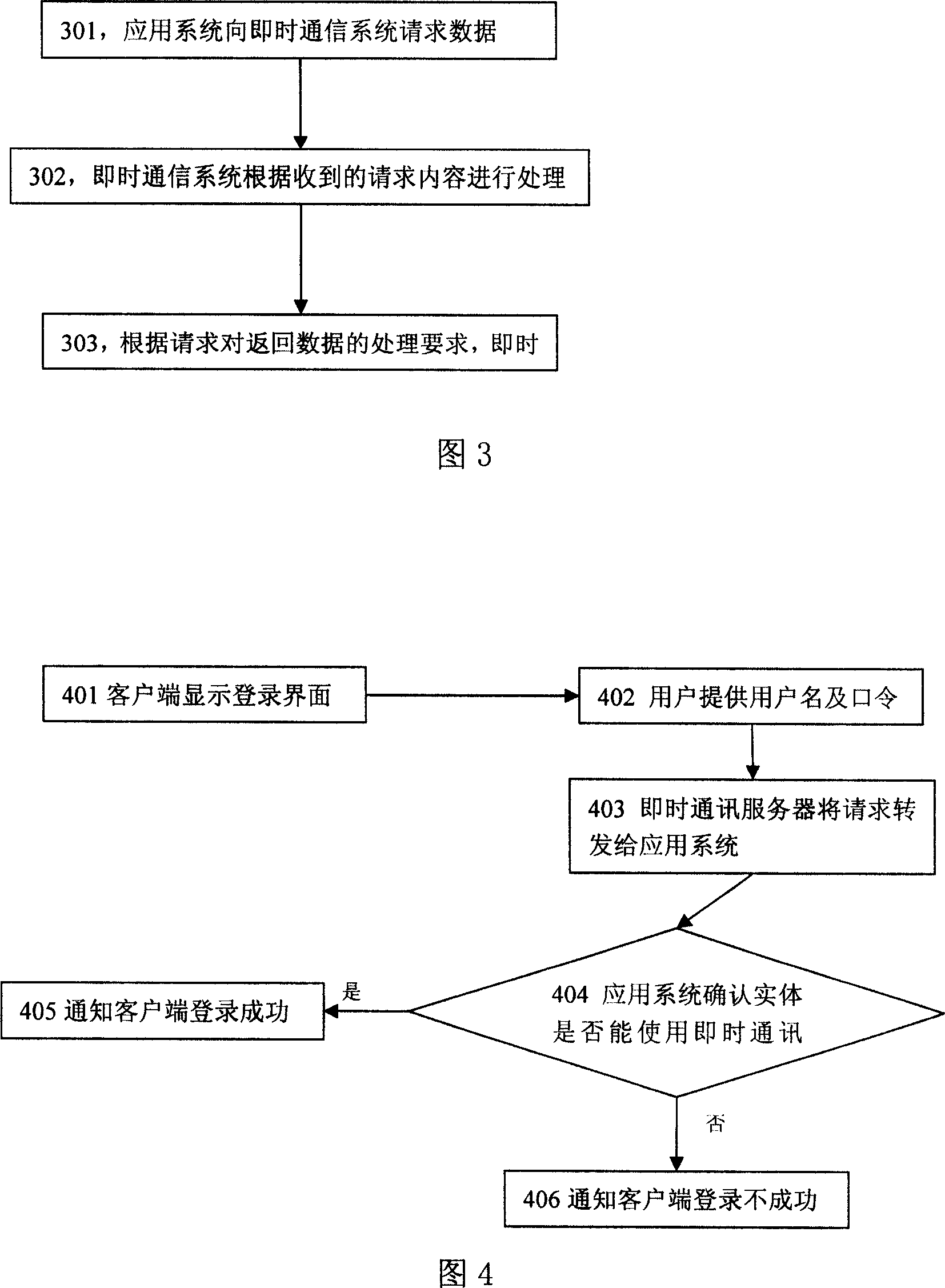

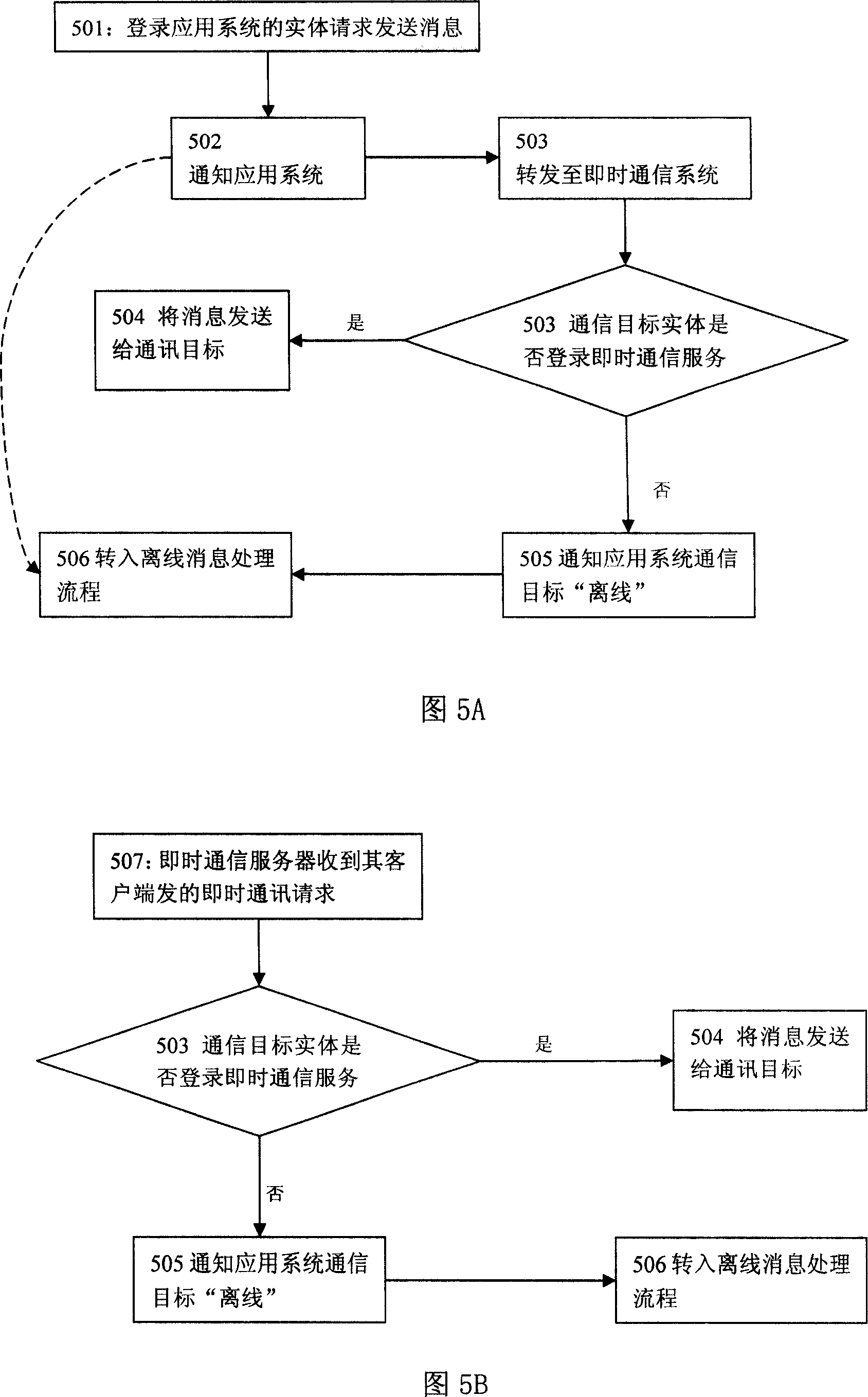

Method and system for providing instant communication function based on application of browser

InactiveCN101094199AReduce development costsFast exchangeData switching networksSpecial data processing applicationsEngineeringCommunications server

In the invention, the opposite communication side is said application system or users using said application system. The method comprises: said browser-based application and instant communication server mutually provides message interfaces; starting up instant communication client side; said client side accesses the browser-based application via the message interface between the instant communication server and said application system; the instant communication client side sends and receives the instant session message to realize the instant communication with the opposite communication side.

Owner:李沫南

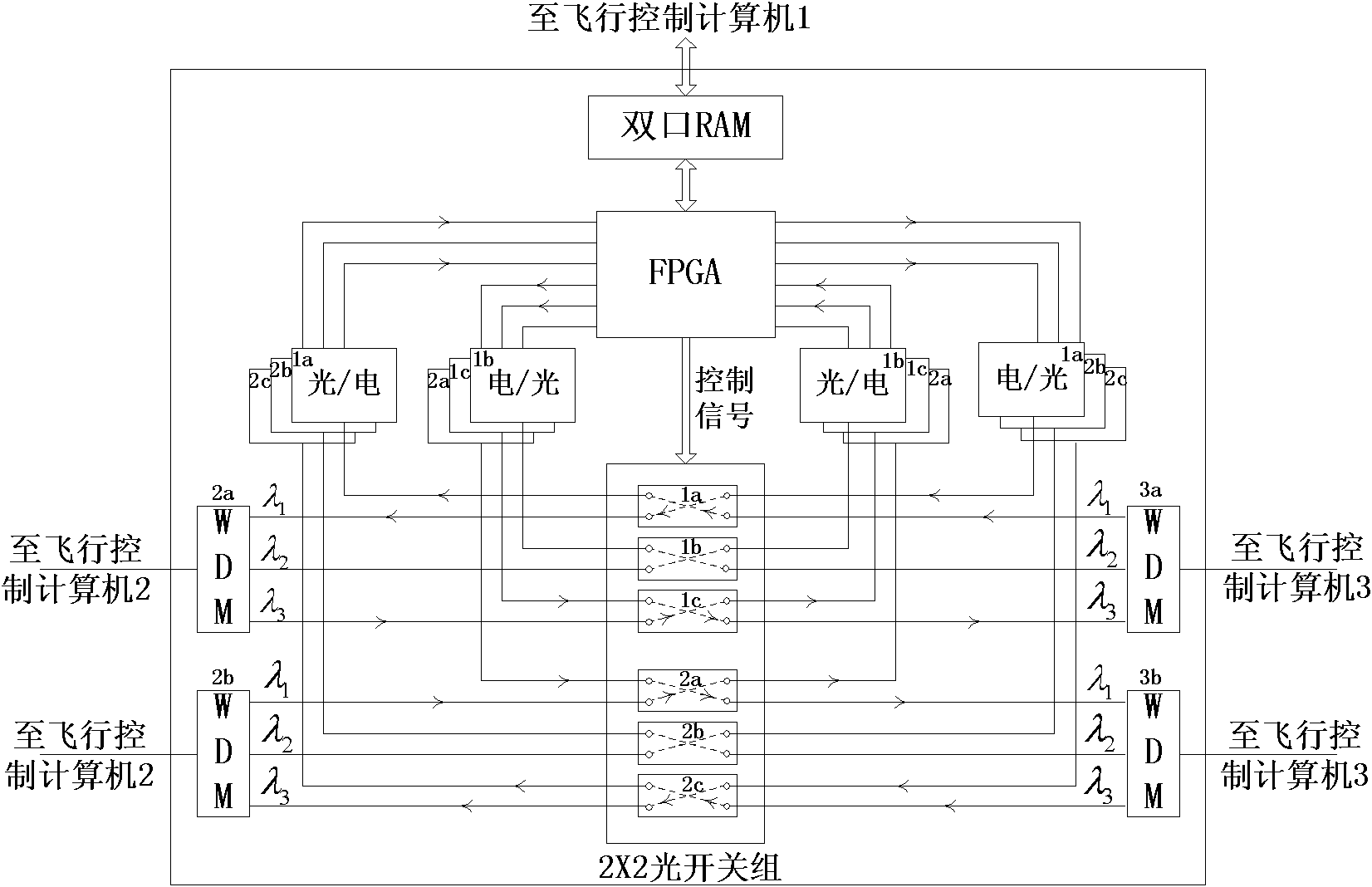

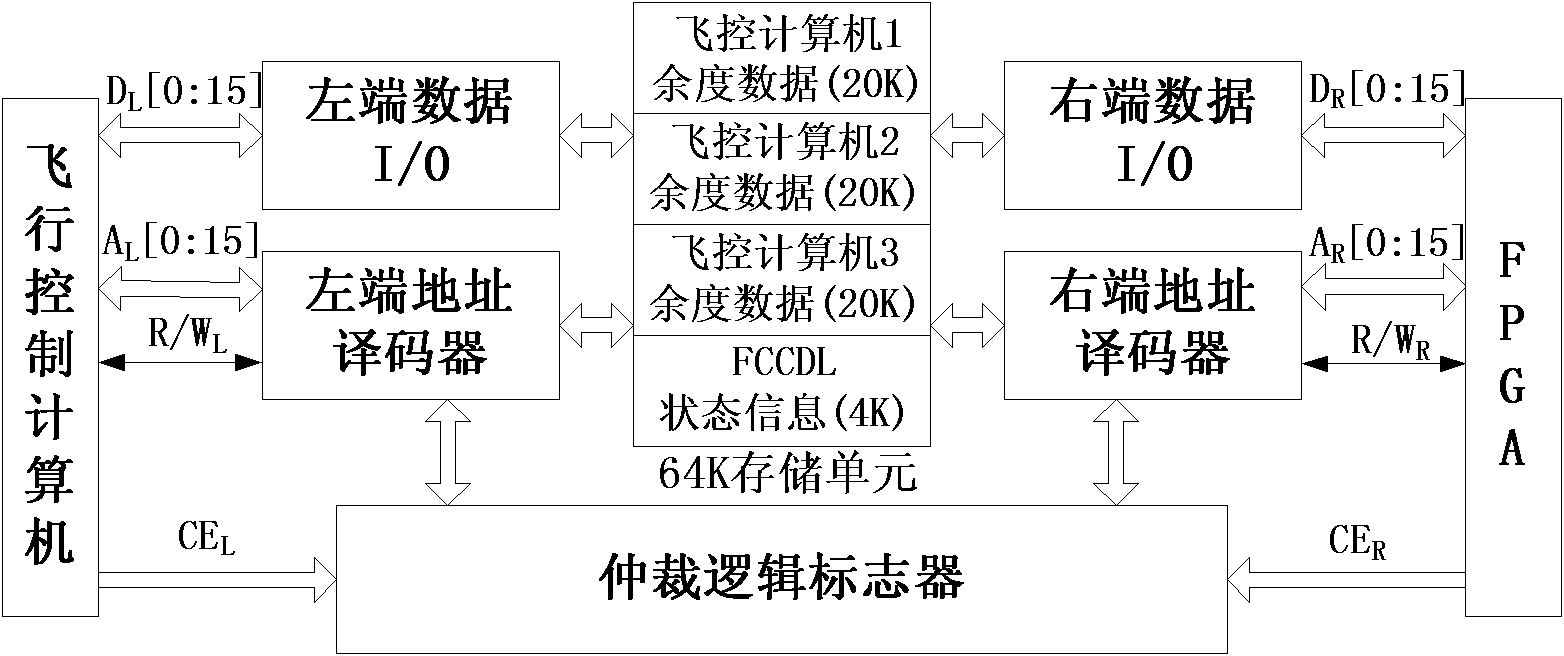

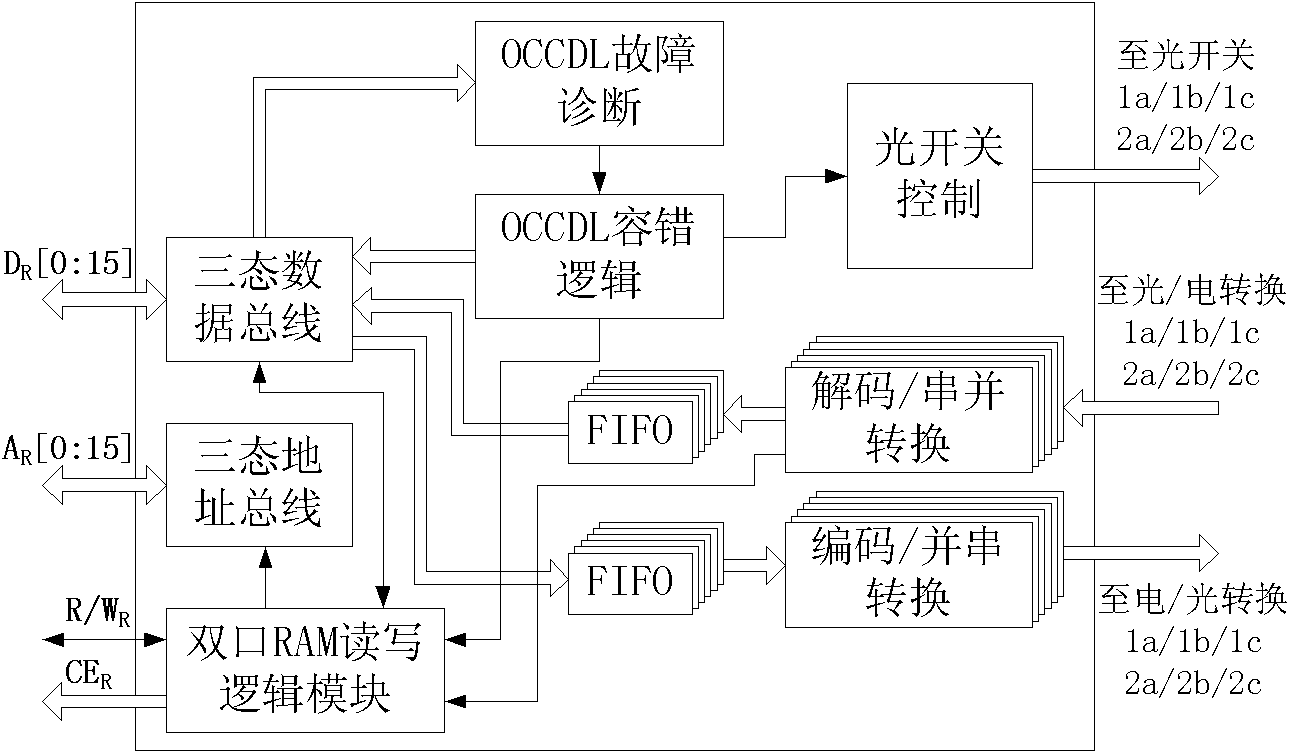

Cross channel (CH) data link system of fly-by-light flight control system

InactiveCN102130722AStrong real-timeGuaranteed real-timeWavelength-division multiplex systemsElectromagnetic transmissionTransmission protocolPhotoswitch

The invention discloses a cross channel (CH) data link system of a fly-by-light flight control system, comprising a field programmable gate array (FPGA) module, a two-port random-access memory (RAM), an optical / electrical switching circuit, an electrical / optical switching circuit, a 2*2 photoswitch and a wavelength division multiplexer (WDM), wherein the FPGA module respectively communicates with the two-port RAM, the optical / electrical switching circuit, the electrical / optical switching circuit and the 2*2 photoswitch; and flight control computers 2 and 3 are respectively connected with the 2*2 photoswitch by the WDM. On the aspect of hardware of the CH data link system provided by the invention, the photoswitch and the WDM are adopted to realize fault inspection and multi-fault operation; meanwhile, a serial transmission protocol of universal serial buses (USB) is taken, thus ensuring the reliability of information transmission.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

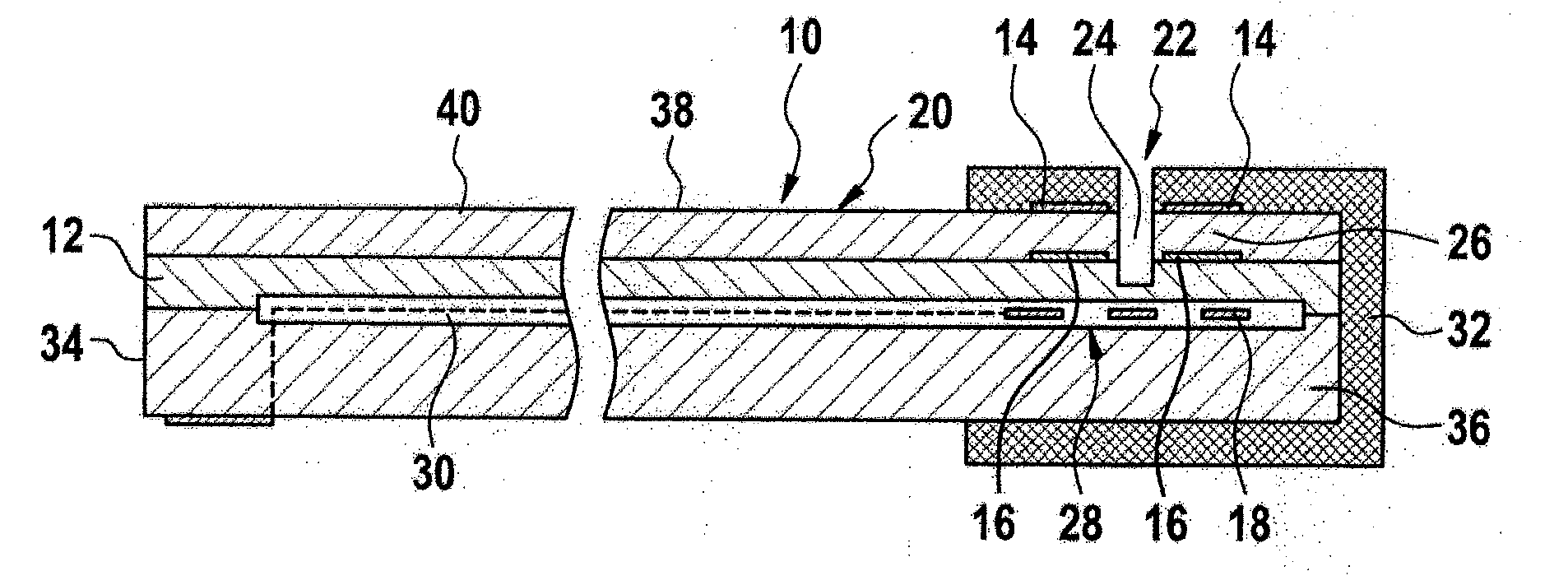

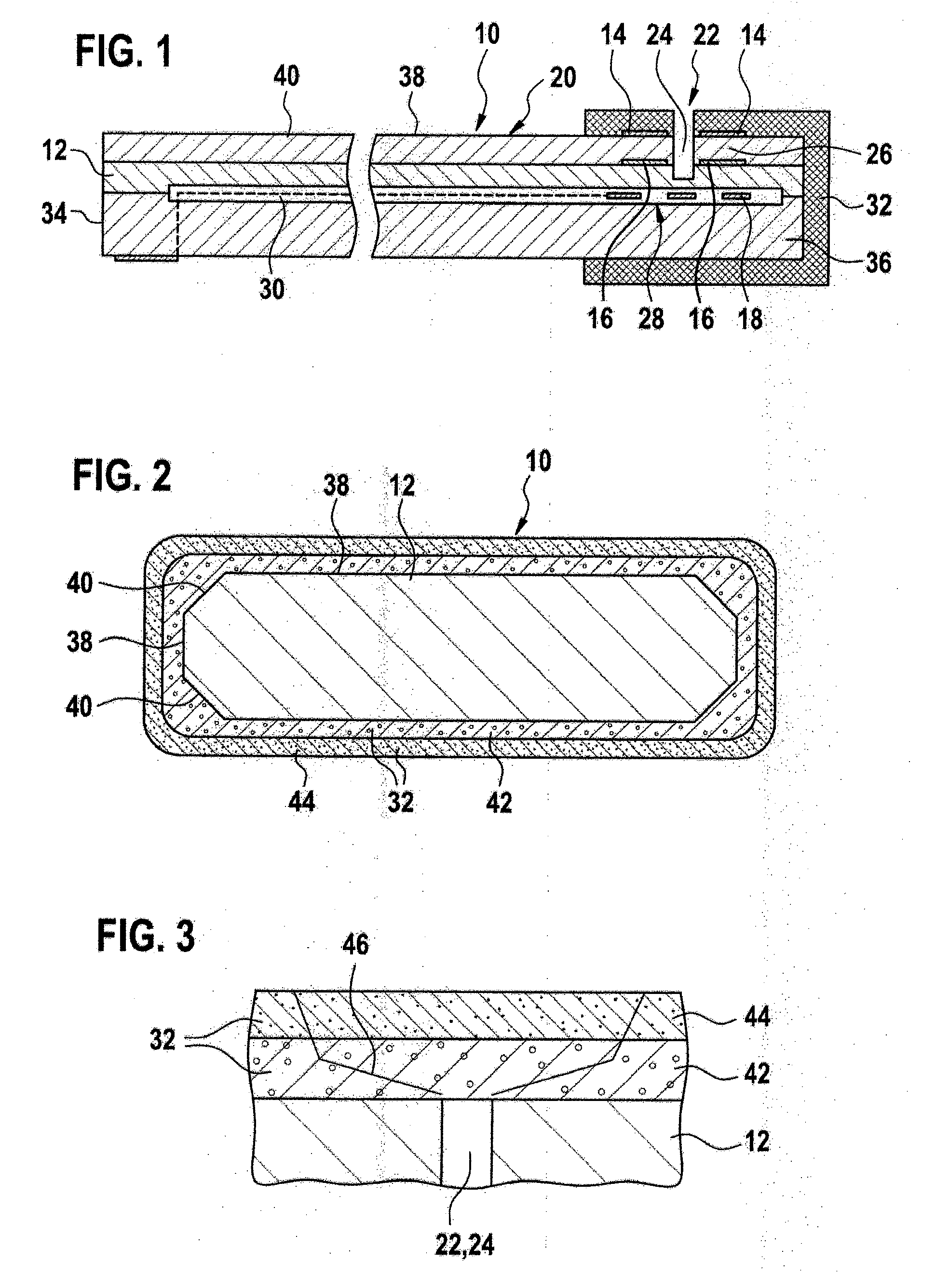

Method for manufacturing a solid electrolyte sensor element for detecting at least one property of a measuring gas in a measuring gas chamber, containing two porous ceramic layers

InactiveUS20160061767A1Increasing thermal massImprove robustnessWave amplification devicesMaterial analysis by electric/magnetic meansMetallurgyGas chamber

A method for manufacturing a sensor element is provided for detecting at least one property of a measuring gas in a measuring gas chamber, in particular for detecting a proportion of a gas component in the measuring gas or a temperature of the measuring gas. The method includes the following steps: providing at least one solid electrolyte which includes at least one functional element; applying, at least in sections, at least one first layer made of a ceramic material to the solid electrolyte, the first layer having a first porosity after the application; and applying, at least in sections, at least one second layer made of a ceramic material, the second layer having a second porosity after the application, and the first layer differing from the second layer with respect to at least one material property. Moreover, a sensor element which is manufacturable according to this method is provided.

Owner:ROBERT BOSCH GMBH

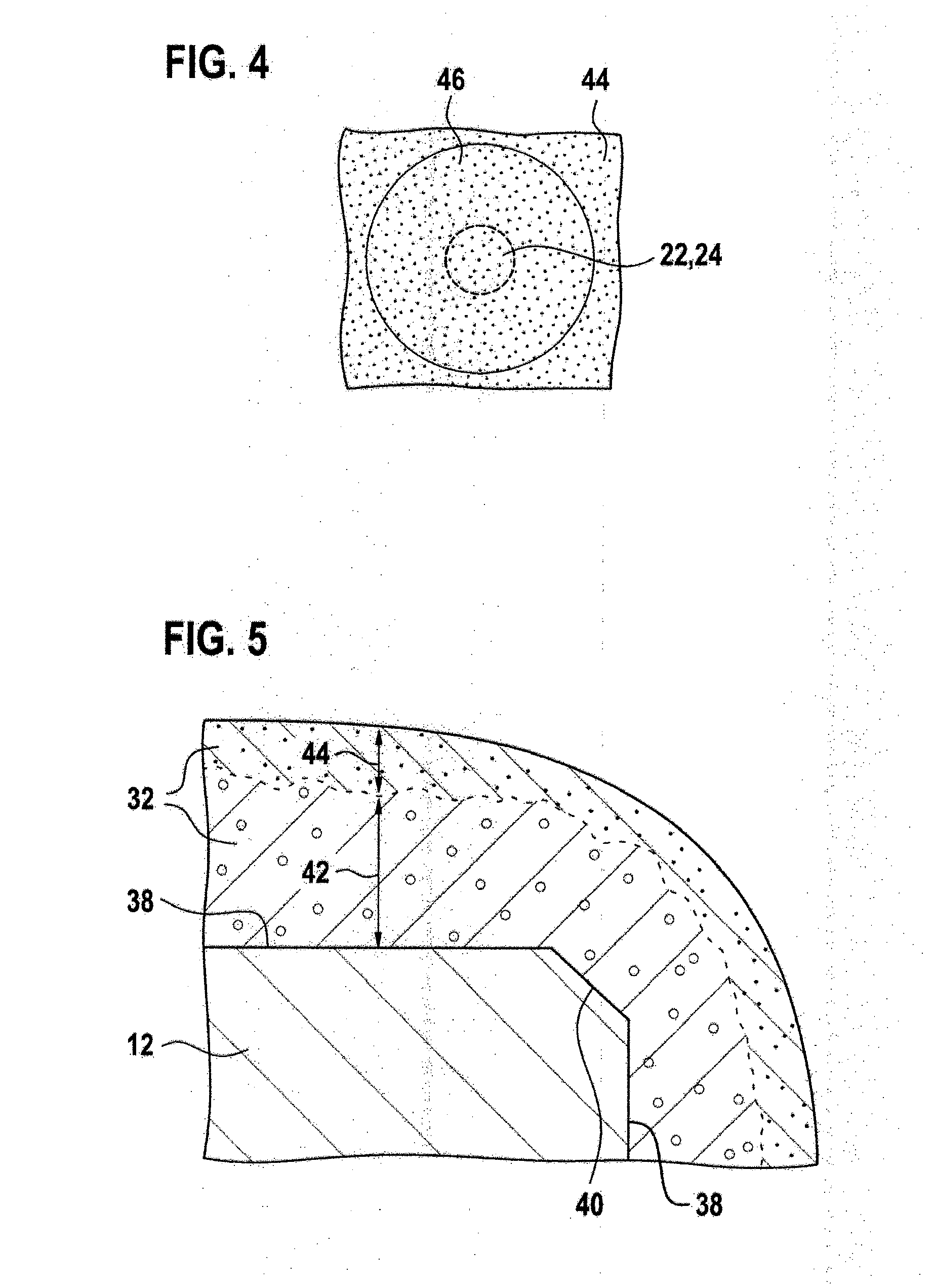

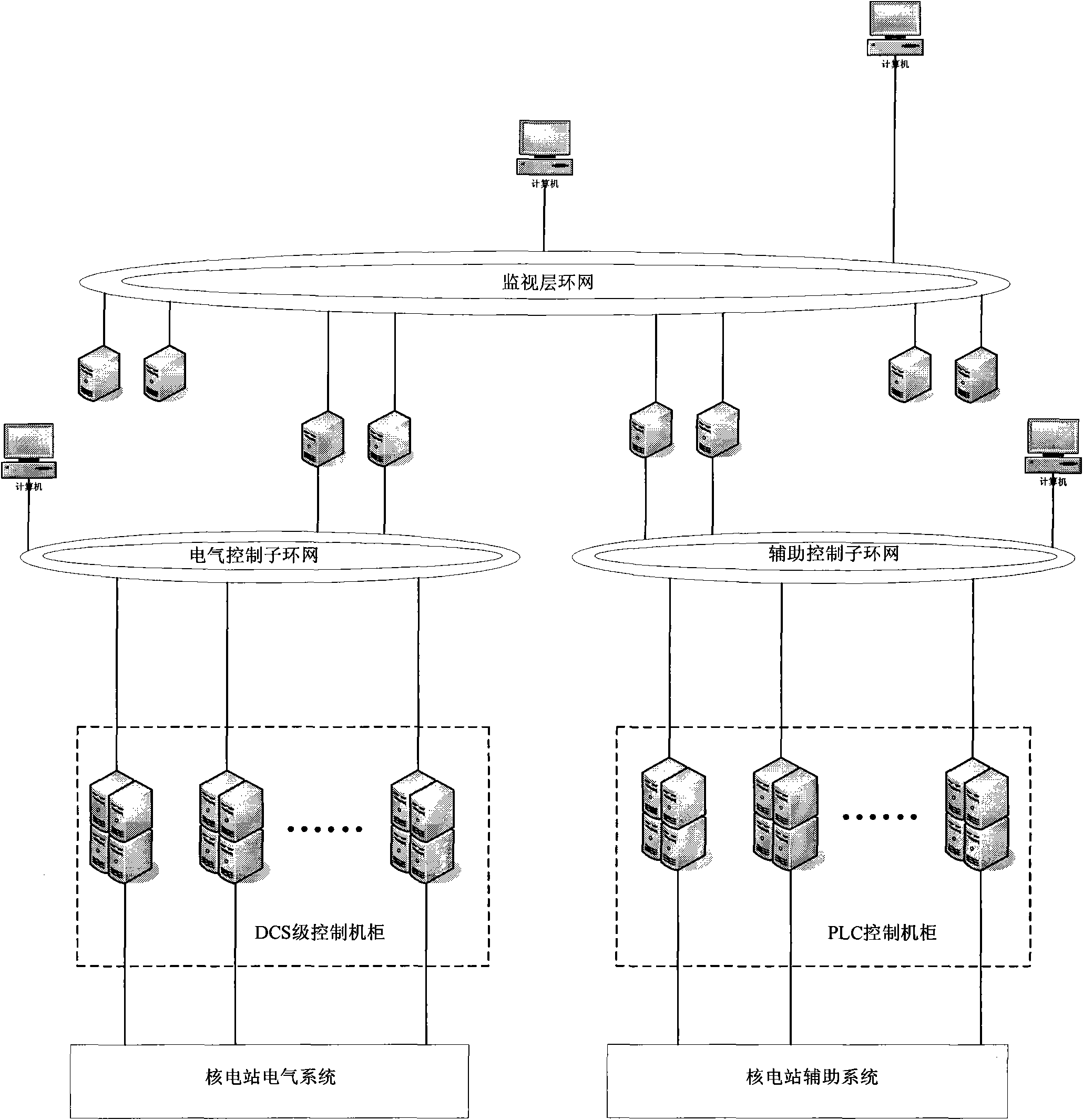

Common control net for nuclear power station

ActiveCN101783192AIncrease the speed of information exchangeIncrease information exchange capacityNuclear energy generationNuclear power plant controlElectrical controlNuclear engineering

The invention relates to a common control net for a nuclear power station, which comprises an electrical control subring net, a sub-control subring net and a monitoring layer ring net, wherein the electrical control subring net is used for being connected with a nuclear power station electrical system, and controlling and monitoring the connected nuclear power station electrical system; the sub-control subring net is used for being connected with a sub-system of the nuclear power station, and controlling and monitoring the connected sub-system of the nuclear power station; and the monitoring layer ring net is respectively connected with the electrical control subring net and the sub-control subring net in order to exchange data with the electrical control subring net and the sub-control subring net respectively and sends a corresponding operation command. The technical scheme of the invention solves the problem that the common system can not be controlled, which is generated by different retirement periods caused by different service life in the nuclear power station management; the invention can not be influenced by the set retirement, realizes the network control of the common system, improves the information exchange speed and increases the information exchange volume, reduces operators, improves the operable rate and the usability of the common system, and further improves the economy of the nuclear power station operation.

Owner:中广核工程有限公司 +1

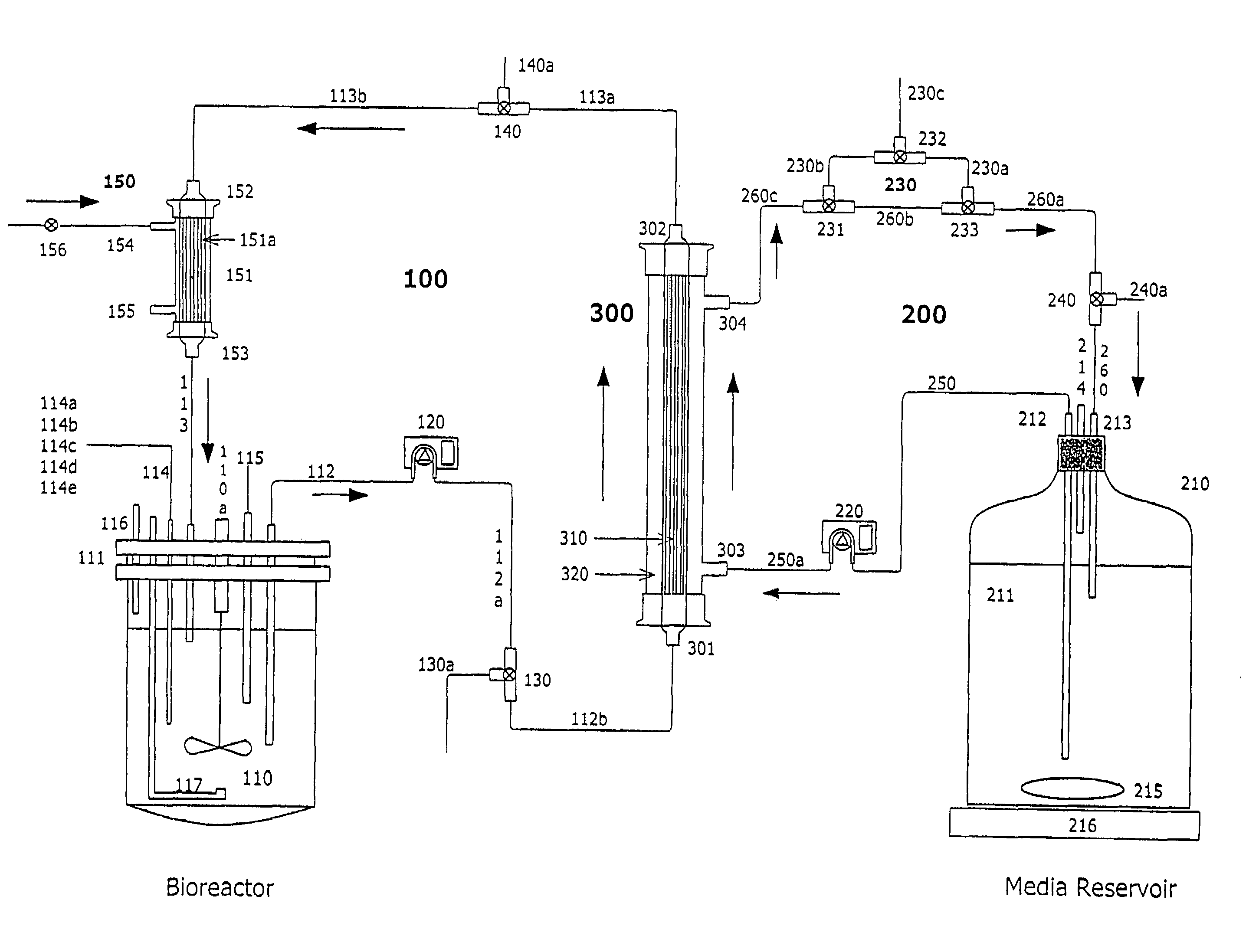

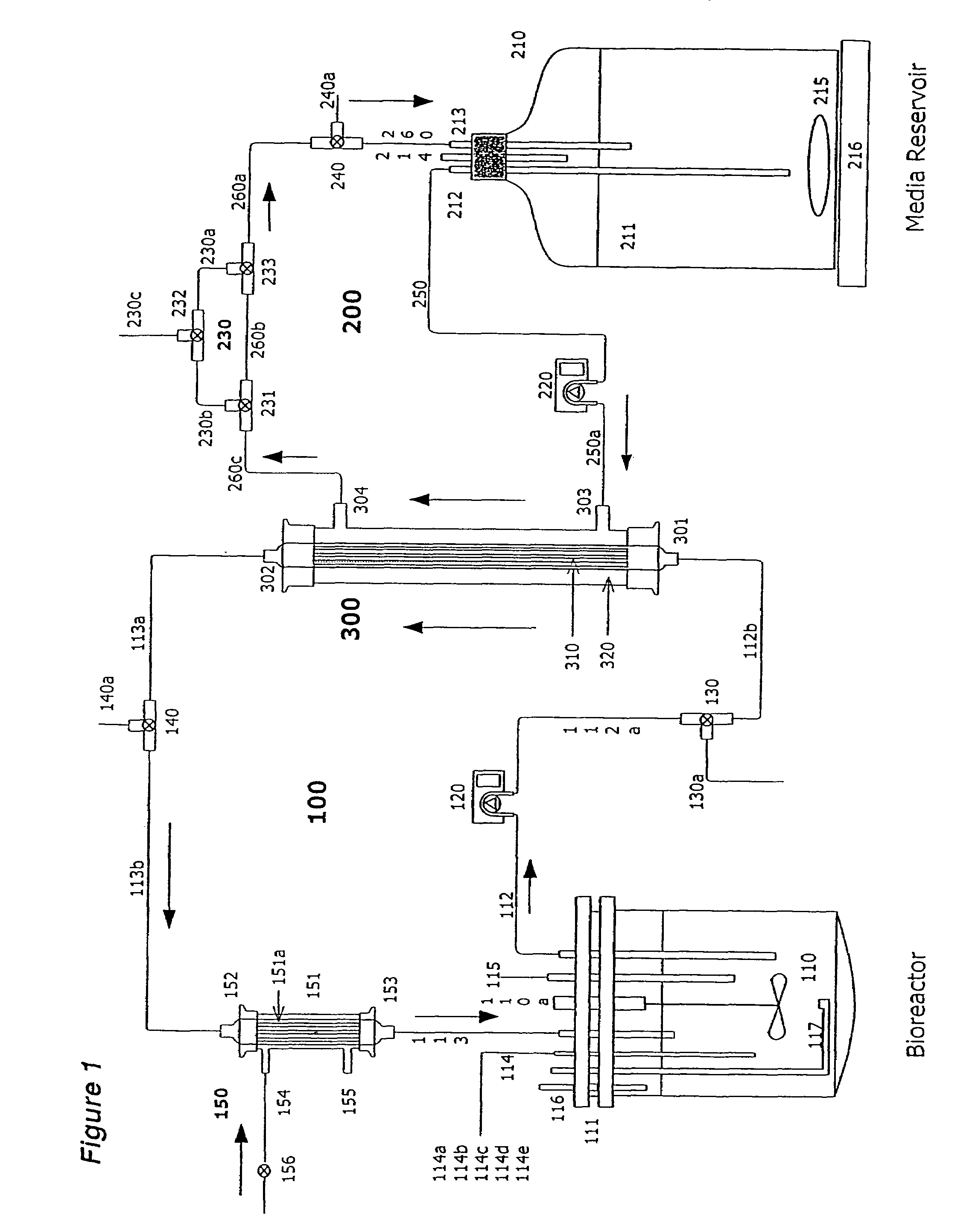

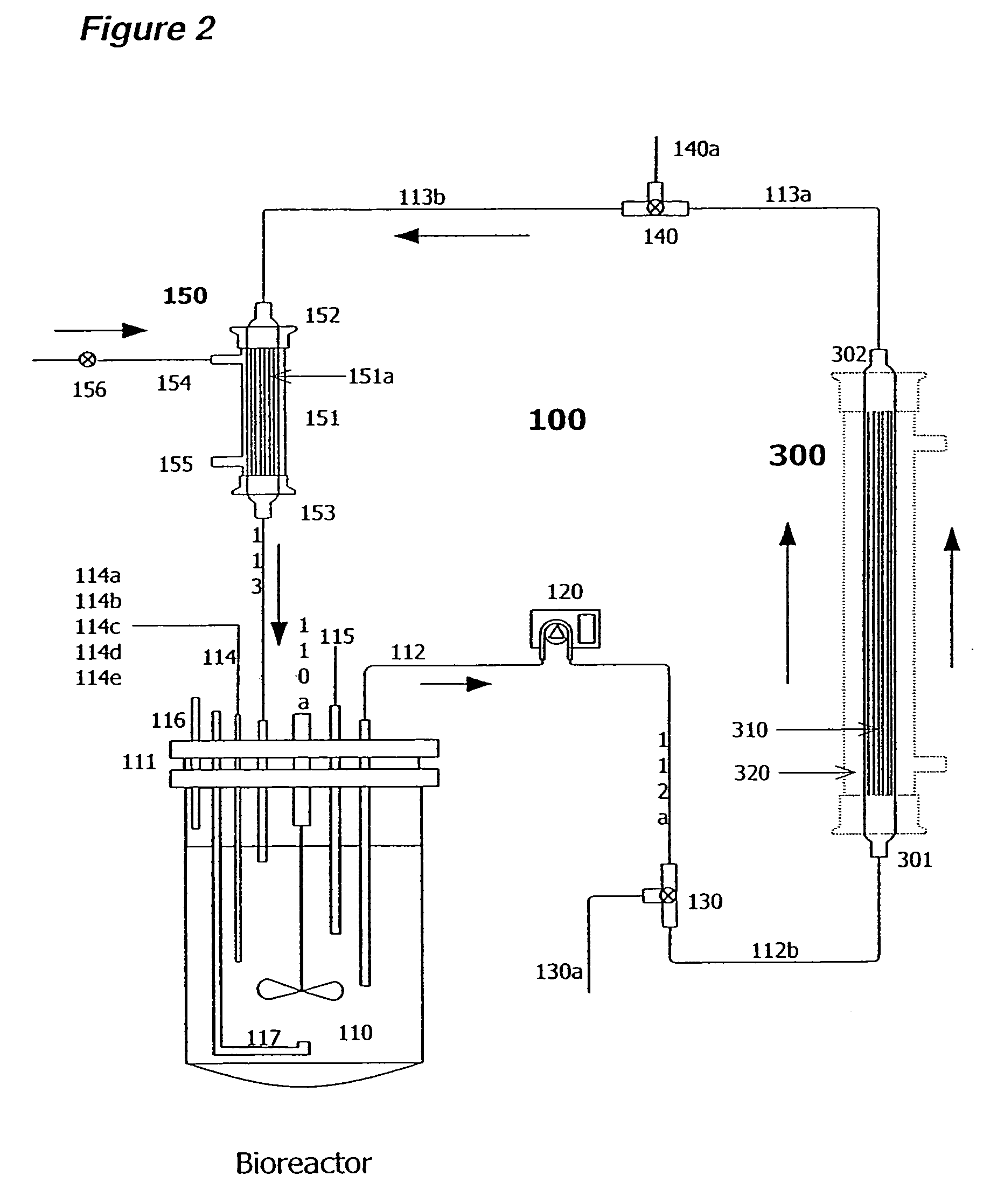

Apparatus and methods for producing and using high-density cells and products therefrom

InactiveUS7598075B2Quick exchangeImprove performanceBioreactor/fermenter combinationsBiological substance pretreatmentsHigh cellHigh density

Disclosed and claimed is apparatus and methods for the growth of cells to high density, products therefrom and uses thereof. Also disclosed and claimed is the use of this method for the growth to high-density insect cells, such as the Spodoptera frugiperda Sf900+ cell line (ATCC: CRL 12579). Further disclosed is the infection of Sf900+ cells at high cell density with wild type and recombinant baculoviruses to produce baculovirus and DNA or gene or expression products.

Owner:PROTEIN SCI

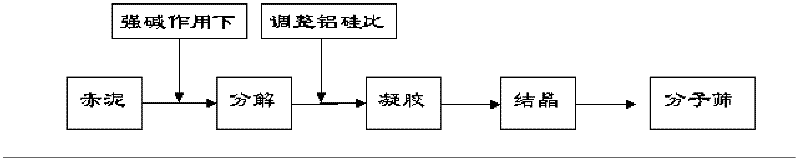

Method for preparing sodium type zeolite molecular sieves by utilizing red mud

InactiveCN102530978AReduce consumptionLow costCrystalline aluminosilicate zeolitesMolecular sieveFiltration

A method for preparing sodium type zeolite molecular sieves by utilizing red mud comprises the steps of regulating the molar ratio of sodium silicon in the red mud to be 1.0-3.0 and regulating the molar ratio of silicon aluminum to be 2.0-5.0; heating to enable the red mud to be mixed with rubber and achieve aging; heating to enable the red mud to achieve crystallization reaction; cooling, filtration washing and drying a solid product after crystallization to obtain the zeolite molecular sieves. The method is cheap in raw material, simple in device, simple and convenient in operation and simple and feasible in preparation of the sodium type zeolite molecular sieves, and simultaneously provides a novel way for comprehensively utilizing the red mud.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

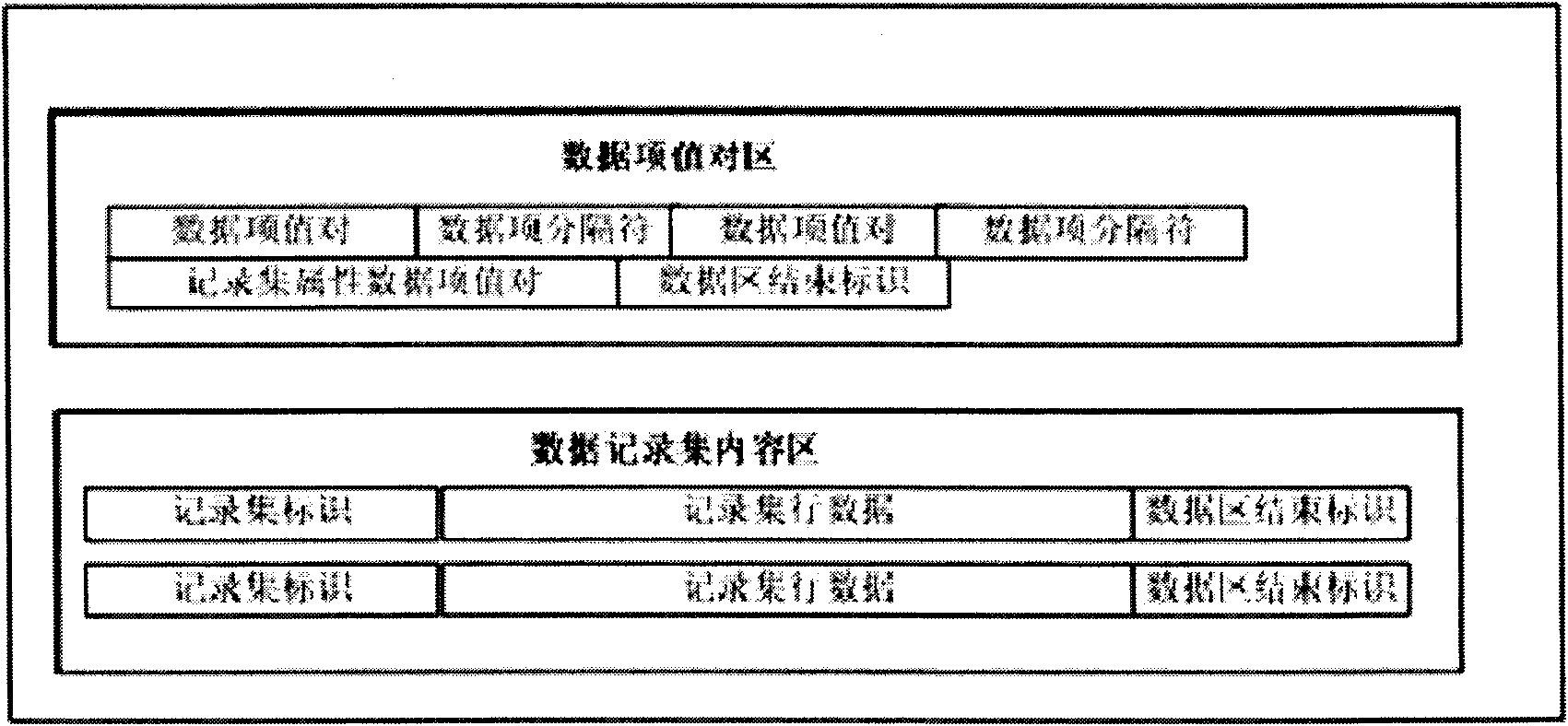

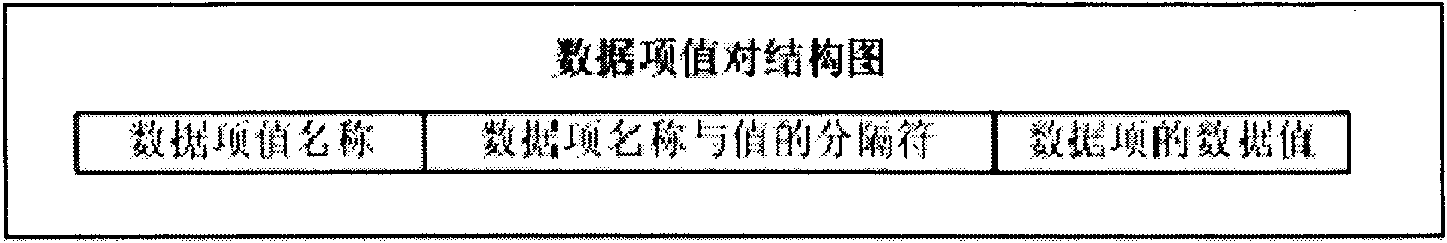

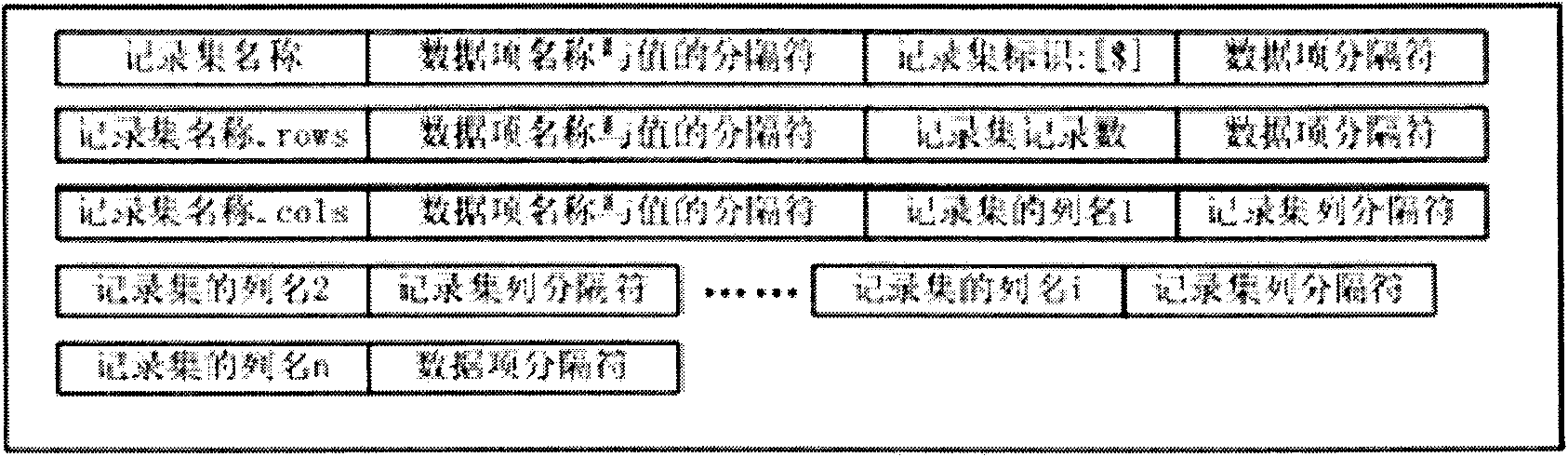

Structured data exchanging method

InactiveCN101930455AFast exchangeSimplified descriptionSpecial data processing applicationsNetwork packetData exchange

The invention provides a structured data exchanging method. In the method, a data exchange packet mainly comprises data item value pairs and a data record set; data can be concisely described; data items are separated by using specific separators which cannot be input; and the format comprising the data item value pairs and the data record set is realized. As only a little redundant data are added, the structured data exchanging method has the advantages of small data packet, fast data exchange and convenient application.

Owner:NANJING LES INFORMATION TECH

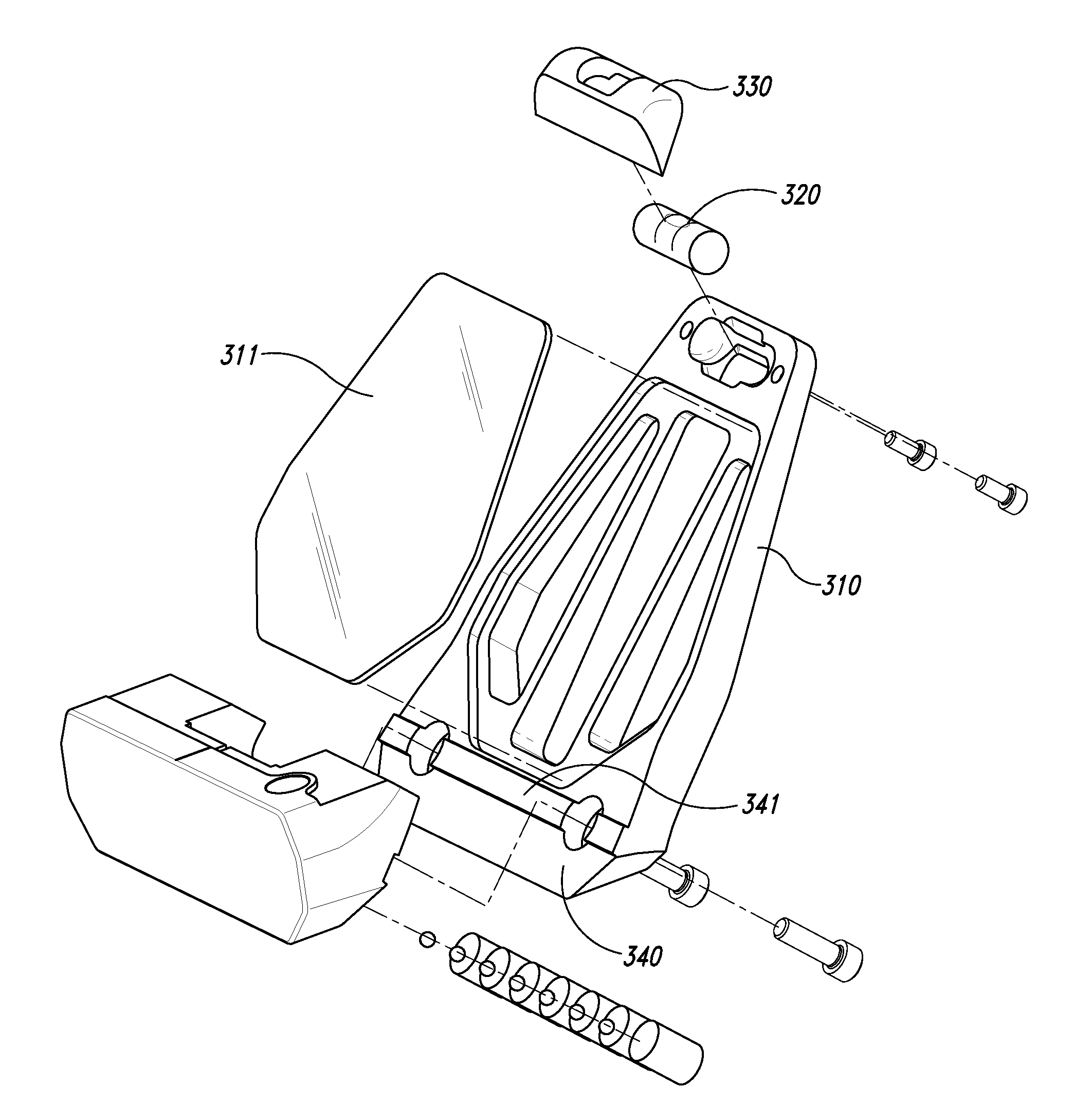

Deep softening method of thick oil sewage

ActiveCN102815765ASolving the scaling problem of boilers reused in thermal recoveryAvoid badWater/sewage treatment by ion-exchangeWater qualitySewage

The invention relates to a deep softening method of thick oil sewage, which comprises the following steps: preterating thick oil sewage to remove impurities in the thick oil sewage, and carrying out preliminary softening treatment with a macroporous weak acid resin until the pH value of the thick oil sewage reaches 7-9 and the temperature reaches 57-80 DEG C; passing the pretreated thick oil sewage through an adsorption tower or adsorption column filled with a chelating resin at the flow rate of 20-30 BV / h to carry out adsorption treatment; and when the adsorption reaches the leakage point, obtaining the thick oil sewage subjected to deep softening. The method provided by the invention is a treatment process capable of efficiently softening thick oil sewage according to the water quality characteristic of the thick oil sewage; and the method provided by the invention can still be used repeatedly in a thermal recovery boiler without generating scales after saving the silicon removal system.

Owner:PETROCHINA CO LTD

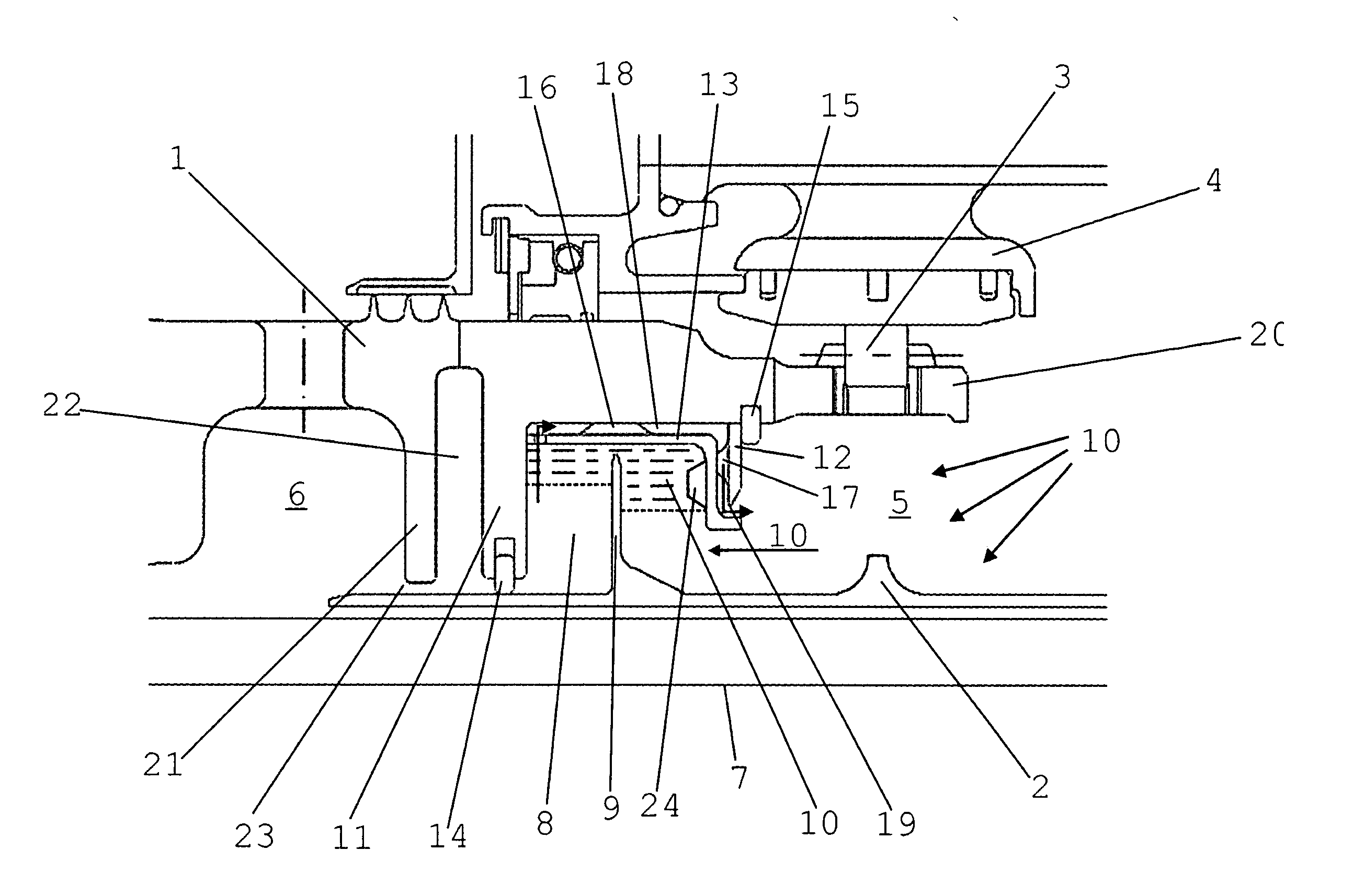

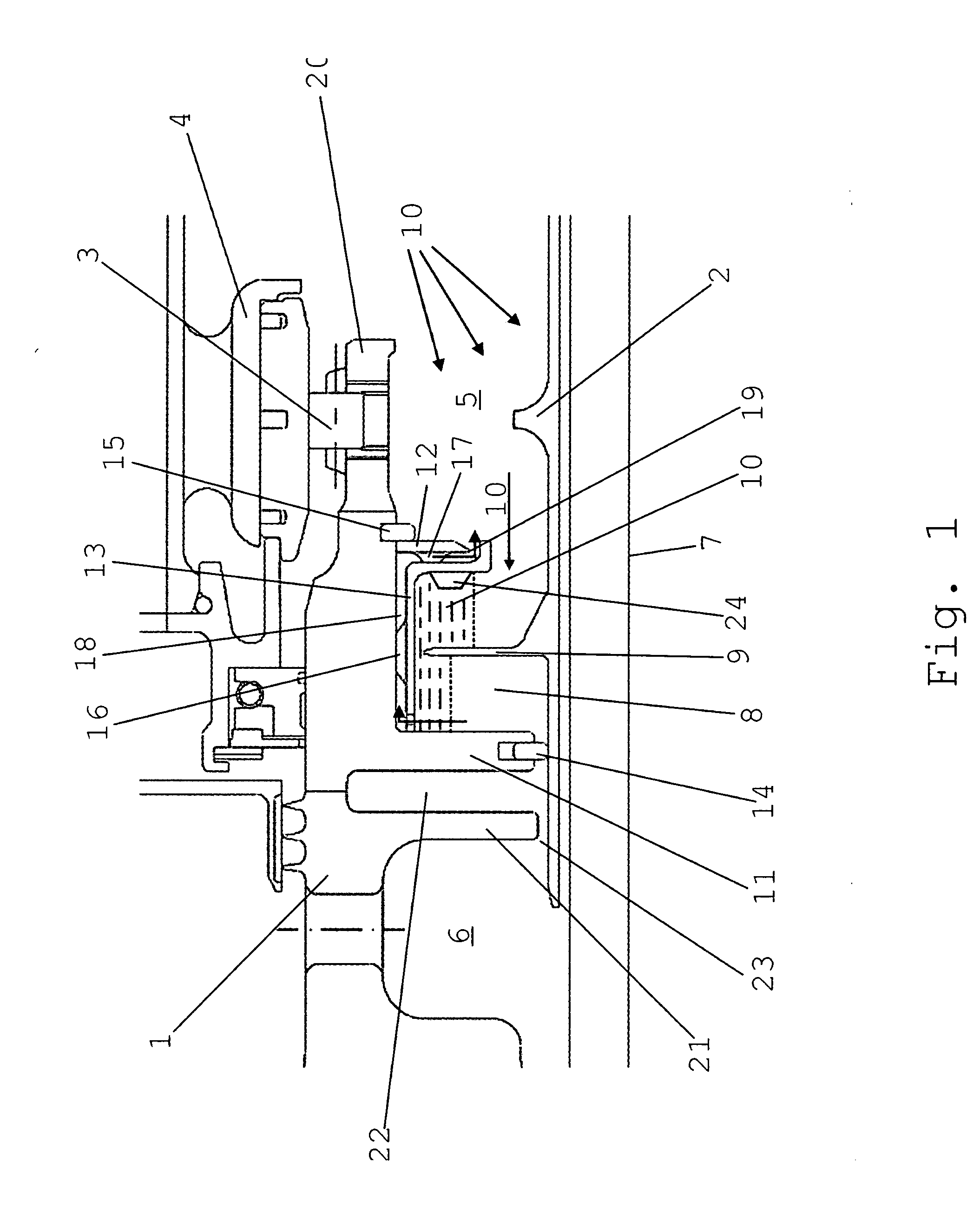

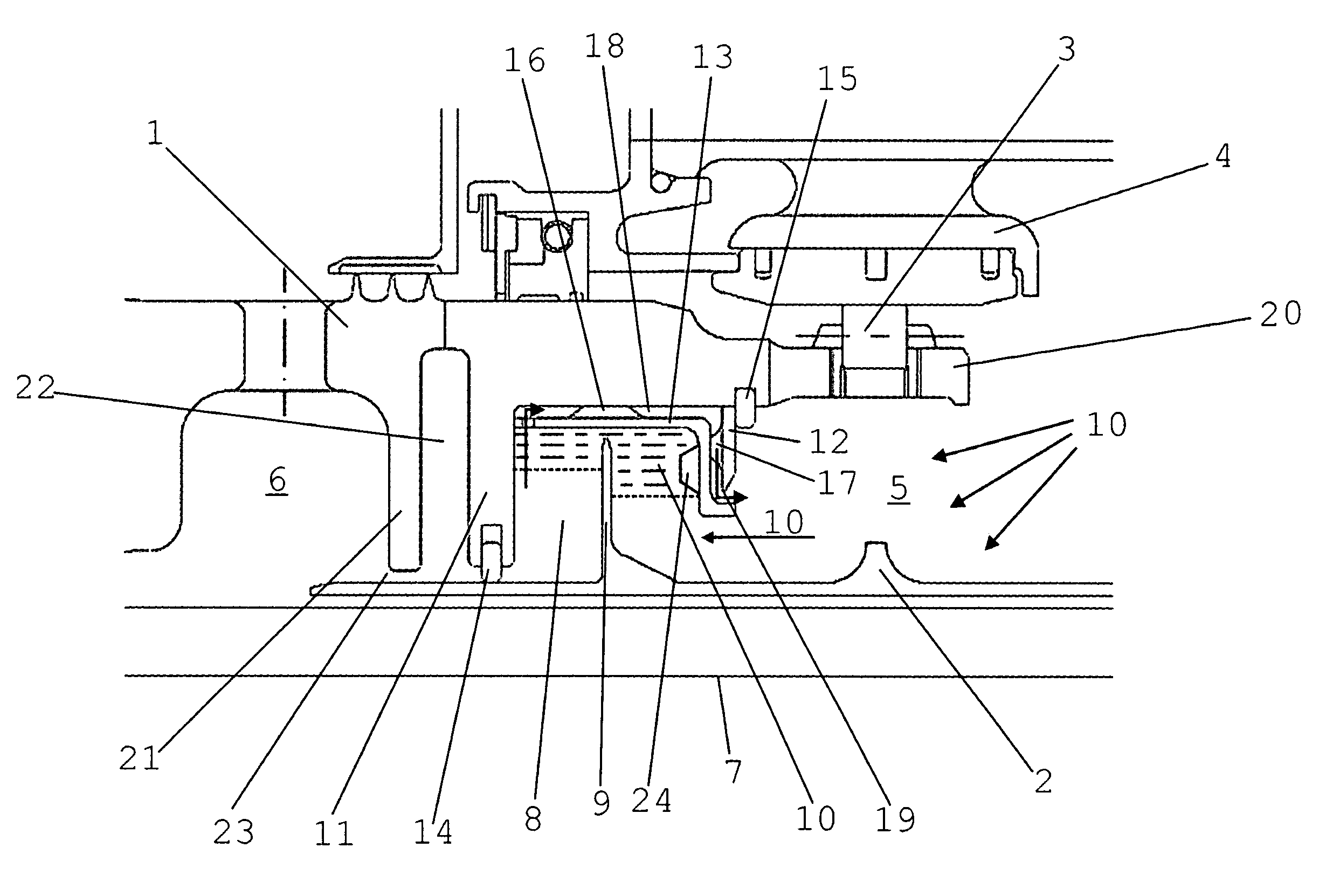

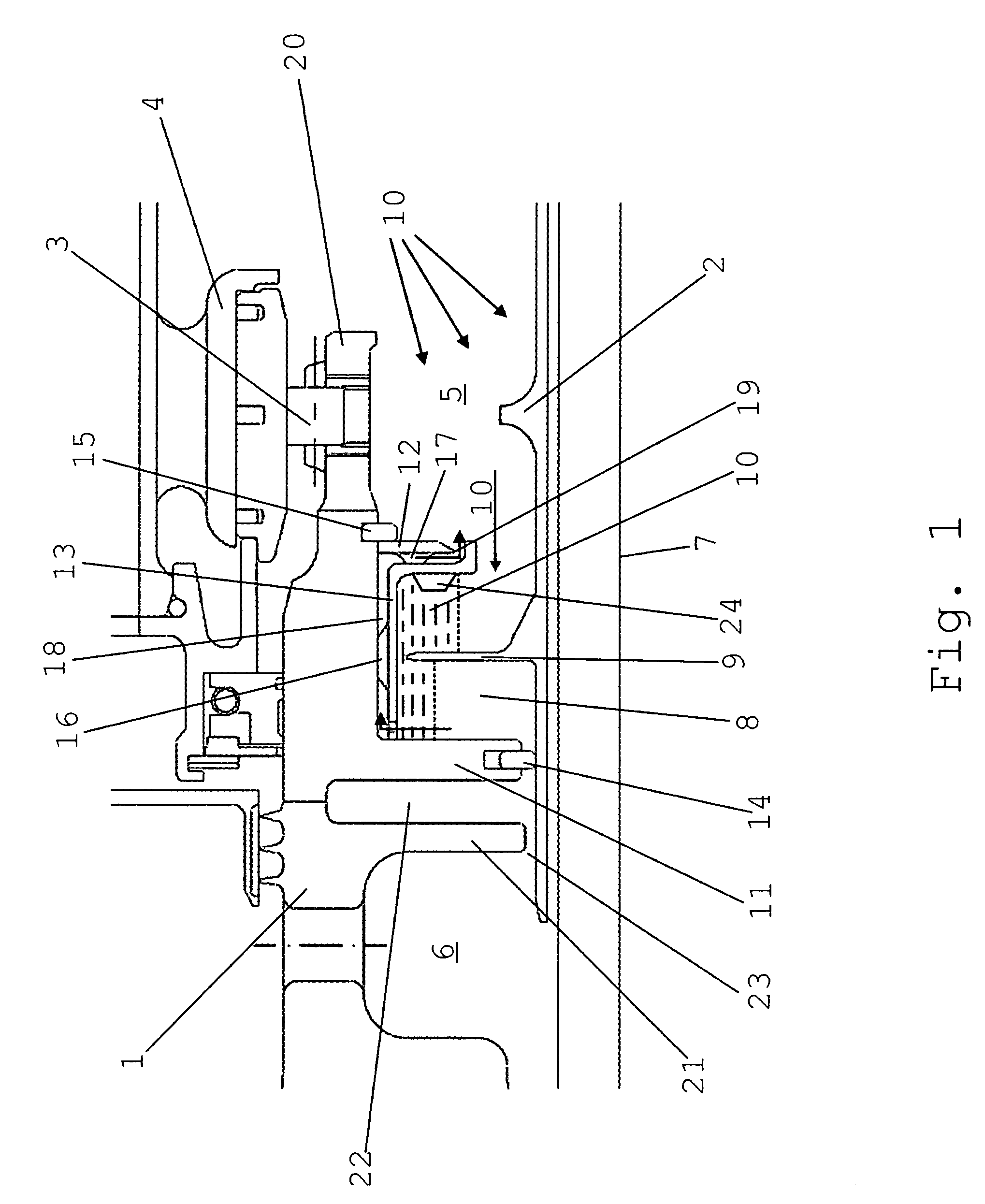

Hydraulic shaft sealing arrangement for high-temperature applications

ActiveUS20060033289A1Save assemblySave spaceEngine sealsEfficient propulsion technologiesThermal insulationEngineering

On a hydraulic shaft sealing arrangement for high-temperature applications, a heat protection ring (21) and an air chamber (22) are arranged before the annulus (8) containing the sealing medium (10) for thermal insulation, while spacers (16, 17) for the generation of a pumping action are provided in the annulus continuously supplied with fresh sealing medium (oil) to accelerate liquid transport. The hazard of coking and oil carbon deposition is thereby minimized. A split design of the annulus with an inserted annular ring also provides for an improved hydraulic shaft sealing arrangement optimized for weight, overall height, manufacture and assembly time.

Owner:ROLLS ROYCE DEUT LTD & CO KG

Method for enriching agaric polysaccharide in purified black agaric by using macroporous absorption resin

The invention belongs to the field of natural organic chemistry, and relates to a method for enriching agaric polysaccharide in purified black agaric by using macroporous absorption resin. The invention is characterized in that a macroporous absorption technology is applied to separate the purified black agaric polysaccharide, the absorption selectivity to the agaric polysaccharide is good, the absorption and analysis are both fast, and the absorption capacity is larger; and the extraction is convenient and fast, the raw material source is rich, the production is low, the separating effect is obvious, the extracting purity is high, semi-finished products of agaric polysaccharide with the content of more than 35 percent and final products of agaric polysaccharide with the content of more than 98 percent can be obtained, and the defects that the conventional method has lower extraction rate and low extraction purity are overcome. The method selects macroporous absorption resin with stable physical-chemical properties, larger surface area, faster exchange velocity, high mechanical strength, strong anti-pollution capability and good heat stability, can absorb the agaric polysaccharide selectively from solution by physical absorption, and has fast absorption and analysis and larger absorption capacity.

Owner:HEILONGJIANG DINGHENGSHENG PHARM CO LTD

Ion exchange method for solid substance containing exchangeable ions

The invention provides an ion exchange method for a solid substance containing exchangeable ions. The method comprises the following step of carrying out bipolar membrane electrodialysis to the slurry of the solid substance containing the exchangeable ions so as to exchange ions. The method can dissociate the water characteristics by utilizing a bipolar membrane electronic dialyzator without additionally adding other ions for exchange. According to the ion exchange method for the solid substance in the invention, ions are exchanged at a higher speed so as to rapidly carry out ion exchange to the solid substance with high efficiency. The method for the electrodialysis of the solid substance in the invention can obtain acid liquor and / or alkali liquor with higher purity level while carrying out ion exchange to the solid substance containing the exchangeable ions to realize the zero emission of wastewater and improve the economic benefits of the method.

Owner:CHINA PETROLEUM & CHEM CORP +1

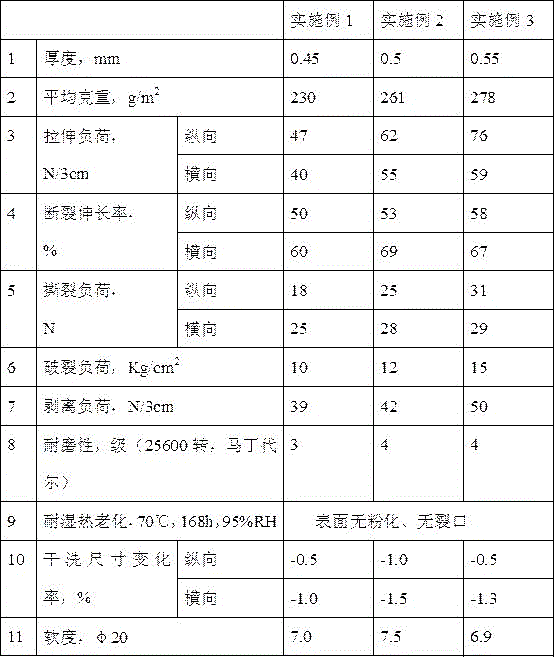

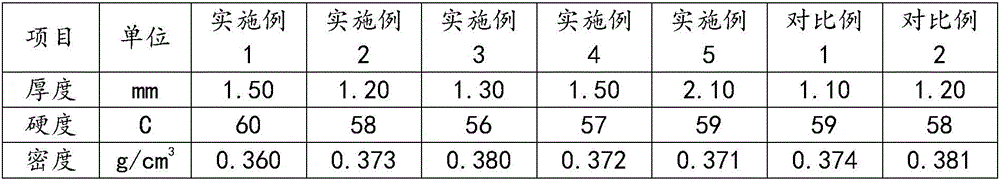

Preparation method for ultrafine fiber clothing leather

InactiveCN105568709AReduce pollutionBig pollutionHeating/cooling textile fabricsTextile treatment machine arrangementsReduction treatmentHigh density

The invention discloses a preparation method for ultrafine fiber clothing leather. The preparation method comprises the following steps that a figured or unfigured sea-island fiber is selected to be prepared into a high-density non-woven cloth, and heat setting is performed; the non-woven cloth is impregnated with polyurethane sizing and then cured to be prepared into semi-finished synthetic leather; quantity reduction treatment is performed on the semi-finished synthetic leather to strip out sea ingredients in the sea-island fiber, and then semi-finished ultrafine fiber clothing leather is prepared; the semi-finished ultrafine fiber clothing leather is treated through splitting, sanding and softening, and then the ultrafine fiber clothing leather is prepared. The ultrafine fiber clothing leather obtained through the method has the advantages that the handfeel is soft, the drape performance is good, the hot iron resisting effect is good, the effect of consistent folding grains in the warp direction and weft drection is achieved, the zigzagged folding grain or thick wrinkle phenomenon cannot occur when the leather is folded in half, the recovery effect is extremely good after the leather is folded in half, and the surface has no fold residue.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

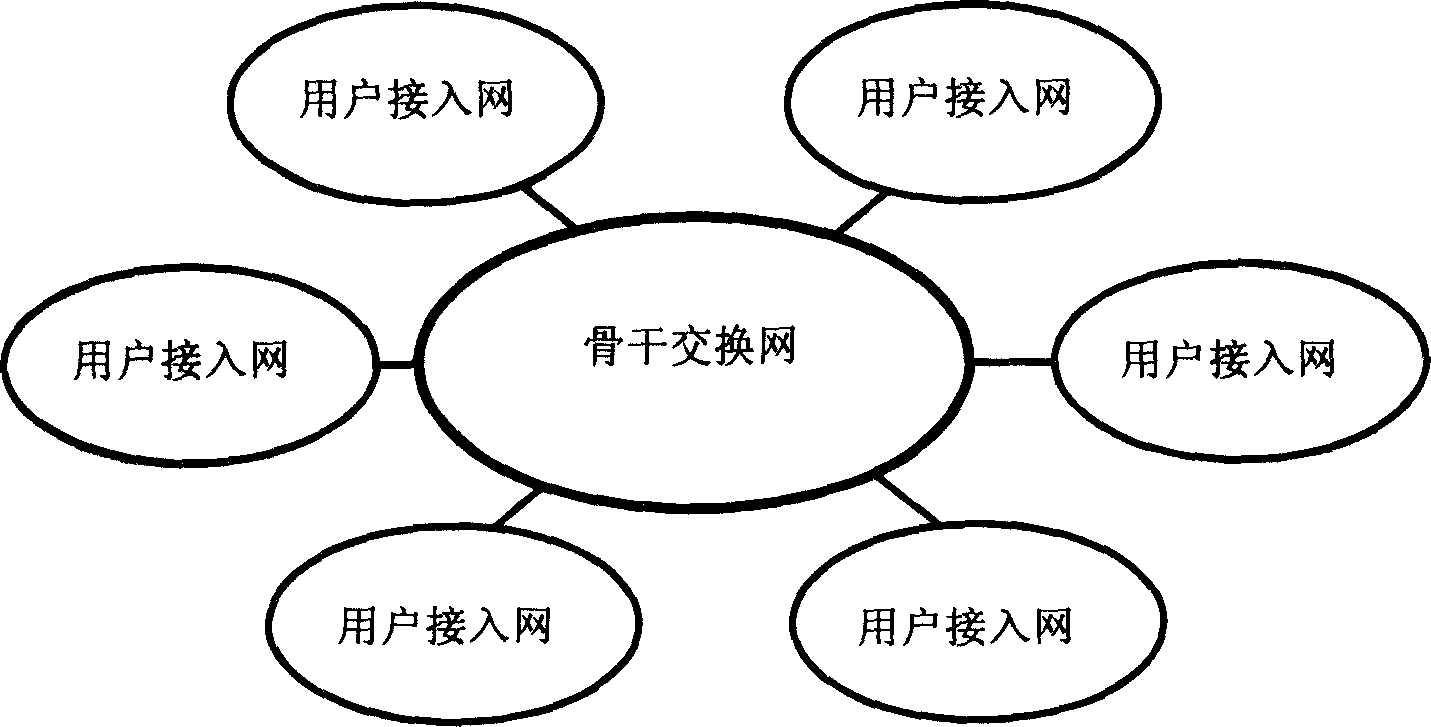

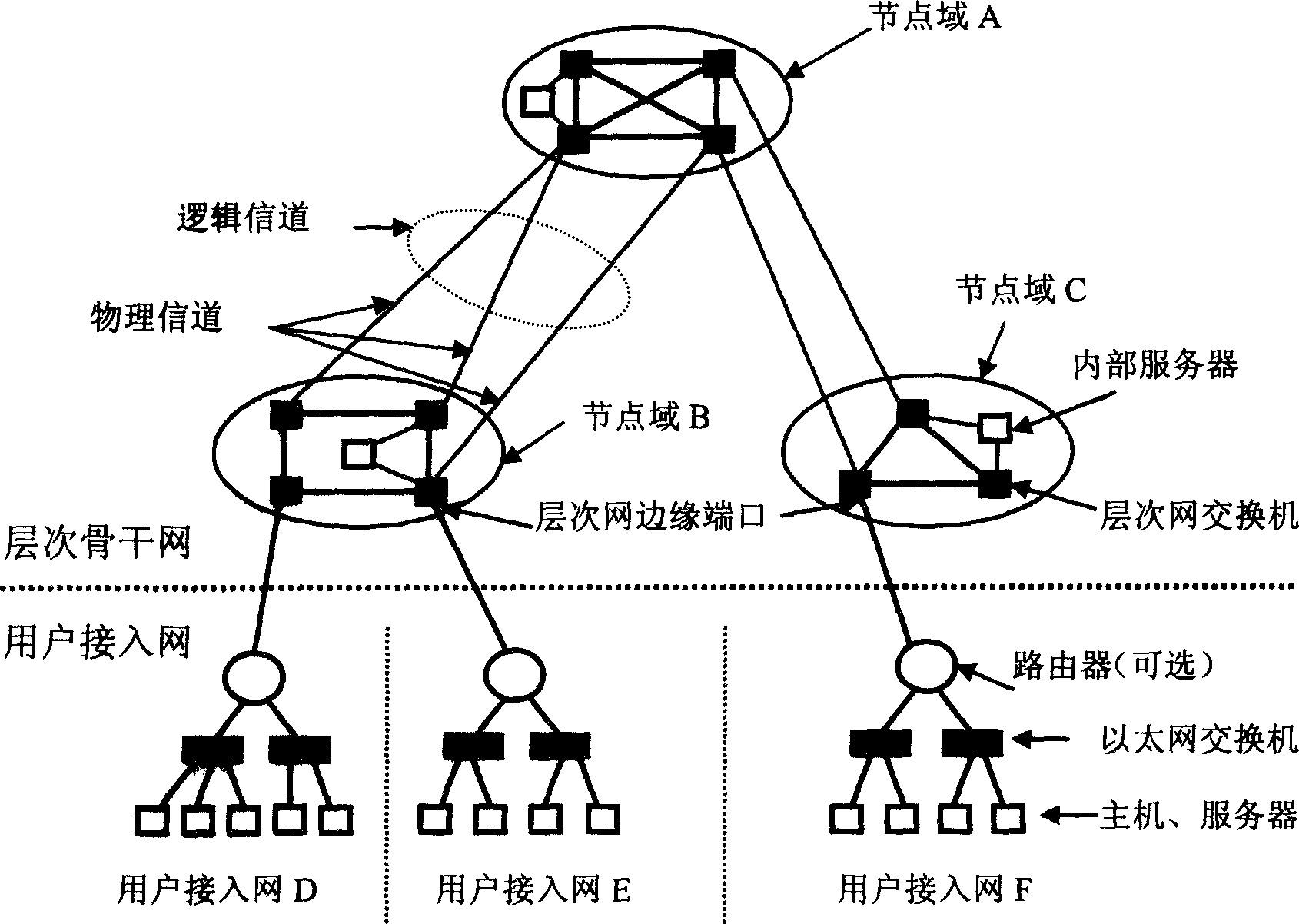

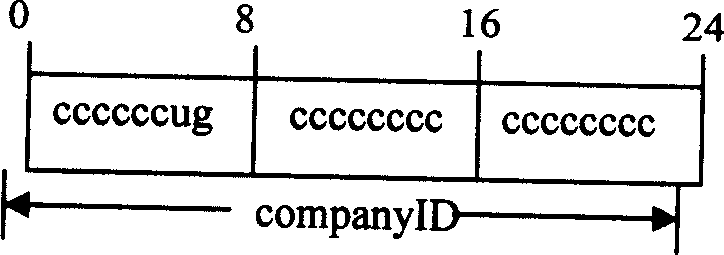

Separating and merging IPv6 address space of switching network in hierarchy mode

InactiveCN1761226AAvoid paralysisIncreased complexityData switching by path configurationNetwork addressAddress space

The invention belongs to network architecture, and design of network address space and planning area. In hierarchy type switched network, network is divided into two parts: backbone network and user access network; the former is owned and managed by network manager, and the later is owned and managed by user self. One of fatal weaknesses is that devices of network manager and devices of users are located at same address space. Thus, any user can access any backbone router of network manager so that backbone router faces to threat of paralysis. The invention separates address space so that use cannot access devices on backbone network of network manager. Thus, safety of devices on backbone network is guaranteed. It is requisite that two address spaces can be merged in order to keep consistency between communication protocols of user data packet for backbone network exchange and exchange inner control packet. Two address spaces are unified from viewpoint of exchange control protocol.

Owner:COMP NETWORK INFORMATION CENT CHINESE ACADEMY OF SCI

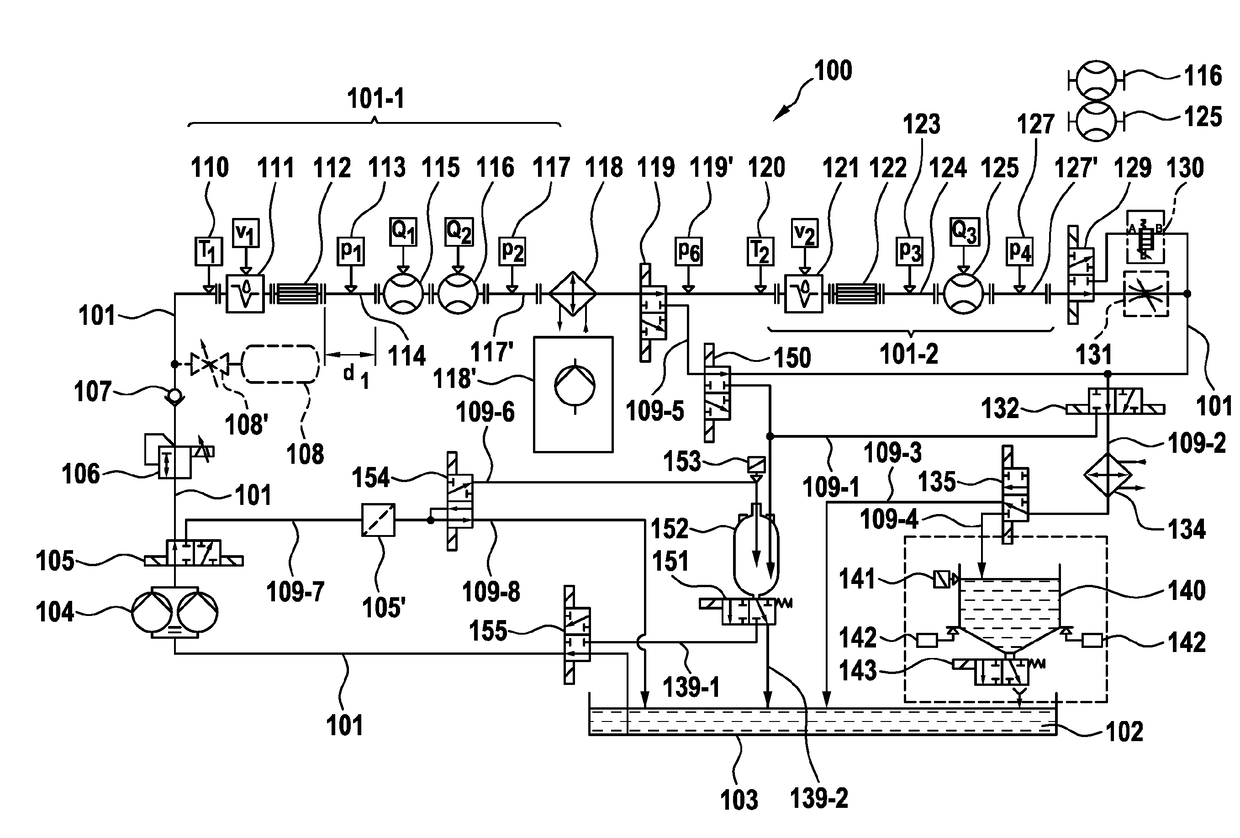

Method for calibrating flow meters for fluid media

ActiveUS20180188101A1Improve accuracyEfficient executionTesting/calibration for volume flowCalibration testMesh grid

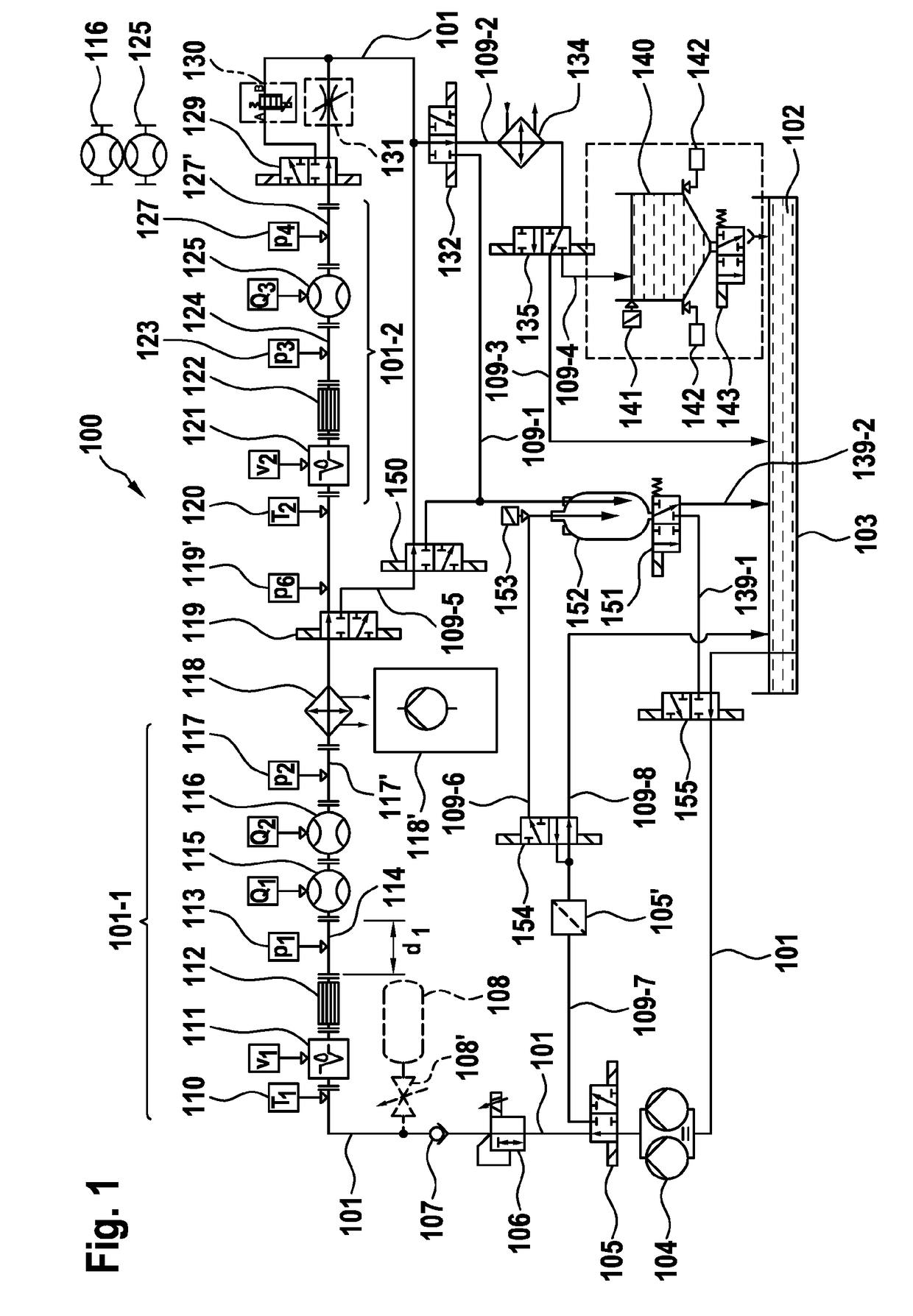

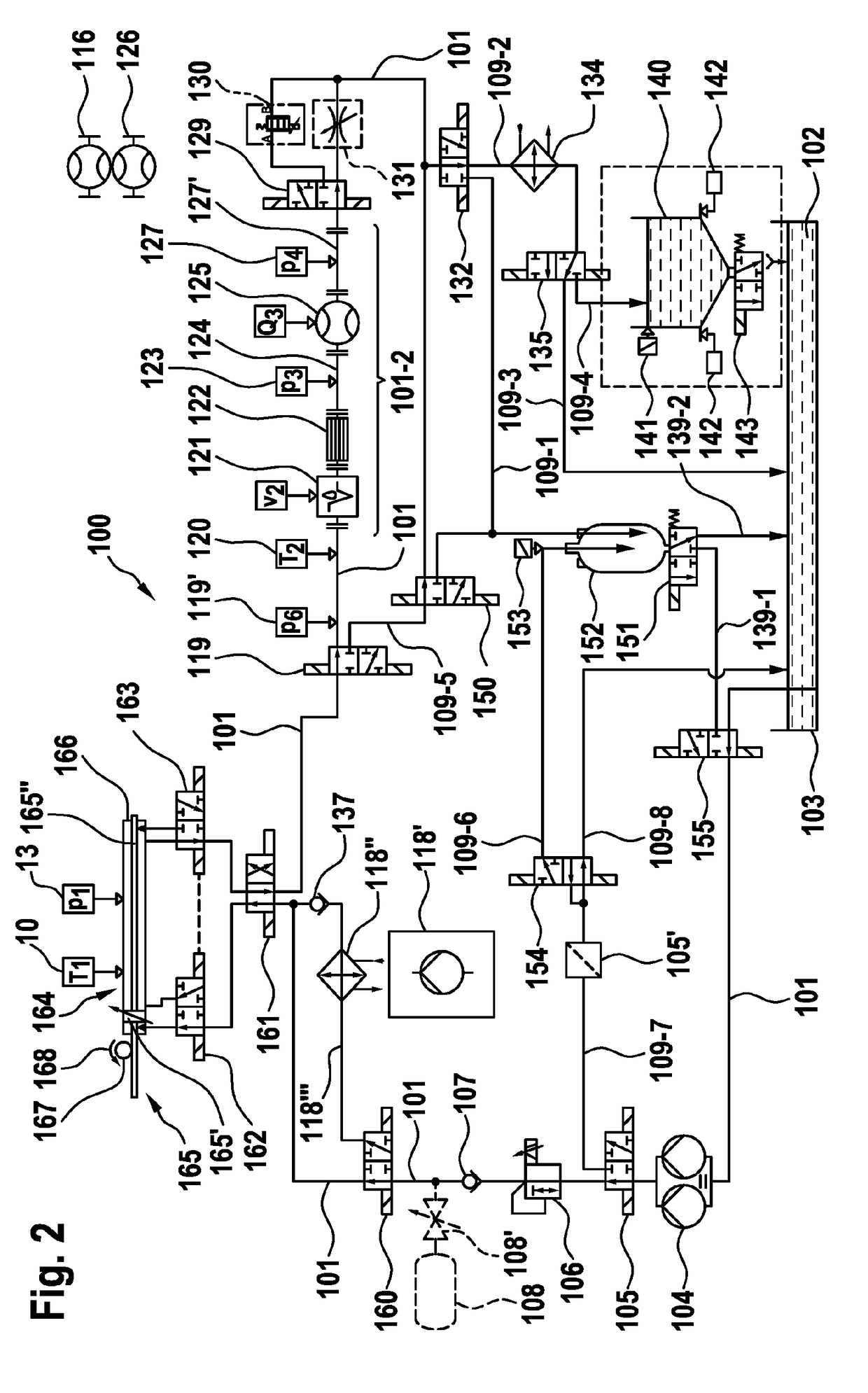

A method for calibrating flow meters for fluid media comprises the steps of guiding a medium (102) through a reference measuring section (101-1) and a test measuring section (101-2) which has a flow meter to be calibrated, establishing at least approximately identical and constant pressure and flow conditions for the medium (102) in both measuring sections (101-1, 101-2), detecting a reference throughflow of the medium (102) through the reference measuring section (101-1) and throughflow values which correspond temporally thereto and are measured by the flow meter (125) to be calibrated of the test measuring section at a preset medium temperature, comparing the detected reference throughflow through the reference measuring section (101-1) with the throughflow values which correspond temporally thereto of the flow meter (125) to be calibrated, in order, based on this, to determine at least one correction value for the calibration of the flow meter (125) at the preset medium temperature, and determining of the respective correction value for the flow meter (125) for different medium temperatures of the medium (102), in order to determine a calibrating function using the temperature-dependent correction values as grid points.

Owner:ROBERT BOSCH GMBH

Polishing pad and preparation method thereof

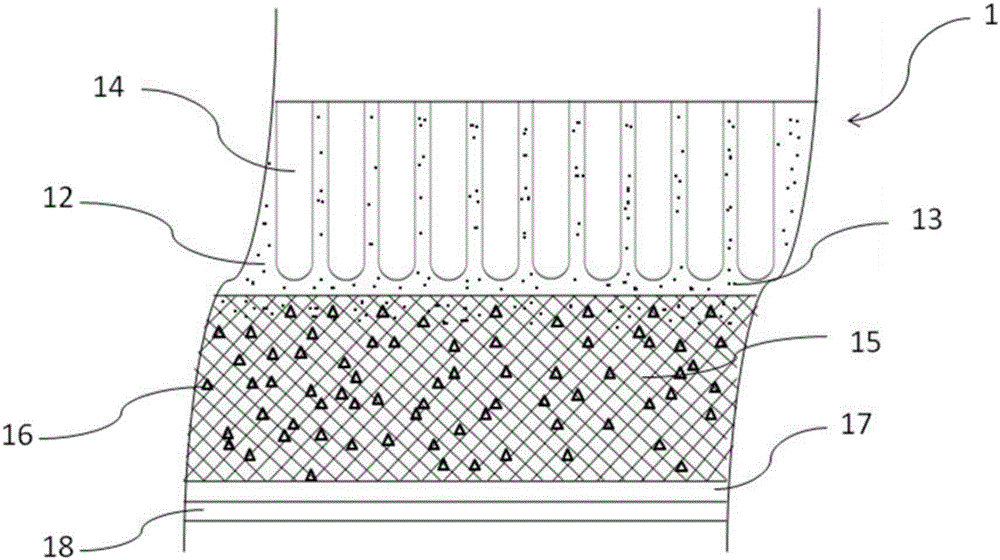

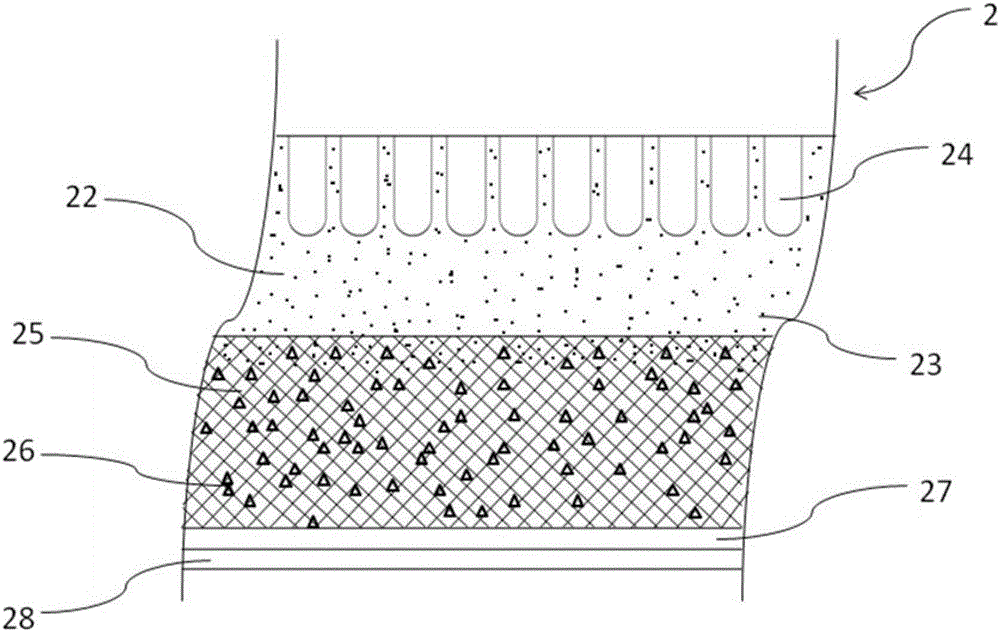

ActiveCN106826541AGood water permeabilityGood and stable polishing effectGrinding devicesLapping toolsMetallurgyAdhesive

The invention discloses a polishing pad. The polishing pad comprises a base material and a polishing layer arranged on the base material, wherein the base material is formed after infiltration with a water-soluble adhesive; the polishing layer comprises a coating body and multiple cylindrical holes, and the coating body is full of three-dimensional through structure holes; the cylindrical holes are longitudinally distributed in the coating body; the top end of each cylindrical hole is connected with the top surface of the coating body, and a space is formed between the bottom end of each cylindrical hole and the bottom surface of the coating body; the height of the space is smaller than 1 / 4 of the height of the coating body. The polishing pad can well store chips produced in the storage and polishing process, prevents a polishing assembly from being scratched and is beneficial to improvement of the polishing effect and long in service life. The invention further discloses a preparation method of the polishing pad. Non-woven fabric is infiltrated into the water-soluble adhesive, dried and subjected to hot roller ironing treatment, a surfactant is applied to the back side, then, the surface is coated with a polyurethane solution, then, the non-woven fabric enters a coagulation bath and is subjected to water washing, drying and surface treatment, and the polishing pad is obtained. The process is simple, the coagulation and water washing efficiency is high, and the production efficiency is greatly improved.

Owner:河南惠强新能源材料科技股份有限公司

Multi-mode 2-stroke/4-stroke internal combustion engine

ActiveUS20090048756A1Increased load rangeImprove efficiencyAnalogue computers for vehiclesElectrical controlCombustionInternal combustion engine

In a multi-mode, 2-stroke / 4-stroke internal combustion engine operation, by switching the engine stroke from 4-stroke operation to 2-stroke operation so that the combustion frequency is doubled, doubling of the engine power is achieved even at the same work output per cycle. In order to meet the demand of extremely high power, the engine operates in 4-stroke boosted SI operation transitioned from 2-stroke HCCI operation at pre-set level of power and crank speed requirements. By combining the multi-stroke (2-stroke HCCI and 4-stroke HCCI) and multi-mode operation (2-stroke HCCI and 4-stroke boosted SI operation), full load range and overall high efficiency with minimal NOx emission are achieved.

Owner:ROBERT BOSCH GMBH

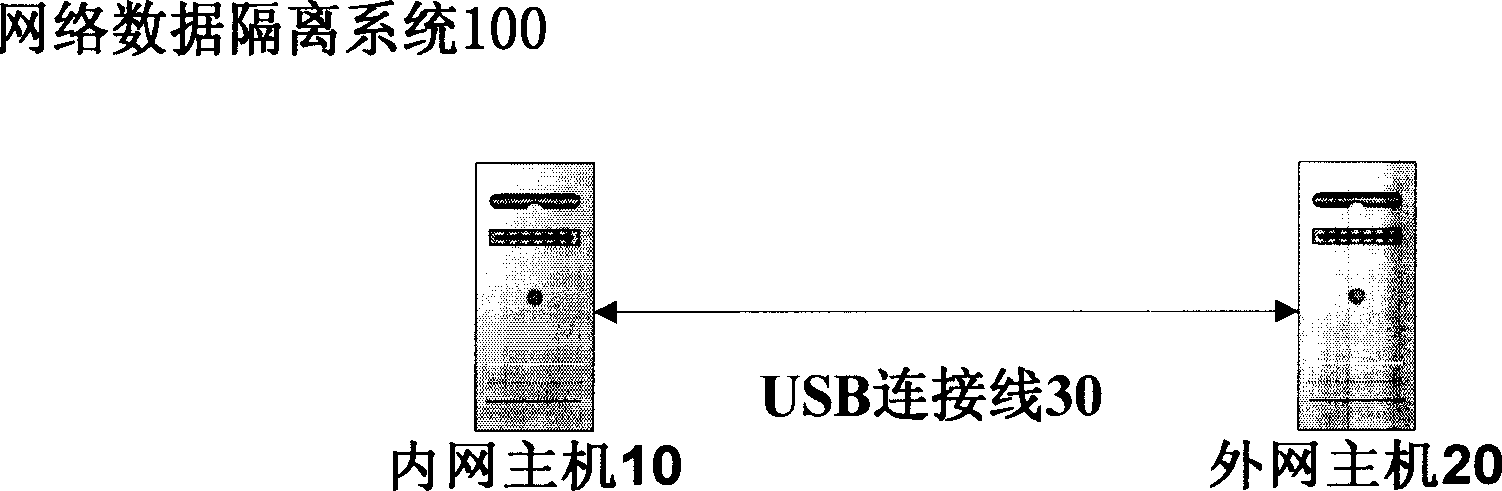

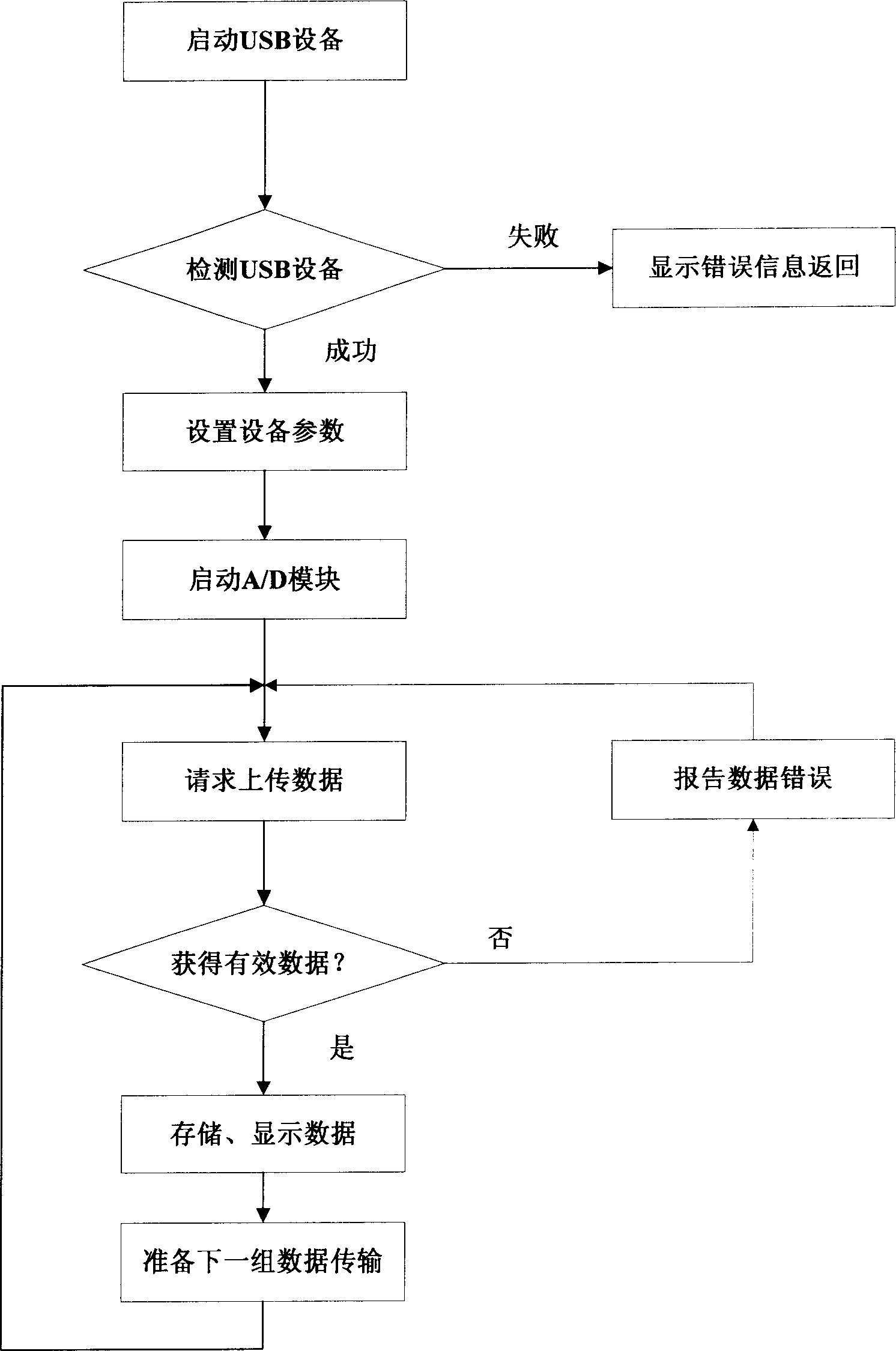

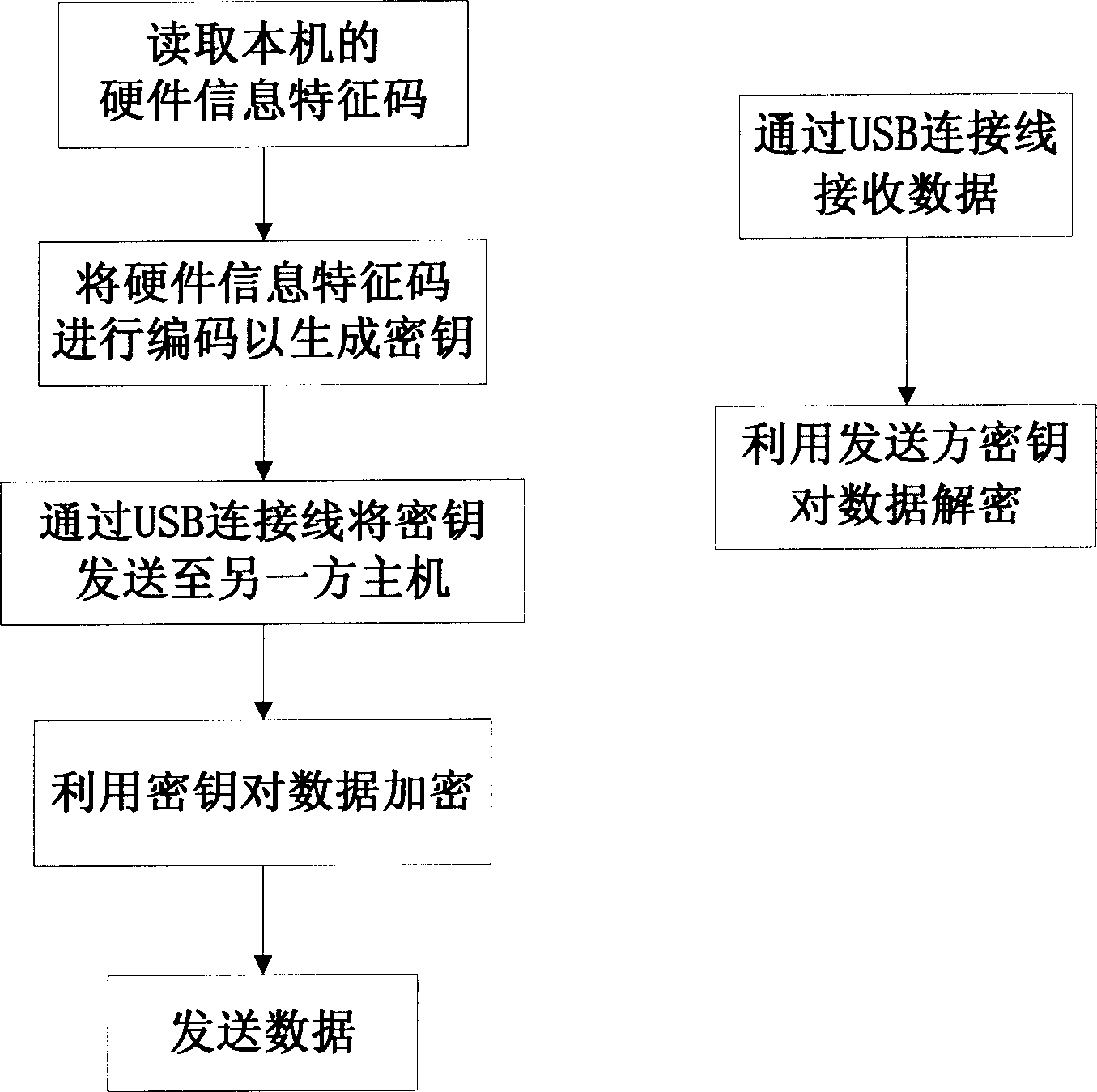

Network data isolation system and data transmission method

InactiveCN1905477AFast exchangeMeet the time requirementData switching by path configurationNetwork dataData transmission

The invention is a network data isolating system, comprising intranet host machine, extranet host machine, and serial interface connector, where the serial interface connector connects with serial interfaces of the two host machines.

Owner:东方惠科防伪技术有限责任公司

Calculation and storage fused cluster system

InactiveCN105657057AImprove acceleration performanceFast exchangeTransmissionResource poolCluster systems

The embodiment of the invention provides a calculation and storage fused cluster system which comprises a resource server cluster and a storage resource control module. The resource server cluster comprises at least two resource servers, wherein each resource server in the resource server cluster is provided with at least one of calculation resources and storage resources, at least one resource server in the resource server cluster is provided with the calculation resources and the storage resources, and the storage resources include persistent disks and caches corresponding to the persistent disks. The storage resource control module is used for constructing the storage resources in the resource server cluster into shared storage resource pools so as to provide storage services, the storage resources included by each shared storage resource pool are from at least two resource servers in the resource server cluster.

Owner:HUAWEI TECH CO LTD

Hydraulic shaft sealing arrangement for high-temperature applications

Owner:ROLLS ROYCE DEUT LTD & CO KG

Novel ion exchange fiber and its application

InactiveCN102872833AEasy to prepareHigh adsorption valueOther chemical processesFibre typesChemical treatmentPolystyrene

The invention discloses a novel ion exchange fiber and its application. The ion exchange fiber is directly prepared by directly selecting raw materials having ion exchange functions without obtaining functional groups through a chemical treatment of grafting. The preparation method of the ion exchange fiber is simple, is in favor of the industrialized continuous production of products, and has a low economic cost. The ion exchange fiber prepared in the invention has the advantages of large exchange capacity, fast elution and adsorption speed, and the like. The filament diameter and the exchange capacity of the ion exchange fiber prepared in the invention are 5-100mum and 3.0-5.8mmol / g respectively. The matrix fiber of the ion exchange fiber has good comprehensive performances comprising good mechanical performances, high temperature resistance, acid and alkali resistance and the like. The preparation method of the novel ion exchange fiber comprises the following steps: mixing the raw materials comprising polystyrene (PS) and polyethylene (PE) with a compatilizer according to a certain weight ratio, adjusting an optimum spinning temperature, and carrying out melt spinning to prepare the base material of the ion exchange fiber; and carrying out chemical treatment of the base material to prepare the cation exchange fiber having sulfonic groups. The novel ion exchange fiber can be widely applied to the environmental protection field, the medicine and health field, the metallurgical filed, the water treatment field, the chemical adsorption field, the resource recovery field and the like.

Owner:冯淑芹

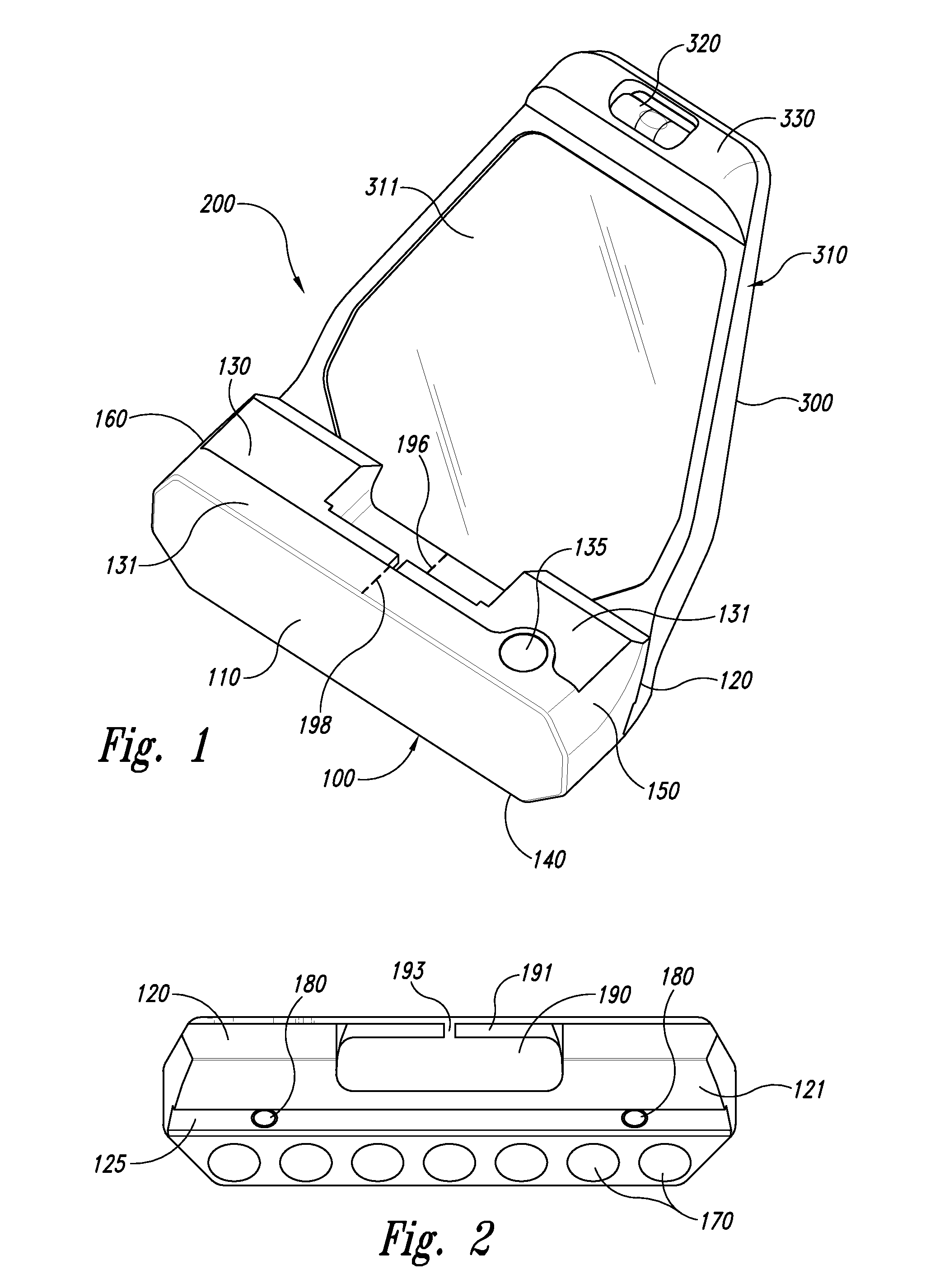

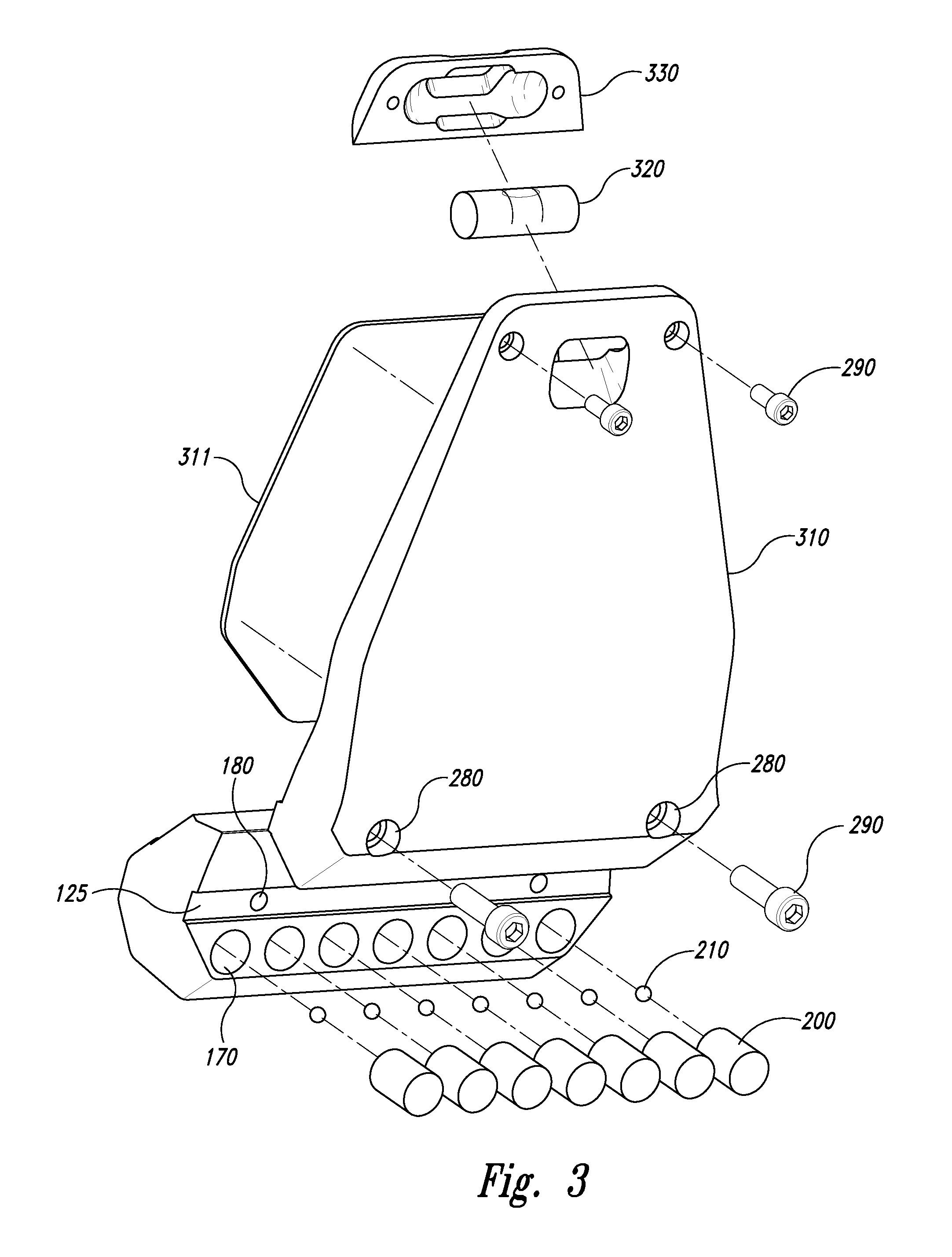

Golf putter and counterbalance system and fitting method

InactiveUS20110092306A1Easy to learnImprove accuracyGolfing accessoriesGolf clubsEngineeringGolf Ball

Golf putters comprising features that assist in locating a directly overhead view of the putter heads include sight aligning marks, sight aligning notch, rods and plates are disclosed. Putter heads with interchangeable mirror, weight and sighting attachments designed for quick release and replacement are described with interconnected attachment mounting faces. The combination of threaded aperture, apertures in the attachments and screws requiring the use of tools releasably interconnect the mirror attachment, sighting attachment or weight attachment to the putter head. Openings or contours are described that assist the golfer in estimating the distance between the golfer and a hole or cup on the green. Methods of customizing, calibrating or indicating in golf putters to individual golfers are also disclosed, including the use of weights to alter the weight distribution of in the putter head.

Owner:LEE MICHAEL +1

Method for enriching and purifying procyanidin in pine bark

ActiveCN102093328AHigh adsorption selectivityParsing fastOrganic chemistryAbsorption capacityDistillation

The invention belongs to the field of natural organic chemistry, relating to a method for enriching and purifying procyanidin in pine bark. The method is characterized in that an intermittent distillation and macropore adsorbent resin coupling technology is used to separate and purify the procyanidin, and the technology is good for absorption selectivity of the procyanidin; and by using the intermittent distillation and macropore adsorbent resin coupling technology, absorption is quick and deabsorption is also quick, absorption capacity is large, extraction is convenient and quick, raw material source is rich, production cost is low, separation effect is obvious, extraction purity is high, above 50% of semi-finished product procyanidin and above 95% of final product procyanidin can be achieved, and the defects of low conventional extraction rate and low extraction purity are overcome. In the method, the macropore adsorbent resin which has the advantages of stable physicochemical property, large surface area, fast exchange speed, high mechanical strength, strong pollution resistance capability and good heat stability is selected, the procyanidin is selectively absorbed from solution through physical absorption, absorption is quick and deabsorption is also quick, and absorption capacity is large.

Owner:DAXINGANLING LINGOBERRY BOREAL BIOTECH CO LTD

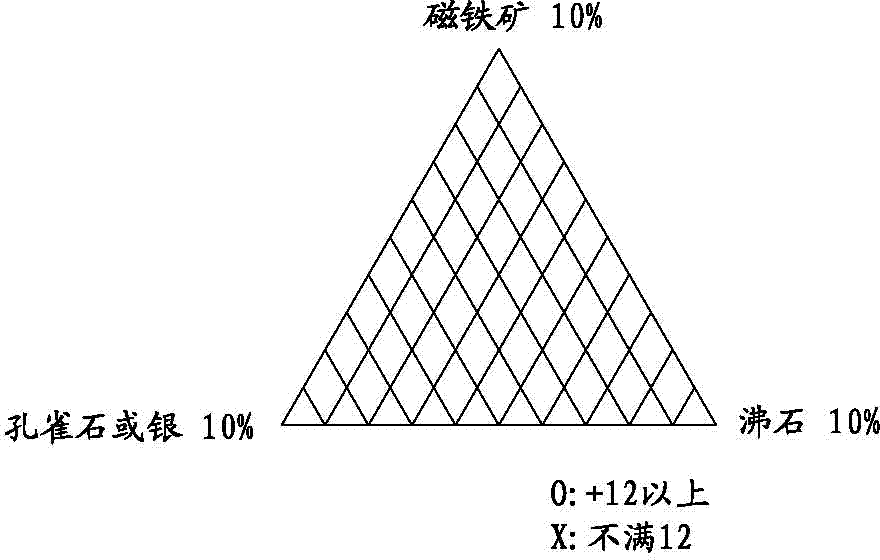

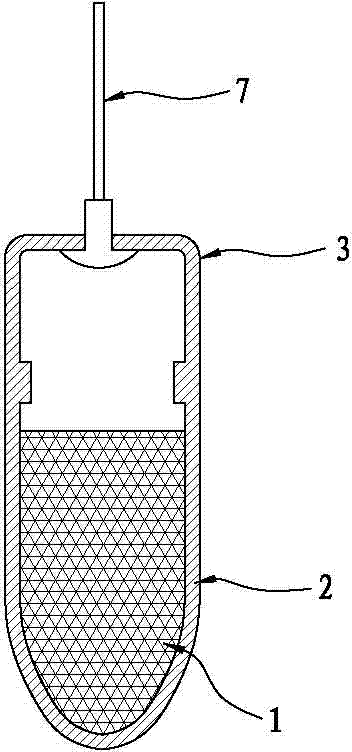

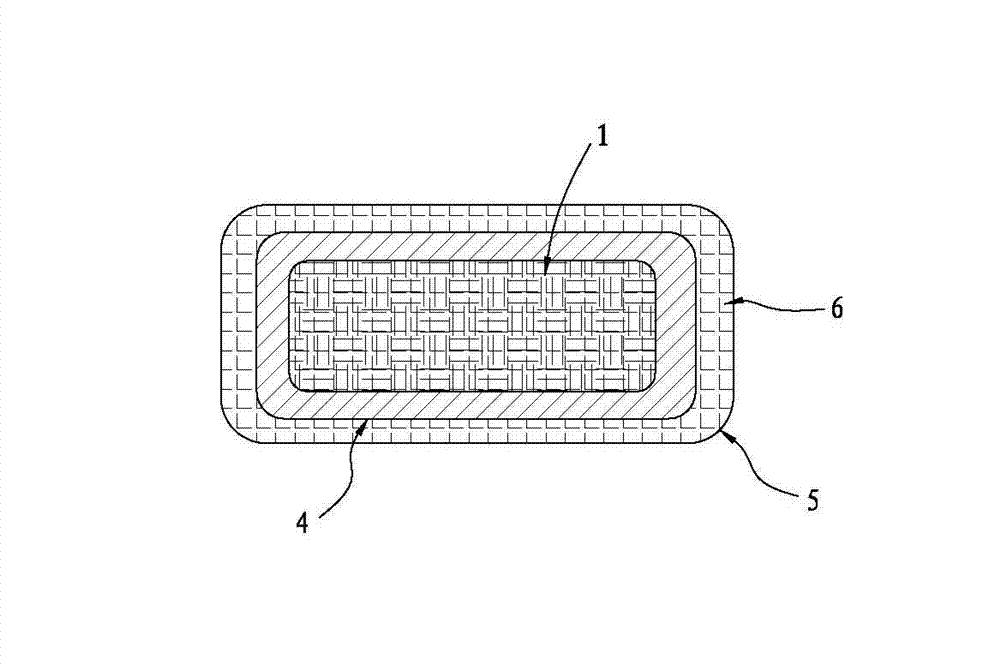

Lead acid battery material

InactiveCN102769150ATexture extensionChange molecular structureLead-acid accumulatorsMetallic materialsIon exchange

The invention discloses a lead acid battery material. According to the invention, an electromagnetic resonant analyzer is used to analyze characteristics of various natural minerals and metal materials. In particular, coal, charcoal, malachite, zeolite, feldspar, Mengmoli pumice stone, limestone, gypsum, powdered steatile, silver or their combined materials are crushed into powders, the powders are added into granite and tourmalinite powders, and all the powders are mixed together to prepare lead plates, ceramic and partition plates for lead acid battery so as to generate highfield-like vibration frequency shared by active molecules. Thereby, the molecular structure of an electrolyte is changed so as to accelerate ion exchange speed, accelerate charging, increase transformation rate, minimize accumulation of sulfuric acid crystals, reduce corrosion speed of an anode checker and prolong battery life.

Owner:黄学鸿

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com