Method for preparing sodium type zeolite molecular sieves by utilizing red mud

A sodium-type zeolite and molecular sieve technology, which is applied in the field of zeolite molecular sieve preparation, can solve the problems of occupying farmland, consuming yard construction and maintenance management costs, water pollution, etc., and achieves the effects of reduced consumption, low cost, and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

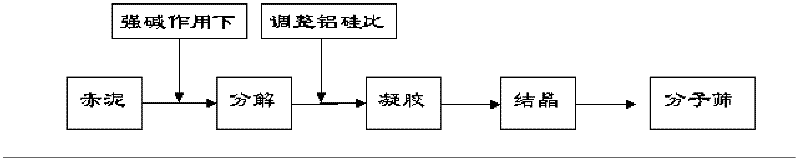

[0039] see figure 1 Steps, the method for preparing sodium-type zeolite molecular sieves using red mud in this embodiment specifically includes the following steps:

[0040] 1. Take red mud and use XRF analysis method to analyze red mud, and the analysis shows that the ratio of silicon to aluminum in red mud is 1.47;

[0041] 2. Take 10g of ground and sieved red mud and mix it with 2mol / L NaOH solution, adjust the sodium-silicon ratio in the mixture to 1.3, stir for five minutes, and then add NaOH solution 2 SiO 3 9H 2 O adjusts the silicon to aluminum ratio in the mixture to 4.5.

[0042] 3. Stir the mixture, mix and age the rubber, the aging temperature is 60°C, and the aging time is 10h;

[0043] 4. Crystallize the above mixture at 110°C for 12 hours;

[0044] 5. The solid product after the crystallization reaction is cooled, filtered, washed and dried to obtain the zeolite molecular sieve.

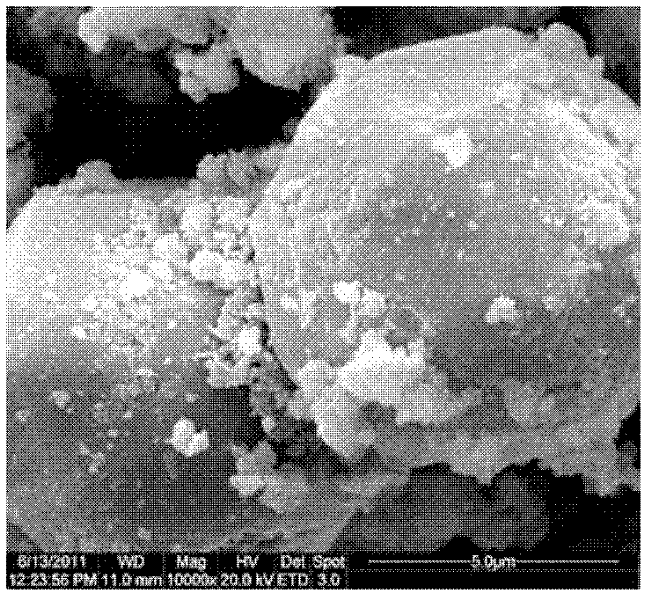

[0045] Measure the phase composition and morphology of the reaction product ...

Embodiment 2

[0047] see figure 1 Steps, the method for preparing sodium-type zeolite molecular sieves using red mud in this embodiment specifically includes the following steps:

[0048] 1. Take red mud and use XRF analysis method to analyze red mud, and the analysis shows that the ratio of silicon to aluminum in red mud is 1.47;

[0049] 2. Take 10g of ground and sieved red mud and mix it with 2mol / L NaOH solution, adjust the sodium-silicon ratio in the mixture to 1.3, stir for five minutes, and then add NaOH solution 2 SiO 3 9H 2 O adjusts the silicon to aluminum ratio in the mixture to 4.5.

[0050] 3. Stir the mixture, mix and age the rubber, the aging temperature is 60°C, and the aging time is 8h;

[0051] 4. Crystallize the above mixture at 120°C for 12 hours;

[0052] 5. The solid product after the crystallization reaction is cooled, filtered, washed and dried to obtain the zeolite molecular sieve.

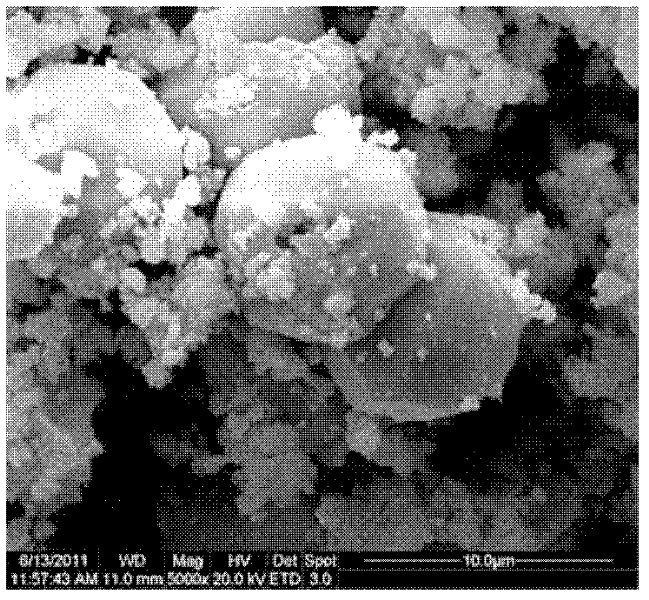

[0053] Measure the phase composition and morphology of the reaction product w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com