Preparation method for ultrafine fiber clothing leather

A technology for superfine fiber and garment leather, applied in the field of preparation of superfine fiber garment leather, can solve the problems of serious pollution of leather tanning technology, limited development of leather, high price of leather, etc., and achieves great difficulty in recycling and high temperature ironing resistance. Good perm effect, excellent recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

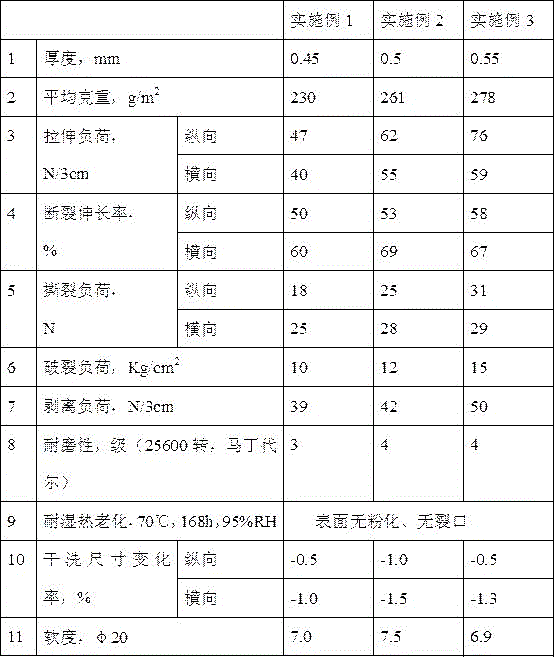

Examples

Embodiment 1

[0040] (1) Production of high-density nonwovens

[0041] Use PET / COPET fixed island and sea-island composite fibers with a length of 51mm, fiber fineness of 6dtex, and a mass fraction of 65 / 35. After opening, carding, laying, pre-punching with a pre-looming machine, and needle-punching with a needle-punching machine, the thickness is made. 3.0mm high-density non-woven fabric; the web width is 1680mm, the number of web layers is 40 layers, the frequency of pre-punching and needle punching is 500 punches / min, and the density of pre-punching and needle punching is 800 thorns / cm 2 , the speed is 3.5m / min, the average weight of the nonwoven fabric is 600g / cm 2 , the apparent density is 0.20g / cm 3 .

[0042] (2) heat setting

[0043] Under the conditions of drying room temperature of 130°C and vehicle speed of 9m / min, the non-woven fabric is rolled and shaped by rollers to make the density reach 0.27g / cm 3 , the thickness is 2.2mm.

[0044] (3) Wet impregnation

[0045] (1) P...

Embodiment 2

[0056] (1) Production of high-density nonwovens

[0057] Select PA6 / LDPE fixed island and sea-island type composite fiber with a length of 51mm, fiber fineness of 7dtex, and mass fraction of 54 / 46. After opening, carding, laying, pre-punching with a pre-punching machine and needle-punching with a needle-punching machine, the thickness is made. It is a high-density nonwoven fabric of 2.6mm; the width of the web is 1680mm, the number of layers of the web is 40 layers, the frequency of pre-punching and needle punching is 800 punches / min, and the density of pre-punching and needle punching is 1200 thorns / cm 2 , the speed is 3.2m / min, the average weight of the nonwoven fabric is 600g / cm 2 , the apparent density is 0.23g / cm 3 .

[0058] (2) heat setting

[0059] Under the conditions of drying room temperature of 130°C and vehicle speed of 9m / min, the non-woven fabric is rolled and shaped by rollers to make the density reach 0.315g / cm 3 , the thickness is 1.9mm.

[0060] (3) We...

Embodiment 3

[0071] (1) Production of high-density nonwovens

[0072] Select PA6 / LDPE indeterminate island-sea-island type composite fiber with a length of 51mm, fiber fineness of 7dtex, and mass fraction of 54 / 46, through opening, carding, web laying, pre-punching with a pre-looming machine, and needle-punching with a needle-punching machine to make a thickness It is a high-density nonwoven fabric of 2.4mm; the width of the web is 1680mm, the number of layers of the web is 40 layers, the frequency of pre-punching and needle punching is 1000 punches / min, and the density of pre-punching and needle punching is 1500 thorns / cm 2 , the speed is 3.2m / min, the average weight of the nonwoven fabric is 600g / cm 2 , the apparent density is 0.25g / cm 3 .

[0073] (2) heat setting

[0074] Under the conditions of drying room temperature of 140°C and vehicle speed of 9m / min, the non-woven fabric is rolled and shaped by rollers to make the density reach 0.33g / cm 3 , thickness 1.8mm.

[0075] (3) Wet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average weight | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com