Patents

Literature

70results about How to "Difficult to recycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

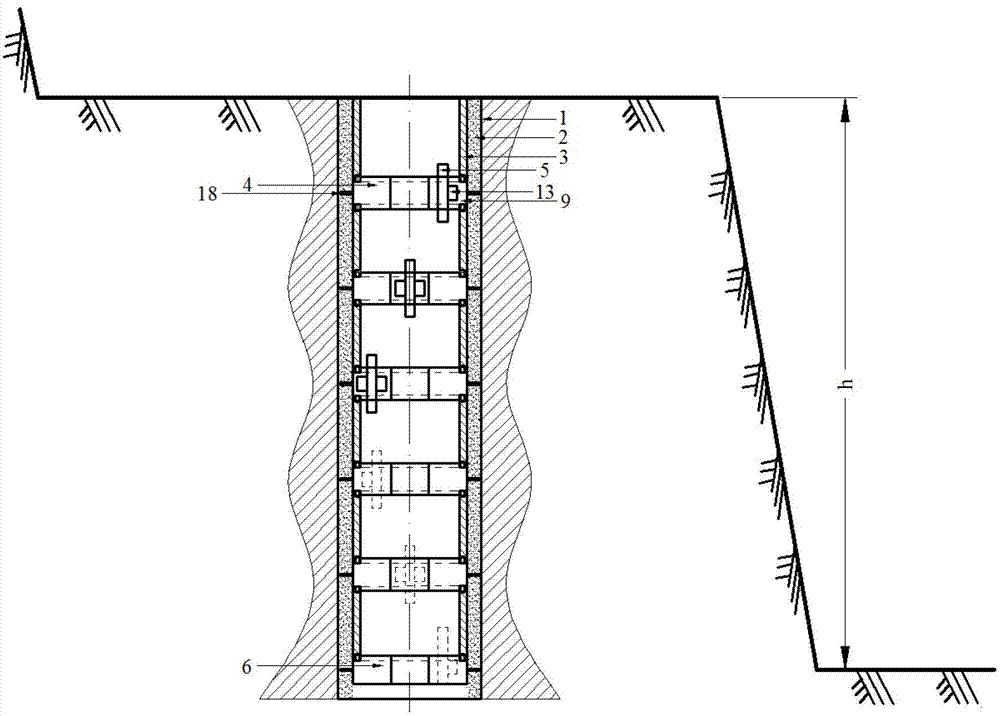

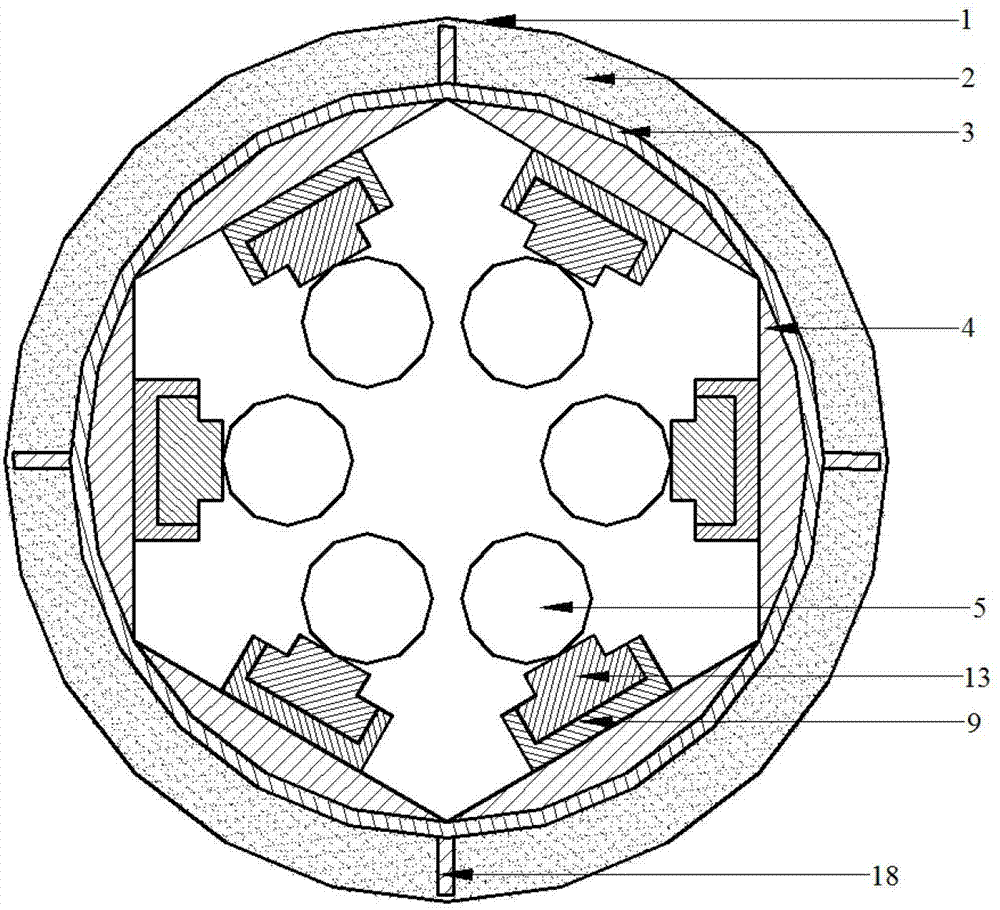

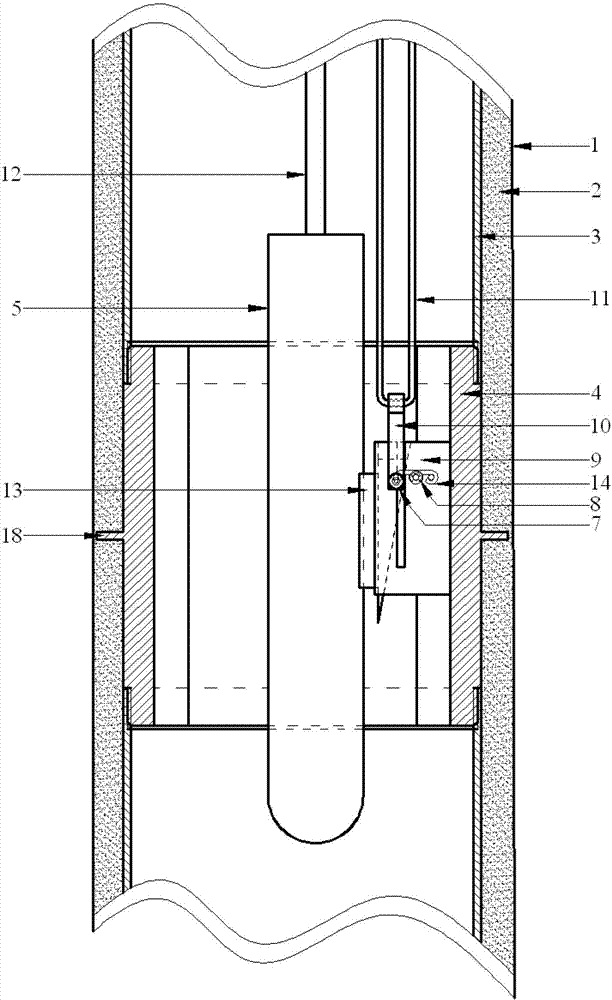

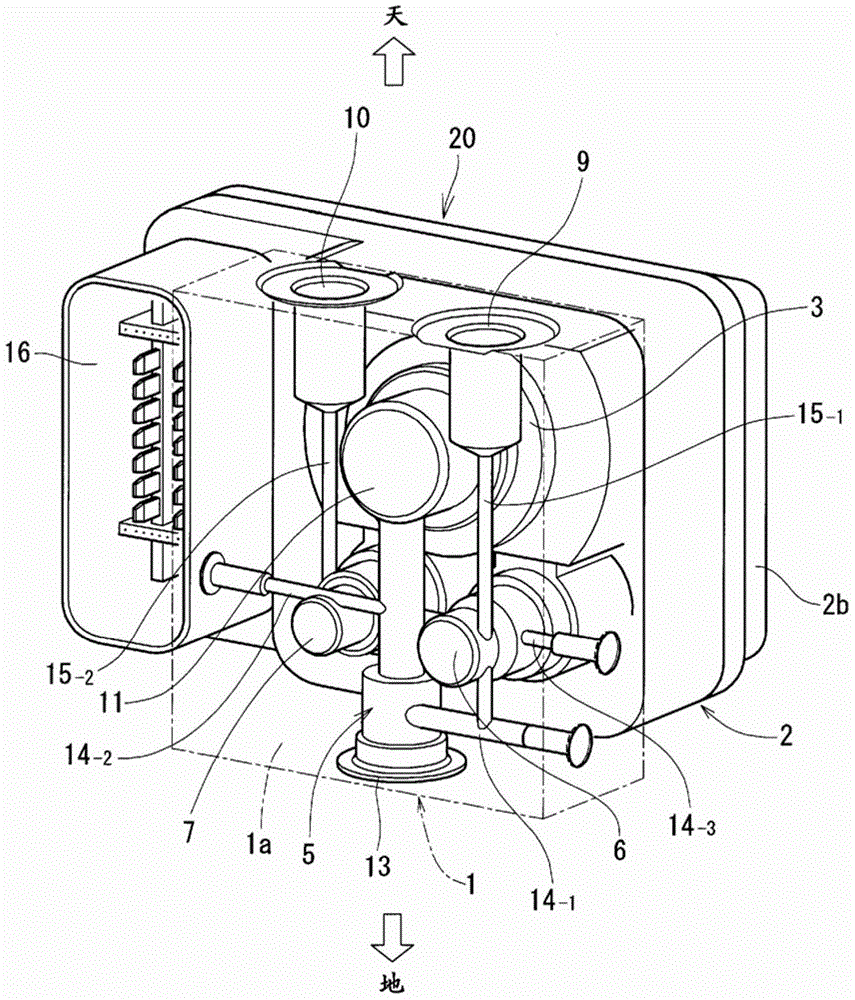

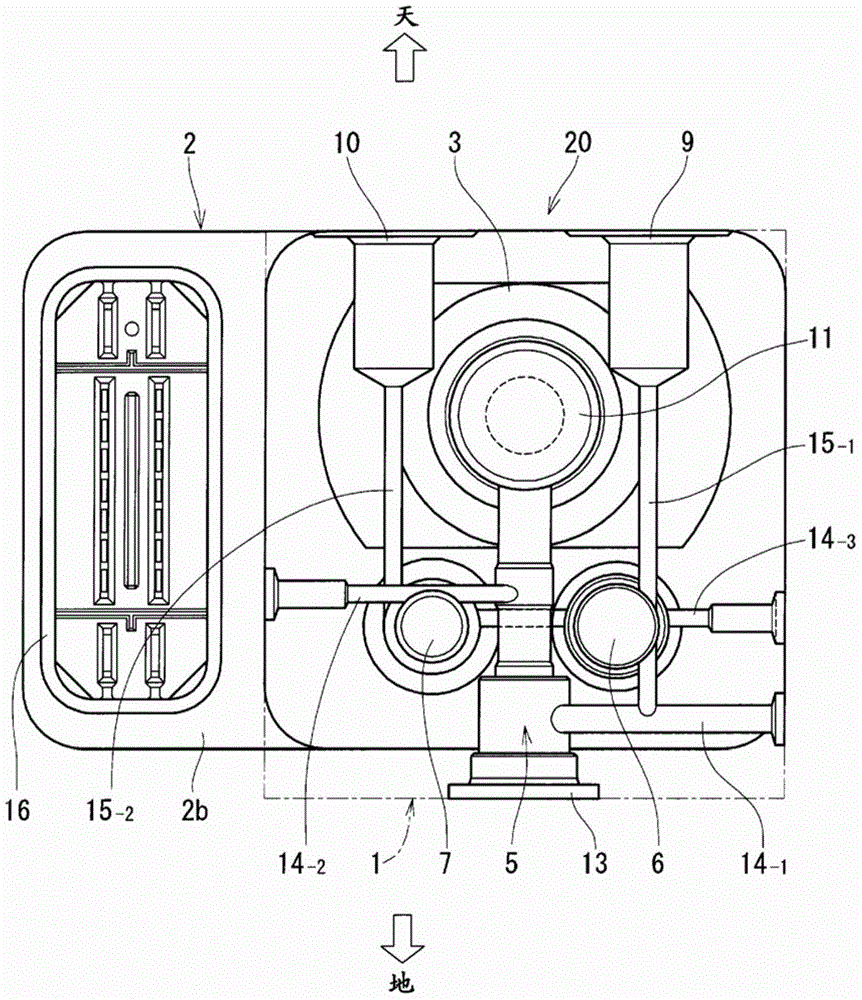

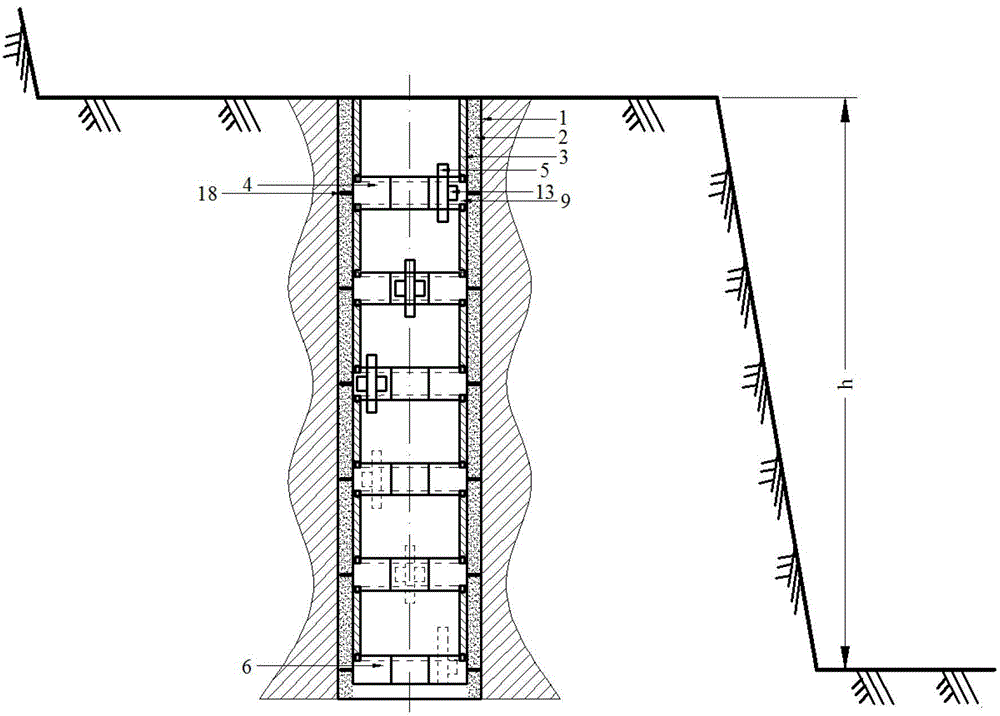

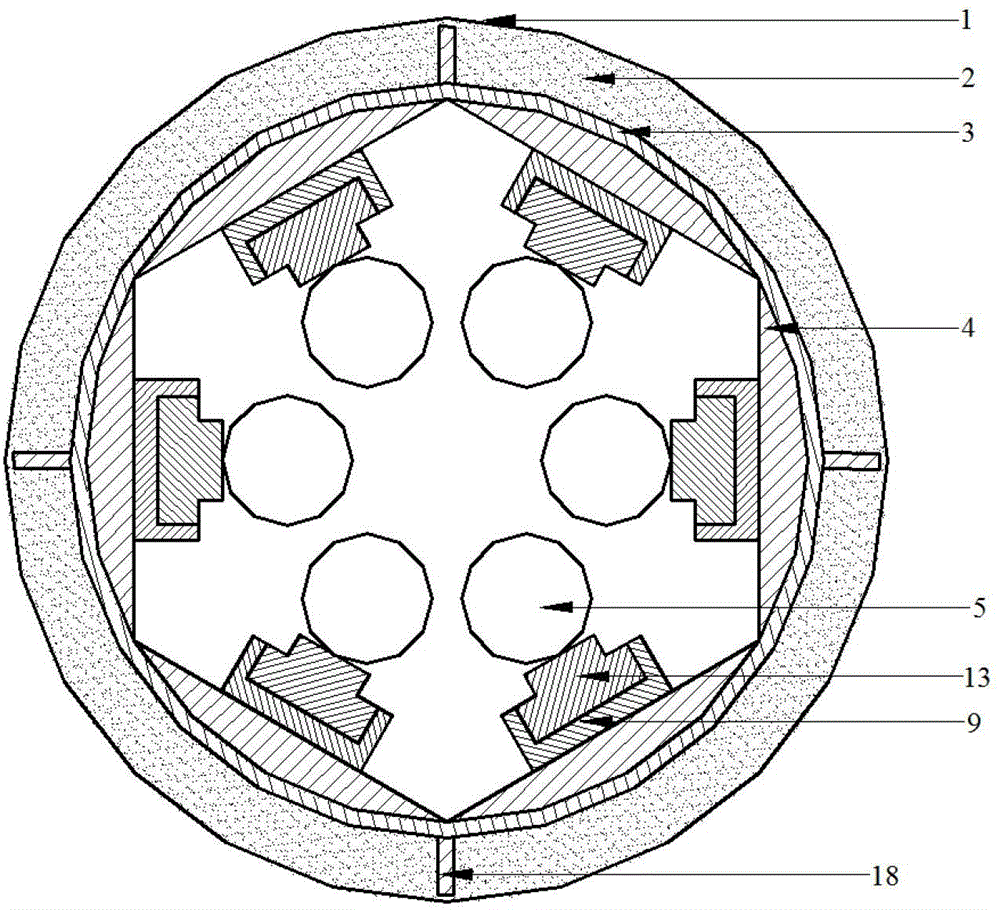

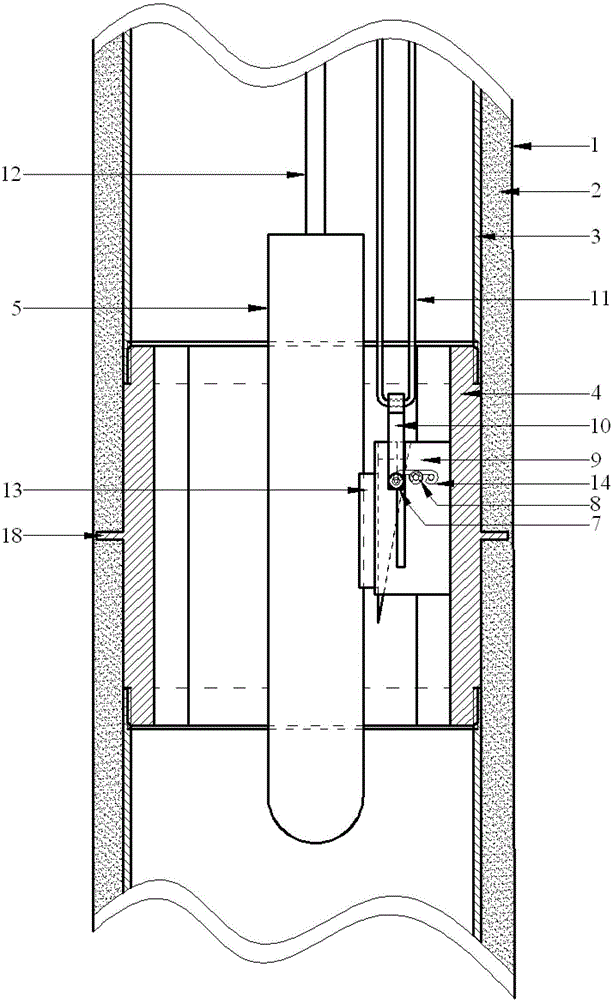

Omnidirectional cataclastic rock mass deep hole installation and recovery device of microseismic unidirectional sensor

InactiveCN102854525ASolve hard-to-couple problemsAvoid easy installationSeismic signal receiversBody femaleDeep hole

The invention discloses an omnidirectional cataclastic rock mass deep hole installation and recovery device of a microseismic unidirectional sensor. The omnidirectional cataclastic rock mass deep hole installation and recovery device comprises a sleeve which is embedded in a rock mass drilling hole, wherein a unidirectional sensor fixing device is installed at each part with a preset depth and direction in the sleeve and comprises an intermediate joint which is connected with the sleeve by inner threads, a wedge body combining body which is connected with the intermediate joint and is provided with a wedge body combining body female groove, a wedge body which is adapted to the wedge body combining body female groove, another unidirectional sensor which is connected with the wedge body, a tensile-resisting cable which is connected with the another unidirectional sensor, an elastic pressing device which is fixed on the wedge body combining body, and a pulling type lifting device which is connected with a second leading-out terminal of a cylindrical helical torsional spring of the elastic pressing device and is used for releasing the wedge body, wherein one end of the elastic pressing device tightly presses the wedge body in the wedge body combining body female groove. With the adoption of the omnidirectional cataclastic rock mass deep hole installation and recovery device, the installation is not limited by severe geological conditions and drilling inclined angles, the installation of a vertical hole and an inclined hole in a cataclastic rock mass can be realized, and the unidirectional sensors are easy to recover.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +1

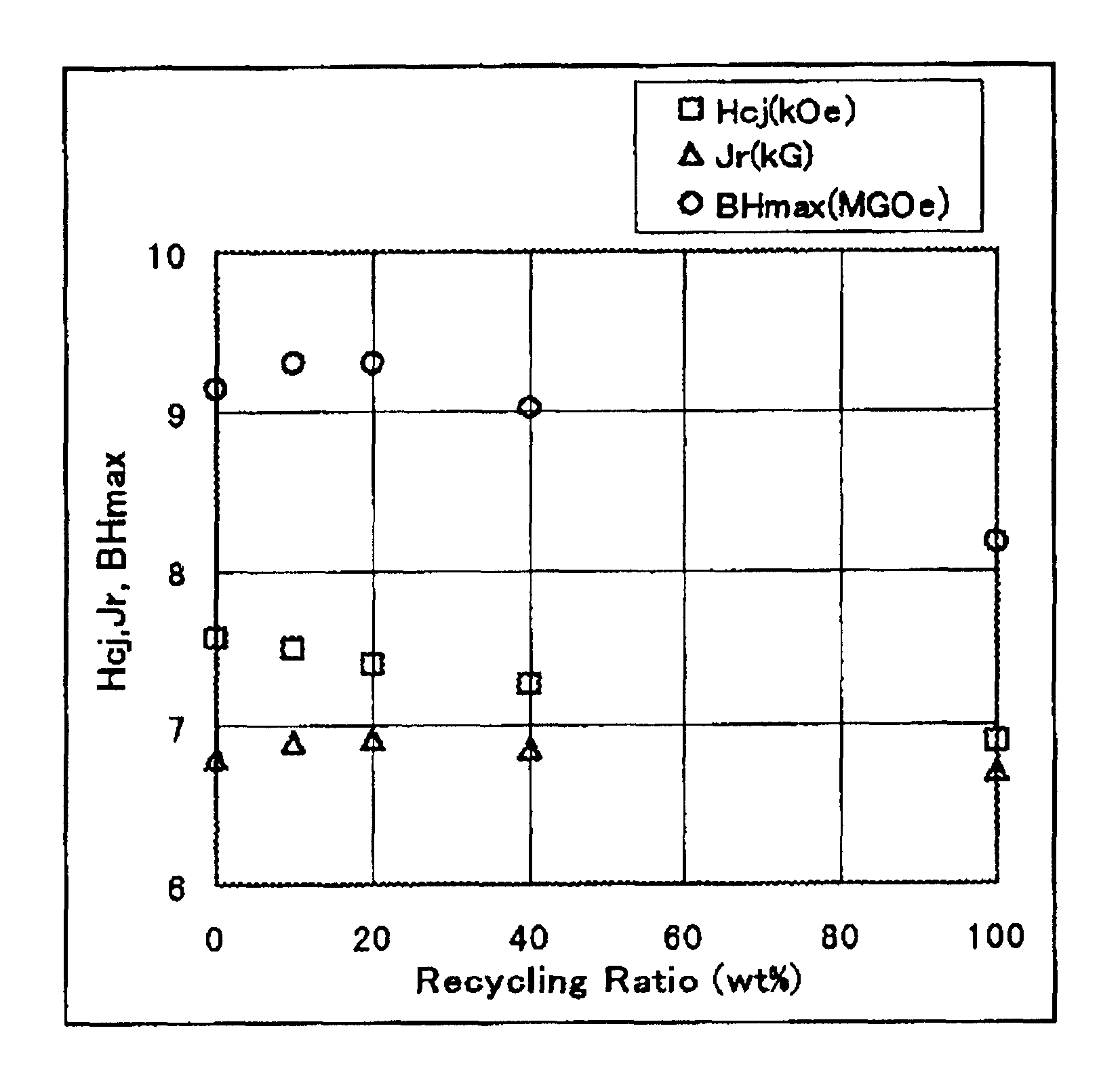

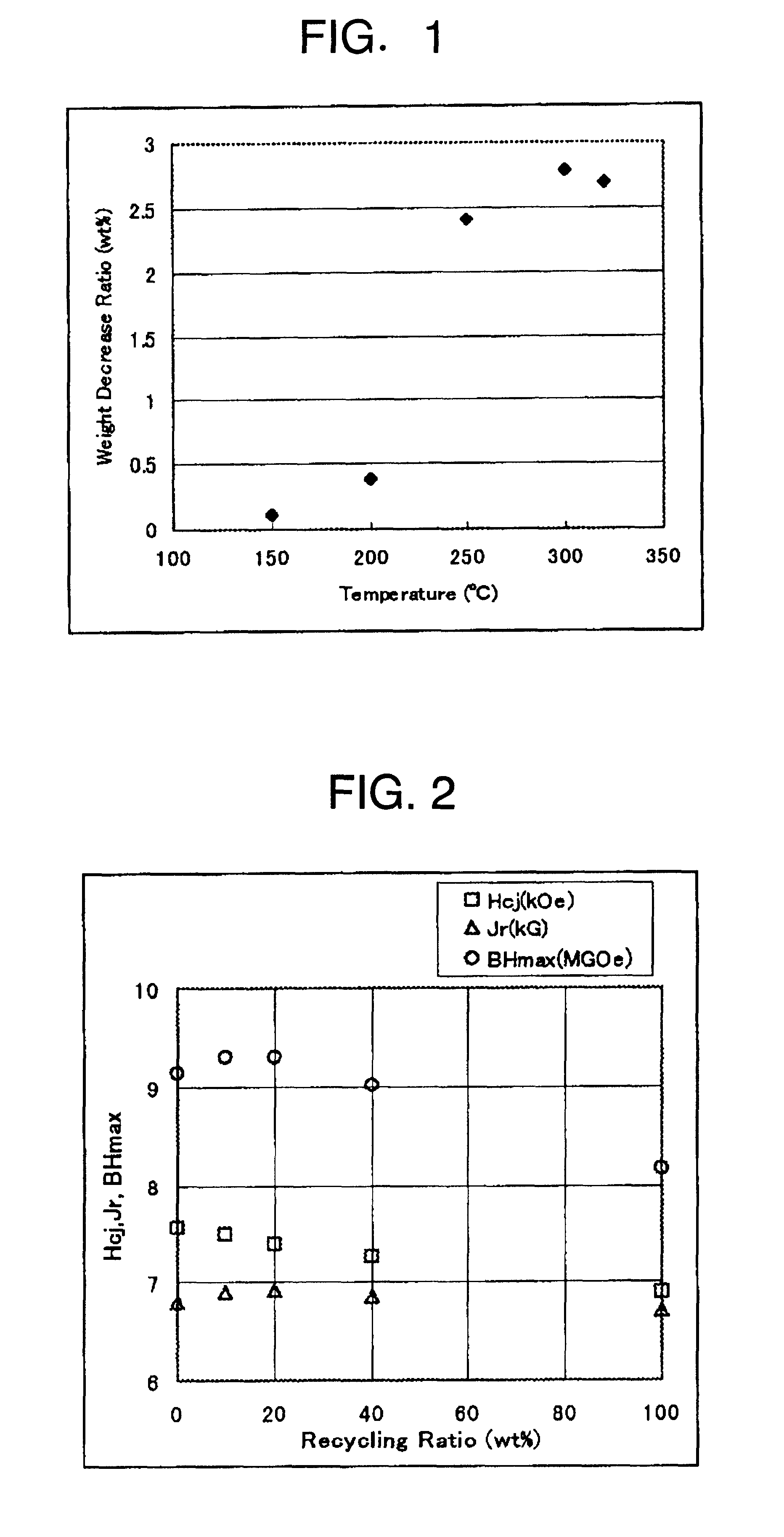

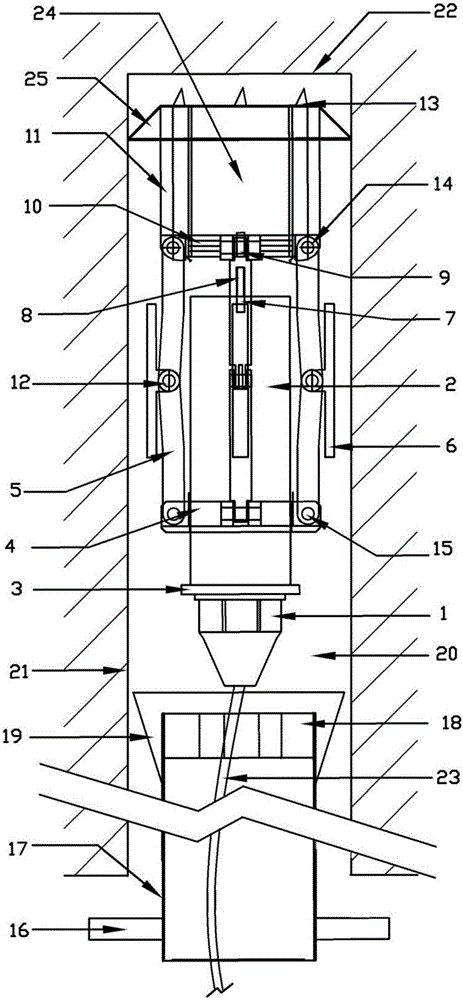

Method of recovering and recycling magnetic powder from rare earth bond magnet

InactiveUS6533837B1Preventing deteriorationReduce pressurePlastic recyclingInorganic material magnetism2-HexanoneDecomposition

A method of recovering magnetic powder from rare earth bond magnet comprising a process of soaking the rare earth bond magnet in a decomposing solution, or holding it in a gas phase of the decomposing solution, containing at least one solvent selected from a group comprising tetralin, naphthalene, 1,4-hydroxynaphthalene, naphthol, biphenyl, 2-hexanone, acetonylacetone, phorone cyclohexanone and methlcyclohexanone, and heating at a temperature not lower than 230° C. A method of recycling recovered magnetic powder by substituting at least a part or all of magnetic powder in the molding compound of a second rare earth bond magnet. For preventing deterioration of magnetic powder from oxidation at surface, air in the decomposition vessel is substituted with nitrogen gas, helium gas and argon gas or is reduced to a pressure not higher than 10-2 Torr.

Owner:PANASONIC CORP

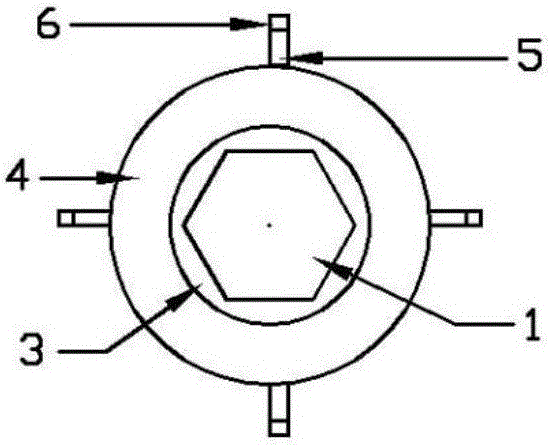

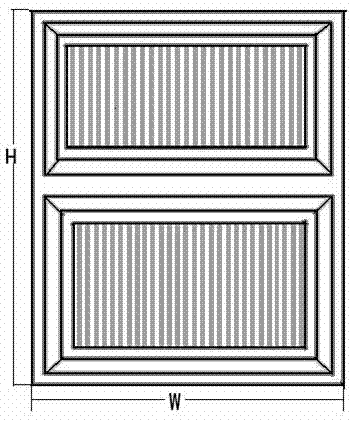

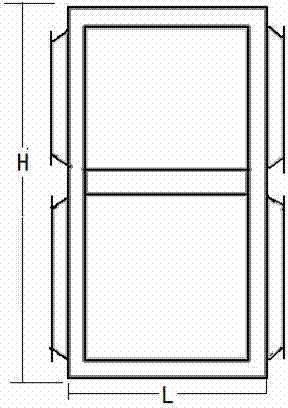

Random-direction whole-hole section three-direction rigid coupling sensor installing and recycling device

The invention discloses a random-direction whole-hole section three-direction rigid coupling sensor installing and recycling device which comprises a fixing, installing and recycling device and an installing and recycling rod.The fixing, installing and recycling device comprises a pushing table, expanding rods, hole wall supporting sheets, a threaded rod, a butt-joint threaded base hole, a butt-joint threaded base, a base, expanding rod and hole wall supporting sheet connecting pins, bottom fixing claws, base and expanding rod connecting pins and pushing table and expanding rod connecting pins.The installing and recycling rod comprises a hand-operated rocker, a titanium alloy steel pipe, a hexagonal mold block and a trumpet-shaped guiding opening.According to the device, the purposes of well coupling a sensor and the rock wall in a rock body and recycling the sensor are achieved, the sensor is separated from the butt-joint threaded base through the threaded rod by rotating the hand-operated rocker, operation is convenient, and the problem that the sensor is difficult to recycle in a deep hole is solved.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +1

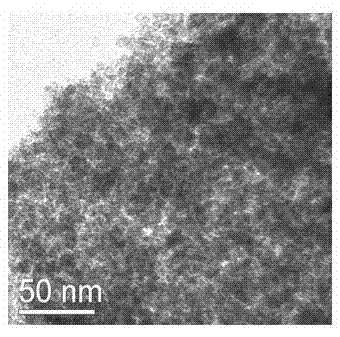

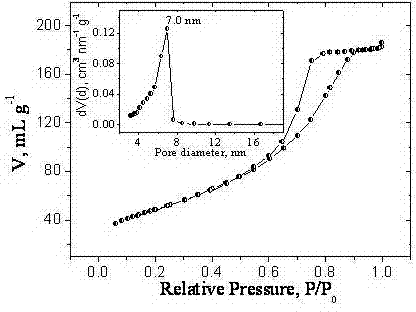

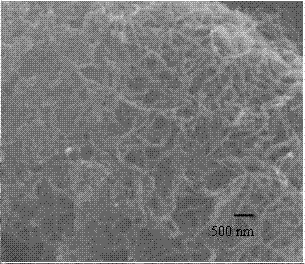

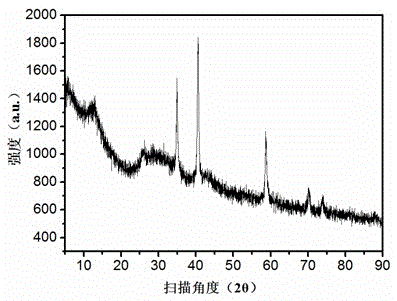

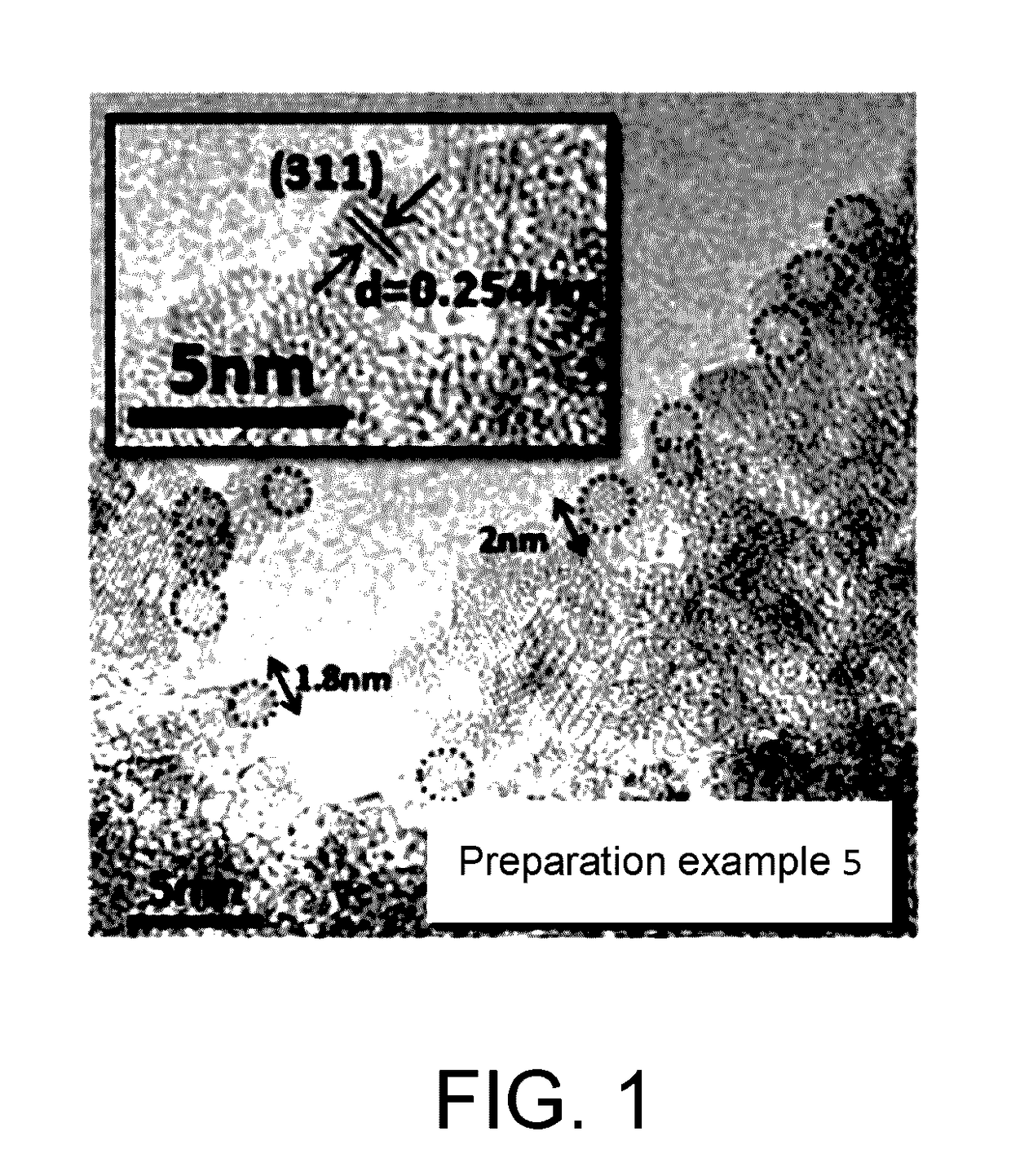

Nanometer porous metal catalyst and its prepn

InactiveCN1887418AImprove solubilityEasy to recycleCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAlloyElectrochemical corrosion

The nanometer porous metal catalyst is alloy sheet of thickness 0.1-100 microns, width 0.1-20 microns and length 0.1-100 cm, in double-continuous nanometer porous structure of pore size and wall size 2-100 nm, comprising Au 80-100 at.% and Ag 0-20 at.%, and covered with black gold oxide. The preparation process of the nanometer porous metal catalyst is also disclosed, and the nanometer porous metal catalyst is prepared through electrochemical corrosion of alloy material inside strong electrolyte solution and via voltage. The nanometer porous metal catalyst has great specific surface area, and preparation process is simple and has convenient operation, high repeatability, no loss of noble metal material and other advantages.

Owner:SHANDONG UNIV

Method for treating sludge containing trivalent chromium and recovering heavy metal

ActiveCN103011537ARemove hidden dangers of pollutionHigh purityZinc sulatesSludge treatmentSludgeResource recovery

The invention discloses a method for treating sludge containing trivalent chromium and recovering heavy metal. The method comprises the following steps: analyzing the content of components in sludge containing chromium to dilute the sludge containing chromium; and treating the sludge containing chromium by ammonium salt, ammonia water, alkali and acid to obtain pigment grade chromium oxide, single metal or other products. The method is applied to the disposal and recovery process of the sludge containing chromium generated in the industries, such as steel, electroplating and tanning to achieve a good pollution control and resource recovery effect.

Owner:武汉巍川环保科技有限责任公司

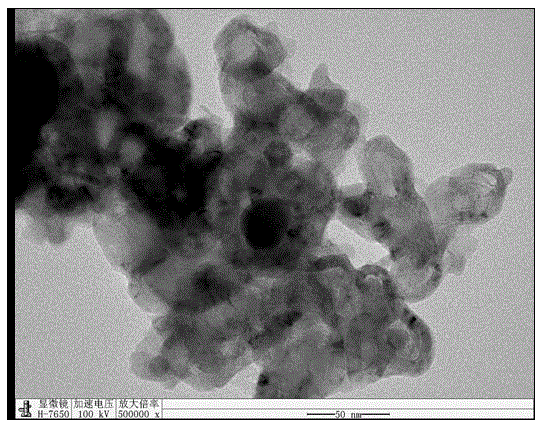

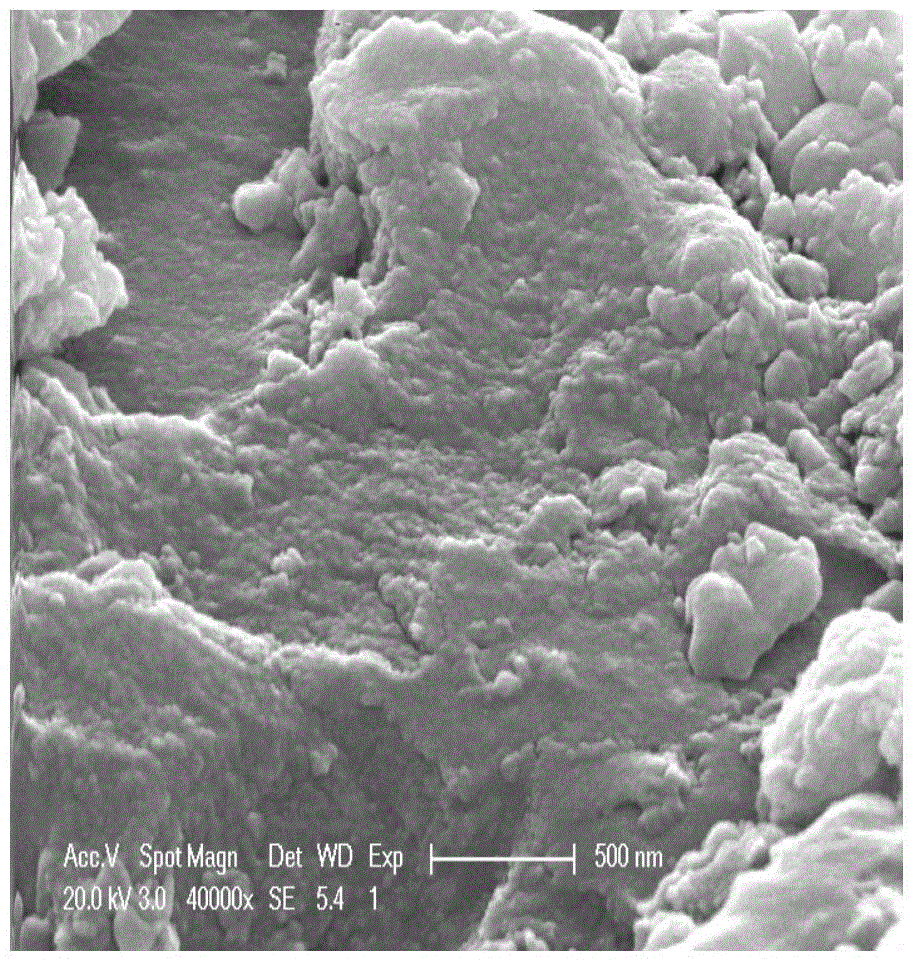

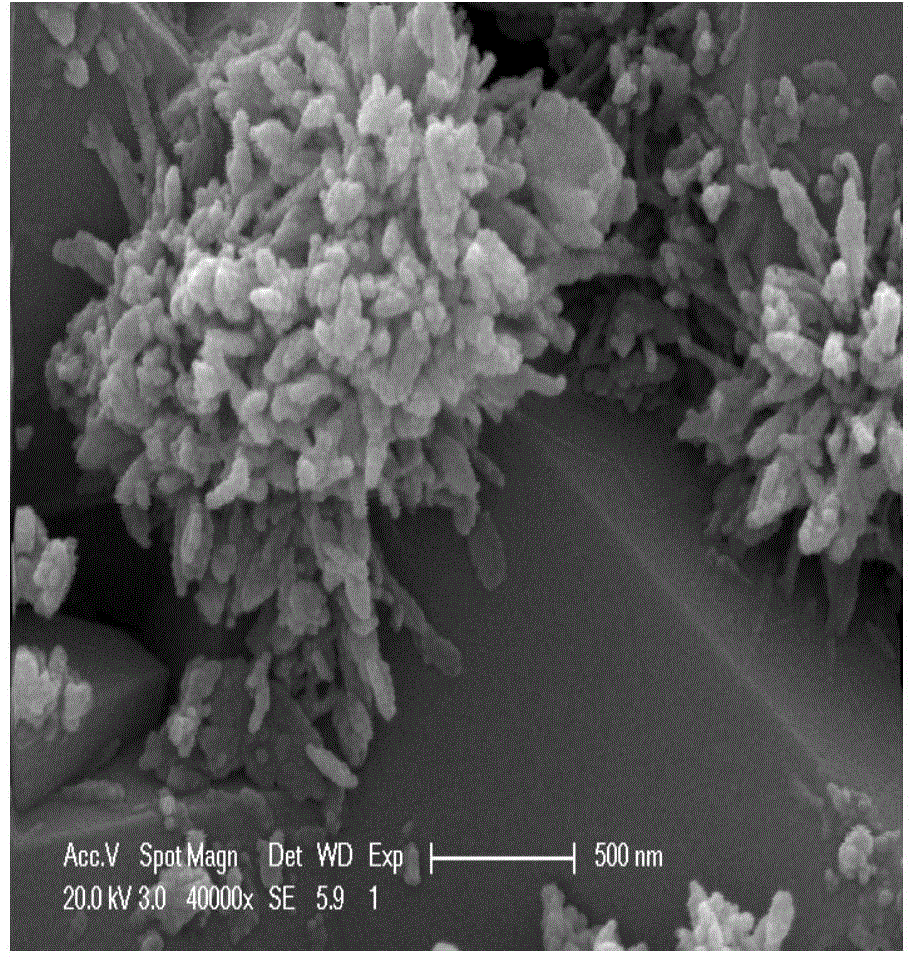

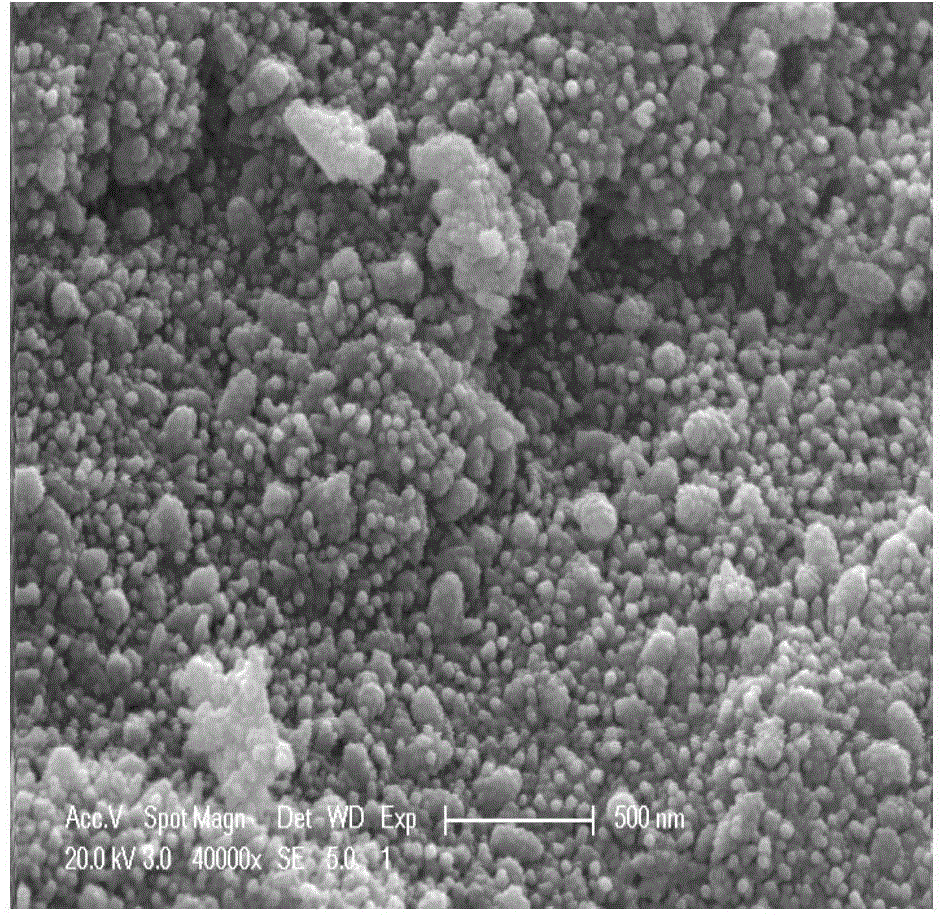

Method for in-situ preparing nano-silver compound bactericide

InactiveCN102657228AImprove the bactericidal effectReduce dosageBiocideDisinfectantsRecovery performanceHigh surface

The invention belongs to the technical field of material chemistry, and particularly relates to a method for in-situ preparing a nano-silver compound bactericide. The method is that a hydroxyapatite nano assembled ball chain with the length of micron order is taken as a carrier, the characteristics of the large surface area and high surface activity of the hydroxyapatite nano assembled ball chain are utilized, silver ions are converted into nano-silver on the hydroxyapatite surface through in-situ reduction reaction, so a hydroxyapatite / silver compound bactericide is prepared. The nano-silver compound bactericide has high chemical stability, good recovery performance, and can effectively kill various bacteria, the bactericidal efficiency is greatly improved because of the larger surface area of the nano-silver compound bactericide, under the premise of realizing the same bactericidal effect, the bactericide usage can be saved by about 30-40% compared with pure nano-silver, and the nano-silver compound bactericide has very strong industrial practicability.

Owner:EAST CHINA UNIV OF SCI & TECH

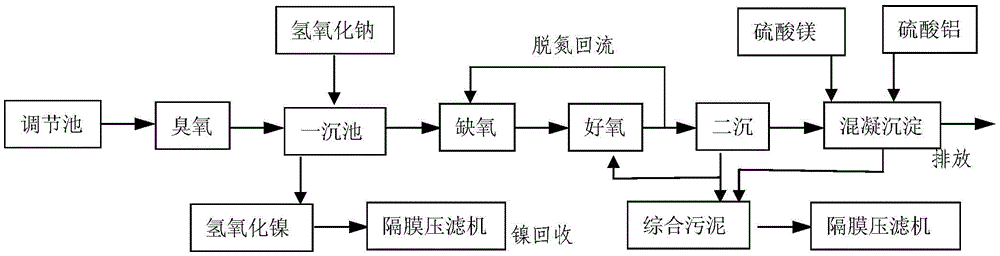

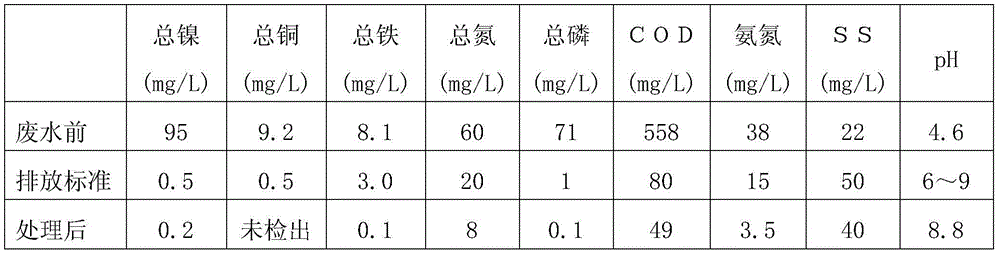

Method for treating chemical nickel plating waste water on basis of ozonation and biochemical technique

ActiveCN105601036ADisposal costs are highRemove completelyWater treatment parameter controlWater contaminantsCompound (substance)Metallic Nickel

The invention relates to a method for treating chemical nickel plating waste water on the basis of ozonation and biochemical technique, and belongs to the field of environment protection. Through ozone pre-oxidation, microbe inhibiting phosphiteis are converted into orthophosphate before the biochemical treatment; meanwhile, ozone can oxidize partial complex compounds; nickel after the complexation relieving becomes free nickel ions; 80 percent or more metallic nickel is precipitated through a primary precipitation pool; the outlet water total nickel of the primary precipitation pool is less than 20mg / L; anaerobic and aerobic microbes can adapt to the environment through domestication; through an aerobic biochemical technology, ammonia nitrogen is converted into trate nitrogen; then, outlet water of an aerobic pool flows back to an anaerobic pool; the heterotrophic nutrition denitrification denitrification is realized; meanwhile, the biological effect is used; organic matters in waste water are thoroughly removed, so that the nickel in the complexation state becomes free nickel ions; then, the metallic nickel can be thoroughly removed by using the good adsorption and flocculation performing of the active sludge. The method has the advantage that the total nitrogen in the treated waste water conforms to national emission standards.

Owner:CHINA NORTH ENERGY CONSERVATION & ENVIRONMENT PROTECTION

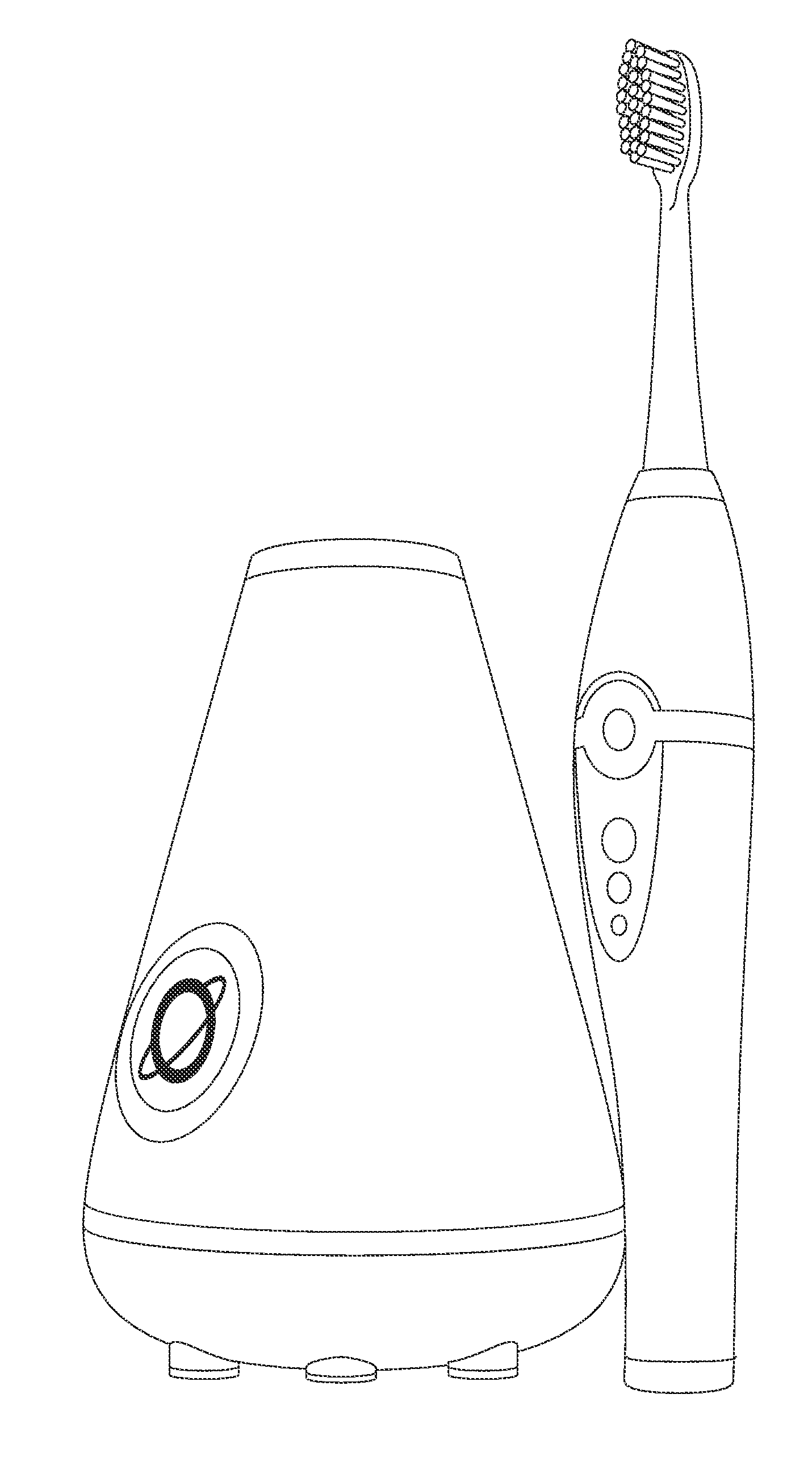

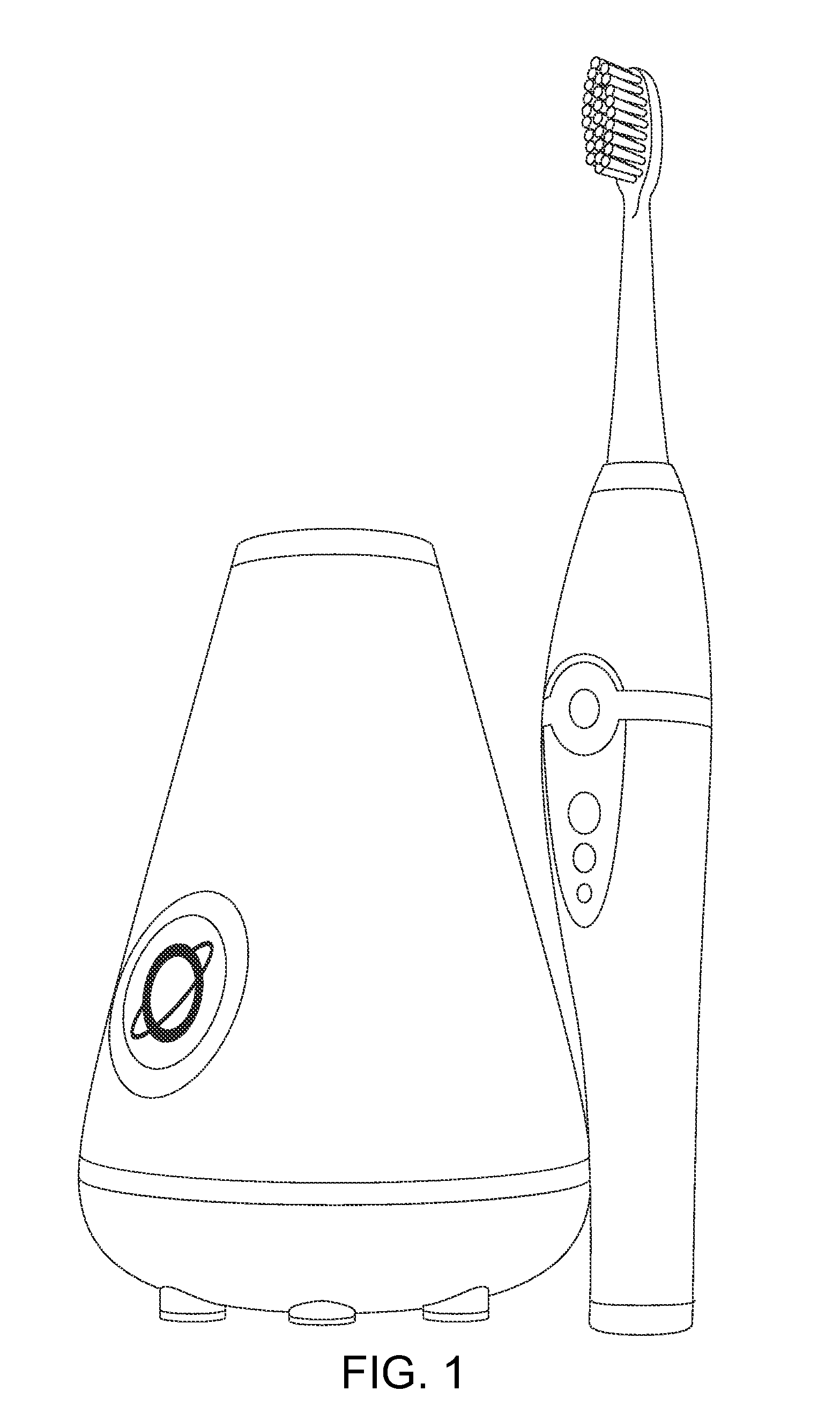

Toothbrush Sterilization System

In one example, we describe a method and system for toothbrush sterilization and / or storage with better quality in terms of hygiene and convenience, where the brush head and the shaft that enter the user's mouth are never contacted by the chamber. Also, below the brush head and shaft, there is no chamber. If any drops of water were to fall off the brush head, they would fall all the way through the chamber and reside on the counter on which the chamber rests, which can be removed or cleaned easily later. In one example, we use a UV-C lamp as our sterilization technique. This selection has many advantages over the other sterilizations techniques. In one example, we use a single lamp, but that lamp is in a ring configuration (otherwise known as annular, torus, or donut), with good coverage of the toothbrush, from all angles.

Owner:TAO CLEAN

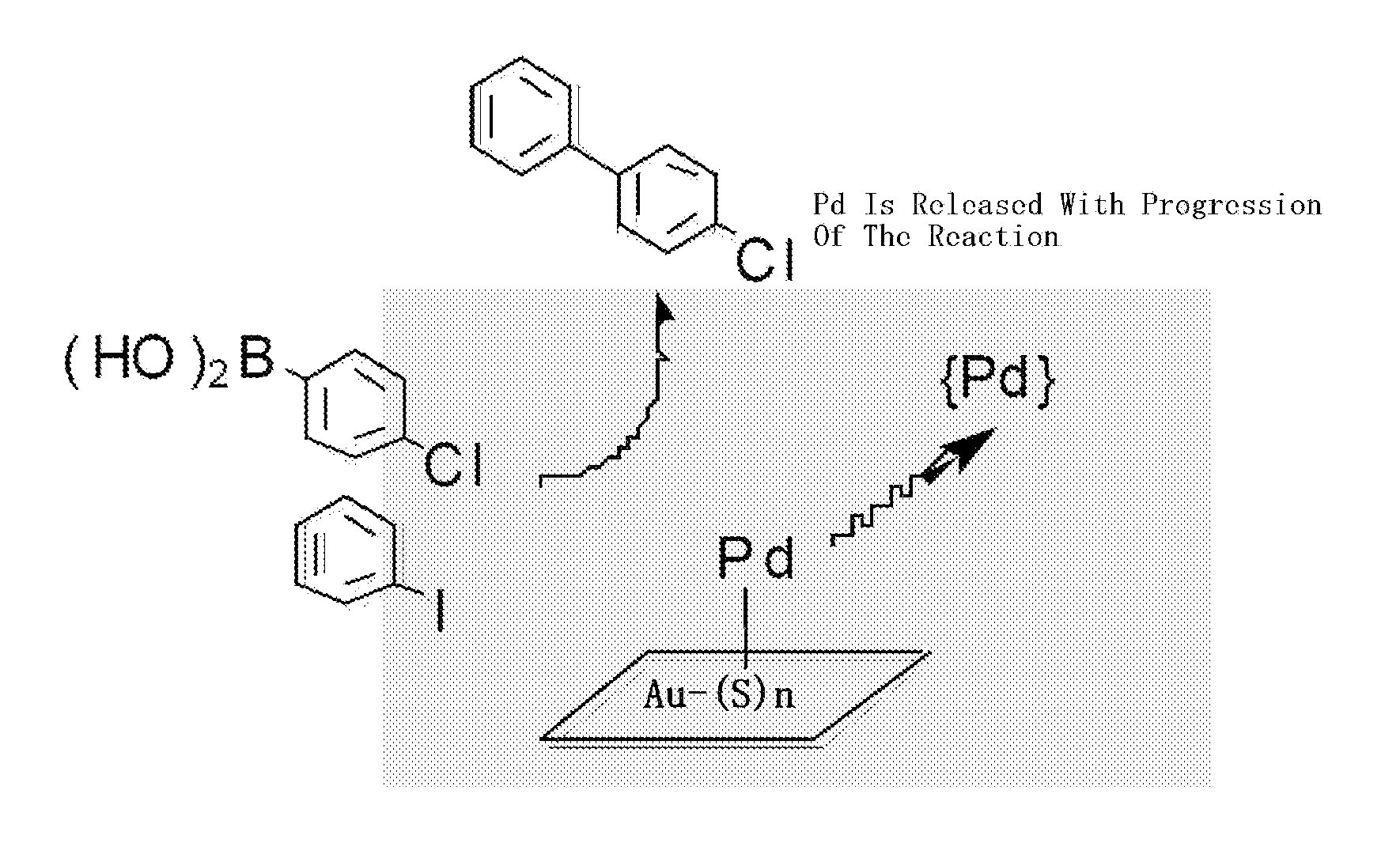

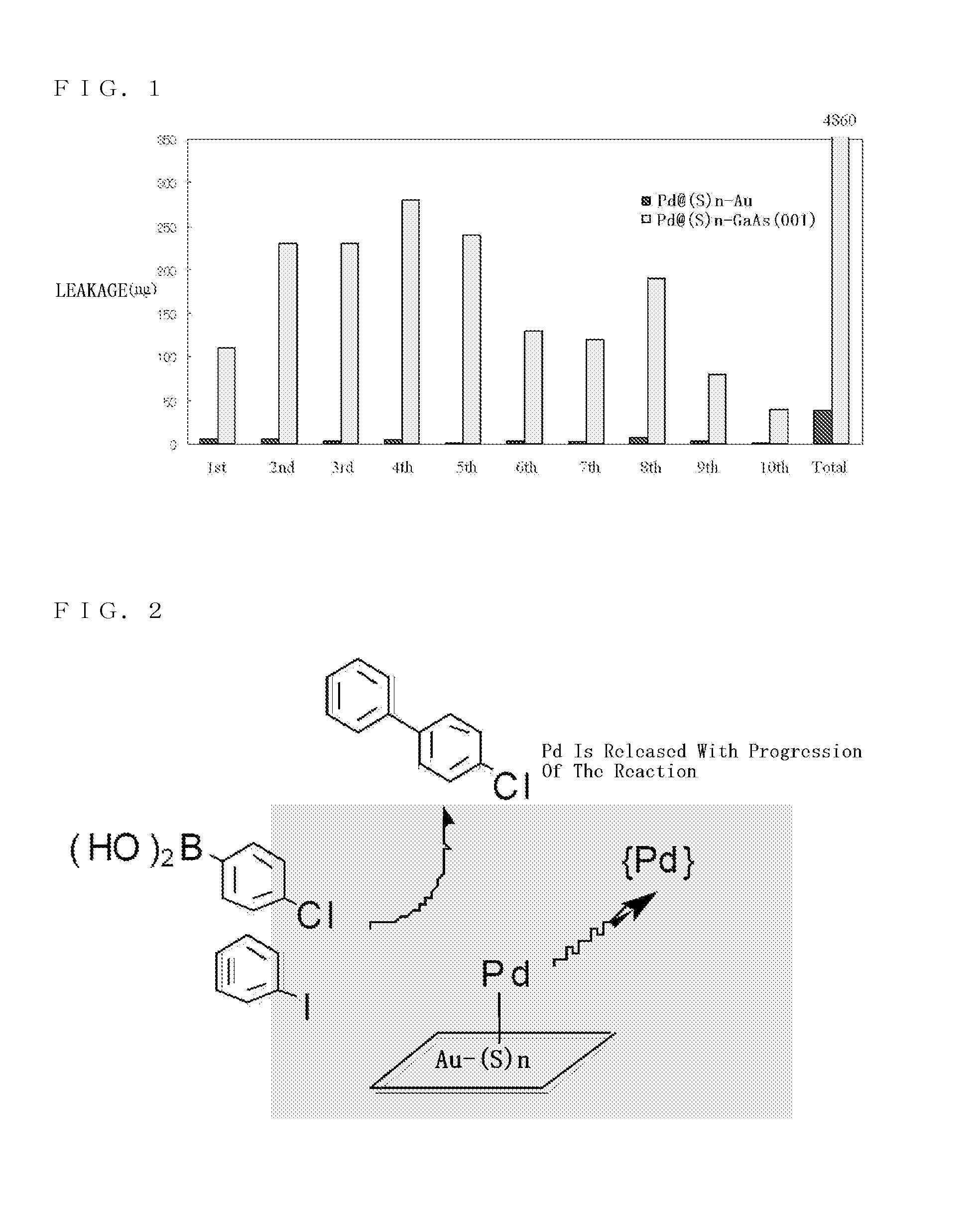

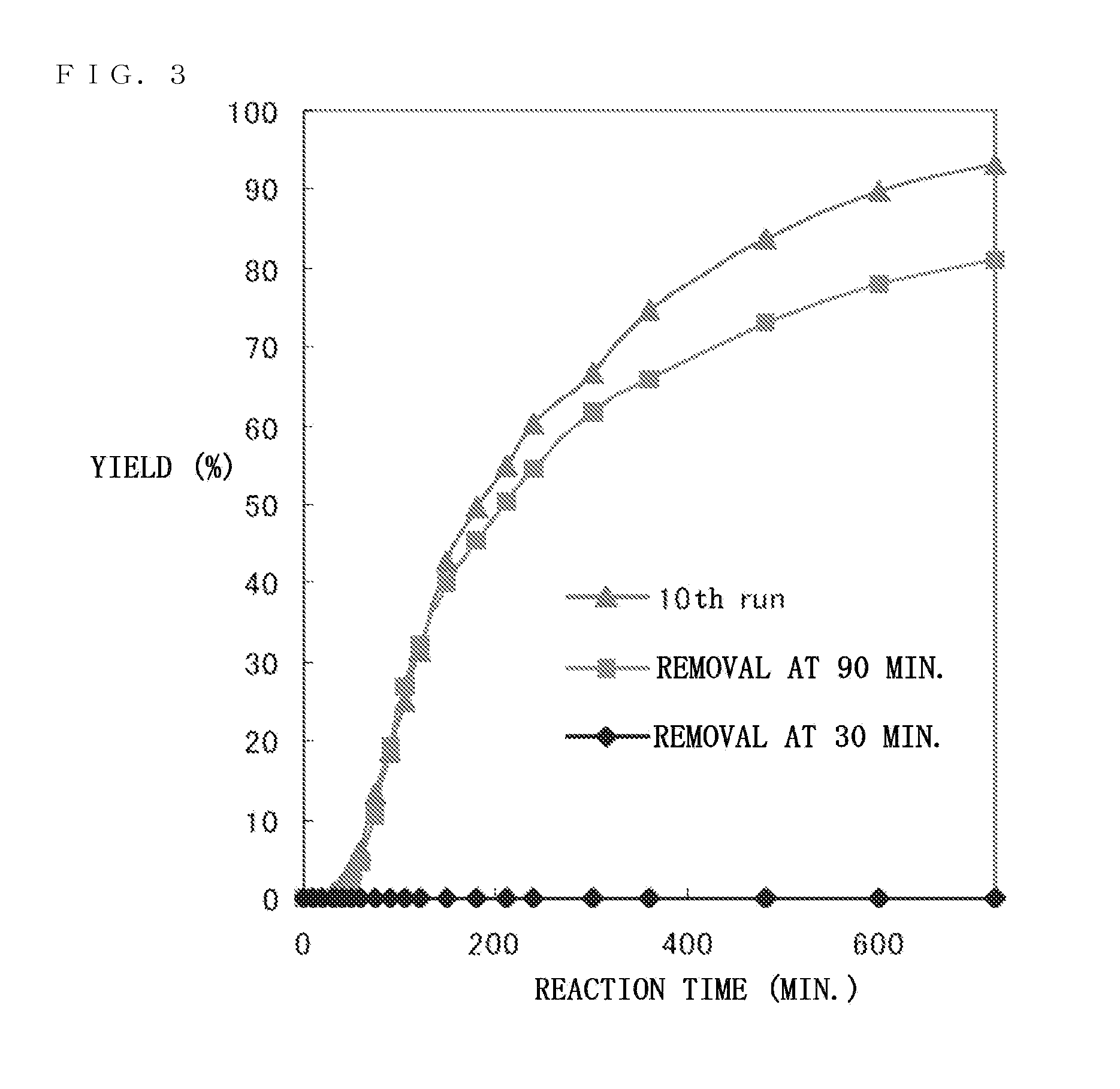

Catalyst precursor, method for producing the same, method for using the same, and reactor that uses the same

InactiveUS20120115714A1Good stability and securityStable rateOxygen-containing compound preparationGroup 8/9/10/18 element organic compoundsSulfurCatalytic metal

The present invention provides the catalyst precursor that has excellent safety and stability, has high stable activity retention rate, can be recycled, increases yield resulted from a reaction, and is easily processed into various forms. The catalyst precursor comprises a structure in which the entire structure is composed of gold or a gold-based alloy and the surface of the structure is modified with elemental sulfur, or at least the surface of the structure is composed of gold or a gold-based alloy and the surface of the structure is modified with elemental sulfur, and a catalytic metal compound supported on the structure, wherein the catalyst precursor has peaks derived from the catalytic metal compound and also sulfur as analyzed by photoelectron spectroscopy, and wherein the peak derived from sulfur is of the sulfur 1s orbital observed within a range of 2470 eV±2 eV in terms of the peak top position.

Owner:HOKKAIDO UNIVERSITY +1

Method for preparing feed additive by using nisin extraction waste liquid

ActiveCN103798515AEasy to recycleDifficult to recycleAnimal feeding stuffOrganic fertilisersMycoproteinUltrafiltration

The invention provides a method for preparing a feed additive by using a nisin extraction waste liquid, belonging to the technical field of the fermentation industry. The method comprises a first step of using a ceramic membrane for circulating filtration so as to intercept thalli and a second step of drying a material liquid containing high-concentration thalli so as to prepare mycoprotein powder and is mainly used in the field of feeds or agricultural fertilizers. With the method, the recovery rate of intercepted protein is high, macromolecular protein in a medium can be intercepted except mycoprotein, and abundant nutrients are obtained. A liquid permeated from the ceramic membrane is subjected to ultrafiltration and concentration and then to salting-out so as to prepare high-purity nisin. A supernatant obtained after salting-out contains considerable sodium chloride and is subjected to spray drying, and an obtained substance is used as a feed additive in the feed industry. Thus, the nisin extraction waste liquid is turned from the waste into the valuable, pollution to the environment caused by discharging of the waste liquid is prevented, sustainable development of the fermentation industry is realized, and a feasible approach is provided for clean production.

Owner:SHANDONG FREDA BIOTECH

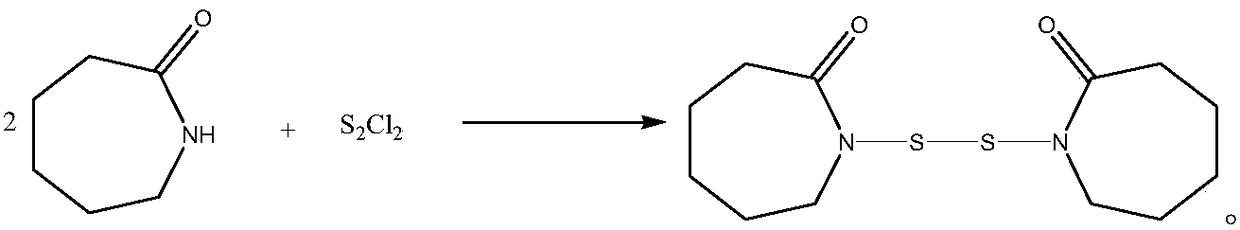

Preparation method of vulcanizer 1,1'-dithiodicaprolactam

The invention belongs to the technical field of rubber synthesis, relates to additives, used to increase the wear resistance and corrosion resistance of rubber, for rubber synthesis, and particularlyto a preparation method of vulcanizer 1,1'-dithiodicaprolactam. The preparation method uses organic amine to replace caprolactam to serve as the acid-binding agent, the organic amine can be recycled,and the defects that the caprolactam cannot be recycled, and great waste is caused are overcome. Compared with the prior art, the preparation method has the advantages that the organic amine used as the acid-binding agent can be recycled after the reaction, cost is lowered, and environments are protected.

Owner:杭州布朗生物医药科技有限公司

Mesoporous zinc ferrite, preparation method thereof, and magnetic carbon nanotube prepared from same

InactiveCN102826607ATake full advantage of the adsorptionEfficient recyclingOther chemical processesCombustible gas purificationMagnetic carbonMetallurgy

The invention discloses mesoporous zinc ferrite, a preparation method thereof, a method of preparing a magnetic carbon nanotube by using mesoporous zinc ferrite, application of mesoporous zinc ferrite in water treatment and application of the magnetic carbon nanotube in water treatment. According to the invention, the magnetic material mesoporous zinc ferrite is combined with the carbon nanotube; adsorptivity of the carbon nanotube is fully utilized, and meanwhile, the carbon nanotube can be effectively recycled, which enables cost to be reduced and secondary pollution to be decreased.

Owner:SUN YAT SEN UNIV

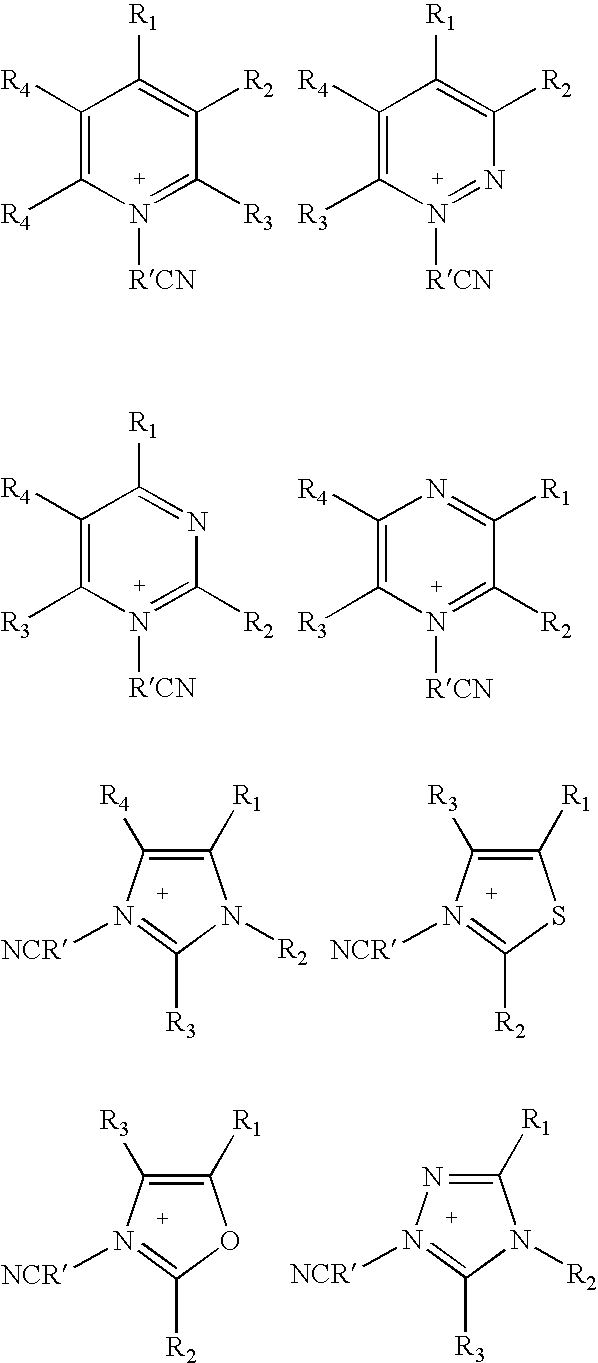

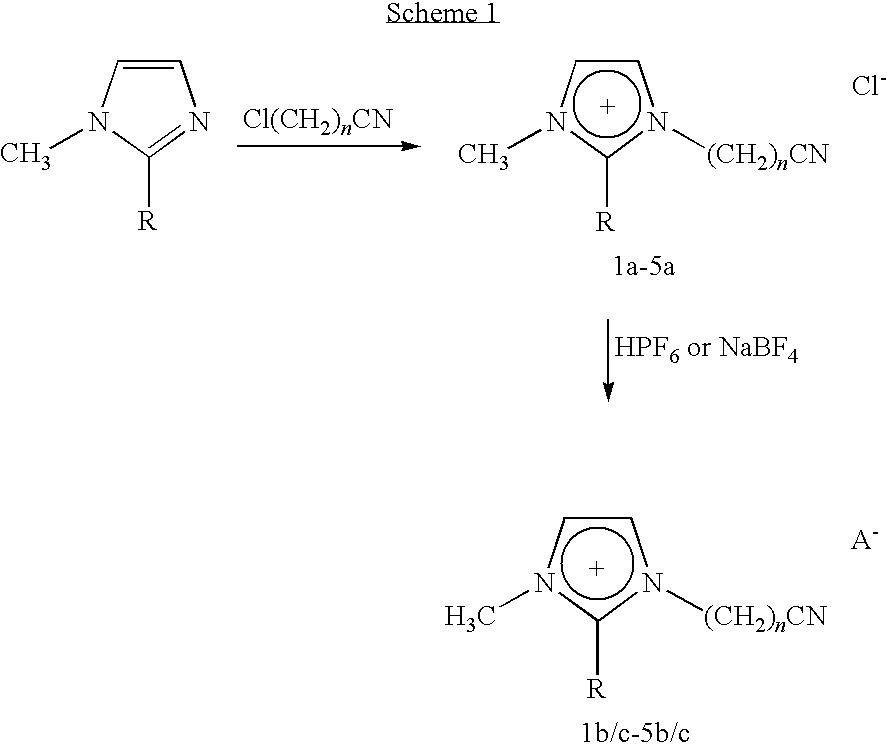

Ionic Liquids Based on Imidazolium Salts Incorporating a Nitrile Functionality

InactiveUS20090143597A1Increased temperature requirementsDifficult to recycleSilicon organic compoundsGroup 5/15 element organic compoundsHalogenChemical compound

Novel chemical compounds of the general formulaK+A−,in which K+is a 5- or 6-membered heterocyclic ring having 1-3 hetereo atoms, which can be independently N, S, or O;with the proviso that at least one of the hetereo atoms must be a quaternized nitrogen atom having a —R′CN substituent, wherein R′ is alkyl (C1 to C12);the heterocyclic ring having up to 4 or 5 substituents independently chosen from the moieties:(i) H;(ii) halogen or(iii) alkyl (C1 to C12), which is unsubstituted or partially or fully substituted by further groups, preferably F, Cl, N(CnF(2n+1−x)Hx)2, O(CnF(2n+1−x)Hx), SO2(CnF(2n+1−x)Hx)2 or CnF(2n+1−x)Hx where 1<n<6 and 0<x<13; and(iv) a phenyl ring which is unsubstituted or partially or fully substituted by further groups, preferably F, Cl, N(CnF(2n+1−x)Hx)2, O(CnF(2n+1−X)Hx), SO2(CnF(2n+1−x)Hx)2 or CnF(2n+1−x)Hx where 1<n<6 and 0<x≦13; andA− is any anion that provides a salt with a low melting point, below about 100° C.; A can be halide, BF4−, PF6−, NO3−, CH3CO2−, CF3SO3−, (CF3SO2)2N−, (CF3SO2)3C−, CF3CO2− or N(CN)2− or [BF3RCN]These compounds can be used as industrial solvents, especially as ligands for efficient catalyst recycling.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

A kind of nanocomposite catalyst that is easy to recycle and preparation method thereof

InactiveCN102274738AImprove catalytic performanceHigh catalytic efficiencyPhysical/chemical process catalystsChemistryNanometre

The invention belongs to the technical field of material chemistry, and in particular relates to an easily recyclable nanocomposite catalyst and a preparation method thereof. The invention uses the hydroxyapatite nano-assembled ball chain with a length of micron as the carrier, utilizes the characteristics of large surface area and high surface activity, and loads titanium dioxide nano-powder on it. The easily recyclable nanocomposite catalyst has high catalytic activity and high chemical stability, and can be widely used in many fields such as the degradation of harmful substances in water bodies and photovoltaic cells.

Owner:EAST CHINA UNIV OF SCI & TECH

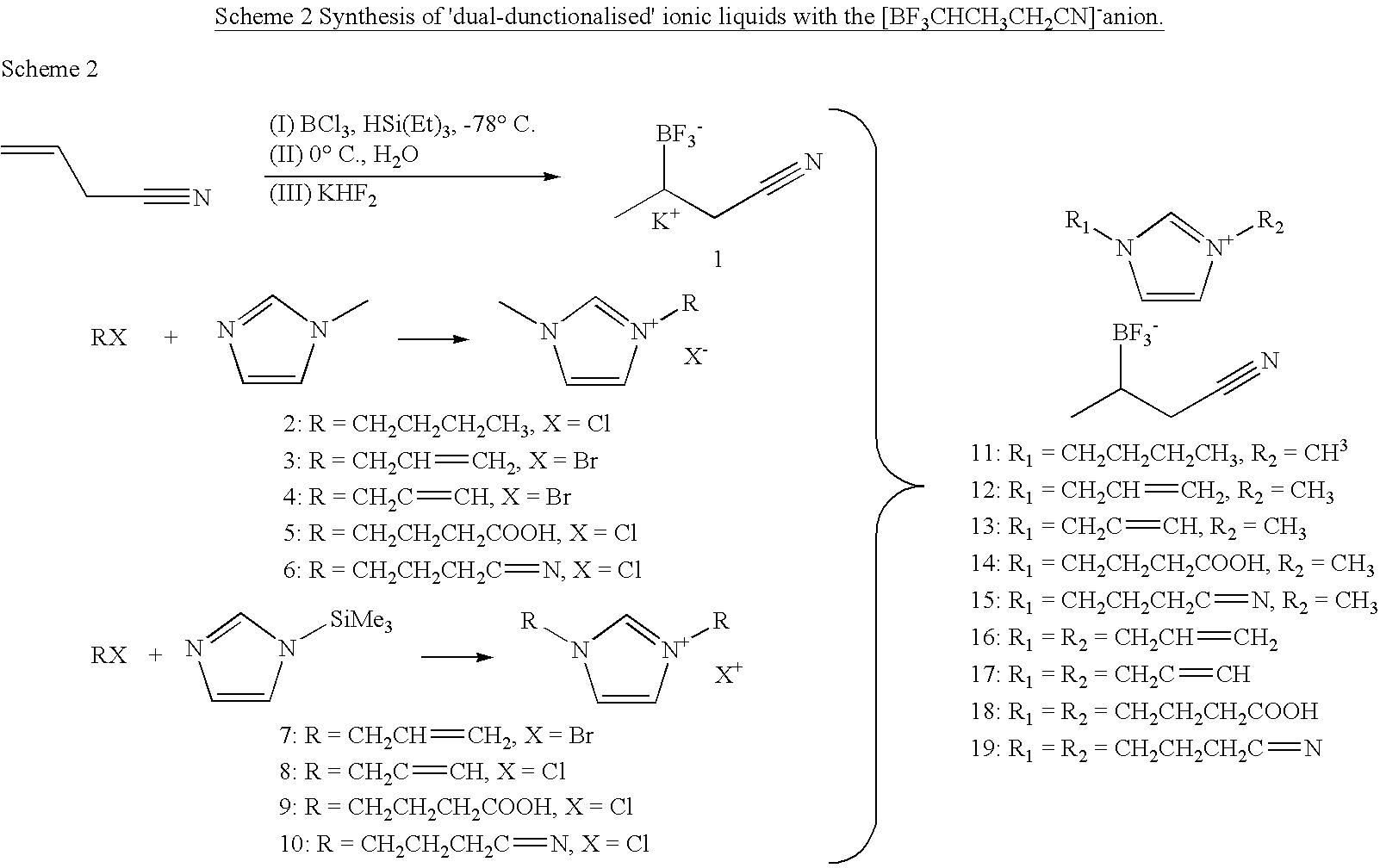

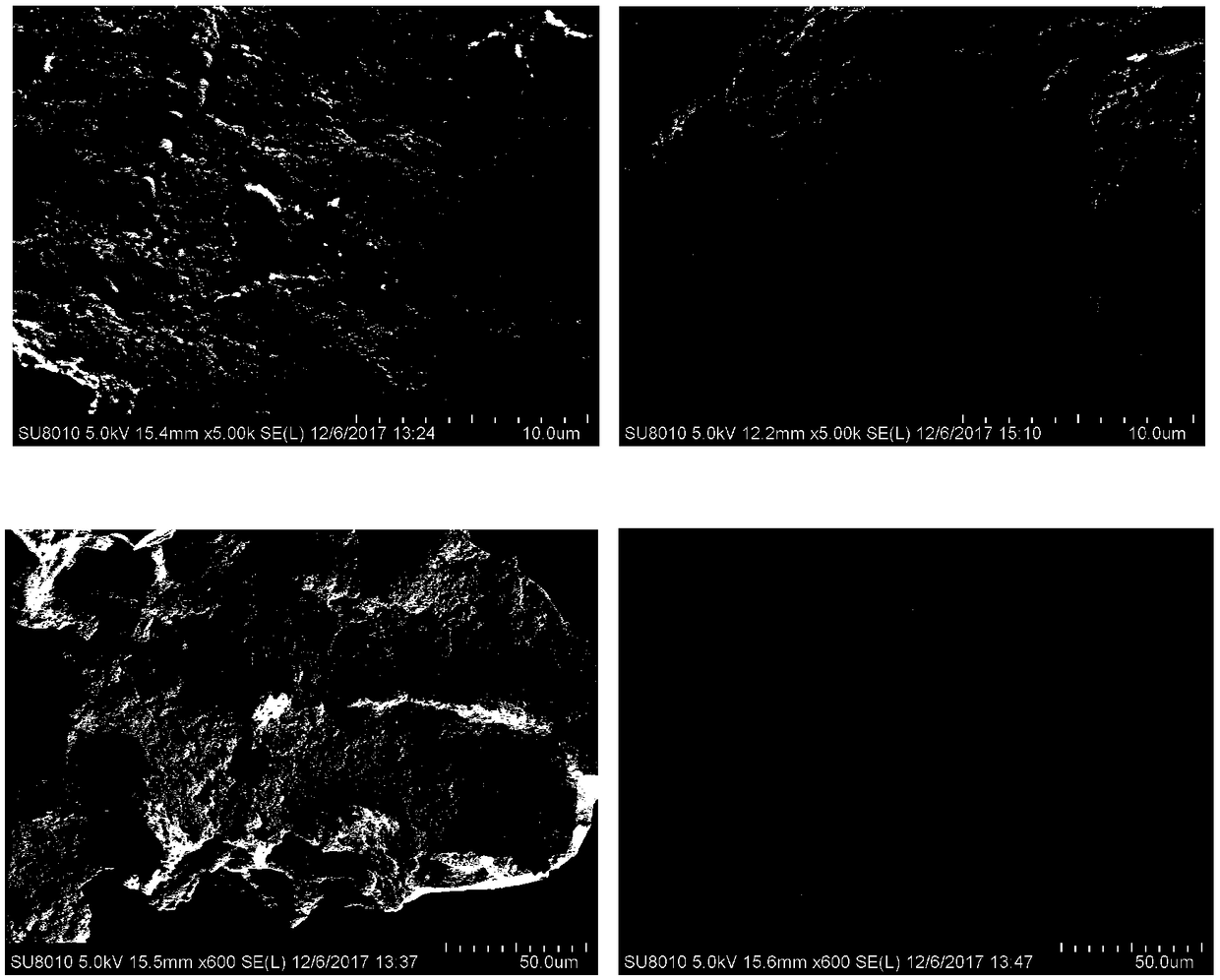

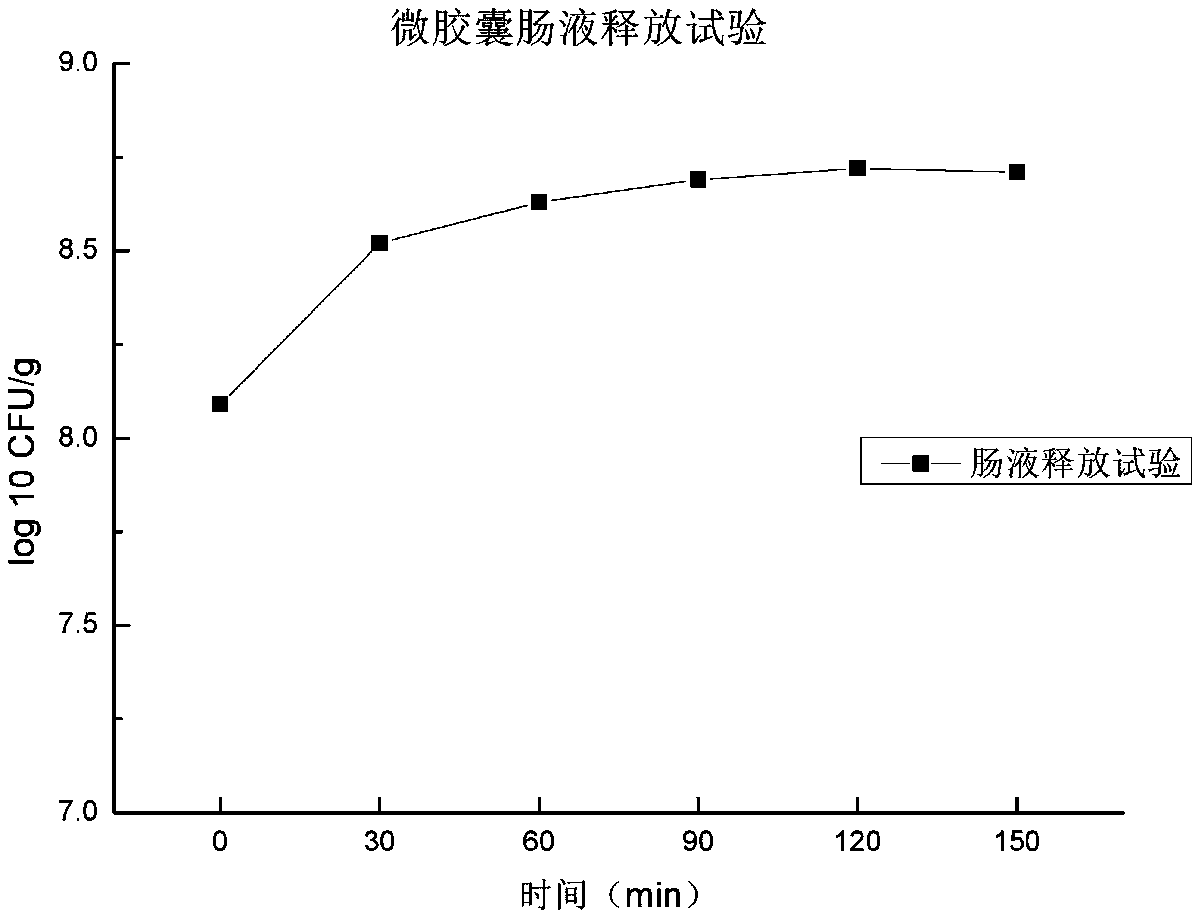

Probiotics microcapsule freeze-dried powder and preparation method thereof

ActiveCN108902982ALarge particle sizeSmall particle sizeFood freezingLactobacillusFreeze-dryingMicrometer

The invention relates to a probiotics microcapsule and a preparation method of probiotics microcapsule freeze-dried powder. The preparation method comprises the following steps: activating a bacterialstrain, preparing a fermented skimmed milk bacterial solution, preparing a microcapsule, freeze drying and the like. The microcapsule particles prepared in the invention are good in morphological characteristics and compact in surface, the particle size is 70 to 130 micrometers, the coating rate is greater than 85 percent, the gastric acid resistance is good, and the intestinal juice release performance, the freeze drying resistance and the storage stability are good, so that the probiotics can be protected against the adverse environment, the health effect of the probiotics in the human bodycan be improved, and the defects of the traditional embedding method are solved. The technology for preparing the probiotics microcapsule can be widely applied to the technical fields such as food, biological technology and the like.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Preparation method of pumice-loaded zinc oxide hydroxide

InactiveCN102059109AComplete crystal formUniform particle size distributionCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPollutionWater treatment

The invention provides a preparation method of pumice-loaded zinc oxide hydroxide, and relates to a preparation method of a pumice-loaded metal oxyhydroxide. The preparation method is used for solving the problems that the existing zinc oxide hydroxide is difficult to separate from water and is easy to result in secondary pollution of effluent post-treatment and poor sedimentation performance. The preparation method comprises the following steps: 1, soaking pumice particles in a soluble zinc salt solution to obtain mixed liquor A; 2, dropwise adding an alkaline solution to the mixed liquor A so as to obtain a turbid liquid B; 3, regulating the pH value of the turbid liquid B, standing and sedimenting, and then activating to obtain mixed liquor C; and 4, filtering the mixed liquor C to obtain a solid phase object, and washing the solid phase object with distilled water and drying to obtain the pumice-loaded zinc oxide hydroxide. The pumice-loaded zinc oxide hydroxide which is taken as a catalyst can be added to the water, and can be sedimented within 30 seconds fast and completely. The pumice-loaded zinc oxide hydroxide has the advantages of wear resistance, high catalytic activity, long service life, fast reaction speed, good water treatment effect and nonoccurrence of the secondary pollution, and is difficult to wash away.

Owner:HARBIN INST OF TECH

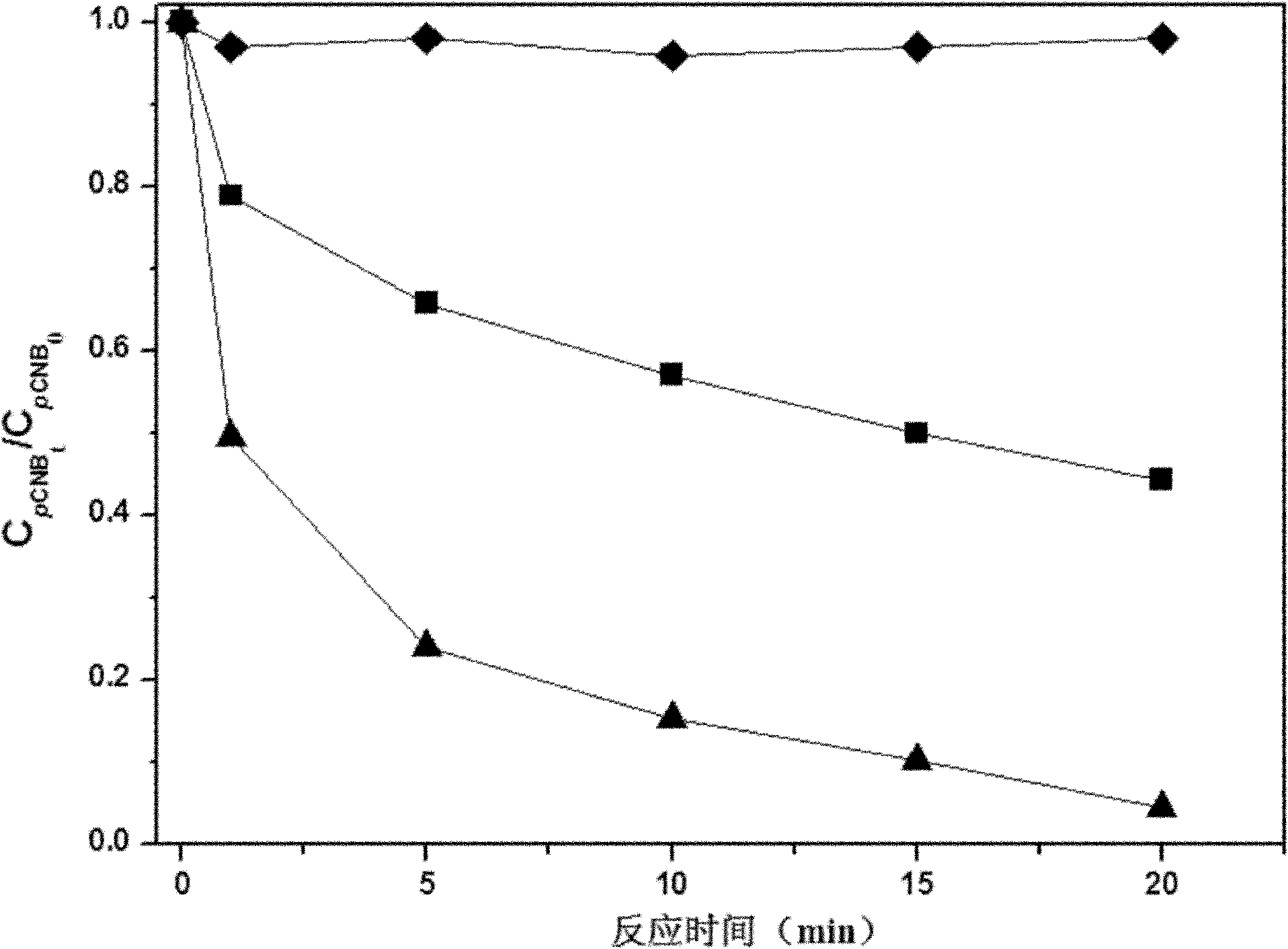

Preparation method of manganese-based MOF (metal-organic framework) magnetic material

InactiveCN105642349AImprove catalytic performanceEasy Magnetic RecyclingOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsHydrogen atmosphereManganese

The invention provides a preparation method of a manganese-based MOF (metal-organic framework) magnetic material. 8-hydroxyquinoline is dissolved in absolute ethyl alcohol, and a solution with the concentration being 10-20 mol / L is formed; manganese salt is dissolved in water, a solution B with the concentration being 5-10 mol / L is formed, then, the solution A is added to the solution B, and reflux is performed for 2-8 h; centrifugation is performed, and obtained precipitates are washed and then dried; the dried solids are heated to 500-900 DEG C at the speed of 0.5-1.5 DEG C / min in the hydrogen atmosphere and calcined for 3-9 h, and the manganese-based MOF magnetic material is obtained. The prepared composite catalytic material can be easily separated and recovered from a reaction system with a magnetic separation method, the reuse efficiency of a catalyst is improved, secondary pollution to the environment is reduced, and the catalytic performance of the MOF structure is greatly improved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Iron carbon material and preparation method and application thereof

InactiveCN104860388ADifficult to recycleAvoid secondary pollutionWater/sewage treatment by sorptionWater/sewage treatment by reductionActivated carbonActive carbon

The invention provides an iron carbon material and a preparation method and an application thereof. The iron carbon material comprises active carbon and nanometer iron carbonyl loaded on the active carbon, and the mass ratio of the nanometer iron carbonyl to the active carbon is 1: (1-5). By means of the iron carbon material, bromate in water can be reduced and degraded into bromide ions, and accordingly, the bromate in water can be removed, and secondary pollution to water is prevented.

Owner:TONGJI UNIV

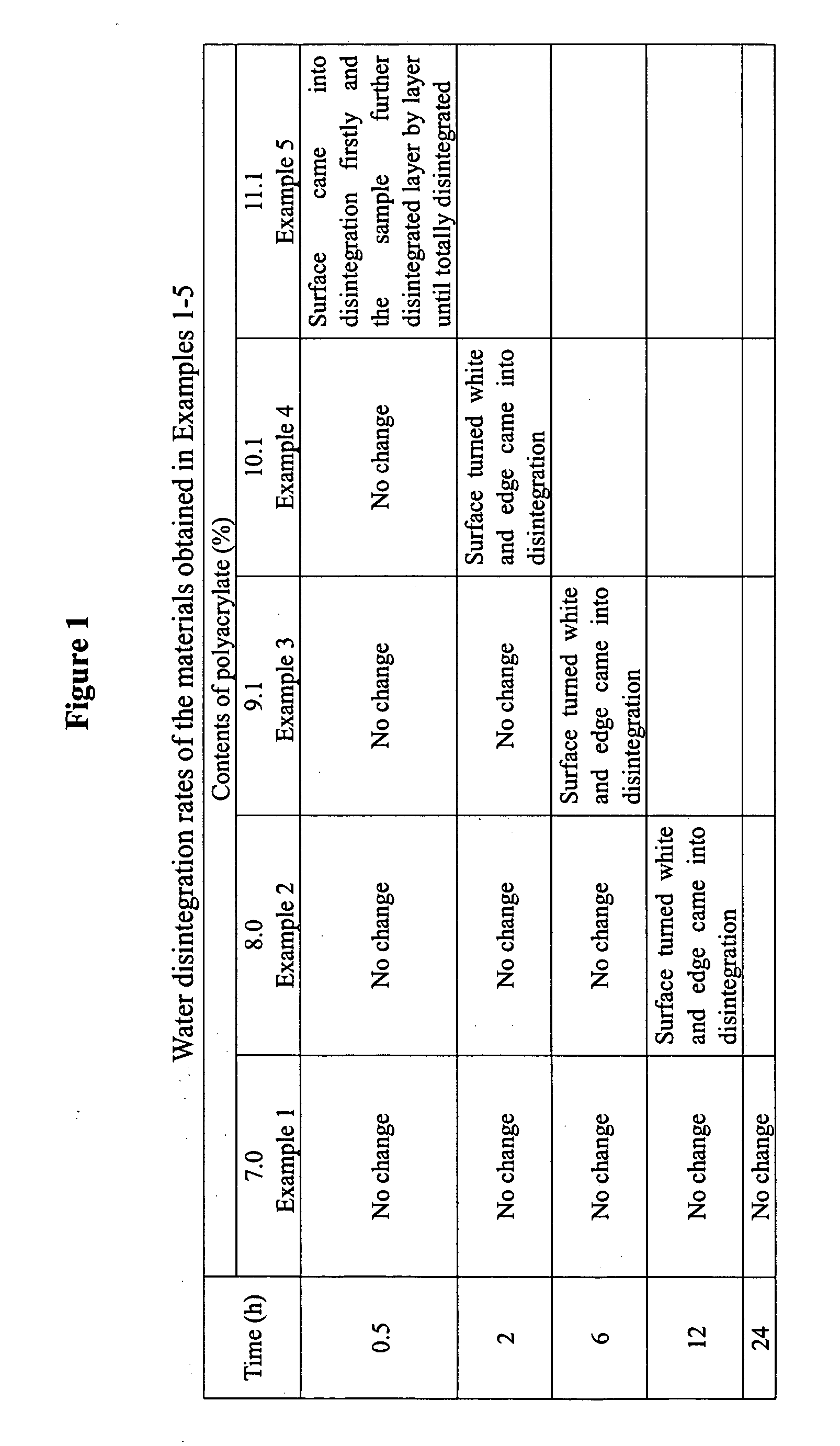

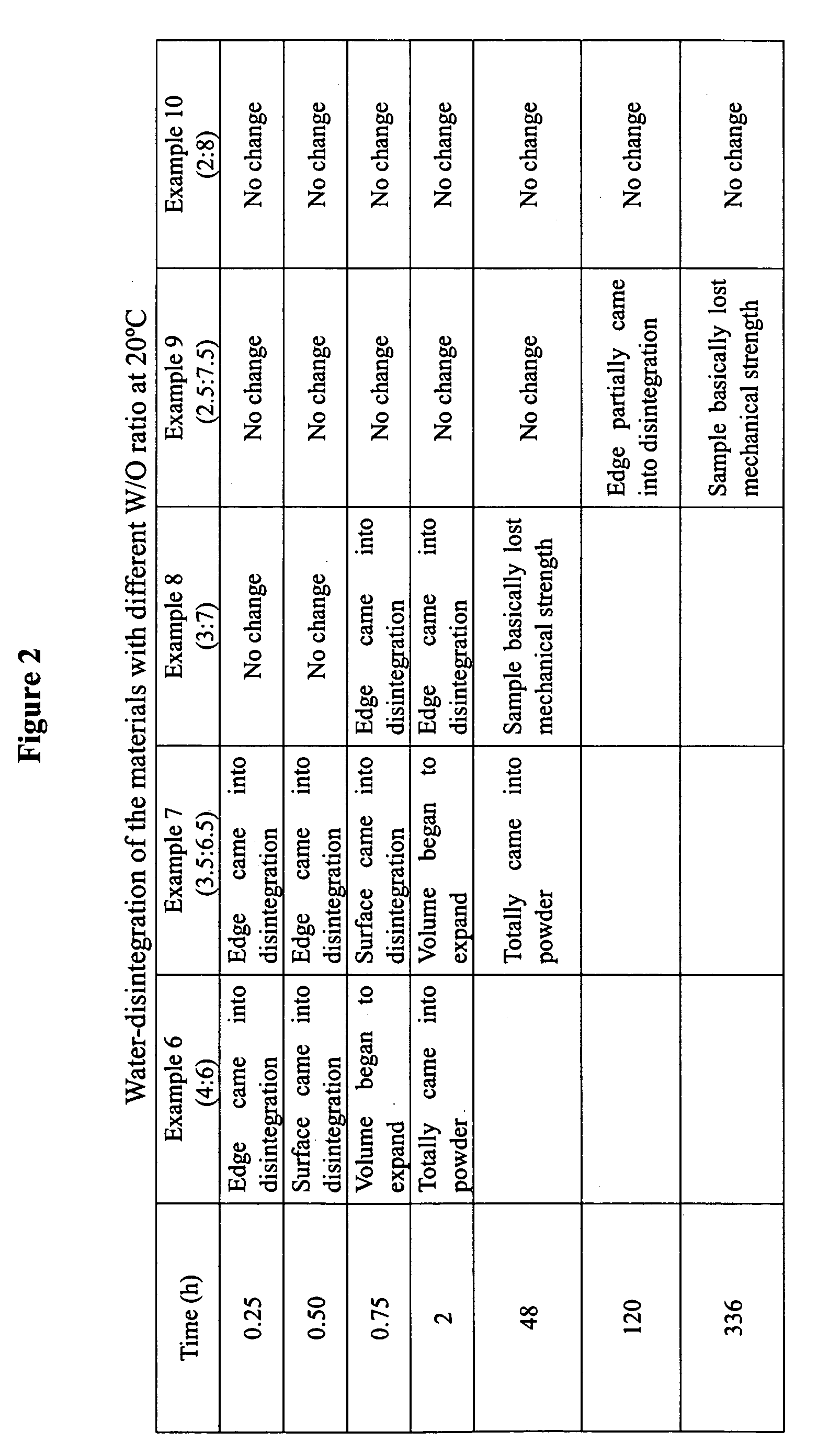

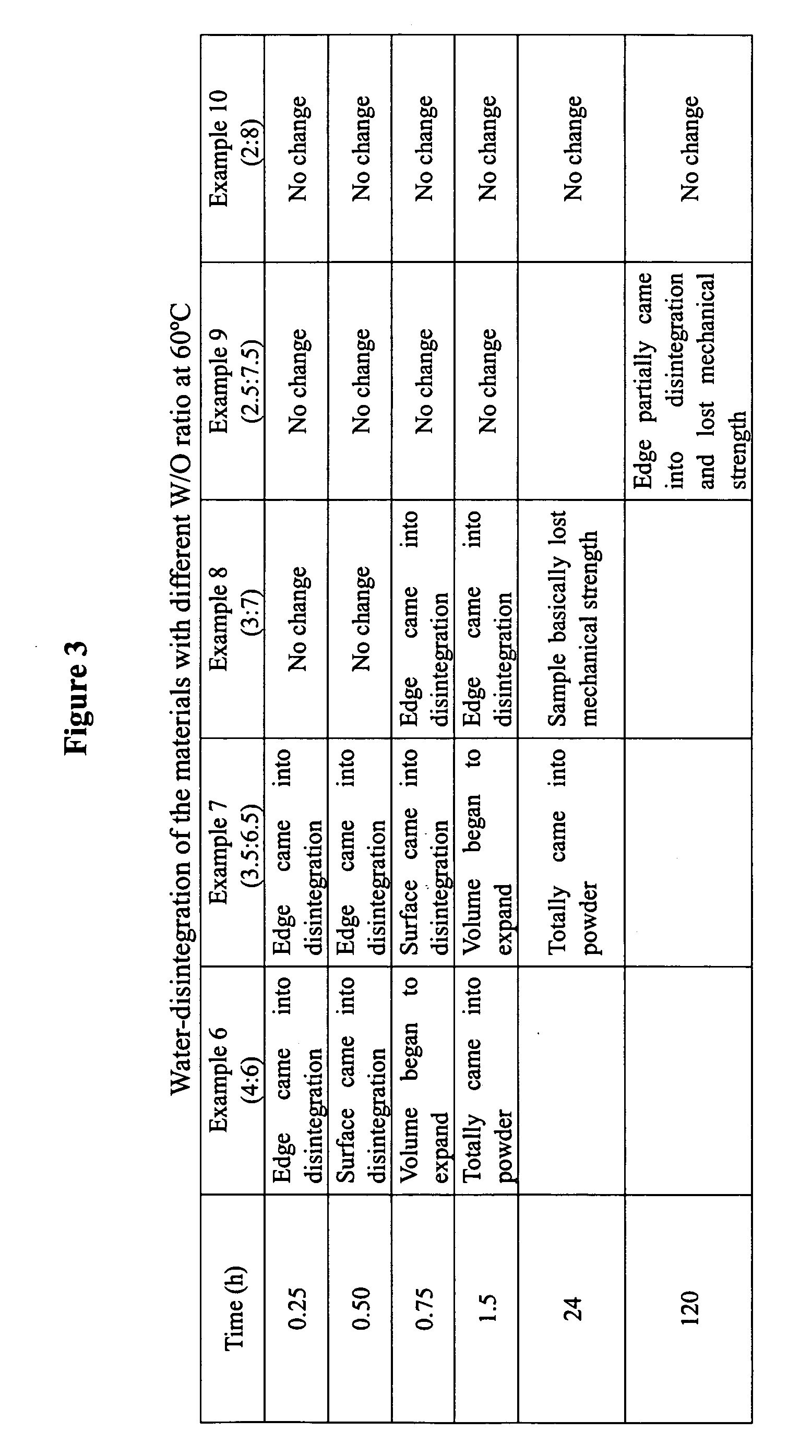

Water-disintegrable enviromentally friendly macromolecular blend materials and the process for preparation thereof

InactiveUS20070149708A1Reduce environmental pollutionEasy to optimizeAbsorbent padsBandagesPolystyrenePack material

The present invention relates to a novel water-disintegrable environment-friendly macromolecular material formed by blending water absorbent resin particles into polymers, such as polystyrene. Said material will disintegrate into powder or lose its intensity at a certain rate in the presence of water. The present invention also relates to two kinds of processes for preparing said material. The first process is called blending-polymerization process, wherein water absorbent resin particles with particle size not more than 5 μm, together with an initiator, are added into one or more monomers, such as styrene, to carry out polymerization. The second process is called reverse-phase emulsion polymerization process, wherein a W / O emulsion was firstly formed by agitating a mixture of one or more oil-soluble monomers, such as styrene, one or more water-soluble monomers that will form water-absorbent polymer after polymerization, such as sodium acrylate and methylene bisacrylamide, water, initiators and a W / O emulsifer, and then a polymerization was carried out. The material of the present invention has advantages that its preparation involves low cost, and its water-disintegrating rate is controllable. The material of the present invention can be used to replace the currently used foamed polystyrene type packing materials, especially the packing materials for disposable meal boxes, which are pollutive and difficult to be recycled and degraded.

Owner:POLYMER SCI & ENG COLLEGE OF QINGDAO UNIV OF SCI & TECH

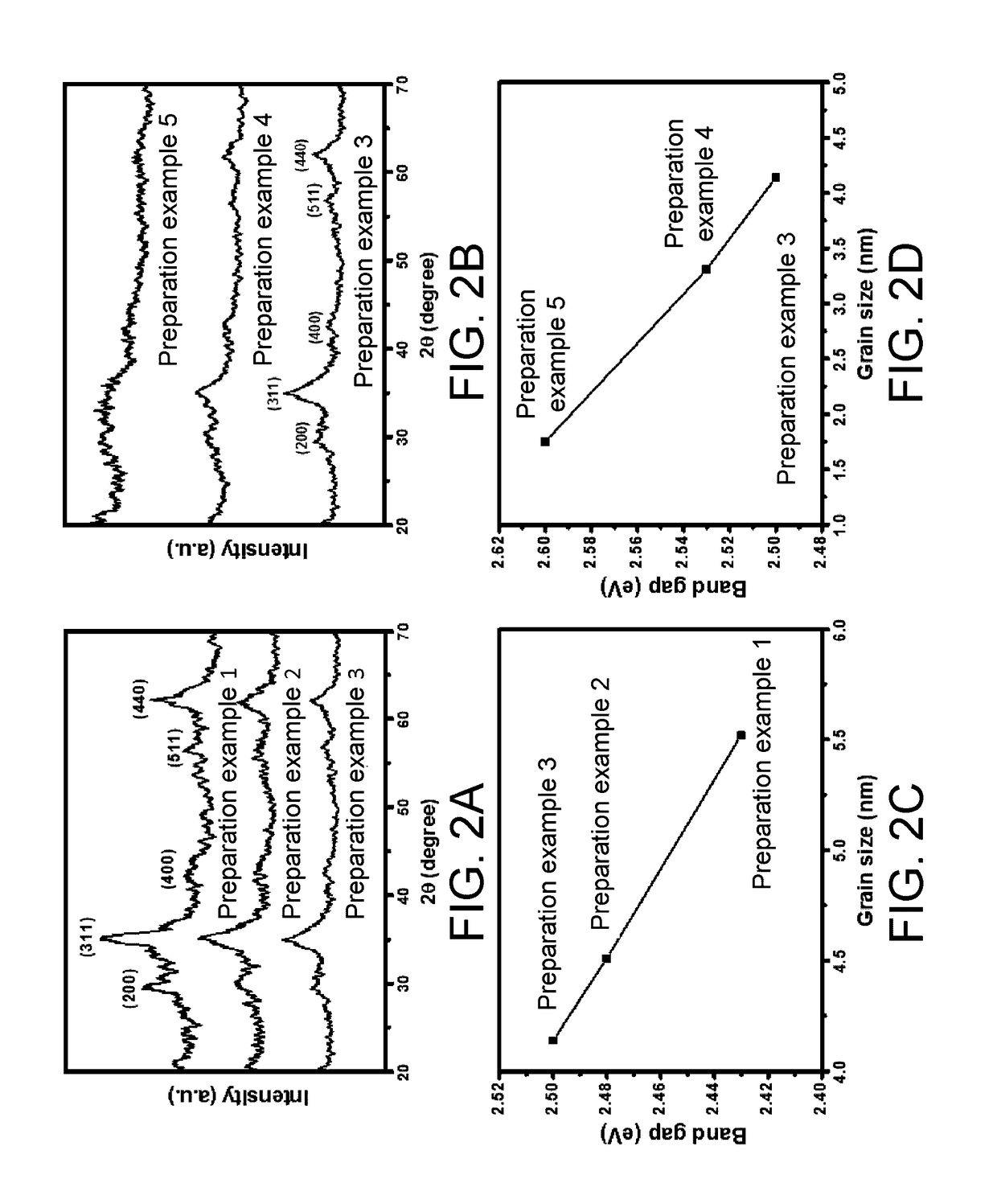

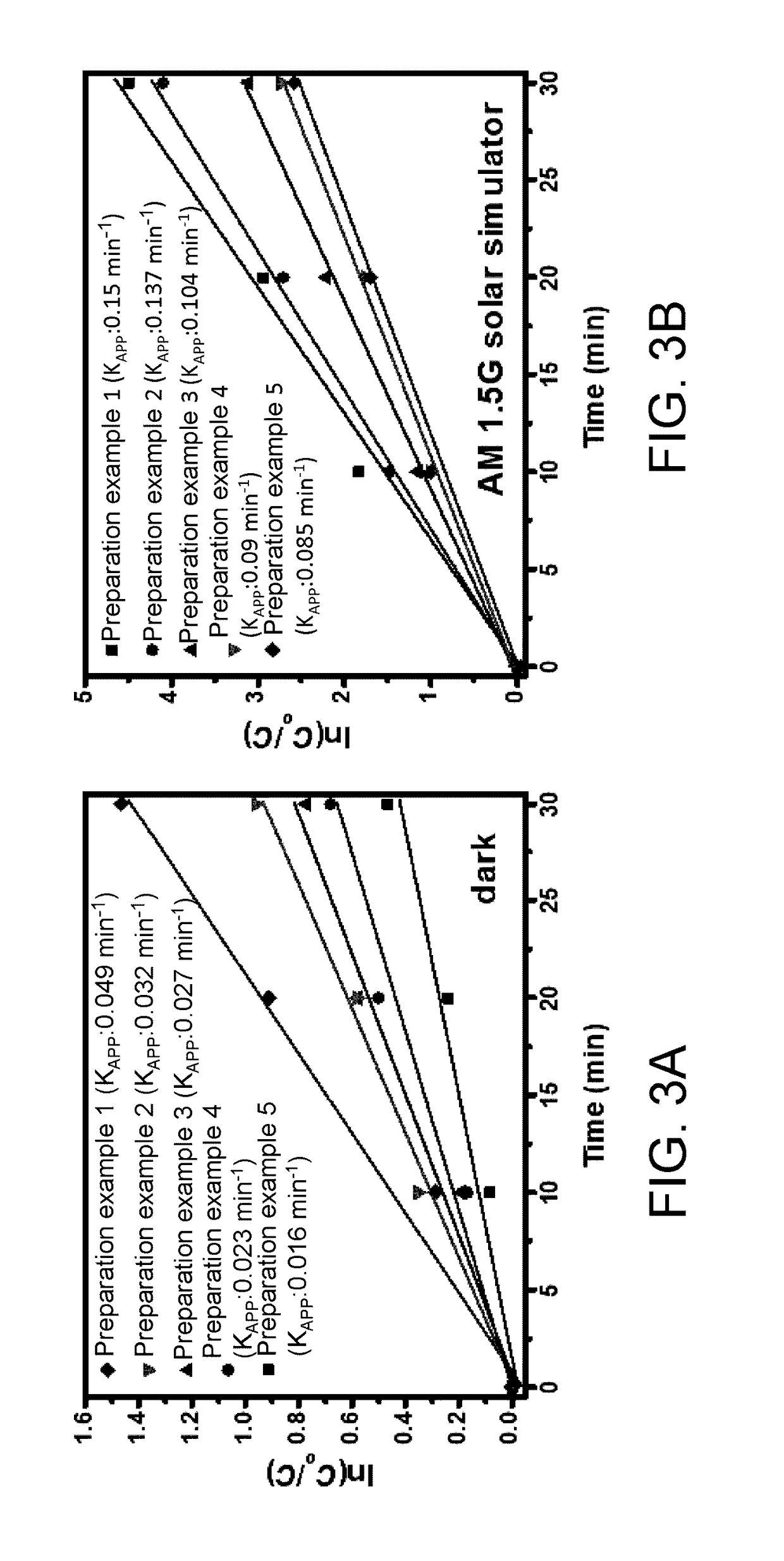

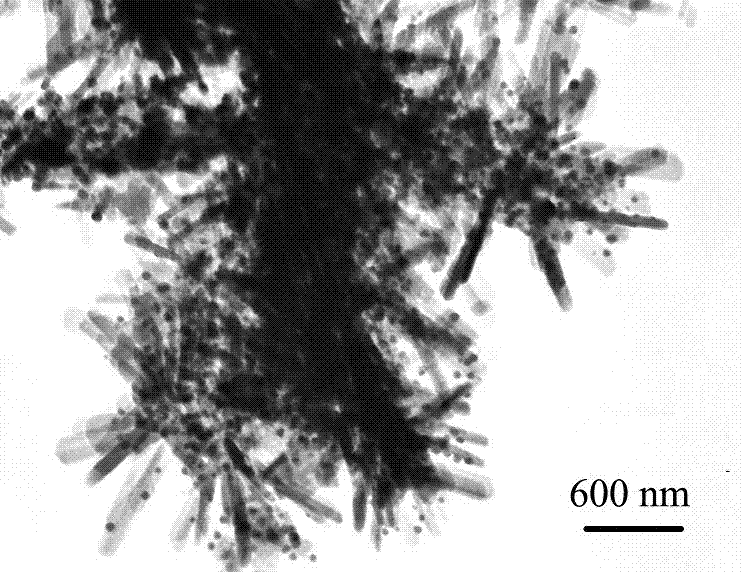

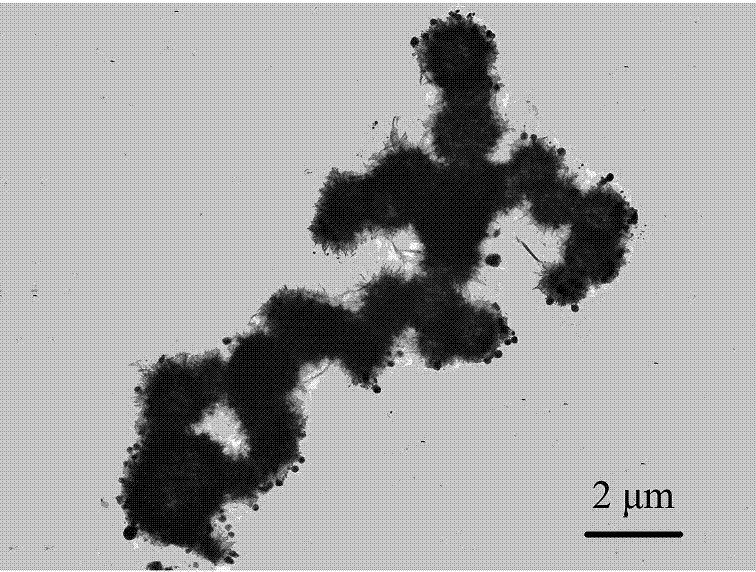

Composite photocatalyst, manufacturing method thereof, kits containing composite photocatalyst, and bactericide photocatalyst

ActiveUS20170144135A1Promote degradationDifficult to recycleWater/sewage treatment by irradiationWater treatment compoundsPlatinumNanocrystal

A composite photocatalyst, a manufacturing method thereof, the kits including the composite photocatalyst, and a bactericide photocatalyst. A composite photocatalyst includes photocatalyst nanocrystals and platinum nanocrystals. The photocatalyst nanocrystals include a compound represented by the following chemical formula (1):A2+(B3+)2X4 chemical formula (1),wherein A2+ represents Zn2+, Cu2+, Fe2+, Mn2+, Ni2+, Co2+ or Ag22+; B3+ represents Fe3+, Mn3+ or Cr3+; and X represents O2−.

Owner:NATIONAL TSING HUA UNIVERSITY

Preparing method of nano-silver-based composite bactericide

InactiveCN107333798AImprove sterilization performanceFungicide consumption savingsBiocideFungicidesNanometreHydroxyapatites

The invention belongs to the technical field of environmental chemistry, and particularly relates to a preparing method of a nano-silver-based composite bactericide. A hydroxyapatite nano-assembling ball chain with the length reaching micron order is used as a carrier, the characteristics of large superficial area and high surface activity of the bactericide are used, and silver ions are converted into nano silver on the surface of hydroxyapatite through in-situ reduction reaction to prepare the silver-based composite bactericide loaded by hydroxyapatite. The nano-silver-based composite bactericide easy to recover is high in chemical stability and large in superficial area and has high industrial feasibility, and compared with pure nano silver, the amount of the bactericide is saved remarkably on the premise of achieving the same sterilizing effect.

Owner:EAST CHINA UNIV OF SCI & TECH

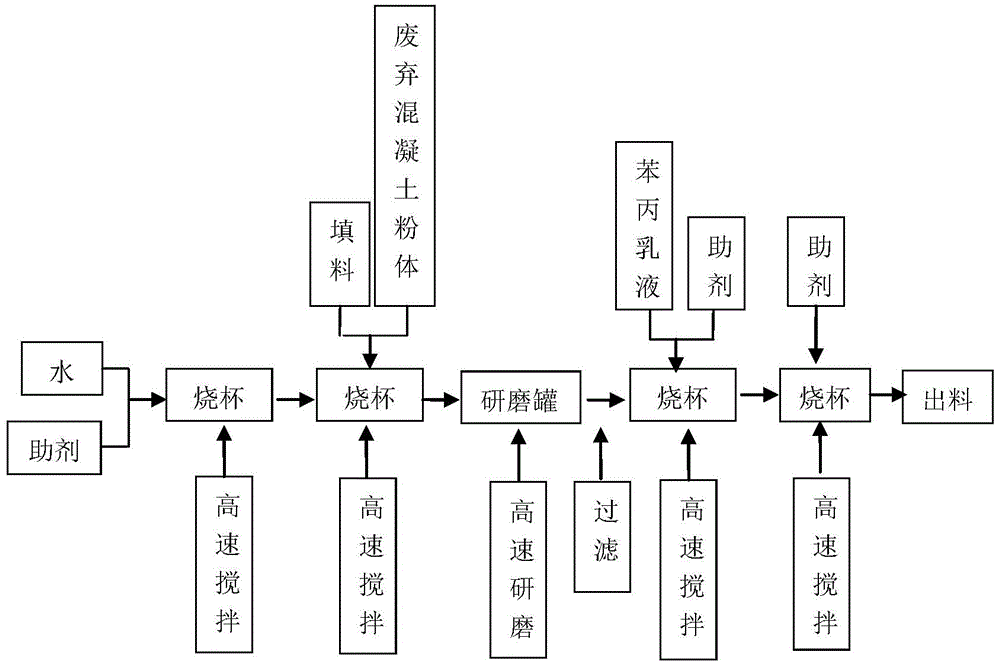

Waste concrete powder paint and preparation method thereof

The invention discloses waste concrete powder paint and a preparation method thereof. According to the paint, a styrene-acrylic emulsion is taken as an adhesive, common filler and waste concrete powder are taken as filler, and other components comprise auxiliaries such as water, a dispersant, a wetting agent, a coalescing agent, a leveling agent, a thickening agent and the like. According to the preparation method, the prepared waste concrete powder paint has high paint film quality and high water resistance, alkali resistance and scrub resistance, the production cost is reduced, conditions are provided for production of a high value-added waste concrete product, and high-quality recycling of building waste is realized.

Owner:SHANDONG JIANZHU UNIV

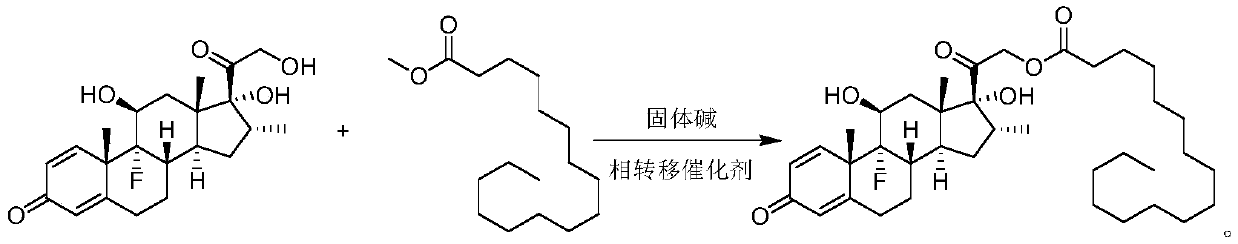

Synthesis method of dexamethasone palmitate

The invention relates to a synthesis method of dexamethasone palmitate. The method comprises the steps as follows: dexamethasone and methyl palmitate are subjected to transesterification under catalysis of solid alkali and a phase transfer catalyst to obtain a target product; a mixture of methyl palmitate and the product obtained after a solvent is removed from solid alkali and the phase transfercatalyst by evaporation is recycled. The method is mild in reaction condition, green, environmentally friendly, simple, efficient and energy-saving, raw materials are easy to obtain, the production cost is reduced, the operation environment is improved, and the method is convenient to operate, high in automation degree and particularly prone to industrialization.

Owner:JIANGSU YUANDA XIANLE PHARMA

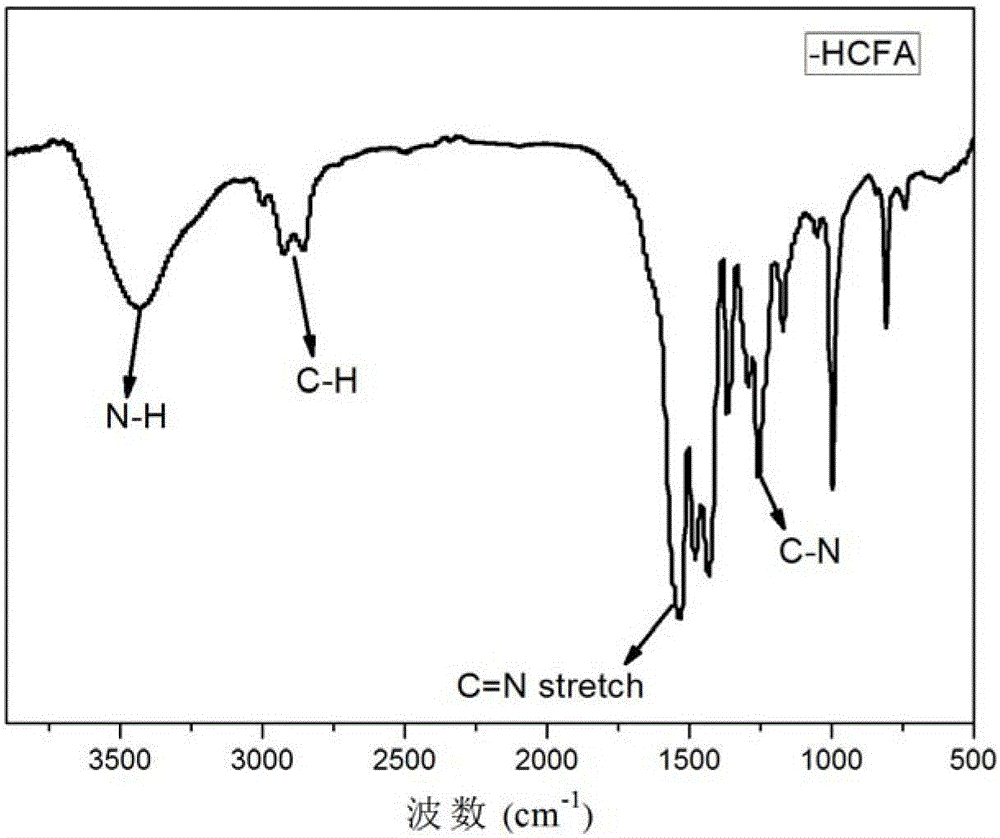

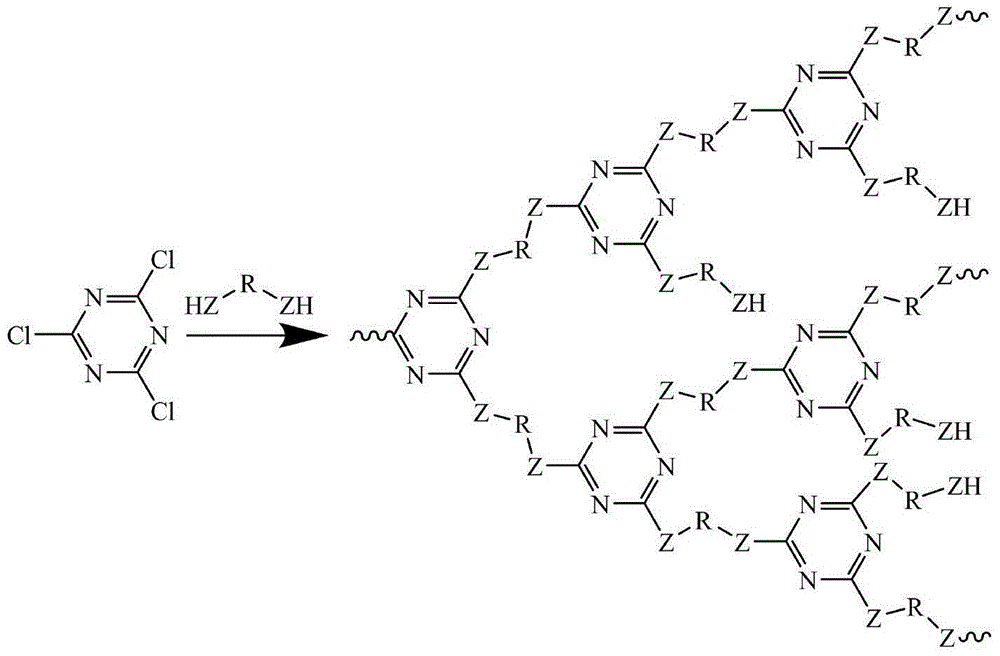

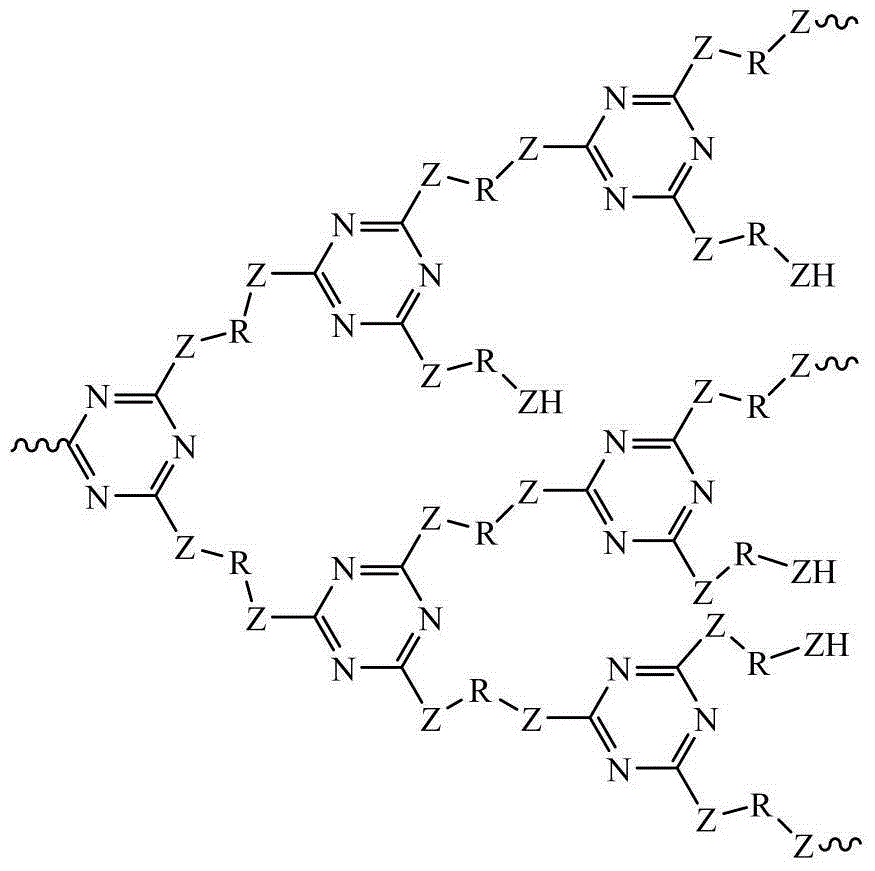

A kind of preparation method of hyperbranched triazine char-forming agent

The invention discloses a preparation method of a novel hyperbranched triazine char forming agent, which comprises the following steps: adding a dissolved diamine solution at 0-10 DEG C, gradually and dropwisely adding a dispersed cyanuric chloride solution, and reacting for 1-4 hours; heating to 30-70 DEG C, adding an acid-binding agent, and reacting for 3-8 hours; heating to 90-150 DEG C, and reacting for 6-10 hours; and stopping stirring, carrying out vacuum filtration, washing with water, and drying to obtain the triazine hyperbranched char forming agent. Compared with the prior art, the invention has the advantages of continuous reaction process, short reaction time, cheap raw materials, low solvent consumption, no addition of any blocking agent in the reaction process, simplified synthesis technique, high heat stability and high char forming ratio.

Owner:合肥安聚达新材料科技有限公司

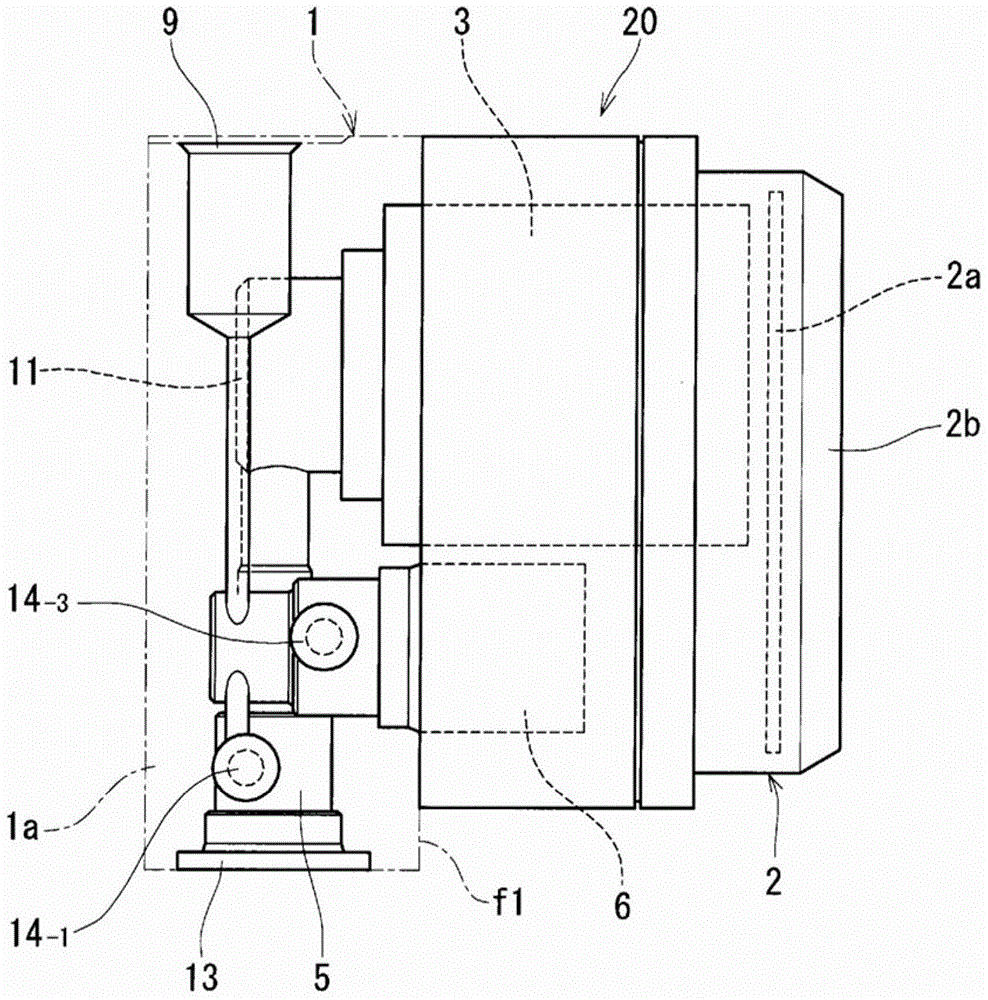

Brake fluid pressure control apparatus

ActiveCN104797471ASave assembly spaceIncrease heightApplication and release valvesEngineeringWheel cylinder

The purpose is to decrease the physical size of a brake fluid pressure control apparatus for implementing pressure increasing / decreasing control for the fluid pressure in a wheel cylinder. A brake fluid pressure control apparatus is provided with: a piston pump (5); a pump drive motor (3); an eccentric cam rotated by the motor to activate the piston pump; a pressure-increasing electromagnetic valve (6); and a pressure-decreasing electromagnetic valve (7), in which the piston pump (5), the eccentric cam, the pressure-increasing electromagnetic valve (6), and the pressure-decreasing electromagnetic valve (7) are assembled in a housing (1a). The single piston pump (5) is installed, with the piston pump (5), when mounted on a vehicle, disposed in an upright posture under or above a cam chamber (11) of the housing in which the eccentric cam is housed.

Owner:ADVICS CO LTD

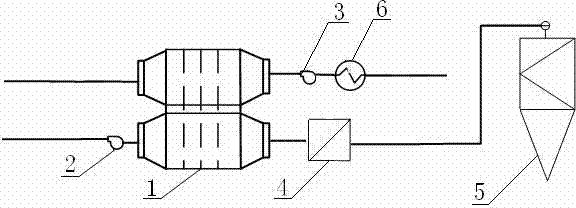

Recycling treatment system and method for municipal solid waste incineration fly ash

PendingCN109482625ADifficult to recycleMeet the requirements of a high degree of resource utilizationSolid waste disposalTransportation and packagingSolid phasesPlasma reactor

The invention discloses a recycling treatment system and method for municipal solid waste incineration fly ash. The recycling treatment system comprises a desorption device, a two-stage heat exchanger, a plasma reactor, a discharge hopper, a slag cooler, a washing tank, a solid-liquid separator and an evaporator; a gas phase outlet of the desorption device is connected with a heat source inlet ofthe two-stage heat exchanger through a fan, and a heat source outlet of the two-stage heat exchanger is connected with the plasma reactor; a cold source inlet of the two-stage heat exchanger is connected with cooling media; a solid phase outlet of the desorption device is connected with the discharge hopper, and a discharging port of the discharge hopper is connected with a slag inlet of the slagcooler; a slag outlet of the slag cooler is connected with the washing tank through heat exchange, and a discharging port of the washing tank is connected with the solid-liquid separator; and a liquidphase outlet of the solid-liquid separator is connected with the evaporator. According to the recycling treatment system and method for the municipal solid waste incineration fly ash, the degradationof dioxins and recycling of mercury and inorganic salt in the municipal solid waste incineration fly ash can be achieved, and the system has no secondary pollution, and can be directly applied to treatment of working procedures after waste incineration; the restriction on implementation depending on a cement kiln is overcome, and the application range of the recycling treatment system is wider; and the recycling and harmlessness of the municipal solid waste incineration fly ash are achieved.

Owner:中洁蓝环保科技有限公司

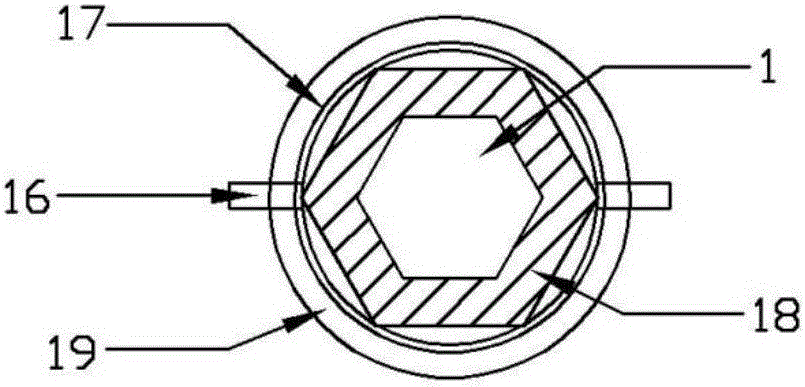

Omnidirectional cataclastic rock mass deep hole installation and recovery device of microseismic unidirectional sensor

InactiveCN102854525BSolve hard-to-couple problemsAvoid easy installationSeismic signal receiversBody femaleDeep hole

The invention discloses an omnidirectional cataclastic rock mass deep hole installation and recovery device of a microseismic unidirectional sensor. The omnidirectional cataclastic rock mass deep hole installation and recovery device comprises a sleeve which is embedded in a rock mass drilling hole, wherein a unidirectional sensor fixing device is installed at each part with a preset depth and direction in the sleeve and comprises an intermediate joint which is connected with the sleeve by inner threads, a wedge body combining body which is connected with the intermediate joint and is provided with a wedge body combining body female groove, a wedge body which is adapted to the wedge body combining body female groove, another unidirectional sensor which is connected with the wedge body, a tensile-resisting cable which is connected with the another unidirectional sensor, an elastic pressing device which is fixed on the wedge body combining body, and a pulling type lifting device which is connected with a second leading-out terminal of a cylindrical helical torsional spring of the elastic pressing device and is used for releasing the wedge body, wherein one end of the elastic pressing device tightly presses the wedge body in the wedge body combining body female groove. With the adoption of the omnidirectional cataclastic rock mass deep hole installation and recovery device, the installation is not limited by severe geological conditions and drilling inclined angles, the installation of a vertical hole and an inclined hole in a cataclastic rock mass can be realized, and the unidirectional sensors are easy to recover.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +1

Man-made board dry waste heat recycle method

InactiveCN102927841ALarge amount of waste heat resourcesDustyCombustion processIndirect heat exchangersCold airEvaporation

The invention relates to a man-made board dry waste heat recycle method which includes the following steps: step one, dry tail gas discharged from a cyclone separator is driven by a hot end fan and flows through a tail gas filter, and therefore dust in the tail gas can be filtered; step two, an evaporation section flowing through a heat pipe exchanger is directly emptied when temperature of the evaporation section is reduced after heat exchange; step three, temperature of cold air driven by a cool end fan is raised after a condensation section of the heat pipe exchanger absorbs heat; and step four, the cold air is used as a material drying medium after being heated by a hot oil exchanger or as preheat air to be delivered to a boiler without entering into the hot oil exchanger. The man-made board dry waste heat recycle method has the advantages that a high-efficiency heat exchanger is used to recover waste heat in man-made board dry tail gas, in the process of heat exchange, heat exchange components are in a phase-change heat exchange state, heat exchange intensity is large, and therefore a great deal of low-temperature waste heat can be effectively recovered. A high-efficiency dust remover is arranged in front of the heat exchanger, and therefore the problems that the heat exchanger is prone to dust stratification and blockage and the like are solved.

Owner:NANJING FORESTRY UNIV

Treatment Method for Resource Recycling of Hexavalent Chromium-Containing Residues

ActiveUS20190284661A1Low costSimple processSolid waste disposalTransportation and packagingSocial benefitsSodium chlorate

The present invention discloses a treatment method for resource recycling of hexavalent chromium-containing residues, belonging to a field of a clean treatment and resource recycling of chromium-containing residues. This method comprises steps as follows: 1) adding water to the hexavalent chromium-containing residues and mixing uniformly; 2) adding mineralizers to a solution obtained in step 1) and stirring sufficiently to obtain a mixed liquid; and the mineralizers are sodium chlorate, sodium perchlorate and hydrochloric acid; 3) treating the mixed liquid by a hydrothermal method or direct heating; 4) after the heating treatment, naturally cooling a solid-liquid mixture to room temperature for holding; 5) separating solid residues and a chromium-containing supernatant, and washing filtered residues with water and then drying; and 6) recycling a chromium-containing solution for returning to a work section, or for a treatment of recycling chromium. This method may achieve full-residue utilization with simple process, low cost, quick effect, large treating capacity and complete detoxification, and has relatively high social benefit and economic benefit.

Owner:SOUTH CHINA UNIV OF TECH

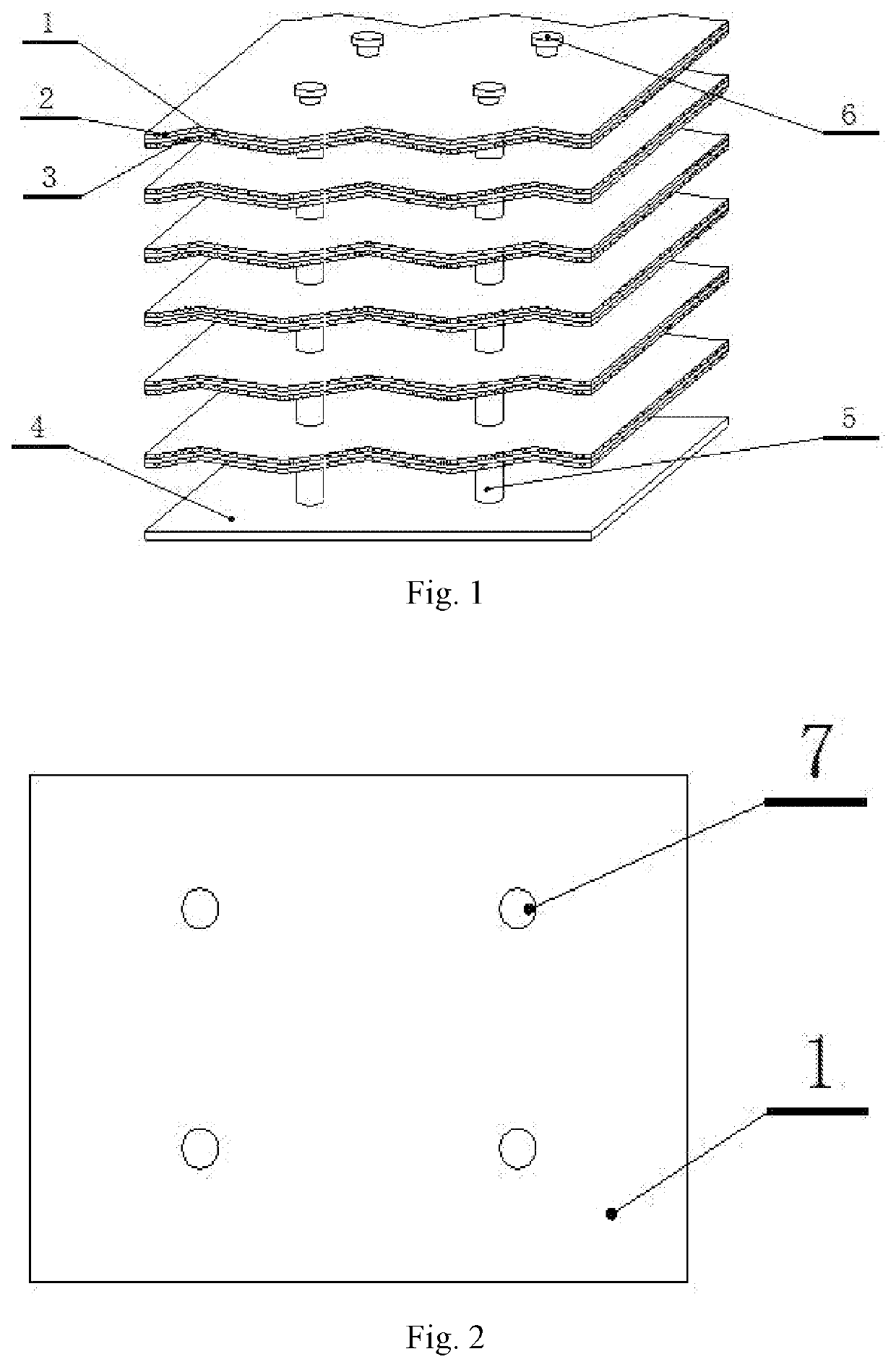

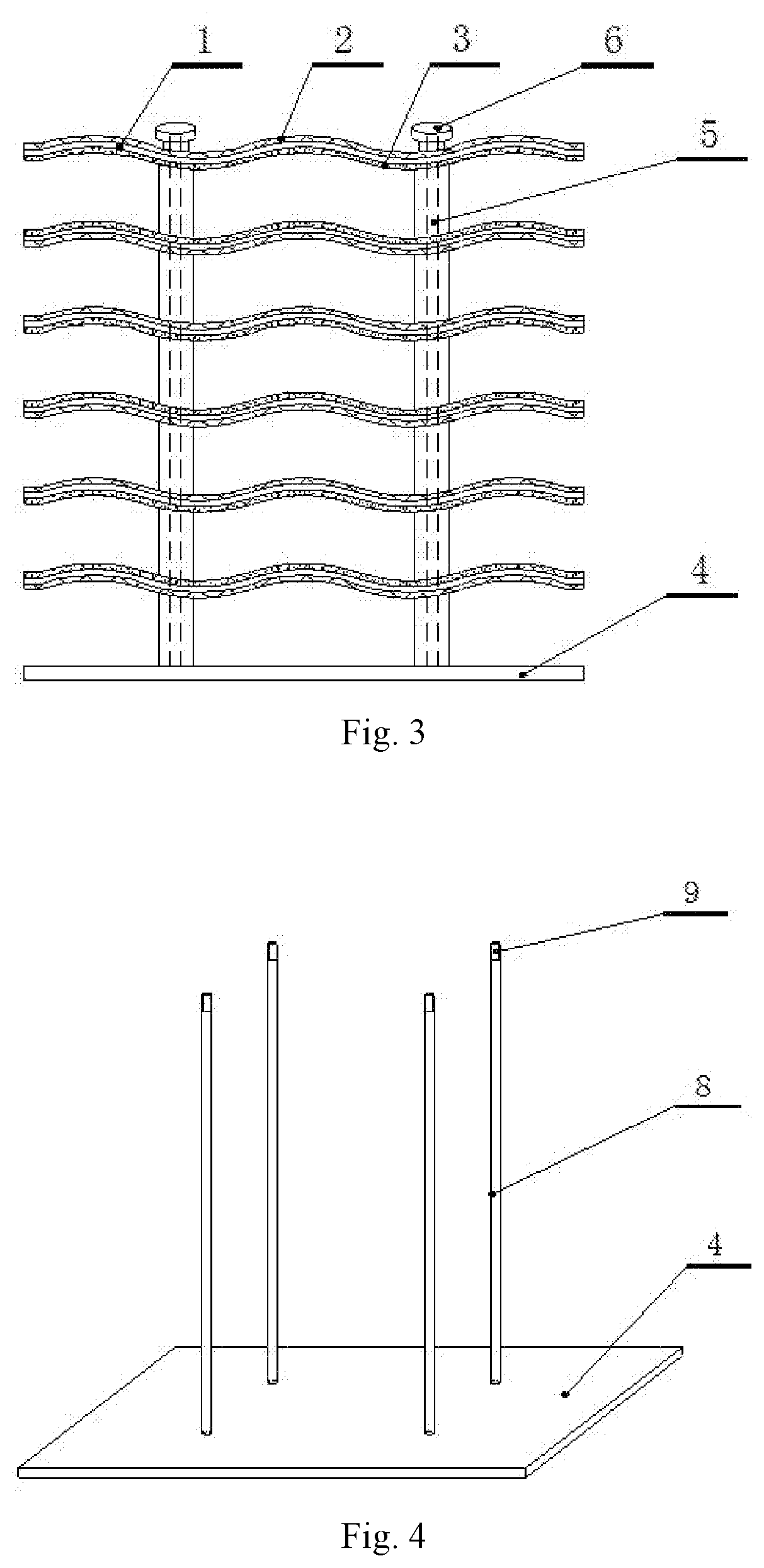

Nanometer photocatalyst-microbe composite multilayer light transmission combination carrier

ActiveUS20200115263A1Improve efficiencyAdjustable spacingWater treatment compoundsSpecific water treatment objectivesMicroorganismEngineering

Provided is a nano-photocatalyst-microorganism composite multilayered light-transmitting combination support, comprising a plurality of wave-shaped plexiglass plates (1), a tandem rod holder (4), hollow elastic spacers (5), and fixing screws (6); each of the wave-shaped plexiglass plates (1) is provided with four fixing holes (7); the tandem rod holder (4) is provided with four tandem rods (8), and the four tandem rods (8) pass through the fixing holes (7); the tandem rods (8) between the two adjacent wave-shaped plexiglass plates (1) pass through the hollow elastic spacers (5); each of the tandem rods (8) is provided with a fixing screw (6) at the top end; each of the wave-shaped plexiglass plates (1) have different loading layers on the upper and lower surfaces, with a nano-photocatalyst-loading layer (2) on one surface and a degrading bacteria-loading layer (3) on the other surface. Also provided is a method of making the nano-photocatalyst-microorganism composite multilayered light-transmitting combination support.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com