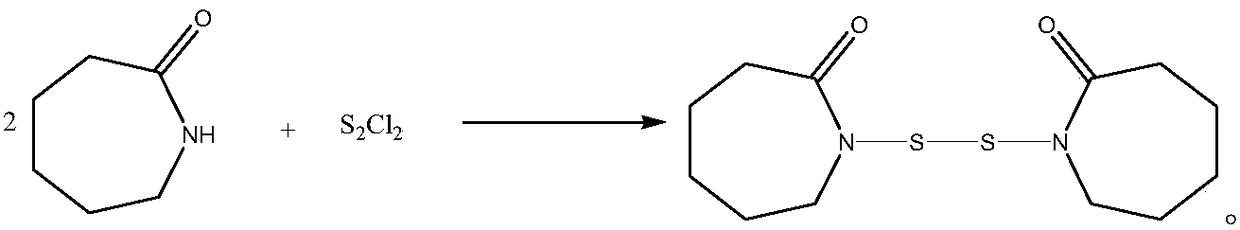

Preparation method of vulcanizer 1,1'-dithiodicaprolactam

A technology of dithiobiscaprolactam and caprolactam, applied in the direction of organic chemistry and the like, can solve the problems of large environmental pollution, cracking and high cost of raw materials, and achieve the effect of protecting the environment and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 100g of caprolactam, 730g of n-heptane and 95g of triethylamine into a 1L reaction kettle, stir mechanically, cool down in an ice bath to below 5-10°C, then add 65g of disulfide dichloride dropwise, finish adding in 30 minutes, and the dropwise addition is complete Afterwards, the temperature was raised to 12-15°C, and the reaction was kept for 7 hours, and the reaction was completed. (Add 200 grams of water, stir for 15 minutes, stir well, stand to separate layers, wash the organic layer with water, wash with brine, and concentrate under reduced pressure n-heptane (0.095MPa) to obtain 111.5 grams of off-white solid, yield 87.5%. Melting point 130-137 ° C. The water layer was adjusted to PH = 13 with 32% aqueous sodium hydroxide solution, and triethylamine was collected by atmospheric distillation at 90 ° C, dried with solid sodium hydroxide and used mechanically.

Embodiment 2

[0021] Add 200g of dichloroethane, 100g of caprolactam, and 121g of N,N-dimethylaniline into a 1L reaction flask in sequence, turn on mechanical stirring, cool down to 0-5°C in an ice bath, and then dropwise add 62.7g of disulfur dichloride, The addition was completed in 1 hour, and after the dropwise addition, the temperature was raised to 15-20°C, and the reaction was kept for 6 hours, and the reaction ended.

[0022] Add 200 g of water, stir for 15 minutes, stop stirring, let stand to separate layers, wash with water, wash with brine, and concentrate dichloroethane under pressure at 0.095 MPa to obtain 71.7 g of off-white solid with a yield of 56.3%. The melting point is 128-135°C. For the water layer, use 32% sodium hydroxide aqueous solution to adjust the pH to 13, let it stand and separate layers, and the upper organic layer is N,N-dimethylaniline, dry it with a small amount of sodium hydroxide, and use it mechanically.

Embodiment 3

[0024] Add 4000g of benzene, 100g of caprolactam, and 105.9g of pyridine to a 1L reaction flask in sequence, stir mechanically, cool down to 0-5°C in an ice bath, and then add 117.4g of disulfide dichloride dropwise for 1 hour. After the addition is complete Raise the temperature to 40-45°C, keep the temperature for 5 hours, and the reaction ends.

[0025] Cool to room temperature, add 200 g of water, stir for 15 minutes, stop stirring, stand to separate layers, wash with water, wash with brine, and concentrate benzene under pressure at 0.095 MPa to obtain 91.4 g of off-white solid with a yield of 73%. Melting point 130-135°C. For the water layer, use 32% sodium hydroxide aqueous solution to adjust the pH to 13, let it stand and separate layers, the upper organic layer is pyridine, dry with a small amount of sodium hydroxide, and use it mechanically.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com