Patents

Literature

49 results about "Disulfur dichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

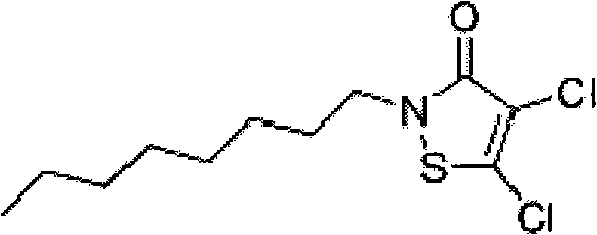

Disulfur dichloride is the chemical compound of sulfur and chlorine with the formula S₂Cl₂. Some alternative names for this compound are sulfur monochloride (the name implied by its empirical formula, SCl), disulphur dichloride (British English Spelling) and sulphur monochloride (British English Spelling). S₂Cl₂ has the structure implied by the formula Cl−S−S−Cl, wherein the angle between the Clᵃ−S−S and S−S−Clᵇ planes is 90°. This structure is referred to as gauche, and is akin to that for H₂O₂. A different isomer of S₂Cl₂ is S=SCl₂; this isomer forms transiently when S₂Cl₂ is exposed to UV-radiation (see thiosulfoxides).

Clean preparation method of ethyl chloride with high purity

The invention discloses a clean preparation method of ethyl chloride with high purity. The method comprises the following steps: firstly, purifying a crude ethyl sulfide product by membrane distillation and molecular distillation in sequence to separate out impurities such as hydrogen sulfide gas, neutral oil and residues, then feeding the purified crude ethyl sulfide product into a chlorination process, thereby reducing byproducts in the chlorination process; filtering a crude ethyl chloride product obtained after chlorination, and then purifying the filtered crude ethyl chloride product by membrane distillation and molecular distillation in sequence to separate out impurities such as chlorine gas, hydrogen chloride and disulfur dichloride. The ethyl chloride produced by the method is high in purity, and no waste water is generated during the whole process, so that pollution to environment is minimized and resources are saved furthest.

Owner:HUANGGANG NORMAL UNIV

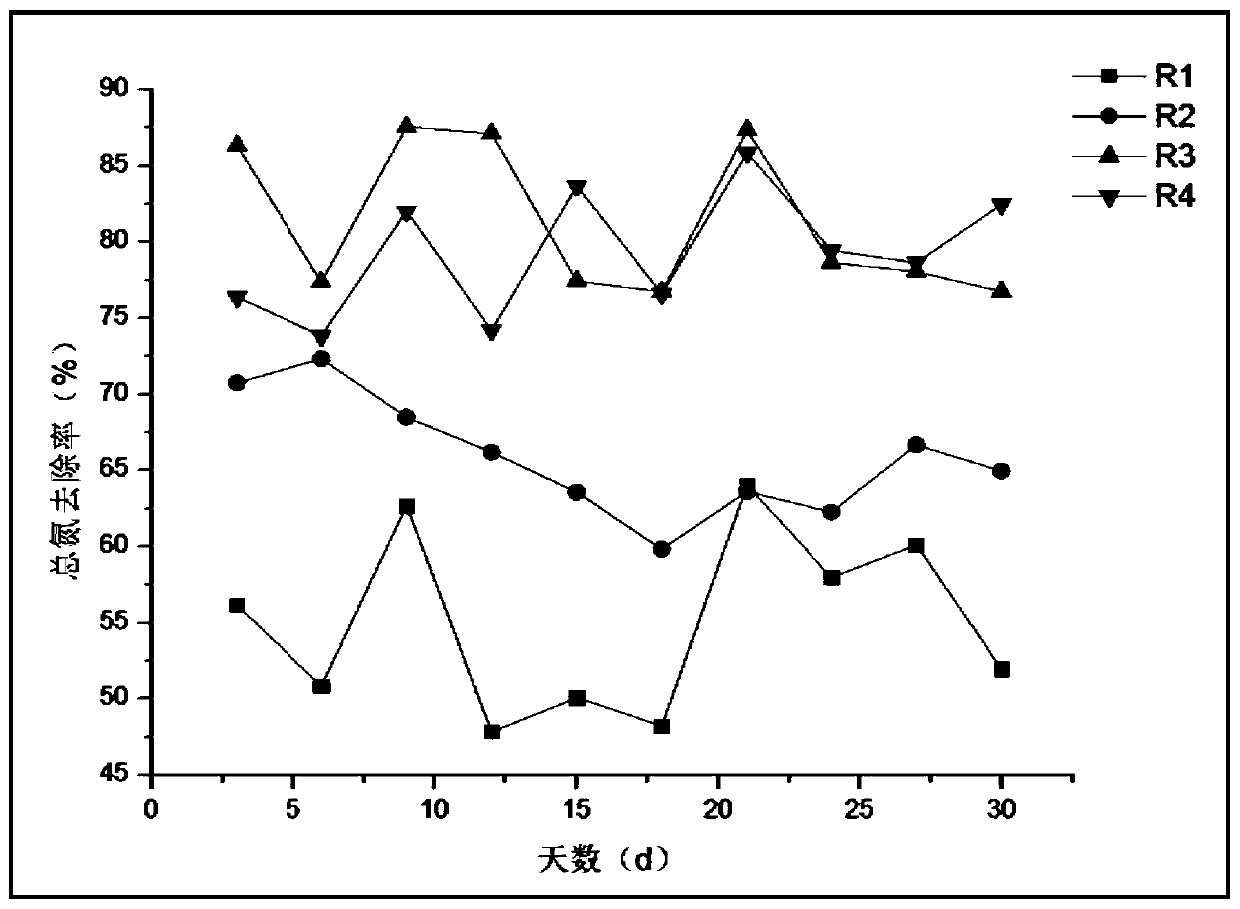

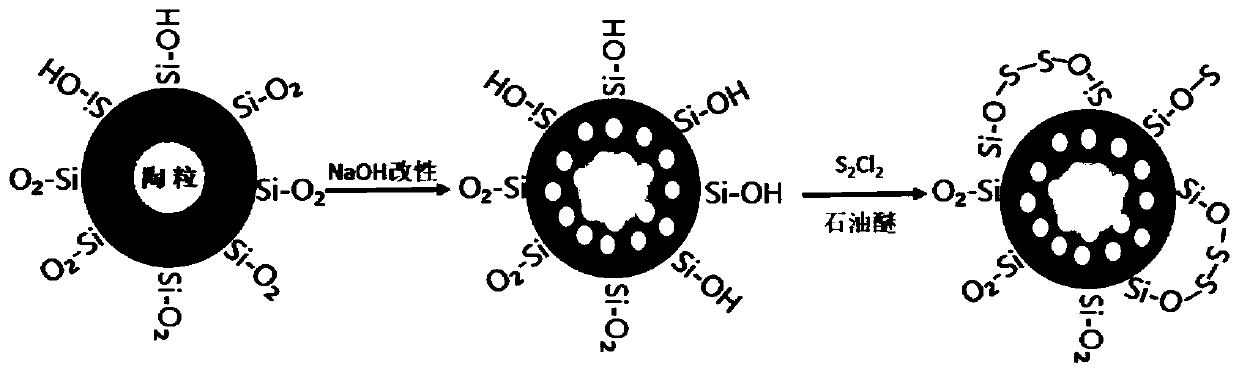

Preparation and application of sulfur-based autotrophic and heterotrophic denitrification nitrogen removal biological filler

ActiveCN110467276AConducive to loadPromote dissolutionWater treatment parameter controlTreatment with anaerobic digestion processesMicroorganismNitrogen removal

The invention discloses preparation and application of a sulfur-based autotrophic and heterotrophic denitrification nitrogen removal biological filler. According to the invention, the number of micropores and silicon hydroxyl groups on the surface of ceramsite is increased through alkali etching; then the surface of the alkali-modified ceramsite is activated by utilizing high-activity disulfur dichloride; and the disulfur dichloride can be chemically bonded with hydroxyl functional groups on the surface of the ceramsite, so sulfur is loaded onto the surface of the ceramsite to form Si-O-S andcross-linking is performed so as to form a stable net-shaped structure. The sulfur-based autotrophic and heterotrophic denitrification nitrogen removal biological filler provided by the invention canrealize coupling of sulfur-based autotrophic and heterotrophic denitrification, is beneficial for the attached growth of microorganisms, reduces the addition of carbon sources, improves population richness, further increases nitrogen removal efficiency and stabilizes effluent quality.

Owner:NANJING UNIV

Efficient scrap rubber regeneration activator and preparation method thereof

InactiveCN102050960AQuality improvementHigh elongation at breakPlastic recyclingDisulfur dichlorideMooney viscosity

The invention discloses an efficient scrap rubber regeneration activator and a preparation method thereof. The preparation method is characterized by comprising the following steps: weighing 2,4,6-tri-tert-butylphenol and disulfur dichloride in weight ratio of 100:(22 to 26); measuring sulfuric acid according to the addition of 3000ml of sulfuric acid / 1000 kilograms of 2,4,6-tri-tert-butylphenol; thawing the 2,4,6-tri-tert-butylphenol and absorbing into an enamel reaction vessel; then adding the sulfuric acid for catalyzing, slowly dripping the disulfur dichloride, and stirring evenly to obtain the efficient scrap rubber regeneration activator. The efficient scrap rubber regeneration activator and the preparation method thereof have simple production process, low production cost and strong activity, dispense with large-scale equipment and can be widely used for scrap rubber regeneration, and the produced regenerated rubber has good quality, the elongation at break and tensile strength are obviously improved, and the mooney viscosity can be effectively reduced.

Owner:胥干

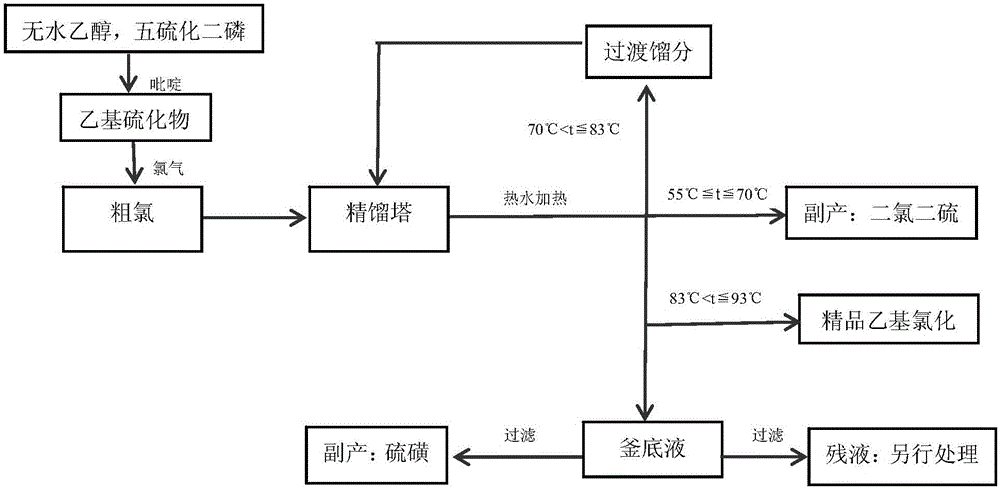

Preparation method of ethyl chloride

InactiveCN104817588AReduce dosageReduce pollutionGroup 5/15 element organic compoundsSulfur preparation/purificationPhosphorus pentasulfideEthyl Chloride

The invention relates to a preparation method of ethyl chloride. The method comprises the following steps: 1, carrying out a sulfuration reaction on phosphorus pentasulfide and anhydrous ethanol under the action of a catalyst to obtain ethyl sulfide and hydrogen sulfide; 2, carrying out a chlorination reaction on ethyl sulfide and chlorine to generate crude chlorine; and 3, introducing hydrogen sulfide obtained after the sulfuration reaction into the crude chlorine, and reacting to obtain ethyl chloride and sulfur. The preparation method has the following advantages: hydrogen sulfide is adopted to remove disulfur dichloride in crude chlorine, so the consumption of an alkali liquid is reduced, and generated tail gas hydrogen chloride can be absorbed by water to prepare hydrochloric acid as a byproduct; obtained sulfur is sandy in shape, and can be directly sold as a raw material without treatment; and no wastewater is generated in the whole preparation process, so environmental pollution is maximally reduced, and the cost is saved.

Owner:湖北犇星新材料股份有限公司

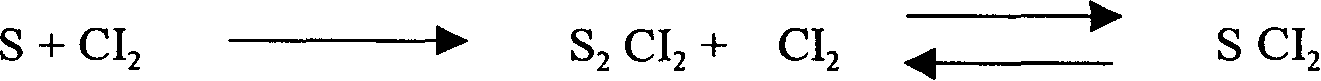

Method for preparing sulfur dichloride

InactiveCN1473758ANo wasteNo pollution in the processPhysical/chemical process catalystsSulfur and halogen compoundsChemical synthesisDisulfur dichloride

The present invention relates to chemical synthesis technology. Sulfur dichloride is prepared through gas-solid reaction between chlorine and sulfur and subsequent cooling. During the reaction between chlorine and sulfur, disulfur dichloride is first produced; after the temperature is lowered and more chloride is introduced, sulfur dichloride is then produced; and after the reaction is finished, stabilizer is added to obtain the product. The said process has high sulfur dichloride yield, has stability, high purity over 98 %, low cost, no environment and is suitable for industrial production.

Owner:淄博市新材料研究所

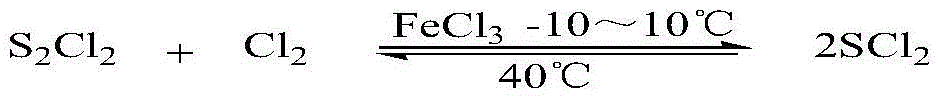

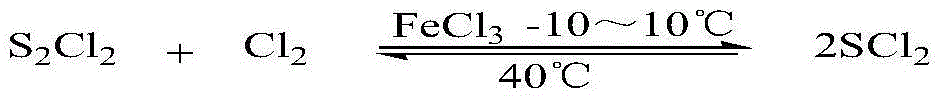

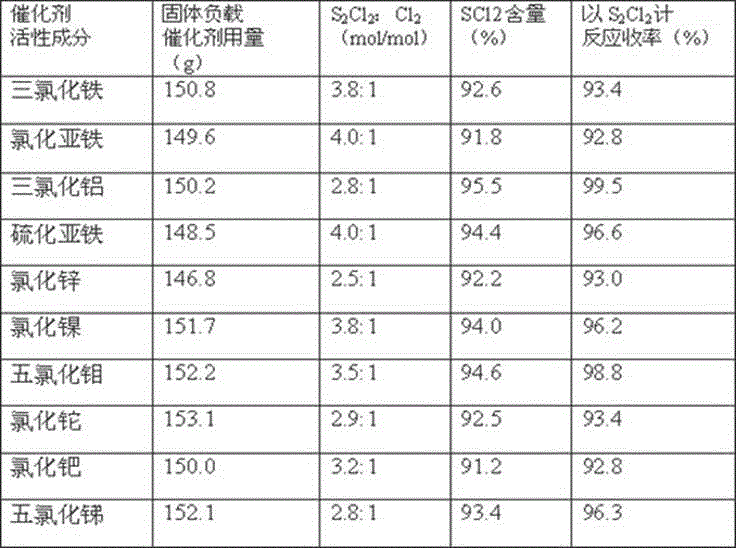

Preparation method for synthetizing sulfur dichloride through gas phase catalysis

The invention discloses a preparation method for synthetizing sulfur dichloride through gas phase catalysis. Granular activated carbon supported by ferric chloride (FeCl3 / C) is taken as a catalyst, disulfur dichloride and chorine are taken as a reaction raw material and a carrier gas, a vaporized gas mixture of the disulfur dichloride and the chorine enters a fixed bed catalysis tubular reactor, the sulfur dichloride is prepared with a continuous gas phase catalysis method, the sulfur dichloride produced through the reaction is cooled by a condenser to be collected, and the excess chlorine is recycled. The sulfur dichloride product obtained with the method is free of catalyst residues, distillation is not required, and the content of sulfur dichloride in the product is higher than 90%. The excess chlorine is recycled. The preparation method is simple to operate, continuous, stable, high in conversion rate and free of waste gas and waste liquor emissions, so that the environmental pollution is reduced.

Owner:湖南海利常德农药化工有限公司

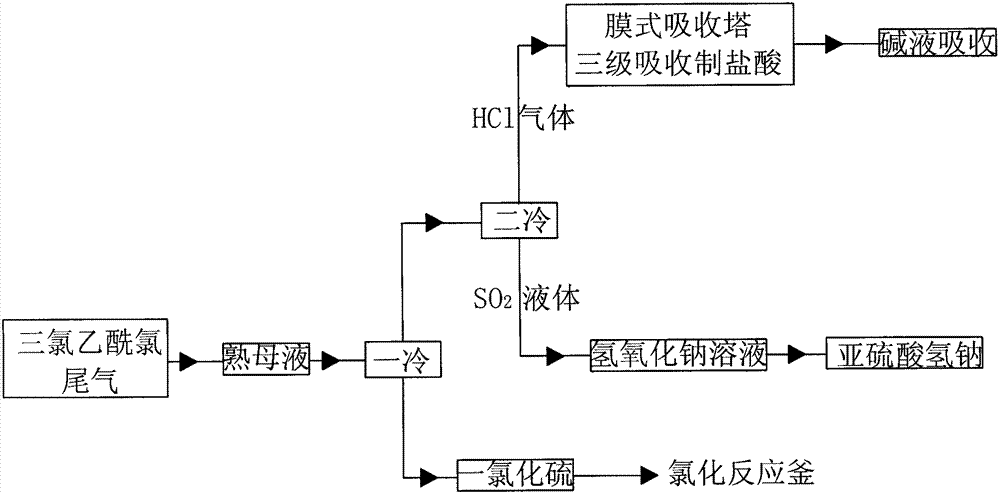

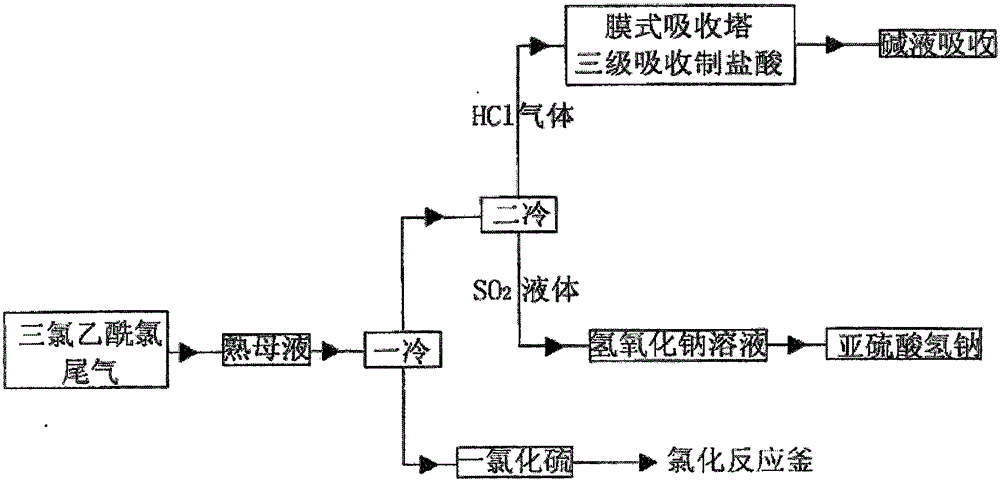

Novel method for absorbing tail gas from trichloro-acetic chloride production through chlorination process

InactiveCN102764572AEfficient separationEfficient recyclingOrganic compound preparationDispersed particle separationDisulfur dichlorideSodium bisulfite

The present invention relates to a novel method for absorbing tail gas from trichloro-acetic chloride production through a chlorination process. The method can realize separation and recovery of hydrogen chloride, sulfur dioxide, sulfur, disulfur dichloride, and chlorine generated in the production process of trichloro-acetic chloride; the method is safe and easily controlled, has no harm to the environment, and generates by-products containing hydrochloric acid with concentration higher than 30% and a sodium bisulfite solution. The invention belongs to the technical field of environmental protection.

Owner:SHANXI SANWEI FENGHAI CHEM

Preparation method of rubber vulcanizing agent dimorpholinyl disulfide

InactiveCN104910102AQuality improvementImprove aging performanceOrganic chemistryMorpholineDisulfur dichloride

The invention discloses a preparation method of a rubber vulcanizing agent dimorpholinyl disulfide. The method comprises the following steps: adding a petroleum ether solvent into a reaction kettle, heating to 45-60DEG C, adding a sodium hydroxide pulvis, uniformly stirring, adding a morpholine solution and a disulfur dichloride solution in a dropwise manner within 1-1.5h, continuously stirring for 3h for a reaction, standing, separating out the petroleum ether solvent, and drying to obtain a white crystal. The method improves the quality and the yield of the above product, allows the acidity of the product to be not greater than 0.05 and the ash content to be not greater than 0.15, and realizes small discharge of three wastes.

Owner:宜兴市聚金信科技有限公司

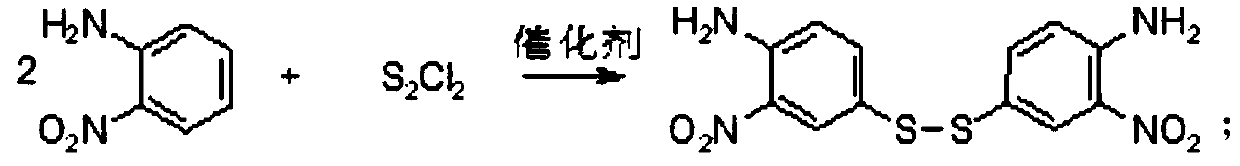

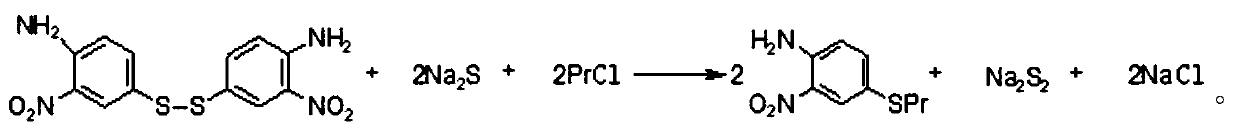

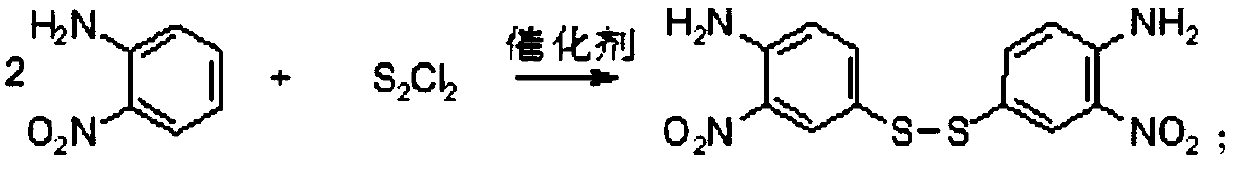

Preparation method of 4-propythio-2-nitroaniline

ActiveCN110498752AHigh yieldImprove securityHydropoly/poly sulfide preparationSulfide preparationAlkyl transfer2-Nitroaniline

The invention discloses a preparation method of 4-propythio-2-nitroaniline, and solves the technical problems of unreasonable preparation method, high raw material price, high toxicity, complex operation, high cost, large production of three wastes, low yield and unsuitability for industrial production in the prior art. The preparation method of 4-propythio-2-nitroaniline provided by the inventiontakes o-nitroaniline, disulfur dichloride and chloropropane as the raw materials, and carries out condensation reaction and alkylation reaction in order under the action of a catalyst so as to obtain4-propythio-2-nitroaniline. The method can be widely applied technical field of synthesis of albendazole.

Owner:SHANDONG GUOBANG PHARMA +1

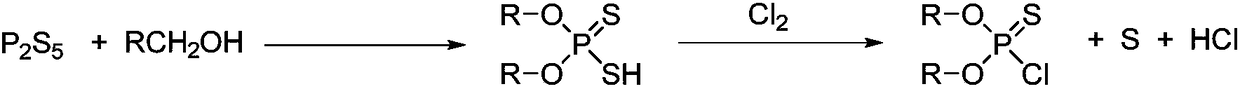

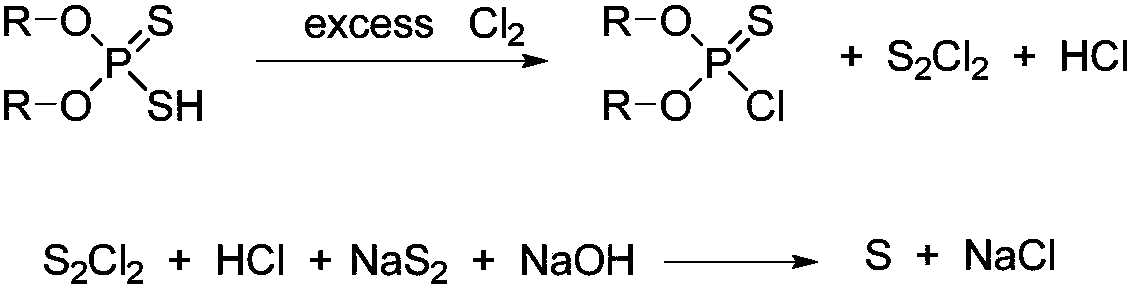

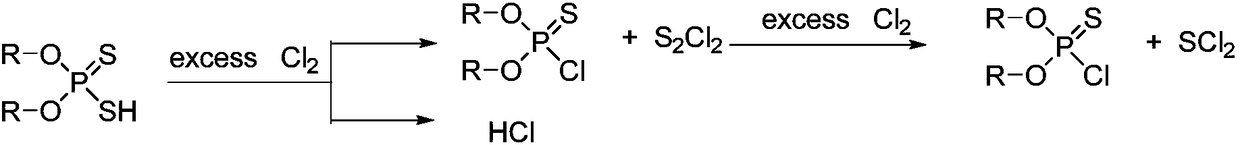

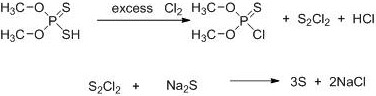

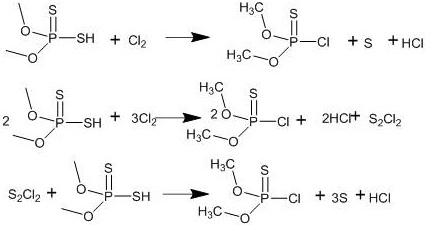

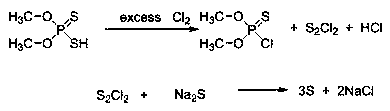

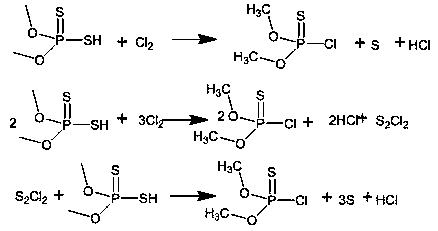

Synthesis method of O, O-dialkyl thiphosphoryl chloride

ActiveCN108329346ALow costAchieving Atomic EconomicsGroup 5/15 element organic compoundsSynthesis methodsDistillation

The invention discloses a synthesis method of O, O-diakyl thiphosphoryl chloride. In a reaction system where O, O-dialkyl S-hydro-phophorodithioate and chlorine are subjected to a chlorination reaction to prepare O, O-dialkyl thiphosphoryl chloride, an excess chlorine is introduced to make sulphur generated in the reaction be converted into disulfur dichloride, and disulfur dichloride is convertedinto sulfur dichloride afterwards; and by controlling the reaction temperature and arranging the reaction system to be in the negative pressure state, sulfur dichloride is moved out of the reaction system in the reaction process through distillation and condensing. The synthesis method substantially achieves the atomic economy based on a green chemistry concept; the overall cost of raw materialsis far lower than that in a traditional method, the amount of the three wastes is less, and the three wastes are easy to dispose; a traditional solid-liquid separation step is cancelled, automated production is facilitated, and meanwhile, improvement of the safety and environment production level of the device is facilitated; and O, O-dialkyl thiphosphoryl chloride is not in contact with water, disintegration of the product is avoided, the yield rate is as high as 93%, and the product content can reach 99%.

Owner:HUNAN CHEM RES INST

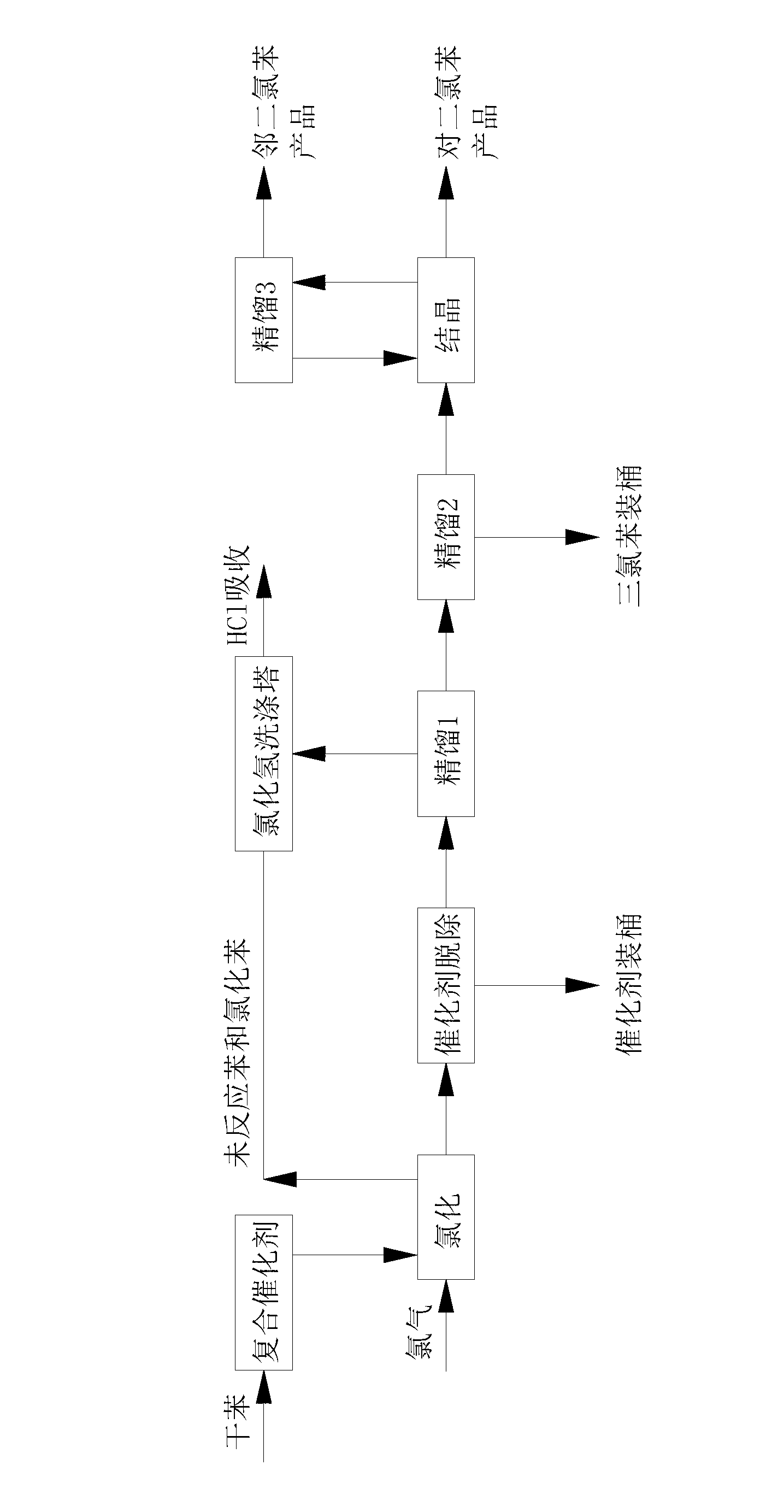

Catalyst used in preparation of paradichlorobenzene and method for preparing paradichlorobenzene by using such catalyst

InactiveCN102836731AHigh yieldReduce pollutionPhysical/chemical process catalystsHalogenated hydrocarbon preparationDisulfur dichlorideParadichlorobenzene

The invention discloses a catalyst used in preparation of paradichlorobenzene and a method for preparing the paradichlorobenzene by using such catalyst, wherein iron trichloride and disulfur dichloride are mixed according to a mass ratio of 5:3-12:7. The catalyst and the method have the advantages that the paradichlorobenzene is prepared by using the composite catalyst of the iron trichloride and the disulfur dichloride, the disulfur dichloride has an orientation effect, the productivity of the paradichlorobenzene is improved, the production of trichlorobenzene is inhibited, the conversion and the selectivity of the reaction are improved, the productivity of the paradichlorobenzene in chlorinated liquid is obviously improved, the purity of the prepared paradichlorobenzene product reaches up to 99.95 percent, washing and alkaline washing are not required during preparation, and the environmental pollution is reduced.

Owner:江苏省格林艾普化工股份有限公司

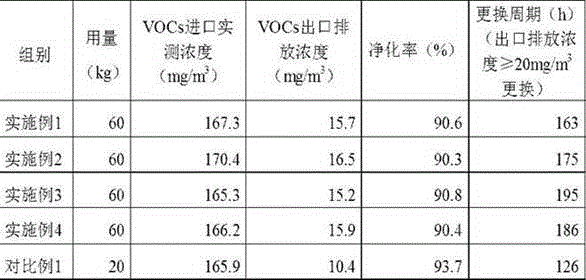

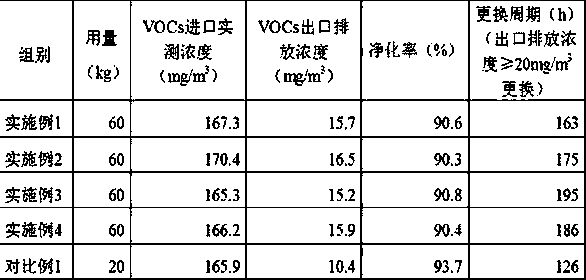

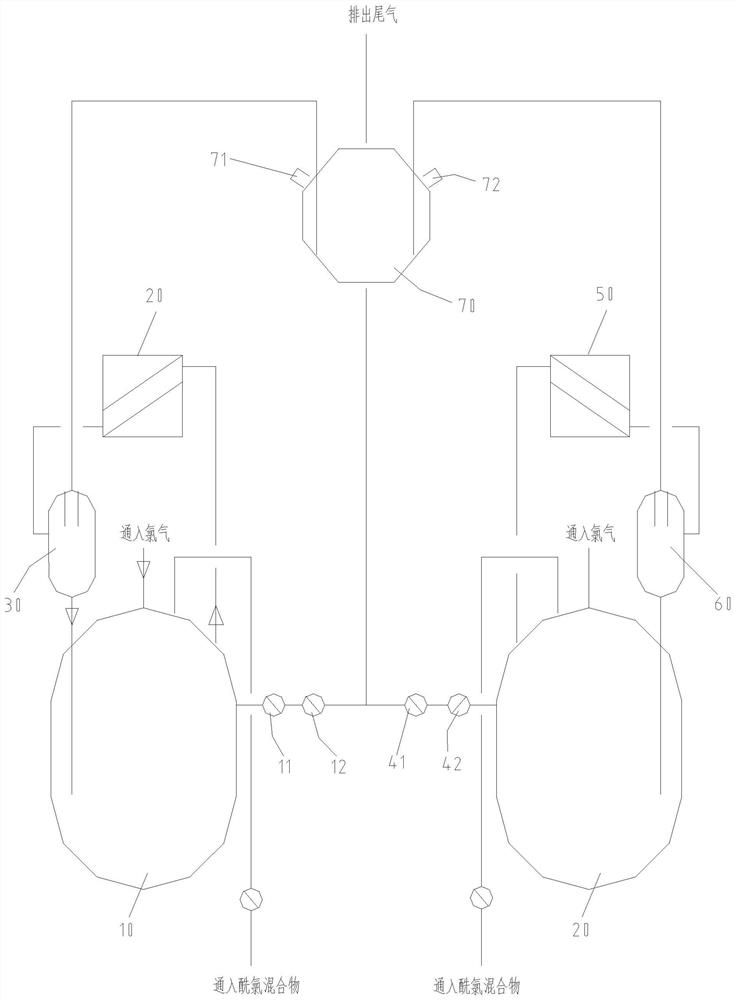

Volatile organic chemicals waste gas activated adsorbent

ActiveCN106732380ALarge adsorption capacityReduce pollutionGas treatmentOther chemical processesFlue gasSorbent

The invention relates to the technical field of volatile organic chemicals waste gas treatment, and particularly relates to a volatile organic chemicals waste gas activated adsorbent, which is characterized by comprising the following components in parts by weight: 100 parts of circulating fluidized bedcoal-fired boilerfly ash, 5 to 10 parts of sulphur, and 1 to 1.5 parts of disulfur dichloride. Flue gas and emission pollutants, such as smoke dust of a boiler are high-value utilized to prepare the VOCs (Volatile Organic Chemicals) adsorbent, so that the aims of providing the cheap VOCs adsorbent, saving energy, reducing emission, recycling resources and the like are achieved.

Owner:苏州环源环保科技有限公司

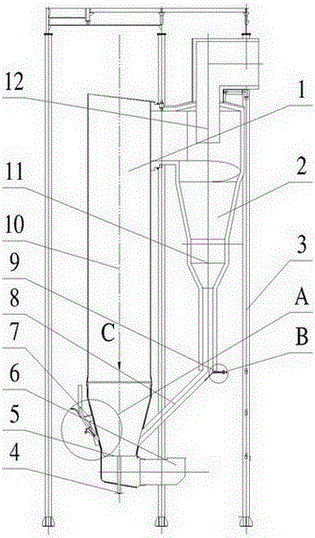

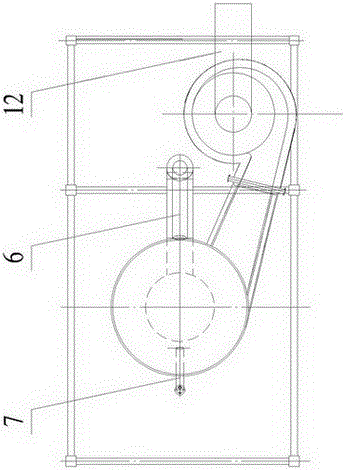

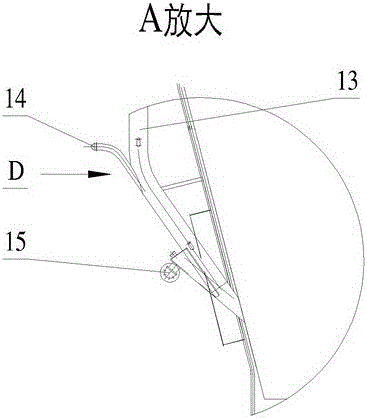

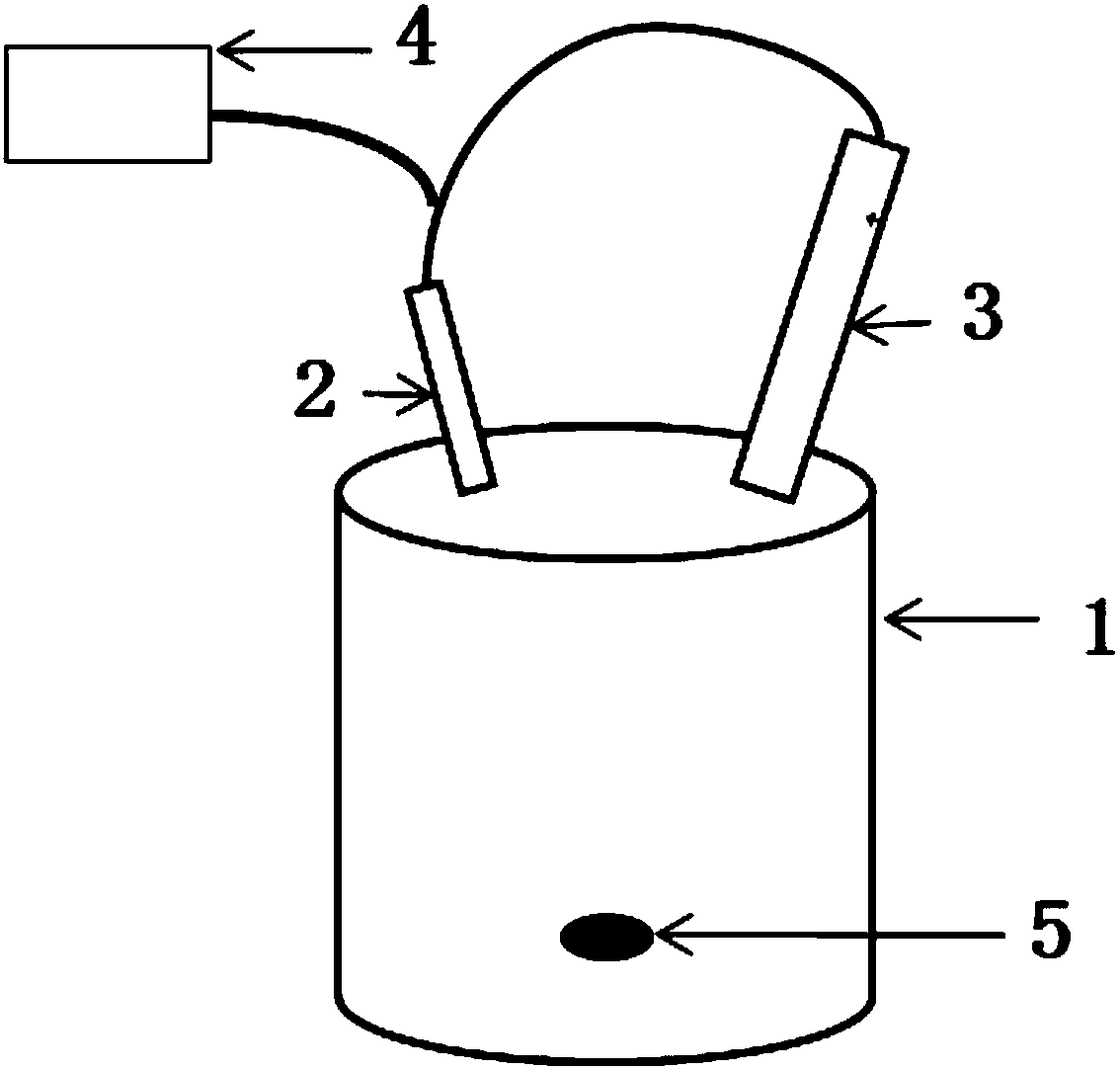

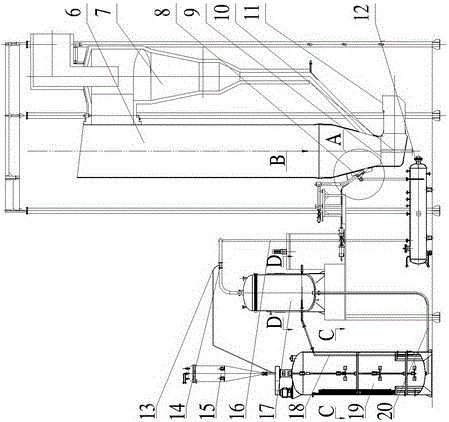

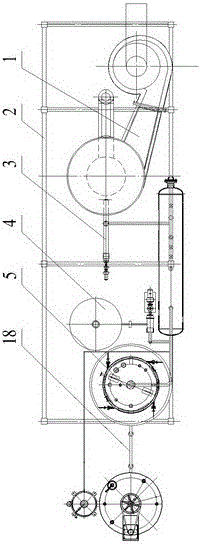

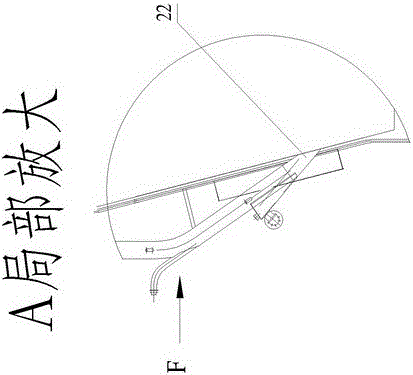

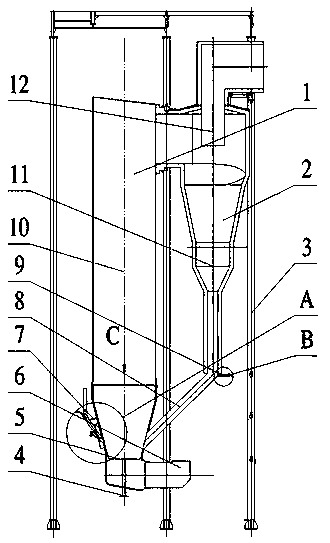

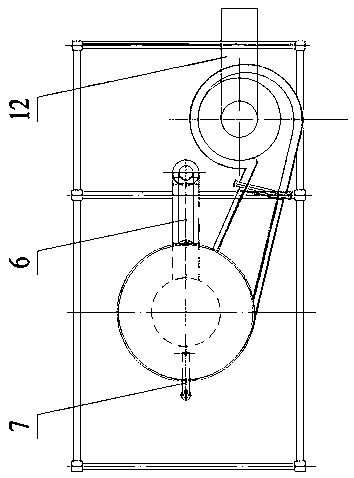

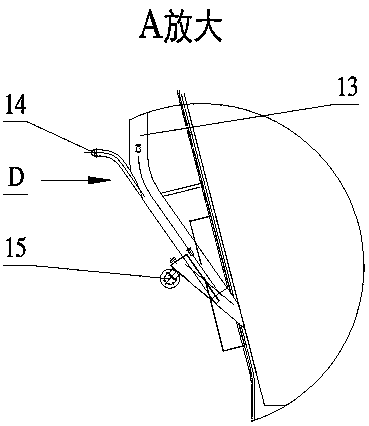

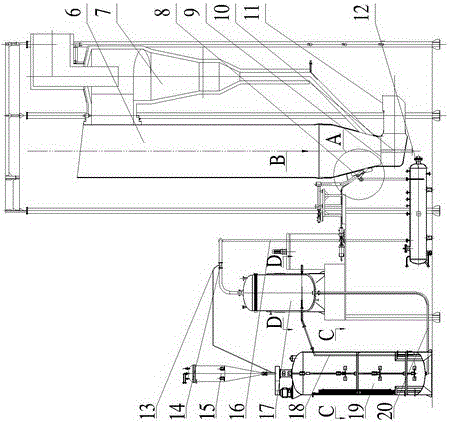

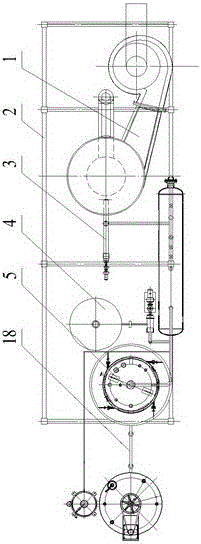

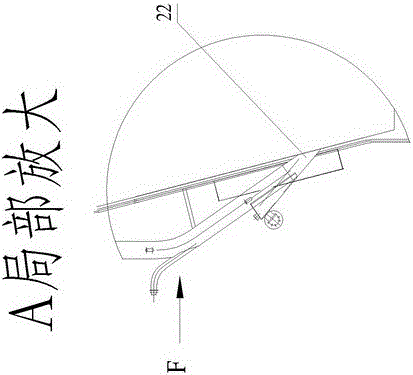

Activating granulation tower special for preparing volatile organic compound waste gas activated adsorbent

ActiveCN106824144AHigh yieldLow probability of explosionOther chemical processesDispersed particle separationSorbentHeat transfer

The invention relates to the technical field of volatile organic compound waste gas treatment, in particular to an activating granulation tower special for preparing a volatile organic compound waste gas activated adsorbent. The activating granulation tower is characterized by comprising an activating granulation tower component, a material returner and a supporting frame. Tail gas discharged by a circulating fluidized bed waste heat boiler spirally rises in the activating granulation tower, full mass and heat transfer is performed through overheating sulfur steam, circulating fluidized bed coal-fired boiler fly ash and disulfur dichloride mist drops, and accordingly the whole activating granulation technology process of the adsorbent is completed in the tower to make batched continuous production possible.

Owner:GUANGZHOU SHIPIN PETROLEUM EQUIP CO LTD

Butyl rubber composite gel oil absorption material and preparation method thereof

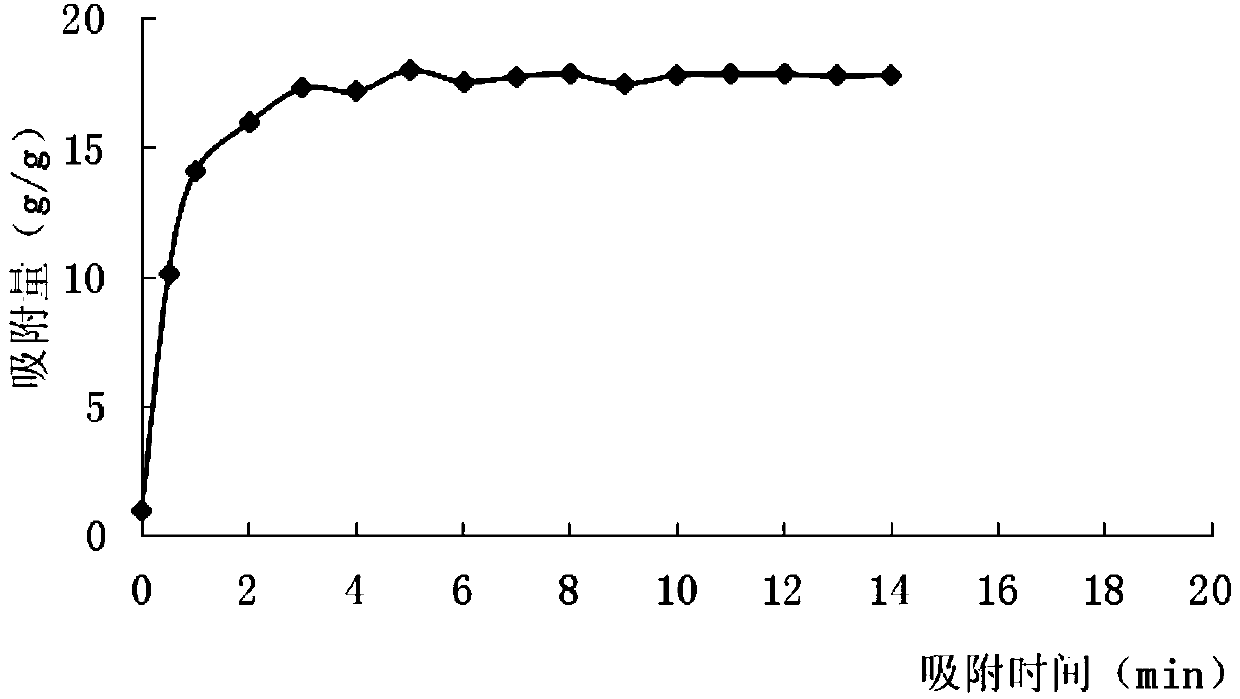

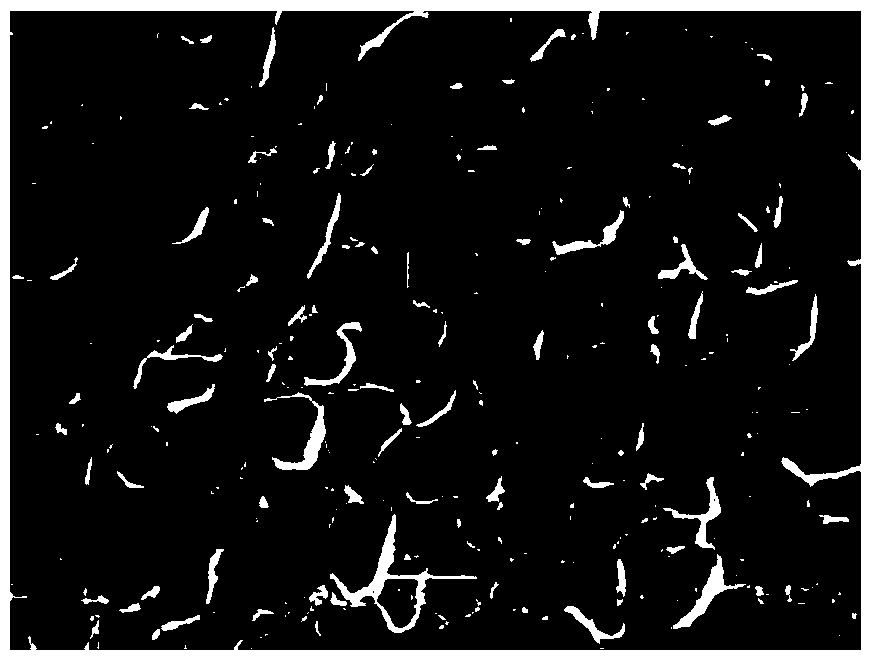

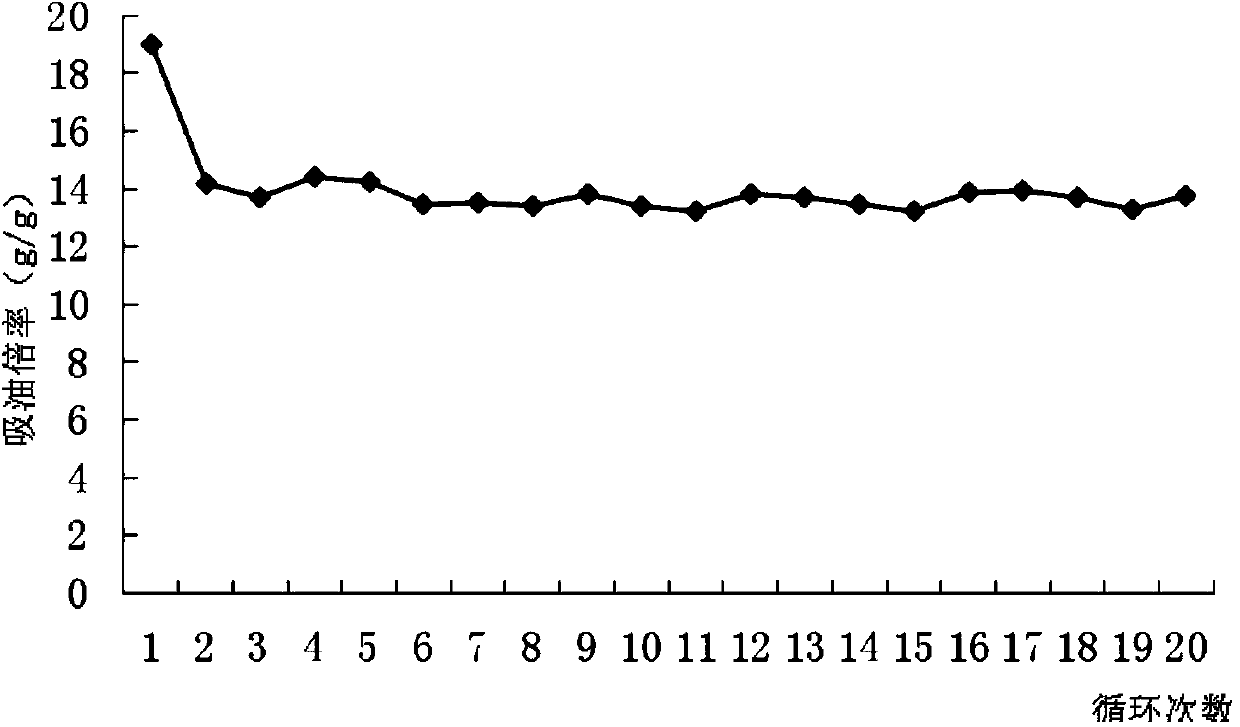

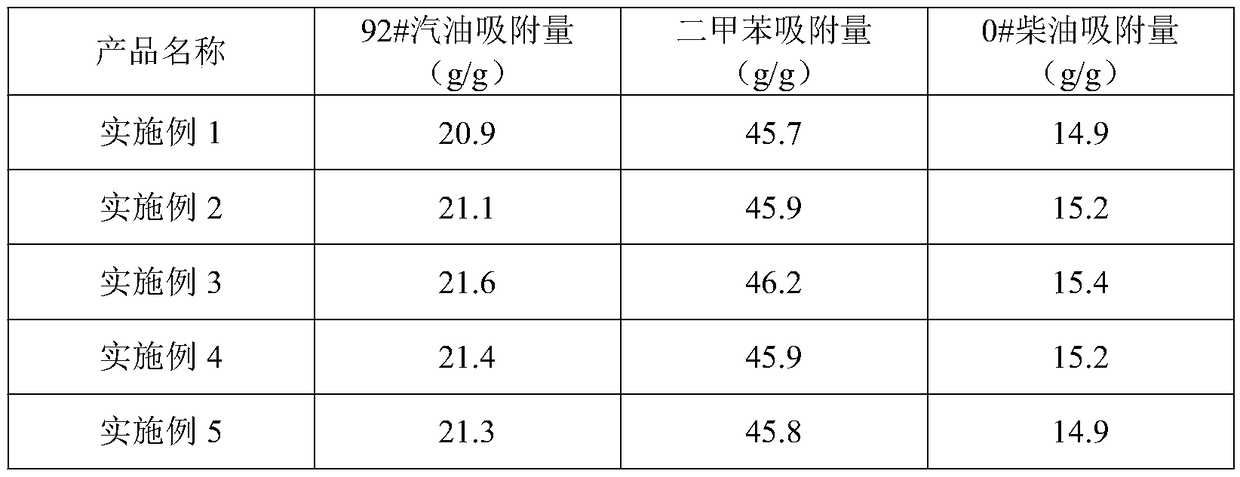

InactiveCN103834047AImprove adsorption capacityStrong oil-water selectivityOther chemical processesCross-linkSpatial structure

The invention relates to a butyl rubber composite gel oil absorption material and a preparation method thereof. A three-dimensional network spatial structure is formed by using butyl rubber as a base material, disulfur dichloride as a cross-linking agent and octyl phenol formaldehyde resin and parabenzoquinone dioxime as accelerants. The obtained oil absorption material is small in density, large in oil absorption, fast in rate of adsorption and capable of adsorbing multiple oil products; the oil absorption material can be repeatedly recycled through simple extrusion treatment, so that the cost is effectively reduced. The oil absorption material is a novel environmental-friendly material and widely applied and can be used for recovery of spilled oil in seaborne or land water bodies, treatment of oily wastewater and the like.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparation method of high-efficiency oil suction rubber material

The invention provides a preparation method of a high-efficiency oil suction rubber material. The preparation method comprises the following steps: modifying natural rubber to obtain modified naturalrubber; modifying guayule rubber to obtain modified guayule rubber; modifying the modified natural rubber, modified guayule rubber, modified oyster shell powder, naphthenic oil, zinc oxide, stearic acid, an antioxidant PPD, disulfur dichloride and an accelerator TBBS, and adding the obtained mixture into an internal mixer, and mixing the mixture; processing the mixed mixture between an upper sheetand a lower sheet of a two-roll mill to form a rubber sheet have a thickness of 4 mm; uniformly lying the rubber sheet in a low-temperature plasma treatment device, and treating the rubber sheet; taking out the treated rubber sheet, and foaming the rubber sheet in an autoclave of a supercritical carbon dioxide foaming device; placing the foamed rubber sheet in an air dry oven, vulcanizing the foamed rubber sheet at 150-155 DEG C for 20-30 min, heating the rubber sheet to 170 DEG C, and carrying out heat treatment for 3 h; immersing the rubber sheet in a fluorine-free waterproof agent NT-X018;and taking out the rubber sheet, and drying the rubber sheet in a drying box to obtain the high-efficiency oil suction rubber material. The high-efficiency oil suction rubber material prepared by themethod has a very good oil suction effect.

Owner:张青美

Absorption method of tail gas produced in production of trichloroacetyl chloride by means of chlorination process

PendingCN105148710AEfficient separationEfficient recyclingChlorine/hydrogen-chlorideDispersed particle separationGeneration processPhysical chemistry

The invention relates to an absorption method of tail gas produced in production of trichloroacetyl chloride by means of chlorination process. By means of the method, separation and recycling of hydrogen chloride, sulfur dioxide, disulfur dichloride, chlorine and the like which are generated in the generation process of trichloroacetyl chloride can be achieved, the process is safe and easy to control, damage is not caused to the environment, and over 30% of hydrochloric acid and sodium bisulfite solutions are obtained as byproducts. The invention belongs to the technical field of environmental protection.

Owner:山东谦诚工贸科技有限公司

Method for preparing tetrasulfur tetranitride by ammoniation of disulfur dichloride

The invention discloses a method for preparing tetrasulfur tetranitride by ammoniation of disulfur dichloride. The reaction is performed in an ice-water bath, and is mainly characterized in that disulfur dichloride is diluted by taking absolute ether as a solvent, dried ammonia gas is introduced into the disulfur dichloride dilute solution in a circulating feeding manner for reaction, and a crudeproduct produced after reaction is completed is subjected to suction filtration to separate out the liquid phase and the solid phase. After the liquid phase is dried by distillation, insoluble substances are rinsed and filtered out with dichloromethane, and the obtained liquid is dried by spinning to obtain a solid; furthermore, the solid obtained by reaction is dissolved in water and filtered, soxhlet extraction is performed on the solid obtained after filtering with dioxane, and the extraction solution is cooled, filtered and dried by distillation to obtain a solid. Furthermore, the solids obtained in two times are combined, and recrystallization is performed by using methylbenzene, so as to obtain tetrasulfur tetranitride crystal. The method is simple in reaction, recyclable in solvent,green, economical and reasonable, and relatively high in yield.

Owner:WUHAN UNIV

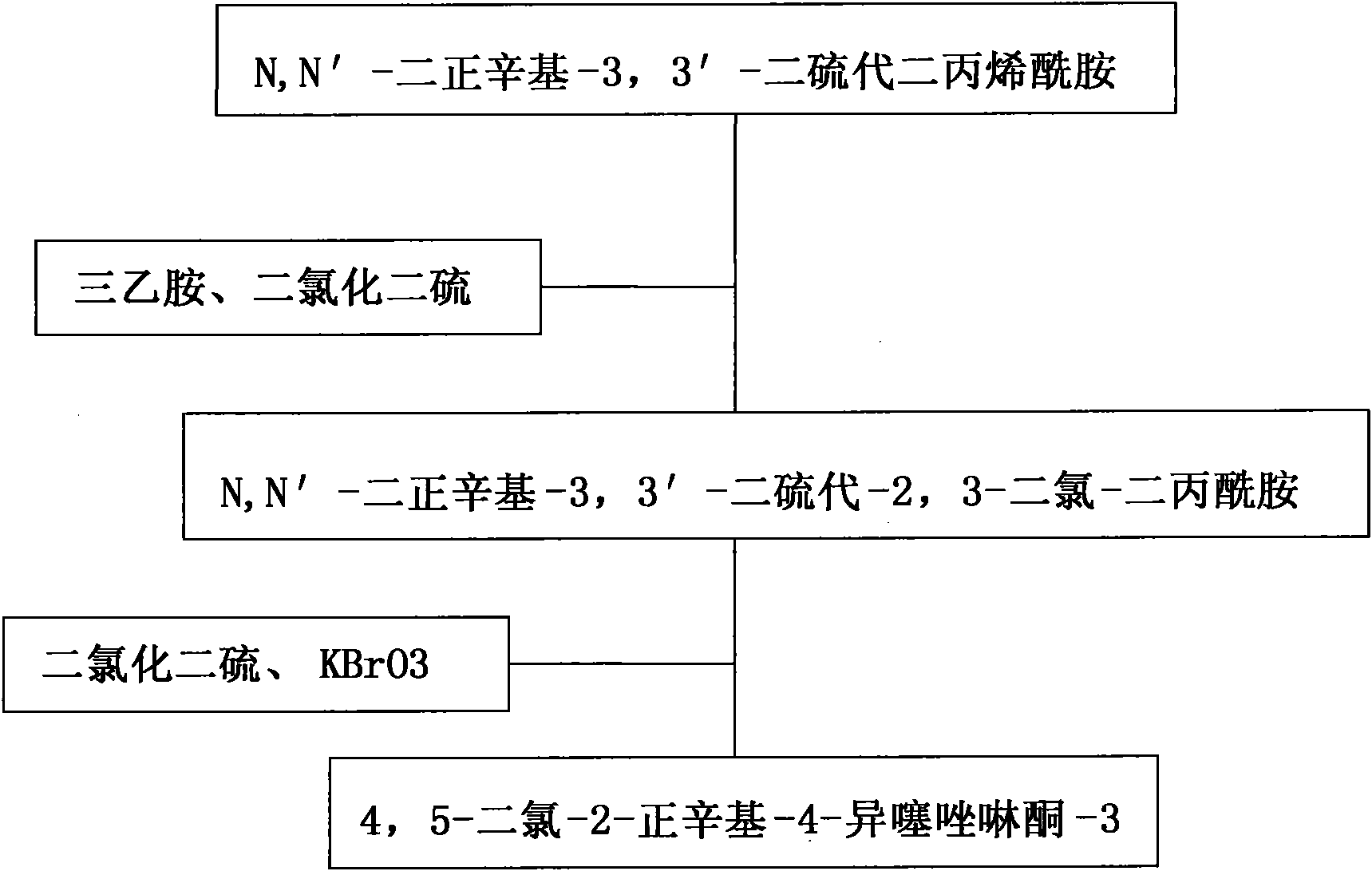

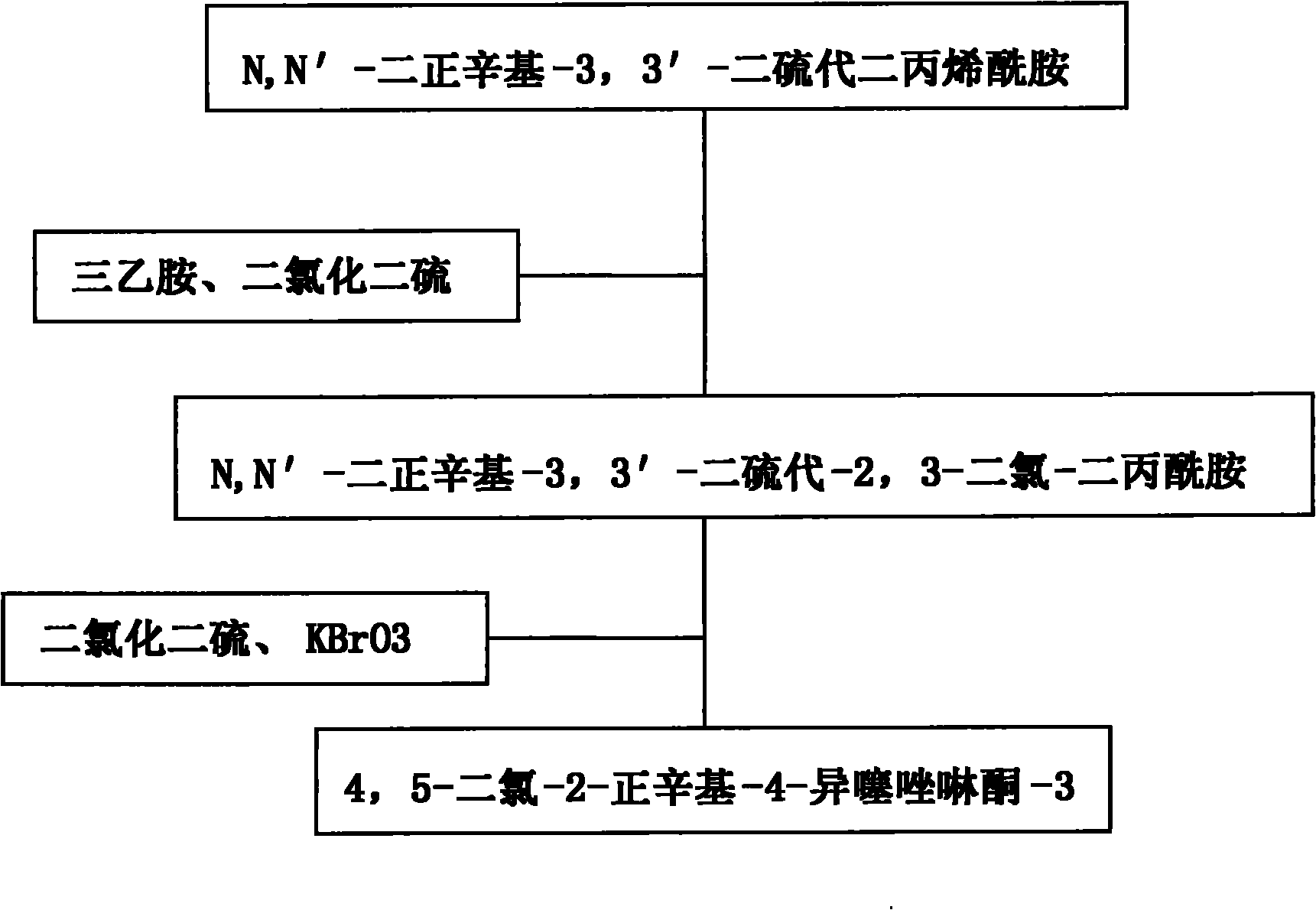

Preparation method of isothiazolinone biocide mildewcide

The invention belongs to the technical field of a biocide mildewcide, and particularly relates to a preparation method of an isothiazolinone biocide mildewcide. The preparation method comprises the specific steps that: N, N'-di-n-octyl-3, 3'-dithio-diacrylamide, disulphur dichloride, potassium bromate and chlorobenzene are mixed for reaction according to the mole ratio of 1:2-3:0.1-0.3:2-2.5, wherein the N, N'-di-n-octyl-3, 3'-dithio-diacrylamide takes the chlorobenzene as a solvent to react with the disulphur dichloride so as to generate N, N'-di-n-octyl-3, 3'-dithio-2, 3-dichloro-dipropionamide; the N, N'-di-n-octyl-3, 3'-dithio-2, 3-dichloro-dipropionamide reacts with the disulphur dichloride under the existence of potassium bromate in a closed-loop manner; and then the generated substances obtained by the reaction are purified to obtain the isothiazolinone biocide mildewcide. The preparation method carries out following closed-loop chlorination by S2Cl2, has little corrosion to equipment, and is safe and reliable, and simultaneously, the addition of KBrO3 can improve the purity of the prepared biocide mildewcide, namely 4, 5-dichloro-2-di-n-octyl-4-isothiazolinone-3.

Owner:HUANGSHAN RUNKE POWDER MATERIALS

Usage method of processing device for preparing volatile organic compound exhaust gas activated adsorbent

ActiveCN106582499AReduce oxygenImprove heat transfer coefficientGas treatmentOther chemical processesSorbentAdhesive

The invention relates to the technical field of treatment of organic compound exhaust gas, in particular to a usage method of a processing device for preparing a volatile organic compound exhaust gas activated adsorbent. The usage method of the processing device for preparing the volatile organic compound exhaust gas activated adsorbent is characterized by comprising usage methods of an activated granulation tower, a support frame, a circulating fluidized bed coal fired boiler flyash spiral feeder, a disulphur dichloride storage tank component, and a sulfur evaporator. A circulating fluidized bed heat recovery boiler discharges exhaust gas which contains extremely low oxygen, has low probability of generation of sulfur explosive under a low-oxygen environment, and is very ideal as a technology cooling medium of a sulfur adhesive, thus giving full play to the functions of the sulfur as an adhesive and an adsorbent; meanwhile, the circulating fluidized bed heat recovery boiler discharged exhaust gas conducts spiral escalation in the activated granulation tower, wraps and activates the circulating fluidized bed coal fired boiler flyash along with the sulfur adhesive and disulphur dichloride atomized liquid drops so that particles can constantly grow large so as to fully conduct mass and heat transferring, therefore the overall technological process of activation and granulation of the adsorbent in the tower can be achieved, and thus industrialization production becomes possible.

Owner:TIANCHANG HUASHENG BIOLOGICAL TECH

A kind of preparation method of gas phase catalytic synthesis sulfur dichloride

The invention discloses a preparation method for synthetizing sulfur dichloride through gas phase catalysis. Granular activated carbon supported by ferric chloride (FeCl3 / C) is taken as a catalyst, disulfur dichloride and chorine are taken as a reaction raw material and a carrier gas, a vaporized gas mixture of the disulfur dichloride and the chorine enters a fixed bed catalysis tubular reactor, the sulfur dichloride is prepared with a continuous gas phase catalysis method, the sulfur dichloride produced through the reaction is cooled by a condenser to be collected, and the excess chlorine is recycled. The sulfur dichloride product obtained with the method is free of catalyst residues, distillation is not required, and the content of sulfur dichloride in the product is higher than 90%. The excess chlorine is recycled. The preparation method is simple to operate, continuous, stable, high in conversion rate and free of waste gas and waste liquor emissions, so that the environmental pollution is reduced.

Owner:湖南海利常德农药化工有限公司

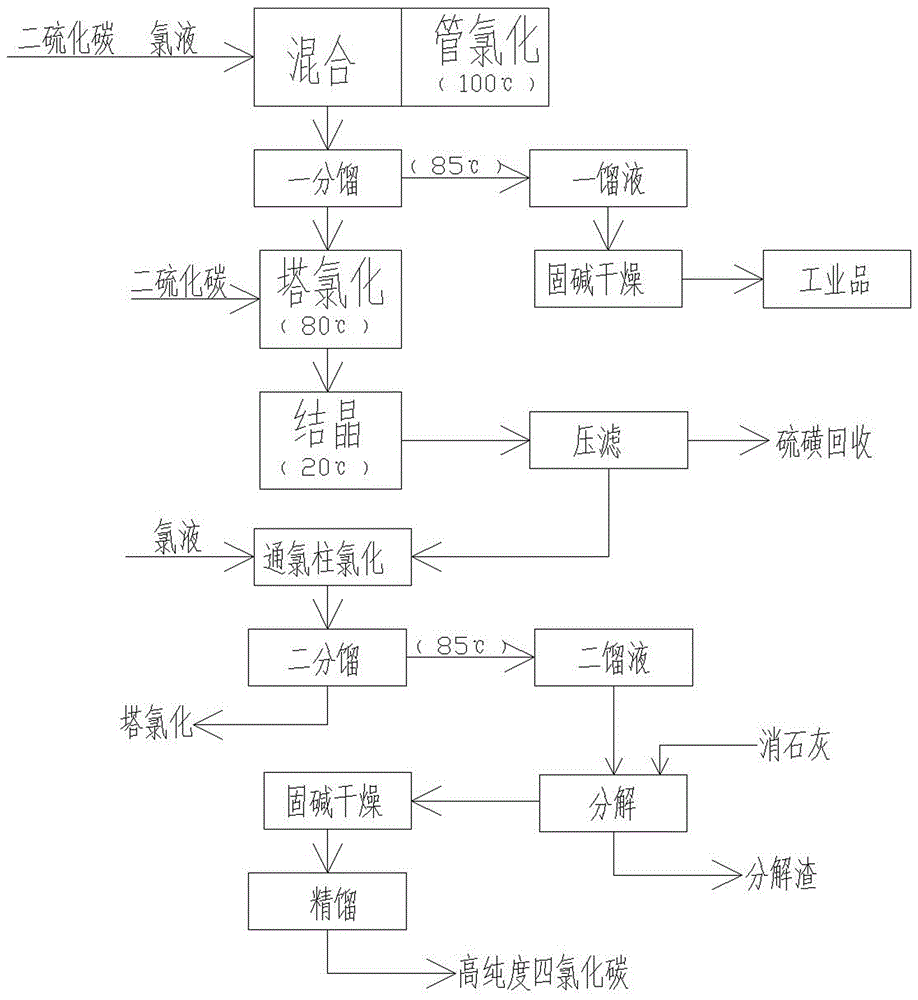

Preparation method for carbon tetrachloride

InactiveCN106478359AAvoid pollutionReduce contentHalogenated hydrocarbon preparationDecompositionChemistry

The invention discloses a preparation method for carbon tetrachloride in the field of preparation of carbon tetrachloride. The preparation method comprises the following steps: step 1, metering carbon disulfide and a chlorine liquid, carrying out mixing, then adding the obtained mixture into a coiled reactor and carrying out a reaction, introducing reaction steam into a fractionating tower, and carrying out first fractionation; step 2, during fractionation of the reaction steam, collecting a first fractionated liquid carbon tetrachloride located at the top of the tower, and carrying out drying so as to prepare an industrial product; step 3, subjecting the tower liquid in the fractionating tower to full reflux, adding excessive carbon disulfide, allowing disulfur dichloride to chlorinate carbon disulfide; step 4, cooling the chlorinated liquid in the tower to 20 DEG C, carrying out crystallization so as to precipitate sulfur, and recycling the precipitated sulfur; step 5, adding a tower parent liquid into a chlorine introduction column, and introducing the chlorine liquid into the chlorine introduction column, and chlorinating excessive carbon disulfide so as to obtain a column chlorinated liquid; step 6, pressing the column chlorinated liquid into the fractionating tower, carrying out fractionation, evaporating a secondary fractionated liquid, and allowing the evaporated secondary fractionated liquid to enter a decomposing tank; and step 7, adding slaked lime into the decomposing tank, decomposing the disulfur dichloride in the secondary fractionated liquid, and subjecting the decomposed decomposition liquid to drying and rectification so as to obtain high-purity carbon tetrachloride. With a scheme provided by the invention, the purity of the carbon tetrachloride is improved; meanwhile, the recycling of by-products is realized.

Owner:王显权

A kind of volatile organic compound waste gas active adsorbent

ActiveCN106732380BLarge adsorption capacityReduce pollutionGas treatmentOther chemical processesSorbentFlue gas

Owner:苏州环源环保科技有限公司

Environmentally friendly catalyst used for synthesizing sulfur dichloride and preparing method thereof

InactiveCN106513034AInactiveReduced activityMolecular sieve catalystsSulfur dichlorideMolecular sieveDisulfur dichloride

The invention relates to an environmental-friendly catalyst used for synthesizing sulfur dichloride and a preparing method thereof. According to the preparing method, an excessive wet soaking method is adopted to prepare supported catalysts of various kinds, catalysts of different kinds are used to conduct a test of synthesizing sulfur dichloride, disulfur dichloride and excessive chlorine are introduced from the lower end of a tubular reactor, and standing time of reaction raw materials in the reactor is increased so that the amount of chlorine is further reduced. The environmentally friendly catalyst used for synthesizing sulfur dichloride and the preparing method thereof have the positive effects that a novel molecular sieve supported catalyst is provided to be used for synthesizing sulfur dichloride, and has the advantages of being simple in manufacturing technological operation, stable, continuously efficient, environmentally friendly, sanitary, and low in pollution.

Owner:CHANGCHUN INST OF TECH

A kind of preparation method of volatile organic compound waste gas active adsorbent

ActiveCN106824082BLarge adsorption capacityReduce pollutionGas treatmentOther chemical processesSorbentFluidized bed

Owner:榆林中科环保科技集团有限公司

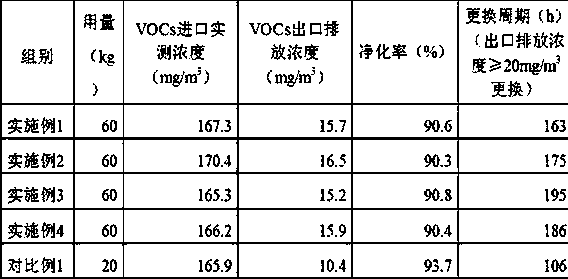

Method for separating disulfur dichloride in preparation process of high-purity ethyl chloride

ActiveCN106349284AReduce processing costsReduce pollutionGroup 5/15 element organic compoundsSulfur and halogen compoundsResource savingDisulfur dichloride

The invention provides a method for separating disulfur dichloride in the preparation process of high-purity ethyl chloride; crude ethyl chloride generated in the reaction of ethyl sulfide with chlorine is separated through a rectifying column, disulfur dichloride fraction is collected when column bottom temperature is 70 DEG C and below, and the fraction refined ethyl chloride is collected when column bottom temperature is 83-84 DEG C and above. According to the method provided herein, the crude ethyl chloride can be rectified and separated to obtain refined ethyl chloride with a content of > / =99.6% and the byproduct disulfur dichloride with a content of > / =99%; little sulfur and liquid residue are generated in the separation process, and the sulfur can be post-processed into byproducts for sale; the whole process is free of wastewater, and environmental pollution reduction and resource saving are achieved to maximum extent.

Owner:湖北犇星农化有限责任公司

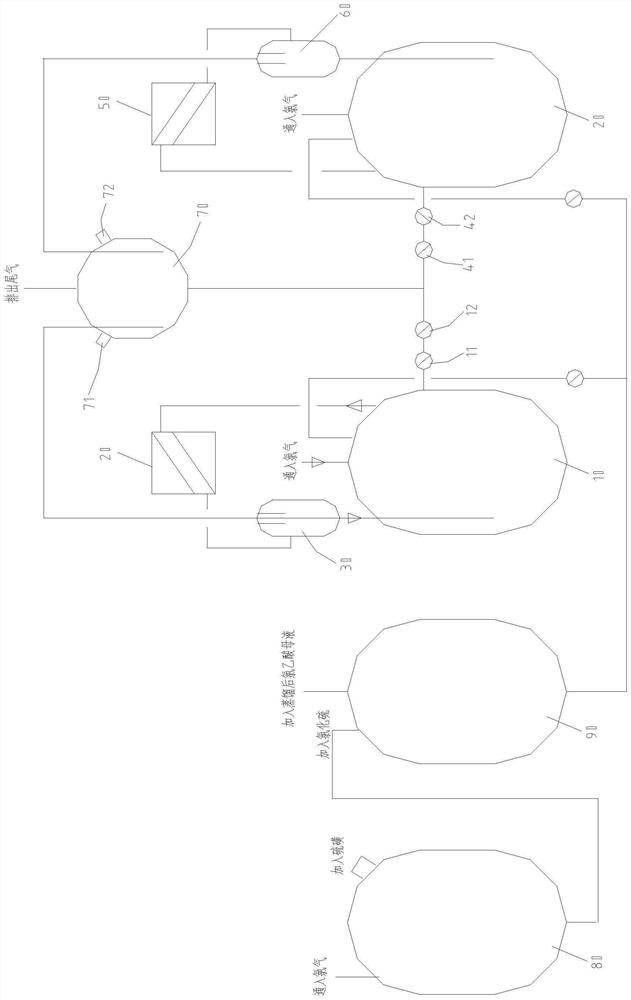

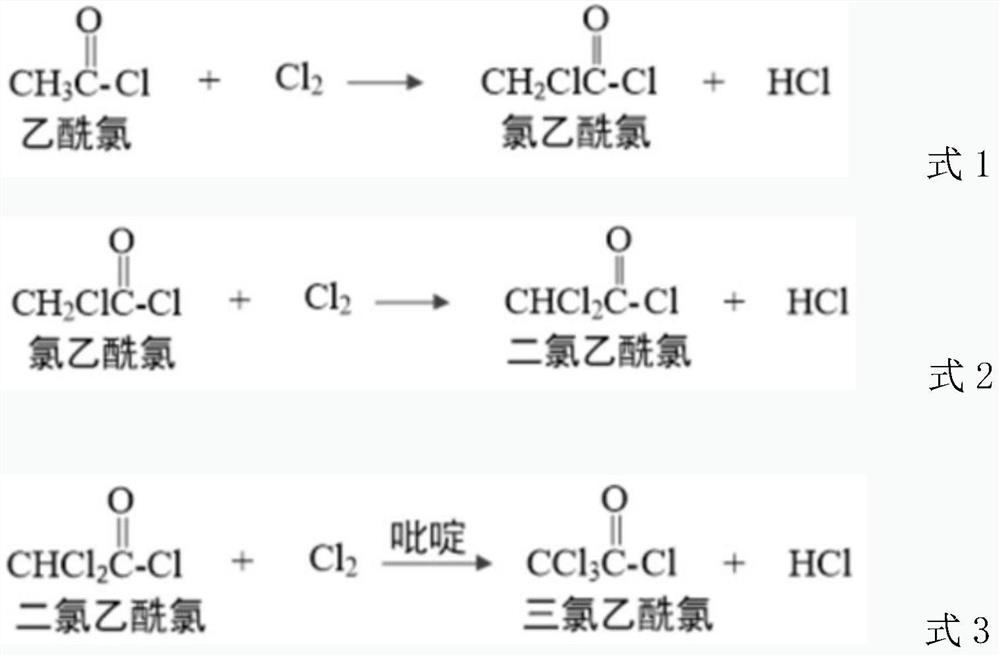

High-yield trichloroacetyl chloride preparation system and method

PendingCN113666821AHigh yieldOrganic compound preparationCarboxylic compound preparationWater chlorinationEngineering

The invention provides a high-yield trichloroacetyl chloride preparation method which comprises the steps of introducing chlorine into an acyl chloride mixture, and carrying out deep chlorination reaction to generate trichloroacetyl chloride; in the later stage of the reaction, detecting the component content of substances in the reaction kettle, if the content of acid components is high, adding disulfur dichloride into the reaction kettle, and enabling the generated acyl chloride mixture to still continue to be subjected to deep chlorination reaction with chlorine to generate trichloroacetyl chloride. According to the scheme, in the reaction process in the reaction kettle, the acyl chloride mixture and chlorine are subjected to deep chlorination, chloroacetic acid and dichloroacetic acid may be remained, components of materials in the reaction kettle are analyzed and detected at the moment, disulfur dichloride is added from a supplementing tank according to a detection result, the adding amount of the disulfur dichloride is controlled through a flow valve and a control valve, then the acid continues to be subjected to chlorination reaction to completely generate monochloroacetyl chloride and dichloroacetyl chloride, and then the monochloroacetyl chloride and the dichloroacetyl chloride continue to be subjected to deep chlorination, and are converted into trichloroacetyl chloride, so that the yield of the trichloroacetyl is improved.

Owner:宁夏荣泰生物科技有限公司

A method of using a dedicated activated prilling tower for the preparation of a volatile organic compound waste gas active adsorbent

ActiveCN106582588BHigh yieldLow probability of explosionGas treatmentOther chemical processesSorbentBiological activation

Owner:江苏洋井环保服务有限公司

Process device for preparing hypersorber for volatile organic compound waste gas

ActiveCN106732483AReduce oxygenImprove heat transfer coefficientGas treatmentOther chemical processesAdhesiveSorbent

The invention relates to the technical field of governance of volatile organic compound waste gas and in particular relates to a process device for preparing a hypersorber for the volatile organic compound waste gas. The process device is characterized by comprising an active granulation tower, a supporting frame, a circulating fluidized bed coal-fired boiler fly ash screw feeder, a disulfur dichloride storing tank assembly and a sulfur evaporator. The content of oxygen in tail gases exhausted by a circulating fluidized bed waste heat boiler is extremely-low, so that the probability of burning explosion of sulfur in a low-oxygen environment is extremely-low, and further safe production is facilitated; meanwhile, the hypersorber serving as a process cooling medium of sulfur adhesive is very ideal, and realizes the functions of the sulfur adhesive serving as an adhesive and an adsorbent; the tail gas exhausted by the circulating fluidized bed waste heat boiler spirally ascends in the active granulation tower, wraps the sulfur adhesive and disulfur dichloride vaporific droplets, and activates fly ash of a circulating fluidized bed coal-fired boiler to form continuously-growing particles for sufficient mass transfer and heat transfer, thereby finishing the whole process flow of activating and granulating an adsorbent in the tower, and enabling industrialized production to become possible.

Owner:无锡金力威环保科技有限公司

Green Synthesis of Methyl Chlorides

ActiveCN110483568BReduce precipitationUniform precipitationGroup 5/15 element organic compoundsPtru catalystWater chlorination

Owner:湖北驰顺化工有限公司 +1

Green synthesis method of methyl-chloride

ActiveCN110483568ALow costAchieving Atomic EconomicsGroup 5/15 element organic compoundsSocial benefitsWastewater

The invention discloses a green synthesis method of methyl-chloride. The method comprises the following steps of S1, in a reaction system for preparing the methyl-chloride by taking the methyl sulfideand the chlorine as the raw materials, utilizing the characteristic that the disulfur dichloride can chlorinate the methyl sulfide, continuously reacting the disulfur dichloride generated during thereaction process with the methyl sulfide to convert into the methyl-chloride and the sulfur by controlling the introduction amount of the chlorine; and S2, after the reaction is completed, adding a catalyst A and a catalyst B into the reaction system, precipitating the sulfur in the system in the form of loose crystals, separating to obtain the sulfur and a methyl-chloride crude product, and carrying out rectification under vacuum to obtain the high-purity methyl-chloride. According to the method, not only the high-purity methyl-chloride can be prepared, the yield is increased, but also the crystalline sulfur with excellent properties can be obtained and can be reused, a large amount of salt-containing wastewater and the elastic sulfur waste residues are effectively avoided, the pollutioncaused by the waste gas is also avoided, the environmental protection is achieved, and the social benefits and the environmental benefits are remarkable.

Owner:湖北驰顺化工有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com