Preparation method for carbon tetrachloride

A technology of carbon tetrachloride and carbon disulfide, applied in chemical instruments and methods, preparation of halogenated hydrocarbons, organic chemistry, etc., can solve problems such as improper handling of by-products, low purity of finished products, and low investment, so as to improve sufficiency and improve reaction Efficiency, the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

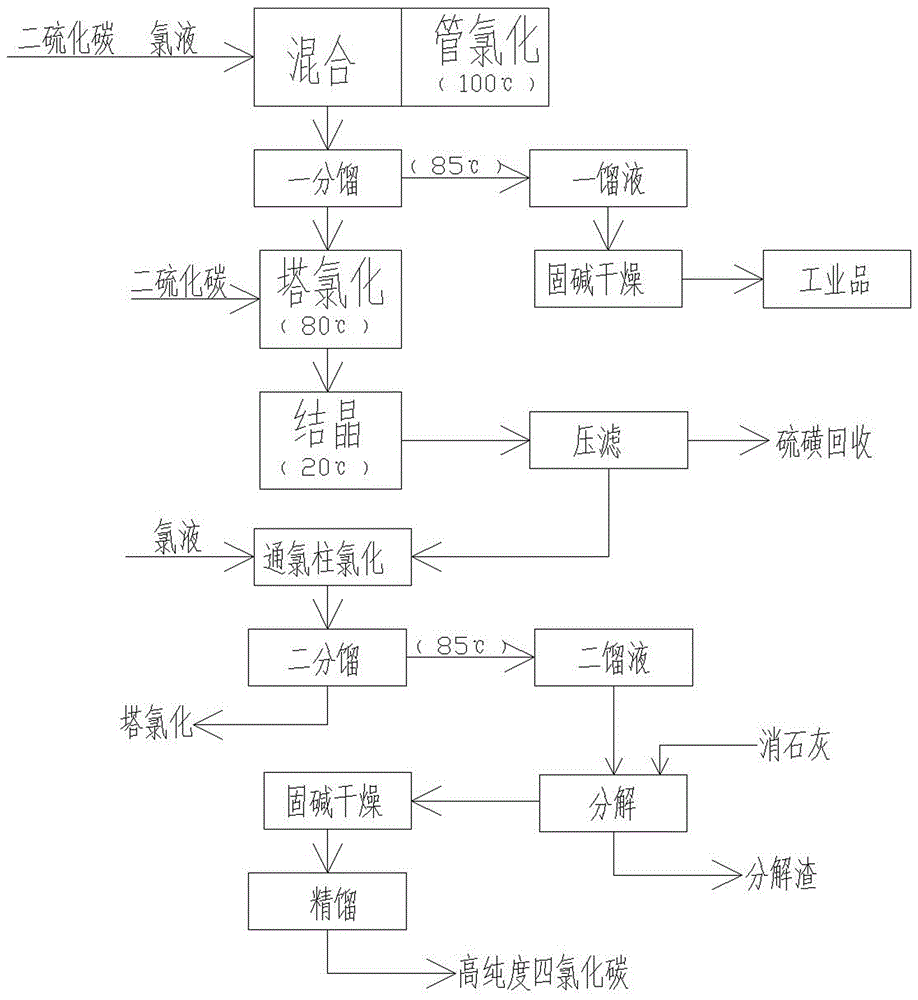

[0020] Such as figure 1 A kind of preparation method of carbon tetrachloride shown, comprises the following steps:

[0021] Step 1: Tube chlorination: Mix carbon disulfide with a purity of 98% and chlorine solution with a purity of 99% at a weight ratio of 1:2, and then add it to a coiled tube reactor for reaction. The coiled tube reactor is placed in water, and the water temperature is controlled at 100°C , the reaction vapor after the reaction is generated and introduced into the fractionation tower to carry out a fractionation;

[0022] Step 2: Fractionation tower one fractionation: Fractionation temperature is 85 ℃, collects a distillate carbon tetrachloride at the top of the fractionation tower, and a distillate is dried through a solid alkali drier to obtain low-purity carbon tetrachloride, a fractionation tower Store liquid disulfide dichloride for tower chlorination;

[0023] Step 3: tower chlorination: the fractionation tower is fully refluxed, and an excess of 25% ...

Embodiment 2

[0029] The difference between Example 2 and Example 1 is that the purity of carbon disulfide in step 1 is 97%, and the water temperature is 95°C; the fractionation temperature in step 2 is 83°C; the fractionation temperature in step 6 is 80°C.

Embodiment 3

[0031] The difference between embodiment 3 and embodiment 1 is that the water temperature in step one is 98°C; the fractionation temperature in step two is 80°C; the fractionation temperature in step six is 82°C.

[0032] Compared with the carbon disulfide chlorination method adopted in the background technology, the purity of the carbon tetrachloride prepared by the present invention is increased by 4 to 5 percentage points, and the by-products are fully utilized simultaneously, greatly reducing the pollution to the environment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com