Patents

Literature

793 results about "Fractional distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fractional distillation is the separation of a mixture into its component parts, or fractions. Chemical compounds are separated by heating them to a temperature at which one or more fractions of the mixture will vaporize. It uses distillation to fractionate. Generally the component parts have boiling points that differ by less than 25 °C (77 °F) from each other under a pressure of one atmosphere. If the difference in boiling points is greater than 25 °C, a simple distillation is typically used.

Premium synthetic lubricant base stock (Law734) having at least 95% noncyclic isoparaffins

A premium synthetic lubricating oil base stock having a high VI and low pour point is made by hydroisomerizing a Fischer-Tropsch synthesized waxy, paraffinic feed wax and then dewaxing the hydroisomerate to form a 650-750° F.+ dewaxate. The waxy feed has an initial boiling point in the range of about 650-750° F., from which it continuously boils up to at least 1050° F. and has a T90-T10 temperature difference of at least 350° F. The feed is preferably hydroisomerized without any pretreatment, other than optional fractionation. The 650-750° F.+ dewaxate is fractionated into two or more base stocks of different viscosity.

Owner:EXXON RES & ENG CO

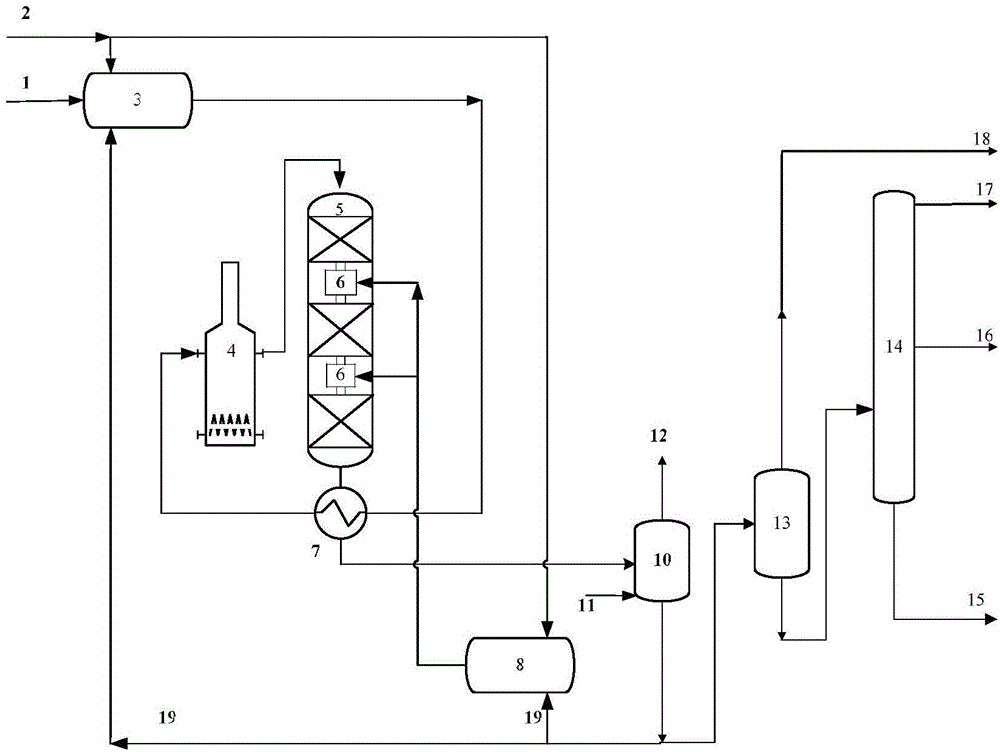

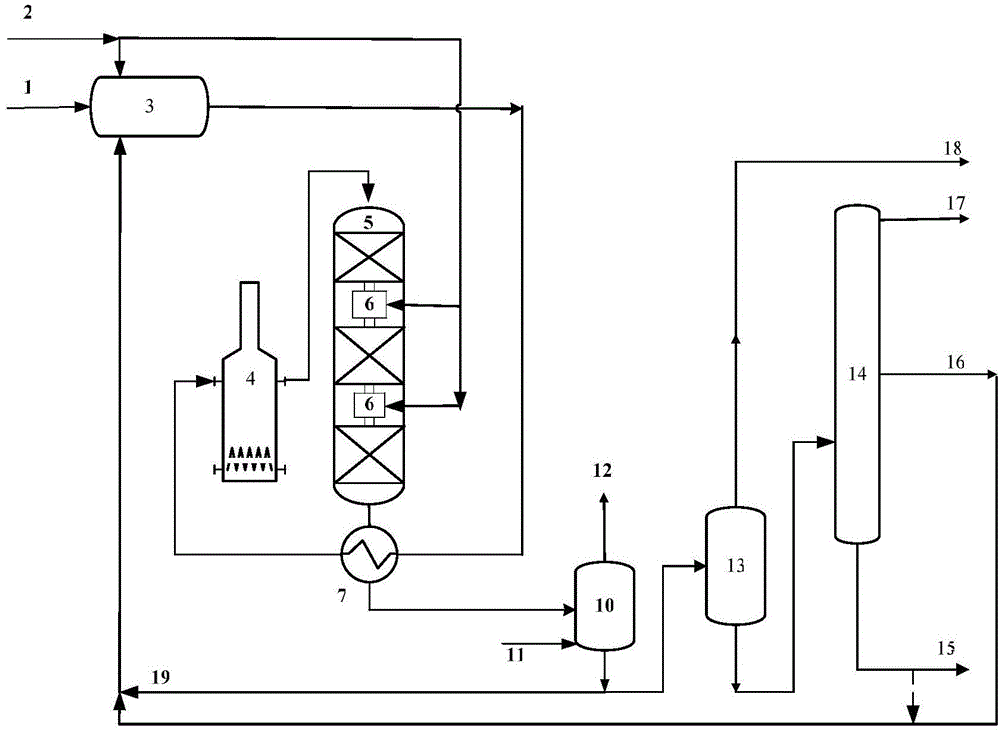

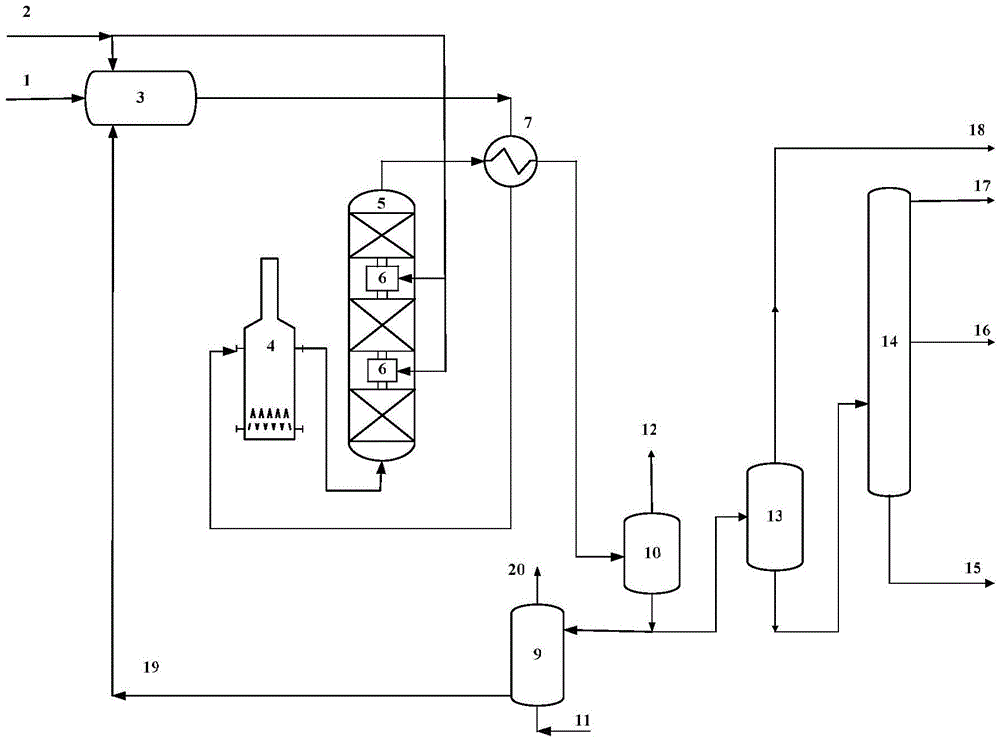

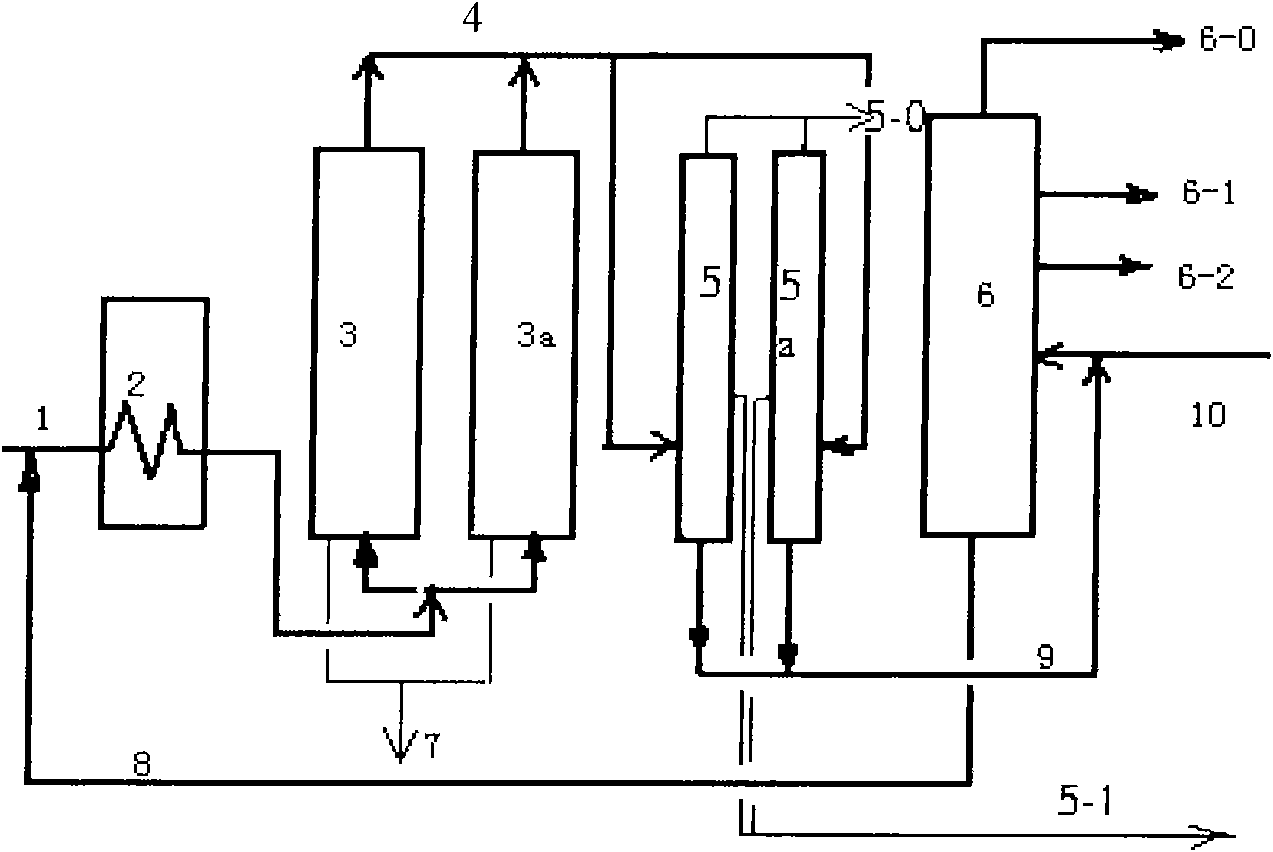

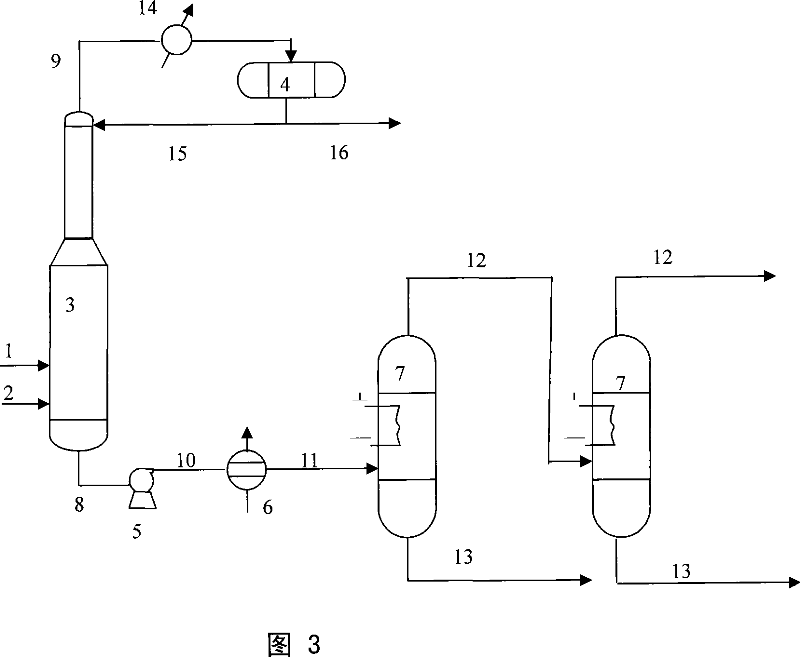

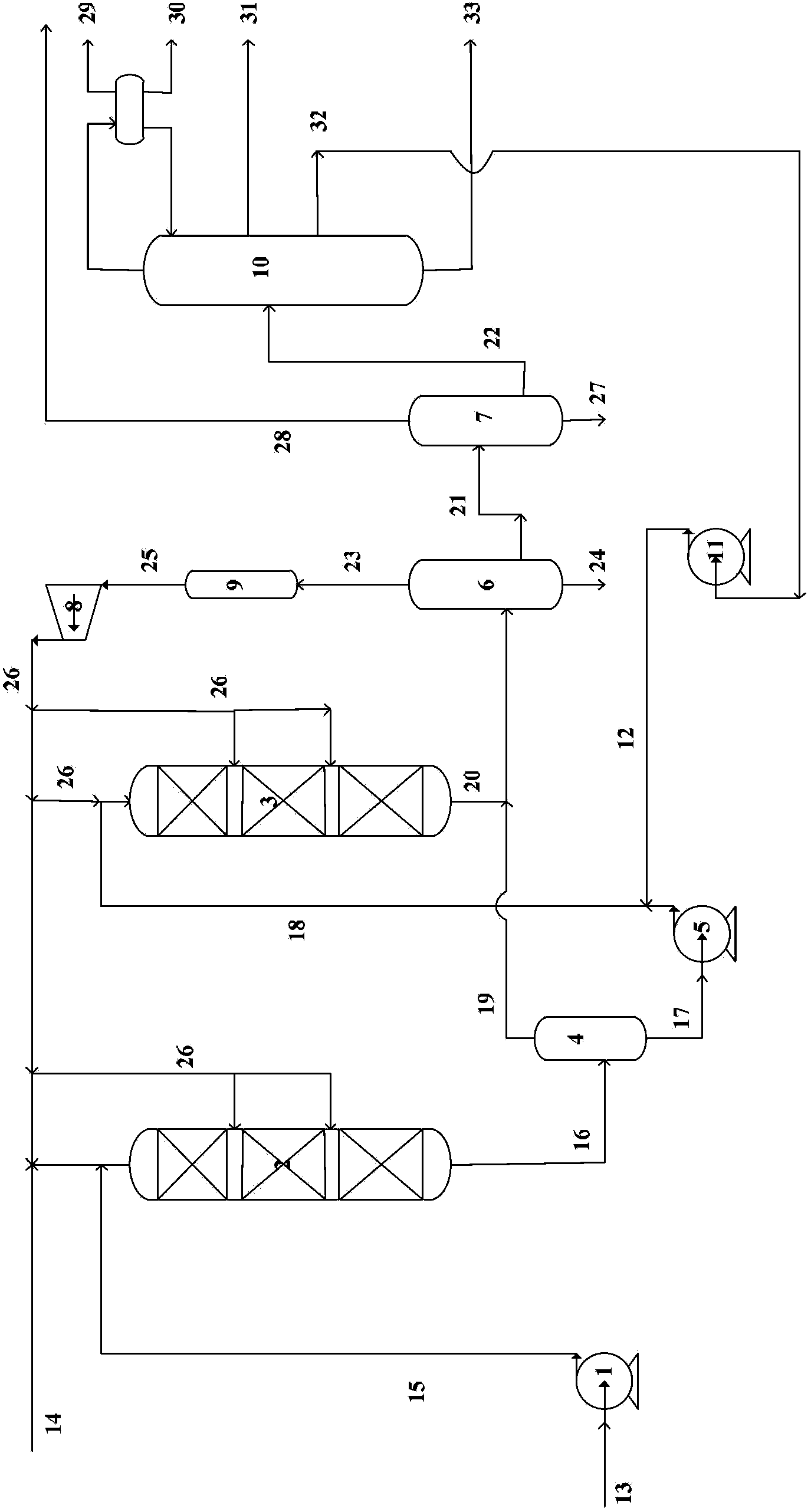

Method for hydrotreatment of continuous liquid-phase wax oil

ActiveCN104560132ALow investment costLow operating costHydrocarbon oils treatment productsRefining to eliminate hetero atomsWaxSulfur

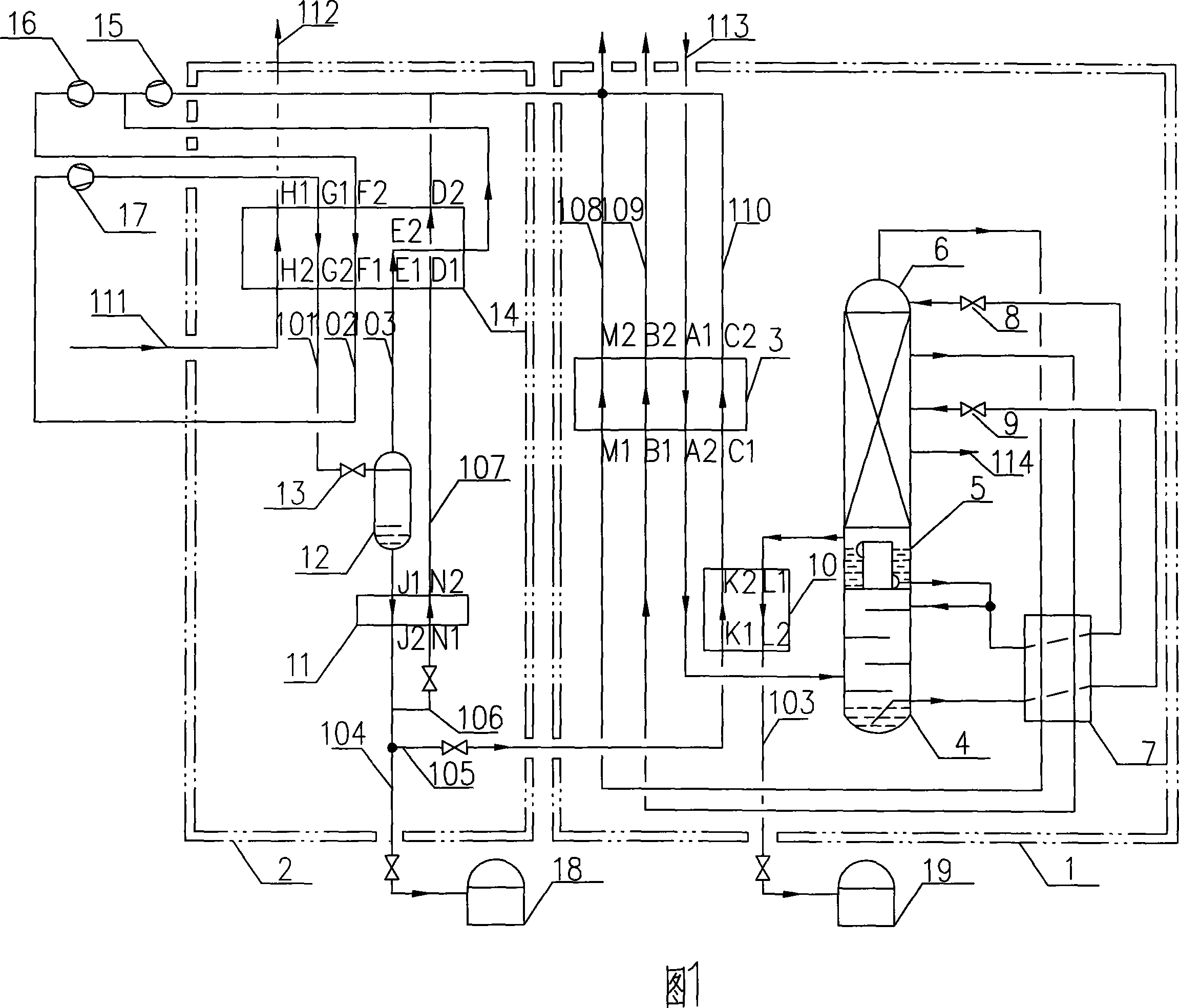

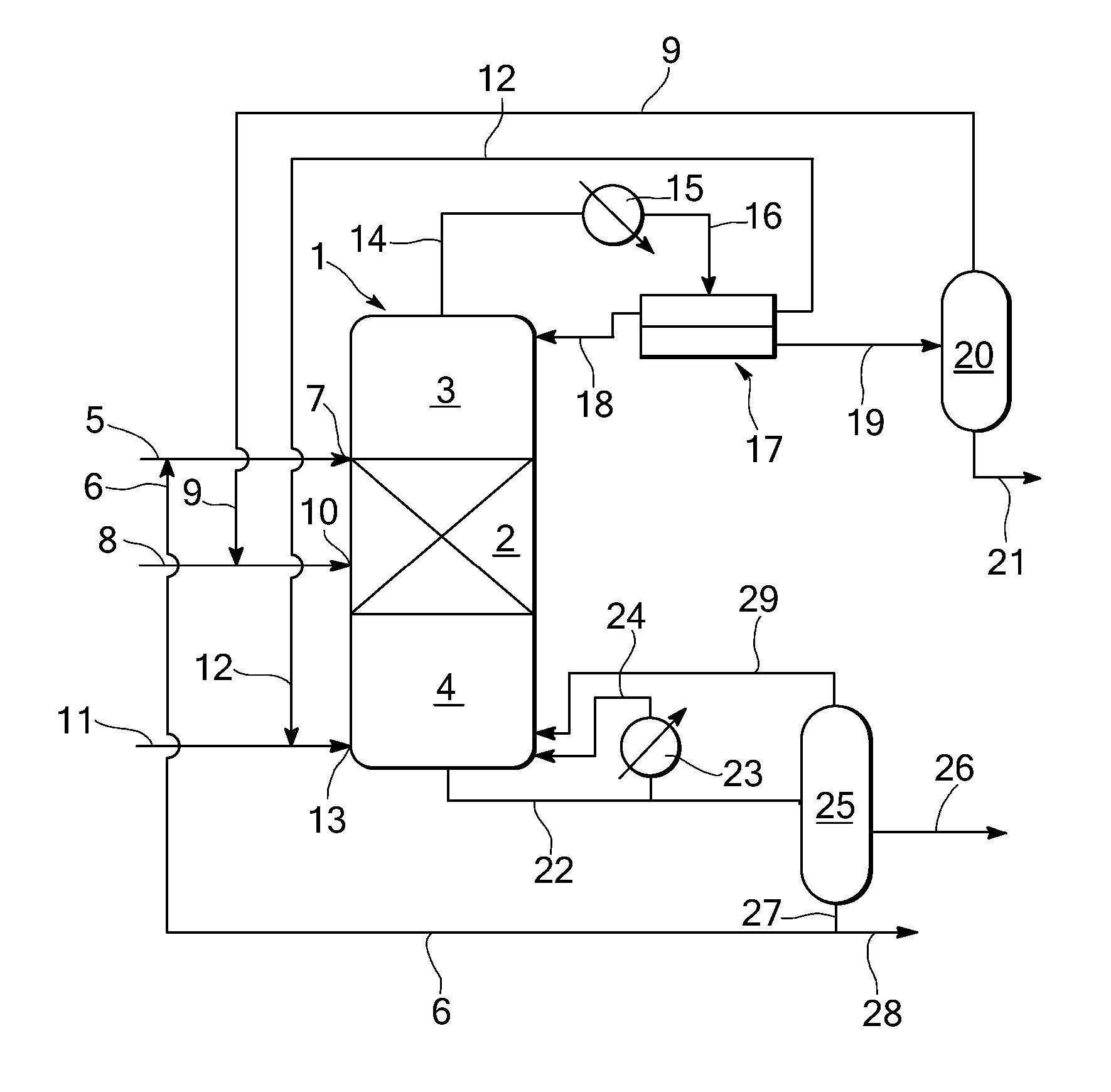

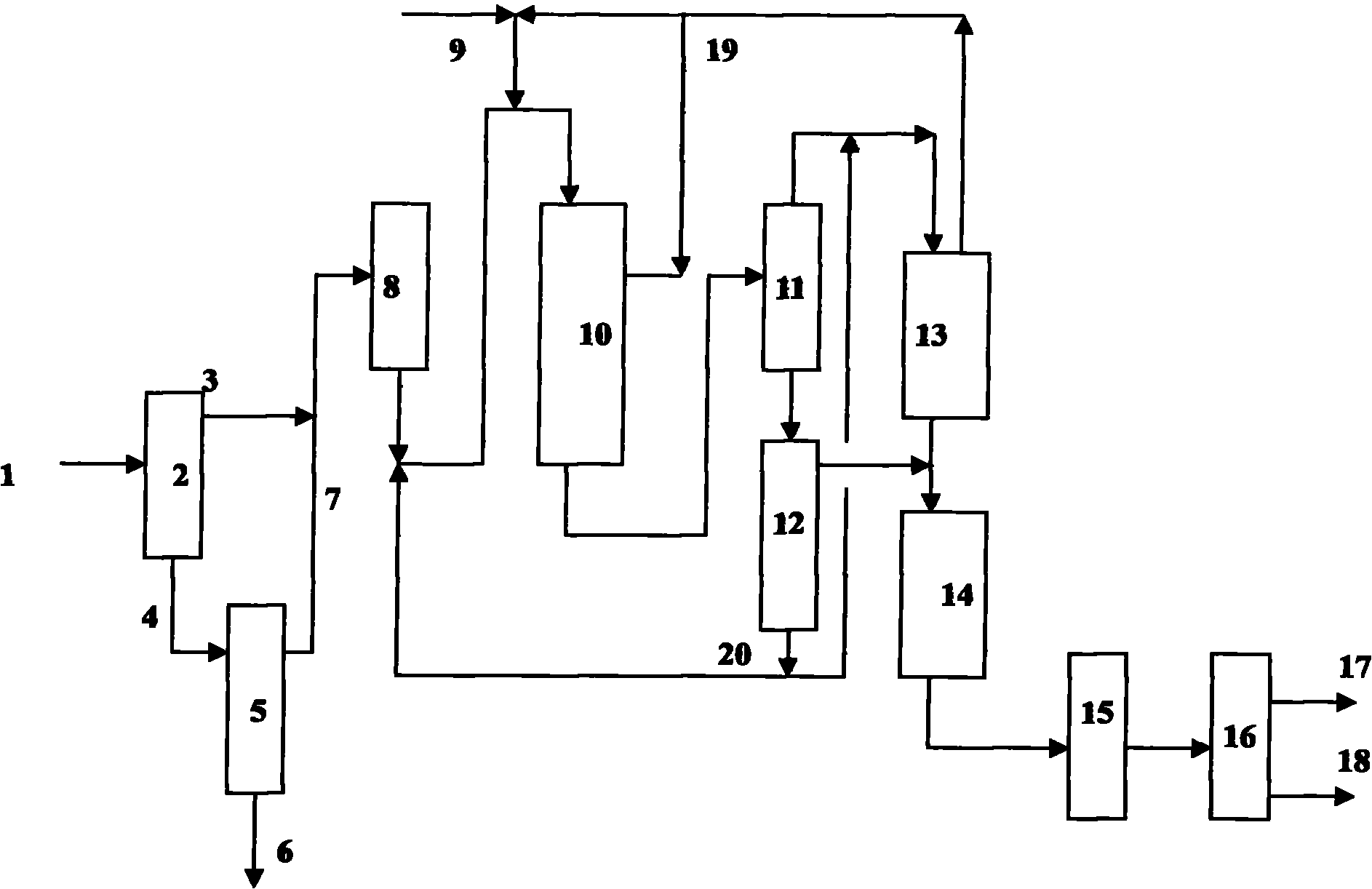

The invention relates to a method for hydrotreatment of continuous liquid-phase wax oil. Wax oil raw oil, an effluent from a reactor and hydrogen are mixed in mixers to form a mixture, hydrogen can be dissolved in hydrocarbon oil in a form of bubbles by virtue of hydrogen distributors arranged inside the mixers, the amount of hydrogen is higher than the saturated solubility of liquid or the total hydrogen consumption, a plurality of bed layers are arranged in the reactor, the mixers are arranged among the bed layers, the mixture and fresh hydrogen or a mixture of hydrogen and partial reaction products are mixed again, a partial effluent from the reactor is partially circulated and a partial effluent is subjected to cooling, separating and fractional distillation to obtain the product. By the method, the problems that reaction process is difficult to process due to the limitation on the solubility of hydrogen in the hydrocarbon oil and the chemical hydrogen consumption is relatively high are solved and the adaptability of raw oil is expanded and furthermore, under the condition of relatively low circulation ratio, low-sulfur refined wax oil can be produced to provide high-quality feedstock for catalytic cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

Trans free non-hydrogenated hard structural fat and non-hydrogenated hard palm oil fraction component

A trans free non hydrogenated high C-16 type palm fat suitable for the manufacture of trans free non hydrogenated hard structural fat that is being suitable for use in the manufacture of low SAFA (Saturated Fatty Acid) poly / mono unsaturated margarine and spreads and shortening and fat blends incorporating such hard Structural fat. The Structural fat is made from selectively fractionated non-hydrogenated high melting palm oil fraction with a C-16 fatty acid residue of at least 70%, which is subjected to chemical random interesterification using alkaline metal catalyst such as sodium methoxide / sodium methylate, with a dry fractionated non hydrogenated hard palm kernel stearin fraction. The structural fat that is produced has high yield ratios that can be economically and commercially incorporated in the oil blends for the manufacture of trans free margarine / spreads / shortening as well as other plastic W / O emulsions. Also described is a process for the manufacturing such structural fat as well as hard palm fraction including process for the manufacture of extra hard trans free structural fat by panning and pressing of above structural fat.

Owner:PREMIUM VEGETABLE OILS

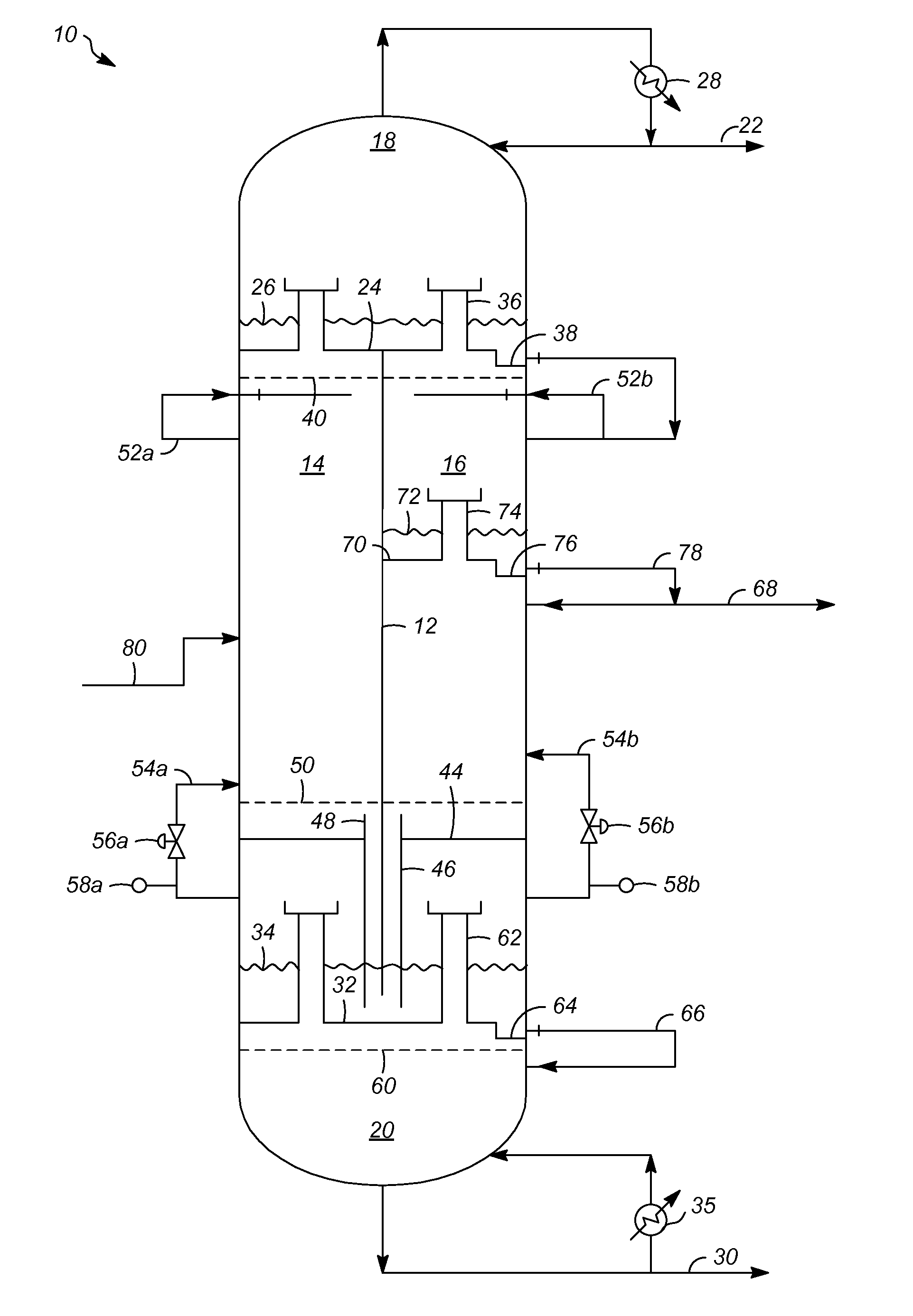

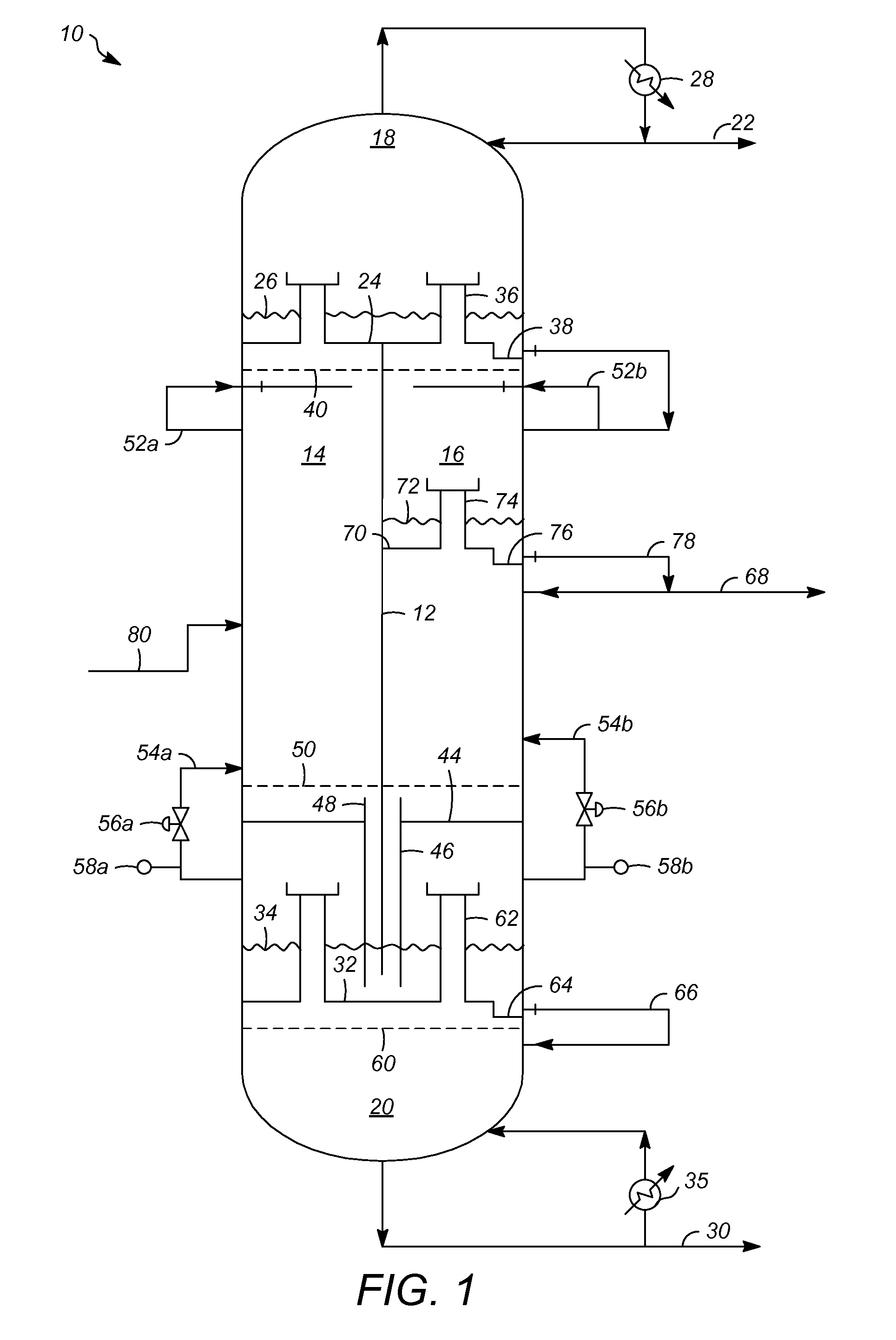

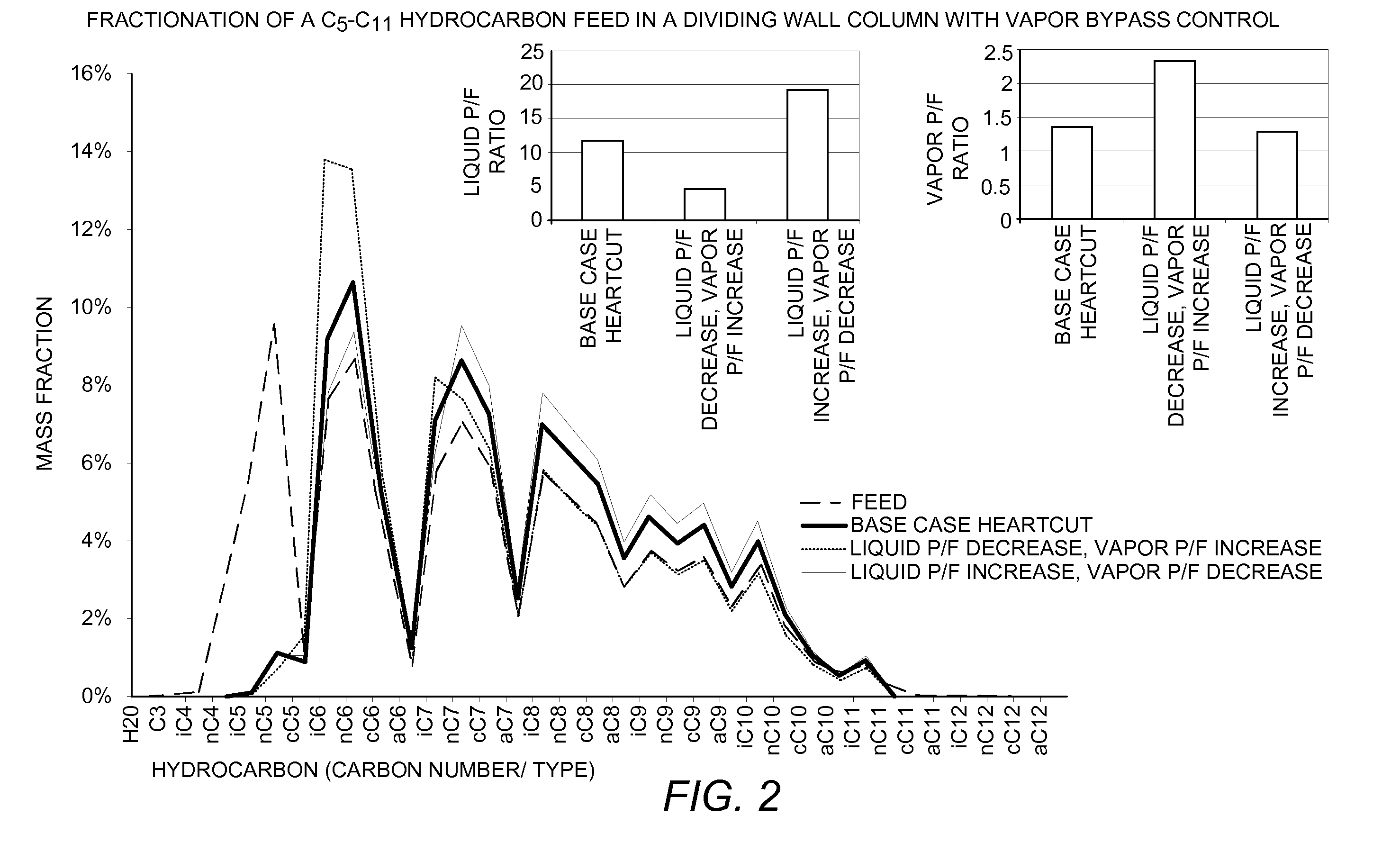

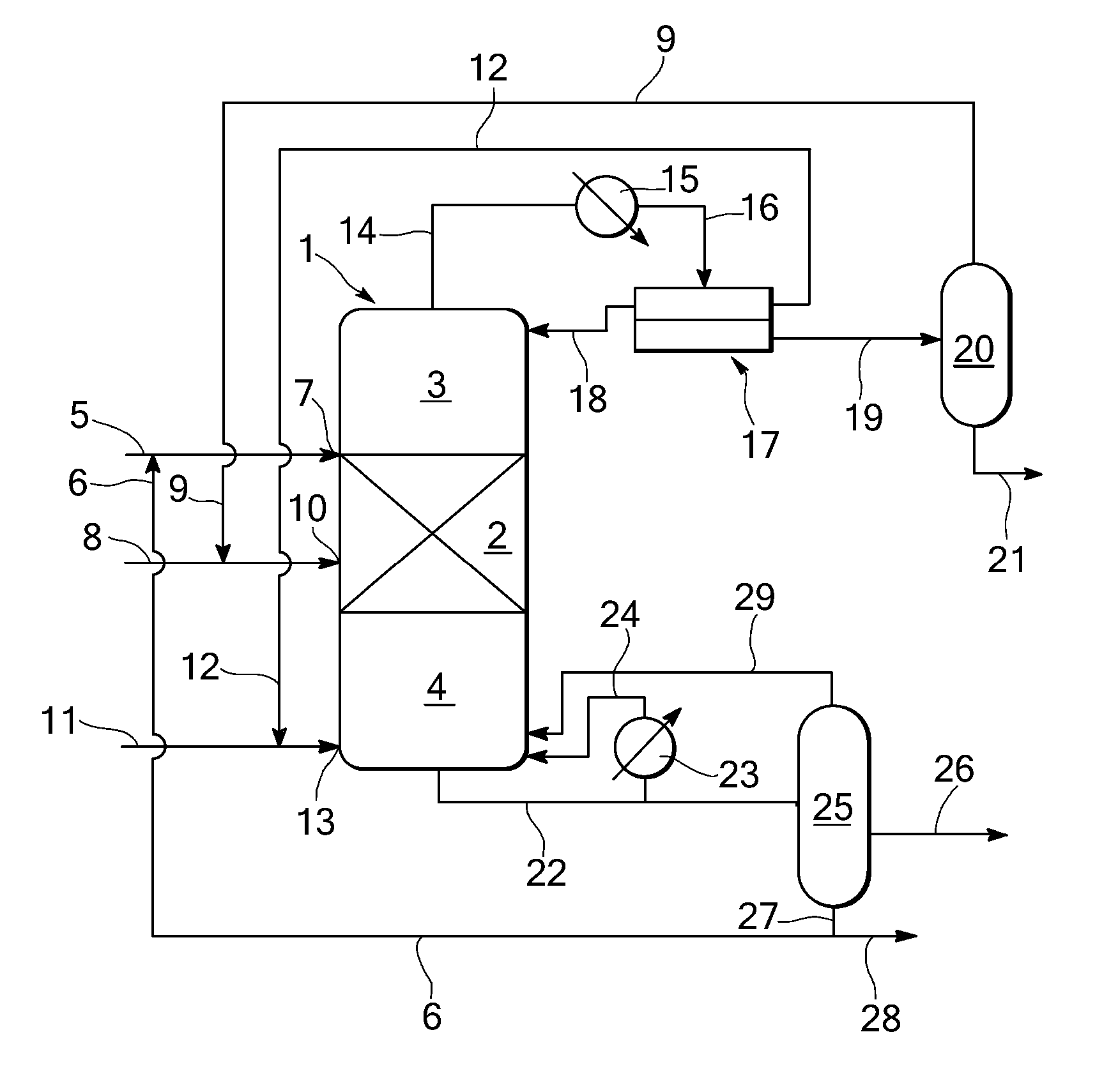

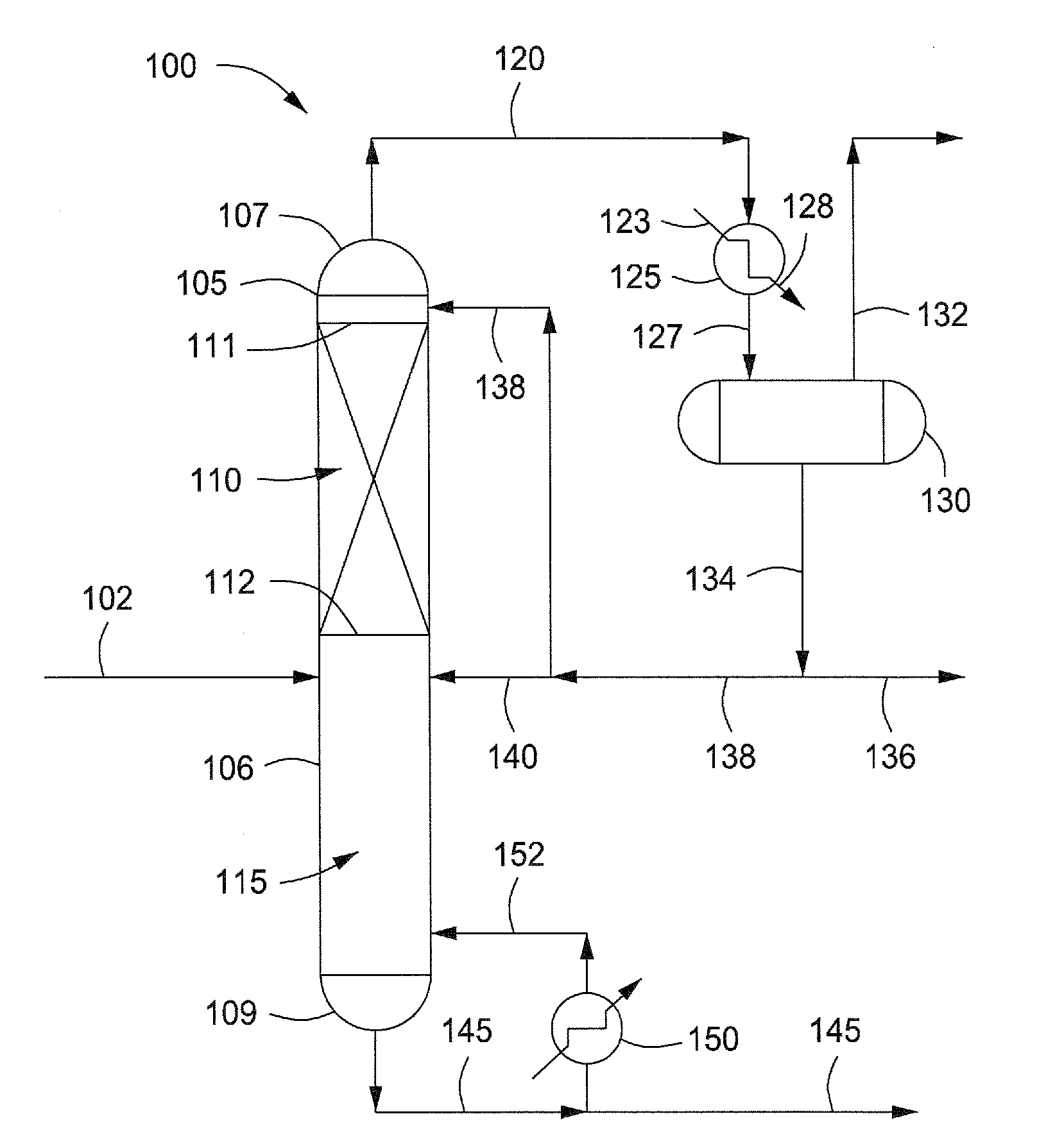

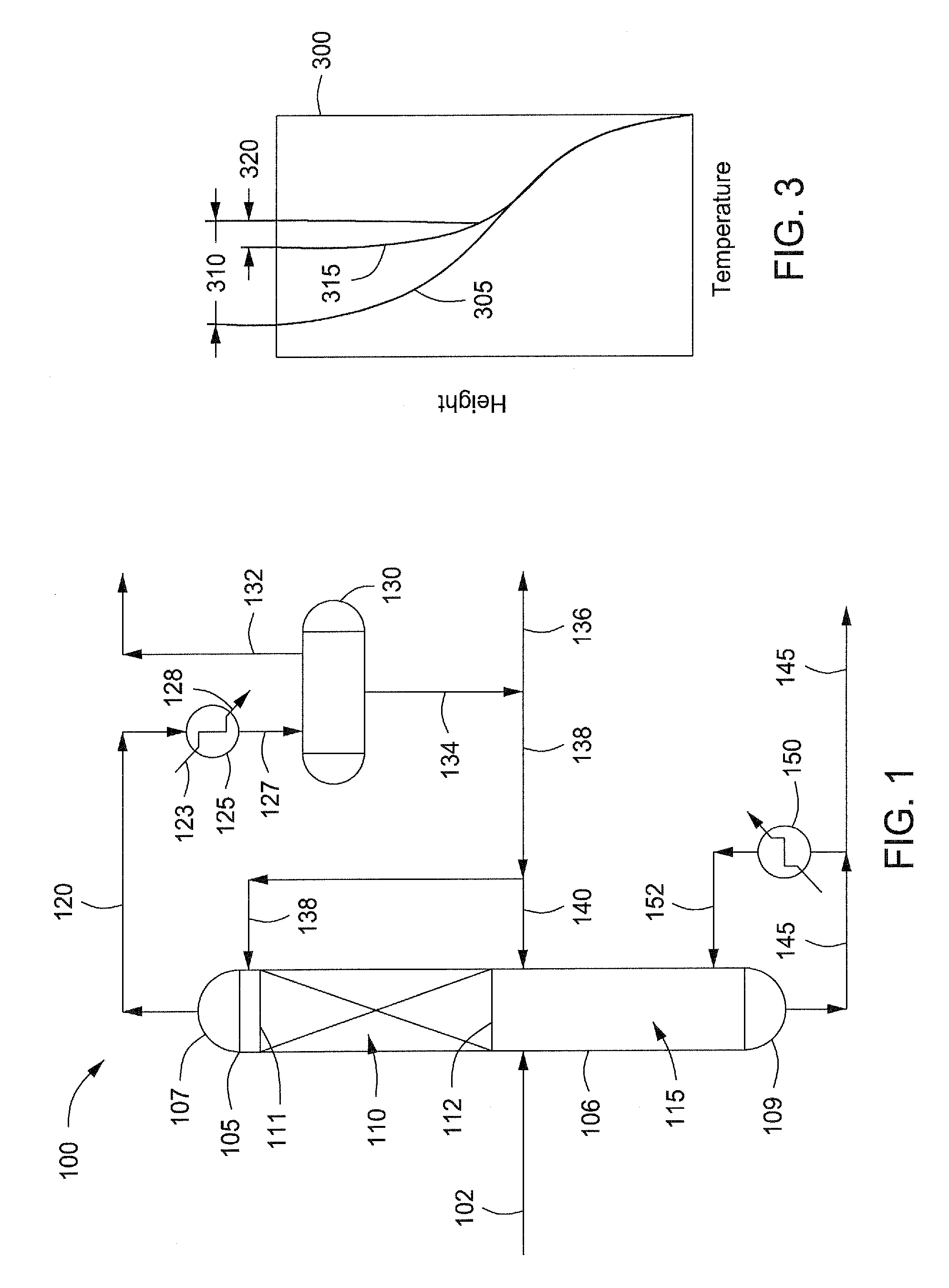

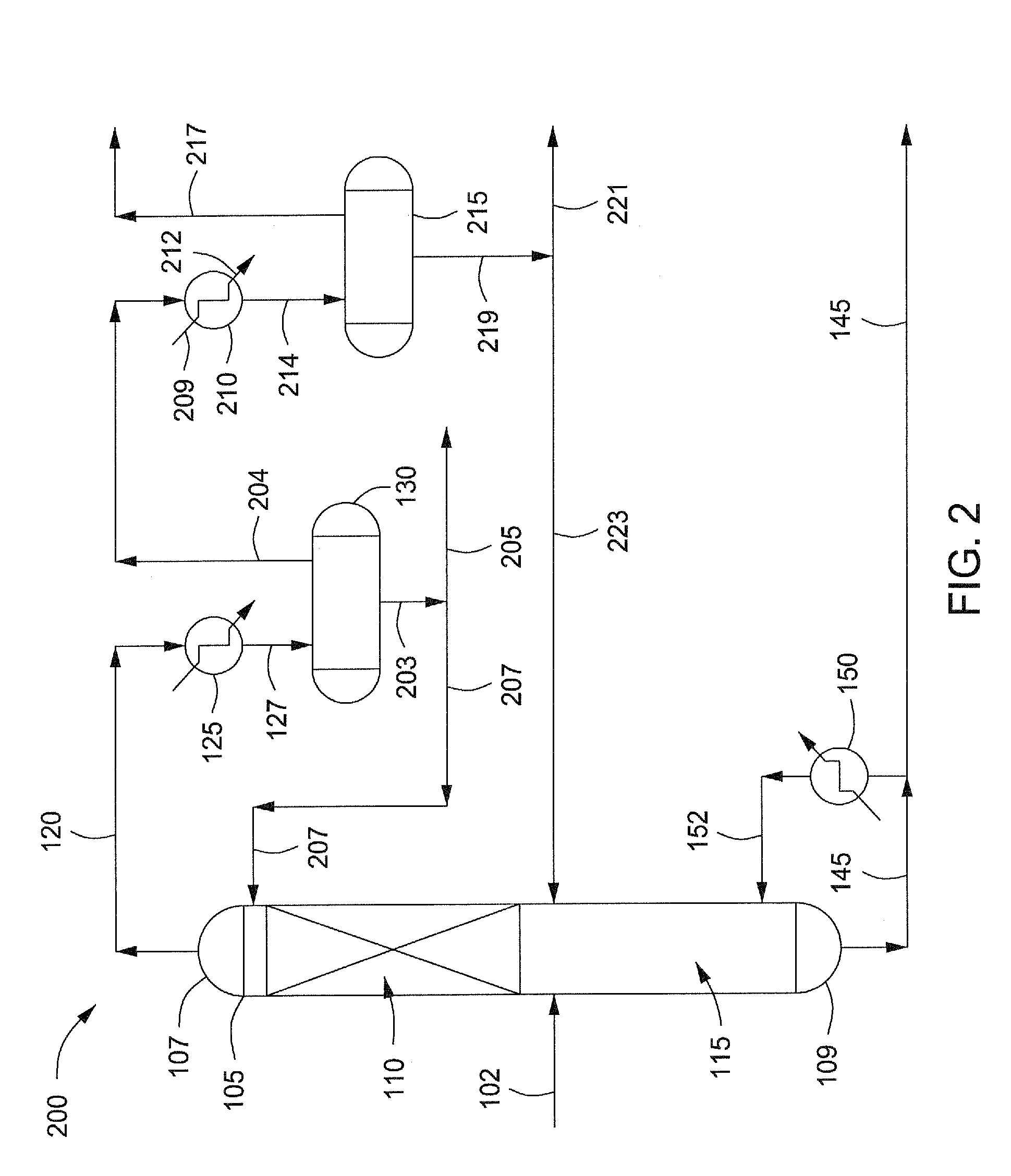

Vapor and liquid flow control in a dividing wall fractional distillation column

ActiveUS20120103013A1Good flexibilityEfficient changeSolidificationLiquefactionFractional distillationStreamflow

Dividing wall fractional distillation columns and methods of operating these columns with greater flexibility, especially in terms of the ability to adjust the composition of the heartcut, intermediate or sidecut product fraction, are described. In particular, this composition may be advantageously “biased” toward higher or lower molecular weight components, depending on operating needs. Changes in feedstock composition may also be managed more effectively. These benefits are obtained by varying the flow rate of vapor and liquid to each side of the dividing wall. The vapor flowrate rising from an undivided portion of the column interior below the dividing wall is varied to the feed and / or product sections on opposite sides of the dividing wall. Also, the liquid flowrate falling from an undivided portion of the column interior above the dividing wall is varied to the feed and / or product sections on opposite sides of the dividing wall.

Owner:UOP LLC

Waste lubricating oil hydrogenation reproducing method

InactiveCN101041789AImprove qualityAchieve hydrogenation saturationLubricant compositionRefining to eliminate hetero atomsColloidBase oil

The invention discloses a waste fluid oil hydrogenation reclaiming method, which comprises the following steps: choosing the waste fluid oil as raw material; dewatering; filtering; proceeding adsorption procession; stripping moisture, mechanical impurity, colloid, asphaltene and most of heavy metal impurities; proceeding pre-hydrofining in the reactor with preservative; further-stripping impurity; leading the waste fluid oil into hydrogenation primary reactor; realizing hydrofining under the function of hydrogenation catalyst; making the non-ideal component of raw oil hydrogenation saturation; getting product yield; proceeding fractional distillation and cutting. This invention possesses merits of convenient operation and clean environment, which can make the reclaiming ratio reach above 90%.

Owner:京福马(北京)石油化工高新技术有限公司

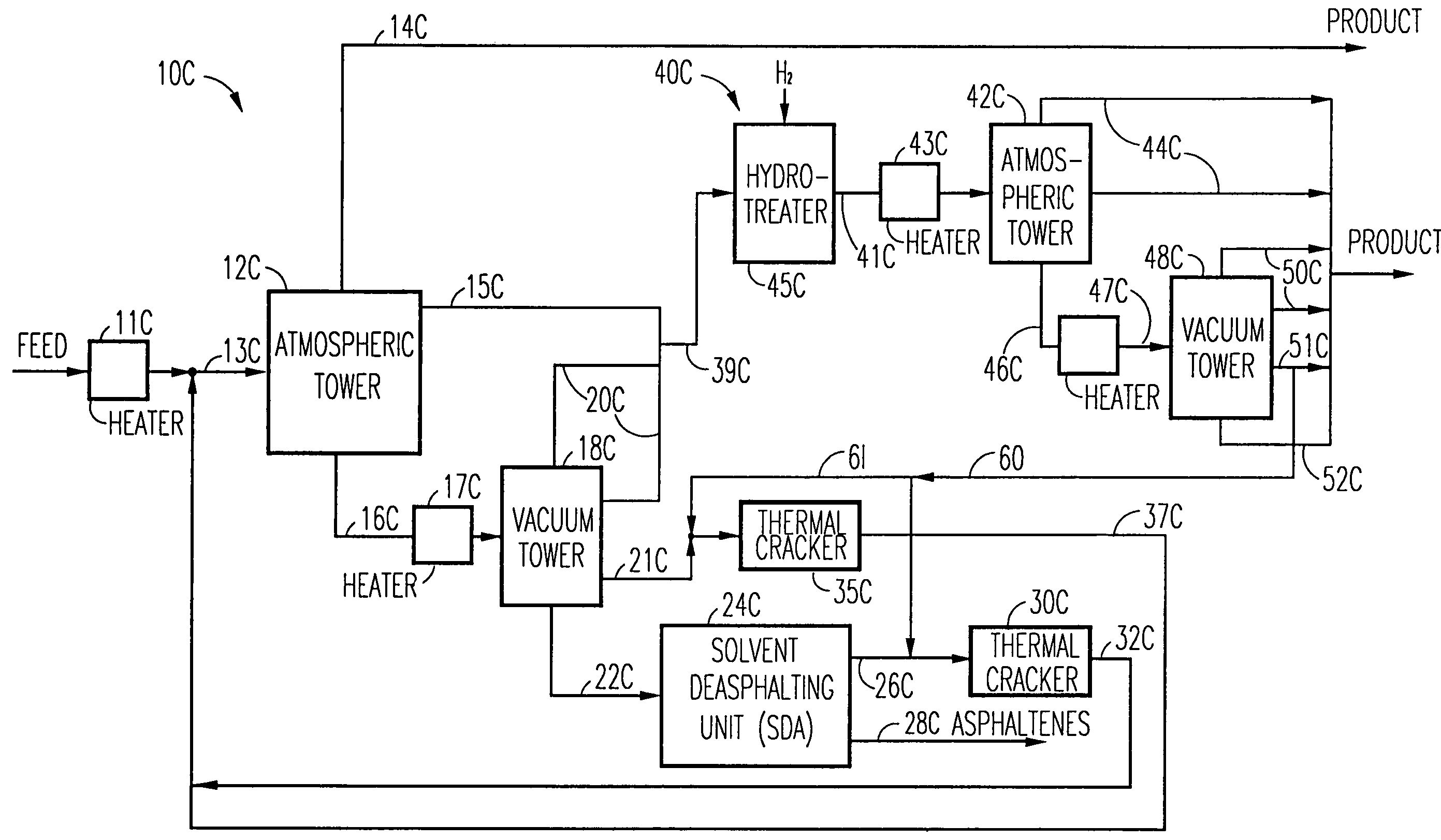

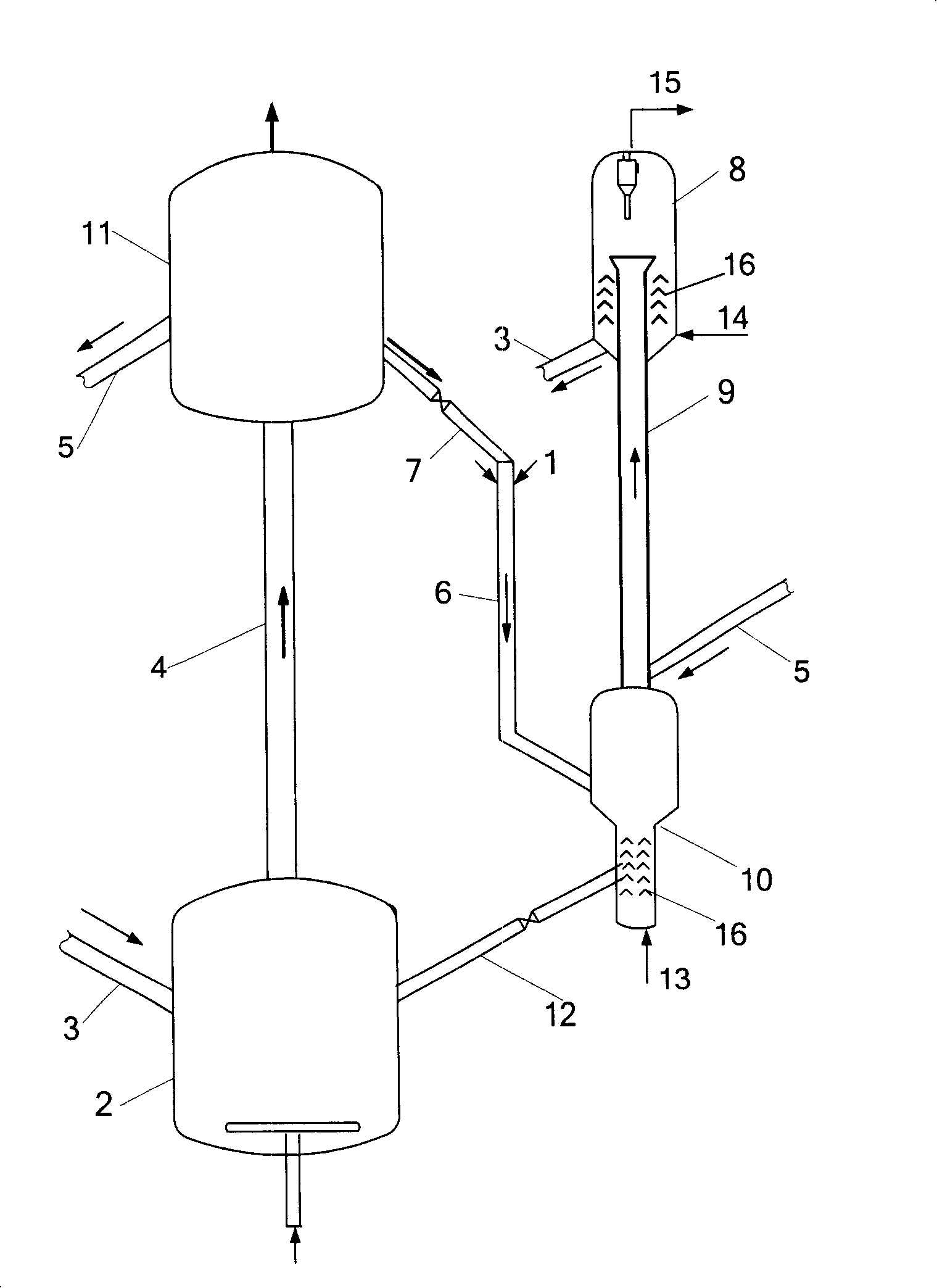

Method of and apparatus for processing heavy hydrocarbon feeds

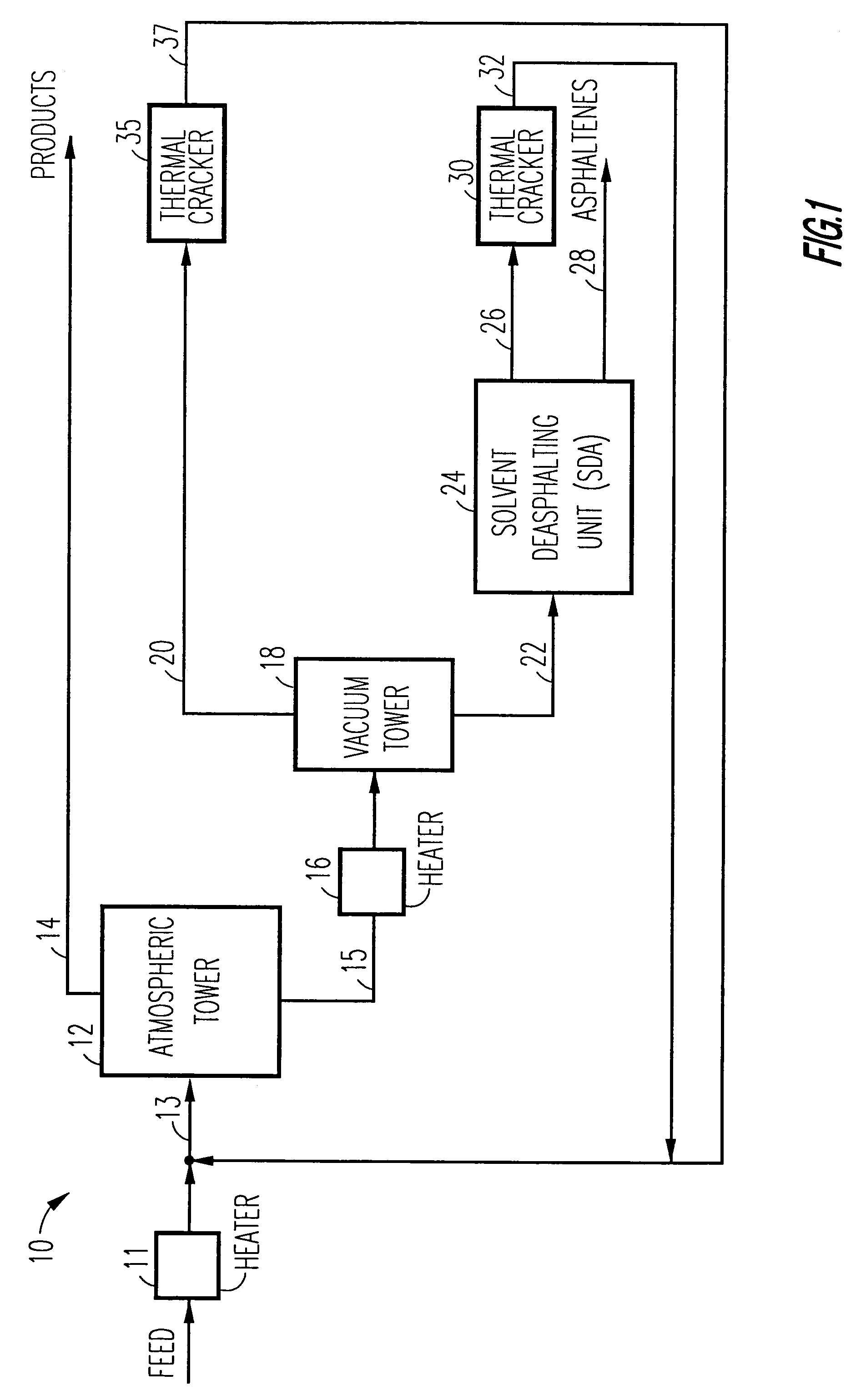

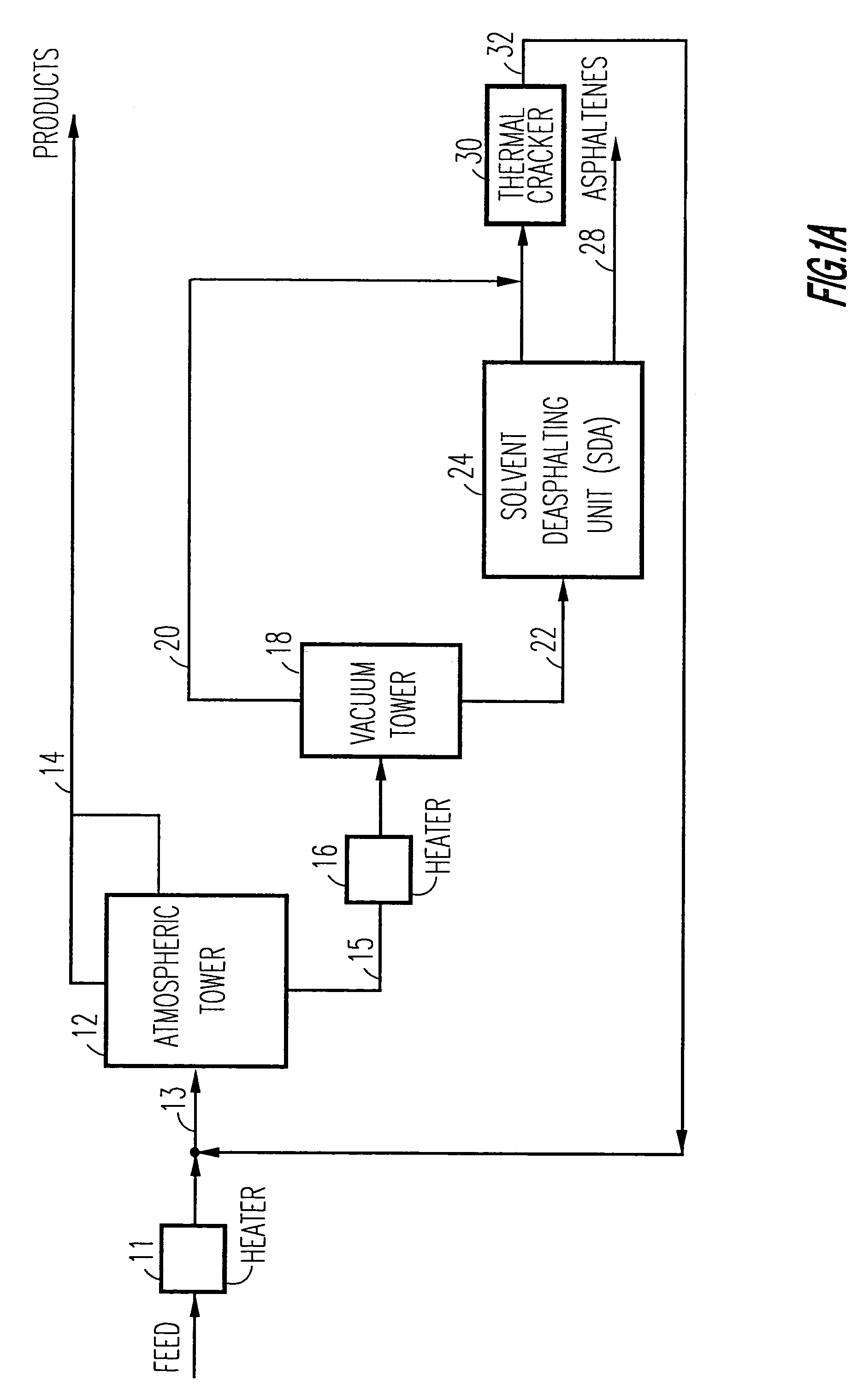

InactiveUS7297250B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyTowerSolvent

The present invention comprises a method for processing a heavy hydrocarbon feed including: supplying the heavy hydrocarbon feed to a heater for heating the heavy hydrocarbon feed; supplying the heated heavy hydrocarbon feed to an atmospheric fractionating tower for fractionating the heated heavy hydrocarbon feed fed to the inlet of the atmospheric fractionating tower producing light atmospheric fractions and atmospheric bottoms; supplying the atmospheric bottoms to a further heater for heating the atmospheric bottoms and producing heated atmospheric bottoms; supplying the heated atmospheric bottoms to a vacuum fractionating tower for fractionating the heated atmospheric bottoms and producing light vacuum fractions and vacuum residue; supplying the vacuum residue to a solvent deasphalting (SDA) unit for producing deasphalted oil (DAO) and asphaltenes from the vacuum residue; supplying the deasphalted oil to a deasphalted oil thermal cracker for thermally cracking the deasphalted oil and producing a thermally cracked product which is recycled only to the inlet of the atmospheric fractionating tower; and supplying the light vacuum fractions to a light vacuum fraction thermal cracker for thermally cracking the light vacuum fractions for producing a further cracked product which is recycled only to the inlet of the atmospheric fractionating tower.

Owner:ORMAT IND LTD

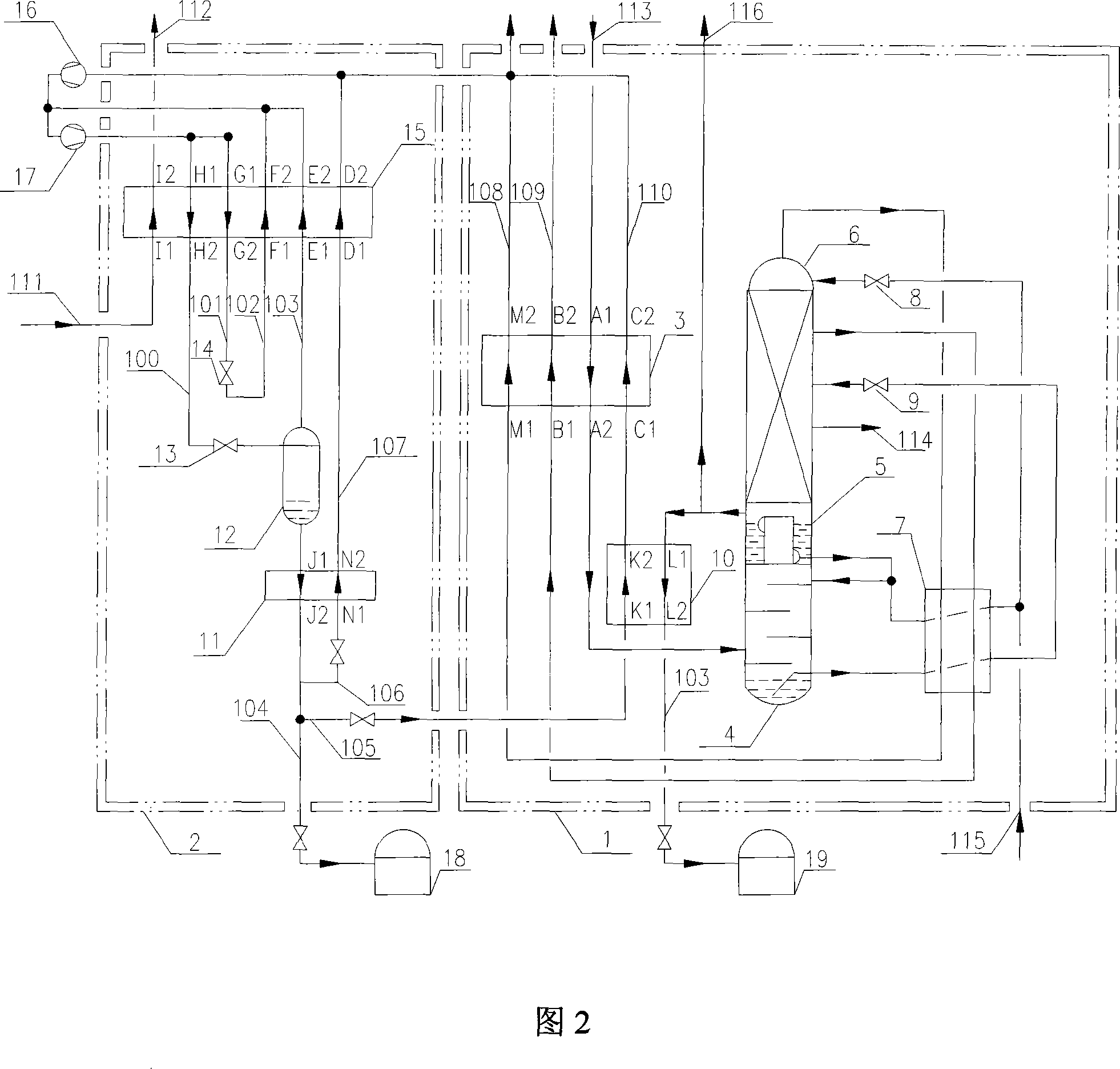

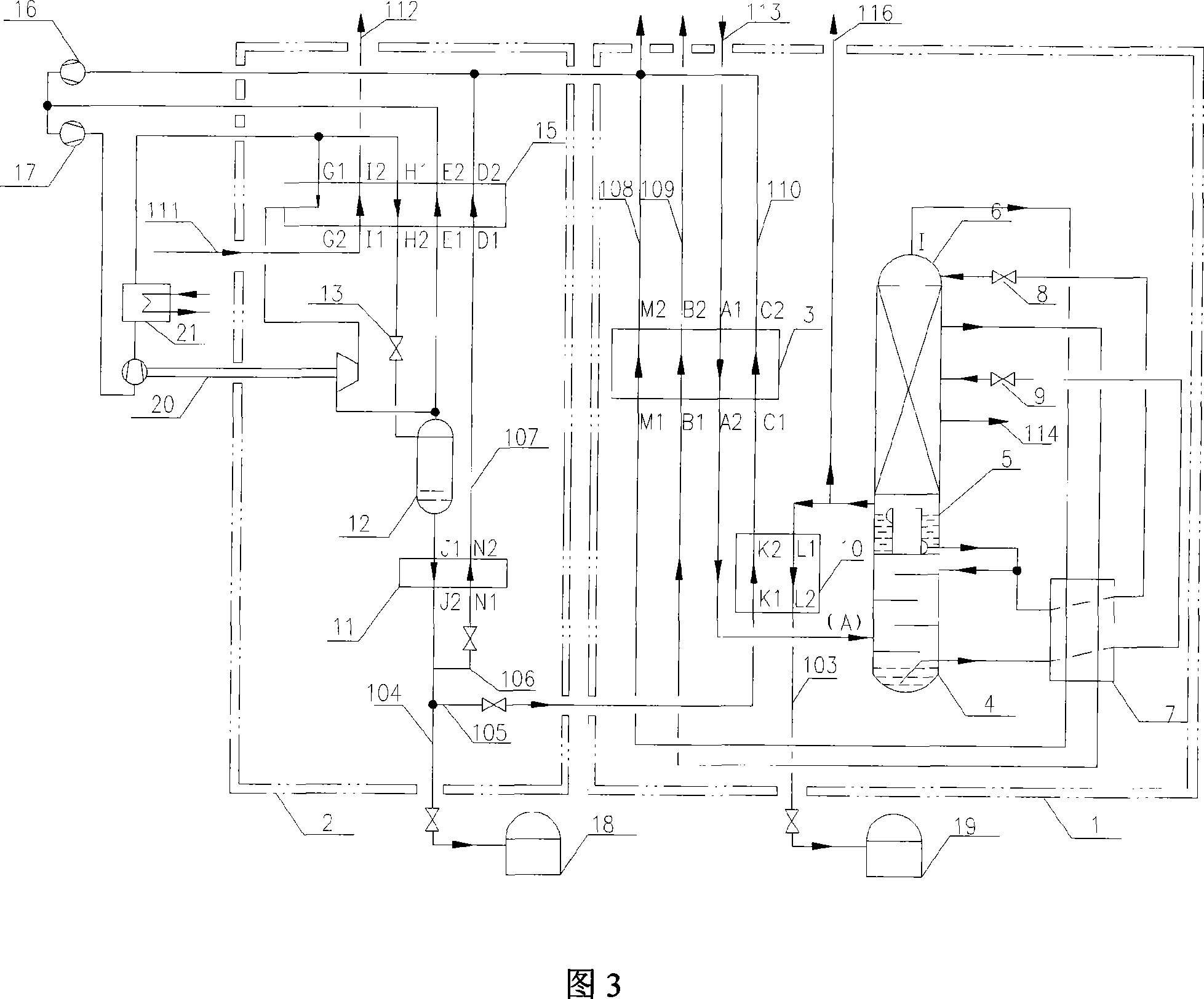

Air separation system for generating liquid oxygen and liquid nitrogen

This kind of air separation system obtaining liquid oxygen and liquid nitrogen at least includes an air separator mainly consisting of a fractionating tower and at least includes an equipment for recovering cold energy of liquefied natural gas mainly consisting of an liquefied natural gas heat exchanger, which still includes main heat exchanger, liquid-oxygen heat exchanger and liquid-nitrogen liquid air subcooler; oxygen is drawn out from the underpart of the upper column on the fractionating tower, and cools and liquefied in the liquid-oxygen heat exchanger as the liquid oxygen products; after nitrogen from the top of the upper column passes through a liquid-nitrogen liquid air subcooler and is reheated by main heat exchanger, some nitrogen enters into liquefied-natural-gas heat exchanger to recool and exchange heat to become high pressure nitrogen through primary compression and pressurization at least. And through throttling expansion and air-liquid separator, nitrogen and liquid nitrogen participate in recycling and other nitrogen as liquid-nitrogen products; energy consumption is reduced notably after using actually, power consumption which produces liquid oxygen of 1kg is 0.39kwh, while the power consumption of the traditional equal air separator is 1.0 to 1.25kwh, which is 2.4 to 3 times than the separator. And it is easy to popularize and apply.

Owner:HANGZHOU HANGYANG

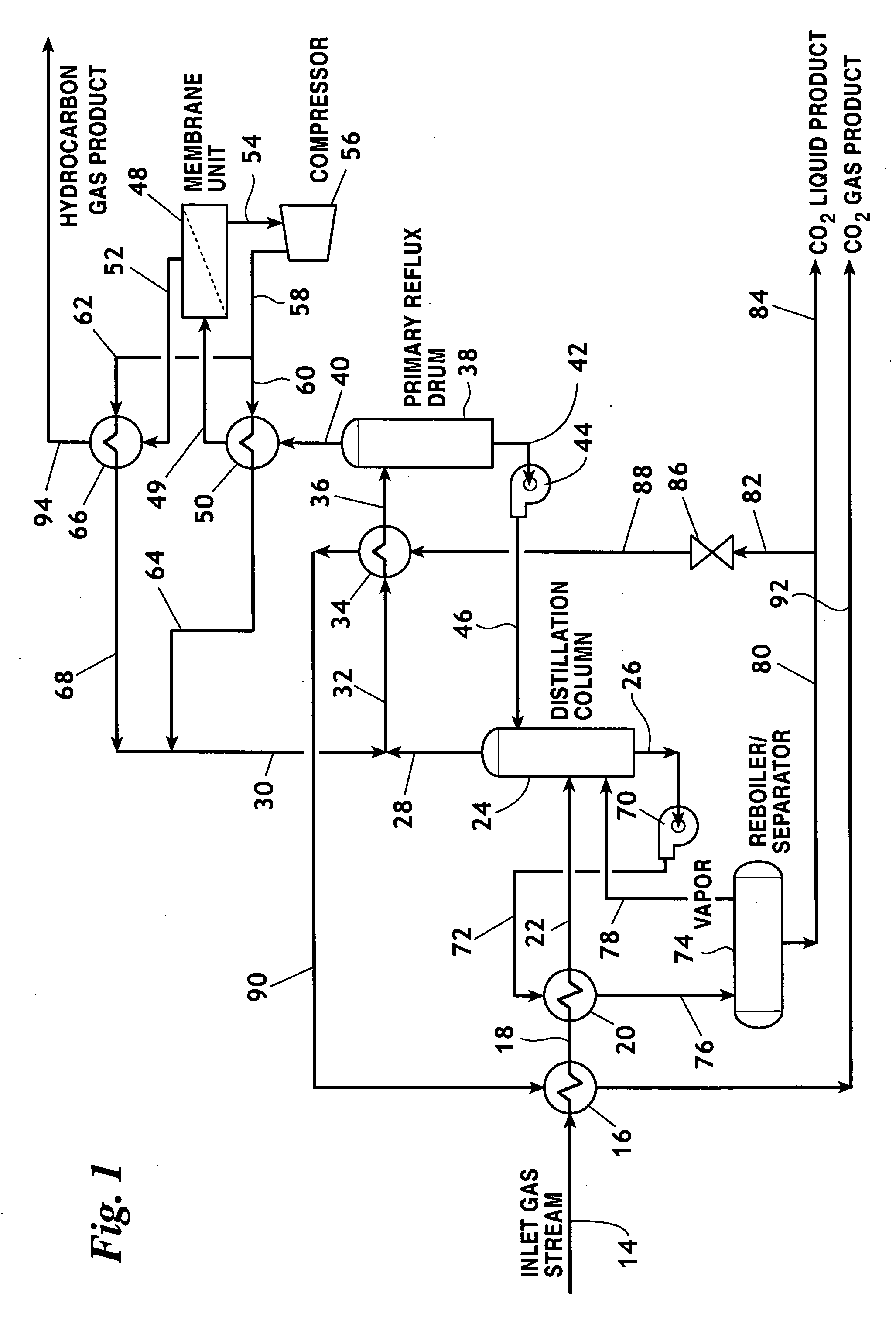

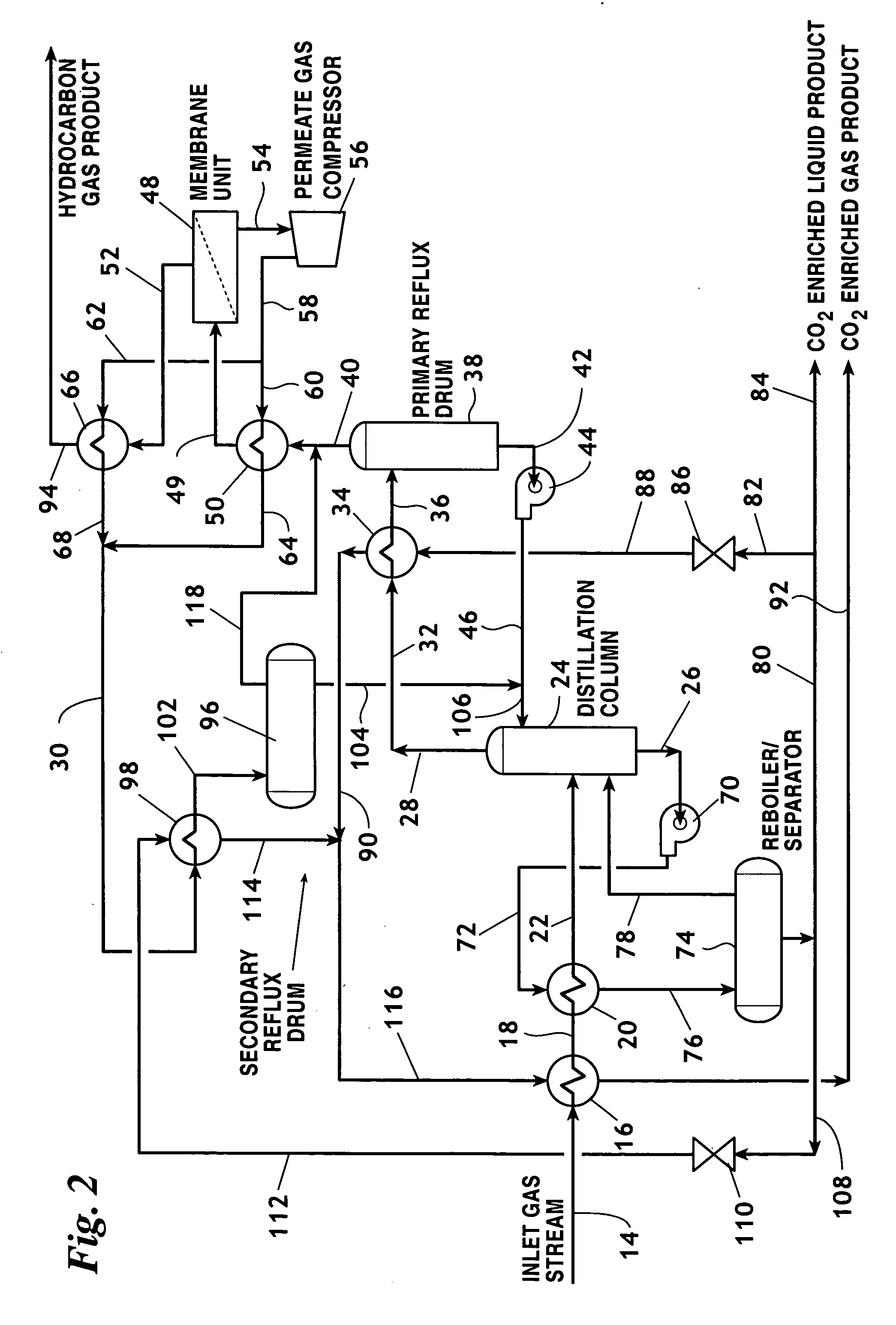

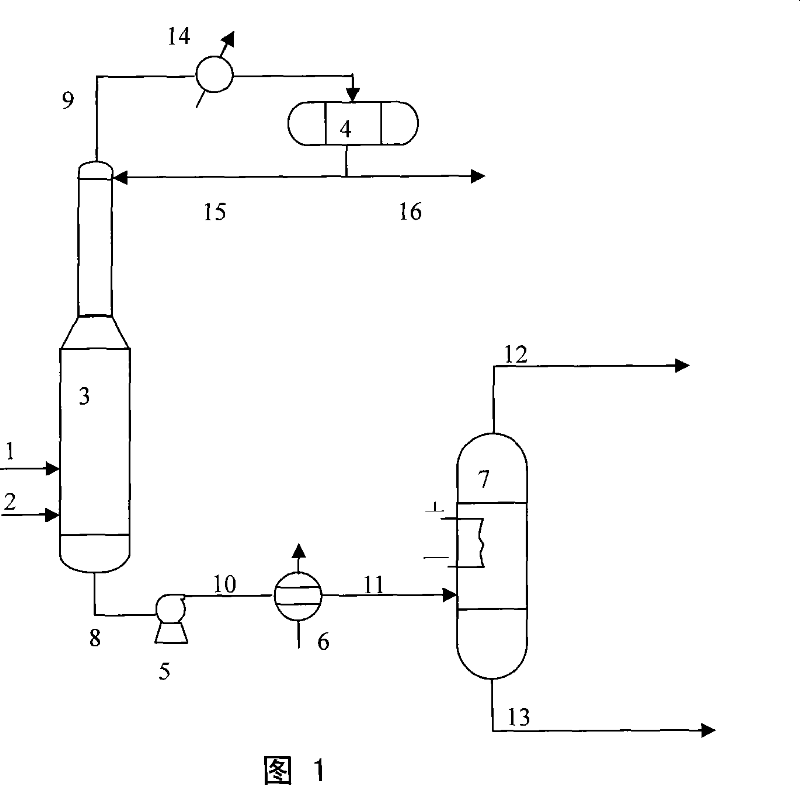

Membrane/distillation method and system for extracting CO2 from hydrocarbon gas

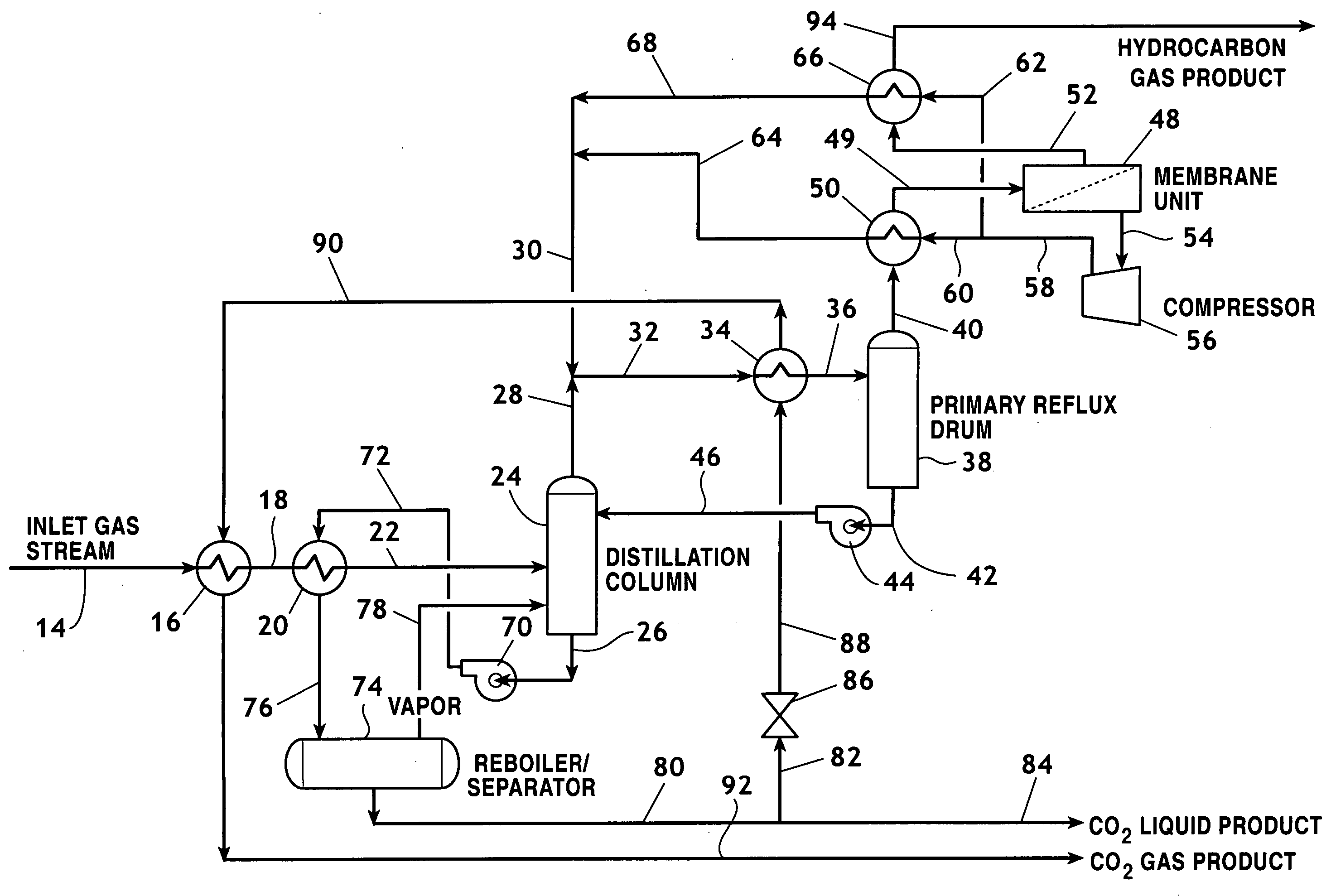

ActiveUS20050092594A1Improve performanceReduce hydrocarbon lossSolidificationLiquefactionLiquid productReflux

A method of separating CO2 from a hydrocarbon gas inlet stream that is within predetermined pressure and temperature ranges, including the steps of subjecting the inlet stream to fractional distillation providing a CO2 bottom product stream and a distillation overhead stream, passing the distillation overhead stream to the inlet of a primary reflux drum producing a primary reflux liquid stream and a hydrocarbon vapor stream, subjecting the hydrocarbon vapor stream to membrane separation to provide a hydrocarbon product stream and a permeate stream, compressing the permeate stream and recycling the compressed permeate stream to the inlet of the primary reflux drum thereby providing a CO2 liquid product and a hydrocarbon gas product.

Owner:NAT TANK

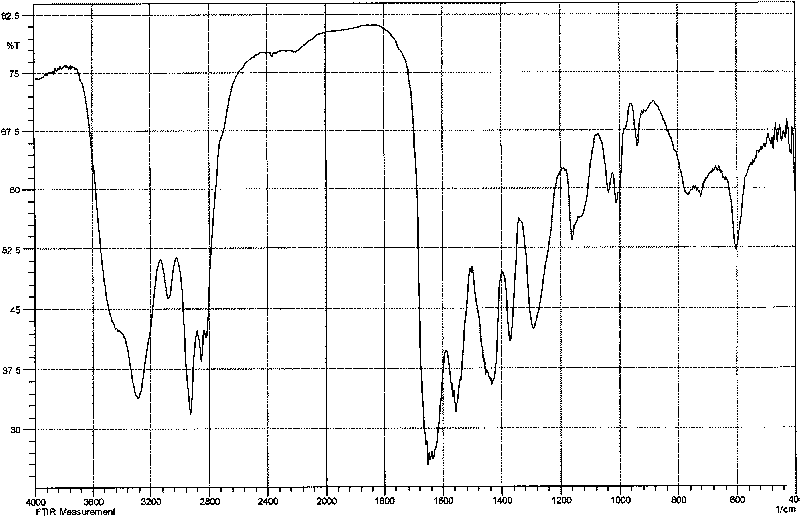

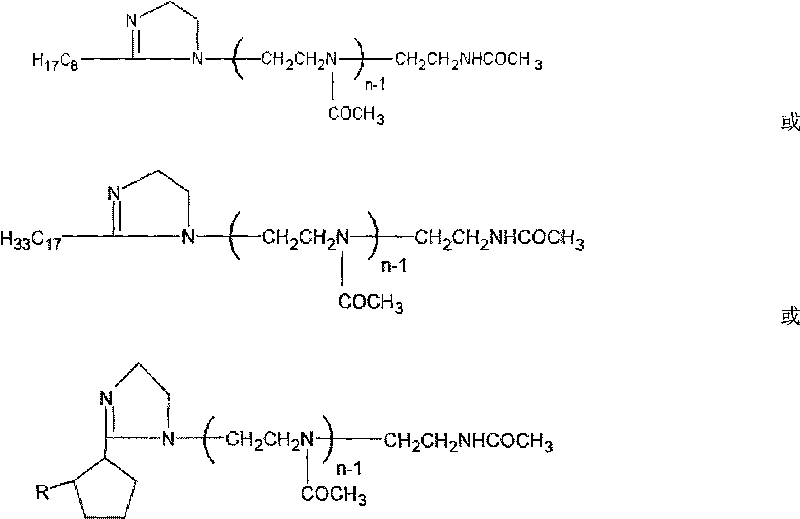

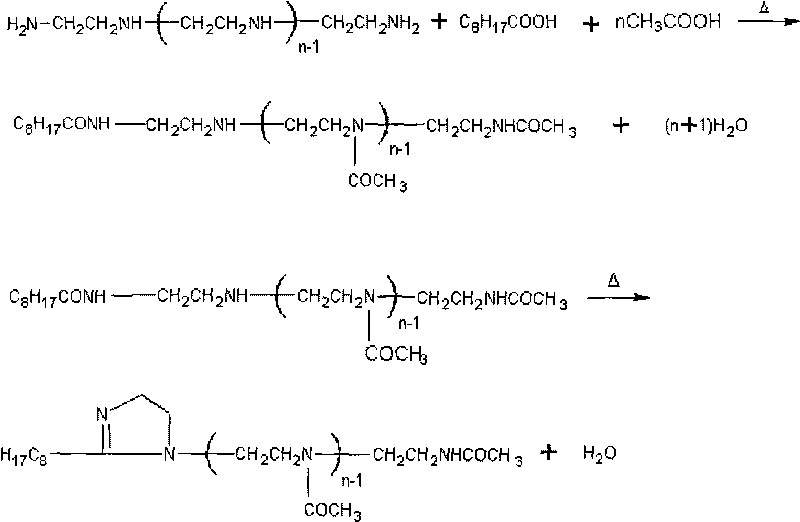

Water-soluble imidazoline amide corrosion inhibitor, preparation method thereof and using method thereof

InactiveCN101705112AEasy to useLow costOrganic chemistryTreatment apparatus corrosion/fouling inhibitionFatty acidRaw material

The invention provides a water-soluble imidazoline amide corrosion inhibitor, a preparation method thereof and a using method thereof, and belongs to the technical field of oil refining. The corrosion inhibitor consists of the following components in percentage by mass: 10 to 30 percent of water-soluble imidazoline amide, 0 to 15 percent of ethylene diamine, 0 to 20 percent of ammonia water with a mass concentration of 25 to 28 percent, 0 to 20 percent of ethanol and 40 to 90 percent of water, wherein the water-soluble imidazoline amide is prepared by the amidation reaction and the ring-closing reaction of polyethylene polyamines, glacial acetic acid and fatty acid serving as raw materials and toluene serving a solvent. When the corrosion inhibitor is continuously added to the top part of a primary distillation tower, the top part of a atmospheric distillation tower, the top part of a vacuum distillation tower or the top part of a hydrogenation fractional distillation tower of an oil refinery, the corrosion of a HCL-H2S-H2O medium on the top part of the tower is inhibited, and simultaneously, the quality of products on the top part of the tower is not affected. In the method for preparing the corrosion inhibitor, water is used as the solvent, so that the method has the advantages of being safely used, having low cost and facilitating the addition of a neutralizing agent.

Owner:SHENYANG POLYTECHNIC UNIV +1

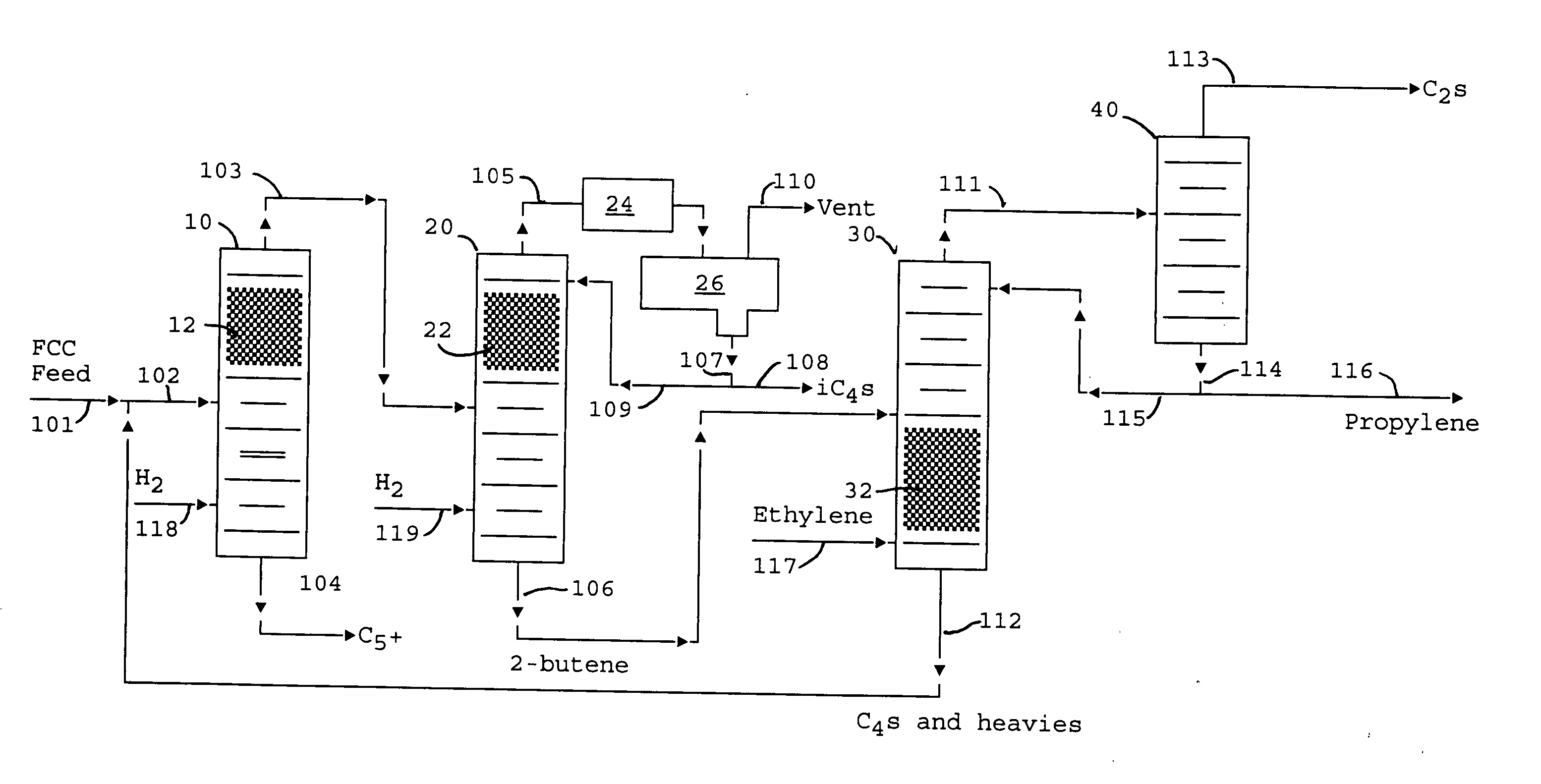

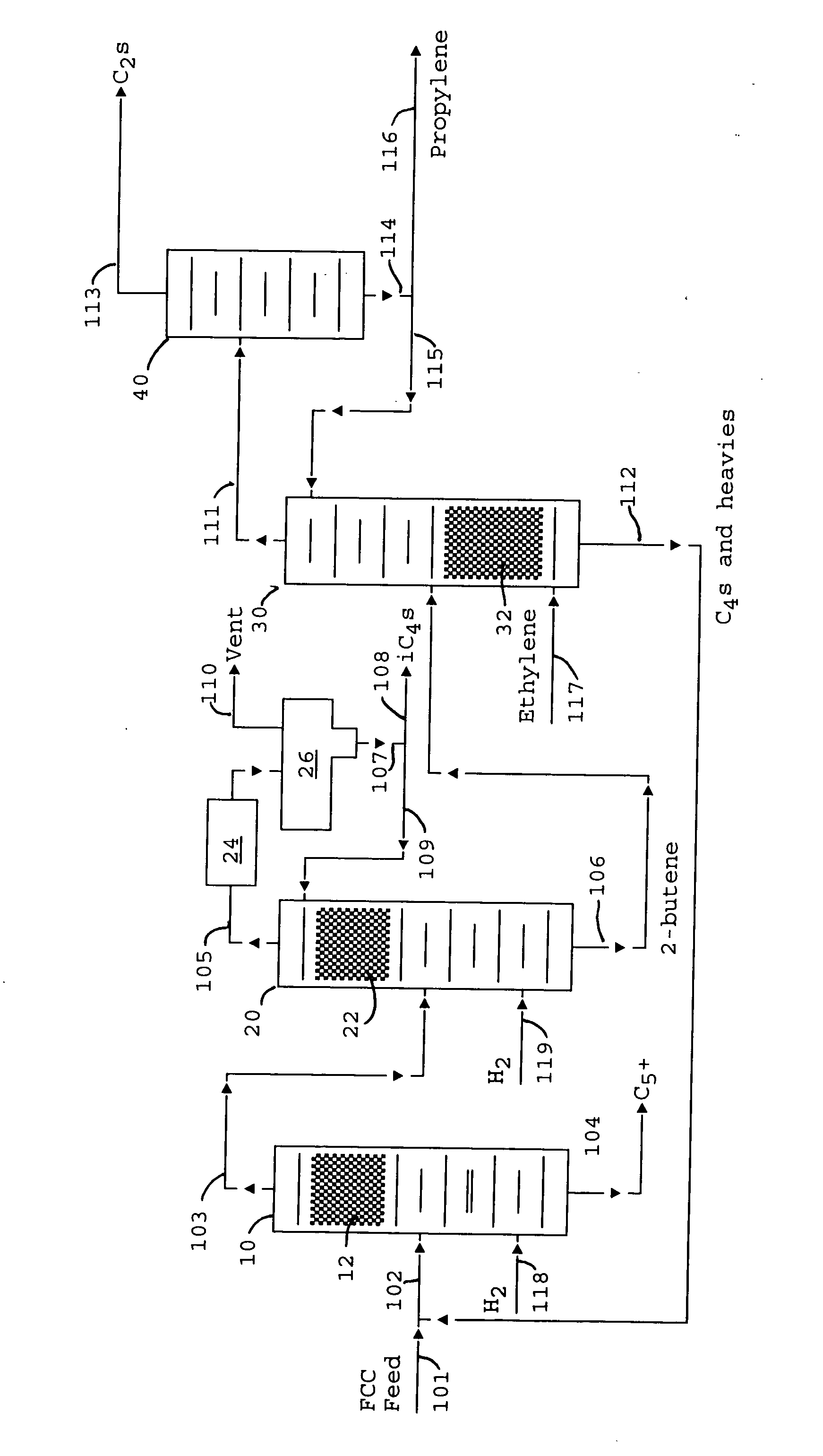

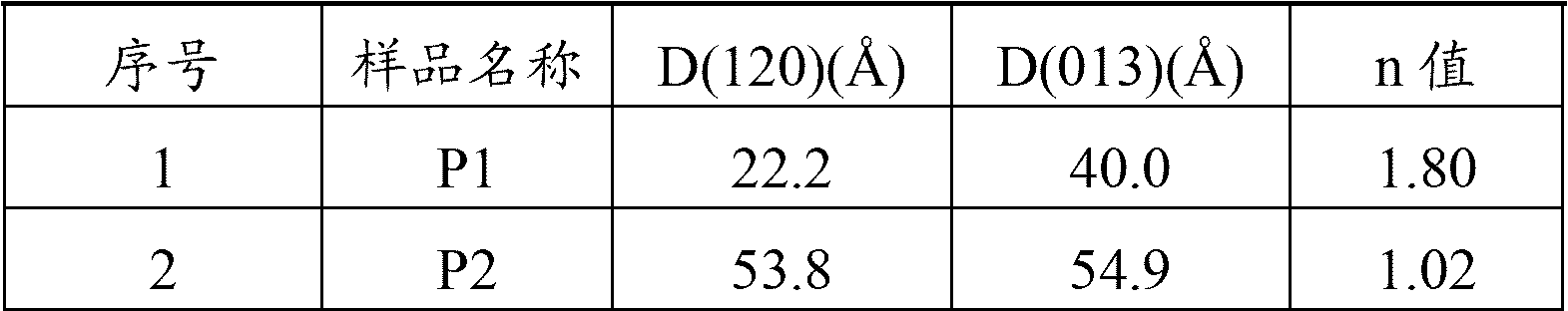

Olefin metathesis

InactiveUS20060089517A1Solution to short lifeHydrocarbon by metathesis reactionHydrocarbonsIsomerizationThiol

A process for the production of propylene from the metathesis of ethylene and 2-butene is disclosed wherein a mixed C4 stream is first treated to enrich and separate the 2-butene from 1-butene and isobutene by isomerization of 1-butene and concurrent fractional distillation of the 2-butene and isobutene to provide the 2-butene feed the metathesis with ethylene. In addition the mixed C4 stream may be treated to remove mercaptans and dienes prior to 2-butene enrichment.

Owner:CHEM RES & LICENSING CO

System integrating air separation with cool capacity recovery of liquefied natural gas

ActiveCN101033910AReduce energy consumptionGuaranteed safe operationSolidificationLiquefactionNitrogen gasCooling capacity

This kind of system separating air and recovering cold energy of liquefied natural gas at least includes an air separator mainly consisting of a fractionating tower and at least includes an equipment for recovering cold energy of liquefied natural gas mainly consisting of an liquefied natural gas heat exchanger, which still includes main heat exchanger, liquid-oxygen heat exchanger and liquid-nitrogen liquid air subcooler; nitrogen drawing out from the underpart of the upper column on the fractionating tower passes through liquid-nitrogen liquid air subcooler and reheated by main heat exchanger, and enters into liquefied-natural-gas heat exchanger to precool and exchange heat; the equipment recovering cold energy of liquefied natural gas at least includes air-liquid separator and liquid nitrogen subcooler, which is placed in a single ice chest II; while main heat exchanger, liquid-oxygen heat exchanger, liquid-nitrogen liquid air subcooler and fractionator consisting of the lower column, the upper column and main evaporator are placed in an ice chest I; it fully utilizes high-grade cooling capacity of liquefied natural gas, and makes energy consumption of air separator reduce notably and ensures it operate safely, and can get the great society and economy benefits.

Owner:HANGZHOU HANGYANG

Process for reducing the toxicity of hydrocarbons

InactiveUS20050197256A1Low toxicityHydrocarbon by isomerisationHydrocarbon distillationFractional distillationHydrocarbon

This invention relates to a method for reducing the toxicity of a mixture of hydrocarbons by means of fractional distillation, a distillate having a reduced toxicity and a composition including the distillate.

Owner:THE PETROLEUM OIL & GAS CORP OS SOUTH AFRICA PTY LTD

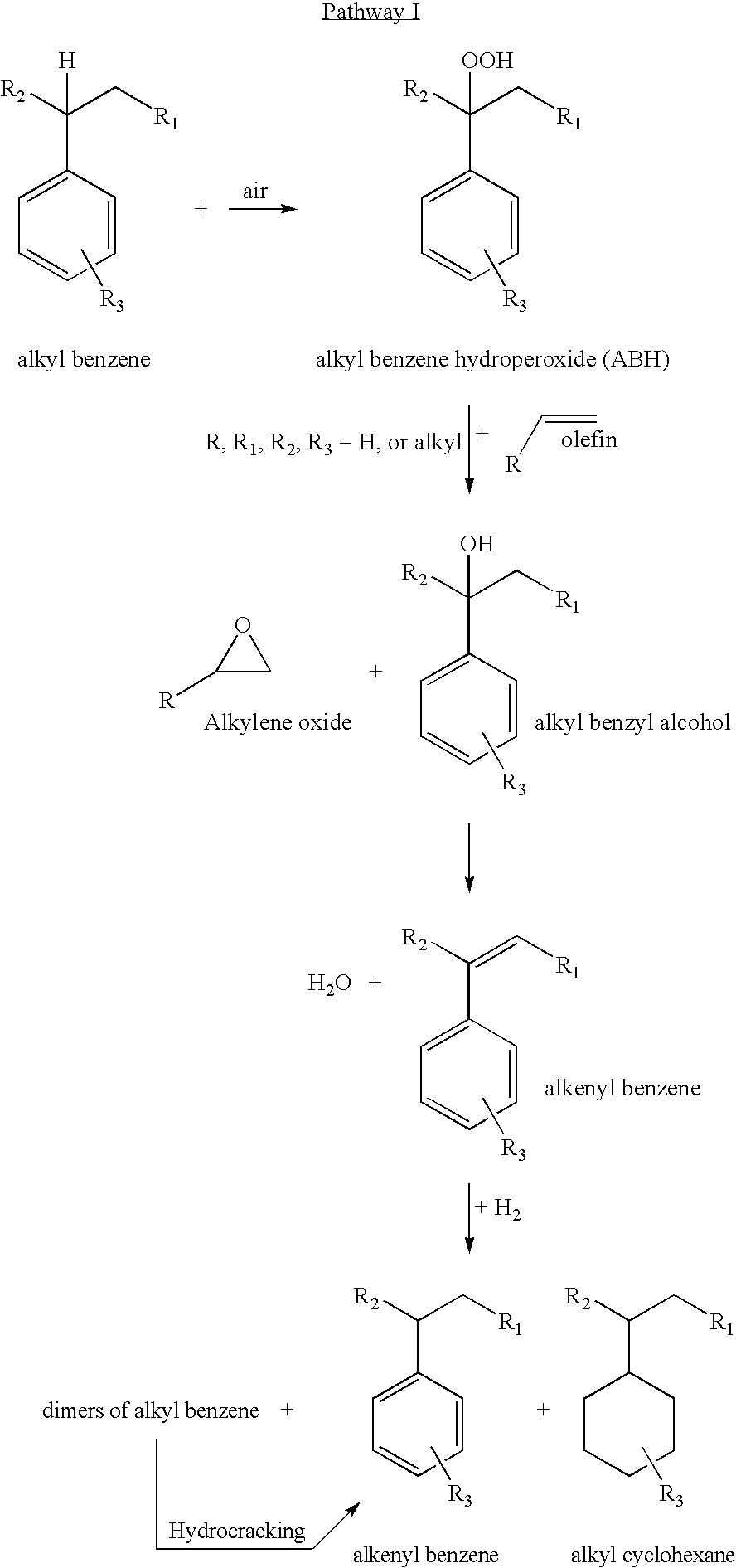

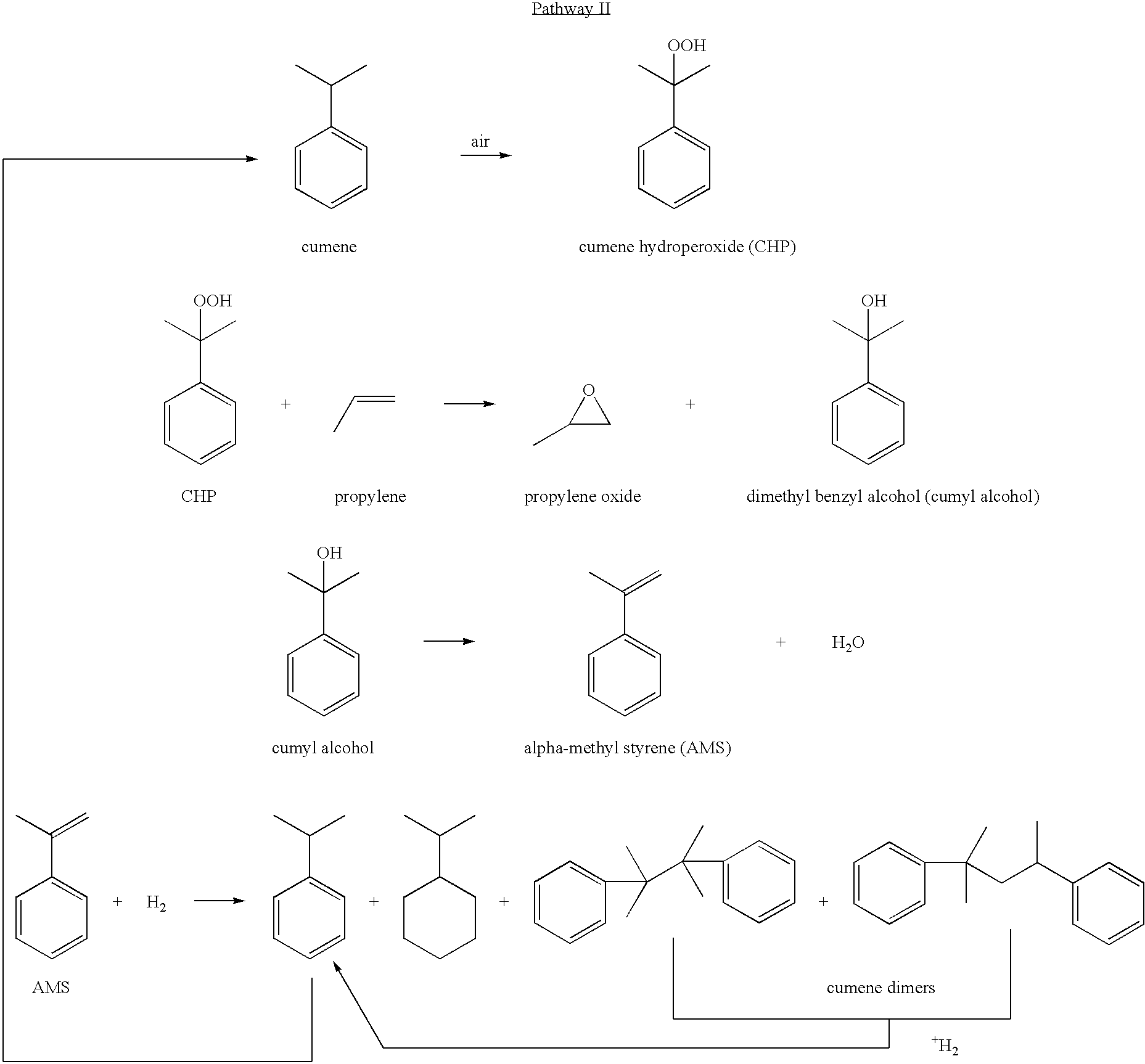

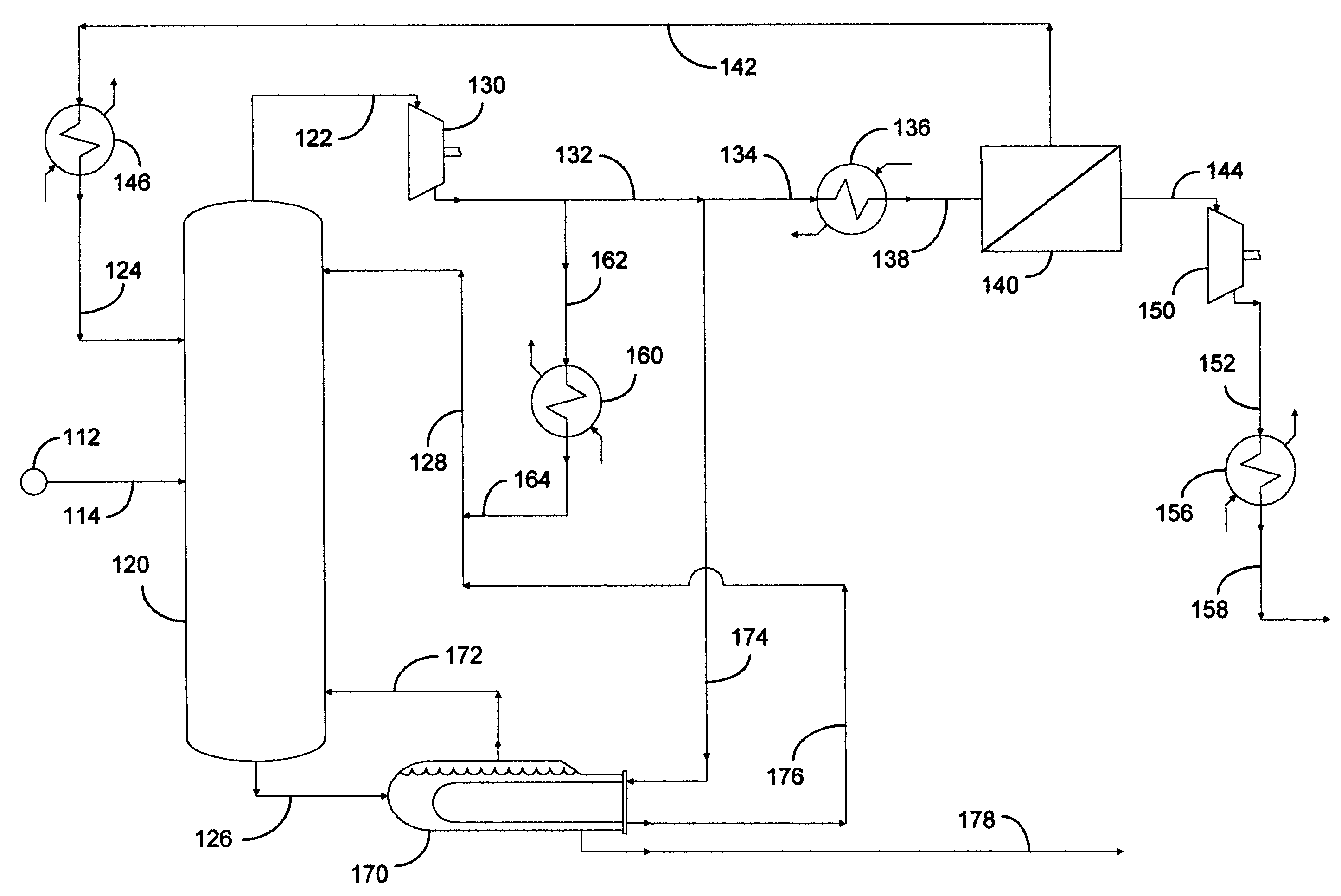

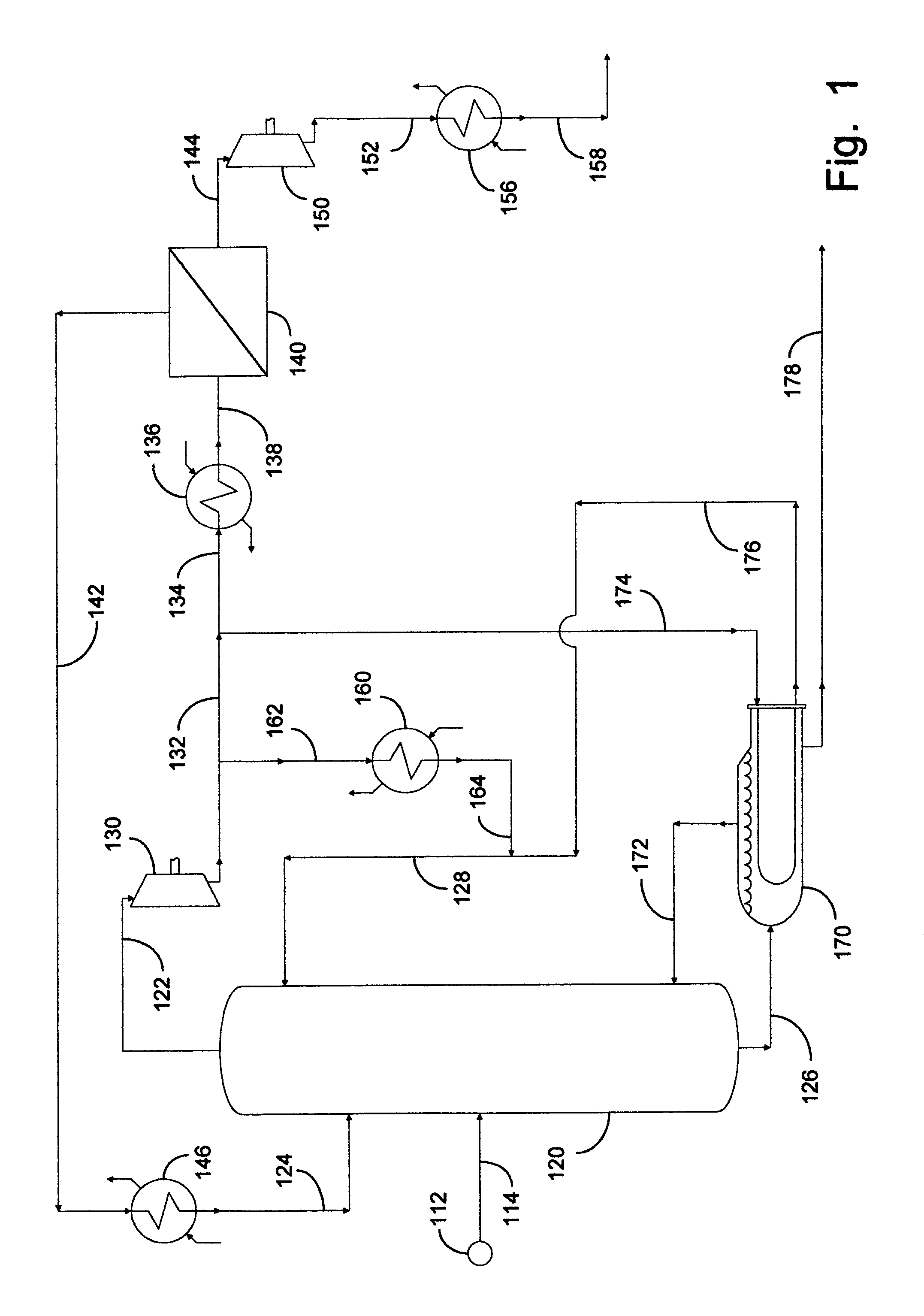

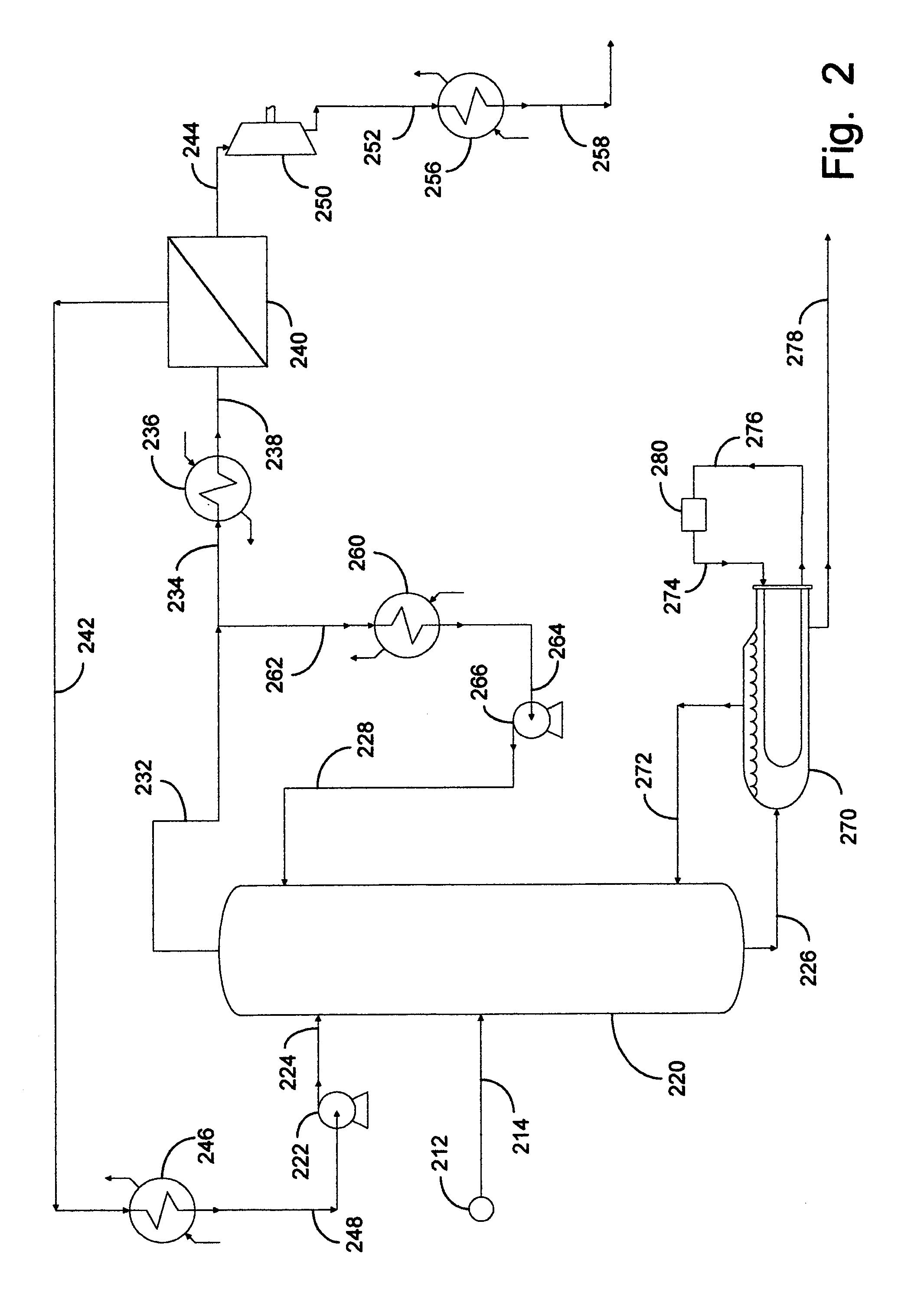

Process for producing alkylene oxide

A process for preparing an alkylene oxide, which process comprises:(i) oxidizing an alkylbenzene to obtain a stream comprising alkylbenzene hydroperoxide,(ii) contacting at least part of the alkylbenzene hydroperoxide obtained in step (i) with an olefin to obtain a product stream comprising an alkylene oxide(iii) separating alkylene oxide compound from the product stream of step (ii) to obtain (a) a residual product stream comprising alkylphenyl alcohol, and (b) alkylene oxide,(iv) feeding at least a part of the residual product stream comprising alkylphenyl alcohol to a reactor having a catalytic distillation zone, and concurrently in the reactor,(a) contacting the residual product stream comprising alkylphenyl alcohol with hydrogen in the catalytic distillation zone to convert the alkylphenyl alcohol in the residual product stream to alkylbenzene and form a reaction mixture, and(b) separating alkylbenzene from the reaction mixture by fractional distillation,(v) withdrawing a stream comprising alkylbenzene and having a reduced concentration of alkylphenyl alcohol than the feed stream from the reactor at a position upper from the catalytic reaction zone;(vi) withdrawing from the reactor at a position lower than the catalytic distillation zone a bottom stream comprising dimer(s) of alkylbenzene;(vii) converting the dimer(s) of alkylbenzene in the bottom stream from (vi) to alkylbenzene; and(viii) recycle at least a part of the alkylbenzene produced from (iv)(b) and / or (vi) to step (i).

Owner:SHELL OIL CO

Purification of fluid compounds utilizing a distillation - membrane separation process

InactiveUS7070694B2Semi-permeable membranesOrganic compound preparationBoiling Point TemperaturesFractional distillation

Apparatus and processes are disclosed for economical separation of fluid mixtures. Broadly, apparatus of the invention is an integrated fractional distillation and perm-selective membrane separation apparatus. More particularly, the integrated apparatus comprises a fractional distillation column and one or more membrane device utilizing solid perm-selective membranes. Processes of the invention are particularly useful for simultaneous recovery of a very pure permeate product, a desired non-permeate stream, and one or more distillate products from a fluid mixture containing at least two compounds of different boiling point temperatures.

Owner:BP CORP NORTH AMERICA INC

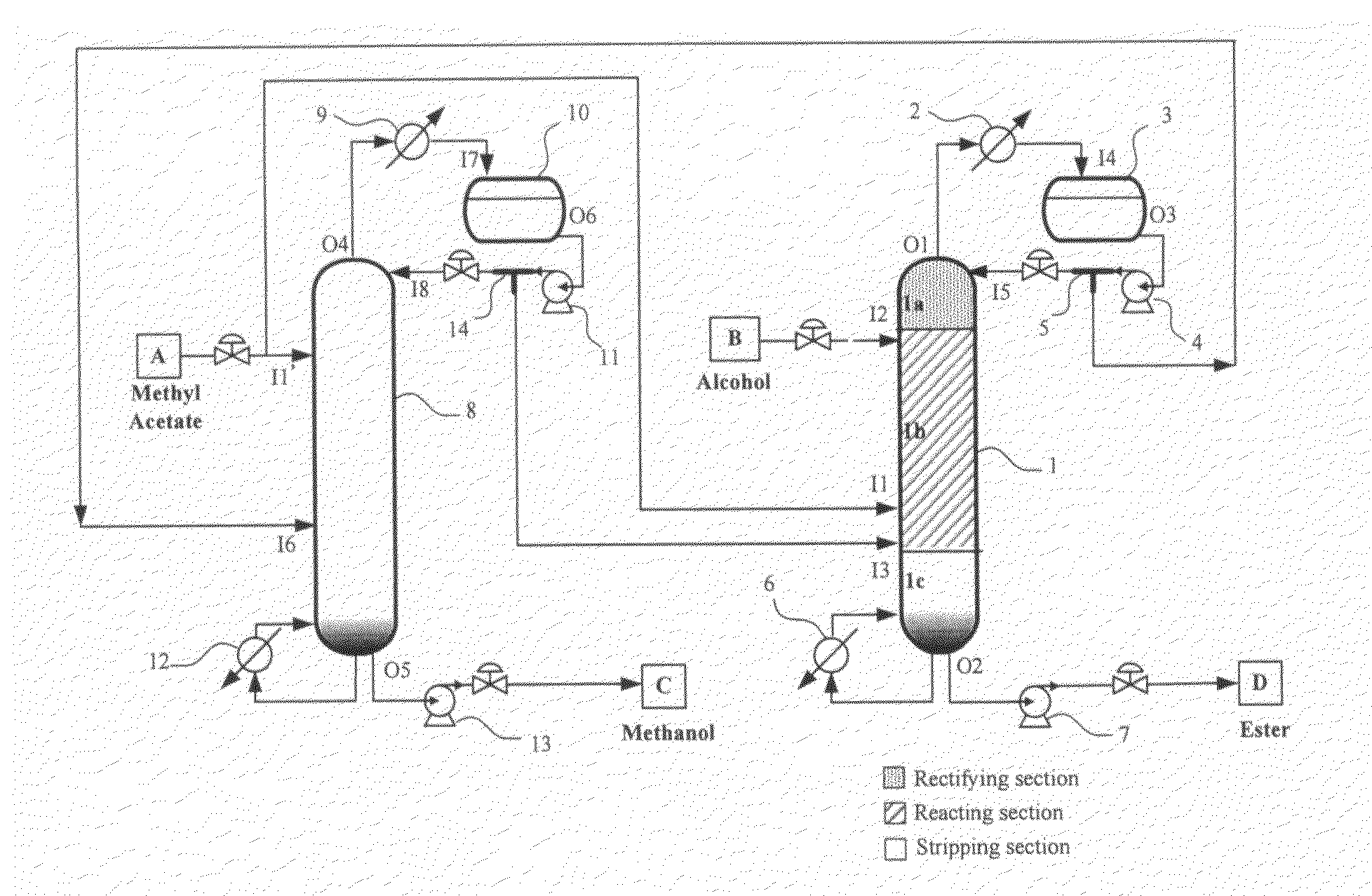

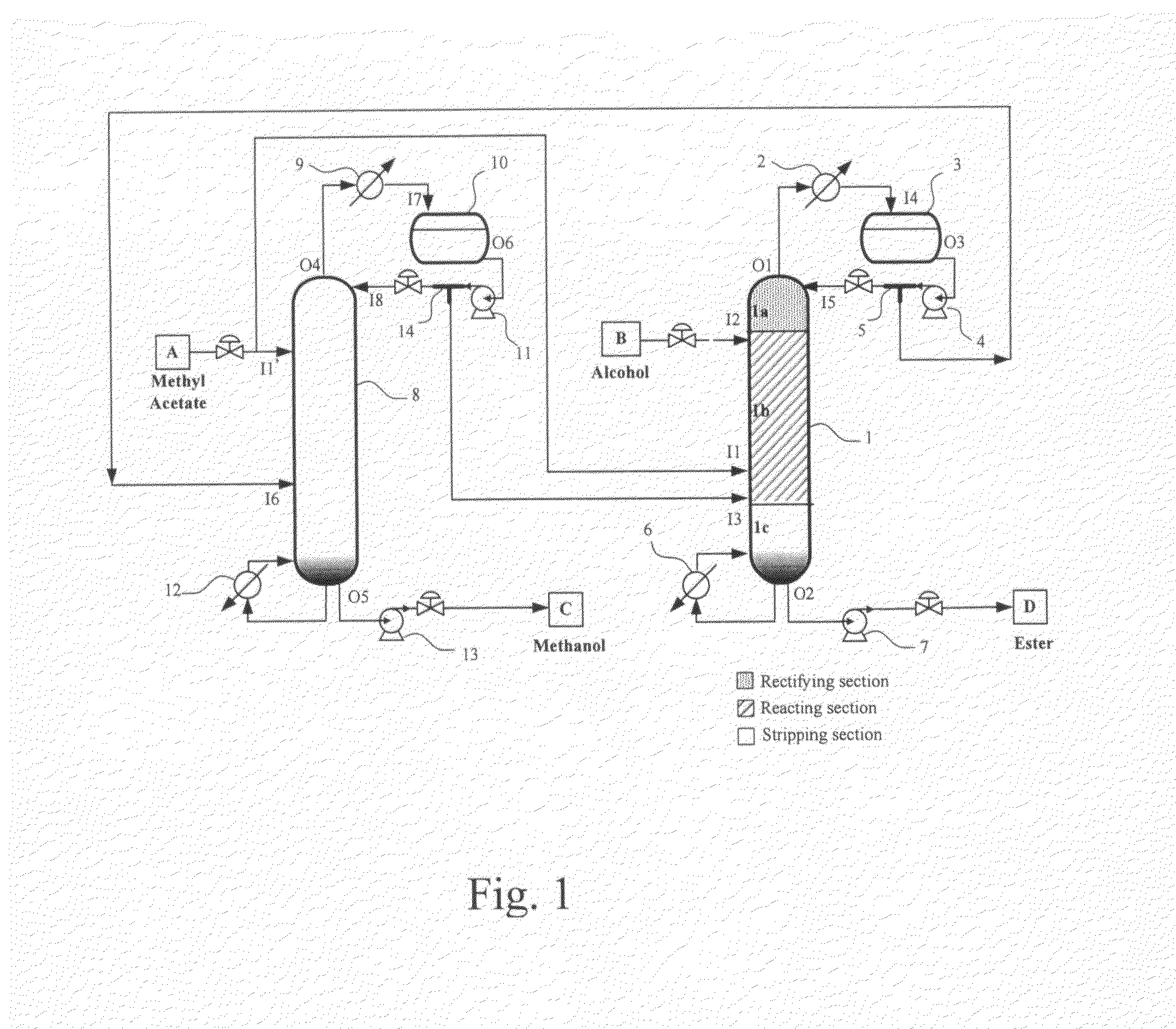

Transesterification process of methyl acetate

ActiveUS20080161595A1Economical and efficient operationOrganic compound preparationPreparation by ester-hydroxy reactionAlcoholTransesterification

A transesterification process of methyl acetate is provided. The process comprises: (a) performing a first reactive distillation of a methyl acetate solution and a first alcohol to generate a first ester and a first mixture; (b) performing a first distillation of a first part of the first mixture to generate a second mixture; and (c) performing a second reactive distillation of a first part of the second mixture and a second alcohol to generate a second ester; wherein the respective one of the first and second alcohols is a limiting reagent. The transesterification process provided in the present invention could highly reduce the investing production cost of the transesterification of the by-product, methyl acetate, in the conventional polyvinyl alcohol plants.

Owner:NAT TAIWAN UNIV

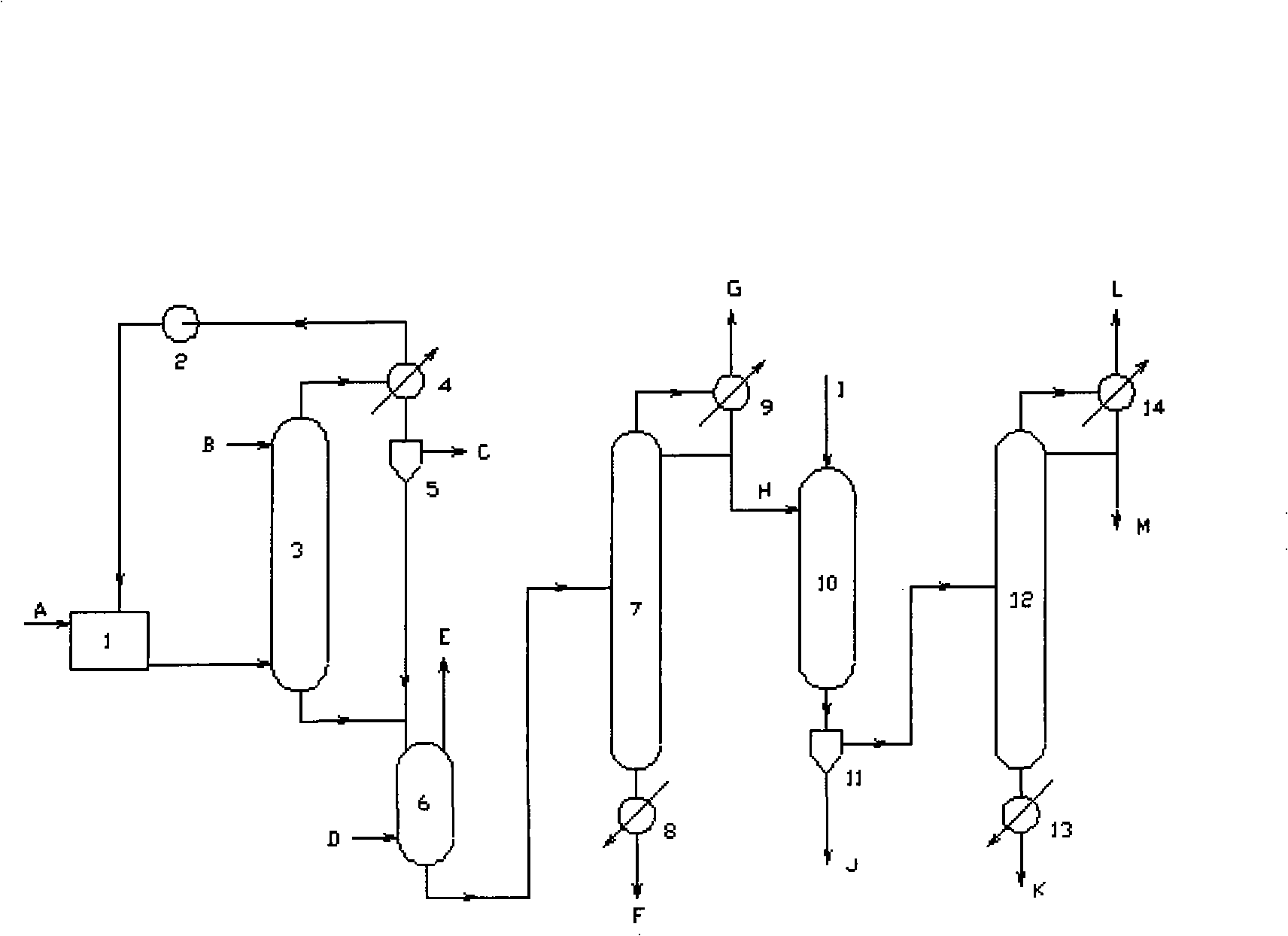

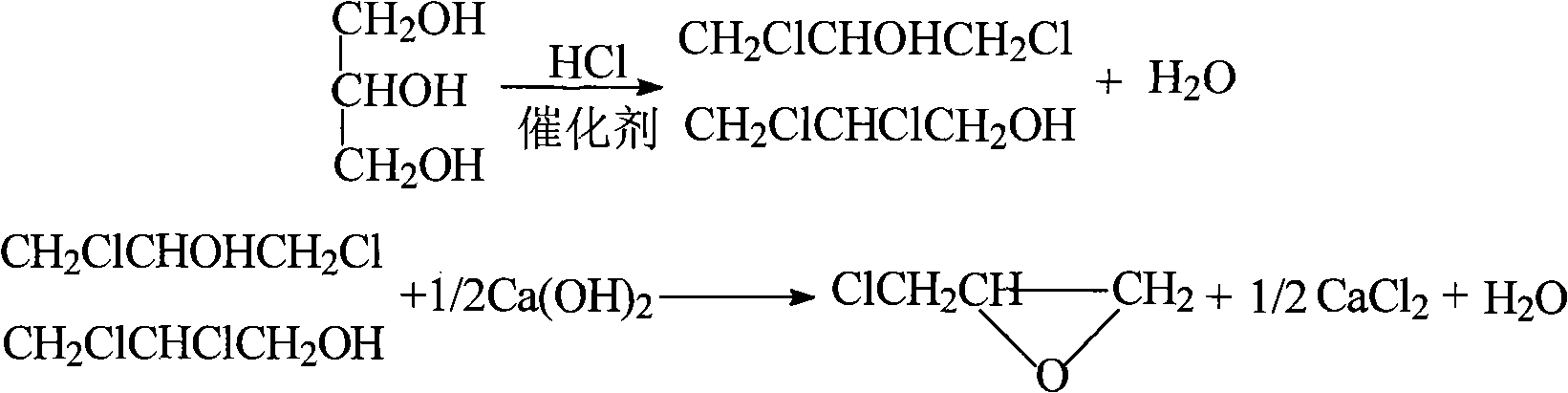

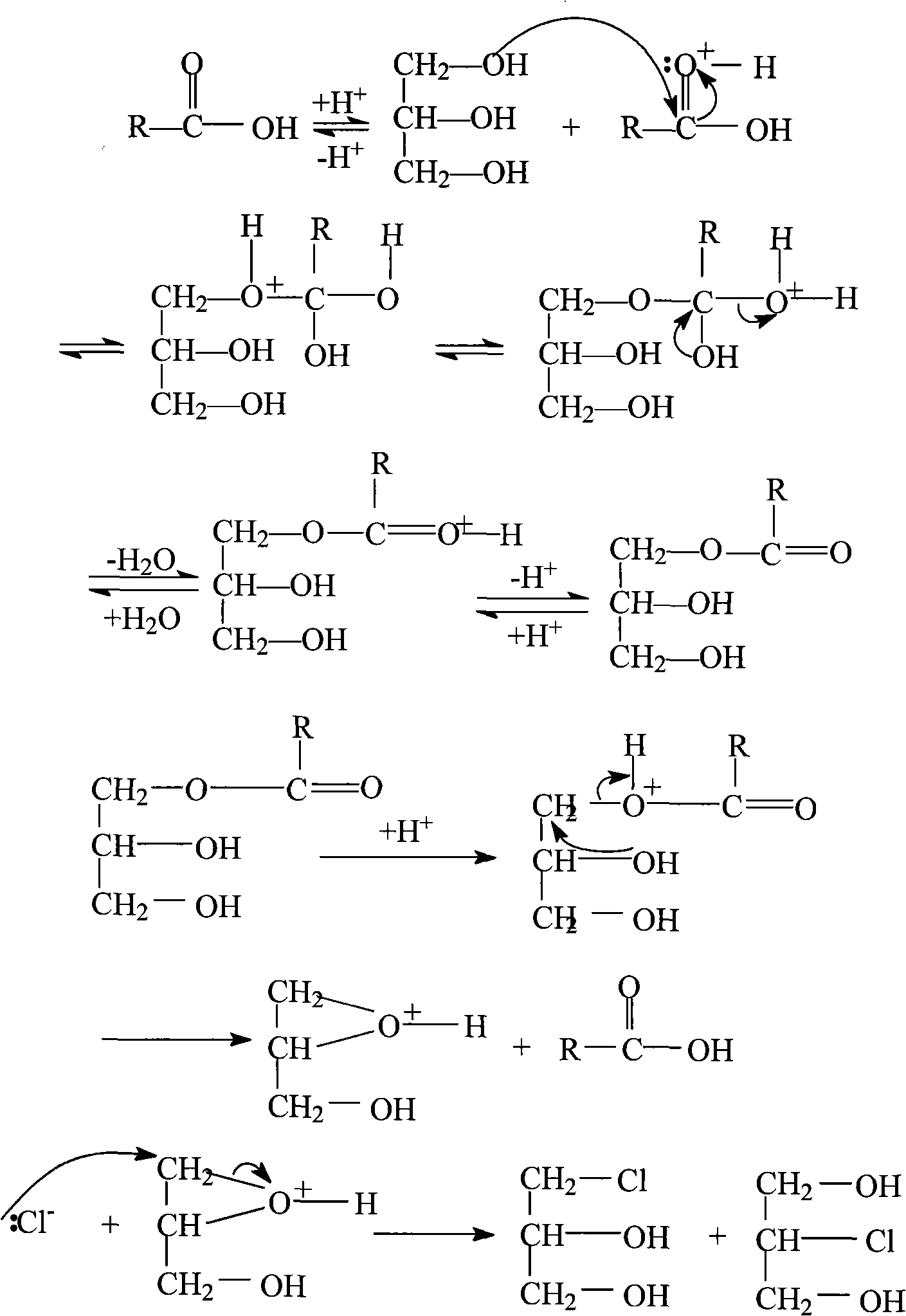

Method for continuously preparing epichlorohydrin by glycerine reaction fractional distillation

InactiveCN101337950AEfficient separationGuaranteed purityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsBiodiesel1-Propanol

The invention relates to a method for preparing epoxy chloropropane which is obtained through successive reaction and distillation coupling technology after glycerine that is the by-product of biological diesel oil reacts with chlorine hydride through substitution reaction under homogeneous multielement catalysis and further performs saponification cyclization reaction. The method comprises the following steps: (1) chlorine hydride is pumped in glycerine that is the by-product of biological diesel oil for reaction under homogeneous multielement catalysis, and the mixture composed of 1, 3-dichloro-2-propanol and 2, 3-dichloro-1-propanol is prepared through the technologies of continuous feeding, continuous catalyzed chlorination and continuous rectification; (2) the isomeride mixture solution of 1, 3-dichloro-2-propanol and 2, 3-dichloro-1-propanol performs the saponification cyclization to generate a product of epoxy chloropropane in alkaline solution. The method has the advantages of mild reaction condition is mild, high catalyst activity, dedicated catalytic performance, high product selectivity, process 'cleaning', easy separation, continuous operation, environment-friendliness, etc.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

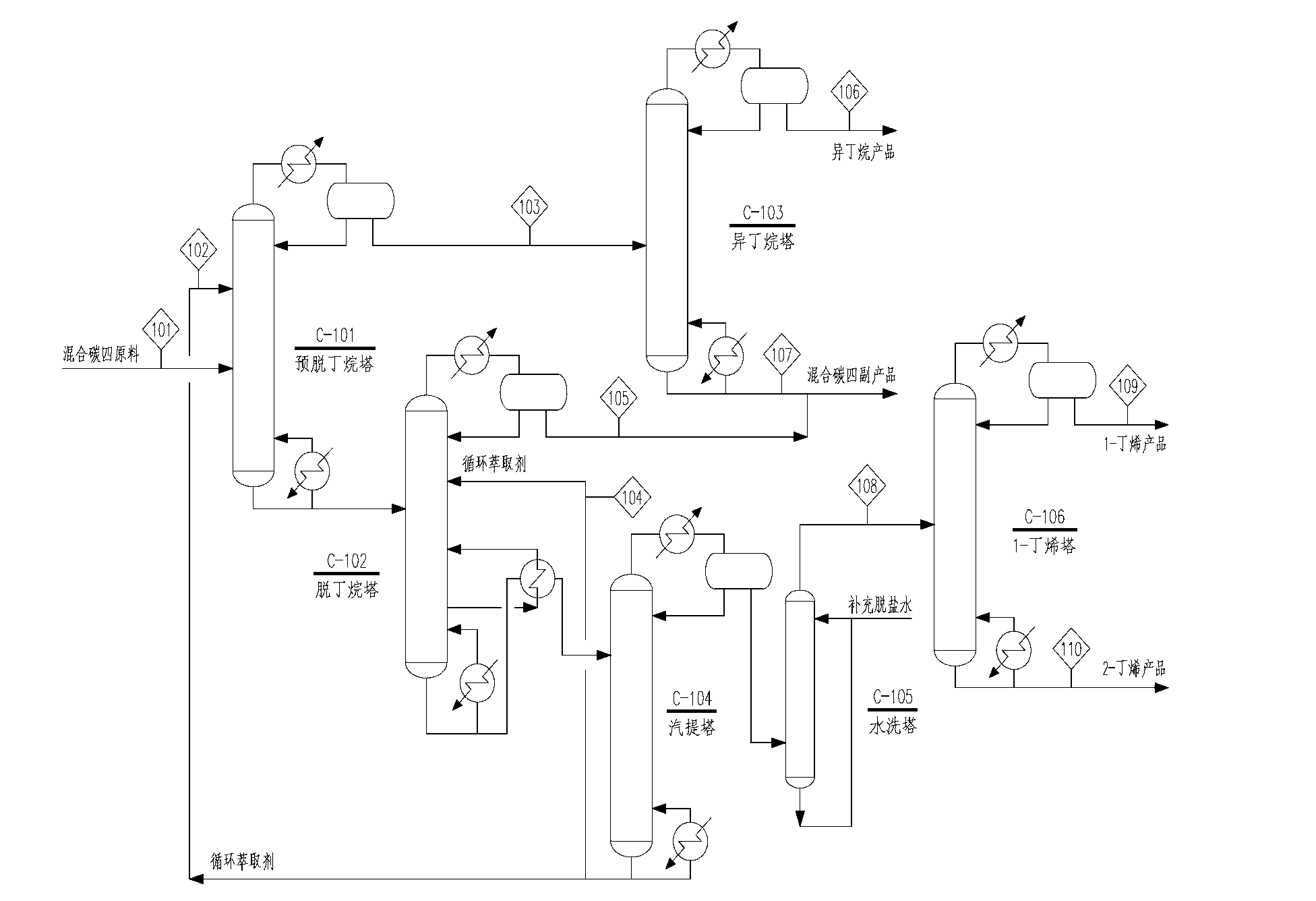

Separation method for mixed C4

ActiveCN102992933AIncrease profitReduce manufacturing costChemical industryDistillation purification/separationButeneHigh concentration

The invention discloses a separation method for mixed C4, which comprises the following steps of separating butene and butane from mixed C4 through extractive distillation, wherein the mixed C4 contains n-butane, iso-butane, 1-butylene and 2-butylene after removal of components such as C3, butadiene, alkyne, isobutene, C5 and the like, furthermore, separating to obtain iso-butane, 1-butylene and 2-butylene and the byproduct of crude n-butane through ordinary distillation, wherein the solvent for extractive distillation is publicly known in the industry, non clear-clear separation method is adopted in extractive distillation technology, namely, the combination of preextraction distillation and extractive distillation. Due to the adoption of the separation method, after the mixed C4 is processed, products of iso-butane, 1-butene and 2-butene of high concentration can be obtained simutaneously, therefore, the separation method has the advantages of being energy-saving, good in economic efficiency, high in resource utilization rate, and the like, reducing the cost and is of great significance in comprehensive utilization of mixed C4 resource.

Owner:EAST CHINA ENG SCI & TECH +1

Combined processing method capable of improving coking liquid-phase product yield

ActiveCN101619237ALow costReduce operating costsThermal non-catalytic crackingVacuum distillationWaxEconomic benefits

The invention discloses a combined processing method capable of improving coking liquid-phase product yield. In the method, coke powder is removed from high-temperature oil gases produced by a delayed coking device in a coke powder-removing tank, light components are extracted at the same time, heavy components enter a reduced pressure distillation device to separate a wax oil fraction, and obtained vacuum residues are used as delayed coking feed. The method avoids product fractionation in the prior coking fractional distillation column, thereby greatly reducing investment and operation cost.The method improves the yield of coking waxy oil and ensures the quality of the coking waxy oil. With the increase of the extraction amount of the coking waxy oil, the amount of coking circulation oil is greatly reduced and the processing capacity of the coking device is improved, so the economic benefits are increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for reactive distillation of a carboxylic acid

InactiveUS7718039B2Speed up the conversion processLower energy requirementsOrganic compound preparationChemical industryAlcoholReactive distillation

A process for reactive distillation wherein a carboxylic acid is reacted in a reaction section of a reactive distillation column with an alcohol under esterifying conditions in the presence of a catalyst to form an ester, wherein a first supply stream comprising the carboxylic acid, a second supply stream comprising the alcohol and a third supply stream comprising an inert entrainer are supplied to the reactive distillation column, wherein the first supply stream is supplied to the column at a first entry level located just above or at the top of the reaction section, the second supply stream is supplied to the column at a second entry level located in or just below the reaction section and below the first entry level, and the third supply stream is supplied to the column at a third entry level located in or below the reaction section and not above the second entry level and wherein a bottom stream comprising the ester formed and unreacted carboxylic acid is obtained and a top stream comprising unreacted alcohol, water and entrainer is obtained.

Owner:SHELL OIL CO

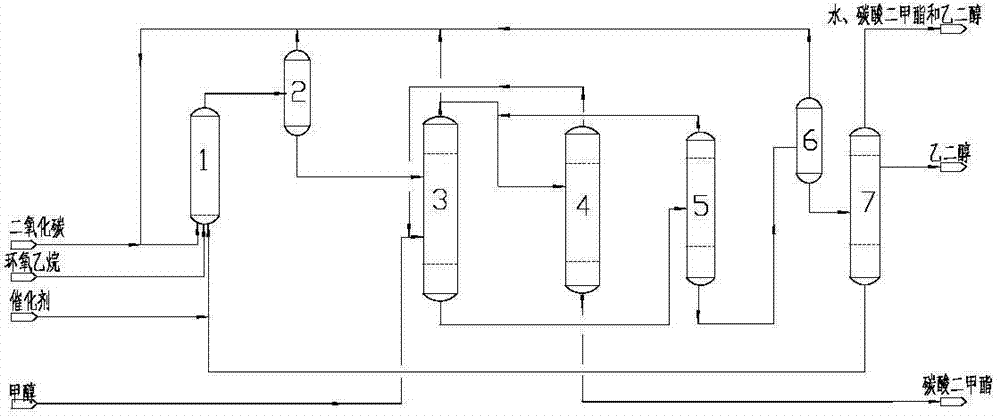

Dimethyl carbonate and ethylene glycol production process

ActiveCN104761429ALow conversion rate per passReduce energy consumptionOxygen-containing compound preparationOrganic compound preparationMethyl carbonateEthylene oxide

The invention relates to a dimethyl carbonate and ethylene glycol production process which is characterized in that the process comprises the following five steps: (a) the carbonylation step for production of ethylene carbonate by catalysis of reaction of ethylene oxide and carbon dioxide by use of an ionic liquid composite catalyst; (b) the step of alcoholysis for ester exchange reaction of the ionic liquid composite catalyst-containing ethylene carbonate solution of the step (a) and methanol in a reaction distillation tower and product separation; (c) the step of purification and refining of dimethyl carbonate from tower top condensate in the reaction distillation tower of the step (b); (d) the step of separation, transformation and refining of ethylene glycol from tower bottom liquid in the reaction distillation tower of the step (b); and (e) the step of circulation cycle of from the ionic liquid composite catalyst in the step (d) to the catalyst in the step (a). The process has the characteristics of high ethylene carbonate one-way conversion rate, simple process flow, small equipment investment, less waste emissions, low energy consumption and the like, and can make companies stronger in competitiveness.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

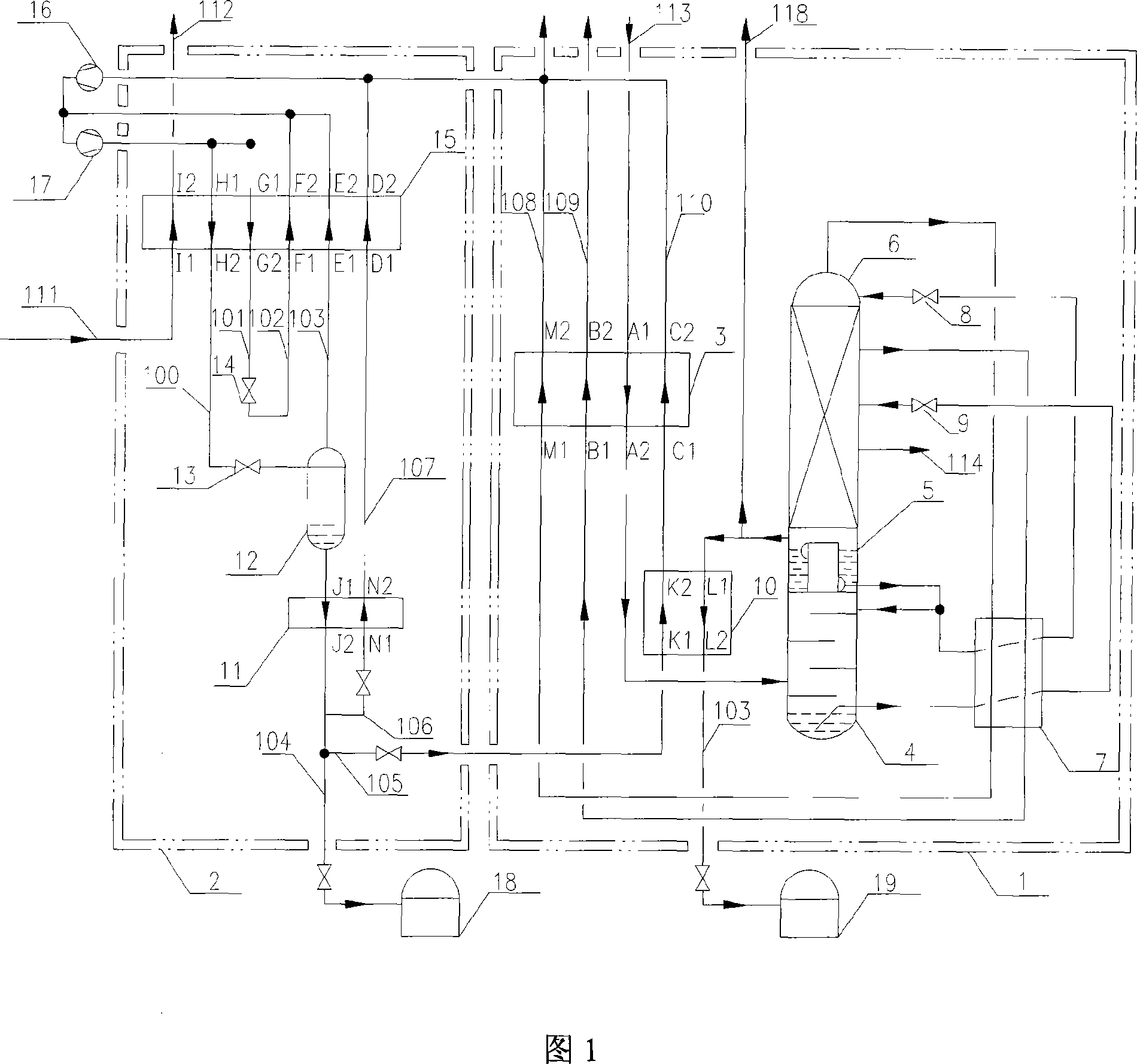

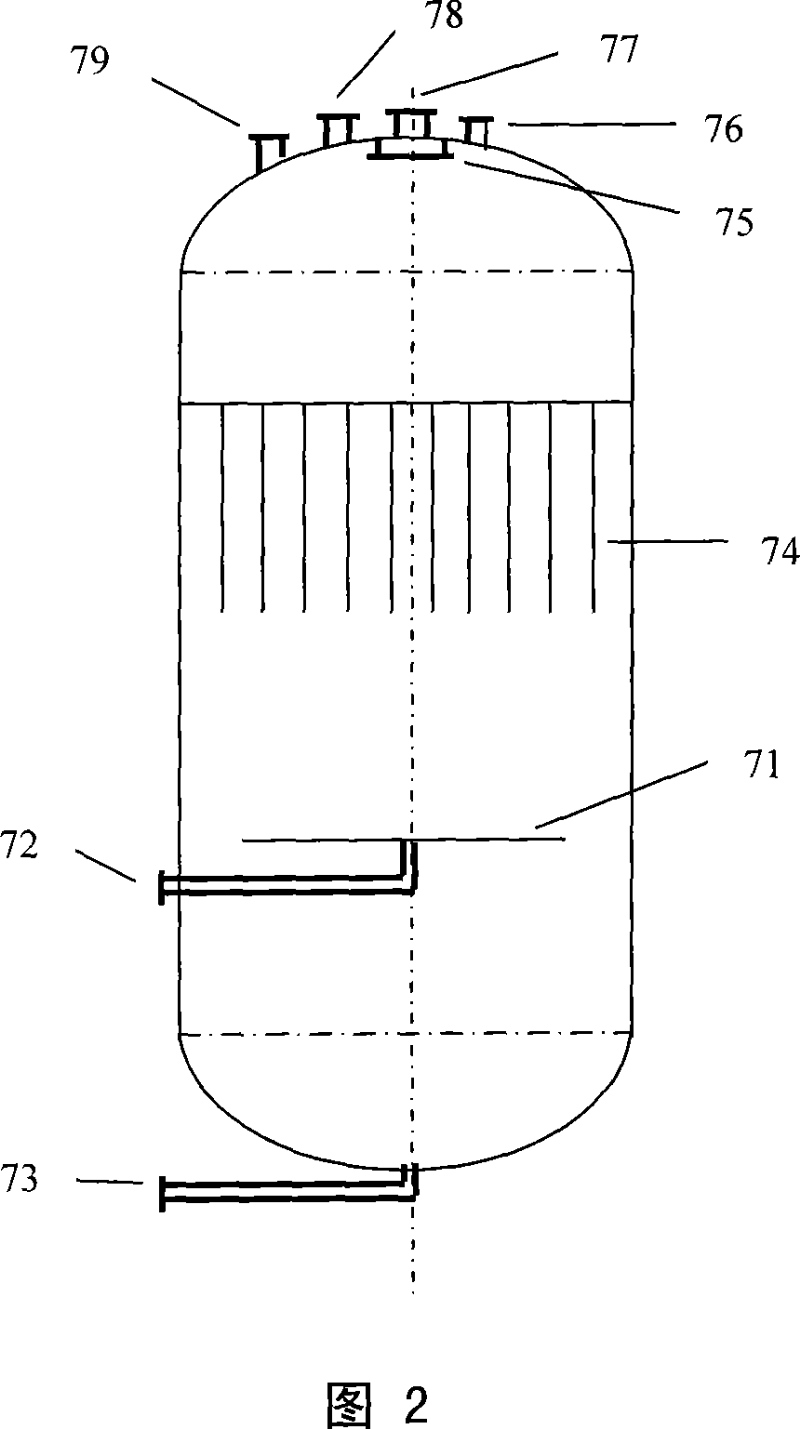

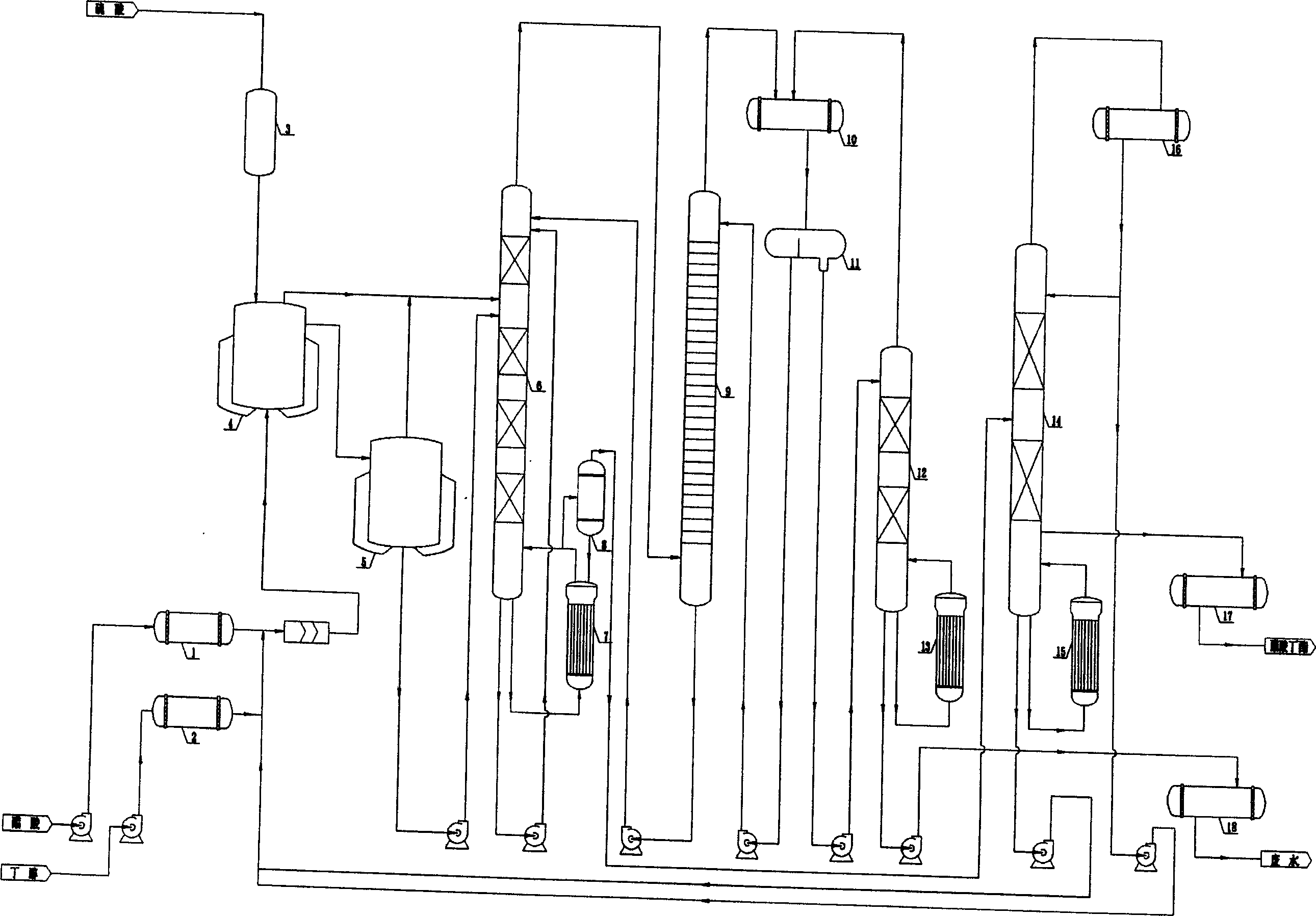

Diesel oil hydrogenation refining fractionation method and device

ActiveCN101037608ASolve the problem of unqualified water contentLess investmentDewatering/demulsification with electric/magnetic meansGasoline stabilisationSteam condensationTower

The invention provides a hydrogenation refining fractionation method for diesel oil, which includes a stripping fractional distillation process for reaction generation oil steam and a dewatering process for refined diesel oil. Concrete technical project of the method is: hydrogenation refining reaction generation oil from low pressure separator enters feed inlet of fractionating tower with certain temperature; the fractionating tower employs steam stripping fractional distillation, superheating stripping steam is charged in tower bottom, tower top oil gas enters reflux pot on tower top after cooling, refined diesel oil at tower bottom enters one or more than one series connected vertical ionization dehydration pot after supercharging by pressure pump, heat exchanging and cooling; micro steam condensation water in the refined diesel oil aggregates to larger drip by high-voltage electric field in the ionization dehydration pot, sedimentates at pot bottom and is removed by dehydration pipeline; refined diesel oil without water comes from top of the ionization dehydration pot is the eligible final product. The invention also provides a device for realizing the method.

Owner:CHINA PETROLEUM & CHEM CORP

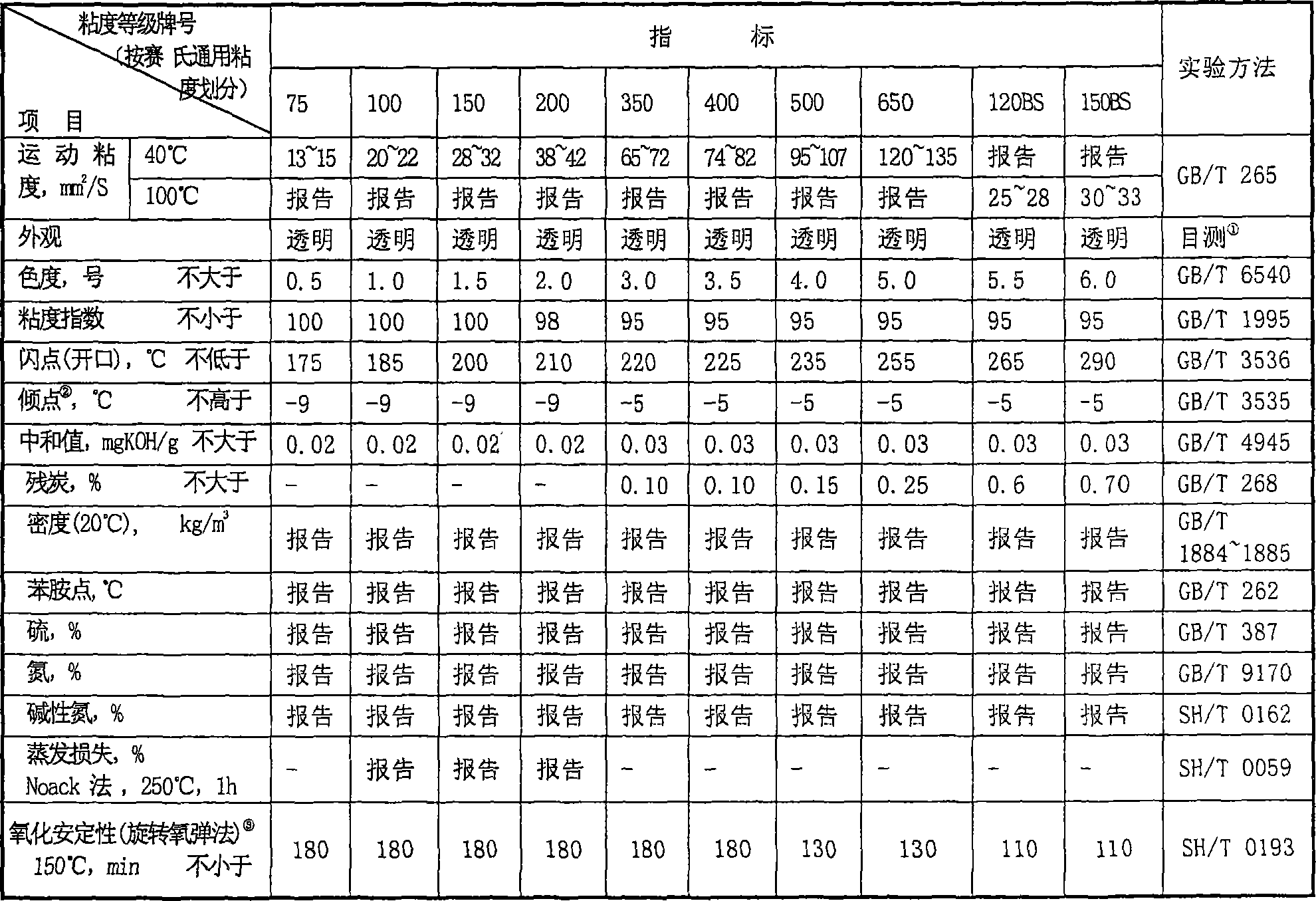

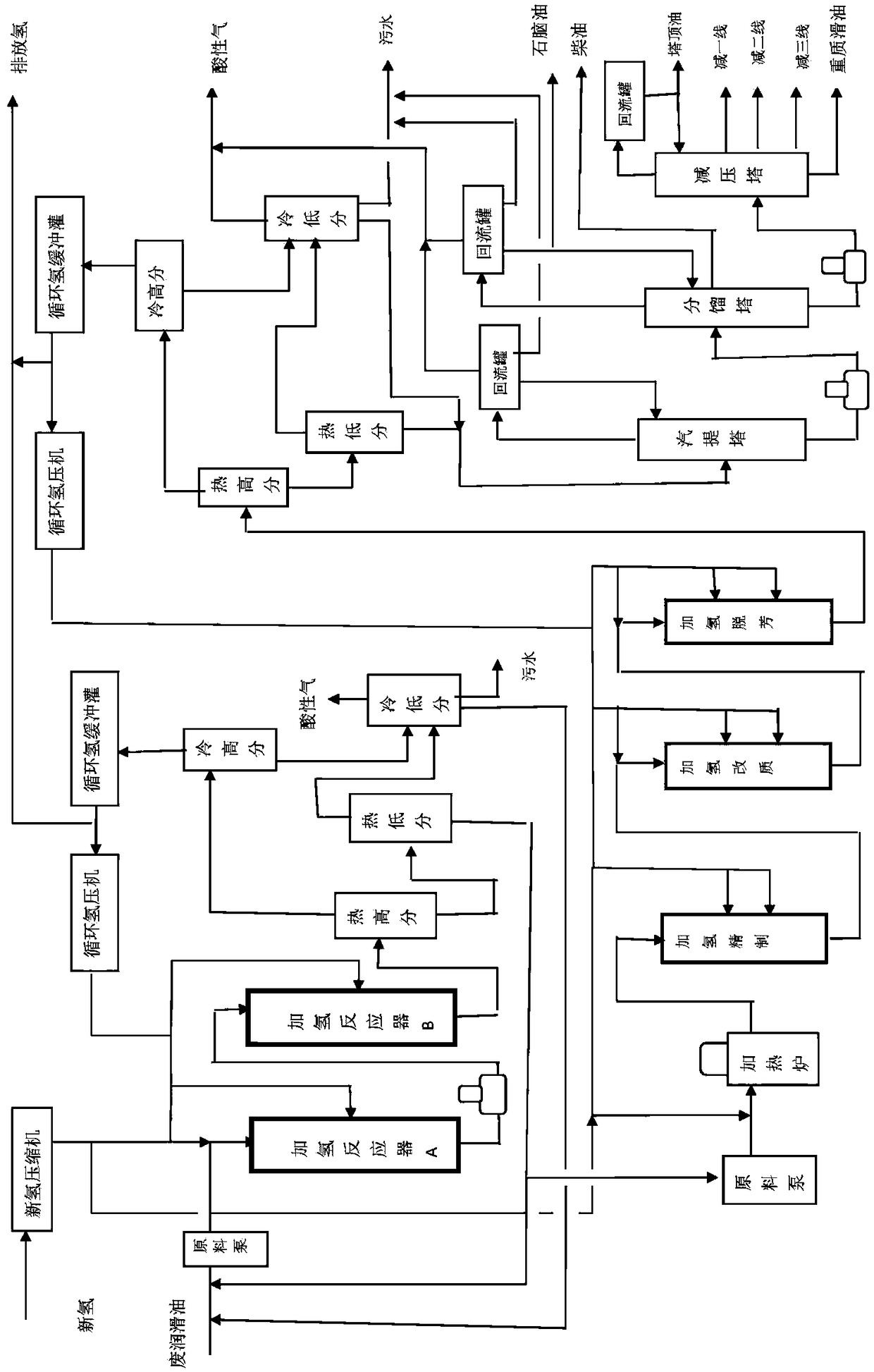

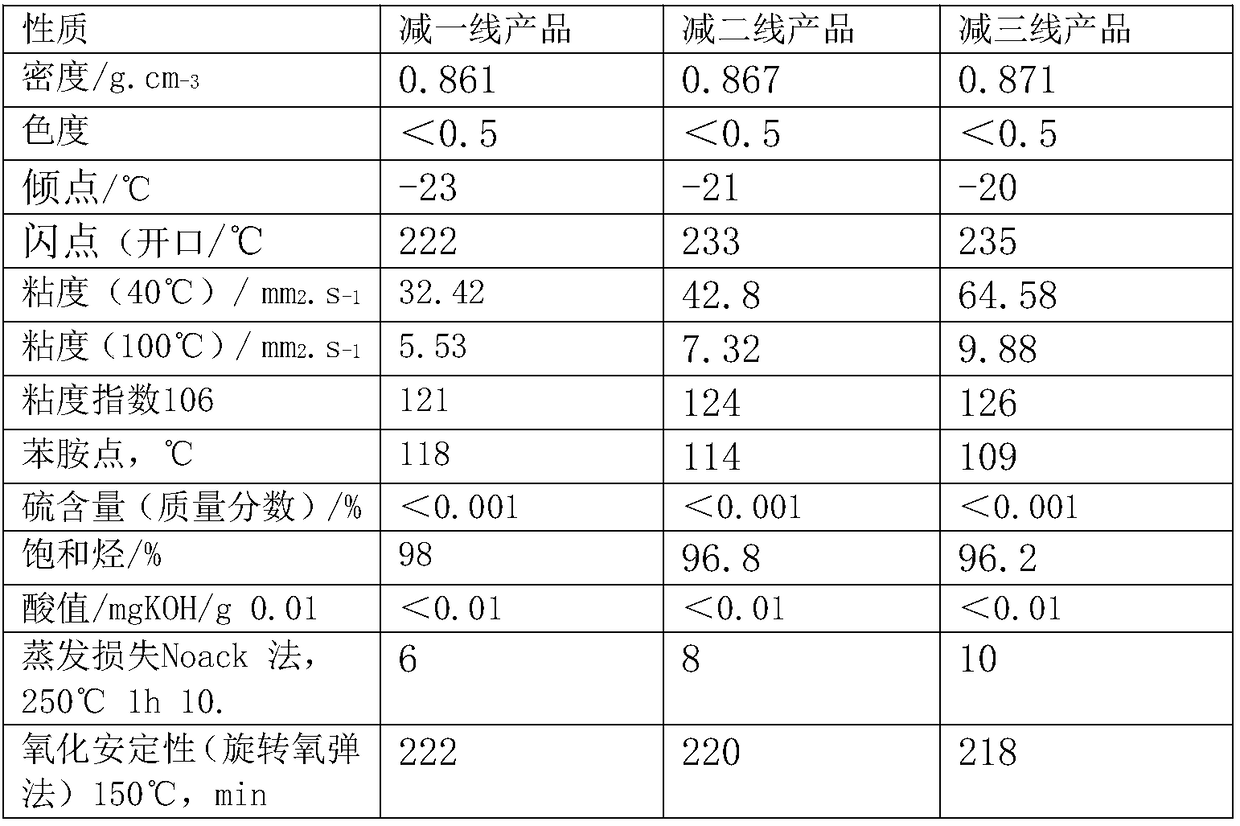

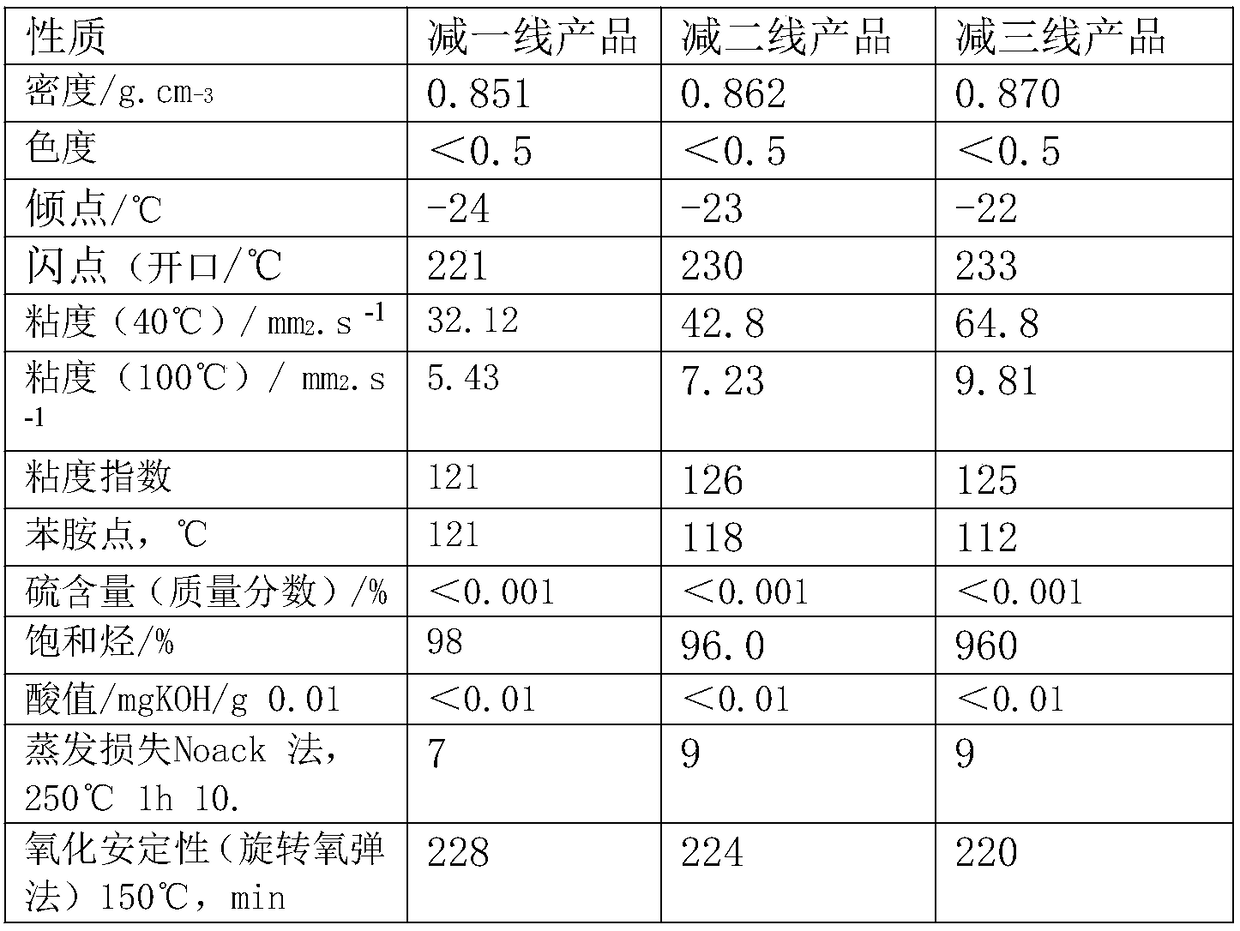

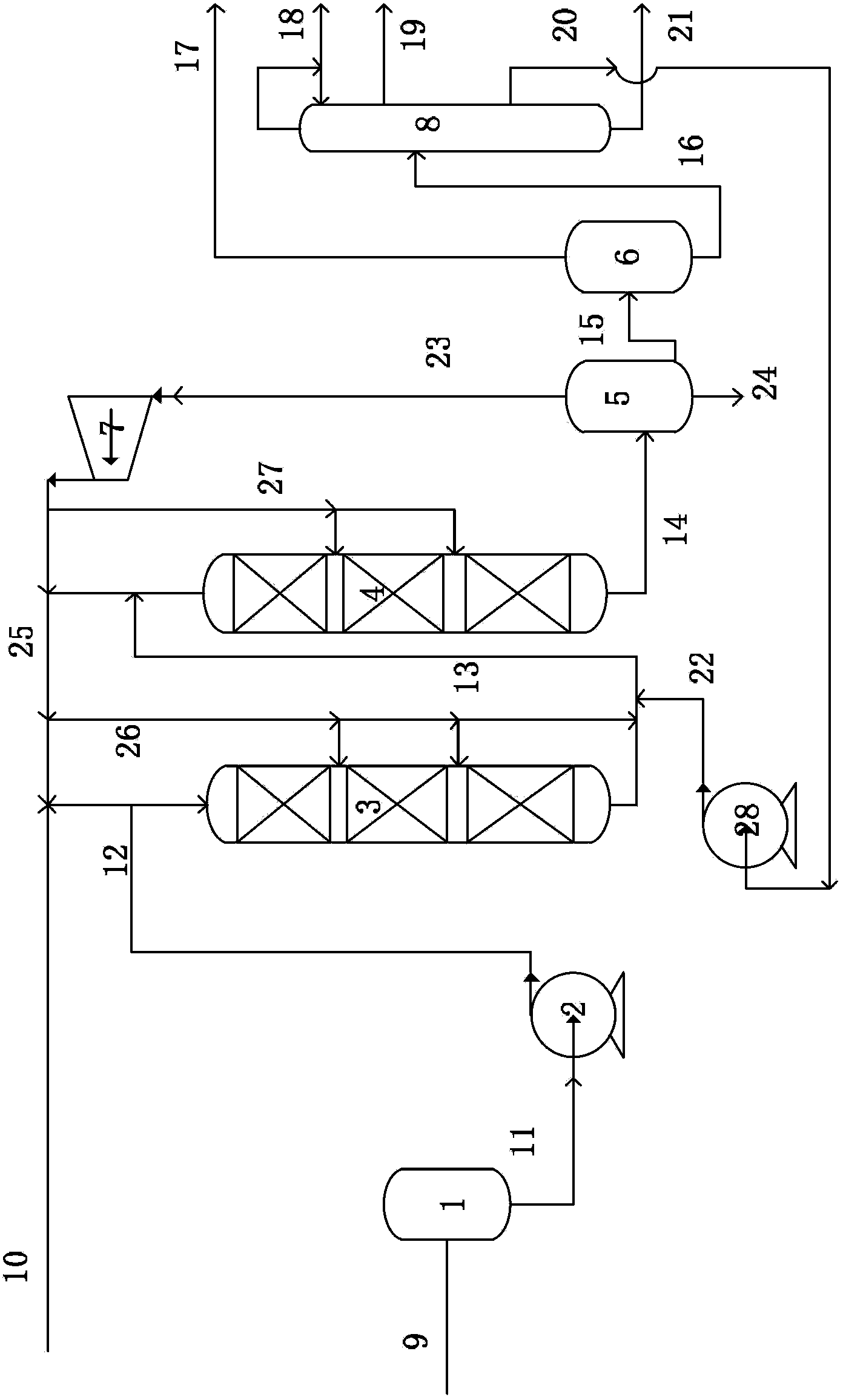

Method of two-stage hydrogenation treatment regeneration technology for full-fraction waste mineral oil

ActiveCN108251156AGuaranteed long-term operationHigh yieldTreatment with hydrotreatment processesHydrocarbon oils treatment productsSeparation technologyEvaporation

The invention discloses a method of a two-stage hydrogenation treatment regeneration technology for full-fraction waste mineral oil. The method comprises the following steps: S1, a filtering treatmenttechnology unit; S2, a low-pressure hydrogenation reaction technology unit; S3, a high-pressure hydrogenation reaction / fractionation technology unit. According to the method disclosed by the invention, the waste mineral oil is not subjected to a pre-treatment process of traditional raw material separation technologies, such as water washing, flocculation, adsorption, extraction, decompression anddistillation (scraping membrane evaporation or molecular distillation), and a combined technology thereof and the like, and full fractions subjected to dehydration and filtering treatment are directly subjected to low-pressure hydrogenation treatment to remove colloid asphalt and impurities including heavy metal and non-metal chlorine, silicon, phosphorus and the like; then hydrogenation treatment including high-pressure hydrogenation refining, modification, aromatic removal and the like is carried out and fractional distillation is carried out to produce basic oil of high-grade III type lubricating oil. According to the method disclosed by the invention, the operation period of a high-pressure hydrogenation and fractionation device can be improved to 20 months or more; the yield of the basic oil of the lubricating oil of a full-fraction low-pressure hydrogenation technology can reach 85 to 95 percent.

Owner:新疆聚力环保科技有限公司

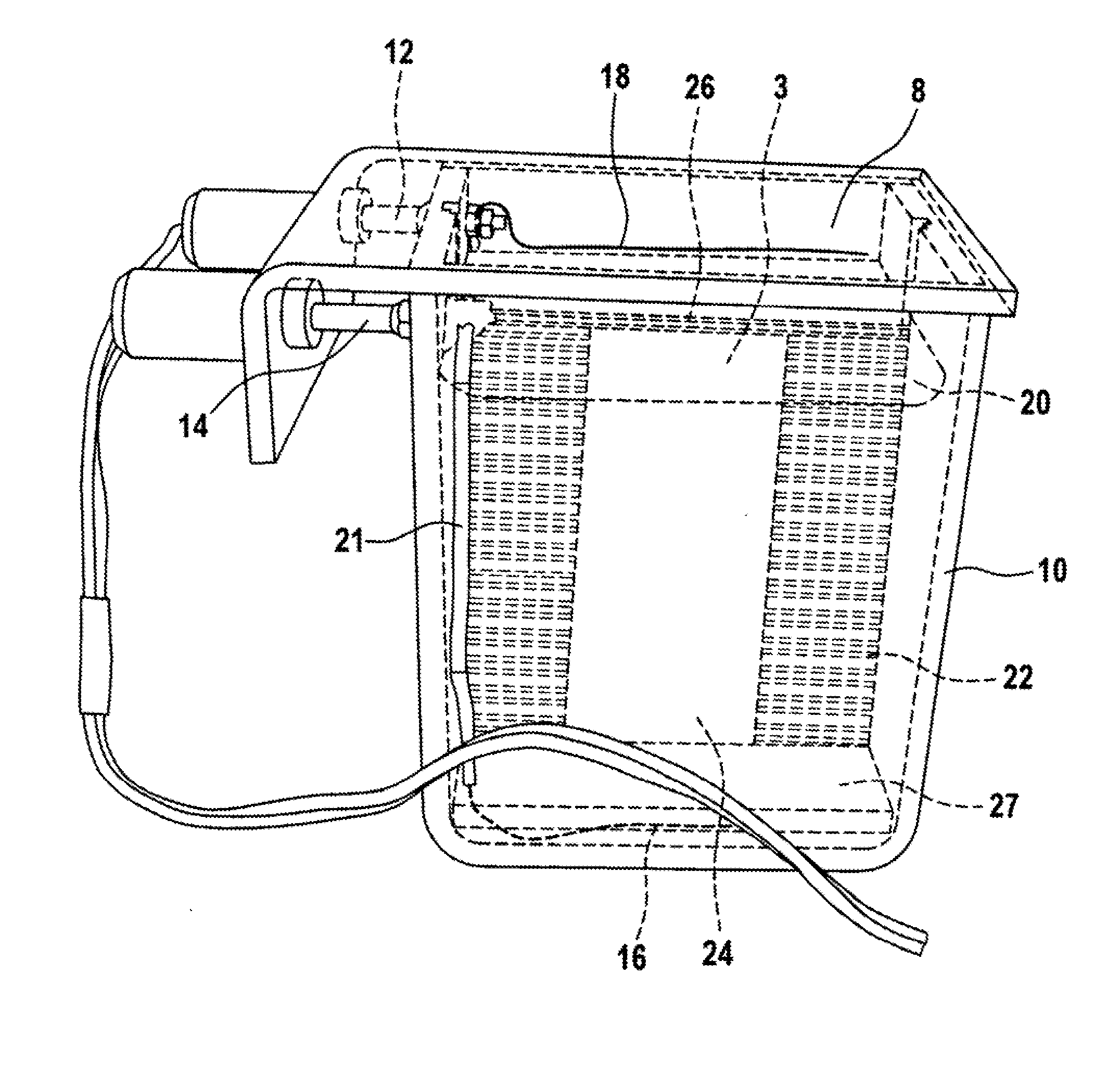

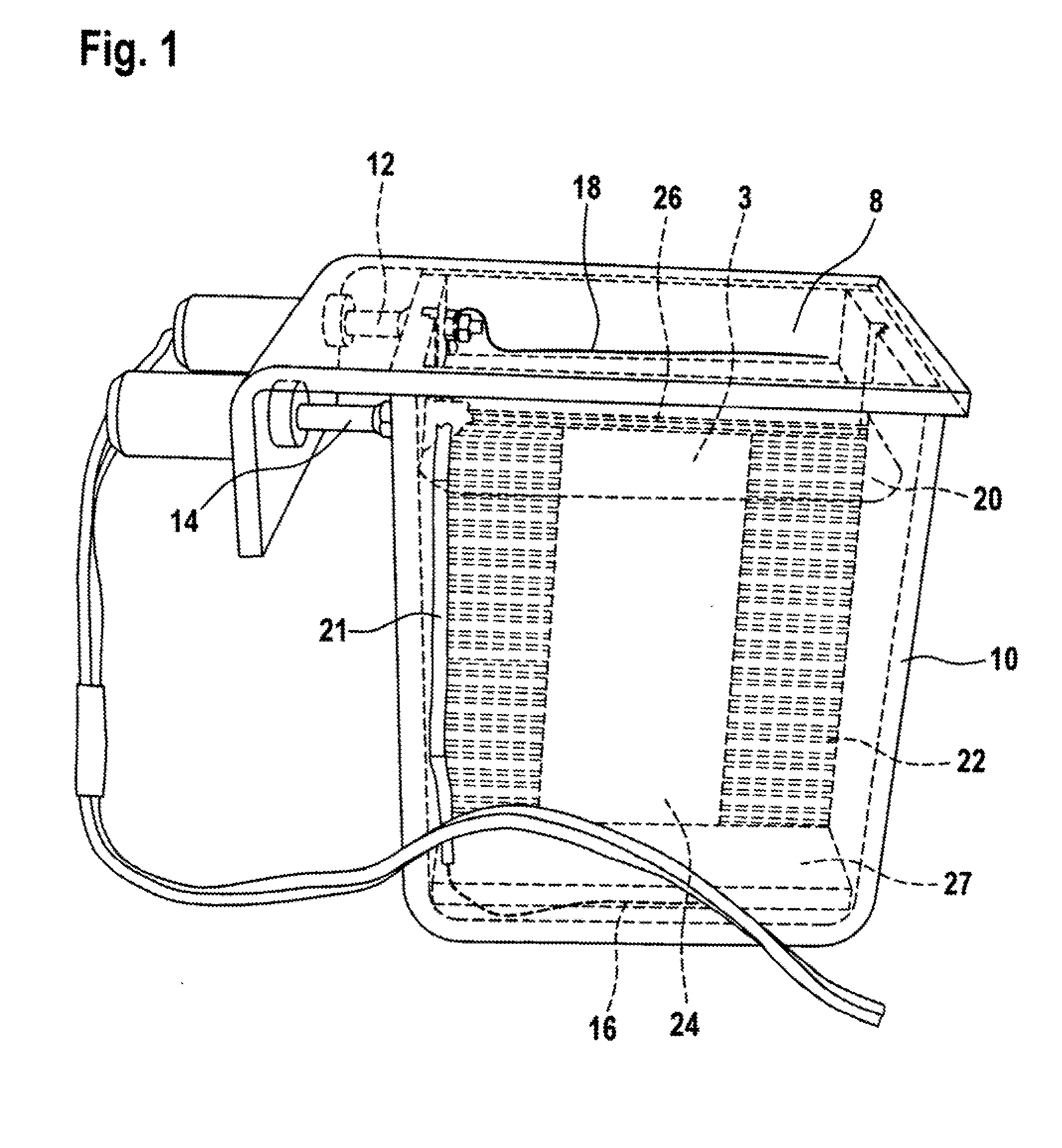

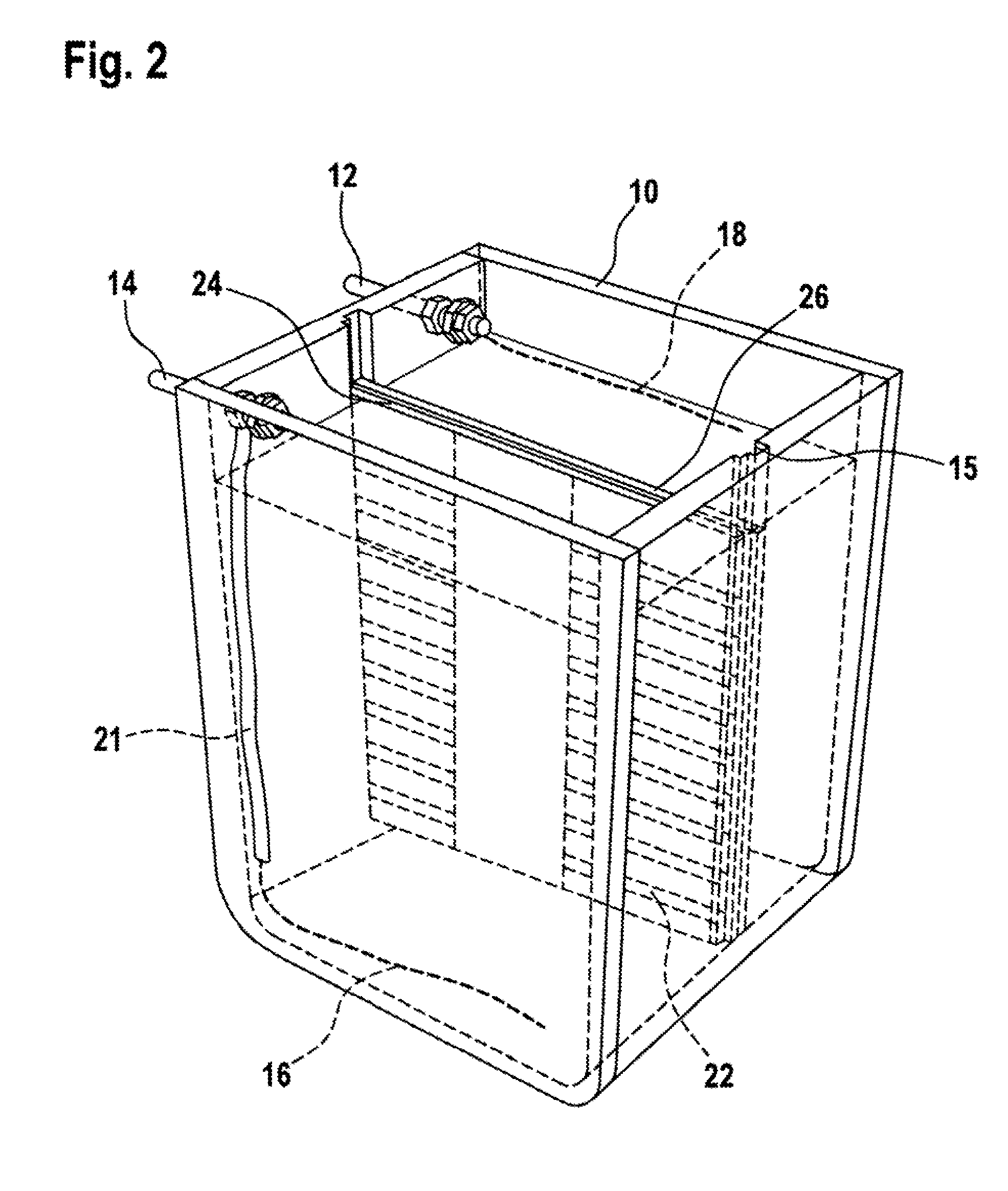

Apparatus, method, and gel system for analytical and preparative electrophoresis

InactiveUS20110114487A1Easy to separateHigh resolutionSludge treatmentVolume/mass flow measurementElectrophoresisFractional distillation

The present invention relates to an electrophoresis apparatus comprising a gel chamber for receiving electrophoresis medium, a removable gel system, which is arranged in the gel chamber, having a separation gel for the electrophoretic separation of biological molecules such as nucleic acids or proteins, electric contact elements for generating an electric field through the separation gel, optionally a lid for fastening on the gel chamber, characterized in that the separation gel is delimited at least at one side by a spacer element which is in the form of a collector and comprises a plurality of sample collection containers, which are arranged one next to the other, for fractionating and for collecting the electrophoretically separated molecules. The invention further relates to a method for the electrophoretic separation and collection of biological molecules by way of a two-dimensional gel electrophoresis.

Owner:JOHANNES GUTENBERG UNIV

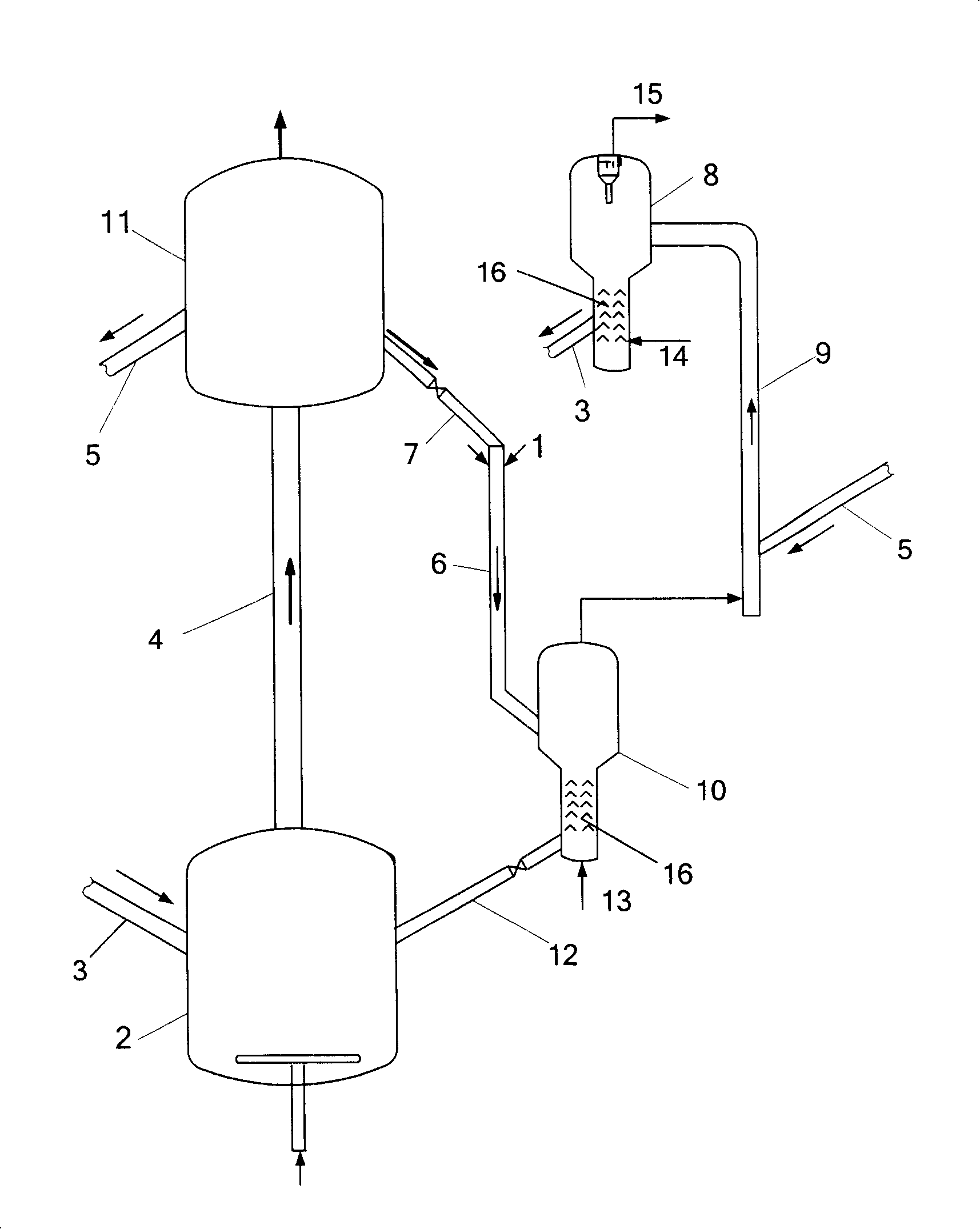

Descending reactor and riser reactor serially connected catalytic cracking method

A catalytic cracking method including a downer reactor and a riser reactor connected with each other in series comprises the follow steps of: injecting preheated raw material oil in the downer reactor to contact a high-temperature regeneration catalyst from a regenerator, vaporizing and cracking, discharging the oil gas from the outlet of the downer reactor to the riser reactor, further reacting, introducing another regeneration catalyst from the inlet of the riser reactor, discharging the oil gas and the catalyst from the outlet of the riser reactor to a settlement separator to separate the oil gas, discharging the separated oil gas to a subsequent fractional distillation system, and stripping the used catalyst separated by the separator and regenerating the catalyst by burning in the regenerator, and circulating the regenerated catalyst to the reactor. According to the different target products, the method provided by the invention can adopt different catalysts and different operation conditions in the riser reactor and the downer reactor. The method can improve the yield of gasoline and improve the product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

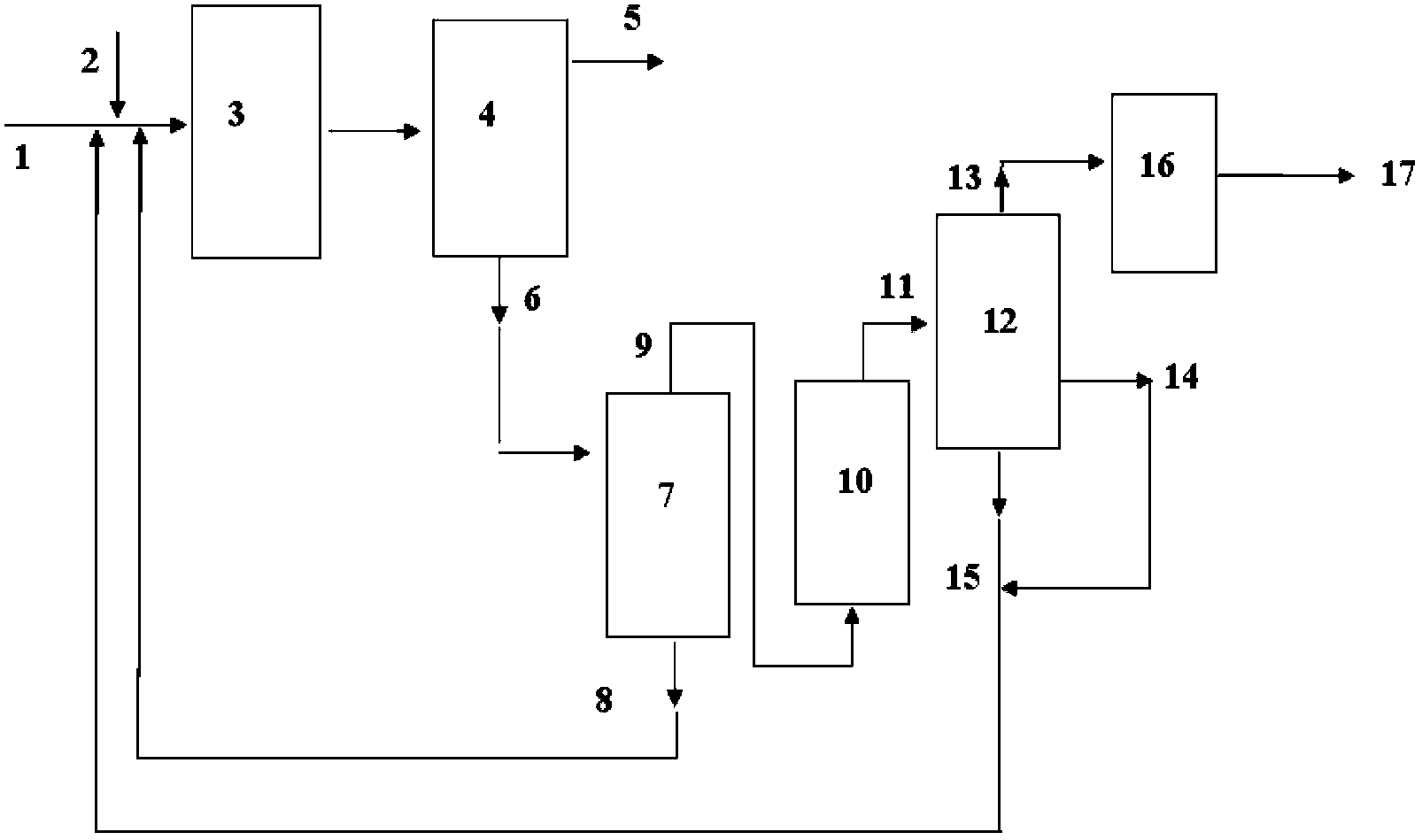

Combination processing method of inferior heavy oil

ActiveCN103789036AHigh yieldHigh residual carbon valueTreatment with hydrotreatment processesHydrogenGasoline

A combination processing method of inferior heavy oil comprises the following steps that: A, a heavy oil feedstock enters into a liquid flow bed reactor for hydrocracking in the effects of hydrogen and a dispersible hydrocracking catalyst; B, the obtained hydrogenation product is fractionally distilled to obtain light oil and heavy oil, the cutting point is 320-380 DEG C, and the light oil is led out of the device; C, the heavy oil obtained by fractional distillation is extracted by a solvent to obtain deasphalted oil and deoiled asphalt; D, the deoiled asphalt is contacted with a catalytic cracking catalyst for cracking reaction in catalytic cracking conditions, and light oil, heavy cycle oil and slurry oil are obtained by fractional distillation; E, the deoiled asphalt obtained by the step C is recycled into the liquid flow bed reactor in the step A. According to the combination processing method provided by the invention, a variety of processes are integrated for processing of the inferior heavy oil, full transformation of the heavy oil can be realized, and more gasoline and diesel oil which are excellent in performances can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for mass producing butyl acetate by reactive distillation method and using sulfuric acid as catalyst

ActiveCN1844076AEasy to separateAvoid corrosionPhysical/chemical process catalystsOrganic compound preparationAcetic acidAlcohol

The refers to a mass production method of isobutyl acetate which uses hydric sulphate as accelerant by reaction fractional distillation, using ethyl acetate and butyl alcohol as raw material, concentrated sulfuric acid as accelerant, continue producing isobutyl acetate by reaction fractional distillation, the whole production system contains three towers, reaction fractionating tower, azeotropy tower and eater fractionating tower, the reaction fractionating tower, azeotropy tower are setted side by side. The ethyl acetate, butyl alcohol and concentrated sulfuric acid are drived into feeder column plate of reaction fractionating tower after esterification prereaction, the gas phase of prereactor going into feeding phase of reaction fractionating tower, the gas phase on top of reaction fractionating tower going into column plate of cellar of azeotropy towder, the liquid phase of towder bottom going into mesomere of eater fractionating tower, the butyl product is continue discharged from side tower. This invention combines the technique which using sulfuric as accelerant by mean improvement of reaction fractional distillation technique, not only ustilizing the advanced technology of reaction fractional distillation, but also making the liquid accelerant's characters of convenience to operate, easy to enlarge production scale getted adequate use.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

Hydrocracking method for catalytic cracking diesel

ActiveCN103773487ASimple compositionHigh yieldTreatment with hydrotreatment processesHydrogenNaphtha

The invention provides a hydrocracking method for catalytic cracking diesel. According to the method, a mixture of the diesel material and hydrogen is in contact reaction with a hydrorefining catalyst in a hydrorefining reactor, liquid efflux from the hydrorefining reactor is not separated and then enters a hydrocracking reactor to be in contact and react with a hydrocracking catalyst, the reaction efflux from the hydrocracking reactor is subjected to separation and fractional distillation to obtain hydrogen-rich gas, then light naphtha fraction, gasoline fraction, recycle fraction and diesel fraction are performed, in the distillation range of the recycle fraction, the temperature is 190 DEG C to 300 DEG C, and the recycle fraction returns to an inlet of the hydrocracking reactor. The method provided by the invention improves the composition of feed hydrocarbon of the hydrocracking reaction region, and the yield and the octane value of the gasoline fraction are effectively increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

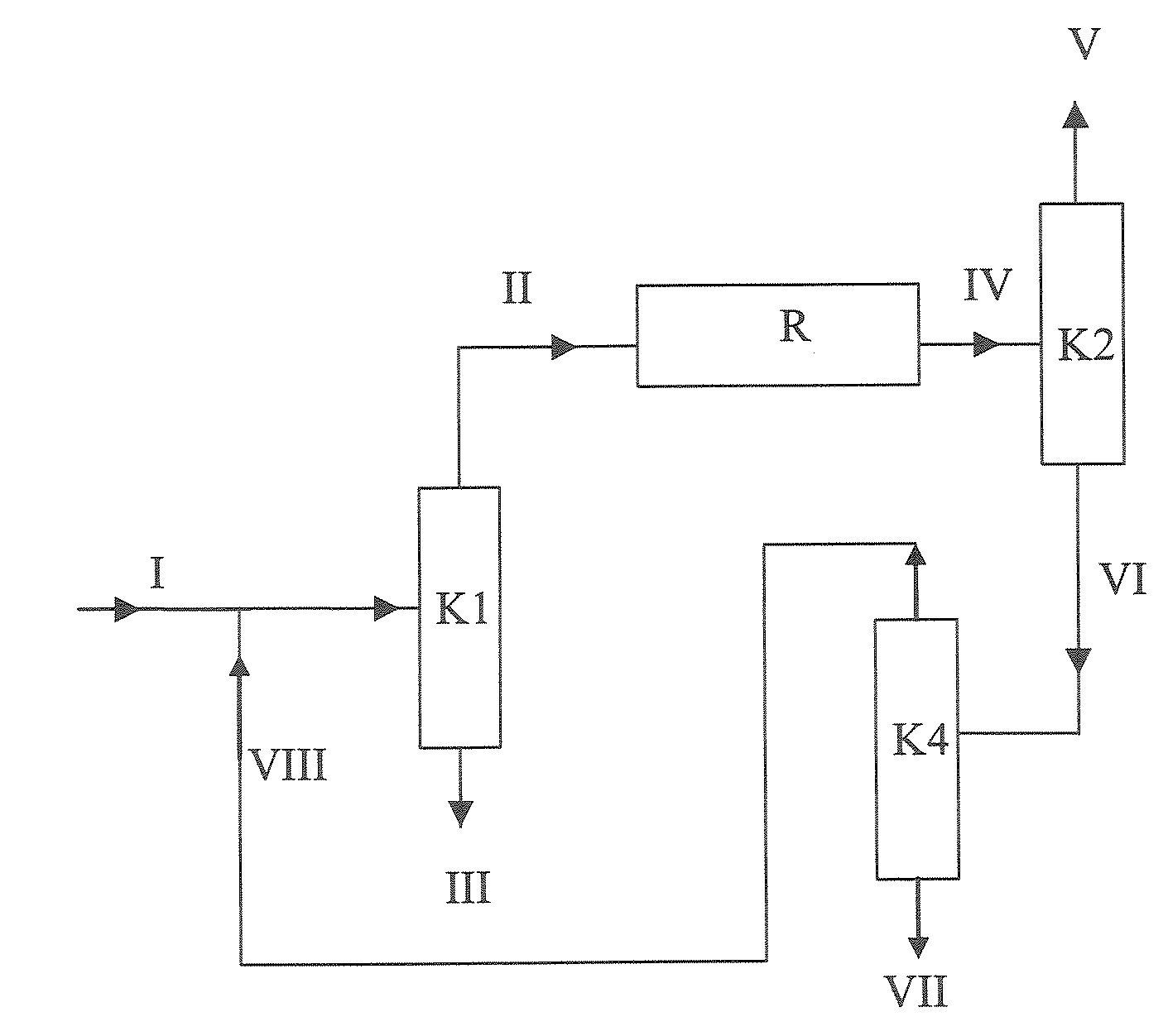

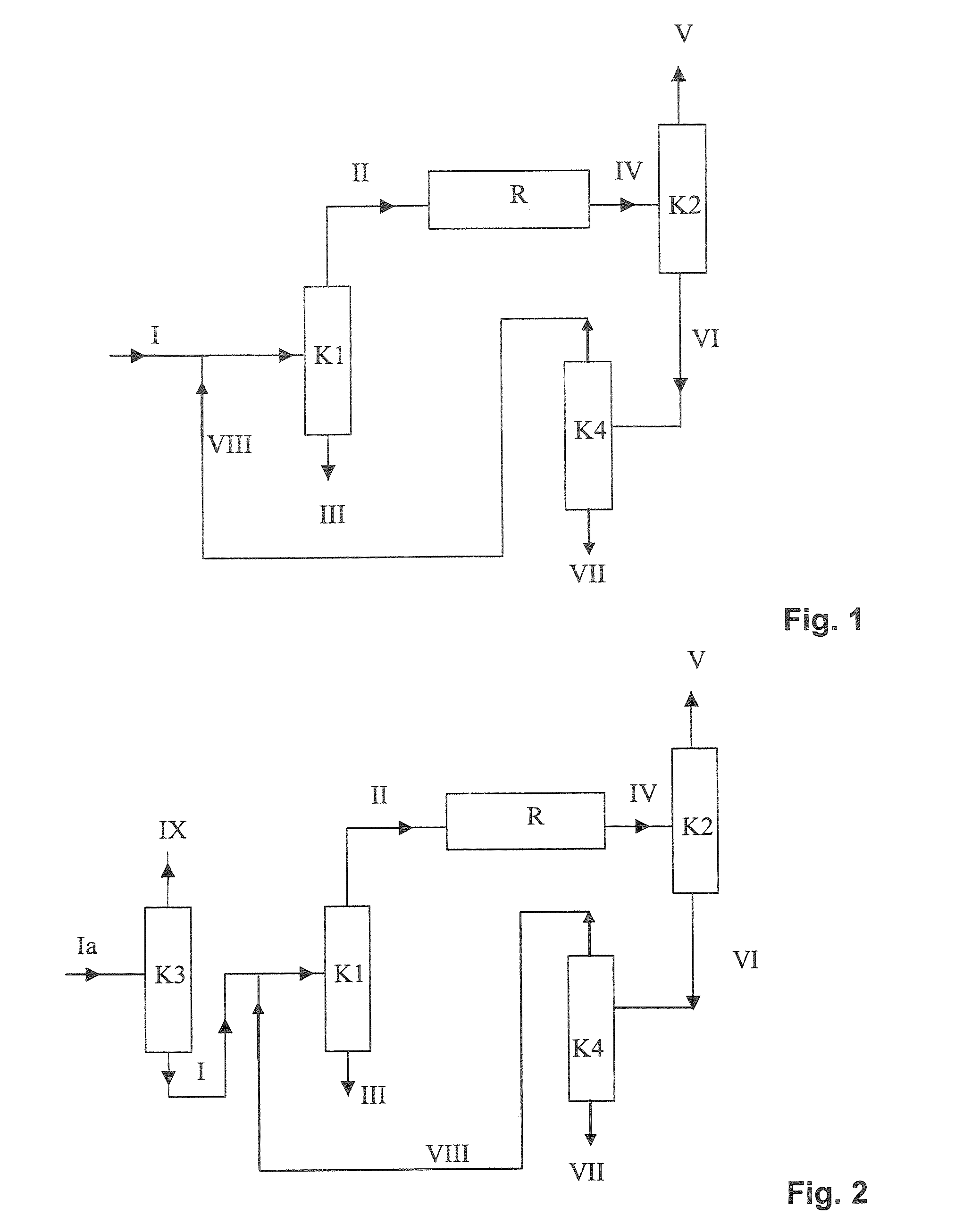

Process for the dissociation of mtbe

ActiveUS20080058575A1Improved and simplifiedWork-up of the bottom products obtainedEther separation/purificationOrganic compound preparationGas phaseBoiling point

Isobutene is prepared by dissociation of MTBE in the gas phase, by a) fractional distillation of an MTBE-containing stream comprising feed MTBE (I) and a recycle stream (VIII) to give an MTBE-containing overhead stream (II) and a bottom stream (III) having a boiling point higher than MTBE, b) catalytic dissociation of the overhead stream (II) obtained in step a) to give a dissociation product (IV), c) separation by distillation of the dissociation product (IV) obtained in step b) into an overhead stream (V) comprising more than 90% by mass of isobutene and a bottom stream (VI) comprising diisobutene, MTBE and more than 50% of the methanol present in the dissociation product (IV), d) fractional distillation of the bottom stream obtained in step c) under conditions under which the methanol is obtained as bottom product (VII) and more than 99% of the MTBE is obtained in the overhead product (VIII), and e) recirculation of the overhead product (VIII) to step a).

Owner:EVONIK OPERATIONS GMBH

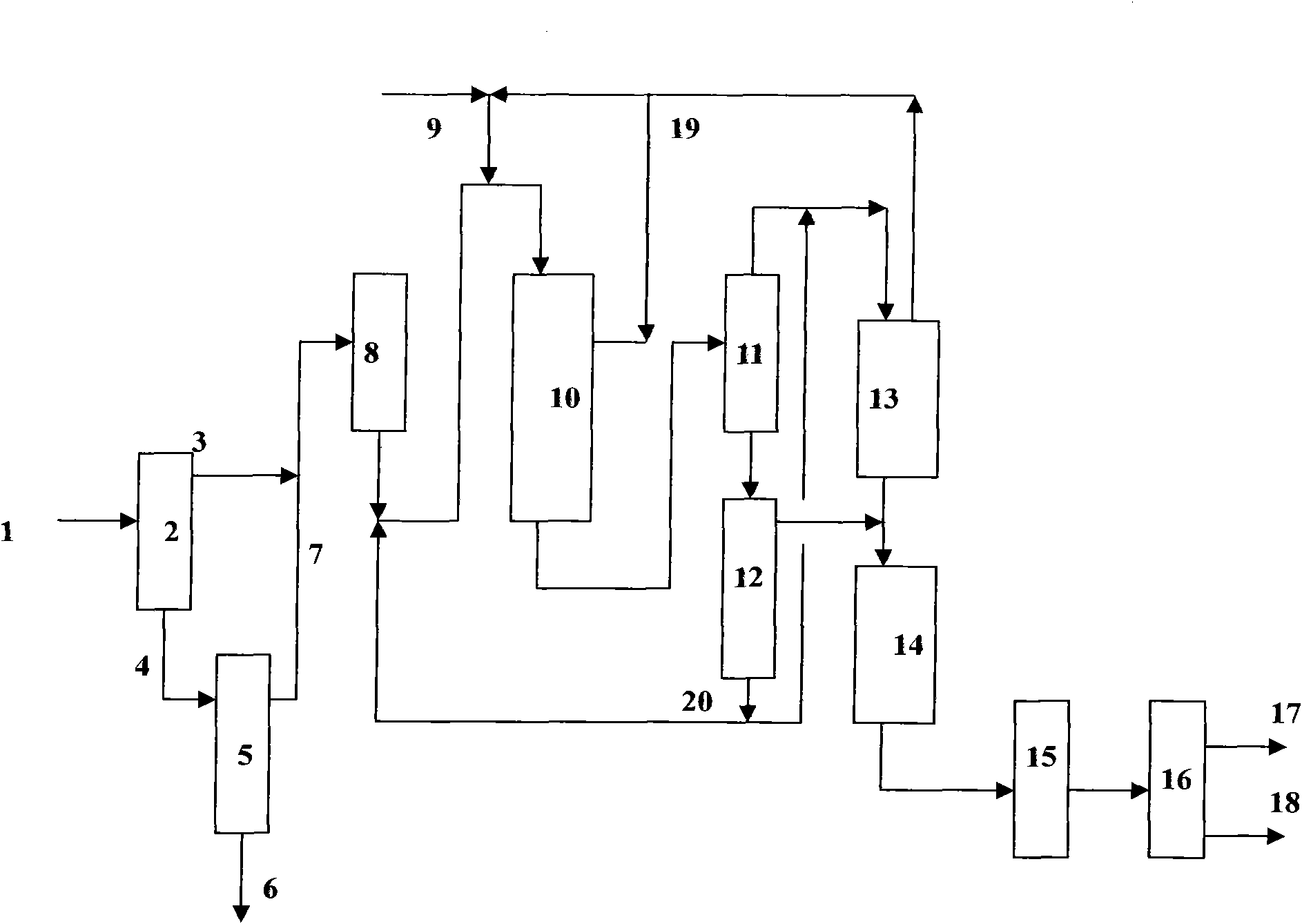

Systems and methods for reactive distillation with recirculation of light components

InactiveUS20100113625A1Organic compound preparationOxygen compounds preparation by reductionGas to liquidsReactive distillation

Systems and methods for producing gas-to-liquids products using reactive distillation are provided. The method for producing gas-to-liquids products can include reacting a feedstock in a column having a distillation zone and a reaction zone to provide a bottoms stream and an overhead stream. A first portion of the overhead stream can be recycled to the column at the top of the reaction zone and second portion of the overhead stream can be recycled to the column at the bottom of the reaction zone.

Owner:STICKNEY MICHAEL J +1

Method for processing ethylene tar

ActiveCN102234539AIncrease added valueTake advantage ofTreatment with hydrotreatment processesFiberCarbon fibers

The invention discloses a method for processing ethylene tar. Aiming at the characteristic of high contents of colloid, asphaltene and carbon residue in the ethylene tar, the method comprises the following steps of: performing fractional distillation on the ethylene tar to obtain light and heavy fractions, and treating heavy fractions by adopting a solvent deasphalting method to obtain deasphalted oil and deoiled asphalt; and mixing the deasphalted oil, the light fraction of the ethylene oil and hot low-grade oil, and making the mixture pass through a hydrogenation protecting reaction area, a hydrogenation refining reaction area and a hydrocracking reaction area in turn to obtain hydrocracking crude oil, wherein partial hydrocracking crude oil is circulated and mixed with the deasphalted oil and the light fraction of the ethylene tar to enter the hydrogenation reaction areas, the rest hydrocracking crude oil is separated to form gasoline and diesel fractions, and the deoiled asphalt serves as a general carbon fiber asphalt material. By the method, the problem of high temperature rise of a hydrogenation reactor bed can be effectively solved, full fractions of the ethylene tar are fully utilized, and the added value of the ethylene tar is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com