Diesel oil hydrogenation refining fractionation method and device

A technology of hydrorefining and fractionation device, which is applied in gasoline stabilization, electricity/magnetic dehydration/demulsification, etc., can solve the problems of increased investment, complicated furnace operation and high operating energy consumption, and achieves investment saving and low operating energy consumption. , the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

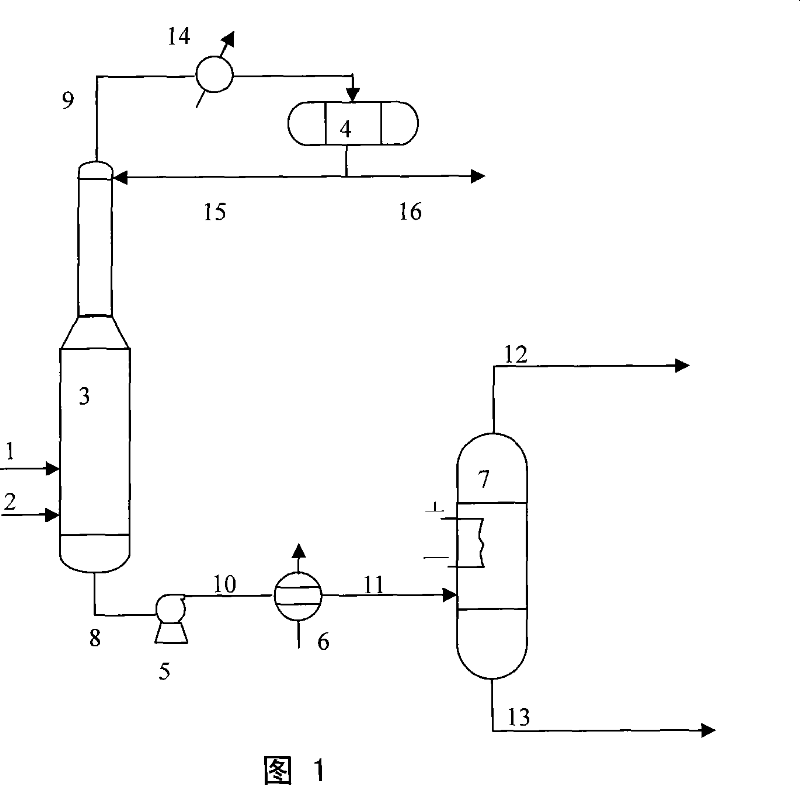

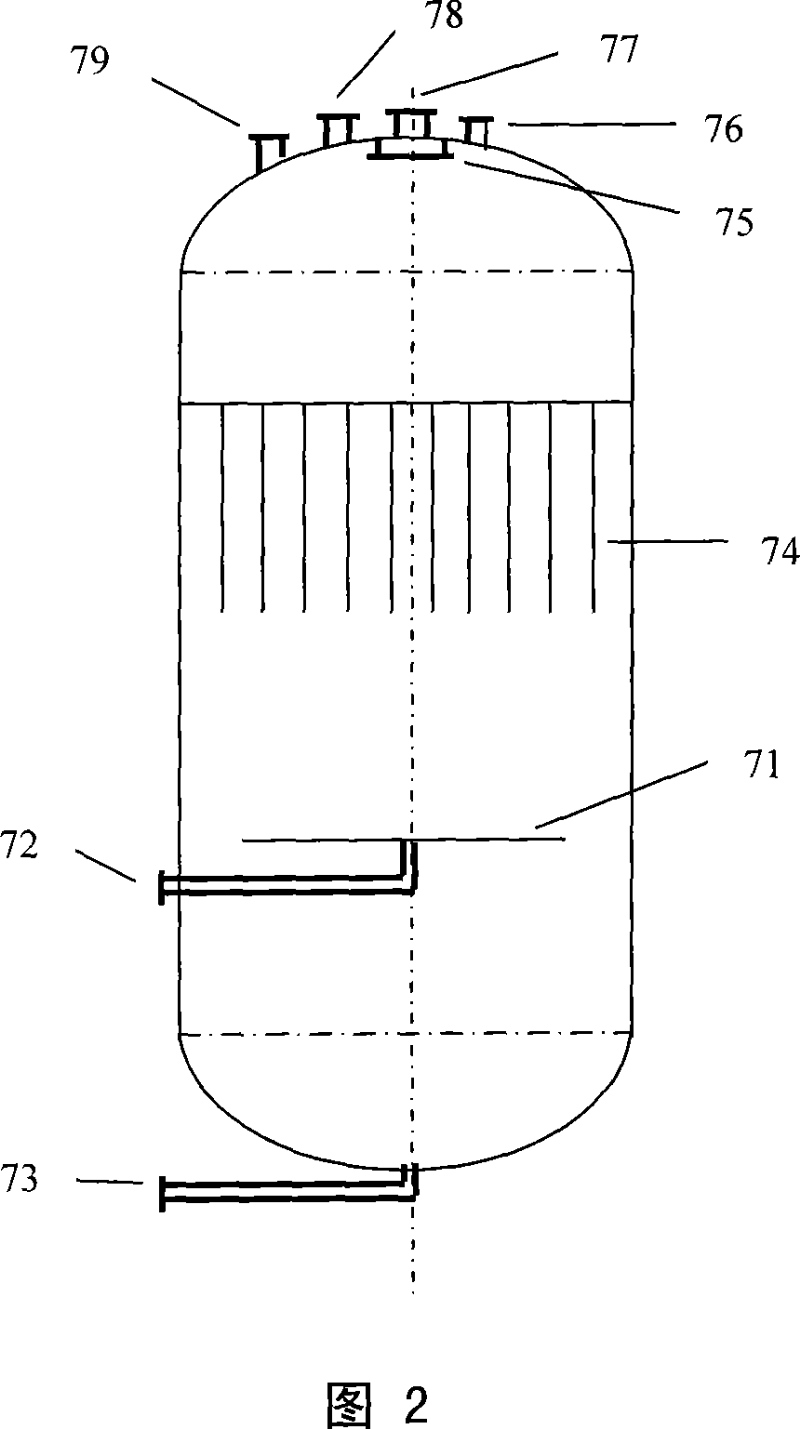

[0043] As shown in Figure 1 and Figure 2, a diesel hydrofining and fractionating device includes a steam stripping and fractionating unit for generating oil from hydrogenation reaction. The steam stripping and fractionating unit includes a fractionation tower 3, a tower top cooler 14 and a tower top reflux unit. The side walls of the tank 4 and the fractionation tower 3 are respectively provided with a feed port 1 and a stripping steam inlet 2 for the oil produced by the hydrogenation reaction. The feed port 1 for the oil produced by the hydrogenation reaction is located above the stripping steam inlet 2 for fractionation. The top of the tower 3 and the top cooler 14 are connected by the top oil and gas volatilization pipeline 9, and two pipelines are led out from the top reflux tank 4, namely the reflux pipeline 15 and the gasoline outlet pipeline 15, in which the reflux pipeline 15 and the fractionation The top of the tower 3 is connected, and the gasoline outlet pipeline 15 dir...

Embodiment 2

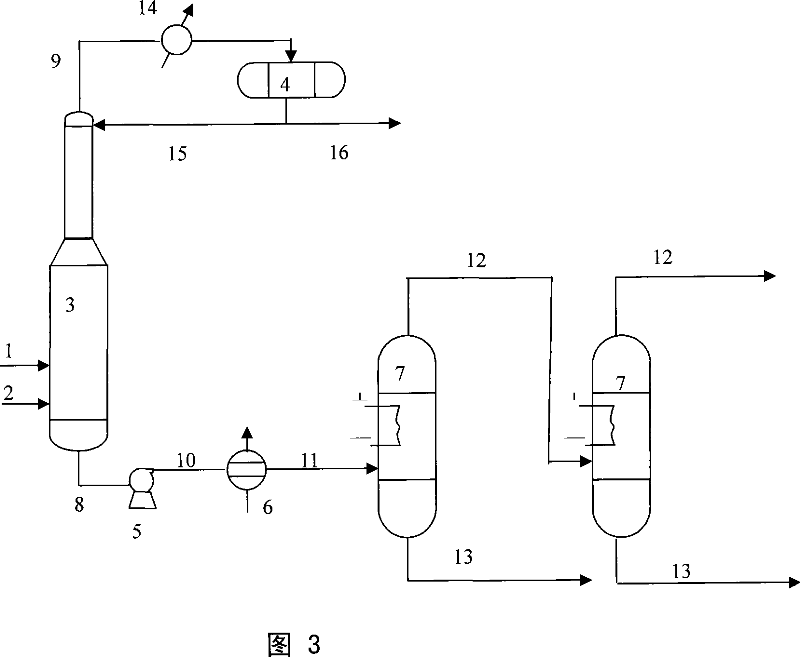

[0068] Figure 3 shows the second embodiment of the diesel hydrofining and fractionating device of the present invention. The difference from the first embodiment is that the present invention uses two series-connected vertical electric dehydration tanks for dehydration. Of course, it can also Multiple vertical electric dehydration tanks are used for dehydration treatment.

[0069] The method of using the device of this embodiment to perform diesel hydrorefining and fractionating can be divided into a hydrogenation reaction to generate oil vapor stripping and fractionating process and a refined diesel ionization dehydration process. Among them,

[0070] The steam stripping process includes the following steps:

[0071] (1) The hydrogenation reaction product oil from the low-pressure separator of the reaction system enters the feed port of the fractionation tower. The feed temperature of the fractionation tower is 250°C, the top temperature of the fractionation tower is 150°C, and t...

Embodiment 3

[0077] The difference from the first embodiment is that the heat exchange and cooling unit in this embodiment adopts a heat exchanger and an air cooler in series combined structure, that is, the heat exchange and cooling unit 6 adopts one or more heat exchangers in series with the air cooler. , The outlet end of the last heat exchanger is connected to the inlet end of the air cooler, the inlet end of the first heat exchanger is connected to the outlet end of the booster pump 5, and the outlet end of the air cooler is connected to the inlet end of the electric dehydration tank 7 .

[0078] The method of using the device of this embodiment to perform diesel hydrorefining and fractionating can be divided into a hydrogenation reaction to generate oil vapor stripping and fractionating process and a refined diesel ionization dehydration process. Among them,

[0079] The steam stripping process includes the following steps:

[0080] (1) The hydrogenation reaction product oil from the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com