Patents

Literature

149results about "Gasoline stabilisation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heavy distillate oil hydrotreating method

ActiveCN101348732AQuality improvementQuality assuranceHydrocarbon oils refiningGasoline stabilisationWaxOil and grease

The invention relates to a method for hydrotreating heavy oil, in particular to the method for hydrotreating heavy oil, which improves the quality of diesel oil. Heavy distillate oil and animal and vegetable oil are used as raw material oil; under the hydrotreatment condition, the raw material oil and hydrogen gas are mixed and pass through a hydrotreatment reaction region; hydrogen-rich gas which is obtained by separating oil generated by hydrotreatment is circulated and utilized; and liquid obtained by separation is distillated to prepare a diesel oil product and hydrogenated wax oil. Compared with the prior art, the method can effectively improve the material source of a wax oil hydrotreatment device, ensure the quality of the hydrogenated wax oil, substantially increase the quality ofthe hydrotreated diesel oil and improve the storage stability of the animal and vegetable oil as fuel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

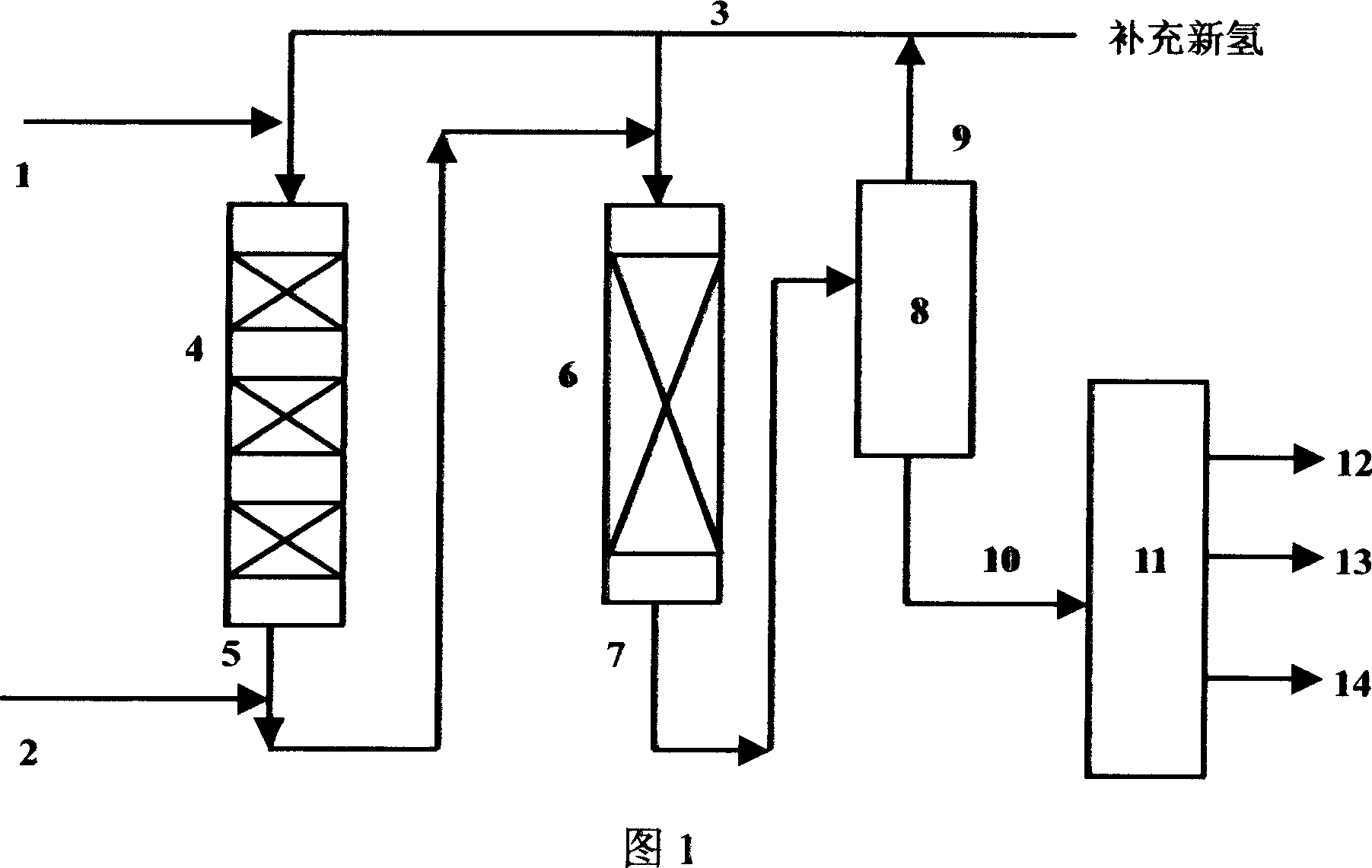

Method of producing fuel oil by coal tar hydrogenation modifying

ActiveCN1903994AReduce temperature riseReduce coking rateTreatment with hydrotreatment processesGasoline stabilisationLow nitrogenSulfur

The present invention relates to a method for producing fuel oil by utilizing coal tar. It is characterized by that said method includes the following steps: after the whole coal tar in which the moisture and ash are removed and diluting oil are mixed according to a certain mixing ratio, making the obtained mixture be successively passed through a shallow hydrogenation unit with hydrogenation protecting agent and prehydrogenation catalyst and a deep hydrogenation unit with main hydrogenation catalyst, then making the product obtained after deep hydrogenation undergo the processes of high-pressure separation, low-pressure separation and fractionation so as to obtain light-oil fraction, medium-oil fraction and tail-oil fraction, namely obtain low-sulfur low-nitrogen fuel oil and light oil product.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

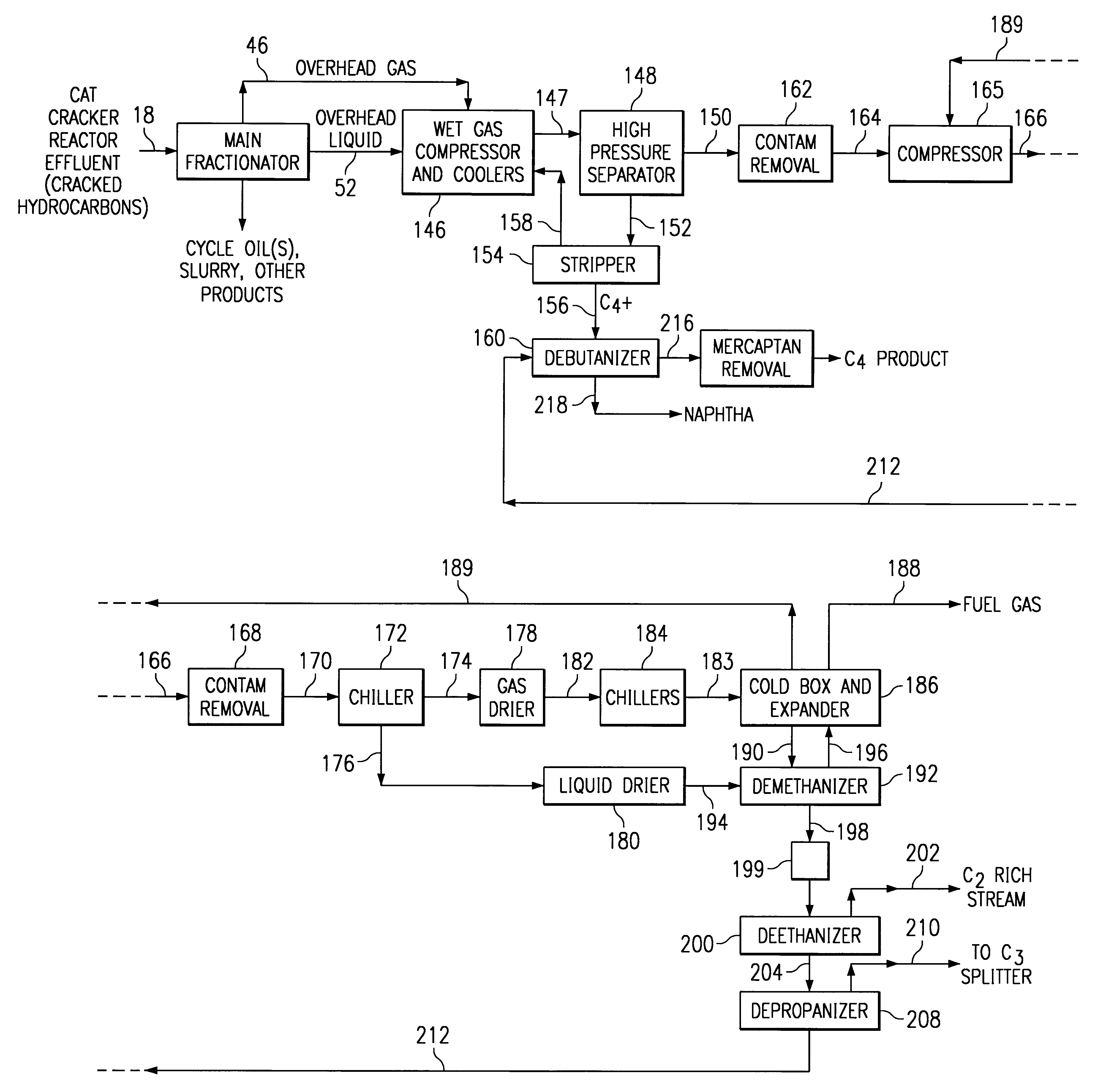

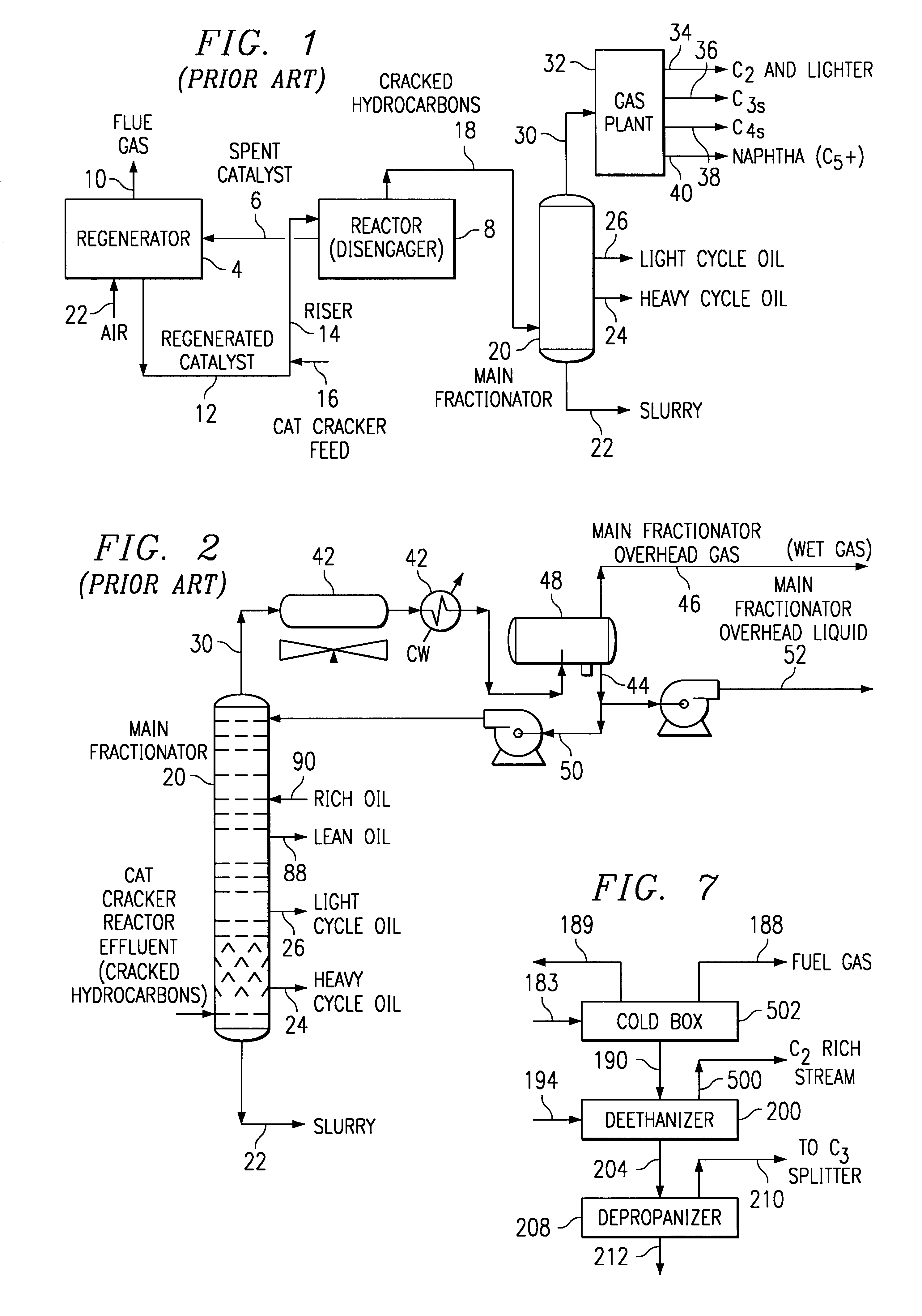

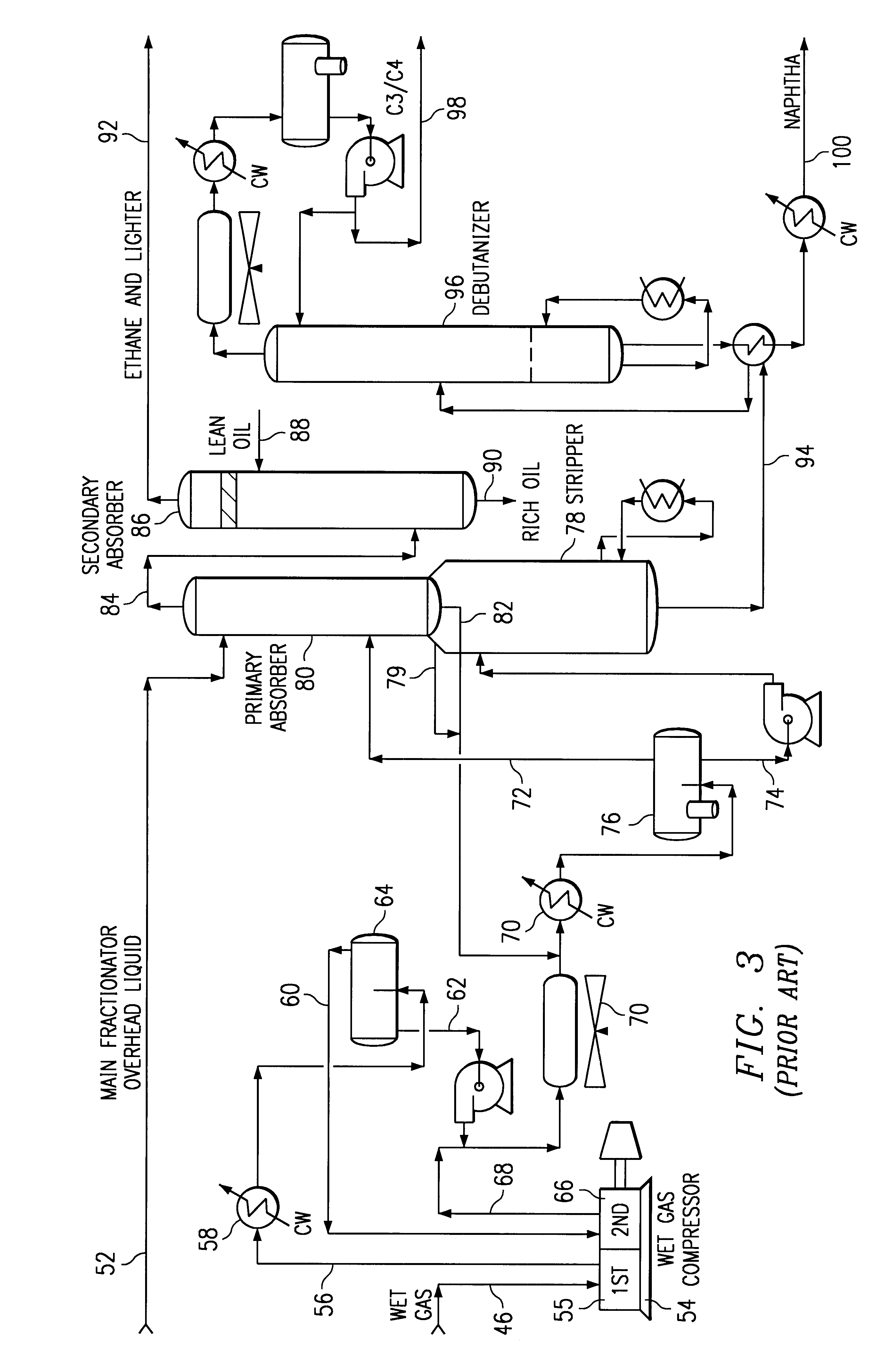

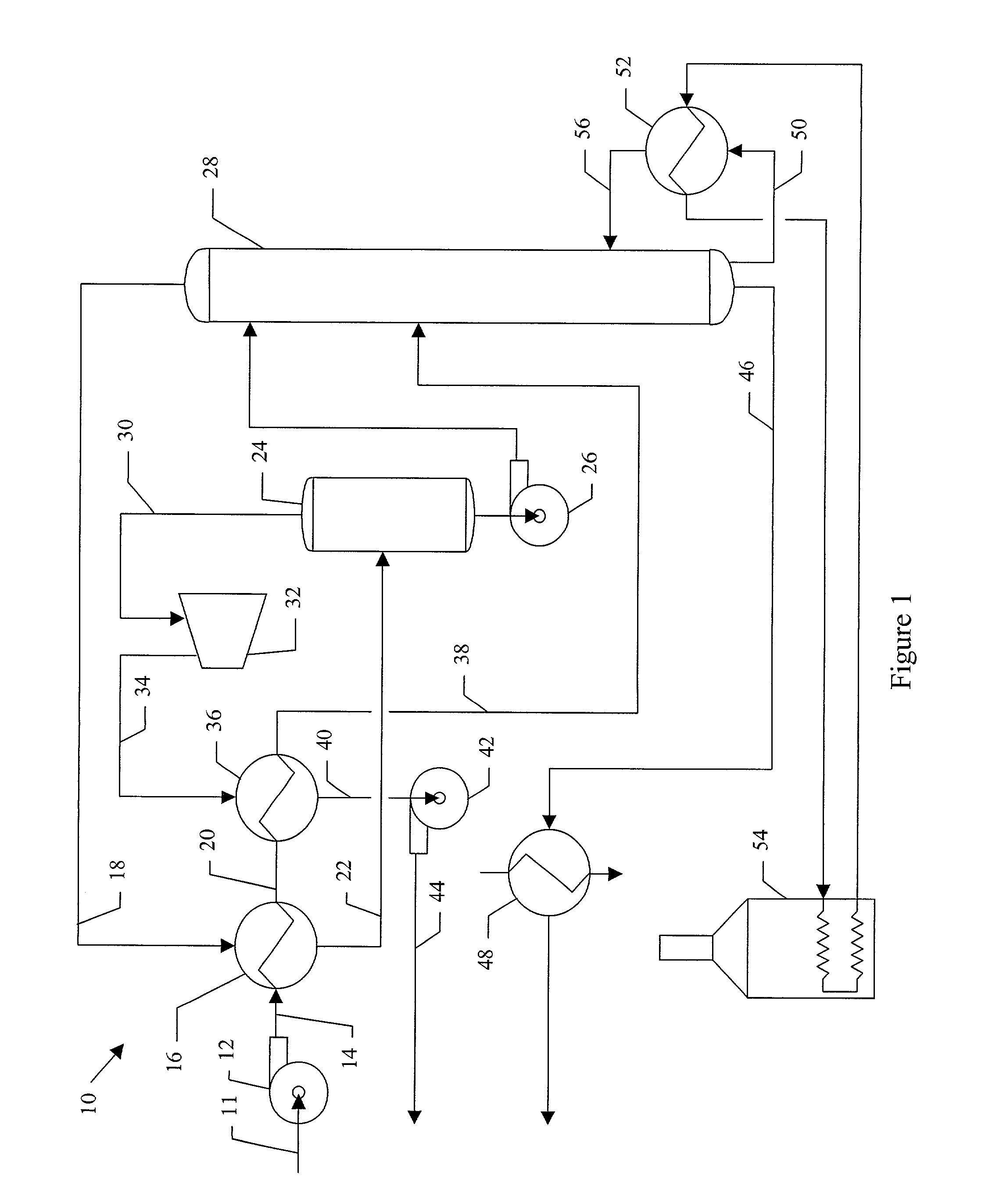

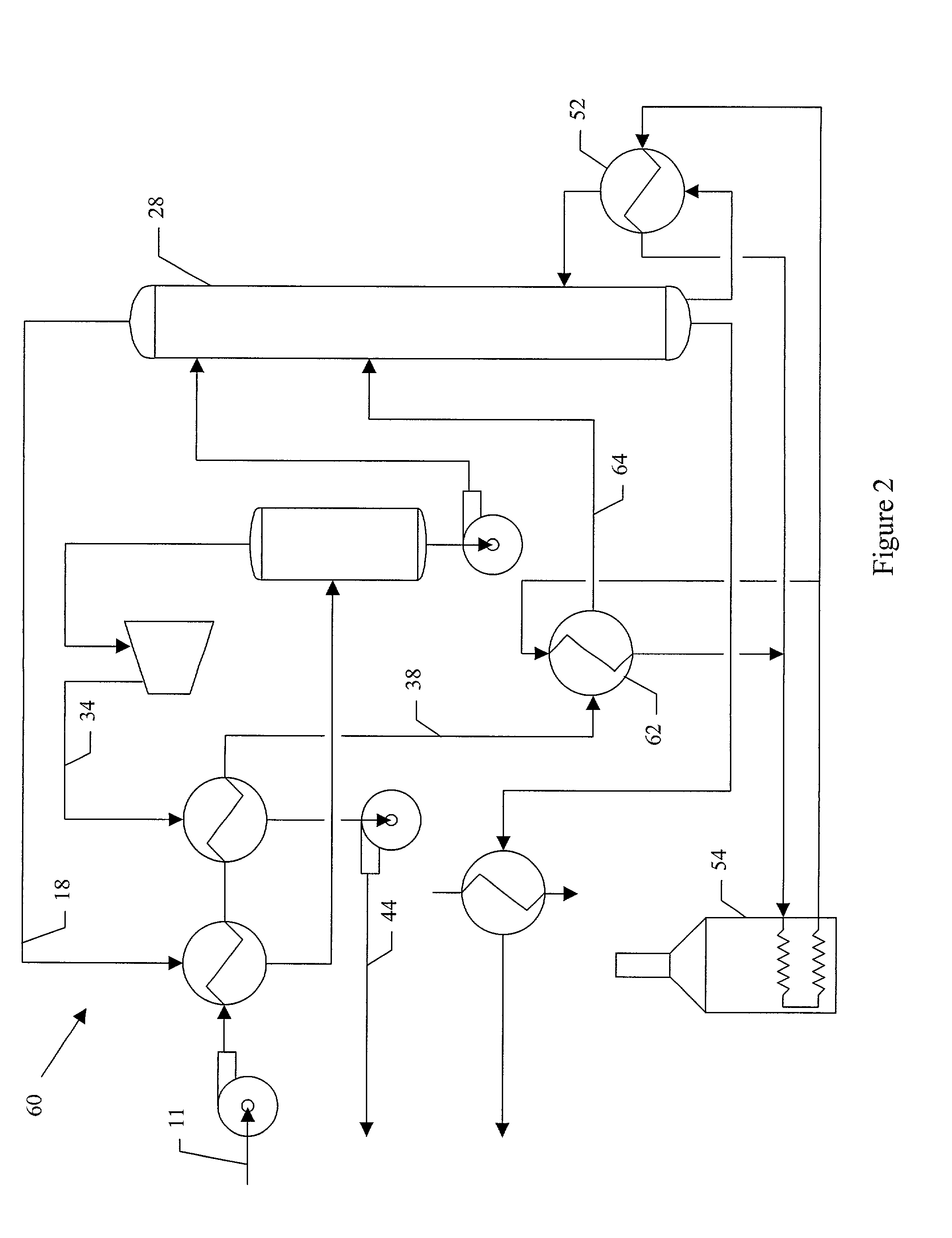

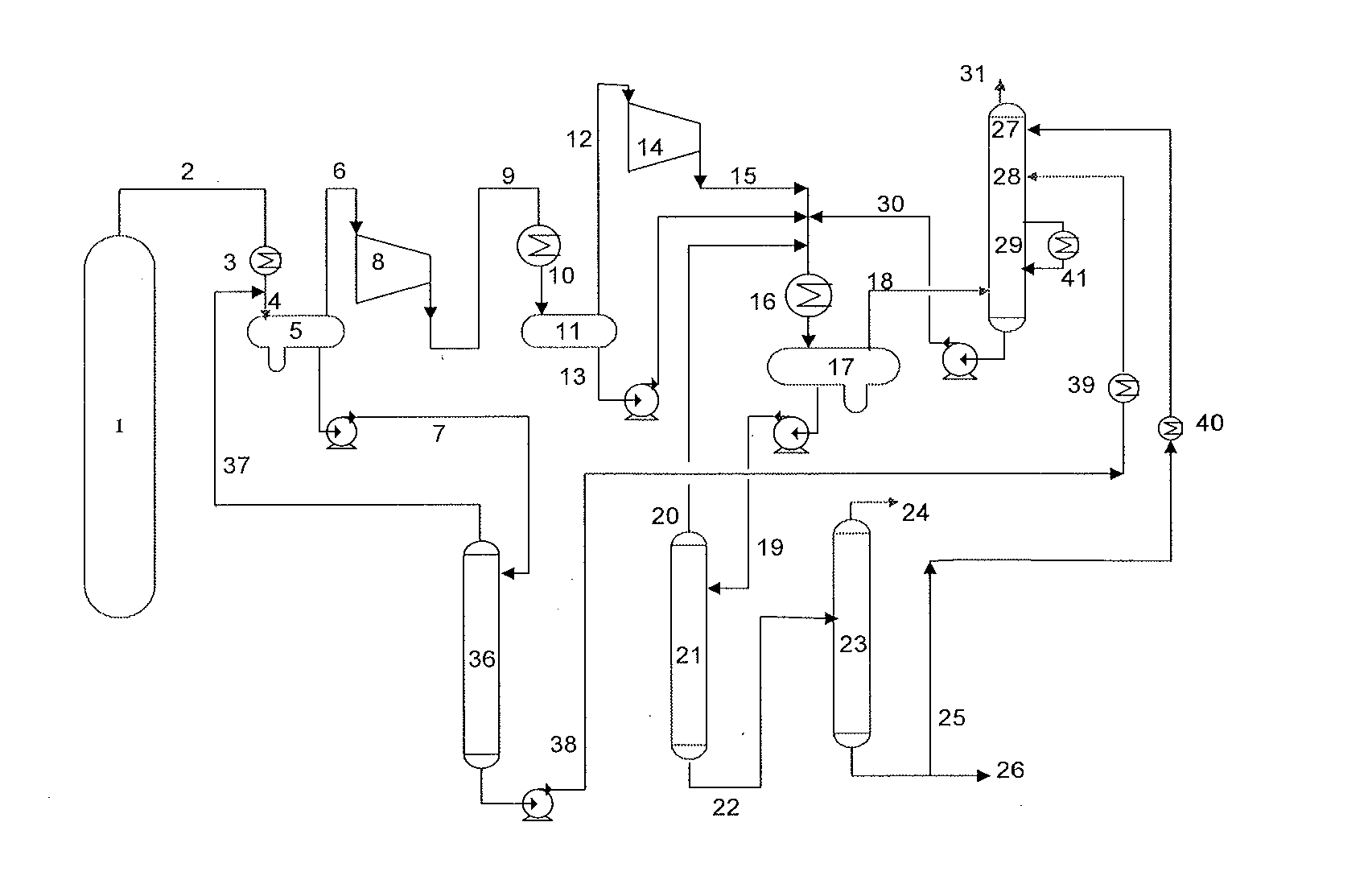

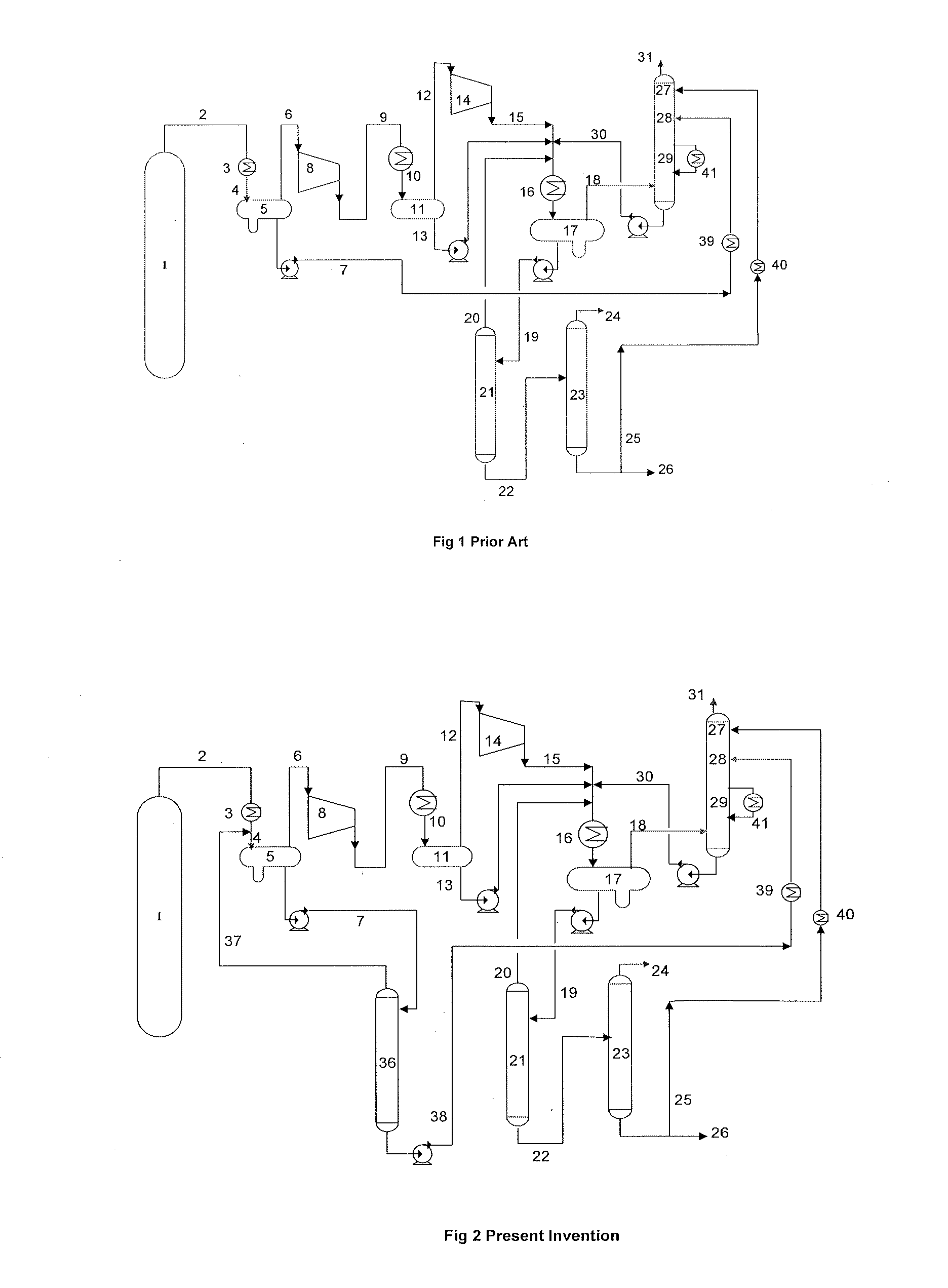

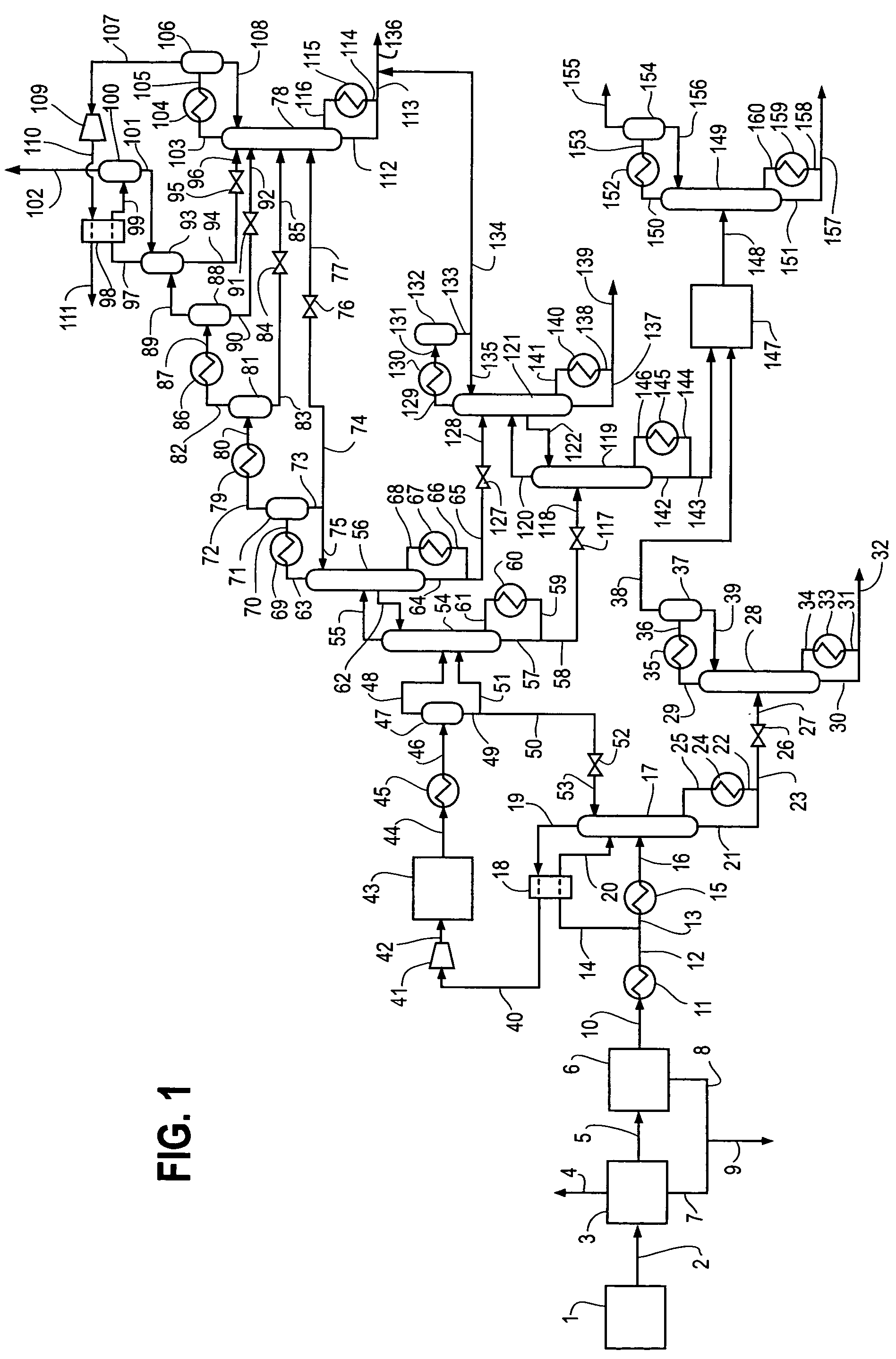

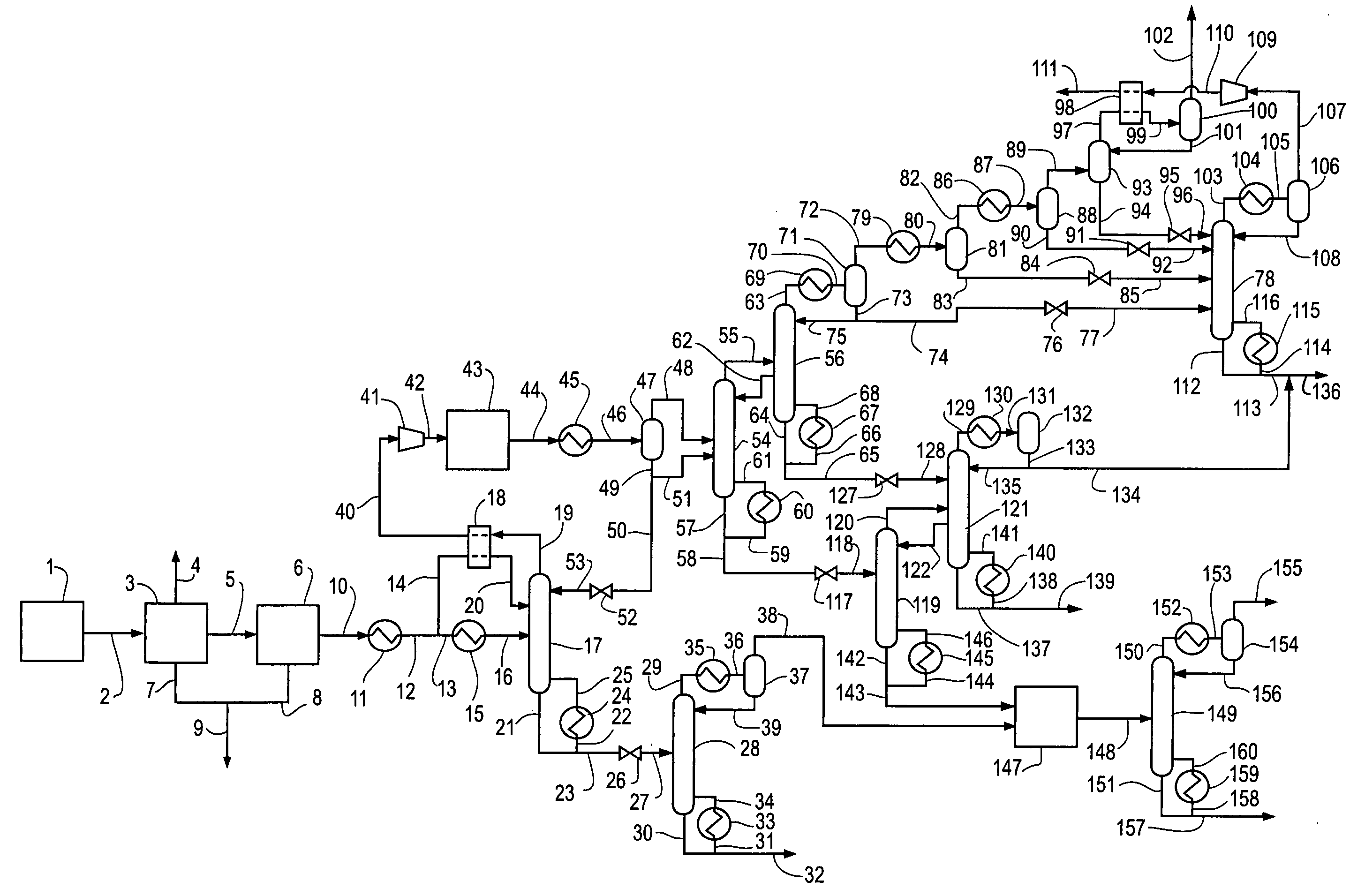

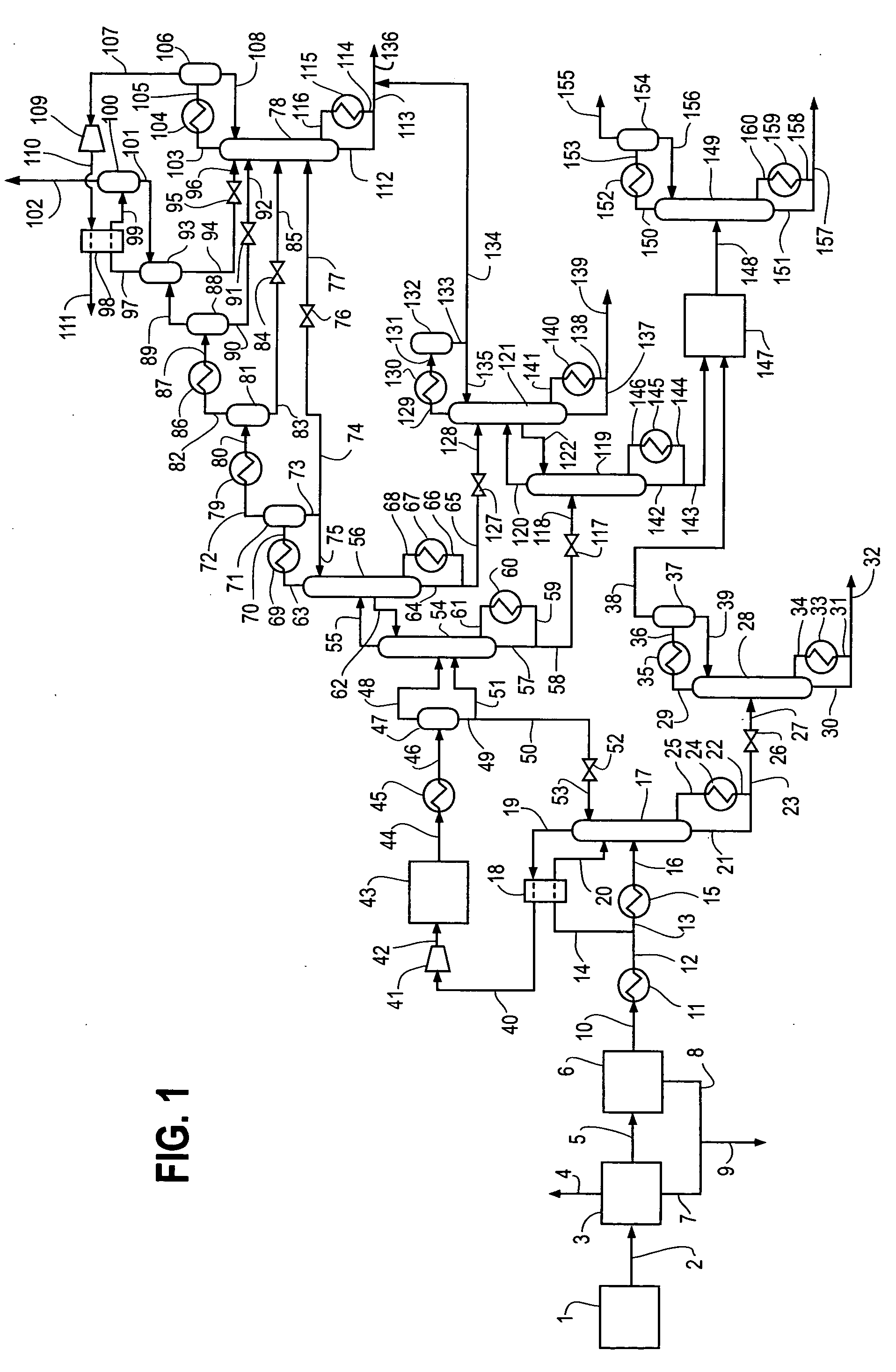

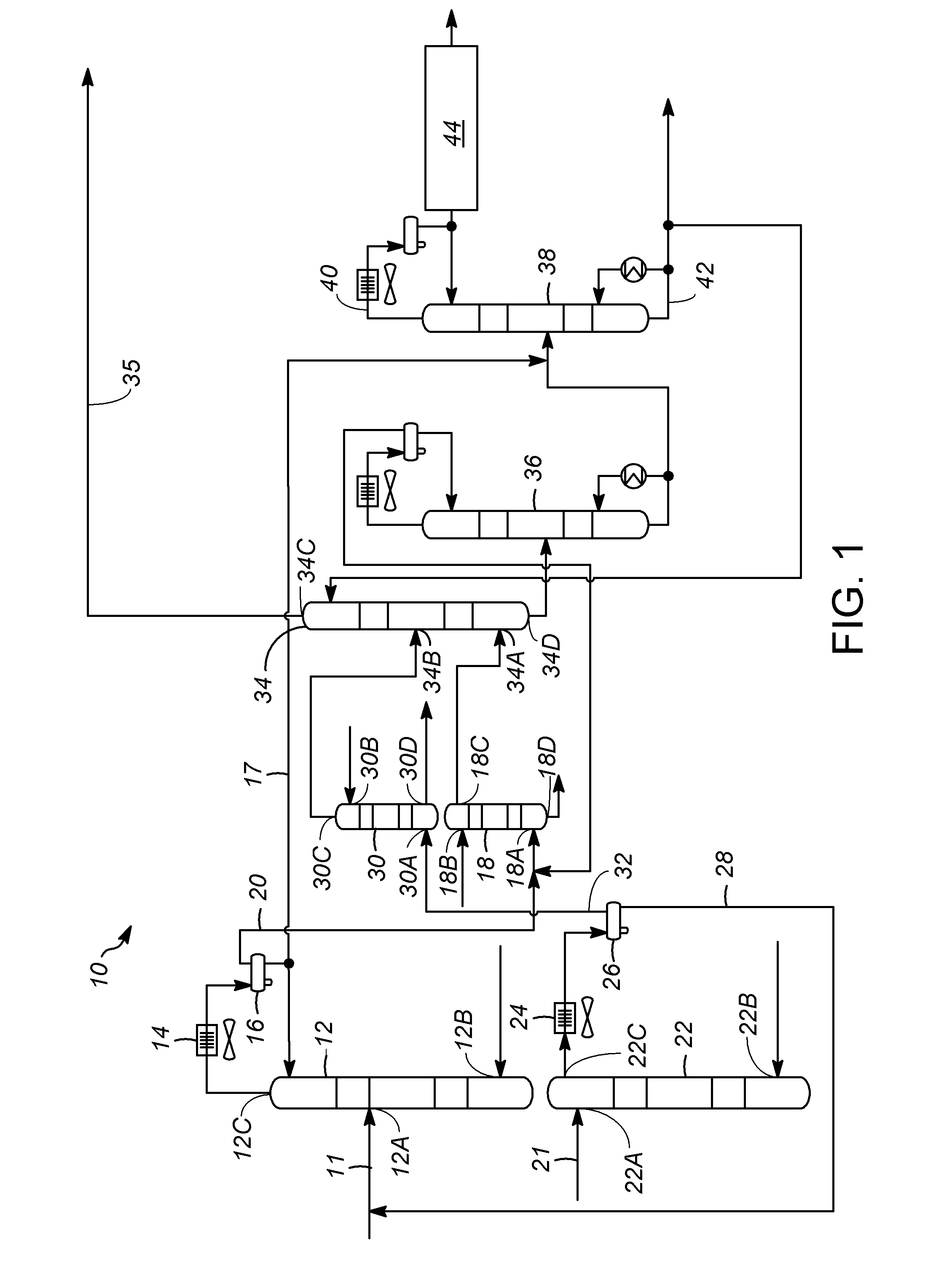

Cat cracker gas plant process for increased olefins recovery

The invention relates to a new process for more efficient separation and recovery of light olefins such as ethylene and propylene from a fluid catalytic cracking unit. The new process invention for recovering olefins from a mixture of cracked hydrocarbons from a fluid catalytic cracker comprises the steps of: (a) providing a mixture of cracked hydrocarbons including methane, ethylene, ethane, propylene, propane, butylene, butane and heavier hydrocarbons such as naphtha produced in a fluid catalytic cracker; (b) separating said mixture into (i) a first stream comprising substantially all of said ethane, ethylene, and methane and a major portion of said propane and propylene and (ii) a second stream comprising a portion of said butylene and butane, and a major portion of said heavier hydrocarbons; and (c) processing said first stream to recover the ethylene and propylene therefrom, and the details of such process described herein.

Owner:STONE & WEBSTER PROCESS TECH

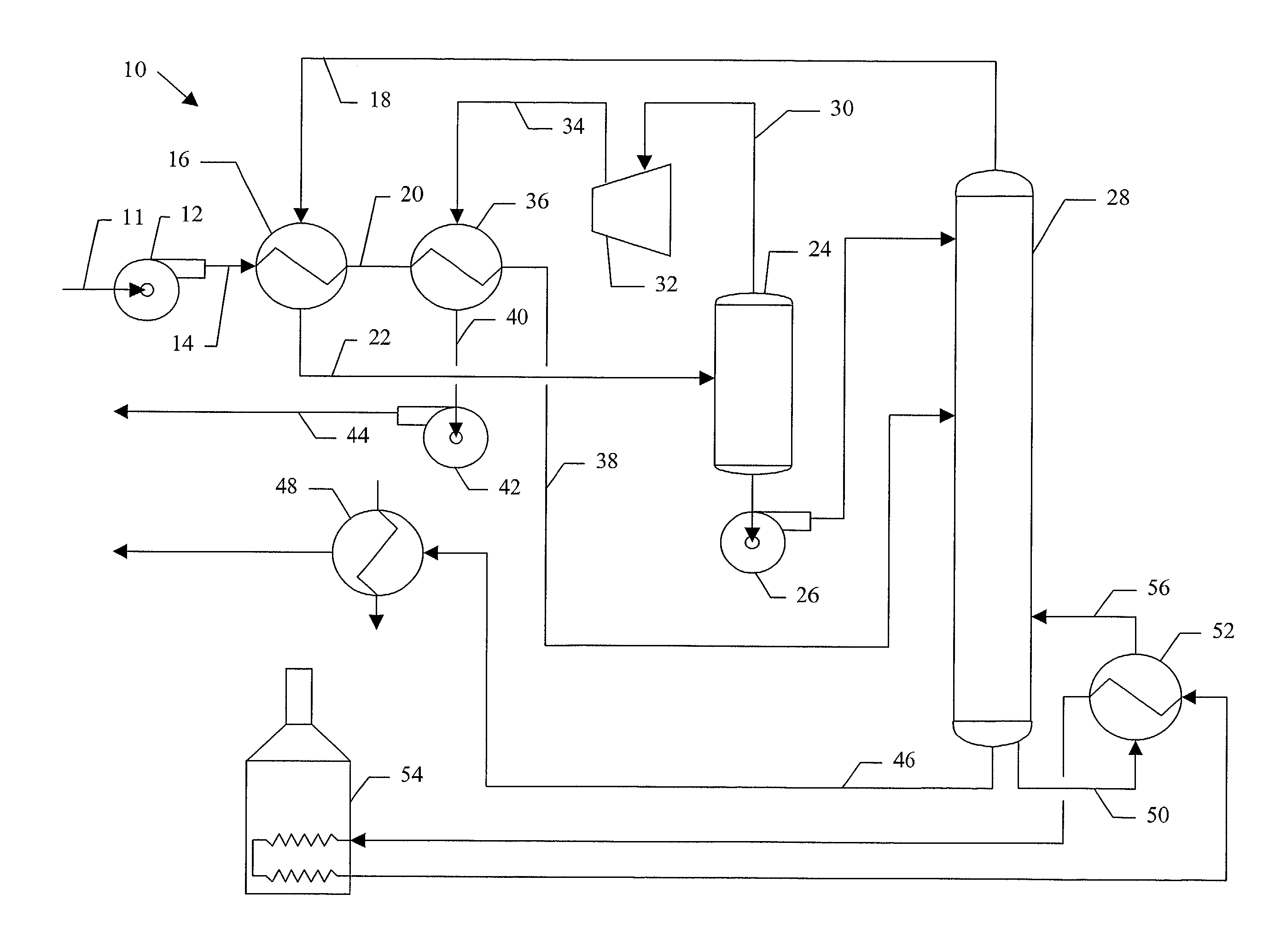

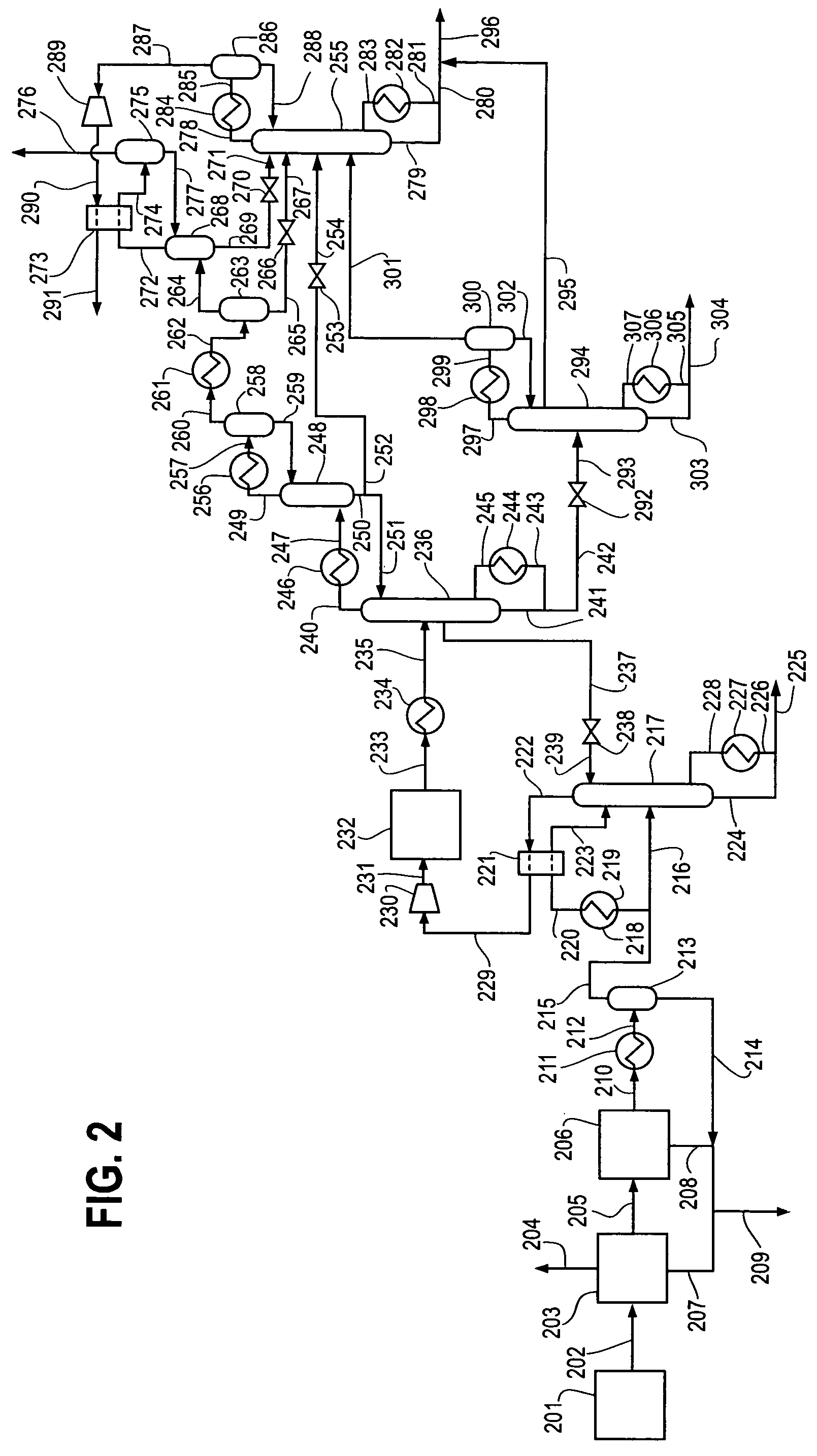

System and method for recovery of C2+ hydrocarbons contained in liquefied natural gas

ActiveUS7069743B2Significant energy savingMinimizing heat inputSolidificationLiquefactionRefluxDistillation

A processing method and system for separating methane-rich and ethane-rich components from an LNG stream. The LNG stream is preheated against a distillation column overhead vapor stream and against an overhead vapor product prior to entering the column. The overhead vapor product is methane-rich. The LNG stream may further be preheated against the column bottoms and another heating medium. The method may also include compressing the methane-rich product, condensing it against the LNG stream, and pumping it. The system may also comprise third and fourth heat exchangers configured to preheat the LNG stream with the bottoms product and the heating medium. Further, the system may provide for compressing the overhead vapor product prior to the its exchanging heat with the LNG stream and a pump for pumping condensed overhead vapor product. Additionally, the system generates all of the required reflux by cross exchanging the column overhead with the incoming LNG stream.

Owner:PILOT ENERGY SOLUTIONS

Use of low pressure distillate as absorber oil in a FCC recovery section

InactiveUS7074323B2Less equipmentImprove throughputThermal non-catalytic crackingCatalytic crackingNaphthaDistillation

A process for the recovery of gaseous products from the product mixture obtained by contacting a hydrocarbon feed with a catalyst in a fluid catalytic cracking process, wherein the liquid, obtained by separating the top product of main fractionators into gaseous and liquid fraction, when supplied to the absorber has a temperature of between about 8–25 DEG C. This liquid may be pre-saturated with gaseous top product from absorber; or also a high boiling fraction (cat cracker naphtha / light cycle oil) may be first separated from this liquid by distillation.

Owner:SHELL OIL CO

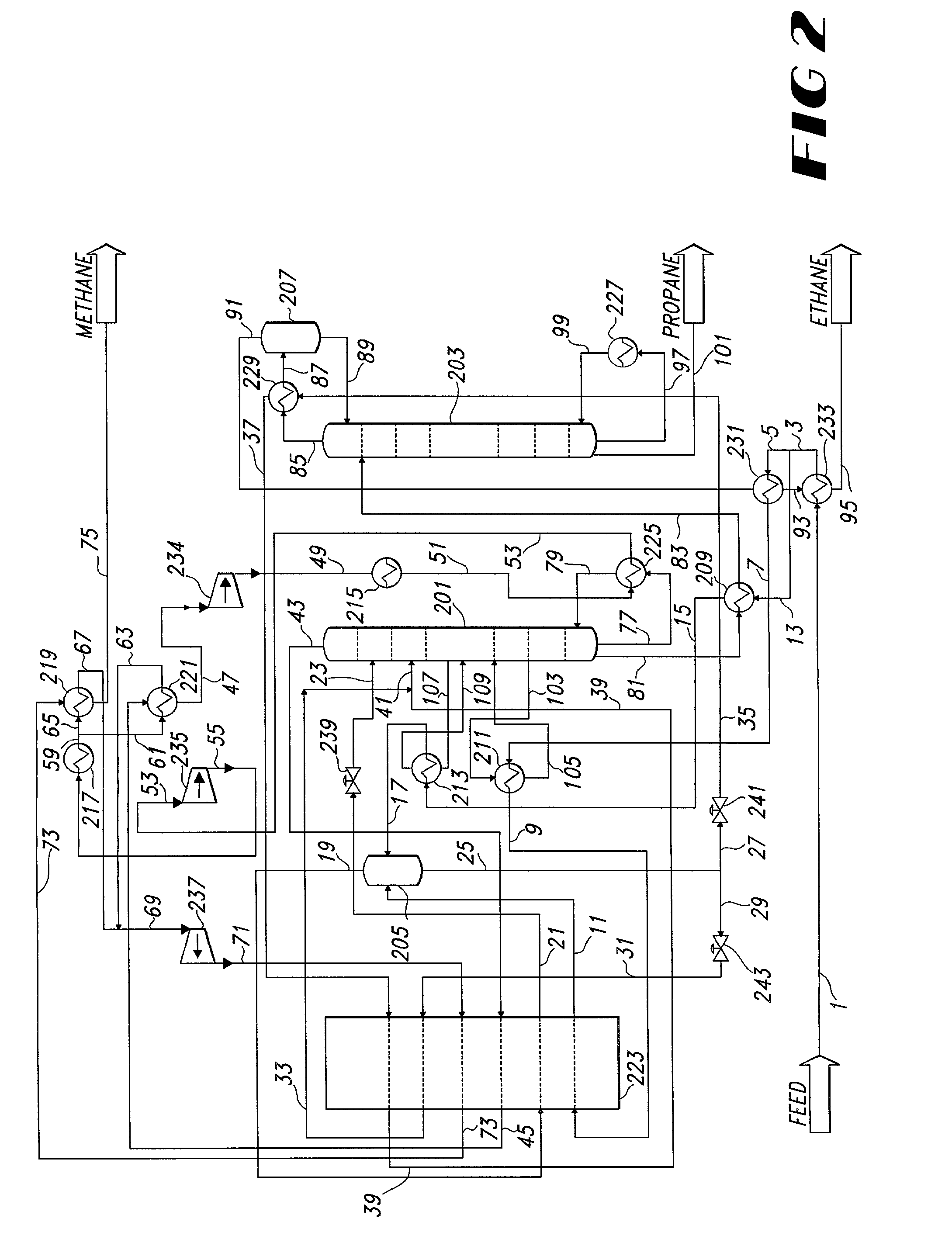

Ethane extraction process for a hydrocarbon gas stream

A process for ethane extraction from a gas stream based on turboexpansion and fractionation with no mechanical refrigeration is provided. The feed gas is sweetened and dehydrated by a conventional amine process and by a molecular sieve unit, to remove carbon dioxide and water. After this pretreatment, the feed gas undergoes to a series of cooling steps through a cryogenic brazed aluminum heat exchanger and fed to a demethanizer column. A stream rich in methane is recovered from the top of this column and fed to a centrifugal compressor and subsequently routed to a booster / turboexpander. The temperature of the methane gas is greatly reduced by the expansion allowing the cooled methane stream to be a cooling source for cryogenic heat exchanger. Feed for a de-ethanizer column comes from the bottom liquids of the de-methanizer column. Ethane is recovered overhead at the de-ethanizer column.

Owner:INELECTRA

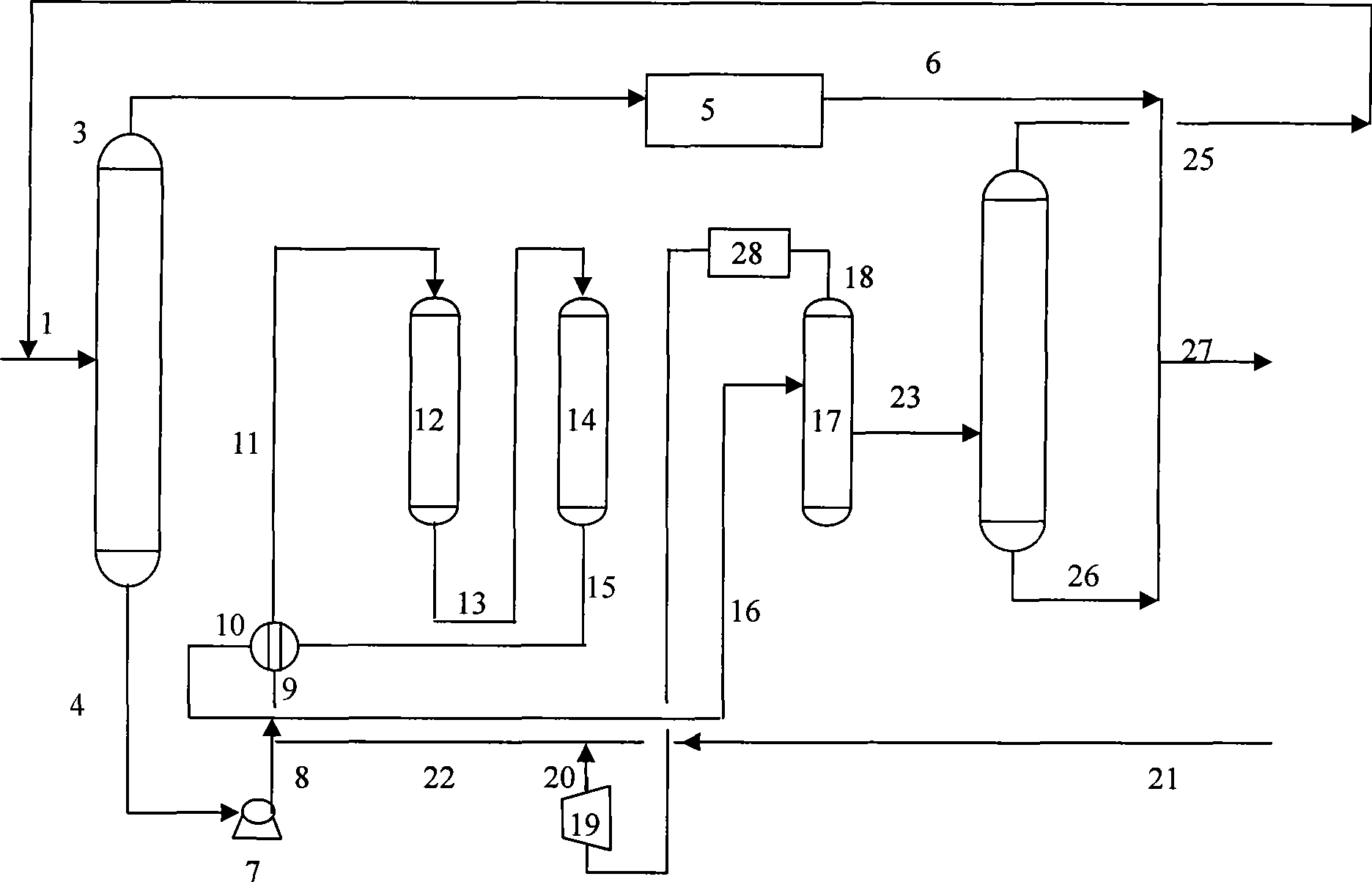

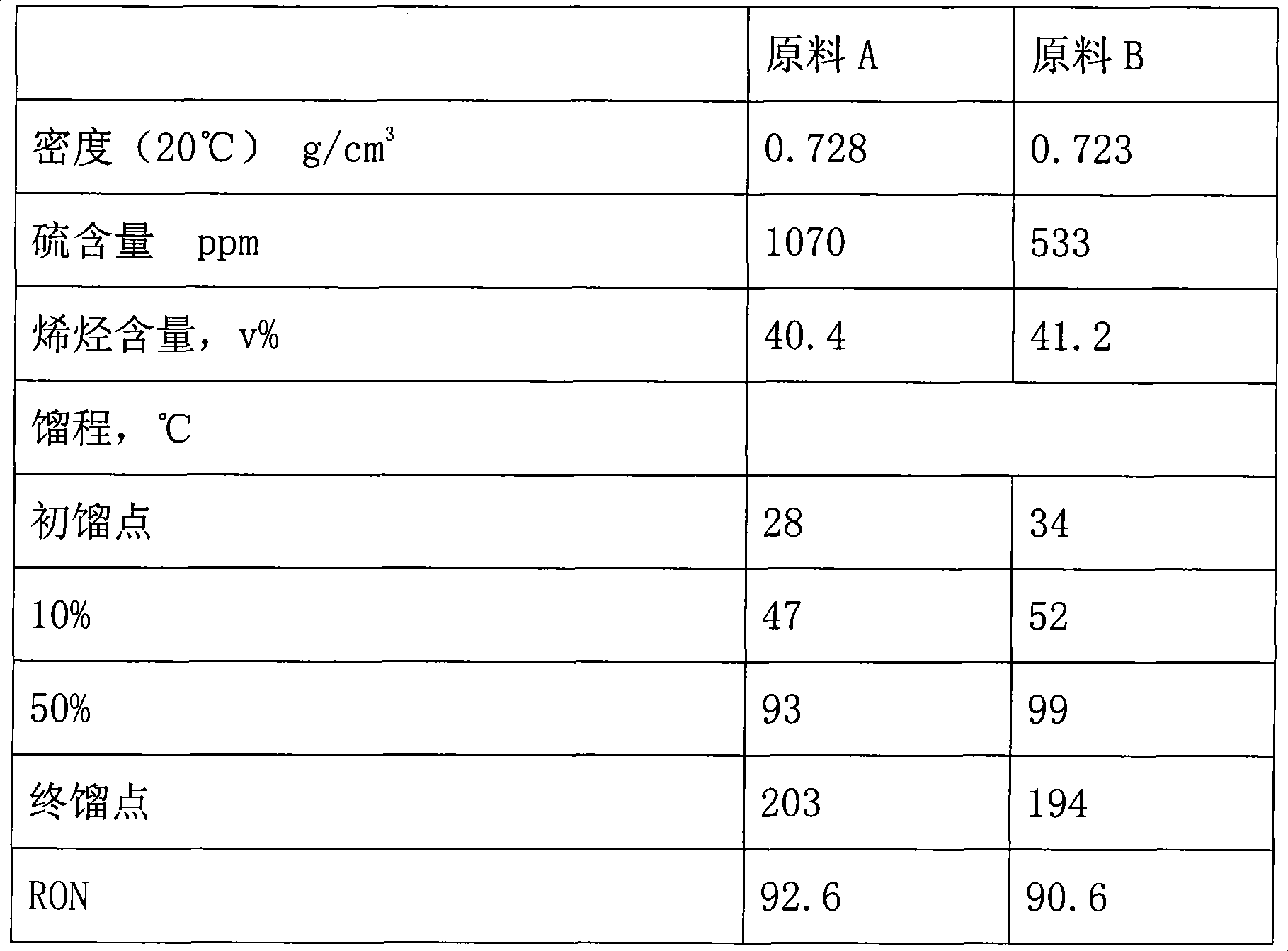

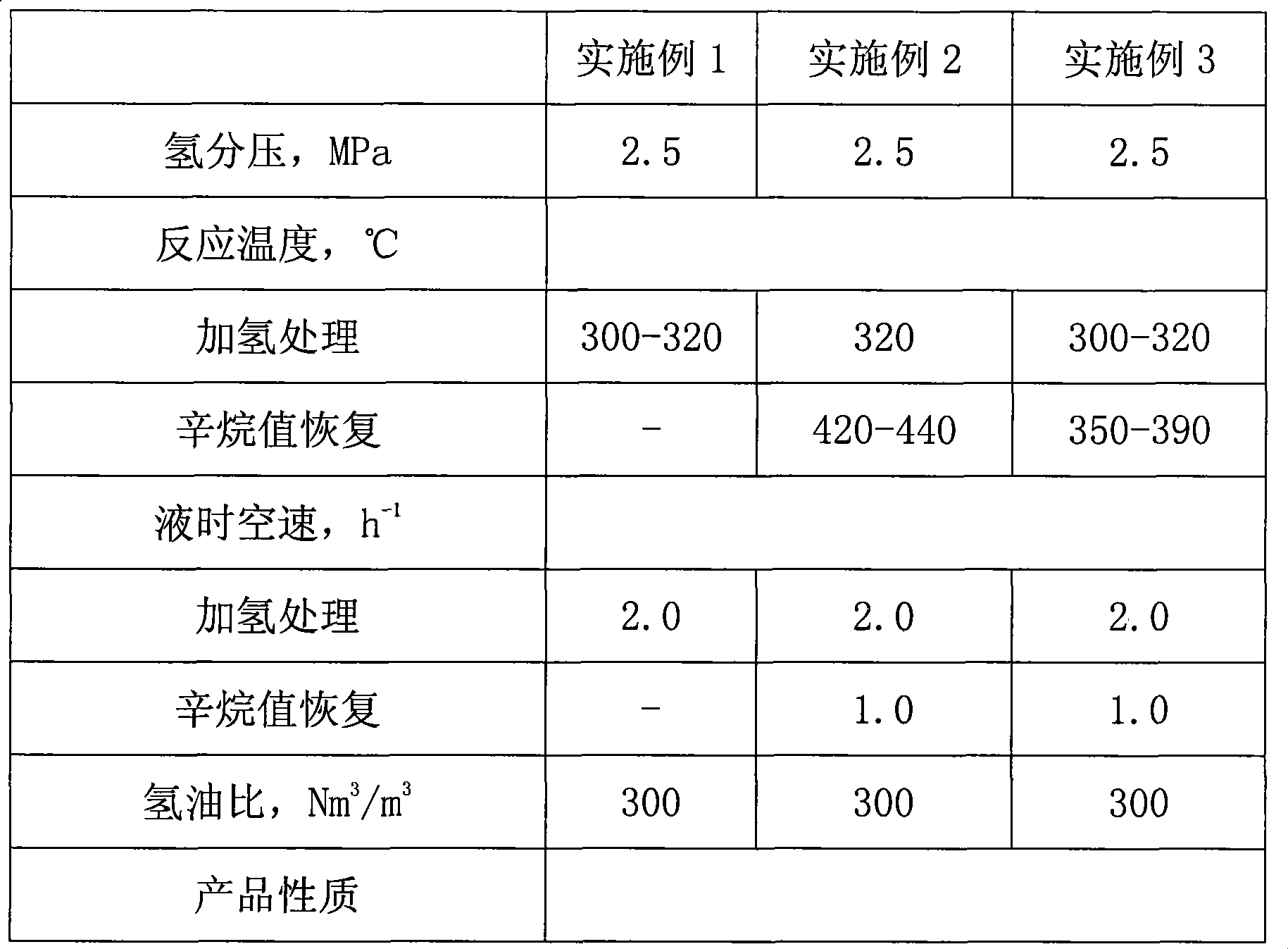

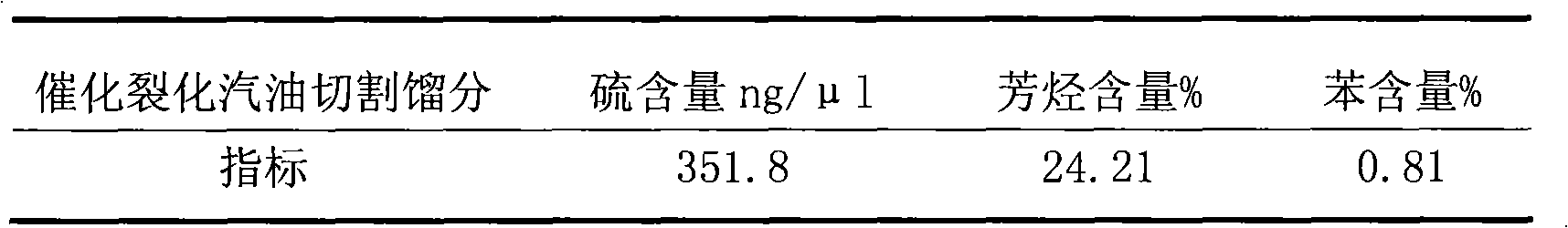

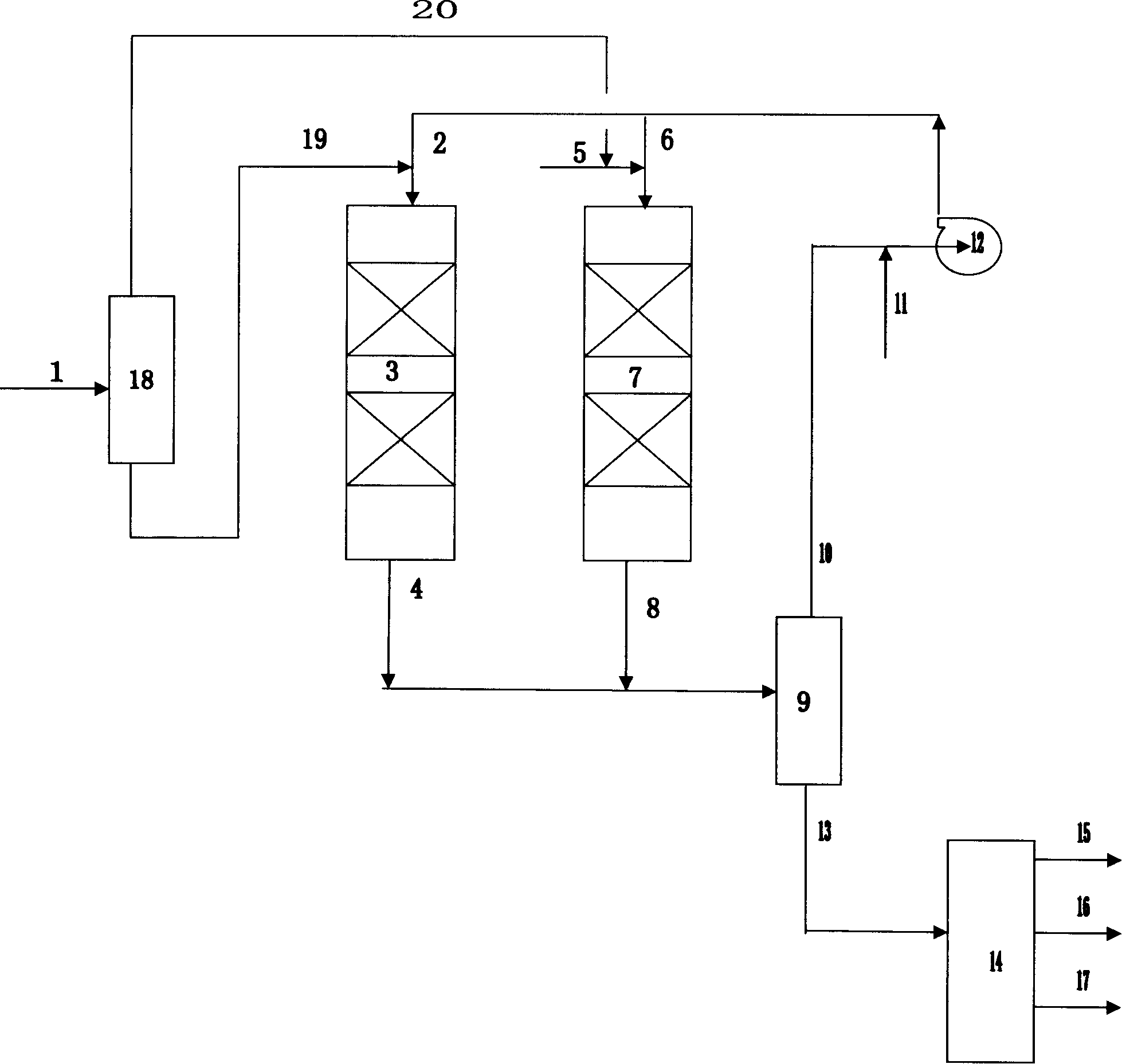

Hydrogenation modification method for catalytically cracked gasoline

ActiveCN101368111ANo change in octaneReduce hydrogen sulfide contentGasoline stabilisationRefining to eliminate hetero atomsIsomerizationHydrodesulfurization

The invention relates to a hydro-upgrading method for catalytic cracking gasoline; the method comprises the following steps: gasoline whole fraction is cut into light fraction and heavy fraction; the cutting point is 60 DEG C to 80 DEG C; mercaptan in the light gasoline fraction is removed through mercaptan removal alkali washing; the heavy gasoline fraction and hydrogen gas have catalytic hydrodesulfurization, denitrogenation and olefin saturated reaction; reactor effluent or the reactor effluent after removing hydrogen sulfide is contacted with octane value restore catalyzer, and isomerization, aromatizatian and building up reaction are implemented, hydrogenated oil is separated and lighter hydrocarbon gasoline fraction is obtained, hydrogen-rich gas at the top of a high partial tank is circularly used through hydrogen sulfide removal, and lighter hydrocarbon at the top of a stabilizer tower is feedback to a fractionation tank to be fractionated again; the condition of the hydrotreating reaction is that hydrogen partial pressure is 1.5 to 3.0 MPa; the reaction temperature is 250 to 320 DEG C; the liquid hourly space velocity is 3.0 to 5.0 h<-1>, and the hydrogen-oil ratio is 200 to 500 Nm<3> / m<3>; the sulfur content of the gasoline product is smaller than 100 ppm, the octane value is unchanged, and the yield of gasoline reaches 98.5 weight percent.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

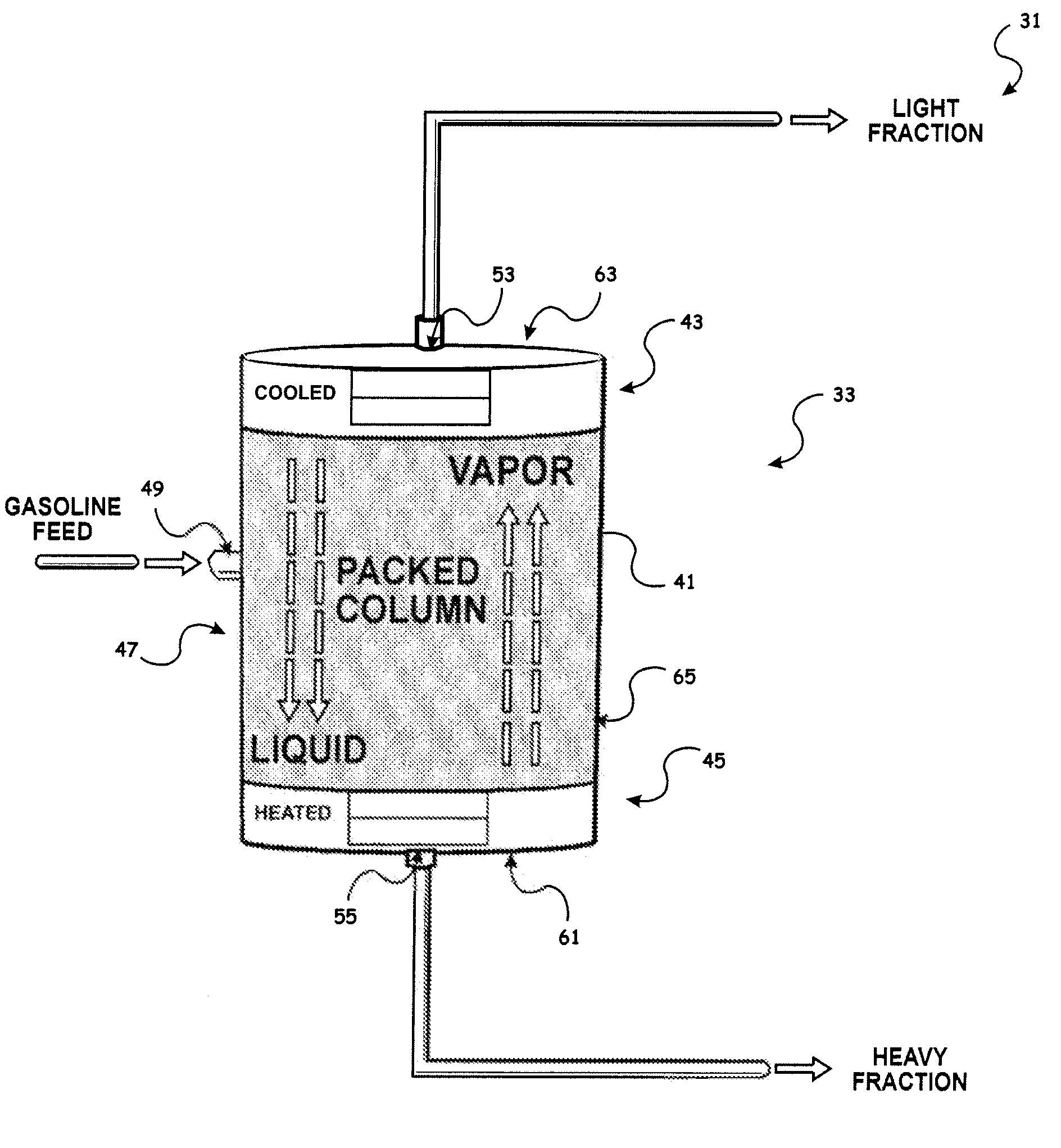

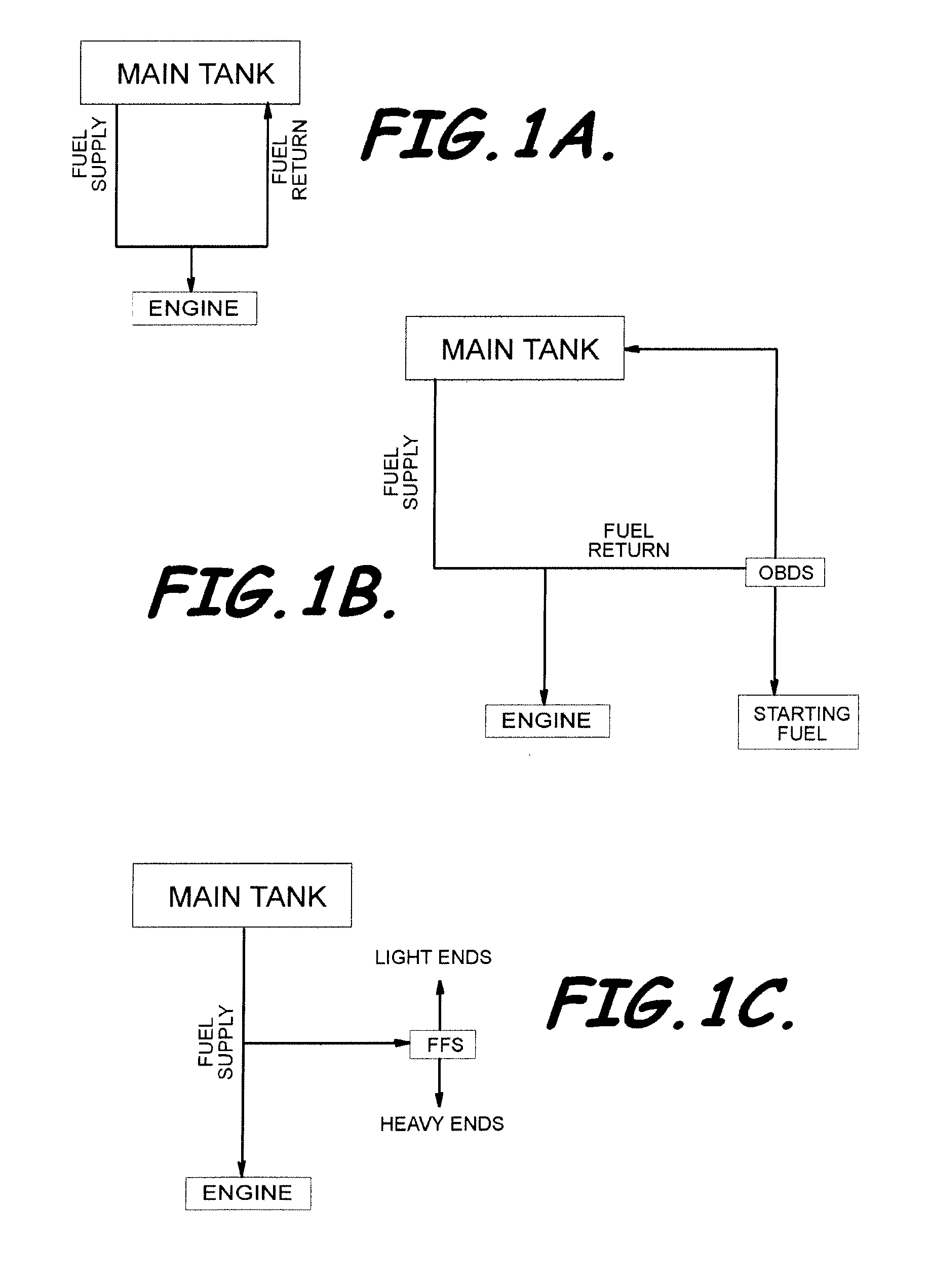

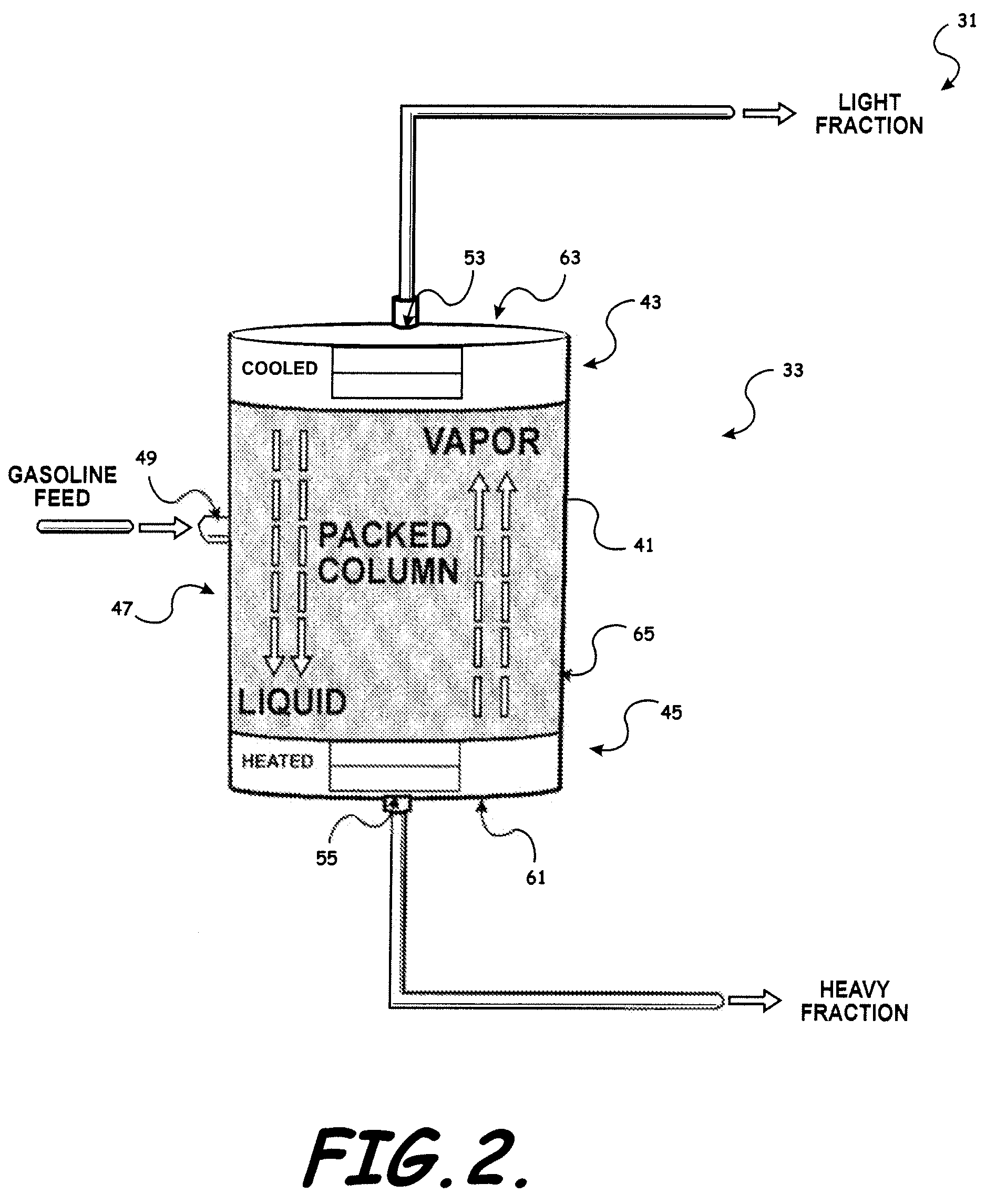

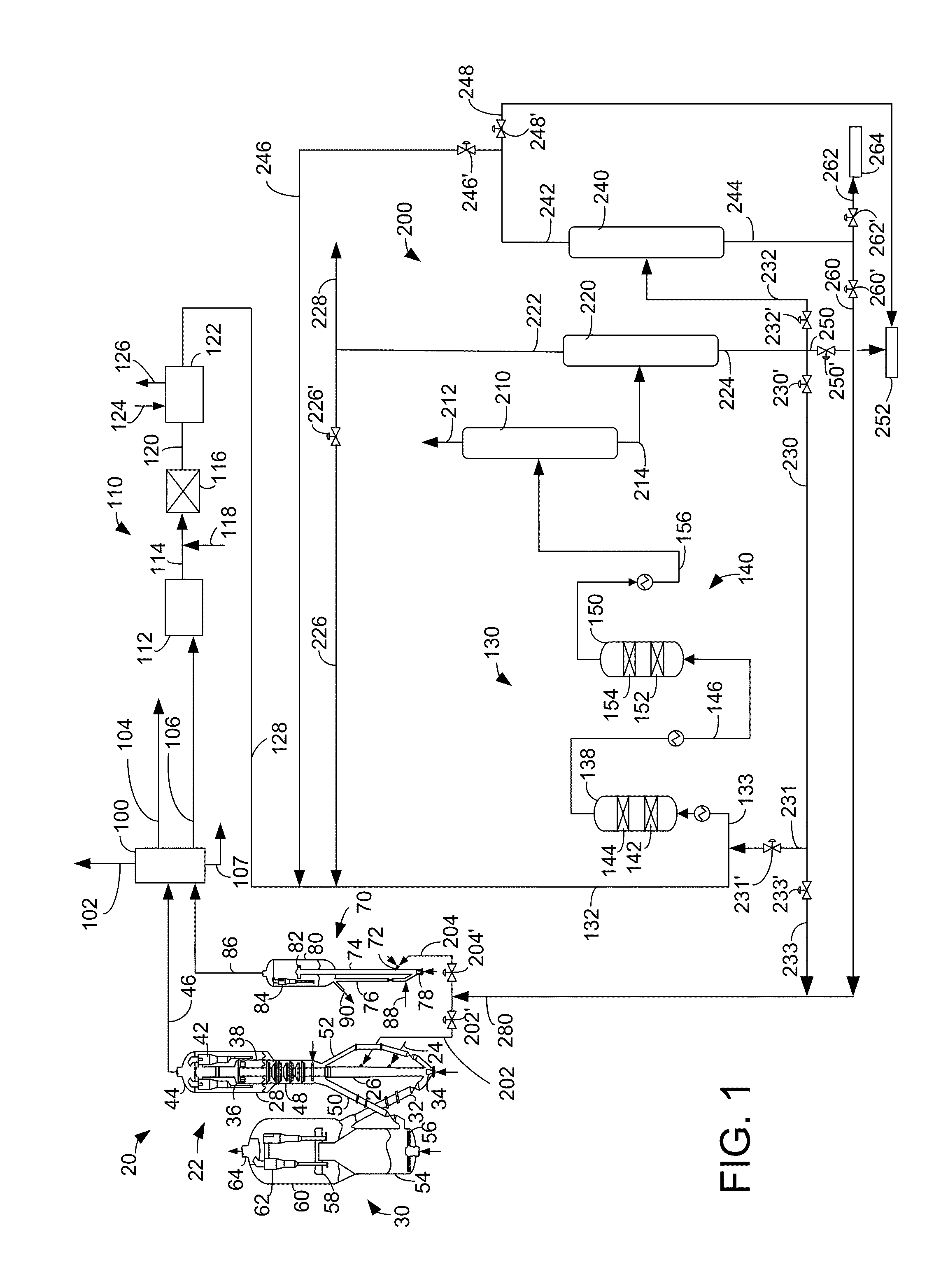

On-board fuel fractionation system and methods to generate an engine starting fuel

InactiveUS7370610B2Efficient separationAccelerate emissionsThermal non-catalytic crackingDistillation regulation/controlDistillationFractionation

A Fuel Fractionation System (FFS) and associated methods to generate and store a fuel for internal combustion engines is provided. FFS provides a distillation column assembly to distill liquid fuel to form a volatile light fraction secondary fuel. The distillation column assembly includes a vaporization module to vaporize a feed fuel in the distillation column and includes a condensation module to condense heavy fraction components of the vaporized feed fuel. FFS also provides a controller positioned to control the vaporization of feed fuel in the distillation column to thereby control the separation of the feed fuel into light fraction fuel and heavy fraction fuel components, and positioned to control the condensation of the heavy fraction components so that fuel exiting a light fraction output port in the distillation column is substantially light fraction fuel components by volume.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

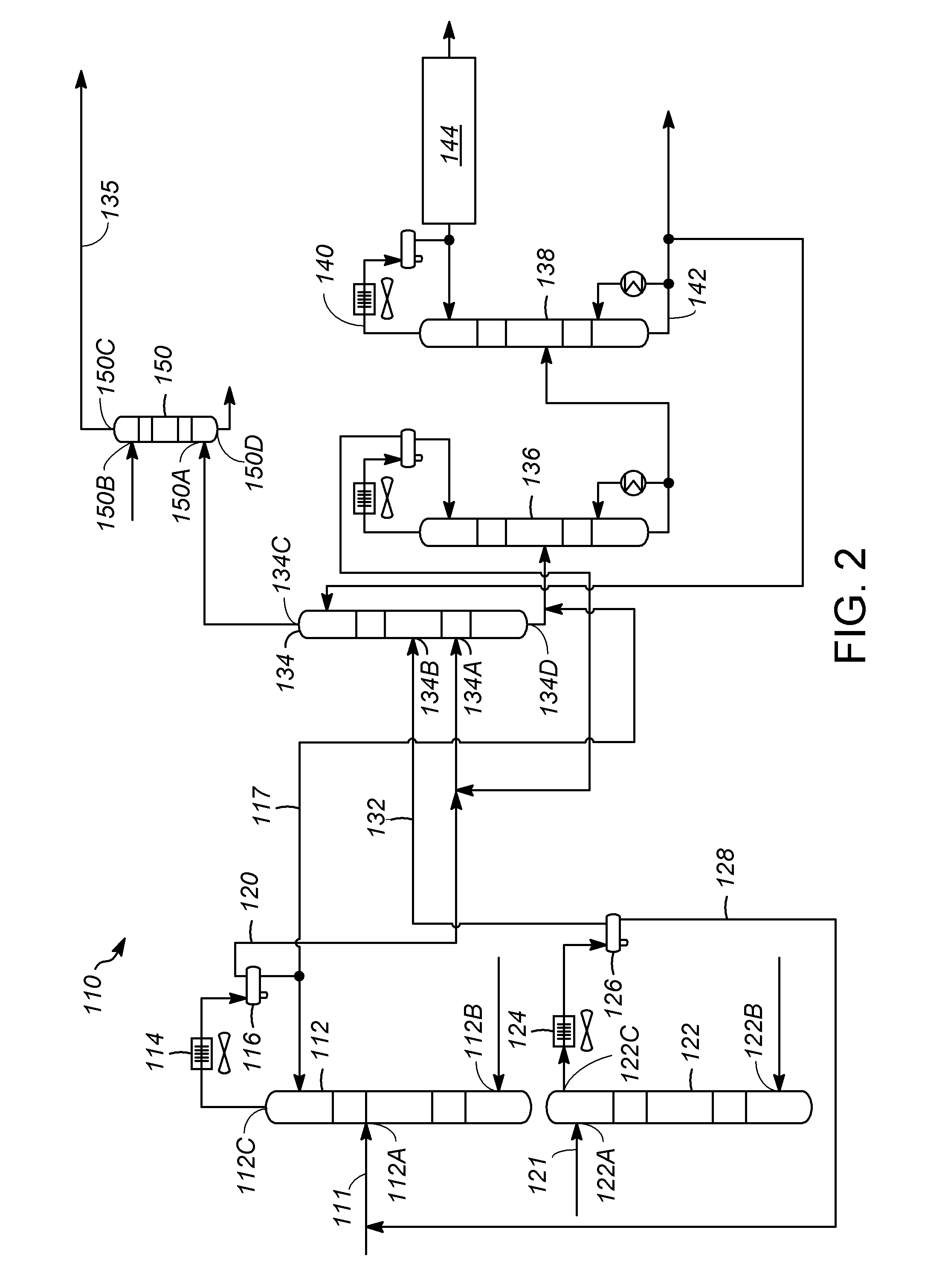

Dividing wall separation in light olefin hydrocarbon processing

ActiveUS20080081937A1Speed up the processIncrease volumeThermal non-catalytic crackingCatalytic crackingNaphthaCell separation

Processing schemes and arrangements for application of a dividing wall separation column in the processing of an effluent resulting from FCC processing modified for increased light olefin production. The dividing wall separation column desirably splits a naphtha feedstock produced or resulting from such modified FCC processing to produce or form a light fraction containing C5-C6 compounds, an intermediate fraction containing C7-C8 compounds and a heavy fraction containing C9+ compounds.

Owner:UOP LLC

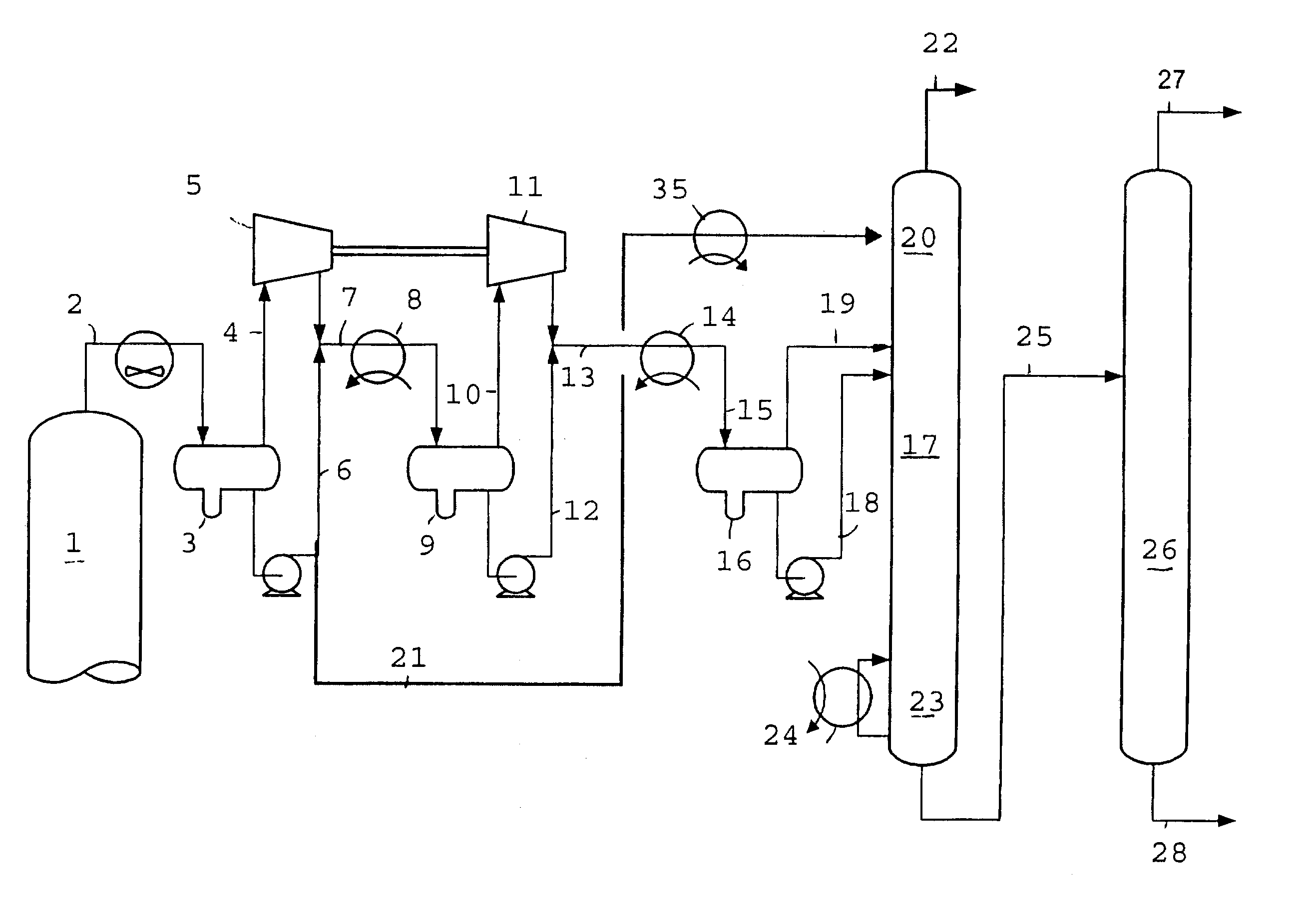

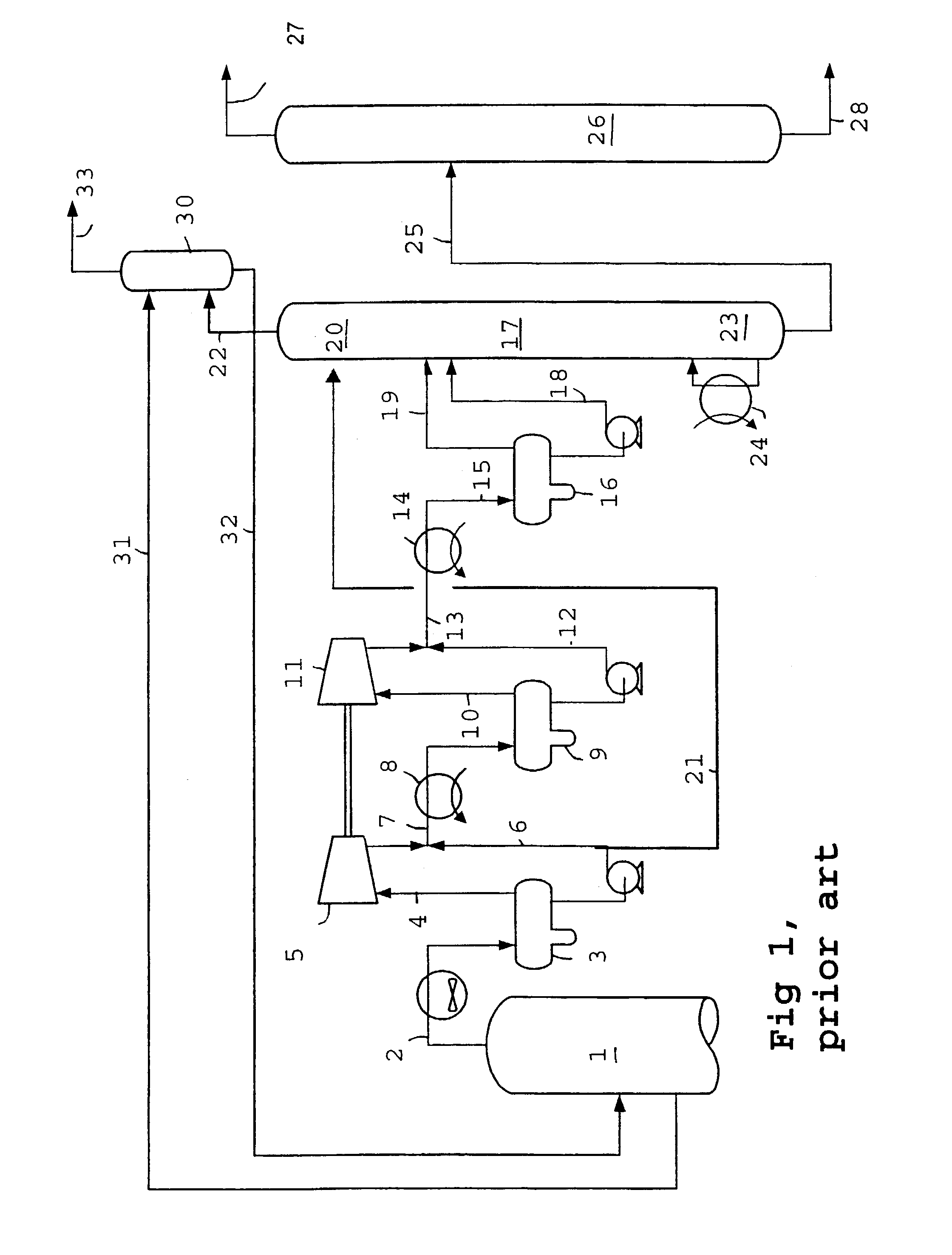

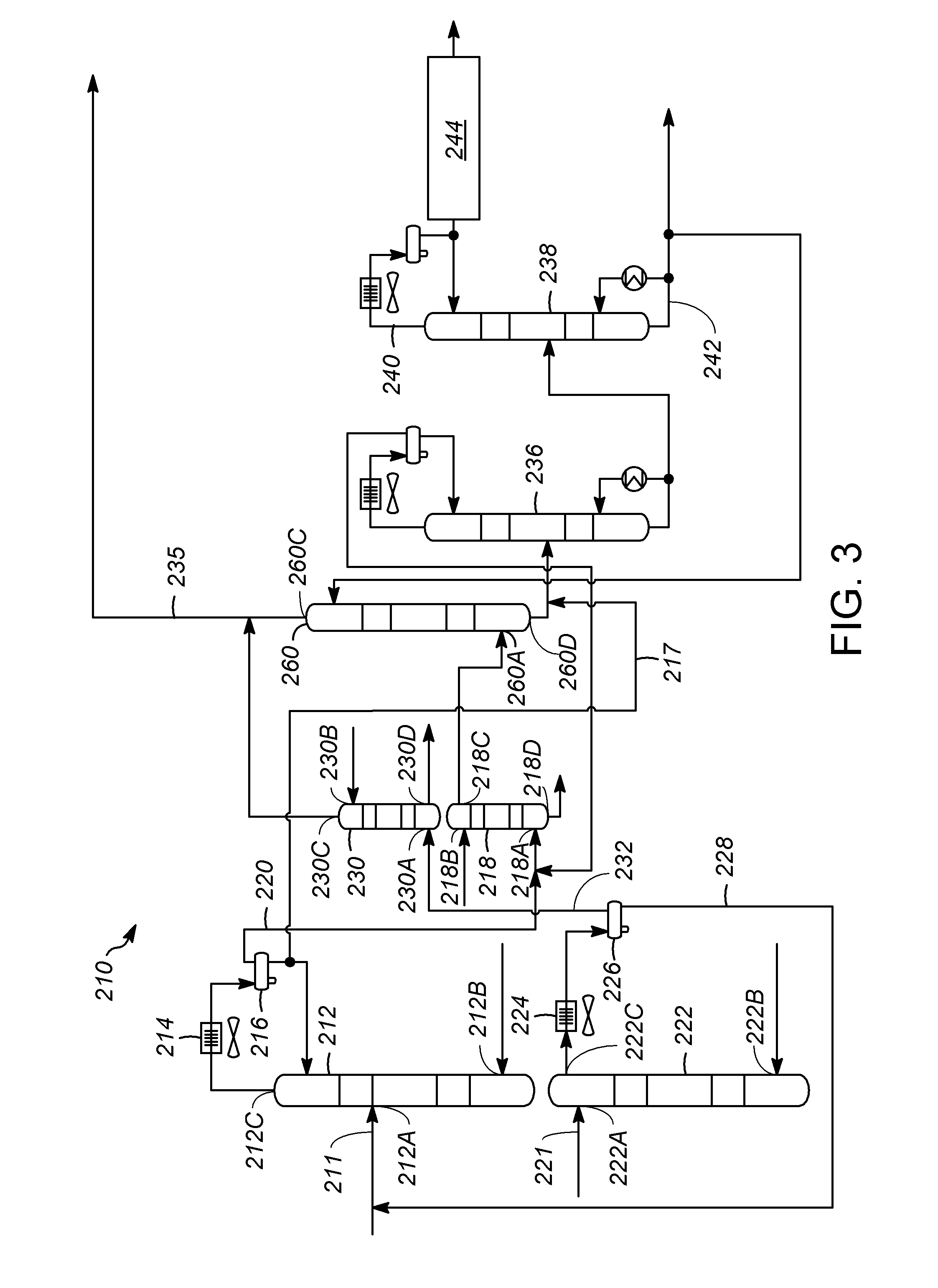

Process for recovery of propylene and LPG from fcc fuel gas using stripped main column overhead distillate as absorber oil

ActiveUS20120172649A1Promote recoveryReduce capacityCatalytic crackingTreatment with plural serial stages onlyNaphthaFuel gas

A process is disclosed for enhanced recovery of propylene and LPG from the fuel gas produced in Fluid catalytic cracking unit by contacting a heavier hydrocarbon feed with FCC catalyst. In the conventional process, the product mixture from FCC main column overhead comprising naphtha, LPG and fuel gas, are first condensed and gravity separated to produce unstabilized naphtha, which is subsequently used in the absorber to absorb propylene and LPG from fuel gas. However, the recovery of propylene beyond 97 wt % is difficult in this process since unstabilized naphtha already contains propylene of 5 mol % or above. In the present invention, C4 and lighter components from unstabilized naphtha are first stripped off in a separate column to obtain a liquid fraction almost free from propylene (<0.1 mol %) and other LPG components. Such a stripped liquid fraction, after cooling to 20° C. to 30° C., is used in the absorber to absorb higher amounts of propylene and LPG from fuel gas, leading to improved recovery of propylene.

Owner:RELIANCE INDUSTRIES LIMITED

Method for producing high grade of diesel oil from charking full distillate oil

ActiveCN101003750ALowering the freezing pointLittle impact on yieldTreatment with hydrotreatment processesGasoline stabilisationNaphthaEnergy consumption

This invention discloses a method for producing high-quality diesel oil from whole fraction oil of coking. The method comprises: separating whole fraction of coking into light fraction oil of coking (containing part of light diesel oil fraction) and heavy fraction oil of coking (containing heavy diesel oil fraction), hydrogenation-modifying heavy fraction oil of coking in the presence of beta-zeolite-containing hydrogenation catalyst, mixing the modification product with light fraction oil of coking, and hydrogenation-refining. The method can obtain high-quality clean diesel oil and high-quality naphtha, and has such advantages as simple process and low energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

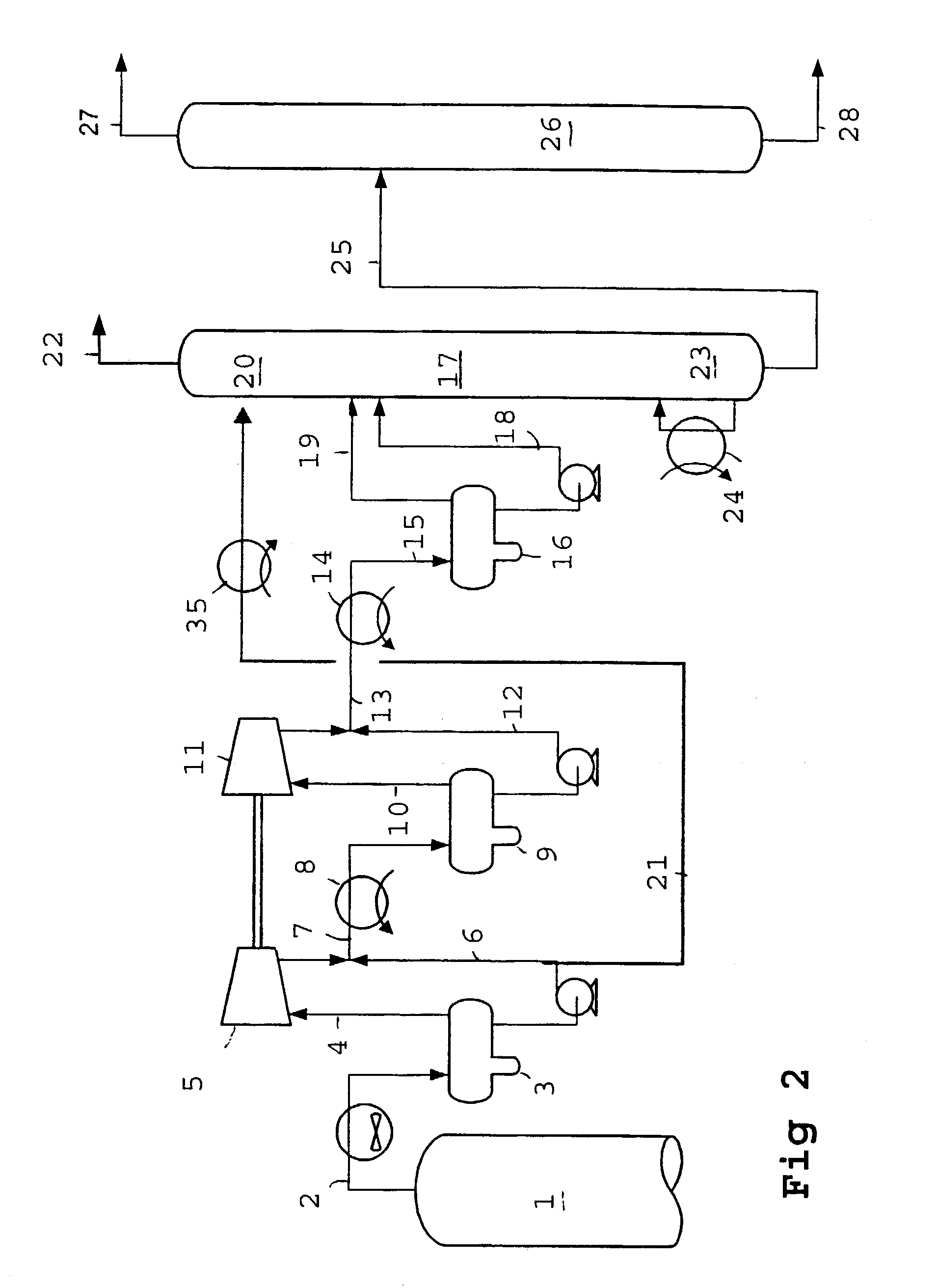

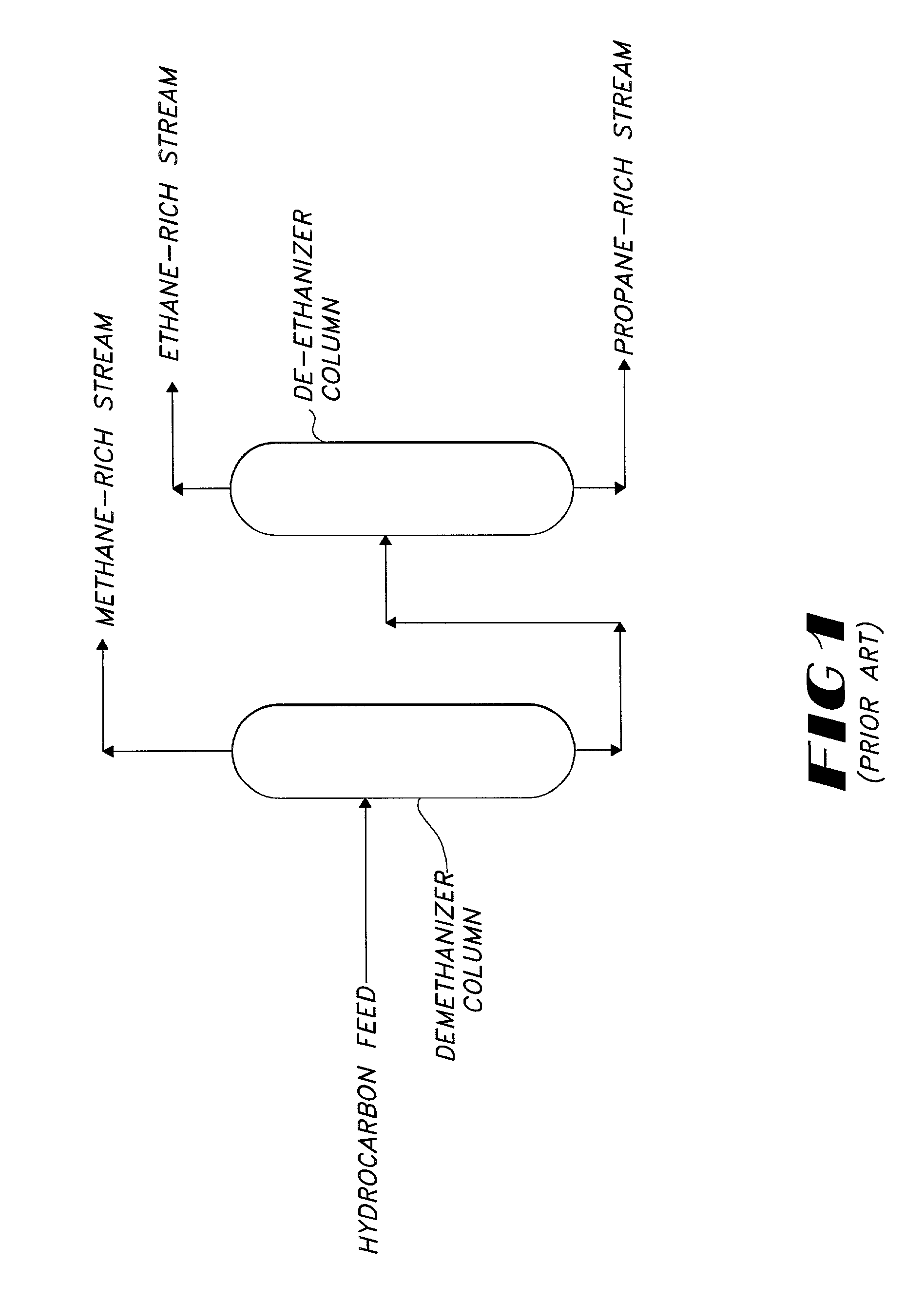

Ethane extraction process for a hydrocarbon gas stream

A process for ethane extraction from a gas stream based on turboexpansion and fractionation with no mechanical refrigeration is provided. The feed gas is sweetened and dehydrated by a conventional amine process and by a molecular sieve unit, to remove carbon dioxide and water. After this pretreatment, the feed gas undergoes to a series of cooling steps through a cryogenic brazed aluminum heat exchanger and fed to a demethanizer column. A stream rich in methane is recovered from the top of this column and fed to a centrifugal compressor and subsequently routed to a booster / turboexpander. The temperature of the methane gas is greatly reduced by the expansion allowing the cooled methane stream to be a cooling source for cryogenic heat exchanger. Feed for a de-ethanizer column comes from the bottom liquids of the de-methanizer column. Ethane is recovered overhead at the de-ethanizer column.

Owner:INELECTRA

Method for producing fuel oil by hydrogenation modification of coal tar

InactiveCN101250432ALower prehydrogenation temperatureRelaxed reaction conditionsGasoline stabilisationRefining to eliminate hetero atomsSulfurLow nitrogen

The invention discloses a method for producing fuel oil through hydrotreating in coal tar, which comprises the following steps: hydrotreating and feeding the coal tar to do pre-hydrotreating reaction and main-hydrotreating reaction after preprocessing coal tar, fractionating hydrogenated oil, and separating out low sulfur and low nitrogen light oil and fuel oil. The method leads a reaction condition to be softer, which inhibits and alleviates the coking process of coal tar hydrogenation material under high temperature with high efficiency, lowers bed layer temperature rising of a reactor, prolongs the service span of pre-hydrogenation catalyst, and assures the operation of longer cycle of the coal tar hydrogenation unit.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

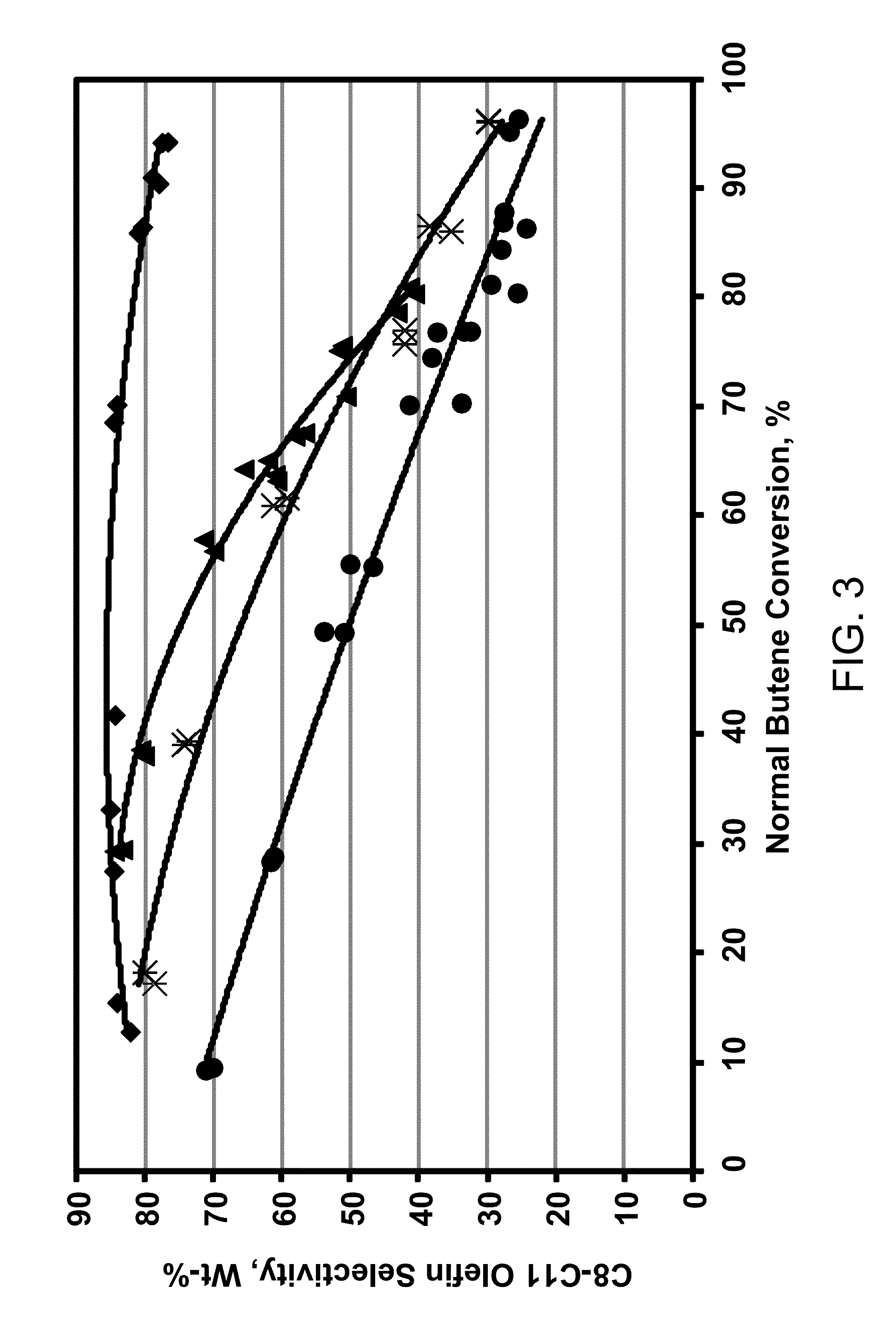

Process and apparatus for recovering olefins

ActiveUS7273542B2Thermal non-catalytic crackingHydrocarbon by isomerisationProcess engineeringHydrocarbon

The present invention relates to a process and apparatus for recovering product from reactor effluent of a reactor for a hydrocarbon feedstream. An indigenous C4 stream is used as lean oil in a demethanizer, which facilitates significant cost and operational savings. C4 bottoms from a downstream depropanizer is used as lean oil recycle.

Owner:EXXONMOBIL CHEM PAT INC

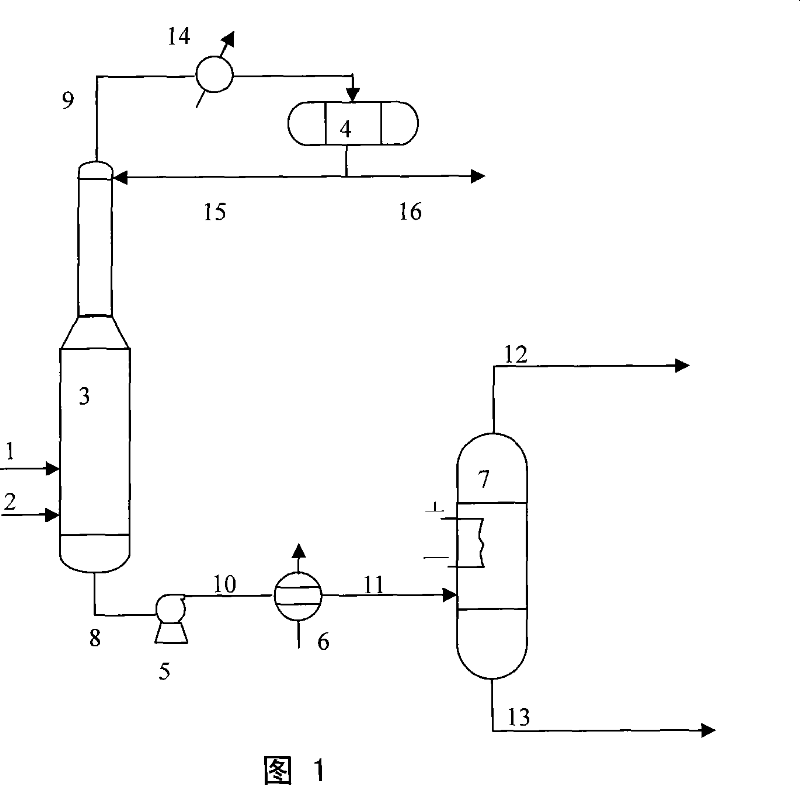

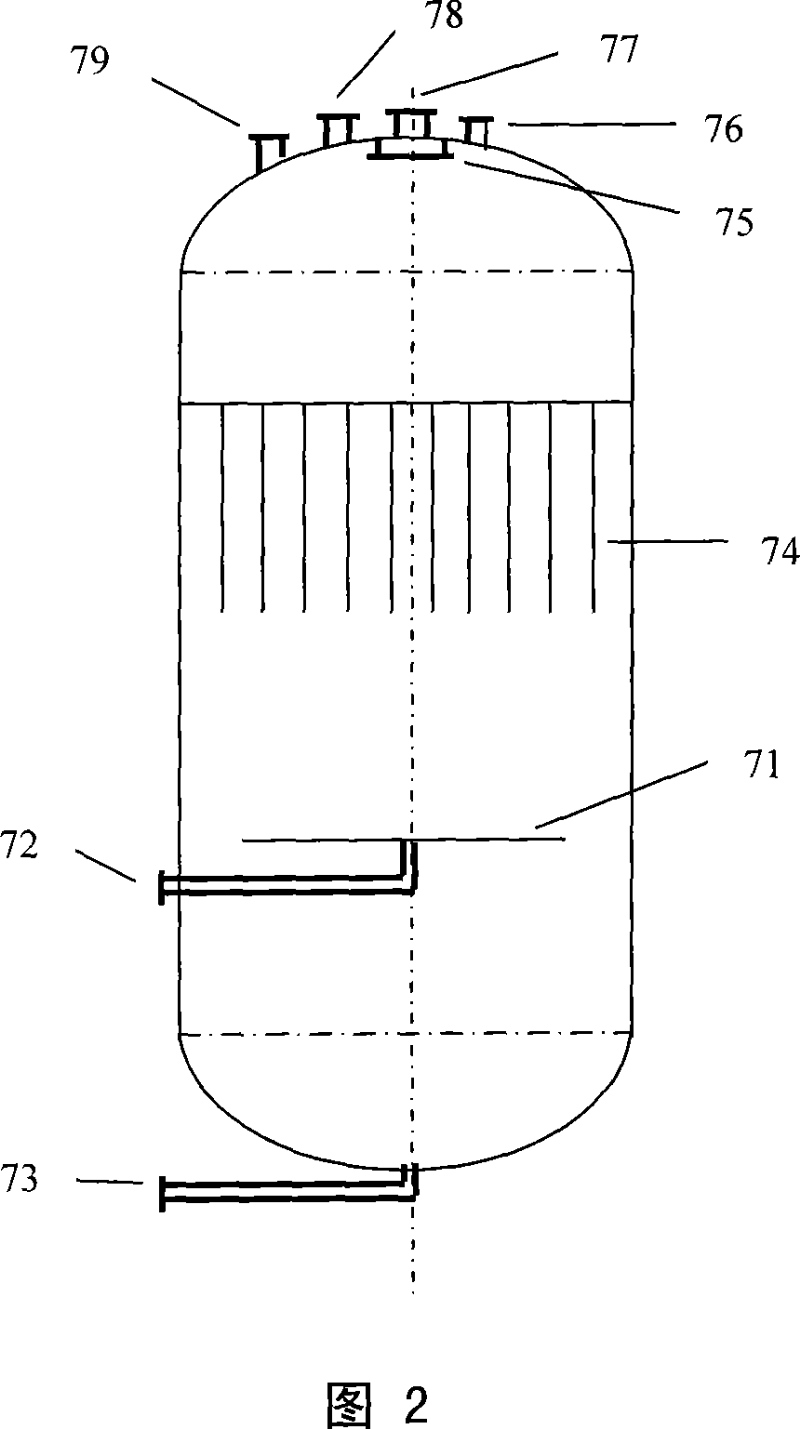

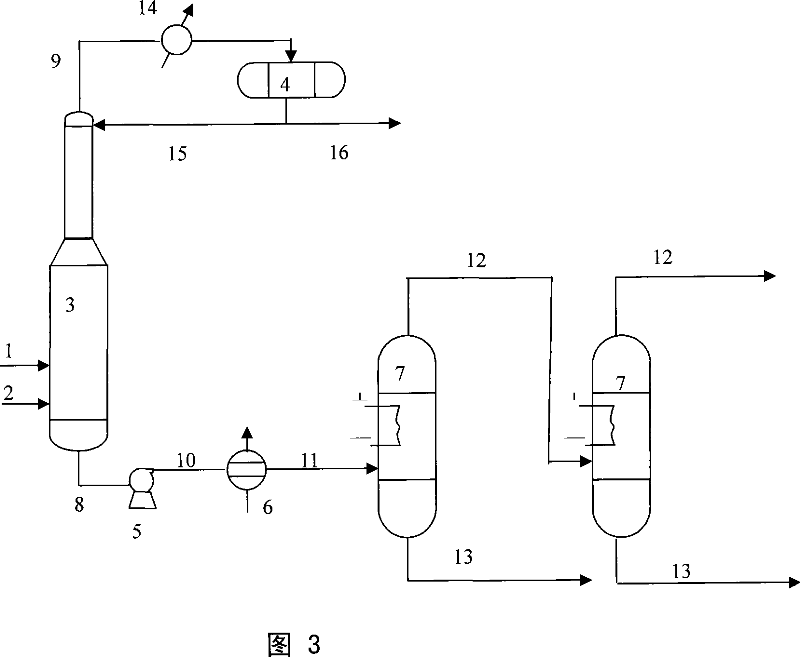

Diesel oil hydrogenation refining fractionation method and device

ActiveCN101037608ASolve the problem of unqualified water contentLess investmentDewatering/demulsification with electric/magnetic meansGasoline stabilisationSteam condensationTower

The invention provides a hydrogenation refining fractionation method for diesel oil, which includes a stripping fractional distillation process for reaction generation oil steam and a dewatering process for refined diesel oil. Concrete technical project of the method is: hydrogenation refining reaction generation oil from low pressure separator enters feed inlet of fractionating tower with certain temperature; the fractionating tower employs steam stripping fractional distillation, superheating stripping steam is charged in tower bottom, tower top oil gas enters reflux pot on tower top after cooling, refined diesel oil at tower bottom enters one or more than one series connected vertical ionization dehydration pot after supercharging by pressure pump, heat exchanging and cooling; micro steam condensation water in the refined diesel oil aggregates to larger drip by high-voltage electric field in the ionization dehydration pot, sedimentates at pot bottom and is removed by dehydration pipeline; refined diesel oil without water comes from top of the ionization dehydration pot is the eligible final product. The invention also provides a device for realizing the method.

Owner:CHINA PETROLEUM & CHEM CORP

Technique for coproducing methanol from coke oven gas and fuel products by hydrogenating coal tar prepared from tail gas of methanol preparation

InactiveCN101239887ATo achieve the effect of energy saving and emission reductionOrganic compound preparationHydroxy compound preparationNitrogen gasHeat energy

The invention relates to a hydrogenation process for preparing oil products from coal tar which is generated together with exhaust gas synthesized during preparation of methanol from a coke oven and coal gas. Methanol is prepared from coal gas which is the by-product of the coke oven, large amount of relief gas and nitrogen gas during the methanol preparation process, hydrogen is extracted from the relief gas and used as one of the materials for hydrogenation preparing light fule oil from tar, nitrogen is extracted as the material of a coke dry quenching unit, the heat energy generated during the coke dry quenching process is used for generating electric power. With the recycling of coke oven coal gas, the prior exhaust gas which is directly exhausted or burnt is changed into a high-value product, such as electricity, methanol, light fuel oil, advanced charcoal material, etc., at the same time, the object of energy conservation can be realized.

Owner:QITAIHE BAOTAILONG COAL CHEM IND

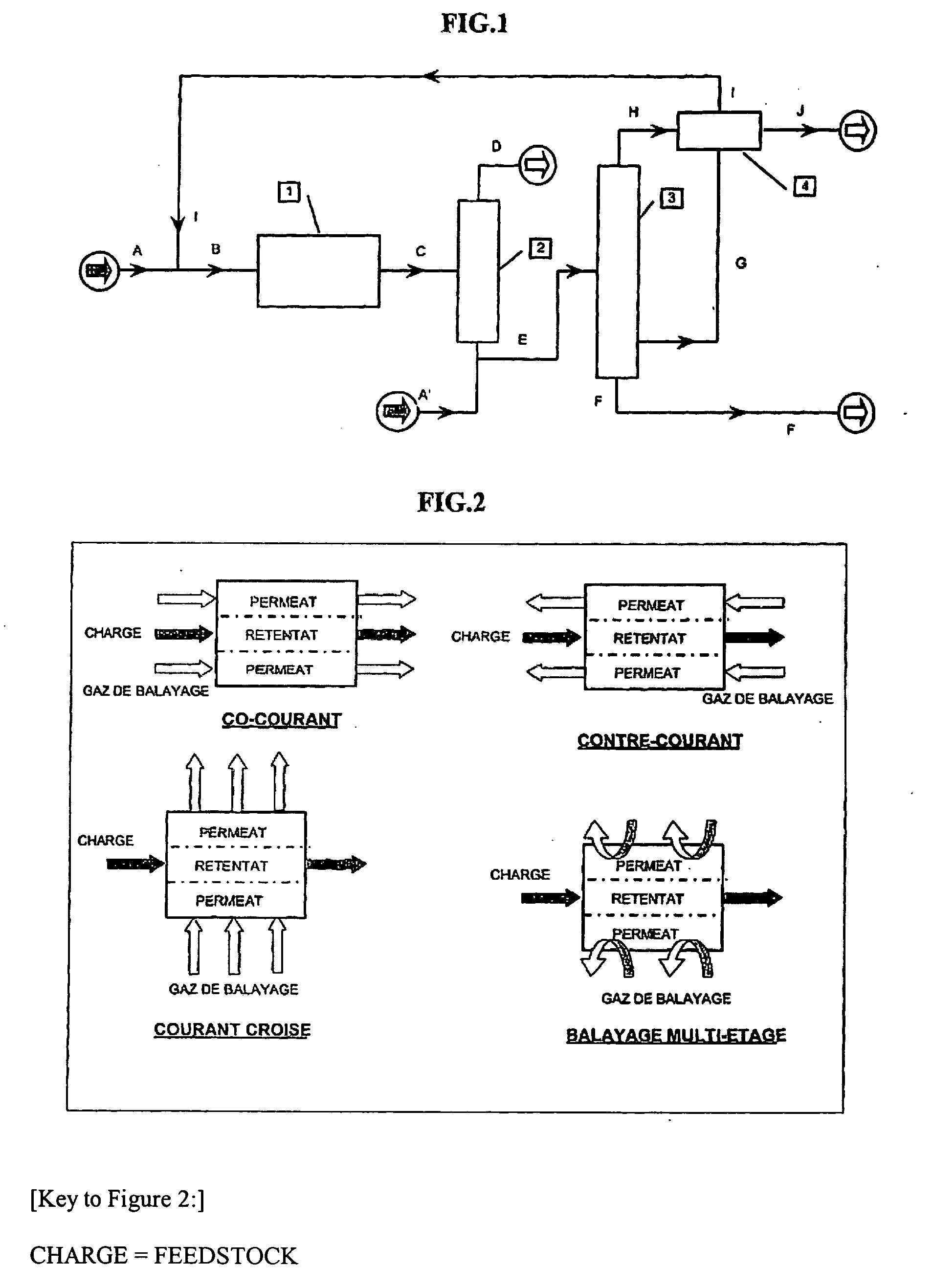

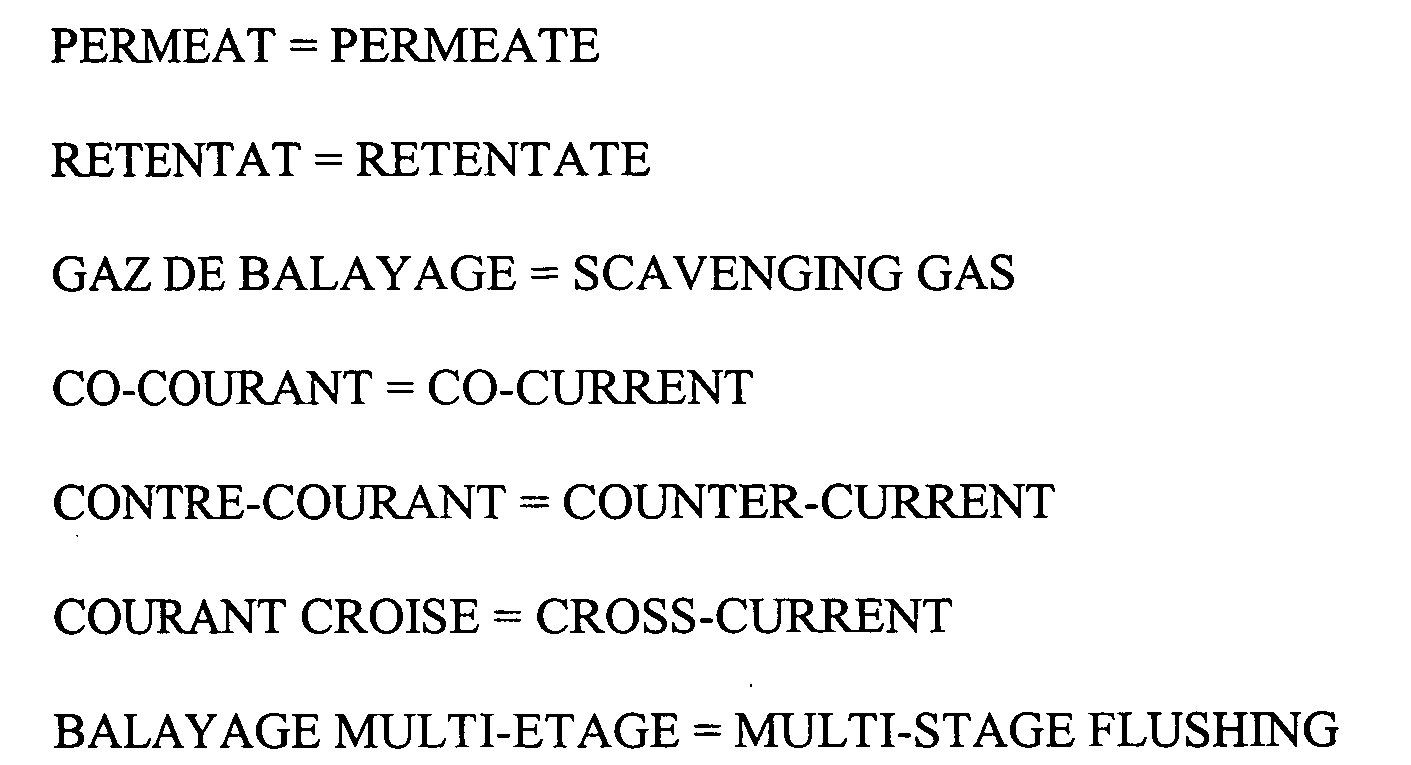

Method For Producing A High-Octane Gasoline From A C5/C6 Fraction By Means Of A Membrane Separation Unit

InactiveUS20090247805A1Liquid degasificationRefining to change hydrocarbon structural skeletonAlkaneGasoline

The invention relates to a method for isomerising typically paraffinic hydrocarbon fractions having 5-7 carbon atoms consisting in using a membrane separation unit which is supplied by an overhead flux from a deisohexaniser which makes it possible to maximise the isopentane quantity in isomerate. Said invention makes it possible to definitely improve the isomerate RON and MON indices by the inventive method.

Owner:INST FR DU PETROLE

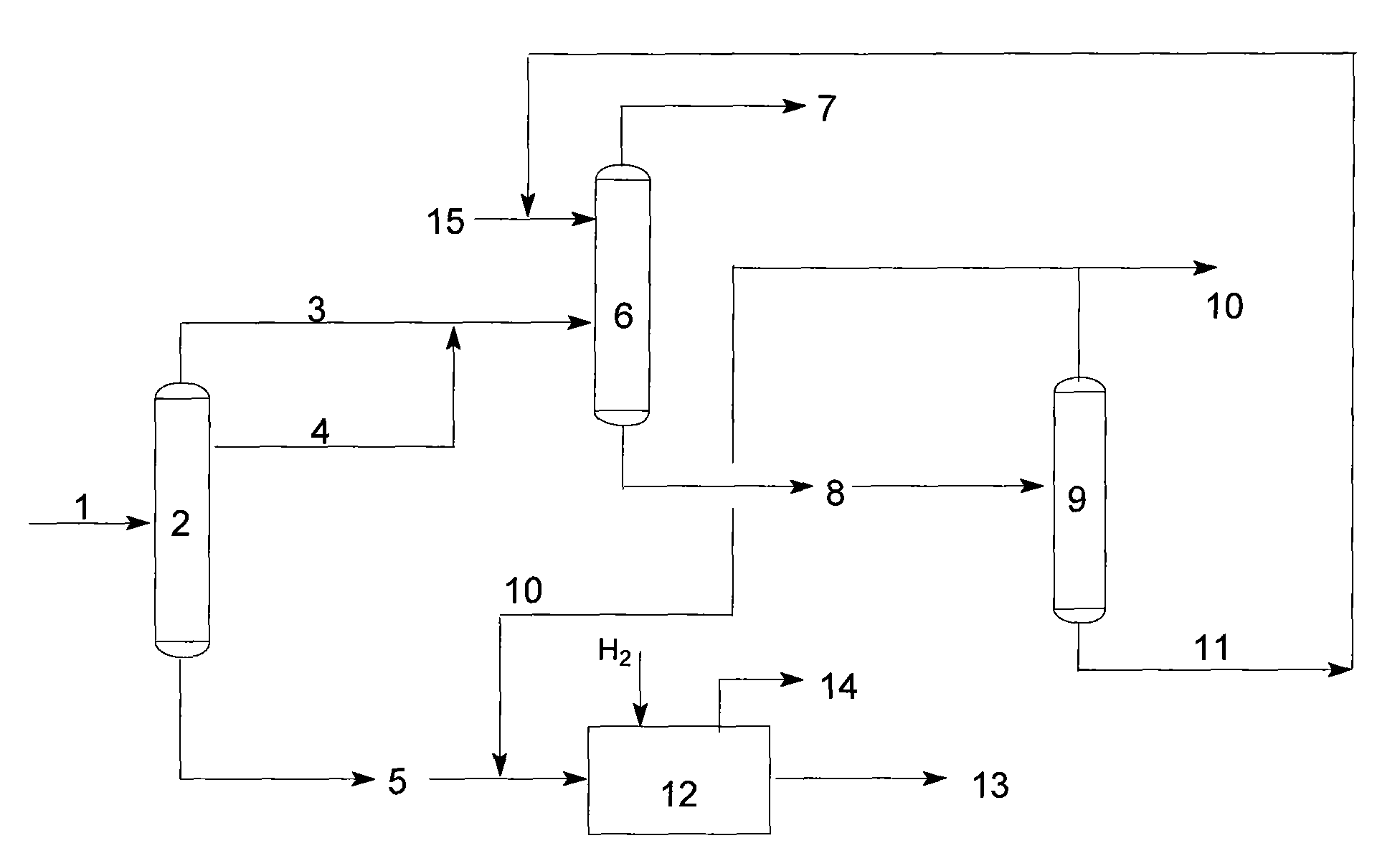

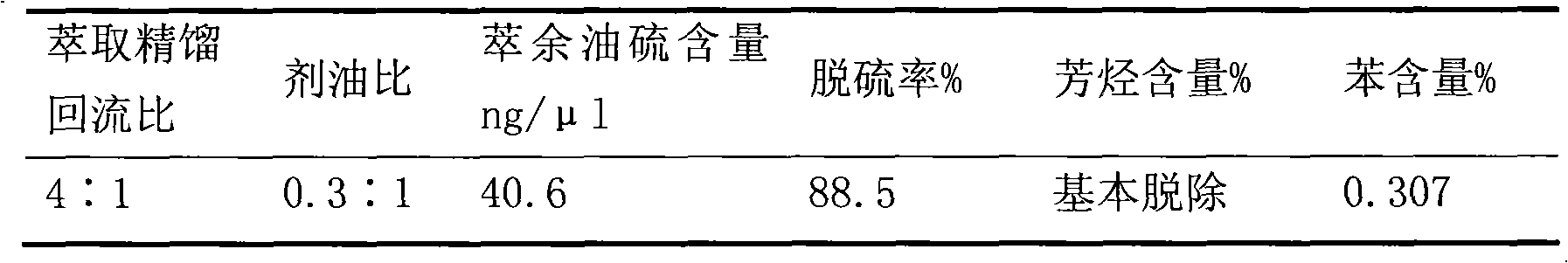

Method for producing reforming feedstock by light and medium gasoline distillates

ActiveCN101649221ASolve protection problemsRelieve pressureCatalytic naphtha reformingHydrocarbon oils refiningCatalytic reformingFractionation

The invention relates to a method for producing catalytic reformed feedstock by taking light and medium gasoline distillates as raw materials and extracting selective solvent to extract and rectify catalytically cracked gasoline in the absence of hydrogen. The method comprises the following steps: 1, fractionation prefabrication of light and medium distillate raw materials of catalytically cracked gasoline; and 2, extraction, rectification, desulfuration and dearomatization of light and medium distillates of catalytically cracked gasoline, wherein light and medium distillates of catalyticallycracked gasoline obtained in step 1 are fed into the middle-lower part of an extraction-rectification tower, while fresh extraction agent or recycled extraction agent is added from the upper part of the extraction-rectification tower; thus, the light and medium distillates contact the extraction agent inside the tower to generate desulfurized and dearomatized light-component raffinate phase (i.e.catalytic reformed feedstock product) rich in olefin hydrocarbon at the top of the tower after extraction, rectification, desulfuration and dearomatization. The method carries out desulfuration and dearomatization of catalytically cracked gasoline at the same time and reclaims solvent, thereby having the advantages of simple process, moderate operation conditions, hydrogen source saving and low production cost.

Owner:PETROCHINA CO LTD +1

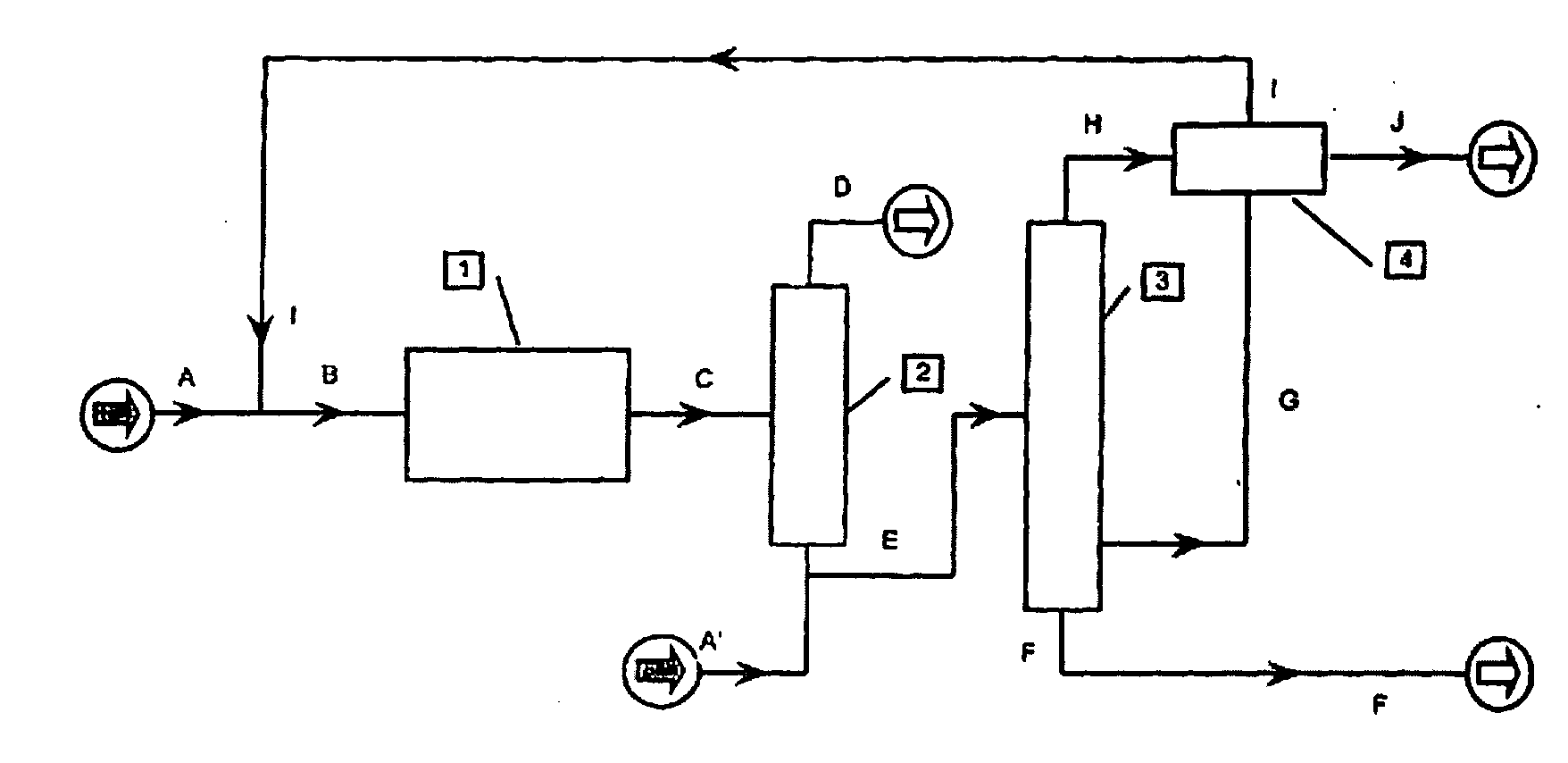

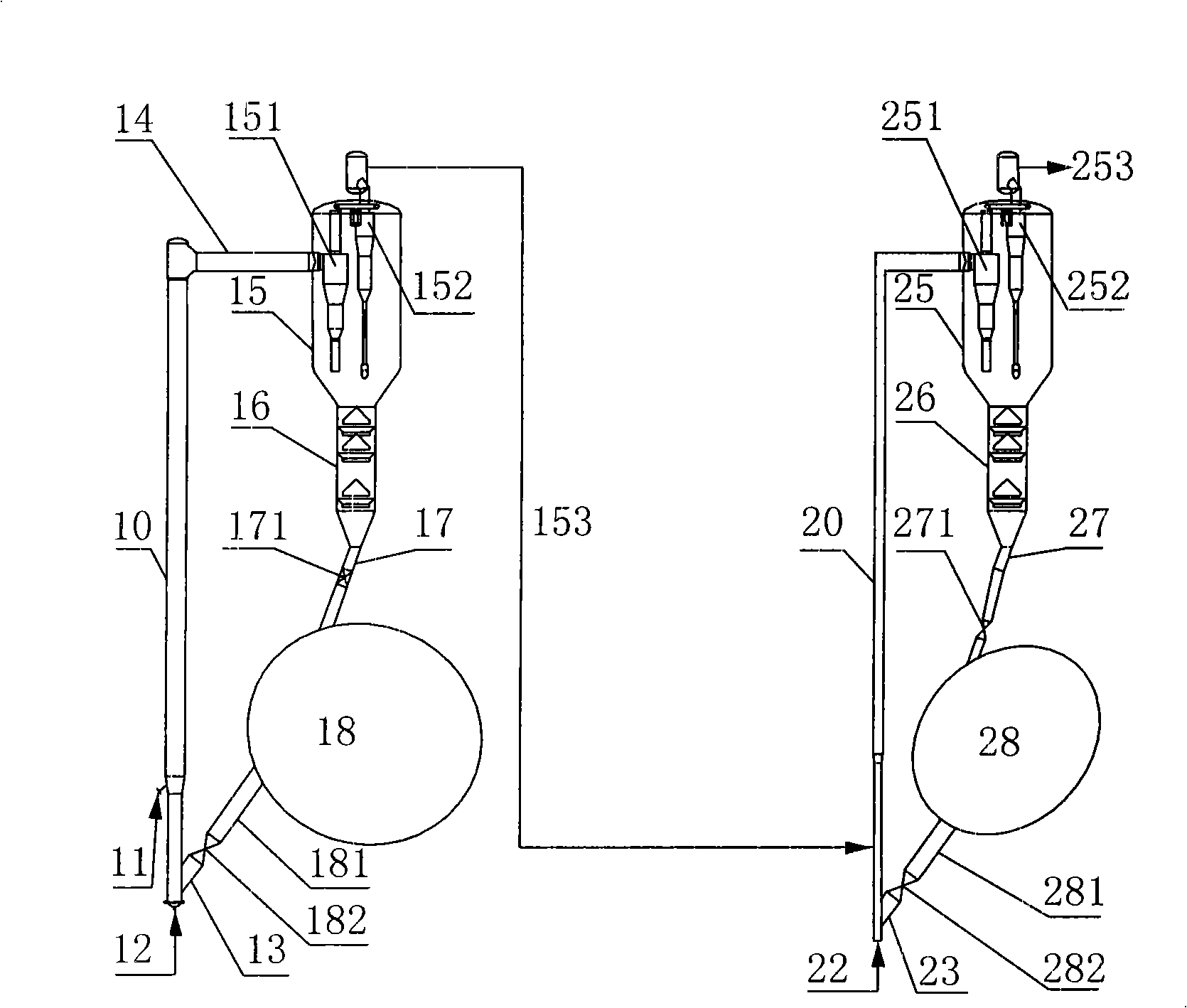

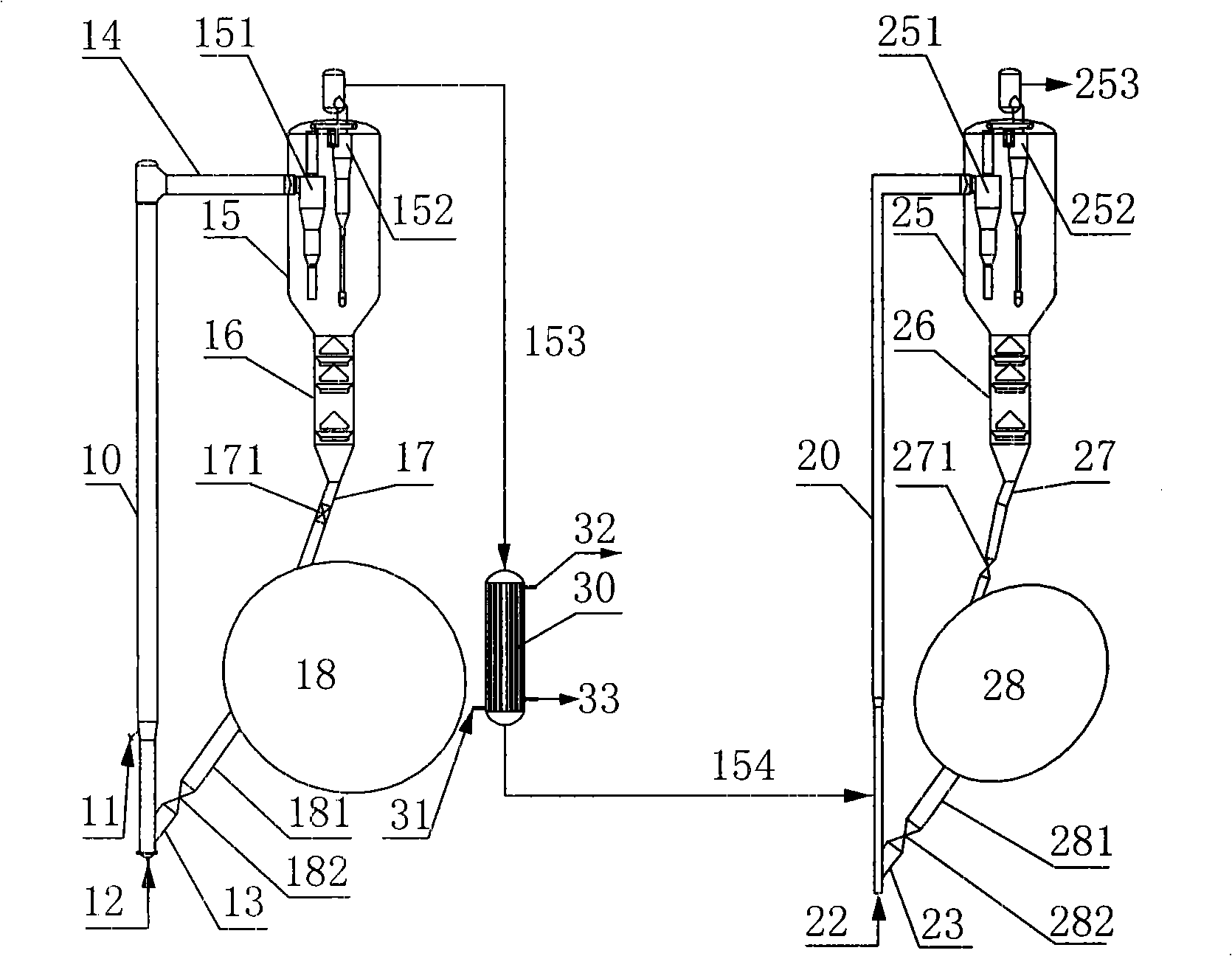

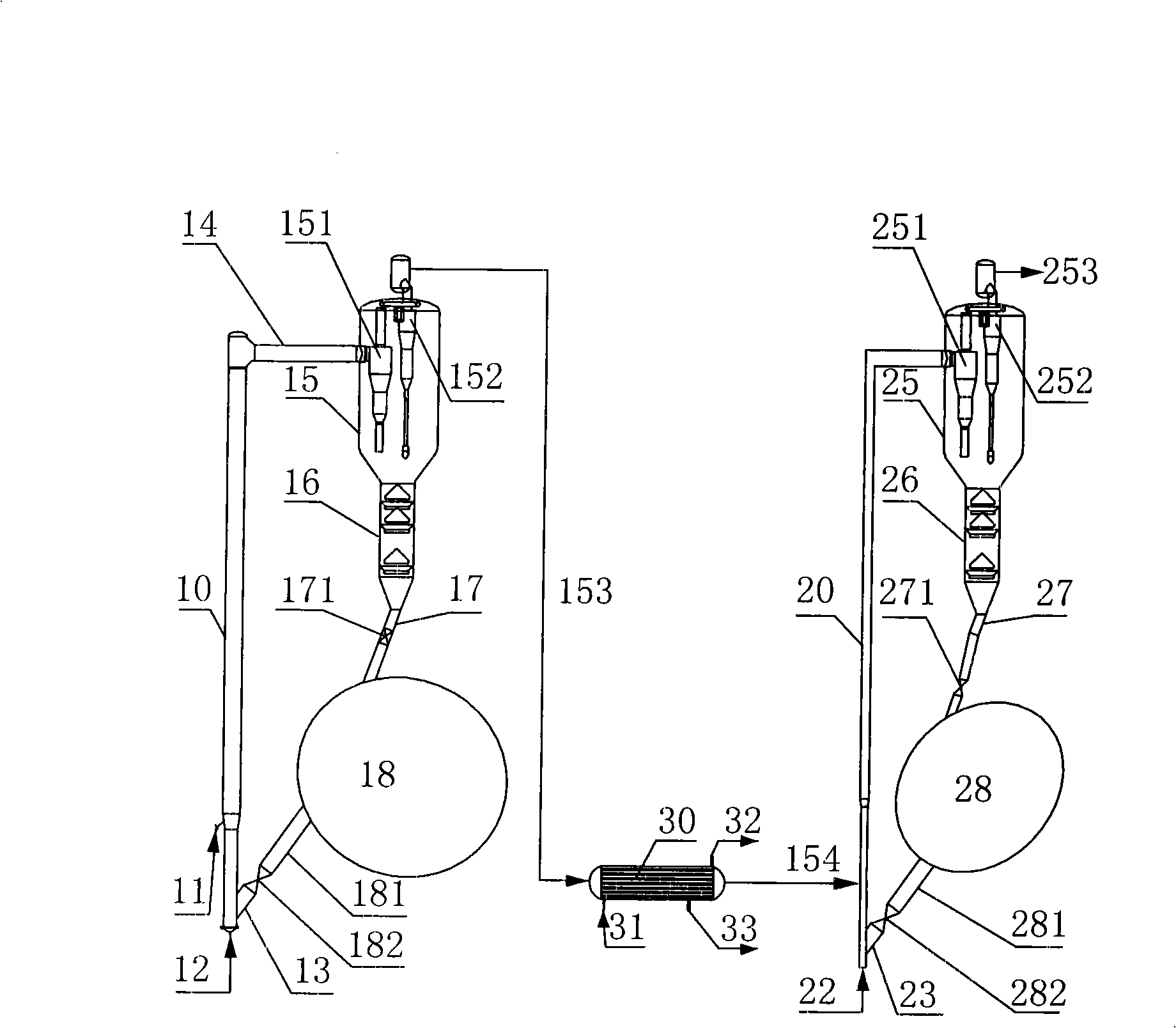

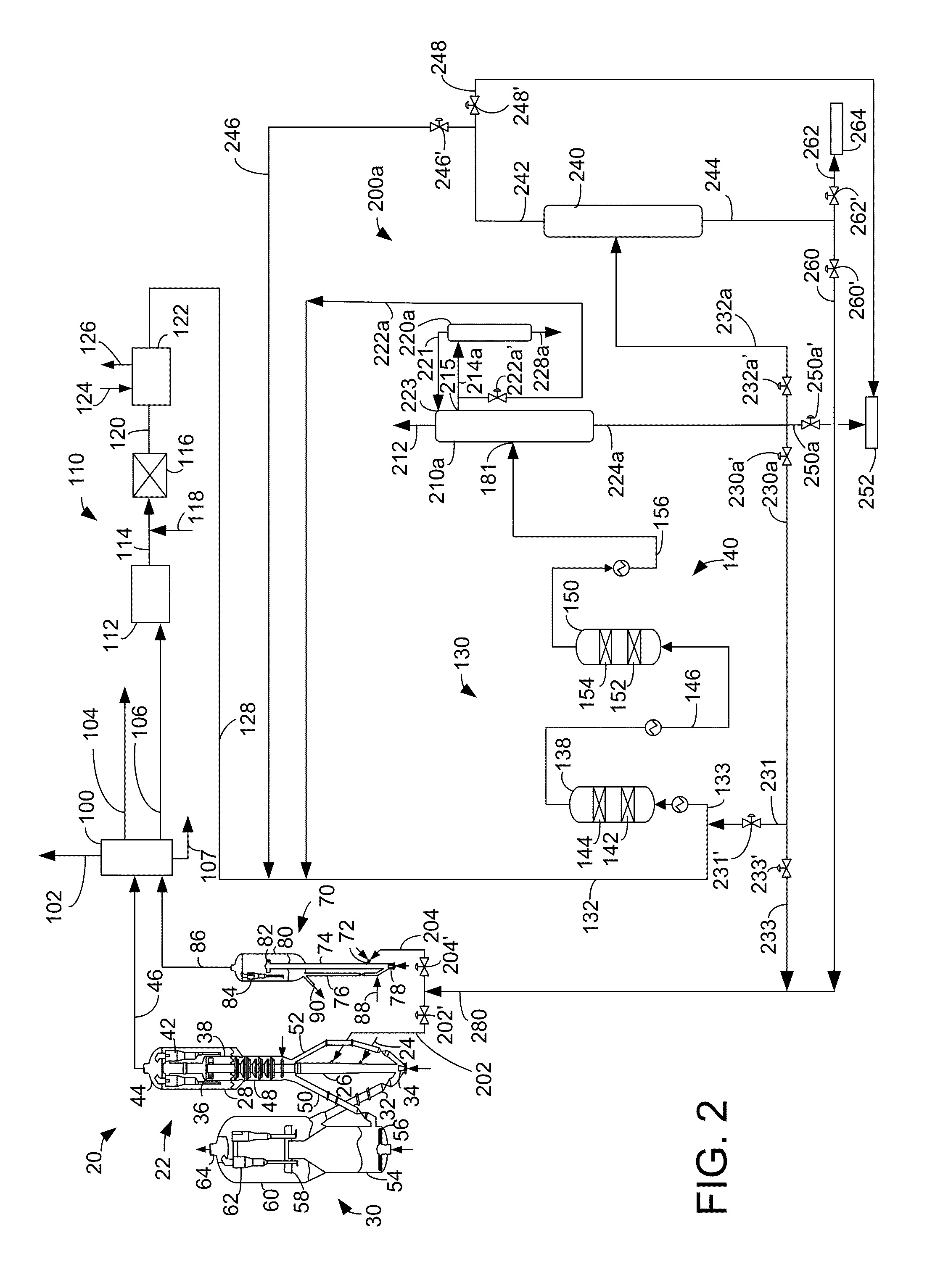

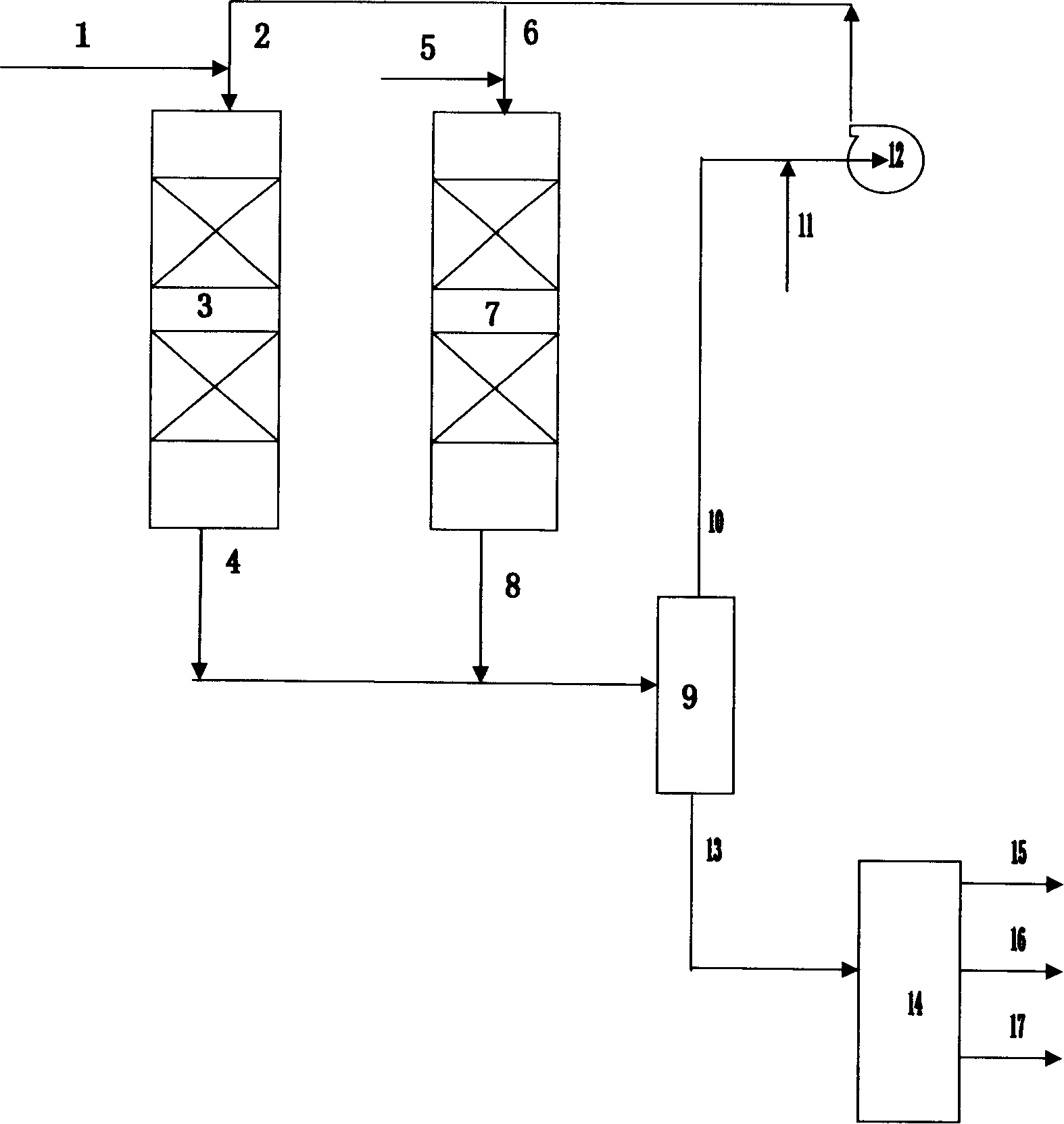

Catalytic conversion method and special apparatus therefor

ActiveCN101323798AOvercoming caloric deficitsHigh selectivityGasoline stabilisationHydrocarbon oils treatmentLiquid stateAlkene

The invention discloses a catalytic conversion method which belongs to the technical field of catalytic conversion of petrolic alkanes. The catalytic conversion is carried out in a first reaction system and a second reaction system sequentially; after raw oil enters the first reaction system for catalytic reaction, all or part of the produced fractions enter the second reaction system in gaseous state and / or liquid state for further catalytic reaction; the first reaction system and the second reaction system respectively use a corresponding catalyst according to different reaction raw materials and target products. By using two reaction systems, the method of the invention using pertinence catalysts to carry out selective catalytic conversion of different fractions, overcomes the deficiencies of poor selectivity and low adjuvant content, and diluting the catalyst when adopting single catalyst, can enhance the productivity of chemical raw materials such as low carbon alkene, etc. and enhance the yield of products; the method overcomes the shortcoming of large energy consumption for cooling and preheating and saves investment, thus greatly enhancing the economical efficiency.

Owner:石宝珍

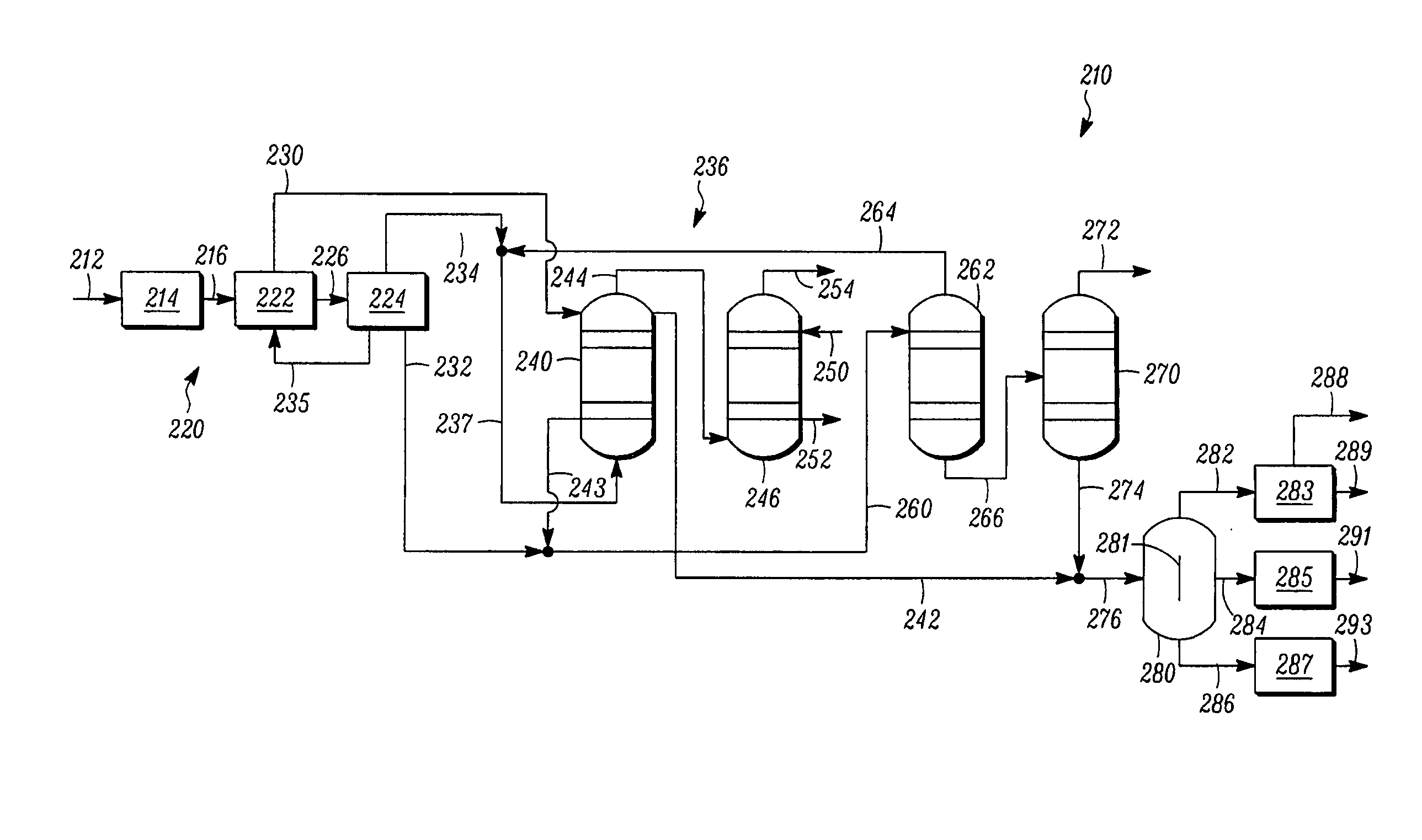

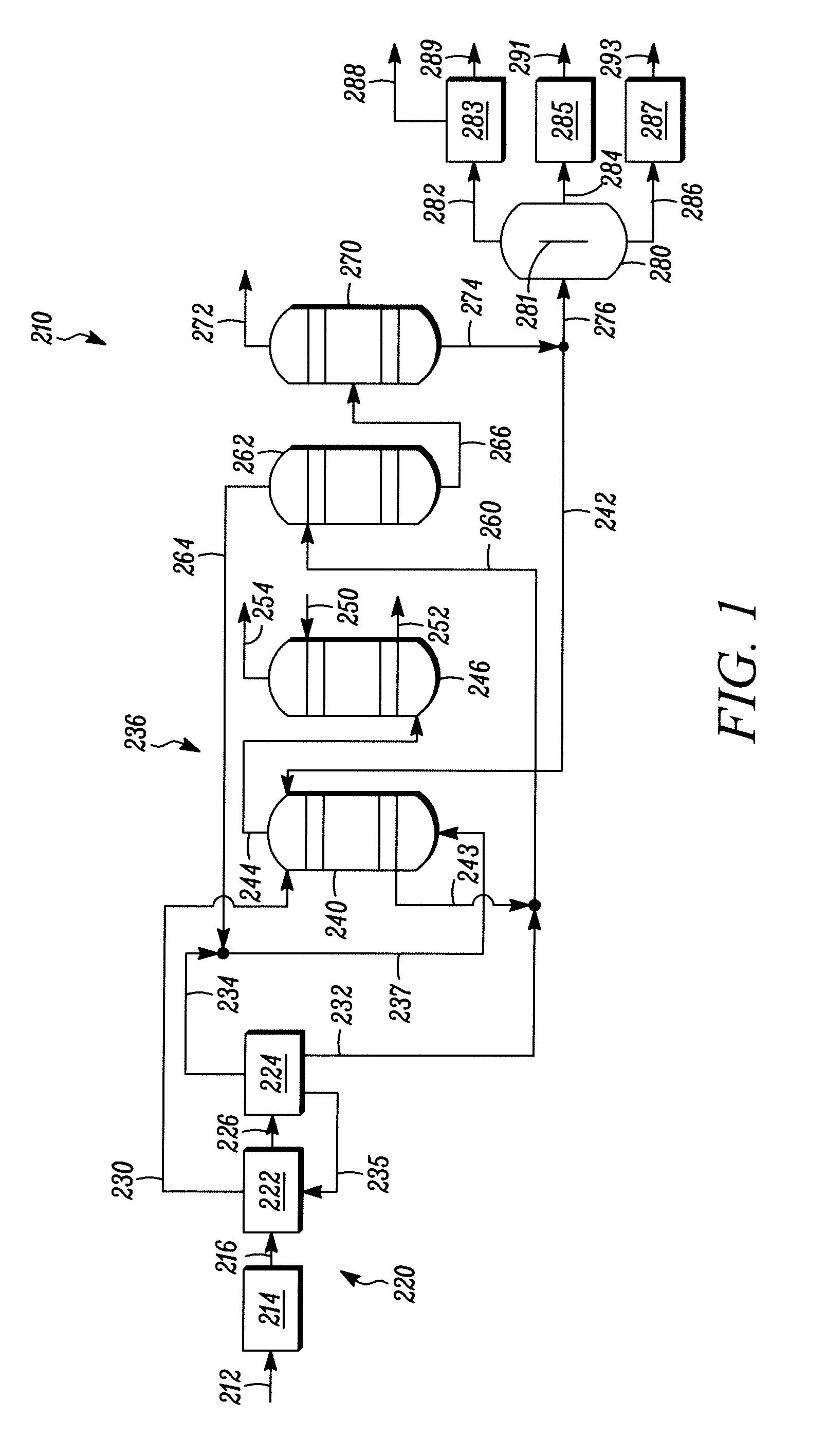

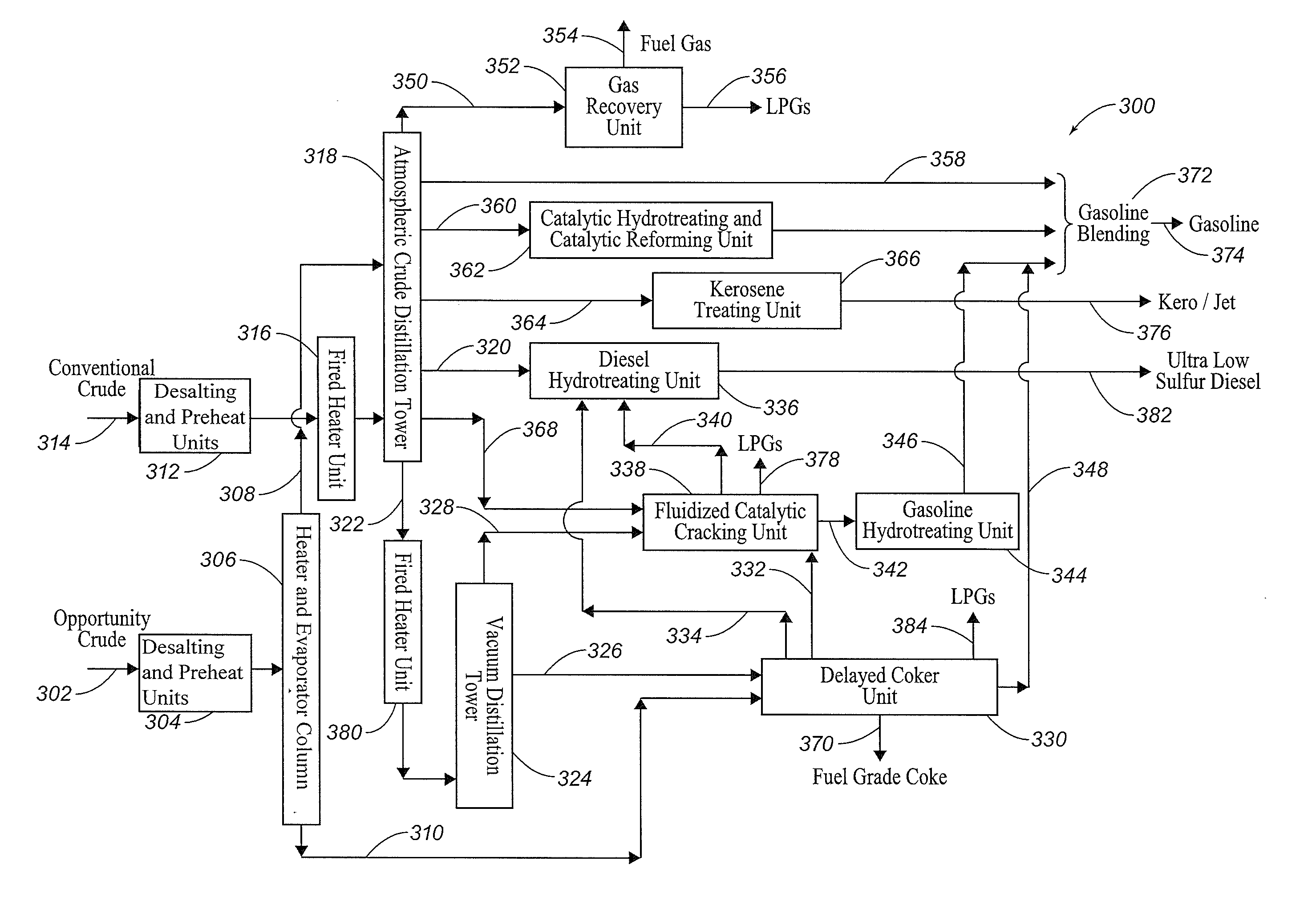

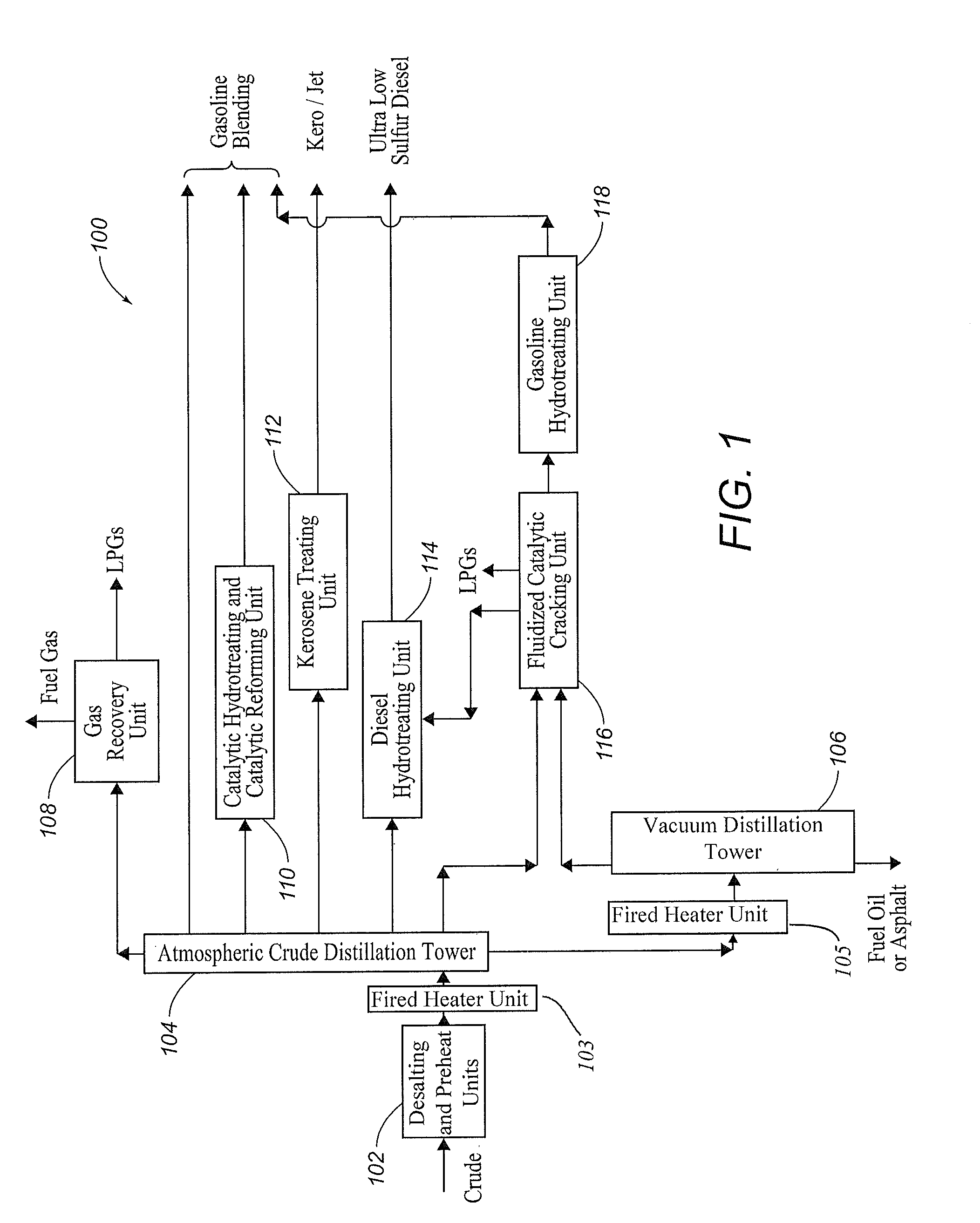

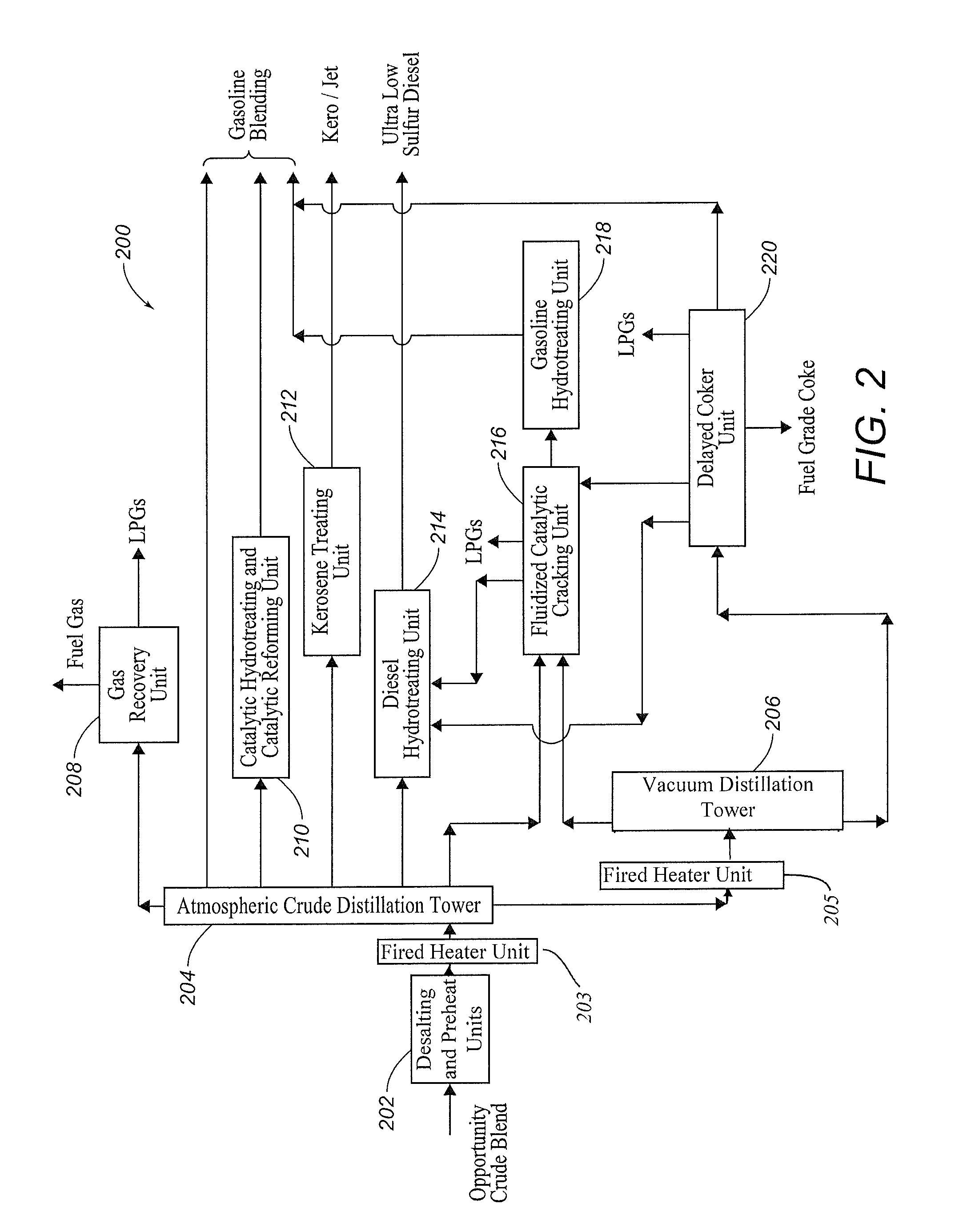

Systems and Methods for Refining Corrosive Crudes

ActiveUS20120261308A1Thermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by distillationMaterials scienceCrude oil

Owner:BECHTEL ENERGY TECH & SOLUTIONS INC

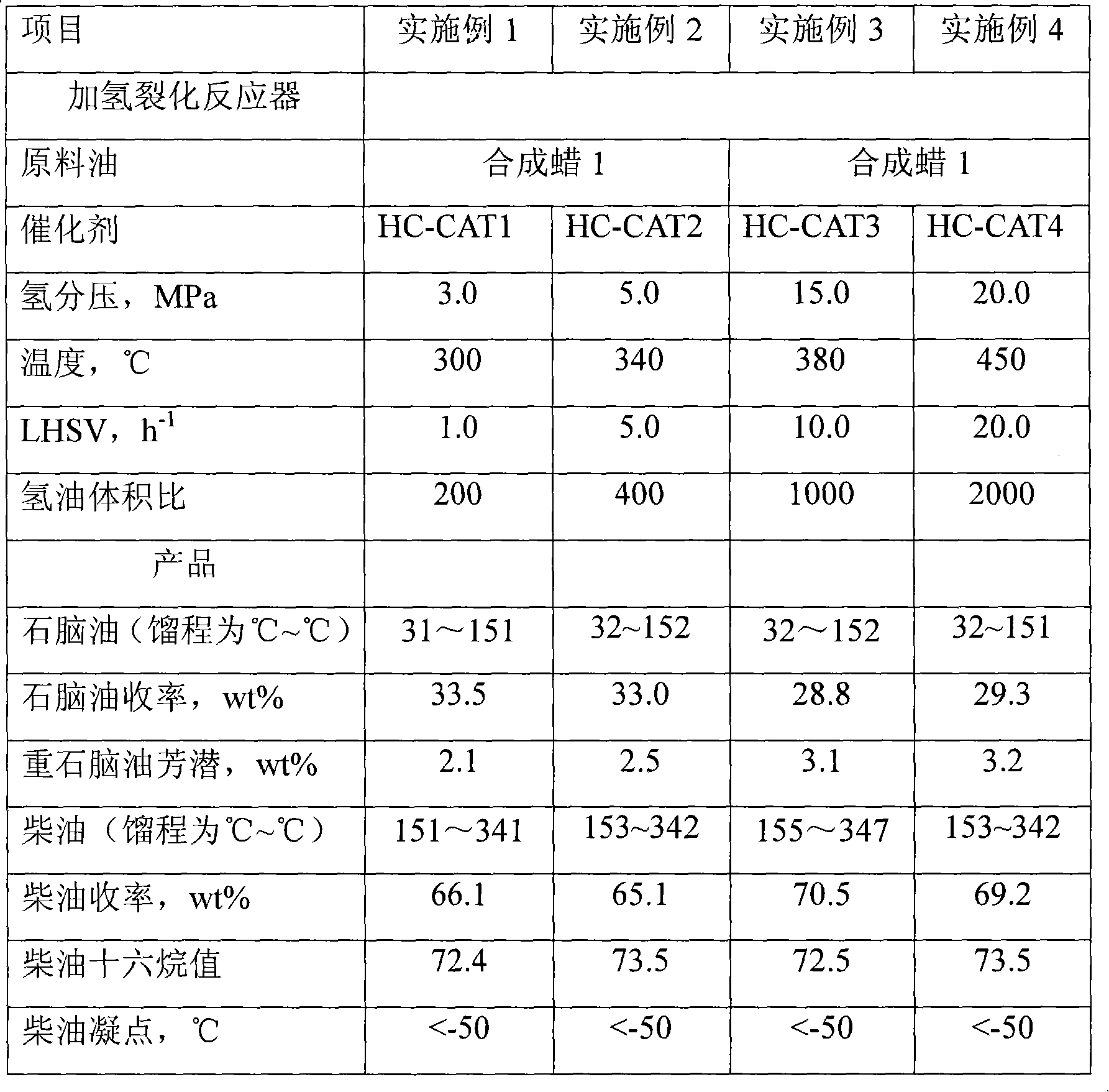

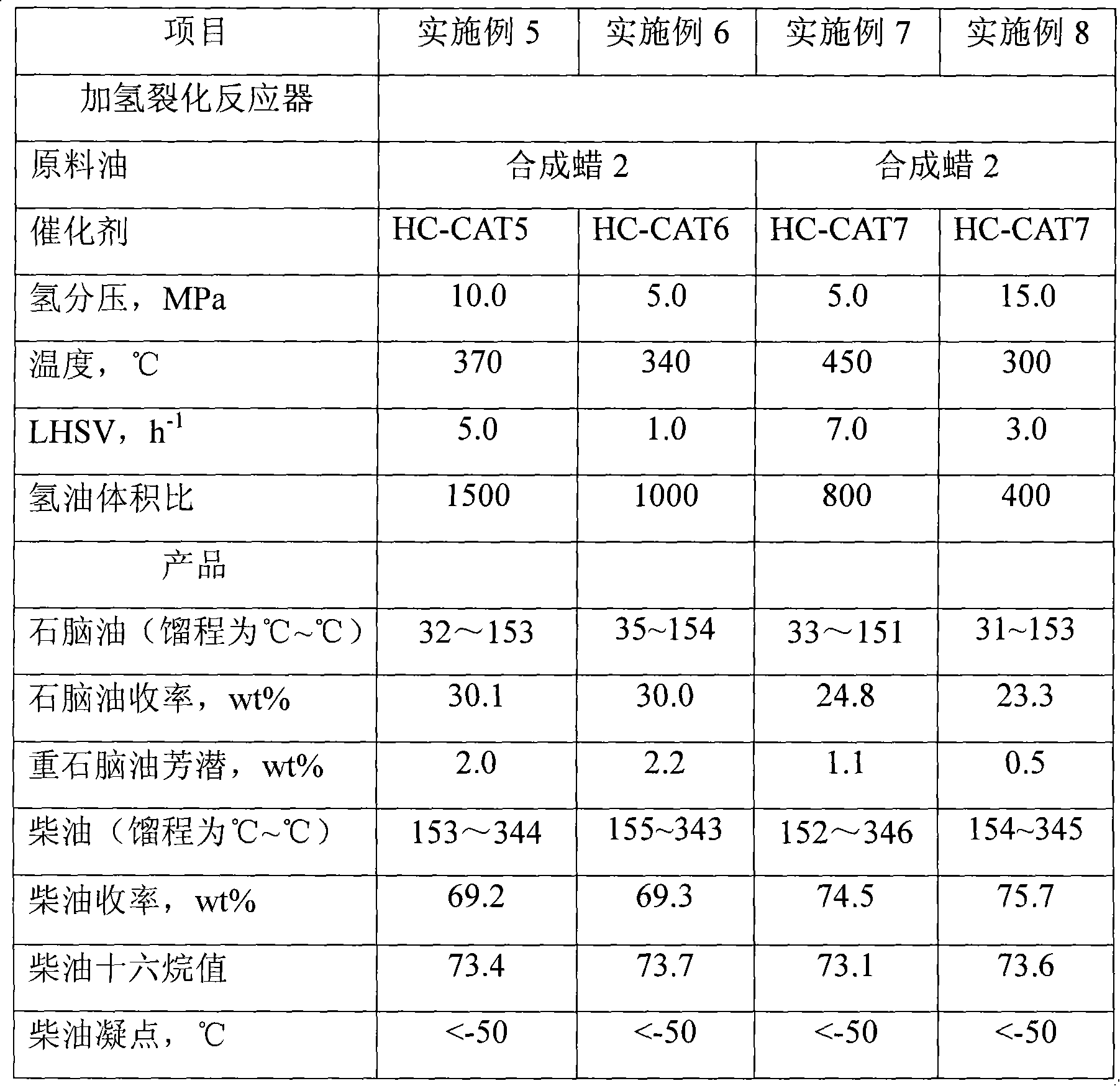

Method for producing diesel oil and chemical materials by f-t synthetic wax

InactiveCN101177619ALowering the freezing pointHigh activityHydrocarbon oil crackingGasoline stabilisationWaxNaphtha

The invention discloses a method for producing chemical raw material and diesel oil by Fischer-Tropsch synthetic wax and the method is that the Fischer-Tropsch synthetic wax and hydrogen gas contact with hydrogen cracking catalyst under hydrogen cracking condition and then the reaction products are treated by fractionation; diesel distillate obtained is the clean diesel with a low freezing point, while the naphtha cut obtained is high-quality raw material used for cracking of steam to ethane, and distillation range is higher than the hydrogen cracking of tail oil circulation of the diesel oil, wherein, the hydrogen cracking catalyst is the hydrogen cracking catalyst containing Beta zeolite and the weight content of the Beta zeolite in the catalyst is 0.5 percent to 60 percent; the Beta zeolite has properties that SiO2 / Al2O3 molar ratio is 20 to 150 and Na2O less than or equal to 0.2w percent. The method of the invention can prepare the Fischer-Tropsch synthetic wax into the clean diesel oil with a low freezing point and high-quality raw material used for producing ethylene by steam cracking.

Owner:SYNFUELS CHINA TECH CO LTD

Recovery and purification of ethylene

Owner:INEOS USA LLC

Apparatus for recovering oligomerate

ActiveUS20140134064A1Promote recoveryCatalytic crackingLiquid hydrocarbon mixtures productionChemistryFluid catalytic cracking

A process and apparatus that uses a debutanizer with a side stripper can recover a light stream, an intermediate stream and a liquid stream. One of the intermediate stream and the liquid stream can be recycled to oligomerization or to fluid catalytic cracking.

Owner:UOP LLC

Method for removing tar oil from gasified combustible gas by using waste rubber and plastic crack oil

InactiveCN101186836AImprove purification effectAdaptableLiquid hydrocarbon mixture productionGasoline stabilisationDistillationWaste rubber

The invention relates to a process for removing tar oil with gasification gas. At present, the operating cost and the maintenance cost of the present process for removing tar oil are high, and the second pollution of the waste water of tar oil is brought out. The concrete steps of the invention are that waste rubber and plastic used for schizolysis are conveyed to a schizolysis furnace and oil gas mixture and solid charcoal are generated after the heat schizolysis reaction, the oil gas mixture produced by the schizolysis reaction is separated via a rectifying tower and then oil products and gas are generated, and the distillate with the temperature of 200-350 DEG C is separated out as oil washing distillation cut which is employed to absorb the tar oil in the gasification gas which contains tar oil. Compared with the existing technology, the process for removing tar oil in gasification gas has high process reliability, increases the thermal value of the gas, reduces the operation cost , produces no waste water of tar oil, and promotes the added value of the tar product .

Owner:南京绿展能源有限公司

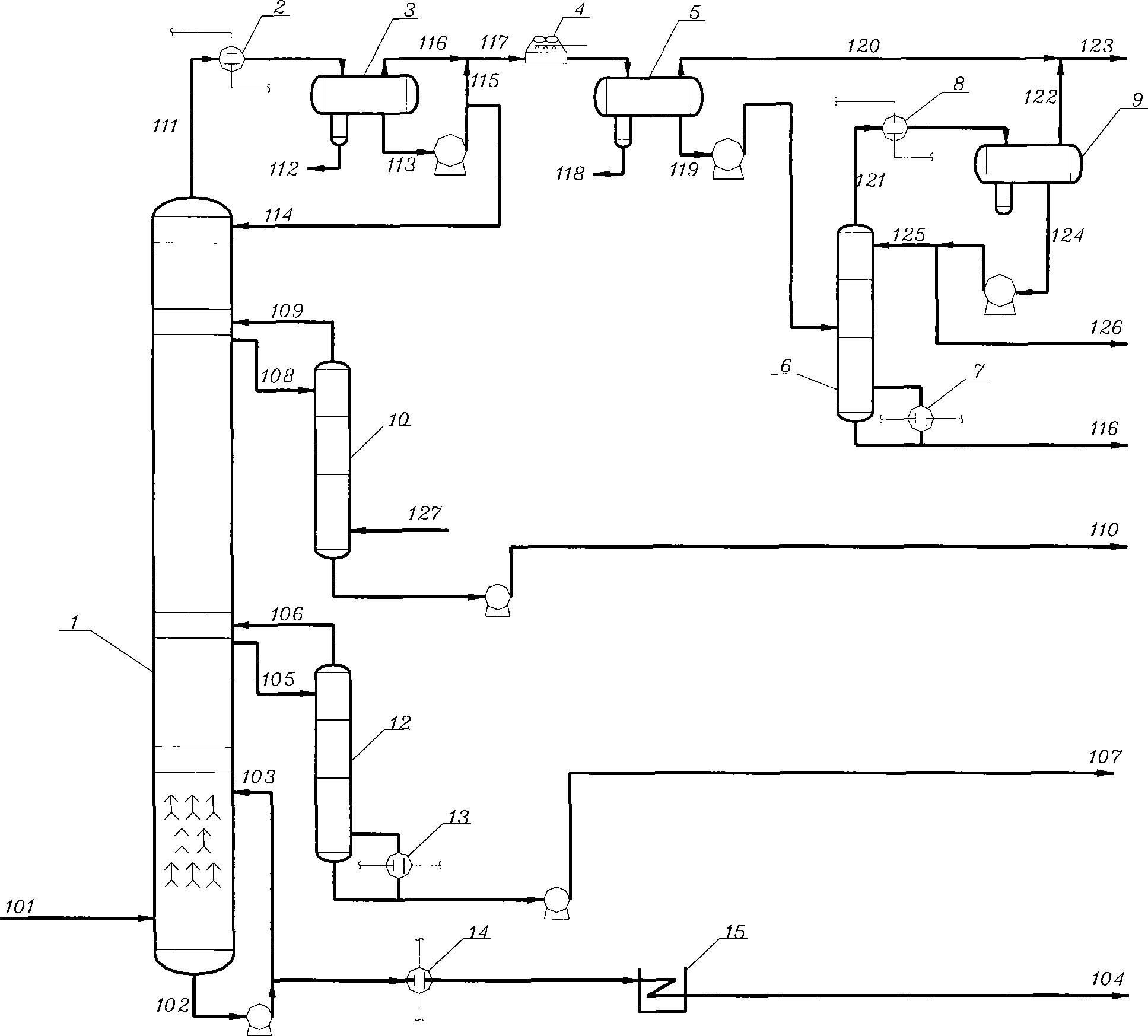

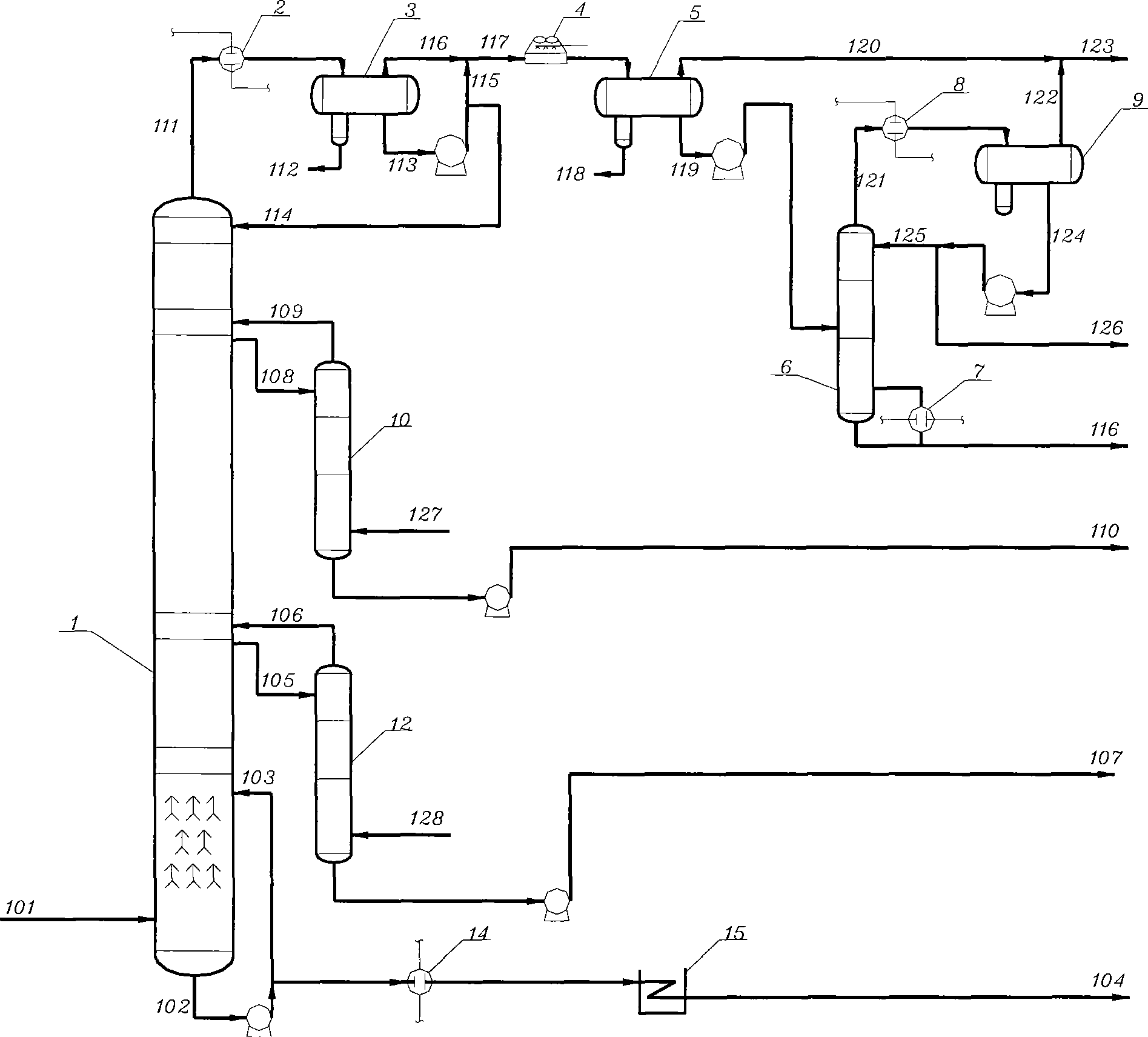

Fractionation method of hydrocarbon mixtures

ActiveCN101381617AImprove efficiencyNo overlapGasoline stabilisationHydrocarbon mixturesDistillation

The invention provides a method for fractionating mixing hydrocarbons. The mixing hydrocarbon raw material enters a fractionating tower, the fraction, of which the distillation range is more than 350 DEG C, is drawn out from the bottom of the fractionating tower; and first material current is drawn out from the middle-lower part of the fractionating tower, and is subjected to steam stripping in a first steam stripping tower to obtain the fraction of which the distillation range is between 250 and 360 DEG C; second material current is drawn out from the middle-upper part of the fractionating tower, and is subjected to steam stripping in a second steam stripping tower to obtain the fraction of which the distillation range is between 160 and 260 DEG C; and the oil gases exhausted from the top of the fractionating tower are subjected to condensation cooling separation to obtain rich gases and liquid, wherein the liquid is subjected to steam stripping in a third steam stripping tower to obtain C5<-> fraction and C6<+> fraction. The method aims at the special needs of the process on producing micromolecule hydrocarbons and aromatic hydrocarbons to the maximum extent to provide cracking materials for the process, and realizes the fine separation by the arrangement of three steam stripping towers of light aromatic hydrocarbon materials, heavy aromatic hydrocarbon materials and remixing materials, thereby improving the separation precision.

Owner:CHINA PETROLEUM & CHEM CORP +1

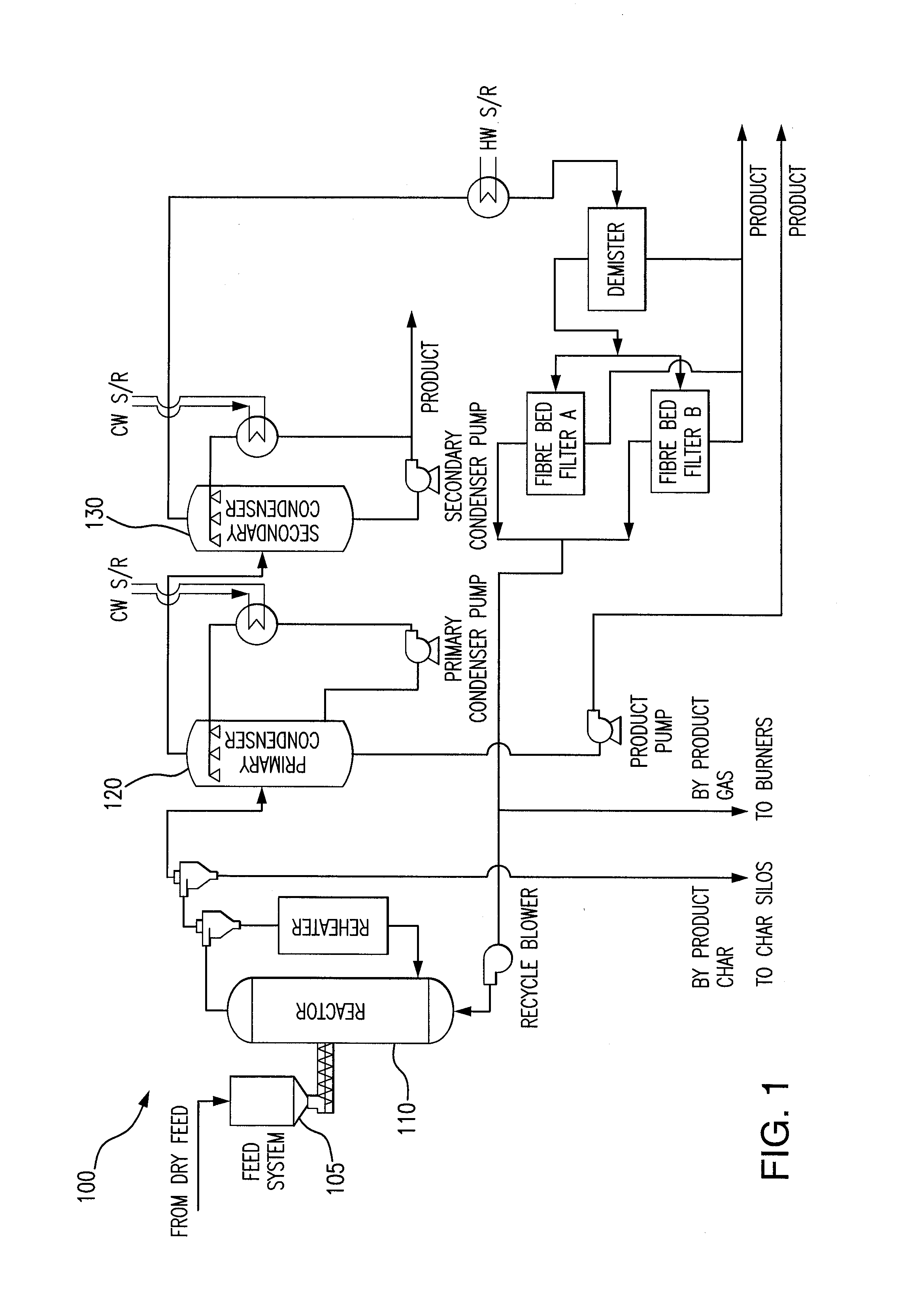

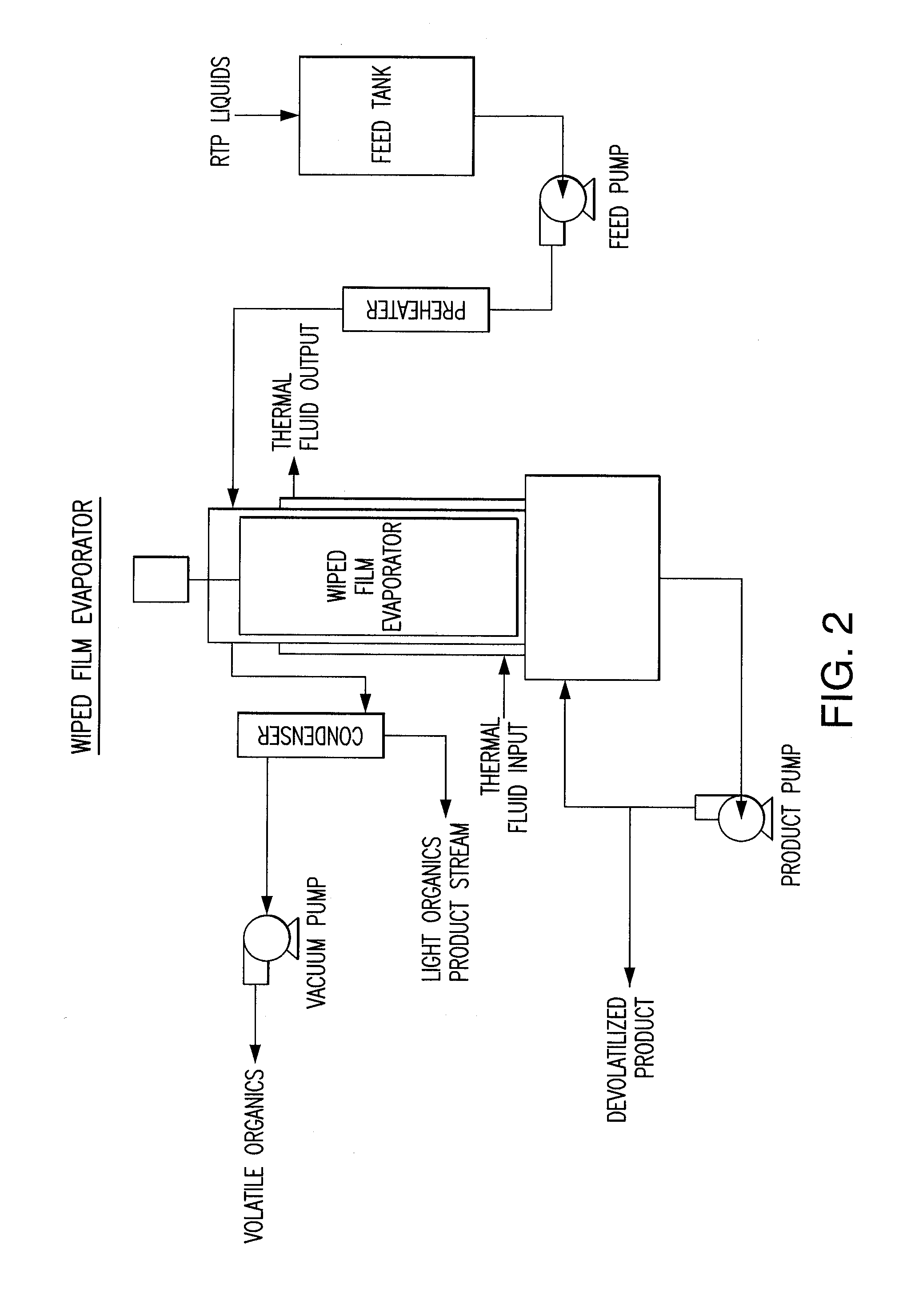

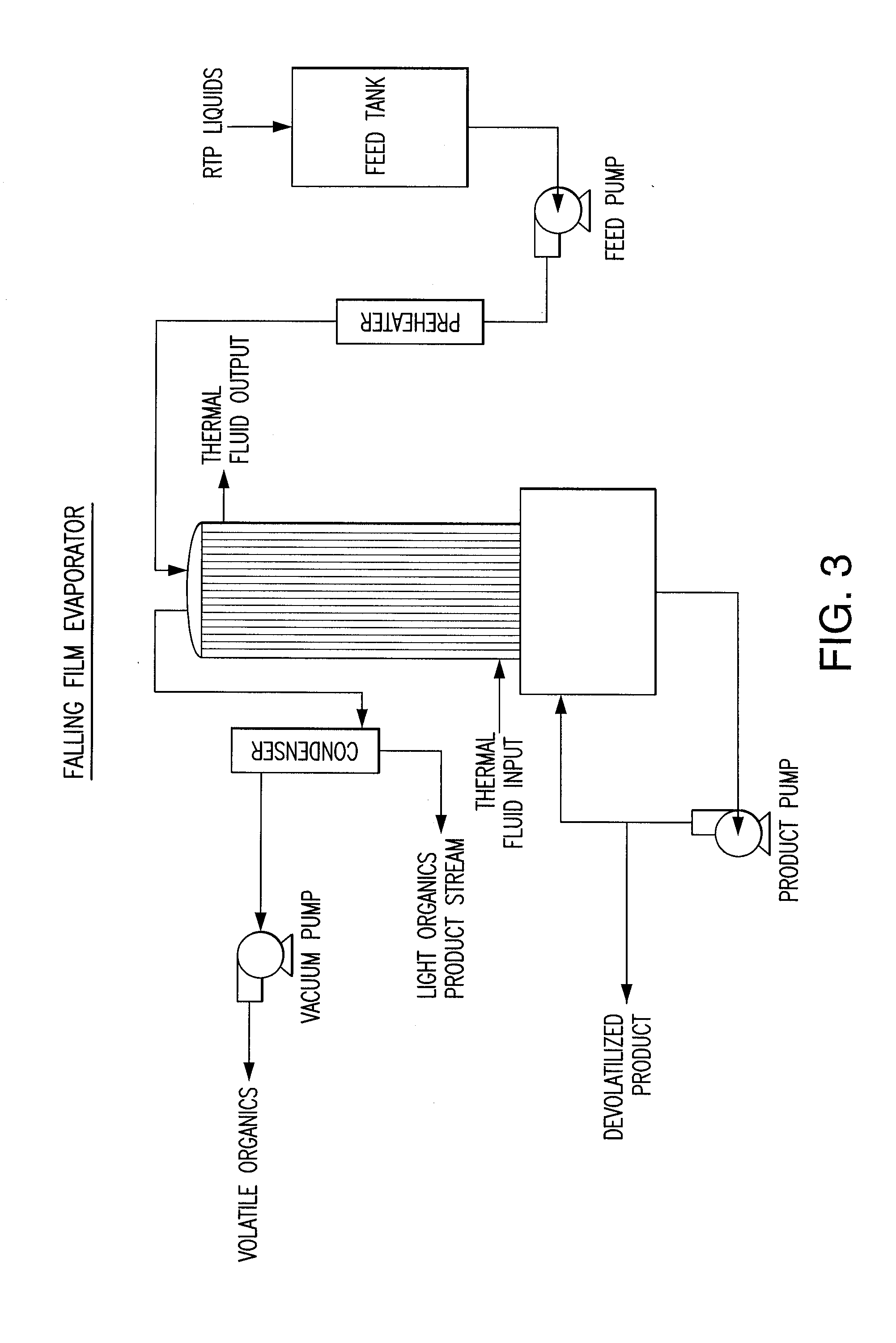

Systems and Methods for the Devolatilization of Thermally Produced Liquids

InactiveUS20140053456A1Increase pointsHigh flash pointThermal non-catalytic crackingCatalytic crackingEngineeringFalling film evaporator

Methods and systems for the devolatilization of thermally produced liquids to raise the flash point are disclosed. Various methods and apparatus can be used to effectively reduce the volatile components, such as wiped film evaporator, falling film evaporator, flash column, packed column, devolatilization vessel or tank.

Owner:ENSYN RENEWABLES

Inferior distillate oil combination hydrogenation modified method

ActiveCN101165142AWide distillation rangeLow yieldTreatment with hydrotreatment processesGasoline stabilisationSulfurNitrogen

The combined inferior distillate oil hydrogenating modification process includes hydrogenation modifying catalytically cracked diesel oil fraction material, hydrogenation refining pyrolytic distillate oil material, and separating the reaction effluent from both hydrogenation modifying and hydrogenation refining in a common separating system. The hydrogenating process of the present invention has high diesel oil yield, and is simple and low in cost, and the hydrogenated product has low content of S, P and other impurities and greatly raised cetane number. The process is suitable for hydrogenating of different types of inferior distillate oil material.

Owner:CHINA PETROLEUM & CHEM CORP +1

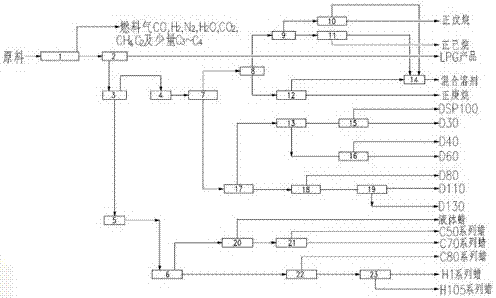

Separation method of Fischer-tropsch synthesized crude product

ActiveCN107325838AEfficient removalMeet different market needsTreatment with plural serial refining stagesMolecular distillationAlkaneWax

The invention relates to a separation method of a Fischer-tropsch synthesized crude product. The method comprises a plurality of technological steps: crude separation of products, oil hydrogenation, alkane refining, solvent oil refining, wax hydrogenation, wax refining and the like, and according to different synthesis temperatures of the Fischer-tropsch synthesized crude product, different quantities of various high-added-value products such as naphtha, n-pentane, n-heptane, DSP100, DSP40, DSP80 or DSP110 solvent oil, C50, C70 or C80 series wax, H1 and H105 series wax and the like can be obtained. The separation method has the advantages of improving the added value of the Fischer-tropsch synthesized crude product, and being simple in technological flow, and easy for industrial production.

Owner:SEDIN ENG

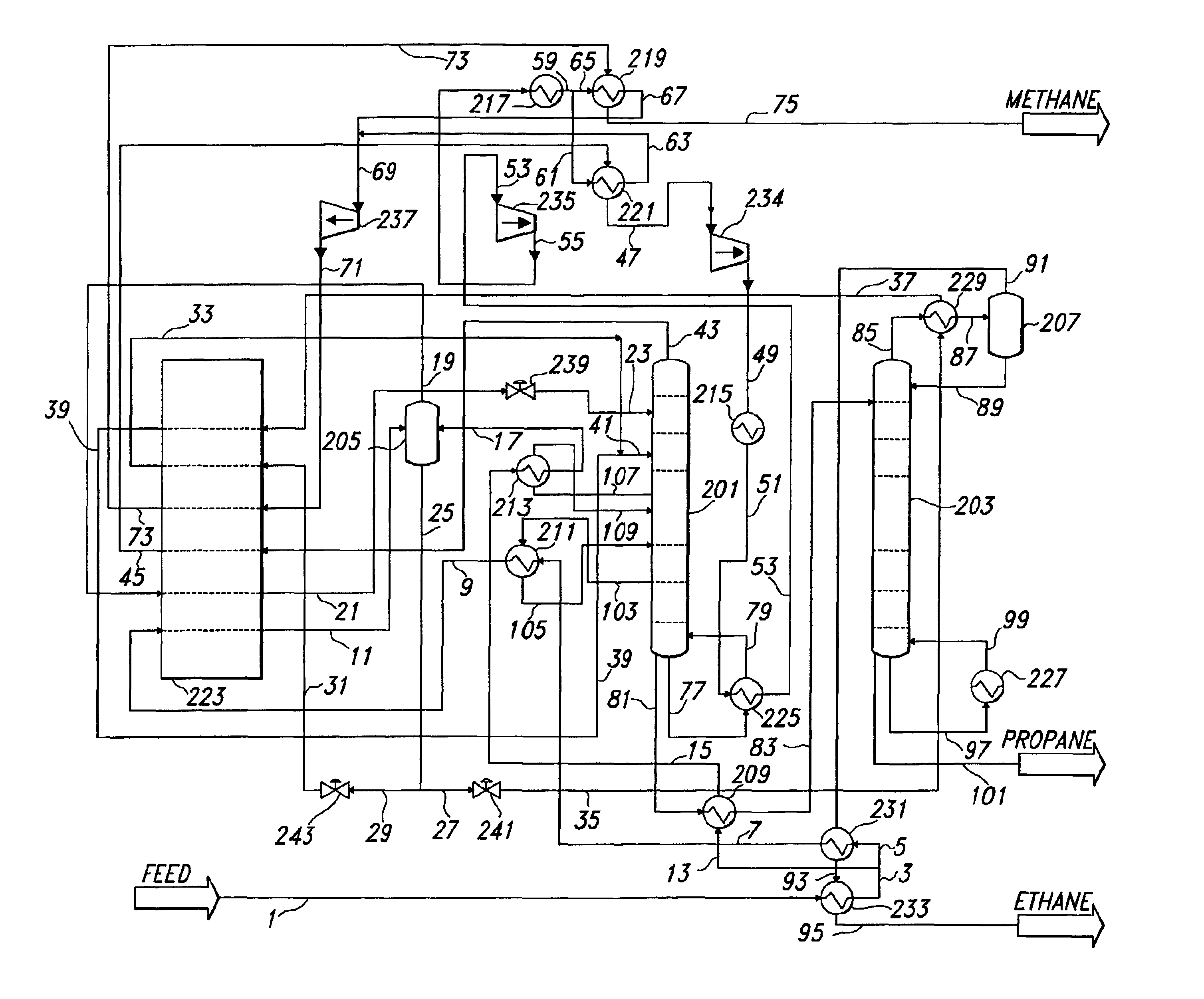

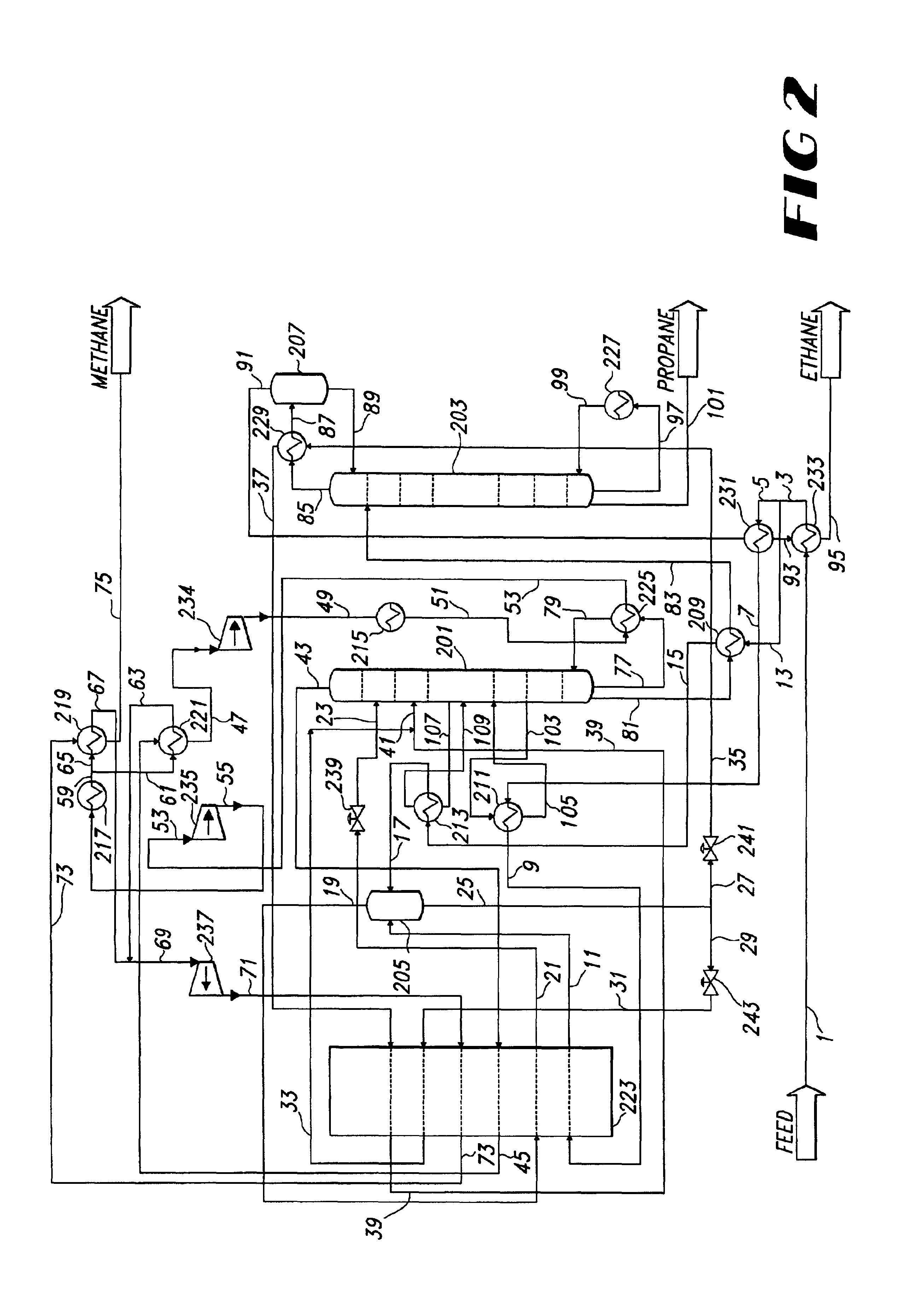

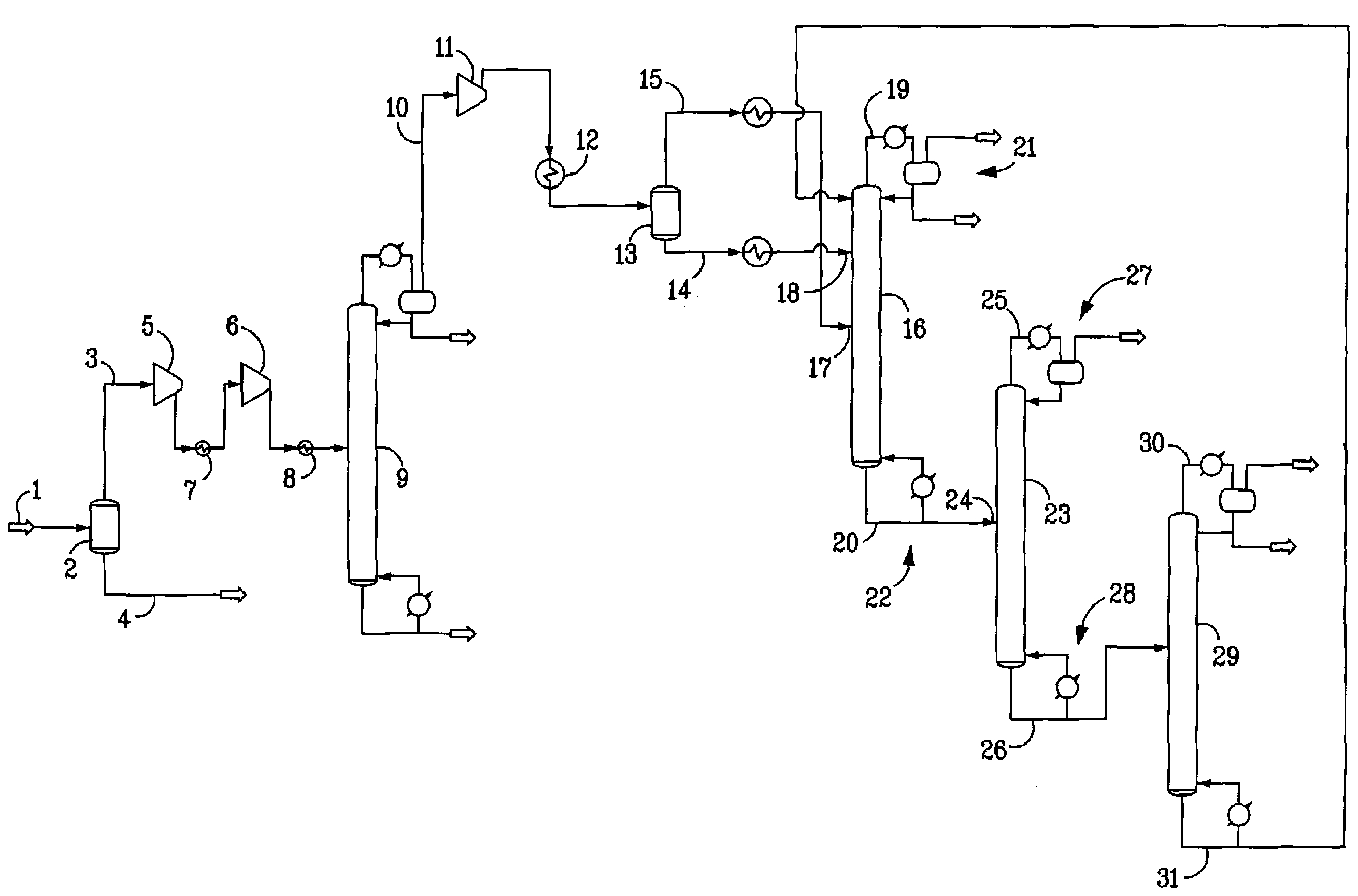

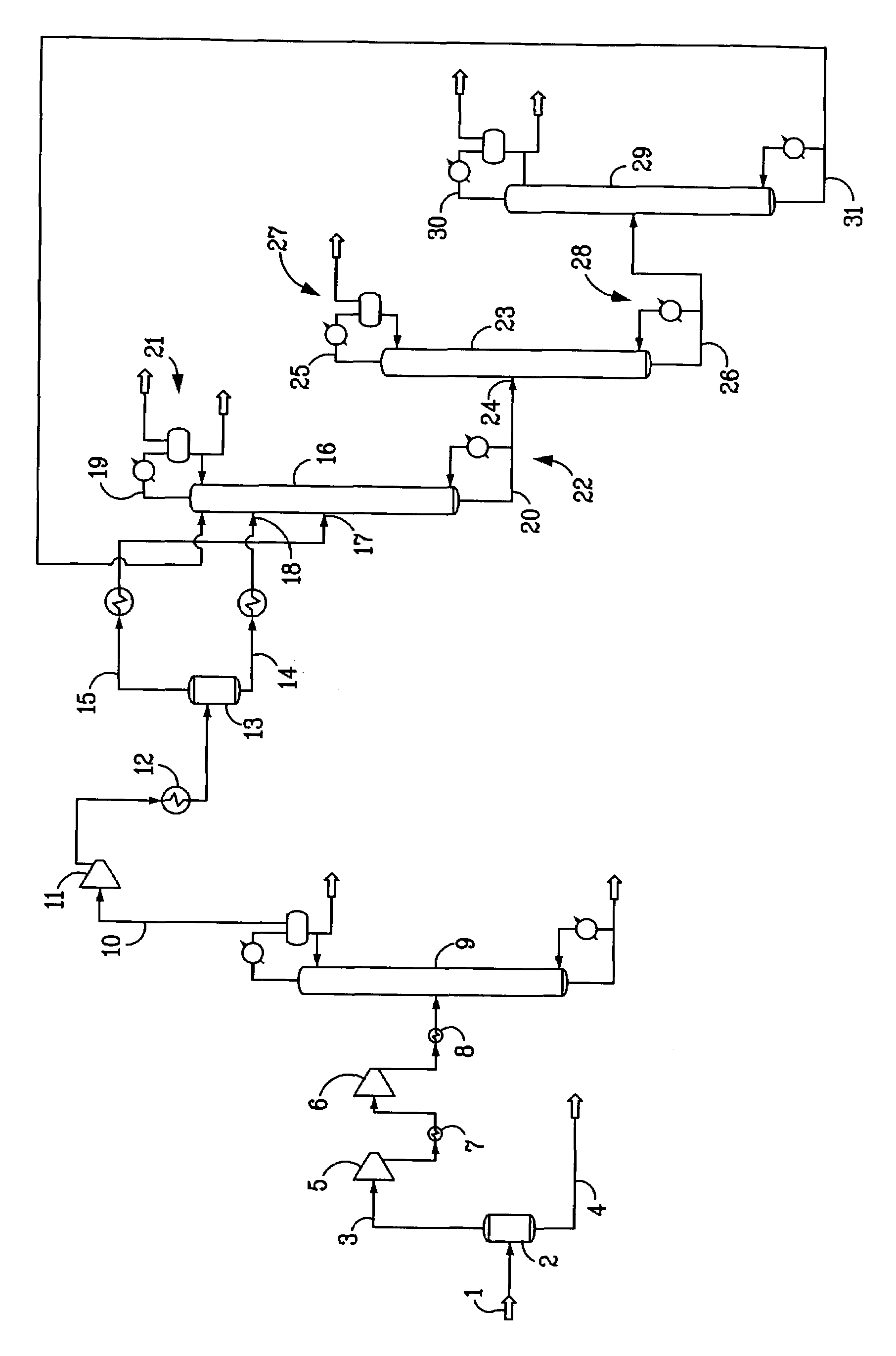

Recovery and purification of ethylene

A process for the recovery and purification of ethylene and optionally propylene from a stream containing lighter and heavier components that employs an ethylene distributor column and a partially thermally coupled distributed distillation system.

Owner:INEOS USA LLC

Method and device for improving efficiency of sponge oil absorption

ActiveUS20150053590A1Improve efficiencyThermal non-catalytic crackingLiquid hydrocarbon mixture recoveryHydrogenProcess engineering

A method for improving efficiency of sponge absorption includes providing cold flash drum liquid to an inlet of a cold stripper to produce a cold stripper net overhead vapor stream rich in liquid petroleum gas, and separately providing hot flash drum liquid to an inlet of a hot stripper to produce a hot stripper net overhead vapor stream rich in hydrogen. The cold stripper net overhead vapor stream and the hot stripper net overhead vapor stream are separately routed to a sponge absorber to recover a liquid petroleum gas output stream using sponge oil. In particular, the cold stripper net overhead vapor stream and the hot stripper net overhead vapor stream are separately routed to the sponge absorber at different tray locations

Owner:UOP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com