Patents

Literature

219results about How to "Relaxed reaction conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

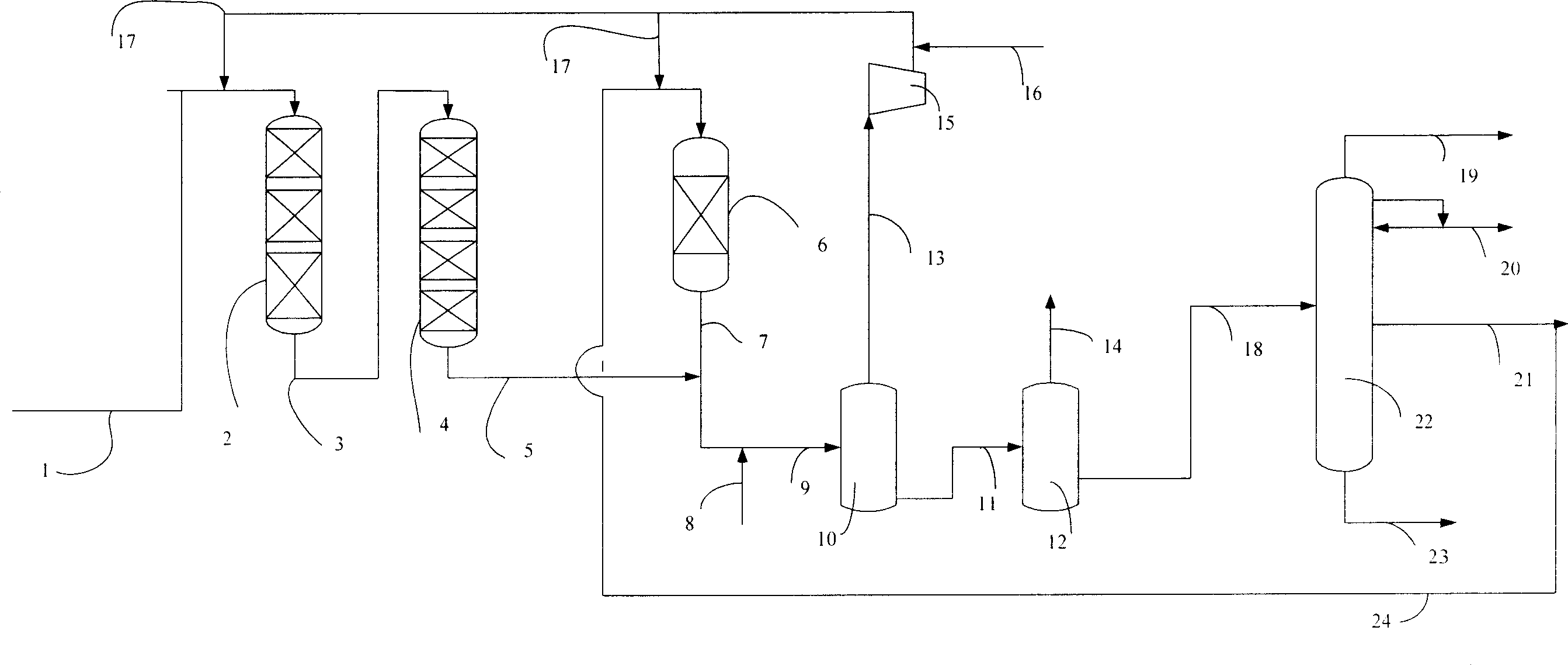

Hydrogenation cracking method of mass production of chemical materials

A kind of hydrocracking method by which the maximum industrial chemicals can be produced, the raw oil and hydrogen will go into the first reaction zone after being heated and contact with hydrofining catalyst and hydrocracking catalyst in turn, the gas which riches in hydrogen and gained after the gas and oil separating of the reactant will be compressed and recycled, the liquid will be fractioned and light naphtha, weight naphtha, diesel oil fraction and tail oil fraction can be gained, the diesel oil fraction will be mixed with the circular hydrogen after the it's press being added, and then contacts with hydrocracking catalyst. The reactant liquor of this step will be mixed with that of above step and go into the separation and fractionation system. The industrial chemicals more than 98% of the raw calculated by weight, which contains liquid gas, light naphtha, weight naphtha, and tail oil can be gained with the method.

Owner:CHINA PETROLEUM & CHEM CORP +1

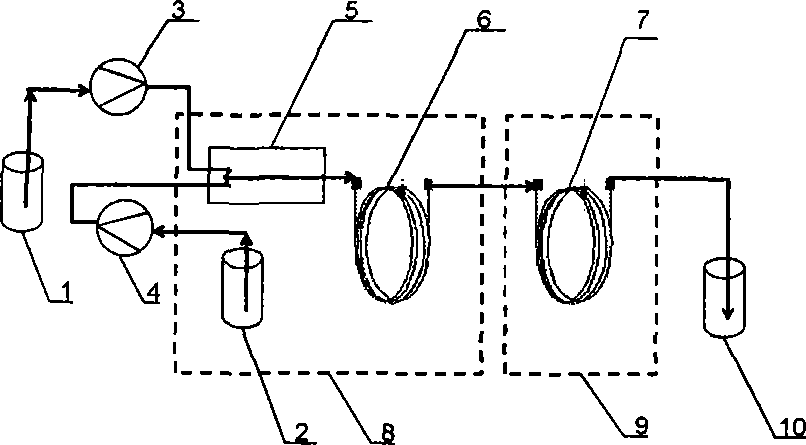

Method of preparing alpha-sulphonic acid fatty acid ester

InactiveCN101508660AImprove securityRelaxed reaction conditionsSulfonic acid preparationState of artReaction temperature

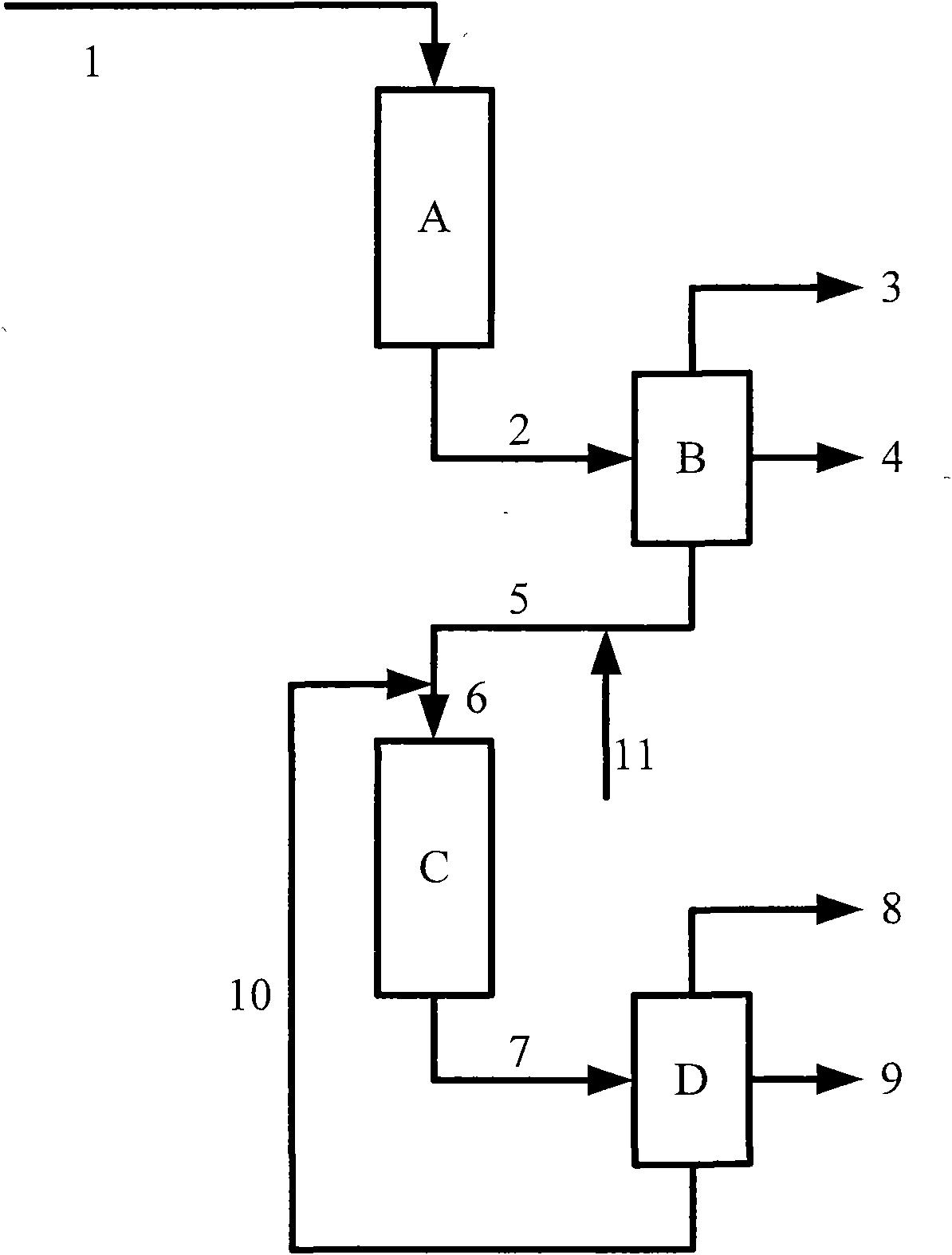

The invention relates to a method for preparing alpha-sulfonic fatty acid ester by sulfonating fatty acid ester, comprising the following steps: injecting the fatty acid ester and a sulfonating agent into a micro-structural reactor (5) and a reactor (6) inside diameter of which is a micro passage respectively, mixing and sulfonating the fatty acid ester and the sulfonating agent, controlling the reaction temperature between 50 and 100 DEG C, and controlling the reaction materials to stay for 1ms to 1s in the micro-structural reactor (5) and stay for 0.5 to 30 minutes in the micro-passage reactor (6); and then injecting the reaction materials into a micro-passage reactor (7), aging the reaction materials at a reaction temperature between 50 and 100 DEG C, and controlling the reaction materials to stay for 0.5 to 30 minutes in the micro-passage reactor to obtain the alpha-sulfonic fatty acid ester. In the method, the novel micro-structural reactor is adopted, the defect of difficult control due to strong reaction heat release in the prior art is overcome, the materials can be mixed evenly, the released reaction heat can be removed in time, the reaction time can be controlled accurately, and the method has the advantages of good sulfonating efficiency, simple and safe operation and good product quality.

Owner:NANJING UNIV OF TECH

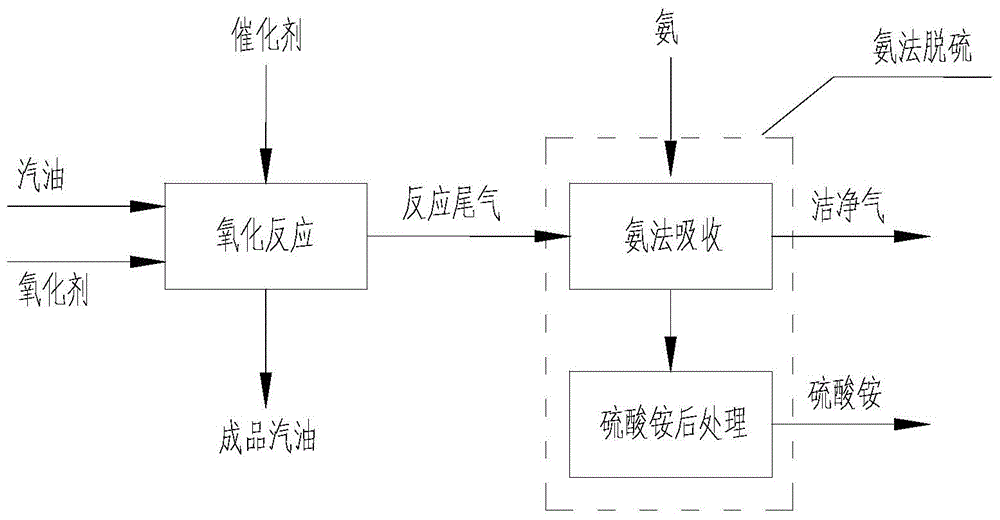

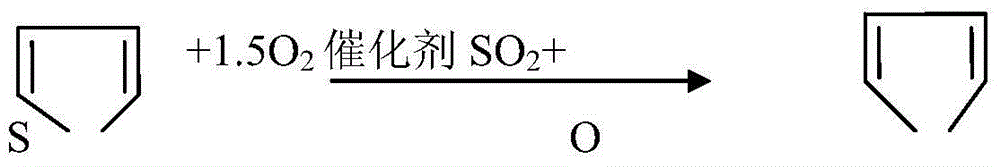

Gasoline-oxidation ammonia-process desulfurization method

InactiveCN104946296ARealize recycling of resourcesImprove desulfurization efficiencyRefining with oxygen compoundsDispersed particle separationGasolineComponents of crude oil

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

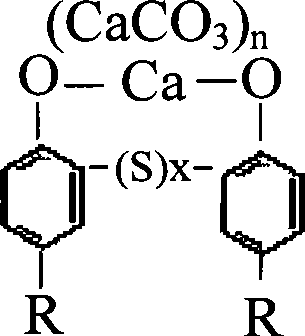

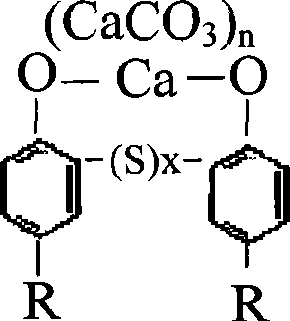

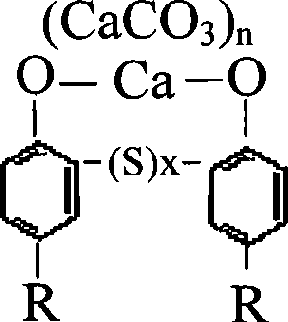

High basic value (TBN400) sulfurized calcium alkyl and preparation method thereof

ActiveCN101423483AWide range of usesImprove performanceAdditivesHydropoly/poly sulfide preparationChemical structureCarboxylic acid

The invention relates to high base number (TBN400) vulcanized alkyl phenol calcium and a preparation method thereof. The vulcanized alkyl phenol calcium has a chemical structure as right. The preparation method is as follows: in a system containing solvent and diluent oil, alkyl phenol compound, shielded phenol compound, calcium oxide and / or calcium hydroxide and sulfur are subjected to sulfonation / neutralization reaction at a temperature of between 60 and 180 DEG C to generate phenolate intermediate; balanced calcium oxide and / or calcium hydroxide are added into the mixture, carbon dioxide is introduced, and the mixture is subjected to carbonation reaction; and alkyl polylol is added into the mixture at the sulfonation / neutralization reaction or respectively at the sulfonation / neutralization reaction and the carbonation reaction to participate in the reaction, long-chain carboxylic acid is added into the mixture at the sulfonation / neutralization reaction or respectively at the sulfonation / neutralization reaction and the carbonation reaction to participate in the reaction, and products are obtained through refining. The vulcanized alkyl phenol calcium has the characteristics of high base number, low viscosity, low precipitation number, good heat storage stability, and the like, and has excellent combination property, does not cause environmental protection problem during use, and belongs to an environment-friendly product, and adopts a one-stage process, has mild reaction conditions, and is easy to filter.

Owner:JINZHOU DPF TH CHEM CO LTD

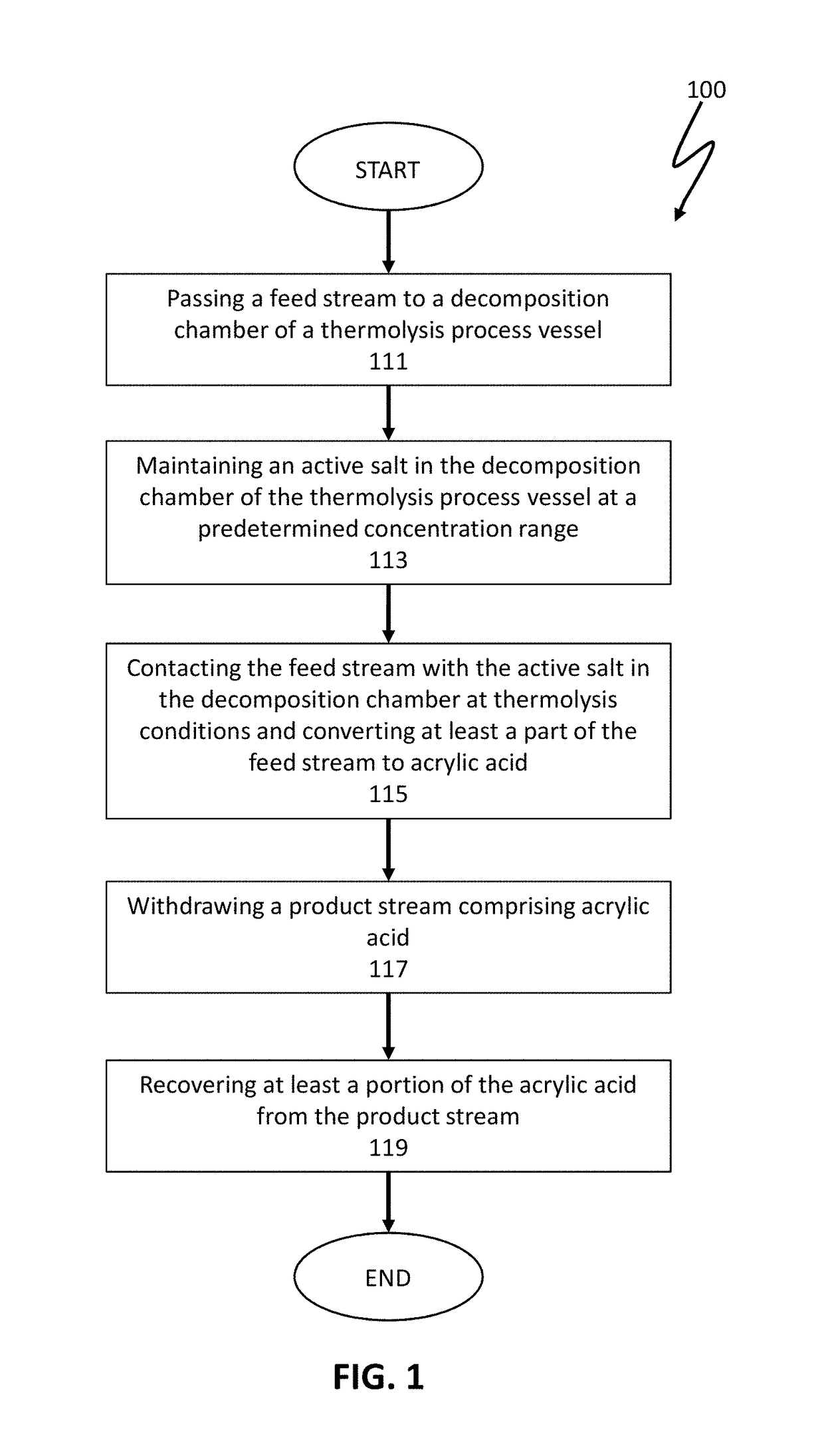

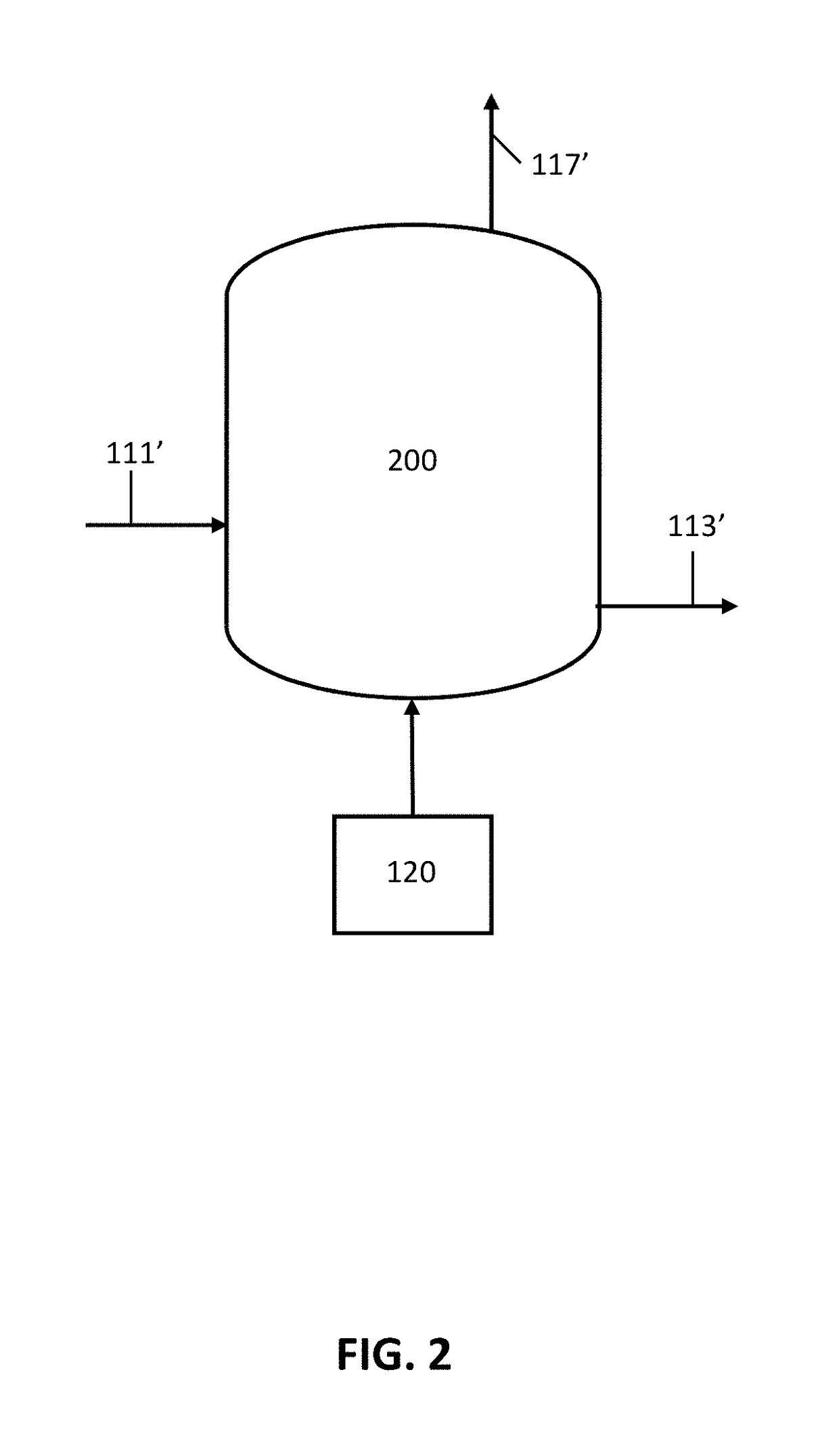

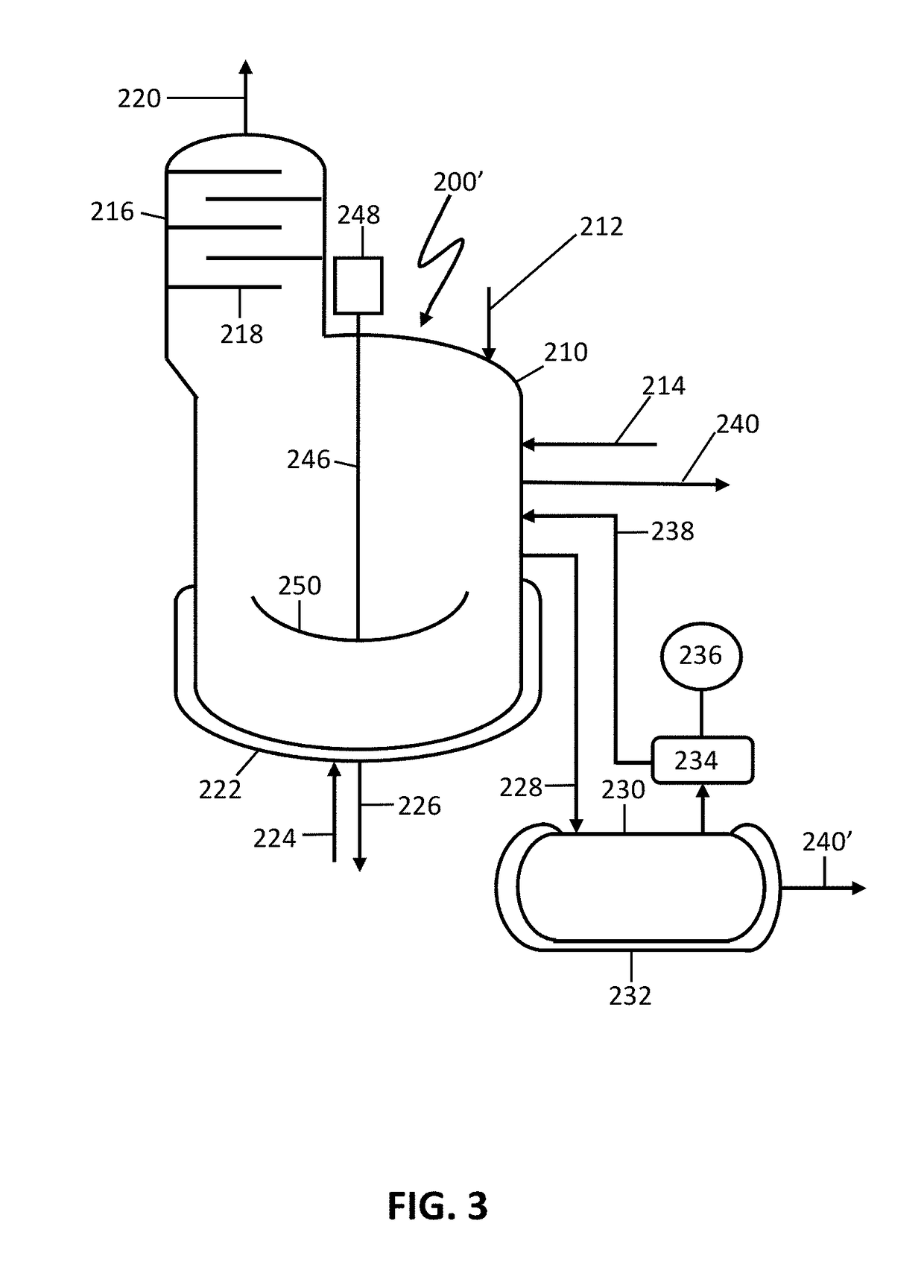

Thermolysis of polypropiolactone to produce acrylic acid

ActiveUS10065914B1High purityReduce and limit polymerizationOrganic compound preparationChemical/physical/physico-chemical stationary reactorsAcrylic acidPolymerization

The present invention is directed to reactor apparatus and processes for thermolysis of polypropiolactone to produce highly pure acrylic acid. In preferred embodiments of the present invention, the processes comprise introducing a feed stream comprising polypropiolactone to a thermolysis process vessel through an inlet; maintaining a concentration of active salt by adding and removing portions of active salt by at least one inlet and at least one outlet; heating the thermolysis process vessel; and recovering a product including acrylic acid from an outlet. In certain preferred embodiments, the active salt may be present as a catalyst used for polymerization of the polypropiolactone in the feed stream. In some embodiments, one or more active salts may be added to the feed stream and / or the thermolysis process vessel.

Owner:NOVOMER INC

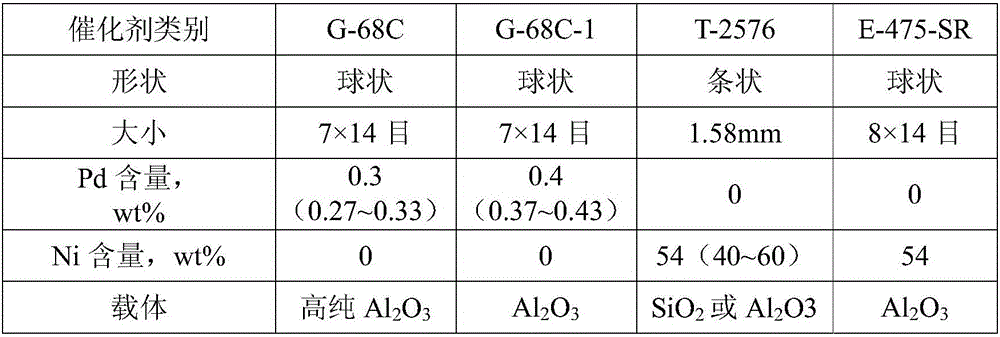

Mercaptan etherification catalyst

ActiveCN102125846AGood selective hydrogenation effectLow priceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsThiolSlag

The invention discloses a mercaptan etherification catalyst. The catalyst is characterized in that: a metal oxide is added into an alumina carrier for modifying, wherein the metal oxide is an oxide of one metal or mixture of a plurality of metal oxides in Be, Mg, Ca, Sr, Ba, La and Ce; the metal oxide is 0.1 to 20 weight percent of the carrier; an active ingredient is loaded on the carrier, the active ingredient is one or two of Fe and Ni, the oxide content of the active ingredient is 5 to 40 weight percent of the total weight of the catalyst, or the active ingredient consists of Mo and one or two of Fe and Ni, the oxide content of one metal of Fe and Ni or the oxide content of two metals of Fe and Ni is 5 to 40 weight percent of the total weight of the catalyst, and the oxide content of Mo is 1 to 10 weight percent of the total weight of the catalyst; and the catalyst is reduced and vulcanized before use. The catalyst is used for removing mercaptan and dialkene in full-fraction catalytically cracked gasoline, the mercaptan removal efficiency is high, and no alkali slag is discharged.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

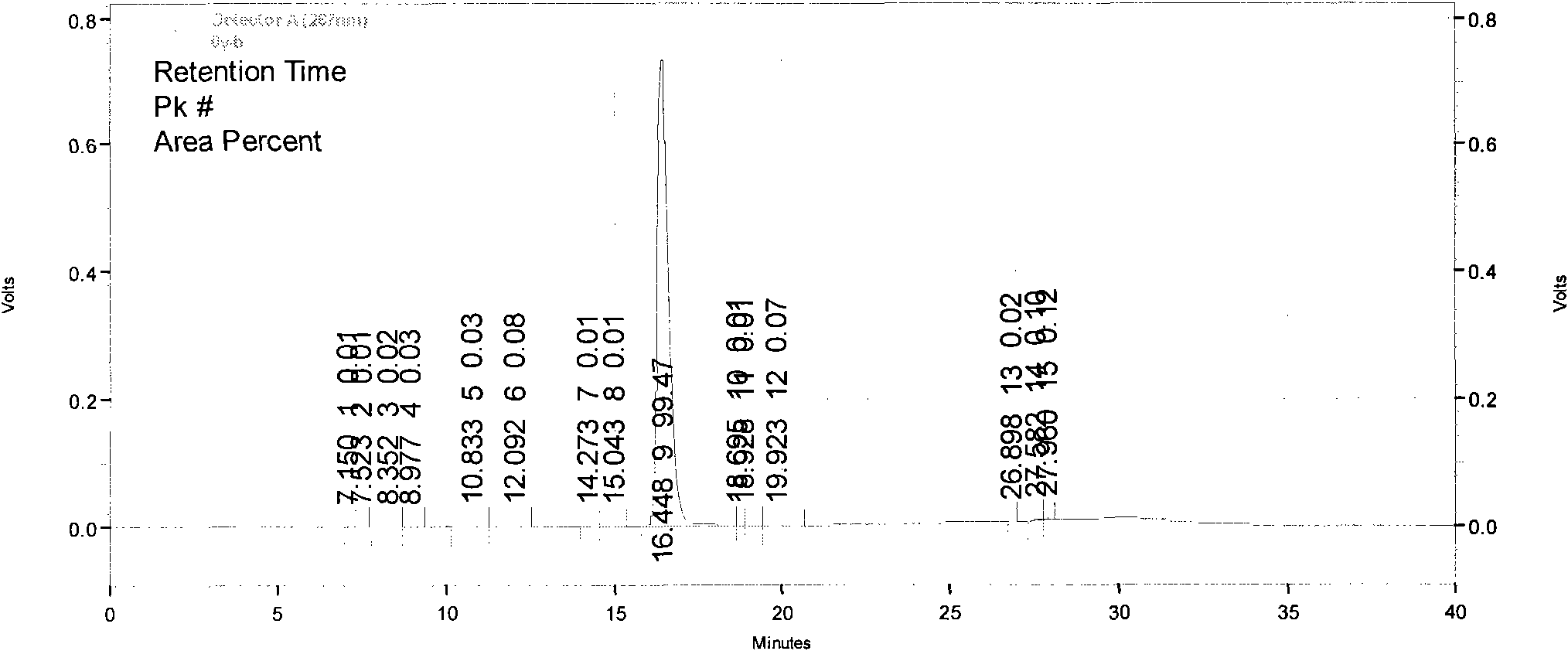

Preparation method of imatinib mesylate

InactiveCN102040587ARelaxed reaction conditionsStable qualityOrganic chemistryComponent separationChemistryPyrimidine

The invention relates to a preparation method of imatinib mesylate using N-(5-amino-2-methylphenyl)-4-(3-pyridyl)-2-pyrimidine amine and 4-[(4-methyl piperazine-1-yl) methyl] benzoic acid hydrochloride as starting materials, and quality control method for intermediate in the preparation process and the final product. The overall yield of the process is about 40%, and the process is characterized in that reaction conditions are mild, operations are simple, column chromatography and other time and energy consuming steps can be avoided, quality of obtained products is stable, the purity is greater than 99%, the production cost is low, and the technology is stable and feasible.

Owner:韩南银 +1

Biological enzyme process antibacterial and anti-wrinkle finishing method of silk fabric

InactiveCN102677475AHigh catalytic efficiencyReduce dosageBiochemical fibre treatmentAnimal fibresCooking & bakingCatalytic oxidation

The invention discloses a biological enzyme process antibacterial and anti-wrinkle finishing method of a silk fabric, belongs to the field of a textile biotechnology, and aims to overcome the defects of high baking temperature, high probability of damage of silk fibers and reduced whiteness in real silk antibacterial and anti-wrinkle treatment of the conventional chemical method and realize enzyme-promoted antibacterial and anti-wrinkle functional modification of a real silk fabric. According to the method, a chitosan natural finishing agent with a primary amine structure is grafted to the surface of the silk fiber by utilizing the catalytic oxidation effect of tyrosinase, so that the antibacterial and anti-wrinkle effects of the silk fabric are improved. The process flow comprises the following steps of: pre-treating the silk fabric; catalyzing grafting modification treatment of chitosan by the tyrosinase; washing; and drying. Through the silk fabric treated by the invention, the antibacterial performance is improved, the wrinkle recovery performance is improved, and the mechanical property and the dyeing performance of the fabric are also improved. Compared with the conventional chemical method, the method has the advantages of adoption of the tyrosinase process for catalysis of the antibacterial and anti-wrinkle treatment process of the real silk, low energy consumption, high efficiency, less pollution and contribution to environmental protection.

Owner:FOSHAN CITY HANHAI YANBU SISTER FLOWER UNDERWEAR

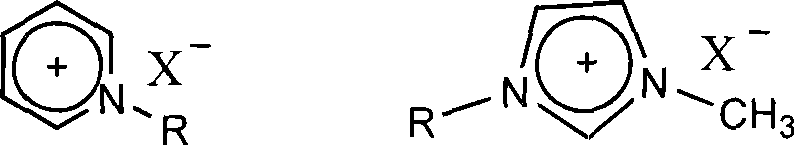

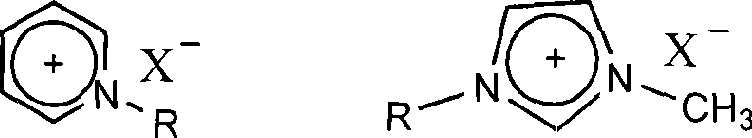

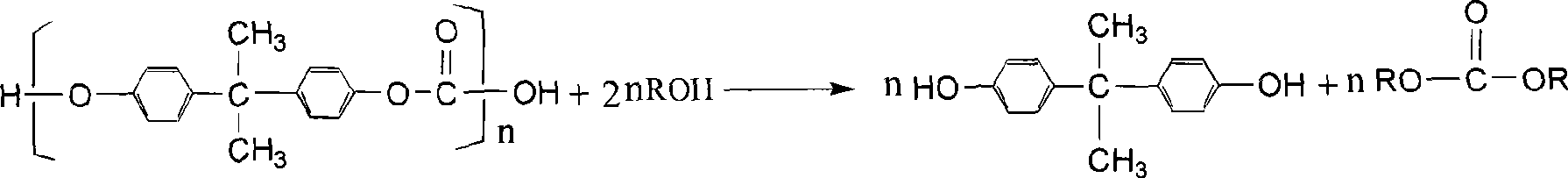

Chemical recovery method for waste polycarbonate material in ionic liquid surrounding

InactiveCN101429100ARelaxed reaction conditionsReduce the discharge of three wastesOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolubilityHigh concentration

The invention relates to a novel method for generating bisphenol A and dialkyl carbonate by chemical degradation of waste polycarbonate (PC) to realize chemical recycling of the bisphenol A and the dialkyl carbonate. The method is characterized in that reusable ionic liquid such as chloridized 1-allyl-3-methylimidazole and bromized 1-butyl-3-methylimidazole is taken as a reaction medium and catalyst, and subjected to hydrolysis reaction or alcoholysis reaction at a temperature of between 60 and 170 DEG C; after reaction is over, bisphenol A products are obtained after extraction, distillation and other operations (as for alcoholysis reaction, the dialkyl carbonate is obtained simultaneously); reclaimed ionic liquid is directly reused without any treatment; and the yield of the bisphenol A is more than 93 percent. Compared with the prior art, the method has the characteristics that: firstly, the method overcomes the defects in the prior art that high-concentration inorganic strong acid / strong alkali is applied and can not be recycled; and secondly, due to adoption of the ionic liquid which has certain solubility on the PC as the reaction medium and the catalyst, the method relieves the reaction conditions on one hand and can realize reutilization of the ionic liquid on the other hand, and obviously solves the problems of equipment corrosion and environmental pollution.

Owner:QINGDAO UNIV OF SCI & TECH

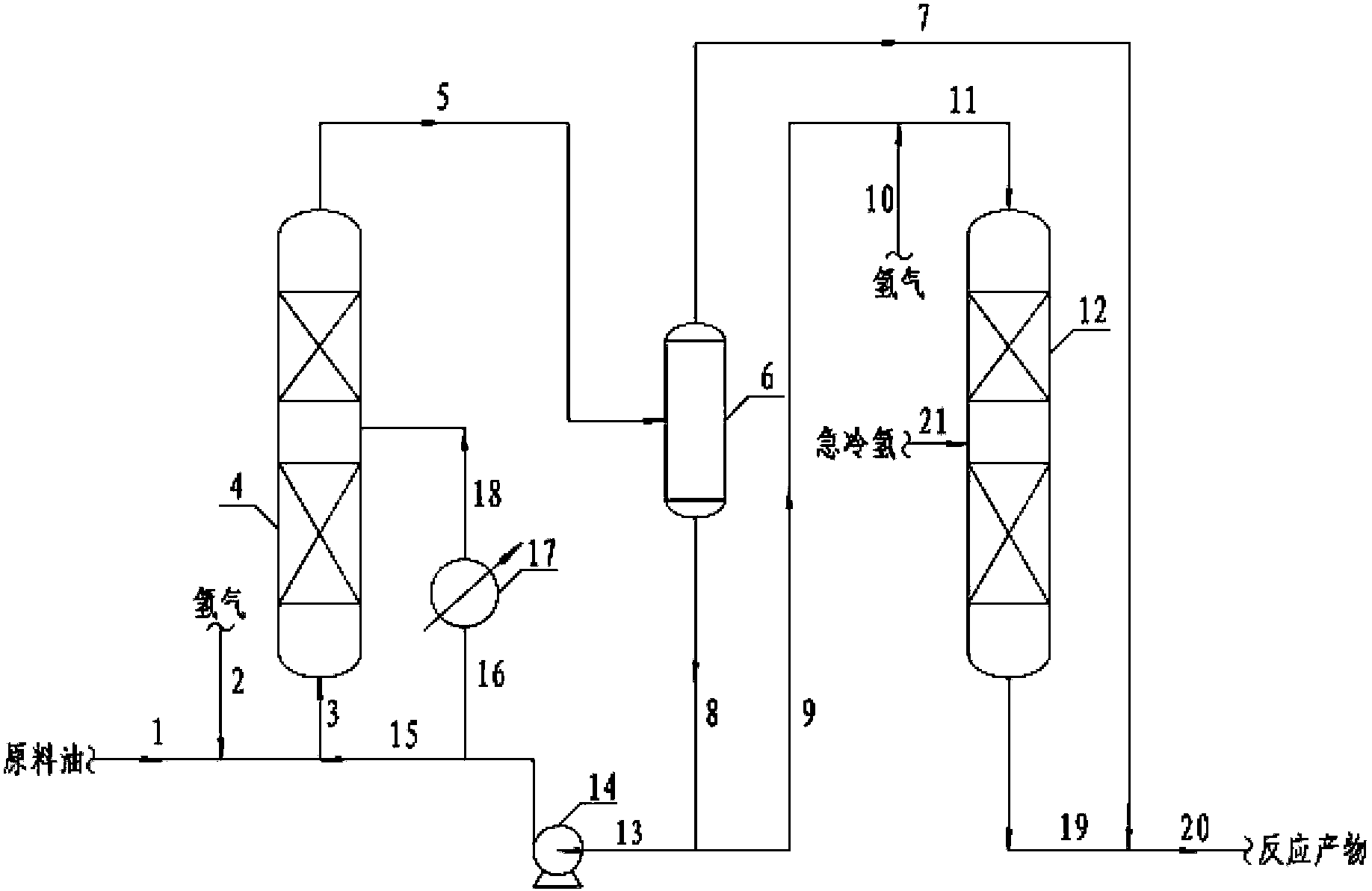

Coal tar hydrogenation system and coal tar hydrogenation method

ActiveCN103571533AExtend your lifeReduce adverse effectsTreatment with hydrotreatment processesHydrogenGas phase

The invention provides a coal tar hydrogenation system and a coal tar hydrogenation method. The method comprises a hydrogenation refining reactor, a separation unit and a hydrogenation cracking reactor, wherein the hydrogenation refining reactor is an up-flow fixed bed reactor, the hydrogenation cracking reactor is a down-flow fixed bed reactor, and the separation unit is a middle liquid separation tank; gas-liquid separation is performed on raw oil and hydrogen after a hydrogenation refining reaction, a part of liquid-phase heavy fractions is separated, one path is used as circulating oil and returned to perform the hydrogenation refining reaction again, and the other path is used as quenching oil after being cooled and added between catalyst bed layers for the hydrogenation refining reaction to play a role of cooling; and the other part of the liquid-phase heavy fractions is used as refined generated oil and mixed with hydrogen to perform a hydrogenation cracking reaction, and the obtained reaction product is combined with gas-phase light fractions after the gas-liquid separation to form the final product. The system and the method provided by the invention are low in equipment cost, simple to operate, capable of prolonging the life of the catalysts of the hydrogenation refining reactor and the hydrogenation cracking reactor, and suitable for raw oil with worse conditions.

Owner:CHINA PETROCHEMICAL CORP +1

Iron-based coal liquefied catalyst and production thereof

ActiveCN1853776ASimple manufacturing methodImprove hydrogenation activityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsSolventHigh activity

An iron-based coal liquefying catalyst with high activity to increase the output coal-liquefied oil is prepared from iron-contained substance, used lubricating oil and powdered coal.

Owner:CHINA PETROLEUM & CHEM CORP +1

Wool dyeing method using enzymic method

ActiveCN104264490AHigh color depthHigh fastnessBiochemical fibre treatmentDyeing processCelluloseProcess conditions

The invention discloses a wool dyeing method using an enzymic method. The wool dyeing method comprises the following steps of (1) enzyme treatment, namely, after wool washing, dipping a wool fiber product into a composite enzyme solution, wherein the technological conditions for enzyme treatment are as follows: papain is 10-12U / mL, polyphenol oxidase is 3-6U / mL, cellulose is 12-15U / mL, pH is 7, the temperature is 30-50 DEG C, the time is 0.5-1 hour, and the bath ratio is 1 to 10; (2) acid dyeing, namely, dyeing the wool fiber product after enzyme treatment in step (1) by acid dyes; and (3) washing aftertreatment, namely, washing dyed fabrics in the step (2) at 30-100 DEG C for 5-20 minutes in the bath ratio of 1 to (5-30).

Owner:CHANGXING GUOYUAN PRINTING & DYEING

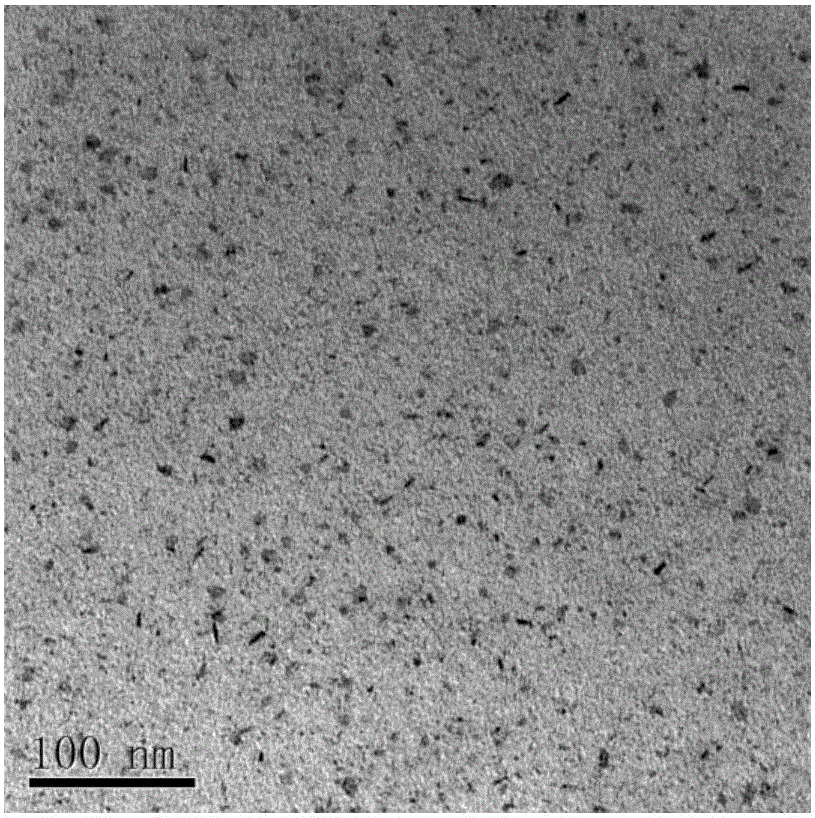

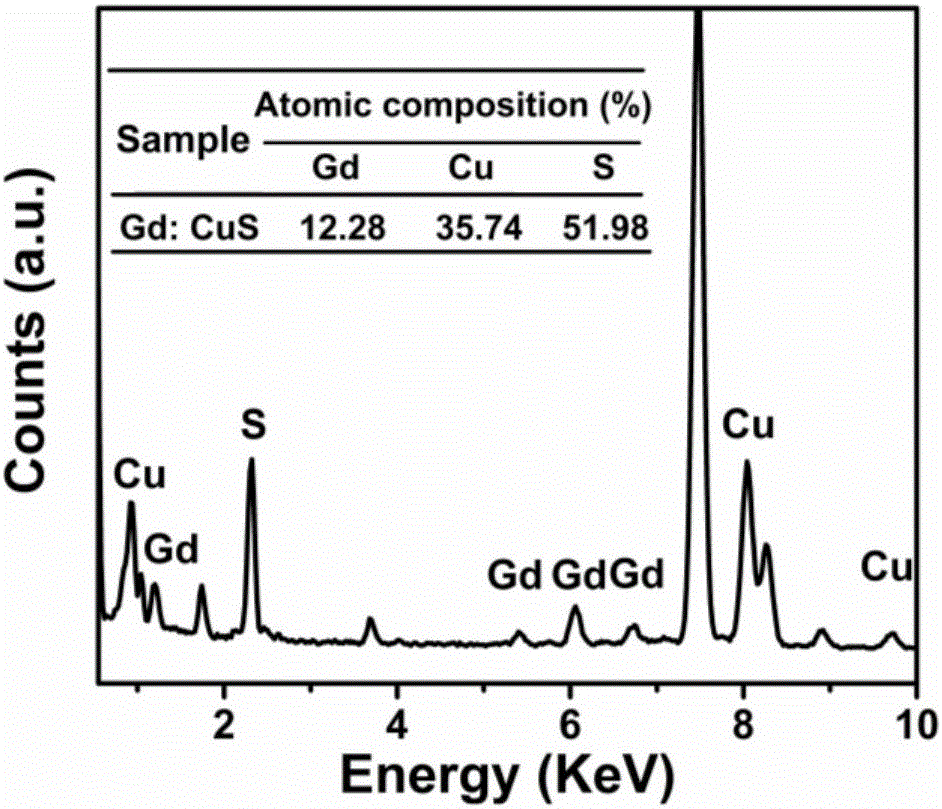

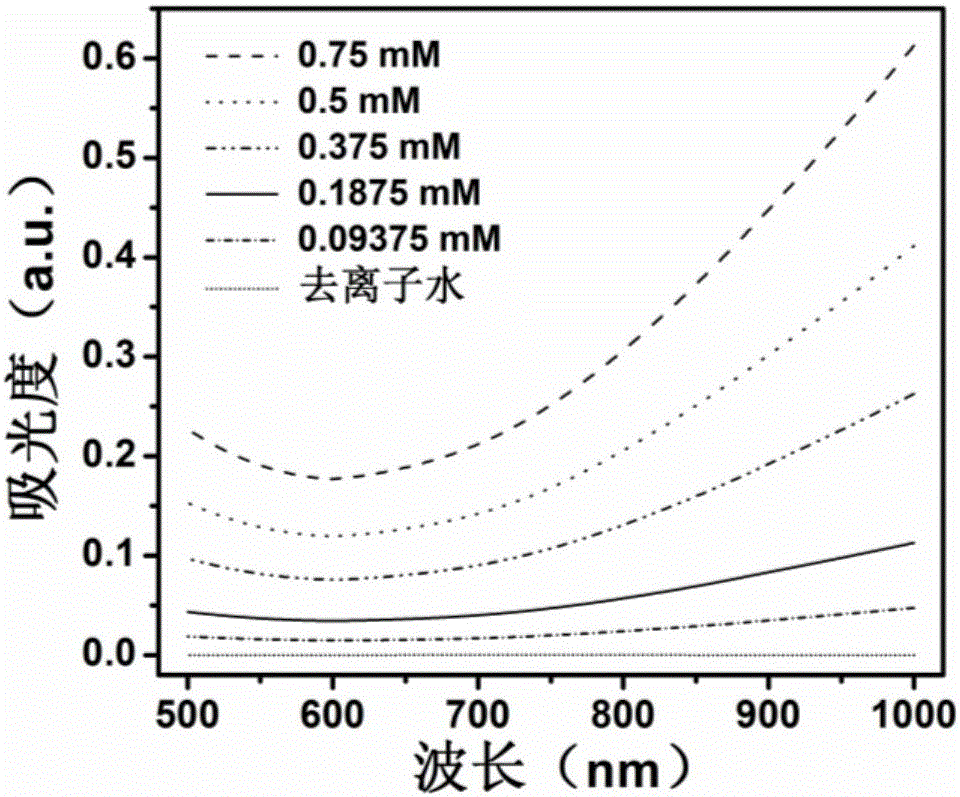

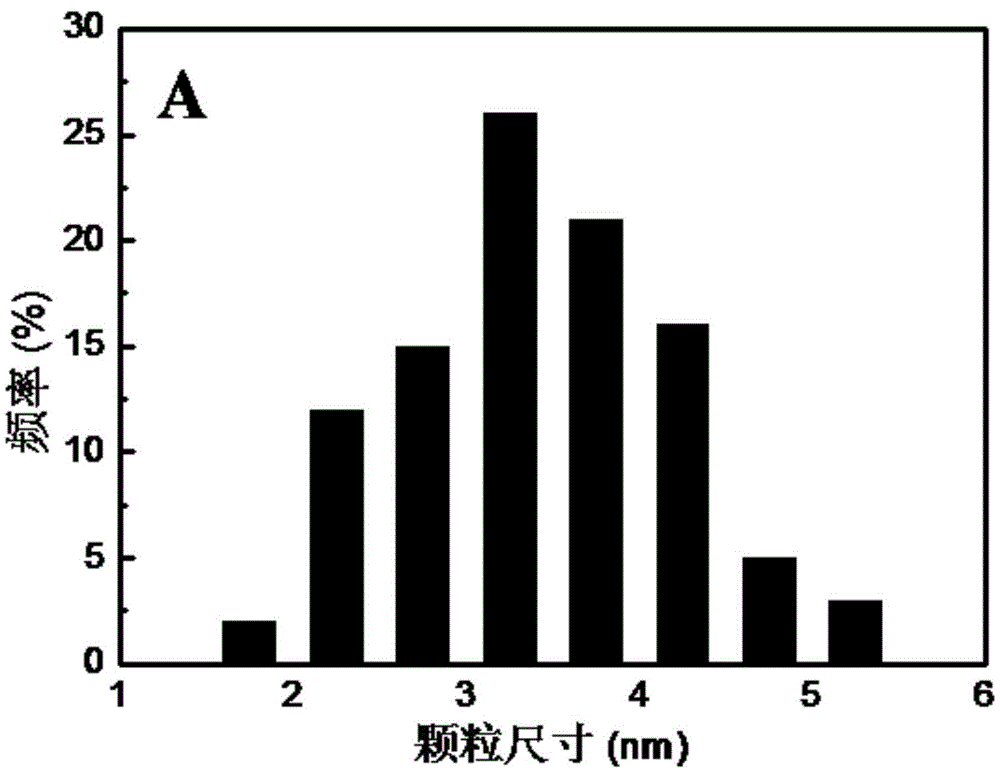

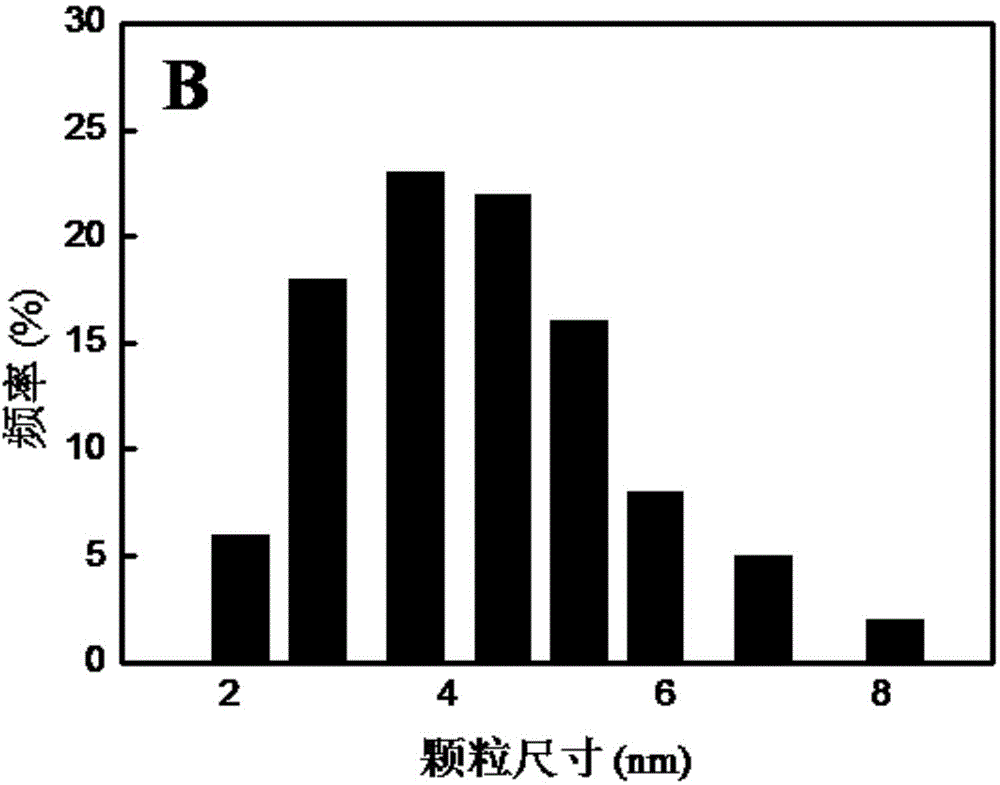

Protein biological template-based gadolinium-doped copper sulfide nano-particles and preparation method thereof

InactiveCN105999309AAvoid practicalityAvoid high temperatureEnergy modified materialsGeneral/multifunctional contrast agentsFreeze-dryingCopper salt

Owner:TIANJIN UNIV

Flame-proof treatment method of real silk fabrics by biological enzyme method

ActiveCN103526543AHigh catalytic efficiencyReduce dosageBiochemical fibre treatmentAnimal fibresTyrosineCatalytic oxidation

The invention discloses a flame-proof treatment method of real silk fabrics by a biological enzyme method, belonging to the biotechnical field of spinning. The method disclosed by the invention aims to overcome the deficiencies that real silk fabrics in flame-proof treatment by conventional chemical methods are not high in washability, the real silk is easy to damage in high temperature baking, the whiteness of fiber products is easy to decrease and the like. According to the method disclosed by the invention, tyrosine residues in silk fibroin are oxidized to dopaquinone structures with stronger reactivity by means of the characteristic of tyrosinase which has a catalytic oxidation effect on the tyrosine residues in real silk fiber to promote a grafting reaction on an organophosphorus flame retardant containing a primary amine base and the dopaquinone structures, and the flame retardant function of the real silk fabrics is improved through a nitrogen-phosphorus synergistic effect, so that flame-proof treatment of the real silk fabrics by the biological enzyme method is realized. The method disclosed by the invention comprises the following process flows: real silk fabric pre-treatment, and catalyzation of the organophosphorus flame retardant containing the primary amine base by the tyrosinase to graft, water-washing and drying post-treatment. For the fabrics treated by the method disclosed by the invention, not only is the flame retardant performance improved, but also the mechanical properties of the fabrics are further enhanced. Compared with conventional chemical methods, with the adoption of flame-proof treatment by tyrosinase catalyzation on the real silk fabrics, the method is low in energy consumption, high in efficiency and less in pollution in the processing process and is beneficial to environment protection.

Owner:苏州大上科高新材料有限公司

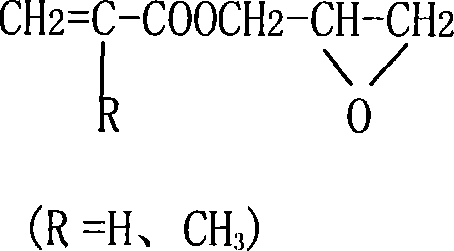

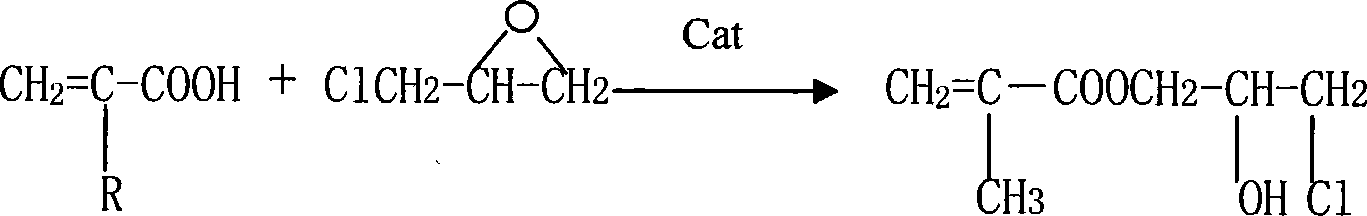

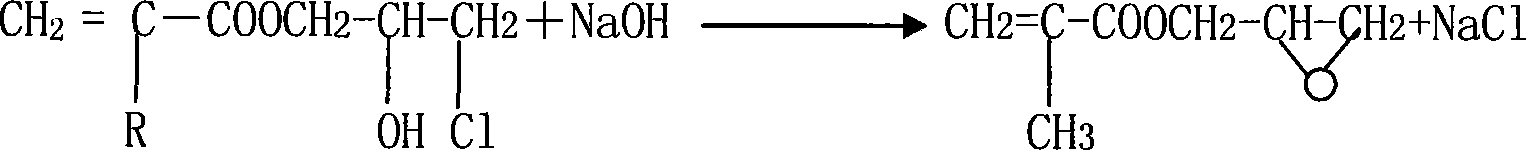

Synthesis method for (methyl)glycidyl acrylate

ActiveCN101085764AReduce dosageHigh ring-opening reactivityOrganic chemistryOrganic solventHexamethylenetetramine

The invention relates to a method for synthesizing a kind of (methyl) acroleic acid glycidic glyceride. It is characterized in that: it takes (methyl) glyceride as raw material, and reacts with epichlorohydrin for ringopening and esterification under catalyst and inhibitor action; then carrying out ring-closure reaction with caustic soda to prepare (methyl) acroleic acid glycidic glyceride. Said catalyst is hexamethylenetetramine or chinoline, 1- methyl glyoxalinyl, and inhibitor is p-hydroxyanisole. The invention is characterized by easy got raw material, low consumption of epichlorohydrin, no utilization of organic disslovant during reaction, short process, simple operation, easy industrialization and little environmental pollution.

Owner:ANHUI XINYUAN CHEM

Preparation method of 6-amino-7-fluoro-1,4-benzoxazine-3(4H)-ketone

ActiveCN102002013ASimple processRelaxed reaction conditionsOrganic chemistryAcetic acidHydrogenation reaction

The invention provides a preparation method of 6-amino-7-fluoro-1,4-benzoxazine-3(4H)-ketone, which comprises the following steps: taking 2-(5-fluoro-2,4-dinitrobenzene oxygen) acetic acid as an initial raw material; carrying out hydrogenation reaction to generate 2-(5-fluoro-2,4-diaminobenzene oxygen) acetic acid; and then, carrying out cyclization reaction to obtain the 6-amino-7-fluoro-1,4-benzoxazine-3(4H)-ketone.

Owner:NUTRICHEM LAB CO LTD

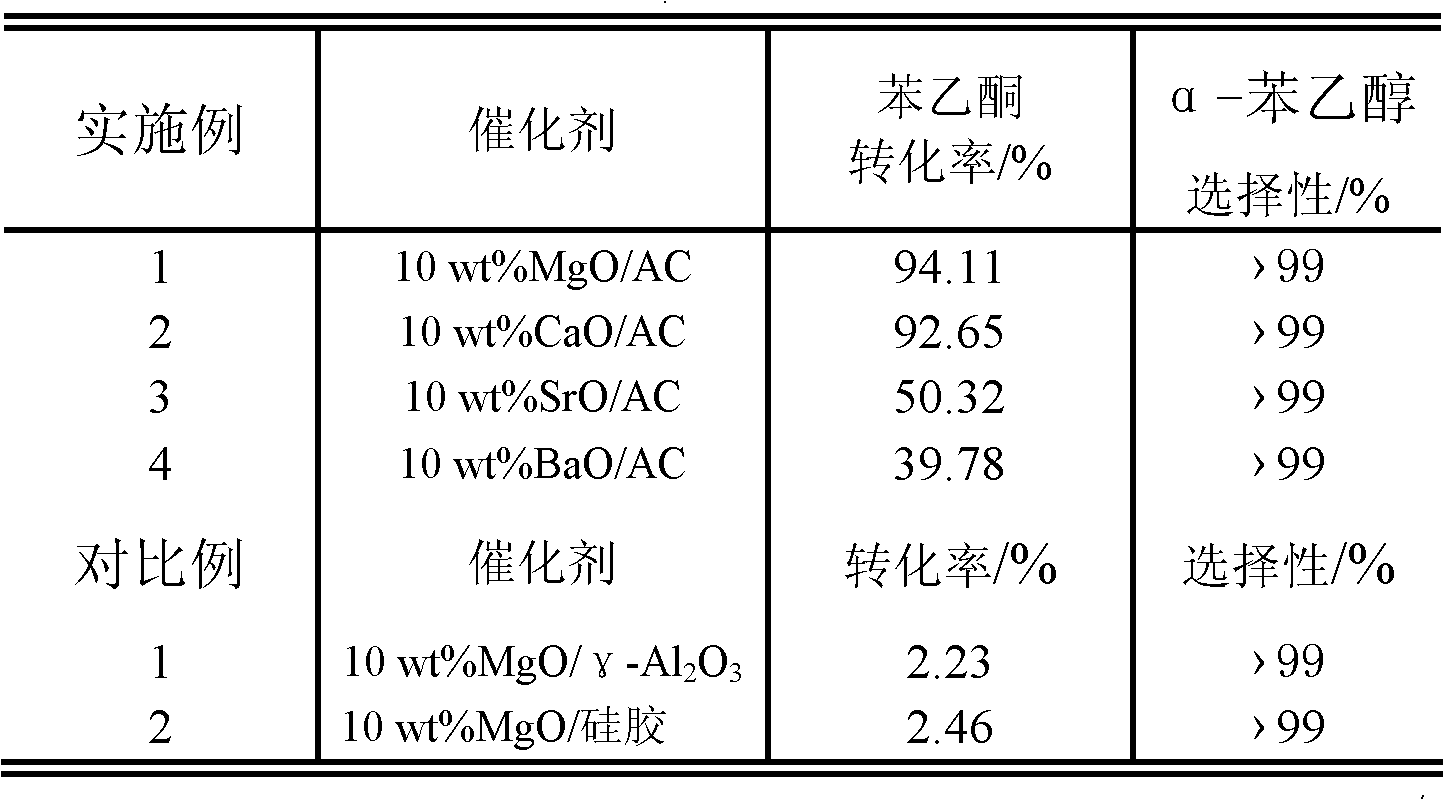

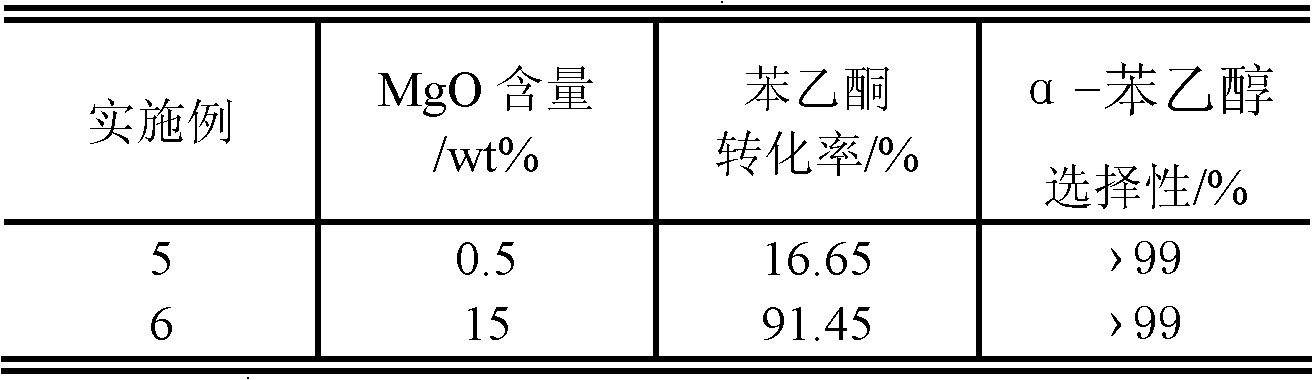

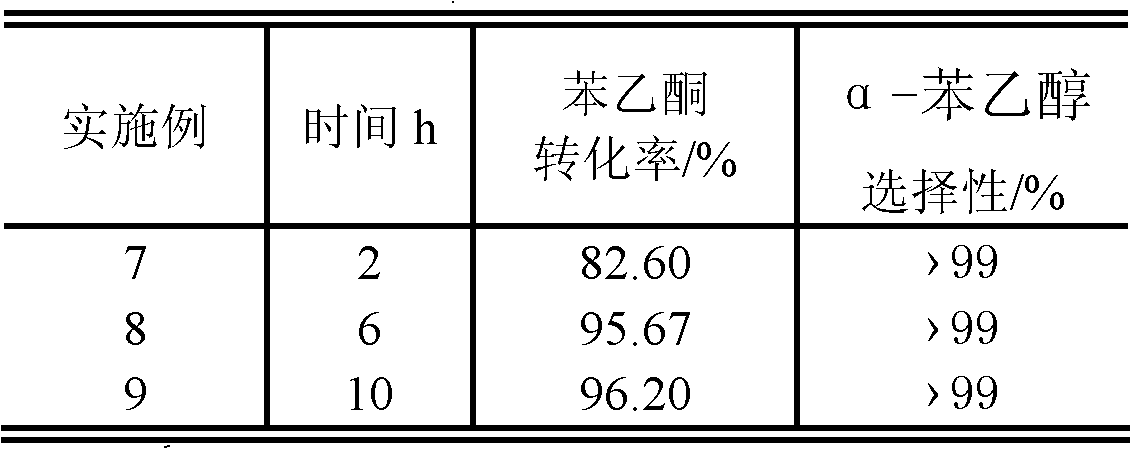

Method for preparing alpha-phenethyl alcohol

ActiveCN101792368ARelaxed reaction conditionsEfficient responseOrganic compound preparationHydroxy compound preparationReaction temperaturePhenethyl alcohol

The invention discloses a method for preparing alpha-phenethyl alcohol. The method comprises the following steps: reacting acetyl benzene serving as the raw material, alcohol serving as a hydrogen source and supported alkaline earth metallic oxide as a catalyst for 1 to 10 hours at a the reaction temperature of between 60 and 130 DEG C; and after the reaction is finished, processing the reaction solution to obtain alpha-phenethyl alcohol, wherein the alcohol is C1 to C7 fatty alcohol or C3 to C7 alicyclic alcohol; the mole ratio of the acetyl benzene to the alcohol is 1:5-30; the supported alkaline earth metallic oxide consists of a carrier and alkaline earth metallic oxide supported on the carrier; the alkaline metallic earth oxide is MgO, CaO, SrO or BaO; the carrier is active carbon; and the supporting capacity of the alkaline earth metallic oxide is between 0.5 and 15 weight percent based on the mass of the carrier. The method for preparing the alpha-phenethyl alcohol has the advantages of mild required reaction condition, high activity and high selectivity of the catalyst, short reaction time, no other by-products in the reaction and no pollution to the environment, and is anenvironmental-friendly green synthetic route.

Owner:日照新睿招商发展有限公司

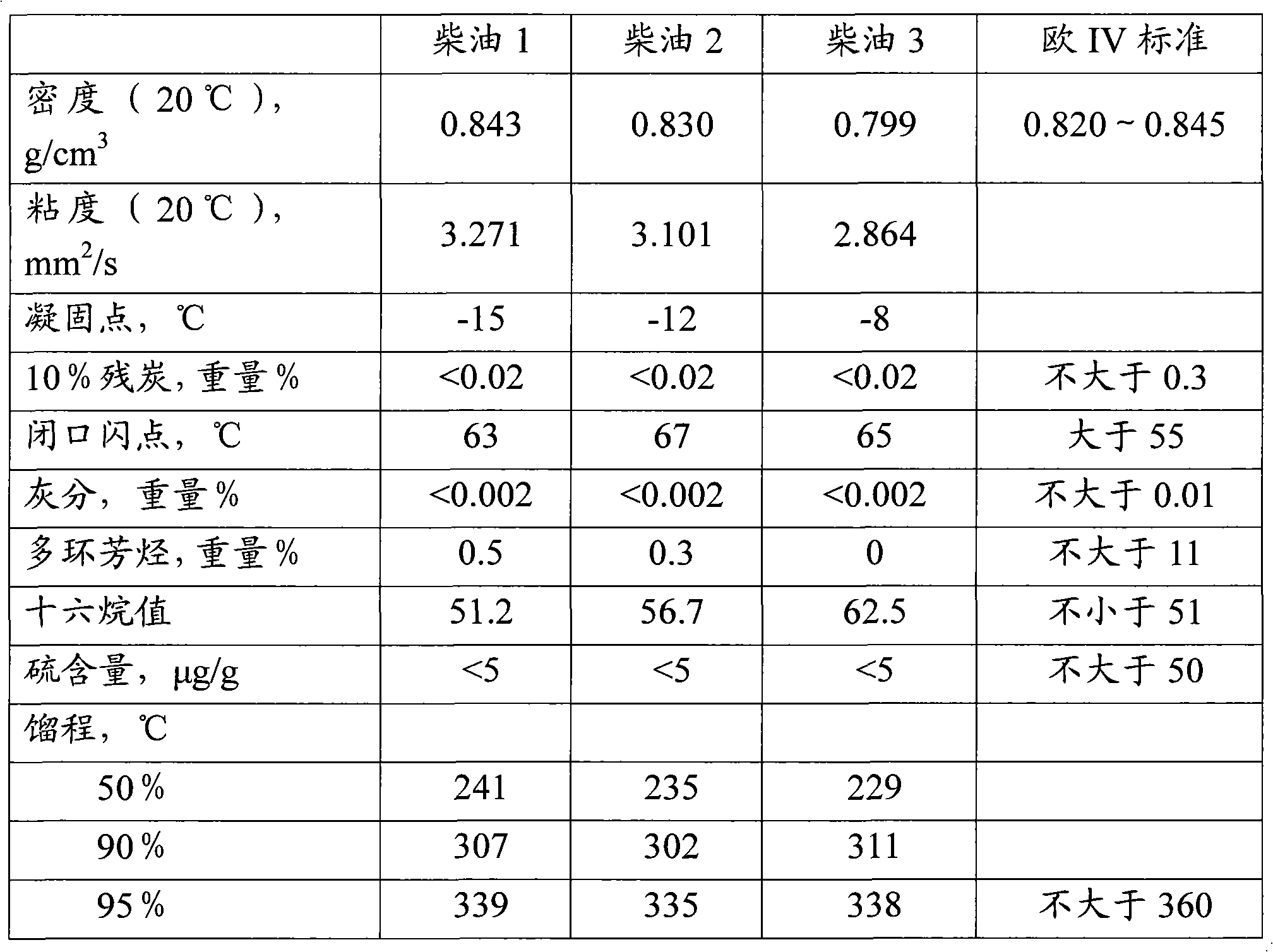

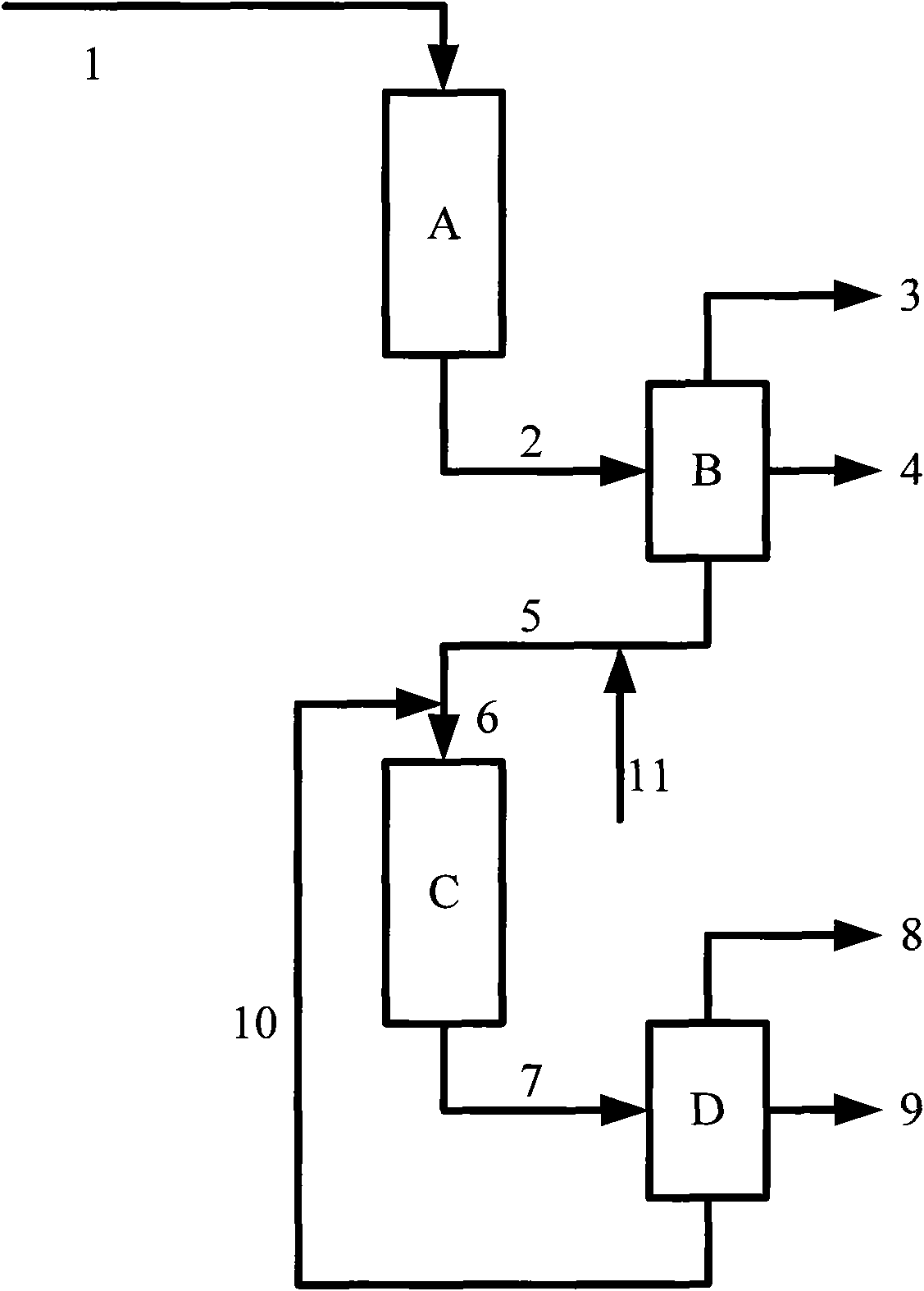

Method for producing diesel oil or diesel oil blending component

ActiveCN101928600ARelaxed reaction conditionsLow operating costTreatment with hydrotreatment processesFractionationCoal liquefaction

The invention discloses a method for producing diesel oil or a diesel oil blending component. The method comprises the following steps of: mixing Fischer-Tropsch synthetic oil and direct coal liquefaction oil to obtain mixed oil; and performing hydrofining and hydrogenation isocracking on the mixed oil and performing fractionation to obtain a diesel oil product or the diesel oil blending component. In the method provided by the invention, two types of oil prepared from coal can be transformed into clean diesel oil which is accordant with a European IV standard or the diesel oil blending component with a large cetane number. Compared with hydrogenation modification of the direct coal liquefaction oil, the method has the advantages of temperate reaction condition, low device investment costand low operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

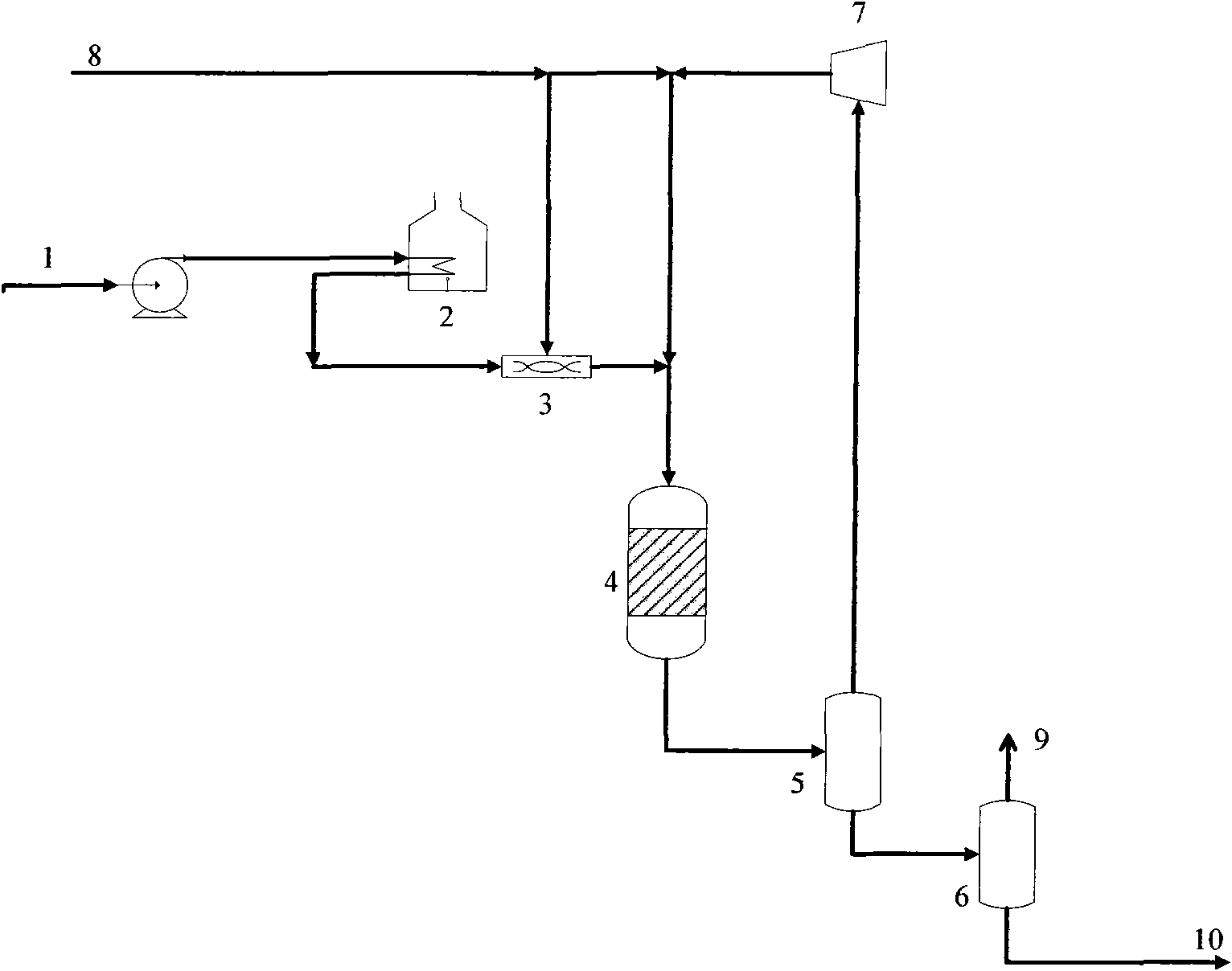

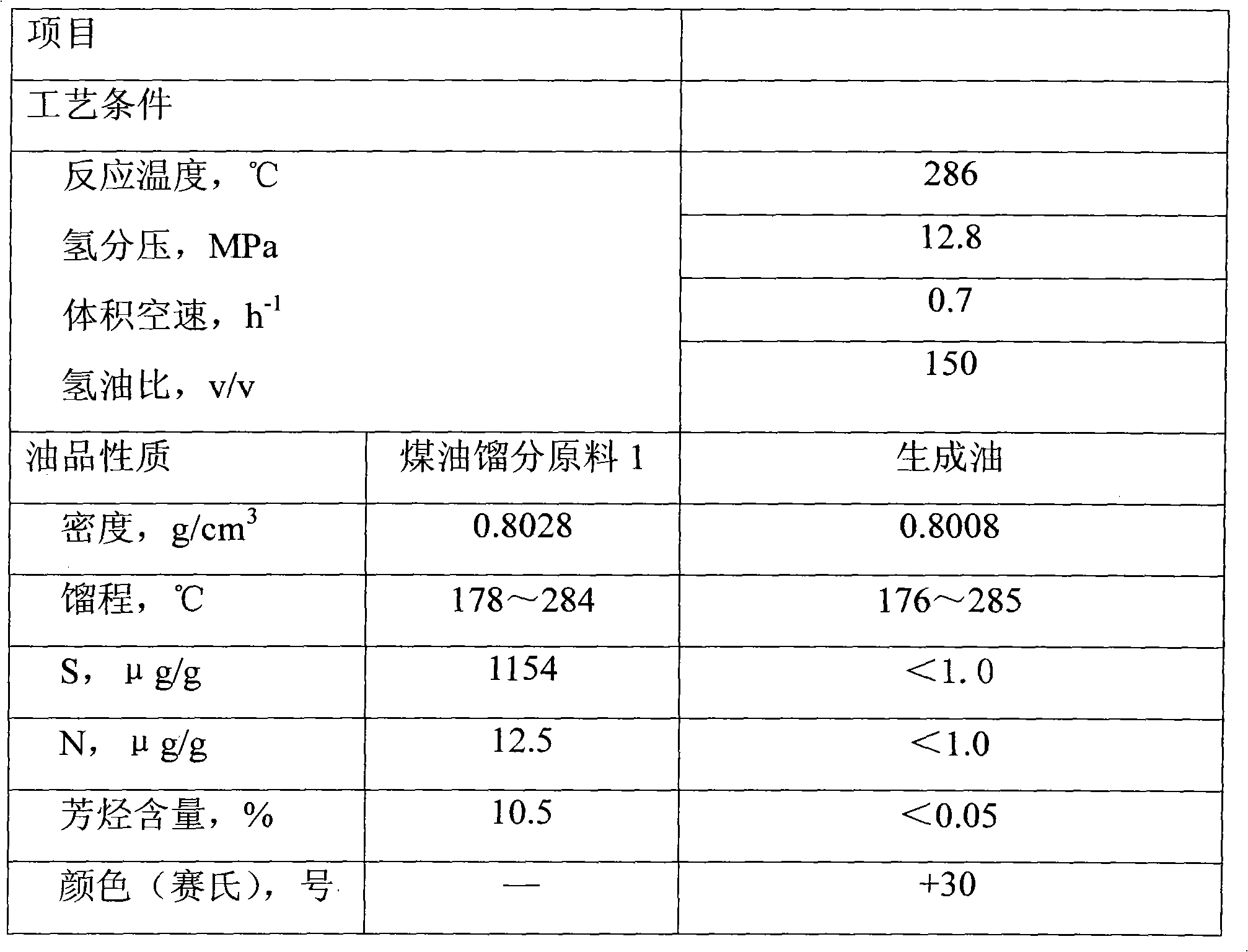

Method for producing low-aromatics solvent oil by hydrogenation

The invention relates to a method for producing low-aromatics solvent oil by hydrogenation. The method comprises the following steps of: passing raw material oil through a heating furnace, then fully mixing the raw material oil and hydrogen gas in an oil-gas mixer, and contacting with a hydrogenation catalyst in a lower hydrogen-oil volume ratio and under milder process conditions to undergo the common hydrogenated purification reaction. Compared with the conventional hydrogenated purification process, the method can achieve the same effect as the conventional purification process under milder process conditions. By the method, the low-sulfur and low-aromatics solvent oil products can be produced. In addition, the method also has the advantages of simple process flow, stable operation, high product properties and low energy consumption, and the new establishment of a hydrogenation device and the modification of the original device are both ok.

Owner:CHINA PETROLEUM & CHEM CORP +1

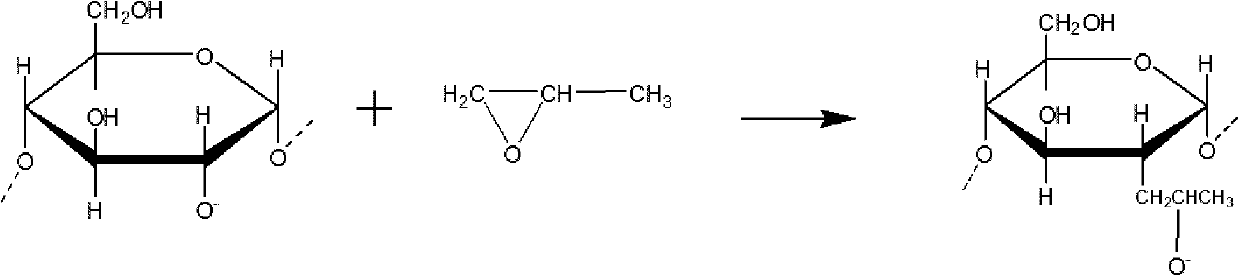

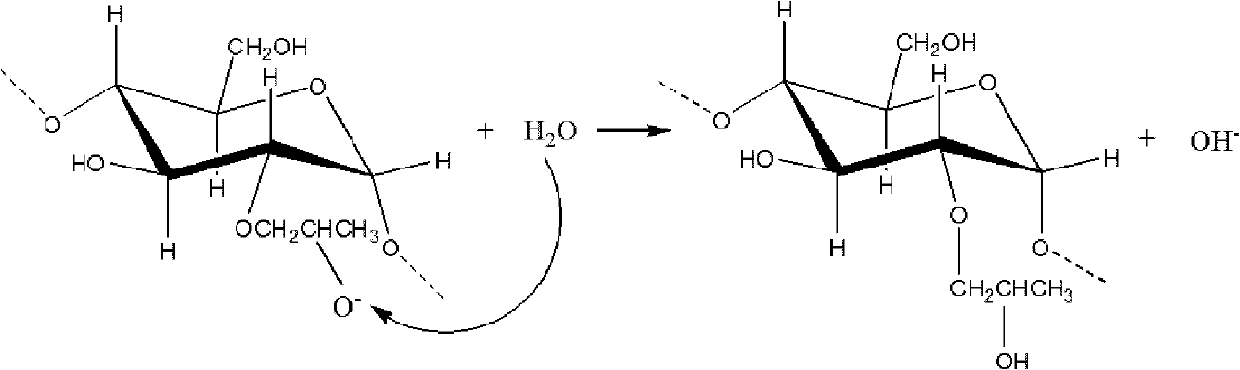

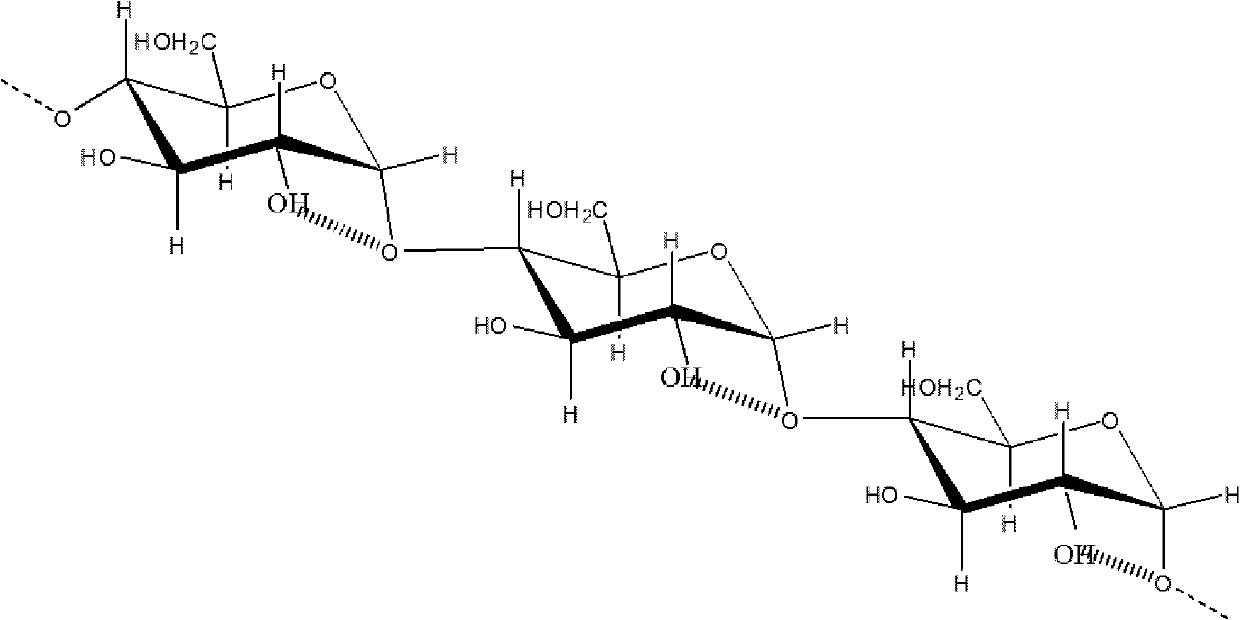

Preparation method of hydroxypropyl starch

The invention discloses a preparation method of hydroxypropyl starch. Before hydroxypropylation reaction, pre-swelling treatment is carried out on the starch, and polarity dispersant is adopted for the pre-swelling treatment and the hydroxypropylation reaction. The preparation method of the hydroxypropyl starch adopts the pre-swelling treatment so as to lead a supermolecular group in the starch to be limitedly expanded, the viscosity of a reaction system is moderate as the hydroxypropylation process has more reaction active centers, and the hydroxypropylation degree is effectively improved; the pre-swelling and the hydroxypropylation are both carried out under the condition of the constant pressure and the temperature not higher than 90 DEG C, the condition is mild, and the implementation is safe; the aqueous solution of common polar solvent such as methanol, alcohol or isopropanol is adopted in the reaction, the dispersibility of the starch and catalyst is good, the reaction rate is improved, the reaction time is shortened, and the reaction condition is reduced; in addition, the diluted acid can be directly adopted for neutralization after reaction, therefore, the operation is simpler, and the method is applicable to industrialized production.

Owner:鲁郑全 +3

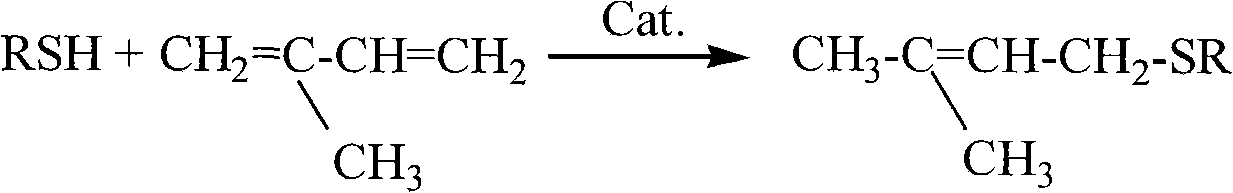

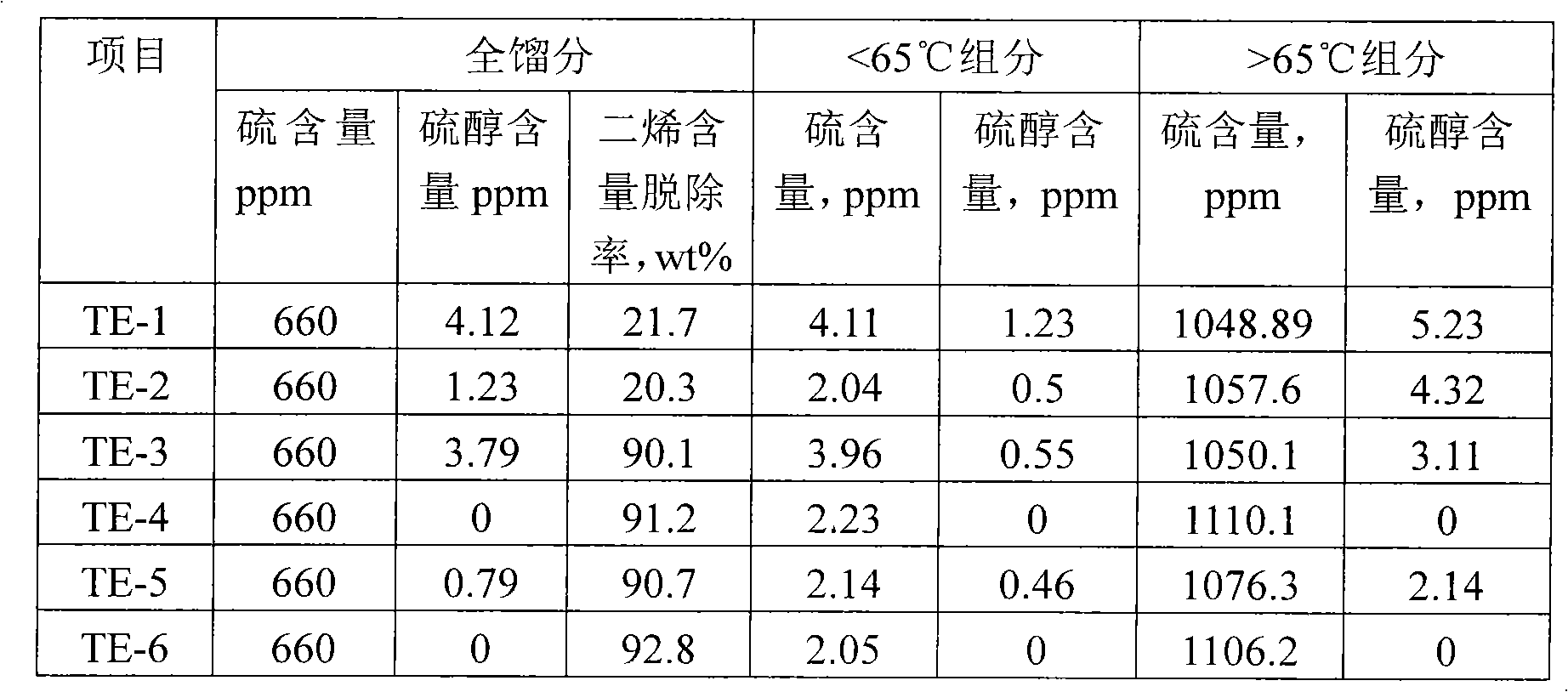

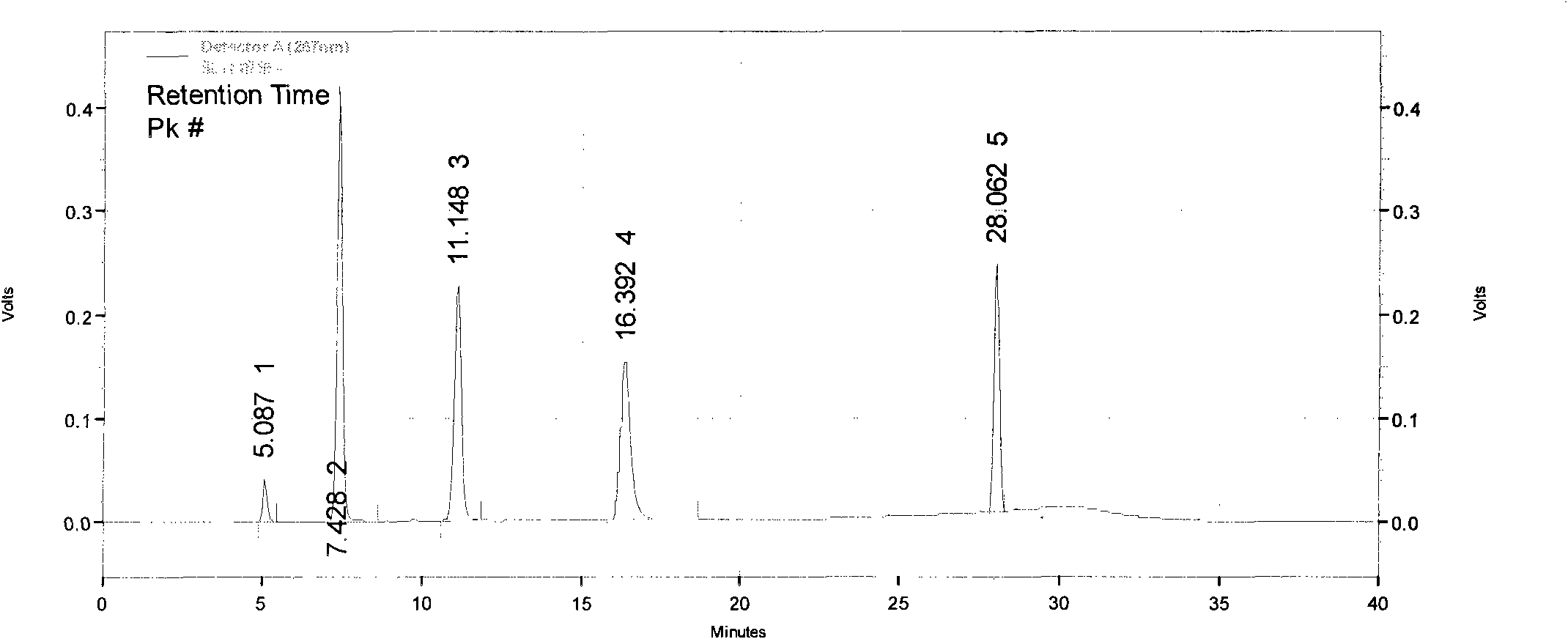

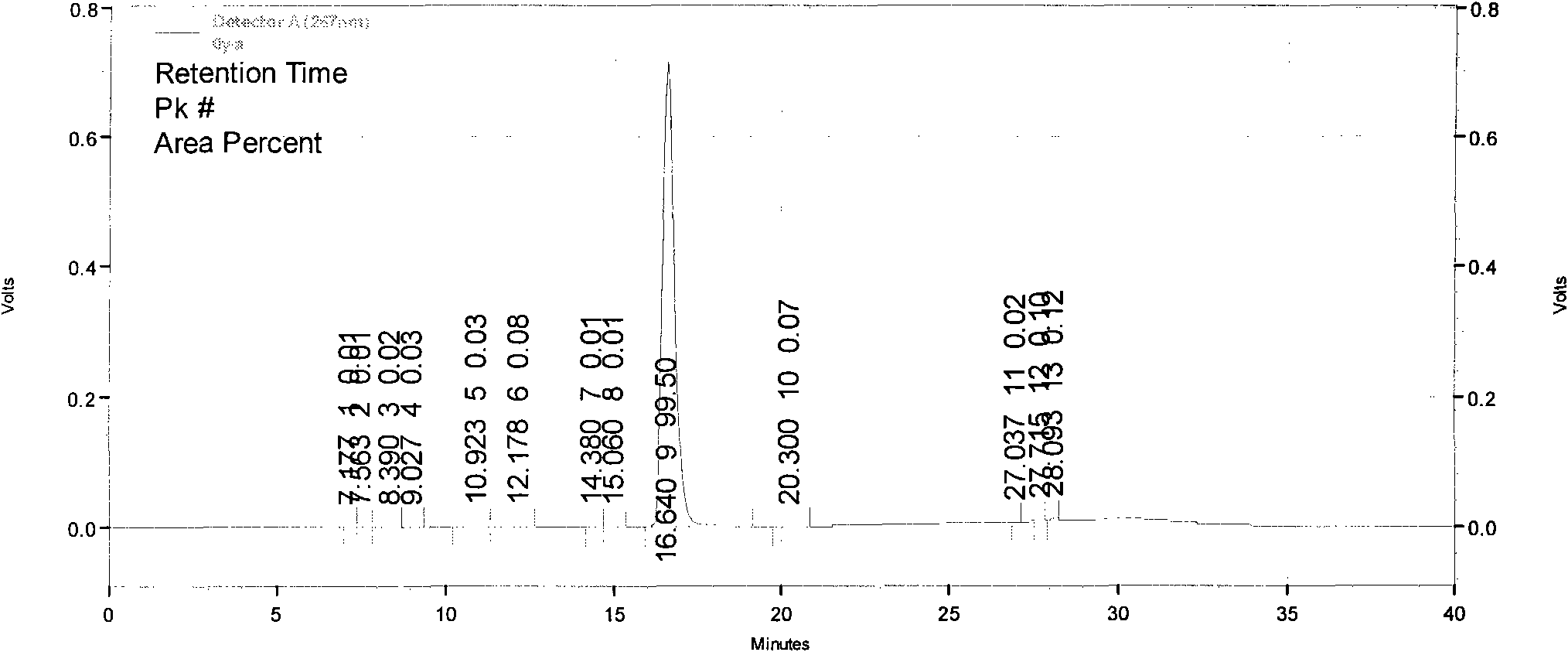

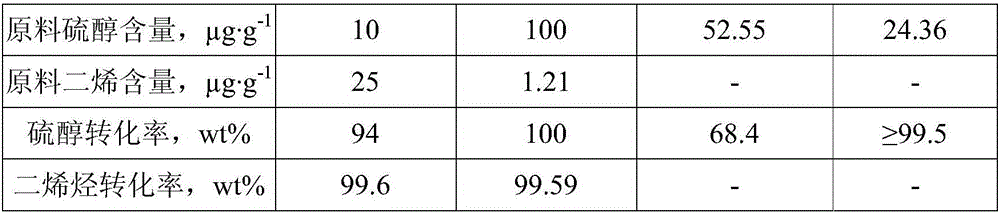

Low-temperature sulfur alcohol etherification catalyst as well as preparation method and application thereof

InactiveCN106732637AGood mercaptan etherification reaction performanceRelaxed reaction conditionsHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsAlcoholSulfur

The invention provides a low-temperature sulfur alcohol etherification catalyst as well as a preparation method and application thereof. According to the catalyst, alkaline aid modified alumina is taken as a carrier, and NiO, MoO3 and WO3 are taken as active components. The low-temperature sulfur alcohol etherification catalyst contains the following components by weight (100% in total): 6wt%-15wt% of NiO, 0.1wt%-10wt% of MoO3, 0.1wt%-10wt% of WO3, 0.1wt%-5wt% of an alkaline aid oxide and the balance of an alumina carrier. The invention further provides the preparation method of the catalyst and application of the catalyst in sulfur etherification reaction for catalyzing sulfur alcohol, olefin or alkadiene in gasoline or liquefied petroleum gas. The catalyst provided by the invention is mild in reaction condition, high in reaction activity, high sulfur-alcohol removal efficiency and low in cost and can be applied to deep desulfurization processes of gasoline and liquefied petroleum gas.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

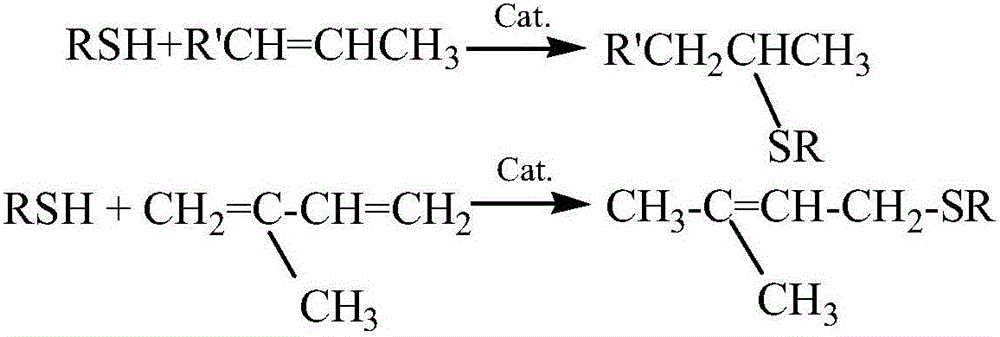

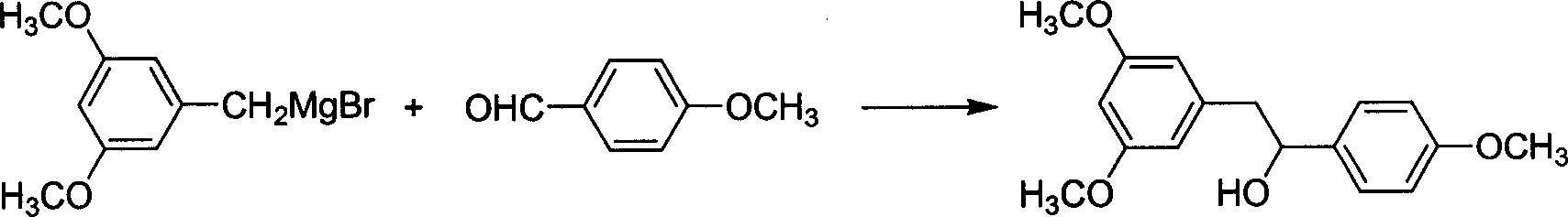

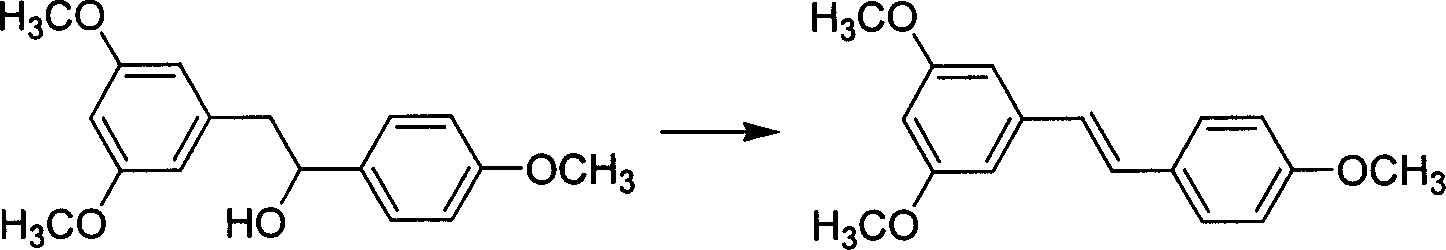

Method for synthesizing resveratrol

ActiveCN1994991ARelaxed reaction conditionsWide range of solventsOrganic chemistryOrganic compound preparationBromineChemistry

The invention discloses a synthesizing method of veralkalcohol, which comprises the following steps: 1) reacting 3, 5-dimethoxy benzyl bromine and metal magnesium to generate 3, 5-dimethoxy benzyl magnesium bromide as Grignard reagent; 2) proceeding nucleophilic additional reaction for 3, 5-dimethoxy benzyl magnesium bromide and anisaldehyde to generate 3,5,4'-trimethoxydiphenyl alcohol; 3) dehydrating 3,5,4'-trimethoxydiphenyl alcohol to produce 3,5,4'-trimethoxydiphenyl ethane; 5) demethylating to obtain the product.

Owner:CHINA RESOURCES SAIKE PHARMA +1

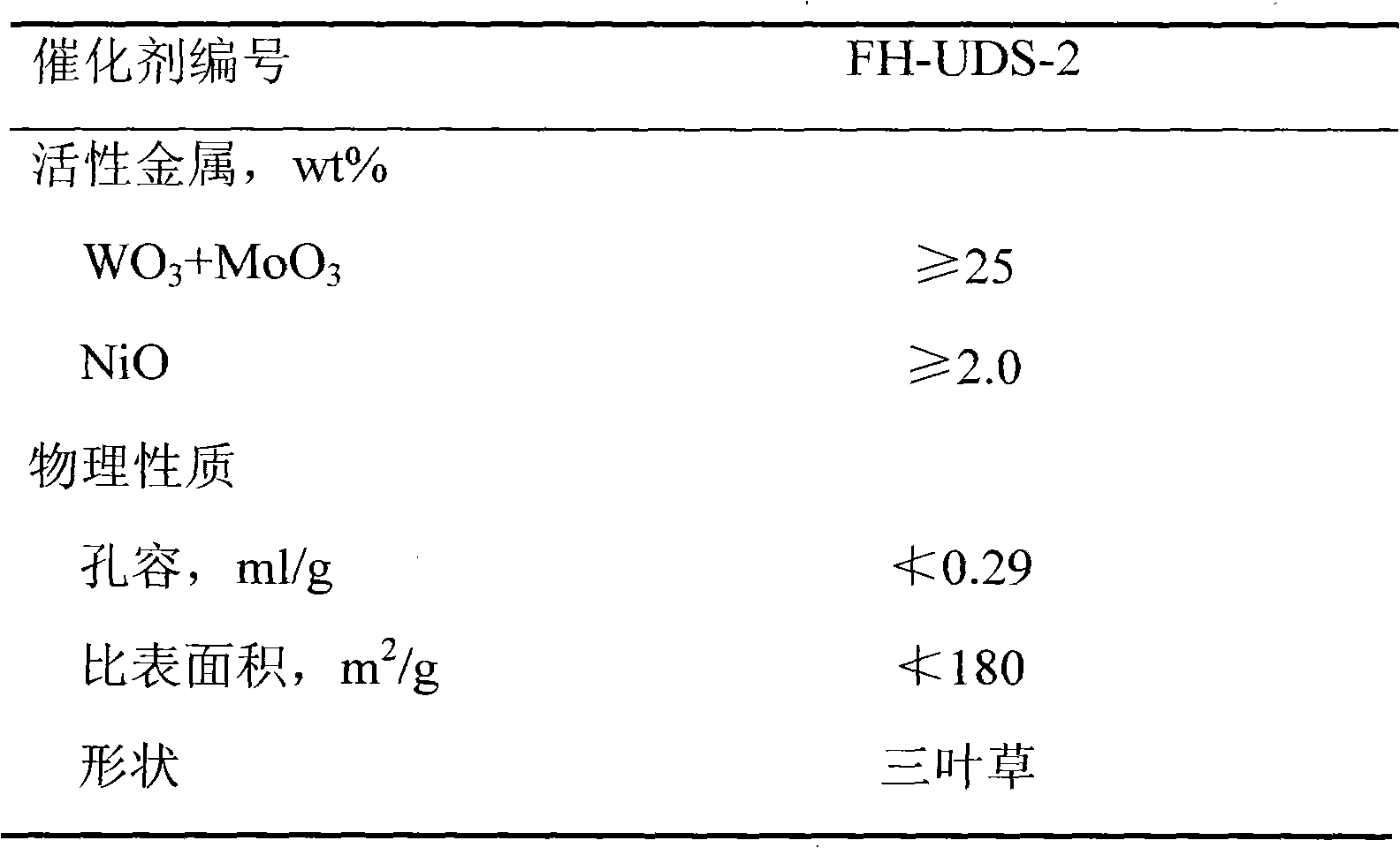

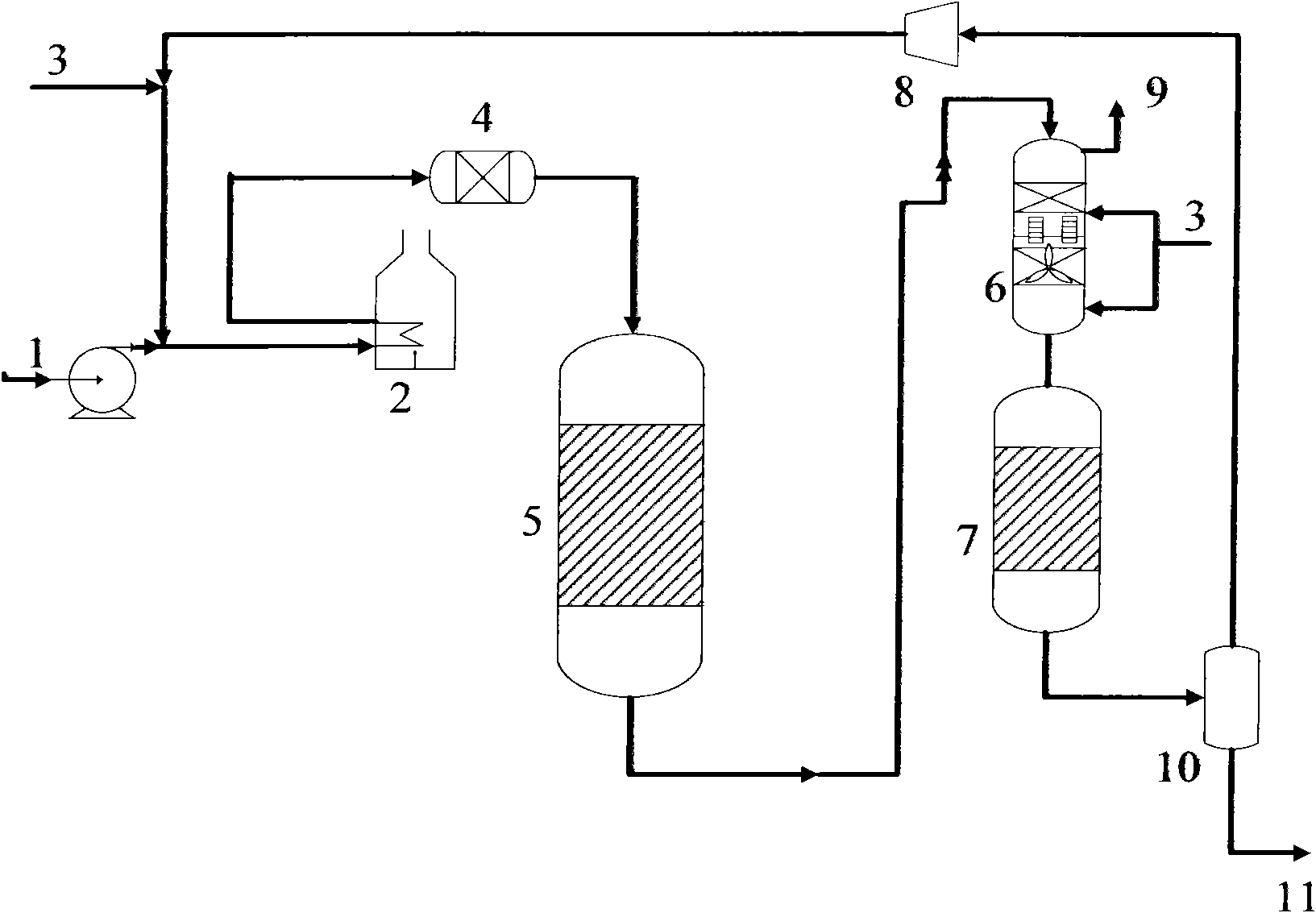

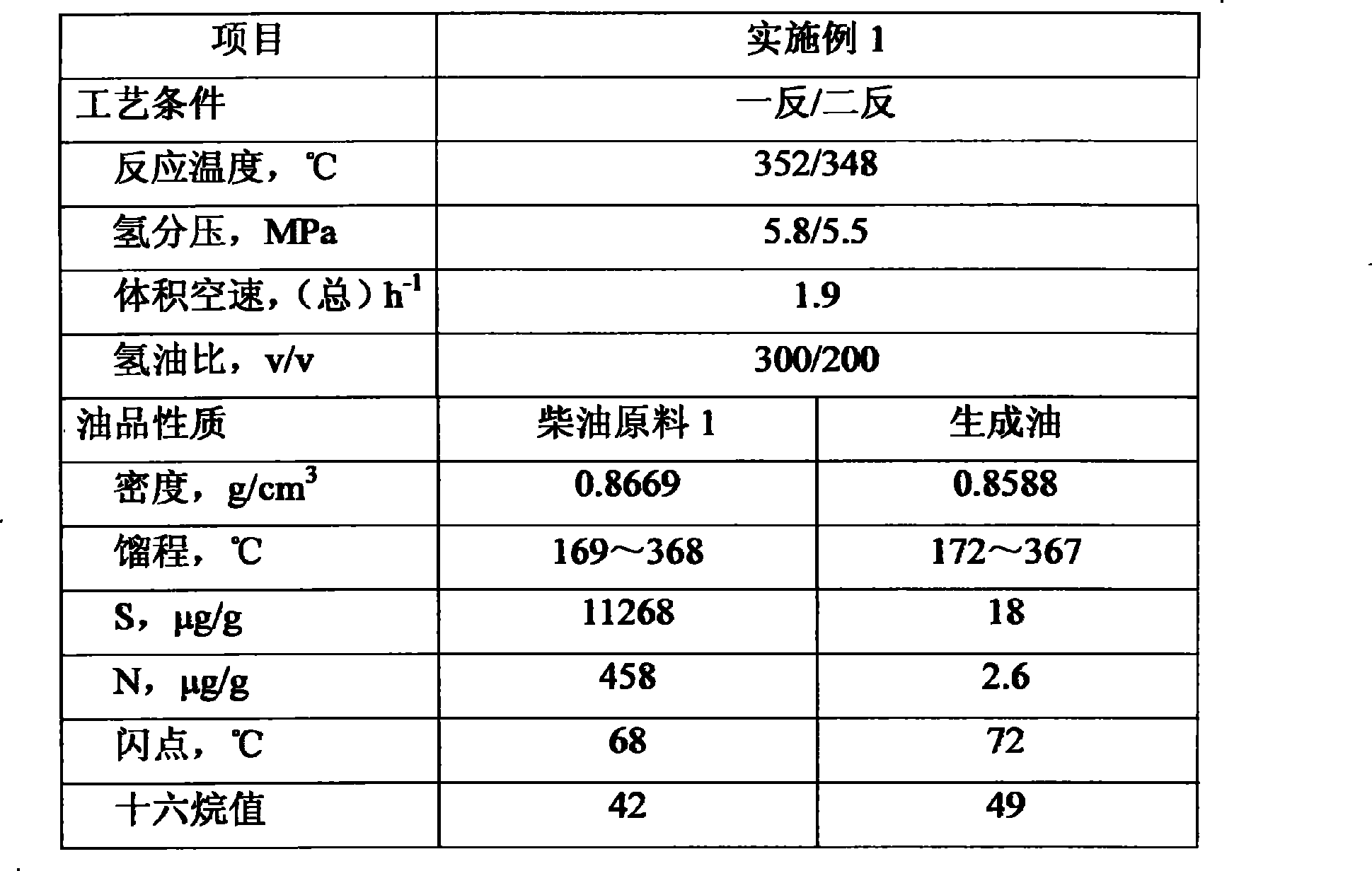

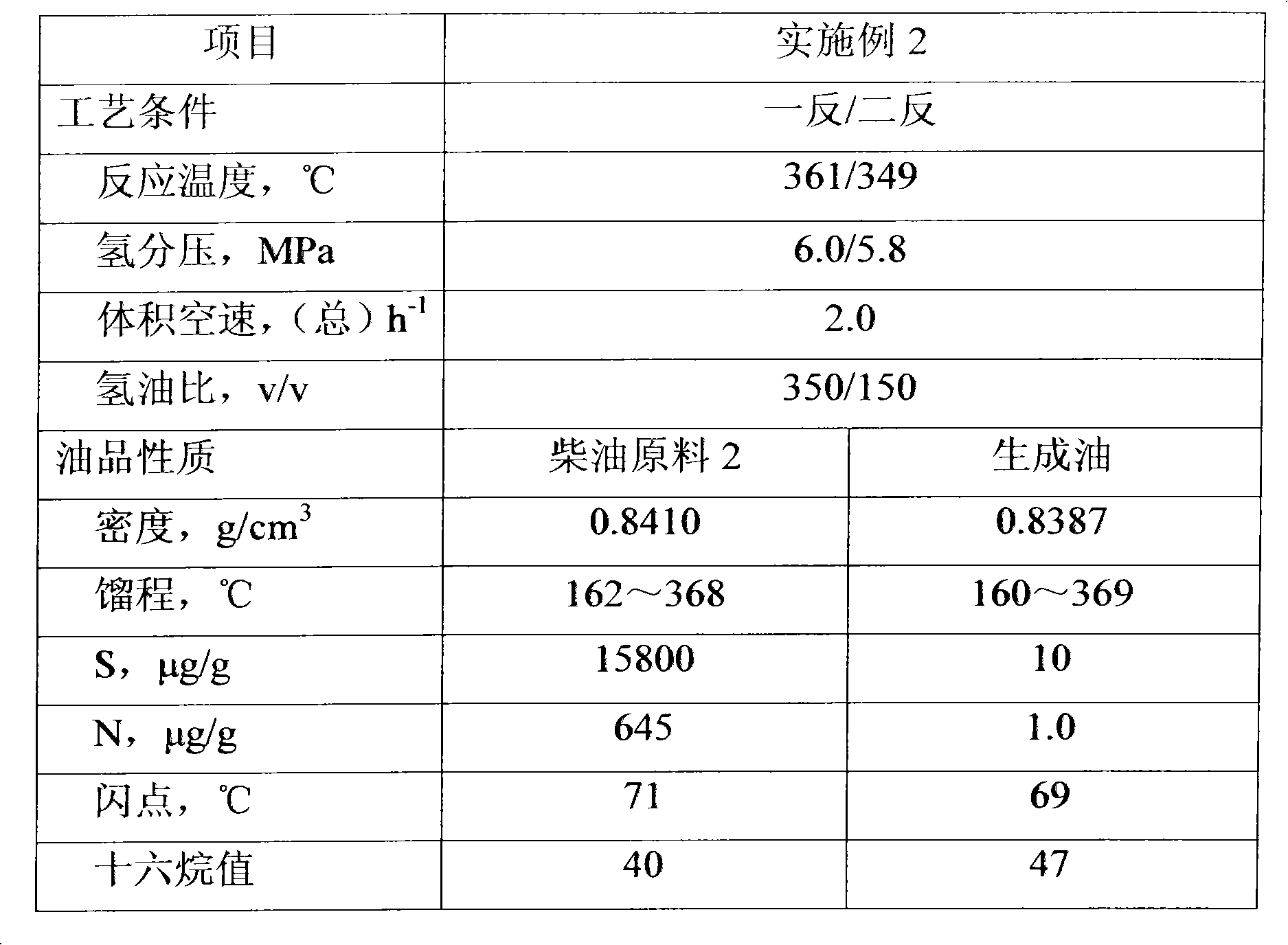

Diesel oil hydrodesulphurization method

ActiveCN102465028ARealize the effect of deep hydrodesulfurizationRelaxed reaction conditionsTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonHydrogen

The invention relates to a diesel oil hydrodesulphurization method. According to the invention, raw oil and hydrogen are first delivered into a gas-liquid mixer through a heating furnace, such that hydrogen and raw oil are fully mixed; the mixture is delivered into a first reactor, and contacts a W-Mo-Ni hydrogenation catalyst under a hydrorefining condition; a common hydrorefining reaction is carried out, such that most of nitrides and part of sulfides are removed, and polycyclic aromatic hydrocarbons are subject to a hydrogenation saturation reaction; generated oil is delivered into stripping and hydrogen mixing equipment, such that hydrogen sulfide and ammonia dissolved in the oil are removed, and hydrogen reaches a dissolved and saturated state in the oil; the oil is mixed with supplemental hydrogen, and the mixture is delivered into a second reactor; the mixture contacts a Mo-Co series hydrorefining catalyst, and a deep desulphurization reaction is carried out, such that a good effect can be achieved. The method is provided aiming at inferior catalytic diesel oil fractions, coked diesel oil fractions or mixed diesel oil fractions of petrochemical enterprises. With the method, ultra-low-sulfur clean diesel oil with a sulfur content lower than 50mug / g or even lower can be produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

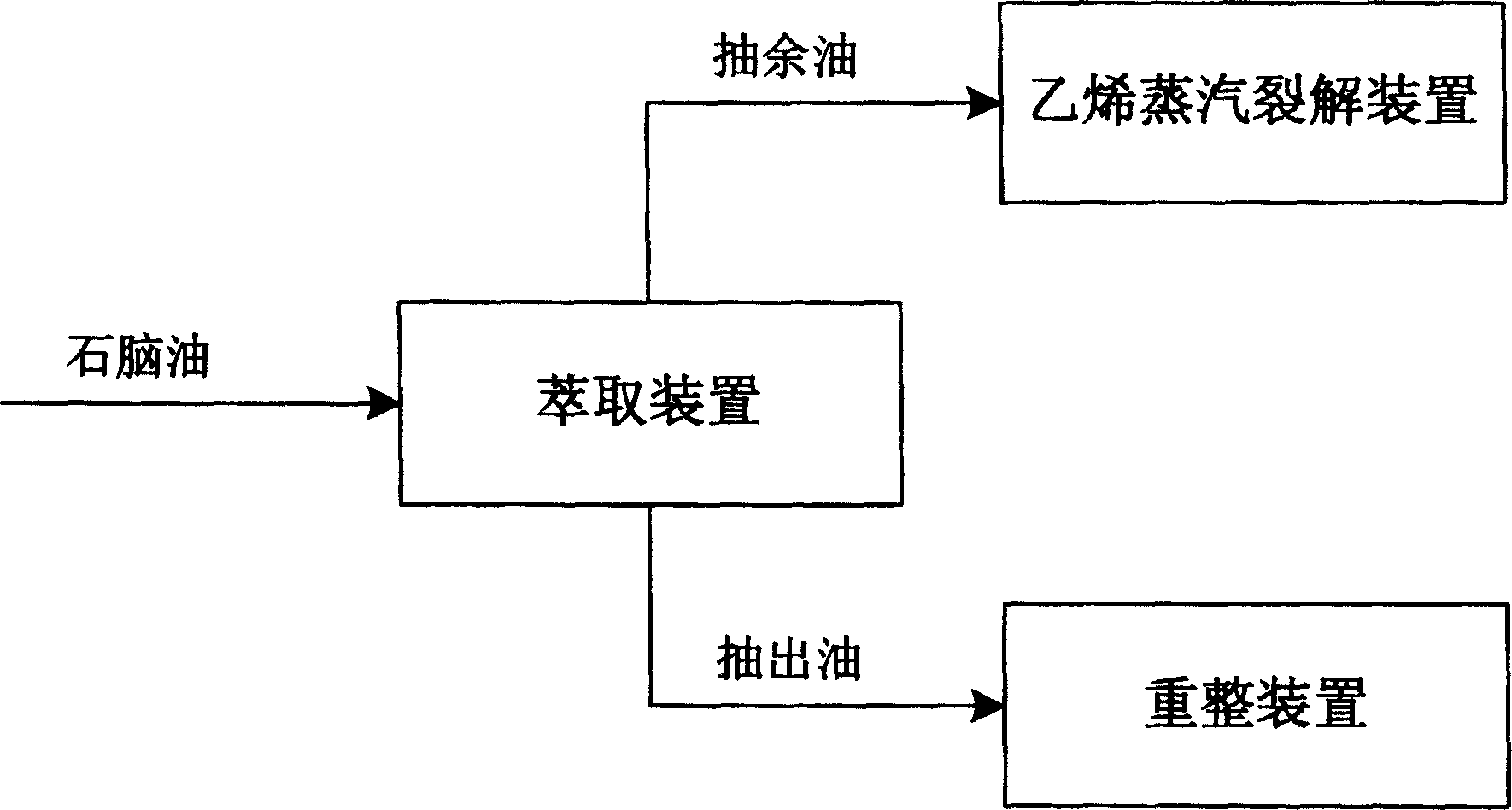

Recombinant processing method for naphtha

The naphtha reconstituting treatment process includes the following steps: extraction separating naphtha to obtain extract oil and raffinate oil; cracking the raffinate oil in an ethylene steam cracking unit; and reforming the extract oil in a reforming unit. Compared with available technology, the present invention has over 30 % raised arene yield and over 40 % raised ethylene yield.

Owner:BEIJING GRAND GOLDEN BRIGHT ENG & TECH

Preparing method of high-purity arene oligomerization asphalt

InactiveCN102977906AGood response controllabilityEnsure safetyWorking-up pitch/asphalt/bitumen by chemical meansSynthesis methodsControllability

The invention belongs to the technical field of mesophase asphalt precursor synthesis methods, and particularly relates to a preparing method of high-purity arene oligomerization asphalt. The preparing method mainly solves the problems that according to an existing preparing method of the high-purity arene oligomeriation asphalt, reaction conditions are rigid, corrosion for equipment is strong, the cost is high and purification is difficult. The technical scheme of the preparing method of the high-purity arene oligomerization asphalt includes that arene chemical compounds are guided into a first stage reactor, catalysts are guided into a catalyst feeding system, after uniform mixing, the catalysts are input into the first stage reactor through the feeding system, after uniform mixing and reaction for 1-50 hours, materials in the first stage reactor are guided into a second stage reactor to react, materials in the second stage reactor are conveyed to a corrosion-resistant film evaporator, the residual catalysts are eliminated, and the arene oligomerization asphalt is formed. The preparing method of the high-purity arene oligomerization asphalt has the advantages of good reaction controllability, low-temperature efficient reaction, catalyst recycling, and good asphalt performance, and the like.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

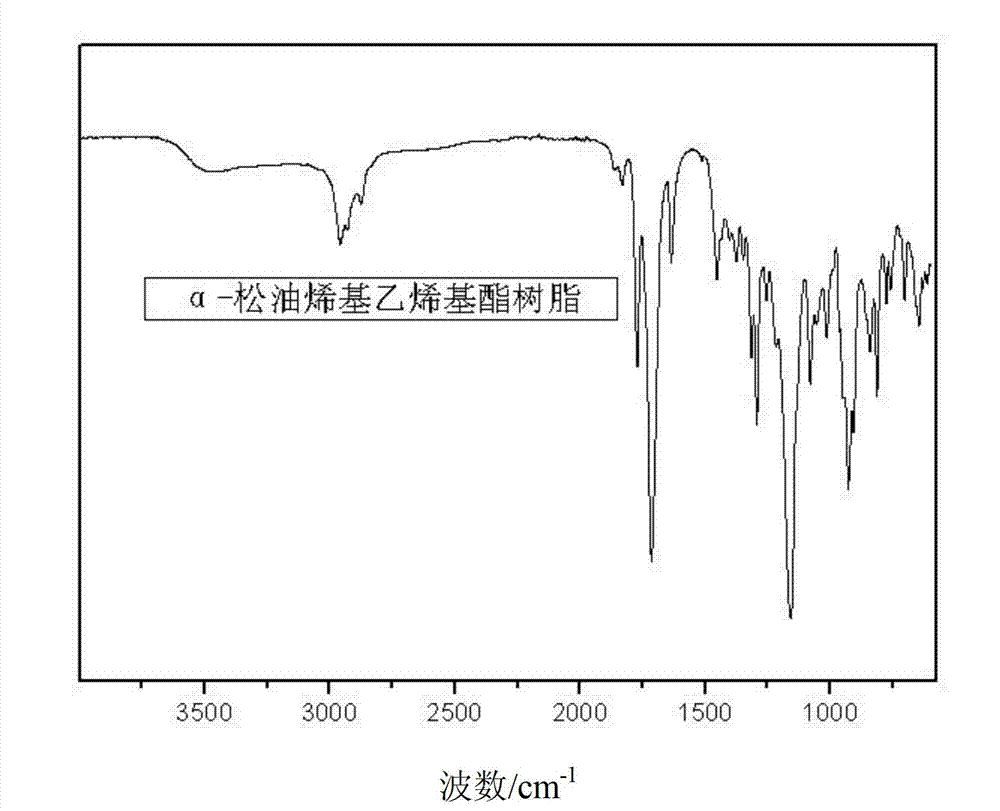

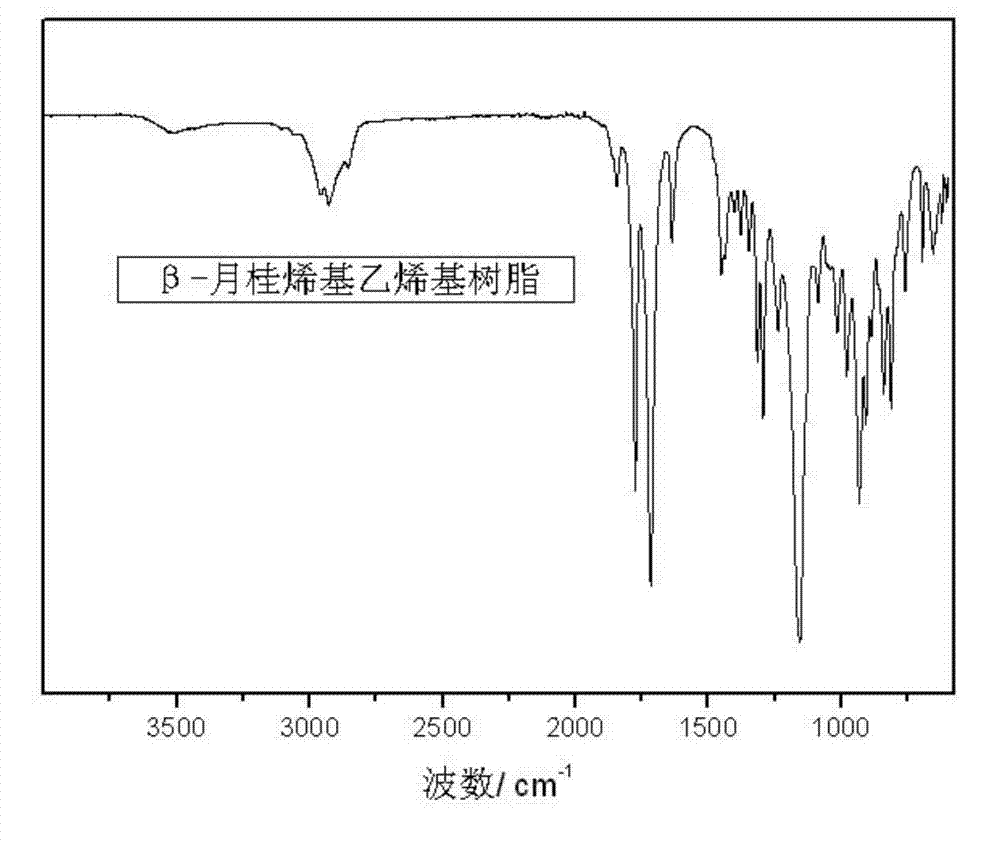

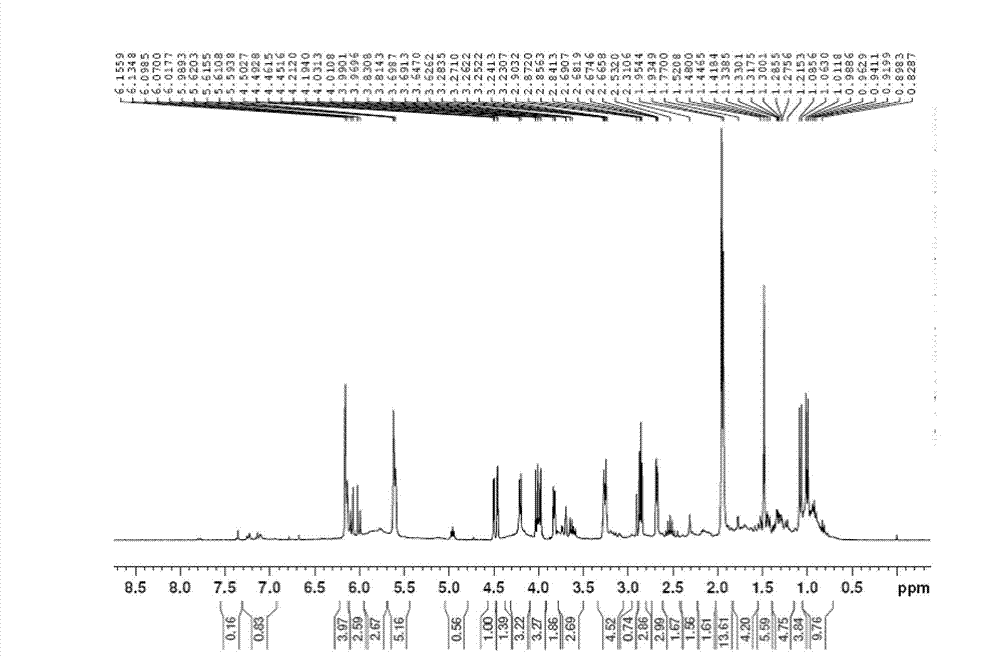

Low-viscosity turpentine-based monoterpene vinyl ester resin monomer and preparation method and application thereof

InactiveCN102826995AGet rid of dependenceLow priceOrganic compound preparationCarboxylic acid esters preparationPolymer scienceTurpentine

The invention discloses a low-viscosity turpentine-based monoterpene vinyl ester resin monomer and a preparation method and application thereof. The preparation method comprises the following steps of: under an oxygen-free environment, enabling turpentine monoterpene monomers to react with unsaturated carboxylic acid or anhydride to obtain monoterpene carboxylic acid or anhydride, then enabling the obtained monoterpene carboxylic acid or anhydride to react with unsaturated carboxylic acid glycidyl ester to obtain monoterpene unsaturated diglyceride, adding modifier for modification, and decolorizing by using activated carbon to obtain the turpentine-based monoterpene vinyl ester resin monomer, wherein the viscosity of the turpentine-based monoterpene vinyl ester resin monomer is 90-130mPa.s, the iodine value is 120-180 and the chromaticity through an iron-cobalt colorimetric method is 4-8. The turpentine-based monoterpene vinyl ester resin monomer prepared by adopting the preparation method has the advantages of low viscosity, low volatility, no toxicity, environmental friendliness and the like, and can be used as thinner of conventional unsaturated polyester resin; and cured resin has the advantages of good toughness, corrosion resistance, weather resistance and high product stability.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

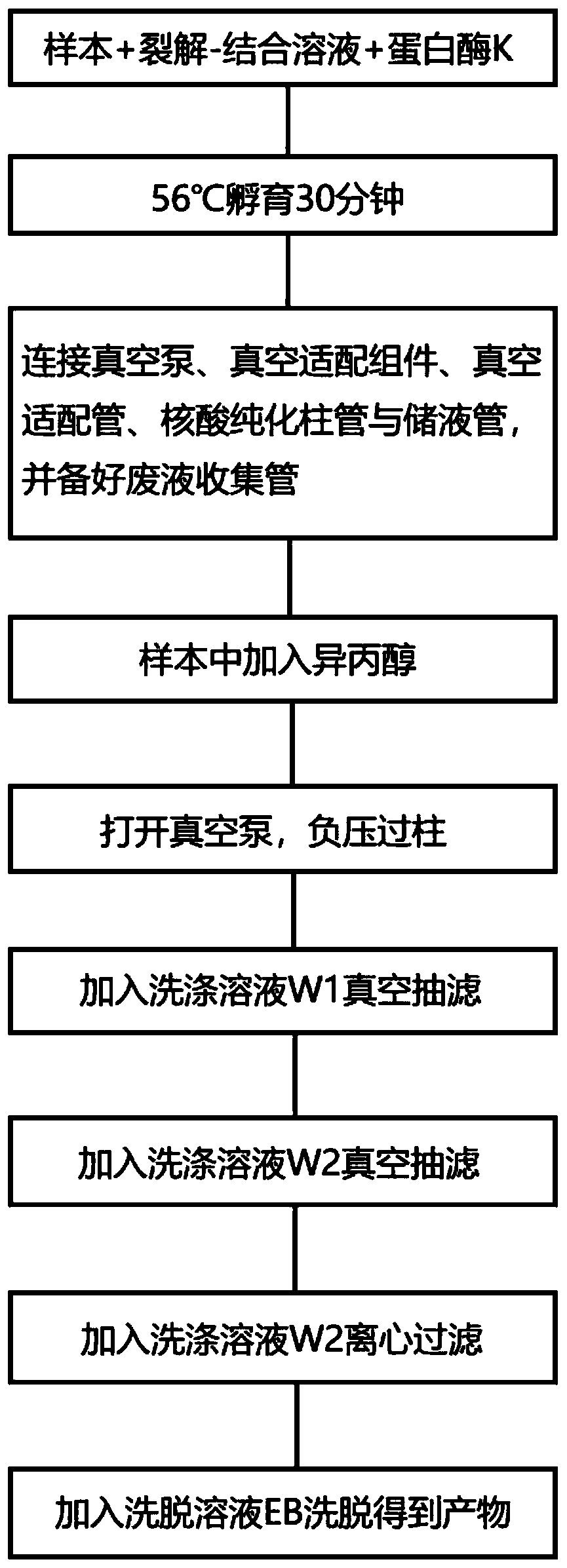

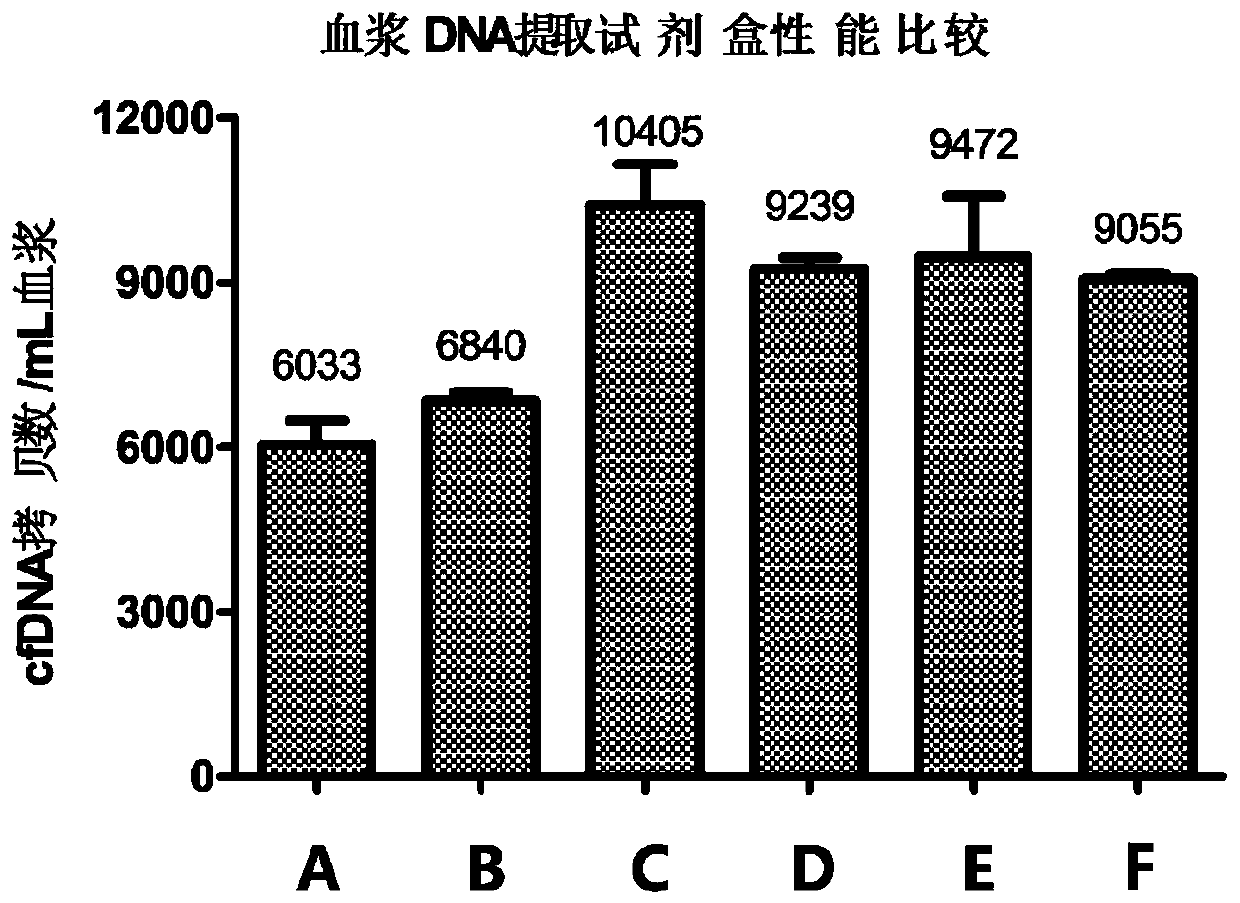

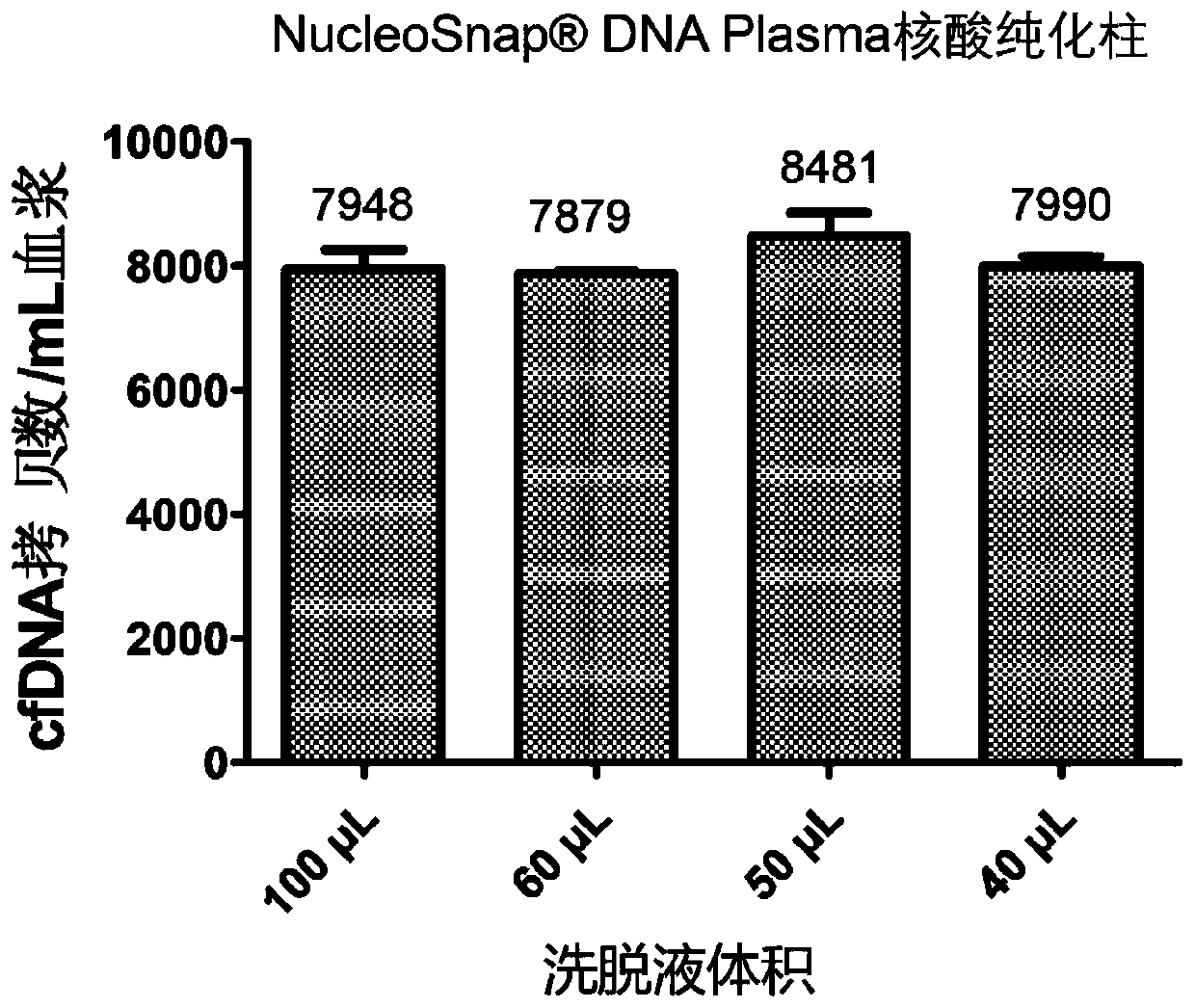

Method and system for separating free nucleic acids from sample containing free nucleic acids

InactiveCN110257368AReduces the number of steps required for separation and extractionRelaxed reaction conditionsDNA preparationLysisAlcohol

The invention discloses a method for separating free nucleic acids from a sample containing free nucleic acids, wherein the method includes the steps: adding protease K and a lysis-binding solution to a test sample, after centrifugation, adding alcohols and making contact with a solid carrier, making the free nucleic acids in the sample bind to the solid carrier, and then washing the solid carrier with one or more washing solutions; and finally, adding an eluant to the solid carrier, to obtain the target product free nucleic acids, wherein the pH of the lysis-binding solution is acidic, and all the steps are carried out at room temperature. The invention also discloses a system for separating the free nucleic acids, wherein the system includes the lysis-binding solution, the washing solution, the eluant, a liquid storage tube, a nucleic acid purification column tube, and a vacuum adapter tube. The method and system for separating the free nucleic acids have the advantages of simple operation, low cost, wide applicability, high yield, and reliable purity, and has wide application value and good market prospect.

Owner:SHANGHAI ZENISIGHT LTD

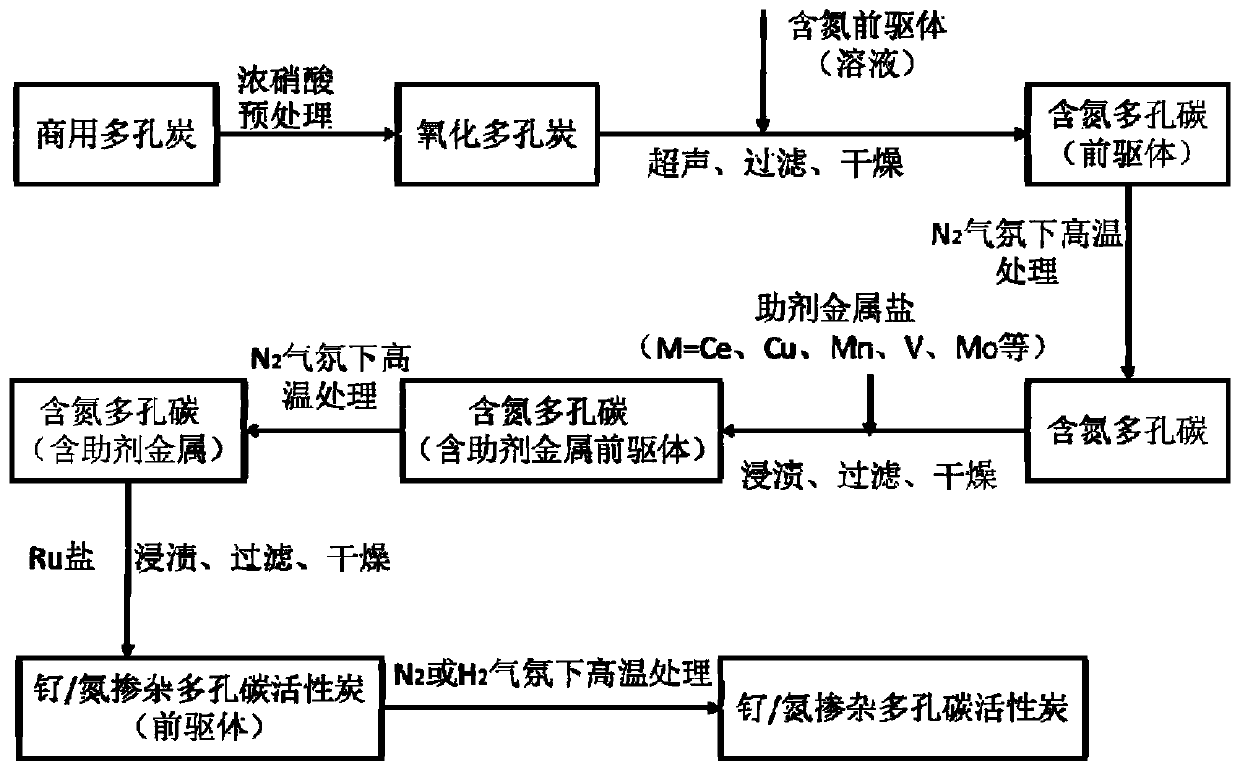

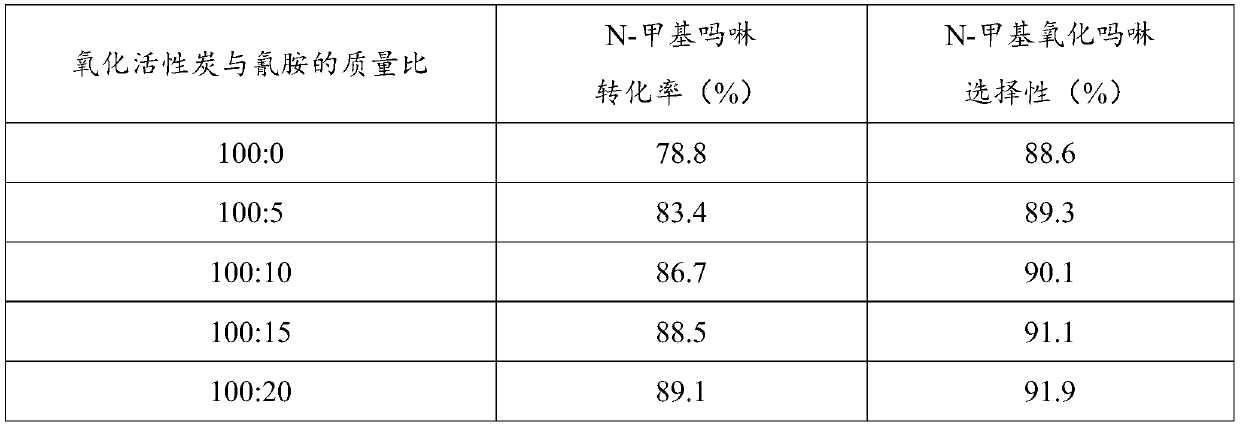

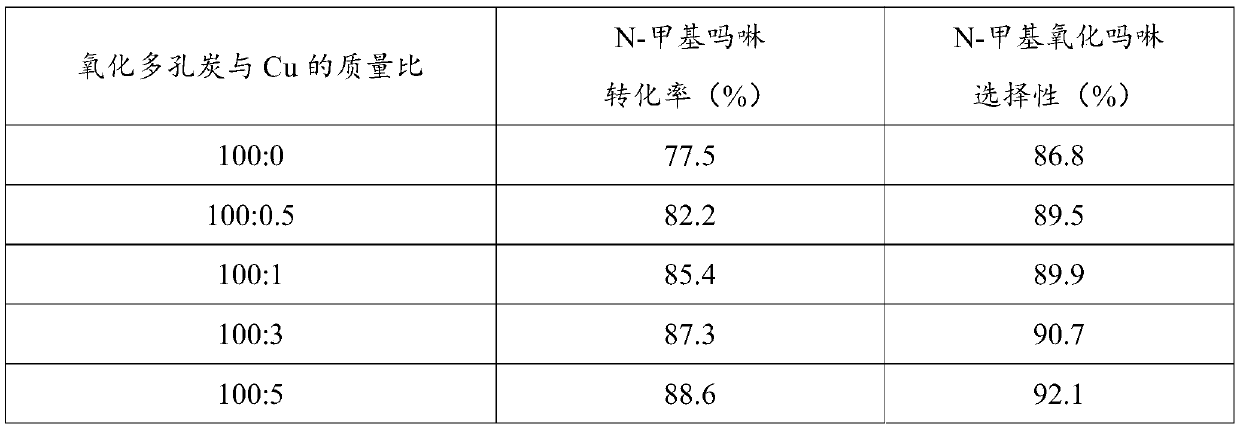

Method for synthesizing 4-methylmorpholine N-oxide based on O2 oxidation catalyzed by ruthenium/nitrogen-doped porous carbon

ActiveCN110467587AReduce generationConvenient sourceOrganic chemistryCatalyst activation/preparation4-methylmorpholine4-methylmorpholine N-oxide

The invention discloses a method for synthesizing 4-methylmorpholine N-oxide based on O2 oxidation catalyzed by ruthenium / nitrogen-doped porous carbon. According to the invention, under the conditionsof a pressure of 0.4-1 MPa and a temperature of 60-90 DEG C, ruthenium / nitrogen-doped porous carbon is used as a catalyst to catalyze a reaction of 4-methylmorpholine with O2 to synthesize 4-methylmorpholine N-oxide, wherein reaction time is 4-8 hours, and the amount of the used catalyst is 0.5 to 5 wt% of the mass of a reaction solution. The method of the invention overcomes the problems of large energy consumption in subsequent separation and wastewater pollution in conventional processes for using synthesizing 4-methylmorpholine N-oxide through H2O2 oxidation. The invention also provides amethod for preparing the ruthenium / nitrogen-doped porous carbon catalyst. The catalyst effectively mildens reaction conditions and improves the activity of 4-methylmorpholine N-oxide synthesized through O2 catalytic oxidation.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

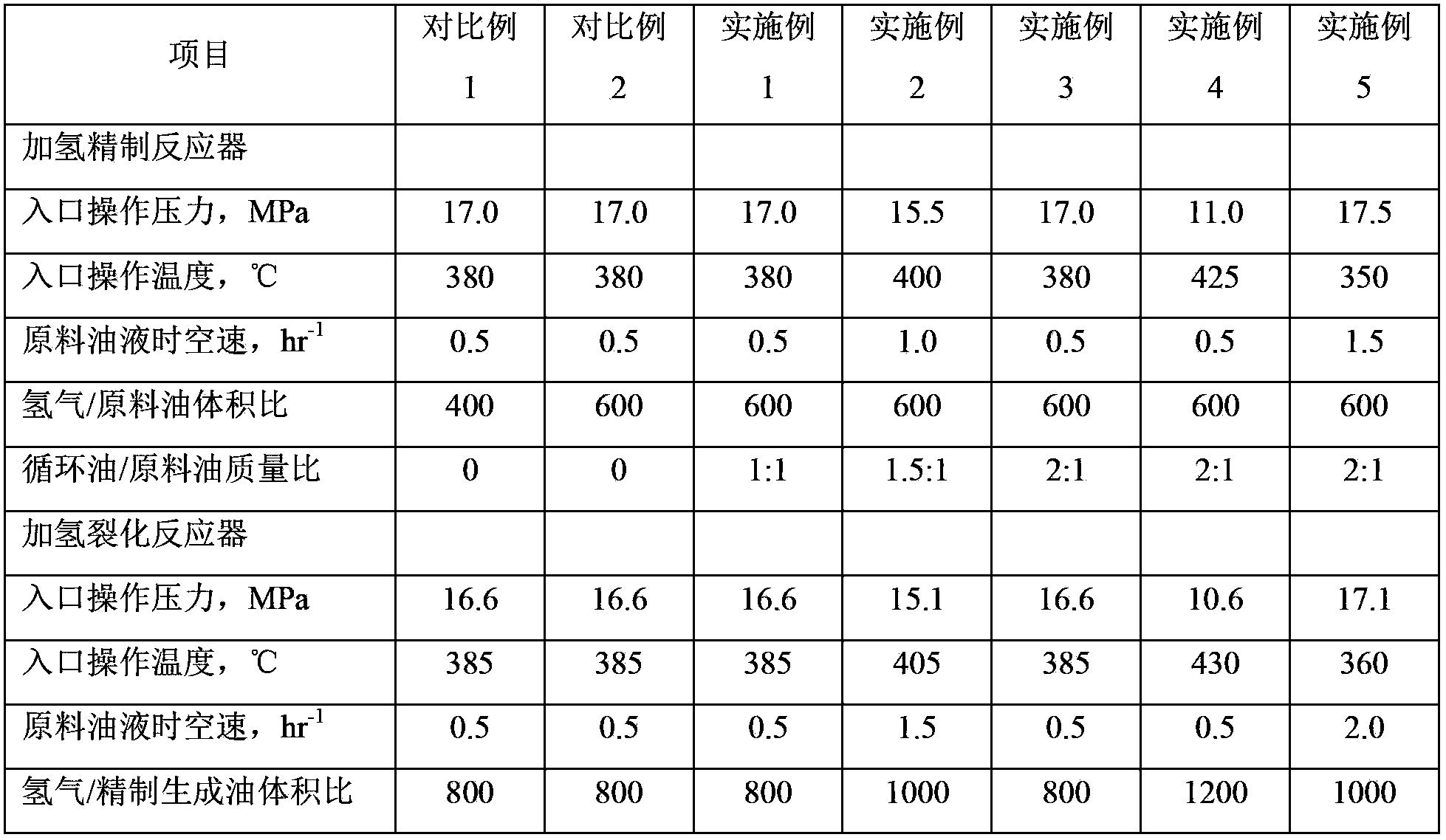

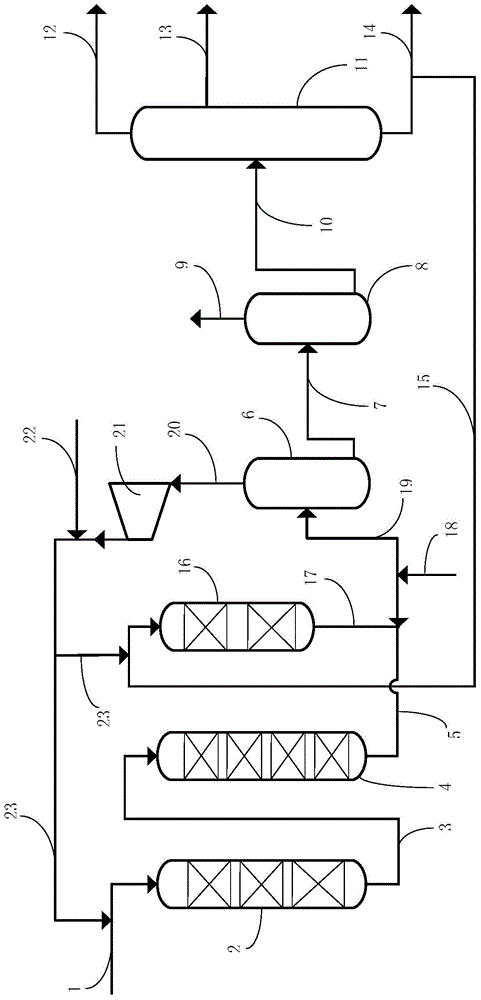

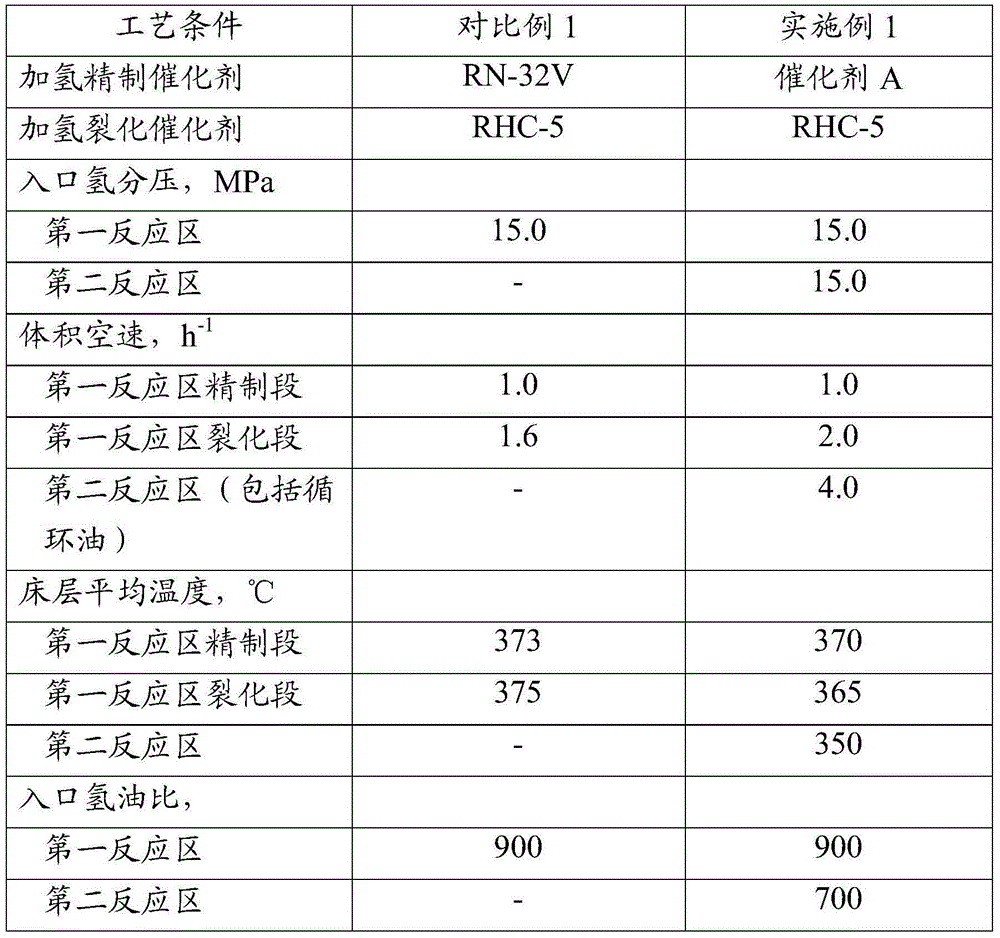

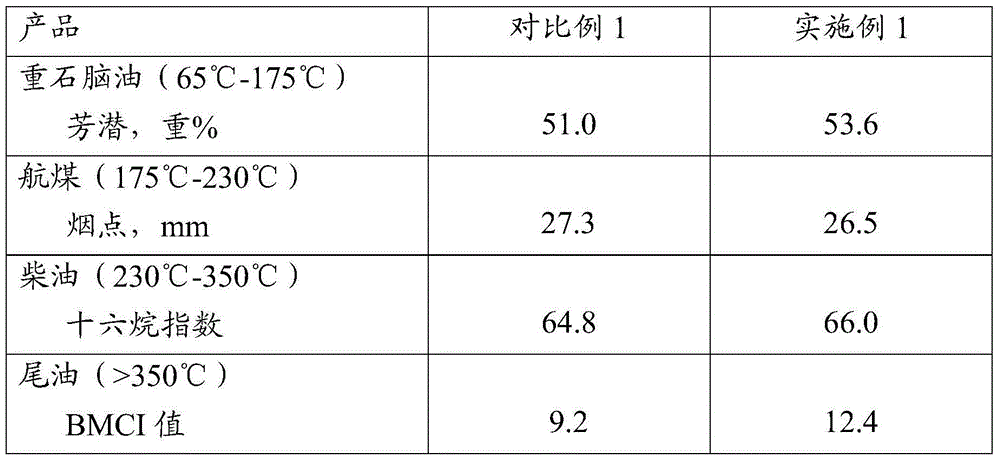

Hydrocracking method for producing heavy naphtha from high-nitrogen stock

ActiveCN104560169AHigh selectivityRelaxed reaction conditionsTreatment with hydrotreatment processesHydrogenNaphtha

A hydrocracking method for producing heavy naphtha from a high-nitrogen stock comprises the following steps: mixing and heating a high-nitrogen raw oil and a hydrogen-rich gas, and enabling the heated mixture to enter a first reaction area to be subjected to hydrofining reaction and hydrocracking reaction; performing cooling, oil-gas separation and fractional distillation on the reactant flow to obtain light naphtha, heavy naphtha and tail oil distillates; and pressurizing the tail oil distillates, then mixing the pressurized tail oil distillates with recycle hydrogen, and enabling the mixture to enter a second reaction area to be subjected to hydrocracking reaction. In the second reaction area, the tail oil distillates which are difficult to convert can be all converted into naphtha distillates under the conditions of high airspeed and low severity. The method provided by the invention can be used for reducing the yield of products with relatively low added value, such as dry gas, liquefied gas and light naphtha, and improving the selectivity of heavy naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alkadiene selective hydrogenation catalyst as well as preparation method and application thereof

ActiveCN104399529AGood dispersionIncreased hydrogenation conversionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationActive componentReaction temperature

The invention provides an alkadiene selective hydrogenation catalyst and a preparation method thereof. The carrier of the catalyst adopts carboxyl-functionalized step hole FZIF-8; active components adopts palladium; the active component palladium accounts for 0.1 to 10 percent on the basis of the total weight of the carrier of the catalyst. The invention further provides the preparation method of the alkadiene selective hydrogenation catalyst. A step hole structure is formed in the carrier of the alkadiene selective hydrogenation catalyst, so that carboxyl groups have accessibility, and the active components and the carboxyl groups can interact mutually; the carboxyl groups are contained in the carrier of the catalyst, can anchor the active components, realize high dispersion of the active components, meanwhile prevent agglomeration and drain of the active components during the process, and ensure that the catalyst is high in activity. The catalyst can be applied to the hydrogenation upgrading of FCC petrol, removal of alkadiene in the petrol, and is mild in reaction condition, low in reaction temperature and pressure, and good in selective hydrogenation effect of products.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com