Coal tar hydrogenation system and coal tar hydrogenation method

A technology of hydrogenation system and coal tar, which is applied in the fields of hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of limited operation period of the device, increase the difficulty of processing, and high content of aromatic hydrocarbons, and increase the heat capacity of materials, The effect of prolonging catalyst life and moderating reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with embodiment, further illustrate the present invention.

[0055] The following is a preferred embodiment of the present invention, through which the method of the present invention is specifically described, but the scope of the present invention is based on the protection scope of the claims, and is not limited by the preferred embodiment.

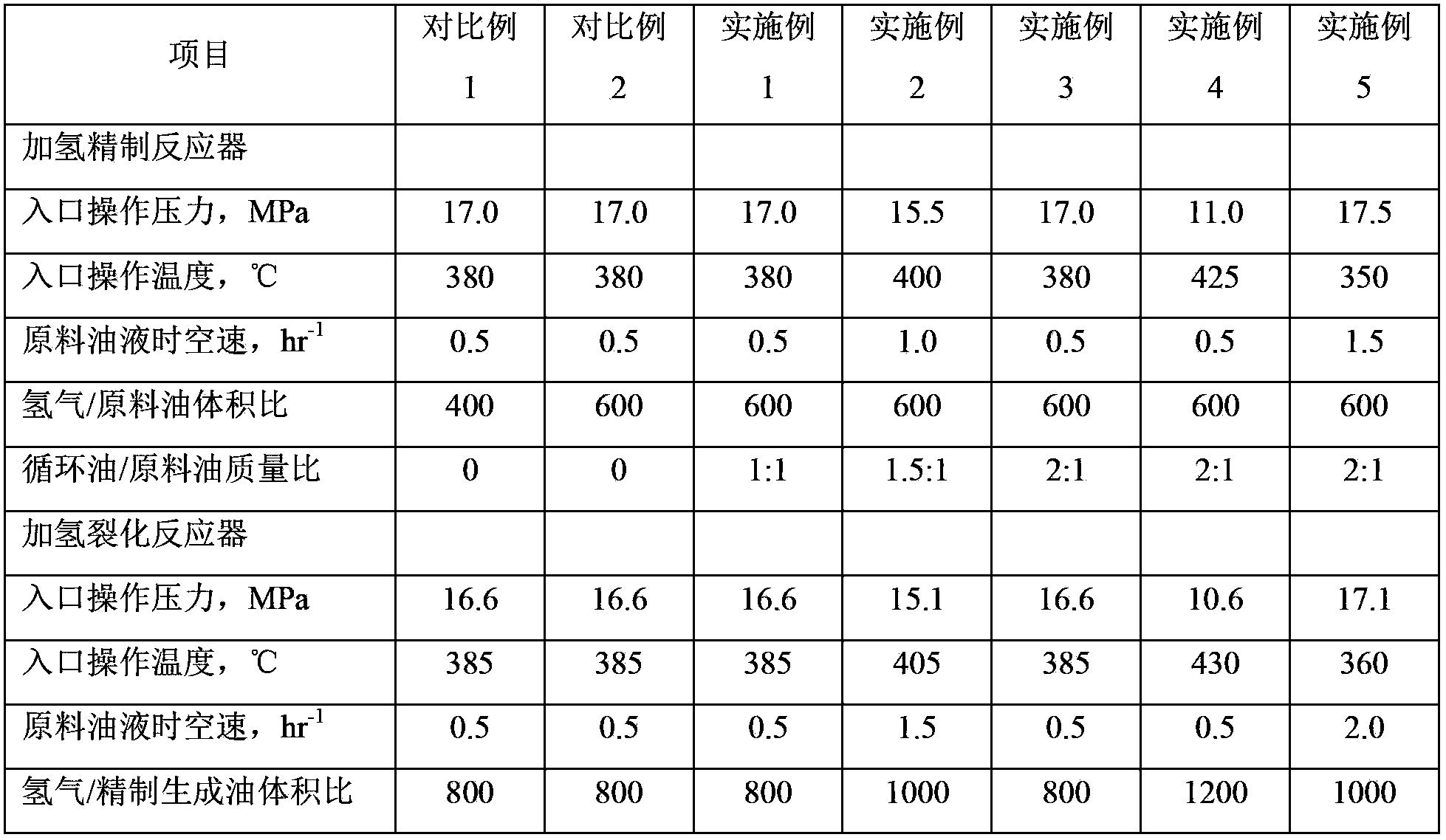

[0056] Embodiment 1~5 The present invention is described in further detail below in conjunction with accompanying drawing:

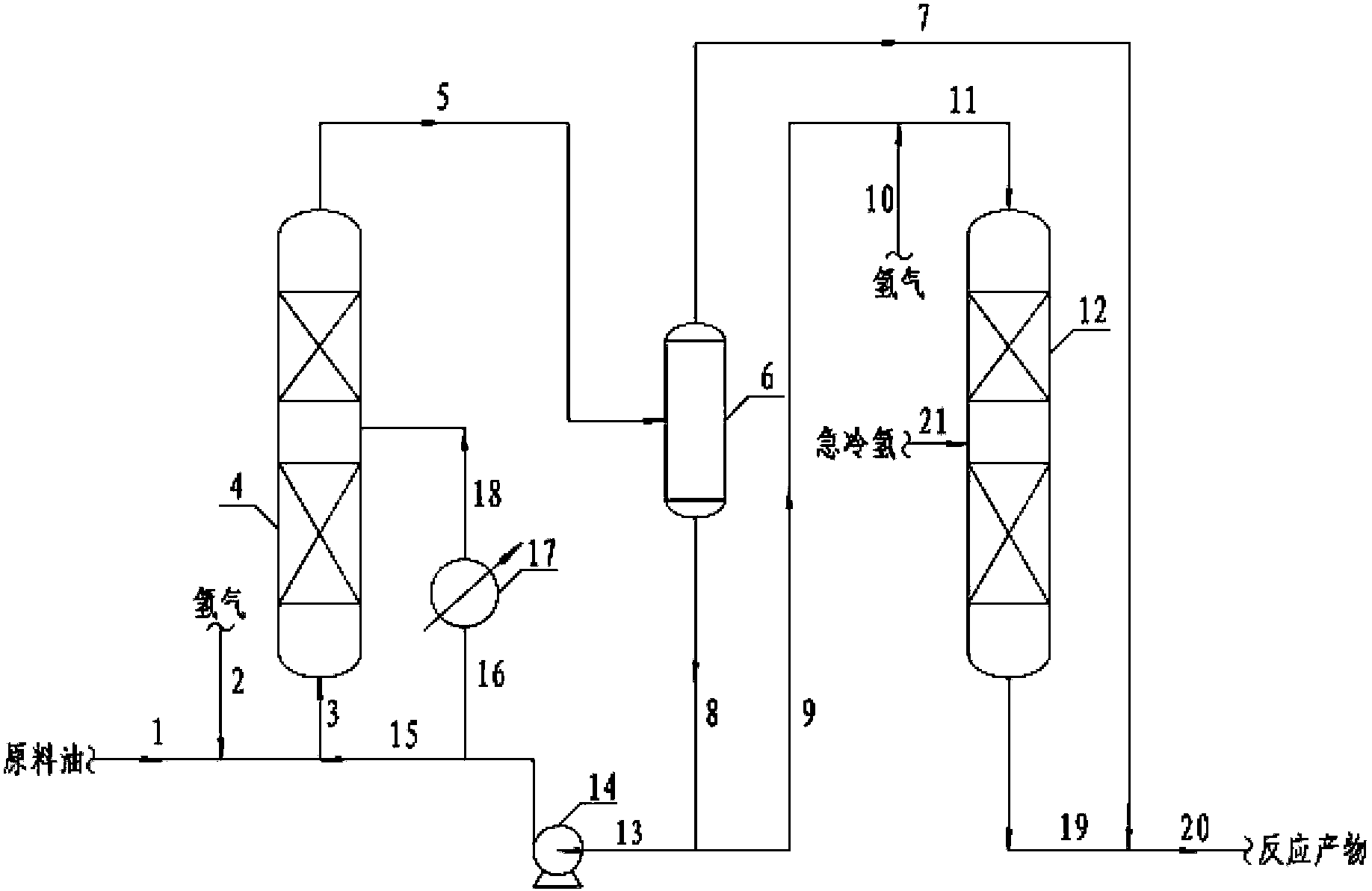

[0057] process such as figure 1 shown. After the pressure-increased and heated raw material oil 1 is mixed with hydrogen 2, it is first mixed with circulating oil 15 to form reaction feed 3, and then enters the up-flow hydrofining reactor (up-flow fixed-bed reactor) 4 from bottom to top , Under the action of the catalyst, a series of hydrofinishing reactions such as hydrodenitrogenation, deoxygenation, desulfurization, olefin saturation and aromatics saturation are carried out. In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com