Patents

Literature

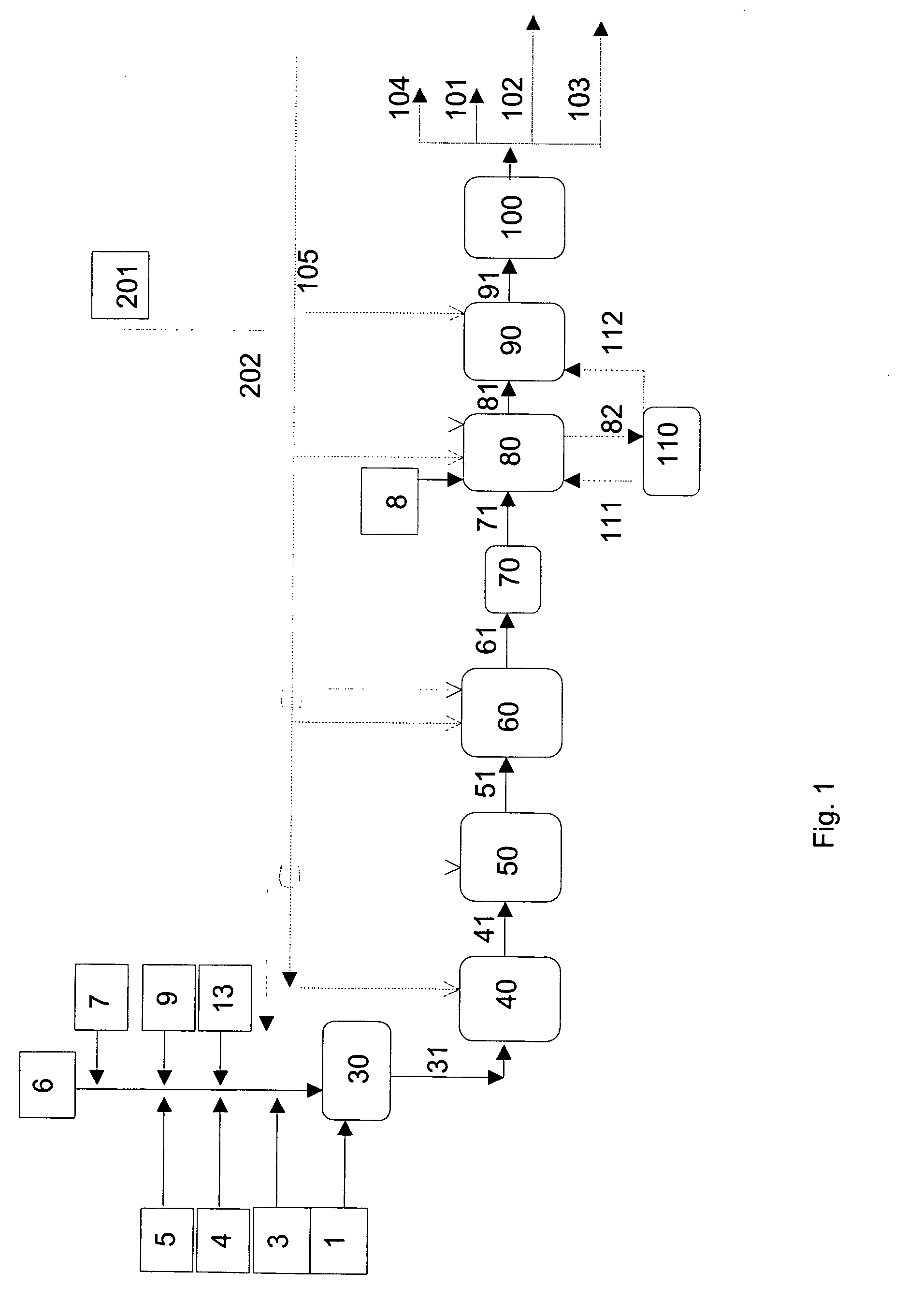

4482results about How to "Reduce temperature rise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

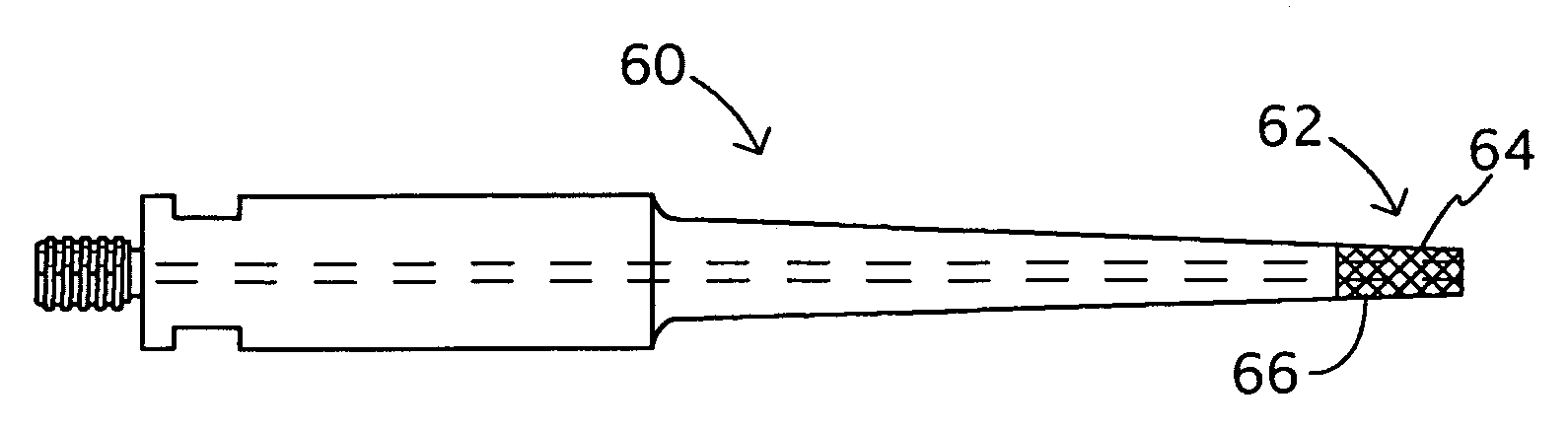

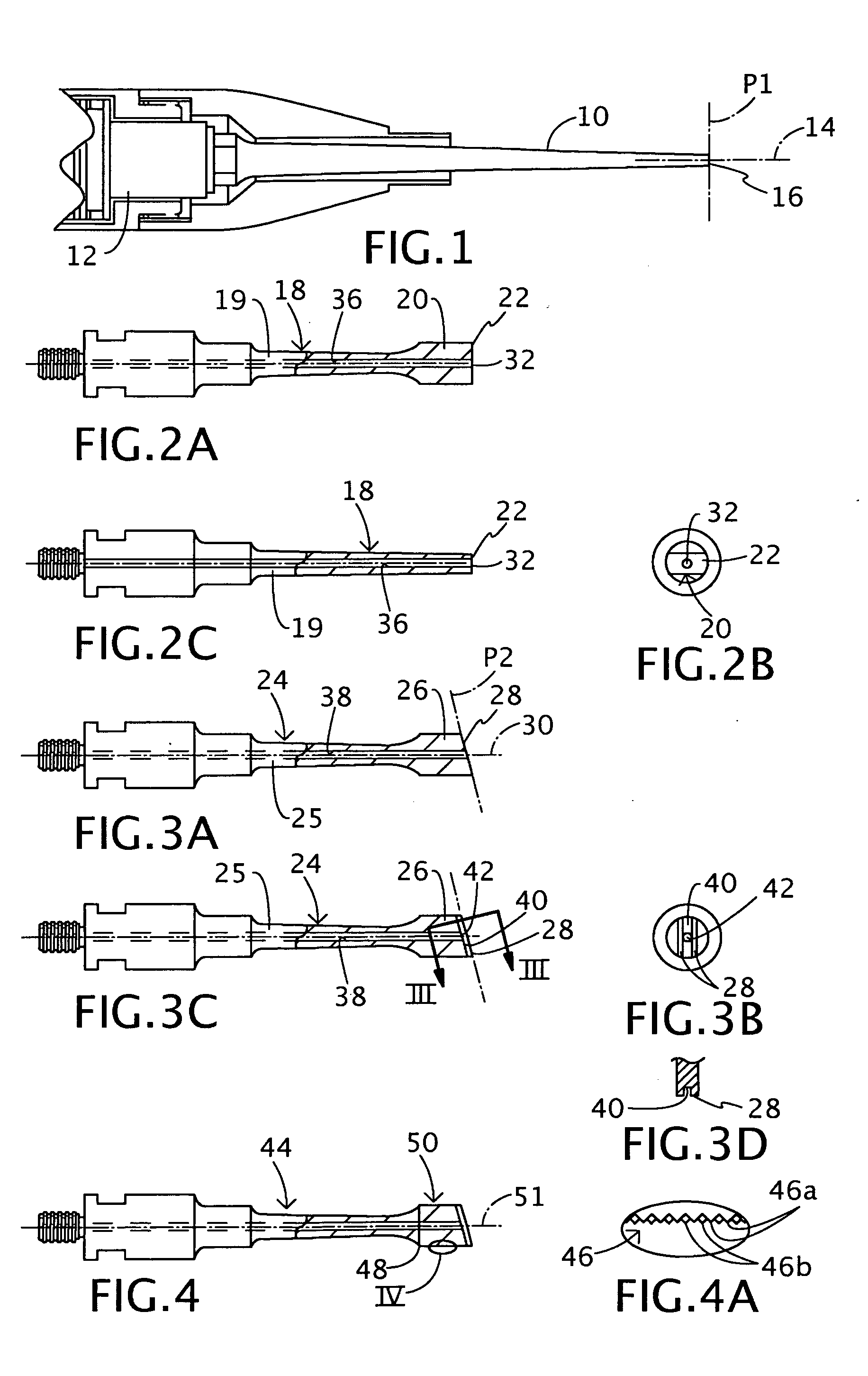

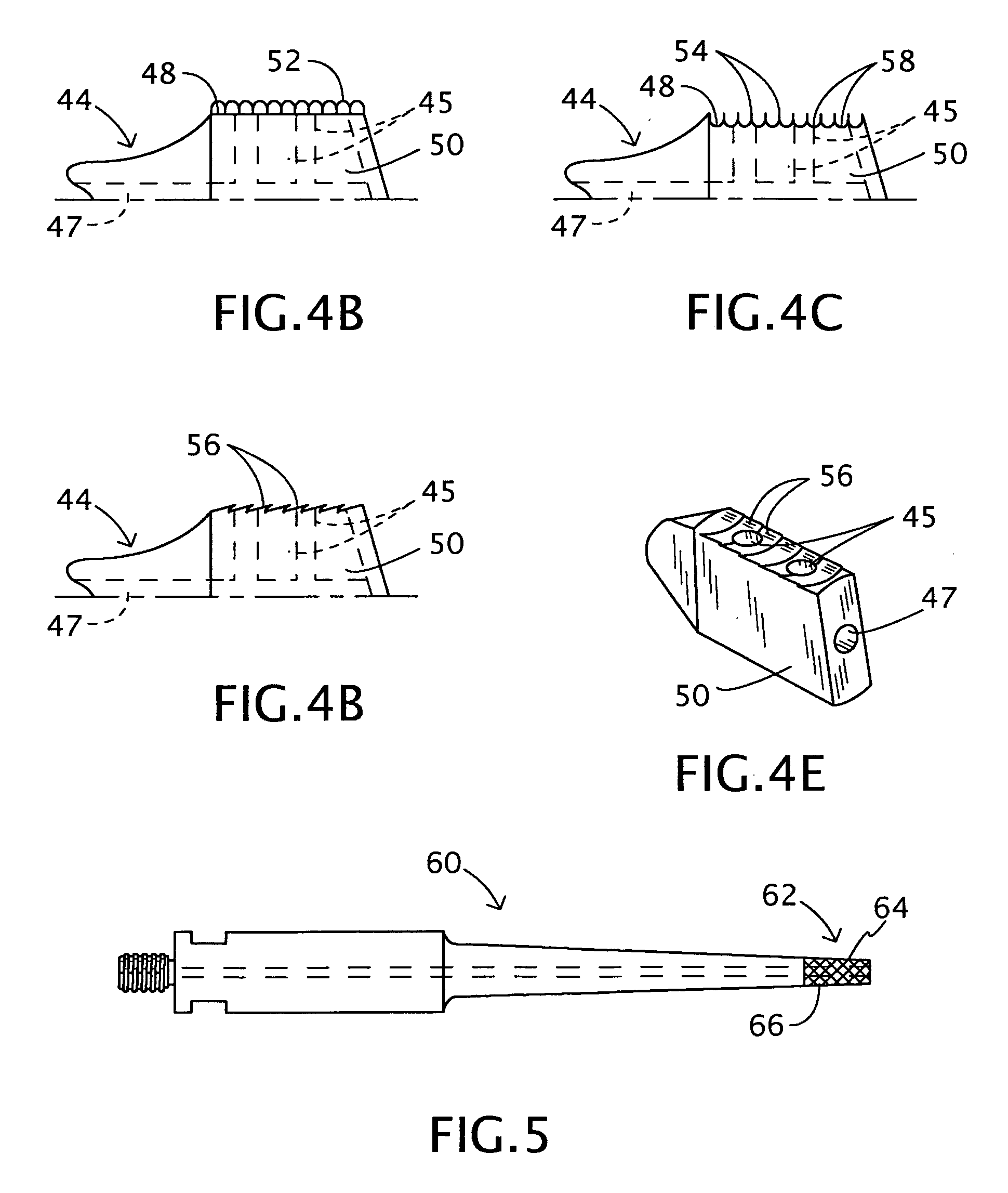

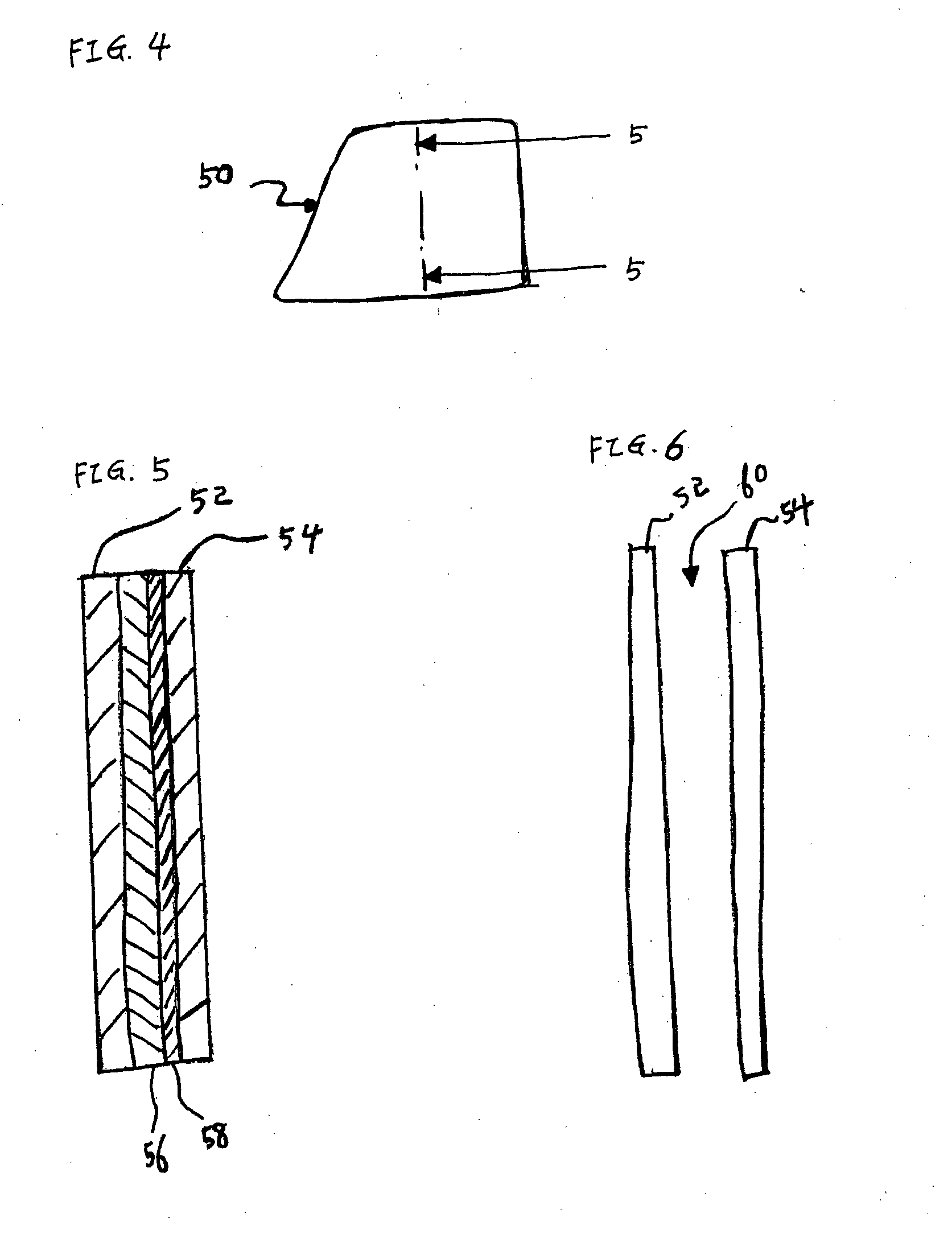

Ultrasonic debrider probe and method of use

InactiveUS20080058775A1Reduce temperature riseAvoid cloggingSurgical instrument detailsBiomedical engineeringMedical treatment

An ultrasonic medical probe has an elongate shaft with a head portion having a distal end face oriented at least partially transversely to a longitudinal axis of the shaft. The head portion has a lateral surface extending substantially parallel to the longitudinal axis, the lateral surface being provided with outwardly or radially extending projections. The shaft of the probe is provided with an internal longitudinal channel or bore and at least one ancillary or tributary channel communicating at an inner end with the longitudinal channel or bore and extending to the lateral surface. The ancillary or tributary channel has an outer end disposed in a region about the projections. The projections may be finely configured and distributed so as to form a knurled surface on the head portion.

Owner:MISONIX INC

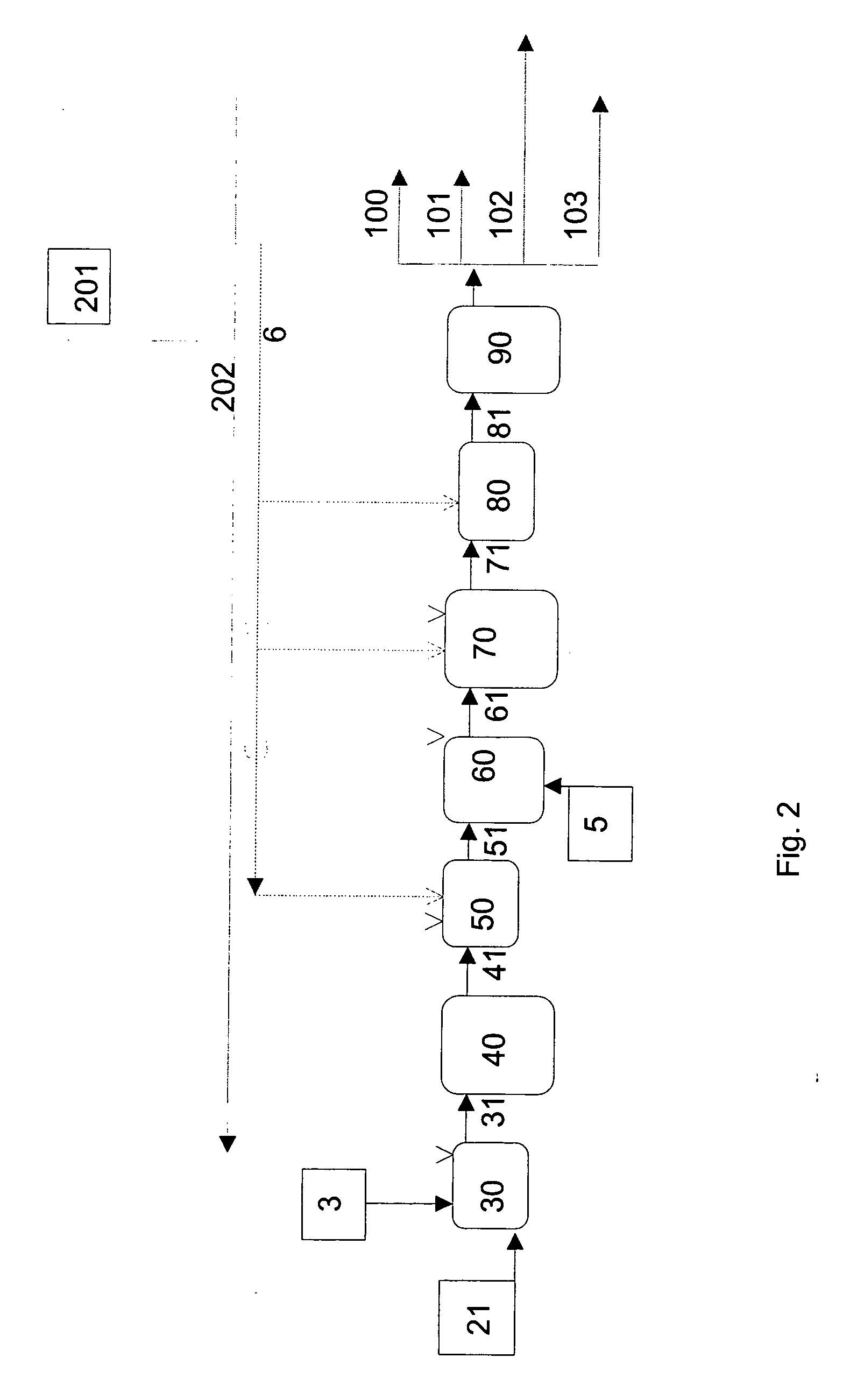

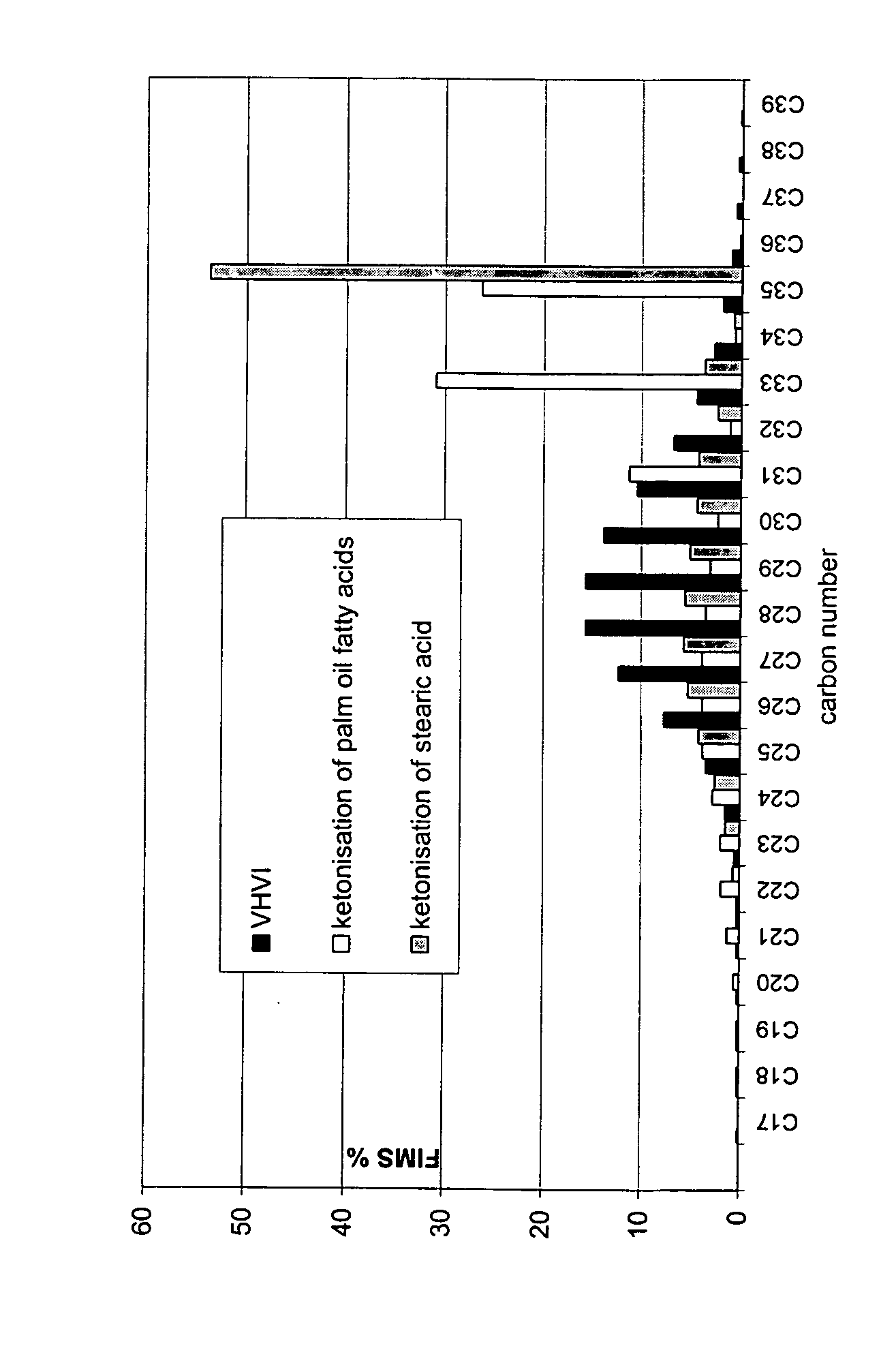

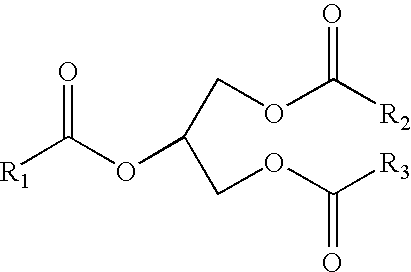

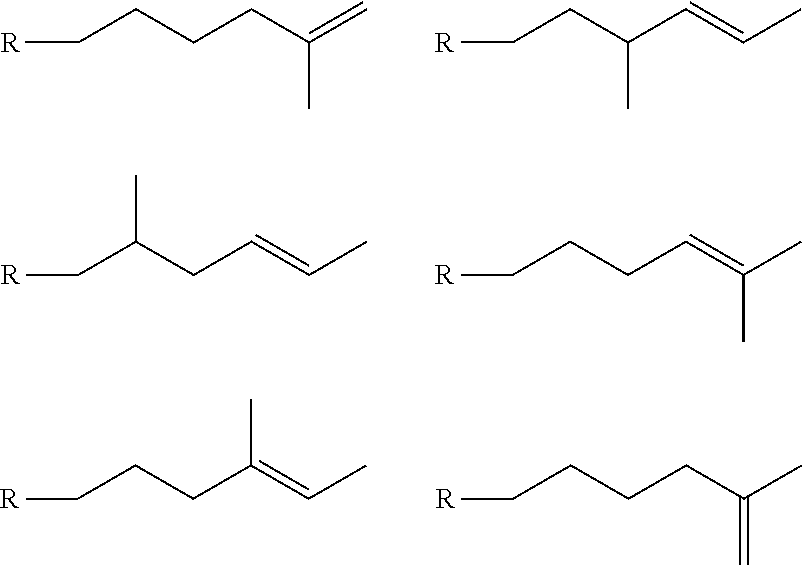

Process for producing a hydrocarbon component

ActiveUS20070161832A1Reduce carbon dioxide emissionsImprove low temperature performanceFatty oils/acids recovery from wasteFatty acid hydrogenationIsomerizationHydrodeoxygenation

The invention relates to a process for producing a new type of high-quality hydrocarbon base oil of biological origin. The process of the invention comprises ketonisation, hydrodeoxygenation, and isomerization steps. Fatty acids and / or fatty acid esters based on a biological raw material are preferably used as the feedstock.

Owner:NESTE OIL OY

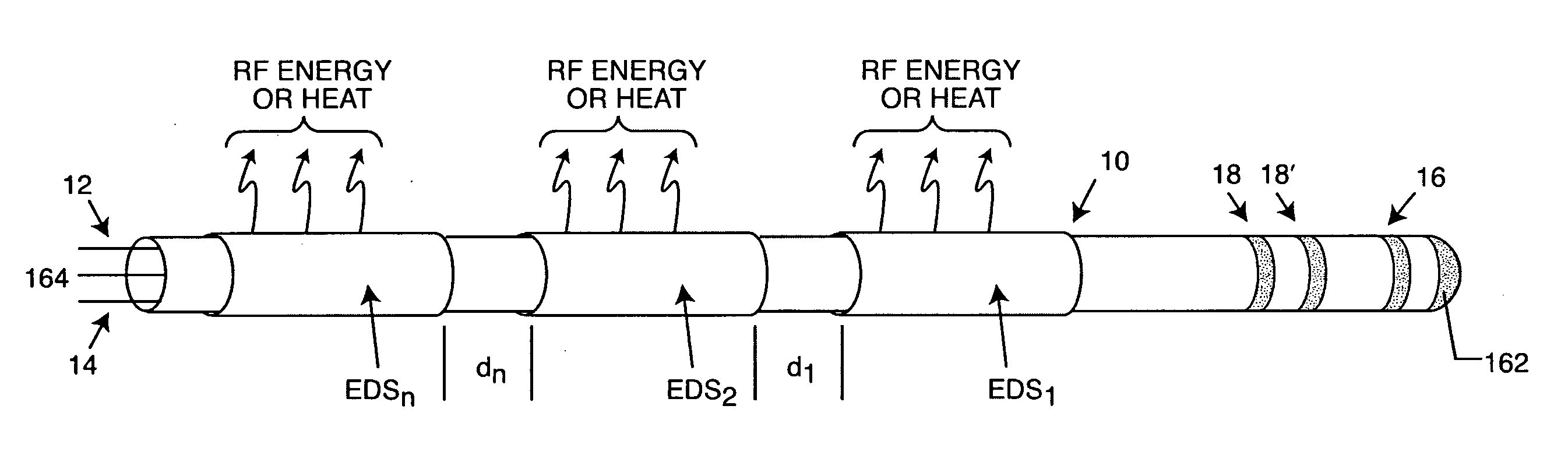

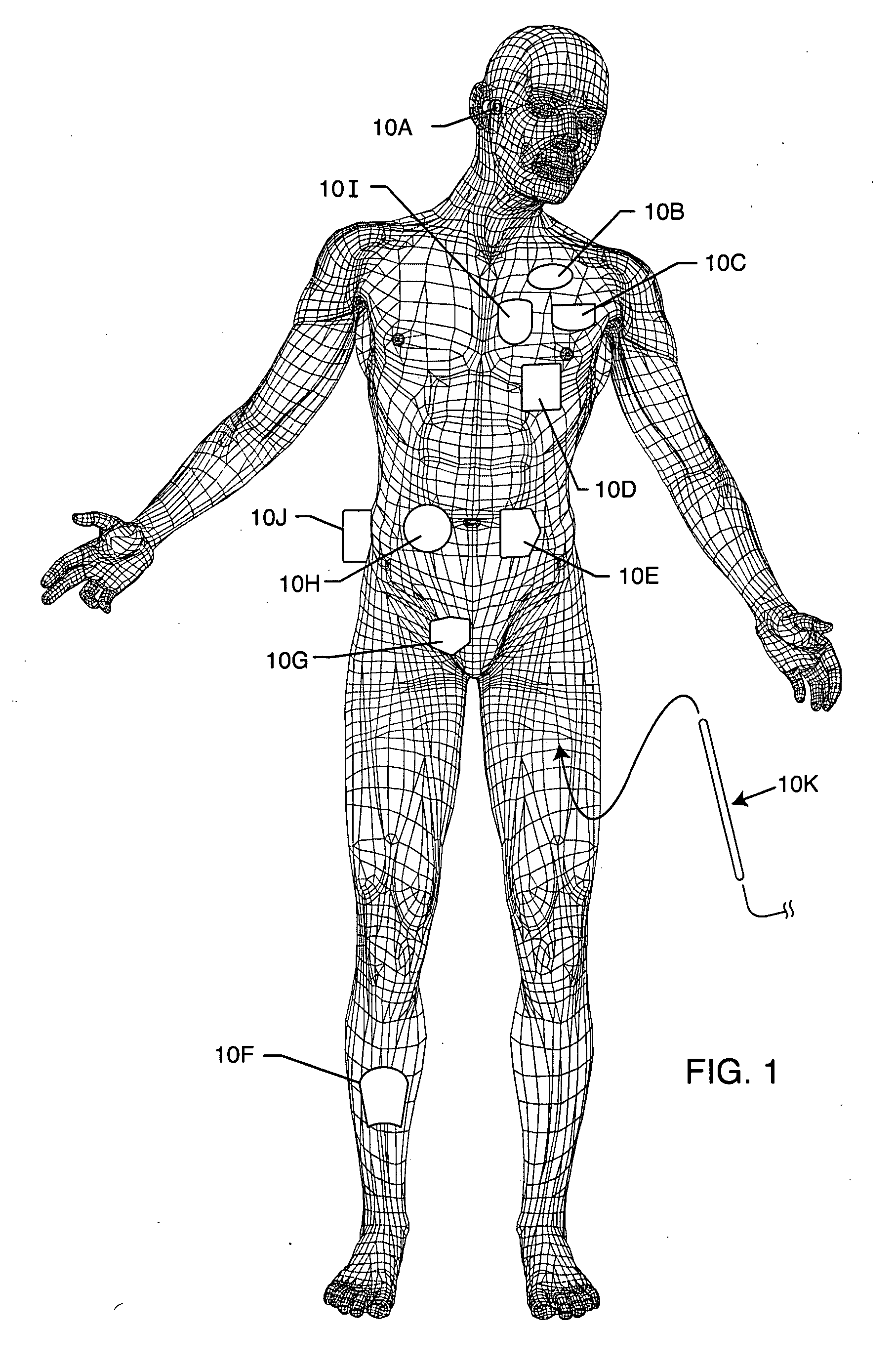

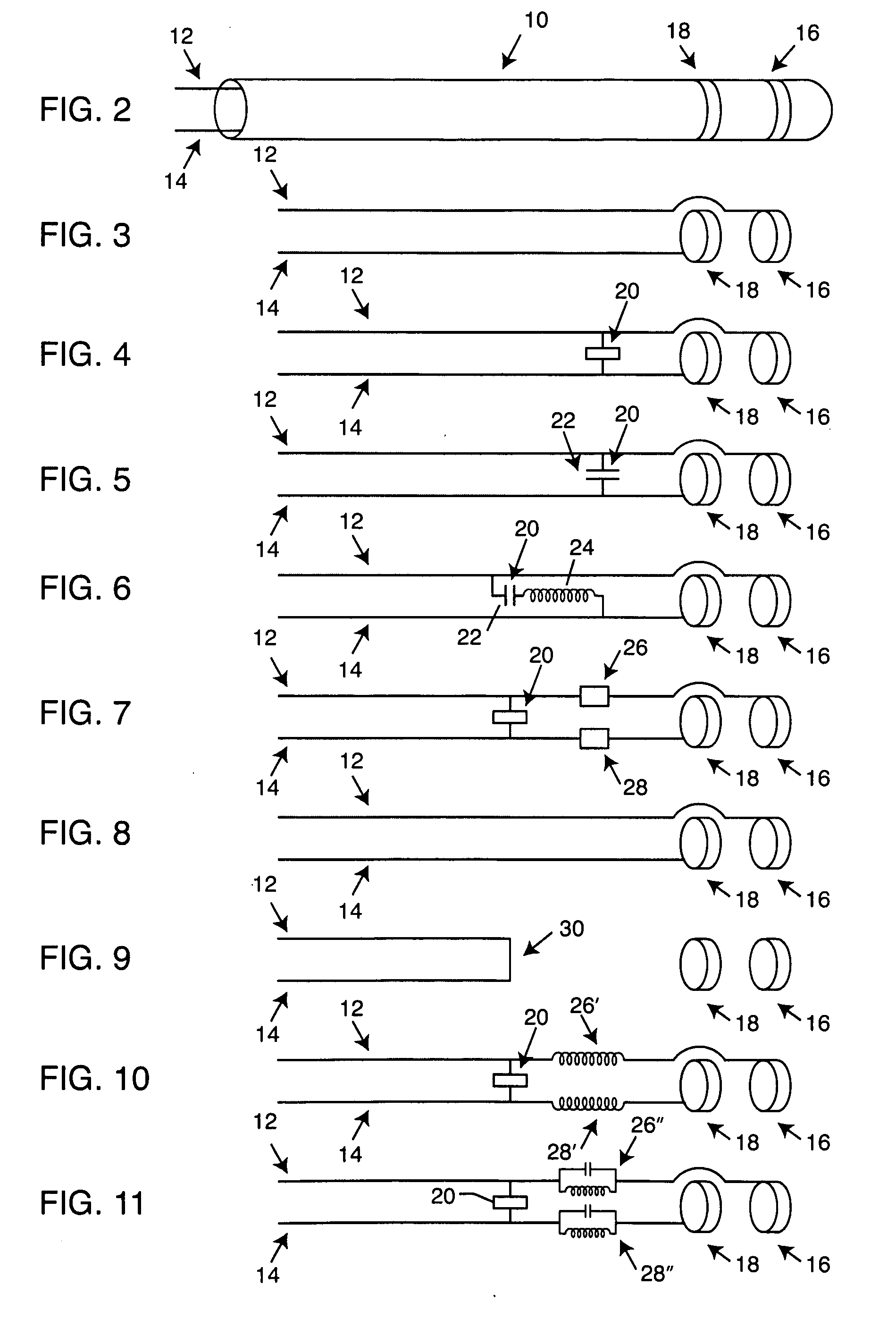

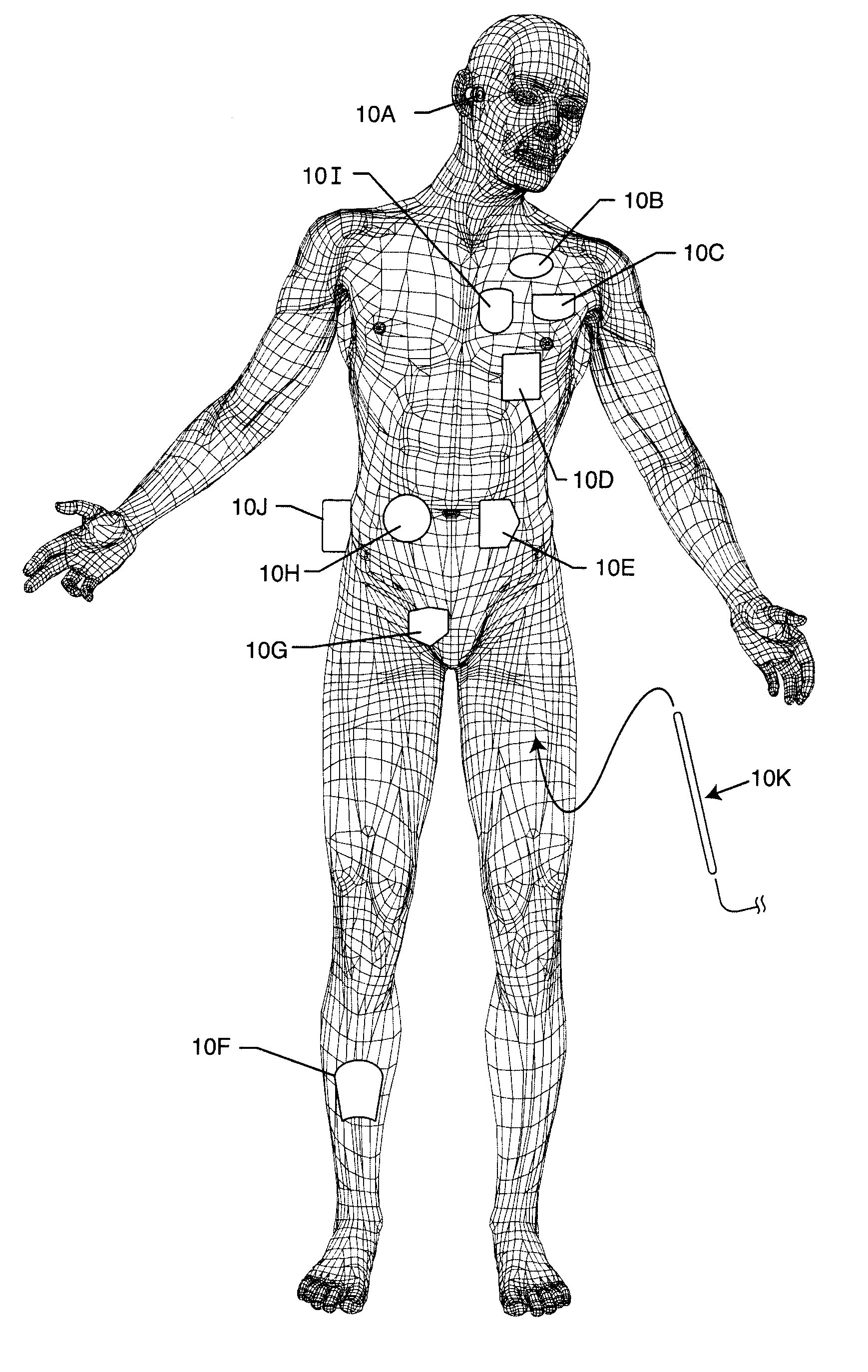

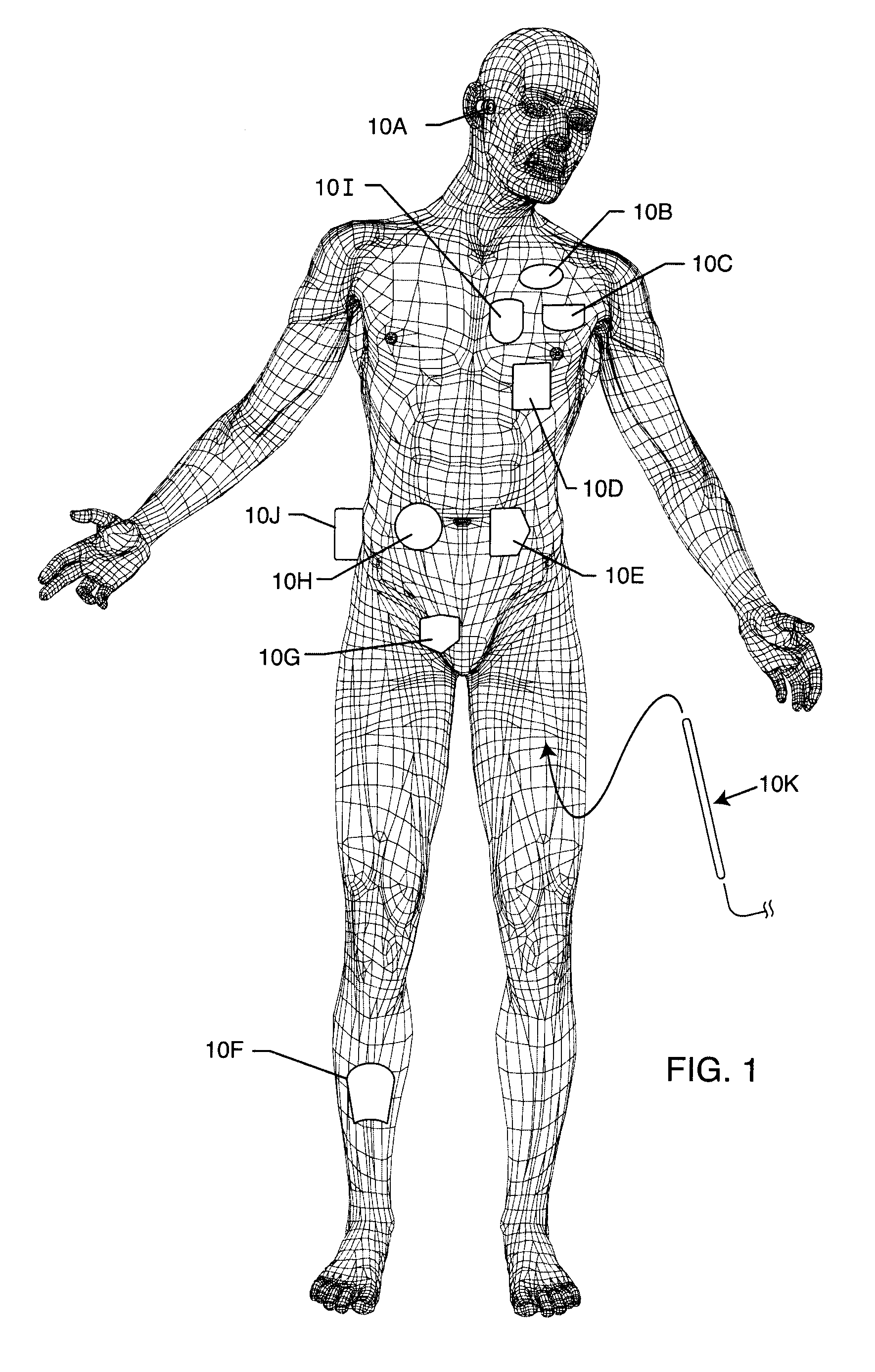

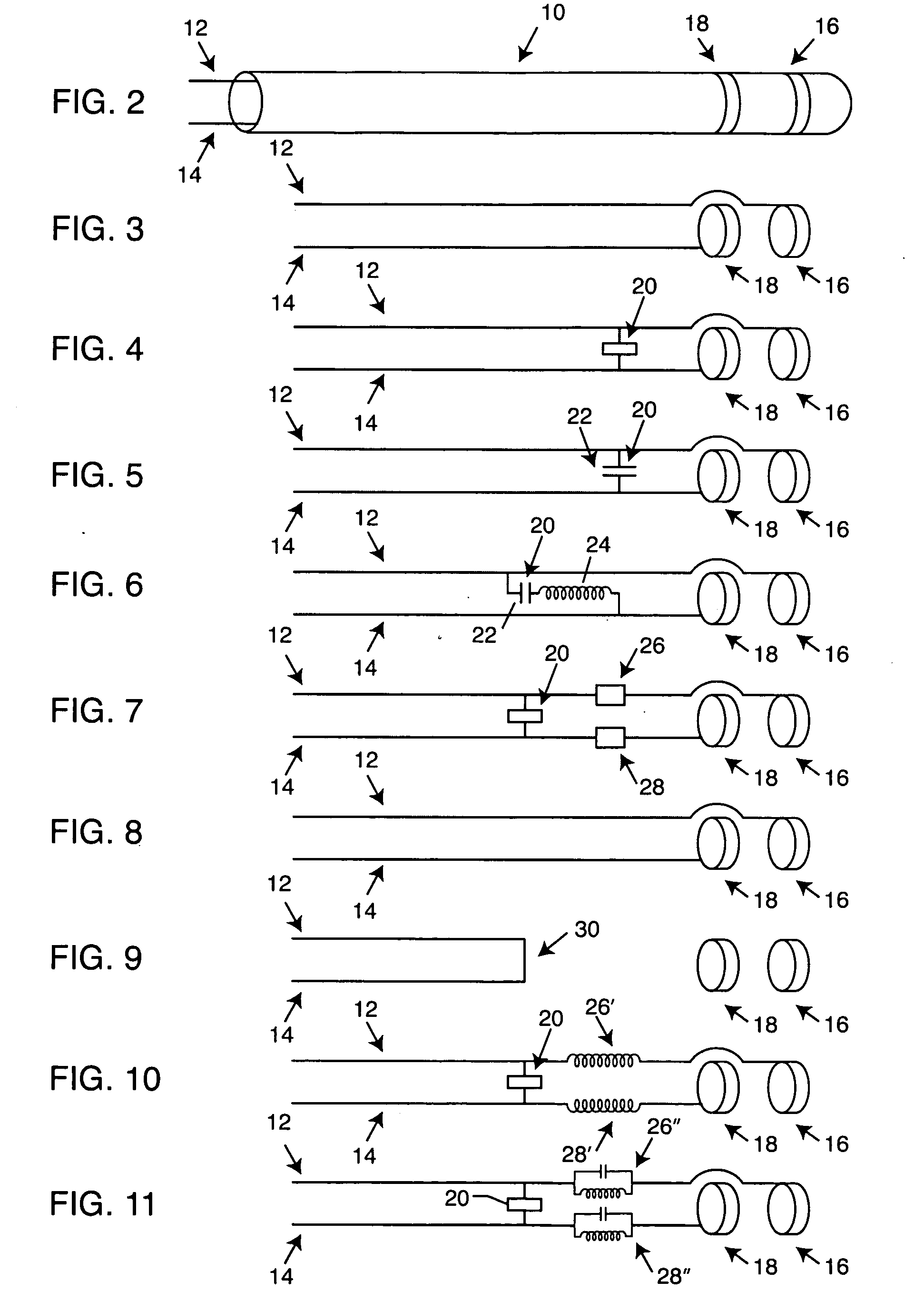

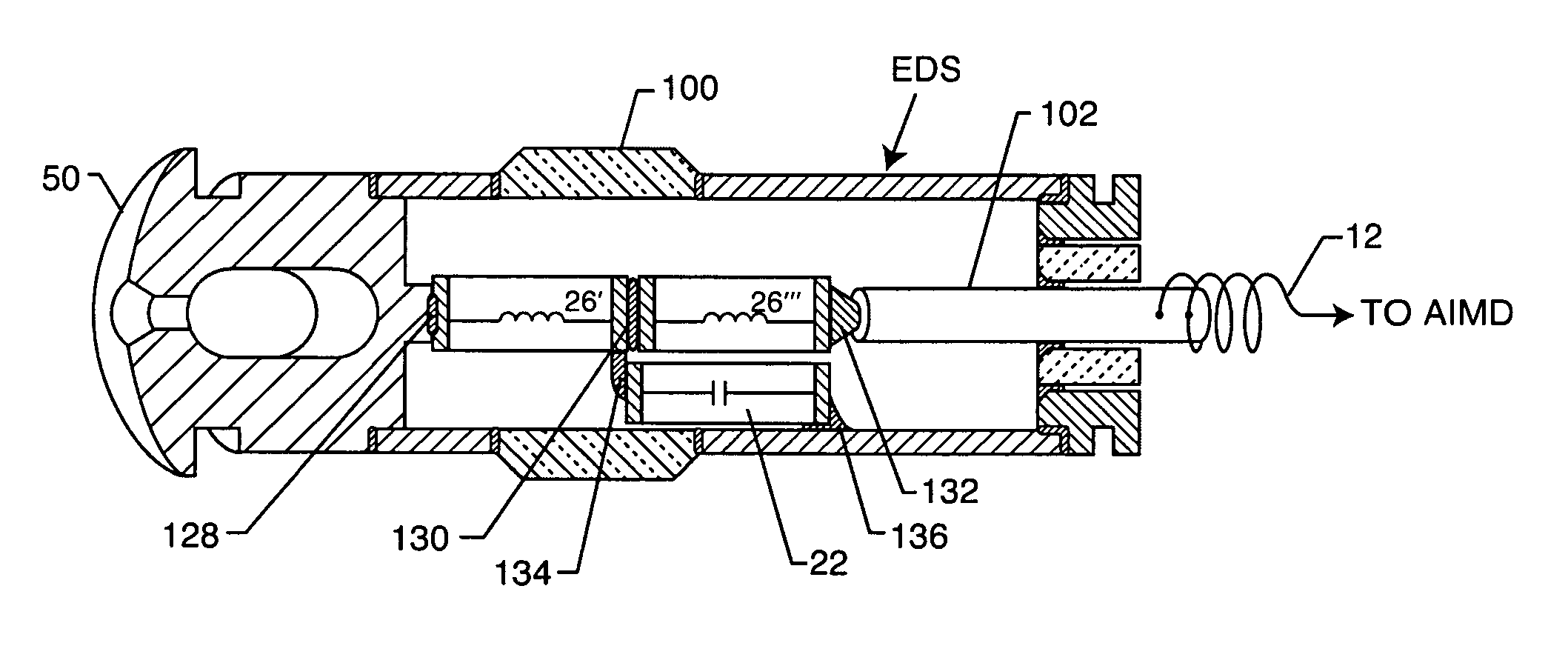

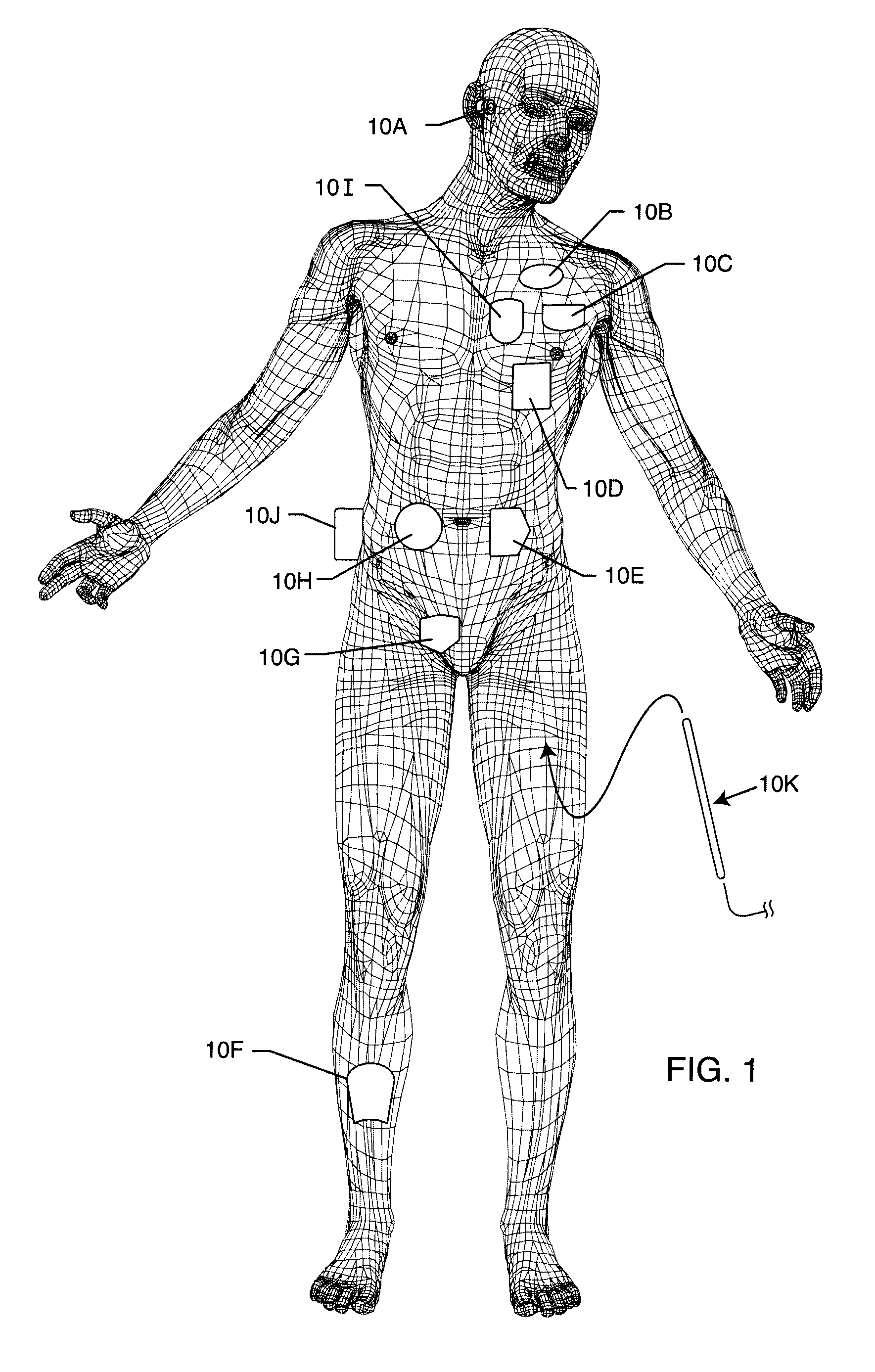

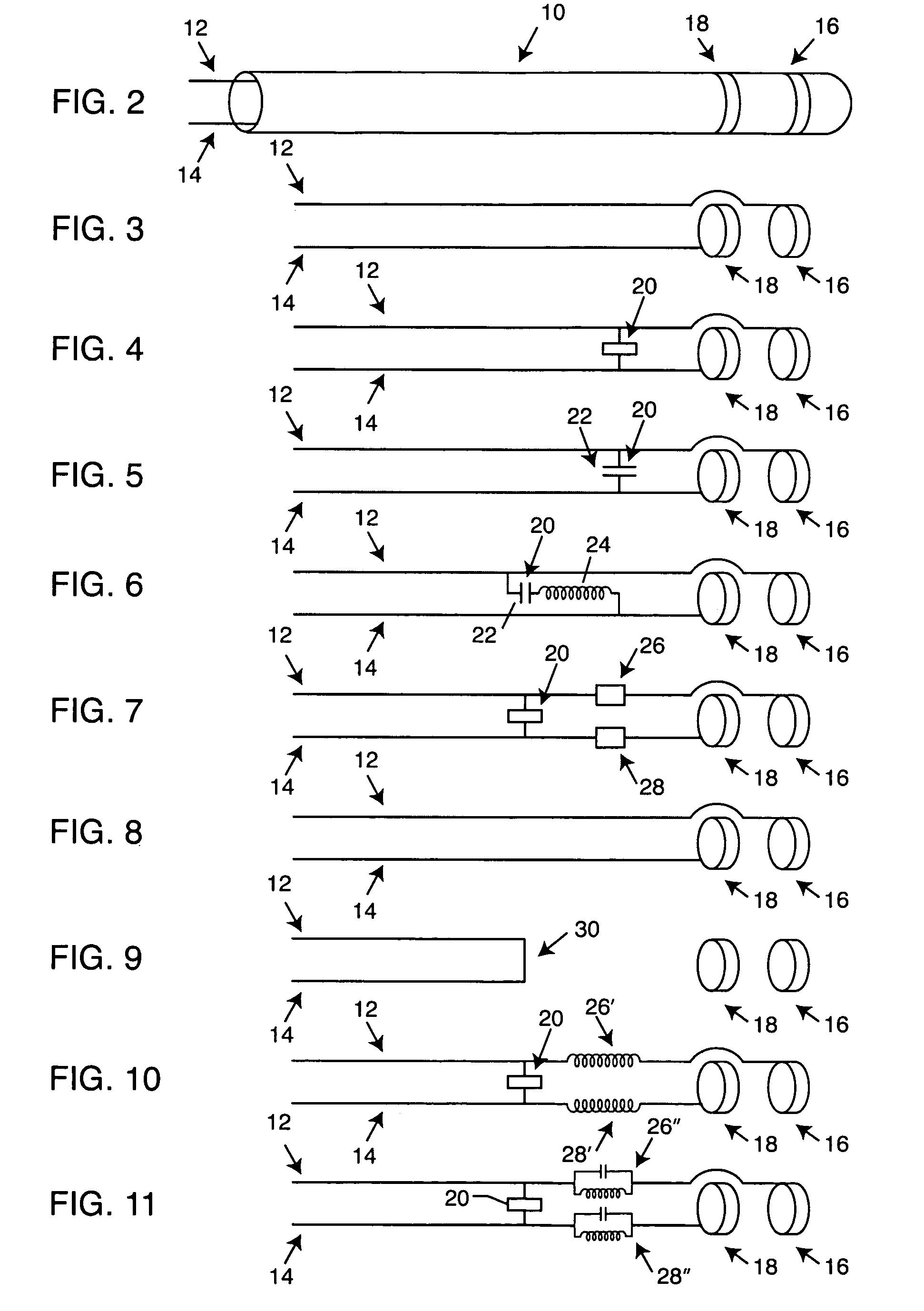

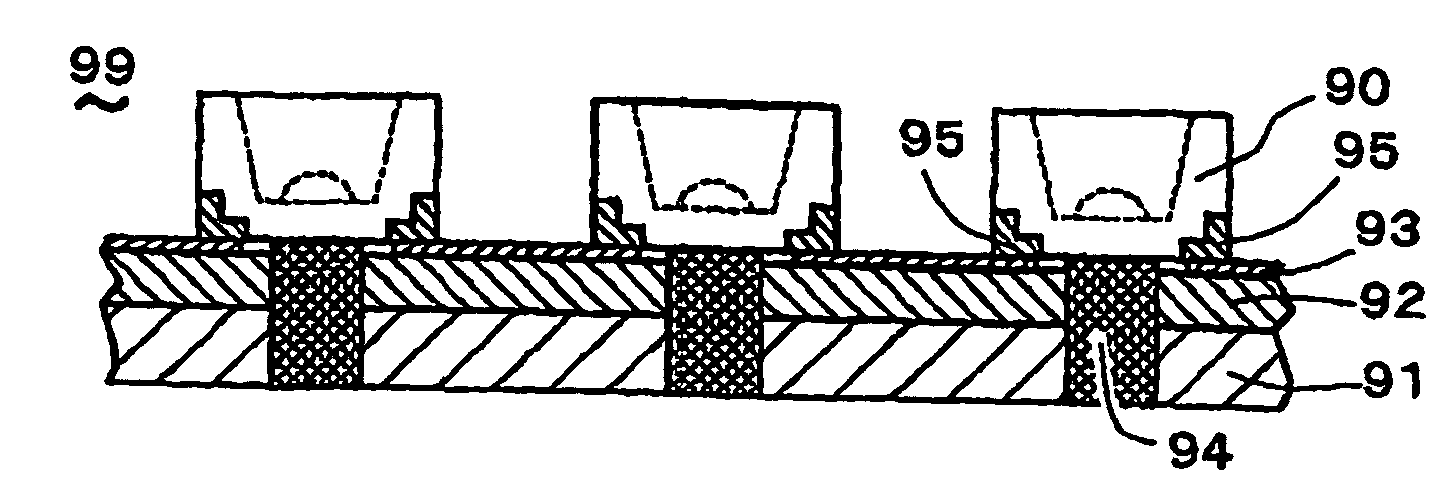

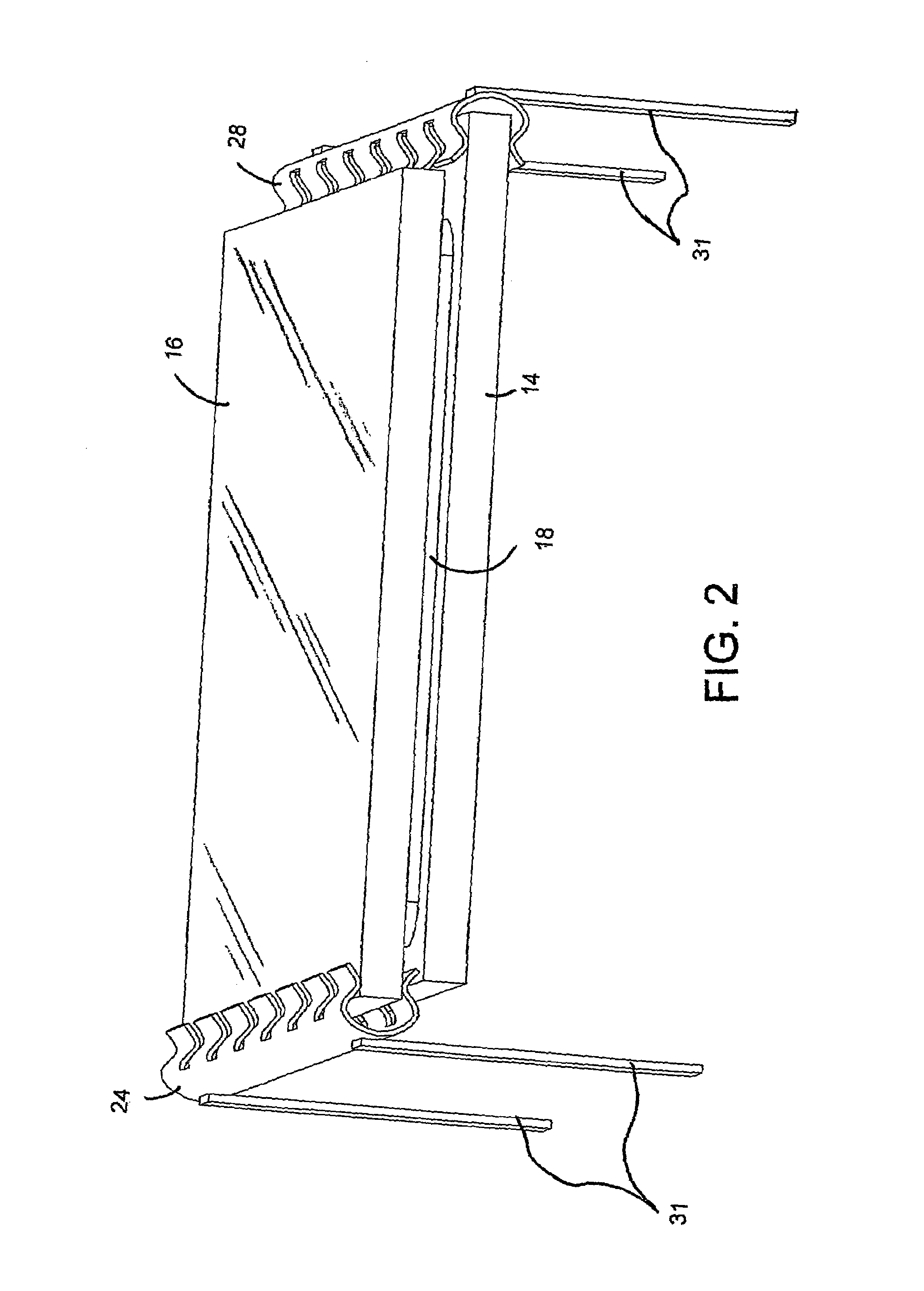

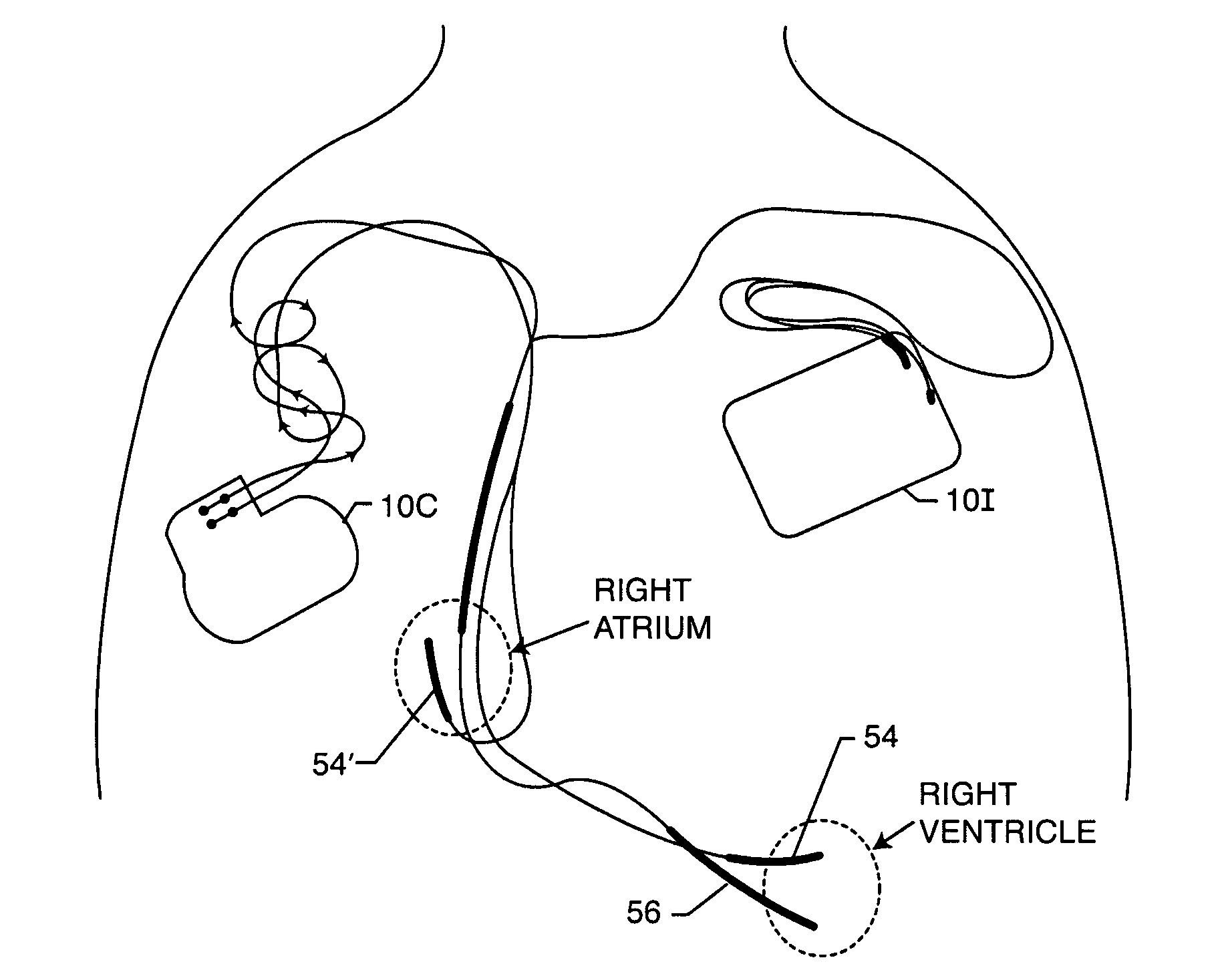

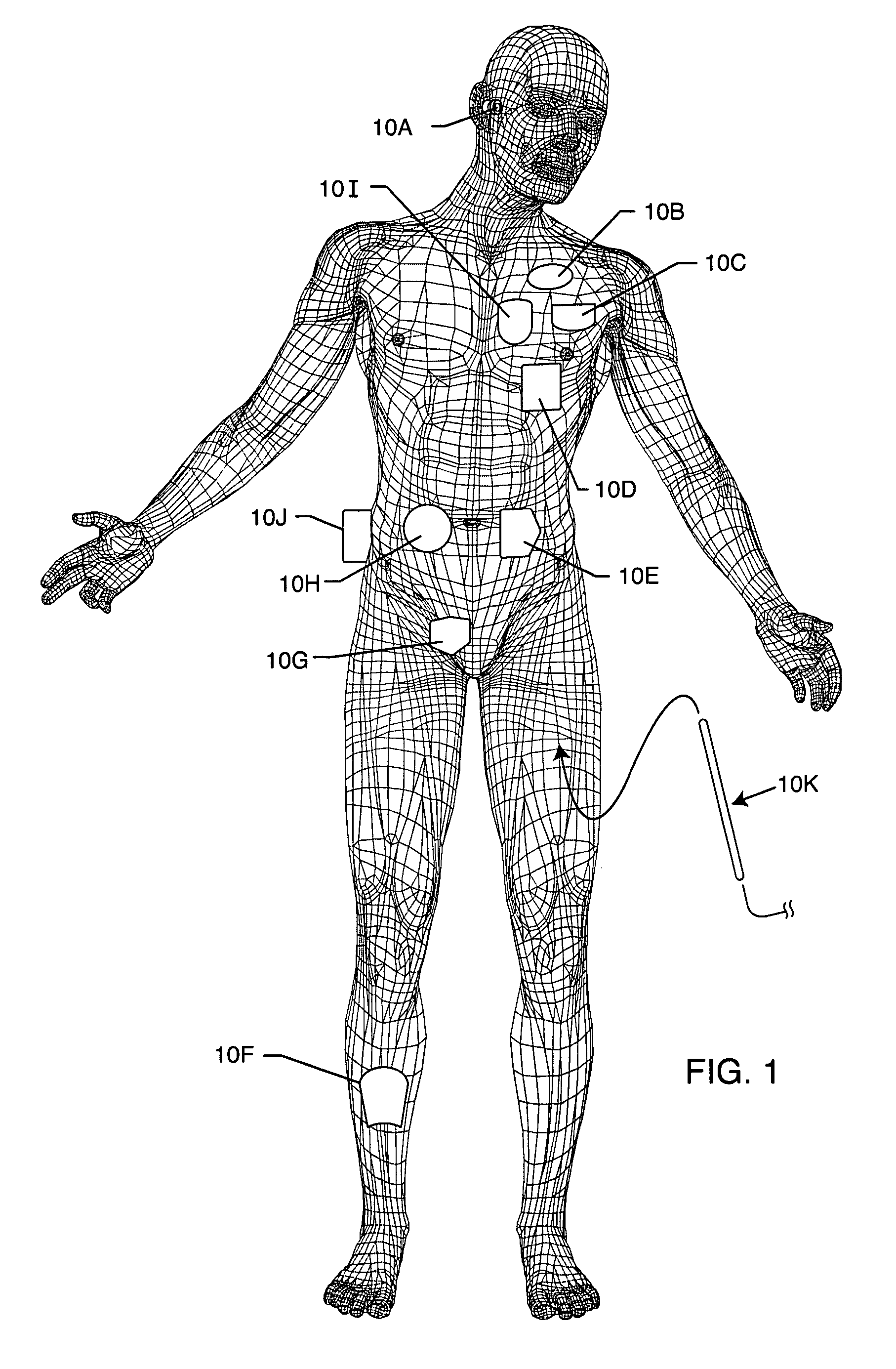

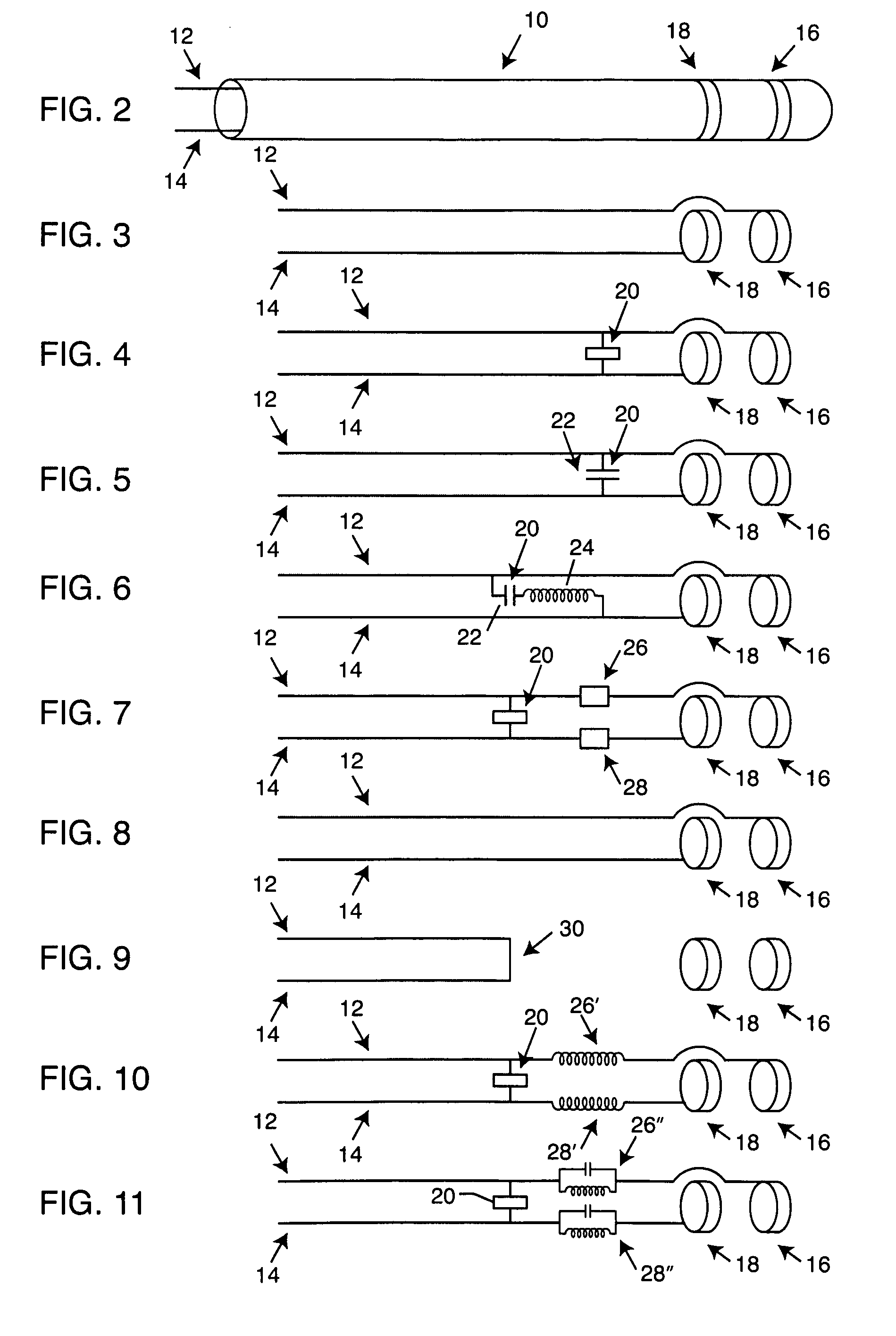

Frequency selective passive component networks for implantable leads of active implantable medical devices utilizing an energy dissipating surface

InactiveUS20100023000A1Increase temperatureAbility to in properMultiple-port networksElectrocardiographyEnergy transferRf field

Decoupling circuits are provided which transfer energy induced from an MRI pulsed RF field to an energy dissipating surface. This is accomplished through broadband filtering or by resonant filtering. In a passive component network for an implantable leadwire of an active implantable medical device, a frequency selective energy diversion circuit is provided for diverting high-frequency energy away from a leadwire electrode to a point or an area spaced from the electrode, for dissipation of high-frequency energy.

Owner:WILSON GREATBATCH LTD

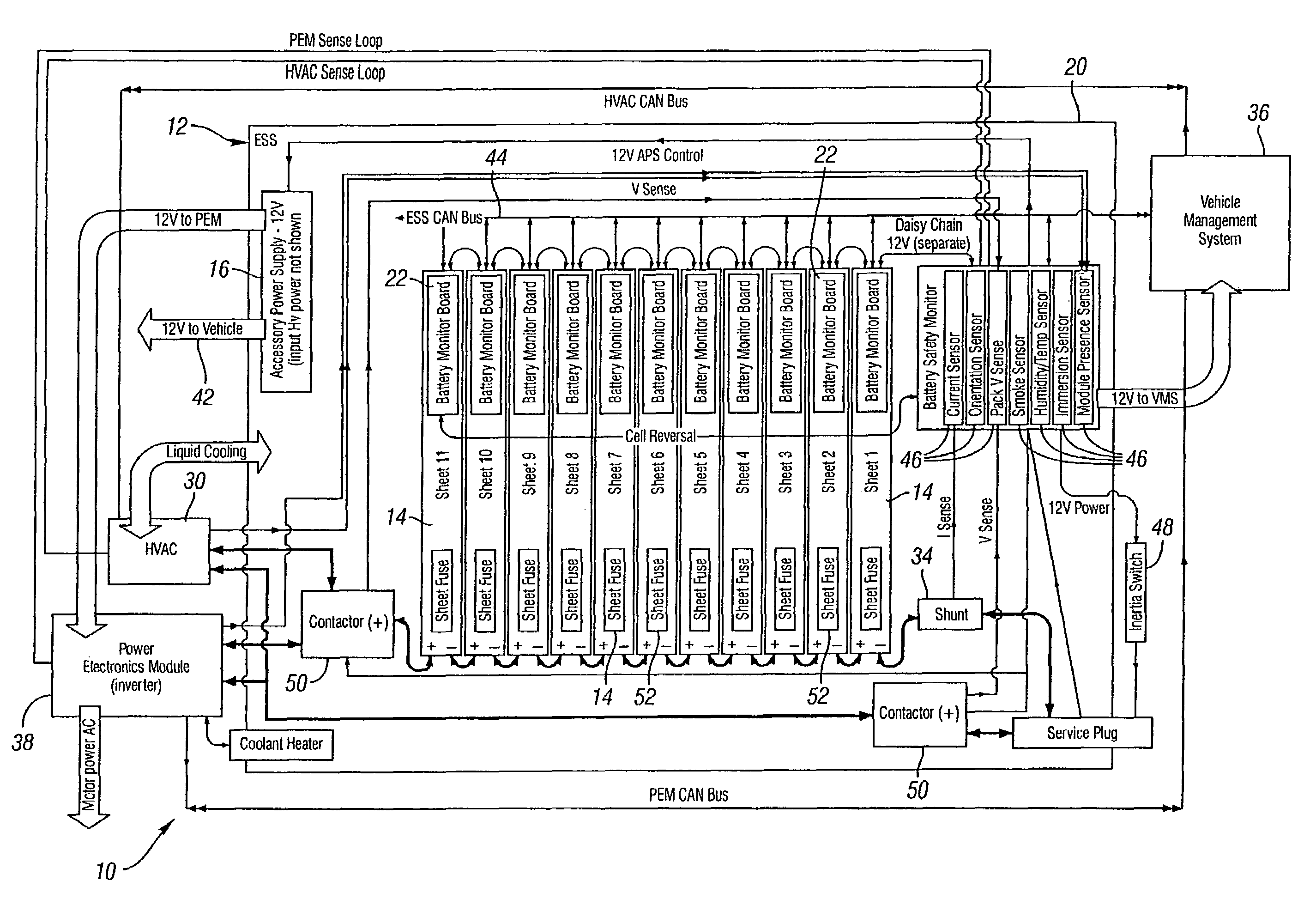

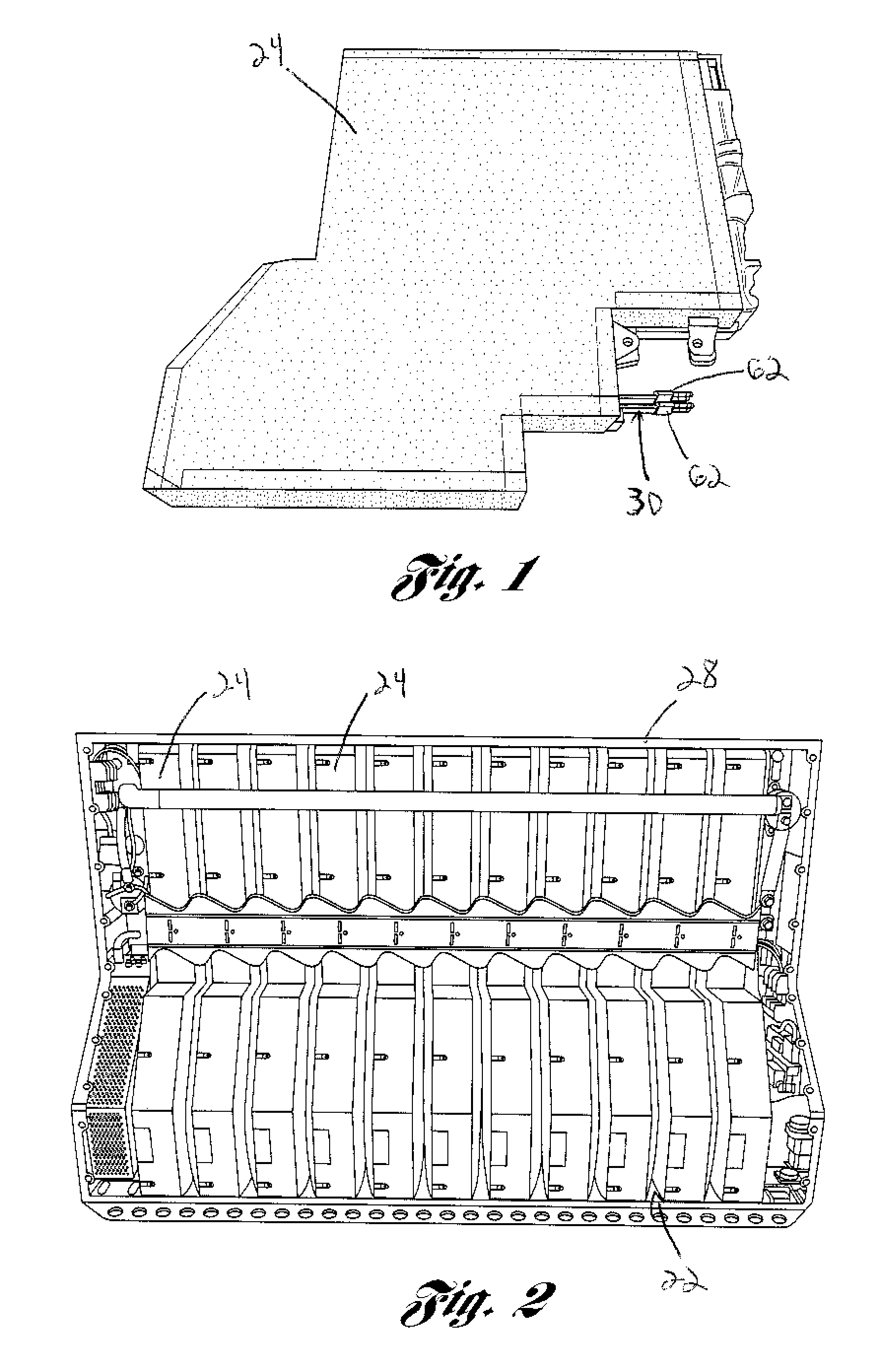

Mitigation of propagation of thermal runaway in a multi-cell battery pack

ActiveUS7433794B1Reduce temperature riseIncrease rangeElectrical testingVehicular energy storageEnergy storageBattery pack

A method of mitigating propagation of a thermal event in an energy storage system having a plurality of cells is disclosed. The method includes the steps of identifying the heat sources within the energy storage system and plurality of cells. The method then controls a temperature of the energy storage system and plurality of cells and also detects predetermined conditions within the energy storage system. The method then performs a predetermined action based on when one of the predetermined conditions is detected. A plurality of sensors and switches along with associated hardware or software will be used to control the temperature of the energy storage system upon detection of predetermined conditions involving overheating, over current, over voltage of the like.

Owner:TESLA INC

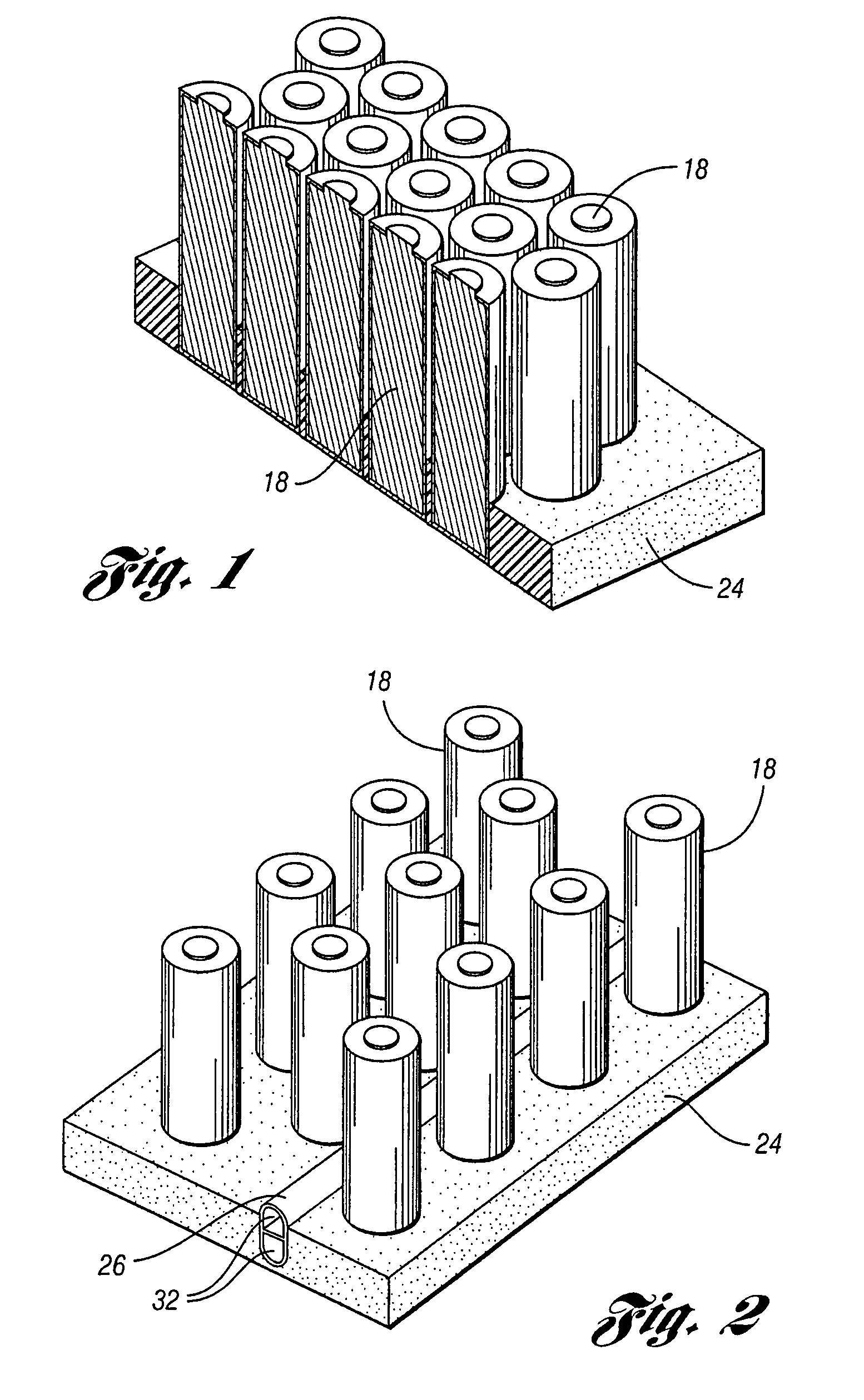

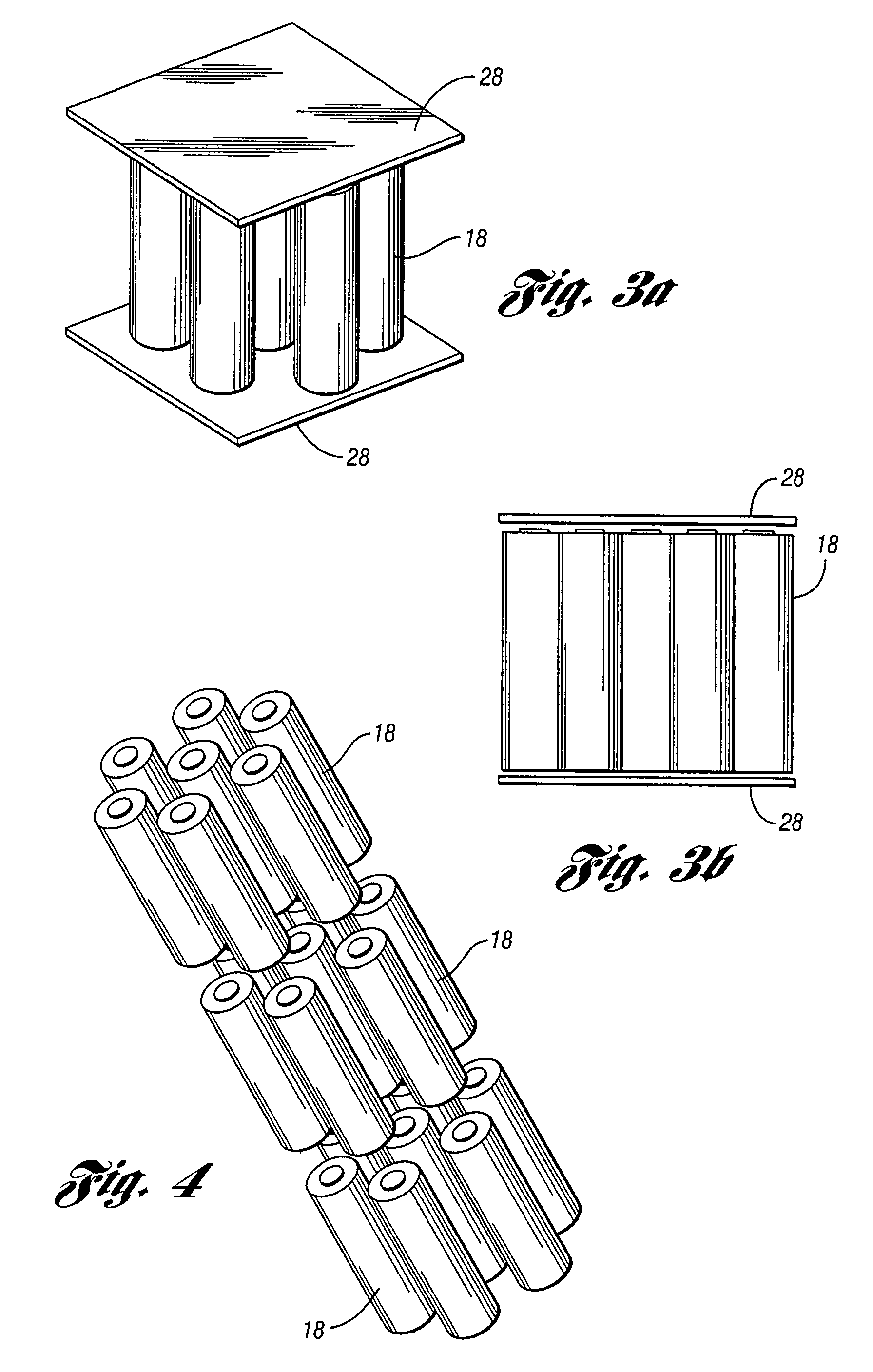

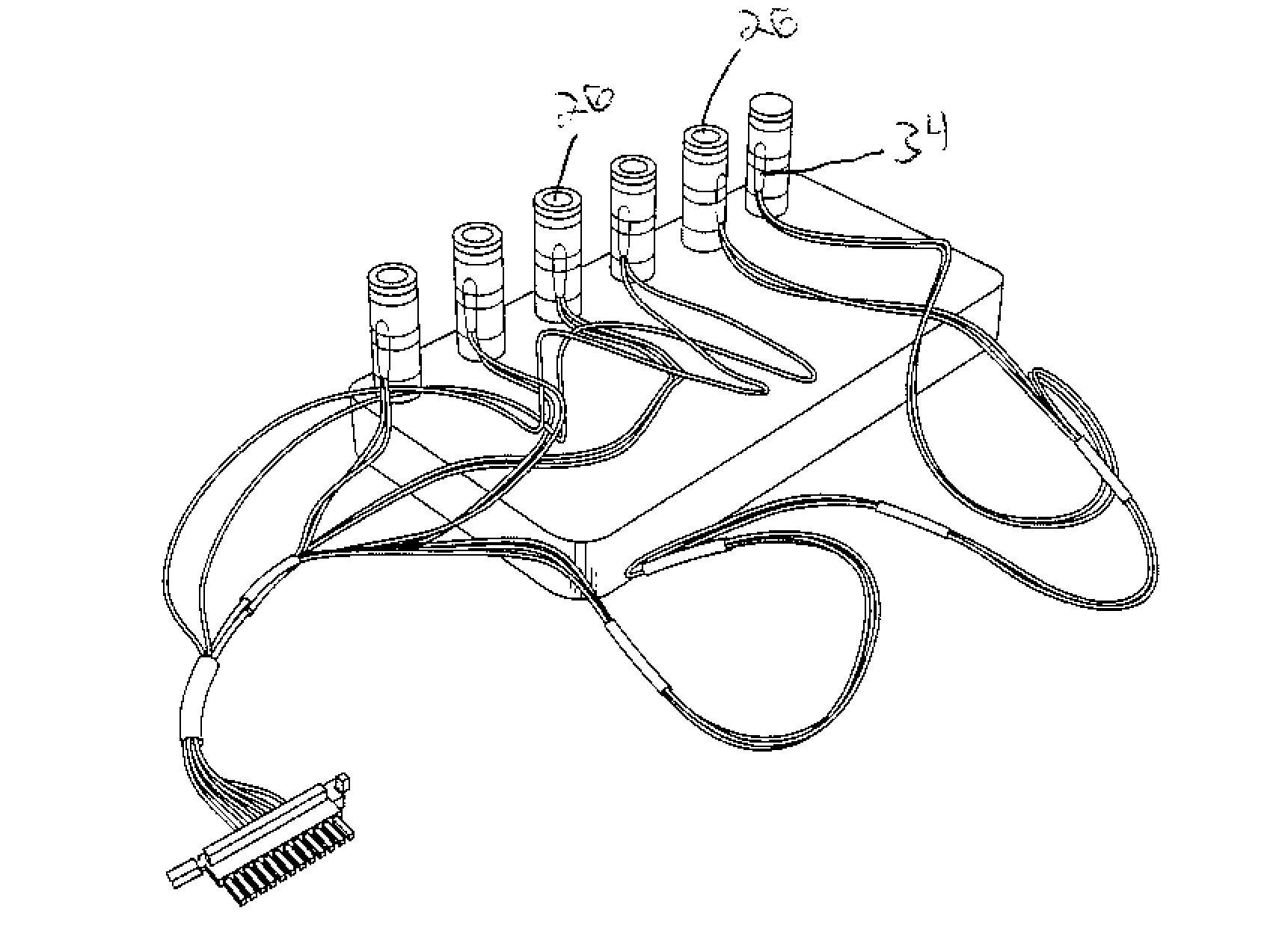

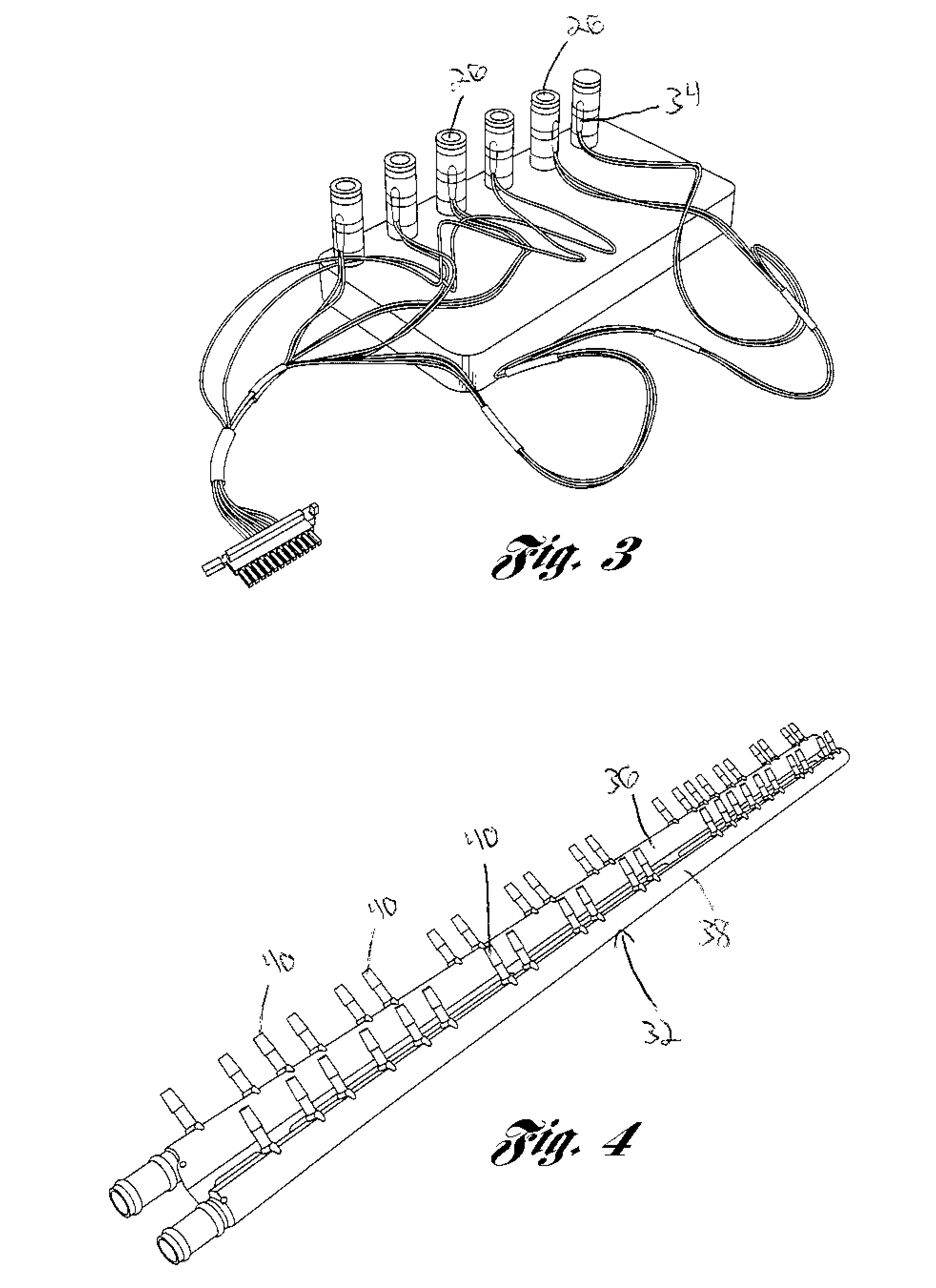

Battery pack thermal management system

InactiveUS20090023056A1Increase thermal massReduce temperature riseAir-treating devicesCell temperature controlElectrical resistance and conductanceThermal management system

A battery pack thermal management system for use in an electric car. The battery pack thermal management system includes a plurality of thermistors connected to a plurality of cells of a battery pack. A battery monitor board is connected to the thermistors. The system also includes a manifold and a plurality of cooling tubes connected to the manifold. A tube seal plug is arranged over an end of the cooling tube and an end fitting is arranged on an end of the cooling tube. The thermal management system will cool the battery pack to predetermined temperatures to increase the longevity of the battery pack within the electric vehicle.

Owner:TESLA INC

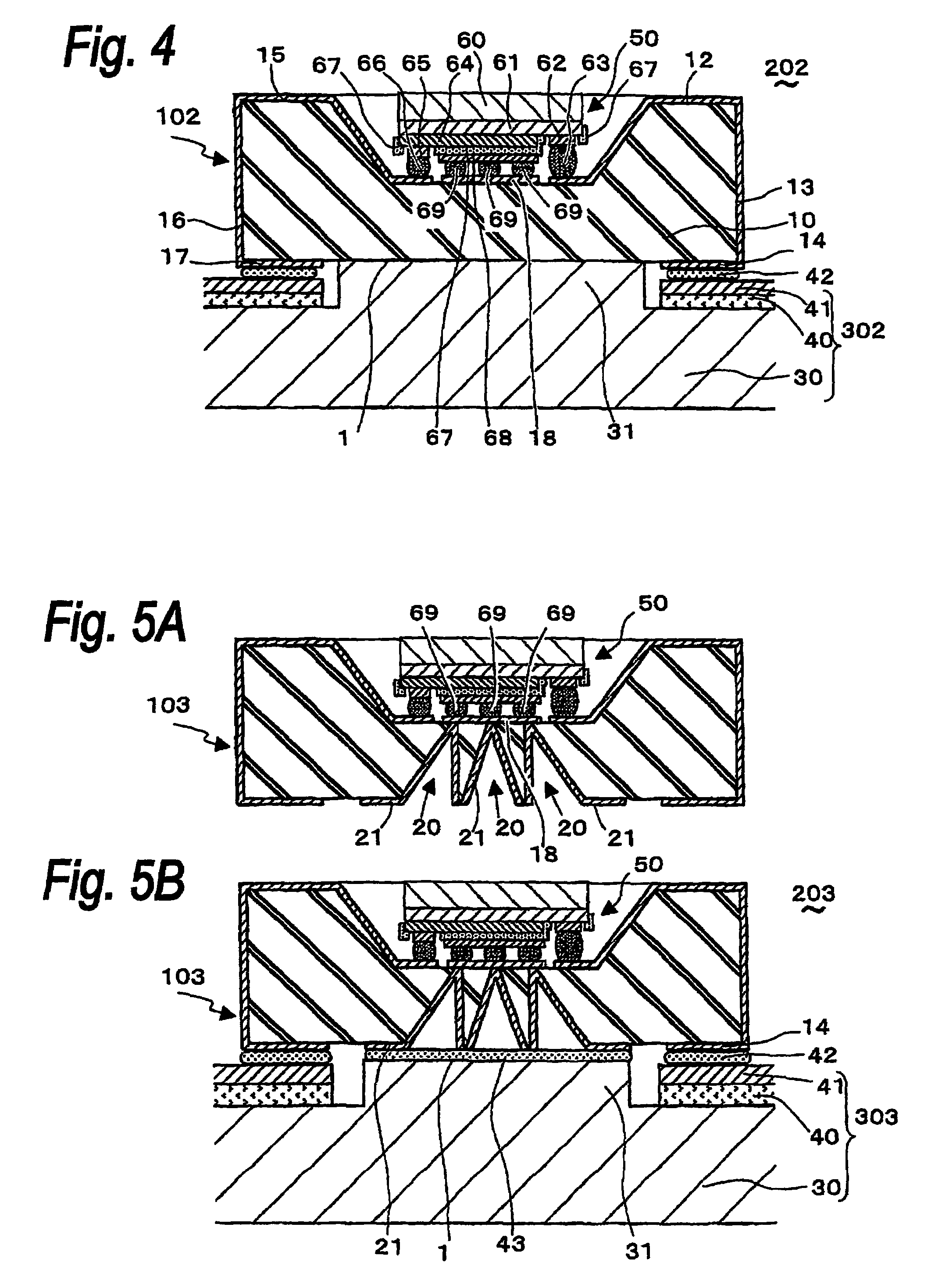

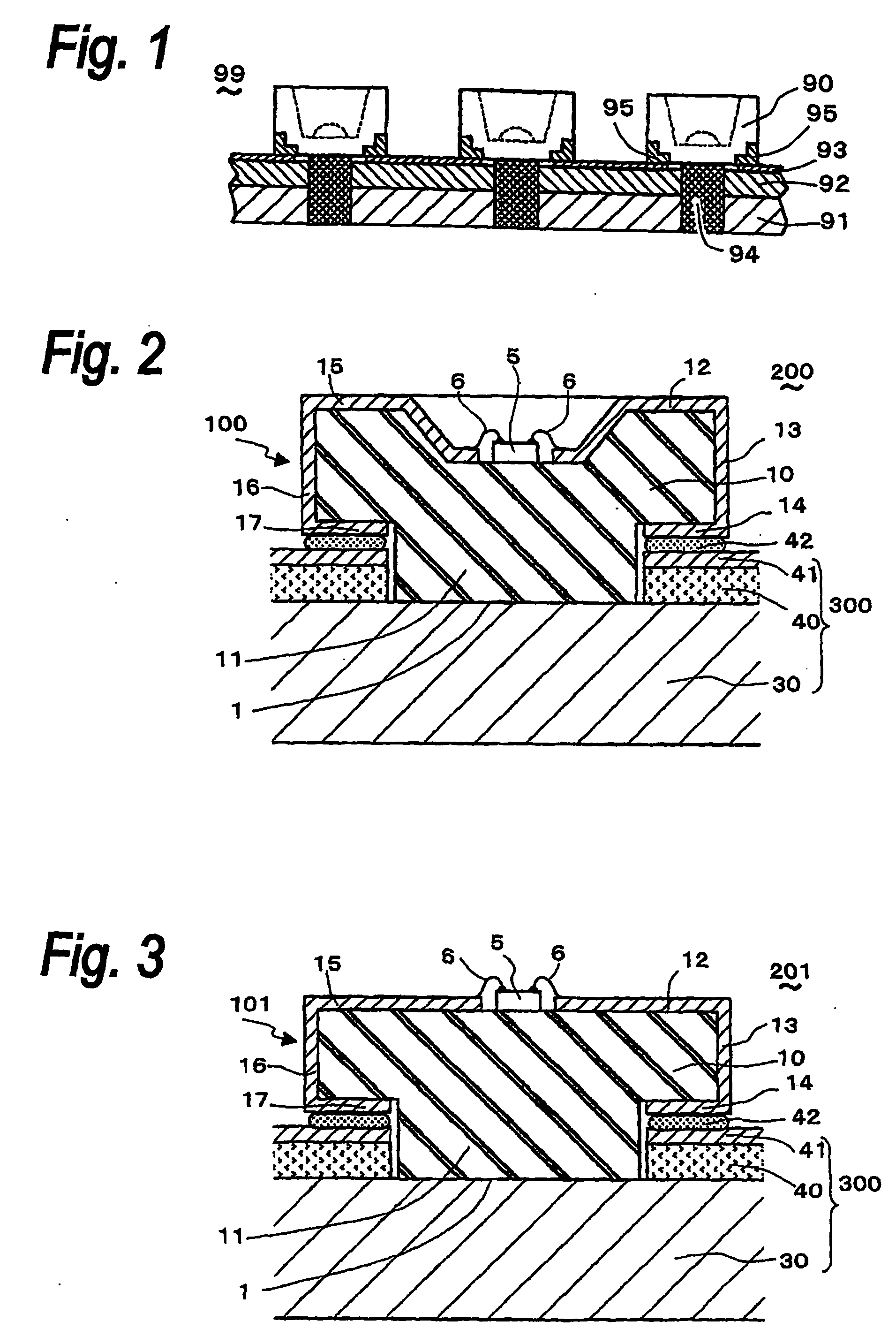

Light-emitting device

ActiveUS7495322B2Easy transferReduce temperature risePoint-like light sourcePortable electric lightingEngineeringLight emitting device

Owner:MATSUSHITA ELECTRIC WORKS LTD

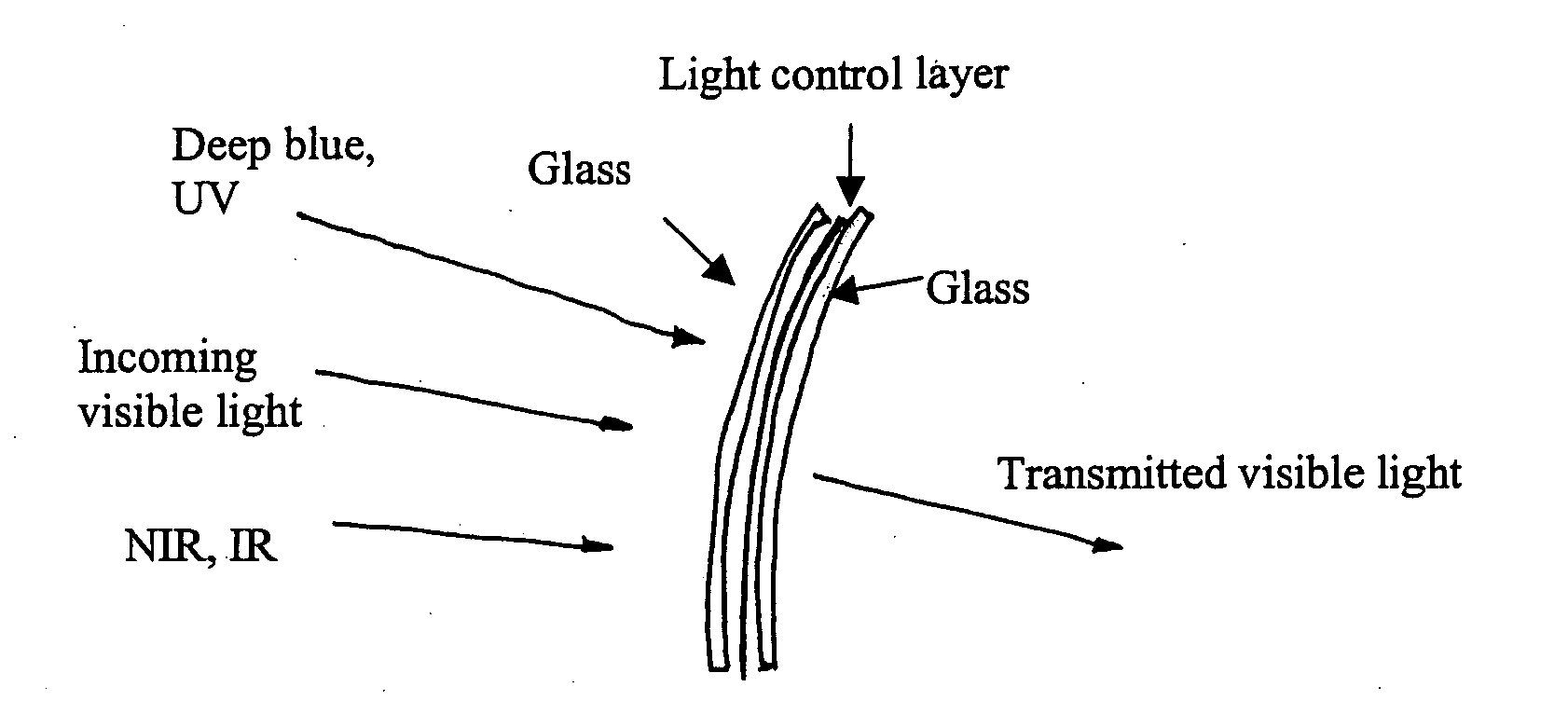

Adjustably opaque window

InactiveUS20050068629A1Reduce decreaseMinimized and eliminatedLight dependant control systemsAntiglare equipmentControl layerLight transmission

An adjustably opaque window including an external pane, an internal pane, a light transmission control layer and a shock-absorbing layer is provided. The external pane and the internal pane provide a cavity between them, and the light transmission control layer and the shock-absorbing layer are positioned in the cavity. The shock-absorbing layer is a flexible sheet that supports and protects the light transmission control layer. The light transmission layer consists of liquid crystal cells. The transmission ratio of the cells can be controlled variably.

Owner:LCT ENTERPRISES

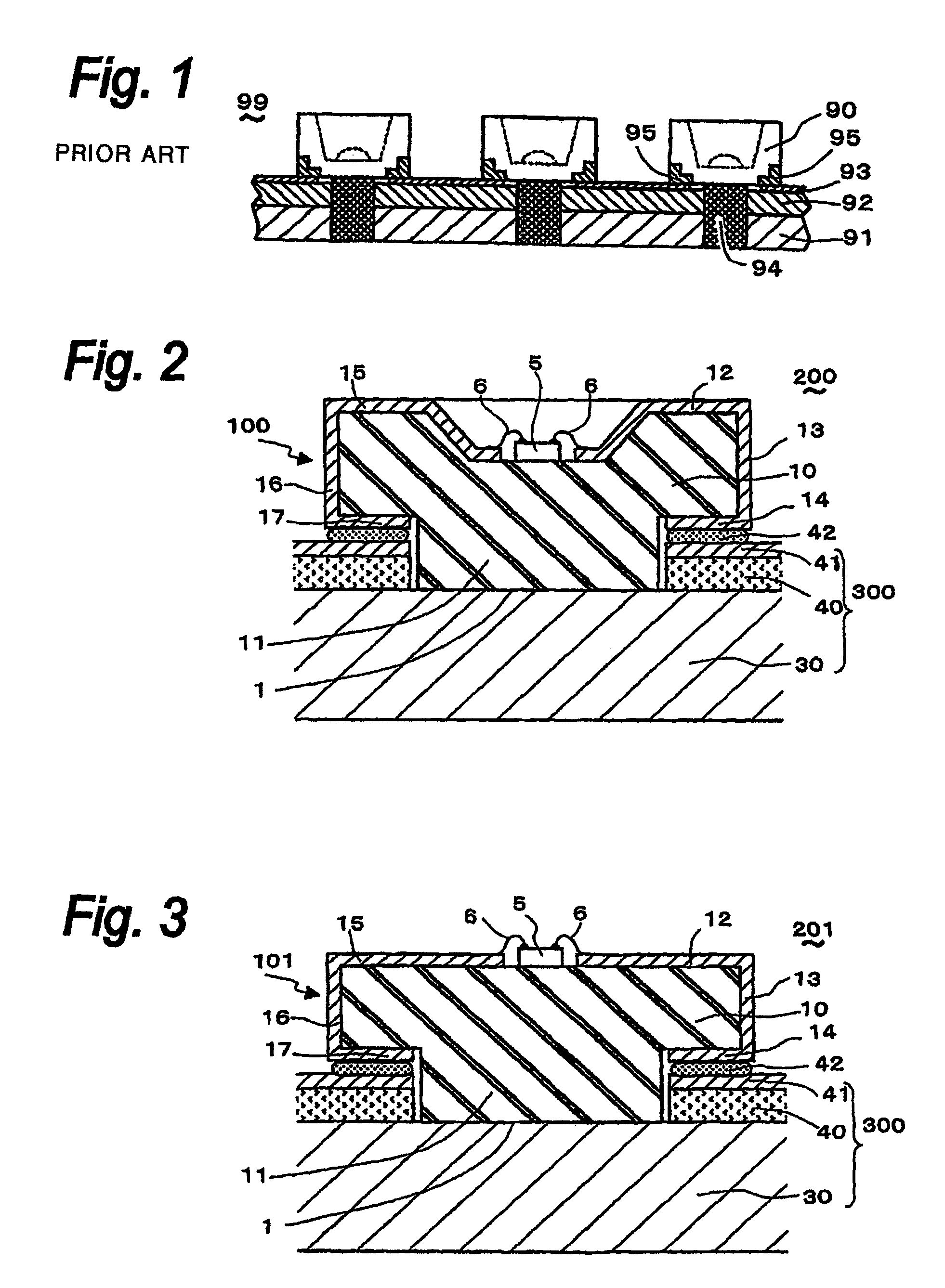

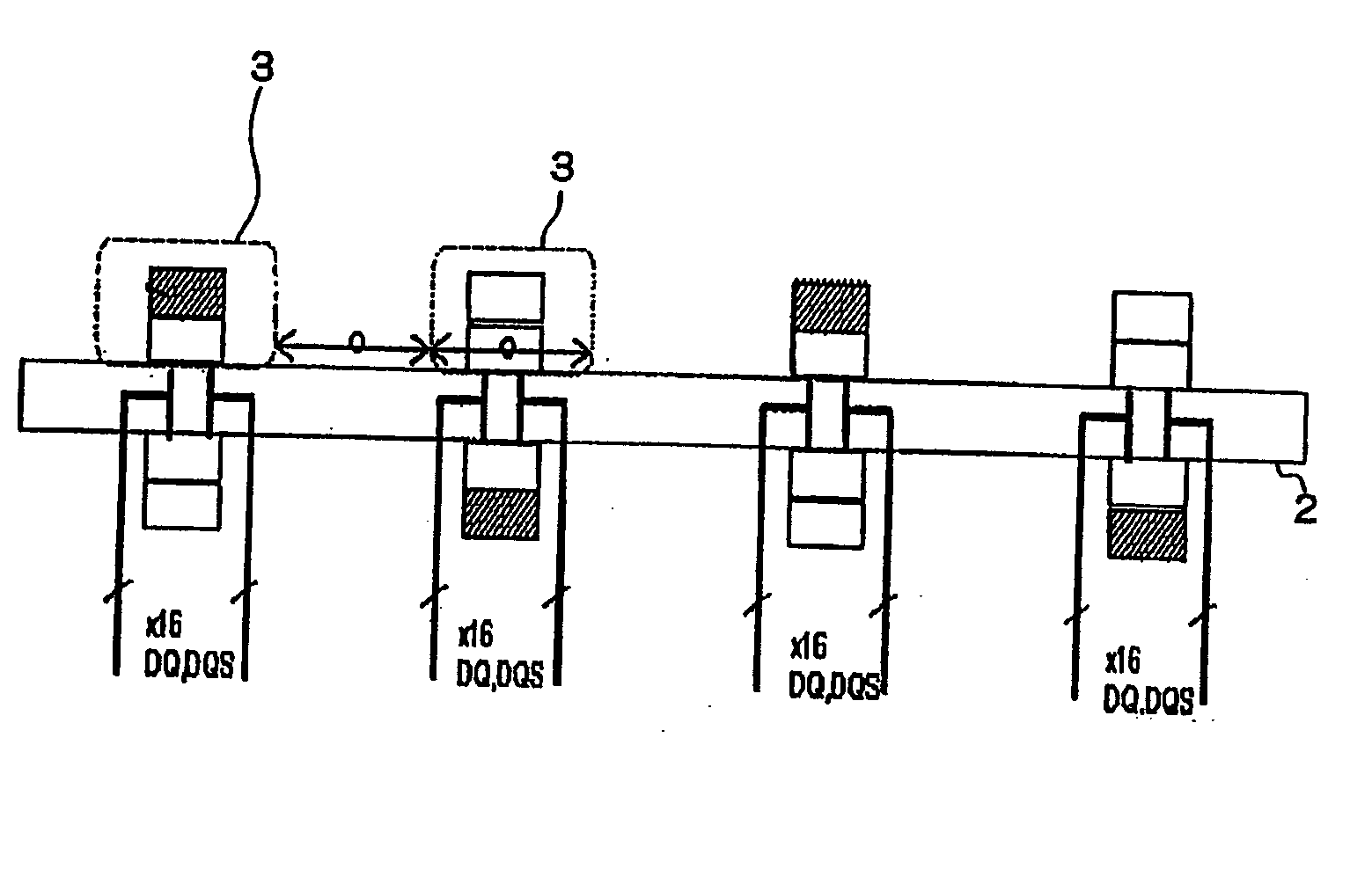

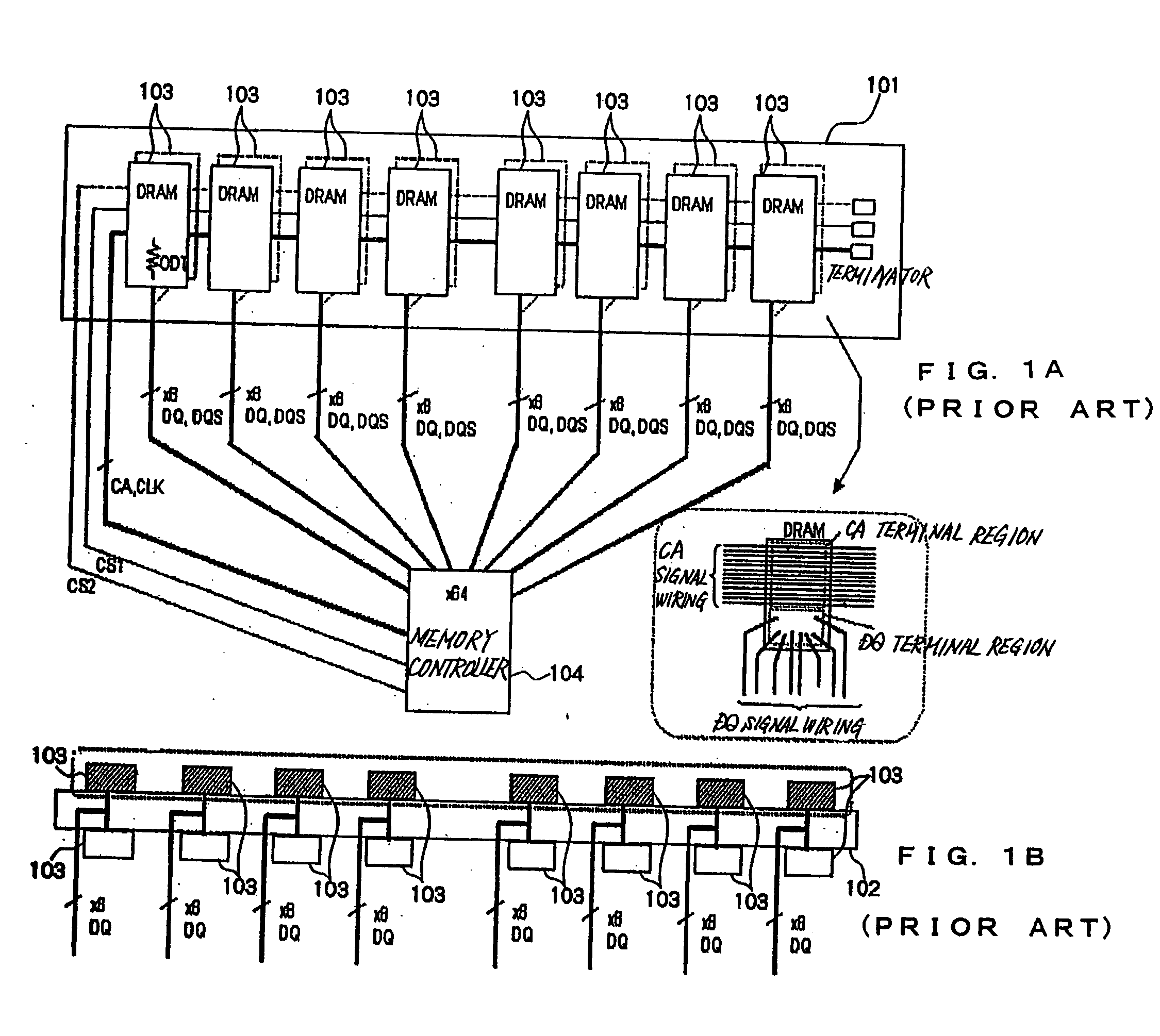

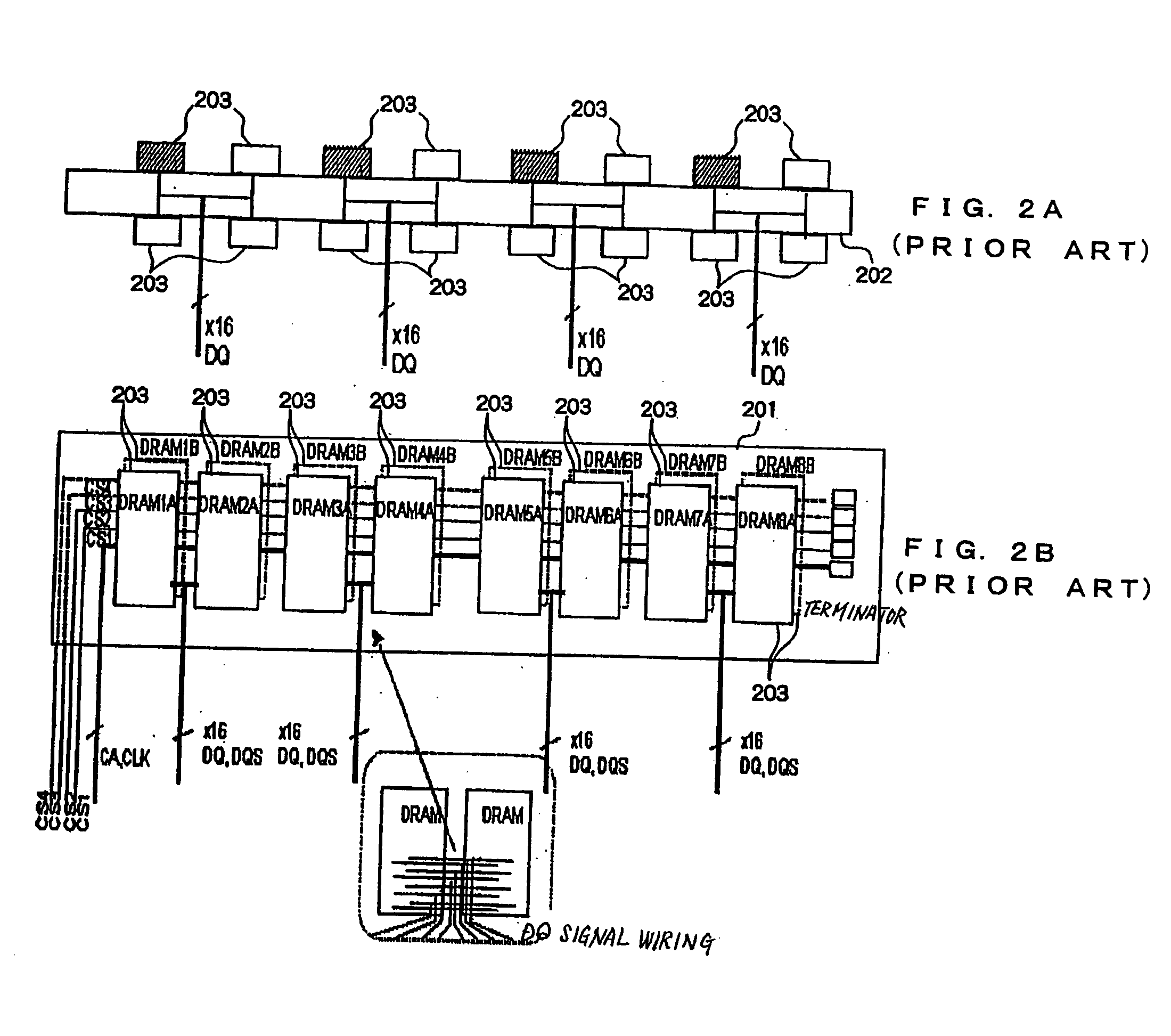

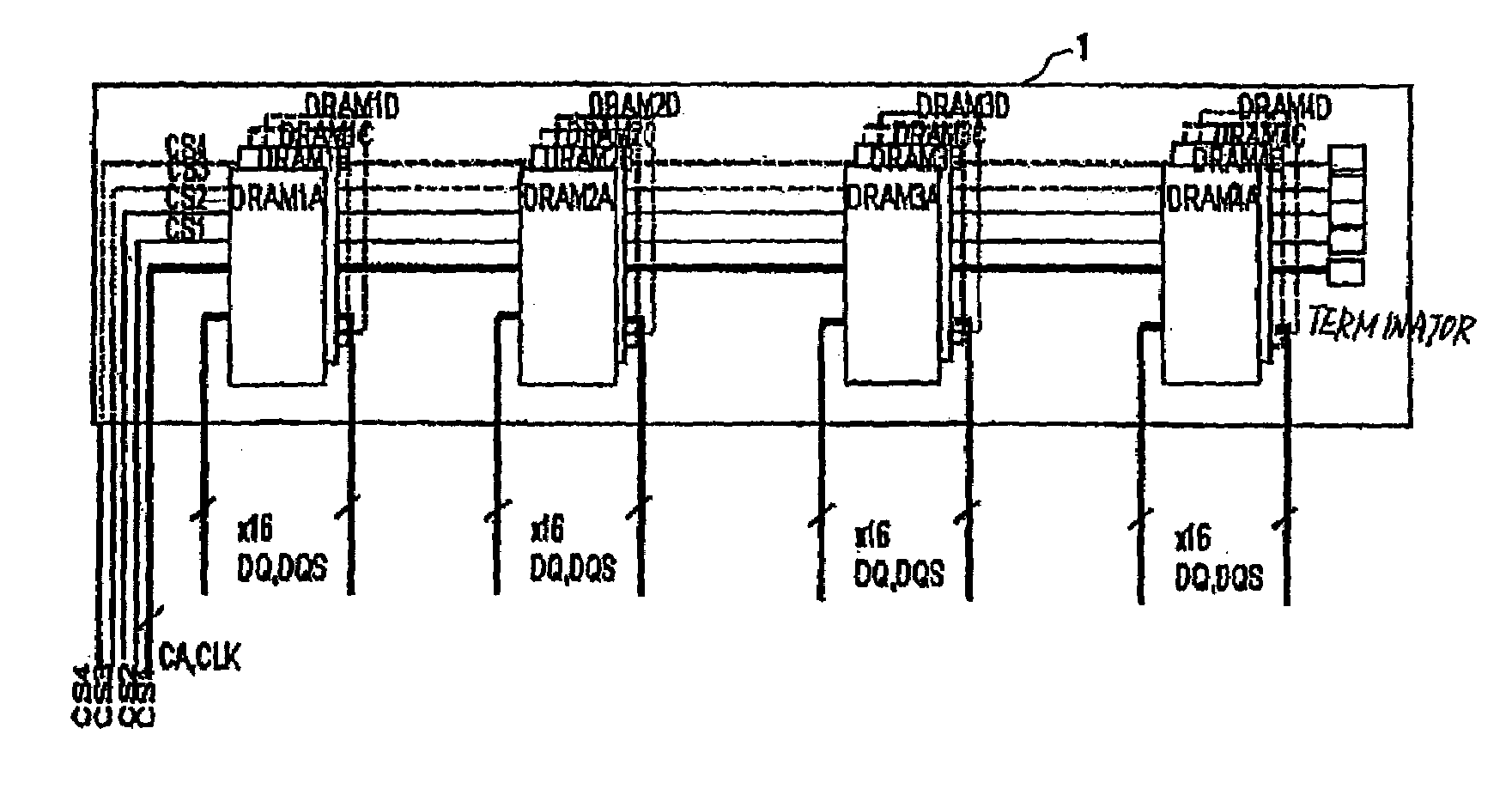

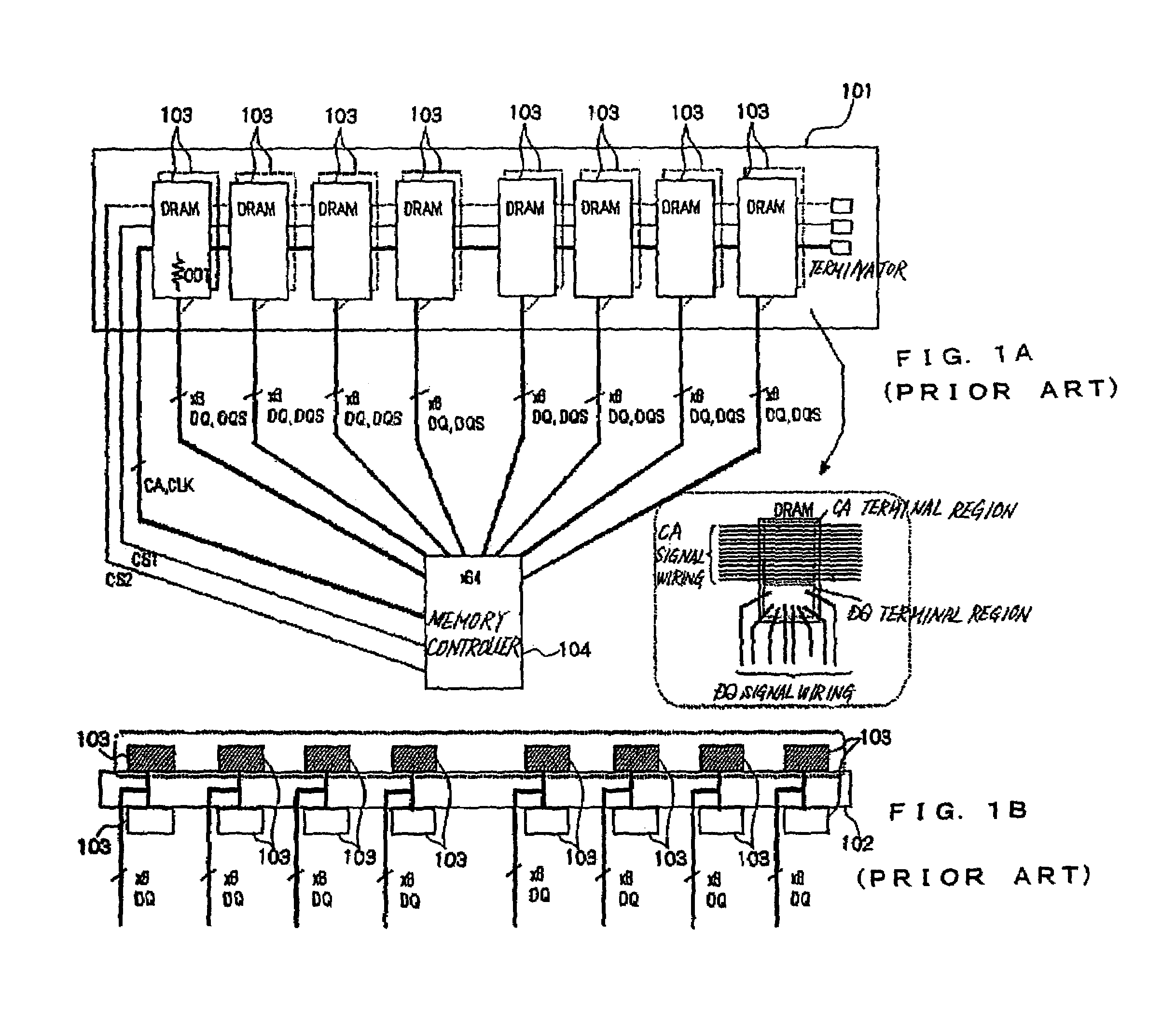

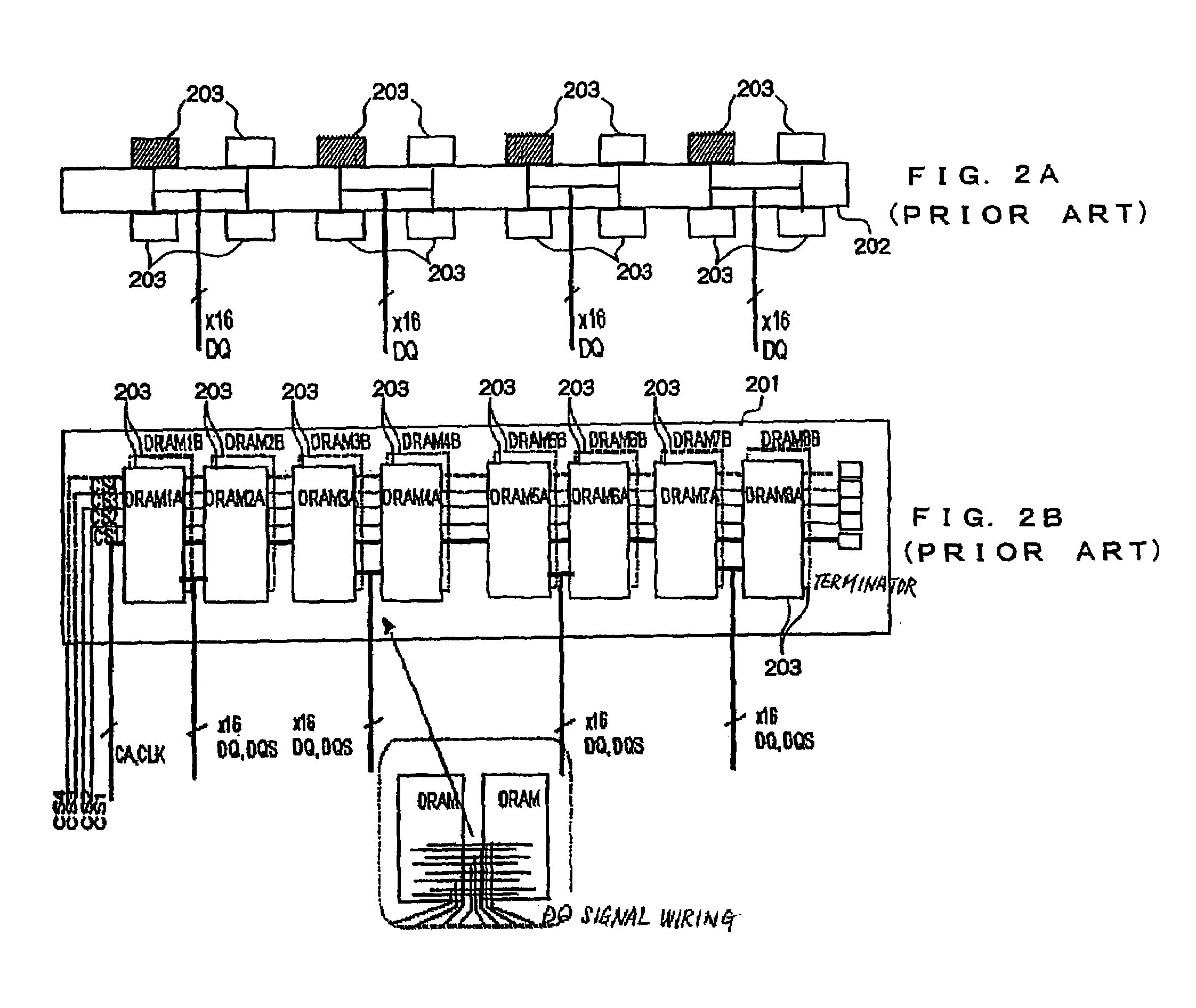

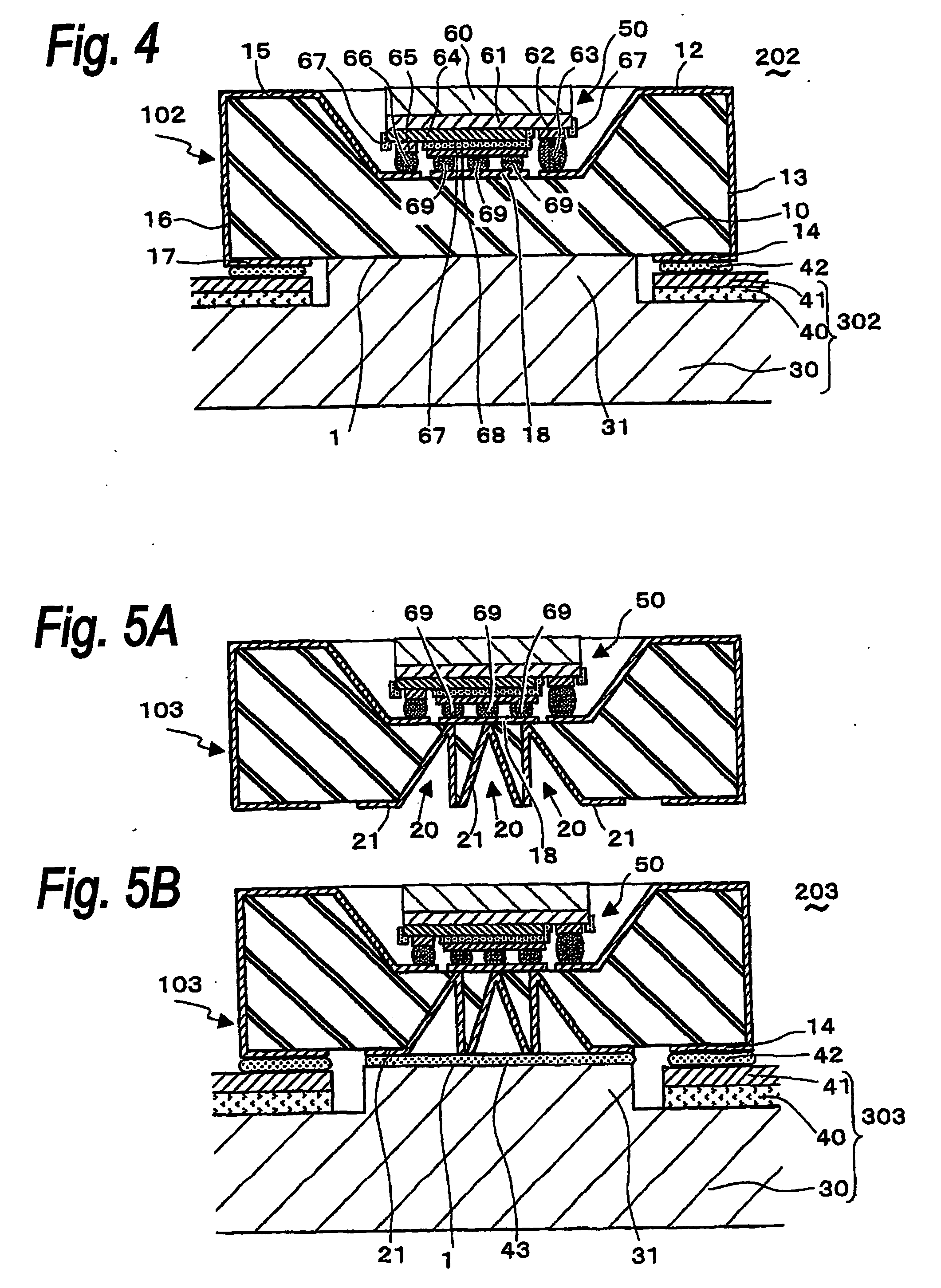

Stacked memory, memory module and memory system

InactiveUS20050099834A1High speed data transmissionReduce power consumptionFinal product manufactureSemiconductor/solid-state device detailsMemory chipTerm memory

A point-to-point bus and a daisy chain bus are provided for supplying signals to stacked memories, and the stacked memories are mounted mutually apart by a distance equivalent to the length of the stacked memory on both surfaces of a module substrate. Furthermore, the memory chips arranged in a stacked memory mounted on one surface are set in an active state at the same time alternately with the memory chips arranged in a stacked memory mounted on another surface of the module substrate.

Owner:LONGITUDE SEMICON S A R L

Stacked memory, memory module and memory system

InactiveUS7102905B2High data transmissionReduce power consumptionFinal product manufactureSemiconductor/solid-state device detailsMemory chipComputer module

Owner:LONGITUDE SEMICON S A R L

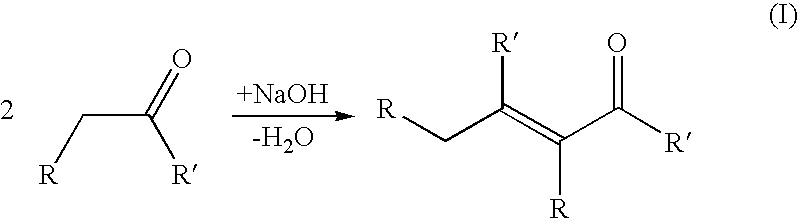

Process for producing a branched hydrocarbon component

InactiveUS20070135316A1Reduce carbon dioxide emissionsImprove stabilityOrganic compound preparationCatalytic naphtha reformingIsomerizationHydrodeoxygenation

The invention relates to a process for producing high-quality hydrocarbon base oil particularly of biological origin. The process of the invention comprises aldol condensation, hydrodeoxygenation, and isomerization steps. Aldehydes and / or ketones, preferably of biological origin are used as the feedstock.

Owner:NESTE OIL OY

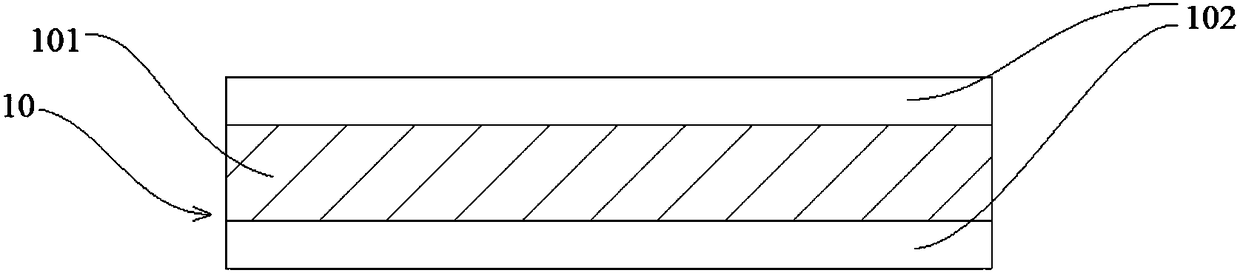

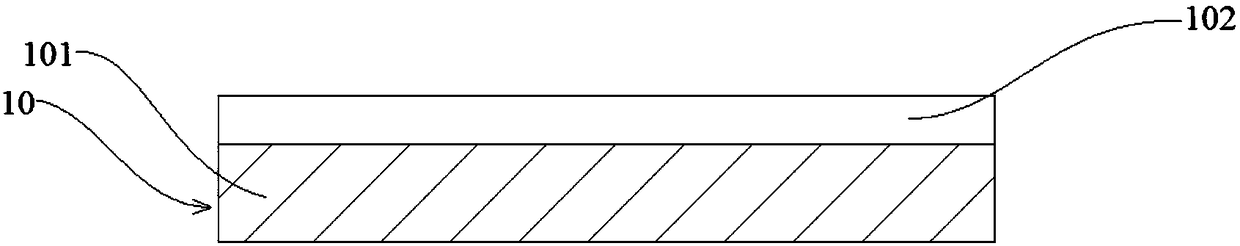

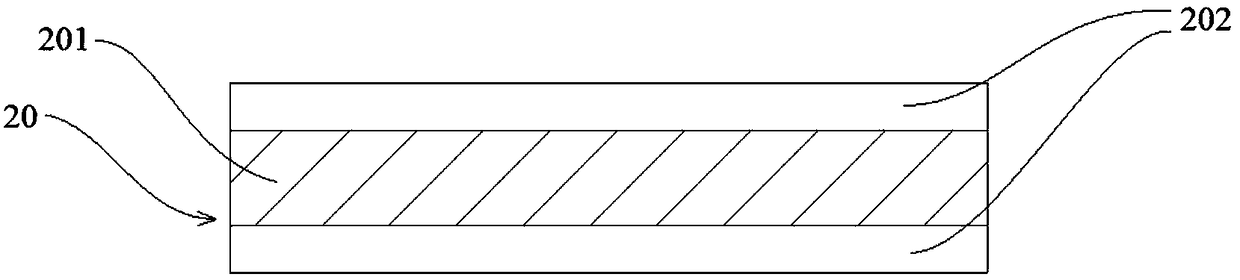

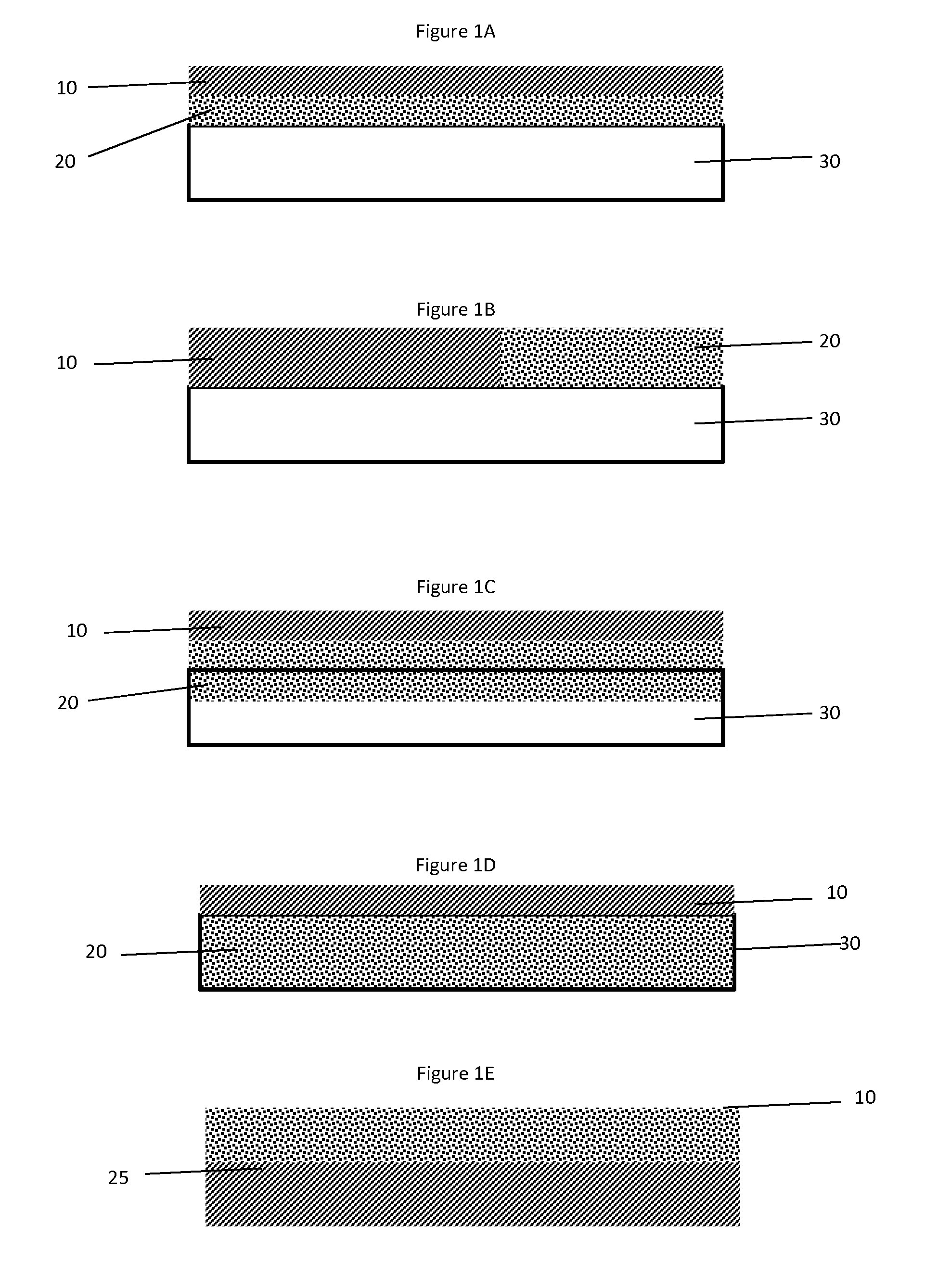

Current collector and application thereof, and pole piece and battery using same

ActiveCN108281662ANo fireThere will be no accidents such as explosionsElectrode carriers/collectorsSecondary cellsElectrical resistance and conductanceFilm resistance

The invention specifically relates to a current collector and application thereof, and a pole piece and a battery using the same, belonging to the field of batteries. The current collector of the invention comprises an insulating layer and a conducting layer, wherein the insulating layer is used for bearing the conducting layer; the conducting layer is used for bearing an electrode active materiallayer; and the normal-temperature film resistance Rs of the conducting layer is no less than 0.016 omega / sq and no more than 420 omega / sq. The current collector provided by the invention can greatlyincrease the short-circuit resistance of the battery in cases of abnormal conditions, allows short-circuit current to be greatly reduced, so heat produced by short circuits is greatly lowered, and heat produced at sites where internal short circuits occur can be totally absorbed by the battery; and thus, the influence of short-circuit damage to the battery is limited to certain points, only pointcircuit break occurs, and the normal operation of the battery in a short period of time is not affected.

Owner:CONTEMPORARY AMPEREX TECH CO

Frequency selective passive component networks for implantable leads of active implantable medical devices utilizing an energy dissipating surface

InactiveUS20100016936A1Increase temperatureAbility to in properDiagnosticsInternal electrodesEnergy transferRf field

Decoupling circuits are provided which transfer energy induced from an MRI pulsed RF field to an energy dissipating surface. This is accomplished through broadband filtering or by resonant filtering. In a passive component network for an implantable leadwire of an active implantable medical device, a frequency selective energy diversion circuit is provided for diverting high-frequency energy away from a leadwire electrode to a point or an area spaced from the electrode, for dissipation of high-frequency energy.

Owner:WILSON GREATBATCH LTD

Frequency selective passive component networks for implantable leads of active implantable medical devices utilizing an energy dissipating surface

InactiveUS7689288B2Increase temperatureAbility to in properDiagnosticsInternal electrodesEnergy transferRf field

Decoupling circuits are provided which transfer energy induced from an MRI pulsed RF field to an energy dissipating surface. This is accomplished through broadband filtering or by resonant filtering. In a passive component network for an implantable leadwire of an active implantable medical device, a frequency selective energy diversion circuit is provided for diverting high-frequency energy away from a leadwire electrode to a point or an area spaced from the electrode, for dissipation of high-frequency energy.

Owner:WILSON GREATBATCH LTD

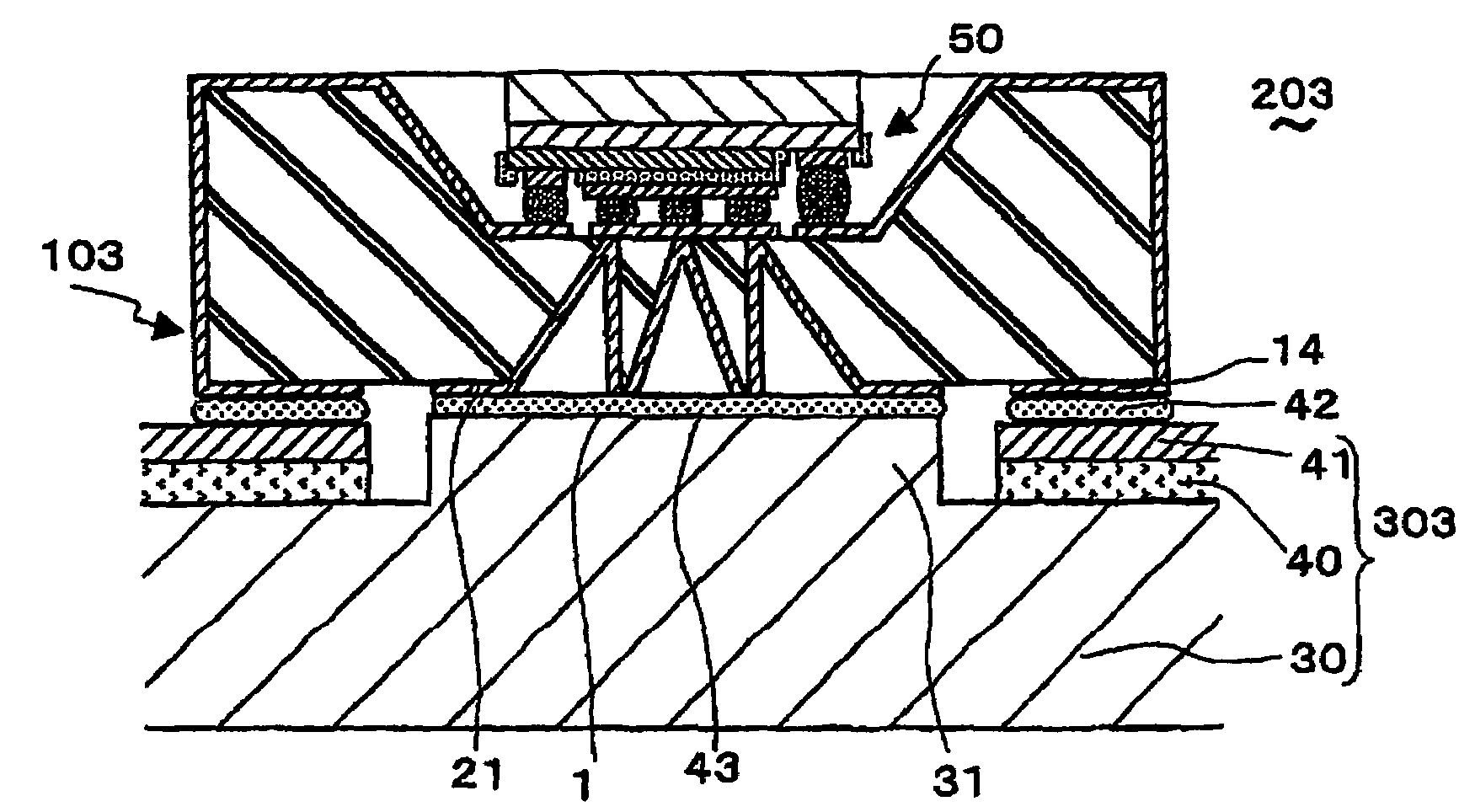

Light-emitting device

ActiveUS20070007540A1Easy transferReduce temperature risePoint-like light sourcePortable electric lightingEngineeringLight emitting device

A light-emitting device (200) has a submount (100) and a plate for heat transfer (300) having a metallic plate (30). The submount (100) has a mount base (10), at least one light-emitting diode chip (5) mounted thereon and electrically conducting lines (12-17) formed on the mount base (10) to be connected electrically to the light-emitting diode chip (5). A first plane (11) of the mount base (10) of the submount (100) is bonded thermally to the first plate (300). For example, the plate is a circuit board having a metallic plate (30), and the submount (100) is bonded thermally to the metallic plate (30) of the one of the at least one plate (300). In an example, a second plate for heat transfer is also bonded thermally to a second plane of the mount base (100) for providing a plurality of heat transfer paths.

Owner:MATSUSHITA ELECTRIC WORKS LTD

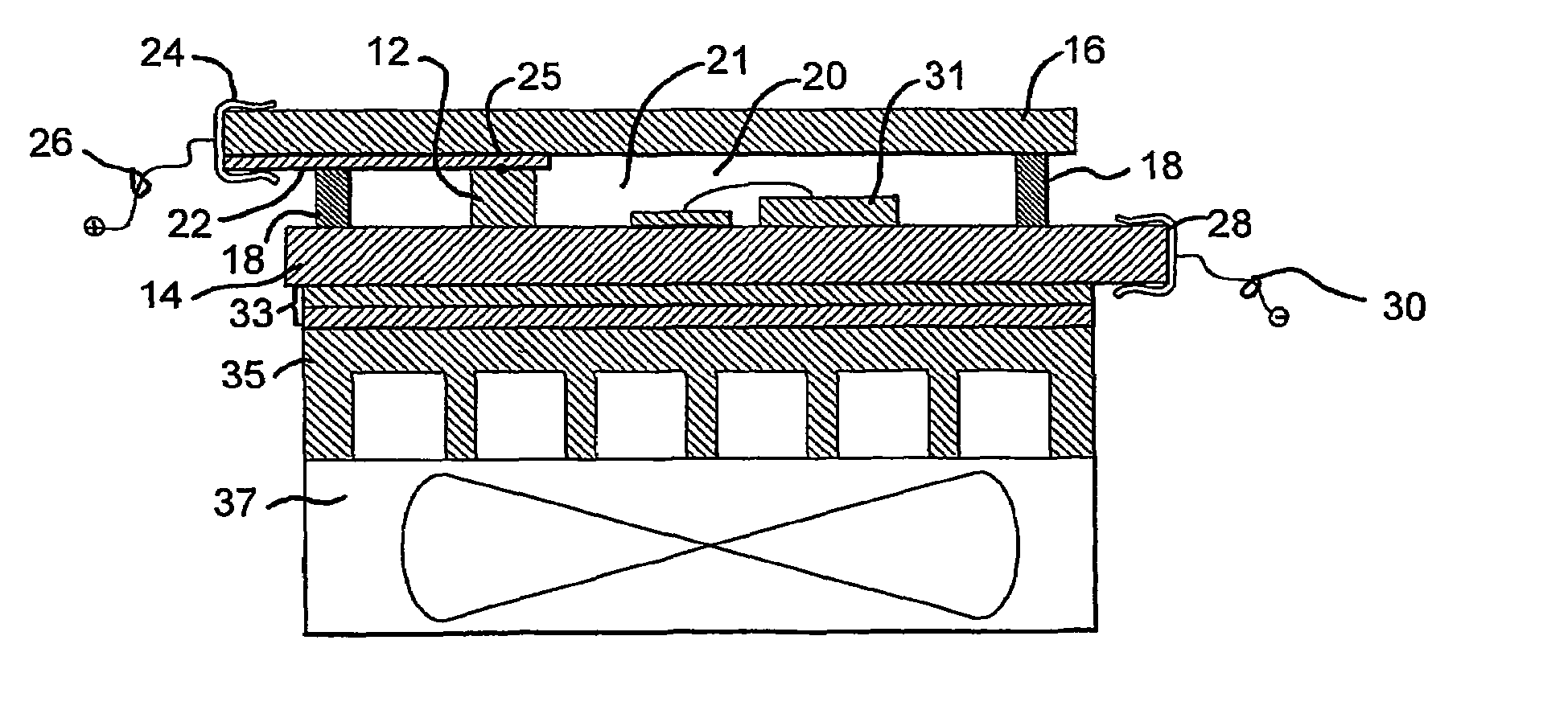

High power radiation emitter device and heat dissipating package for electronic components

InactiveUS7075112B2Increase powerReduce temperature riseSemiconductor/solid-state device detailsElectroluminescent light sourcesElectricityElectrical conductor

The electronic component package (10) of the present invention includes a sealed chamber; a liquid or gel (20) contained in the sealed chamber; at least one electronic component (12) disposed in the sealed chamber in physical and thermal contact with the liquid or gel (20); and at least one electrical conductor electrically coupled to the electronic component and extending out of the sealed chamber. The electronic component(s) (12) may include any one or combination of a radiation emitter, a thermal or optical sensor, a resistor, and a microprocessor or other semiconductor component.

Owner:GENTEX CORP

Frequency selective passive component networks for implantable leads of active implantable medical devices utilizing an energy dissipating surface

InactiveUS7751903B2Increase temperatureAbility to in properMultiple-port networksElectrocardiographyRf fieldEnergy transfer

Decoupling circuits are provided which transfer energy induced from an MRI pulsed RF field to an energy dissipating surface. This is accomplished through broadband filtering or by resonant filtering. In a passive component network for an implantable leadwire of an active implantable medical device, a frequency selective energy diversion circuit is provided for diverting high-frequency energy away from a leadwire electrode to a point or an area spaced from the electrode, for dissipation of high-frequency energy.

Owner:WILSON GREATBATCH LTD

Process for making an overbased, sulfurized salt of an alkylated hydroxyaromatic compound

ActiveUS20110124539A1Improve compatibilityReduced and had no endocrine disruption effectOrganic chemistryAdditivesIsomerizationAlpha-olefin

An overbased, sulfurized salt of at least one alkylated hydroxyaromatic compound, wherein the alkyl substituent of the hydroxyaromatic compound is a residue of at least one isomerized olefin having from about 15 to about 99 wt. % branching is disclosed. The overbased, sulfurized salt of at least one alkylated hydroxyaromatic compound is produced by the process comprising: (a) alkylating at least one hydroxyaromatic compound with at least one isomerized olefin having from about 15 to about 99 wt. % branching obtained by isomerizing at least one normal alpha olefin having from about 10 to about 40 carbon atoms, to provide at least one alkylated hydroxyaromatic compound; (b) neutralizing and sulfurizing the alkylated hydroxyaromatic compound in any order to provide at least one neutralized, sulfurized alkylated hydroxyaromatic compound; and (c) overbasing the at least one neutralized, sulfurized alkylated hydroxyaromatic compound.

Owner:CHEVRON ORONITE CO LLC +1

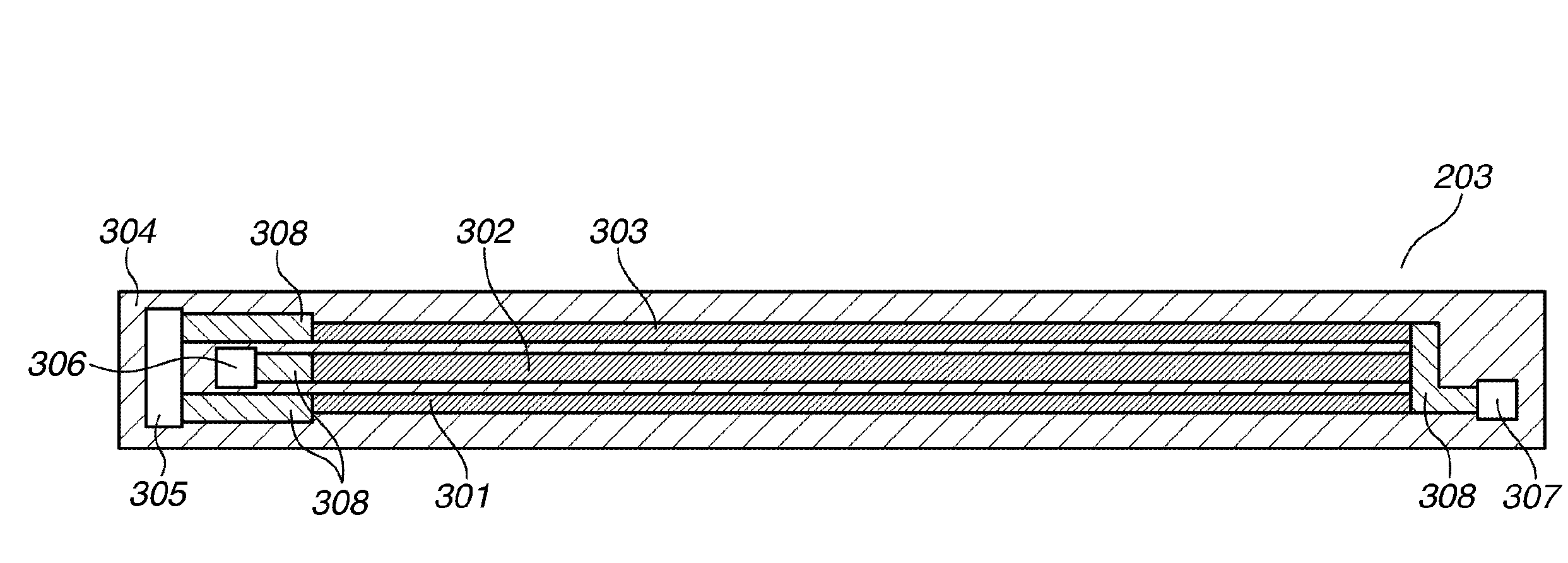

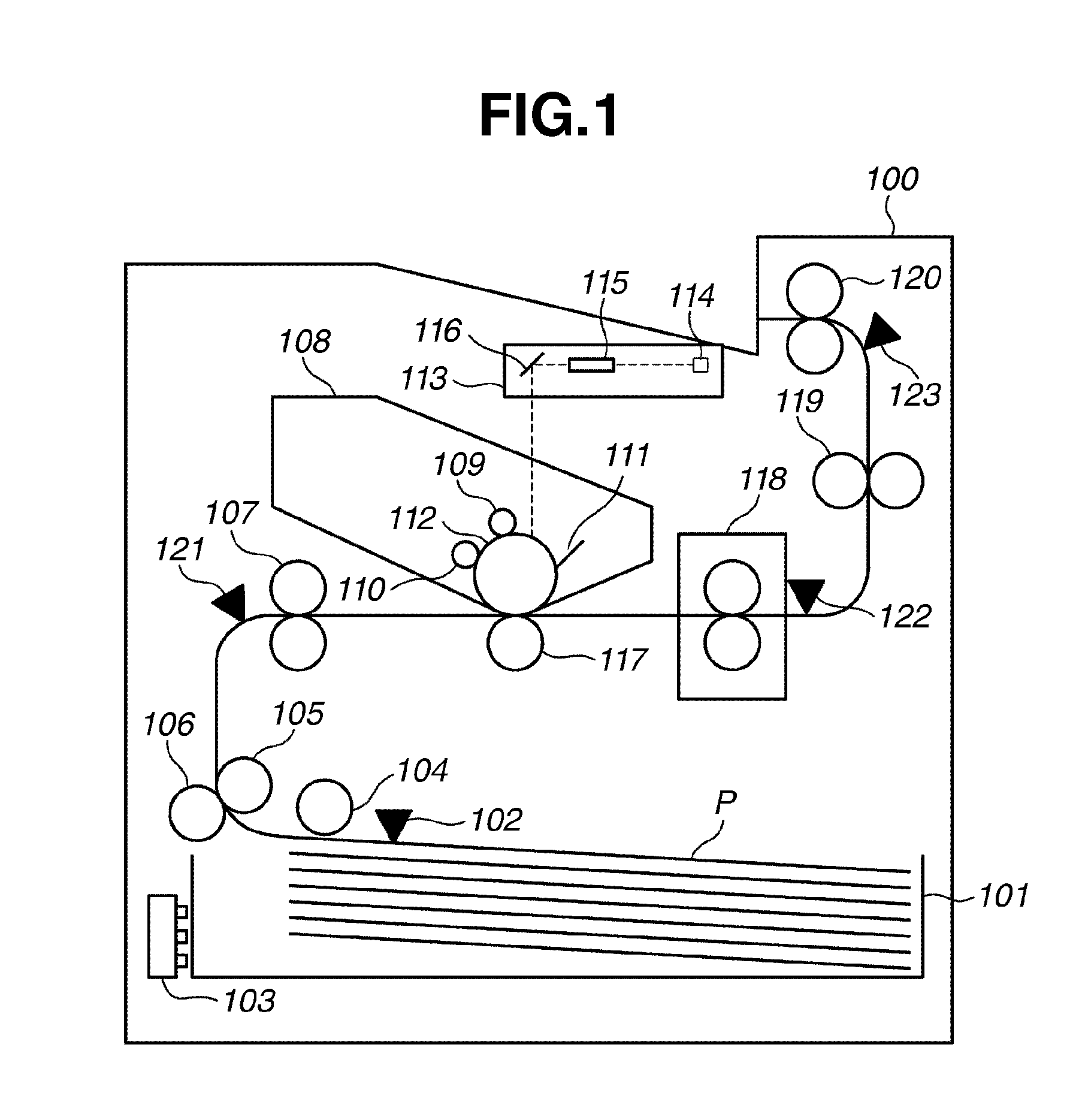

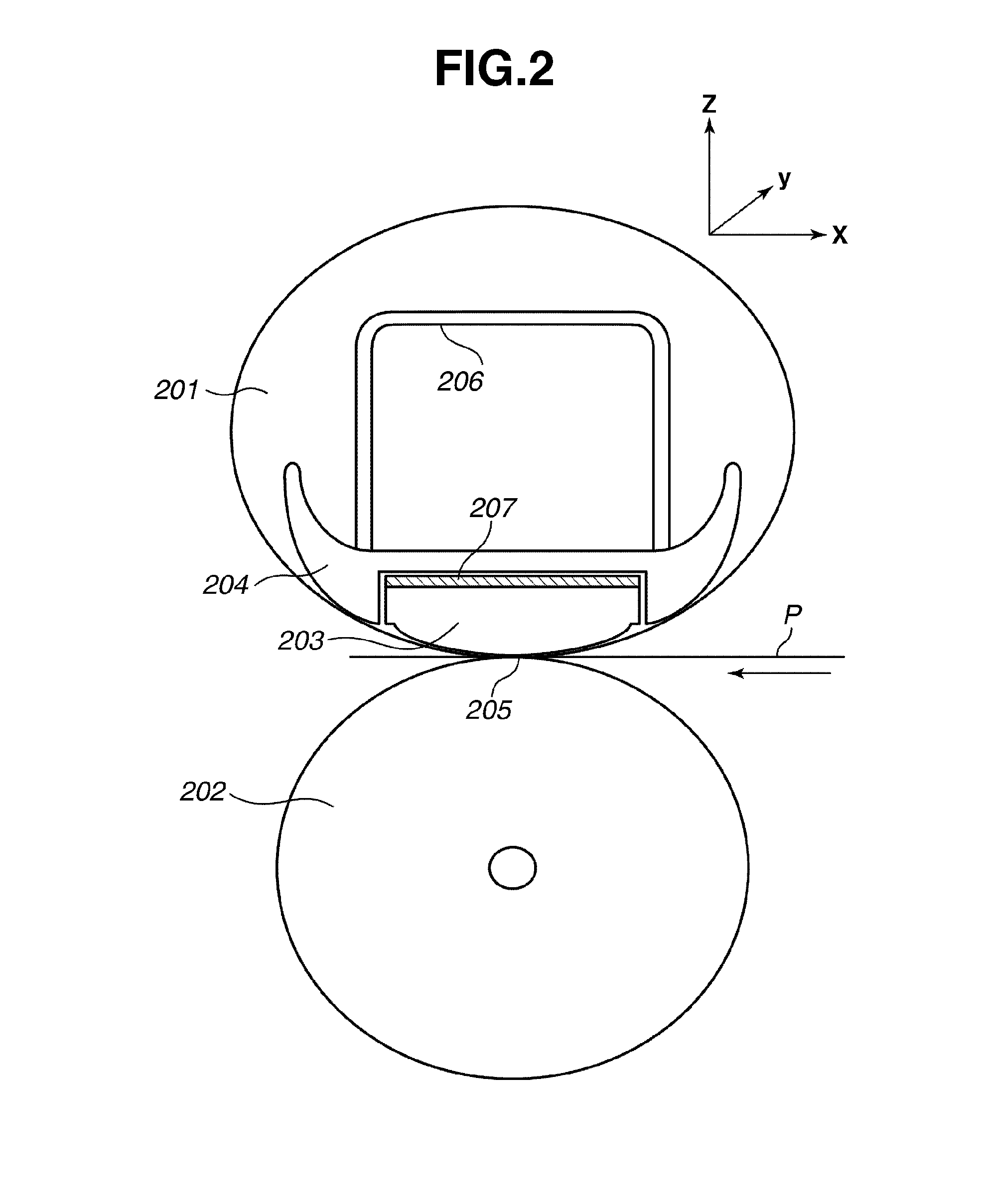

Image heating apparatus and heater used in the same

ActiveUS20140138372A1Improve responsivenessAlleviating non-sheet-passing part temperature riseOhmic-resistance heatingElectrographic process apparatusEngineeringElectrical and Electronics engineering

Owner:CANON KK

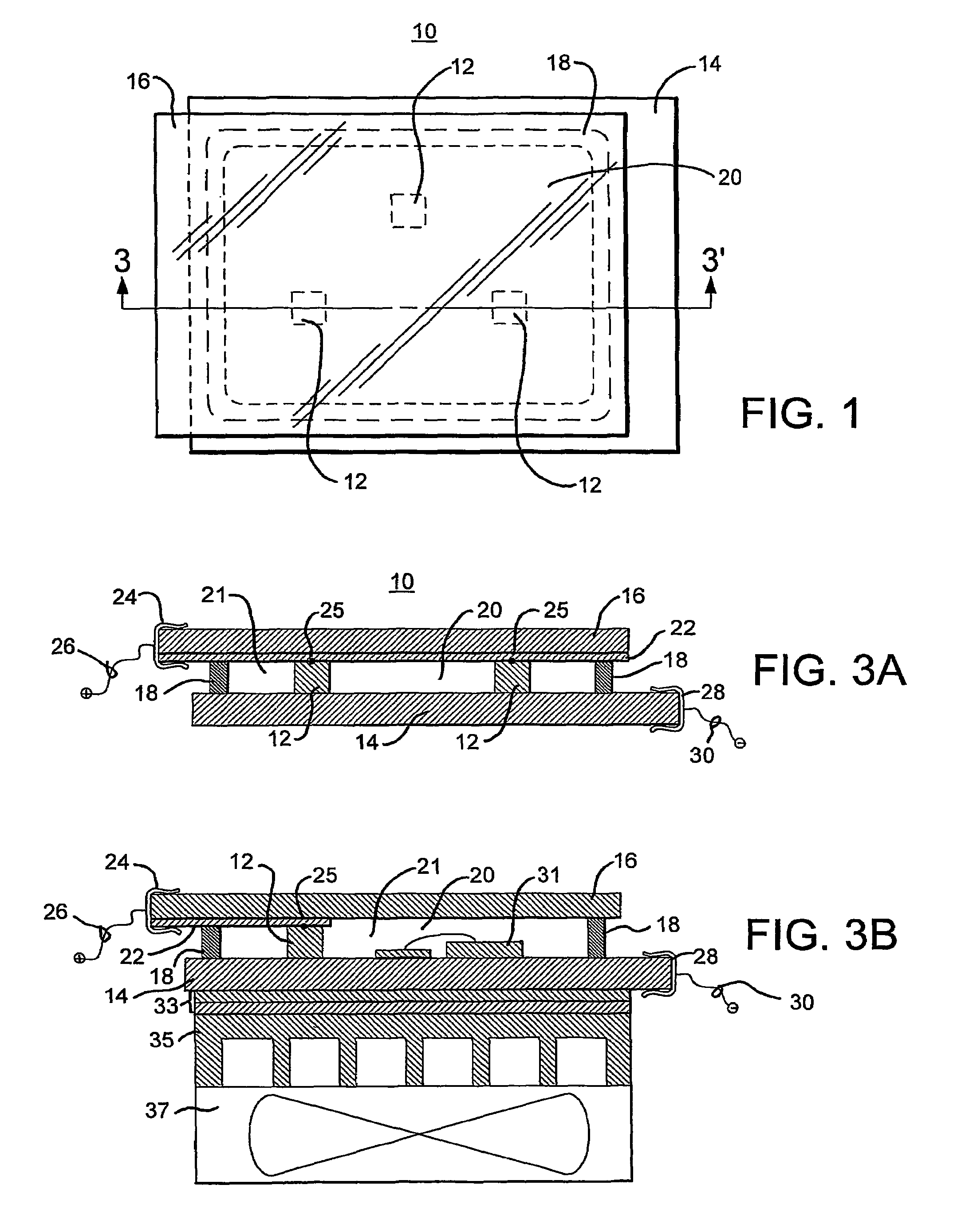

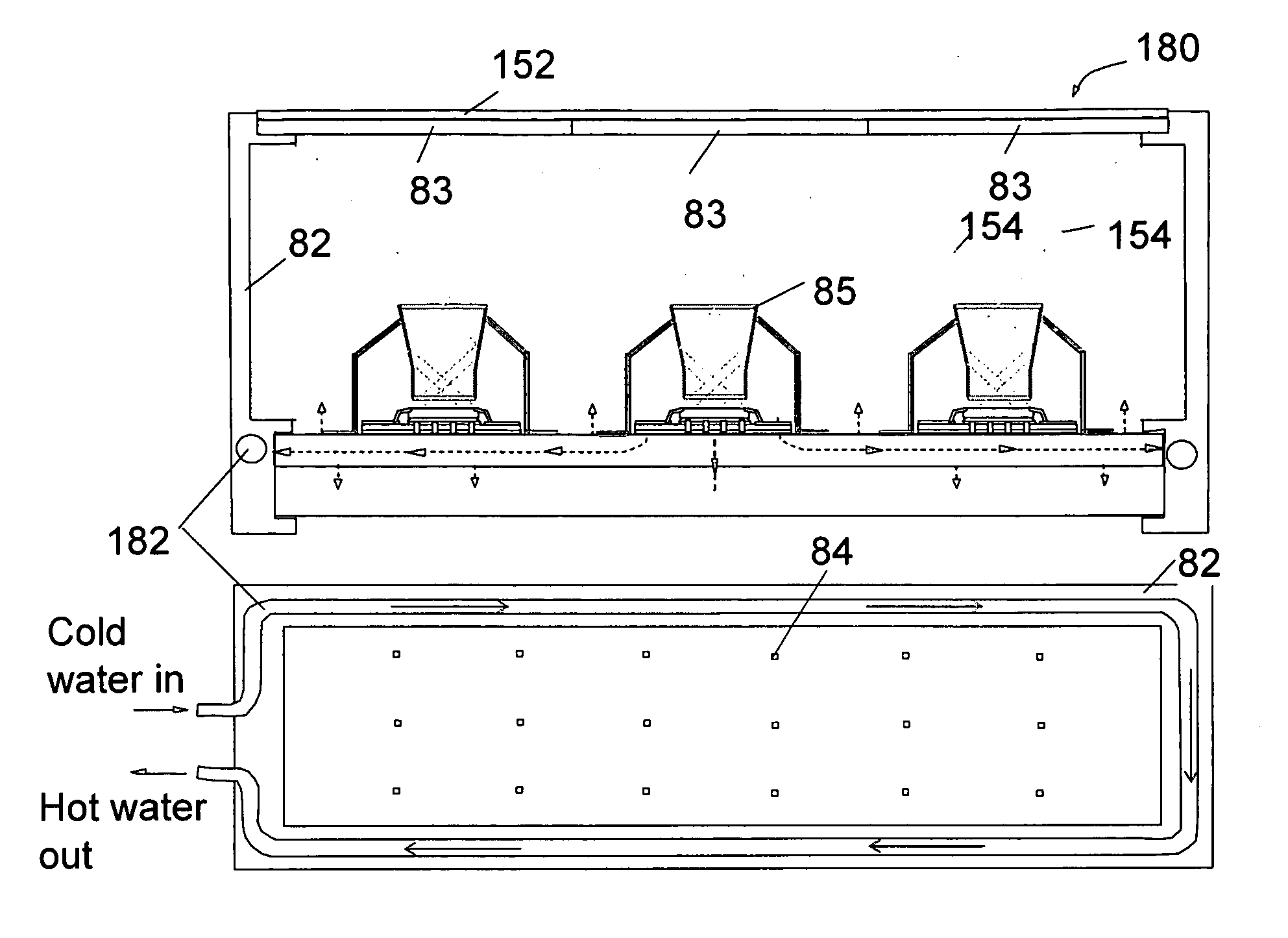

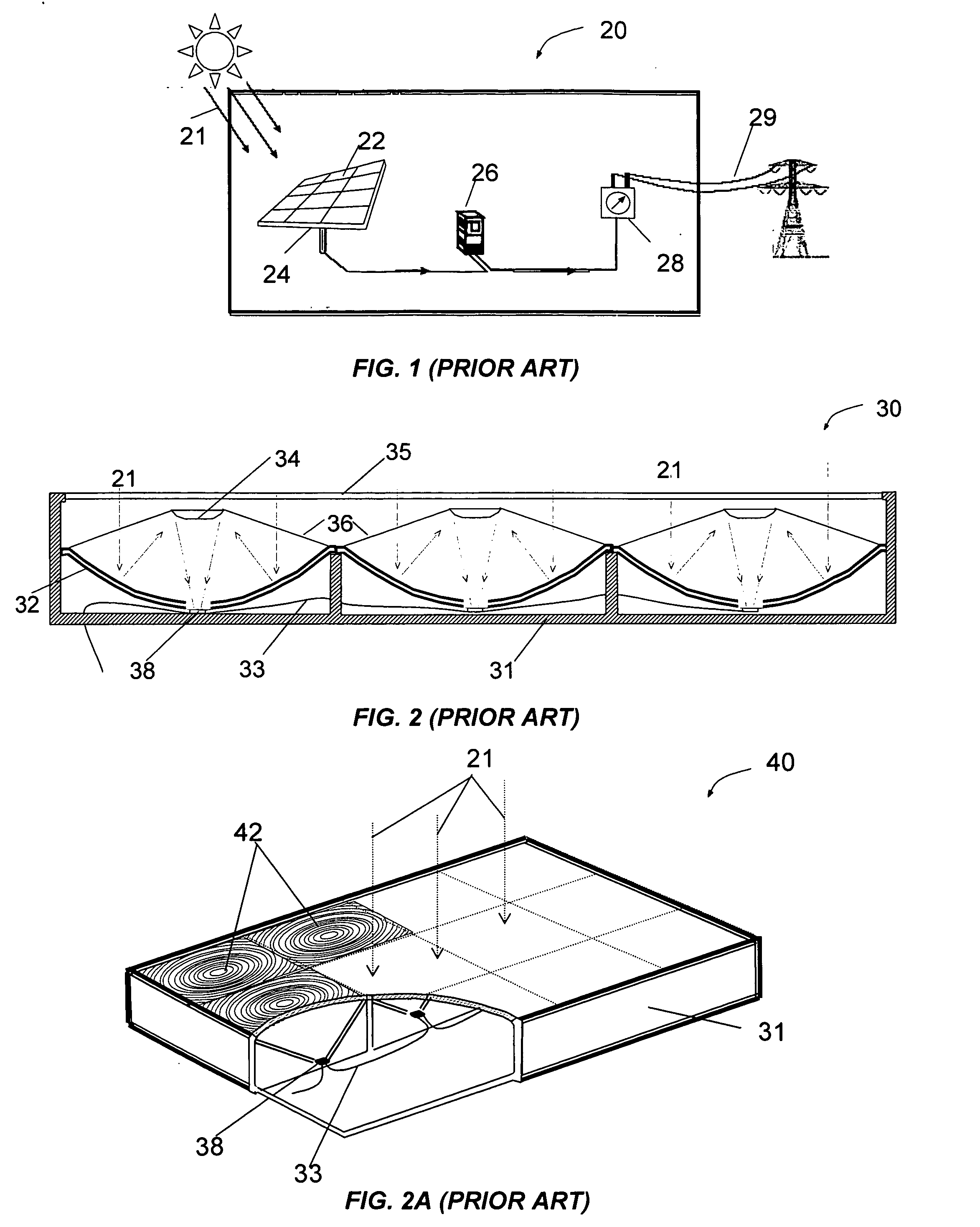

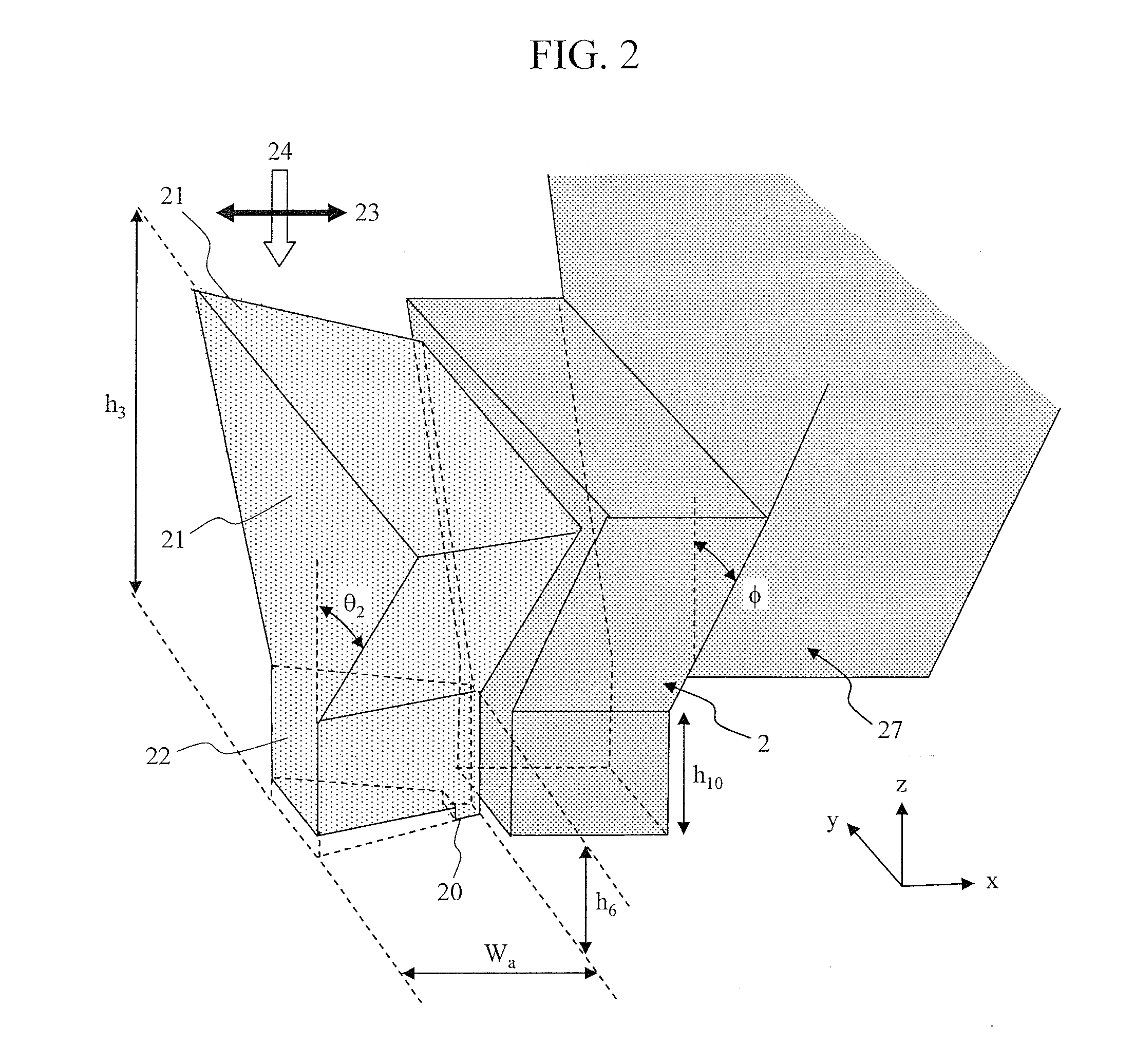

High efficiency concentrating photovoltaic module with reflective optics

InactiveUS20100012171A1Low costImprove solar conversion efficiencyPV power plantsPhotovoltaic energy generationElectricityThermal expansion

A Concentrating Photovoltaics (CPV) module includes light weight housing, a number of Cassegrain type reflective solar concentrators, a number of multi-junction solar cells and a novel heat spreading system. The primary and secondary reflectors focus the sun over 500 times to maximize the amount of photons collected by the solar cells and converted to electricity. A newly designed soft board material provides coefficient of thermal expansion (CTE) matched carrier for the solar cells and an efficient electrical connectivity method. The carrier board is attached to a specially formulated heat spreader that is specially formulated to conduct heat longitudinally away from the solar cells. The combination of the above creates CPV modules with the highest efficiency and lowest cost per Watt.

Owner:AMMAR DANNY F

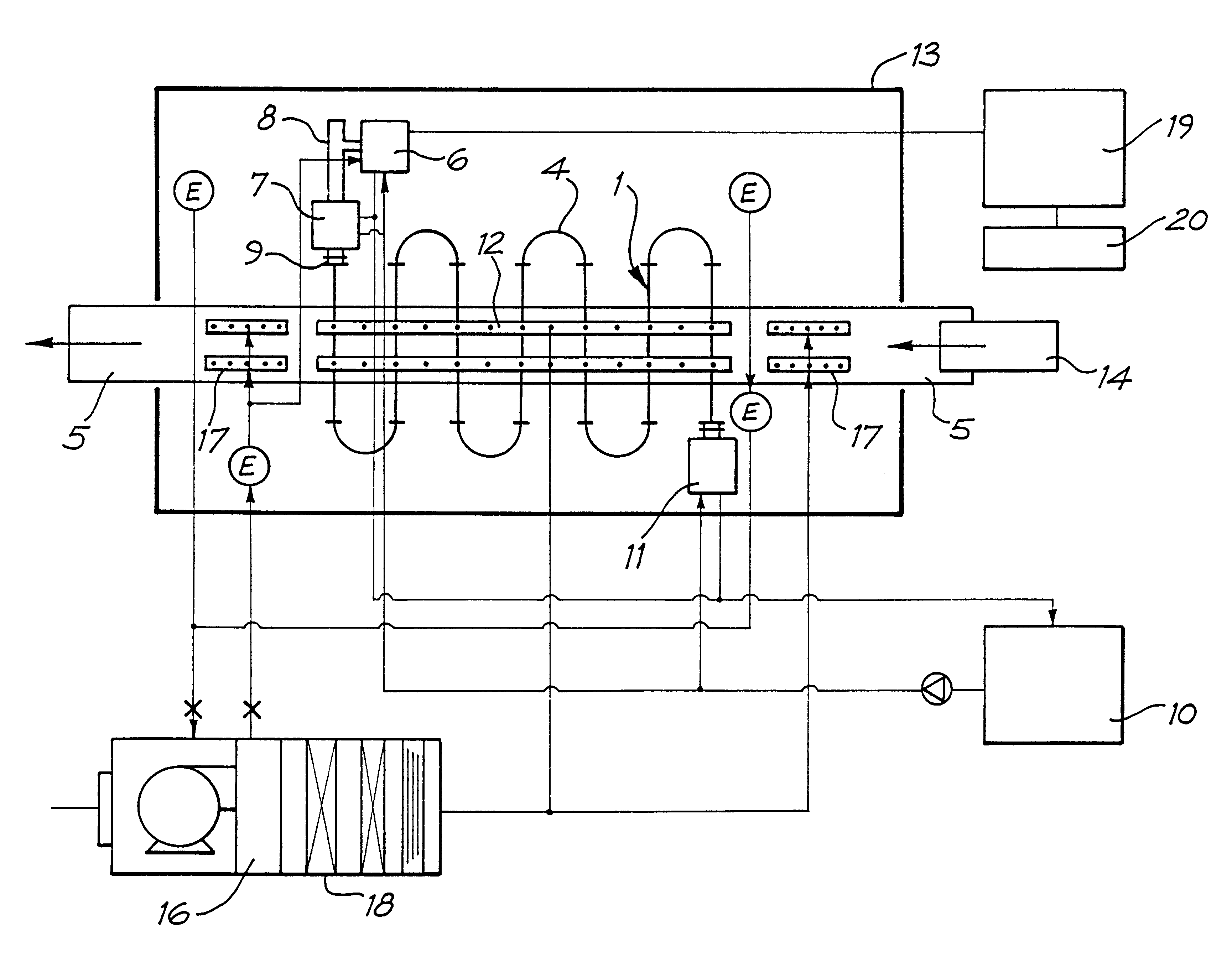

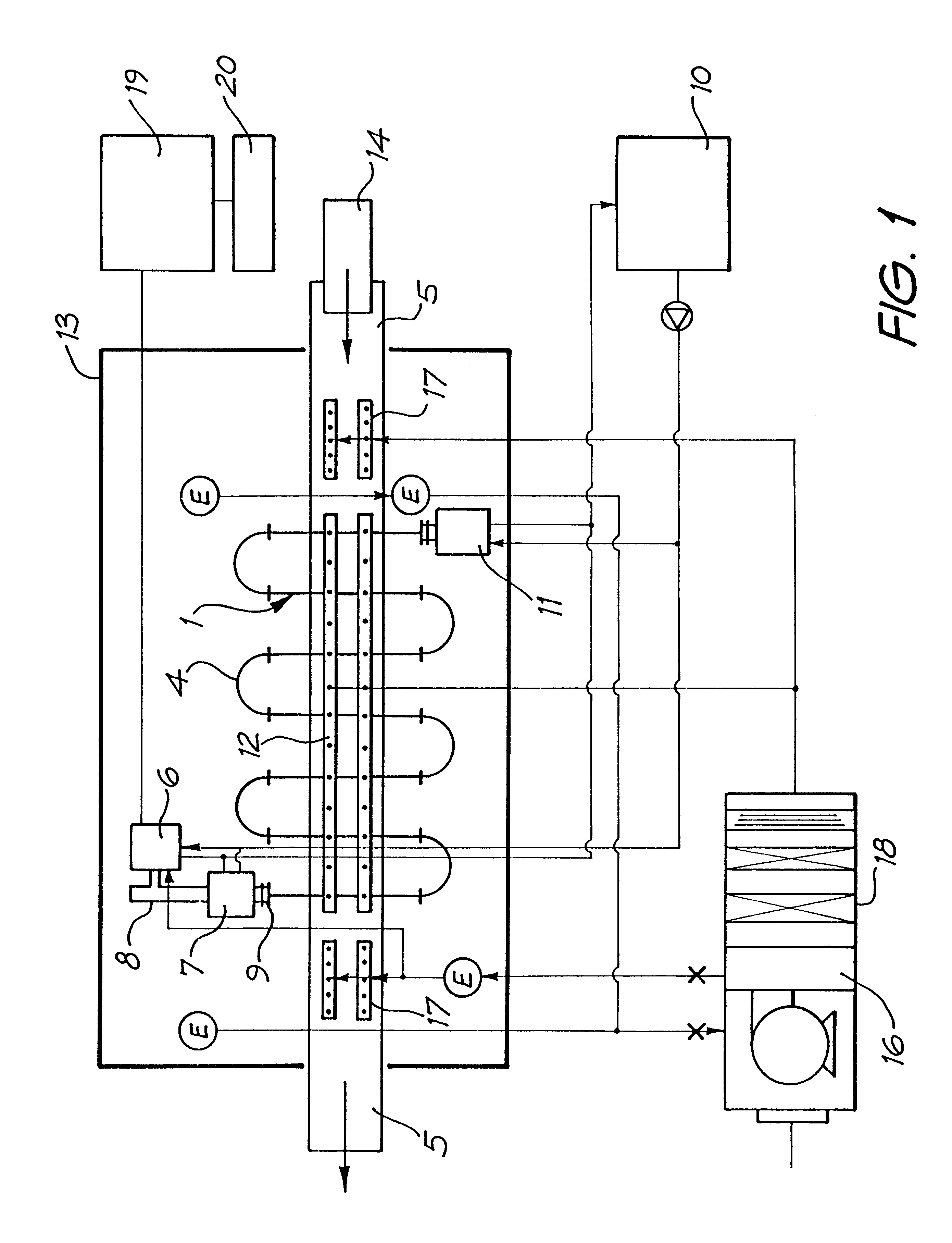

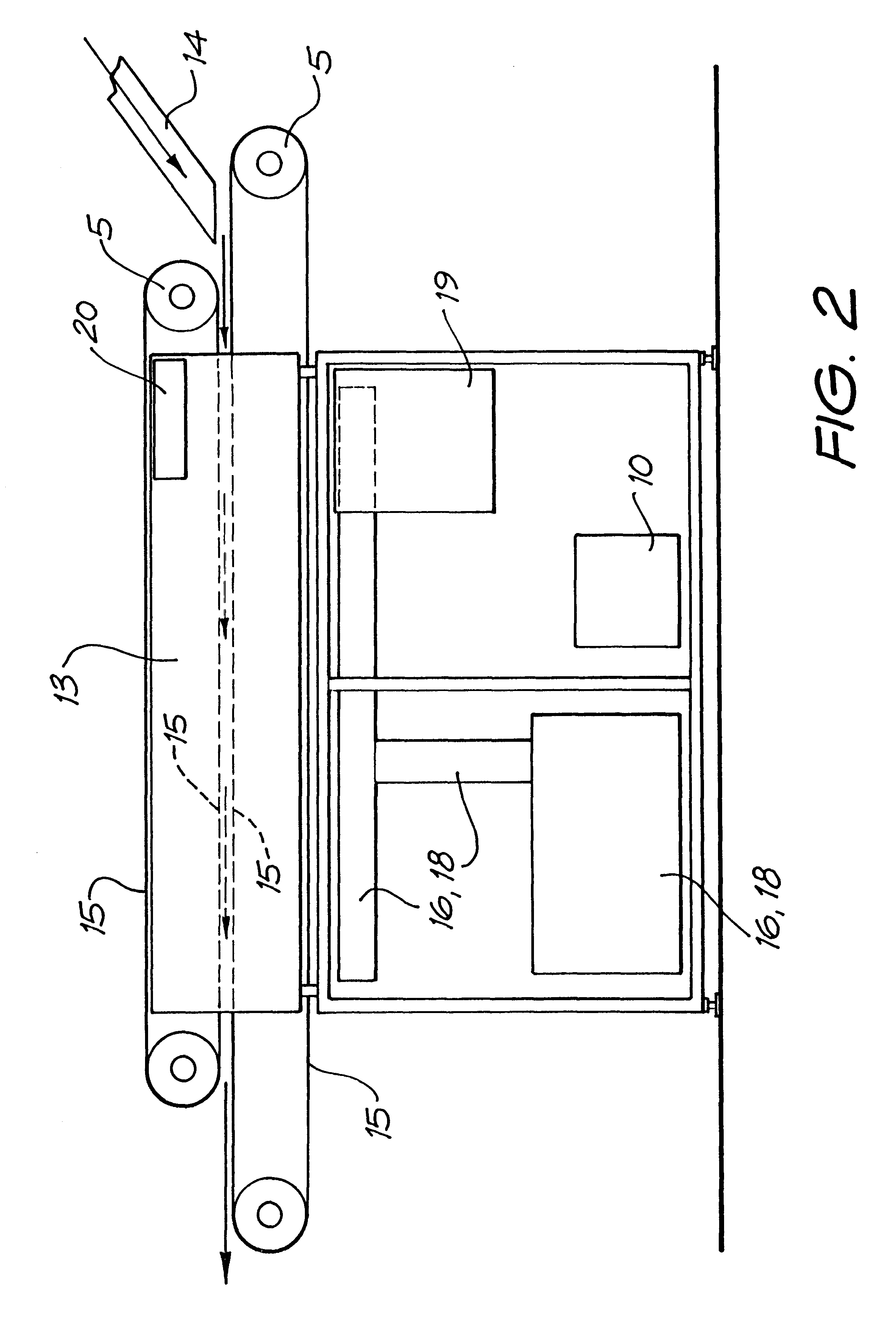

Method and apparatus for microwave processing of planar materials

InactiveUS6546646B1Remove moistureEliminate warpingMilk preparationDough treatmentVaporizationEngineering

A process and apparatus for removing moisture from a material, without spoiling the processed product, through the implementation of microwave irradiation heating, drying, dehydration, curing, disinfection, pasteurization, sterilization or vaporization or any combination thereof. The process and apparatus provide for a controlled processing of planar material, a combination of materials organic or inorganic, in natural or processed form, in sheet leaf, granular, prepared or transportable planar form.

Owner:SUSTAINABLE WORLD TECH

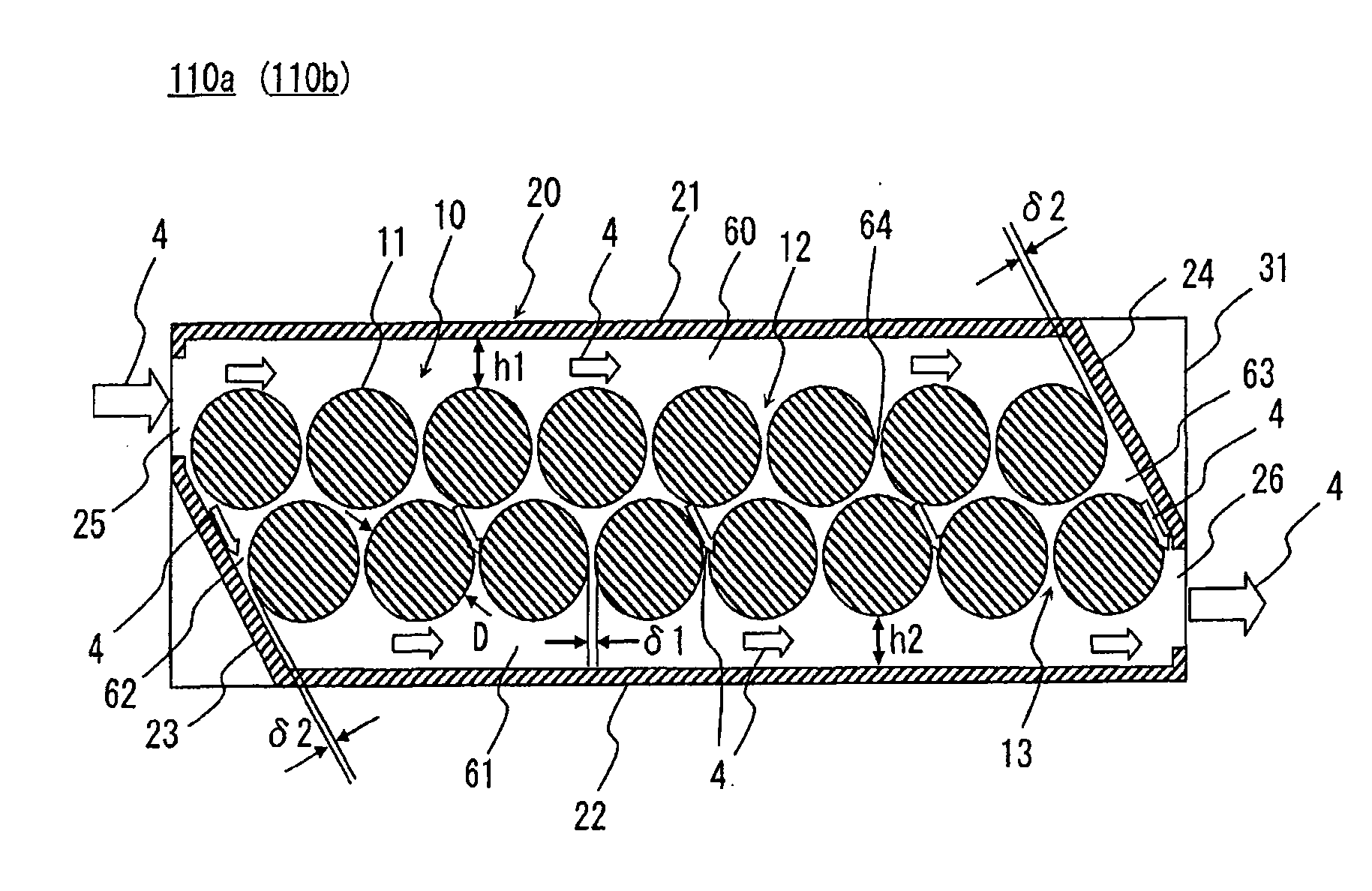

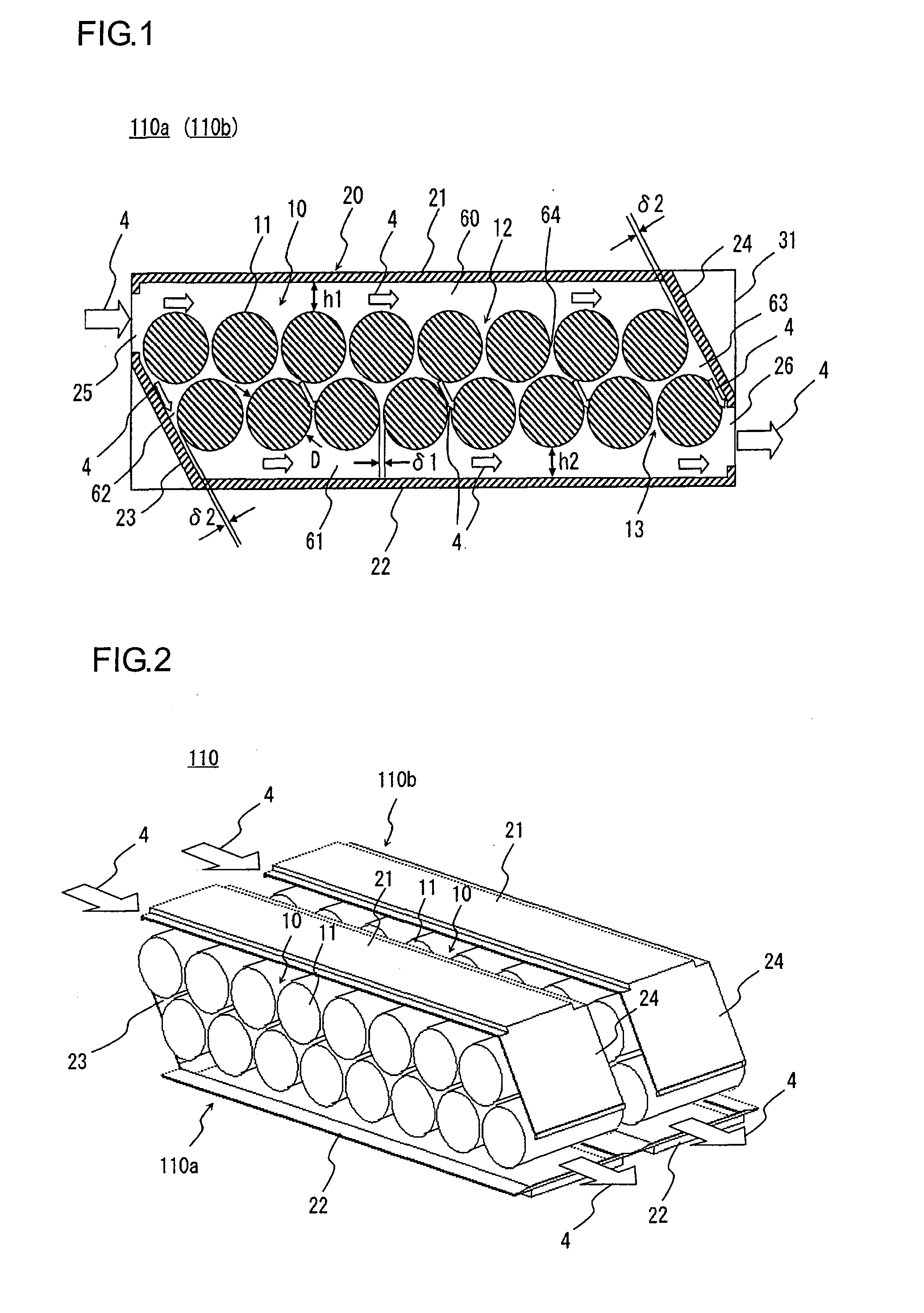

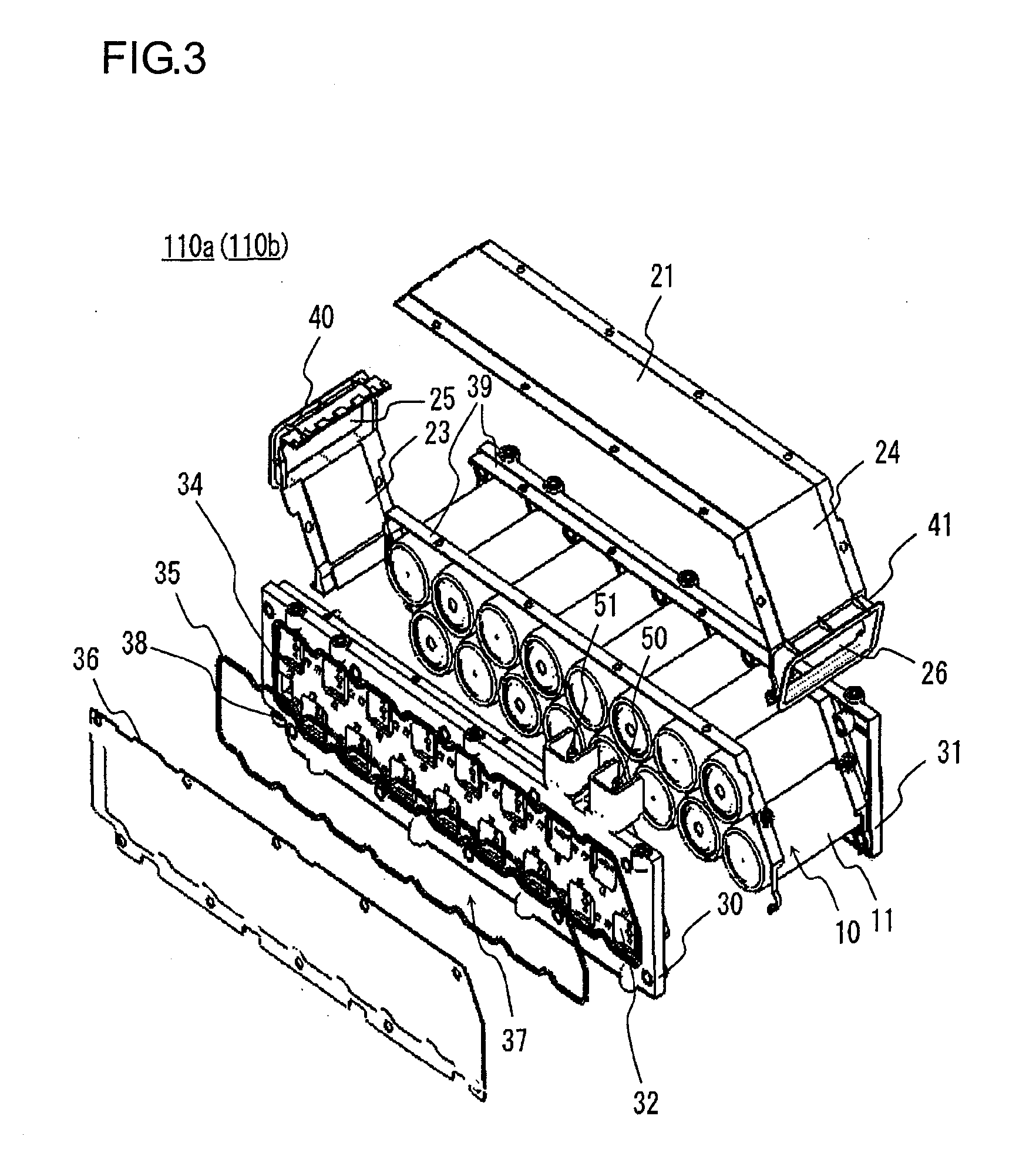

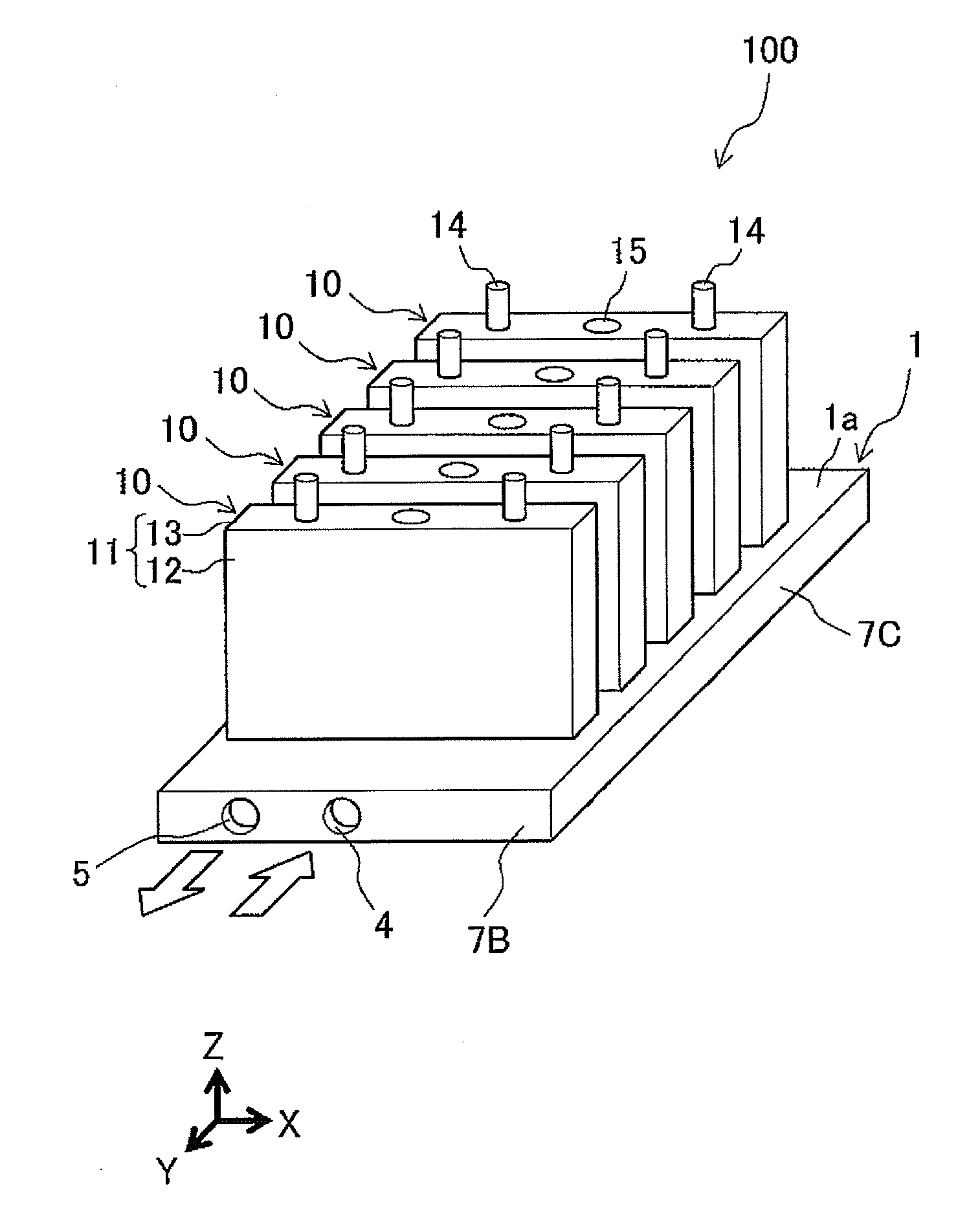

Battery Module, Electric Storage Device and Electric System

ActiveUS20090258282A1Large thicknessImprove cooling effectCell temperature controlCell component detailsEngineeringElectrical battery

A battery module is configured so that the first cell string and the second cell string are arranged between the first plate member and the second plate member and the second cell string is arranged closer to the second plate member side than the first cell string is and is arranged closer to the outlet side than the first cell string is. At the inlet side of the housing, the inlet is arranged closer to the first plate member than to the second cell string, at least a part between the inlet side of the second cell string and the second plate member is covered by the inlet-side guide plate, and the cooling air is introduced into the housing through the inlet so as to form a flow of the cooling air along the first plate member and a flow of the cooling air along the inlet-side guide plate.

Owner:HITACHI VEHICLE ENERGY

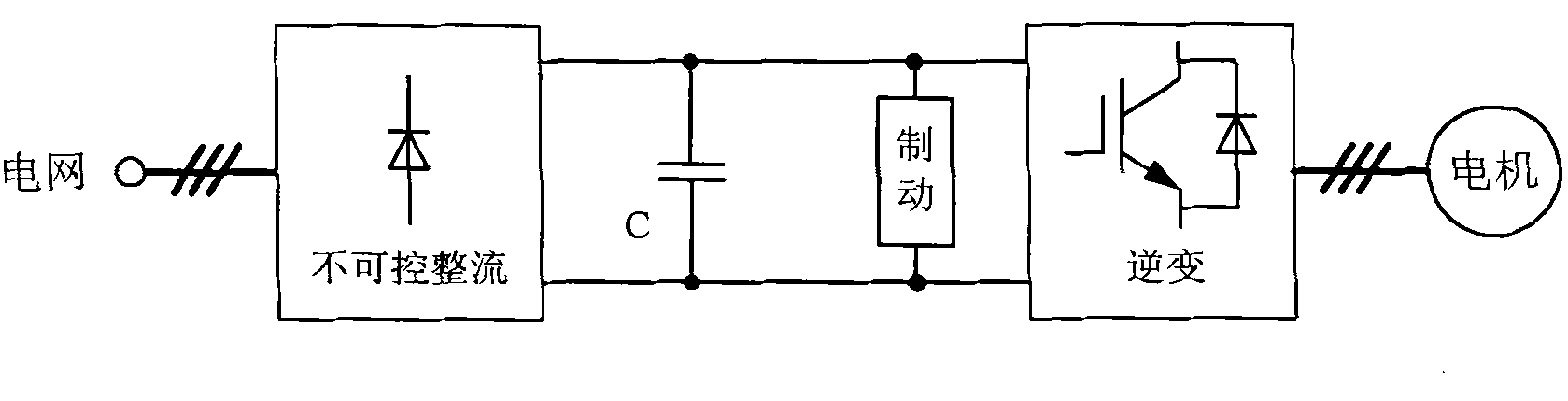

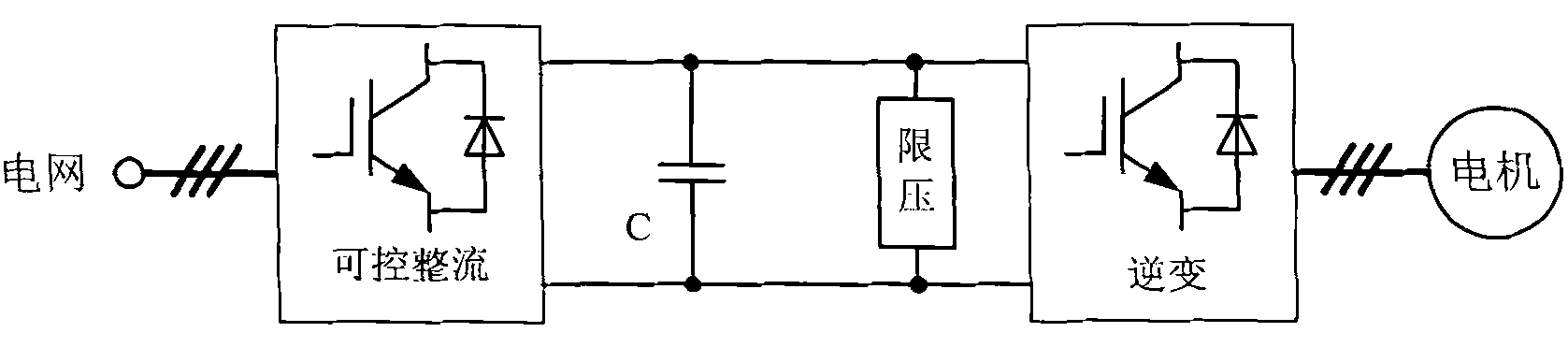

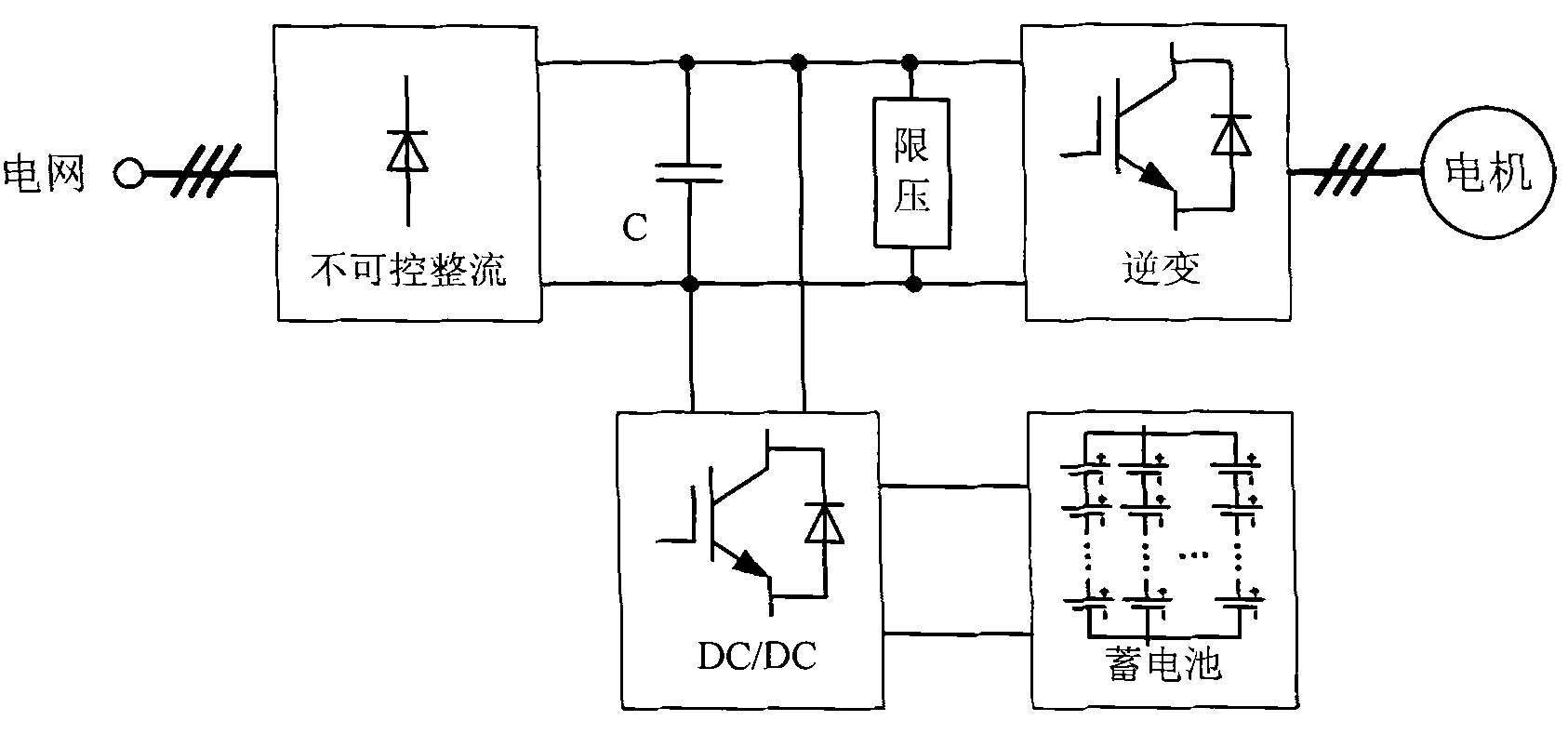

Super capacitor-based energy-saving drive circuit of motor and control method

InactiveCN101931366ARealize the power peak absorption functionReduce shockElectrical storage systemAC motor controlElectricityCapacitance

The invention relates to an energy-saving drive circuit of a motor, and aims to provide a super capacitor-based energy-saving drive circuit of a motor and a control method. The main circuit of the circuit consists of a super capacitor bank, a super capacitor charge / discharge management circuit, a controllable rectifying circuit, a controllable rectifying control circuit and the like. Impact to a power grid when an elevator runs is reduced by optimized control of the controllable rectifying circuit and the super capacitor charge / discharge circuit and absorption of running power peak of the elevator, the controllable rectifying circuit bears the smooth part of the electric and generating power of the motor and has emergency power supply function after the elevator is cut off electricity, and the super capacitor and a DC bus form through connection in a normal state to achieve high efficiency. The drive circuit has the advantages of compact line and high integral work efficiency, the service life of the super capacitor is prolonged, and the integral technical and economic performance of the energy feedback elevator is improved. The drive circuit is particularly suitable for driving the energy feedback energy-saving elevator, and is also suitable for motor energy-saving drive situations of a crane and the like.

Owner:ZHEJIANG UNIV

Method of manufacturing transition metal oxide having spinel structure

ActiveUS20100193104A1Fully sinteredHigh strengthFuel cells groupingFinal product manufactureOxideMetal

A novel method of manufacturing a transition metal oxide having a spinel structure is provided. A mixture of powdery metals of metal elements constituting the transition metal oxide is heated in an oxidizing atmosphere to generate the transition metal oxide.

Owner:NGK INSULATORS LTD

Asphalt composition comprising linear diblock copolymer

InactiveUS20050004273A1Good dispersionReduce temperature riseBuilding insulationsPolymer scienceSulfur

The present invention relates to an asphalt composition comprising a linear diblock copolymer. Particularly, an asphalt composition comprising a linear diblock copolymer consisting of a vinyl aromatic hydrocarbon / conjugated diene has superior dispersion, elongation and a high softening point, and an asphalt composition to which a small amount of sulfur compound is further added has more improved dispersion and thus elongation and softening temperature can be improved more effectively.

Owner:LG CHEM LTD

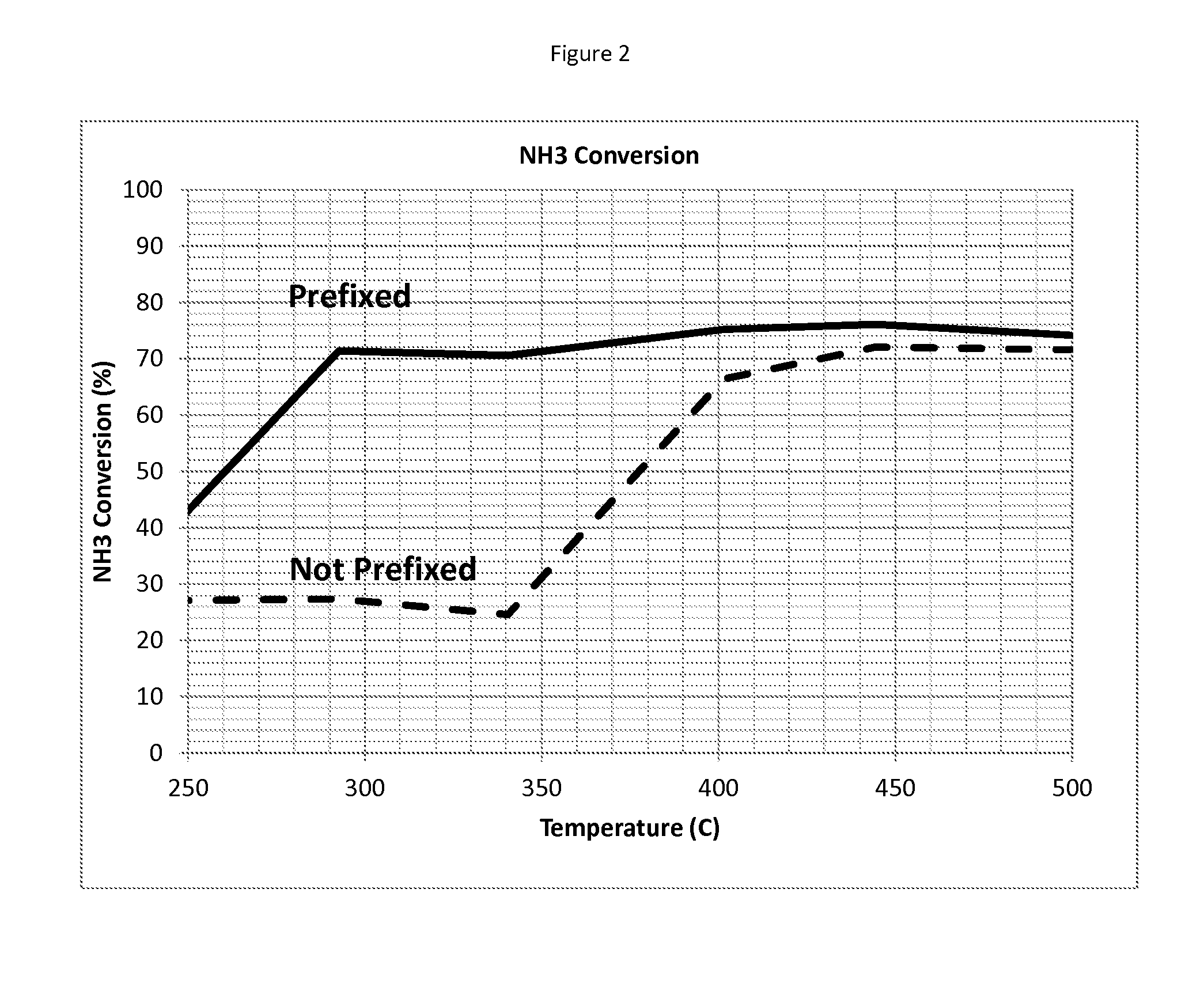

Ammonia oxidation catalyst

ActiveUS20140154163A1High catalytic activityImproving low temperature ammonia conversionCombination devicesCyanogen compoundsPtru catalystSilicon oxide

Provided is a catalyst article for treating an emission gas comprising (a) a noble metal catalyst layer comprising one or more noble metals disposed on a first refractory metal oxide support; and (b) a vanadium catalyst layer comprising vanadium pre-fixed on a second refractory metal oxide support selected from alumina, titania, zirconia, ceria, silica, and mixtures of these, wherein the first catalyst layer is in physical contact with said second catalyst layer. Also provided is a method for making such a catalyst article, a method for treating gas emissions using such an article, and an emission gas treatment system incorporating such an article.

Owner:JOHNSON MATTHEY PLC

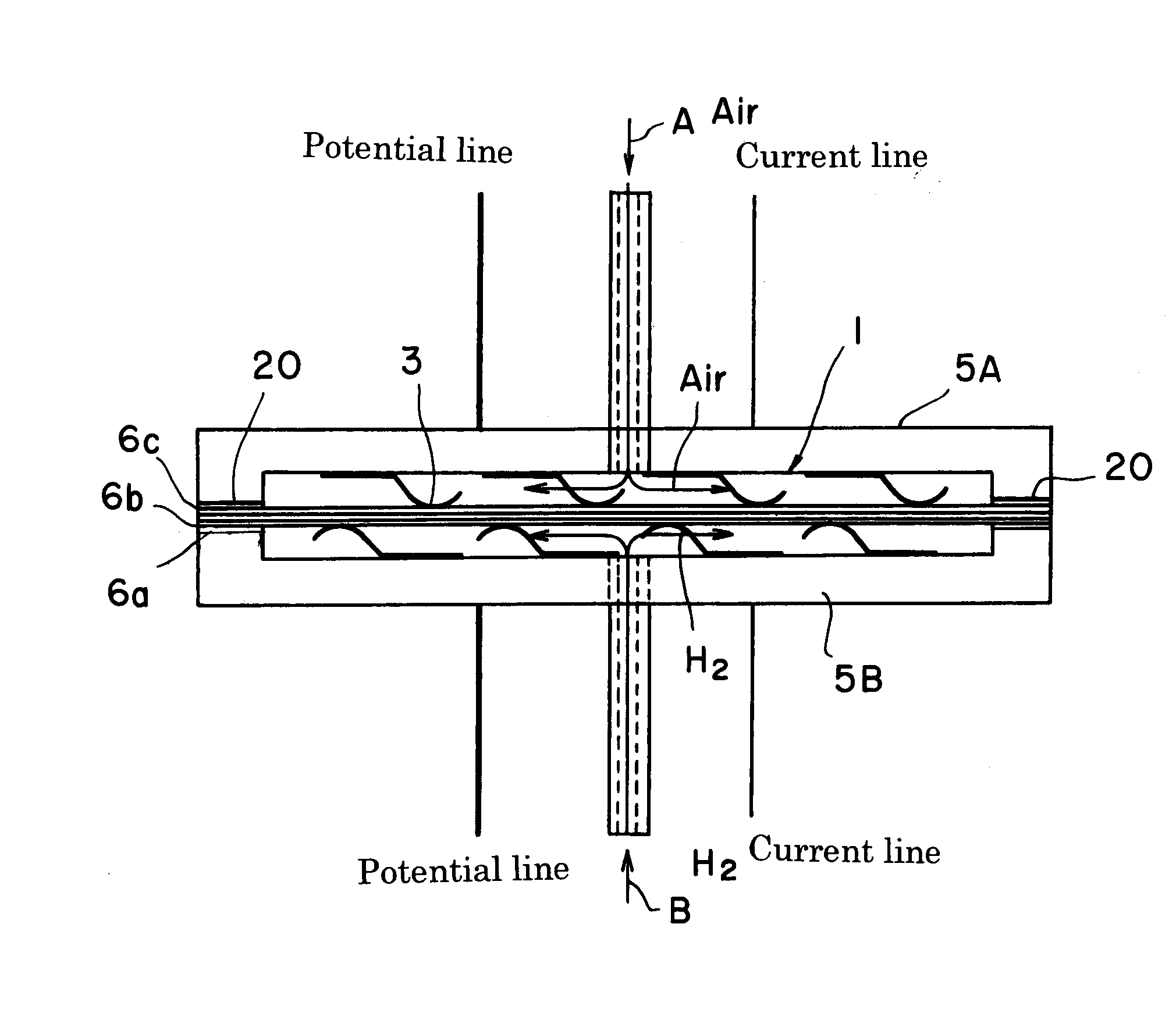

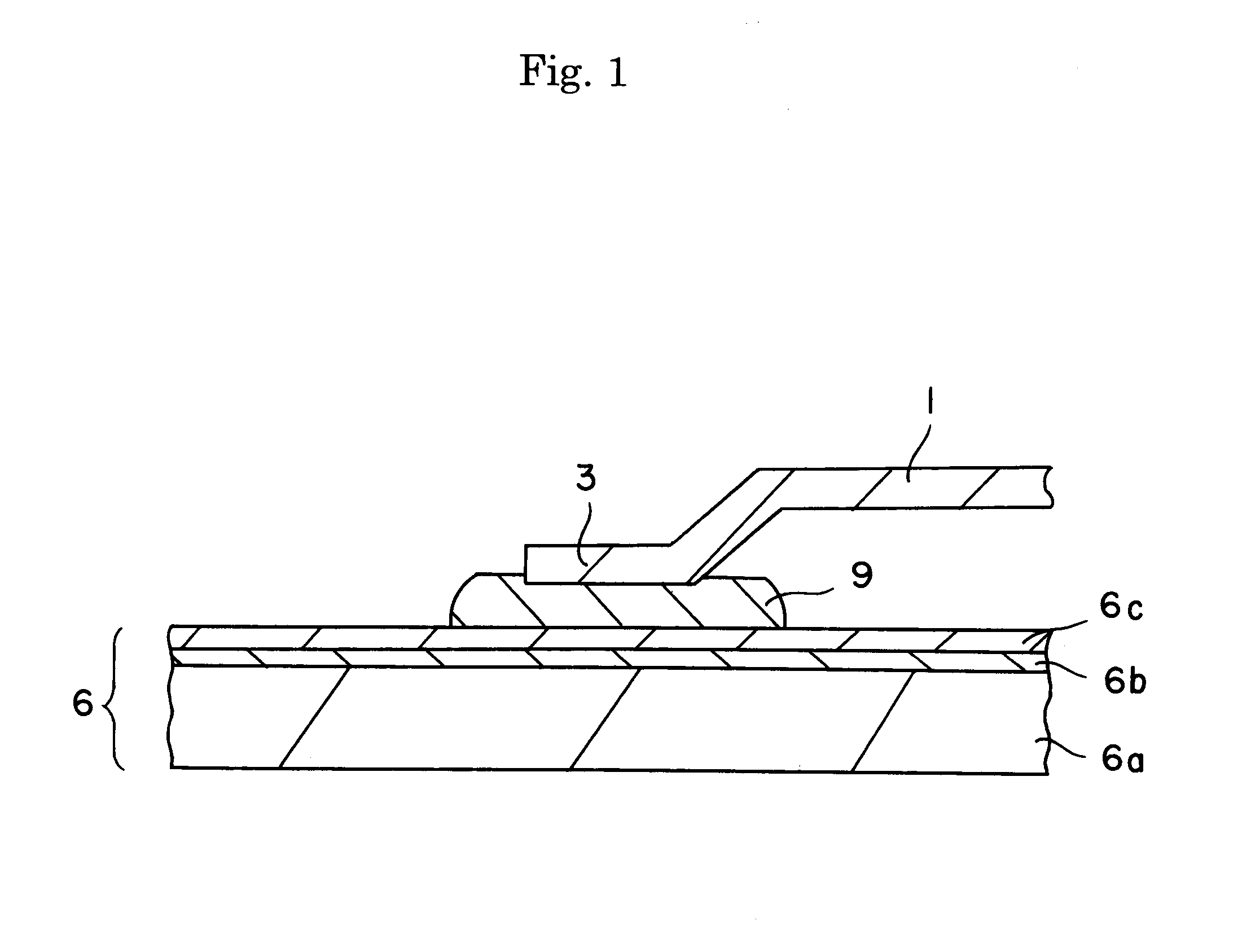

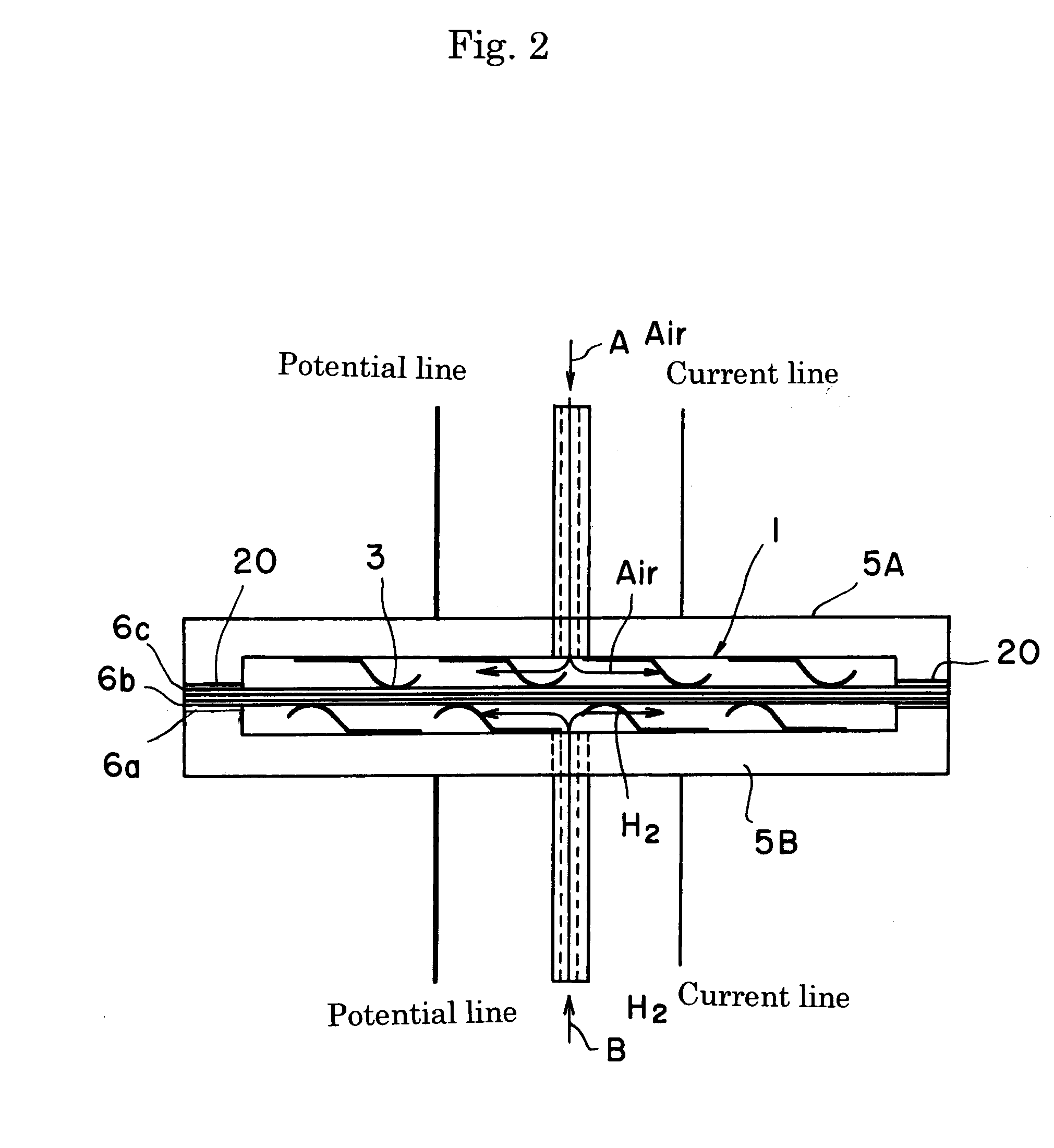

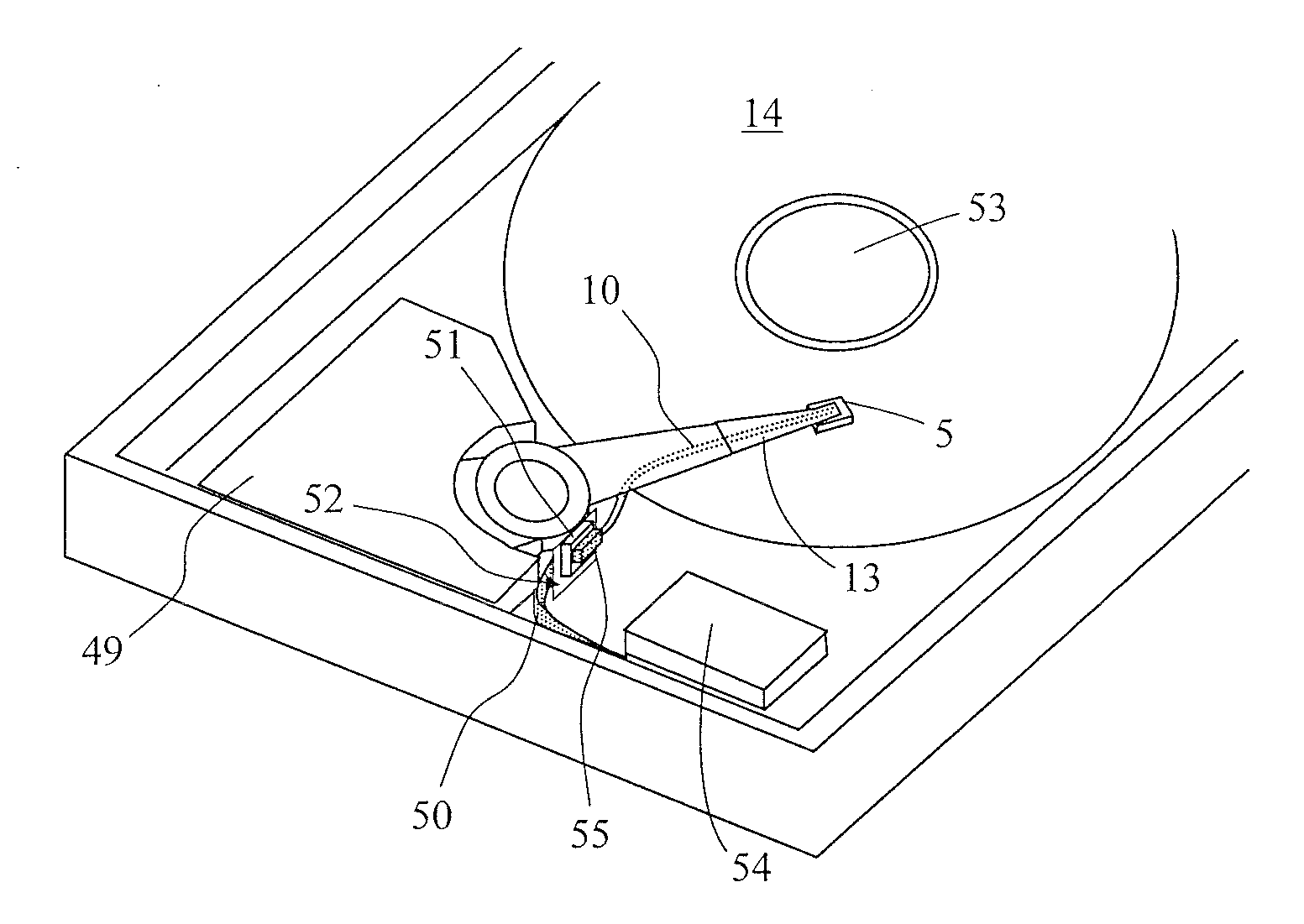

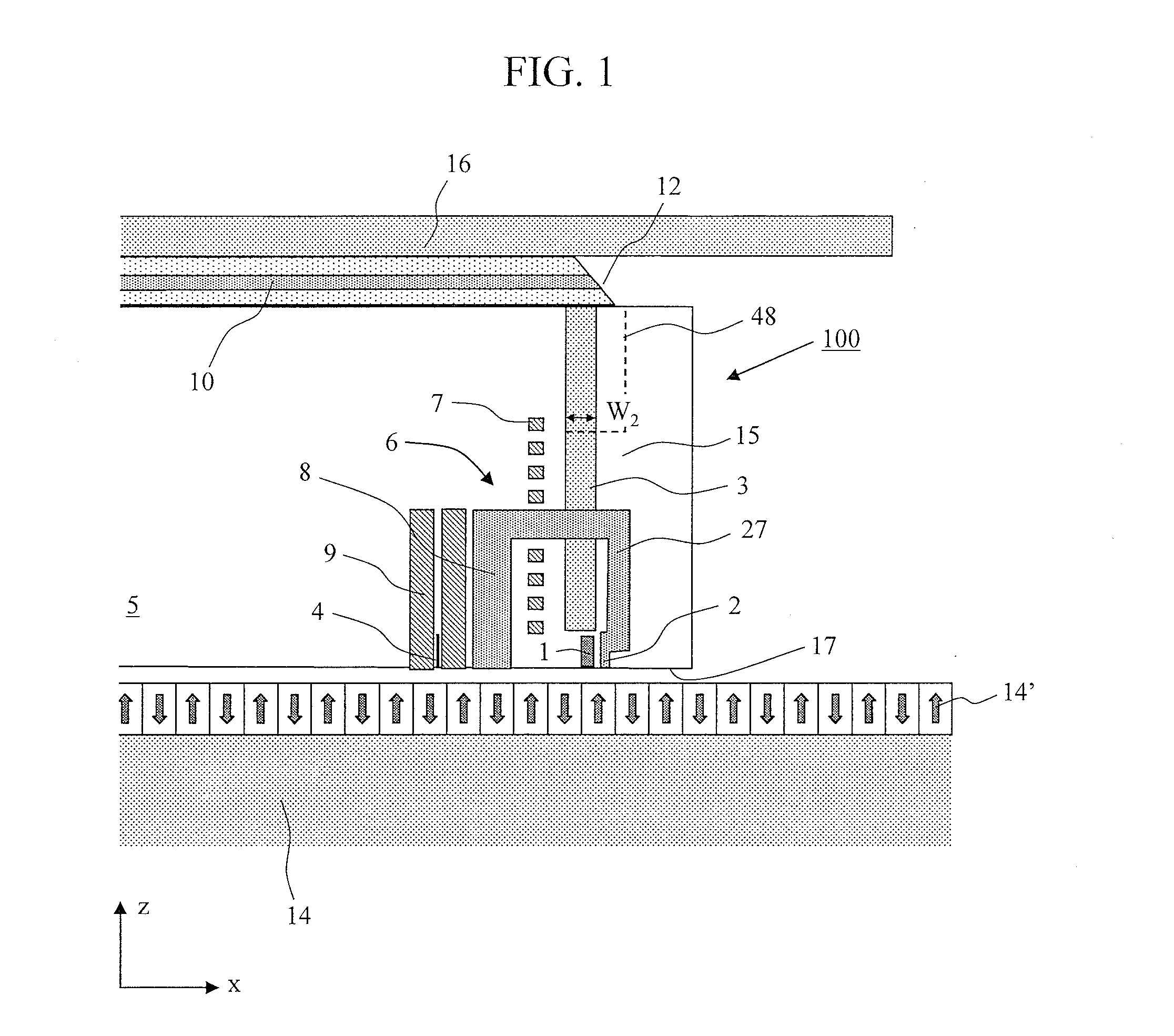

Head for thermal assisted magnetic recording device, and thermal assisted magnetic recording device

InactiveUS20110096639A1High strengthAvoid temperature riseCombination recordingRecord information storageHeat-assisted magnetic recordingField intensity

The present invention suppresses temperature rise of an optical near-field generator while increasing optical near-field intensity in a thermally assisted magnetic recording head using a conductive scatterer as the optical near-field generator. The present invention uses a conductive scatterer having a cross-sectional shape in which its width is gradually reduced toward an apex where an optical near-field is generated, and also has a shape in which its width is reduced gradually or in a stepwise fashion toward the apex where the optical near-field is generated in a traveling direction of incident light.

Owner:HITACHI LTD

Random ethylene/alkyl acrylate copolymers, compounds and elastomeric compositions thereof with improved low temperature properties

Disclosed are random copolymers derived from ethylene and at least two different alkyl acrylate comonomers, with or without an acid cure site-containing comonomer. In particular, disclosed are copolymers derived from copolymerization of (a) from 10 to 50 weight % of ethylene; (b) from 5 to 55 weight % of a first alkyl acrylate; (b) from 15 to 80 weight % of a second alkyl acrylate; and (d) from 0 to 7 weight % of a monoalkyl ester of 1,4-butene-dioic acid. Such copolymers exhibit lower glass transition temperatures (Tg) relative to previous ethylene copolymers comprising a single alkyl acrylate comonomer and maintain the good heat and fluid resistance when employed to produce cured elastomeric compositions as well as the improved low temperature properties. This invention also provides compounded compositions comprising these copolymers, and cured compositions (i.e., vulcanizates) as well as rubber articles formed from these compounded compositions, such as hoses, dampers, seals, gaskets, constant velocity joint (CVJ) boots and shaft boots.

Owner:DUPONT POLYMERS INC

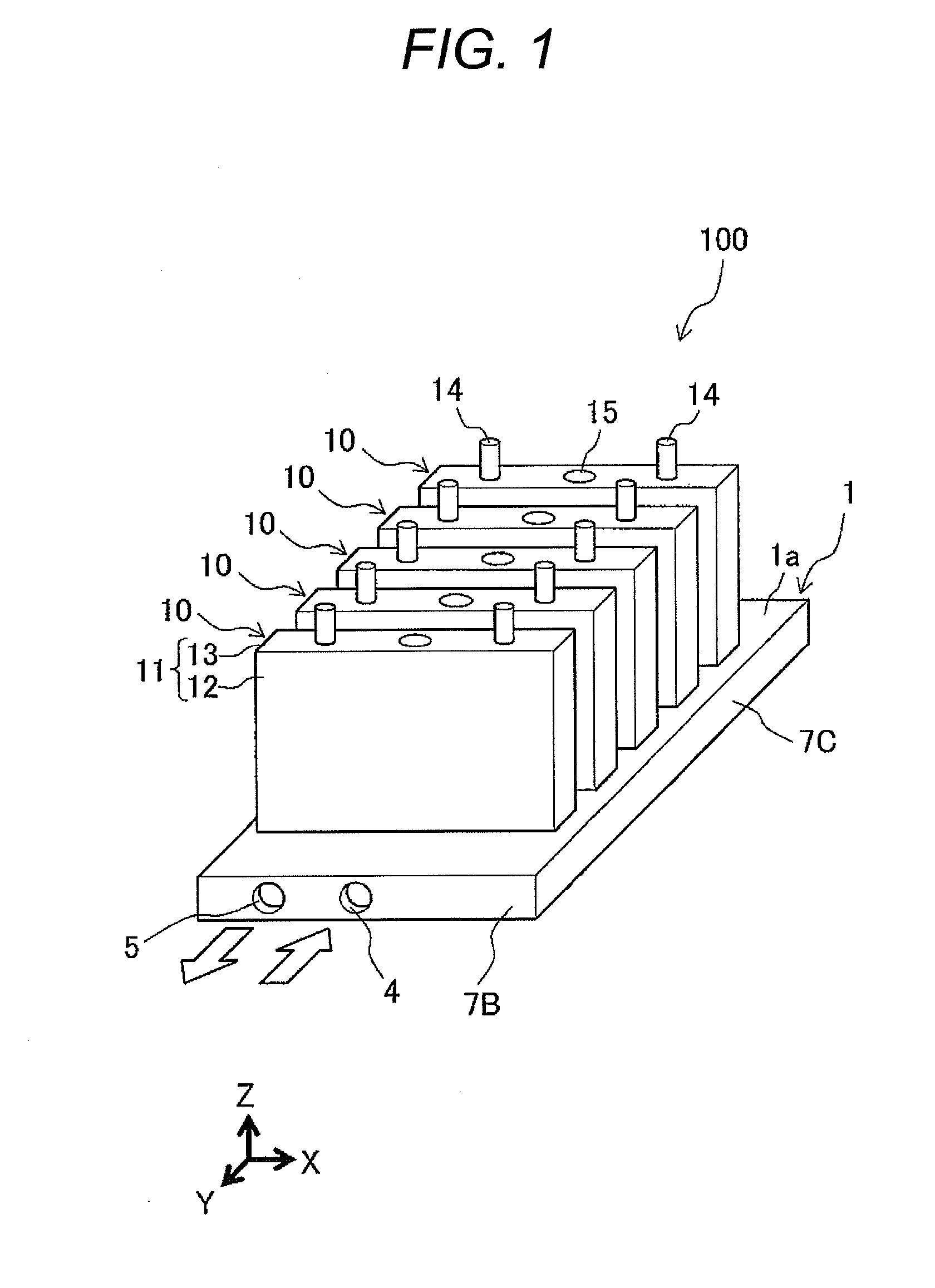

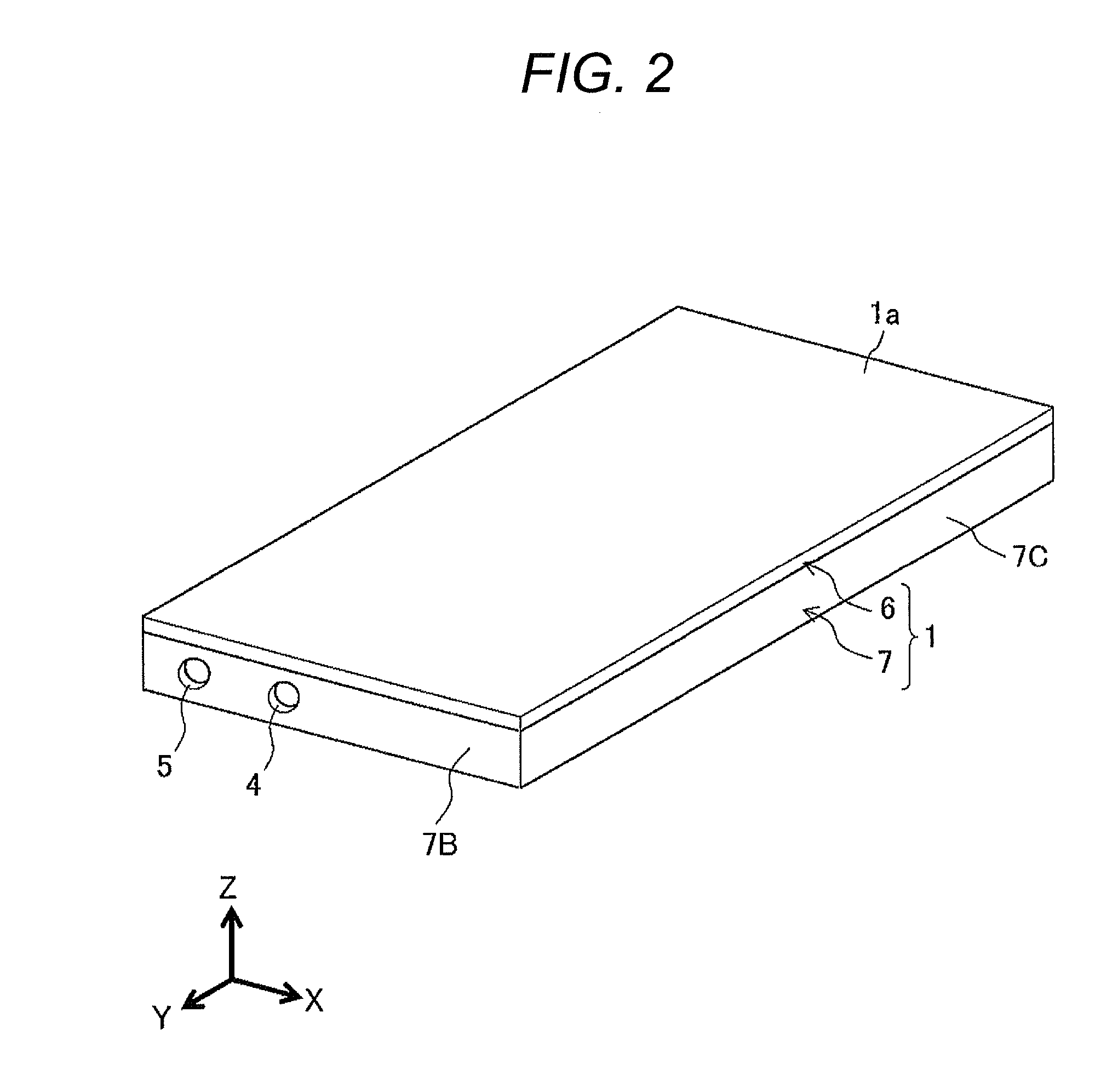

Battery module

ActiveUS20150140388A1Increase temperatureSmall temperature riseCell temperature controlCell lids/coversEngineeringCoolant

A battery module of includes a plurality of cells, a cooling plate, and a channel part formed in the cooling plate. The channel part includes a first channel part extending in an arrangement direction of the plurality of cells, a second channel part extending in parallel to the first channel part along the arrangement direction with a first partition part interposed between the first channel part and the second channel part, and a first communication part which brings one end of the first channel part of the arrangement direction and one end of the second channel part of the arrangement direction into communication with each other, and which turns a flowing direction of coolant in the first channel part and the second channel part.

Owner:HITACHI VEHICLE ENERGY

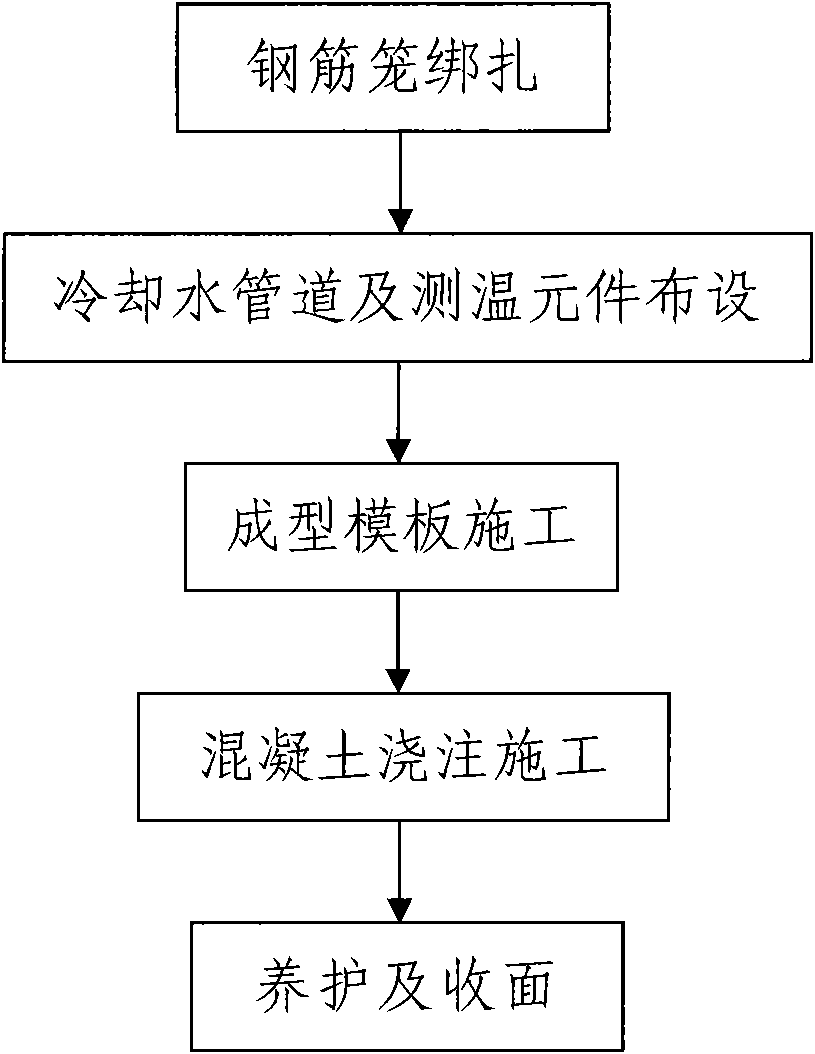

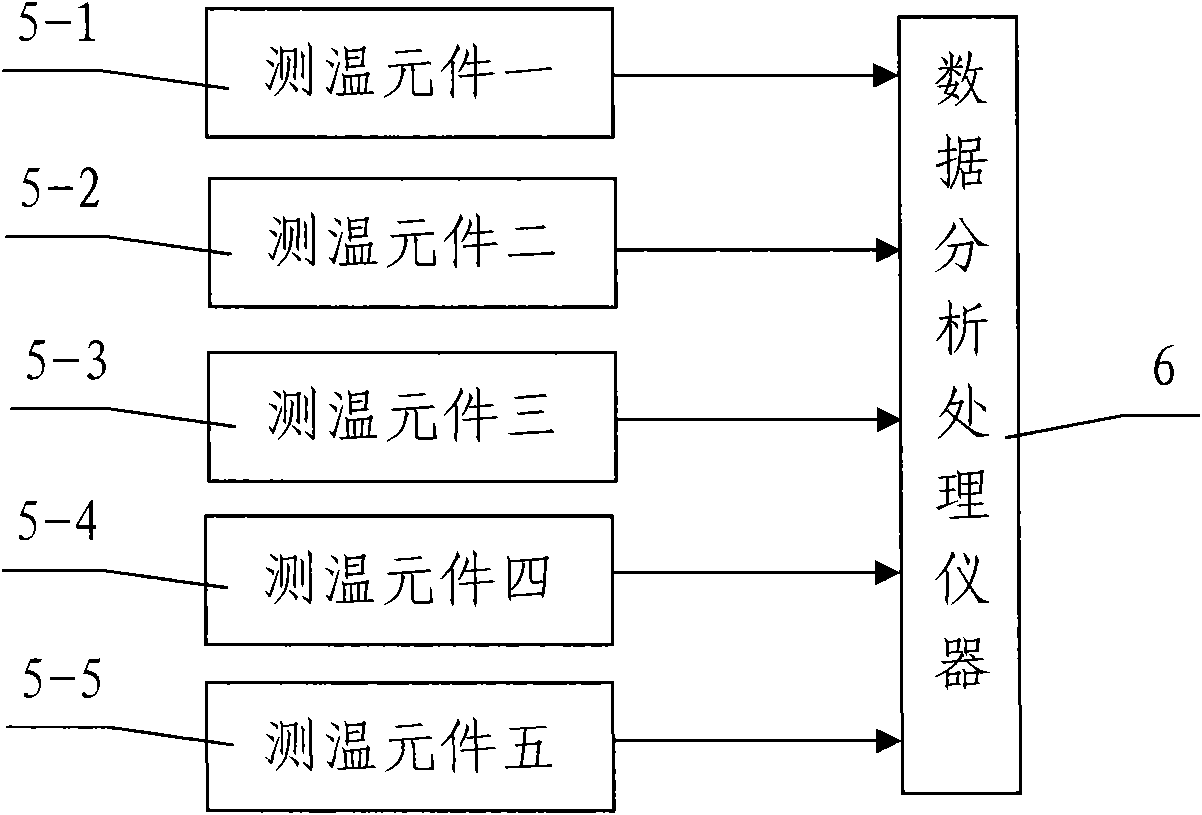

Construction method of large-volume concrete bearing platform with one-time pouring in winter

The invention discloses a construction method of a large-volume concrete bearing platform with one-time pouring in winter, comprising the following steps of: step 1, binding steel reinforcement cages; step 2, laying cooling water pipelines and temperature measuring elements; step 3, constructing formed templates, wherein the construction process comprises delimiting template lines and constructing formed brick dies; step 4, pouring concrete; and step 5, conserving and finishing surface: finishing surface in time when completing the pouring of the concrete, carrying out the surface finishing twice, carrying out the first surface finishing when pouring the concrete to the top, carrying out the second surface finishing when the concrete is initially congealed, and adopting a mode that external stores water for conserving when the concrete is initially congealed. The invention has the advantages of reasonable design, simple construction method step, convenient operation, short construction period, one-time pouring molding and strong maneuverability, the large-volume concrete bearing platform constructed for molding in winter has good quality, the poured concrete is not frozen, and the surface of the bearing platform can not have temperature cracks.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

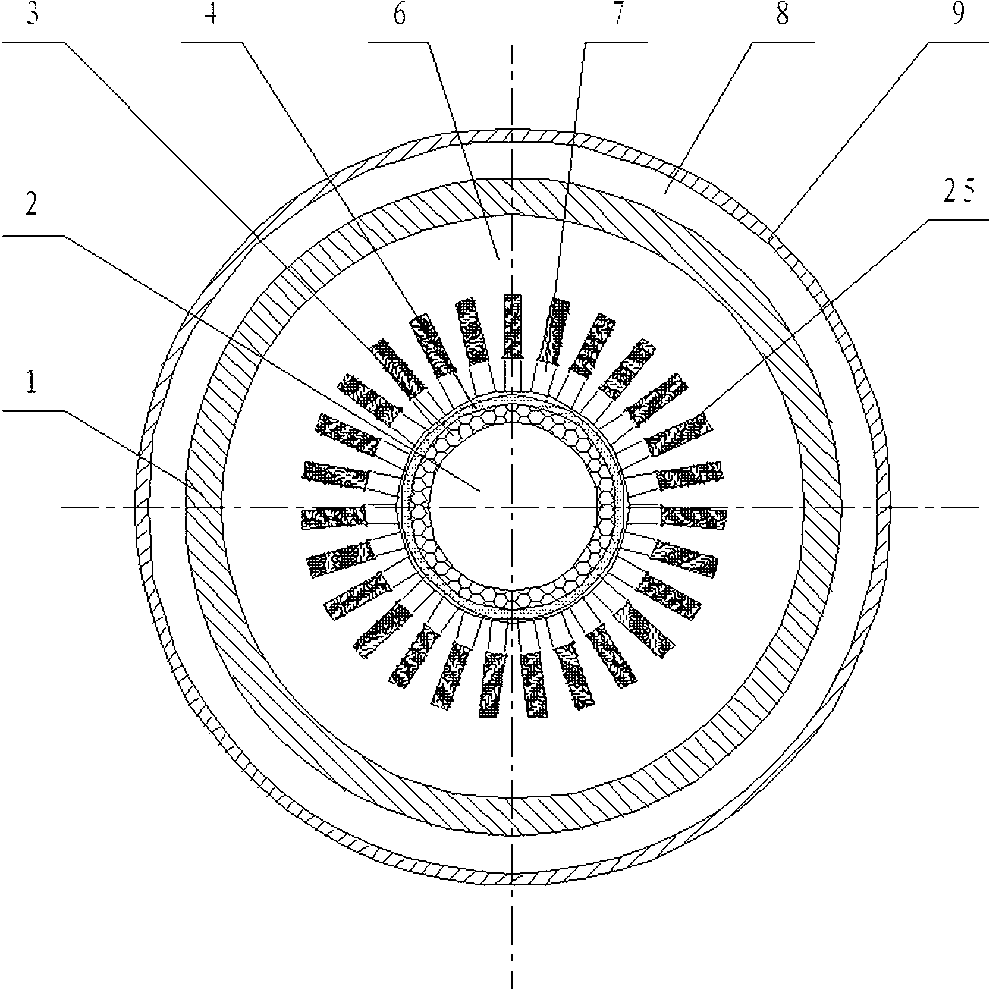

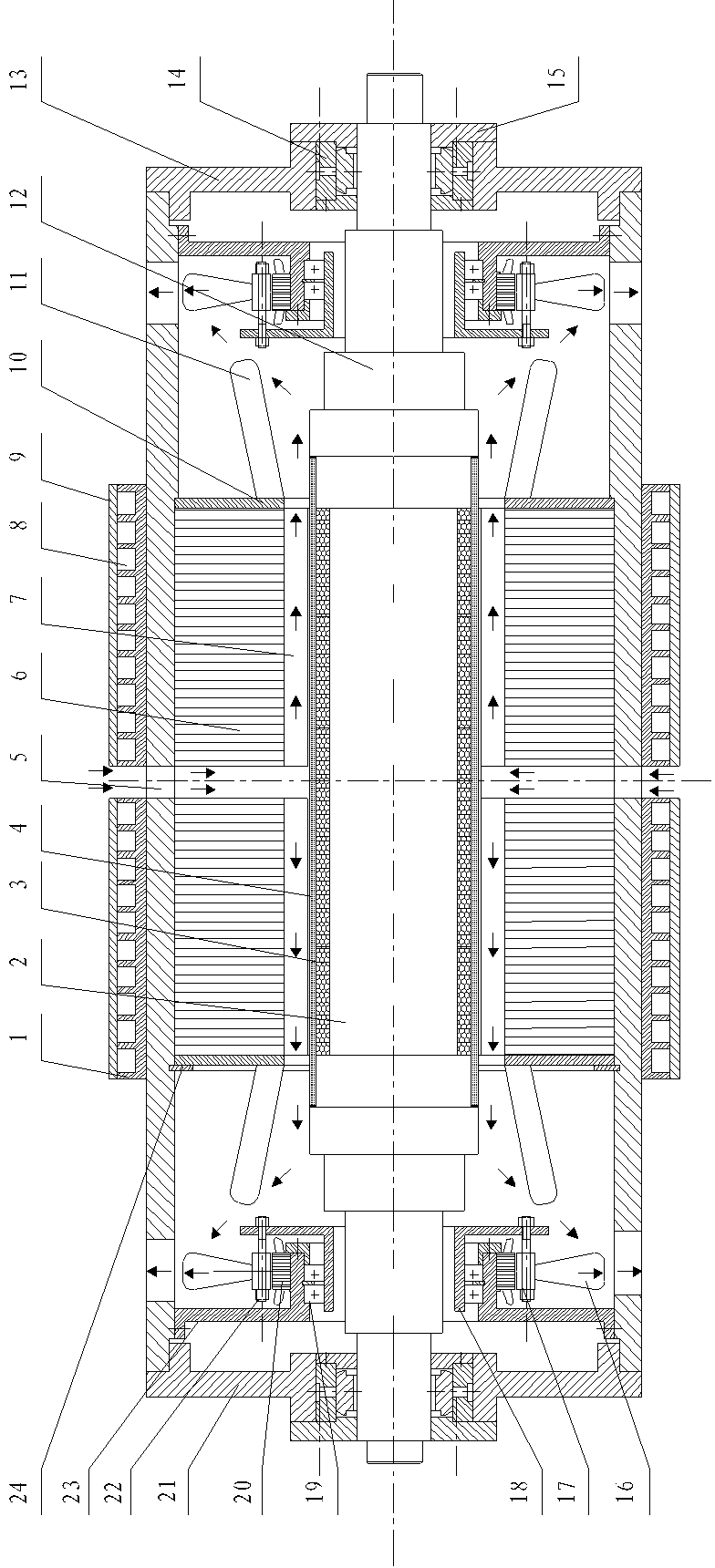

Air and water hybrid cooling high-speed permanent-magnet motor

InactiveCN102983680AReduce eddy current lossLow heat generationMagnetic circuit rotating partsMagnetic circuit stationary partsWater flowPermanent magnet motor

The invention discloses an air and water hybrid cooling high-speed permanent-magnet motor and belongs to the technical field of motors. The large-power high-speed permanent-magnet motor comprises a casing, a cooling water jacket, a stator core, a stator radial air duct, a stator inner air duct, a motor rotor, an outer rotor axial fan, an outer rotor fan fixing frame and two sliding bearings. The stator core is divided into two sections, the radial air duct is reserved in the middle, and the inner air duct is reserved in a stator slot close to the air gap position. The cooling water jacket is arranged outside the stator casing, a spiral water way is arranged in the water jacket, and water flows into the water way from the middle of the water way and flows out from a left spiral water outlet and a right spiral water outlet which are arranged at two ends of the water way. The air and water hybrid cooling high-speed permanent-magnet motor can mechanically solve the problem that a permanent magnet is broken when bearing large pulling stress during high-speed rotating, further solves the problems that the large-power high-speed motor is large in loss density, difficult in heat dissipation and over high in temperature rising, and prevents the permanent magnet from having irreversible demagnetization easily at high temperature.

Owner:SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com