Patents

Literature

1069results about How to "Large thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

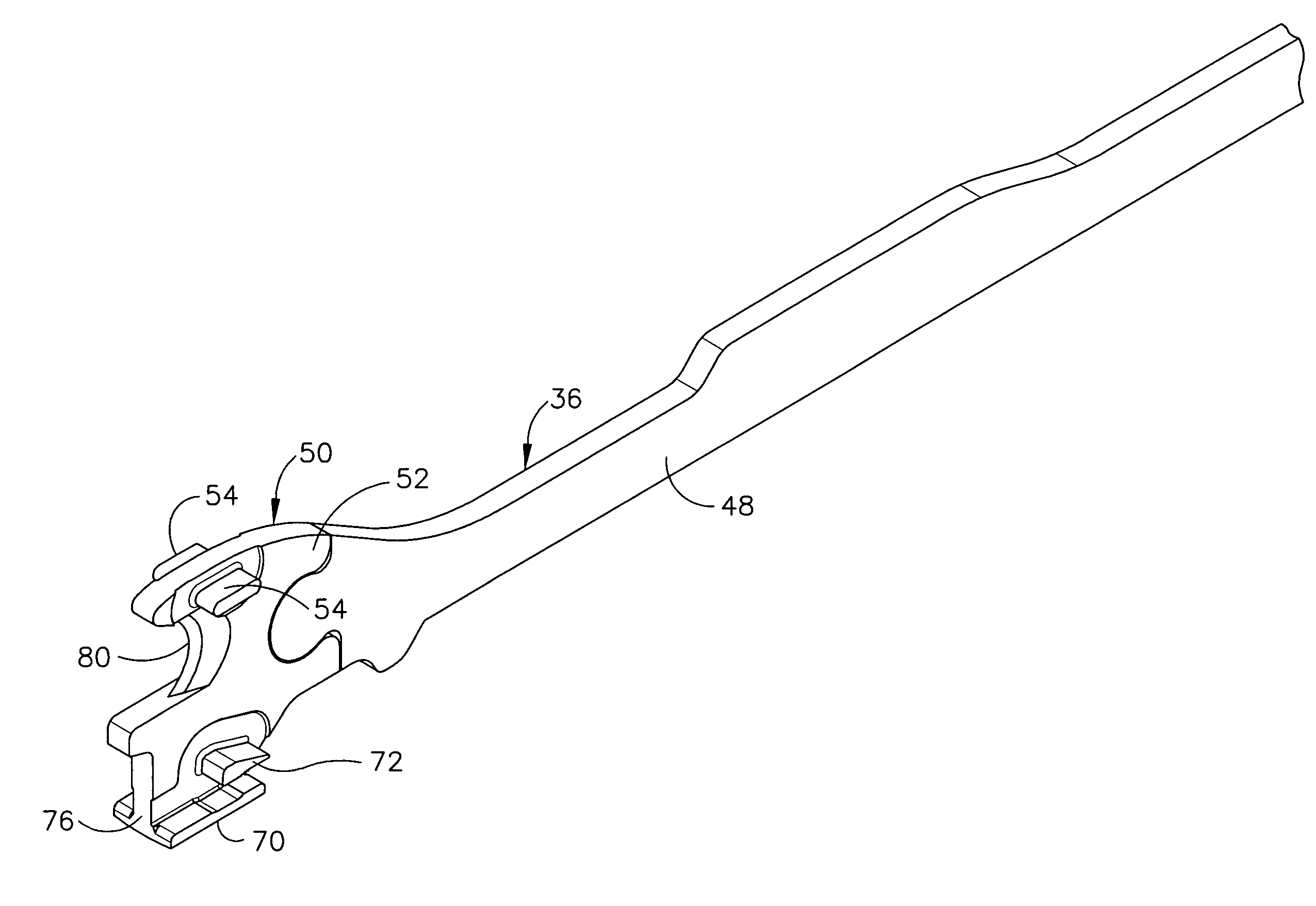

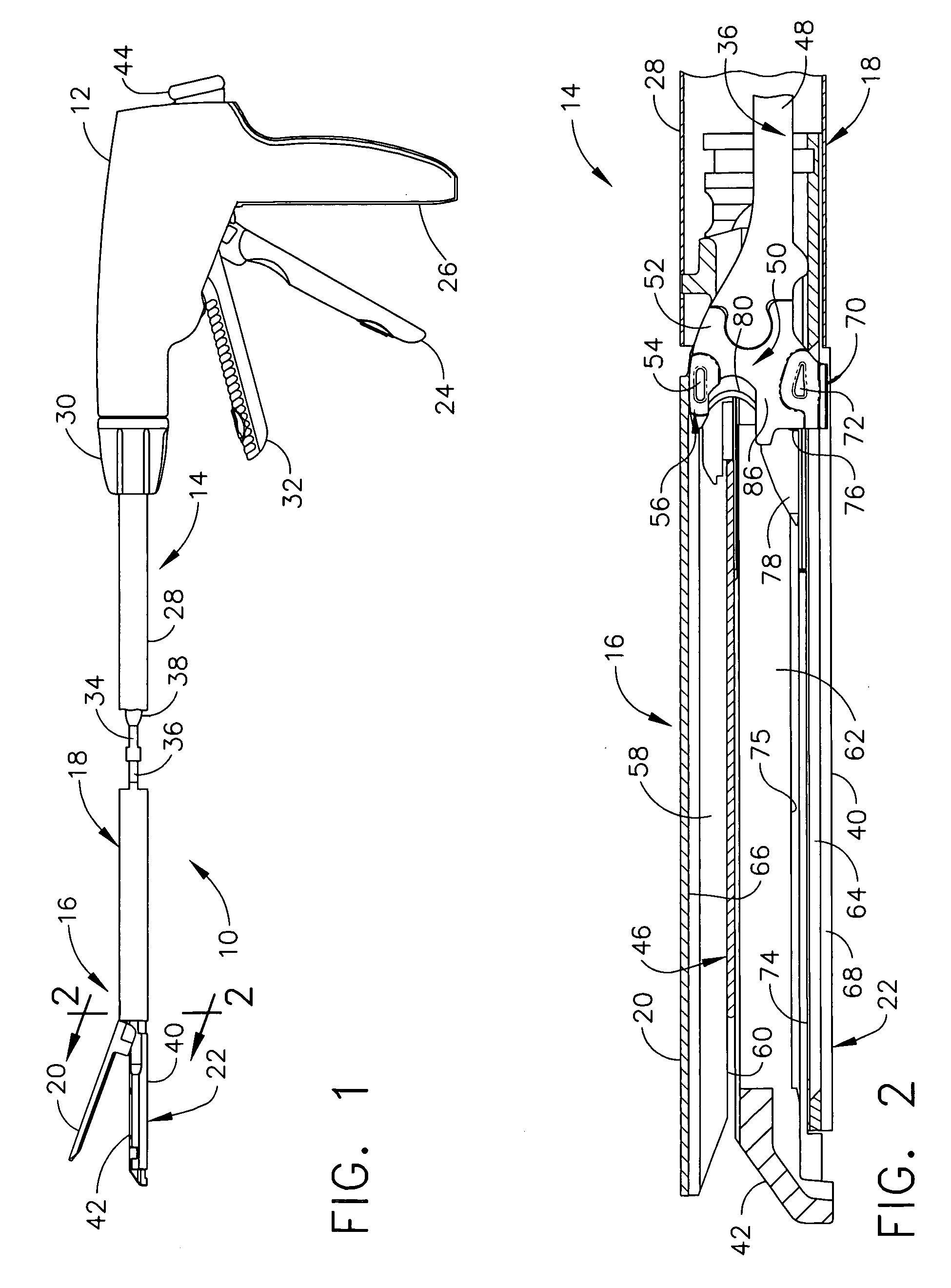

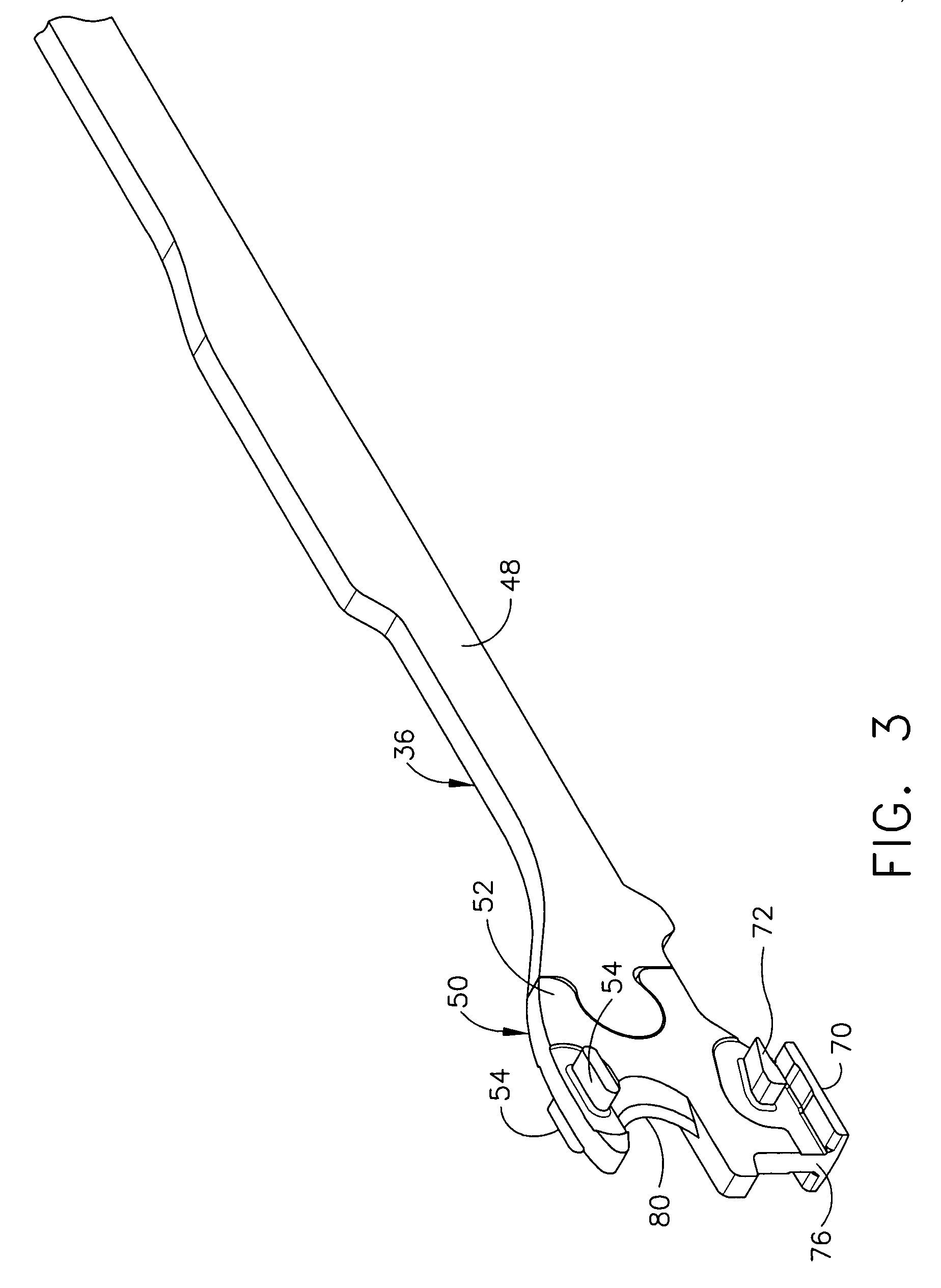

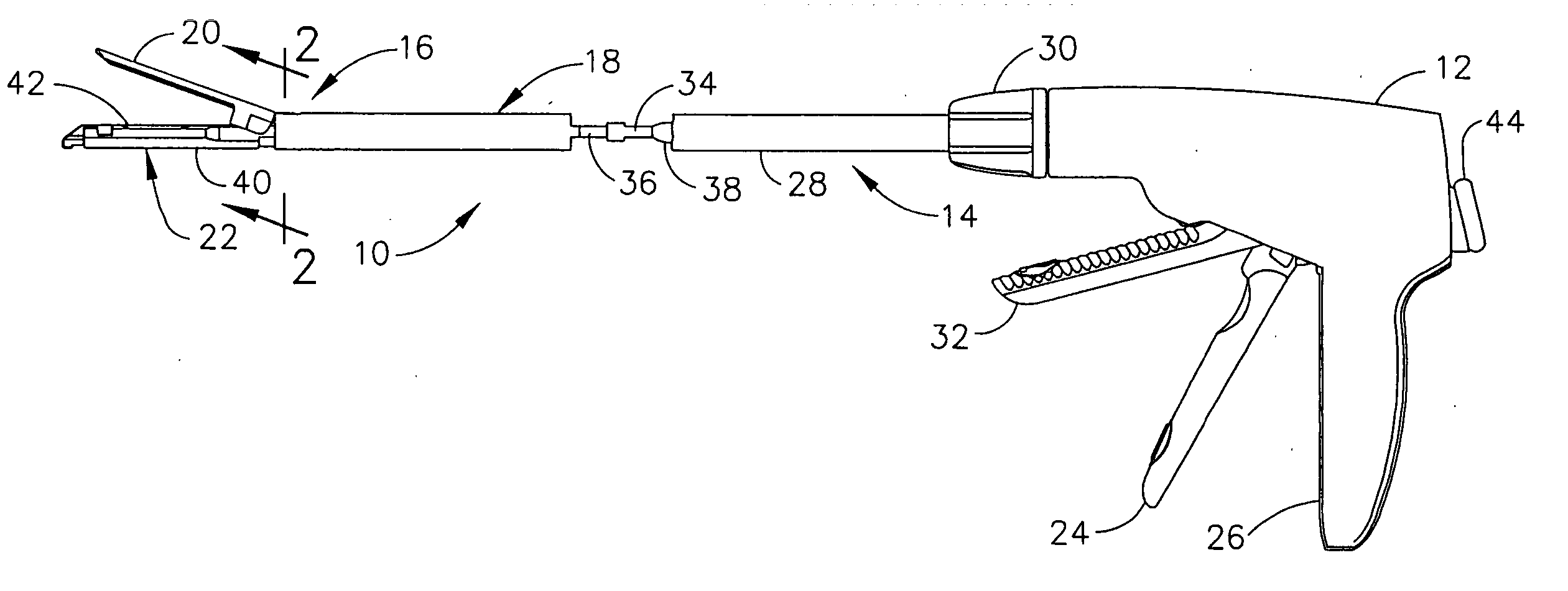

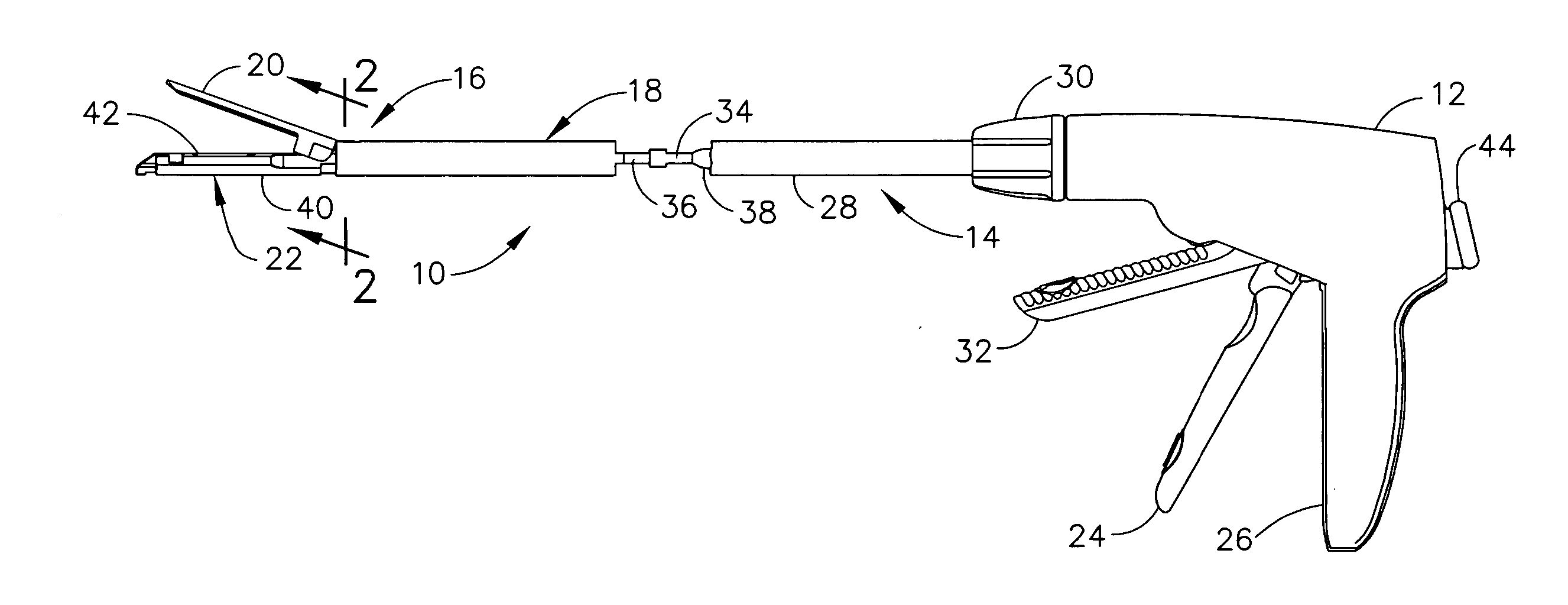

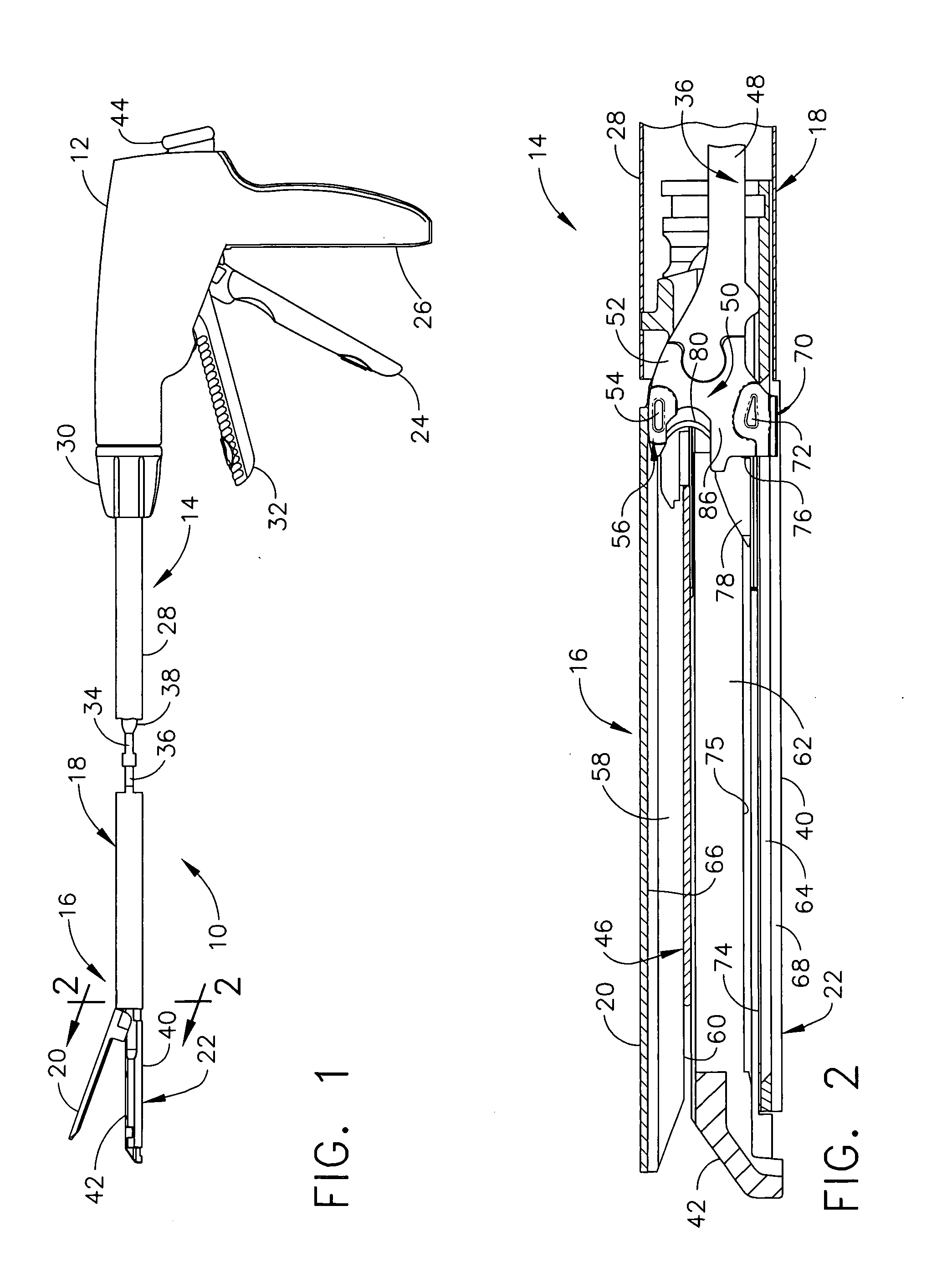

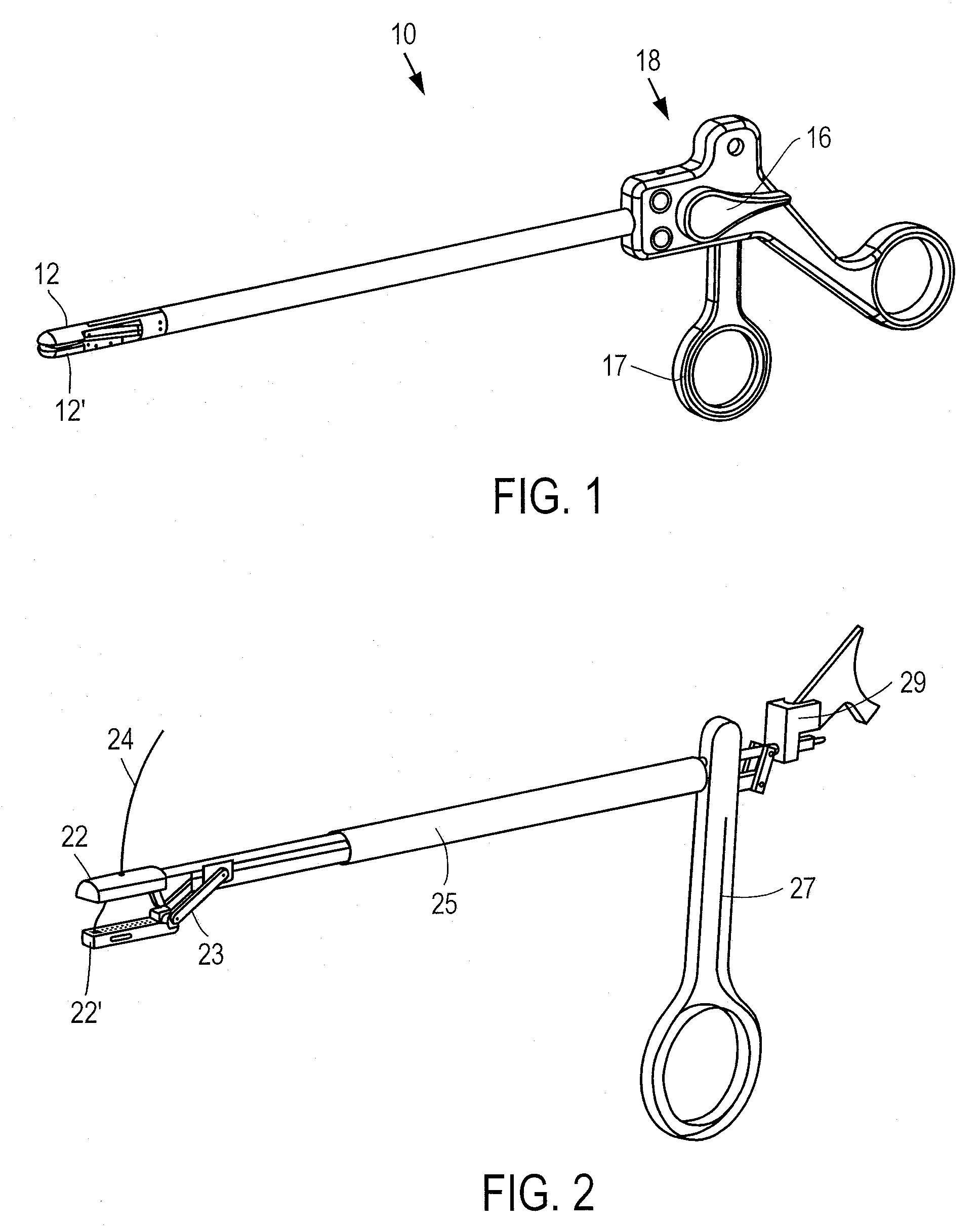

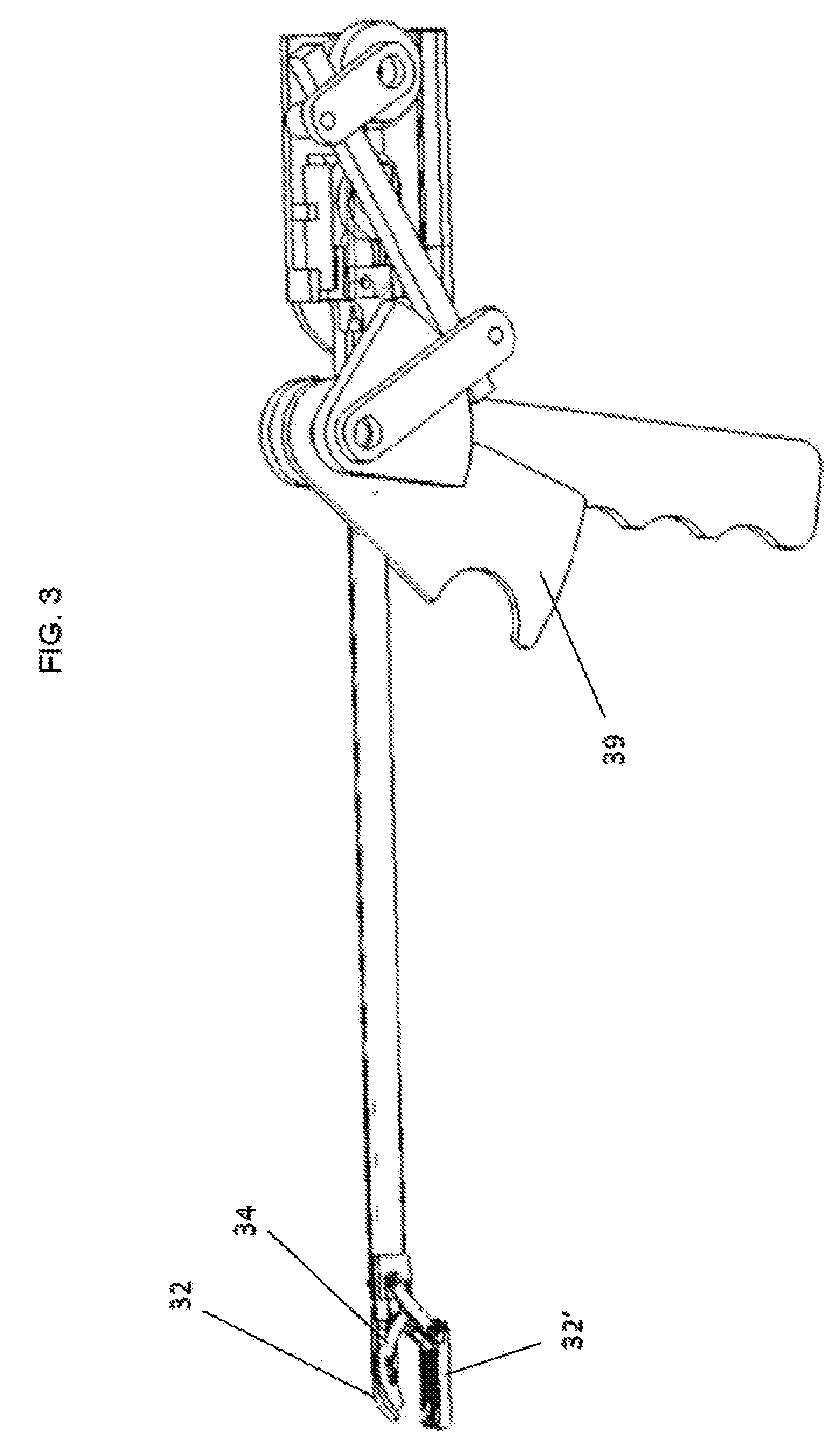

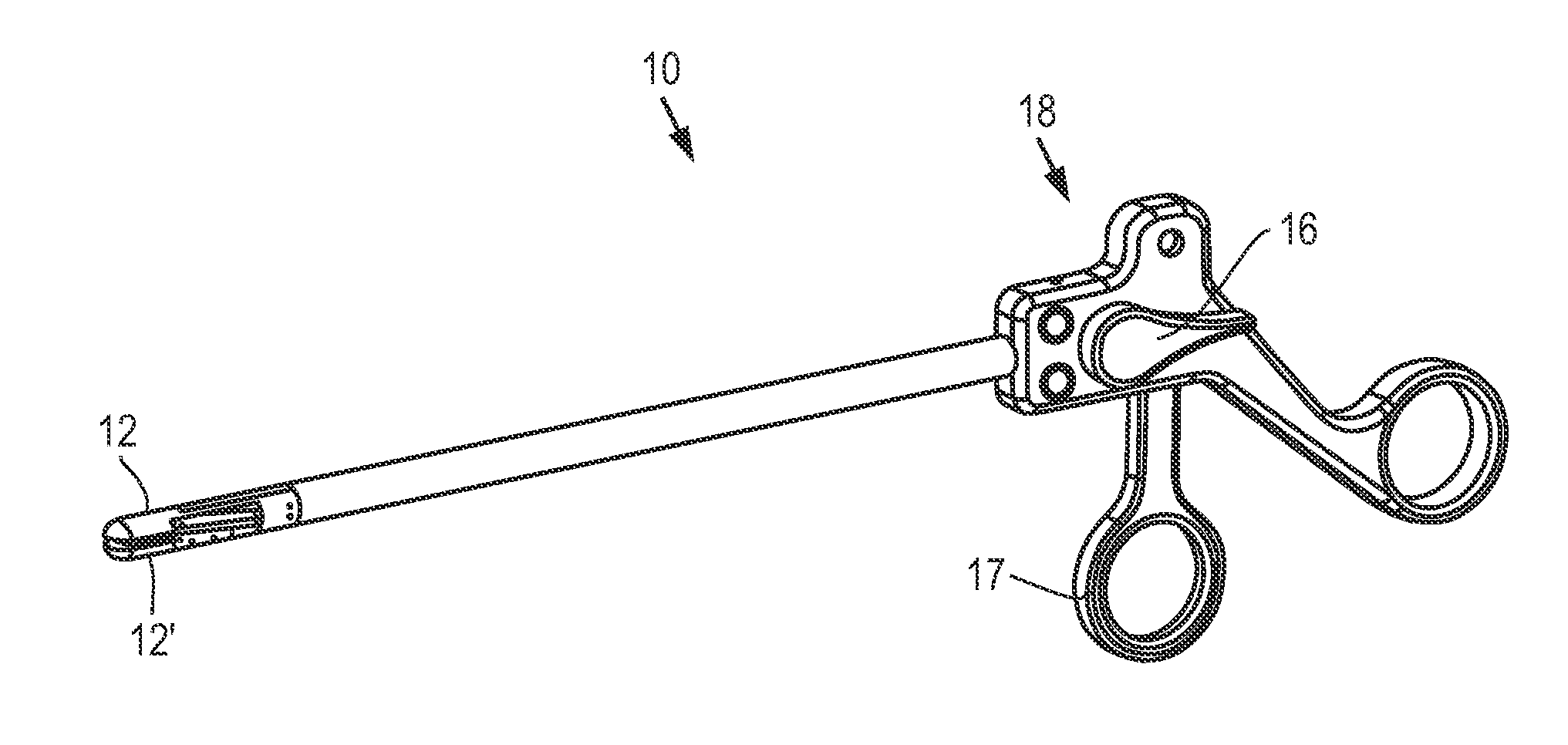

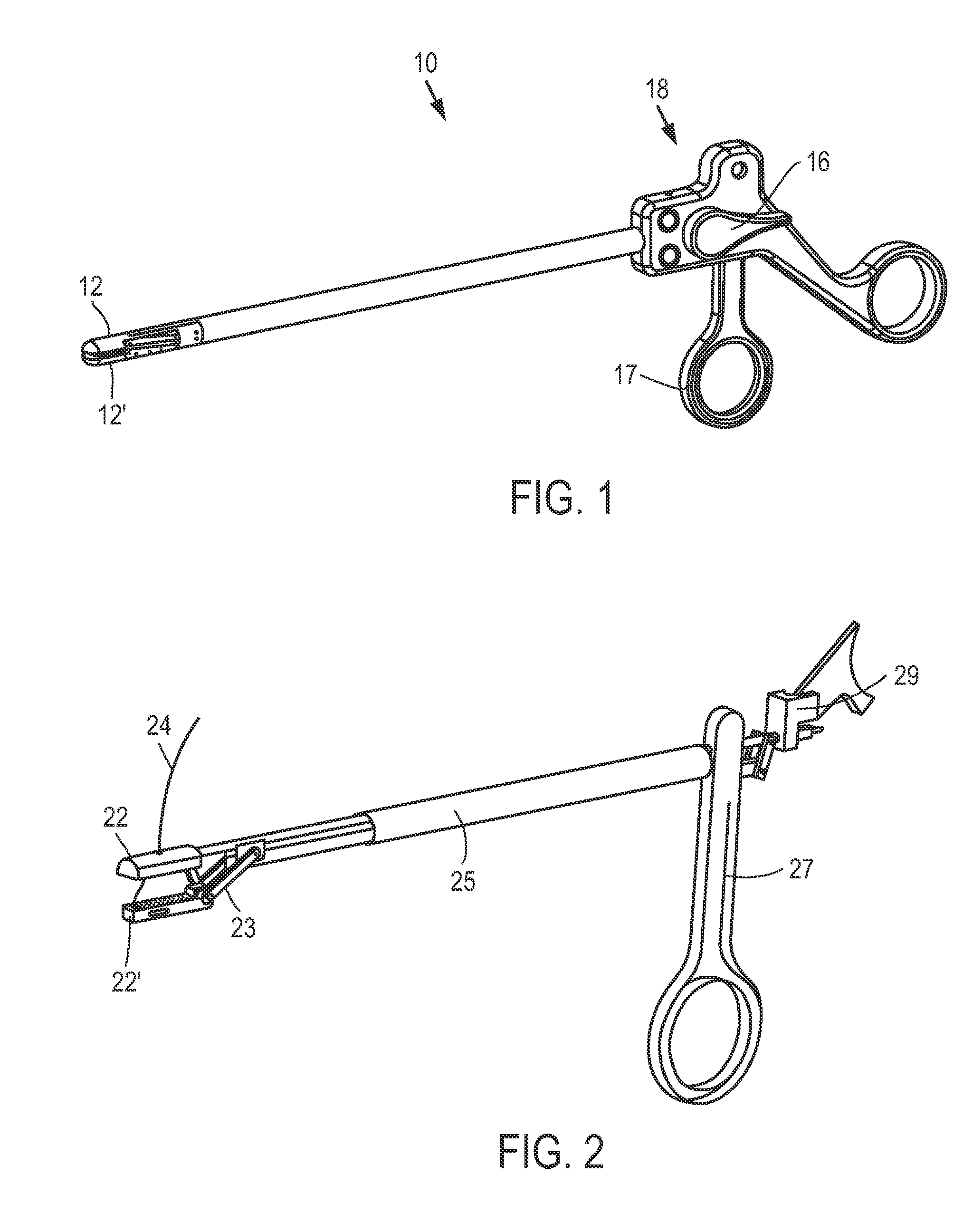

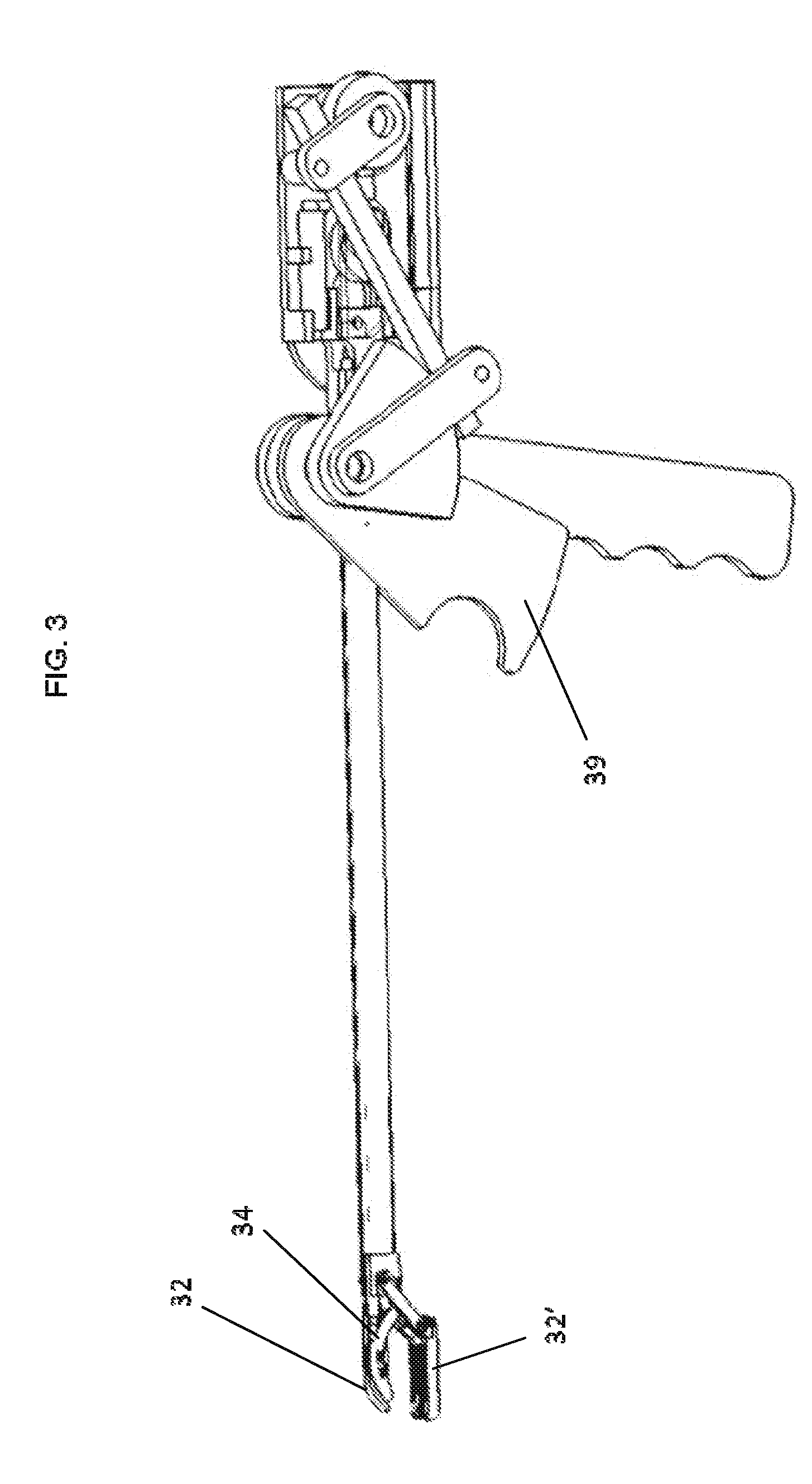

Surgical stapling instrument having force controlled spacing end effector

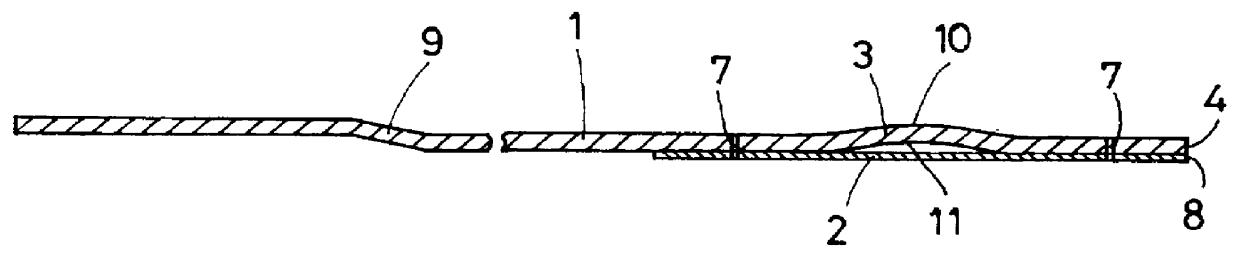

InactiveUS7407078B2Large thicknessPrevents excessive flexureSuture equipmentsStapling toolsSurgical staplePERITONEOSCOPE

Owner:ETHICON ENDO SURGERY INC

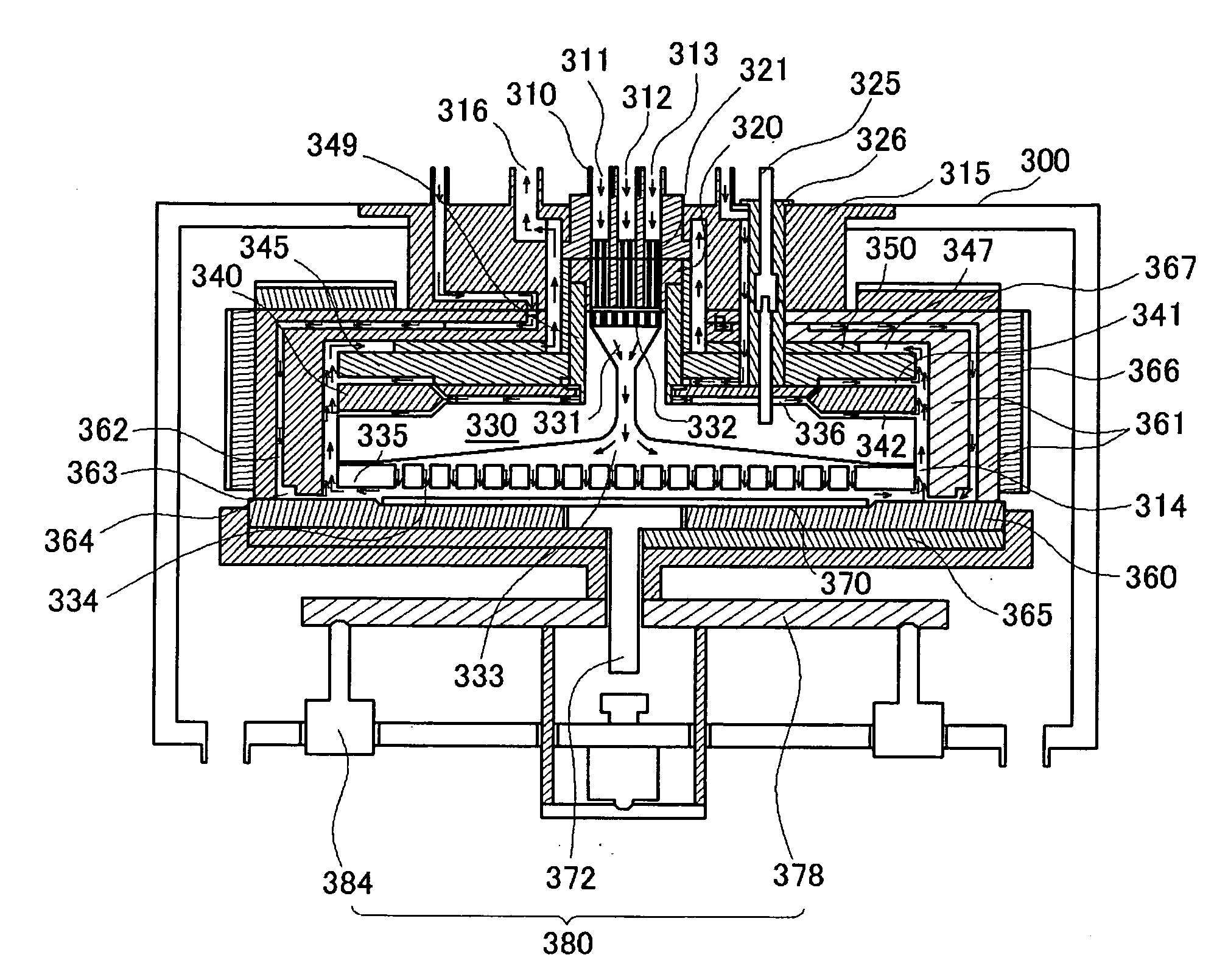

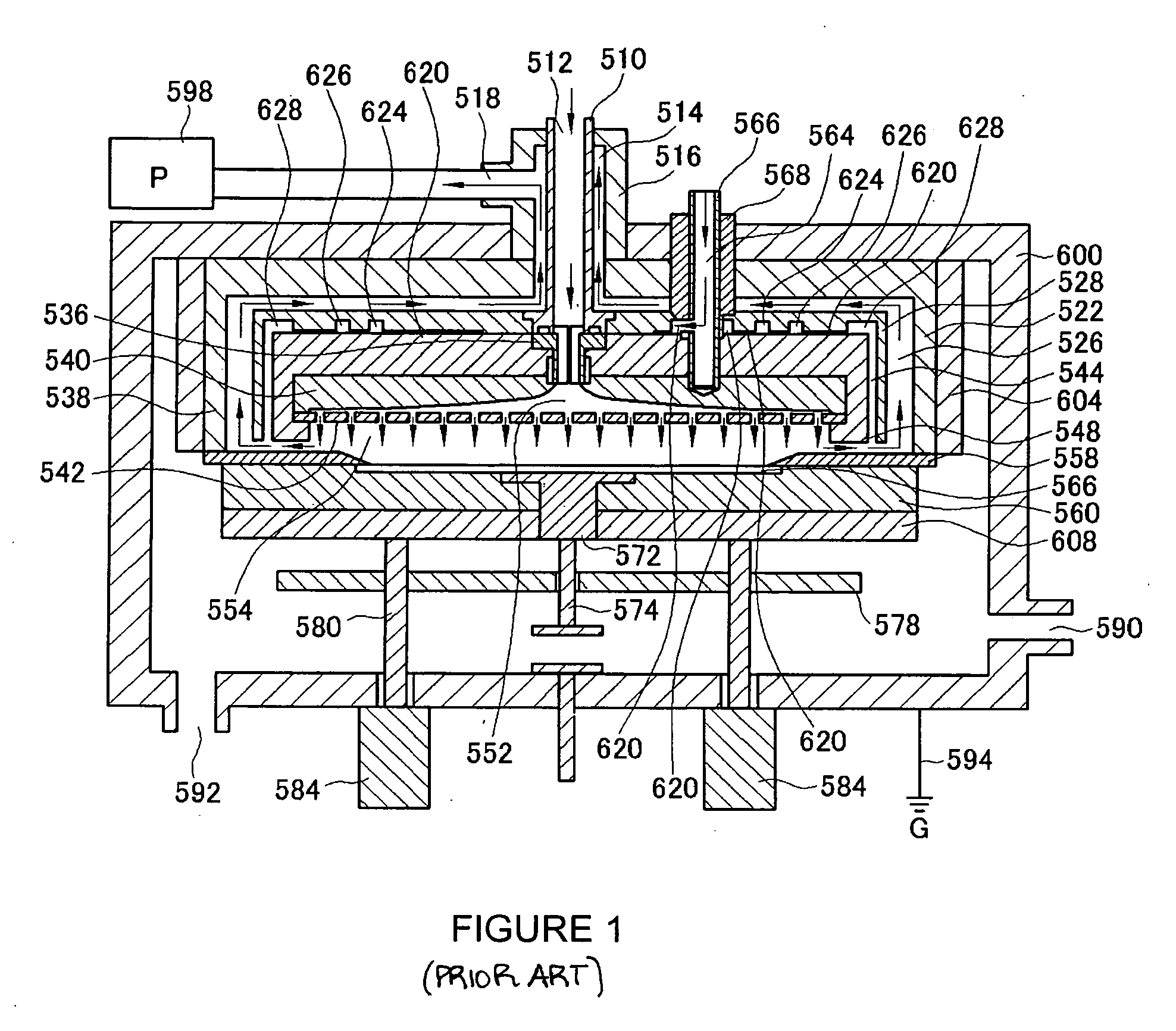

Atomic layer deposition apparatus

InactiveUS20060137608A1Uniform thicknessEasy to controlChemical vapor deposition coatingEngineeringAtomic layer deposition

An atomic layer deposition (ALD) apparatus is, suitable for thermal ALD and plasma-enhanced ALD of conductive and non-conductive films. The ALD apparatus can maintain electrical insulation of a gas dispersion structure, such as a showerhead assembly, which acts as an RF electrode to generate plasma inside a reaction chamber while depositing electrically conductive films in the reaction chamber. Fine tubules of micro-feeding tube assembly prevents plasma generation in them and reactive gases each have separate flow paths through the micro-feeding tube assembly. Process gases out of the micro-feeding tube assembly enter narrow grooves of a helical flow inducing plate and form helical flows which mix well each other. Symmetrically mounted pads on showerhead assembly and flow guiding plate maintain a symmetrical gap through which an inert gas flows continuously to keep reactive gases outside the gap and unwanted film deposition in the gap. Longer operating time before maintenance (cleaning) and thus higher productivity can be achieved.

Owner:ASM GENITECH KOREA

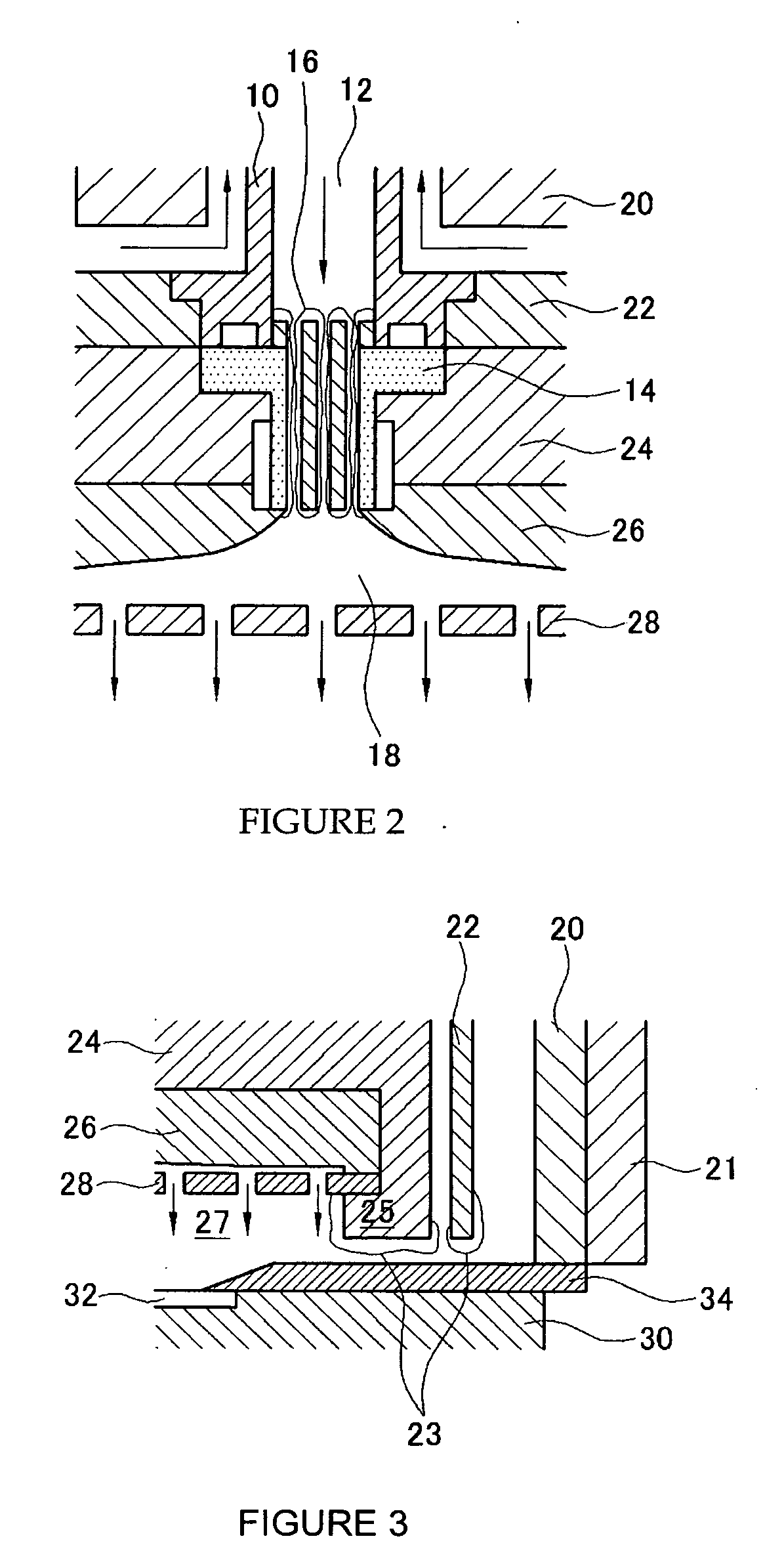

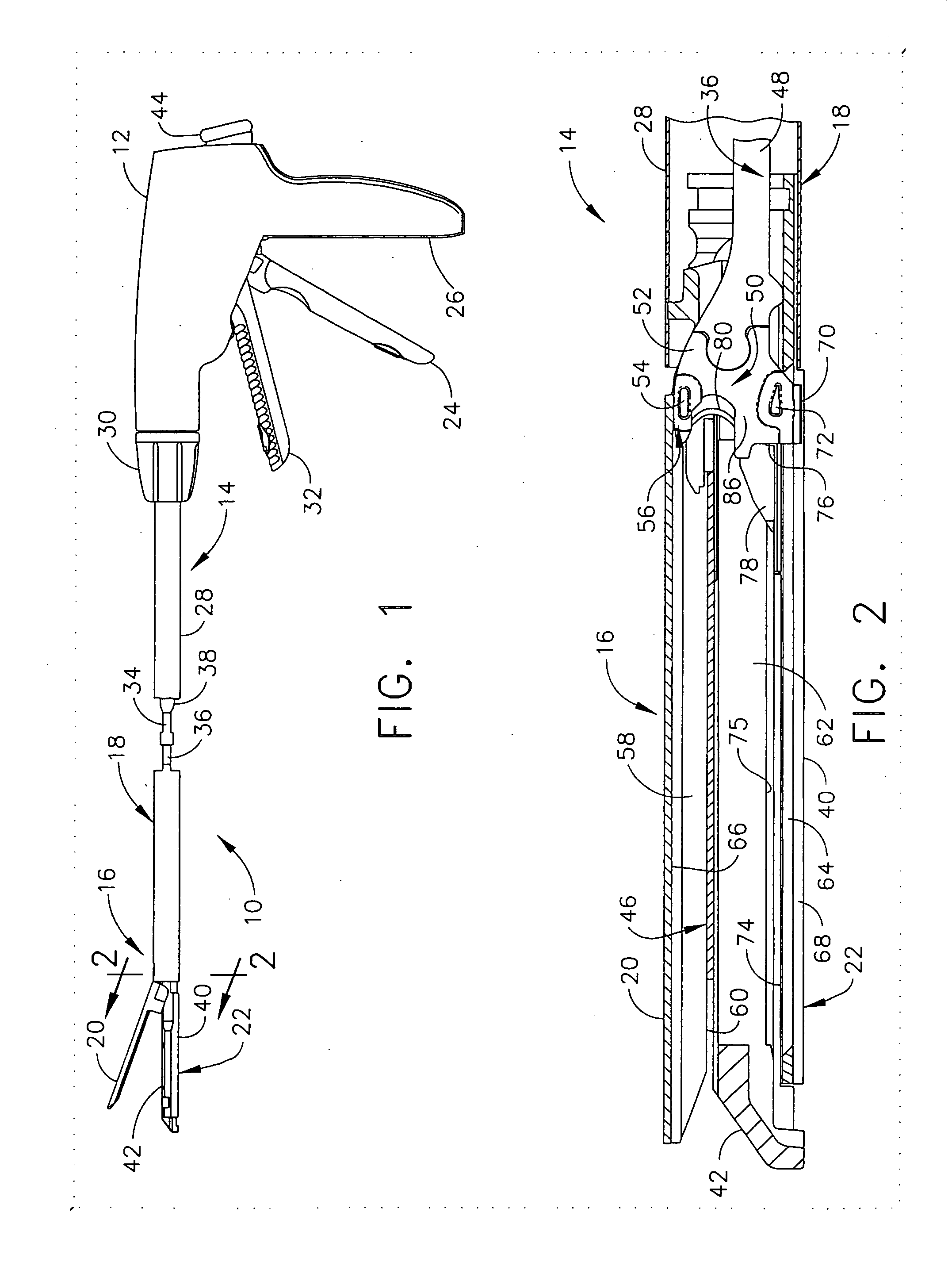

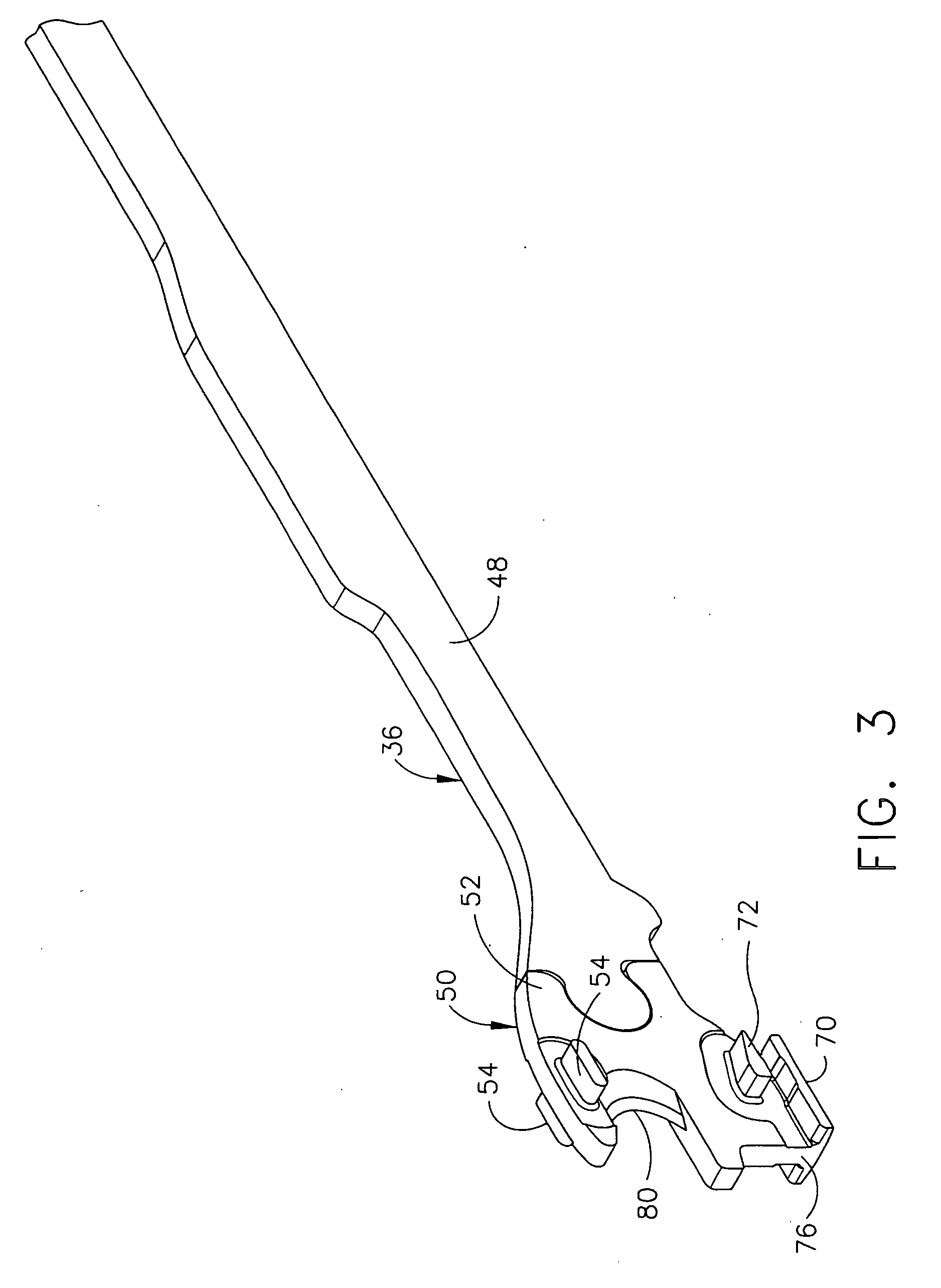

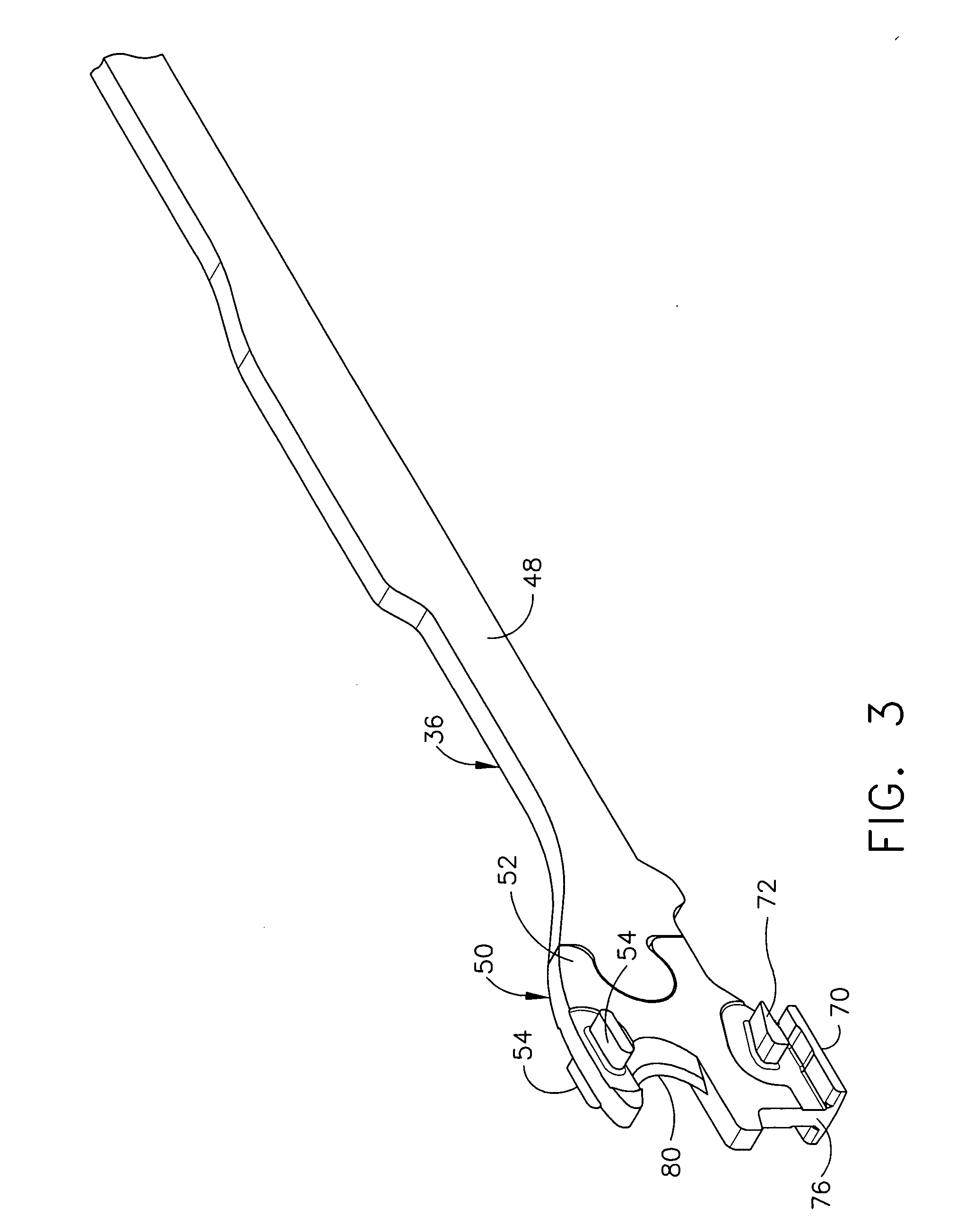

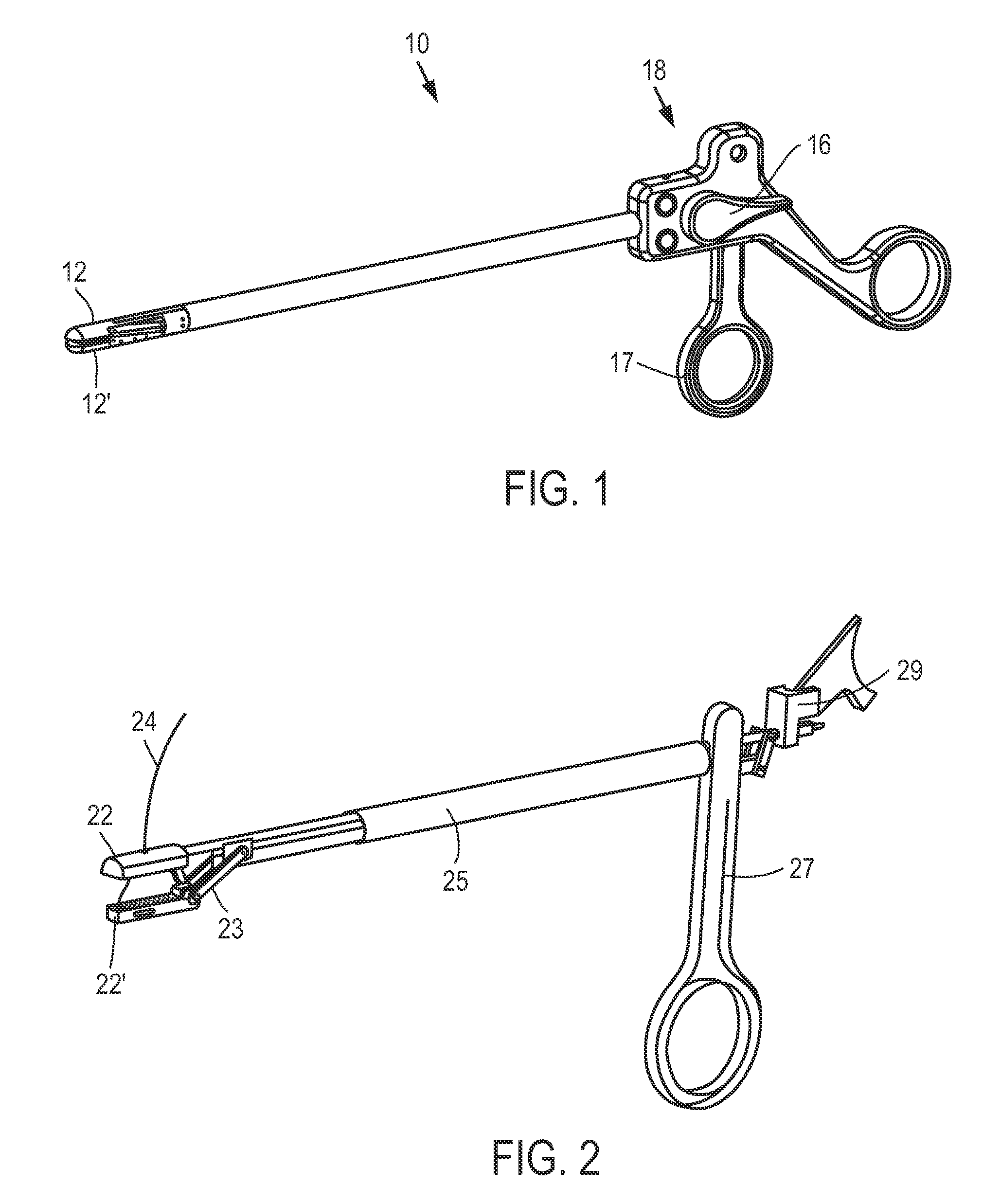

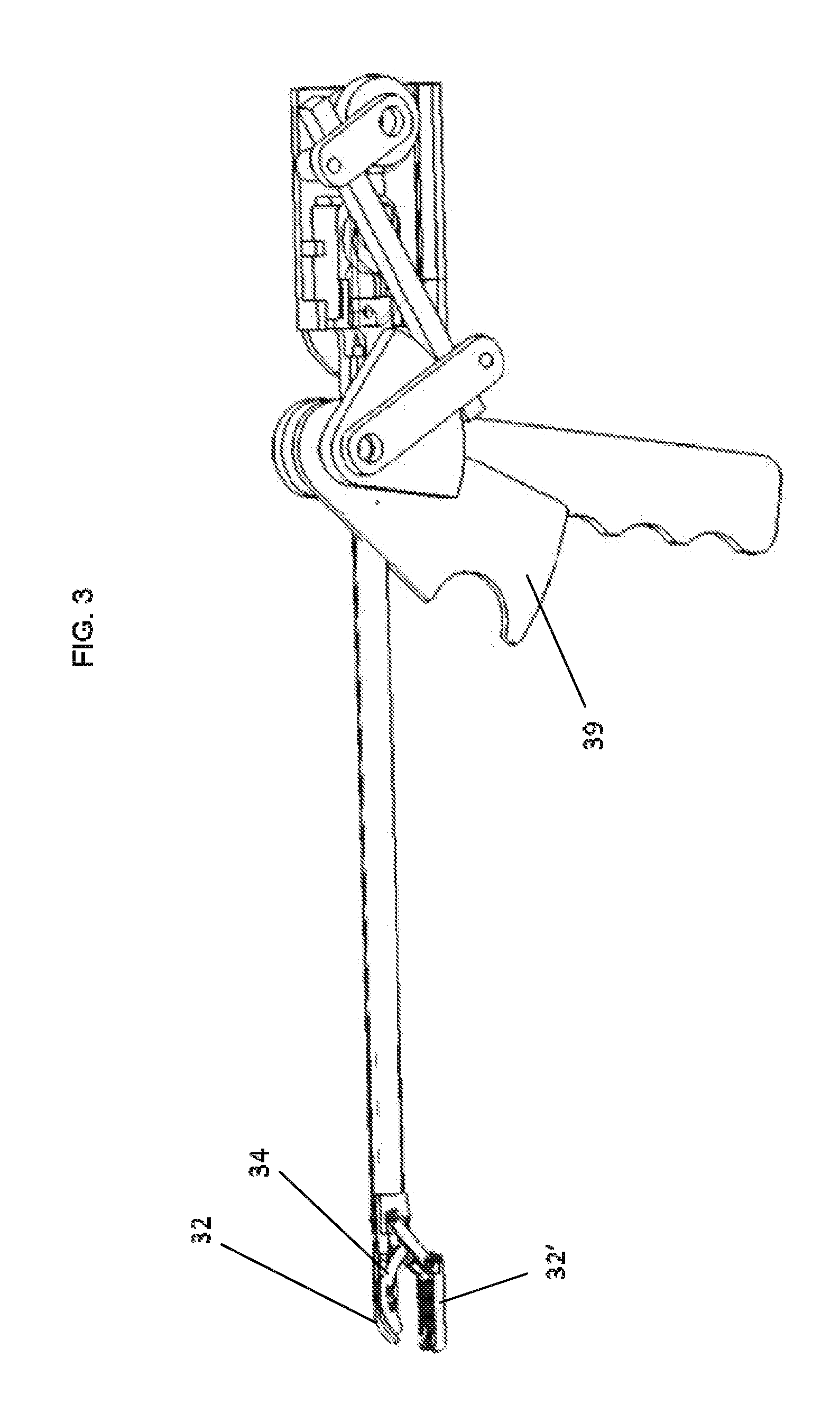

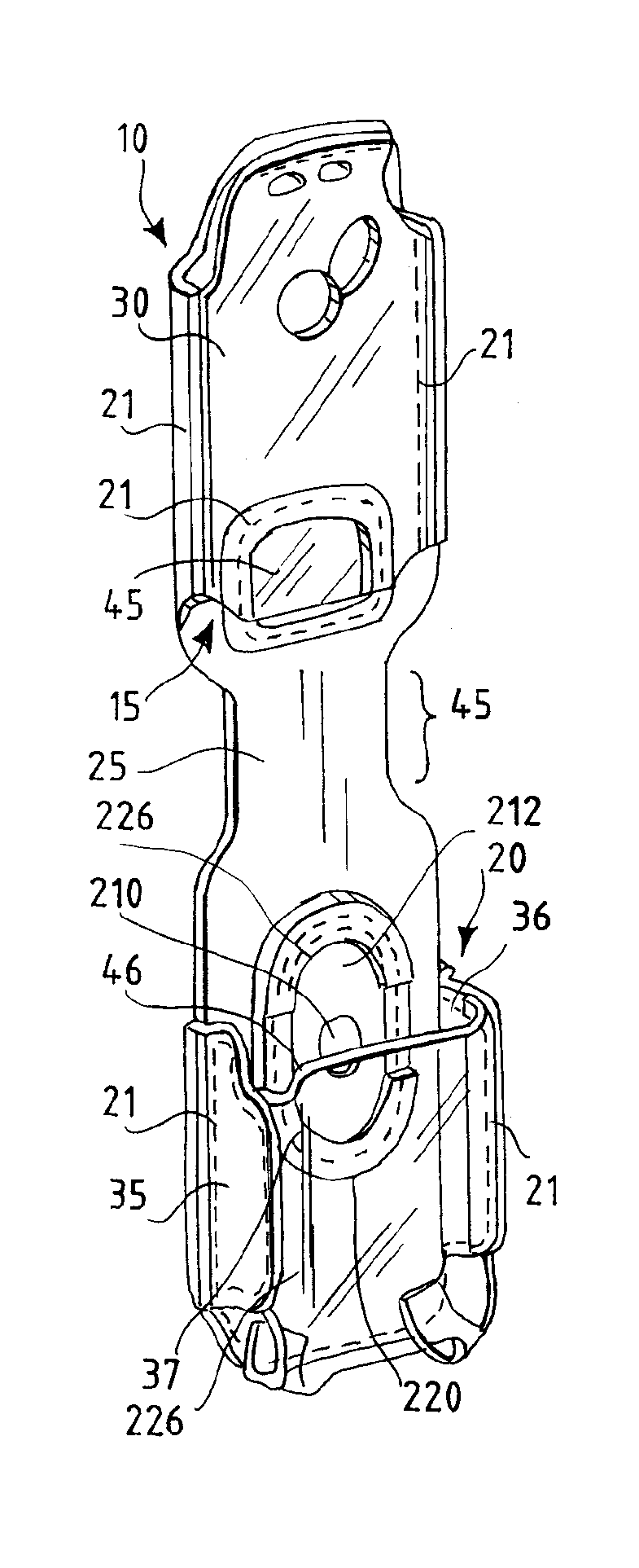

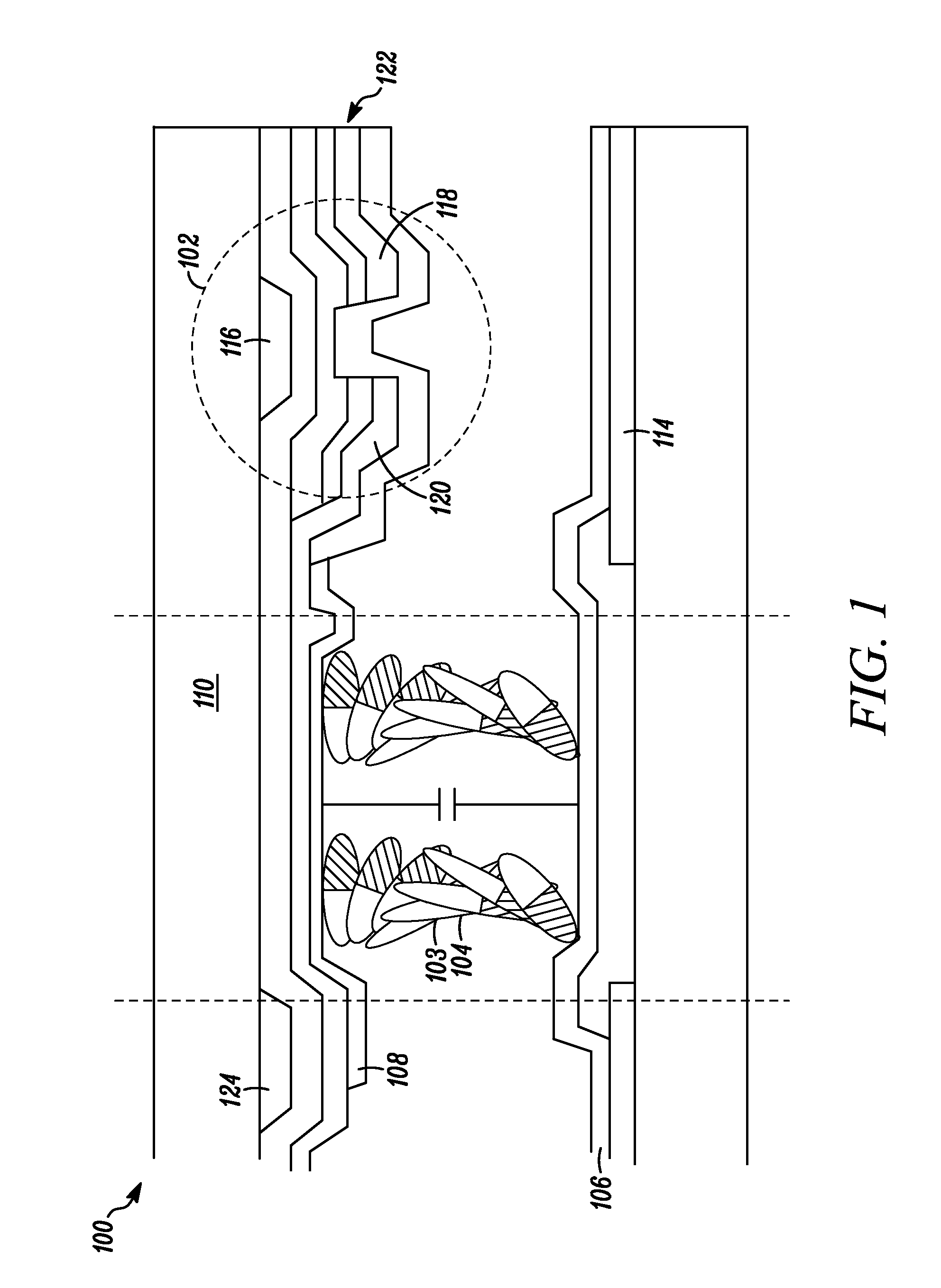

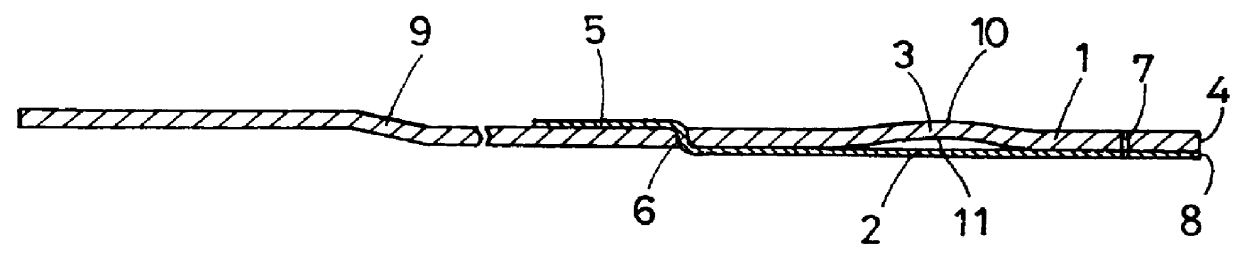

Surgical stapling instruments having flexible channel and anvil features for adjustable staple heights

ActiveUS20070083234A1Large thicknessPrevents excessive flexureSuture equipmentsStapling toolsSurgical siteEngineering

A surgical instrument for being endoscopically or laparoscopically inserted into a surgical site for simultaneous stapling and severing of tissue includes force adjusted spacing between an upper jaw (anvil) and a lower jaw (staple cartridge engaged to an elongate staple channel) so that the height of staple formation corresponds to the thickness of the tissue, yet does not exceed the height range that may be accommodated by the length of the staples. In particular, resilient structures may be formed into one or more of the elongate channel that supports the staple cartridge, the anvil that is pivotally attached to the elongate channel, and / or a firing member that includes a cutting surface (knife) that severs tissue between a top pin that engages the anvil and a lower foot that engage the elongate channel. The resilience responds to the force exerted by clamped tissue to vary the spacing between the anvil and the staple cartridge supported within the elongate channel.

Owner:ETHICON ENDO SURGERY INC

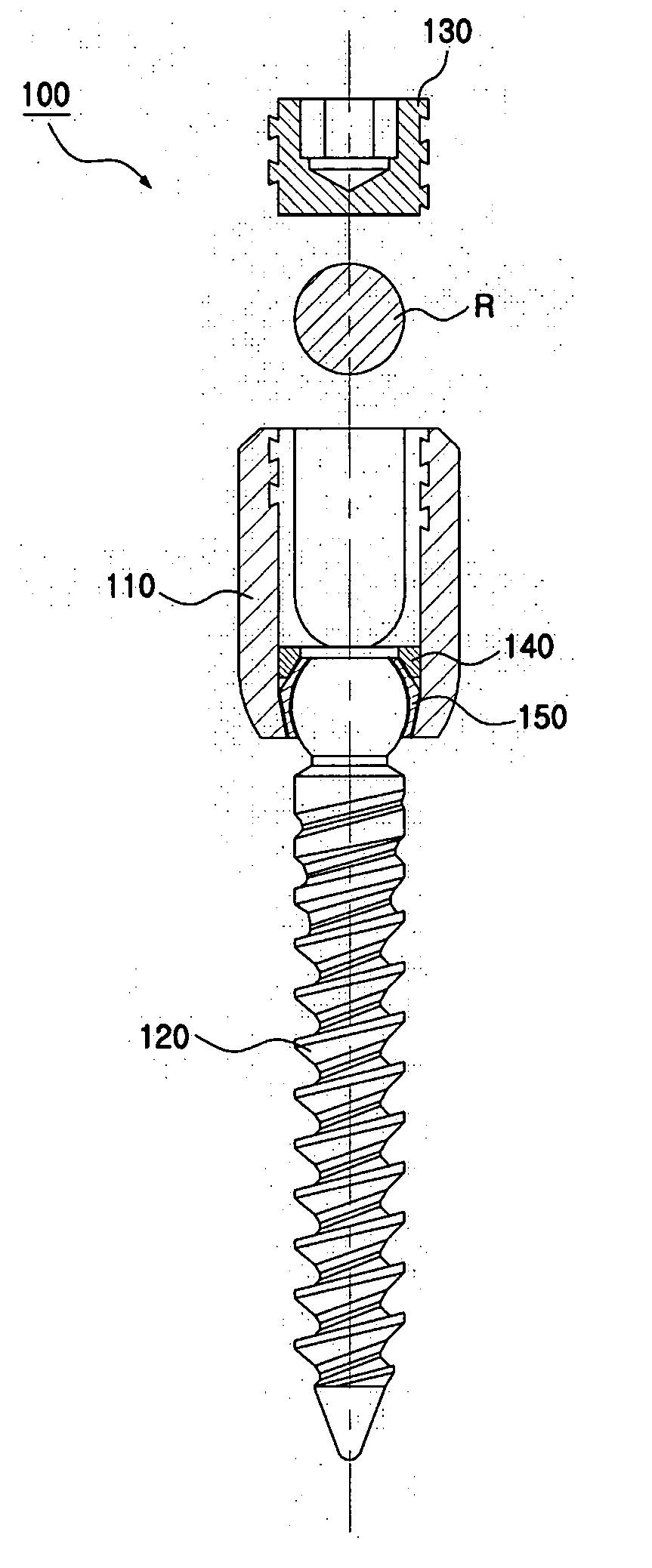

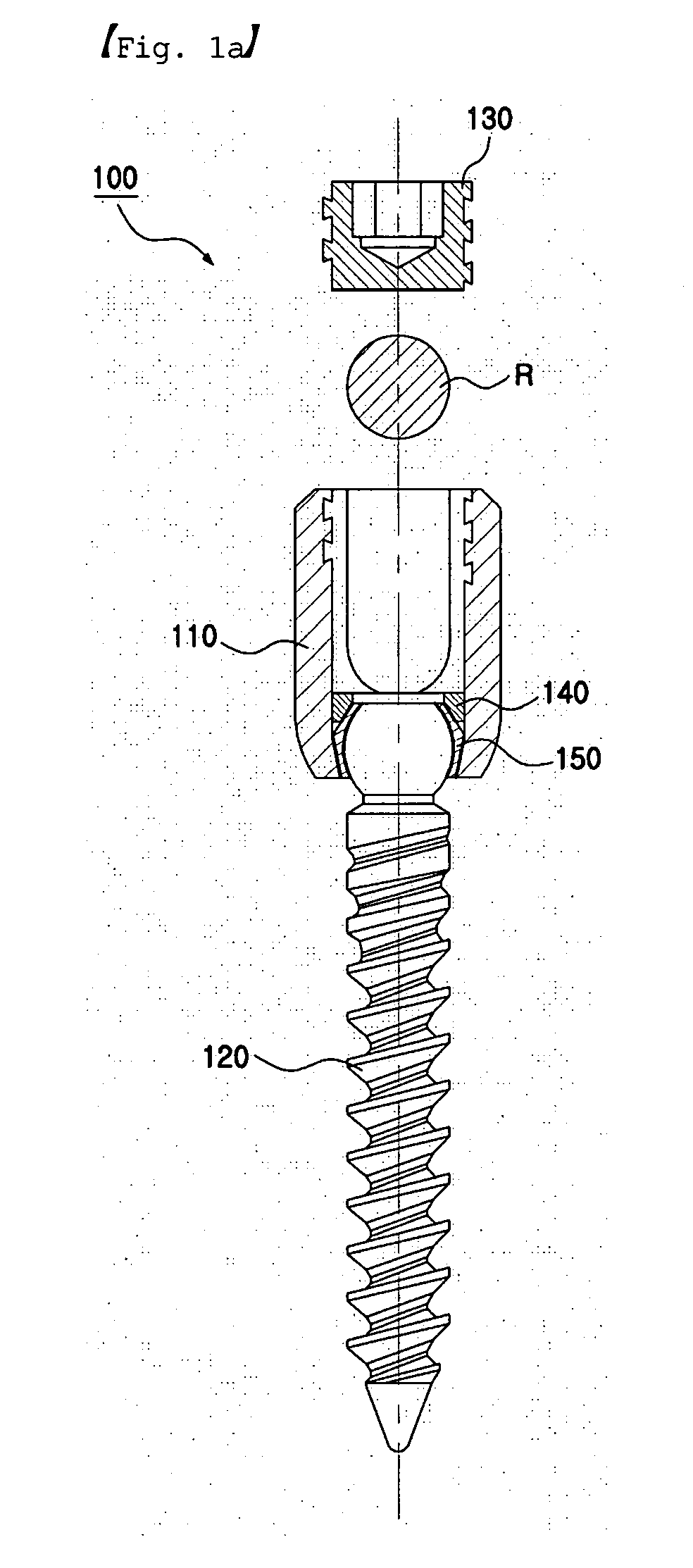

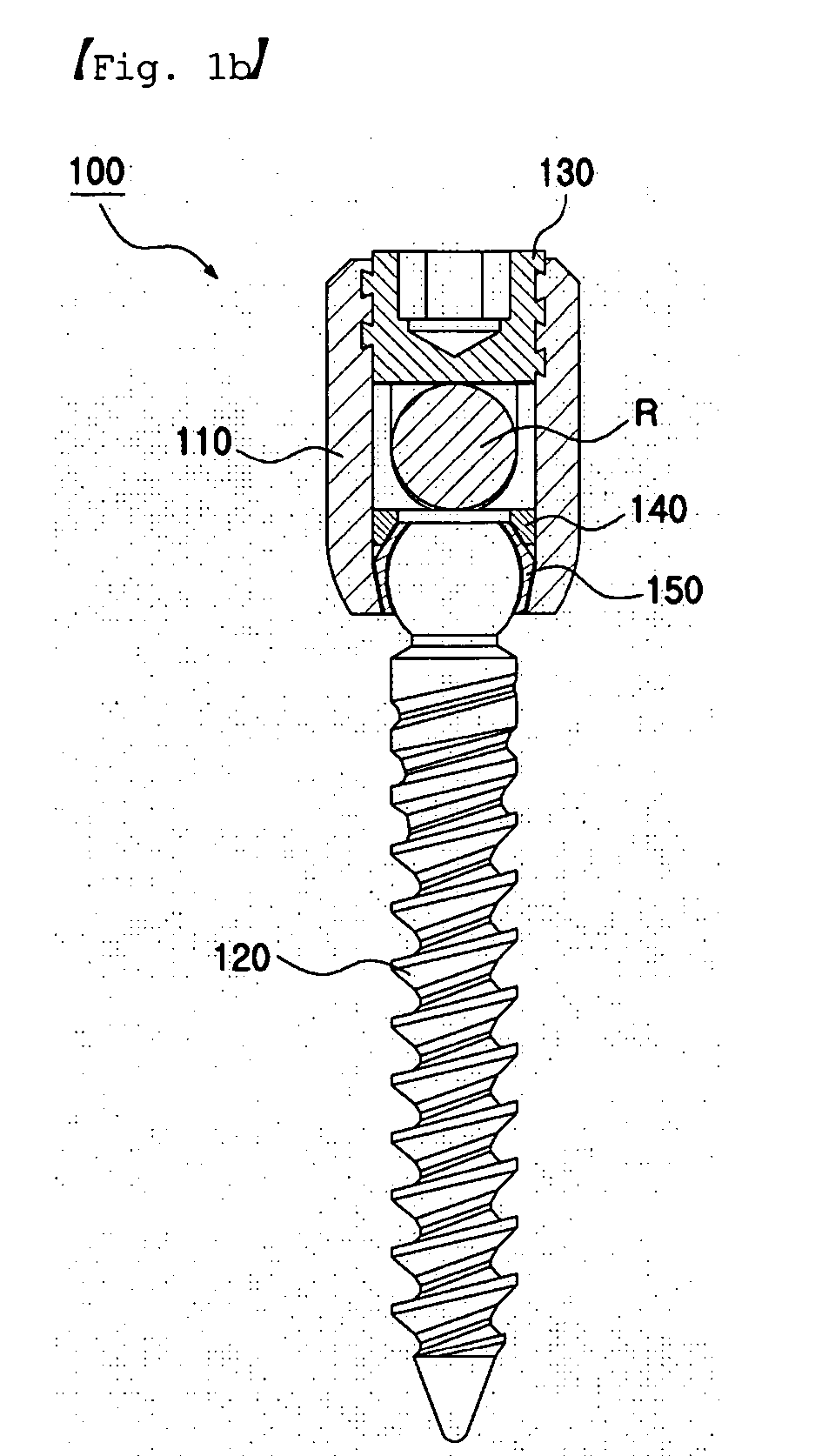

Multi-axial spinal pedicle screw

InactiveUS20070049933A1Inhibition releaseStably fixing the spineInternal osteosythesisJoint implantsSpheroidal jointIliac screw

Disclosed is a multi-axial spinal pedicle screw engaged with a spinal rod and inserted into and fixed to a pedicle. The multi-axial spinal pedicle screw includes: a screw rod in which a spherical articulation is integrally formed at an upper portion thereof, the screw rod being inserted into and fixed to the pedicle through a screw thread formed on the outer surface of a lower portion thereof; a spherical chuck having a plurality of claws, for surrounding and fixing the spherical articulation; a head section in which a receiving hole for receiving the spherical chuck fixing the spherical articulation is formed at a lower portion thereof so as to penetrate the lower portion, a rod receiving channel for receiving the spinal rod is opened upward, and an engagement screw root is formed on the inner surface of the rod receiving channel; and a tightening screw in which an engagement screw thread corresponding to the engagement screw root is formed on the outer surface thereof, the tightening screw being engaged with the head section through the rod receiving channel to fix the spinal rod.

Owner:KIM HOON +1

Surgical stapling instrument having force controlled spacing end effector

ActiveUS20070075114A1Large thicknessPrevents excessive flexureSuture equipmentsStapling toolsSurgical staplePERITONEOSCOPE

A surgical instrument for being endoscopically or laparoscopically inserted into a surgical site for simultaneous stapling and severing of tissue includes force adjusted spacing between an upper jaw (anvil) and a lower jaw (staple cartridge engaged to an elongate staple channel) so that the height of staple formation corresponds to the thickness of the tissue, yet does not exceed the height range that may be accommodated by the length of the staples. In particular, resilient structures are formed into an E-beam firing bar that includes a cutting surface (knife) that severs tissue between a top pin that engages the anvil and a middle pin and lower foot that engage the lower jaw. The resilience responds to the force exerted by clamped tissue to vary the spacing.

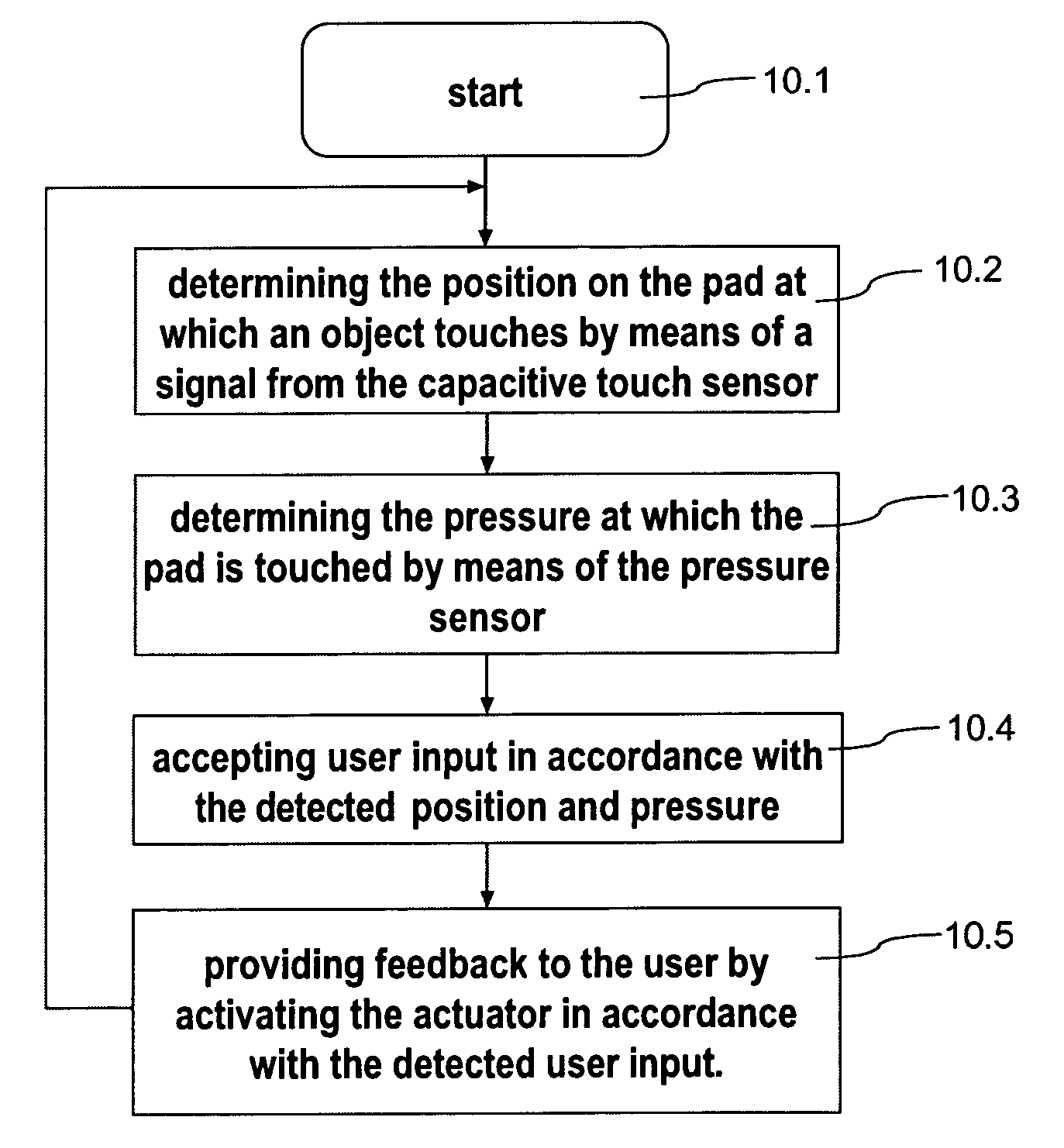

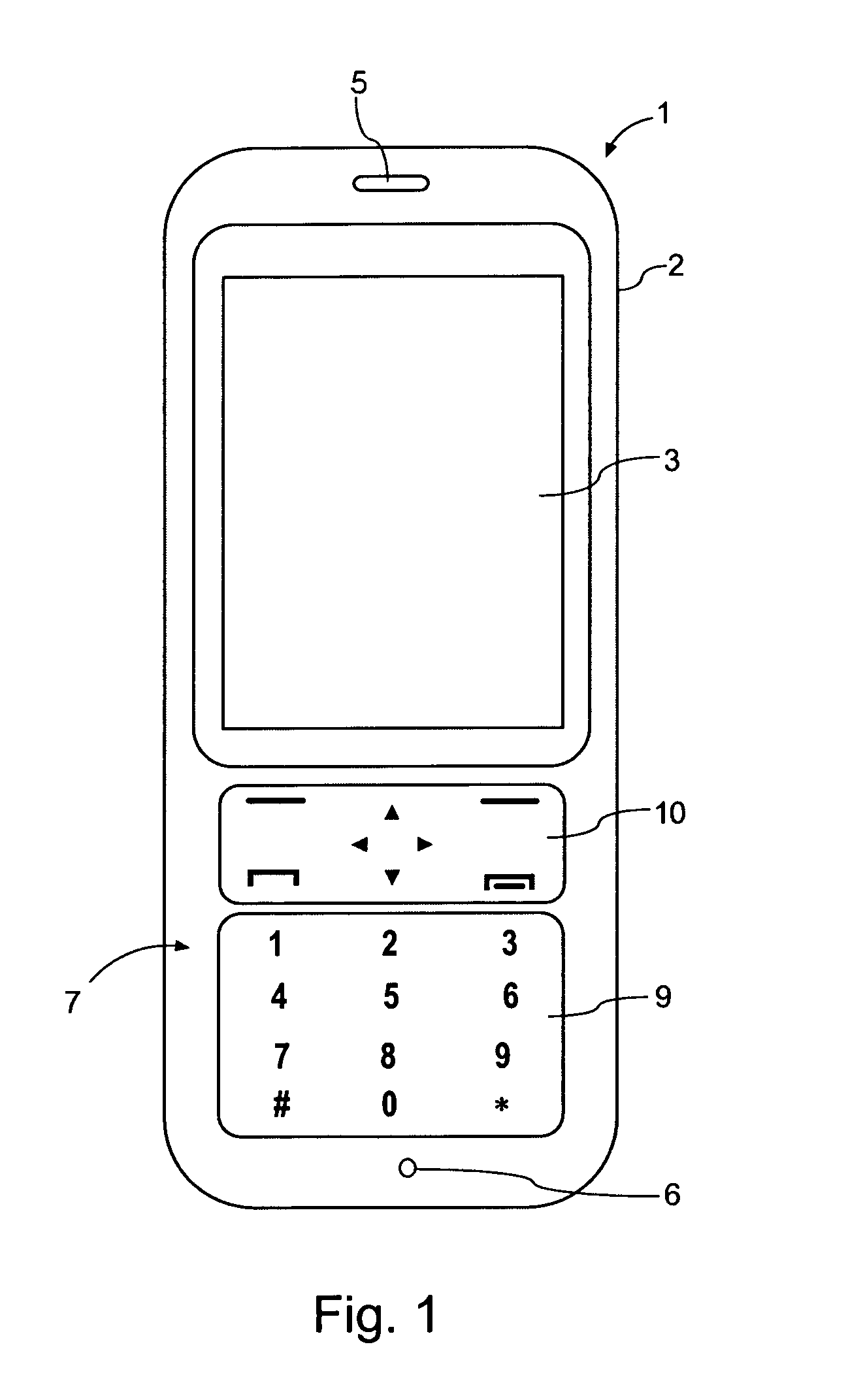

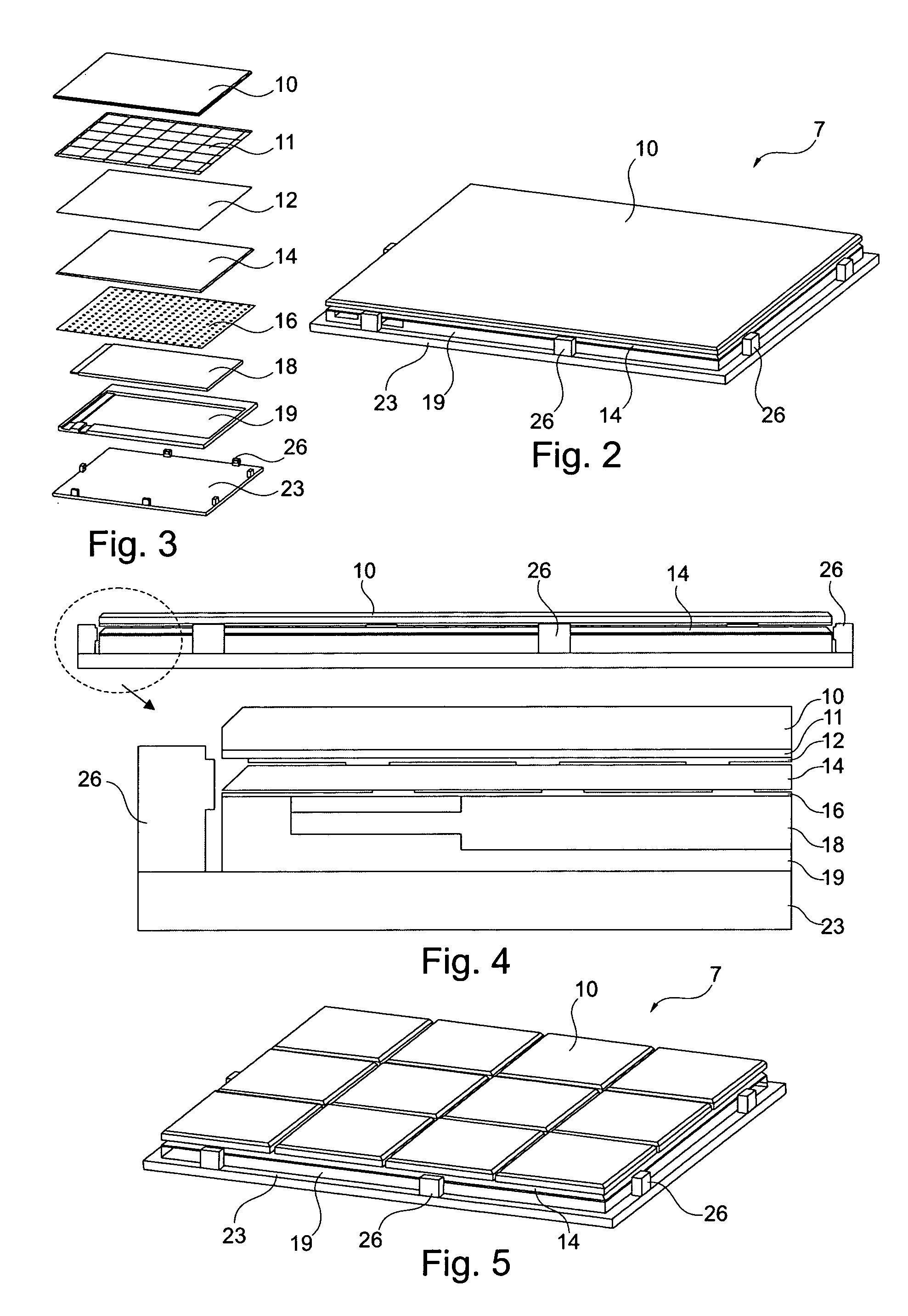

Keypad

ActiveUS20100052880A1Reduce thicknessImproved determinationInput/output for user-computer interactionRepeater circuitsSurface layerLight guide

A thin keypad including a top surface layer, a light guide layer, a capacitive sensing layer and a piezo layer provides for touch input, pressure input and haptic feedback.

Owner:NOKIA TECHNOLOGLES OY

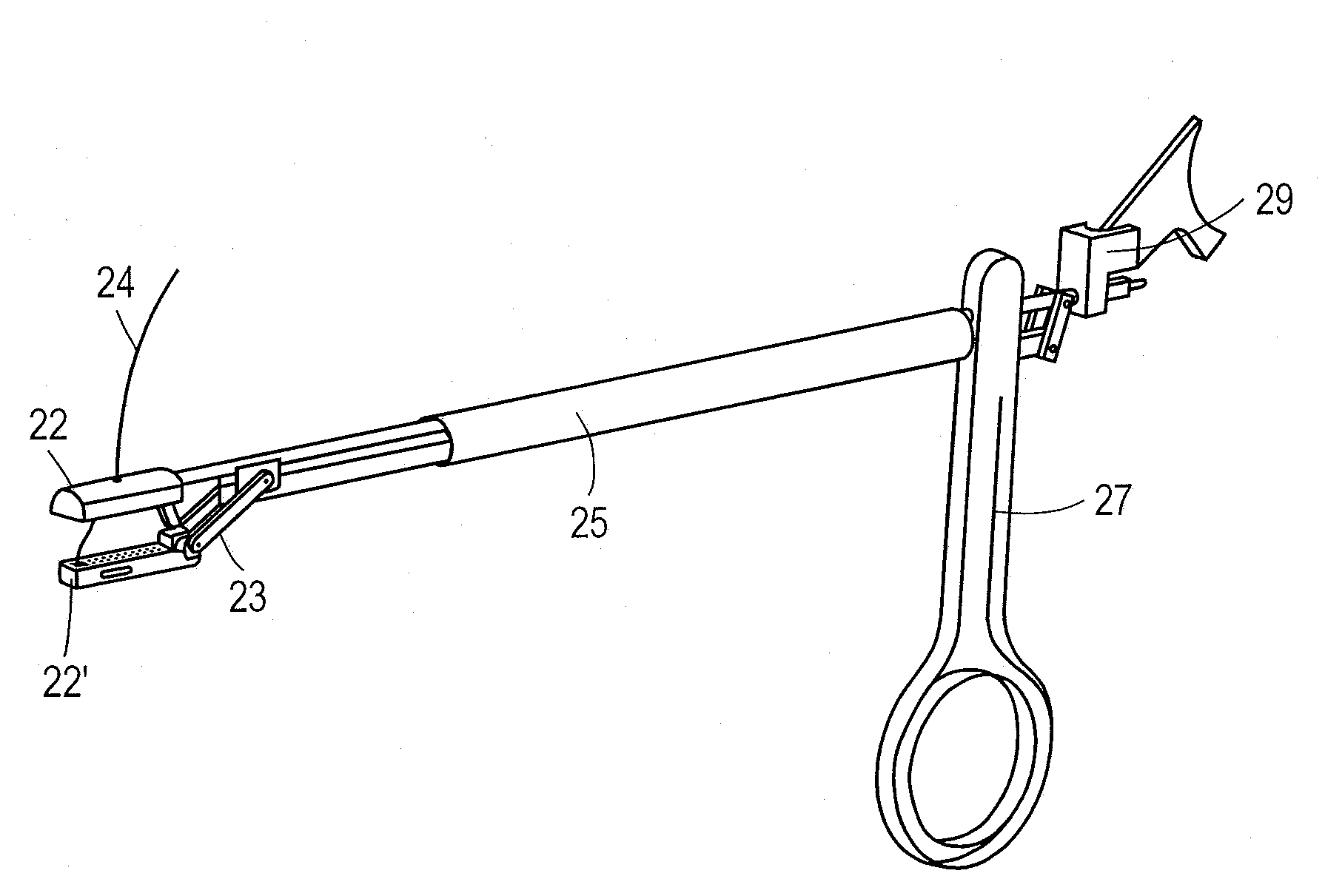

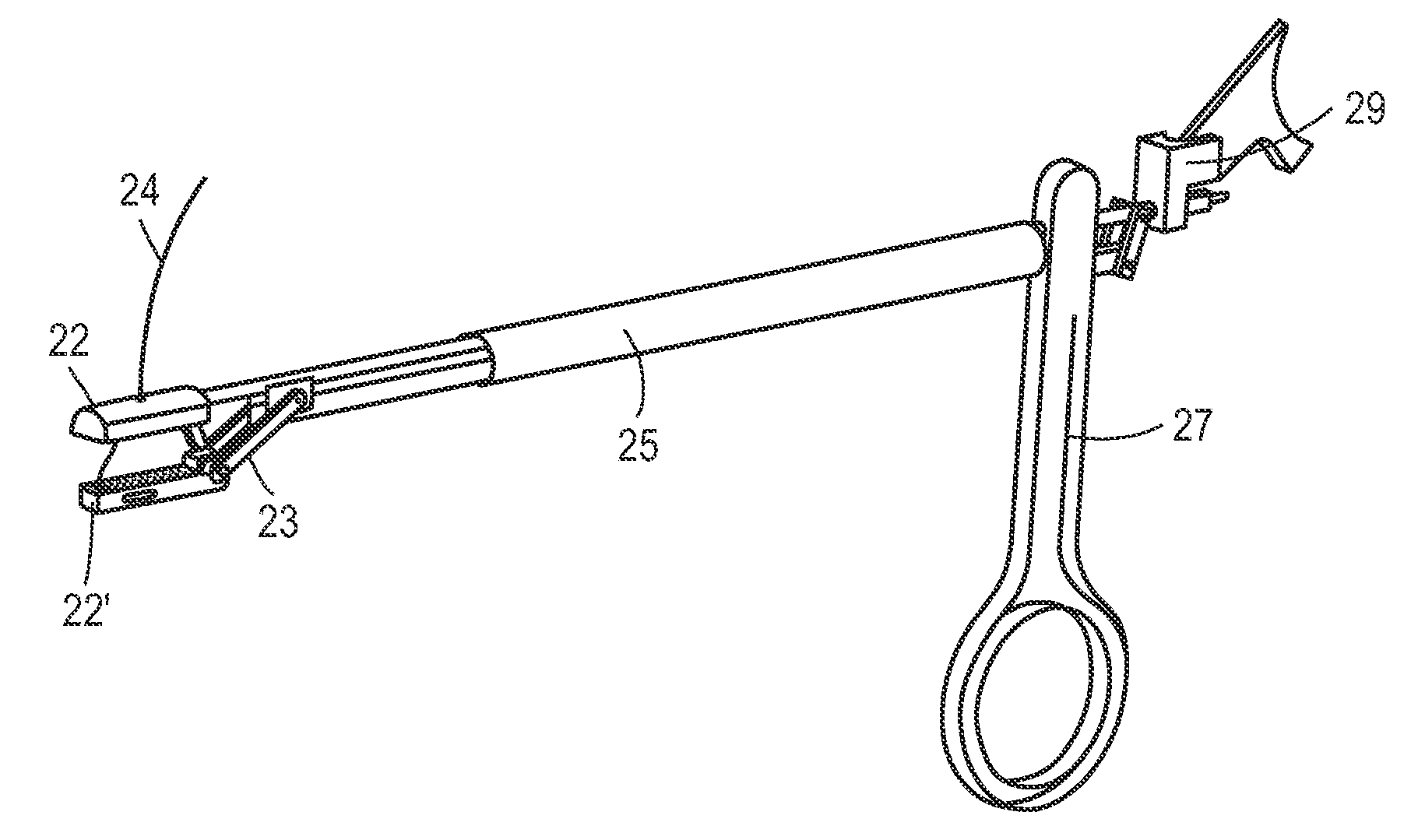

Methods and devices for continuous suture passing

InactiveUS20090012538A1Prevent “ pinching ” and damageIncrease the areaSuture equipmentsSurgical needlesContinuous sutureGeneral surgery

Described herein are suture passers for suturing tissue in a continuous manner by passing a suture attached to a suture shuttle through. A suture passer may include a first jaw, a second jaw, and a tissue perpetrator that is retractable and extendable from the first jaw. The tissue penetrator may have a suture shuttle engagement region, and the second jaw may include a shuttle dock. The suture shuttle may be transferred between the first and second jaws as the tissue penetrator is extended from the first jaw and engages the second jaw. In some variations of the tissue passer, one or both jaws are tissue penetrating. In some variations, the jaws open in parallel, allowing large tissue regions to be positioned between the jaws. Methods of using these devices are also described, as are systems and kits including these devices.

Owner:CETERIX ORTHOPAEDICS

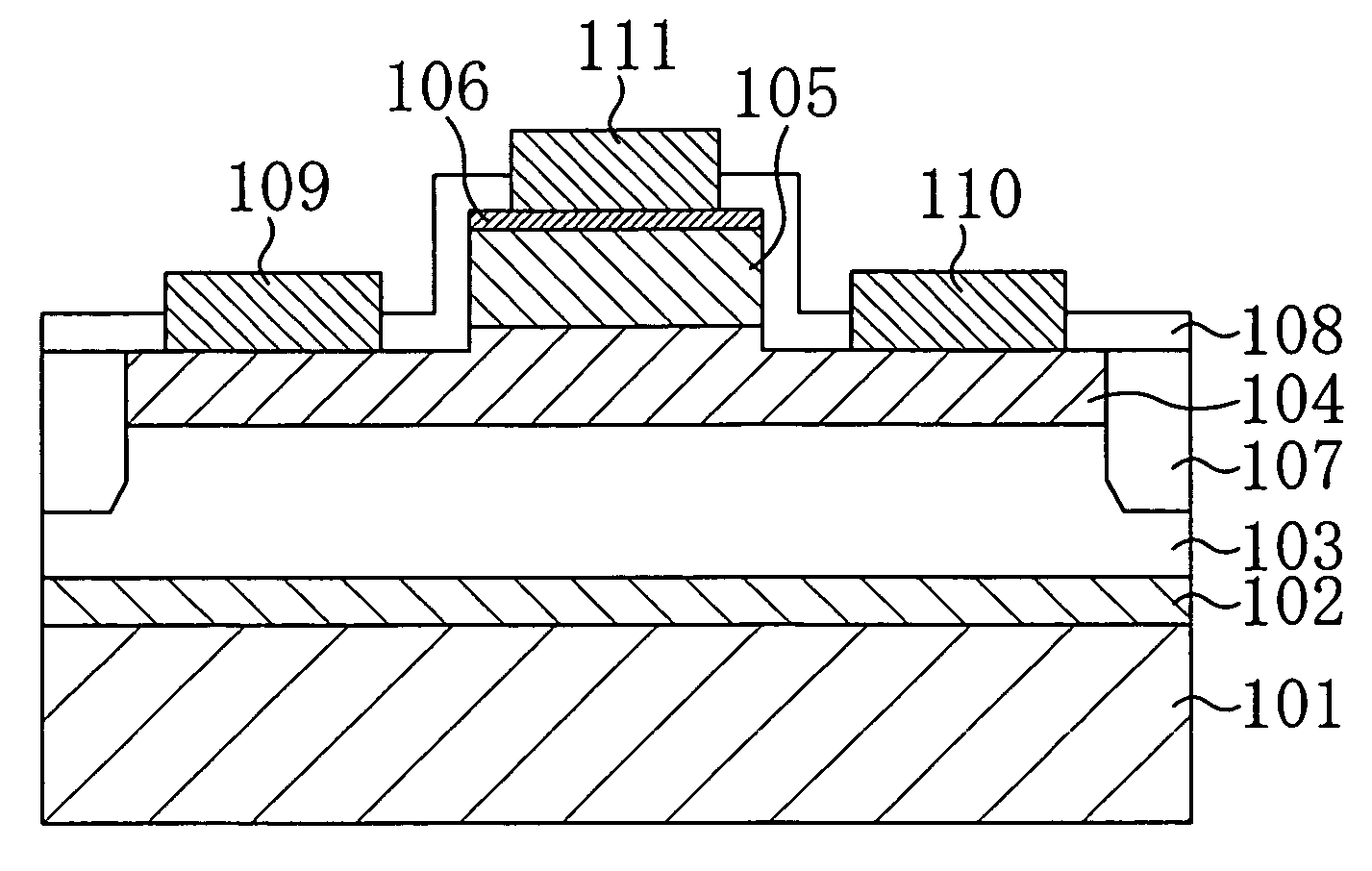

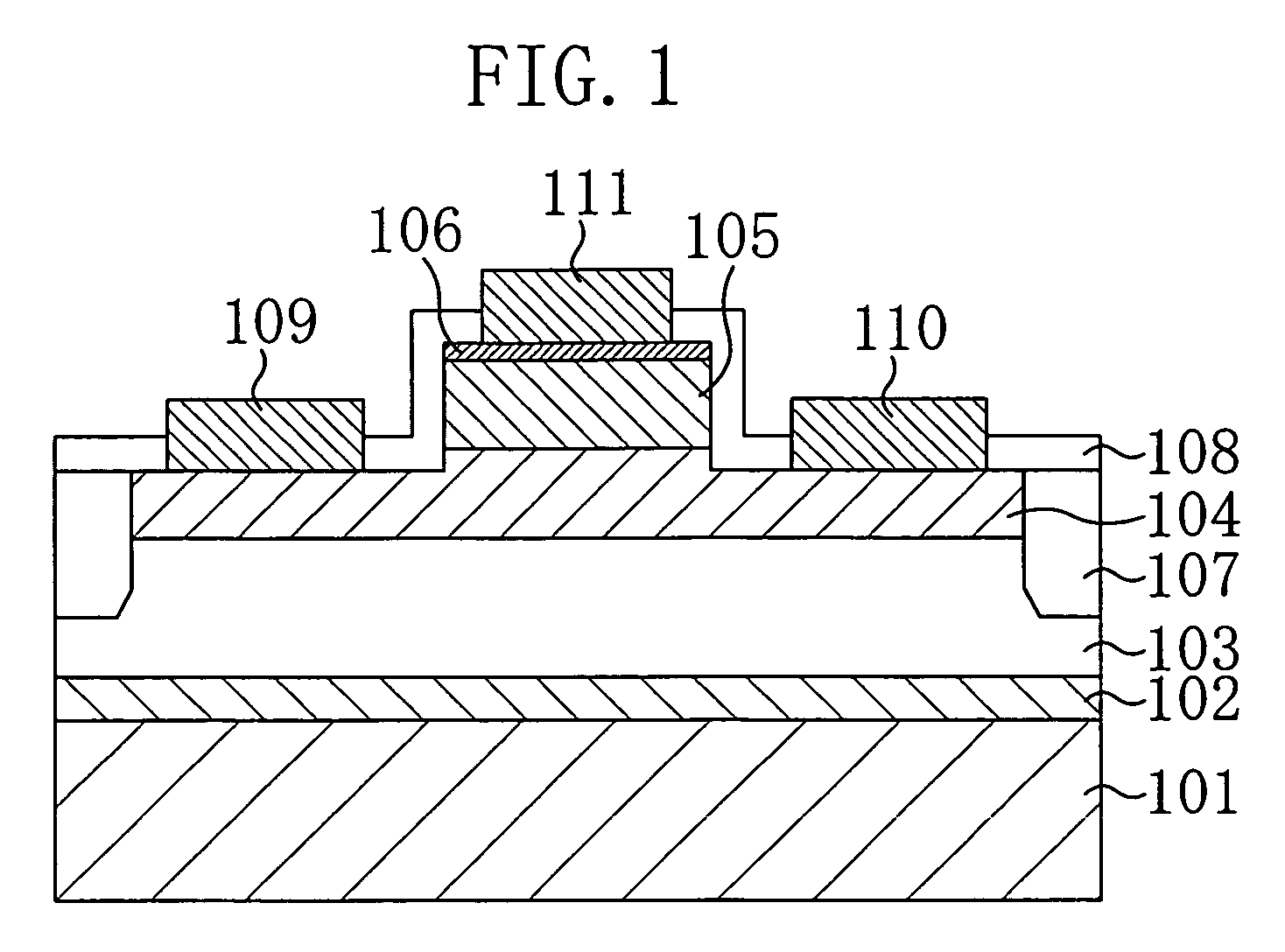

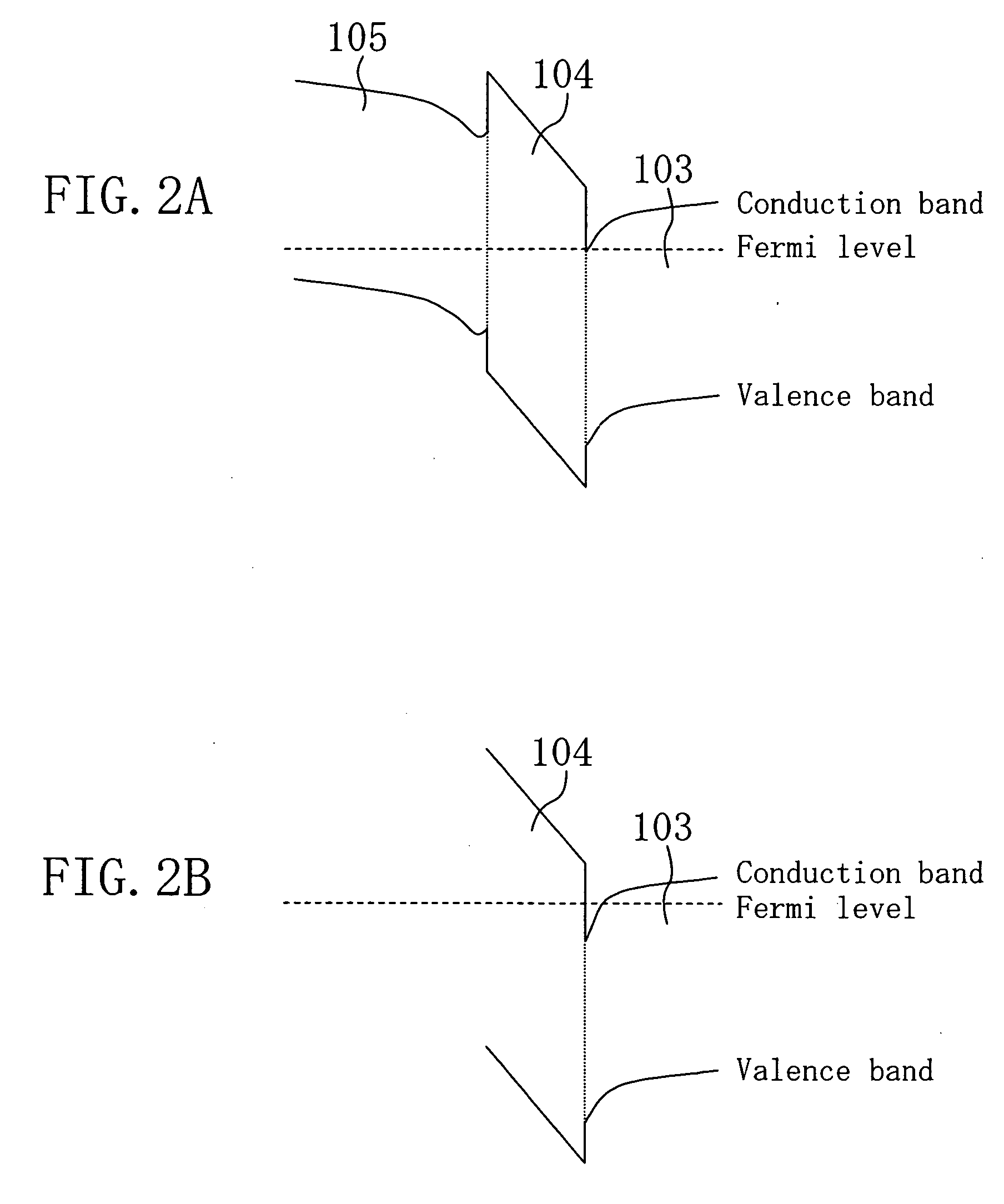

Field-effect transistor and method for fabricating the same

ActiveUS20060273347A1Small gateHigh currentSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactOptoelectronics

An AlN buffer layer, an undoped GaN layer, an undoped AlGaN layer, a p-type GaN layer and a heavily doped p-type GaN layer are formed in this order. A gate electrode forms an Ohmic contact with the heavily doped p-type GaN layer. A source electrode and a drain electrode are provided on the undoped AlGaN layer. A pn junction is formed in a gate region by a two dimensional electron gas generated at an interface between the undoped AlGaN layer and the undoped GaN layer and the p-type GaN layer, so that a gate voltage can be increased.

Owner:PANASONIC CORP

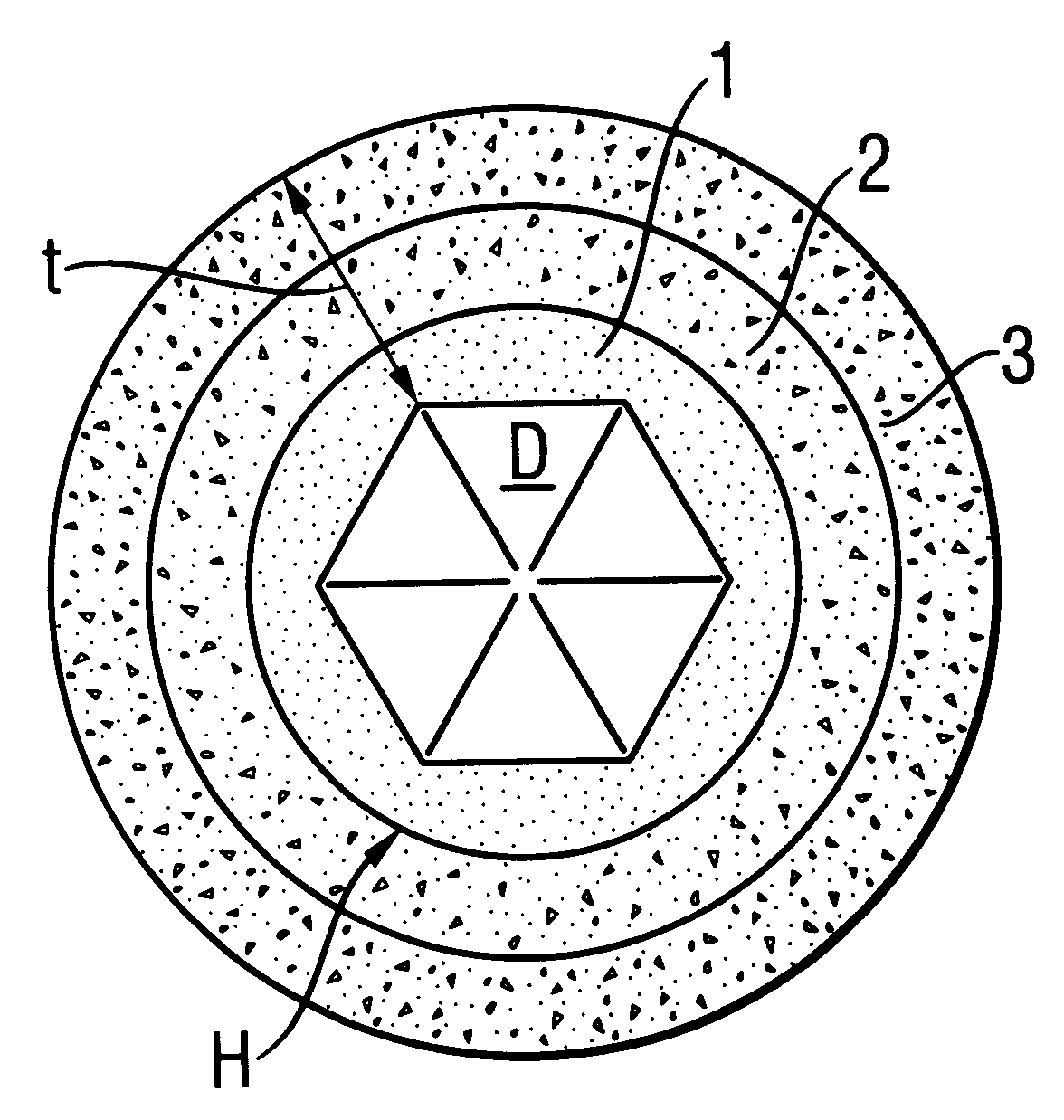

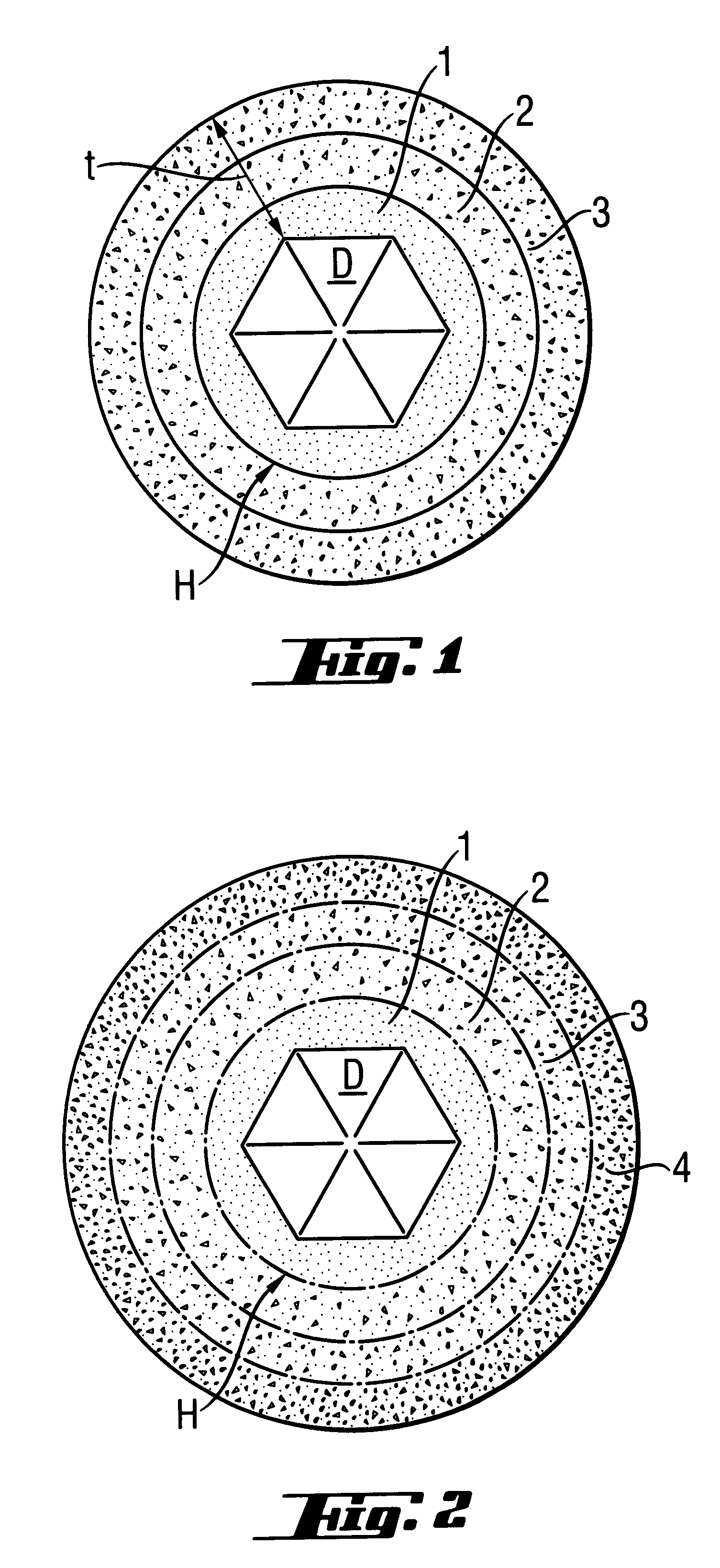

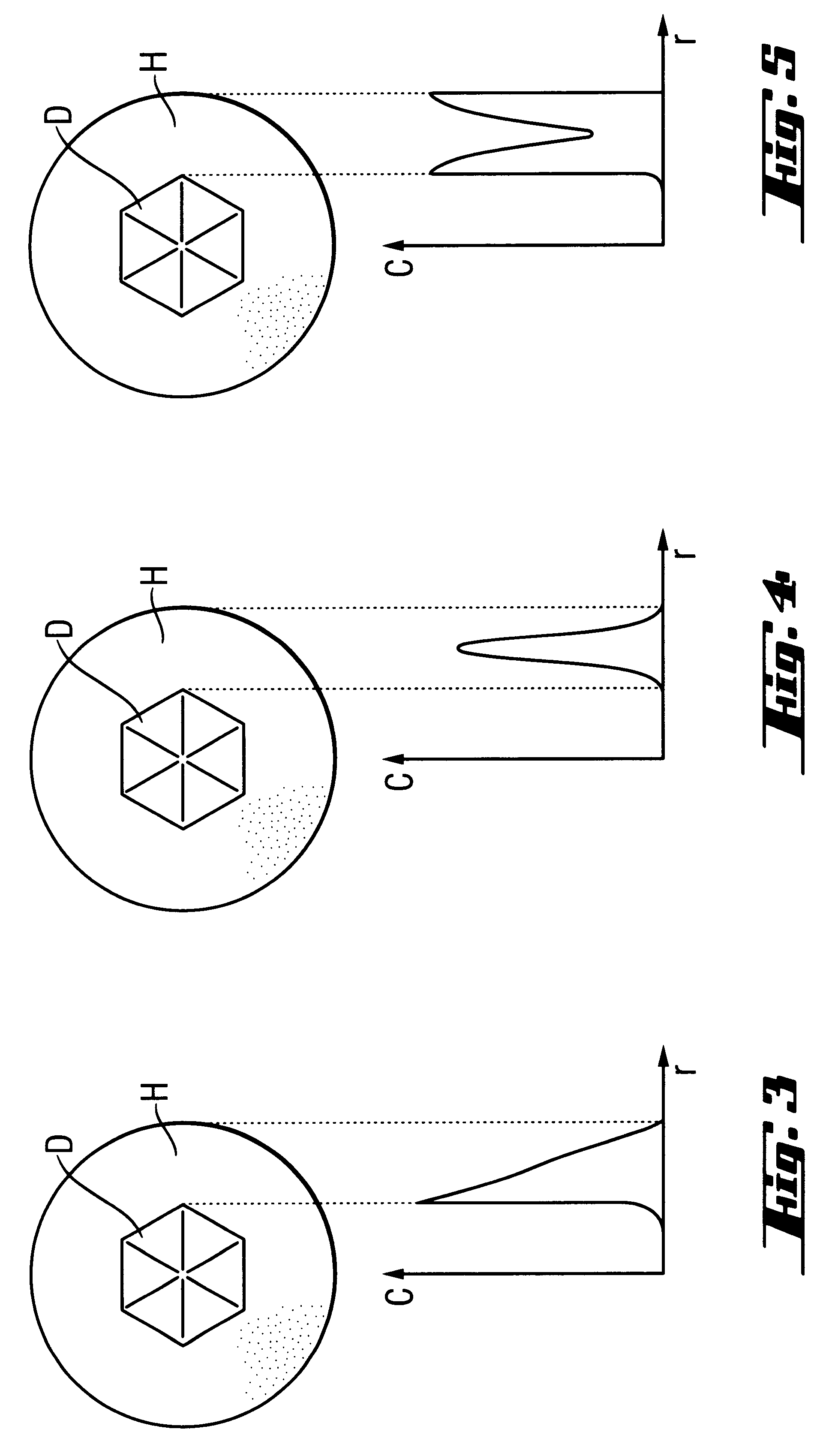

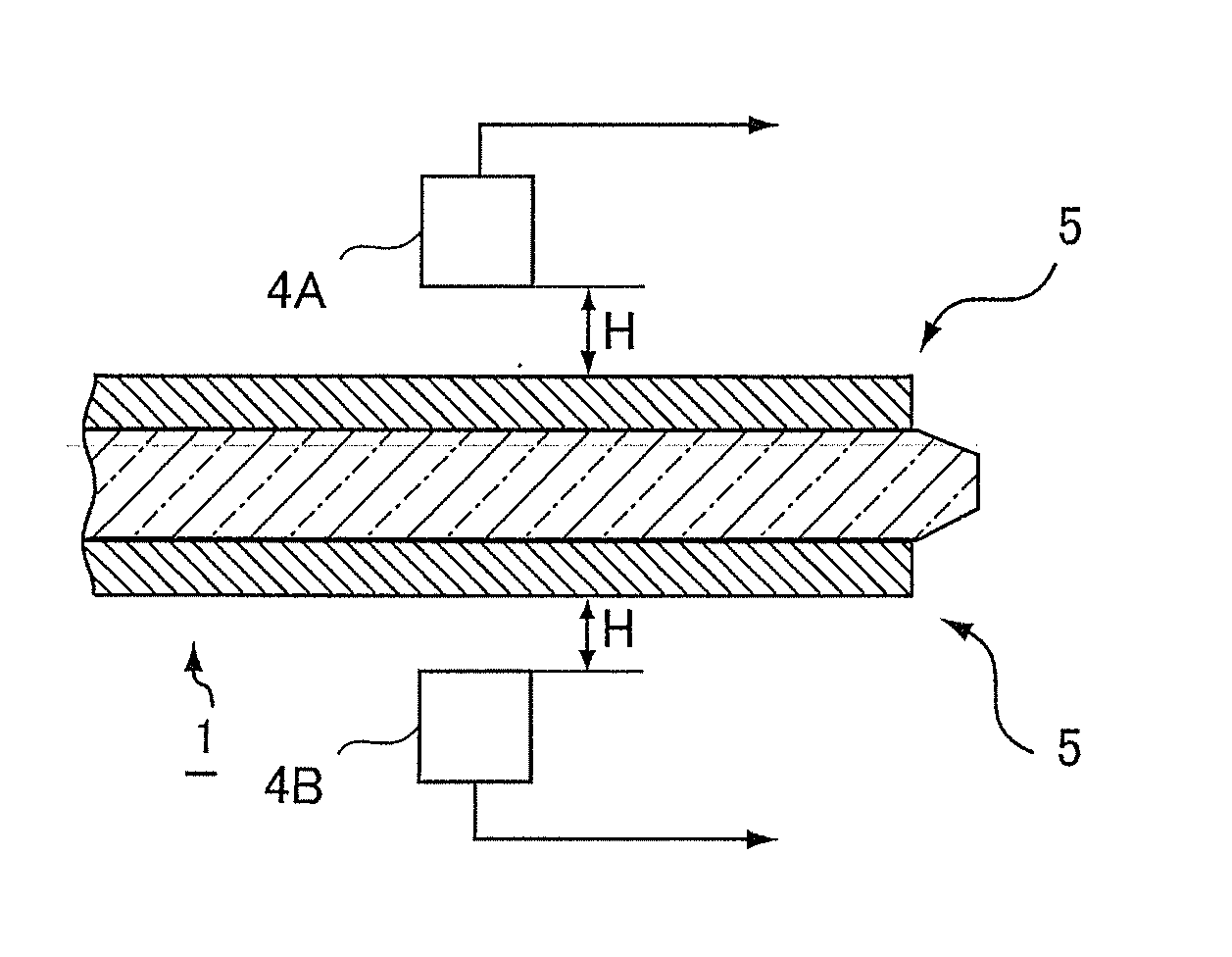

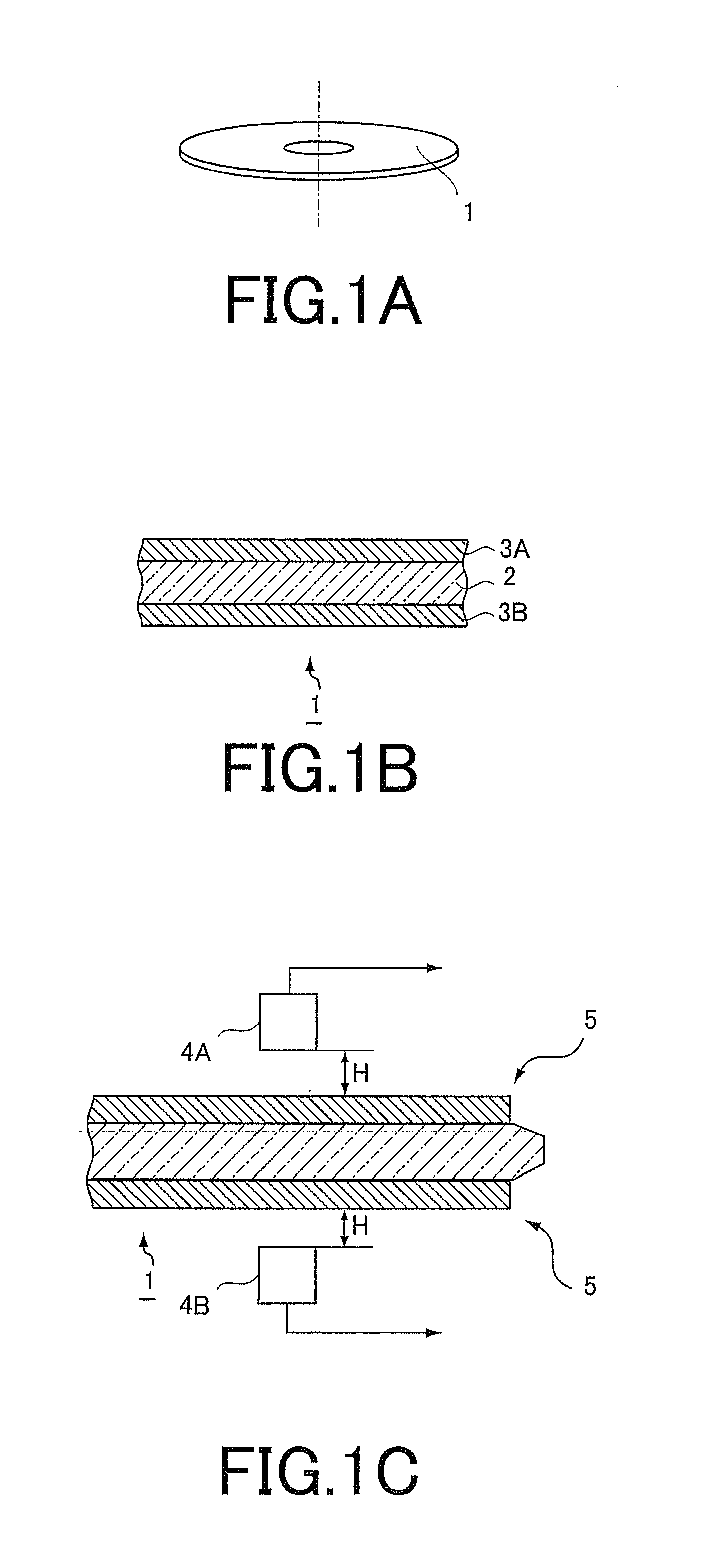

Abrasive cutter containing diamond particles and a method for producing the cutter

InactiveUS6238280B1Eliminate disadvantagesAvoid attenuationRevolution surface grinding machinesBonded abrasive wheelsMetal coatingDiamond crystal

An abrasive cutter formed of at least one diamond particle, preferably at least one mono-diamond crystal and metallic binder material distinguished by the fact that the diamond particle (D) has a size of about 50 mum to about 500 mum and each diamond particle (D) is enclosed by a coating (H) produced in a fluidized bed with the coating having a wall thickness of about 10 mum to about 200 mum. The volume of the coating (H) constitutes at least 30% of the volume of the diamond particles (D) in the fully consolidated state following individual sintering of the coated diamond particles (D, H). The abrasive cutters can be applied directly onto an abrasive tool. Further they can be processed to form composite cutters or cutting segments. In the method of forming the abrasive cutter, the diamond particle (D) is brought into a fluidized bed reactor and enclosed in a metallic coating (H). Coated diamond particle (D, H) can be processed into larger cutters or segments in each case individually sintered and fixed directly on an abrasive tool.

Owner:HILTI AG

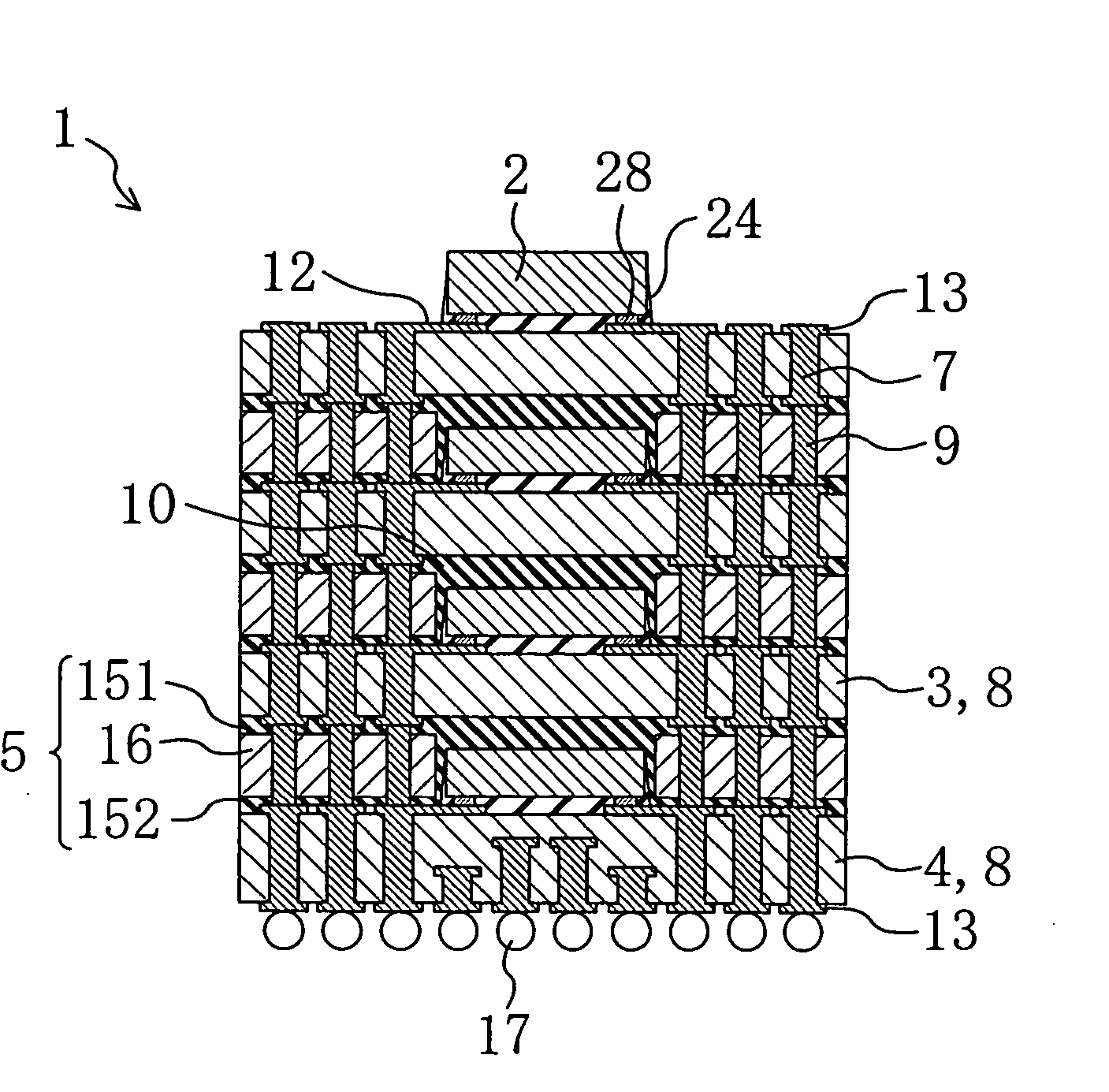

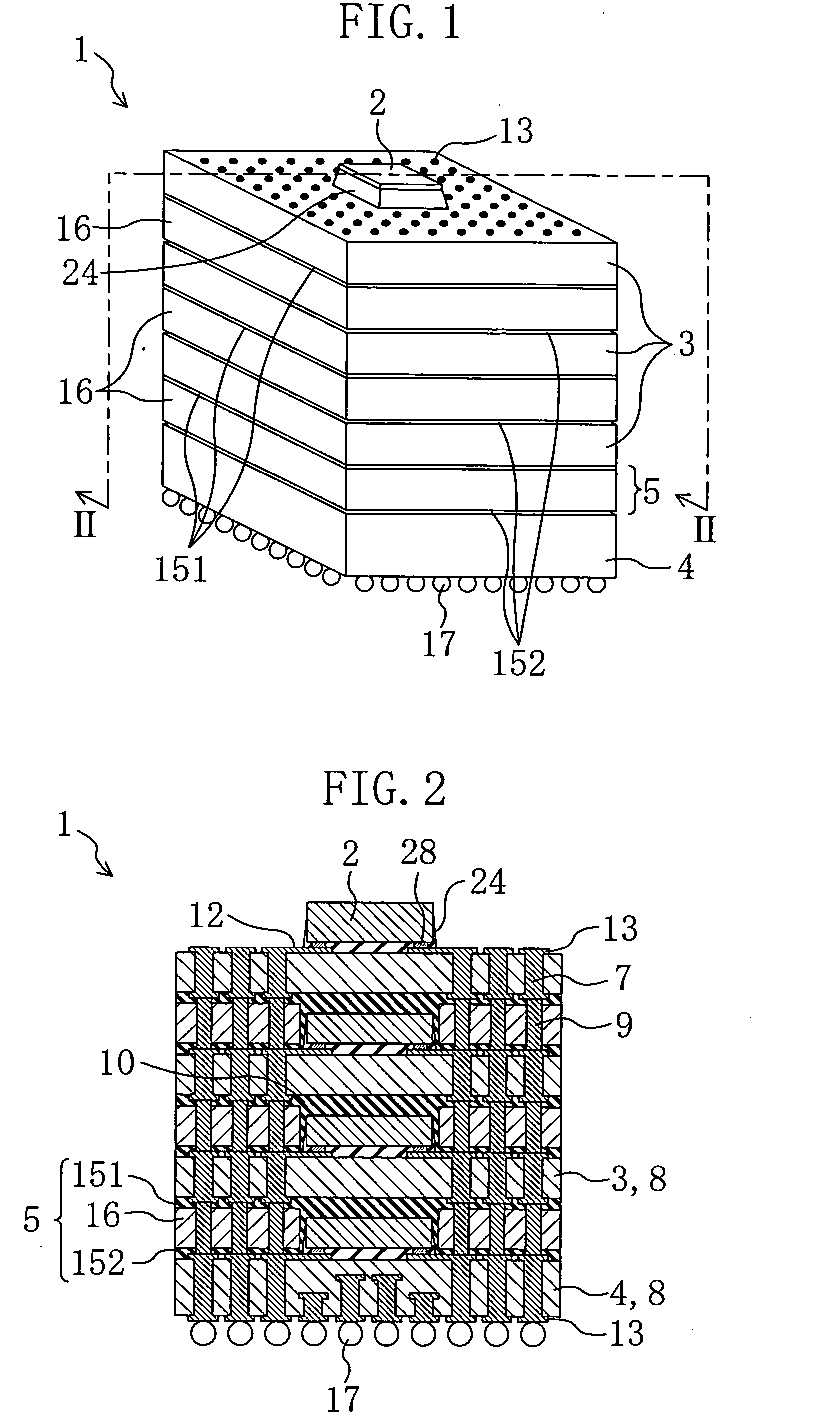

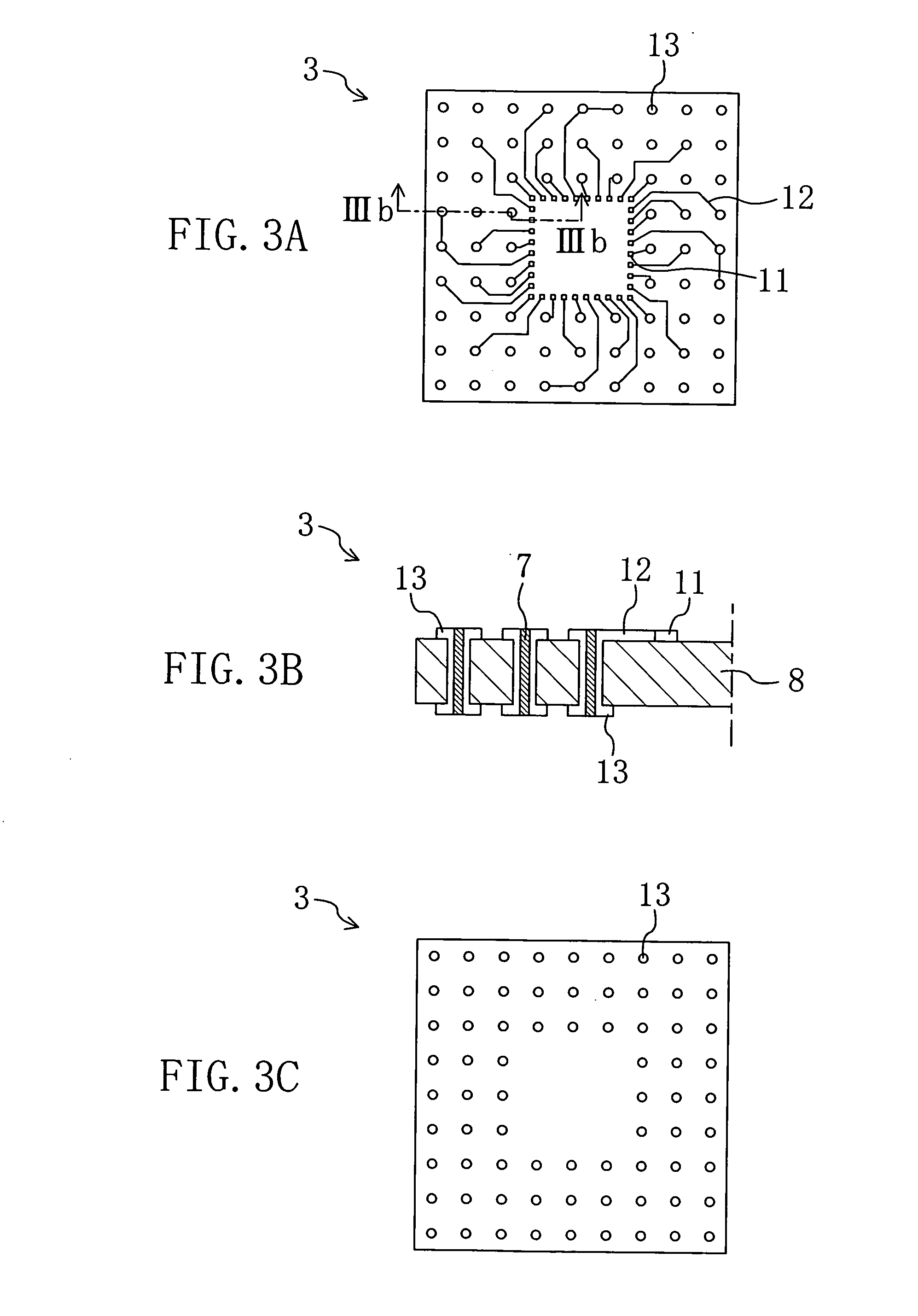

Multilevel semiconductor module and method for fabricating the same

InactiveUS20060231939A1InhibitionReduce thicknessSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor chip

A semiconductor module is formed by alternately stacking resin boards and sheet members. Each of the resin boards includes first buried conductors. A semiconductor chip is mounted on the upper face of each of the resin boards. Each of the sheet members having an opening for accommodating the semiconductor chip and including second buried conductors electrically connected to the first buried conductors. A first resin board located at the bottom is thicker than second resin boards. Each of the sheet members includes an adhesive member covering the upper and side faces of the semiconductor chip.

Owner:PANASONIC CORP

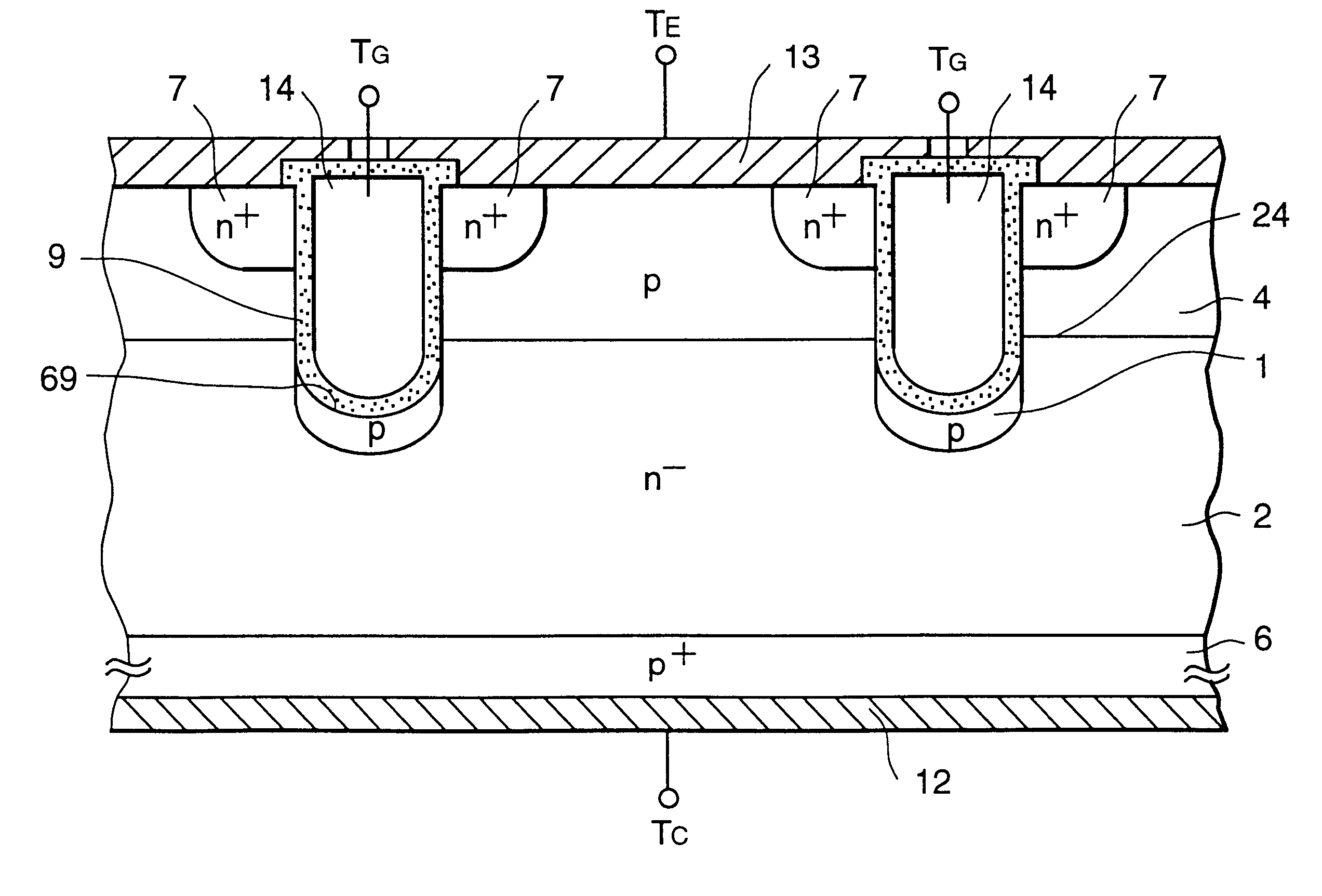

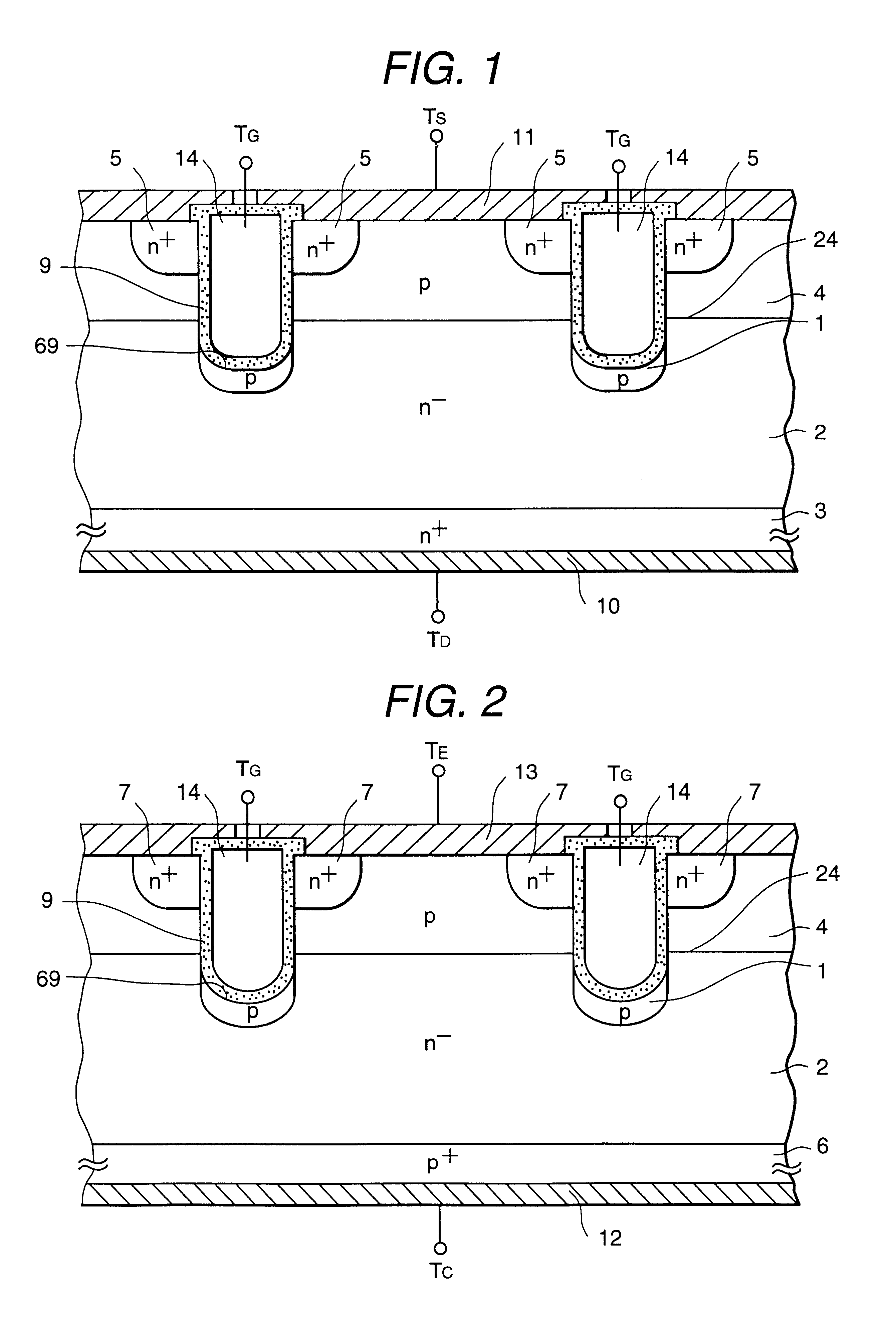

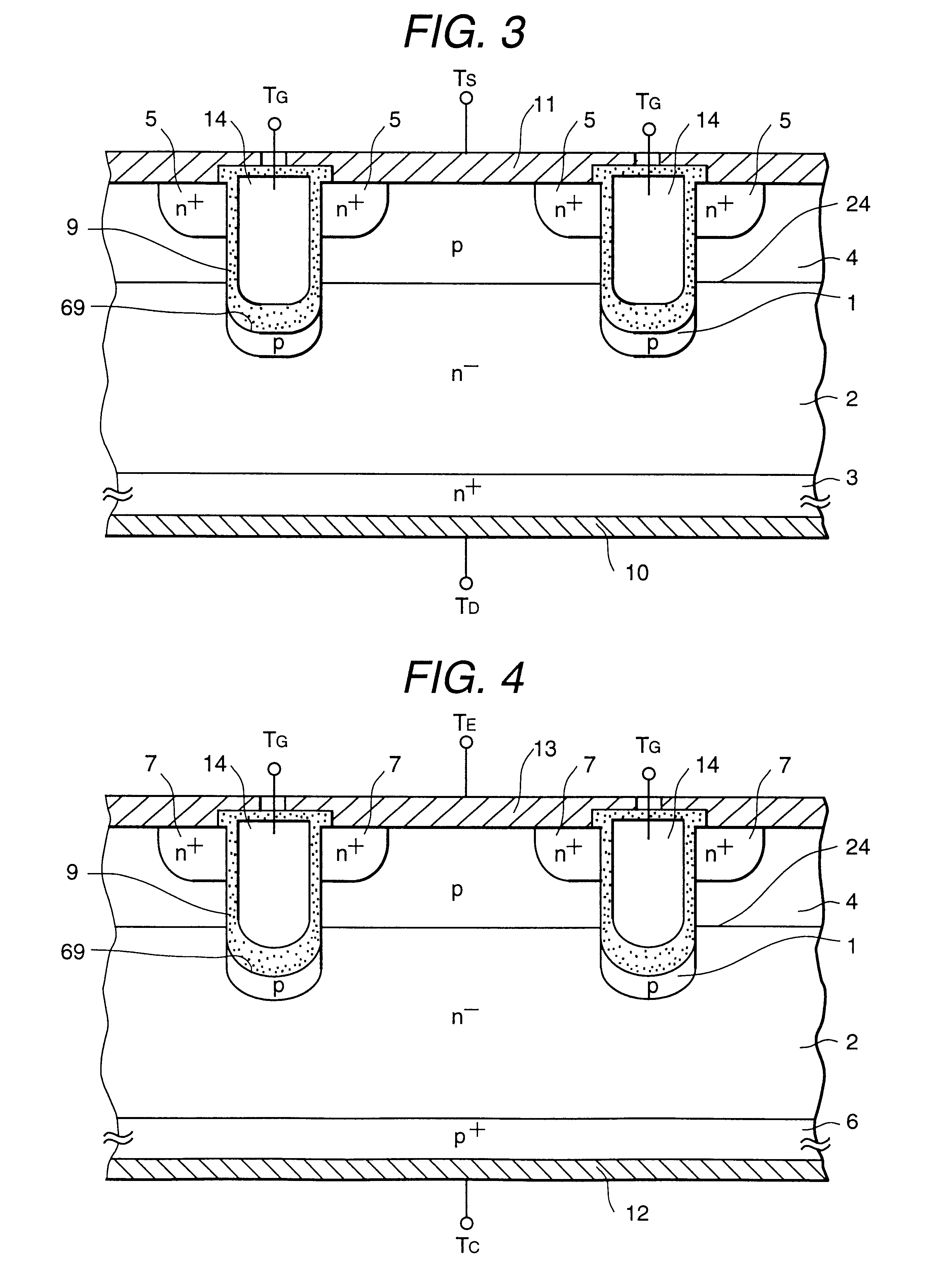

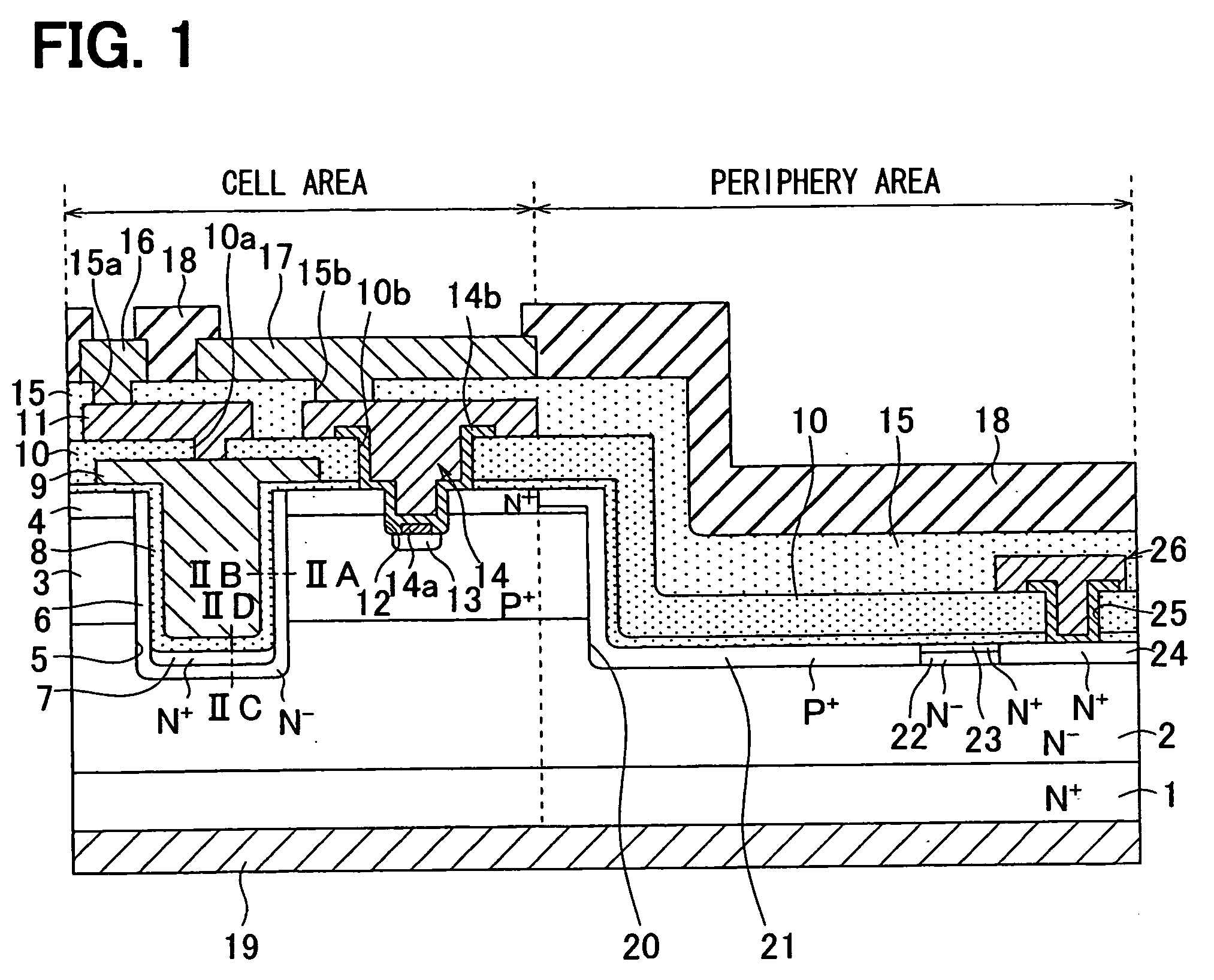

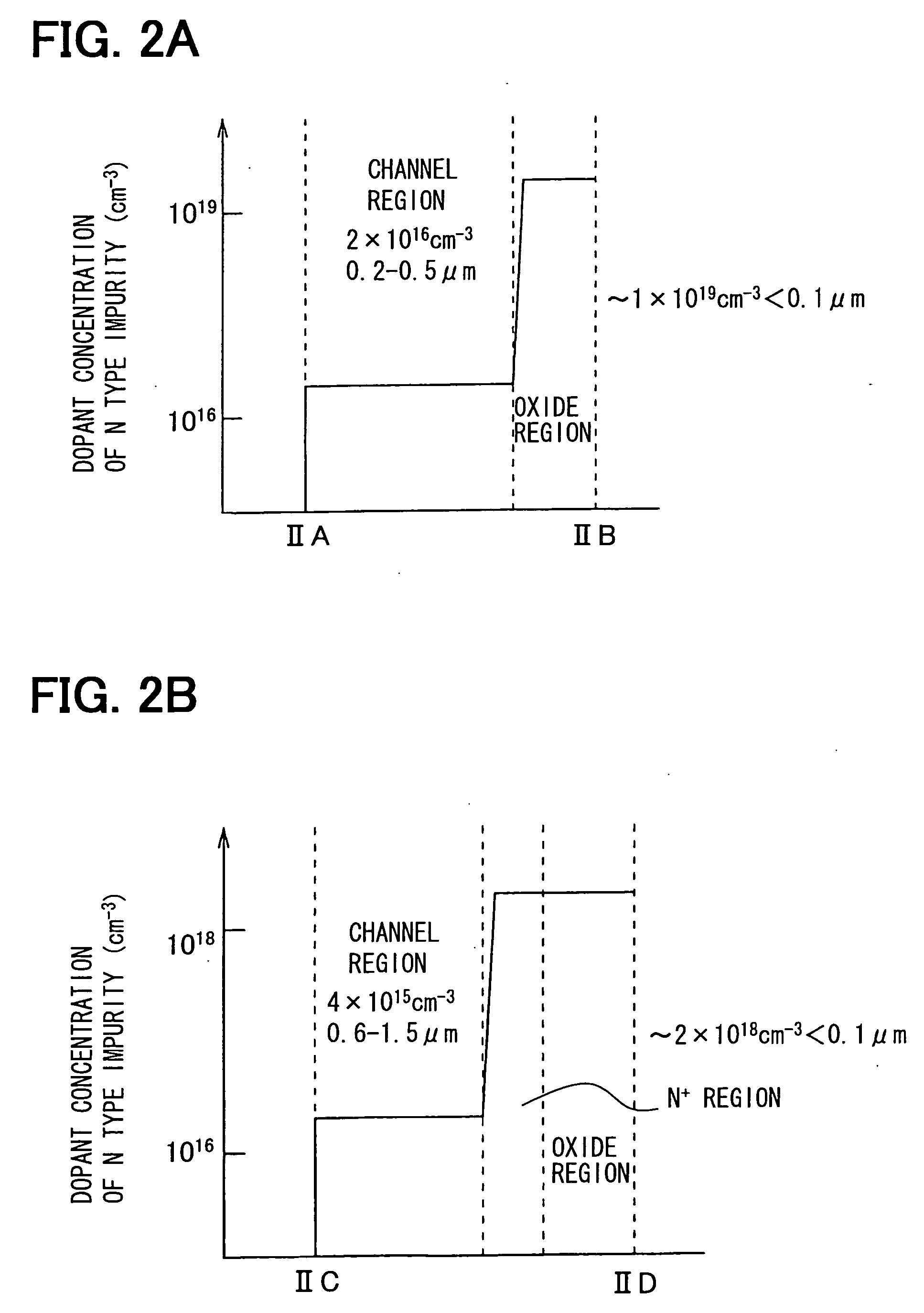

Insulated gate semiconductor device

InactiveUS6342709B1Improve reliabilityImprove adaptabilitySemiconductor devicesHigh voltageElectric field

In a semiconductor device having a trench type insulated gate structure, in the case where a drift layer 2 of an n- conduction type has a high carrier density, when a high voltage is applied between a drain and a source in such a manner that a channel is not formed, the electric field strength of an insulator layer 9 below the trench type insulated gate is increased, thus causing breakdown. The withstand voltage of the semiconductor device is limited by the breakdown of the insulator layer 9, and it is difficult to realize high withstand voltage.In the characteristic of the present invention, a field relaxation semiconductor region 1 of a conduction type opposite to the conduction type of the drift layer 2 is formed within the drift layer 2 below the insulator layer 9 in the trench of the trench type insulated gate semiconductor device. Also, the thickness of a bottom portion of the insulator layer 9 provided in the trench of the trench type insulated gate semiconductor device is made significantly greater than the thickness of a lateral portion thereof.

Owner:HITACHI LTD

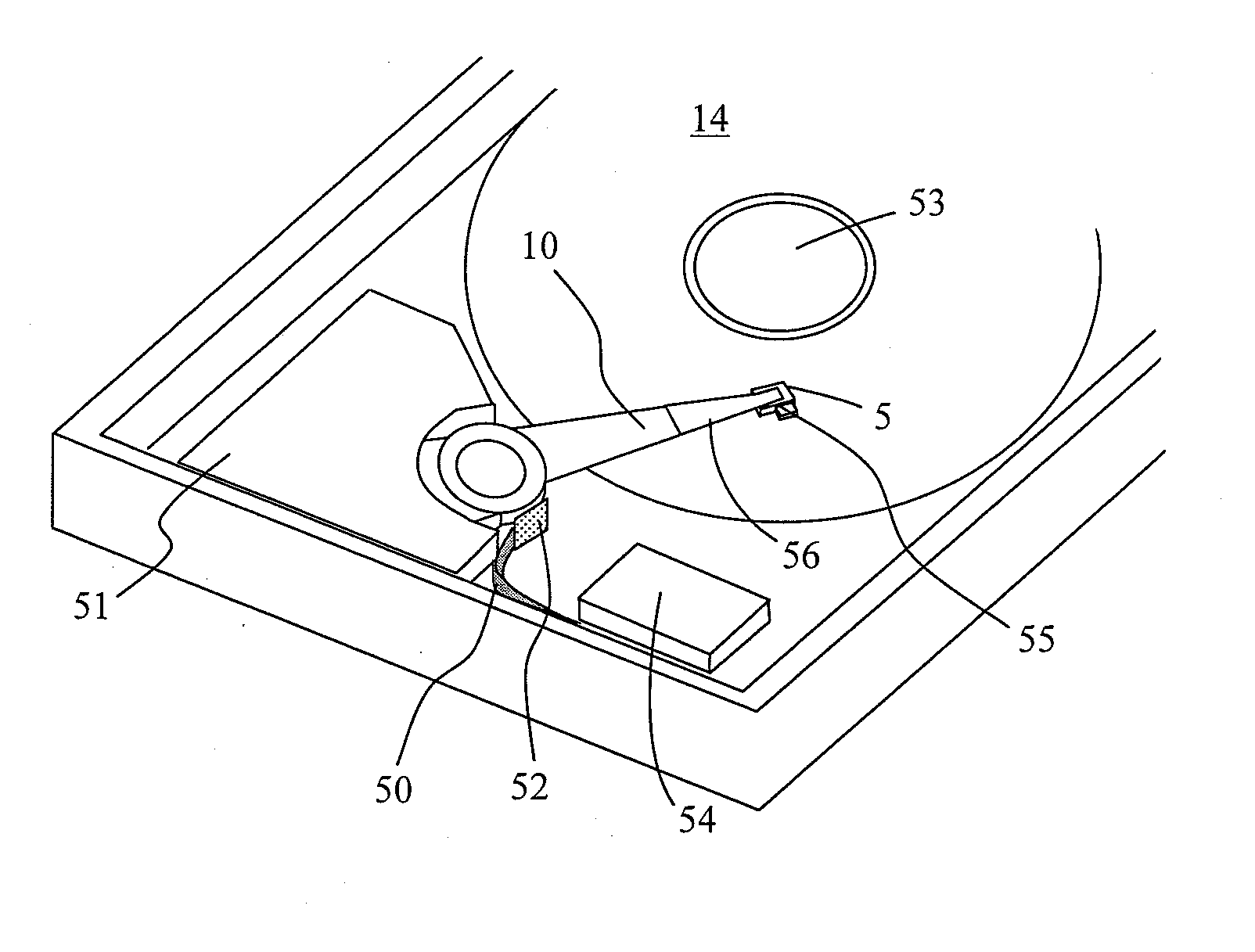

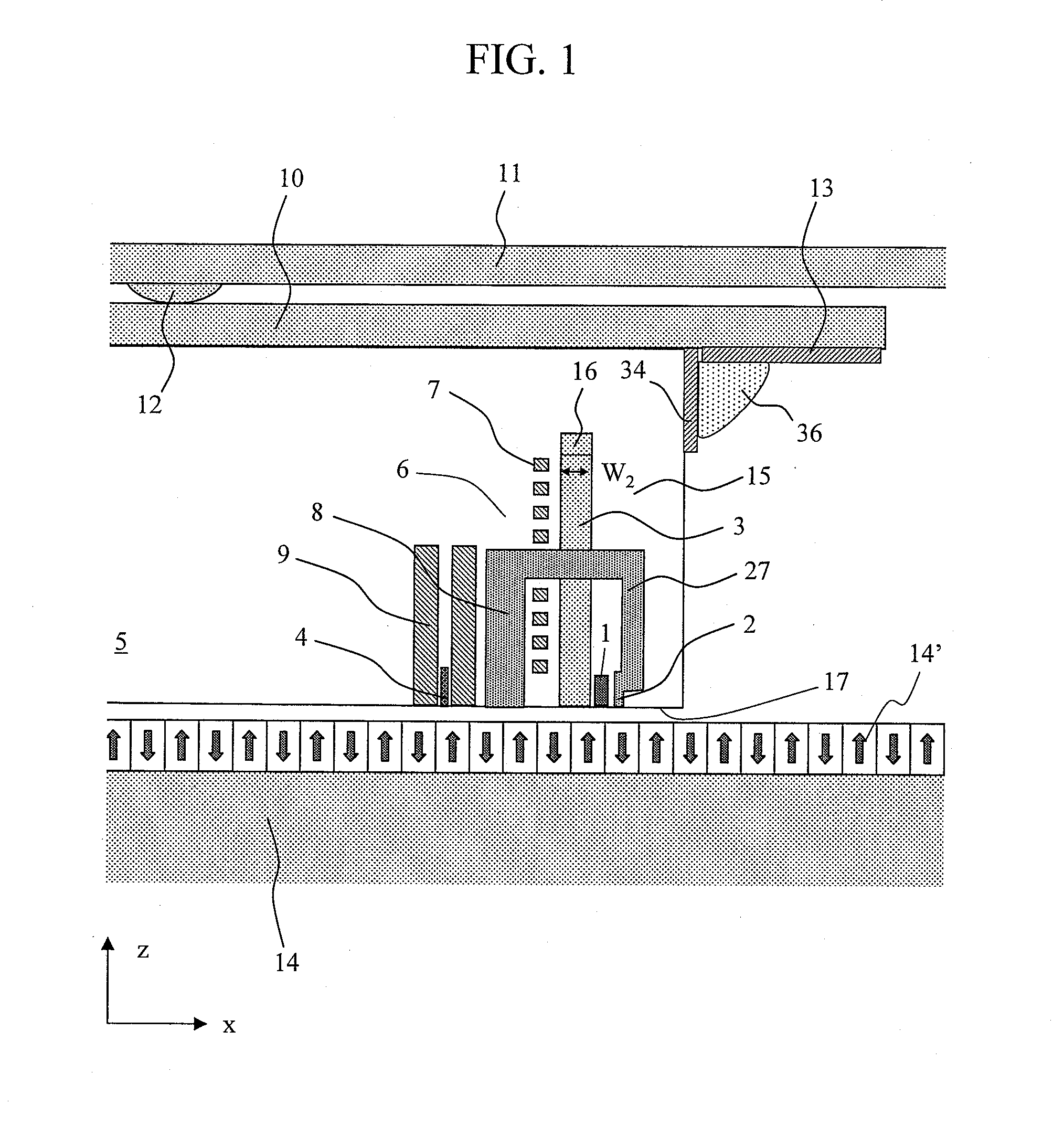

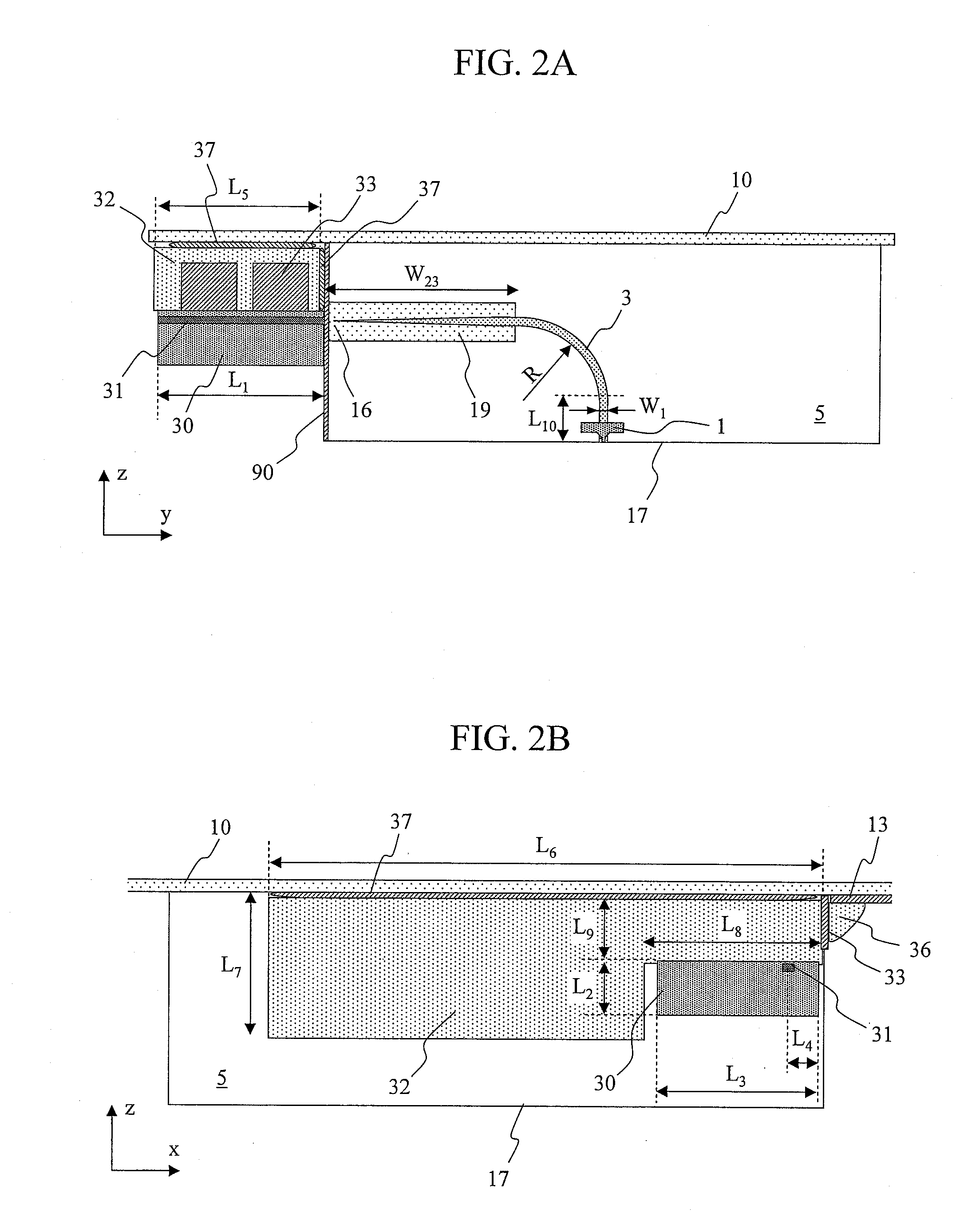

Head for thermal assisted magnetic recording device, and thermal assisted magnetic recording device

ActiveUS20110216635A1Increase head heightImprove floating stabilityCombination recordingRecord information storageHeat-assisted magnetic recordingEngineering

In a head for thermal assisted magnetic recording device, a semiconductor laser is mounted so that the total height of the head does not become larger and light power fluctuation due to wavelength fluctuation occurs less frequently. In addition, the rise in temperature of the mounted semiconductor laser is suppressed. A semiconductor laser is placed on a side surface which is different from surfaces on an inflow end side and a trailing side, of four side surfaces of a floating slider. An entrance of a waveguide is placed on the side surface of the floating slider, to thereby cause emitted light from the semiconductor laser to directly enter the waveguide. A curved line part or a reflective mirror is formed in the middle of the waveguide so that the light which has entered the waveguide travels toward an optical near-field generating element.

Owner:HITACHI LTD

Methods for continuous suture passing

InactiveUS20110130773A1Prevent “ pinching ” and damageIncrease the areaSuture equipmentsSurgical needlesContinuous sutureGeneral surgery

Suture passers for suturing tissue in a continuous manner by passing a suture attached to a suture shuttle through. A suture passer may include a first jaw, a second jaw, and a tissue penetrator that is retractable and extendable from the first jaw. The tissue penetrator may have a suture shuttle engagement region, and the second jaw may include a shuttle dock. The suture shuttle may be transferred between the first and second jaws as the tissue penetrator is extended from the first jaw and engages the second jaw. In some variations of the tissue passer, one or both jaws are tissue penetrating. In some variations, the jaws open in parallel, allowing large tissue regions to be positioned between the jaws. Methods of using these devices are also described, as are systems and kits including these devices.

Owner:CETERIX ORTHOPAEDICS

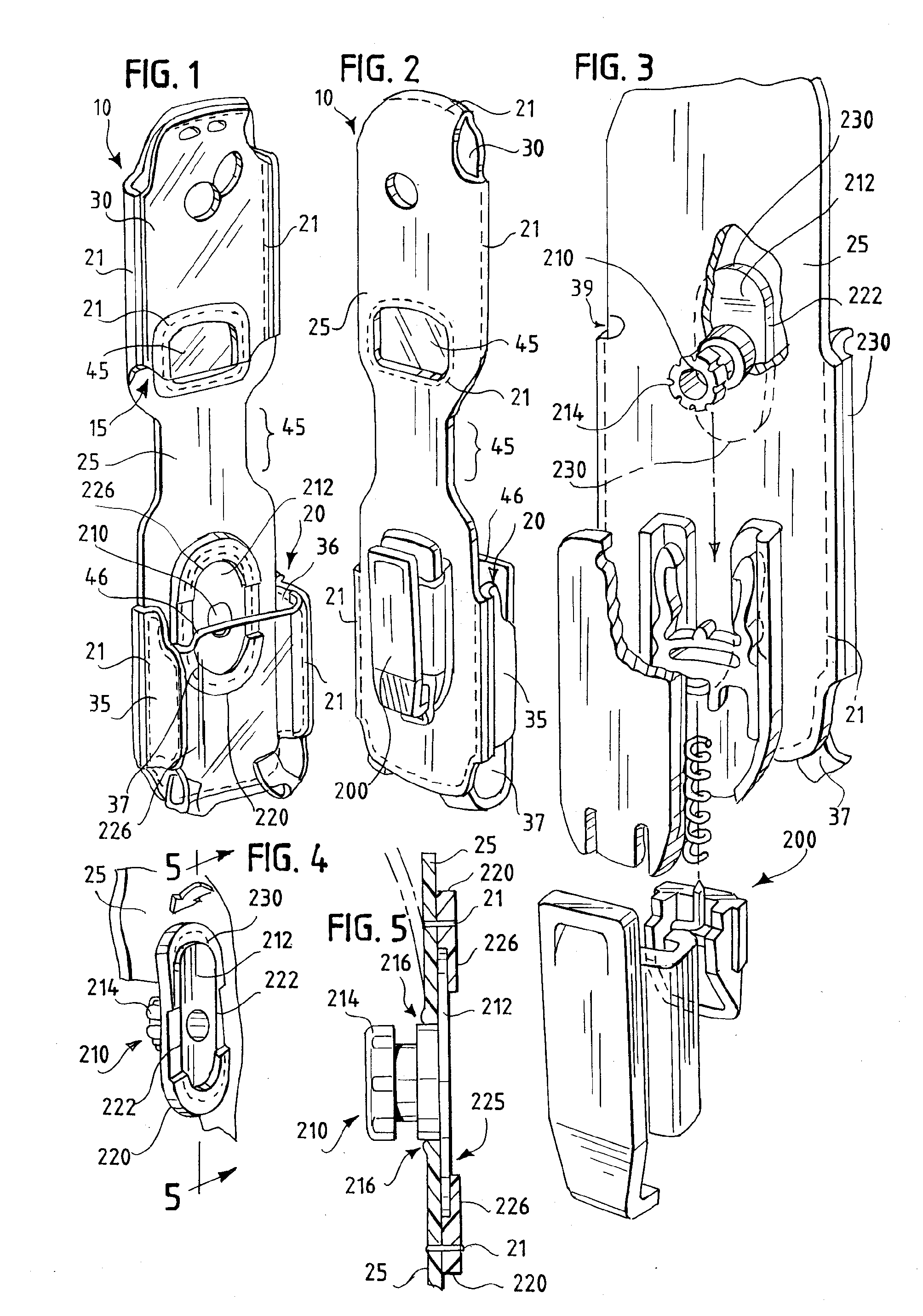

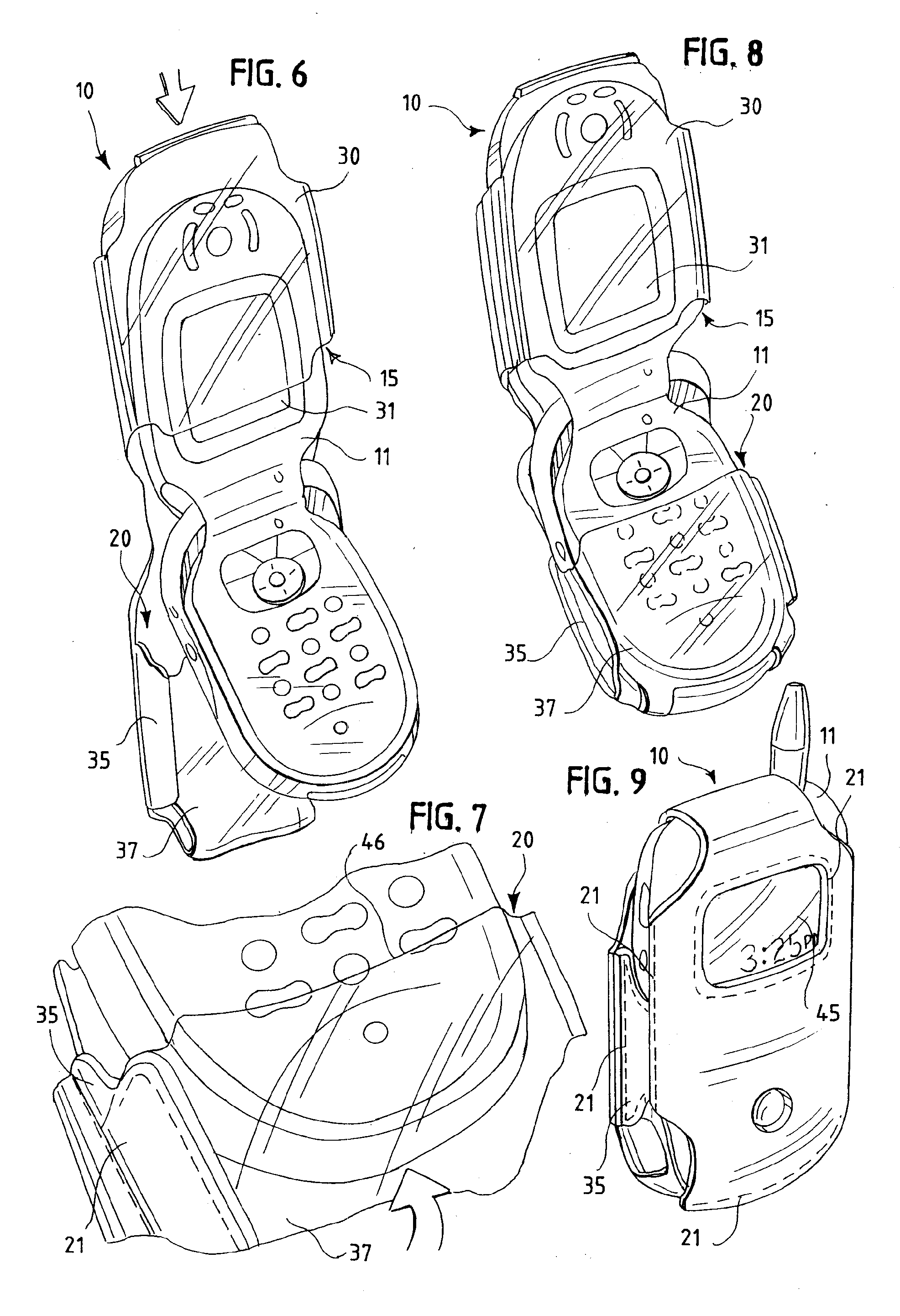

Portable device case with corner protector

ActiveUS20070225031A1Reduce thicknessReduce bulkTwo-way loud-speaking telephone systemsTravelling sacksElectronic equipmentMP3 player

A case for a portable electronic device such as cell phones, cameras, MP3 players and PDAs wherein said case includes material at the corners to provide protection to the electronic device. To reduce bulk at the corners and allow the material forming the case to conform with the contours of the device, the protection at the corners includes strips of material defining apertures there between. The apertures provide reduction in bulk and allow the case to conform to the corners of the device therein. Alternately, the protection at the corners can be provided by other structures co-molded into the corners of the cases. Such structures include material that is of a reduced thickness than other material used in the case, or structures that are formed to conform to the corners of the case. Such structures can be joined to the material forming the panels of the case by co-molding.

Owner:SAMSONITE IP HLDG SARL

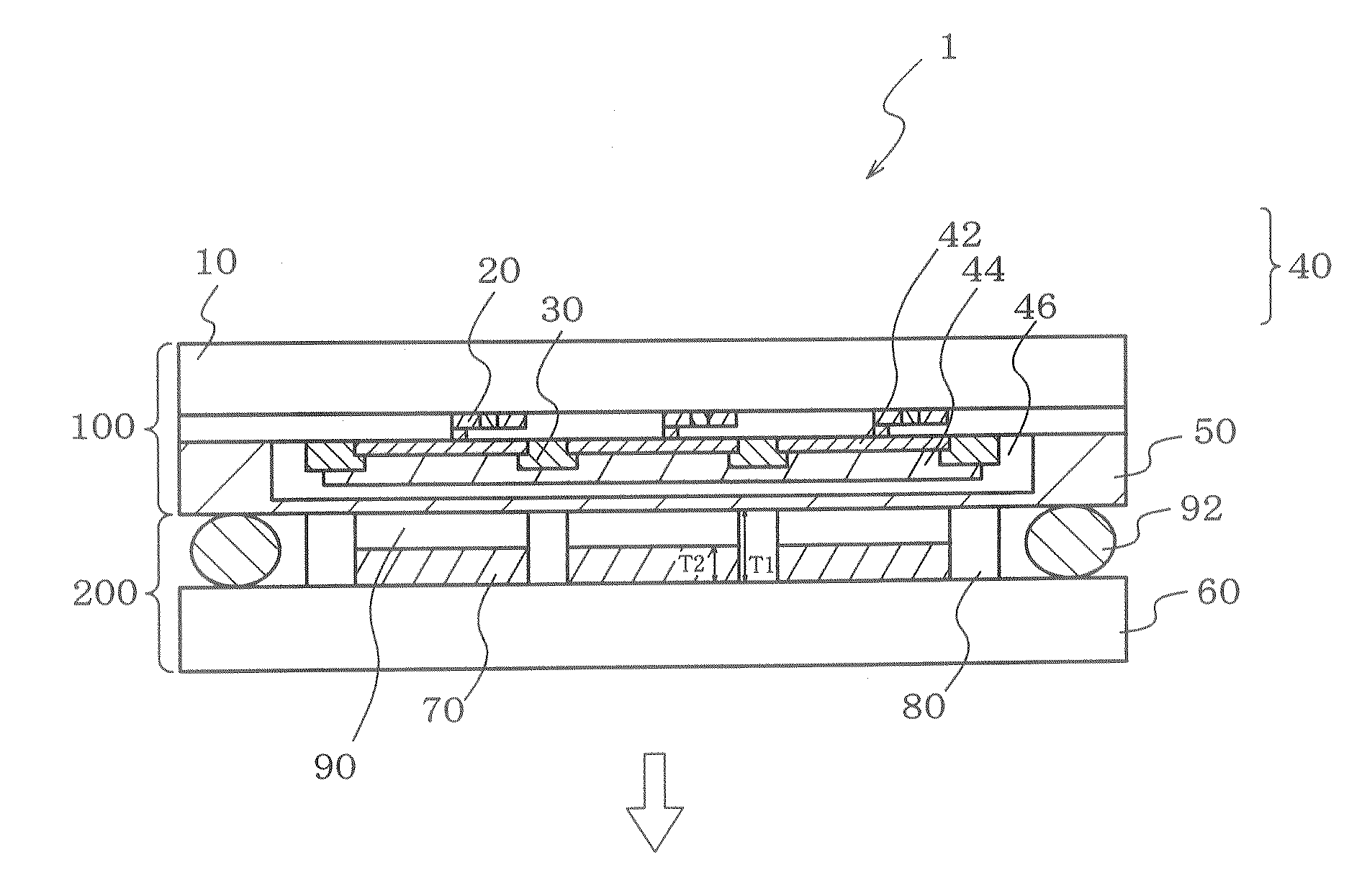

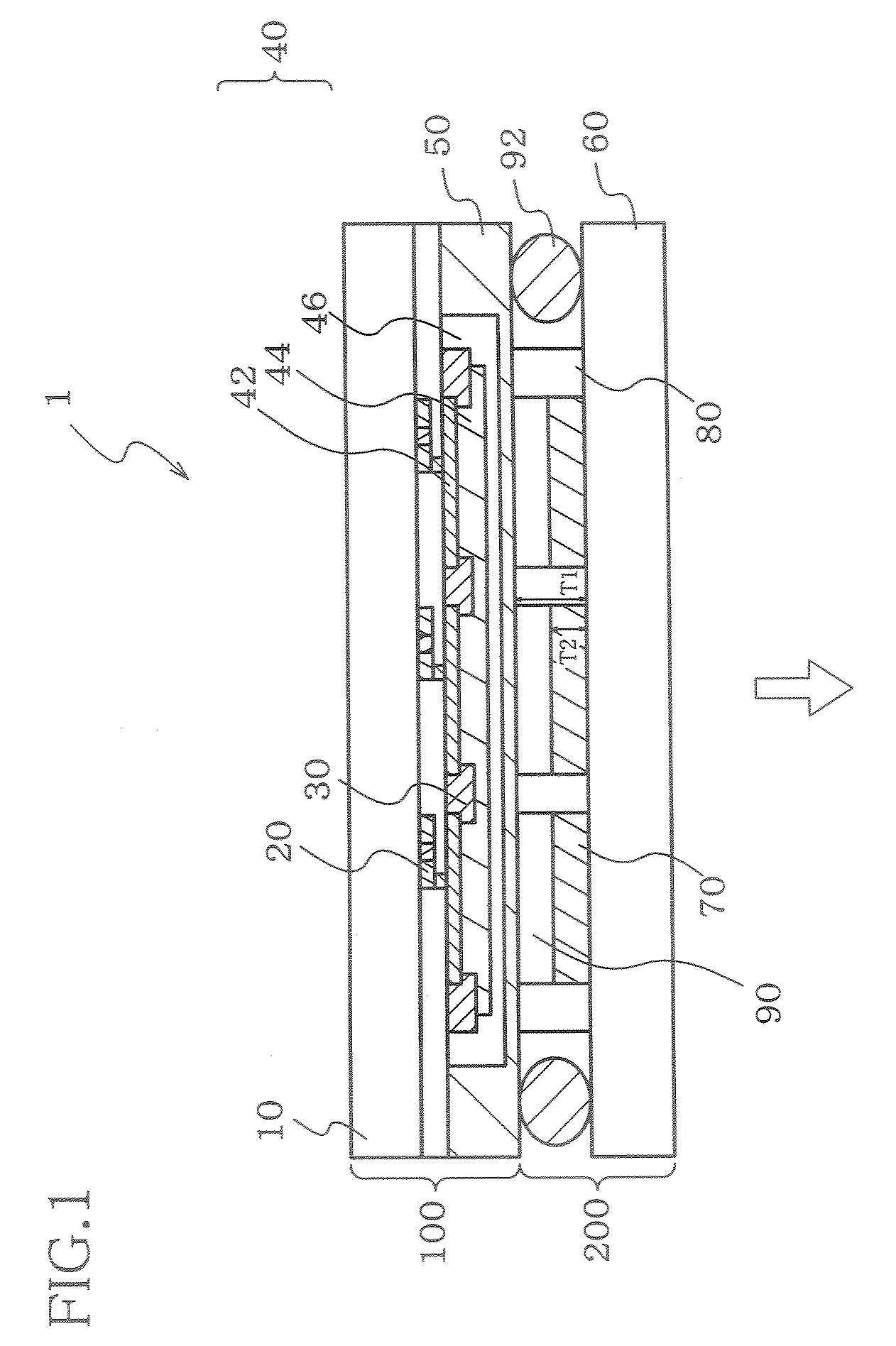

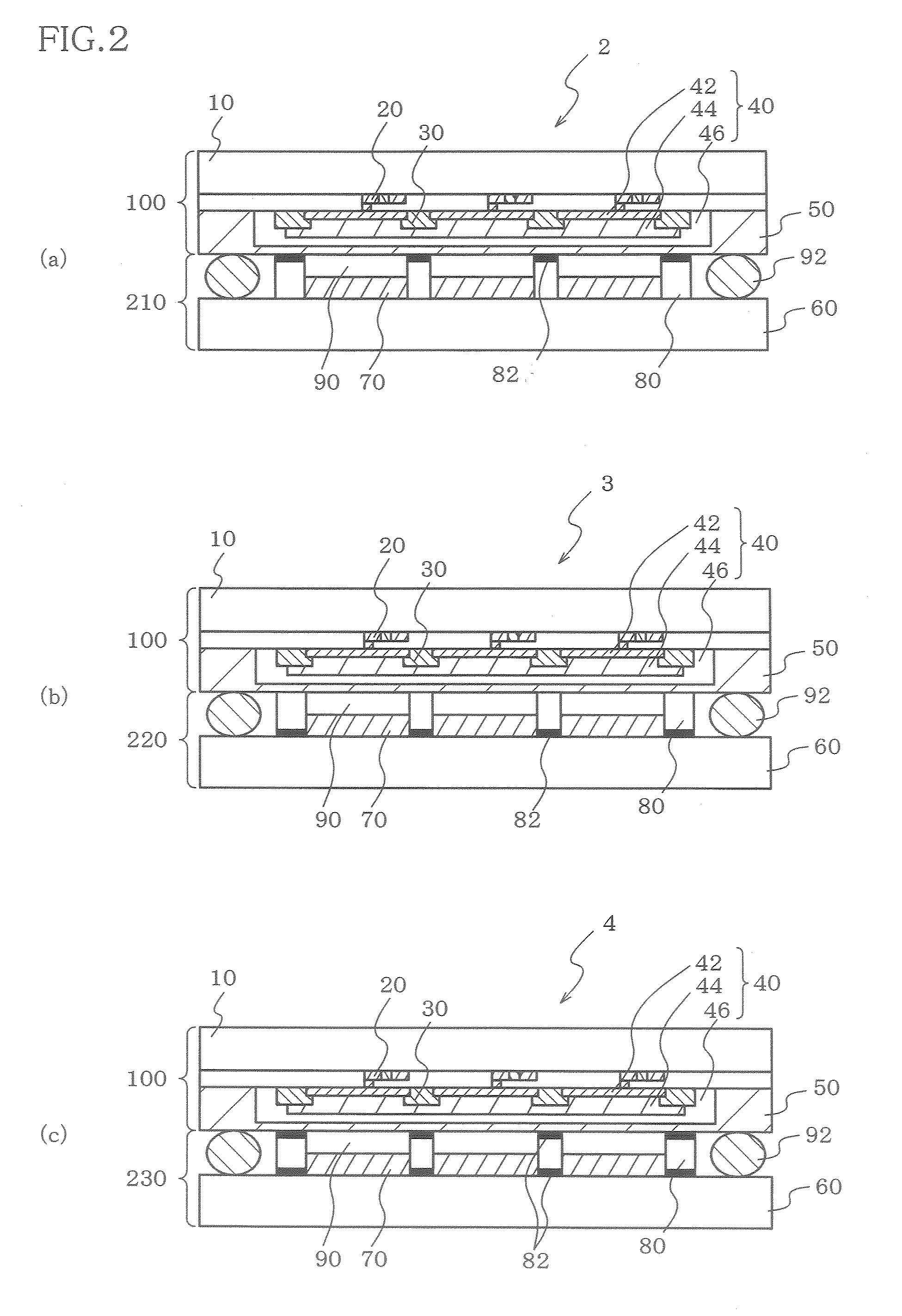

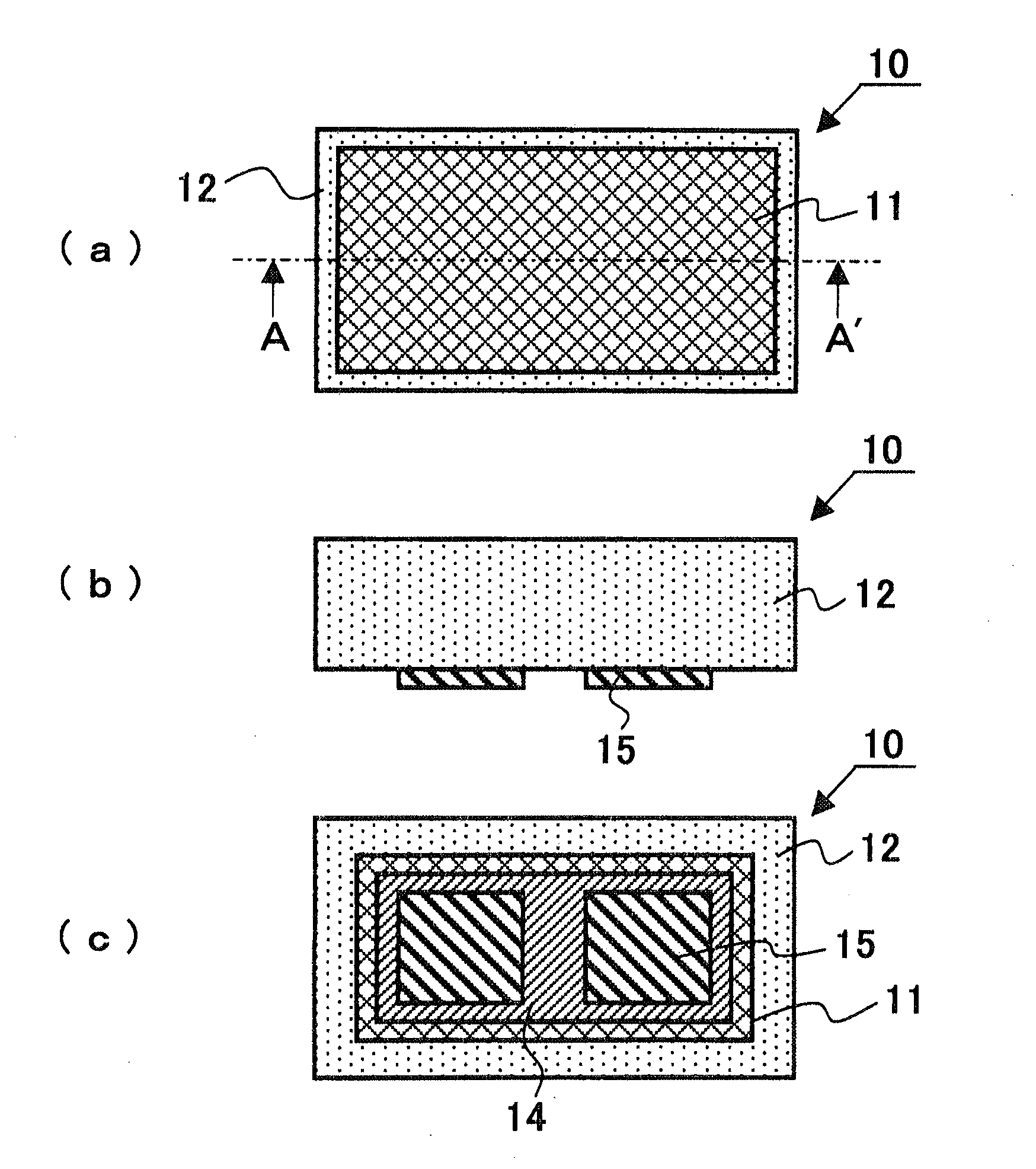

Organic El Display Device

InactiveUS20080036367A1Large thicknessHigh resolutionDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceOptoelectronics

An organic EL display comprising: an organic EL substrate (100) wherein organic EL devices (40) are formed on a first substrate (10), a color conversion substrate (200) wherein color conversion layers (70) are formed on a second substrate (60), the organic EL substrate (100) and the color conversion substrate (200) being arranged in such a way that the organic EEL devices (40) face the color conversion layers (70), transparent walls (80) which are thicker than the color conversion layers (70) and are provided between the color conversion layers (70) of the color conversion substrate (200), the transparent walls (80) being partition walls for separating the color conversion layers (70) and being spacers between the organic EL substrate (100) and the color conversion substrate (200), and a sealing medium (90), the sealing medium (90) and the color conversion layers (70) being provided between the transparent walls (80).

Owner:IDEMITSU KOSAN CO LTD

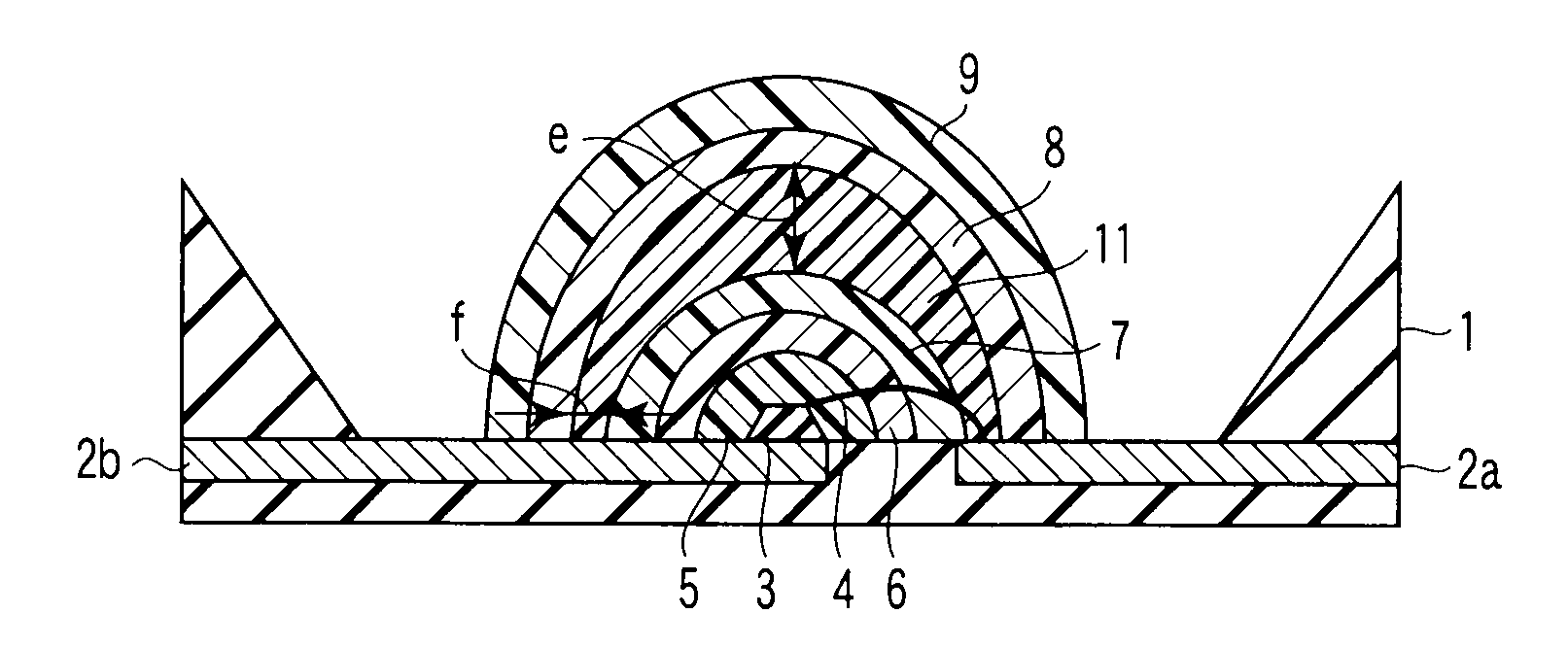

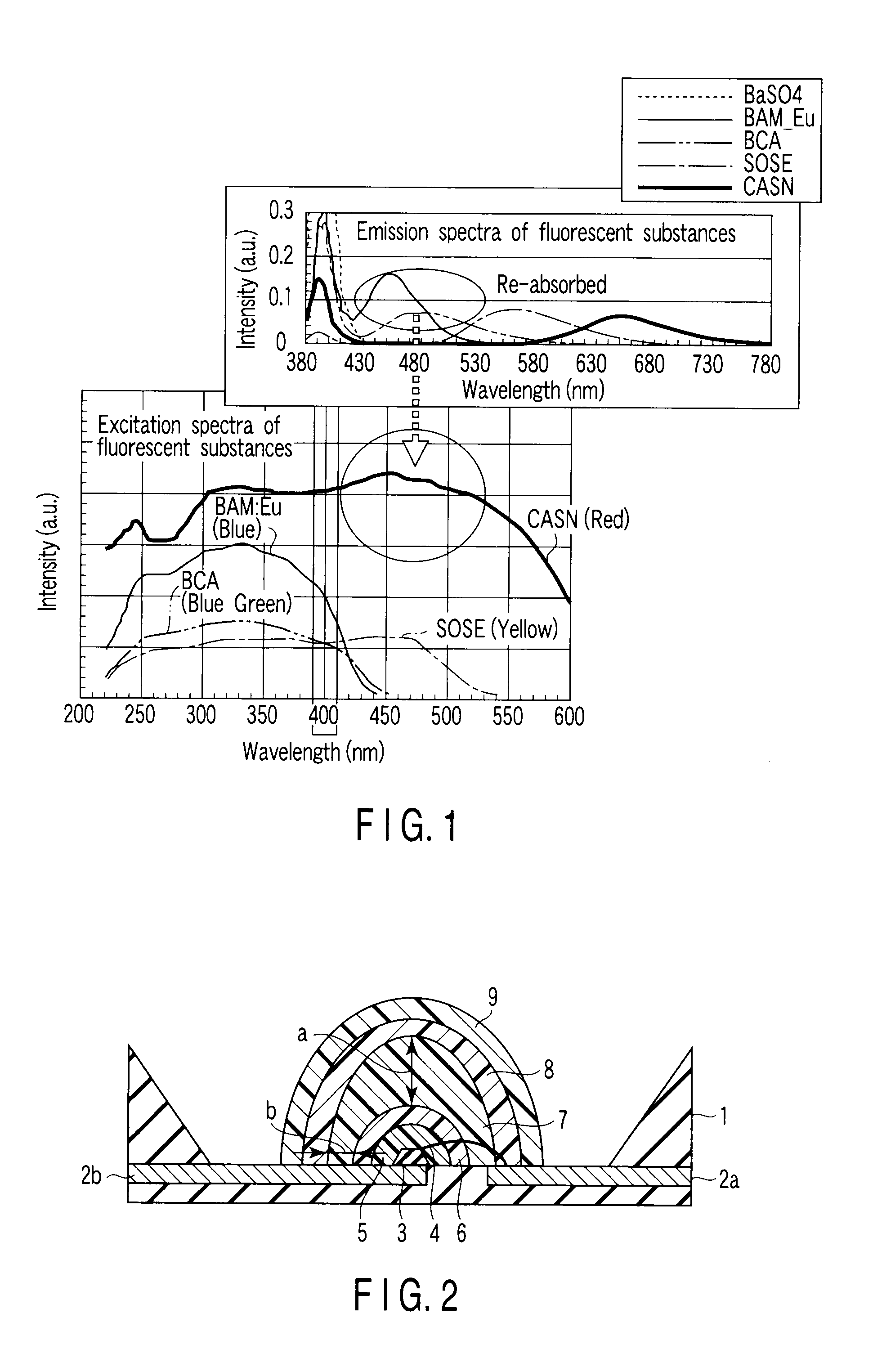

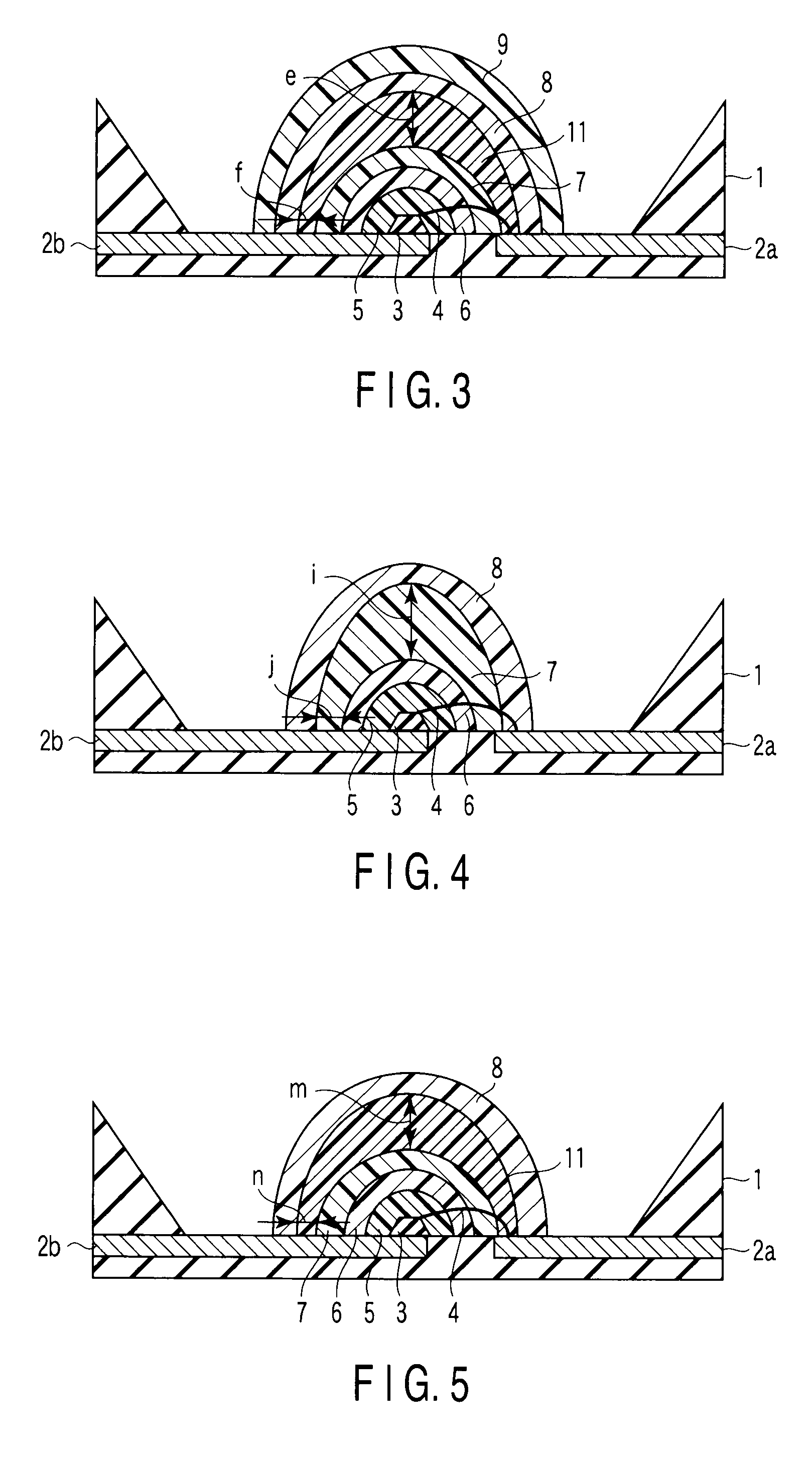

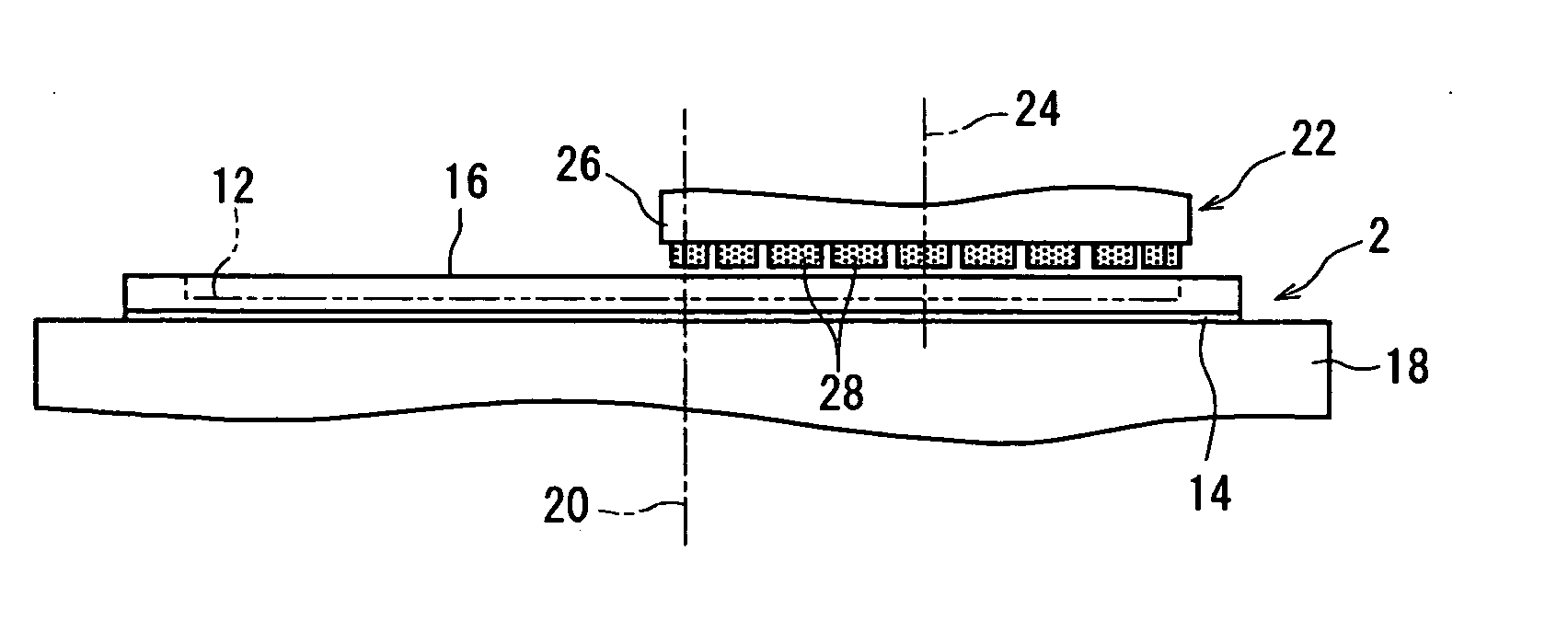

Light-emitting device

ActiveUS20090058256A1Large thicknessImprove efficiencyDischarge tube luminescnet screensLamp detailsFluorescenceEngineering

A light-emitting device is provided, which includes a package having a first portion and a second portion surrounding it, a semiconductor light-emitting element mounted on the first portion and emitting a light having an emission peak in a near-ultraviolet region, a transparent resin layer covering the semiconductor light-emitting element and contacted with the package, and a laminated body formed on the transparent resin layer with end faces of the laminated body being contacted with the second portion. The transparent resin layer has an arch-like outer profile perpendicular cross section. The laminated body has an arch-like outer profile in perpendicular cross section and comprises a red fluorescent layer, a yellow fluorescent layer, a green fluorescent layer and a blue fluorescent layer laminated in the mentioned order. The yellow fluorescent layer has a top portion which is made larger in thickness than that of the end face portions thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

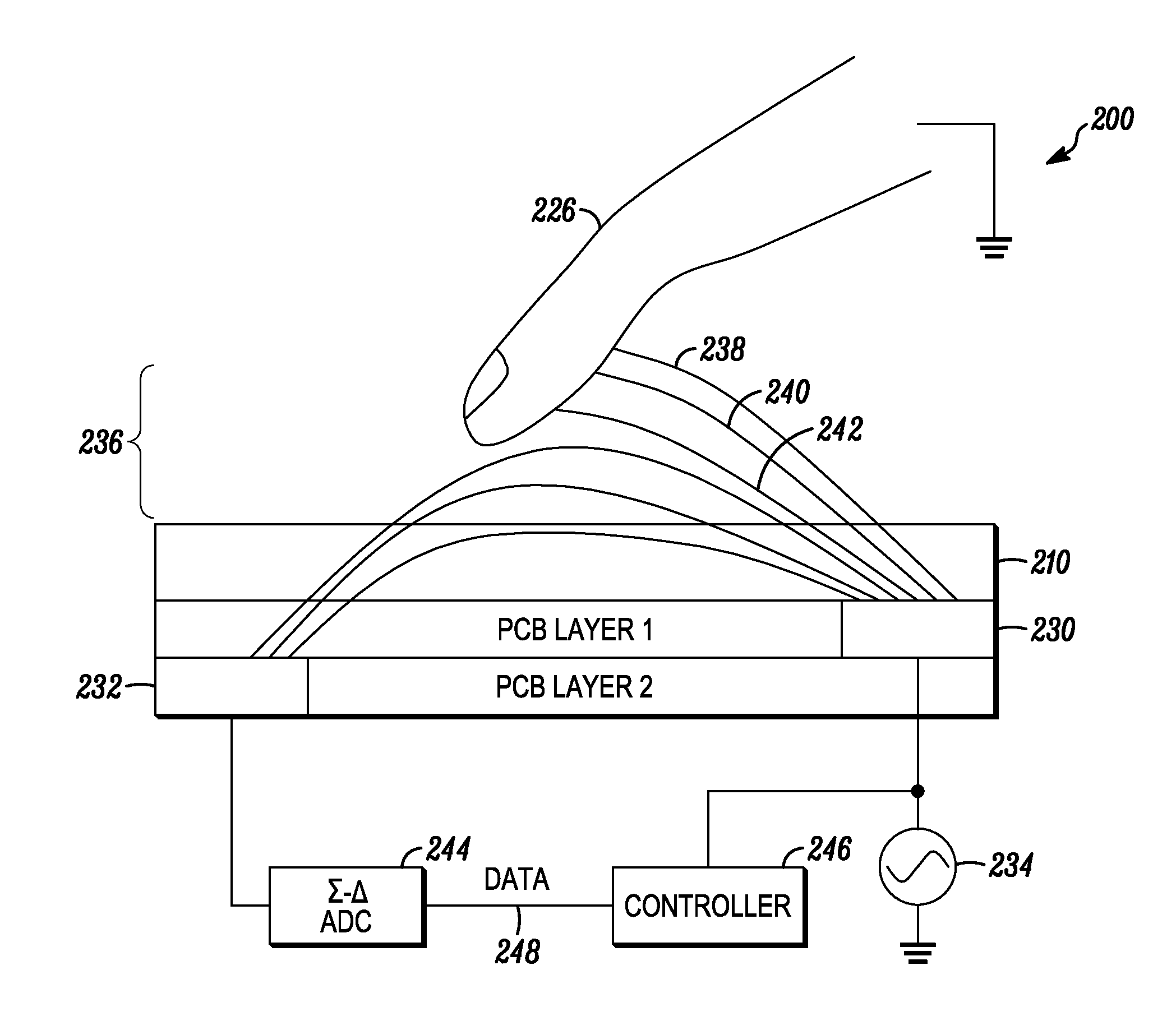

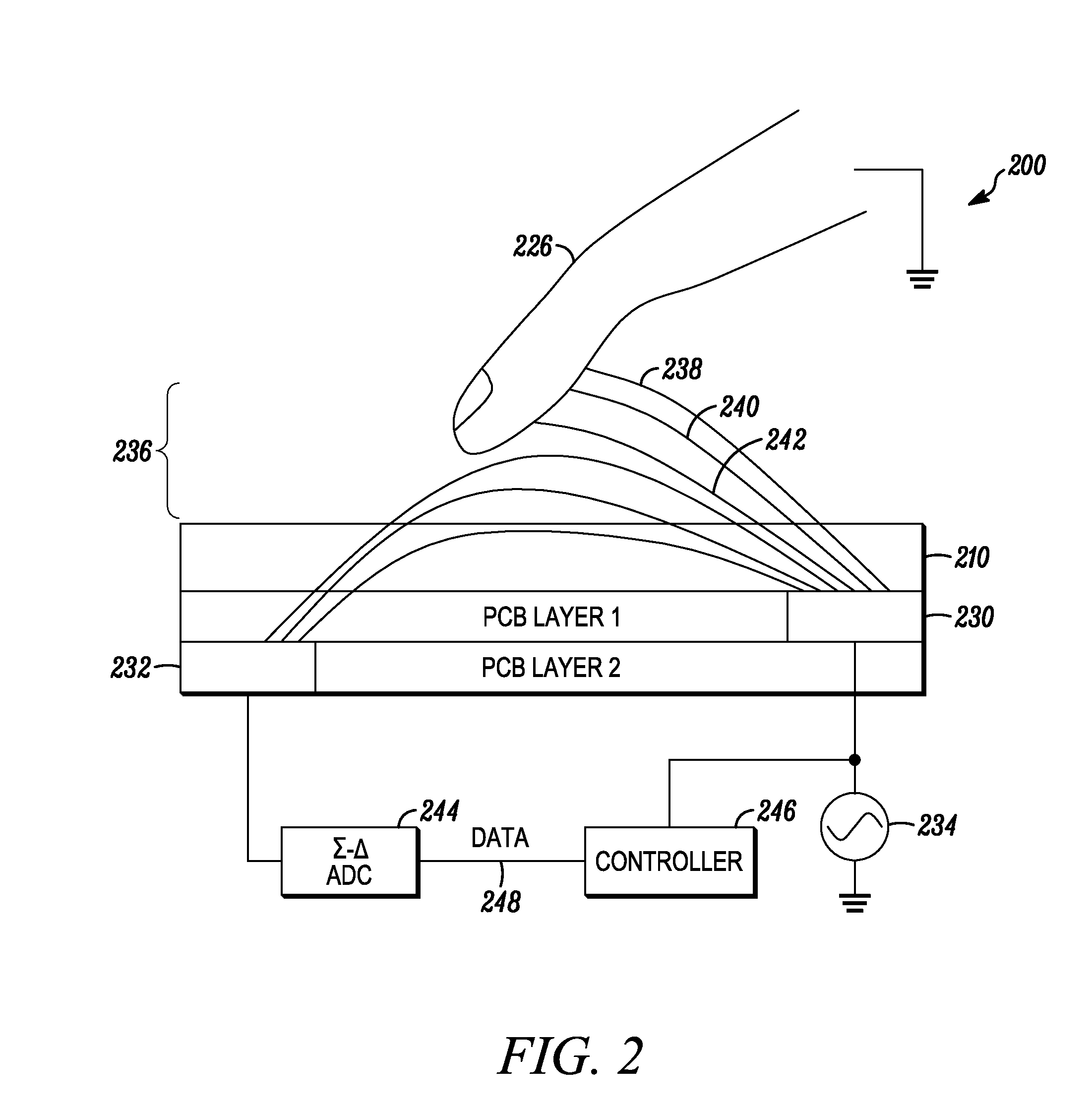

Integrated capacitive sensing devices and methods

InactiveUS20090079707A1Improve experienceLarge thicknessInput/output processes for data processingLiquid-crystal displayDisplay device

Disclosed are touch screen devices and methods of sensing an object near the surface of a touch screen device. A capacitive sensor is integrated into display electronics by flipping the traditional thin film transistor liquid crystal display (TFT) stack-up which has a bottom gate structure so that it is an inverted bottom gate structure. Accordingly, the gate structure is near the top of the display and the gate drive lines are re-used as excitation lines in addition to their function as display lines. The excitation lines therefore drive excitation to generate an induced electric field at the surface of the display device. Additionally, other lines are used as sensor lines so that sensor signals are input to the device controller to determine the position of an object at the surface of the display device. Accordingly, the excitation lines are scanned to detect the presence of a finger or other object.

Owner:MOTOROLA MOBILITY LLC

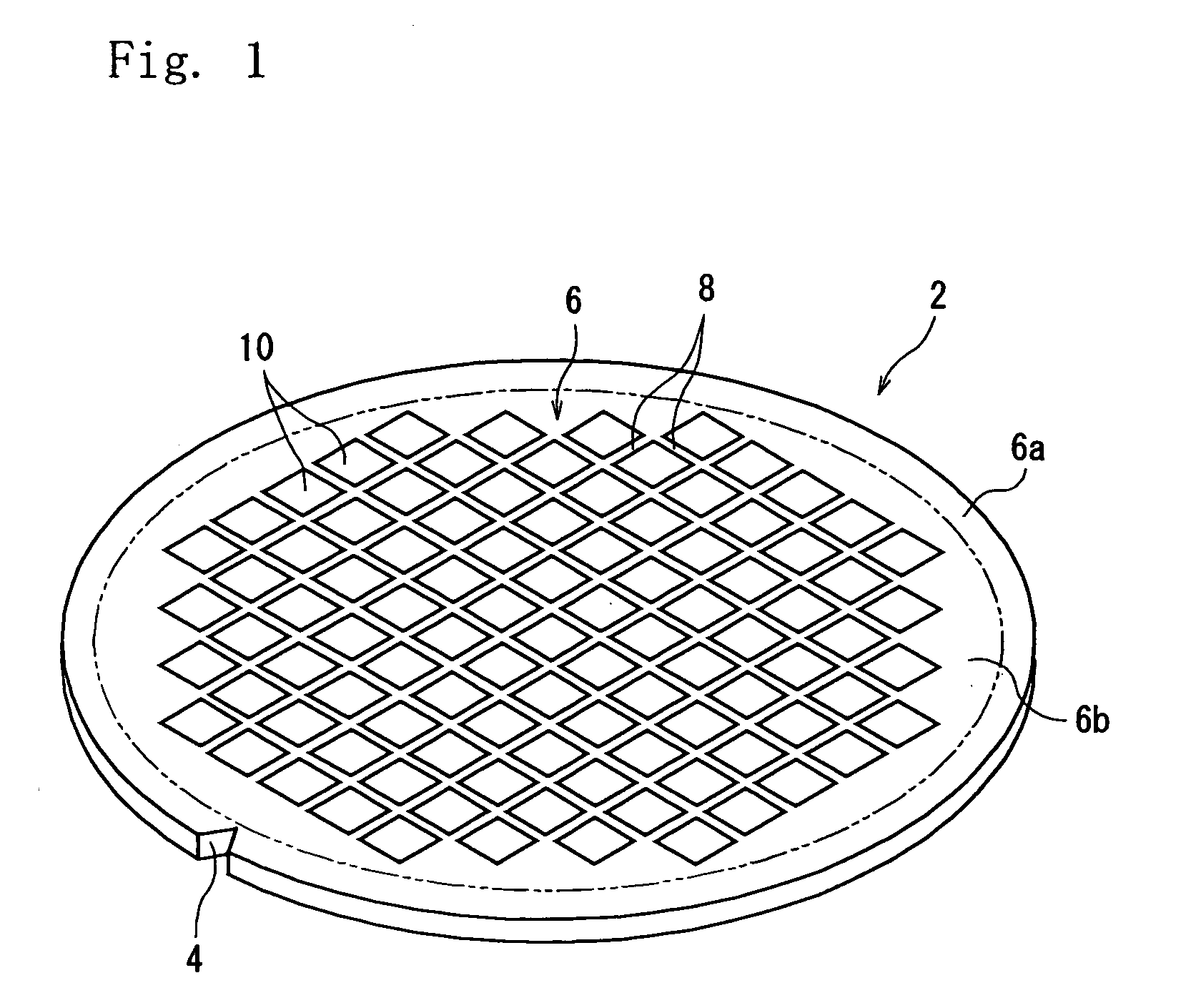

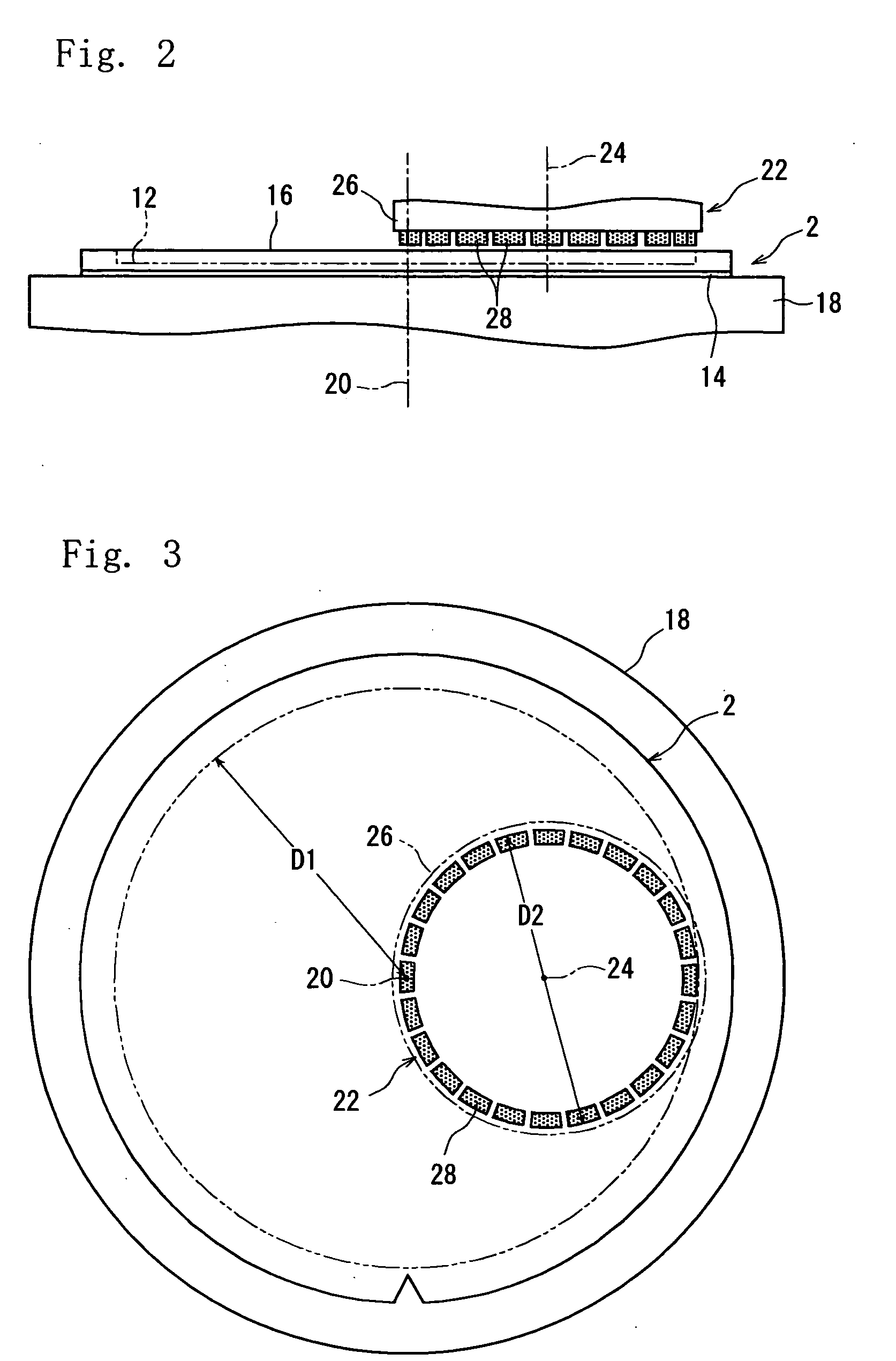

Semiconductor wafer and processing method for same

ActiveUS20060244096A1Avoid difficultyRisk minimizationSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingDevice materialSemiconductor

A semiconductor wafer which is generally circular, and which has on its face an annular surplus region present in an outer peripheral edge portion of the face, and a circular device region surrounded by the surplus region, the device region having many semiconductor devices disposed therein. A circular concavity is formed in the back of the semiconductor wafer in correspondence with the device region, and the device region is relatively thin, while the surplus region is relatively thick.

Owner:DISCO CORP

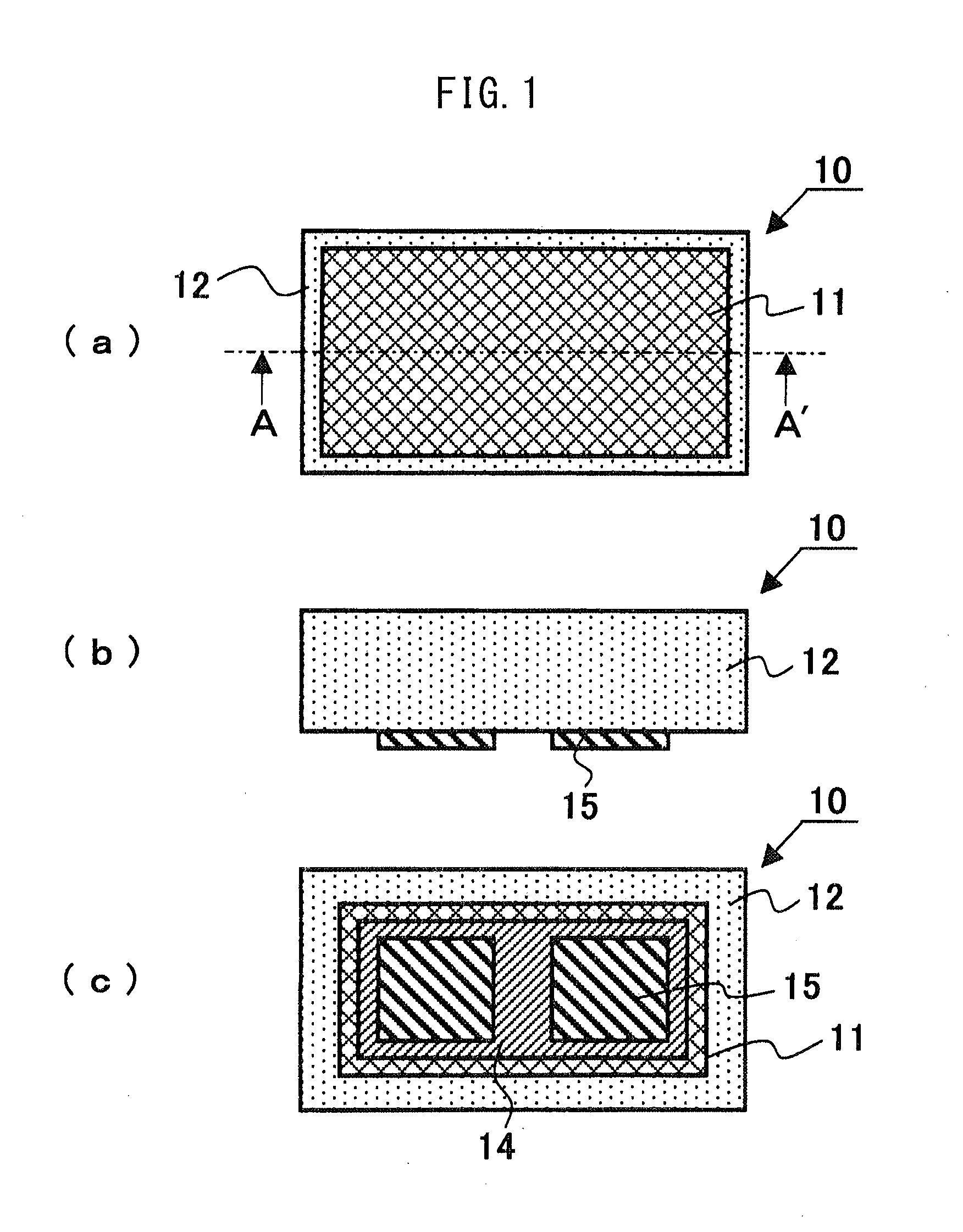

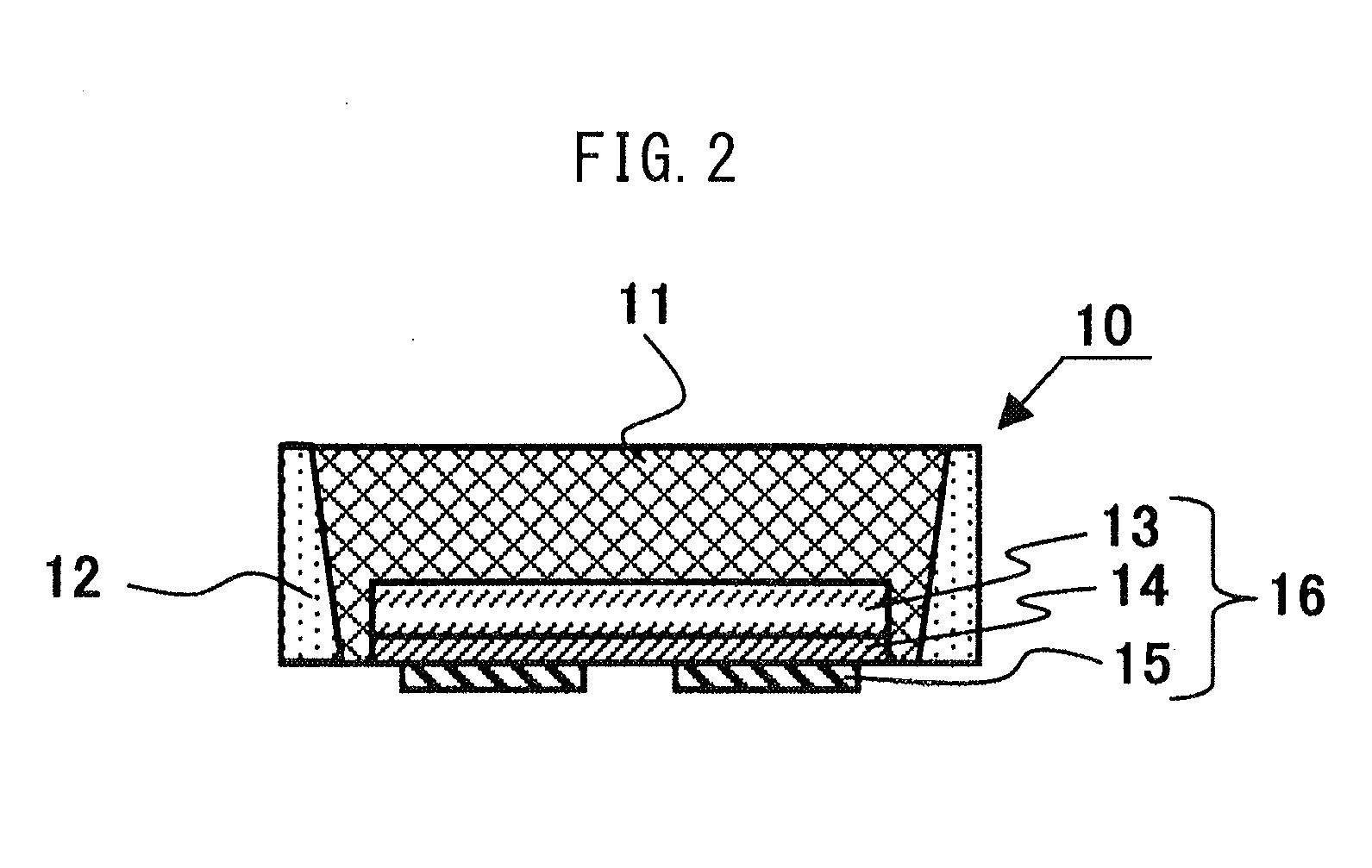

Glass substrate for magnetic disk and manufacturing method thereof

InactiveUS20110159321A1Good surface irregularity accuracyImprove impact resistanceMagnetic materials for record carriersRecord information storageFlat glassSurface roughness

The present invention provides a method for efficiently manufacturing a glass substrate for magnetic disk having good accuracy of a surface irregularity and an impact resistance. The method includes the steps of: performing press forming to molten glass to prepare a sheet glass material, the sheet glass material having a roughness of the principal surface of 0.01 μm or less and target flatness of a glass substrate for magnetic disk; chemically strengthening the sheet glass material by dipping the sheet glass material in a chemically strengthening salt, thereby preparing a disk substrate; polishing the principal surfaces of the disk substrate. A thickness of the sheet glass material prepared in the press forming step is larger than a target thickness of the glass substrate for magnetic disk by a polishing quantity of the principal surface polishing step.

Owner:HOYA CORP

LED device and manufacturing method thereof

ActiveUS20150311405A1Improve luminous efficiencyConfine light distributionSolid-state devicesSemiconductor/solid-state device manufacturingFluorescenceEngineering

Provided is an LED device which is compact while having good luminous efficiency and a focused light distribution. This LED device is provided with: a reflective frame around the outer periphery of the LED device; an LED die which has a transparent insulating substrate, a semiconductor layer formed on the bottom surface of the transparent insulating substrate, and an outer connection electrode disposed on the semiconductor layer; and a fluorescent member which is disposed on at least the top surface of the LED die and which converts the wavelength of the light emitted from the LED die. On the inside of the reflective frame is an inclined surface in contact with the lateral surface of the fluorescent member, and the inclined surface is formed such that the inner diameter of the reflective frame widens from the bottom surface towards the top surface of the LED die. Also provided is a manufacturing method of the LED device.

Owner:CITIZEN WATCH CO LTD +1

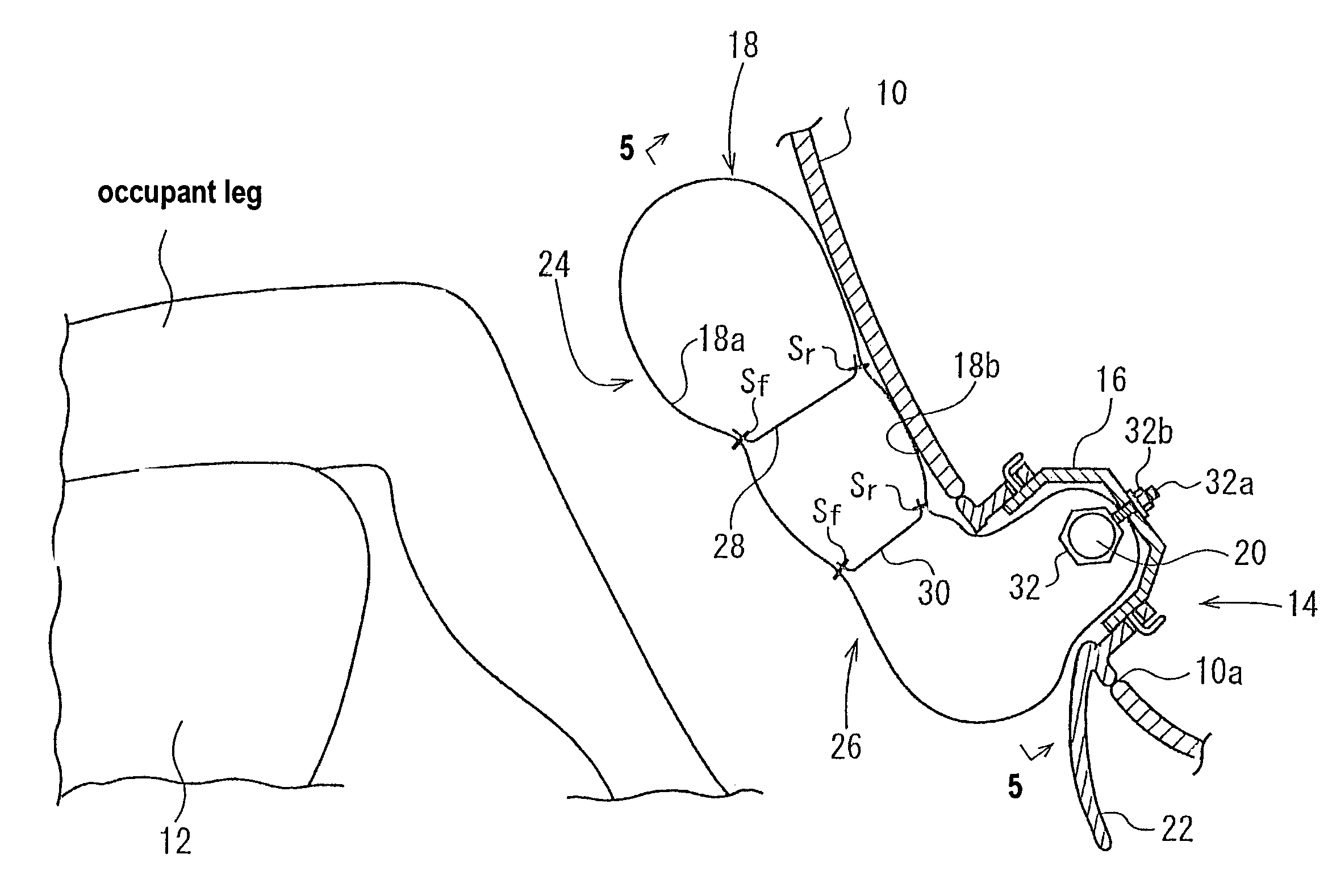

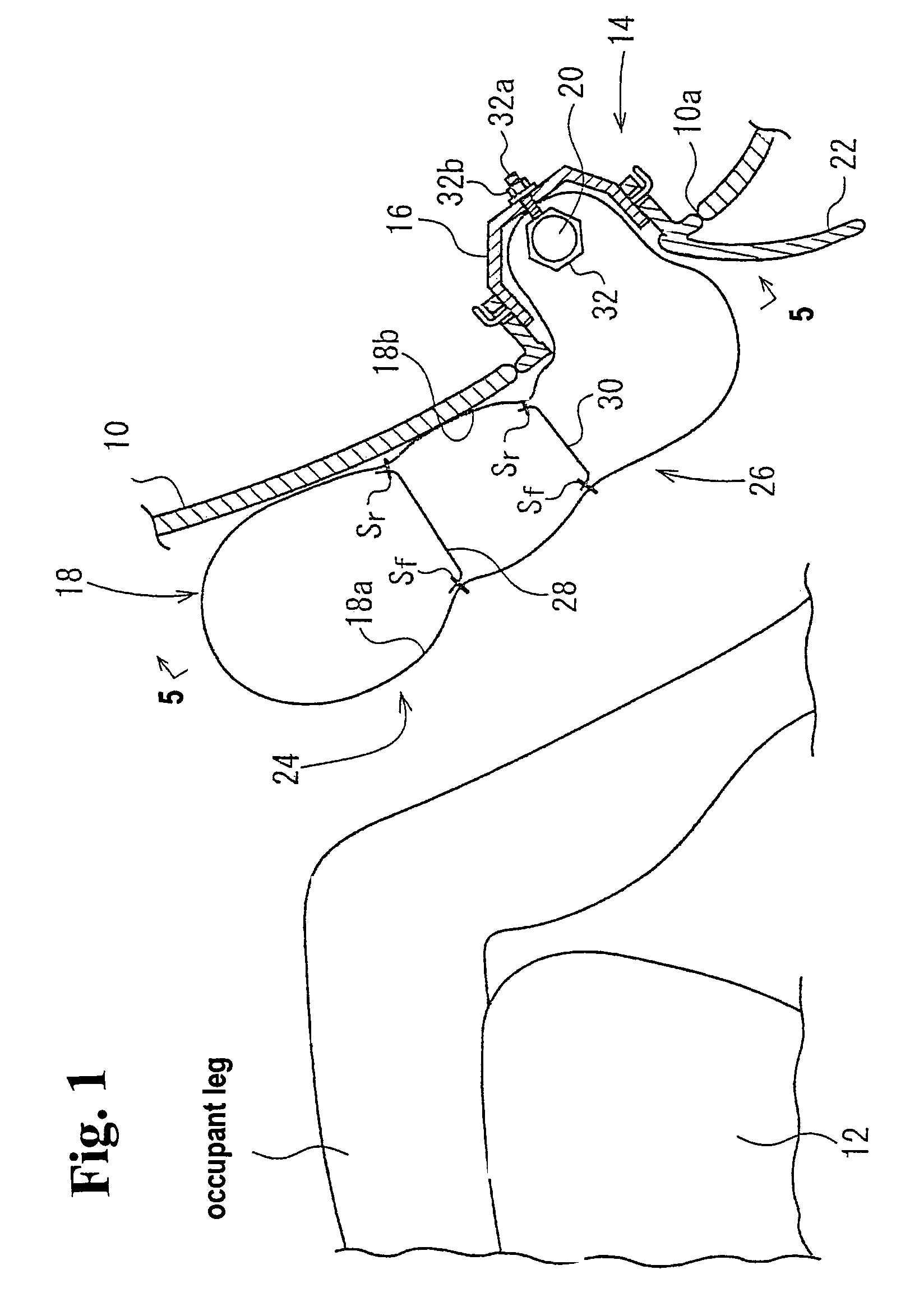

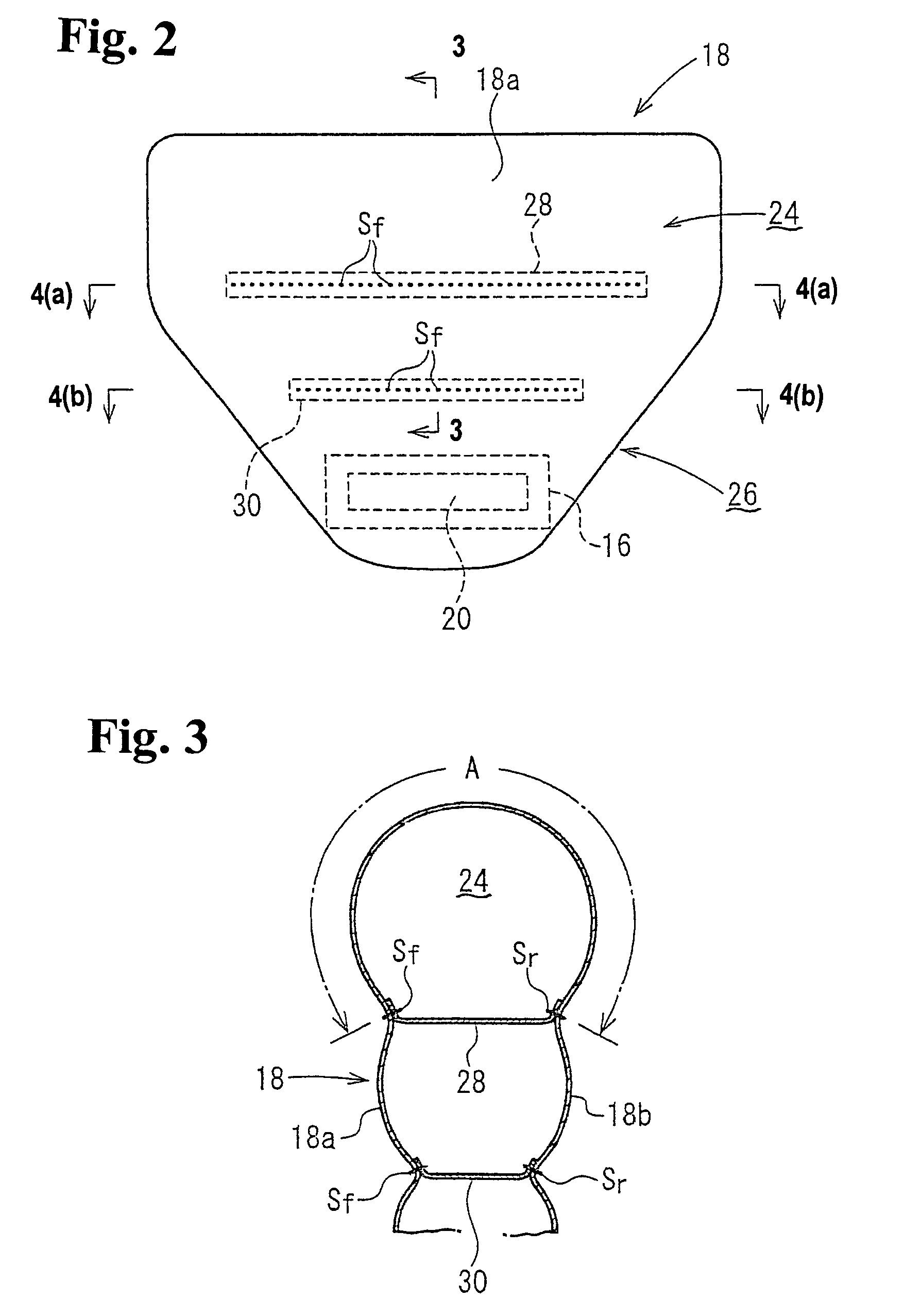

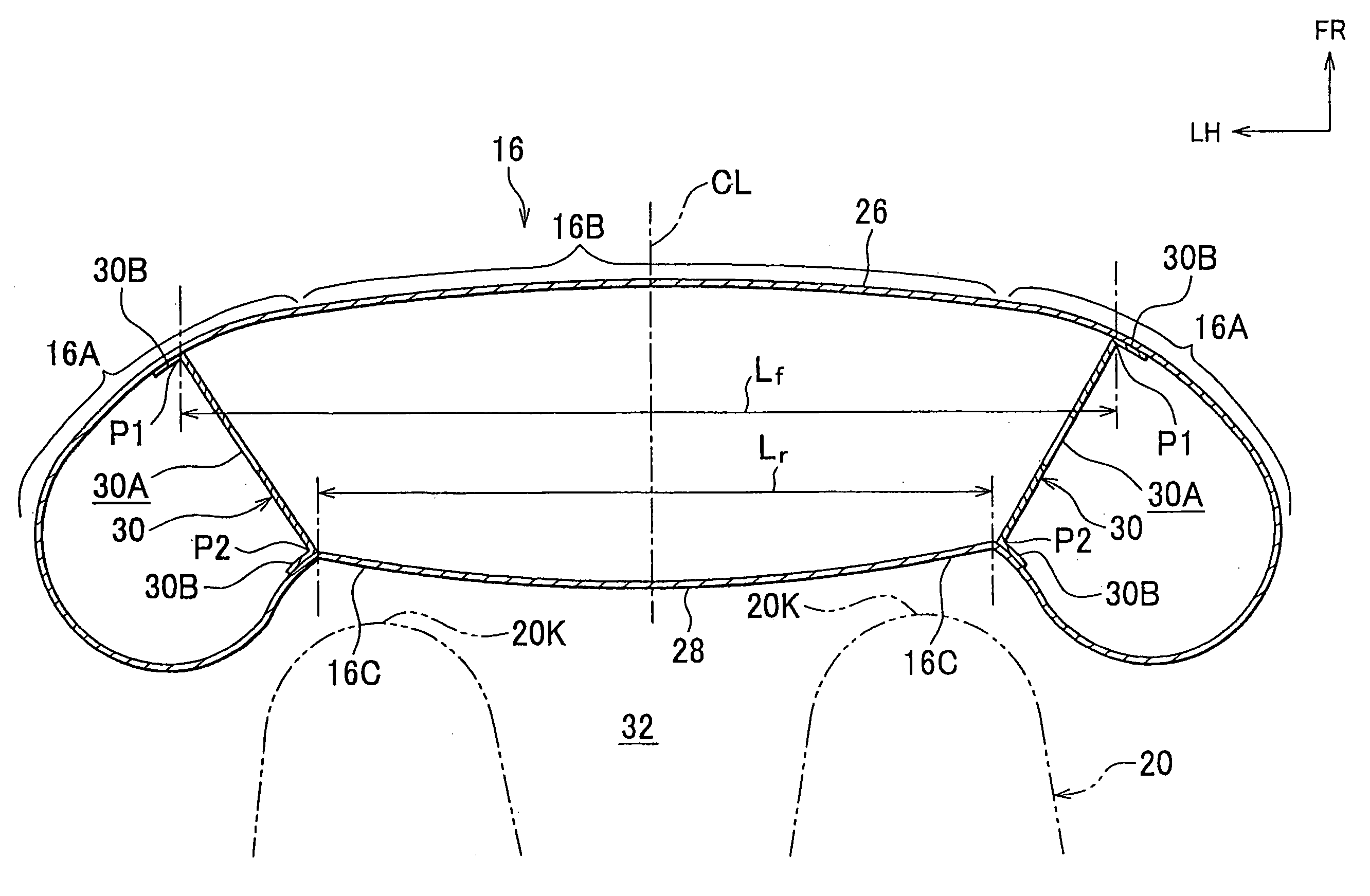

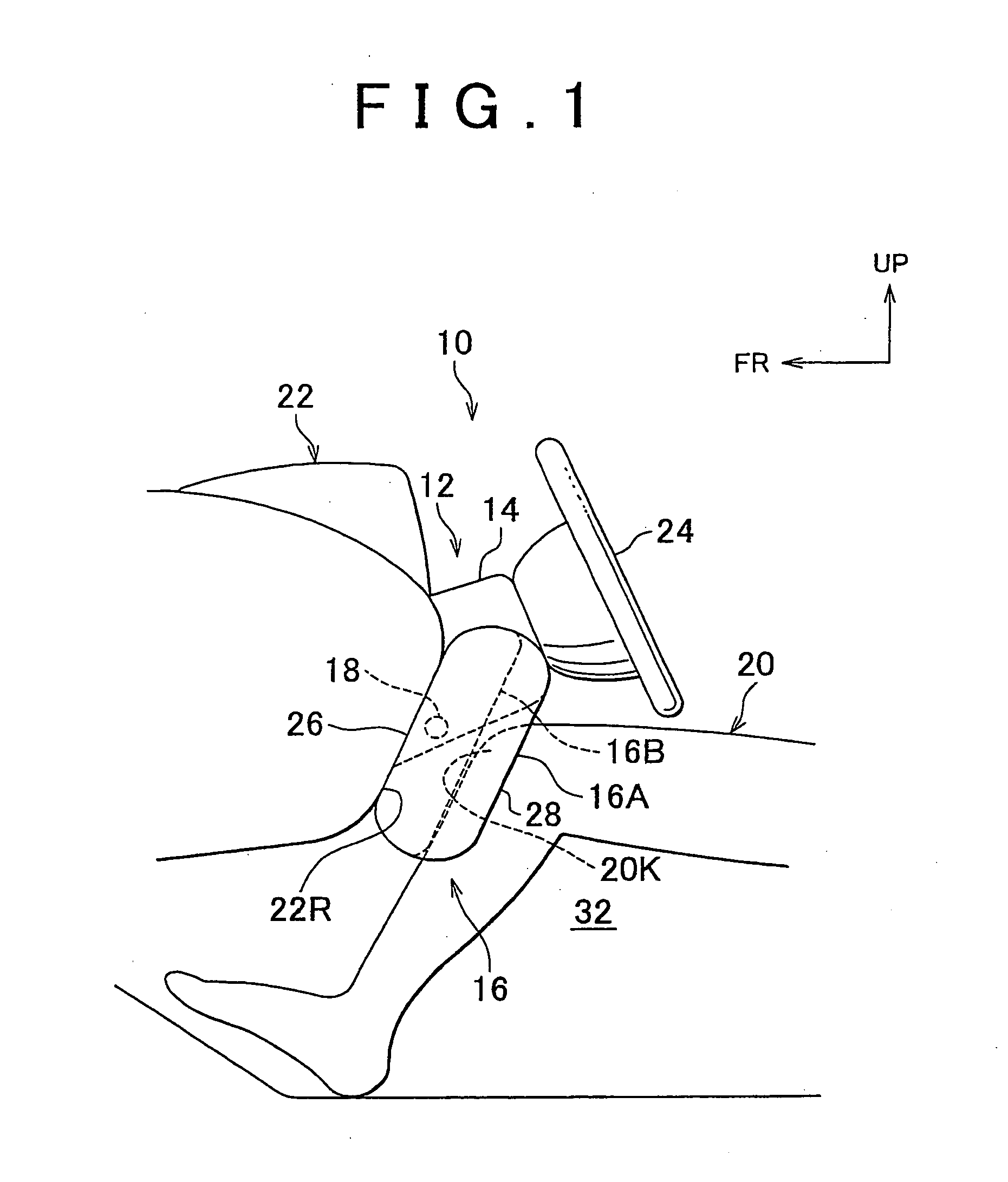

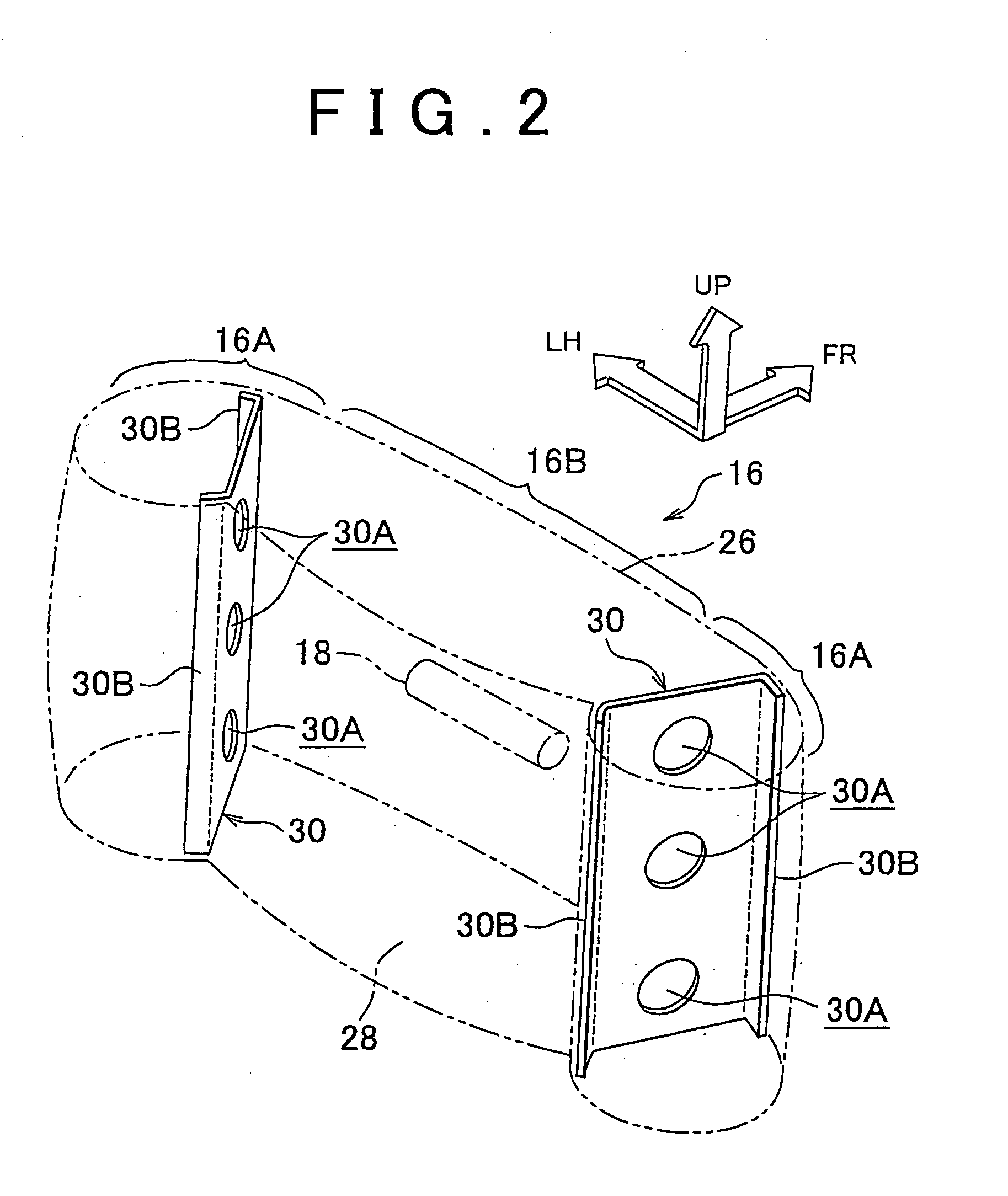

Kneebag and occupant leg protection system

ActiveUS7314230B2Large thicknessSmall thicknessPedestrian/occupant safety arrangementProtection systemMechanical engineering

Owner:JOYSON SAFETY SYST JAPAN GK

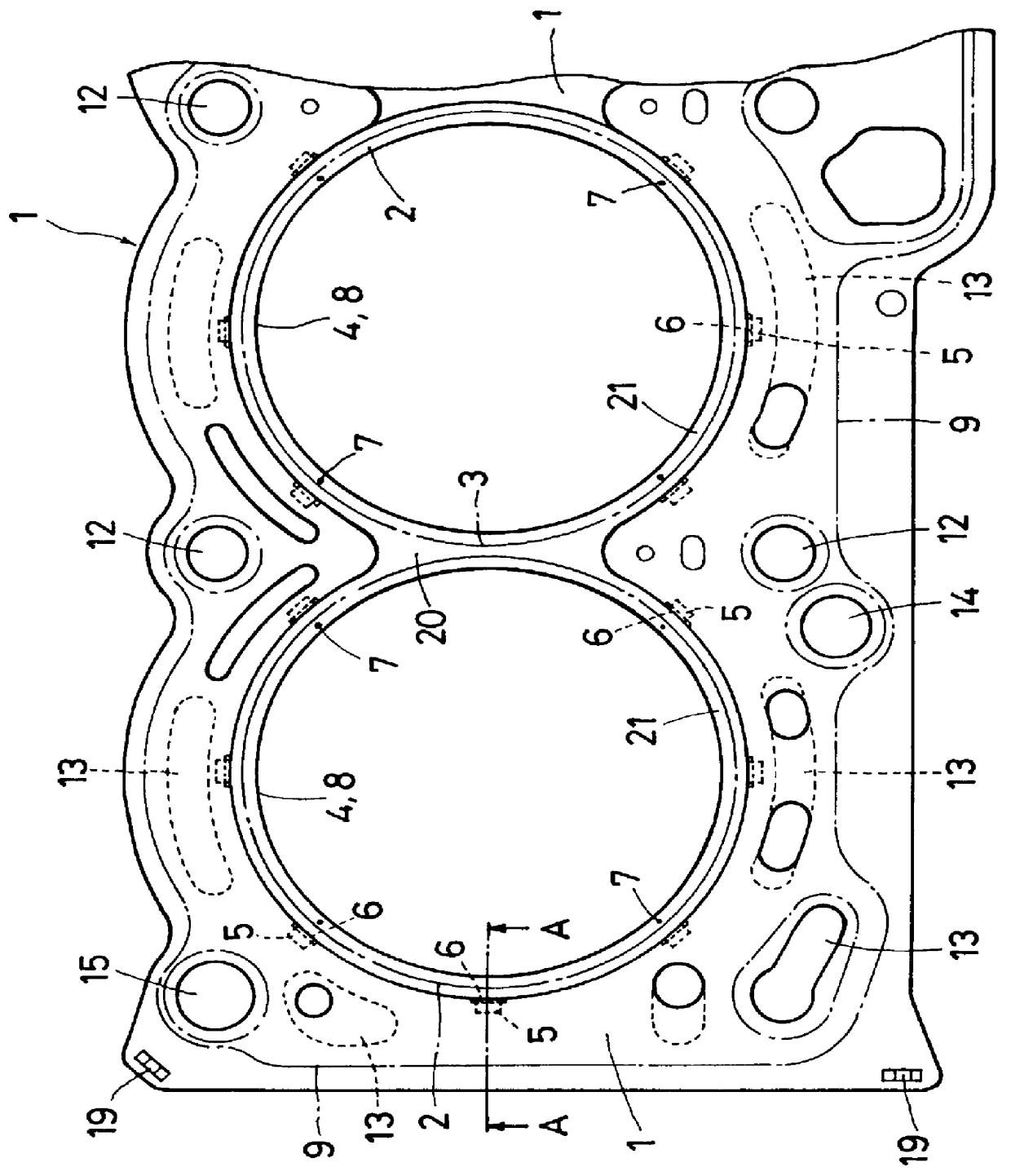

Metal gasket

InactiveUS6027124AImprove sealingImprove balanceEngine sealsSealing arrangements for enginesThin metalCombustion chamber

A metal gasket in which a thin metal plate for reinforcing the beads of an elastic metal plate is laminated on bead regions only of the elastic metal plate, whereby a stable sealing performance is secured for a long period of time. This metal gasket comprises a thin metal plate provided with beads extending around the circumferences of parallel arranged combustion chamber holes, and an elastic metal plate having combustion chamber holes and extending with a predetermined width and laminated on the portions of the thin metal plate which are around the combustion chamber holes so as to be opposed to valley portions of the beads. The thickness of the thin metal plate is set smaller than that of the elastic metal plate. The thin metal plate is fixed to the elastic metal plate with locking portions formed at the outer circumference of the former engaged with slits formed in the regions of the latter which are on the outer sides of the beads, the thin metal plate being combined with the elastic metal plate at joint portions thereof by spot welding or laser welding.

Owner:NIPPON GASKET CO LTD

Knee airbag apparatus

InactiveUS20080122205A1Increase distanceRegulate a thickness of the knee airbagPedestrian/occupant safety arrangementSteering columnEngineering

A knee airbag device includes a knee airbag that is disposed in a folded state inside a steering column cover. When the knee airbag receives gas, the knee airbag is inflated and deployed from an inside of the steering column cover toward knees of an occupant. The thickness of outer portions of the knee airbag, which are positioned outside centers of the knees when the knee airbag is deployed, is set to be larger than the thickness of a general portion of the knee airbag, which is positioned in front of the knees when the knee airbag is deployed.

Owner:TOYOTA JIDOSHA KK

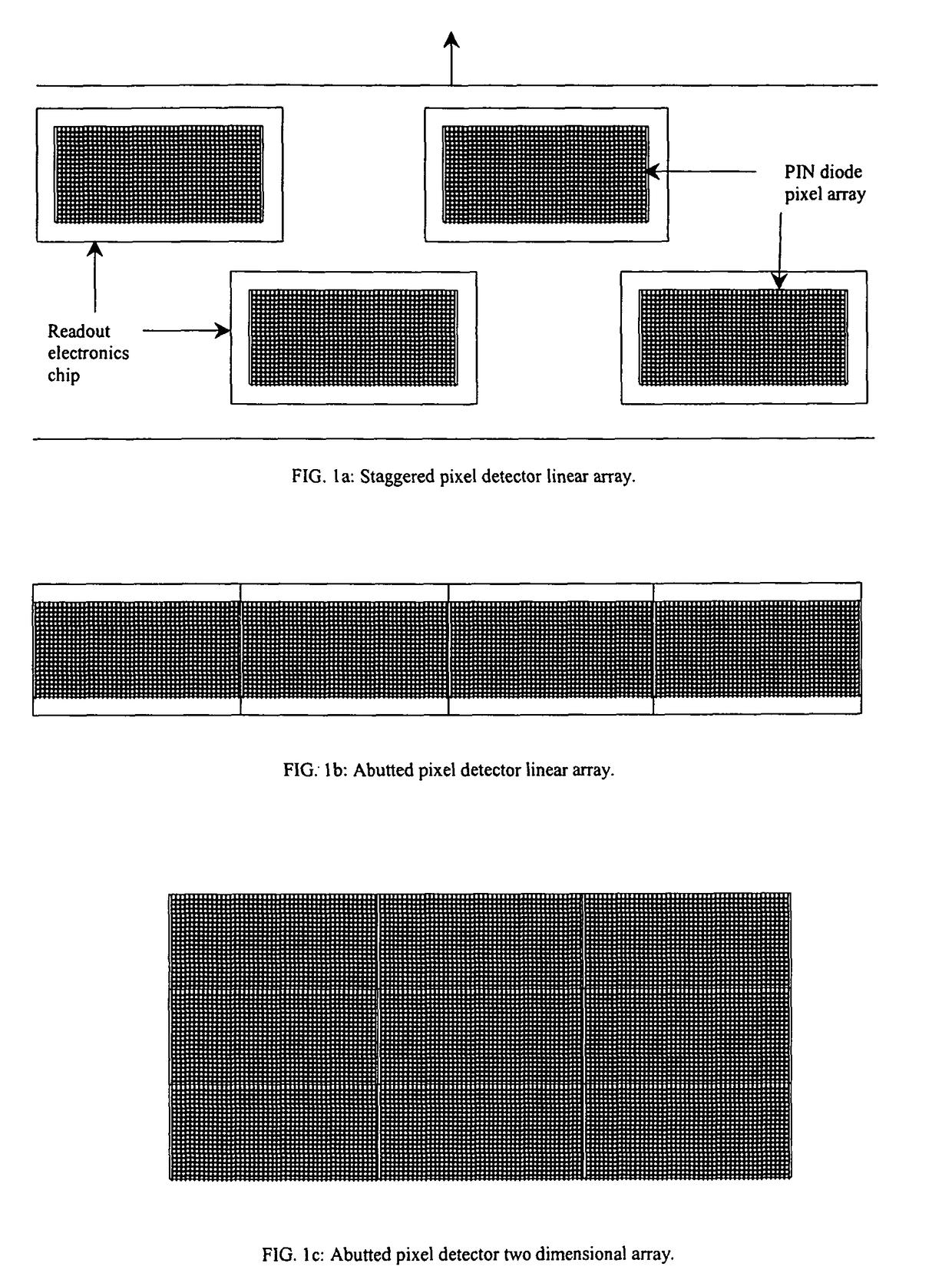

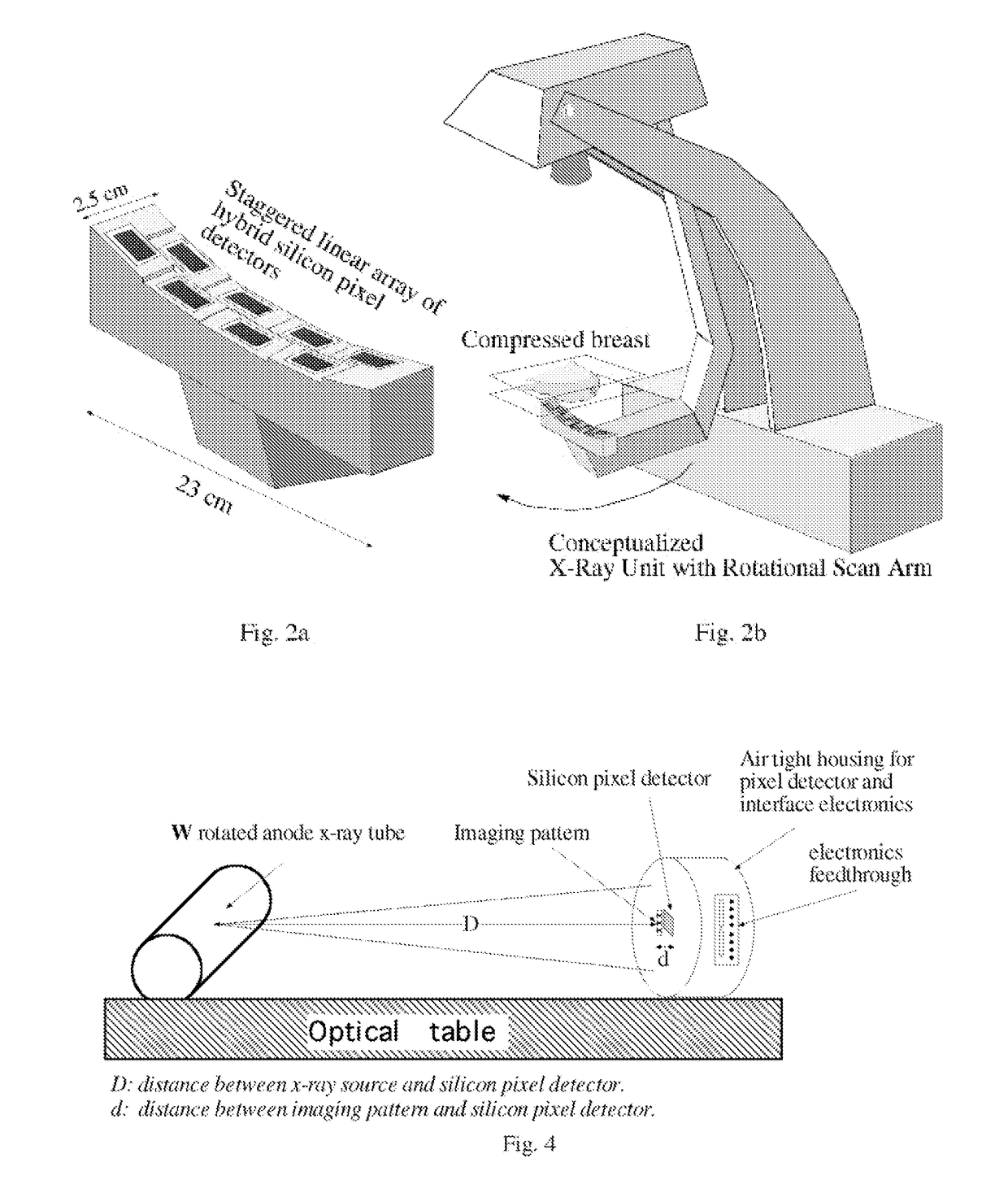

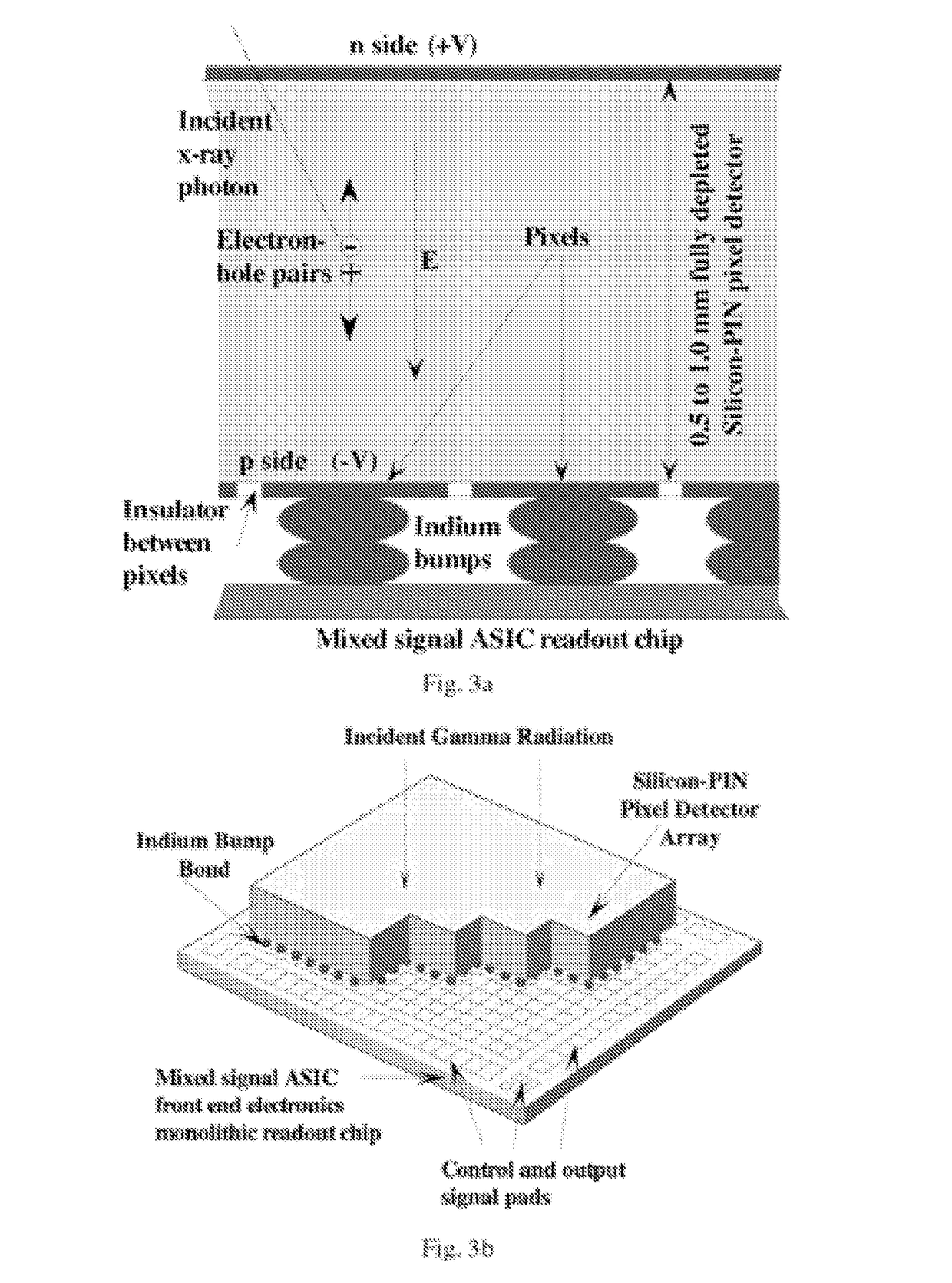

High resoultion digital imaging apparatus

InactiveUS8120683B1Improve quantum efficiencyImprove the immunityTelevision system detailsTelevision system scanning detailsDigital imagingData acquisition

An integrated application specific integrated circuit having a detection layer, a time delayed integration capability, data acquisition electronics, and a readout function is provided for detecting breast cancer in women. The detection layer receives x-ray radiation and converts the received energy to electron pairs, one of which is received by pixels. The time delay integration is on the chip and a part of the readout architecture. The detector may be a hybrid silicon detector (SiPD), a CdZnTe detector, or a GaAs detector.

Owner:NOVA R&D

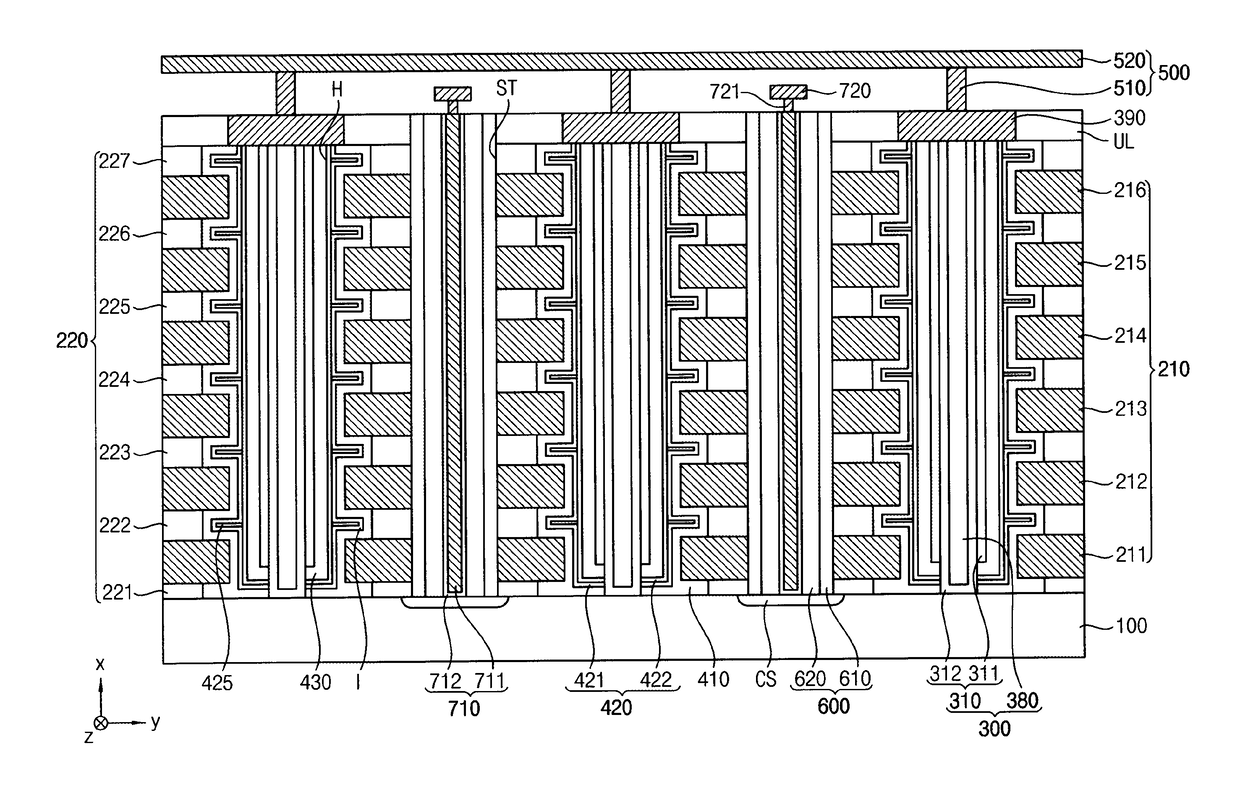

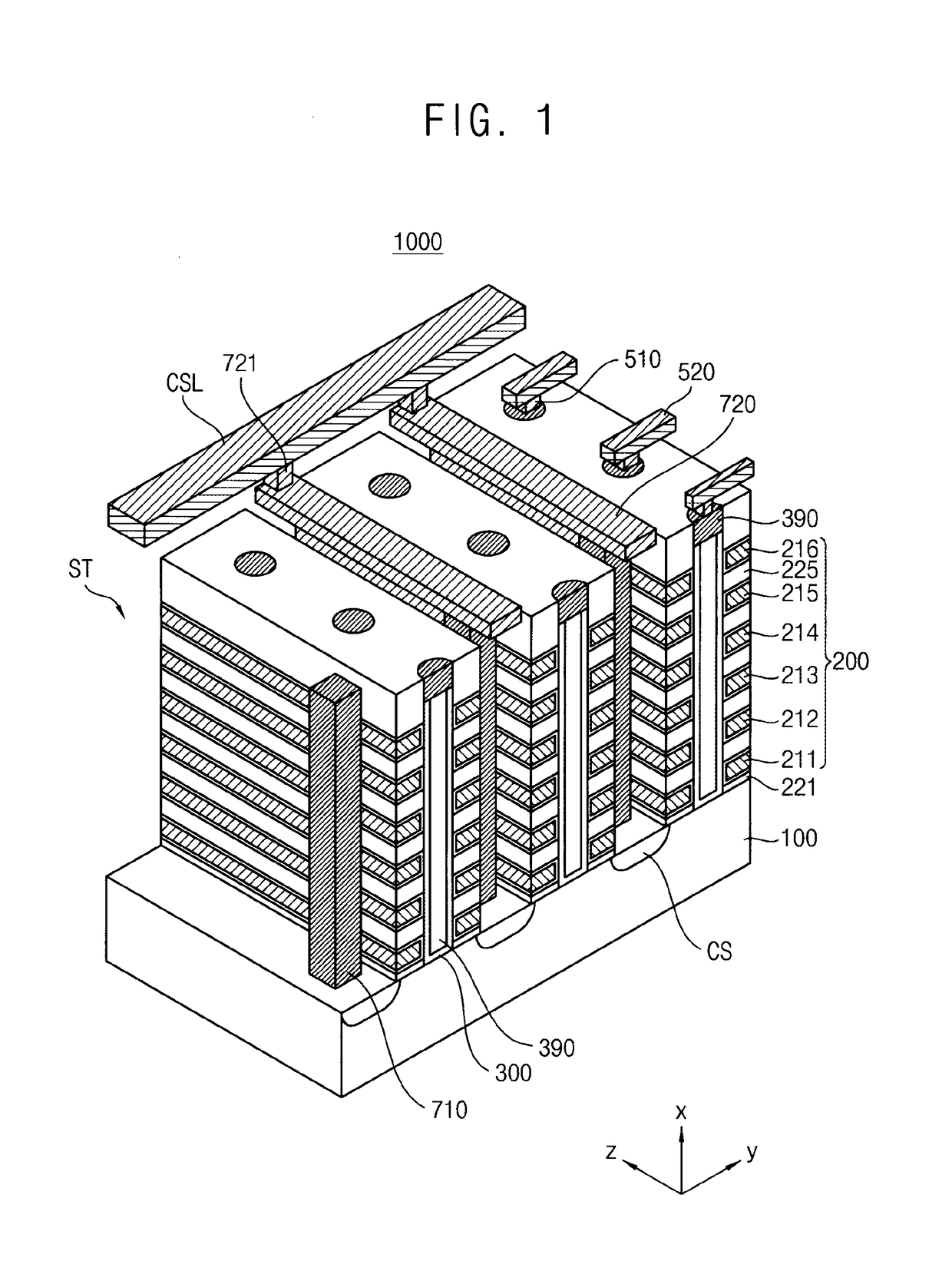

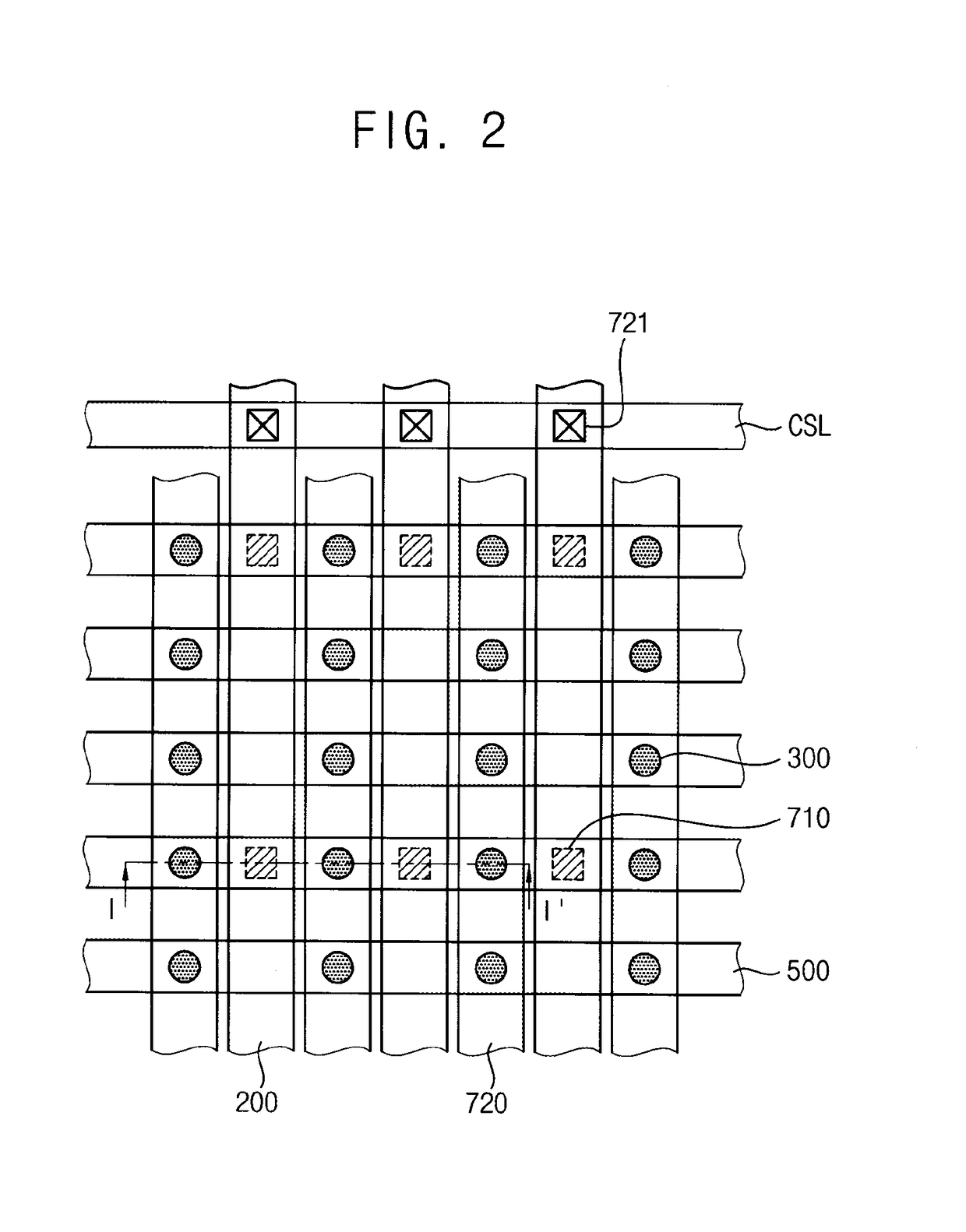

Vertical memory device and method of manufacturing the same

ActiveUS20180033799A1Reduce crosstalkIncrease trap density of charge trapSolid-state devicesSemiconductor devicesCouplingCell region

Disclosed are vertical memory devices and methods of manufacturing the same. The vertical memory device may include includes a substrate, a gate stack structure and channel structure on the substrate, and a charge trap structure between the gate stack structure and the channel structure. The gate stack structure includes conductive structures and insulation interlayer structures that are alternately stacked on each other in a vertical direction on the substrate such that cell regions and inter-cell regions are alternately arranged in the vertical direction. The channel structure penetrates through the gate stack structure in the vertical direction. The charge trap structure and the conductive structures define memory cells at the cell regions. The charge structure is configured to selectively store charges. The charge trap structure includes an anti-coupling structure in the inter-cell region for reducing a coupling between neighboring memory cells adjacent to each other in the vertical direction.

Owner:SAMSUNG ELECTRONICS CO LTD

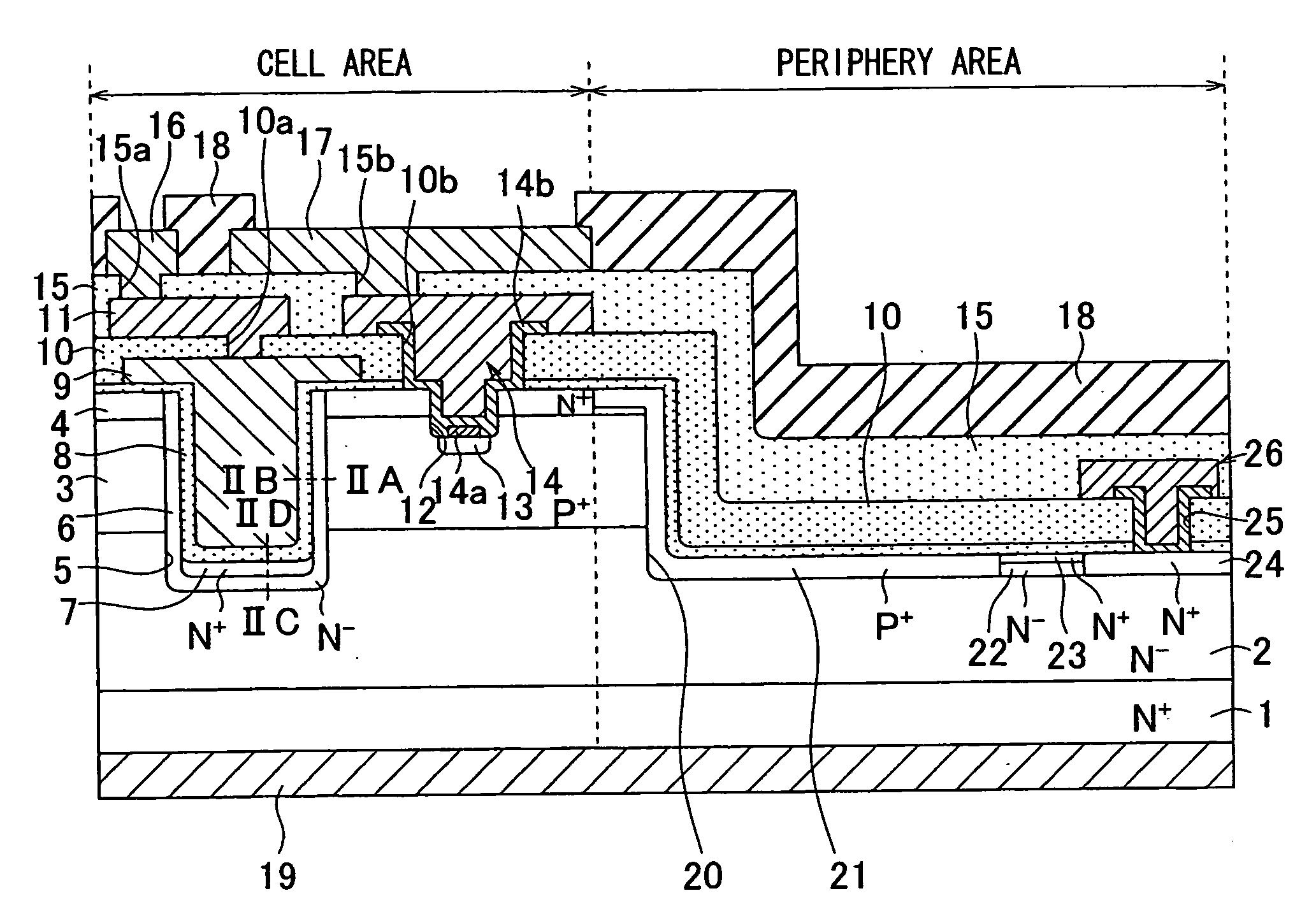

Silicon carbide semiconductor device and method for manufacturing the same

ActiveUS20060097267A1Reliability and high performance be improveON-state resistance be reduceSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorSemiconductor

A method for manufacturing a silicon carbide semiconductor device includes the steps of: preparing a semiconductor substrate including a silicon carbide substrate and first to third semiconductor layers; forming a trench in a cell region of the semiconductor substrate; forming a fourth semiconductor layer in the trench; forming an oxide film in the trench such that a part of the fourth semiconductor layer on a sidewall of the trench is thermally oxidized; forming a gate electrode on the oxide film in the trench; forming a first electrode electrically connecting to the third semiconductor layer; and forming a first electrode electrically connecting to the silicon carbide substrate.

Owner:DENSO CORP

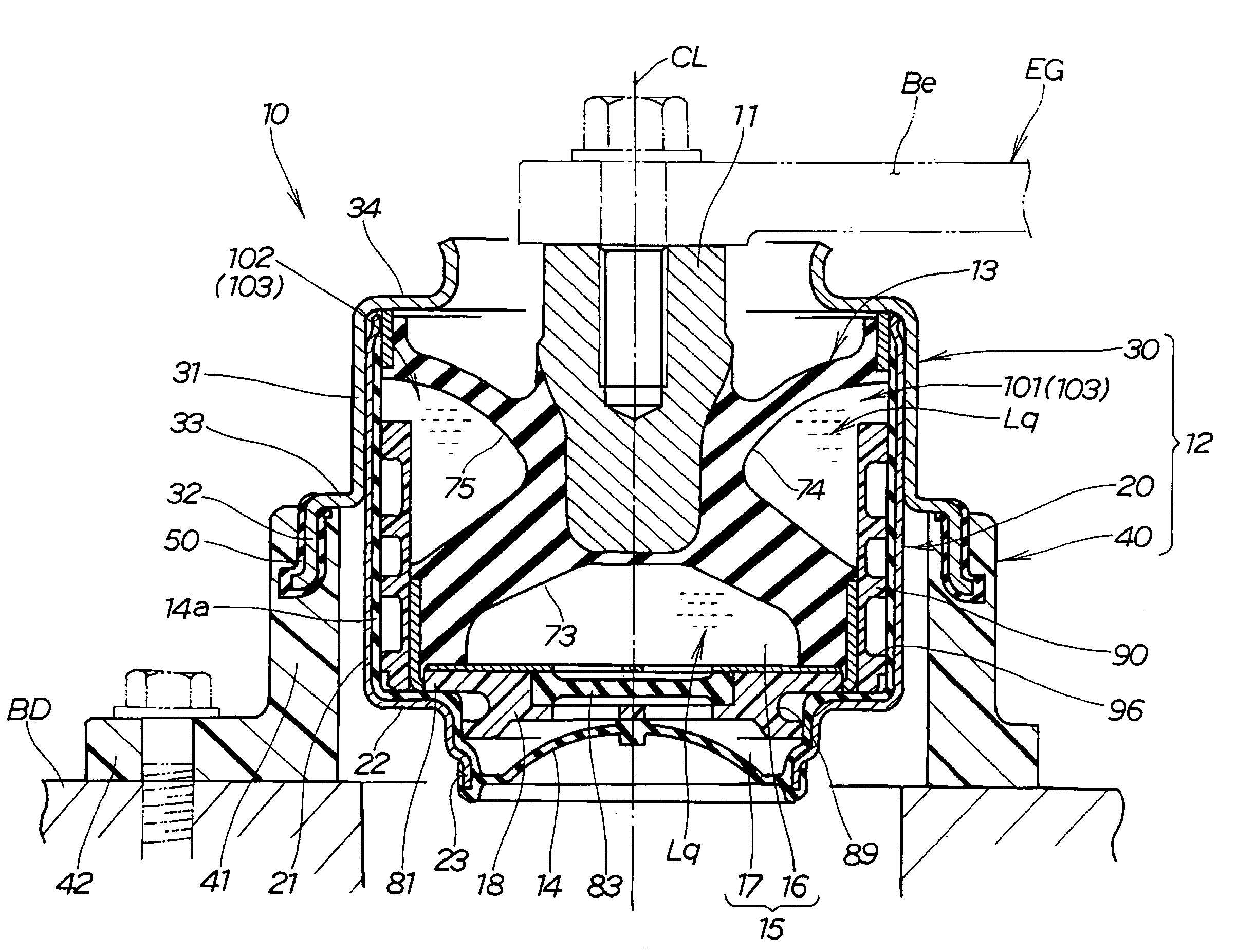

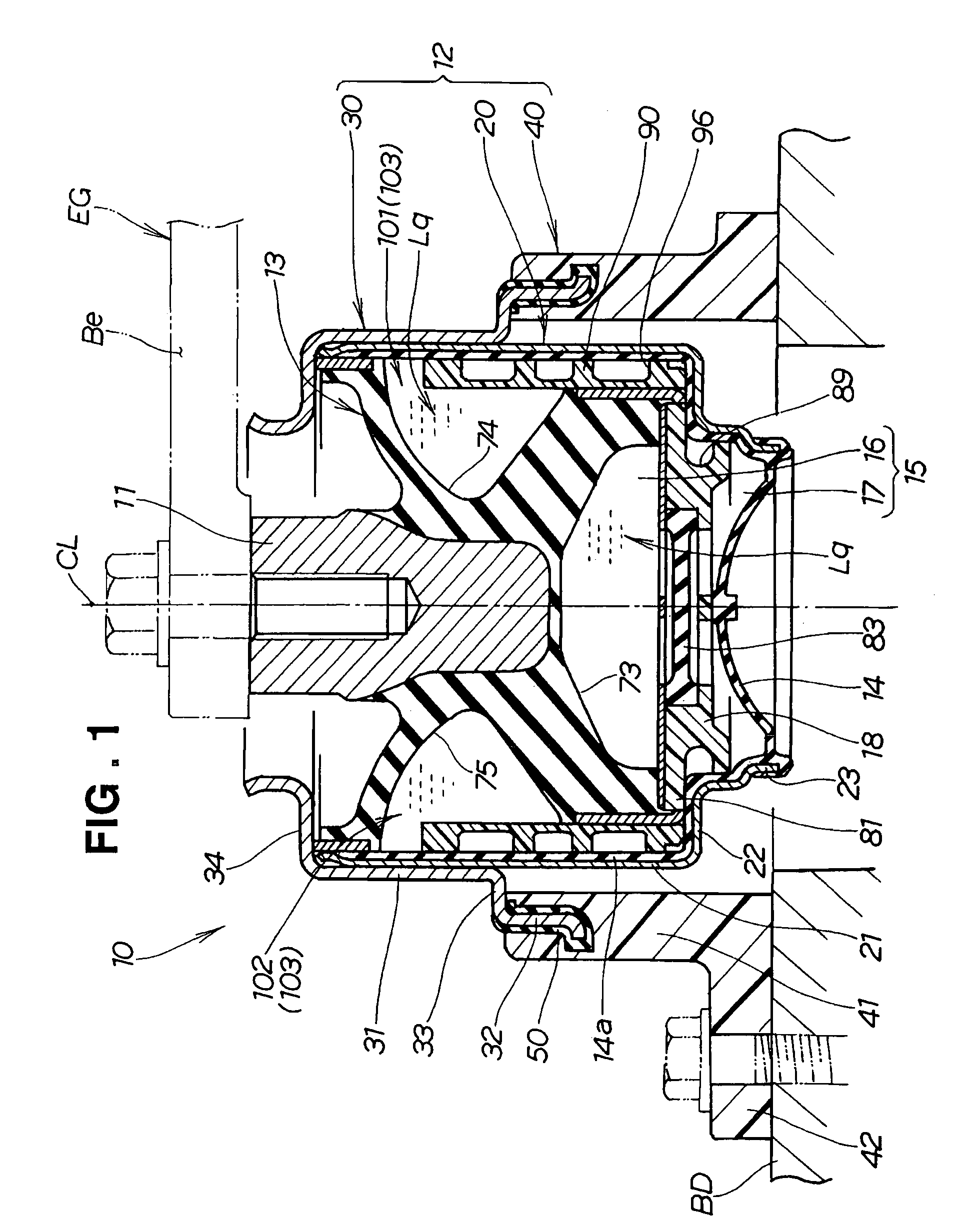

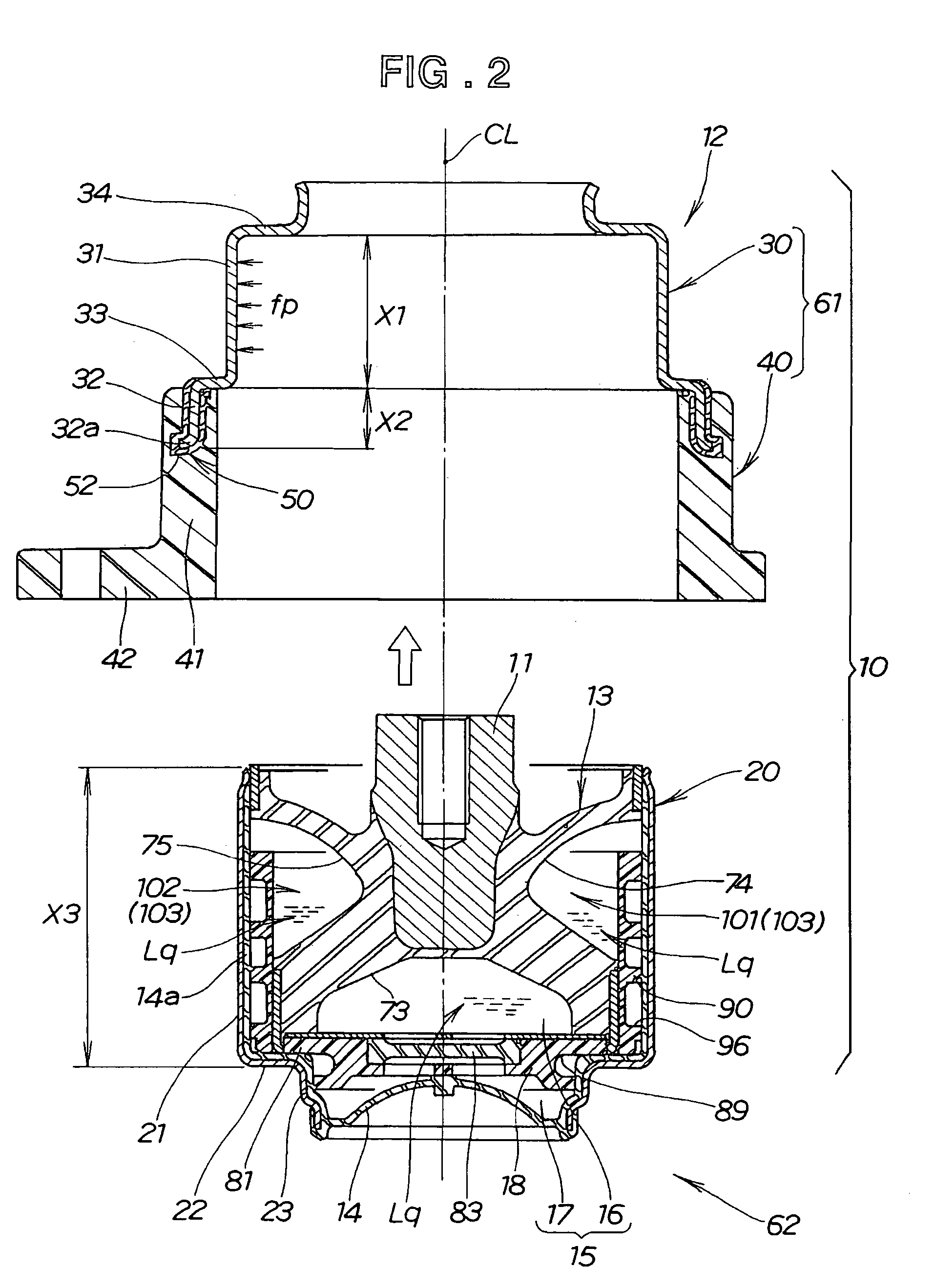

Vibration isolation device

Owner:HONDA MOTOR CO LTD +1

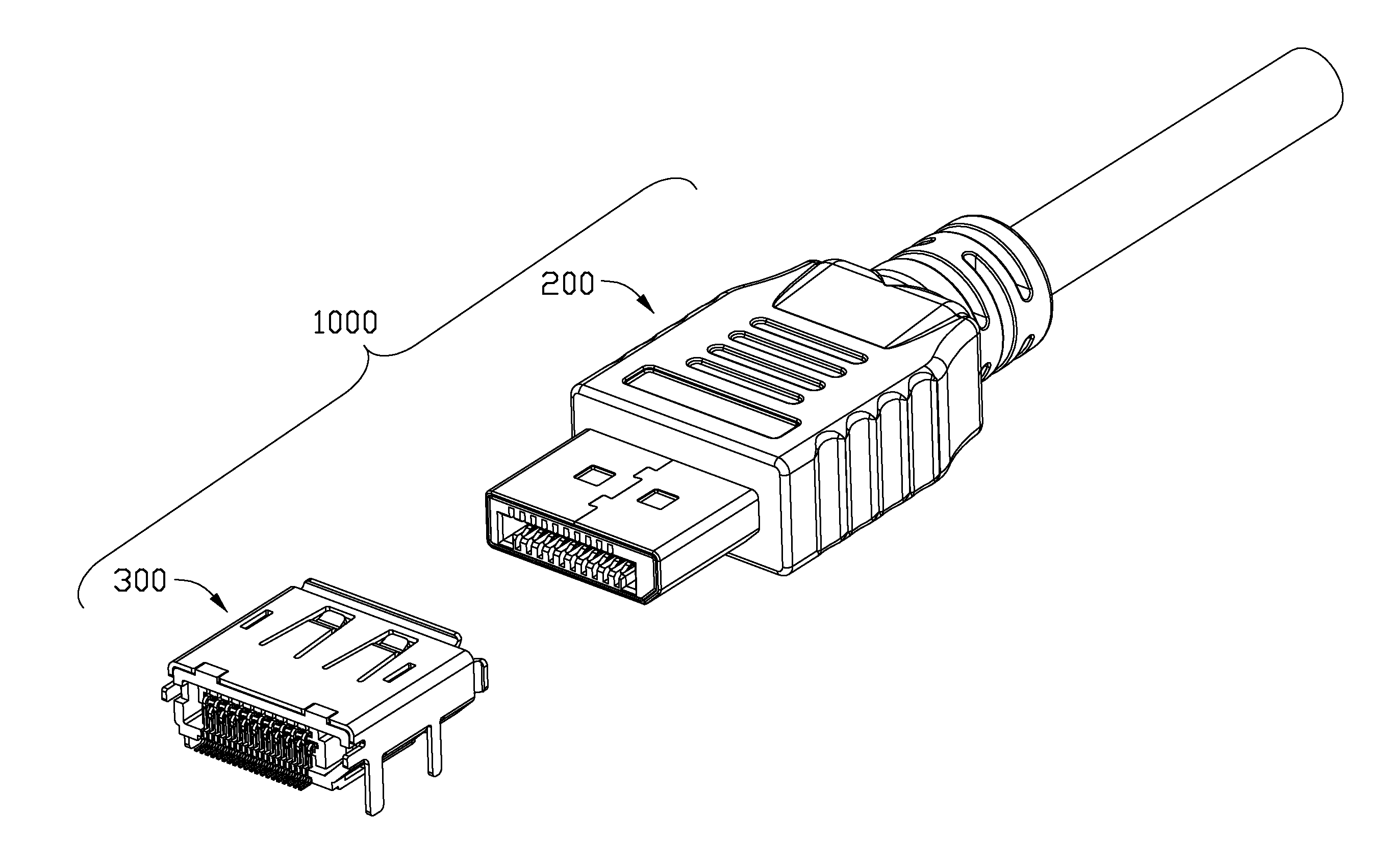

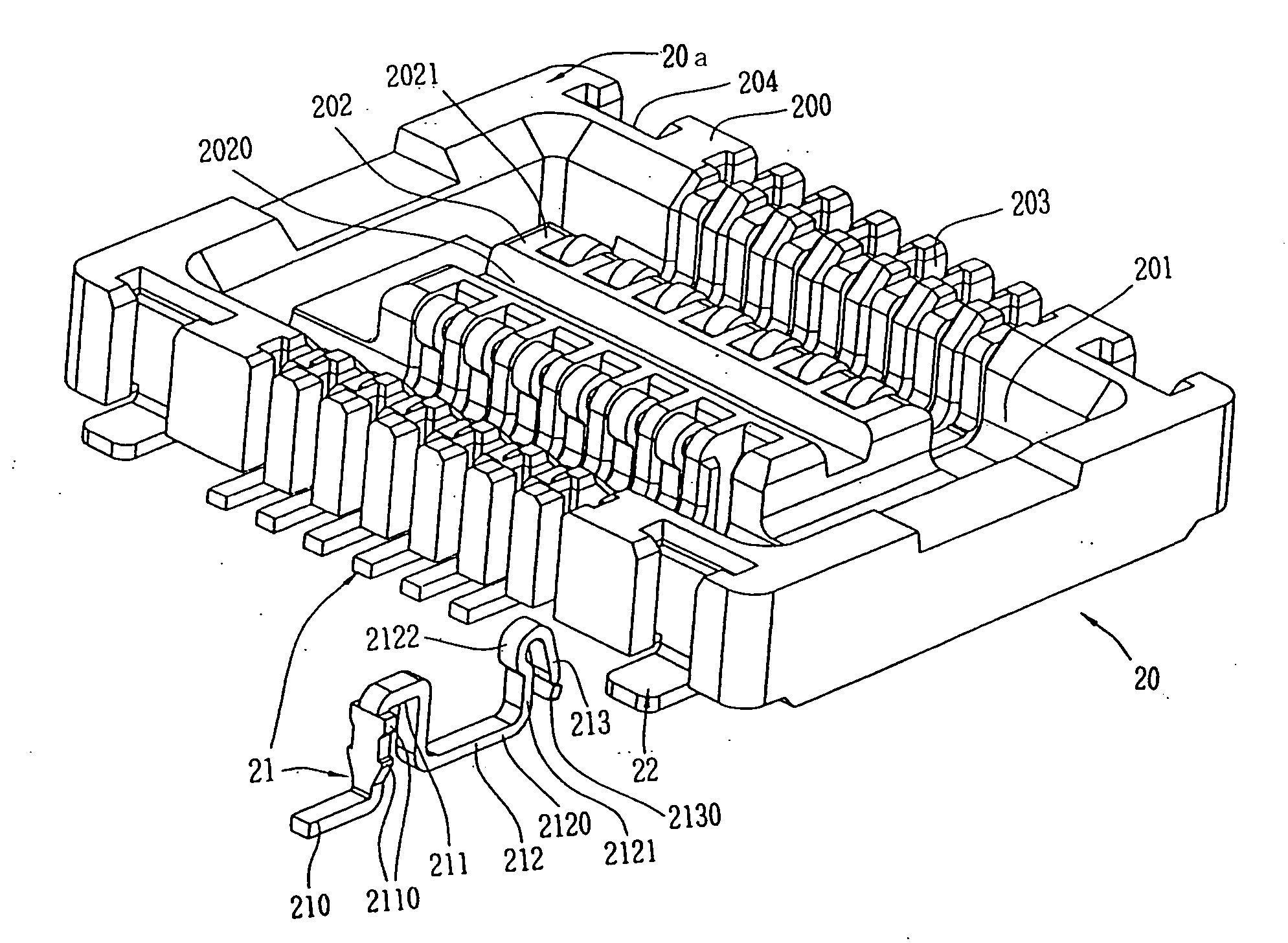

Electrical connector with improved contacts

InactiveUS20150111427A1Large thicknessTwo-part coupling devicesCoupling protective earth/shielding arrangementsEngineeringElectrical connector

An electrical connector includes a first insulative housing (21), a number of first contacts (22) retained in the first insulative housing, and a metallic shell shielding on the first insulative housing. Each first contact comprises a main portion, a contacting section (2211) in front of the base portion, and a soldering section (2201) behind the base portion. Each first contact has a first sub-contact (220) and a second sub-contact (221) stacked with each other. The first sub-contact (220) comprises a first main section (2202) and the soldering section, the second sub-contact (221) comprises a second main section (2210) and the contacting section, the first main section is superimposed on the second main section to form the main portion, and the main portion of the first contact has a larger thickness than the contacting section and the soldering section.

Owner:FOXCONN INTERCONNECT TECHNOLOGY LIMITED

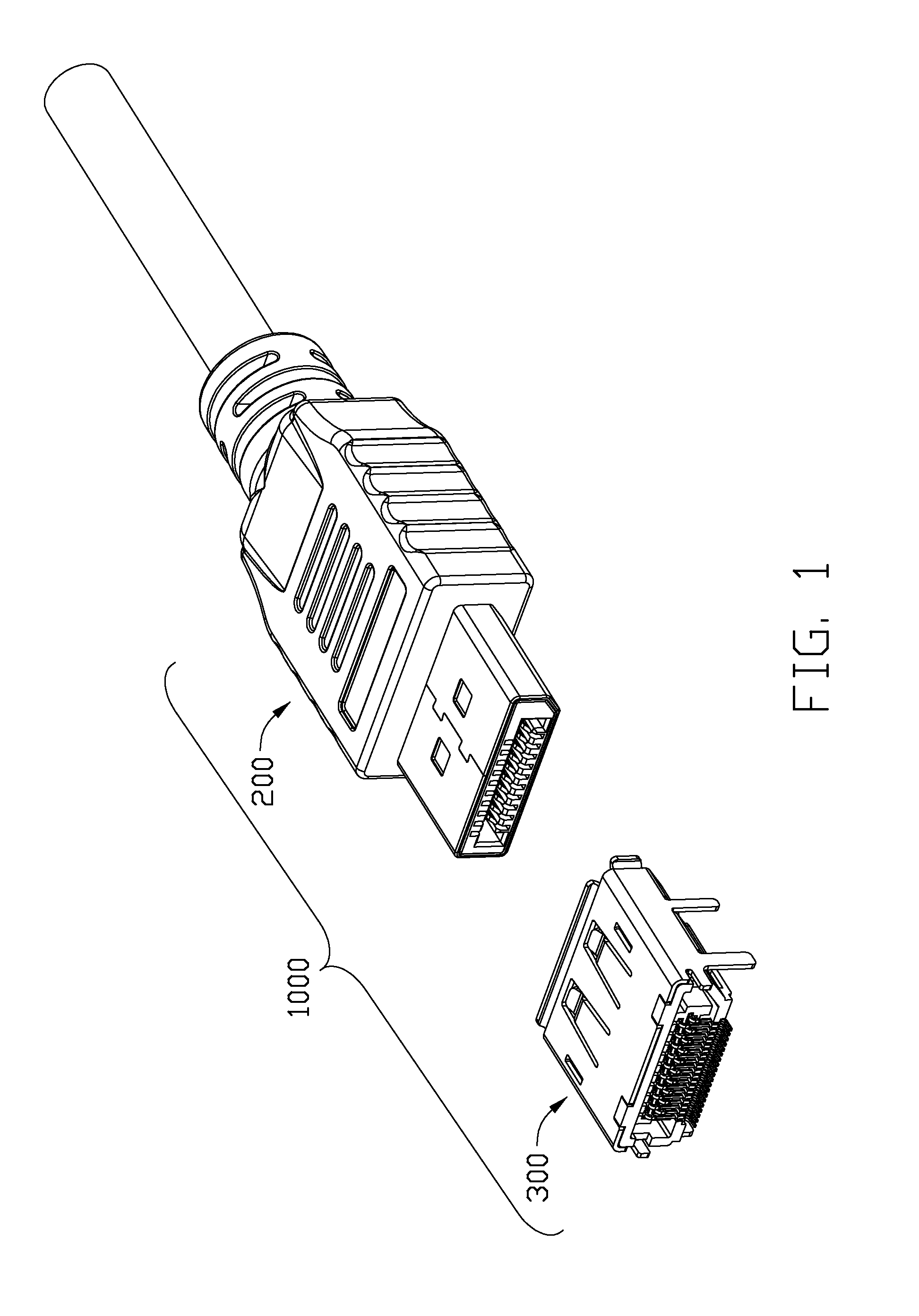

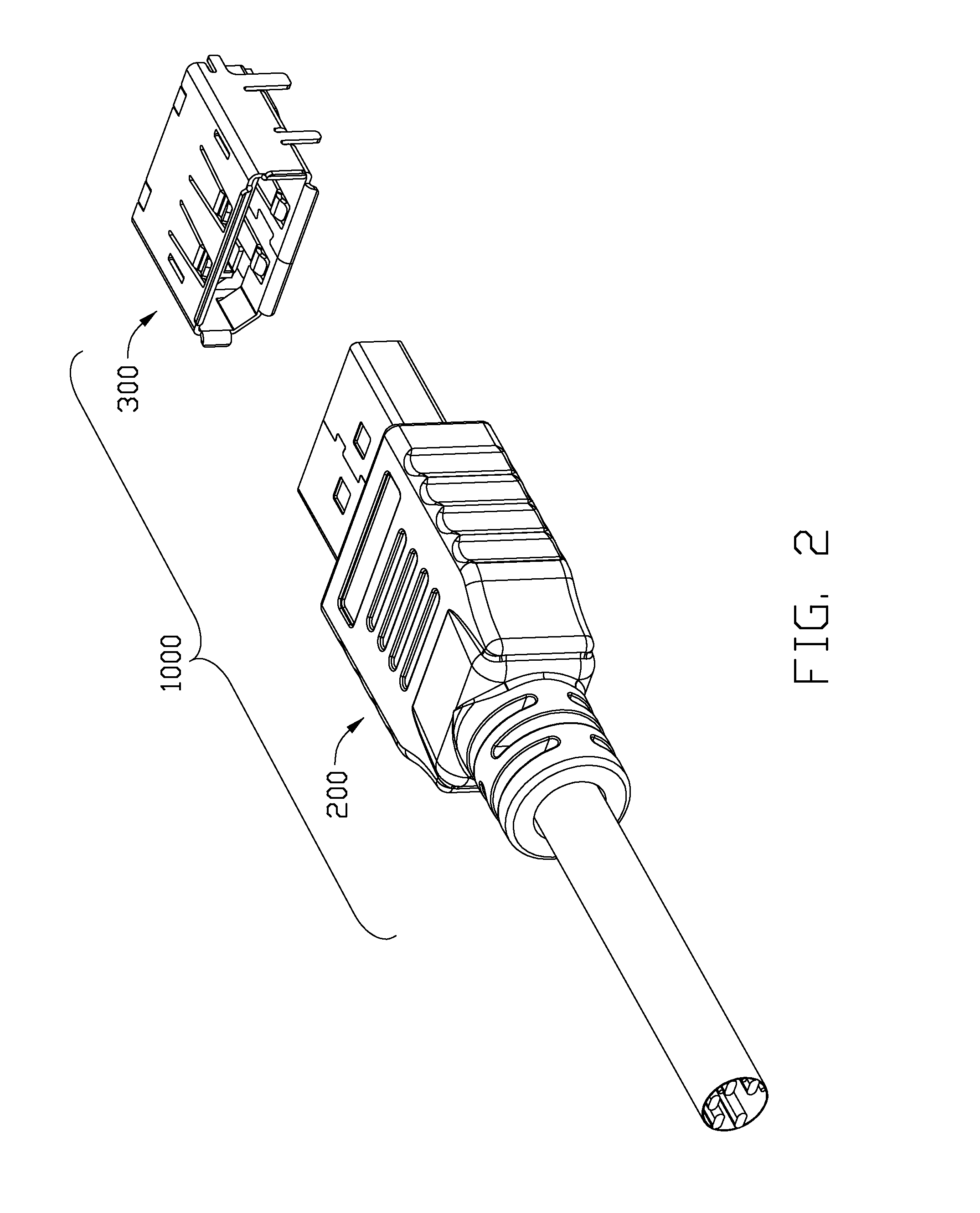

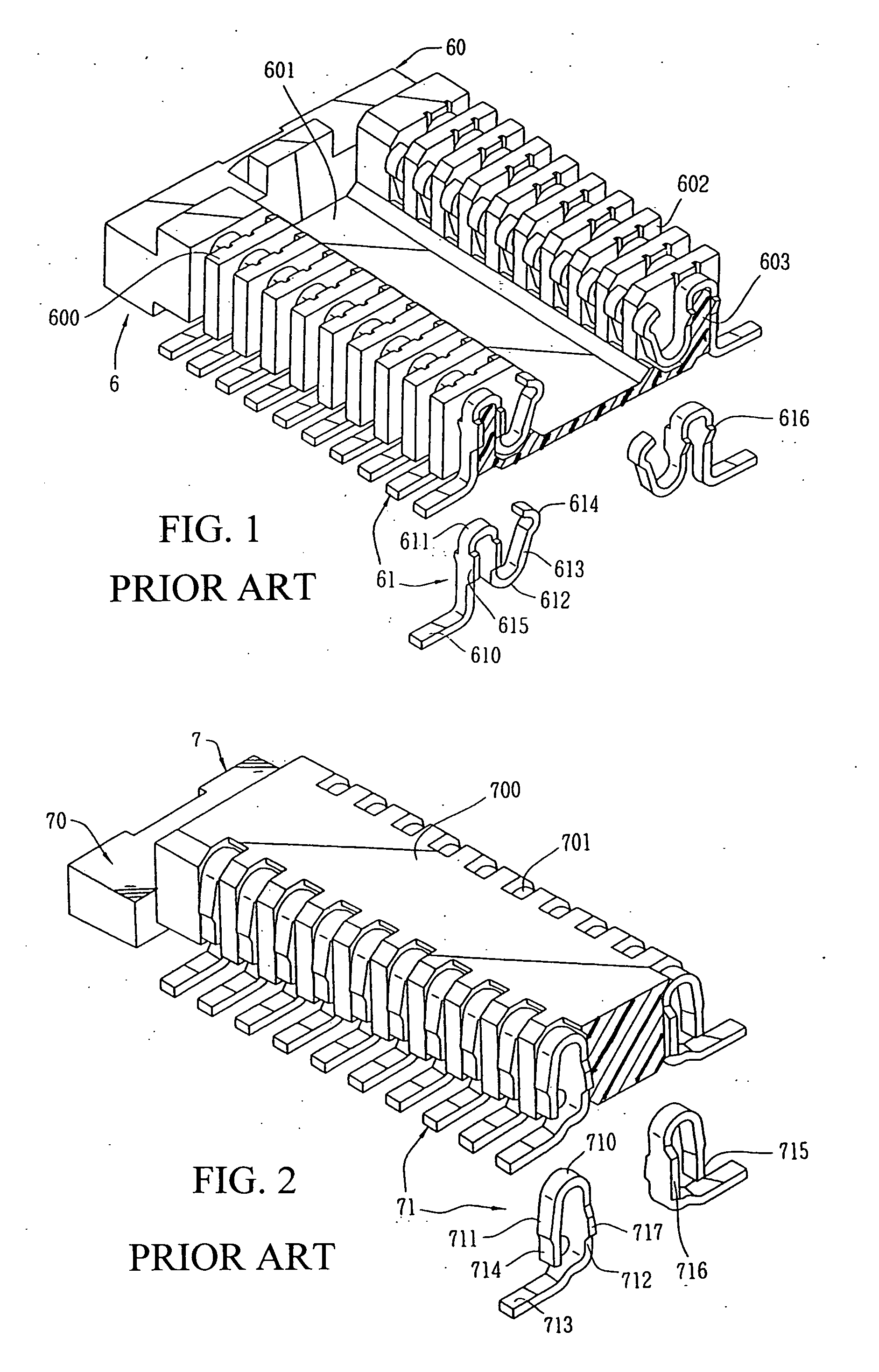

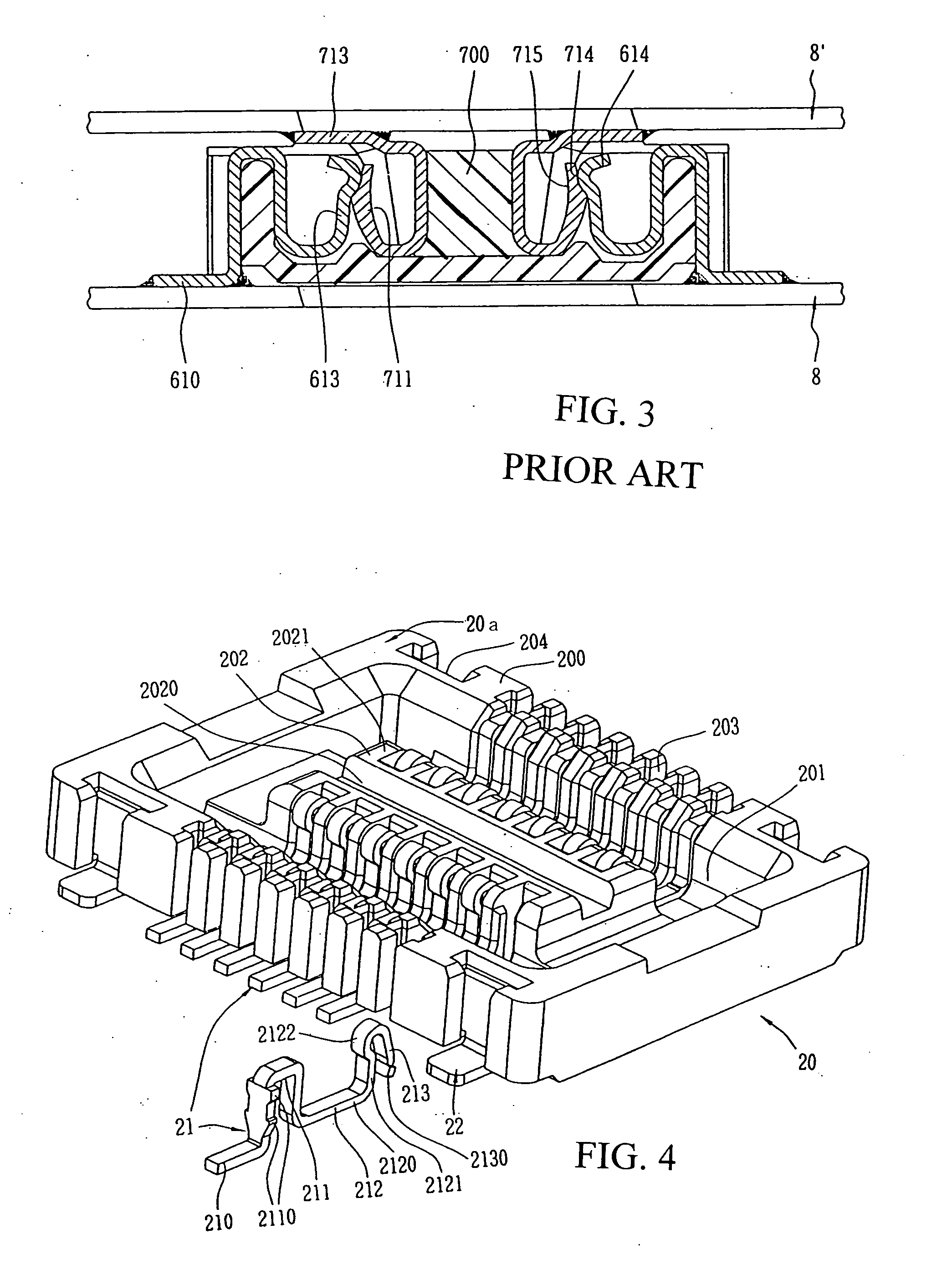

Contacts of board-to-board connector

InactiveUS20060178022A1Reliable electrical connectionAccurate contactCoupling contact membersTwo-part coupling devicesElectrical connectionBoard-to-board connector

An electrical connector assembly includes a socket connector soldered on one circuit board and a plug connector soldered on another circuit board. The socket connector includes an insulating socket base and a plurality of first terminals received in the first terminal-receiving slots of the insulating socket base. Each first terminal successively extends to form a first terminal lead, a first inverted U-shaped portion, a base U-shaped portion and an auxiliary-clamping portion. One leg of the base U-shaped portion includes a first elastic-contact portion. The plug connector includes an insulating plug base and a plurality of second terminals received in the second terminal-receiving slots of the insulating plug base. Each second terminal successively extends to form a second terminal lead and a second inverted U-shaped portion having a second elastic-contact portion. The second inverted U-shaped portion of the second terminal is inserted into the base U-shaped portion of the first terminal, and the first elastic-contact portion contacts the second elastic-contact portion when mating. The invention can provide stable mating and electrical connection and is in compliance with recent downsizing trends.

Owner:MOLEX INC

Methods and devices for continuous suture passing

InactiveUS20110087246A1Prevent “ pinching ” and damageIncrease the areaSuture equipmentsSurgical needlesContinuous sutureGeneral surgery

Owner:CETERIX ORTHOPAEDICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com