Patents

Literature

158results about How to "Eliminate warping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

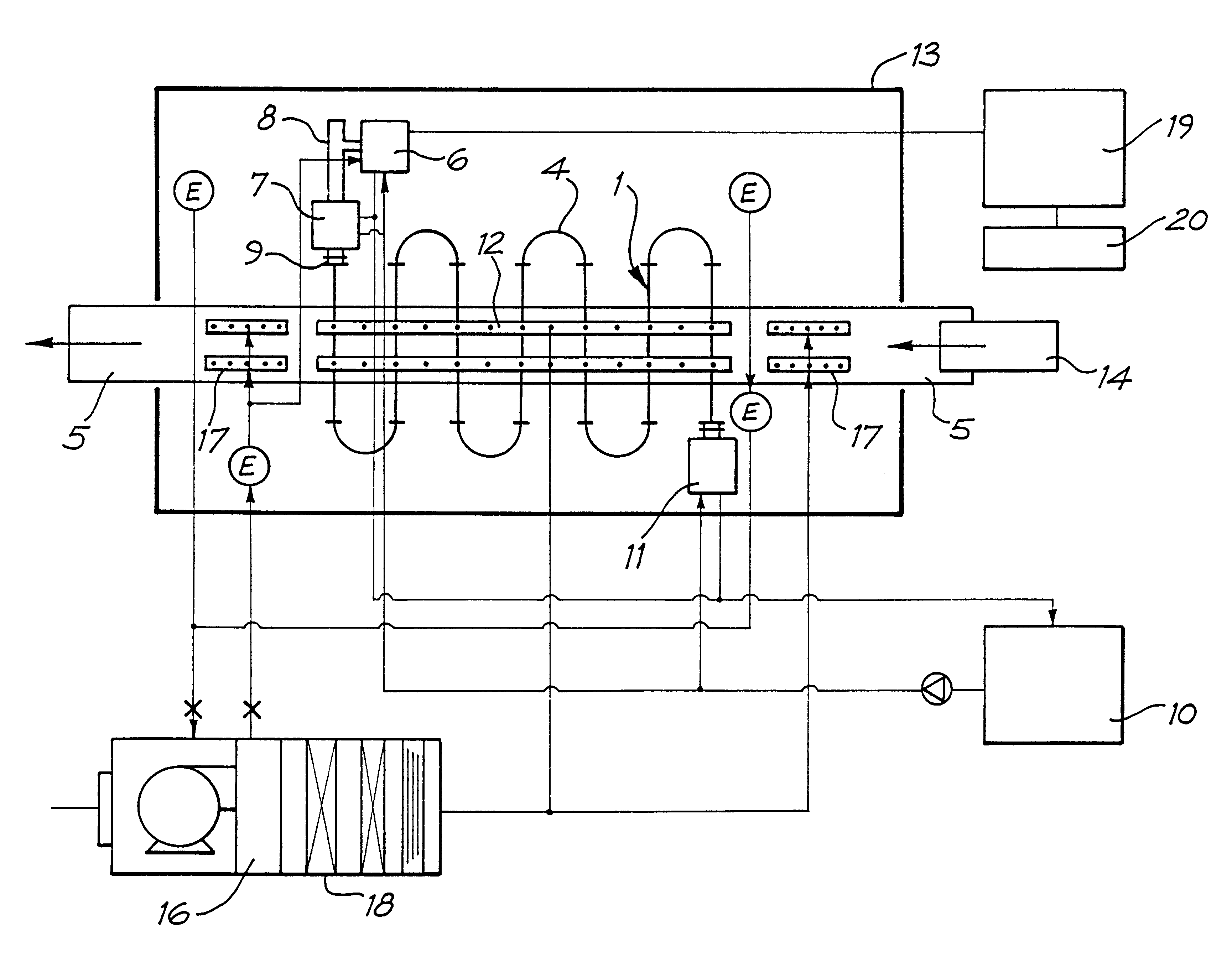

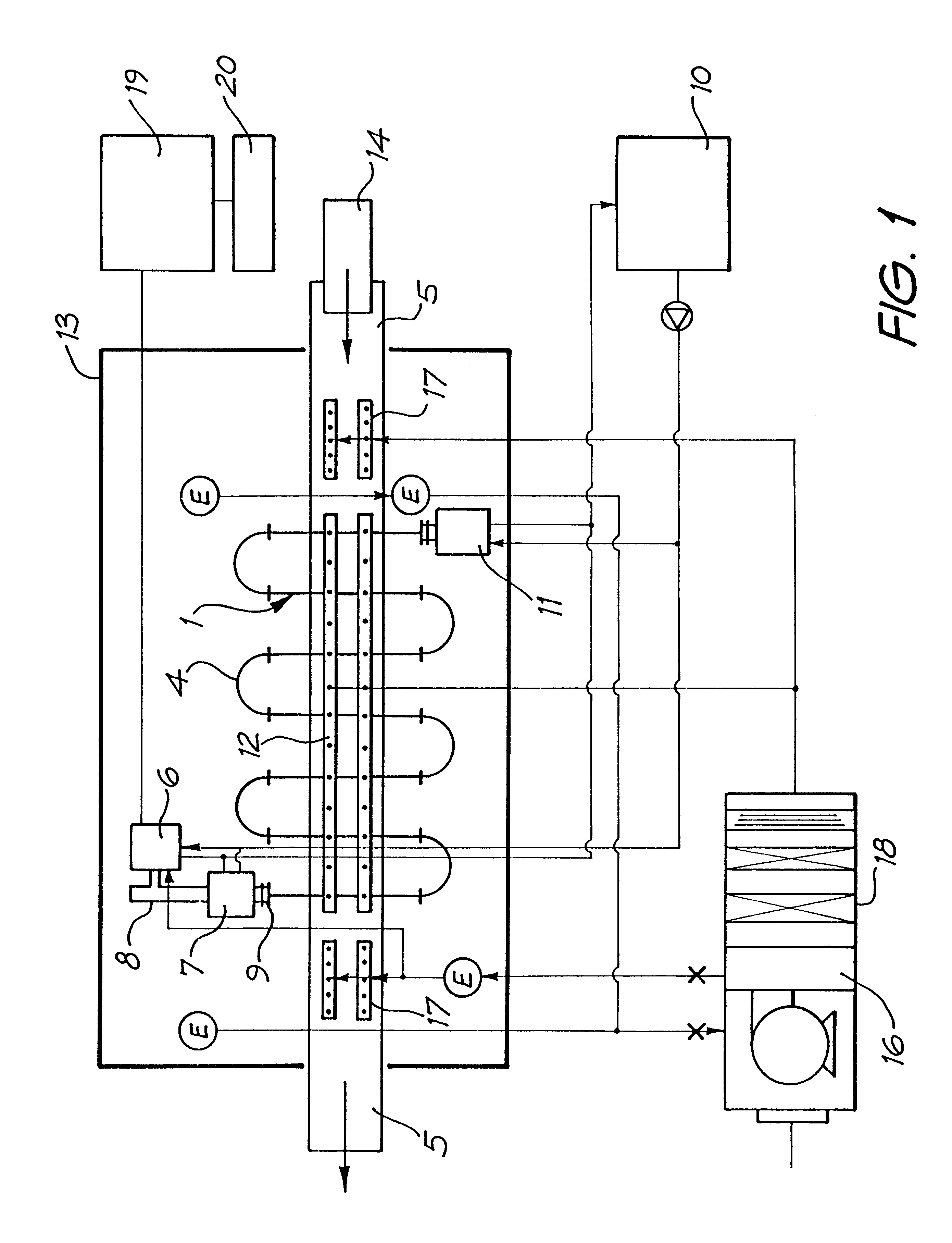

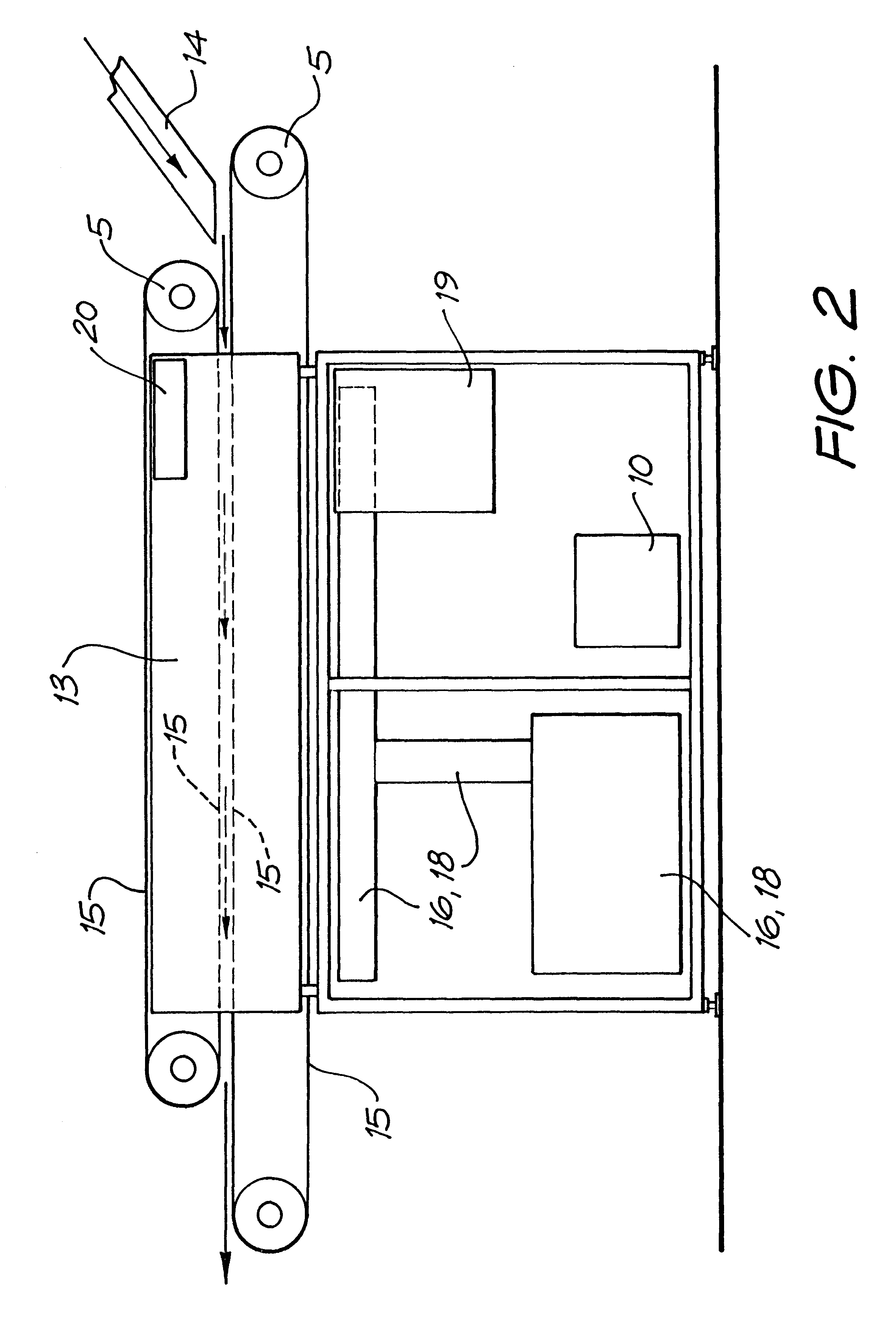

Method and apparatus for microwave processing of planar materials

InactiveUS6546646B1Remove moistureEliminate warpingMilk preparationDough treatmentVaporizationEngineering

A process and apparatus for removing moisture from a material, without spoiling the processed product, through the implementation of microwave irradiation heating, drying, dehydration, curing, disinfection, pasteurization, sterilization or vaporization or any combination thereof. The process and apparatus provide for a controlled processing of planar material, a combination of materials organic or inorganic, in natural or processed form, in sheet leaf, granular, prepared or transportable planar form.

Owner:SUSTAINABLE WORLD TECH

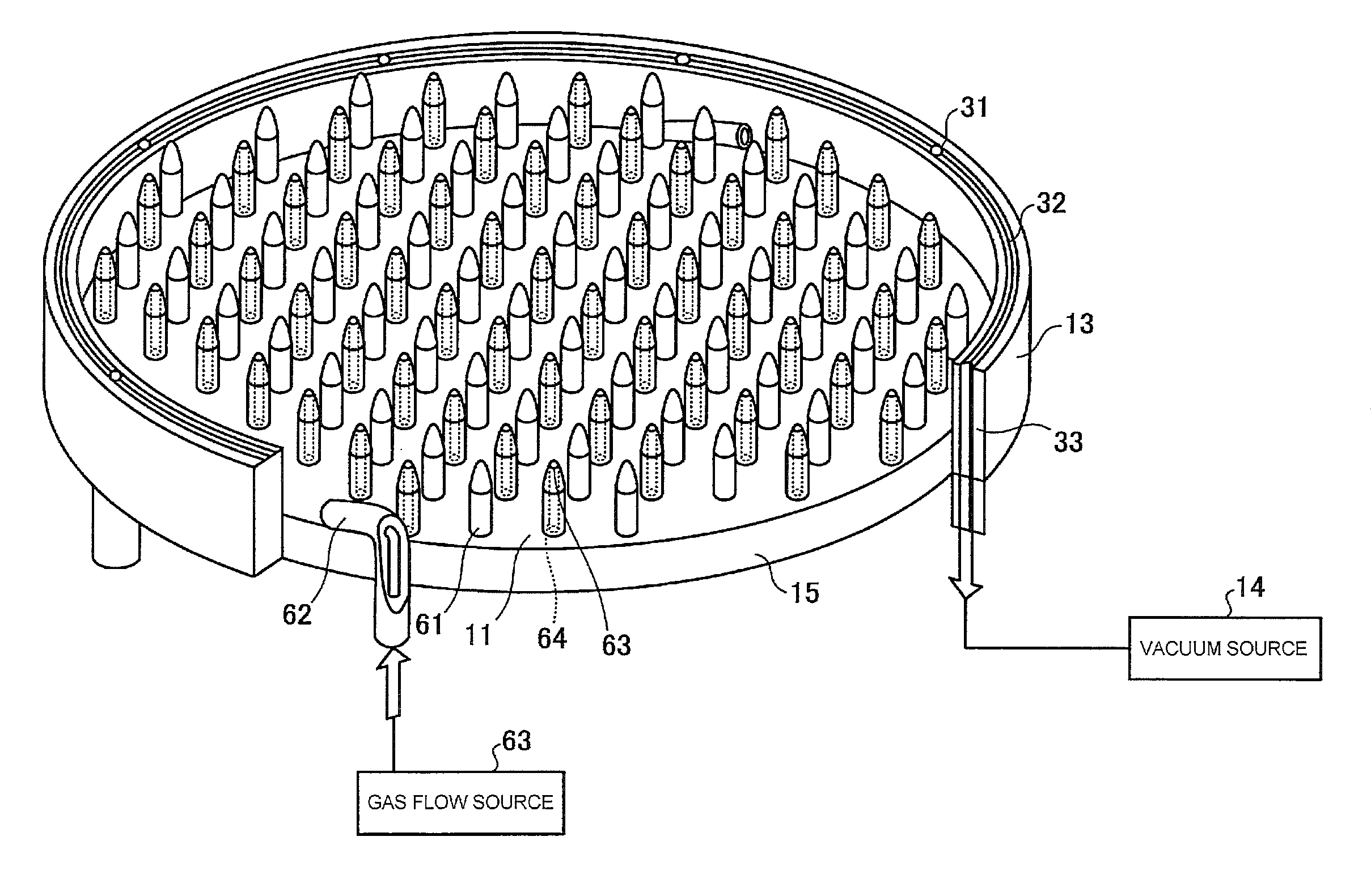

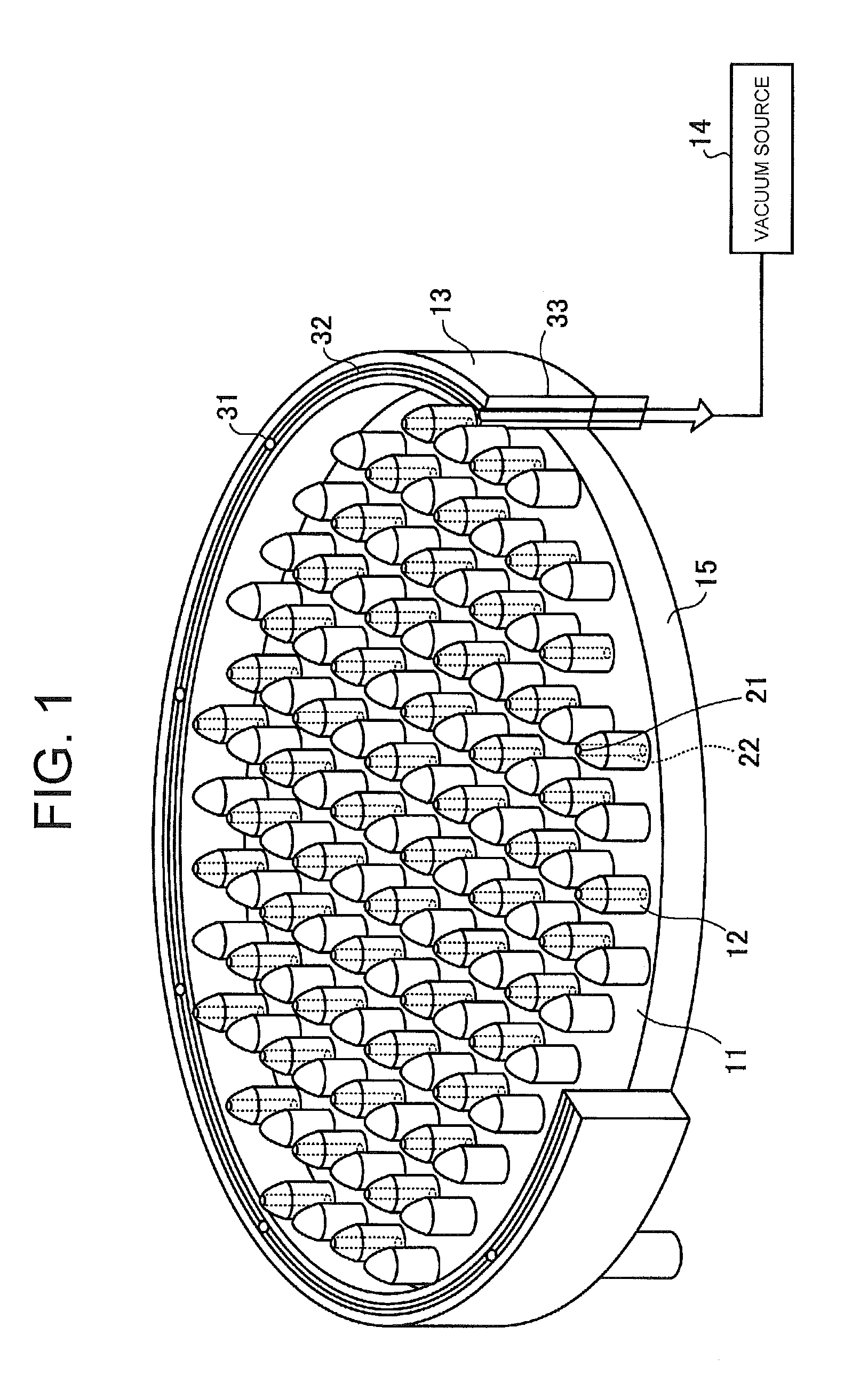

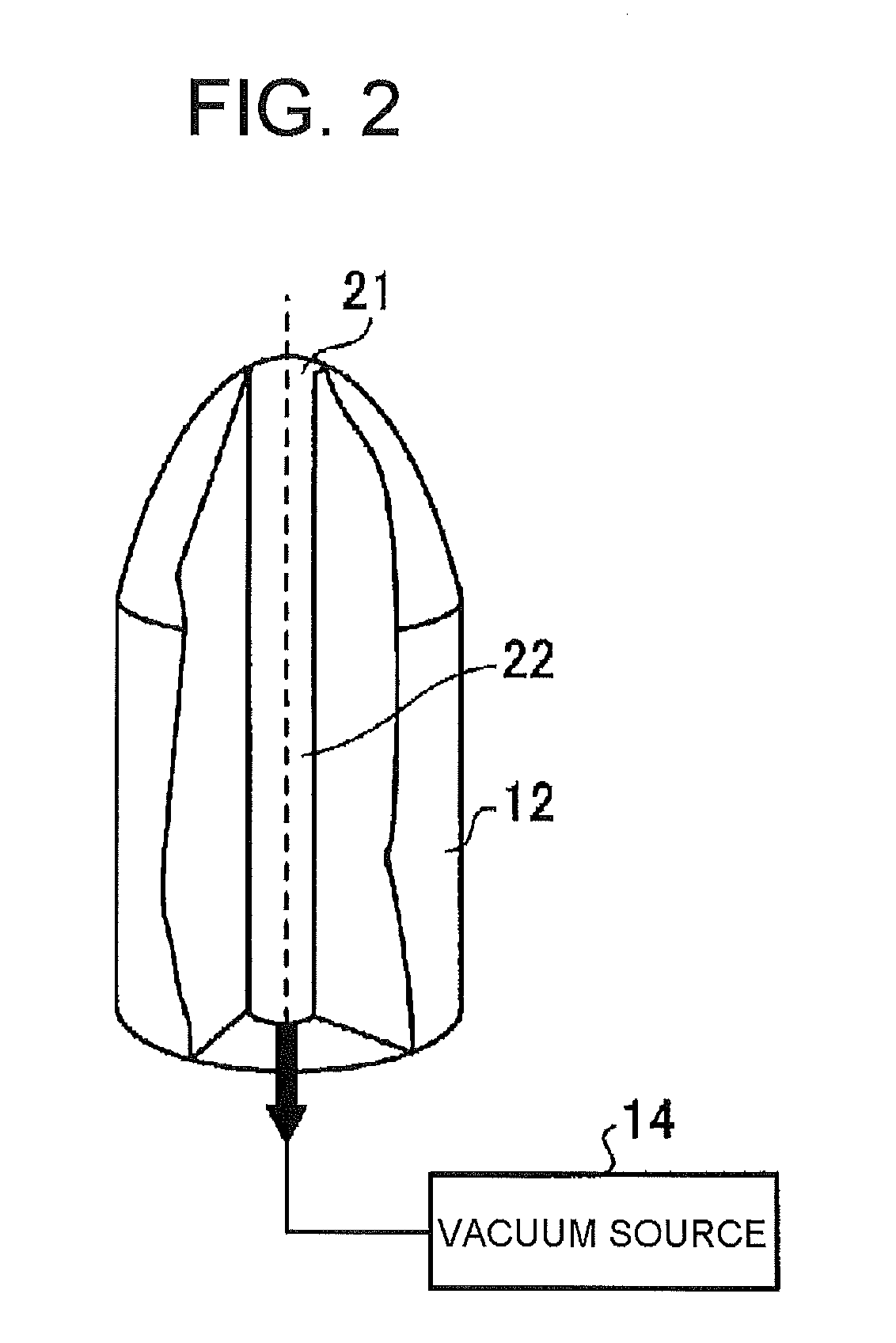

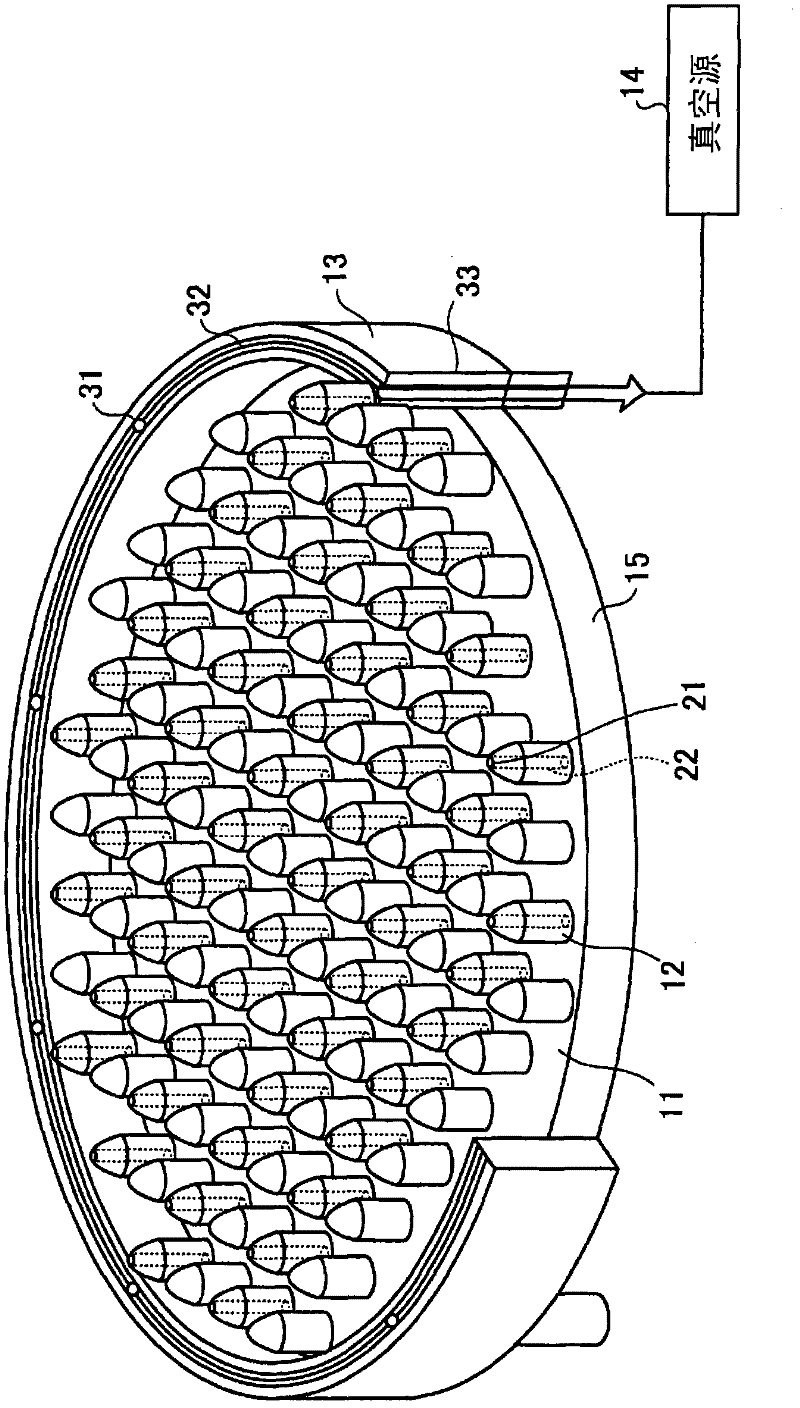

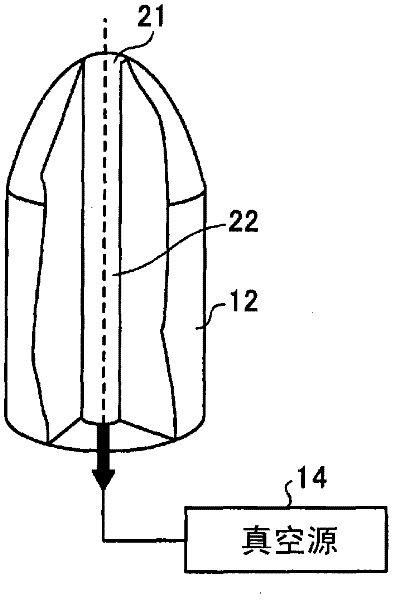

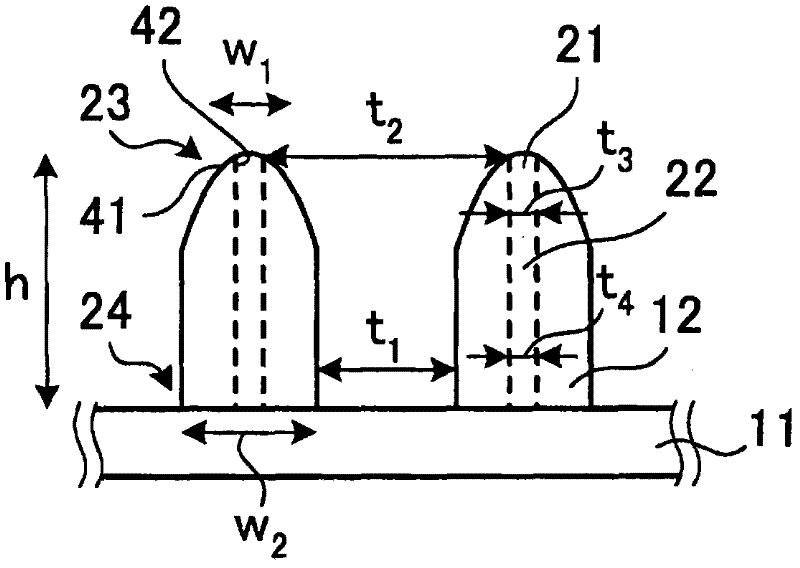

Chucking device and chucking method

InactiveUS20120139192A1Eliminate warpingImprove flatnessSleeve/socket jointsSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A chucking device is disclosed. The chucking device includes plural protruding portions that support the central portion of a semiconductor substrate and that are provided on a base portion. The chucking device also includes a cylindrical peripheral portion that supports the outer peripheral portion of the semiconductor substrate, plural suction holes that chuck the semiconductor substrate, and a vacuum source that vacuum draws the plural suction holes at differing timings. A plurality of mutually independent vacuum drawable suction holes are provided in at least one portion of the protruding portions.

Owner:FUJI ELECTRIC CO LTD

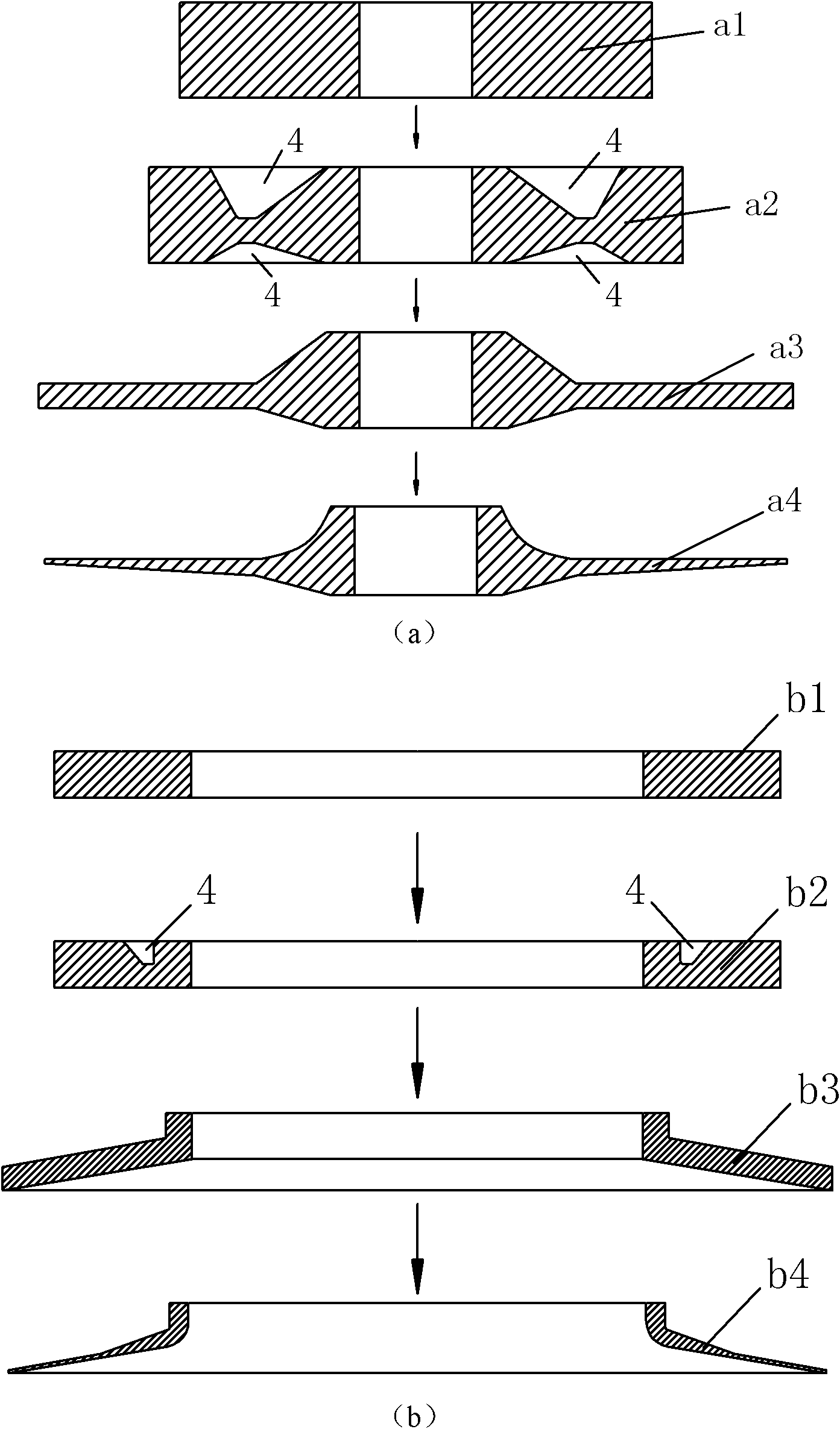

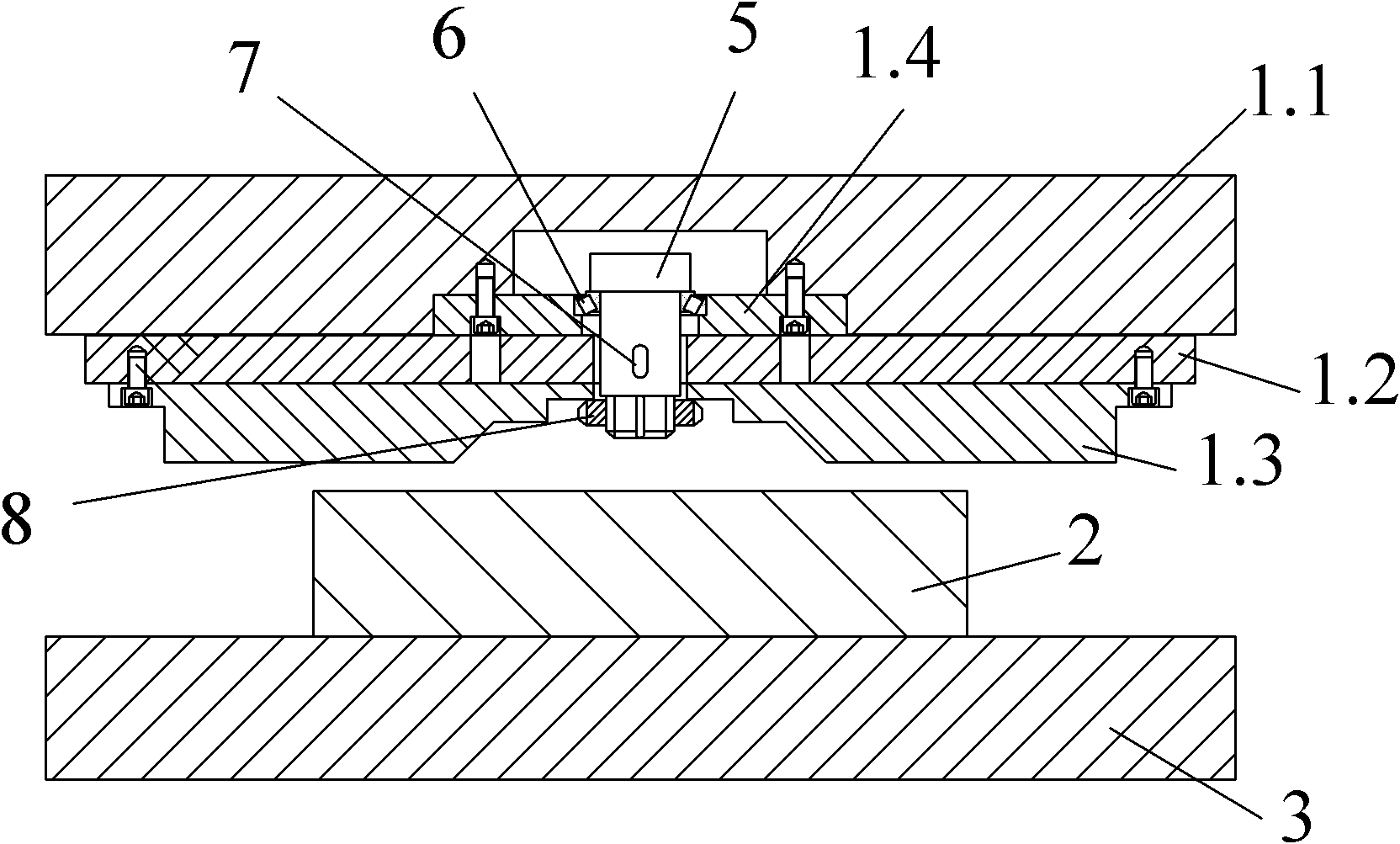

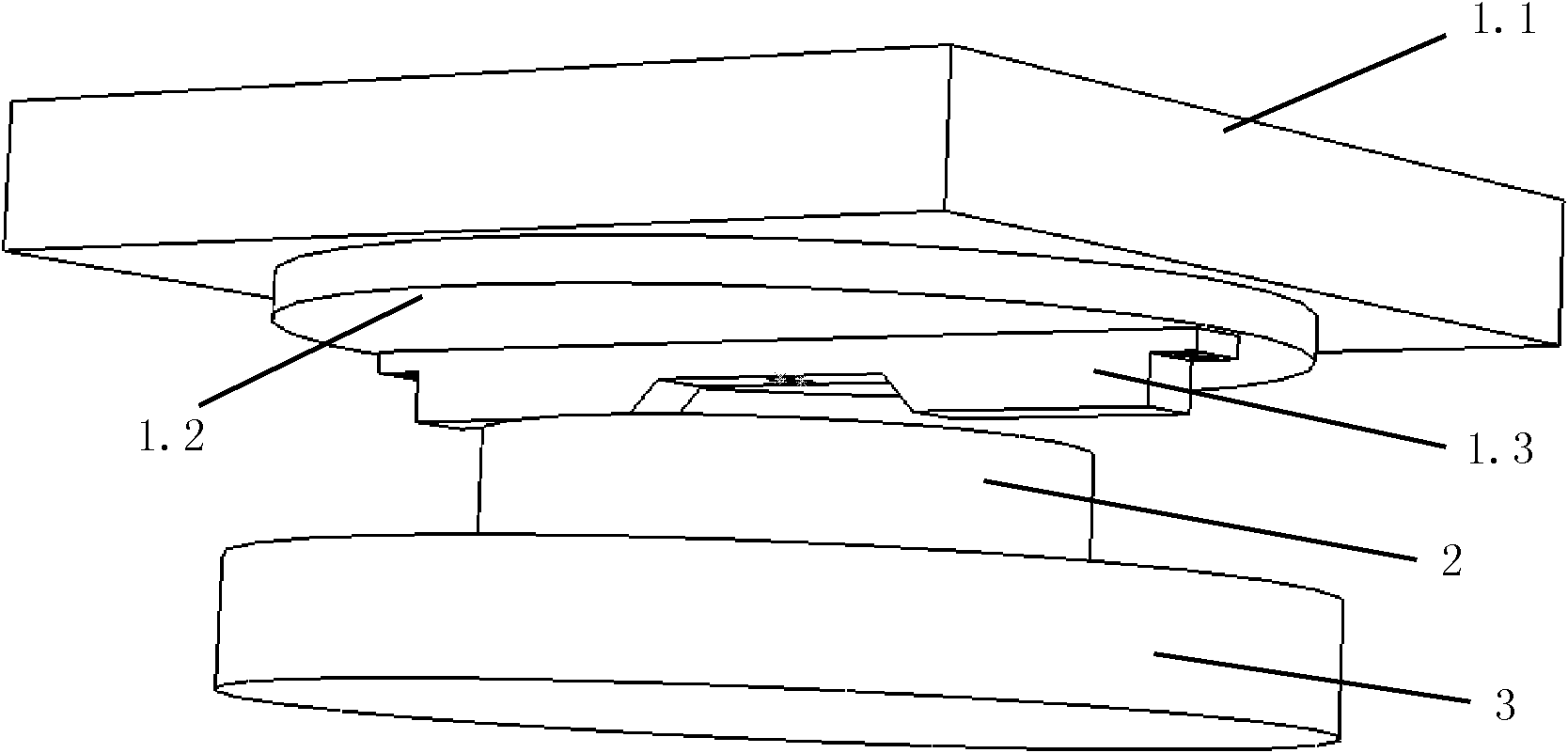

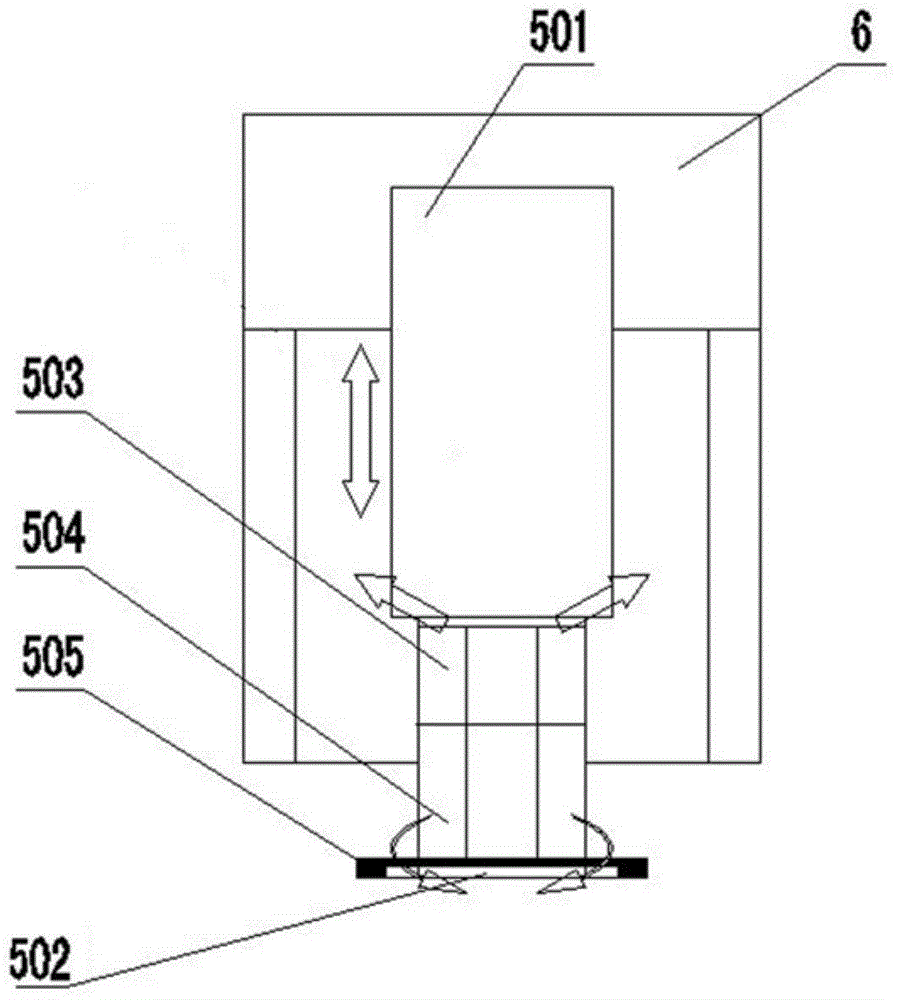

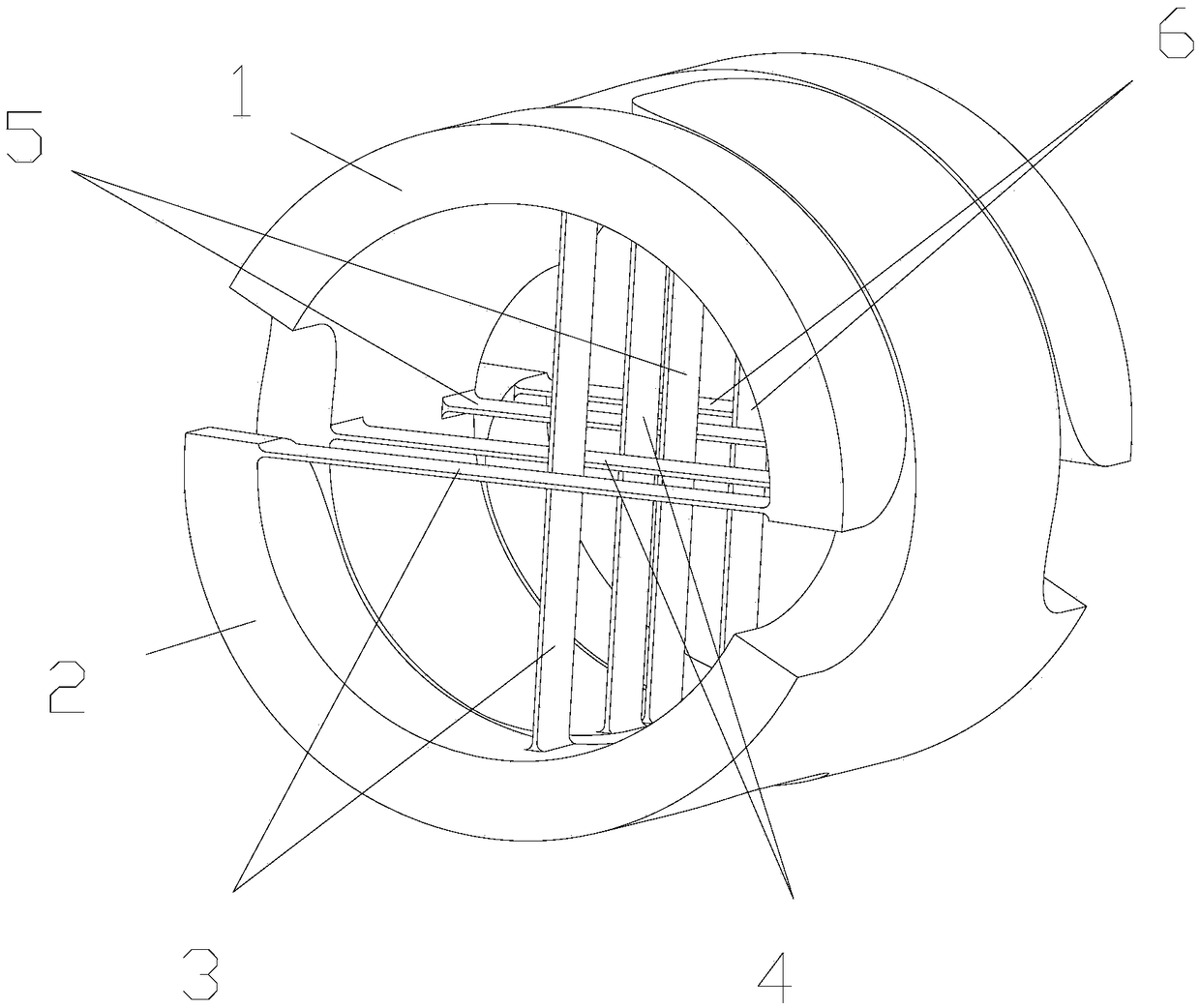

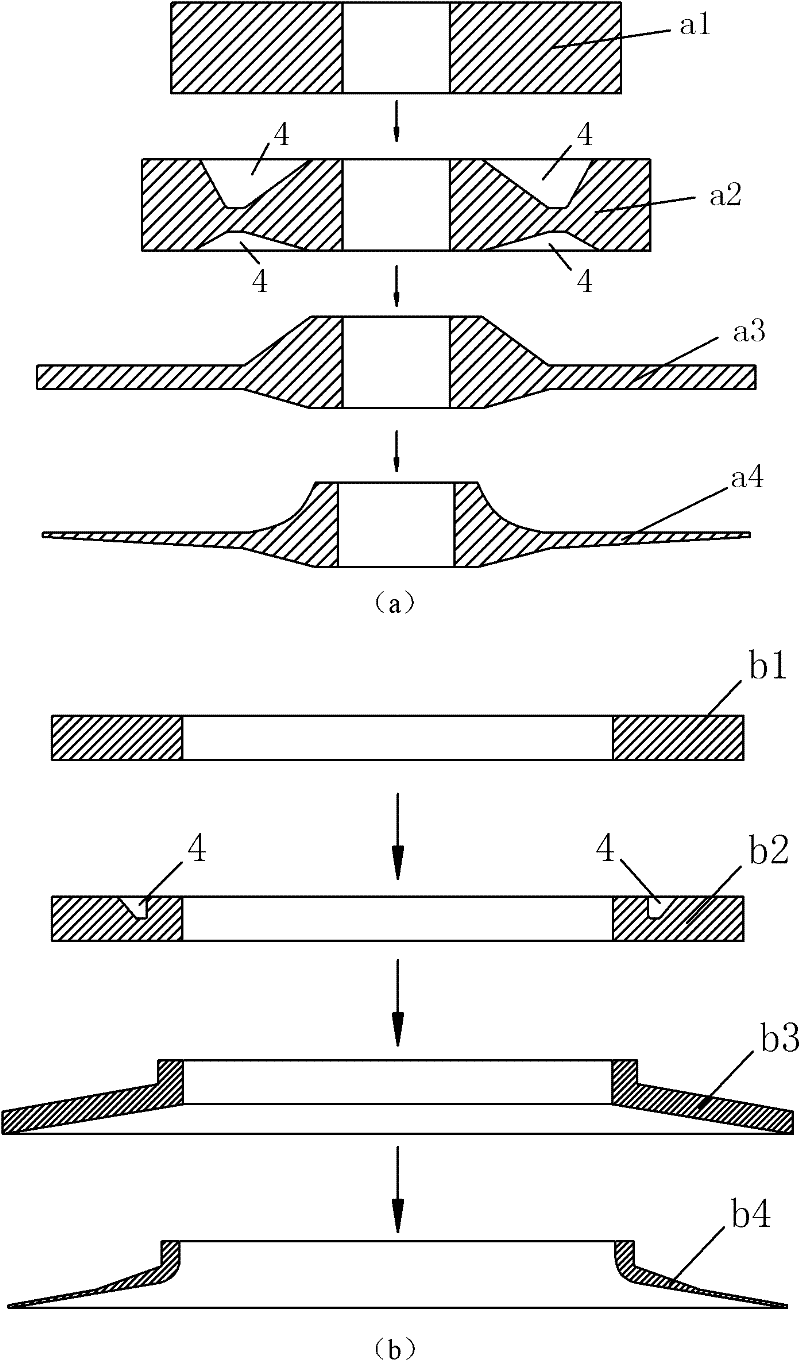

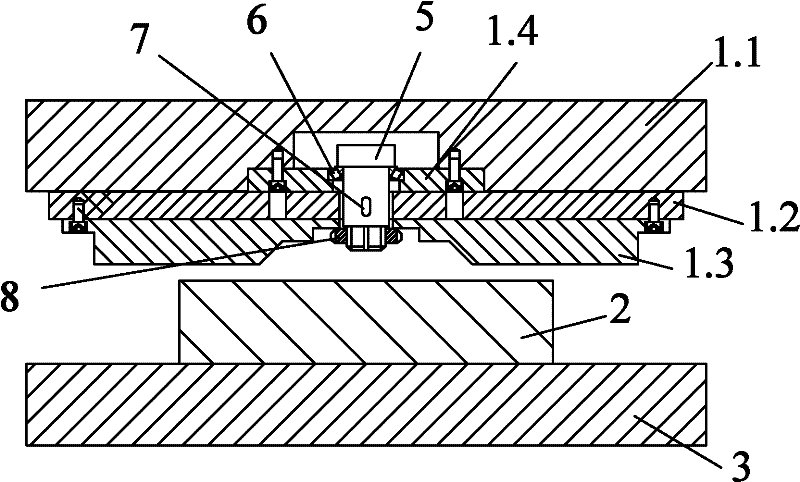

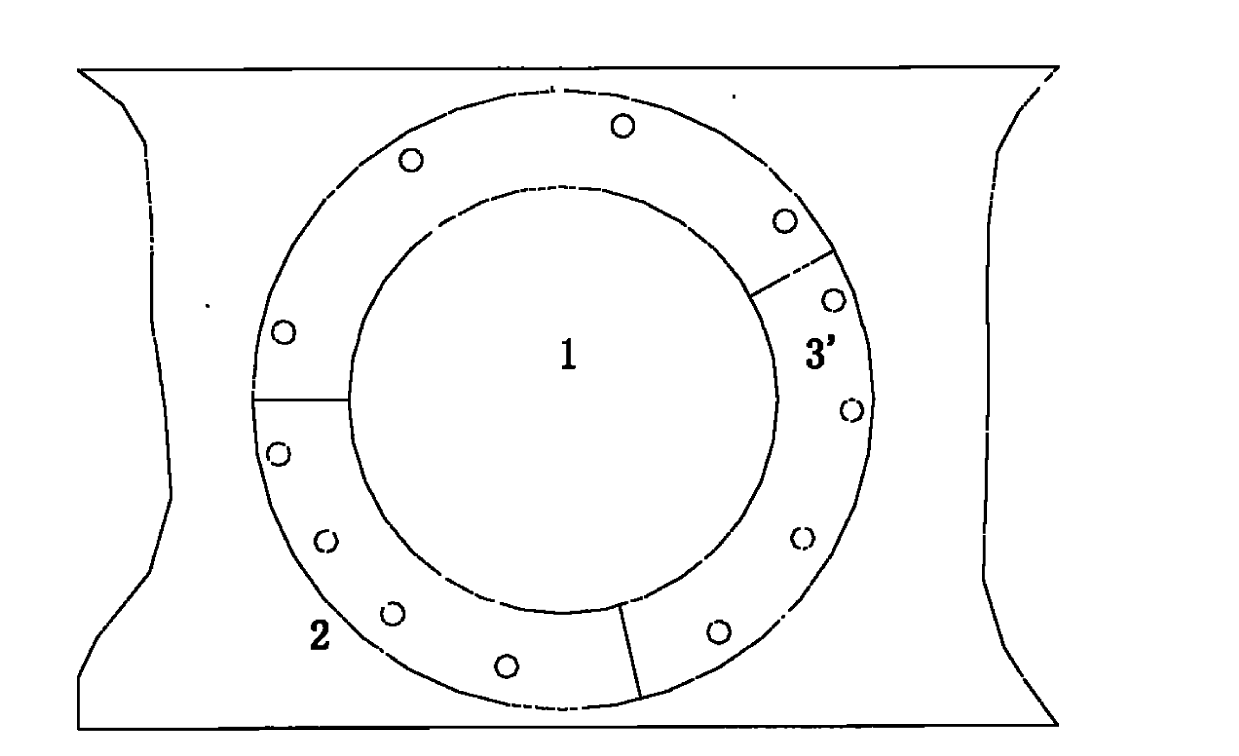

Rotary forging method for large disc type work piece and forging device

InactiveCN101862807ALow manufacturing costReduce the amount of machiningForging/hammering/pressing machinesWheelsForgingMaterials science

The invention provides a rotary forging method for large disc type work pieces and a forging device. The method comprises preparing a forging die, preparing blanks, pre-forging a shunt slot, positioning the blanks and carrying out rotary forging in steps. Based on the method, the invention also provides a forging device which can realize relative rotation of an upper forging die and a lower die, and the local forming process for the disc type work pieces can be carried out through rotary forging of the upper forging die and the lower die. In order to control metal flow in the forging process, the procedure of pre-forging the shunt slot is added prior to the rotary forging. Moreover, the upper forging die with a special structure is adopted to overcome the warpage of the work pieces during rotary forging. The forming method has the advantages of low forming load, simple dies and low processing cost, and can greatly reduce the manufacturing cost of existing large disc type work pieces.

Owner:XI AN JIAOTONG UNIV +1

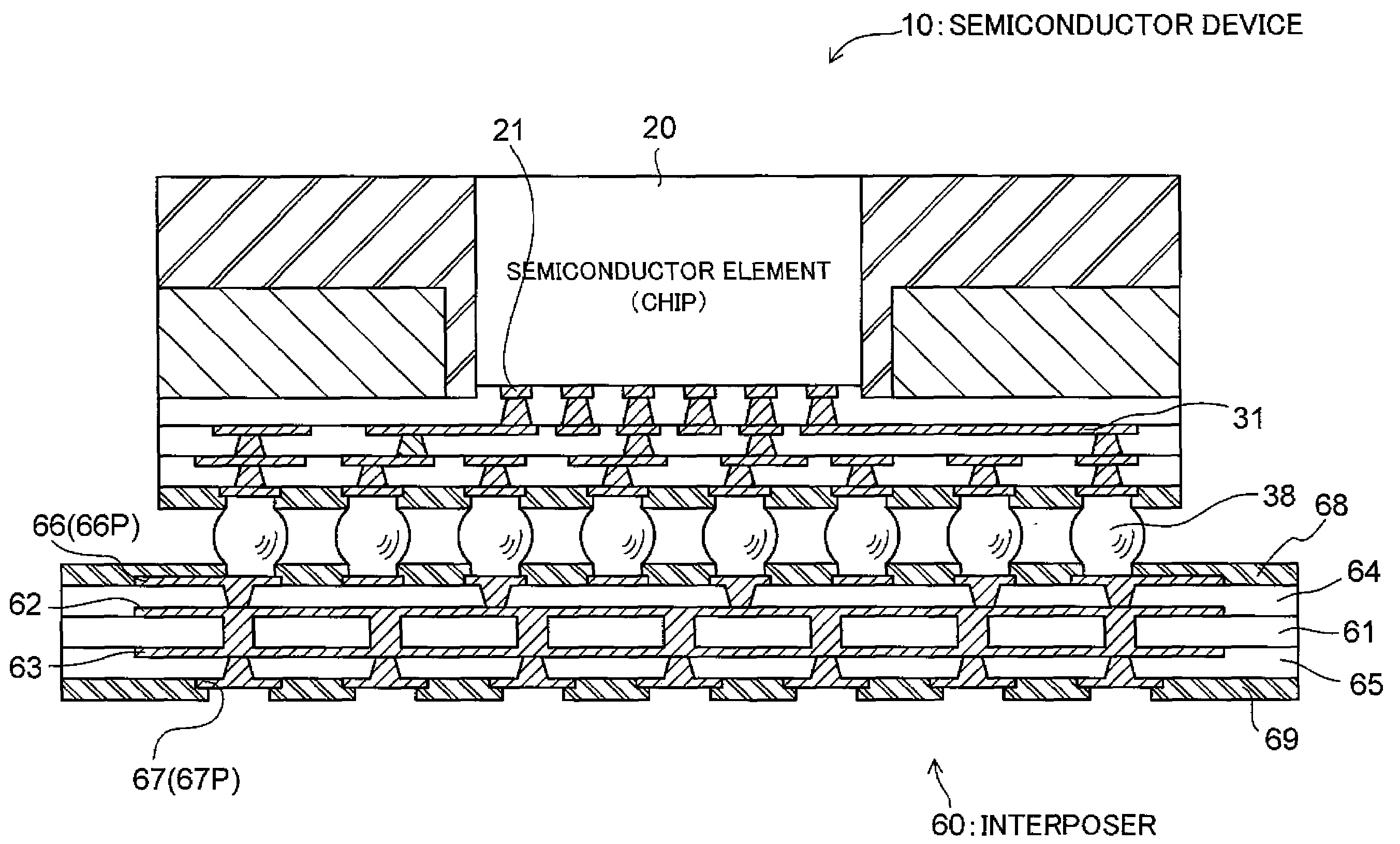

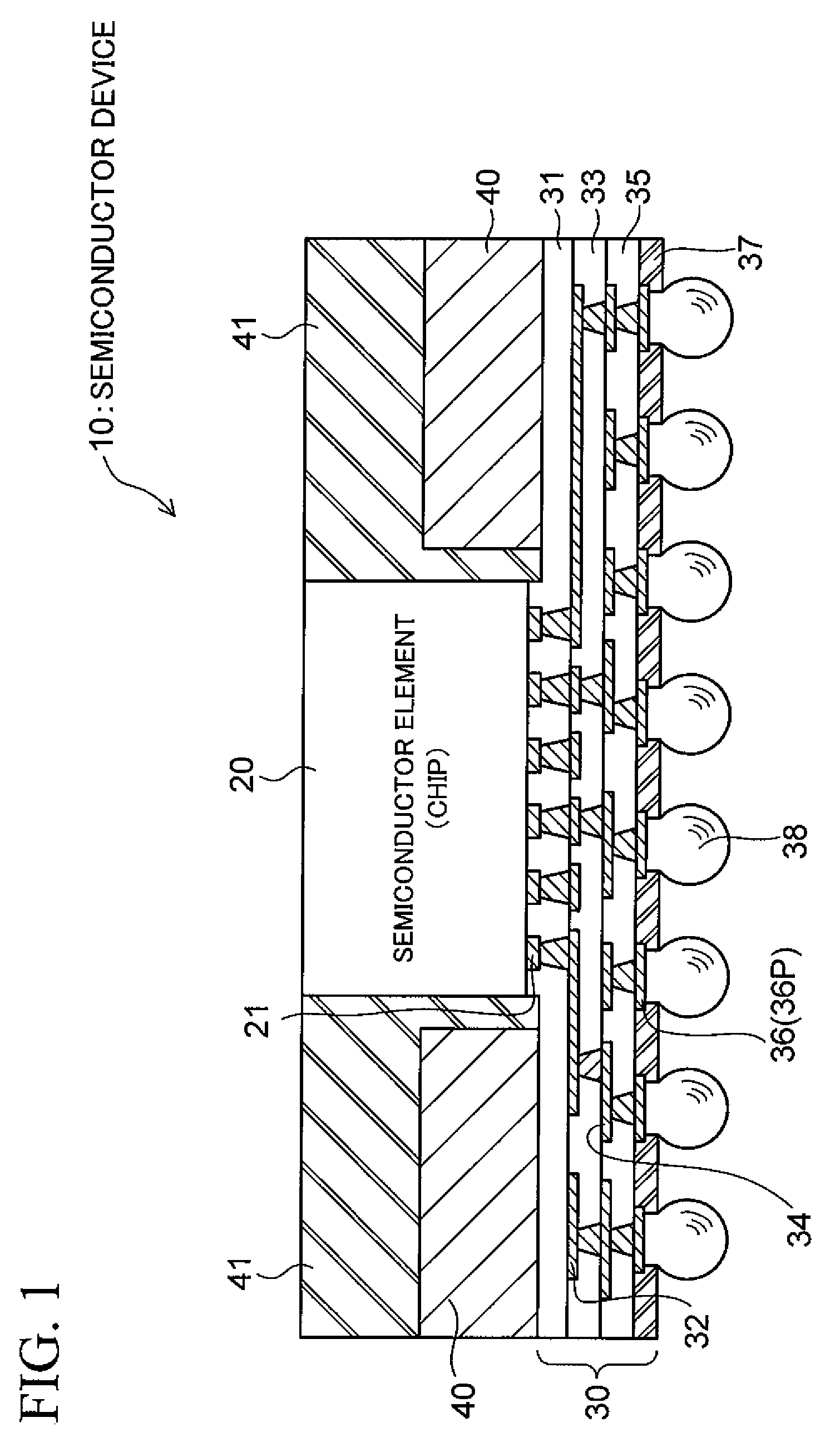

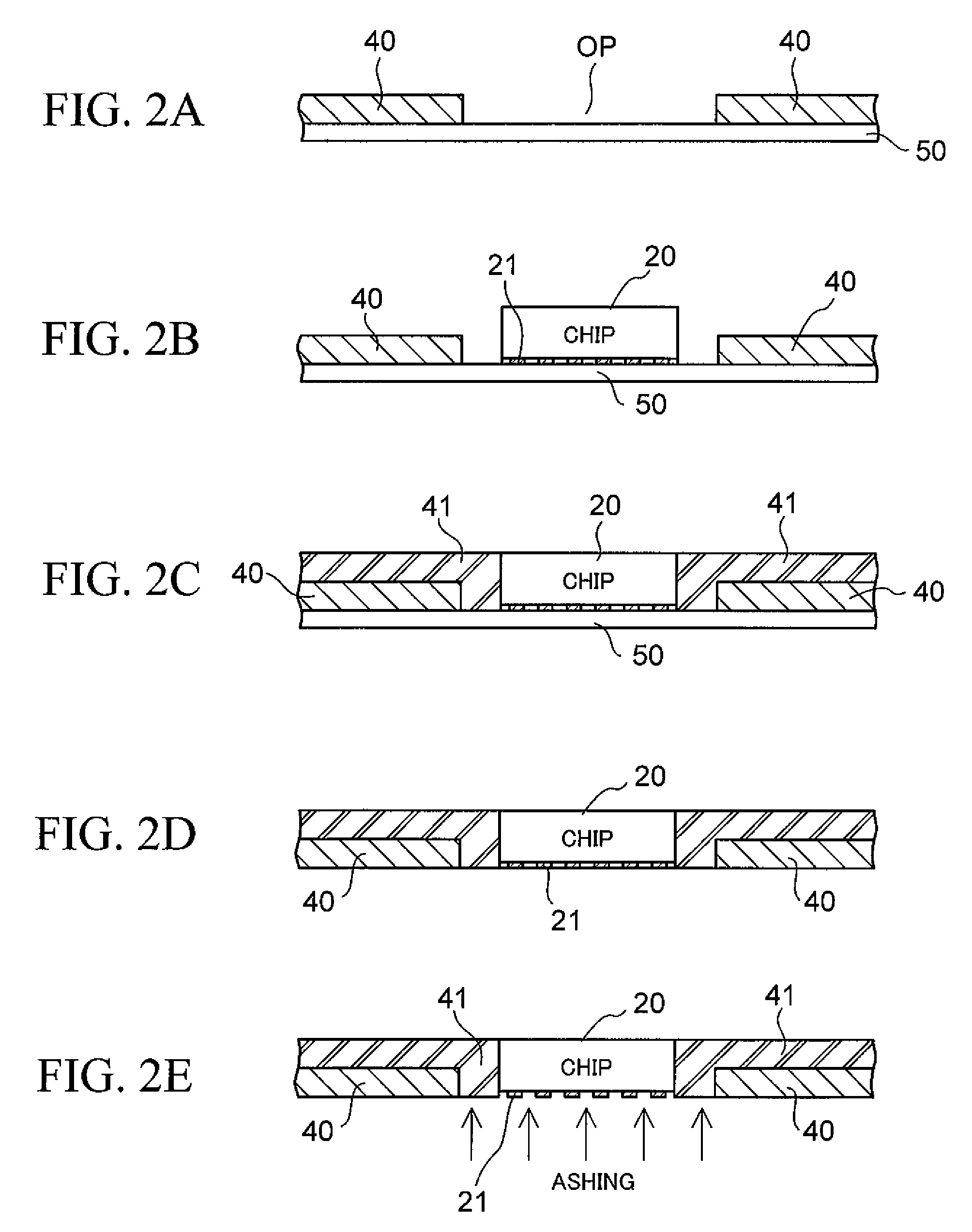

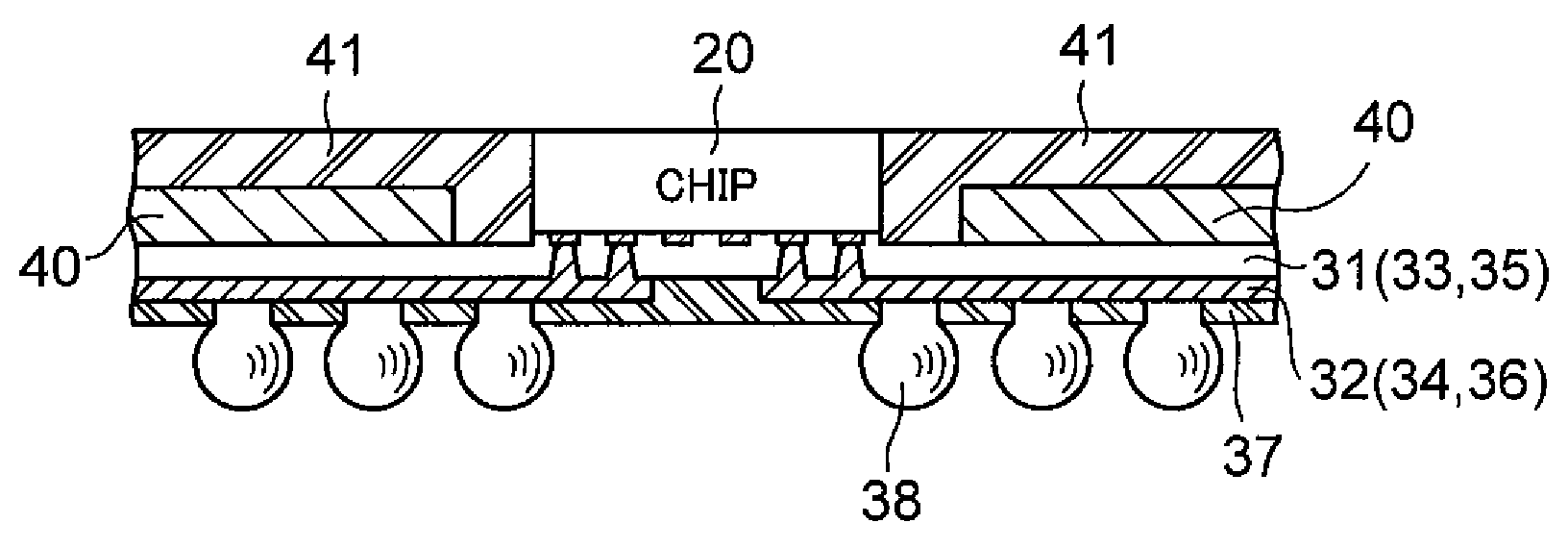

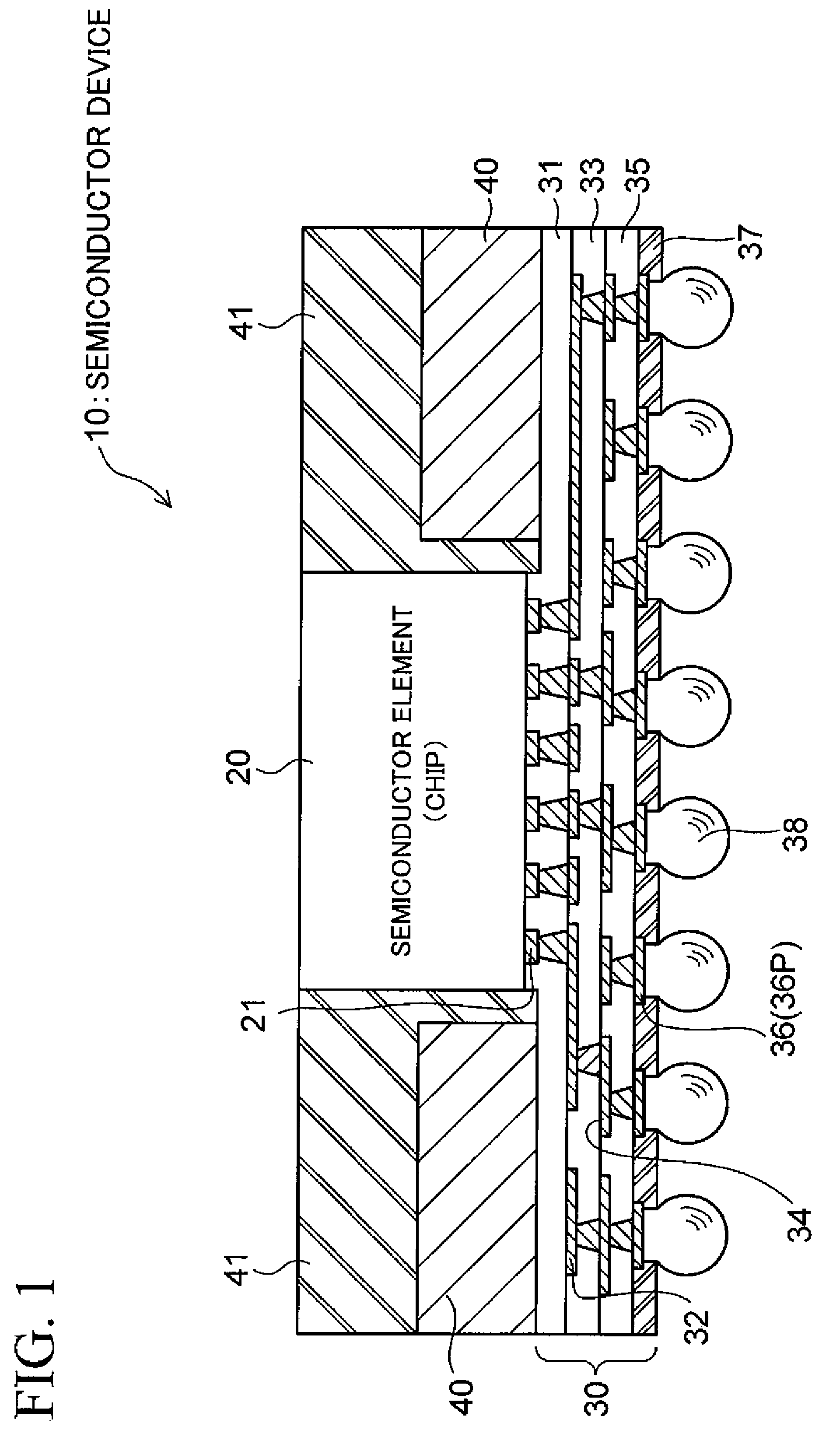

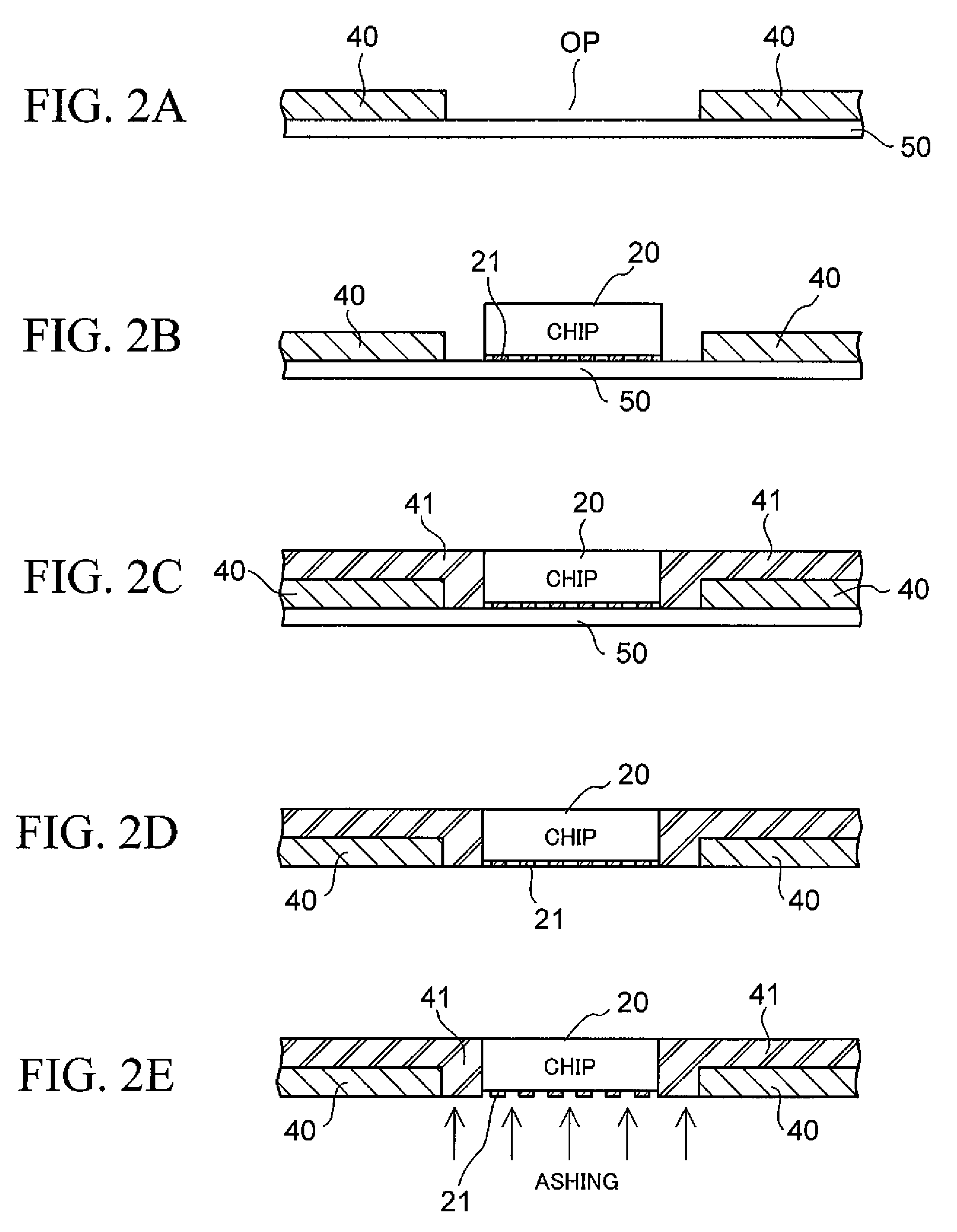

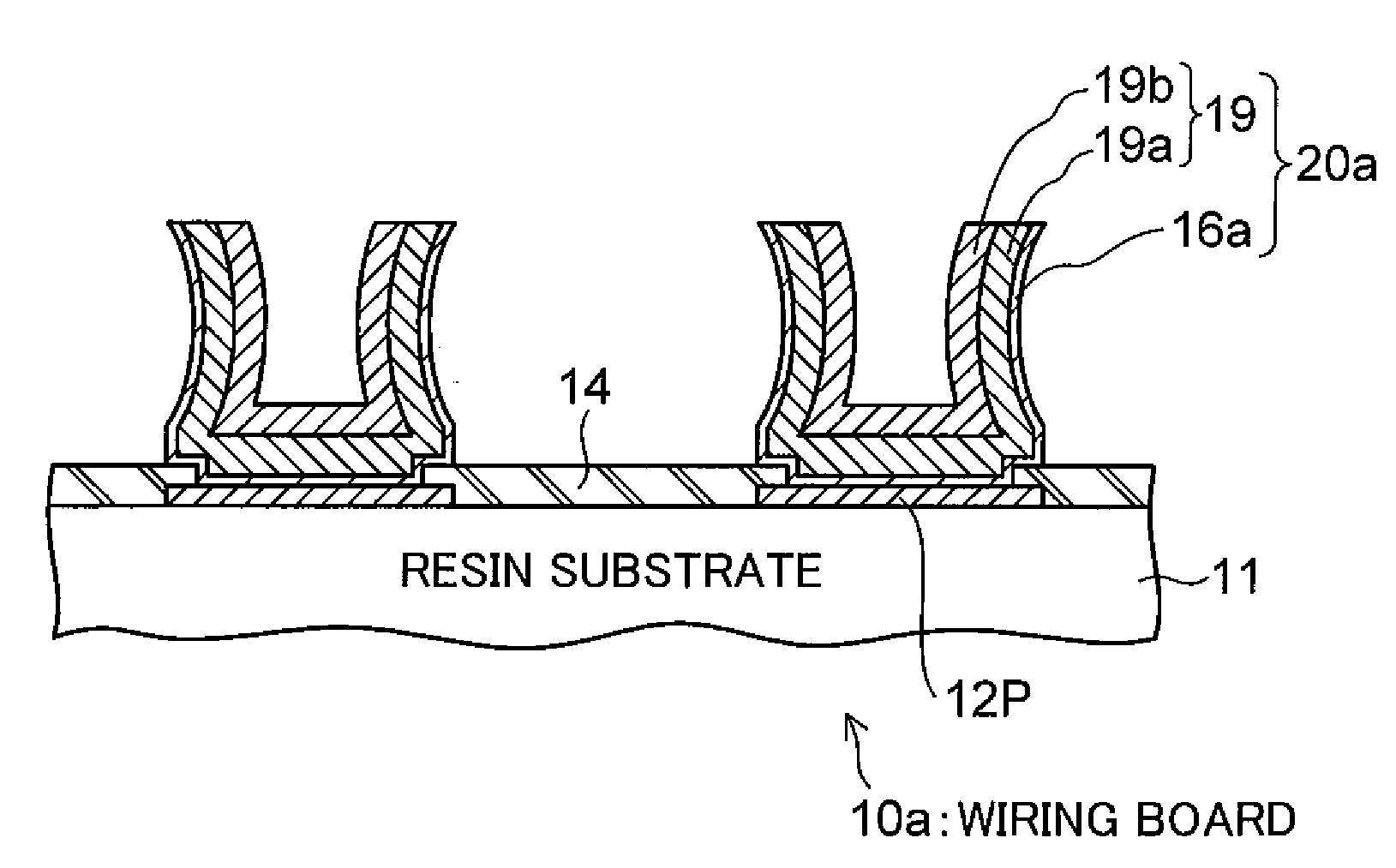

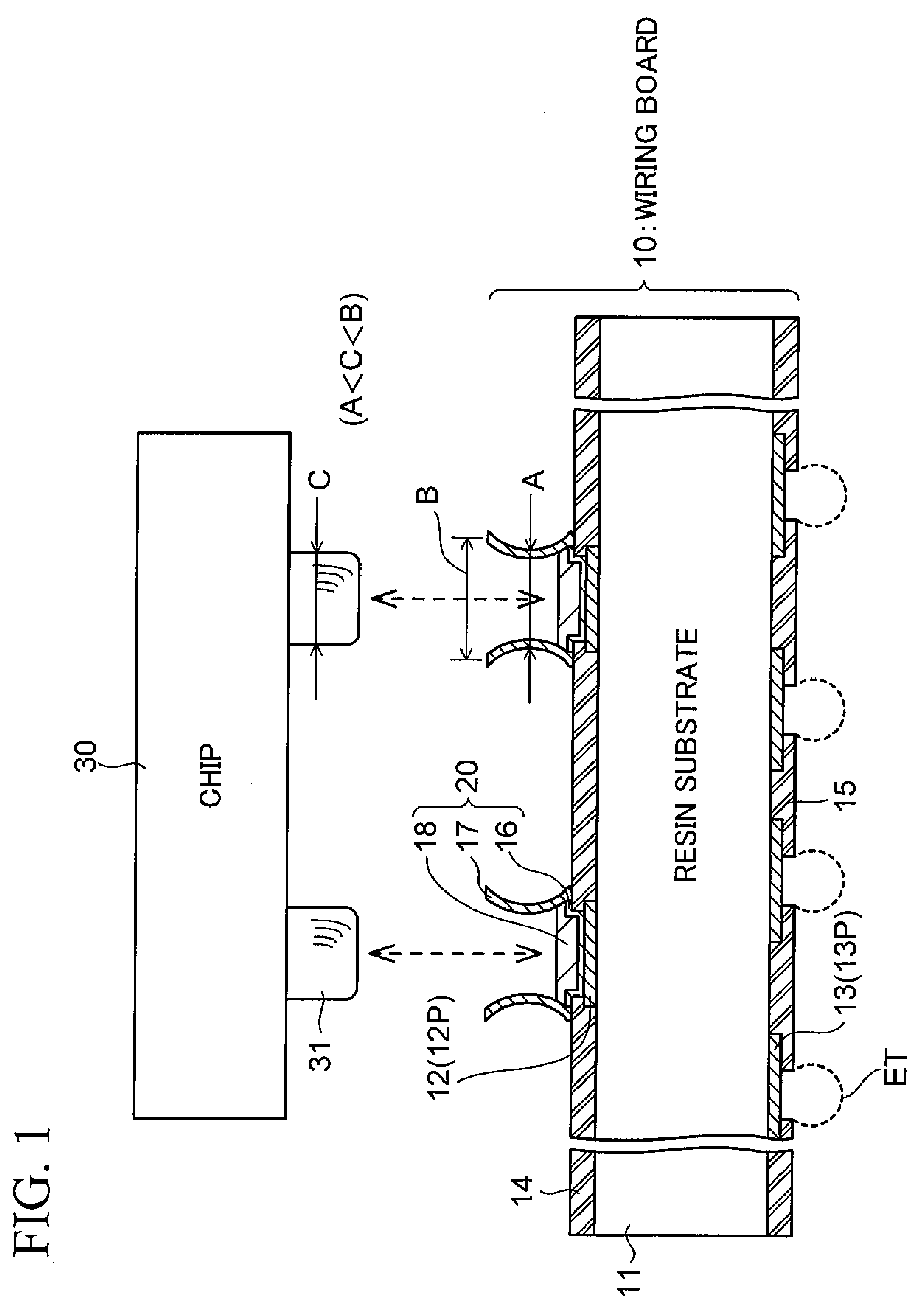

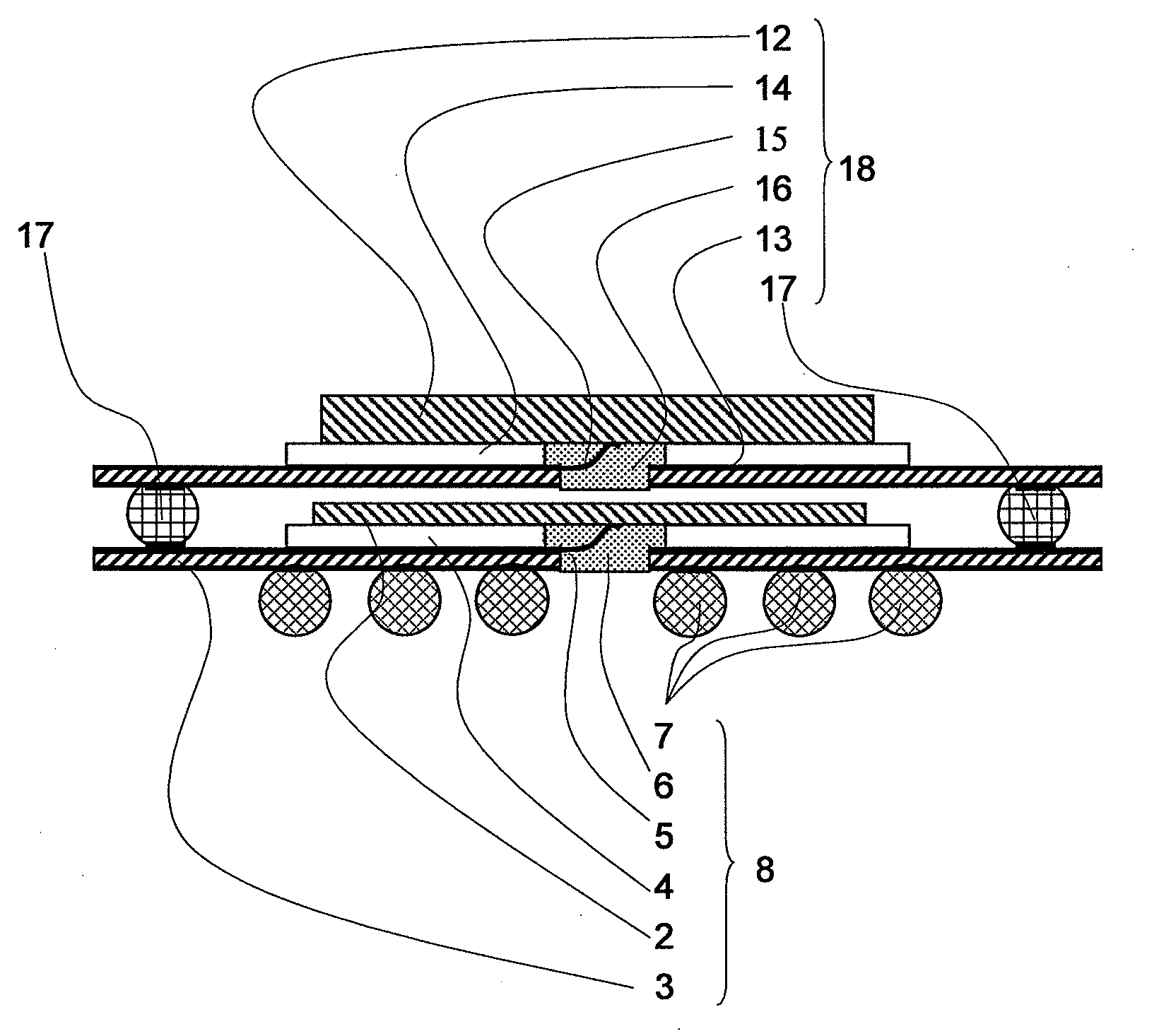

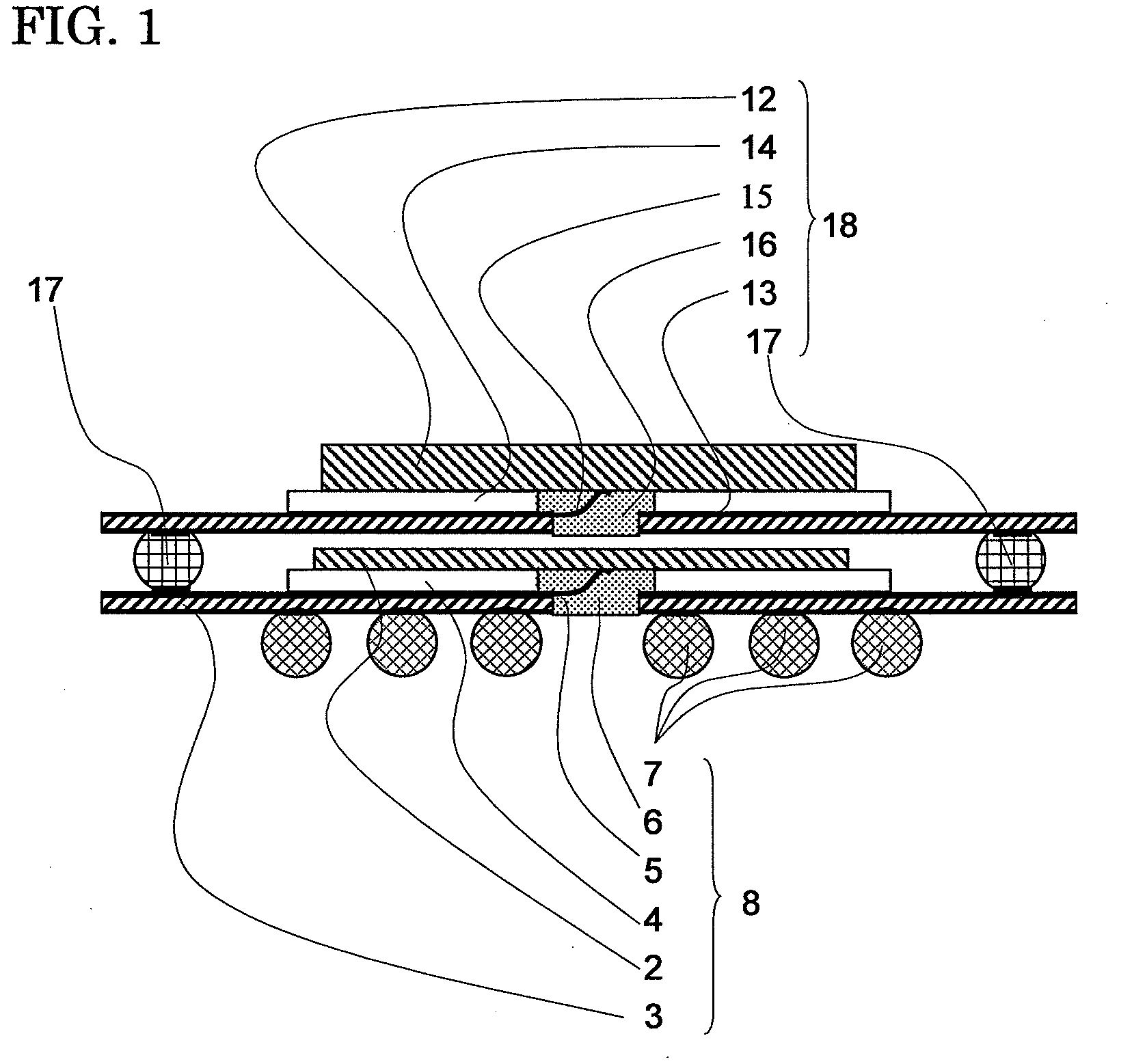

Semiconductor device and method of manufacturing the same

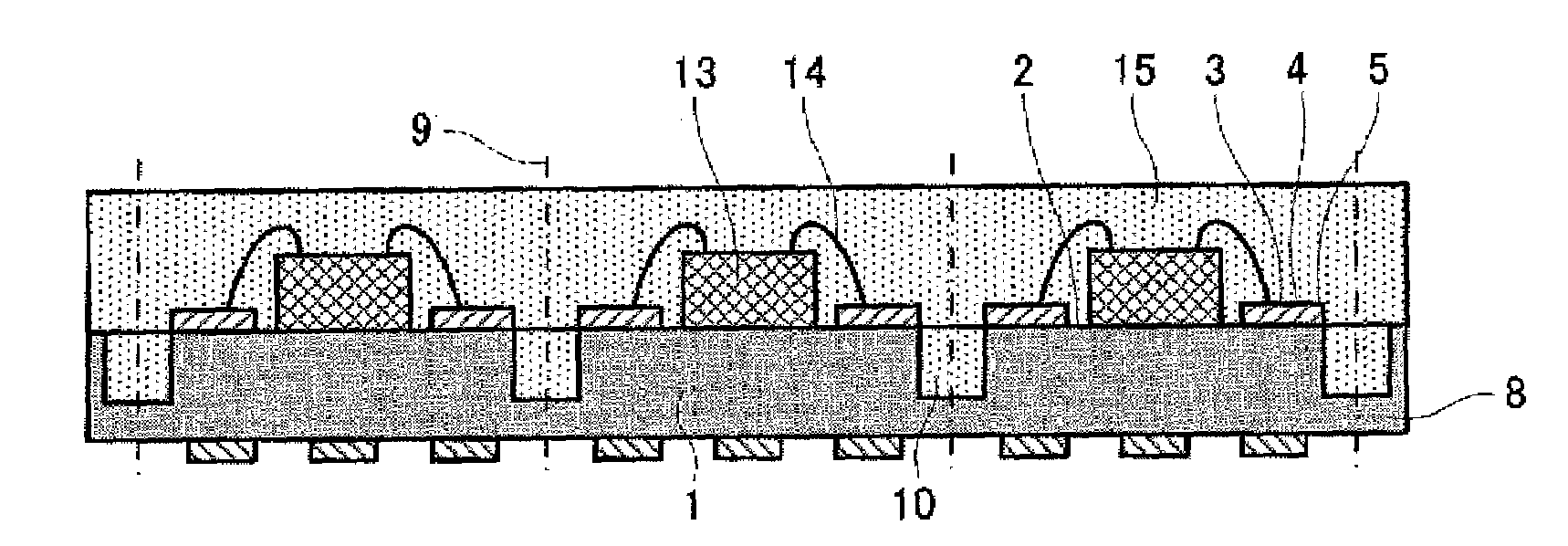

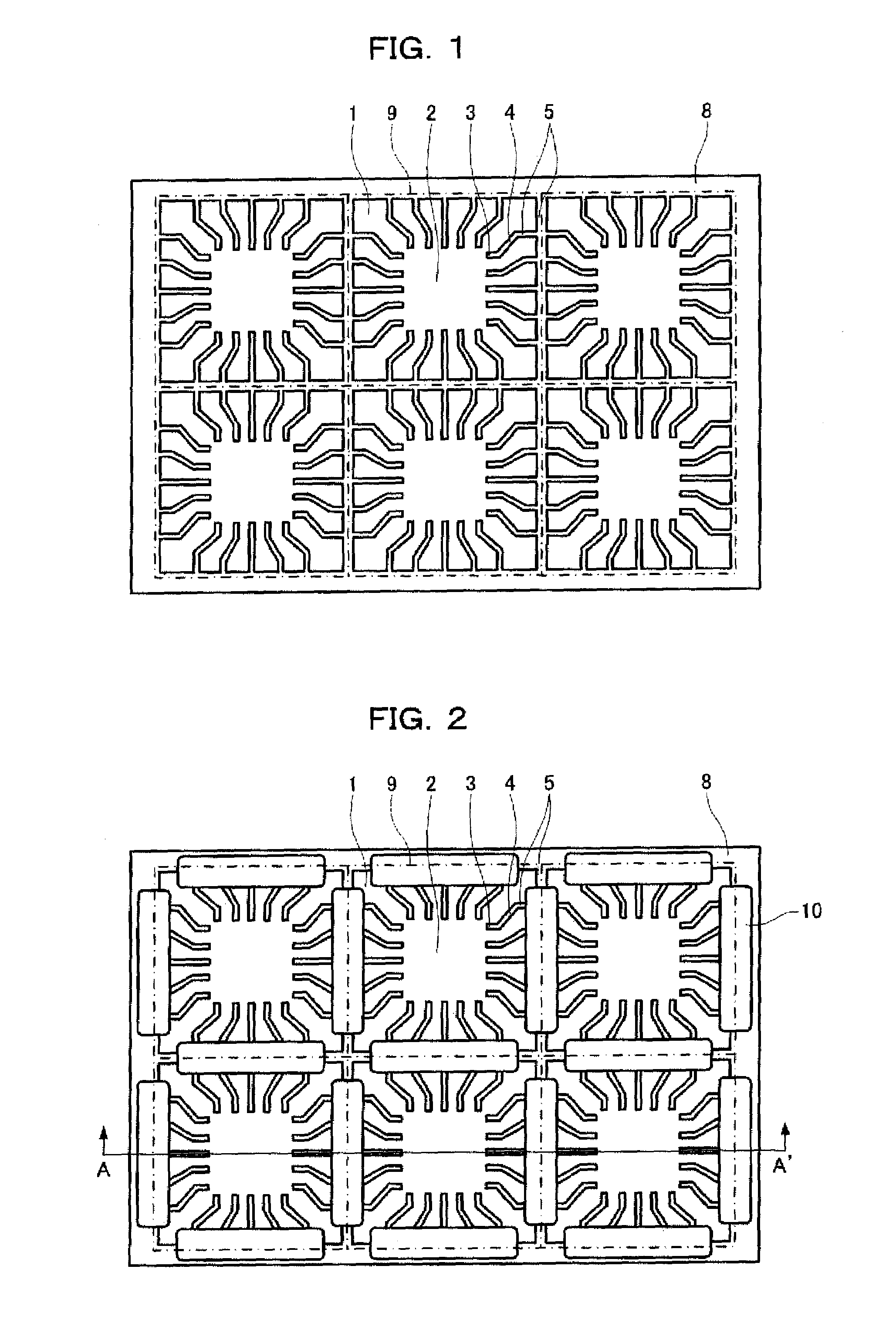

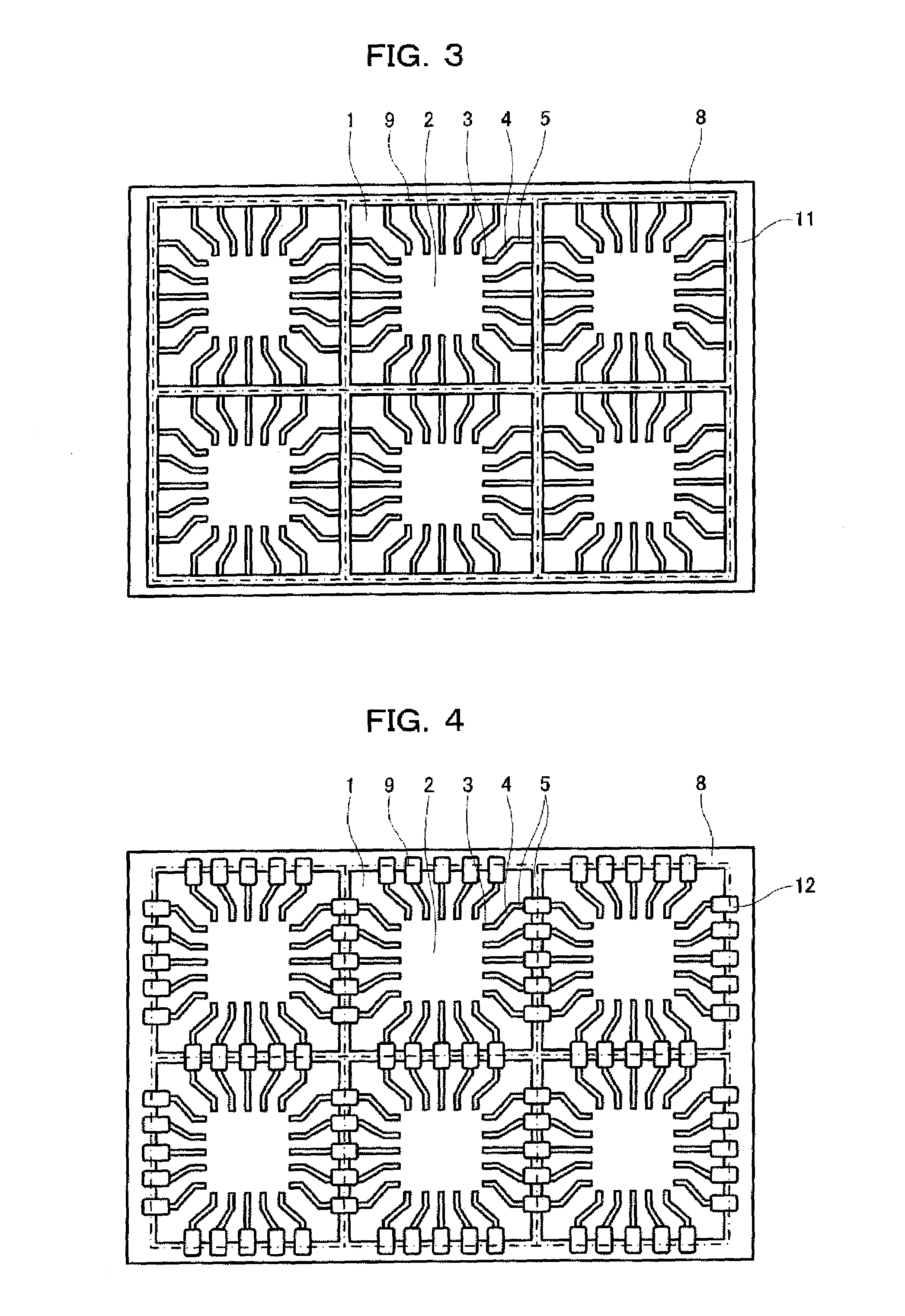

ActiveUS20090250803A1Eliminate warpageIncrease in numberSemiconductor/solid-state device detailsSolid-state devicesExternal connectionSemiconductor

A semiconductor device includes a chip, a laminated wiring structure formed integrally with the chip, a frame disposed to surround the chip and made of a material having stiffness, and a sealing resin formed to bury therein the frame and at least the periphery of the side surface of the chip. The laminated wiring structure includes a required number of wiring layers, which are formed by patterning in such a manner that a wiring pattern directly routed from an electrode terminal of the chip is electrically connected to pad portions for bonding external connection terminals, the pad portions being provided, at a position directly below a mounting area of the chip and at a position directly below an area outside the mounting area, on a surface to which the external connection terminals are bonded.

Owner:SHINKO ELECTRIC IND CO LTD

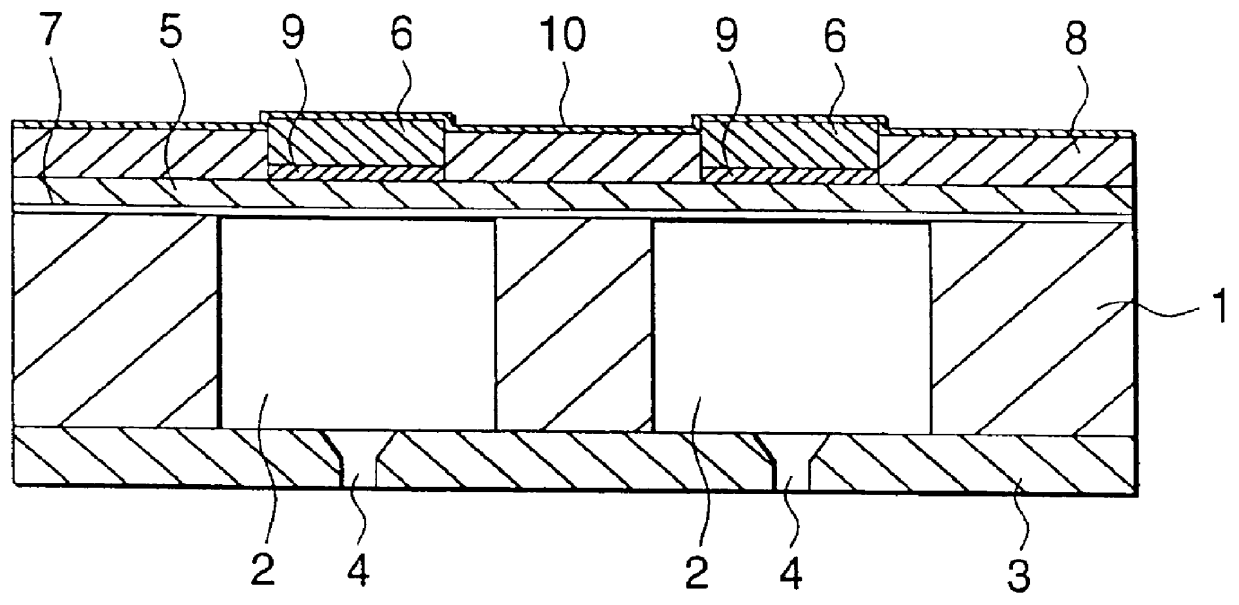

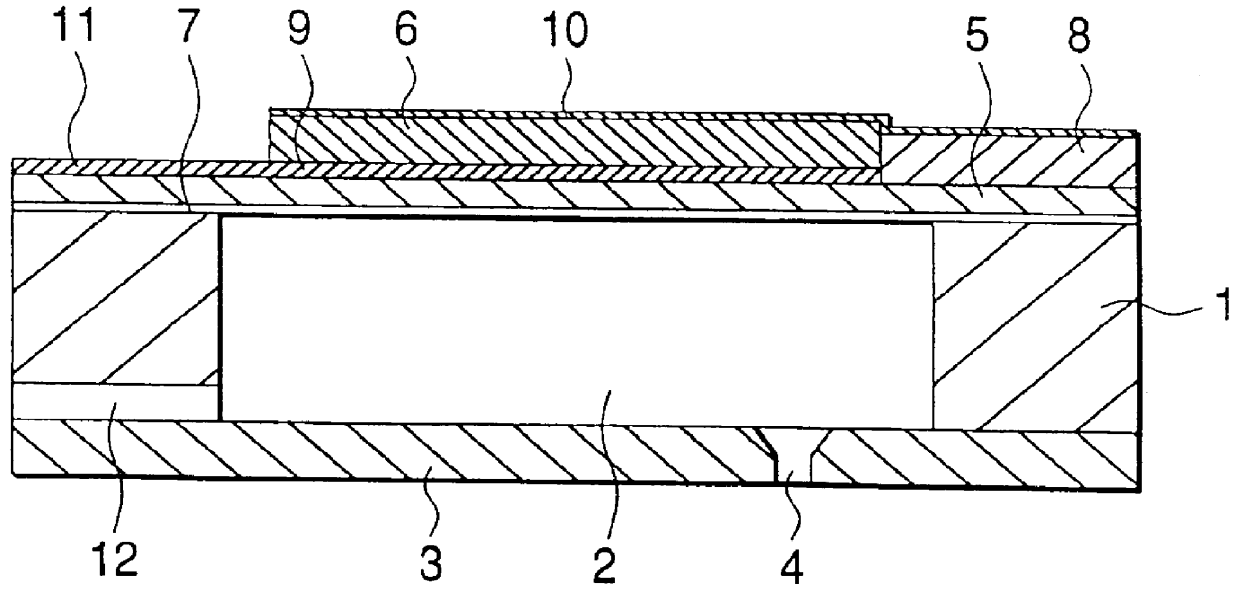

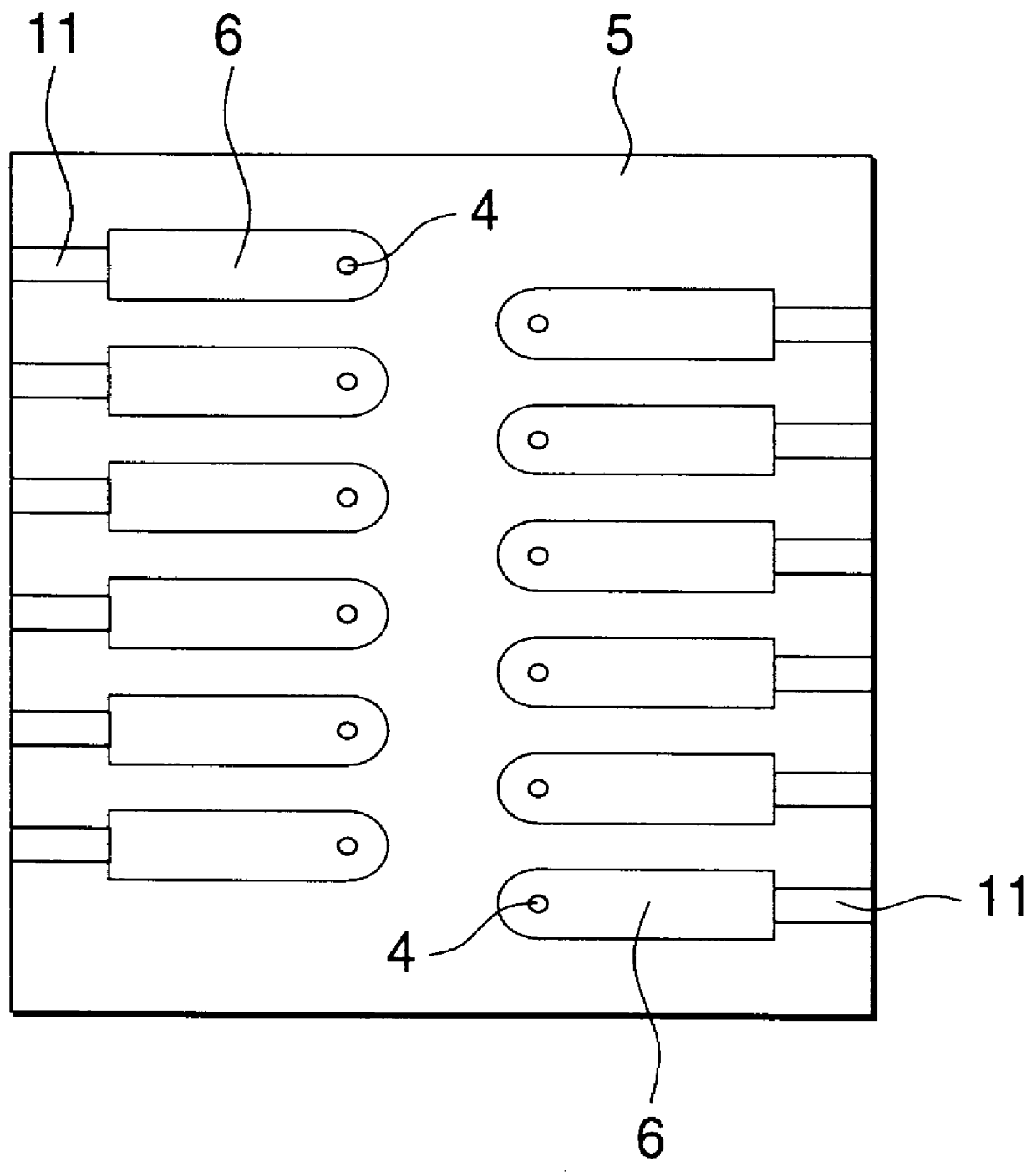

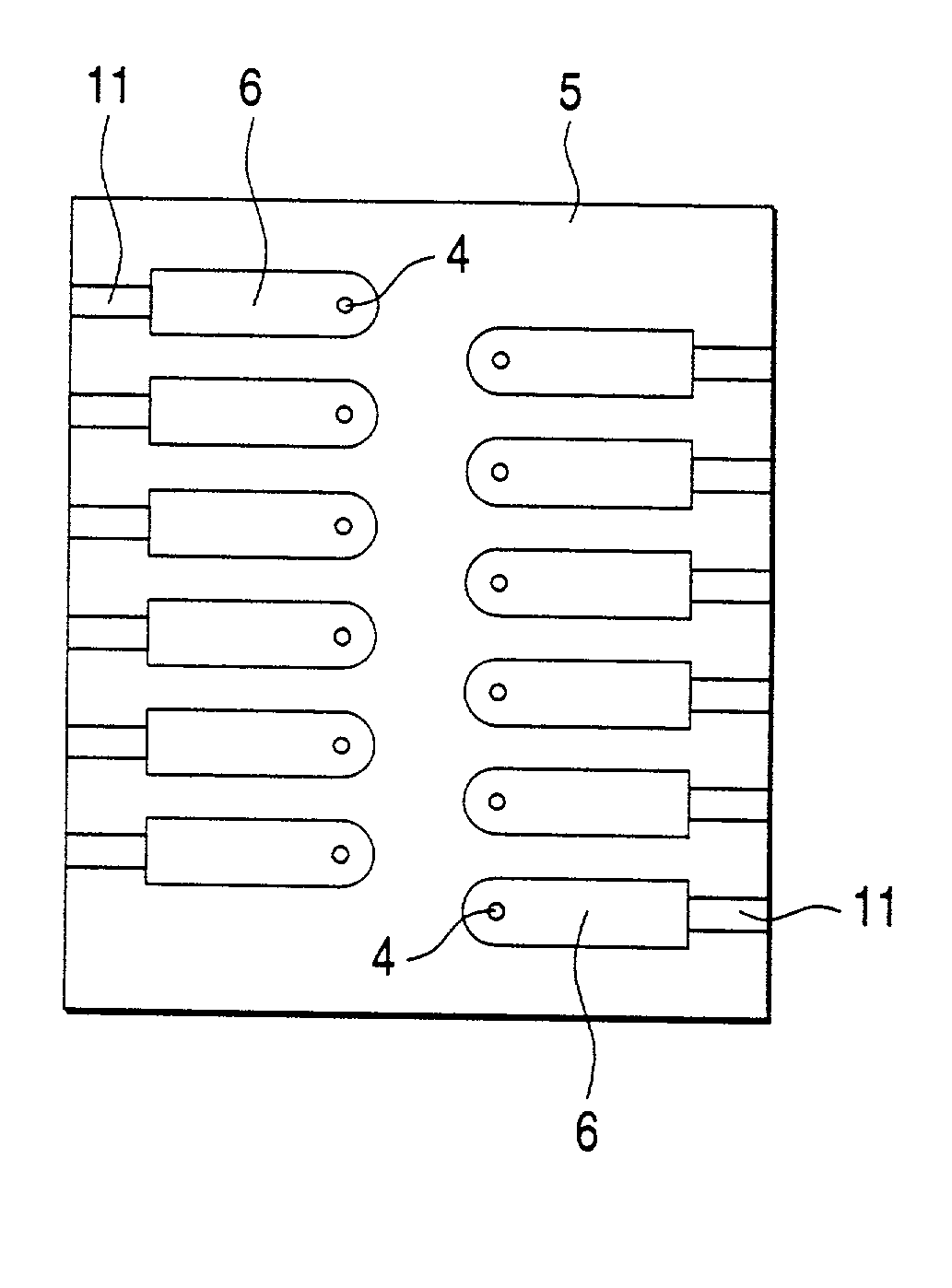

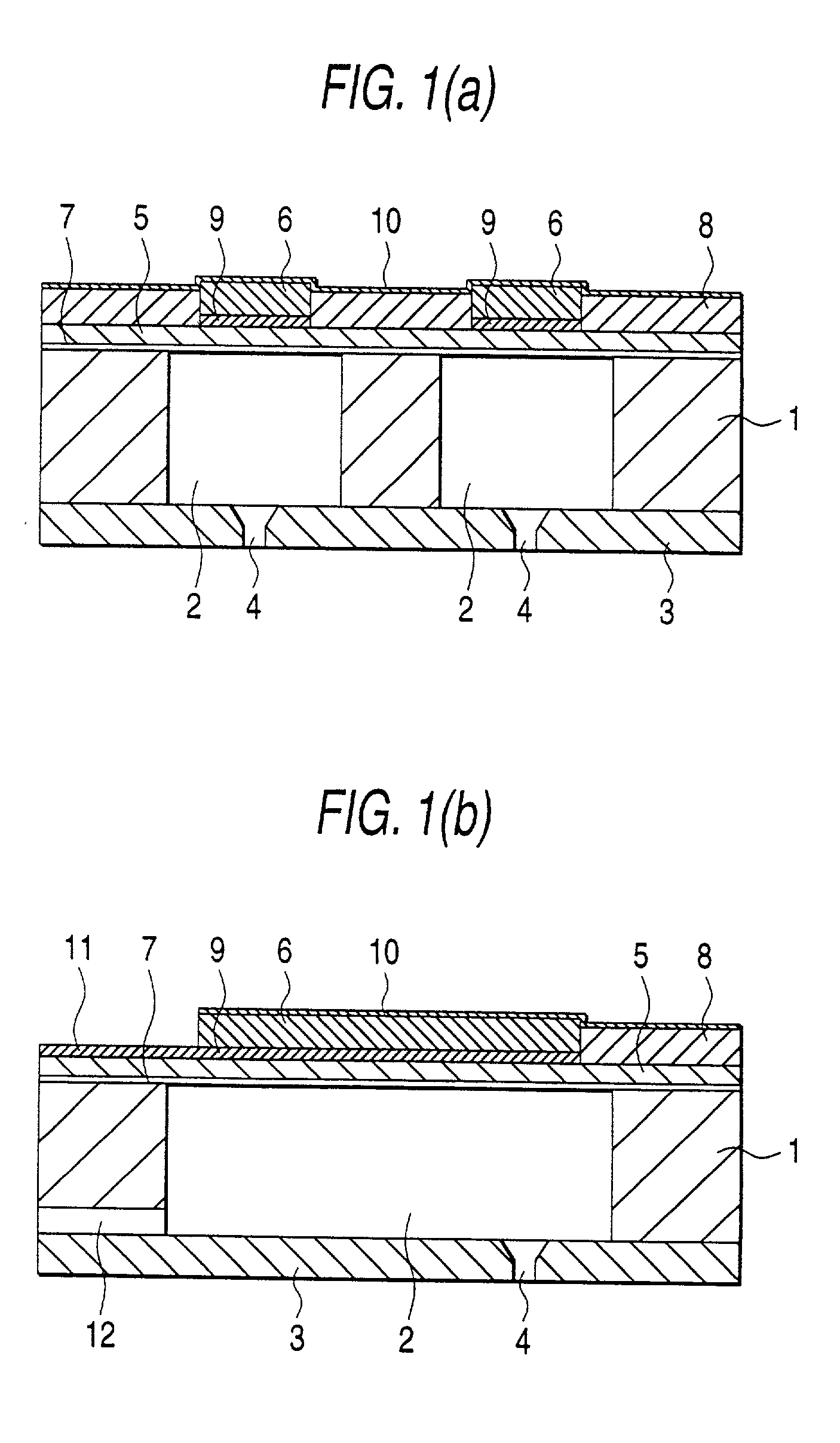

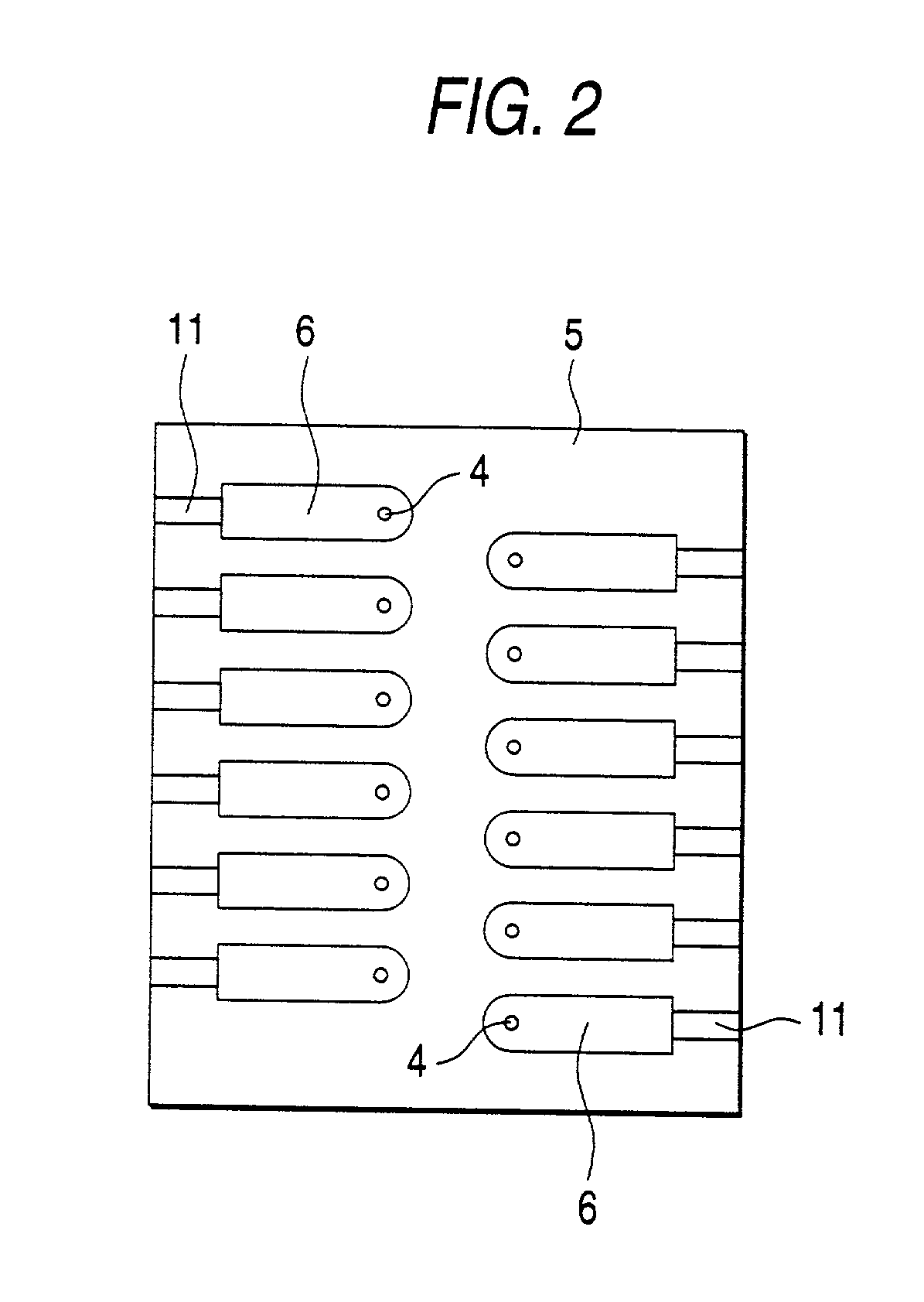

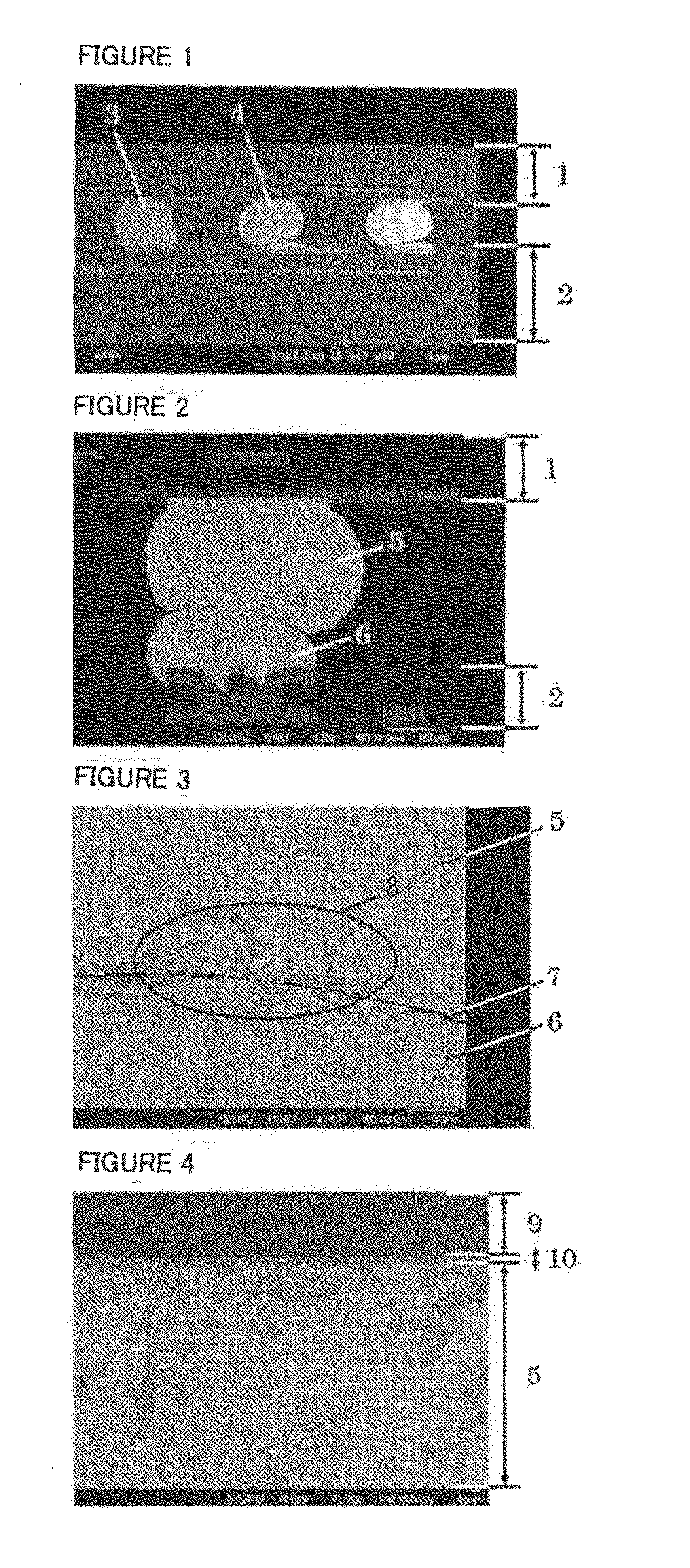

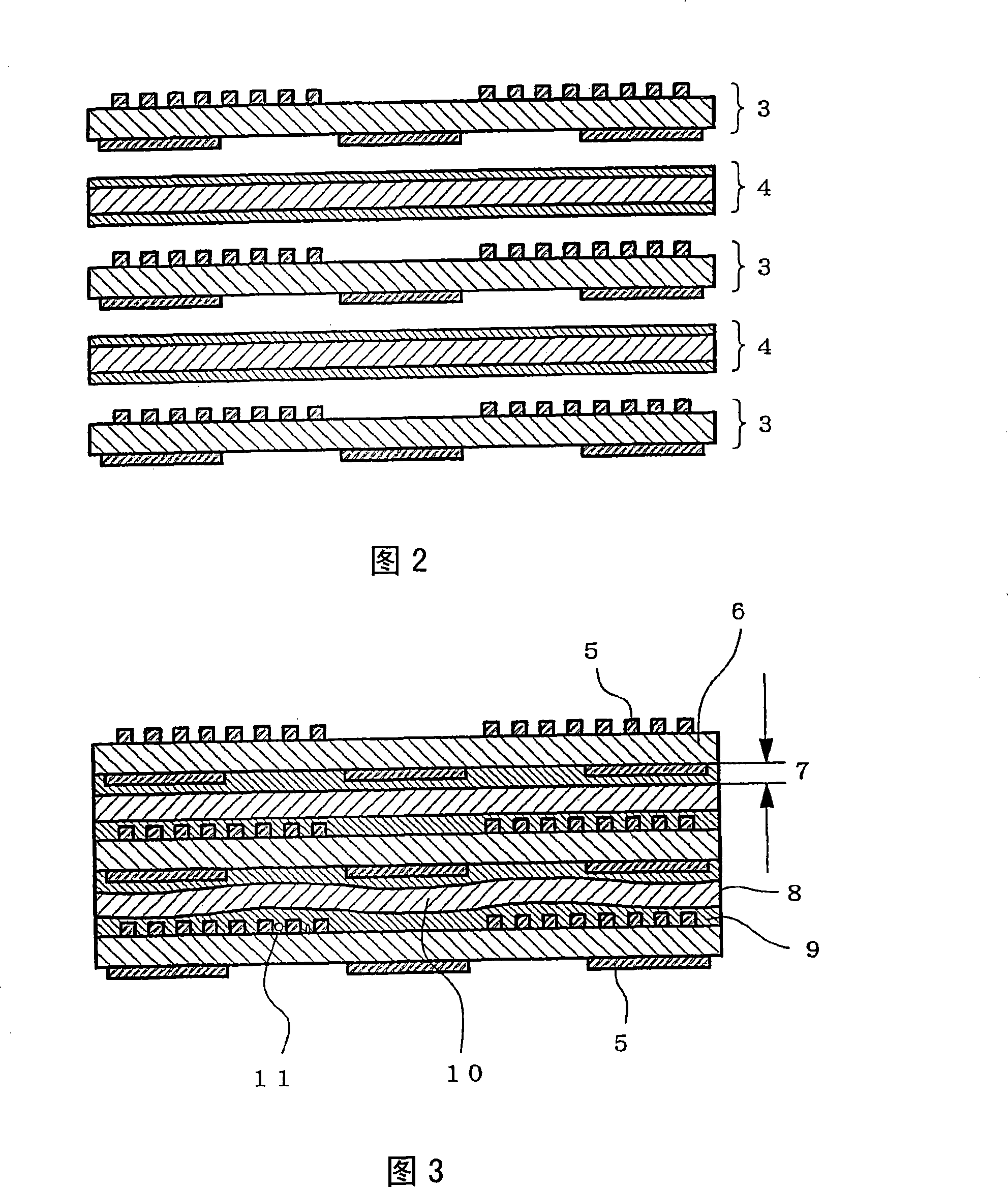

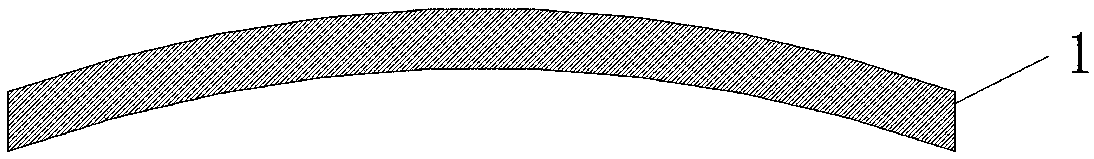

Laminated ink-jet recording head, a process for production thereof and a printer equipped with the recording head

InactiveUS6158847ASmall film thicknessEfficiently issuedInking apparatusPiezoelectric/electrostrictive/magnetostrictive devicesLow voltageBiomedical engineering

PCT No. PCT / JP96 / 01924 Sec. 371 Date May 14, 1997 Sec. 102(e) Date May 14, 1997 PCT Filed Jul. 11, 1996 PCT Pub. No. WO97 / 03834 PCT Pub. Date Feb. 6, 1997A laminated ink-jet recording head is provided that has a strong joint between the diaphragm and the piezoelectric vibrating element and which can be driven on low voltage. The recording head is of such a design that a lower electrode is provided on the diaphragm in at lest a region that corresponds to said pressure generating chamber, the lower electrode being overlaid with the piezoelectric vibrating element formed by a hydrothermal method, said piezoelectric vibrating element in turn being overlaid with an upper electrode and having a film thickness of not less than 1 mu m but not more than 10 mu m. The invention further provides a process for producing this recording head, as well as an apparatus such as a printer that is equipped with this recording head.

Owner:SEIKO EPSON CORP

Semiconductor device and method of manufacturing the same

ActiveUS7944039B2Eliminate warpingIncrease the number ofSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceEngineering

A semiconductor device includes a chip, a laminated wiring structure formed integrally with the chip, a frame disposed to surround the chip and made of a material having stiffness, and a sealing resin formed to bury therein the frame and at least the periphery of the side surface of the chip. The laminated wiring structure includes a required number of wiring layers, which are formed by patterning in such a manner that a wiring pattern directly routed from an electrode terminal of the chip is electrically connected to pad portions for bonding external connection terminals, the pad portions being provided, at a position directly below a mounting area of the chip and at a position directly below an area outside the mounting area, on a surface to which the external connection terminals are bonded.

Owner:SHINKO ELECTRIC IND CO LTD

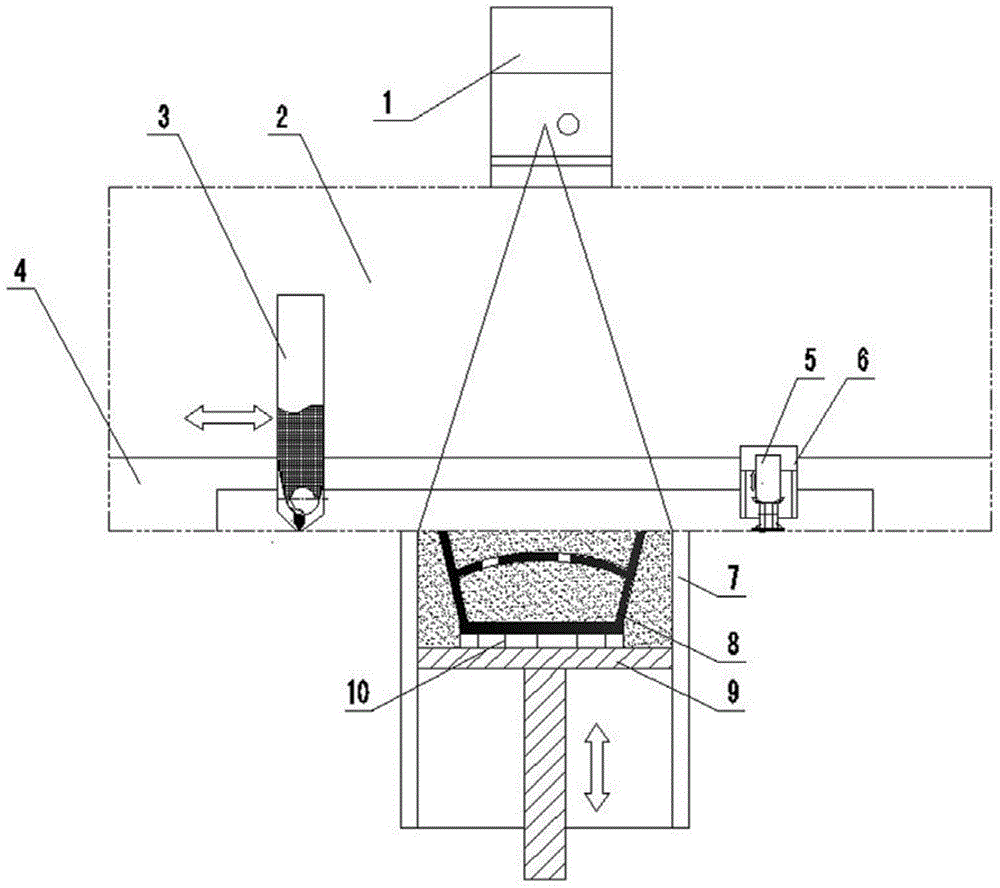

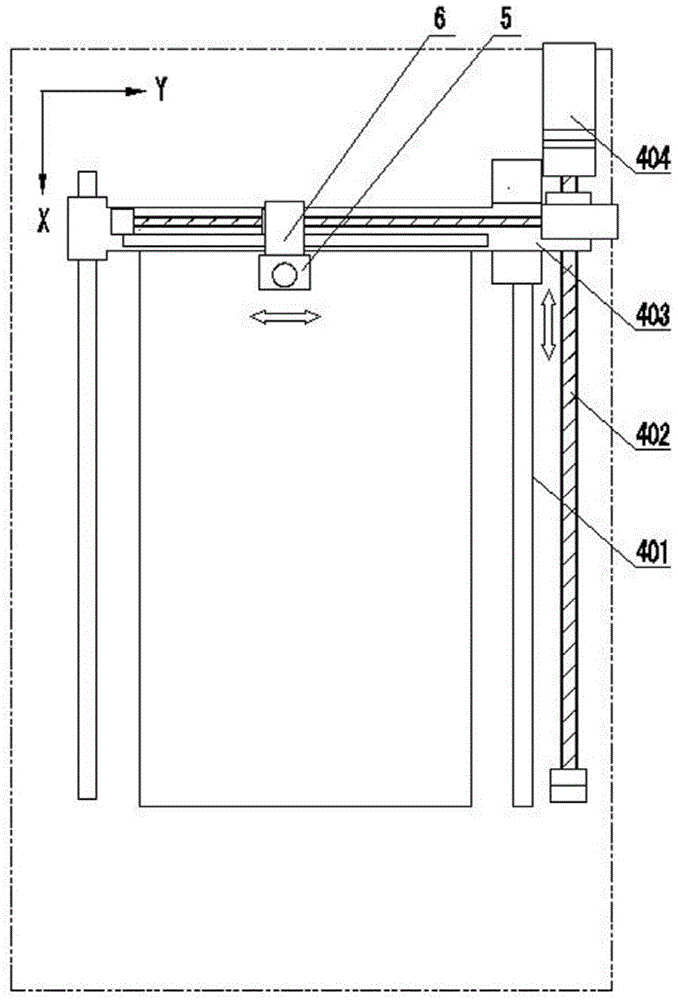

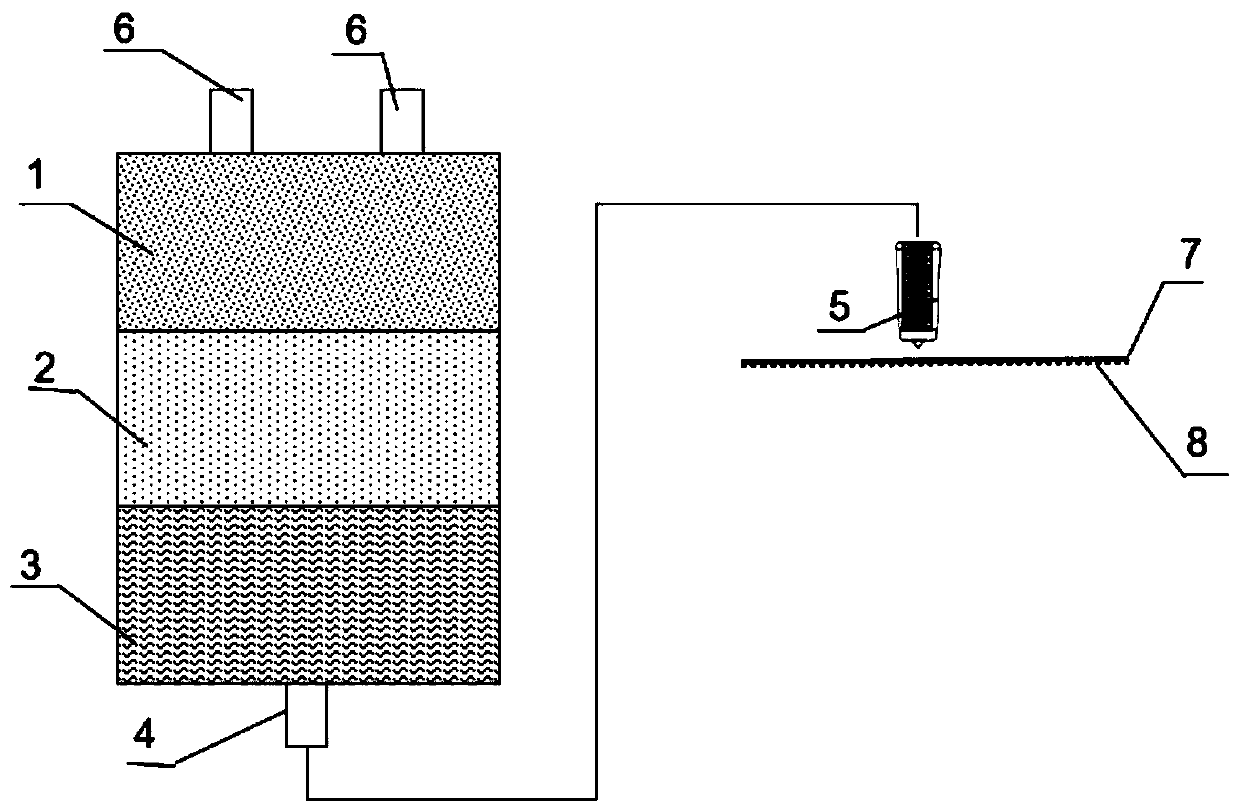

System suitable for metal powder melting material increasing manufacturing

InactiveCN104959603AEliminate bumpsEliminate warpingAdditive manufacturing apparatusIncreasing energy efficiencyHigh-speed grindingGalvanometer

The invention discloses a system suitable for metal powder melting material increasing manufacturing. The system is formed by compositing of a fiber laser galvanometer scanning mechanism and a high-speed grinding head. The fiber laser galvanometer scanning mechanism is provided with an XY workbench. The high-speed grinding head is arranged on a Y axis of the XY workbench through a Y axial sliding block. After multiple layers are manufactured on a workpiece, the high-speed grinding head slides along the Y axis of the XY workbench and carries out the feeding motion in the X axial direction at the same time, and high-speed grinding is carried out on the workpiece. The system suitable for the metal powder melting material increasing manufacturing has the advantages that after the high-speed grinding head is composited with the fiber laser galvanometer scanning mechanism, in the material increasing manufacturing process, scanning is carried out on a powder bed through the fiber laser galvanometer scanning mechanism, metal in a selected area is melted, a protrusion and a warpage in the partial workpiece can be removed by the high-speed grinding head, the upper surface of the workpiece can be maintained in smooth, the residual protruding peak on the surface of the workpiece and the plastic deformation degree can be effectively lowered, and the roughness on the surface of the workpiece is favorable to be lowered.

Owner:GUANGZHOU OGGI3D ELECTROMECHANICAL

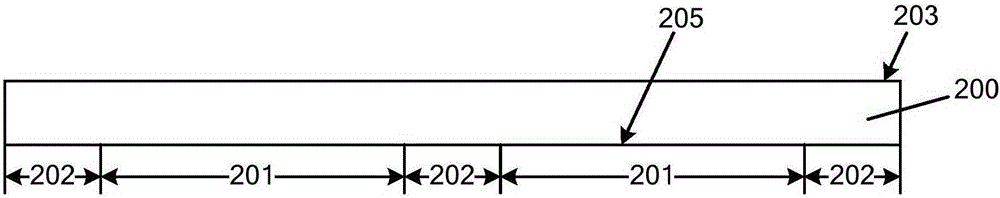

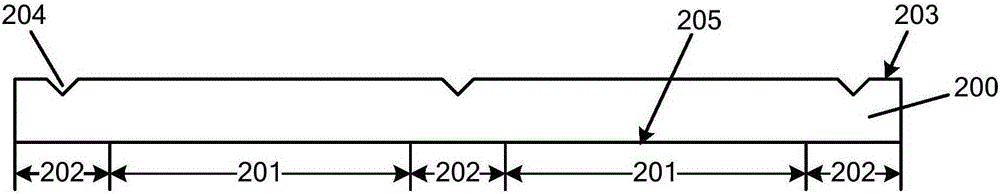

Packaging method

InactiveCN105355569AEliminate driftDrift suppressionSolid-state devicesSemiconductor/solid-state device manufacturingPlastic packagingNon functional

A packaging method comprises the steps of: providing a carrier plate, wherein the carrier plate comprises a plurality of chip regions and cutting regions arranged between the adjacent chip regions, the carrier plate further comprises a first surface, and a plurality of grooves are formed in the cutting regions in the first surface of the carrier plate; providing chips, wherein each chip comprises a functional surface and a non-functional side surface which are opposite to each other, the surface of each functional surface is provided with bumps, and the bumps protrude out of the functional surfaces; fixing the non-functional side surfaces of the chips with the first surface of the carrier plate in the chip regions; forming a plastic packaging layer on the first surface of the carrier plate and the surfaces of the chips, wherein the plastic packaging layer exposes top part surfaces of the bumps; removing the carrier plate after forming the plastic packaging layer; forming a rewiring structure on the surface of the plastic packaging layer and the functional surfaces of the chips; and cutting the plastic packaging layer and the rewiring structure, so that the plurality of chips are separated from one another, thereby forming an independent packaging structure. The yield and reliability of the formed packaging products are improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

Process for producing a laminated ink-jet recording head

InactiveUS20020018105A1Reduce voltageLow-voltage drivingPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusTitaniumMaterials science

Owner:SEIKO EPSON CORP

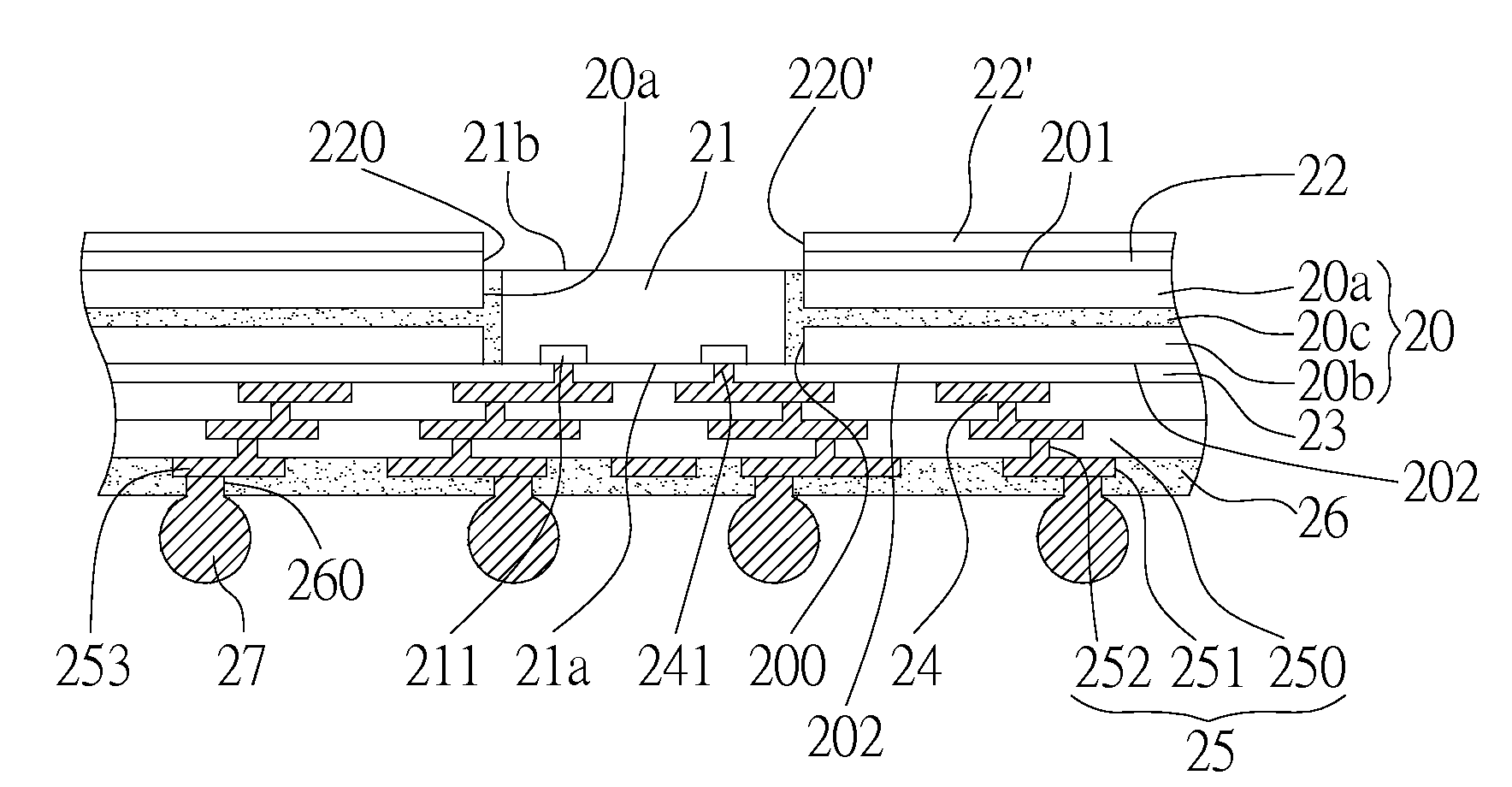

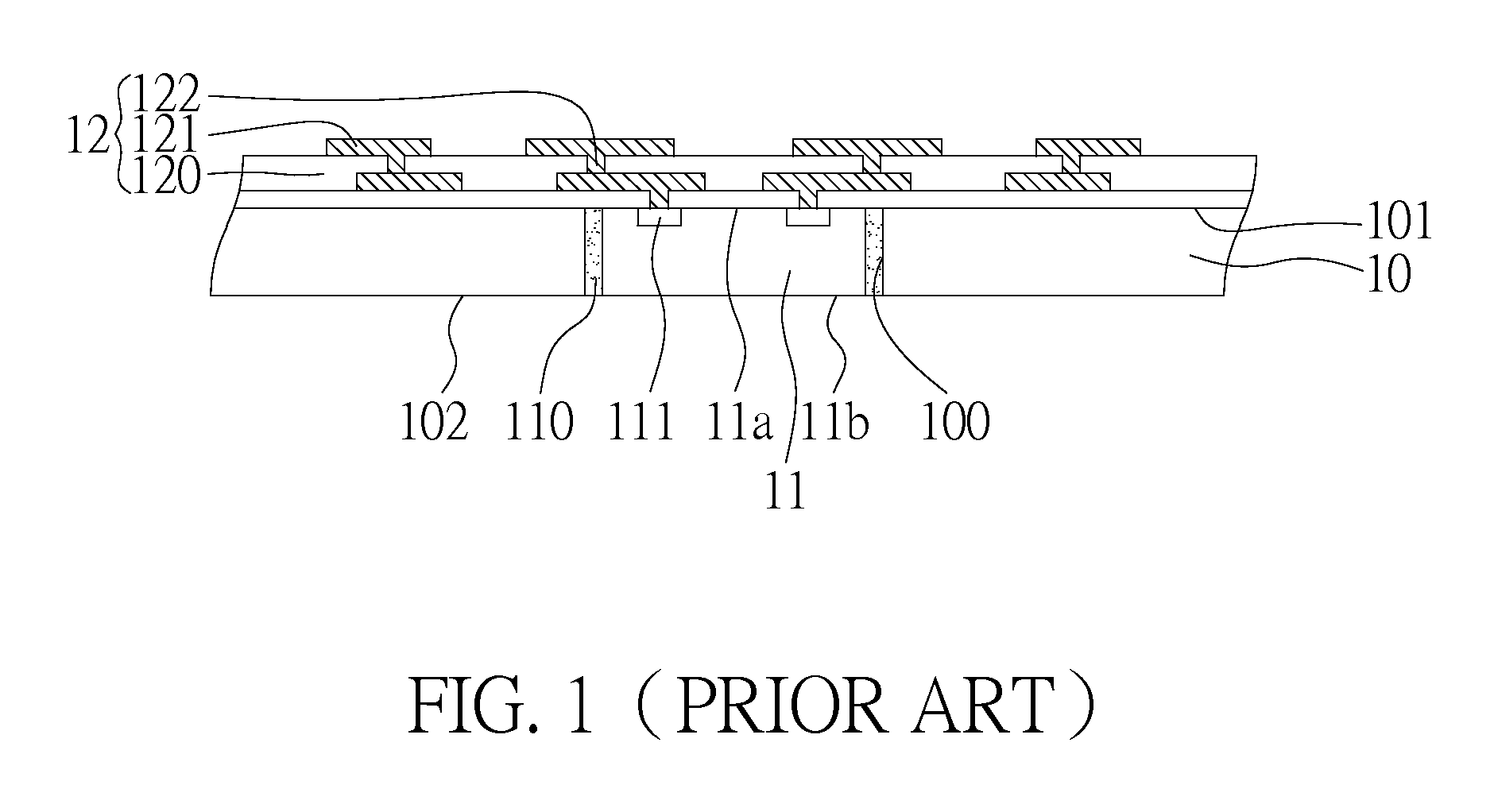

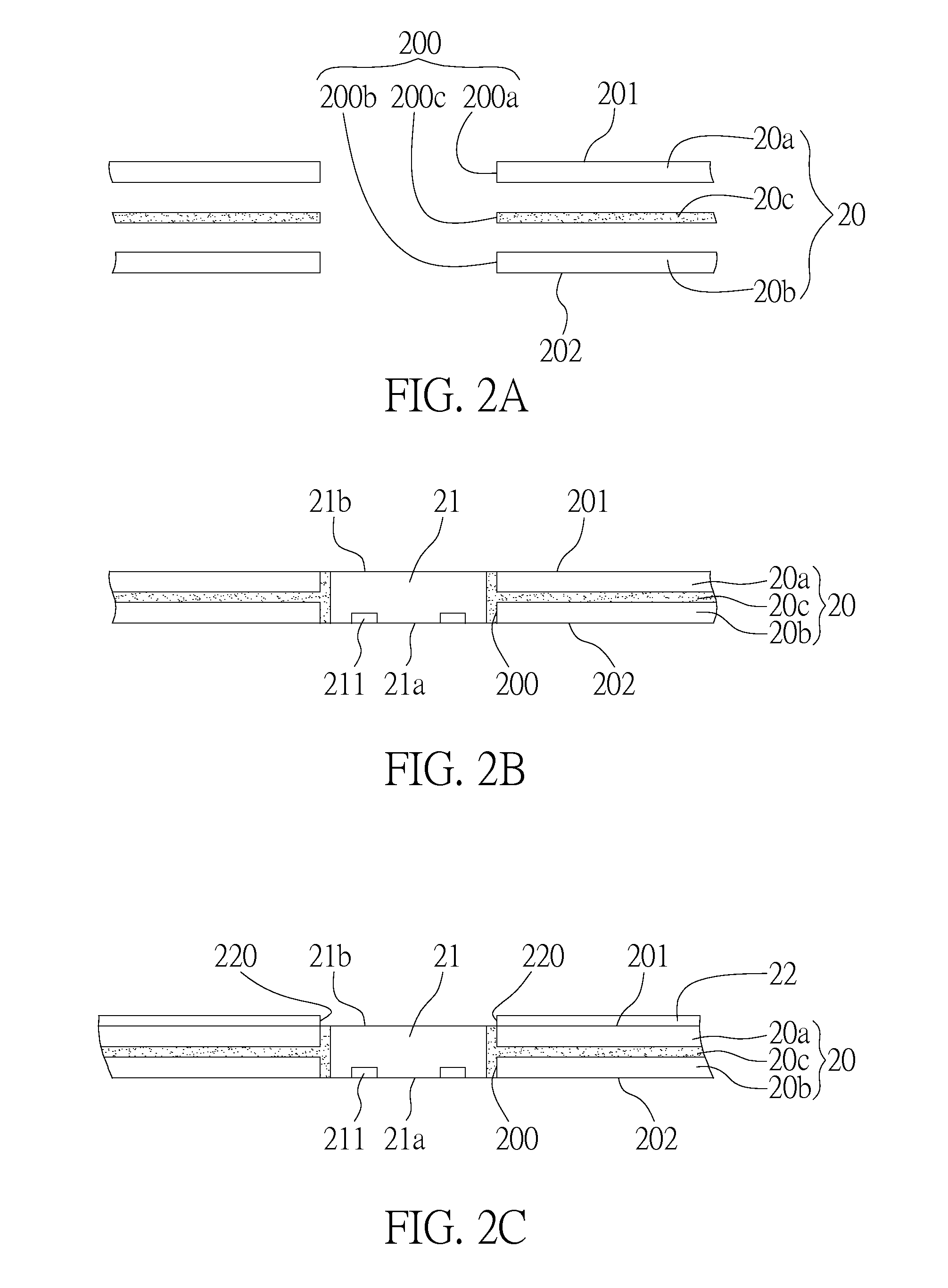

Circuit board structure with embedded semiconductor chip

InactiveUS20080142951A1Avoid warpingAvoid damageSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipPrinted circuit board

The invention provides a printed circuit board having an embedded semiconductor chip, includes: a carrier board having a first and an opposing second surface and a through hole penetrating the first and second surfaces; a semiconductor chip disposed in the through hole and having an active surface and an inactive surface, wherein the active surface includes a plurality of electrode pads; at least one non photoimagable laminating layer formed on the first surface of the carrier board and with a through hole to expose the inactive surface of the semiconductor chip; a dielectric layer and a circuit layer formed on the second surface of the carrier board and the active surface of the semiconductor chip, wherein the circuit layer electrically connects to the electrode pads of the semiconductor chip, thereby preventing the carrier board from warpage due to temperature variations and an asymmetric structure during a single-side circuit formation process of the carrier board.

Owner:PHOENIX PRECISION TECH CORP

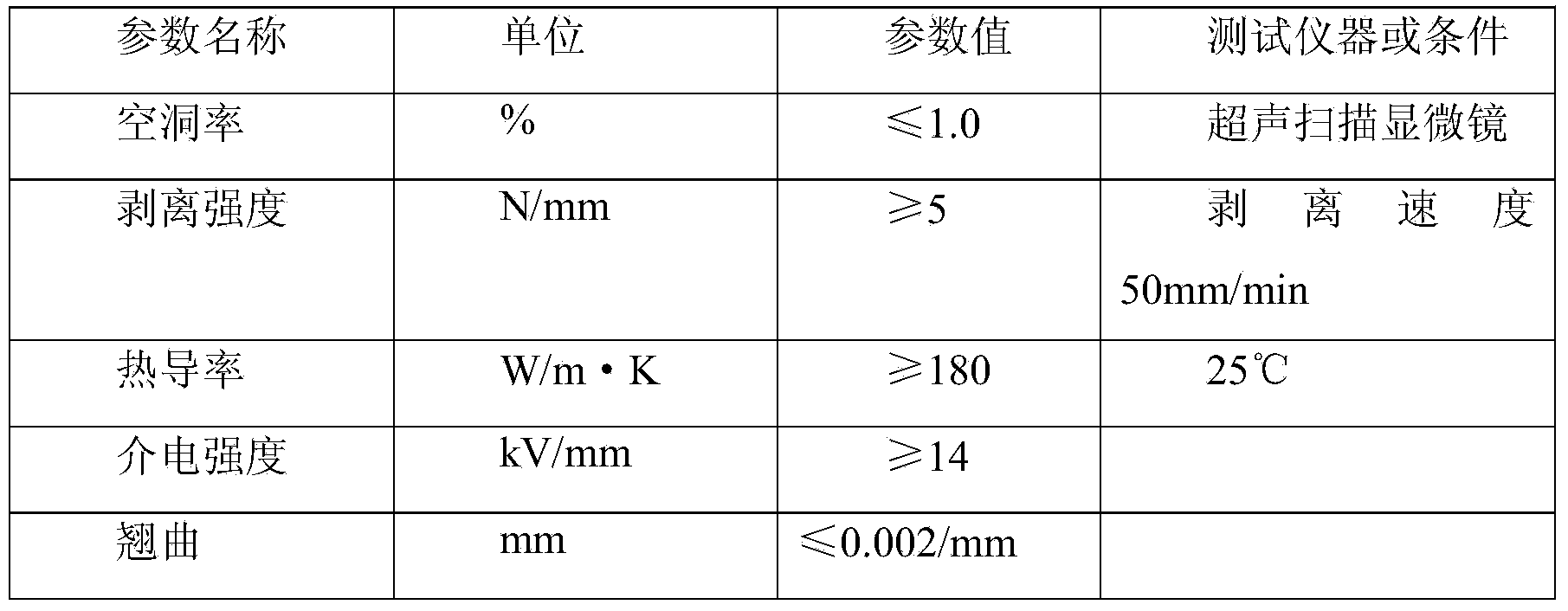

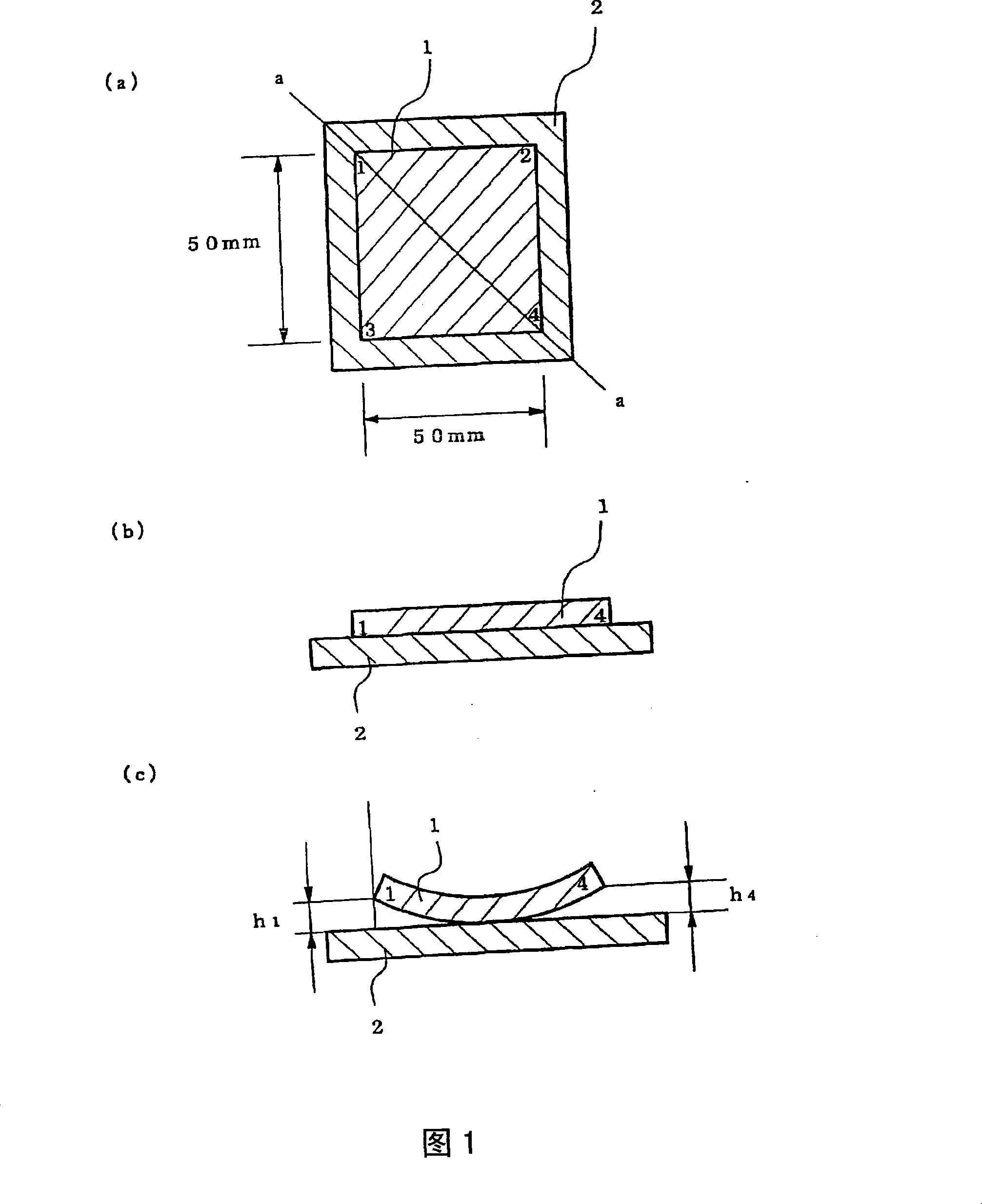

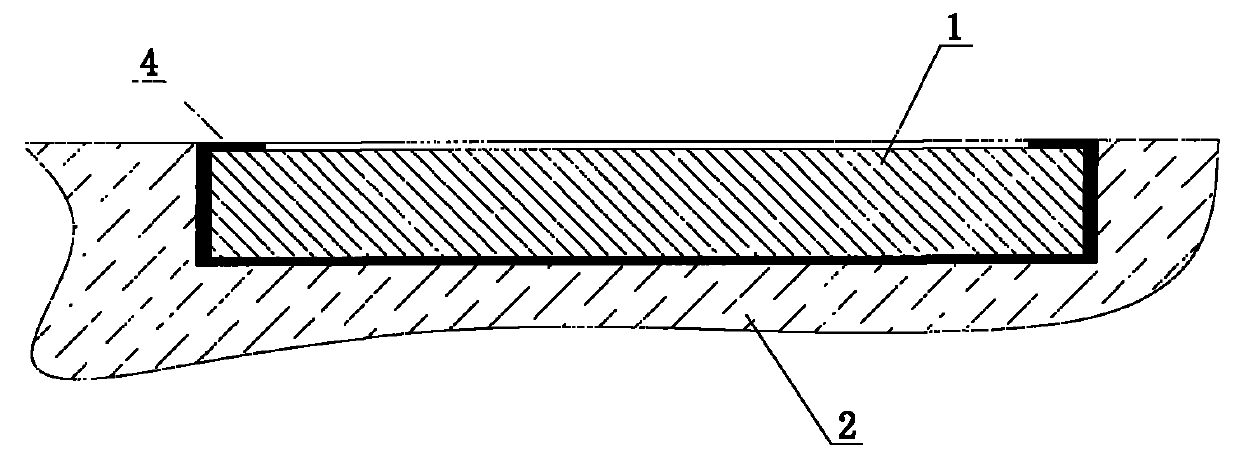

Preparation method of aluminium nitride base ceramic copper-clad plate

ActiveCN103819215AEasy to excludePrevention of unsatisfactory peel strengthVoid ratioThermal expansion

The invention belongs to the technical field of copper-clad plate manufacturing, and particularly relates to a preparation method of an aluminium nitride base ceramic copper-clad plate. The preparation method comprises the following steps: pretreating an oxygen-free red copper foil, then putting the pretreated oxygen-free red copper foil in molten sodium nitrate, and carrying out medium temperature chemical oxidation treatment; pretreating an aluminum nitride substrate, and then carrying out high-temperature oxidation treatment; and carrying out magnetron sputtering treatment on the aluminum nitride substrate subjected to high temperature oxidation, prepressing the treated oxygen-free red copper foil into a circular arc shape, stacking the circular arc-shaped oxygen-free red copper foil and the aluminum nitride substrate together, putting in a chained bonding furnace, carrying out high temperature dynamic continuous bonding, and then treating by adopting a sequential temperature difference alternative falling temperature method, thus obtaining the aluminium nitride base ceramic copper-clad plate. The preparation method is simple in production efficiency, stable in quality and low in cost. The prepared aluminium nitride base ceramic copper-clad plate has the characteristics of low void ratio, low coefficient of thermal expansion, low stress, high thermal conductivity, high peel strength and large bonding area.

Owner:李磊 +1

Molding method for casting and forging structure piece of wheelchair frame

ActiveCN102363259AGood shape consistencyEliminate warpingMetal-working apparatusSolution treatmentWheelchair

The invention provides a molding method for casting and forging a structure piece of a wheelchair frame, which comprises the steps of: sawing and cutting an aluminum cast ingot with the outer circle of phi 200mm with a material trade mark of 6061 into blank with the length of 800mm; smelting; pouring; modeling; cutting a dead head; charging a casting blank, heating and fixing the temperature at 530 DEG C; forging and pressing the casting blank by a 5000-ton oil press and a forging mould; forging and pressing to obtain a forged piece; etching and washing; treating with solid solution; and manually correcting the specific deformation degree of the forged piece. The precast blank is cast and molded by the method, the shape of the blank is good in consistency, the shape of a curved surface iseasy to control, a casting material can be cyclically utilized, and the material utilization can be furthest improved; and the batch production practice proves that the finished forged piece producedby a casting and forging technological process has no forging defects, the thermal treatment performance meets the demand, and the final status of the forged piece completely accords with user demand.

Owner:HARBIN HAFEI IND

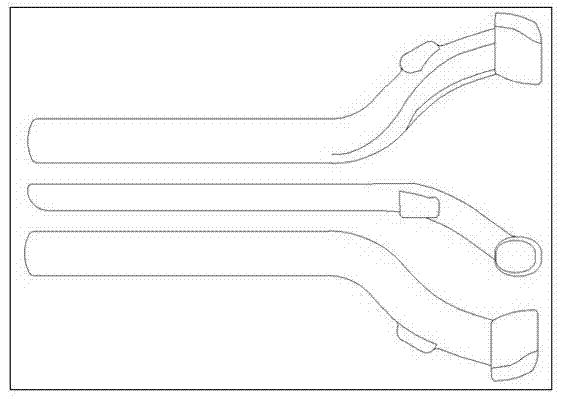

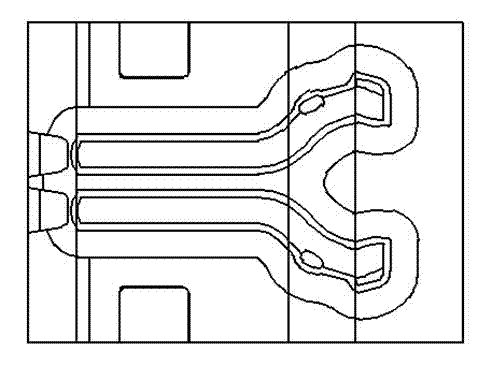

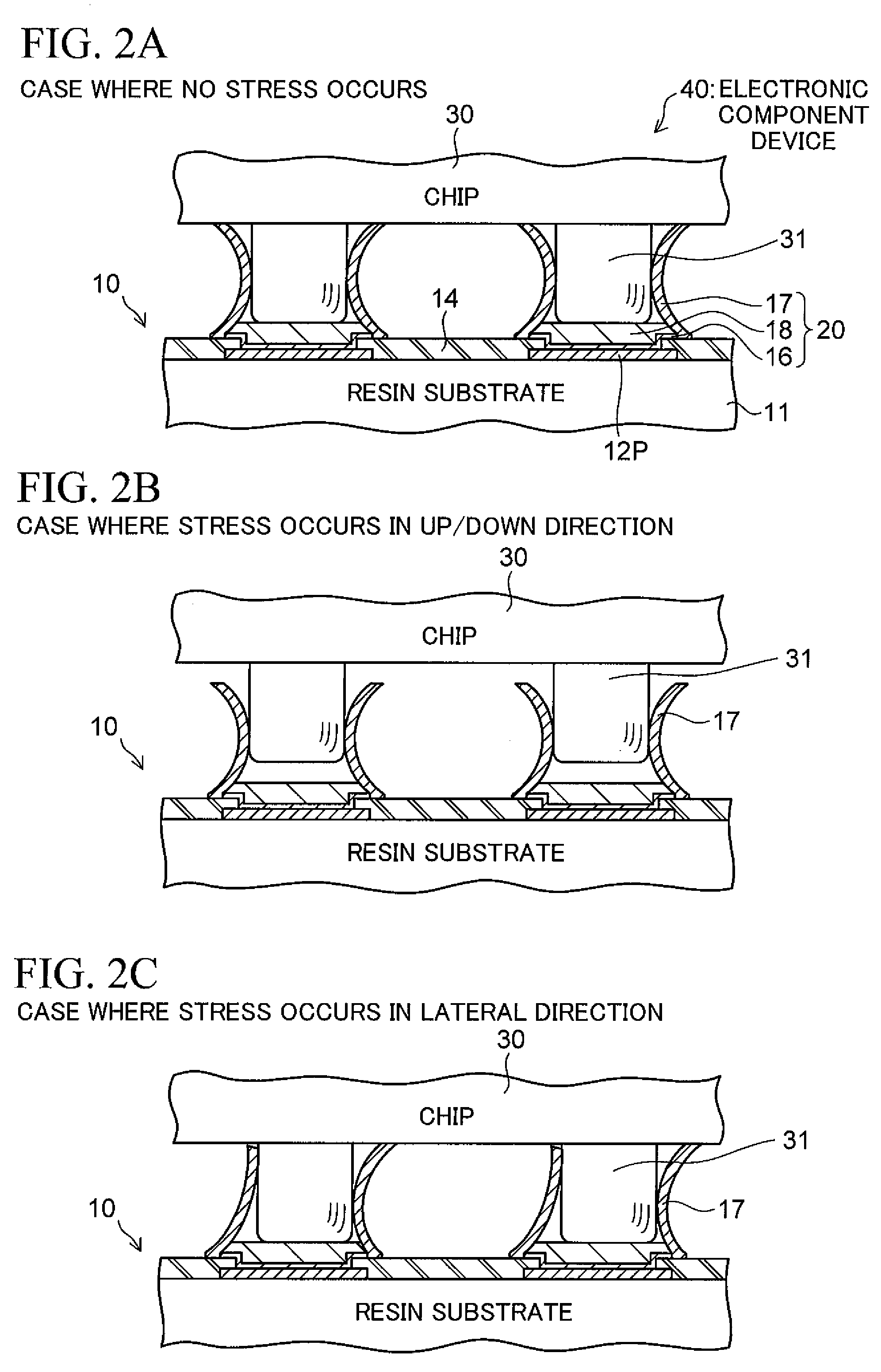

Wiring board and method of manufacturing the same

ActiveUS20090183911A1Eliminate warpingLow costPrinted circuit aspectsSolid-state devicesElectronic componentExternal connection

A wiring board includes an external connection terminal of a cylindrical shape, in which an electrode terminal of the electronic component to be mounted is fitted. In one configuration, a portion of the external connection terminal is electrically connected to a pad portion formed on an electronic component mounting surface side of the wiring board, and the external connection terminal is curvedly formed in such a shape that the outer periphery of the electrode terminal comes into close contact with the inner periphery of the middle portion of the external connection terminal when the electrode terminal is inserted into the external connection terminal.

Owner:SHINKO ELECTRIC IND CO LTD

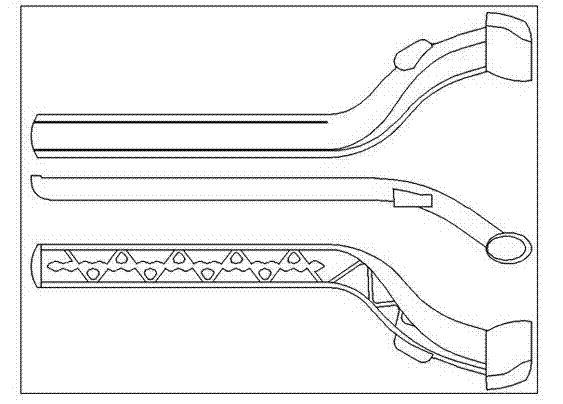

Leaf-spring type flexible hinge of null-axis shift

A leaf-spring type flexible hinge of a null-axis shift comprises a left intersecting leaf spring set, a right intersecting leaf spring set, a lower rotating part and an upper rotating part, wherein the lower rotating part and the upper rotating part are connected through the left intersecting leaf spring set to form a flexible hinge body set; the lower rotating part and the upper rotating part areconnected through the right intersecting leaf spring set to form another flexible hinge body set; the ideal rotating center shafts of the two flexible hinge body sets are coaxial; and moreover, the left intersecting leaf spring set and the right intersecting leaf spring set of the two flexible hinge body sets are symmetrically arranged. With the adoption of the leaf-spring type flexible hinge ofthe null axis shift, the rotating accuracy is greatly improved, and the null-axis shift of the flexible hinge is achieved.

Owner:HUNAN UNIV

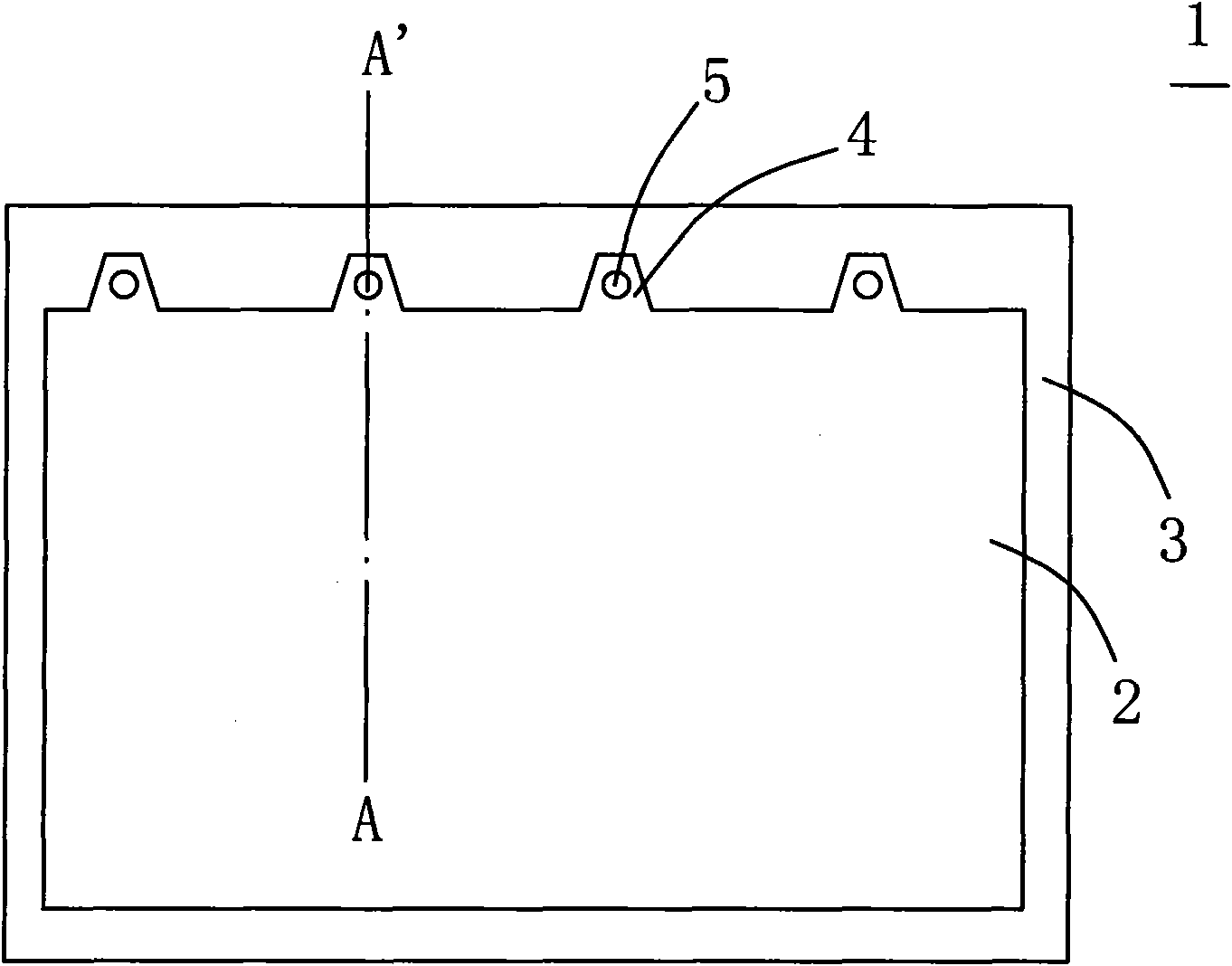

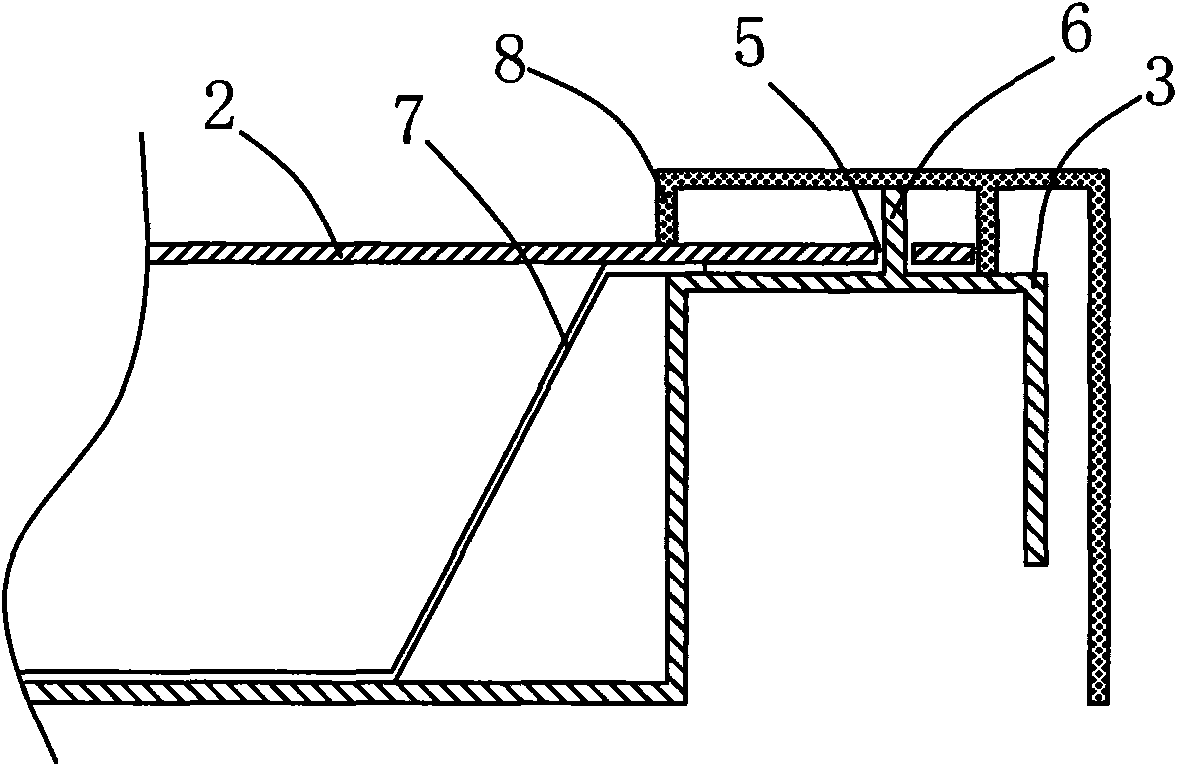

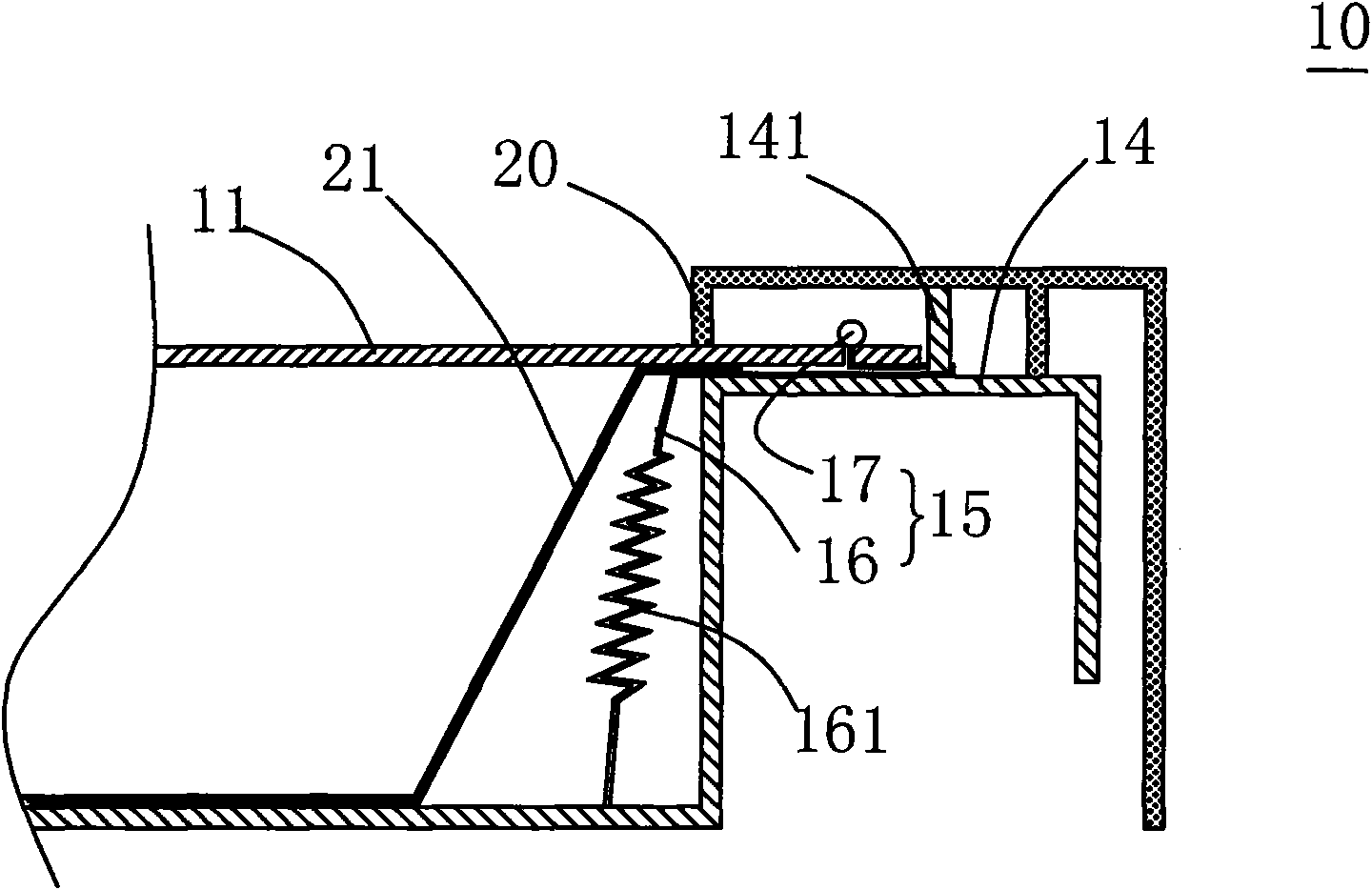

Positioning mechanism and back light module

InactiveCN101907262ASolve warpingEliminate warpingLight fasteningsNon-linear opticsEngineeringMembrane configuration

The invention provides a positioning mechanism and a back light module. The positioning mechanism is used for positioning a membrane, and the edge of the membrane is provided with at least one position limiting part. The positioning mechanism comprises a frame and an elastic structure, wherein the elastic structure is provided with a first part and a second part, the first part is combined and fixed with the frame, and the second part is matched with the position limiting part to provide pretension force on the membrane. The pretension force for the membrane is provided by using the elastic structure of the positioning mechanism and is used for regulating the expansion and shrinking amount of the membrane due to temperature and humidity variation so as to eliminate the problem of membrane wrapping.

Owner:AU OPTRONICS CORP

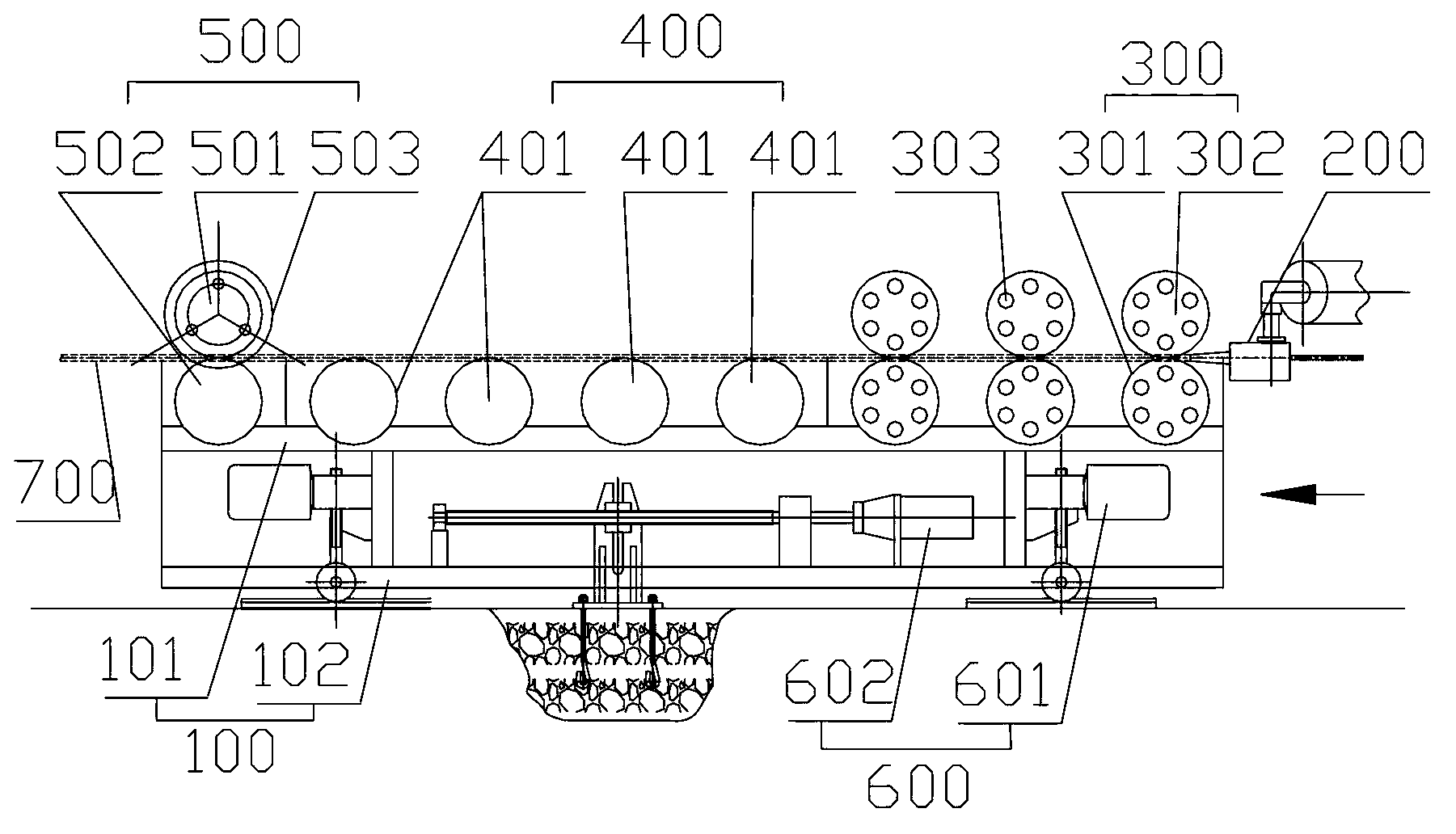

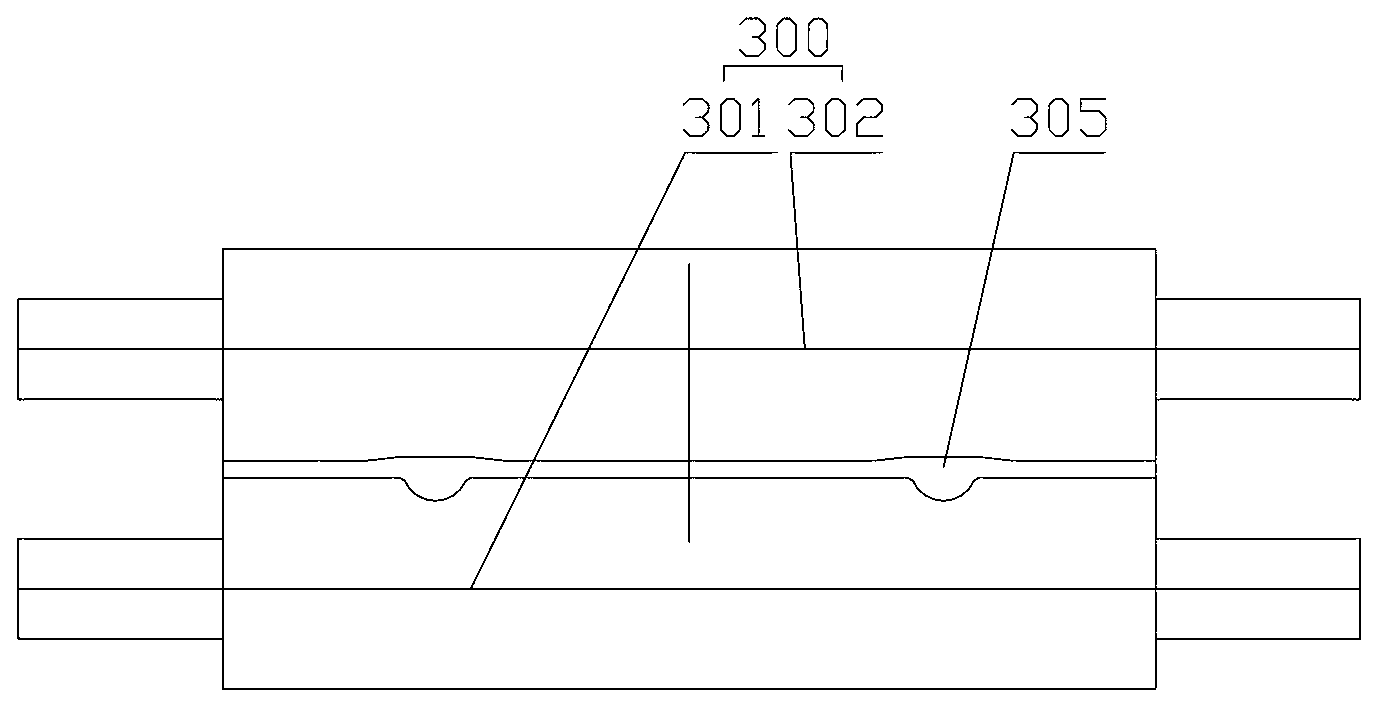

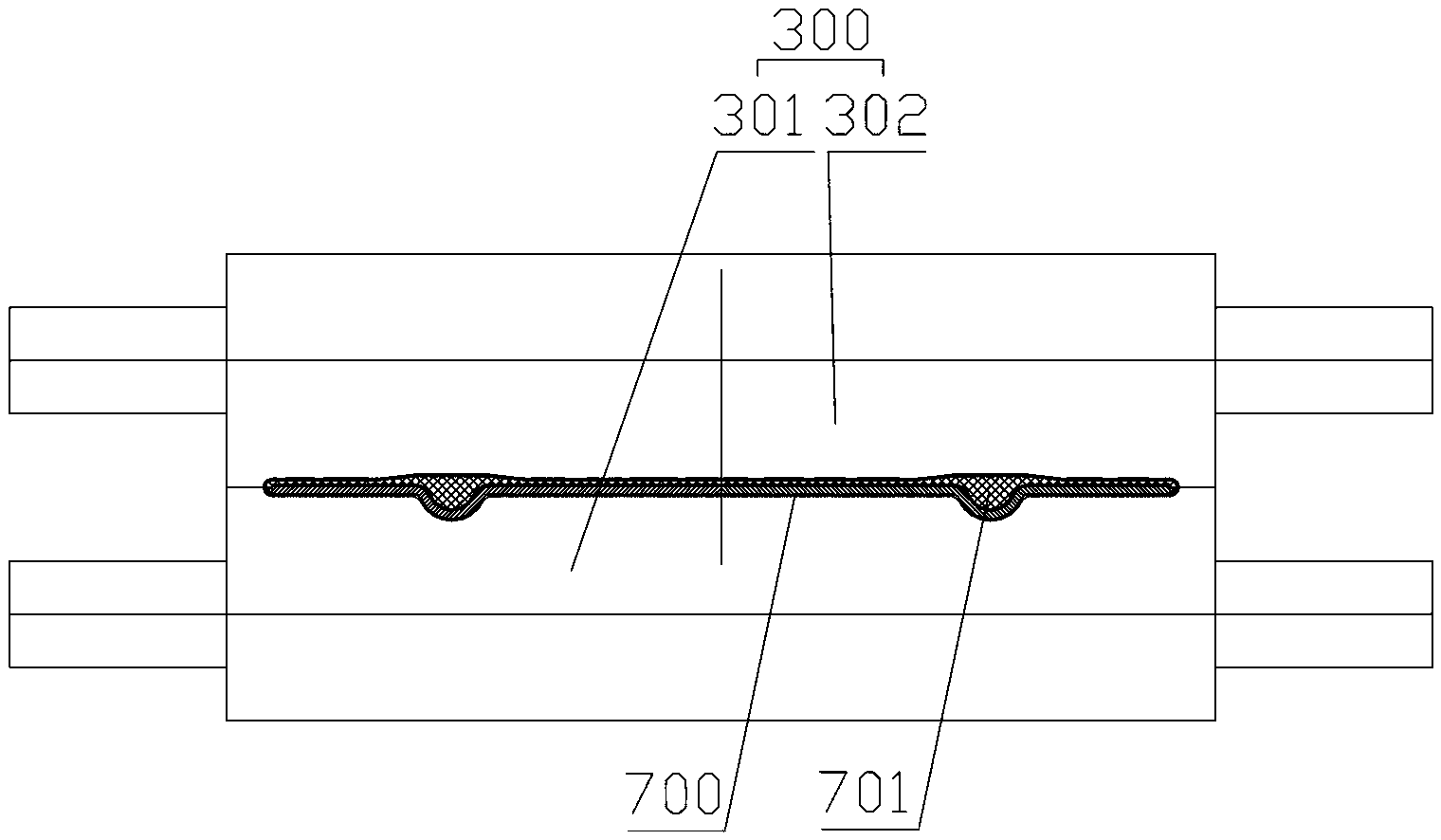

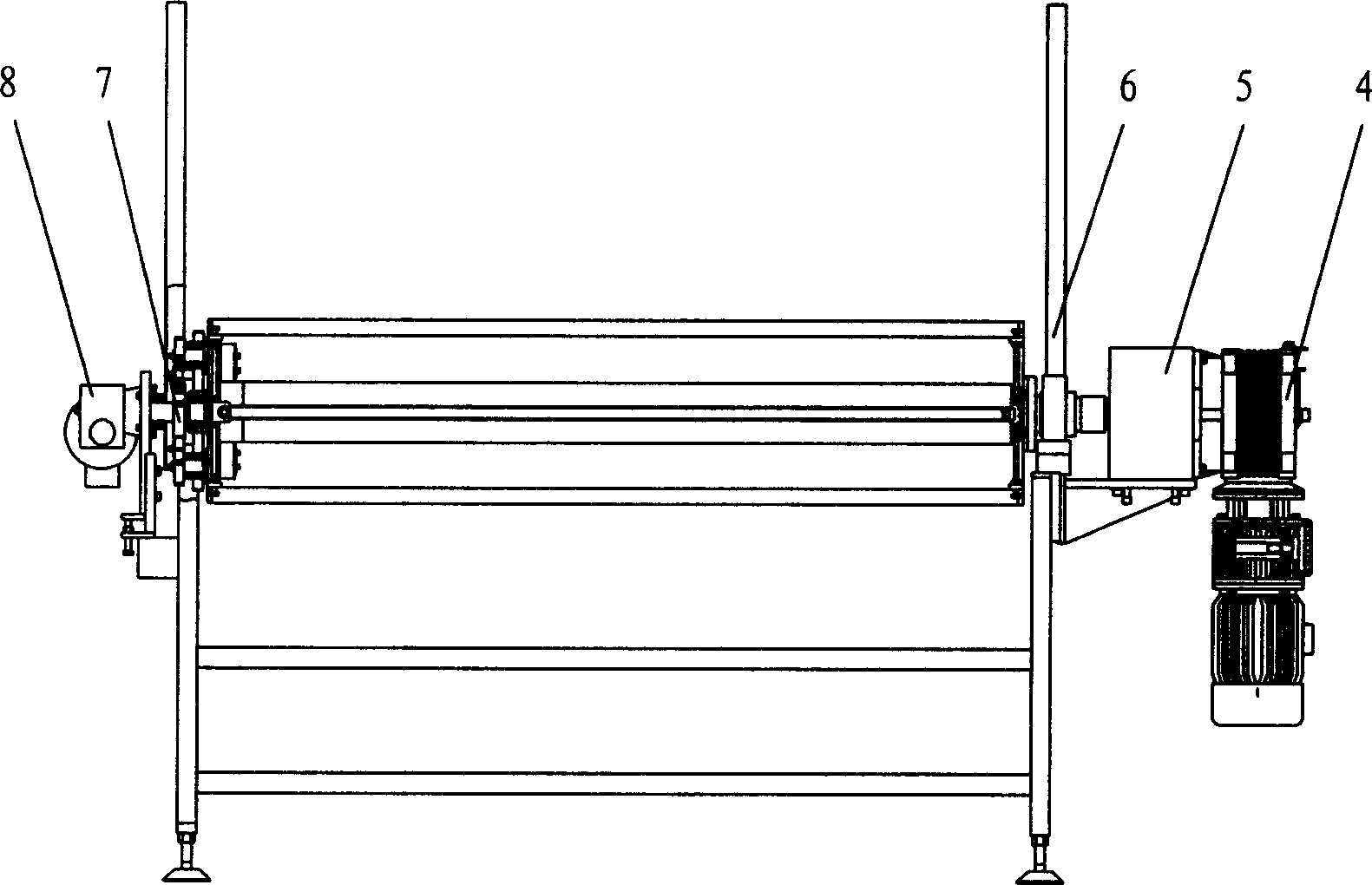

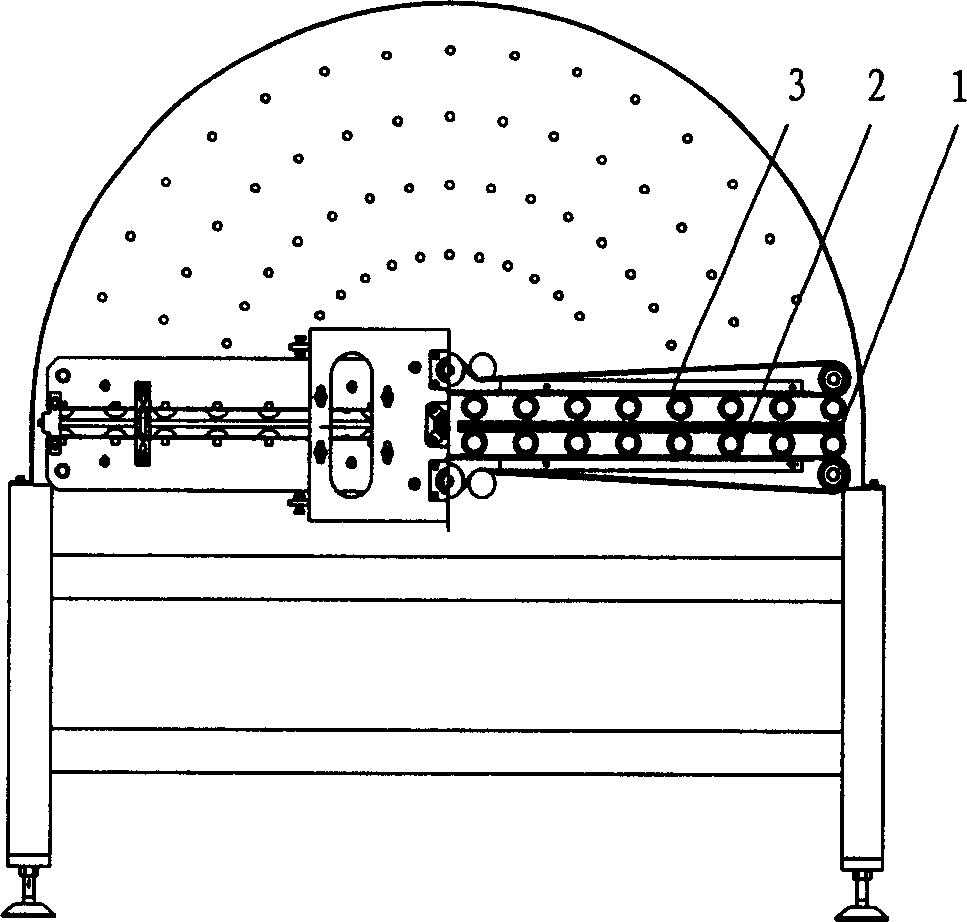

Rolling sizing device

The invention discloses a rolling sizing device comprising a frame. The following components are sequentially arranged on the frame: a rolling roller set used for carrying out drawing and progressive extrusion and sizing upon a strip-shaped thermoplastic composite material, a slow-cooling guide roller set used in further sizing, and an edge-cutting roller set used for trimming the edge of the strip-shaped thermoplastic composite material. The rolling roller set, the slow-cooling guide roller set, and the edge-cutting roller set are linearly arranged. The rolling sizing device also comprise a position adjustment mechanism used for adjusting the relative positions of the rolling roller set, the slow-cooling guide roller set, the edge-cutting roller set, and an extrusion mold. With the strip-shaped thermoplastic composite material rolling sizing device provided by the invention, strip-shaped thermoplastic composite material continuous sizing can be carried out, and the sizing is precise.

Owner:四川江瀚工业股份有限公司

Glass fiber reinforced PBT (Poly Butylenes Terephthalate) combination special for large thin-wall part and preparation method thereof

The invention discloses a glass fiber reinforced PBT (Poly Butylenes Terephthalate) combination special for a large thin-wall part and a preparation method thereof, the PBT combination comprises the following raw materials in percentage by weight: 60-90 percent of PBT, 0-25 percent of glass fiber, 1-5 percent of compatilizer, 0-20 percent of talcum powder, 0-20 percent of micro beads, 0.1-1 percent of antioxidant and 0.1-0.5 percent of lubricant. According to the invention, the problem of serious warping of the glass fiber reinforced PBT is solved by taking general PBT as a main raw material and adopting a method of double-modifying the PBT through adding minerals into the short glass fiber, and the prepared PBT combination has the advantages of low warping degree, high gloss, high flowability and excellent mechanical property, and is very suitable for the large thin-wall part.

Owner:SHANGHAI SUNNY

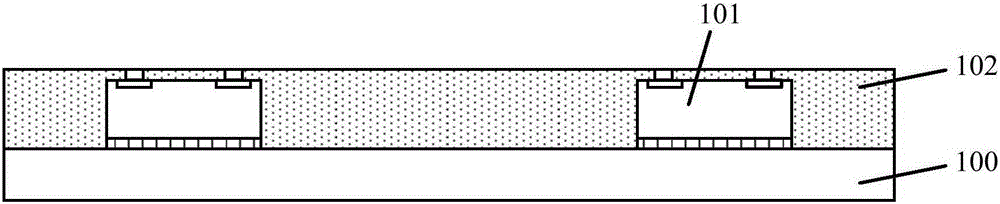

Substrate and semiconductor device using the same

InactiveUS20080179711A1Improve reliability and productivityWarpage of the entire substrate can be reducedSemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor chipSemiconductor package

According to the present invention, a plurality of semiconductor devices having semiconductor chips 13 molded on a semiconductor package substrate 1 by a molding resin 15 can be manufactured by forming recesses 10 around each semiconductor package substrate 1 composing a substrate 8 for a BGA package, and in the state where a molding resin 15 is filled on the substrate 8 including the recesses 10 for resin molding, cutting the substrate 8 and the molding resin 15 along partition lines 9.

Owner:PANASONIC CORP

Rotary forging method for large disc type work piece and forging device

InactiveCN101862807BIncrease profitReduce manufacturing costForging/hammering/pressing machinesWheelsProcessing costIndustrial engineering

The invention provides a rotary forging method for large disc type work pieces and a forging device. The method comprises preparing a forging die, preparing blanks, pre-forging a shunt slot, positioning the blanks and carrying out rotary forging in steps. Based on the method, the invention also provides a forging device which can realize relative rotation of an upper forging die and a lower die, and the local forming process for the disc type work pieces can be carried out through rotary forging of the upper forging die and the lower die. In order to control metal flow in the forging process, the procedure of pre-forging the shunt slot is added prior to the rotary forging. Moreover, the upper forging die with a special structure is adopted to overcome the warpage of the work pieces during rotary forging. The forming method has the advantages of low forming load, simple dies and low processing cost, and can greatly reduce the manufacturing cost of existing large disc type work pieces.

Owner:XI AN JIAOTONG UNIV +1

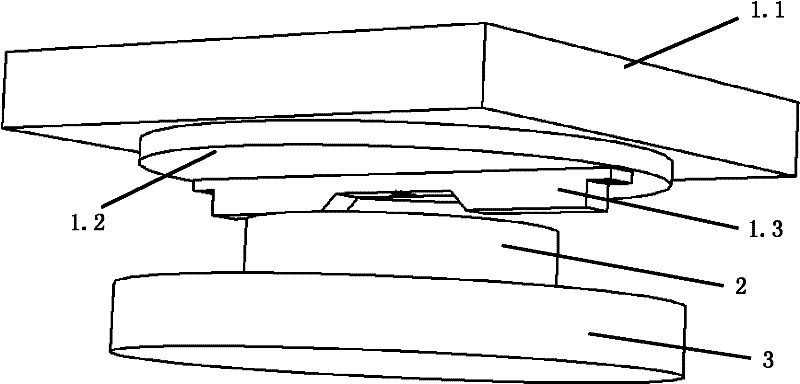

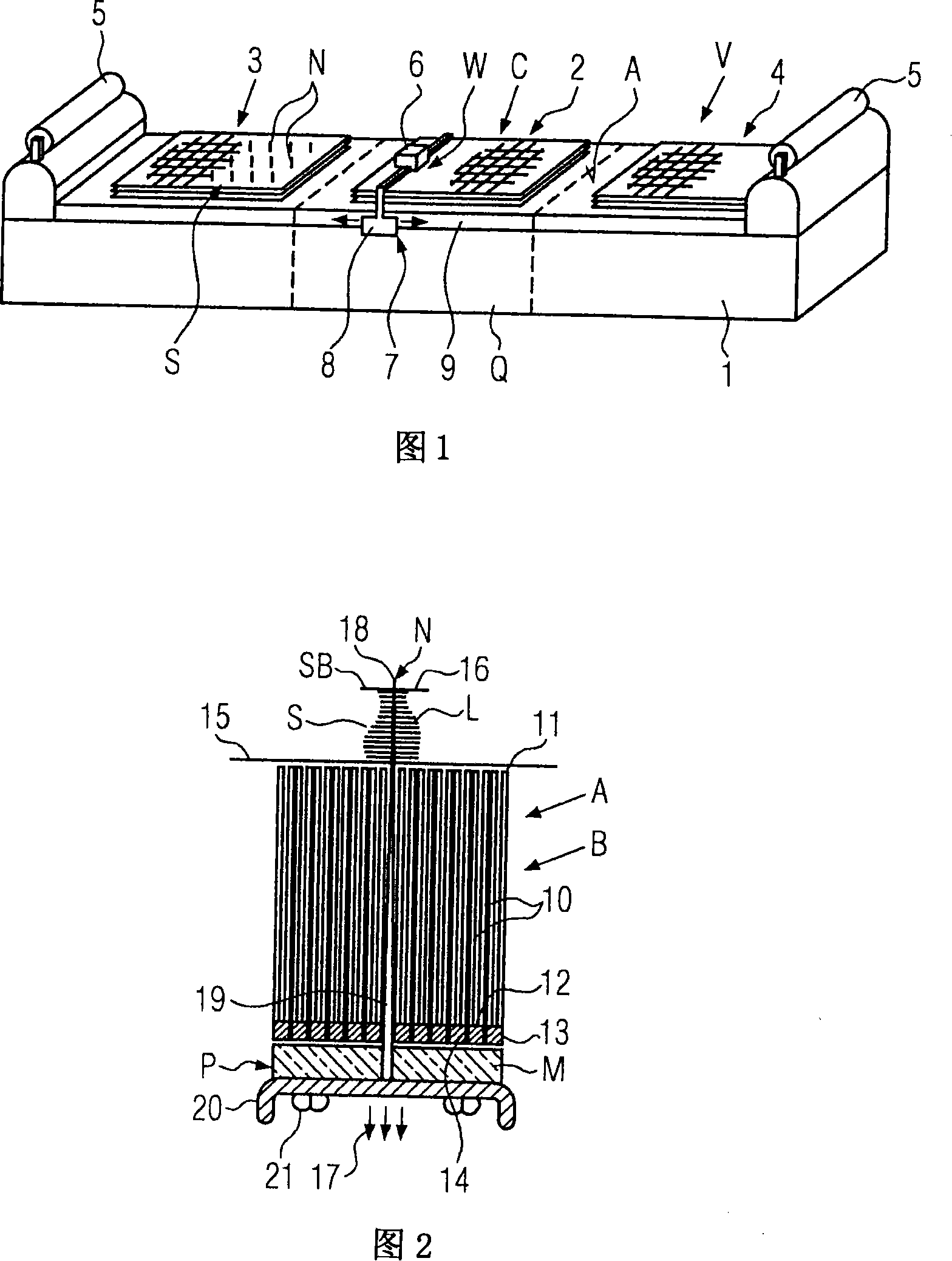

Method and apparatus for pattern cutting

InactiveCN101135111APrecise positioningDoes not affect movementSevering textilesMetal working apparatusBristleBiomedical engineering

A method for tailoring material constituted by pattern material is provided, wherein multilayer cloth layers (L) are aligned with each other accurately through inserted needle (N) according to the position selected by the pattern, the lamination with needles is positioned on a tailoring backing plate (A) and enters into a tailoring cutter (W) thereof to cut the tailoring layers, before the cloth layers are aligned, the needle (N) is positioned in the tailoring backing plate (A), the lamination (S) is formed directly on the tailoring backing plate (A) and perforated by the needle, the lamination with needles is guaranteed without relative position change relative to the tailoring backing plate (A) by the needle before being positioned through the negative pressure, before fixing tailoring, the needle (N) of the lamination is removed when necessary. In a device used in the method, the tailoring backing plate (A) is a bristle layer (B, B') provided with a needle bed layer (P) for positioning needles inserting into bristle (10) temporarily, the length of each needle is at least equal to the summation of the height of the lamination, the thickness of the needle bed layer and the bristle length on the eedle bed layer.

Owner:ESCADA SE

Semiconductor device including semiconductor chips with different thickness

ActiveUS20090184409A1Useful heatEliminate warpingSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor chip

In a stacked-type semiconductor device, a first semiconductor device and at least one second semiconductor device are stacked. The first semiconductor device includes a wiring board and a first semiconductor chip mounted on the wiring board. The second semiconductor device includes a wiring board and a second semiconductor chip mounted on the wiring board. The thickness of the second semiconductor chip of each second semiconductor device is thicker than the thickness of the first semiconductor chip.

Owner:LONGITUDE LICENSING LTD

Heating and rolling method for wide thick titanium-steel composite plate

InactiveCN109351774AHeating evenlyEliminate head tearsWork heating devicesMetal rolling arrangementsForeign matterTitanium

The invention discloses a heating and rolling method for a wide thick titanium-steel composite plate. The heating and rolling method comprises the heating step and the rolling step. In the heating step, a titanium-steel composite plate blank is heated under the atmosphere of micro positive pressure and weak oxidability; heat preservation is conducted for 1.0-1.5 h at the temperature of 650 DEG C-700 DEG C in the preheating section; then, the temperature is rapidly increased to 880 DEG C-900 DEG C with 1.0-2.0 h in the heating section, and heat preservation is conducted for 1.0-2.0 h; and finally, heat preservation is conducted for 4.0-5.0 h at the temperature of 900 DEG C-930 DEG C in the soaking section. According to the method, in the heating step, heating of the titanium-steel compositeplate is uniform, the phenomena of head tearing, head buckling, upwarping and edge part folding in the titanium-steel composite plate rolling process are eliminated, the rolled plate shape is good, the surface is clean and tidy, edge part folding and foreign matter pressing-in are avoided, the performance is excellent, and the yield and the production efficiency are improved. The titanium-steel composite plate rolled through the method is free of the tearing phenomenon, the performance meets the GB / T8547 requirement, the surface is clean and tidy, edge part folding and foreign matter pressing-in are avoided, and the plate shape is good.

Owner:WUYANG IRON & STEEL

Lead-Free Solder Ball

ActiveUS20150221606A1Reduce the amount requiredFusion defectPrinted circuit assemblingNon-insulated conductorsBond interfaceThermal fatigue

A lead-free solder ball is provided which suppresses interfacial peeling in a bonding interface of a solder ball, fusion defects which develop between the solder ball and solder paste, and which can be used both with Ni electrodes plated with Au or the like and Cu electrodes having a water-soluble preflux applied atop Cu. The lead-free solder ball for electrodes of BGAs or CSPs consists of 1.6-2.9 mass % of Ag, 0.7-0.8 mass % of Cu, 0.05-0.08 mass % of Ni, and a remainder of Sn. It has excellent resistance to thermal fatigue and to drop impacts regardless of the type of electrodes of a printed circuit board to which it is bonded, which are Cu electrodes or Ni electrodes having Au plating or Au / Pd plating as surface treatment. The composition may include at least one element selected from Fe, Co, and Pt in a total amount of 0.003-0.1 mass % or at least one element selected from Bi, In, Sb, P, and Ge in a total emount of 0.003-0.1 mass %.

Owner:SENJU METAL IND CO LTD

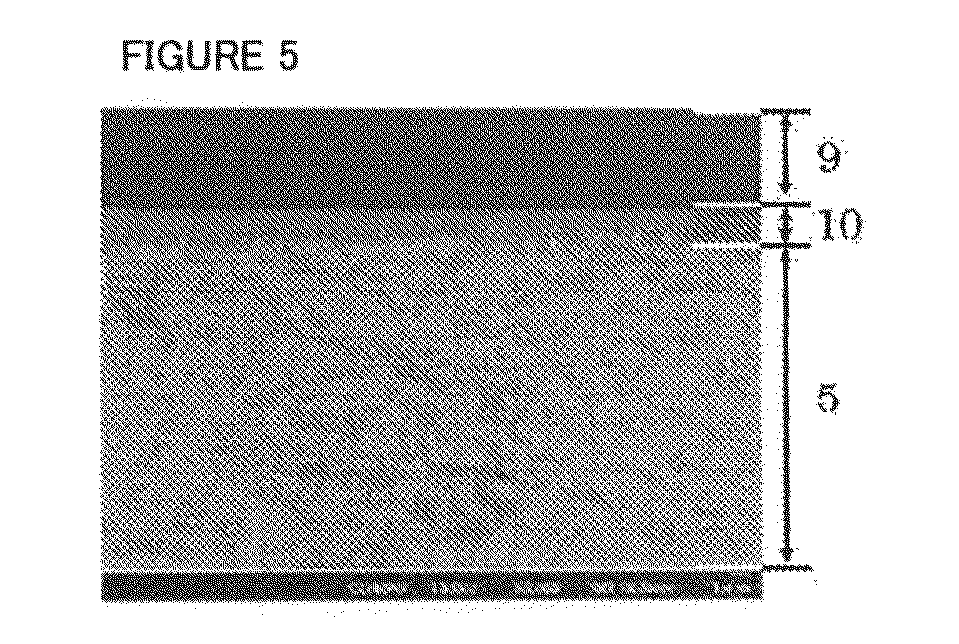

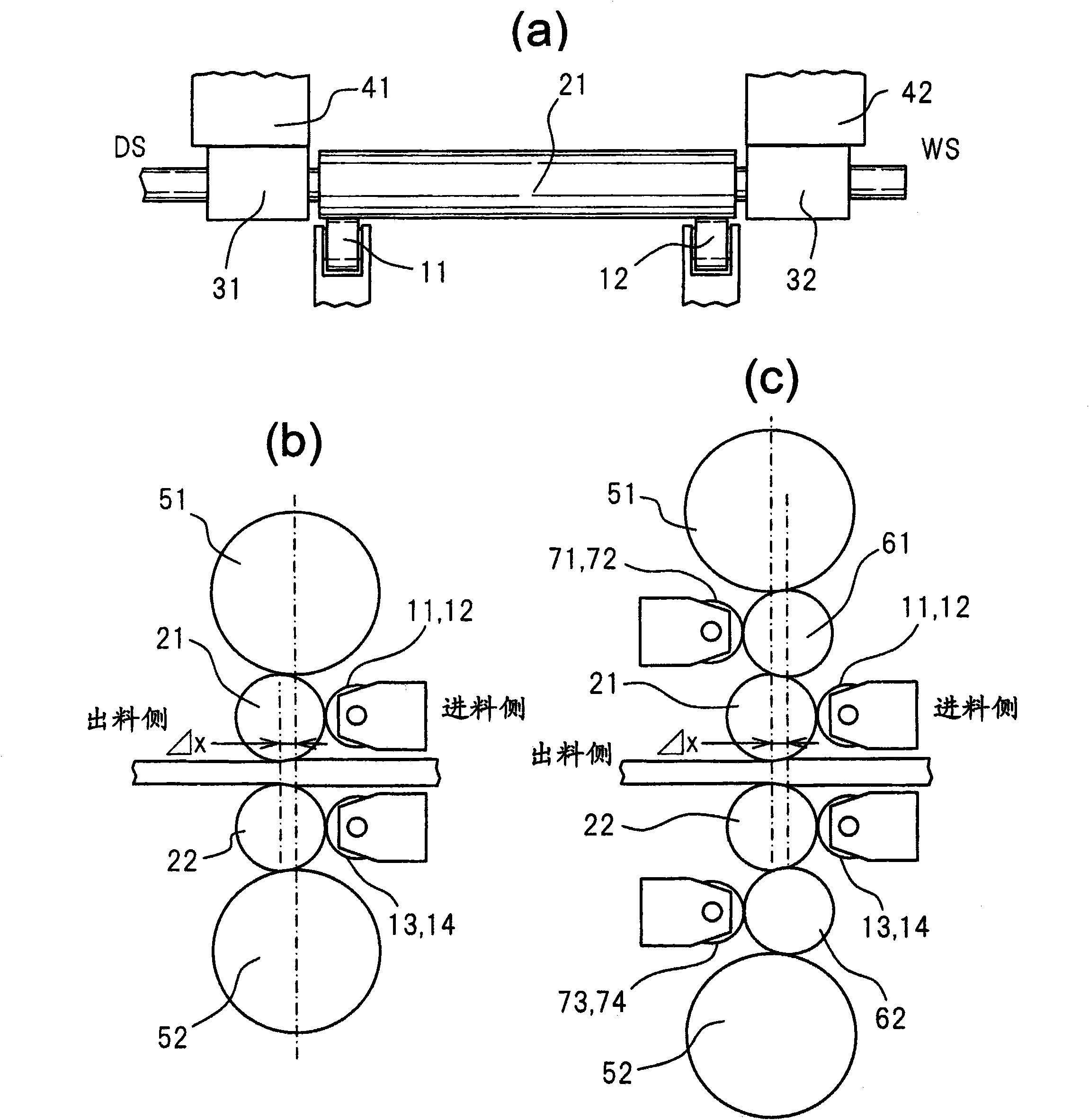

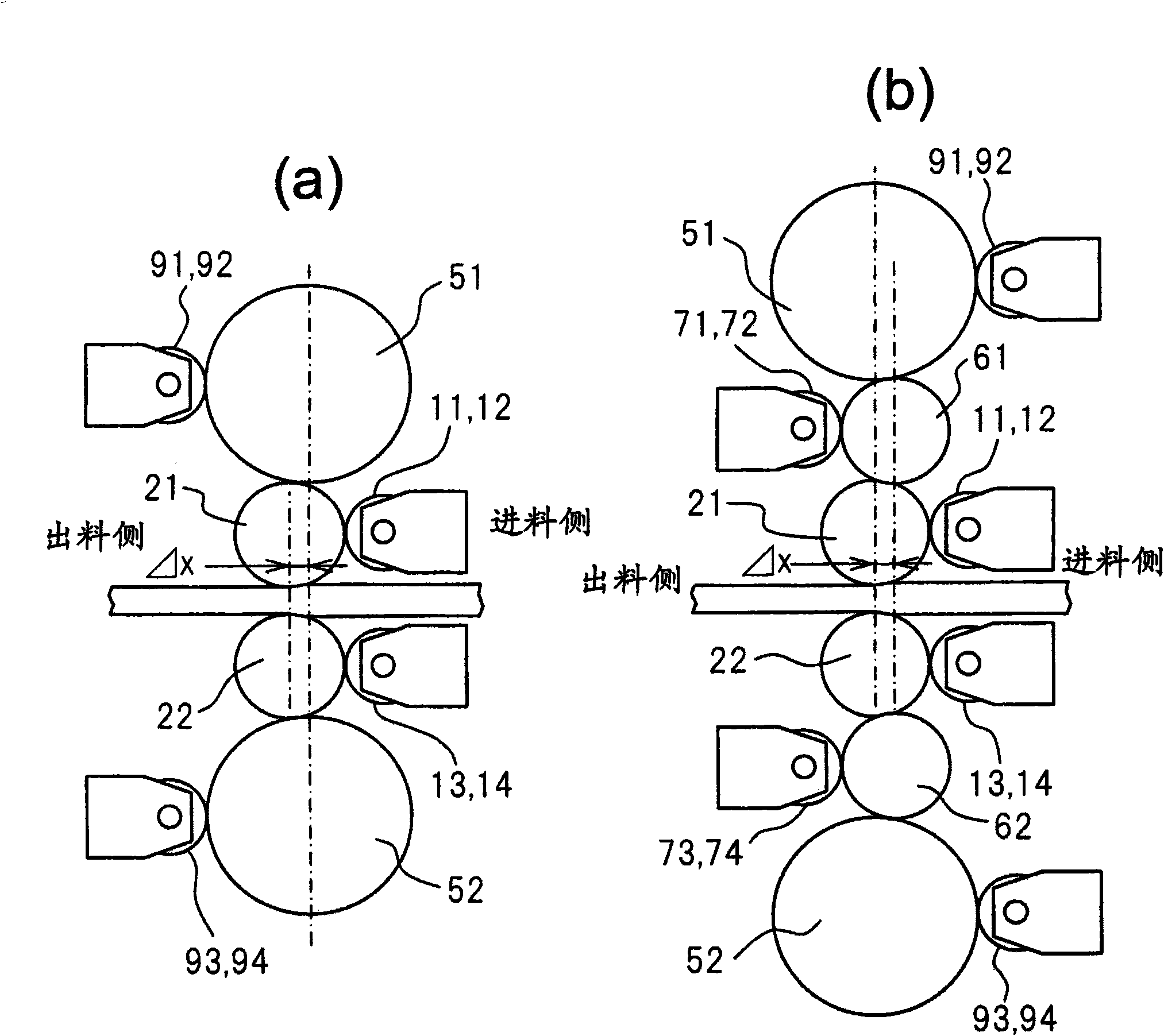

Plate rolling mill and plate rolling method

ActiveCN101918155ALarge deflectionConducive to loadMetal rolling stand detailsRoll mill control devicesWork rollElectric motor

Disclosed is a plate rolling mill wherein a kiss roll-tightening state such as zero point adjusting work before rolling, and deviations in offset of work rolls in the right / left or up / down directions of a rolling mill during rolling are eliminated, and such problems as warpage of a plate and meandering or camber caused by a thrust force produced between a work roll and a reinforcing roll are eliminated. The plate rolling mill comprises a pair of upper and lower work rolls being driven by an electric motor, a pair of upper and lower reinforcing rolls for supporting rolling reactions being loaded on to the work rolls by touching the work rolls, and a device for loading an external force substantially in the horizontal direction on to the upper and lower work rolls, respectively, characterized in that the external force in the horizontal direction being loaded on to the work rolls is in the same direction as the horizontal components of rolling reactions being loaded on to the work rolls by offset in the rolling direction, and the external force in the horizontal direction loaded on to the work rolls is supported by the project block of a rolling mill housing or a supporting member of a work roll chock. A plate rolling method using the plate rolling mill is also provided.

Owner:NIPPON STEEL CORP

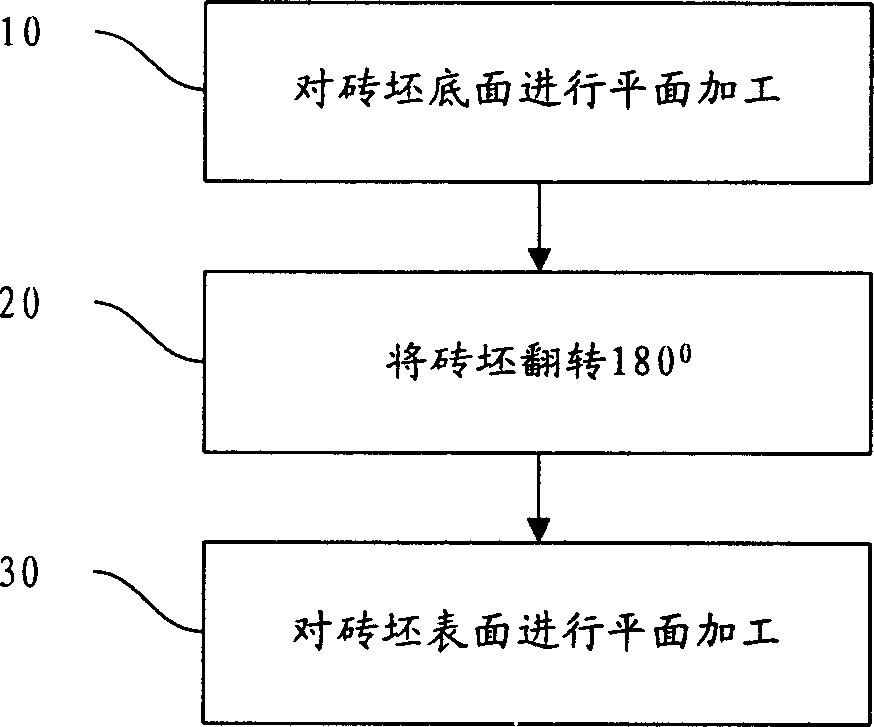

Ceramic polishing brick surface processing method and device

InactiveCN1876346ASolve rationalitySolve the accuracy problemPolishing machinesCeramic shaping plantsBrickMaterials science

The invention relates to a method for preparing ceramic burnishing brick surface and the device, the process comprises surface working for brick blank floor, inverting brick for 180 degree and surface working the brick blank, the surface working for brick blank floor is dubbing the brick blank floor, the working for brick blank surface comprising butting, surface milling and grinding and polishing brick blank surface in sequence. The preparing device comprises conveying line for brick blank, bottom milling device for surface working of brick blank bottom, reversing device and surface treating device assembly, which are connected together through conveying line. The invention is characterized by increased working efficiency by 10-20%, reduced damage rate for brick blank preparation by 20-40 %, and increased surface plainness of ceramic polishing brick by 20-30%.

Owner:KEDA INDUSTRIAL GROUP CO LTD

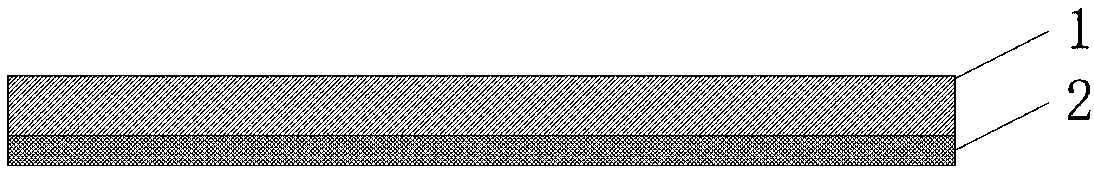

Adhesive sheet, metal laminate sheet and printed wiring board

ActiveCN101193751AEliminate warpingEliminate deformationSynthetic resin layered productsPrinted circuit aspectsEngineeringPolyimide membrane

Disclosed is an adhesive sheet comprising a base film and an adhesive layer formed on at least one side of the base film. The base film is composed of a polyimide film whose degree of curling is not more than 10% after a heat treatment at 300 DEG C. Since this adhesive sheet is suppressed in warping or strain caused by high-temperature treatments, it can be used for electronic devices and the like which are exposed to high temperatures and enables to improve the qualities and yields of the electronic devices and the like.

Owner:TOYOBO CO LTD

Wafer warping elimination method and composite substrate

InactiveCN108183065AEliminate warpingEasy to identify and locateSemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideComposite substrate

The invention discloses a wafer warping elimination method and a composite substrate. The method comprises steps that S1, a warped wafer (1) is selected; S2, a stress compensation film (2) internallyhaving the stress is deposited at a back surface of the wafer (1), and the internal stress of the stress compensation film (2) is made to offset the internal stress of the wafer (1) to acquire a flatcomposite substrate; and the wafer (1) is a silicon carbide based silicon carbide wafer or a silicon-based gallium nitride wafer; the composite substrate comprises the wafer (1) and the stress compensation film (2), wherein the stress compensation film (2) covers the back surface of the wafer (1), the internal stress of the stress compensation film (2) is made to offset the internal stress of thewafer (1), and the wafer (1) is the silicon carbide based silicon carbide wafer or the silicon-based gallium nitride wafer. The wafer warping elimination method is advantaged in that the stress compensation film internally having the stress is deposited at the back surface of the warped wafer, the internal stress of the stress compensation film (2) is made to offset the internal stress of the wafer (1), and the warping phenomenon is eliminated.

Owner:BEIJING PINJIE ELECTRONICS TECH CO LTD

Preparation method and device of LED epitaxial wafer

InactiveCN102074624AReduce manufacturing costEliminate warpingSemiconductor devicesEngineeringSingle crystal

The invention relates to a preparation method and device of an LED epitaxial wafer. The method comprises the following step of applying a pressure which is opposite to the direction of a force capable of resulting in partial warping of a substrate to partial substrate during the process for heating the substrate to grow a single crystal film so as to control the substrate at a flat state. The method is carried out by means of fixed mechanism. The preparation method and device of an LED epitaxial wafer provided by the invention have the advantages that the warping phenomenon of sapphire wafers and the like substrates can be effectively removed at a high temperature, the substrate with a relatively small thickness can be directly applied to epitaxial growth, the substrate material is saved, the normal reduction and the like operations are prevented, the manufacture cost of LED epitaxial wafers is reduced greatly, and the production efficiency and the production yield of LED epitaxial wafer are effectively improved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Chucking device and chucking method

InactiveCN102543814AEliminate warpingImprove flatnessSleeve/socket jointsSemiconductor/solid-state device manufacturingForeign objectEngineering

The invention provides a chucking device and chucking method that can prevent a foreign object being caught between the device and a semiconductor substrate and can hold the semiconductor substrate in a condition in which the semiconductor substrate flatness is maintained or increased. The chucking device includes plural protruding portions that support the central portion of a semiconductor substrate and that are provided on a base portion. The chucking device also includes a cylindrical peripheral portion that supports the outer peripheral portion of the semiconductor substrate, plural suction holes that chuck the semiconductor substrate, and a vacuum source that vacuum draws the plural suction holes at differing timings. A plurality of mutually independent vacuum drawable suction holes are provided in at least one portion of the protruding portions. The vacuum drawable suction holes are independently arranged in the peripheral portion. After the semiconductor substrate is arranged on the protruding portions and the peripheral portion, the suction holes are drawable by using the vacuum source and on the semiconductor substrate at differing timings.

Owner:FUJI ELECTRIC CO LTD

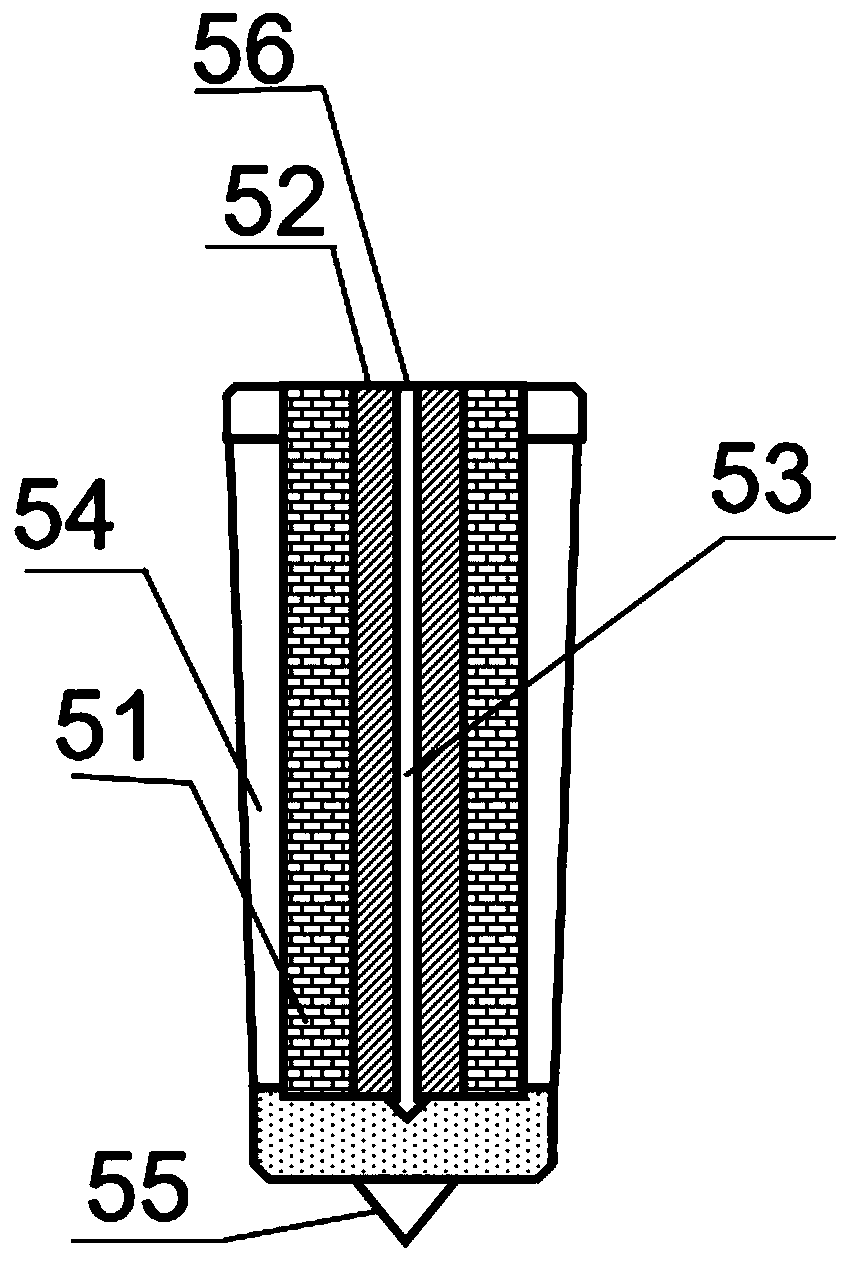

Spray type 3D printing device and method based on composite material

ActiveCN110355993AOvercome the problem of many internal defectsSimple structureAdditive manufacturing apparatus3D object support structuresSpray nozzleEngineering

The invention discloses a spray type 3D printing device and method based on a composite material, and belongs to the technical field of 3D printing. The problem that many internal defects of a 3D printing product in the prior art exist is solved. Powder of an object to be printed is thoroughly mixed through a mixing system, then raw materials are fully melted through a dispersion system, a meltingsystem and a cooling system, and printing is completed by an atomizing spray head after dispersion even distribution is carried out; a heating chamber in the spray head heats and melts a wire in a molten throat pipe, complete melting of the wire is further ensured, and liquid can stably flow after melting; and in addition, air pressure in an air supply passage is accurately controlled, the size and shape of jet nozzles of the spray head are intelligently selected according to the object to be printed, one from point spray, line spray and surface spray can be selected according to the conditions, uneven temperature release in the printing process is reduced, the influence of material stress is eliminated, the warpage of time is eliminated, the defects are reduced, and the processing efficiency is improved.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com