Preparation method and device of LED epitaxial wafer

A technology for LED epitaxial wafers and preparation devices, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as waste of materials, expensive equipment, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

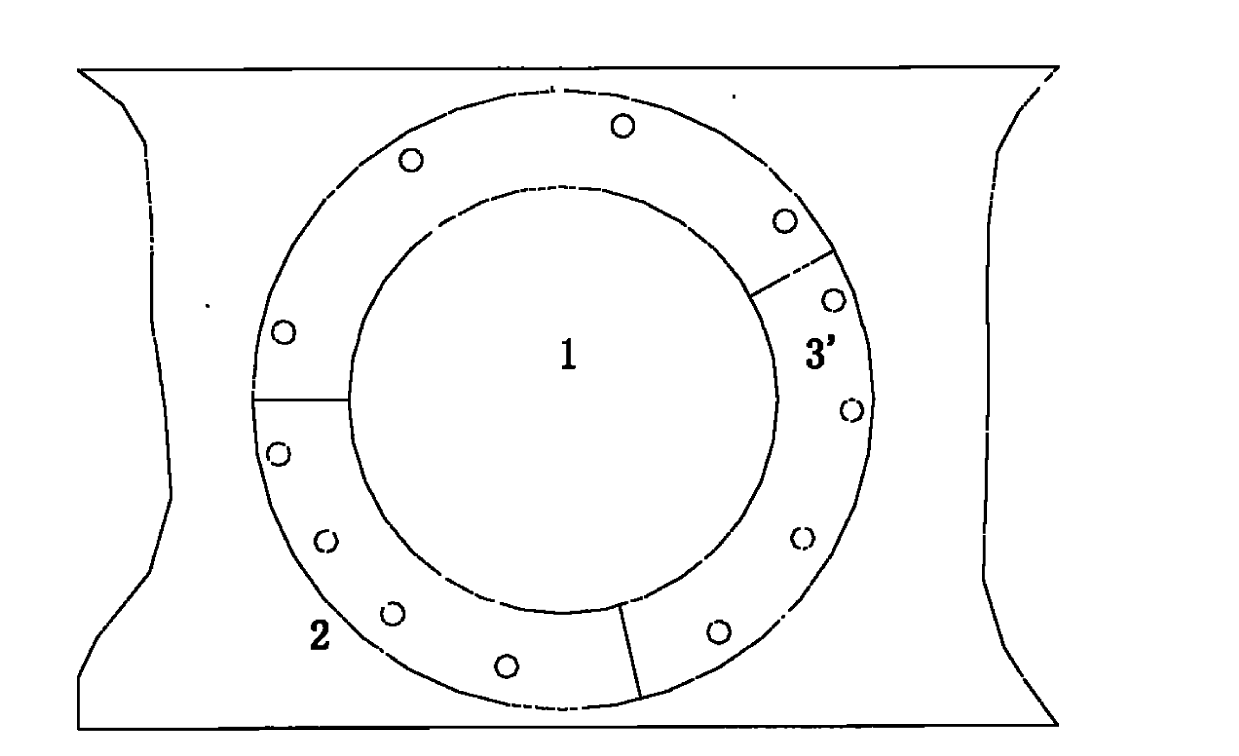

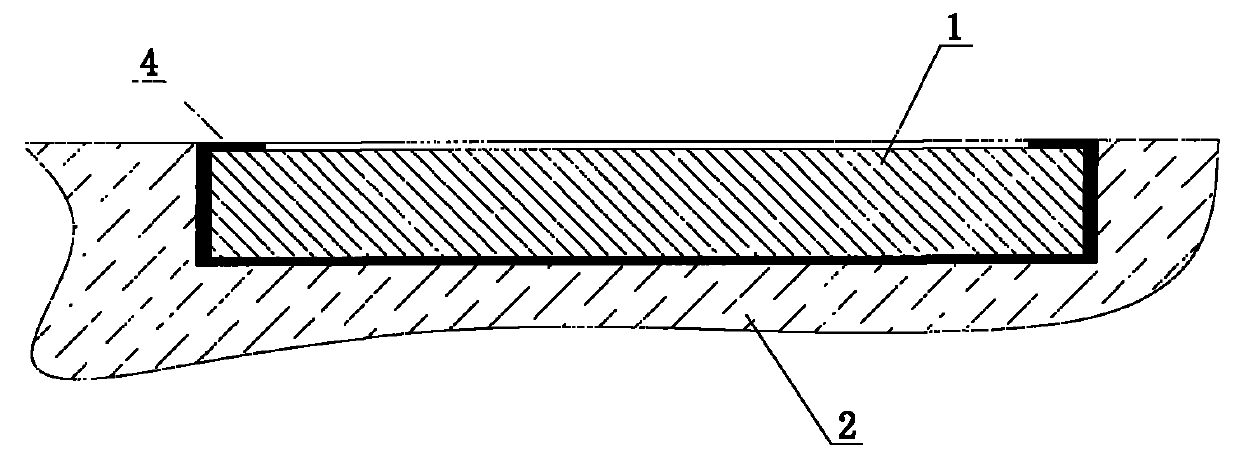

[0038] Embodiment 1 In the preparation method of the LED epitaxial wafer, a sapphire substrate 1 with a thickness of about 100 μm is placed in a holding tank on a graphite disk 2 for heating, and a plurality of pressing sheets are distributed in a ring around the holding tank, so One end of the pressing sheet is fixed on the graphite disc, and the other end is pressed on the ring-shaped area of the upper end surface of the sapphire substrate except for the epitaxial wafer growth area, and the sapphire substrate is locally applied and causes the substrate to be locally warped. The pressure in the opposite direction of the force keeps the substrate flat.

[0039] The aforementioned pressed sheet is made of a material capable of maintaining the original shape at the aforementioned heating temperature, such as boron nitride.

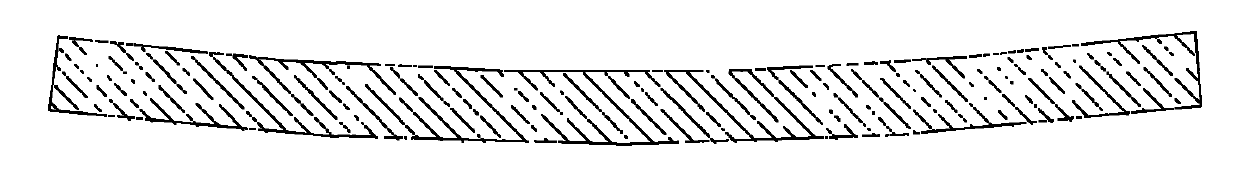

[0040] refer to Figure 2-3 , the pressing sheet can be a plurality of strip pressing sheets 3, one end of each pressing sheet is fixed on the graphite d...

Embodiment 2

[0042] Example 2 In the preparation method of the LED epitaxial wafer, a 2-inch sapphire substrate with a thickness of about 100 μm is placed in a holding tank on a graphite disk for heating, and a set of The upper end surface of the sleeve is provided with an annular opening, and the annular surface is pressed on the upper end surface of the sapphire substrate along the circumferential direction, and the local pressure on the sapphire substrate is opposite to the direction of the force that causes the local warping of the substrate. , the area on the sapphire substrate corresponding to the opening of the casing is the area reserved for epitaxial wafer growth.

[0043] The aforementioned casing includes at least two parts that can be detached along the horizontal direction.

[0044]The aforementioned casing is made of materials capable of maintaining the original shape at the aforementioned heating temperature, such as graphite, tungsten alloy, boron nitride, and the like.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com