Rotary forging method for large disc type work piece and forging device

A rotary forging and rotary forging technology, which is applied in forging/pressing/hammer devices, manufacturing tools, vehicle parts, etc., can solve the problems of low material utilization rate, large amount of machining, and high manufacturing cost, so as to reduce the amount of machining, Less stress and deformation, lower manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

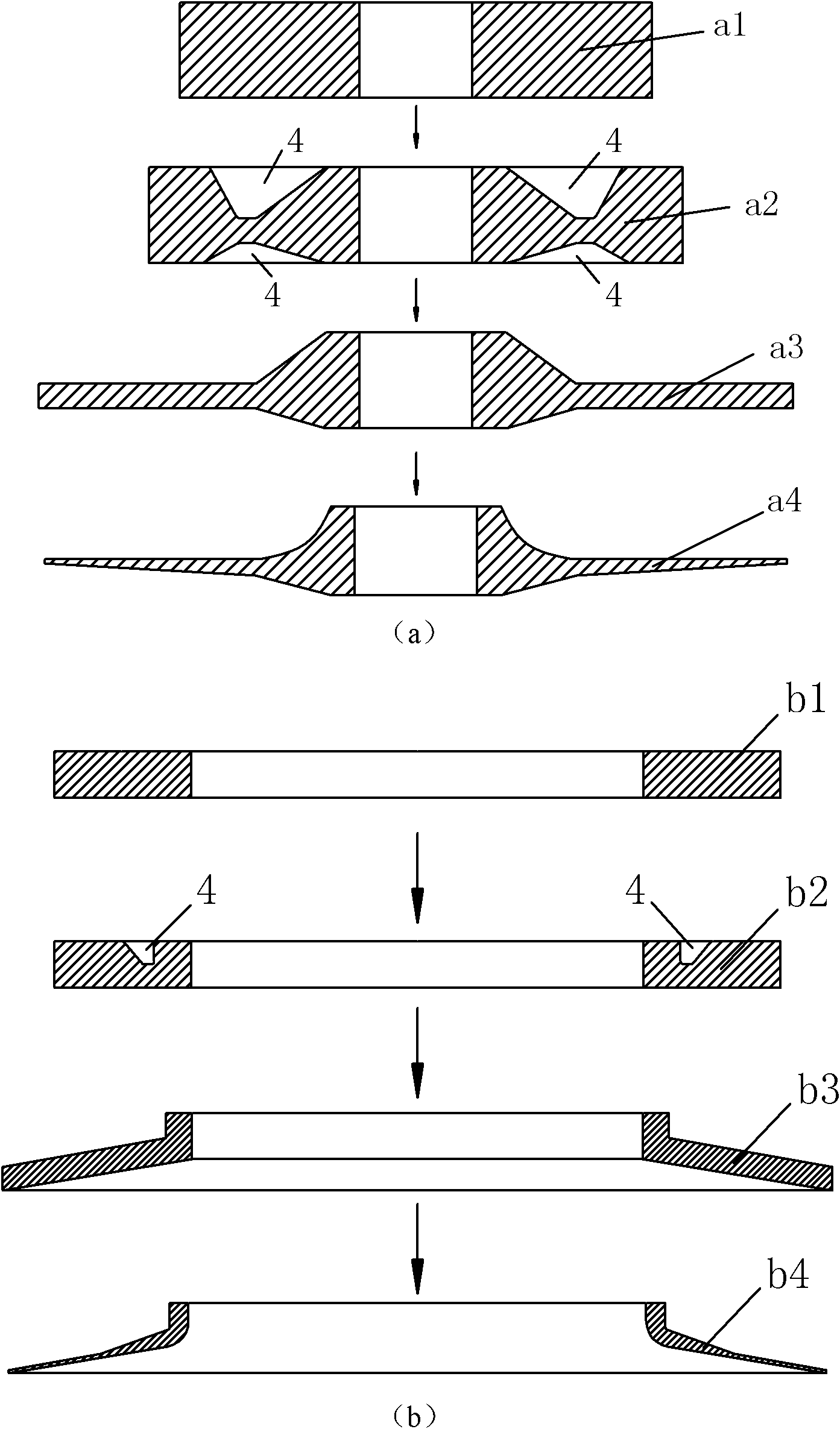

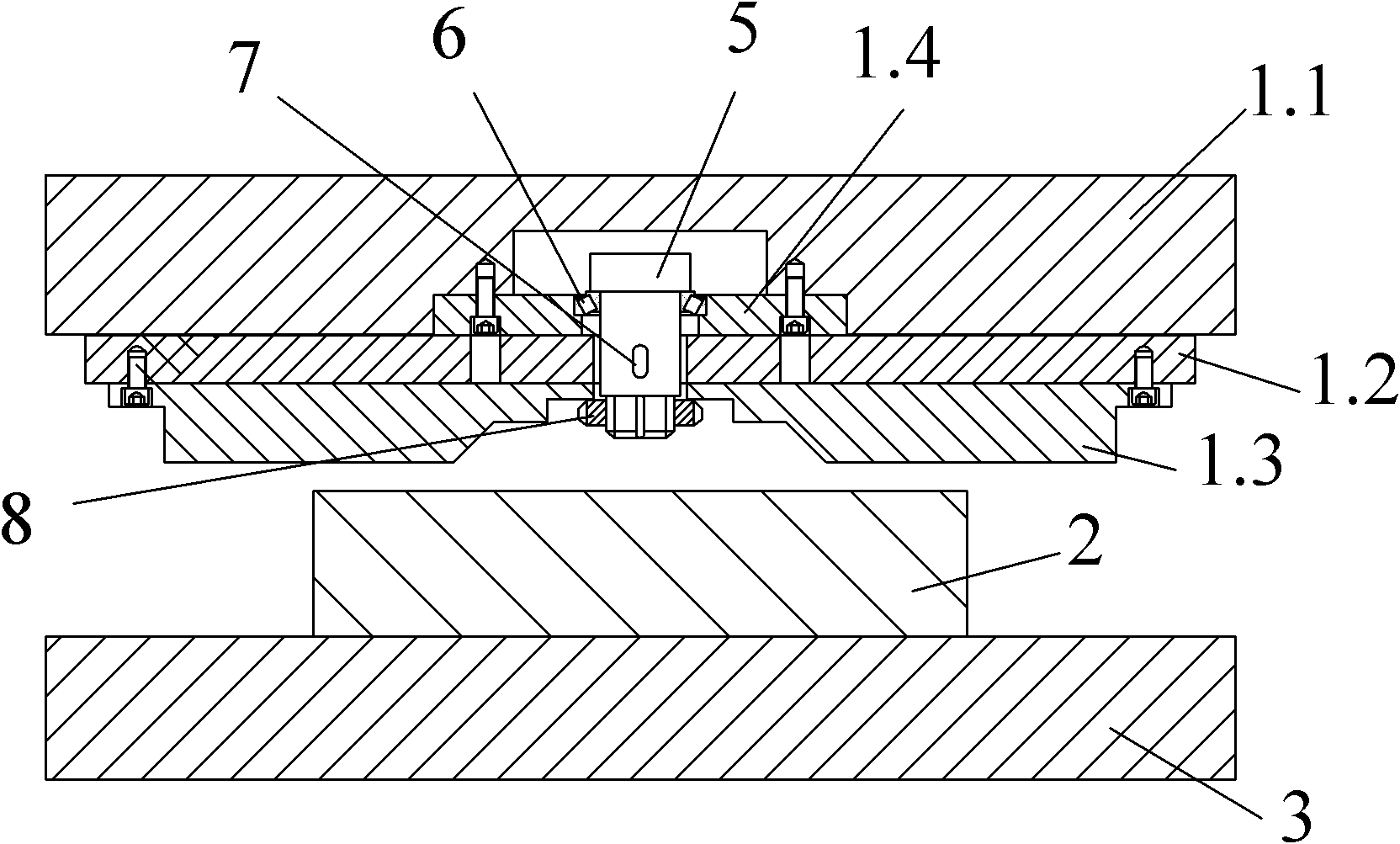

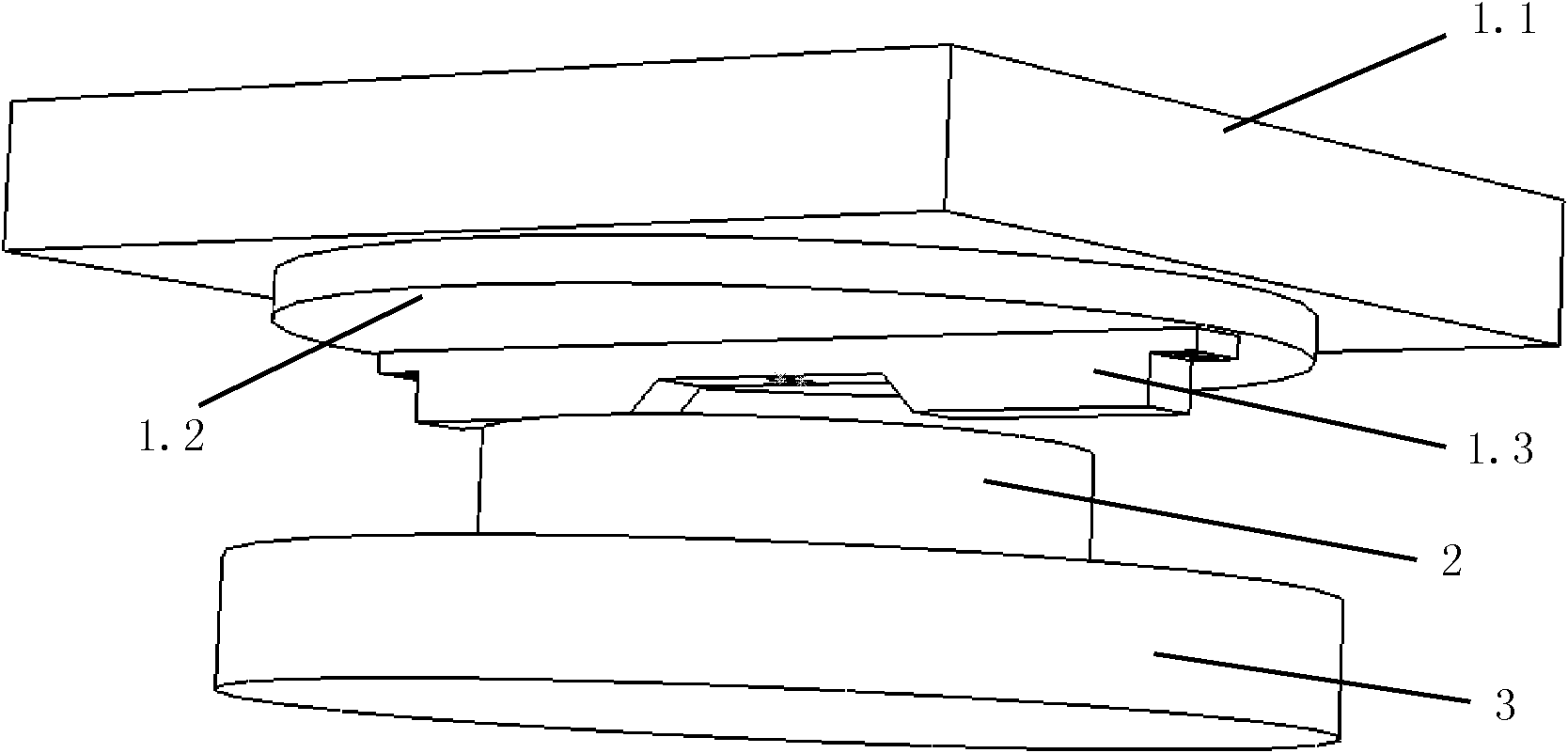

[0027] The rotary forging method of the large disk type parts of the present invention specifically follows the steps: A. The design of the forging die makes the forging die consist of an upper forging die and a lower die, and the upper forging die is designed to be composed of one or more rectangular strips Shaped forging die assembly constitutes an axisymmetric structure, the lower profile of the vertical section of the rectangular strip-shaped forging die assembly is the same as the upper profile of the central section of the processed large-scale disc workpiece; B. blank preparation, pre-forging split Slot preparation of circular plates or round blanks (eg figure 1 a1 or b1) and heated to the initial forging temperature of the blank metal material; then adopt the integral die forging method to shape or the step-by-step rotary forging method to pre-forge the splitter groove 4 on the blank; then heat the pre-forging to the initial forging temperature; C. Positioning the blan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com