Patents

Literature

260results about How to "Reduce the amount of machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

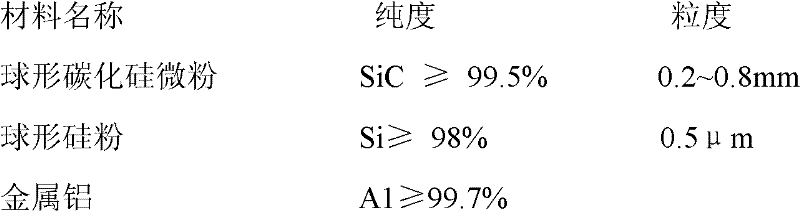

Method for preparing aluminum silicon carbide composite material

The invention discloses a method for preparing an aluminum silicon carbide composite material. Liquid metal aluminum is filled in a porous silicon carbide substrate which is prepared from spherical silicon carbide powder and spherical silicon powder which serve as raw materials and has a three-dimensional through hole structure through an injection molding process so as to form a bicontinuous phase, the density of the aluminum silicon carbide composite material and the product uniformity are improved, and a high-strength AlSiC substrate is obtained by changing molding pressure, adjusting ingredients of the spherical powder with different particle sizes, adding a pore-forming agent, and sintering at the temperature of between 1,400 and 2,400 DEG C. The porous substrate is fixed in a cavityof an injection machine, and the liquid metal aluminum enters the cavity from an injection port and is filled in through holes of the AlSiC substrate through a gas-liquid mixed injection process so as to form the aluminum silicon carbide composite material with a silicon carbide and metal aluminum bicontinuous phase structure. The aluminum silicon carbide composite material prepared by the process has the heat conductivity of 190 to 280 W / mK and the thermal expansion coefficient of 5.5 to 11.5*10(-6)K at room temperature of 200 DEG C, and has high rigidity, low density, high weldability and low machining amount.

Owner:CENT SOUTH UNIV

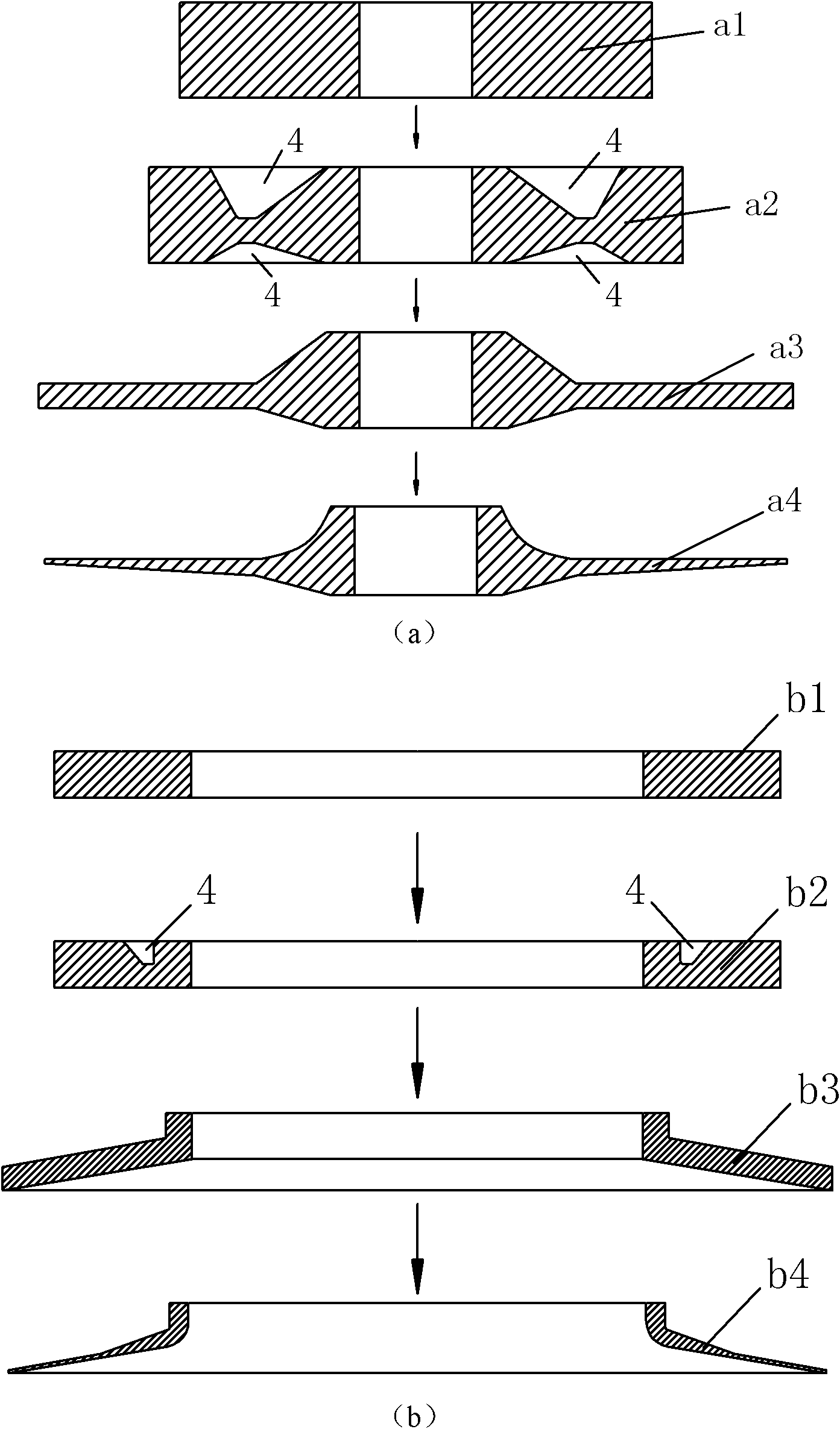

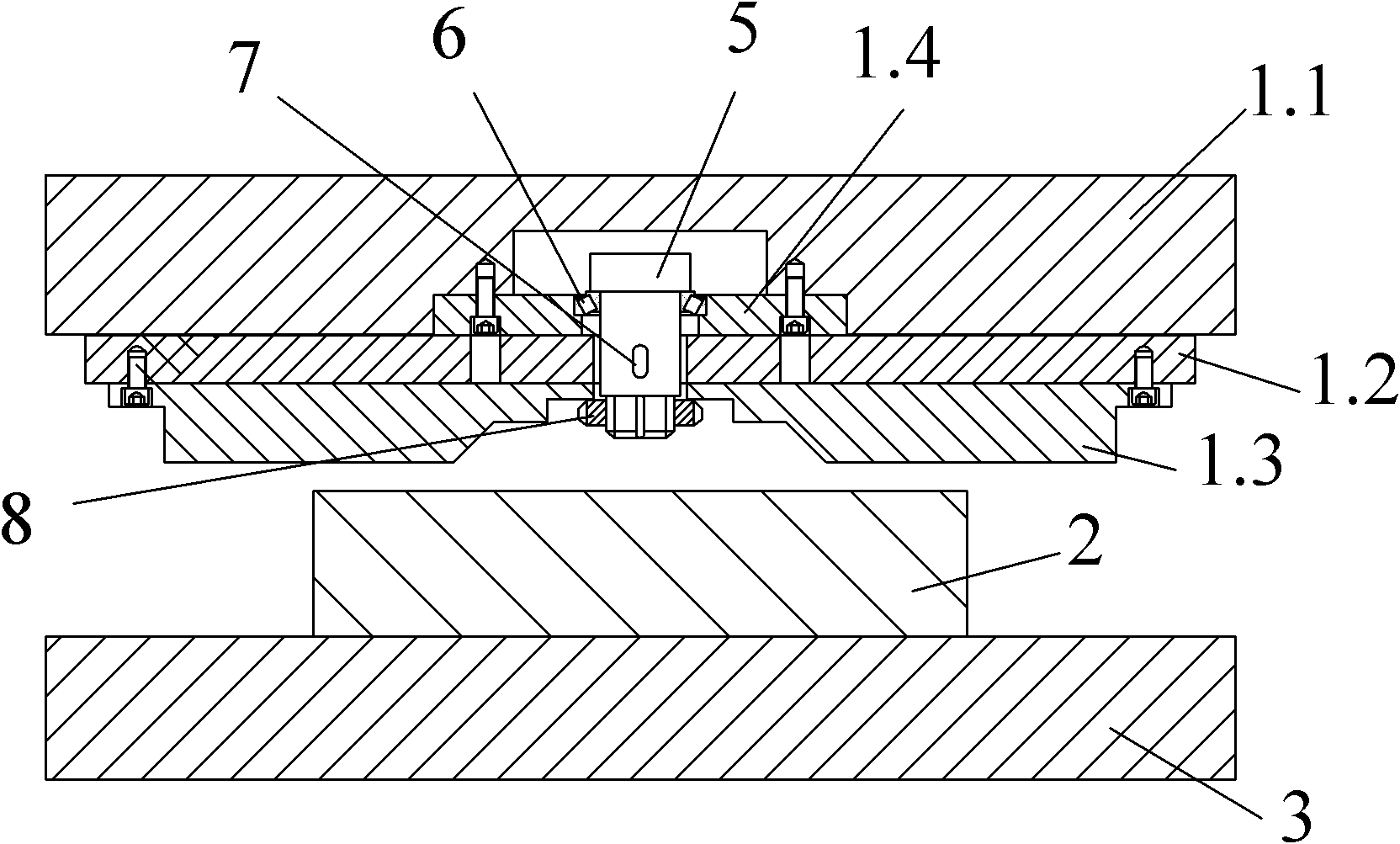

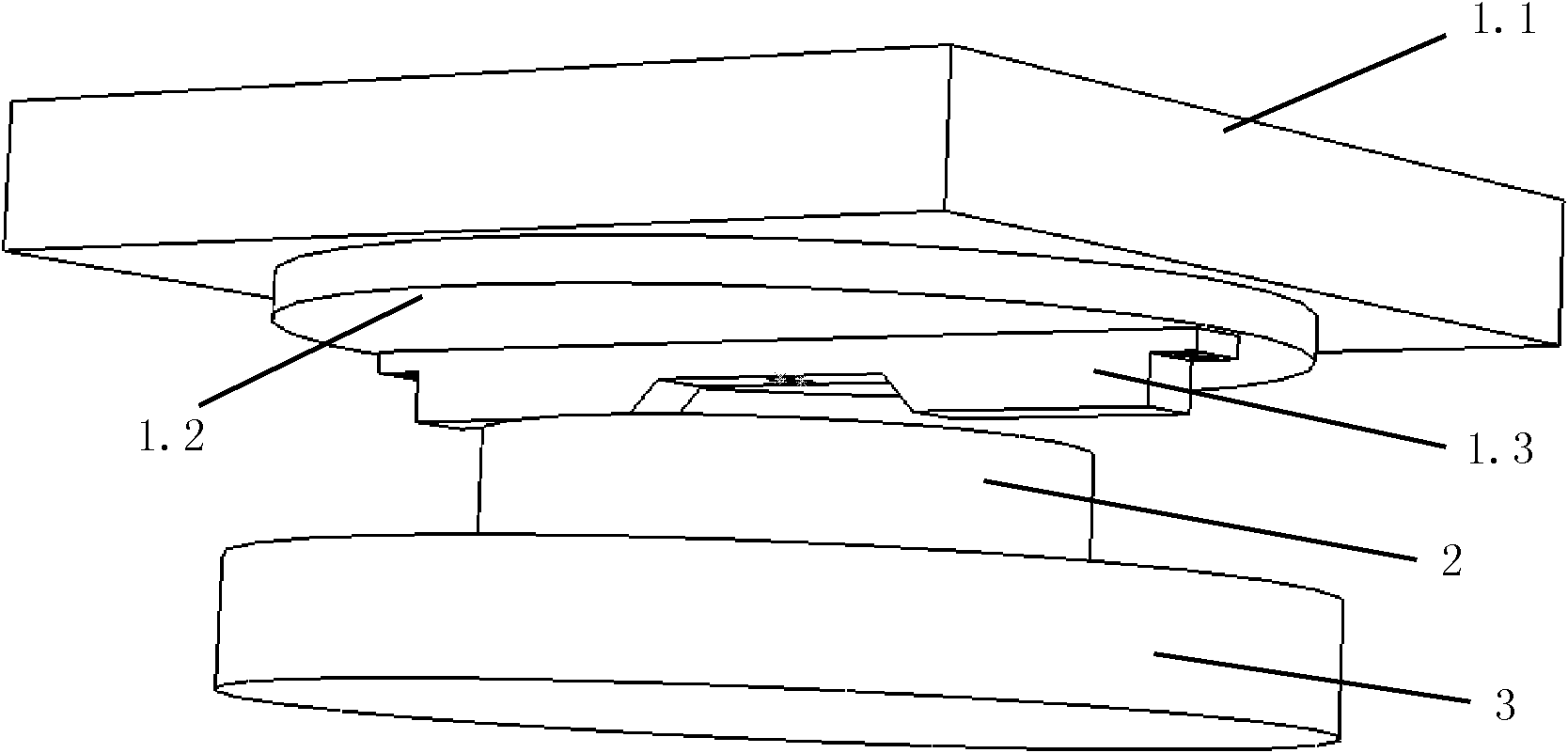

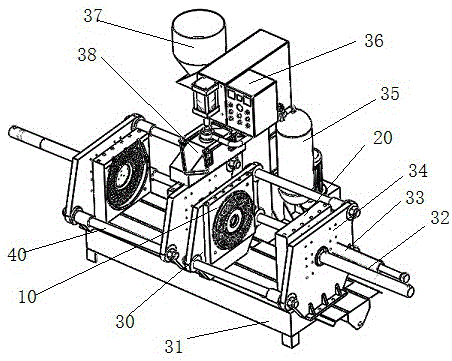

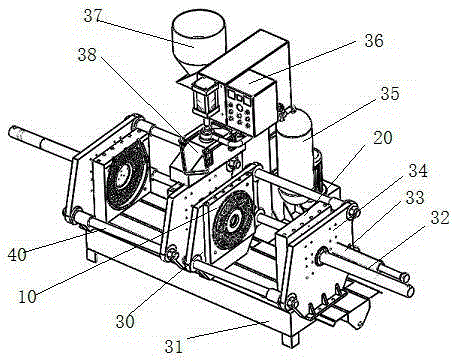

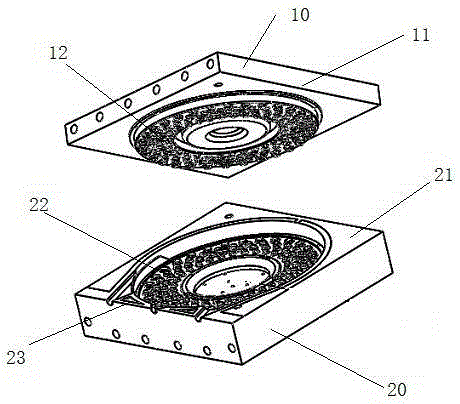

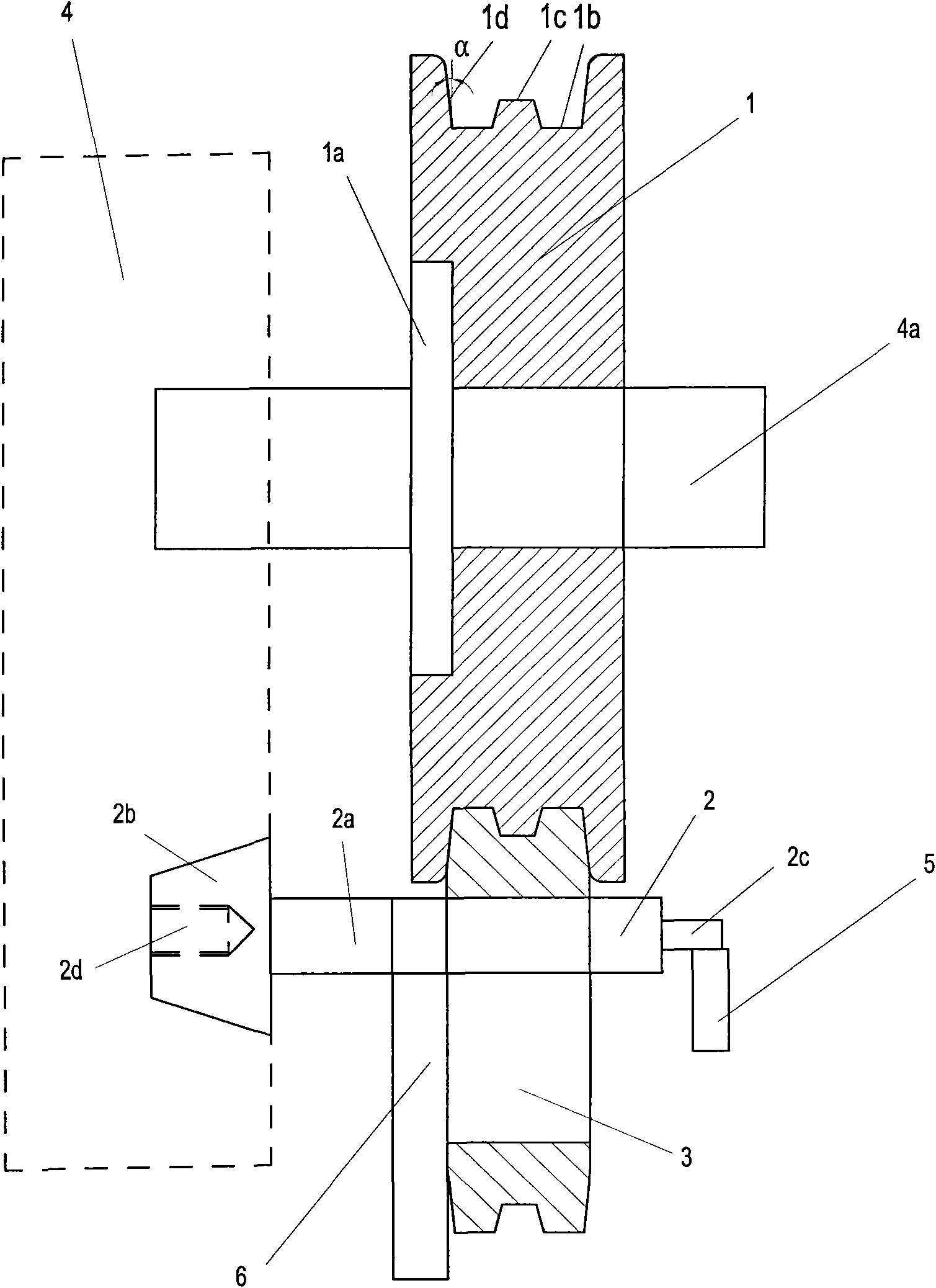

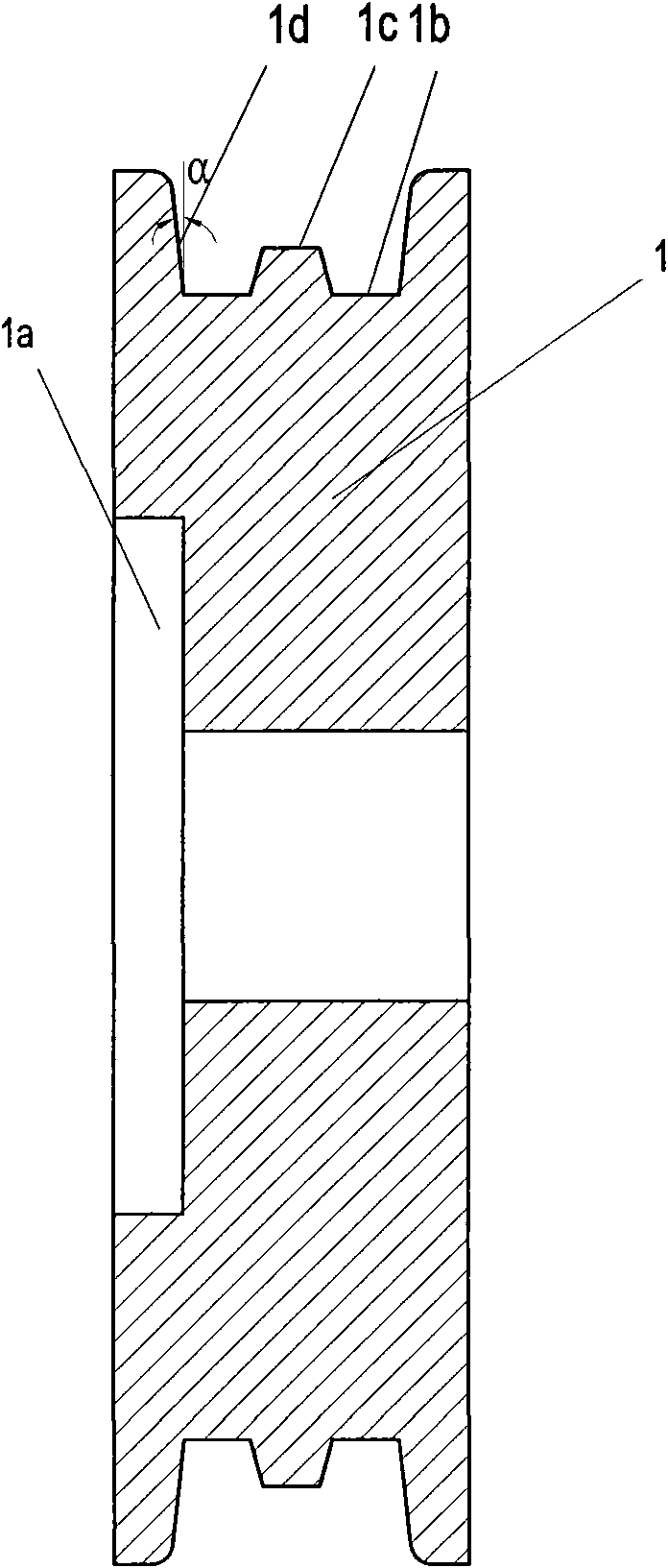

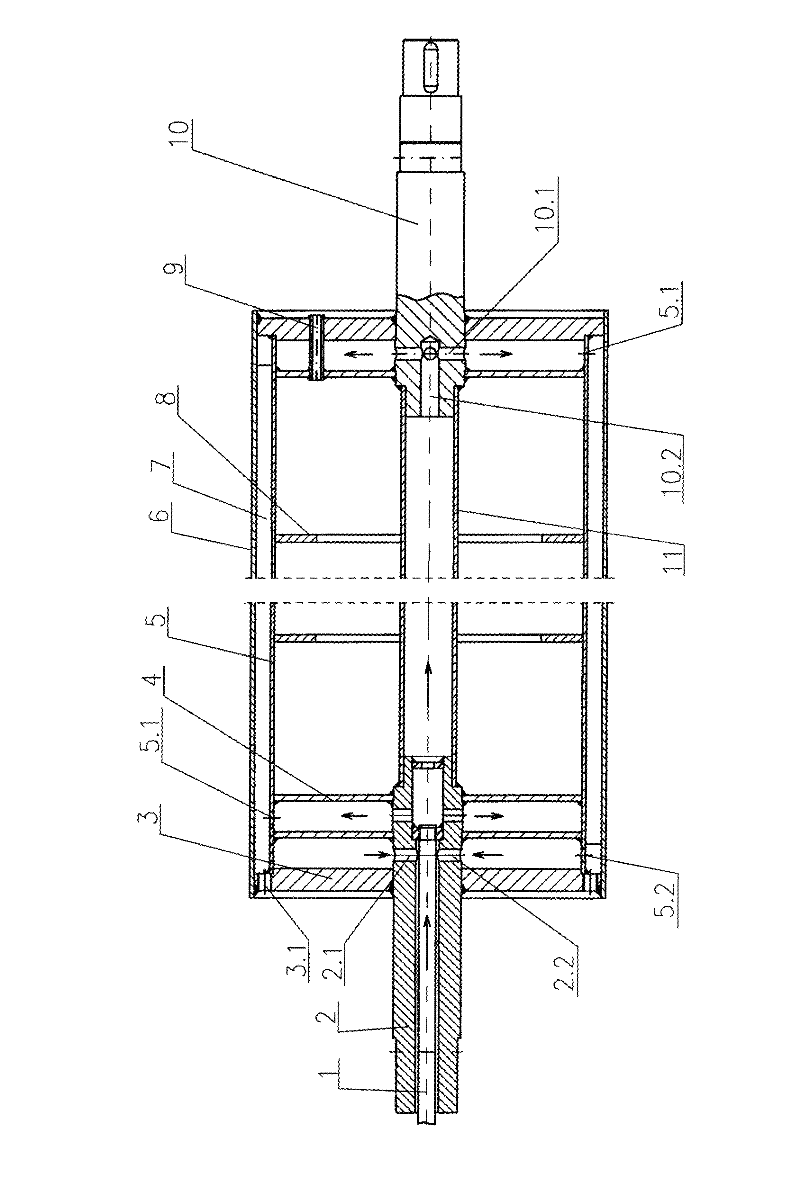

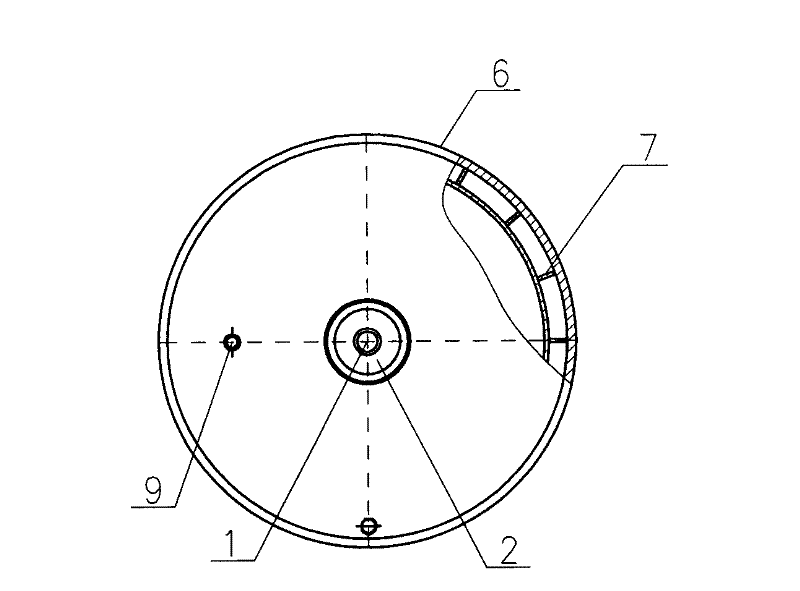

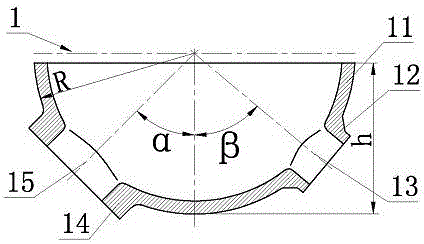

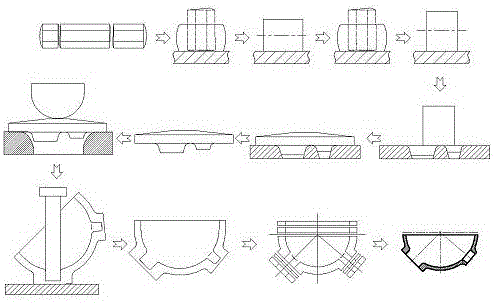

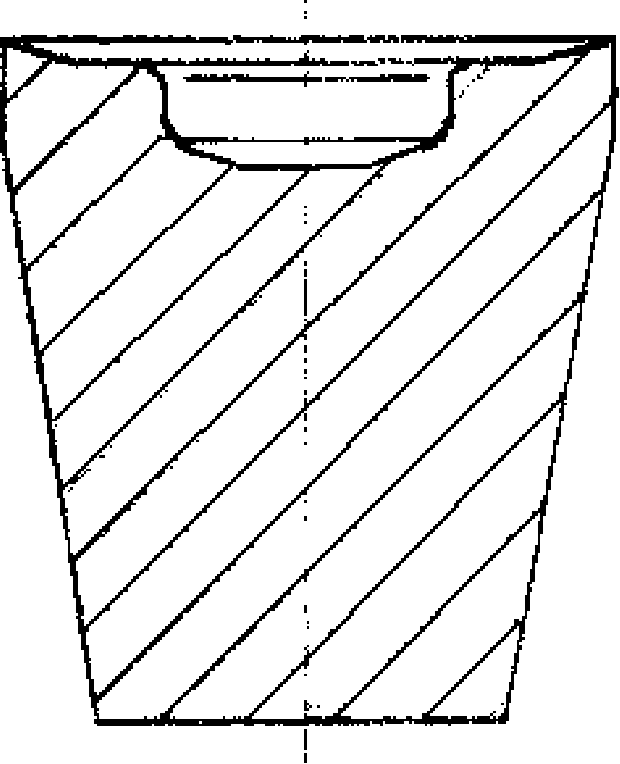

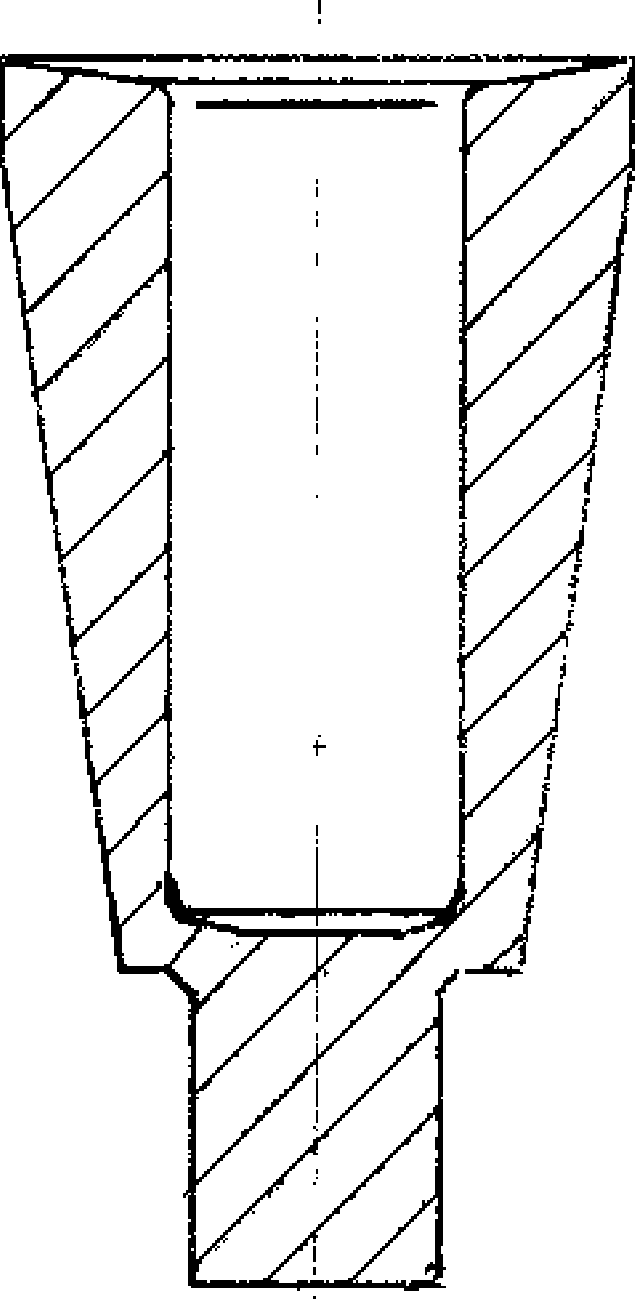

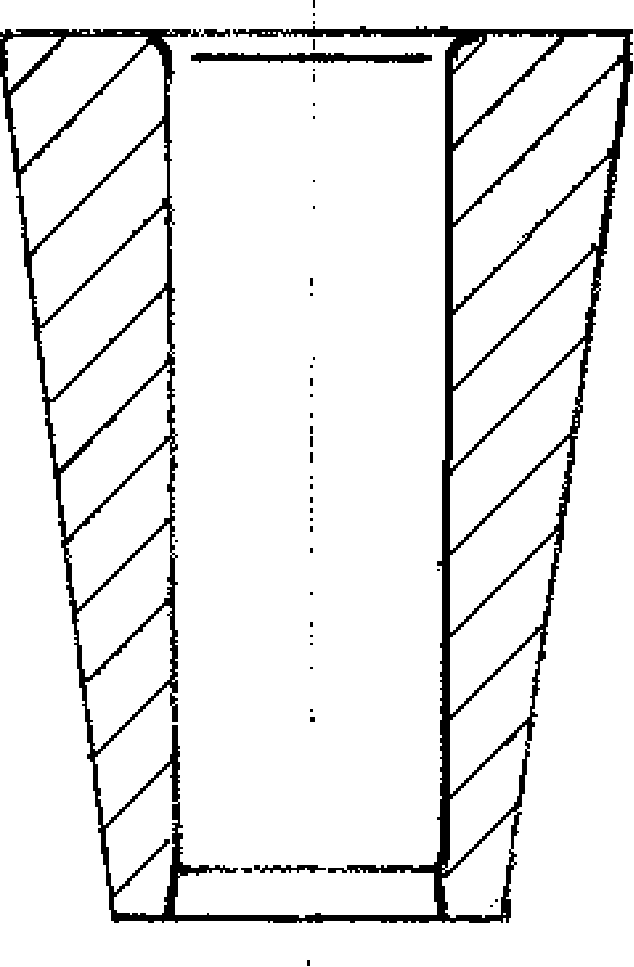

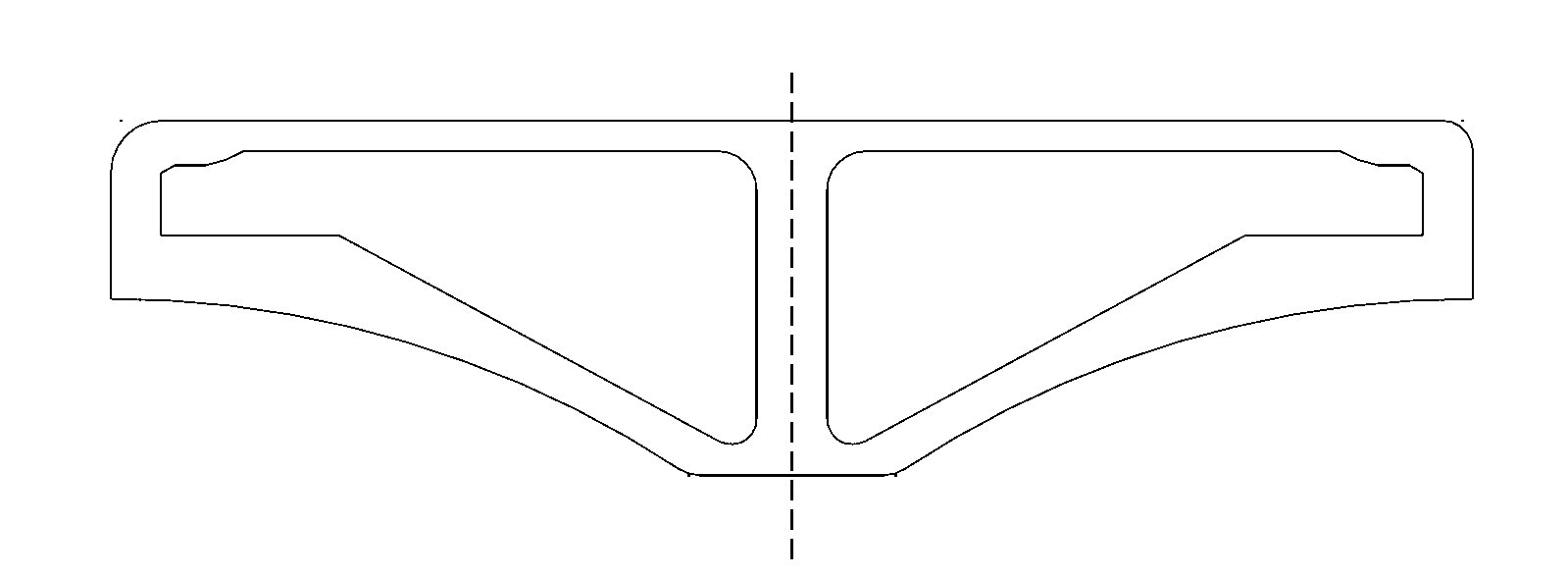

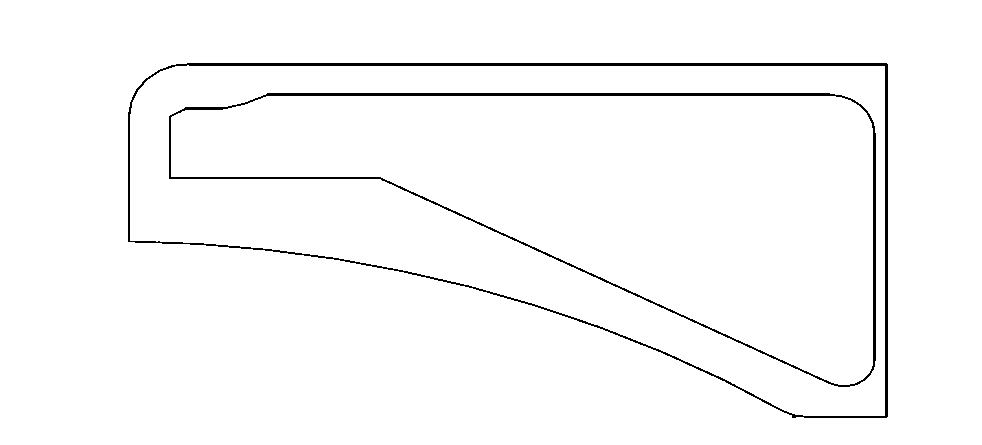

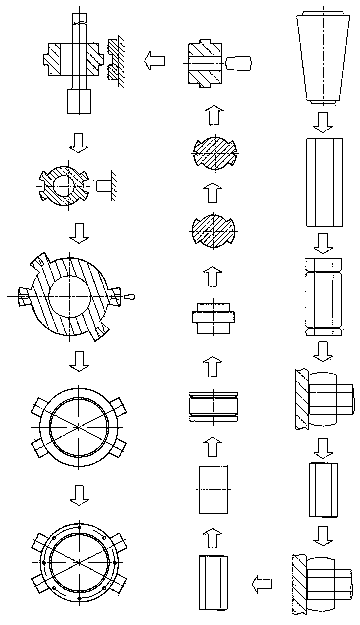

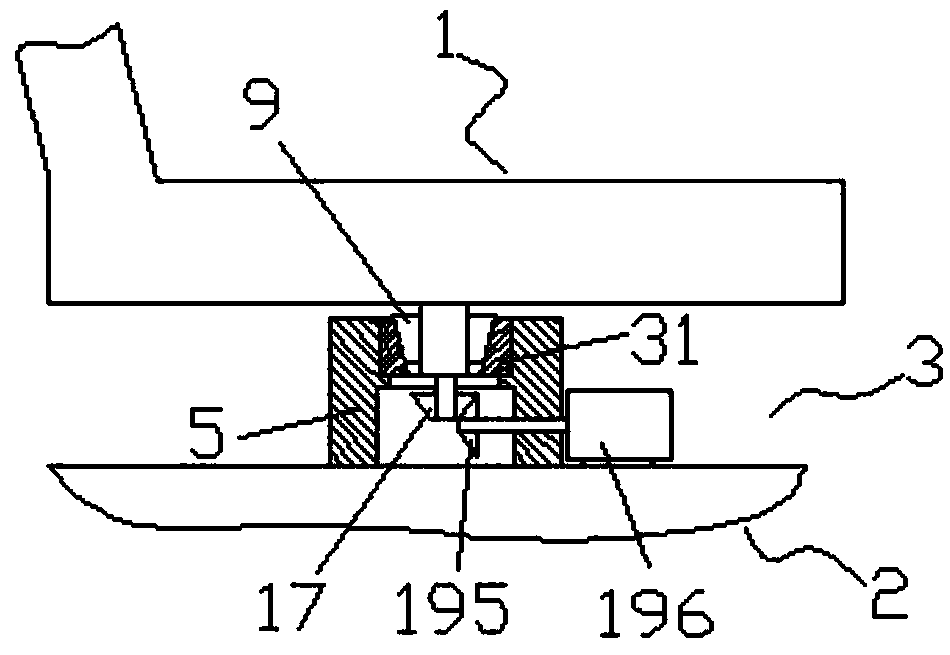

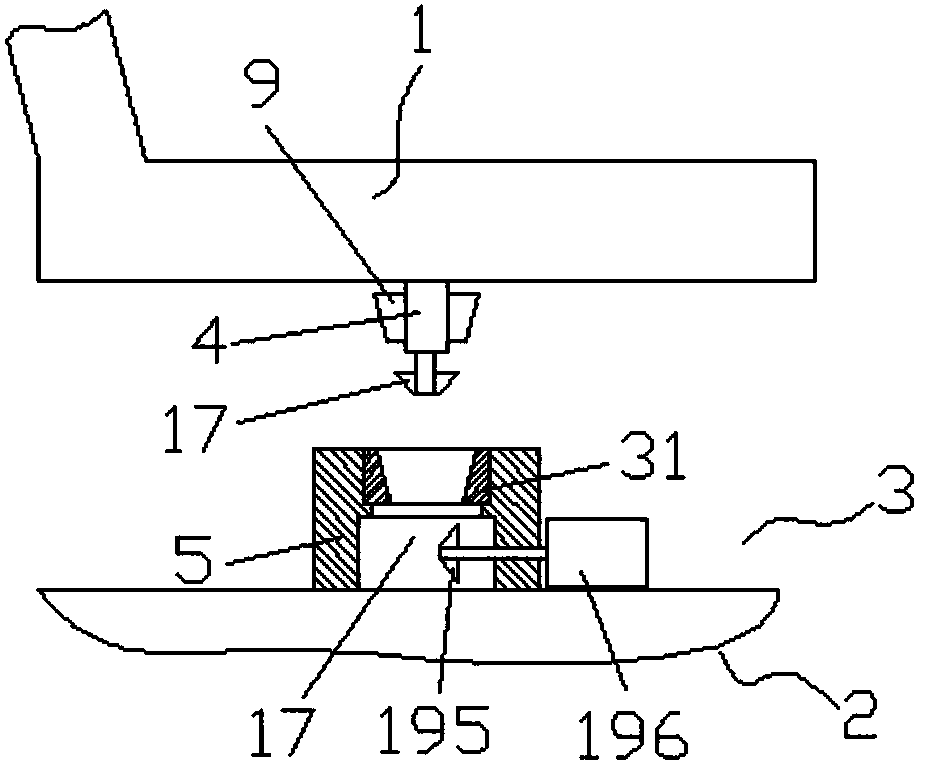

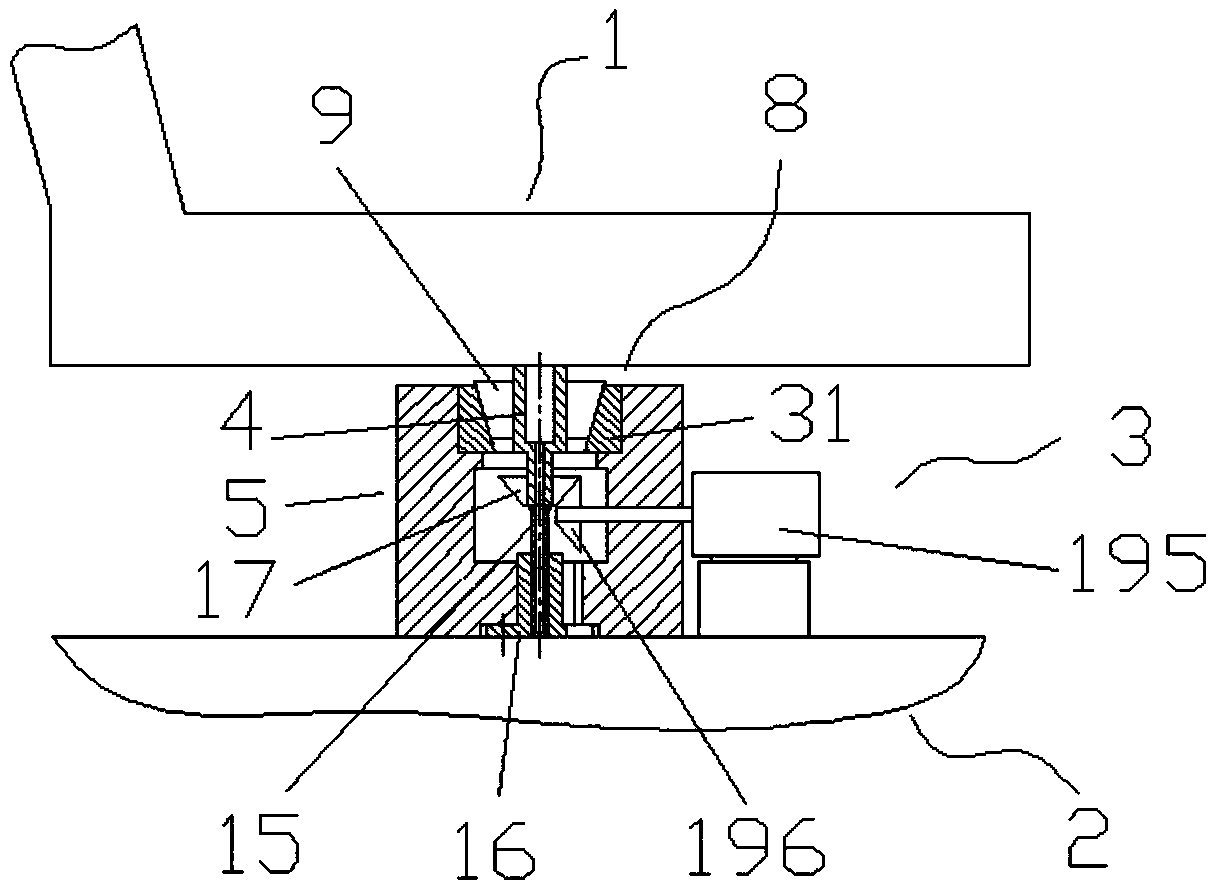

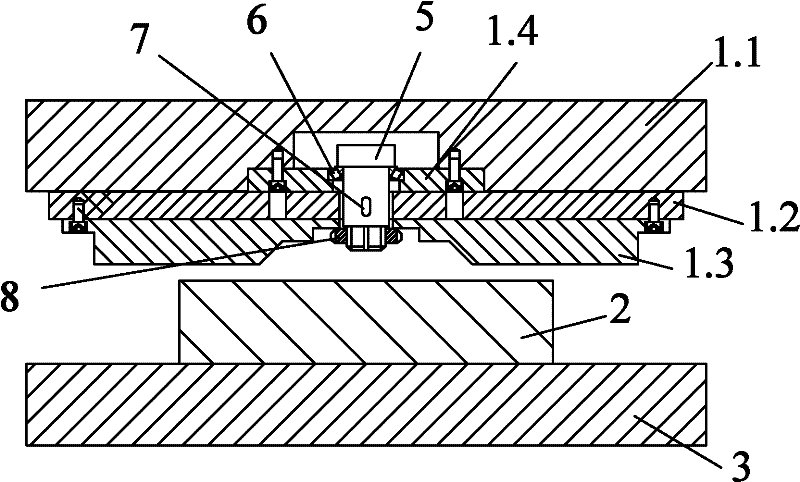

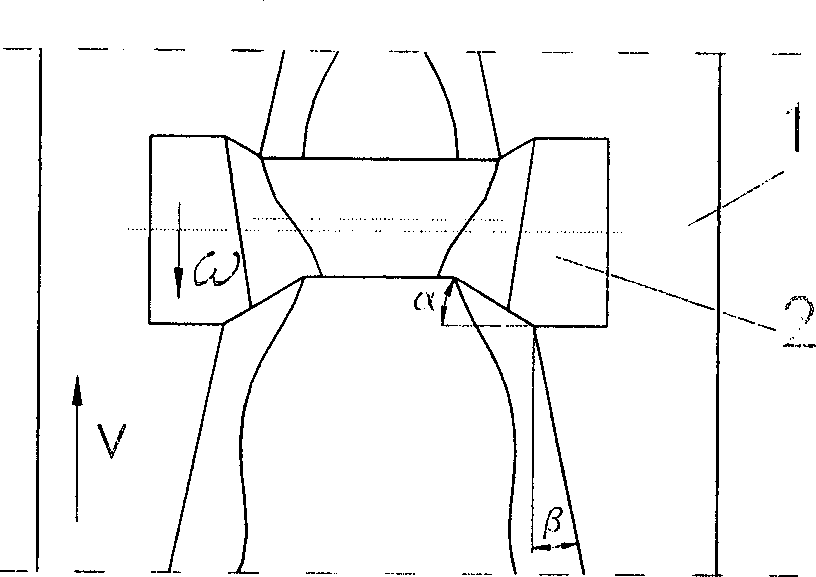

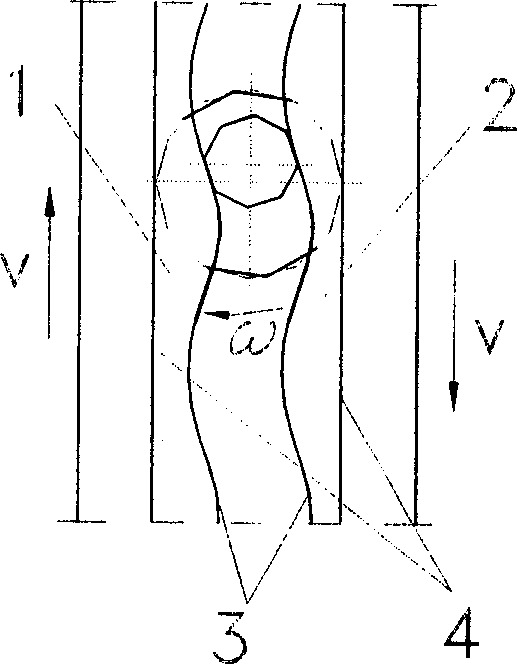

Rotary forging method for large disc type work piece and forging device

InactiveCN101862807ALow manufacturing costReduce the amount of machiningForging/hammering/pressing machinesWheelsForgingMaterials science

The invention provides a rotary forging method for large disc type work pieces and a forging device. The method comprises preparing a forging die, preparing blanks, pre-forging a shunt slot, positioning the blanks and carrying out rotary forging in steps. Based on the method, the invention also provides a forging device which can realize relative rotation of an upper forging die and a lower die, and the local forming process for the disc type work pieces can be carried out through rotary forging of the upper forging die and the lower die. In order to control metal flow in the forging process, the procedure of pre-forging the shunt slot is added prior to the rotary forging. Moreover, the upper forging die with a special structure is adopted to overcome the warpage of the work pieces during rotary forging. The forming method has the advantages of low forming load, simple dies and low processing cost, and can greatly reduce the manufacturing cost of existing large disc type work pieces.

Owner:XI AN JIAOTONG UNIV +1

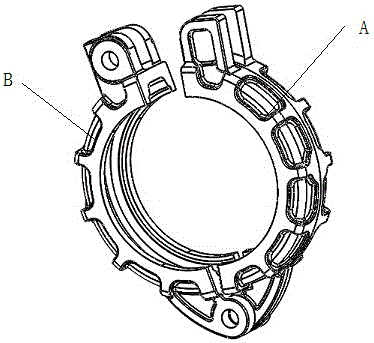

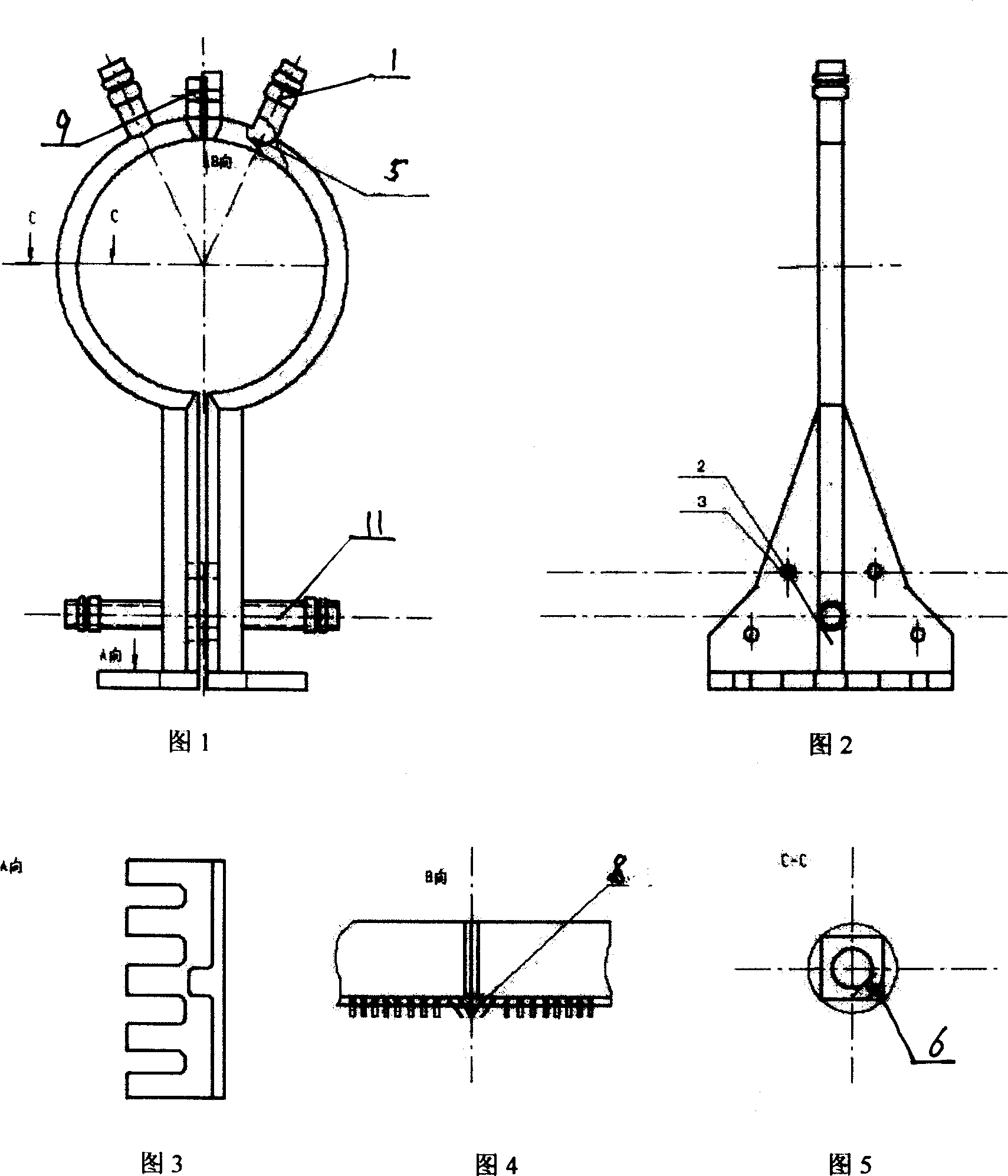

Method for manufacturing blank of pipe clamp

InactiveCN105728648AAchieve productionSave materialFoundry mouldsFoundry coresMolding machineCasting defect

The invention discloses a method for manufacturing a blank of a pipe clamp and belongs to the field of construction. The method comprises the following steps that 1, a pipe clamp precoated sand mold is designed and manufactured according to a design drawing of the pipe clamp; 2, the precoated sand mold of the pipe clamp is placed on an automatic molding machine, and a precoated sand pouring sand shell model and a sand core model are manufactured; 3, pouring is carried out; and 4, a casting is taken out and cleaned. The method has the beneficial effects that production of the blank of the pipe clamp can be efficiently achieved, materials and manpower can be saved, and the mechanical machining amount can be reduced; and casting defects can be reduced, the yield is increased, and automatic production can be easily achieved.

Owner:YUZHOU KUNLUN MOLD CO LTD

Semi-solid die-casting aluminum alloy material and die-casting molding method using same

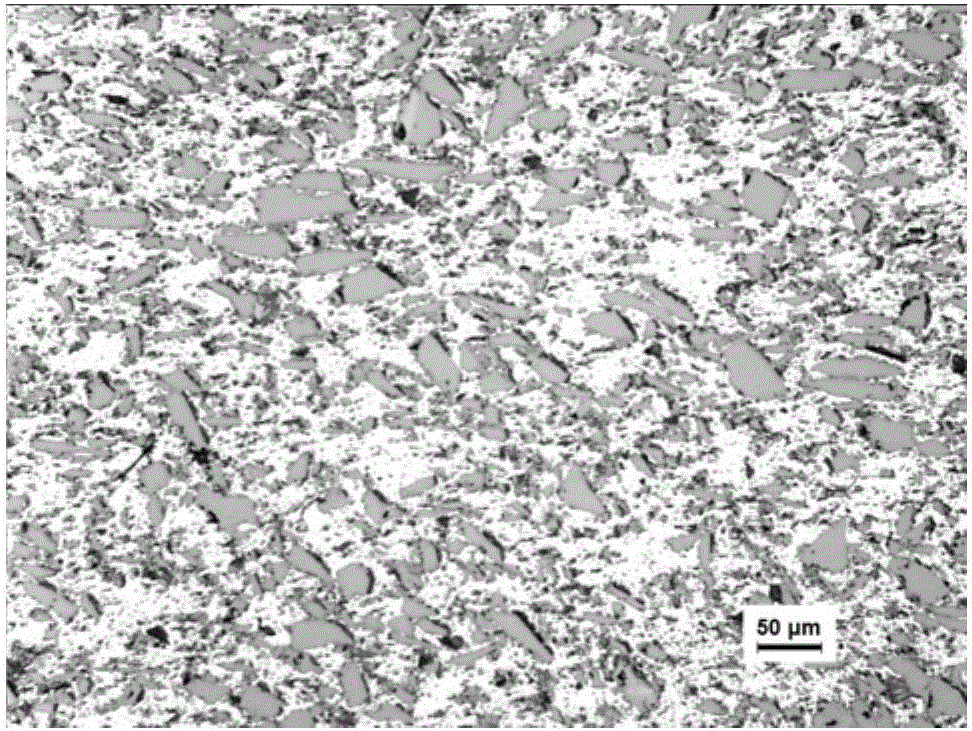

A semi-solid die-casting aluminum alloy material comprises 6%-9% of Si, 0-0.3% of Cu, 0.25%-0.55% of Mn, 0.2%-0.5% of Mg, 0.6%-1.2% of Fe, 0-0.15% of Ni, 0-0.15% of Zn, 0-0.15% of Pb, 0-0.05% of Sn, 0-0.2% of Ti, 0-0.15% of impurities, and the balance Al. The content of Si is controlled to be 6%-9% and the content of Fe is controlled to be 0.6%-1.2%, so that the good die-casting molding performance, corrosion resistance and demoulding effect are ensured; meanwhile, 0.25%-0.55% of Mn is added to form a MnAl6 compound, so that the harmful effect of iron is effectively weakened; also, Mn can hinder the recrystallization process of aluminum alloy, the recrystallization temperature is increased, and favorable conditions are provided for the semi-solid pulping process of alloy slurry; in addition, 0.2%-0.5% of Mg is contained properly so as to improve the tensile strength.

Owner:FUJIAN KINRUI HIGH TECH CO LTD

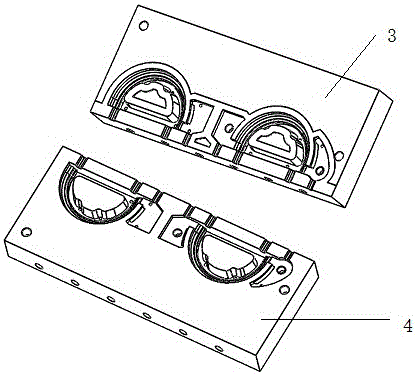

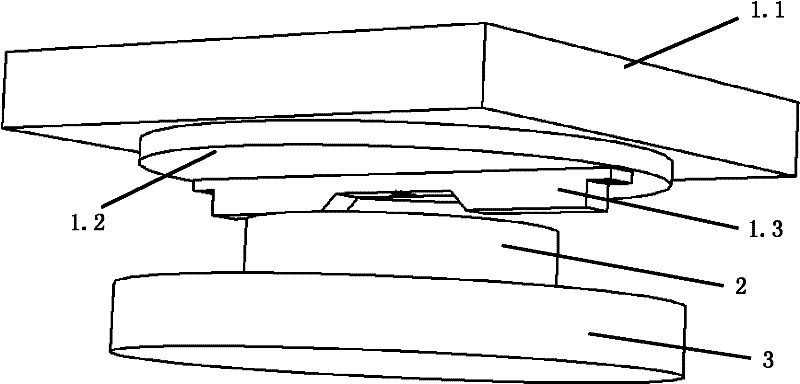

Workblank manufacturing method of automobile brake disc

InactiveCN105458184AAchieve productionSave materialFoundry mouldsMoulding machinesSand castingCasting defect

The invention discloses a workblank manufacturing method of an automobile brake disc, and belongs to the field of automobile accessory manufacturing. The method comprises the following steps that firstly, according to design paper of the brake disc, and a precoated sand shell mold and a sand core mold are designed and manufactured; secondly, the sand shell mold or sand core mold is placed on a sand shell or sand core automatic forming machine to manufacture a precoated sand casting sand shell model and a sand core model; thirdly, pouring is carried out; and fourthly, a casting is taken out and cleaned. The beneficial effects that production of the brake disc workblank can be efficiently achieved, materials and manpower are saved, mechanical allowance is reduced, casting defects are reduced, the yield is improved, and automation production is easily achieved are achieved.

Owner:YUZHOU KUNLUN MOLD CO LTD

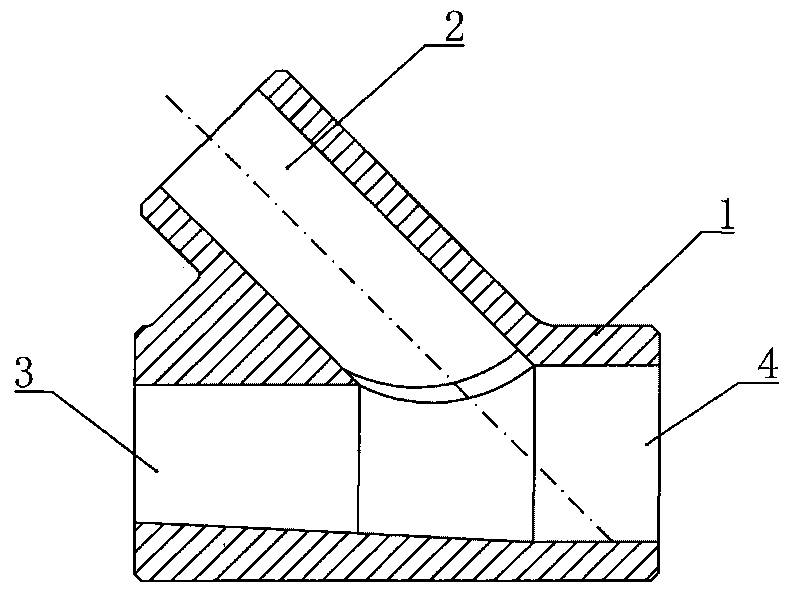

Forging process of large tee and large skew tee

ActiveCN101695739AQuality improvementImprove mechanical propertiesForging/hammering/pressing machinesEngine componentsWater basedGraphite

The invention relates to a forging process of a large tee and a large skew tee, which comprises the steps of: putting cut blanks in a heating furnace to heat to 1200 DEG C; preheating a forging die to 200-250 DEG C, respectively coating water base graphite and glass lubricant on the forging die and the cut blanks; putting the cut blanks on a multi-direction die liquid forging press mould, moving an upper cylinder to enable an upper die to mutually press a lower die; starting an upper oil cylinder, a left oil cylinder and a right oil cylinder of a forging press for forging; releasing pressure to move the mould after molding by the forging die, taking a semi-finished product out to be put into a heat treatment furnace for furnace cooling and annealing, carrying out heat treatment, nondestructive recheck and mechanical behavior check according to the steel material requirement, and preparing for the next machining; and machining the treated semi-finished product according to the drawing requirement. The invention has the advantages of reducing energy resources and improving the production efficiency.

Owner:HEBEI FOCUS PIPING

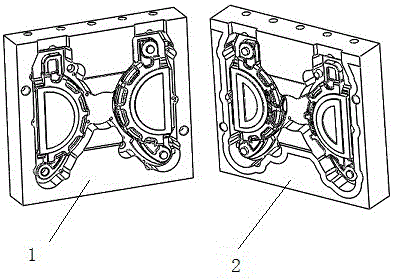

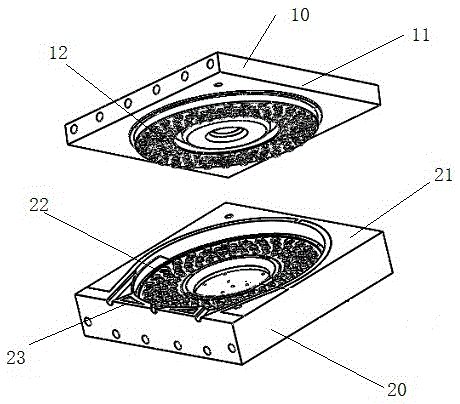

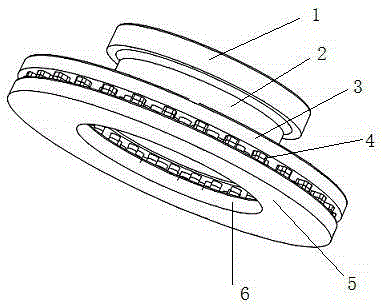

Sand shell mold for manufacturing blank of vehicle braking disc

InactiveCN105397024ASave labor and materialsReduce the amount of machiningFoundry mouldsFoundry coresVehicle brakeMaterials science

A sand shell mold for manufacturing the blank of a vehicle braking disc belongs to the field of manufacturing of car accessories, and comprises an upper mold and a lower mold; the junction surface between the upper mold and the lower mold is a poured parting surface of the braking disc; the upper mold comprises an upper mold plate and an upper cavity; the lower mold comprises a lower mold plate and a lower cavity; the lower mold plate is positioned at the periphery of the lower cavity; the lower cavity is formed inside the lower mold plate; the lower cavity is the same as a part below the parting surface of the braking disc in shape; and the size of the lower cavity is equal to the size of the part below the parting surface of the braking disc and the thickness of a sand shell. The sand shell mold has the characteristics that the production of the blank of the braking disc can be realized efficiently, materials and labors are saved, the mechanical processing capacity is reduced, casting flaws are reduced, the yield is improved, and the automatic production is easy to realize.

Owner:YUZHOU KUNLUN MOLD CO LTD

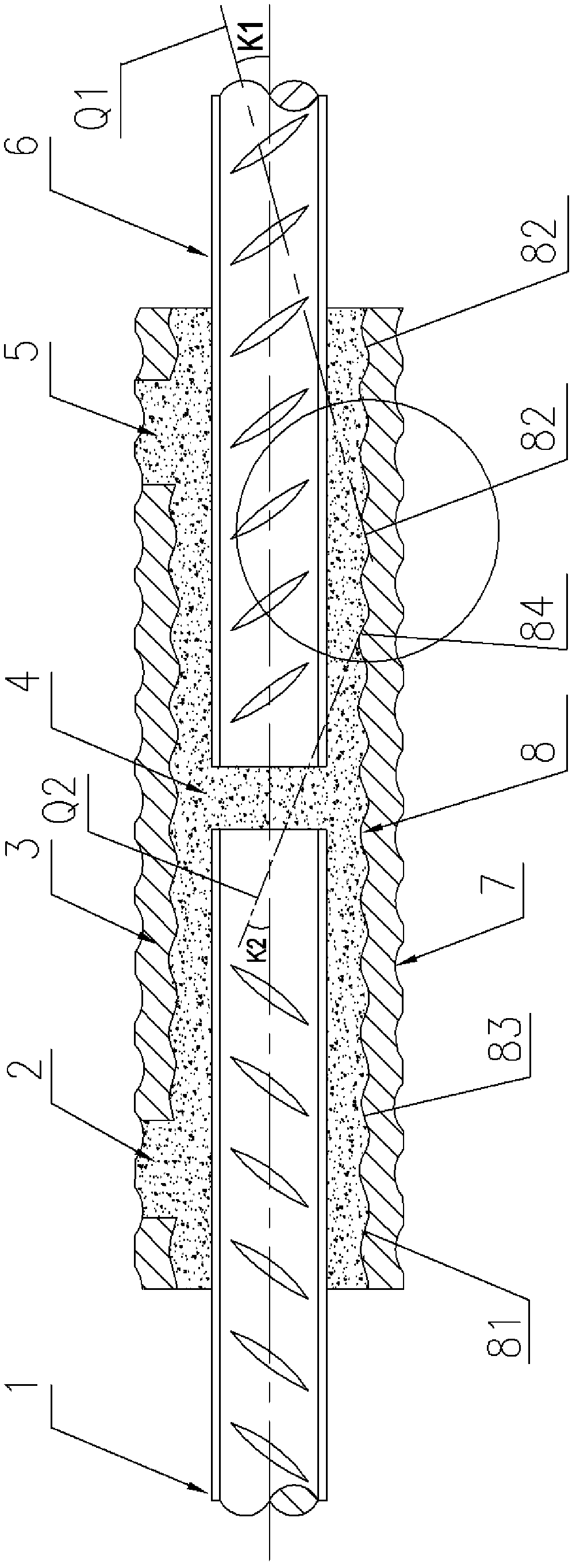

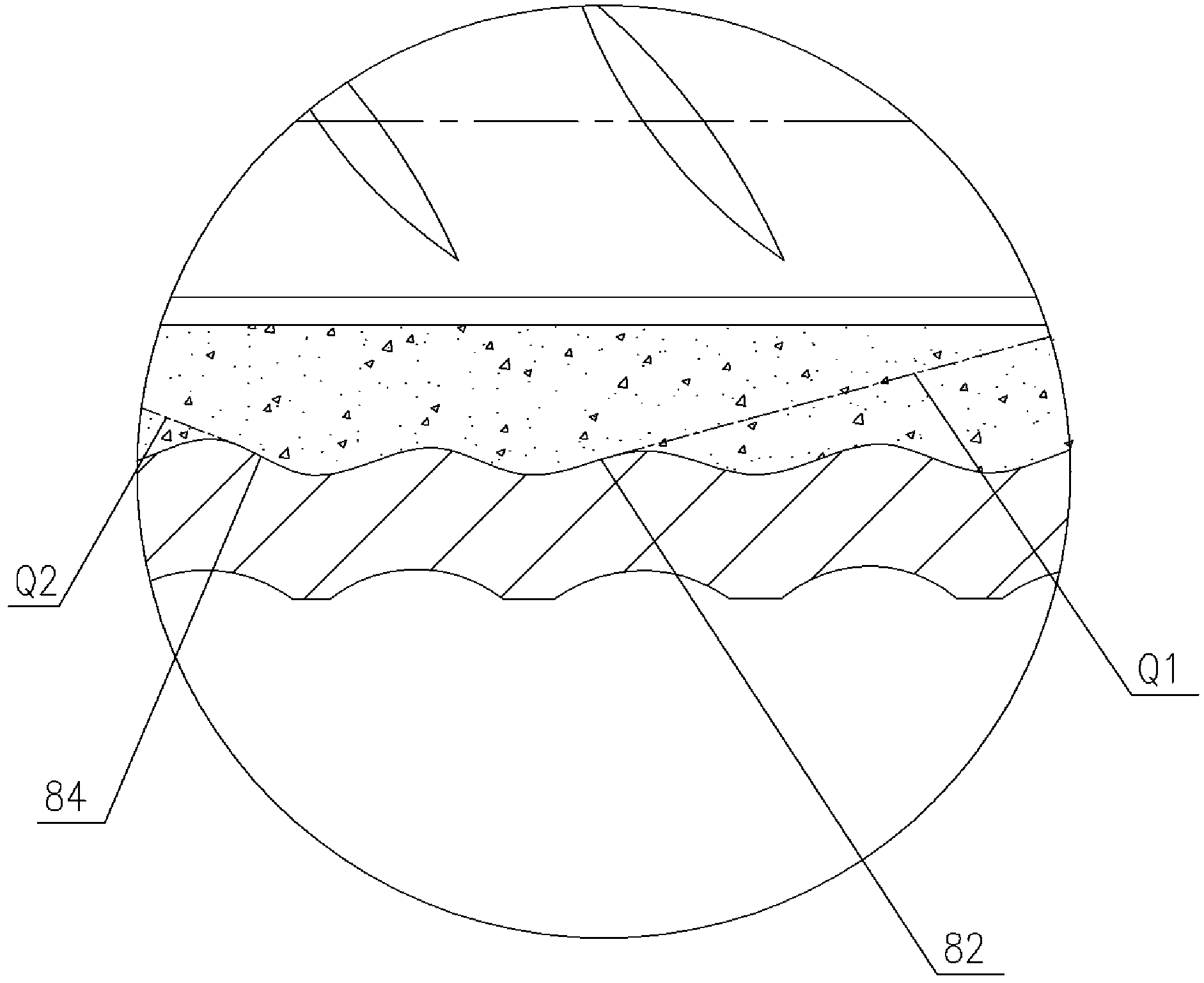

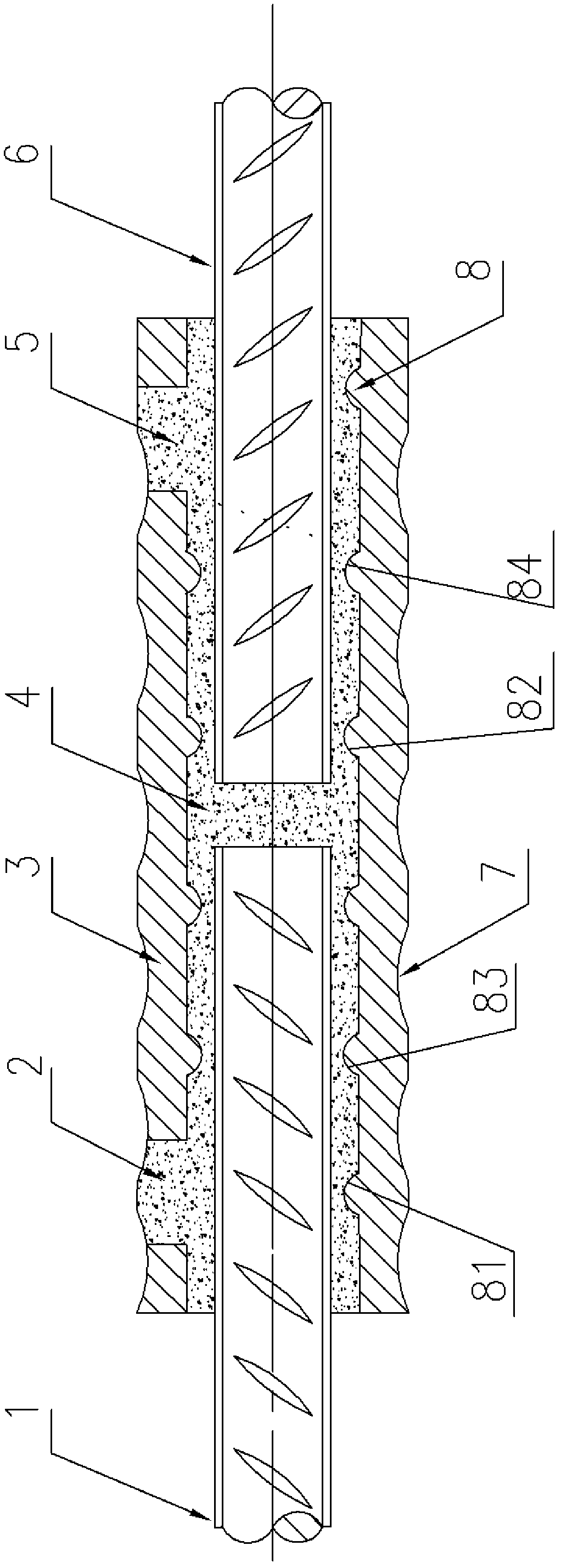

Cement grouting reinforcement connector

InactiveCN102828580AImprove mechanical performanceIncreased durabilityBuilding reinforcementsCement groutRebar

A cement grouting reinforcement connector comprises connecting reinforcements, a connecting sleeve and cement mortar; and the abutted ends of the two connecting reinforcements are combined into a connection body by the connecting sleeve and hardened cement mortar full of the gap of the connecting sleeve. The outer surface of the connecting sleeve and the inner wall of the sleeve are respectively provided with continuous or discontinuous grooves or bosses. The connector has the following advantages that a seamless steel pipe, a forged steel cylinder or a stamped steel cylinder which has high strength and stable property is used as the connecting sleeve, and the grooves in the outer surface of the connecting sleeve and the bosses on the wall of the inner holes are formed by using a rolling-pressing or rotary-pressing method. The raw material dosage is greatly reduced by the improvements of the structure and the material of the sleeve; and the cutting processing amount is greatly reduced by the improvement of the machining technique of the sleeve, and therefore, the cost of the sleeve is reduced and the production efficiency is increased; and the economic and technical indexes of the connector exceed those of the known cement grouting reinforcement connectors.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

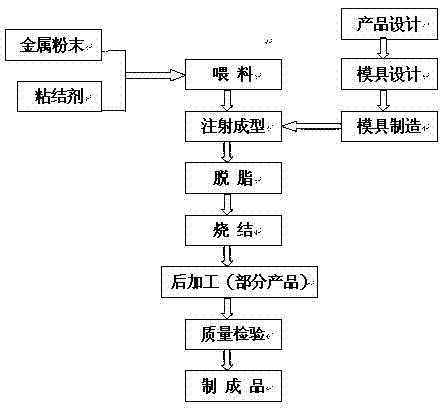

Powder metallurgy injection molding process

InactiveCN102962455ASolve liquidity problemsAddressing the Weakness of Mixed PoorMetallurgyInjection molding process

The invention provides a powder metallurgy injection molding process, belonging to the technical field of powder metallurgy. The powder metallurgy injection molding process comprises the following steps of: 1), mixing metal powder and a bonding agent according to a ratio; 2), feeding: putting a mixture of the metal powder and the bonding agent into a pre-designed and manufactured mould cavity; heating to 120-140 DEG C under the protection of ammonia gas to carry out warm pressing molding; and in a molding process, vibrating the mould cavity; 3), degreasing: after de-molding, heating a molded product to 250-300 DEG C; and 4), sintering: sintering at a vacuum state, wherein the sintering temperature is 850-1000 DEG C and the heat-preservation time is 1-2.5 hours. The invention provides a pulse periodic vibration mixing method aiming to solve the technical problems of defects of the prior art that the agitation is not uniform and the product stability is poor; and the disadvantages of poor mobility and mixing performance of raw materials in an injection molding process are overcome, the product density is high and the distribution is uniform.

Owner:LANZHOU JINHAO MACHINERY MFG

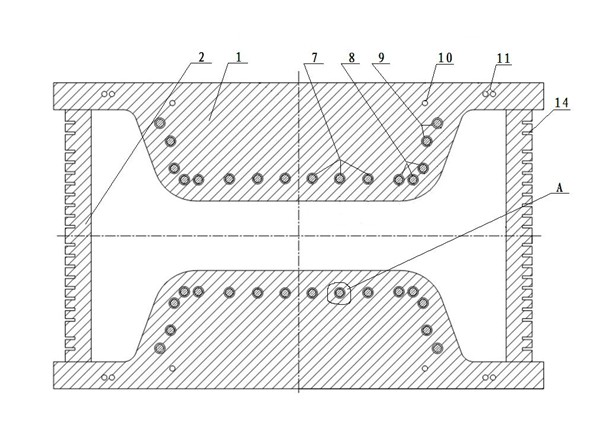

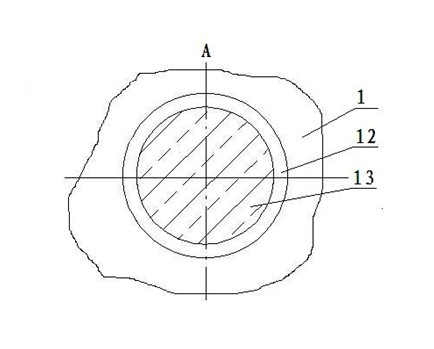

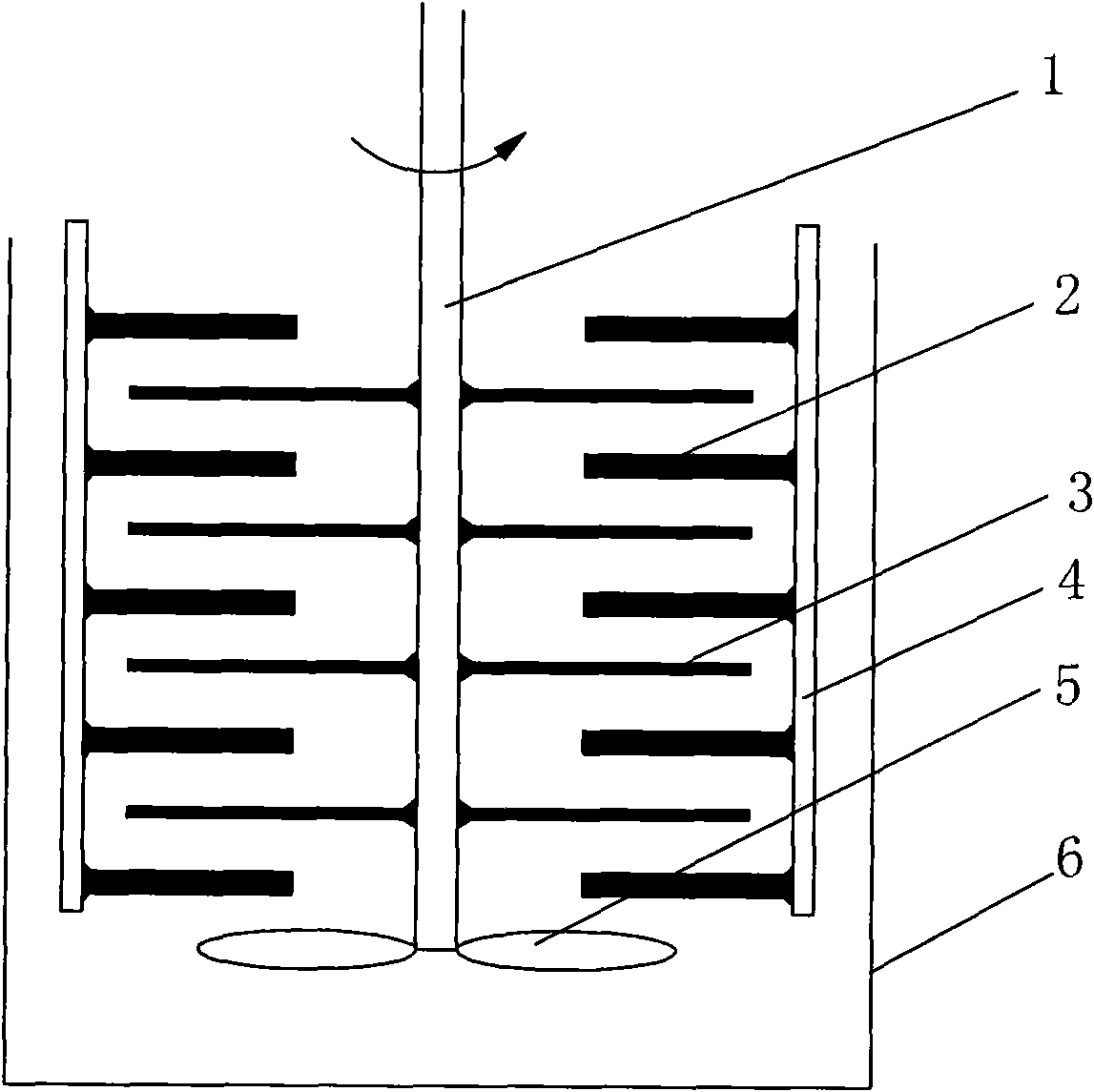

Water cooling channel for large beam blank continuous casting crystallizer

The invention belongs to a cooling casting blank or casting mould device and relates to a water cooling channel for a large beam blank continuous casting crystallizer,,and particularly to a copper plate cooling device for a beam blank continuous casting crystallizer. The copper plate cooling channel is characterized in that: a web water gap, a R angle water gap, a bevel water gap, a flange inner angle water hole and a flange top water hole are formed on a broadside copper plate according to the characteristics of the copper plate shape and heat face heat flux; the water gaps without corners are distributed uniformly, and the water gaps at R angle are dense, and few water holes are arranged at concave corners; and a cooling water tank is arranged outside a narrow side copper plate. The copper plate cooling channel has the advantages that cooling water channels are arranged in areas, the number of cooling water channels is reduced, water gap diameter is reduced, and processing quantity is reduced; the water gaps are arranged reasonably, temperature peak value at the R angle is eliminated, the temperature gradient is reduced, the cooling strength of the flange top is weakened, the overall temperature of the copper plate tends to be uniform, the working environment of the copper plate and blank heat transmission condition are improved, the cooling effect is good, and water is saved; deformation and abrasion of the copper plate are reduced, and service life is prolonged; the surface quality of blanks is remarkably improved, the cogging yield is improved, and continuous casting production can be performed smoothly.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

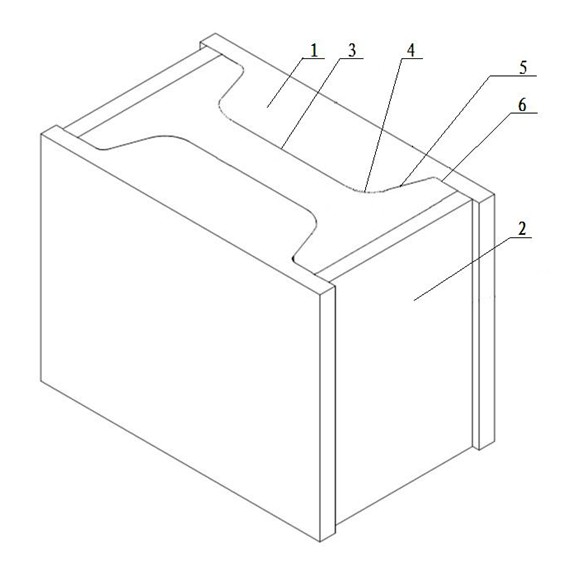

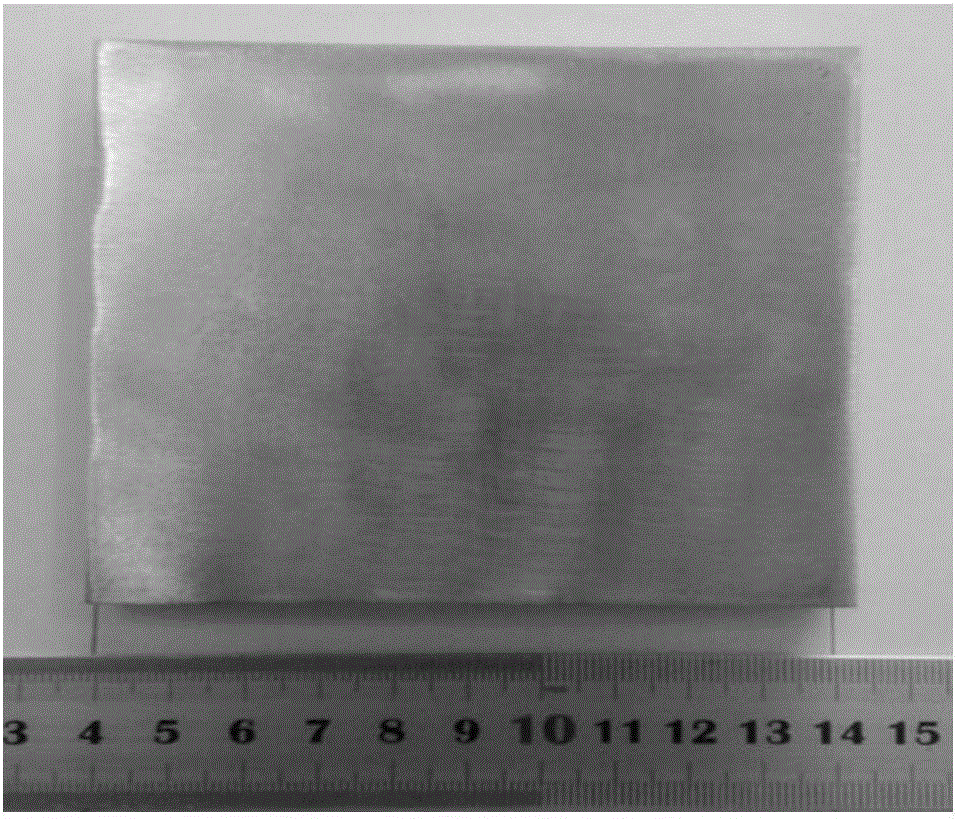

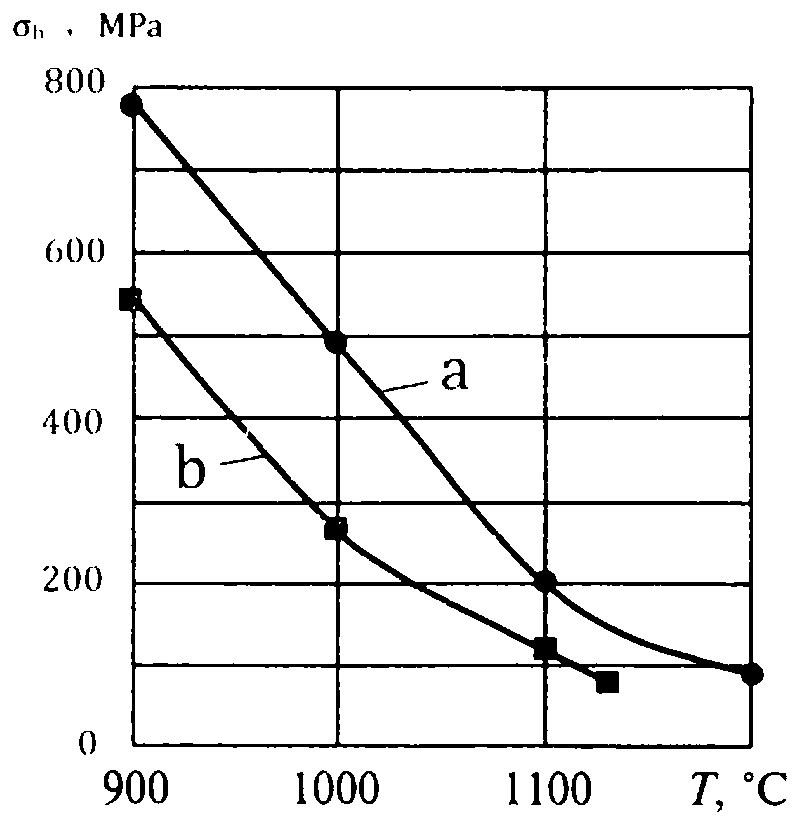

Blank-making rolling method for synchronous sliding sleeve of automotive transmission

The invention discloses a blank-making rolling method for a synchronous sliding sleeve of an automotive transmission using circular steel as a blank material. The method comprises the steps of cutting, heating, upsetting, punching a blind hole and pre-forming, punching a wad and pressing an end face, performing ring rolling forming, shaping, normalizing, performing impeller blasting and the like, wherein the key point is that a rolling wheel used in the step of the ring rolling forming is provided with an annular groove corresponding to a blank of the synchronous sliding sleeve of the automotive transmission. By applying ring rolling process to the blank of the synchronous sliding sleeve of the transmission, the subsequent machining amount is reduced to the greatest extent, the material consumption is reduced and the service life of the finished product is prolonged.

Owner:重庆市平岗机械有限公司

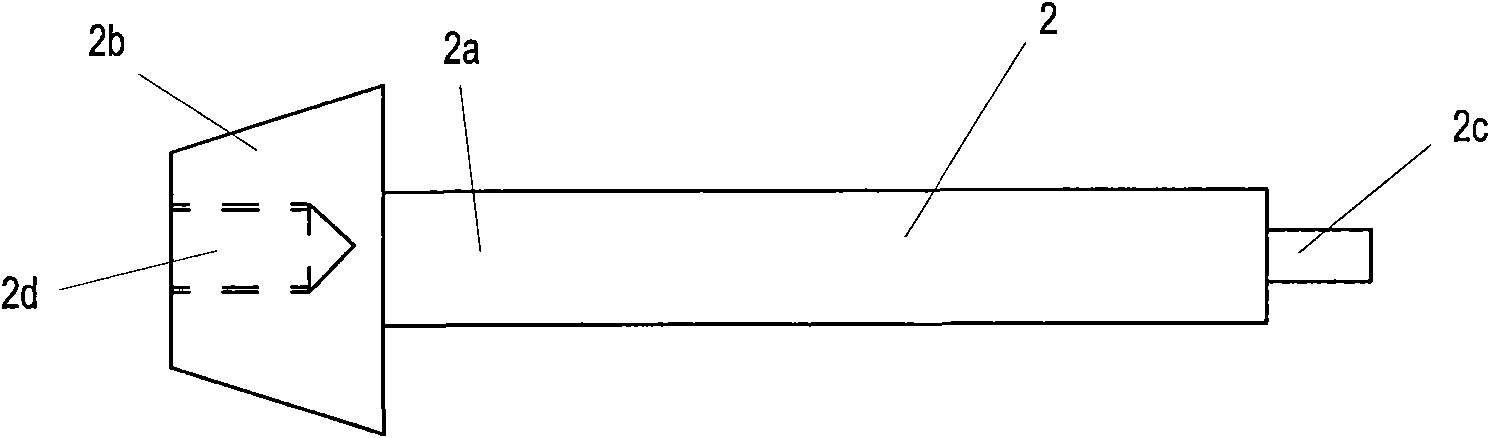

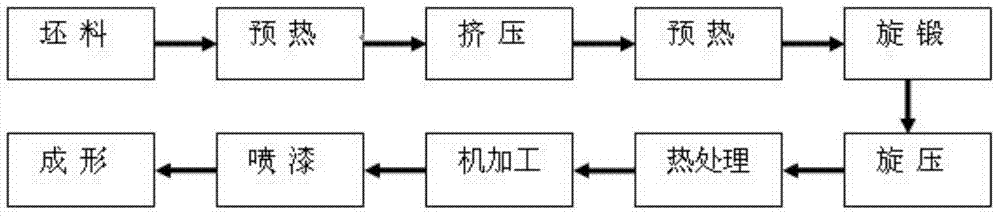

Truck and motor coach magnesium hub rotary-swaging forming method

InactiveCN104759839AReduce consumptionReduce subsequent processingMetal-working apparatusWheelsTruckMachining

The invention relates to a truck and motor coach magnesium hub rotary-swaging forming method. The method utilizes certain temperature and pressure and adopts rotary-swaging forming to enable magnesium alloy to be formed according to a predetermined die shape. The method comprises the technological steps of blank preparation, blank preheating, extrusion (pre-machining), blank pre-heating, rotary-swaging forming, heat treatment, machining, paint spraying and forming. Magnesium alloy automobile hubs produced by means of the method is high in finished product rate and stable in mechanical property, follow-up machining can be decreased, and machining amount and energy consumption can be reduced. By means of the method, large-sized hubs can be produced, and hub weight can be decreased.

Owner:山西晋隆发科技有限责任公司

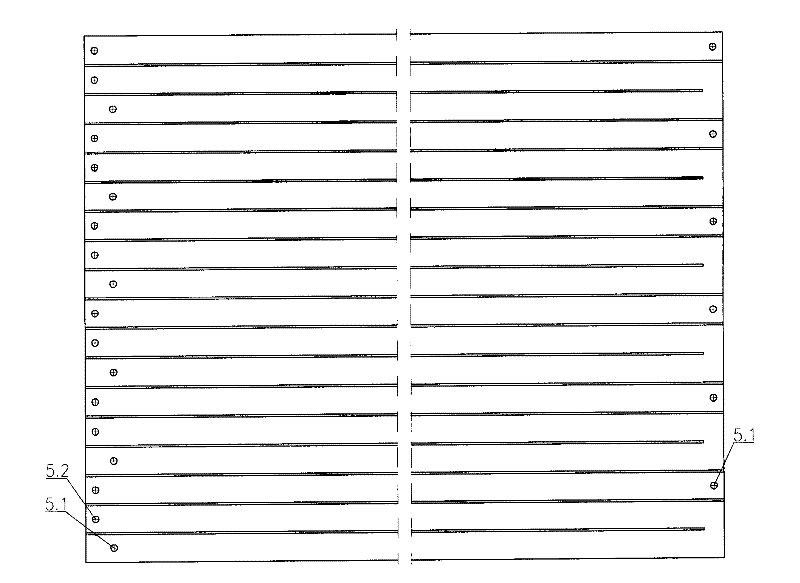

Strip-shaped jacketed oil-heat roller

ActiveCN102189743ASmall temperature errorEquilibrium Heat ReplacementRotary pressesPulp and paper industryBlind hole

The invention discloses a strip-shaped jacketed oil-heat roller, which comprises an inner pipe, an input shaft, an end cover, a partition plate, an inner cylinder, an outer cylinder, a strip, an inner ring plate, a ventilating pipe, a supporting shaft and a connecting pipe, wherein the input shaft is a hollow shaft, the jointing end of the input shaft and the connecting pipe is provided with a left radial hole and a right radial hole, and the inner pipe is inserted into the inner hole of the input shaft and connected with a step by crossing the left radial hole to form a bidirectional independent channel. The jointing end of the supporting shaft and the connecting pipe is provided with an axial blind hole channel which is communicated with the radial holes. The inner cylinder is connectedwith the input shaft and the supporting shaft through the inner ring plate, the baffle plate and the end cover; and a strip-shaped groove consisting of the strip is arranged in a jacket between the inner cylinder and the outer cylinder, and is communicated with an oil inlet cavity, an oil return cavity and the bidirectional independent channel through oil inlets at two ends of the wall of the inner cylinder and an oil return hole at one end of the wall of the inner cylinder. The strip-shaped jacketed oil-heat roller ensures that the error of a temperature on the surface of the roller is less than 5 DEG C through bidirectional equivalent heat exchange, thereby improving product quality. The invention is suitable for being matched with various specifications of rollers.

Owner:泰州科世茂工程设备有限公司

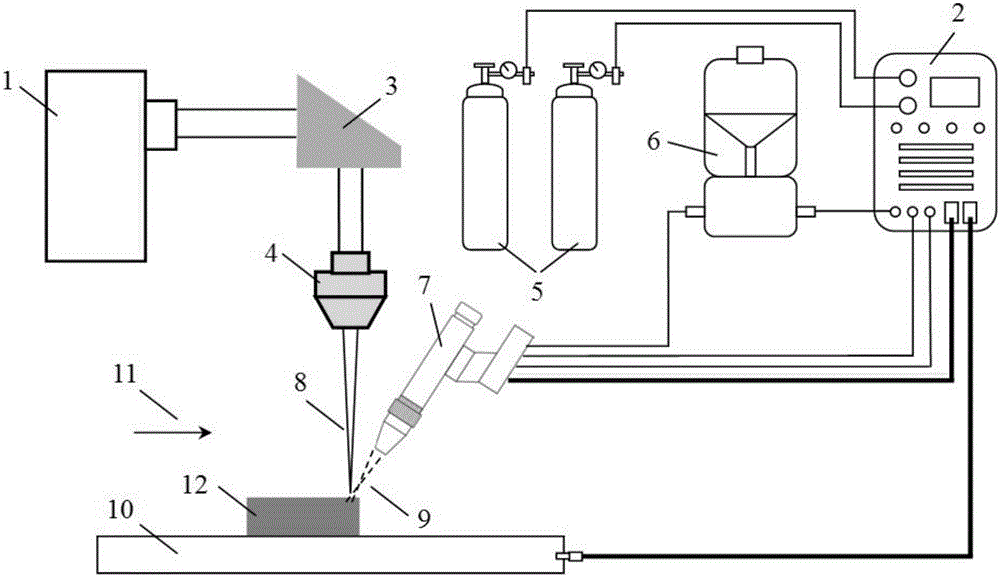

Laser three-dimensional fast forming and manufacturing method based on micro arc powder carrying

ActiveCN105834428AIncrease energy densityLow heat inputAdditive manufacturing apparatusIncreasing energy efficiencyArc stabilityOptoelectronics

The invention discloses a laser three-dimensional fast forming and manufacturing method based on micro arc powder carrying. By means of the method, flow carrying and synchronous powder sending of powder are achieved by means of a micro-beam plasma arc, and main energy needed for forming a metal structure is provided by means of a pulse laser heat source. The powder sending precision of powder materials is improved by means of the good arc stability and stiffness of the micro-beam plasma arc; and by means of the characteristic that the energy function of the micro-beam plasma arc is concentrated is utilized, so that the melting rate and the deposition rate of the powder are increased, and the heat absorbing rate of the powder materials and a forming area on the energy of the laser heat source is increased. The main arc current of the micro-beam plasma arc in the method is 30 A-50 A, the pulse peak power of a pulse laser beam is 4 kW-10 kW, and three-dimensional fast forming and manufacturing of metal materials and the structure are achieved by adjusting the relative position relation between the laser beam and the powder carrying flow of the micro-beam plasma arc, the beam spot coinciding ratio and the output energy of the micro-beam plasma arc and the laser beam. The laser three-dimensional fast forming and manufacturing method has the beneficial effects of being high in forming efficiency, high in precision, little in deformation, high in technical adaptability and the like.

Owner:CHONGQING UNIV OF TECH

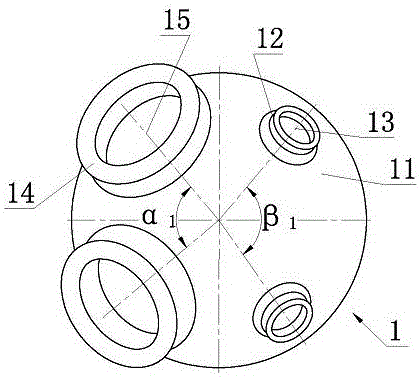

Pressure vessel integrated end socket for nuclear power, end socket plate blank of pressure vessel integrated end socket and forging method of pressure vessel integrated end socket

ActiveCN106051721AImprove mechanical propertiesImprove operational safetyMetal-working apparatusSteam boilersFiberPunching

The invention discloses a pressure vessel integrated end socket for nuclear power, an end socket plate blank of the pressure vessel integrated end socket and a forging method of the pressure vessel integrated end socket. According to the pressure vessel integrated end socket for nuclear power, a manhole base and a pipe hole base are arranged on an end socket body which is of a spherical crown structure; the manhole base and the pipe hole base are integrated with the end socket body in a forged mode; and the intersection point of the hole center line of a manhole and the hole center line of a pipe hole is located in the center of the sphere where the end socket body is located. A plate blank body of the end socket plate blank is of a circular plate structure, one surface of the plate blank body is provided with two manhole circular truncated cones and two pipe hole circular truncated cones, and the other surface of the plate blank body is a large-cone-angle circular truncated cone surface. The forging method comprises the following steps of steel ingot heating, forged blank blanking, forged blank upsetting and drawing, die forging formation, plate blank heat treatment, plate blank rough machining, end socket formation, end socket punching, forge piece heat treatment, machining of a forge piece, performance heat treatment and finished product machining. The integrated formation of the end socket of a vapor generator is achieved, the forge piece is uniform and compact in texture, the metal flow line is complete, and the fiber texture and the appearance of the forge piece tend to be more coincident.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

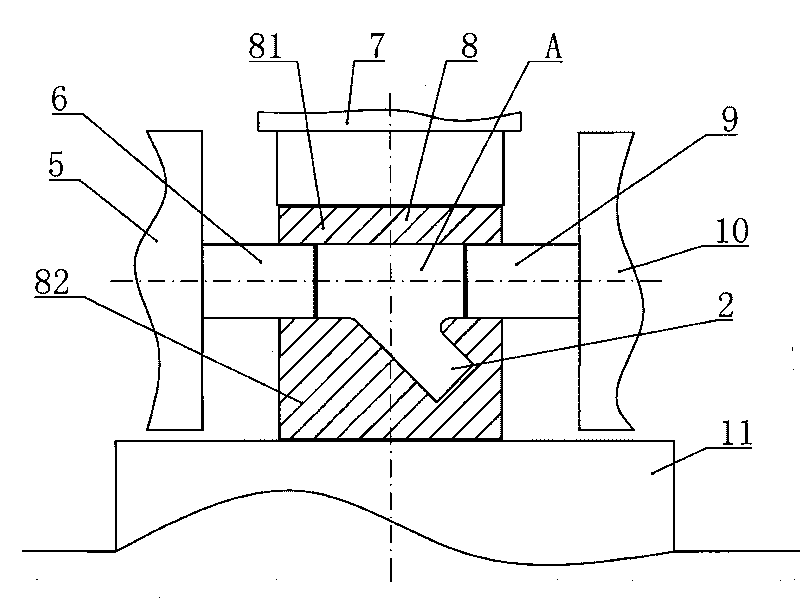

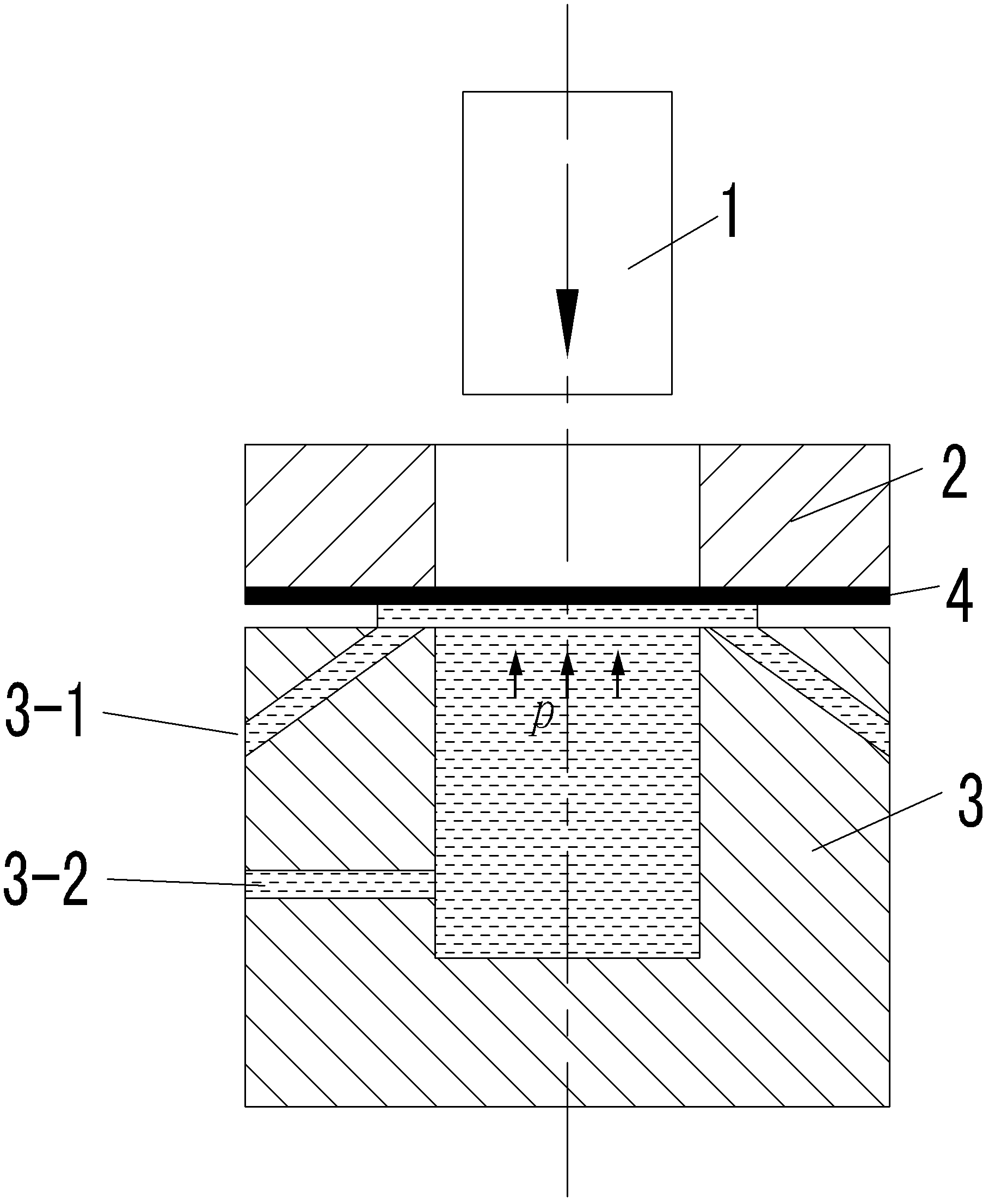

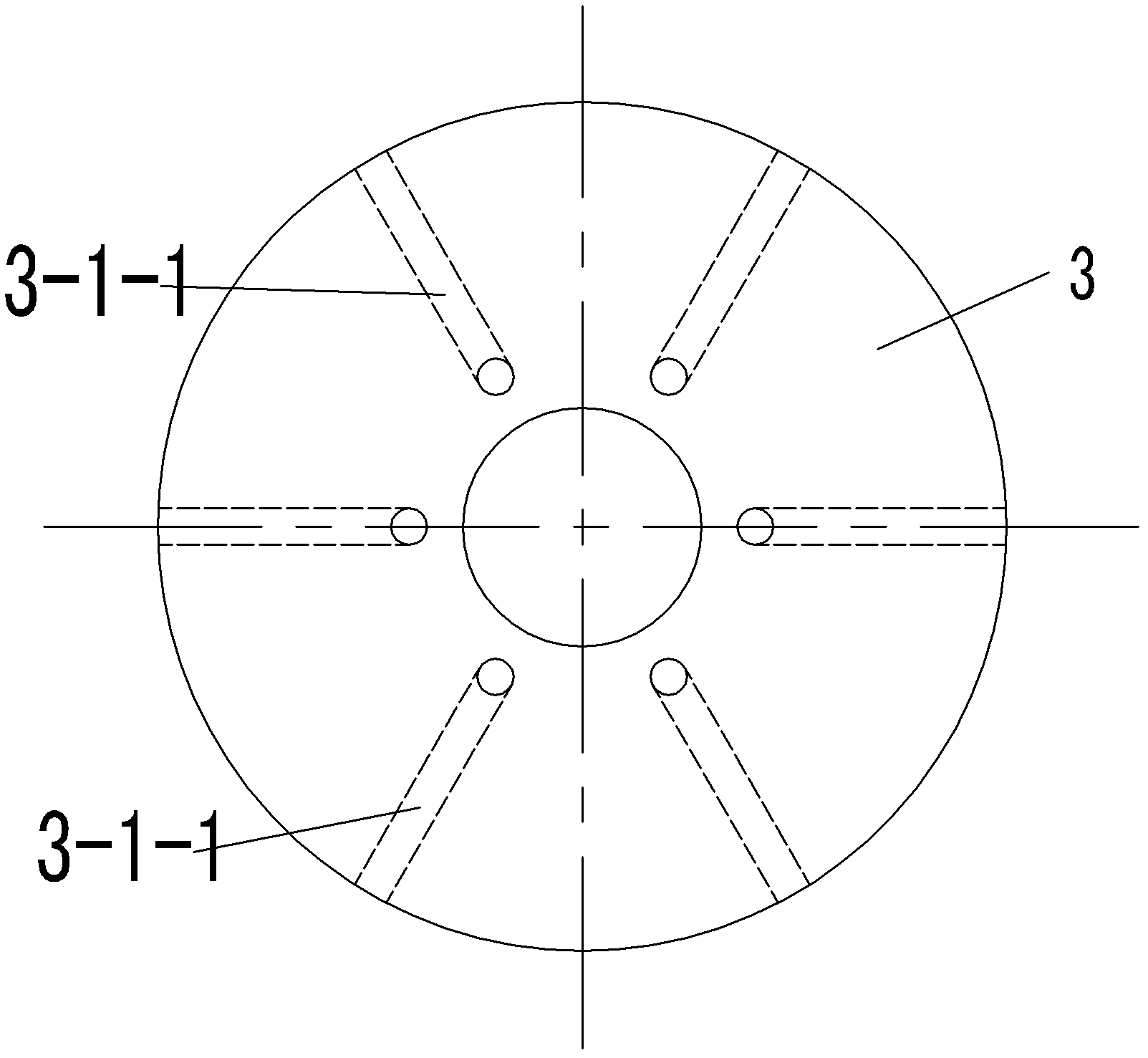

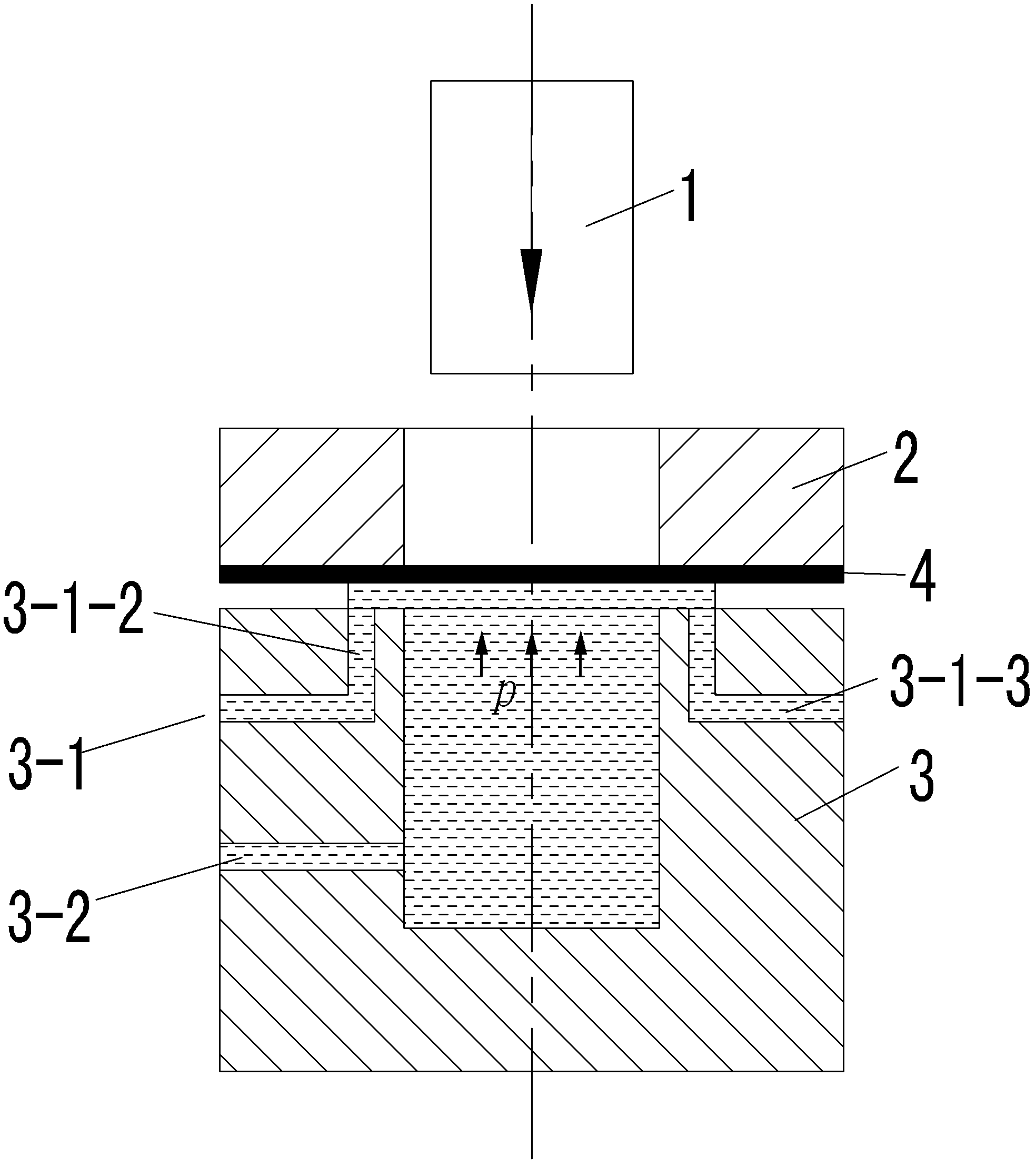

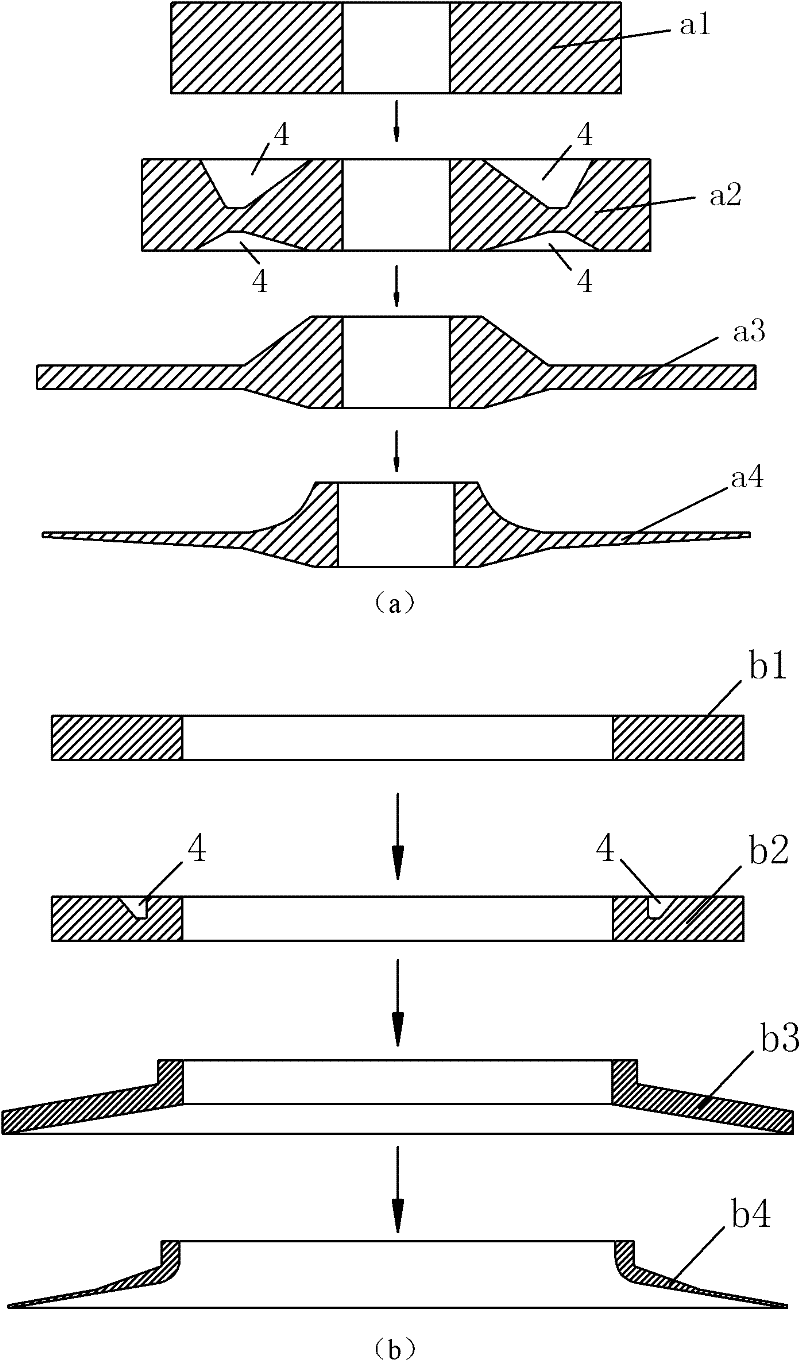

Device and method capable of reducing hydrodynamic deep drawing pressure pad force

The invention provides a device and method capable of reducing hydrodynamic deep drawing pressure pad force, relating to a hydrodynamic deep drawing device and method used for reducing pressure pad force. The invention provides a processing device and a processing method capable of reducing the pressure pad force, aiming at reducing the pressure pad force required in a hydrodynamic deep drawing process and improving forming limit. The device comprises a male die (1), a pressure pad (2) and a charging chamber (3), the upper end of the charging chamber (3) is open, and the end face of the charging chamber (3) is provided with a liquid drainage channel (3-1) which is communicated with the side wall of the charging chamber (3). The processing method sequentially comprises the following steps of: injecting fluid medium into the charging chamber (3), placing plate blank, applying the pressure pad force, and controlling the male die (1) to move down so as to pressurize. By adopting the device and method provided by the invention, the pressure pad force can be reduced, friction between blank and the pressure pad can be reduced, and the forming limit of a plate part can be further improved; and tonnage of equipment can be reduced, and processing capacity of the equipment can be obviously improved.

Owner:天津哈工永兴科技有限公司

Anchor clipper through hole type workblank cold pressing technique

The invention relates to an anchorage device clamping piece through-hole type blank cold flow pressing process used in a pre-stressed anchorage device system, which is characterized in that after a round bar and a stock are chosen, the following steps are performed in sequence: discharging, shot blasting treatment, phosphorizing and saponifying treatment, performing, normalizing treatment, shot blasting treatment, phosphorizing and saponifying treatment, extrusion forming, punching forming, shot blasting treatment, phosphorizing and saponifying treatment and extrusion forming, the anchorage device clamping piece through-hole type blank similar to the finished product clamping piece can be prepared out by adopting the steps. The invention has the advantages that the availability and the saving rate of material are high; the machine processing amount is greatly reduced; the compactness of the clamping piece is increased.

Owner:阚柳凤

Mobile phone shell and amorphous alloy reinforcement block thereof and manufacturing method of amorphous alloy reinforcement block

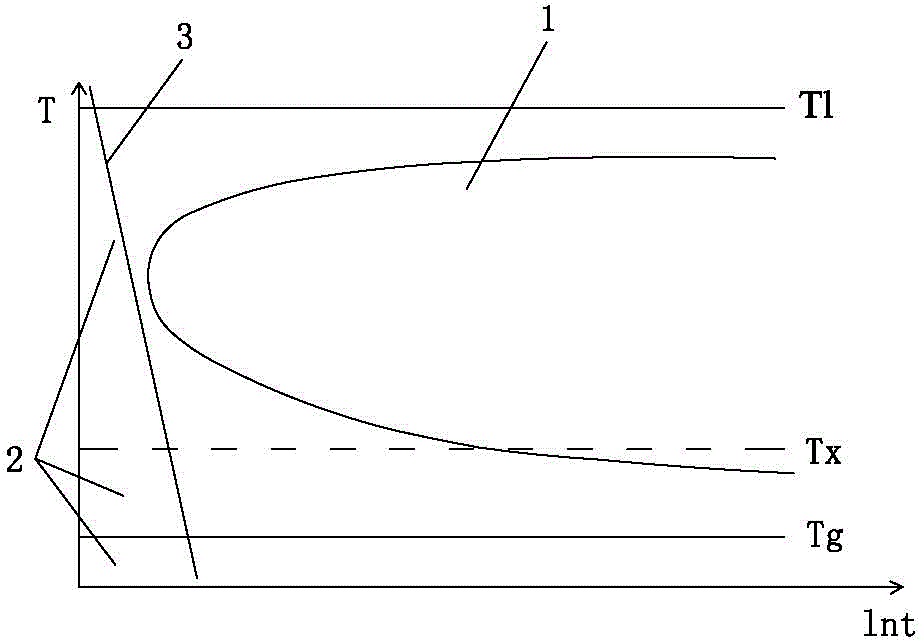

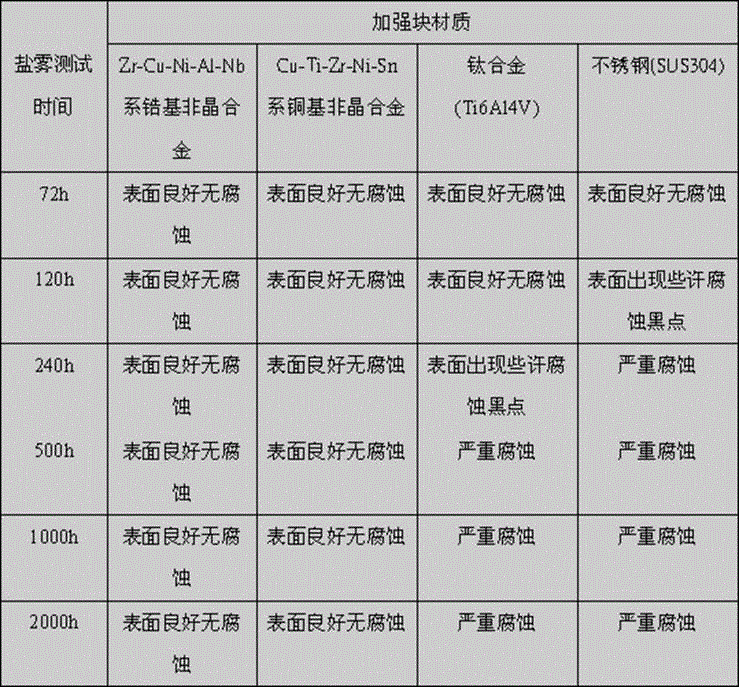

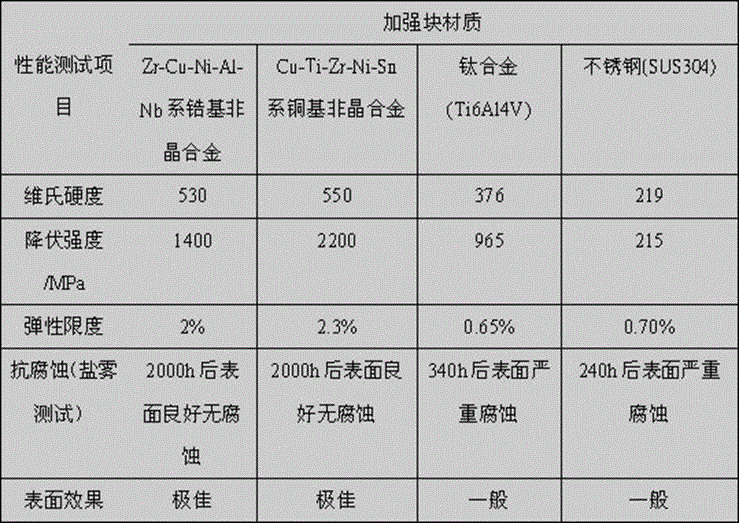

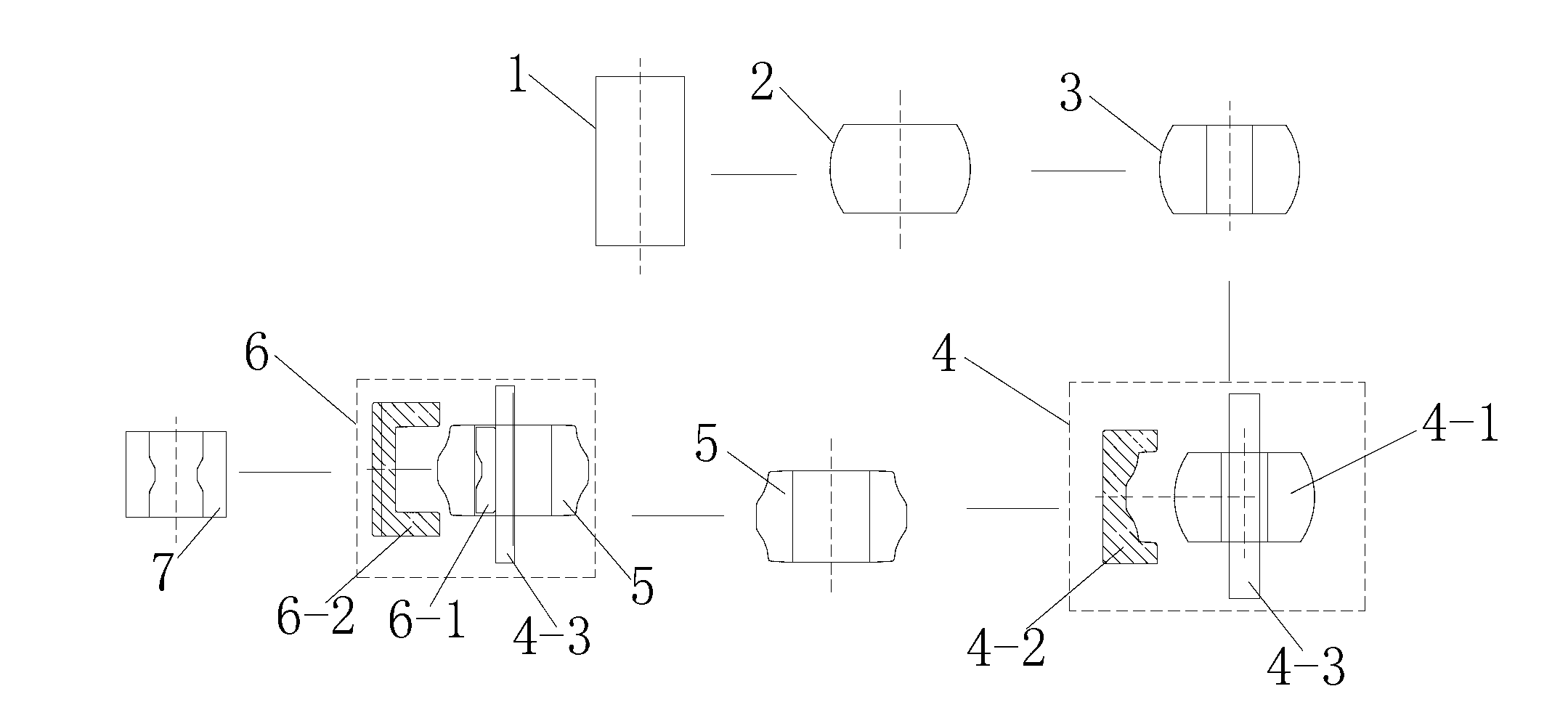

The invention relates to the technical field of application of amorphous alloy, in particular to a mobile phone shell and an amorphous alloy reinforcement block thereof and a manufacturing method of the amorphous alloy reinforcement block. The reinforcement block is the amorphous alloy reinforcement block made of zirconium-based amorphous alloy, copper-based amorphous alloy, titanium-based amorphous alloy, nickel-based amorphous alloy, palladium-based amorphous alloy or iron-based amorphous alloy. The reinforcement block is 400-600 in hardness, 1000-3000MPa in strength and 2-3% in elastic limit, and is non-corrosive on the surface after 500-2000h salt spray test. Amorphous-alloyed alloy ingot is adopted in the method to manufacture the amorphous alloy reinforcement block through a die casting molding method, a melt spinning method, a suction casting method, a rapid discharge molding method, a continuous casting method or a thermoplastic molding method. The amorphous alloy reinforcement block manufactured by the method has the advantages of high strength, high hardness, high elasticity and anti-corrosion, and the situation that a mobile phone is bent when the mobile phone shell is highly stressed can be avoided.

Owner:DONGGUAN PROMETAL TECH CO LTD

Small abnormal-shape combined forging and ring-rolling process

The invention discloses a small abnormal-shape combined forging and ring-rolling process which comprises the following process steps of inspecting a blank, cutting and grinding a rounded corner, upsetting and punching, conducting reversed ring-rolling, conducting ring-rolling on an abnormal shape, reeling, cutting in a back-to-back manner, inspecting the process, treating thermally, inspecting hardness, testing performances, machining, and finally inspecting, marking and packaging. The small abnormal-shape combined forging and ring-rolling process has the beneficial effects that the small abnormal-shape combined forging and ring-rolling process is provided, the quantity of machining is small, the stock utilization is high, the production efficiency is high, the streamline of a material can be prevented from being damaged, the product percent of pass is high, and the process can also be used to manufacture a small abnormal-shaped forged ring.

Owner:江苏翔能科技发展有限公司

Heat machining and heat treatment process of aluminum-silicon alloy plate prepared by powder sintering

The invention discloses a heat machining and heat treatment process of an aluminum-silicon alloy plate prepared by powder sintering. The content of Si in an Al-Si alloy is controlled in a range of 10-40%; after a high-silicon aluminum alloy blank ingot obtained by sintering is uniformly annealed at 300-500 DEG C for heat forging with deformation of not more than 20%, the multi-pass hot rolling with the pass reduction of not more than 30% is performed; or the multi-pass hot rolling with the pass reduction of not more than 30% is directly performed for the blank ingot after homogenization in the step 2; and a product obtained by hot rolling is annealed to obtain the Al-Si alloy plate product. The prepared high-silicon-content aluminum-silicon alloy blank ingot is precise in component control, compact, and short in heat deformation and heat treatment process flow; and the obtained Al-Si alloy plate has such physical and mechanical performances as air tightness, heat conductivity, thermal expansion coefficient, tensile strength and bending strength needed by application of electronic packing materials, reduces the subsequent mechanical workload of the materials, and improves the utilization rate and the production efficiency of the materials.

Owner:HUNAN HYDRO DYNAMIC NEW MATERIAL CO LTD

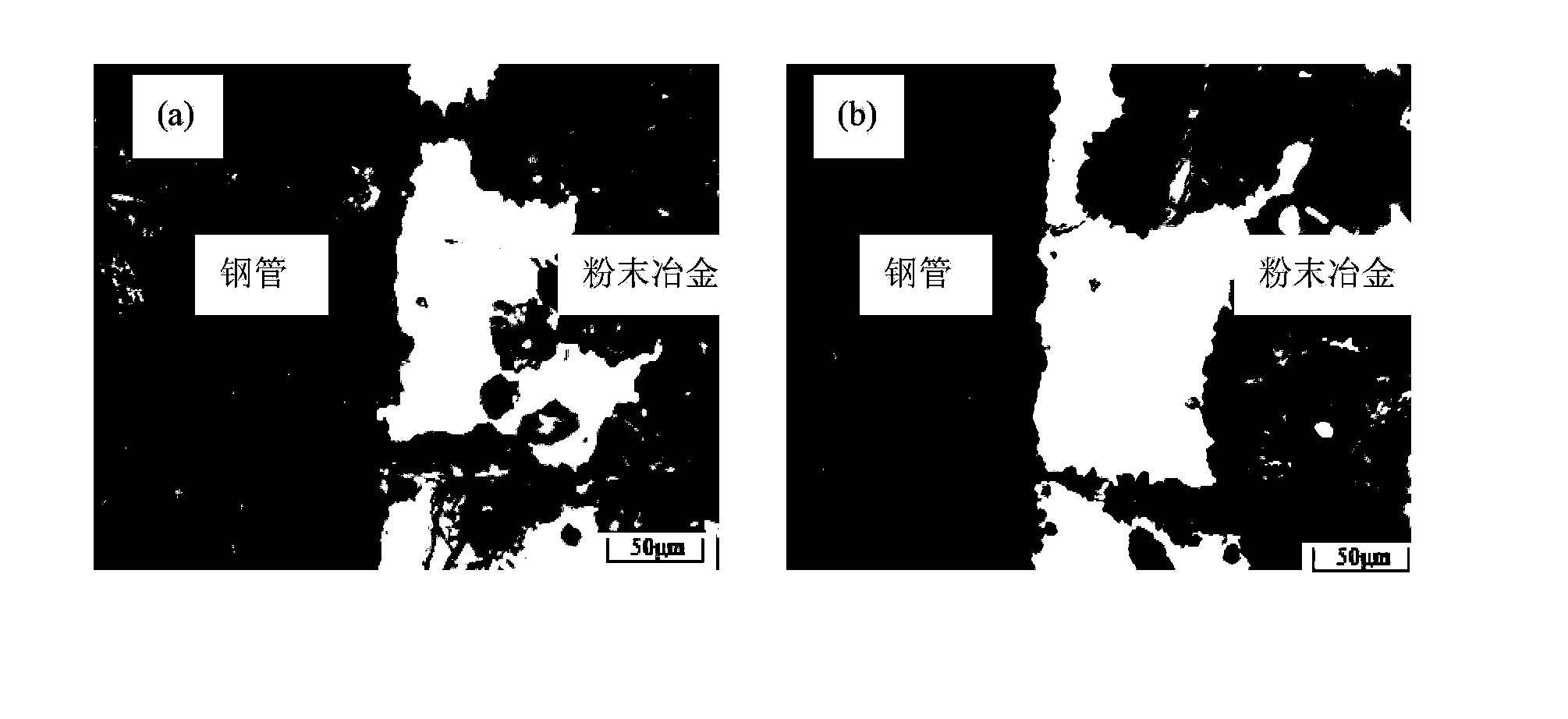

Combined powder metallurgy hollow camshaft cam material and preparation method

ActiveCN103898416AIncrease profitReduce manufacturing costTurbinesOther manufacturing equipments/toolsCombustionAlloy

The invention discloses a combined powder metallurgy hollow camshaft cam material and a preparation method, belonging to the technical field of camshafts for internal combustion engines like automobile engines. The alloy components of the camshaft material comprise 1.5-3% of C, 3-7% of Cr, 0.5-1.5% of Mo, 0.3-0.6% of P, 1-3% of Cu, 0.05-1.5% of Si, 0.05-1.5% of Mn, 0.01-1.5% of Ti, and the balance of Fe. The powder is pressed into a cam sheet, the mandrel adopts a seamless steel tube, the cam sheet and the seamless steel tube are in clearance fit, and the cam sheet and the steel tube are assembled and then are sintered. The green body of the cam is directly assembled with the steel tube and then is sintered. In sintering, the powdery material shrinks and is densified and also forms metallurgical bonding with the steel tube, so that the bonding strength is high, the performance is reliable, the prepared cam has advantages of high torque, small stress, light weight and good abrasion resistance.

Owner:GRIPM ADVANCED MATERIALS CO LTD +1

Integrated forging and forming method for reactor pressure vessel barrel flange adapter tube section

ActiveCN110090914AReduce potential riskWork stress homogenizationEngine componentsReactor pressure vesselIngot

The invention discloses an integrated forging and forming method for a reactor pressure vessel barrel flange adapter tube section. The integrated forging and forming method for the reactor pressure vessel barrel flange adapter tube section comprises the steps of (1) heating a steel ingot, and pressing the steel ingot to obtain an eight-edge prism steel billet; (2) blanking a forging billet: cutting a head part and a tail part of the eight-edge prism steel billet so as to obtain an eight-edge prism forging billet; (3) upsetting and drawing the forging billet: upsetting and drawing out the forging billet; (4) carrying out upsetting and rolling: upsetting and rolling the forging billet to obtain a short cylindrical forging billet; (5) carrying out marking and dividing in the circumferential direction: cutting two marking and dividing grooves at two ends of the short cylindrical forging billet; (6) carrying out rolling and necking: forming an adapter tube billet with a convex ring in the middle section; (7) carrying out marking and dividing in the axial direction: cutting four axial dividing grooves arranged along the axial direction; (8) circularly pressing a hemline; (9) marking anddividing a hemline boss: forming four sections of bosses on a hemline adapter tube billet; (10) punching a main hole; (11) carrying out chambering and forming; (12) carrying out shaping and chambering; (13) punching an adapter tube hole; (14) carrying out heat treatment after forging; (15) roughly machining the billet; (16) carrying out quenching; (17) carrying out hardening and tempering; and (18) processing a finished product. According to the method, integrated forming and forming is realized, the structure is uniform and dense, and a metal flow line is complete.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

Surface hardening treatment method for large-power low-speed diesel engine piston bar

ActiveCN101148688AHigh heating and quenching efficiencyImprove quenching efficiencyFurnace typesIncreasing energy efficiencyMicro structureLow speed

The surface hardening treatment process for piston rod of great power low speed diesel engine includes continuous surface heating to 900-940 deg.c in an intermediate frequency inducing heater of the quenching apparatus, quenching through spraying water, tempering through heating to 200-270 deg.c, and rotating the piston rod while heating in the inducing heater and spraying water. The present invention has high quenching efficiency, environment friendship, homogeneous heating and quenching, and capacity of reaching required surface hardness, quench hardened layer depth and micro structure.

Owner:DALIAN MARINE DIESEL

Rotary module of wheelchair

PendingCN107638257AEasy to operateCompact structureWheelchairs/patient conveyanceGear driveWheelchair

The invention discloses a rotary module of a wheelchair. The rotary module is used for making a seat of the wheelchair to rotate relative to a wheelchair body of the wheelchair. The rotary module comprises a rotating shaft, a rotating body, a gear, a base and a gear driving unit, the upper end of the rotating shaft is fixed to the bottom of the seat, the rotating body and the gear are arranged onthe rotating shaft, the base is arranged on the wheelchair body, and a supporting sleeve is arranged on the base; the seat is connected with the supporting sleeve in an inserted mode through the rotating shaft, the rotating body on the rotating shaft is assembled on the supporting sleeve, and the gear on the rotating shaft meshes with the gear driving unit and is rotationally connected with the wheelchair body. The seat on the wheelchair can be combined with and separated from the wheelchair body in an inserted connection mode, so that transportation and carrying of the wheelchair are facilitated. Mechanical connection and electric connection of the wheelchair and the wheelchair body are achieved through inserted connection of the wheelchair and the wheelchair body in a one-time mode; mechanical connection is rotational connection so that the driving mode of the wheelchair can be changed through rotation of the seat to adapt to different passing conditions, and the operability of the wheelchair is greatly improved; meanwhile, the overall size of the wheelchair is greatly reduced by the adoption of the base of the sectional material structure, the structure is compact, and the machining amount of wheelchair production is greatly reduced.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL

Rotary forging method for large disc type work piece and forging device

InactiveCN101862807BIncrease profitReduce manufacturing costForging/hammering/pressing machinesWheelsProcessing costIndustrial engineering

The invention provides a rotary forging method for large disc type work pieces and a forging device. The method comprises preparing a forging die, preparing blanks, pre-forging a shunt slot, positioning the blanks and carrying out rotary forging in steps. Based on the method, the invention also provides a forging device which can realize relative rotation of an upper forging die and a lower die, and the local forming process for the disc type work pieces can be carried out through rotary forging of the upper forging die and the lower die. In order to control metal flow in the forging process, the procedure of pre-forging the shunt slot is added prior to the rotary forging. Moreover, the upper forging die with a special structure is adopted to overcome the warpage of the work pieces during rotary forging. The forming method has the advantages of low forming load, simple dies and low processing cost, and can greatly reduce the manufacturing cost of existing large disc type work pieces.

Owner:XI AN JIAOTONG UNIV +1

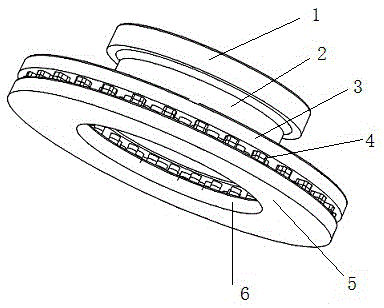

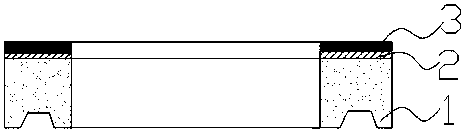

Aluminum-based titanium surface brake disc for high-speed heavy haul train and molding method thereof

ActiveCN110205530AImprove wear resistanceImprove high temperature resistanceAdditive manufacturing apparatusBraking discsTitanium surfaceWear resistant

The invention discloses an aluminum-based titanium surface brake disc for a high-speed heavy haul train and a molding method thereof. The aluminum-based titanium surface brake disc comprises a brake disc base body, wherein the brake disc base body is an aluminum alloy brake disc base body, a wear-resistant layer is compounded on the aluminum alloy brake disc base body, the wear-resistant layer ismade from a titanium alloy material, a transition layer is further arranged between the aluminum alloy brake disc base body and the wear-resistant layer, and metallurgical bonding is carried out on the wear-resistant layer, the transition layer and the aluminum alloy brake disc base body by adopting an injection molding 3D printing technology; and the wear-resistant layer is 4-10 mm in thickness,and the transition layer is 1-4 mm in thickness. By printing a ceramic particle reinforced titanium alloy brake surface on the aluminum alloy base body with light weight, high strength and great heatdissipation, the wear resistance and the high temperature resistance of the brake disc can be effectively improved, and the aluminum-based titanium surface brake disc for the high-speed heavy haul train, with high comprehensive properties, is prepared.

Owner:HUNAN UNIV OF TECH

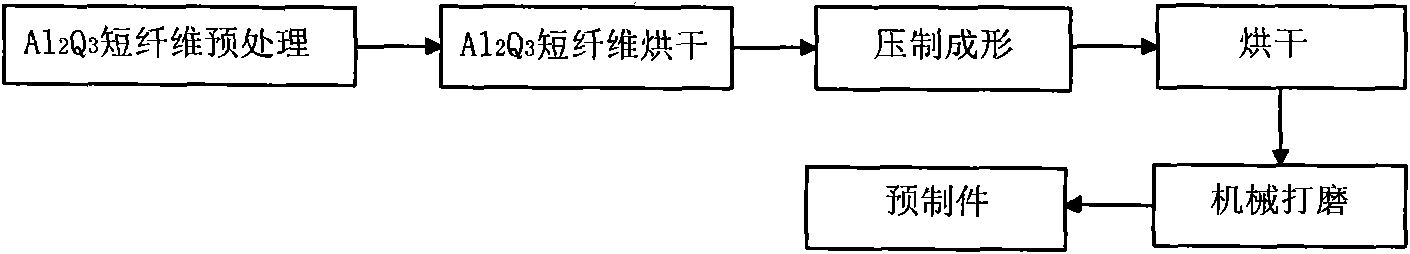

Preparation method of Al*O* short fiber reinforced composite prefabricated part

InactiveCN101575687ASolve fixed-length technologyEliminate pollutionFiltrationFiber-reinforced composite

The invention discloses a preparation method of an Al2O3 short fiber reinforced composite prefabricated part, which is characterized by comprising the following steps of: (1) pretreatment of Al2O3 short fiber; (2) drying of the Al2O3 short fiber; (3) fabrication of an Al2O3 short fiber prefabricated part; (4) drying of the Al2O3 short fiber prefabricated part; and (5) polishing of the Al2O3 short fiber prefabricated part: the Al2O3 short fiber reinforced composite prefabricated part is obtained after mechanical polishing. The invention improves the production efficiency, reduces the cost, eliminates environmental pollution through a mechanical liquid smashing device, adopts a method of vacuumized pressure filtration, and is easy to control the dimension.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

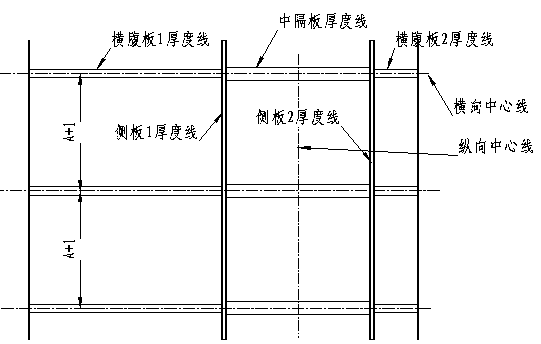

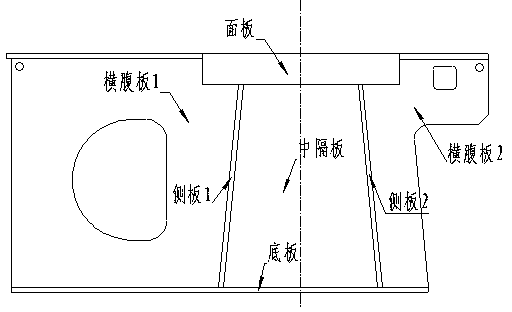

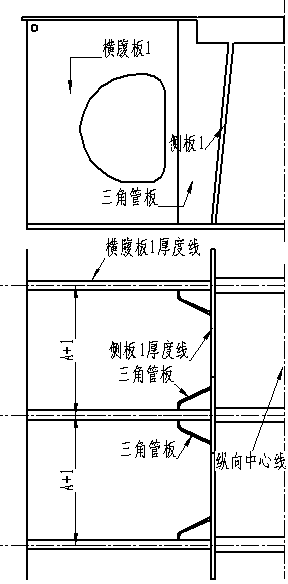

Manufacturing method of welding type cylinder block of marine diesel engine

InactiveCN103506763AReduce scrap rateReduce the amount of machiningWelding/cutting auxillary devicesAuxillary welding devicesPulp and paper industryCylinder block

The invention discloses a manufacturing method of a welding type cylinder block of a marine diesel engine. The method comprises the steps of (1) drawing lines on a platform, (2) assembling a box body of the cylinder block, (3) assembling a triangular tube plate, and (4) assembling a scavenging device. According to the manufacturing method of the welding type cylinder block of the marine diesel engine, production cost is reduced; due to the fact that the structure of the welding type cylinder block is a combination of a cylinder block body and a scavenging collecting pipe, the machining amount of the cylinder block and the scavenging pipe is greatly reduced, the workload for secondary assembly is greatly reduced, assembly errors are reduced, the defect that cold cracks appear easily during casting is overcome, defect repairing is easy, and the discarding rate of cylinder blocks is reduced.

Owner:HUDONG HEAVY MACHINERY

Plate type wedge lateral rolling forming method for eccentric step shalf

InactiveCN1820871AIncrease productivityExtend your lifeRollsMetal rolling arrangementsMetal formingRadial compression

The present invention provides a kind of plate type wedge rolling forming method for eccentric stepped shaft, and belongs to the field of plastic metal forming technology. The forming method includes moving two plate type molds with wedge mold face to face, and extruding heated circular rod in the molds for continuous radial compression and axial extending deformation to become eccentric stepped shaft gradually. The mold for forming eccentric circular shaft section has wedge work surface comprising inclined wedge surface and mold top surface, and curved top surface, with the curved surface being one corrugate envelope surface formed by the corrugate motion of the eccentric rolled workpiece circle and the mold top surface during the rolling process. The present invention has the advantages of high production efficiency, high material utilizing rate, low production cost, high size precision and high product quality, and realizes the precise formation of eccentric stepped shaft.

Owner:UNIV OF SCI & TECH BEIJING

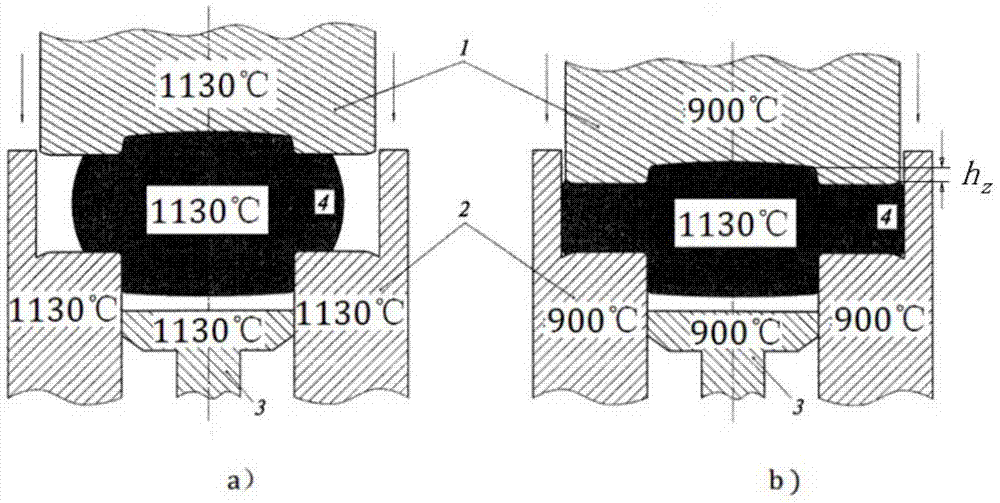

Engine turbine disc optimizing manufacturing process and device based on heat-resisting alloy

InactiveCN103934397ALarge diameterStable mechanical propertiesForging/hammering/pressing machinesManufacturing technologyAlloy

Provided is an engine turbine disc optimizing manufacturing process and device based on heat-resisting alloy in the technical field of engine part manufacturing technologies. GH4145 workblanks are preheated and then are subjected to primary extrusion, secondary extrusion is performed by independently reducing the temperatures of a male die and a female die, accordingly knots formed on the surfaces of the workblanks are eliminated, and a turbine disc forge piece is manufactured. The dies are made of cheap nickel base alloy and are of closed structures free of flash gutters, the die forging force is reduced, and precious metal is saved. Compared with the prior art by which work can performed under vacuum or inert gas shielding condition, the engine turbine disc optimizing manufacturing process and device can manufacture a high-quality turbine disc with double hubs in the air in a constant-temperature die forging mode ad has the batch production condition while improving the metal utilization rate and reducing mechanical machining allowance.

Owner:上海驳原金属材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com