Device and method capable of reducing hydrodynamic deep drawing pressure pad force

A technology of liquid-filled deep drawing and blank-holding force, which is applied in the field of liquid-filled deep-drawing devices, can solve problems such as high blank-holding force, unfavorable flange deformation and flow, and increased frictional resistance, so as to reduce equipment requirements and avoid cracking defects , the effect of reducing the tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

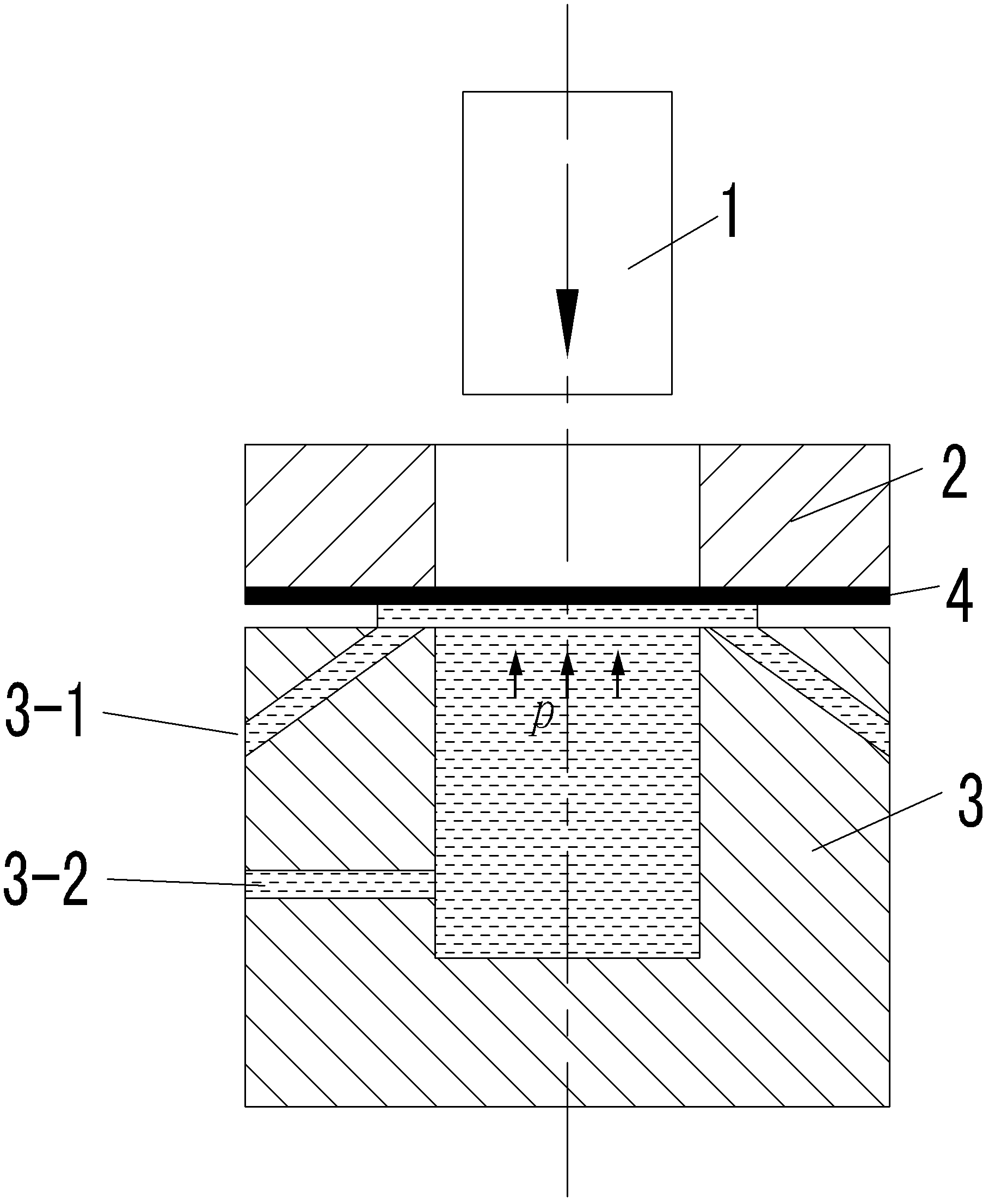

[0017] Specific implementation mode one: as Figure 1~5 As shown, the device for reducing the blank-holding force in liquid-filled deep drawing described in this embodiment includes a punch 1, a blank-holder 2 and a liquid-filled chamber 3. The upper end of the liquid-filled chamber 3 is open, and the punch 1 is placed in the filled Above the liquid chamber 3 and corresponding to the opening of the liquid-filled chamber 3, the blank holder 2 is located above the liquid-filled chamber 3 for fixing the sheet blank 4; its feature is that a liquid drainage channel is provided on the upper end surface of the liquid-filled chamber 3 3-1, the liquid drainage channel 3-1 communicates with the atmosphere from the inlet on the upper end surface of the liquid-filled chamber 3 until it passes through the outlet on the side wall of the liquid-filled chamber 3 (the inlet of the liquid drainage channel 3-1 is in the liquid-filled On the upper end surface of the chamber 3, the outlet of the l...

specific Embodiment approach 2

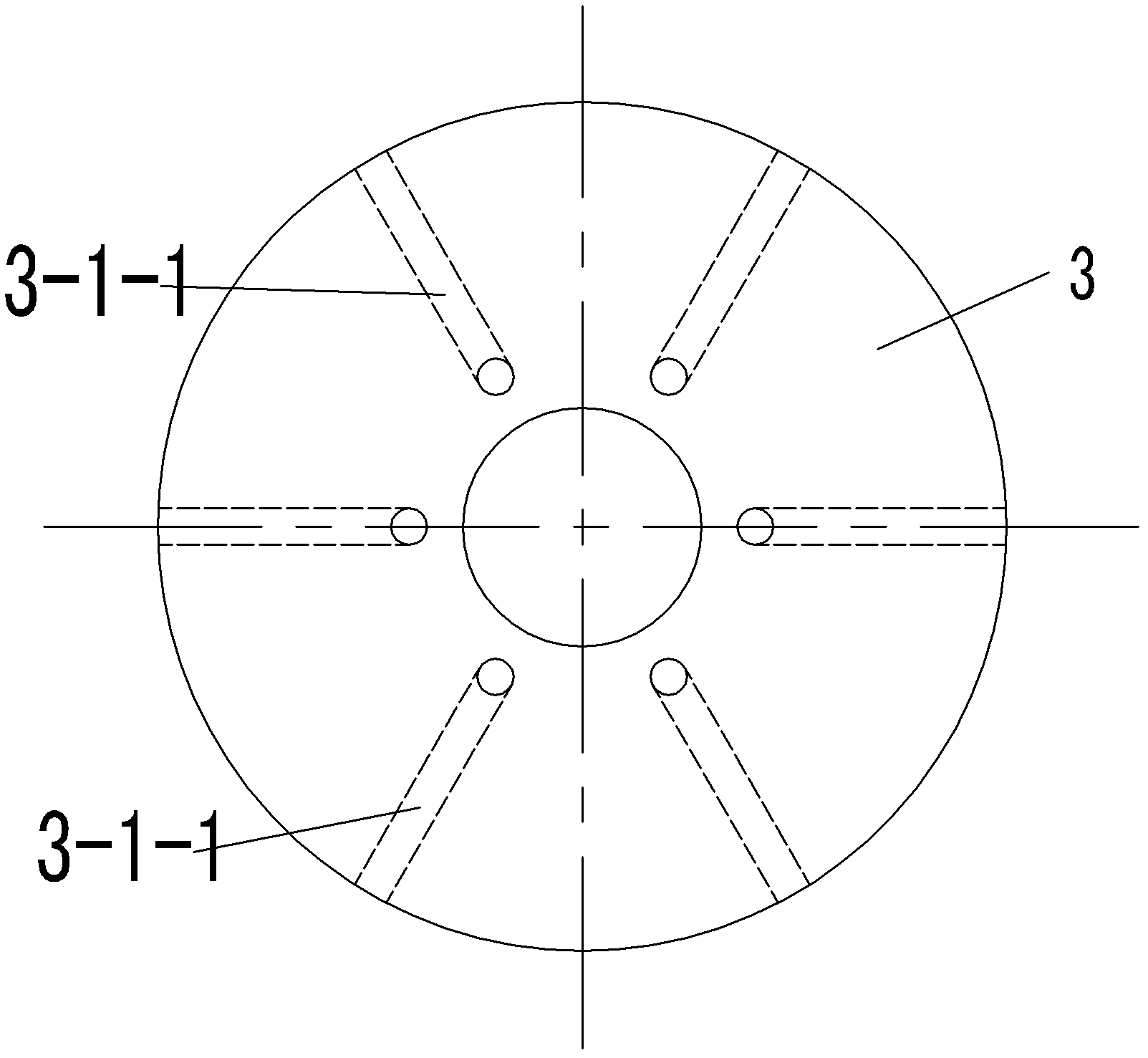

[0019] Specific implementation mode two: as Figure 1~2 As shown, the liquid drainage channel 3-1 in this embodiment is composed of a plurality of liquid drainage holes 3-1-1, and the plurality of liquid drainage holes 3-1-1 are uniformly arranged in the liquid-filled chamber 3 along the circumference. In the side wall, each liquid drainage hole 3-1-1 is arranged obliquely; the inlet of each liquid drainage hole 3-1-1 is on the upper end surface of the liquid-filled chamber 3, and each liquid drainage hole 3-1-1 The outlet of 1-1 is on the outer wall of the liquid-filled chamber 3 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

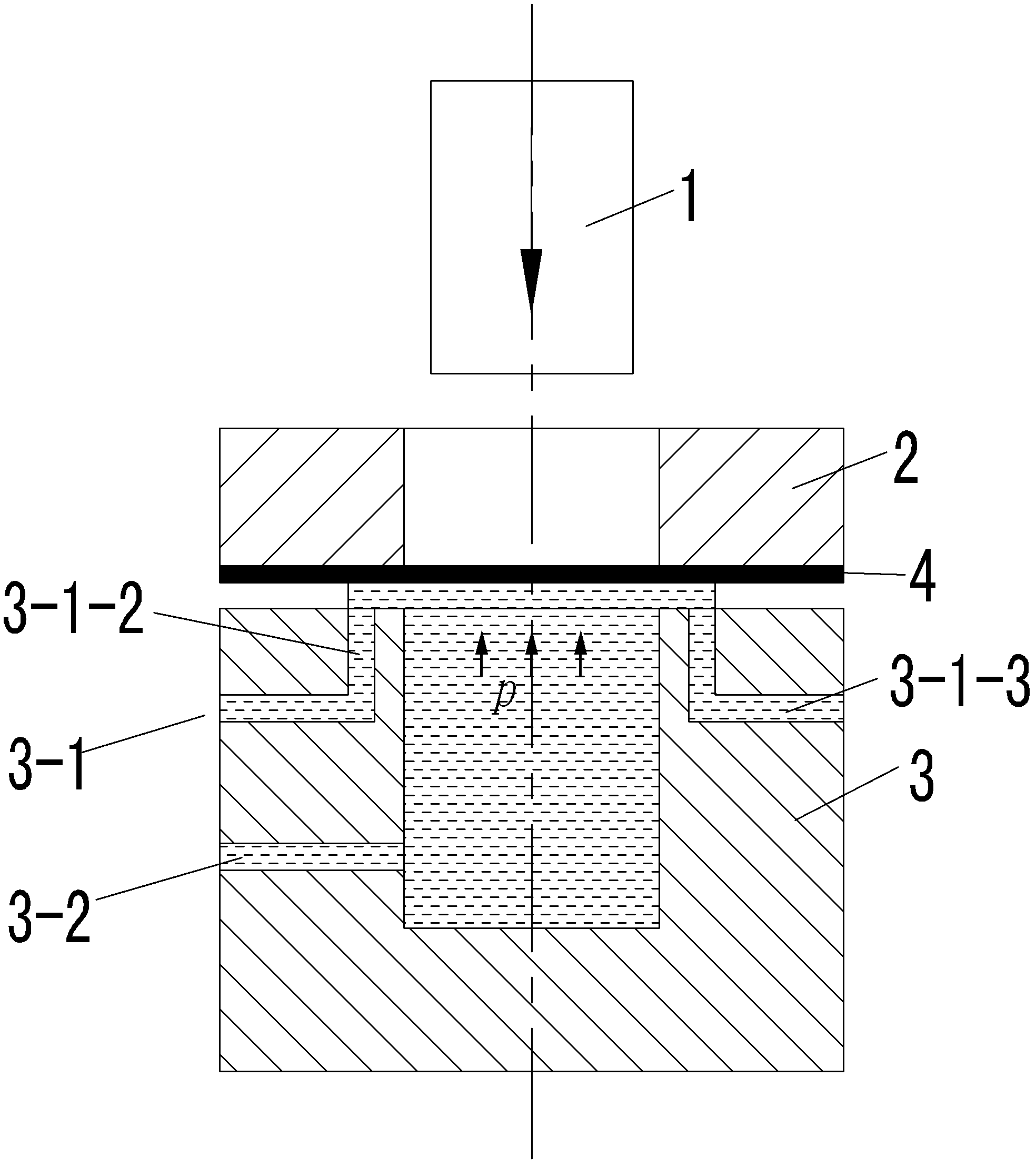

[0020] Specific implementation mode three: as Figure 3-4 As shown, the liquid drainage channel 3-1 in this embodiment is composed of an annular drainage groove 3-1-2 and a plurality of liquid drainage holes 3-1-3 located at the lower part of the drainage groove 3-1-2. The annular drainage groove 3 -1-2 is opened on the upper end surface of the liquid-filled chamber 3, a plurality of liquid drainage holes 3-1-3 are uniformly arranged in the side wall of the liquid-filled chamber 3 along the circumference, and each liquid drainage hole 3-1- 3 are arranged horizontally, and the inner end of each liquid drainage hole 3-1-3 communicates with the inner cavity of the annular drainage groove 3-1-2. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com