Patents

Literature

306results about How to "Raise the forming limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

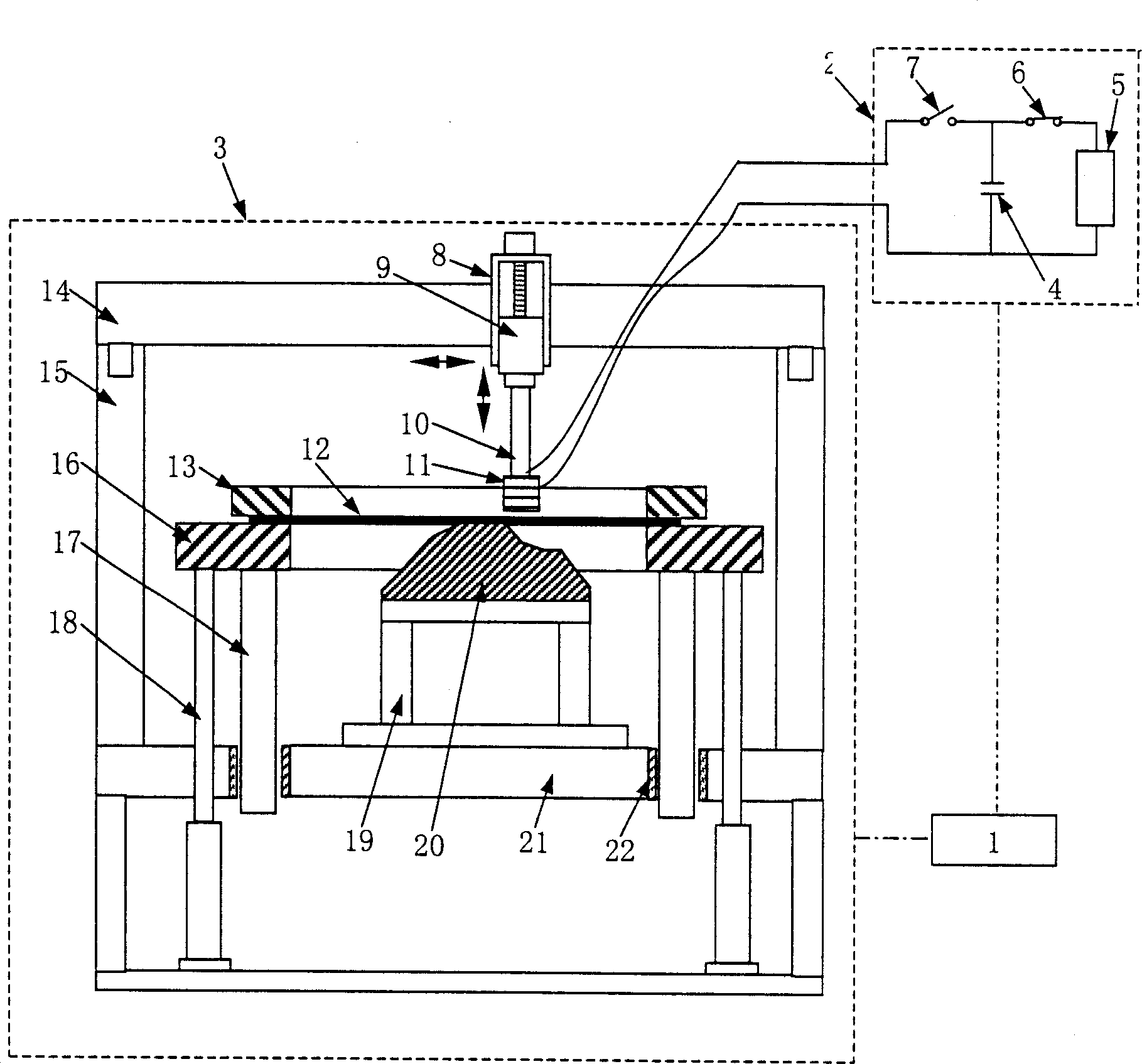

Electromagnetic inching forming method and its device for plate moving coil

InactiveCN1821910AGood repeatabilityEasy energy control and automated productionProgramme controlComputer controlEngineeringElectromagnetic pulse

This invention relates to an electromagnetic progressive shaping method for plate moving coils and a device, in which, said device includes a computer control system, an electromagnetic force generation system and a three-shaft digital control shaping system including a plate clamping elevating device, a supporting model frame and an electromagnetic shaping clamping rod, in which, the computer controls the coil to move downward along the contour of a model profile from the top according to the contour data of the model profile and the plate is formed partly relying on the magnetic force of coil till to the bottom of the model and finish the entire process.

Owner:HUAZHONG UNIV OF SCI & TECH

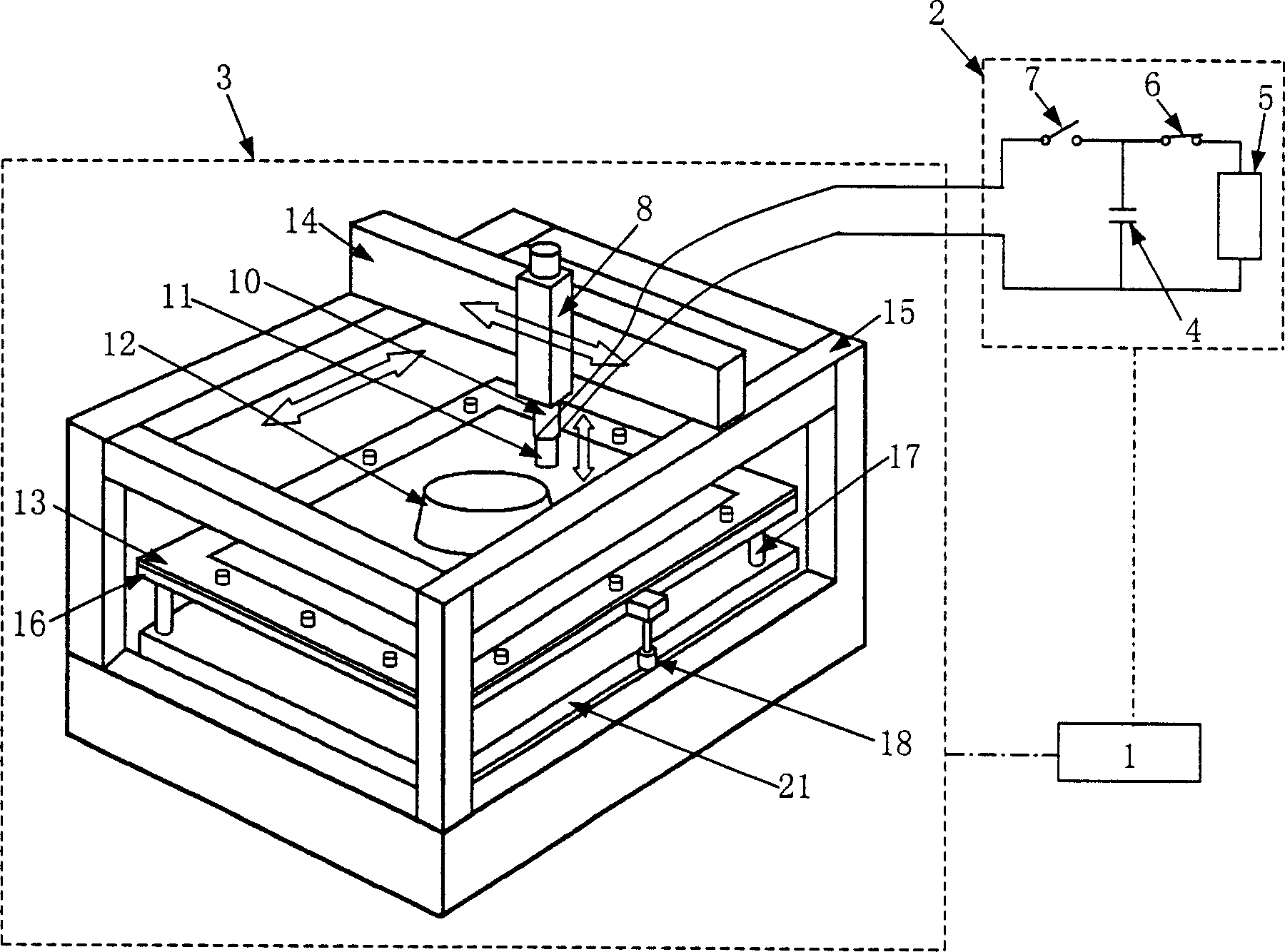

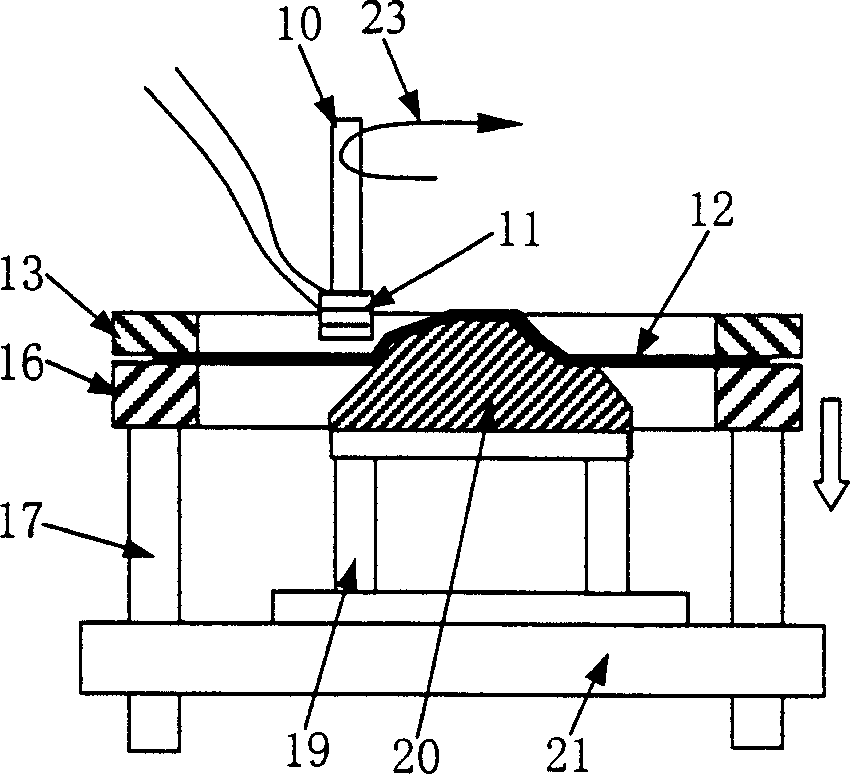

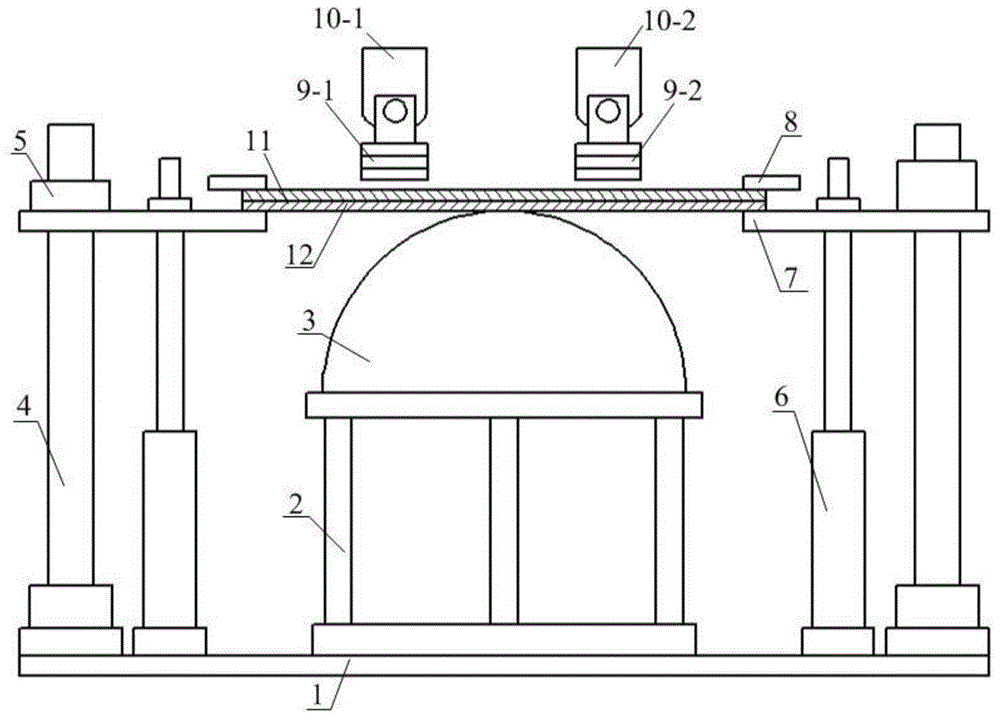

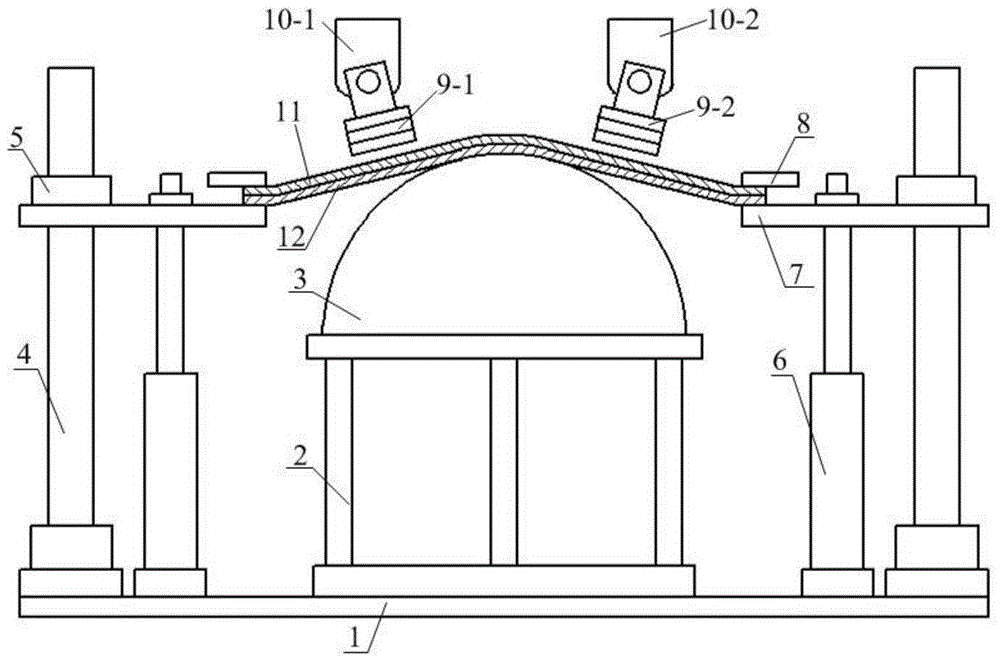

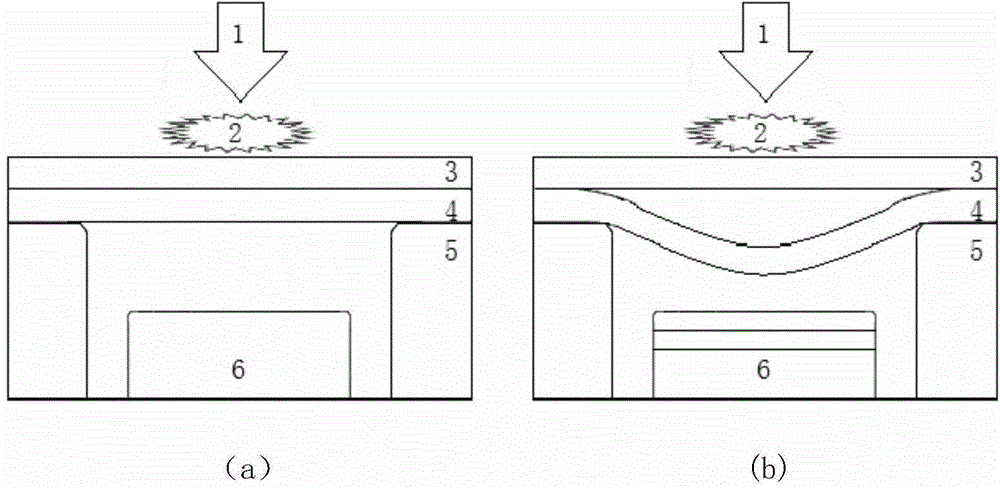

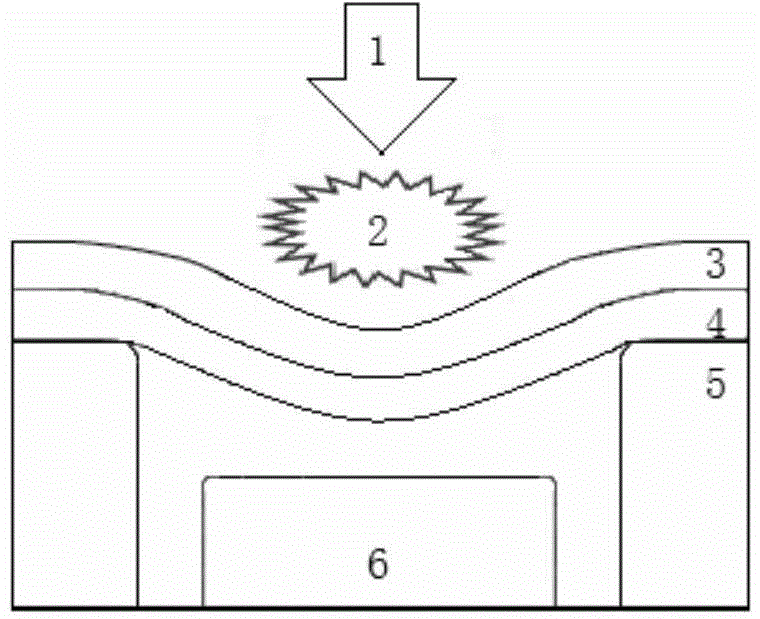

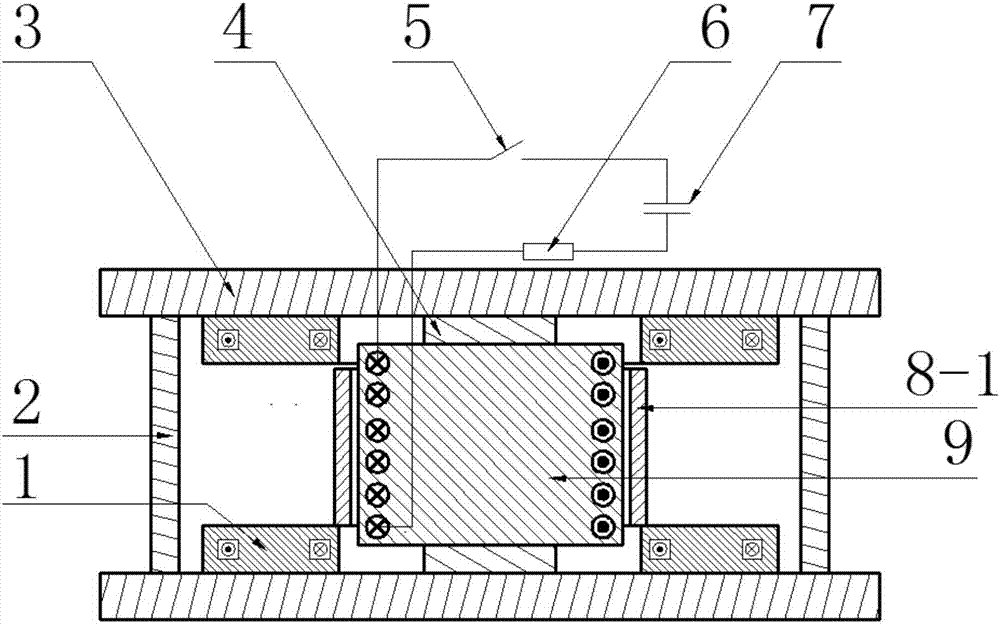

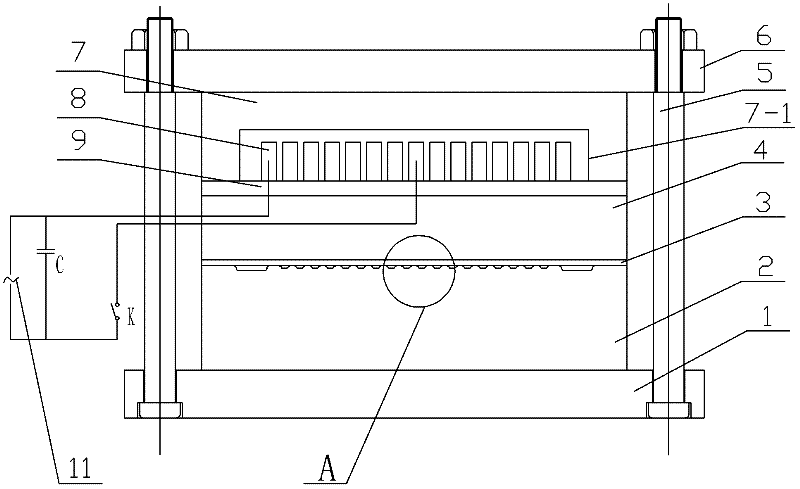

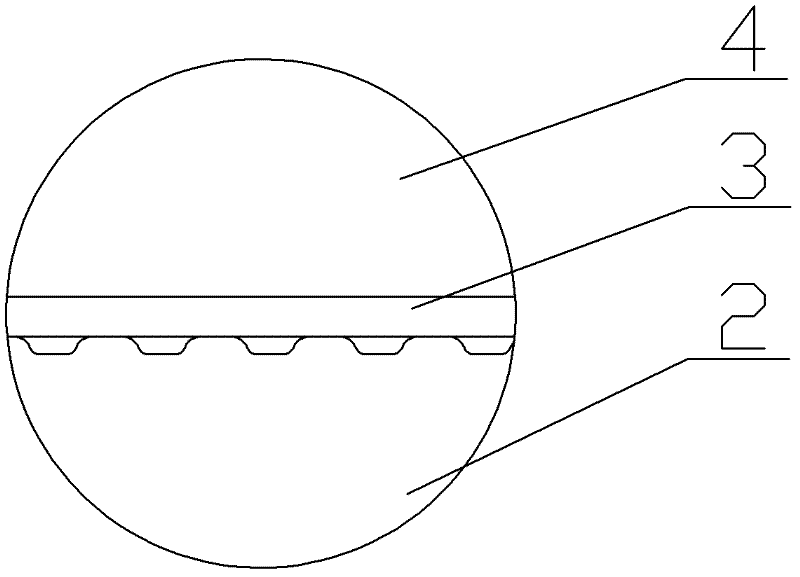

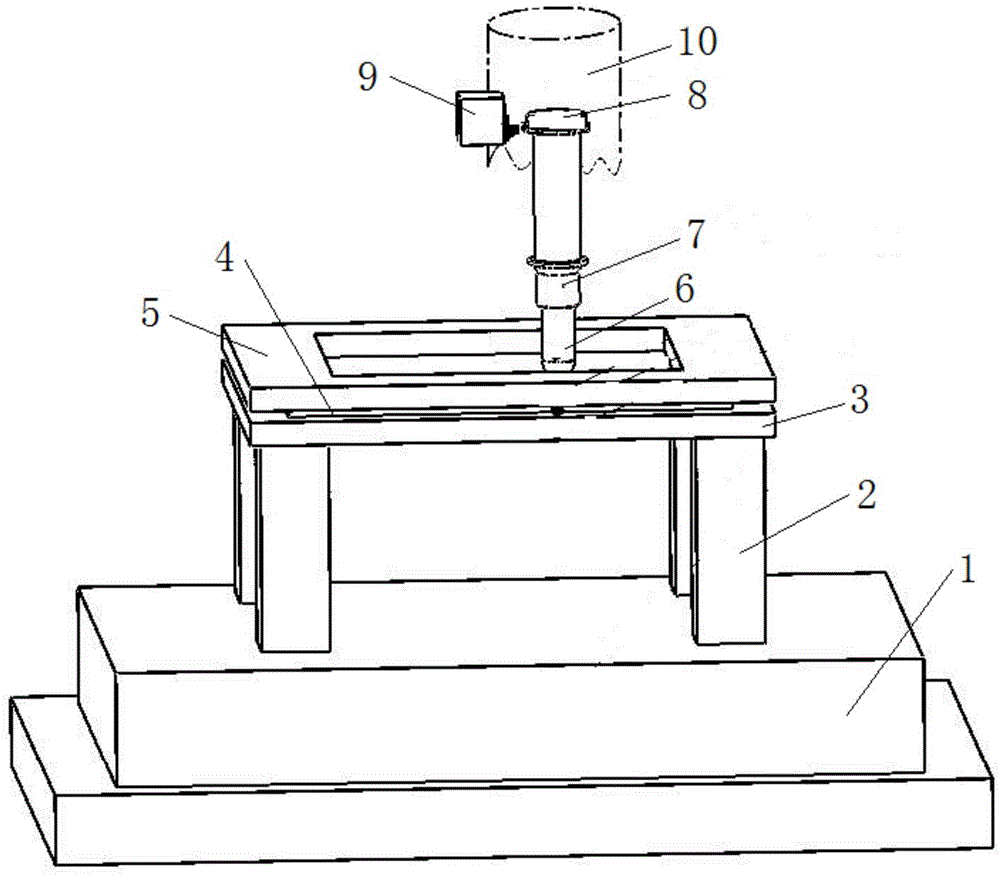

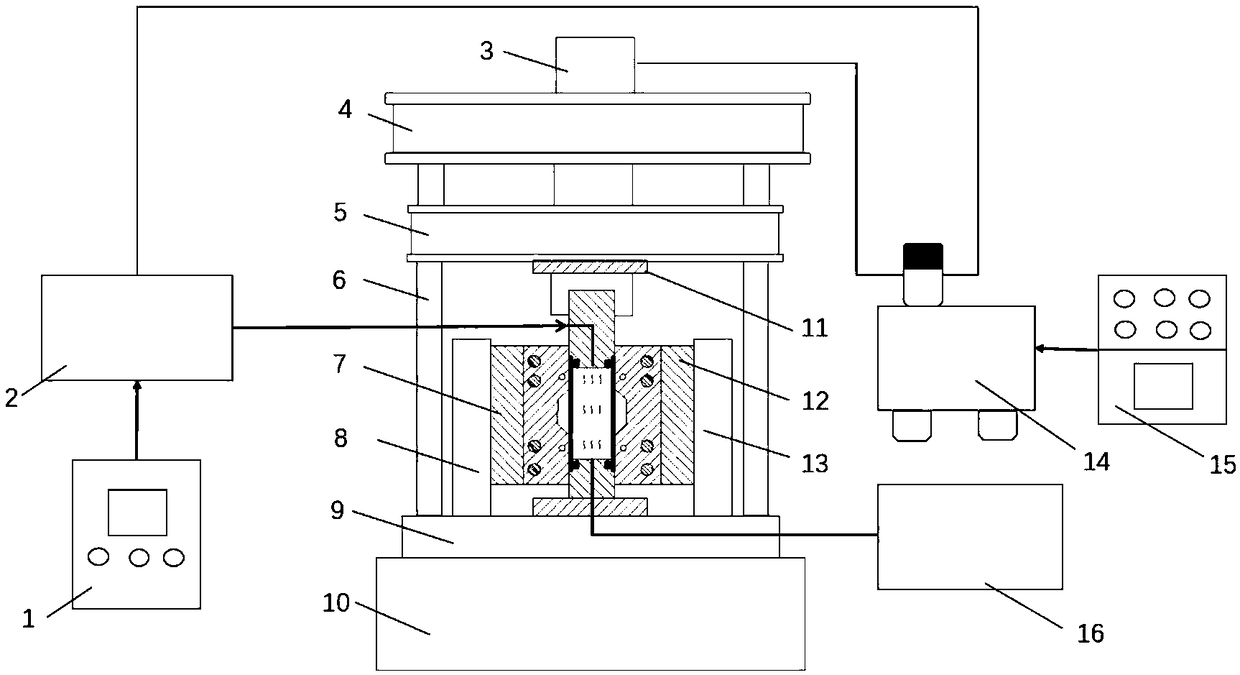

Stretch-forming and electromagnetic combining incremental forming method and device of large thin-wall part

The invention discloses a stretch-forming and electromagnetic combining incremental forming method and device of a large thin-wall part. The method comprises the steps that a driving plate is arranged above a plate to be deformed, the driving plate and the plate to be deformed are clamped by a pressing plate and a supporting plate, and a lifting oil cylinder drives the supporting plate to move, so that the driving plate and the plate to be deformed are stretch-bent and tightened preliminarily, and the stretch-forming process is achieved; the position of an electromagnetic coil is adjusted, the electromagnetic coil is made to exactly face the driving plate to be deformed to discharge electricity, the coil rotates on the surface of the driving plate for a circle around the axis of a male die, and the plate to be deformed is attached to the male die at the same height; then, the oil cylinder descends again to stretch-bend the plate, the coil discharges electricity to deform the plate to be deformed again, the plate to be deformed is attached to the male die, and the alternate forming process of stretch-forming, discharging, re-stretch-forming and re-discharging of the plate is achieved in the same way till deformation of the plate is finished. The flowing evenness of materials can be improved, the thinning ratio of the plate can be reduced, and flexible processing and precise plastic manufacturing of large plates hard to deform can be achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

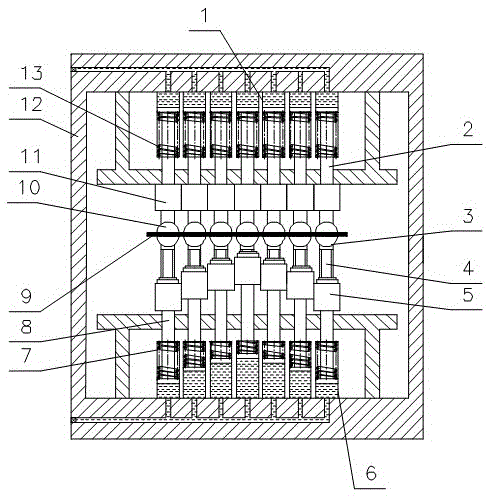

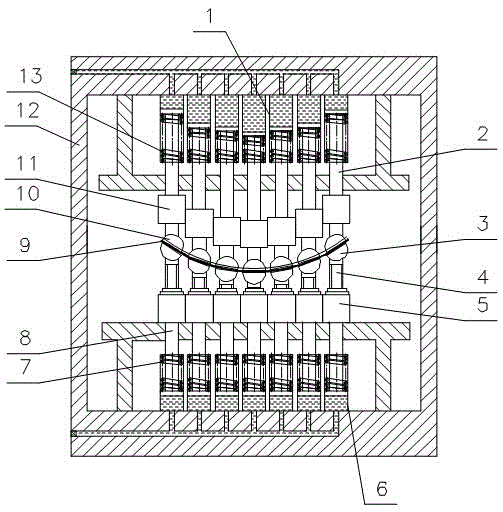

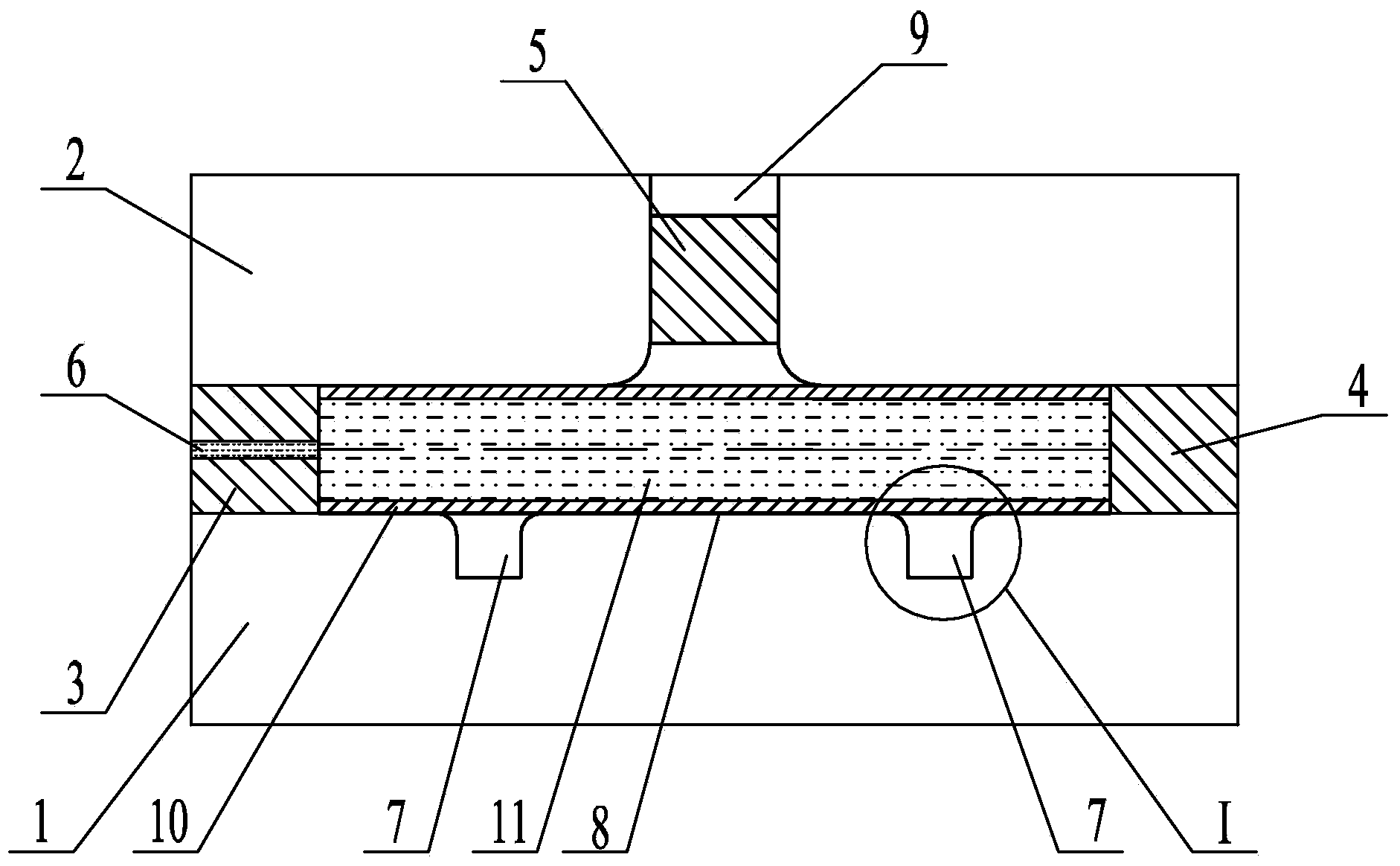

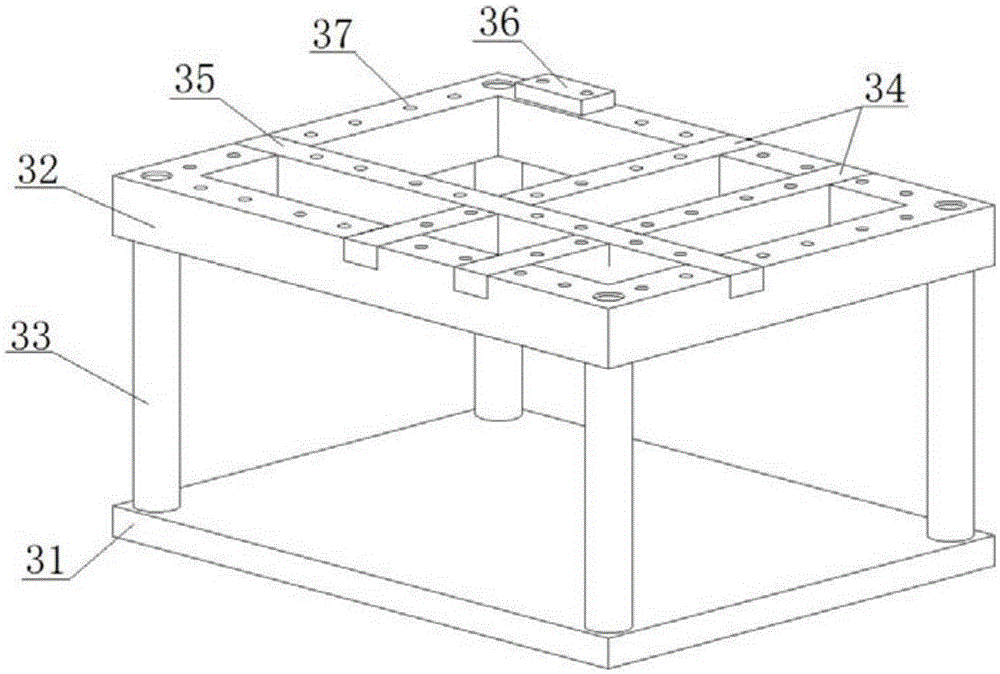

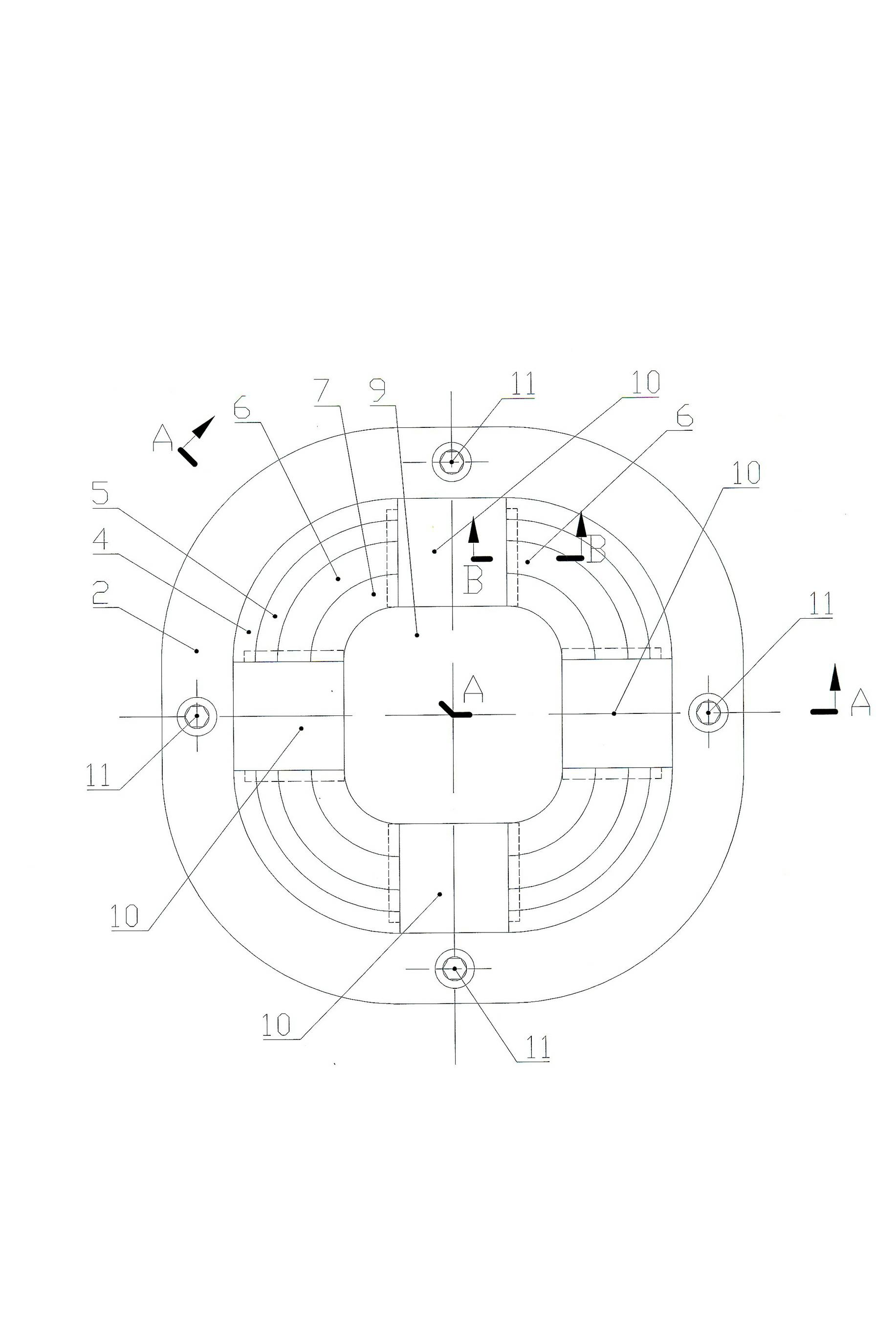

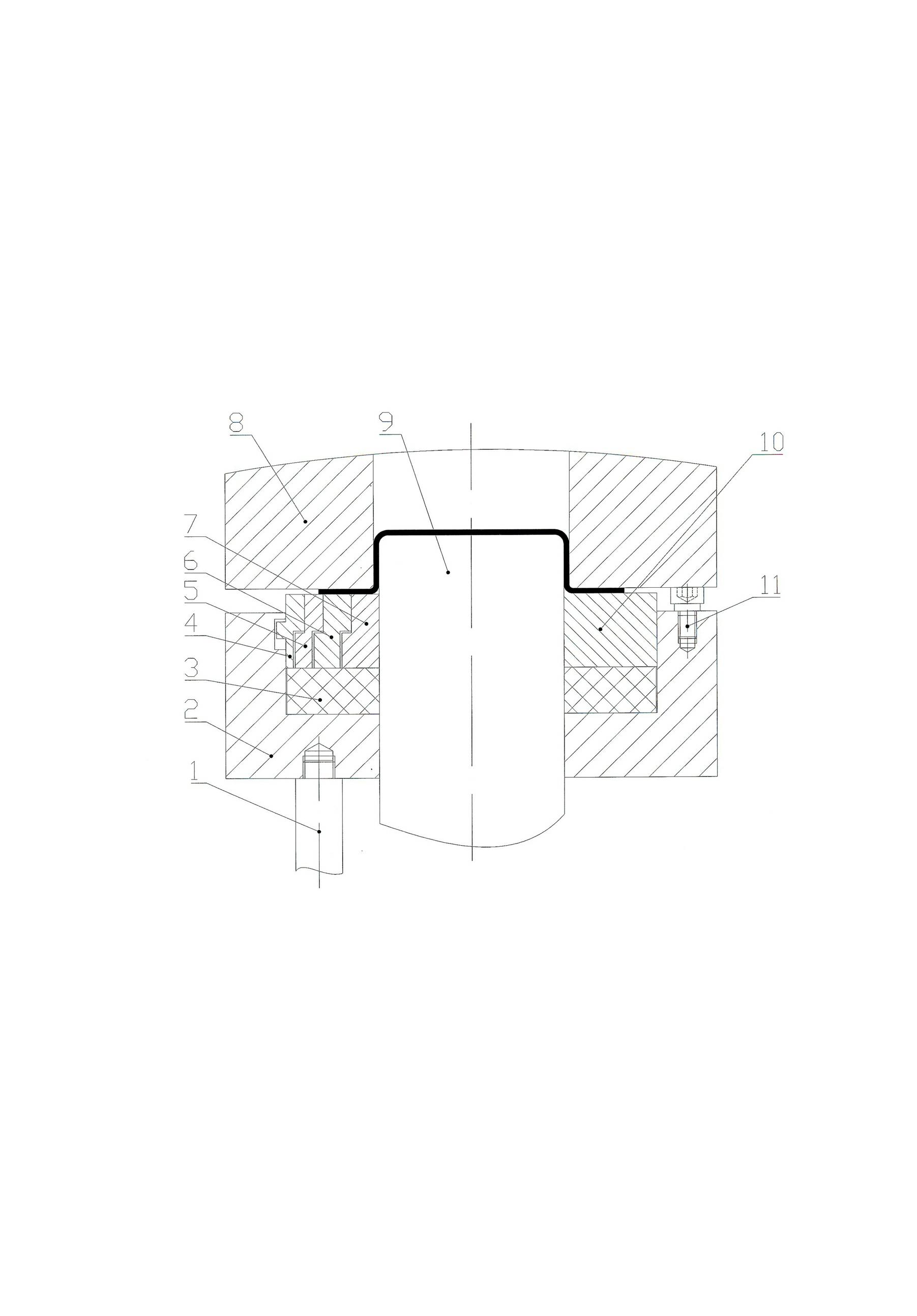

Plate multipoint progressive forming device

ActiveCN105478539AOptimal forming pathRaise the forming limitShaping toolsPress ramPistonEngineering

The invention relates to a plate multipoint progressive forming device which comprises a mould stand, a plurality of driving pressurization units and a plurality of shape adjusting and supporting units, wherein the driving pressurization units are mounted on a top plate of the mould stand; each driving pressurization unit consists of an upper pressing head, a driving basic body, a spring, a piston and a driving hydraulic cylinder; the upper pressing heads are movably mounted at the bottom ends of the driving basic bodies; the driving hydraulic cylinders are fixed to the top plate of the mould stand; the shape adjusting and supporting units are mounted on a bottom plate of the mould stand; each shape adjusting and supporting unit consists of a lower pressing head, a supporting basic body, a spring, an adjusting bolt and a supporting hydraulic cylinder; the lower pressing heads are movably mounted at the top ends of the adjusting bolts; the supporting hydraulic cylinders are fixed to the bottom plate of the mould stand; and under the action of the driving hydraulic cylinders and the supporting hydraulic cylinders, multipoint progressive forming of a plate between the upper pressing heads and the lower pressing heads is realized. The plate multipoint progressive forming device is reasonable in structure; by controlling the pressure difference between the two sides of the plate, the optimal forming effect is realized; the forming precision of the plate is high; and the surface quality of the plate is good.

Owner:HARBIN INST OF TECH AT WEIHAI

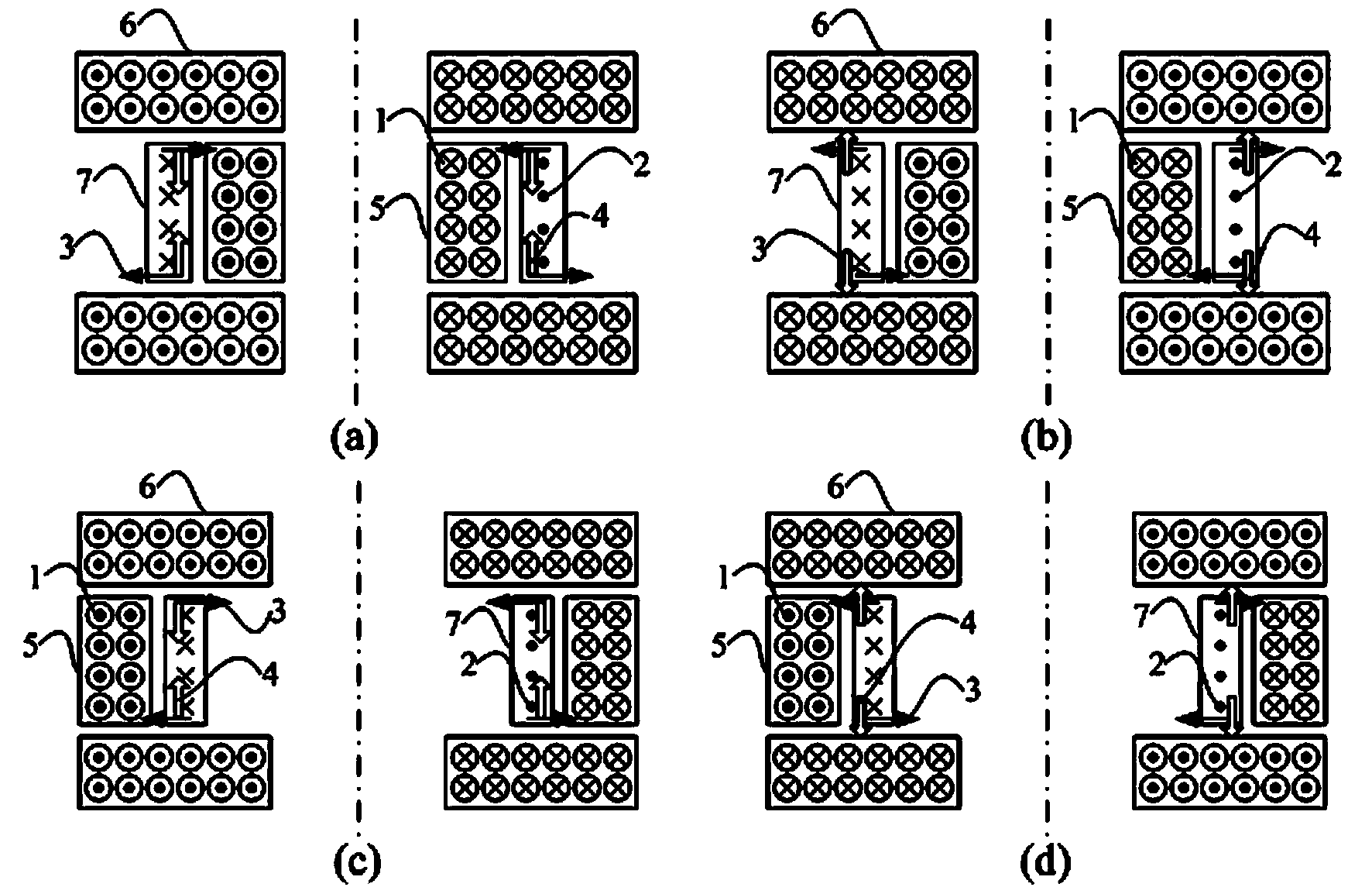

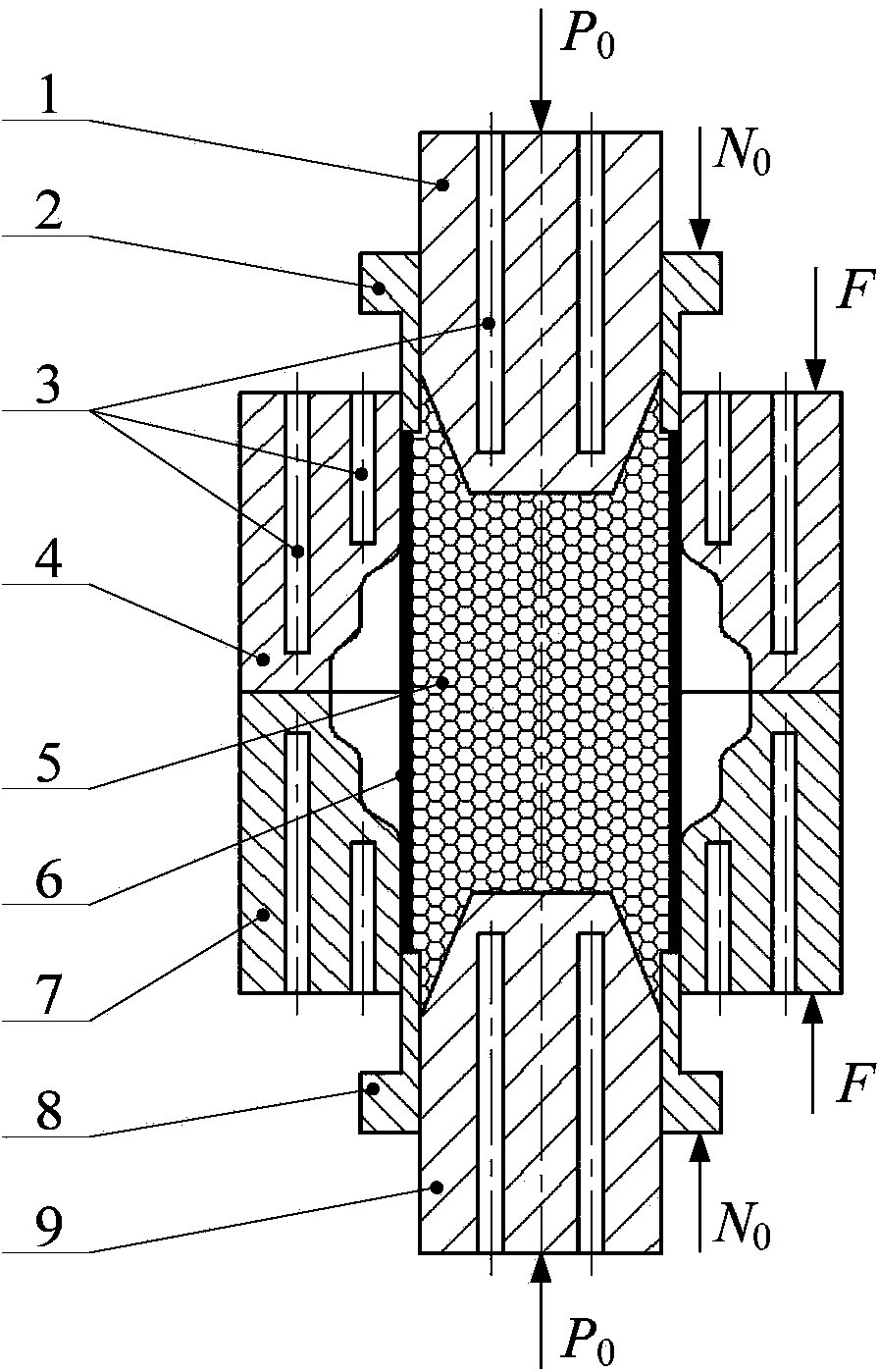

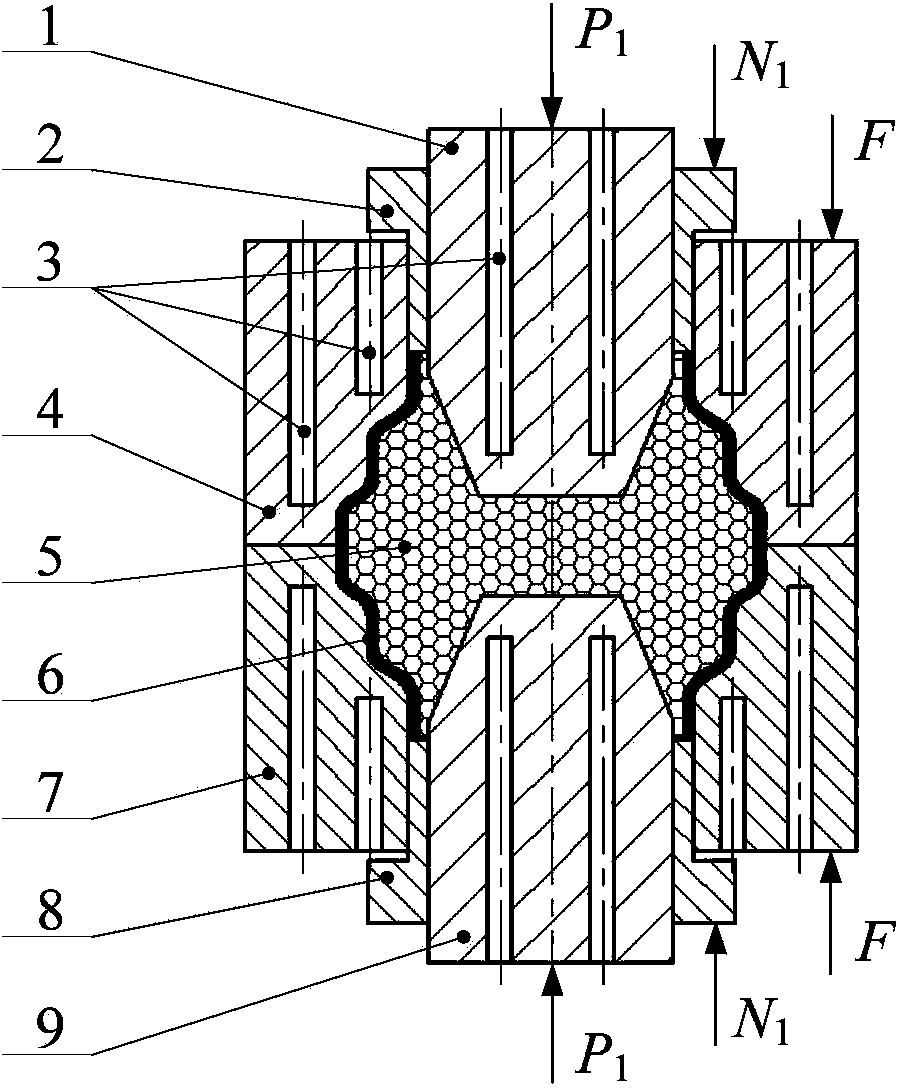

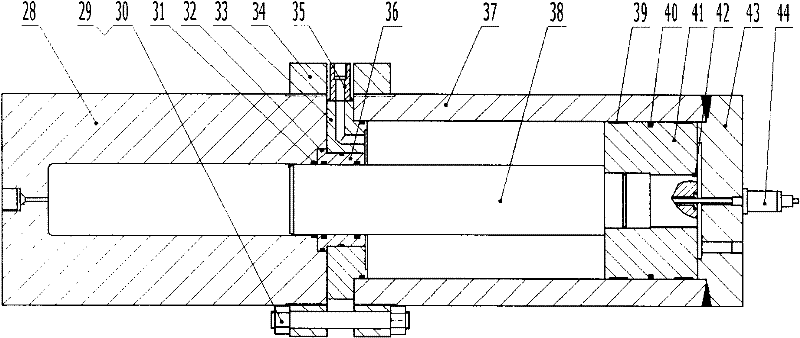

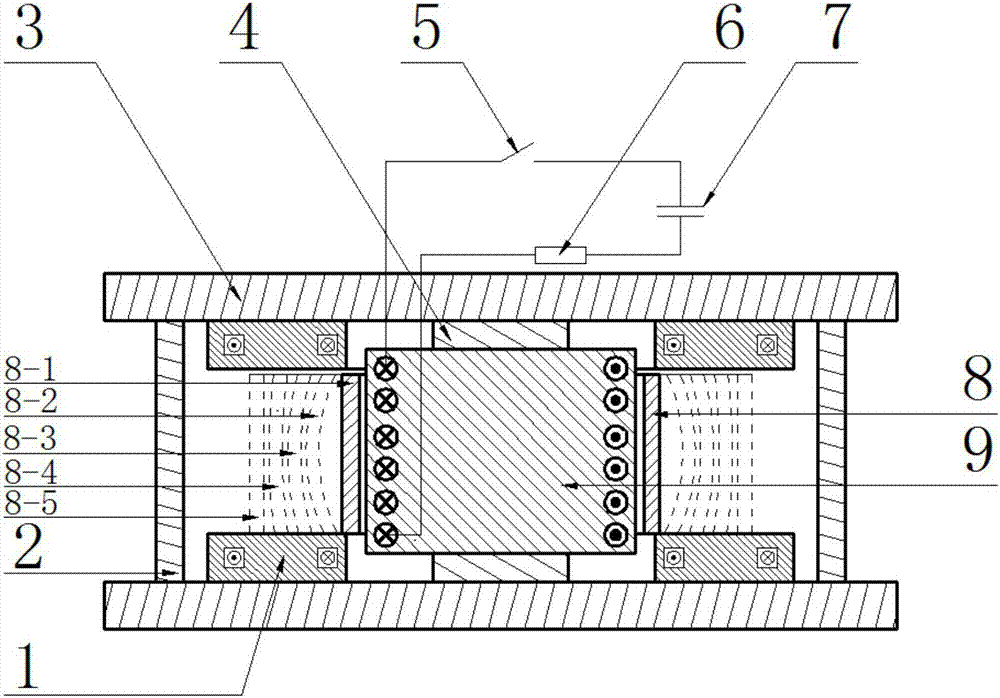

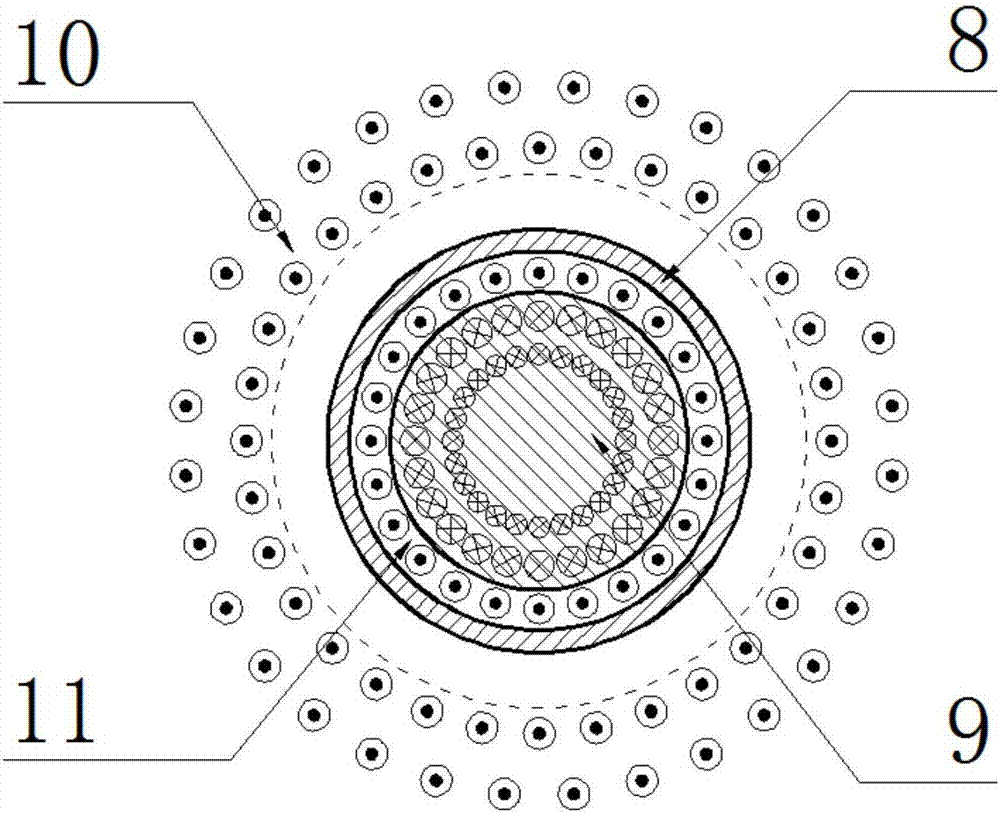

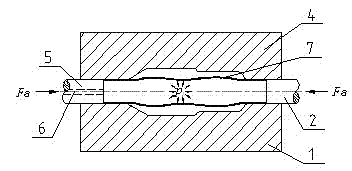

Method and device for electromagnetically forming metal pipe fitting in radial and axial loading mode

ActiveCN103406418ASolve the single load of electromagnetic forming factorSolve the problem caused byAxial compressionPipe fitting

The invention discloses a method and a device for electromagnetically forming a metal pipe fitting in a radial and axial loading mode. The device mainly comprises an eddy current coil, magnetic field coils and power systems. The eddy current coil generates induced eddy currents, the magnetic field coils generate radial magnetic fields, and the eddy current coil and the magnetic field coils are powered by the power systems. The method and the device have the advantages that electromagnetic force can be radially and axially loaded simultaneously in a procedure for electromagnetically forming the metal pipe fitting, an electromagnetic force loading mode can be adjusted, and accordingly machining requirements of different workpieces can be met; the axial compression type pipe fitting is electromagnetically expanded, so that the thickness reduction of a pipe wall in an expansion procedure can be effectively reduced, the forming limit of a formed workpiece is increased, and the forming performance of the formed workpiece is improved; high-speed deformation experiment conditions in different load forms can be provided for metal pipe fittings by the method for electromagnetically forming the metal pipe fitting in the radial and axial loading mode, and novel experiment measures are provided for research on high-speed deformation mechanisms of materials.

Owner:湖北继扬电力科技有限公司

Procesing equipment capable of improving plate part formation limitation and method therefor

Owner:HARBIN INST OF TECH

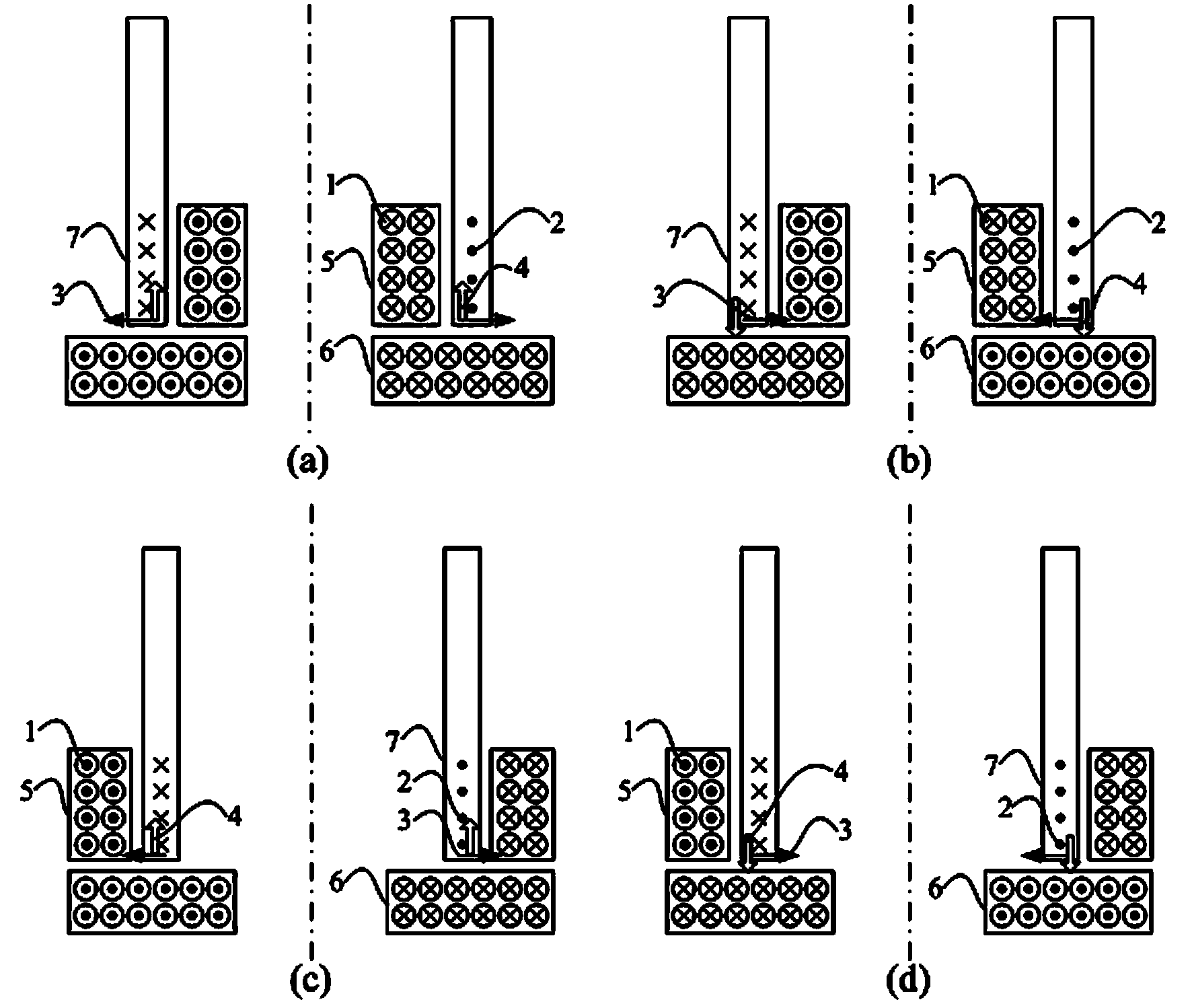

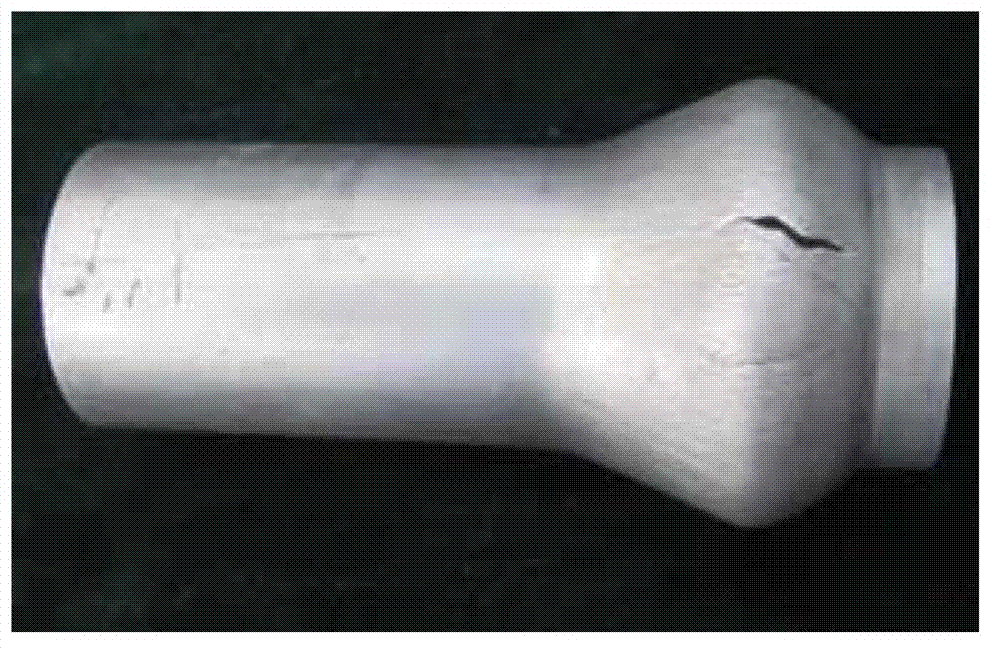

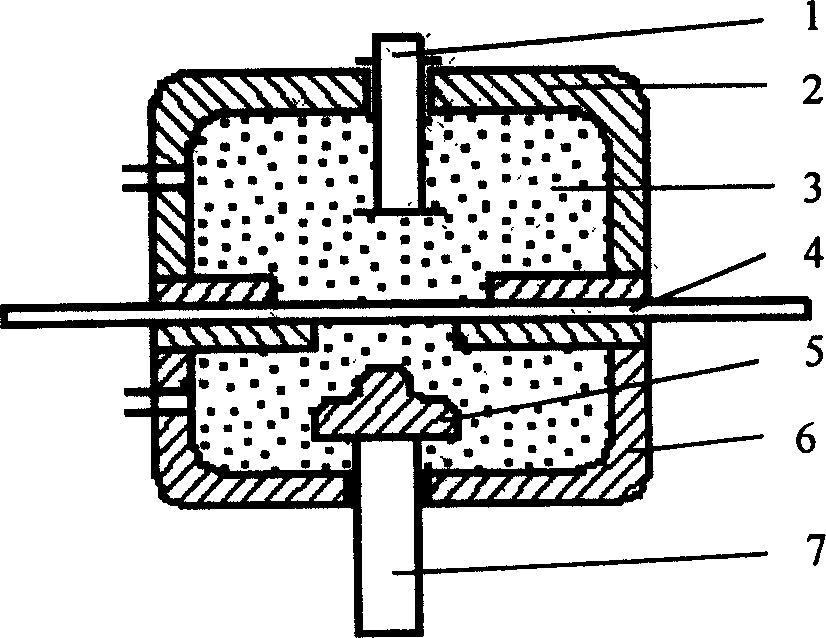

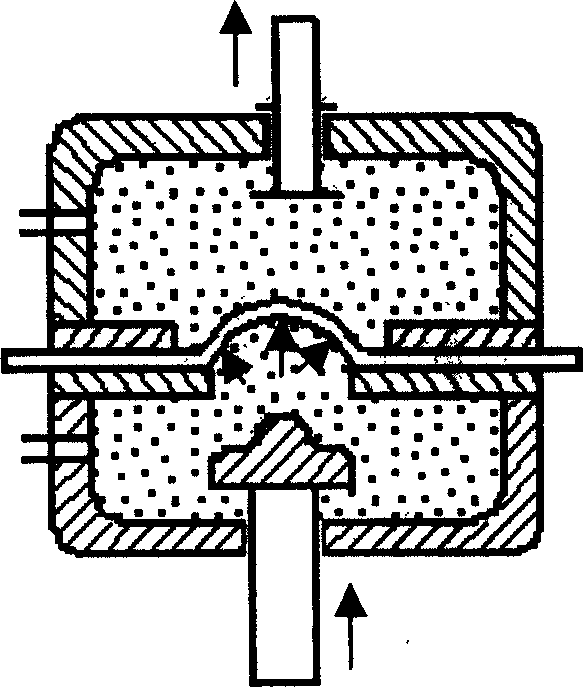

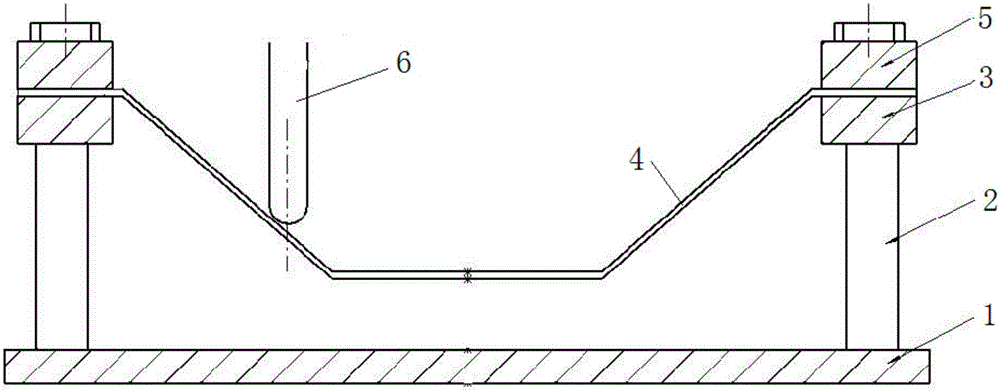

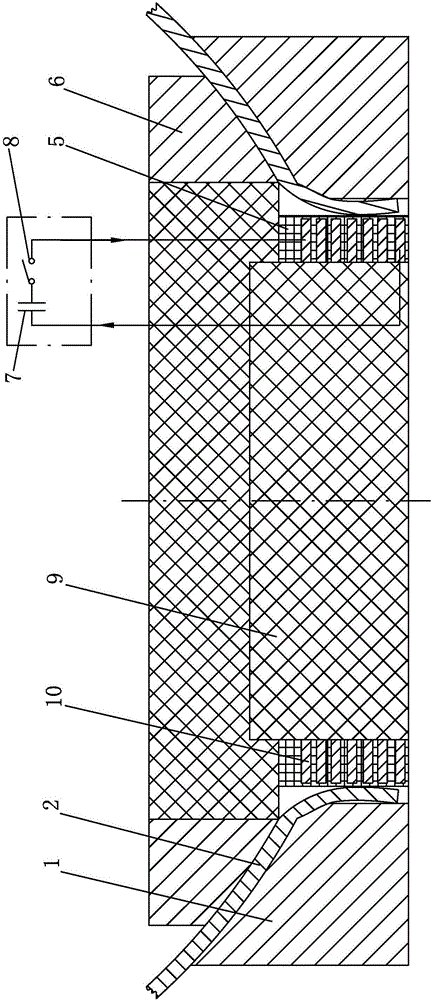

Device and method for axial loading to assist bulging of magnetic pulse pipe

The invention discloses a device and a method for axial loading to assist bulging of a magnetic pulse pipe, relates to a device and a method for bulging of a magnetic pulse pipe, and aims to solve the problem of breakage due to the fact that when a pipe fitting is locally bulged by existing magnetic pulse forming technology, deformation of a pipe wall is uneven and the pipe wall is excessively thinned. A lead guiding block is connected with a rectangular bottom plate, an upper clamp block and a lower clamp block are connected with the rectangular bottom plate, a lead screw is connected with the lead screw guiding block in a threaded manner, bumps on two push plates are slidably arranged in guide grooves of the rectangular bottom plate, the right end of the lead screw is arranged in a lead screw limiting sleeve fixedly connected with the left push plate, a spring is arranged in spring limiting sleeves fixedly connected with the two push plates, a coil is arranged between the right push plate and a fixture, two lead wire sections of the coil are serially connected onto a discharge control switch, and a capacitor bank is serially connected with a power source. The method includes sleeving a pipe fitting on the coil; exerting axial pre-tightening force; and taking out the formed pipe fitting after discharge forming. The device and the method are used for bulging and machining pipe fittings difficult to form.

Owner:HARBIN INST OF TECH

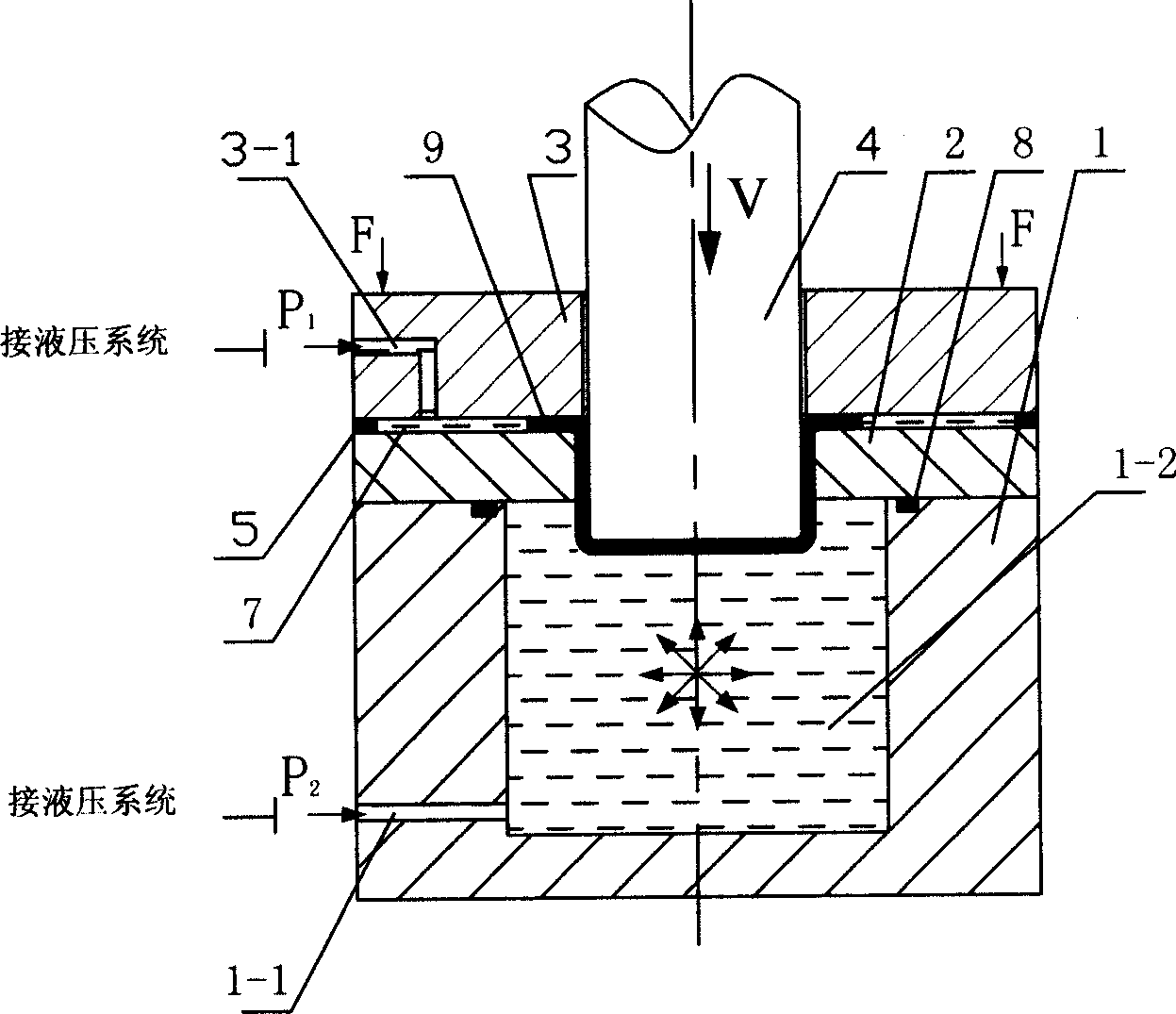

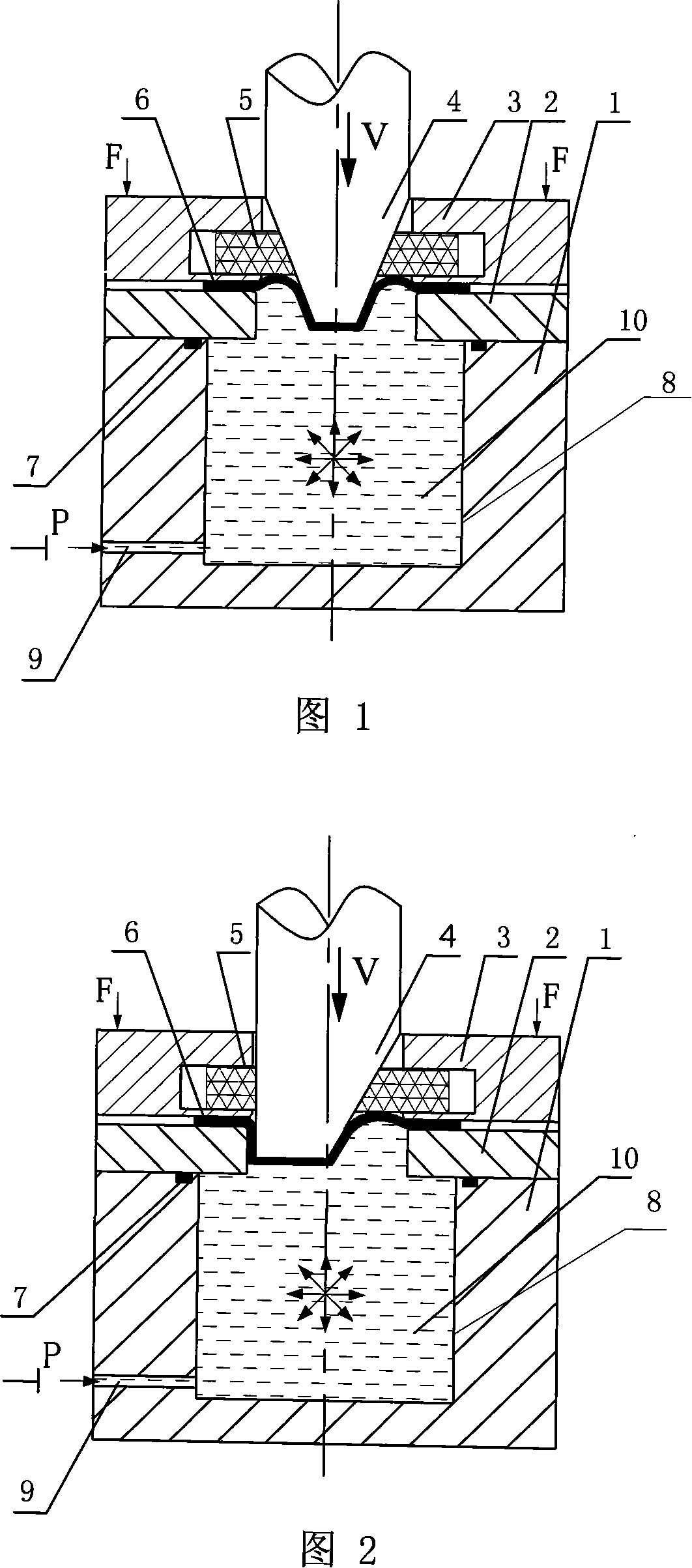

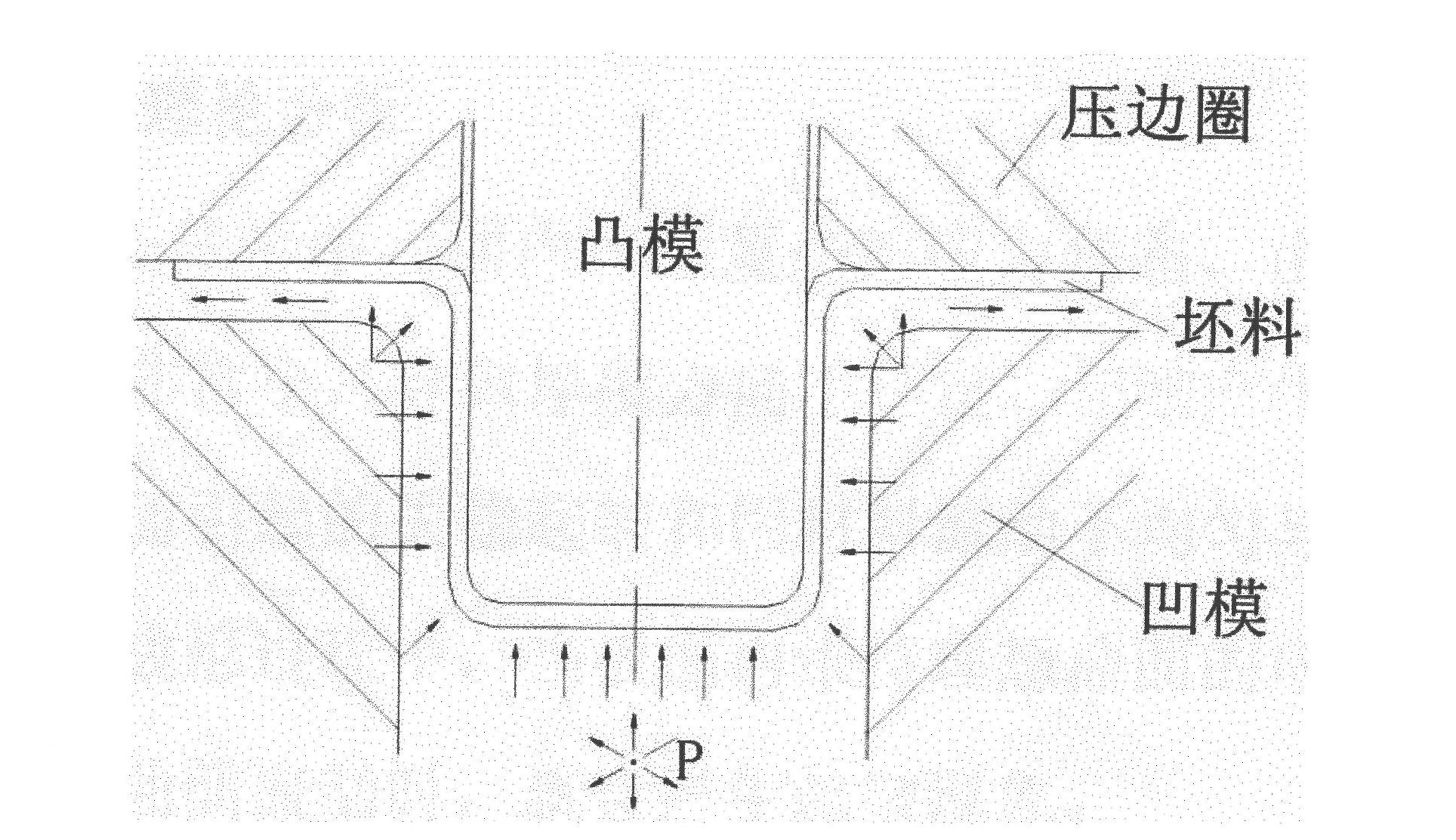

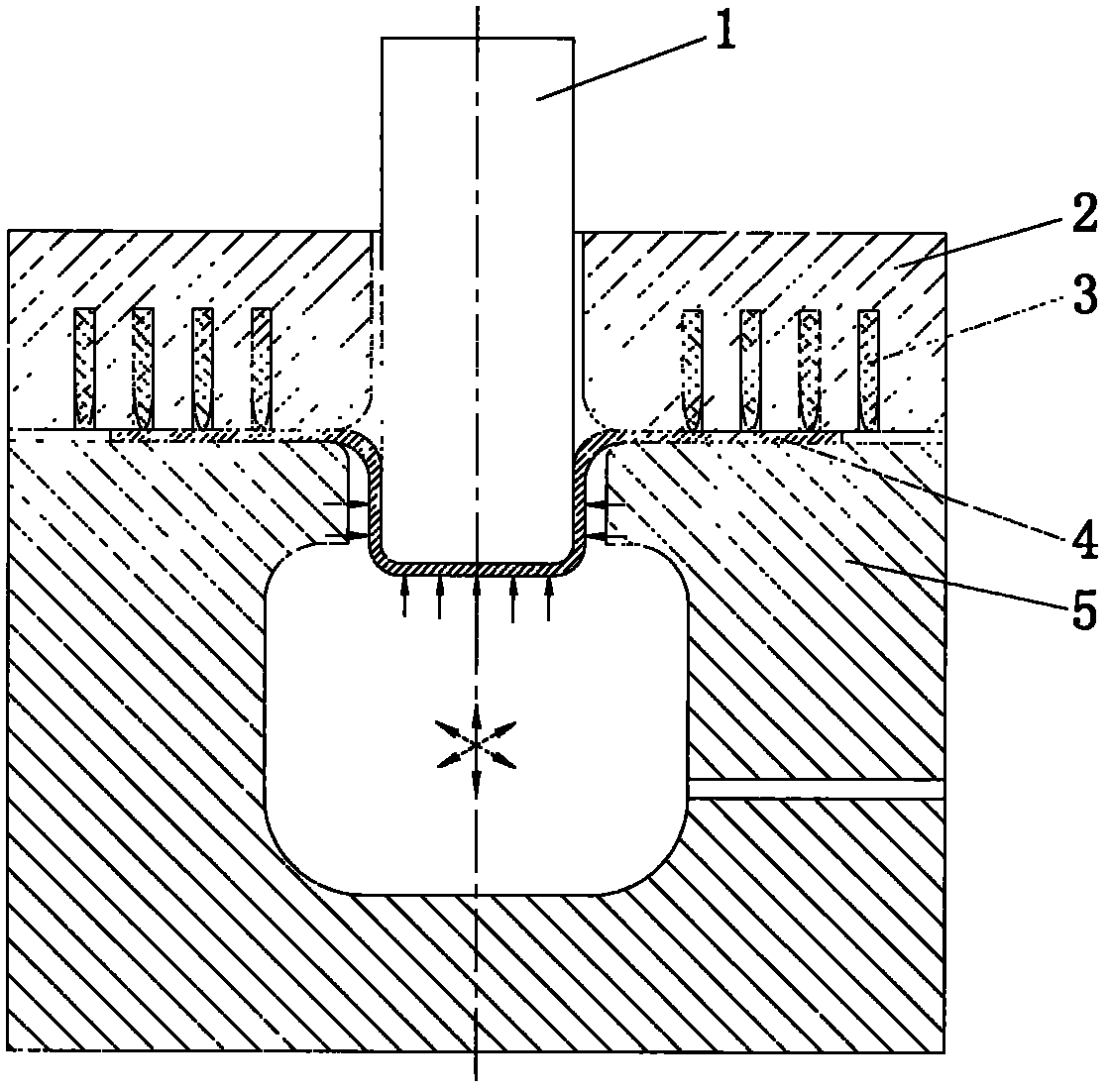

Device for preventing suspension area from breaking while taper piece filling liquid and drawing deep forming and forming method

InactiveCN101147940AReduce frictionReduce friction, so that the surface of the billet is fully protectedShaping toolsEngineeringMechanical engineering

The present invention relates to a conical component forming device capable of preventing floating zone from being broken when the conical component is formed by adopting liquid-charging and drawing process and its forming method. Said conical component forming device is characterized by that its rigid edge-pressing ring is set over a concave die, in said rigid edge-pressing ring interior a recessed groove is cut, a flexible supporting ring is placed in the recessed groove interior, said concave die is placed on the fluid medium cavity, and its liquid-injecting hole is connected with its hydraulic system. Its forming method includes the following steps; (1), making the liquid-injecting hole on the cavity body be communicated with the hydraulic system; (2), placing a plate blank on the concave die; (3), making the rigid edge-pressing ring be moved downwards and apply edge-pressing force; and (4), making convex die be downwards moved until the plate blank is drawn into the concave die interior with the convex die so as to obtain a formed conical component.

Owner:HARBIN INST OF TECH

Sheet material mold-free multi-point forming device based on viscous medium transfer force and method

The invention relates to a sheet multipoint molding device and relative method, based on adhesive medium force transmission. Wherein, the lower die cavity is formed by concave mould and the bottom plate of concave mould; the bottom of concave mould has the discharge hole of adhesive medium, which is connected to the cylinder via the channel inside the bottom plate; the fixing compress device is formed by the upper mould, motor, mounting element, convex mounting plate and the punch head connected to the flexible sheath; the flanging ring, convex mould fixing plate, flexible sheath and the punch head form the upper die chamber; the sheet compress device is formed by the upper edge of concave mould and the flanging ring. The invention uses adhesive medium with uniform force transmission, to reduce the producing period, the producing cost, avoid the surface crack caused by rigid mould, while the thickness is uniform.

Owner:重庆工学院

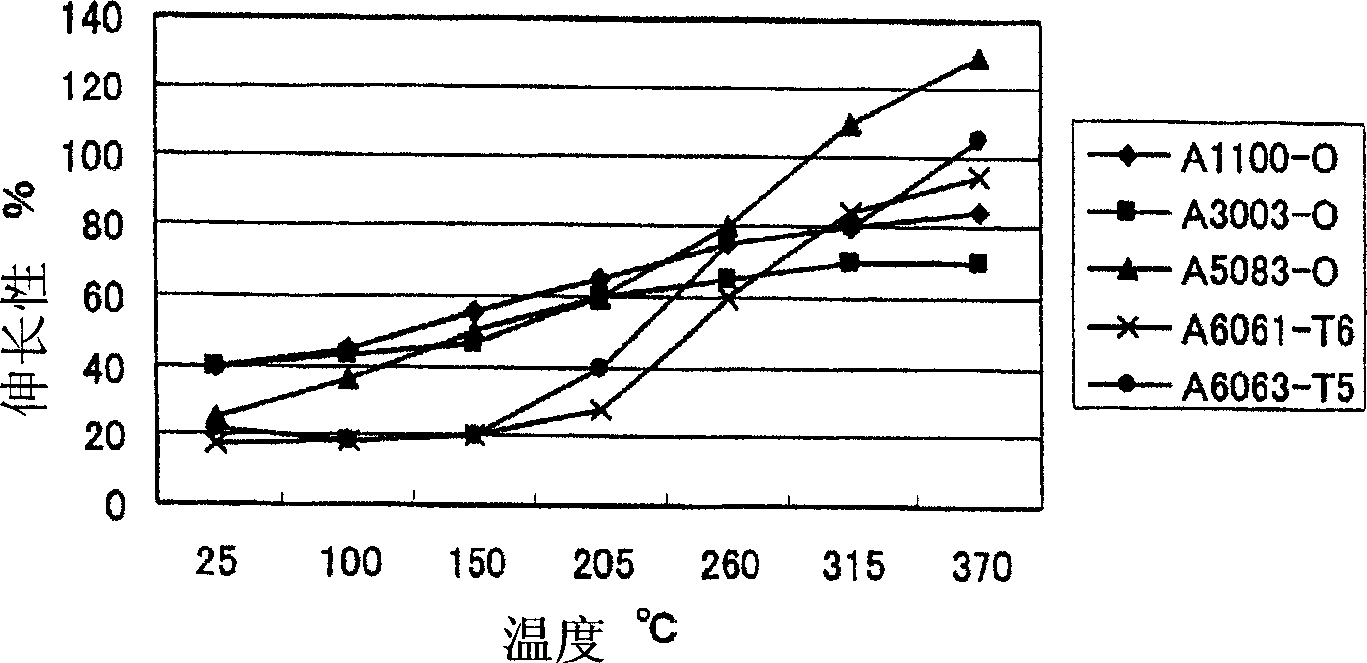

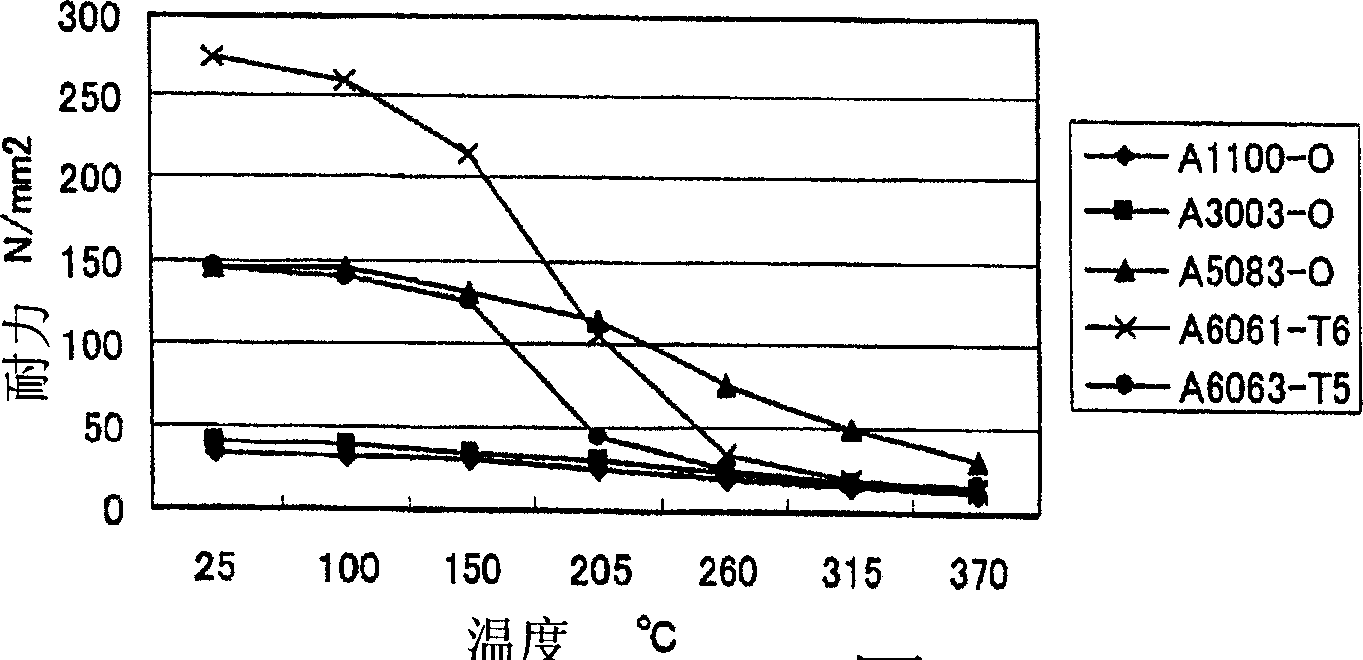

Solid particle medium thermal expansion forming method for light alloy tubular component

InactiveCN103894469ASimple process controlLow input costShaping toolsEnvironmental resistanceThermal expansion

Owner:YANSHAN UNIV

Method for forming thin-walled parts through stamping and drawing

The invention discloses a method for forming thin-walled parts through stamping and drawing, which is used for reducing the thicknesses (0.4-2mm) of raw materials to 50-100% of the original thicknesses the raw materials; the raw materials comprise magnesium alloys, aluminum alloys, titanium alloys, high temperature alloys and complex splice-welded plates; and the method specifically comprises the following steps that: a flexible forming technique is adopted with the aid of moulds and a hydraulic machine, wherein the moulds are in concave-convex fit with the hydraulic machine; upper and lower blank holders and concave and convex moulds are respectively subjected to hydraulic pressure exertion control; the nominal pressure of a main hydraulic cylinder exerted on the concave and convex moulds is 25000-4500 KN, and the nominal pressure of a side-pressing hydraulic cylinder accounts for 50-67% of the nominal pressure of the main hydraulic cylinder; and the maximum operating pressure of a liquid chamber is 150MPa. By using the method disclosed by the invention, an expected effect is obtained, and the qualification rates and efficiencies of parts are obviously improved; and meanwhile, the hydroforming technology fills in the gaps in industry application, and lays a solid foundation for the thorough solving of technical bottlenecks existing in actuating cylinder cover forming and the research and preparation of future novel thin-wall parts and sheet metal forming parts.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

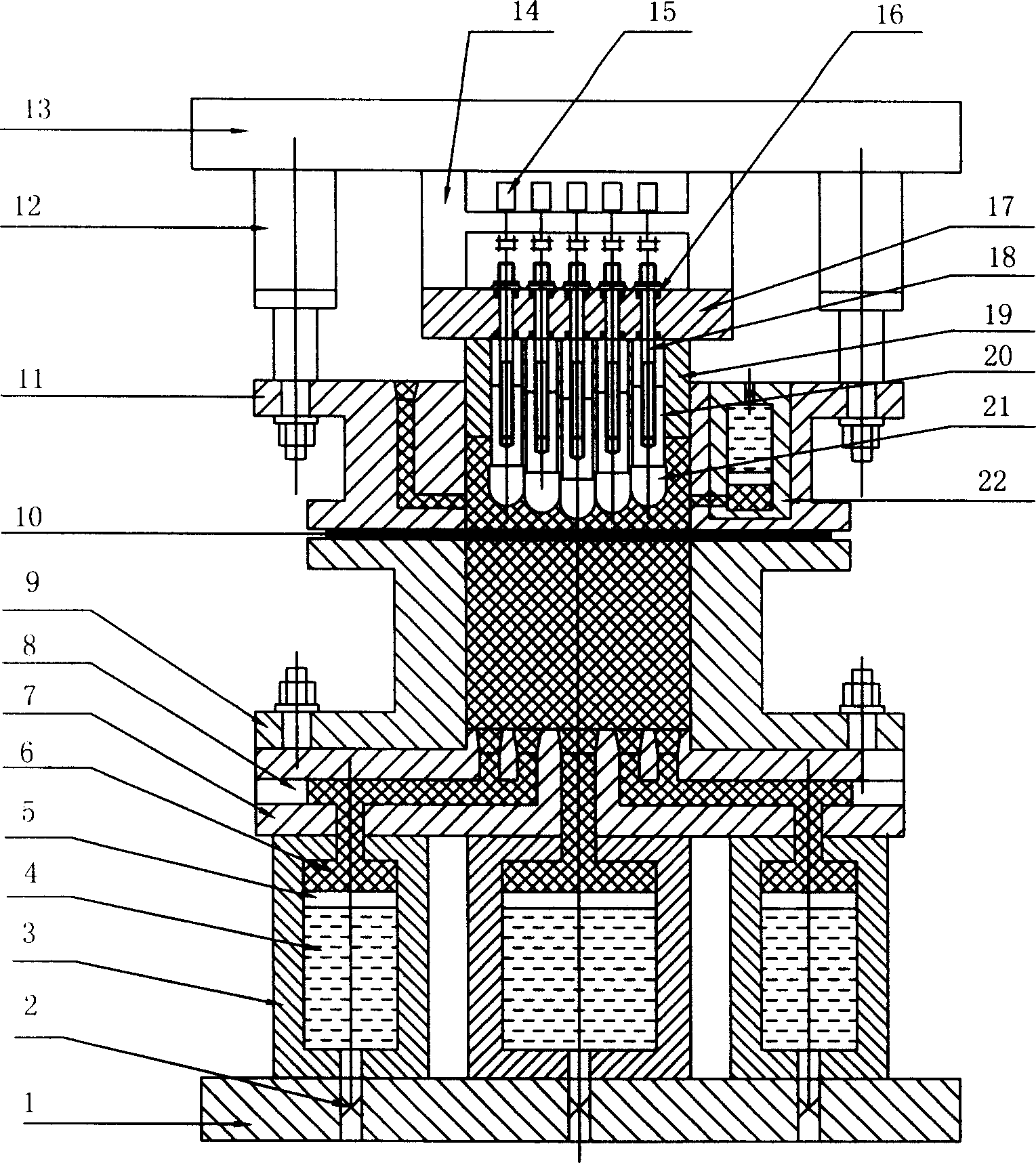

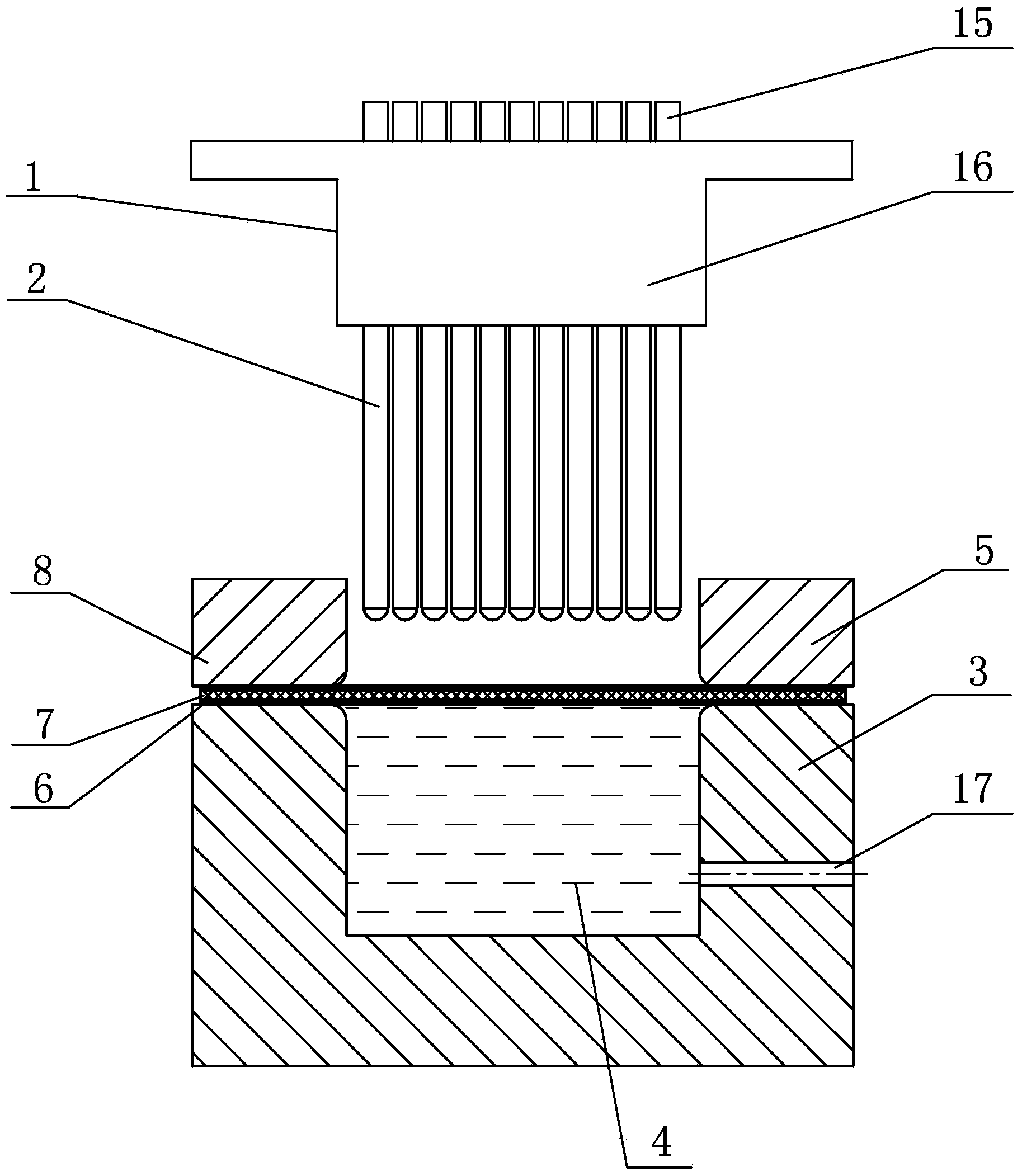

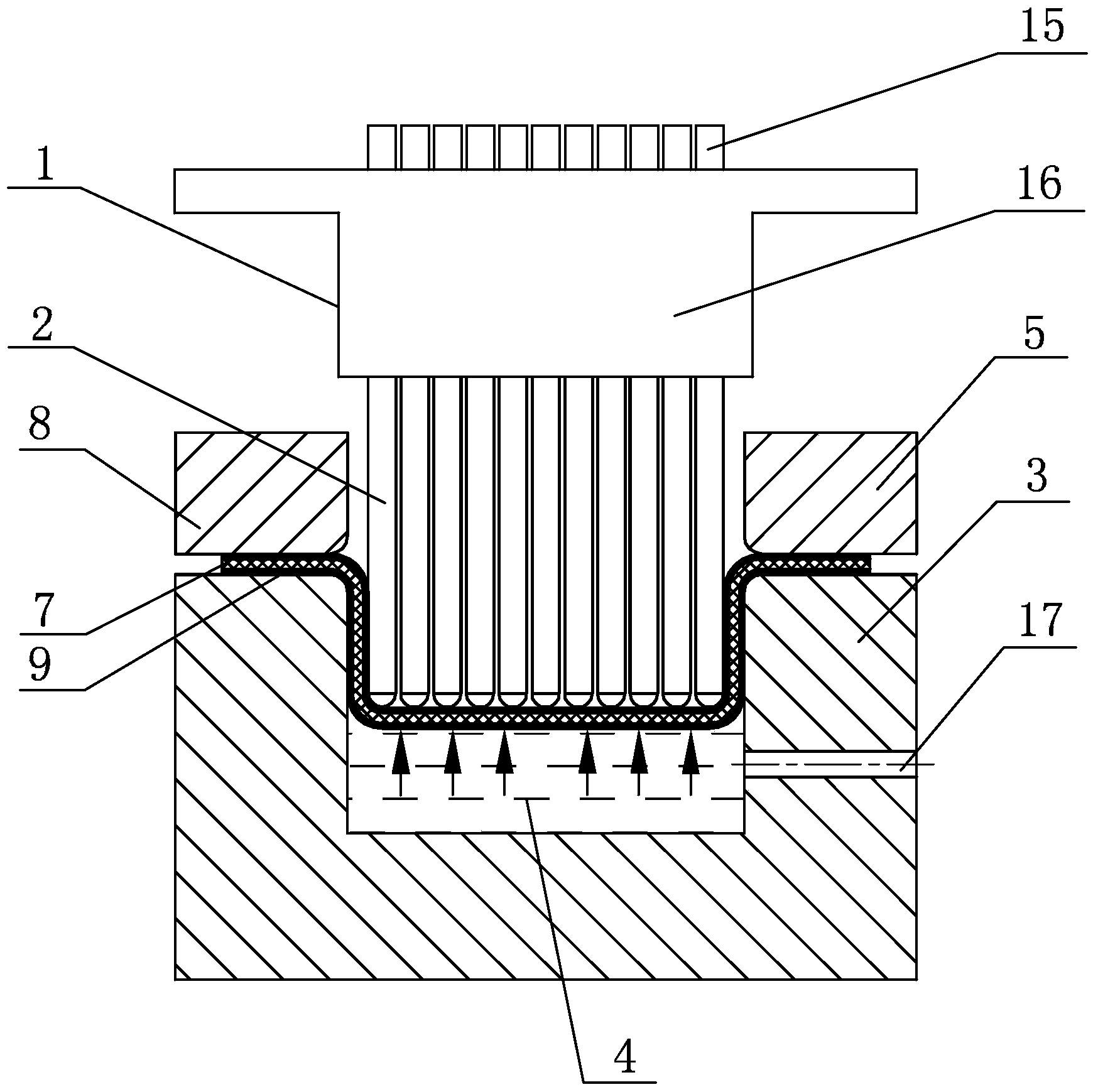

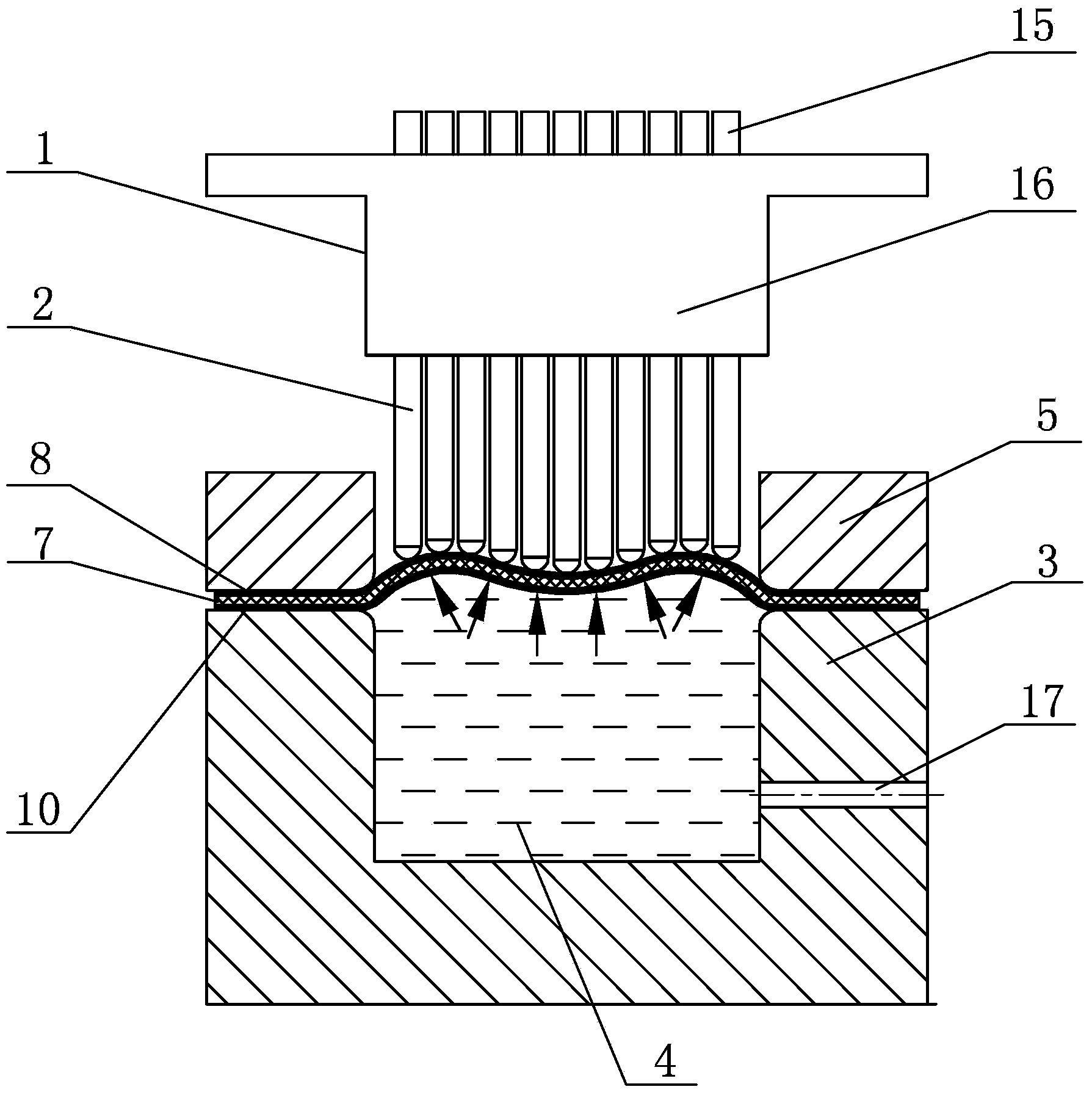

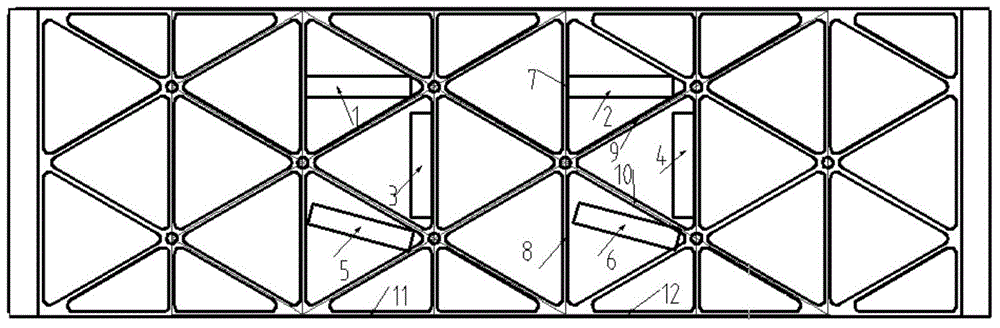

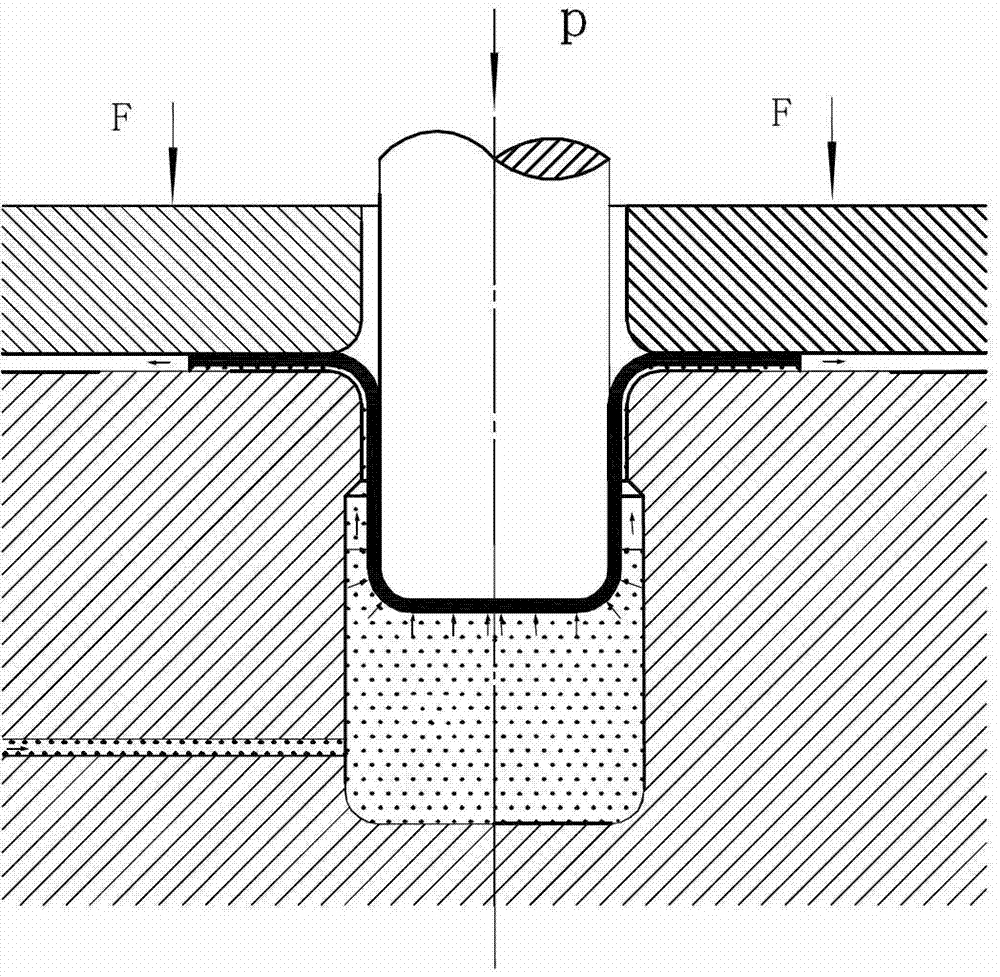

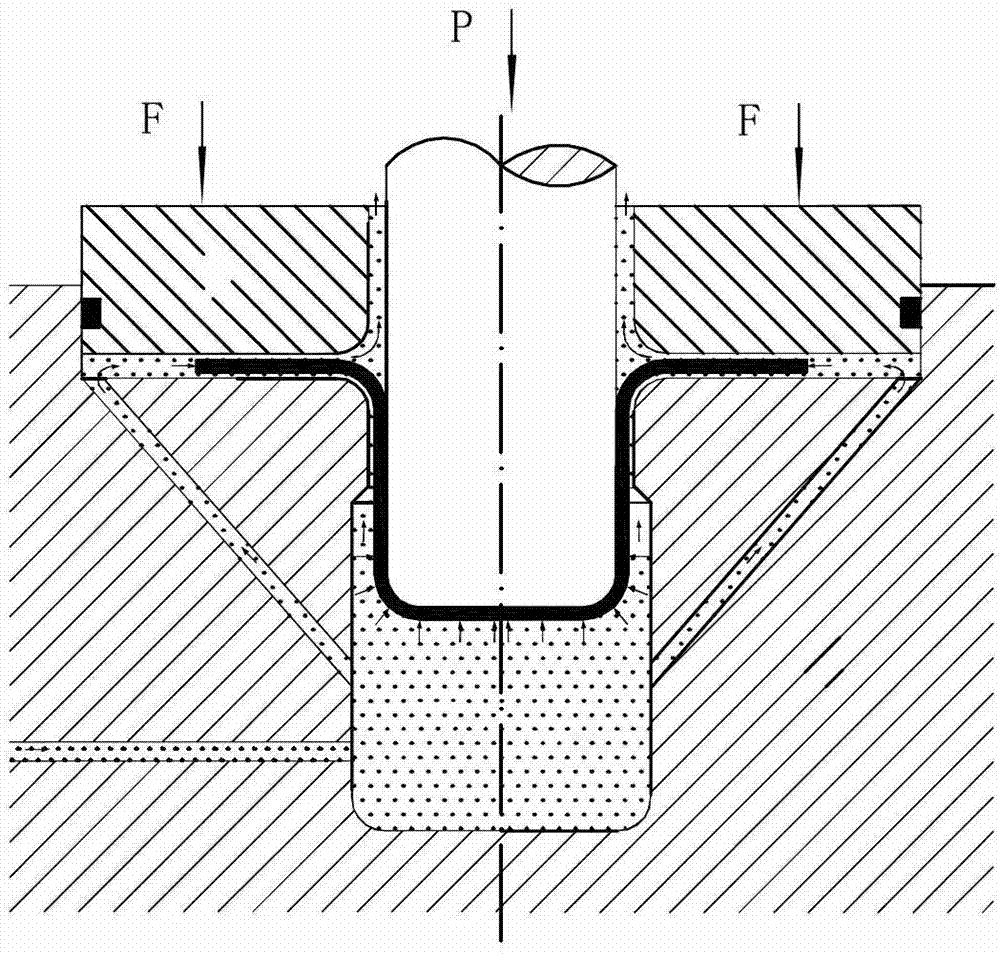

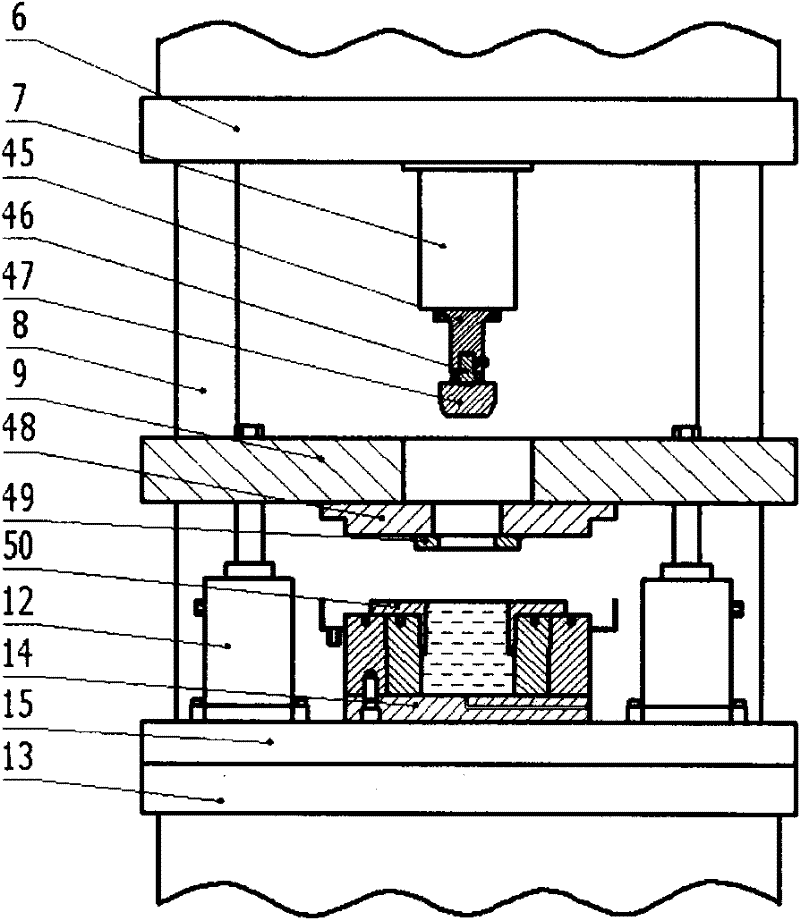

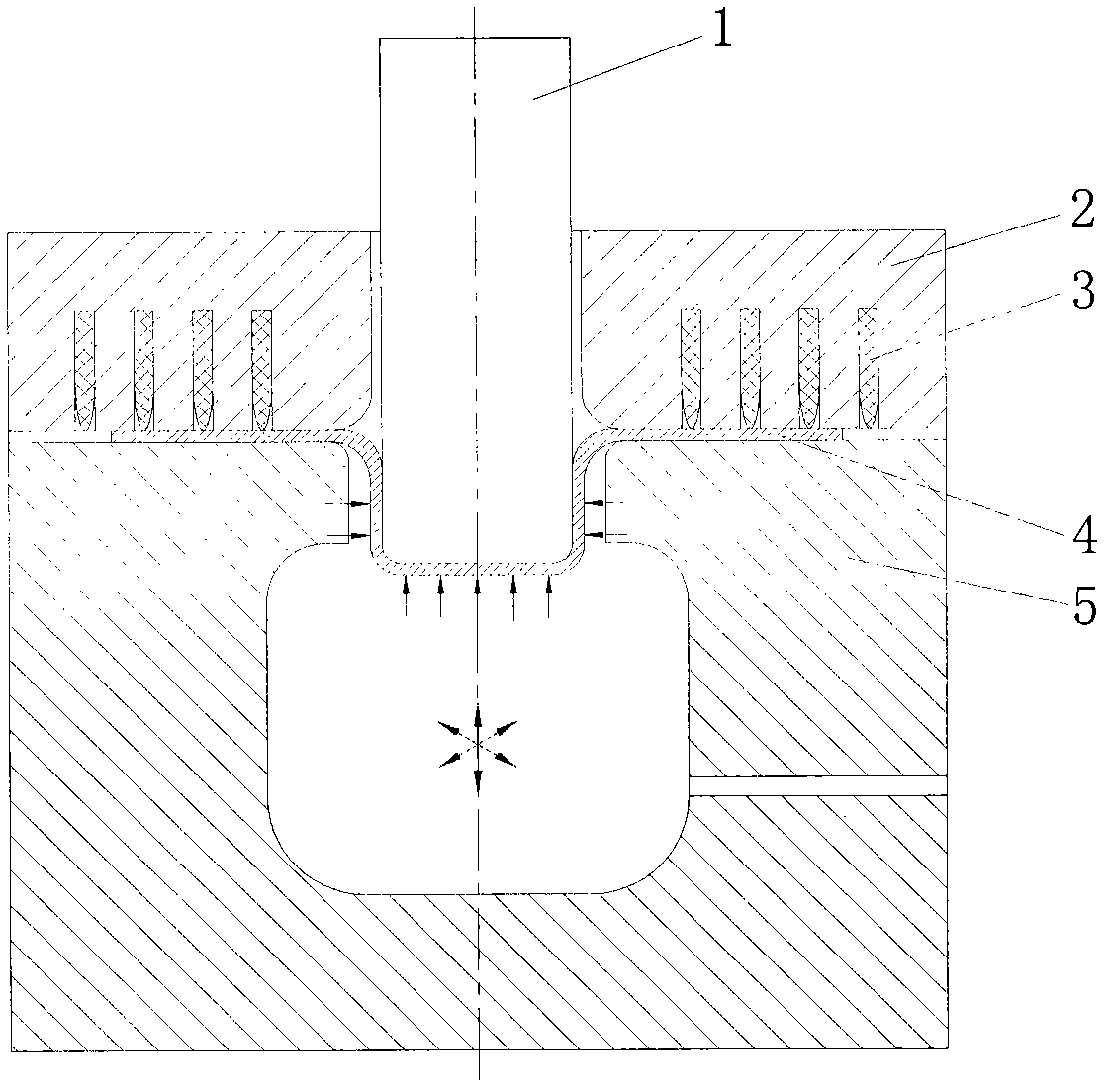

Multi-point male die liquid-filling drawing forming device and method for plate

The invention discloses a multi-point male die liquid-filling drawing forming device and a multi-point male die liquid-filling drawing forming method for a plate, relates to a device and a method for forming thin-walled curved plate parts, and aims to solve the problem of difficulty in forming of thin-walled and deep-cavity parts with complicated curved surfaces. A plurality of small punches are independently arranged; the upper ends of the small punches penetrate into through holes in a male die body; the upper end of each small punch is connected with a linear driving device; a female die is a semi-closed cavity of which the upper end is opened and the lower end is closed; an elastic base plate and a metal protection plate are superposed on the upper end surface of the female die from bottom to top. The heights of the small punches are adjusted to realize the construction of an outer contour of a multi-point male die; a to-be-formed plate blank, the elastic base plate and the metal protection plate are sequentially arranged on the upper end surface of the female die; a blank holder moves down to be assembled with the female die, and the multi-point male die moves down and applies a drawing force to the to-be-formed plate blank; meanwhile, a liquid medium is filled into an inner cavity of the female by the aid of a pressurizing system until drawing is completed to obtain parts of a required shape. The device and the method are used for forming the plate, and the thin-walled and deep-cavity parts with the complicated curved surfaces can be formed.

Owner:HARBIN INST OF TECH

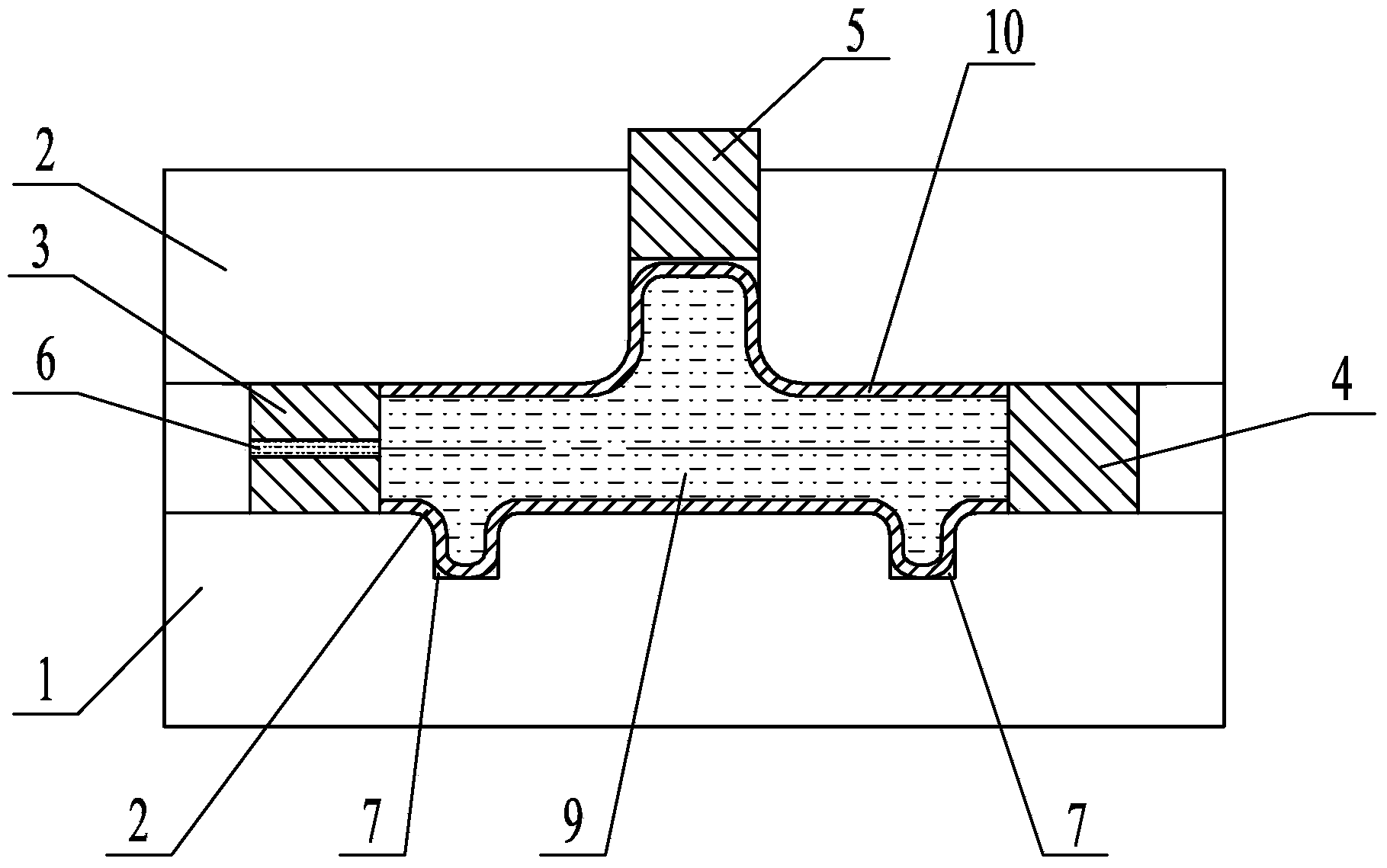

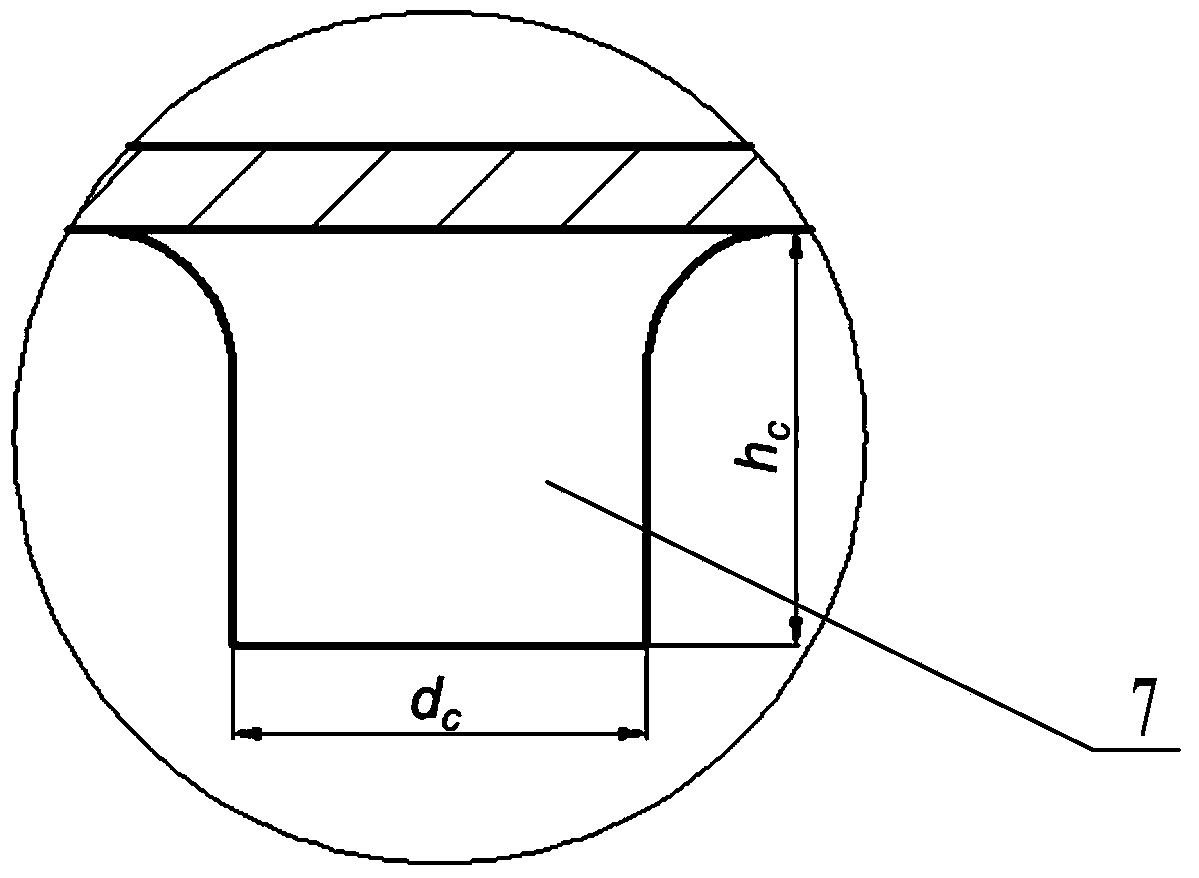

Internal high pressure forming die and method of elbow T-branch pipe

The invention discloses an internal high pressure forming die and method of an elbow T-branch pipe, relates to an internal high pressure forming die and method of a T-branch pipe, and aims to solve the problems that the bottom of a main cavity of an existing internal high pressure forming die is not provided with storage bins, and therefore the bottom of the formed T-branch pipe is compressed, deformed, and then seriously thickened. The die is characterized in that a branch pipe cavity communicated with a main cavity is formed in the top of the main cavity, and two storage bins are arranged at the bottom of the main cavity. The method includes the steps that firstly, the diameter D of the main cavity is determined; secondly, the diameter and the depth of the storage bins are determined; thirdly, a pipe blank is placed in a cavity of a lower die; fourthly, the two ends of the pipe blank are sealed through a first punch and a second punch; fifthly, internal pressure is injected; sixthly, the first punch and the second punch move towards the middle through external force for feed supplement, and extruded materials flow into the storage bins and the branch pipe cavity after the pipe fitting blank bulges; seventhly, the die is opened, and a part is taken out; eighthly, the process section of the part is cut off, and then bent and formed elbow T-branch pipe is obtained. The internal high pressure forming die and method are used for forming of the T-branch pipe.

Owner:HARBIN INST OF TECH

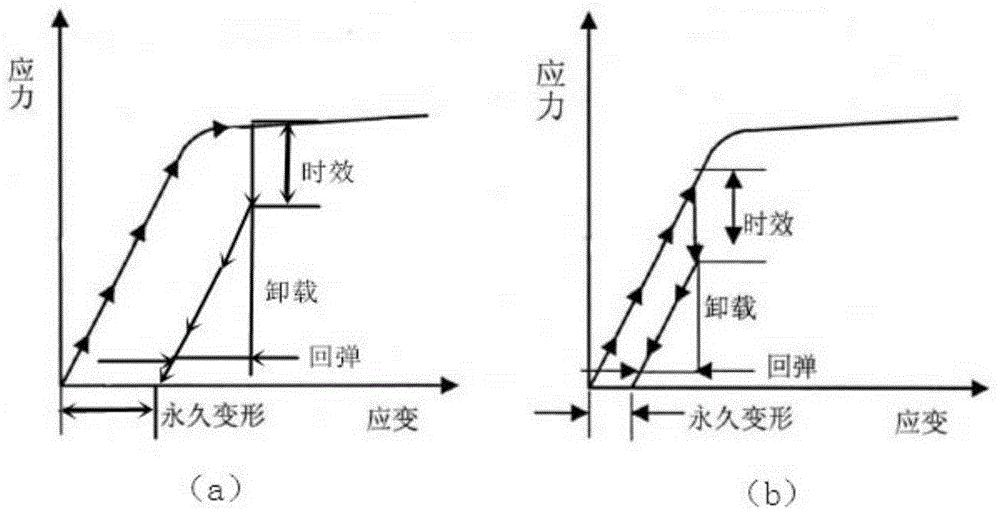

Method for manufacturing large-curvature aluminum alloy integral wall board component

The invention provides a method for manufacturing a large-curvature aluminum alloy integral wall board component. The method includes the steps that A, solution hardening is conducted on a wall board; B, the wall board obtained in the step A is arranged in a sealed environment formed by a thin film covering layer and a forming die jointly, the wall board is elastically deformed and plastically deformed in sequence under the vacuumized condition, and then the deformed wall board is obtained, wherein the temperature in the sealed environment where the wall board is located ranges from 15 DEG C to 35 DEG C, the vacuum degree ranges from -0.1 MPa to -0.05 MPa, and the treatment time ranges from 5 min to 60 min; C, in-situ creep stress relaxation aging is conducted on the deformed wall board obtained in the step B, wherein creep stress relaxation aging time is more than 2 h; D, unloading operation is conducted, and then the large-curvature aluminum alloy integral wall board component is obtained. When the method is used for manufacturing the large-curvature aluminum alloy integral wall board component, the residual stress of the product is greatly reduced, the strength of the product is improved, and the product with high forming accuracy and good performance is obtained.

Owner:CENT SOUTH UNIV

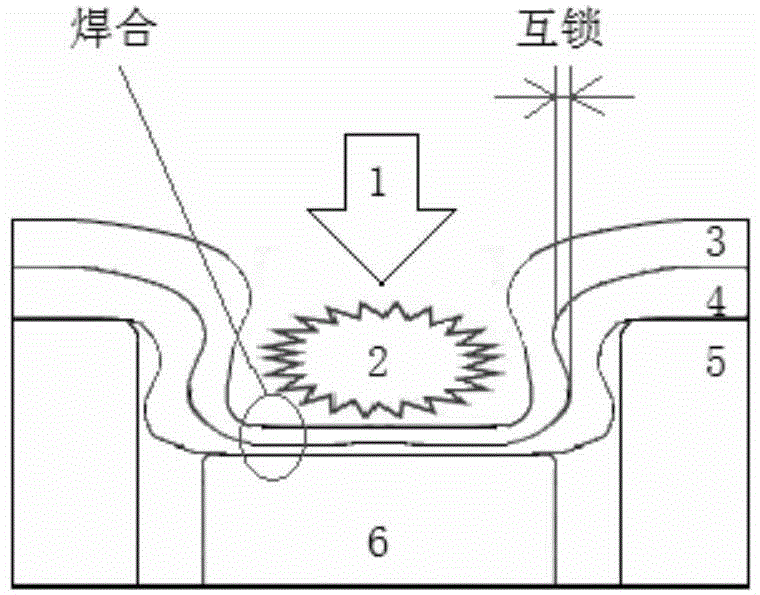

Pulse laser synchronous riveting and welding method and device of ultrathin plates

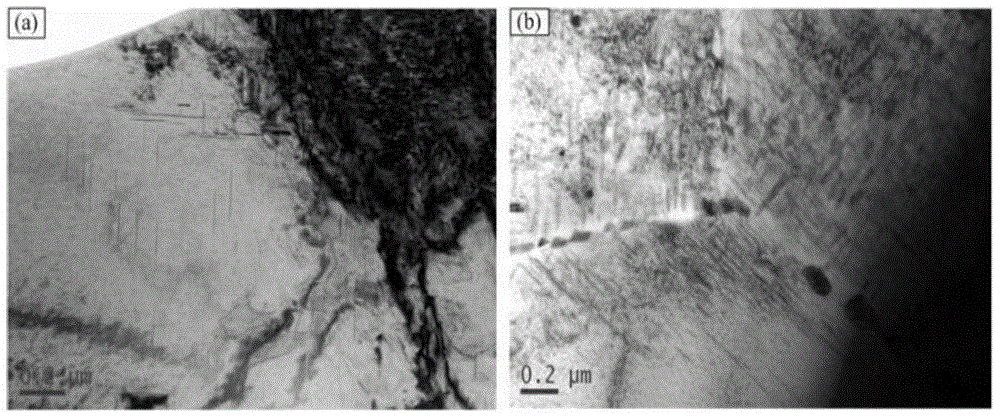

ActiveCN104816091ALow openness requirementsHigh strengthShaping toolsLaser beam welding apparatusEnergy absorptionShearing deformation

The invention relates to a pulse laser synchronous riveting and welding method and a device of ultrathin plates. An upper layer of plate and a lower layer of plate are stacked and positioned on a concave mold having mold holes; a bottom mold is arranged on the concave mold; a pulse laser beam is used for acting on the upper layer of plate or an energy absorbing layer coated on the surface of the upper layer of plate to form an explosive plasma; the lower layer of plate is collided by the upper layer of plate; the upper layer of plate and the lower layer of plate generate high-strain-rate plastic flow coupling; and under the restraint of the bottom mold, the upper layer of plate and the lower layer of plate are plasticized to form rivet button shapes so as to generate mechanical interlocking for riveting. In the plastic deformation process, the pressure stress exists on the contact interfaces of the upper layer of plate and the lower layer of plate, and the high-speed sliding and the shearing deformation are generated, so that the interfaces generate the melting and the atomic diffusion, and the upper layer of plate and the lower layer of plate are welded when colliding the bottom mold. The method and the device synchronously realize the riveting and the welding of the upper layer of plate and the lower layer of plate; and joints formed by the method and the device have higher connecting strength and fatigue resistance through the compounding effect characteristic of the mechanical bonding and the metallurgic bonding.

Owner:SHANDONG UNIV

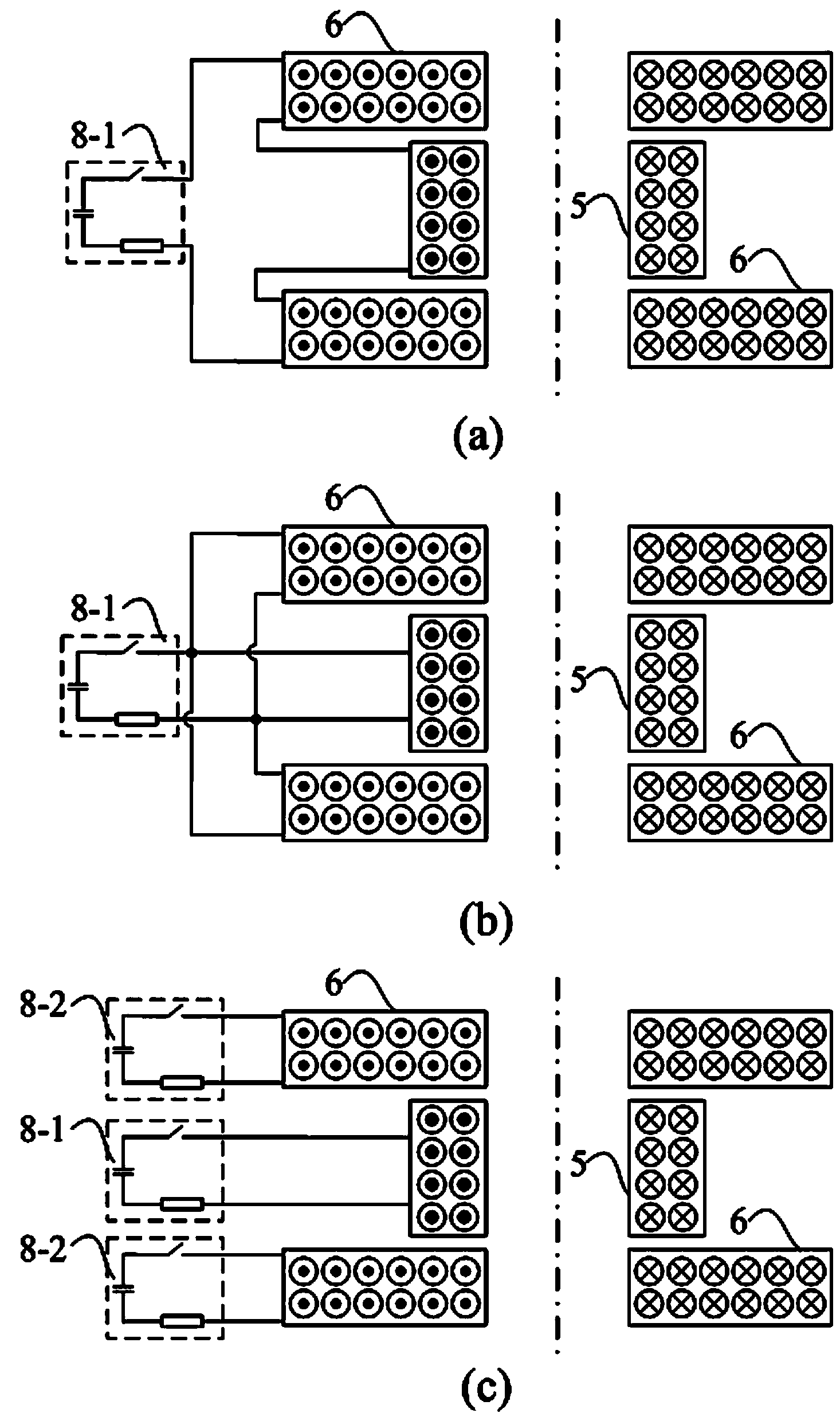

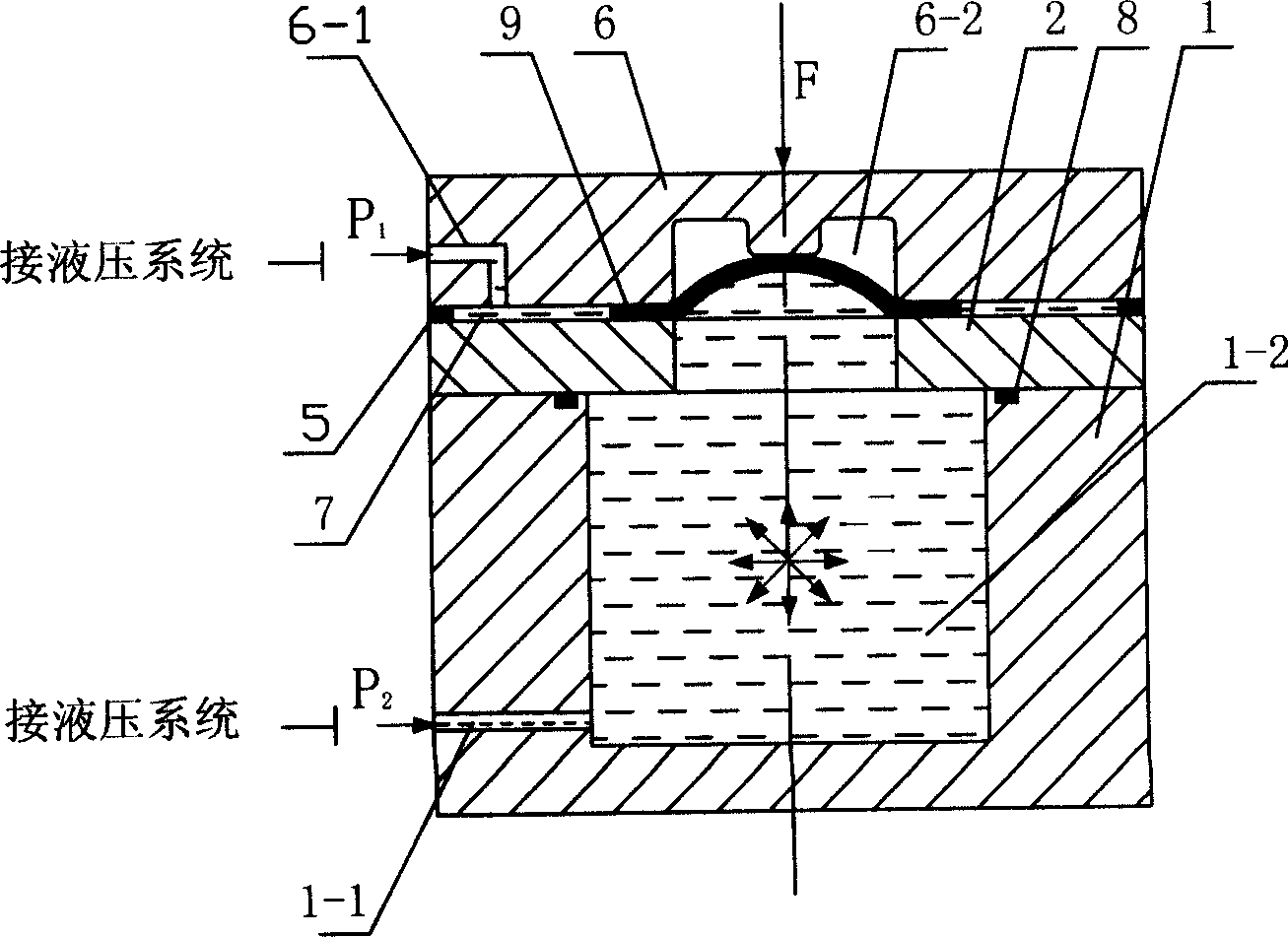

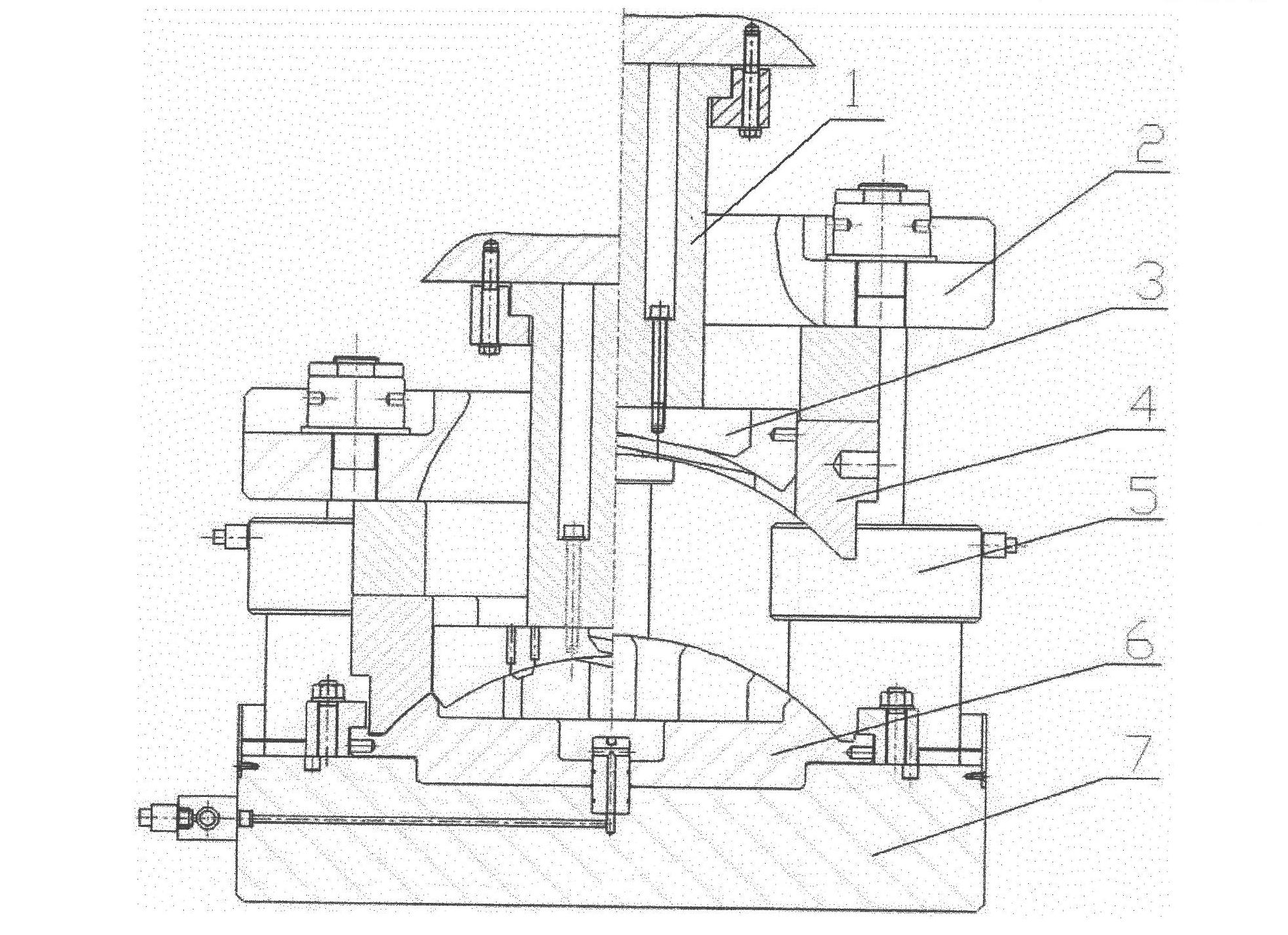

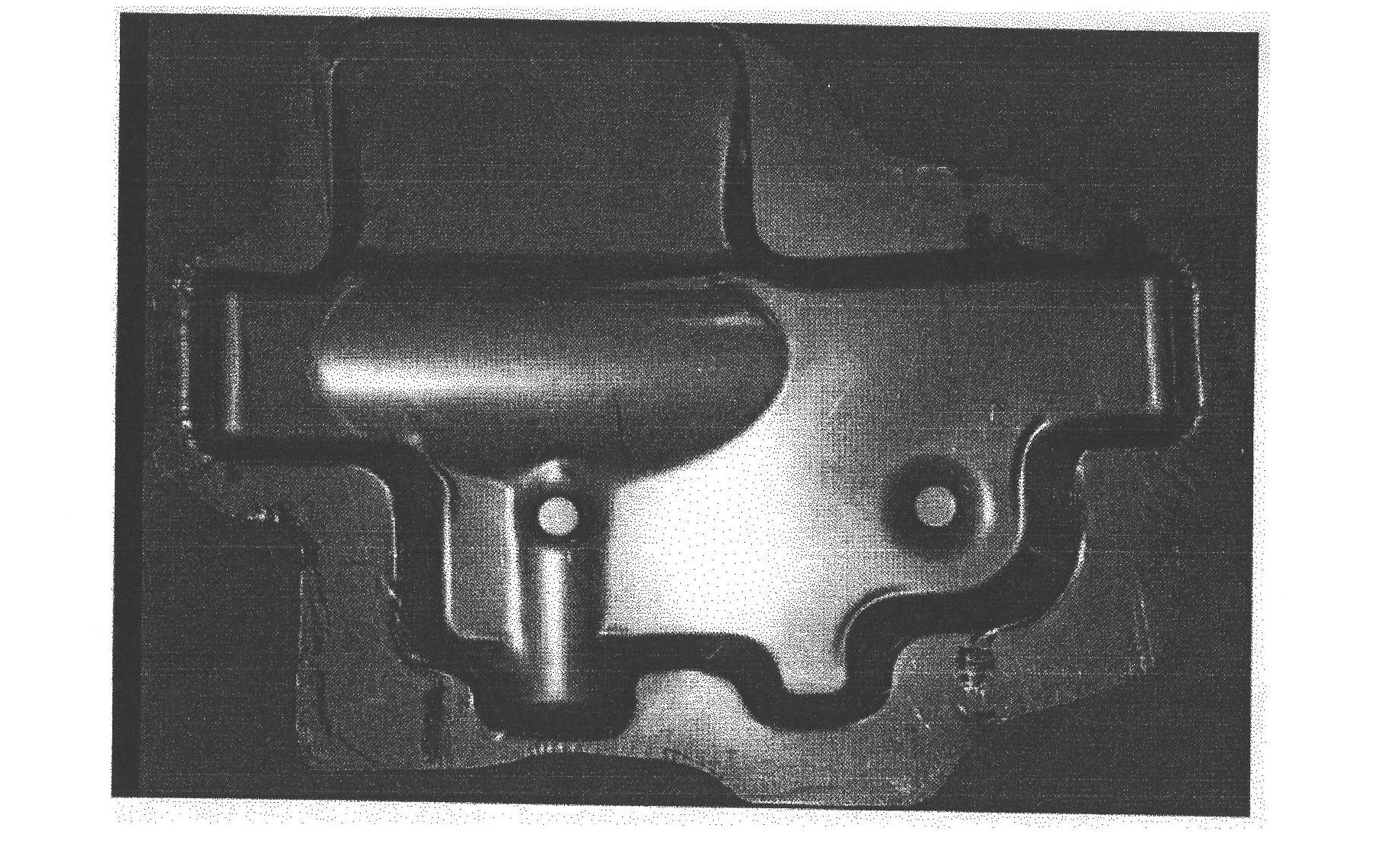

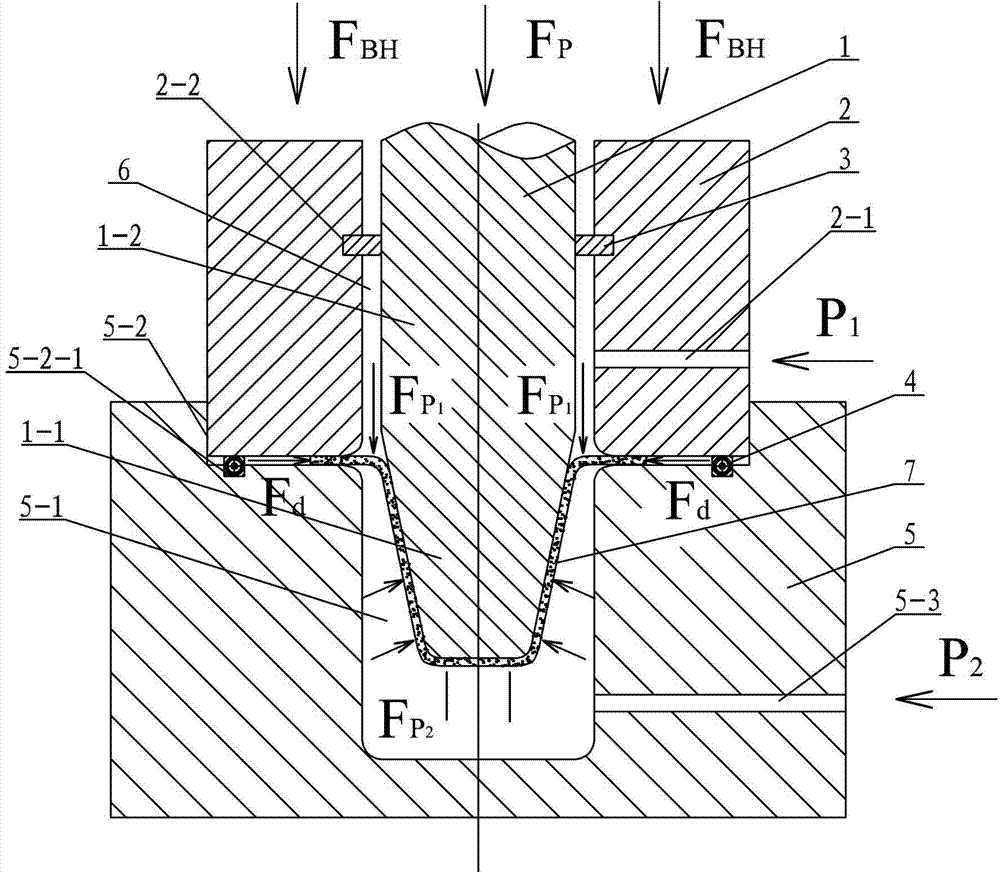

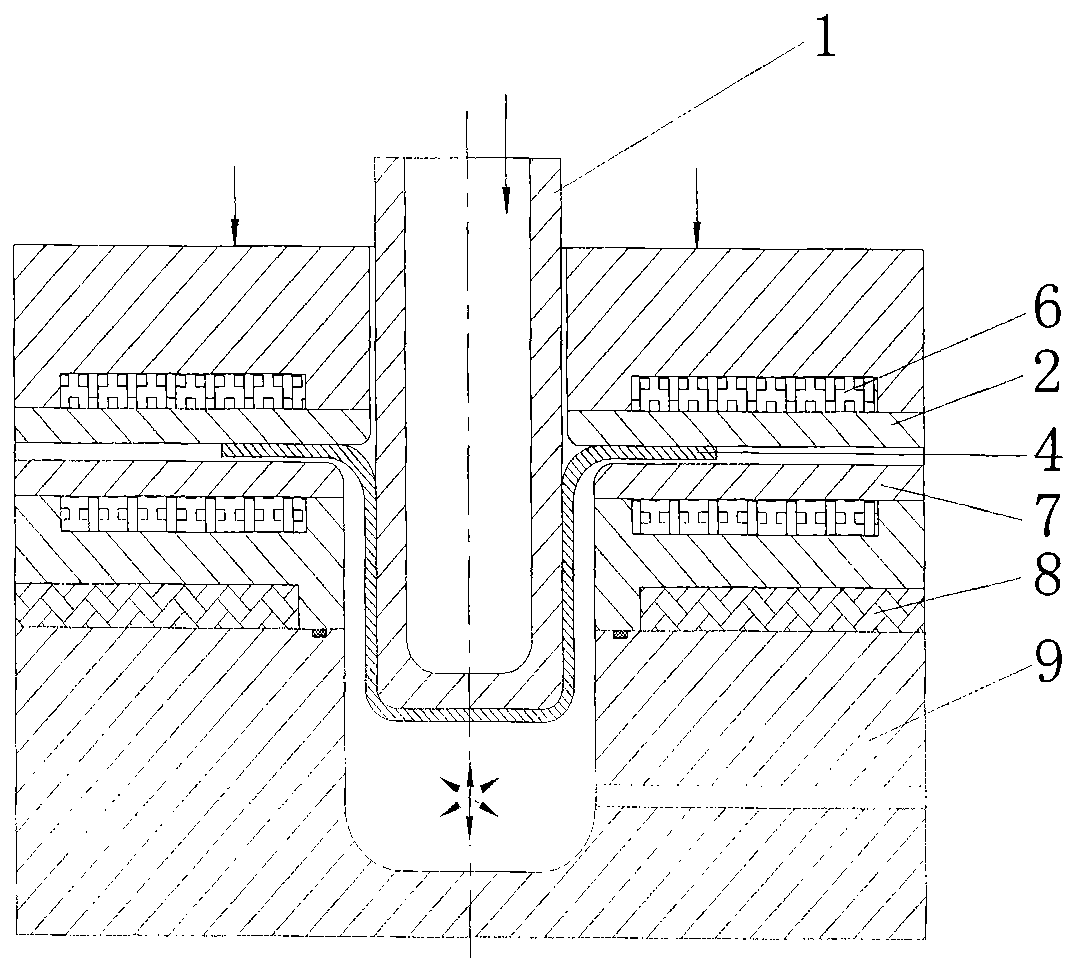

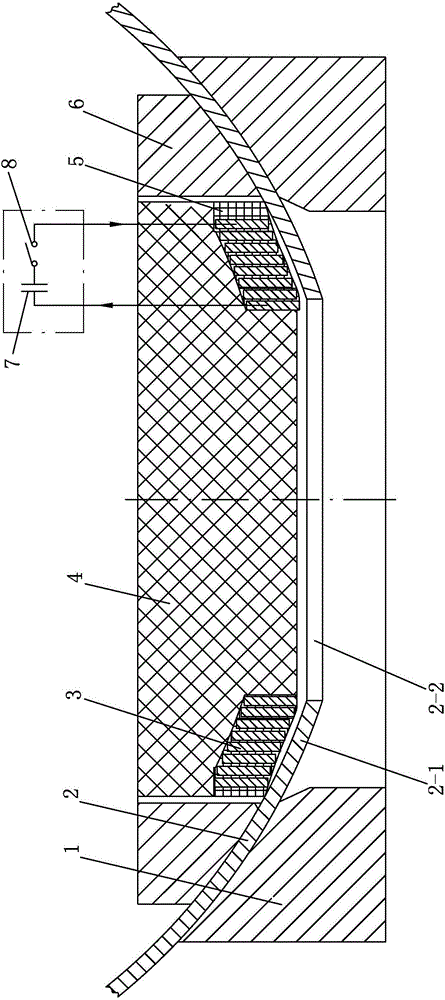

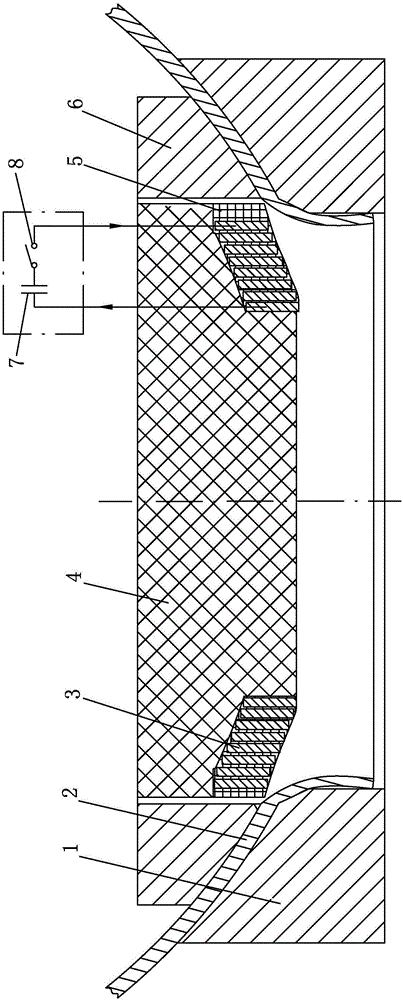

Electromagnetism-assisted forming device and method for dissimilar metal composite boards

The invention relates to an electromagnetism-assisted forming device and method for dissimilar metal composite boards and aims to solve the problem that existing metal composite boards are severely lapped and even broken in a drawing process. According to the forming device, a coil is arranged in an annular coil groove, a liquid channel is disposed between the inner wall of a blank holder and a cylinder, an upper liquid inlet channel is transversely arranged on the side wall of the blank holder, and a lower liquid inlet channel is transversely arranged on the side wall of a female die. The method includes placing the composite boards on the bottom surface of the blank holder; filling forward liquids into the liquid channel, filling reverse liquids into the female die, and exerting radial electromagnetic force Fd on the periphery of a flange of the composite board through the coil; forming the composite board under the combined action of a reverse pressure Fp2, a forward pressure Fp1 and the radial electromagnetic force Fd; and unloading a forward liquid pressure P1 and then a reverse liquid pressure P2, returning a male die and taking the formed part.

Owner:HARBIN INST OF TECH

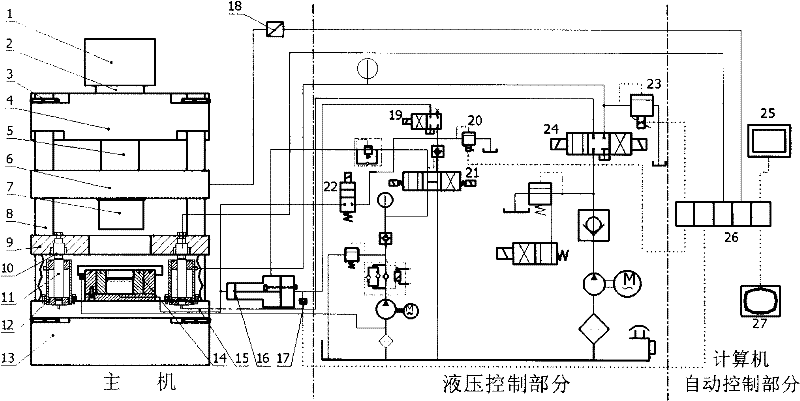

Hydrodynamic deep drawing equipment for forming deep cavity parts

InactiveCN102327945AHigh forming precisionImprove the sticking degreeAutomatic controlControl system

The invention relates to hydrodynamic deep drawing equipment for forming deep cavity parts, which is capable of deep drawing the deep cavity parts with complicated shapes such as necking-type parts with negative draft angles. The equipment is formed by three parts, i.e. a host machine, a hydraulic control system and an automatic control system of a computer. The host machine is a hydraulic machine with three beams and four columns; the hydraulic control system provides motion power to the host machine and mainly comprises two main loops, i.e. a side pressing control loop and a charging chamber control loop; and the automatic control system of the computer is used for collecting data of a displacement sensor and a pressure sensor in real time, accurately controlling and recording formed parameters, and also accurately controlling pressure according to a set curve. The equipment provided by the invention can be used for forming the parts which cannot be formed by a traditional forming process or can be formed only by a plurality of processes; has the advantages of high forming accuracy, good surface quality of the parts, high die fitting degree and the like; and has the characteristics of simplicity and convenience in operation, high control accuracy, high universality, high automation degree and the like.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

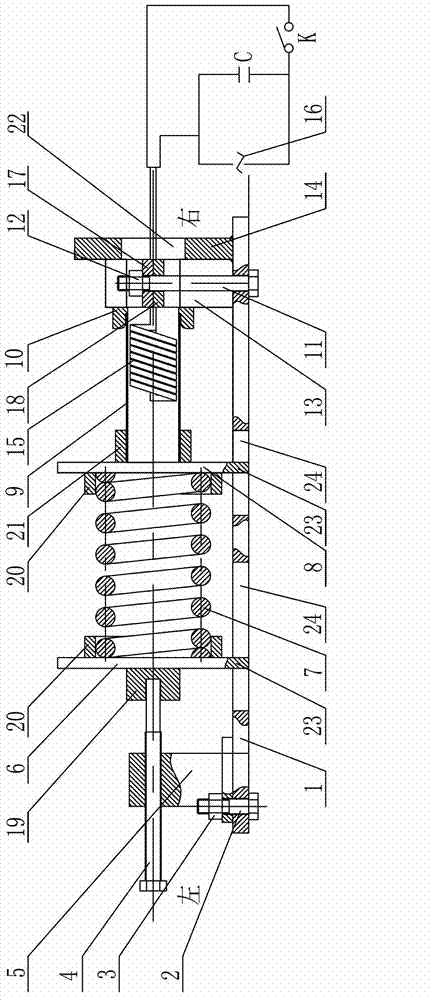

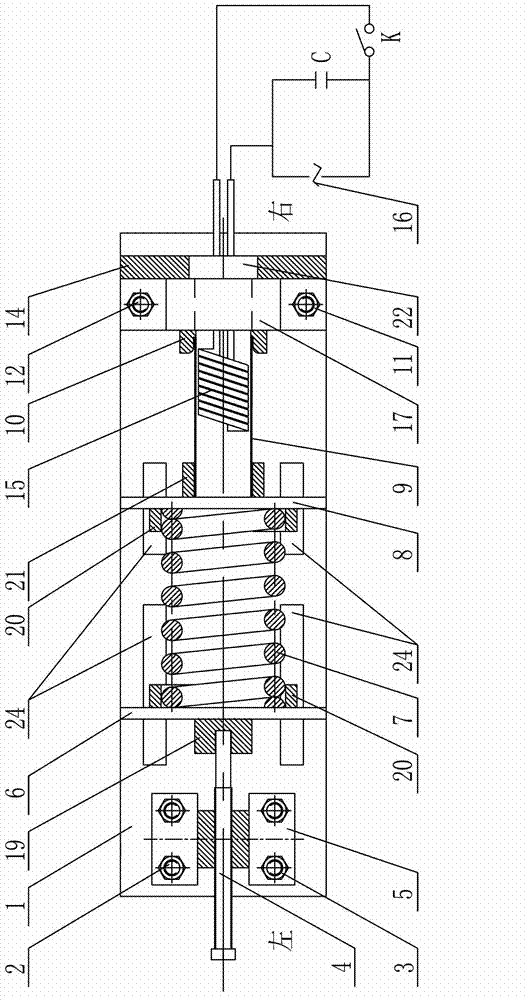

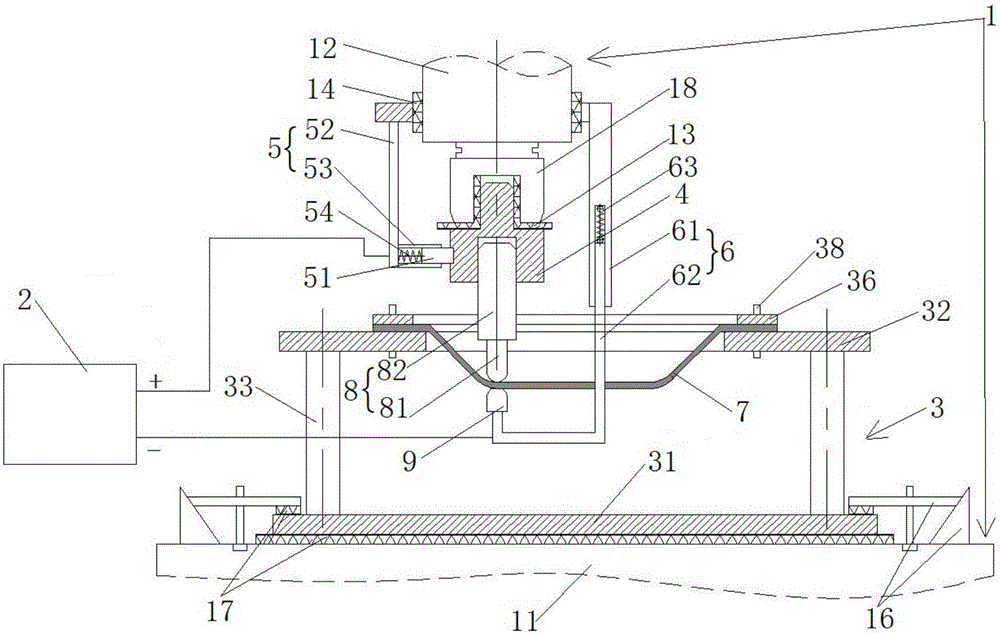

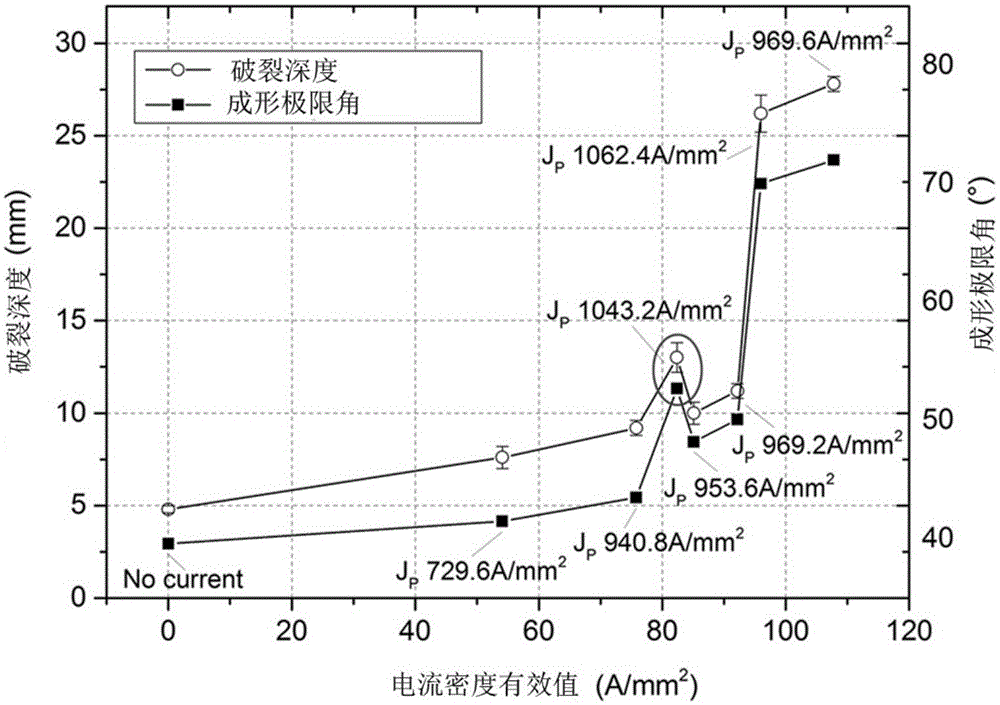

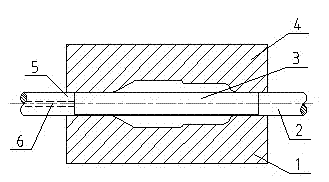

Electroplastic incremental forming device for plate and working method thereof

The invention discloses an electroplastic incremental forming device for a plate and a working method thereof, and belongs to the field of metal processing. The device comprises a machine tool and a pulse power supply, wherein a plate clamping device is fixed on a workbench of the machine tool; a clamping block, an electric brush holder and a retainer are arranged on a main shaft of the machine tool; the clamping block is connected with a tool head used for processing the plate; the electric brush holder is L-shaped, one end of the electric brush holder is fixed on the main shaft, and the other end of the electric brush holder is connected with an electric brush used for being abutted against the clamping block; the retainer is U-shaped, one end of the retainer is fixed on the main shaft, and the other end of the retainer stretches to a place below the plate and is connected with a lower press head used for being abutted against the lower surface of the plate; the tool head faces the lower press head; and the two poles of the pulse power supply are connected with the electric brush and the lower press head respectively. The electroplastic incremental forming device for the plate disclosed by the invention is simple in structure, easy to control, and low in processing cost; the forming accuracy of the plate is high; and the forming limit and the forming quality of the plate are increased and improved.

Owner:山东大学(威海)

Electromagnetic moldless forming method and device of pipes based on background magnetic field

The invention discloses an electromagnetic moldless forming method and device of pipes based on a background magnetic field. The device comprises a Helmholtz coil system, a support rod, upper and lower support plates, a driving rod, a pulse discharge circuit and a forming coil. The background magnetic field is combined with a pulse magnetic field to realize uniform electromagnetic bulging of the pipes (such as aluminum alloy pipes). The nonuniform flowing of corresponding plastic deformation areas of the pipes deformed at high speed is stopped by a nonuniform resistance field formed by electromagnetic damping in the background magnetic field, so that the pipes generate no local thinning or spalling, and qualified expansion pipe fittings with uniform plastic flowing are obtained. The Helmholtz coil system can accurately control the input energy of the background magnetic field, so that the final forming shapes of the pipes are precisely controlled, such defects as high size fluctuation and weak process repeatability of expansion pieces in a traditional electromagnetic free expansion process are prevented, and the batching, the mechanization and the standardization of the process are realized.

Owner:HUAZHONG UNIV OF SCI & TECH

Thermal hydro-mechanical drawing forming method for dot matrix self-impedance electrical heating plates

InactiveCN102139304ARealize controllable flexible heatingRaise the forming limitShaping toolsOhmic-resistance heating detailsDot matrixEngineering

The invention relates to a thermal hydro-mechanical drawing forming method for dot matrix self-impedance electrical heating plates, and belongs to the technical field of the thermal hydraulic forming of the plates. The method comprises the following steps of: fully filling liquid into a cavity of a female die serving as a liquid pond; when the plates are driven by a male die to enter the female die, forming the plates by reverse pressure generated when the liquid is compressed; embedding pin type electrodes inside pressure plates according to the distribution of dot matrixes, and performing self-impedance electrical heating on flanges of the plates by using contact resistors between the electrodes and the plates; adjusting the distribution of temperature fields of the flanges by changing the distribution law of the dot matrixes of the electrodes and adjusting the heating current of each heating electrode; adjusting the flow stress of heating points by changing the temperature of each mass point on the flanges so as to control the flow of metal by the asynchronous flow of the metal mass points on the flanges; and coordinating the deformation process of the metal by the asynchronousdeformation of each mass point on the flanges due to the temperature to fulfill the aim of improving the limit drawing ratio of the plates. The method has the advantages that: the heating speed is high, the effect is good, the plates can be heated controllably and flexibly, and the forming limit of the plates is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

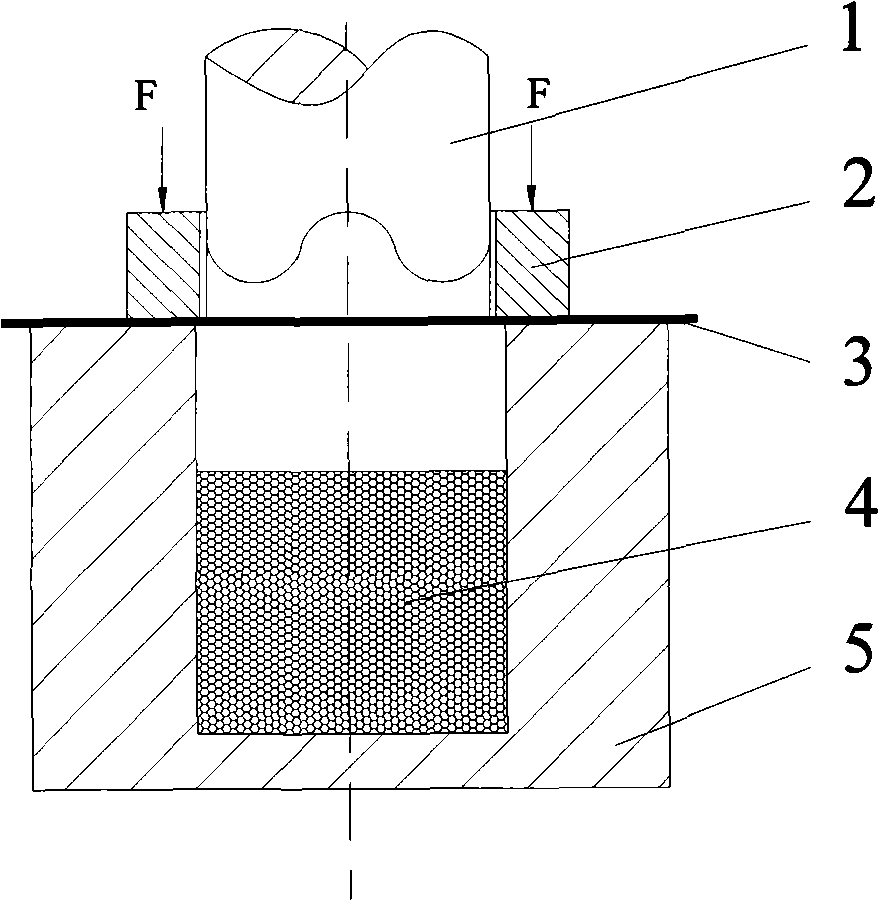

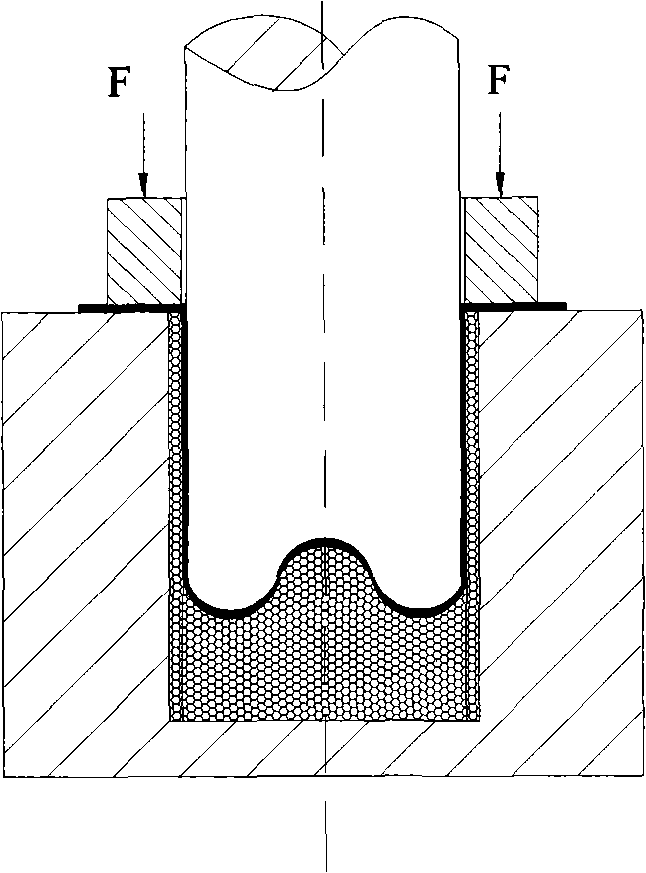

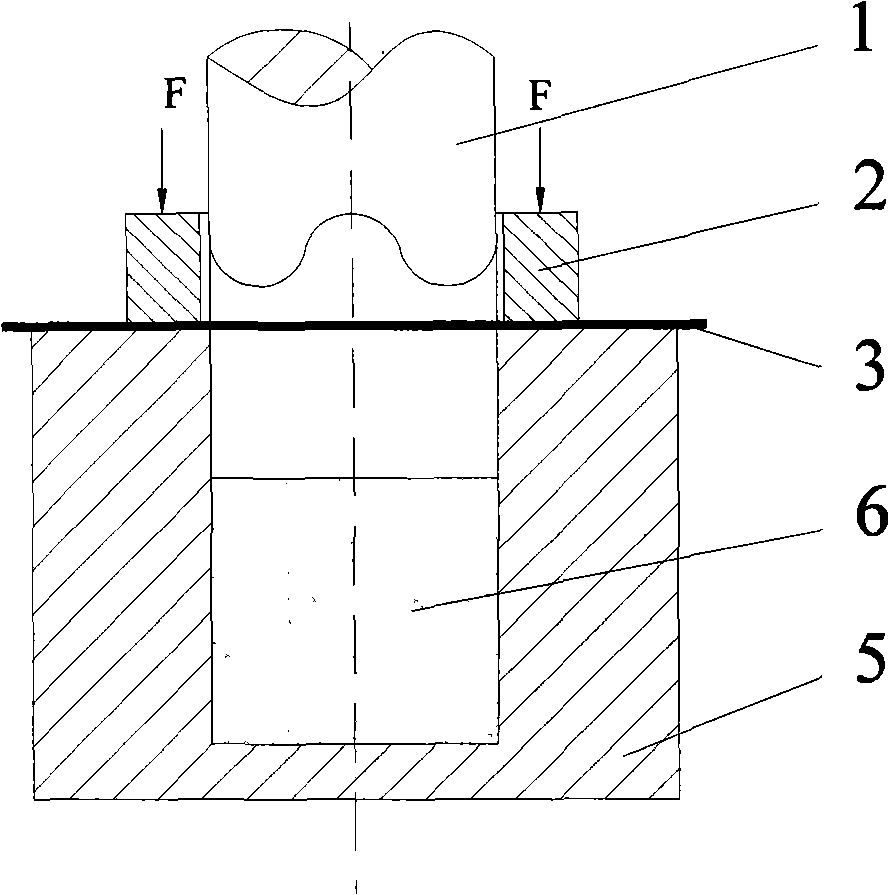

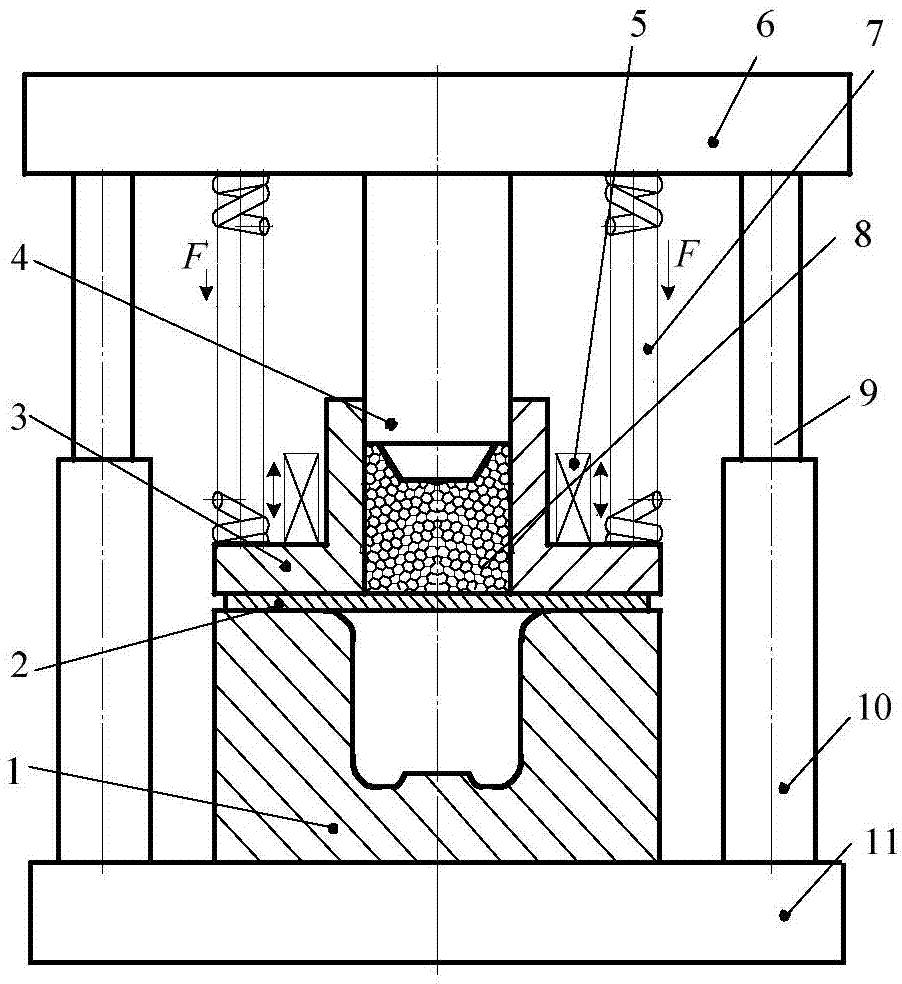

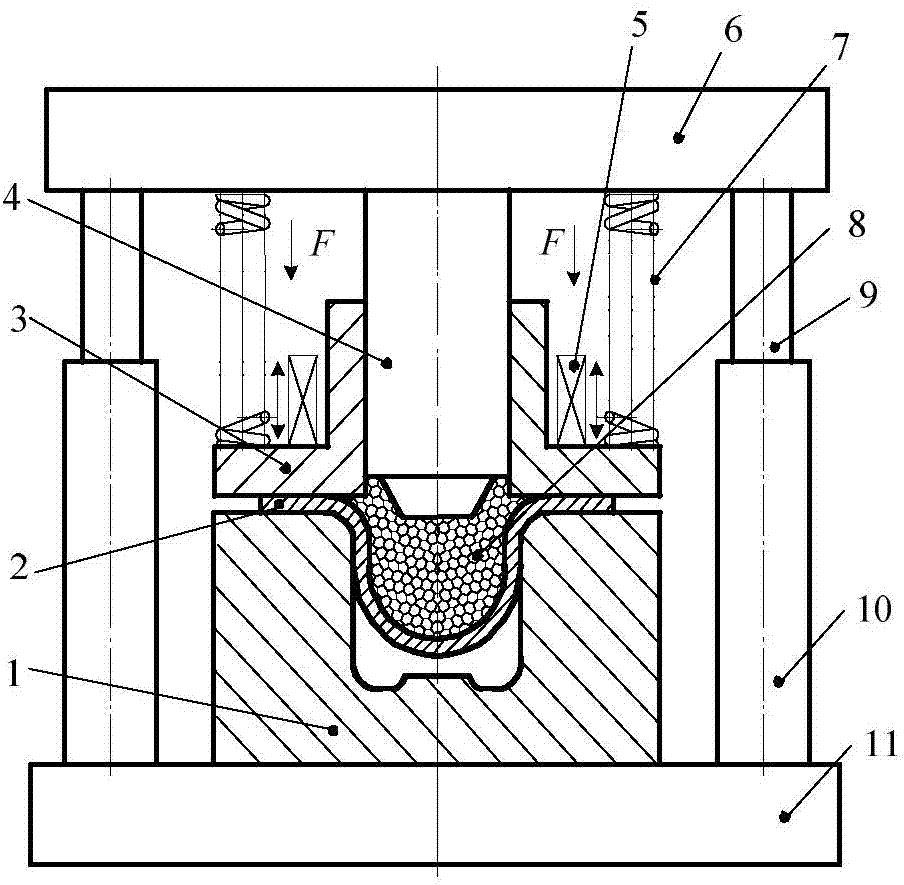

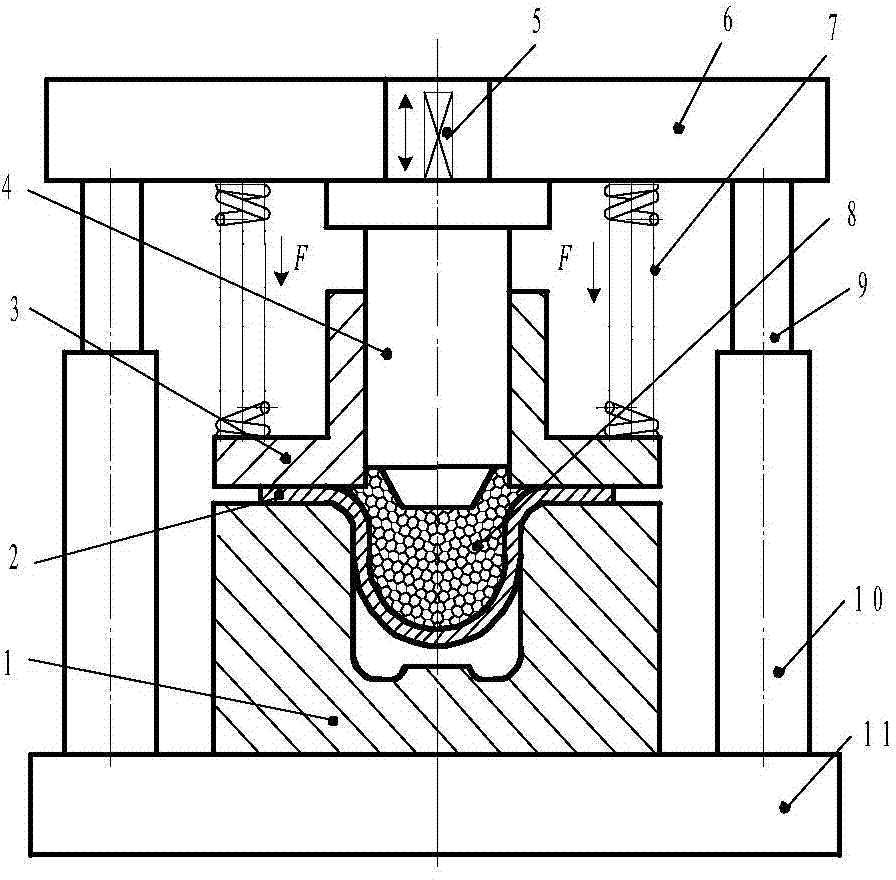

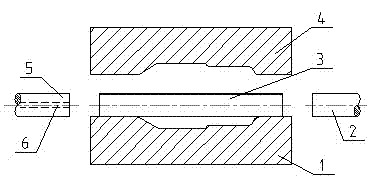

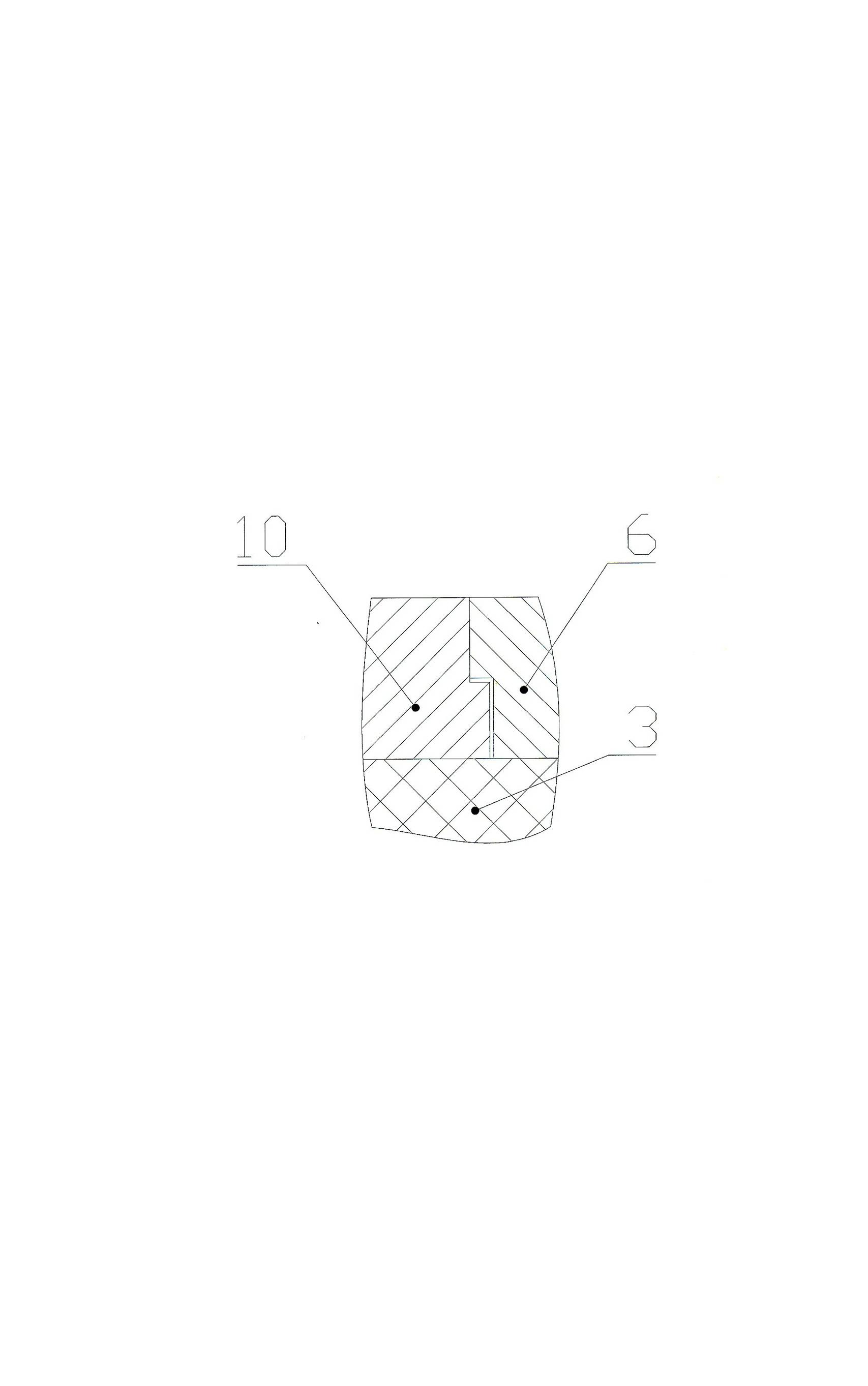

Sheet metal rigid particles or compressible powder half-module shaping technique

InactiveCN101306448ARaise the forming limitEasy to processShaping toolsSolid particleProcessing cost

The invention discloses a flexible die forming technique of sheet metal rigid particles or compressible powder, which is characterized in that: a. a male die (1) of a die is designed, processed and manufactured based on the shape and the size of forming sheet metal parts; b. a case body (4) is designed, and the rigid particles or the compressible powder is placed in the case body (4); c. the sheet metal (3) is placed on the case body (4), and is held down by a blank holder (2); d. under the action of a pressure P, the male die (1) of the die moves downwards, the female die shape is formed by the movement of the solid rigid particles (4), or is formed by compressing the compressible powder (6), thus forming the sheet metal; e. the male die (1) of the die returns, the parts are ejected or directed taken down from the case body (4), and the forming of the next part goes on; and f. if the case body (4) is filled with the solid rigid particles (4), the particles automatically reset after the die (1) of the die returns; and if the case body (4) is filled with the compressible powder (6), the forming of the next part goes on after adding a certain amount of power again, or after dispersing the powder by adopting a stirring device or a vibrating device. The technique of the invention can increase the forming limit of the sheet metal, facilitate the machining forming of the parts with complex shapes, reduce the processing cost of the die, improve the labor efficiency and facilitate the realization of automation.

Owner:YANSHAN UNIV

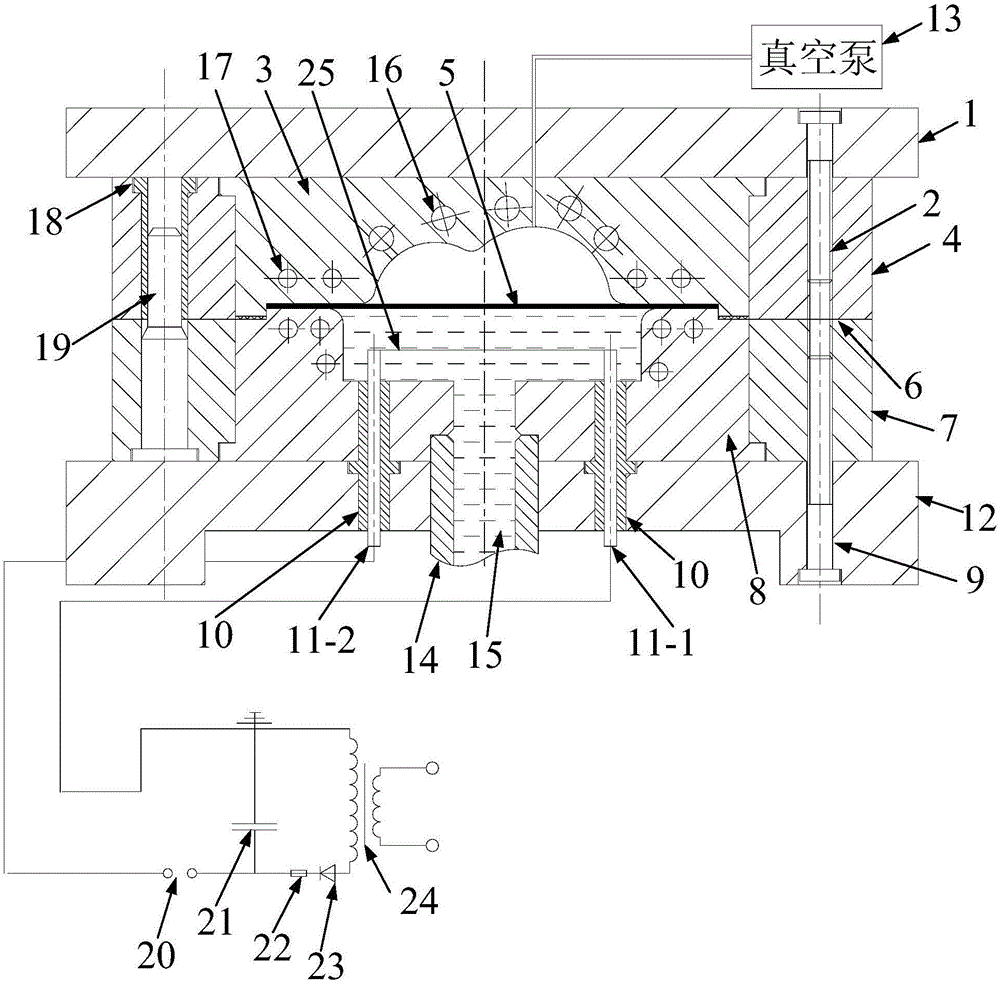

Plate warm electro-hydraulic high-speed impact-quasi static hydraulic composite forming device and plate forming method achieved by adopting device

InactiveCN106734499AGuaranteed forming qualityAvoid crackingShaping toolsElectro hydraulicEngineering

The invention discloses a plate warm electro-hydraulic high-speed impact-quasi static hydraulic composite forming device and a plate forming method achieved by adopting the device and relates to the field of metal material processing forming to solve the problems that forming of plates and complex parts is difficult, film attaching is poor, and deformation is not even. A vacuum pump is used for pumping out gas in a female die cavity; a fluid injection device is adopted for injecting high-temperature-resisting liquid to a liquid chamber; a heating device is used for heating the female die cavity, the high-temperature-resisting liquid in the liquid chamber is heated, preheating on a to-be-processed plate is completed, and heat preservation is conducted on the to-be-processed plate; an electromagnetic forming system is used for conducting discharging forming on the to-be-processed plate; high-pressure warm liquid is slowly injected into the liquid chamber under the quasi static condition, and quasi static hydraulic forming is conducted on the to-be-processed plate; and the high-pressure warm liquid in the liquid chamber is cooled to the room temperature within a period of time, waste liquid is recycled, an electro-hydraulic forming die is opened, and the to-be-processed plate is taken away. The device and the method are used for forming plates.

Owner:XIANGTAN UNIV

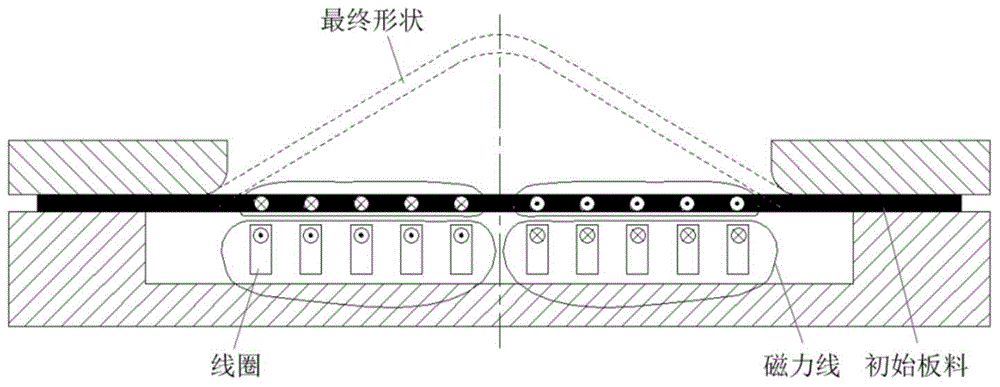

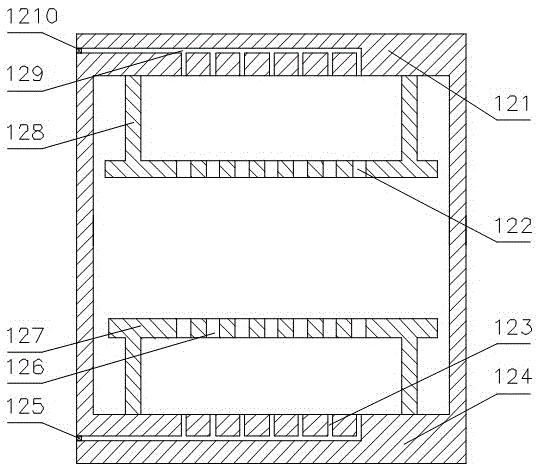

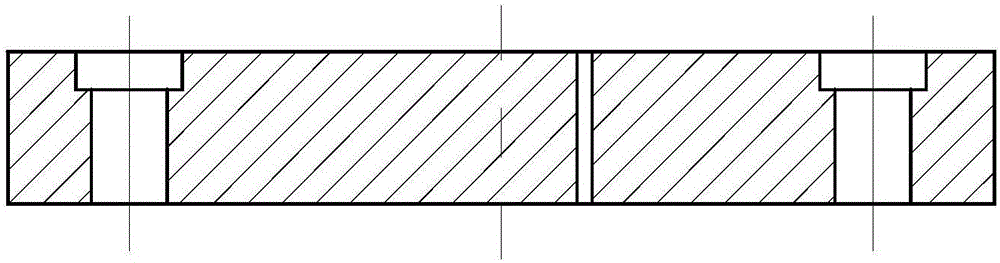

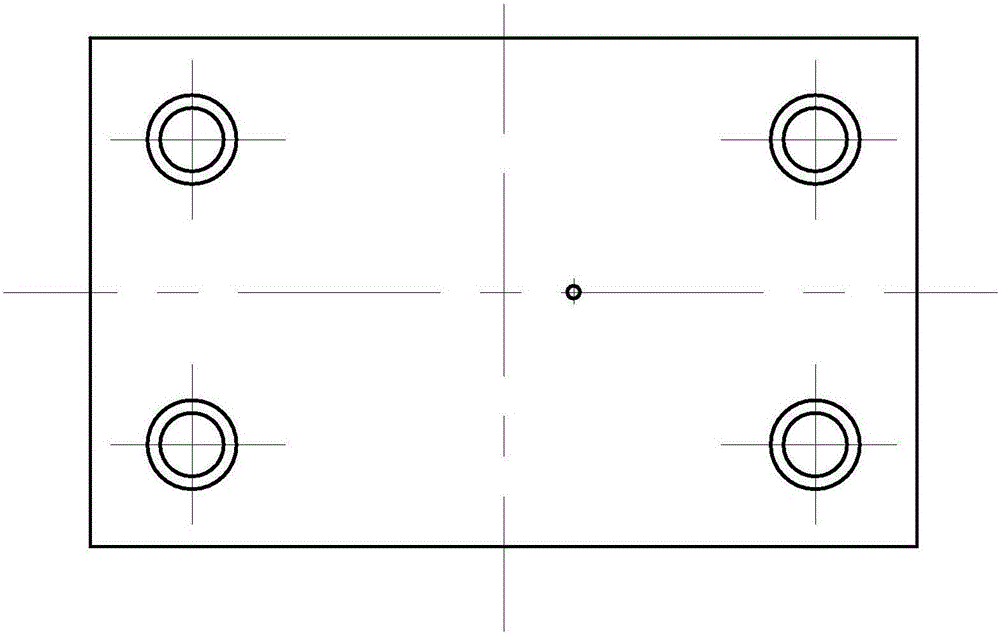

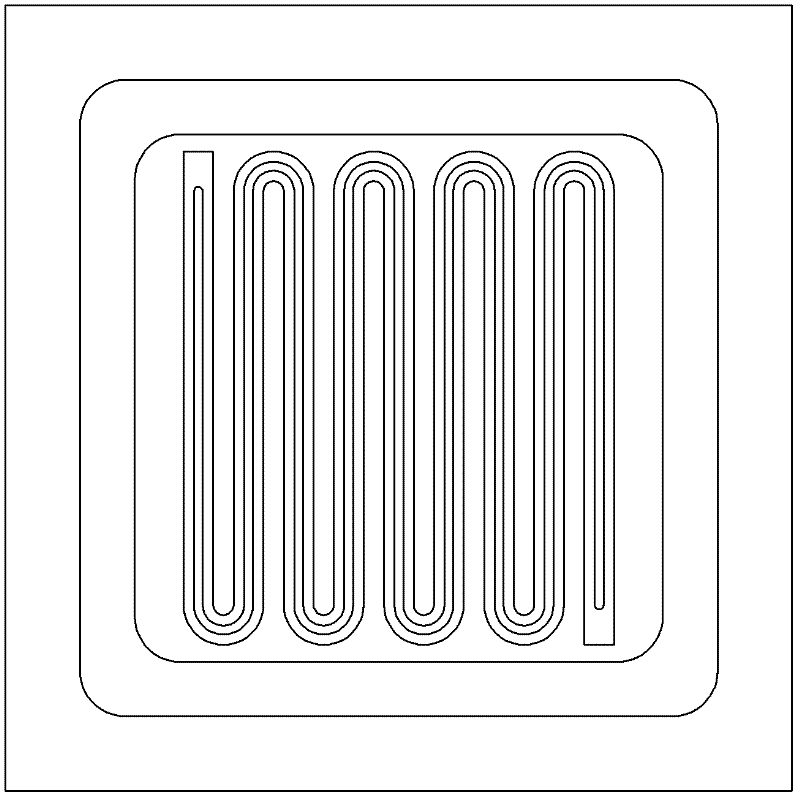

Electromagnetic force driven soft mold forming device and method for metal bipolar plate of fuel cell

The invention relates to a method for forming a fuel cell metal bipolar plate. The invention aims at the problems of a conventional plastic deformation means (such as a punching forming means) for forming a metal sheet that a raised mould and a concave mould are difficult to match with each other and a driving sheet cannot be reused in a process of electromagnetically forming a metal bipolar plate. The device is characterized in that a forming mould, a flexible mould, a driving plate, a support frame and an upper fixing plate are stacked on a lower fixing plate from bottom to top, wherein a coil is arranged in a groove on a lower end face of the support frame; two adjacent circles of leads are separated by high-pressure isolating material; high-pressure high-strength isolating materials are filled between the groove and the coil and on the surface of the coil, thereby forming a flat coil; two ends of the coil are serially connected to a capacitor bank; and the upper fixing plate and the lower fixing plate are fixedly connected through a fastening bolt. The method comprises the following steps: placing a plate blank on the forming mould and fastening the upper fixing plate and the lower fixing plate; and performing discharging forming; and taking out a formed piece, thereby acquiring the metal bipolar plate. The device and the method provided by the invention are used for forming the fuel cell metal bipolar plate.

Owner:HARBIN INST OF TECH

Method for forming plates on basis of vibration by aid of flexible male die

The invention discloses a method for forming plates on the basis of vibration by the aid of a flexible male die. Machining equipment for implementing the method mainly comprises a lower die holder, a female die, a blank holder, granular media, a blank holder force applying device, a vibration device, a punch, an upper die holder, guide columns, guide sleeves and the like. The method includes placing a metal plate between the female die and the blank holder when the metal plate is about to be machined and formed, enabling the blank holder to apply blank holder force, then adding the granular media into a barrel formed by the blank holder and the metal plate, enabling a pressure head to compress the media under the effect of pressure, applying the pressure to the plate and performing deep drawing forming on the plate by the aid of the flexible male die; enabling the vibration device to apply vibration on the punch, the blank holder and the female die individually or jointly. The method has the advantages that friction and deformation resistance among the plate and the dies can be reduced under the effect of vibration excitation, the flowability and the force transfer property of the granular media can be promoted, plate forming limit can be upgraded, and the method is favorable for machining and forming components in complicated shapes; the granular media can be reused, accordingly, the die machining cost and energy consumption can be reduced, and the method is favorable for environmental protection.

Owner:YANSHAN UNIV

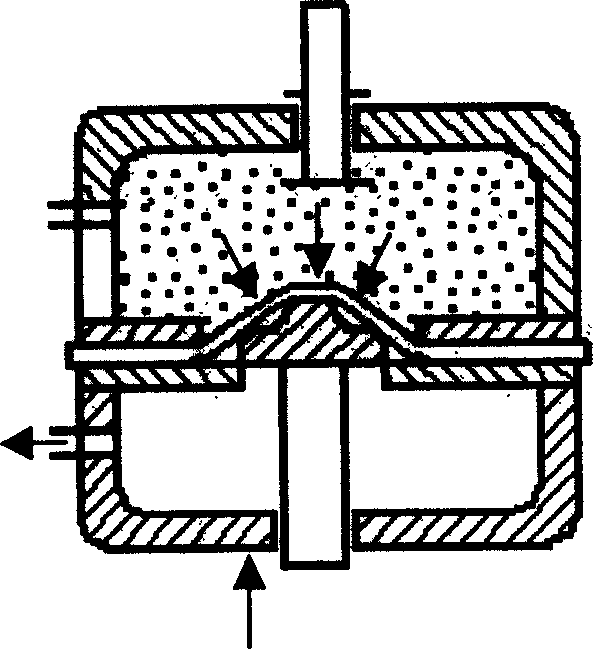

Sheet bar reciprocating type forming method based on force transferring by viscoelastic medium

The invention is a type way based on the flexibility plate. It uses the flexibility material as the medium, utilizing the shape equipment of up and down cavities and pistons put the material between the two cavities, bulge film is fixed on the piston top, by the moving of piston, the material type first. Then type last by opposite direction, and we get the product. The type way can increase the material transform degree and the product transform limit, and decrease the steps to produce and get the high quality product, so it has very good foreground to apply.

Owner:CHONGQING UNIV OF TECH

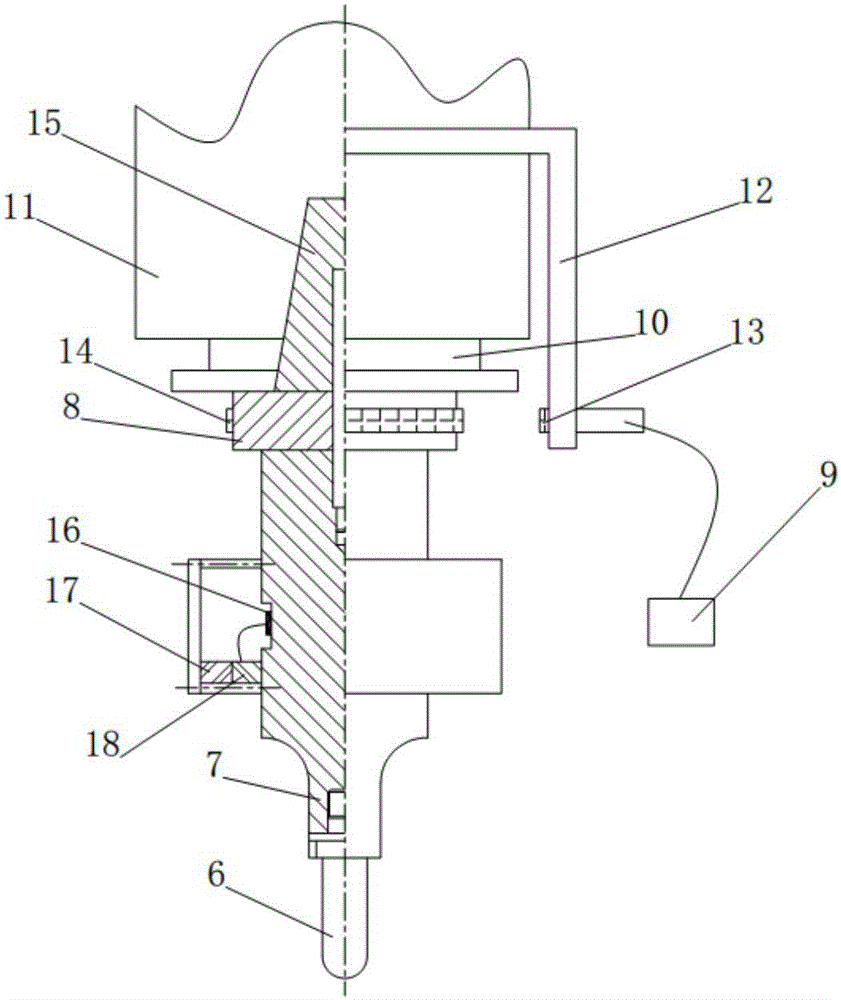

Rotary ultrasonic compound incremental forming device and method based on real-time feedback

ActiveCN106670297AImproved plastic deformation behaviorImprove surface qualityInformation processingPower sensor

The invention discloses a rotary ultrasonic compound incremental forming device and method based on real-time feedback. The rotary ultrasonic compound incremental forming device comprises a plate incremental forming fixture unit. A rotary ultrasonic cutter handle machining unit is arranged above the plate incremental forming fixture unit. The rotary ultrasonic utter handle machining unit comprises a machining main shaft which is connected with an installation taper shank. An ultrasonic energy exchanger is arranged in a cylindrical hole of the installation taper shank. An electrode copper sheet of the ultrasonic energy exchanger is connected with a receiving coil of a magnetic receiver through a wire, a magnetic generator is arranged opposite to the magnetic receiver, and the magnetic generator is connected with the magnetic receiver. The ultrasonic energy exchanger is connected with an amplitude transformer, and the amplitude transformer is connected with a forming tool head. An annular groove is formed in the outer circle of the amplitude transformer, the annular groove is used for sticking a strain gage serving as a power sensor, the strain gage is connected with a signal acquiring and emitting module, and the signal acquiring and emitting module is connected with an information processing and displaying device.

Owner:SHANDONG UNIV

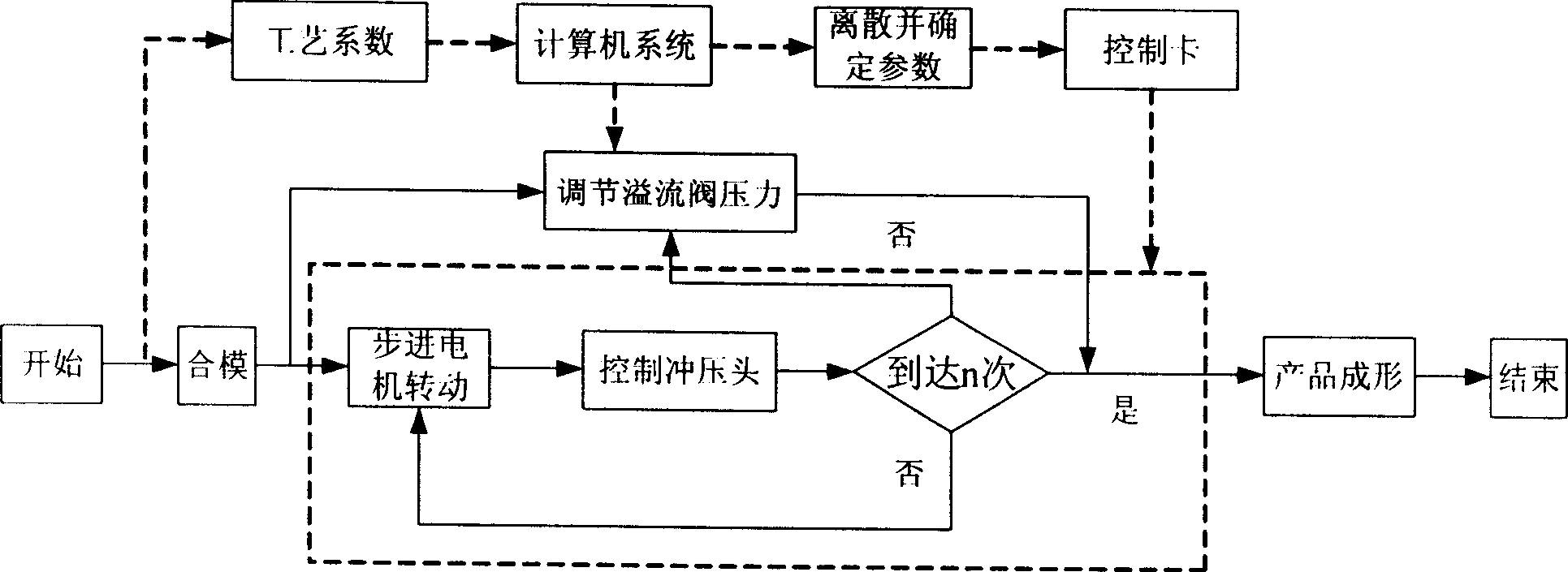

Process method for improving high pressure forming limit in tube

InactiveCN102248058AImprove uniform deformation abilityRaise the forming limitThermal treatmentInternal pressure

The invention relates to the field of machine manufacturing, in particular to a process method for improving high pressure forming limit in a tube. The invention adopts the technical scheme that the process method comprises the following steps of: firstly providing axial supplementation at the end part of a tube billet under relatively lower pressure, ensuring that the tube billet is smoothly conveyed to a bulging region to form tiny beneficial creases, and then stopping the axial supplementation; then raising pressure, re-shaping the tube billet in the bulging region until the tiny beneficial creases disappear, and then reducing the pressure; repeating the processes until a part contact die is formed; removing inner pressure, withdrawing a punch at the end part until the punch and a die cavity are completely separated, and opening the die, and taking out the part from the die. According to the method, the defects that unstability and corrugation are easily generated at the end part of the tube billet due to excessive friction force under the condition of performing axial supplementation and inner pressure reforming at the same time and the bulging region is easily broken because of insufficient supplementation and the beneficial creases can not be repeatedly utilized are avoided, therefore, the forming limit of the tube can be greatly improved, the steps of performing and thermal treatment are reduced, meanwhile, the abrasion of the die cavity is greatly reduced, and the die life is prolonged.

Owner:HARBIN INST OF TECH AT WEIHAI +1

Magnetic pulse flanged hole method for shells

The invention relates to shell flanged hole part forming methods, in particular to a magnetic pulse flanged hole forming method for shells. The method aims at solving the problems that in the flanged hole manufacturing process of an existing steel die hole flanging method, the technology is complex, the production efficiency is low, and the production cycle is long. The method comprises the steps that firstly, the shape of a flanged hole coil bobbin is designed according to a curved surface shell with pre-manufactured holes; secondly, the curved surface shell with the pre-manufactured holes is arranged on a flanged hole forming female die, an edge pressing ring is arranged on the inner surface of the curved surface shell in the periphery direction, a hole flanging coil matched with the hole flanging deforming area is wound on the flanged hole coil bobbin, covers the hole flanging deforming area and is attached to the hole flanging deforming area, one end of a capacitor set is connected with one terminal of the hole flanging coil, the other end of the capacitor set is connected with one end of a gap switch, the other end of the gap switch is connected with the other terminal of the hole flanging coil, and the capacitor set is charged to reach the preset voltage value; thirdly, magnetic pulse flanged hole forming is carried out; fourthly, flanged holes are corrected. The method is used for forming flanged hole parts of shells.

Owner:HARBIN INST OF TECH +1

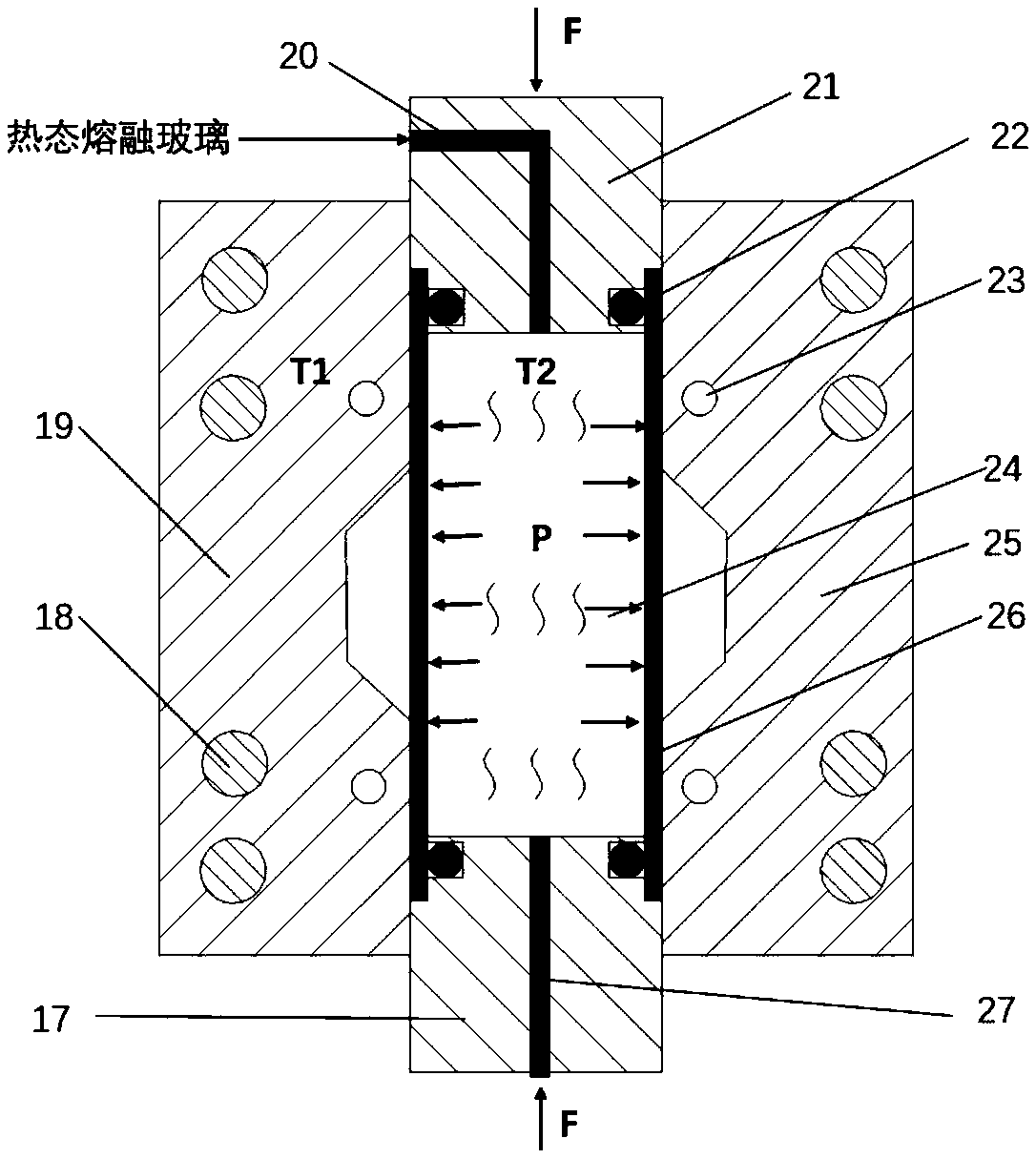

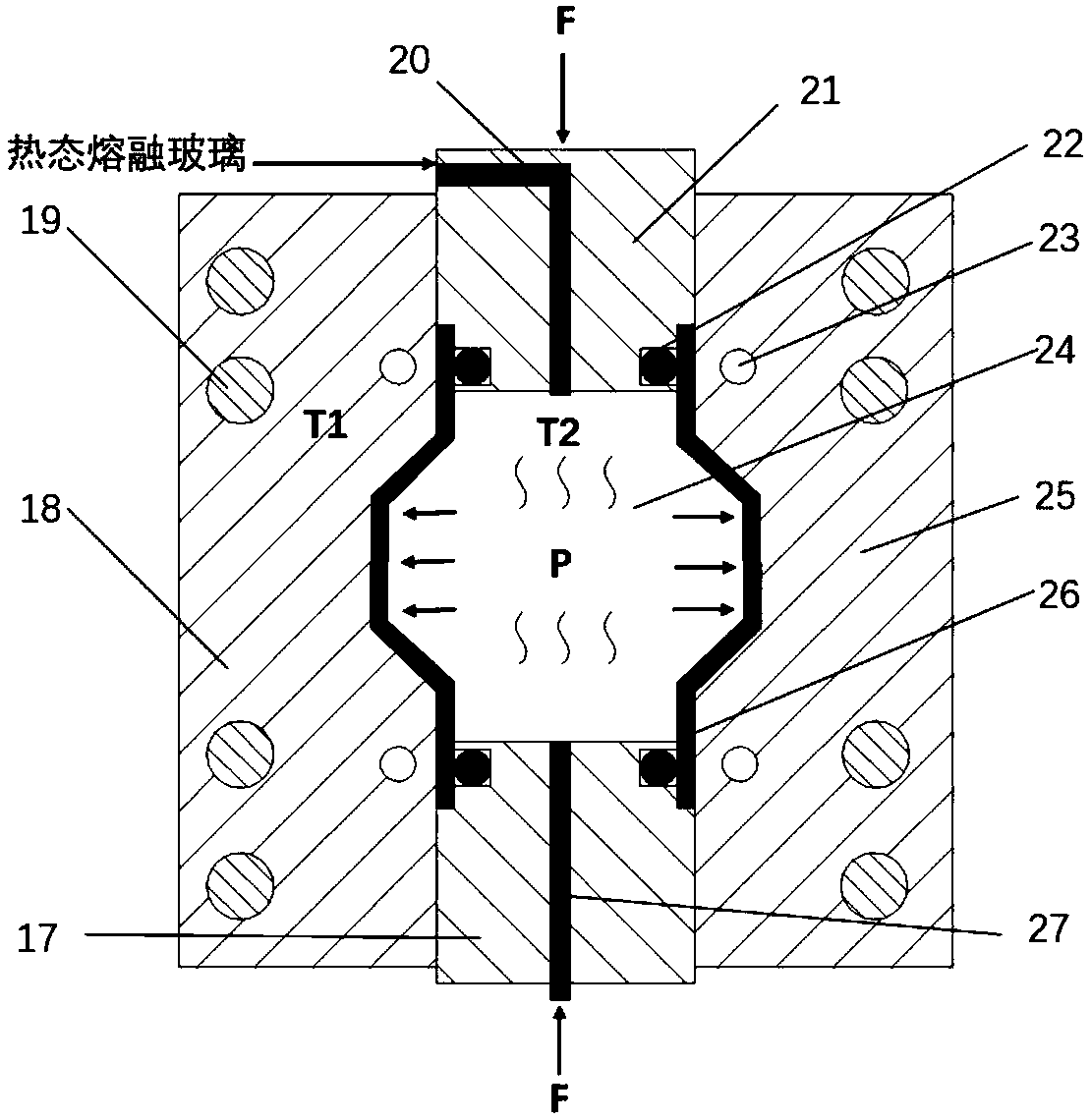

Pipe hot medium internal pressure forming method based on molten glass

ActiveCN108856441AMeet the forming temperature process requirementsReduce compressionInternal pressureHeat conducting

The invention discloses a pipe hot medium internal pressure forming method based on molten glass, and relates to a metal pipe forming method. The problems that according to existing hot medium internal high pressure forming methods, the heating speed is low, heat conducting coefficients are low, sealing is difficult, and forming pressure only can reach about 0-50MPa are solved. The method comprises the steps that 1, a pipe internal high pressure forming temperature interval is determined according to the pipe variety; 2, according to the pipe internal high pressure forming temperature, glass materials are selected; 3, a pipe to be formed is preheated; 4, a pipe blank is vertically placed into a forming die, and die closing and sealing are carried out; 5, the glass materials are heated to obtain molten glass; 6, the glass media are injected into the sealed pipe blank; 7, the pipe blank is heated to internal high pressure forming temperature under high-temperature filling; and 8, material supplementing is carried out; and 9, pressure maintaining is carried out, the molten glass flows out through an overflow valve, die opening is carried out, and the formed deformed-section pipe partis obtained. The pipe hot medium internal pressure forming method is used in the field of internal high pressure forming.

Owner:HARBIN INST OF TECH

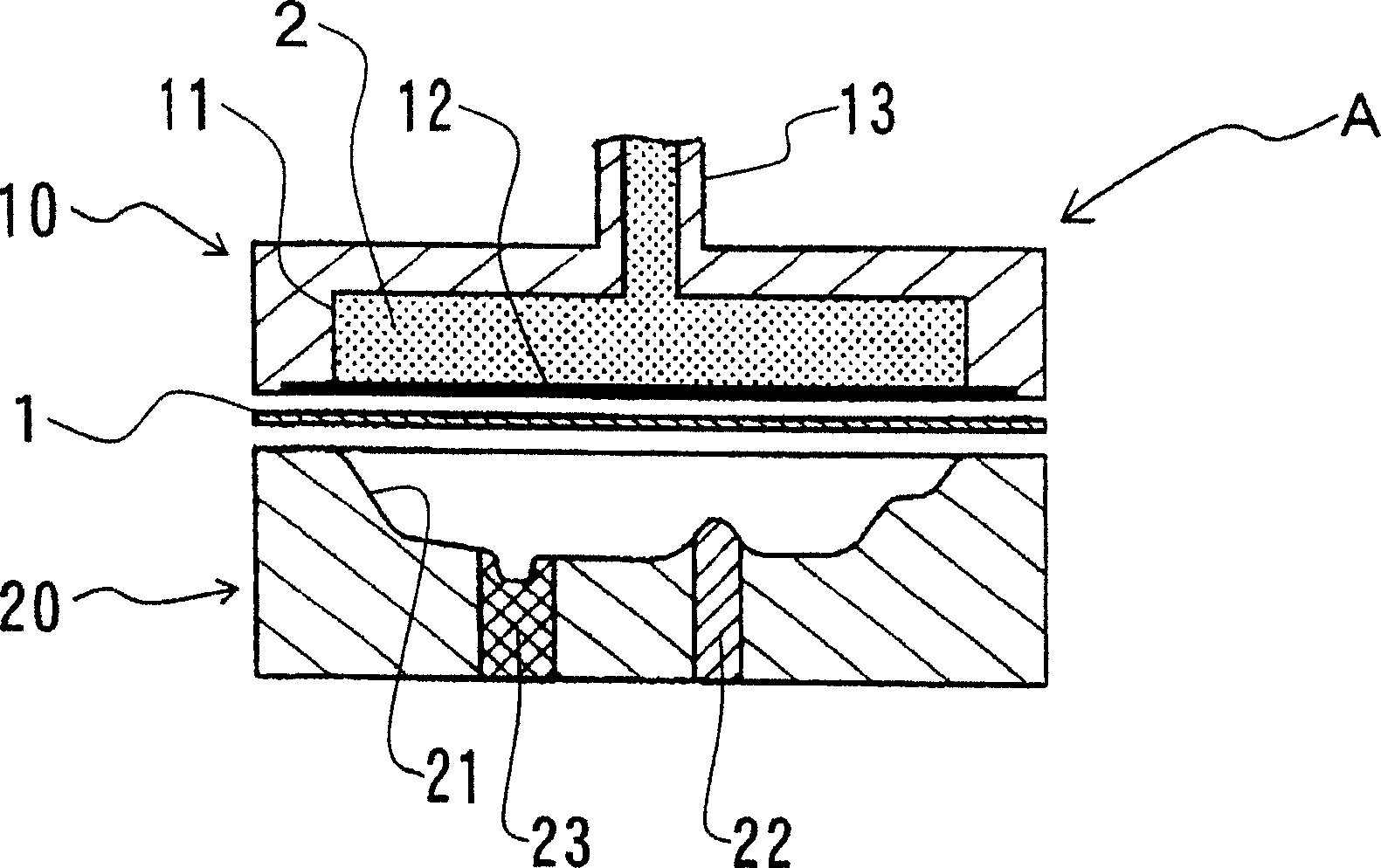

Hydraulic pressure molding device and hydraulic pressure molding method

A hydraulic pressure molding device (A) and a hydraulic pressure molding method for molding a molded body of a specified shape by holding a material plate (1) by a first mold (10) pressing the material plate (1) with a pressurized liquid medium (2) and a second mold (20) in which a molding recessed surface (21) of a specified shape is formed and pressing the material plate (1) with the liquid medium (2) to bring the material plate (1) into contact with the molding recessed surface (21). The second mold (20) comprises deformation resistance adjusting means (22) and (23) locally differentiating the deformation resistance of the material plate (1). The deformation resistance adjusting means (22) and (23) are formed of a local cooling means (22) locally cooling the material plate (1) and a local heating means (23) locally heating the material plate (1). In addition, the deformation resistance adjusting means (22) and (23) are formed movable forward and backward relative to the second mold (20).

Owner:RINASCIMETALLI

Multi-blank-holder radial blocking-blank pressing method applied to nonaxisymmetrical piece

The invention relates to a multi-blank-holder radial blocking-blank pressing method applied to a nonaxisymmetrical piece. The multi-blank-holder radial blocking-blank pressing method is characterized in that the nonaxisymmetrical piece adopts the circumferential blocking and blank pressing at a straight side part of a female die, and a fillet part of the female die adopts the radial blocking and blank pressing; and all blank holders in radial blocking and flange pressing move independently in the vertical direction, and blank holder forces are respectively provided for the corresponding position of each blank holder in a plate material flange deforming area. The multi-blank-holder radial blocking-blank pressing method has the advantages that the problem that different deformation particles are subjected to blank pressing in the radial direction respectively in the fillet area in the deep drawing process of the nonaxisymmetrical piece (a box-shaped piece) can be solved, and the defect of single circumferential blank pressing can be compensated, so that the further blank pressing effect can be optimized, and the nonaxisymmetrical piece (the box-shaped piece) forming quality is improved.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com