Sheet bar reciprocating type forming method based on force transferring by viscoelastic medium

A viscoelastic and reciprocating technology, which is applied in the field of sheet metal forming, can solve the problems of forming difficult parts and not being able to use the forming properties of materials more effectively, and achieve the effects of good product quality, increased limit forming degree, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

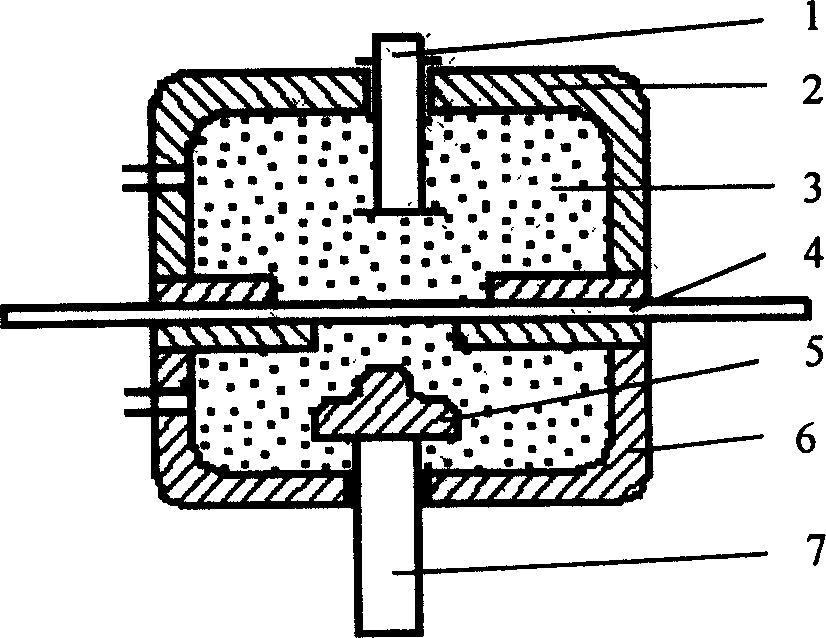

[0023] The forming device used in this method is as figure 1 As shown, it consists of two upper and lower cavities 2 and 6, upper and lower pistons 1 and 7.

[0024] The following to produce Figure 5 Using the final product shown as an example, the operation of the method is described in detail:

[0025] 1. See figure 1 Place the blank 4 to be formed between the upper and lower cavities 2 and 6 of the forming device, install the punch 5 on the top of the piston 7 of the lower cavity 6, and fill the upper and lower cavities with viscoelastic medium alkyd resin 3 ;

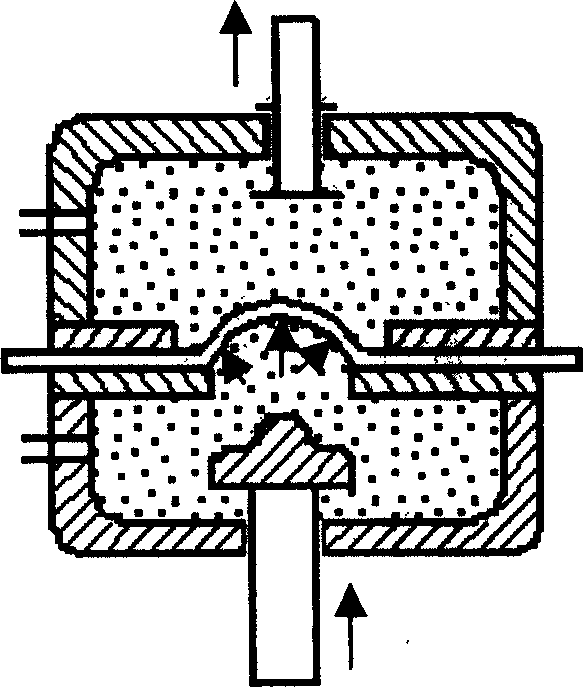

[0026] 2. Push the lower piston 7 where the punch is located by external power to make it go up, and the pressure in the lower chamber 6 increases, causing the sheet 4 to deform upwards, and at the same time, the upper piston 1 moves upward under pressure to achieve the purpose of pressure relief, such as figure 2 ;

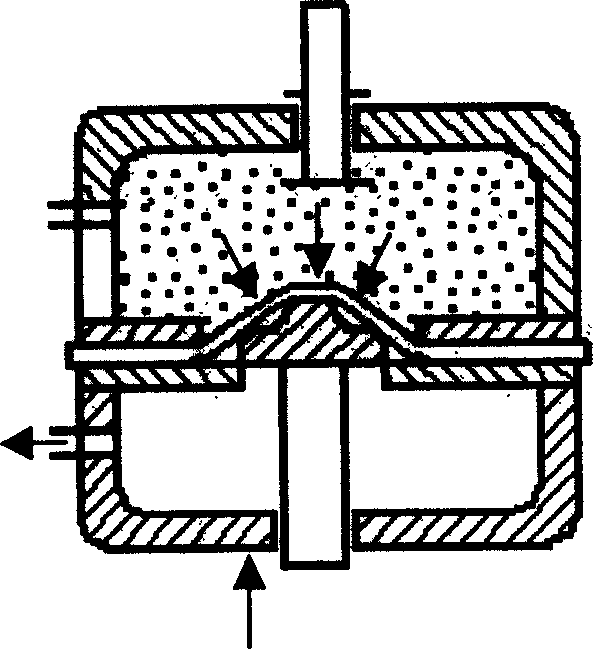

[0027] 3. When the deformation reaches the pre-forming requirements predicted by the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com