Patents

Literature

228 results about "Viscous medium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Viscous Medium. This example shows two bodies connected by a spring in a viscous medium. This model simulates two bodies in an isotropically viscous medium with a Hooke's force law between them. The Body Spring & Damper models an undamped spherical spring whose rest length is 5 m.

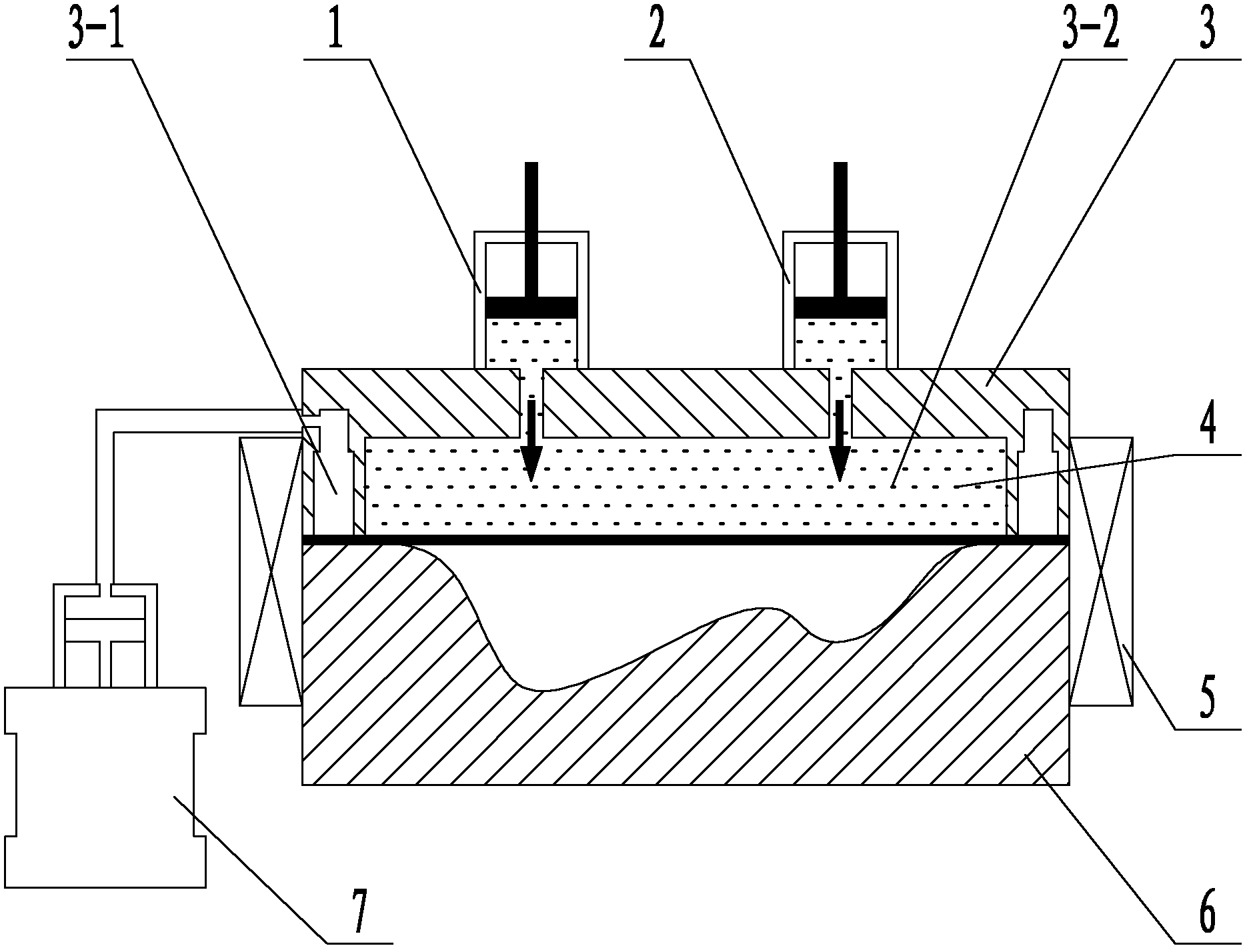

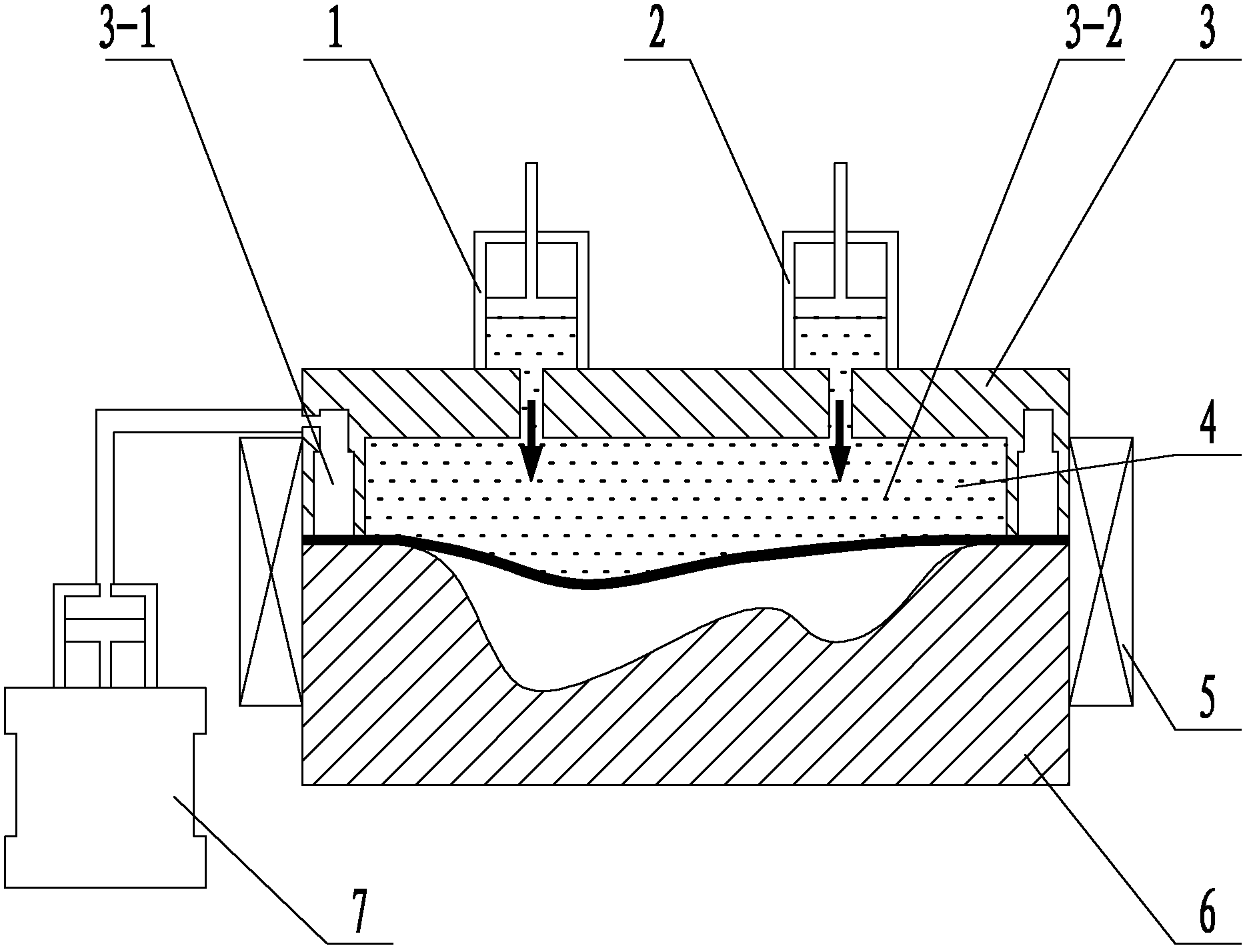

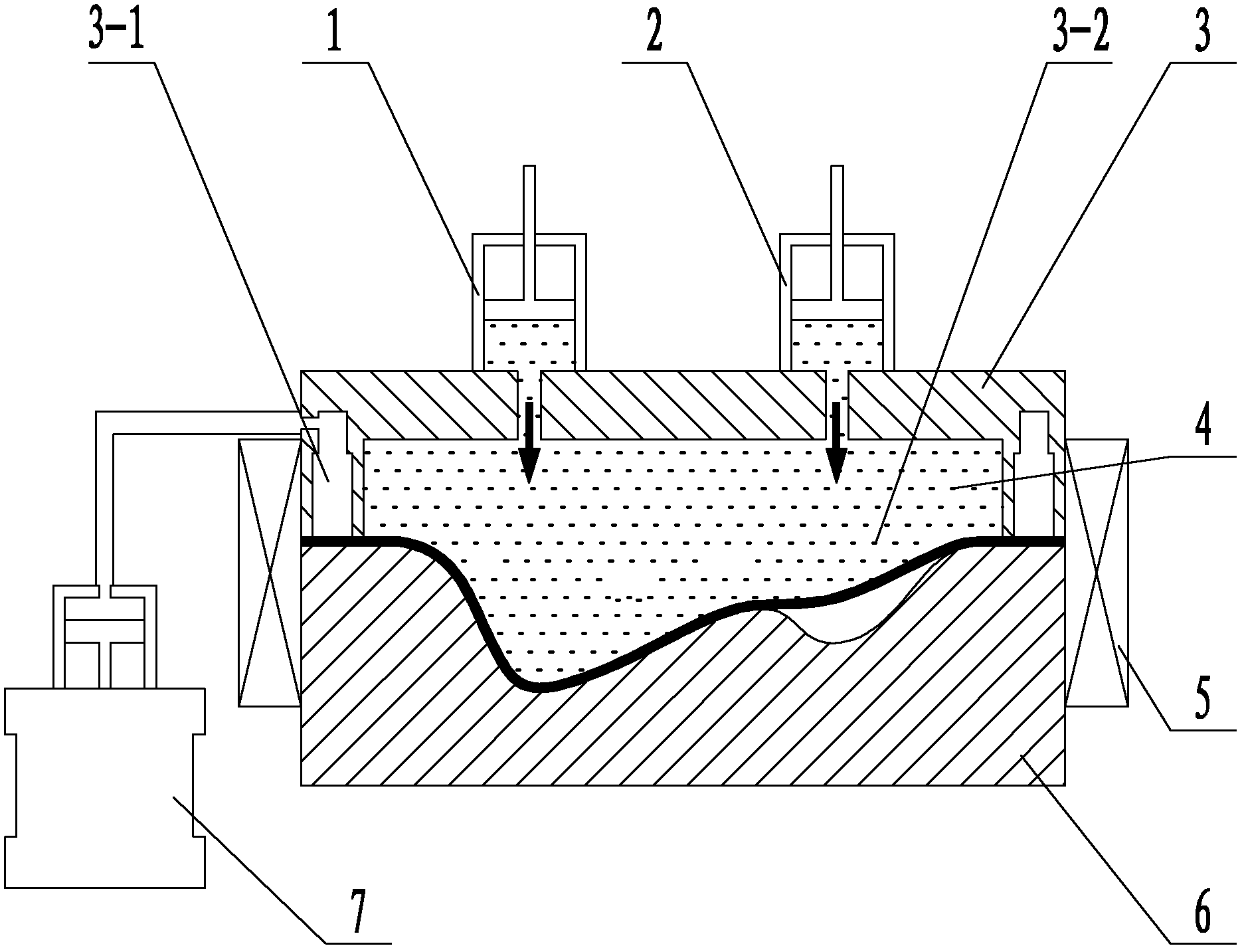

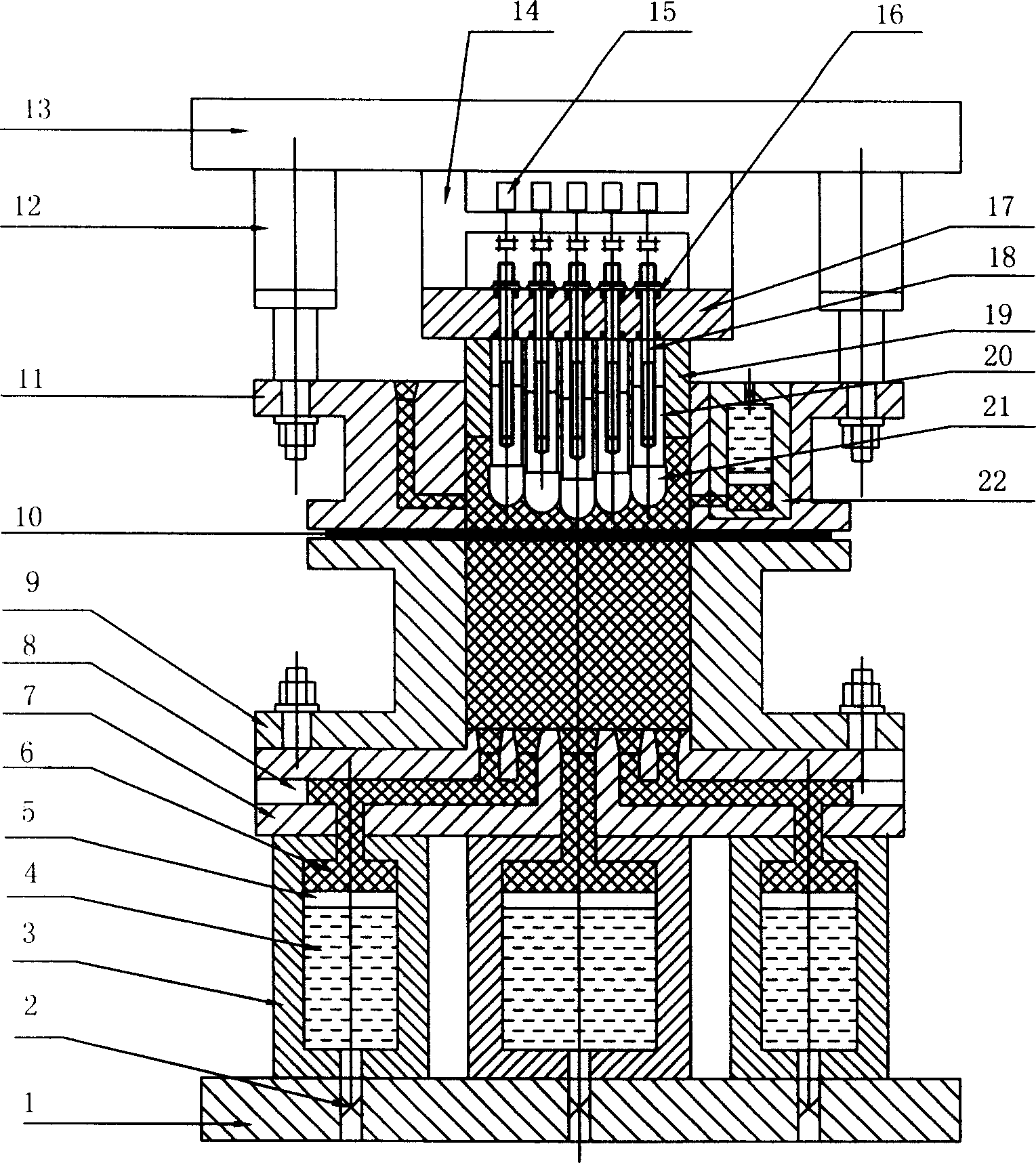

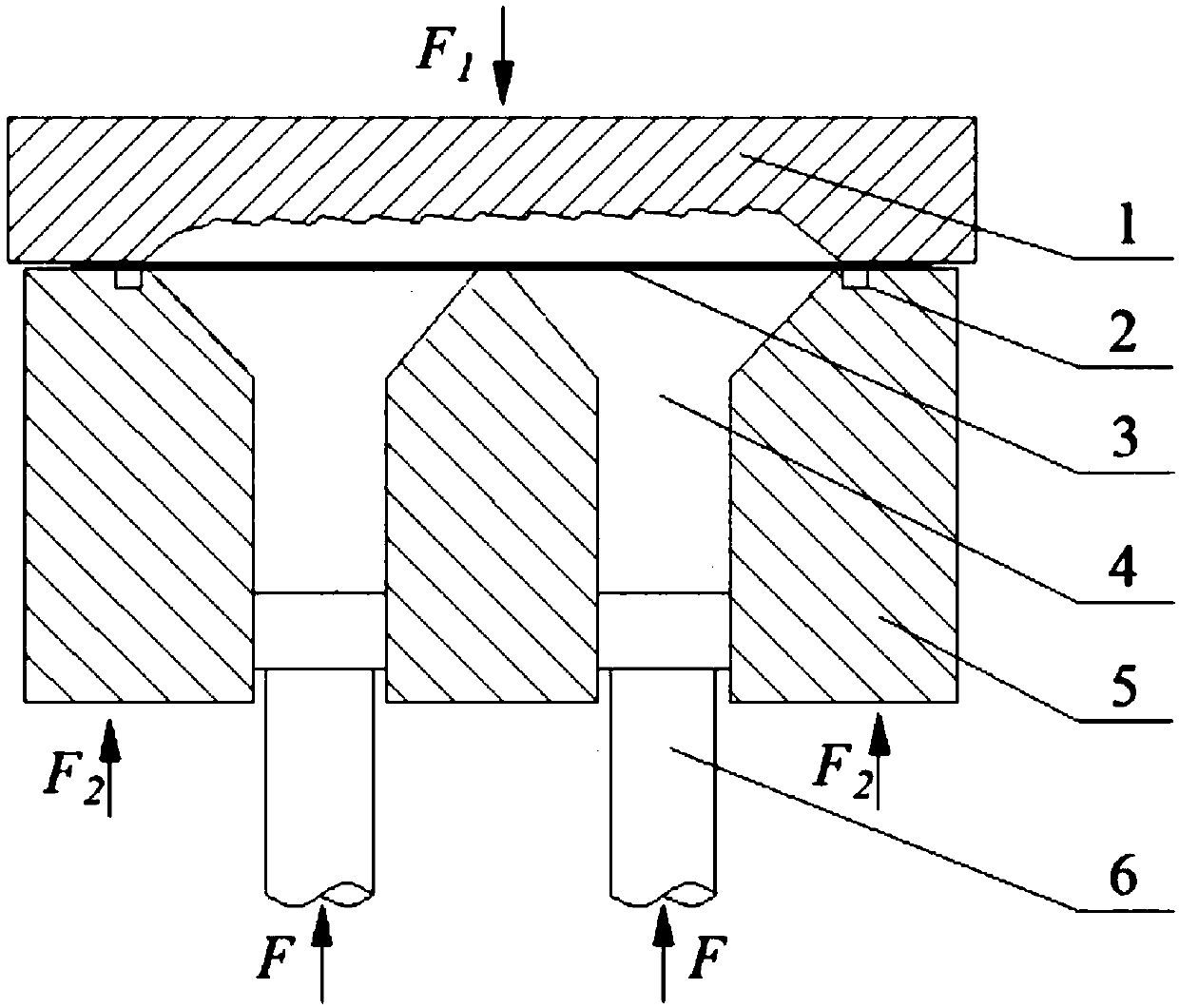

Magnetorheological fluid flexible die forming device and magnetorheological fluid flexible die forming method for plates

ActiveCN102615164ARaise the forming limitOptimize deformation flowPress ramElectricityMagnetorheological fluid

The invention relates to a plate forming device and a plate forming method, in particular to a magnetorheological fluid flexible die forming device and a magnetorheological fluid flexible die forming method for plates, which aims to solve the problem that existing hydraulic forming, semisolid viscous medium pressure forming and polyurethane rubber forming are suitable for certain plate forming range respectively and advantages of the three cannot be combined in a plate forming process. The forming device comprises a first magnetorheological fluid injection cylinder, a second magnetorheological fluid injection cylinder, a magnetorheological fluid container, magnetorheological fluids, solenoids, a die, a side pressing cylinder, a third magnetorheological fluid injection cylinder and a fourth magnetorheological fluid injection cylinder. During the forming process, the first magnetorheological fluid injection cylinder and the second magnetorheological fluid injection cylinder injects the magnetorheological fluids into a first cavity, magnetic field intensity of the magnetorheological fluids region is changed through regulating electricity, and then shapes needed of the plates to be formed can be formed. The magnetorheological fluid flexible die forming device and the magnetorheological fluid flexible die forming method for plates are applicable to the field of plate forming.

Owner:HARBIN INST OF TECH

Processes for dispersing substances and preparing composite materials

InactiveUS20100152326A1Improve dispersion stabilityGood dispersionOther chemical processesOrganic dyesNanoparticleCarbon nanotube

Disclosed herein are processes for dispersing a plurality of unaggregated particles, such as nanoparticles and microparticles, in a viscous medium. The dispersions can be used for making a variety of useful materials, such as carbon nanotube composites.

Owner:MINUSNINE TECH

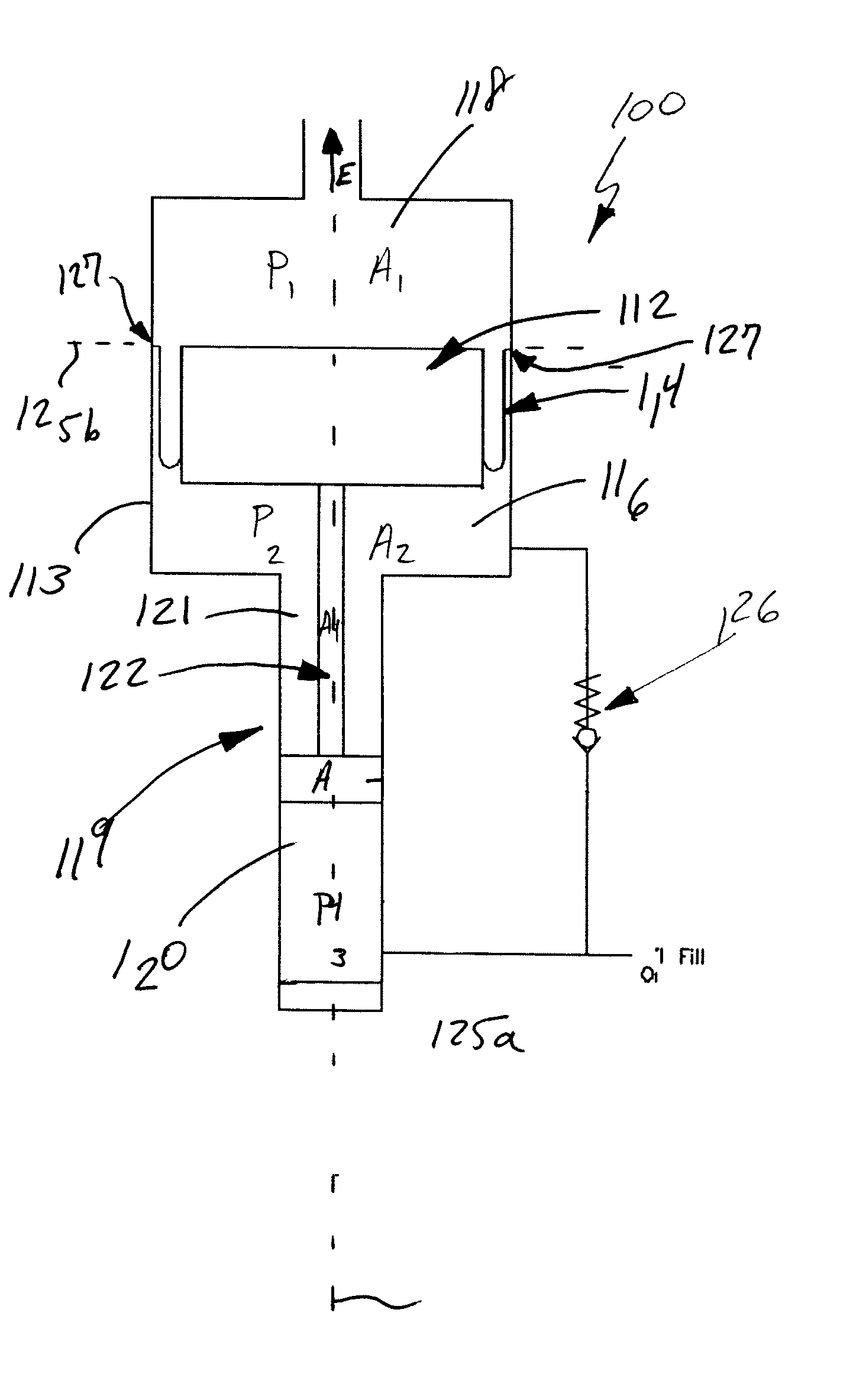

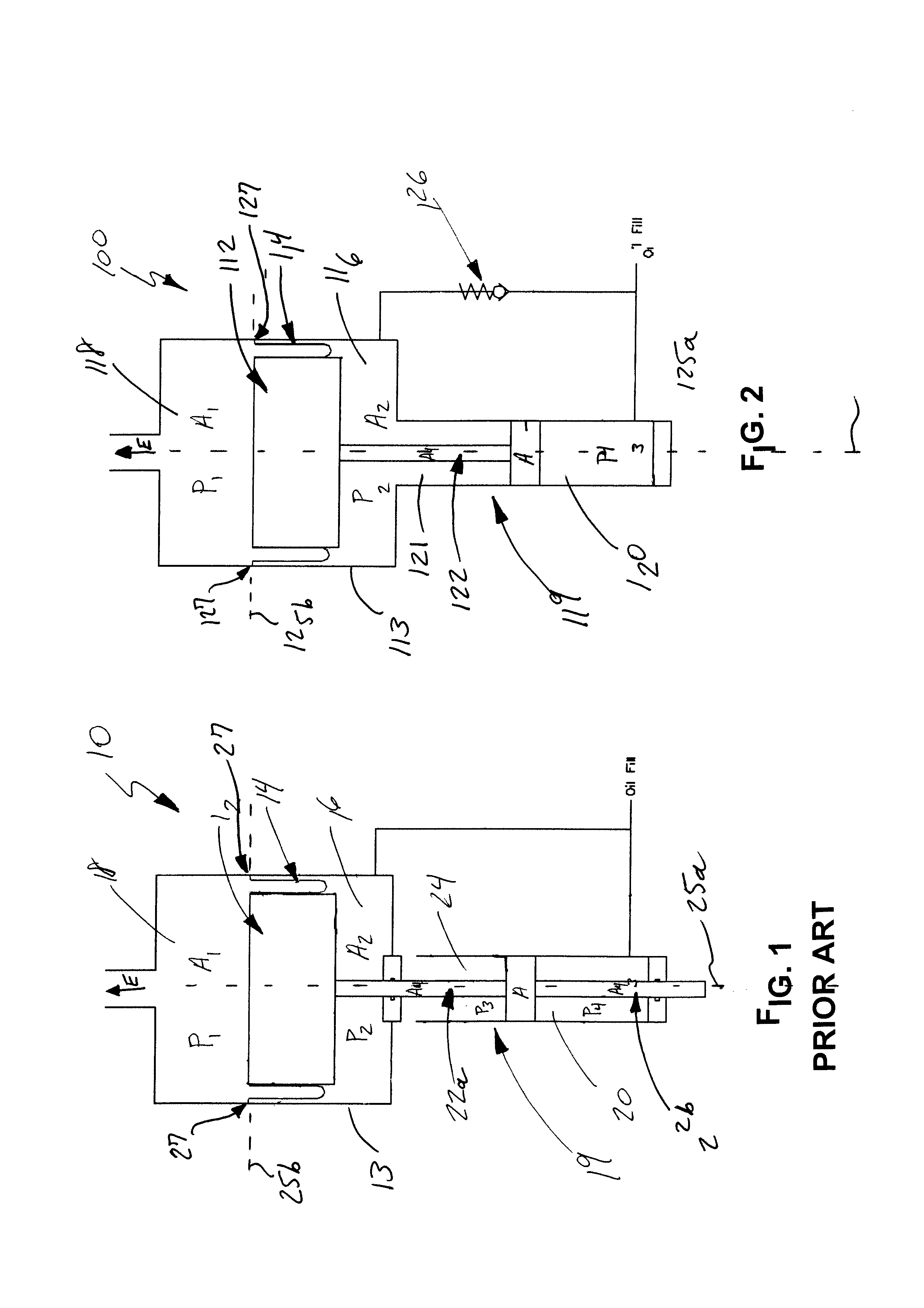

Rolling diaphragm pump

InactiveUS20080260551A1Increased pressure rangeVariable controlFlexible wall reciprocating enginesFlexible member pumpsDiaphragm pumpWorking fluid

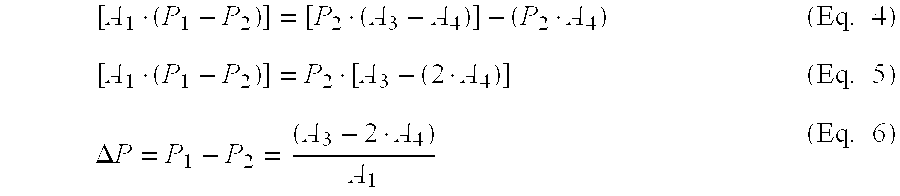

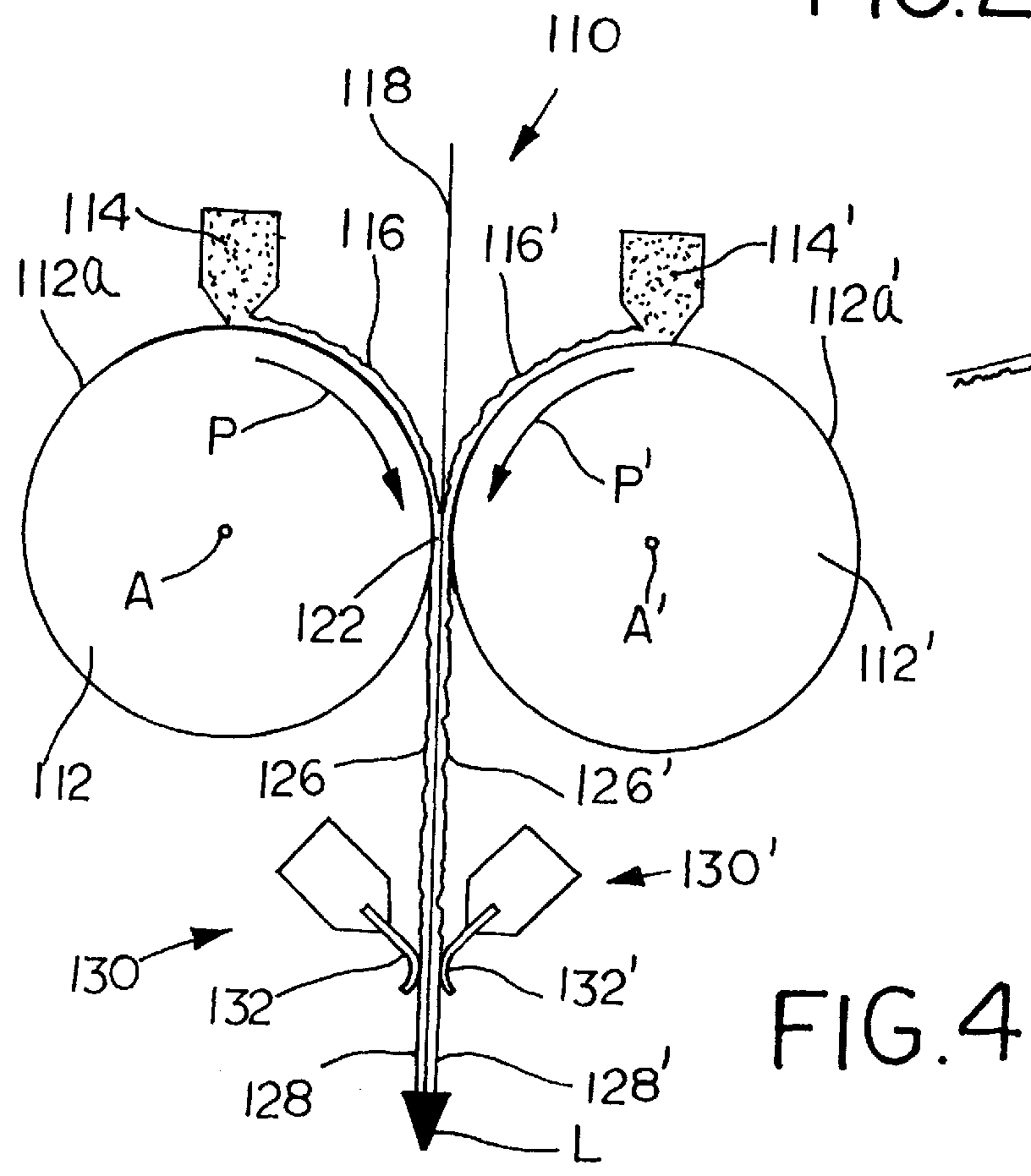

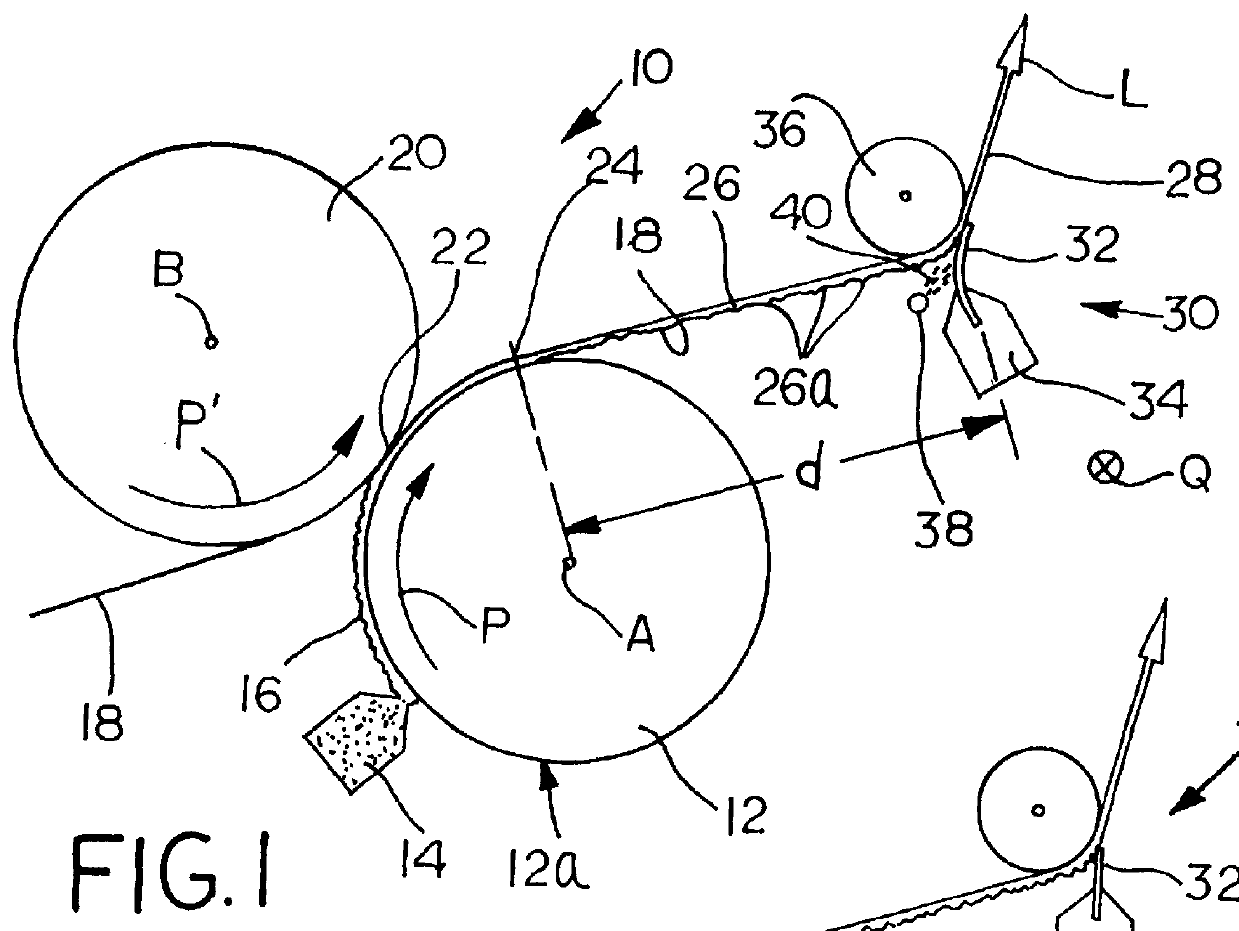

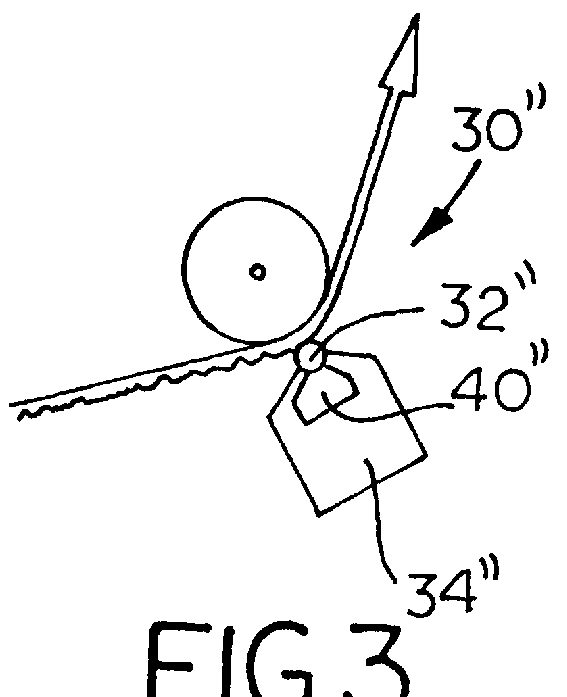

A rolling diaphragm pump includes a housing, a rolling seal diaphragm disposed in the housing, a piston for driving the diaphragm, and a valve for regulating the flow of working fluid in a portion of the housing. A constant differential pressure is maintained across the diaphragm independent of discharge pressure of the pump. A method of pumping a viscous medium includes pumping the viscous medium by maintaining a constant differential pressure across a rolling seal diaphragm independent of discharge pressure of the viscous medium, with the diaphragm disposed between the viscous medium and a working medium and being driven by a piston.

Owner:TERRASIMCO

Device used to indirectly apply a liquid or viscous medium onto a material web, specifically a paper or cardboard web

InactiveUS6126750AEvenly layeredAvoid pollutionLiquid surface applicatorsMachine wet endCardboardEngineering

A device for indirect application of a liquid or viscous medium onto a traveling material web, specifically a paper or cardboard web, includes an applicator device for the application of a layer of liquid or viscous medium onto a surface of a transfer element. The transfer element is in contact with the moving material web and transfers the coating onto the web. A leveling unit is equipped with a leveling element positioned against the material web for smoothing of the coating layer on the material web. The leveling element is mounted rigidly in cross direction to the material web, that is, in a direction substantially orthogonal and in a local material web progression to the direction of travel of the material web.

Owner:VOITH PATENT GMBH

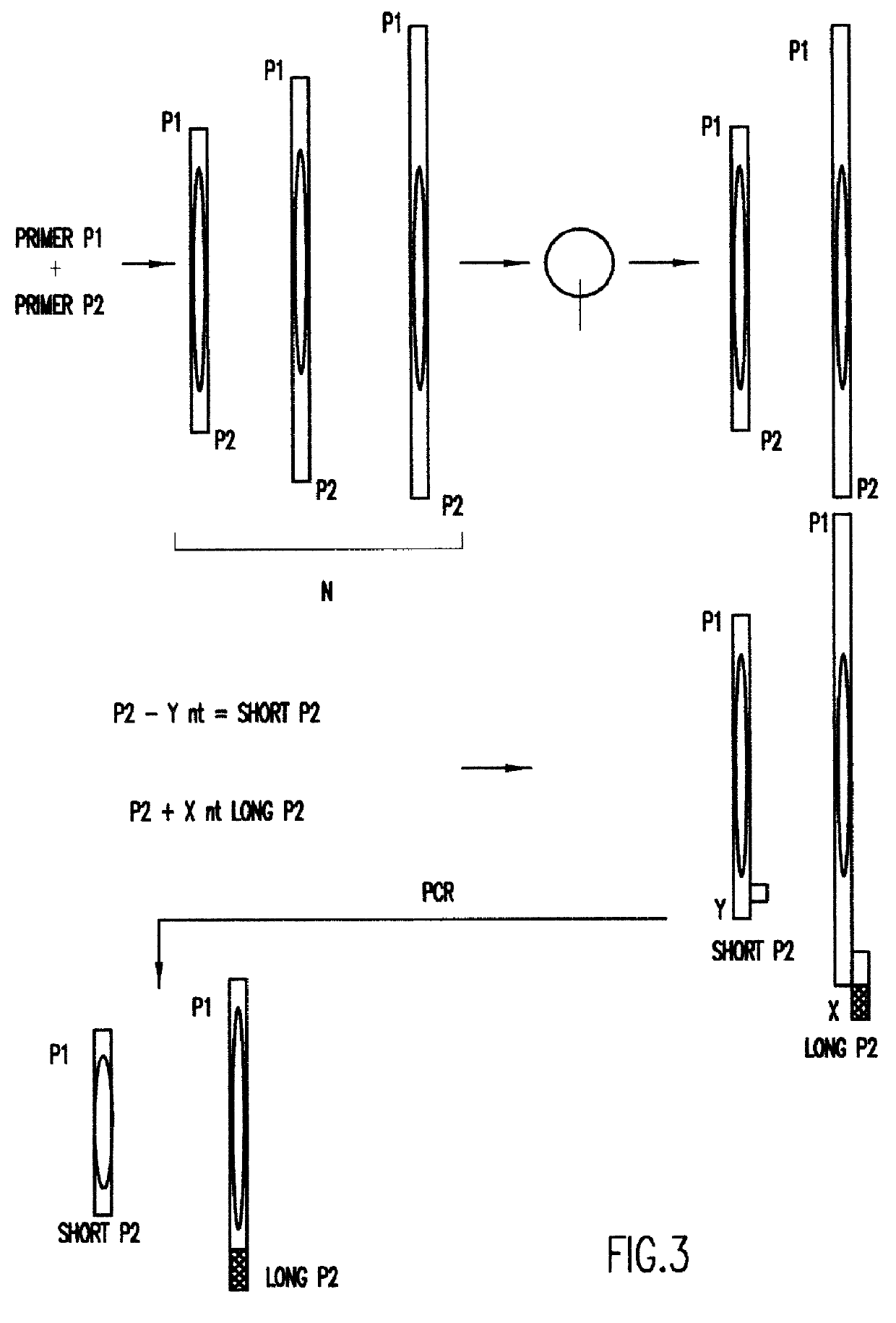

DNA bracketing locus compatible standards for electrophoresis

InactiveUS6013444ABioreactor/fermenter combinationsBiological substance pretreatmentsAssayElectrophoresis

The present invention is directed to an assay system, a kit, and a process for detecting the length of a polymorphic region of a genetic locus by means of bracketing locus compatible or specific calibrating DNA markers upon electrophoresis in a viscous medium.

Owner:OLIGOTRAIL

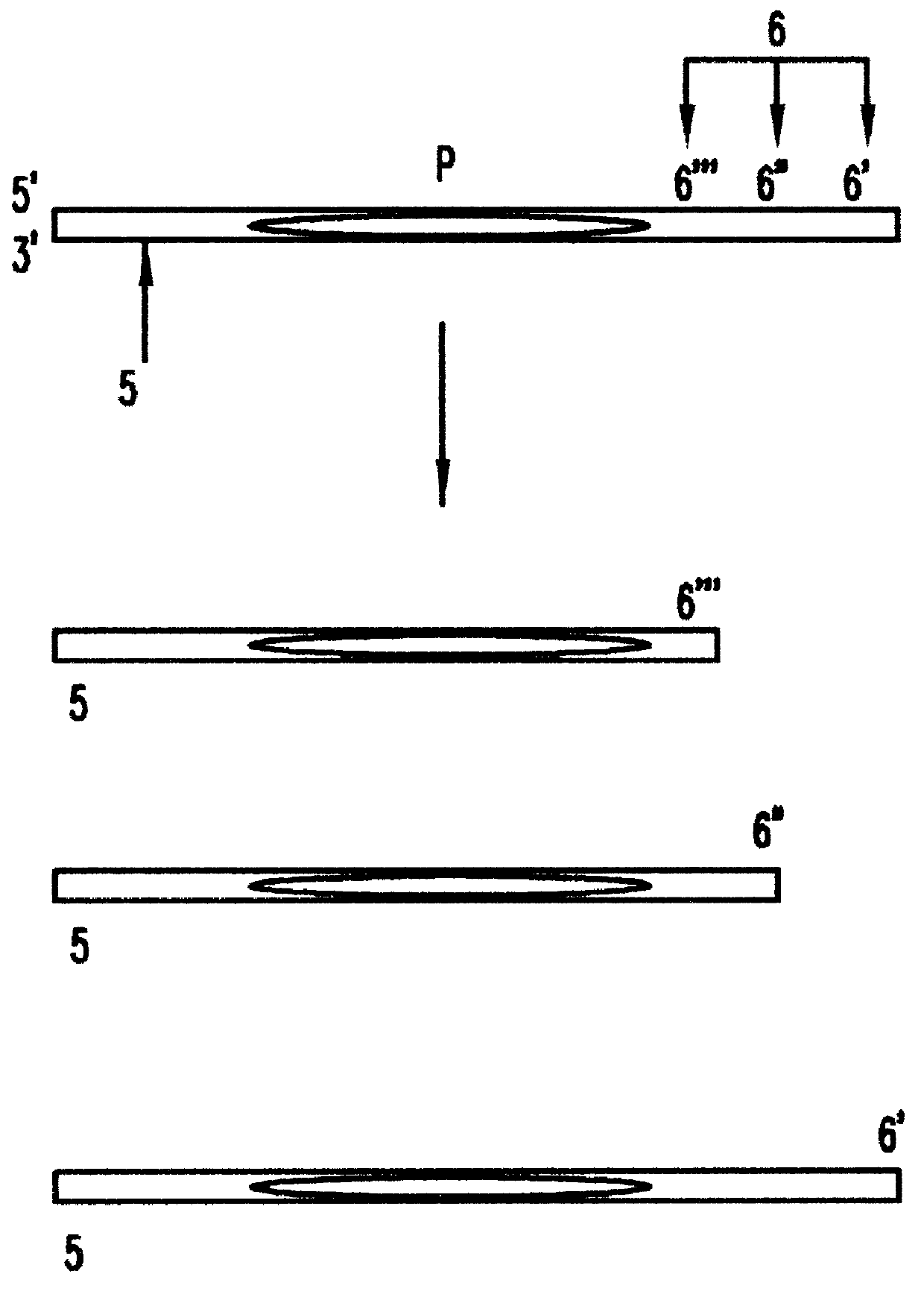

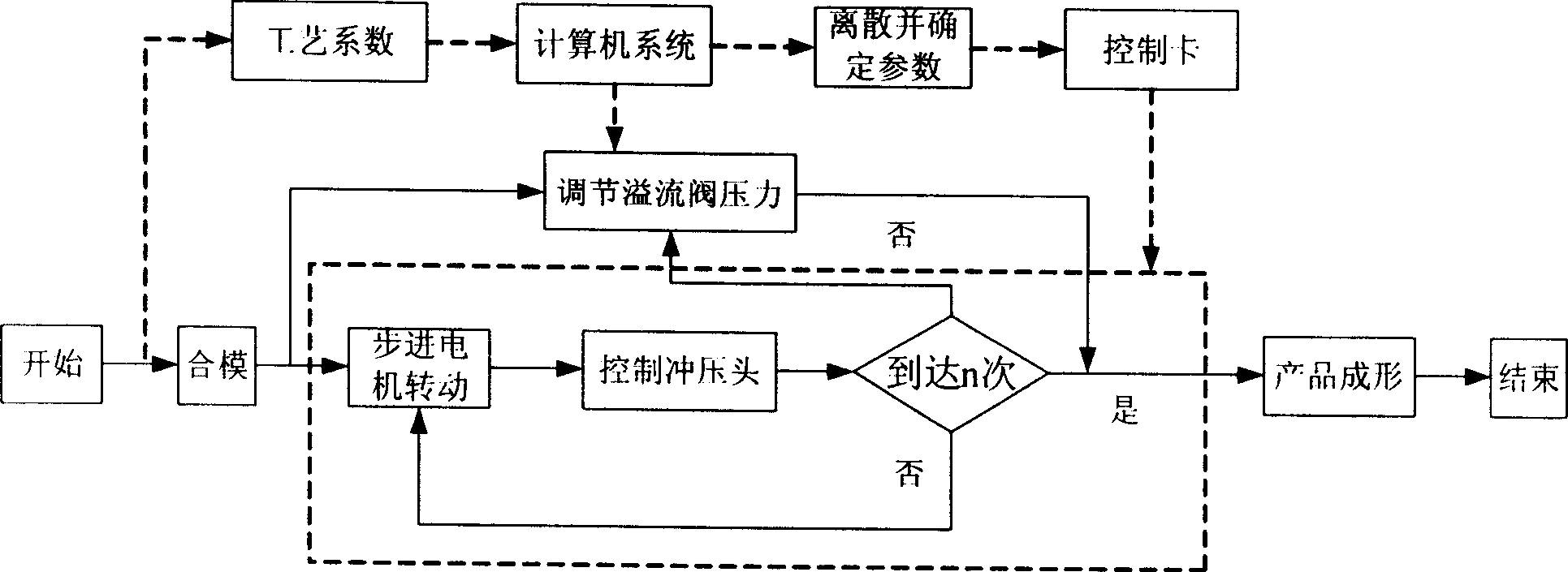

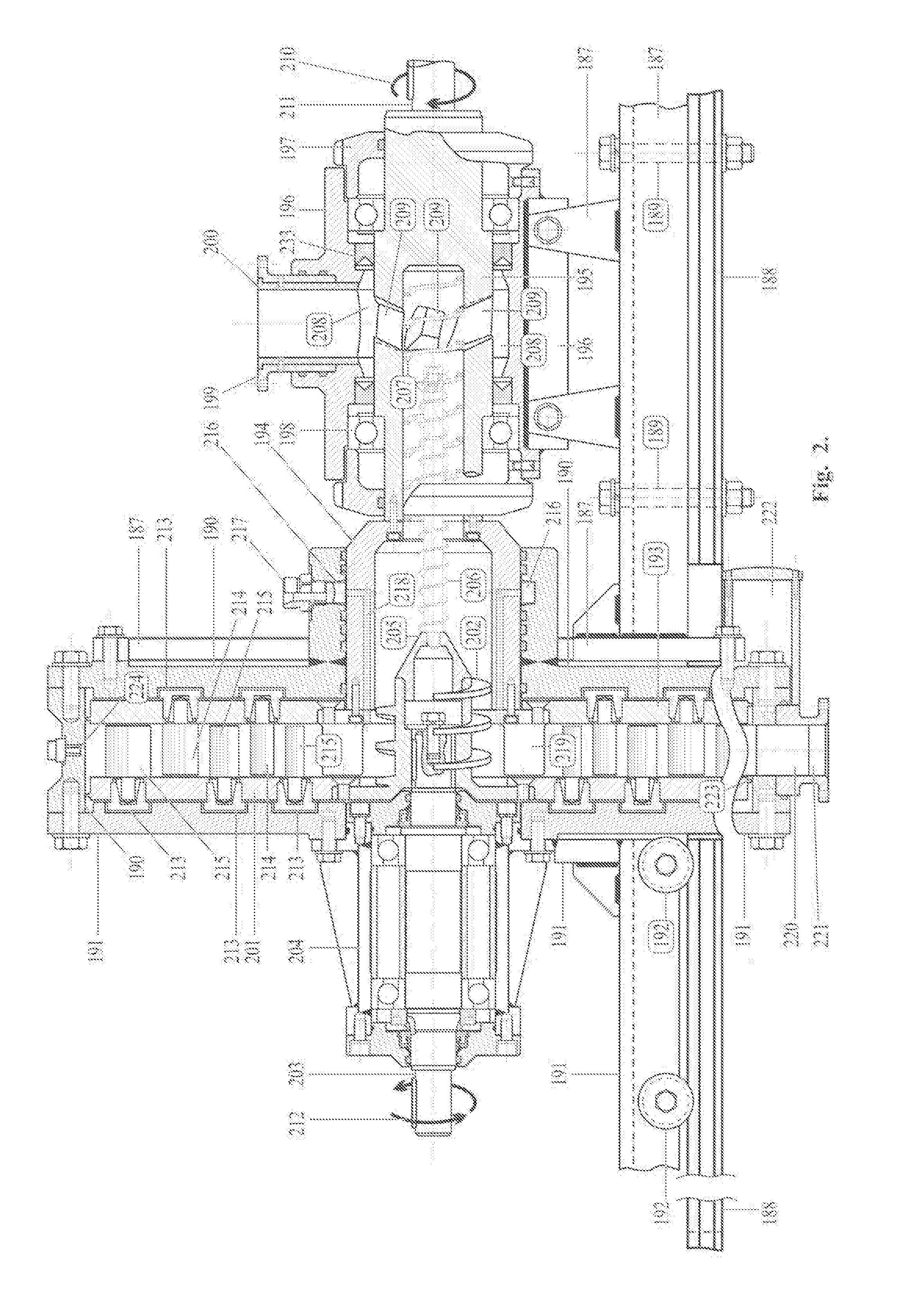

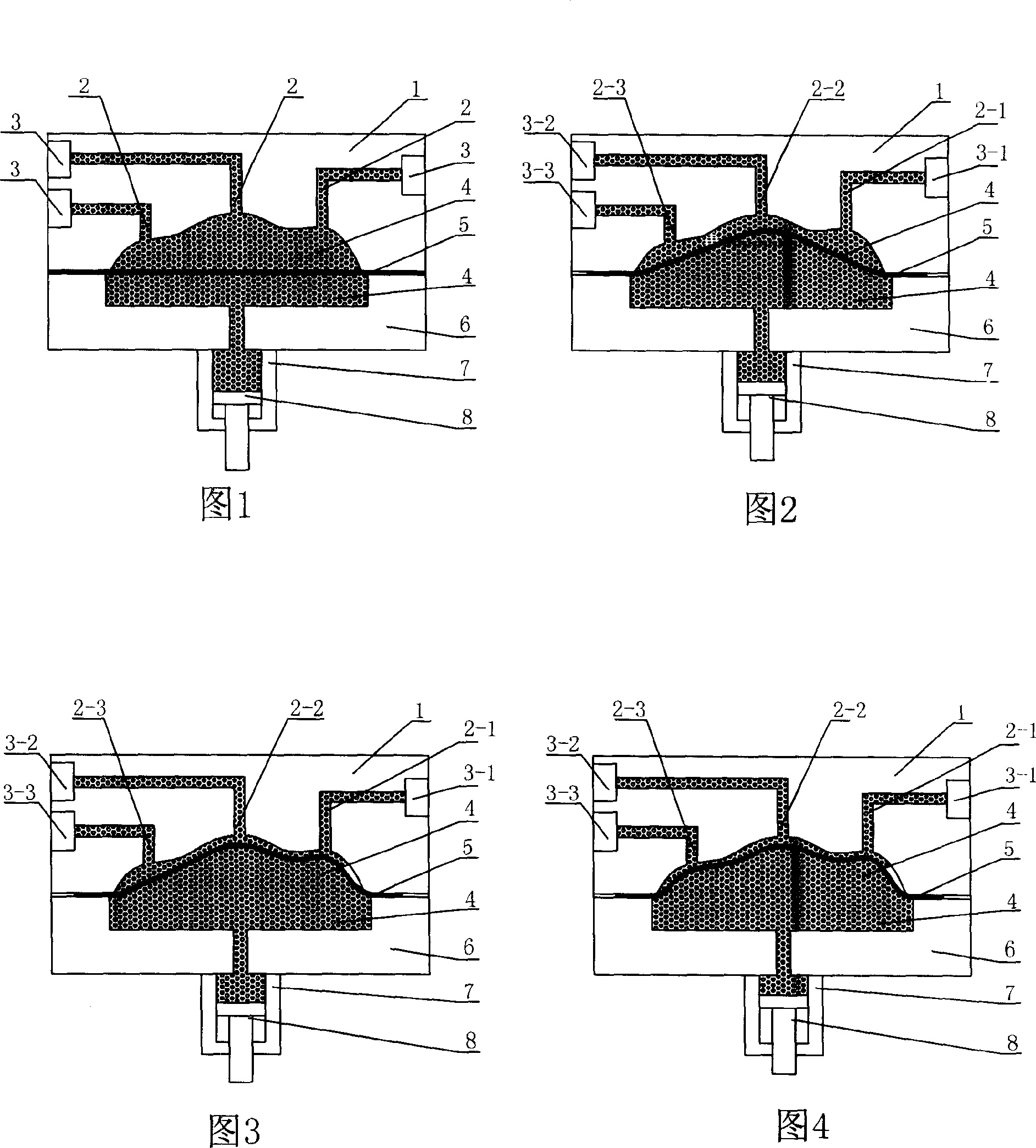

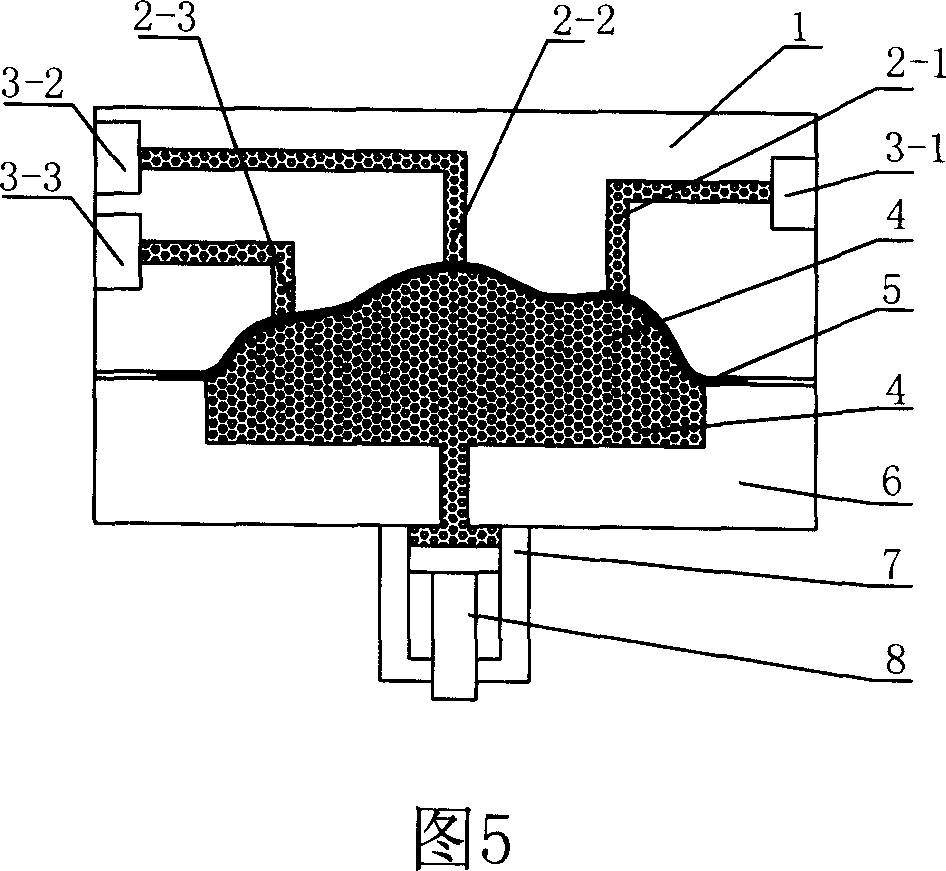

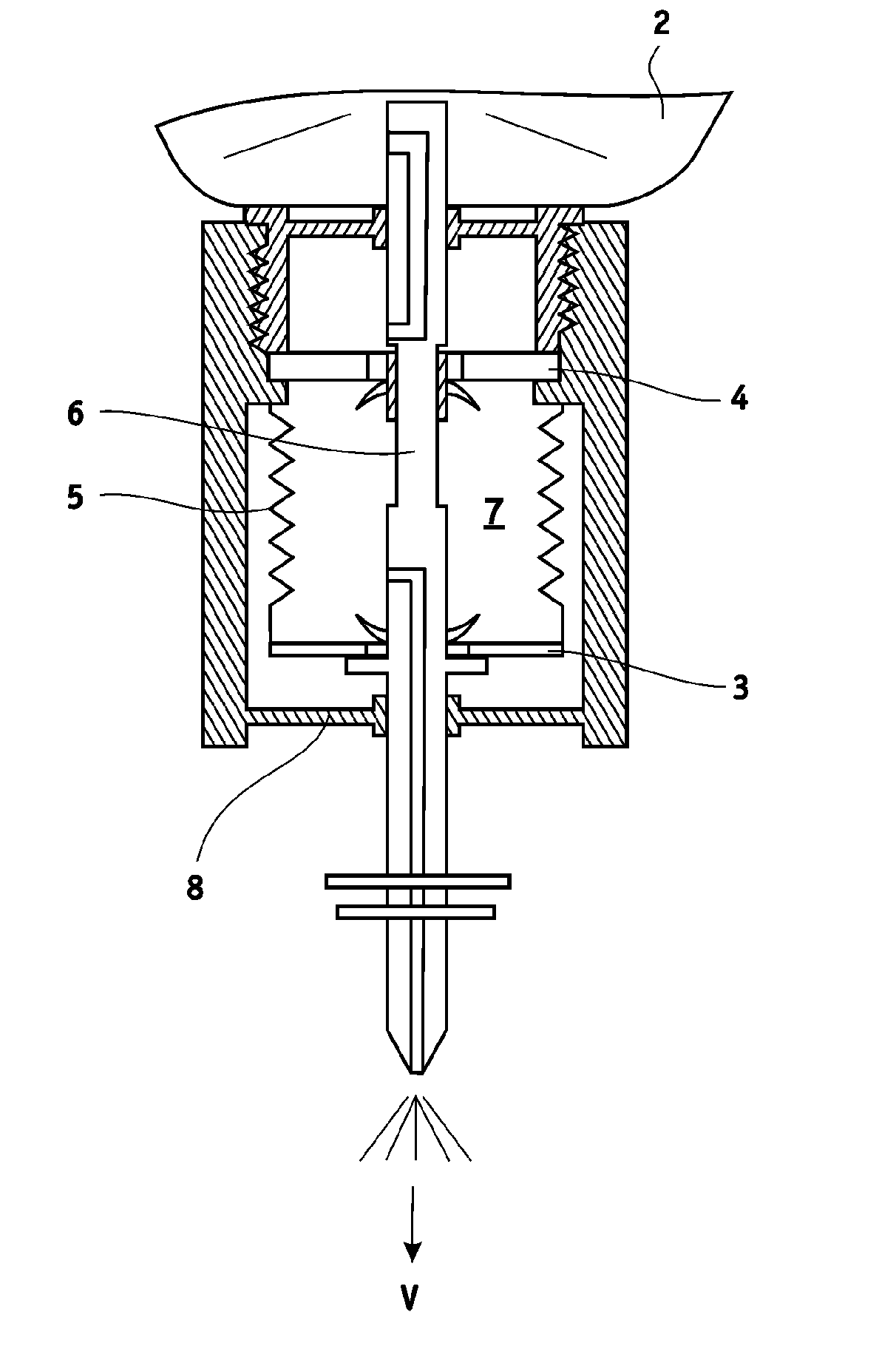

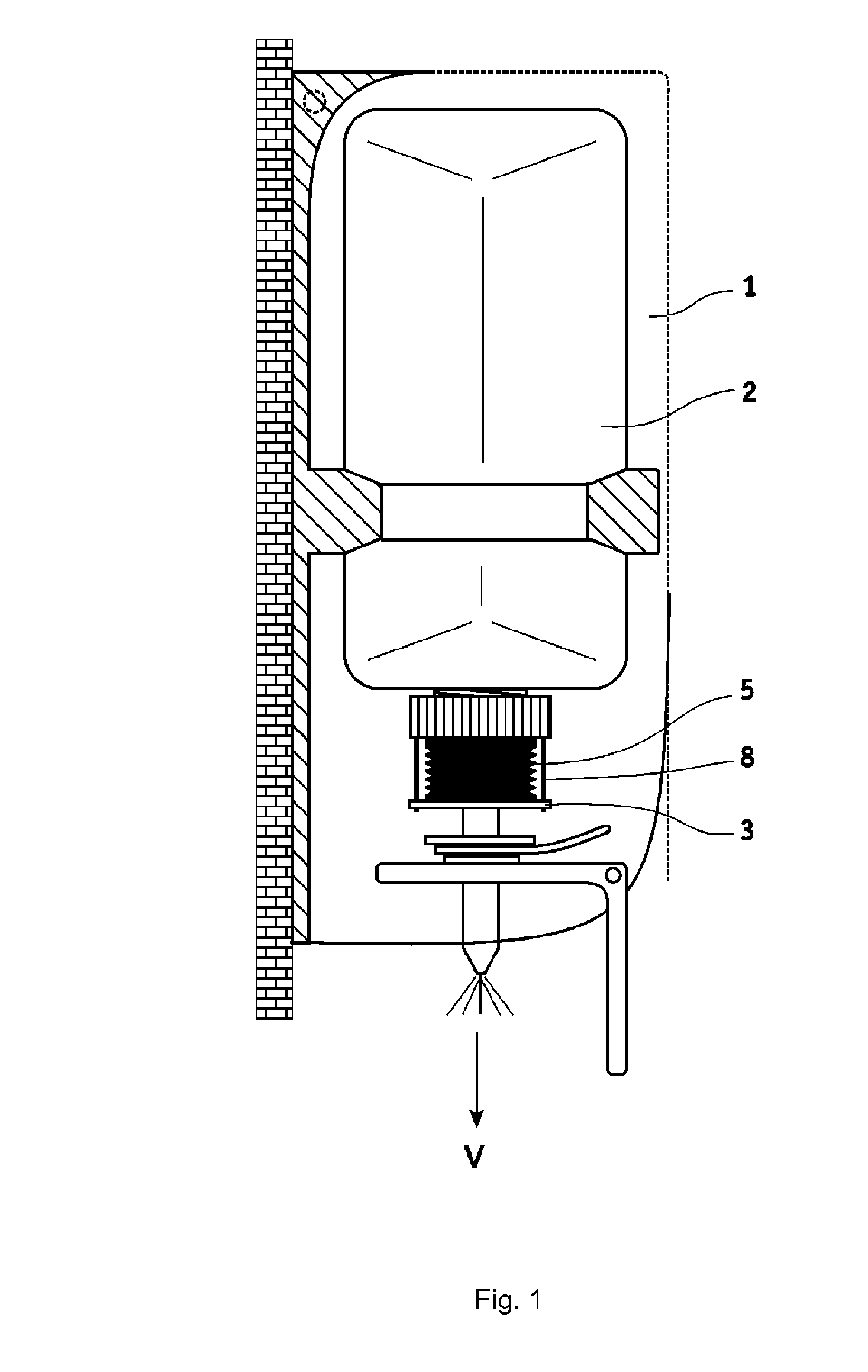

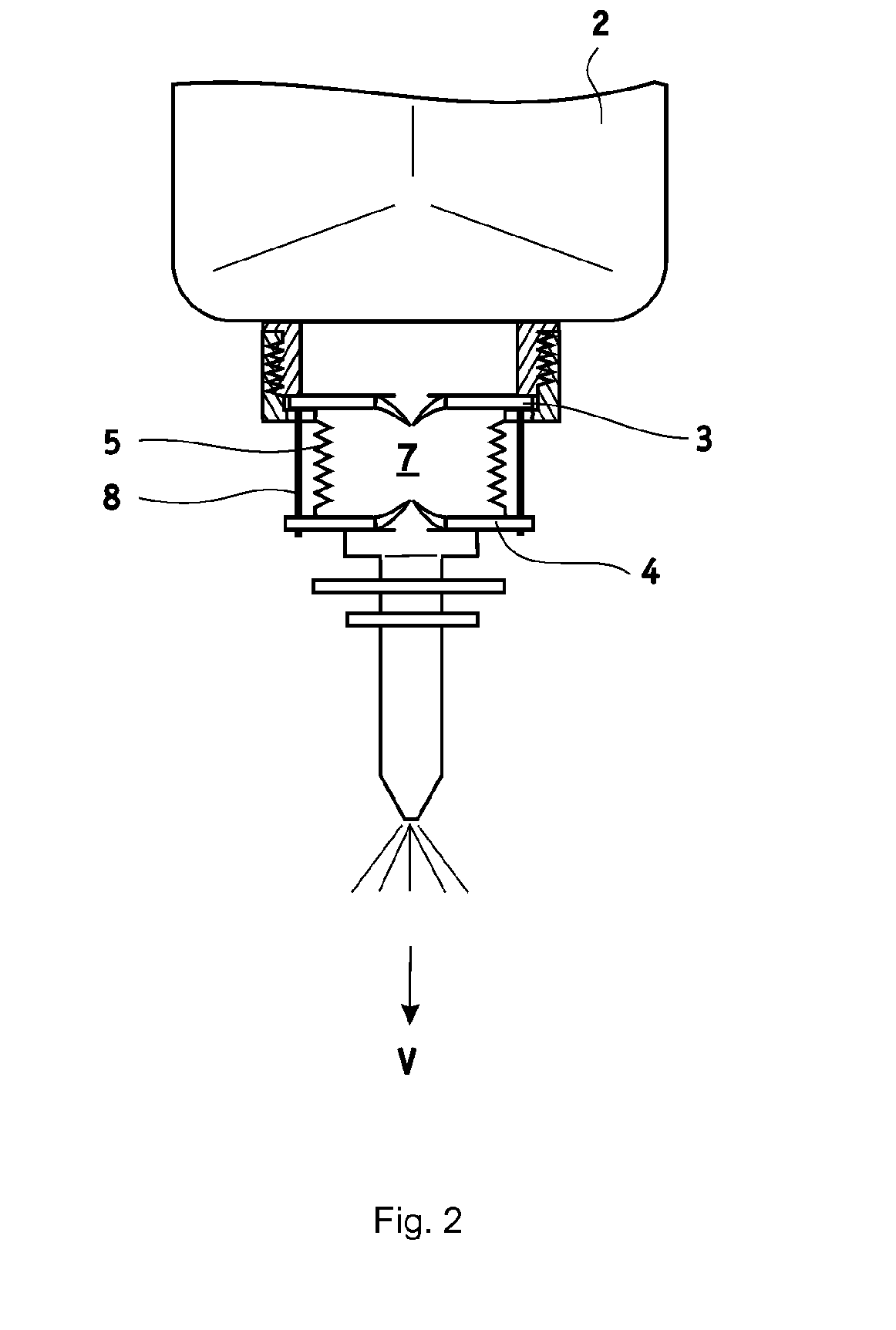

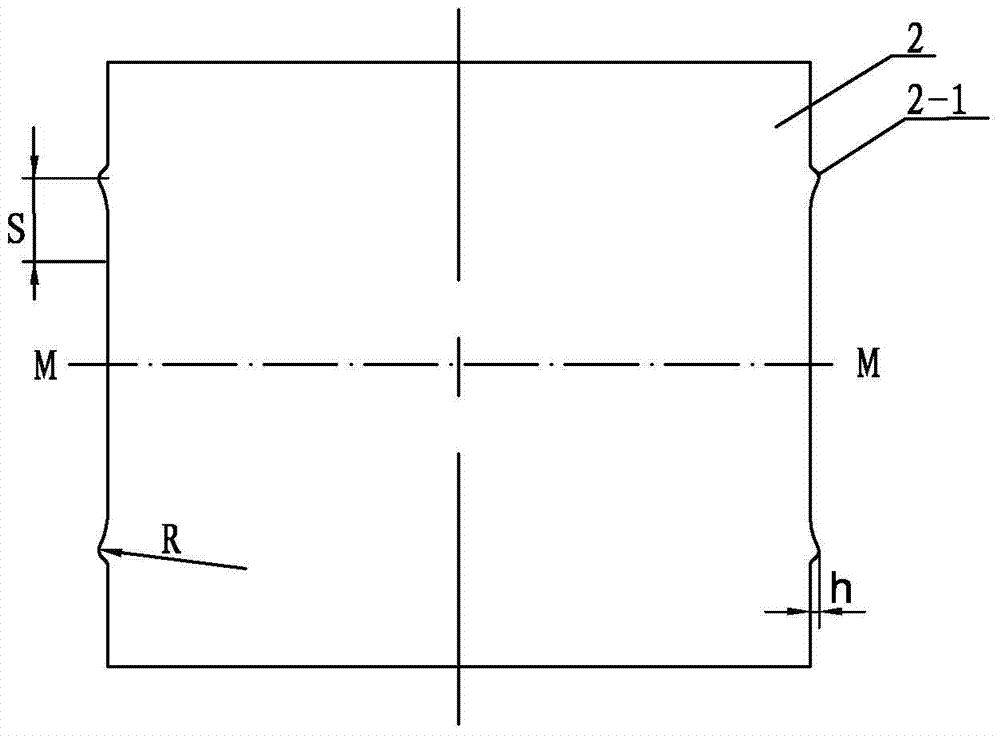

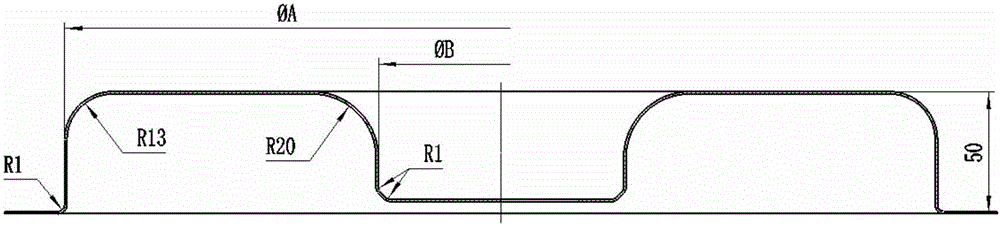

Sheet material mold-free multi-point forming device based on viscous medium transfer force and method

The invention relates to a sheet multipoint molding device and relative method, based on adhesive medium force transmission. Wherein, the lower die cavity is formed by concave mould and the bottom plate of concave mould; the bottom of concave mould has the discharge hole of adhesive medium, which is connected to the cylinder via the channel inside the bottom plate; the fixing compress device is formed by the upper mould, motor, mounting element, convex mounting plate and the punch head connected to the flexible sheath; the flanging ring, convex mould fixing plate, flexible sheath and the punch head form the upper die chamber; the sheet compress device is formed by the upper edge of concave mould and the flanging ring. The invention uses adhesive medium with uniform force transmission, to reduce the producing period, the producing cost, avoid the surface crack caused by rigid mould, while the thickness is uniform.

Owner:重庆工学院

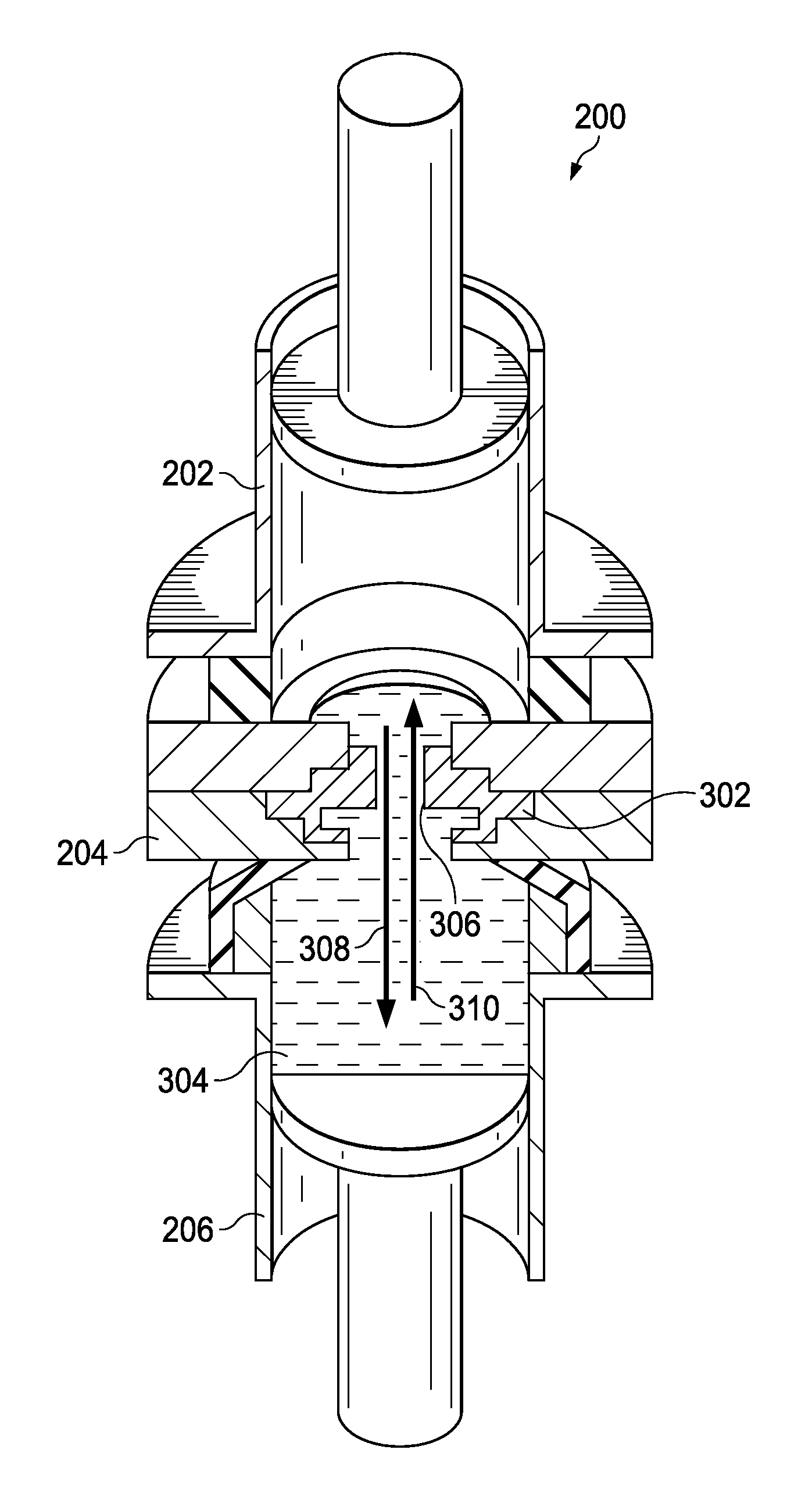

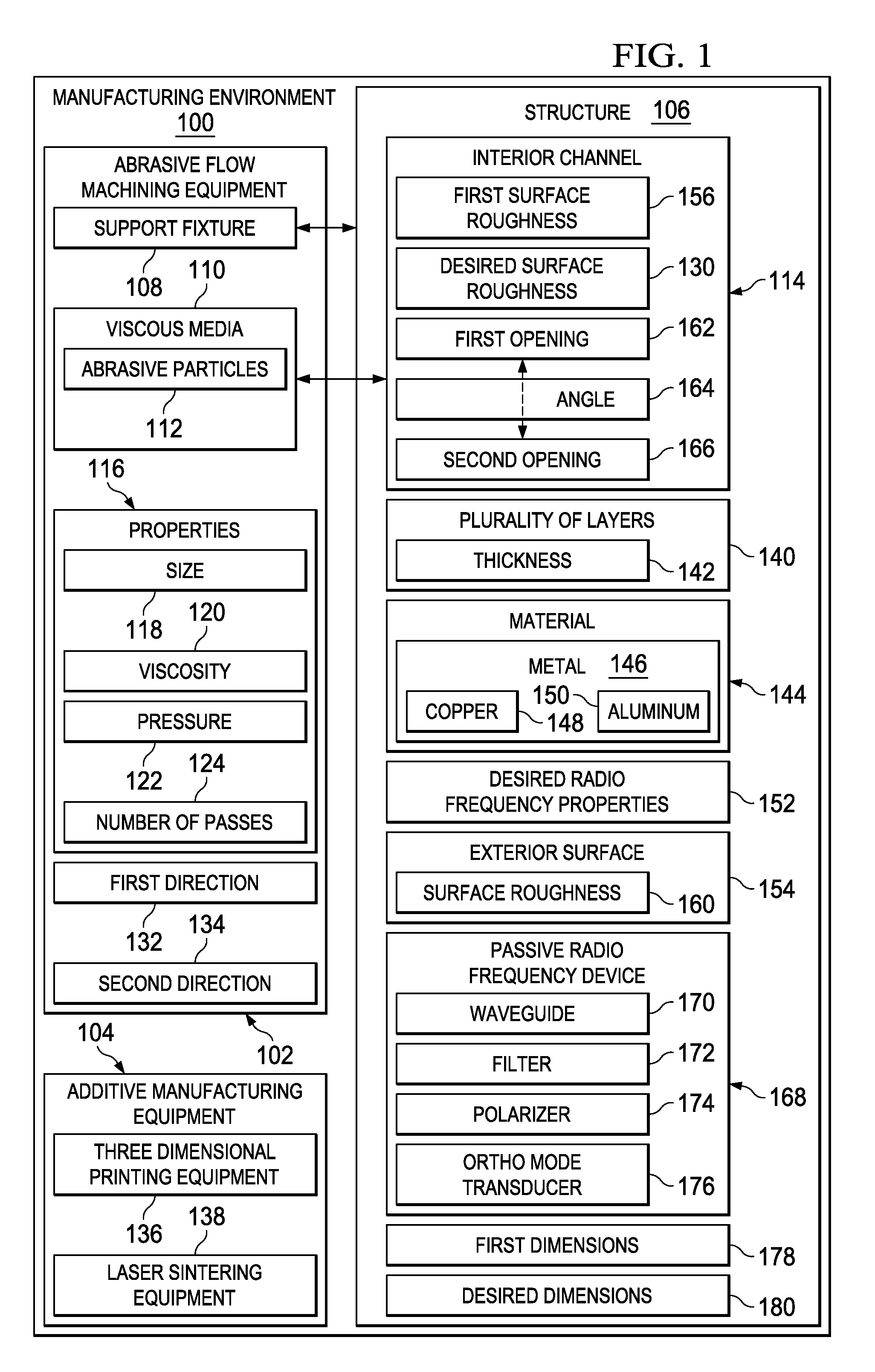

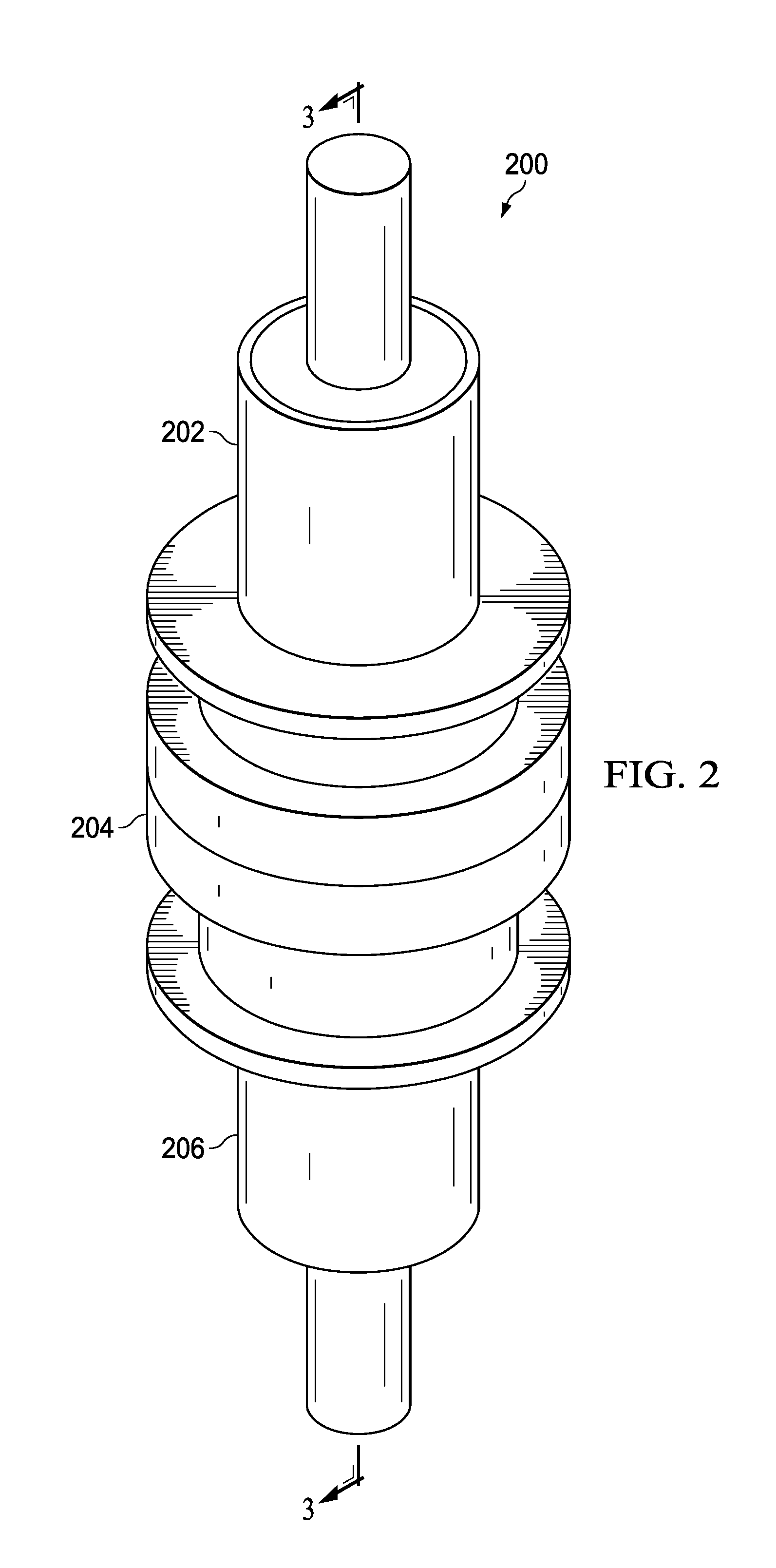

Additive Manufacturing for Radio Frequency Hardware

A method and apparatus is presented. A structure having an interior channel is formed using additive manufacturing equipment. A viscous media containing abrasive particles is sent through the interior channel using abrasive flow machining equipment to form a desired surface roughness for the interior channel.

Owner:THE BOEING CO

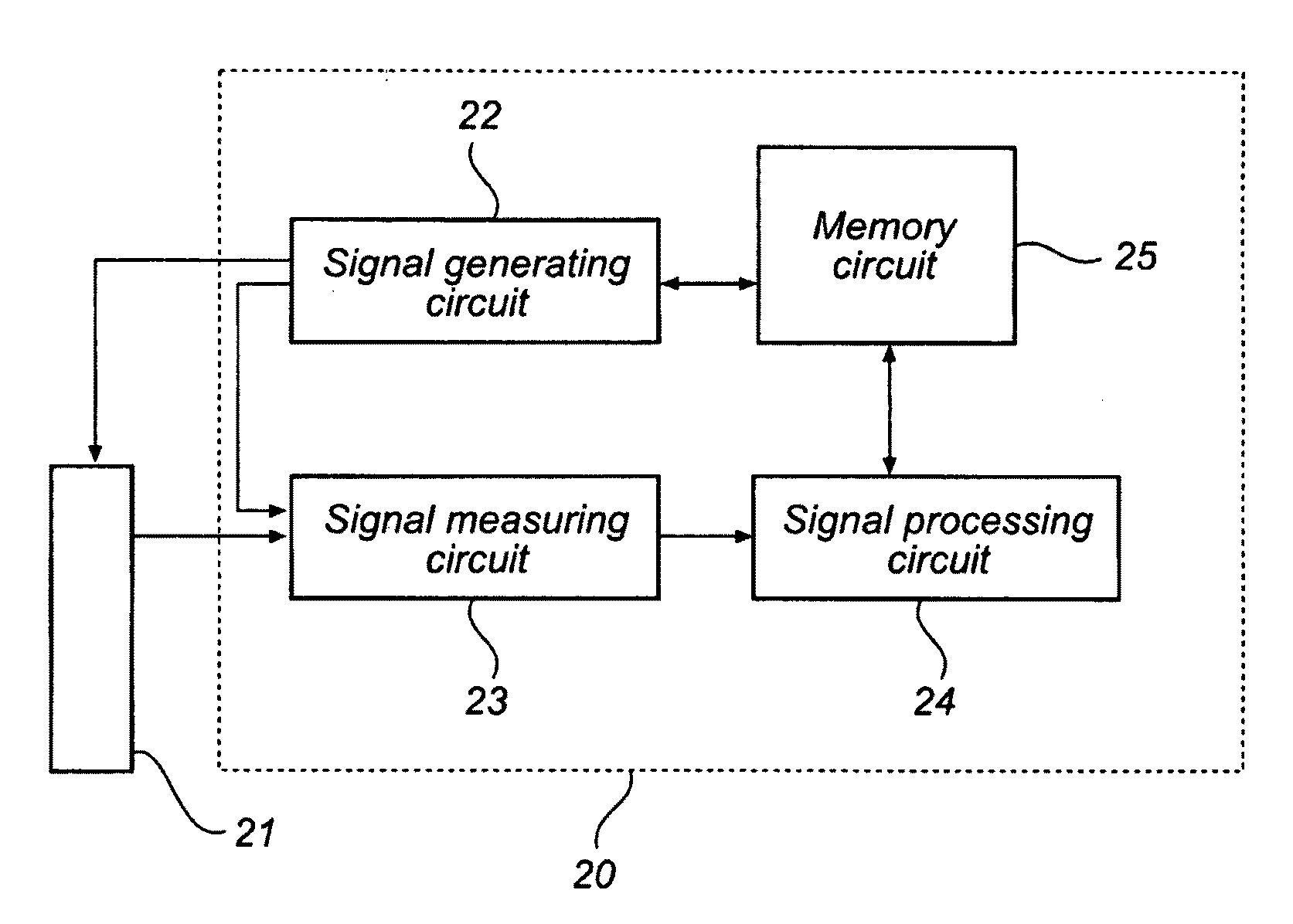

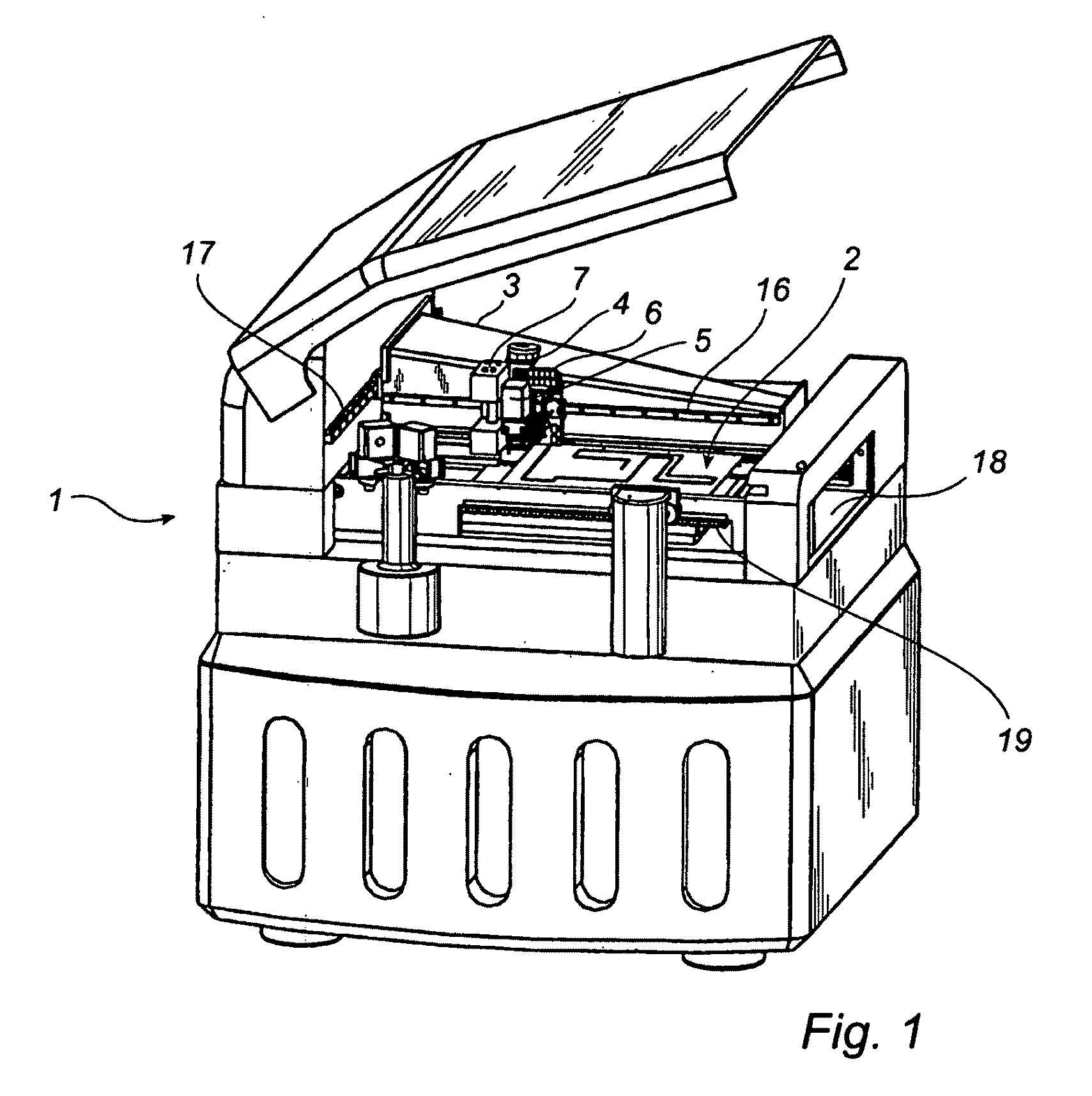

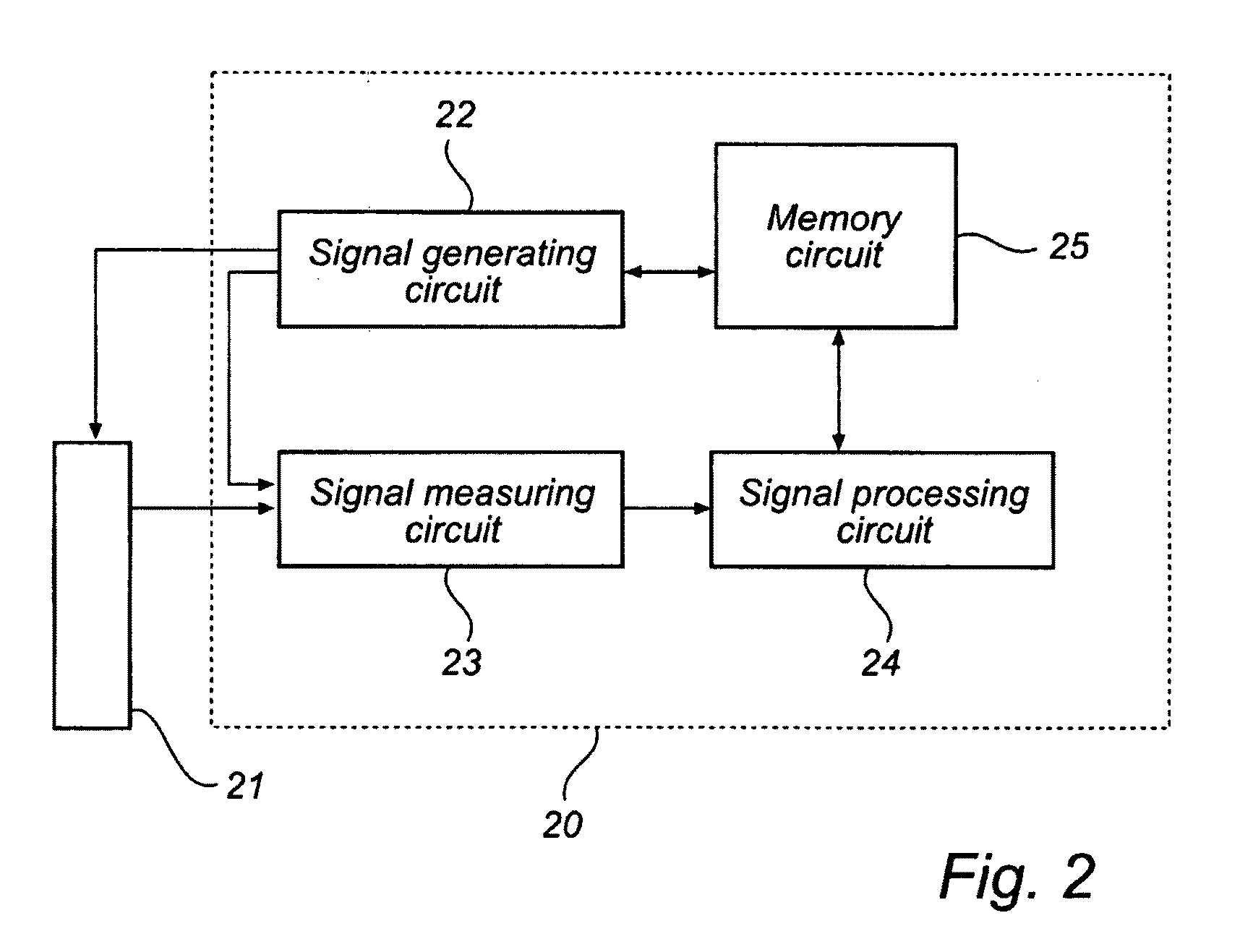

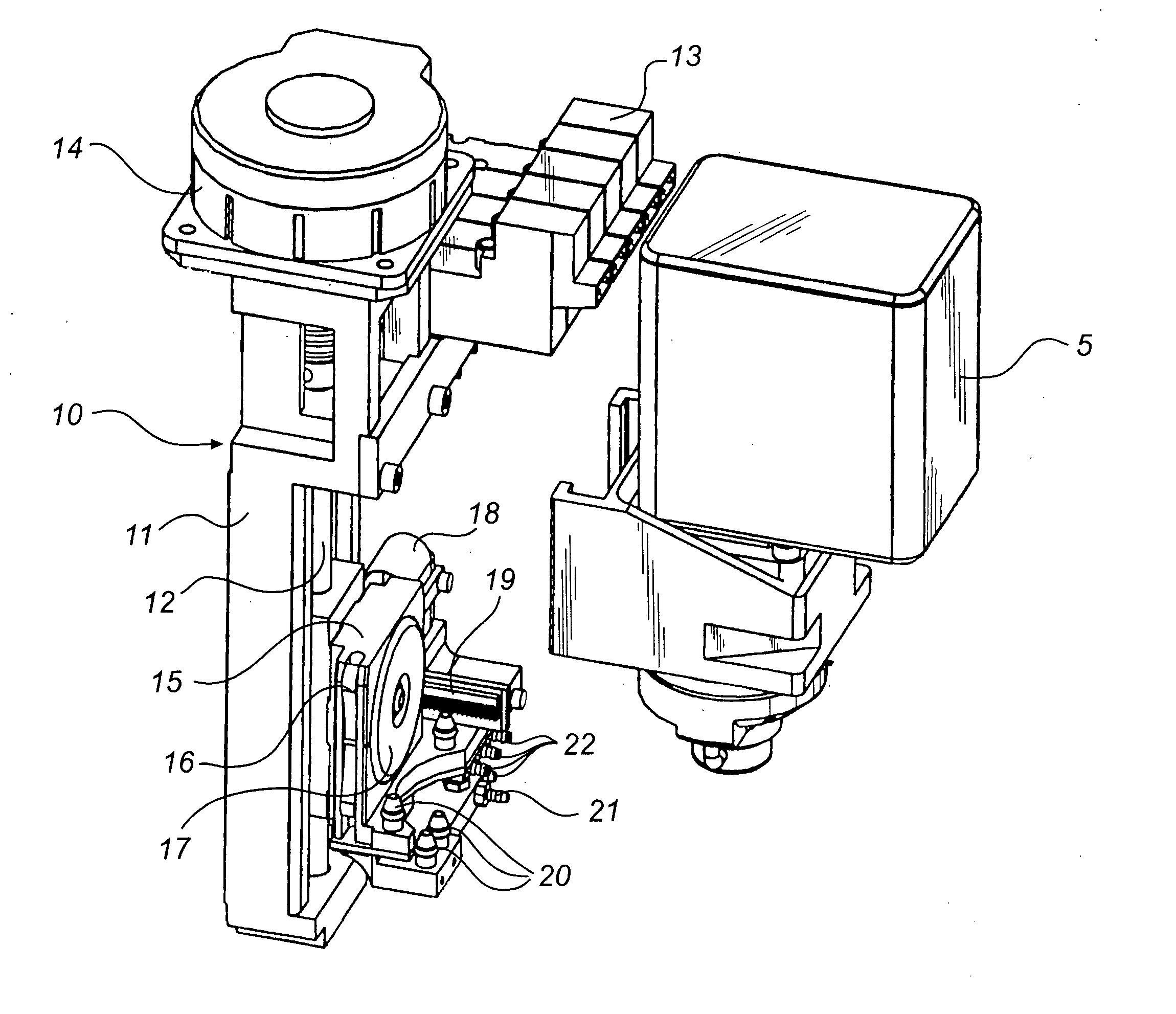

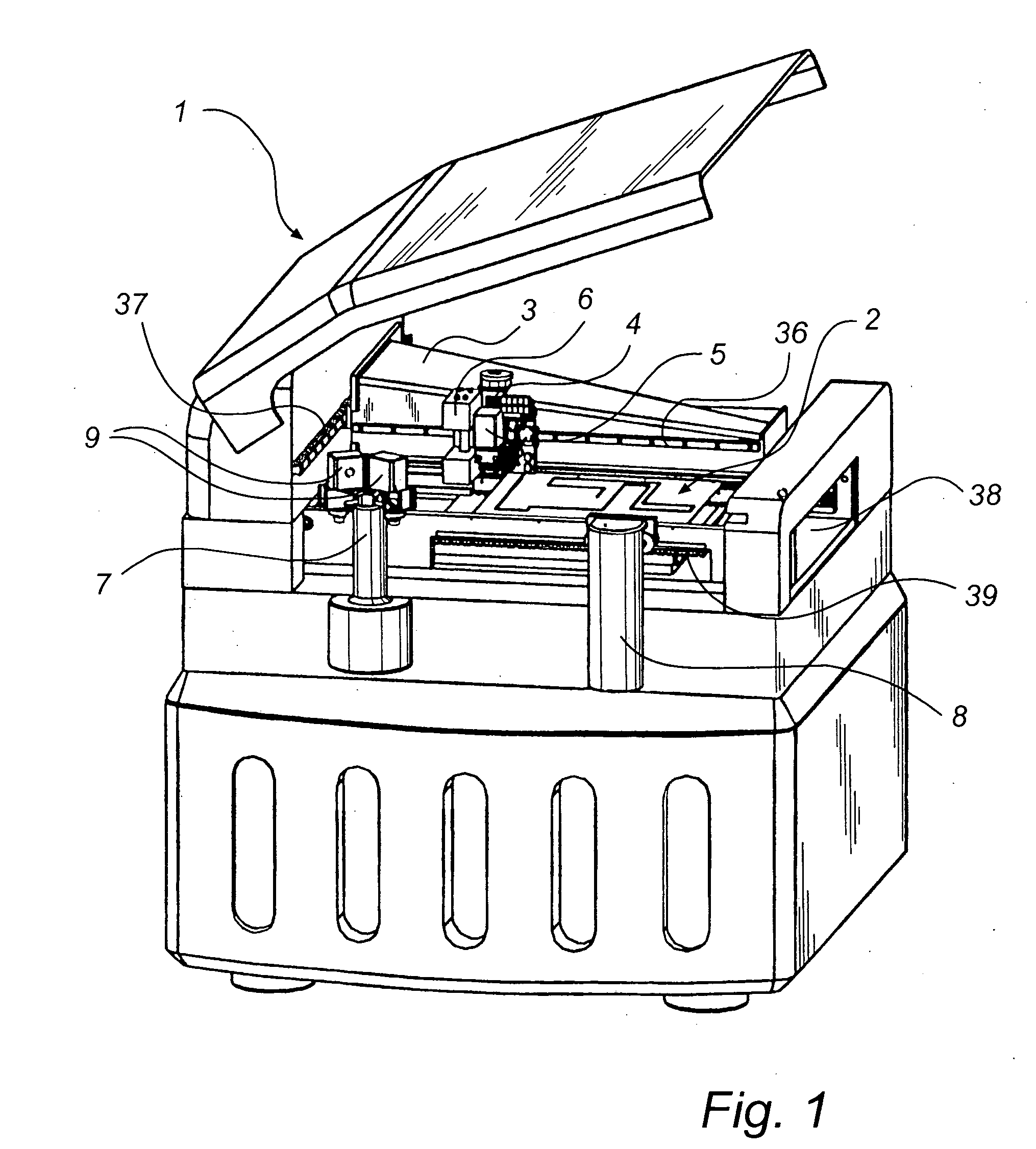

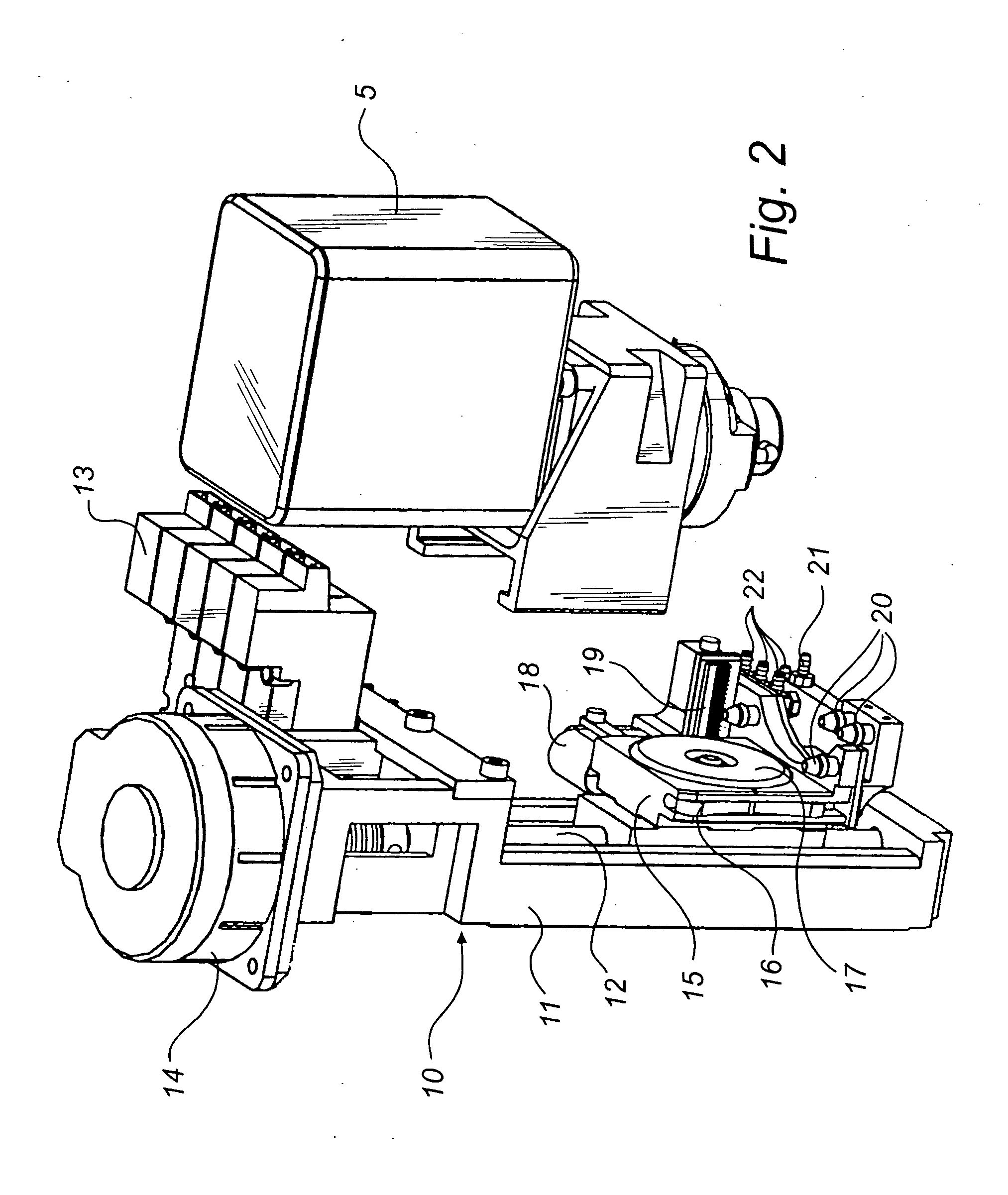

Jetting Apparatus and Method of Improving the Performance of a Jetting Apparatus

InactiveUS20090278875A1Improve device performanceImproved and reliableLiquid surface applicatorsLiquid spraying apparatusMeasurement deviceEngineering

Owner:MYDATA AUTOMATION

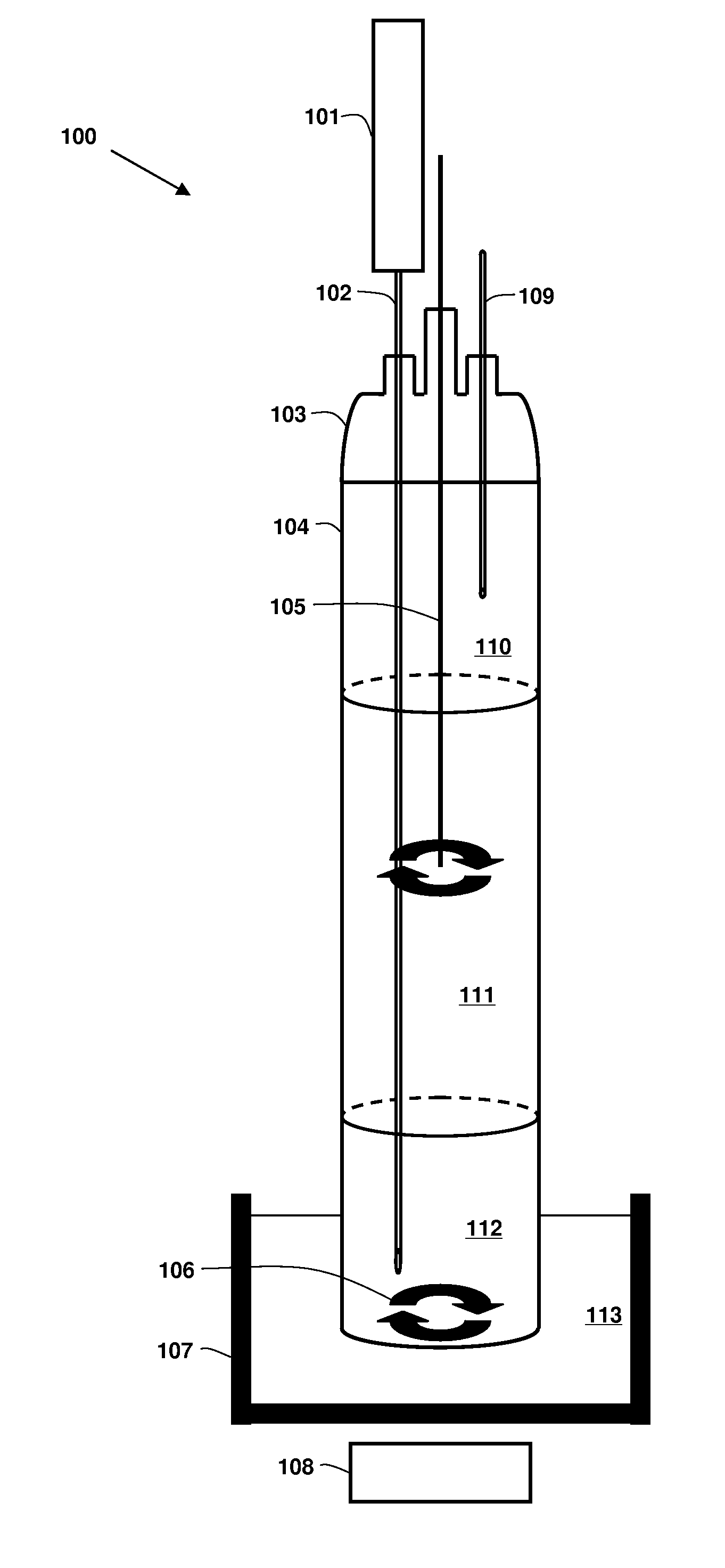

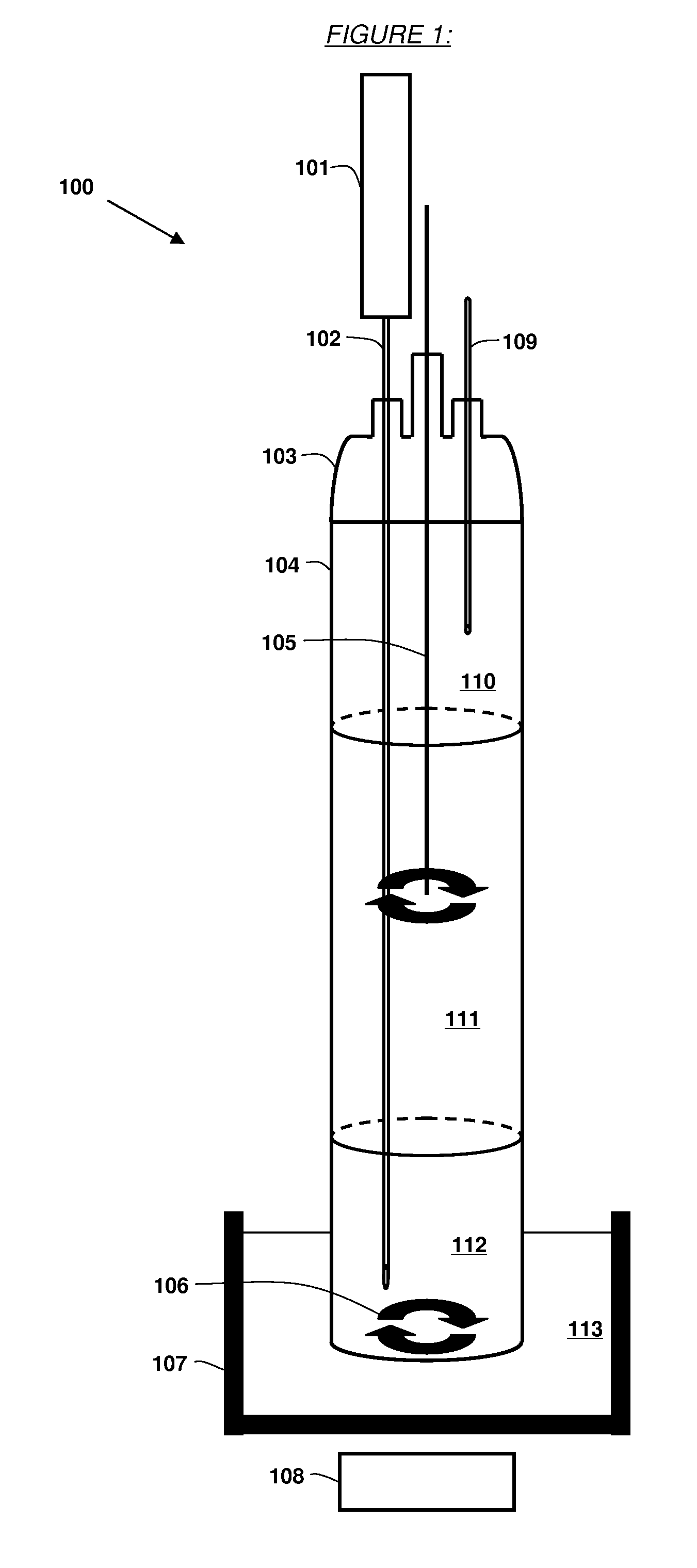

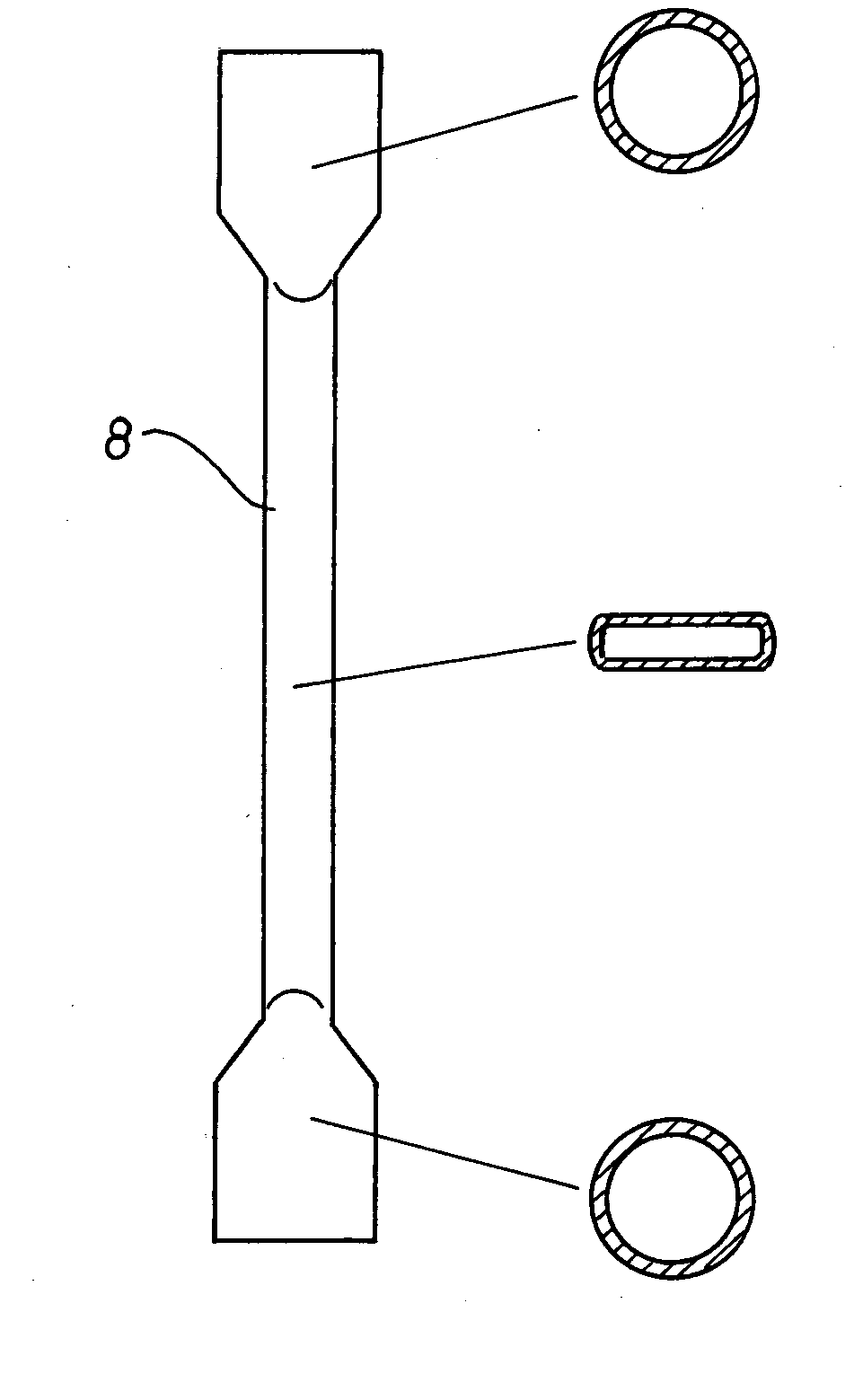

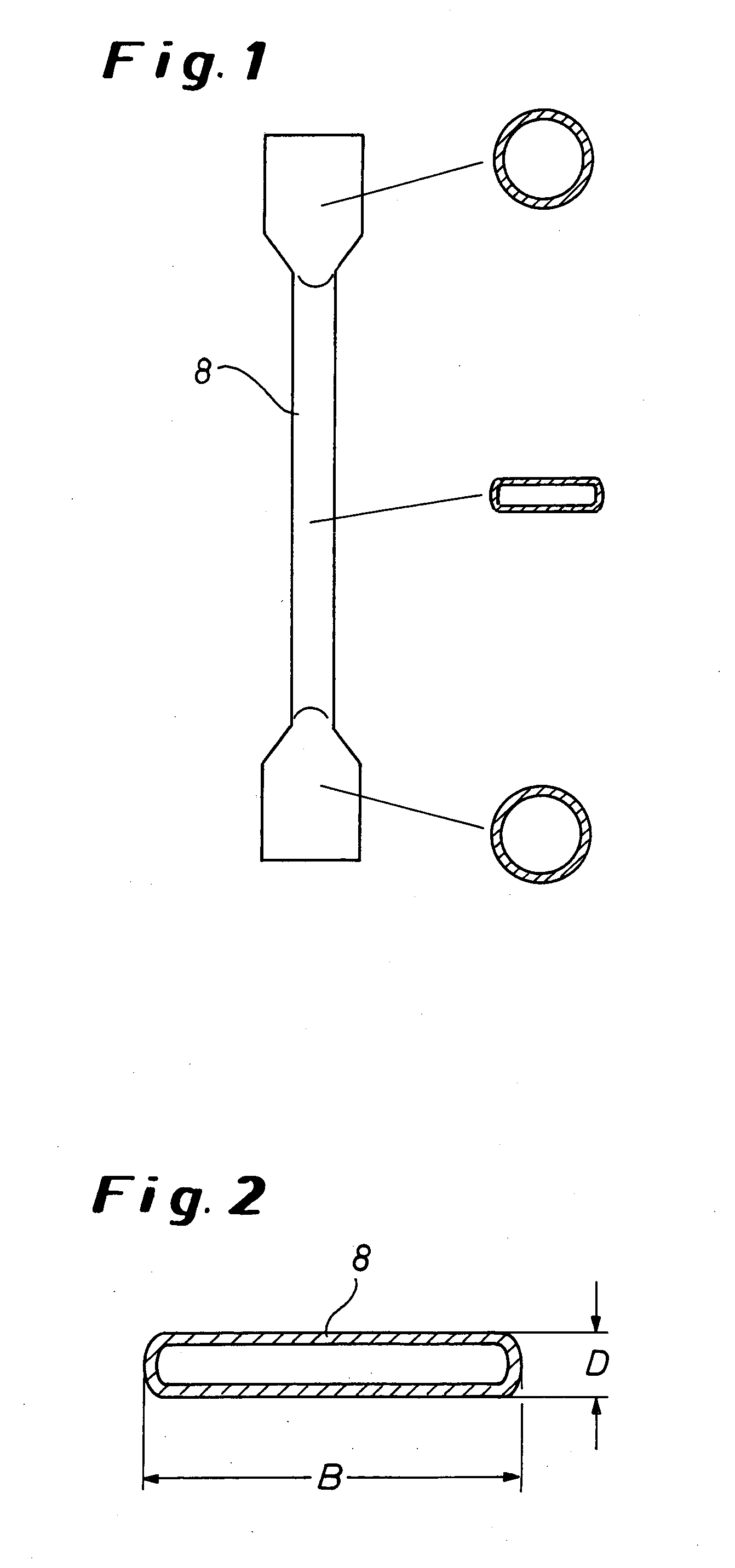

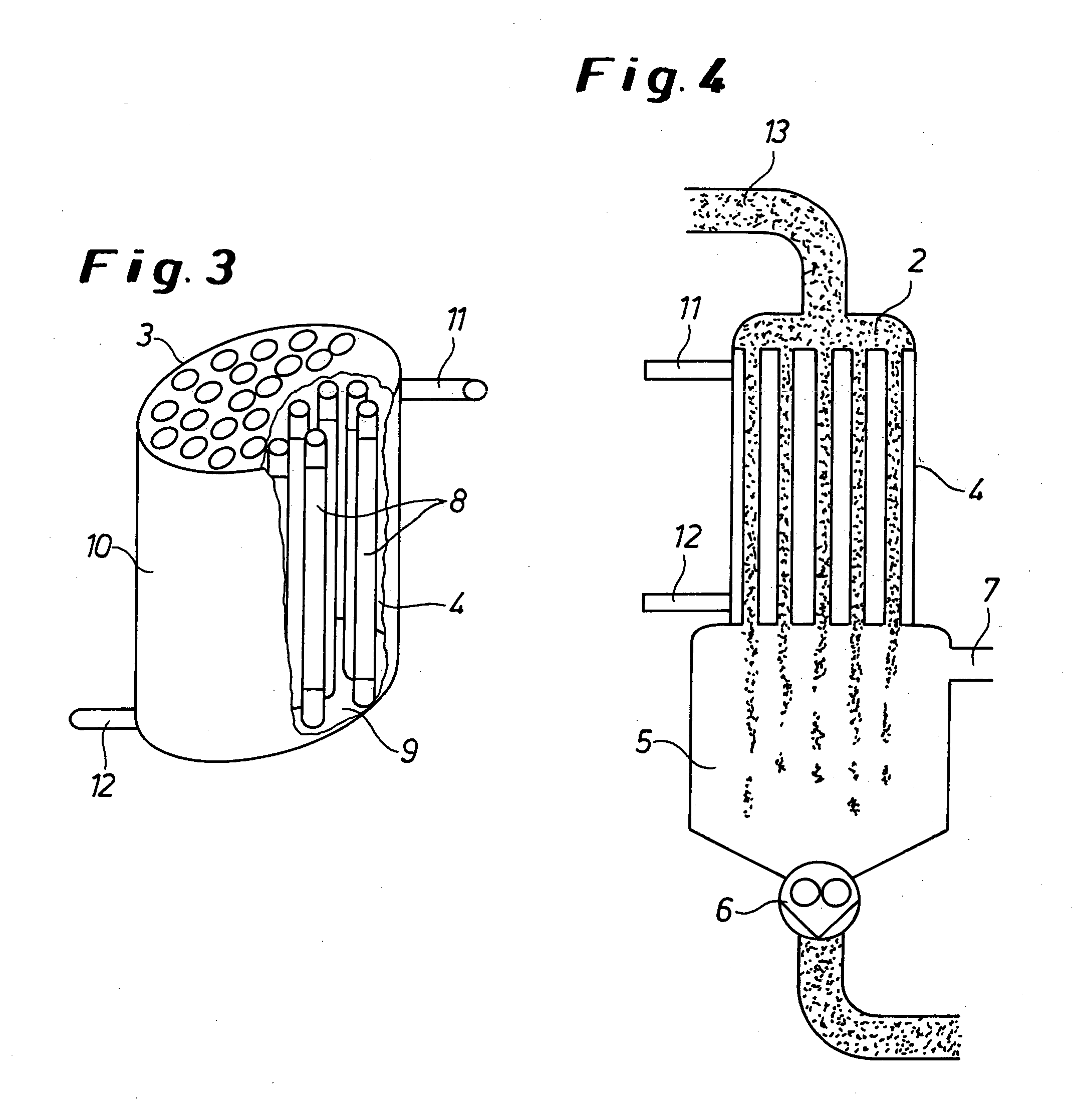

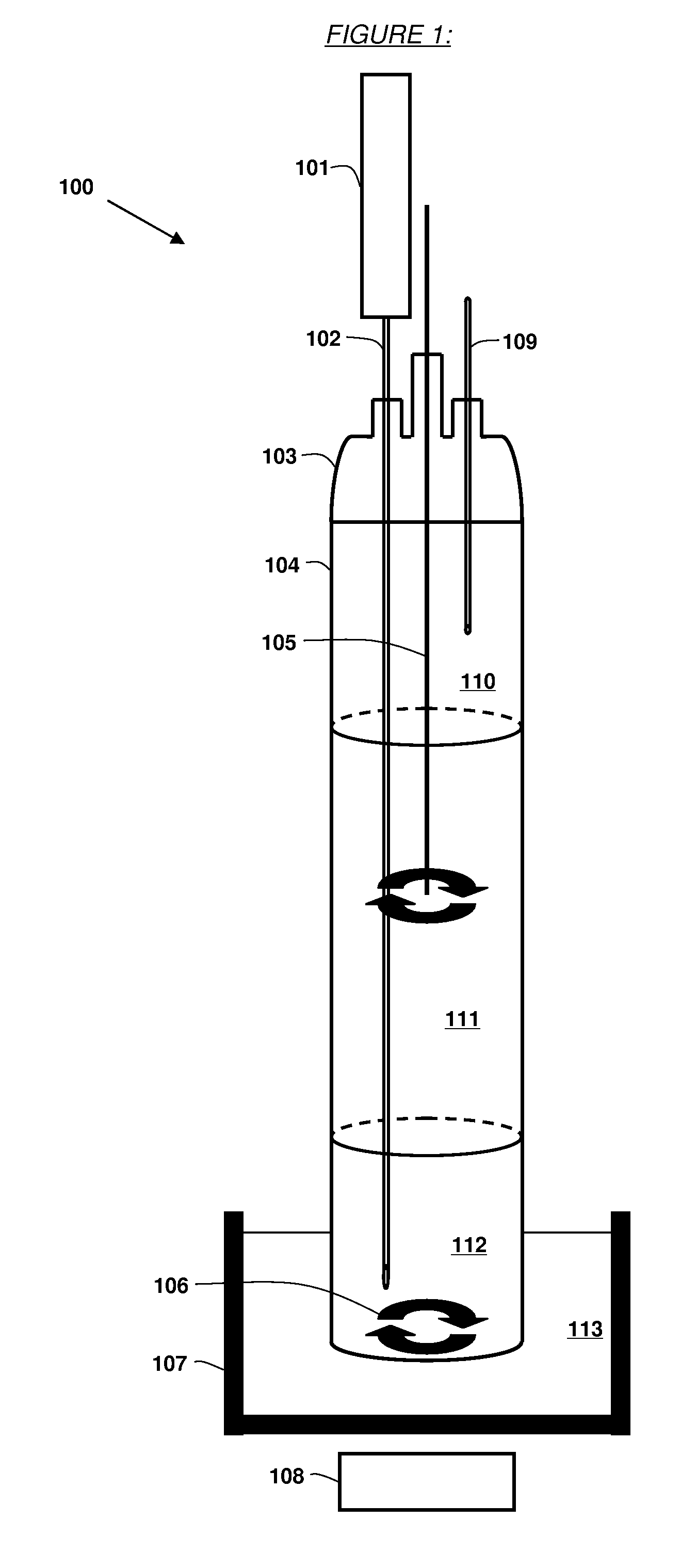

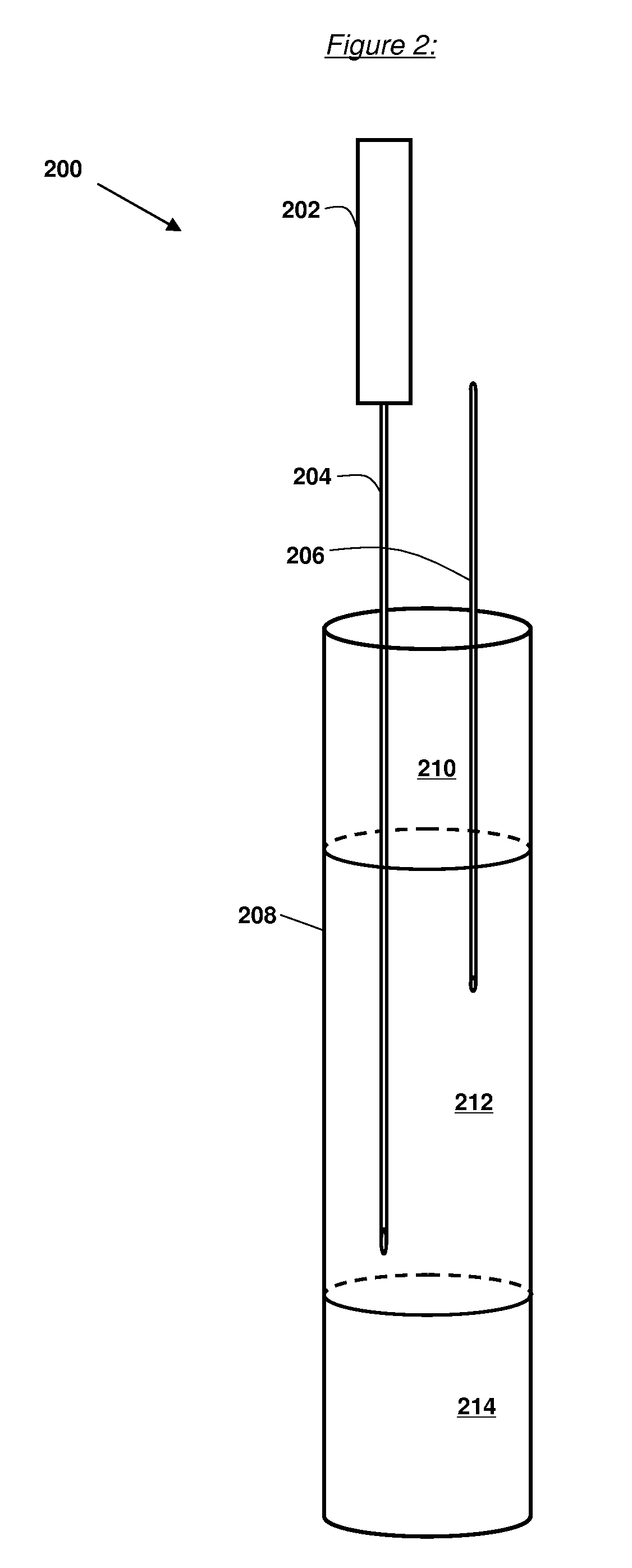

Process and apparatus for removing volatile substances from highly viscous media

InactiveUS20050092444A1Reduce heat loadNarrow residence time distributionDrying using combination processesEvaporation with vapour compressionProcess engineeringViscous medium

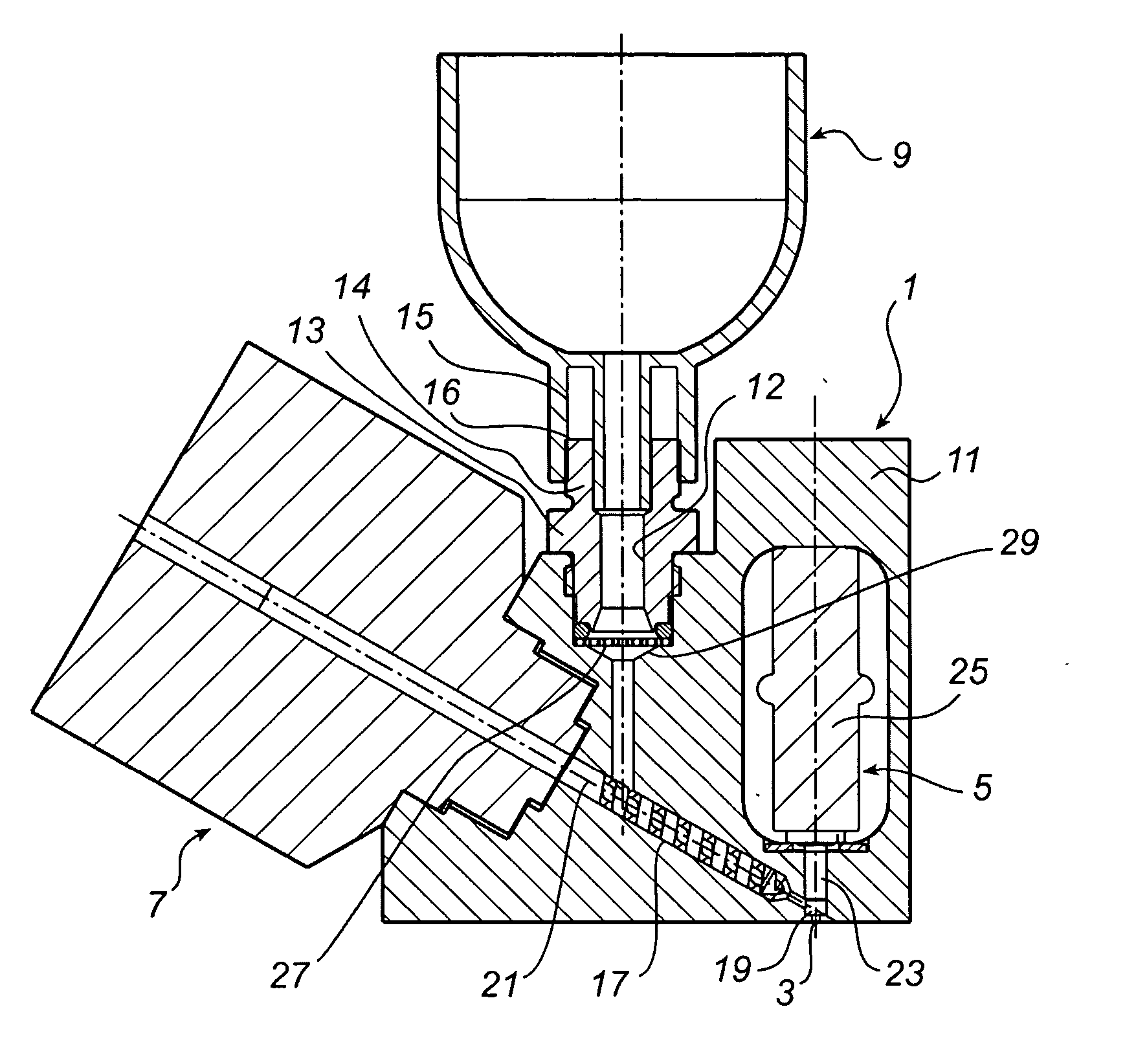

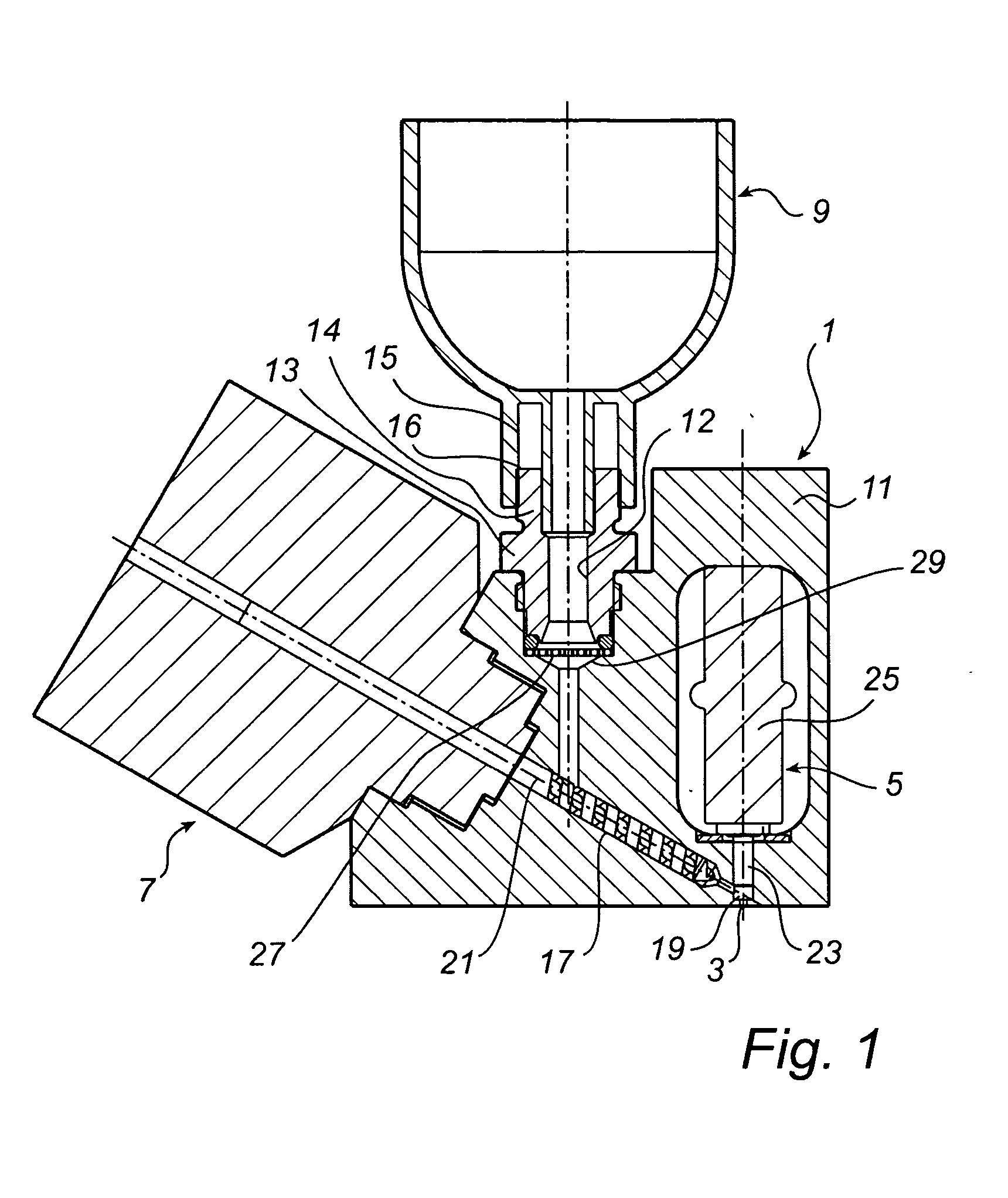

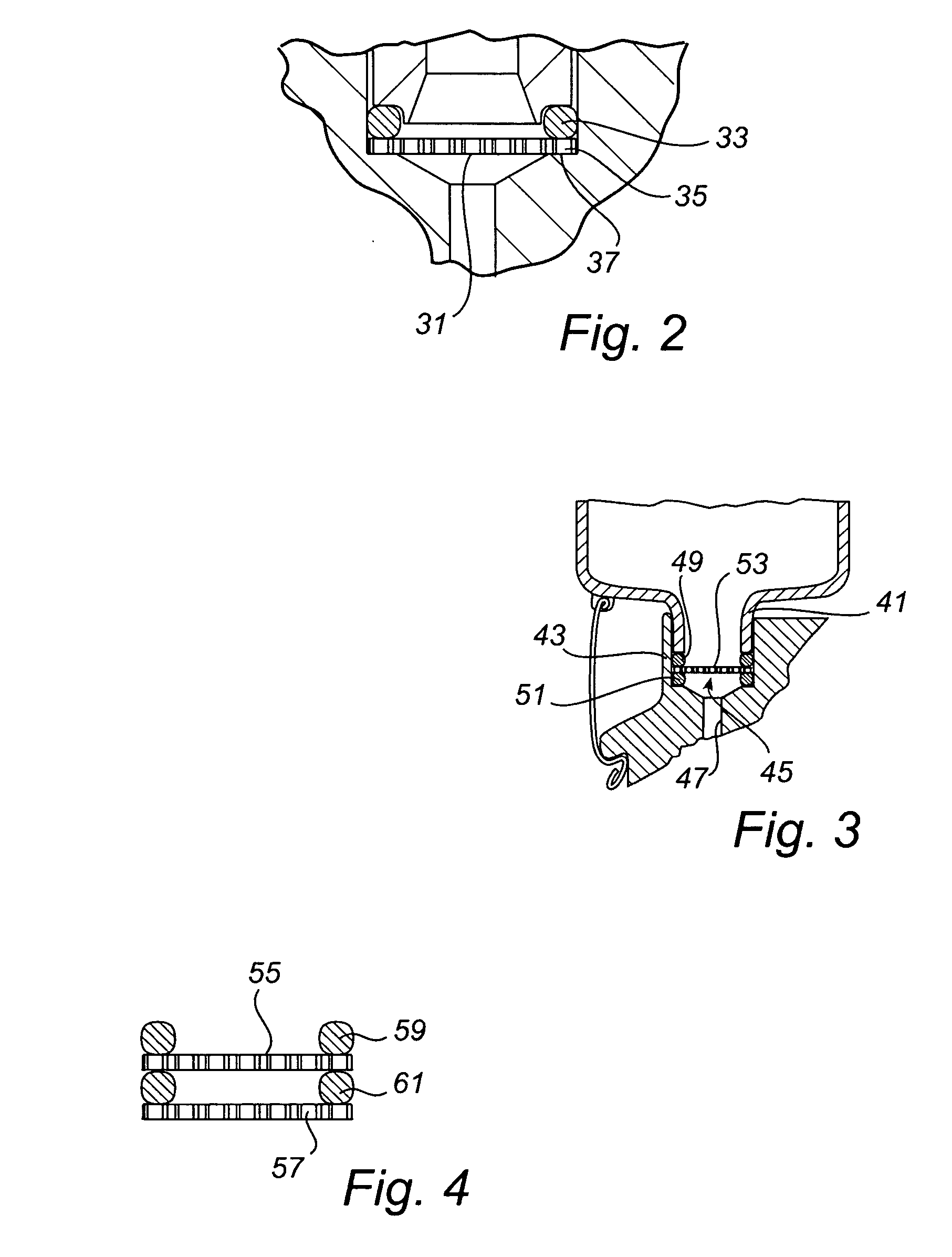

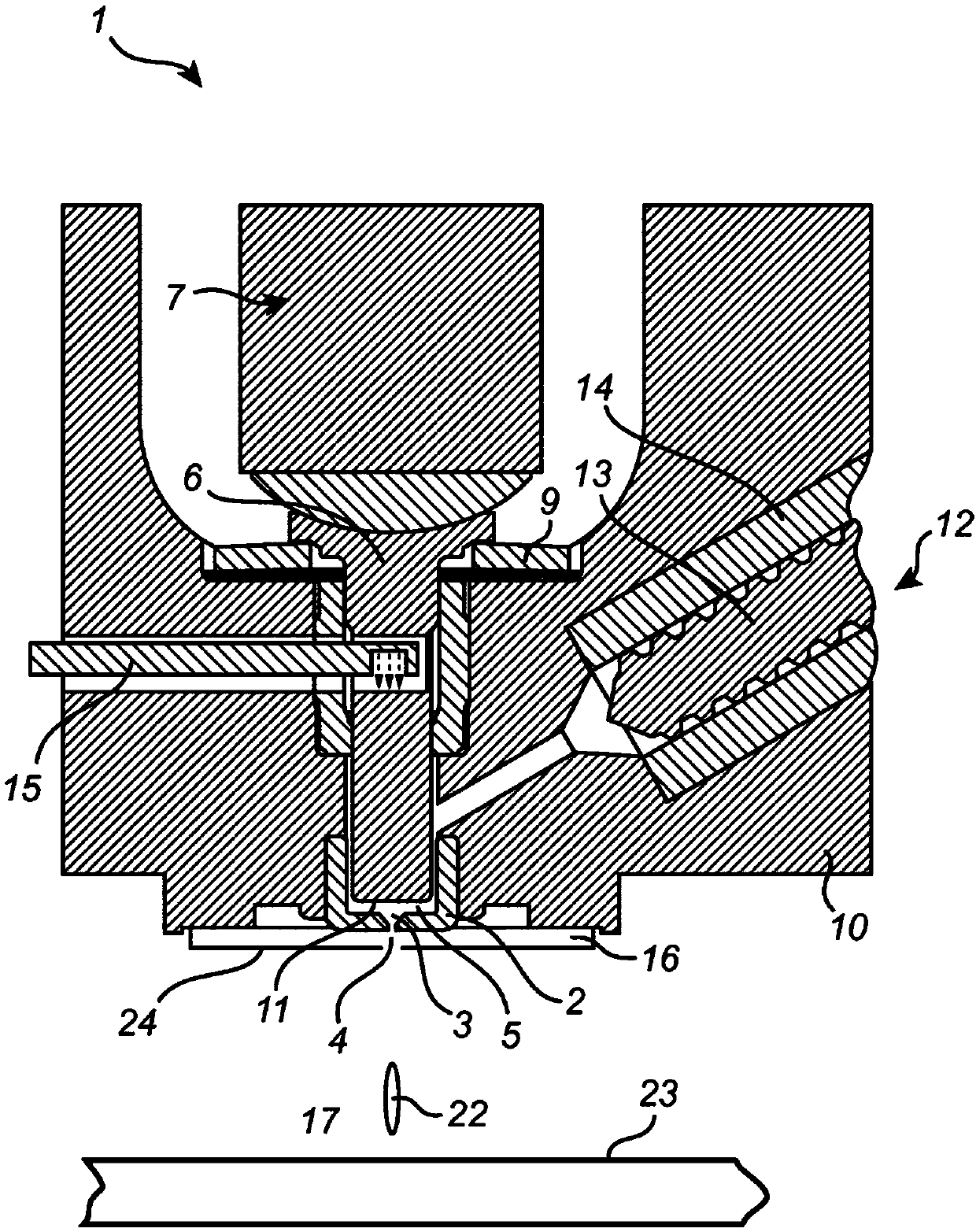

Evaporator apparatus (1) for the treatment of viscous media comprised of at least a feed chamber (2) having a perforated tray (3), a tube-bundle heat exchanger (4) connected thereto having perpendicularly arranged tubes (8) and a devolatilization chamber (5) connected thereto, a discharge unit (6) for the product and a vapor take-off (7) for removing volatile components, the tubes (8) of the heat exchanger (4) having a rectangular cross section over the greater part of their length.

Owner:BAYER TECH SERVICES GMBH

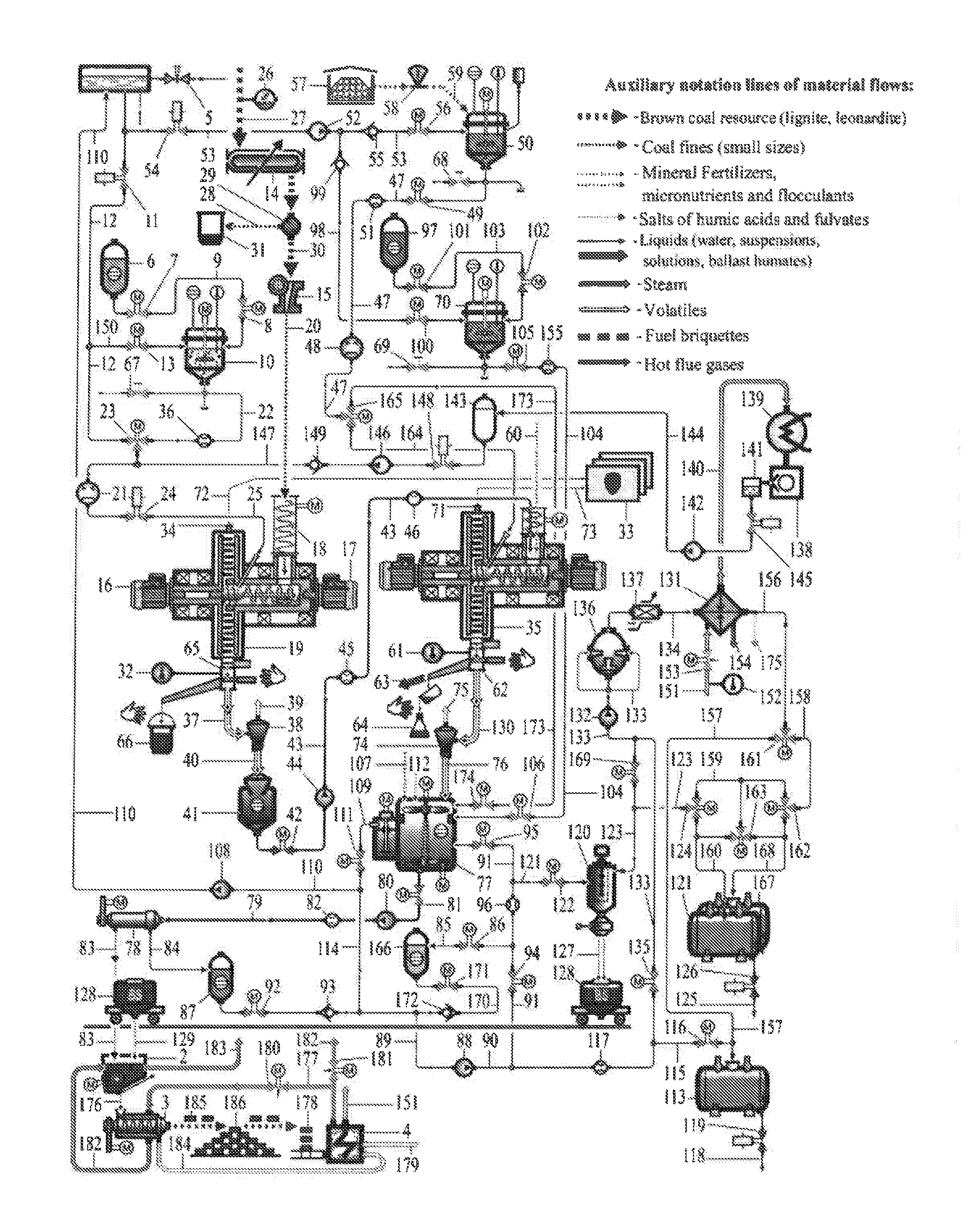

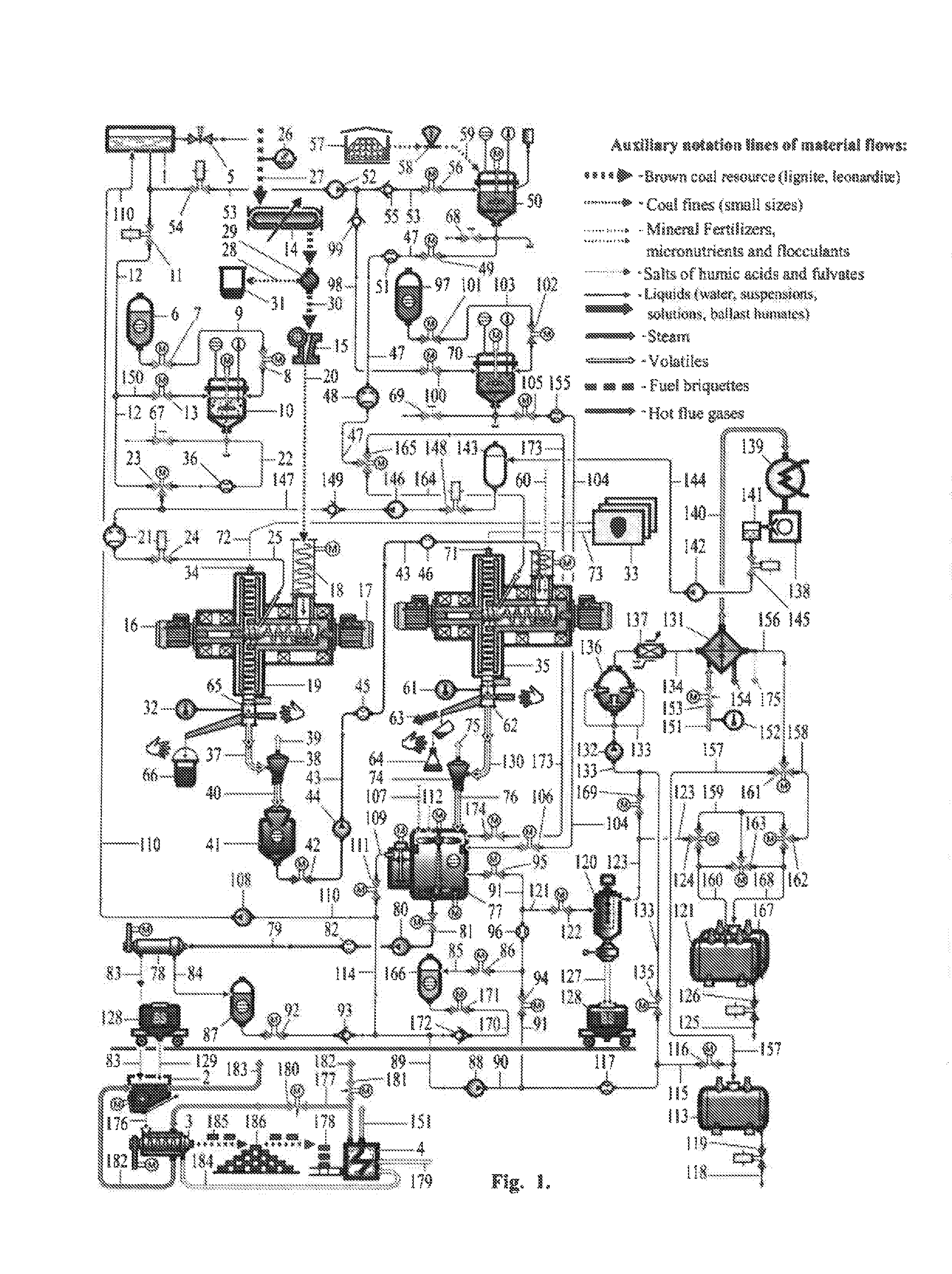

Method for comprehensively processing brown coal and leonardite into humic fertilizers and preparations and into fuel briquettes, and mechanochemical reactor for processing highly-viscous media

ActiveUS20170036967A1Improve soil structureMaintain stabilityBio-organic fraction processingEnergy inputRaw materialPhase separation process

A method for comprehensively processing coal-type caustobiolites, predominantly brown coal and leonardite, into humic organic and organomineral fertilizers and intor preparations producing fuel briquettes, including carrying out main processes in a continuous flow; carrying out leaching processes based on aqueous solutions with hydromodules of close to 2, carrying out acidification processes with the formation of humic acid released from a liquid phase into a heavy phase of a coagulated pulp, carrying out mechanical phase separation processes in a centrifugal field, carrying out liquid-phase mechanoactivation and the dispersion of reaction compositions via grinding, using residual “water” in recycling, and including the production of water-soluble humic acids and fuel briquettes and allowing for the production of a wide range of products; preliminarily grinding raw materials to a 03 mm class, and cleaning and electrochemically softening water in preparing reaction aqueous solutions; using a liquid-phase raw material oxidation process, and using liquid-phase mechanoactivation and / or mechanochemical activation, with the dispersion of reaction compositions by means of grinding and by means of dynamically shifting layers having statistical shift rate components, of a medium to be processed, which range from single-digit meters per second to tens of meters per second; accompanying said mechanoactivation with the dosed input into said medium of 1040 MJ of mechanical energy per cubic meter, with the stabilization of said dosing regardless of the drift of all other parameters in said medium to be processed; wherein, said grinding and shifting processes are formed by means of statistical and dynamic characteristics; in this way, a dynamic hydro-pulse effect on a medium to be processed is carried out within a range of frequencies floating between infrasound and frequencies bordering on ultrasound, wherein the processing is carried out beginning with higher frequencies; in addition, providing for automatically maintaining maximum parameters for inputting mechanical energy into the medium to be processed, while automatically restricting same within a sub-cavitation zone in order to prevent the transition of the mechanochemical reactors into cavitation modes.

Owner:SEVASTYANOV VLADIMIR PETROVICH +3

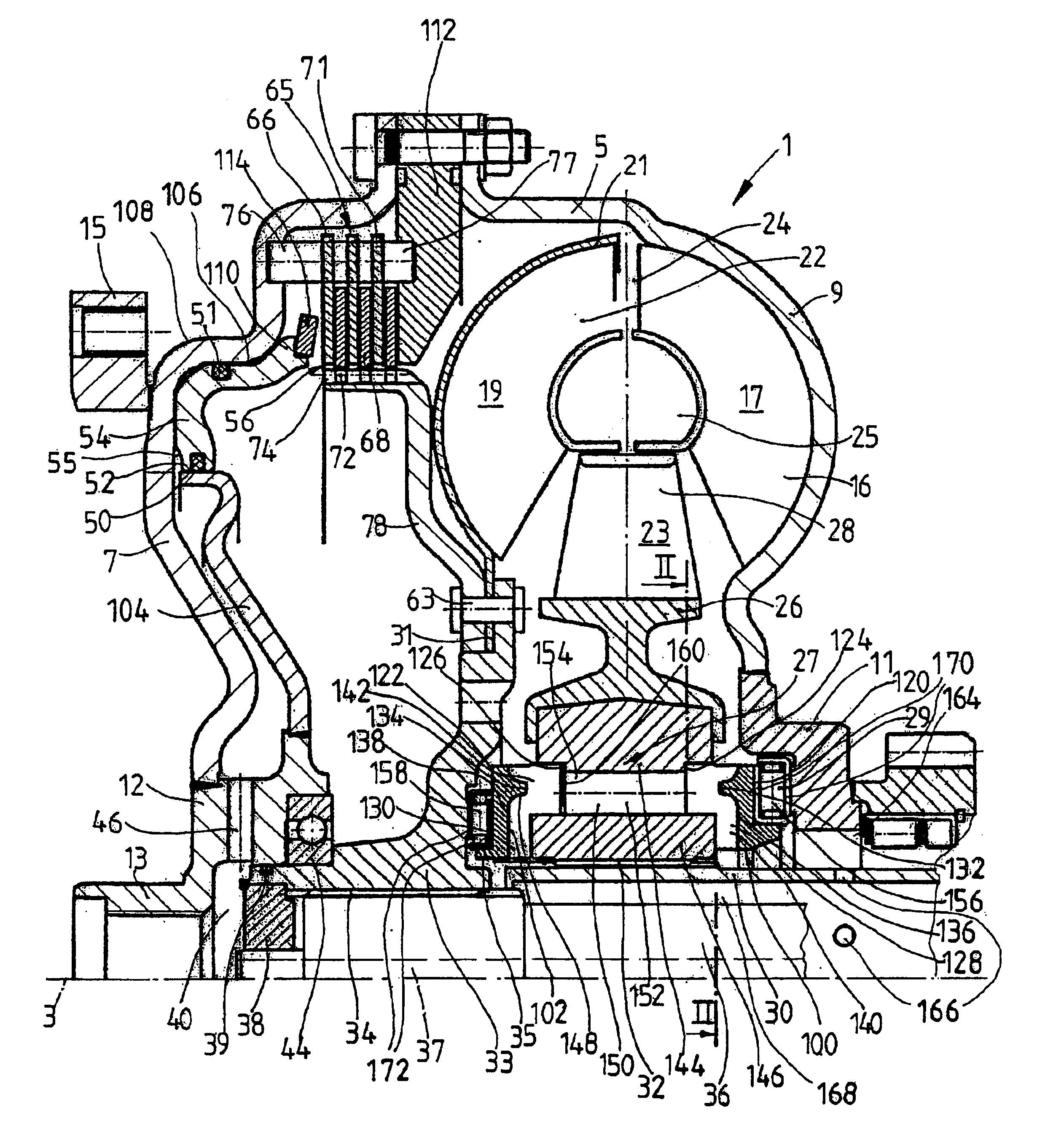

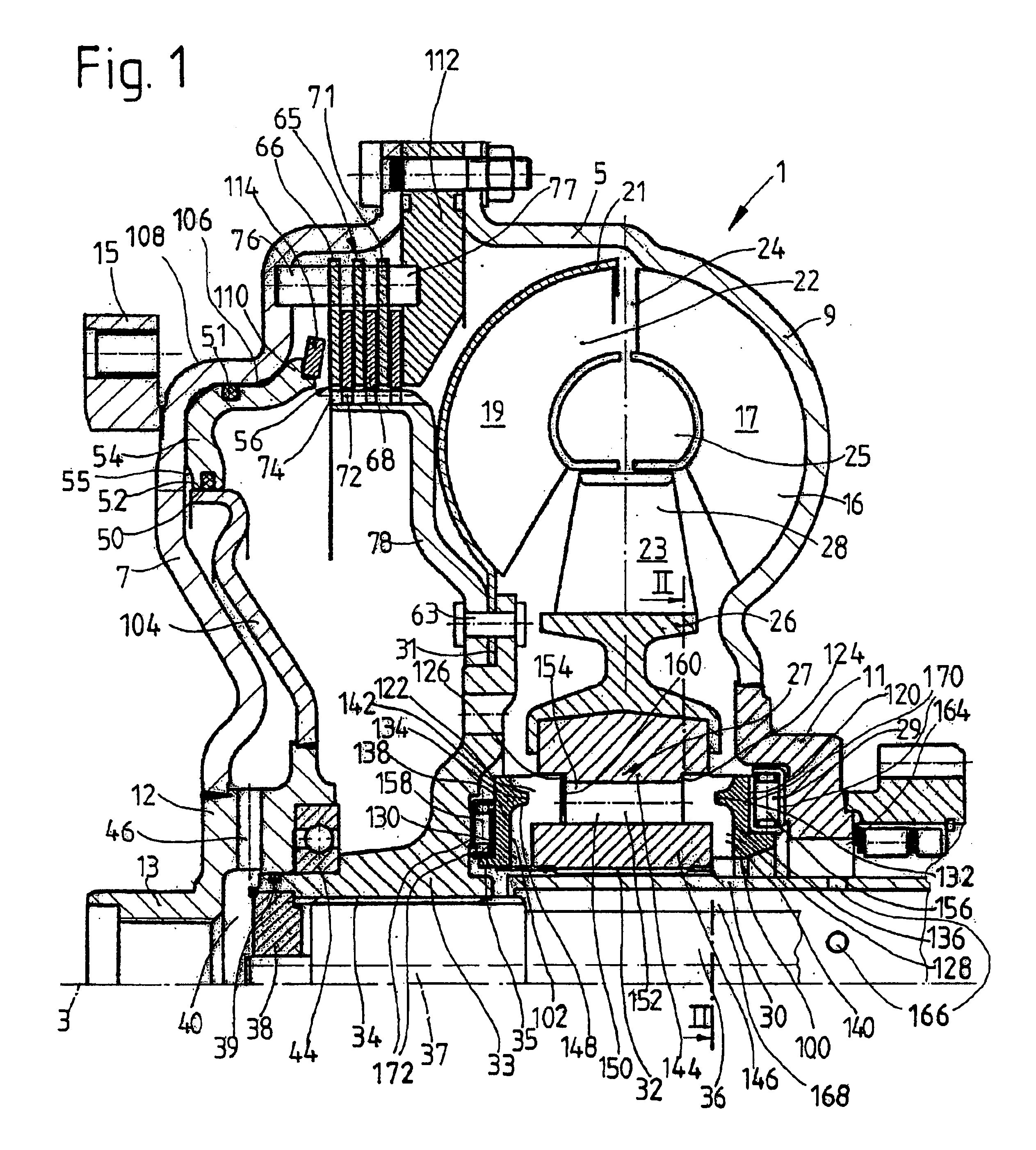

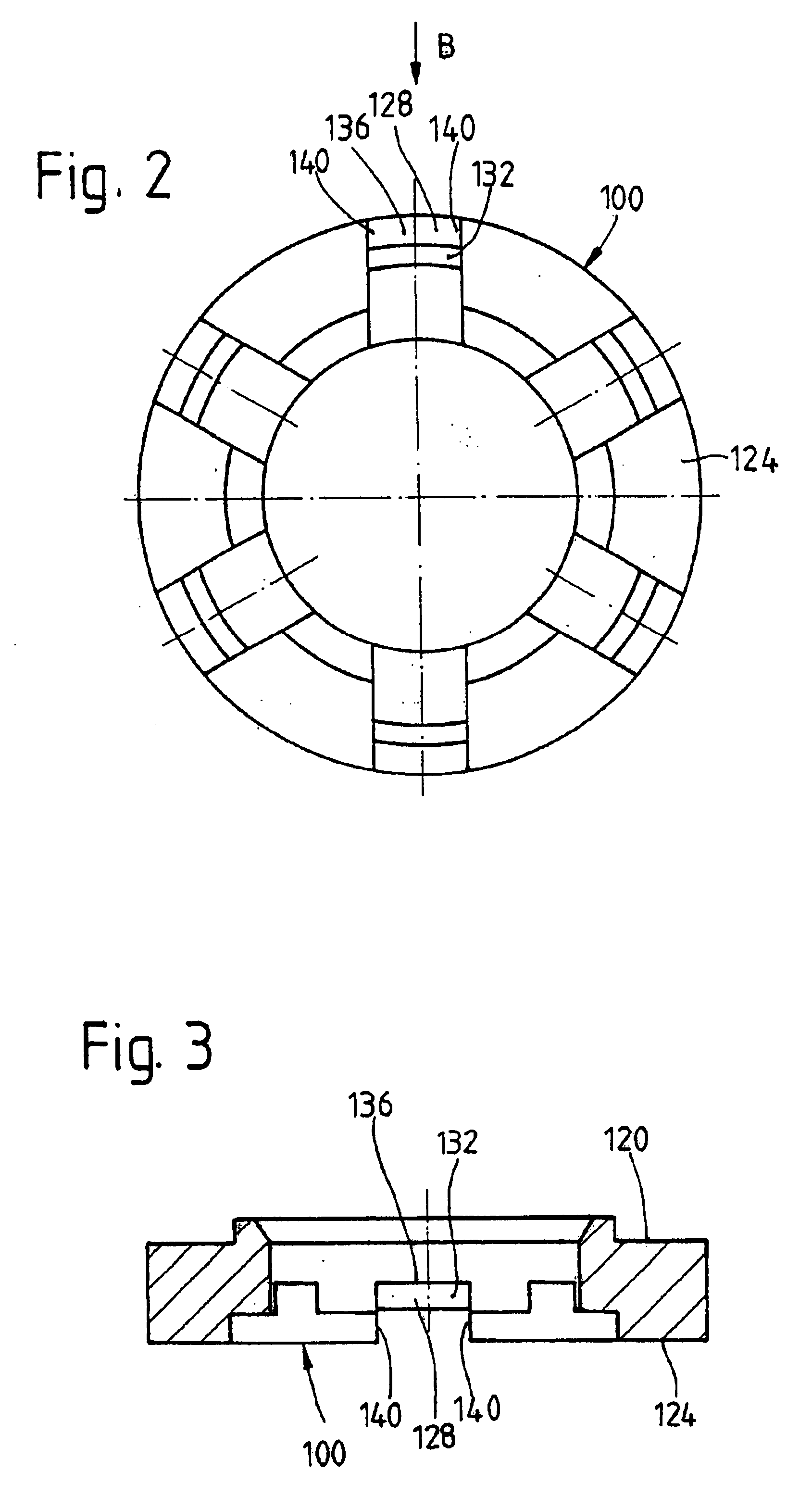

Hydrodynamic torque converter with at least one axial bearing arrangement for supporting the stator

InactiveUS6814202B1Excessive deformationSmall volume flowRotary clutchesFriction clutchesImpellerTurbine wheel

A hydrodynamic torque converter is provided with a converter housing to hold at least one pump wheel, one turbine wheel, and one stator to form a hydrodynamic circuit and with at least one axial bearing arrangement for supporting the stator. At least one support element has a bearing side which rests against the axial bearing arrangement, and a stator side which rests against a component of the stator and is designed with at least one flow passage for viscous medium, which forms a connection between at least one flow conduit and the hydrodynamic circuit. The flow passage has a flow bed and, contiguous with that, at least one boundary wall, which leads from the flow bed to the axial level of the corresponding support element side. The bearing side of the support element is essentially flat and the stator side is provided with at least one flow passage, in the extension area of which a stiffener is provided, which produces at least a partial connection between the flow bed of the flow passage and the at least one boundary wall.

Owner:ZF FRIEDRICHSHAFEN AG

Method of jetting viscous medium

InactiveUS20040118935A1Improve spraying effectScaling errorSelf-acting watering devicesWatering devicesViscous mediumLiquid drop

The invention relates to a method of improving the performance of a jetting assembly in an apparatus for jetting droplets of viscous medium on the fly onto a substrate. The jetting assembly is releasably mounted in the apparatus and comprises a nozzle, an ejection mechanism connected to the nozzle, and a viscous medium container connect to the eject mechanism. Information relating to an XY-position and a Z-position is obtained together with information regarding the exit velocity a droplet of viscous medium has when it exits the nozzle. The information is used as a basis for adjusting a trigger position of the nozzle for the subsequent jetting of droplets. The invention also concerns such a jetting assembly comprising storage means arranged to receive and hold calibration information of properties of the assembly obtained during calibration measurements.

Owner:MYDATA AUTOMATION

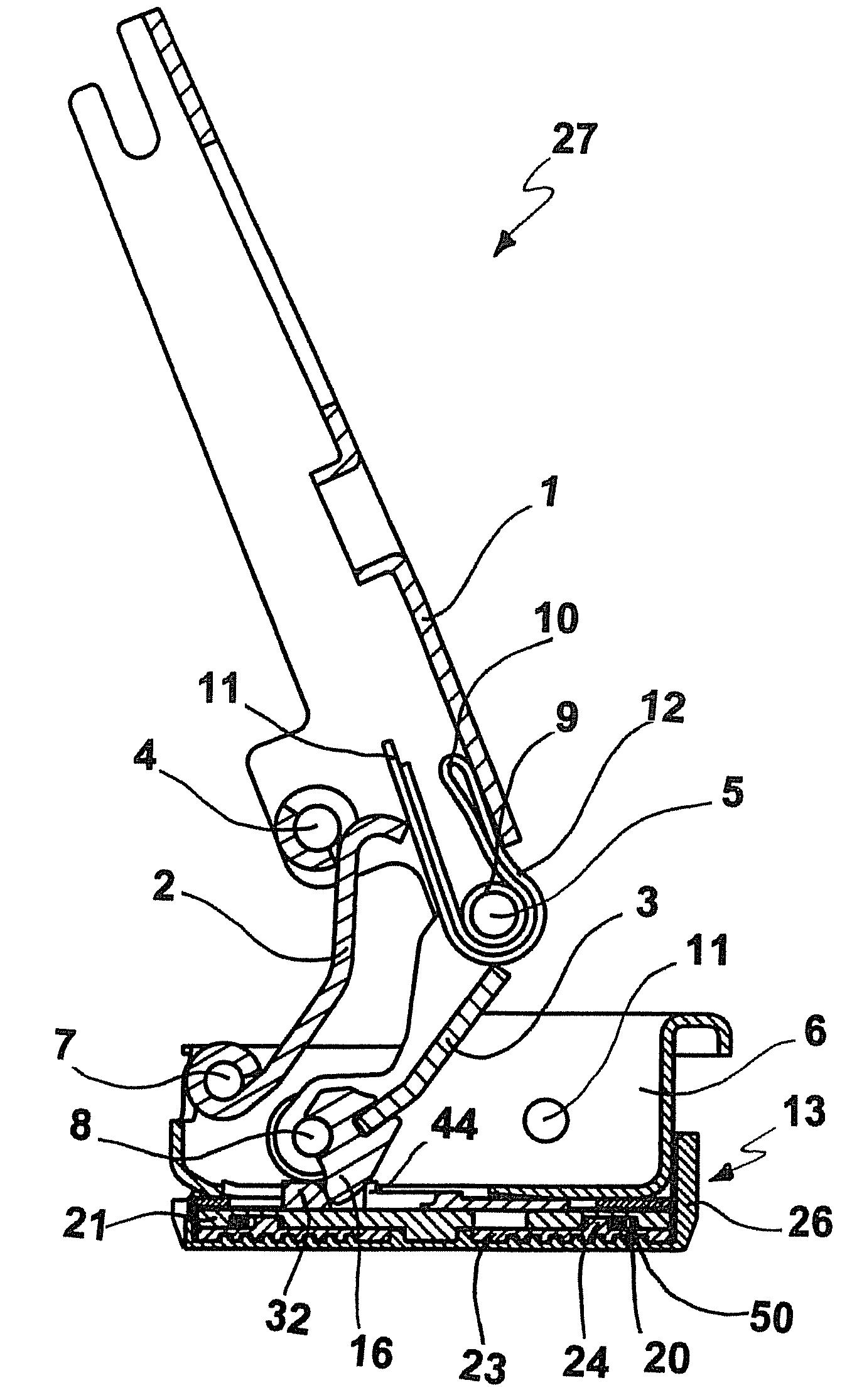

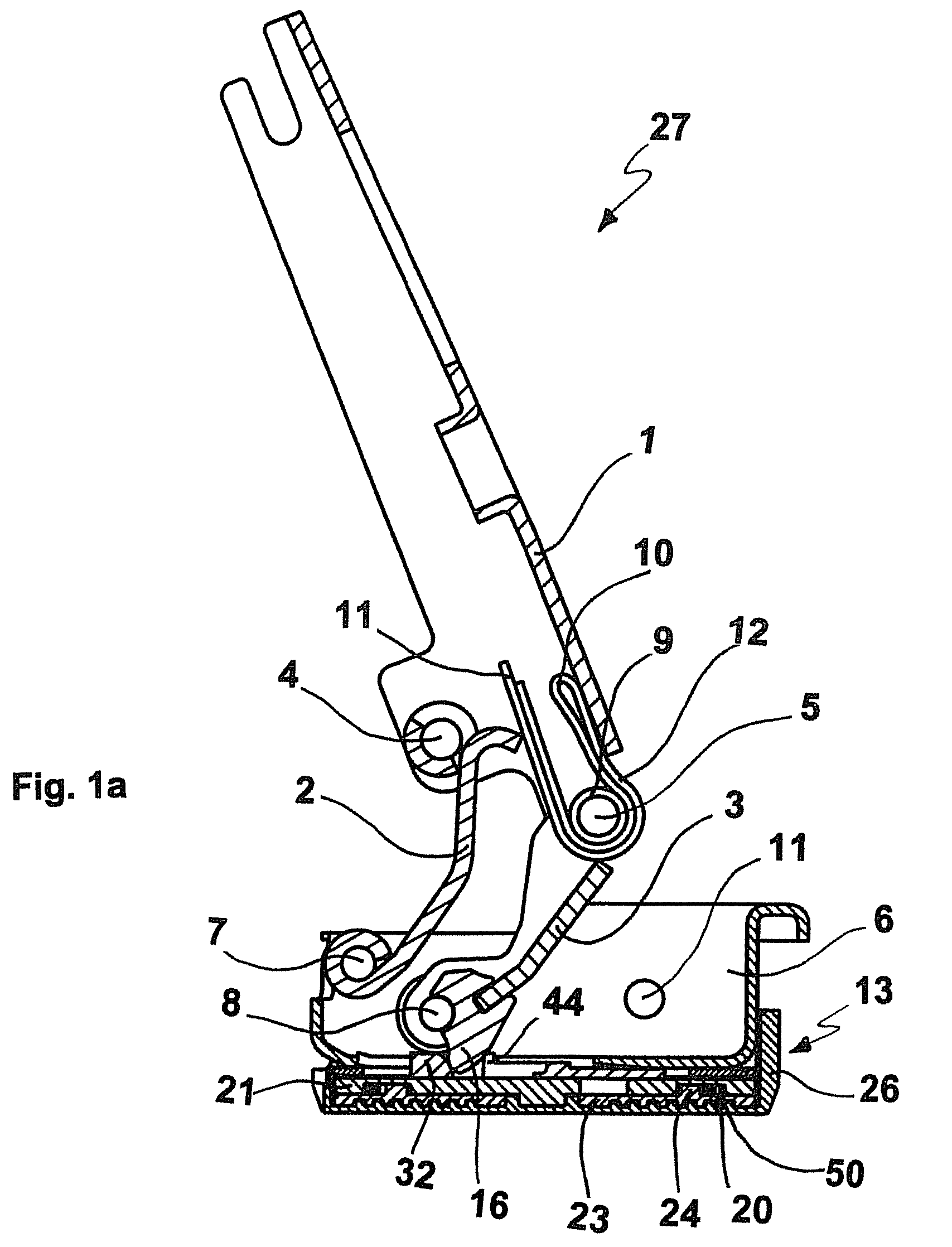

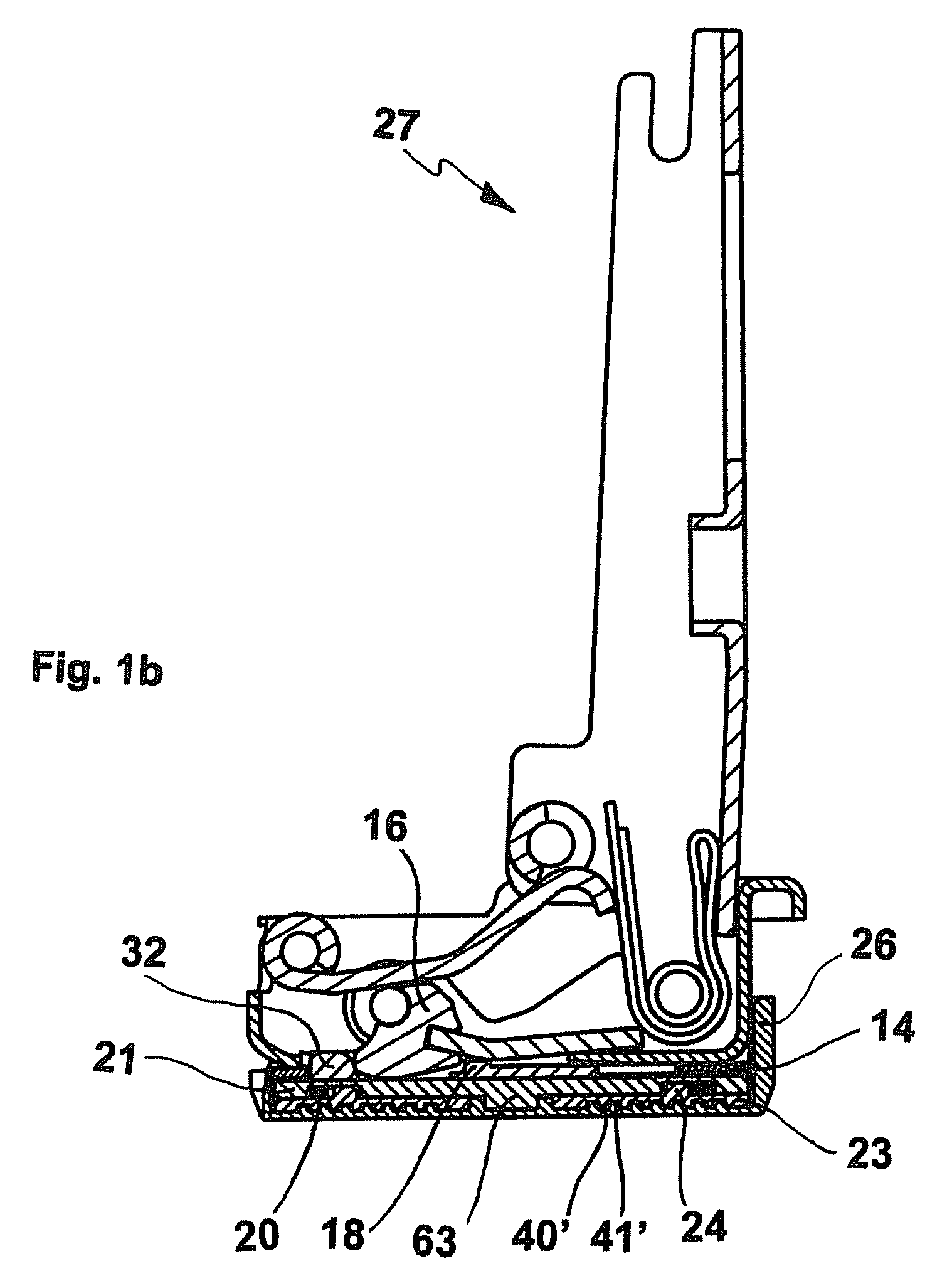

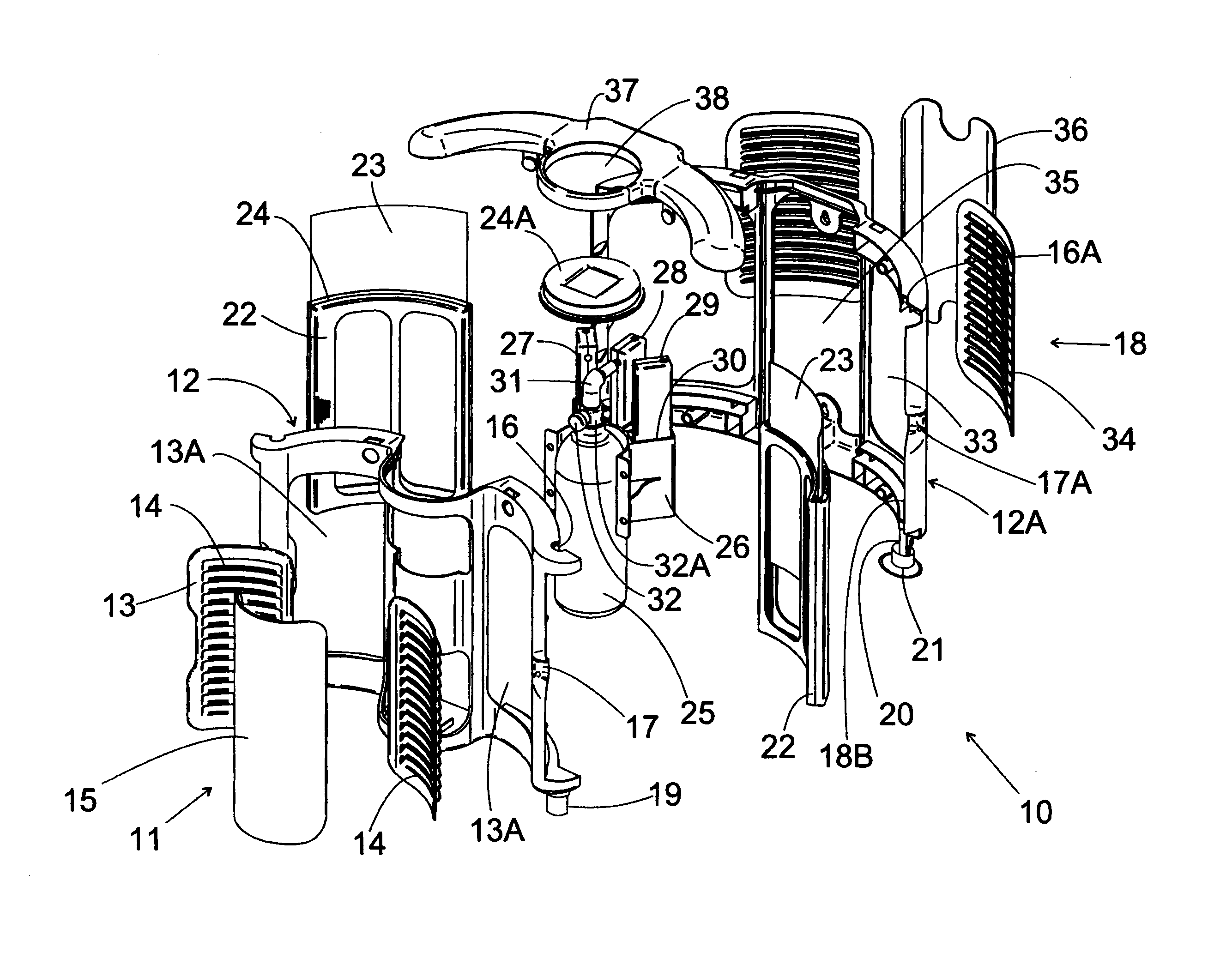

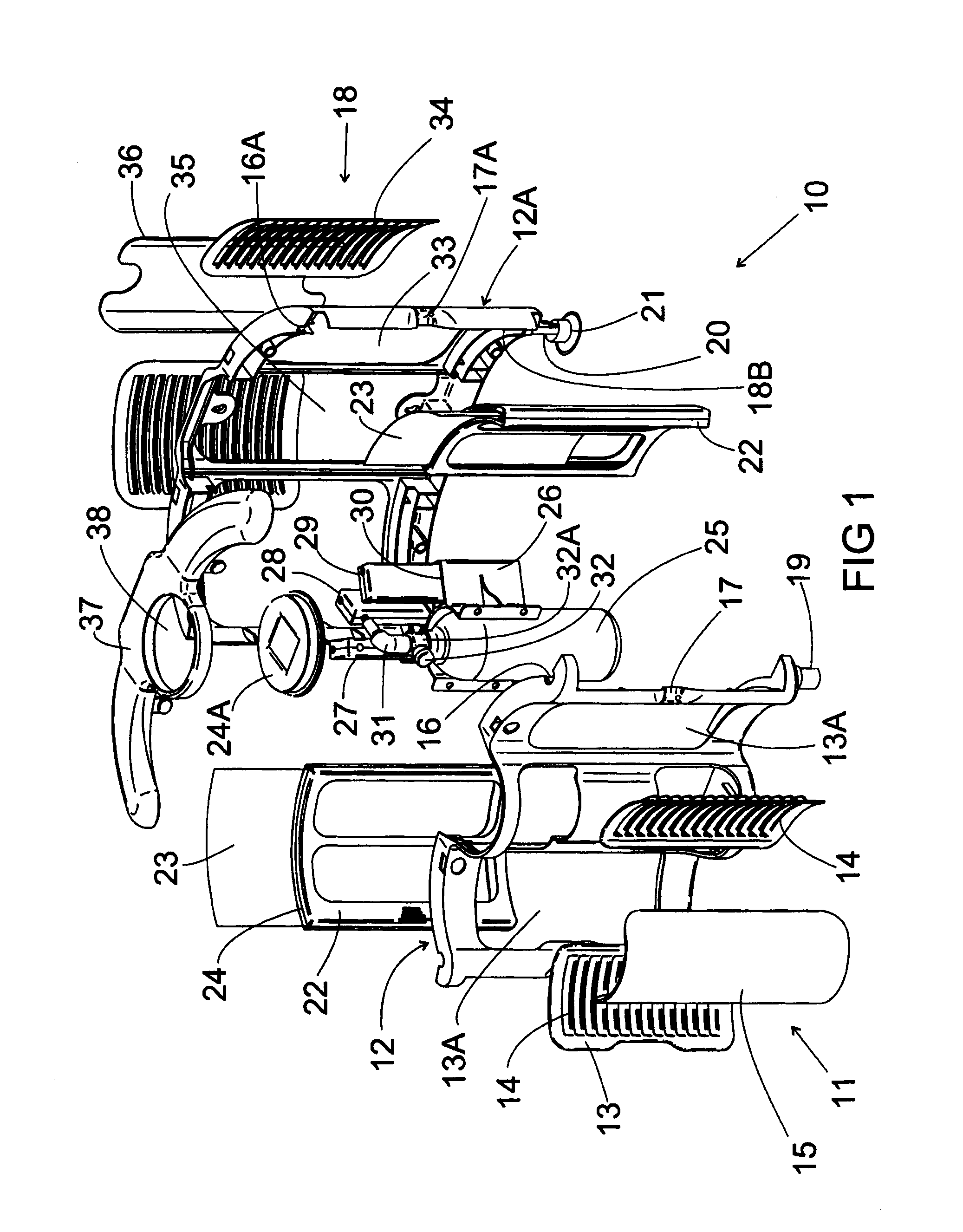

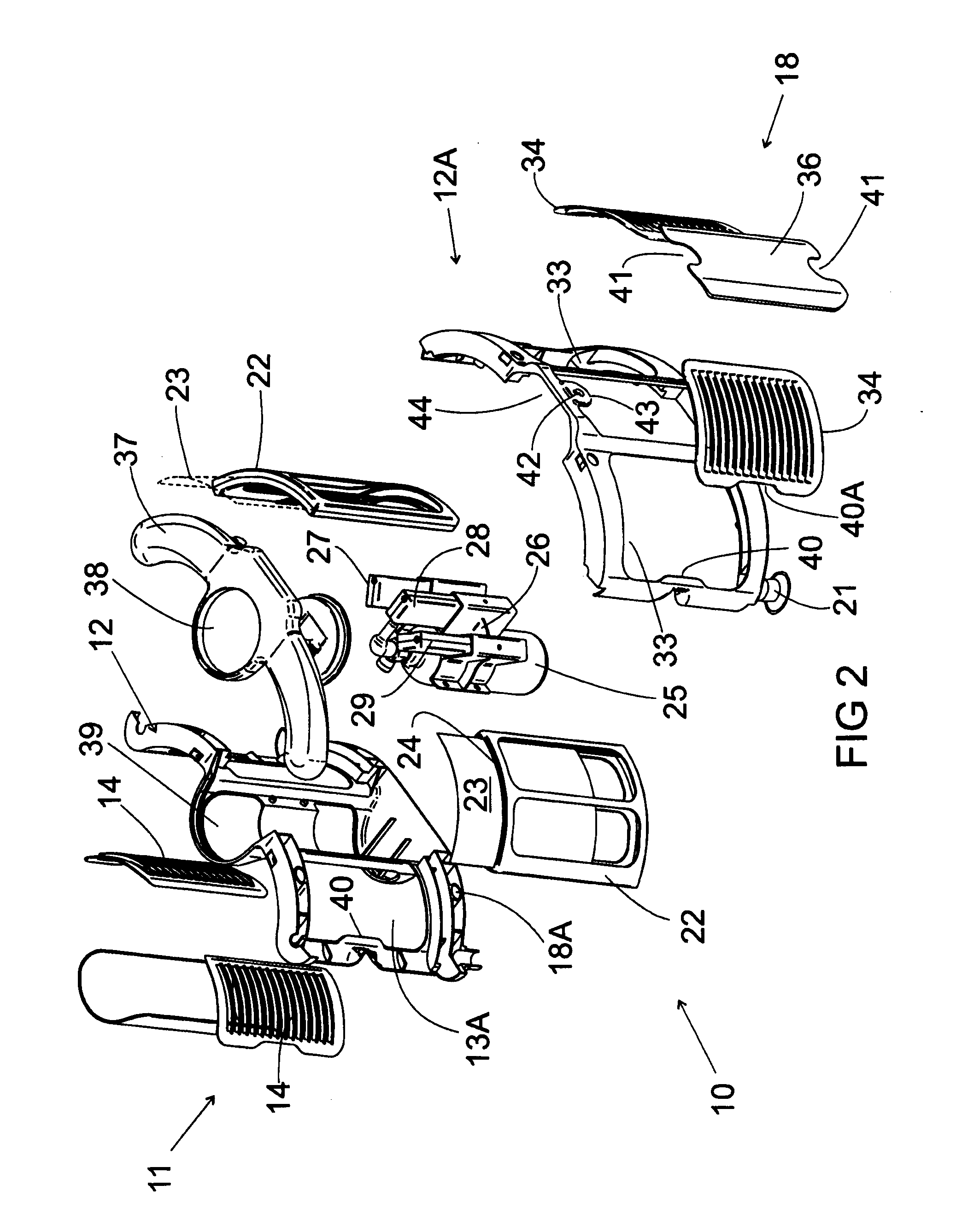

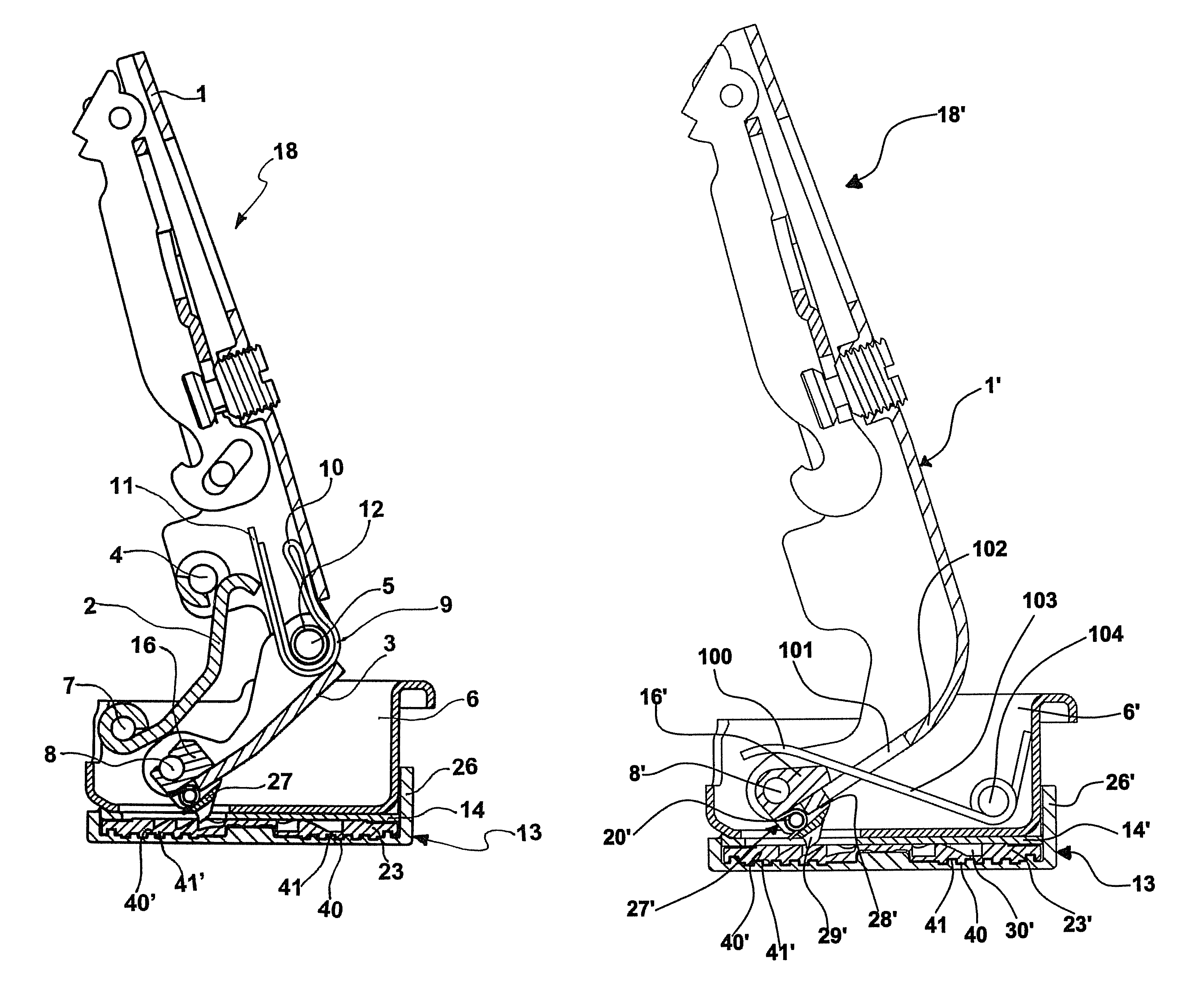

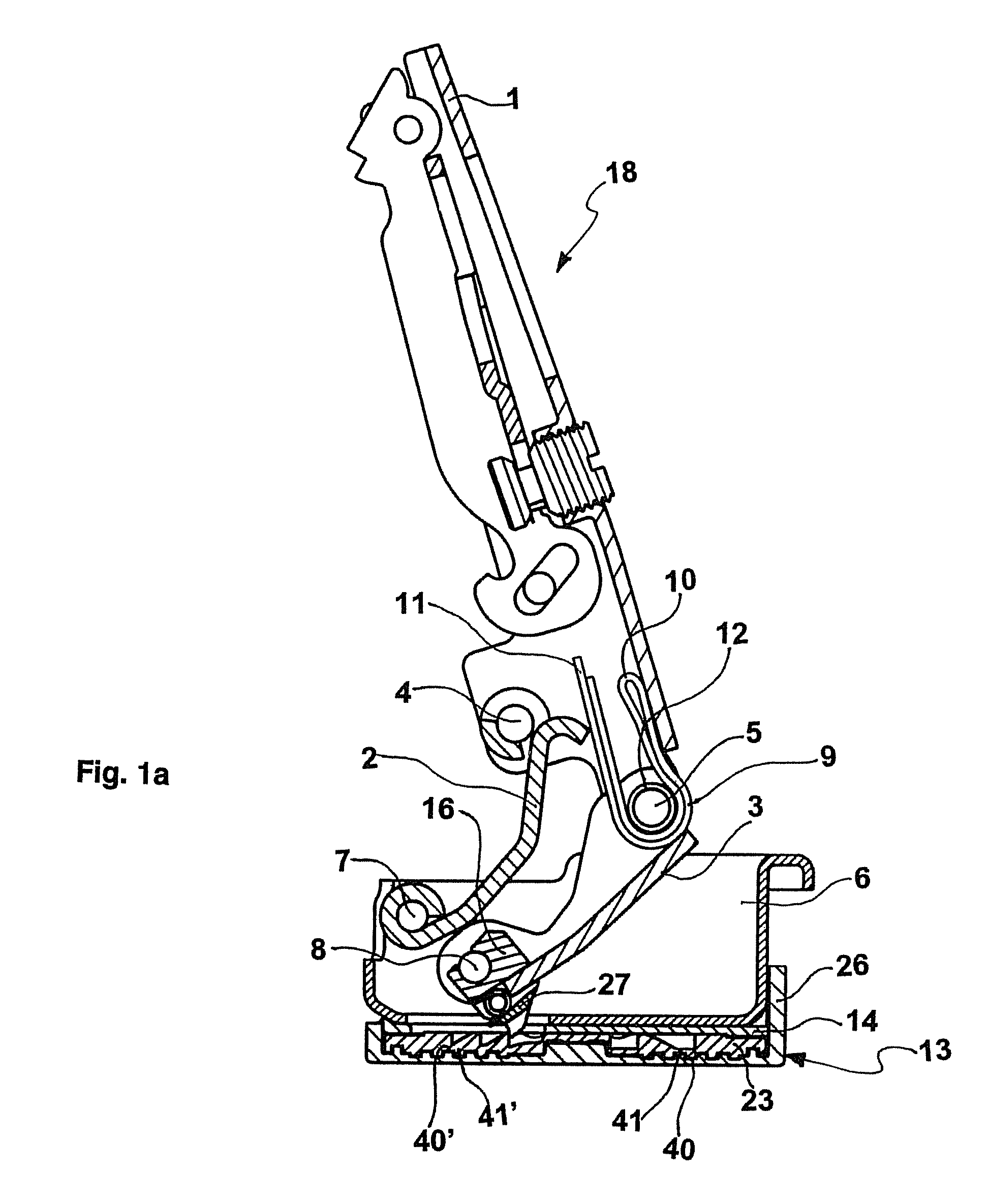

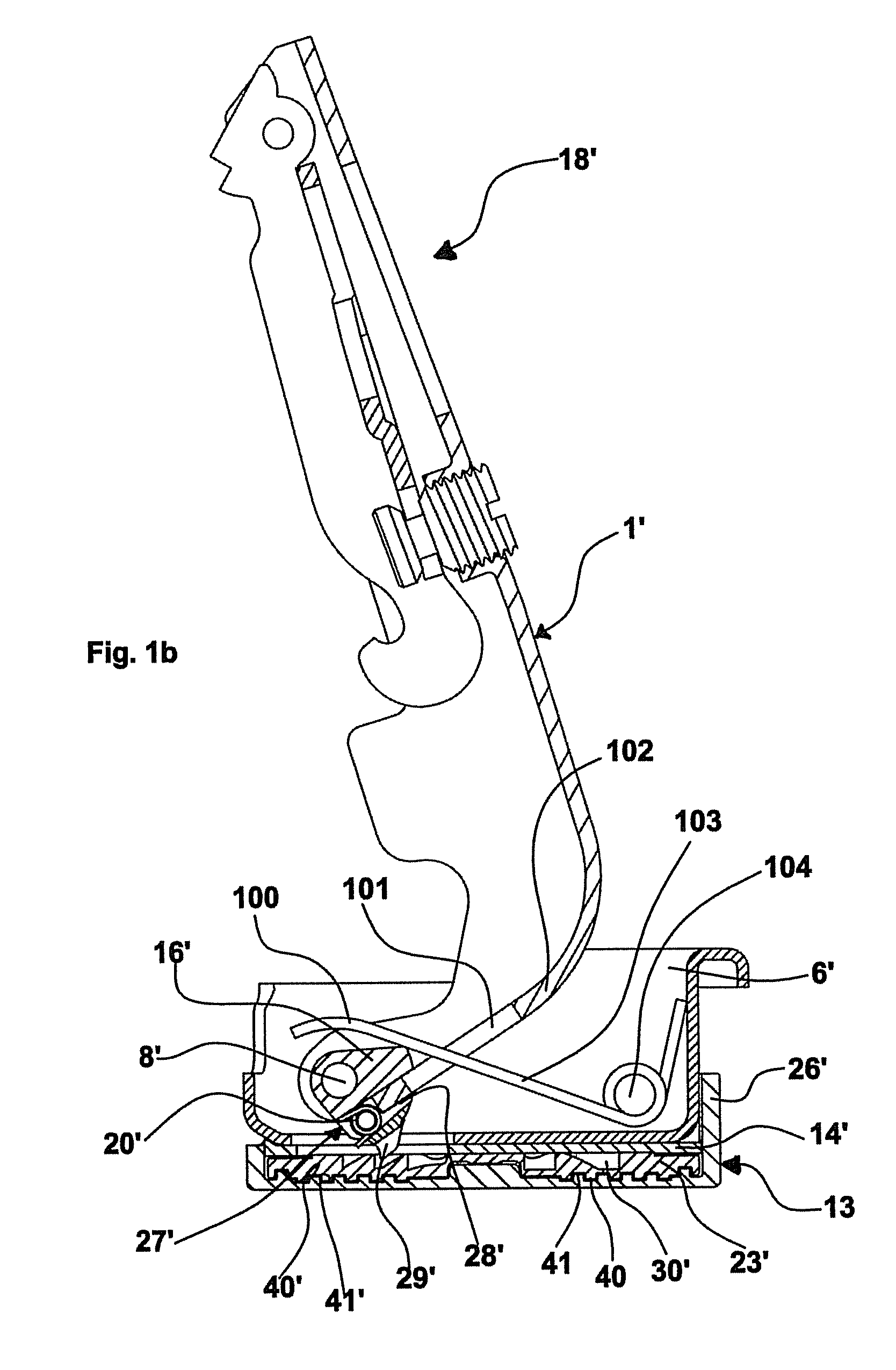

Furniture hinge with damping device

InactiveUS7730583B2Improve efficiencyGreat silenceBuilding braking devicesPin hingesAngular velocityEngineering

Furniture hinge with damping and / or braking device in alternative to those already existing and capable of guaranteeing an improved efficiency during the closing or opening operation of the doors, or other furniture parts, thanks to an improvement of the kinematic motion for transmitting motion from one of the rockers to the damping elements. The improved efficiency of this hinge is also obtained by increasing the friction surfaces with a viscous medium present in suitable areas of the hinge and by allowing regulation of the trend of the angular velocity of a circular shaped element, for example a disc, which acts as braking element in contact with the viscous medium.

Owner:ARTURO SALICE

Viscous medium bidirection press cold shaping method of titanium and titanium alloy plate material parts

The present invention relates to a viscous medium bidirectional pressure cold forming method of titanium and titanium alloy plate component. Said method includes the following steps: (1) placing slab billet material on the viscous medium bin, and using the female die whose die cavity is filled up with semi-solid viscous medium to tightly press slab billet material and closing die cavity; (2), utilizing plunger to make the viscous medium bin be filled up with viscous medium in the viscous medium injection cylinder; (3) utilizing plunger to continuously inject the viscous medium into the viscous medium bin and apply the forming pressure to the slab billet material; (4), regulating pressure control valve positioned in the medium discharge outlet to make the viscous medium in the female die be controllably flowed out and apply reverse pressure to said slab billet material; under the action of upper and lower two-side bidirectional pressures the slab billet material can be progressively pulled into the die cavity of concave die; and (5), finally, the viscous medium can be discharged to the exterior of die cavity of female cavity, under the enough pressure the slab billet material can be completely closed to the die so as to obtain the required component.

Owner:HARBIN INST OF TECH

Suction pump for a dispenser unit and dispenser unit

InactiveUS20100301070A1Great freedomSimple and favourably priced constructionHolders and dispensersPortable flexible containersLiquid mediumPressure difference

The invention relates to a method for filling and evacuating a dispenser unit for paste-like, foam-form or liquid media. In the known methods, a storage container is evacuated via a suction pump, which otherwise serves for the delivery of the medium, after filling. The risk exists hereby that medium is drawn in. In order to make the drawing-off process more effective and more reliable, a method and a filling insert for a dispenser unit are proposed according to the invention, wherein at least one air duct is provided parallel to the suction pump. The evacuation takes place by the application of a pressure difference between storage container and the environment, which is just so great that air can in fact be drawn through the air duct but no viscous medium can be drawn.

Owner:EVONIK DEGUSSA GMBH

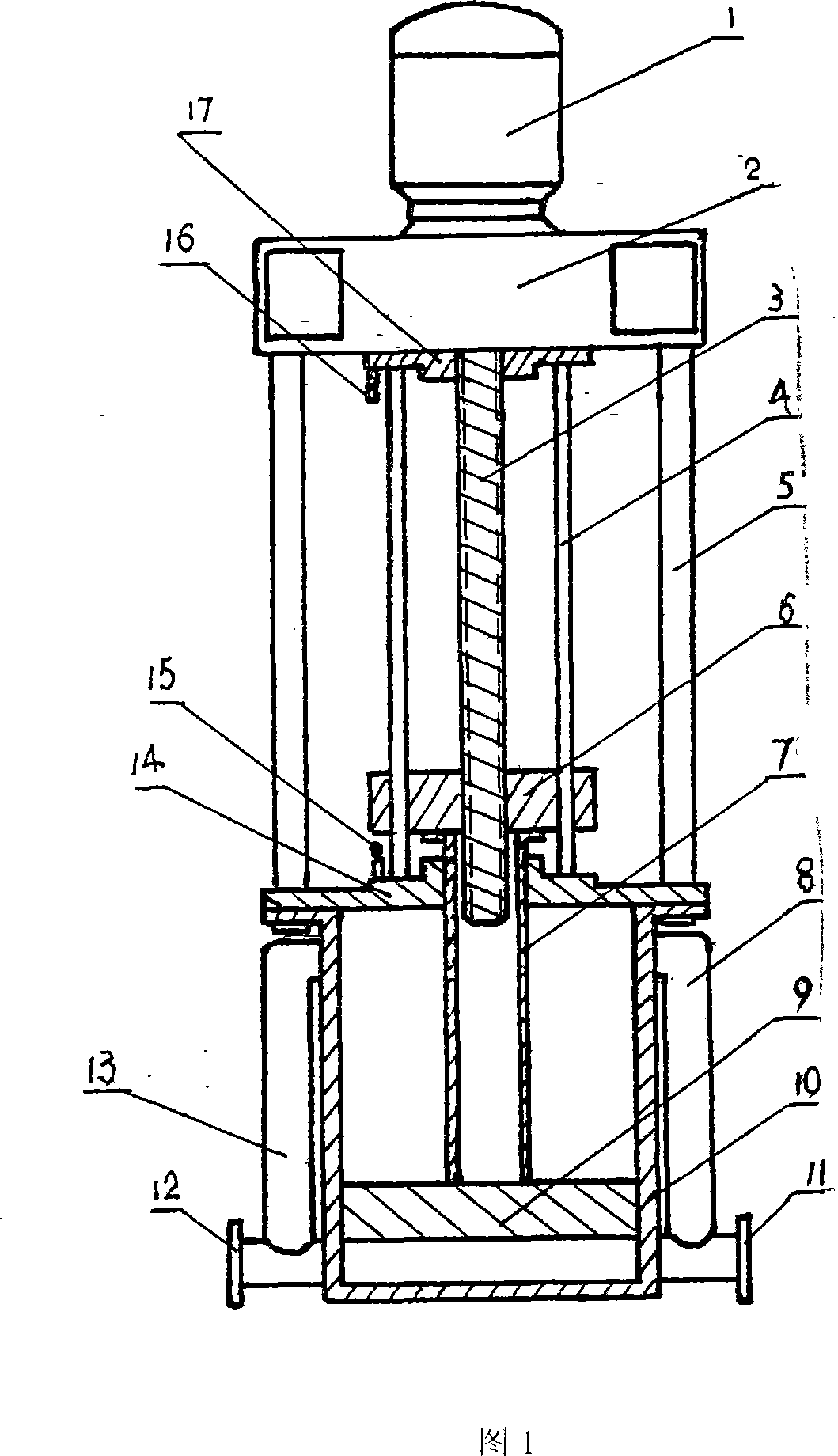

Screw piston pump

InactiveCN101169111AStrong discharge pressureStructural with few moving partsPositive displacement pump componentsPumpsLower limitEngineering

The invention belongs to a pump, in particular to a guide screw piston pump. The guide screw piston pump consists of an electromotor, a main shaft commutator, a guide screw, a nut leader, a connecting supported lever, a nut, a piston rod, a discharging valve, a piston, a cylinder, an outlet flange, an inlet flange, a sucking valve, an upper support seat, a lower support seat, a lower limit switch, and an upper limit switch. The piston, the piston rod, and the nut are connected together, and the nut and the guide screw are meshed. The invention adopts the structure that the piston, the piston rod and the nut are connected into a whole, the meshed motion of the nut and the guide screw is used as the power of the pump body, the discharging pressure is strong, the structural action parts are less, the cost is low, and the power is high. The invention is in particular applicable for the viscous medium and long-distance transmission, and is energy-saving and efficient.

Owner:王桐梅

Insect trap

The invention provides an insect trap including a housing having located therein a gas bottle or container, one or more modulators having a viscous medium to produce a pulsed flow of gas and a capillary tube interconnecting the gas bottle or container and a respective modulator; a conduit assembly interconnecting a modulator at one end and connectable to a gas bottle or container at another end; an attachment body for attachment to a gas bottle or container; and a method of producing a pulsed flow of gas from a container or source of said gas.

Owner:BANTIX WORLDWIDE

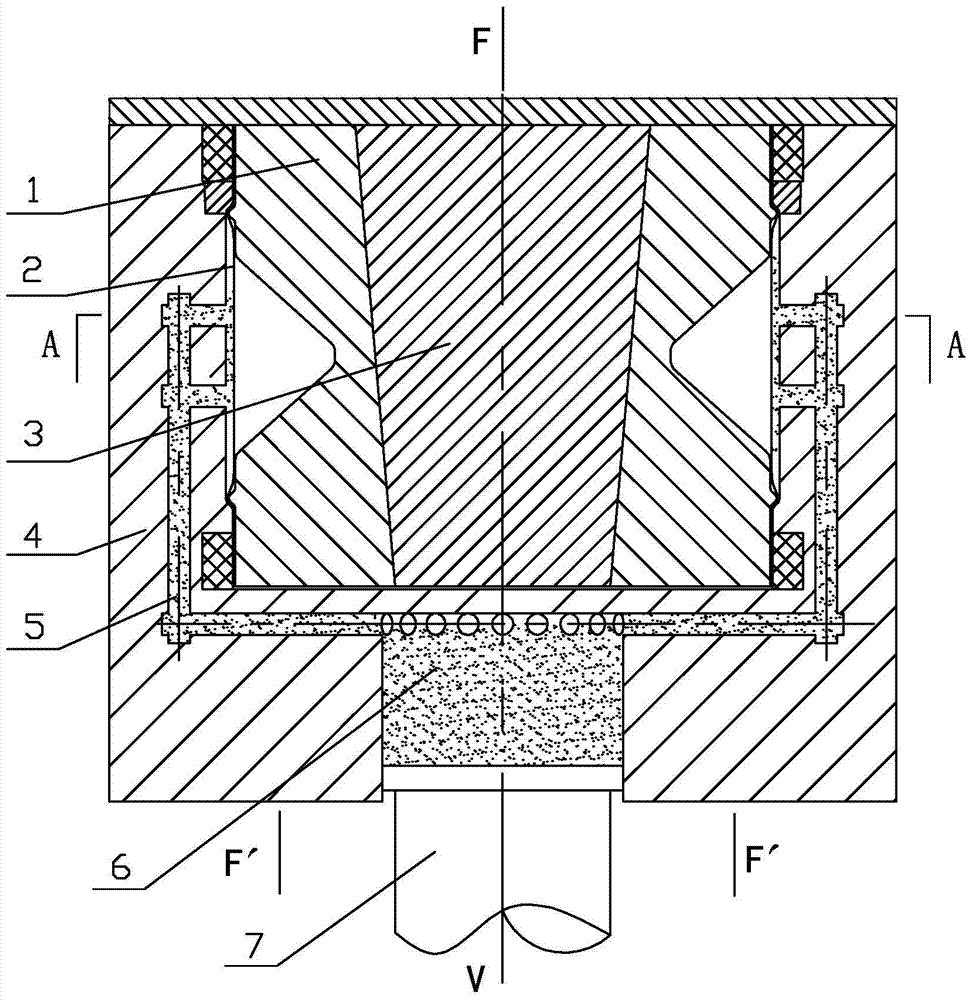

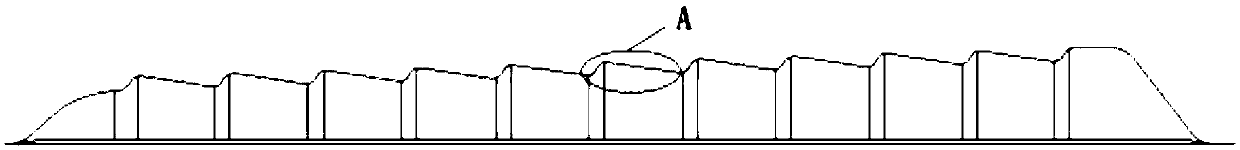

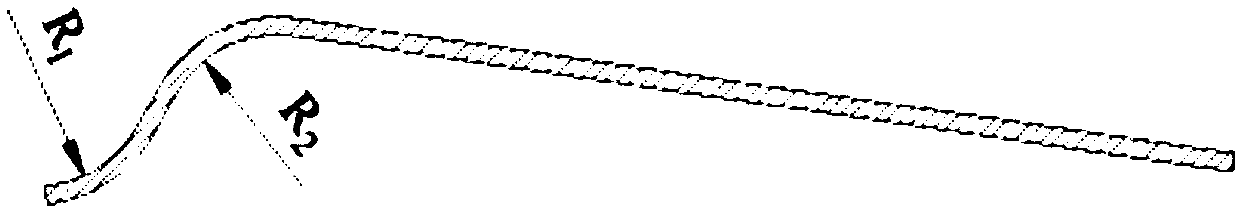

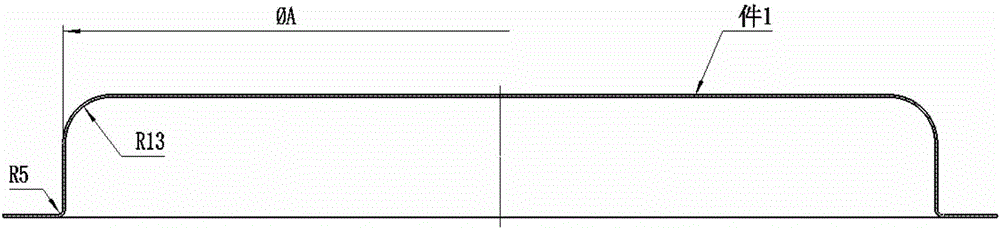

Viscous medium external pressing forming method for large-curvature thin-wall component

ActiveCN104226777ALarge diameter reductionSmall change in wall thicknessEngineeringMechanical engineering

The invention relates to an external pressing forming method for large-curvature thin-wall components, in particular to a viscous medium external pressing forming method for a large-curvature thin-wall component. The viscous medium external pressing forming method for the large-curvature thin-wall component aims to solve the problems that under the condition that pure external pressing forming is conducted on the large-curvature thin-wall component, when the two ends of a blank are restrained, the wall thickness of a formed component is greatly reduced, and even the wall of the formed component fractures; when the two ends of the blank are not restrained, the formed component is prone to being instable and wrinkling. The viscous medium external pressing forming method for the large-curvature thin-wall component comprises the steps that firstly, a plate is coiled and welded into a cylinder, and material flow control ribs are symmetrically arranged on the wall of the cylinder with the length center of the cylinder as the datum; secondly, the cylinder blank is installed in an external pressing forming die; thirdly, a plunger is pushed so that viscous soft die materials are injected in through an injecting channel from the outer side of the part, shrinkage deformation of a part of the cylinder blank occurs until the cylinder blank is attached to a core die; fourthly, the die is opened, an external pressing formed part is taken out, the viscous soft die materials are removed, and then the formed component is obtained; the material flow control ribs at the two ends are removed, and a finished product is obtained. The viscous medium external pressing forming method is applied to large-curvature thin-wall components.

Owner:HARBIN INST OF TECH

Method and apparatus for providing a substrate with viscous medium

InactiveUS7931933B2Increase productivityHardening of the viscous mediumPrinted circuit assemblingScreen printersMetallurgySolder paste

Solder paste application, inspection and correction. Following or during application of solder paste on a substrate, the result thereof is inspected and any detected errors are registered. Following an evaluation as to whether correction of these errors is required and if it would be worthwhile, the errors are corrected. The correction involves removing solder paste from locations where so required, and jetting of additional solder paste to locations where so required.

Owner:MYDATA AUTOMATION

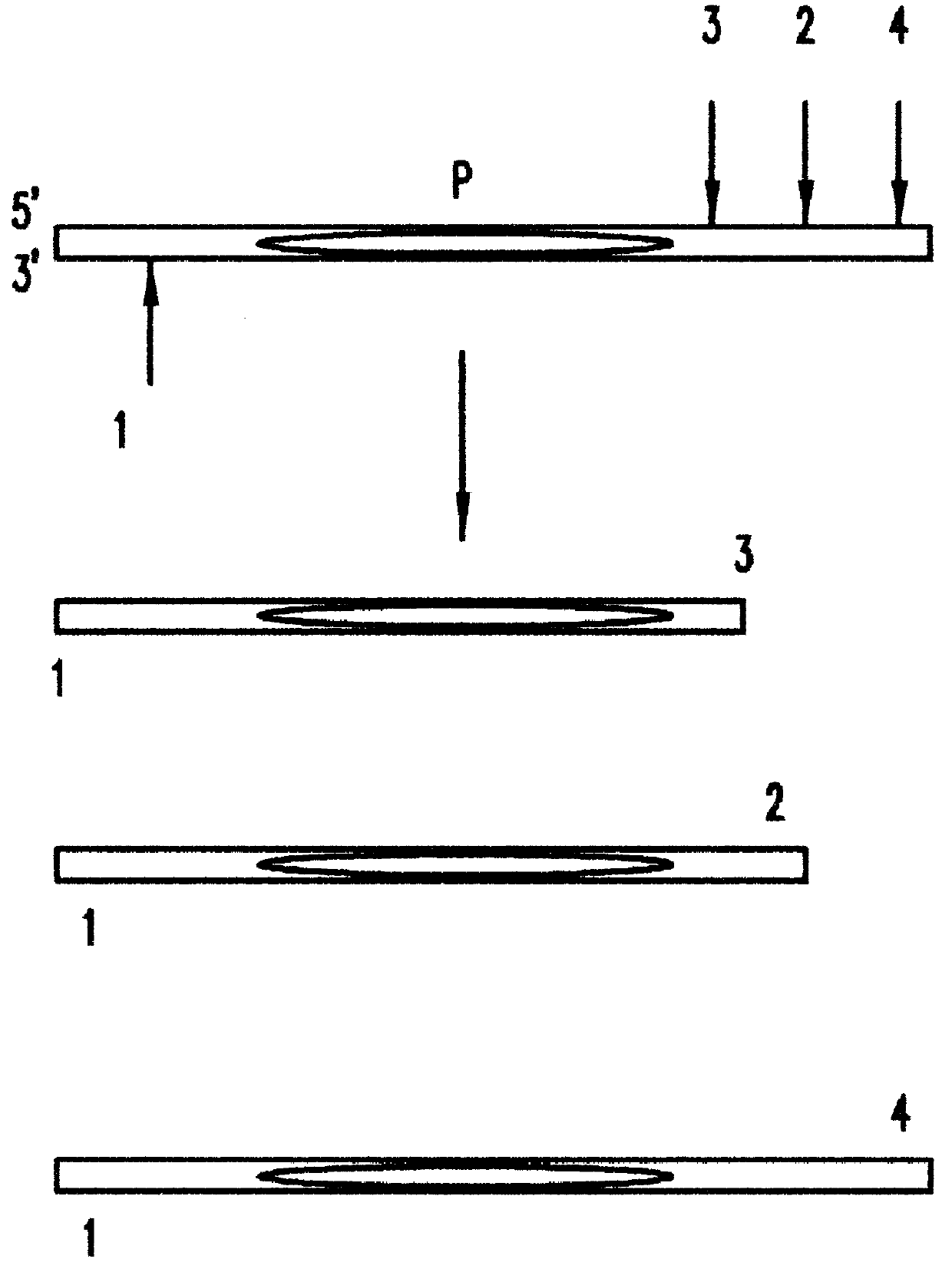

Viscous medium pressure forming method for local curvature sudden change thin-wall coverage piece

The invention belongs to the field of aerospace equipment thin-wall coverage piece manufacturing, and particularly relates to a viscous medium pressure forming method for a local curvature sudden change thin-wall coverage piece. According to the method, a plunger in a viscous medium bin is pushed, so that viscous media load the viscous medium pressure P to a plate blank from the viscous medium bin, under the action of the viscous medium pressure P, the plate blank is gradually attached to a cavity of a die, and at the cavity curvature sudden change position, a plate is promoted to flow throughthe viscous attaching stress tau of the viscous media, shape local sudden change area materials are supplemented, the area wall thickness is prevented from being reduced, the wall thickness uniformity is improved, finally, the plate blank is completely attached to the surface of the cavity of the die, and accordingly a good forming effect is achieved. According to the viscous medium pressure forming method, the forming technology is simple, the quality is stable, reliability is high, cost is low, and the viscous medium pressure forming method is suitable for forming machining of high-strengthheat resisting alloy local curvature sudden change thin-wall coverage pieces.

Owner:HARBIN INST OF TECH

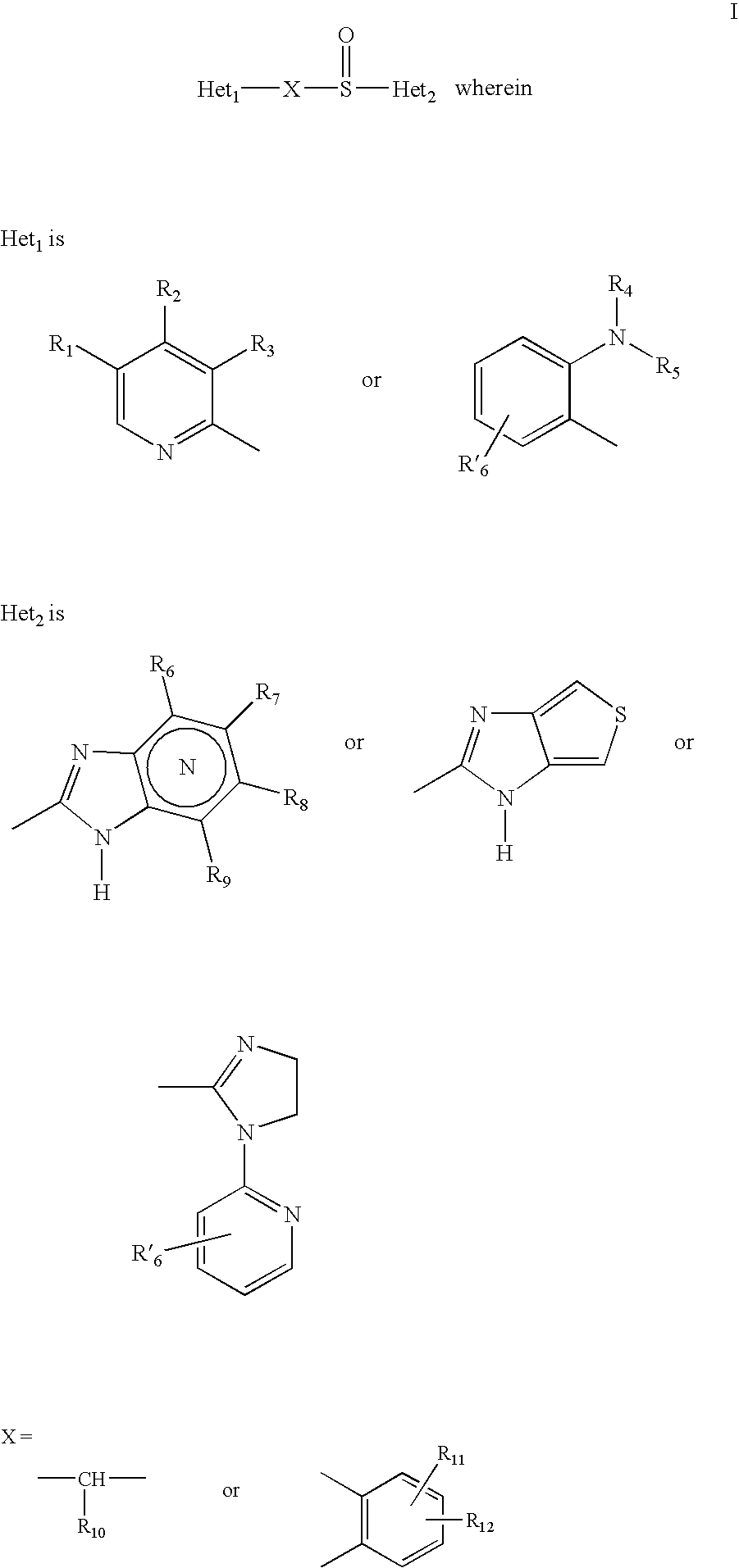

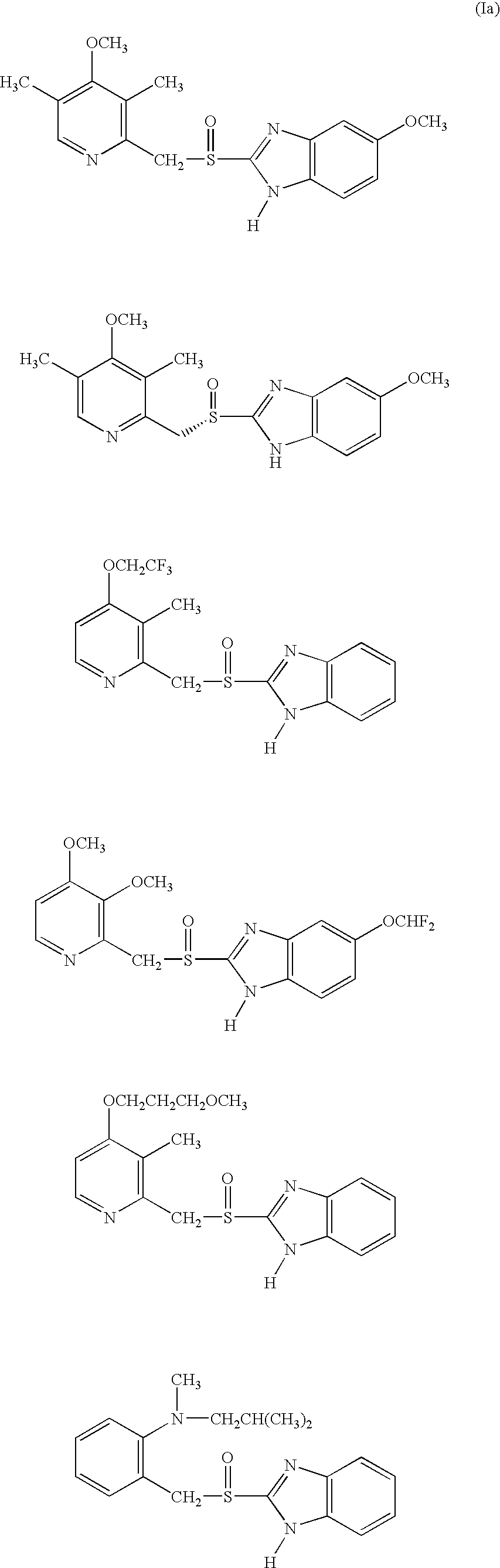

Solid composition comprising a proton pump inhibitor

The present invention related to a method for oral administration of a solid composition comprising an acid labile proton pump inhibitor compound in the form of a multiple of enteric coating layered pellets, wherein the pellets are in admixture with one or more pharmaceutically acceptable thickeners capable of forming a viscous medium when dispersed in an aqueous carrier. Alternatively, the enteric coated pellets are in admixture with a viscous medium. The formed aqueous viscous suspension is administered through a gastric tube. The method and composition are especially aimed for treatment of patients in need of a proton pump inhibitor and having difficulties to swallow or for pediatric patients.

Owner:ASTRAZENECA AB

Device for jetting droplets of a particle filled viscous medium

ActiveUS20040262824A1Improve sealingKeep in placeMelt-holding vesselsLiquid surface applicatorsEngineeringViscous medium

This invention relates to a device for jetting droplets of a particle filled viscous medium. The device has a nozzle, an eject mechanism connected to the nozzle, a medium feeding mechanism connected to the eject mechanism, a particle filled viscous medium container connected to the medium feeding mechanism, and a filter arranged between an outlet of the particle filled viscous medium container and the medium feeding mechanism.

Owner:MYCRONIC

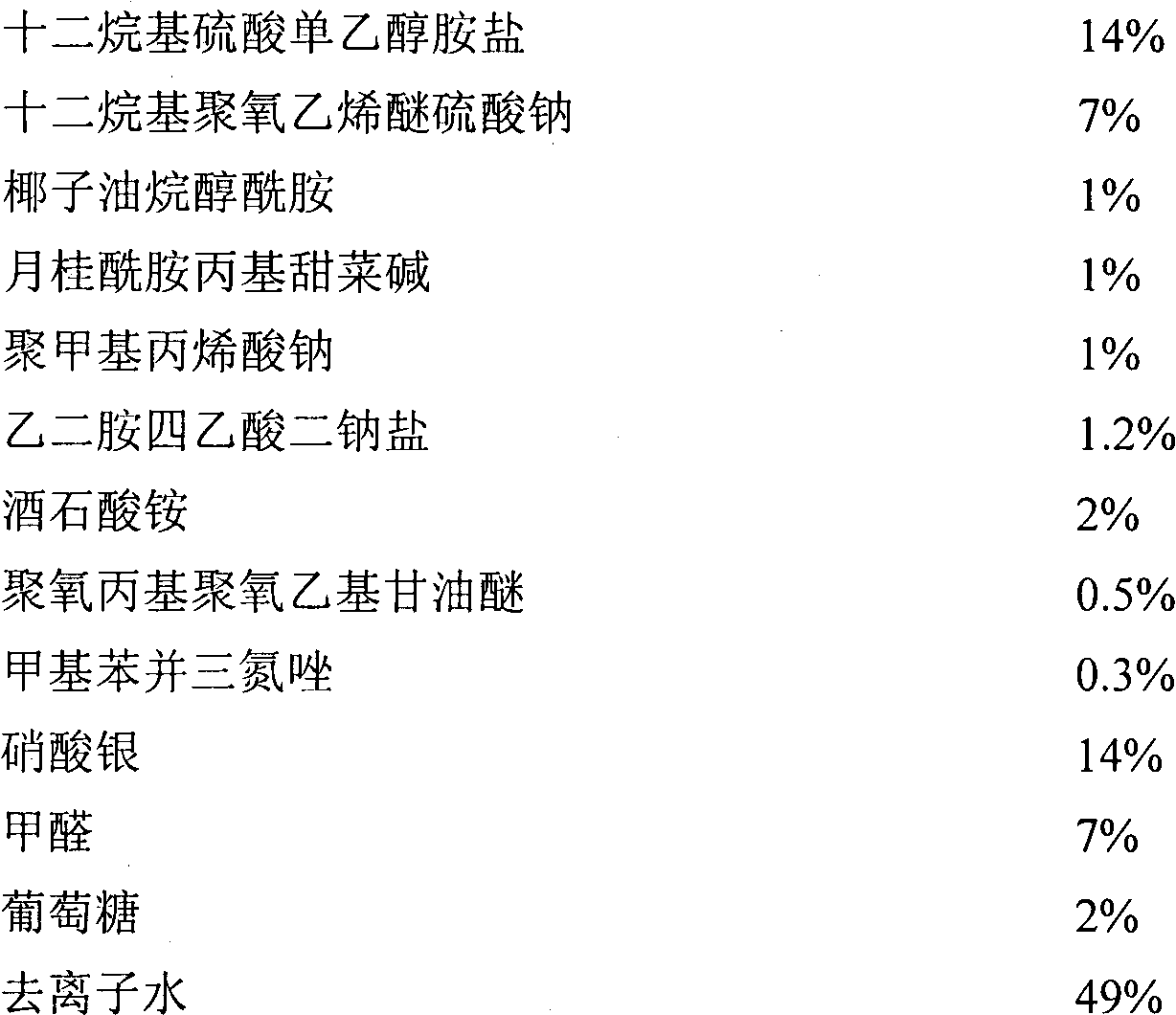

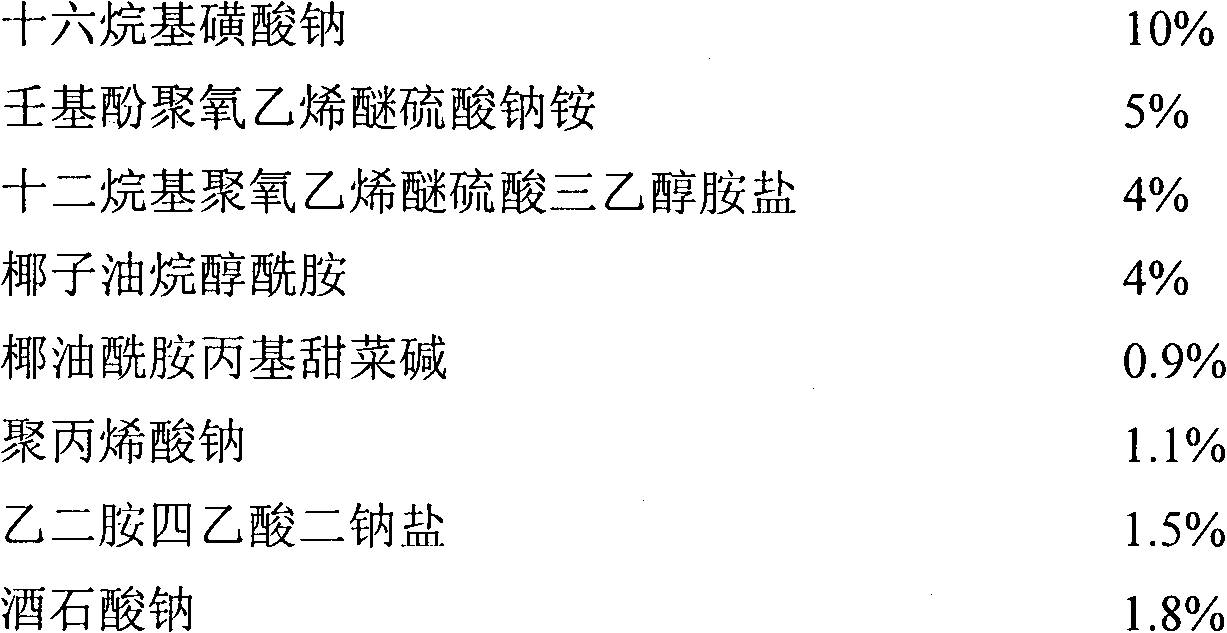

Method for preparing nano silver powder in viscous medium

InactiveCN102303125AReduce migration rateEffective control of unit cell growth rateFiltrationVacuum drying

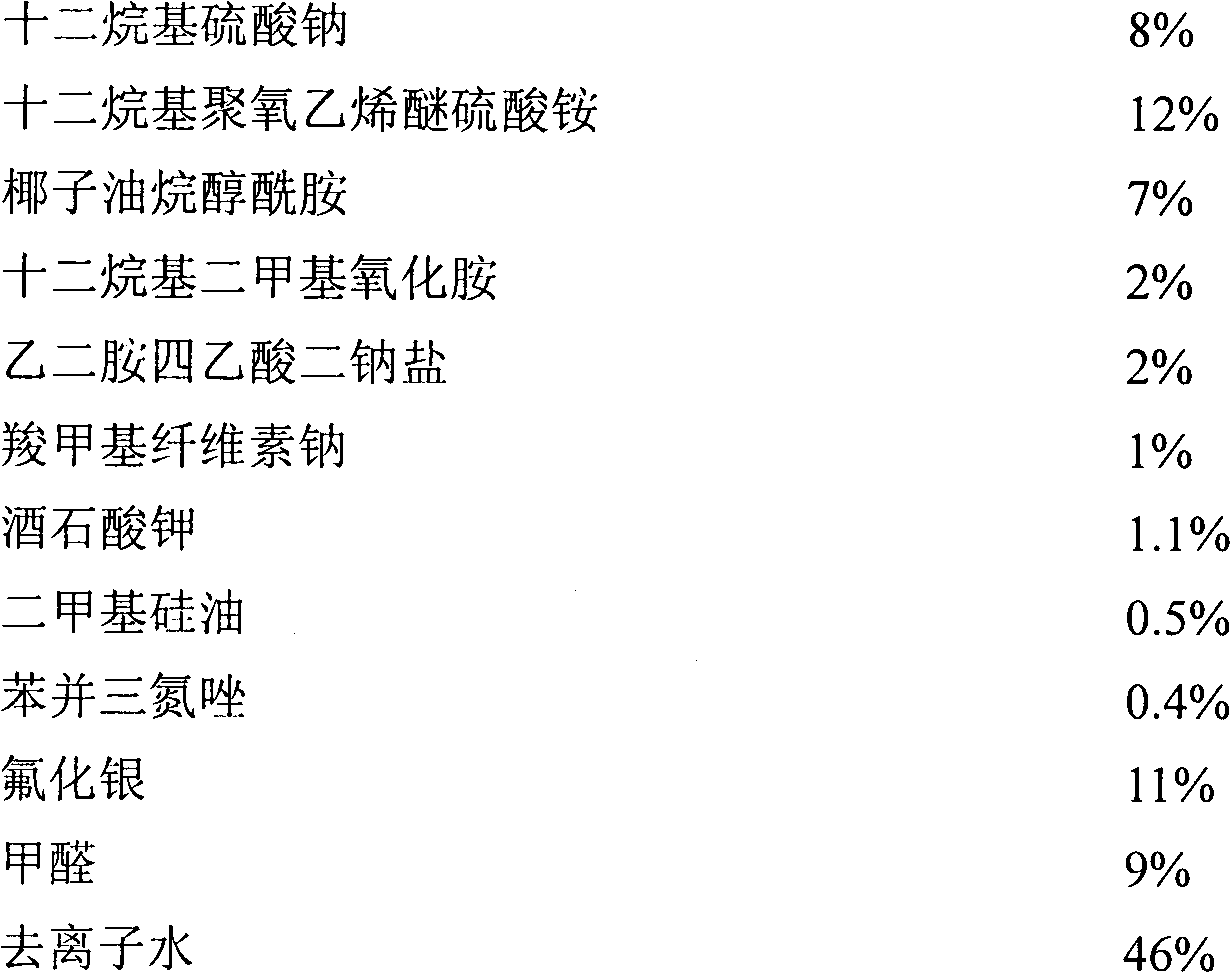

The invention discloses a method for preparing nano silver powder in viscous medium. The method comprises the following steps of: mixing sodium nonylphenol polyoxethyiene ether sulfate, TEA dodecylbenzenesulfonate, ammonium dodecylbenzenesulphonate, coconut oil alcohol acylamide, octadecyl dimethyl amine oxide, sodium carboxymethylcellulose, polyoxyethylene glycol 6000 bisstearate, ethylenediamine tetraacetic acid disodium salt, ethylene oxide, benzotriazole and deion water and stirring uniformly, preparing the viscous medium, adding silver acetate and silver lactate and stirring uniformly, adding sodium hypophosphite and stirring till full reaction, then adding the deion water for dilution according to a ratio of 1:1.5 of the all material amount to the deion water, reducing the viscosity, and obtaining the nano silver powder by pressure filtration, washing with the deionized water, washing with acetone and vacuum drying. The selected raw materials are easily obtained; the method is short in production process, high in production efficiency, low in production cost and low in energy consumption; the powder is not easily agglomerated, and the powder has good dispersibility; and the method is suitable for large-scale production, and solves the problems that the nano silver powder prepared by the conventional chemical preparation method is easily oxidized and easily agglomerated.

Owner:NANJING FORESTRY UNIV

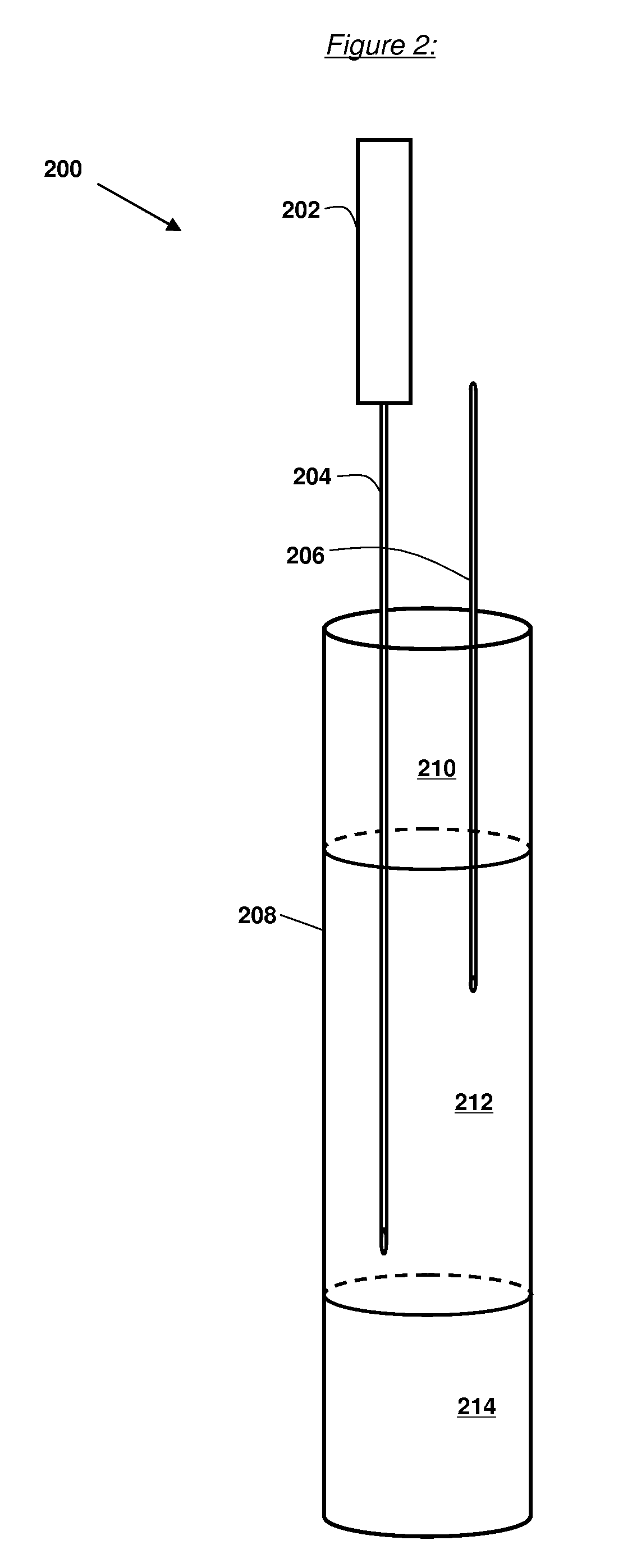

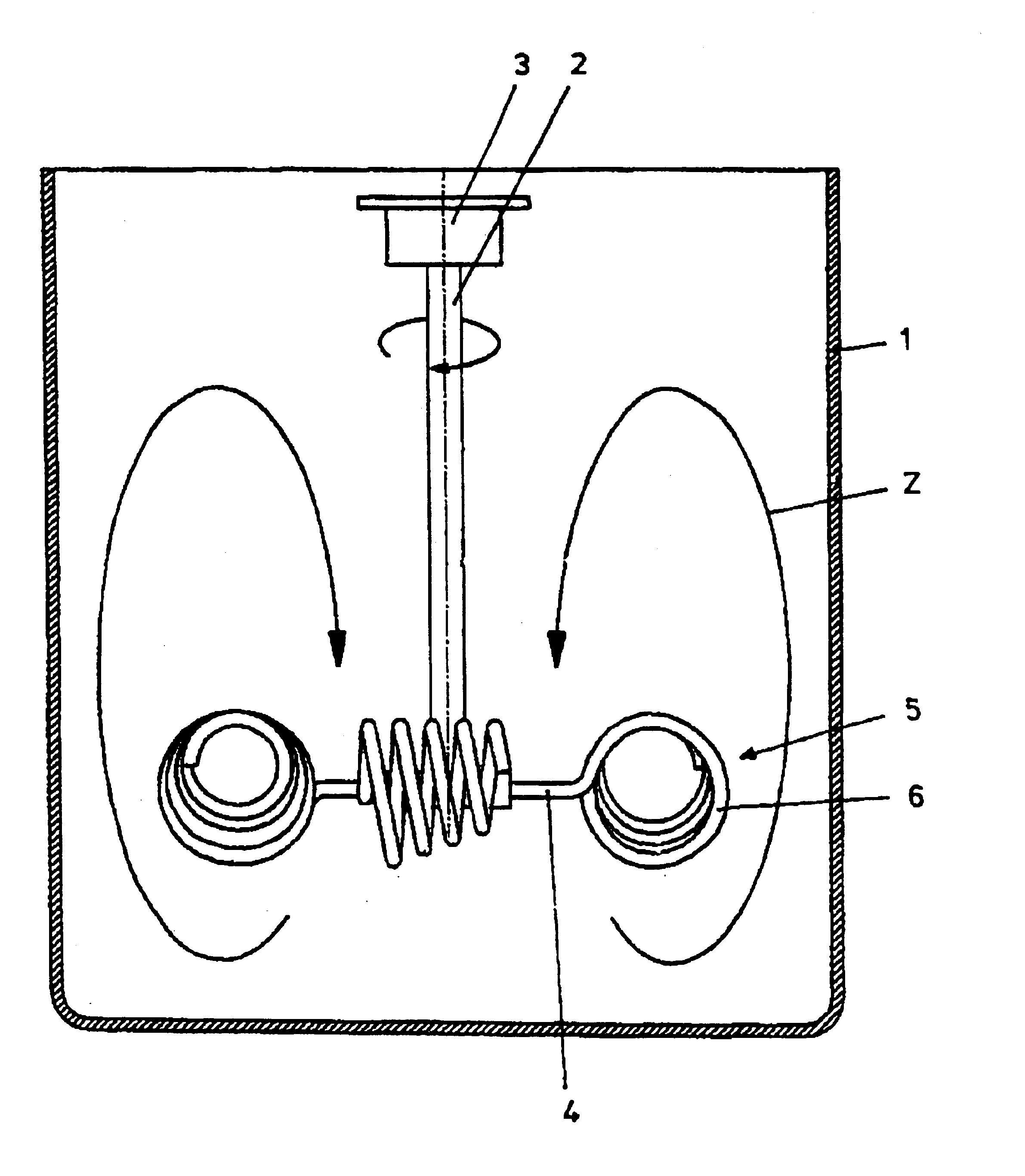

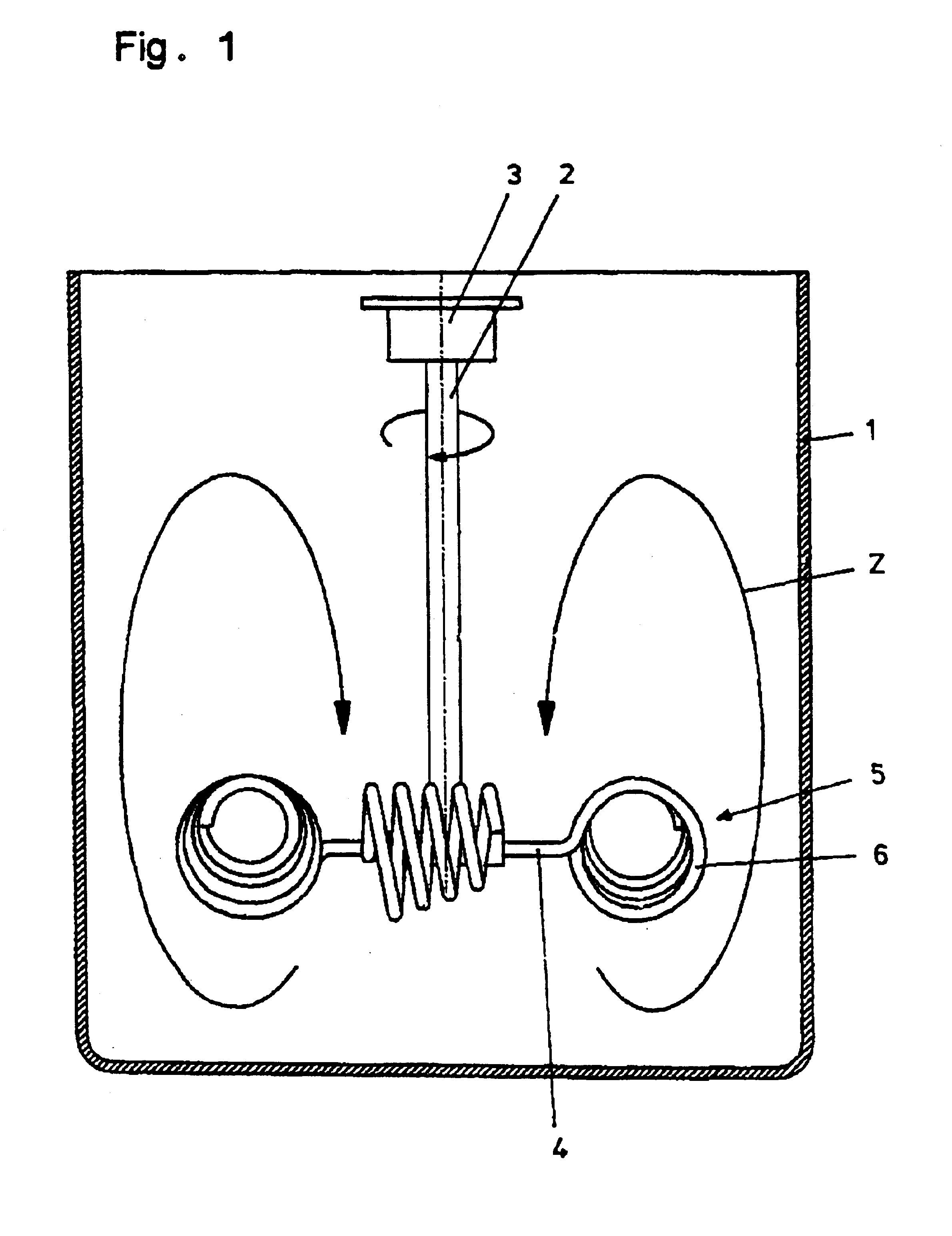

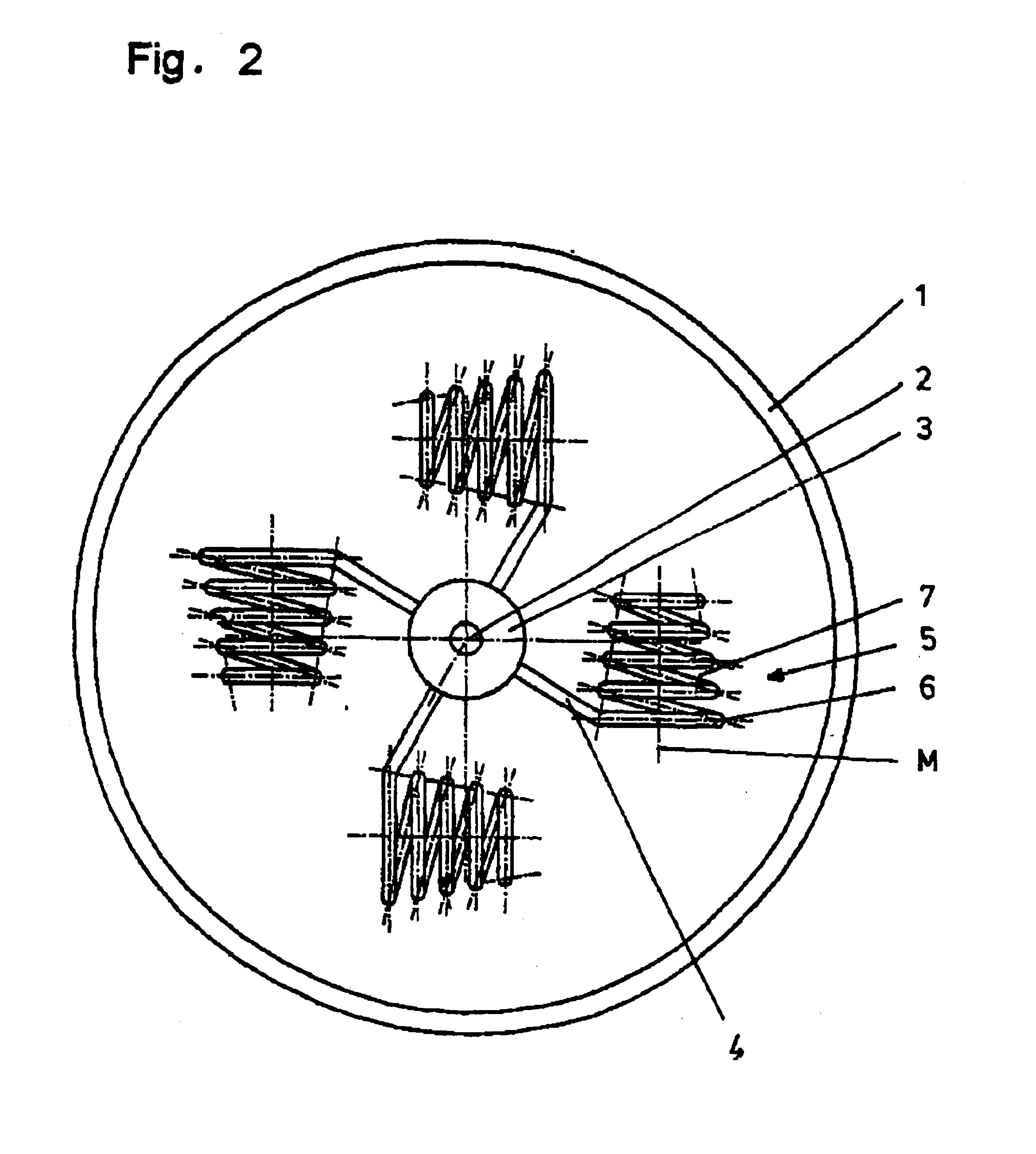

Device for mixing a flowable or pourable medium, especially a highly viscous medium

InactiveUS6921194B2High viscosityEasy to produceRotary stirring mixersTransportation and packagingSlant angleEngineering

A device for mixing a flowable or pourable medium has a container for receiving the medium and a rotatable shaft having radially projecting support arms and rotatable in a direction of rotation. Mixing elements are connected to the radially projecting support arms. The mixing elements are tubular and formed as coil-shaped spirals conically shaped at least across a partial length of the coil-shaped spirals. The coil-shaped spirals have a first end face and a second end face. The first end face points in the direction of rotation and has a cross-section greater than the cross-section of the second end face. The coil-shaped spirals have a central axis having a slant angle relative to a plane of rotation of the two mixing elements. The support arms and the coil-shaped spirals connected to the support arms, respectively, are formed of a single wire as a monolithic part, respectively.

Owner:VISCO JET RUHRSYST

Processes for dispersing substances and preparing composite materials

InactiveUS8030376B2Improve dispersion stabilityGood dispersionOther chemical processesOrganic dyesNanoparticleCarbon nanotube

Owner:MINUSNINE TECH

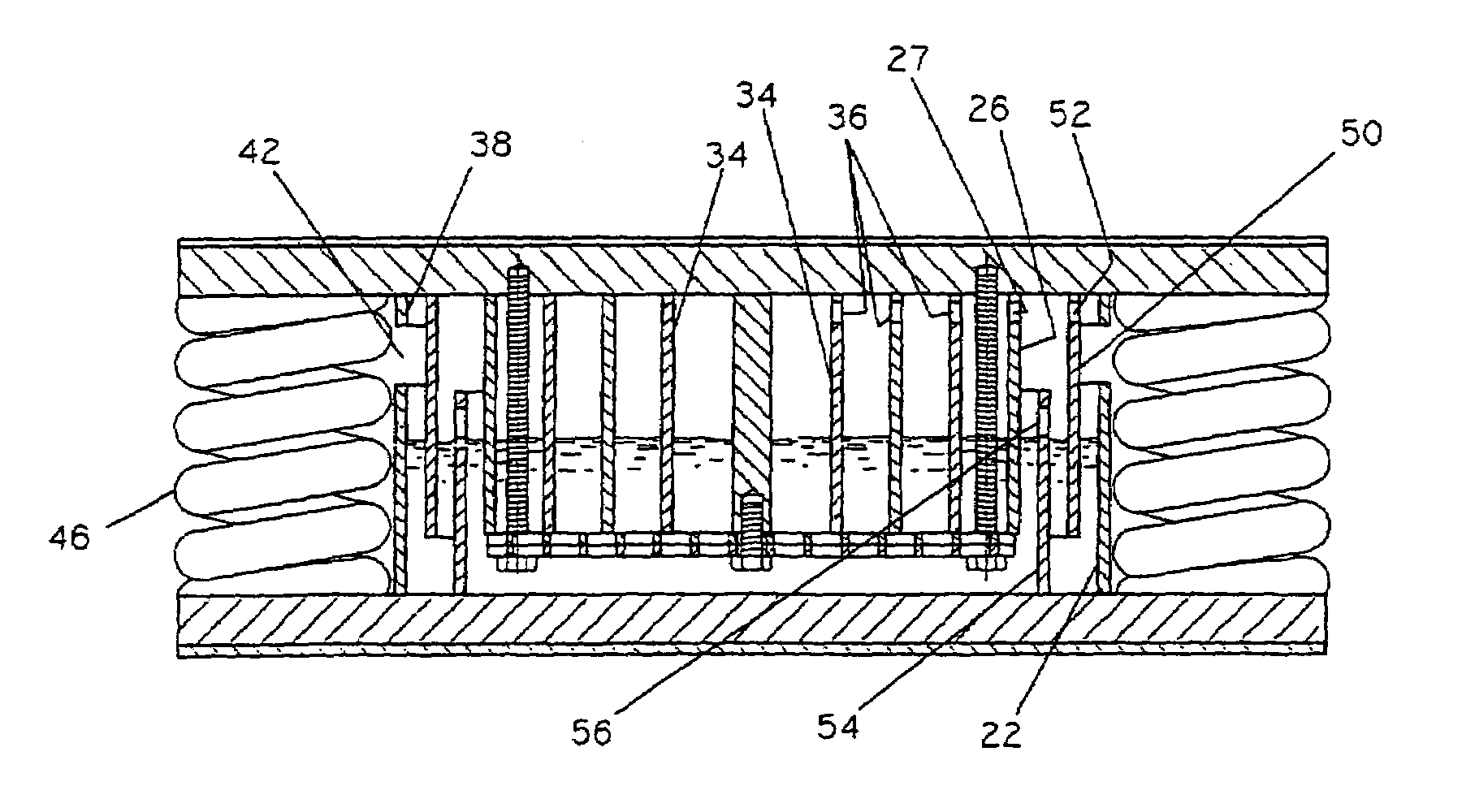

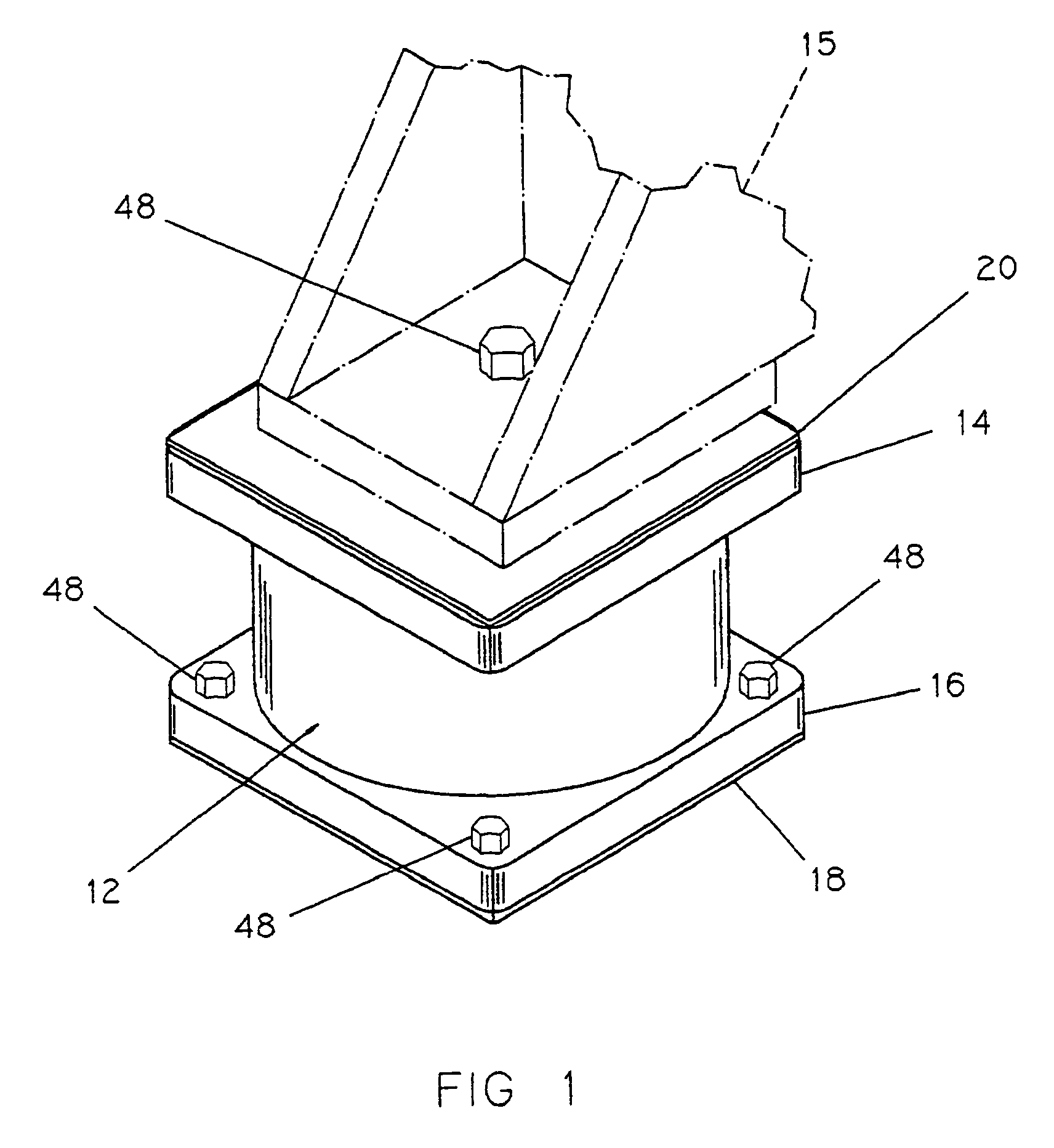

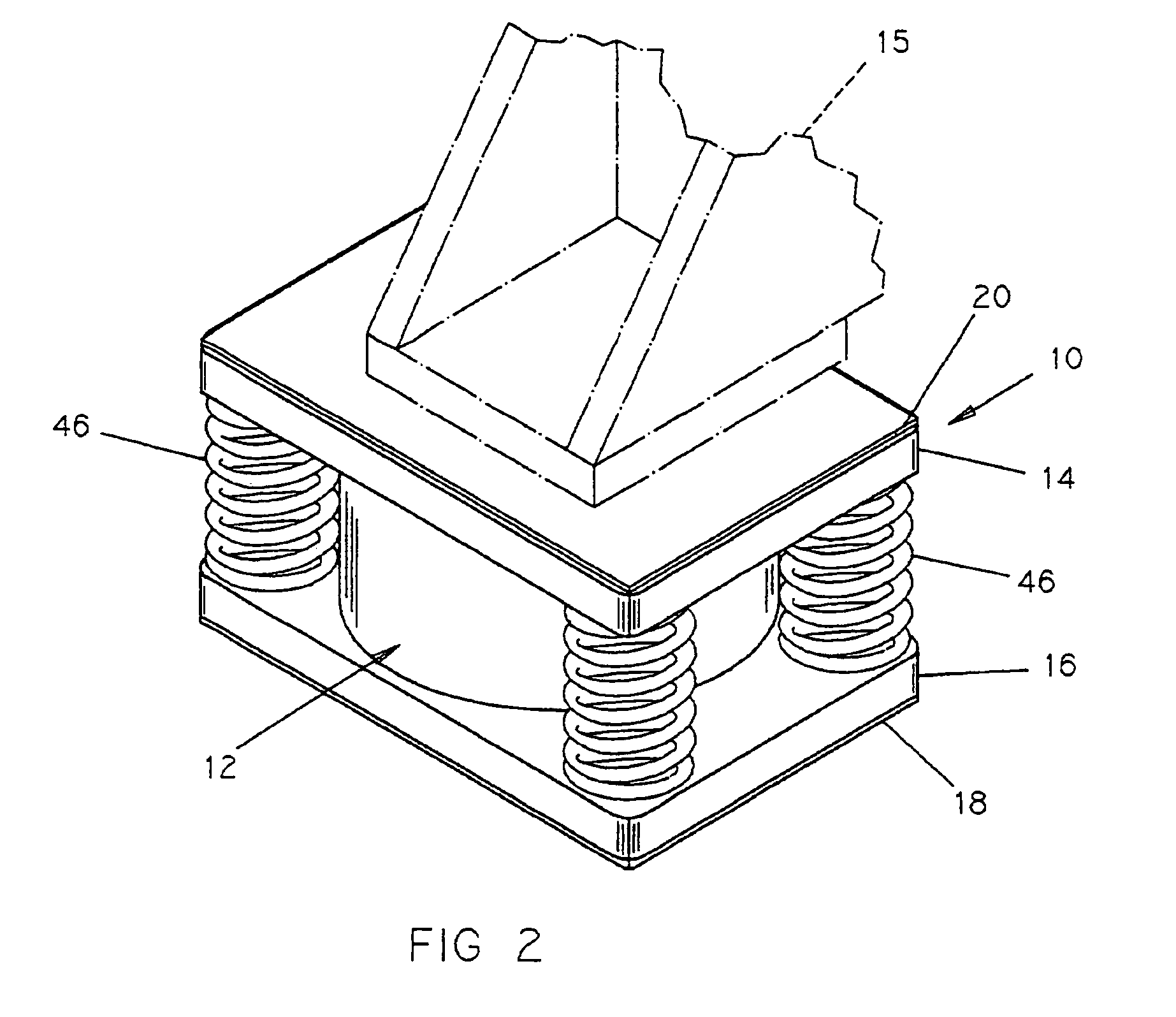

Viscous damper for machinery mounting

InactiveUS7077250B2Easy to optimizeReduce vibrationSpringsNon-rotating vibration suppressionEngineeringViscous medium

A viscous damper for a machinery mount having a damping member disposed intermediate a top support engageable with at least a portion of a load and a bottom plate disposed beneath the support and spaced therefrom to thereby decrease or deaden vibrations. The damper includes a receptacle for vertical disposition, which is closed at the bottom and opened at the top, and is adaptable for containing a viscous fluid. A plunger of smaller lateral dimensions is arranged concentrically and co-axially within the receptacle, and depends downwardly from the horizontally disposed support, and is of such a longitudinal dimension as to be spaced from the closed bottom of the receptacle so as to be submerged partially in the viscous fluid and is therefore free to move vertically. A perforated plate is affixed at the bottom of the plunger, and provides fluid communication between the receptacle and the plunger. The damping effected by the vibrations will force the viscous medium through the apertures in the bottom plate in one direction or the other.

Owner:VIBRODYNAMICS

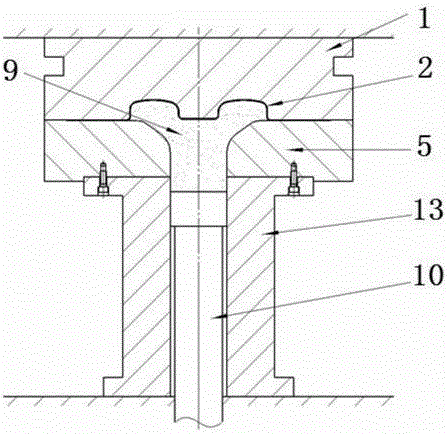

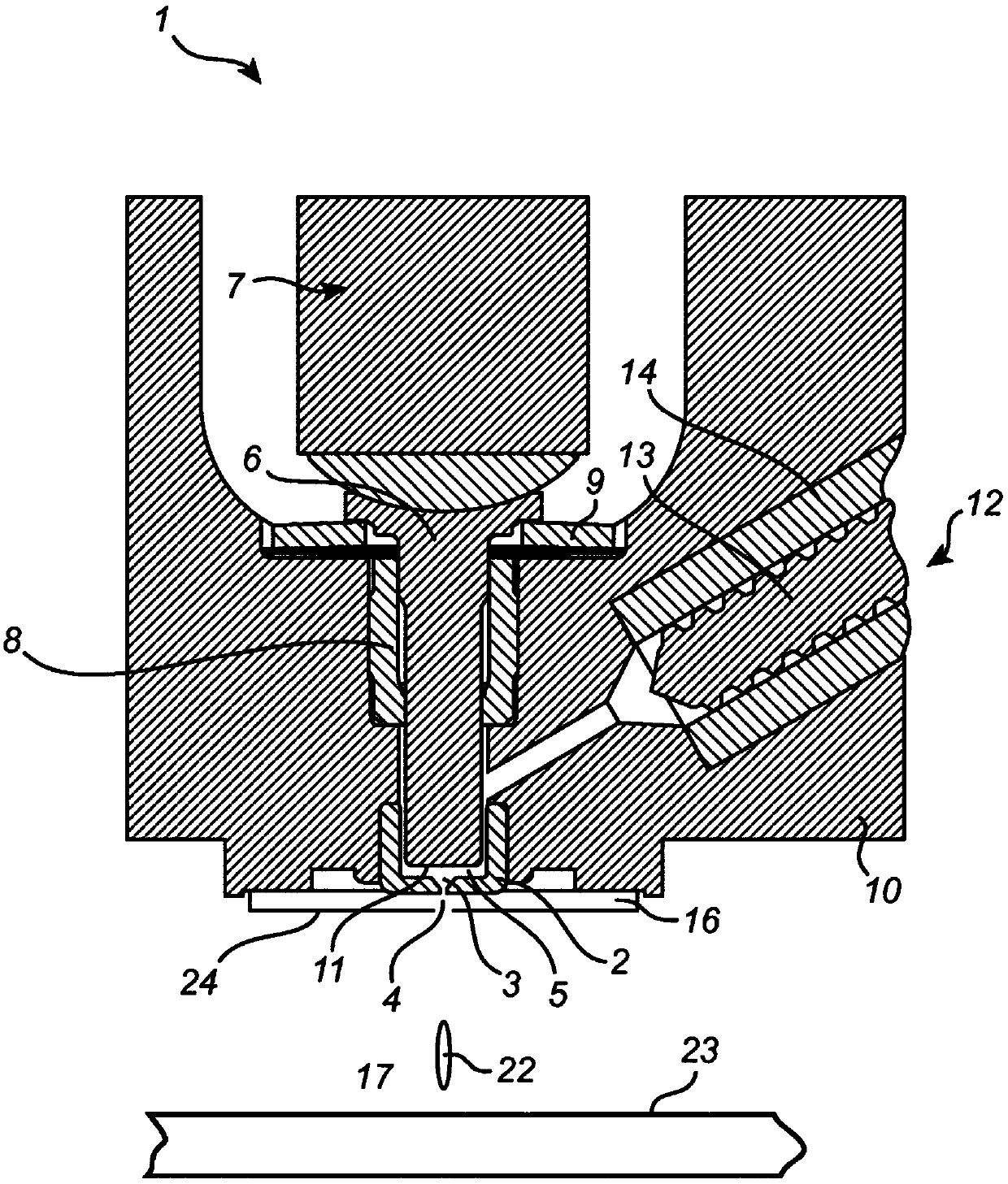

Thin-wall sheet metal part stamping molding method

The invention discloses a thin-wall sheet metal part stamping molding method which comprises the following steps: firstly, pre-machining a general outline of an overall thin-wall sheet metal part blank in a front procedure, and performing stamping molding machining on a half finished product of the thin-wall sheet metal part to be machined by using a special overall stamping molding correction mold, thereby obtaining a qualified product, wherein the special overall stamping molding correction mold consists of a concave mold (1), a thin-wall sheet metal part (2), a piston cylinder (13), a lower mold plate (5), a cavity (9) and a step-up piston (10); the cavity (9) for accommodating a viscous medium is formed in the center of the lower mold plate (5); the step-up piston (10) for exerting pressure to the viscous medium is arranged on the cavity (9). By adopting the thin-wall sheet metal part stamping molding method, overall stamping molding is achieved, argon arc welding joints are avoided, the part appearance and surface quality can be improved, and potential safety hazard can be eliminated. The thin-wall sheet metal part stamping molding method has relatively great predictable economic values and social values.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

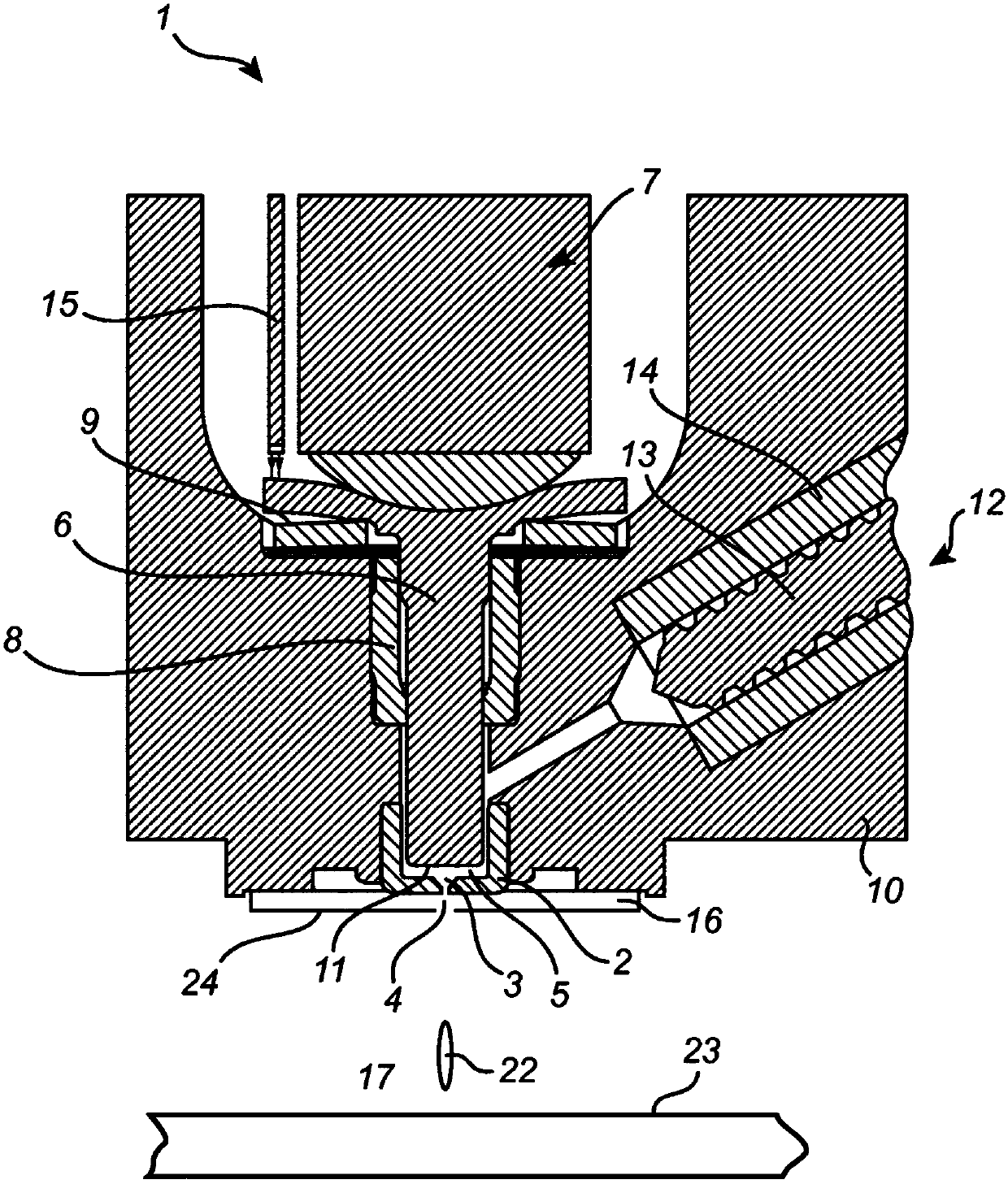

Method and apparatus for controlling jet dispensing by displacement measurement

PendingCN109644560ADetect and compensate for rheological differencesReduce the number of toolsLiquid surface applicatorsSpray nozzlesSpray nozzleEngineering

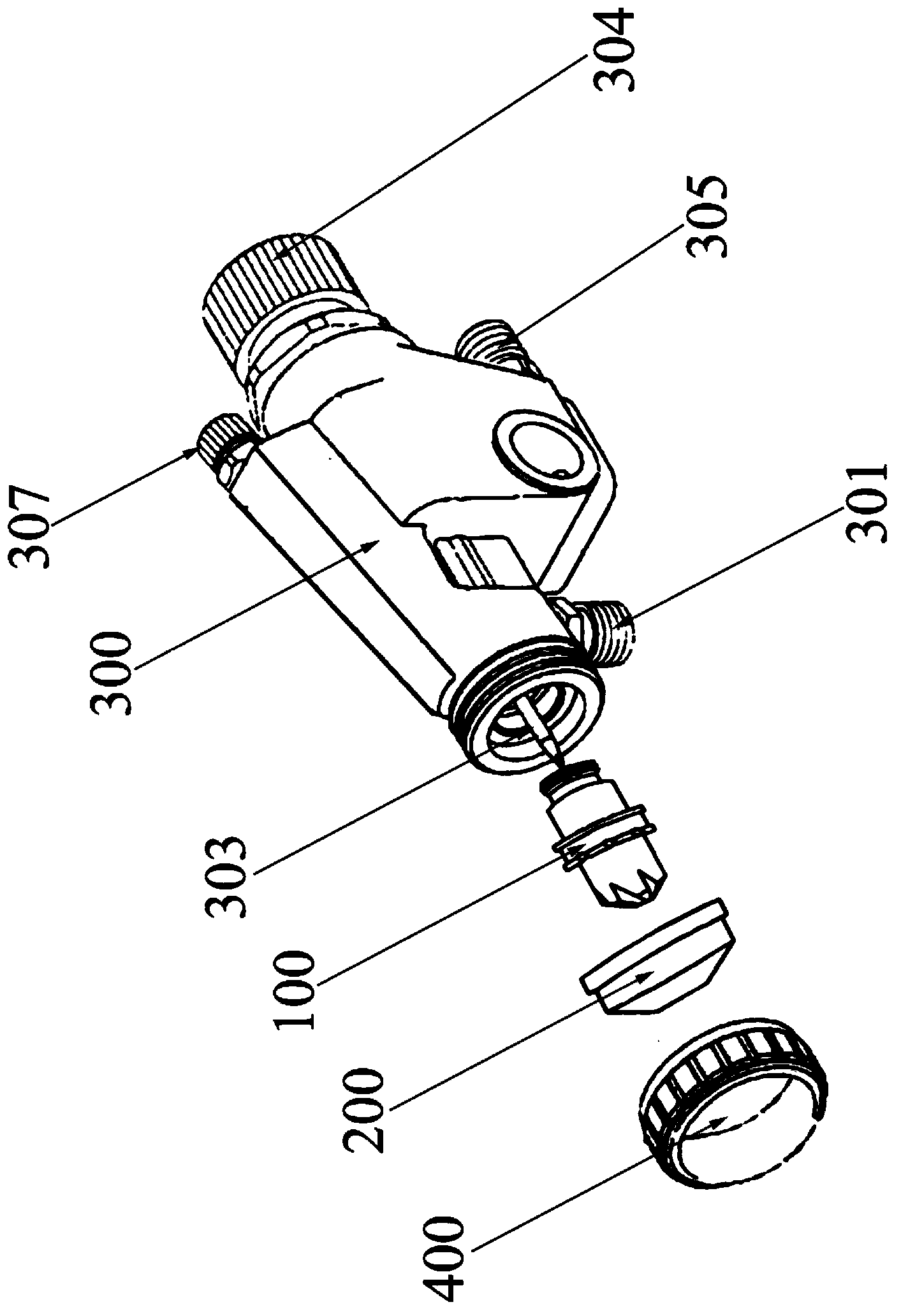

A method for jetting a viscous medium onto a substrate (23) is disclosed. The method comprises providing (110) viscous medium to a jetting chamber (5) of an ejector (1), operating (120) an impacting device (6, 7) to impact a volume of the viscous medium in the chamber such that viscous medium is jetted through a nozzle (4), connected to the chamber, towards the substrate, and monitoring (130) a displacement of the impacting device during the impact. An ejector and a system comprising such an ejector and a control unit (32) is also disclosed. The monitoring of the displacement allows for the operation of the impacting device to be controlled accordingly, thereby providing for an improved control of the jetting process.

Owner:MYCRONIC

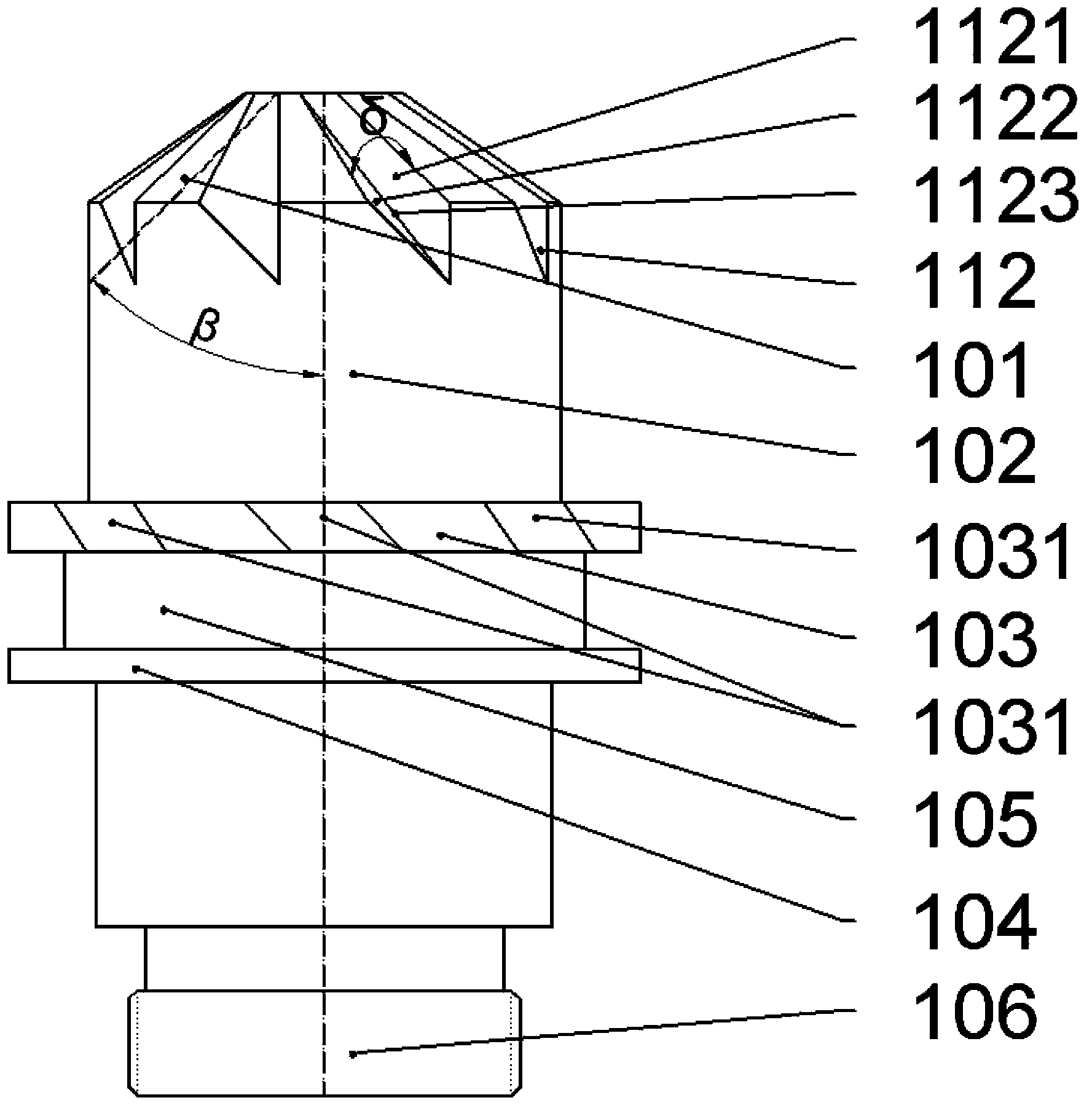

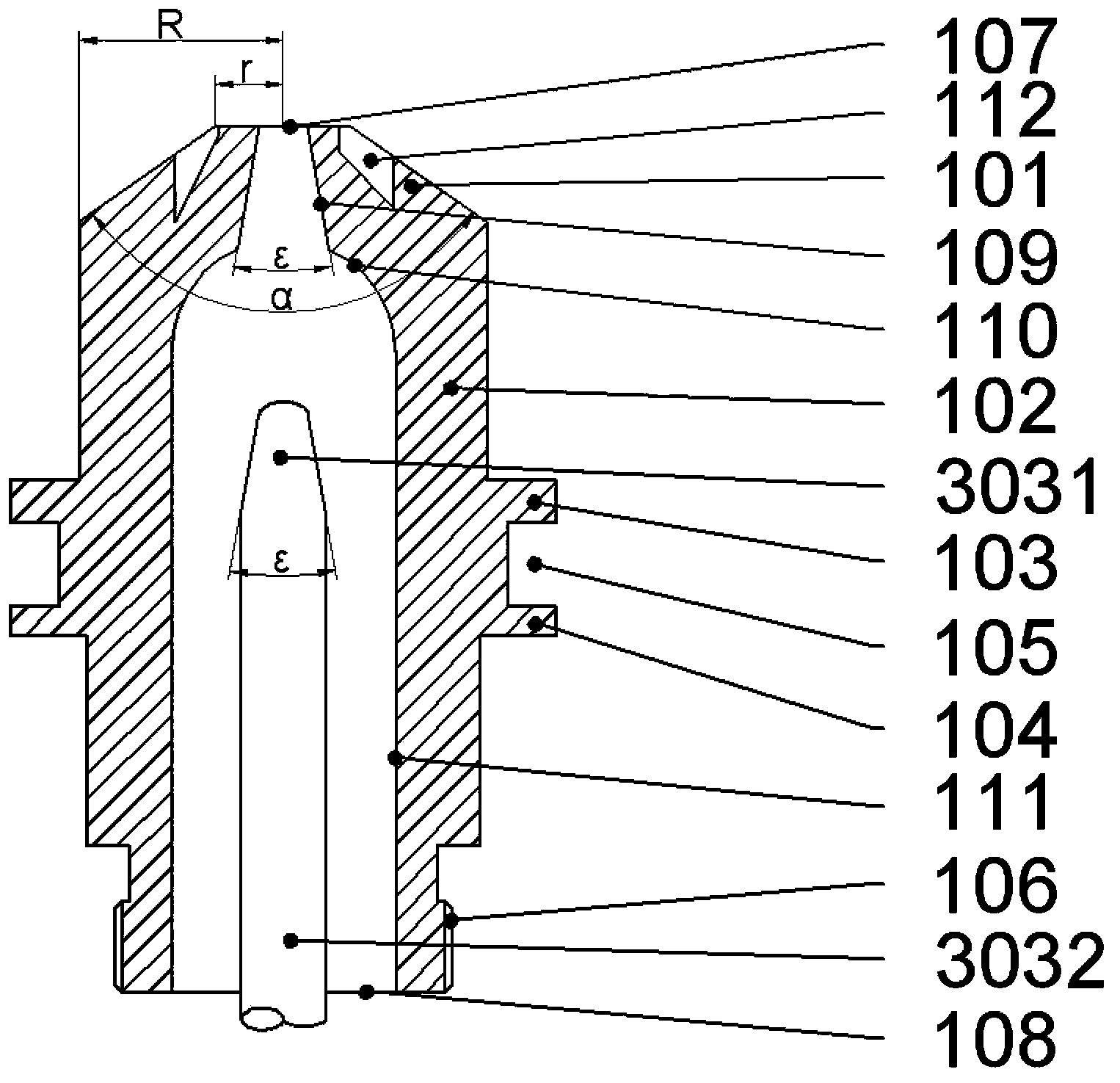

Nozzle component for viscous liquid and spray gun with nozzle component

The invention relates to mechanical devices for dispersing liquid, in particular to a nozzle component for viscous liquid and a spray gun with the nozzle component. The nozzle component is composed of a nozzle with a head portion in the shape of a circular truncated cone and an air cap, an air groove with a function of restraining the gas jet direction is formed on the side face of the head portion, an outlet section of an inner cavity of the air cap is provided with a beveled first inner wall coincident with the head portion in conical degree, the spray gun comprises a spray gun body with a gas inlet, a liquid inlet, a gun head and the nozzle component, and a gas outlet and a liquid outlet are arranged in the gun head. The nozzle component and the spray gun have the advantages that spray floating is reduced substantially, and liquid consumption is greatly reduced compared with conventional modes; service life of a container is prolonged, and operating cost and maintenance cost of enterprises are saved; the spray gun is large in spraying angle, can reach 120 degrees to great extent and is uniform in spraying; the problem that common nozzles are difficult to spray viscous media is solved; the liquid is sprayed out in a rotating mode, so that the problem of nonuniformity in spraying of inner walls of cup-shaped objects is solved.

Owner:康泽士上海洁净设备有限公司

Furniture hinge

InactiveUS7757348B2Improve efficiencyImprove rigidityBuilding braking devicesHingesAngular velocityEngineering

Furniture hinge with damping and / or braking device in alternative to those already existing and capable of guaranteeing an improved efficiency during the closing or opening operation of the doors, or other furniture parts, thanks to an improvement of the characteristics of rigidity and, simultaneously, elasticity of the means for transmitting motion from one of the rockers to the damping elements. The improved efficiency of this hinge is also obtained by increasing the friction surfaces with a viscous medium present in suitable areas of the hinge and by allowing regulation of the trend of the angular velocity of a circular shaped element, for example a disc, which acts as braking element in contact with the viscous medium.

Owner:ARTURO SALICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com