Device used to indirectly apply a liquid or viscous medium onto a material web, specifically a paper or cardboard web

a technology of liquid or viscous medium and moving material, applied in the direction of papermaking, press section, coating, etc., can solve the problem of structurally expensive design in the known applicator uni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

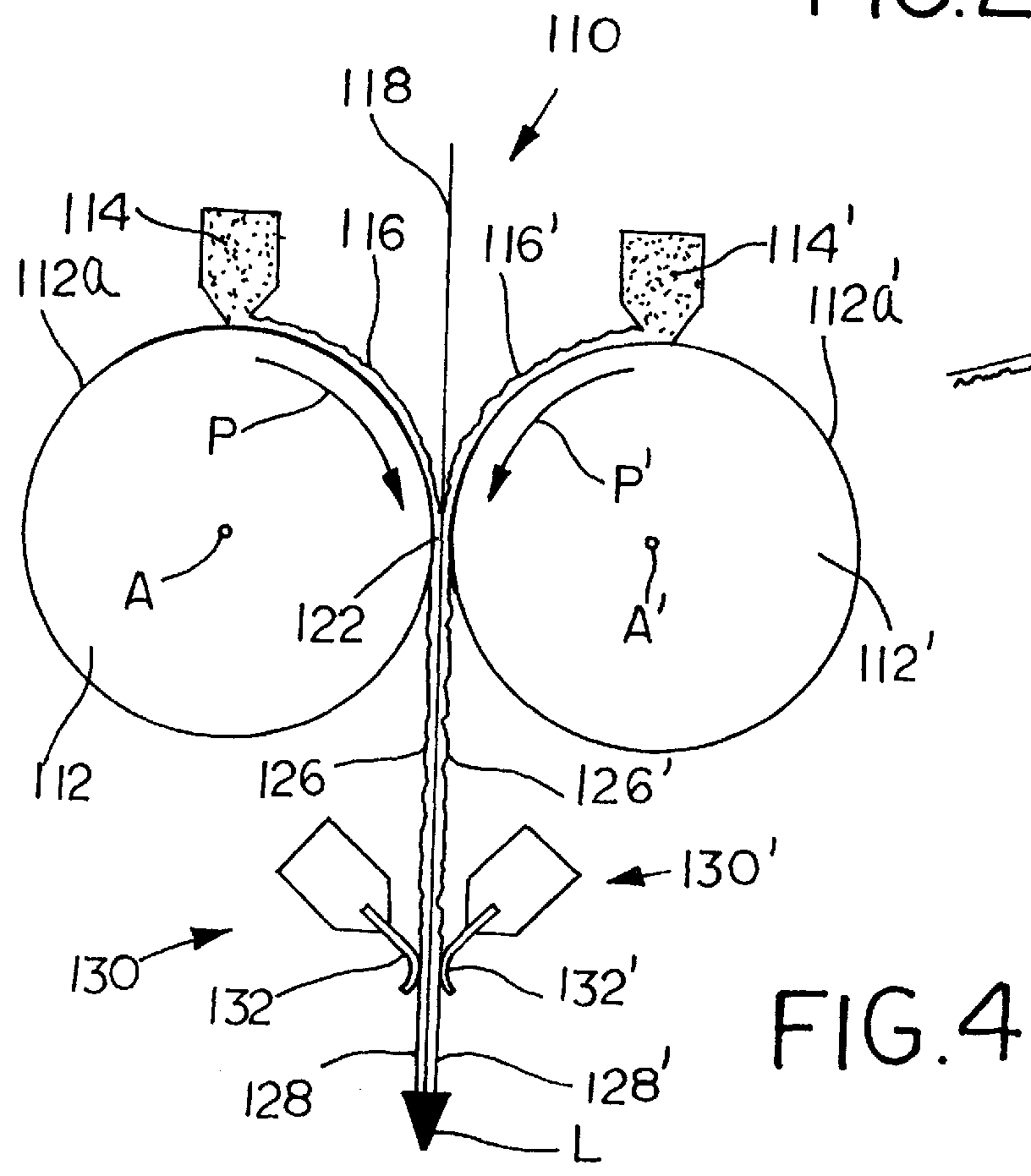

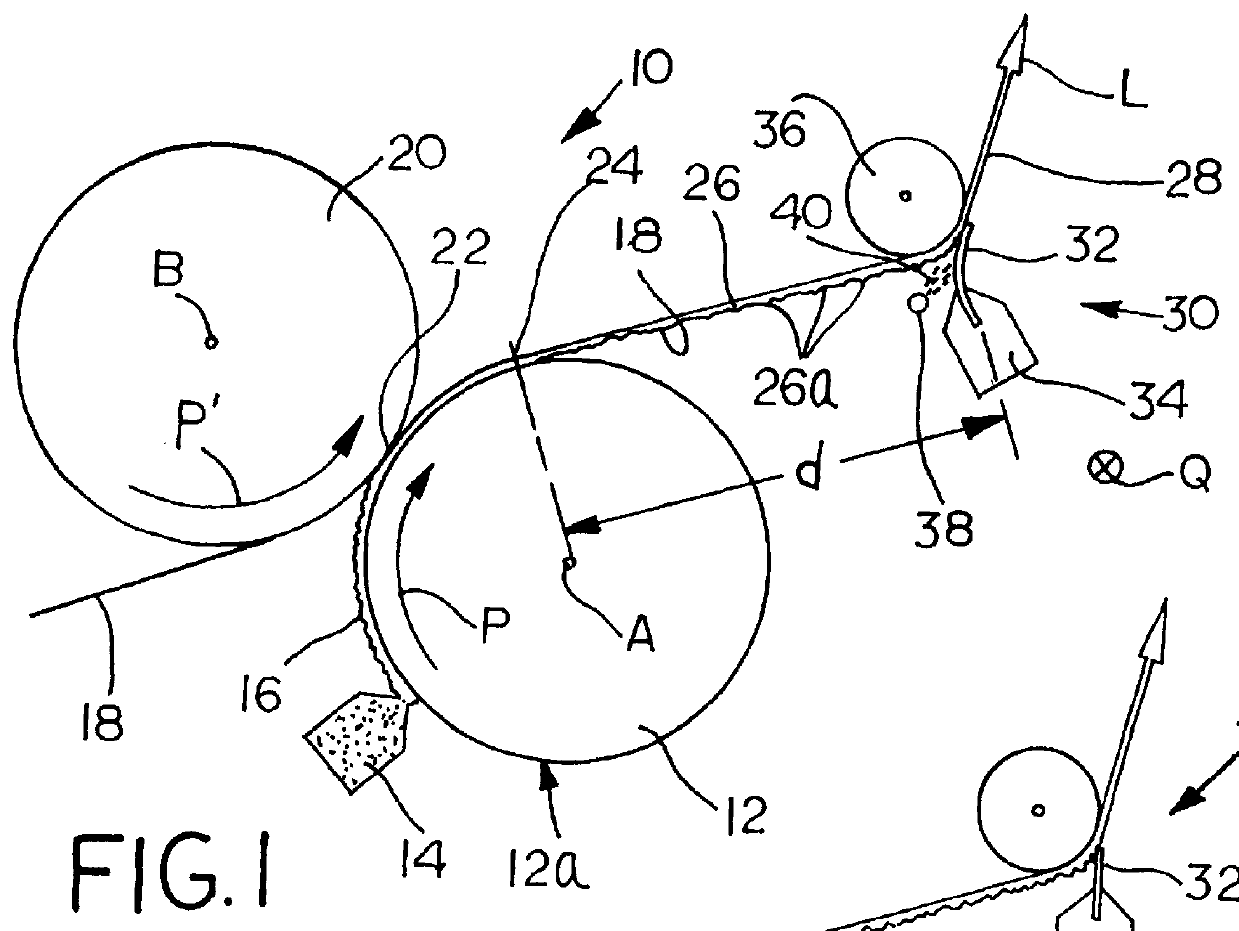

Referring now to the drawings and particularly to FIG. 1, there is shown an applicator device in accordance with the invention, generally identified with 10. It includes a transfer roll 12 onto the surface 12a of which a layer of liquid or viscous medium 16 is applied by an applicator unit 14. The transfer roll 12 rotates around an axis A in direction of arrow P. As a result of the rotation of transfer roll 12, the coating medium 16 is brought to a material web 18 which is traveling in direction L and which wraps partially around the circumference of the transfer roll 12.

A support or backing roll 20 is provided on the side of material web 18 which faces away from the transfer roll 12. It rotates around axis B in direction of arrow P', that is, in opposite direction to transfer roll 12. Transfer roll 12 and back-up roll 20 form a transfer nip 22 in which the liquid or viscous medium 16 is brought into contact with, and transferred onto material web 18. To improve contact of coating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com