Patents

Literature

82results about How to "Evenly layered" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

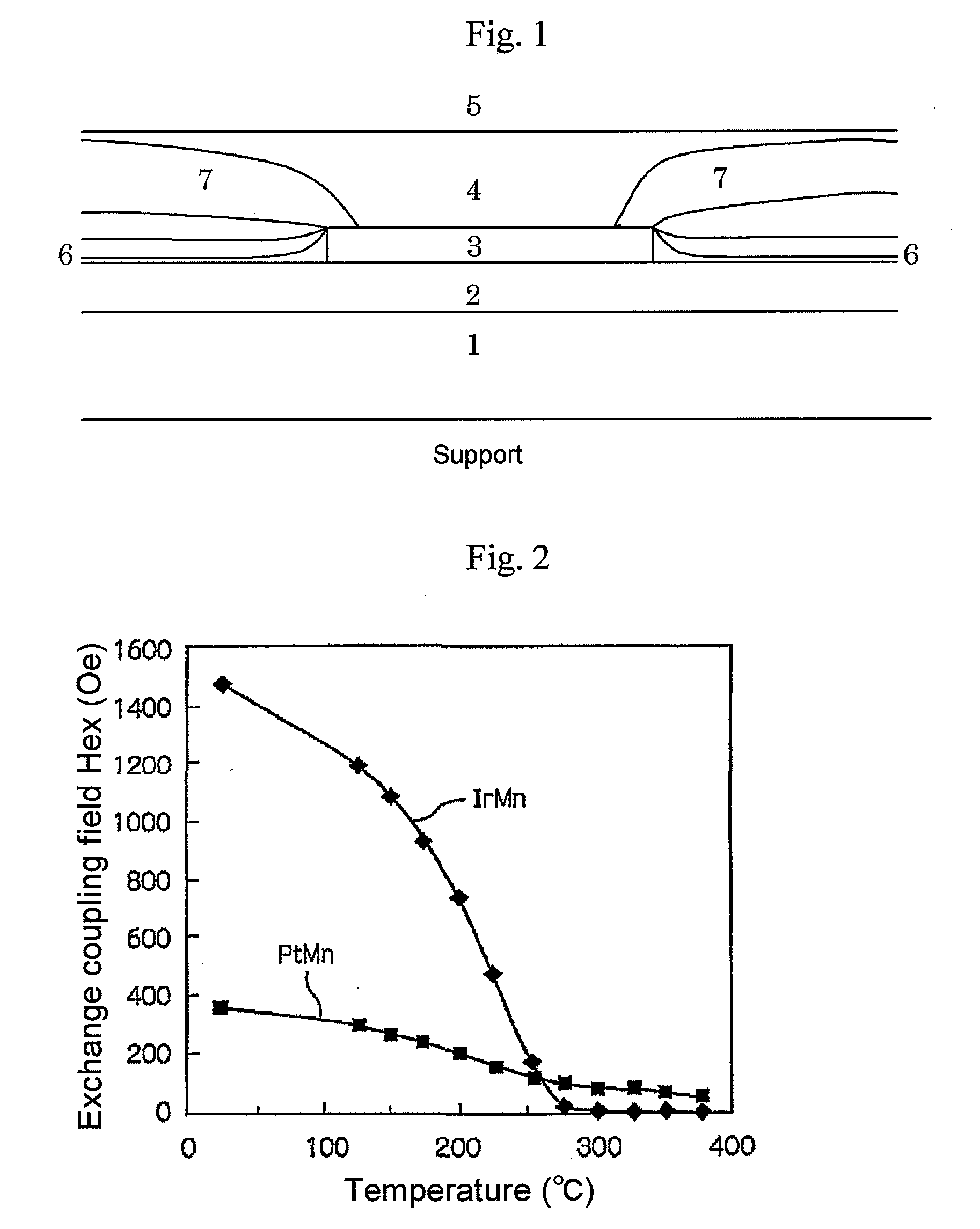

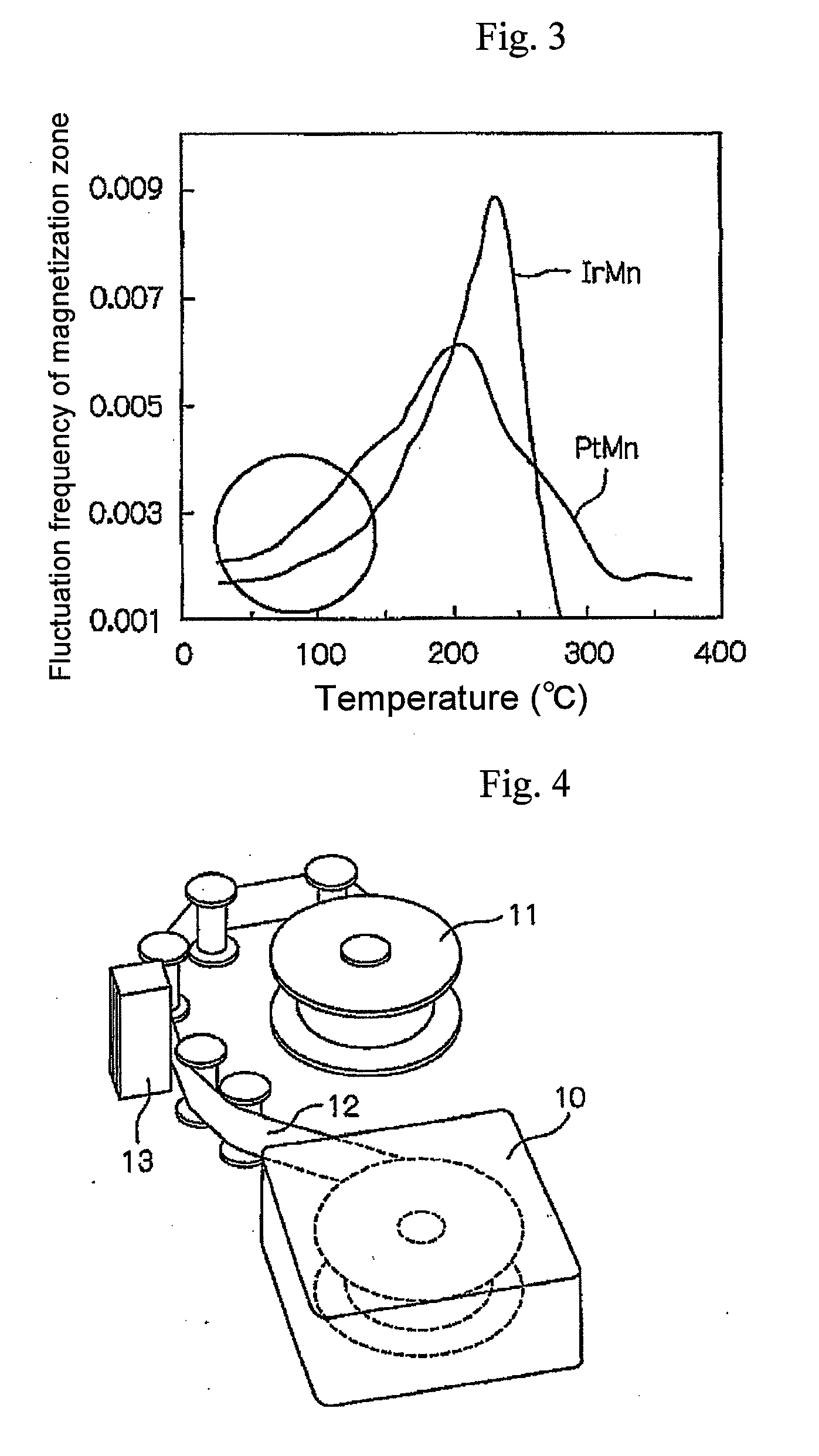

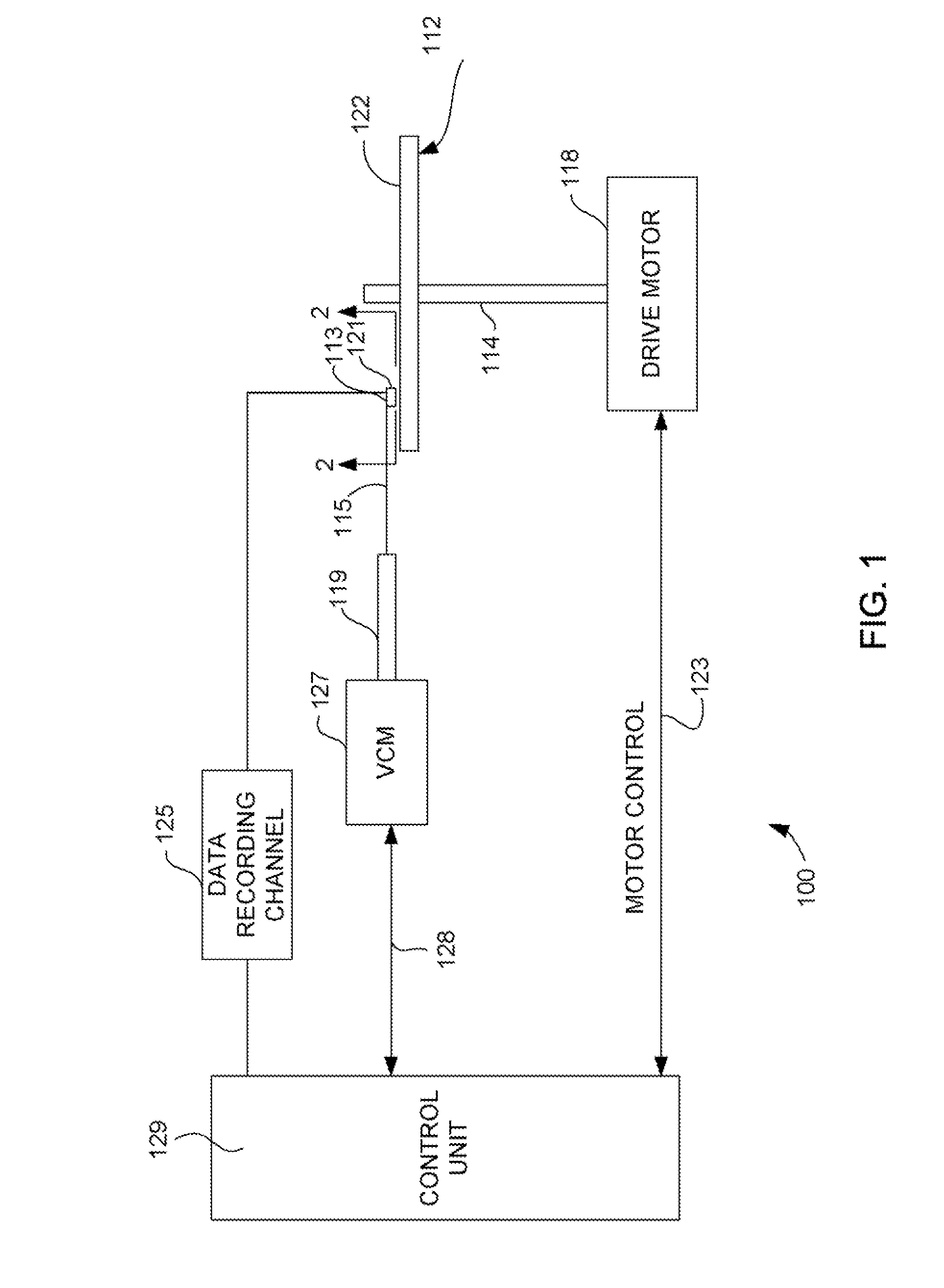

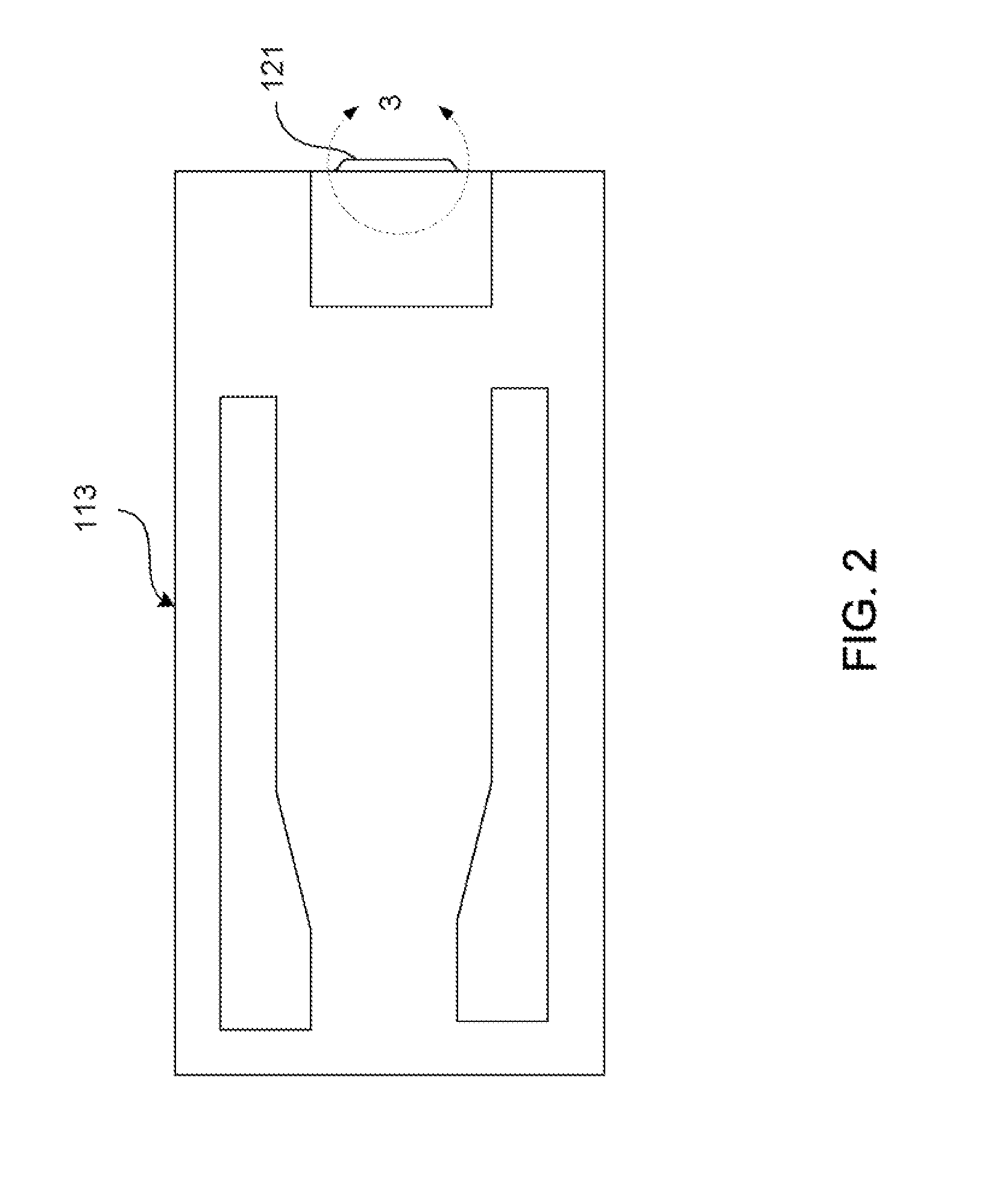

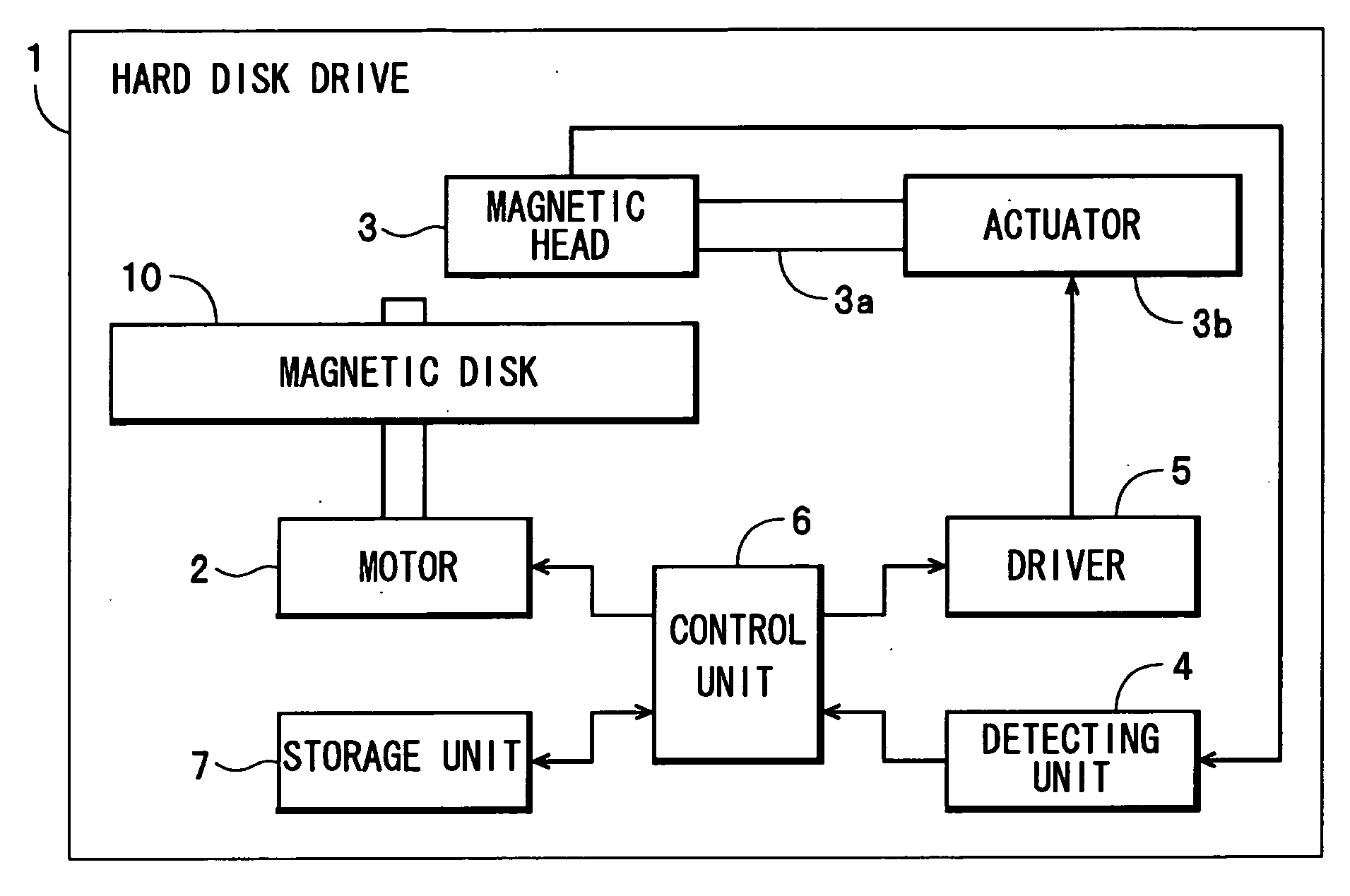

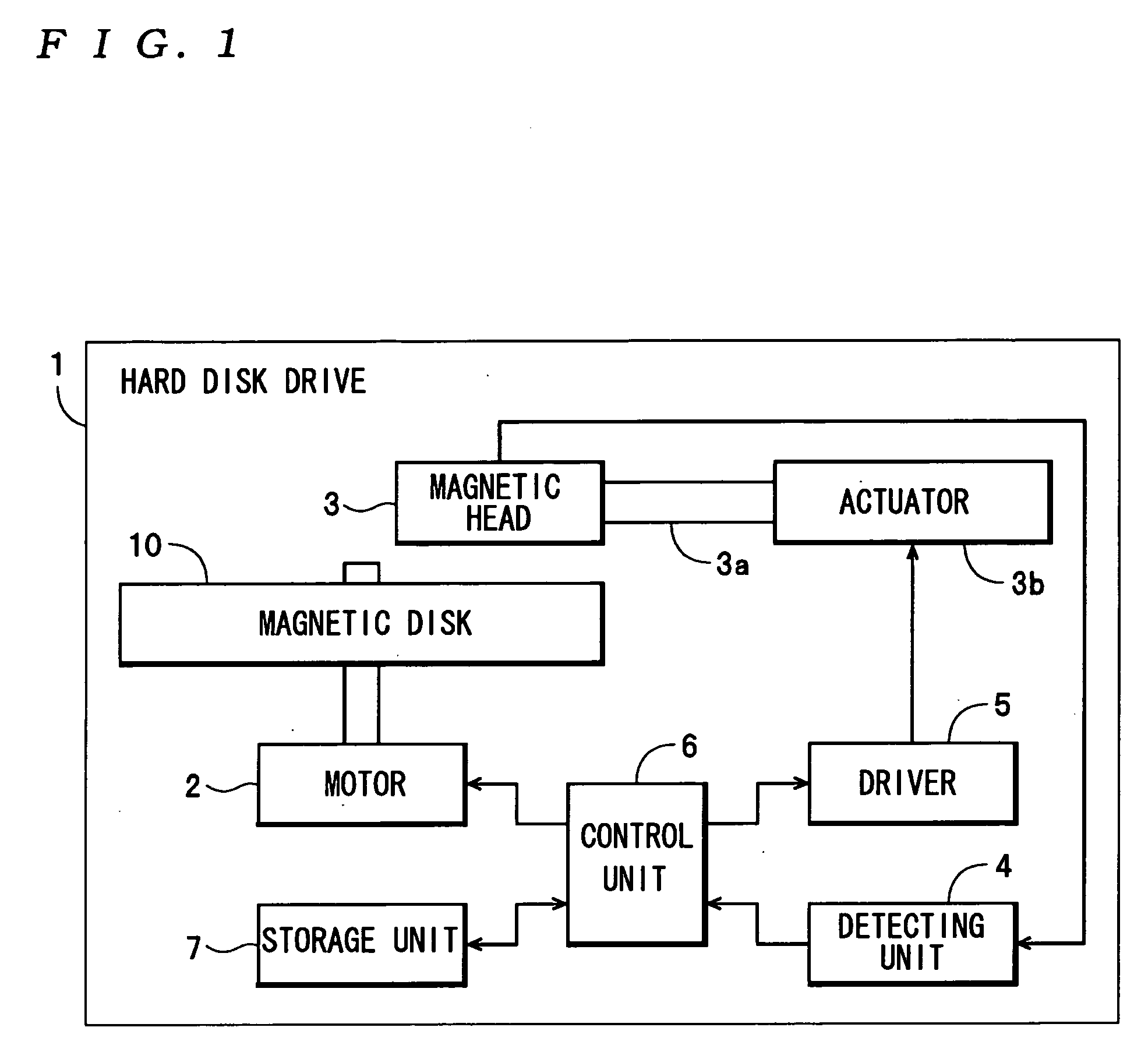

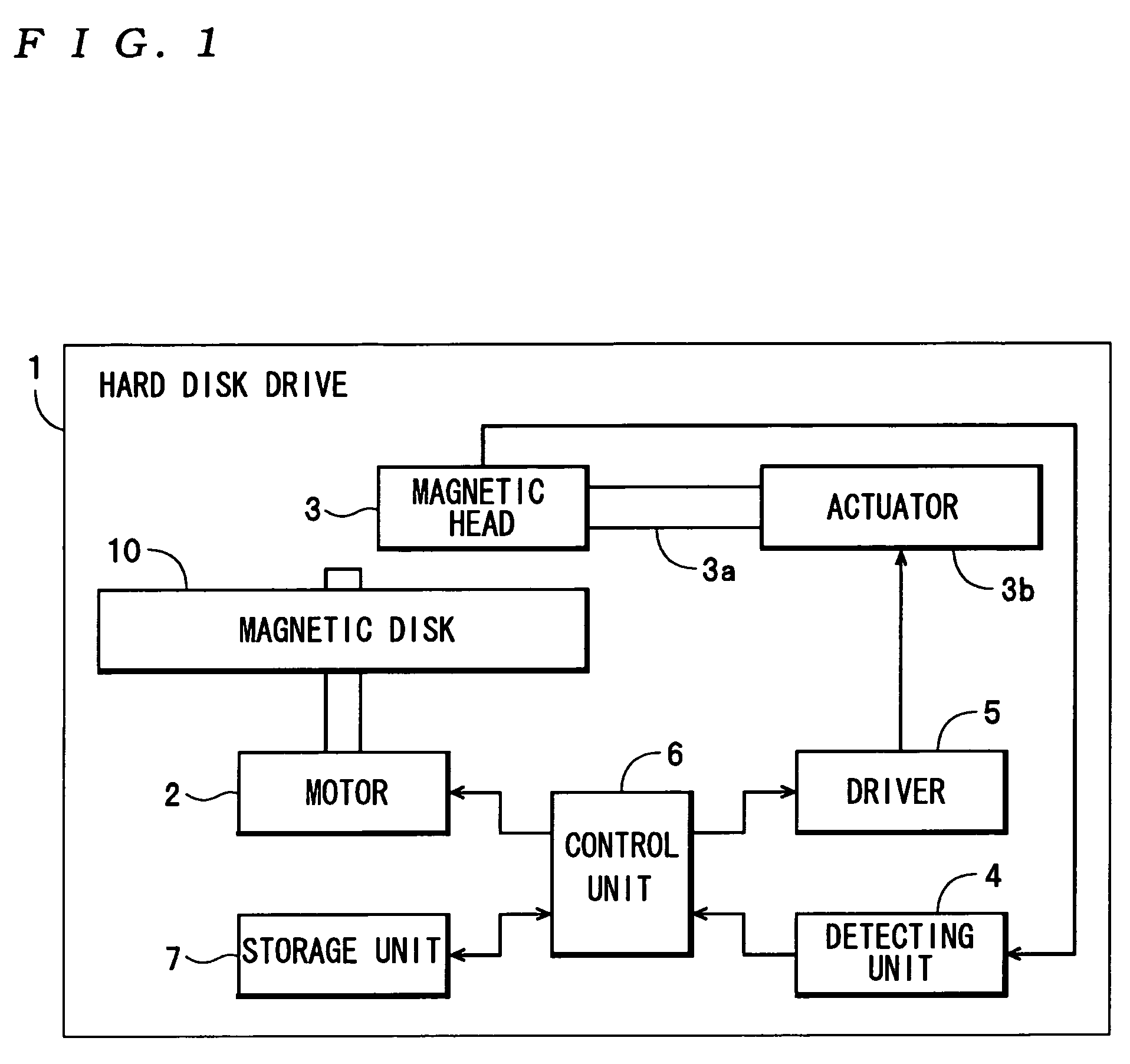

Magnetic signal reproduction system and magnetic signal reproduction method

InactiveUS20090027812A1Stable reproduction propertyDeterioration of reproduction propertyManufacture unitary devices of plural headsRecord information storageIridiumAlloy

The magnetic signal reproduction system comprises a magnetic recording medium comprising a magnetic layer comprising a ferromagnetic powder and a binder on a nonmagnetic support and a reproduction head, wherein a number of protrusions equal to or greater than 10 nm in height on the magnetic layer surface, as measured by an atomic force microscope, ranges from 50 to 2500 / 10,000 μm2, a quantity of lubricant on the magnetic layer surface, denoted as a surface lubricant index, ranges from 0.5 to 5.0, a surface abrasive occupancy of the magnetic layer ranges from 2 to 20 percent, the reproduction head is a magnetoresistive magnetic head comprising a spin-valve layer, the spin-valve layer comprises a magnetization free layer, a magnetization pinned layer and an antiferromagnetic layer, and the antiferromagnetic layer is comprised of alloy comprising iridium and manganese, and the reproduction head comes in sliding contact with the magnetic recording medium during signal reproduction.

Owner:FUJIFILM CORP +1

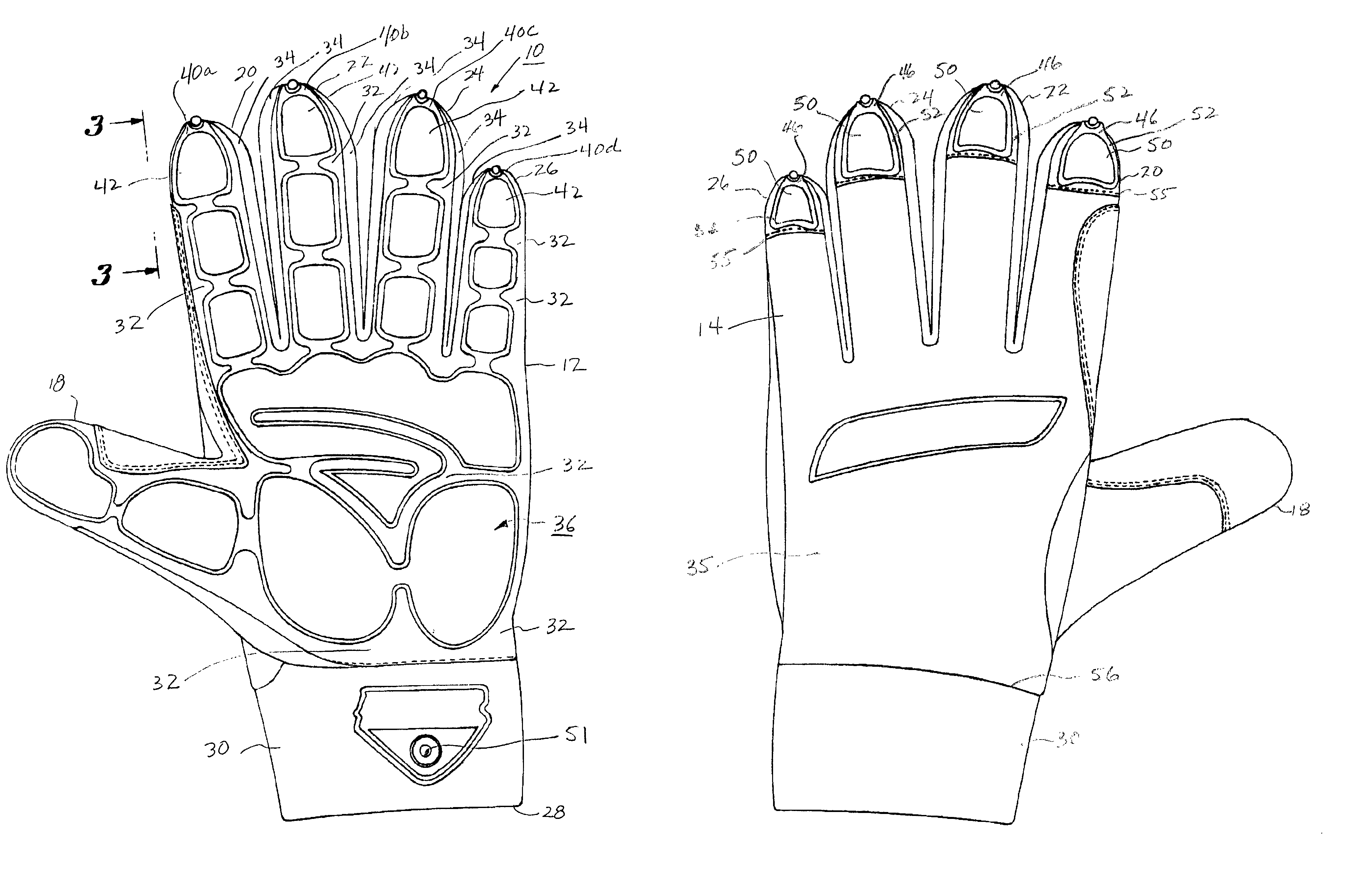

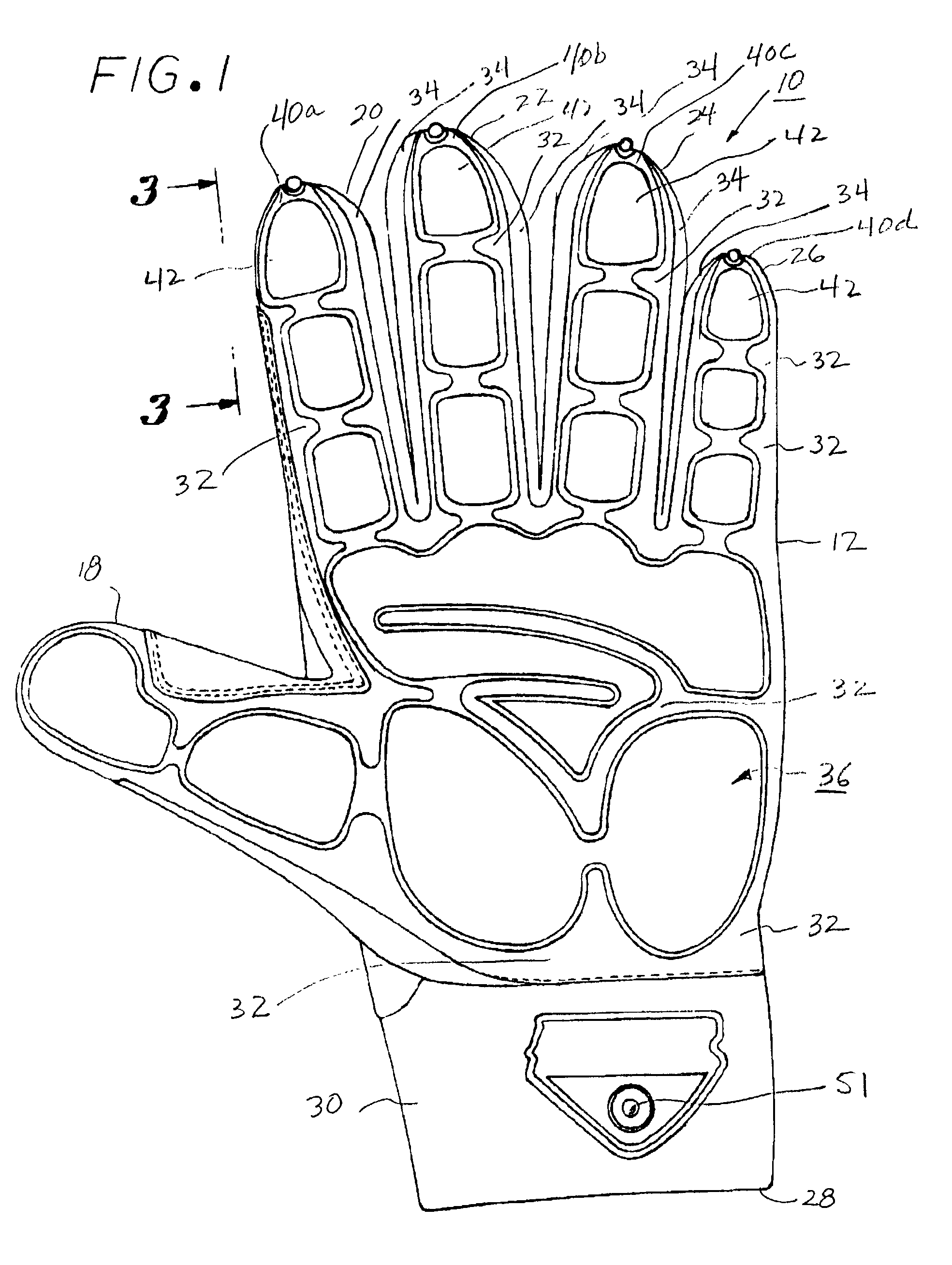

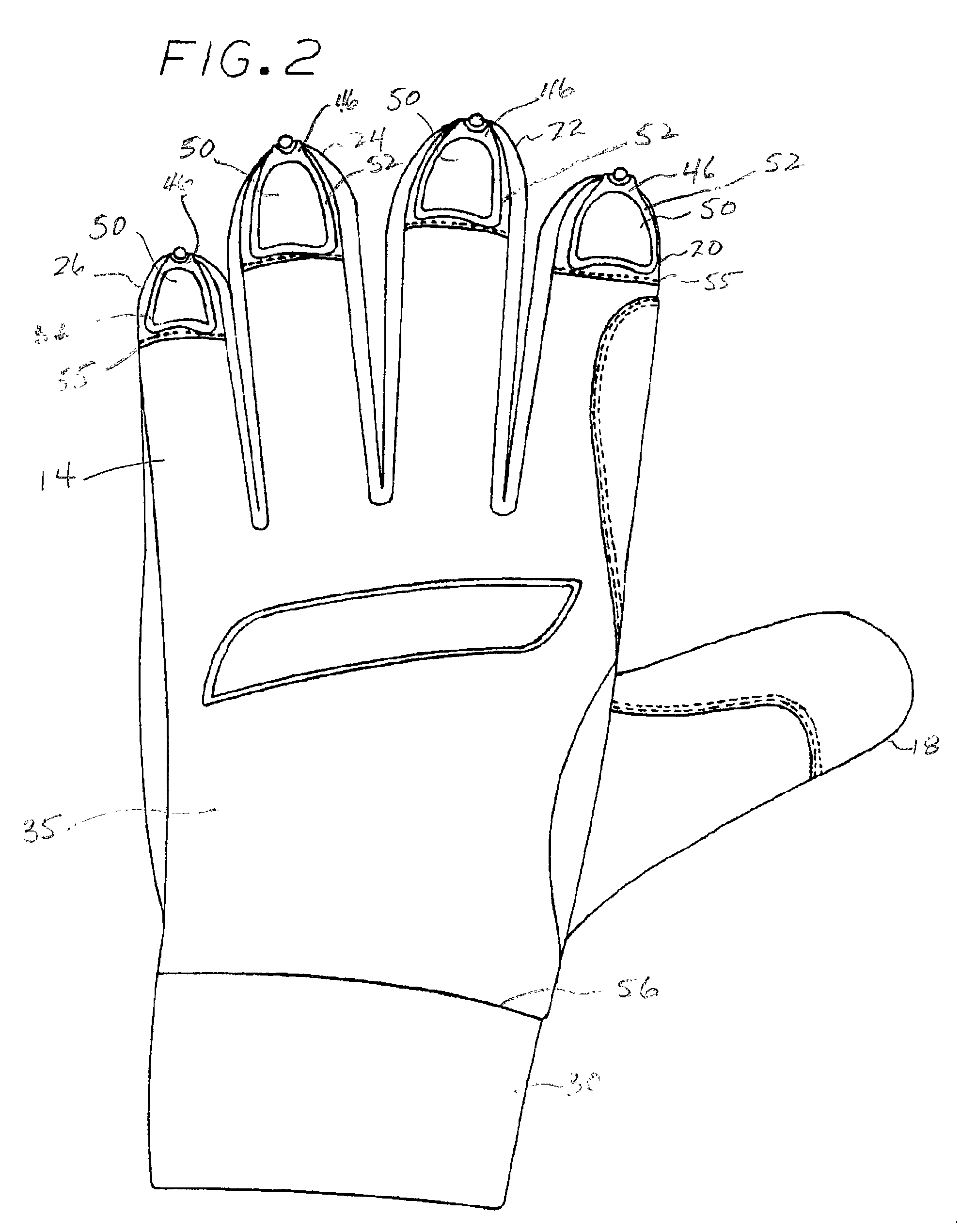

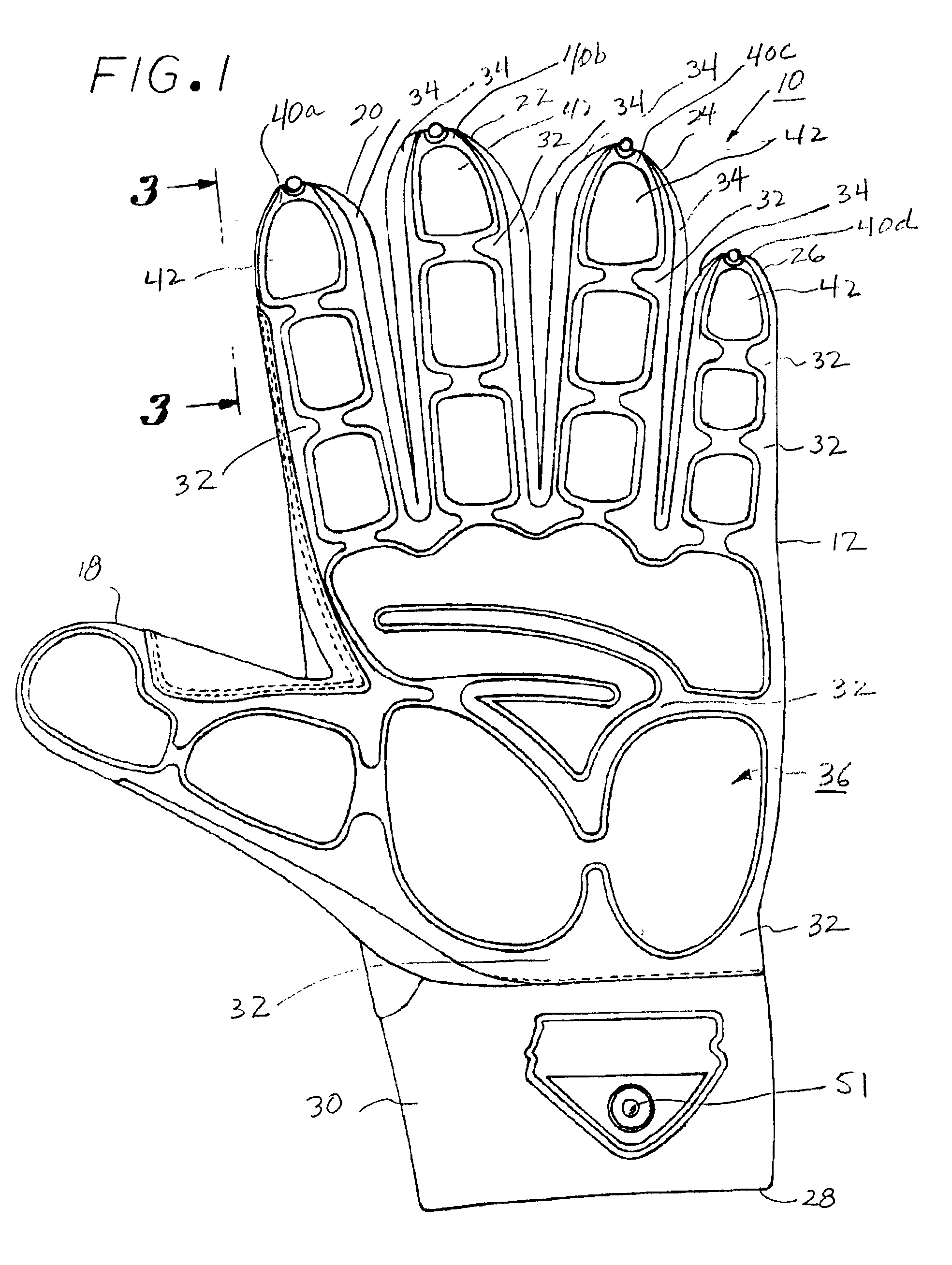

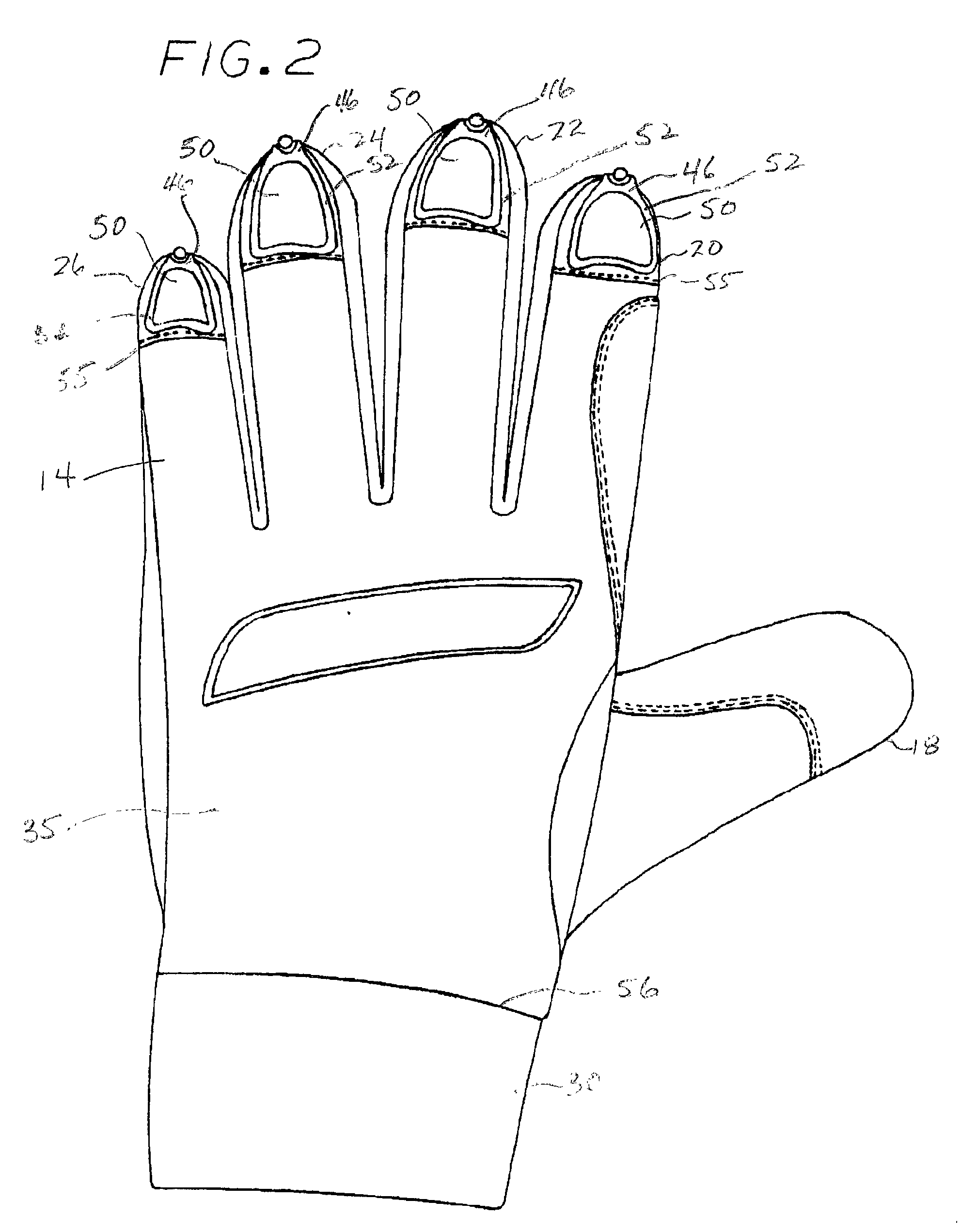

Glove having molded rubber palm pattern with a portion that rolls over fingertips

InactiveUS7100212B2High sensitivityImprove efficiencyGlovesEye treatmentMechanical engineeringHand palms

Owner:BRIGHTON BEST INT INC

Glove having molded rubber palm pattern with a portion that rolls over fingertips

InactiveUS20040025227A1Eliminates seam lineIncrease awarenessGlovesEye treatmentHand palmsEngineering

Owner:BRIGHTON BEST INT INC

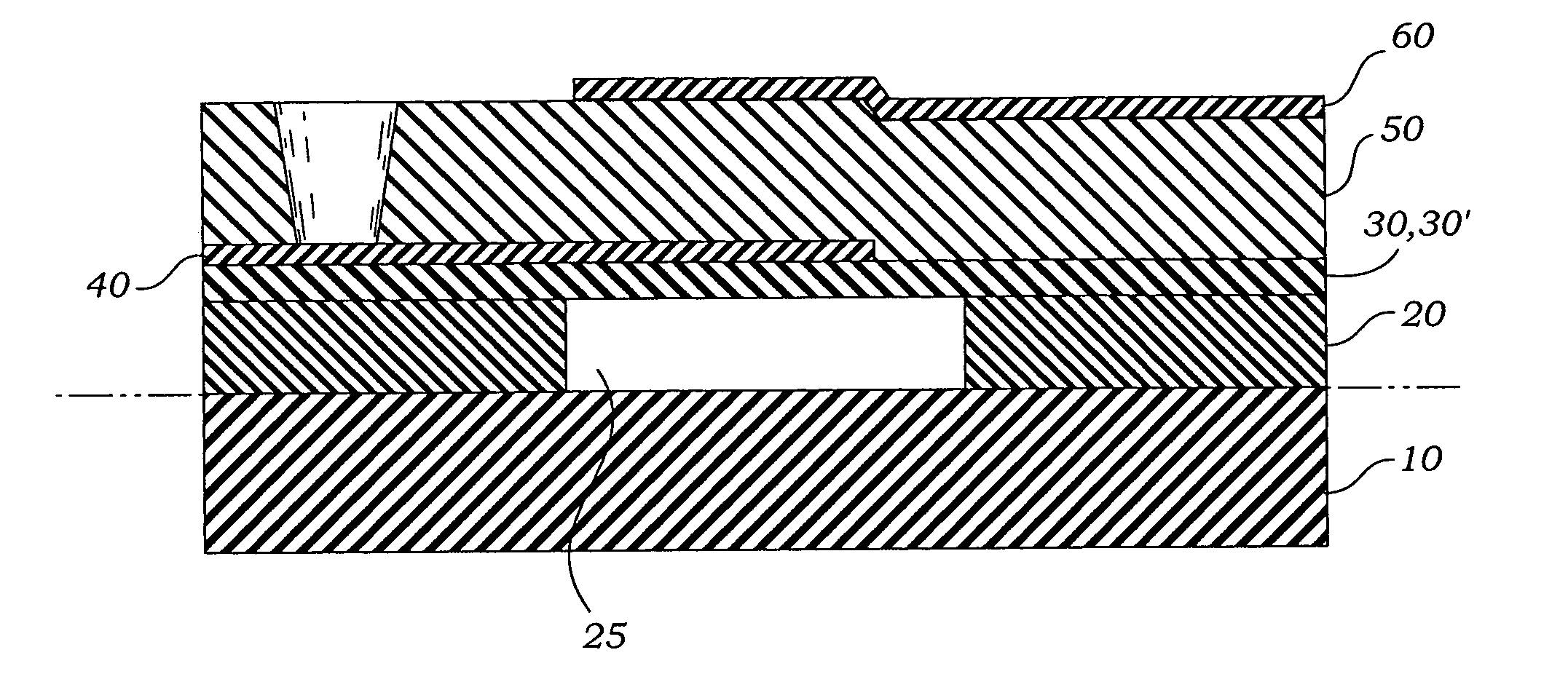

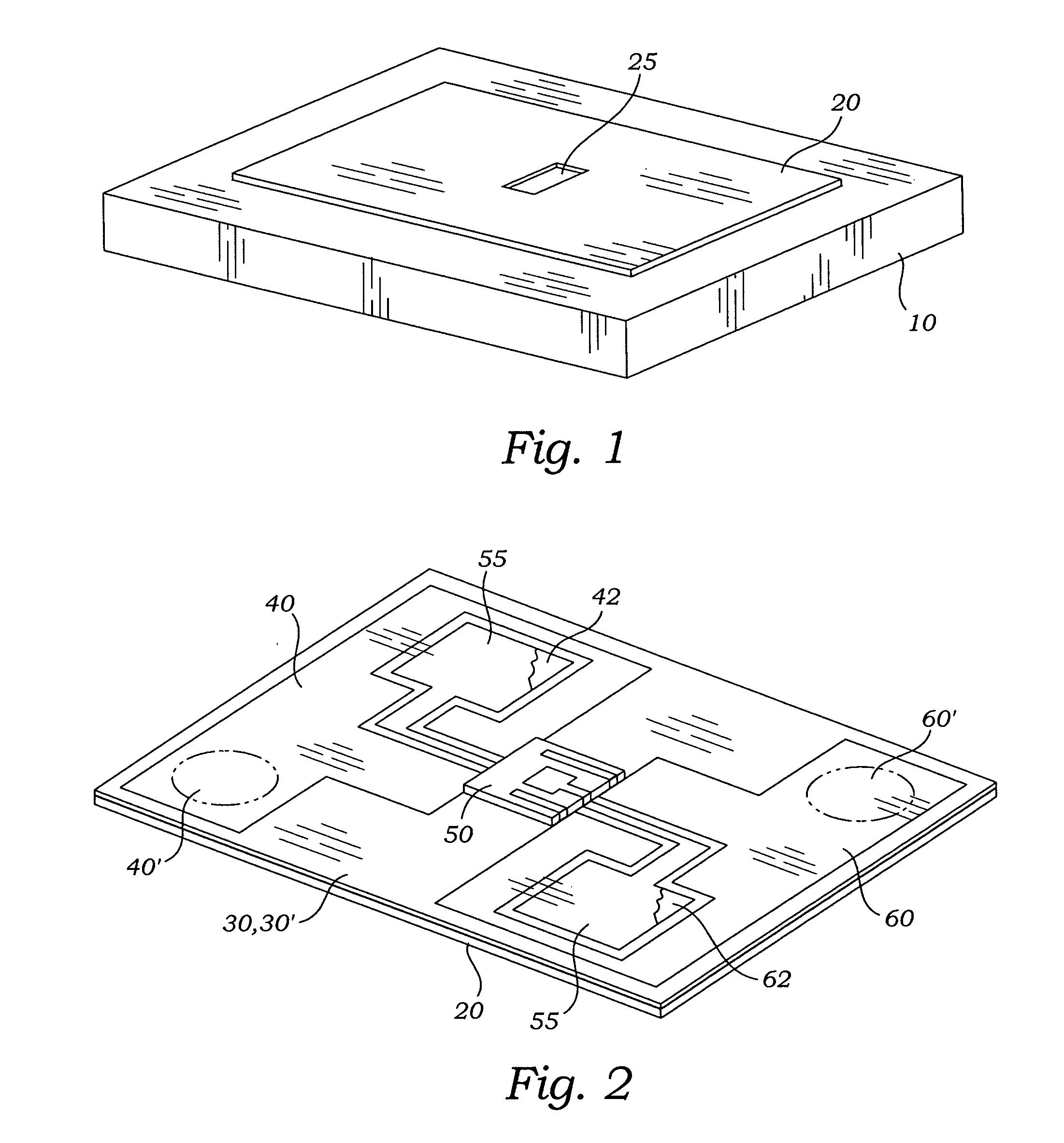

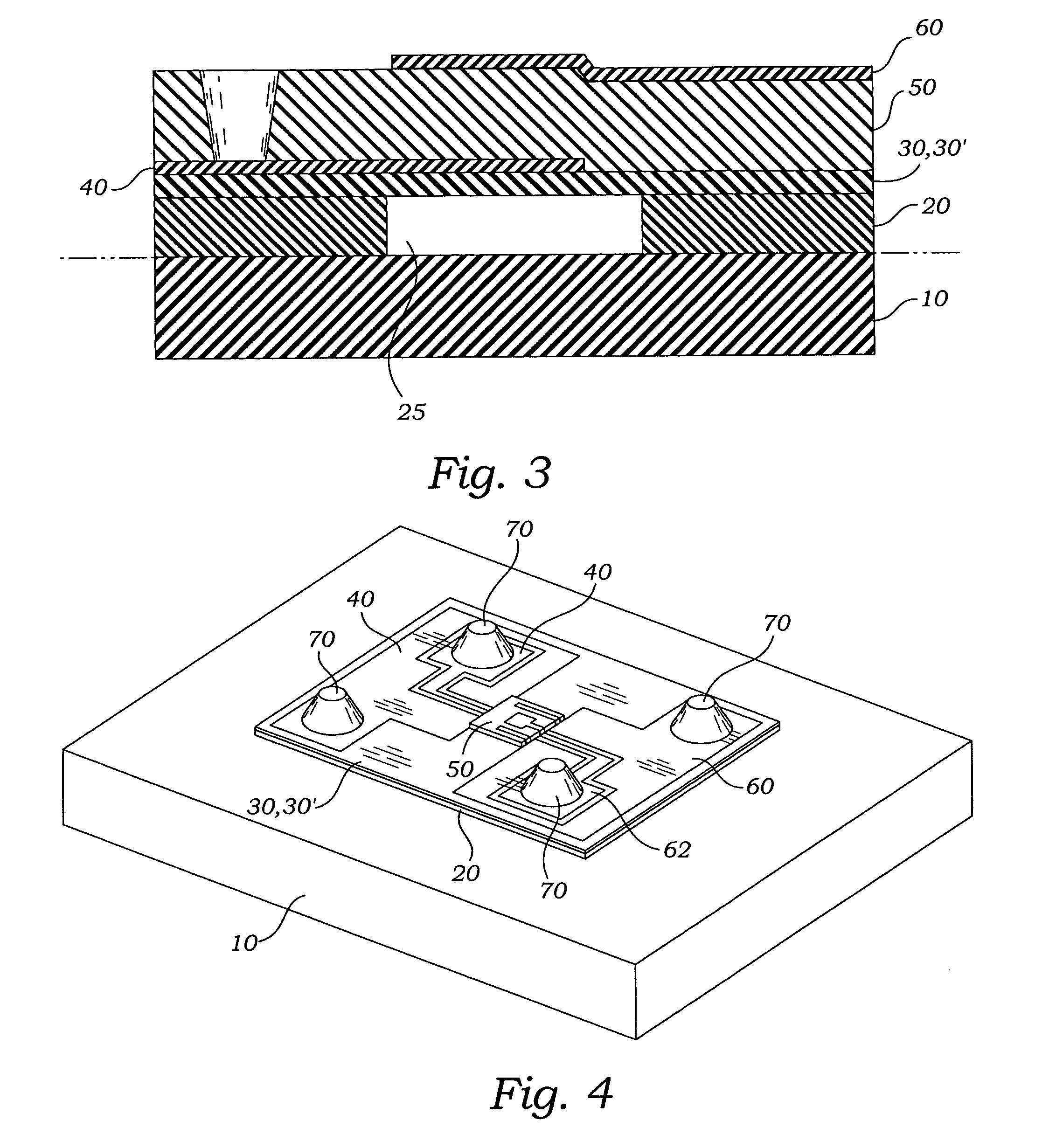

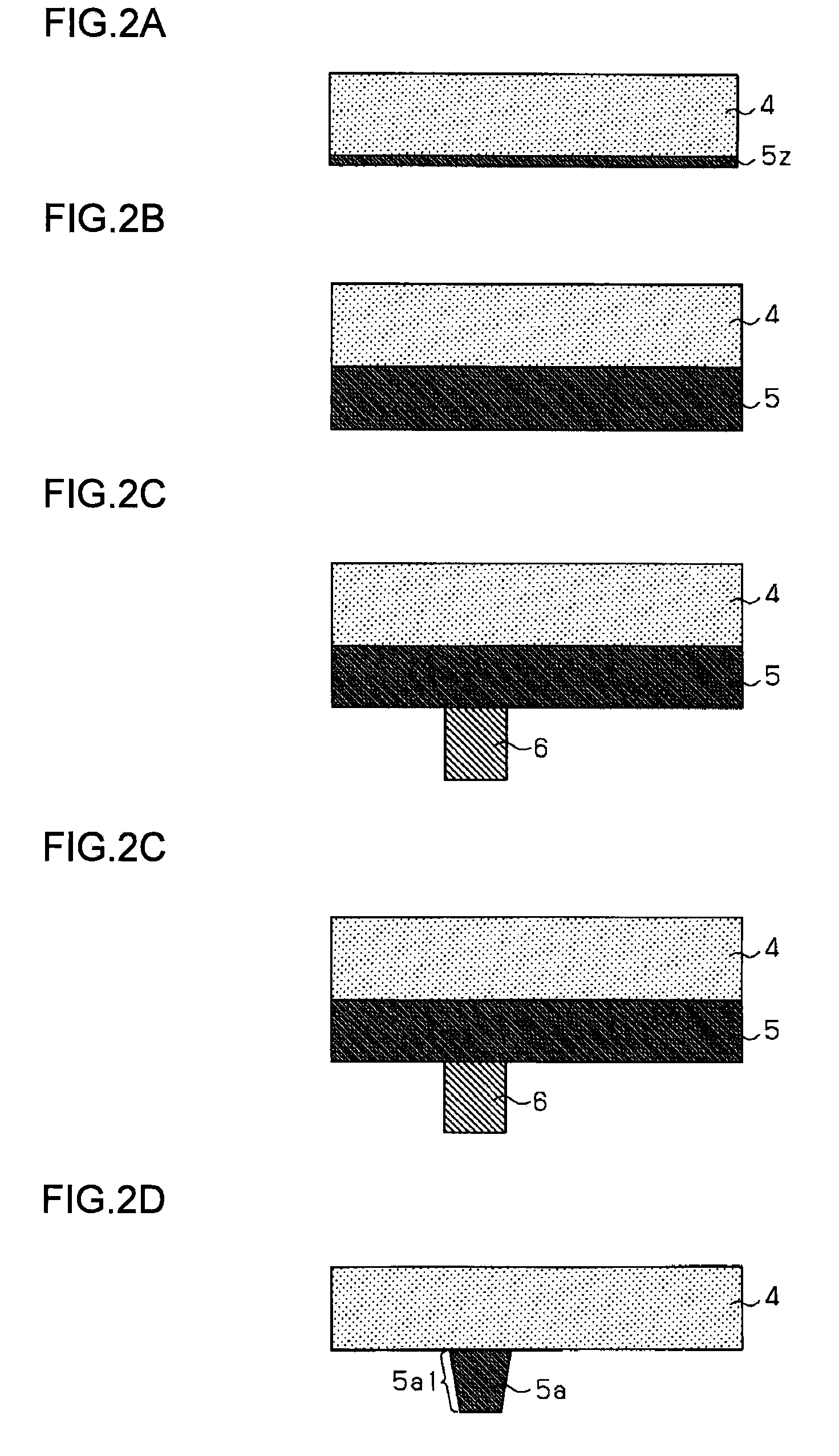

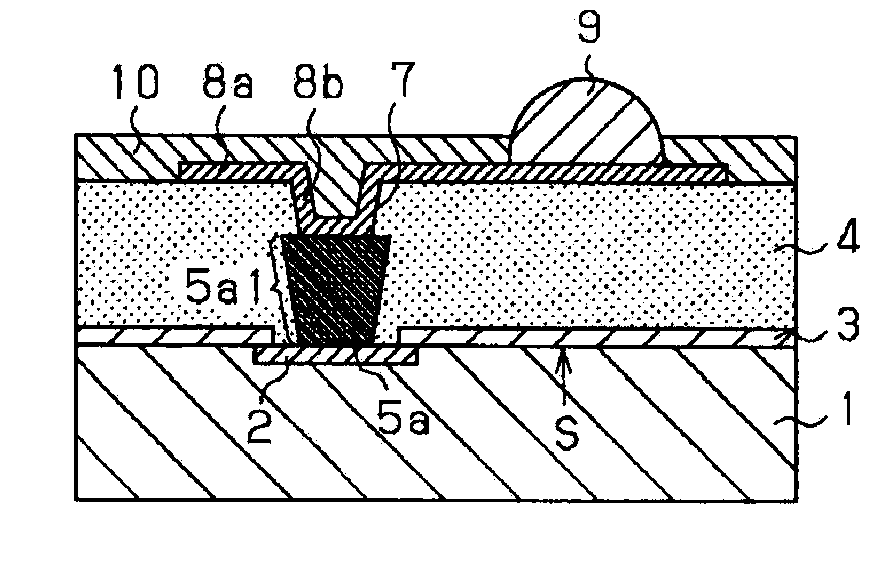

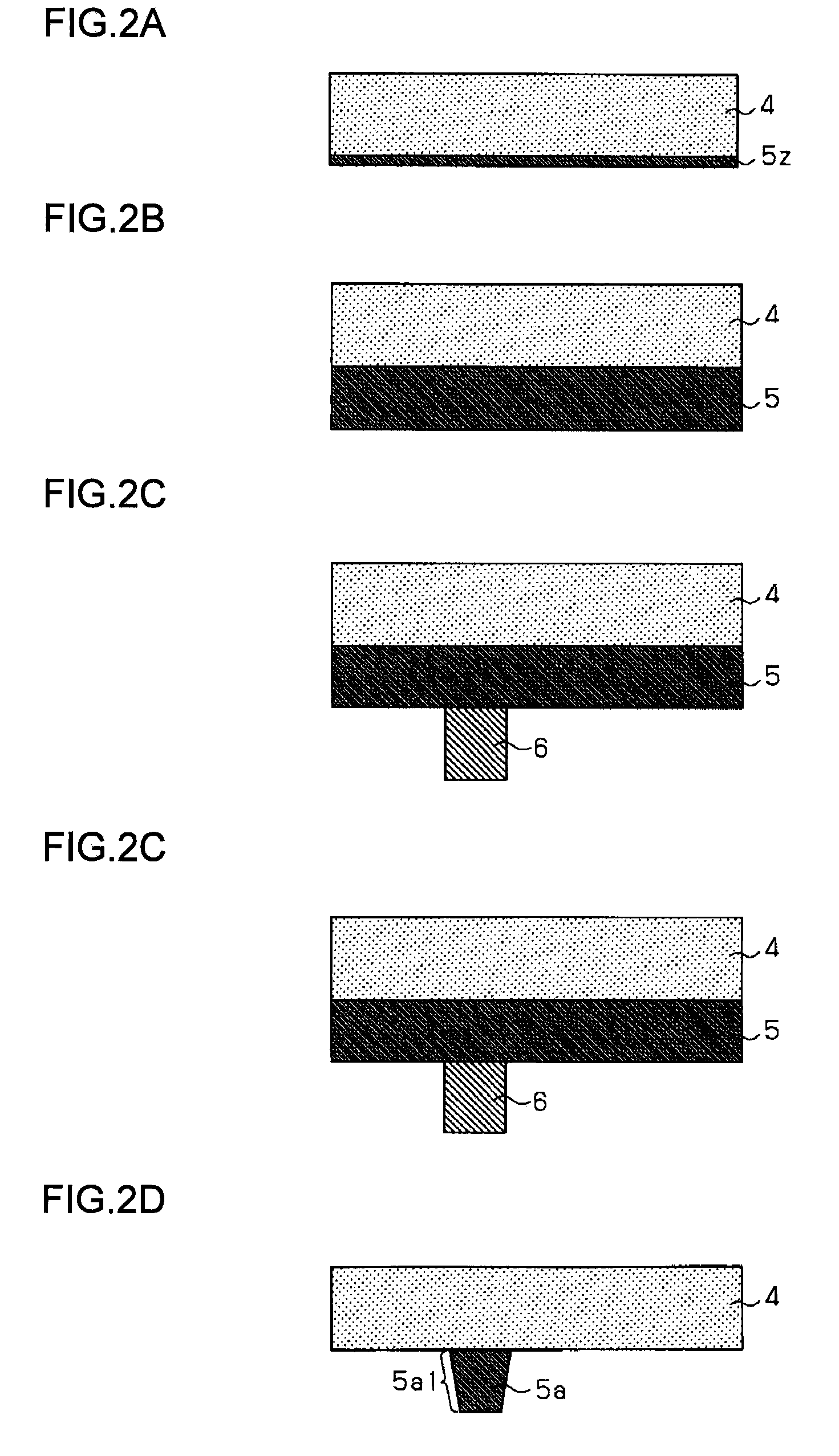

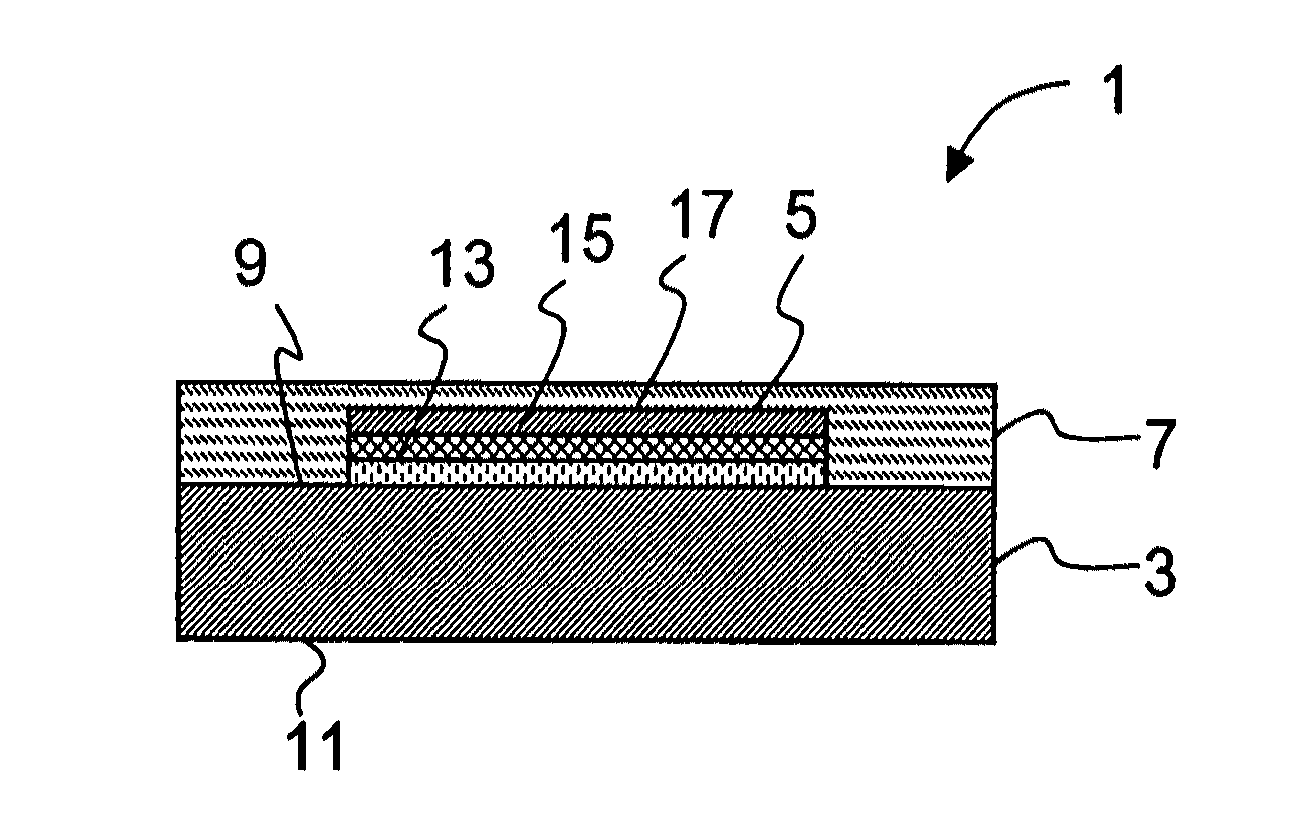

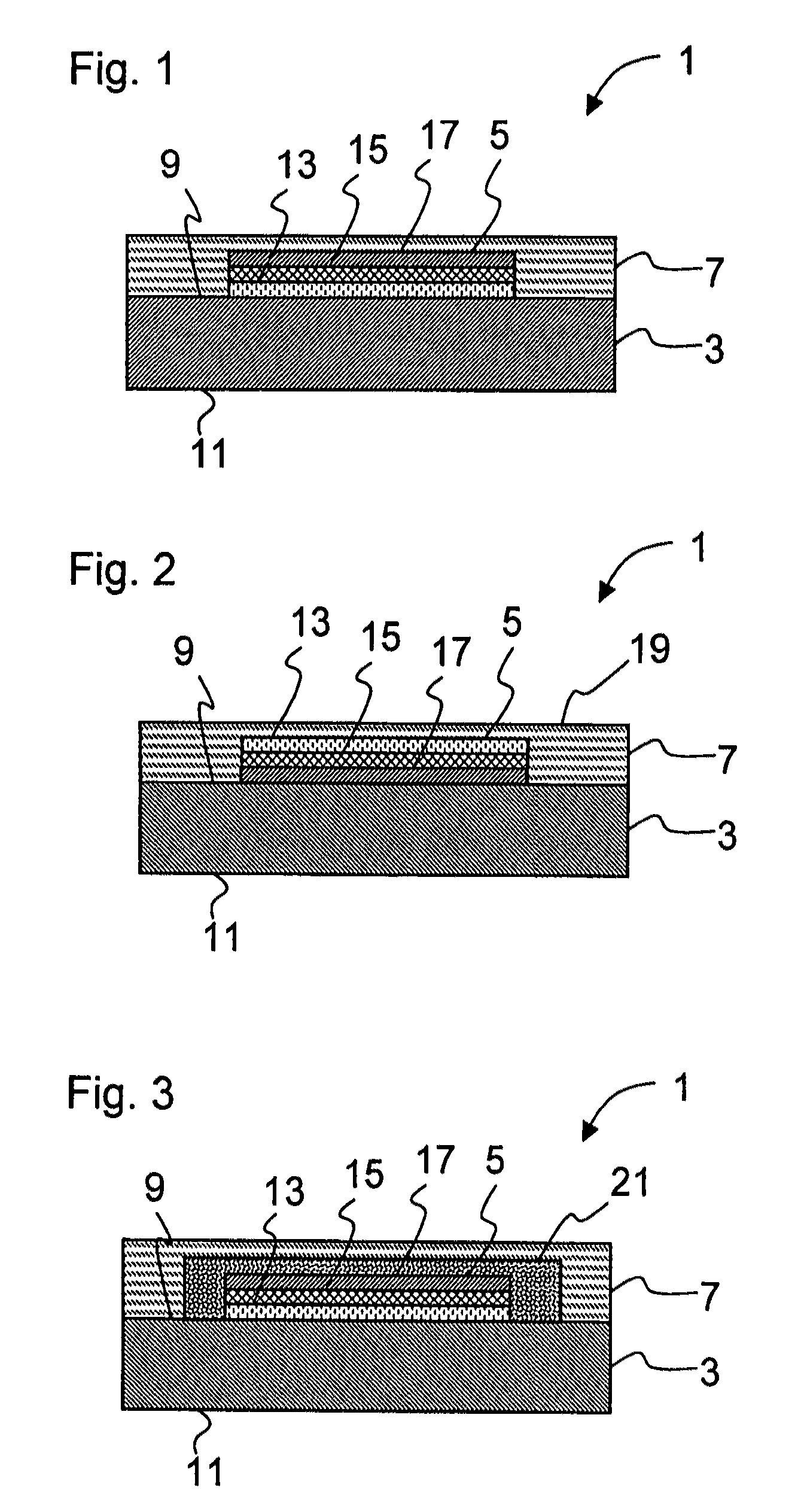

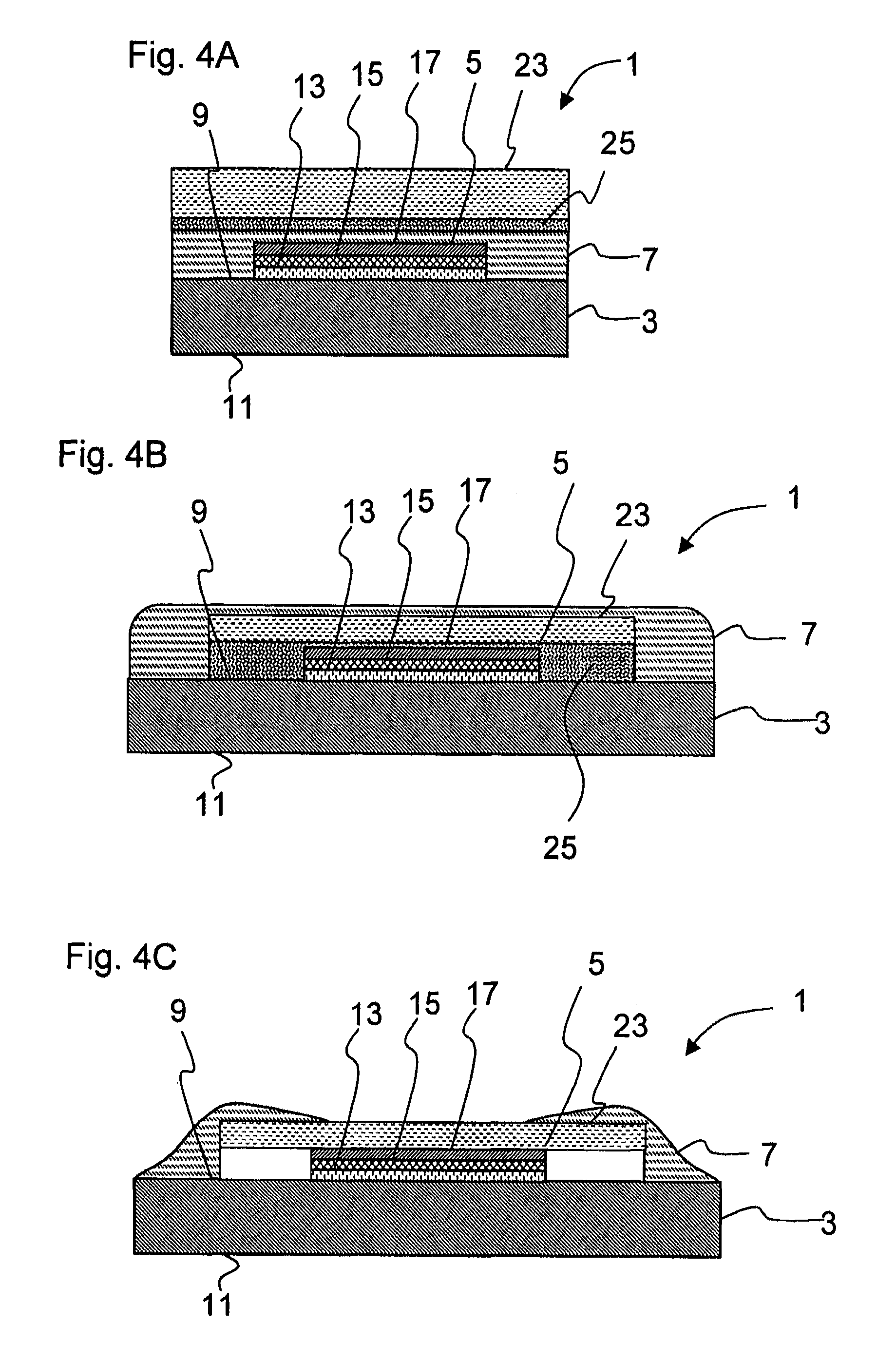

Thin device and method of fabrication

InactiveUS20060017352A1Improve performanceEasily etched awayImpedence networksPiezoelectric/electrostriction/magnetostriction machinesAir bridgeAcoustic wave

A method of fabricating air-bridge type FBAR devices provides for a piezoelectric material sandwiched between two electrodes with an air / crystal interface on each electrode to trap sound waves within the film structure. Copper is used as a sacrificial material deposited in cavities in the substrate. Following deposition of the electrodes and piezoelectric material, the copper is etched away leaving the bottom electrode suspended over a cavity void.

Owner:TOKO JAPANESE

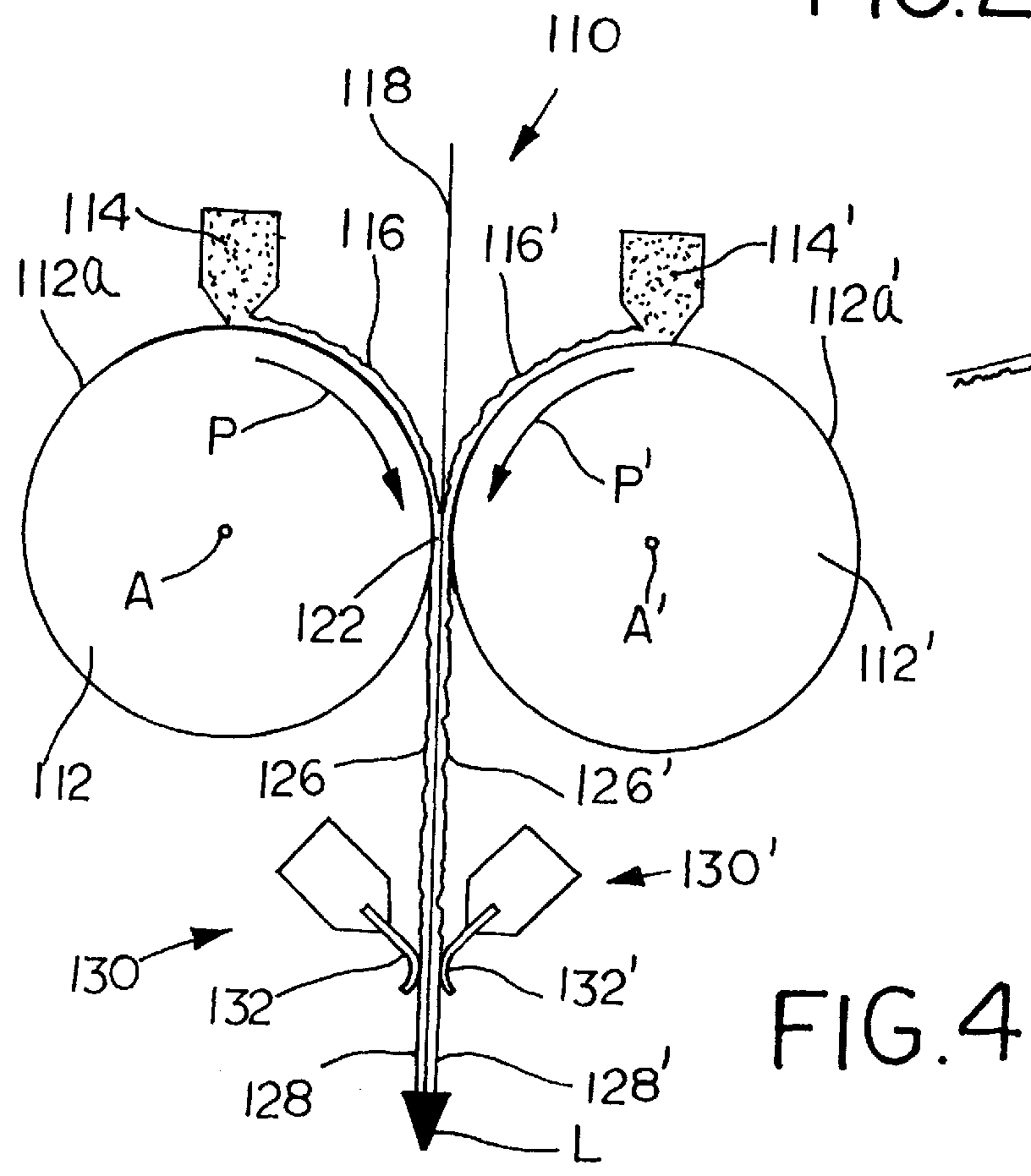

Device used to indirectly apply a liquid or viscous medium onto a material web, specifically a paper or cardboard web

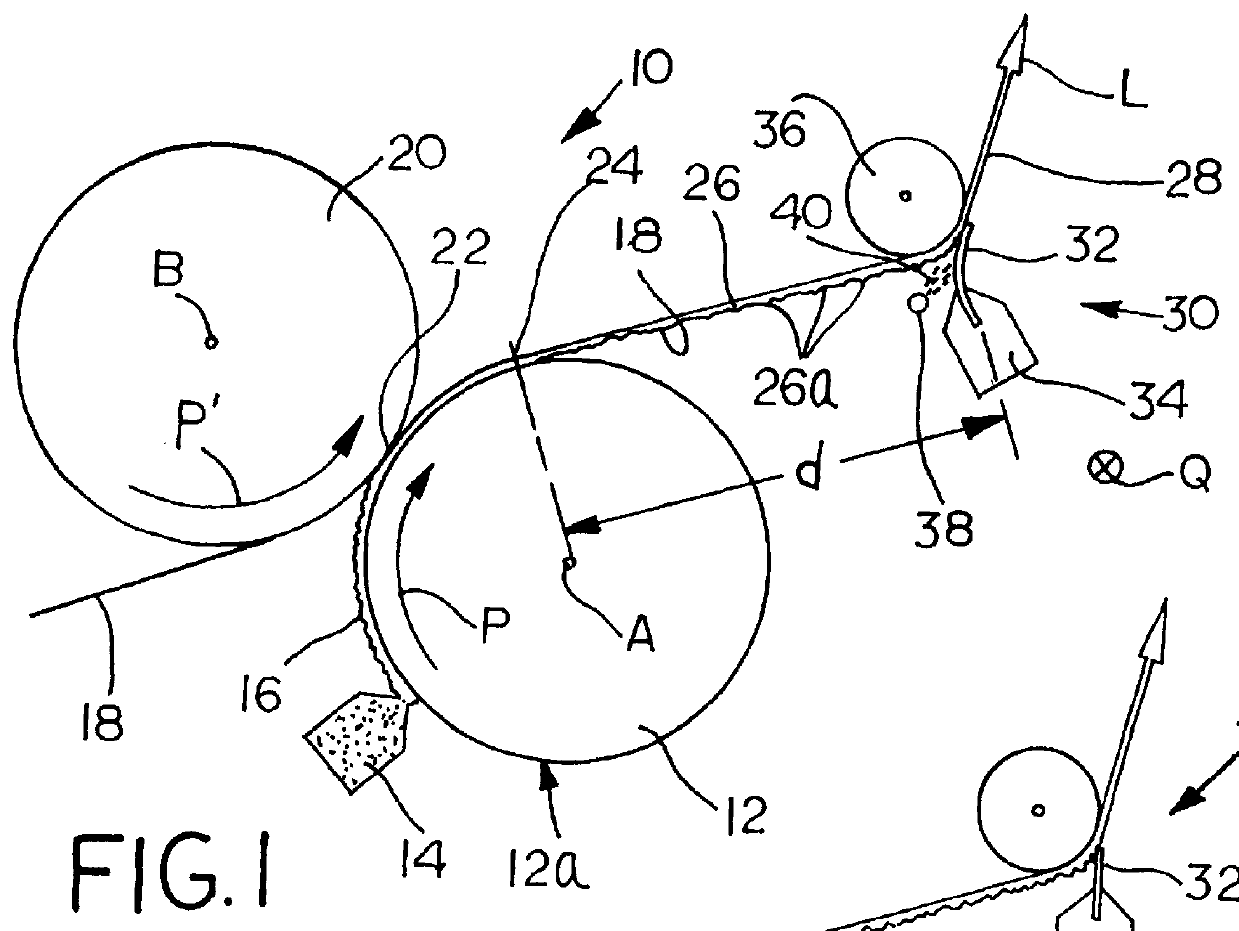

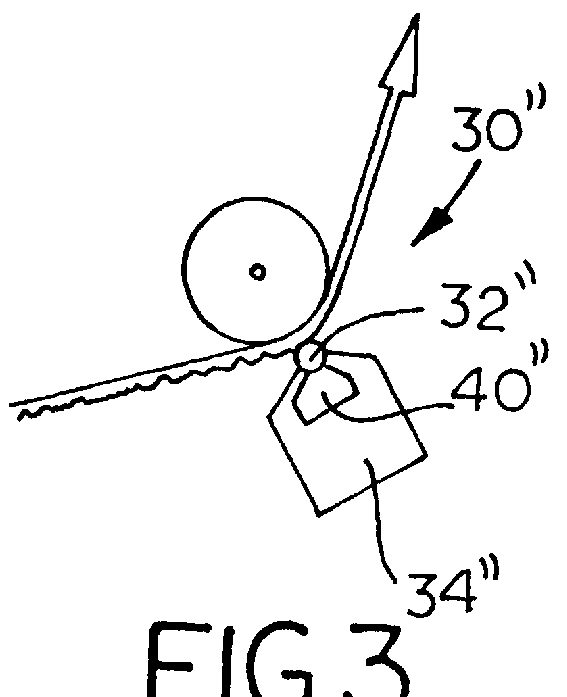

InactiveUS6126750AEvenly layeredAvoid pollutionLiquid surface applicatorsMachine wet endCardboardEngineering

A device for indirect application of a liquid or viscous medium onto a traveling material web, specifically a paper or cardboard web, includes an applicator device for the application of a layer of liquid or viscous medium onto a surface of a transfer element. The transfer element is in contact with the moving material web and transfers the coating onto the web. A leveling unit is equipped with a leveling element positioned against the material web for smoothing of the coating layer on the material web. The leveling element is mounted rigidly in cross direction to the material web, that is, in a direction substantially orthogonal and in a local material web progression to the direction of travel of the material web.

Owner:VOITH PATENT GMBH

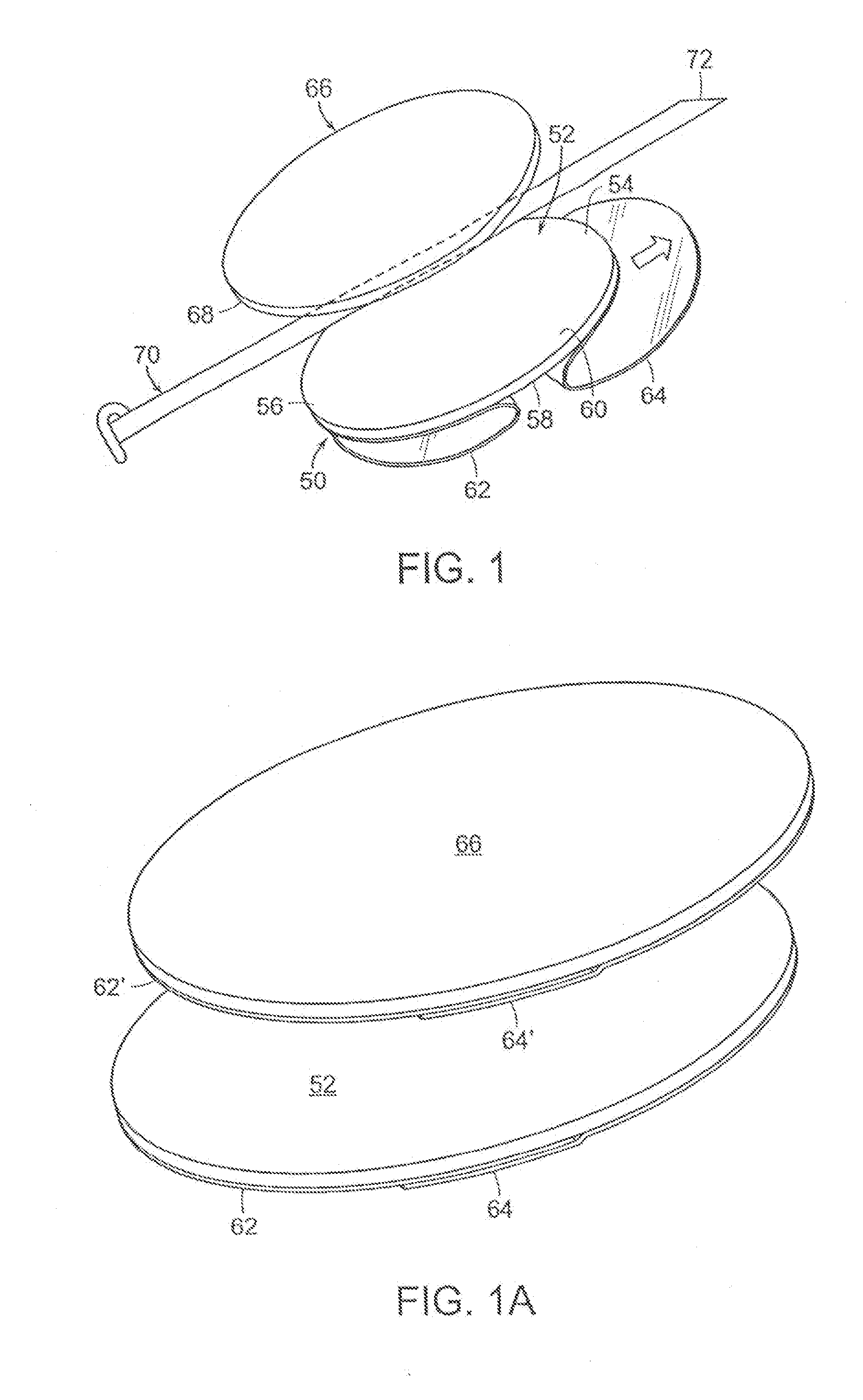

Adhesive layer arrangements and methods for securing medical tubing

InactiveUS20120203182A1Avoid disadvantagesBroaden applicationSurgical adhesivesSurgical needlesCatheter deviceCatheter Insertion Site

Owner:BIODERM

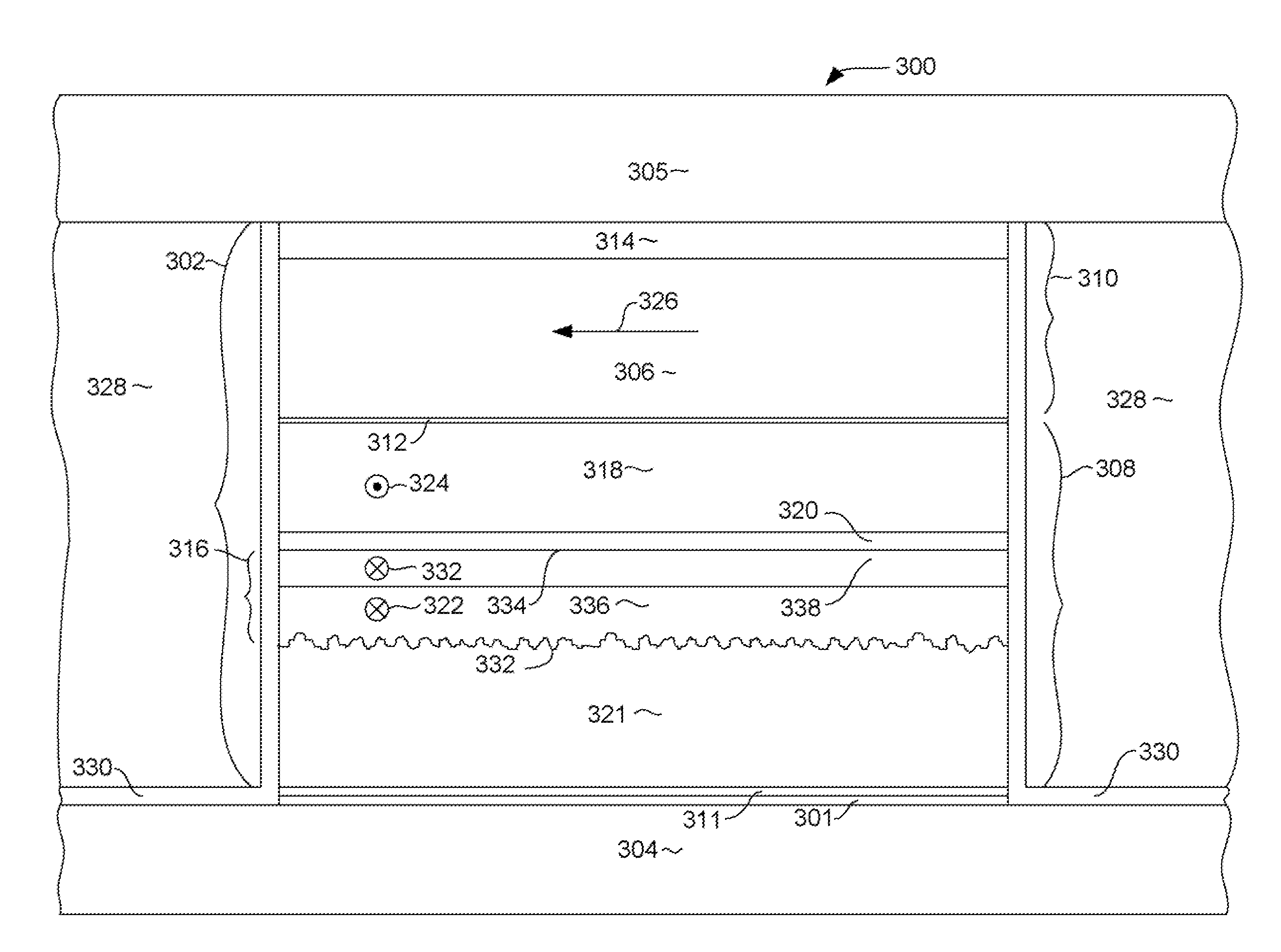

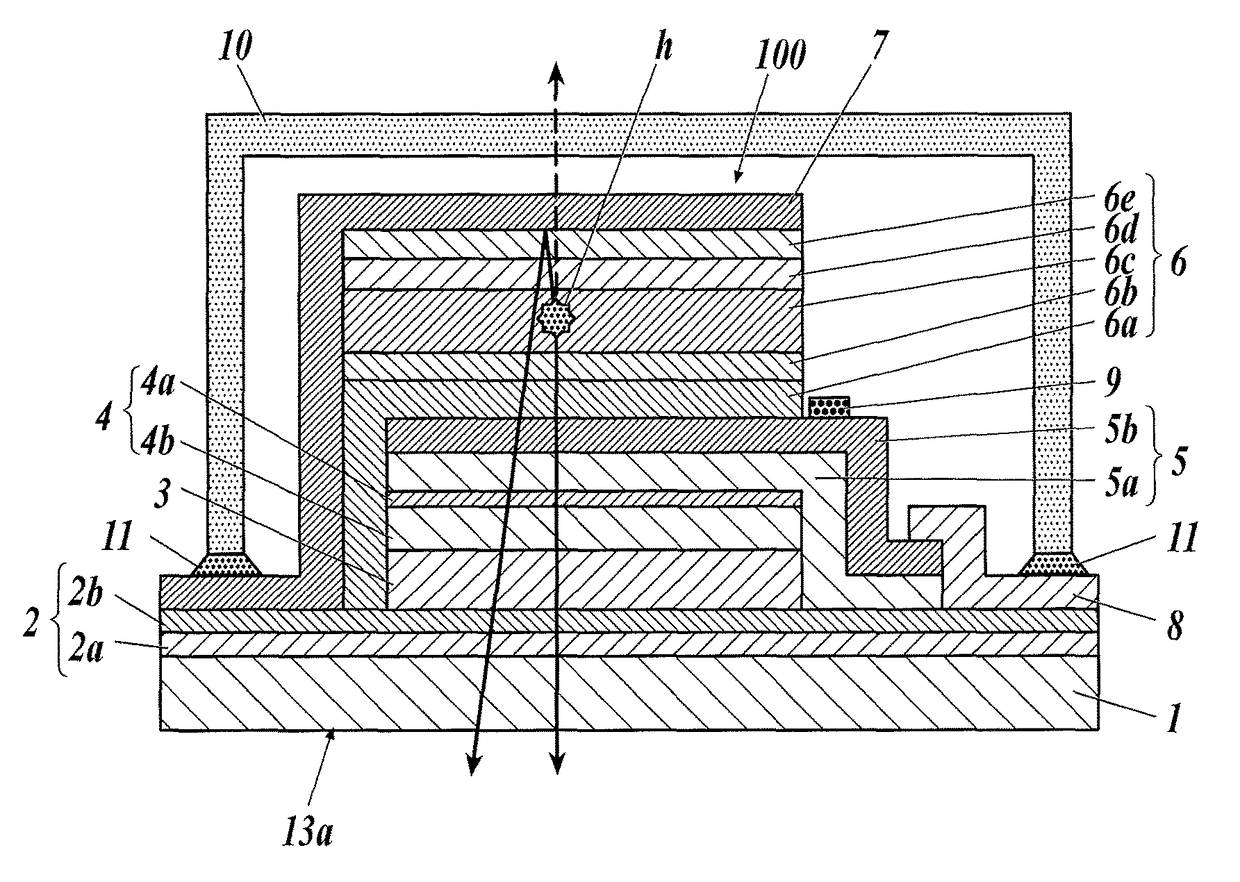

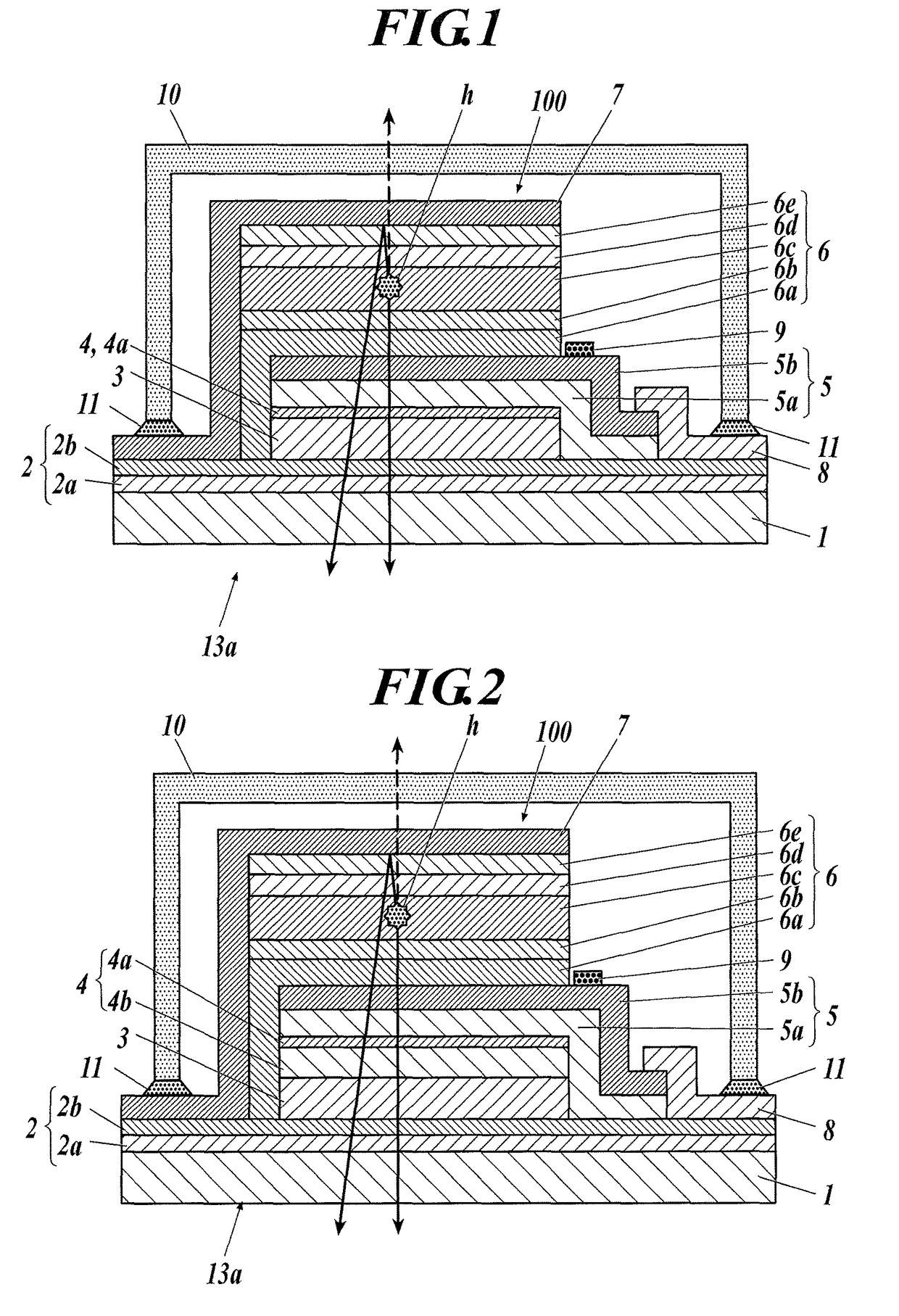

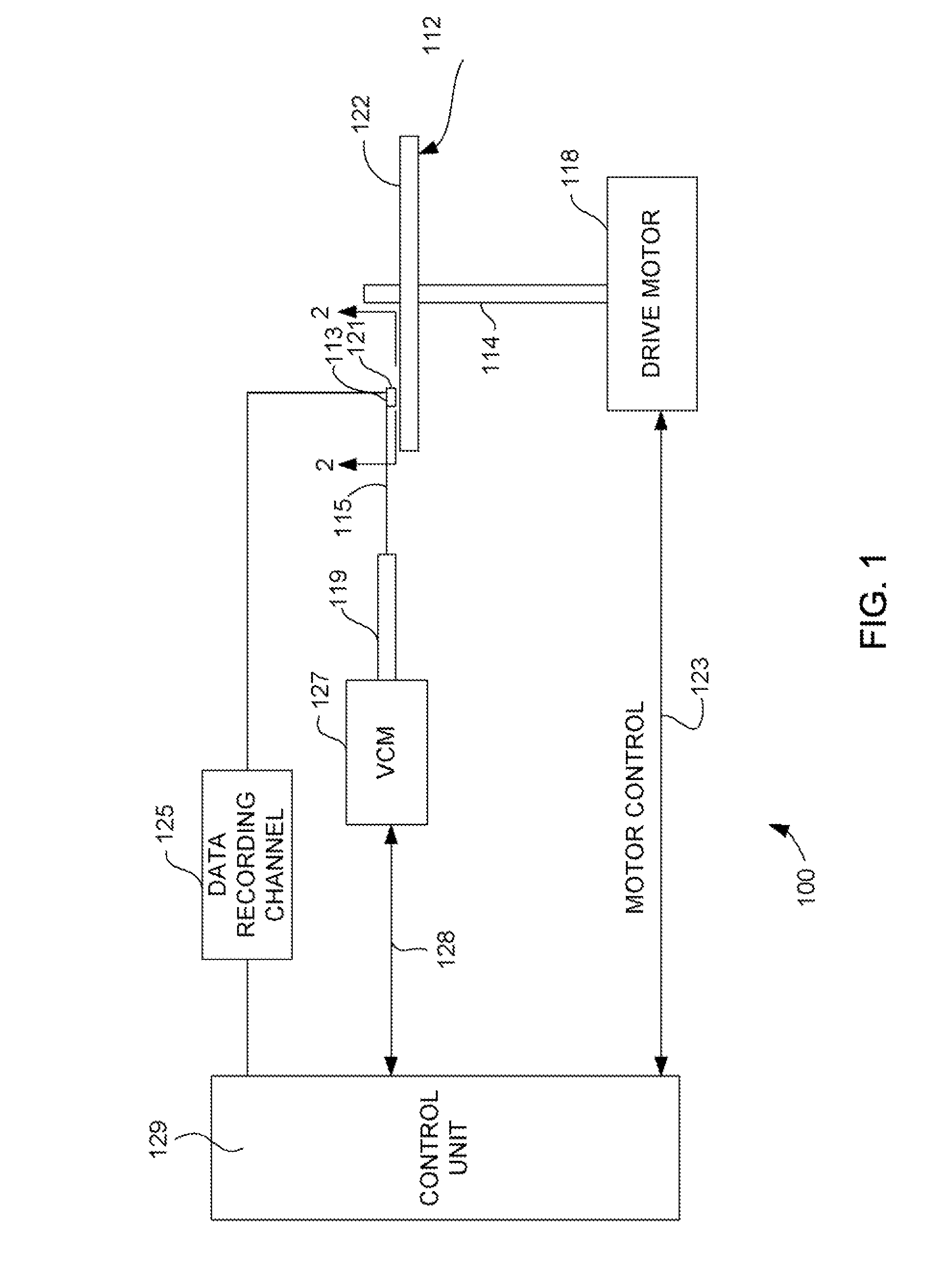

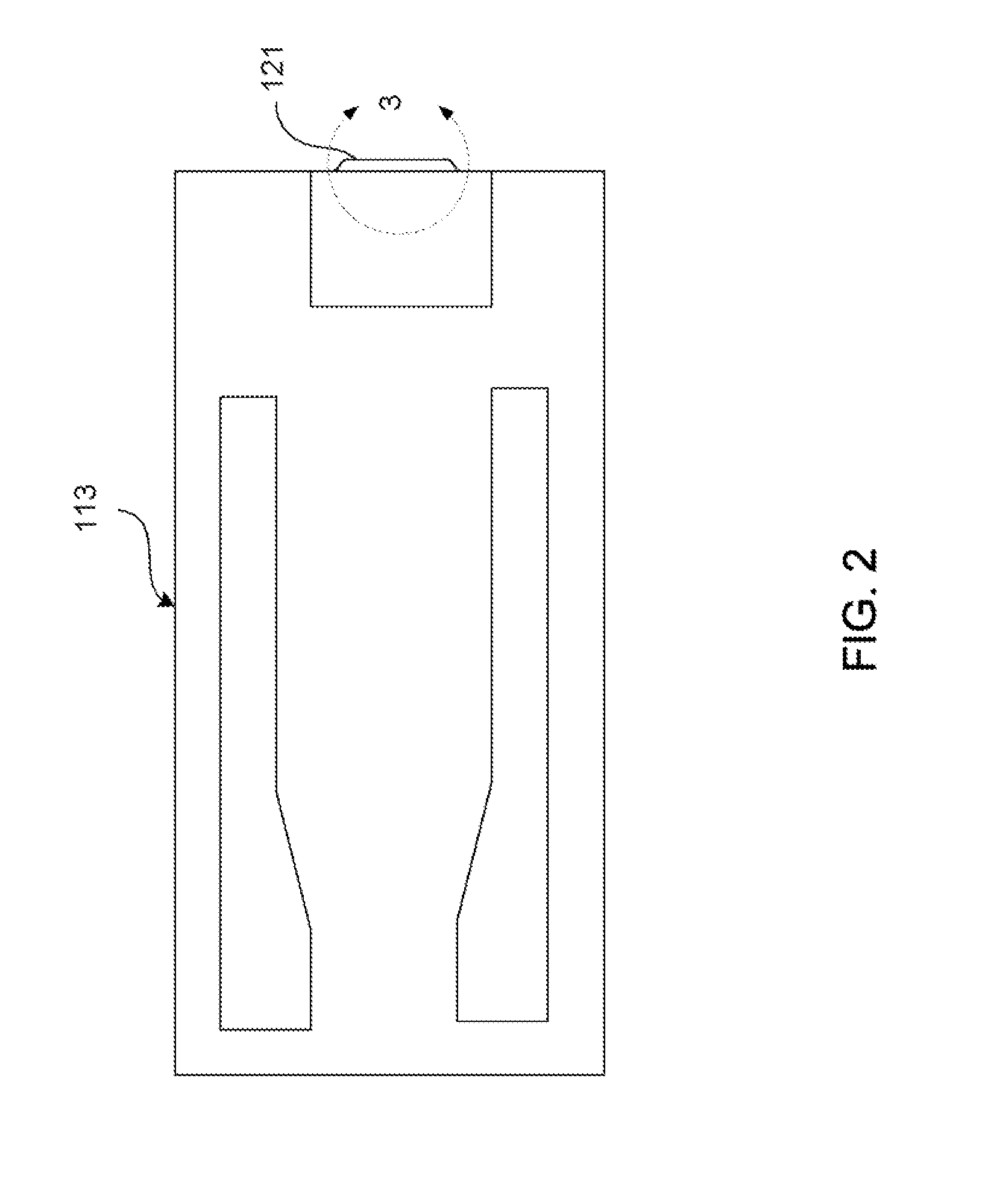

Current-perpendicular-to-plane sensor with dual keeper layers

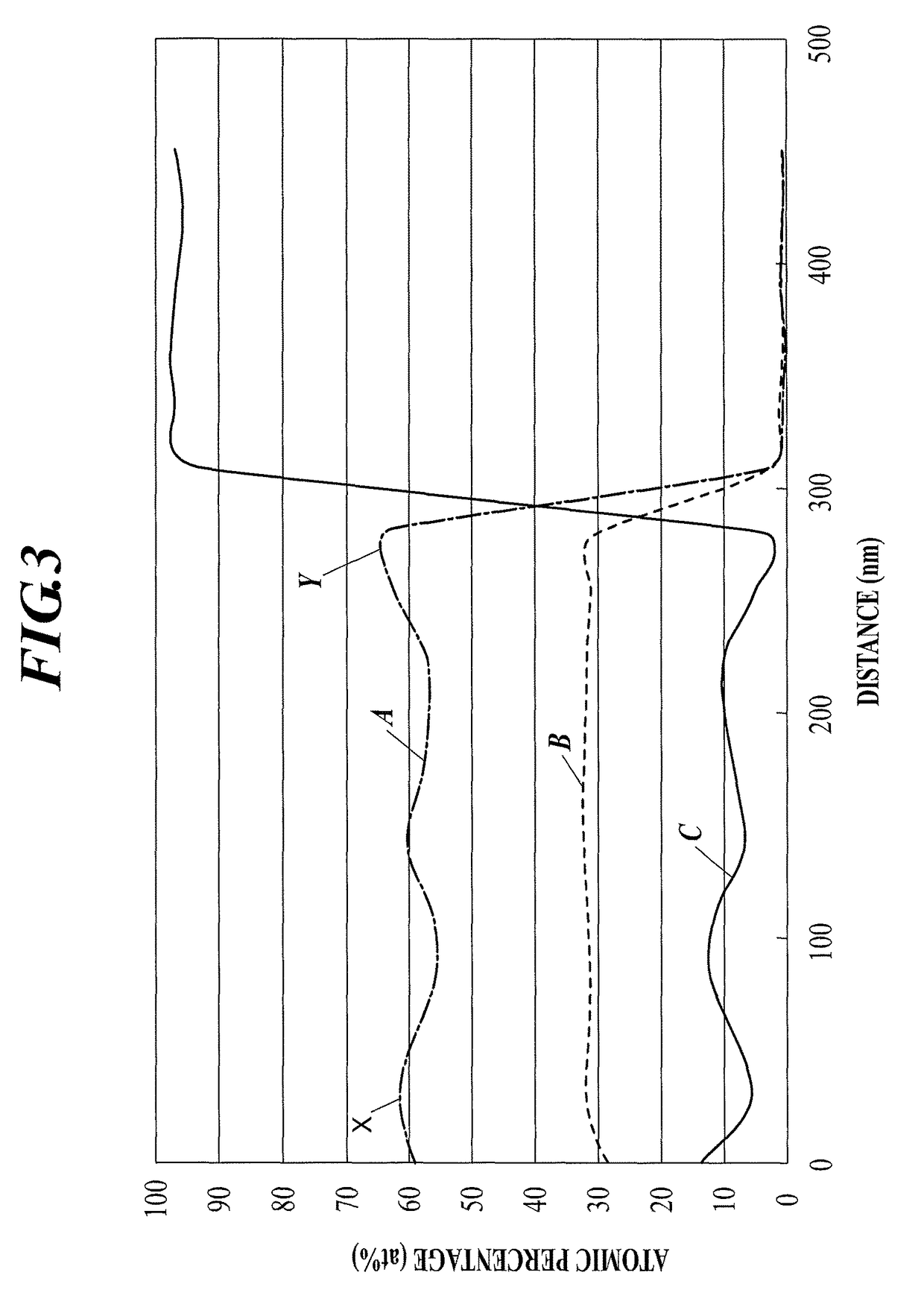

InactiveUS20080144234A1Reduce couplingLower junction resistance-area productNanomagnetismMagnetic measurementsRough surfaceAmorphous phase

This invention provides a CPP TMR or GMR sensor with an amorphous ferromagnetic lower keeper layer and a crystalline ferromagnetic upper keeper layer. The amorphous ferromagnetic lower keeper layer strongly exchange-couples to an underlying antiferromagnetic pinning layer and planarizes its rough surface. The crystalline ferromagnetic upper keeper layer strongly antiparallel-couples to an adjacent ferromagnetic reference layer across a nonmagnetic spacer layer. The amorphous ferromagnetic lower keeper layer is preferably made of a Co—Fe—B alloy film with an Fe content high enough to ensure strong exchange-coupling to the underlying antiferromagnetic pinning layer, and with a B content high enough to ensure the formation of an amorphous phase for planarizing an otherwise rough surface due to the underlying antiferromagnetic pinning layer. The crystalline ferromagnetic upper keeper layer is preferably made of a Co—Fe alloy film with an Fe content low enough to ensure strong antiparallel-coupling to the adjacent ferromagnetic reference layer across the nonmagnetic spacer layer. The sensor is annealed at temperatures low enough to prevent the amorphous phase from transforming into a polycrystalline phase, but also high enough to maximize TMR.

Owner:WESTERN DIGITAL TECH INC

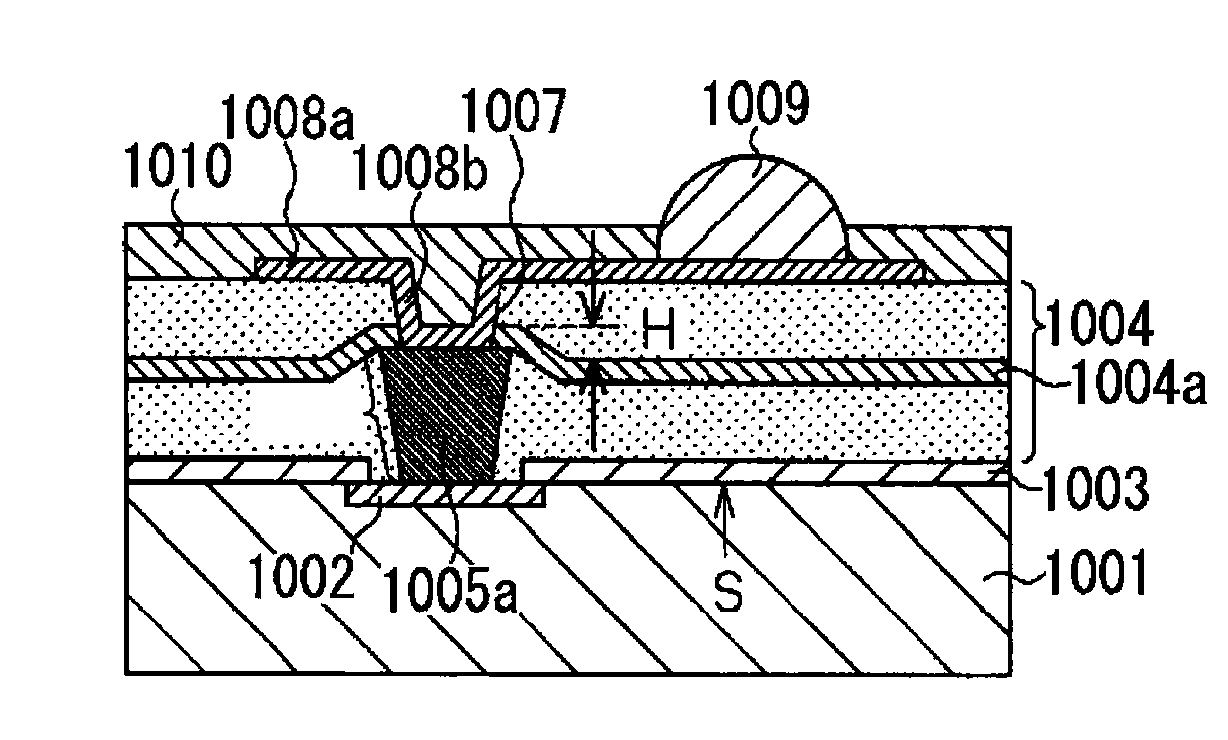

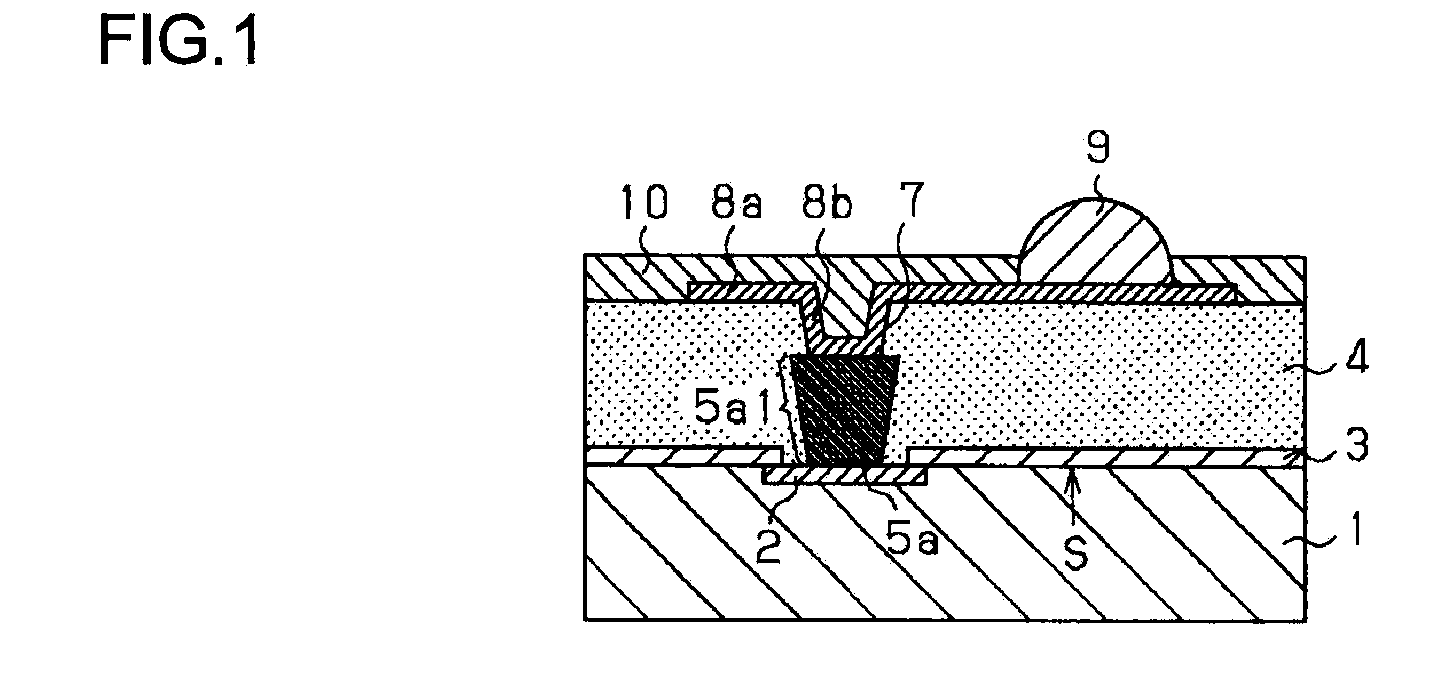

Packing board for electronic device, packing board manufacturing method, semiconductor module, semiconductor module manufacturing method, and mobile device

InactiveUS7915737B2Improve reliabilityImprove connection reliabilitySemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyElectrical conductor

Owner:SANYO ELECTRIC CO LTD

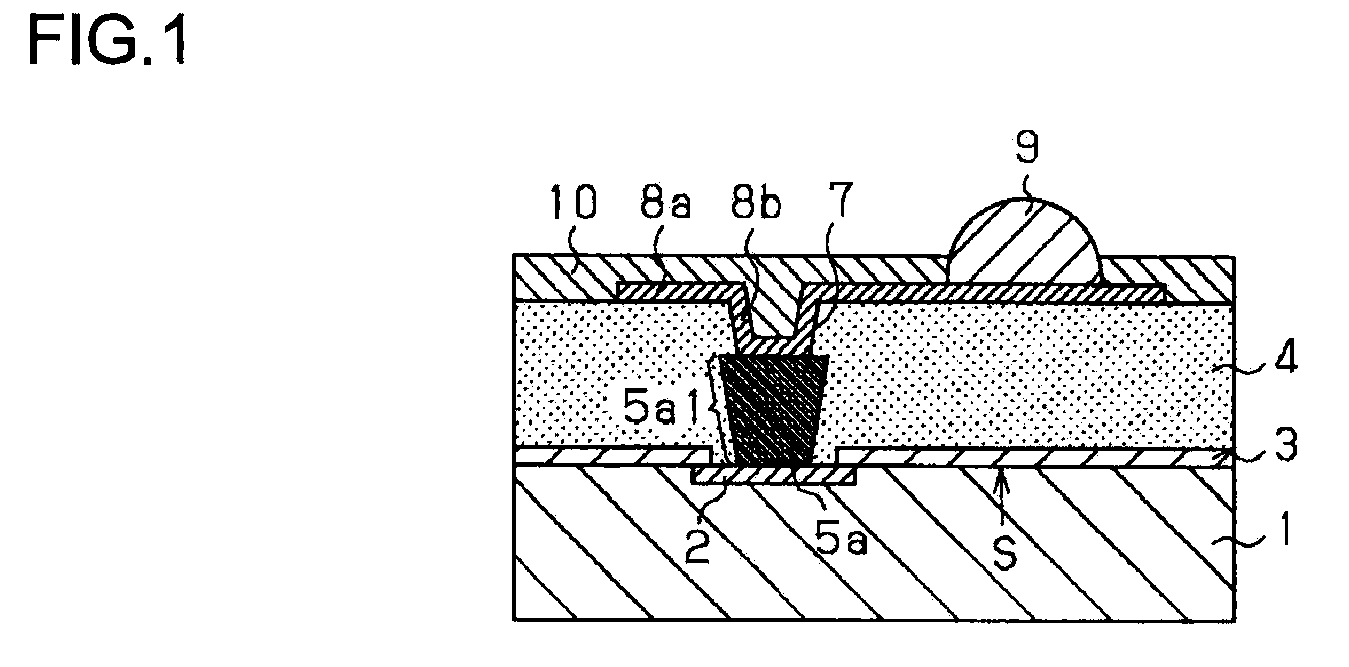

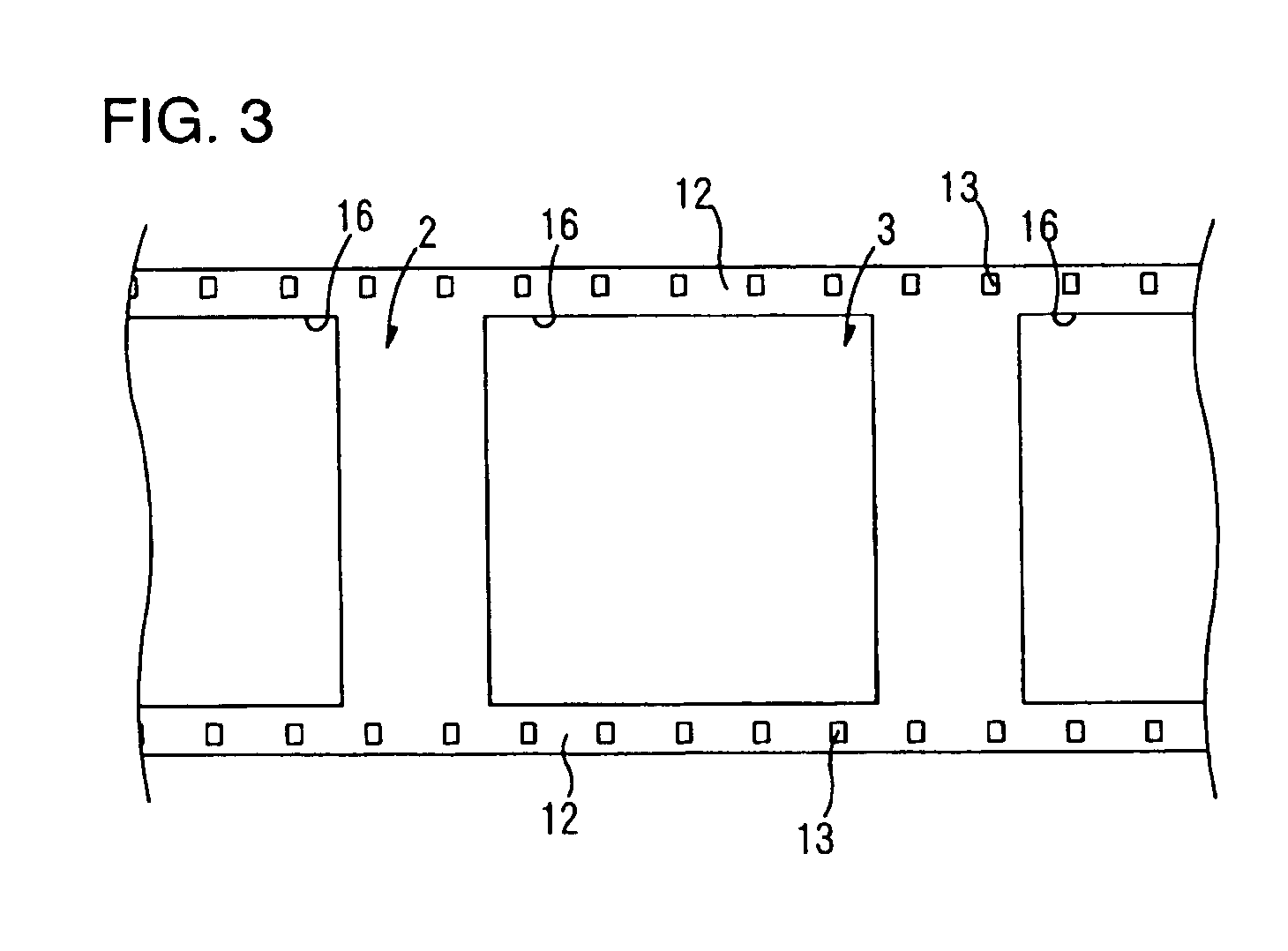

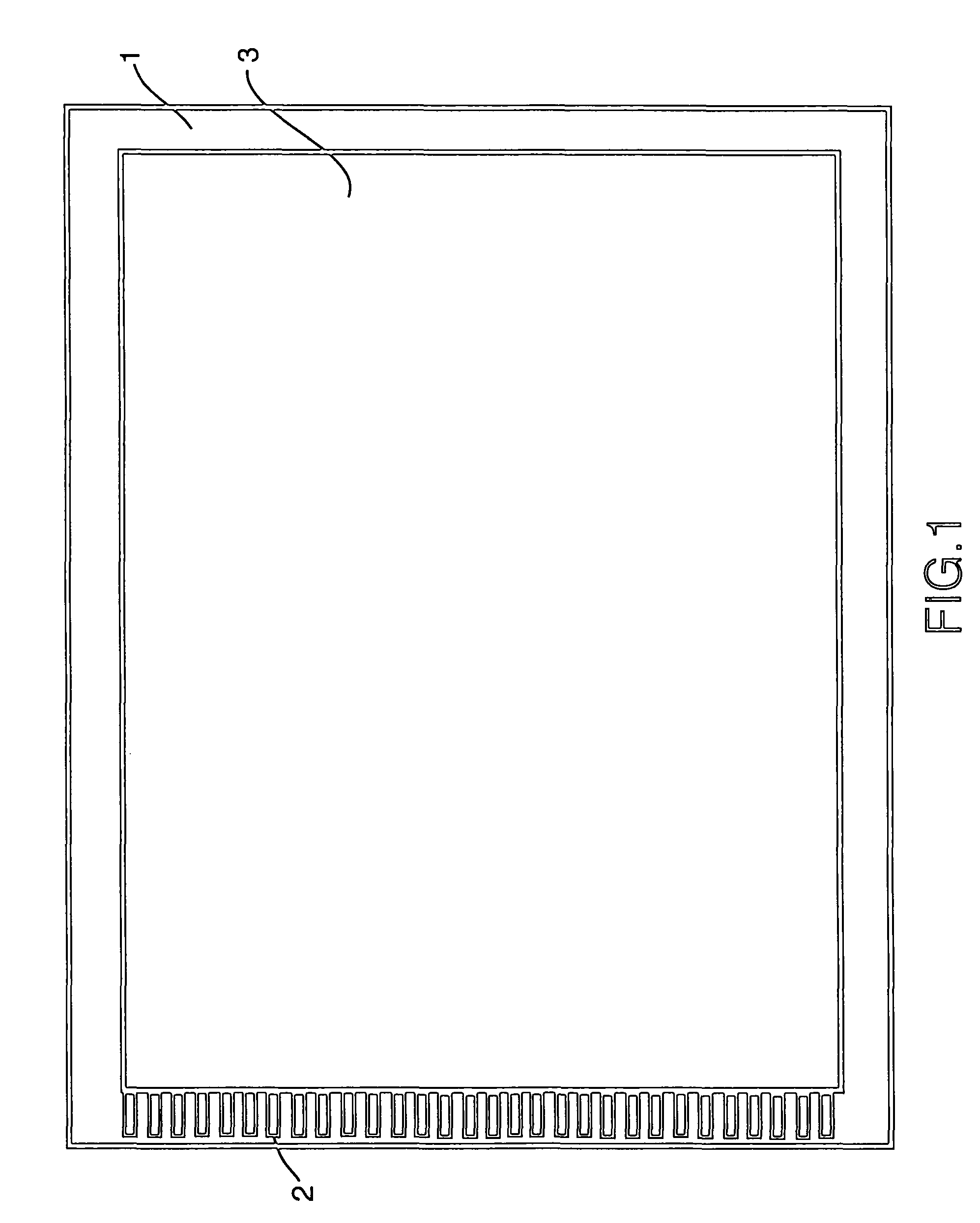

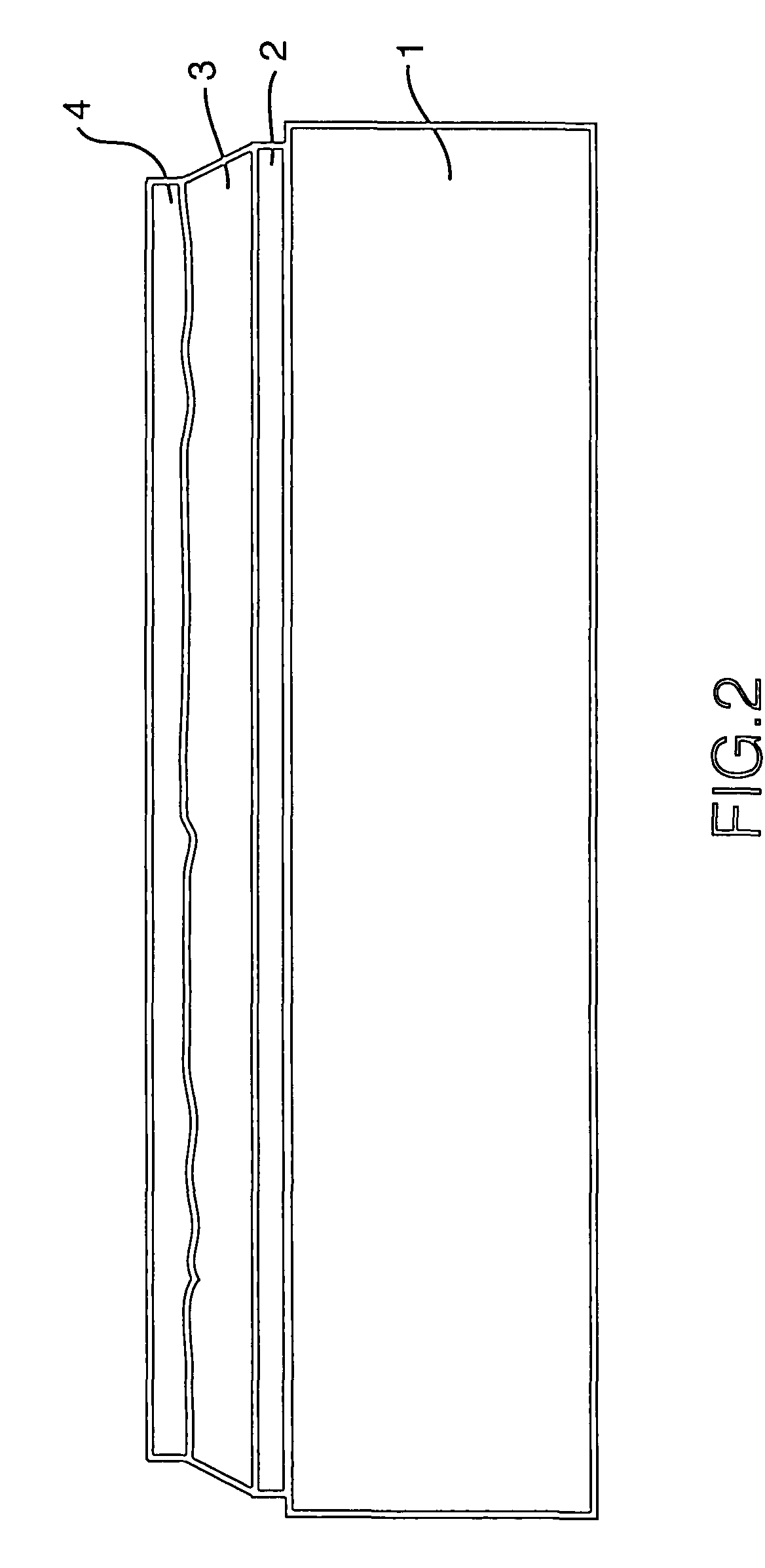

Wired circuit board

InactiveUS20050260391A1Improve accuracyReduce misjudgmentFinal product manufactureSemiconductor/solid-state device detailsElectrical conductorElectronic component

A wired circuit board on which a highly reliable conductor pattern is formed, to allow an electronic component to be mounted on it with improved accuracy. An insulating layer 3 is formed on a metal supporting layer 2 having a degree of surface brilliancy of 150-500% in such a manner as to have a haze value of 20-50% and also a conductor pattern 4 is formed on the insulating layer 3, thereby producing a TAB tape carrier 1. In this TAB tape carrier 1, since the metal supporting layer 2 has a specified degree of surface brilliancy of 500% or less, the pattern design of the conductor pattern 4 is optically examined to determine whether it is good or bad with high accuracy. Also, since the metal supporting layer 2 has a specified degree of surface brilliancy of 150% or more and the insulating layer 3 has a specified haze value ranging from 20% to 50%, the light for the alignment of an electronic component 21 can be allowed to smoothly pass through the insulating layer 3, and as such can allow the electronic component 21 to be mounted with high accuracy.

Owner:NITTO DENKO CORP

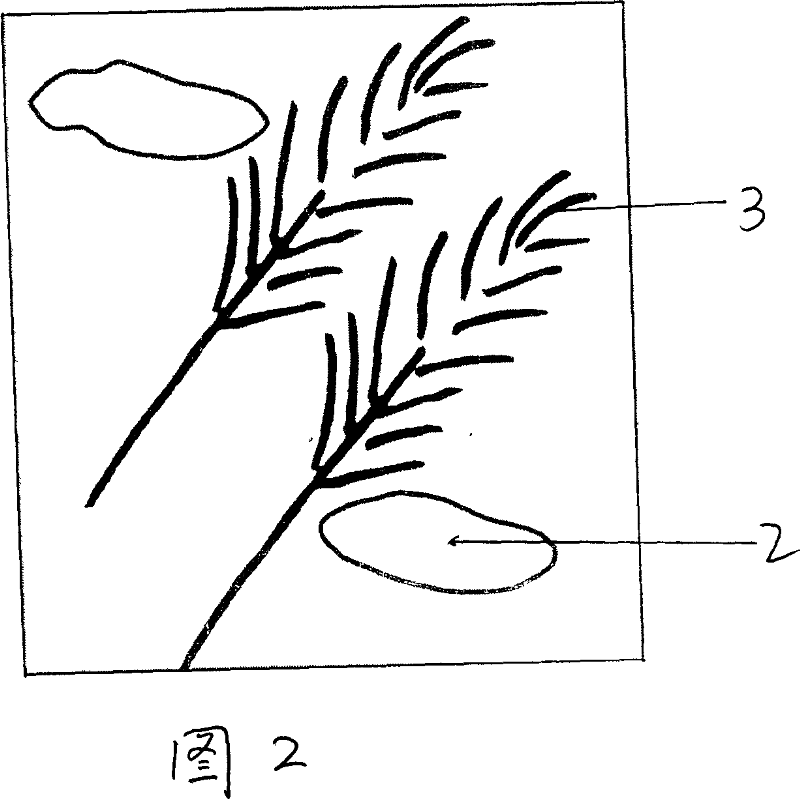

Making method for pastry nutlet mooncake

The invention relates to a making method for a pastry nutlet mooncake. Stuffing is prepared by taking wax gourd pulp, cooked sticky rice powder, white sugar, edible plant oil, sunflower seeds, sesame seeds, cashew kernels, black garlics and shredded coconut stuffing as main raw materials; the pastry nutlet mooncake is made by the working procedures of uniformly mixing and stirring the stuffing with low-gluten flour, high-gluten flour, the white sugar, granular vegetable shortening, water and the like which serve as main raw materials, adding the granular vegetable shortening, slightly stirring the mixture, performing folding to obtain cake skins, then covering the stuffing, and performing forming, arrangement on a plate, baking, cooling and packaging. The conventional technology is improved, so that the making technology is mature, easy to operate and convenient for production. The folded pastry five-nutlet mooncake is more and more favored by the customers due to the characteristics of clear pastry layer, uniform hierarchy, pastry and sweet fragrance, melting in mouth, light pastry fragrance, bright color, unique flavor, fashionable appearance and the like and has a good market prospect.

Owner:JUXIANGYUAN HEALTH FOOD ZHONGSHAN

Ultrafine glass wool obtained by centrifugation and preparation method thereof

The invention discloses ultrafine glass wool obtained by centrifugation. The ultrafine glass wool comprises 63.0-66.5wt% of SiO2, 1.4-3.0wt% of Al2O3, 5.5-7.5wt% of CaO, 1.5-3.0wt% of MgO, 0.4-1.3wt% of K2O, 14.2-16.0wt% of Na2O and 5.5-7.6wt% of B2O3. The Al2O3 content is in a range of 1.4-3.0% so that liquid glass crystallization tendency is reduced, fibers are flexile and burr and fractures are avoided; and the B2O3 content is in a range of 5.5-7.6% so that liquid glass viscosity is reduced at a fiber formation temperature of 1050+ / -10 DEG C and fibers are thinned easily. The diameters of 90% of the glass wool fibers are normally distributed in a range of 2-4 microns and the lengths of 92% of the glass wool fibers are normally distributed in a range of 2-3 centimeters. The invention also discloses a preparation method of the ultrafine glass wool. The preparation method comprises the following steps of selecting raw materials satisfying requirements, putting the raw materials into a kiln, carrying out melting to obtain transparent liquid glass, introducing the transparent liquid glass into centrifugation heads, and carrying out fibration at a flow rate of 76+ / -2kg / h at each centrifugation head to obtain the ultrafine glass wool. The ultrafine glass wool has a low heat conduction coefficient, uniform layering and good sound-absorbing and heat-insulation performances. The ultrafine glass wool can be used for preparation of sound-insulation and noise-reduction cotton felt in an airplane cabin plate, sound-insulation and heat-insulation cotton felt for the wall and roofing, heat insulation plates, and other sound-absorbing and heat-insulation products.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

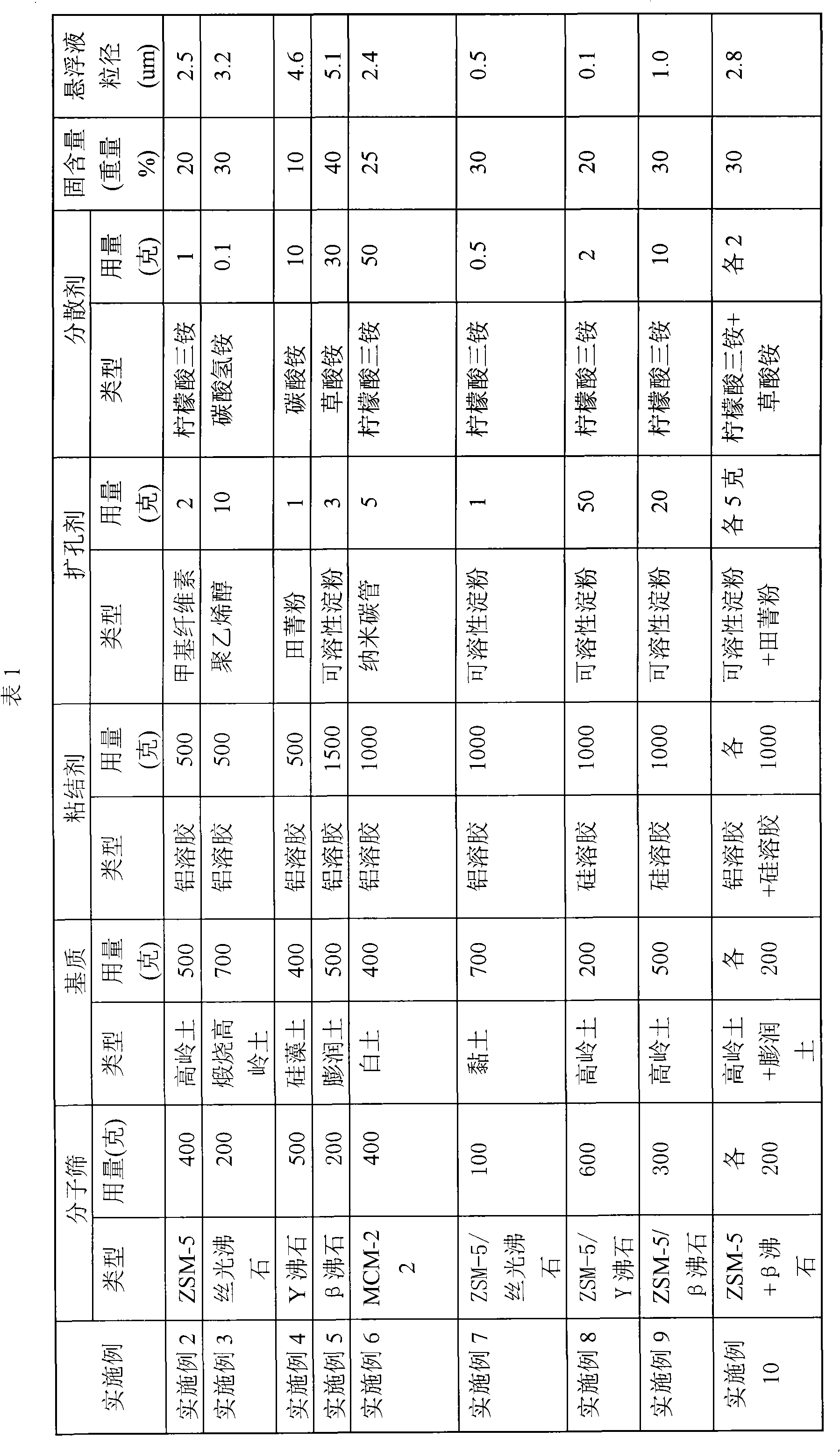

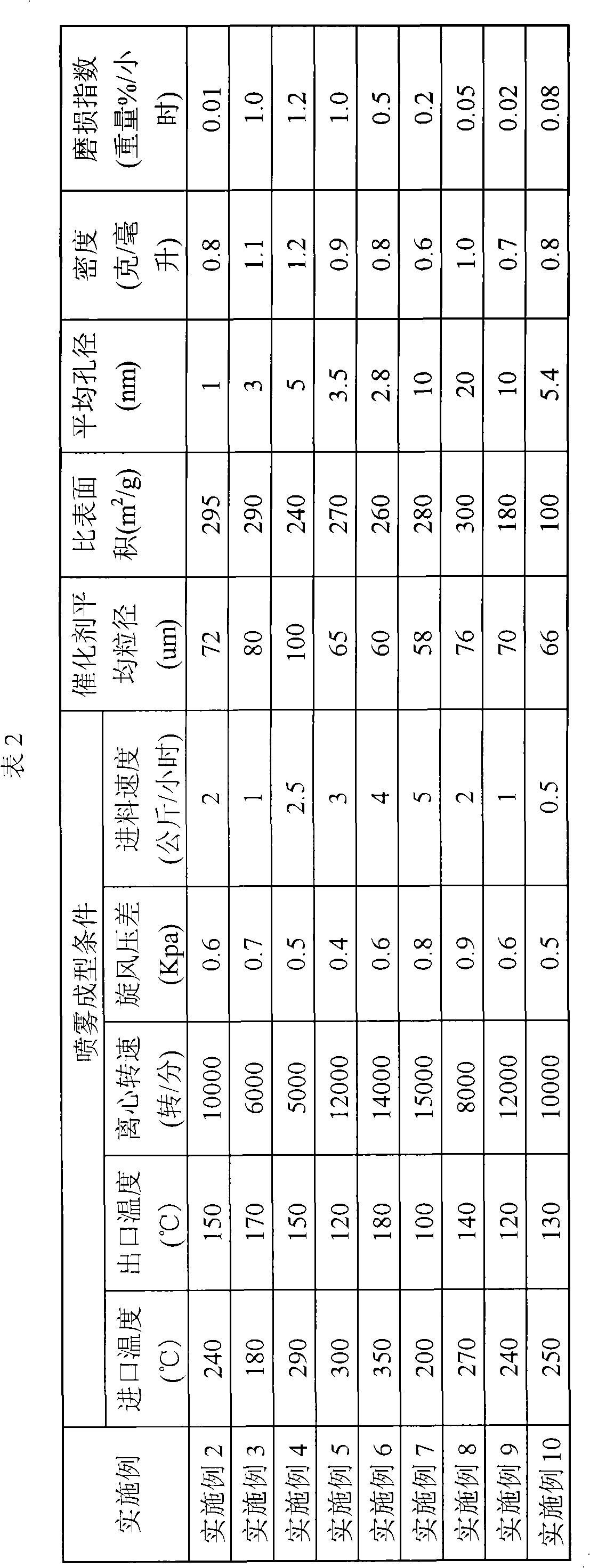

Preparation method of fluid catalyst

ActiveCN102371168AHigh activityEvenly dispersedMolecular sieve catalystsCatalyst activation/preparationMolecular sieveCatalytic pyrolysis

The invention relates to a preparation method of a fluid catalyst, and mainly solves the problem of low wear resistance of fluid catalysts in existing technologies. The method comprises the following steps of: (a) mixing a molecular sieve, a binder, a matrix material, a pore-expanding agent, a dispersing agent and a liquid medium uniformly so as to form a suspension; (b) controlling the particle size of materials in the suspension ranging from 0.1 to 5 micrometers; (c) conducting spray drying to the suspension so as to form a microsphere catalyst; (d) roasting the microsphere catalyst, thus obtaining a finished catalyst. The technical method provided in the invention well solves the above problem, and can be used in the reaction process of carbon olefin production through light oil catalytic pyrolysis.

Owner:CHINA PETROLEUM & CHEM CORP +1

Magnetic recording medium containing a binder of trifunctional or higher aliphatic (meth) acrylate compound

InactiveUS6610426B2Reduce molecular weightImprove compatibilityMagnetic materials for record carriersRecord information storageMethacrylateNon magnetic

Provided is a magnetic recording medium achieving high durability, a high degree of smoothness, and a magnetic layer of uniform thickness, and having substantially better electromagnetic characteristics. A magnetic recording medium comprising a nonmagnetic layer comprising a nonmagnetic powder and at least one magnetic layer comprising a ferromagnetic powder and binder provided on a support in this order. The binder contained in the magnetic layer comprises at least a trifunctional or greater aliphatic acrylate compound having a molecular weight ranging from 250 to 1,000 or a trifunctional or greater aliphatic methacrylate compound having a molecular weight ranging from 250 to 1,000 that has been cured by exposure to radiation, and optionally followed by heat treatment. The compound is employed in a ratio of 5 to 30 mass parts per 100 mass parts of ferromagnetic powder.

Owner:FUJIFILM CORP

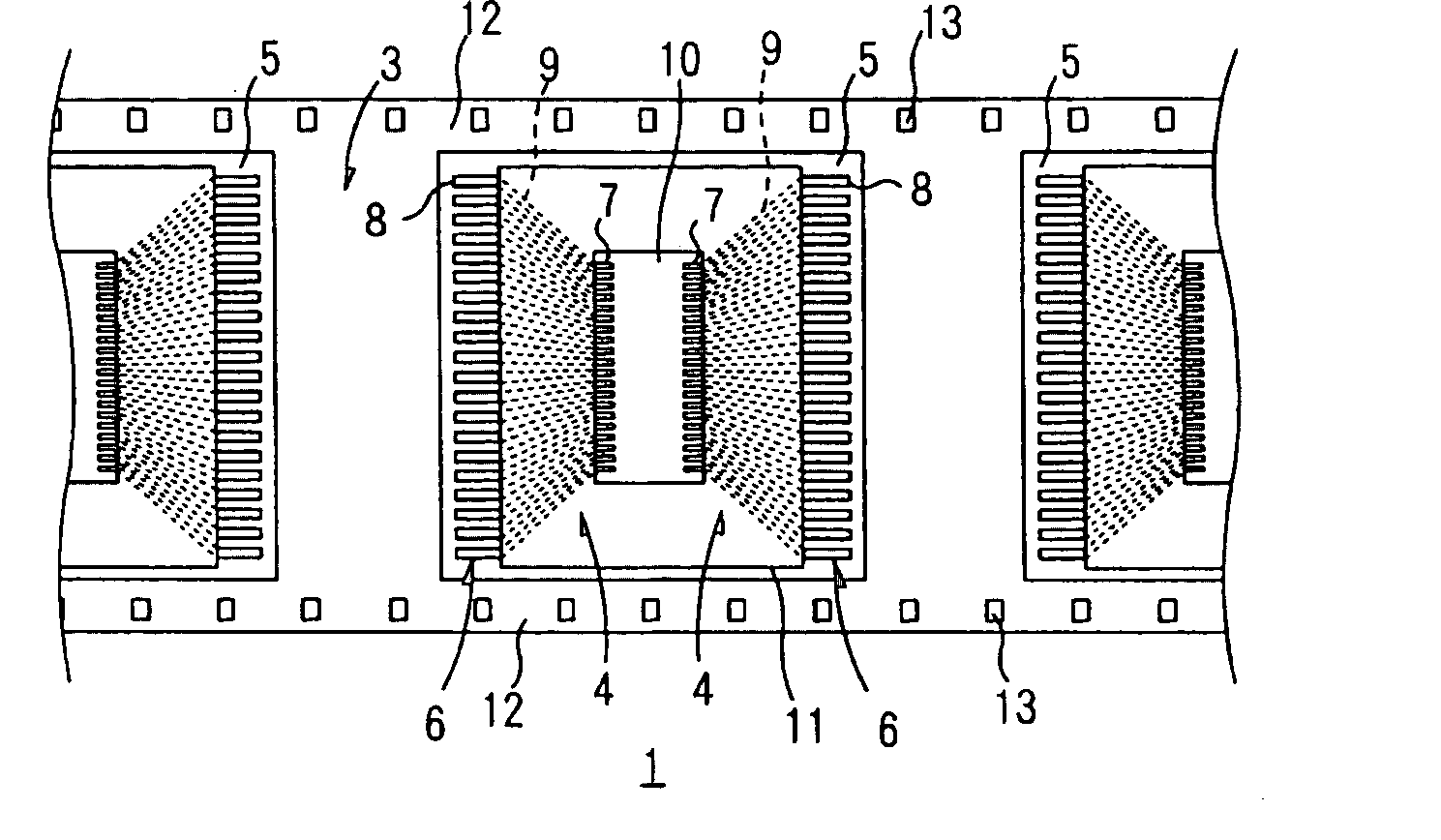

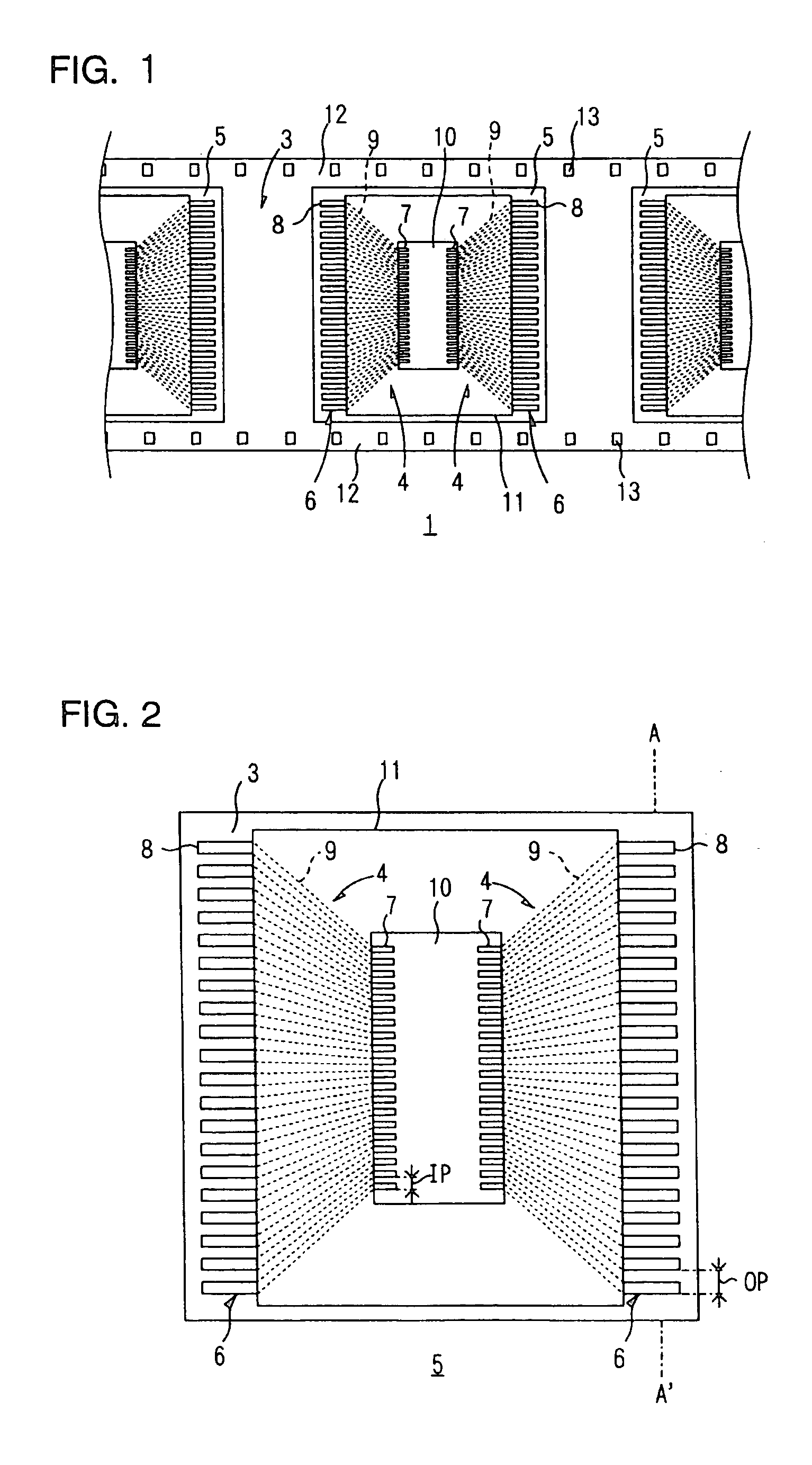

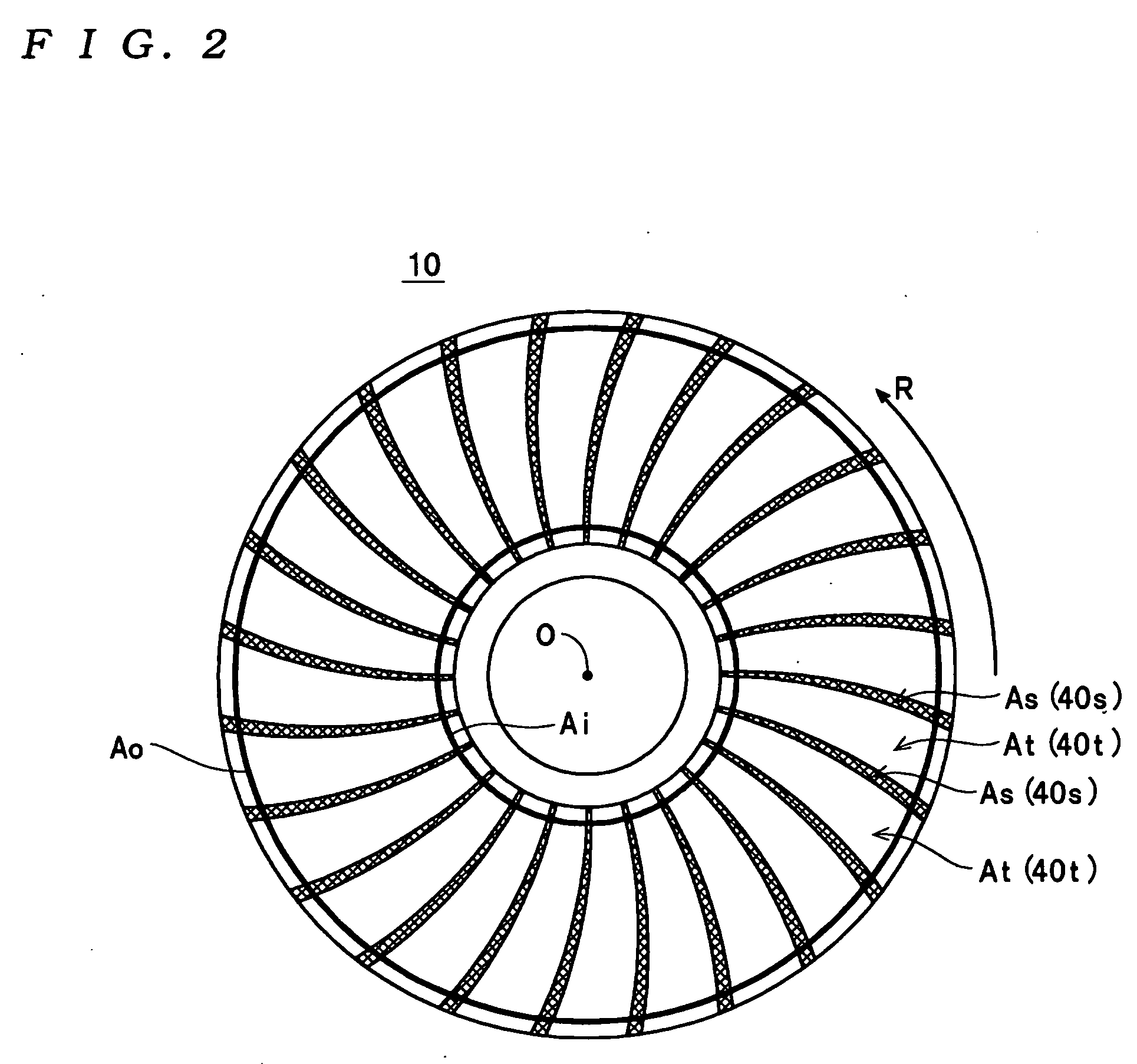

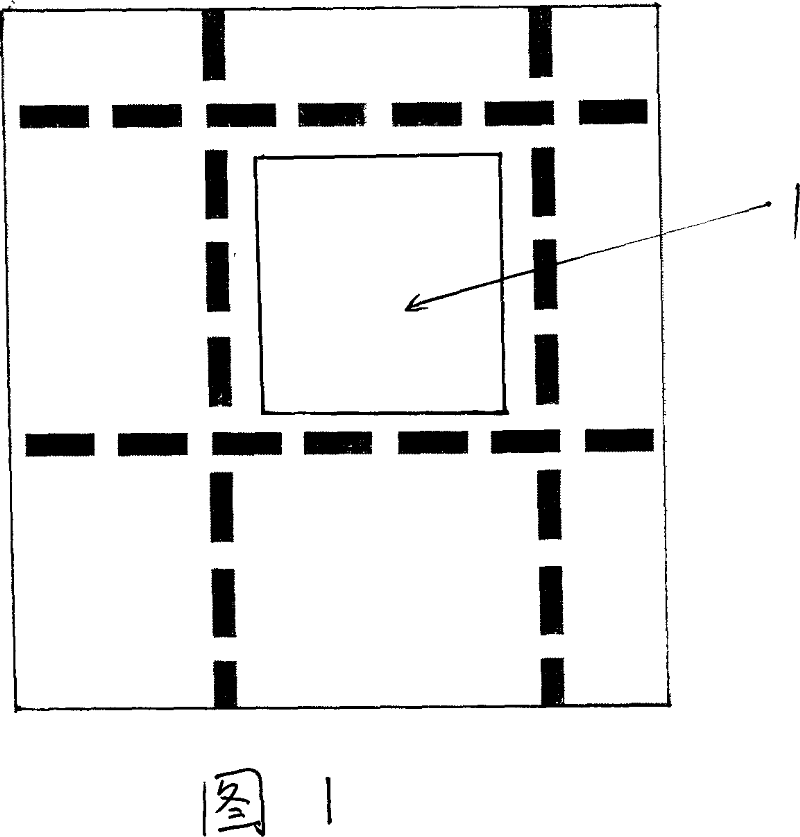

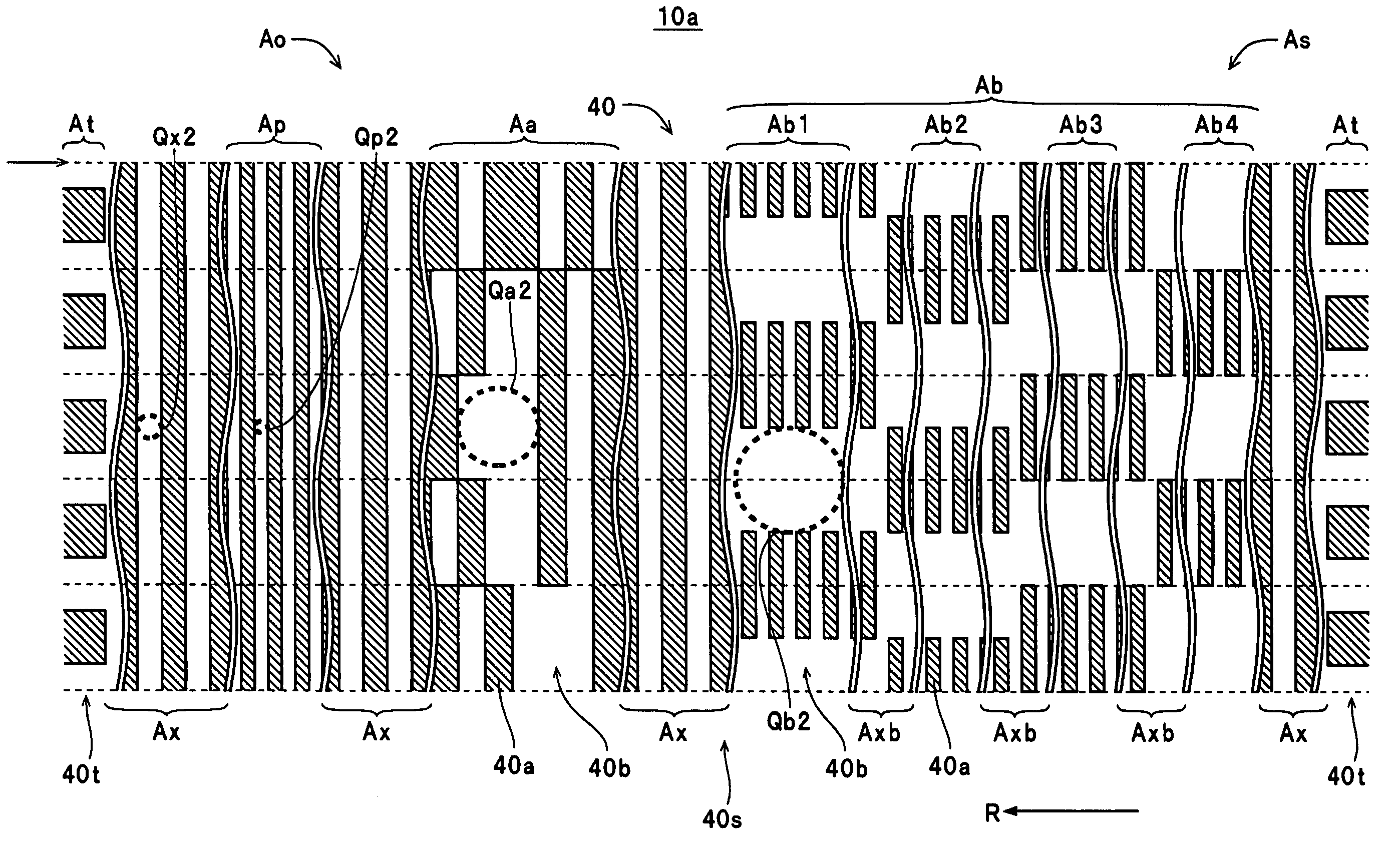

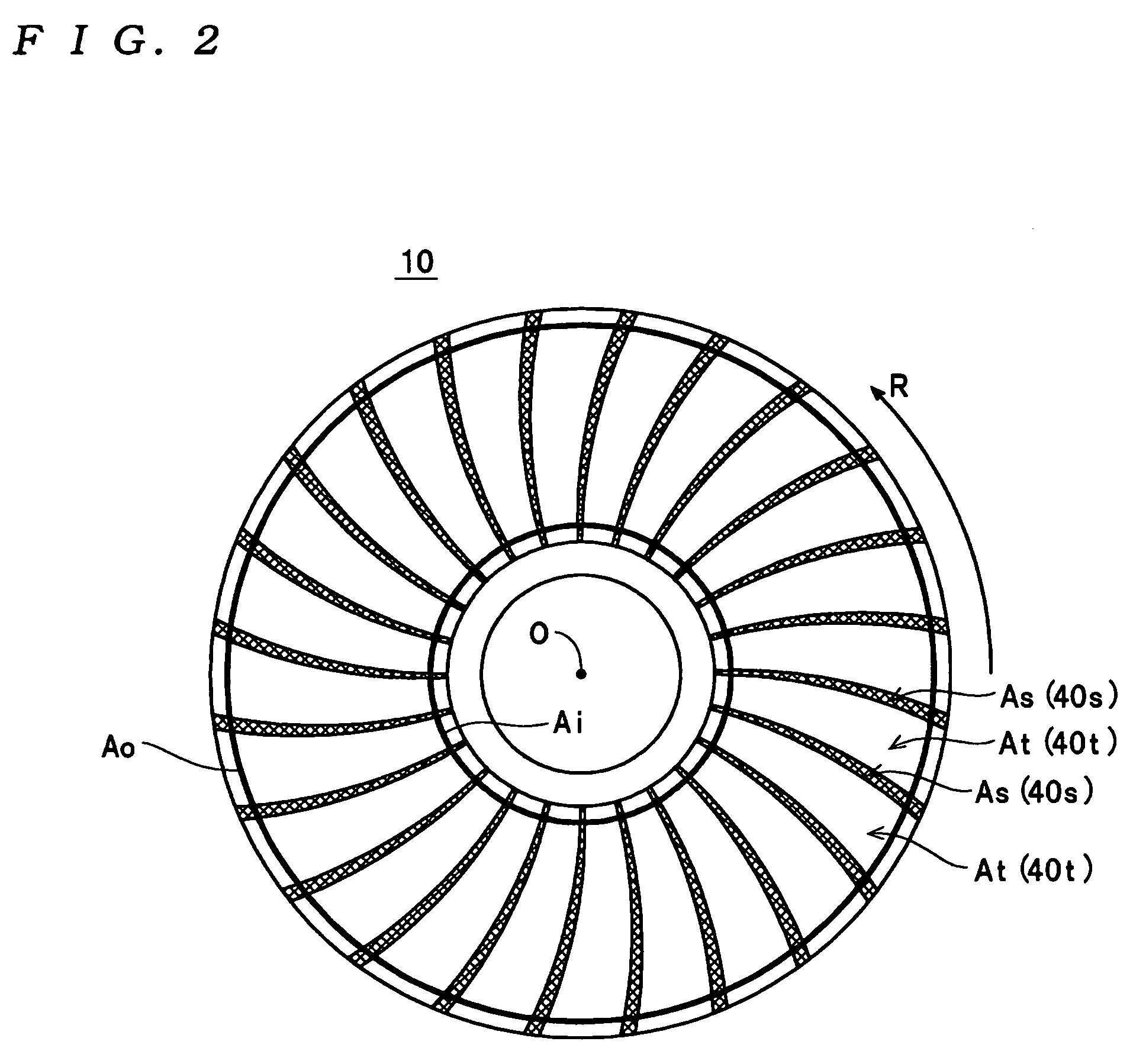

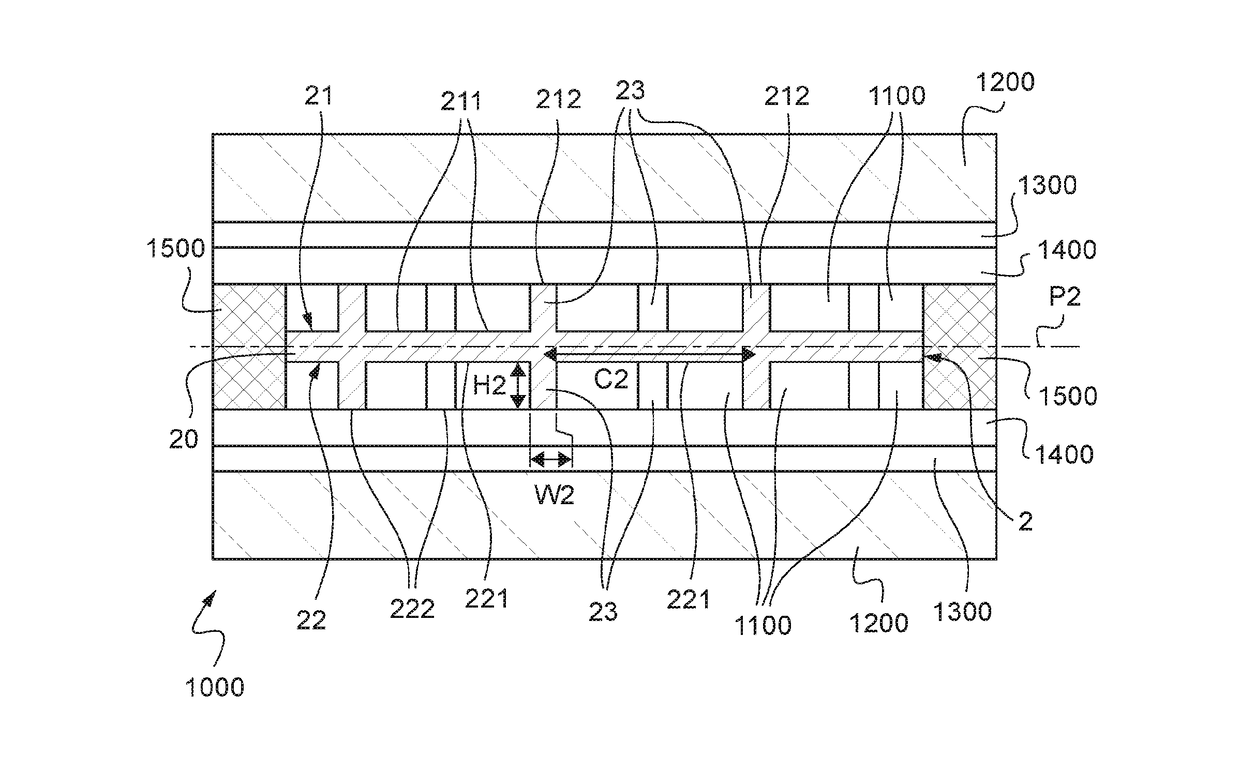

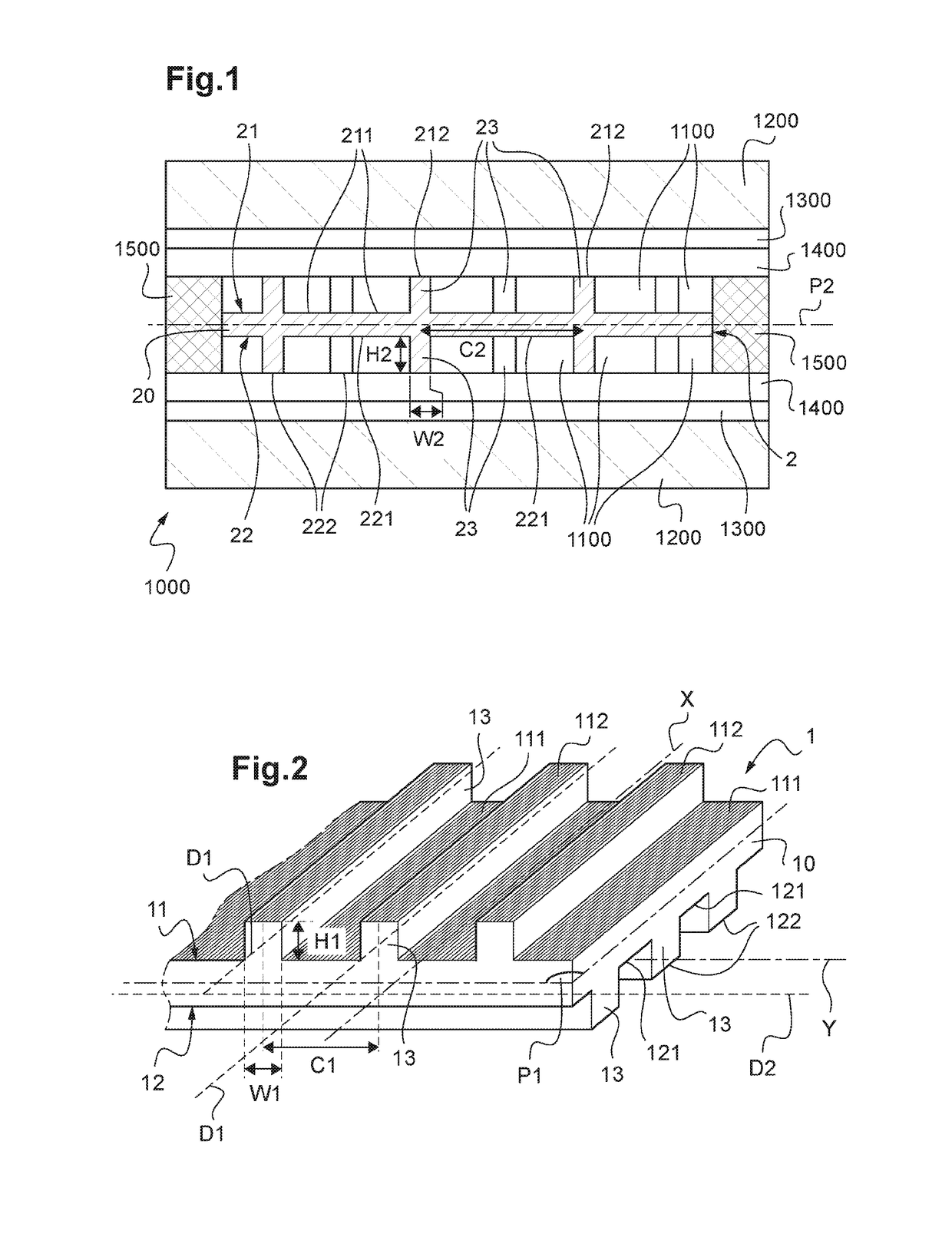

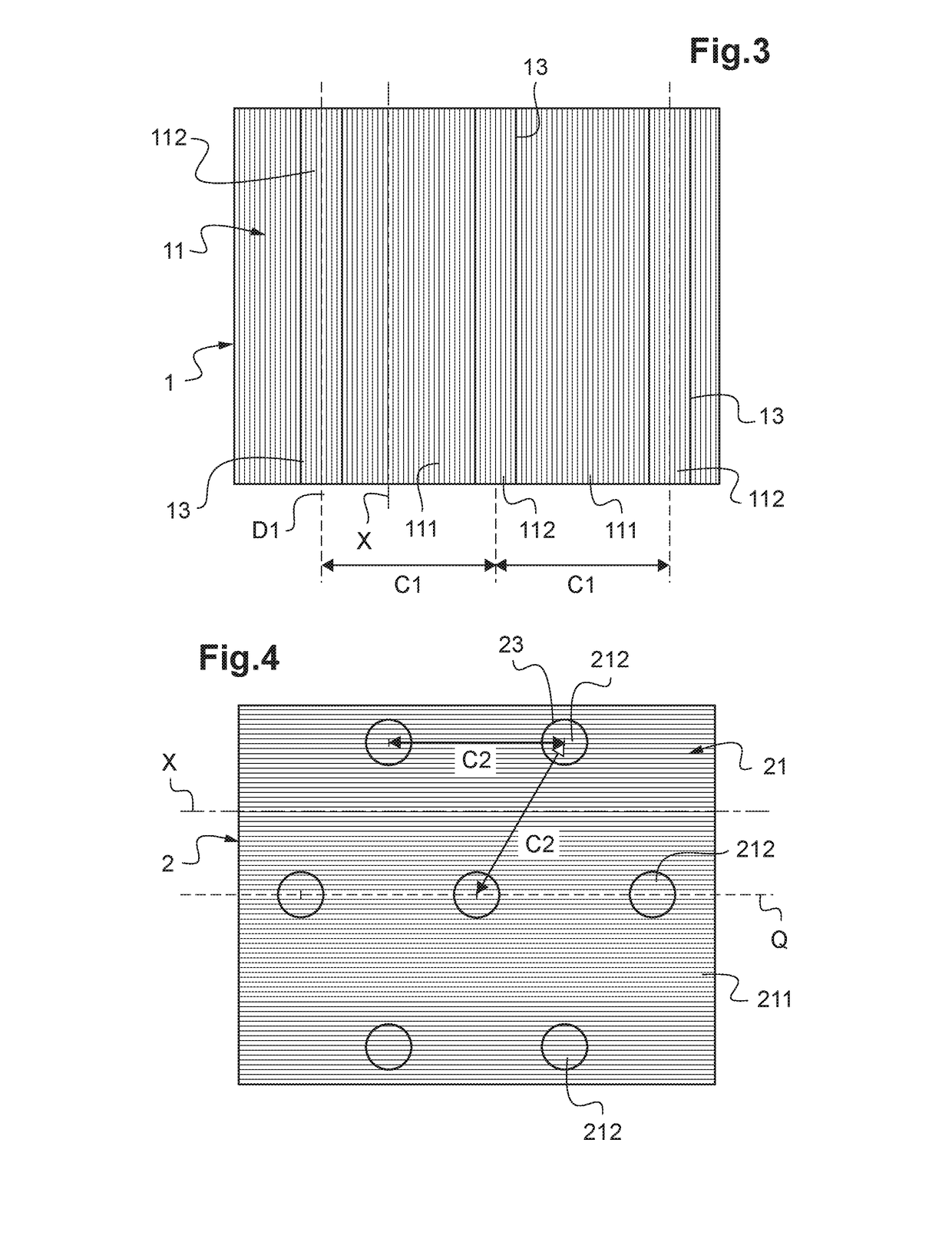

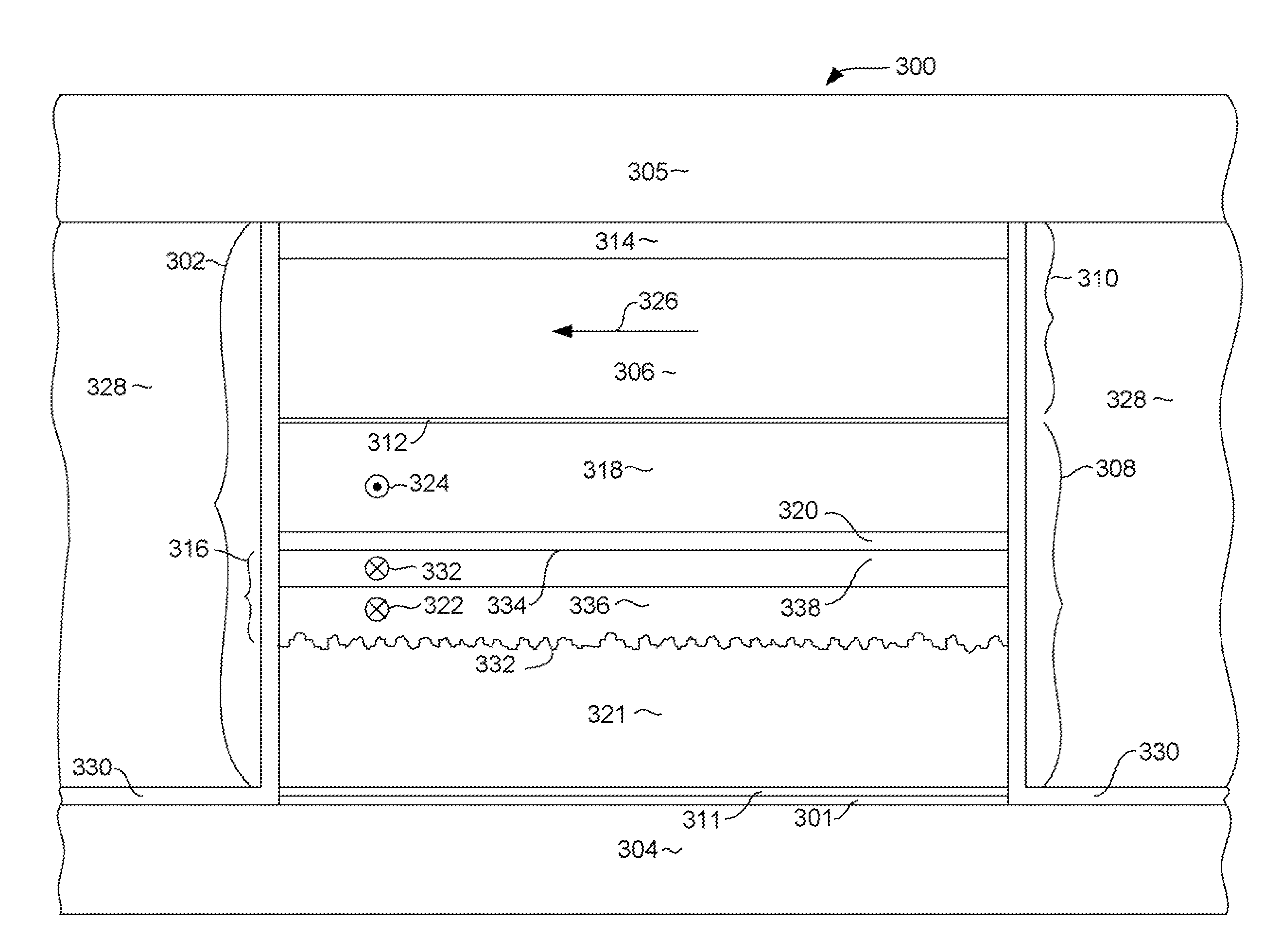

Magnetic recording medium, recording/reproducing apparatus, and stamper

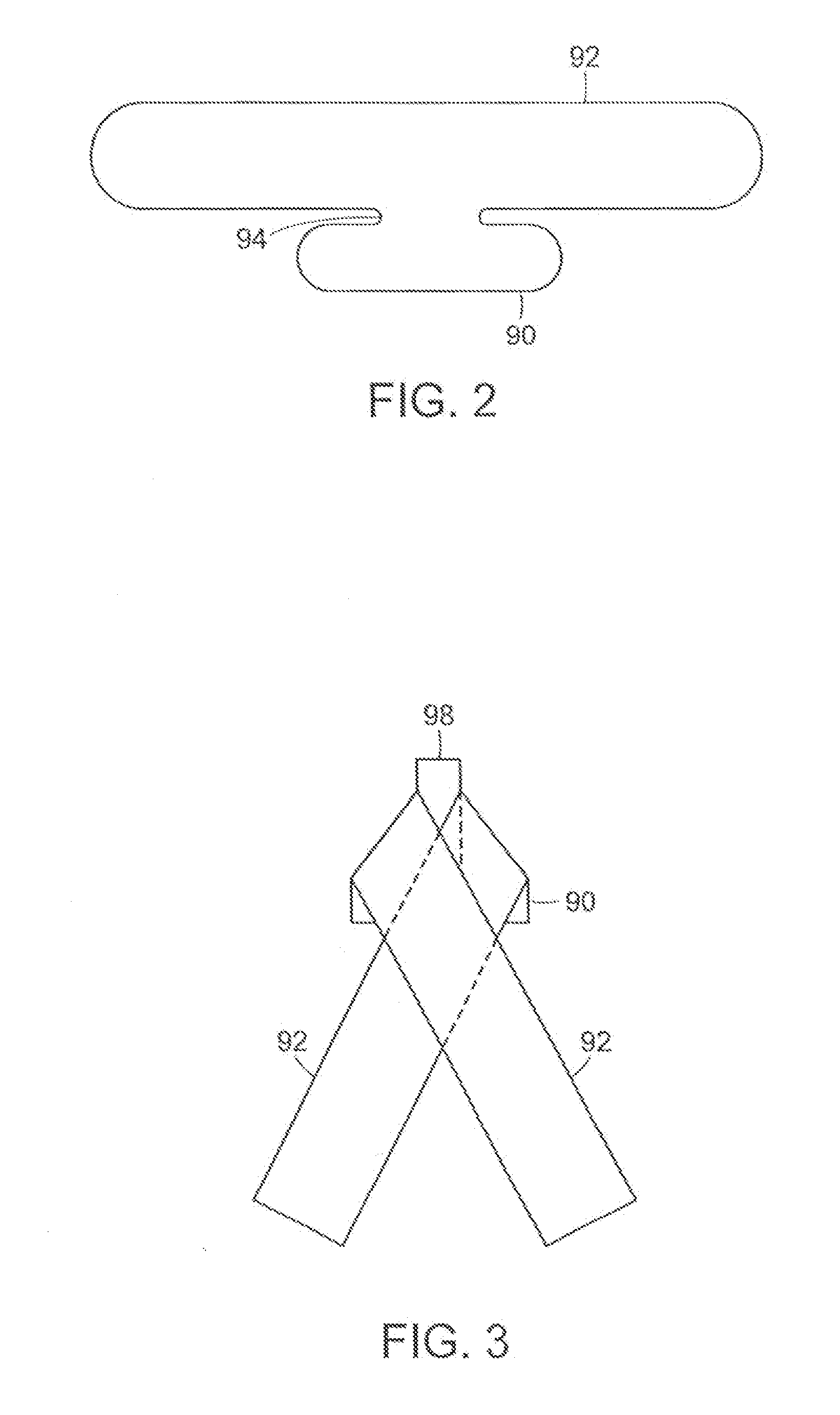

InactiveUS20060198052A1Reliable readEvenly layeredCarrier storage meansNanoinformaticsMaximum diameterEngineering

On a magnetic recording medium, a servo pattern is formed in a servo pattern region on at least one surface of a substrate by a concave / convex pattern including a convex part, at least protruding end part of which is formed of magnetic material, and a concave part. The servo pattern region includes an address pattern region and a burst pattern region, wherein the convex part is formed in the servo pattern region so that a larger of an inscribed circle with a largest diameter out of inscribed circles on an open surface of the concave part formed in the address pattern region and an inscribed circle with a largest diameter out of inscribed circles on an open surface of the concave part formed in the burst pattern region is an inscribed circle with a largest diameter out of inscribed circles on an open surface of the concave part formed in the servo pattern region.

Owner:TDK CORPARATION

Packing board for electronic device, packing board manufacturing method, semiconductor module, semiconductor module manufacturing method, and mobile device

InactiveUS20080157338A1Improve reliabilityImprove connection reliabilitySemiconductor/solid-state device detailsSolid-state devicesCopper platingManufacturing technology

A manufacturing technology is provided capable of improving the reliability of a semiconductor module having a via contact connected to an electrode part of a semiconductor device. A conductive bump is formed on an insulating layer such that the end of the conductive bump is in contact with an electrode of a semiconductor substrate. By pressure-molding the assembly using a press machine, the semiconductor substrate, the conductive bump, and the insulating layer are integrated. With this, the conductive bump is allowed to embed itself in the insulating layer while maintaining contact with the electrode. The insulating layer is subject to laser irradiation from above so as to form an aperture exposing the conductive bump. Subsequently, the upper surface of the insulating layer and the interior surface of the aperture are plated with copper by electroless plating and electroplating so as to form a copper plating layer, and a via contact is formed in the aperture so as to coat the inner wall of the aperture.

Owner:SANYO ELECTRIC CO LTD

Ornamental glass having etching pattern and multicolor pattern and and method for manufacturing same

InactiveCN101041555AHigh precisionFull of three-dimensional senseSurface treatment compositionsFlat glassScreen printing

The invention discloses a decorative glass with acid-frosted pattern and colored pattern and preparing method, which comprises the following steps: one, acid-frosting to acid-frosting pattern on the plate glass through acid-frosting treatment; two, cleaning; airing or drying; three, combining with self pattern of acid-frosting glass; adopting silk-printing or spraying method; printing or spraying coloured material on the acid-frosting glass; forming colored pattern; four, natural drying or drying the coloured glass; getting end product.

Owner:ZHENGZHOU HENGHAO GLASS TECH

Method for forming an interfacial passivation layer on the Ge semiconductor

ActiveUS8071458B1Quality improvementPromote innovationSemiconductor/solid-state device manufacturingGate insulatorSemiconductor

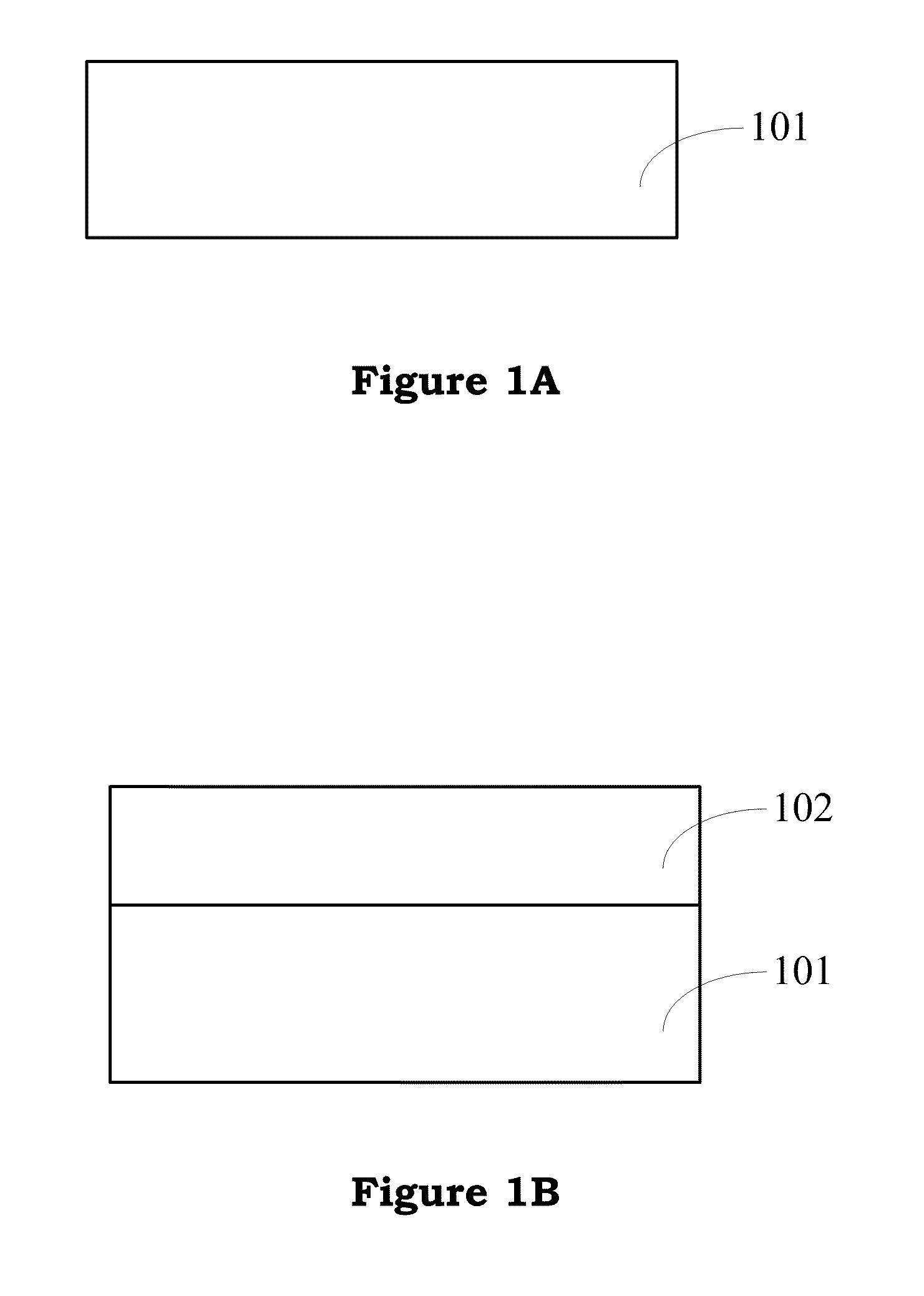

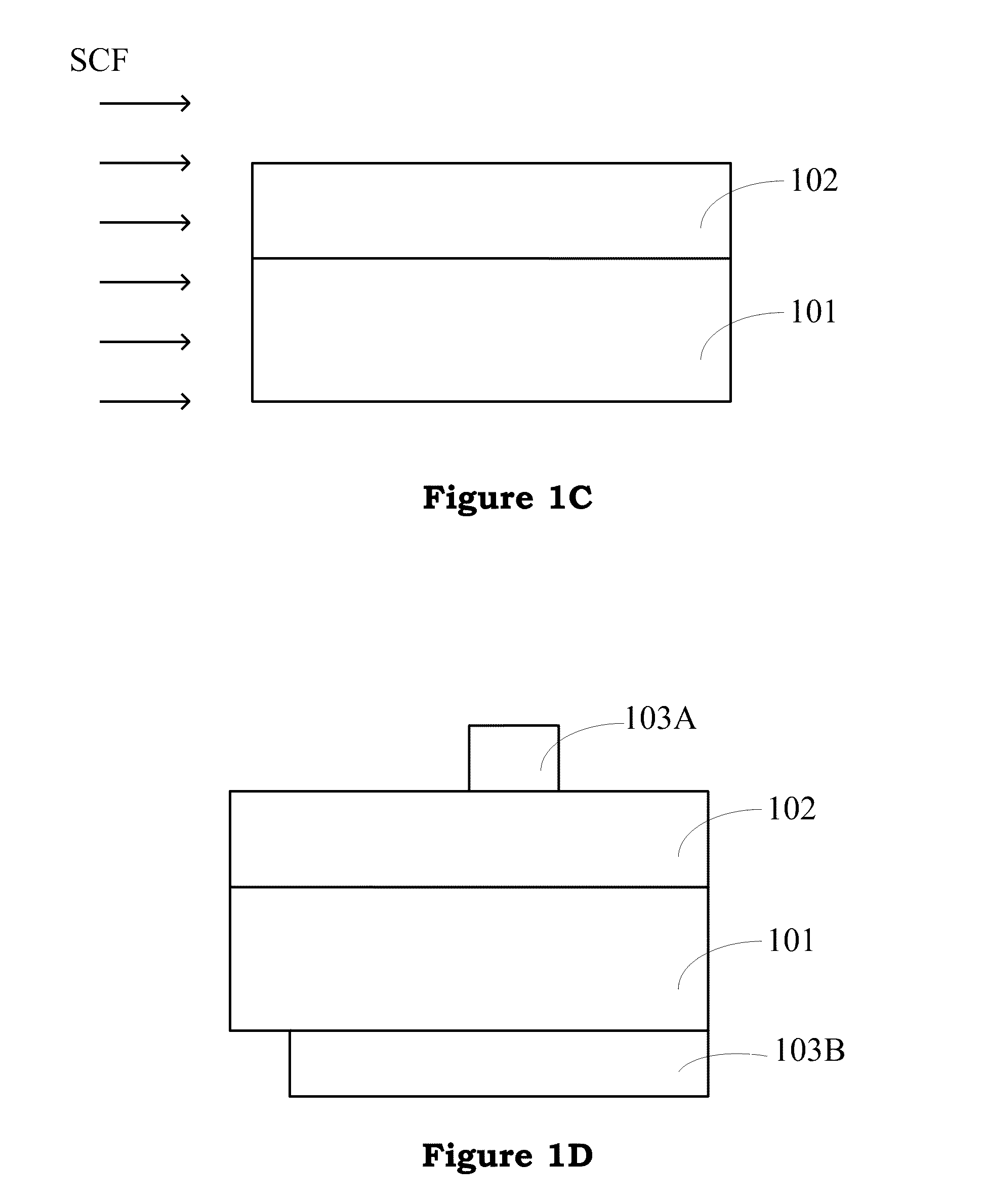

The invention discloses a method for forming an interfacial passivation layer on the Ge semiconductor. The supercritical CO2 fluids is used to form an interfacial passivation layer between Ge channel and gate insulator layer, and improve the dielectric characteristics of gate insulator after high-temperature thermal annealing process.

Owner:NAT CHIAO TUNG UNIV

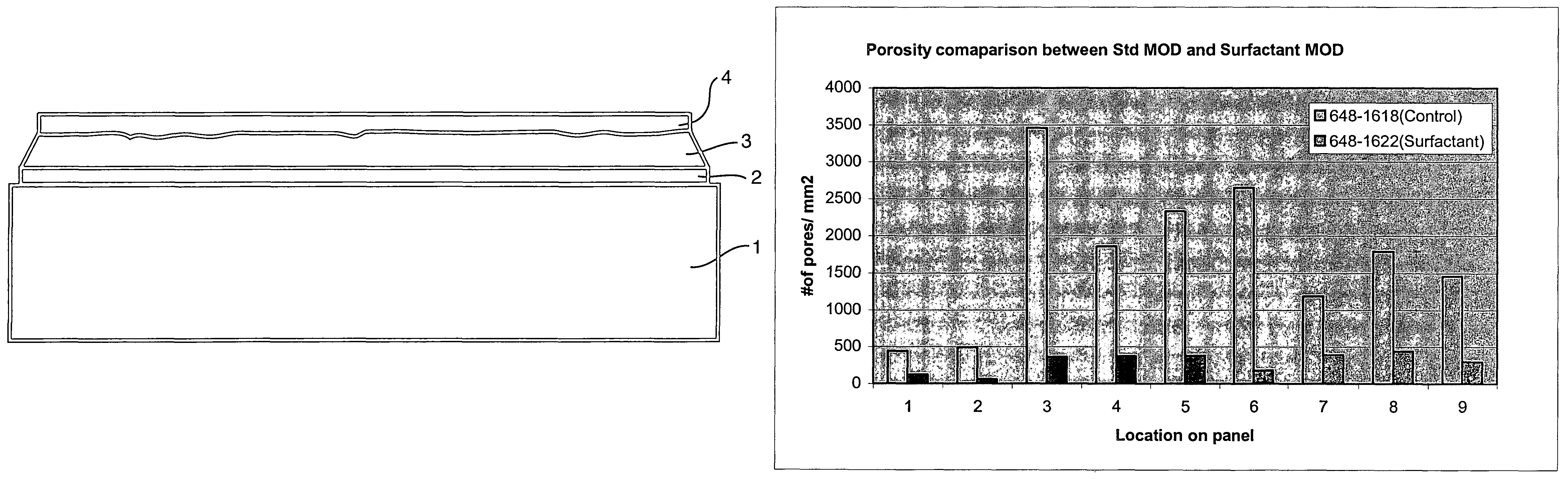

Thick film dielectric structure for thick dielectric electroluminescent displays

InactiveUS7741773B2Low densityPromote wettingLiquid surface applicatorsDischarge tube luminescnet screensHYDROSOLDielectric structure

An improved smoothing layer for use with a thick film dielectric layer, and improved composite thick film dielectric structure is provided. The smoothing layer is a piezoelectric or ferroelectric material that has a reduced amount of defects. The smoothing layer is formed by the addition of surfactant to a sol gel or metal organic solution of organo metallic precursor compounds. The composite thick film dielectric structure comprises a thick film dielectric composition having a PZT smoothing layer thereon, the smoothing layer being made by a process incorporating surfactant. Both the smoothing layer and the composite thick film dielectric structure are for use in electroluminescent displays.

Owner:IFIRE IP CORP

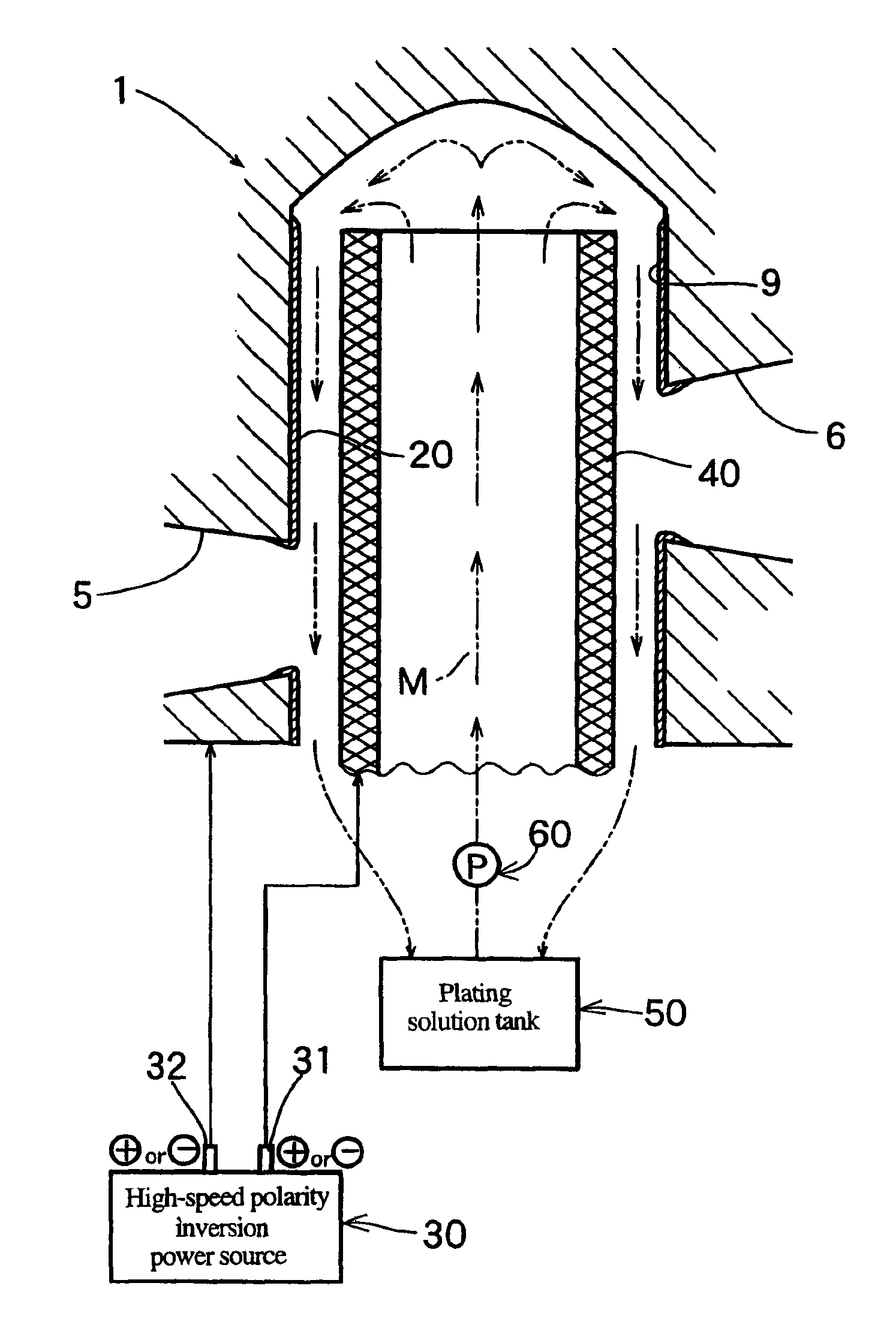

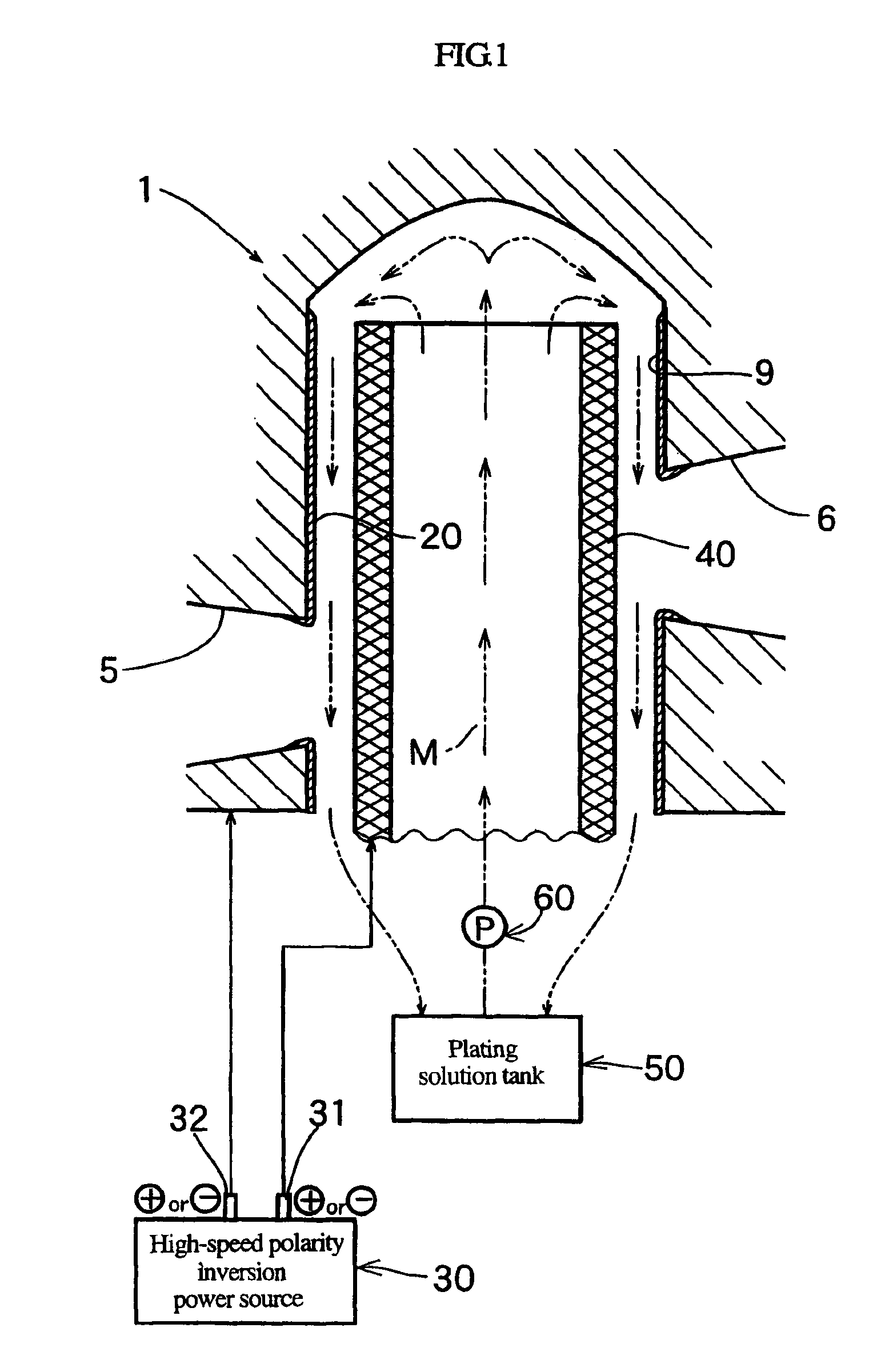

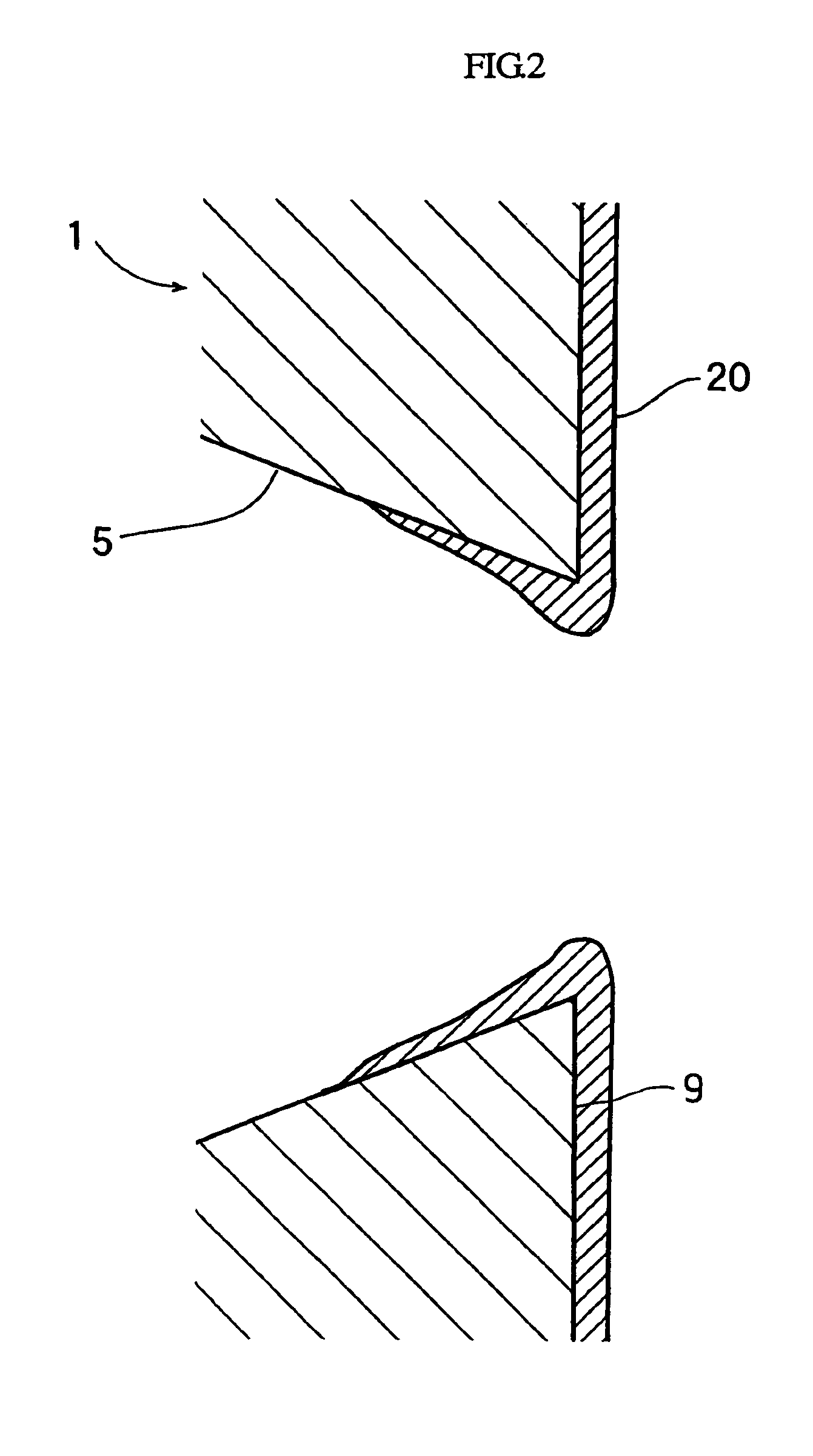

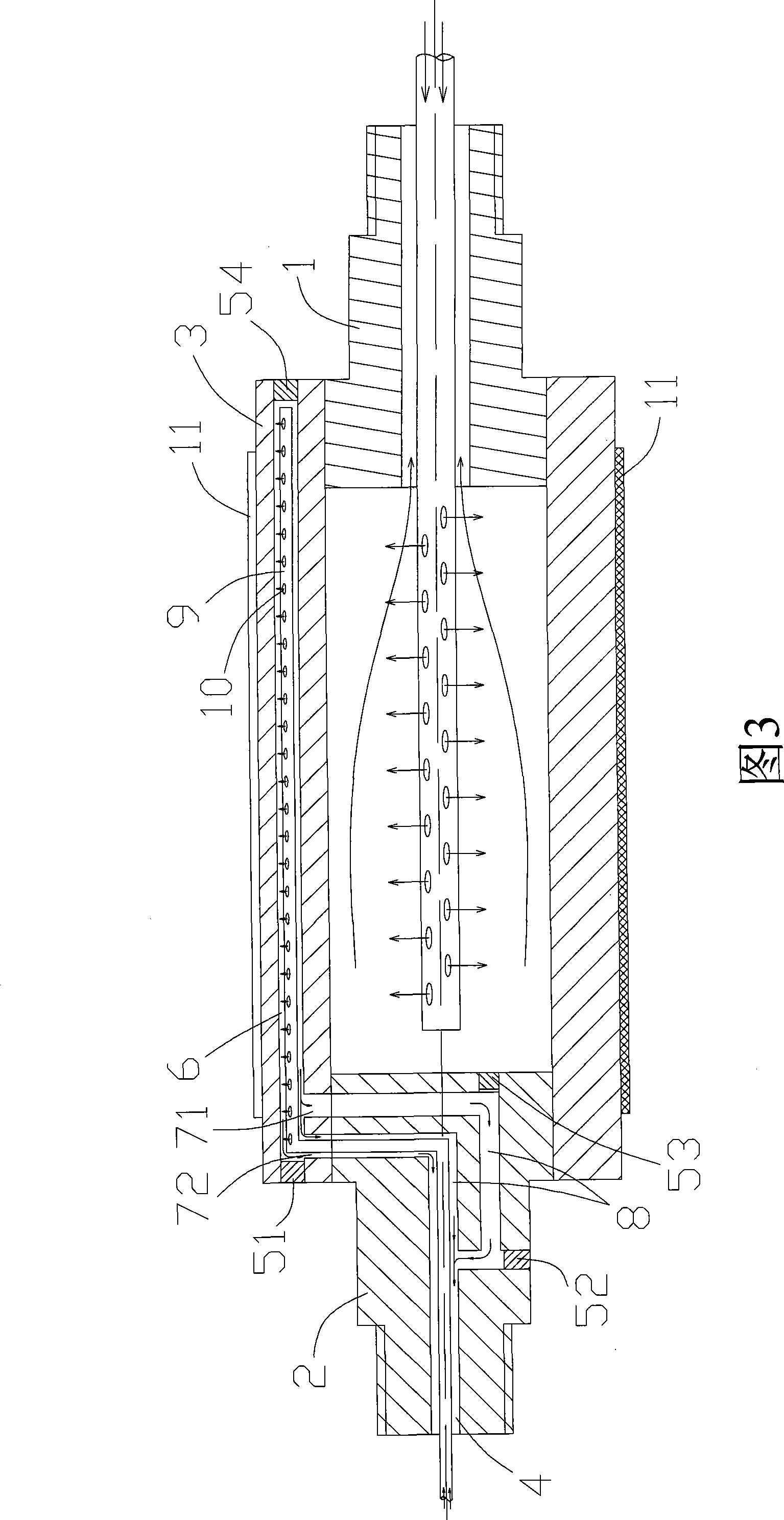

Cylinder for internal combustion engine and method of treating inner surface of the cylinder

InactiveUS6886520B2Quality improvementUniform thicknessCylinder headsCylindersExternal combustion engineEngineering

A cylinder for an internal combustion engine and a method for treating the inner surface of the cylinder, which enables the inner surface constituting a piston-sliding surface of the cylinder to have a high quality plated layer which is uniform in thickness and smooth in surface at low cost without necessitating grinding work such as honing work. The cylinder and the method of the present invention are characterized in that the inner surface of the cylinder is provided with a plated layer which is deposited thereon by a PR (Periodical Reverse) method employing a high-speed polarity reversal power source.

Owner:KIORITZ

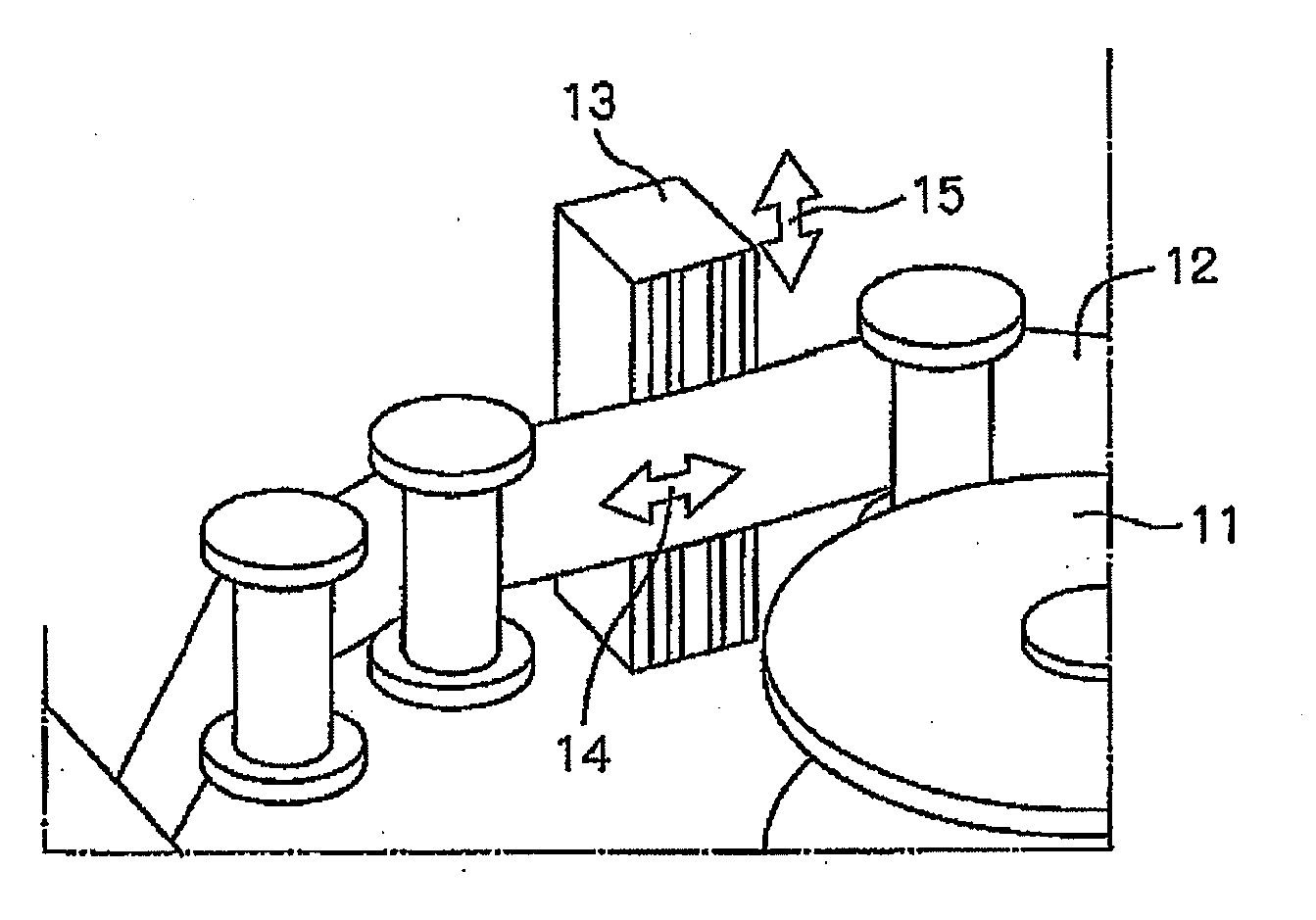

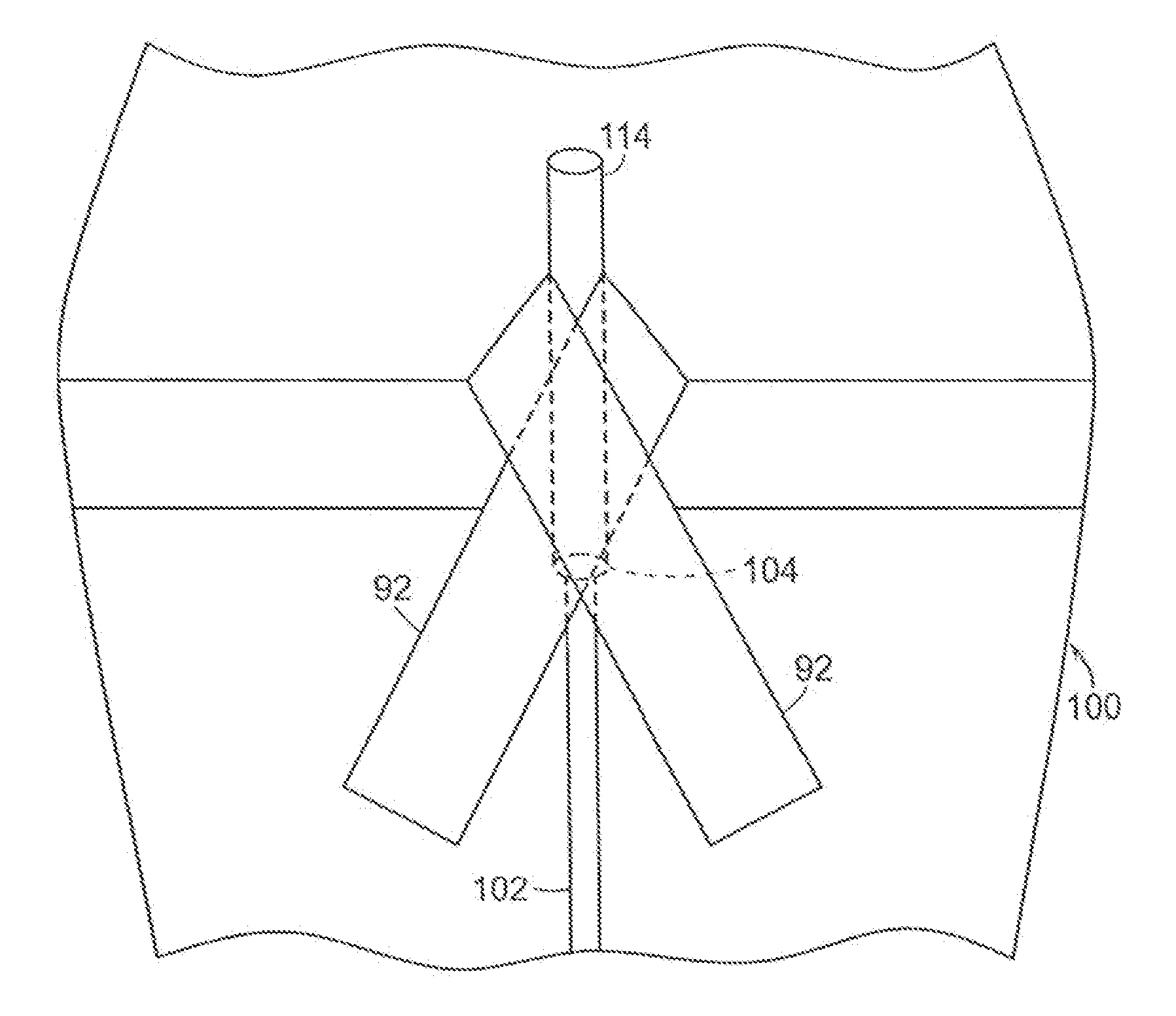

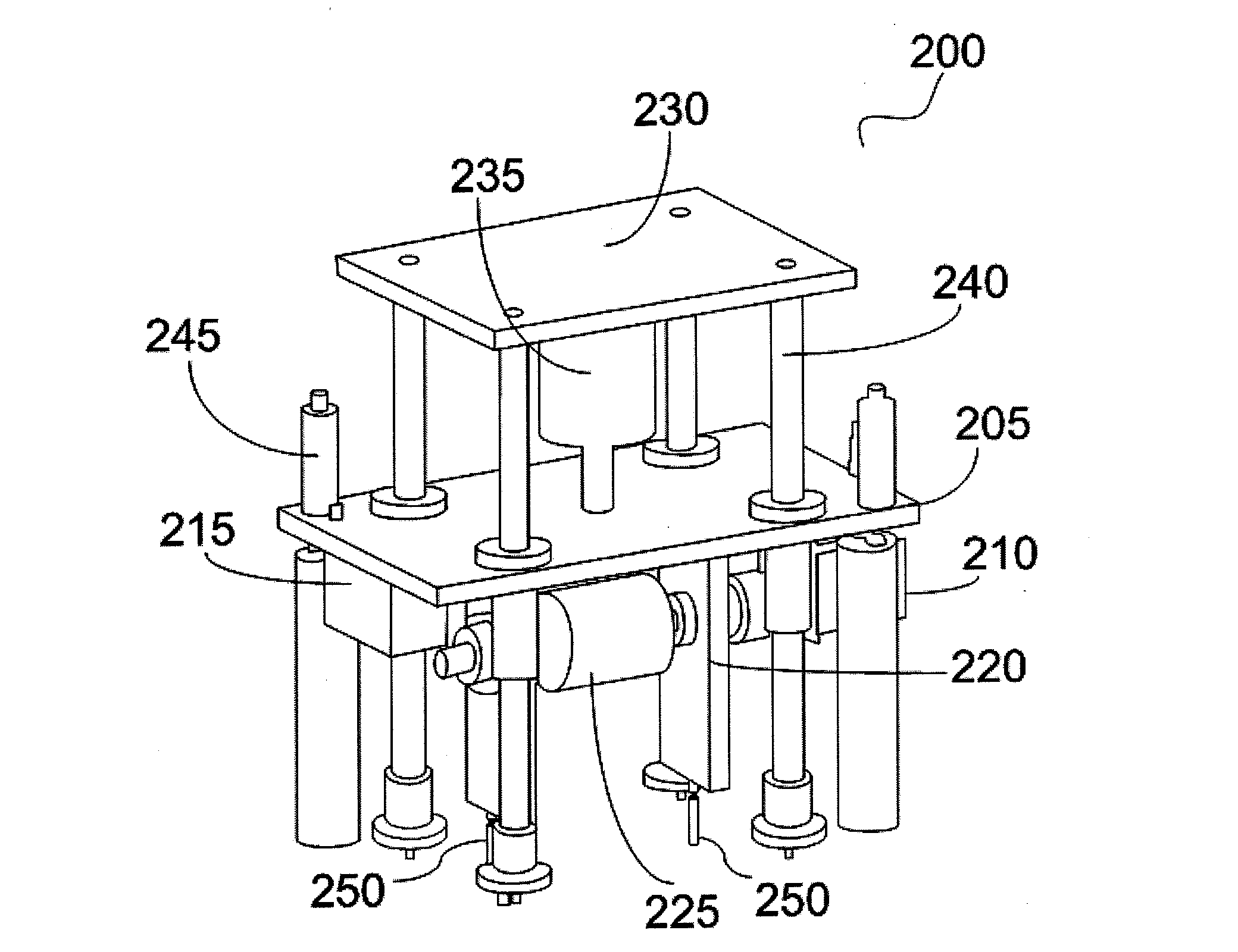

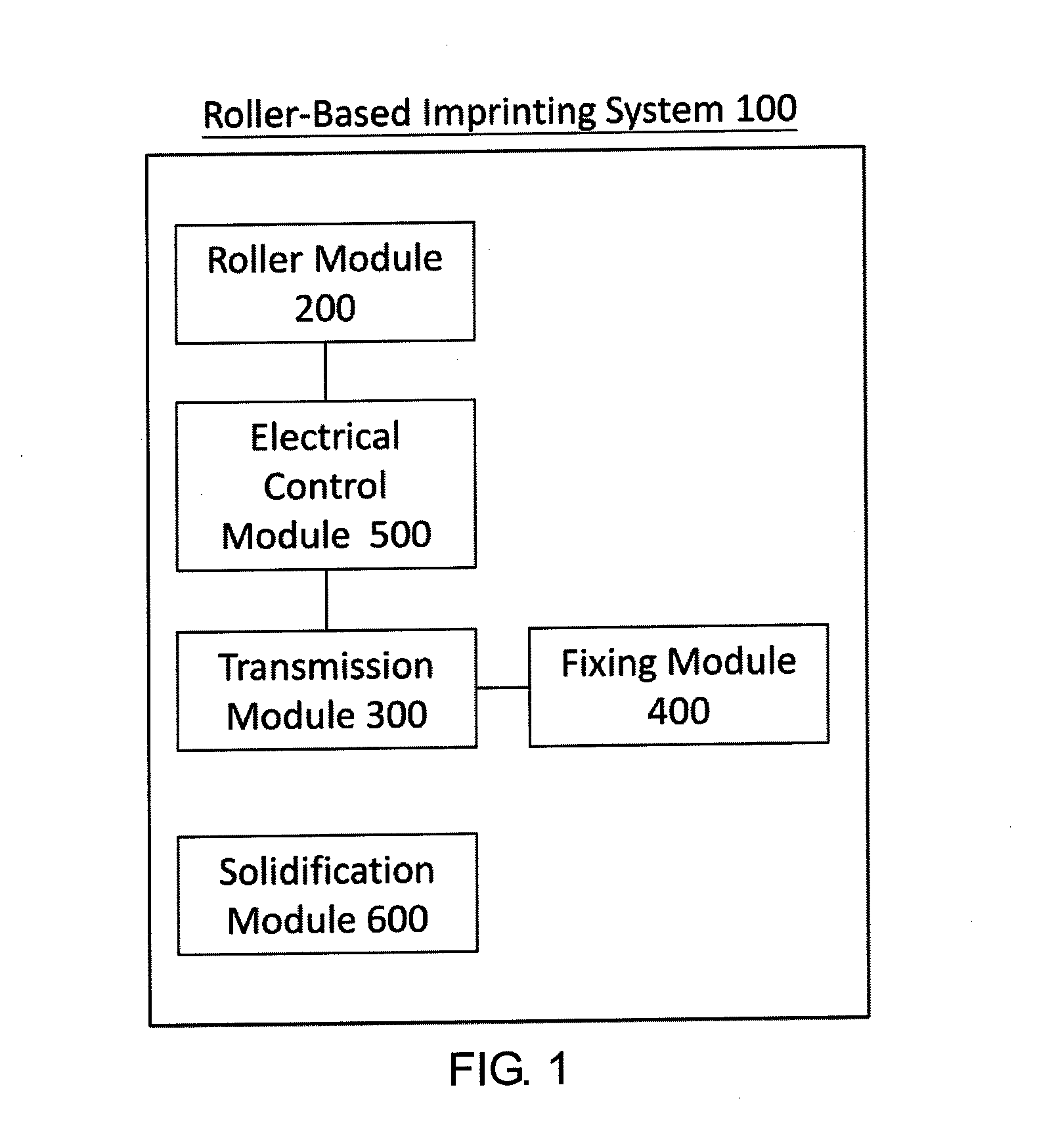

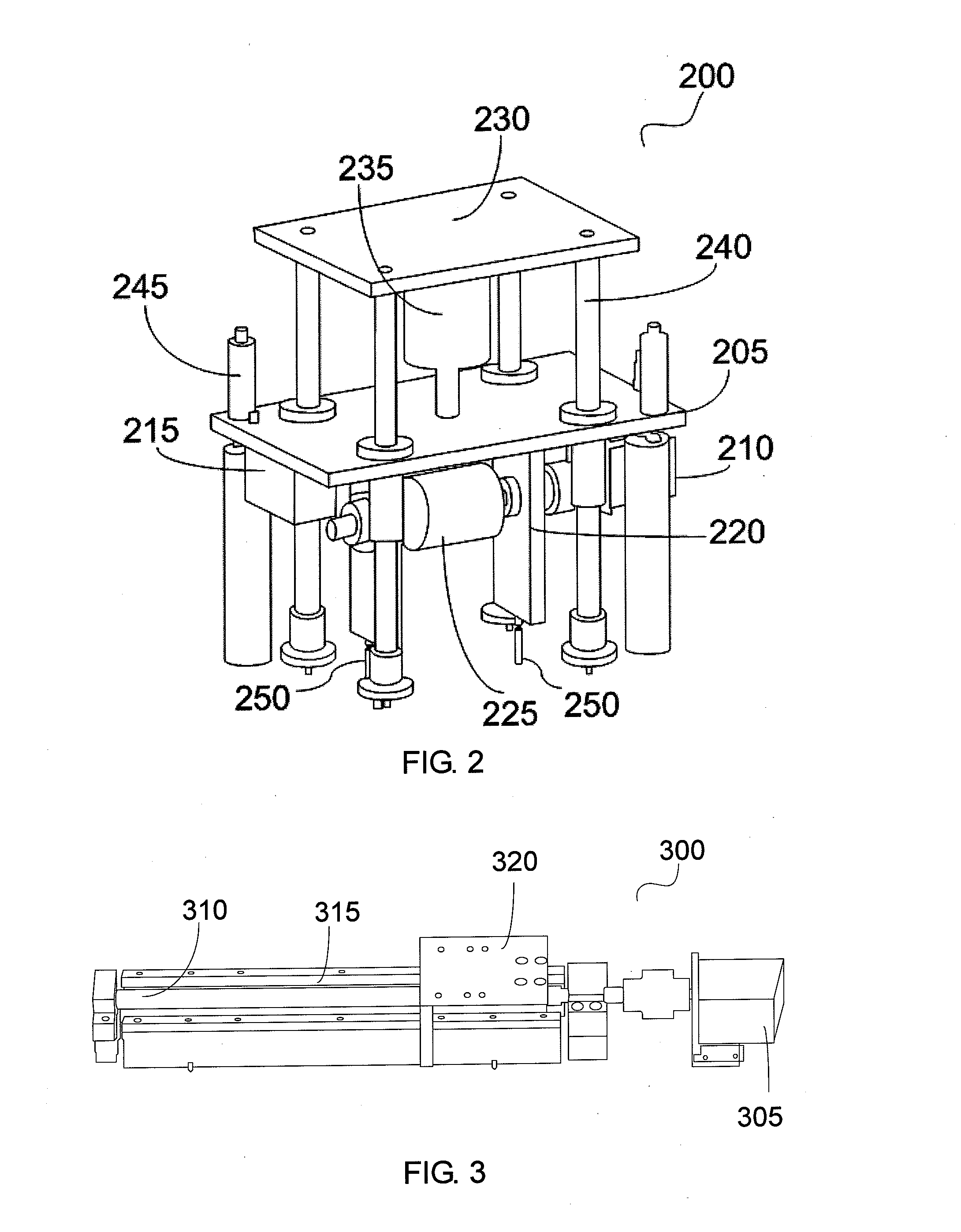

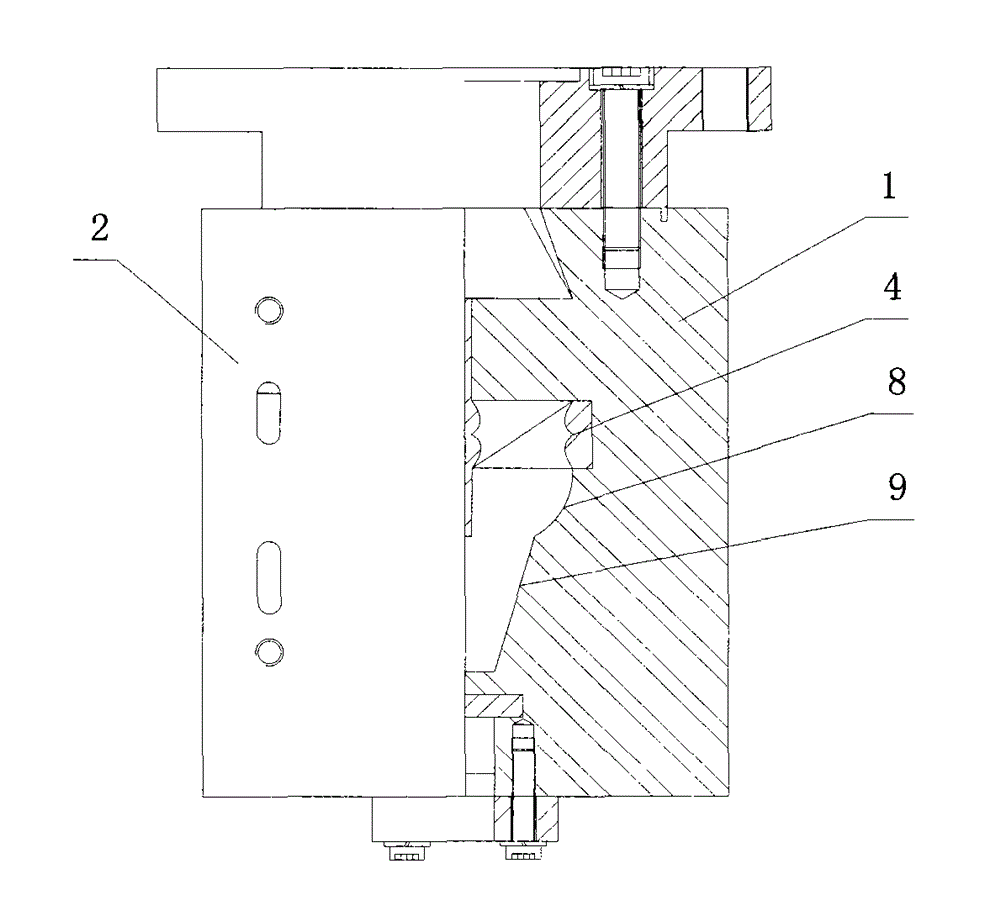

Roller-based imprinting system

InactiveUS20130139712A1Evenly layeredCylinder pressesNanoinformaticsEngineeringMechanical engineering

A roller-based imprinting system includes a roller module, a transmission module, a fixing module, a solidification module, and a controlling module. The roller-based imprinting system imprints and transfers a pattern located on the surface of a soft mold to the substrate through the pressing force of the roller.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

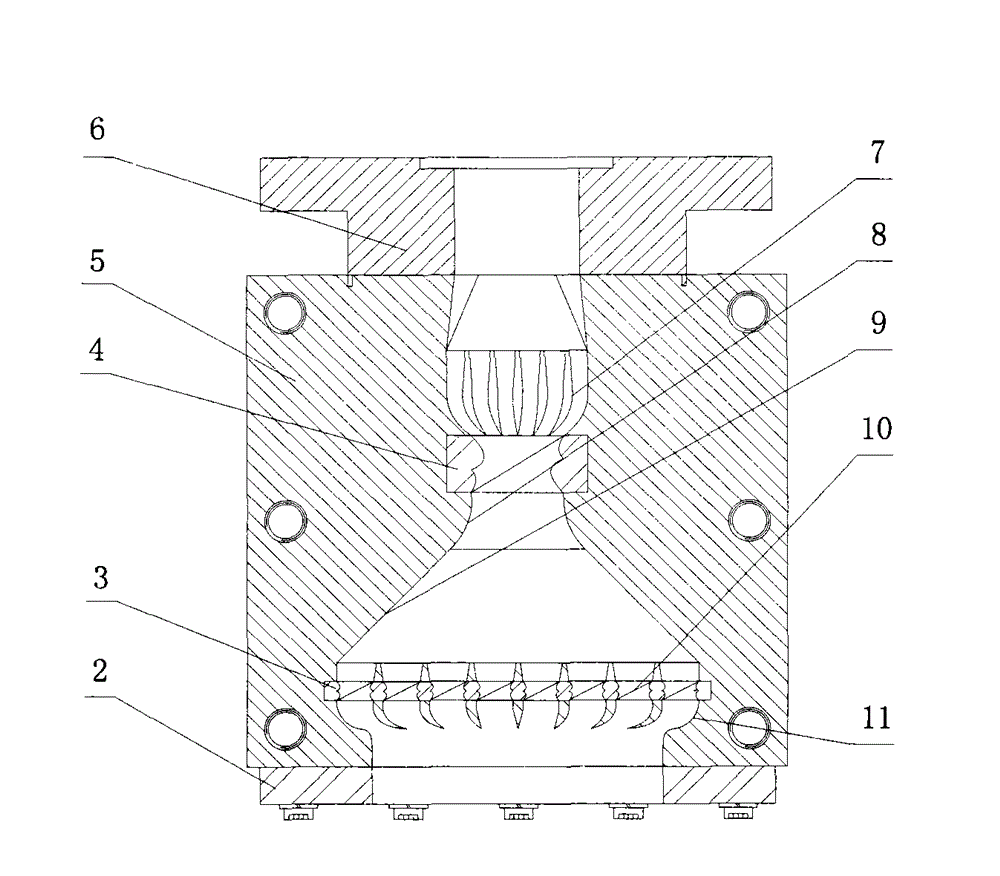

Contour forging printing plate roller

The invention aims to provide a holographic embossing printing roller, wherein, the working surface has an unequal temperature. The printing roller is utilized to conduct twice mould pressing to raw material film, so as to eliminate the quality problem of a finished film caused by print seam to a largest extent. A left chock plug and a right chock plug are respectively and fixedly connected to two ends of the pipe wall of the printing roller; an oil guide port formed on the right chock plug can be connected with an oil pipe connector; at least a longitudinal oil passage is formed on the pipe wall of the printing roller; a cooling oil port is formed on the left chock plug; at least an oil passage arranged inside the left chock plug makes the longitudinal oil passage arranged on the pipe wall of the printing roller to connected with the cooling oil port; the cooling oil port can be connected with the oil pipe connector; and the longitudinal oil passage arranged on the pipe wall of the printing roller and the oil passage inside the left chock plug together form a cooling oil passage. The invention has the beneficial effects that the pattern levels on a painting and press film after being subject to mould pressing by the printing roller are in natural transition; and the patterns after twice mould pressing are complementarily superimposed, so that the finished film has even levels and natural colors visually.

Owner:FOSHAN NAN HAI DISTRICT SANJIAN PACKING CO LTD

Bighead atractylodes rhizome poria cocos butter biscuits

InactiveCN103564023AFine particleEvenly layeredDough treatmentBakery productsSodium bicarbonateAntioxidant

The invention discloses bighead atractylodes rhizome poria cocos butter biscuits. According to the formula, raw materials for making the bighead atractylodes rhizome poria cocos butter biscuits comprise 96kg of wheat flour, 4kg of starch, 34kg of white granulated sugar powder, 4kg of malt sugar, 8kg of refined oil, 18kg of margarine, 5kg of milk powder, 3kg of eggs, 3.5kg of poria cocos, 3.46kg of bighead atractylodes rhizome, 0.5kg of table salt, 0.3kg of sodium bicarbonate, 0.2kg of ammonium bicarbonate, 0.035kg of vanillin, 0.003kg of citric acid and 0.002kg of antioxidants. The bighead atractylodes rhizome poria cocos butter biscuits have the effects of protecting health, preventing tumors, protecting the livers, invigorating spleen and supplementing qi, preventing miscarriage, adjusting gastrointestinal motility, preventing anabrosis, enhancing body immunity, resisting stress and enhancing the hematopoietic function.

Owner:JIANGXI YUQINSAO FOOD TECH

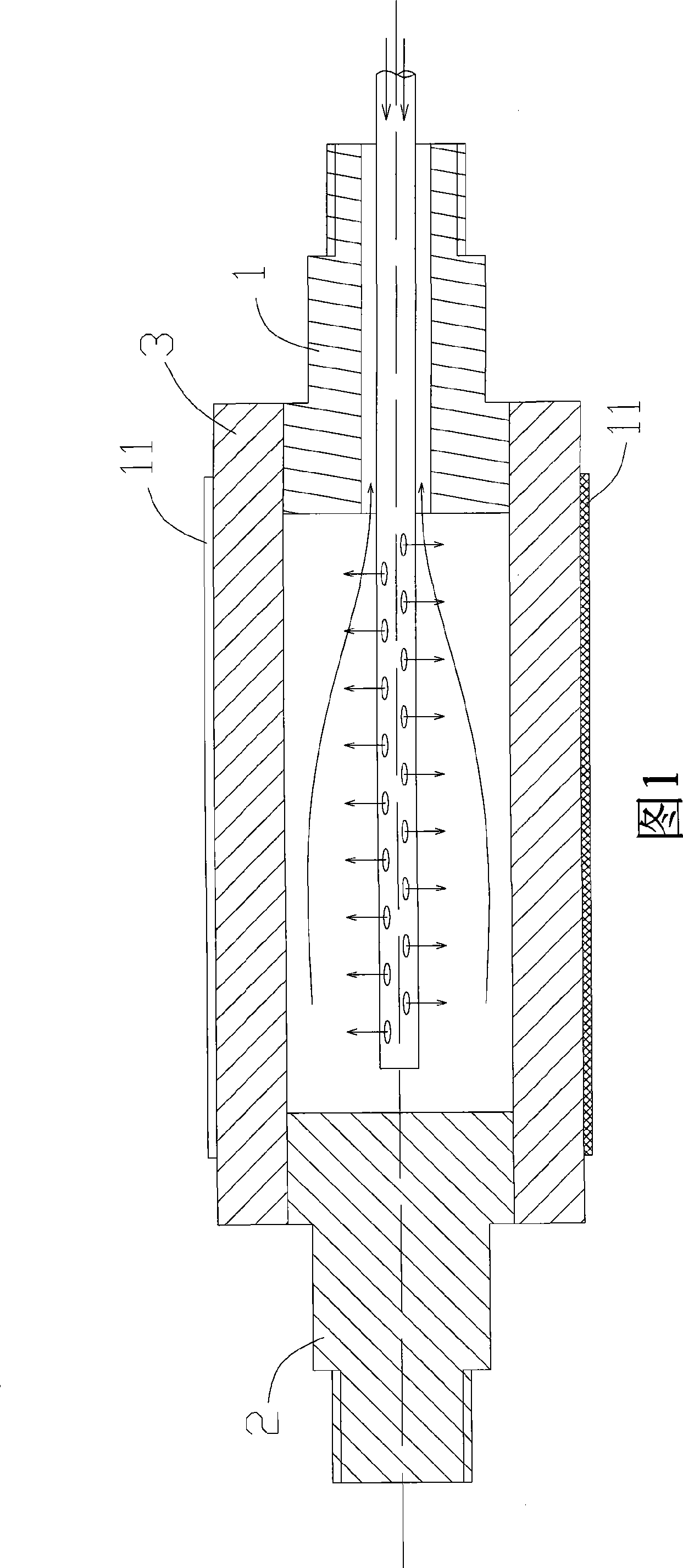

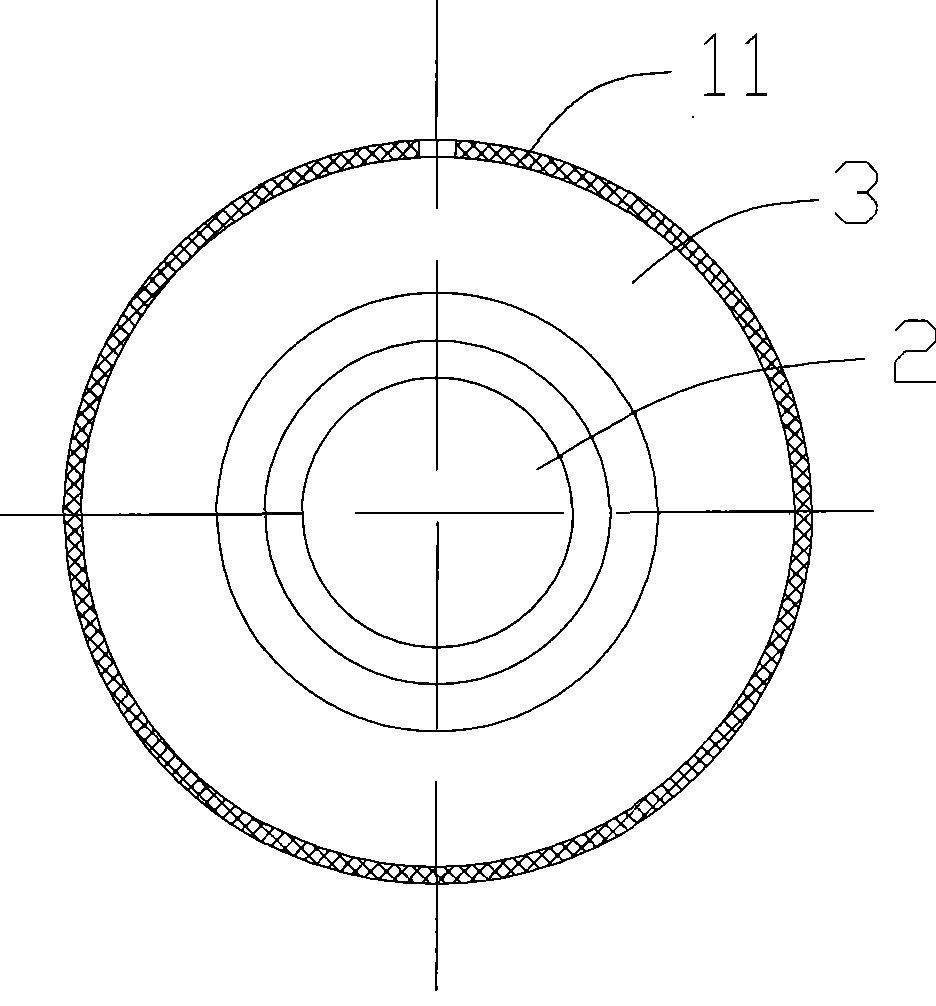

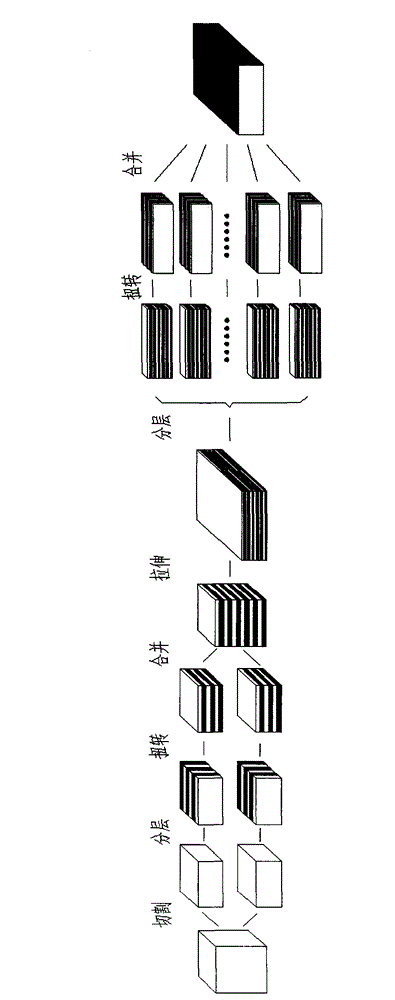

Laminating orientation extrusion method of rubber short fiber and extrusion device

The invention provides a laminating orientation extrusion method of rubber short fiber and an extrusion device. A number of laminating, torsion and merging stages are employed to suit extrusion molding control accuracy of a short fiber-rubber composite material, and the laminating orientation of short fiber is controlled in an extrusion process, so as to realize uniform distribution of short fibers in each film layer along horizontal and vertical direction, and improve wear resistance of the composite film. The extrusion method is as below: compounding the short fibers to the film; in the extrusion process, subjecting a monolayer film to at least 2 stages of stratification, torsion and combination, and stretching the film at least once between adjacent stages, so as to eventually form a composite layer film structure; and multiplying the number of layer at each stage to obtain the number of layer of a final film composite layer, wherein in each layer of film, short fibers are distributed along horizontal and vertical direction of the film.

Owner:QINGDAO UNIV OF SCI & TECH

Magnetic recording medium, recording/reproducing apparatus, and stamper

InactiveUS7505220B2Reliable readEvenly layeredCarrier storage meansNanoinformaticsMaximum diameterEngineering

On a magnetic recording medium, a servo pattern is formed in a servo pattern region on at least one surface of a substrate by a concave / convex pattern including a convex part, at least protruding end part of which is formed of magnetic material, and a concave part. The servo pattern region includes an address pattern region and a burst pattern region, wherein the convex part is formed in the servo pattern region so that a larger of an inscribed circle with a largest diameter out of inscribed circles on an open surface of the concave part formed in the address pattern region and an inscribed circle with a largest diameter out of inscribed circles on an open surface of the concave part formed in the burst pattern region is an inscribed circle with a largest diameter out of inscribed circles on an open surface of the concave part formed in the servo pattern region.

Owner:TDK CORPARATION

Organic electroluminescence element

ActiveUS9871225B2Stay flexibleStable storageSolid-state devicesSemiconductor/solid-state device manufacturingNiobiumOrganic electroluminescence

Provided is an organic electroluminescent element including a film substrate having thereon: at least one gas barrier layer, a light scatter layer, at least one smooth layer, and a light-emitting unit containing an organic functional layer interposed between a pair of electrodes, laminated in this order, wherein the light scatter layer contains a binder and light scatter particles having an average particle size of 0.2 μm or more to less than 1 μm; and the smooth layer contains an oxide or a nitride of silicone or niobium as a main component.

Owner:KONICA MINOLTA INC

Oil-in-water type margarine for pies and preparation method of oil-in-water type margarine

ActiveCN105638925AImprove ductilityEvenly layeredEdible oils/fats production/working-upOil and greaseMoisture

The invention belongs to the technical field of grease deep processing, and particularly relates to an oil-in-water type margarine for pies and a preparation method of the oil-in-water type margarine. The oil-in-water type margarine for pies is prepared from, by weight, 80-82% of a grease composition, 16-20% of water, 0-2% of an emulsifying agent A and 0-1% of an emulsifying agent B with an oil-in-water emulsification and homogenization technology. The prepared product belongs to oil-in-water type lumpy margarine, the grease content can reach 80% or above, the moisture content can reach 20% or lower, the surface is dry, the ductility is good, and efficient and easy making of pie products is successfully achieved.

Owner:TIANJIN NANQIAO FOOD

Thin-film alignment layer provided with integrally-formed spacing structures and forming an intermediate layer for an optical article comprising liquid crystals

InactiveUS20180101037A1Easy to controlEvenly layeredNon-linear opticsLiquid crystalElectrical and Electronics engineering

Owner:NIKON CORP +1

Current-perpendicular-to-plane sensor with dual keeper layers

InactiveUS7672089B2Reduce couplingLower junction resistance-area productNanomagnetismMagnetic measurementsRough surfaceAmorphous phase

This invention provides a CPP TMR or GMR sensor with an amorphous ferromagnetic lower keeper layer and a crystalline ferromagnetic upper keeper layer. The amorphous ferromagnetic lower keeper layer strongly exchange-couples to an underlying antiferromagnetic pinning layer and planarizes its rough surface. The crystalline ferromagnetic upper keeper layer strongly antiparallel-couples to an adjacent ferromagnetic reference layer across a nonmagnetic spacer layer. The amorphous ferromagnetic lower keeper layer is preferably made of a Co—Fe—B alloy film with an Fe content high enough to ensure strong exchange-coupling to the underlying antiferromagnetic pinning layer, and with a B content high enough to ensure the formation of an amorphous phase for planarizing an otherwise rough surface due to the underlying antiferromagnetic pinning layer. The crystalline ferromagnetic upper keeper layer is preferably made of a Co—Fe alloy film with an Fe content low enough to ensure strong antiparallel-coupling to the adjacent ferromagnetic reference layer across the nonmagnetic spacer layer. The sensor is annealed at temperatures low enough to prevent the amorphous phase from transforming into a polycrystalline phase, but also high enough to maximize TMR.

Owner:WESTERN DIGITAL TECH INC

Hermetic encapsulation of organic, electro-optical elements

ActiveUS8299706B2Improve adhesionImprove mechanical stabilityDecorative surface effectsSemiconductor/solid-state device detailsOptical materialsMaterials science

Owner:SCHOTT AG

Yoghurt and processing technology

The present invention discloses a yogurt and a processing technology, wherein per 1000 L of the yogurt comprises 800-1000 kg of fresh milk, 40-90 kg of white granulated sugar, 10-30 kg of defatted powder, 5-100 U of a strain, and the balance of distilled water. The yogurt processing technology comprises six steps such as material preparing, shearing, homogenization and sterilization, inoculation and filling, warehousing and cold preservation, and inspection. The yogurt produced through the steps has characteristics of no particle and uniform layering.

Owner:重庆光大(集团)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com