Patents

Literature

399results about "Manufacture unitary devices of plural heads" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

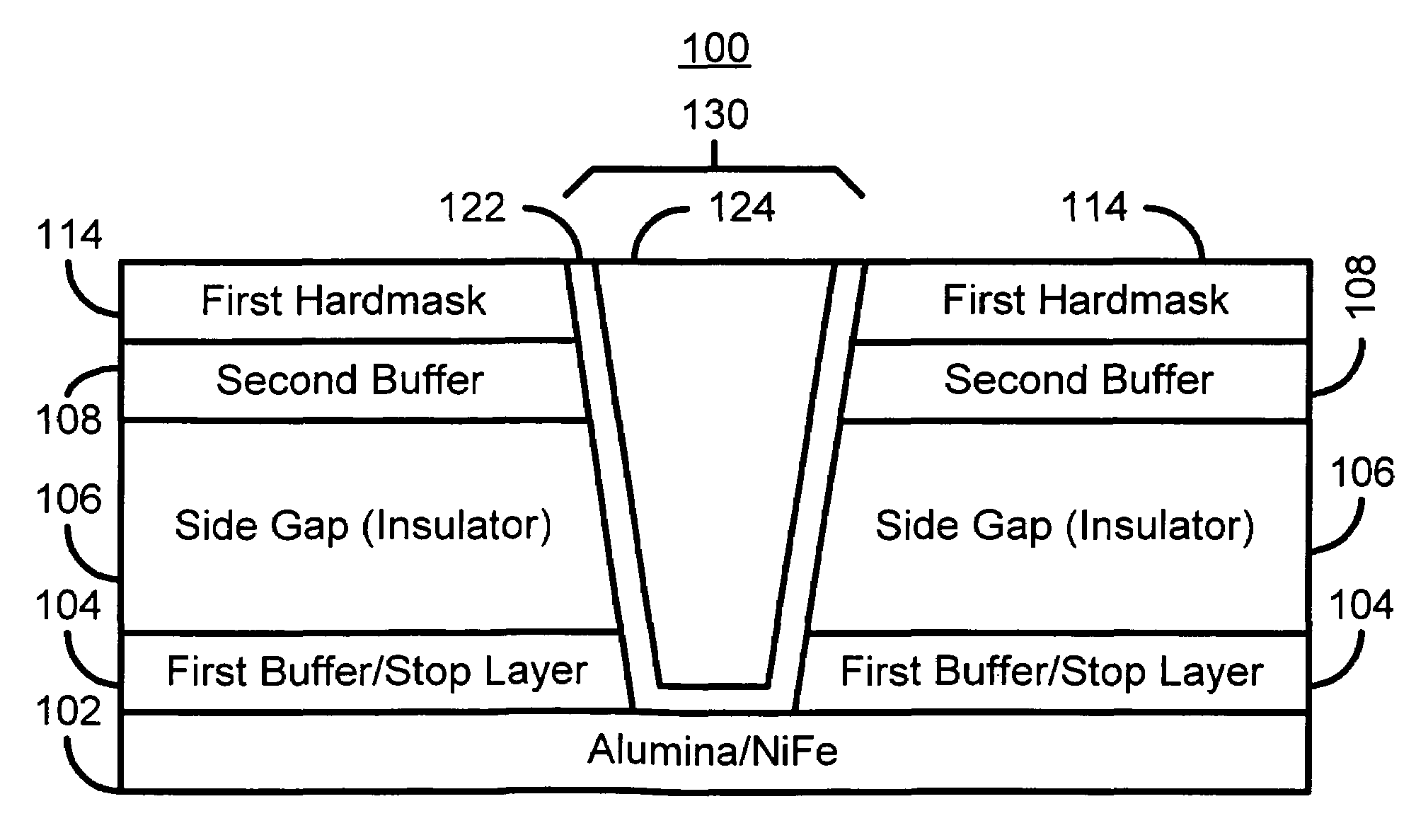

Damascene process for fabricating poles in recording heads

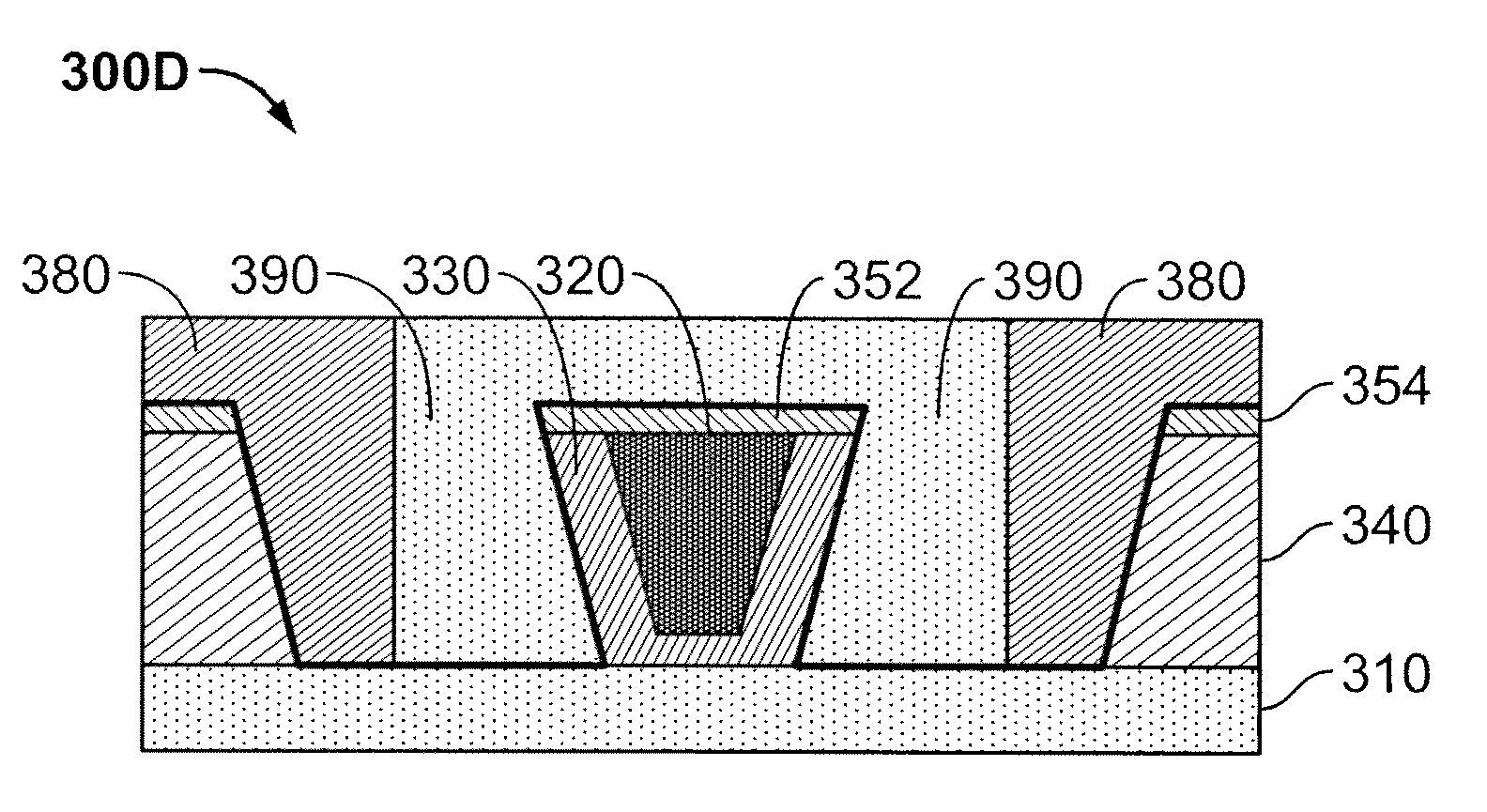

A method and system for manufacturing a pole for a magnetic recording head. The method and system include providing an insulator and fabricating at least one hard mask on the insulator. The at least one hard mask has an aperture therein. The method and system also include removing a portion of the insulator to form a trench within the insulator. The trench is formed under the aperture. The method and system further include depositing at least one ferromagnetic material. The pole includes a portion of the ferromagnetic material within the trench.

Owner:WESTERN DIGITAL TECH INC

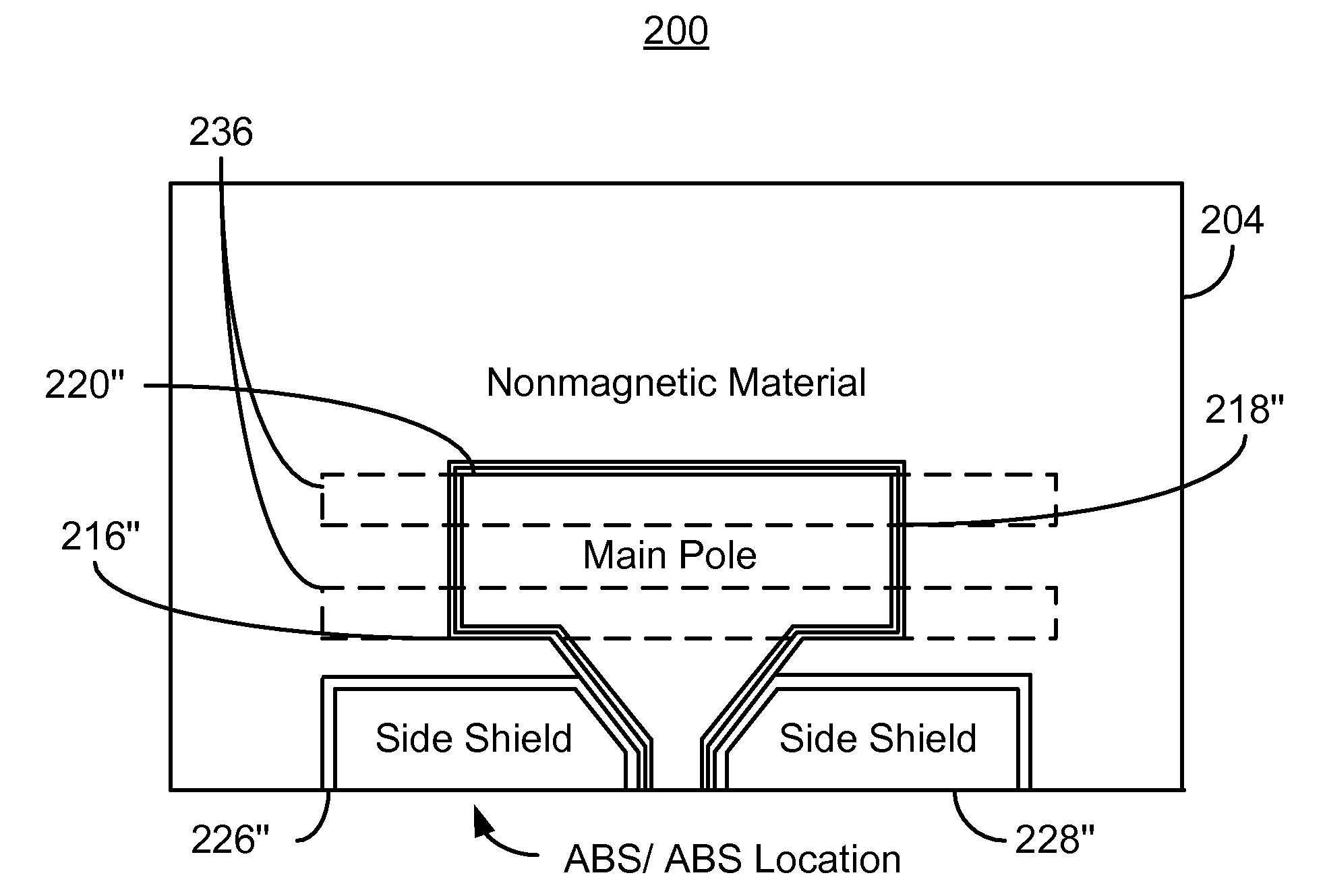

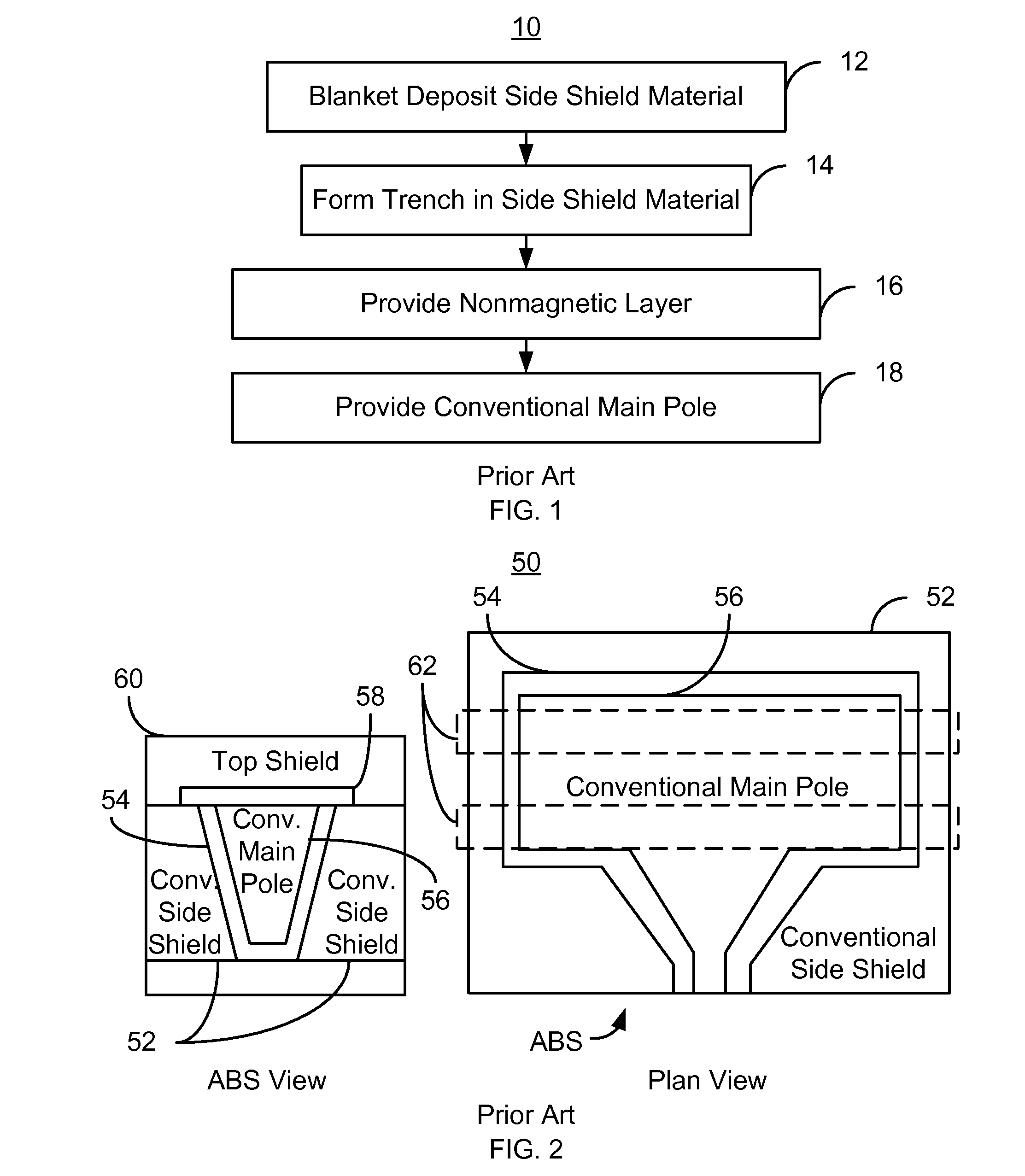

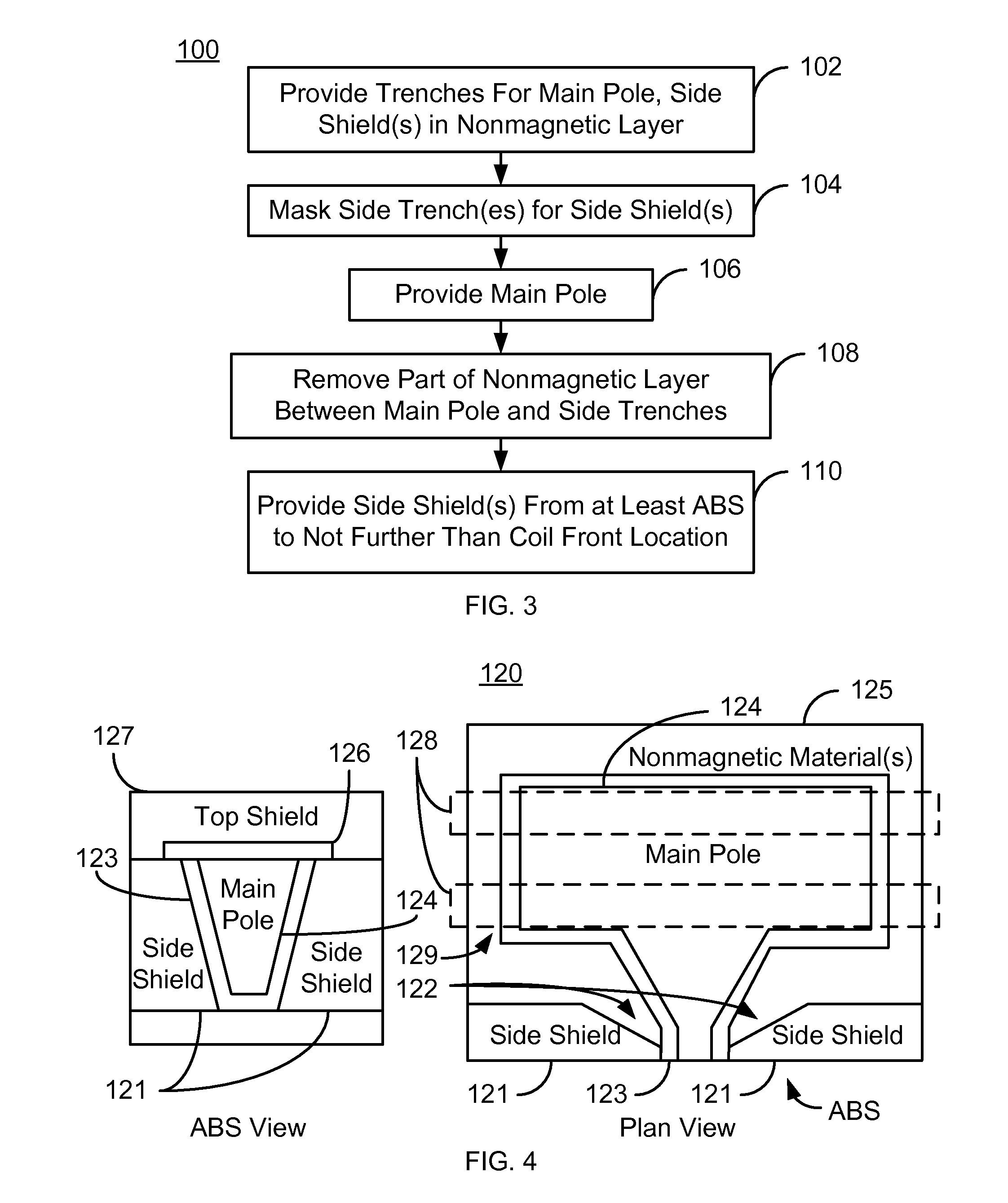

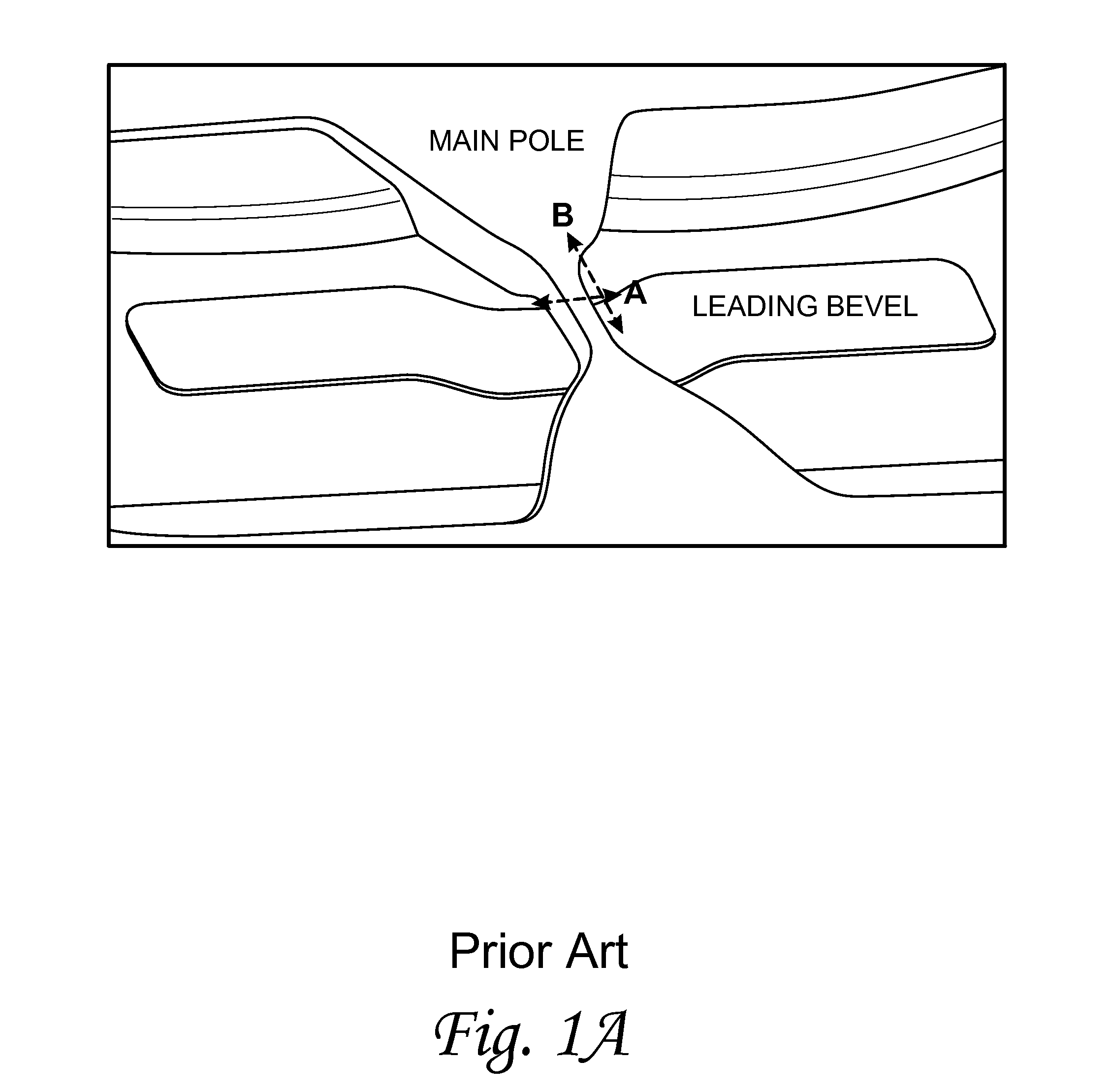

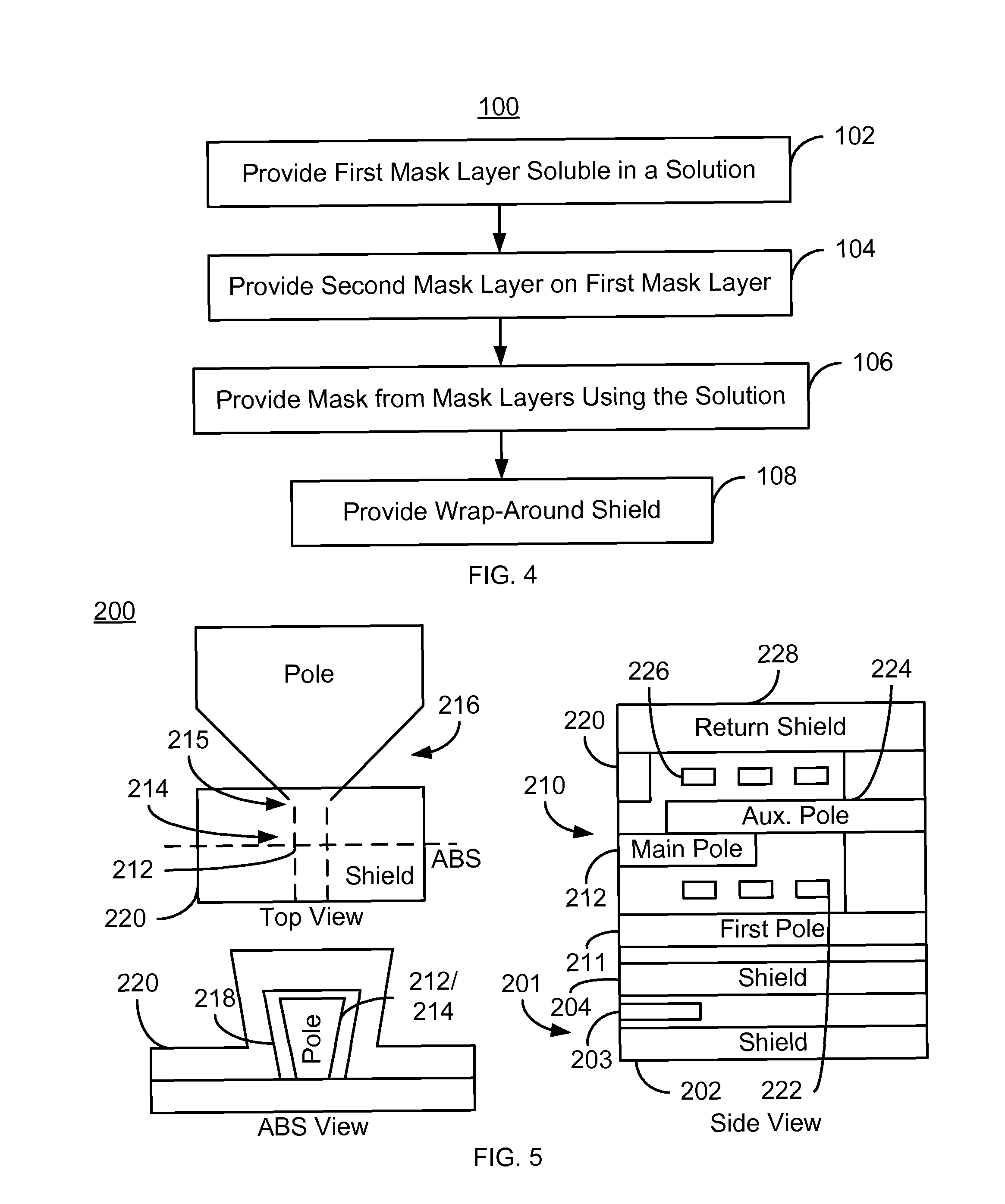

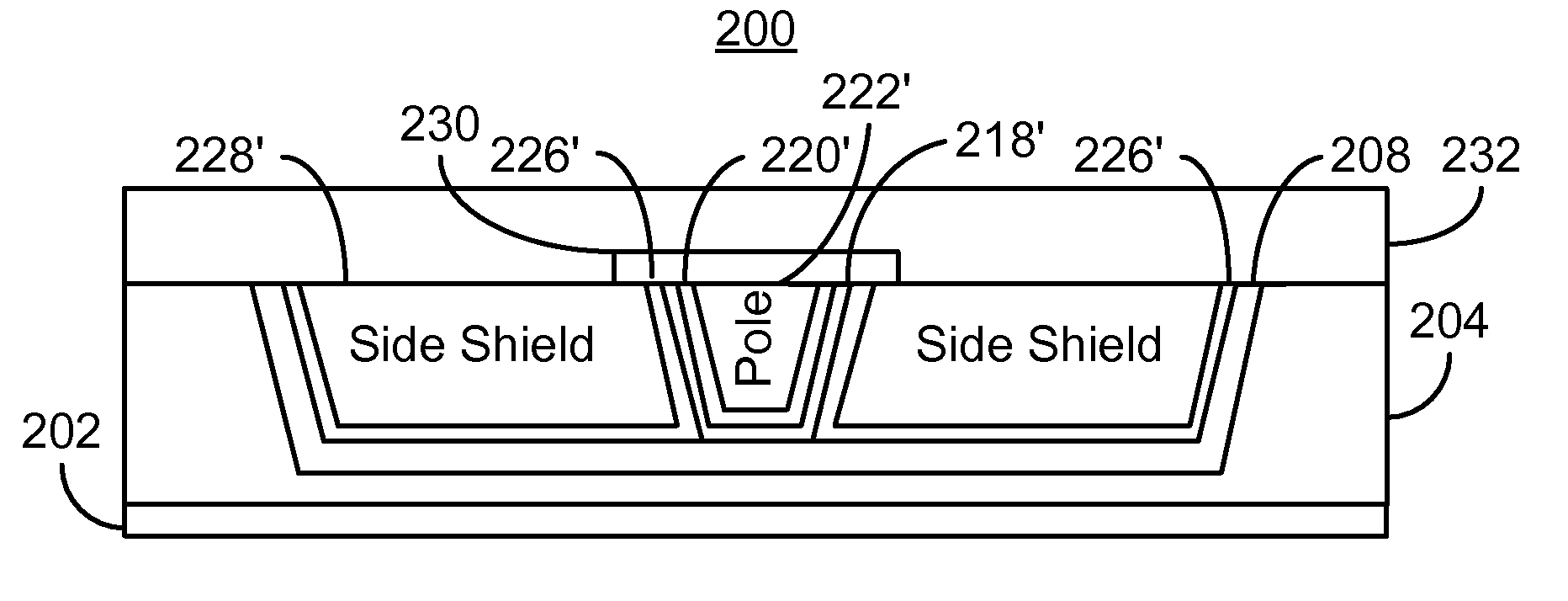

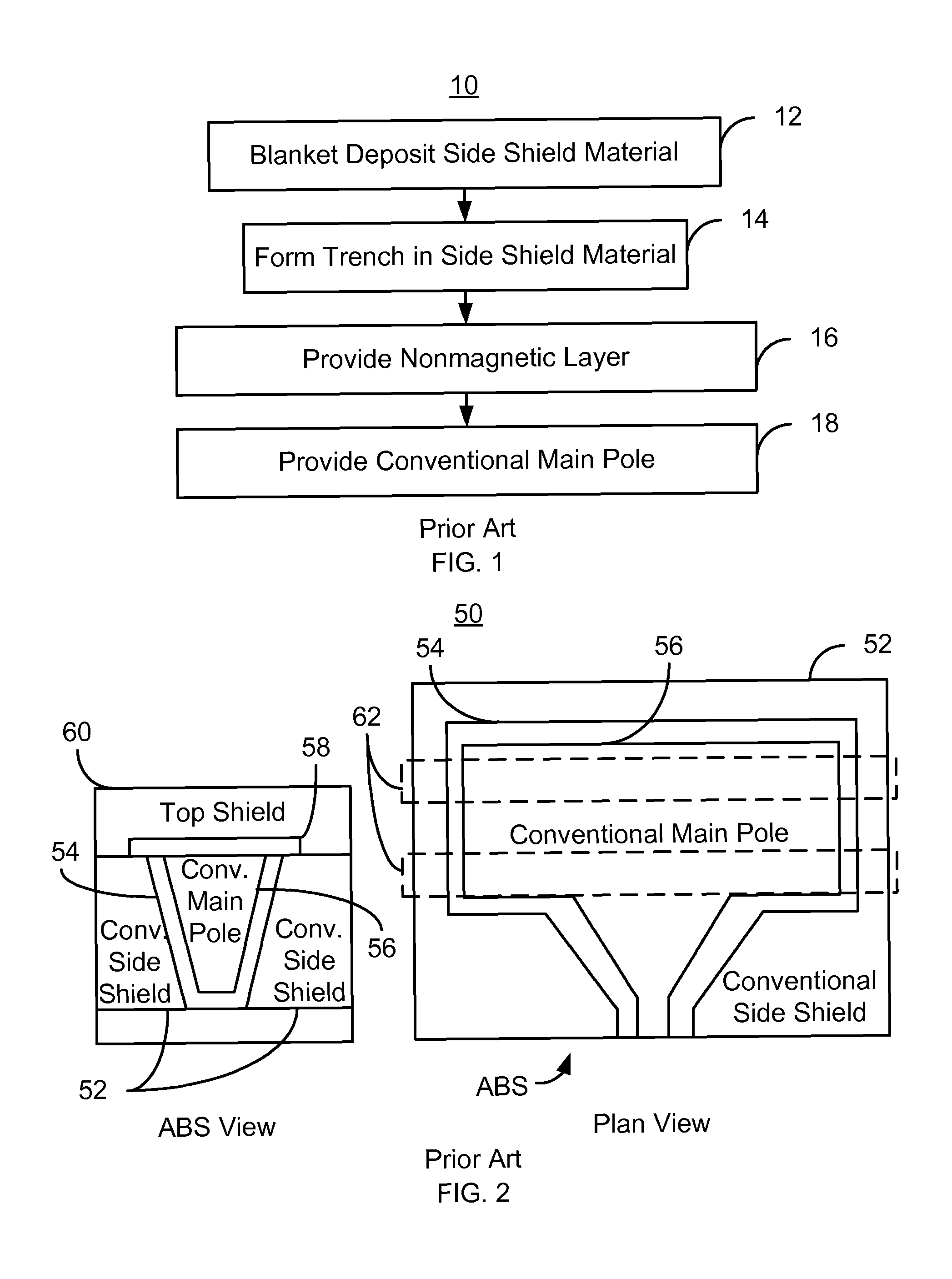

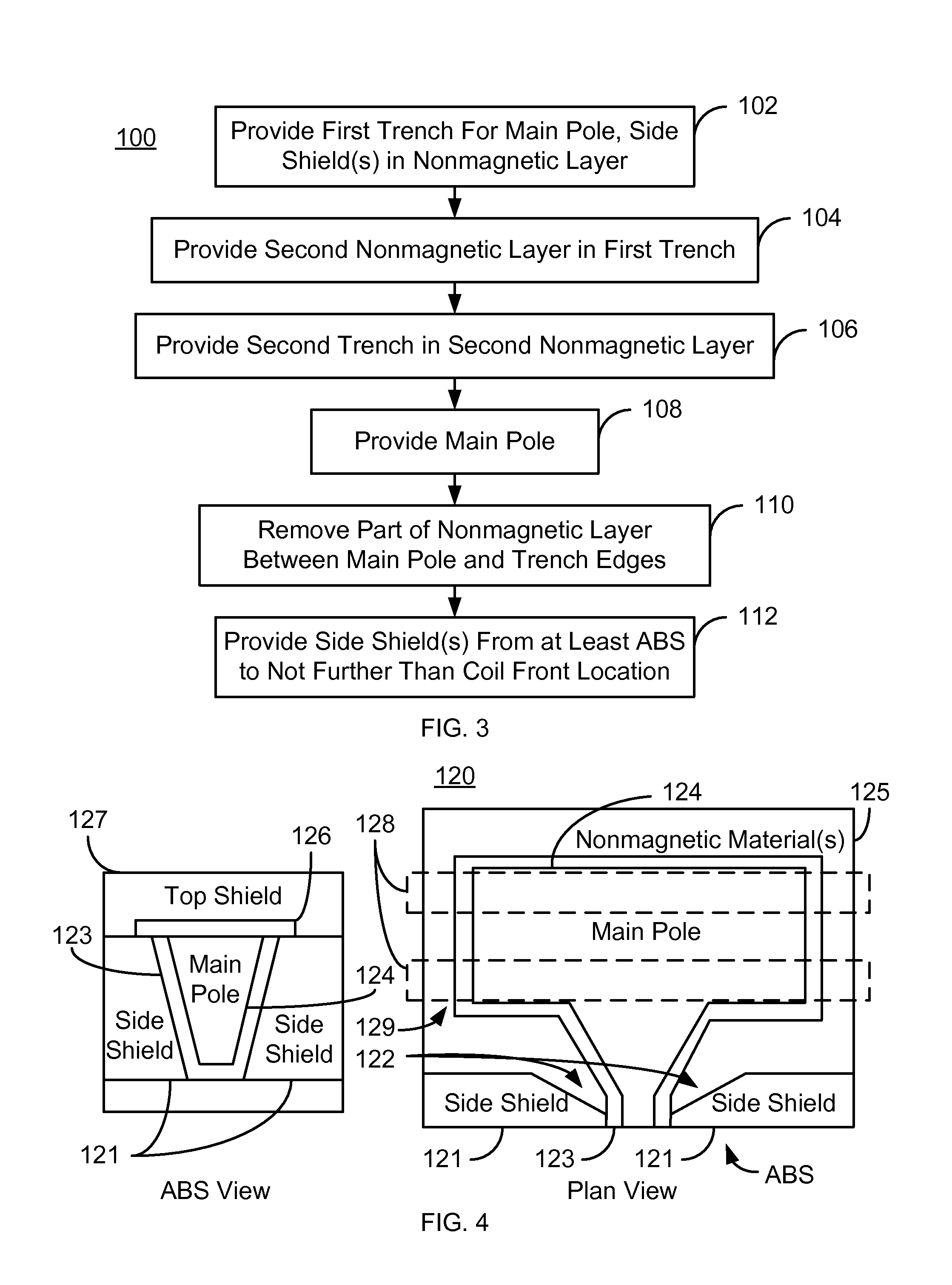

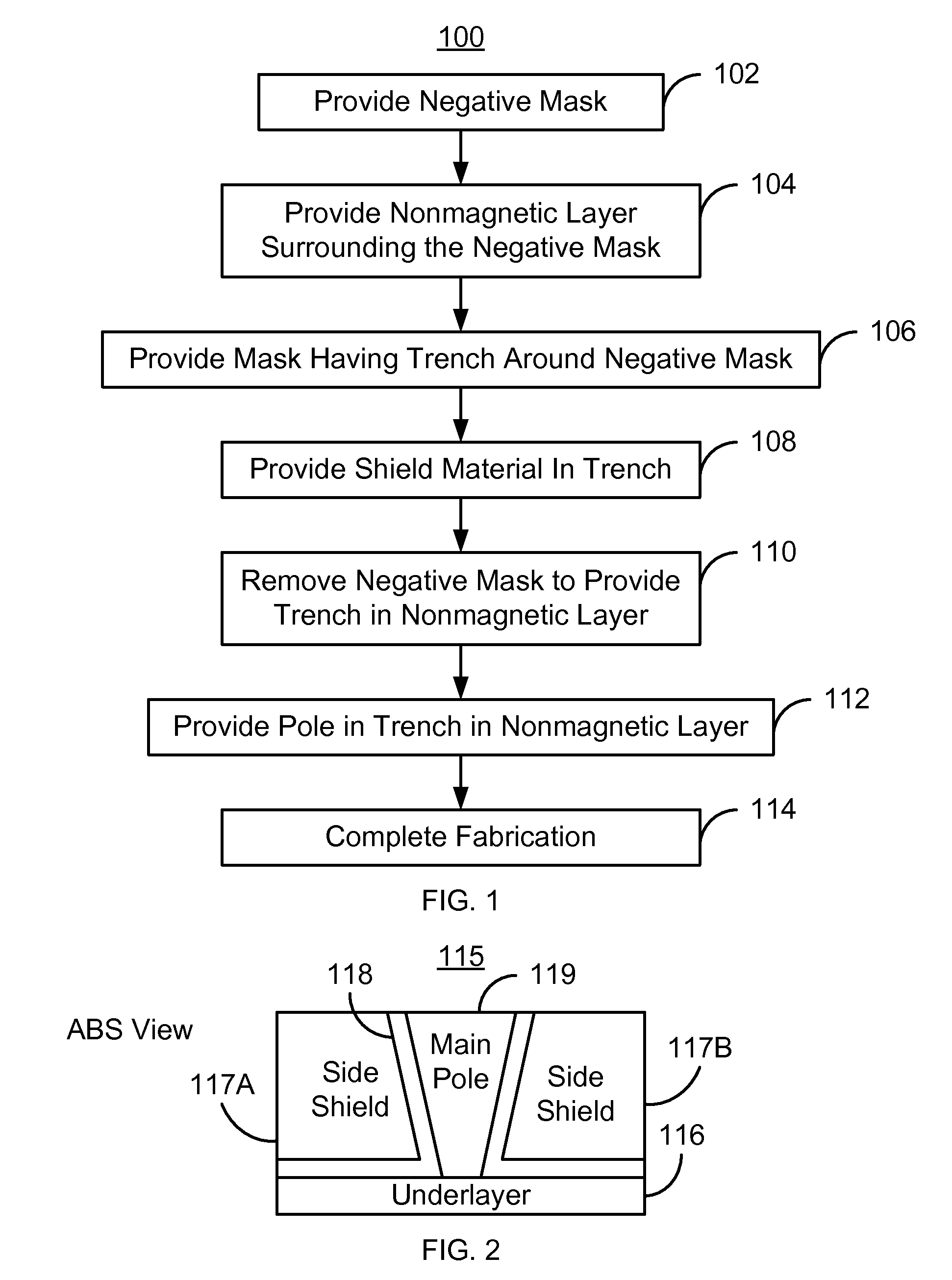

Method for fabricating a magnetic recording transducer having side shields

A method provides a magnetic transducer that includes an underlayer and a nonmagnetic layer on the underlayer. The method includes providing a plurality of trenches in the nonmagnetic layer. A first trench of corresponds to a main pole, while at least one side trench corresponds to at least one side shield. The method also includes providing mask covering the side trench(es) and providing the main pole. At least a portion of the main pole resides in the first trench. The method also includes removing at least a portion of the nonmagnetic layer residing between the side trench(es) and the main pole. The method also includes providing at least one side shield. The shield(s) extend from at least an air-bearing surface location to not further than a coil front location.

Owner:WESTERN DIGITAL TECH INC

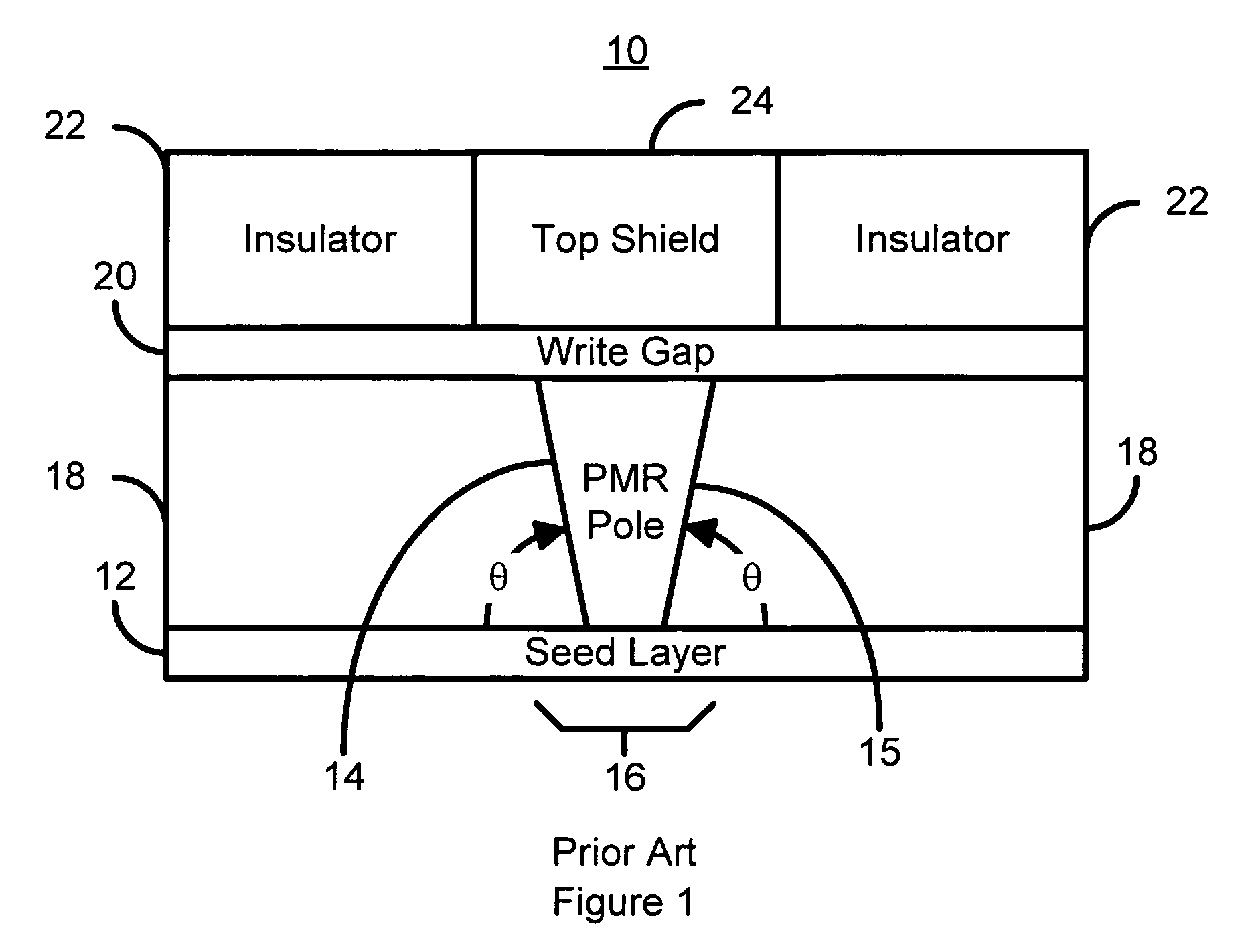

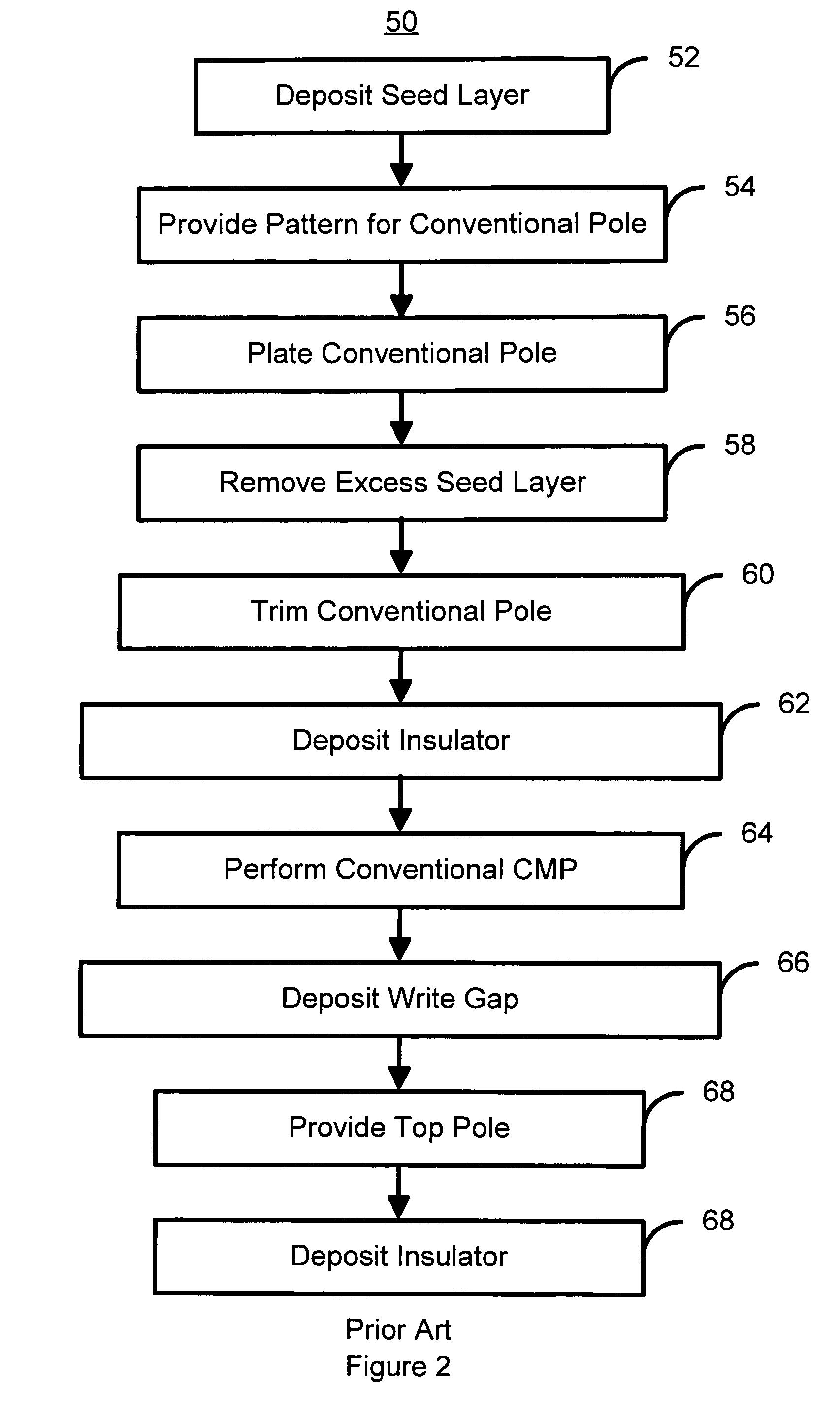

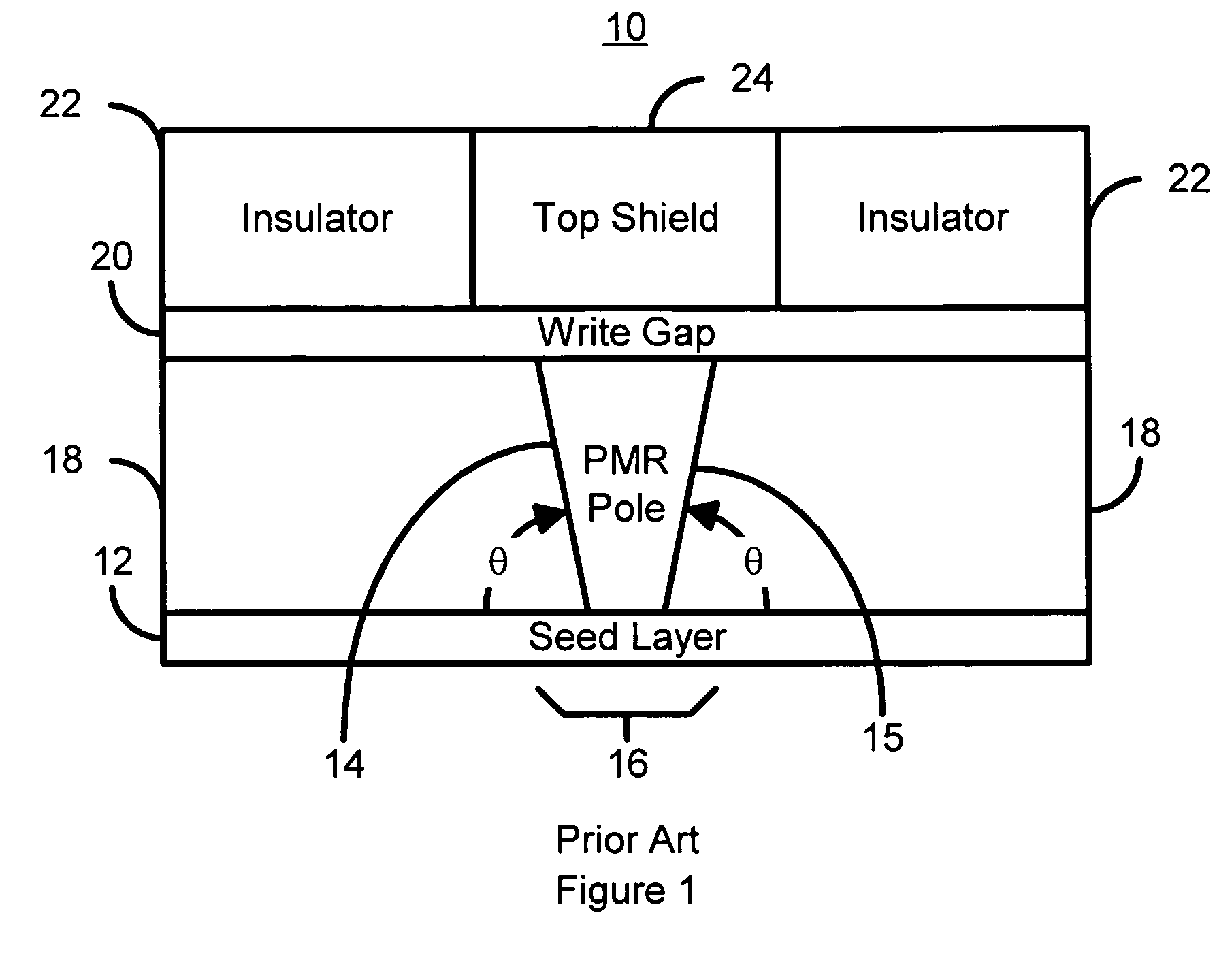

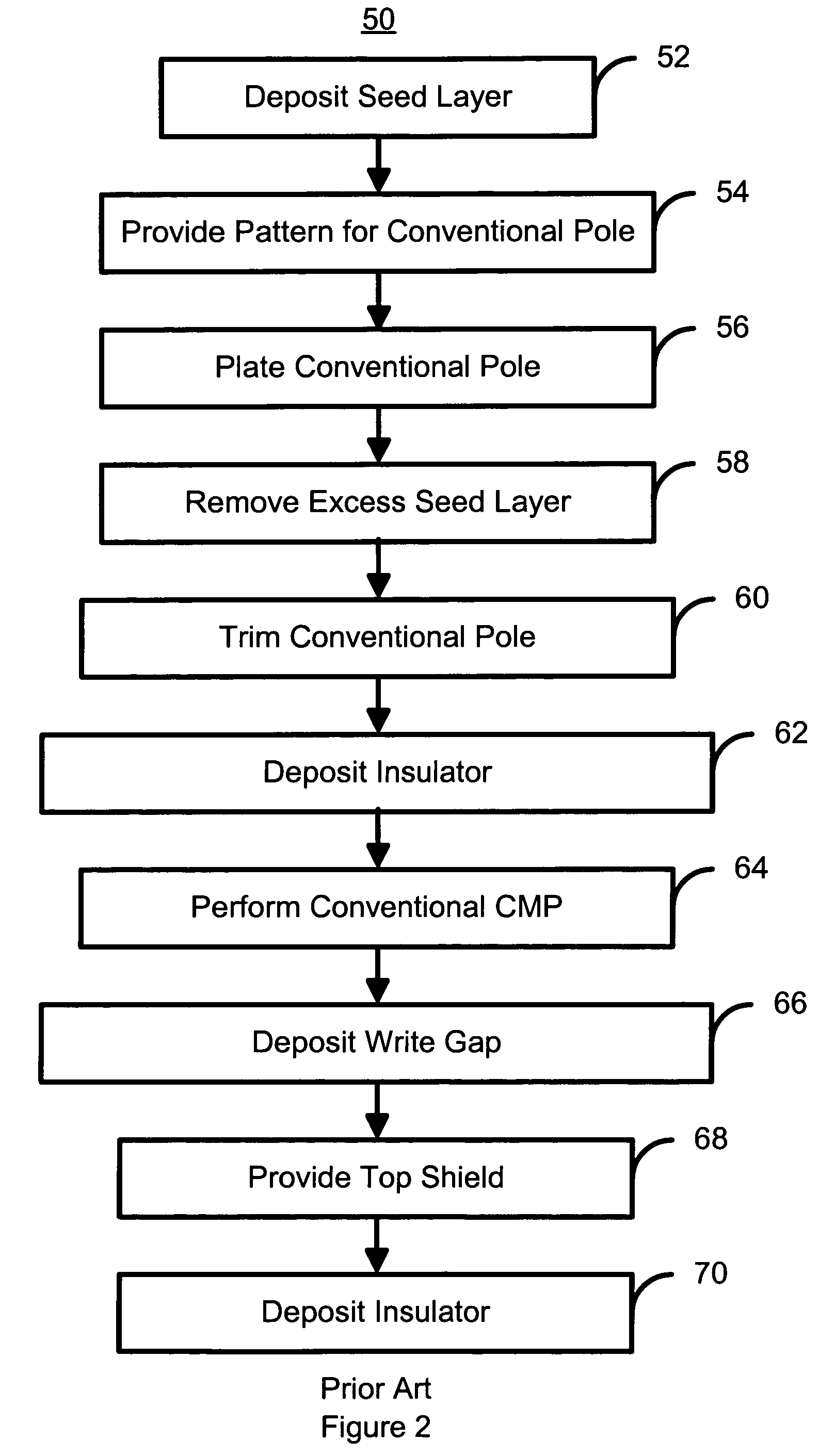

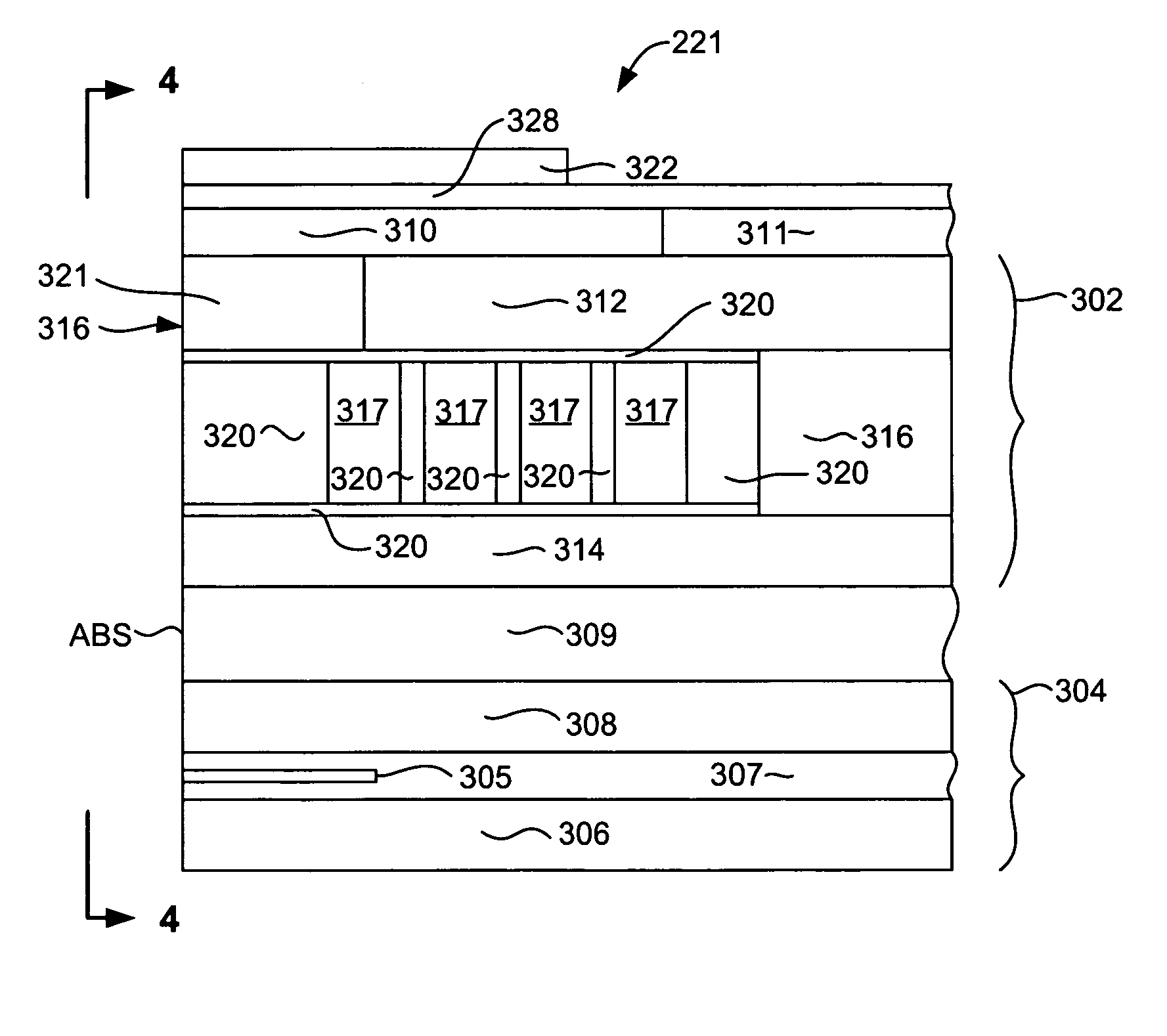

Method for manufacturing a perpendicular magnetic recording head

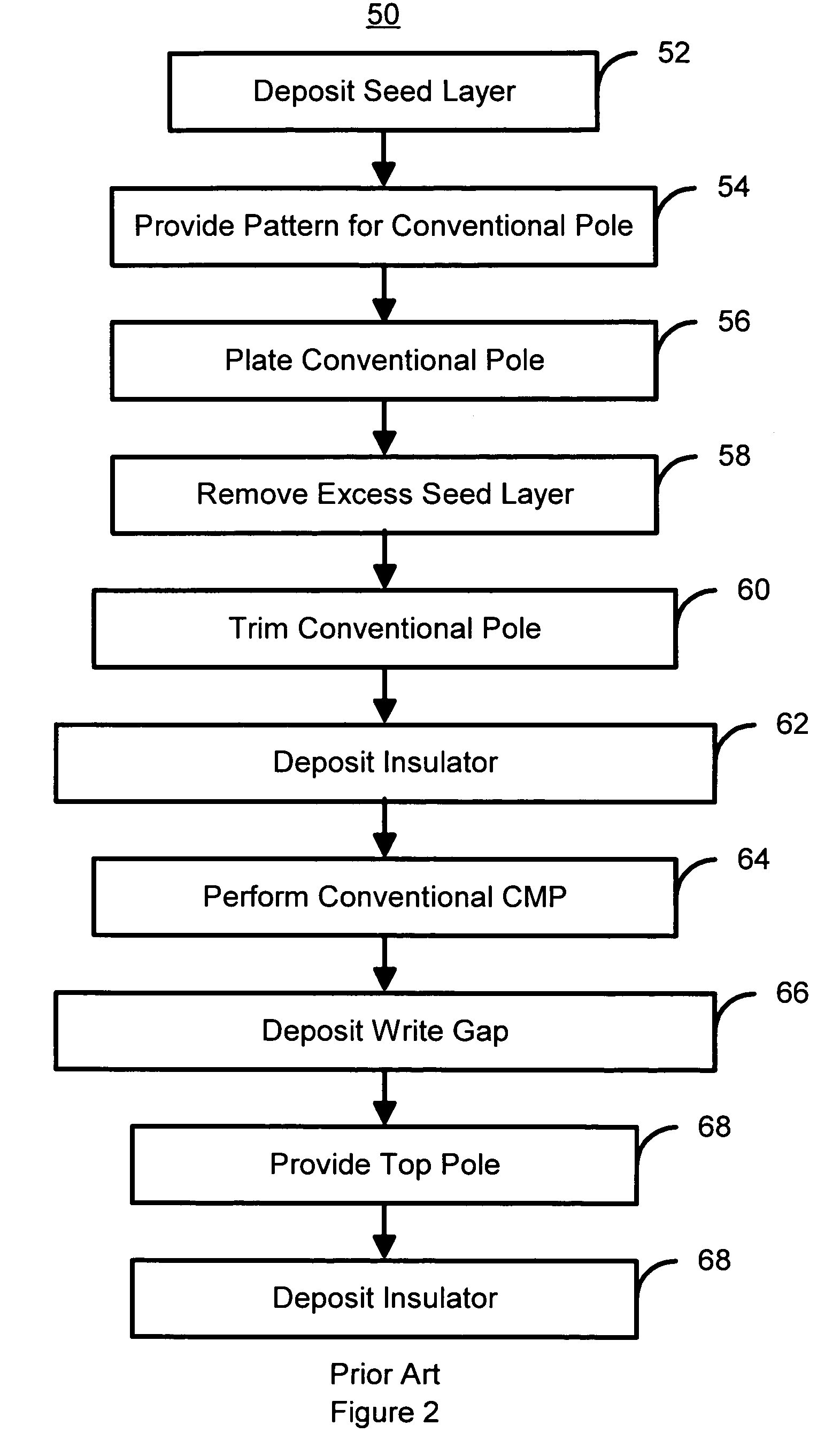

InactiveUS7296339B1Construction of head windingsElectrical transducersEngineeringChemical-mechanical planarization

A method and system for manufacturing a perpendicular magnetic recording head is disclosed. The method and system include providing a chemical mechanical planarization (CMP) uniformity structure having an aperture therein and forming a perpendicular magnetic recording pole within the aperture. The CMP uniformity structure may include a CMP barrier layer. The method and system further include fabricating an insulator after formation of the perpendicular magnetic recording pole and performing a CMP to remove a portion of the insulator, expose a portion of the perpendicular magnetic recording pole and planarize an exposed surface of the perpendicular magnetic recording head.

Owner:WESTERN DIGITAL TECH INC

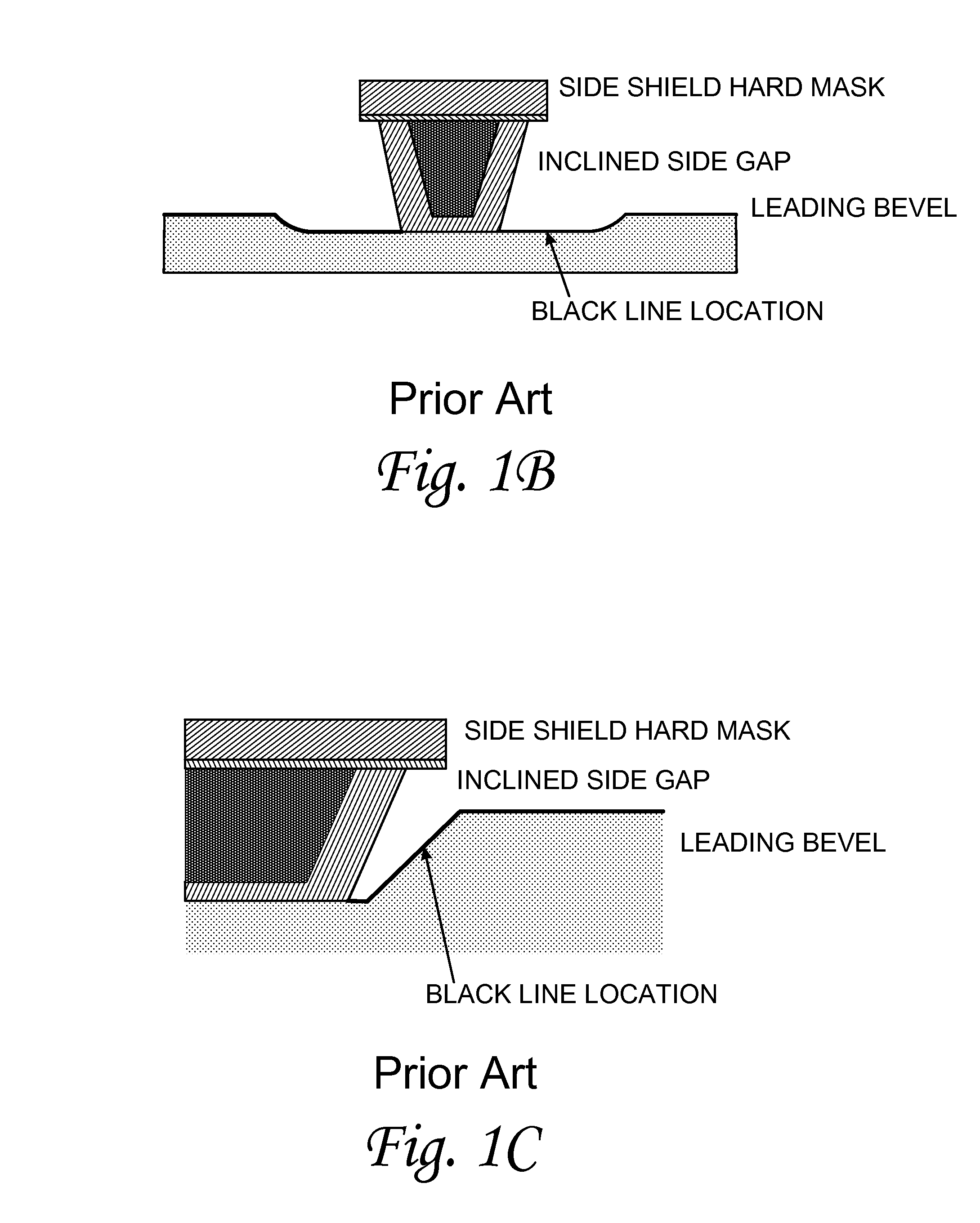

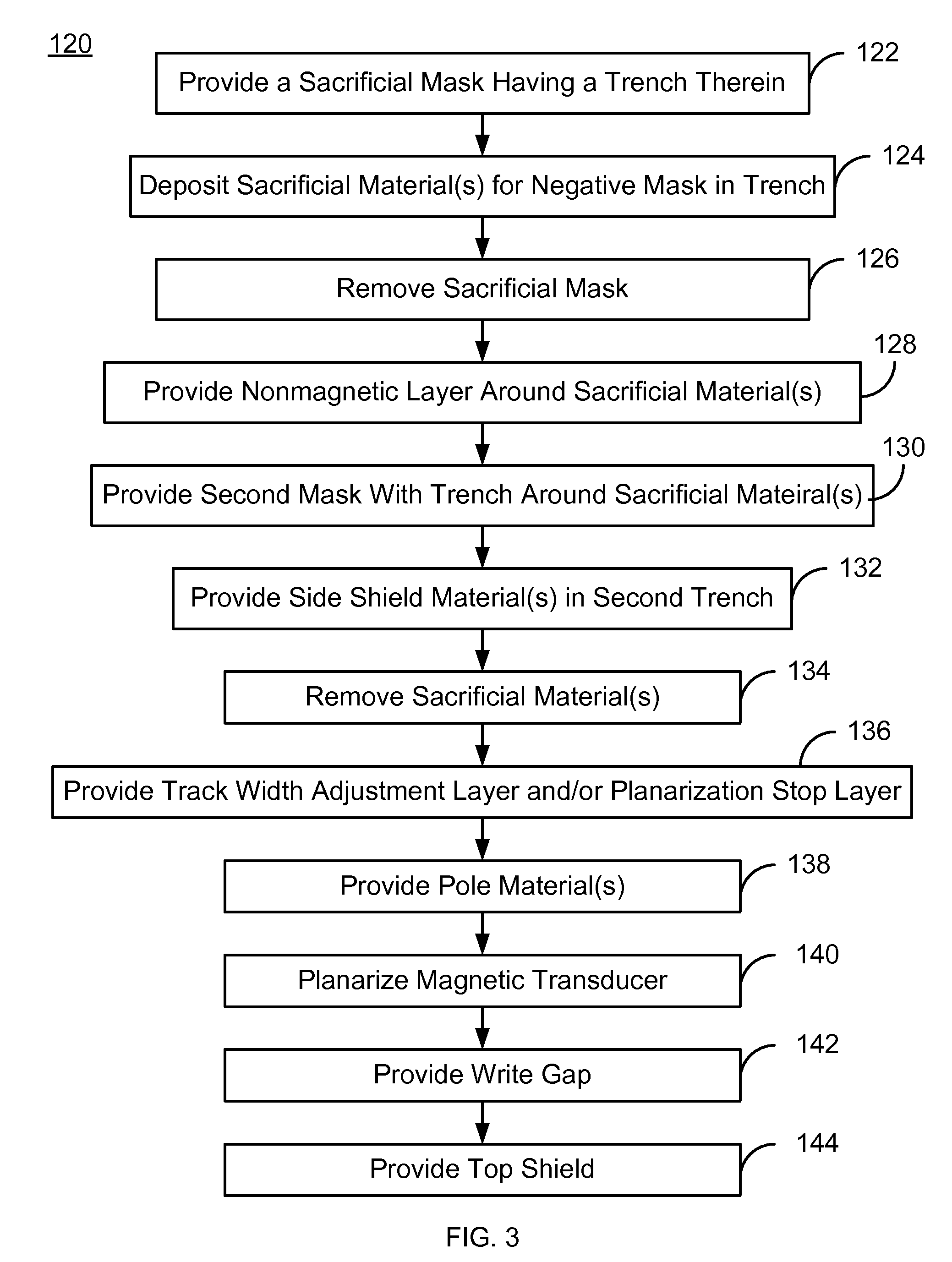

Method of forming a fully wrapped-around shielded PMR writer pole

InactiveUS8533937B1Reduce and eliminate shadowing effectGood deposition coverageElectrical transducersManufacture head surfaceEngineeringNon magnetic

A method or forming a wrapped-around shielded perpendicular magnetic recording writer pole is disclosed. A structure comprising a leading shield layer and an intermediate layer disposed over the leading shield layer is provided, the intermediate layer comprising a pole material and a dielectric material. A trench is formed in the dielectric material. A non-magnetic layer in the trench is removed via an ion beam etching process. A seed layer is deposited in the trench and over the pole material. A magnetic material comprising a side shield layer is deposited on at least a portion of the seed layer.

Owner:WESTERN DIGITAL TECH INC

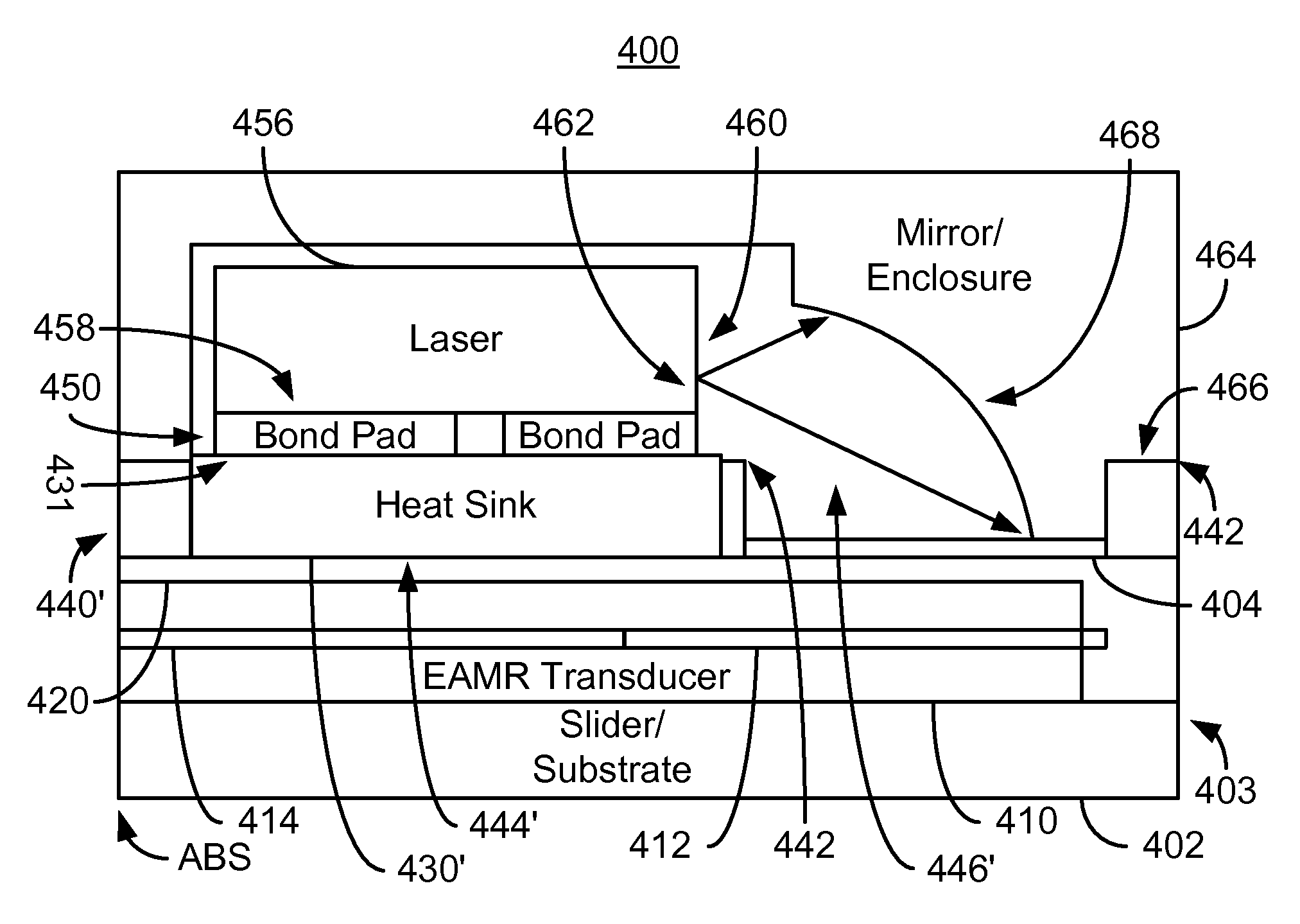

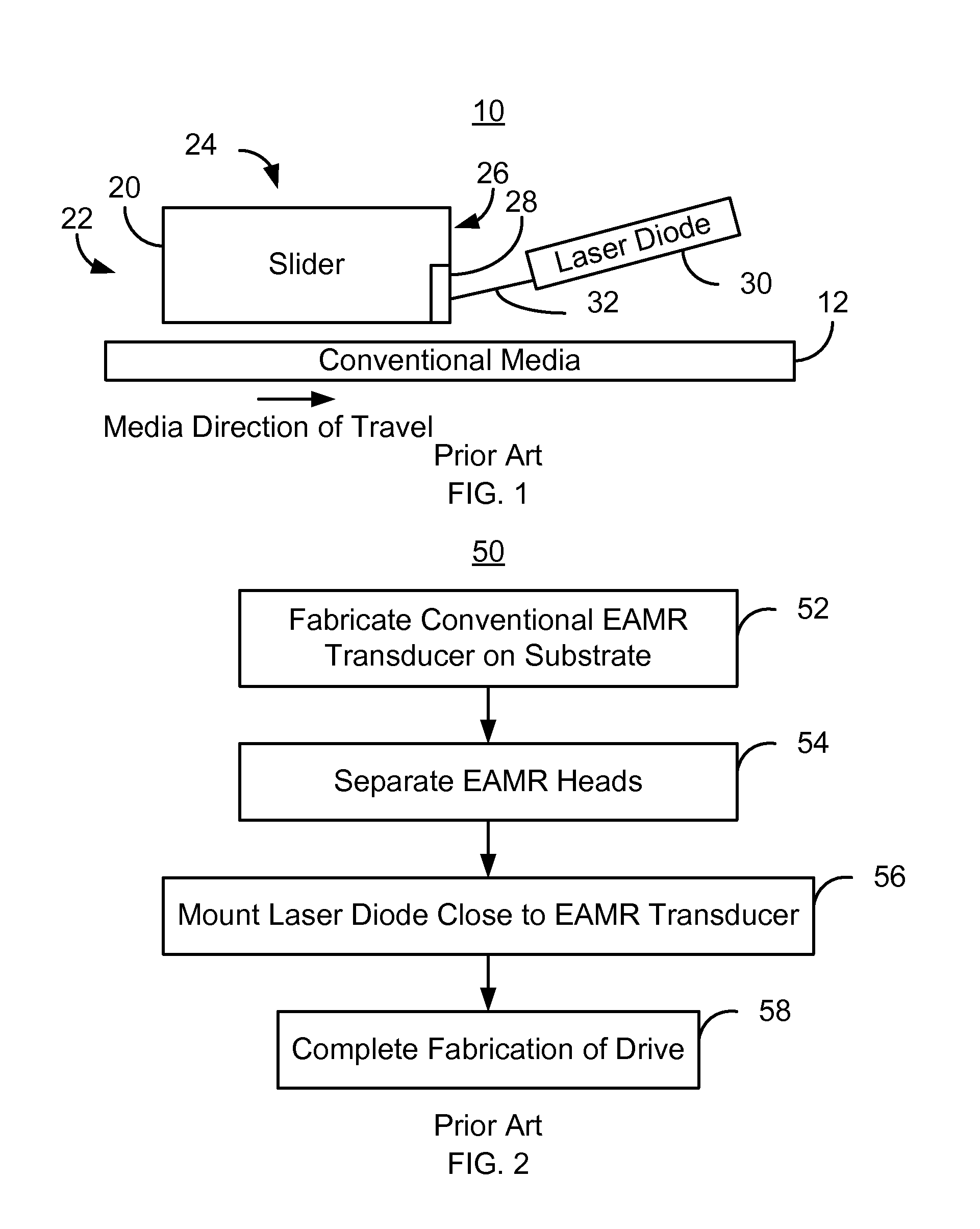

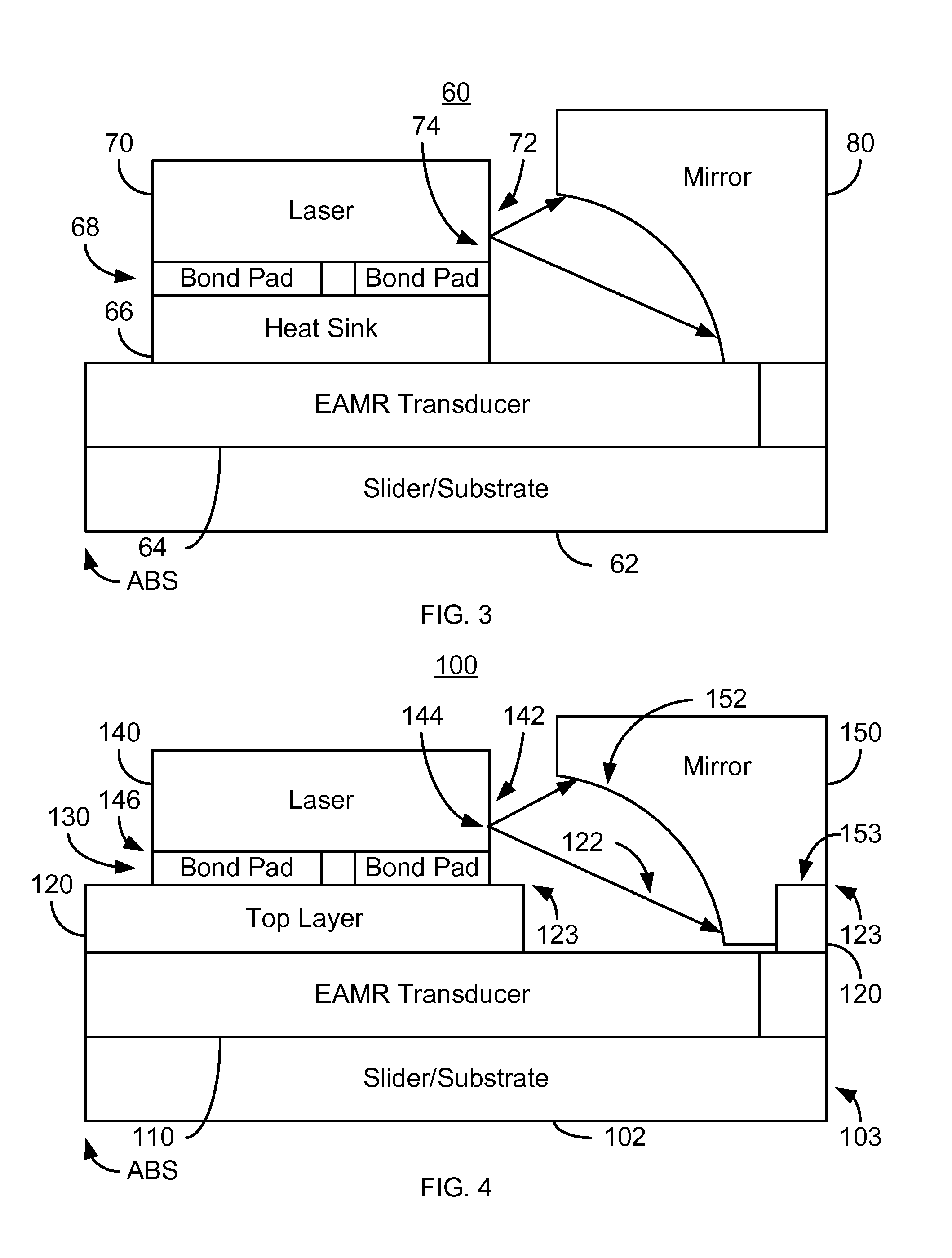

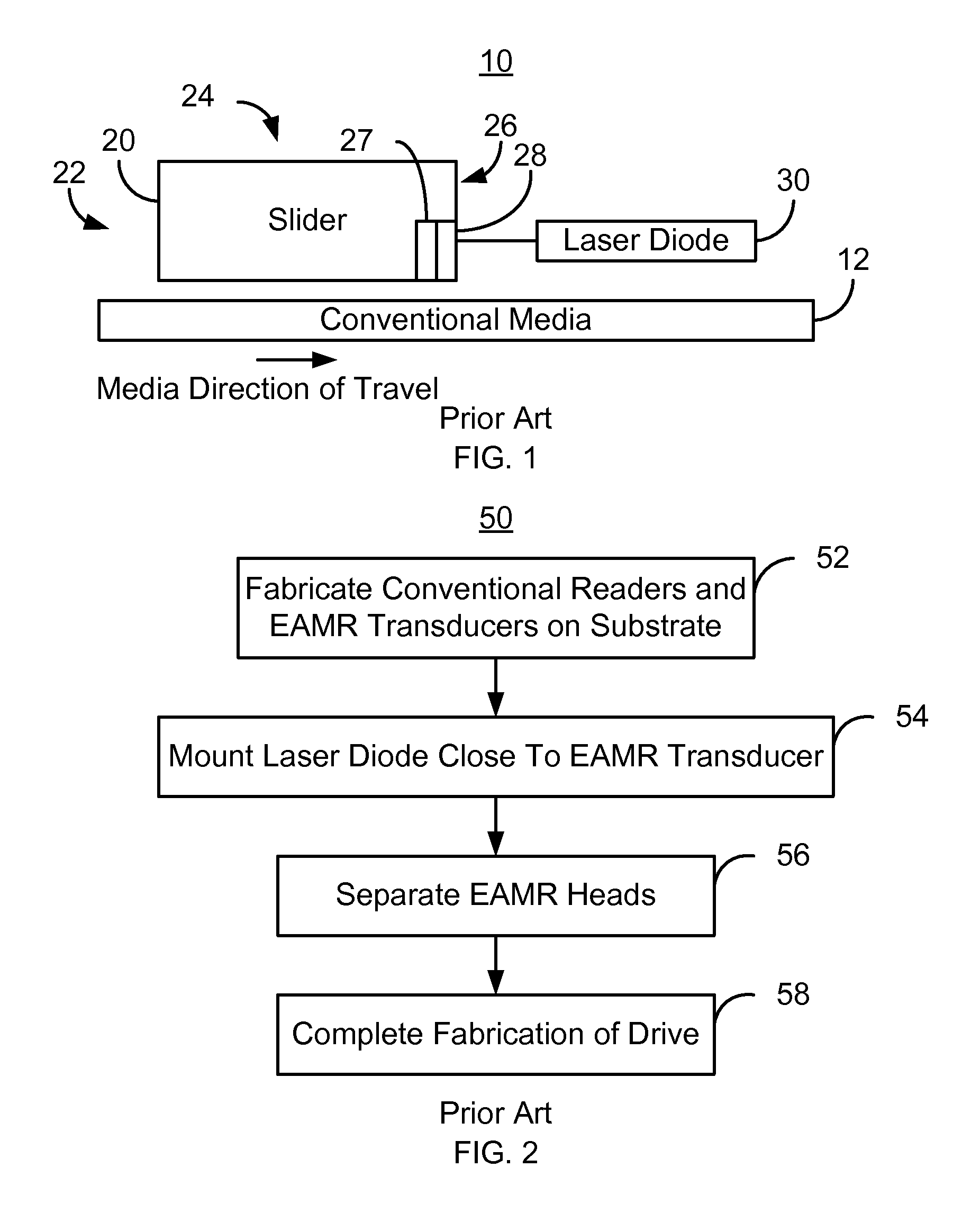

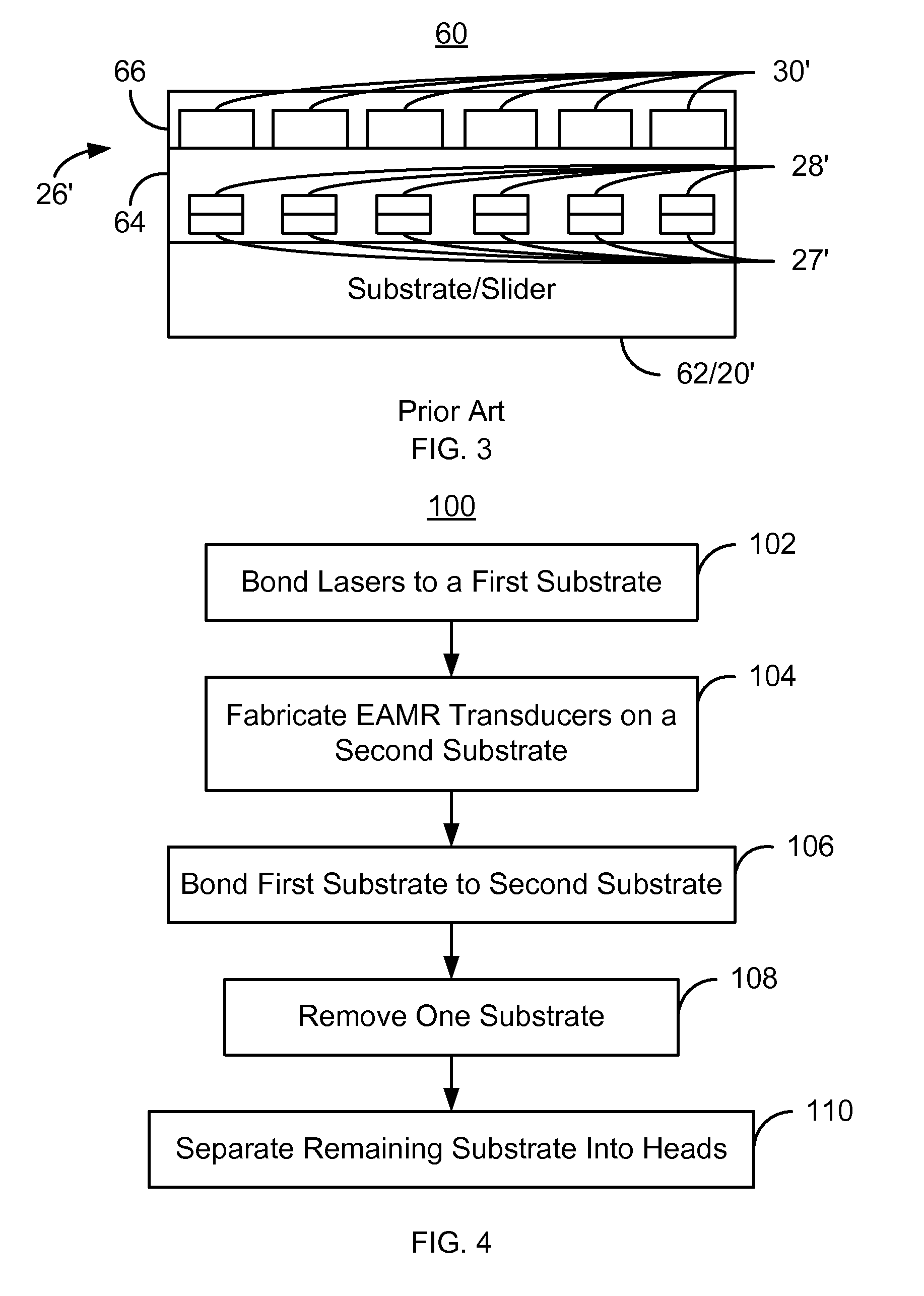

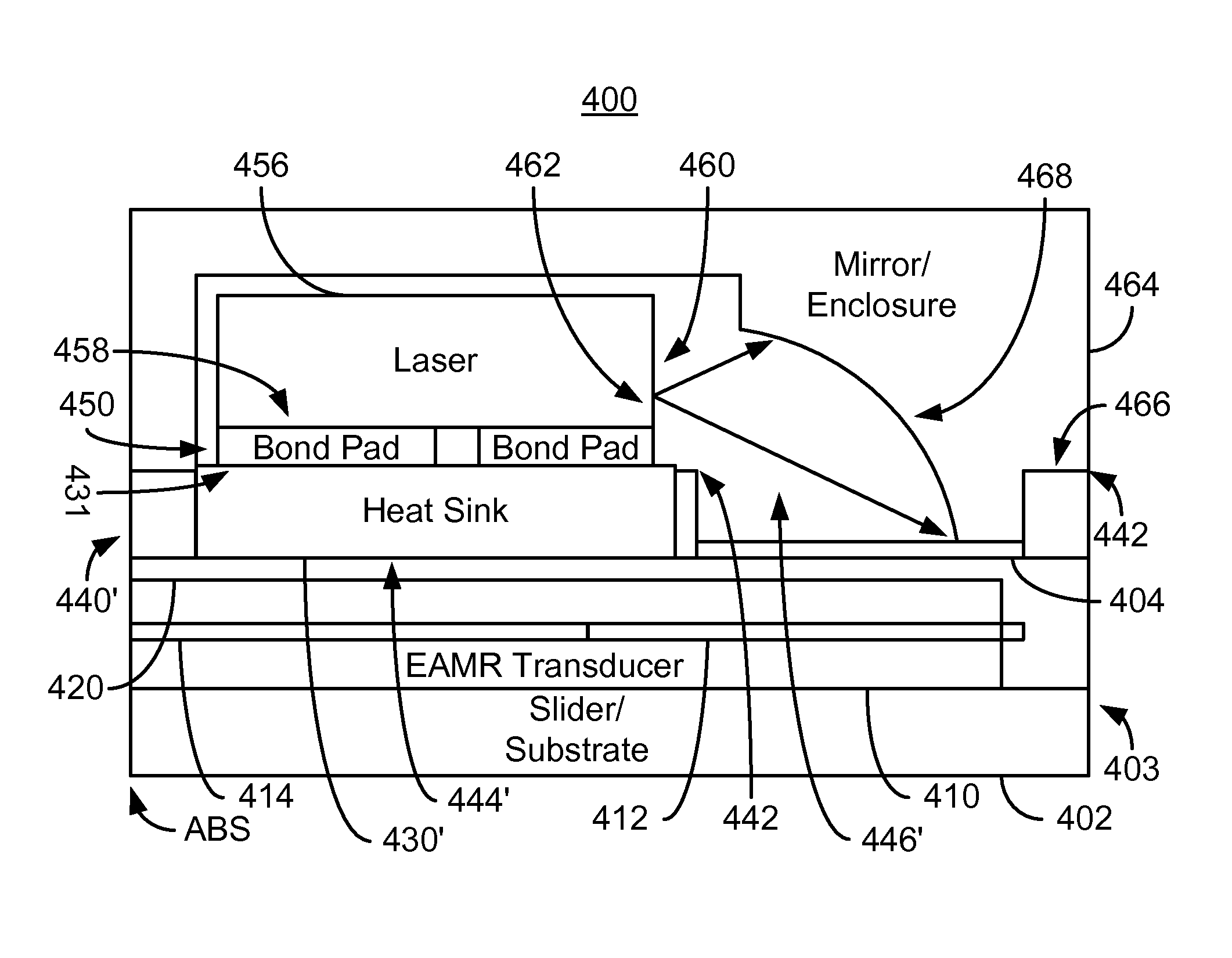

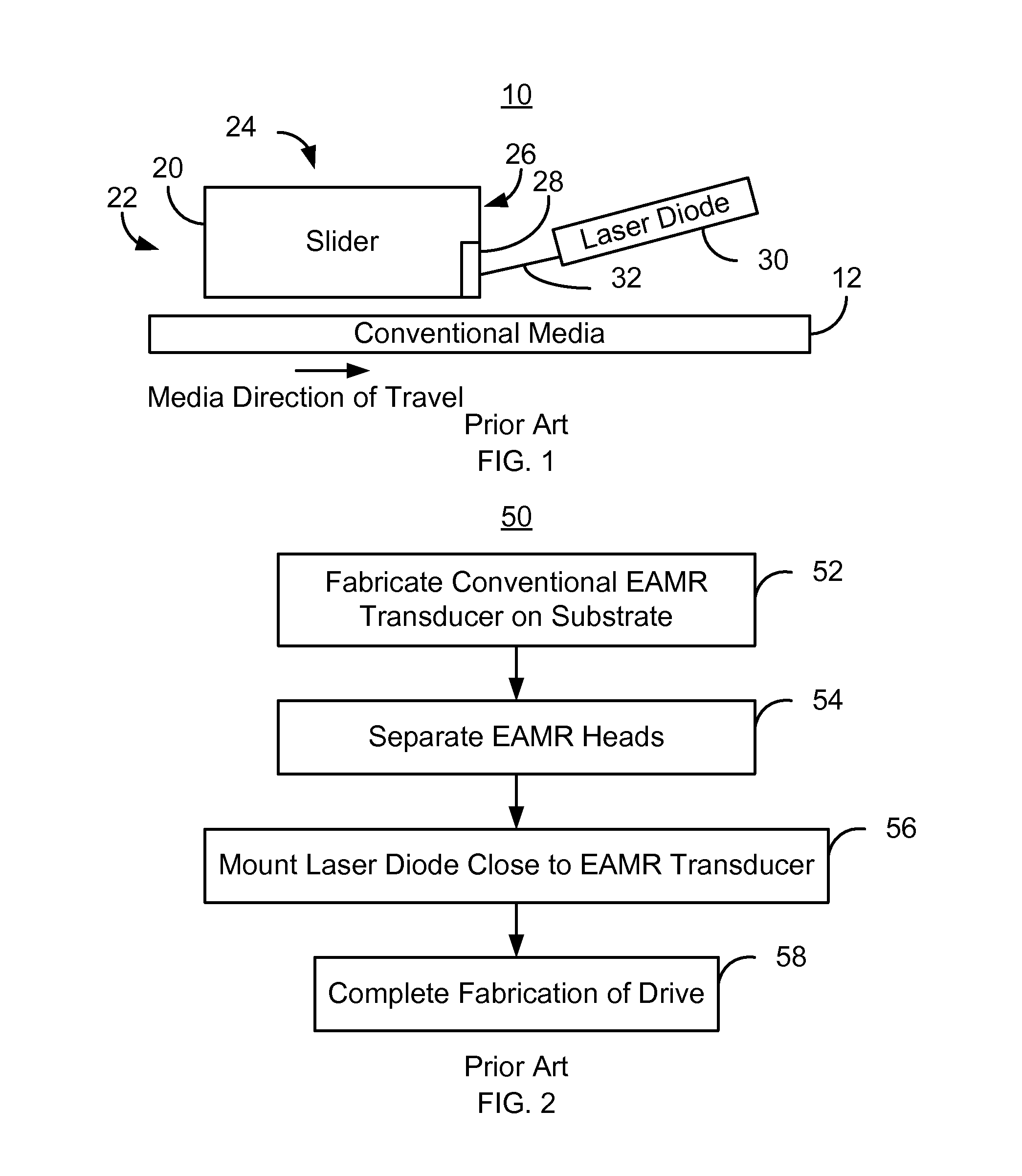

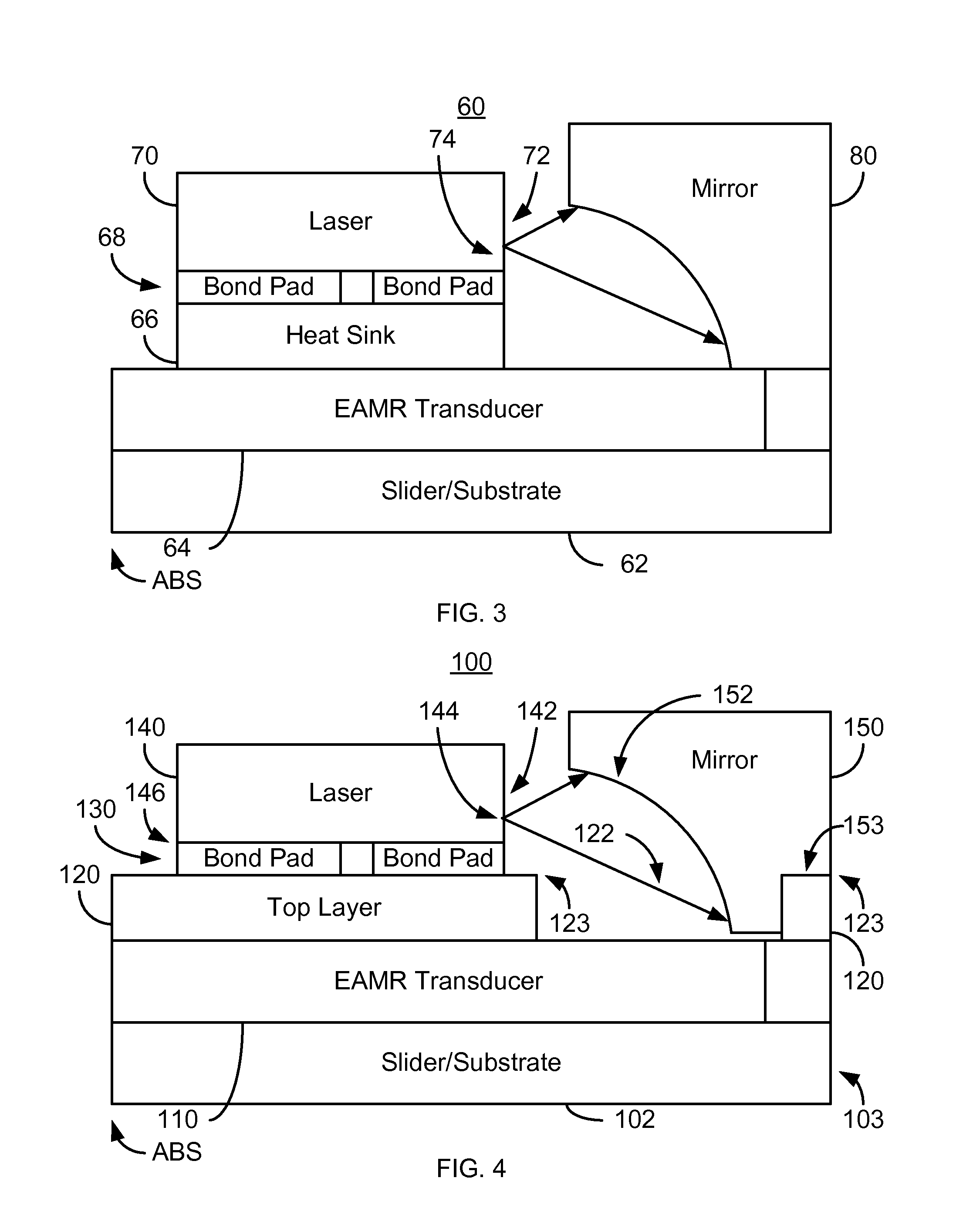

Method for providing an energy assisted magnetic recording (EAMR) head

A method and system for providing an energy assisted magnetic recording (EAMR) head are described. The method and system include providing a slider, an EAMR transducer coupled with the slider, and a top layer on the slider. The top layer includes a mirror well therein and has a substantially flat top surface. The method and system further includes providing a laser including a light-emitting surface and providing a mirror optically coupled with the laser. The laser is coupled to the top surface of the top layer external to the mirror well. The mirror has a bottom surface and a reflective surface facing the light-emitting surface of the laser. A portion of the bottom surface of the mirror is affixed to the top surface of the top layer. A portion of the mirror resides in the mirror well.

Owner:WESTERN DIGITAL TECH INC

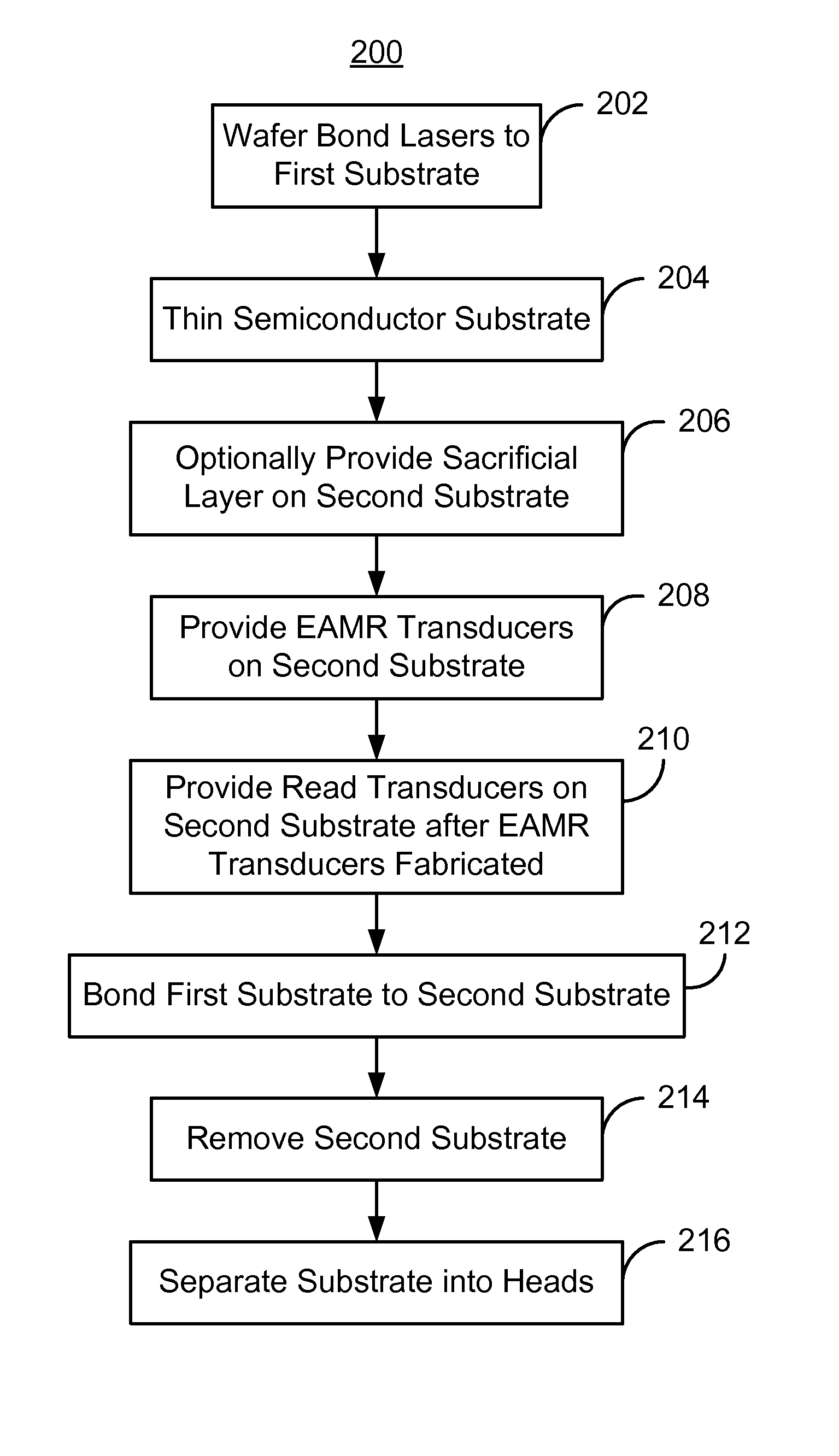

Method for providing an energy assisted magnetic recording head in a wafer packaging configuration

Owner:WESTERN DIGITAL TECH INC

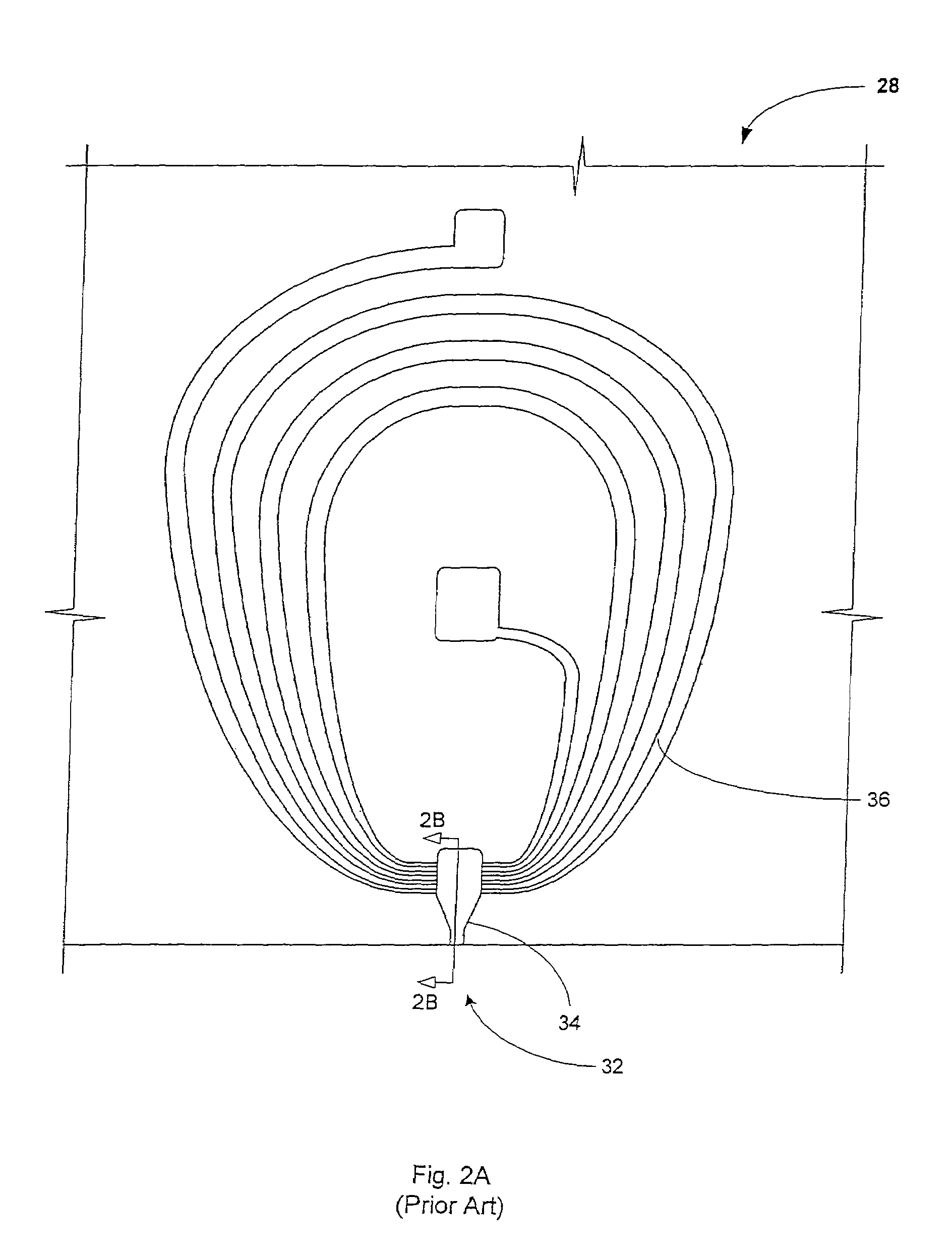

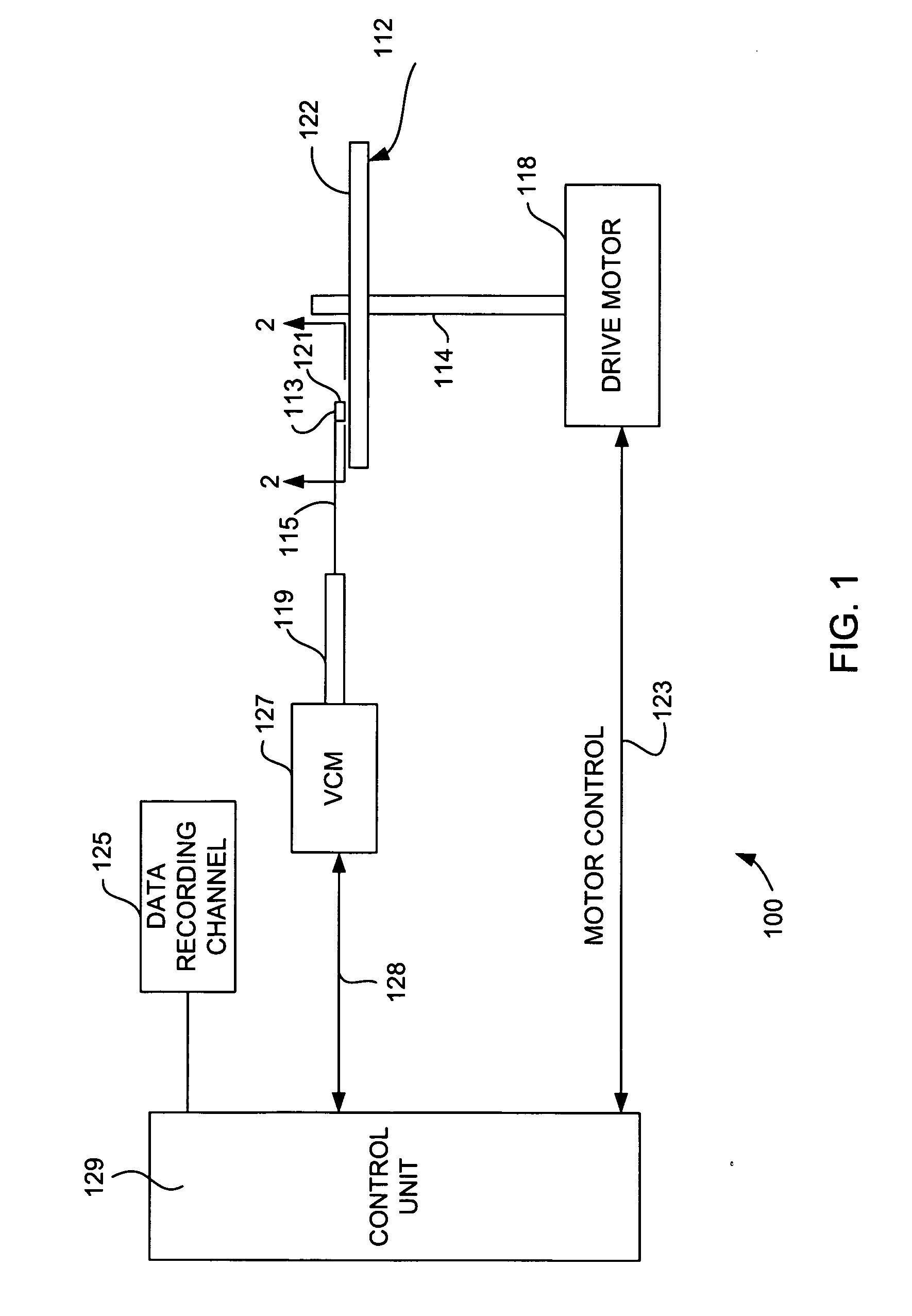

Method for making high speed, high areal density inductive write structure

InactiveUS7007372B1Excellent magnetic propertiesIncrease coverageDecorative surface effectsVacuum evaporation coatingMagnetic mediaMagnetic poles

An inductive write element is disclosed for use in a magnetic data recording system. The write element provides increased data rate and data density capabilities through improved magnetic flux flow through the element. The write element includes a magnetic yoke constructed of first and second magnetic poles. The first pole includes a pedestal constructed of a high magnetic moment (high Bsat) material, which is preferably FeRhN nanocrystalline films with lamination layers of CoZrCr. The second pole includes a thin inner layer of high Bsat material (also preferably FeRhN nanocrystalline films with lamination layers of CoZrCr), the remainder being constructed of a magnetic material capable of being electroplated, such as a Ni—Fe alloy. An electrically conductive coil passes through the yoke between the first and second poles to induce a magnetic flux in the yoke when an electrical current is caused to flow through the coil. Magnetic flux in the yoke produces a fringing field at a write gap whereby a signal can be imparted onto a magnetic medium passing thereby.

Owner:WESTERN DIGITAL TECH INC

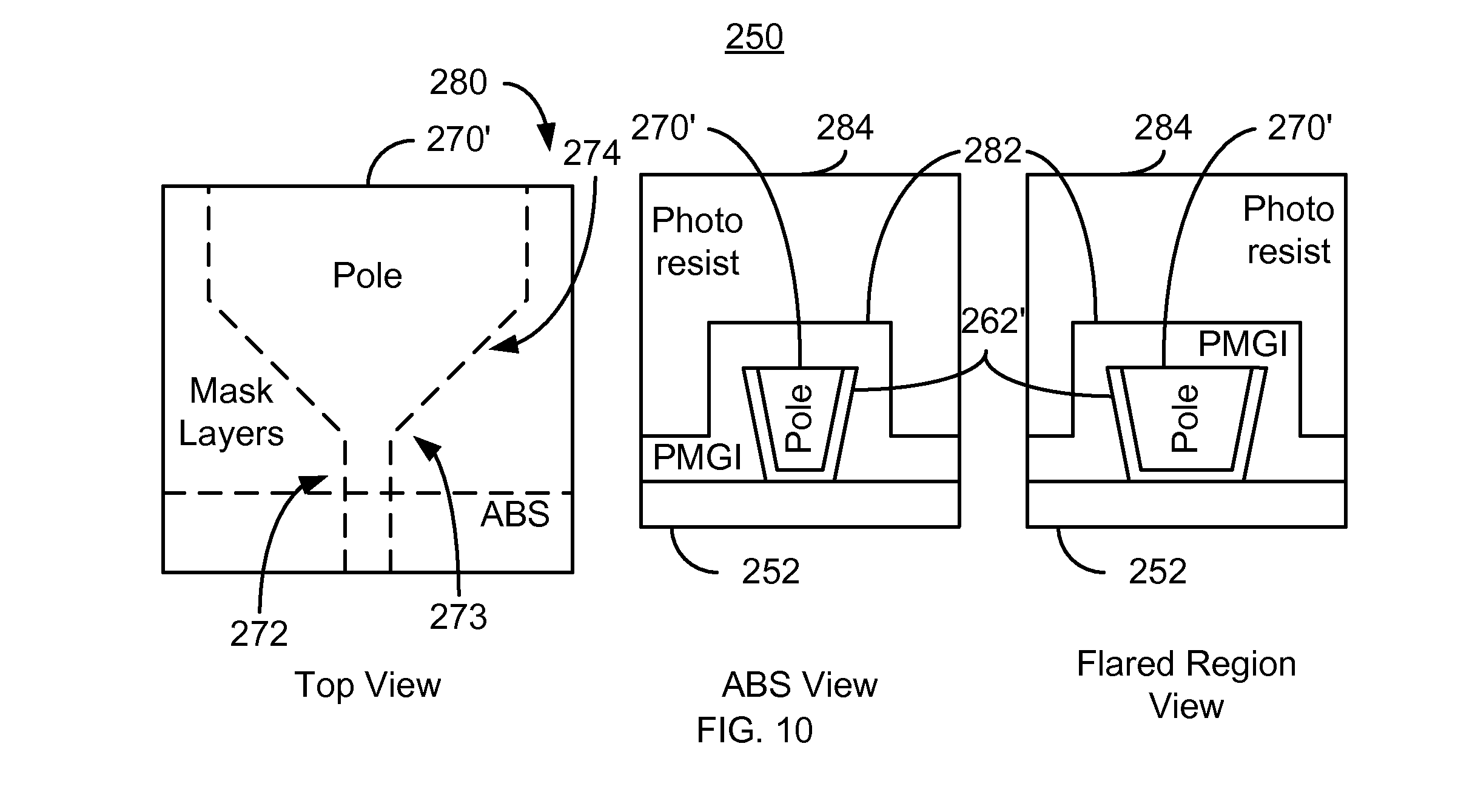

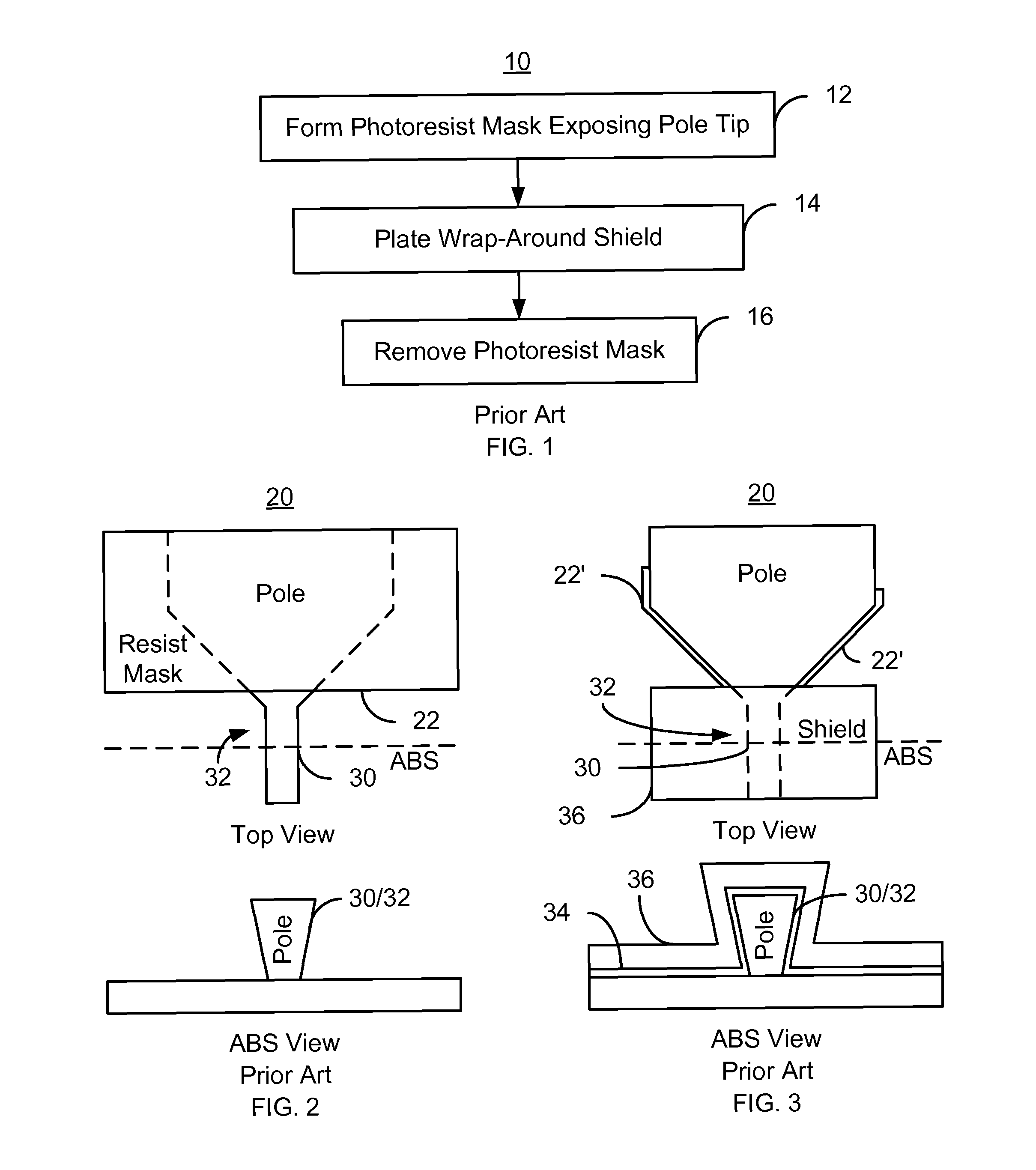

Method for providing a wrap-around shield for a magnetic recording transducer

A method for fabricating a magnetic transducer is described. The magnetic transducer includes a pole having a pole tip and a flared region. The method Includes providing a first mask layer on the pole and providing a second mask layer on the first mask layer. The first mask layer is soluble in a predetermined solution and has a first thickness. The second mask layer has a second thickness greater than the first thickness. The method also includes forming a mask from the first mask layer and the second mask layer. The step of forming the mask layer includes using the predetermined solution. The mask has a pattern that exposes a portion of the pole tip and covers a portion of the flared region. The method also includes providing a wrap-around shield on at least the pole tip.

Owner:WESTERN DIGITAL TECH INC

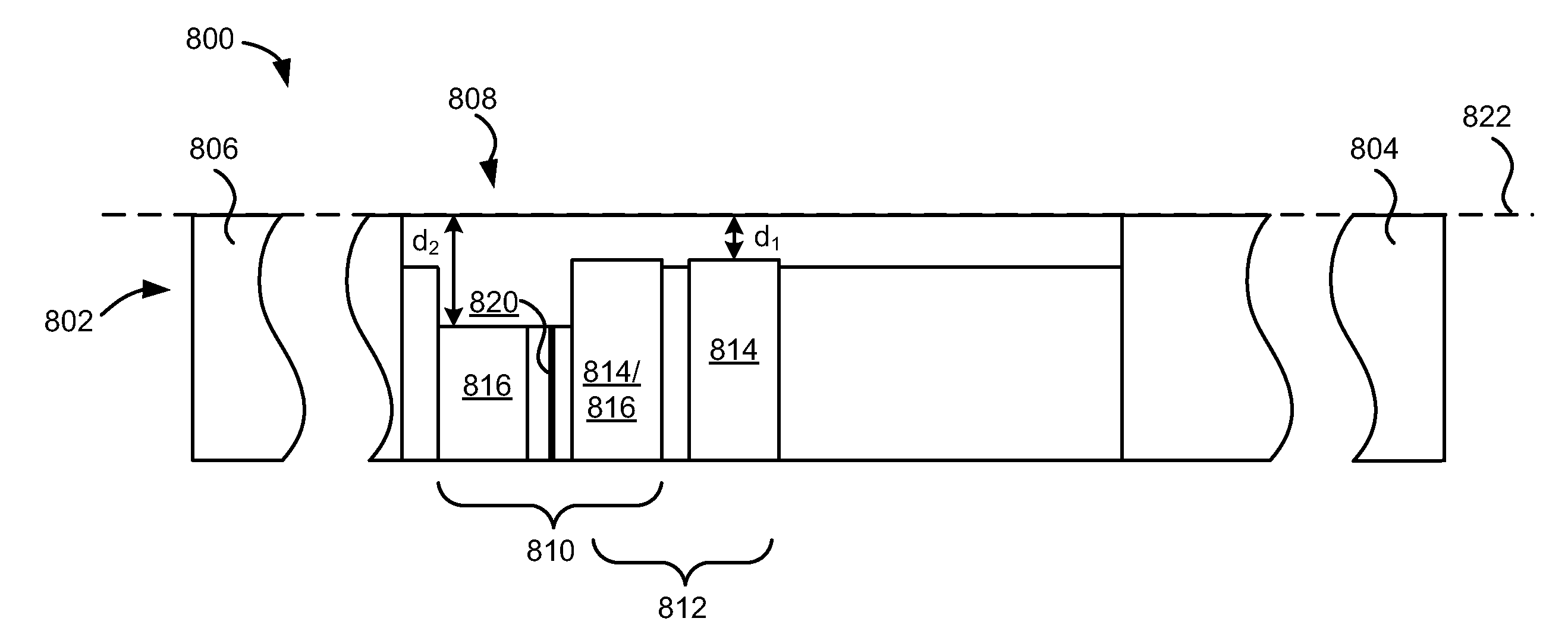

Method for fabricating a magnetic recording transducer

ActiveUS8276258B1Manufacture head surfaceElectrical transducersMagnetic transducersAir bearing surface

A method and system provide a magnetic transducer that includes an underlayer and a first nonmagnetic layer on the underlayer. The method and system include providing a first trench in the first nonmagnetic layer. The first trench has at least one edge corresponding to at least one side shield. The method and system also include providing a second nonmagnetic layer in the first trench and providing a second trench in the second nonmagnetic layer. The method and system include providing the main pole. At least part of the main pole resides in the second trench. The method and system further include removing at least a portion of the second nonmagnetic layer between the edge(s) and the main pole. The method and system also provide the side shield(s) in the first trench. The side shield(s) extend from at least an air-bearing surface location to not further than a coil front location.

Owner:WESTERN DIGITAL TECH INC

Method of measuring a bevel angle in a write head

A method of measuring a bevel angle in a write pole comprises the step of providing a mask over a wafer containing the write pole. The mask has a first opening over the write pole and a second opening over a sacrificial region of the wafer. The sacrificial region comprises a same material as the write pole. The method further comprises the steps of performing a beveling operation on the write pole and the sacrificial region to form a first bevel in the write pole and a second bevel in the sacrificial region, and measuring an angle of the second bevel in the sacrificial region to determine the bevel angle of the write pole.

Owner:WESTERN DIGITAL TECH INC

Method for providing a magnetic recording transducer

Owner:WESTERN DIGITAL TECH INC

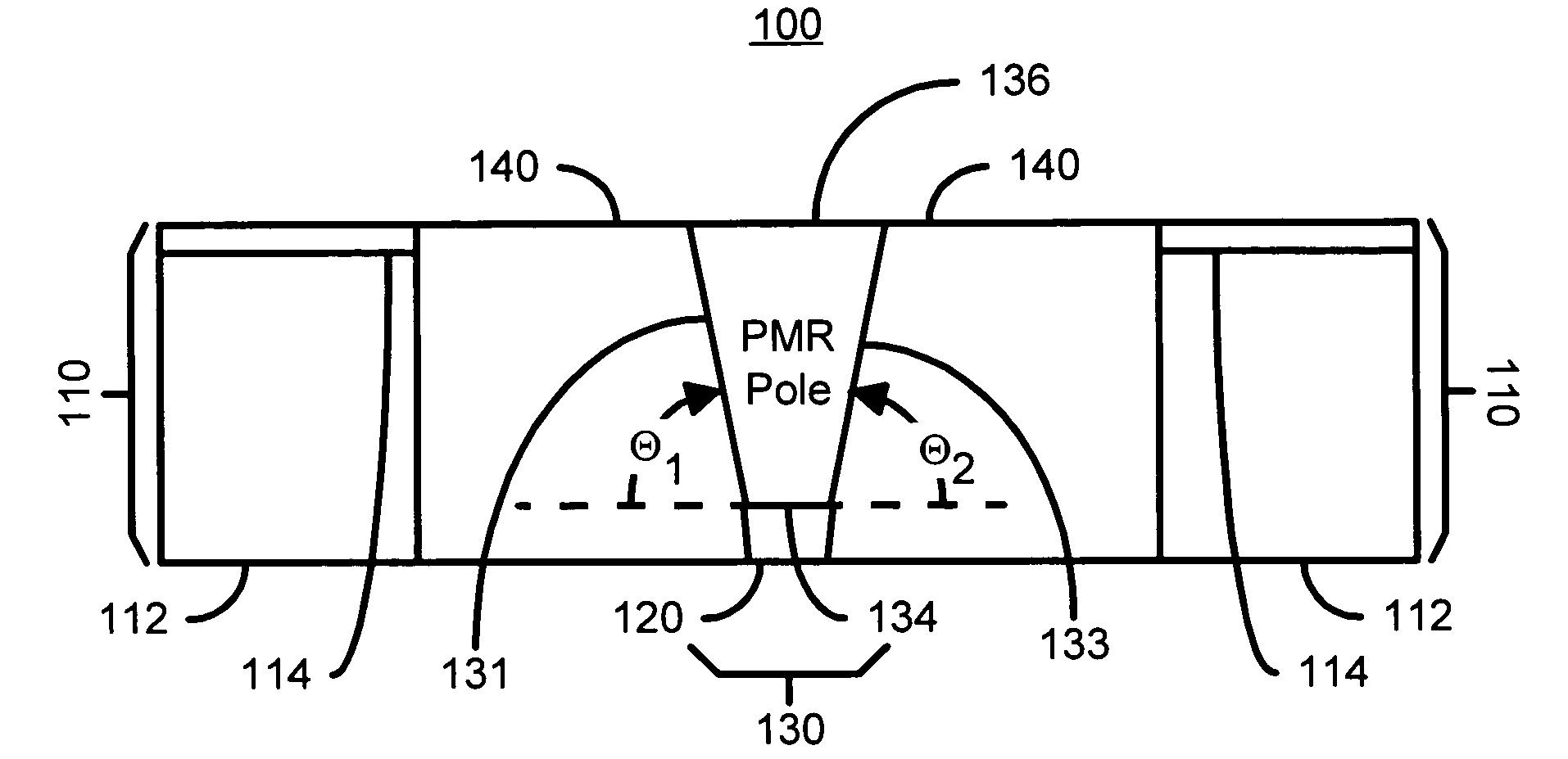

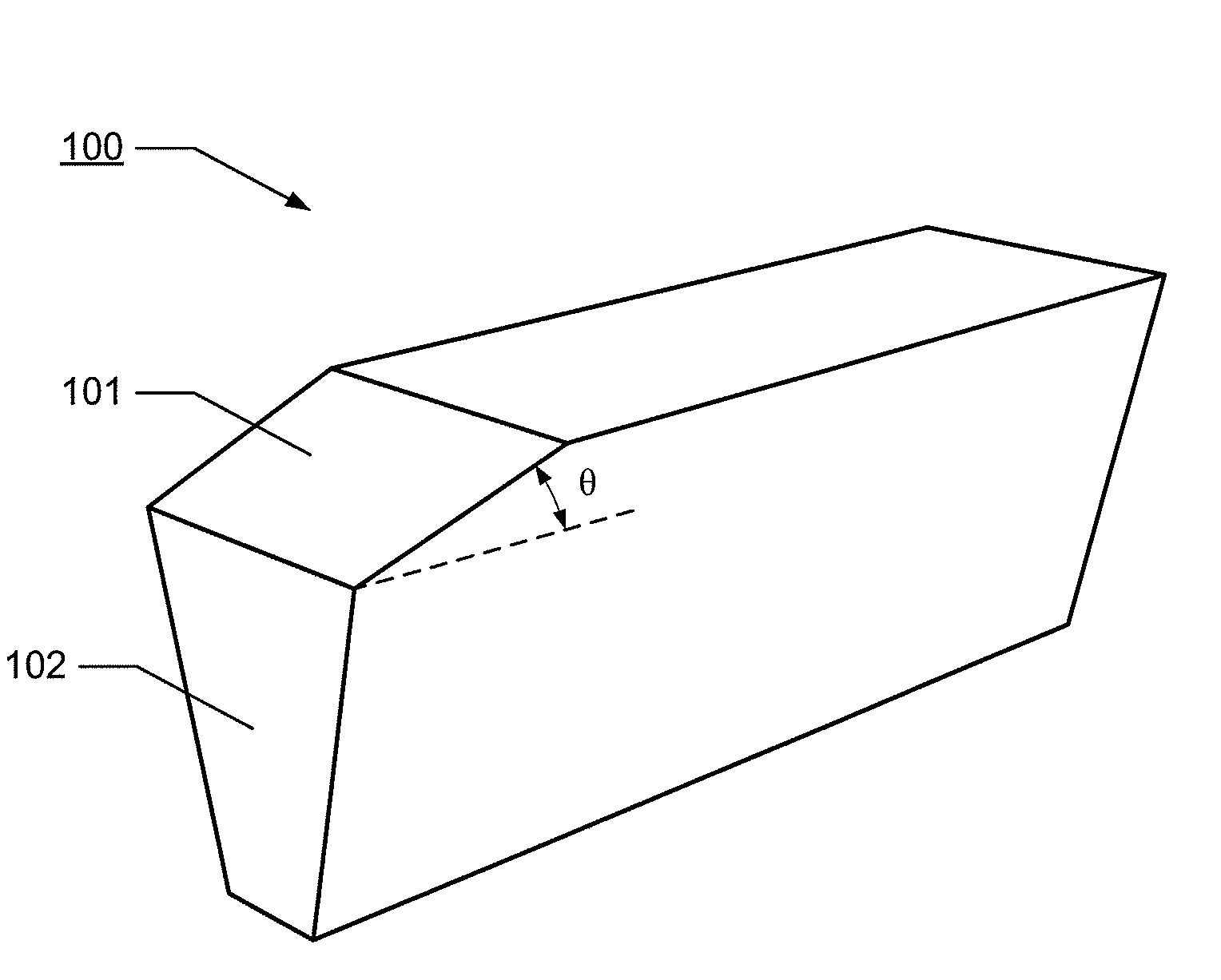

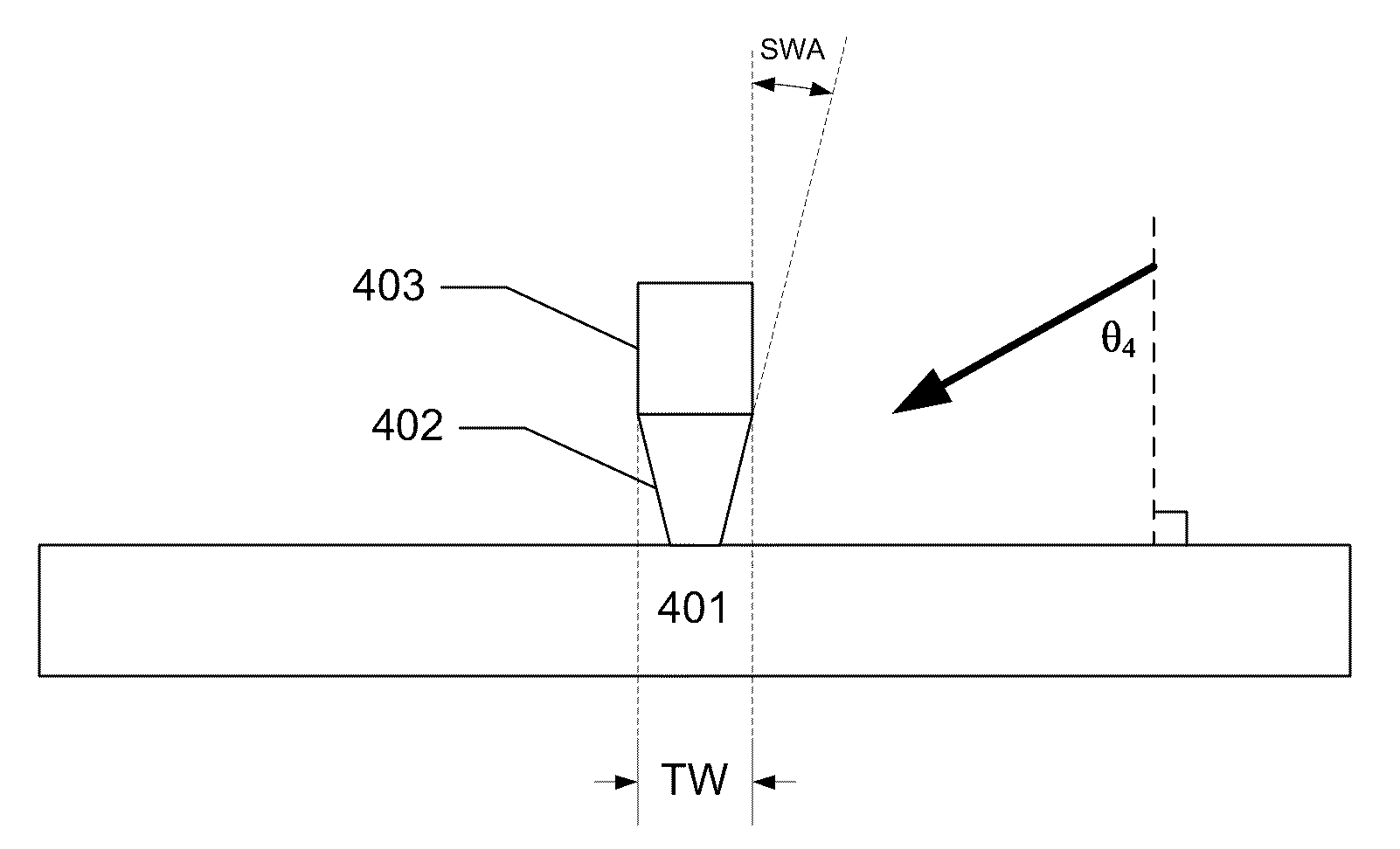

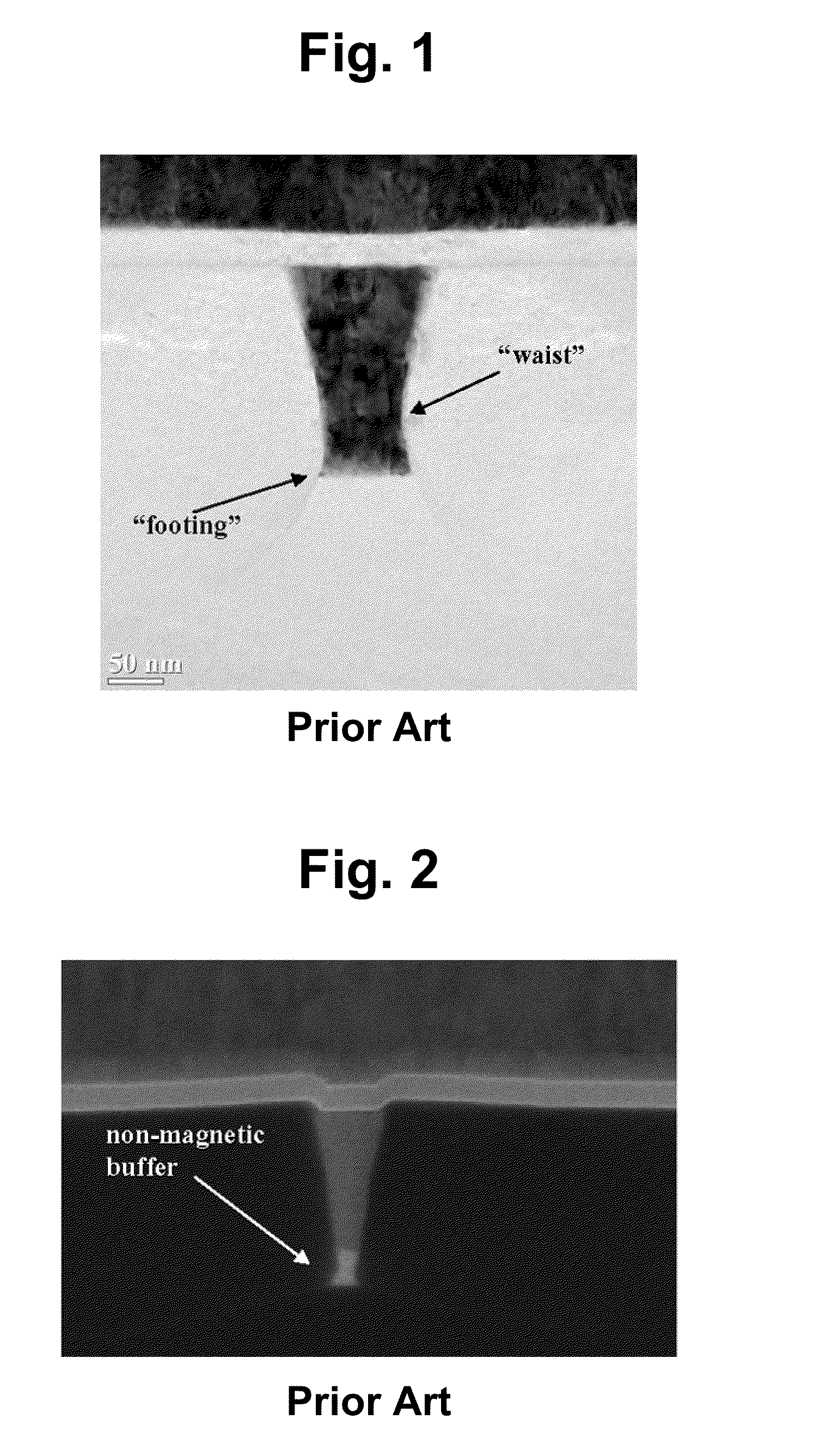

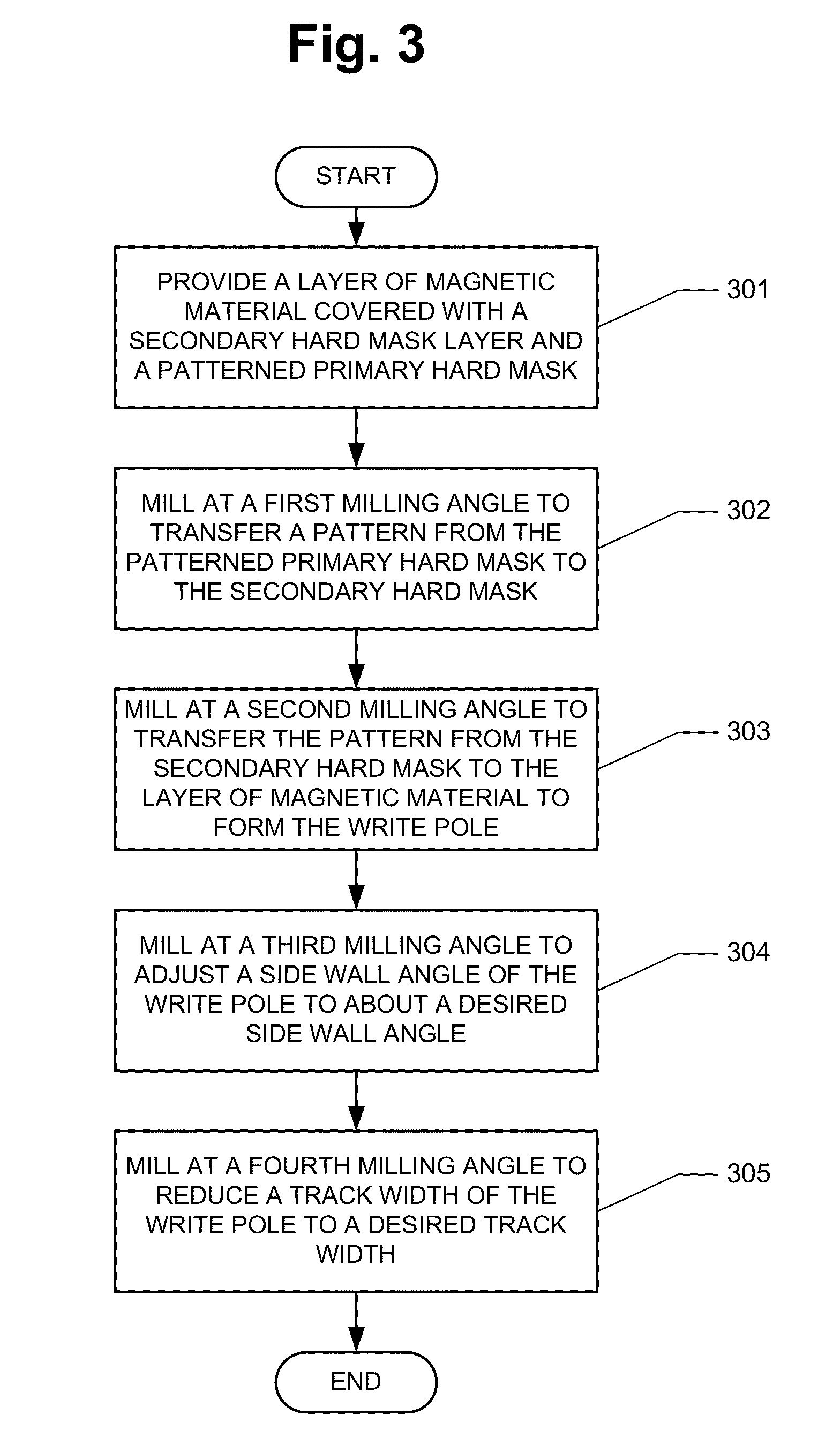

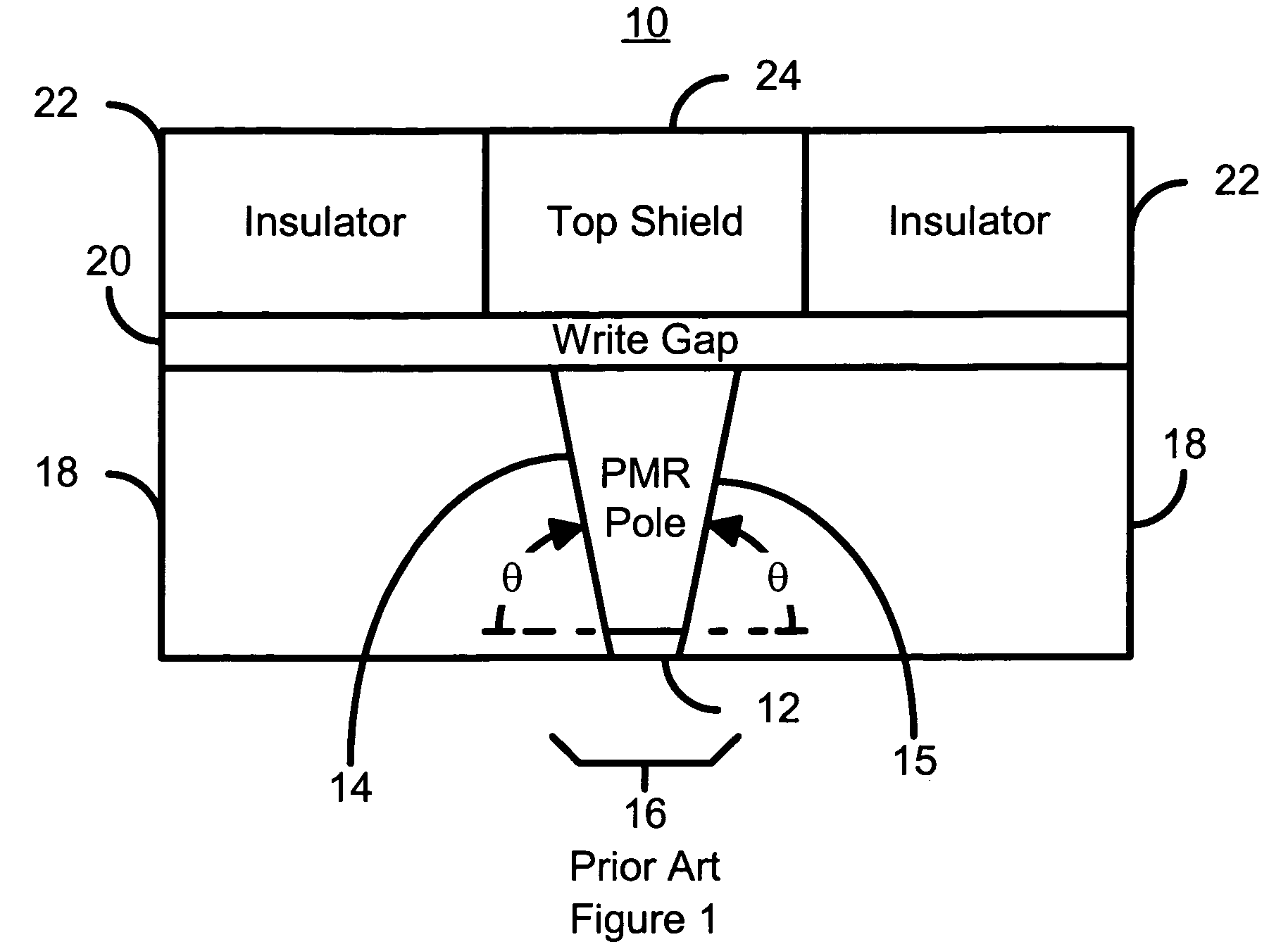

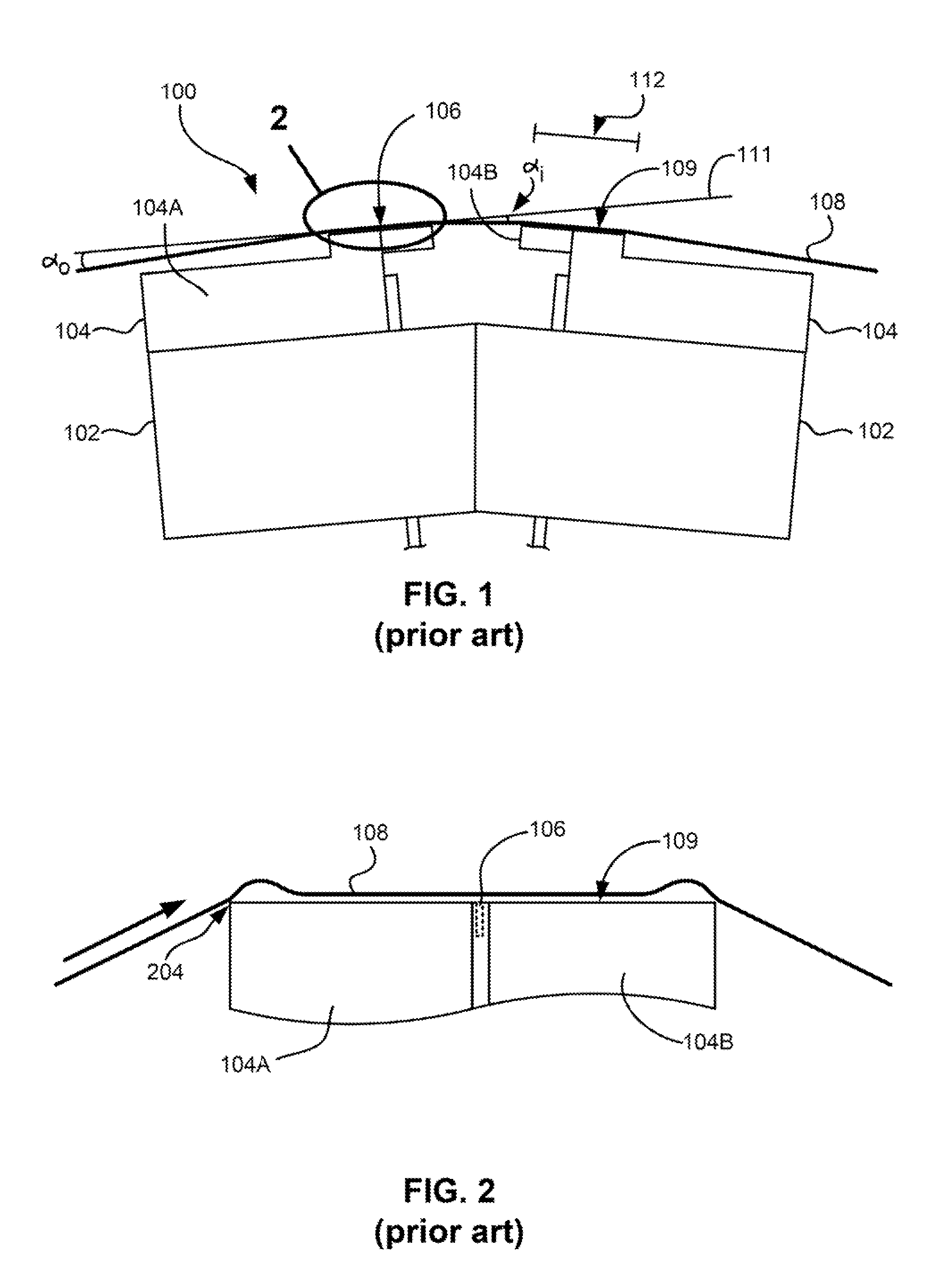

Tunable pole trim processes for fabricating trapezoidal perpendicular magnetic recording (PMR) write poles

A method of forming a write pole for a magnetic recording device is provided. The method comprises providing a layer of magnetic material covered with a secondary hard mask layer and a patterned primary hard mask, milling at a first milling angle to transfer a pattern from the patterned primary hard mask to the secondary hard mask, and milling at a second milling angle to transfer the pattern from the secondary hard mask to the layer of magnetic material to form the write pole. The second milling angle is greater than the first milling angle. The method further comprises milling at a third milling angle to adjust a side wall angle of the write pole to about a desired side wall angle, and milling at a fourth milling angle to reduce a track width of the write pole to a desired track width.

Owner:WESTERN DIGITAL TECH INC

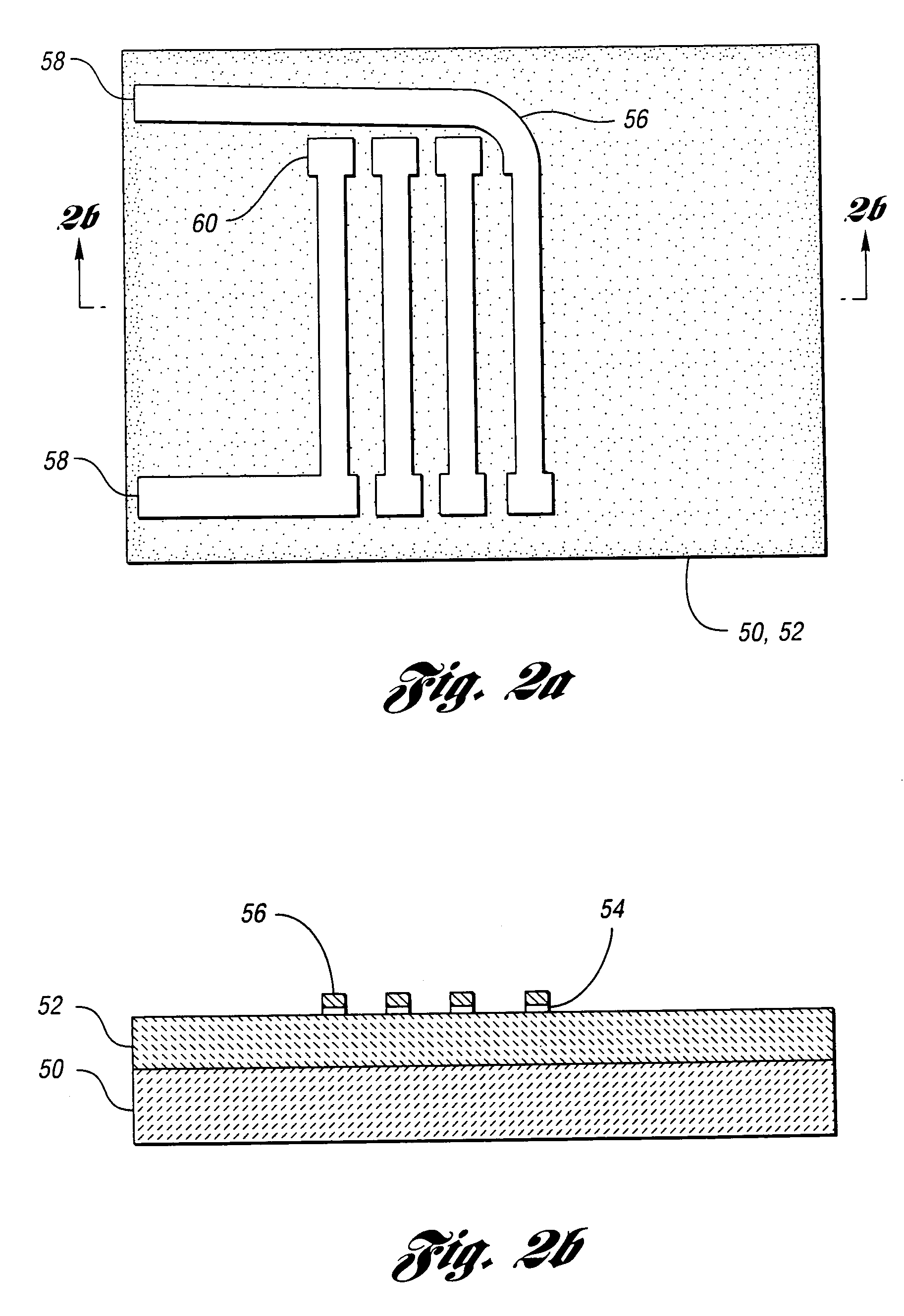

Method for manufacturing a pole for a magnetic recording head

A method and system for manufacturing a pole on a recording head is disclosed. The method and system include sputtering at least one ferromagnetic layer and fabricating a hard mask on the ferromagnetic layer. The method and system also include defining the pole and depositing a write gap on the pole. A portion of the pole is encapsulated in an insulator.

Owner:WESTERN DIGITAL TECH INC

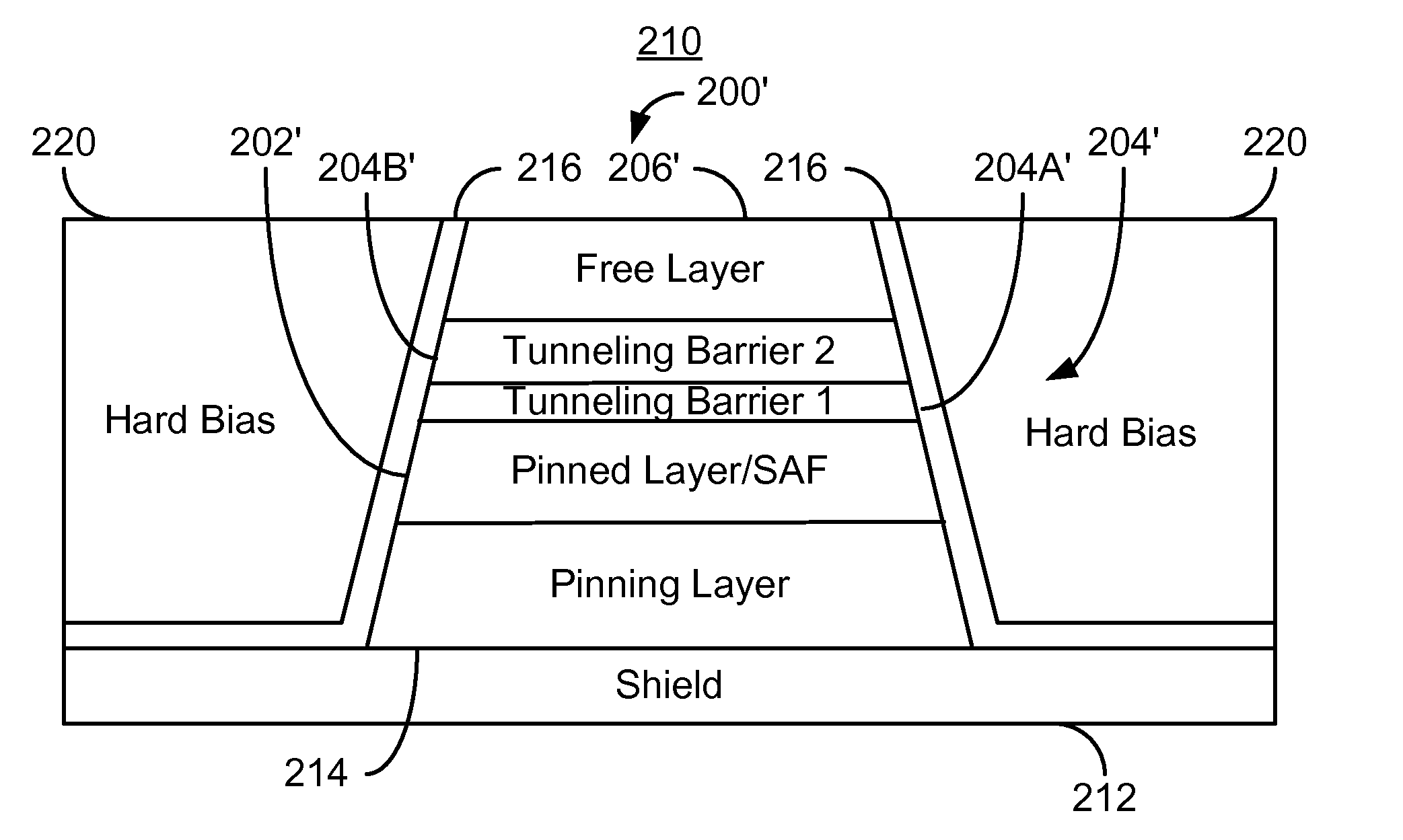

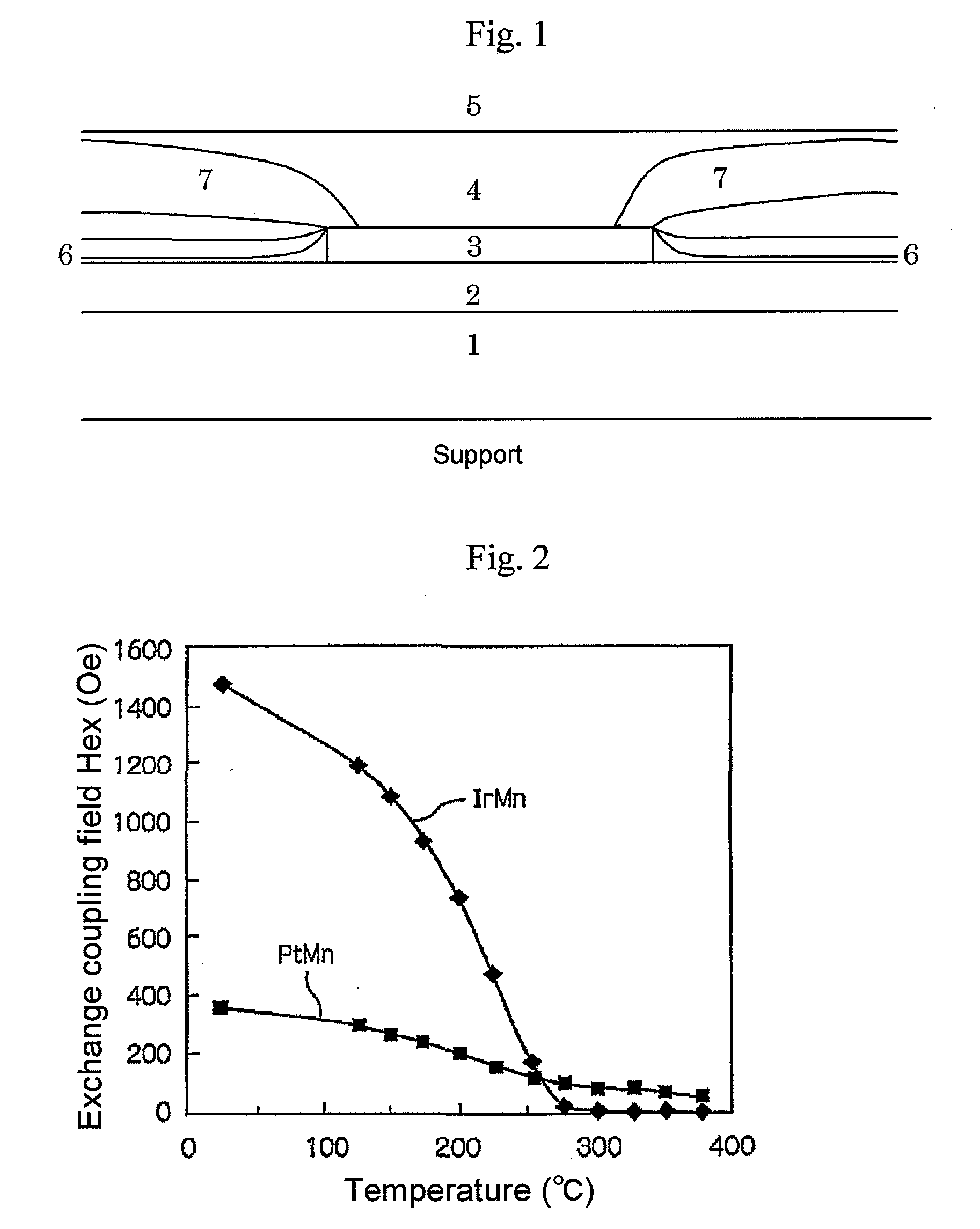

Magnetic signal reproduction system and magnetic signal reproduction method

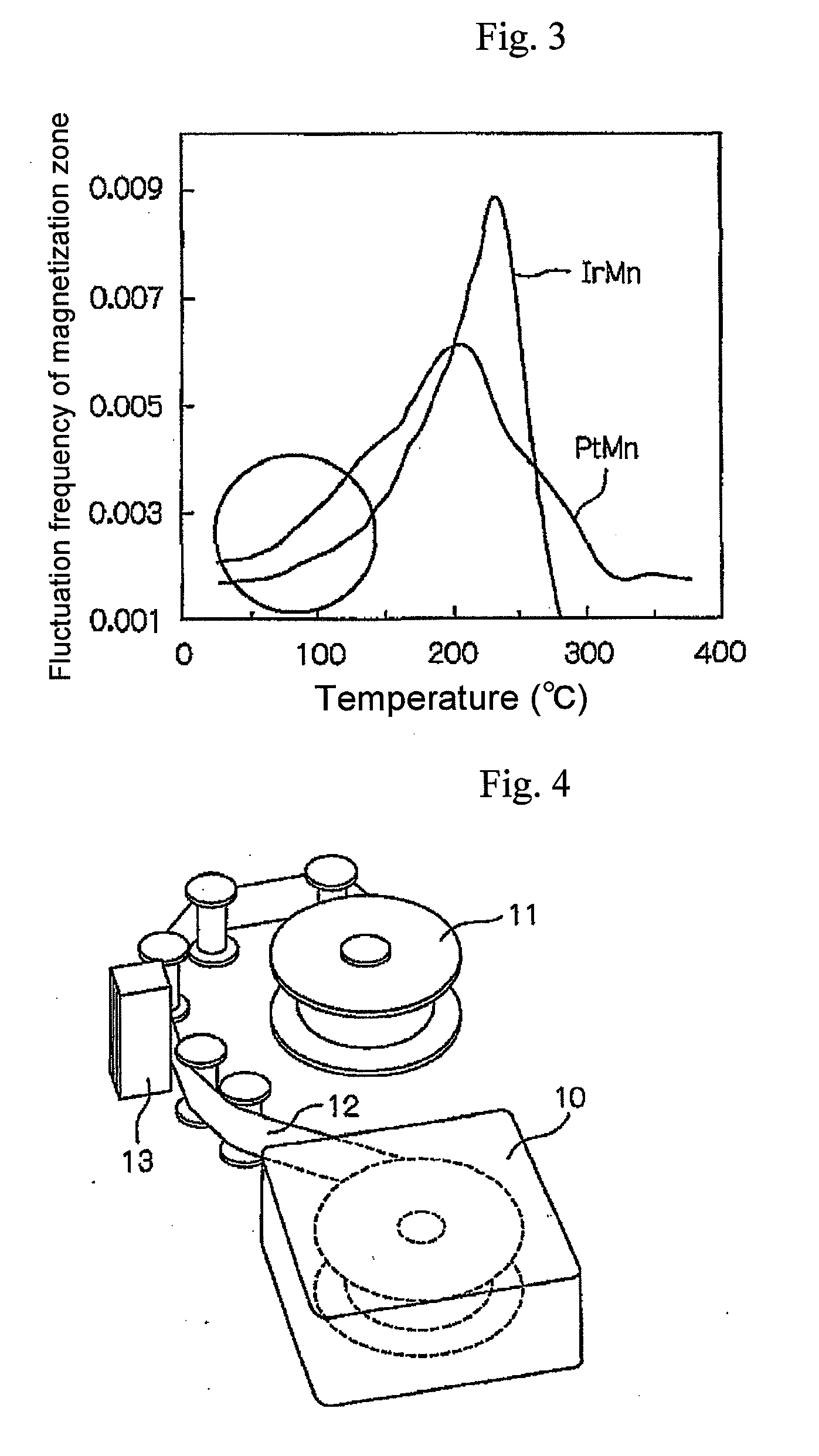

InactiveUS20090027812A1Stable reproduction propertyDeterioration of reproduction propertyManufacture unitary devices of plural headsRecord information storageIridiumAlloy

The magnetic signal reproduction system comprises a magnetic recording medium comprising a magnetic layer comprising a ferromagnetic powder and a binder on a nonmagnetic support and a reproduction head, wherein a number of protrusions equal to or greater than 10 nm in height on the magnetic layer surface, as measured by an atomic force microscope, ranges from 50 to 2500 / 10,000 μm2, a quantity of lubricant on the magnetic layer surface, denoted as a surface lubricant index, ranges from 0.5 to 5.0, a surface abrasive occupancy of the magnetic layer ranges from 2 to 20 percent, the reproduction head is a magnetoresistive magnetic head comprising a spin-valve layer, the spin-valve layer comprises a magnetization free layer, a magnetization pinned layer and an antiferromagnetic layer, and the antiferromagnetic layer is comprised of alloy comprising iridium and manganese, and the reproduction head comes in sliding contact with the magnetic recording medium during signal reproduction.

Owner:FUJIFILM CORP +1

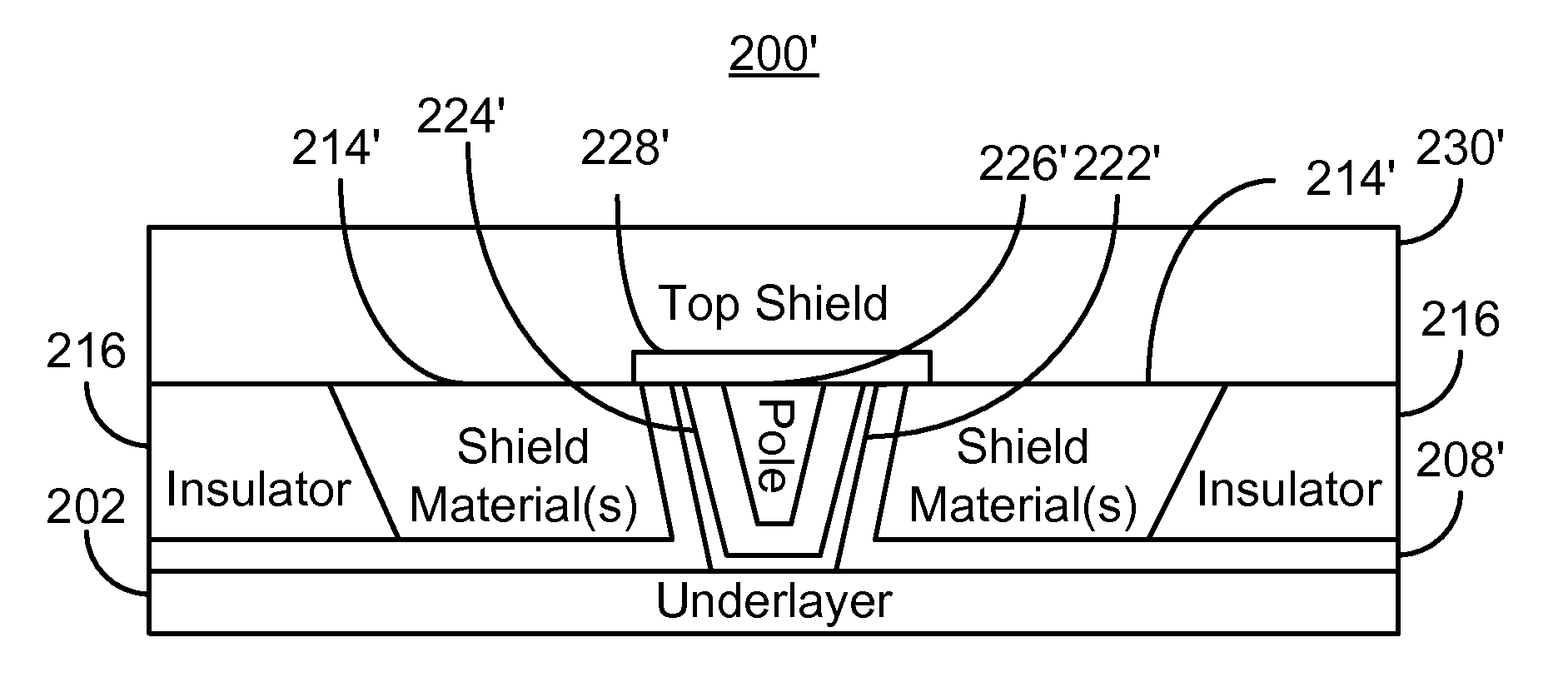

Method for manufacturing a magnetic recording transducer having side shields

A method for manufacturing a magnetic transducer is described. The method includes providing a negative mask having a bottom, a plurality of sides, and a top wider than the bottom. The method also includes depositing a nonmagnetic layer on the negative mask. The nonmagnetic layer has a plurality of portions covering the plurality of sides of the negative mask. The method also includes providing a first mask having a first trench therein. The negative mask resides in the first trench. The method further includes depositing side shield material(s), at least a portion of which resides in the first trench. The method further includes removing the negative mask to create a second trench between the plurality of portions of the nonmagnetic layer and form a pole, at least a portion of which resides in the second trench.

Owner:WESTERN DIGITAL TECH INC

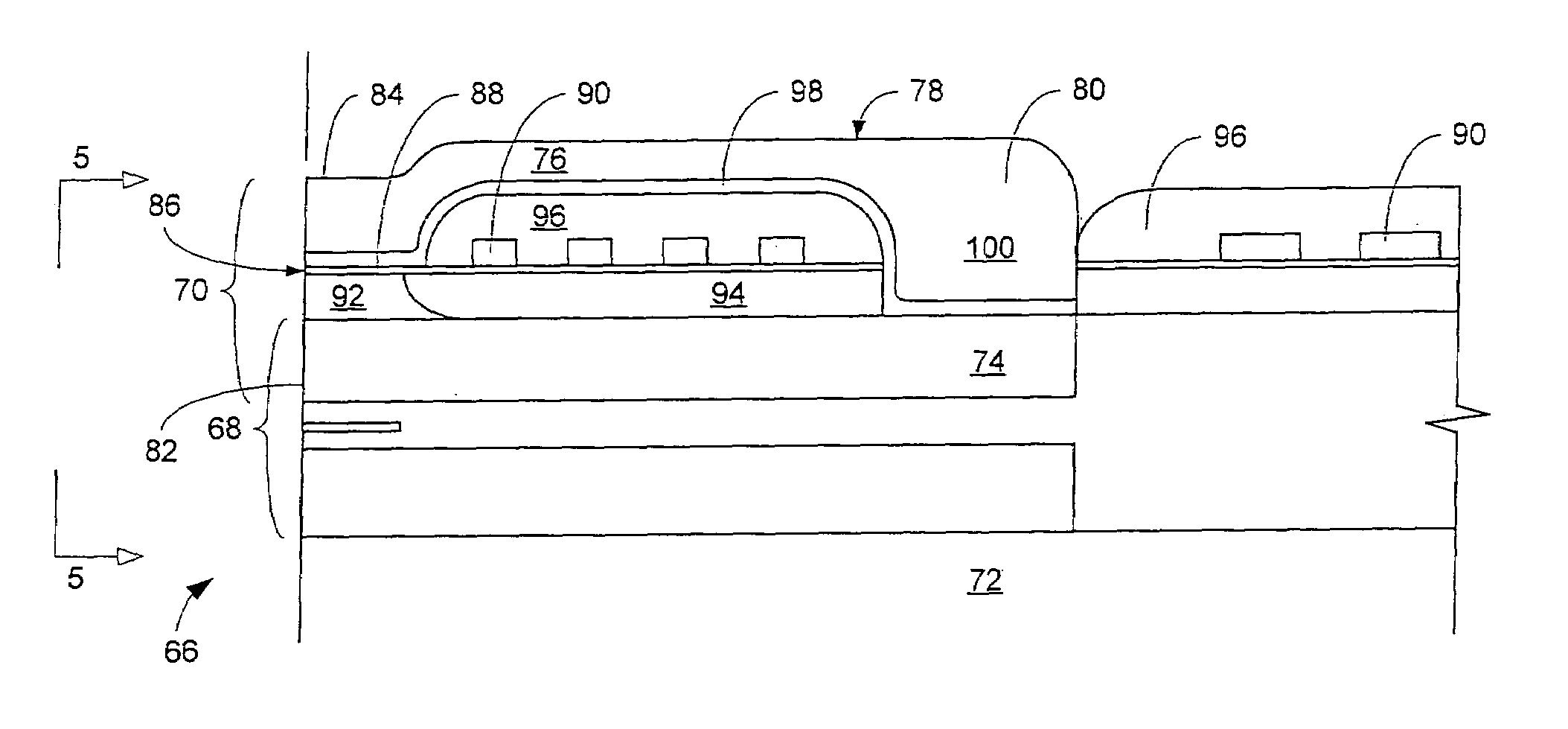

Method and system for providing an energy assisted magnetic recording head

A method and system for providing an energy assisted magnetic recording (EAMR) head are described. The method and system include providing a slider, an EAMR transducer coupled with the slider, and a top layer on the slider. The top layer includes a mirror well therein and has a substantially flat top surface. The method and system further includes providing a laser including a light-emitting surface and providing a mirror optically coupled with the laser. The laser is coupled to the top surface of the top layer external to the mirror well. The mirror has a bottom surface and a reflective surface facing the light-emitting surface of the laser. A portion of the bottom surface of the mirror is affixed to the top surface of the top layer. A portion of the mirror resides in the mirror well.

Owner:WESTERN DIGITAL TECH INC

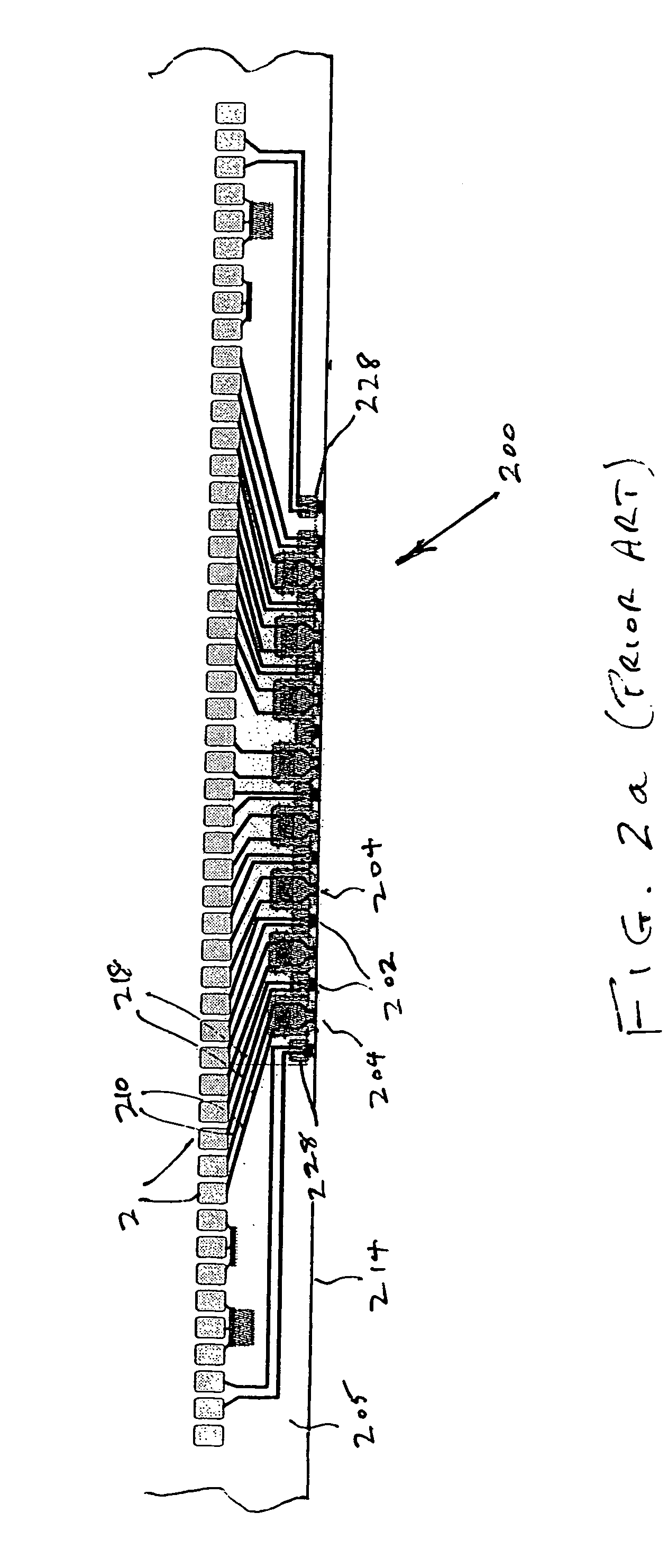

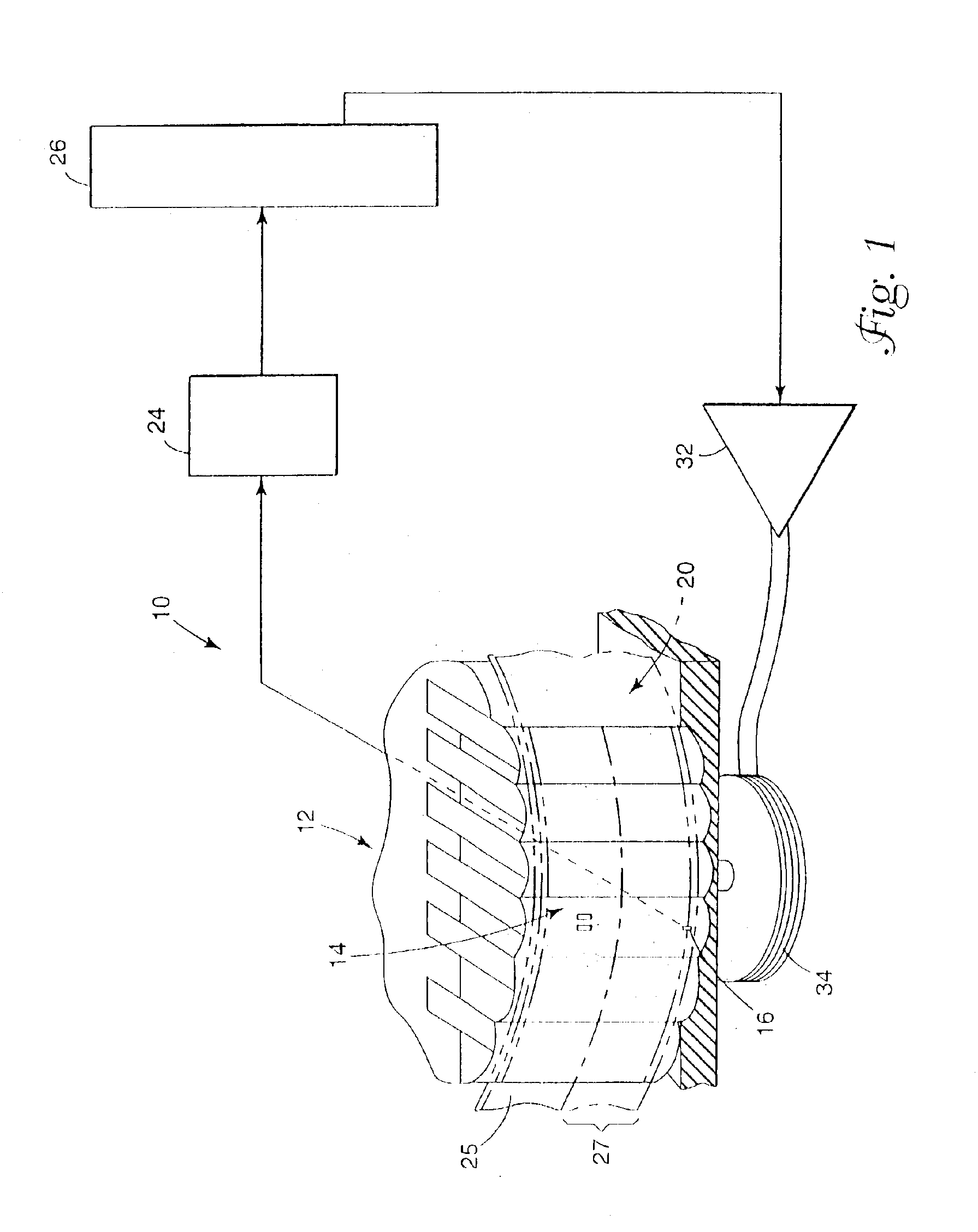

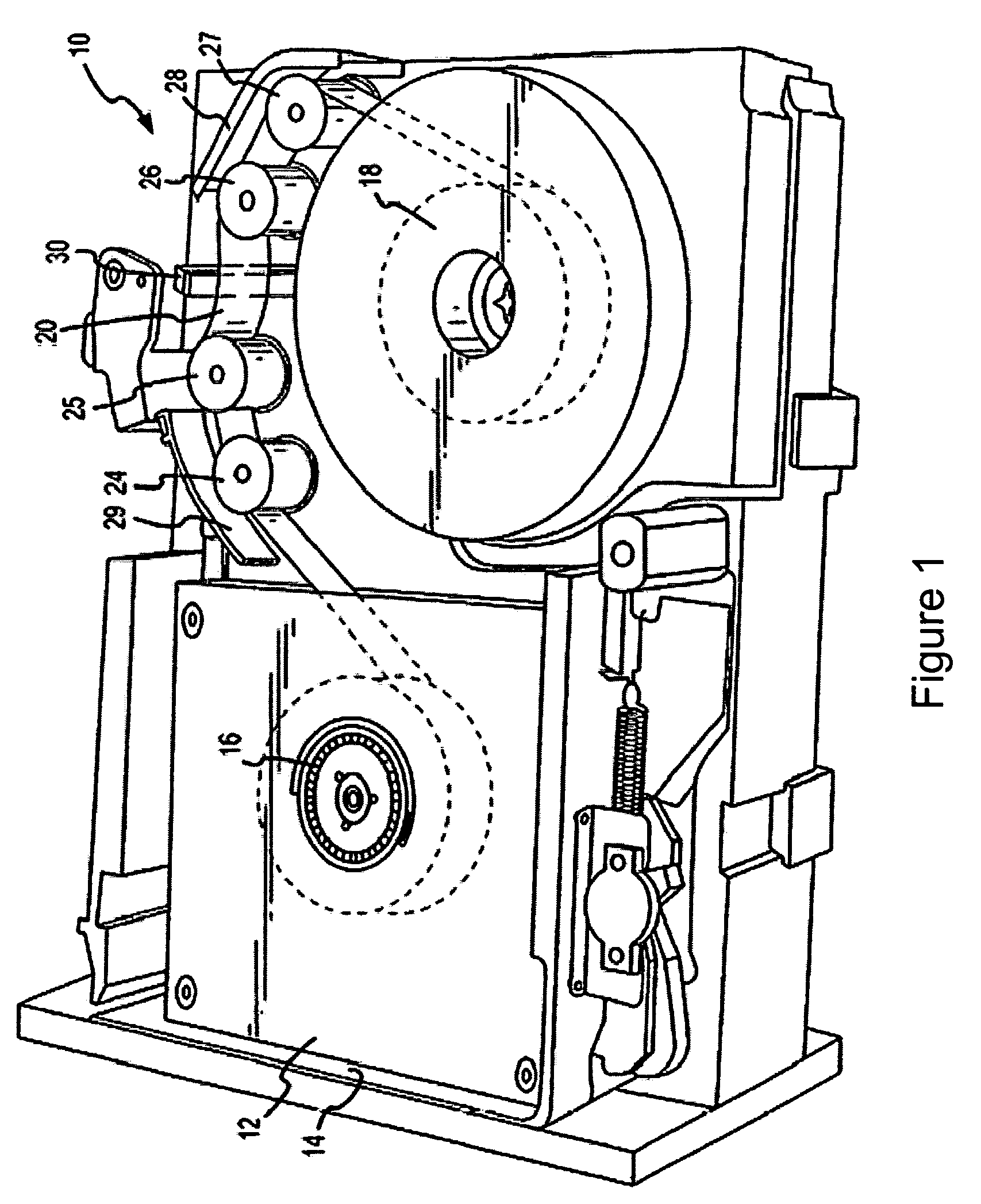

Filled-gap magnetic recording head and method of making

InactiveUS20060232883A1Reduce thicknessManufacture head surfaceManufacturing heads with multiple gapsMagnetic transducersInsulation layer

A filled-gap magnetic recording head is provided comprising a flat or cylindrical contour head having a row of magnetic transducers in a gap region disposed between a rowbar substrate and a closure. The gap region is intentionally recessed to have a predetermined recess profile below a tape support surface. An electrical insulation layer is deposited on the tape support surface and on the recess profile of the gap region. The insulation layer prevents electrical shorting between the magnetic transducers and other conductive elements in the gap due to accumulations of conductive debris from the magnetic recording tape. A method of making the filled-gap magnetic recording head by intentionally recessing the gap region, cleaning the recessed profile and depositing an insulator layer is provided.

Owner:IBM CORP

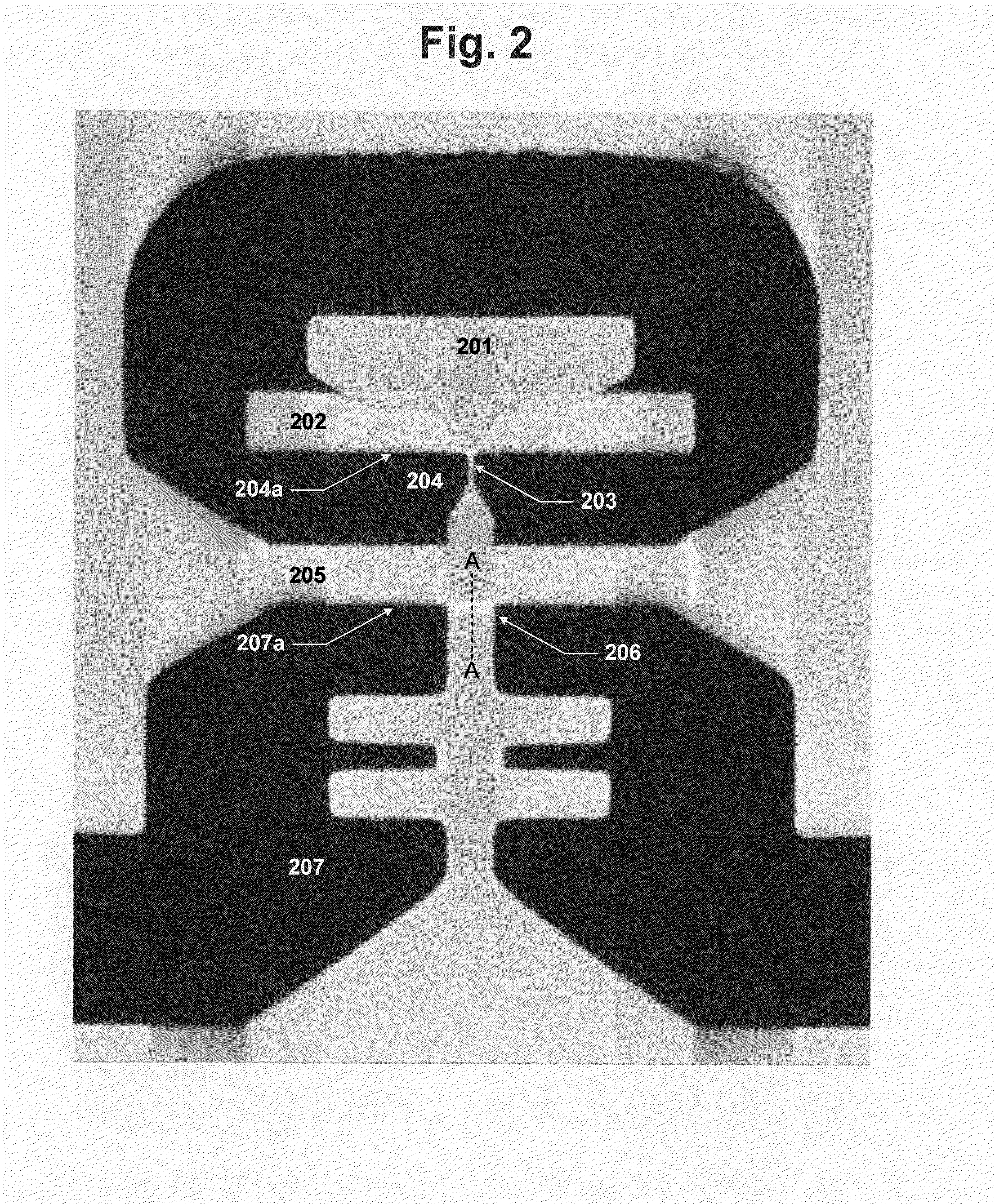

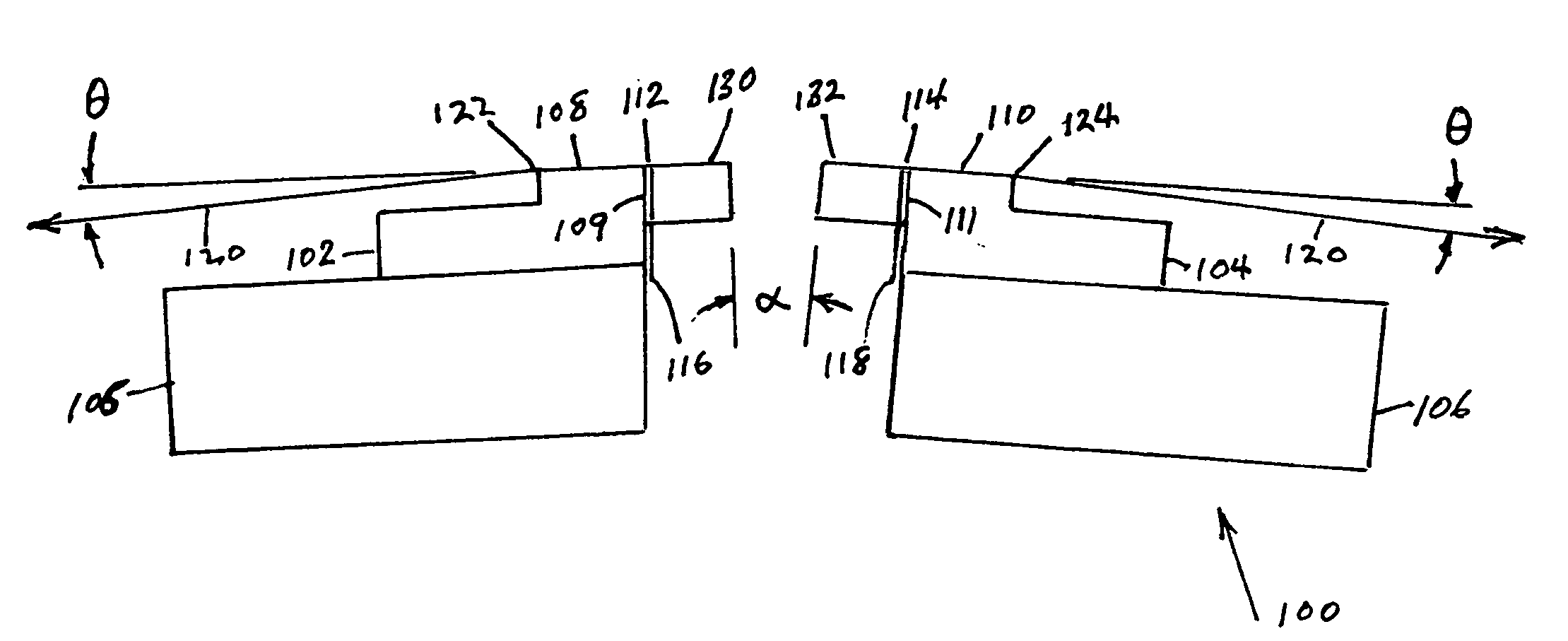

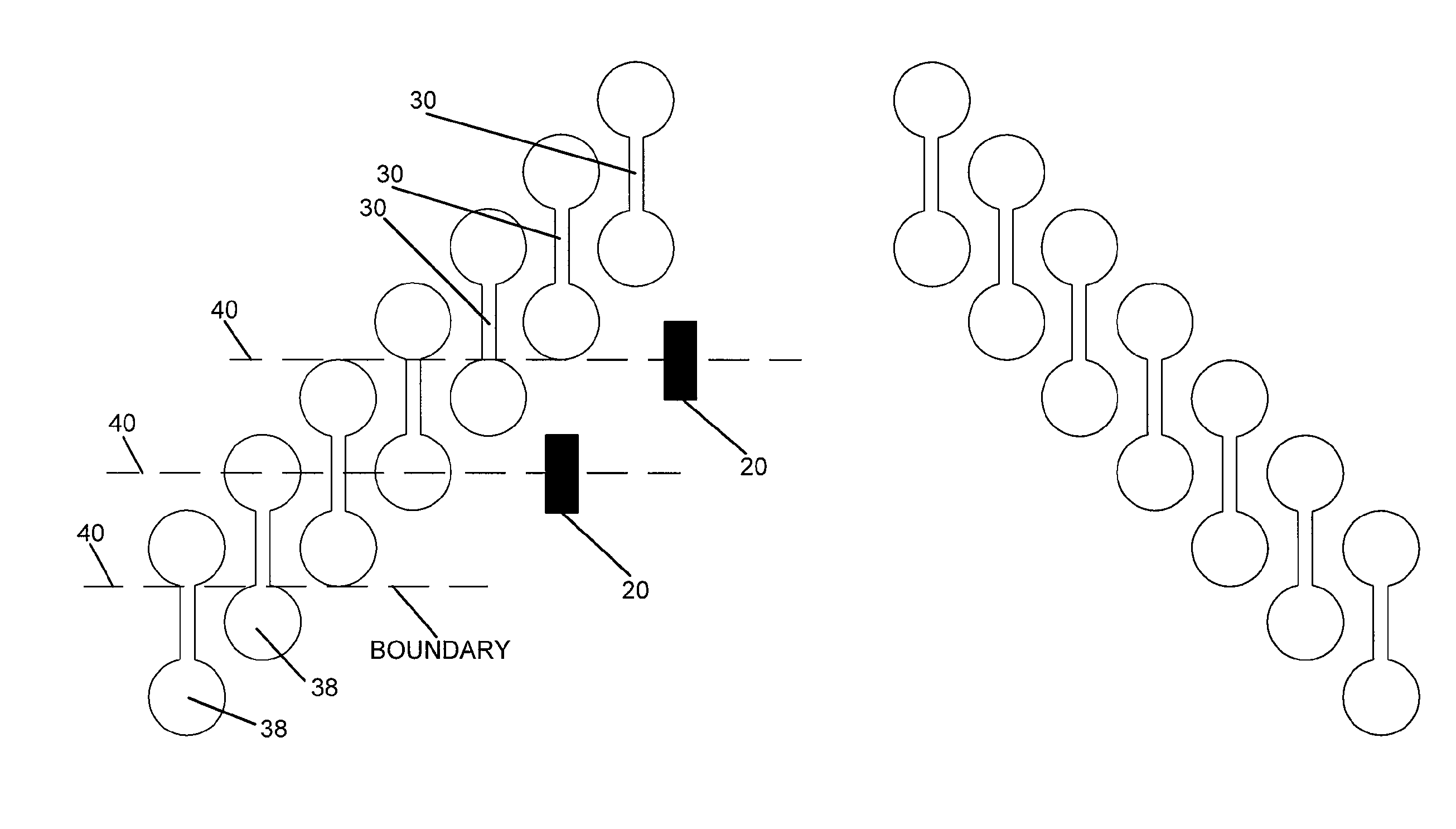

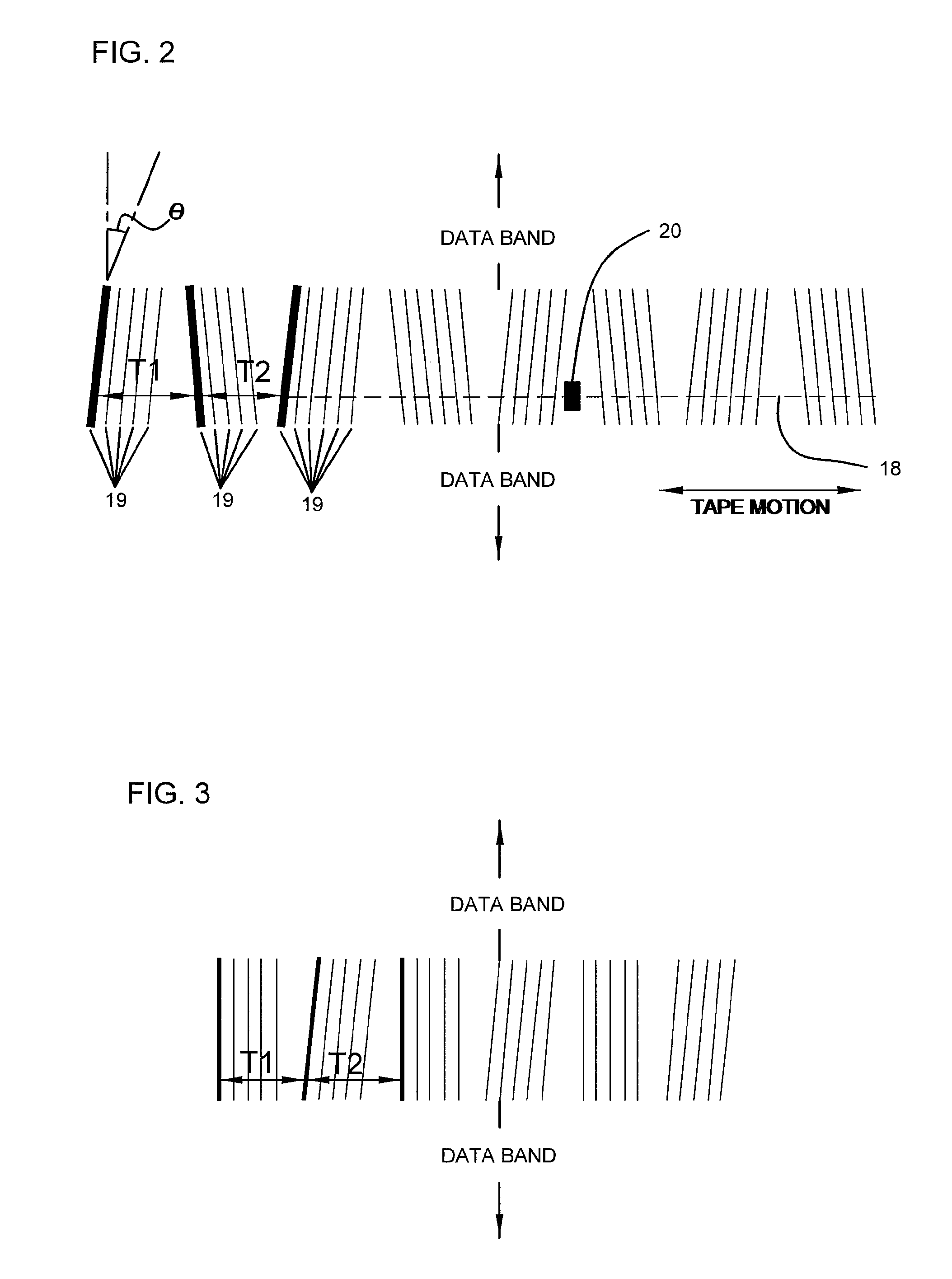

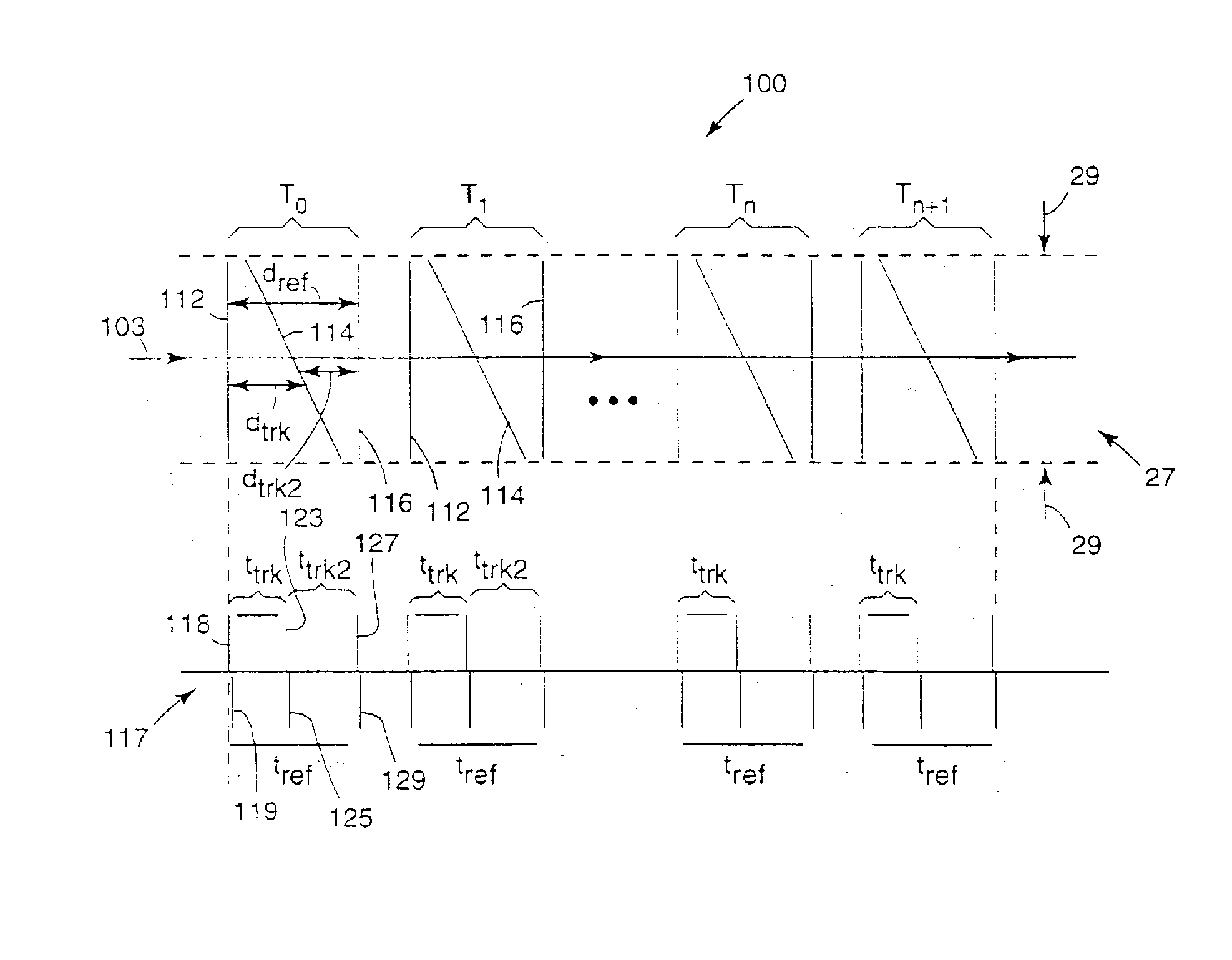

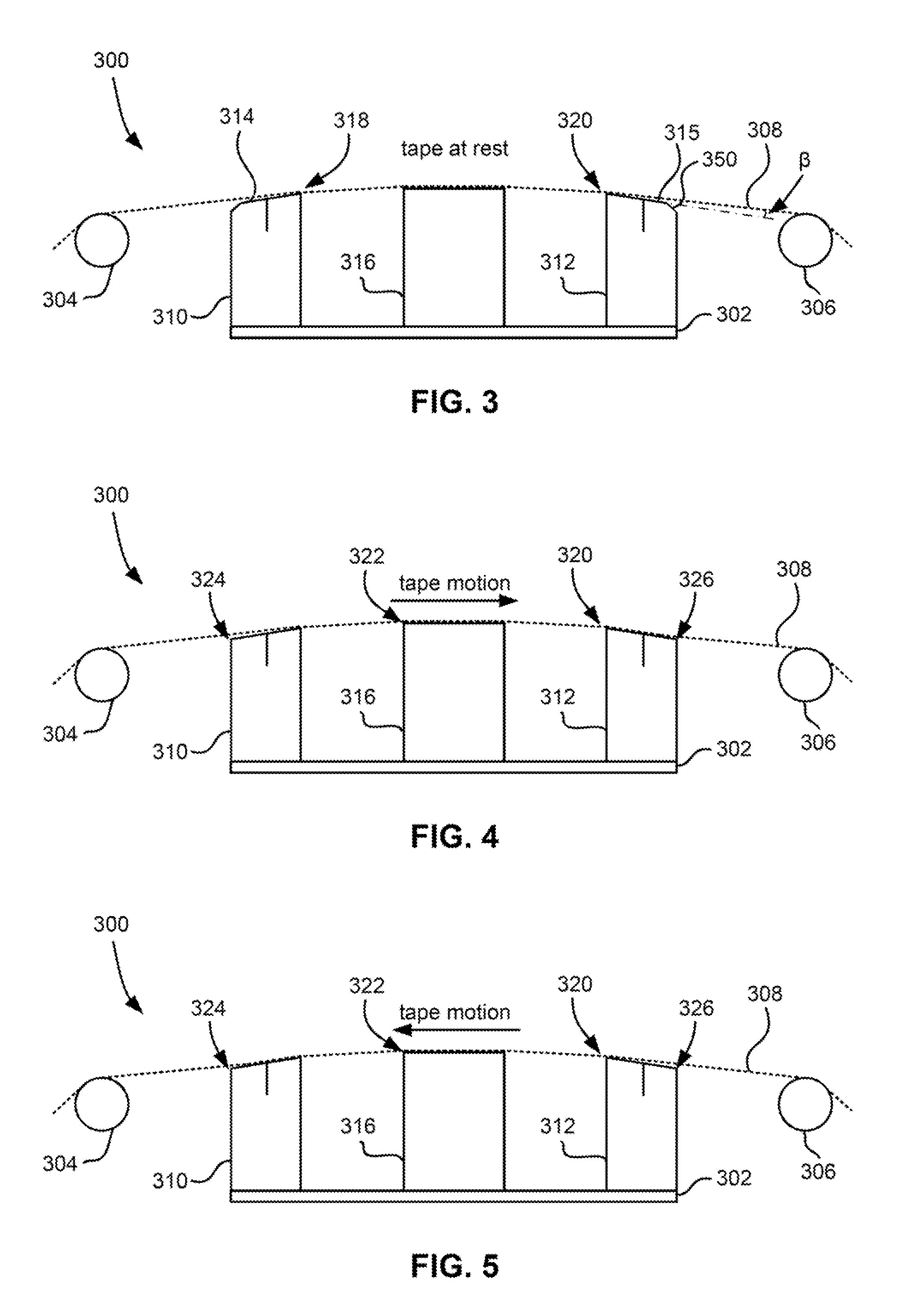

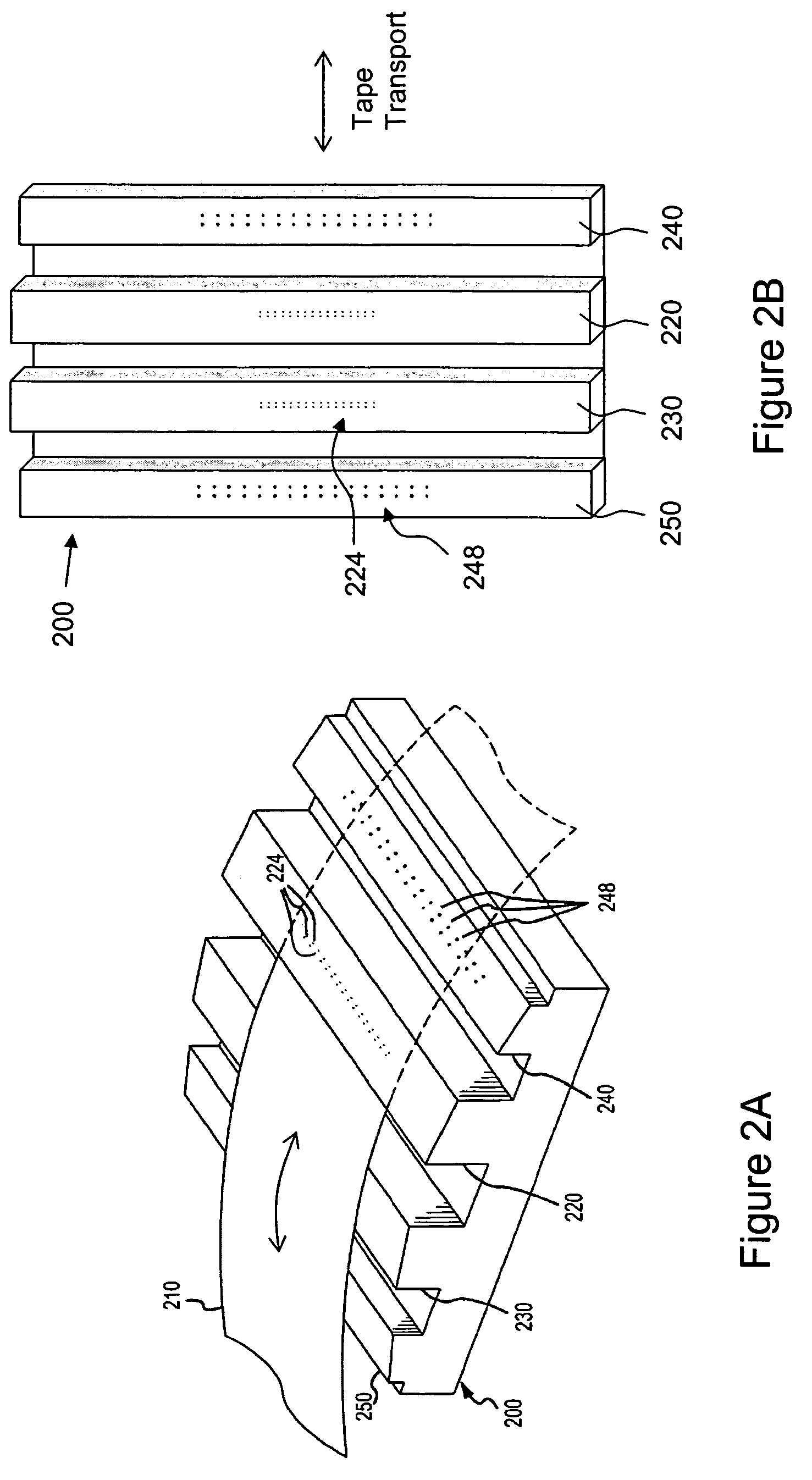

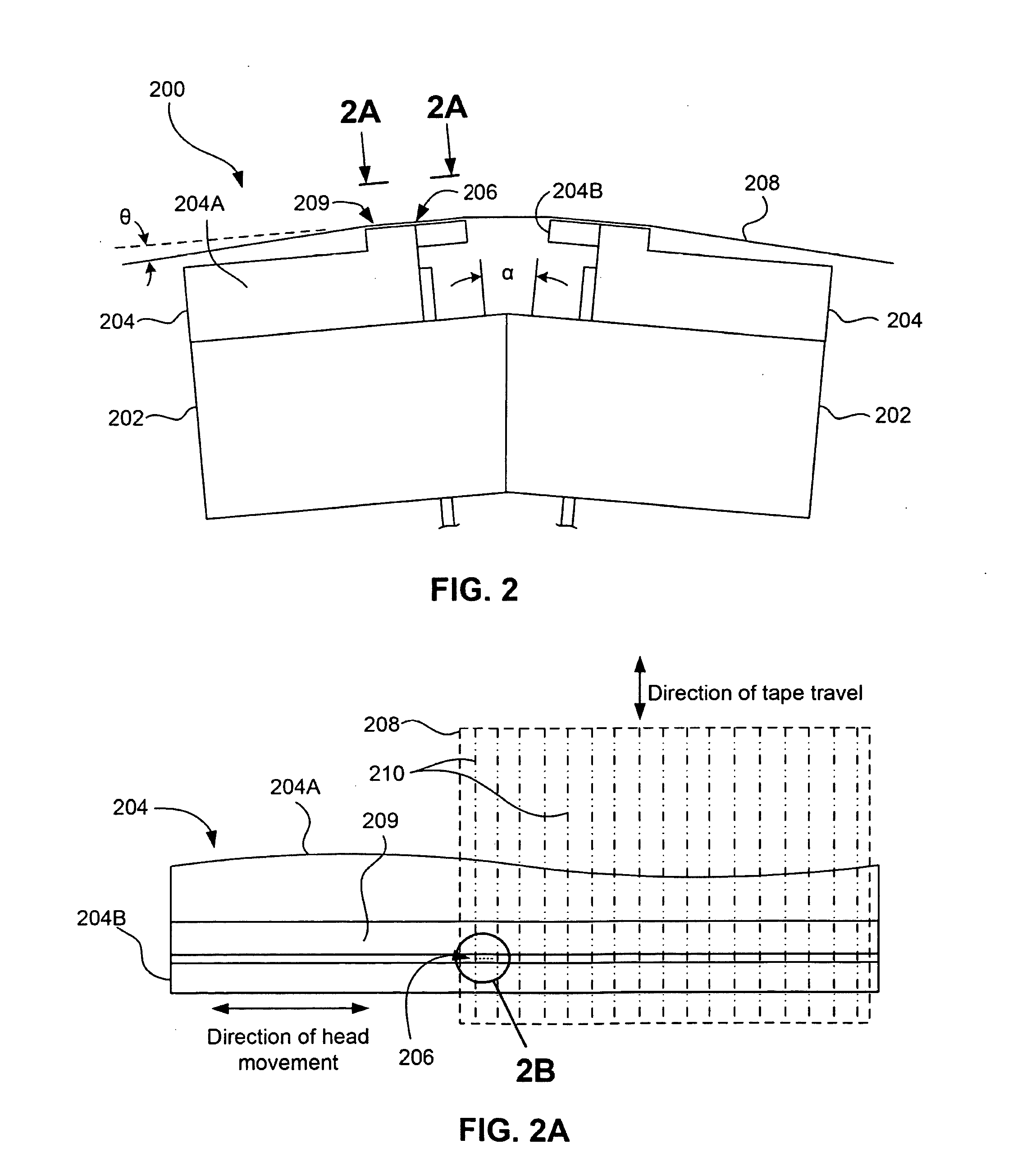

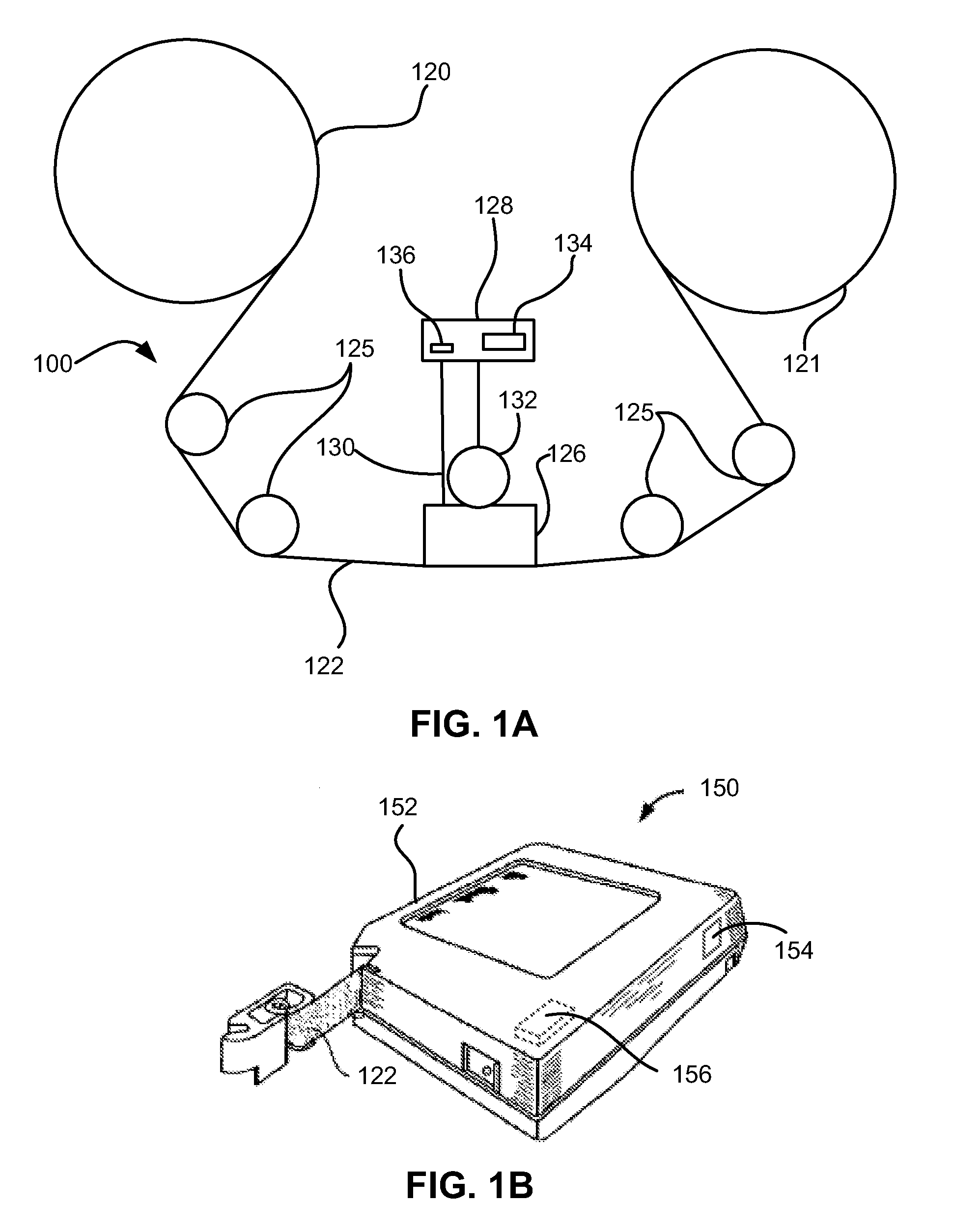

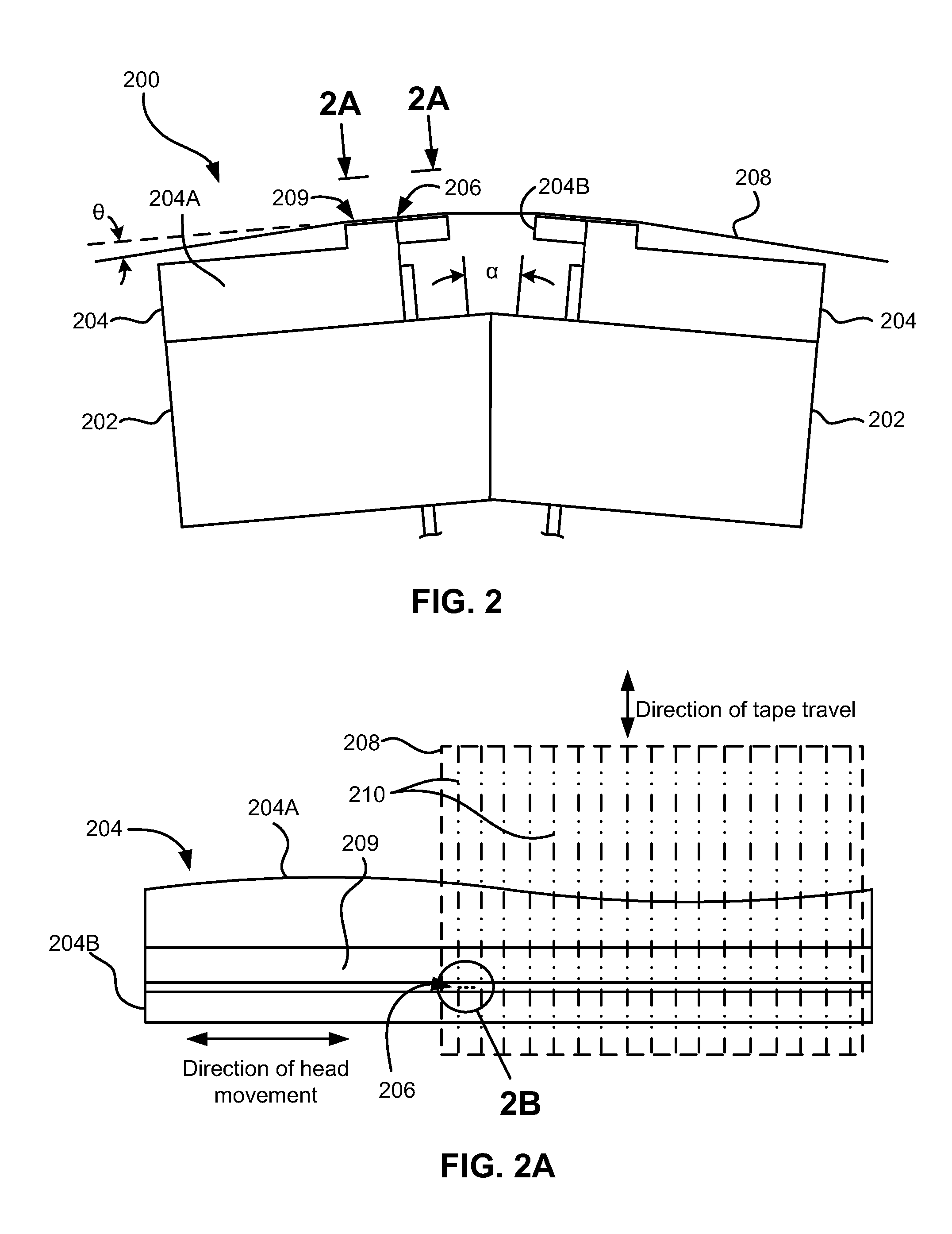

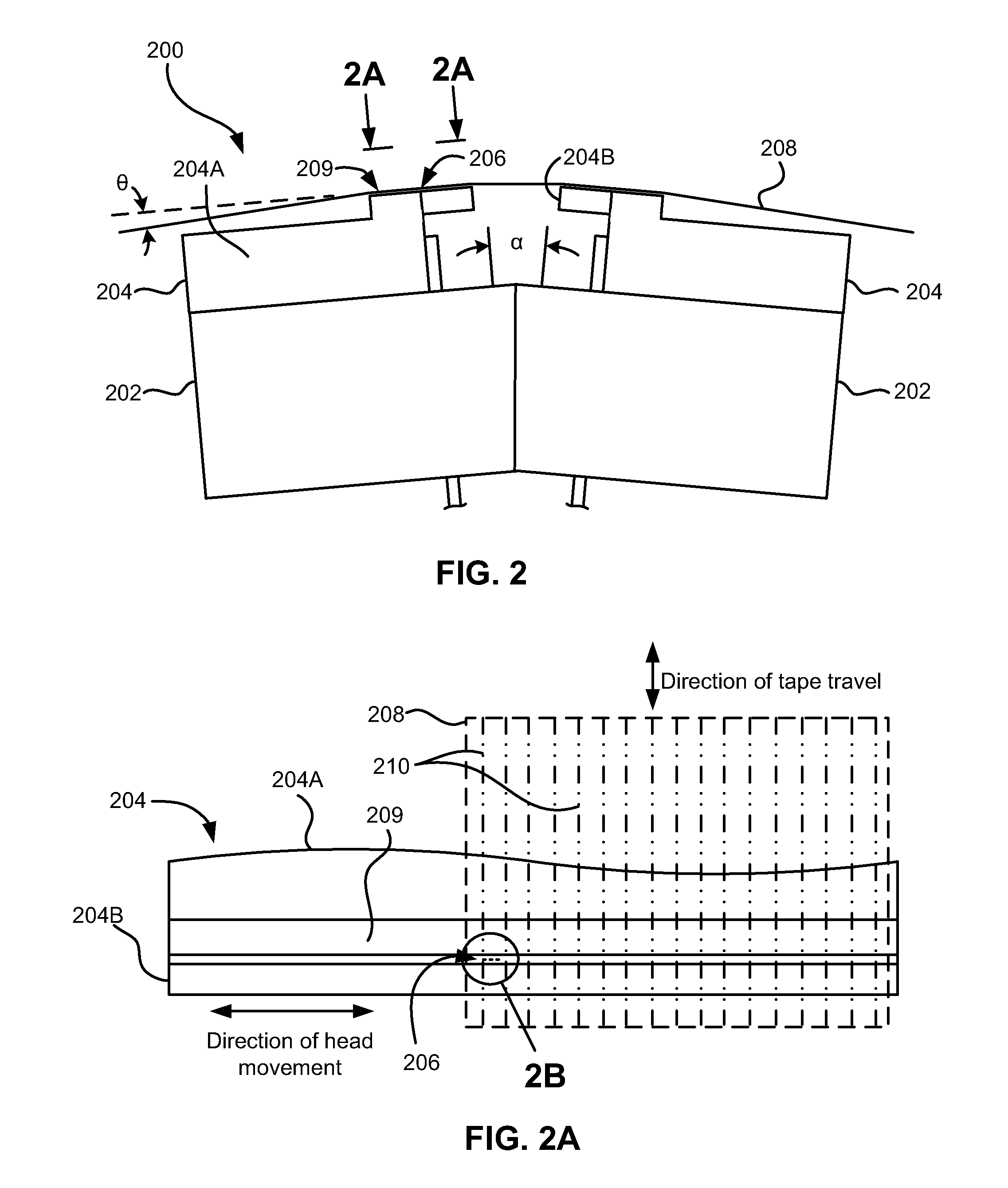

Stepped time based servo pattern and head

InactiveUS7511907B2Driving/moving recording headsManufacturing heads with multiple gapsGraphicsMagnetic tape

The present invention relates to apparatuses and methods used in manufacturing magnetic tape. More specifically, the present invention relates to a method of writing a servo pattern on magnetic tape so as to minimize errors in the servo pattern, the heads used to write such servo data, and the magnetic tape manufactured with such heads. Errors in the servo pattern may be minimized by synthesizing the slanted transitions in a time based servo pattern using servo write gaps that are perpendicular to the tape motion. In so minimizing errors, distortion in the reading and / or writing of the data tracks can be prevented.

Owner:ADVANCED RES

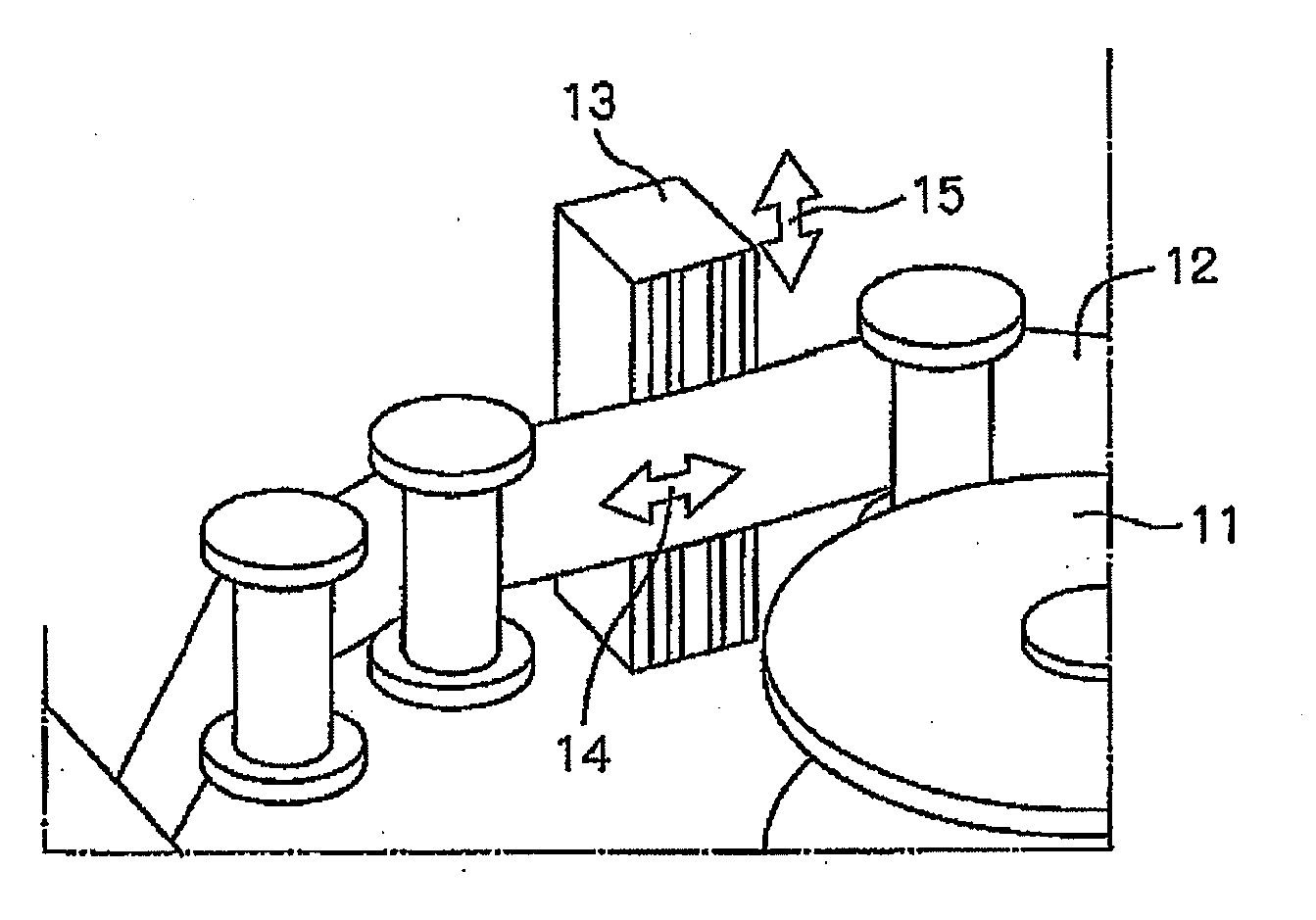

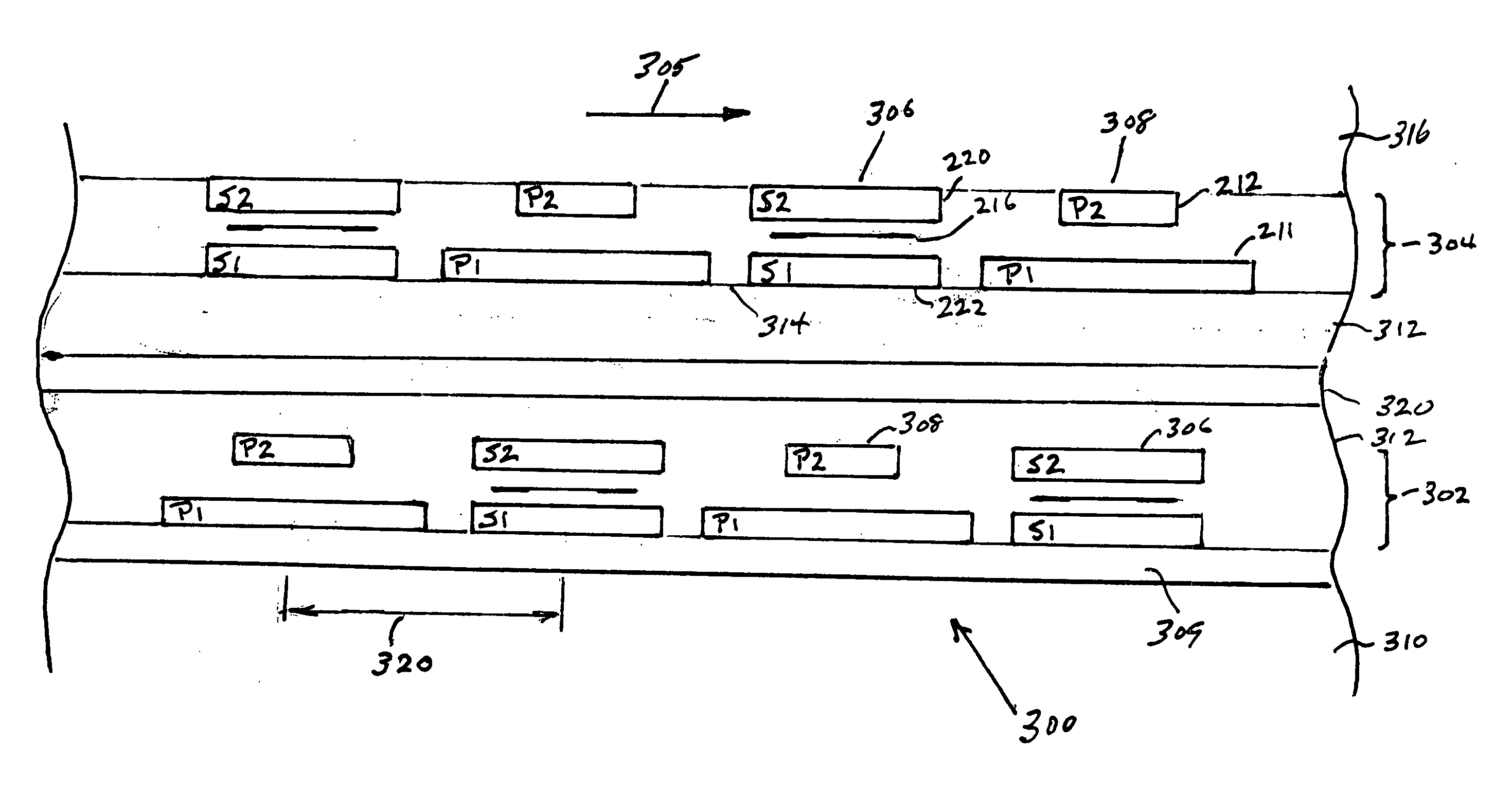

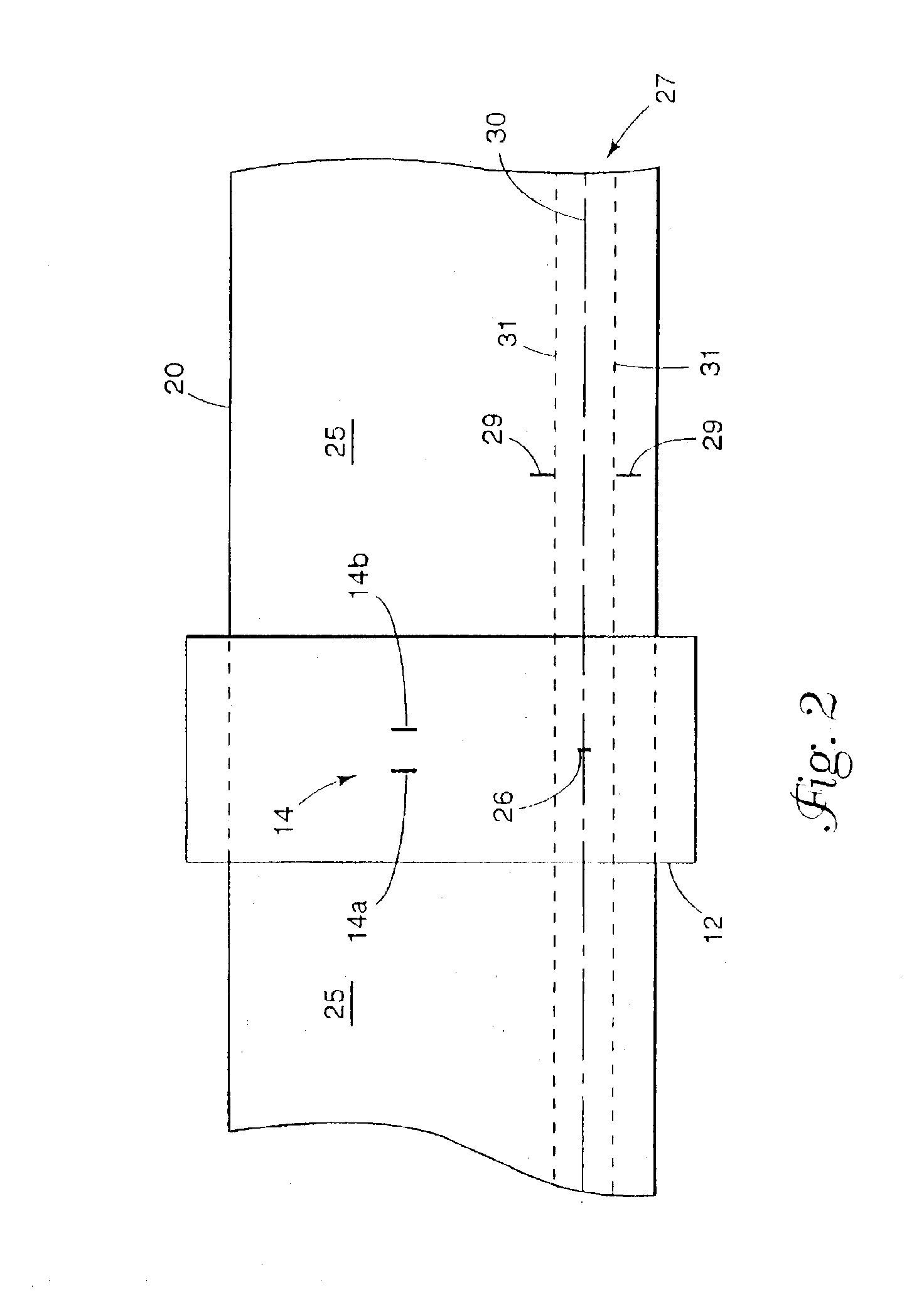

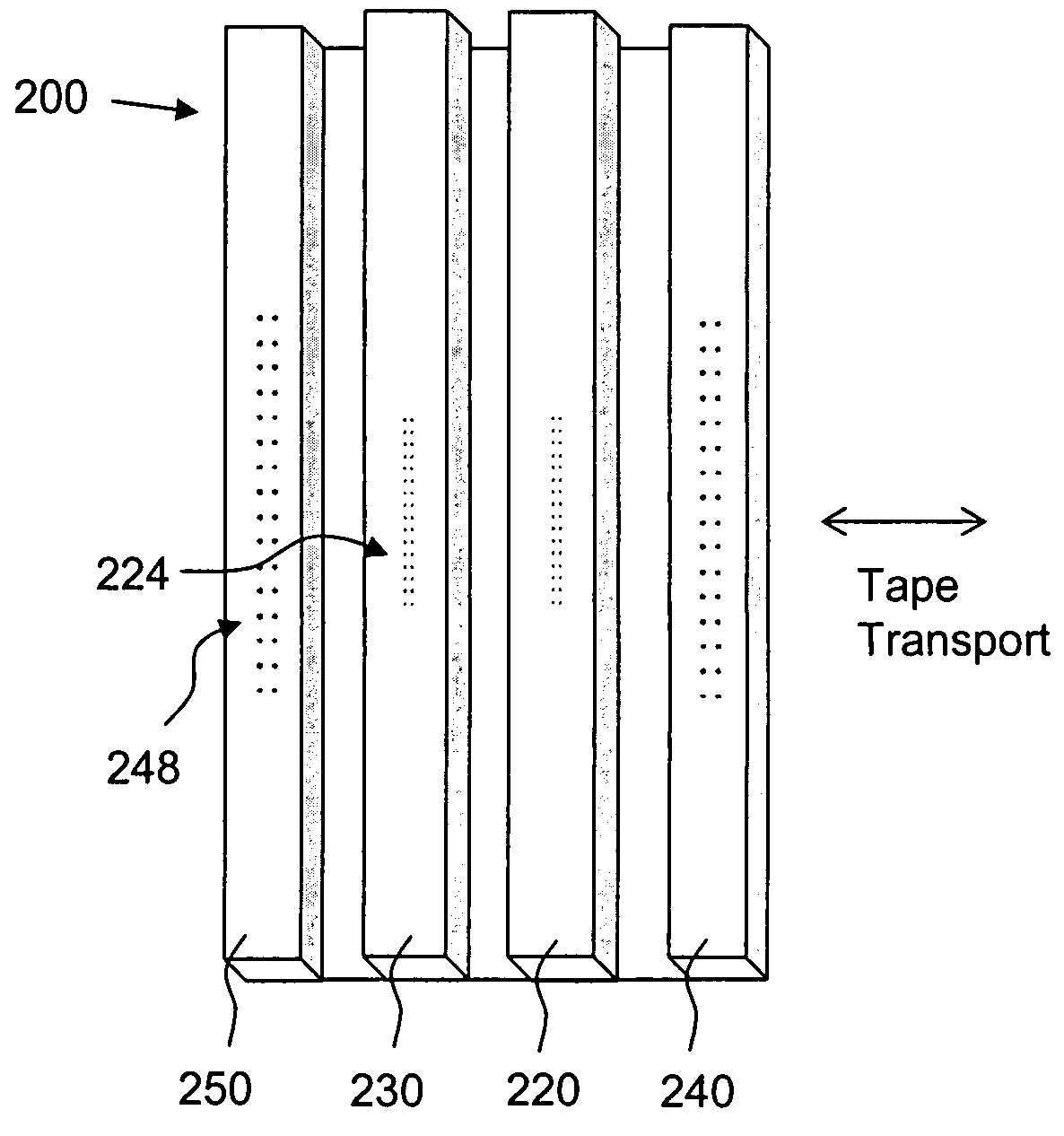

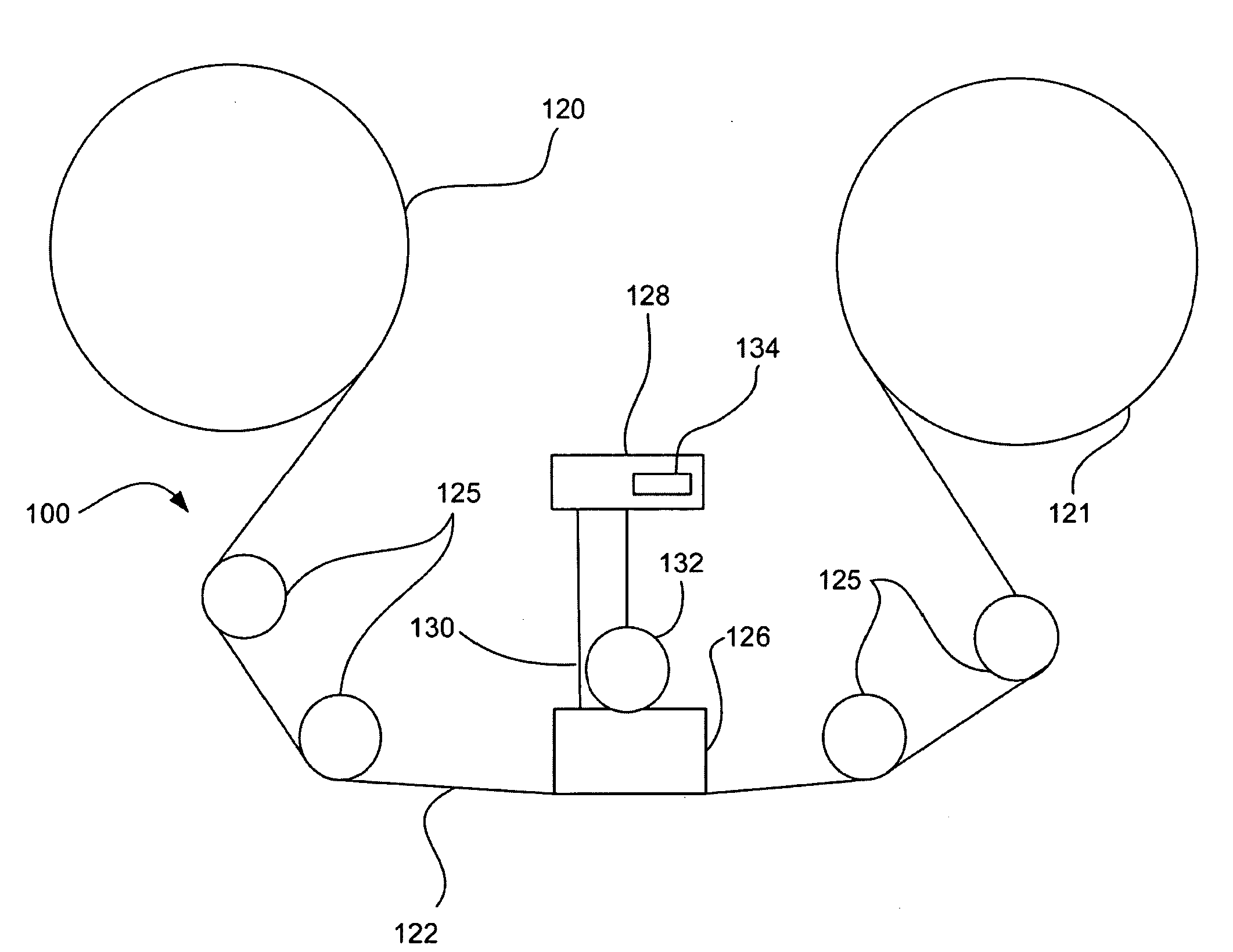

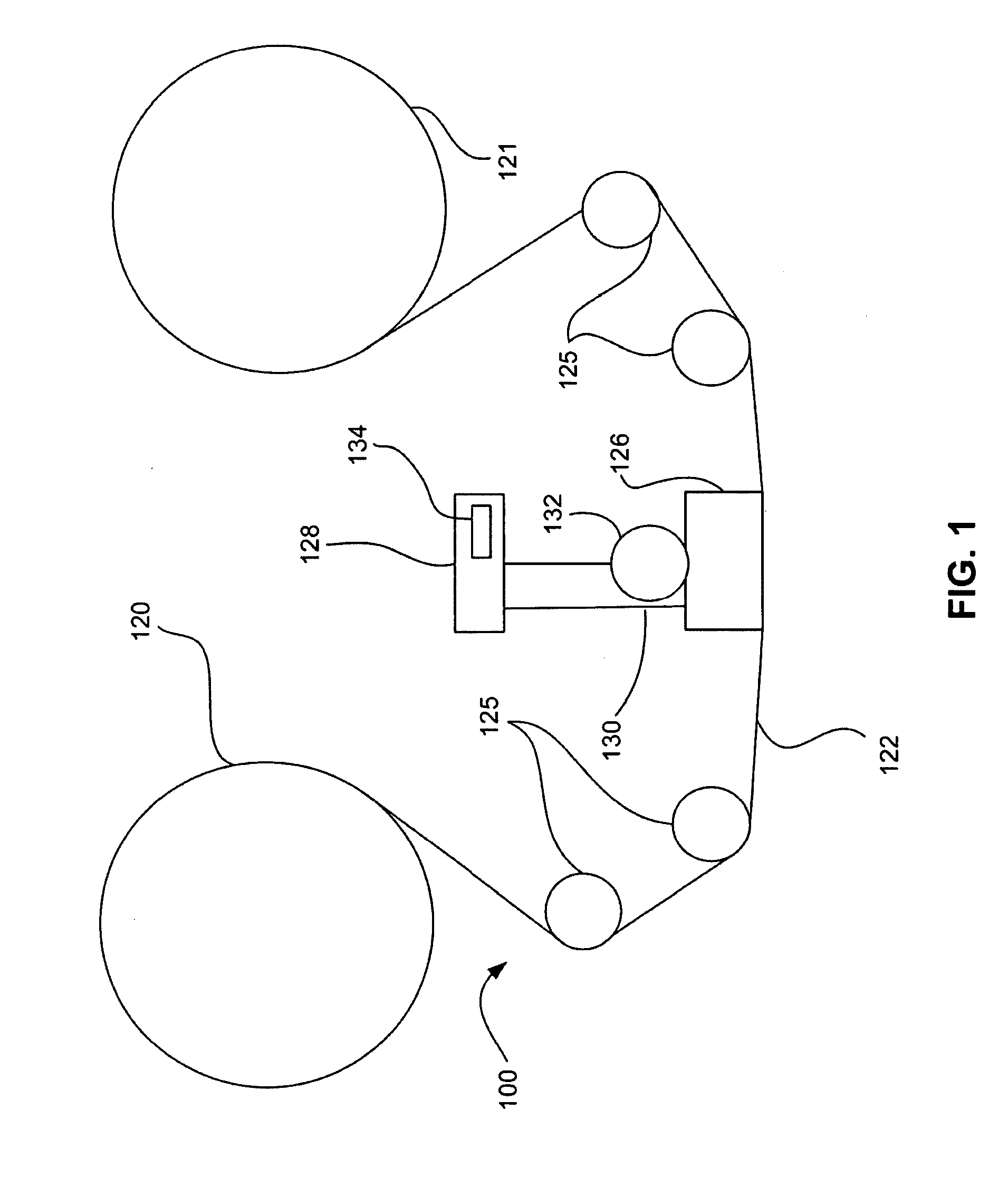

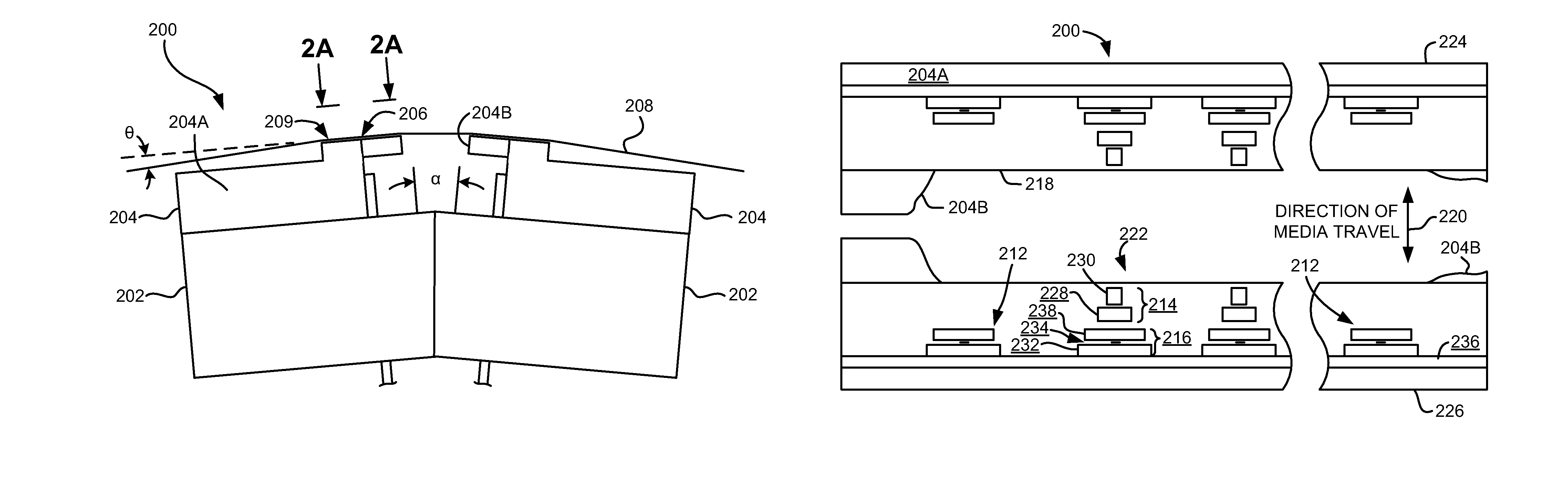

Tape recording head with multiple planes of transducer arrays

InactiveUS20060039082A1Manufacturing heads with multiple gapsManufacture unitary devices of plural headsLinear motionMagnetic tape

A tape recording head is provided comprising a multiple plane transducer row having a plurality of planes of transducer arrays fabricated on a substrate and which may be staggered or offset relative to one another in a direction perpendicular to the direction of linear motion of the recording tape over the recording head. The multiple plane recording head provides a significant advantage over a head having a single transducer plane by allowing simultaneous reading (or writing) of data tracks on a magnetic recording tape that are more closely spaced apart with respect to one another than the spacing of the read (or write) transducers in a single plane.

Owner:IBM CORP

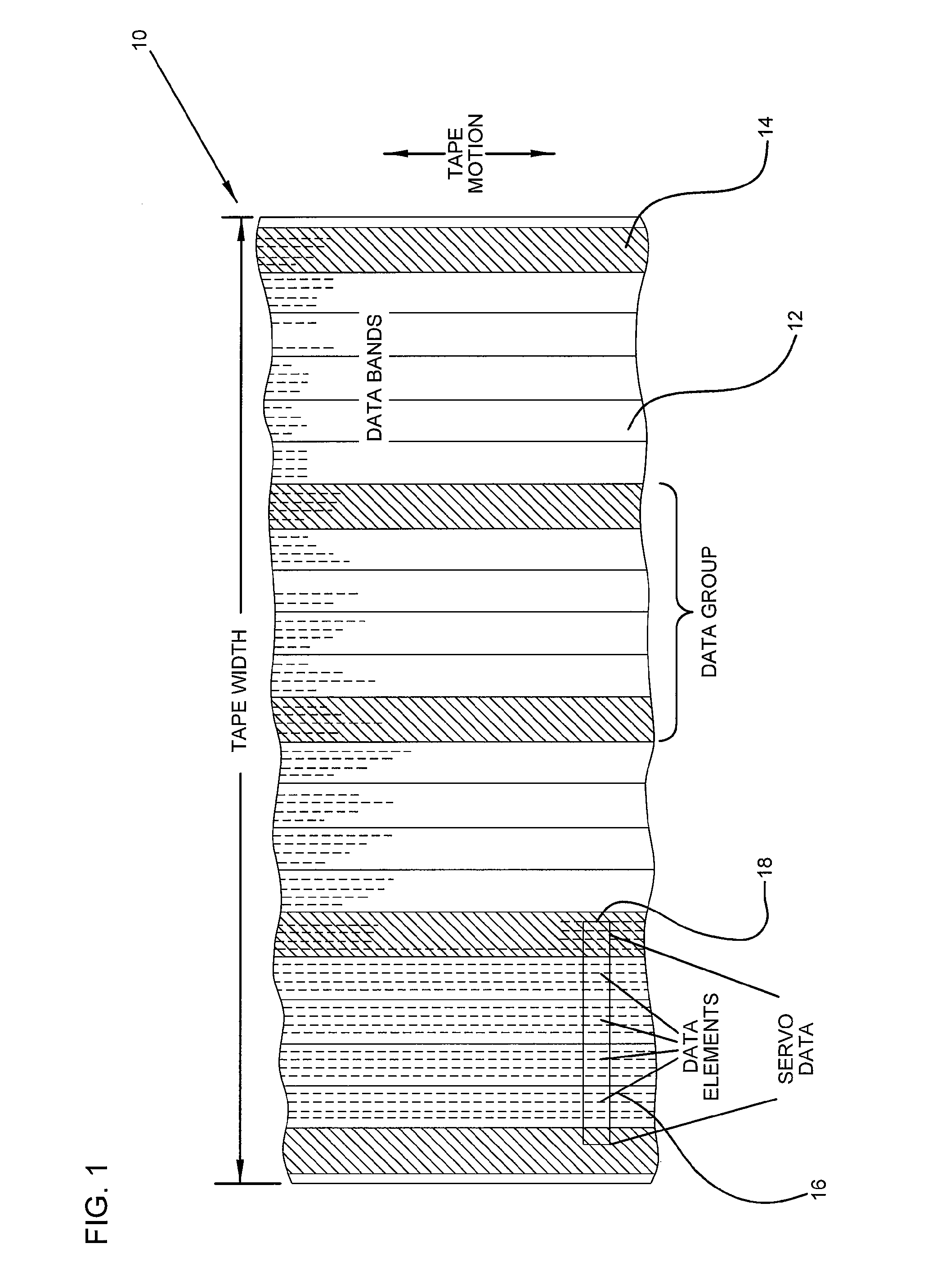

Time-based servo for magnetic storage media

InactiveUS6842305B2Driving/moving recording headsManufacturing heads with multiple gapsMagnetic storageReference patterns

A servo track configuration includes at least one servo track having a width. A servo pattern is repeatedly recorded in the at least one servo track. Repeatedly recording the servo pattern includes repeating the simultaneous recording of first and second reference pattern lines and a track pattern line in the at least one servo track. Each of the first and second reference pattern lines has an identical predetermined geometry and extends across the width of the at least one servo track. Further, the track pattern line has a predetermined geometry that is different than the predetermined geometry of the first and second reference pattern lines and extends across the width of the at least one servo track.

Owner:IMATION

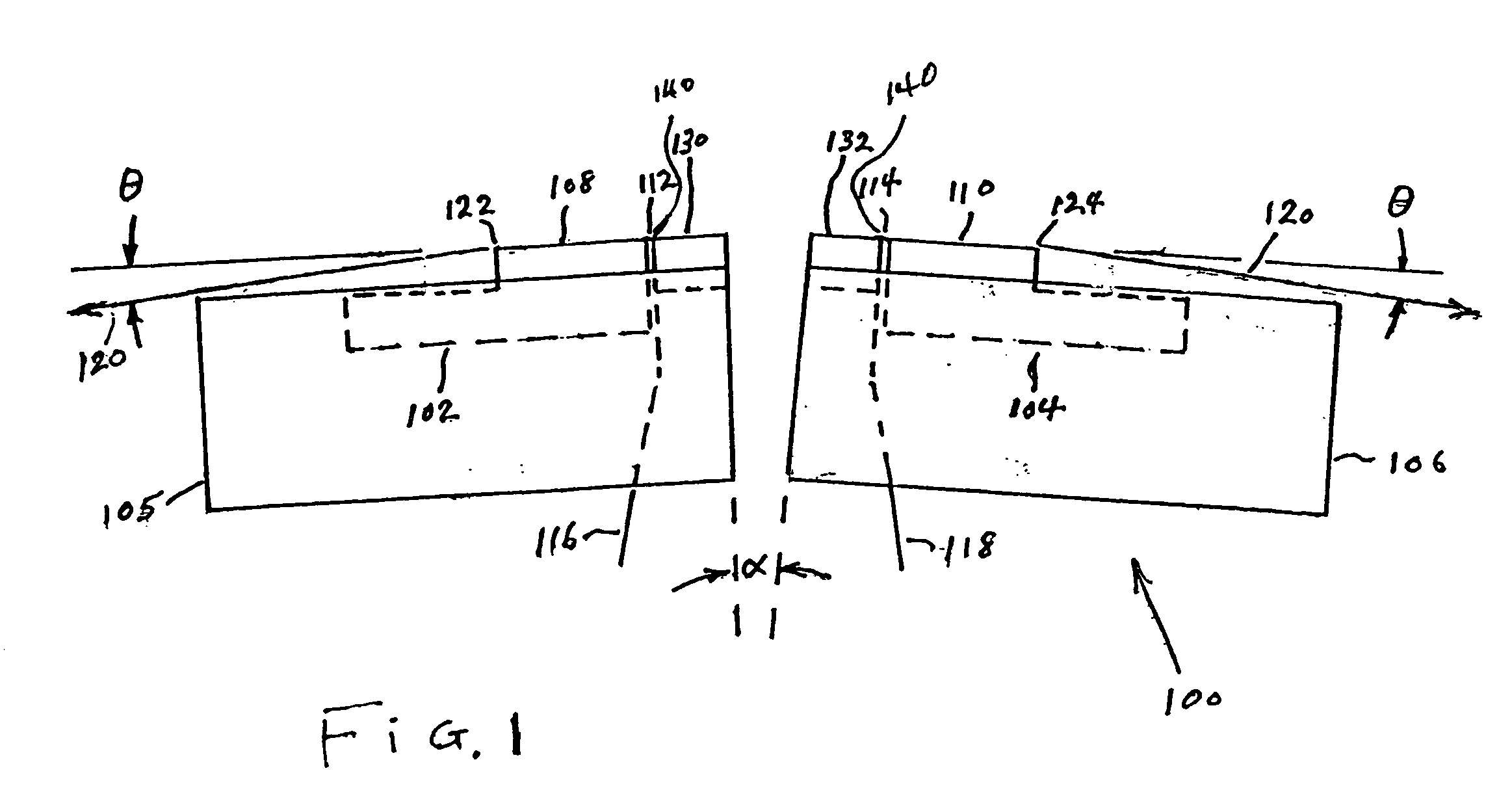

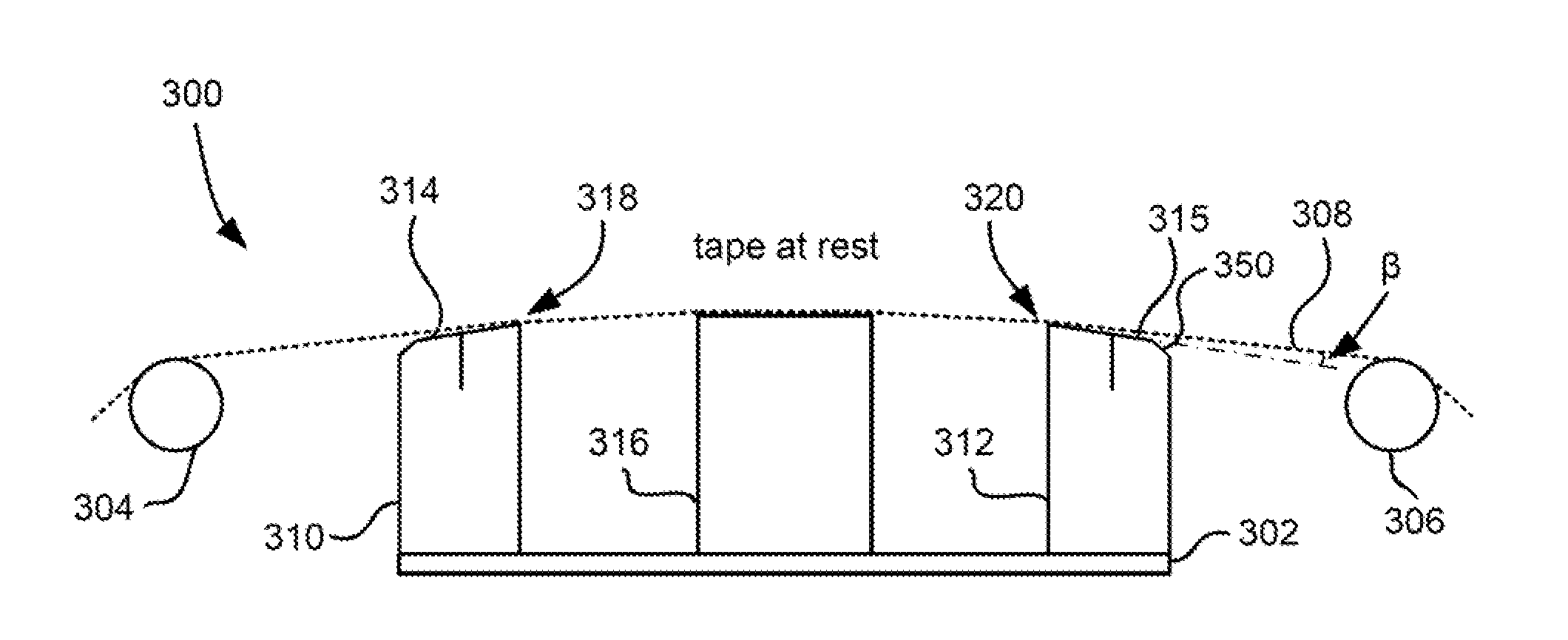

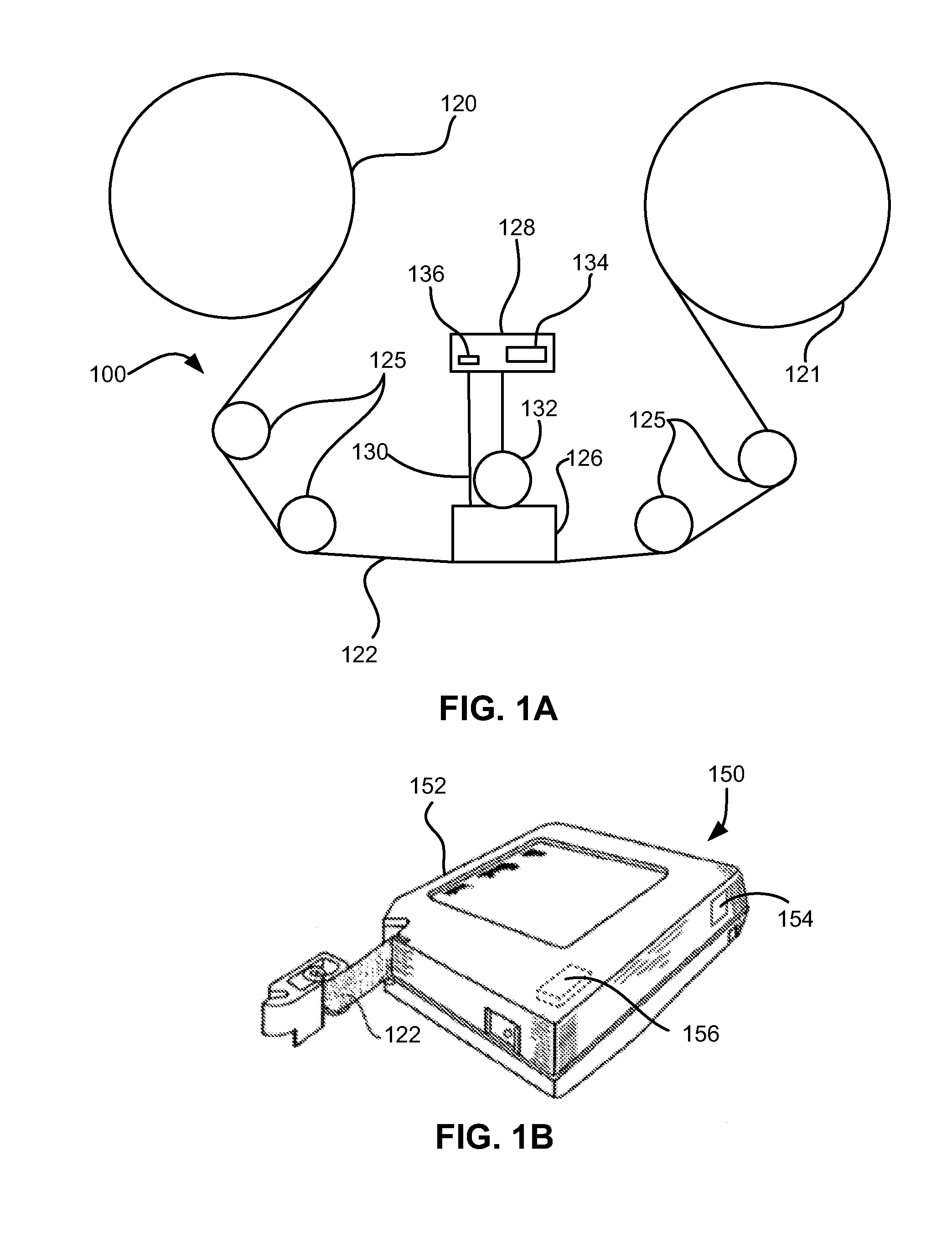

Low friction tape head and system implementing same

InactiveUS20120008234A1Manufacture head surfaceManufacturing heads with multiple gapsMagnetic mediaMechanical engineering

A magnetic data storage system according to one embodiment includes a magnetic head; and guides on opposite sides of the magnetic head for directing a magnetic medium over the magnetic head. The magnetic head includes: outer portions each having a tape bearing surface and an array of transducers selected from a group consisting of readers and writers; and a central portion positioned between the outer portions, the central portion having a tape bearing surface and an array of transducers selected from a group consisting of readers and writers. An inner edge of each of the tape bearing surfaces of the outer portions is adapted for skiving air from the magnetic medium when the magnetic medium travels in a direction from the central portion towards the respective outer portion. The guides are oriented to direct the magnetic medium to fly over a leading one of the outer portions, engage a leading edge of the tape bearing surface of the central portion, and engage an inner edge of the tape bearing surface of a trailing one of the outer portions.

Owner:IBM CORP

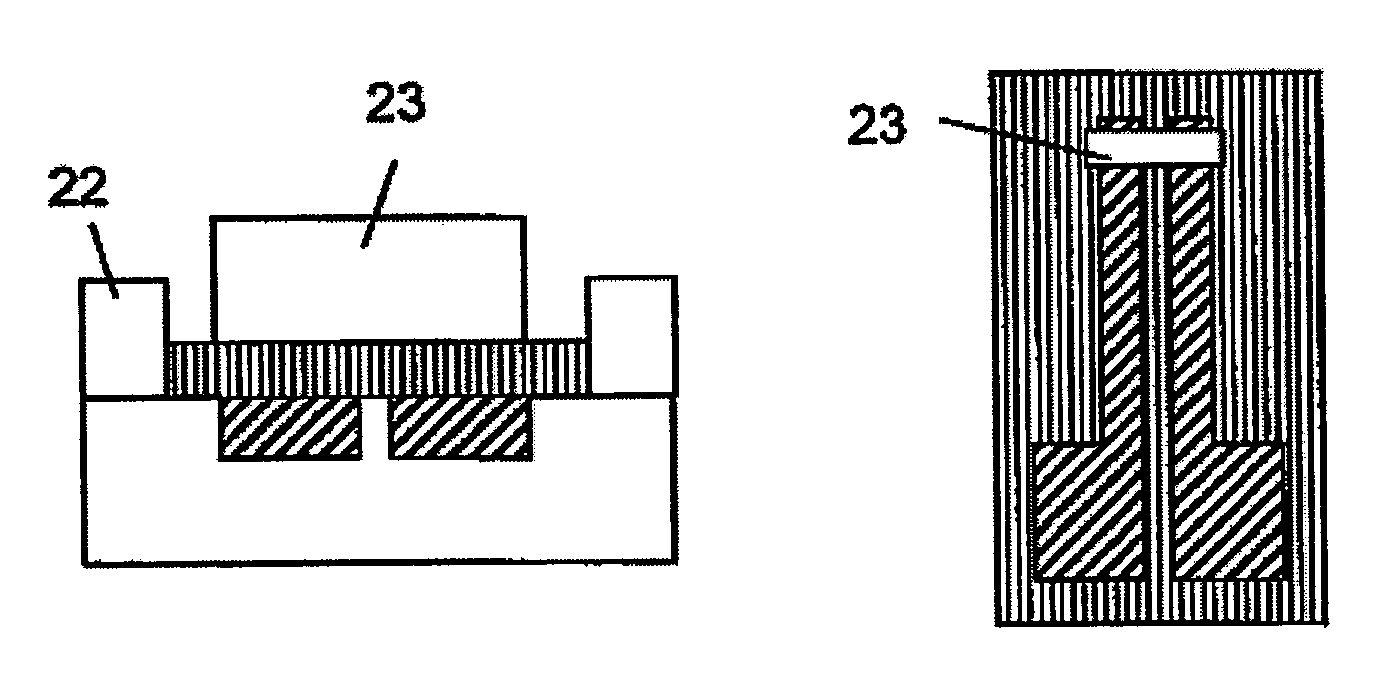

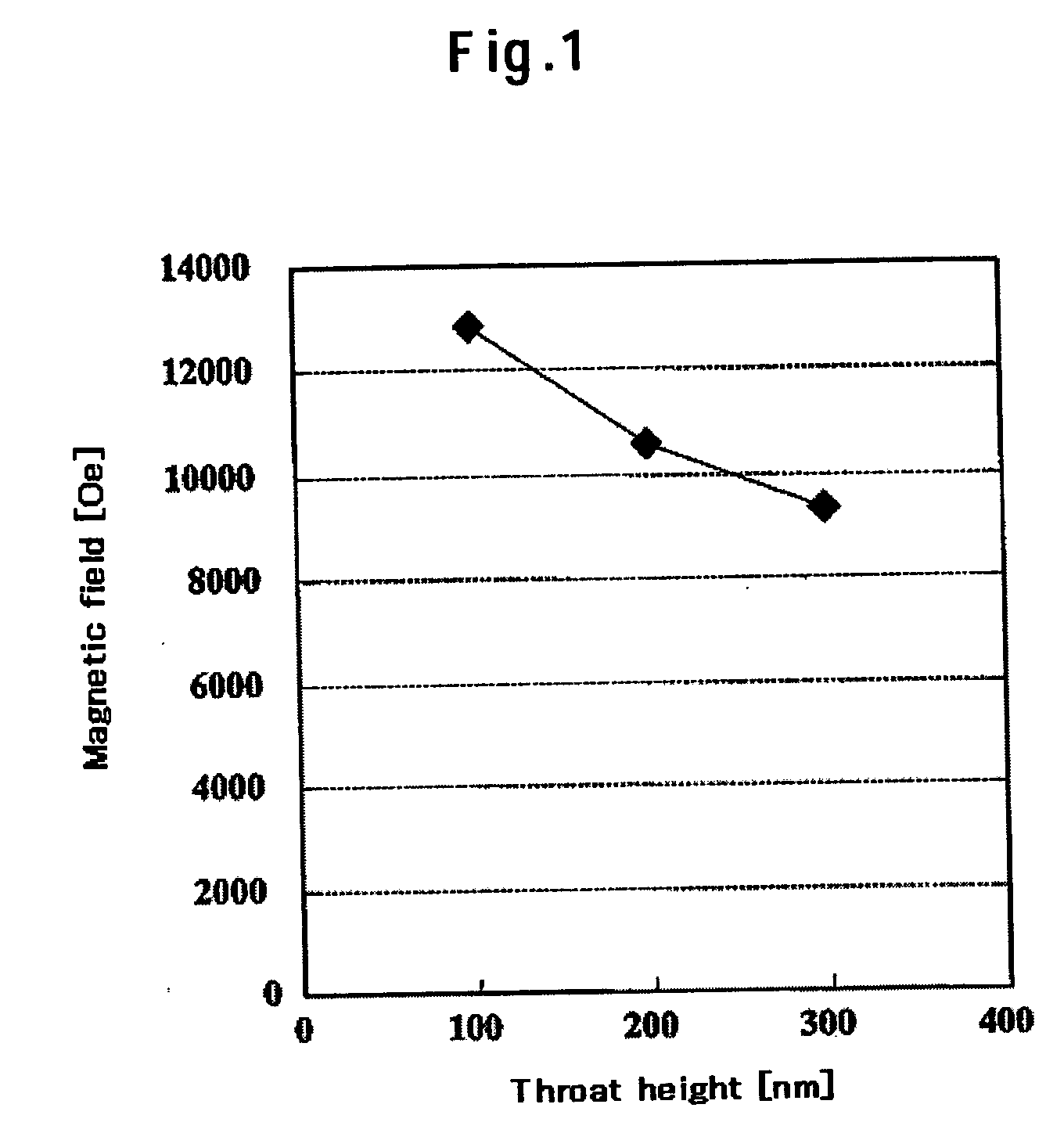

Magnetic head with electro lapping guide and manufacturing method

InactiveUS20060028770A1Throat heightImprove accuracyElectrical transducersManufacturing heads with multiple gapsElectronElectroplating

Embodiments of the invention reduce the throat height of a single pole type head with high accuracy. In one embodiment, a head with an electro lapping guide for controlling a write head's throat height during air bearing surface processing is made. Air bearing surface processing is performed using the electro lapping guide. For a read head, processing is performed using the read head itself or an electro lapping guide for the read head so that both the throat height of write head and the element height of read head are controlled.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Multi-format thinfilm head and associated methods

InactiveUS7154691B2Filamentary/web carriers operation controlManufacture head surfaceMagnetic tapeTransducer

Owner:QUANTUM CORP

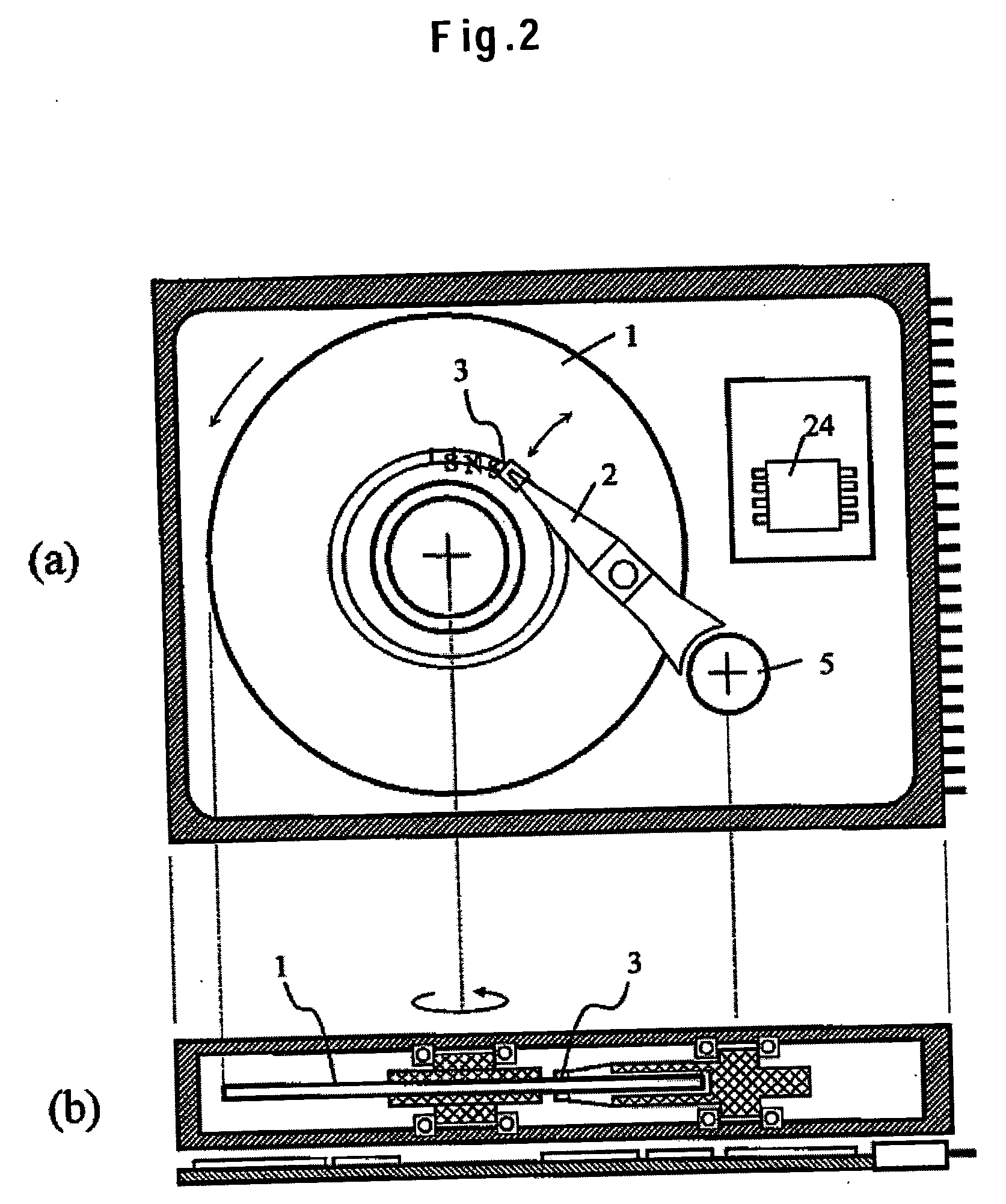

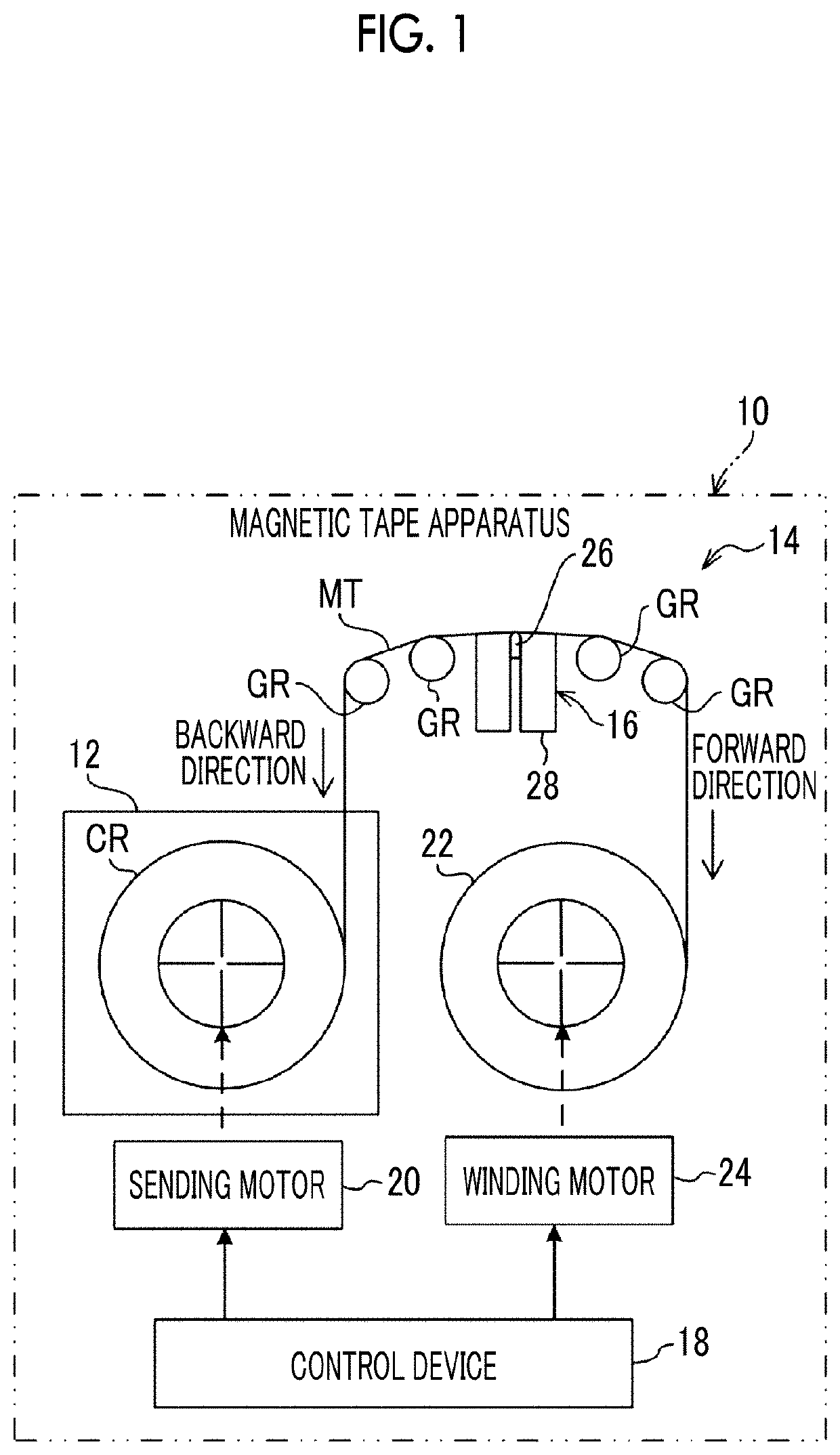

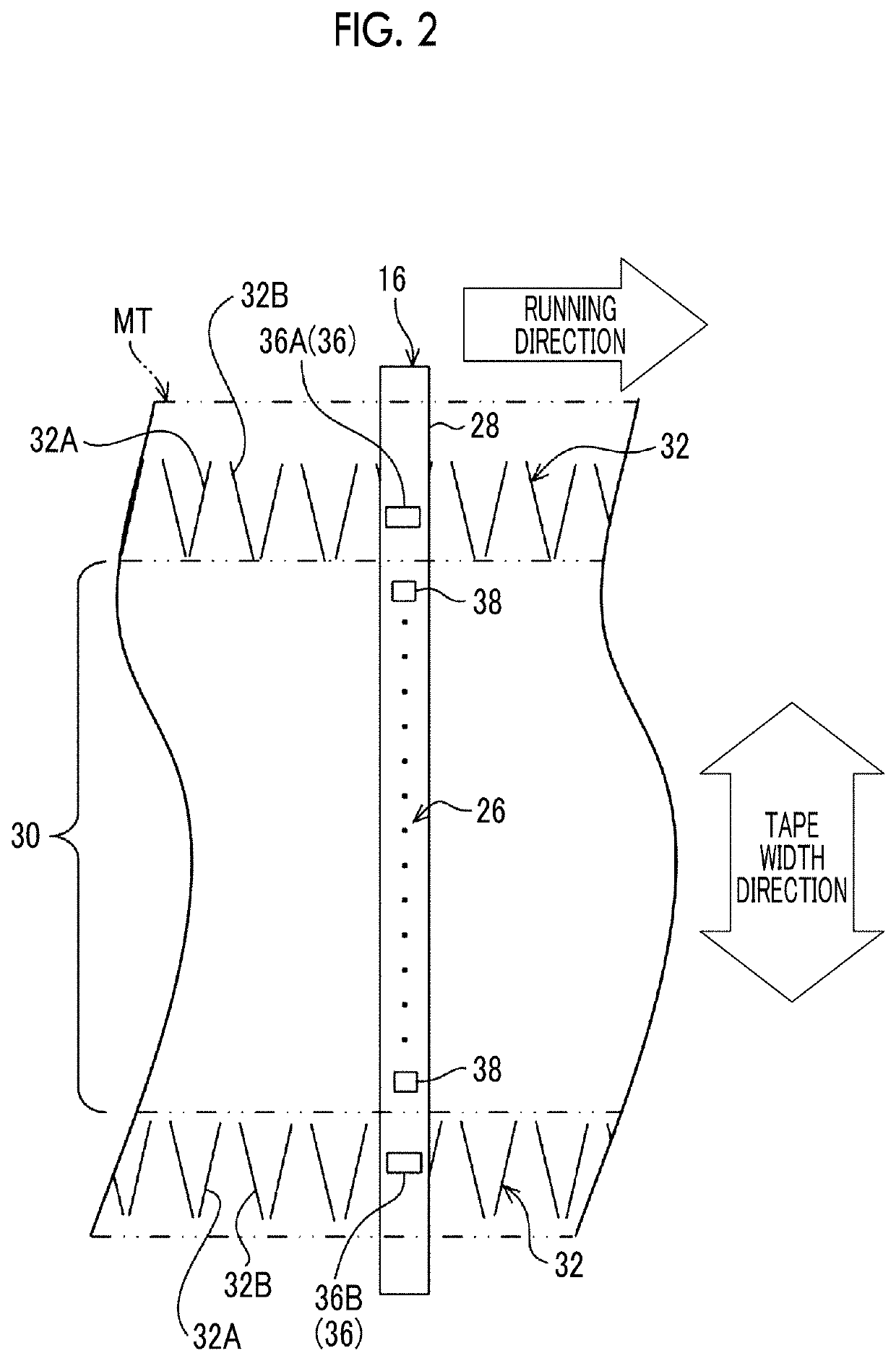

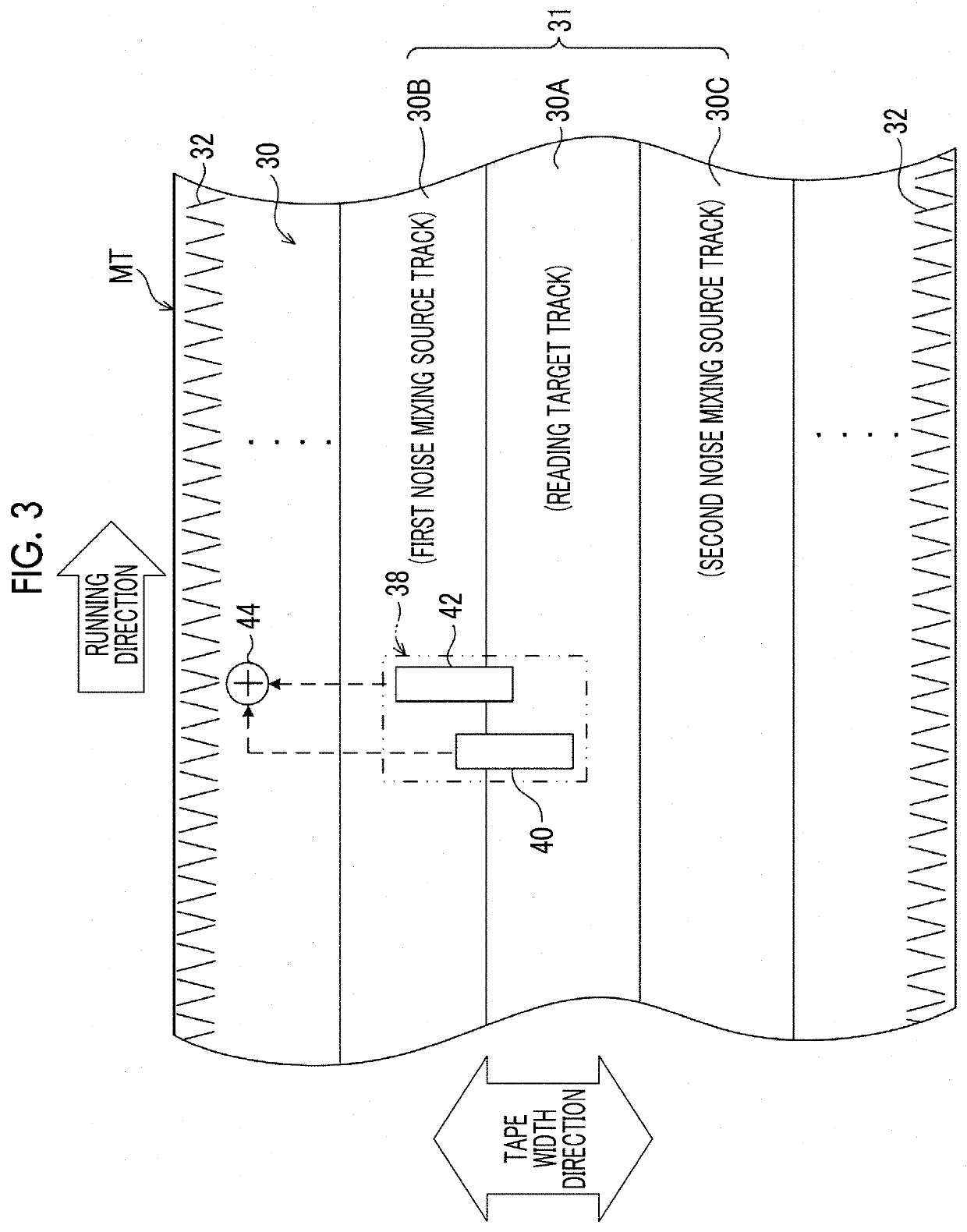

Magnetic tape apparatus

ActiveUS20200005827A1High reproduction qualityPromote reproductionManufacture unitary devices of plural headsRecord information storageMagnetic tapeComputational physics

A magnetic tape apparatus includes a magnetic tape, a reading element unit and an extraction unit, in which a coefficient of friction measured regarding a base portion of a surface of the magnetic layer is equal to or smaller than 0.35, the reading element unit includes a plurality of reading elements each of which reads data by a linear scanning method from a specific track region including a reading target track in a track region included in the magnetic tape, and the extraction unit performs a waveform equalization process according to a deviation amount between positions of the magnetic tape and the reading element unit, with respect to each reading result for each reading element, to extract data derived from the reading target track from the reading result.

Owner:FUJIFILM CORP

Head for tape drive with transversely varying contour

InactiveUS20090231757A1Big spaceManufacture head surfaceManufacturing heads with multiple gapsMagnetic tapeTransducer

A system comprises a head having a tape bearing surface and an array of transducers in the tape bearing surface, the transducers being selected from a group consisting of readers, writers and servo readers, a length of the array being defined between outer transducers thereof, the head having a feature that induces formation of a larger spacing between a tape and portions of the tape bearing surface positioned laterally to the array in a direction about perpendicular to a direction of tape travel thereacross than between the tape and a contiguous portion of the tape bearing surface wherein the feature has a continuous length that is at least as long as the plurality of transducers, wherein the feature has a continuous length that is at least as long as the plurality of transducers.

Owner:IBM CORP

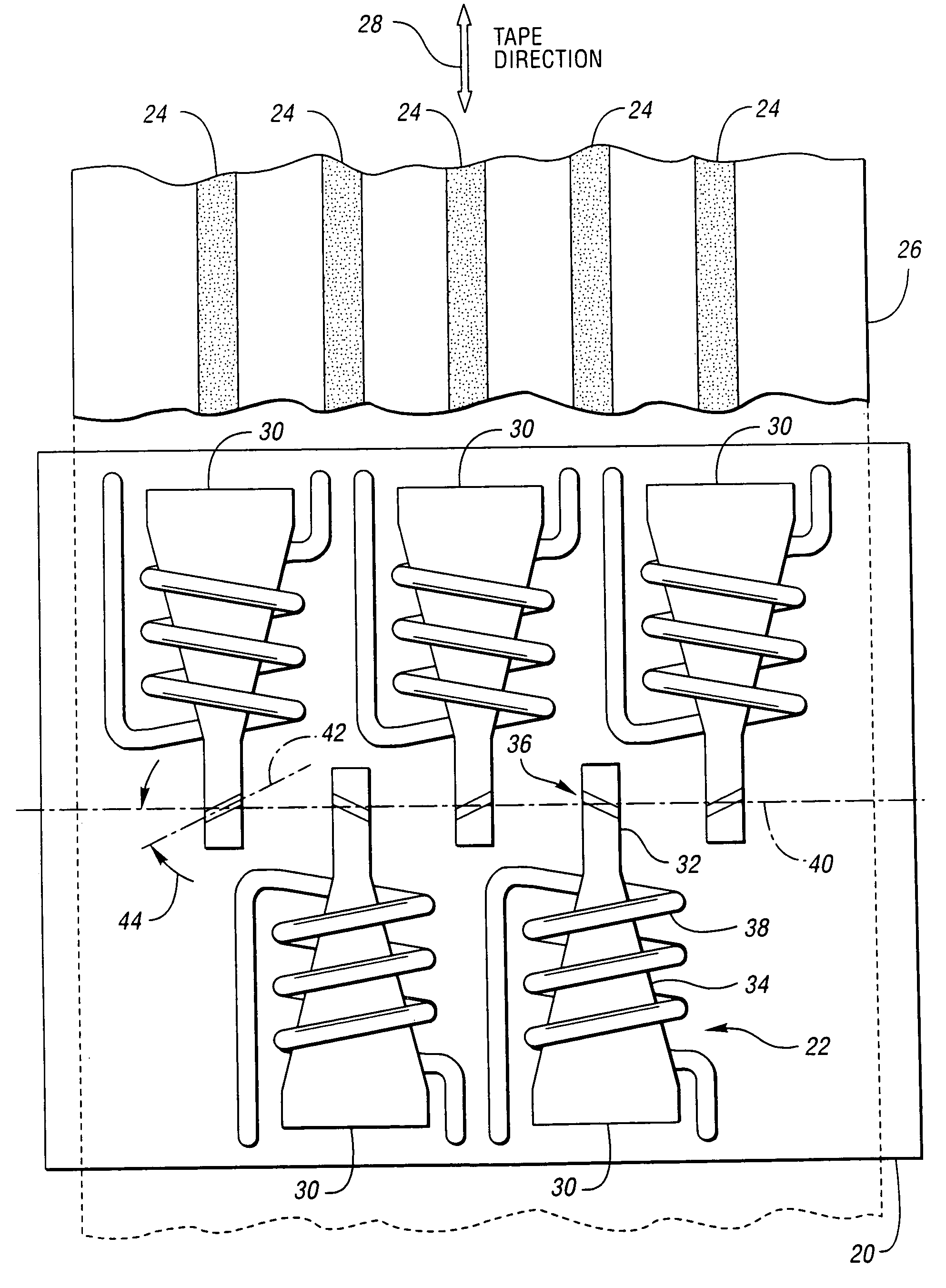

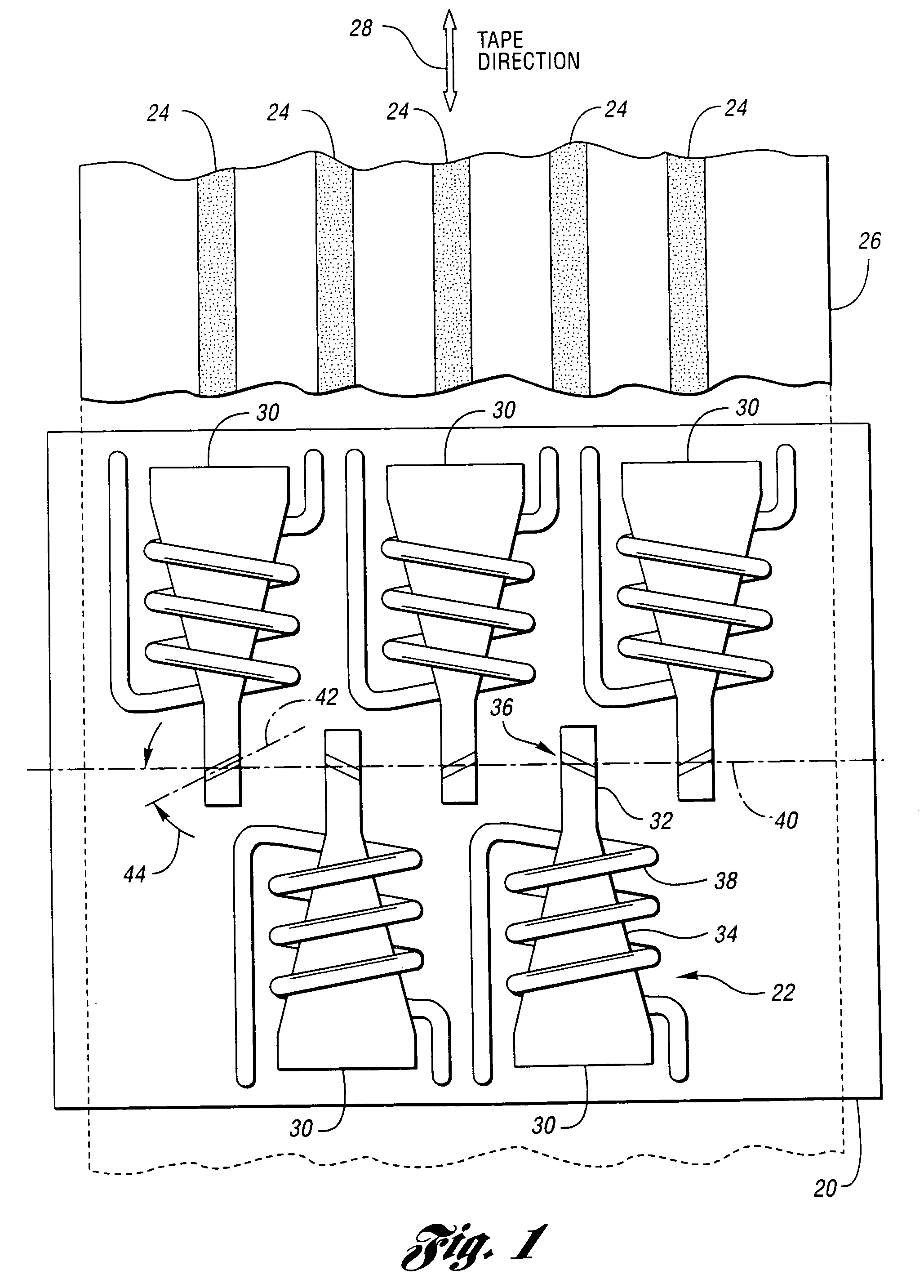

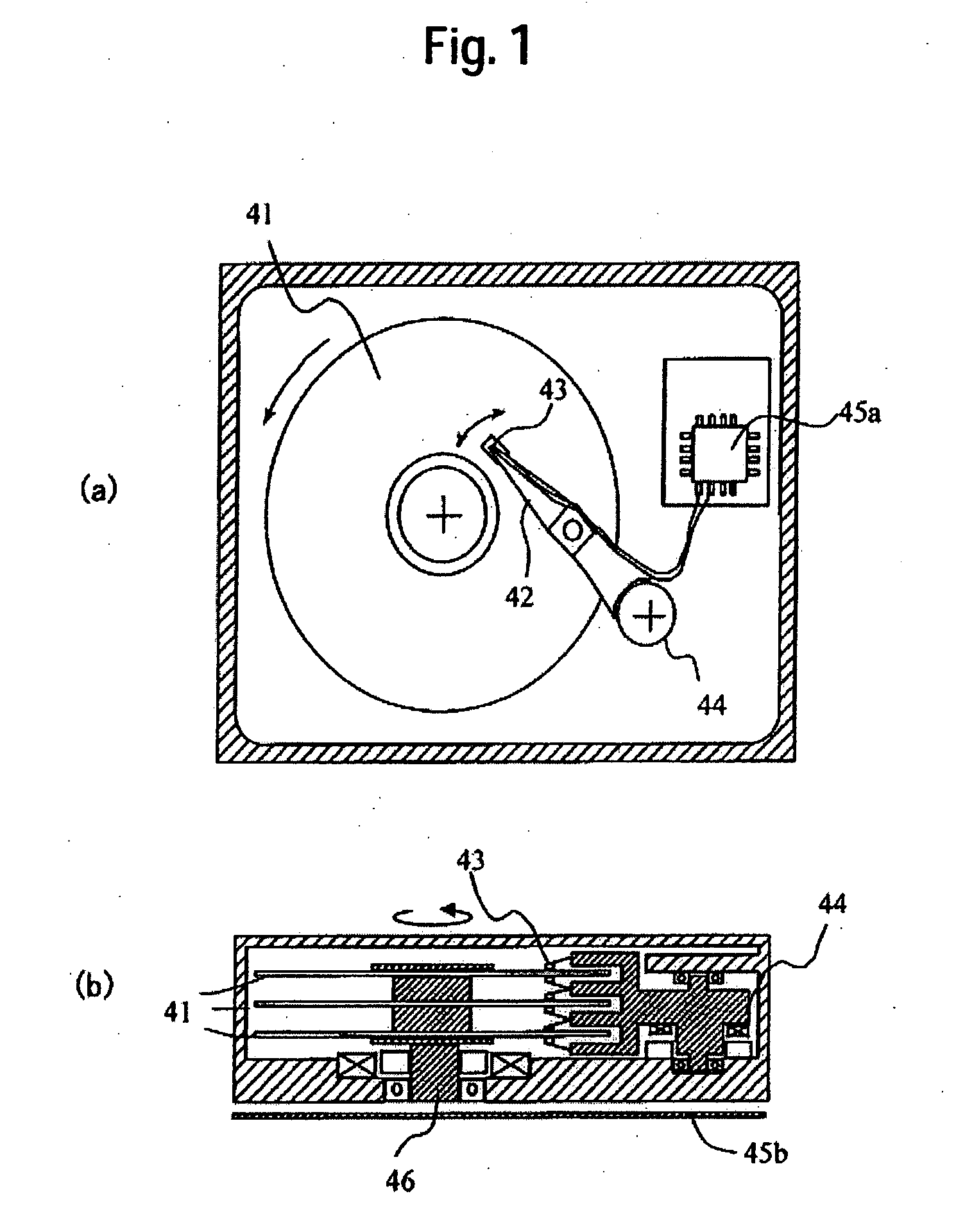

High track density magnetic recording head

ActiveUS7130152B1High track densityMade preciselyManufacturing heads with multiple gapsManufacture unitary devices of plural headsTrack densityMagnetic media

Closer spacing of elements for writing multiple tracks onto a magnetic media increases the areal density of stored information. A thin film multiple track recording head includes recording gaps in a plane parallel with the head substrate. This configuration allows for flexible placement of the elements within the head, improved control of recording gap geometry, and alternating azimuth gap angles.

Owner:ORACLE INT CORP

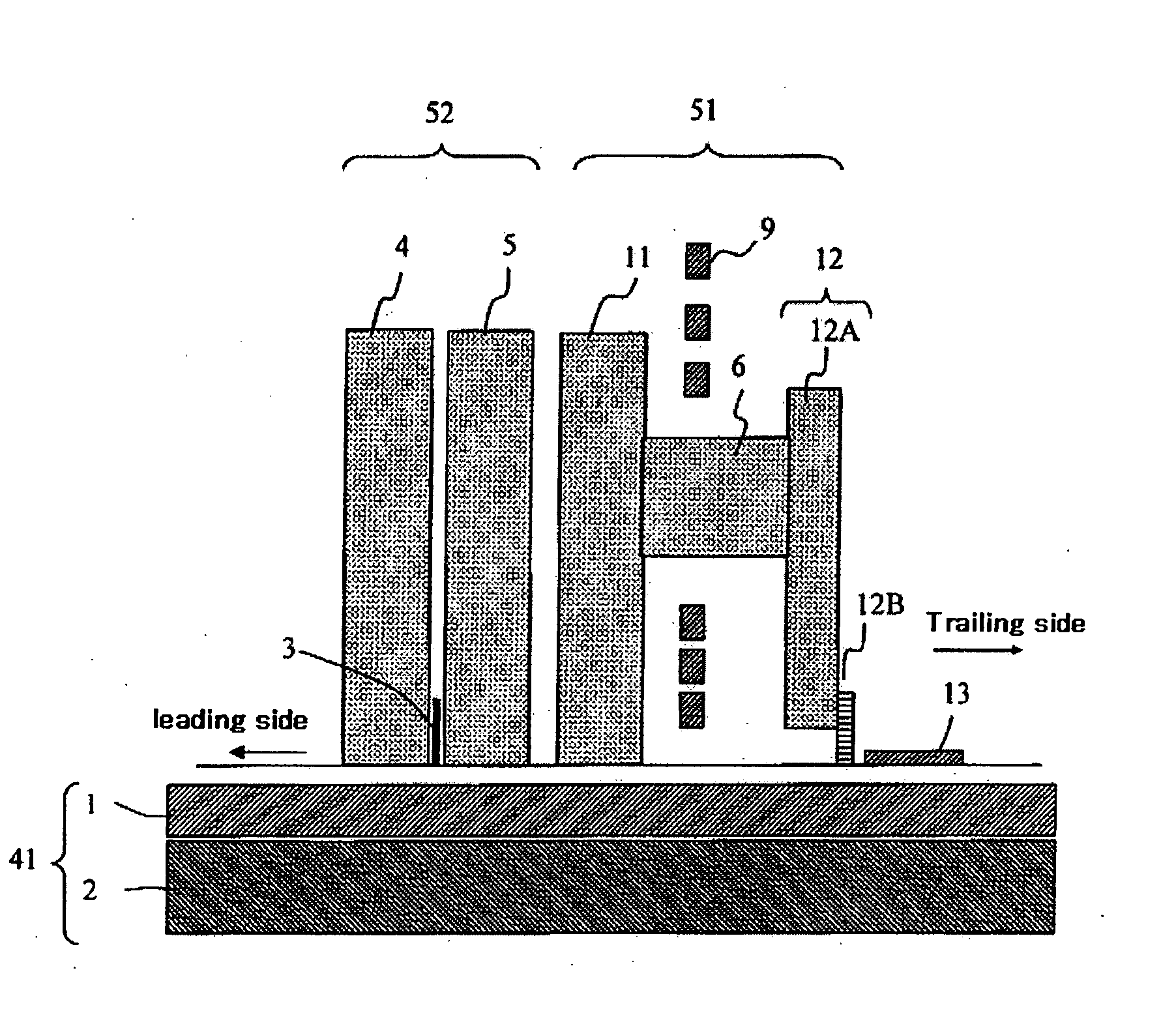

Magnetic recording head having protected reader sensors and near zero recessed write poles

InactiveUS20140063646A1Manufacture head surfaceDriving/moving recording headsComputer hardwareMagnetic poles

A magnetic head according to one embodiment includes a module, the module having both read and write transducers positioned towards a media facing side of the module, wherein the read and write transducers are selected from a group consisting of piggyback read-write transducers, merged read-write transducers, interleaved read and write transducers, and an array of write transducers flanked by servo read transducers; wherein the write transducers include write poles having media facing sides with negative, zero or near-zero recession from a plane extending along the media facing side of a substrate of the module; wherein the read transducers each have at least one shield, wherein a media facing side of the at least one shield is more recessed from the plane than the write poles.

Owner:IBM CORP

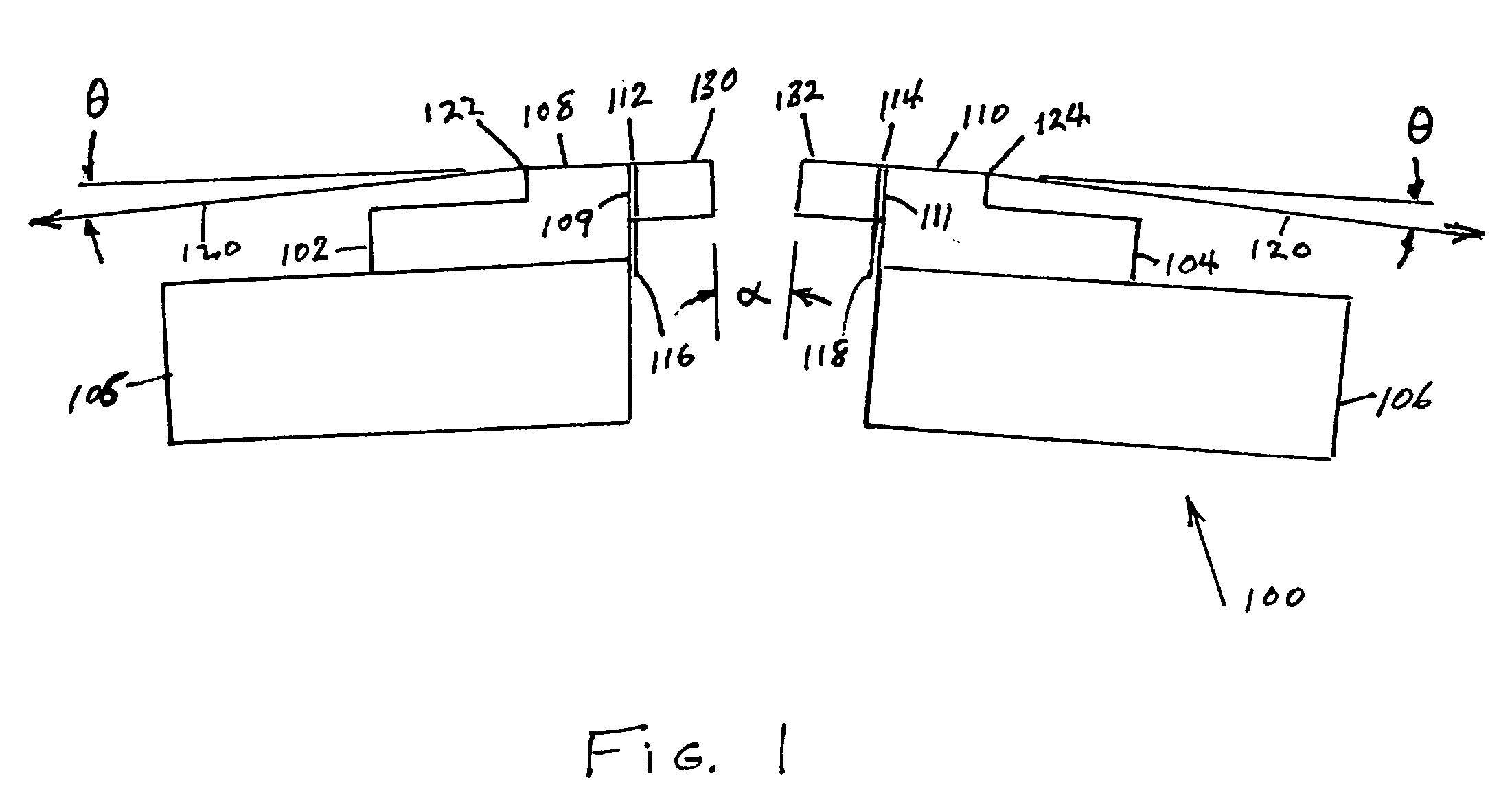

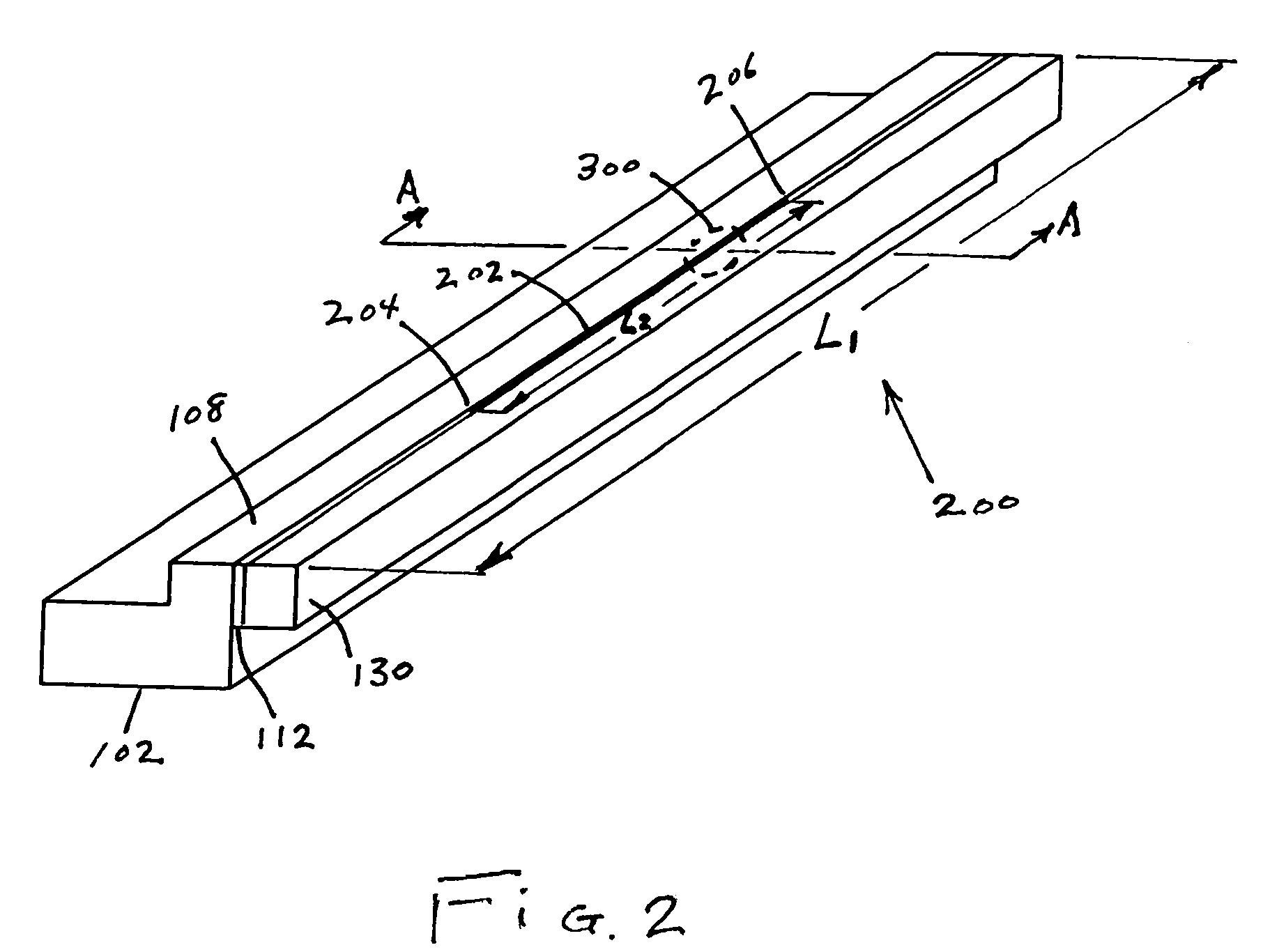

Quasi-statically tilted magnetic tape head having backward compatibility

InactiveUS8797682B1Manufacturing heads with multiple gapsManufacture unitary devices of plural headsSensor arrayMagnetic tape

In one general embodiment, an apparatus includes a magnetic head. The magnetic head has a first array of data transducers; a second array of data transducers spaced from the first array; and a third array of data transducers positioned between the first and second arrays. The magnetic head is positionable between a first position and a second position. A pitch of the data transducers of at least two of the arrays presented to the tape is compatible with a first format when the magnetic head is positioned between the first and second positions. The pitch of the data transducers of at least one of the arrays is compatible with a second format when the longitudinal axis of the third array is oriented about perpendicular to the intended direction of tape travel. A data track pitch of the first format is different than the data track pitch of the second format.

Owner:IBM CORP

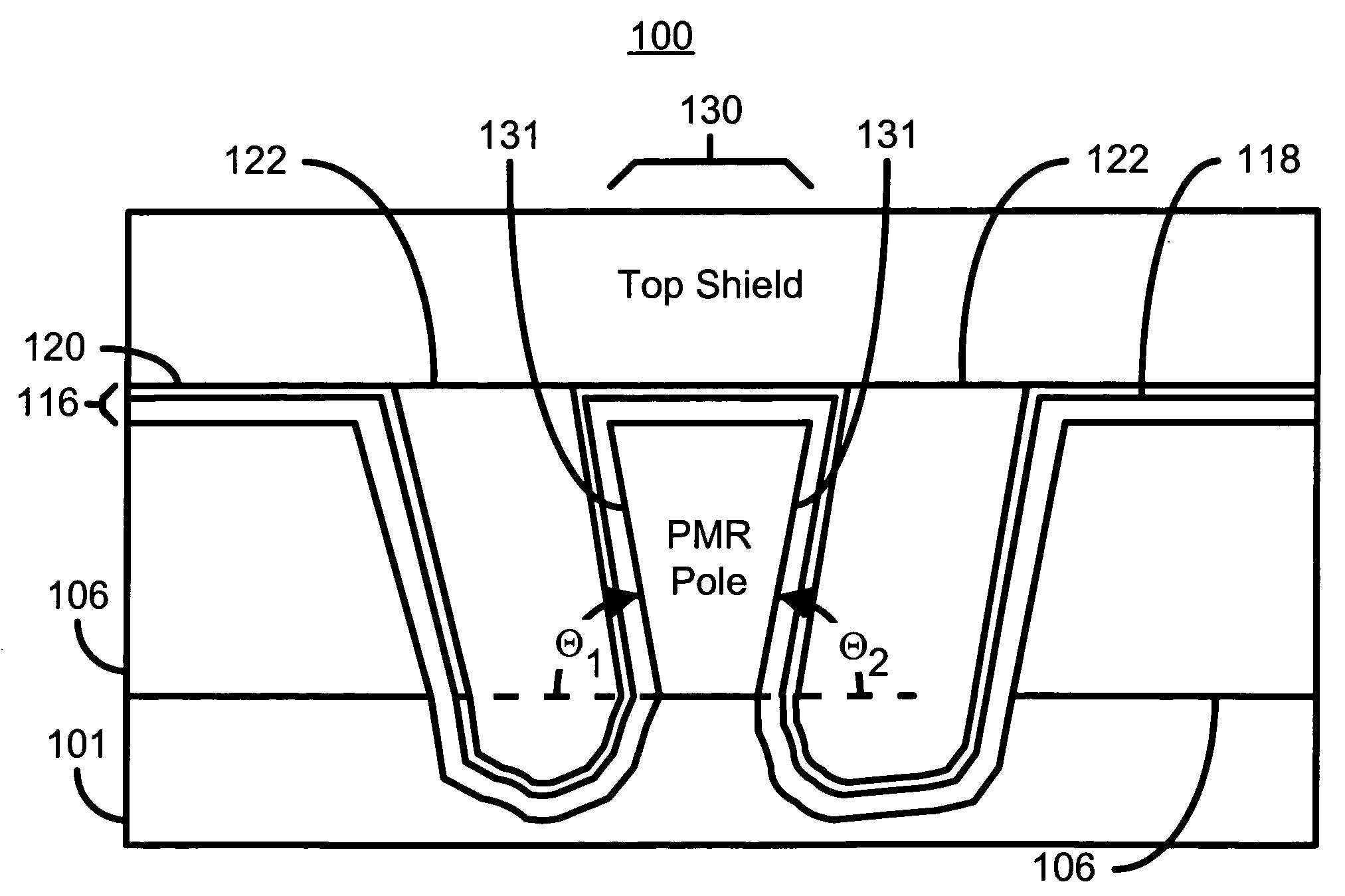

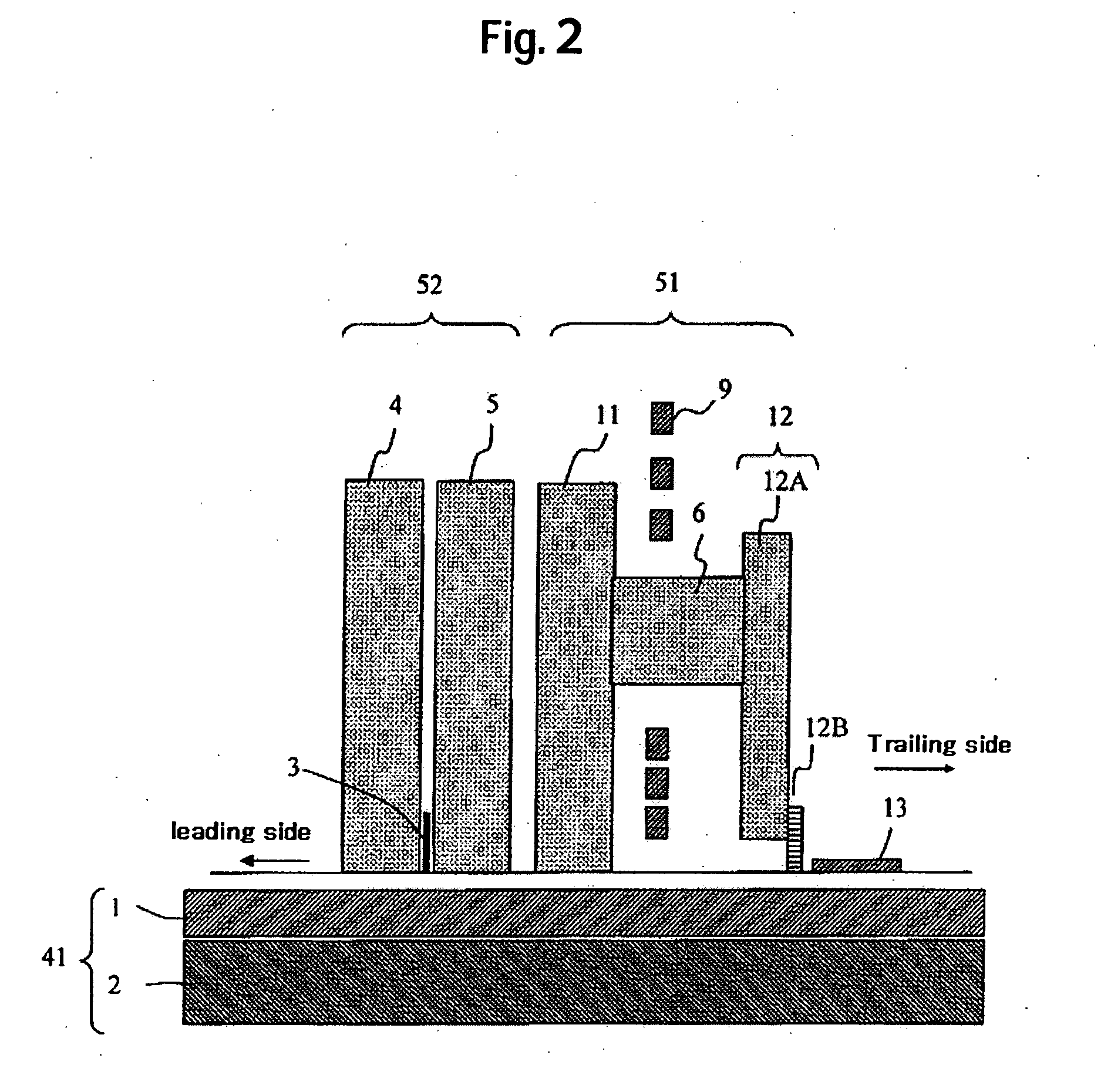

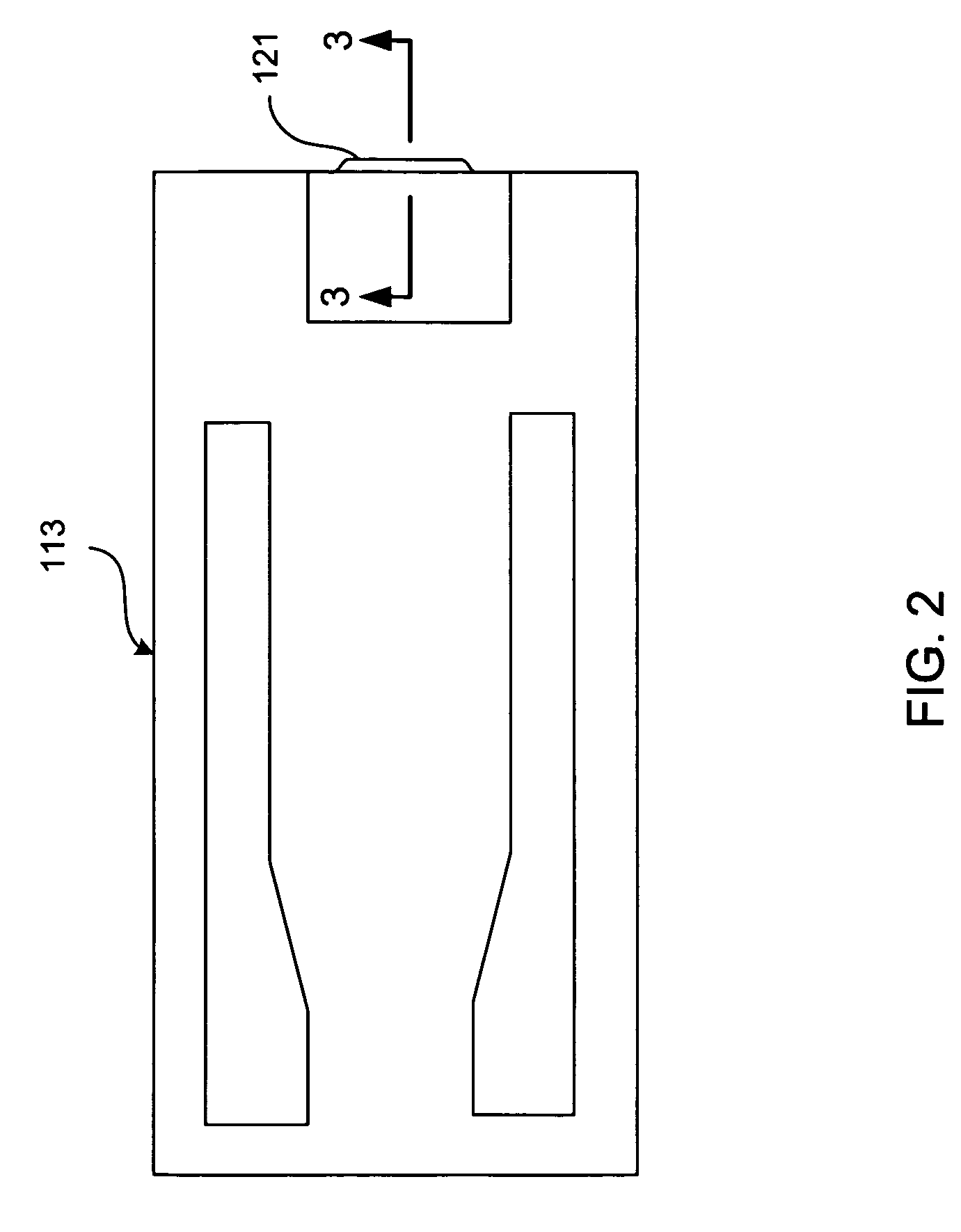

Perpendicular magnetic recording head and method of manufacturing the same

InactiveUS20070217069A1High gradientImprove accuracyManufacture head surfaceElectrical transducersMagnetic field gradientEngineering

Embodiments in accordance with the present invention provide a trailing side shield around a main pole and control the gap length on its trailing side to high accuracy so as to increase a recording magnetic field gradient. An etching signal layer is provided on a main pole, and the gap length on the trailing side of the main pole is controlled to high accuracy by stopping ion milling when a signal from this layer is detected.

Owner:WESTERN DIGITAL TECH INC

Method of manufacturing a wrap around shield for a perpendicular write pole using a laminated mask

InactiveUS20070245545A1Construction of head windingsManufacture head surfaceTrailing edgeNon magnetic

A method for constructing a magnetic write head for use in perpendicular magnetic recording, the write head having a write pole with a trailing shield that wraps around the write pole. The method allows the trailing shield to be constructed with a very well controlled trailing gap thickness and also allows the write pole to be constructed with a well controlled track width and a straight, flat trailing edge. The method includes depositing a magnetic write pole over a substrate and forming a mask structure over the write pole layer. The mask structure includes an end point detection layer that can be removed by reactive ion etching. An ion mill is performed to form a write pole by removing magnetic write pole material that is not covered by the mask layer. A layer of non-magnetic material such as alumina is deposited and is ion milled to expose the end point detection layer. The end point detection layer is then removed by reactive ion etch and a magnetic wrap around trailing shield is deposited.

Owner:WESTERN DIGITAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com