Patents

Literature

186results about "Mounting head within housing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

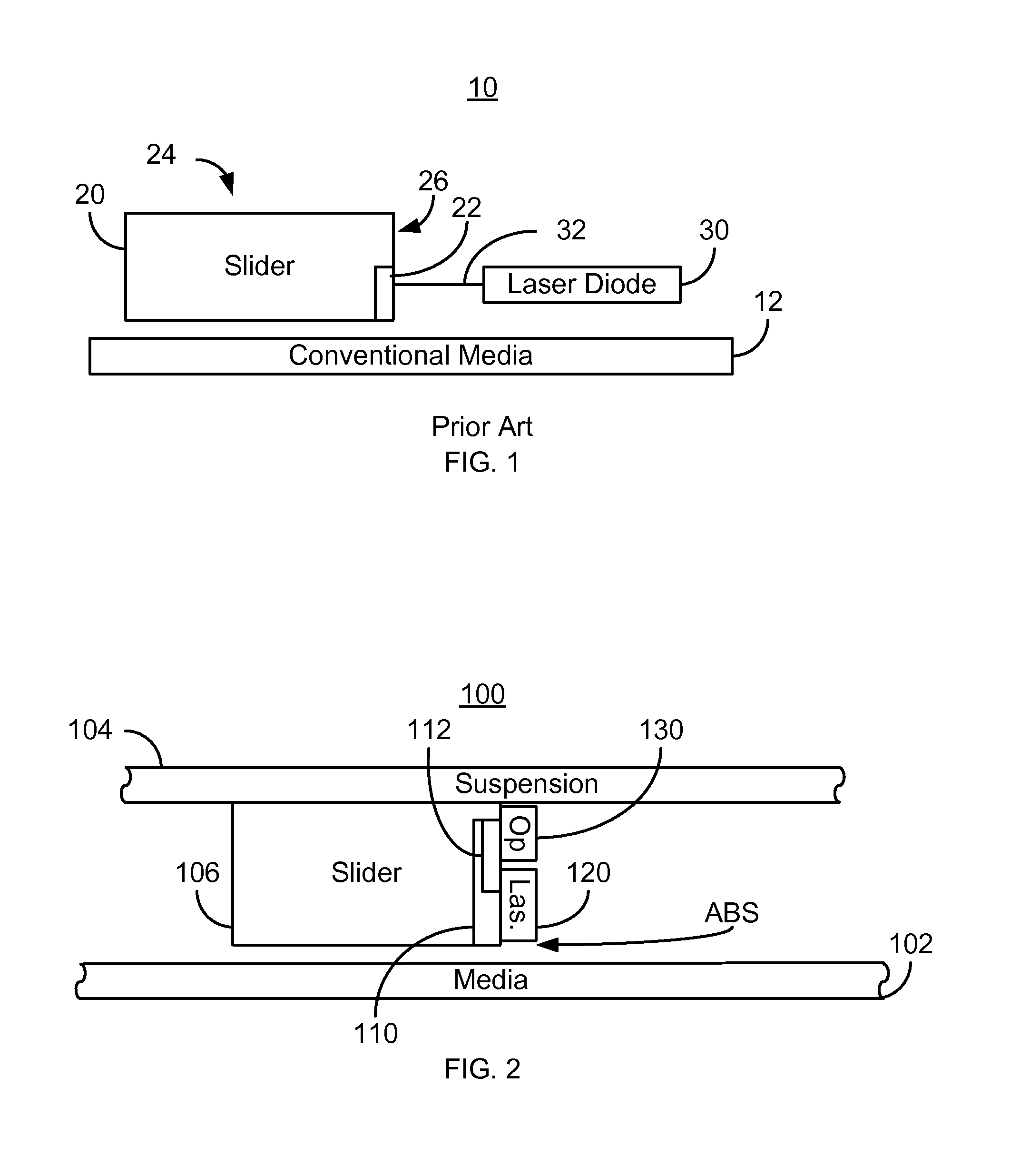

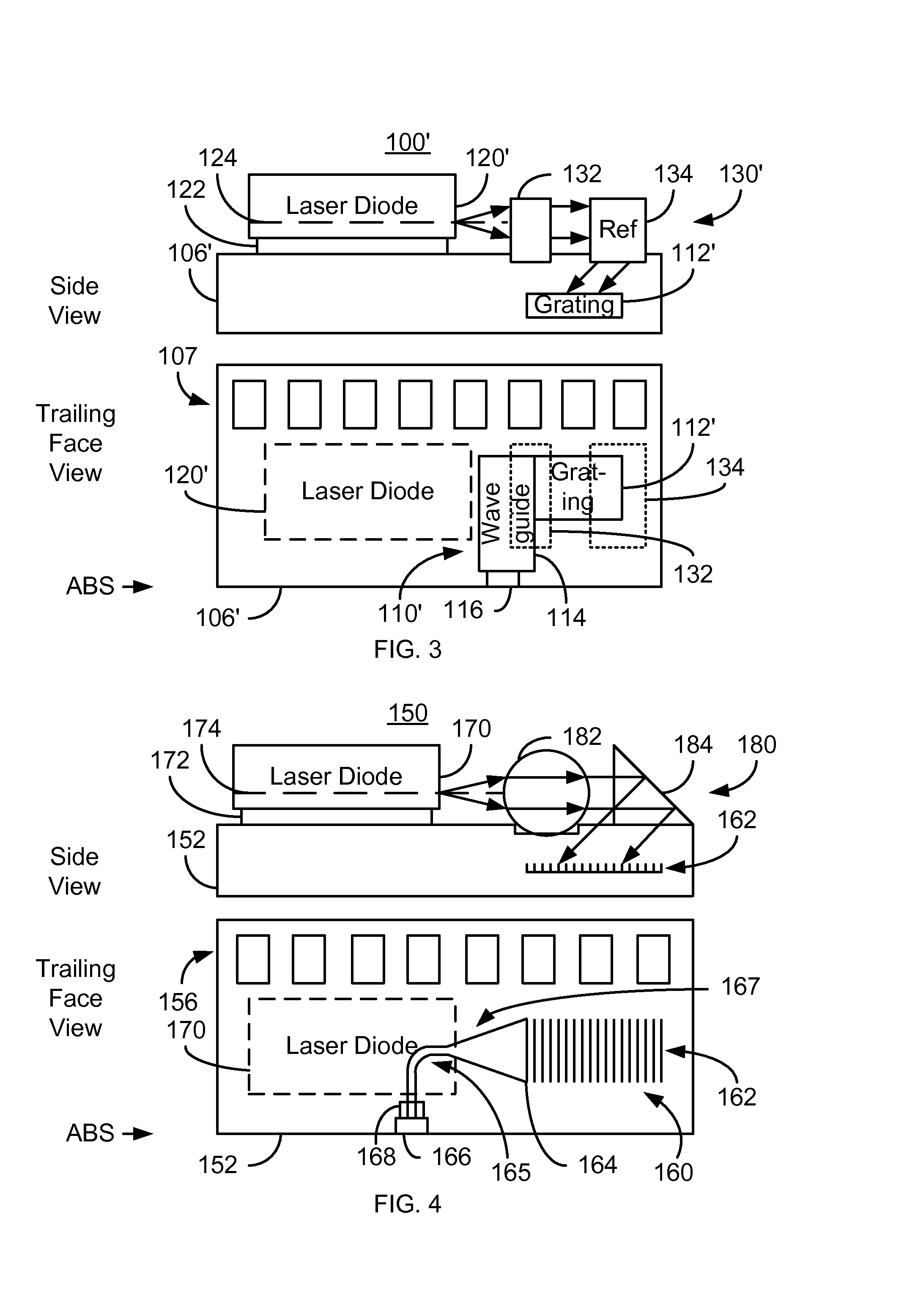

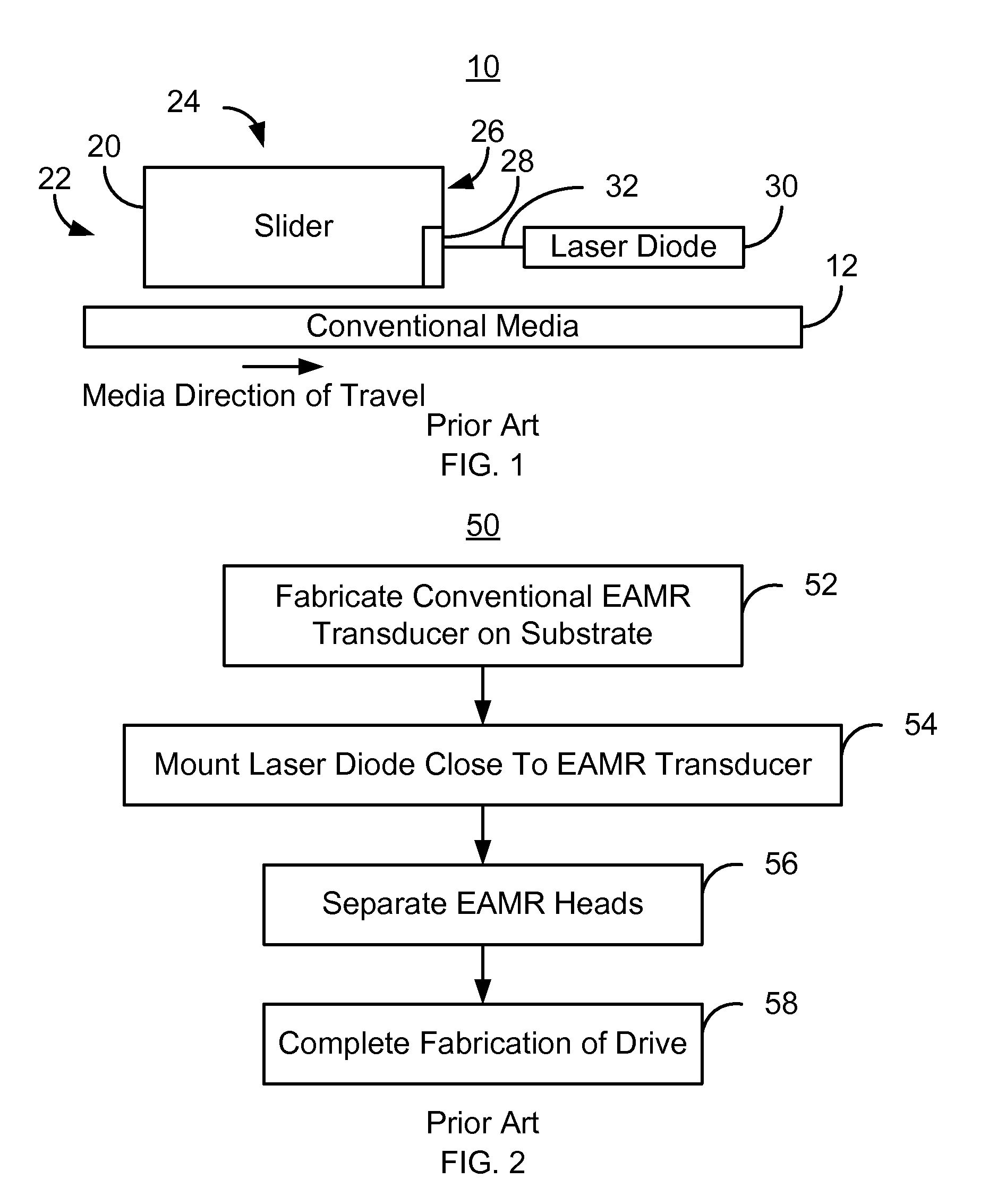

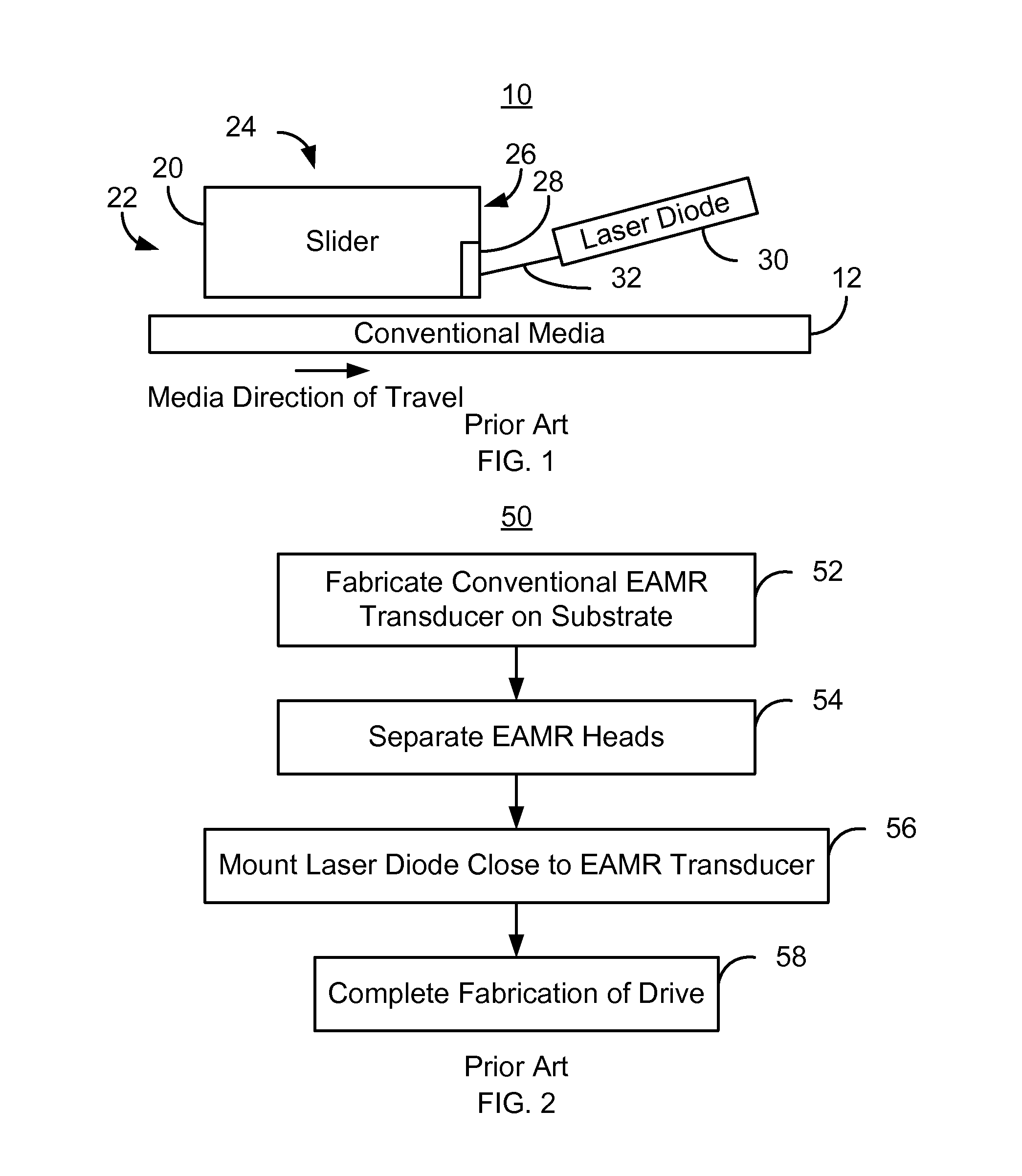

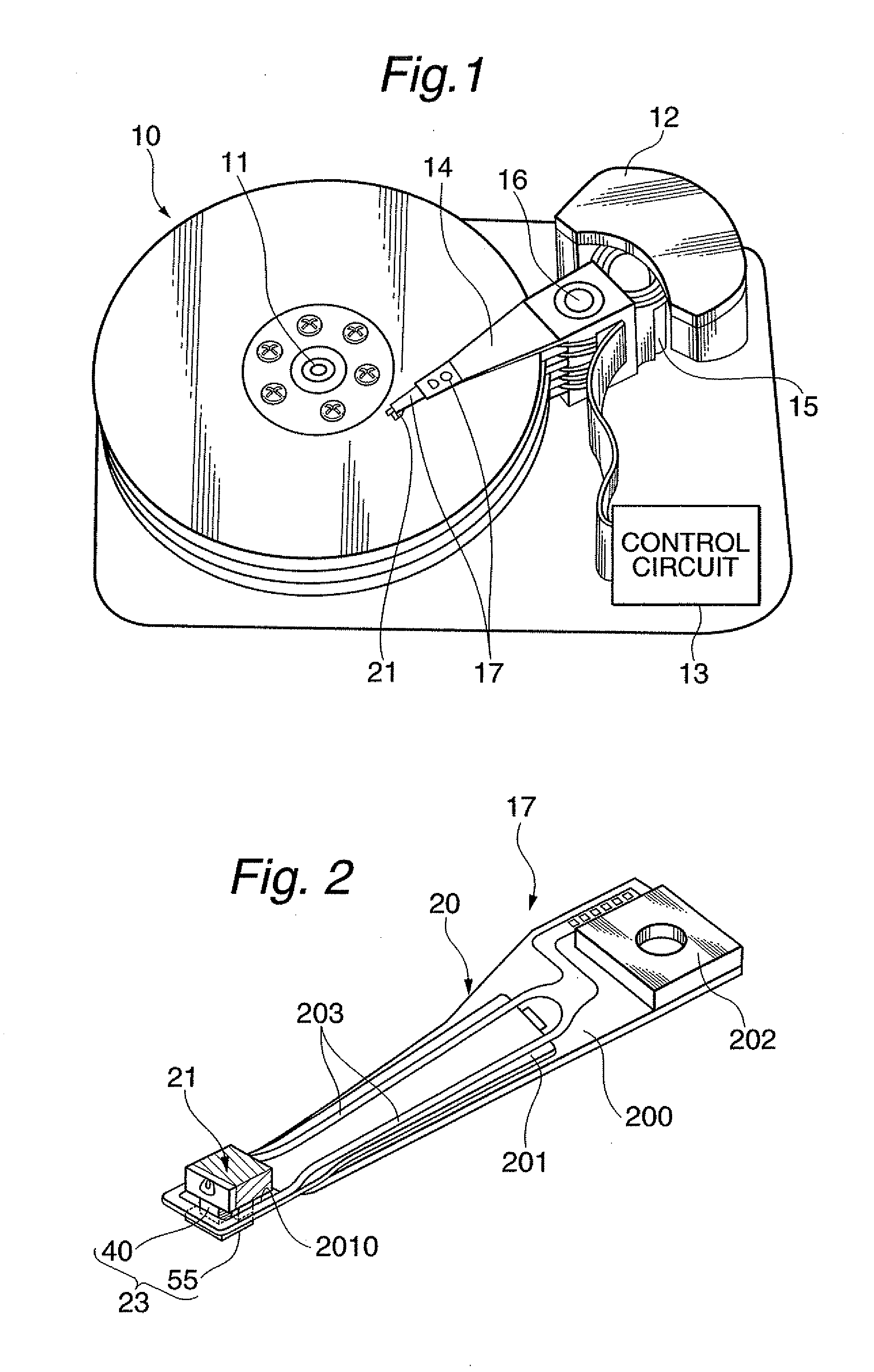

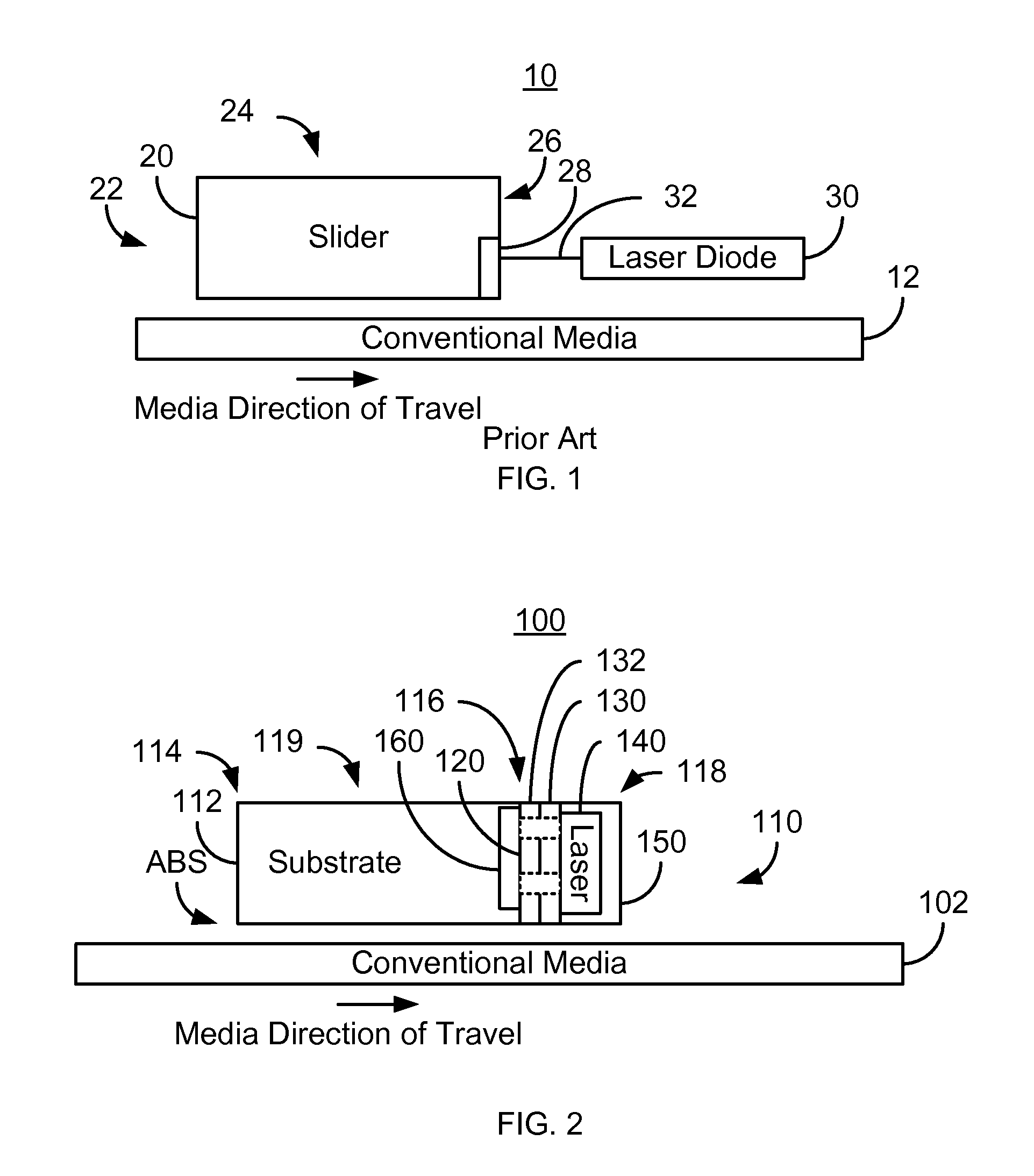

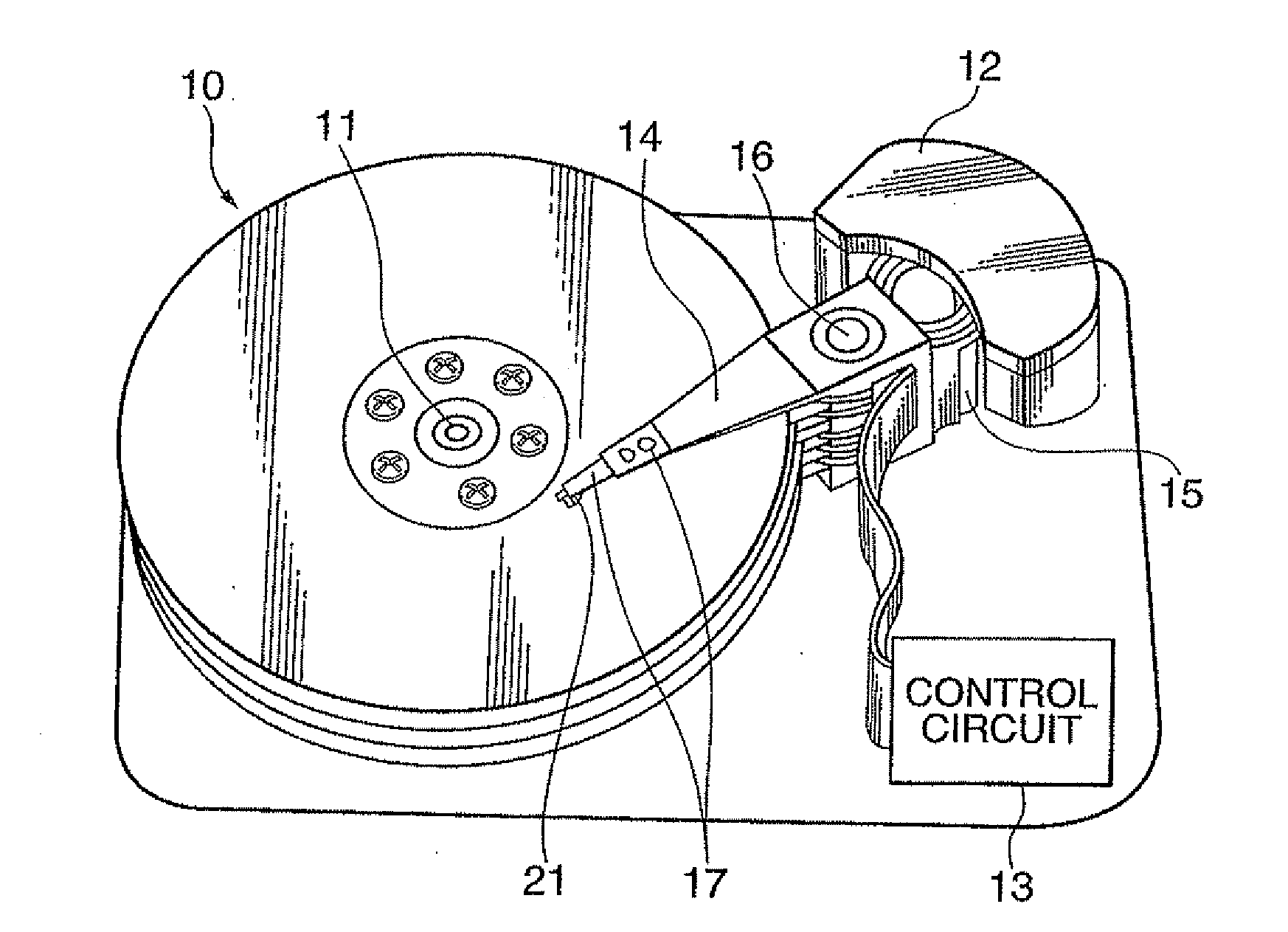

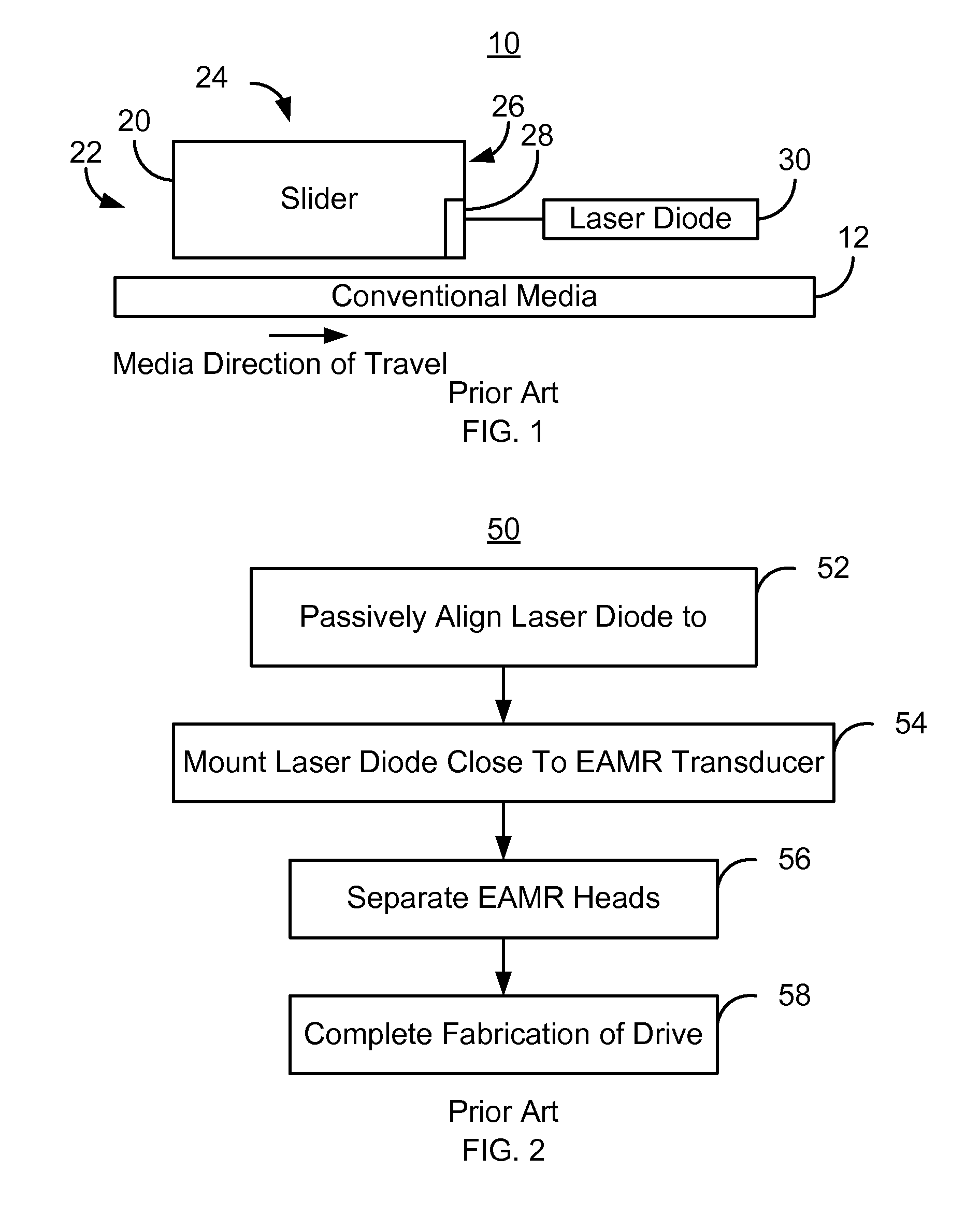

Method and system for optically coupling a laser with a transducer in an energy assisted magnetic recording disk drive

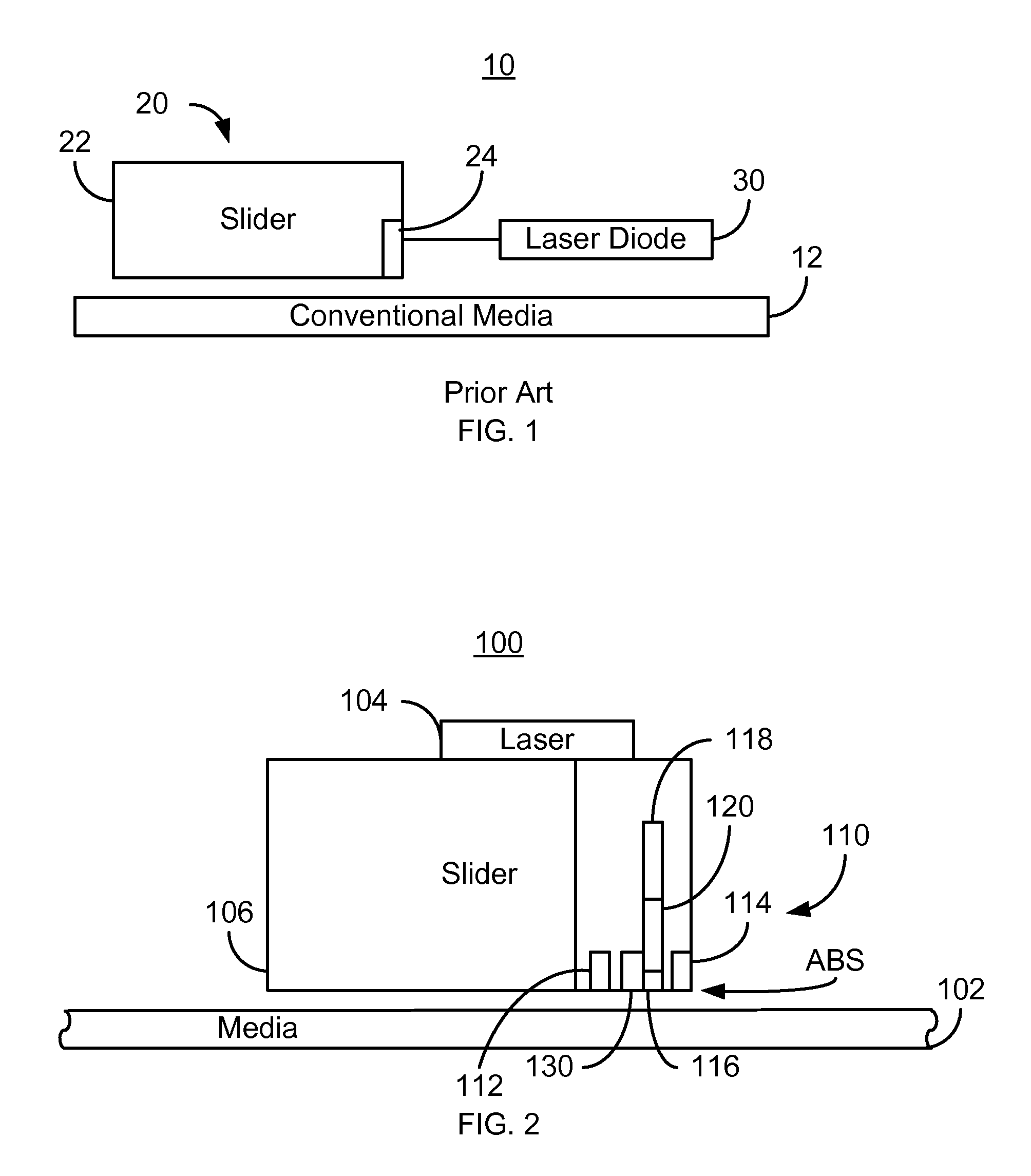

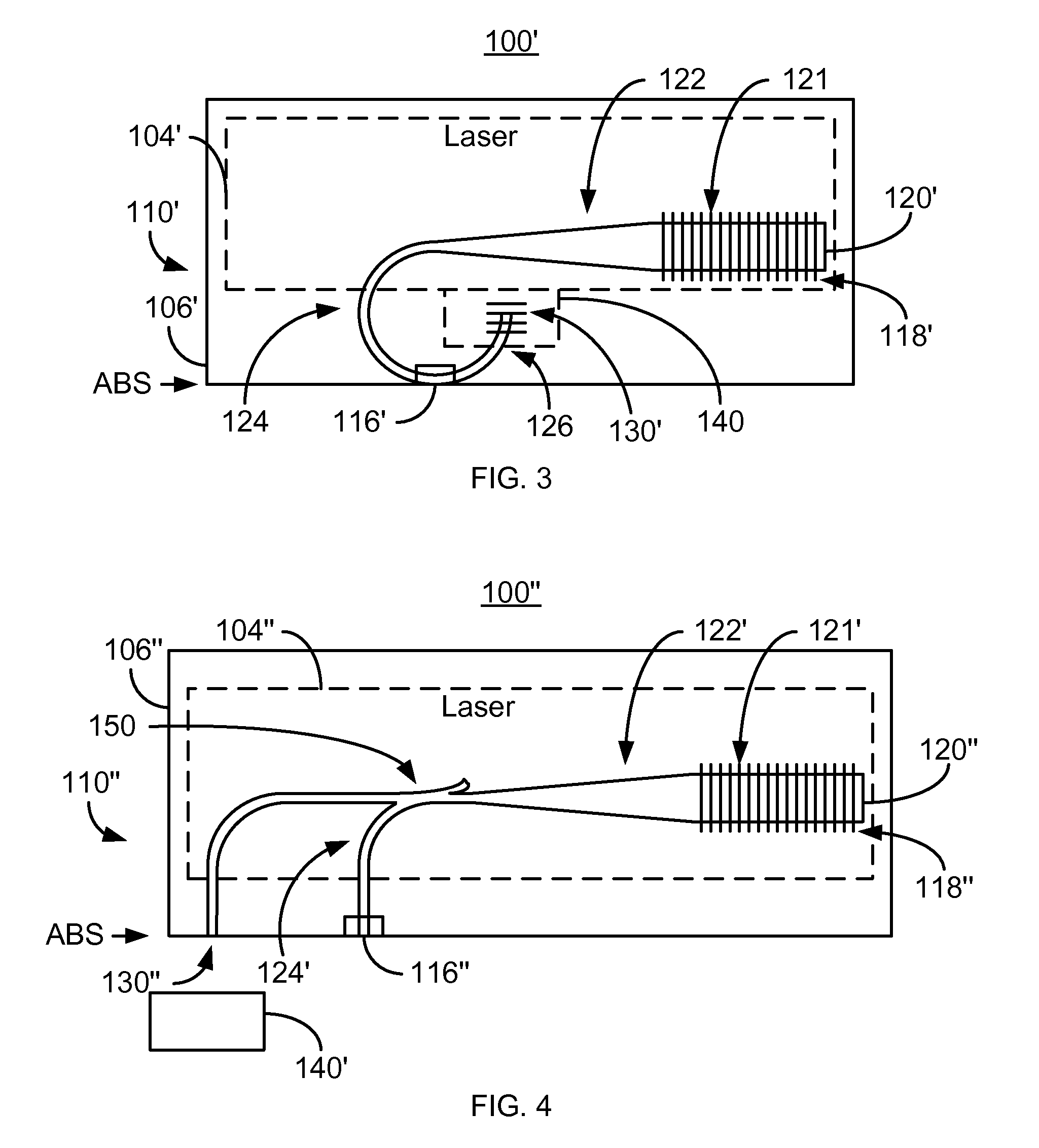

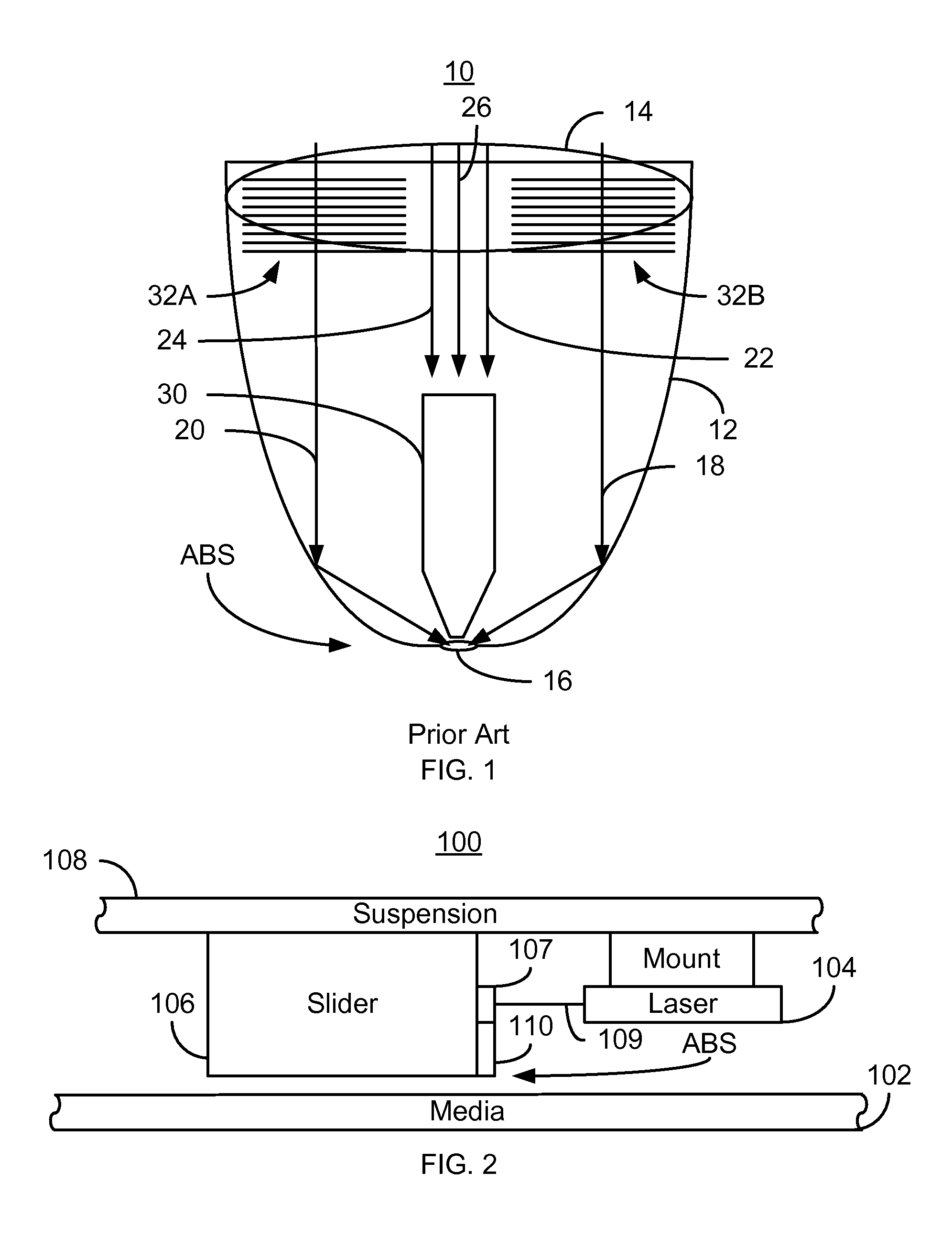

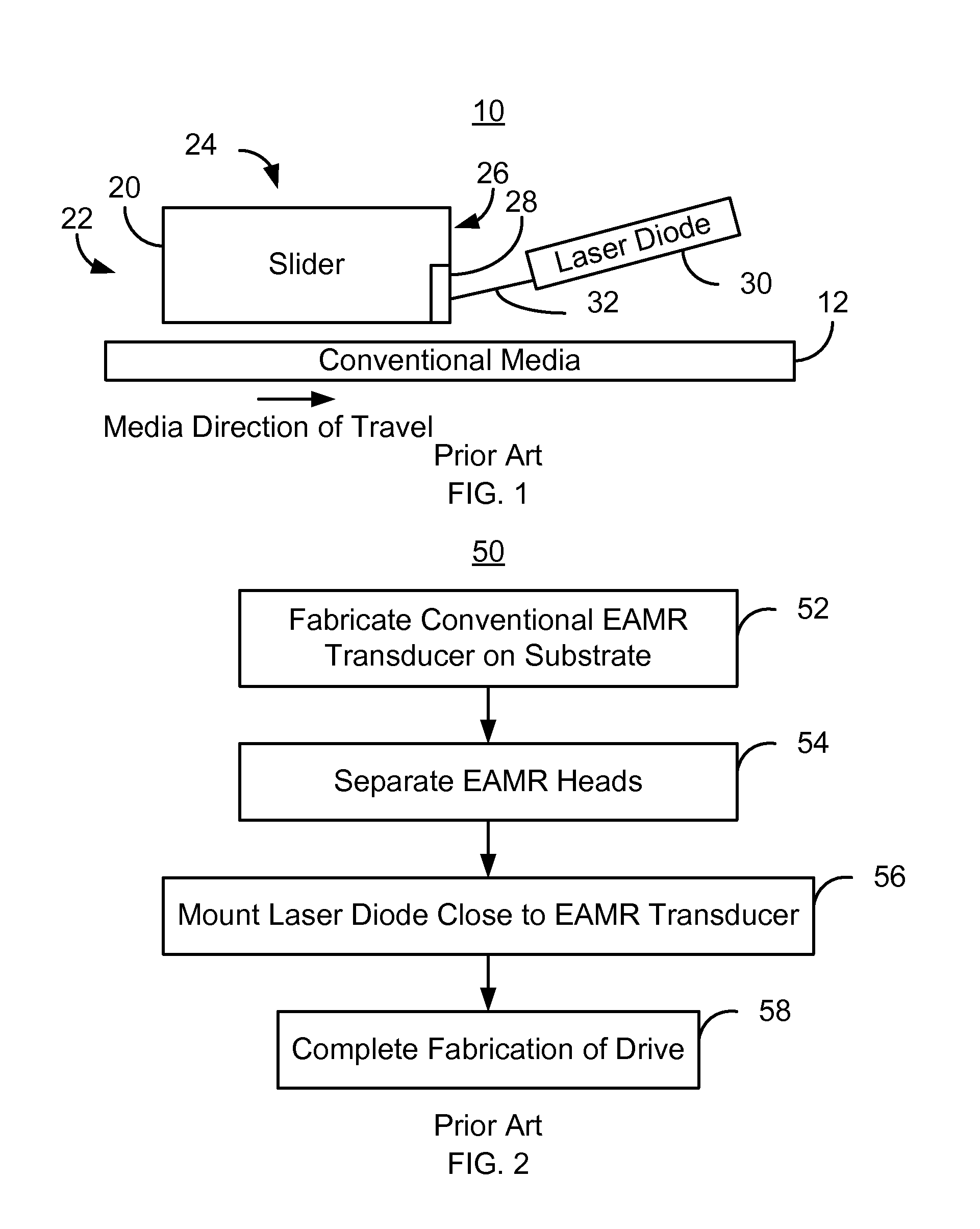

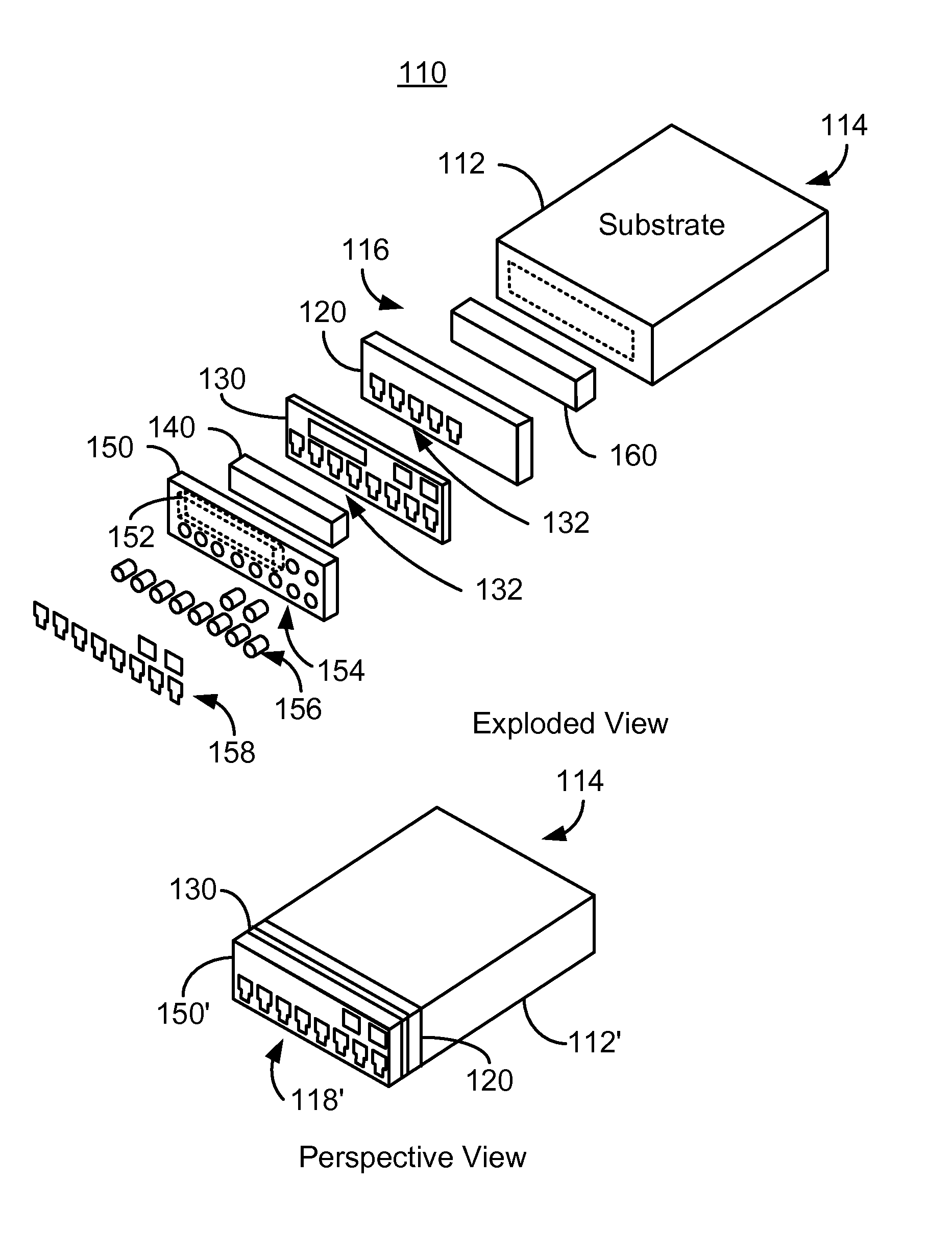

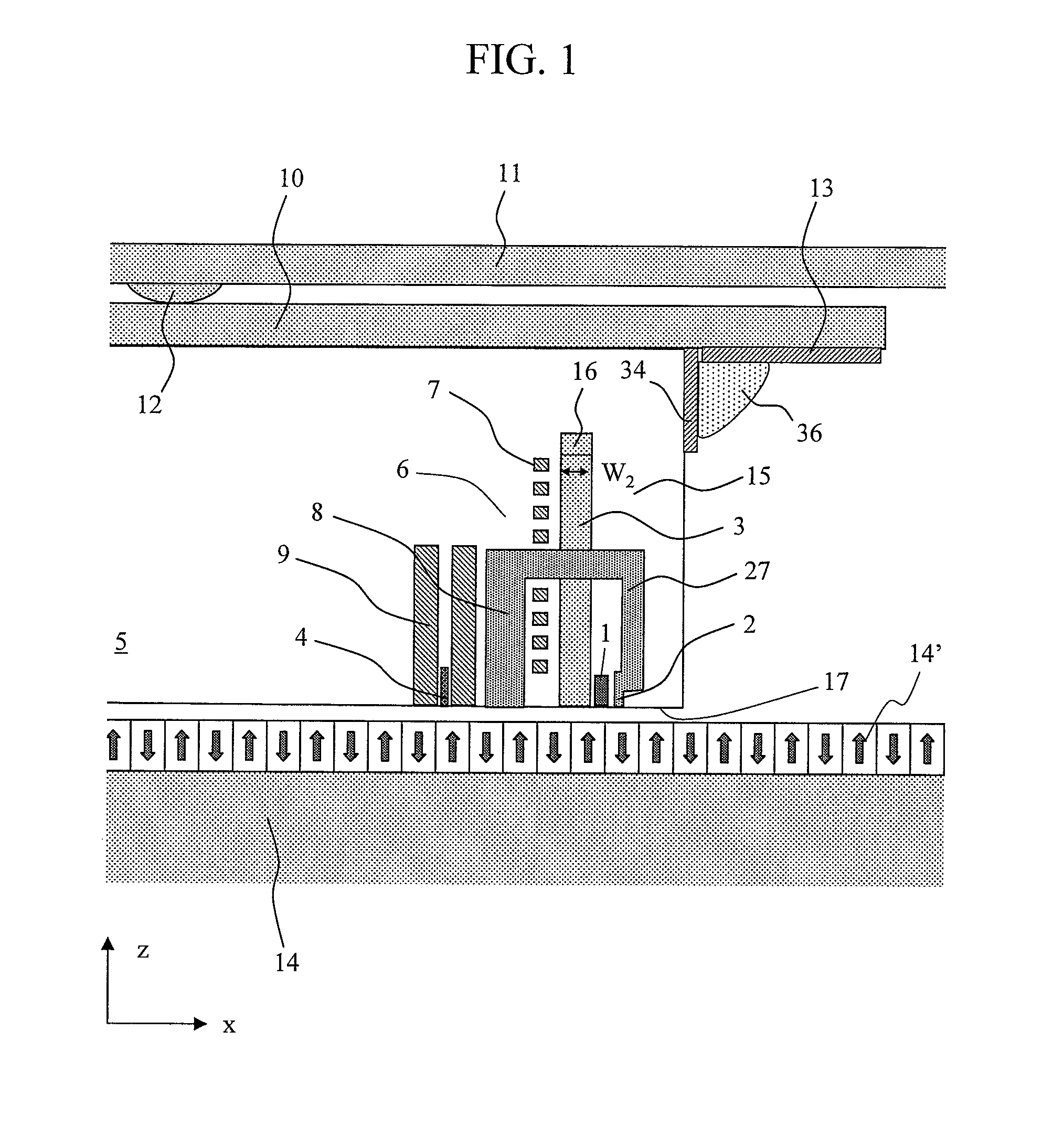

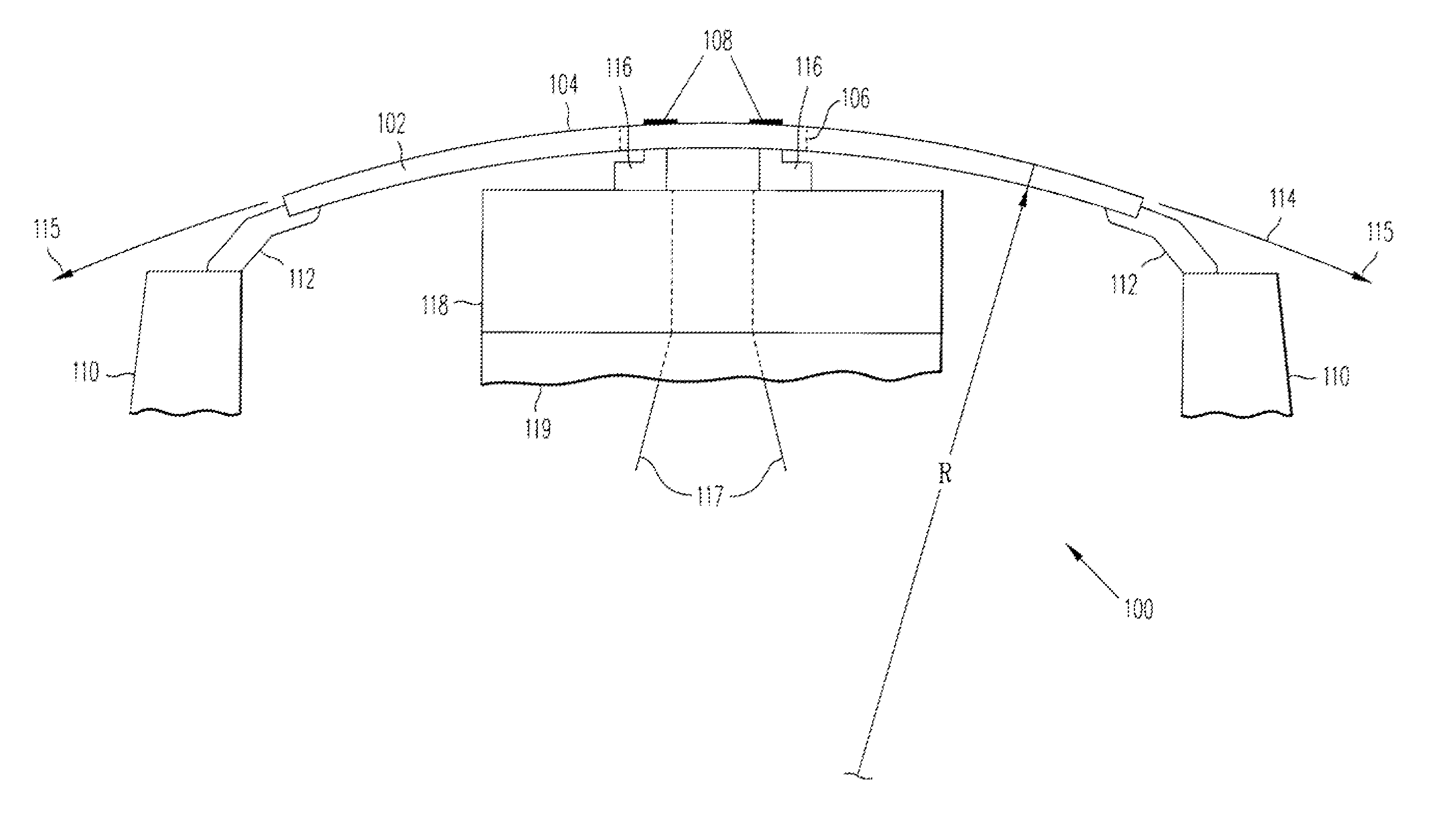

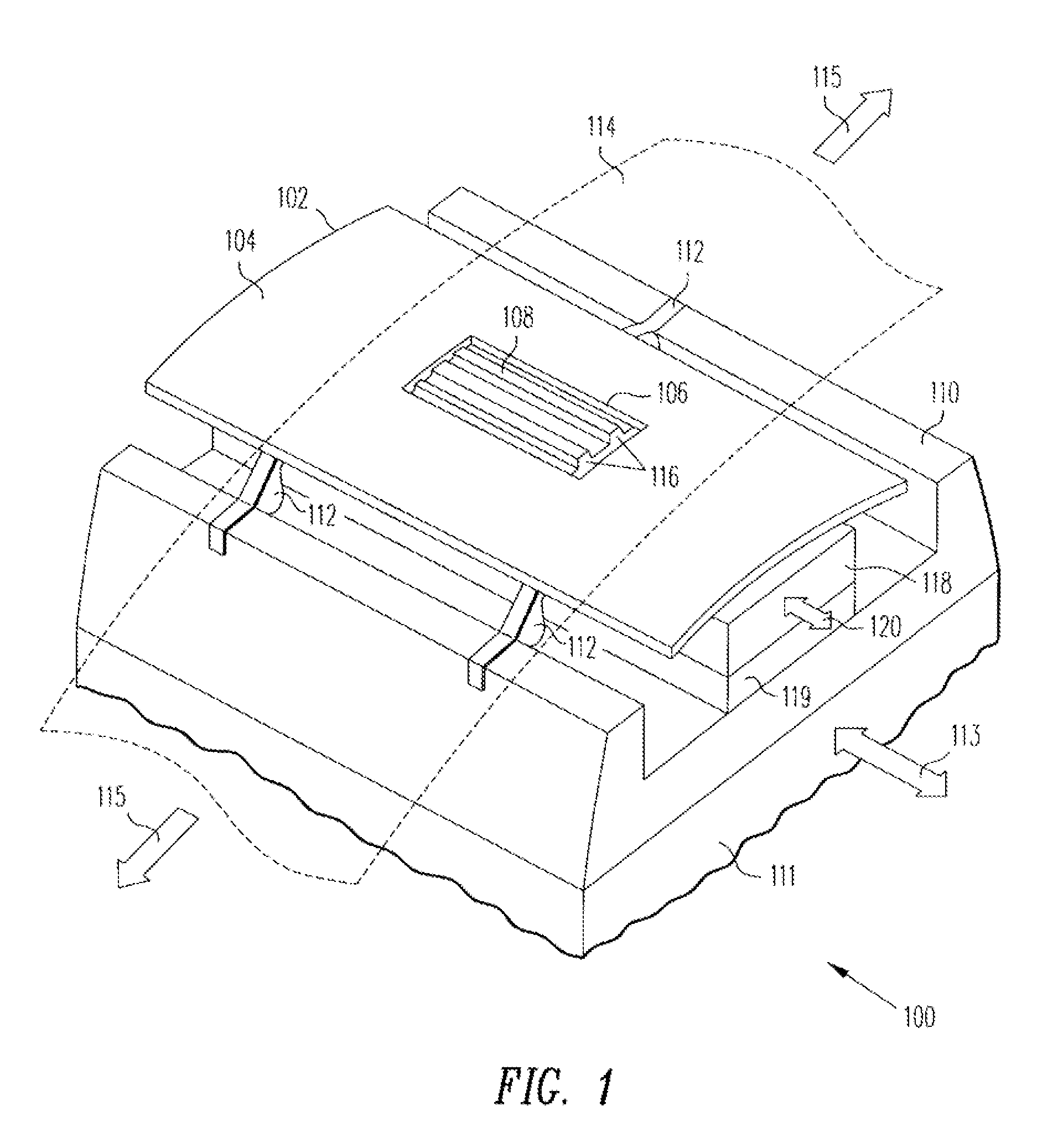

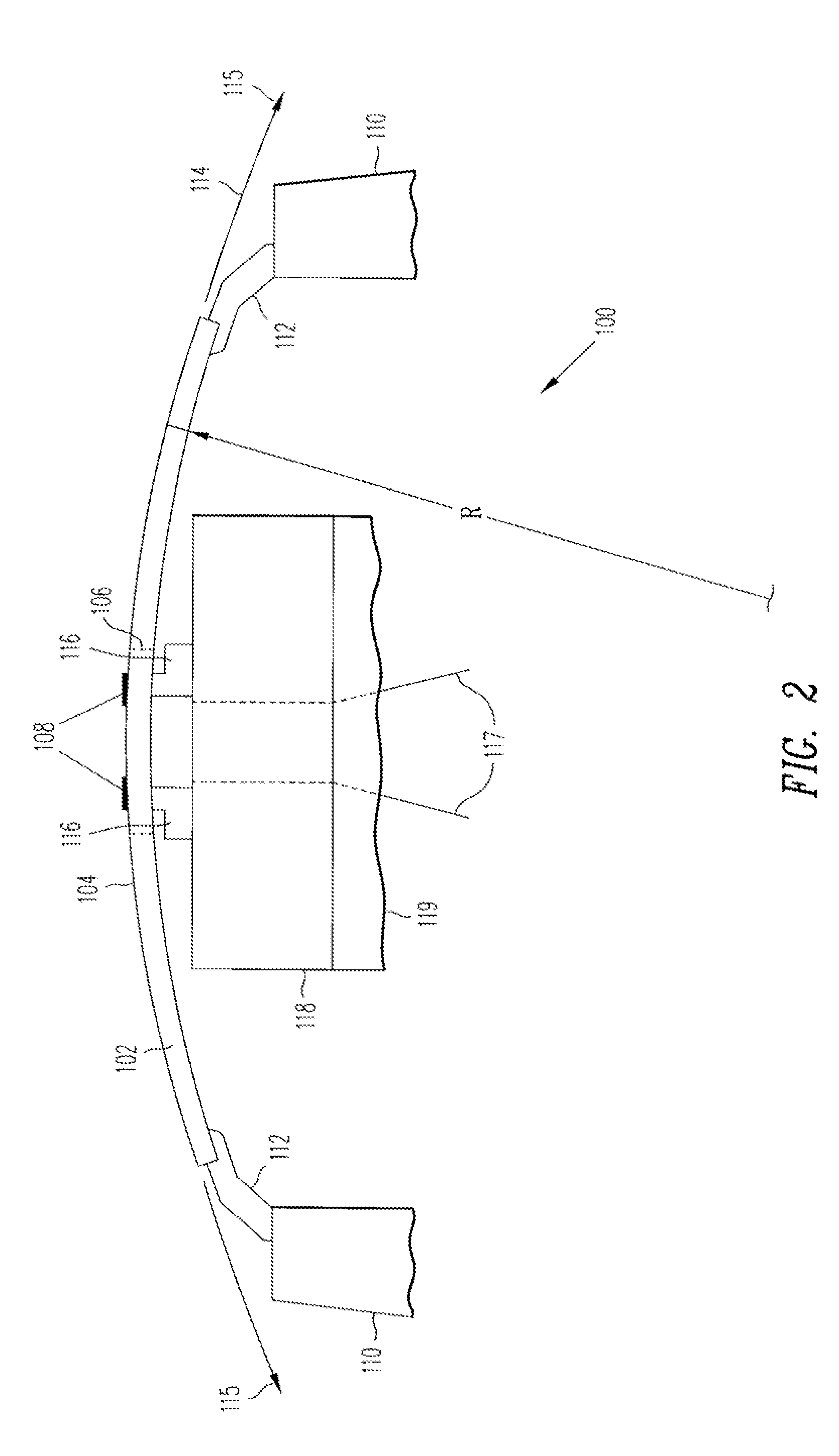

A method and system for providing an energy assisted magnetic recording (EAMR) disk drive are described. A media for storing data and a slider are provided. The slider has a back side, a trailing face, and an air-bearing surface (ABS) opposite to the back side. At least one laser is coupled with the trailing face of the slider, and has an optic axis substantially parallel to the trailing face. The laser(s) provide energy substantially along the optic axis. Optics are coupled with the trailing face of the slider and receive the energy from the laser(s) via free space. At least one EAMR transducer coupled with the slider. At least part of the EAMR transducer resides in proximity to the ABS. The optics direct the energy from the laser(s) to the EAMR transducer(s). The EAMR transducer(s) receive the energy from the optics and write to the media using the energy.

Owner:WESTERN DIGITAL TECH INC

Method and system for optically coupling a laser with a transducer in an energy assisted magnetic recording disk drive

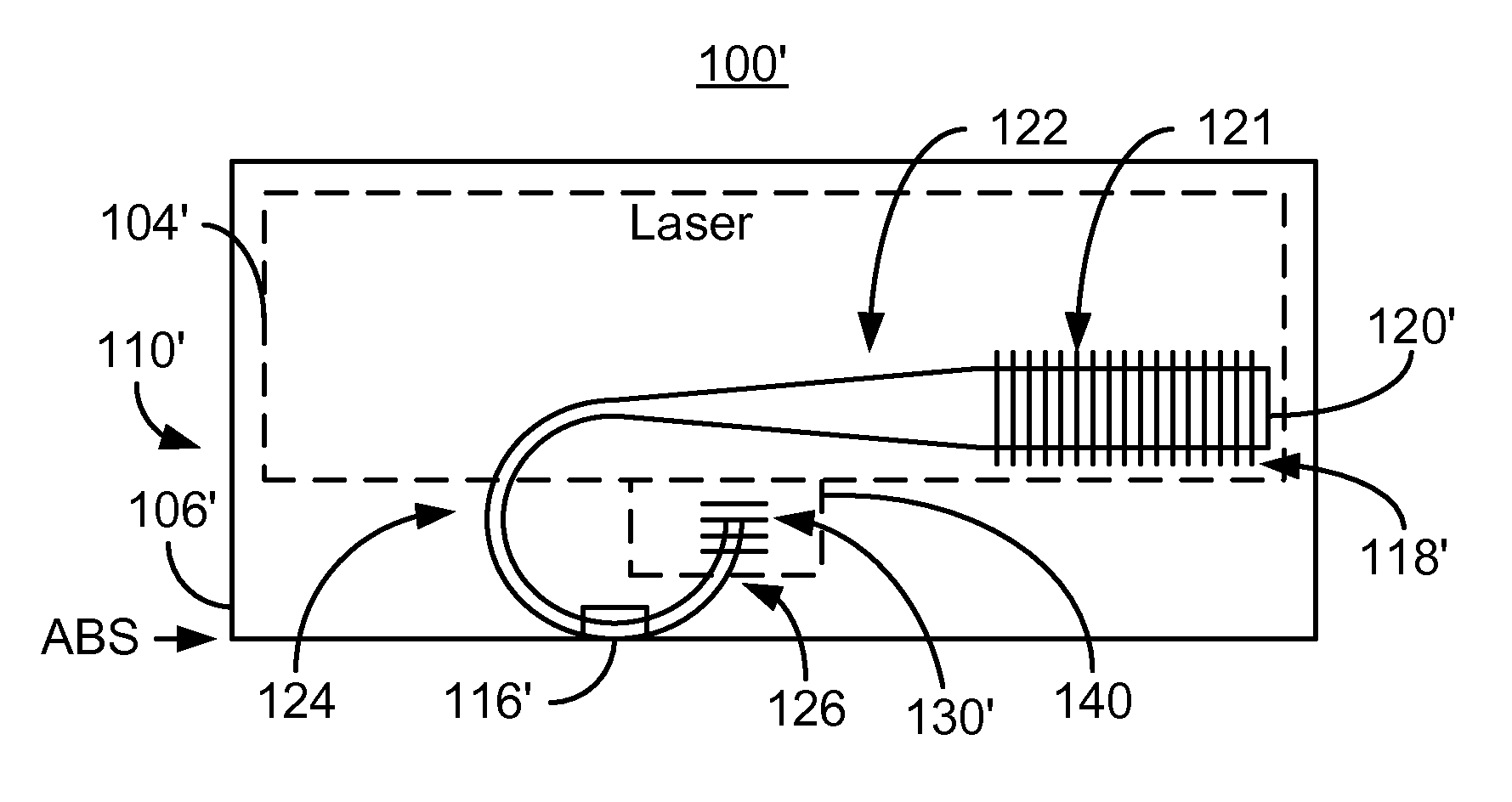

A method and system for providing an energy assisted magnetic recording (EAMR) transducer coupled with a laser. The EAMR transducer has an air-bearing surface (ABS) configured to reside in proximity to a media during use. The EAMR transducer includes a write pole, at least one coil, a waveguide and an output device. The write pole is configured to write to a region of the media. The at least one coil is for energizing the write pole. The waveguide has an input optically coupled to the laser and configured to direct energy from the laser toward the ABS for heating the region of the media. The output device is optically coupled to the waveguide. The output device coupling out a portion of the energy not coupled to the media.

Owner:WESTERN DIGITAL TECH INC

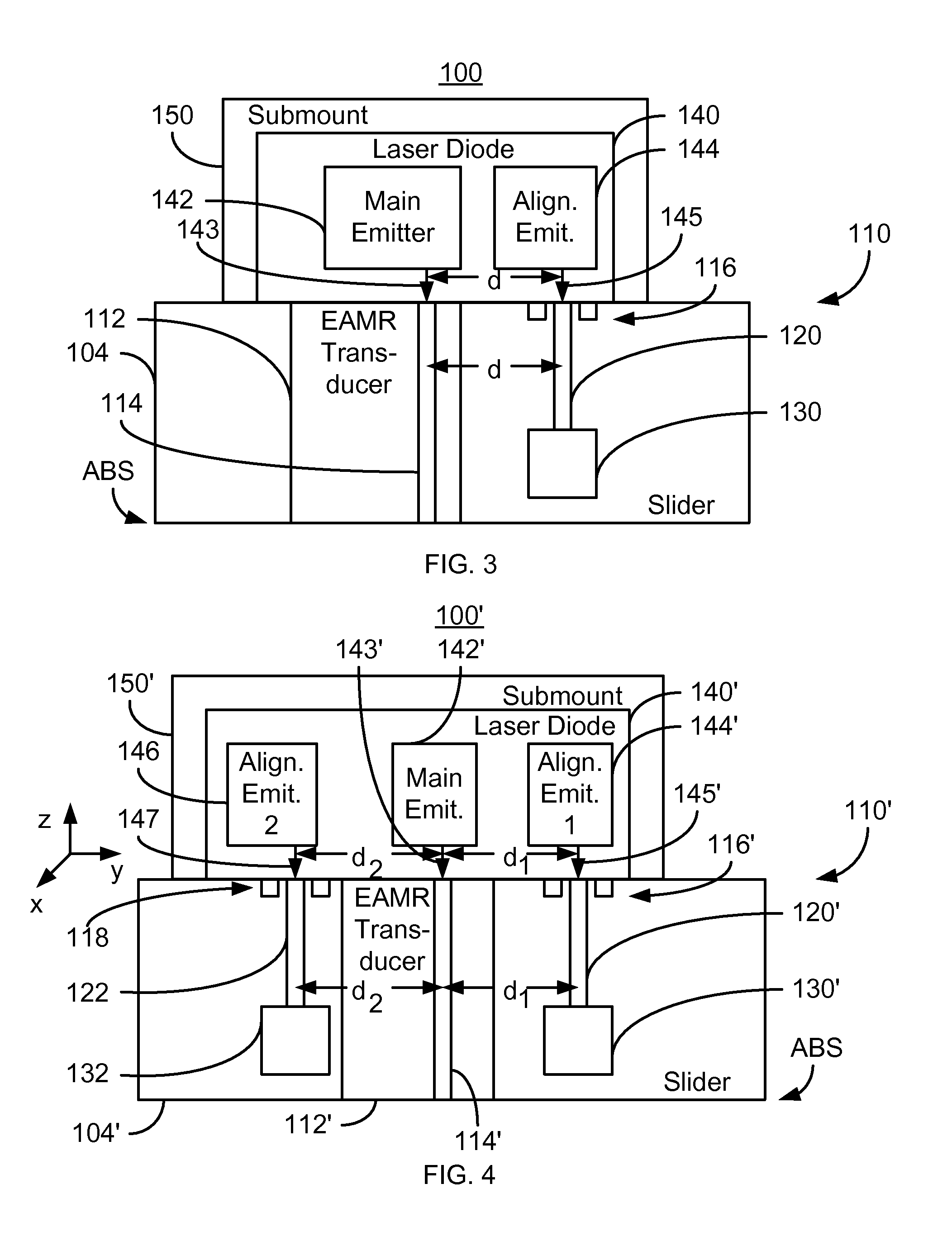

Method and system for optically coupling a laser with a transducer in an energy assisted magnetic recording disk drive

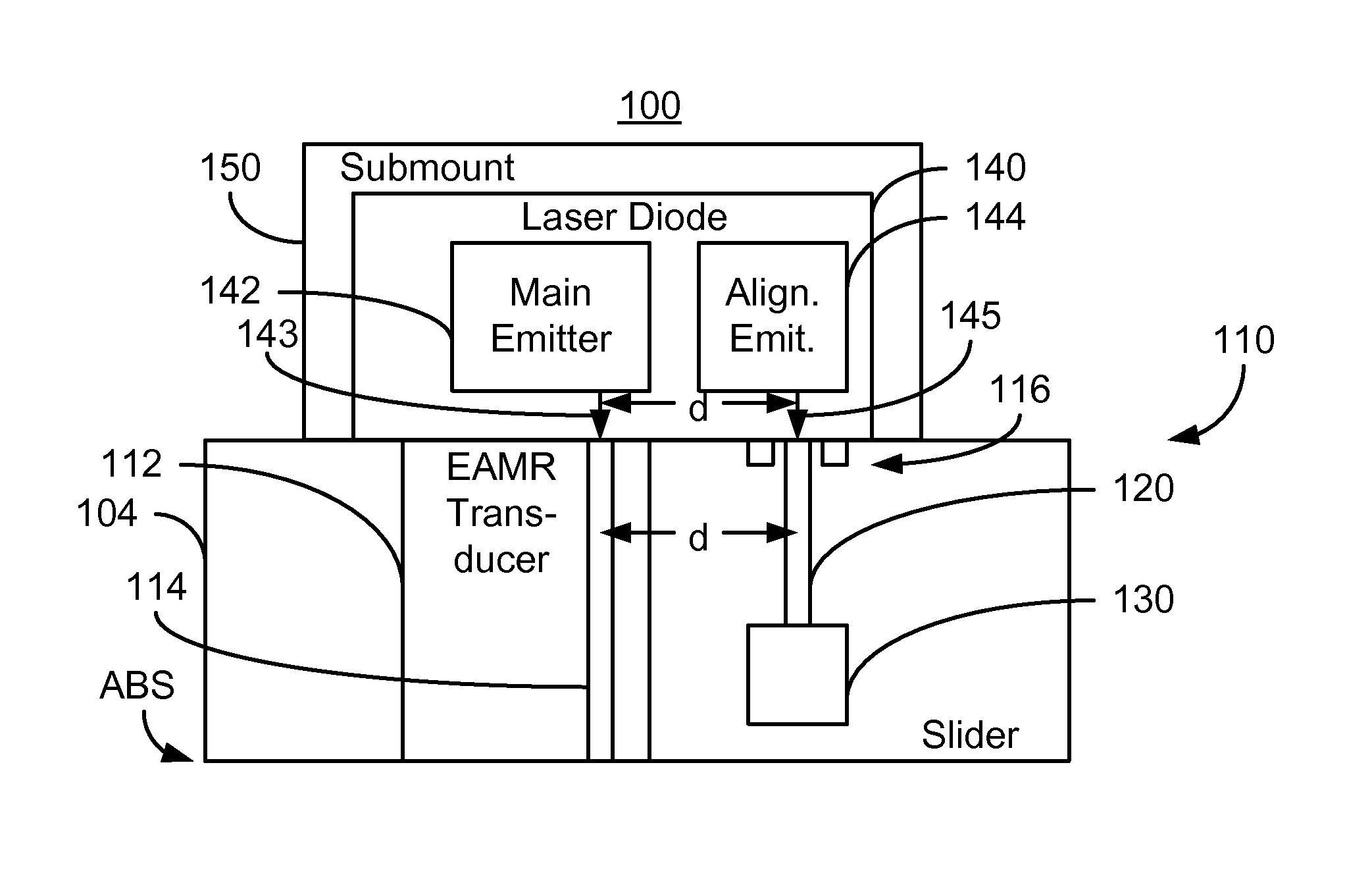

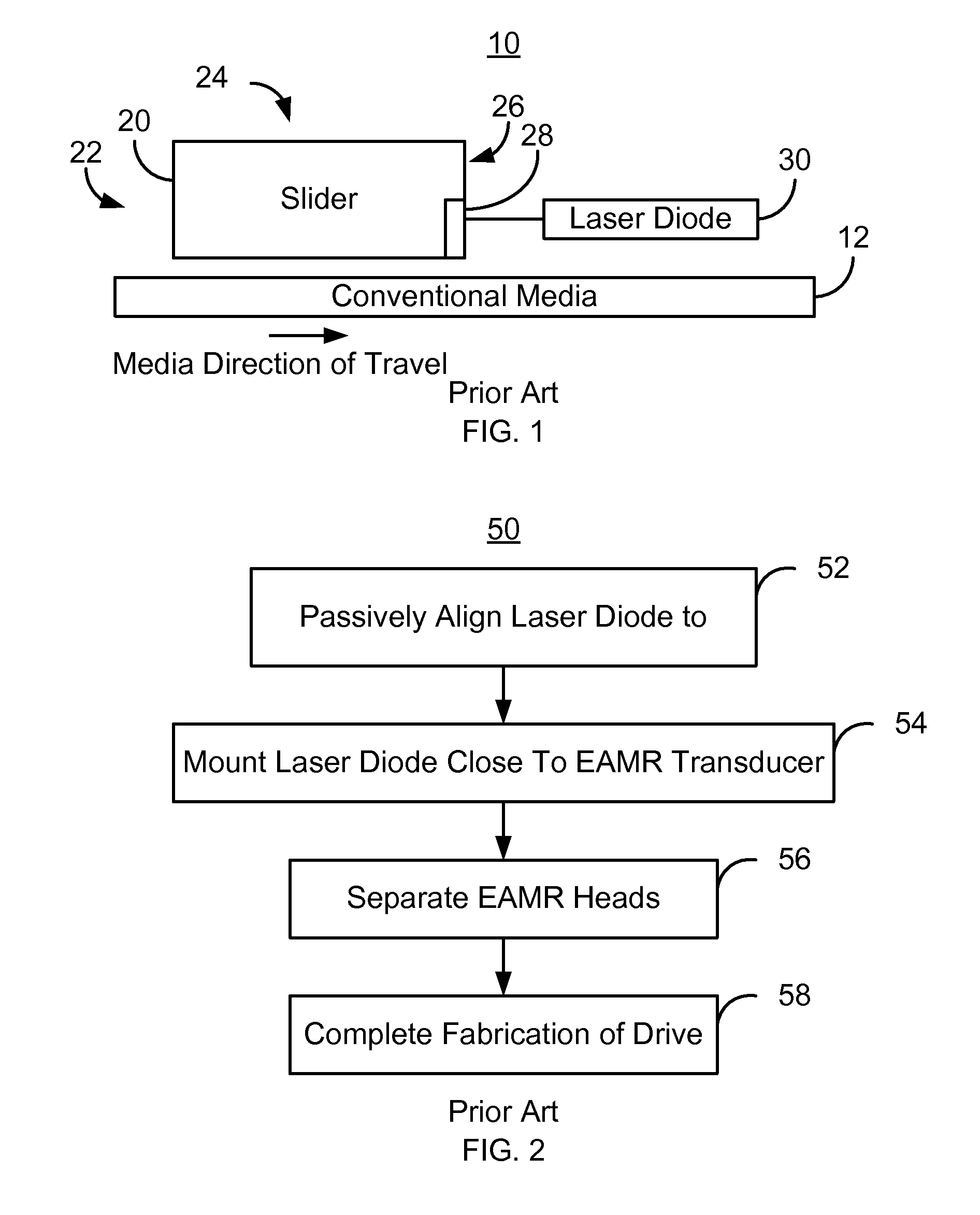

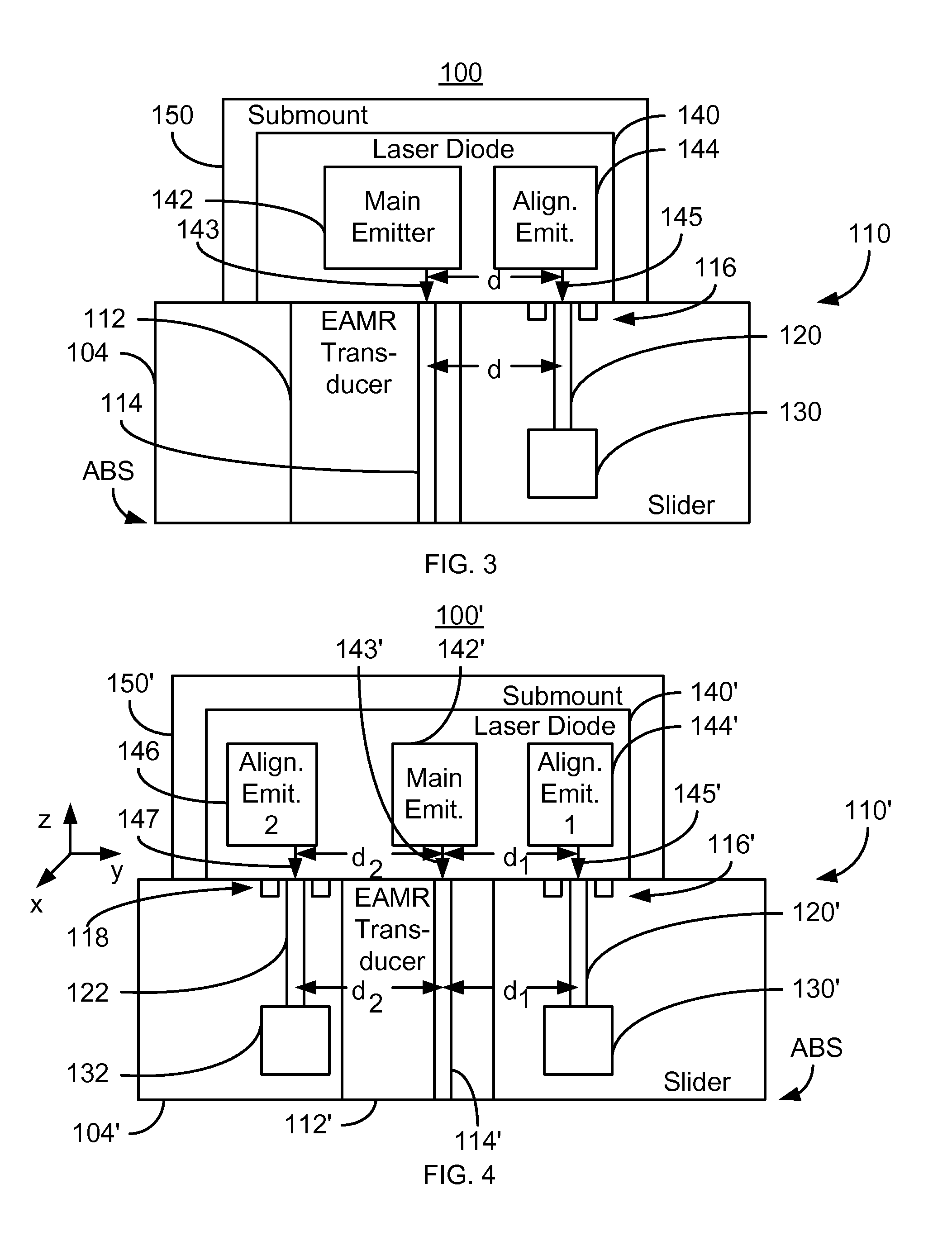

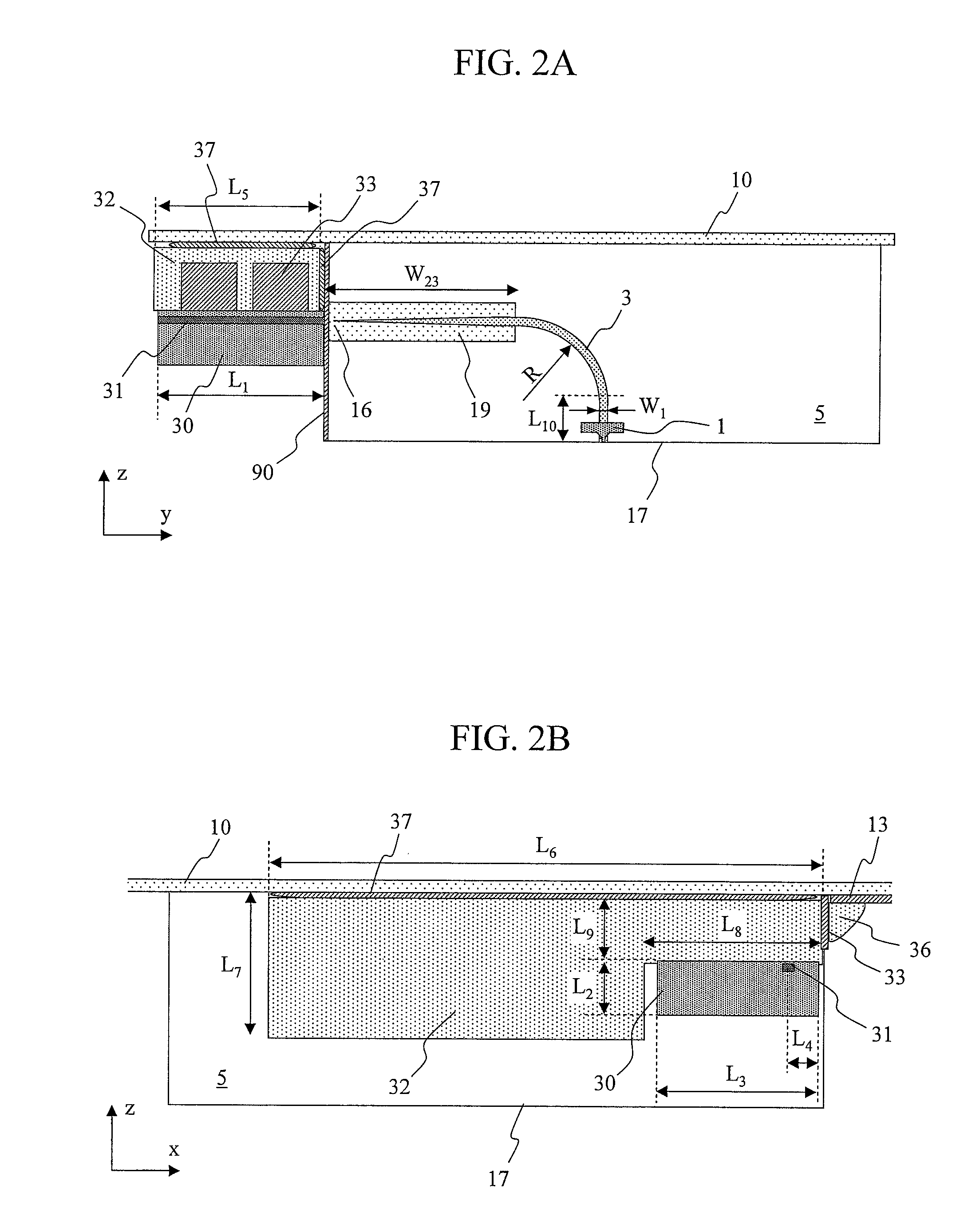

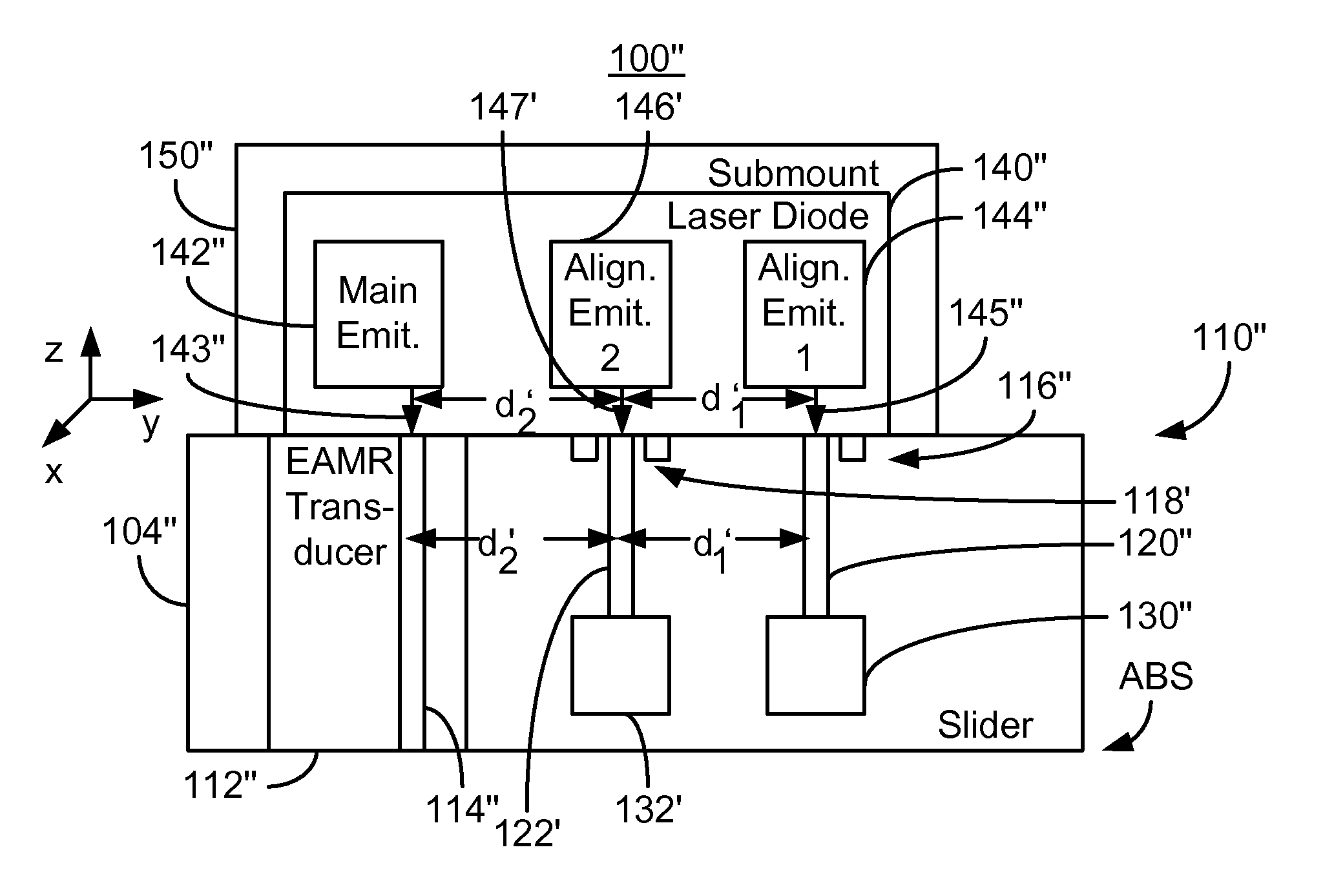

A method and system for providing an energy assisted magnetic recording (EAMR) head are described. The EAMR head includes a laser, a slider, and an EAMR transducer. The laser has a main emitter and at least one alignment emitter. The slider includes at least one alignment waveguide, at least one output device, and an air-bearing surface (ABS). The alignment waveguide(s) are aligned with the alignment emitter(s). The EAMR transducer is coupled with the slider and includes a waveguide aligned with main emitter. The waveguide is for directing energy from the main emitter toward the ABS.

Owner:WESTERN DIGITAL TECH INC

Method and system for coupling a laser with a slider in an energy assisted magnetic recording disk drive

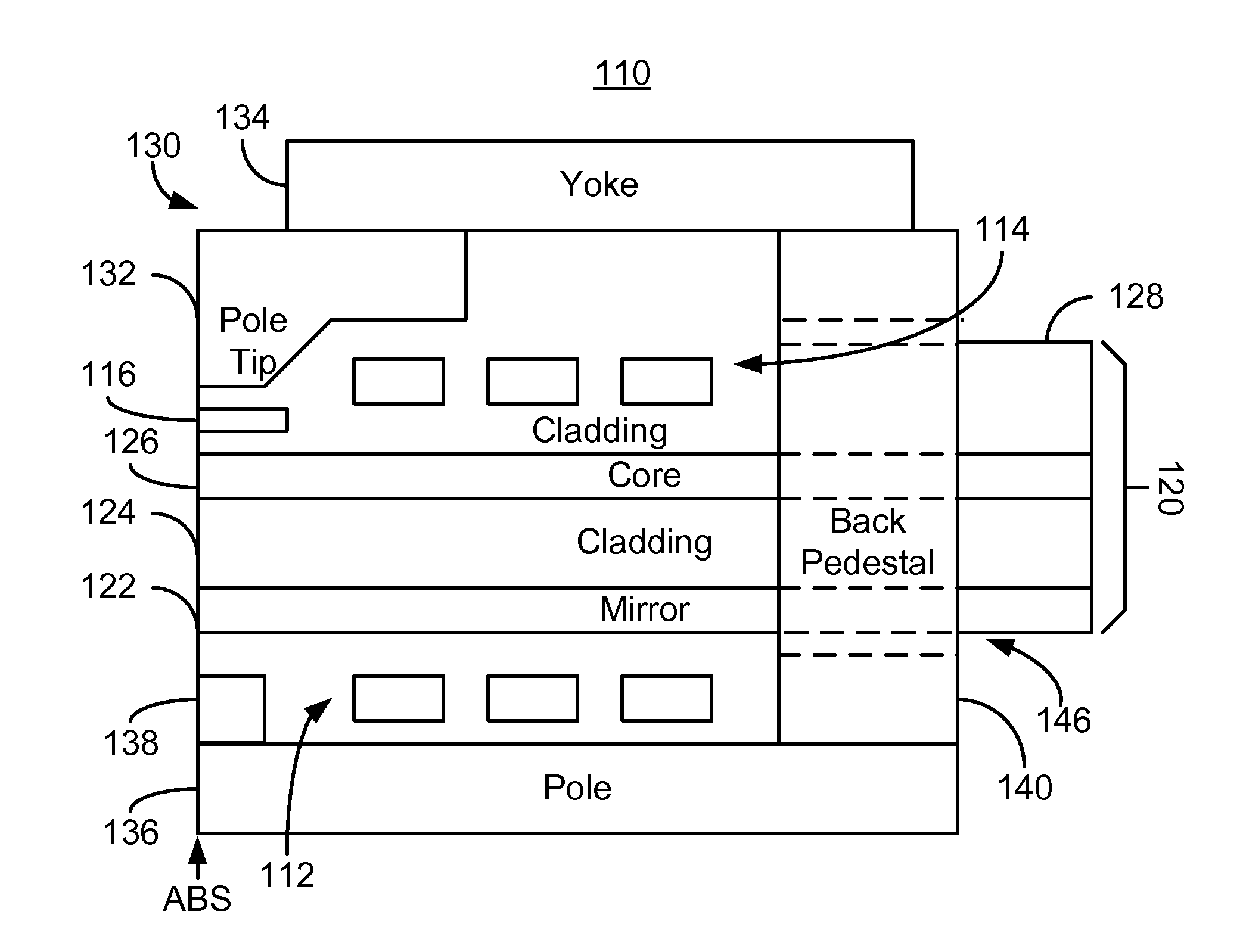

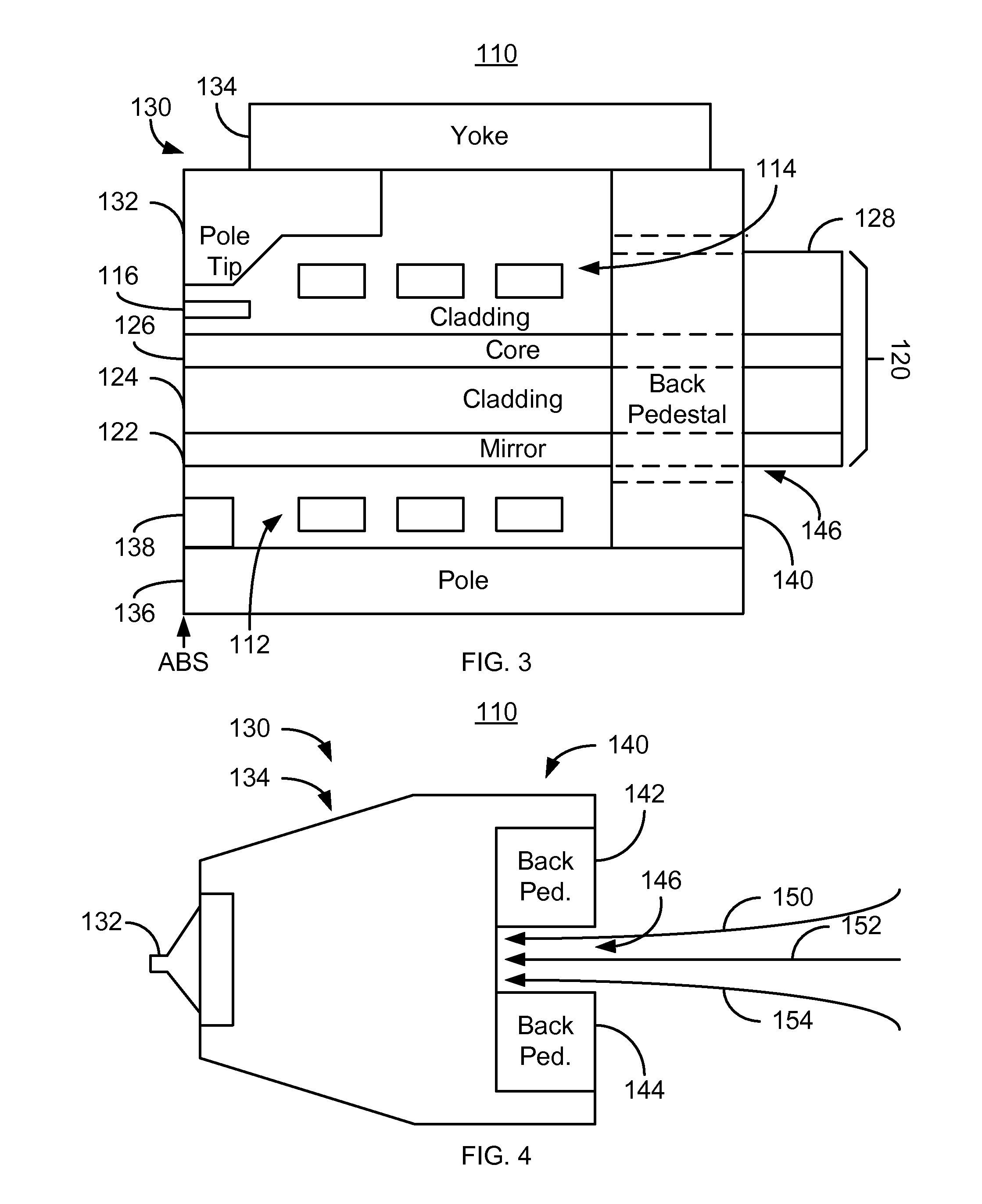

A method and system for providing an energy assisted magnetic recording (EAMR) transducer coupled with a laser are described. The EAMR transducer has an air-bearing surface (ABS) configured to reside in proximity to a media during use. The method and system include providing at least one waveguide, at least one write pole, and at least one coil. The waveguide(s) are for directing the energy from the laser toward the ABS. The write pole(s) each include a write pole tip, a yoke, a back pedestal and a return pole. The write pole tip is coupled to the back pedestal through the yoke. The back pedestal has at least one aperture therein. The aperture(s) are configured to allow the energy from the laser to pass therethrough. The coil(s) are for energizing the at least one write pole.

Owner:WESTERN DIGITAL TECH INC

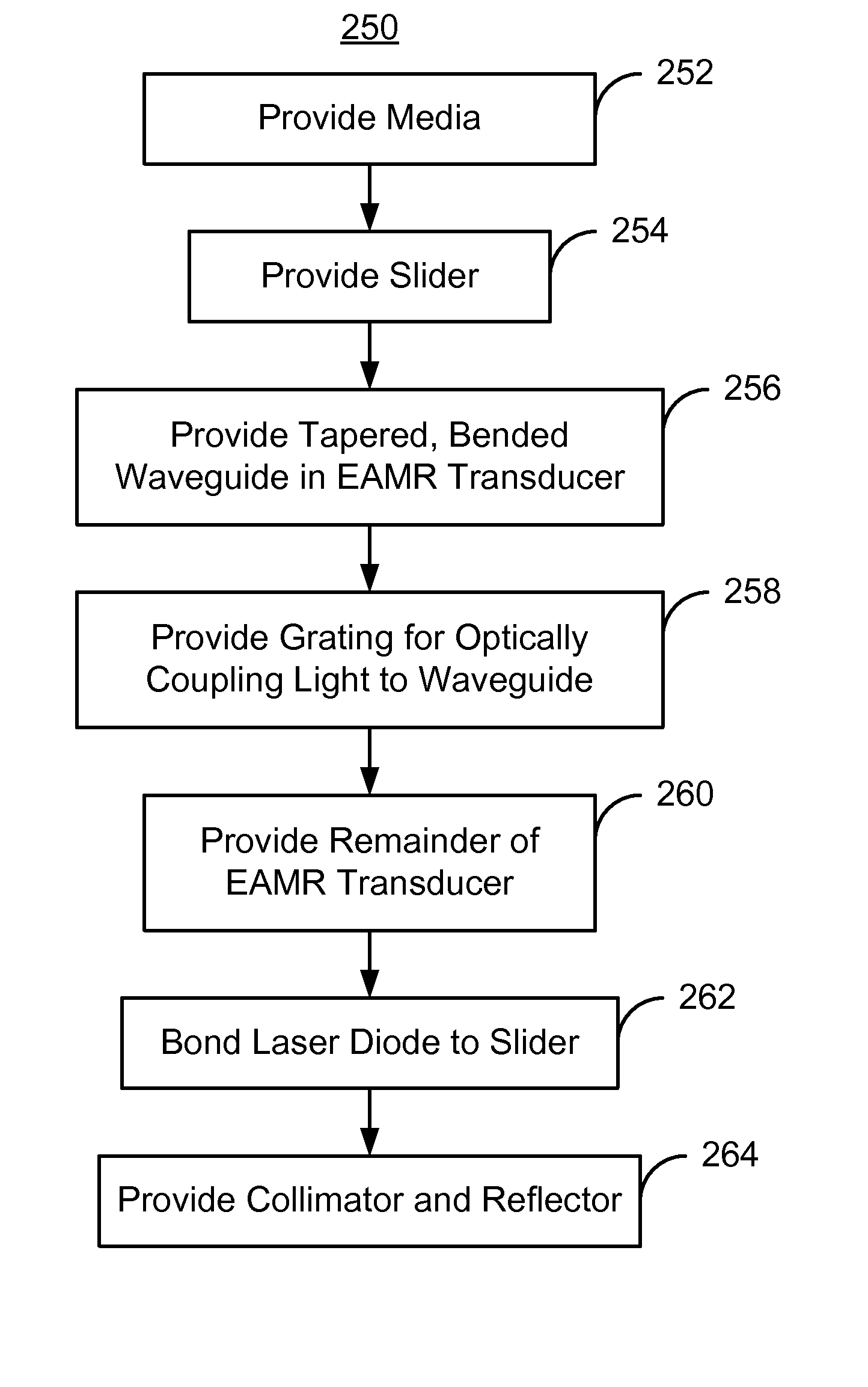

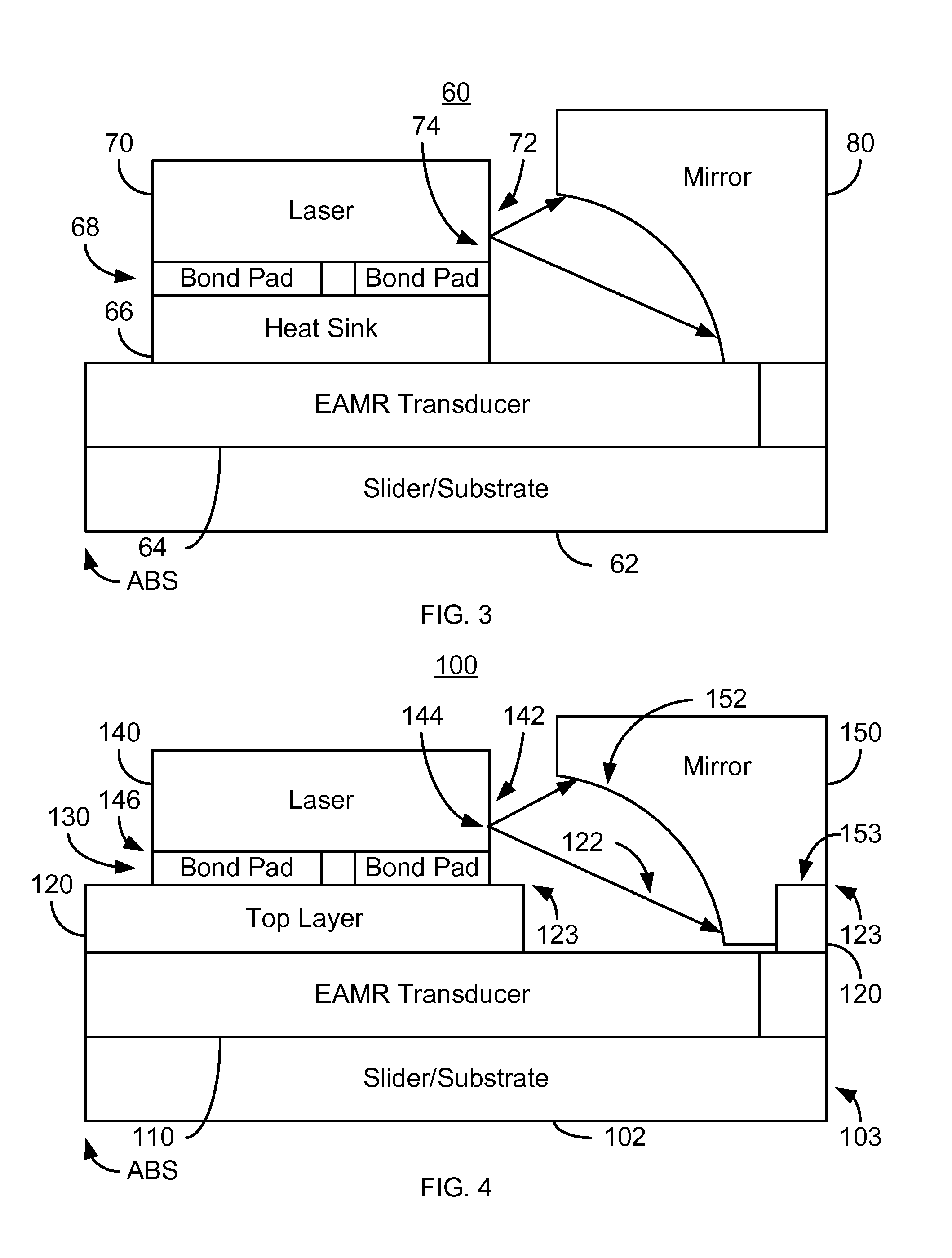

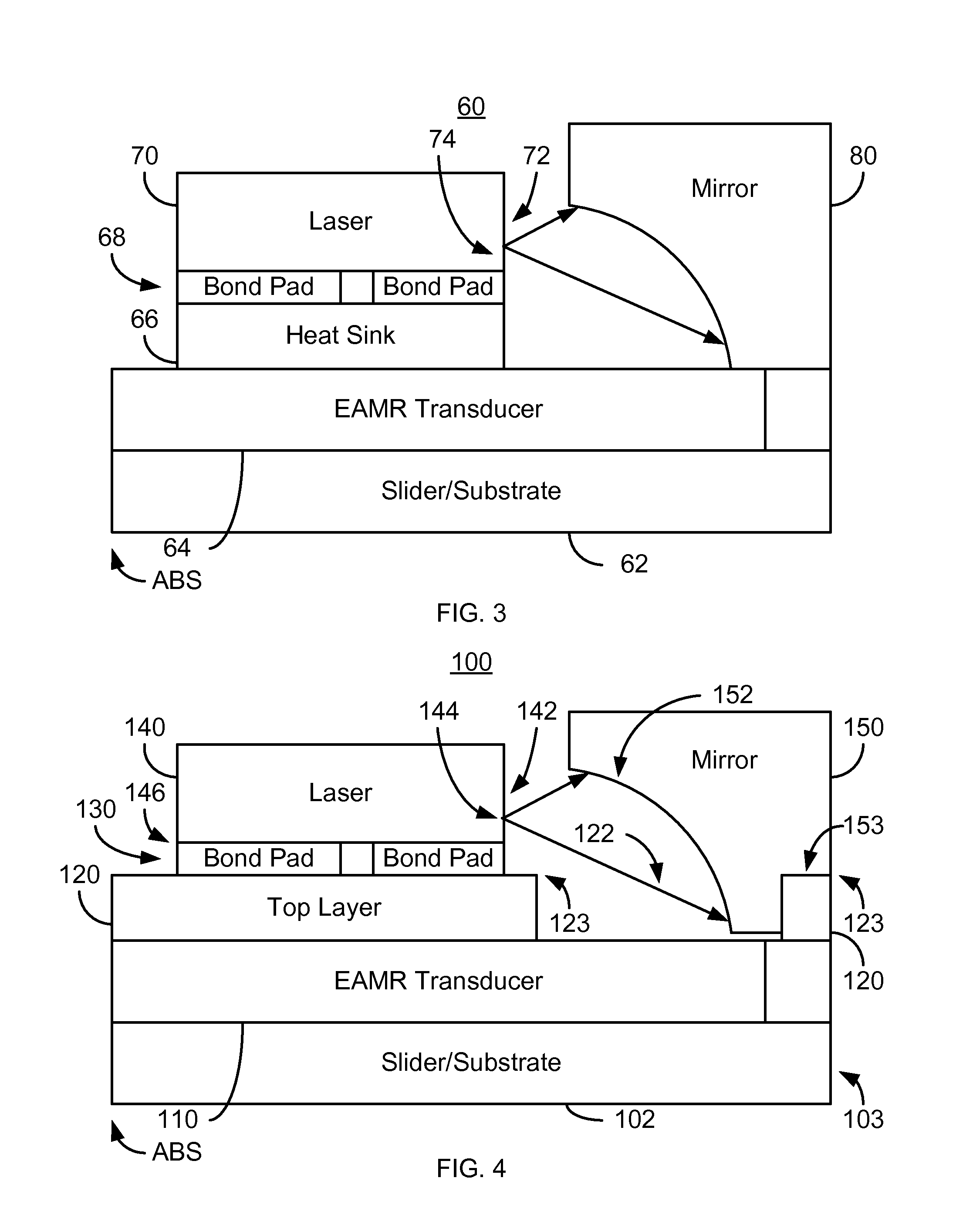

Method for providing an energy assisted magnetic recording (EAMR) head

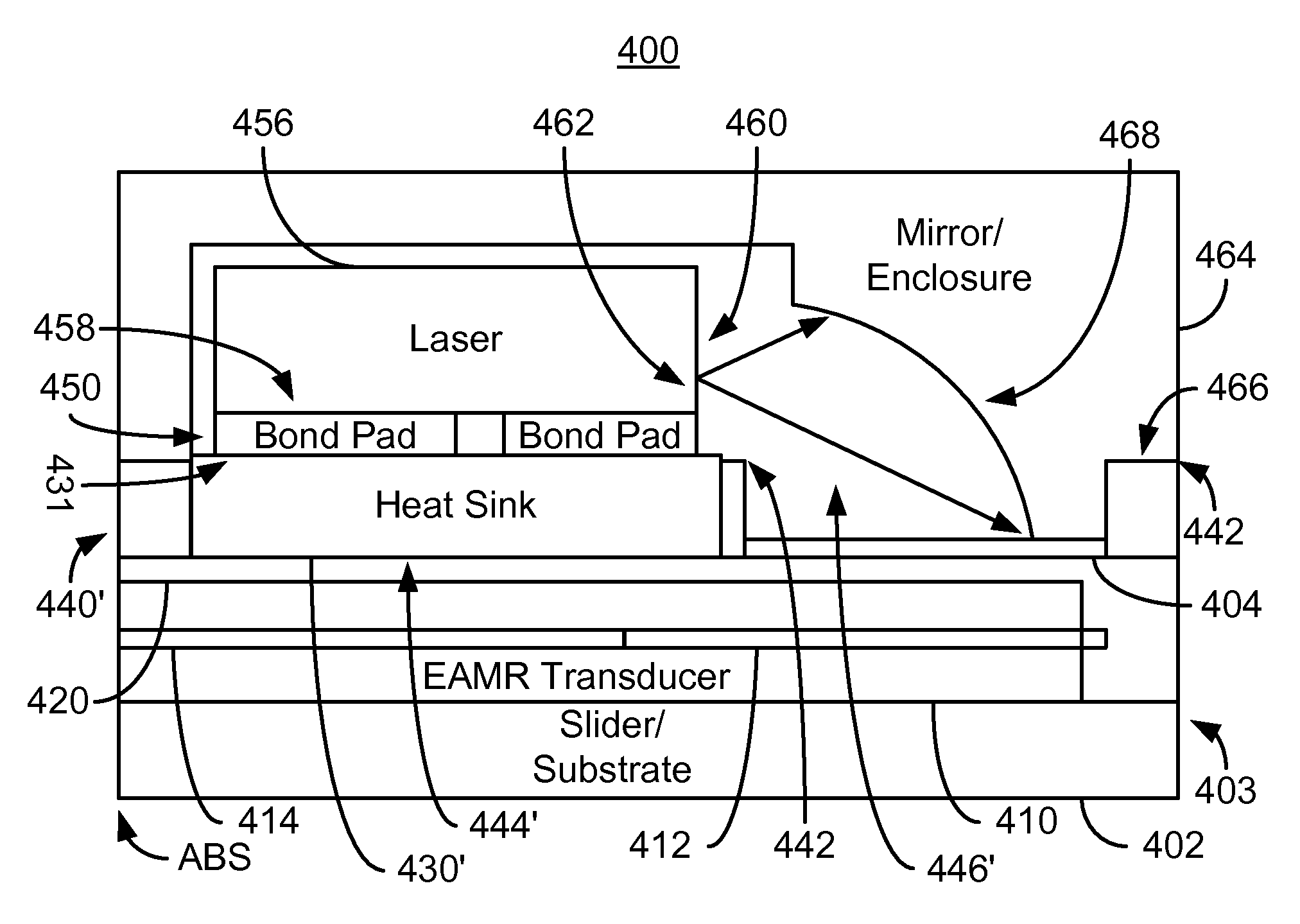

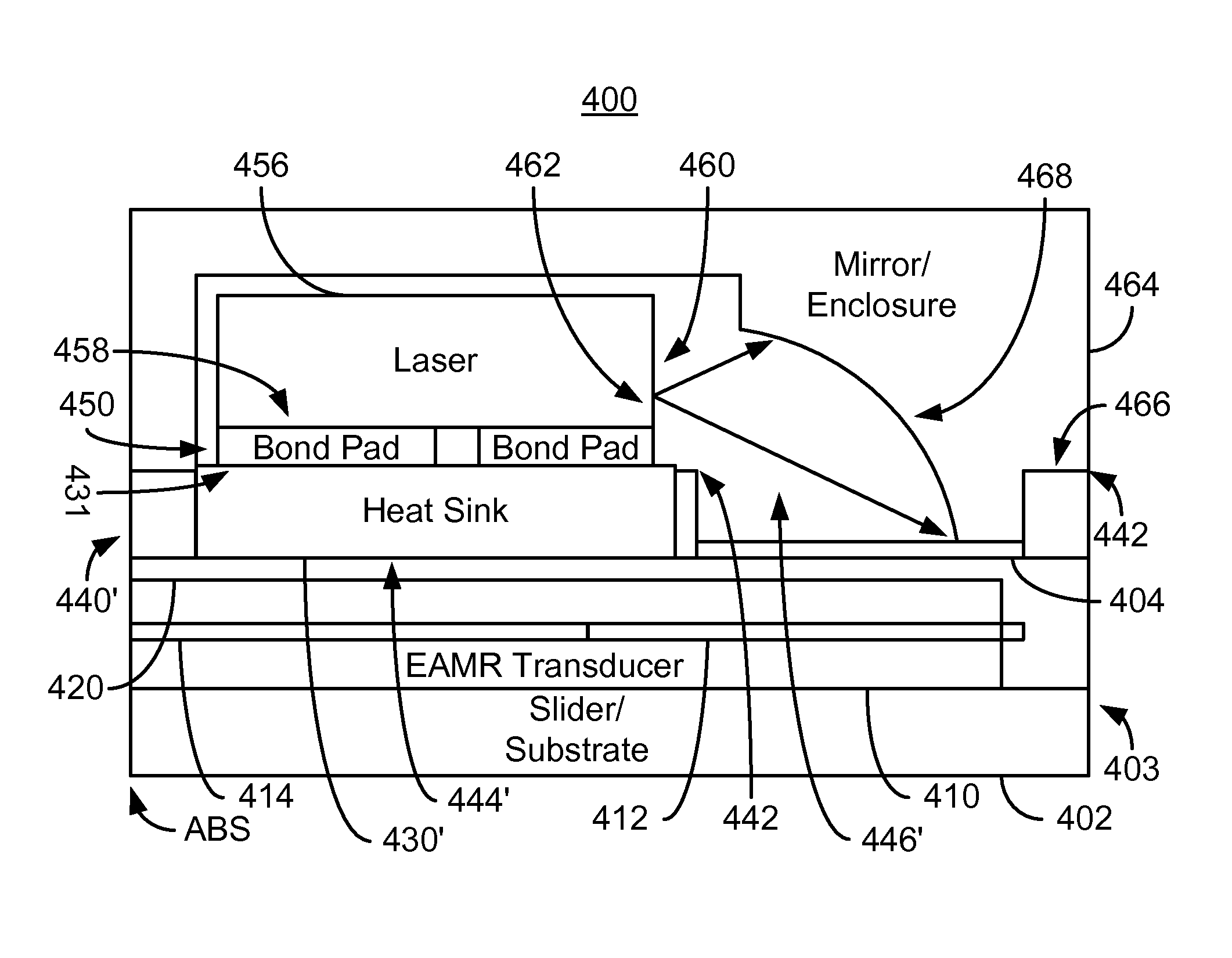

A method and system for providing an energy assisted magnetic recording (EAMR) head are described. The method and system include providing a slider, an EAMR transducer coupled with the slider, and a top layer on the slider. The top layer includes a mirror well therein and has a substantially flat top surface. The method and system further includes providing a laser including a light-emitting surface and providing a mirror optically coupled with the laser. The laser is coupled to the top surface of the top layer external to the mirror well. The mirror has a bottom surface and a reflective surface facing the light-emitting surface of the laser. A portion of the bottom surface of the mirror is affixed to the top surface of the top layer. A portion of the mirror resides in the mirror well.

Owner:WESTERN DIGITAL TECH INC

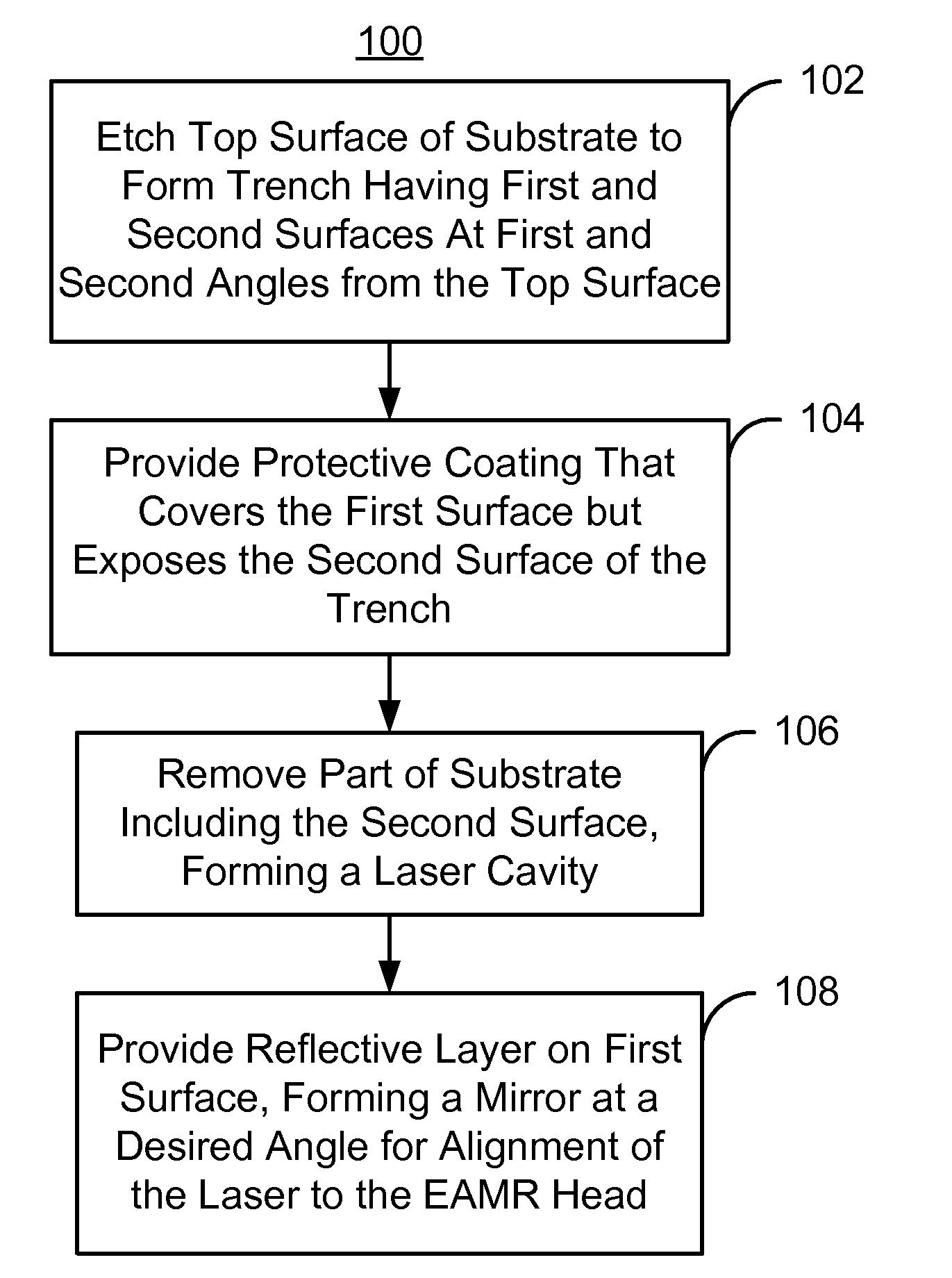

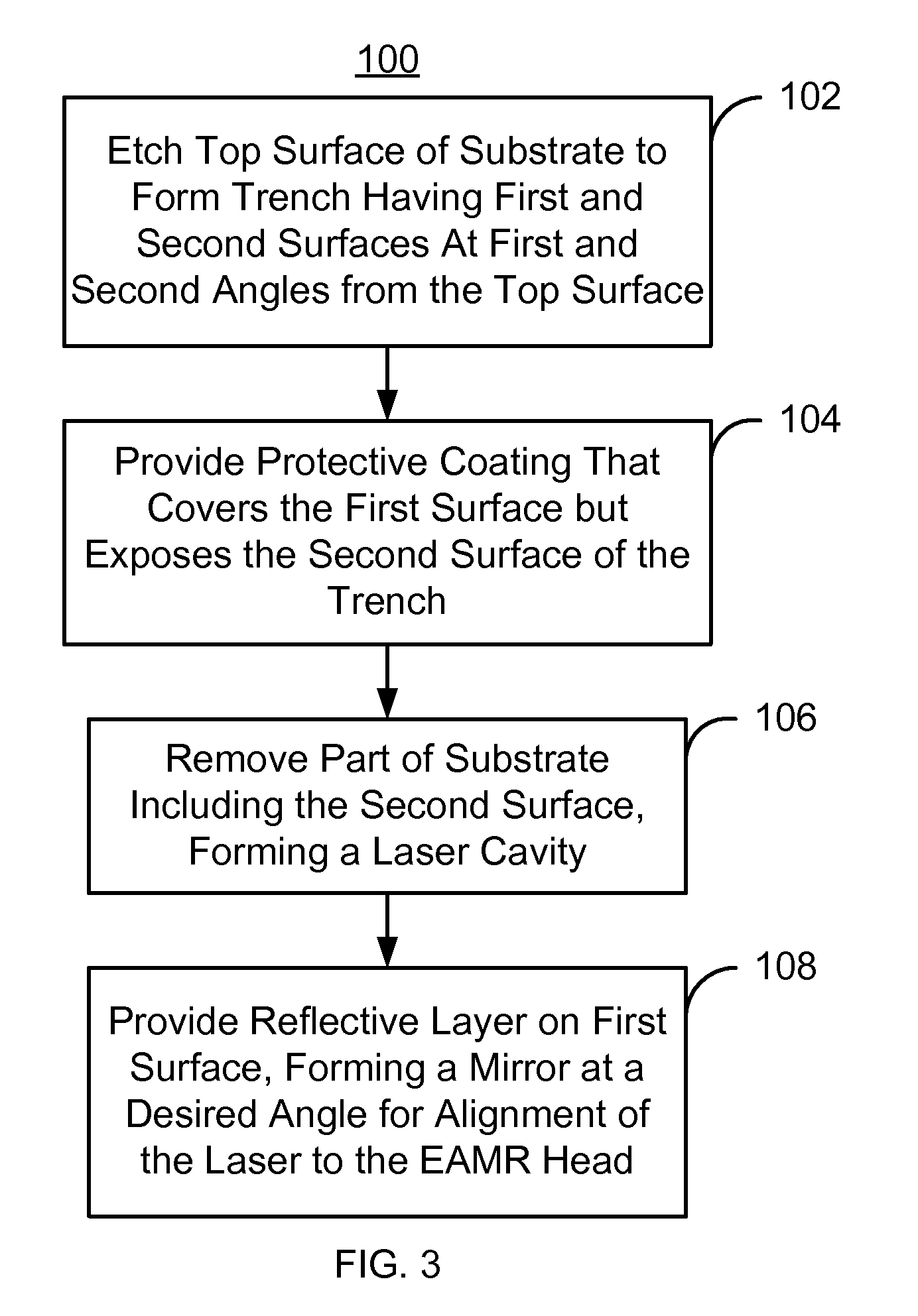

Method and system for providing a laser cavity for an energy assisted magnetic recording head

A method for providing a capping layer configured for an energy assisted magnetic recording (EAMR) head including at least one slider. The method comprises etching a substrate having a top surface using an etch to form a trench in the substrate, the trench having a first surface at a first angle from the top surface and a second surface having a second angle from the top surface. The method further comprises providing a protective coating exposing the second surface and covering the first surface, removing a portion of the substrate including the second surface to form a laser cavity within the substrate configured to fit a laser therein, and providing a reflective layer on the first surface to form a mirror, the cavity and mirror being configured for alignment of the laser to the laser cavity and to the mirror and for bonding the laser to the laser cavity.

Owner:WESTERN DIGITAL TECH INC

Method and system for providing an energy assisted magnetic recording head

A method and system for providing an energy assisted magnetic recording (EAMR) head are described. The method and system include providing a slider, an EAMR transducer coupled with the slider, and a top layer on the slider. The top layer includes a mirror well therein and has a substantially flat top surface. The method and system further includes providing a laser including a light-emitting surface and providing a mirror optically coupled with the laser. The laser is coupled to the top surface of the top layer external to the mirror well. The mirror has a bottom surface and a reflective surface facing the light-emitting surface of the laser. A portion of the bottom surface of the mirror is affixed to the top surface of the top layer. A portion of the mirror resides in the mirror well.

Owner:WESTERN DIGITAL TECH INC

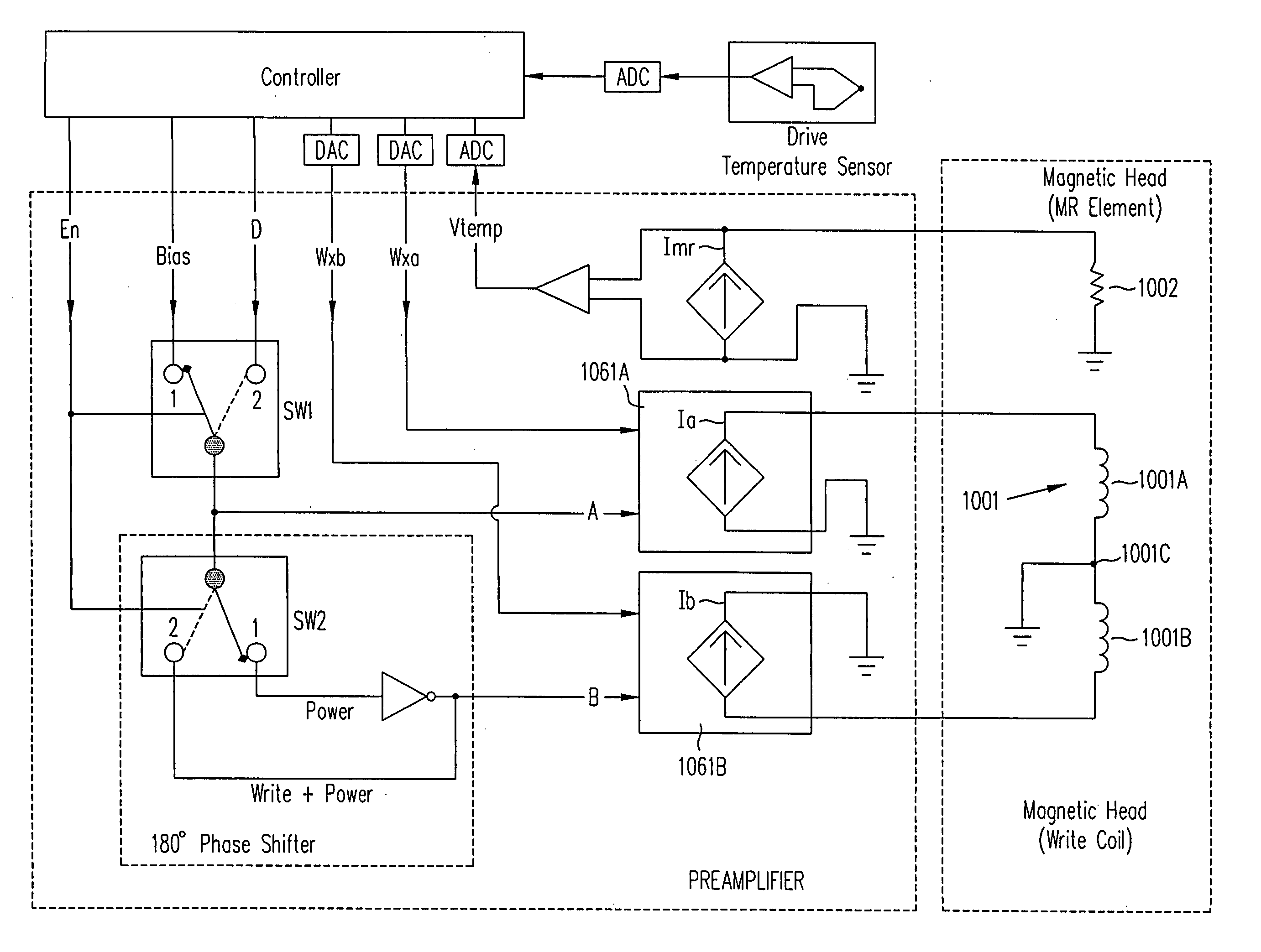

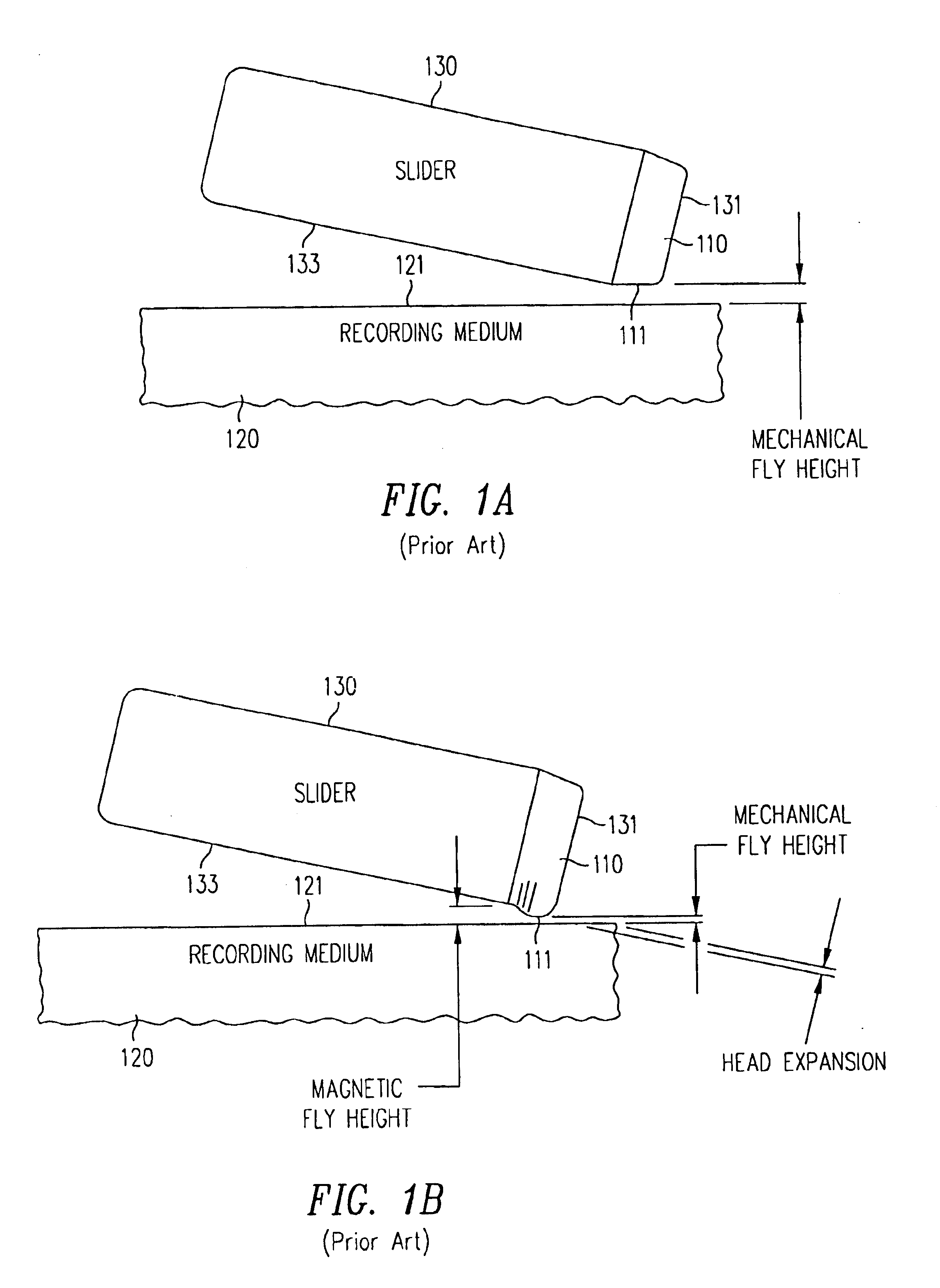

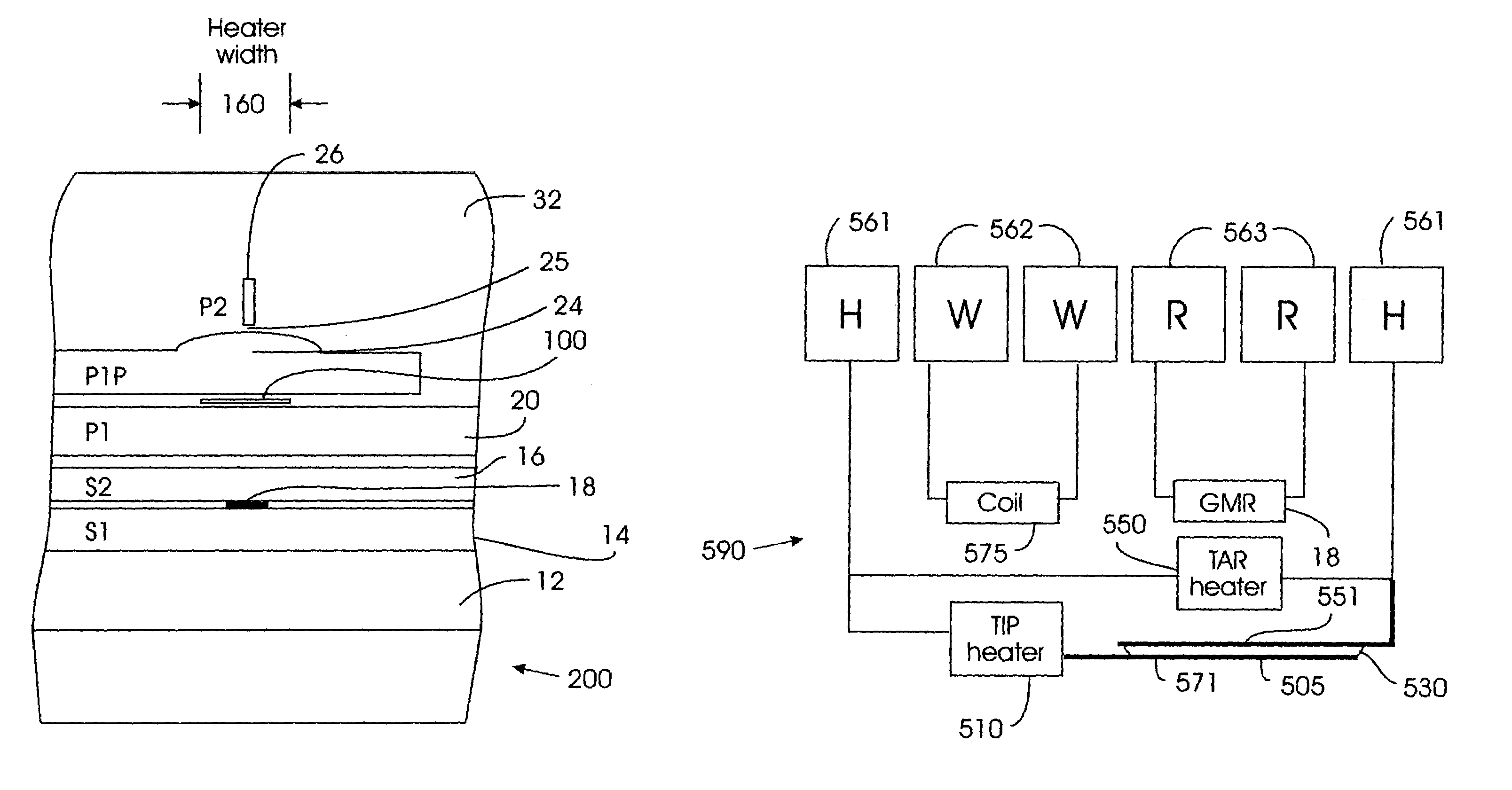

Storage device including a center tapped write transducer

A head for use in a drive includes a heating element capable of generating heat sufficient to cause the head to have a shape that is similar or identical to the shape that the head has when performing an operation (e.g. writing) on a recording medium in the drive. The heating element is activated when the operation is not being performed. Hence, a head generates the same amount (or similar amount) of heat and is therefore at the same temperature (also called “operating temperature”), regardless of whether or not an operation (such as writing) is being performed. Therefore, the head maintains a fixed shape or has a shape that varies minimally, within a predetermined range around the fixed shape, that in turn results in maintaining fly height (distance between the head and the recording medium). The heating element may be implemented to use loss mechanisms inherent in a write transducer, e.g. by providing a center tap to the write transducer. When using a center tapped write transducer, currents in phase with one another are provided to perform a write operation. When not performing the write operation, the same currents are provided, but out of phase.

Owner:WESTERN DIGITAL TECH INC

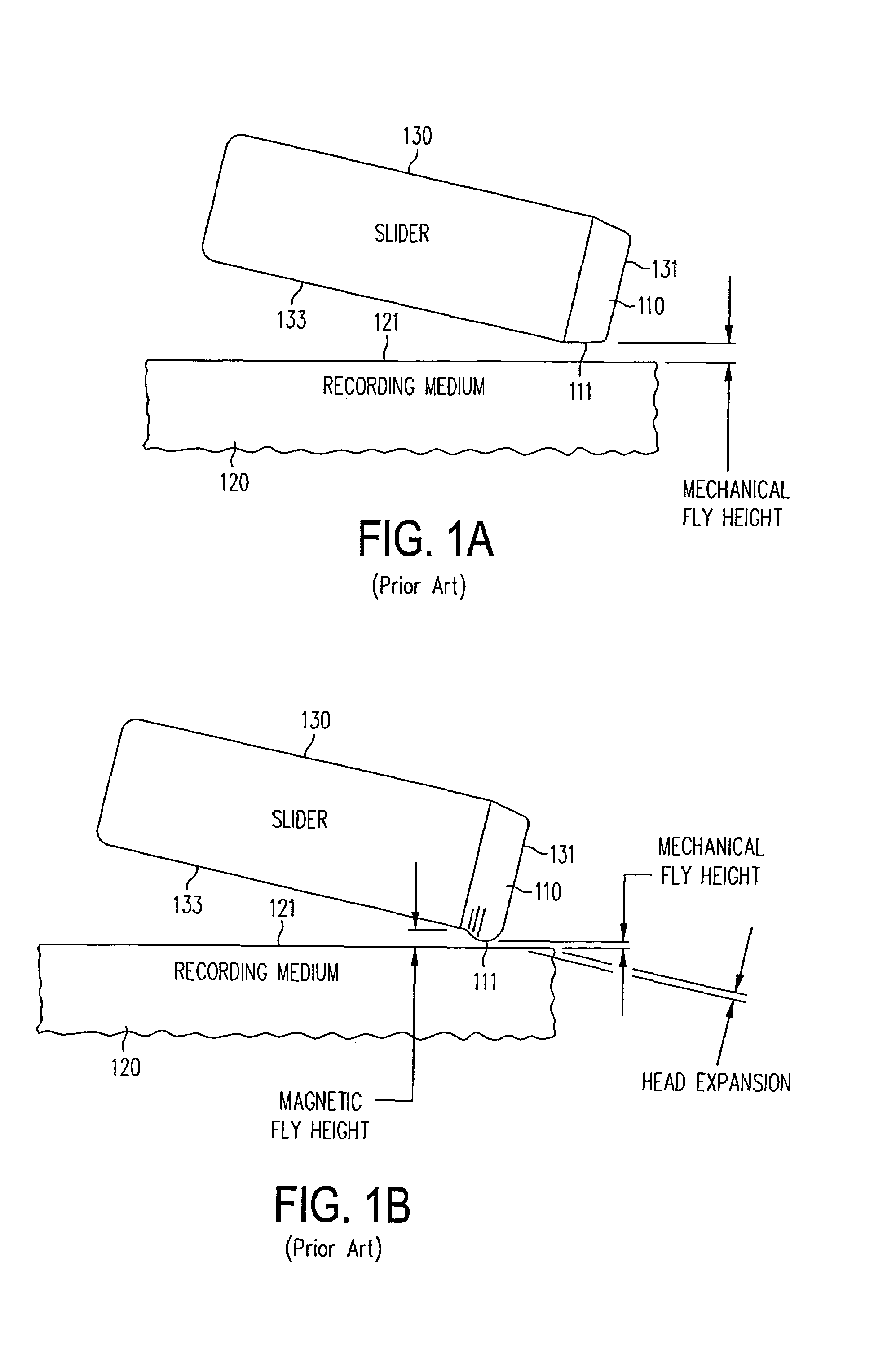

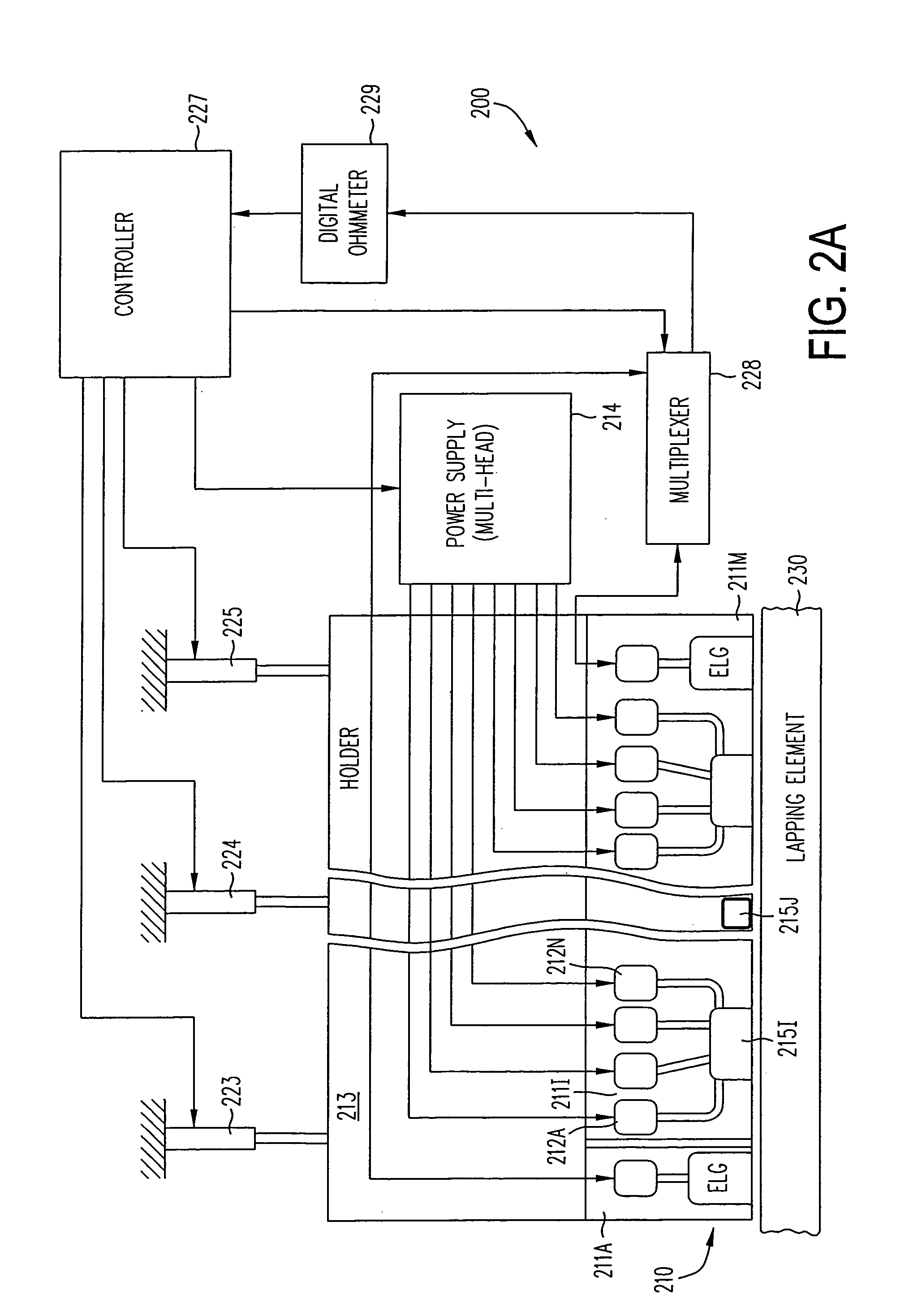

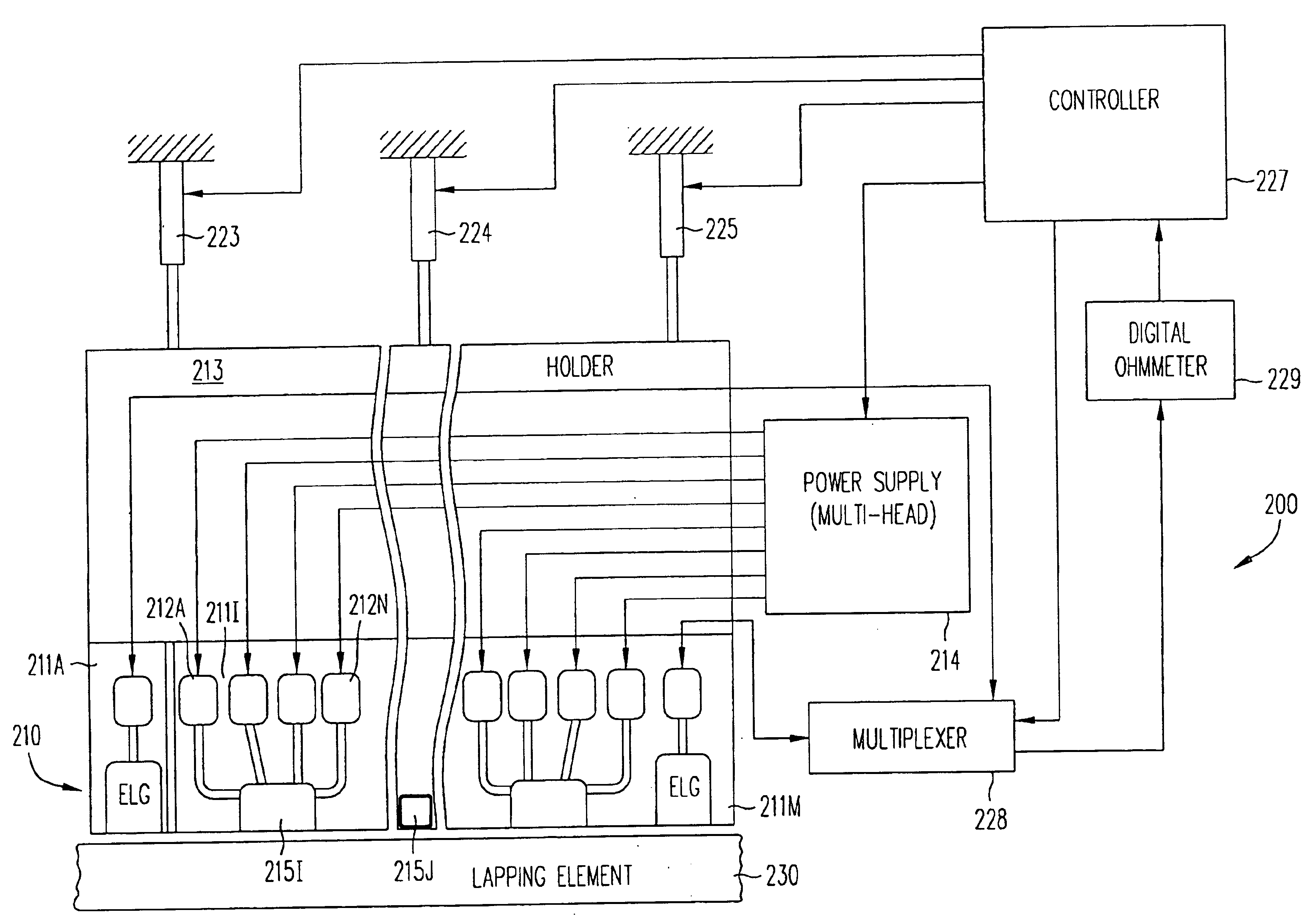

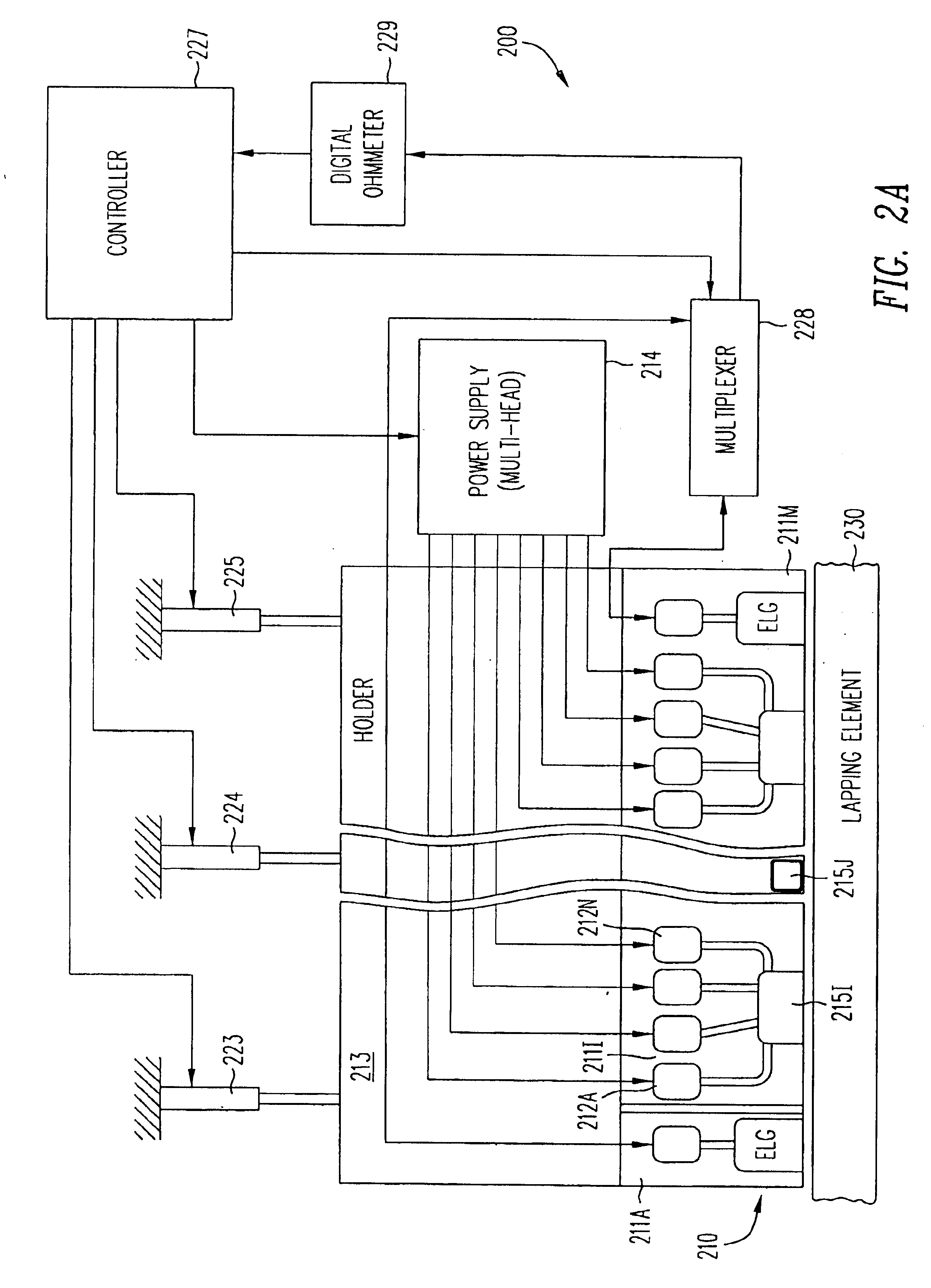

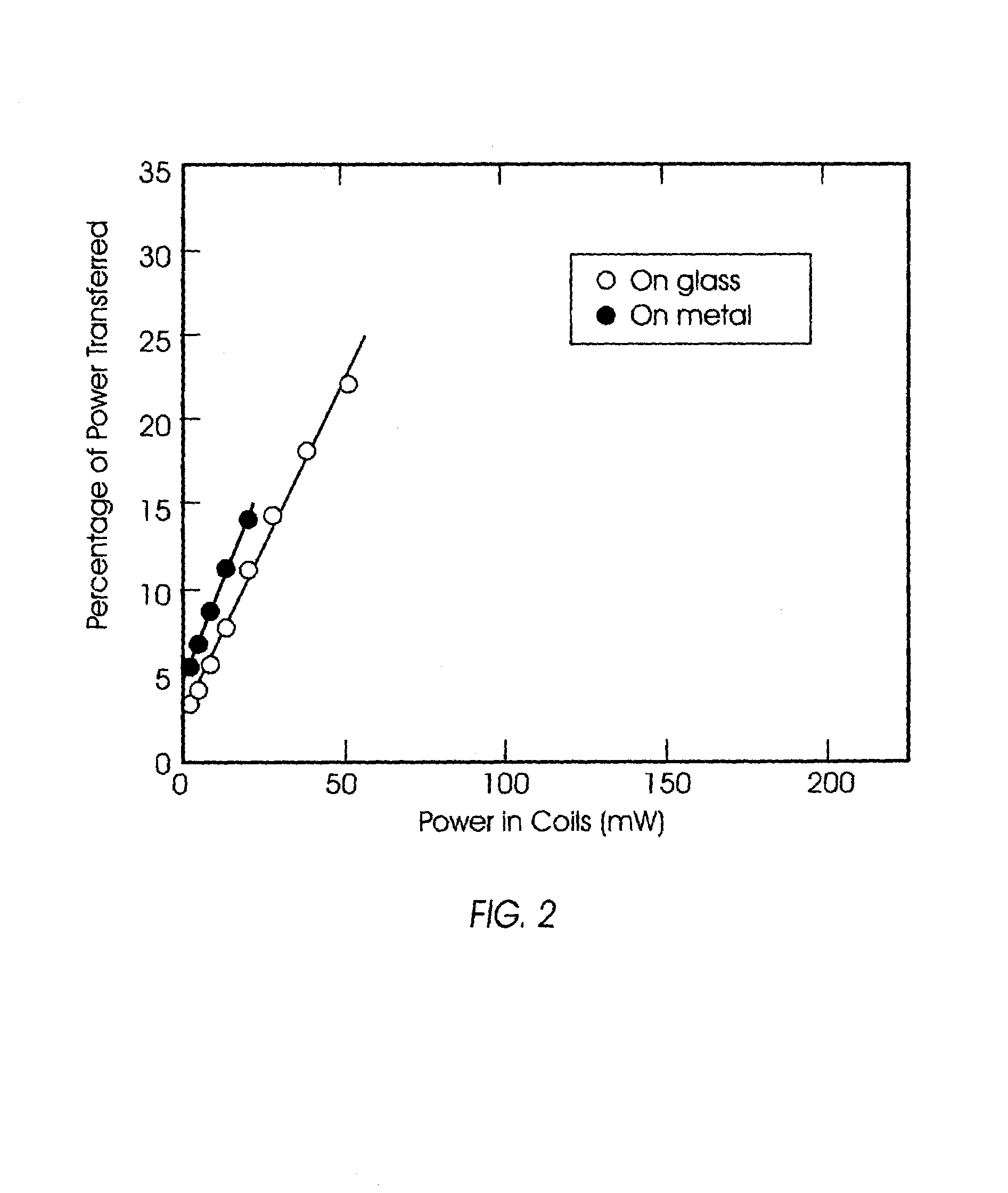

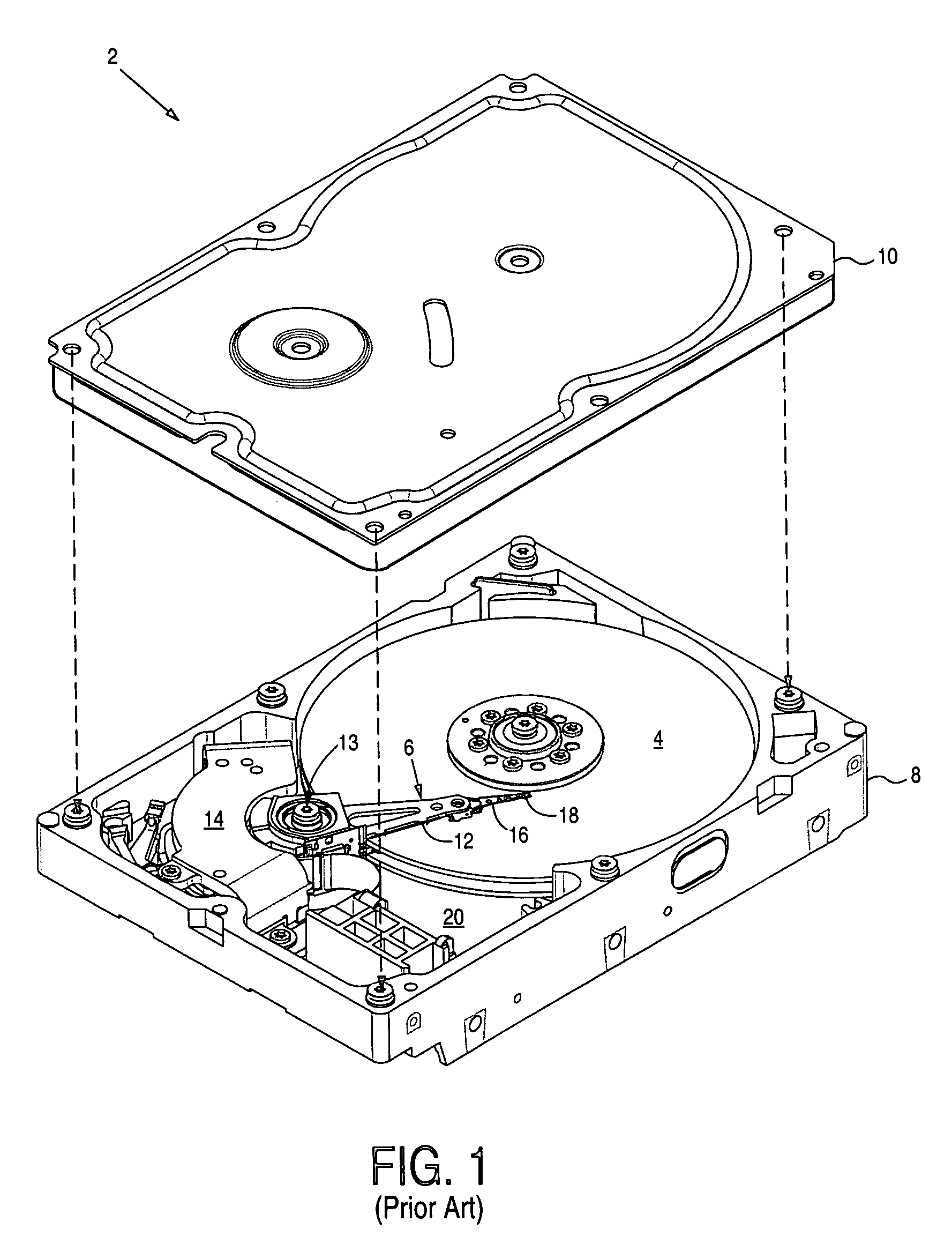

Lapping a head while powered up to eliminate expansion of the head due to heating

A head is fabricated using photolithography, and the head is purposely powered up during a material removal process, such as lapping, so that the head's expansion (that would be formed on being powered up during normal usage in a drive) is planarized. Specifically, the head is energized in a manner identical (or similar) to energization of circuitry in the head during normal operation in a drive, even though fabrication of the head has not yet been completed. When energized, a shape that the head would have during normal operation is replicated (or approximated). Therefore, the head's shape includes a expansion of the pole tip region, although the head is only partially fabricated. Thereafter, a portion of the head in the expansion is partially or completely removed, by lapping while energized. The depth of material removal from the head is monitored e.g. by a controller sensitive to a change in electrical characteristic of a device (such as a resistor) that is normally fabricated during photolithography of the head.

Owner:WD MEDIA

Recording head

InactiveUS20080056073A1Reduce lossesEffective guidanceCombination recordingIntegrated optical head arrangementsHeat-assisted magnetic recordingLight beam

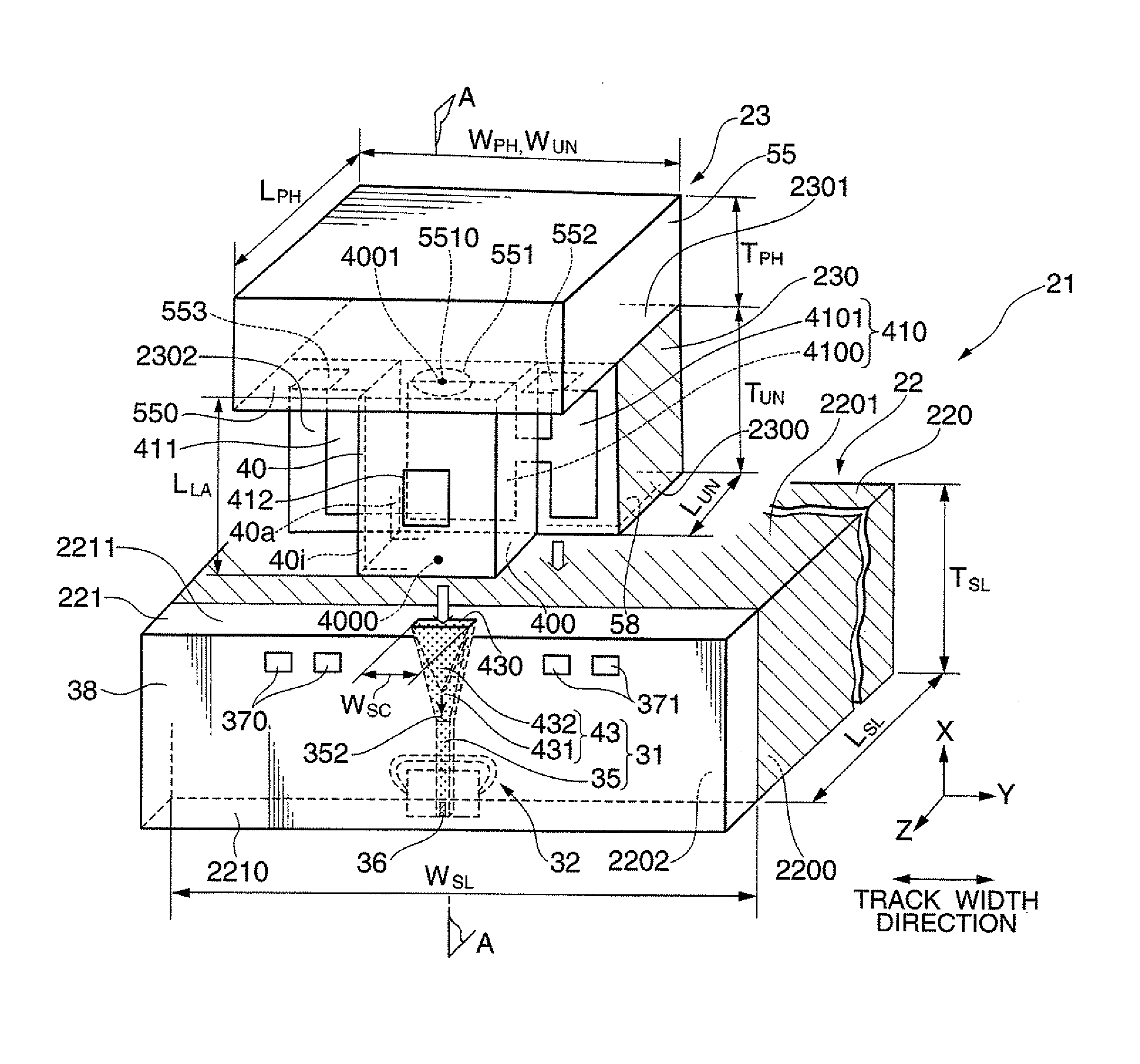

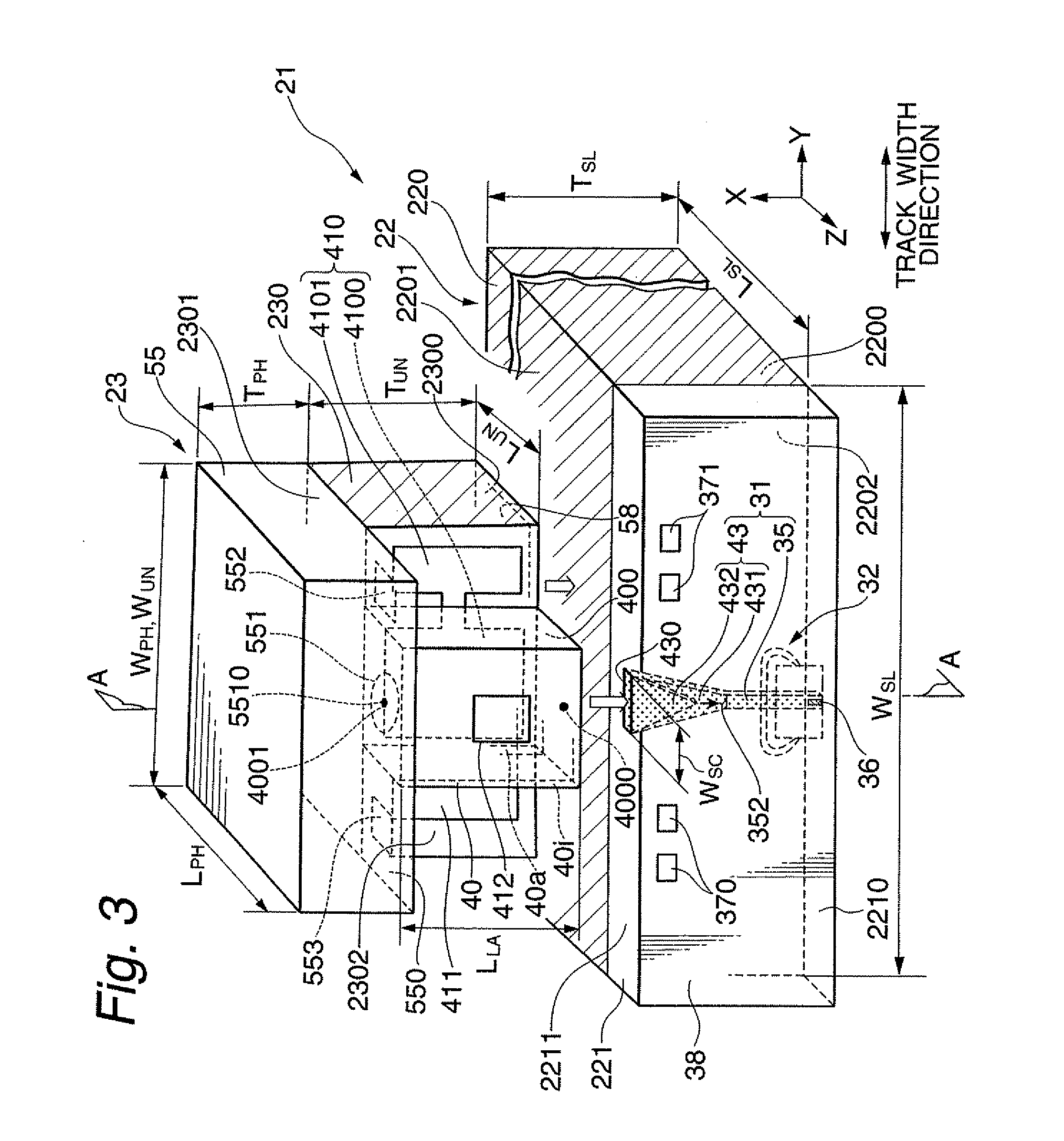

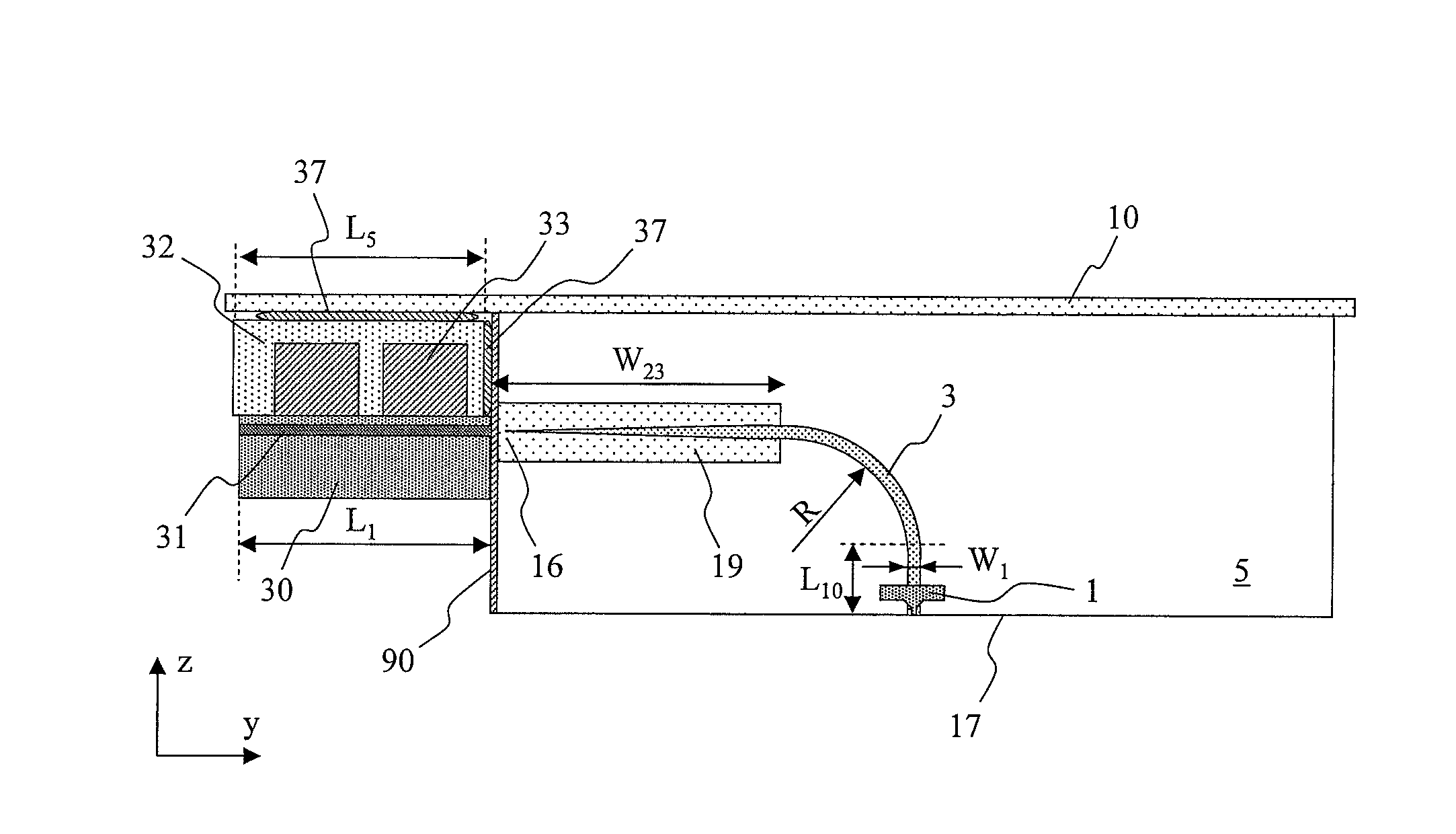

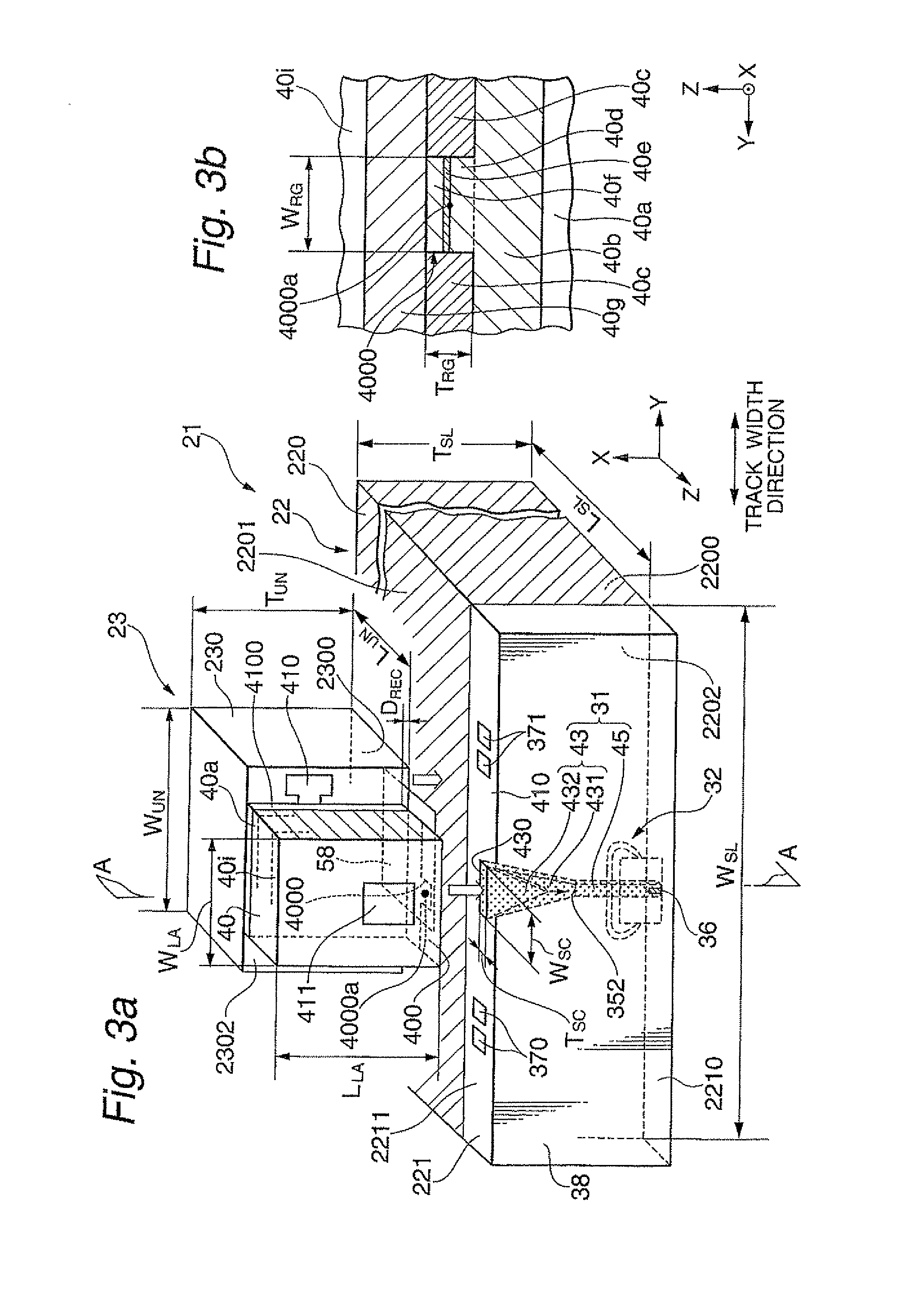

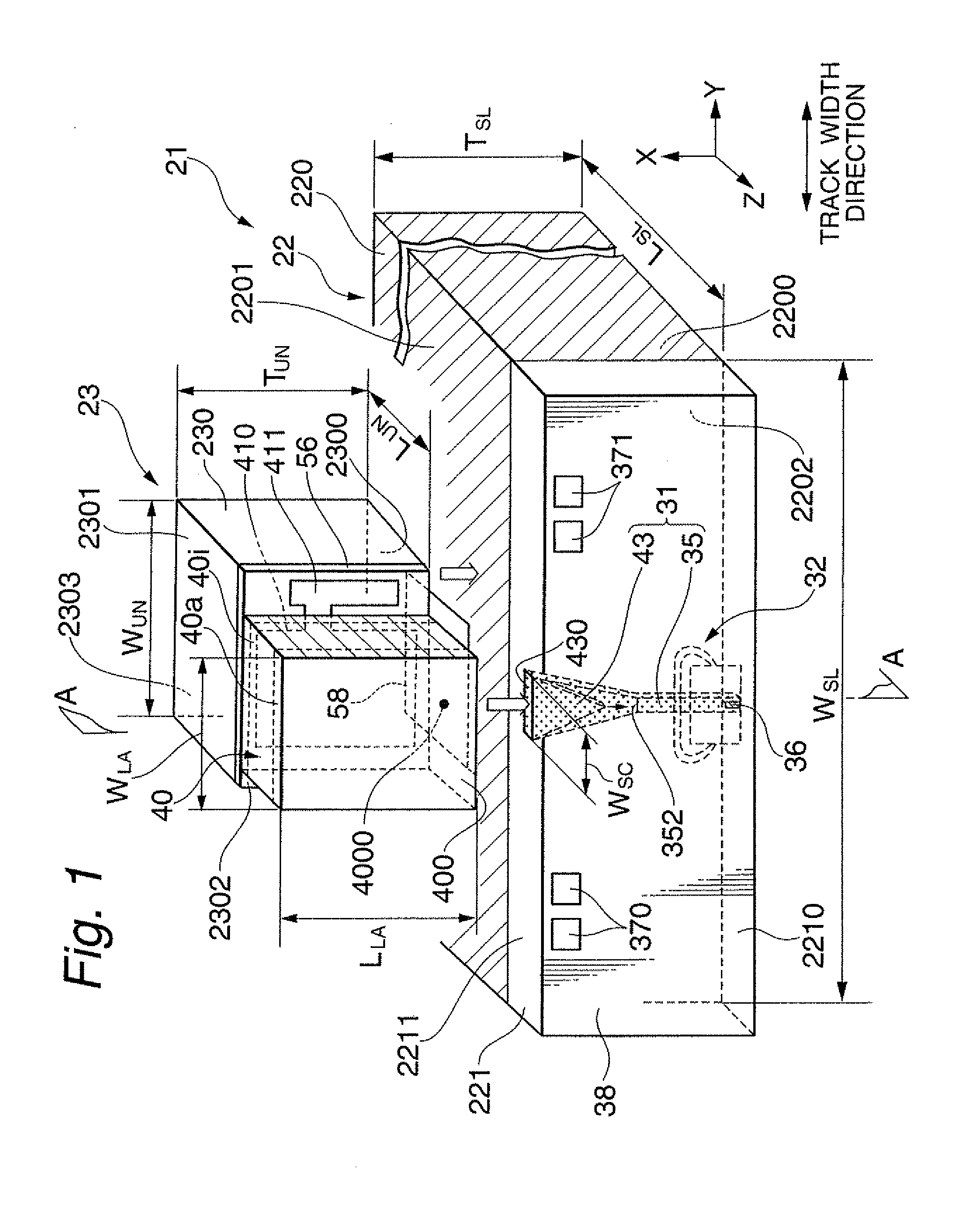

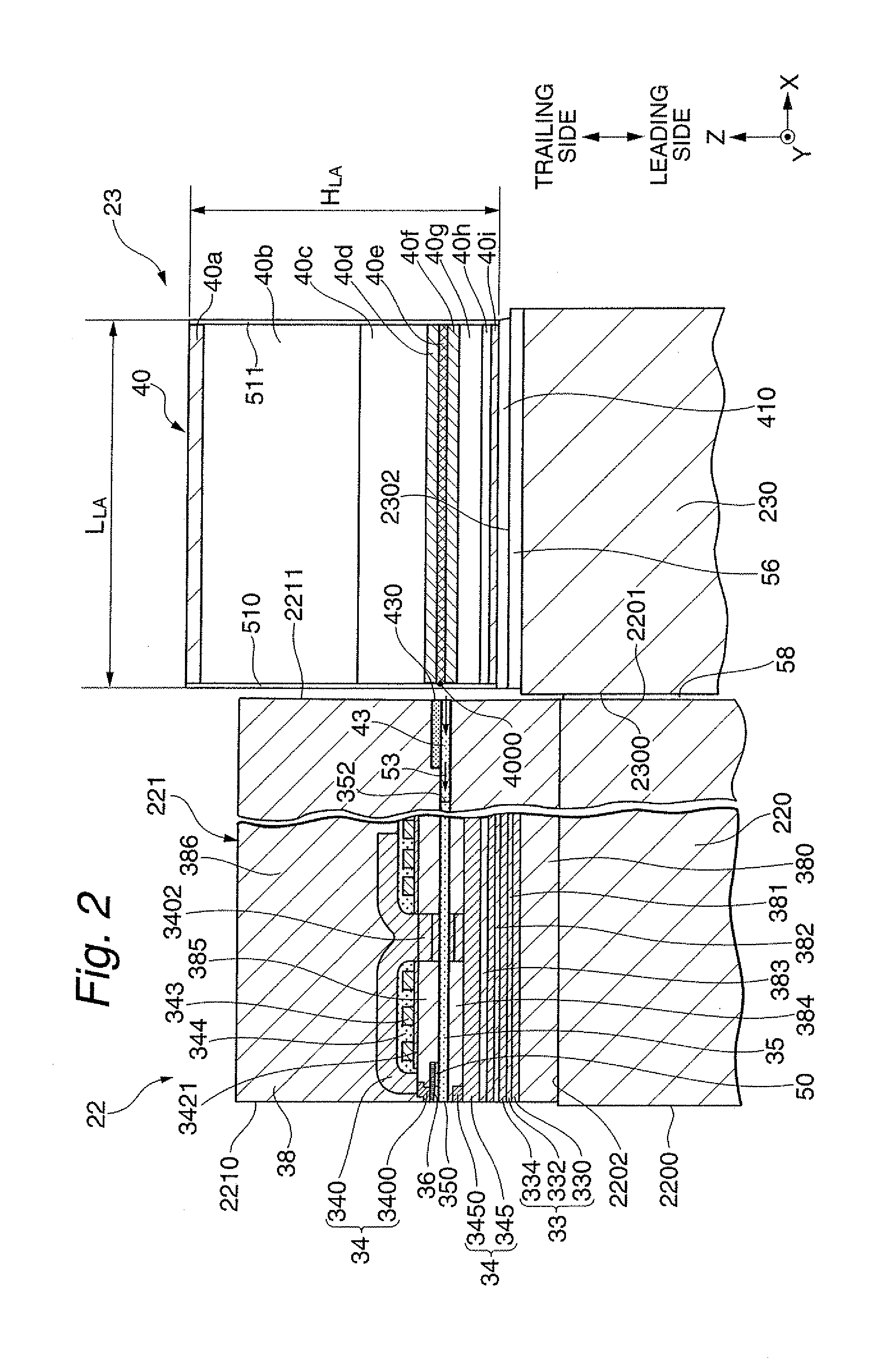

It is an objective that the optical loss and the number of optical components are reduced in an optical recording head using a near-field where a laser beam is guided from a light source to the tip of the head and a thermally assisted magnetic recording head. A structure where the traveling direction of emitted beam is rotated in the direction of the cavity of the laser diode element and a reflector for guiding the beam to the surface of the surface of the laser diode element is monolithically integrated in the laser diode element is mounted over the slider so that the direction of the cavity of the laser diode element is parallel to the surface of the recording medium, and the substrate side of the laser diode element is mounted to be in the direction opposite the face adjacent to the upper face of the slider.

Owner:HITACHI LTD

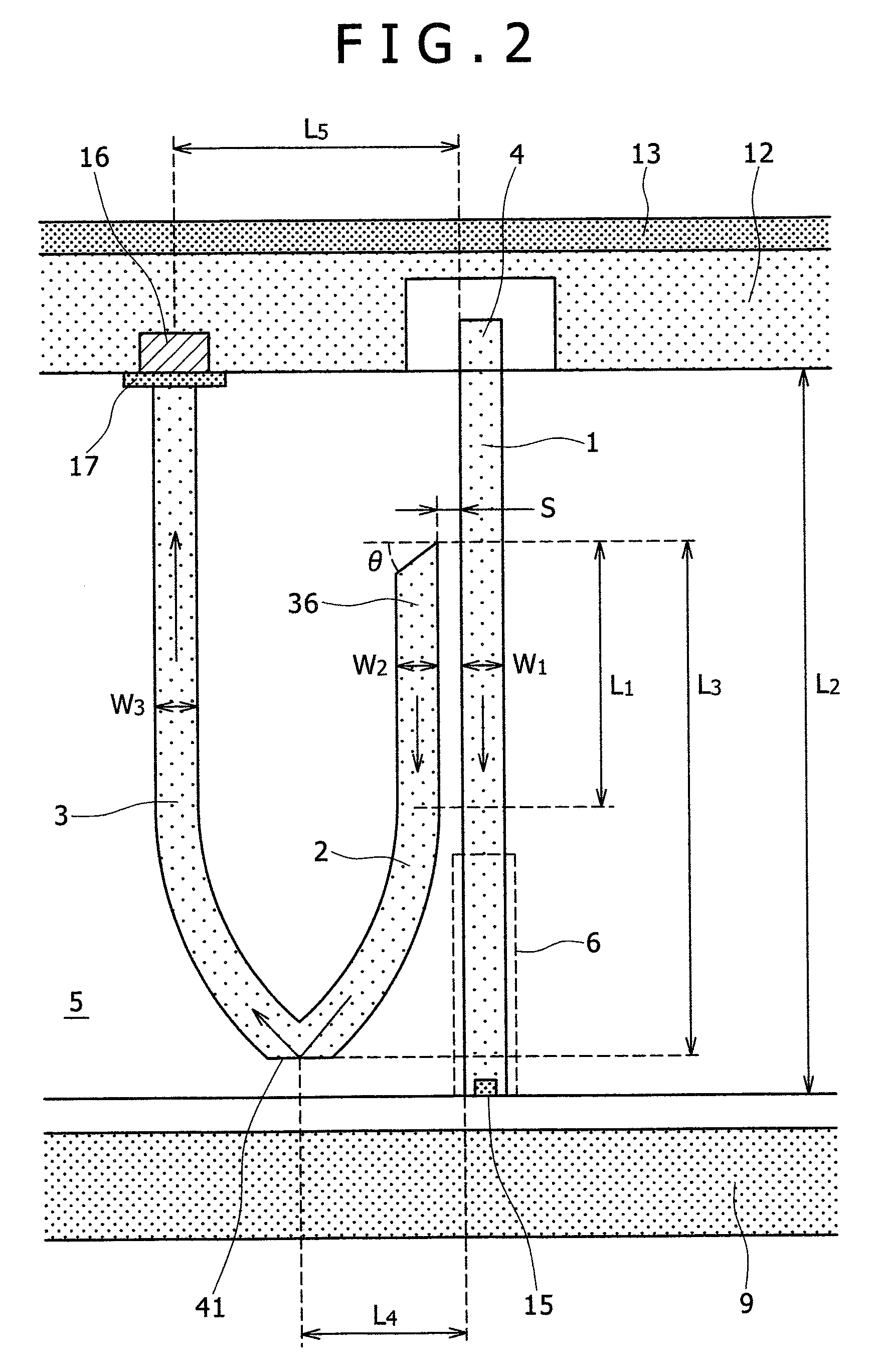

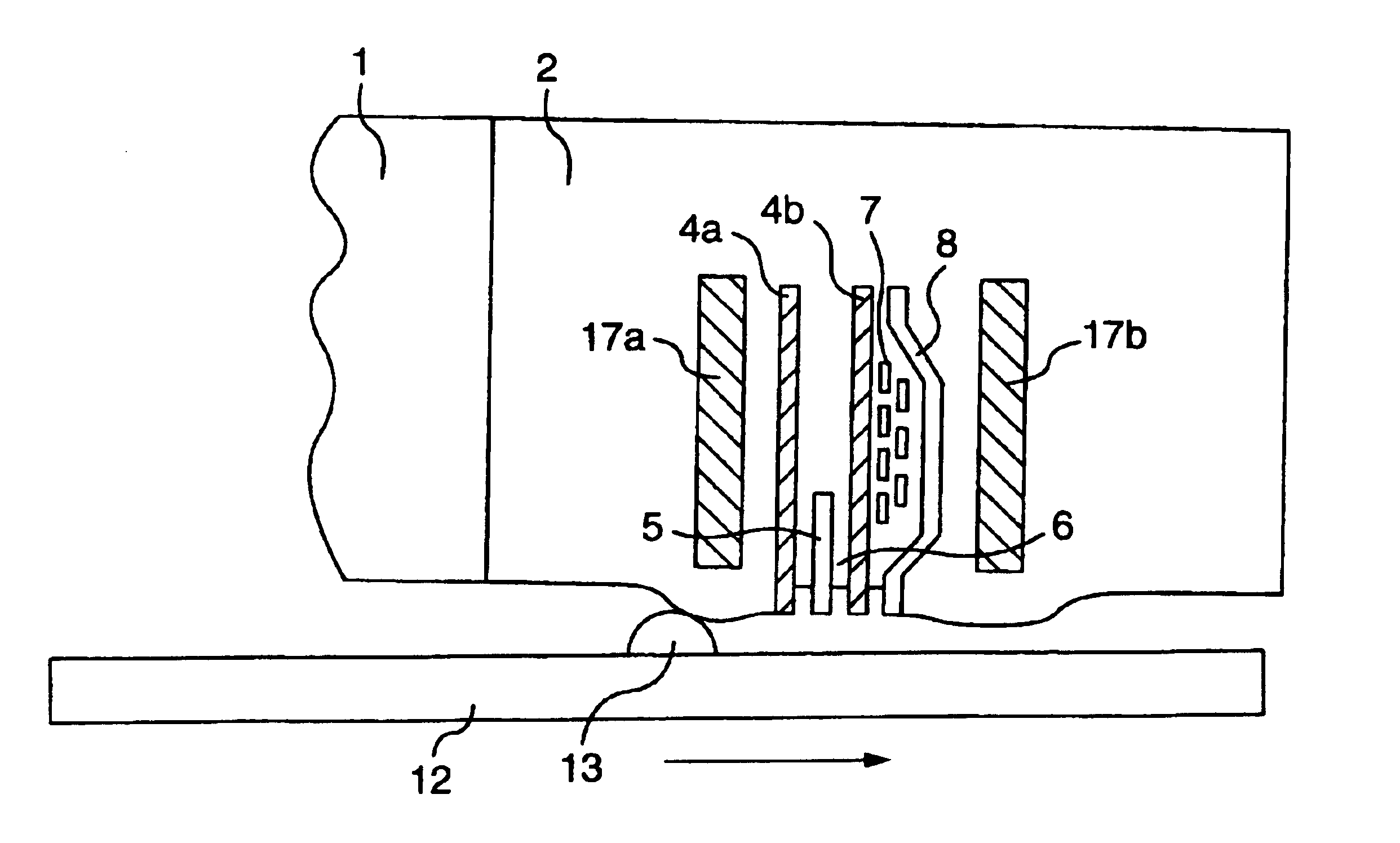

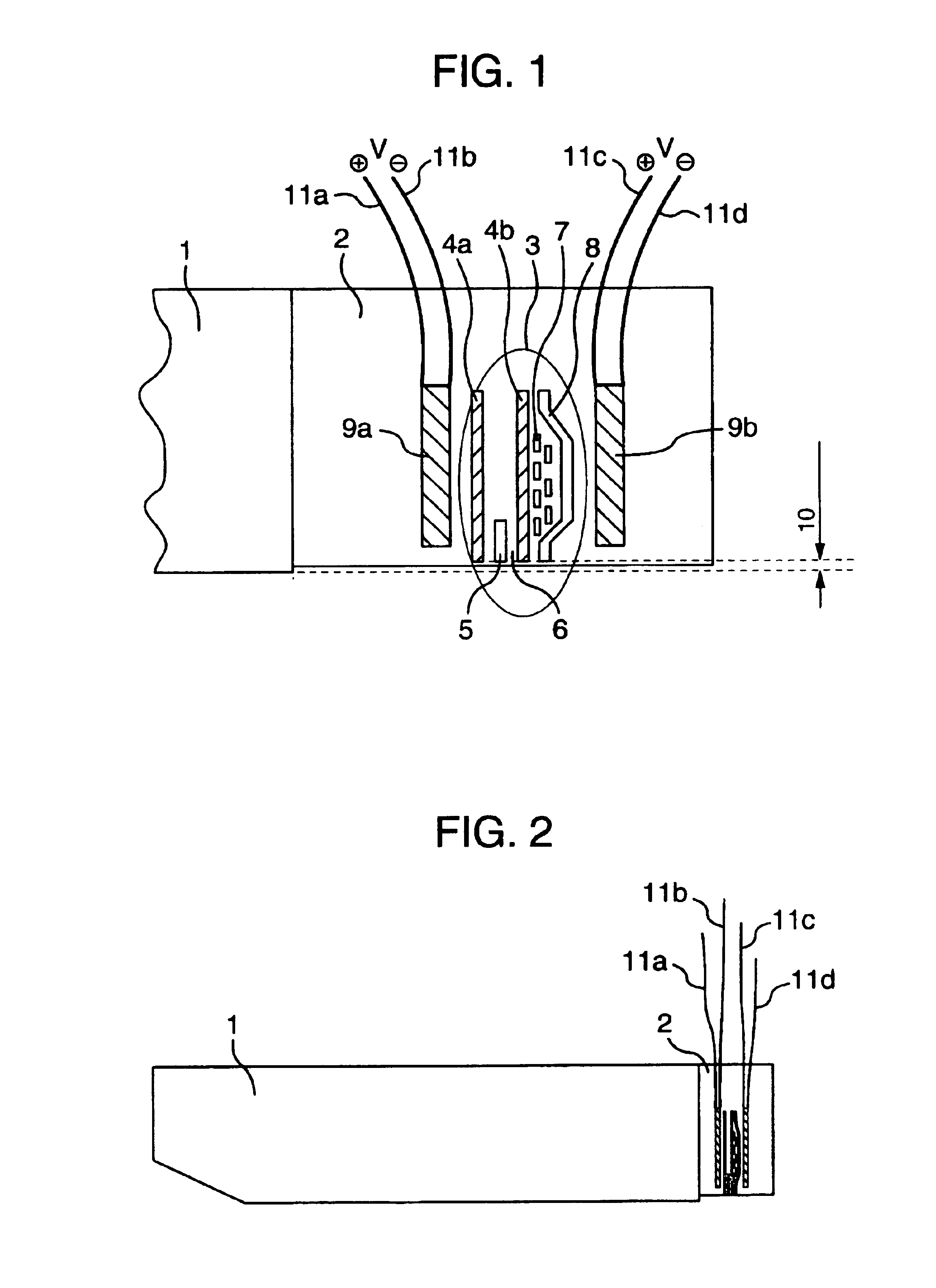

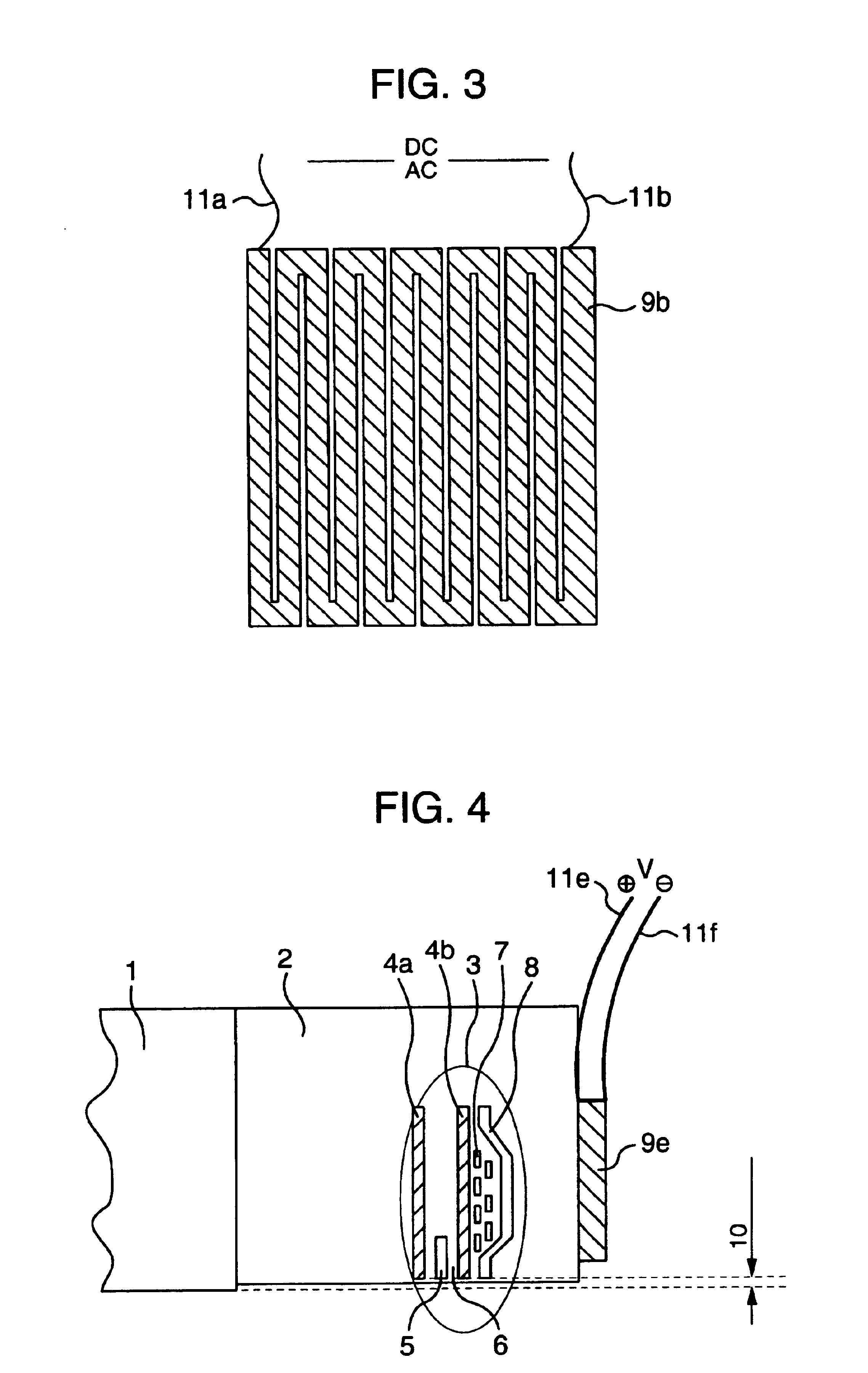

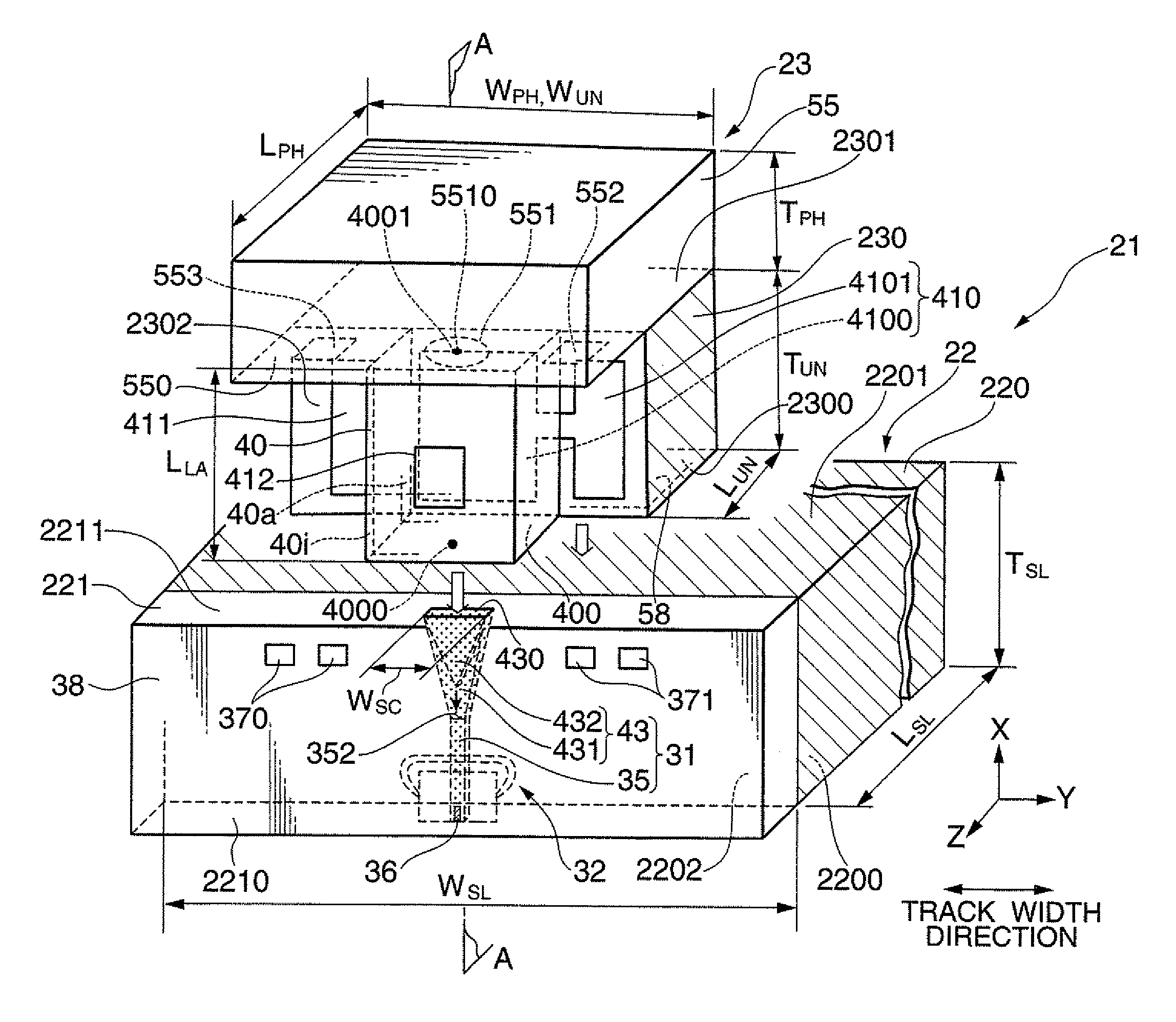

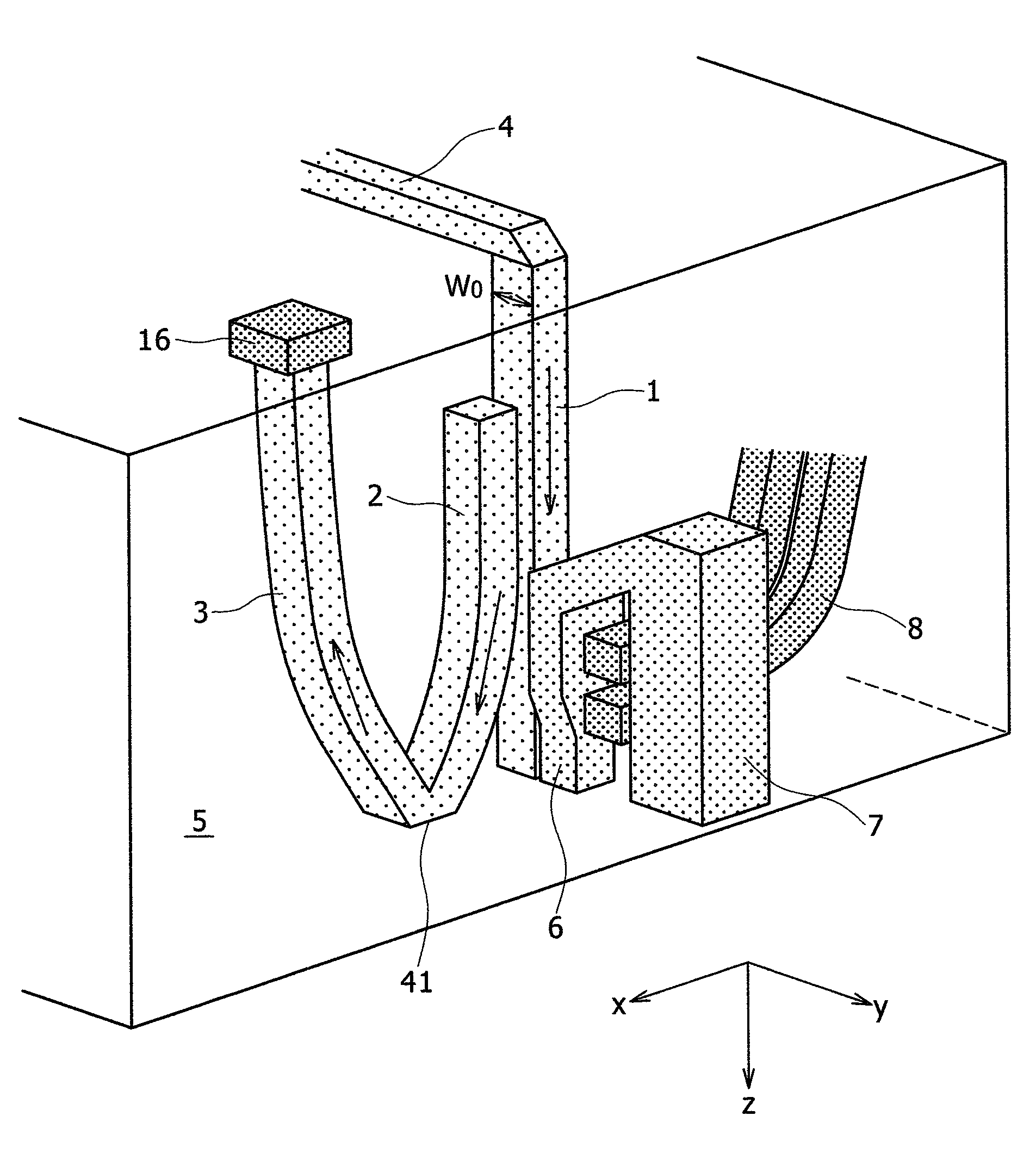

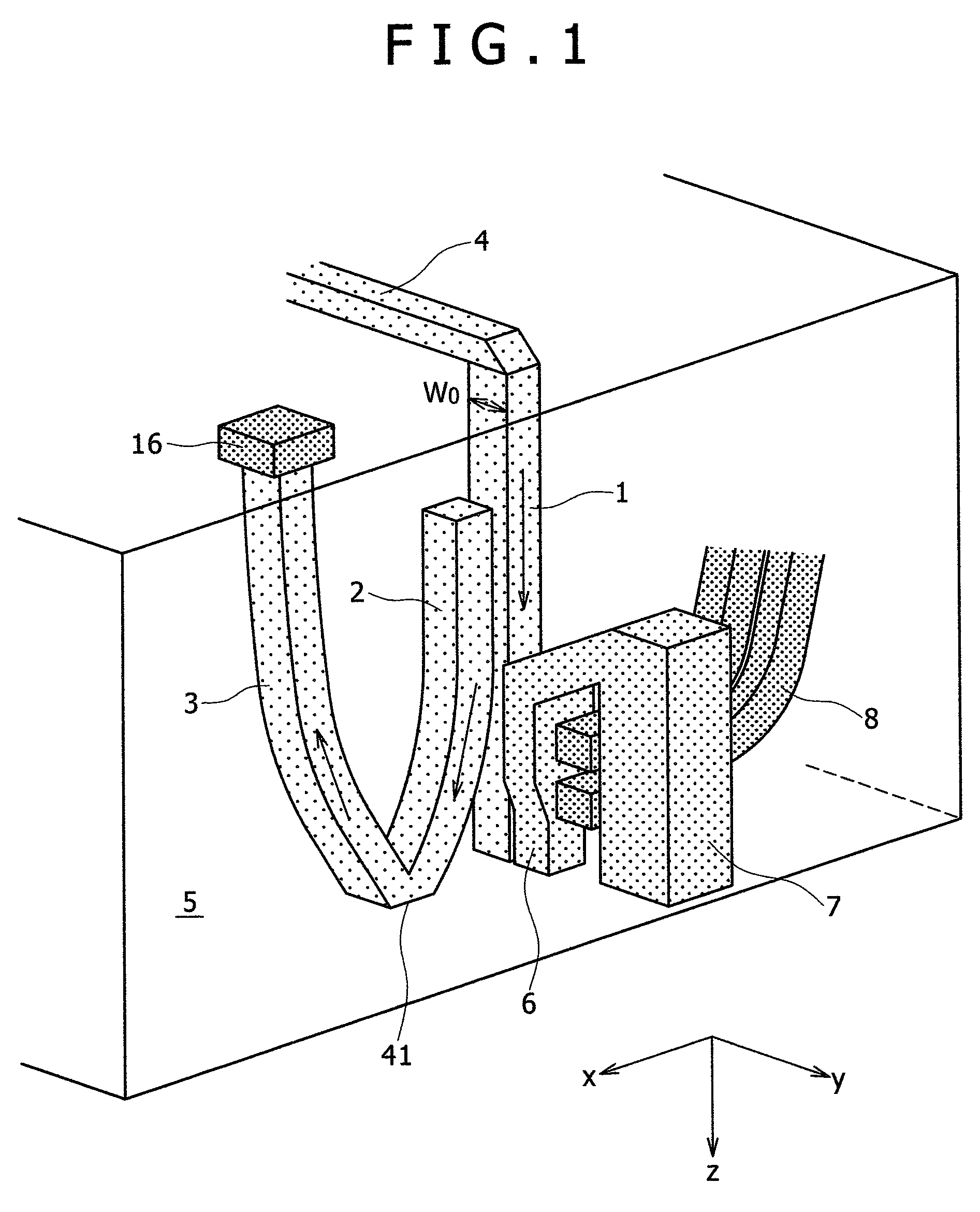

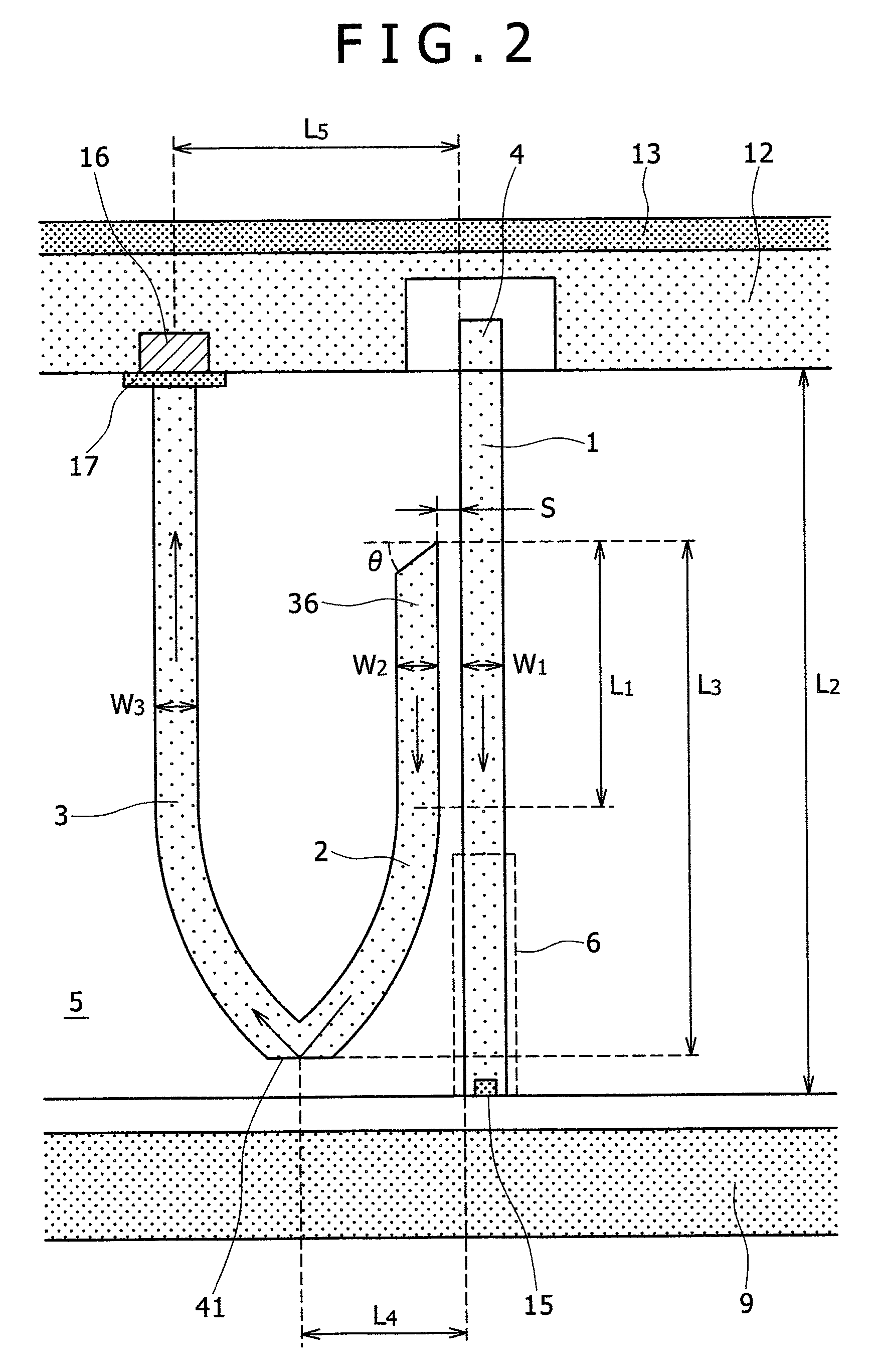

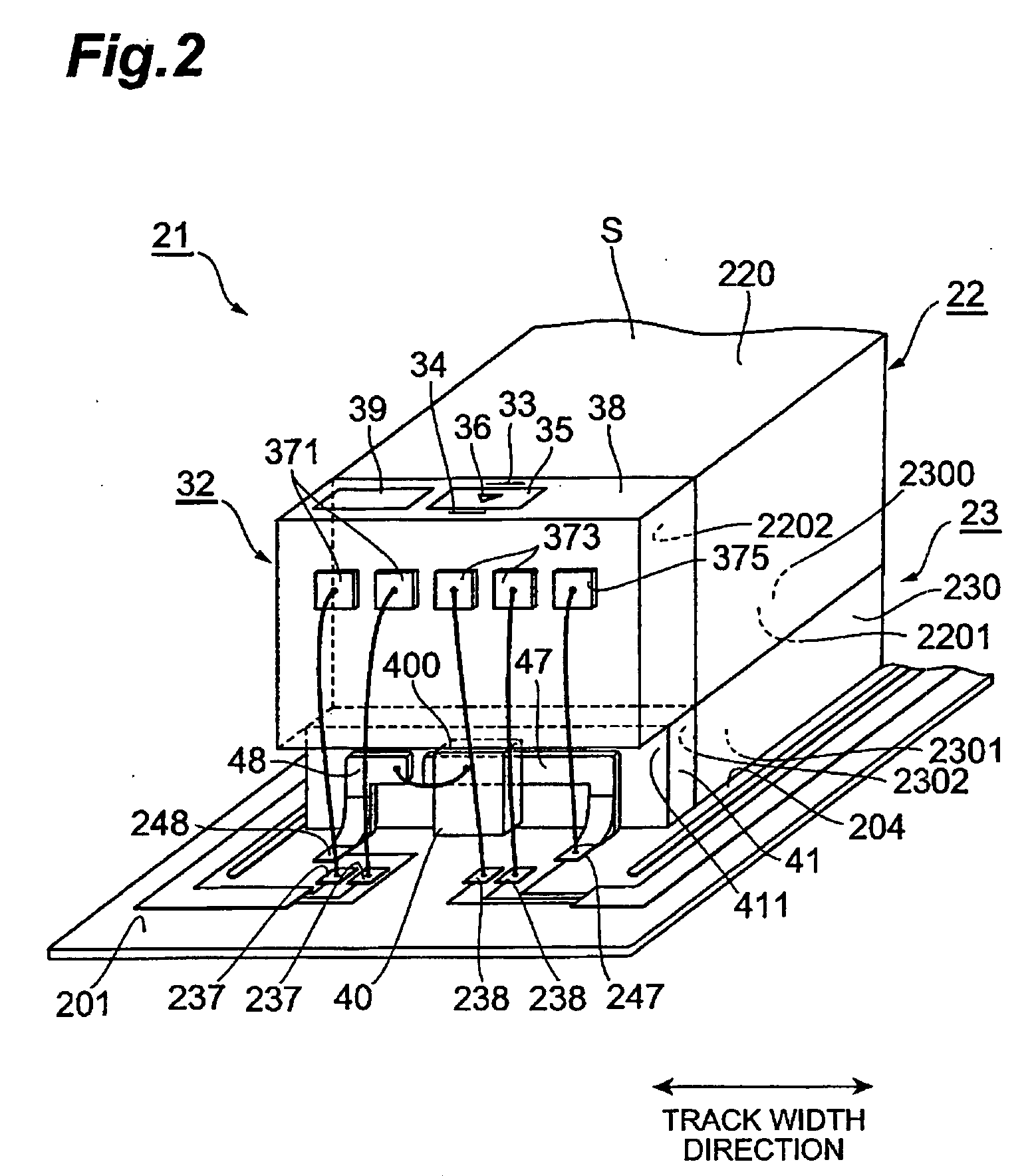

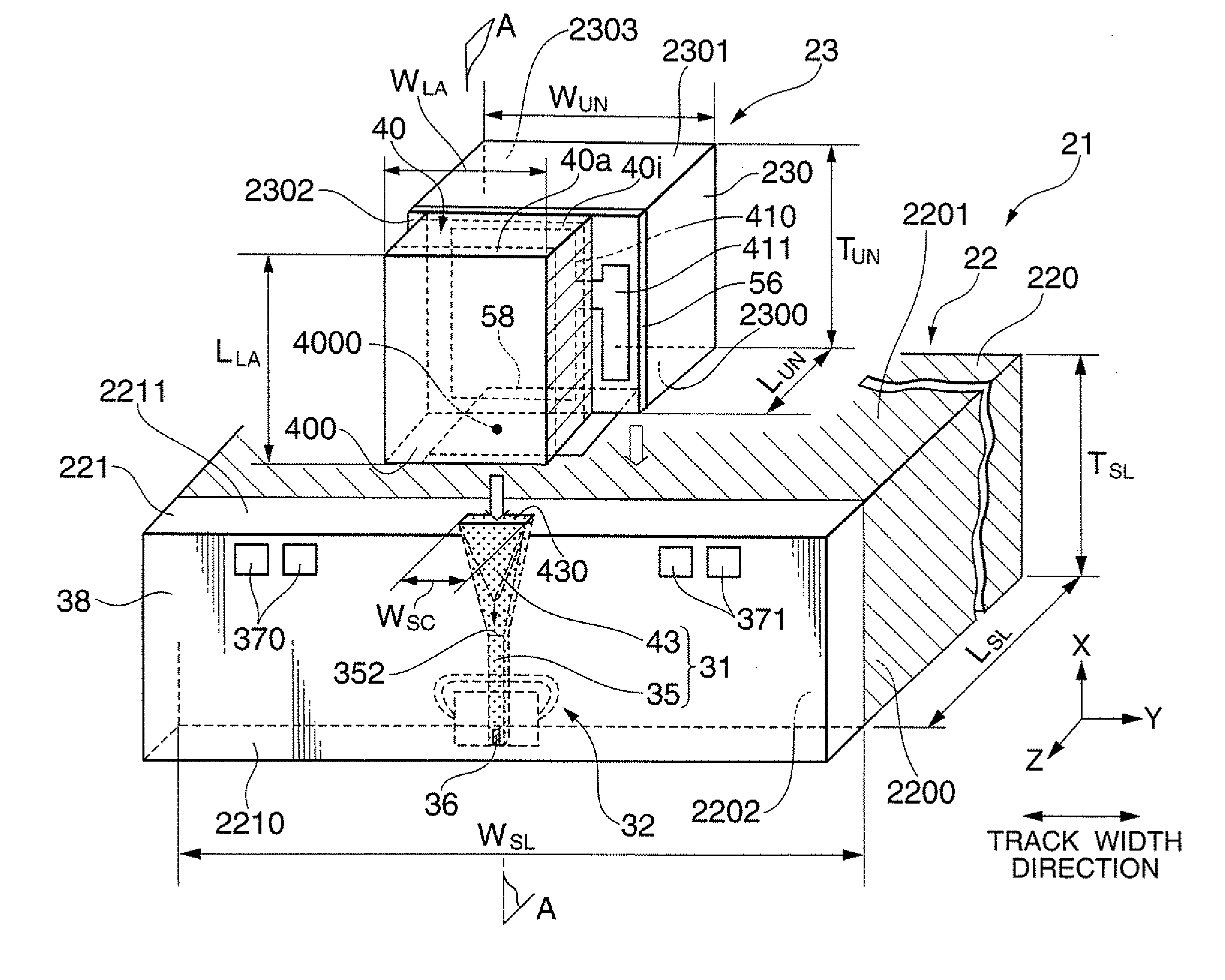

Thermally assisted magnetic recording head and magnetic recording apparatus

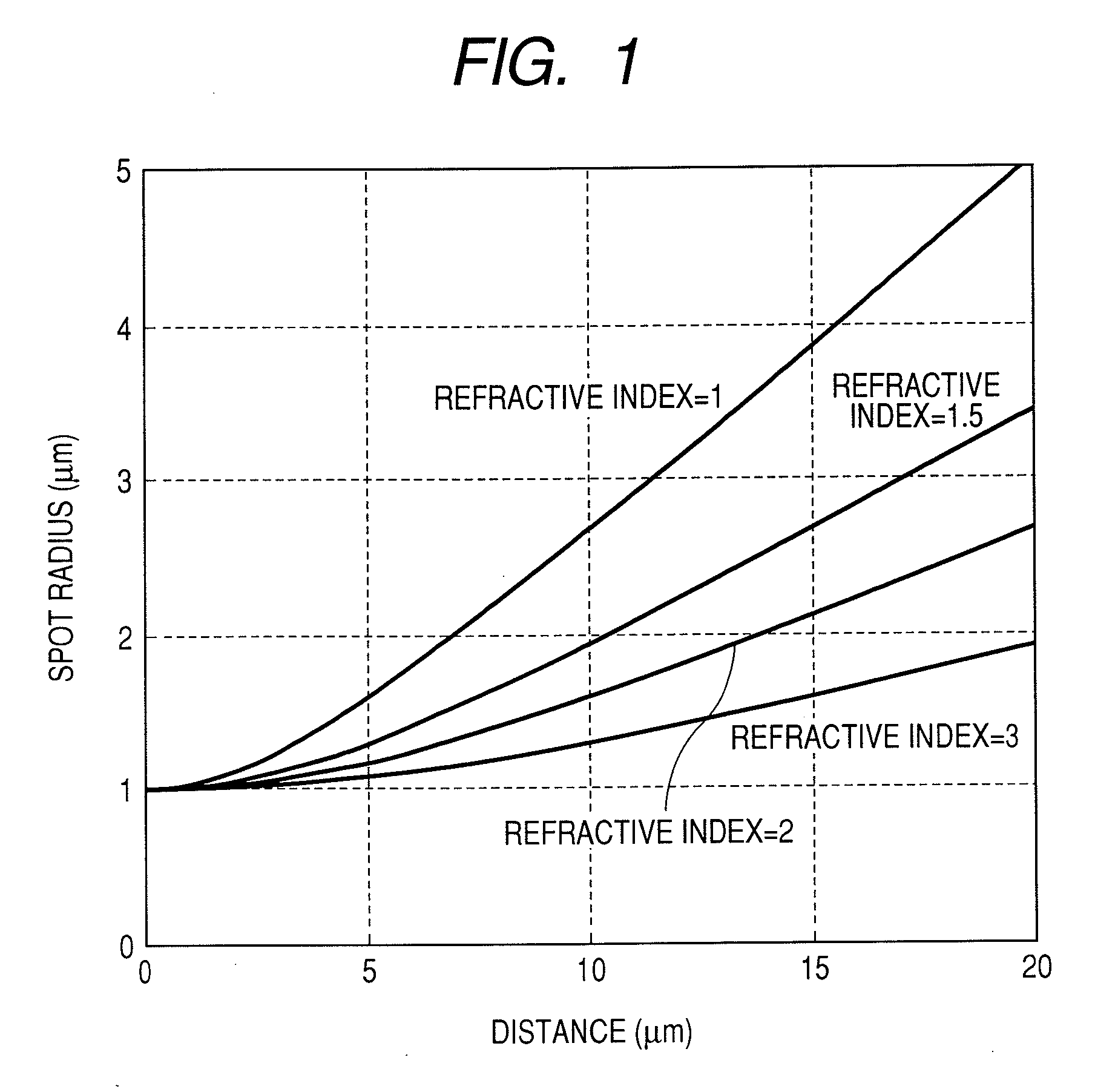

InactiveUS20080204916A1Coupling efficiency is improvedOptical power in fluctuatesDriving/moving recording headsRecord information storageHeat-assisted magnetic recordingPhotodetector

A second waveguide is formed near a first waveguide for guiding light to the vicinity of a main pole of a thermally assisted magnetic recording head, and a portion of light propagated through the waveguide 1 is branched to the second waveguide. The light transmitting in the second waveguide is detected by a photodetector to detect an intensity of the light propagated through the first waveguide. In the magnetic recording apparatus, an intensity of a semiconductor laser is decreased when an amount of light incident to the photodetector is large and the intensity of the semiconductor laser is increased when the amount of light incident to the photodetector is small. By constituting a feedback loop as described above, the intensity of the light propagated through the first waveguide is kept constant.

Owner:HITACHI LTD

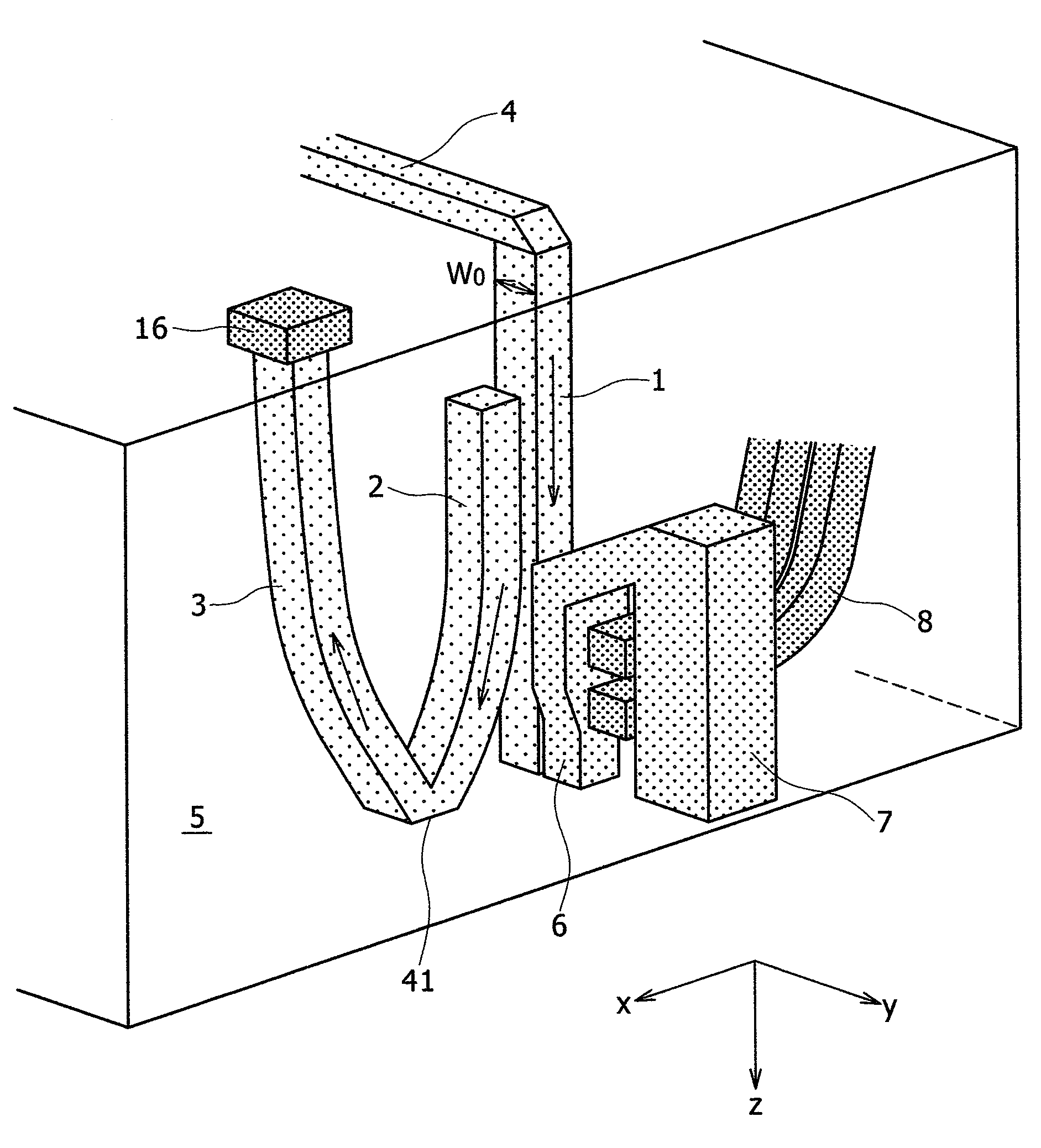

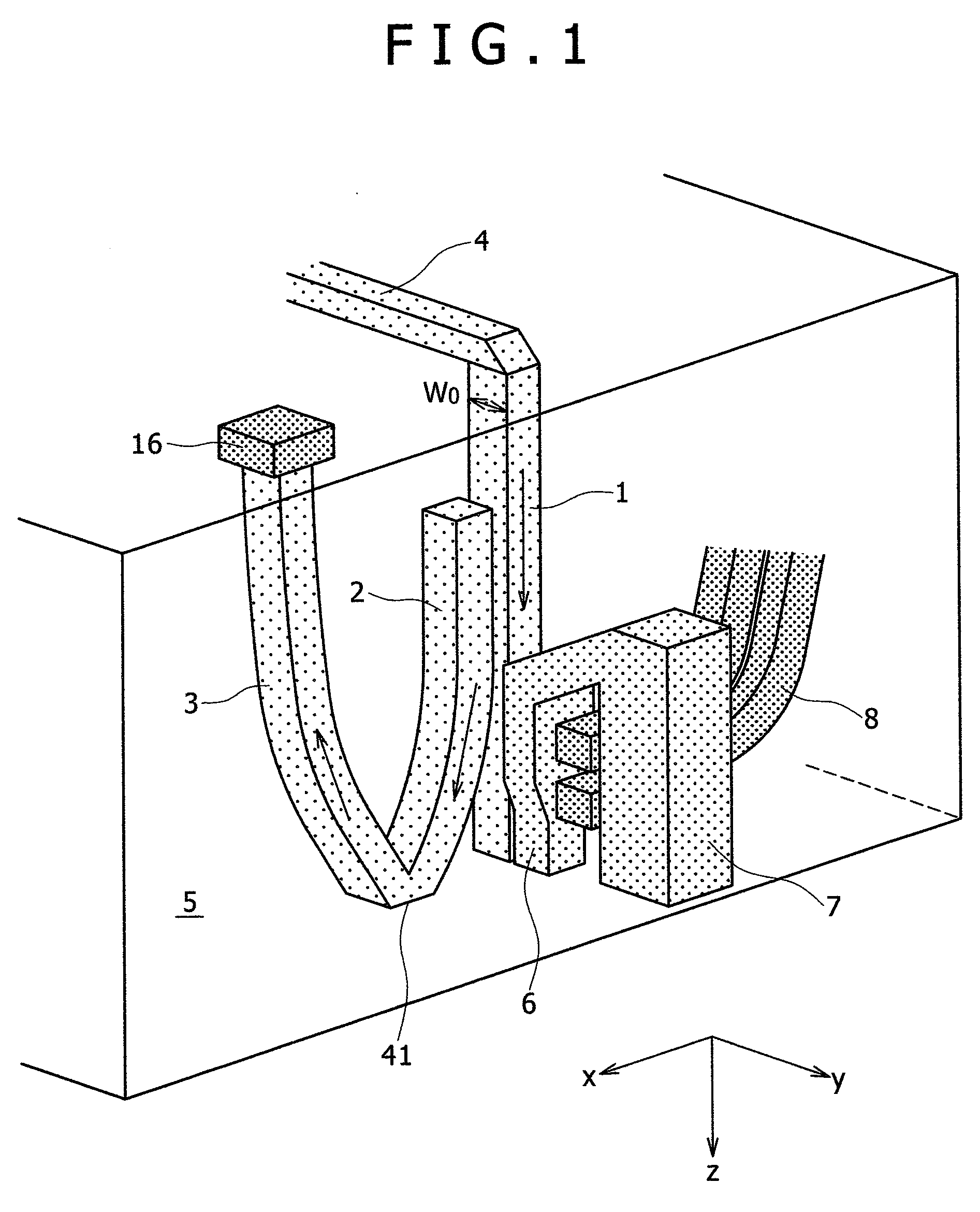

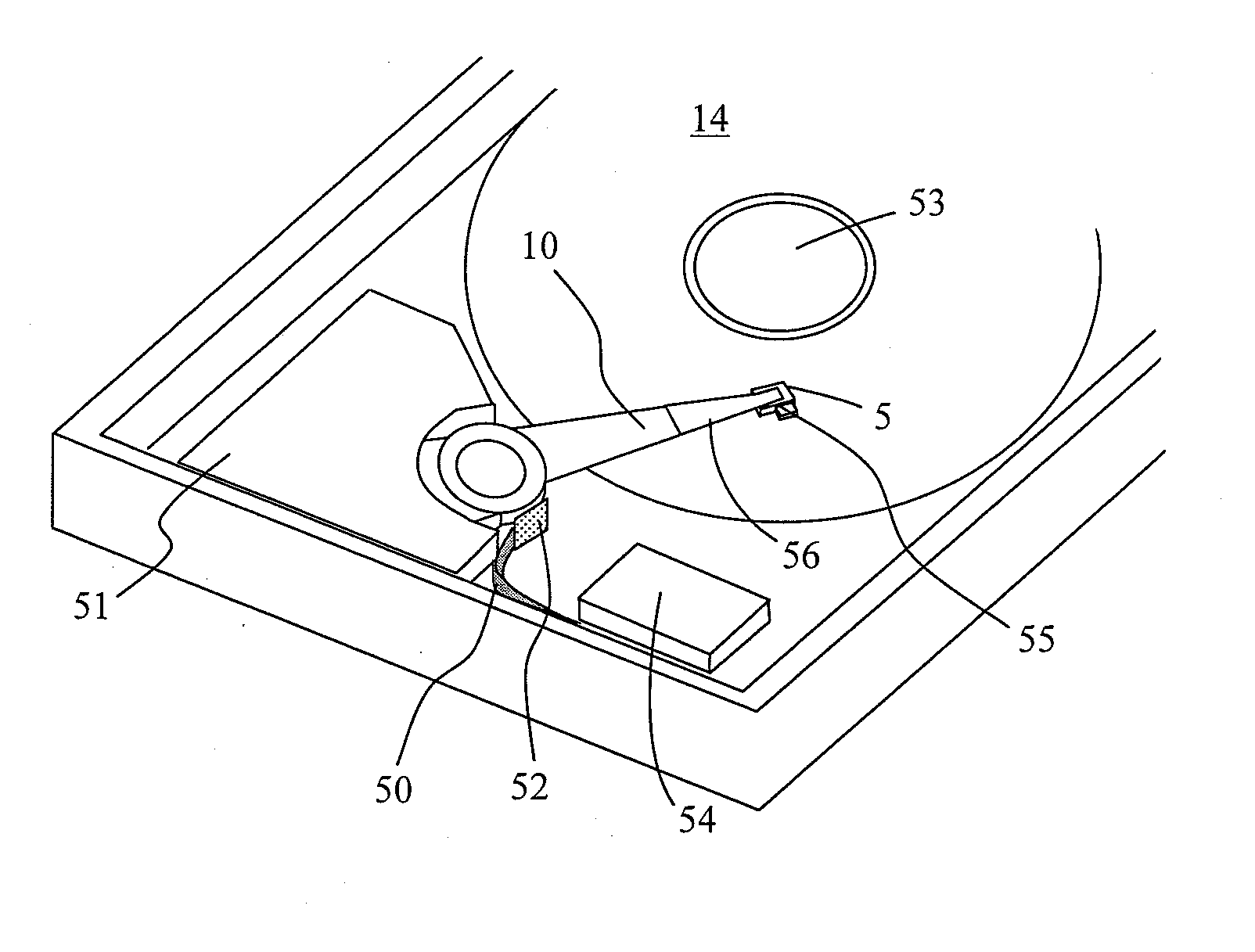

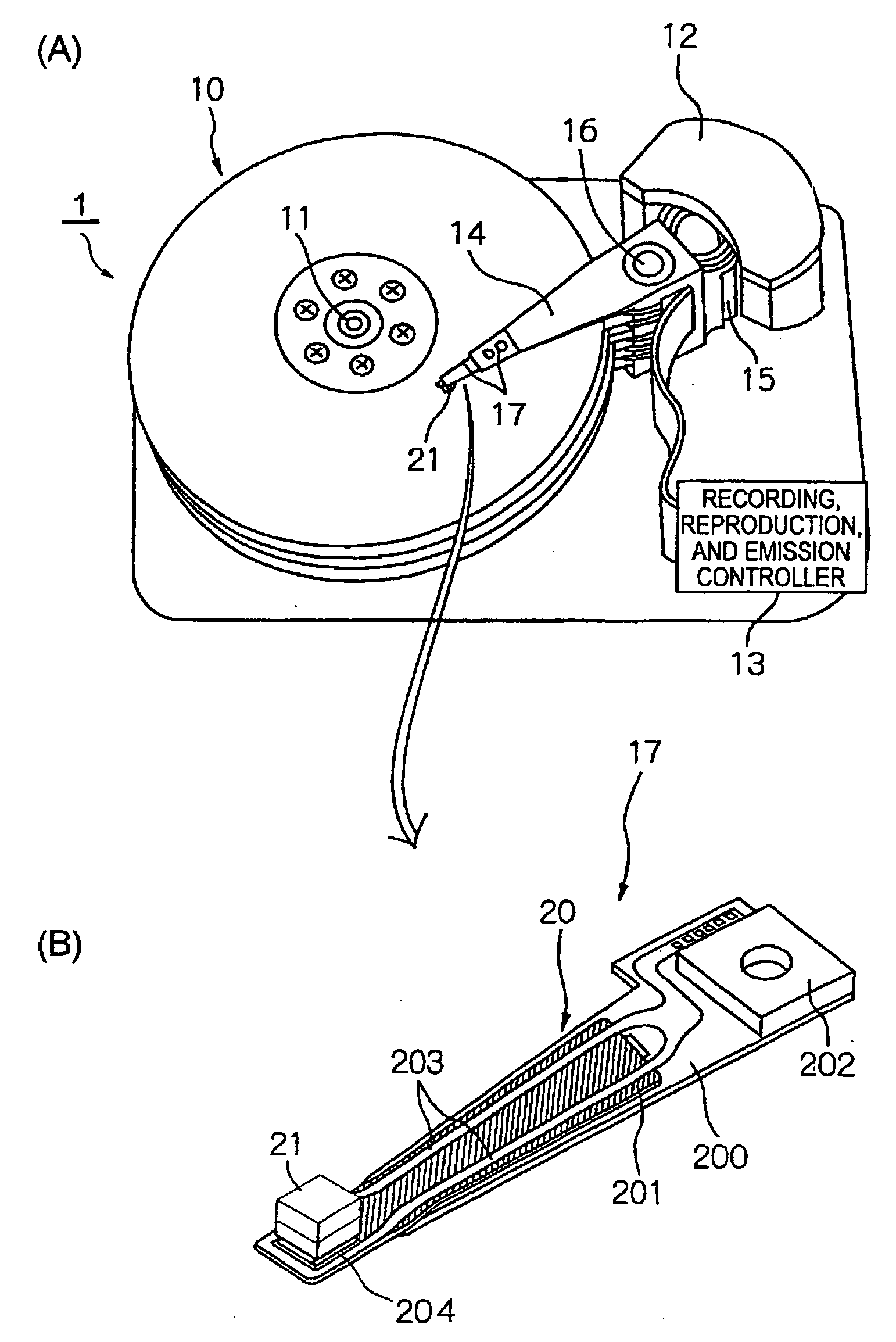

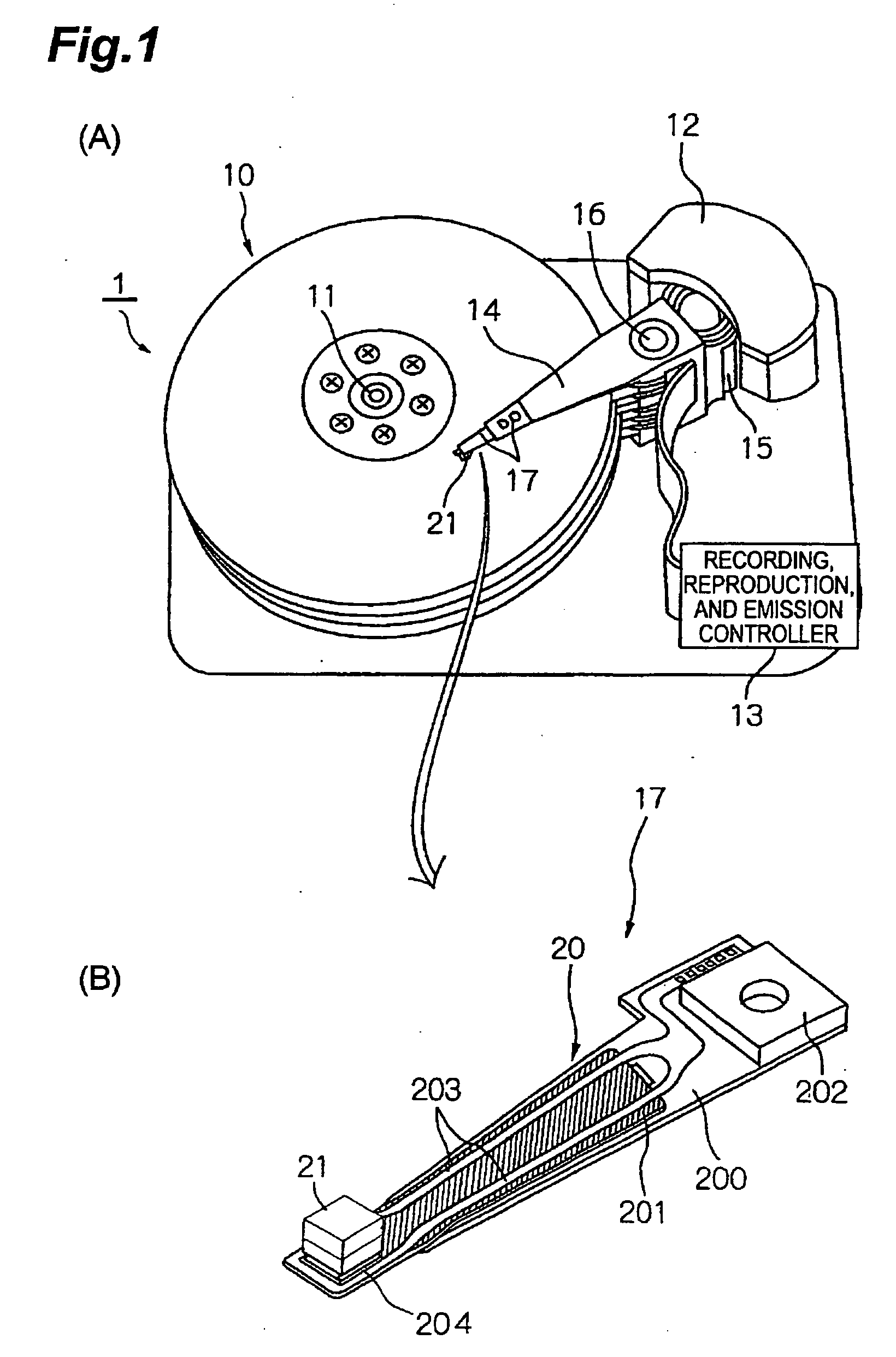

Head for thermal assisted magnetic recording device, and thermal assisted magnetic recording device

ActiveUS20110216635A1Increase head heightImprove floating stabilityCombination recordingRecord information storageHeat-assisted magnetic recordingEngineering

In a head for thermal assisted magnetic recording device, a semiconductor laser is mounted so that the total height of the head does not become larger and light power fluctuation due to wavelength fluctuation occurs less frequently. In addition, the rise in temperature of the mounted semiconductor laser is suppressed. A semiconductor laser is placed on a side surface which is different from surfaces on an inflow end side and a trailing side, of four side surfaces of a floating slider. An entrance of a waveguide is placed on the side surface of the floating slider, to thereby cause emitted light from the semiconductor laser to directly enter the waveguide. A curved line part or a reflective mirror is formed in the middle of the waveguide so that the light which has entered the waveguide travels toward an optical near-field generating element.

Owner:HITACHI LTD

Magnetic head heating element in a disk drive

An object of the present invention is to prevent a spacing between a magnetic head and a writing medium at low temperature from increasing to cause a writing / reading error, and to prevent the magnetic head element protruded by a temperature increase from colliding with small protrusions on a magnetic disk surface, and to prevent damage on the element, and to prevent the occurrence of thermal asperity. In order to attain the object, a magnetic head slider is provided, which includes a magnetic head element supported on a rotating magnetic disk via a gap to write or read information on the magnetic disk, and a heat source for heating the magnetic head element. A magnetic disk device is further provided, which includes a magnetic head slider.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD +1

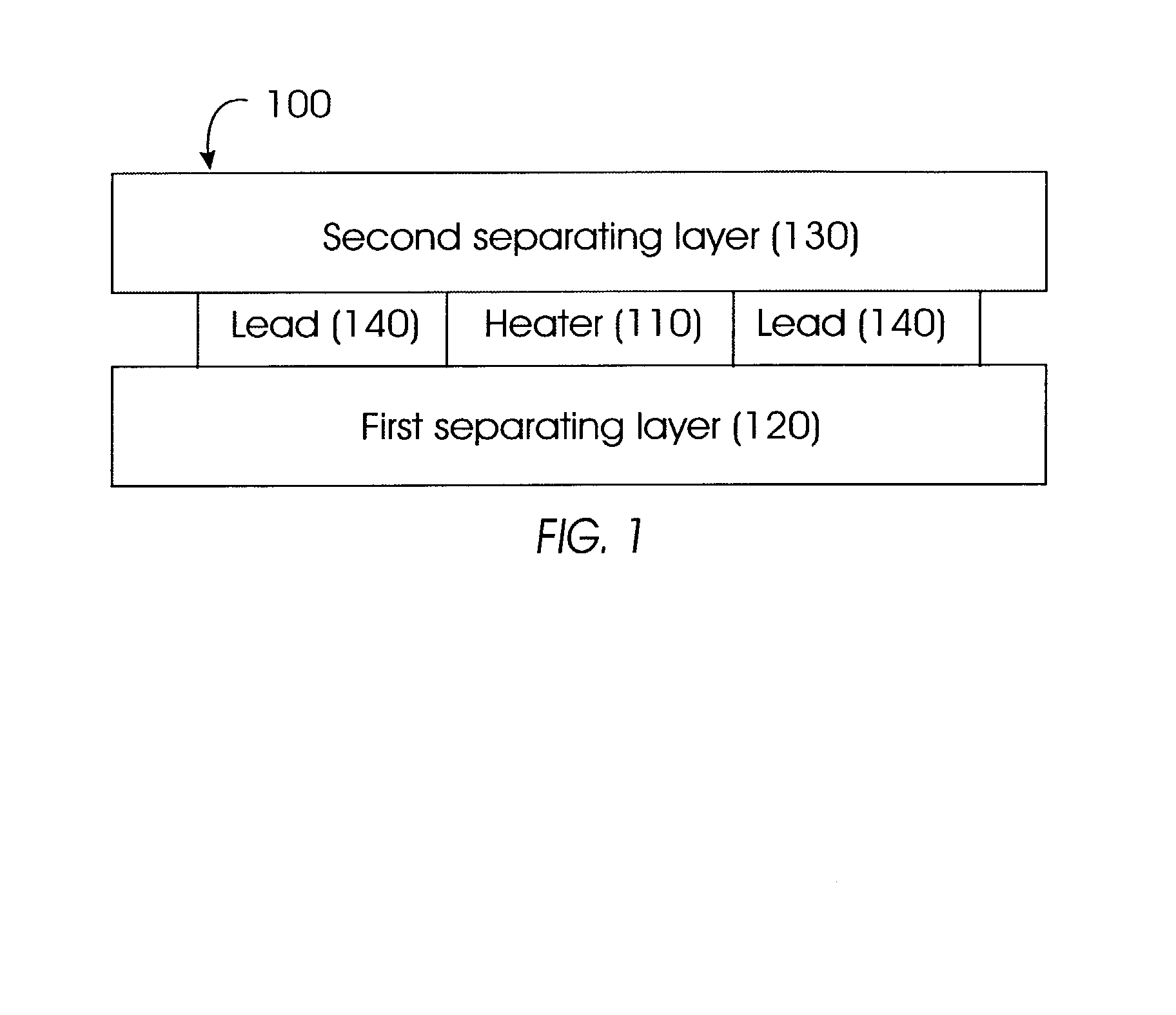

Magnetic recording head with heating device

InactiveUS7133254B2Reduce the overall heightImprove thermal conductivityDriving/moving recording headsHeads using thin filmsRecording mediaElectrical and Electronics engineering

A magnetic recording disk drive has a magnetic recording head that includes first and second separating layers, and a heater formed between the first and second separating layers. The heater has a dimension such a thermal protrusion is induced in the recording head and a thermal conductance between the recording head and a recording medium is enhanced.

Owner:WESTERN DIGITAL TECH INC

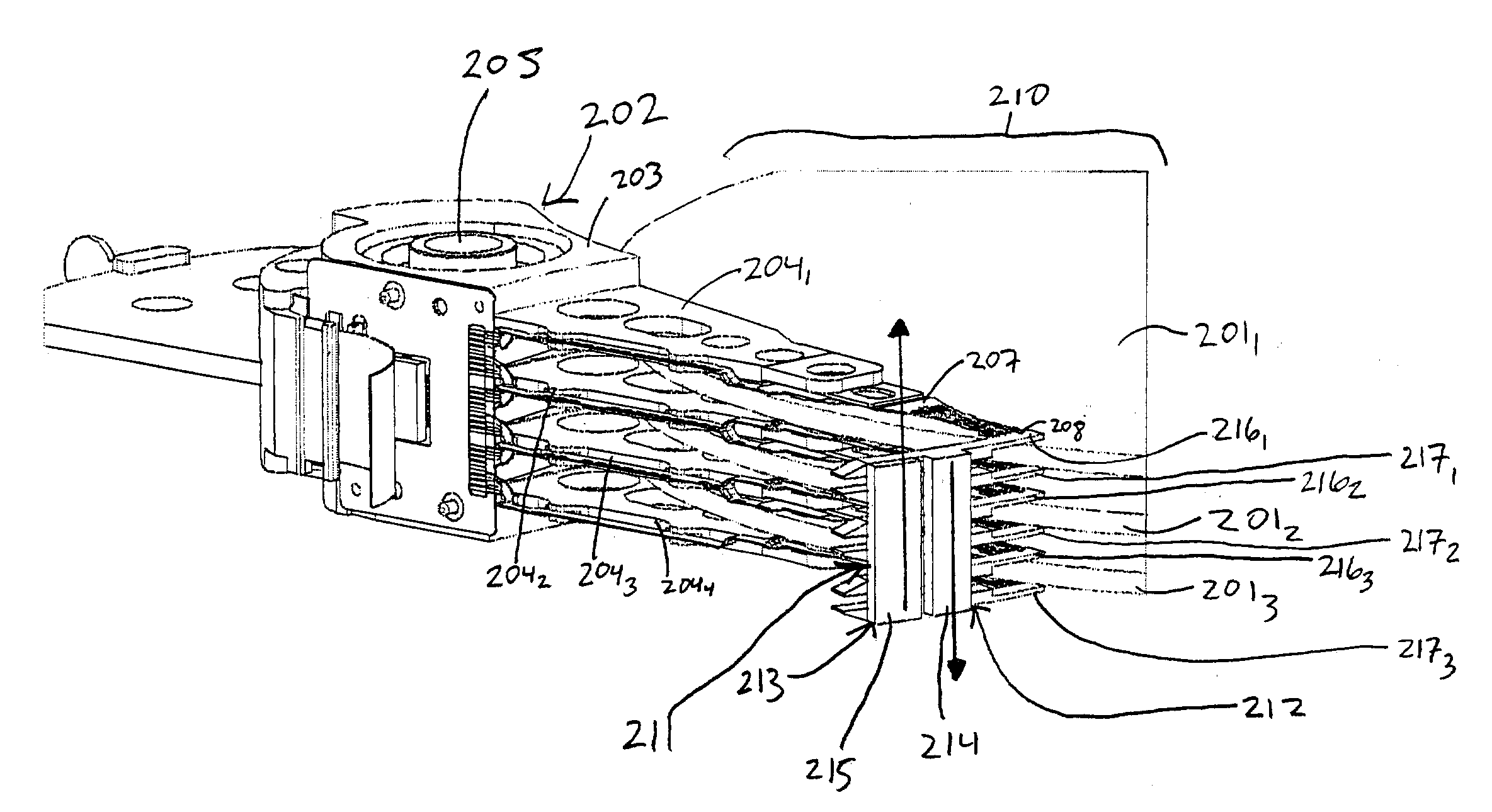

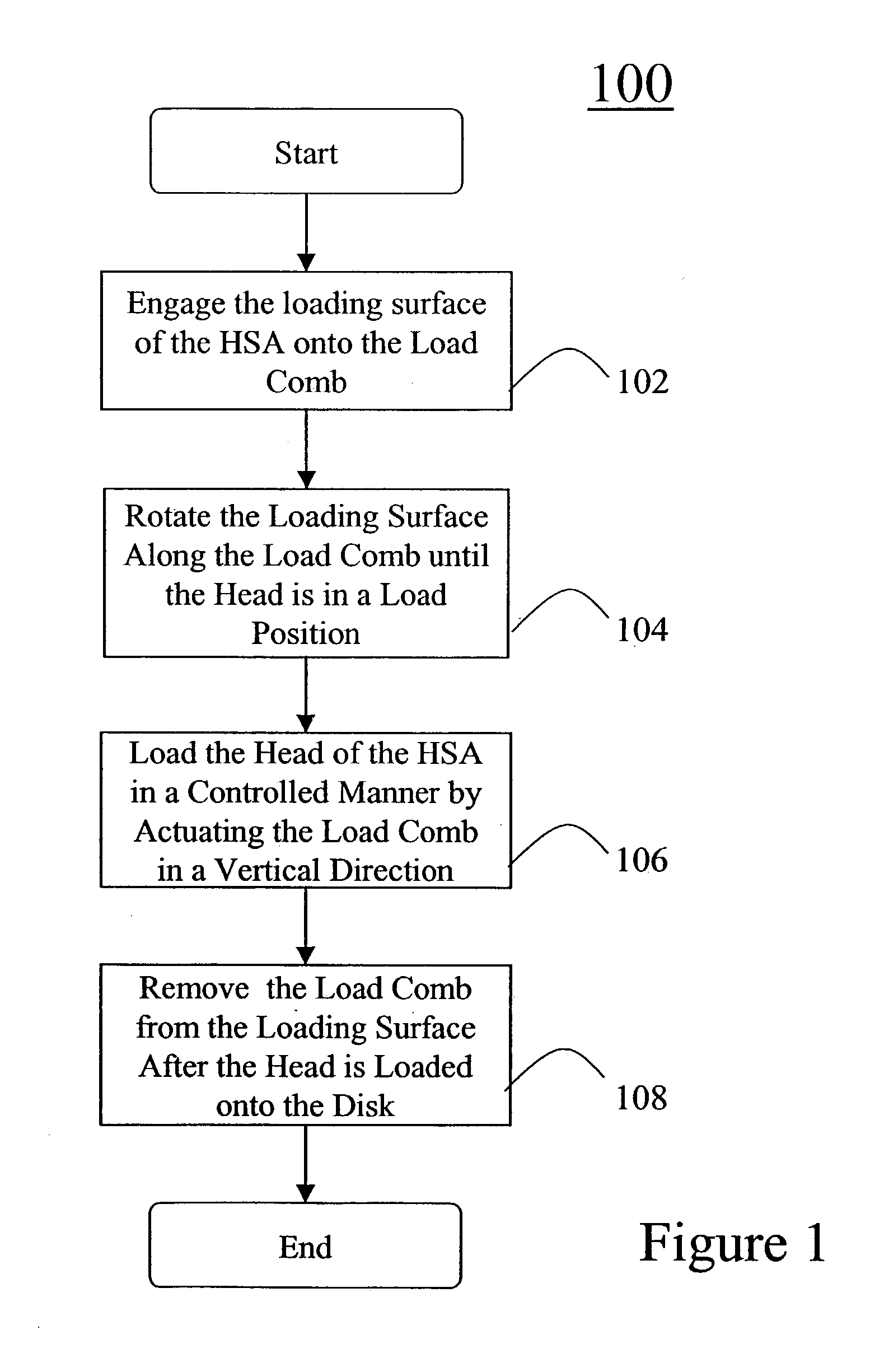

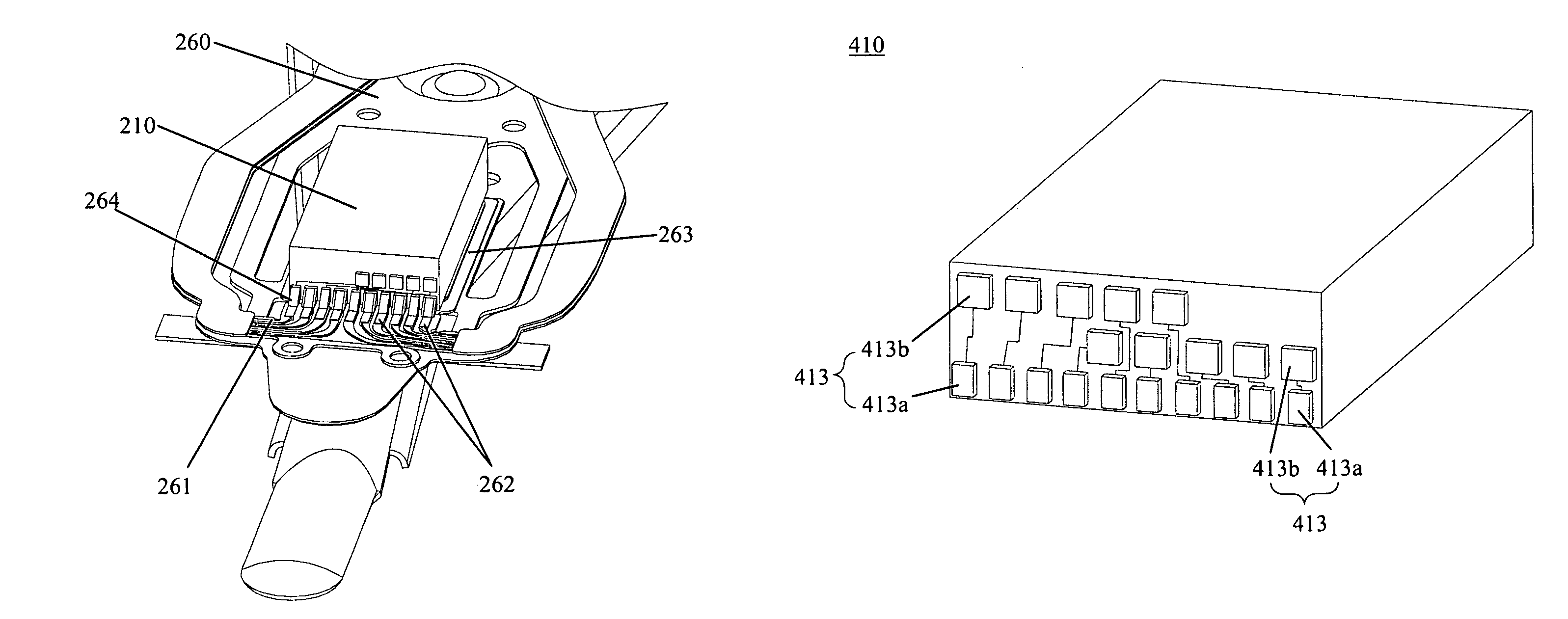

Head stack load comb for controlled head loading

InactiveUS6941642B1Electrical transducersDisposition/mounting of recording headsControl mannerEngineering

Disclosed is a head stack load comb used in the controlled loading of a head of a head stack assembly (HSA) onto a disk during the assembly of a disk drive. The HSA includes an actuator arm, a head, and a loading surface. The load comb includes a base structure and at least one ramp finger projecting approximately perpendicularly from the base structure. In order to load the head in a controlled manner onto the disk, the loading surface of the HSA is rotated along the ramp finger until the head is in a load position and then the base structure is actuated in a vertical direction such that the ramp finger is correspondingly actuated in the vertical direction towards the disk until the head is loaded onto the disk.

Owner:WESTERN DIGITAL TECH INC

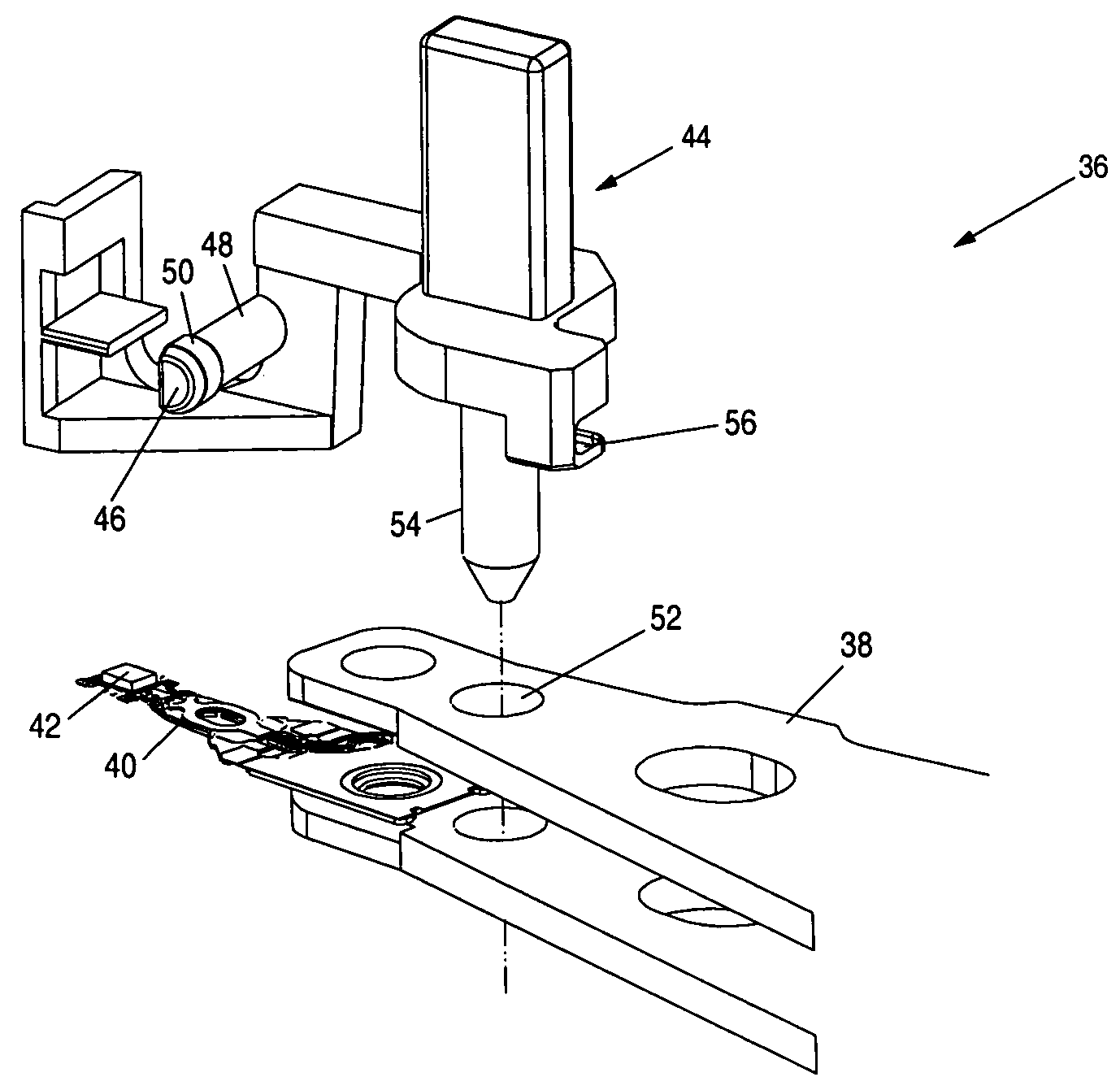

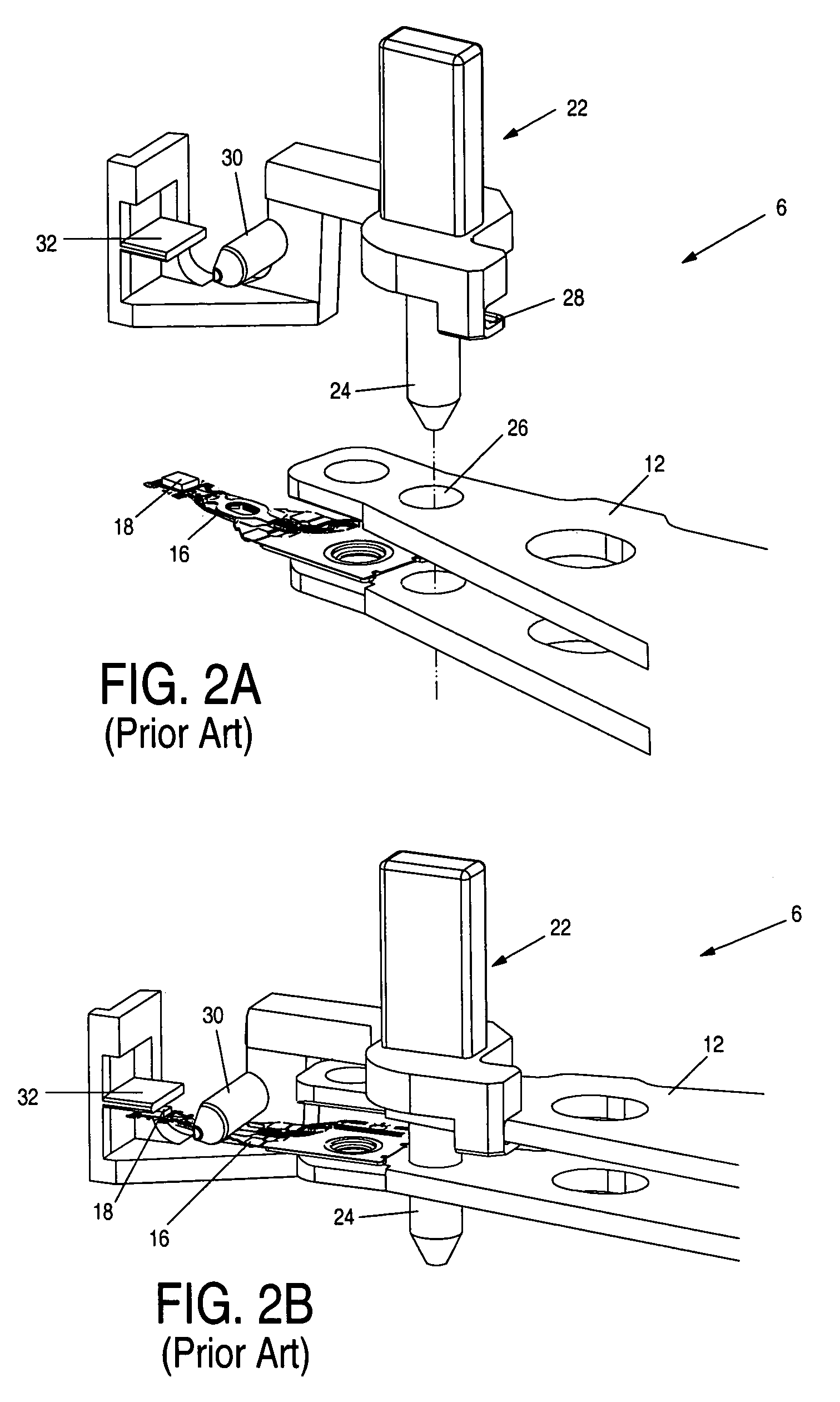

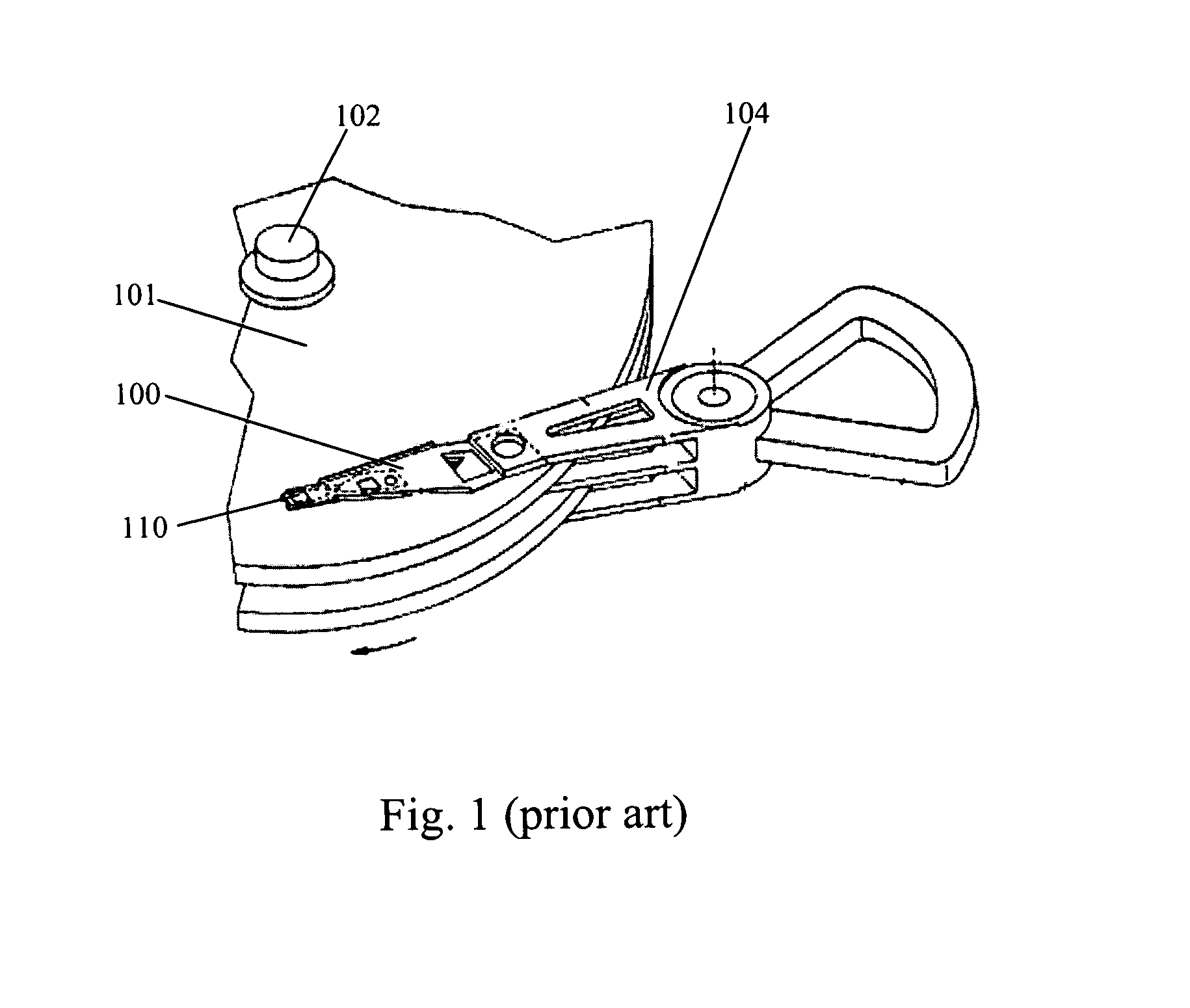

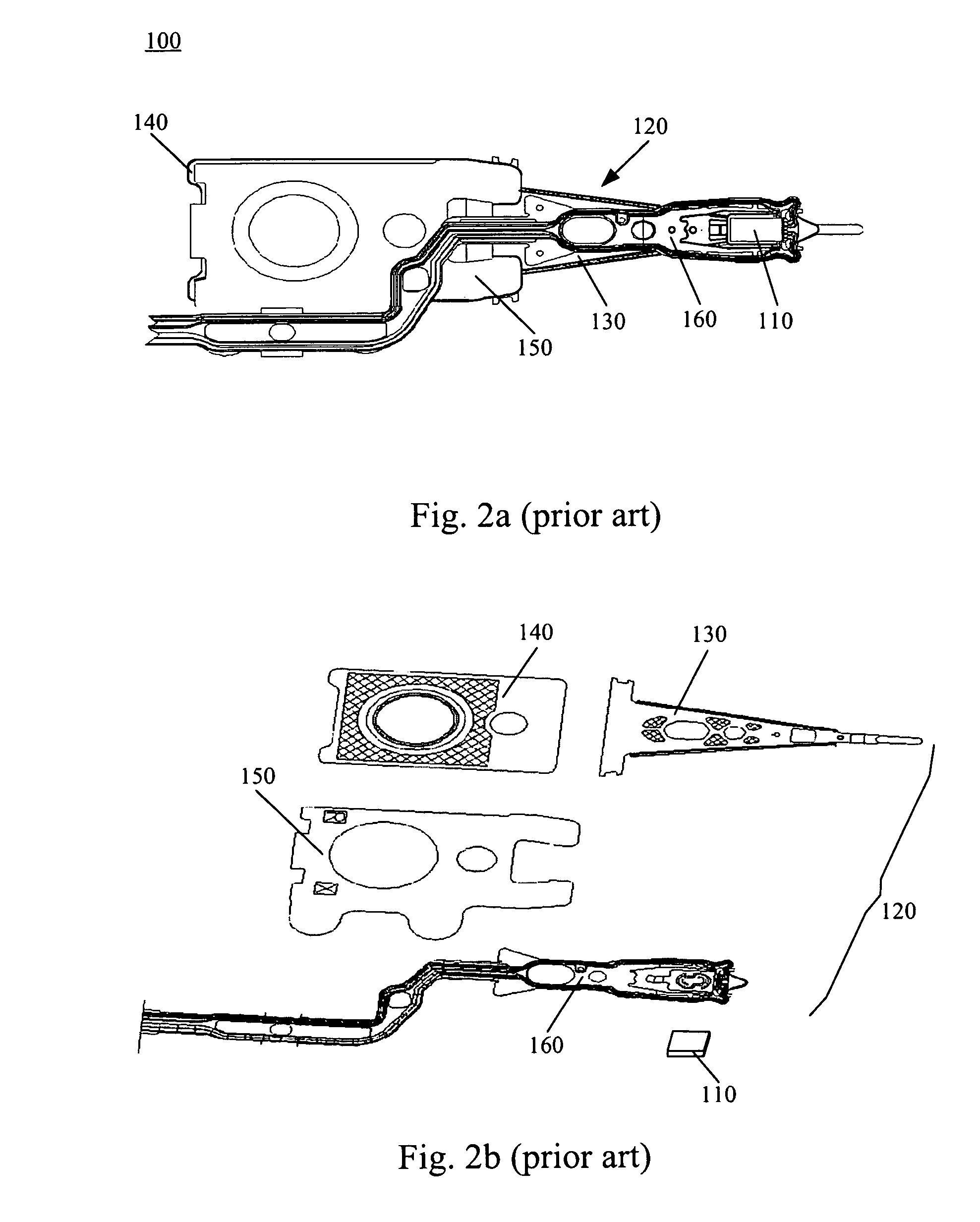

Method of assembling a disk drive including actuating a shipping comb to bend a suspension vertically to facilitate a merge tool

InactiveUS7193819B1Reduce frictionRecord information storageMounting head within housingEngineeringActuator

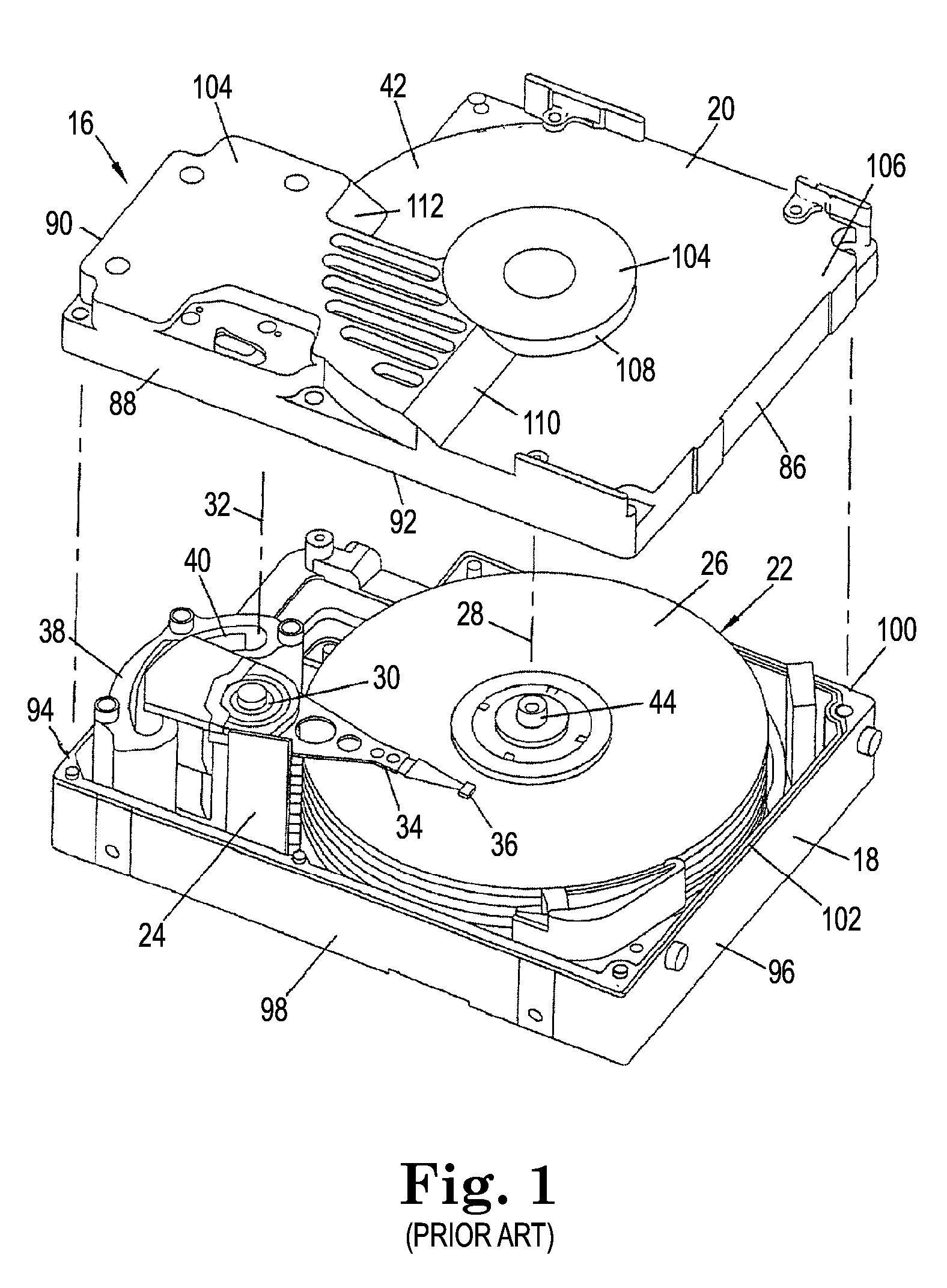

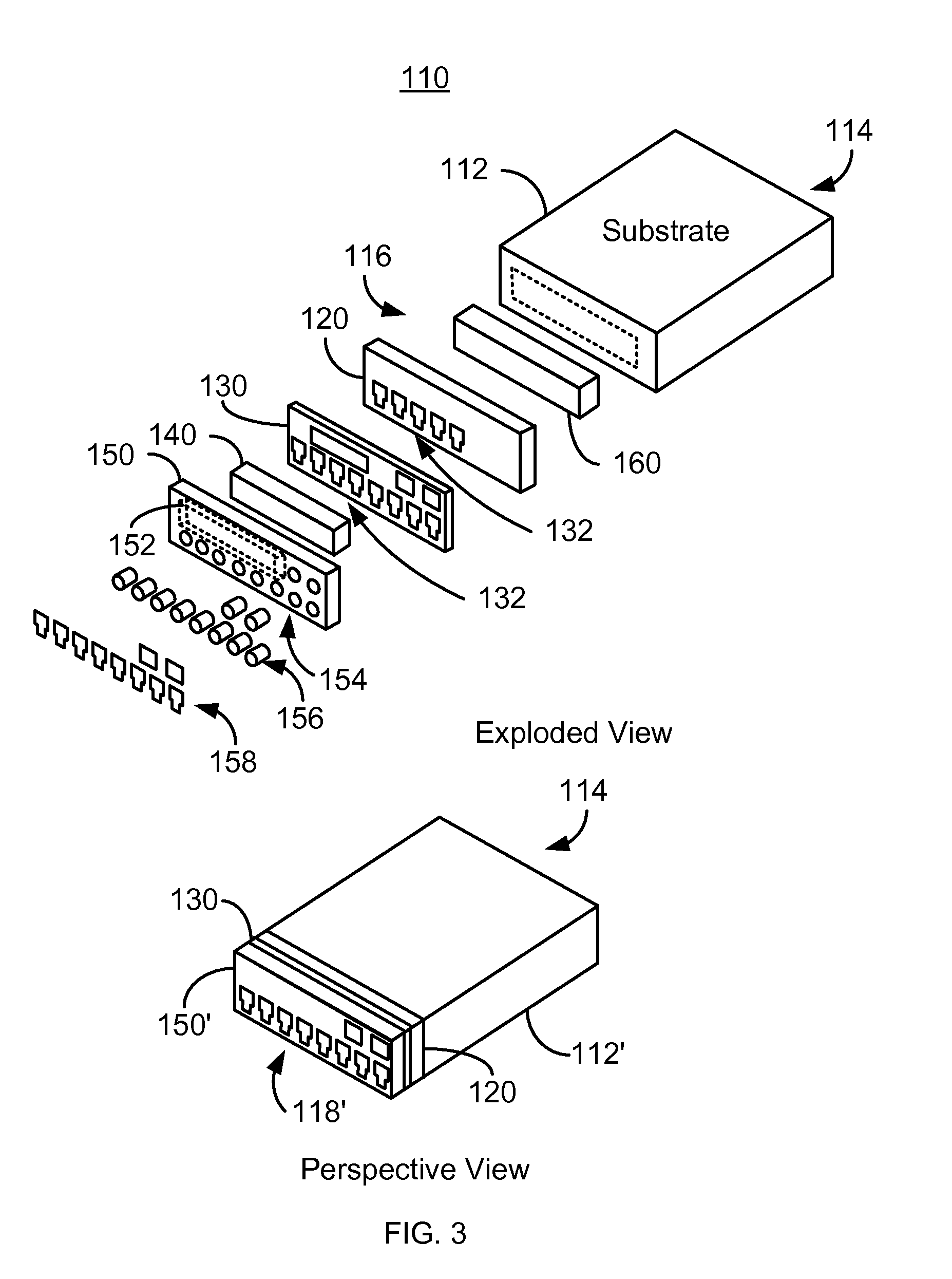

A head stack assembly (HSA) is disclosed for use in a disk drive comprising a disk, wherein a merge tool is used to merge the HSA with the disk. The HSA comprises at least one actuator arm with a suspension connected to the distal end of the actuator arm. A multi-level shipping comb attached to the actuator arm comprises a finger having a first surface and a second, raised surface. During shipping of the HSA, the first surface of the finger contacts the suspension to protect against overstressing. During manufacture of the disk drive, the shipping comb is actuated so that the second surface contacts the suspension thereby bending the suspension in a vertical direction to facilitate the insertion of the merge tool.

Owner:WESTERN DIGITAL TECH INC

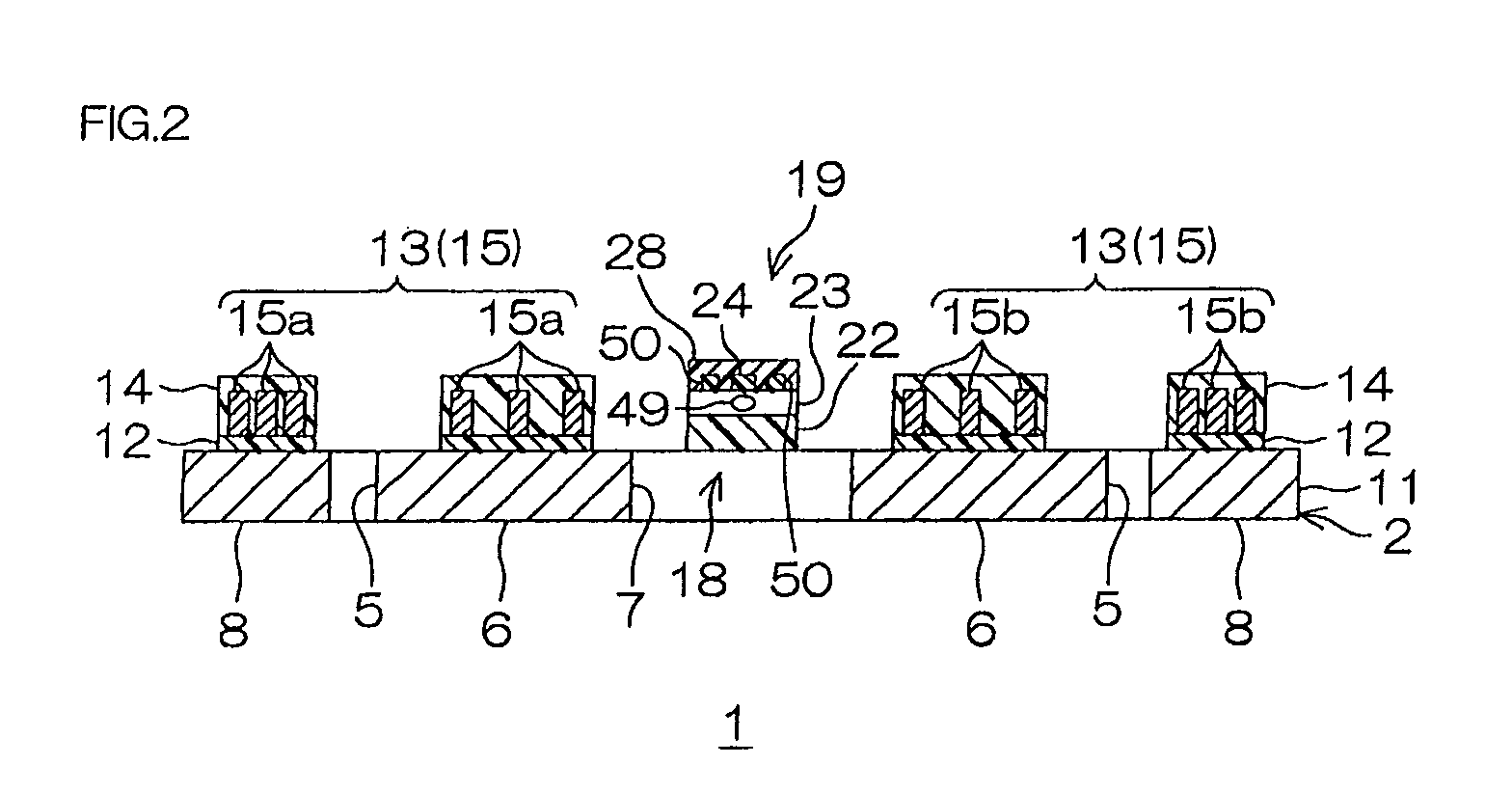

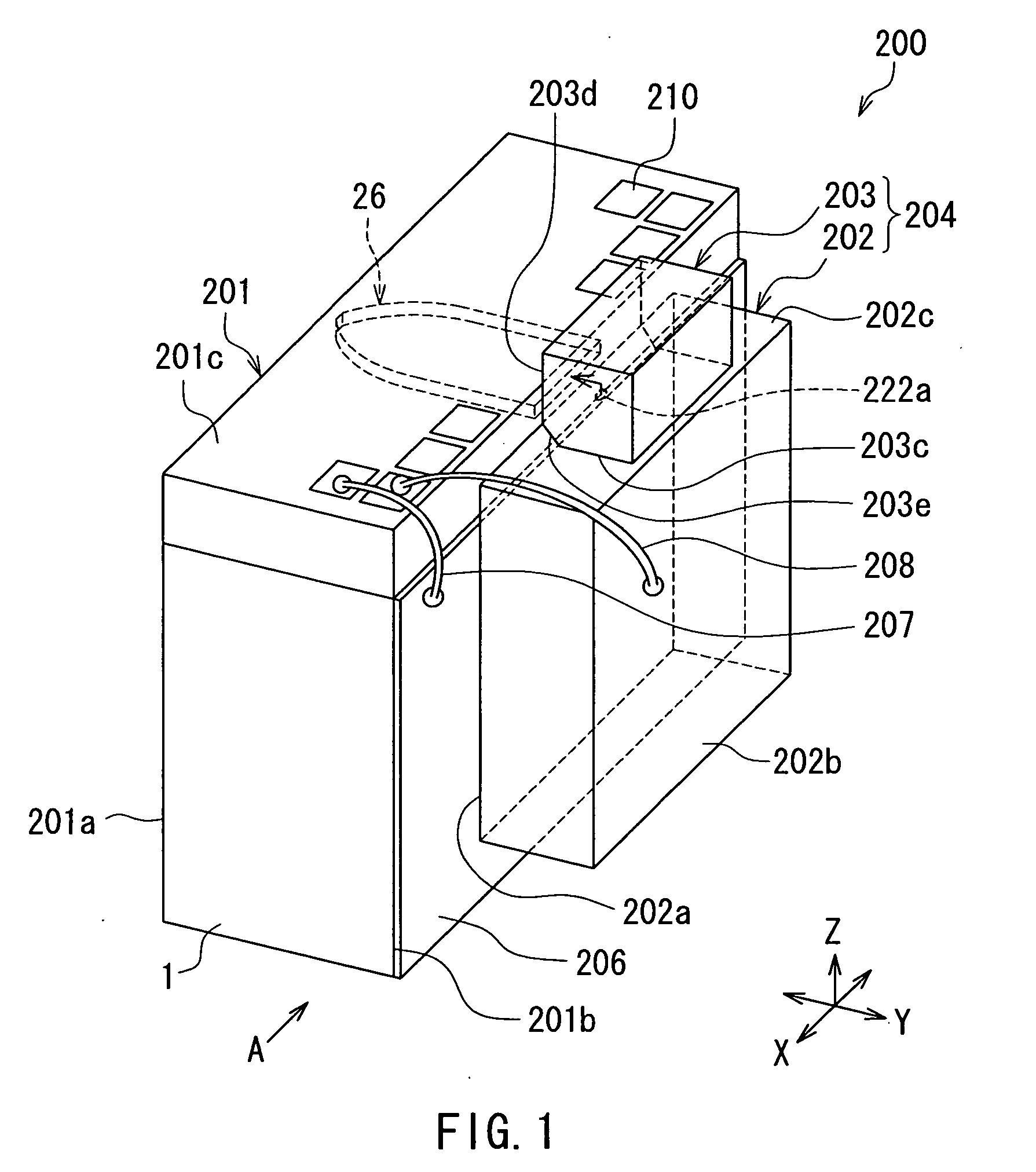

Light source unit for thermally-assisted magnetic recording capable of monitoring of light output

ActiveUS20110228653A1Properly and stably heatedImprove efficiencyCombination recordingPhotometry using reference valuePhotovoltaic detectorsHeat-assisted magnetic recording

Provided is a light source unit that is to be joined to a slider to form a thermally-assisted magnetic recording head. The light source unit comprises: a unit substrate having a source-installation surface; a light source provided in the source-installation surface and emitting thermal-assist light; and a photodetector bonded to a rear joining surface of the unit substrate in such a manner that a rear light-emission center of the light source is covered with a light-receiving surface of the photodetector. The photodetector can be sufficiently close to the light source; thus, constant feedback adjustment with high efficiency for the light output of the light source can be performed. This adjustment enables light output from the light source to be controlled in response to changes in light output due to surroundings and to changes with time to stabilize the intensity of light with which a magnetic recording medium is irradiated.

Owner:TDK CORPARATION +1

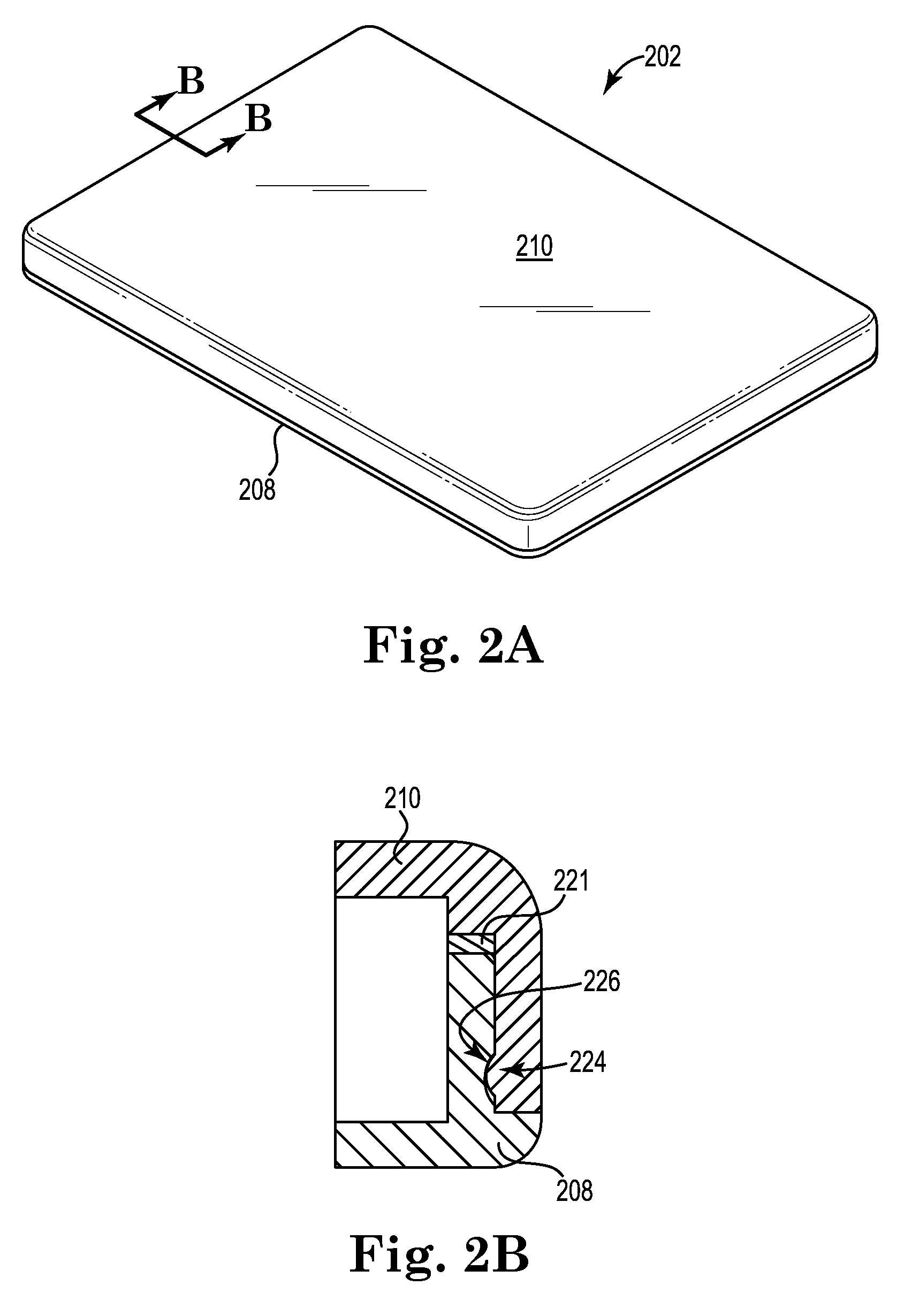

Coupling of Hard Disk Drive Housing and Related Methods

InactiveUS20120275287A1Easy to useEnhanced couplingElectrical transducersElectronic circuit testingHard disc driveComputer engineering

A disk drive assembly of the invention comprises: a hard disk drive; a base; and a cover, wherein the base and the cover are mechanically coupled without using essentially any discrete mechanical fasteners to form an enclosed housing comprising internal hard disk drive components between the base and the cover and to irreversibly hermetically seal the hard disk drive. Methods for forming such disk drive assemblies are also disclosed.

Owner:ENTROTECH

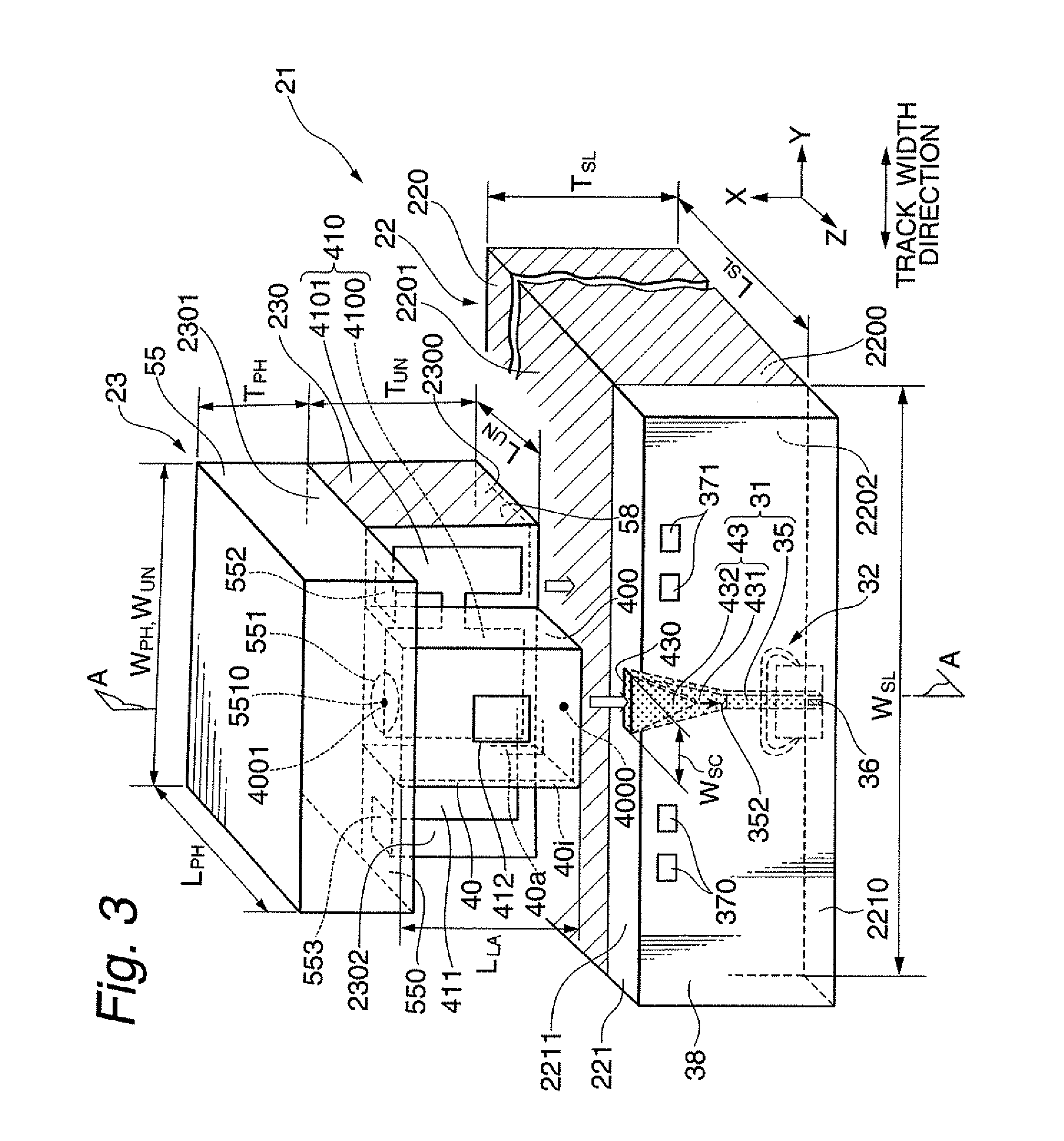

Energy assisted magnetic recording head having laser integrated mounted to slider

Owner:WESTERN DIGITAL TECH INC

Head for thermal assisted magnetic recording device, and thermal assisted magnetic recording device

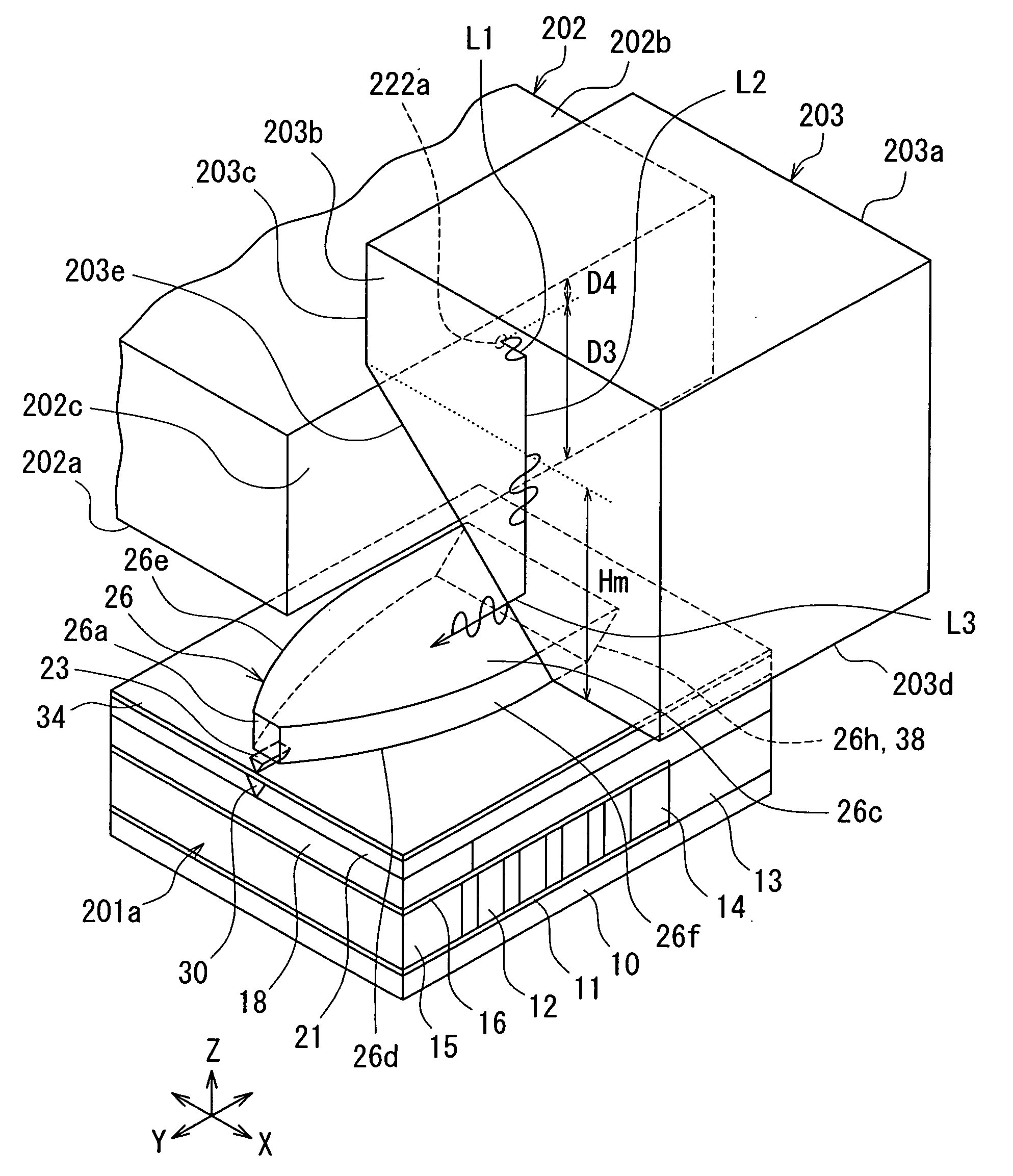

ActiveUS8243561B2Reduce in quantityIncrease recording capacityCombination recordingRecord information storageHeat-assisted magnetic recordingEngineering

In a head for thermal assisted magnetic recording device, a semiconductor laser is mounted so that the total height of the head does not become larger and light power fluctuation due to wavelength fluctuation occurs less frequently. In addition, the rise in temperature of the mounted semiconductor laser is suppressed. A semiconductor laser is placed on a side surface which is different from surfaces on an inflow end side and a trailing side, of four side surfaces of a floating slider. An entrance of a waveguide is placed on the side surface of the floating slider, to thereby cause emitted light from the semiconductor laser to directly enter the waveguide. A curved line part or a reflective mirror is formed in the middle of the waveguide so that the light which has entered the waveguide travels toward an optical near-field generating element.

Owner:HITACHI LTD

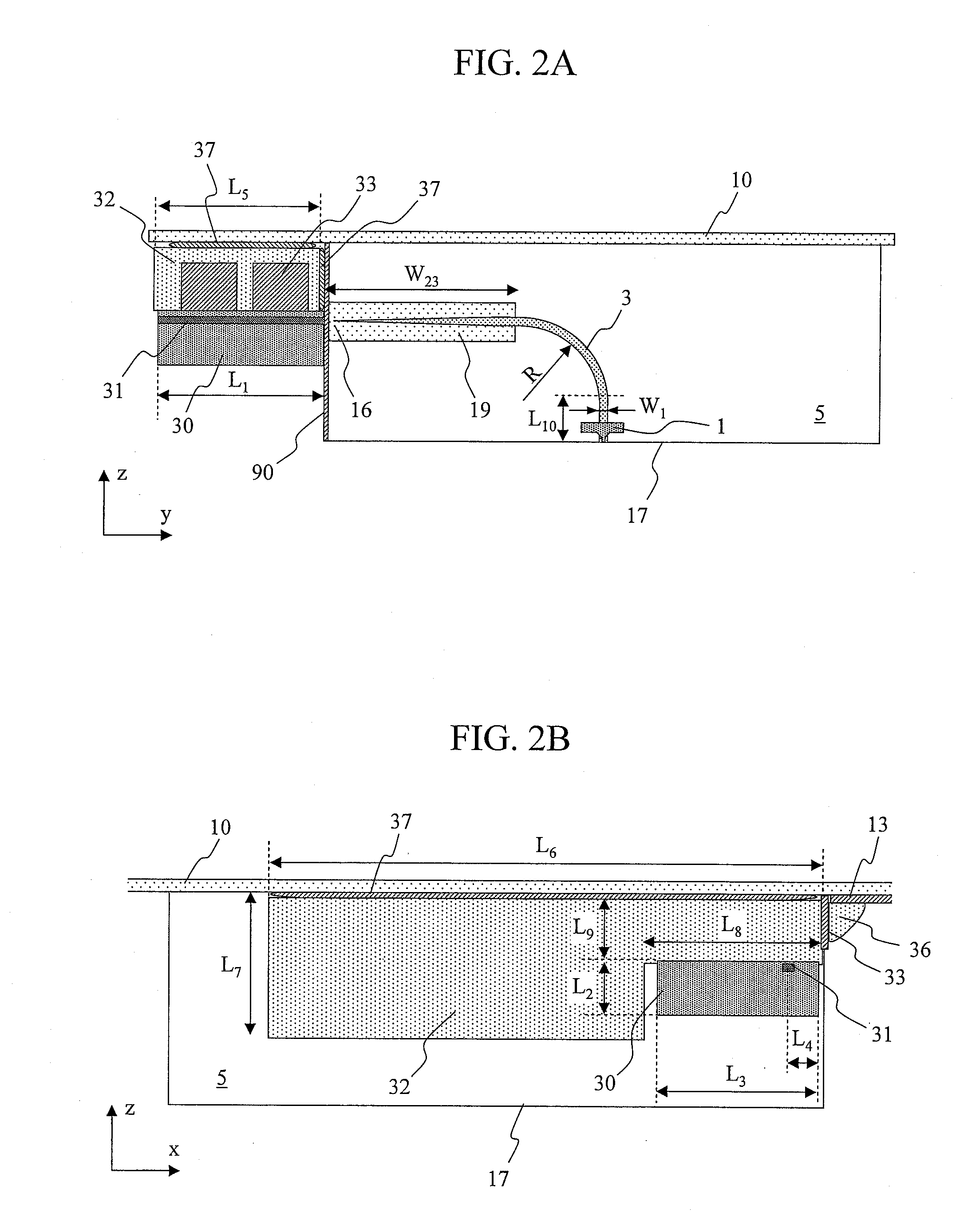

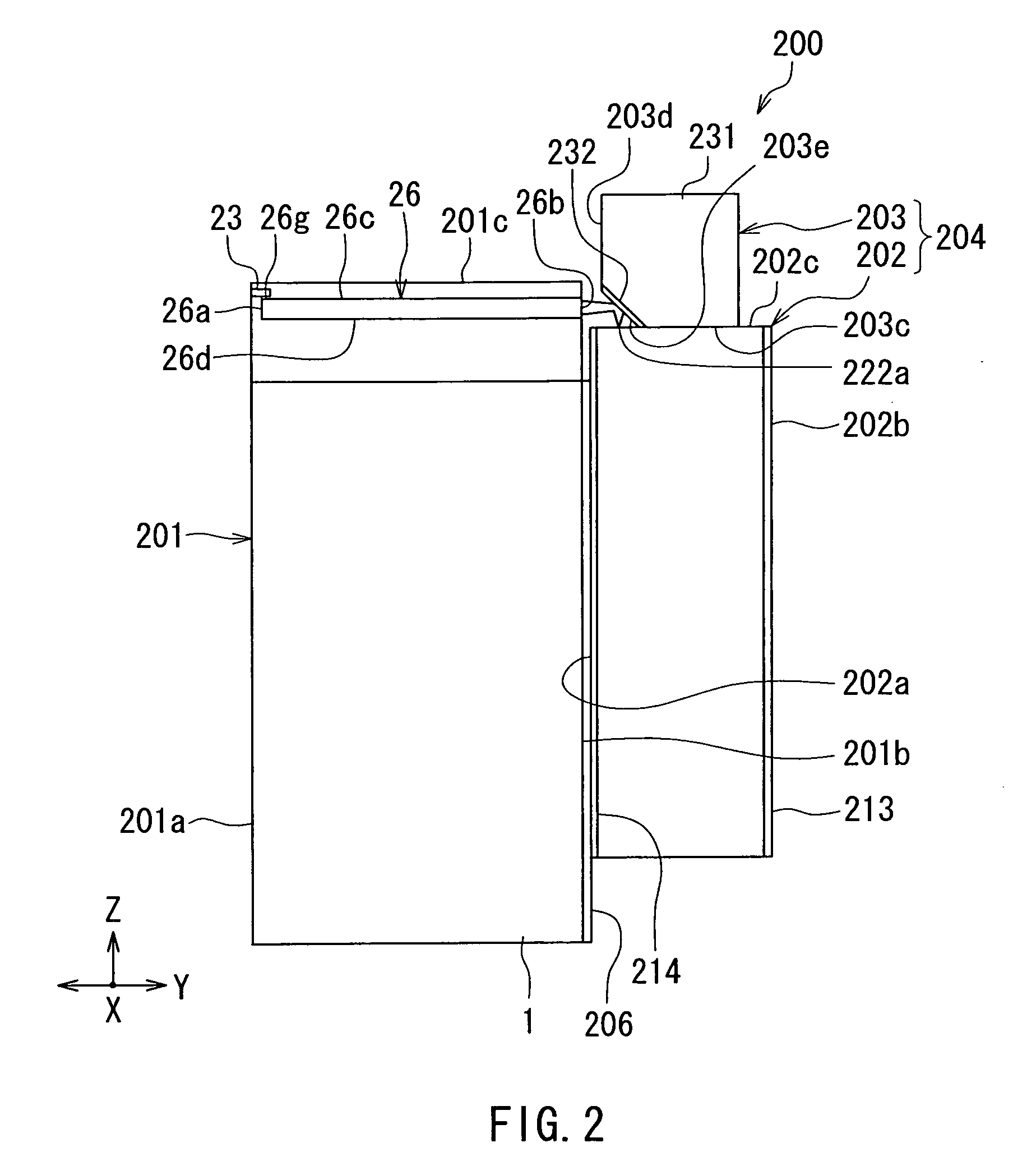

Method for manufacturing thermally-assisted magnetic recording head with light source unit

ActiveUS20110242697A1Improve efficiencyImprove performanceCombination recordingElectrical transducersHeat-assisted magnetic recordingWaveguide

Provided is a method for manufacturing a thermally-assisted magnetic recording head with “composite slider structure”. In the method, the waveguide is irradiated with a first light from opposed-to-medium surface side, and the passing first light is detected on back surface side to obtain an image of the light-receiving end surface, and a light-receiving center position is determined from the image. Further, the light source is irradiated with a second light from opposite side to joining surface, and the passing second light is detected on the joining surface side to obtain an image of the light-emitting end surface, and a light-emitting center position is determined from the image. Then, the slider and the light source unit are moved based on the determined positions of the light-receiving and light-emitting centers, aligned and bonded. As a result, alignment can be performed with high accuracy in a short process time under simplified process.

Owner:TDK CORPARATION

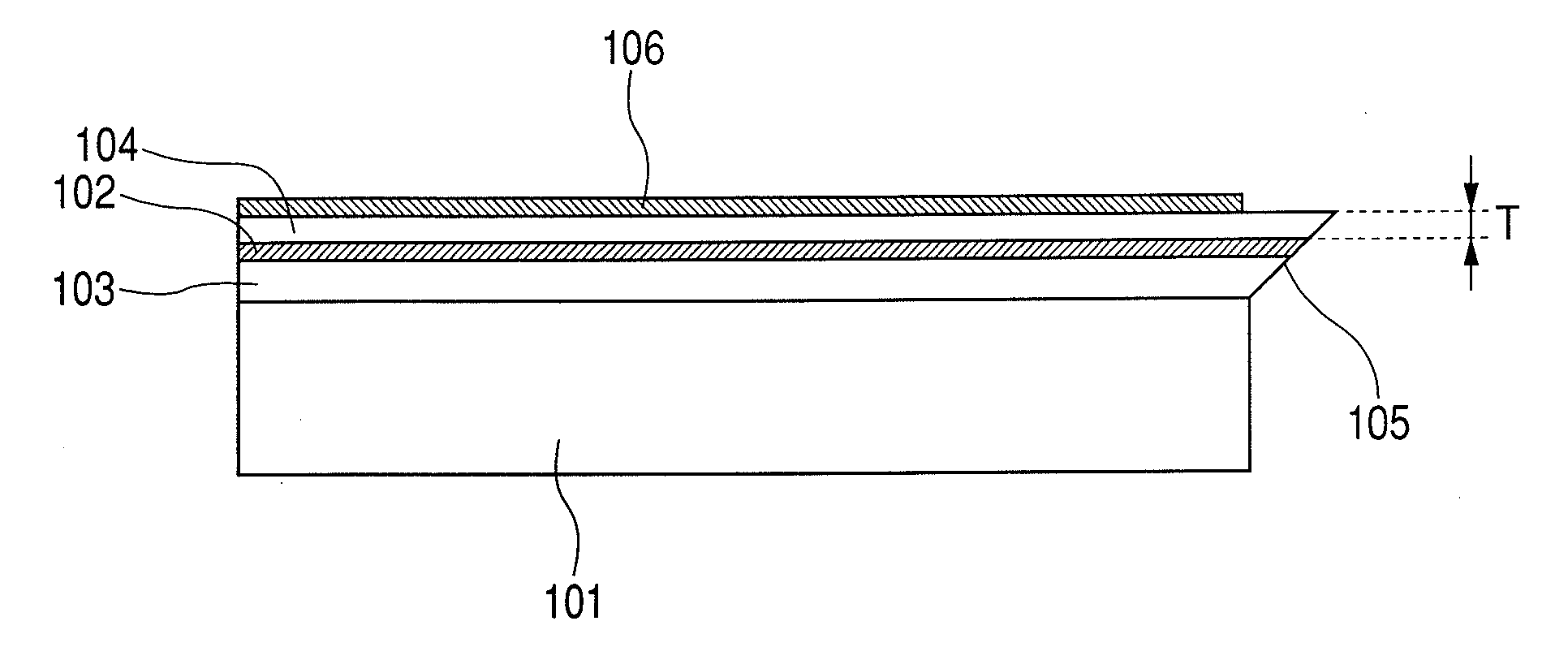

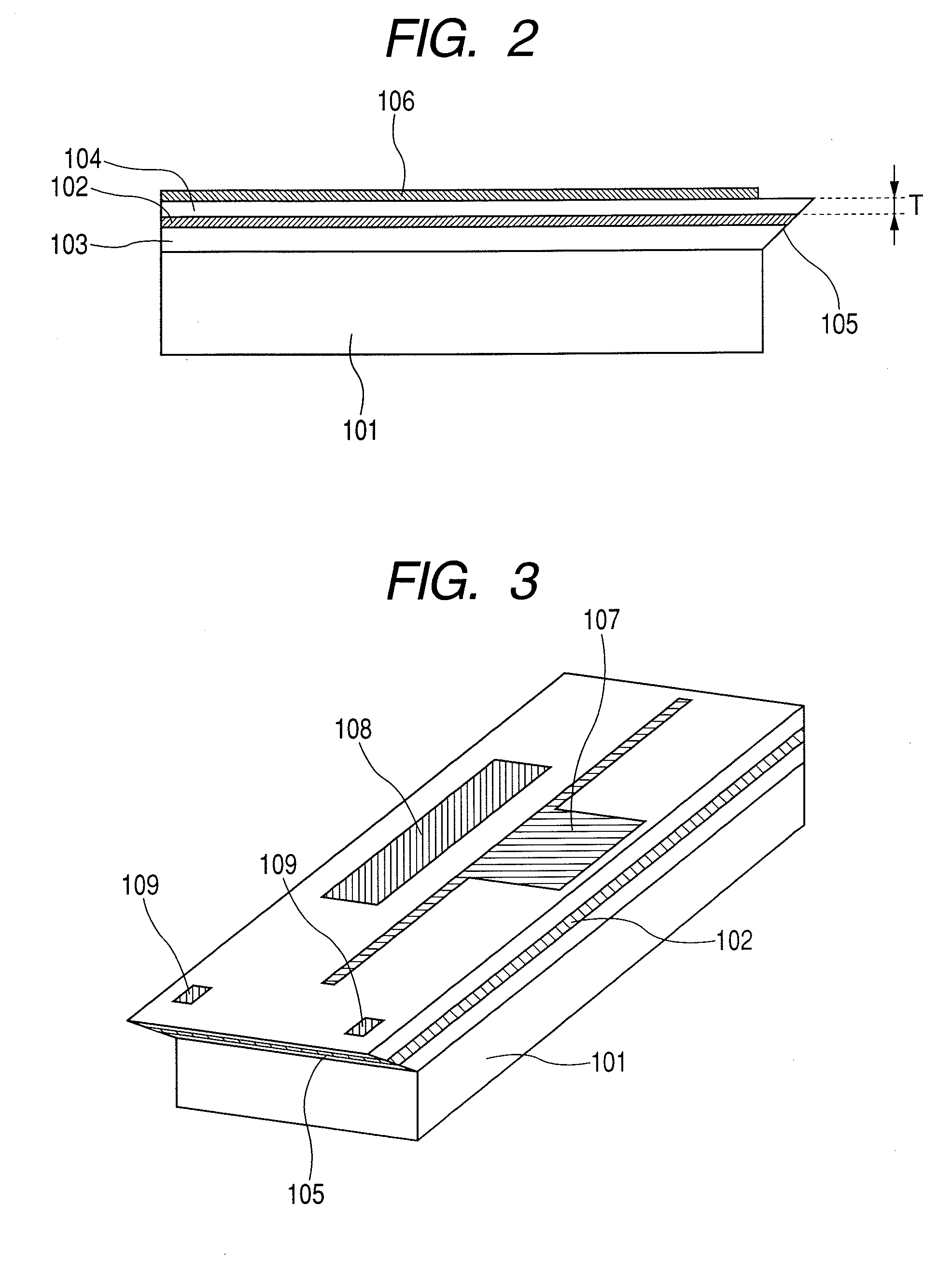

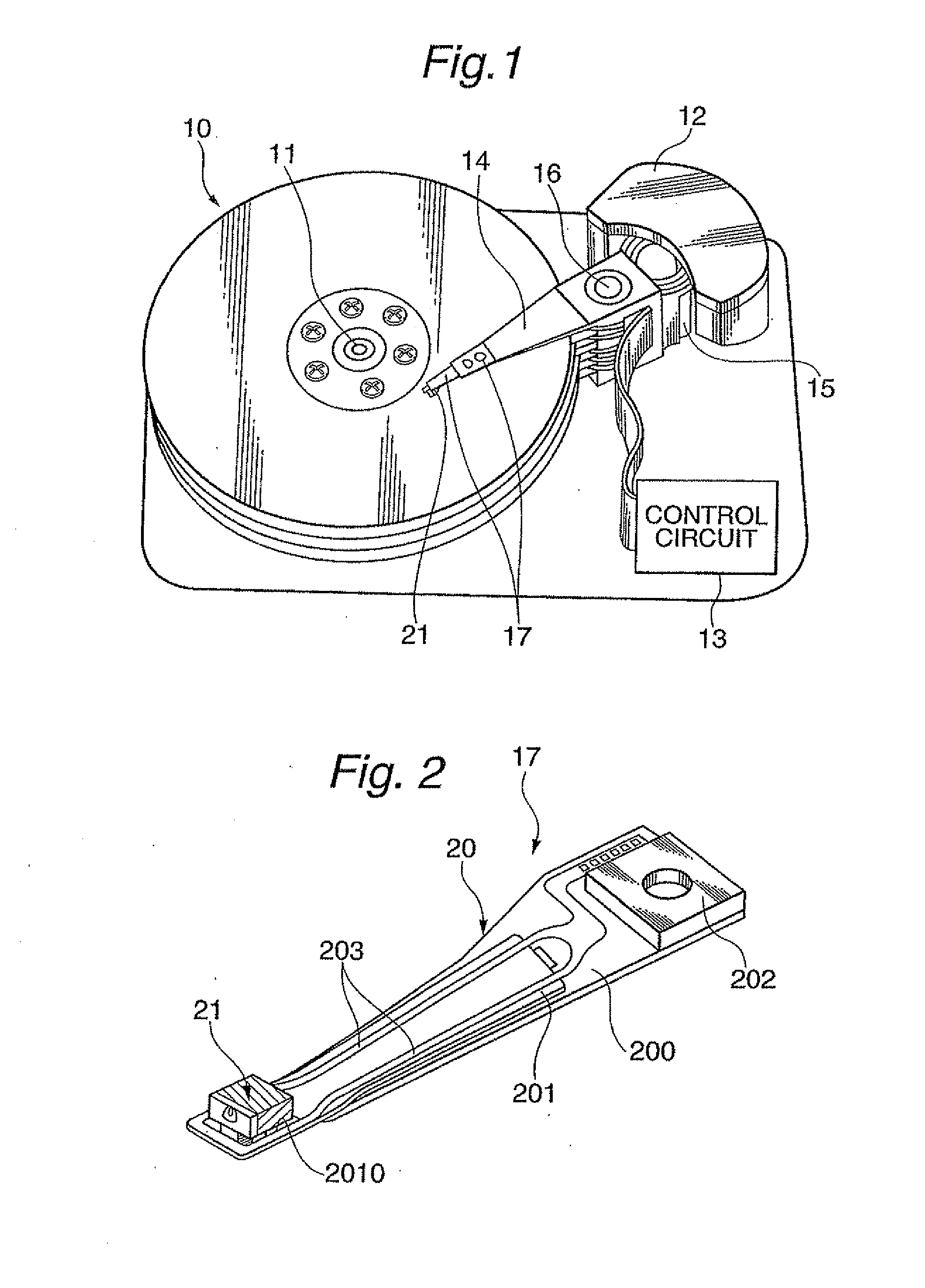

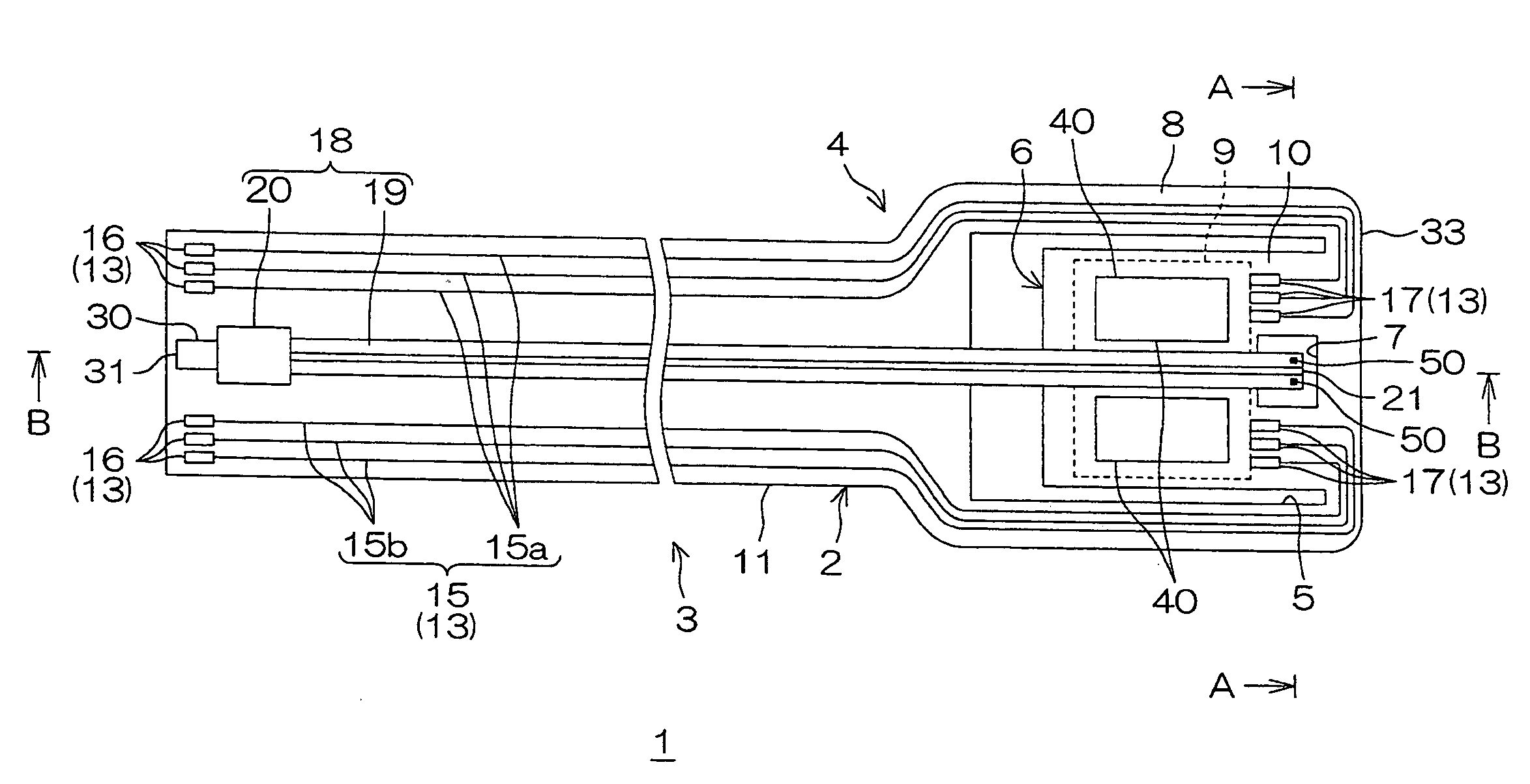

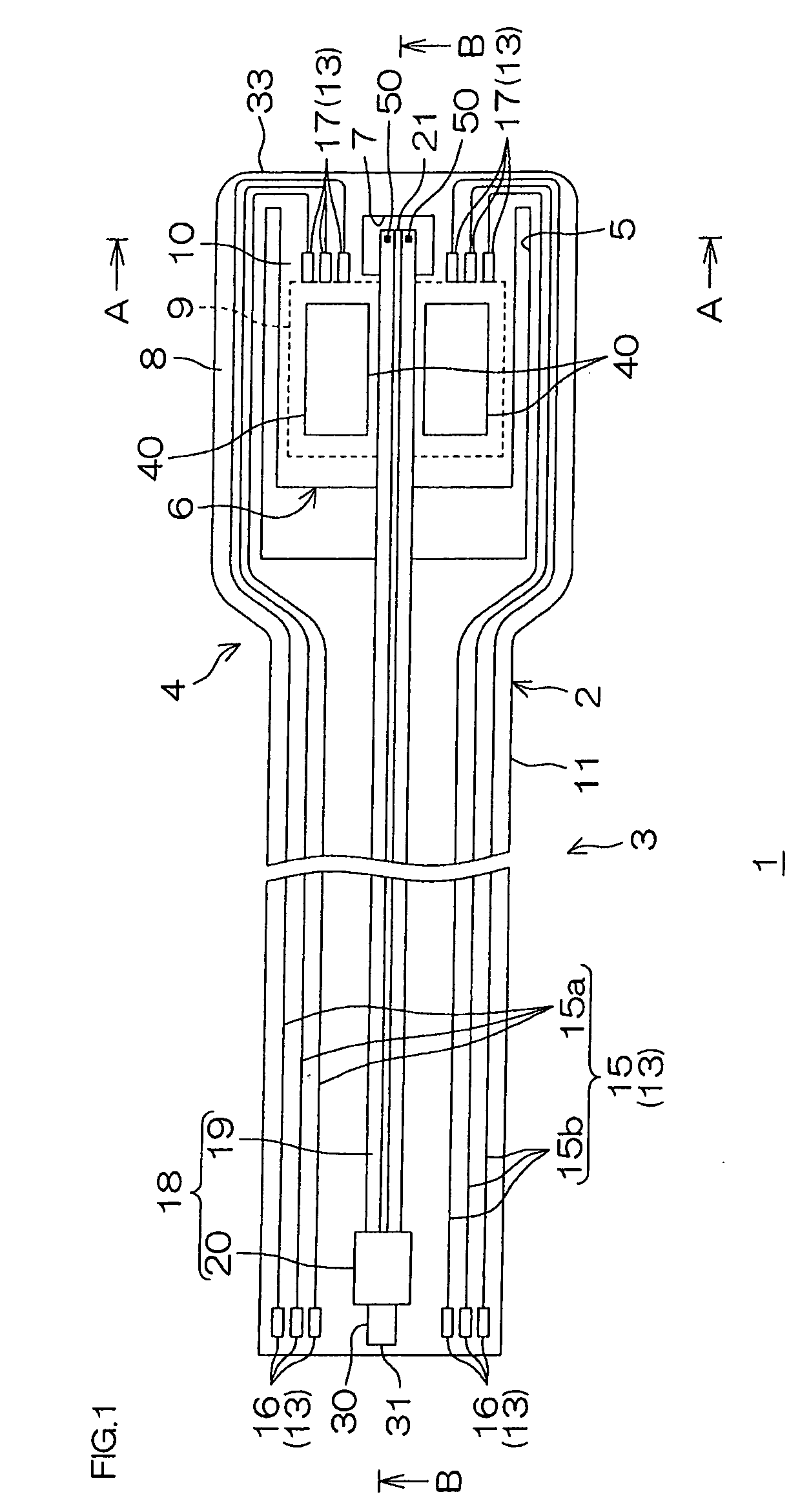

Suspension board with circuit

A suspension board with circuit includes a circuit board including a metal supporting board, an insulating layer formed on the metal supporting board, a conductive layer formed on the insulating layer, and an optical waveguide disposed on the circuit board. The optical waveguide includes an under clad layer, a core layer formed on the under clad layer, and an over clad layer formed on the core layer and included in the core layer when projected in the thickness direction of the core layer. The optical waveguide is provided with a positioning portion to position the optical waveguide and a near-field light generating unit for generating near-field light by a light emitted from the optical waveguide, and a protective layer to cover the positioning portion.

Owner:NITTO DENKO CORP

Light source unit for thermally-assisted magnetic recording capable of monitoring of light output

ActiveUS8149653B2Properly and stably heatedImprove efficiencyCombination recordingPhotometry using reference valuePhotovoltaic detectorsHeat-assisted magnetic recording

Provided is a light source unit that is to be joined to a slider to form a thermally-assisted magnetic recording head. The light source unit comprises: a unit substrate having a source-installation surface; a light source provided in the source-installation surface and emitting thermal-assist light; and a photodetector bonded to a rear joining surface of the unit substrate in such a manner that a rear light-emission center of the light source is covered with a light-receiving surface of the photodetector. The photodetector can be sufficiently close to the light source; thus, constant feedback adjustment with high efficiency for the light output of the light source can be performed. This adjustment enables light output from the light source to be controlled in response to changes in light output due to surroundings and to changes with time to stabilize the intensity of light with which a magnetic recording medium is irradiated.

Owner:TDK CORPARATION +1

Thermally assisted magnetic recording head and magnetic recording apparatus

InactiveUS7898759B2Reduce outputIncrease productionDriving/moving recording headsRecord information storageHeat-assisted magnetic recordingPhotodetector

A second waveguide is formed near a first waveguide for guiding light to the vicinity of a main pole of a thermally assisted magnetic recording head, and a portion of light propagated through the waveguide 1 is branched to the second waveguide. The light transmitting in the second waveguide is detected by a photodetector to detect an intensity of the light propagated through the first waveguide. In the magnetic recording apparatus, an intensity of a semiconductor laser is decreased when an amount of light incident to the photodetector is large and the intensity of the semiconductor laser is increased when the amount of light incident to the photodetector is small. By constituting a feedback loop as described above, the intensity of the light propagated through the first waveguide is kept constant.

Owner:HITACHI LTD

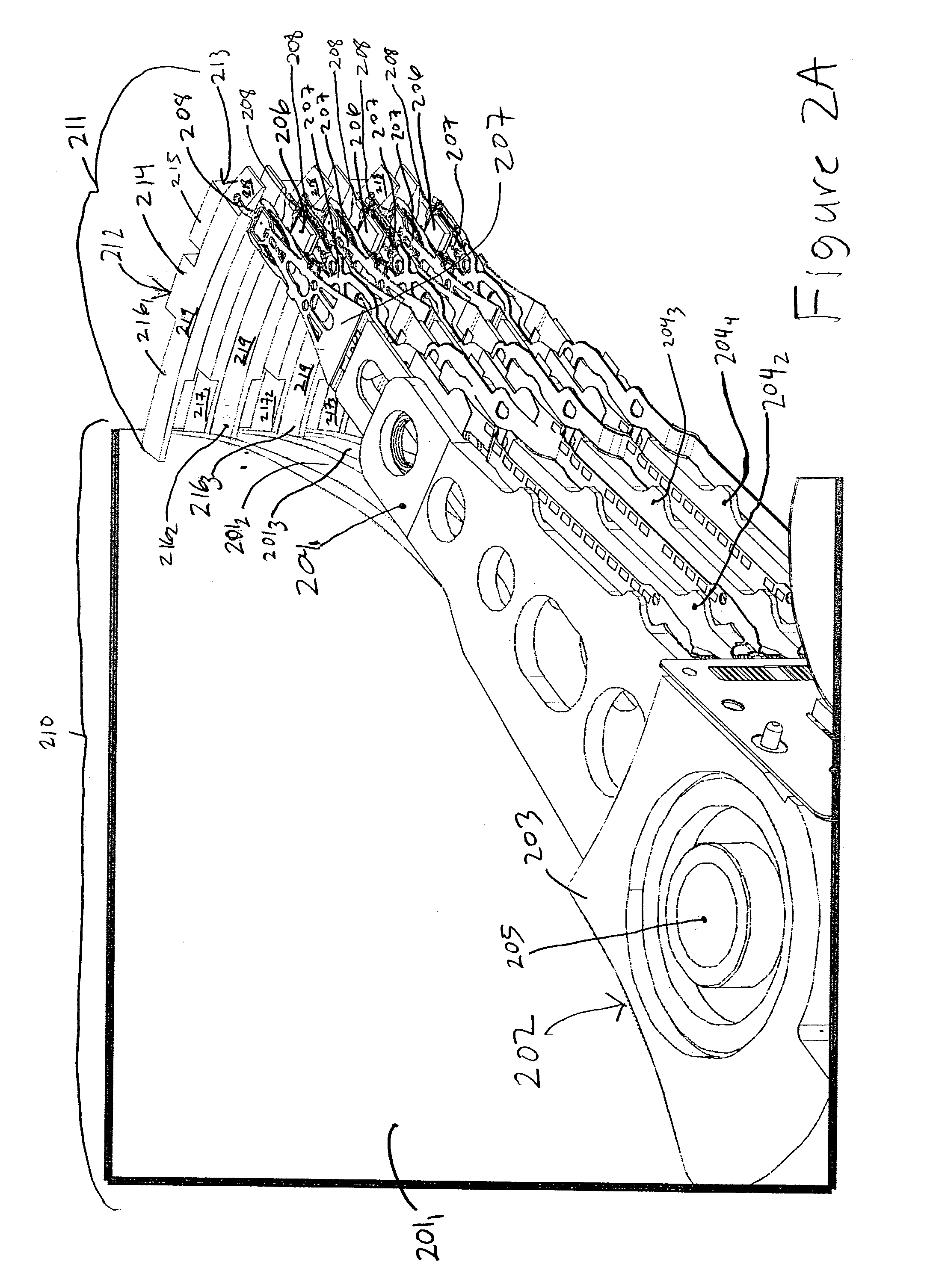

Tape head having a support plate with contoured surface

ActiveUS20060232884A1Disposition/mounting of recording headsManufacturing heads with multiple gapsEngineeringActuator

Owner:META PLATFORMS INC

Method and system for optically coupling a laser with a transducer in an energy assisted magnetic recording disk drive

A method and system for providing an energy assisted magnetic recording (EAMR) head are described. The EAMR head includes a laser, a slider, and an EAMR transducer. The laser has a main emitter and at least one alignment emitter. The slider includes at least one alignment waveguide, at least one output device, and an air-bearing surface (ABS). The alignment waveguide(s) are aligned with the alignment emitter(s). The EAMR transducer is coupled with the slider and includes a waveguide aligned with main emitter. The waveguide is for directing energy from the main emitter toward the ABS.

Owner:WESTERN DIGITAL TECH INC

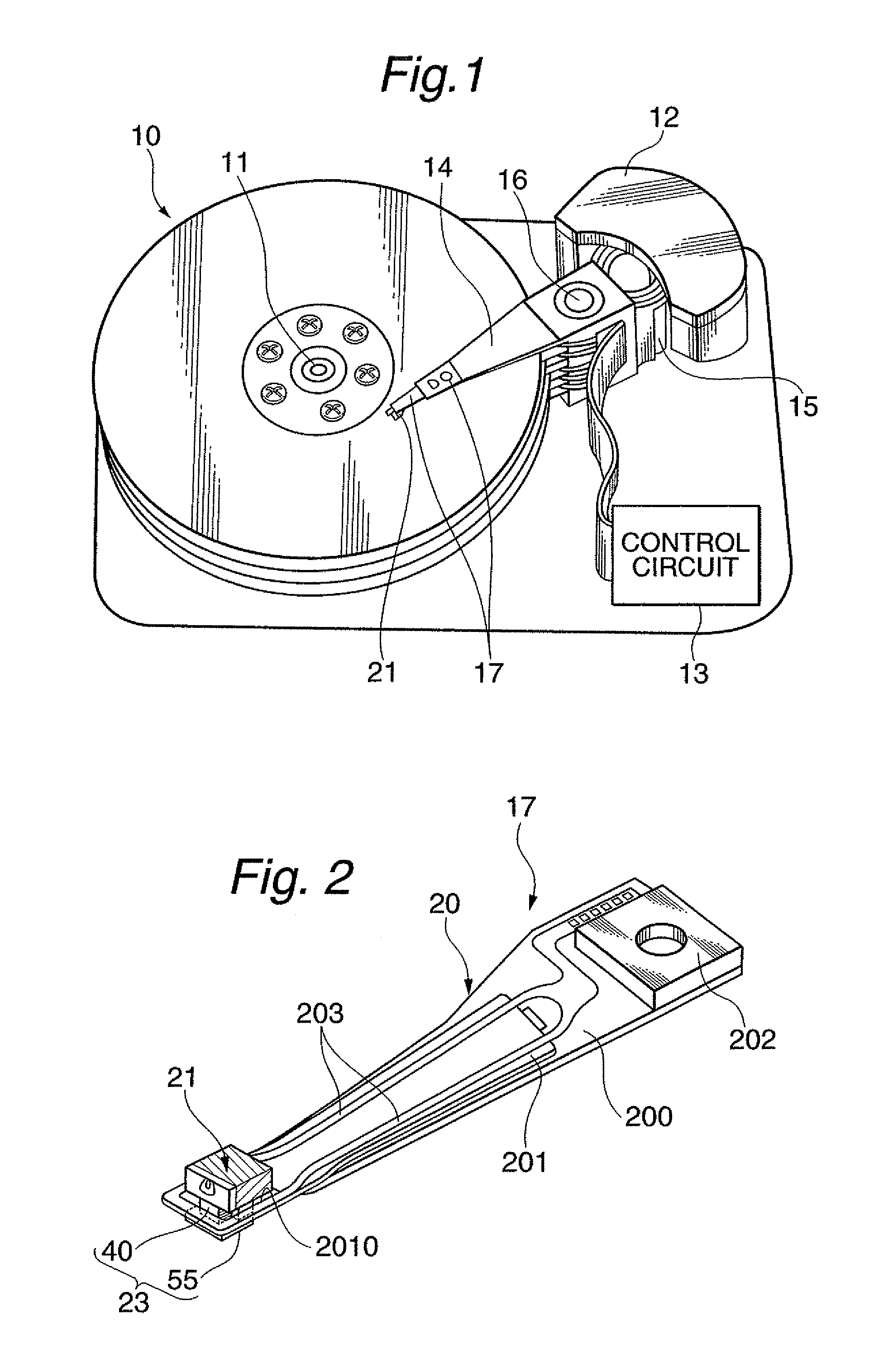

Slider, head gimbal assembly and disk drive unit with the same

ActiveUS8295011B2Improve performanceImprove bindingElectrical connection between head and armHeads using thin filmsGimbalElectrical and Electronics engineering

A slider for a head gimbal assembly includes a trailing surface, a plurality of connection pads arranged on the trailing surface adapted for both bonding the slider to a suspension of the head gimbal assembly and testing the performance of the slider. At least a part of the connection pads each comprises a bonding portion and a testing portion electrically connected to the bonding portion and larger than the bonding portion, all the bonding portions and the rest part of the connection pads are arranged in a first row and the testing portions are arranged outside the first row. The slider of the present invention has a new pad layout to facilitate bonding of the connection pads and permit to provide additional pads thereon to connect the additional sensors therein for precise reading and writing, thereby improving the performance of the slider. The invention also discloses a head gimbal assembly and a disk drive unit including the same.

Owner:SAE MAGNETICS (HK) LTD

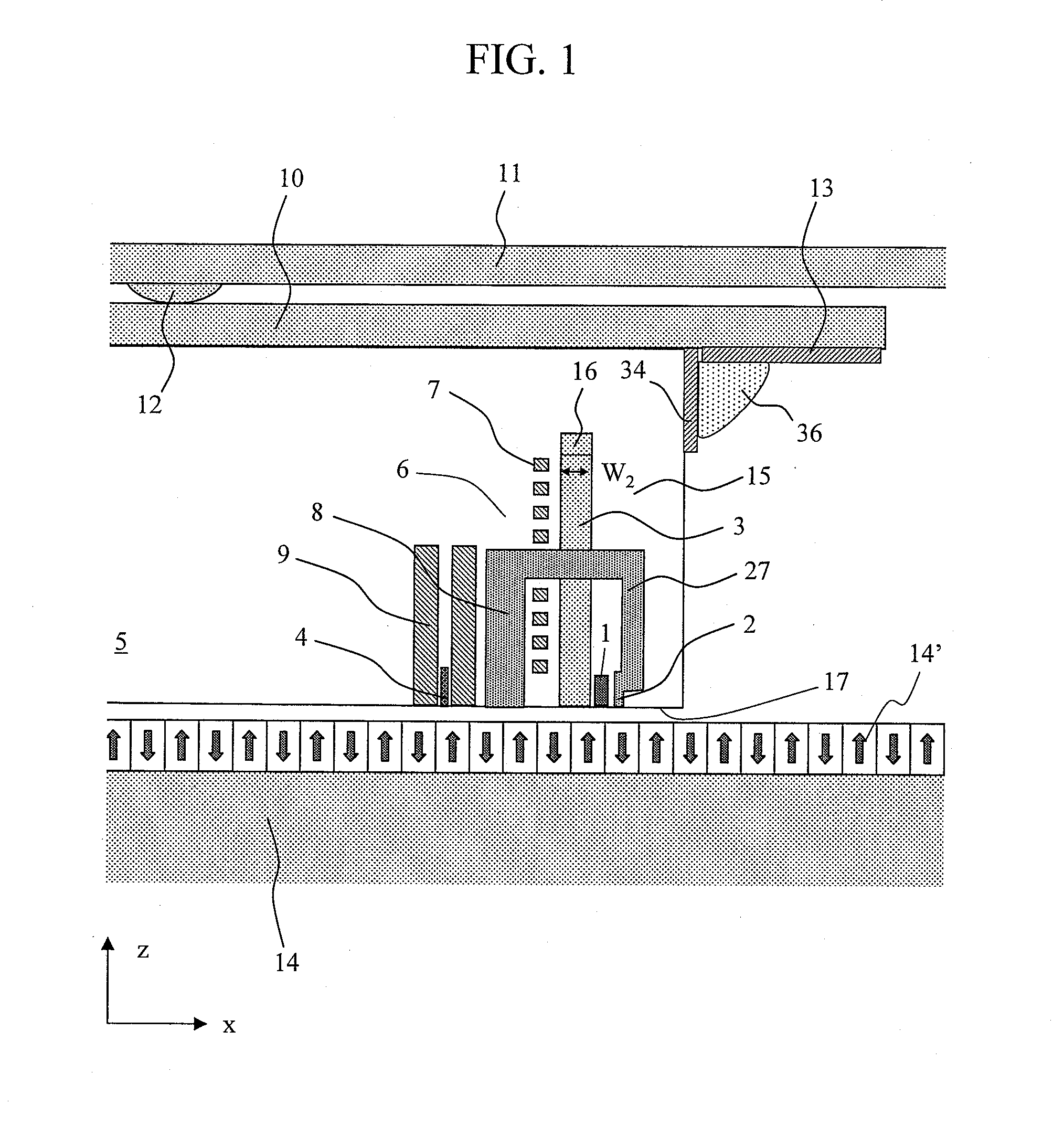

Heat-assisted magnetic recording head with laser diode fixed to slider

ActiveUS20110058273A1Easy alignmentShorten the pathCombination recordingDisposition/mounting of recording headsHeat-assisted magnetic recordingMagnetic poles

A heat-assisted magnetic recording head includes a slider, an edge-emitting laser diode fixed to the slider, and an external mirror provided outside the slider. The slider includes a magnetic pole, a waveguide, and a near-field light generating element. The laser diode includes: an emitting end face that lies at an end in a direction parallel to the plane of an active layer and includes a laser-light emission part; and a mounting surface that lies at an end in a direction perpendicular to the plane of the active layer and faces the slider. The external mirror includes: a first reference surface that is parallel to the emitting end face and faces the emitting end face; a second reference surface that is parallel to the mounting surface and faces toward the same direction as the mounting surface does; and a reflecting surface that connects the first and second reference surfaces to each other and reflects the laser light emitted from the emission part toward the waveguide.

Owner:HEADWAY TECH INC

Thermally assisted magnetic head

ActiveUS20080055784A1Increase productionEasy to adjustCombination recordingRecord information storageEngineeringWaveguide

A thermally assisted magnetic head has a slider having a medium-facing surface, and a light source unit having a light source support substrate, and a light source disposed on the light source support substrate; the slider has a slider substrate and a magnetic head portion disposed on a side surface of the slider substrate; the magnetic head portion has a magnetic recording element for generating a magnetic field, first and second waveguides, for receiving light through an end face and guiding the light to the medium-facing surface, and a near-field light generator disposed on an end face; the light source support substrate is fixed to a surface of the slider substrate so that light emitted from the light source can enter the end face of the first waveguide.

Owner:TDK CORPARATION

Method for manufacturing head including light source unit for thermal assist

Provided is a method for manufacturing a thermally-assisted magnetic recording head in which a light source unit including a light source and a slider including an optical system are joined. The method comprises steps of: adhering by suction the light source unit with a back holding jig; bringing the light source unit into contact with a slider back surface of the slider; applying a load to a load application surface of the light source unit by a loading means to bring a joining surface of the light source unit into conformity with the slider back surface; positioning the light source unit apart from the slider, and then aligning the light source with the optical system; bringing again the light source unit into contact with the slider; and applying a load again to the load application surface to bring the joining surface into conformity with the slider back surface. Thus, the conformity between them can be significantly increased, thereby achieving adequately strong junction and adequately high accuracy in position.

Owner:TDK CORPARATION

Popular searches

Semiconductor/solid-state device manufacturing Optical beam guiding means Heads for perpendicular magnetisations Manufacture unitary devices of plural heads Manufacture of flux-sensitive heads Housing manufacture Optical articles Recording/reproducing/erasing methods Galvano-magnetic device manufacture/treatment Thin material handling

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com