Patents

Literature

59 results about "Thermal asperity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

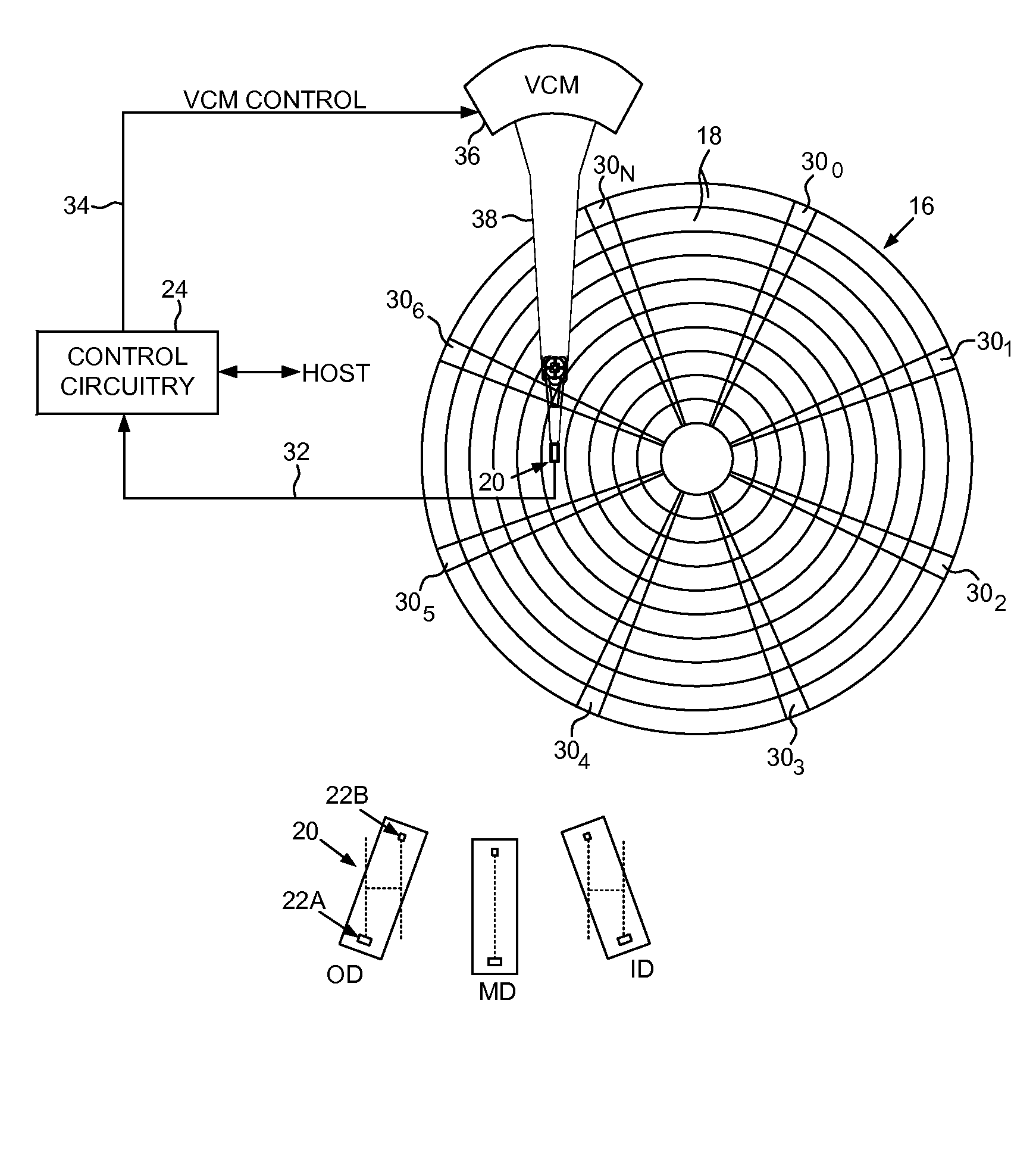

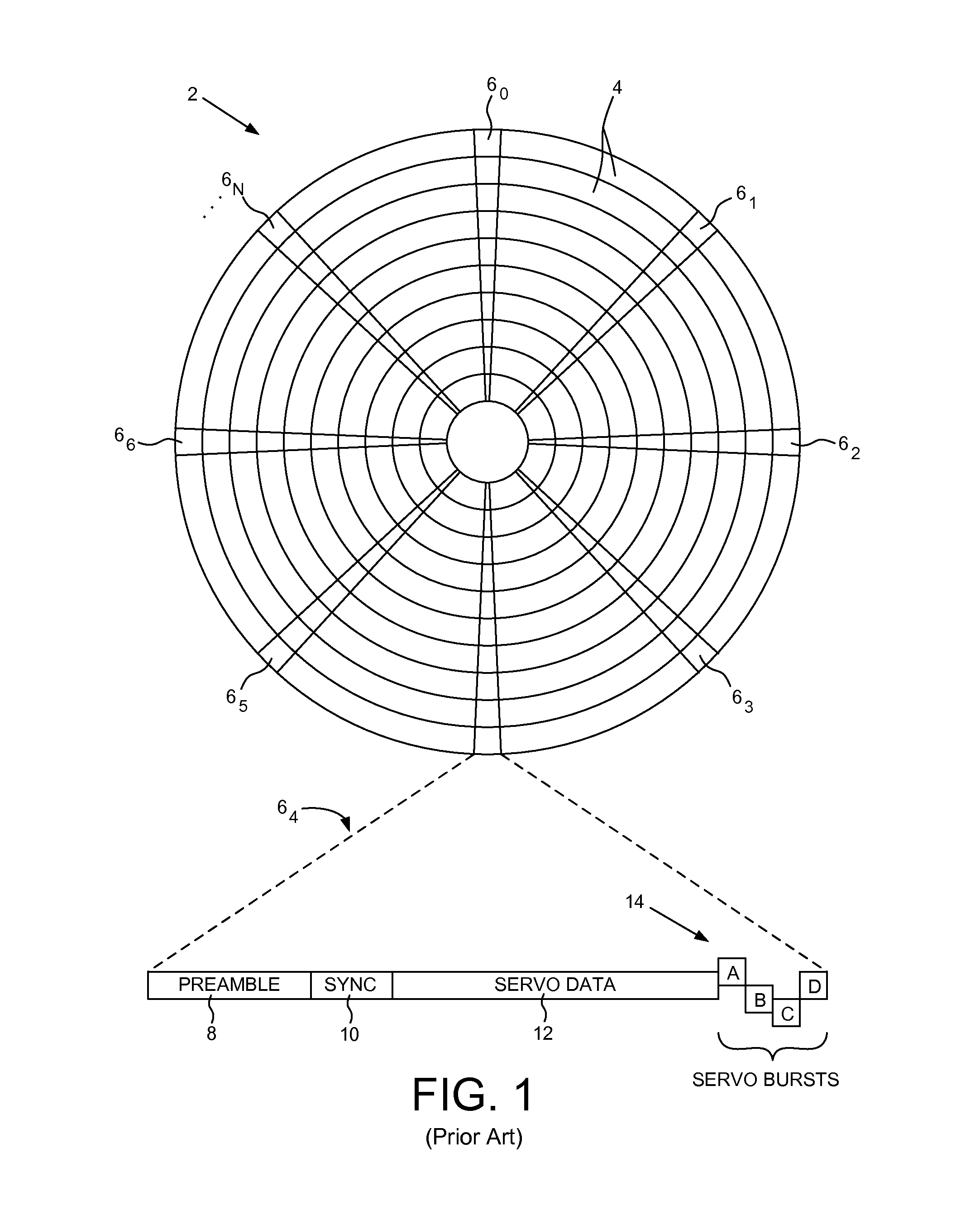

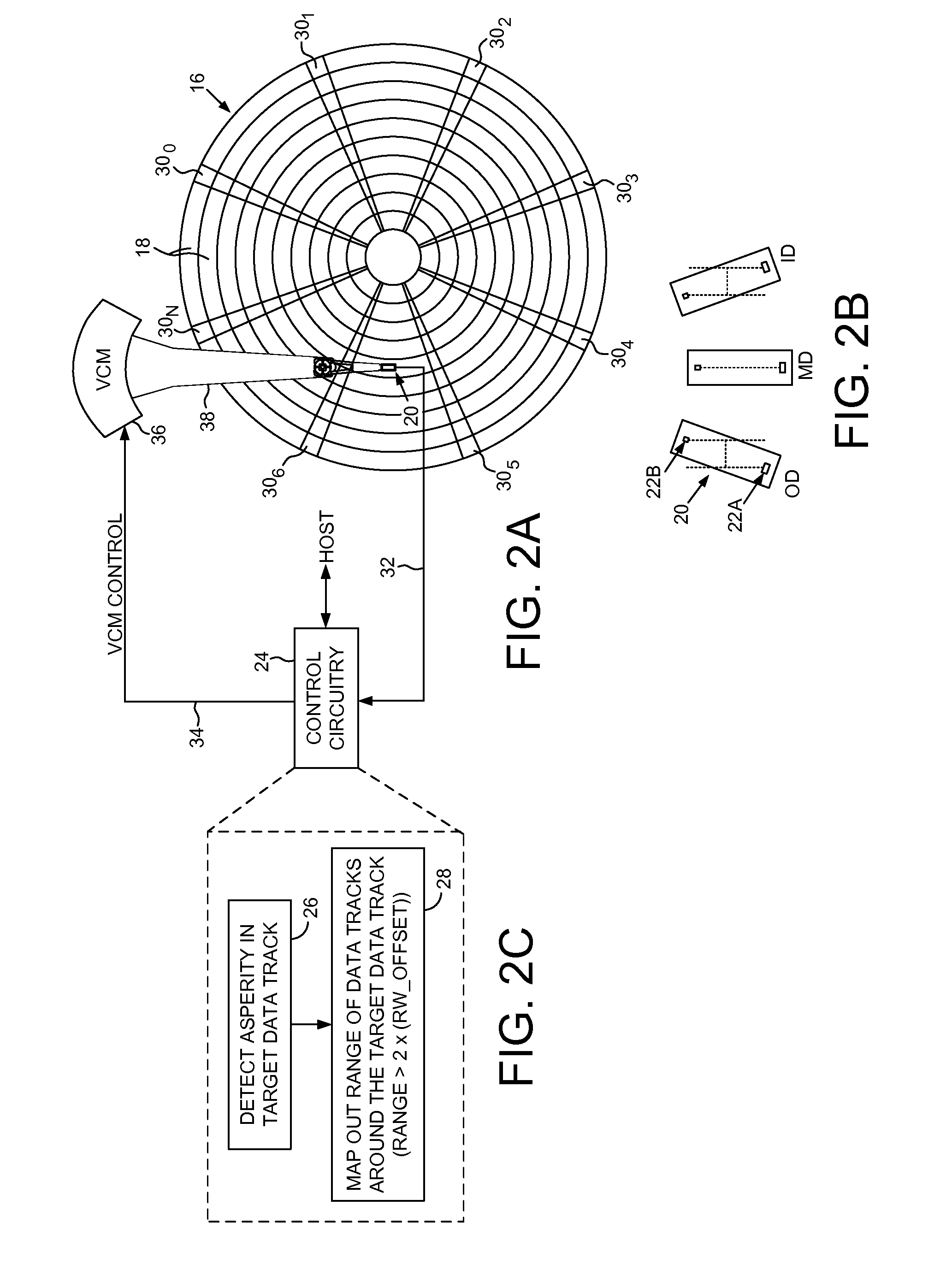

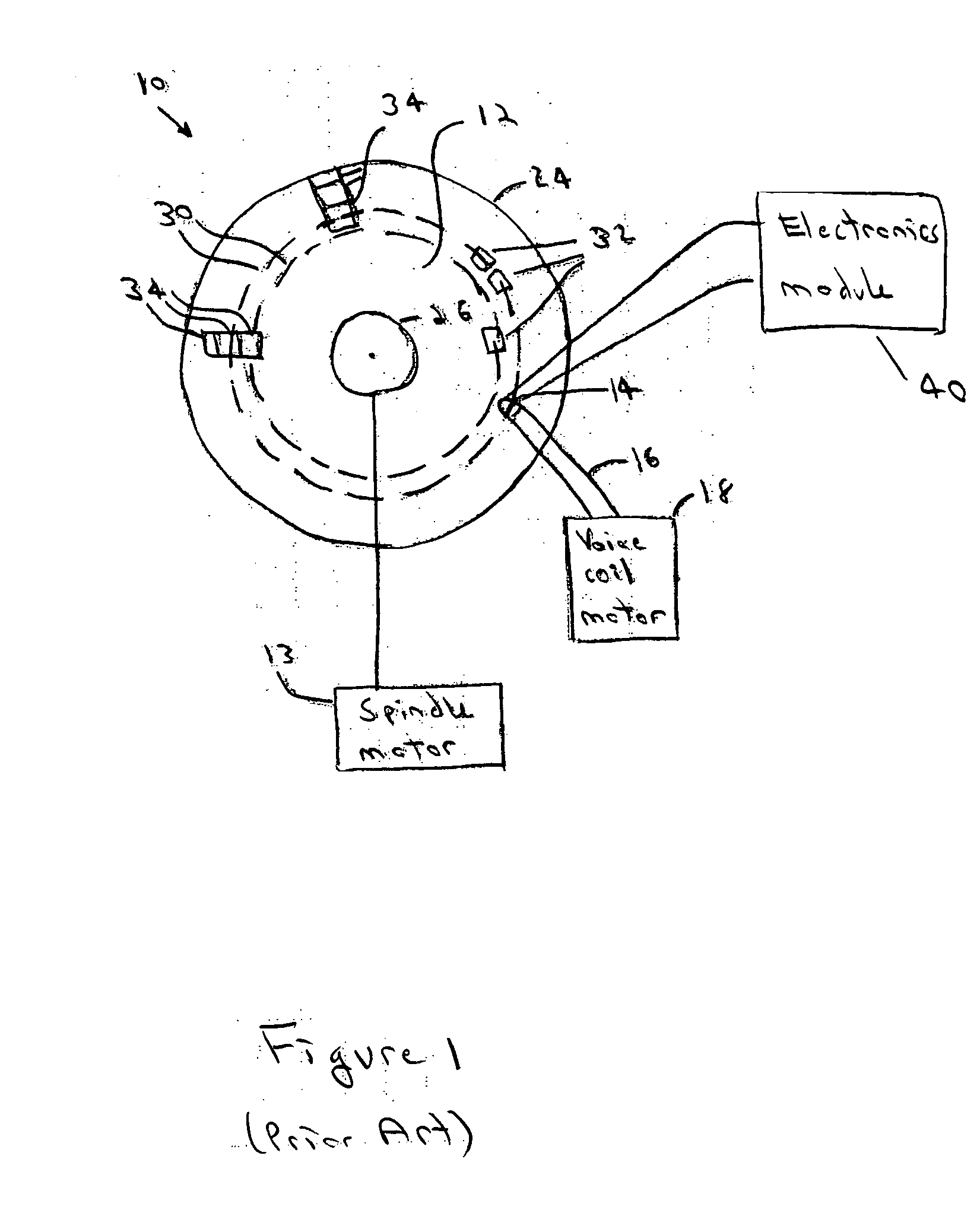

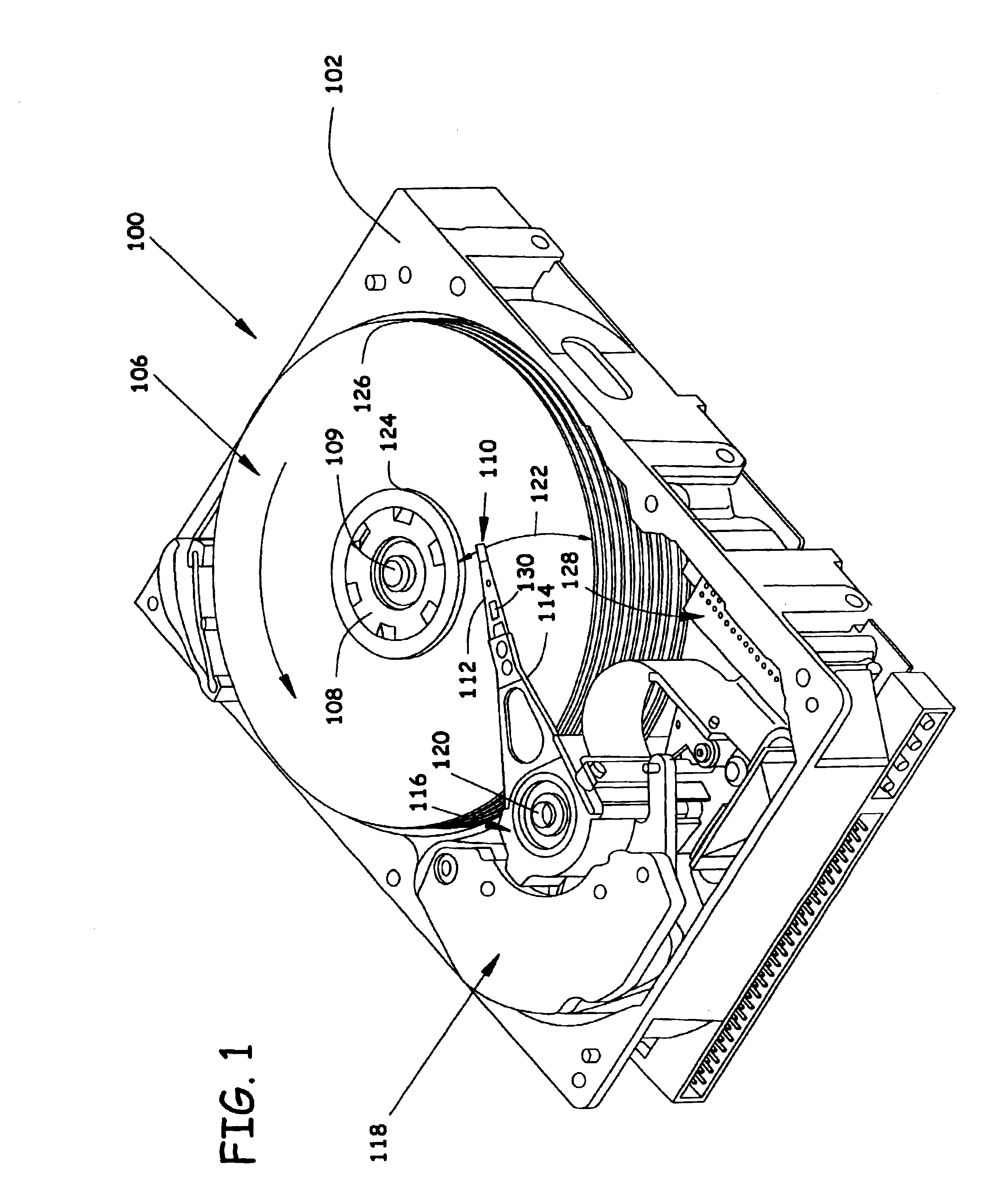

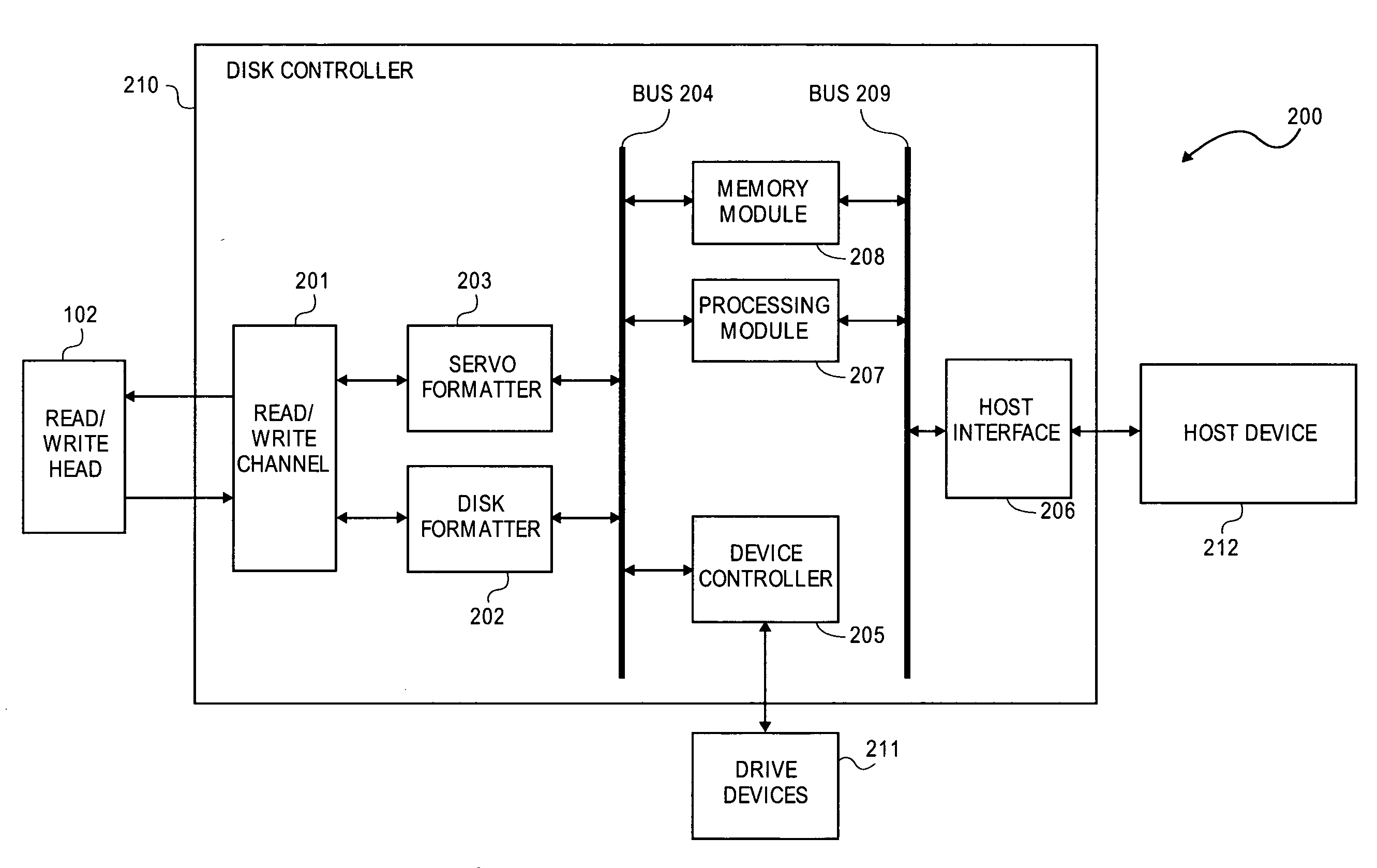

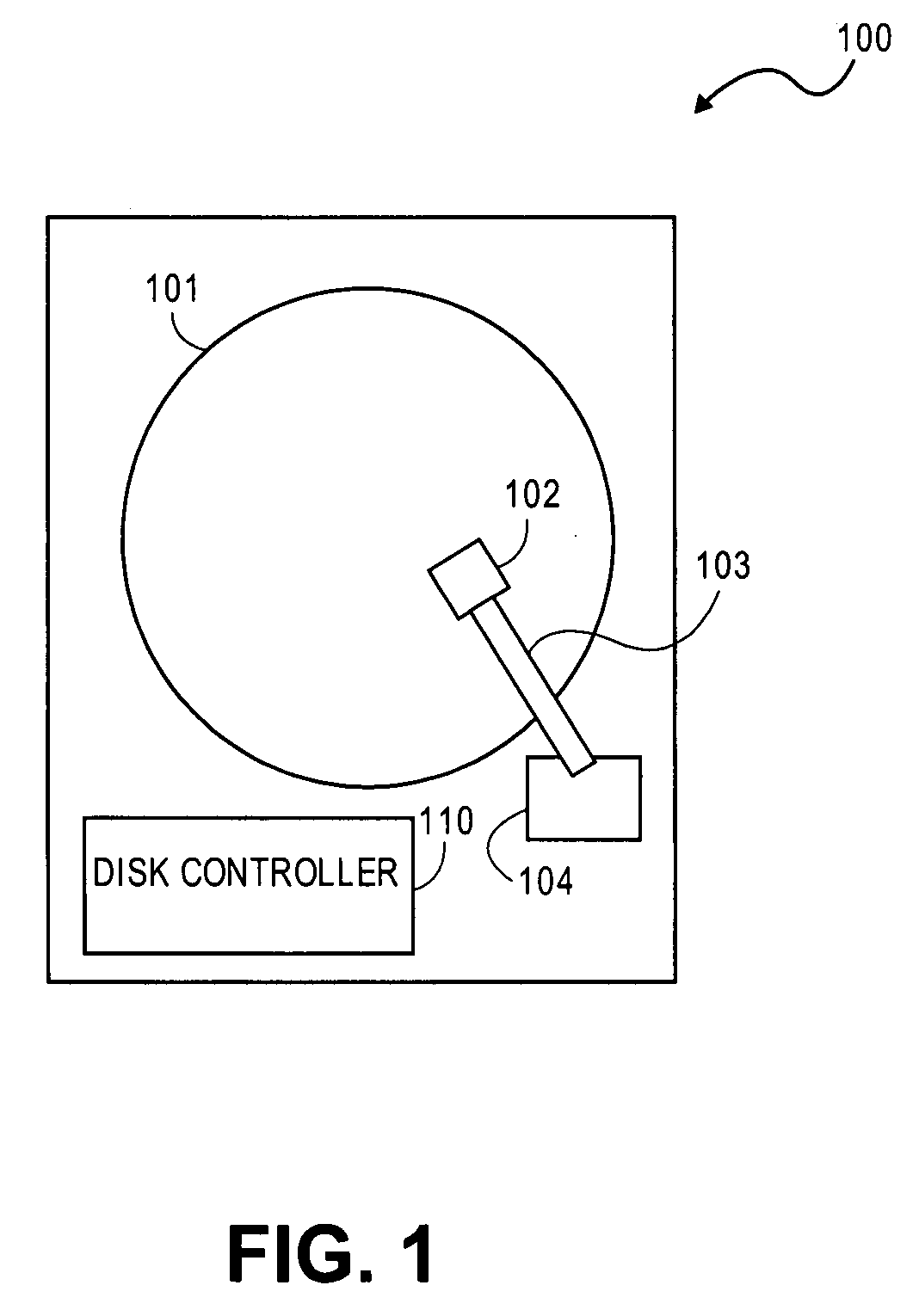

Disk drive mapping out data tracks to avoid thermal asperities

ActiveUS8687313B2Driving/moving recording headsRecord information storageDrive mappingComputer science

A disk drive is disclosed comprising a head actuated over a disk comprising a plurality of data tracks, wherein the head comprises a write element and a read element. An asperity in a target data track is detected, and a range of data tracks proximate the target data track is mapped out, wherein the range of data tracks spans at least twice a radial offset between the read element and the write element at the radial location of the target data track.

Owner:WESTERN DIGITAL TECH INC

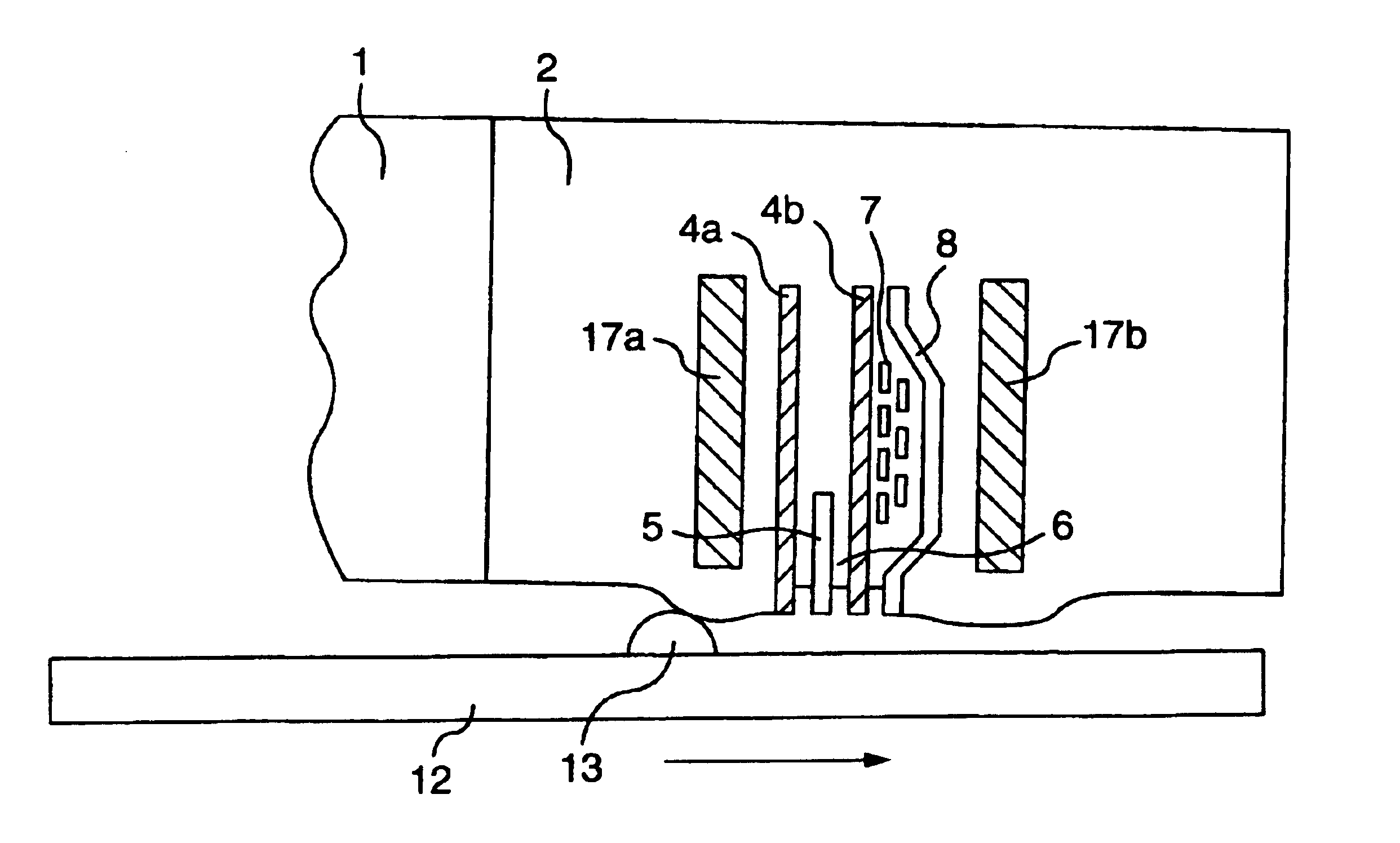

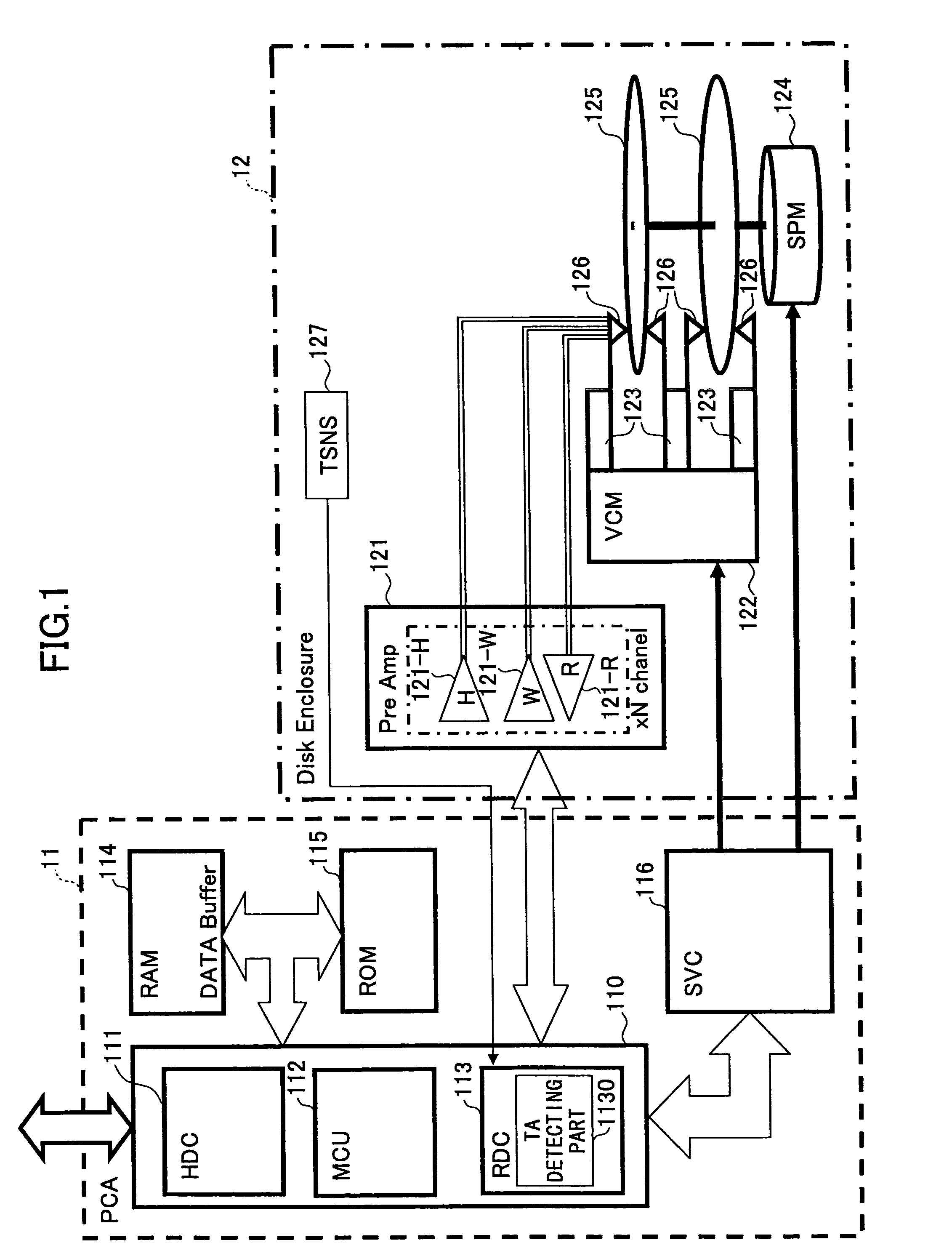

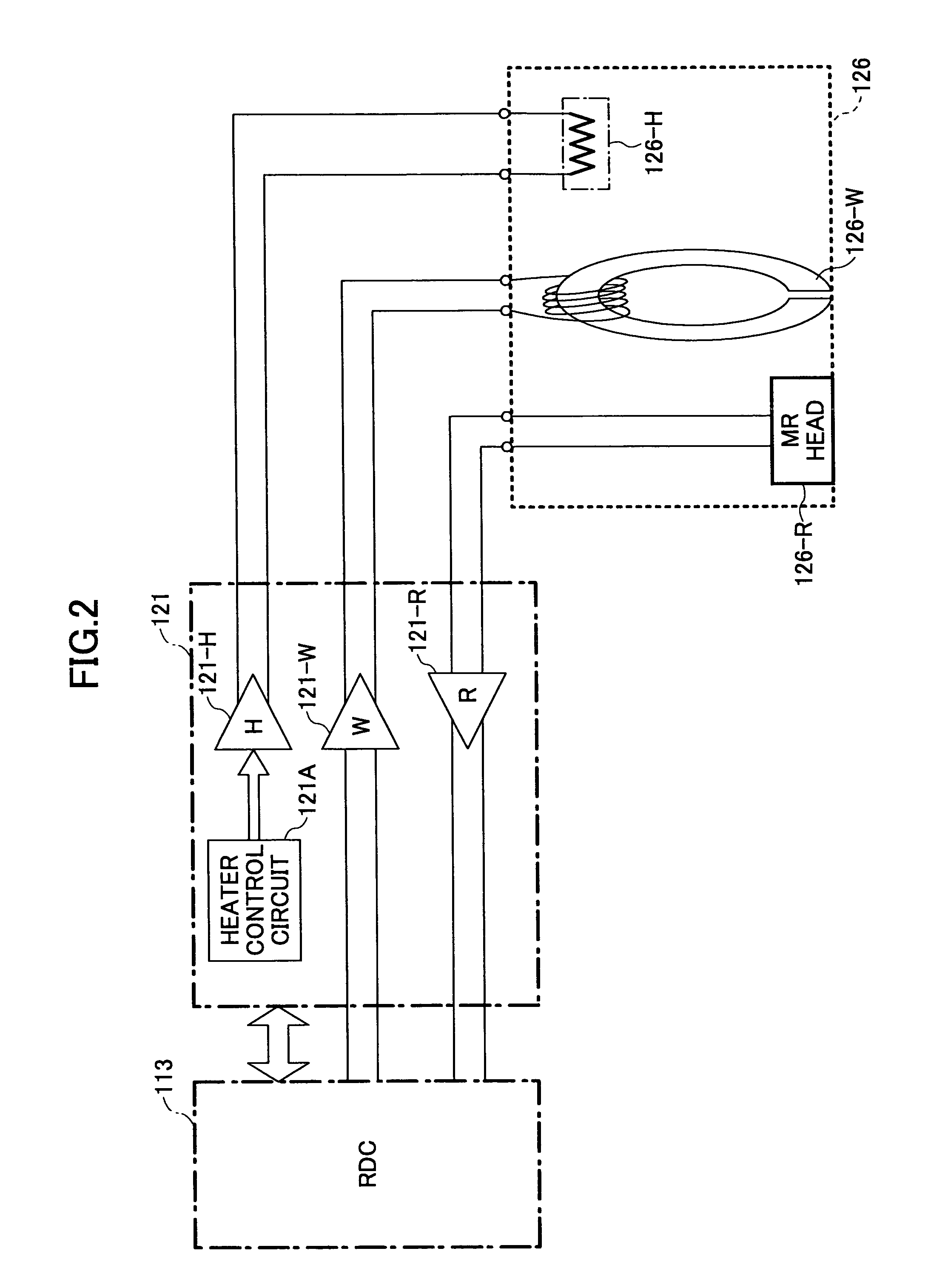

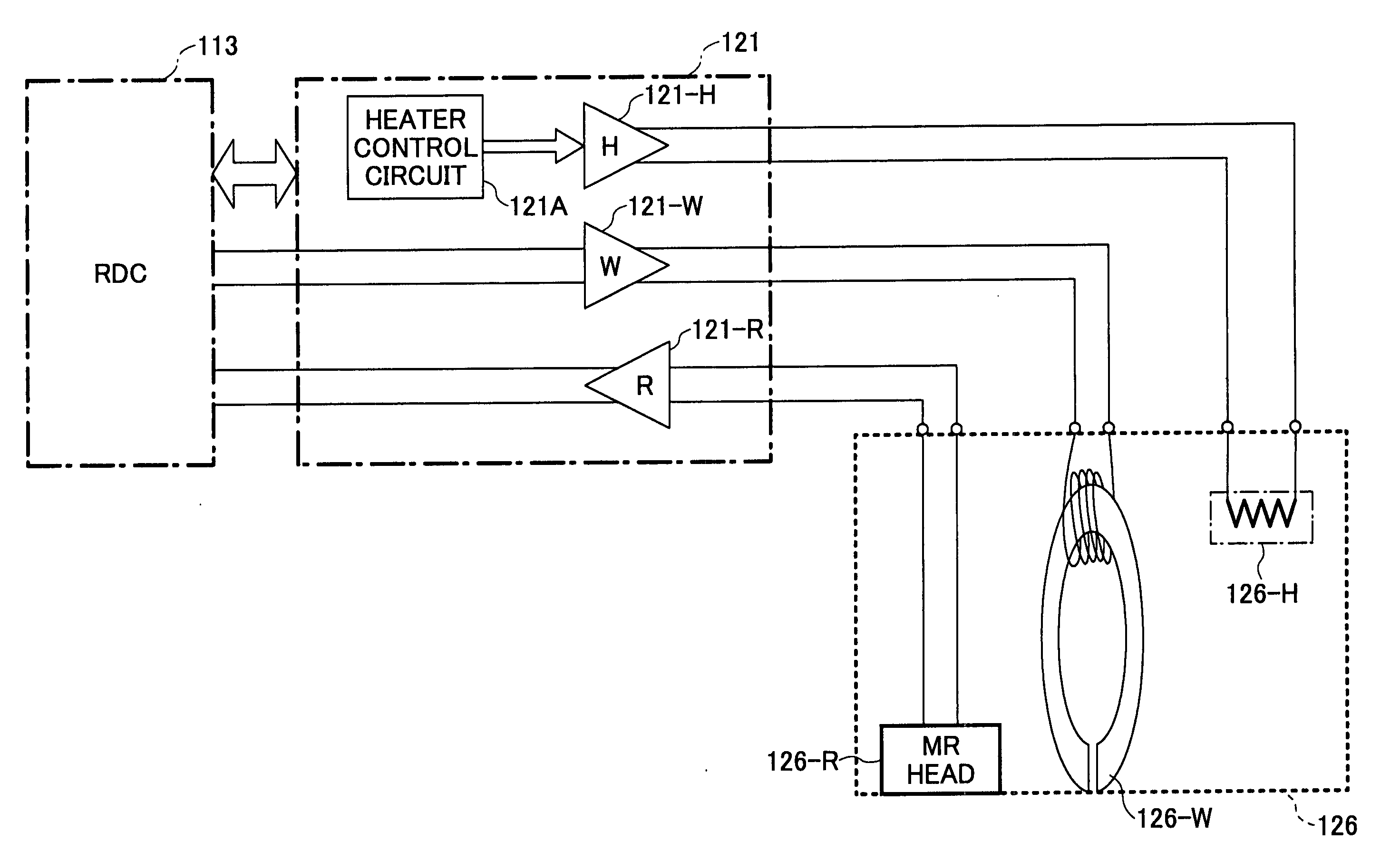

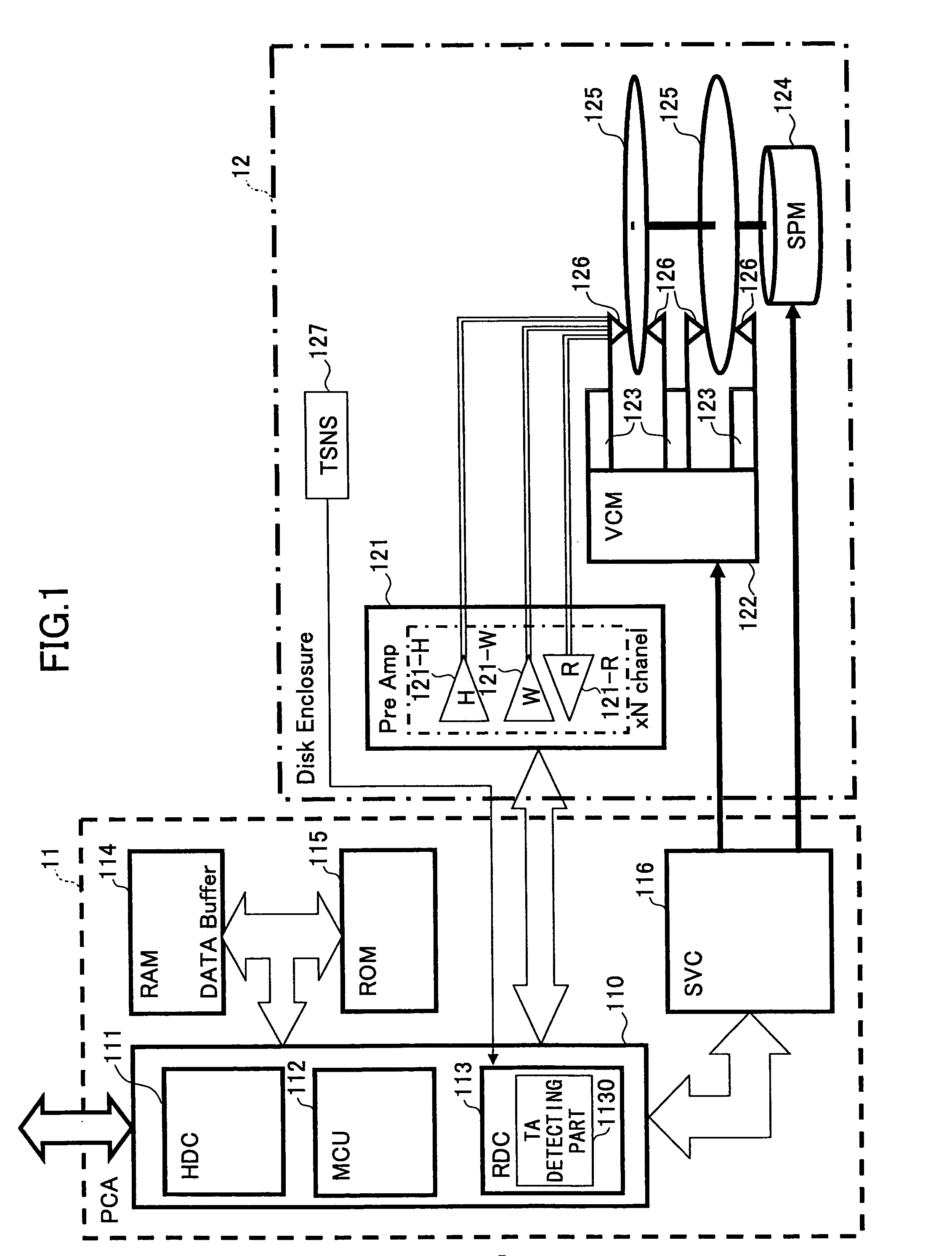

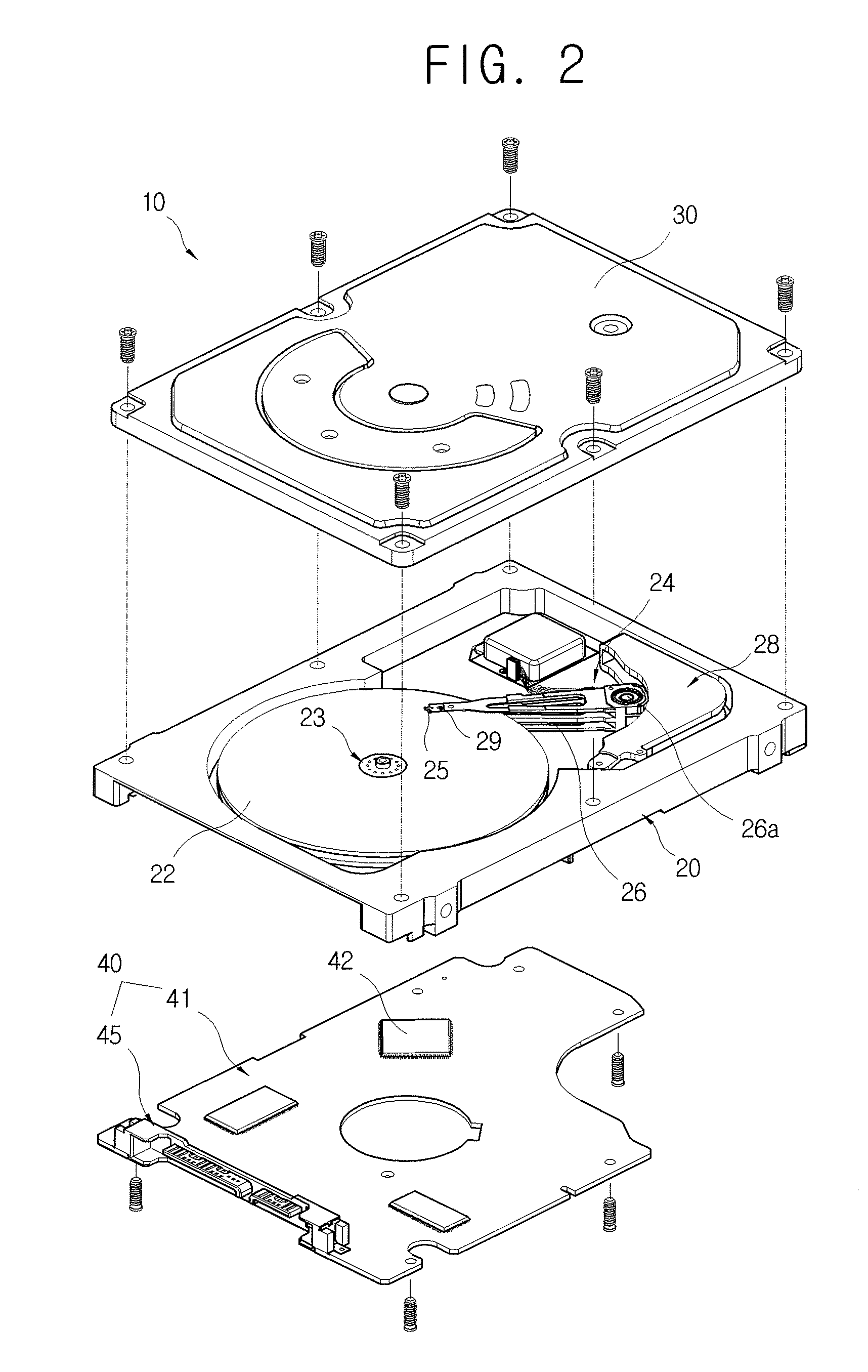

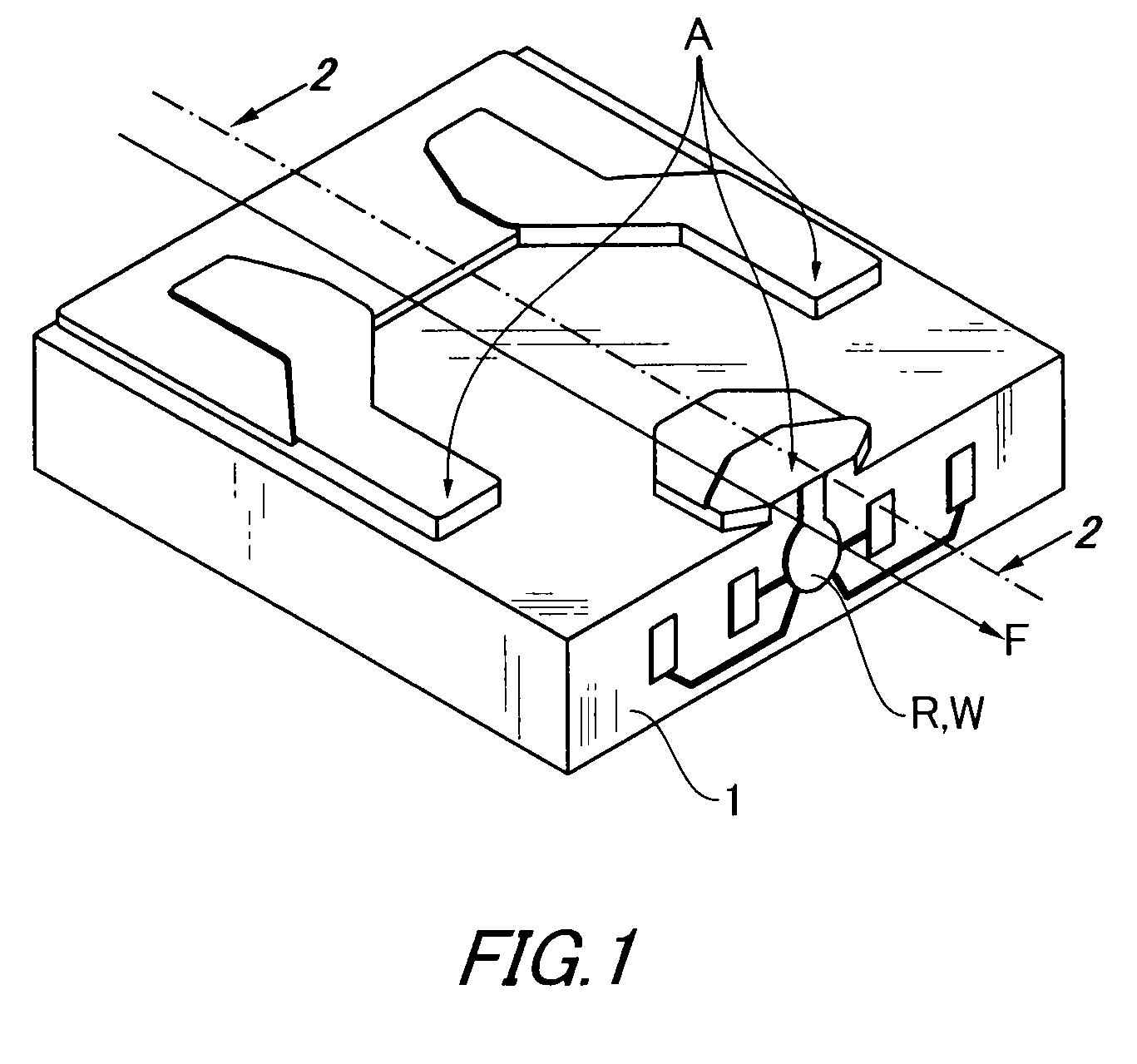

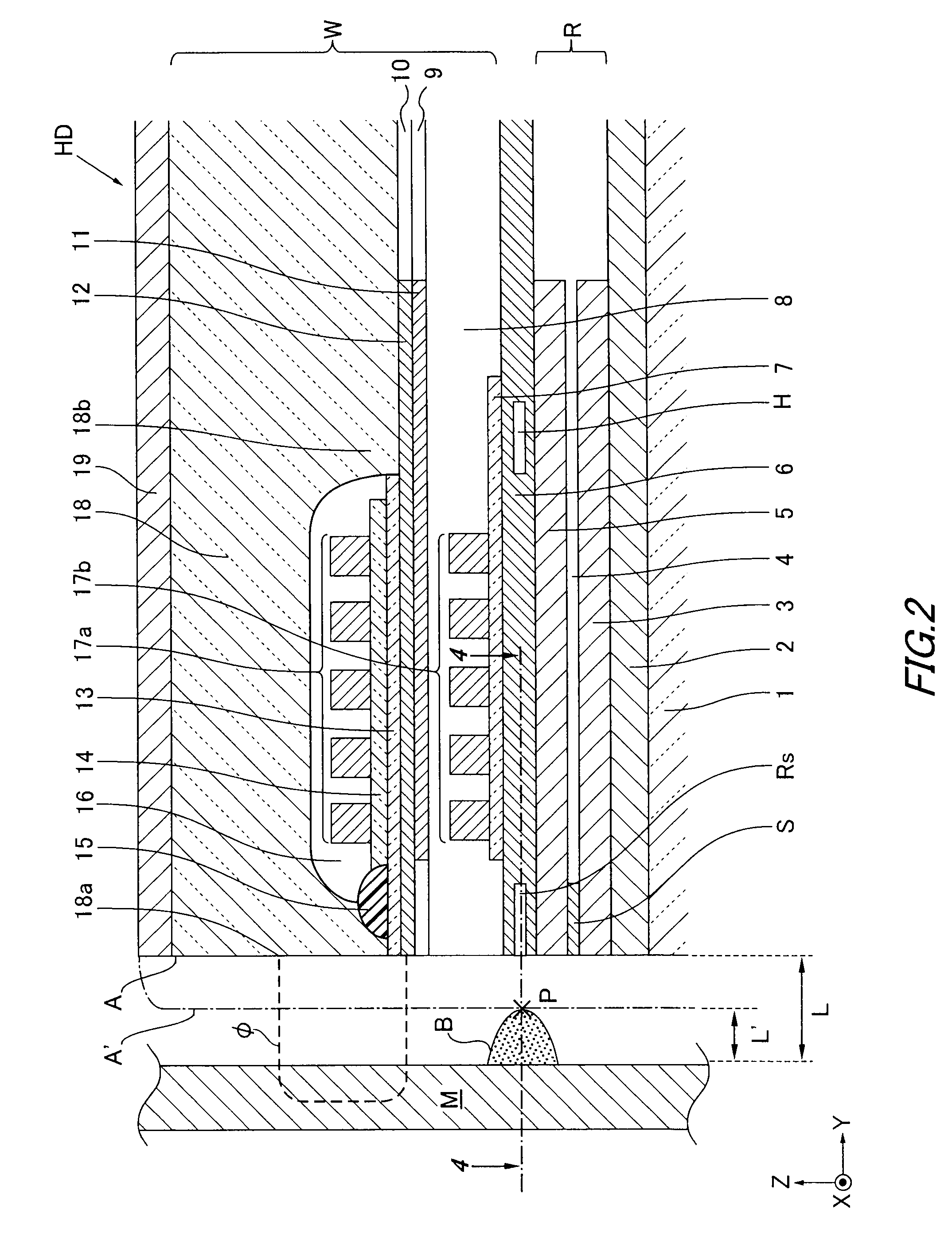

Magnetic head heating element in a disk drive

An object of the present invention is to prevent a spacing between a magnetic head and a writing medium at low temperature from increasing to cause a writing / reading error, and to prevent the magnetic head element protruded by a temperature increase from colliding with small protrusions on a magnetic disk surface, and to prevent damage on the element, and to prevent the occurrence of thermal asperity. In order to attain the object, a magnetic head slider is provided, which includes a magnetic head element supported on a rotating magnetic disk via a gap to write or read information on the magnetic disk, and a heat source for heating the magnetic head element. A magnetic disk device is further provided, which includes a magnetic head slider.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD +1

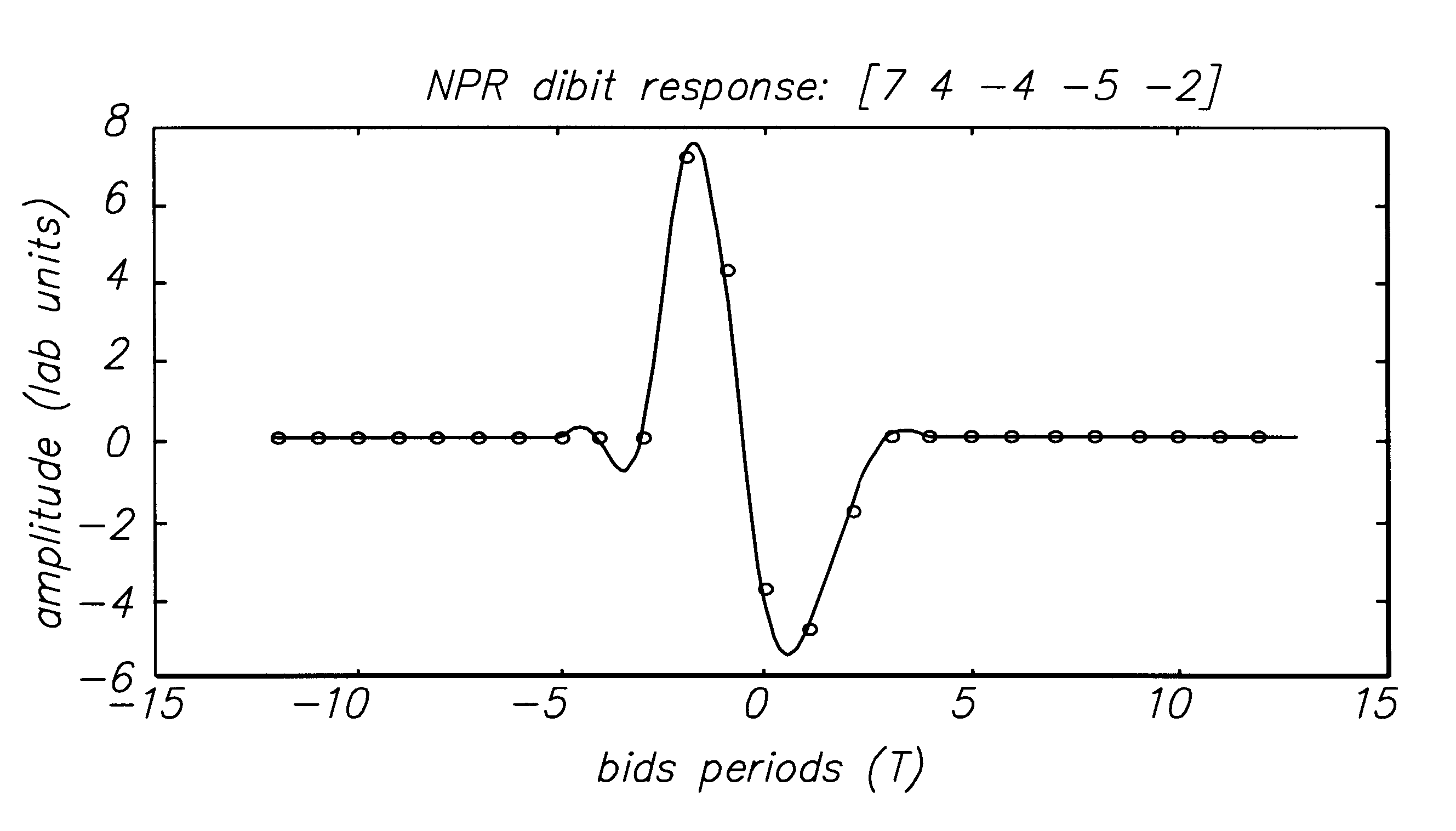

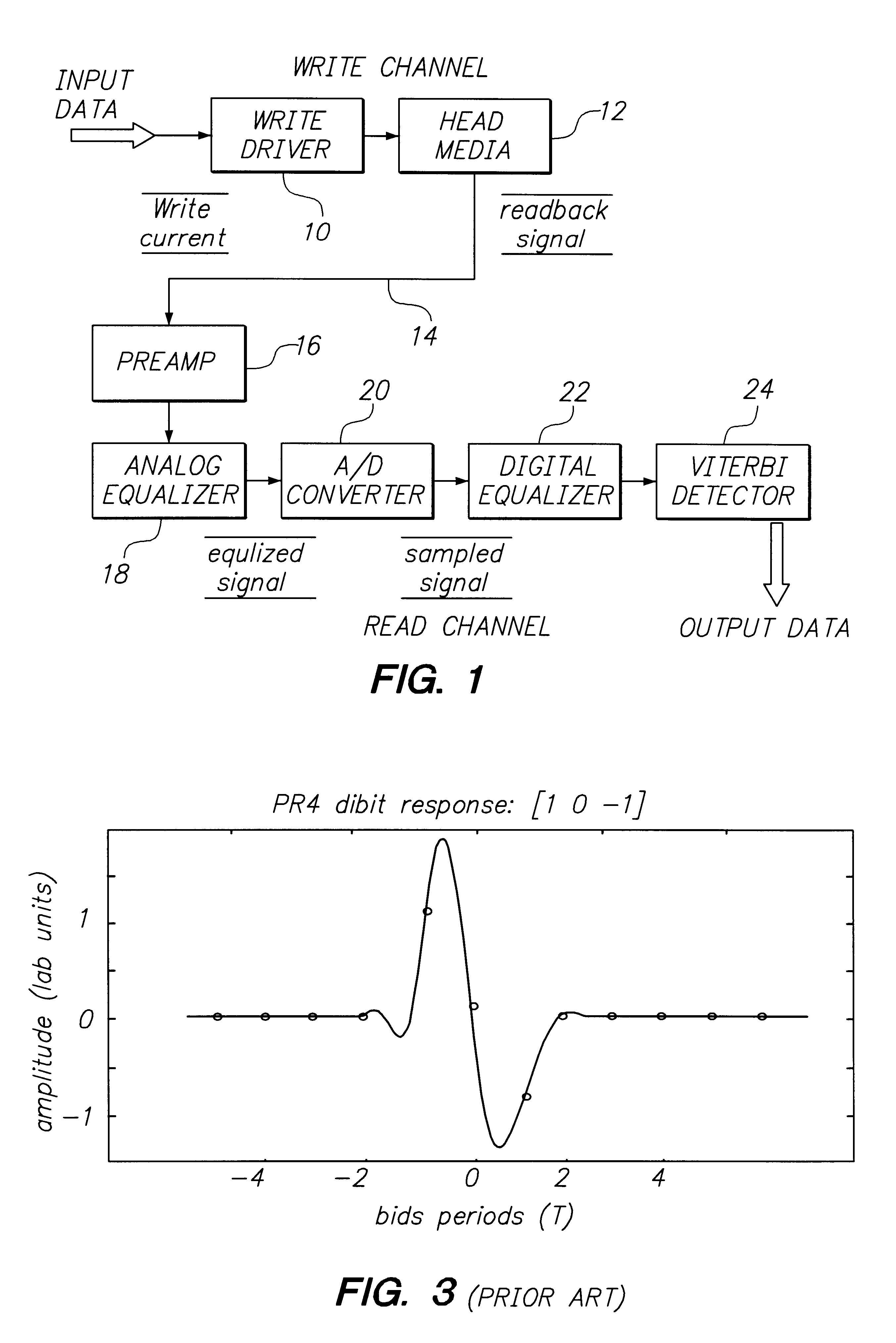

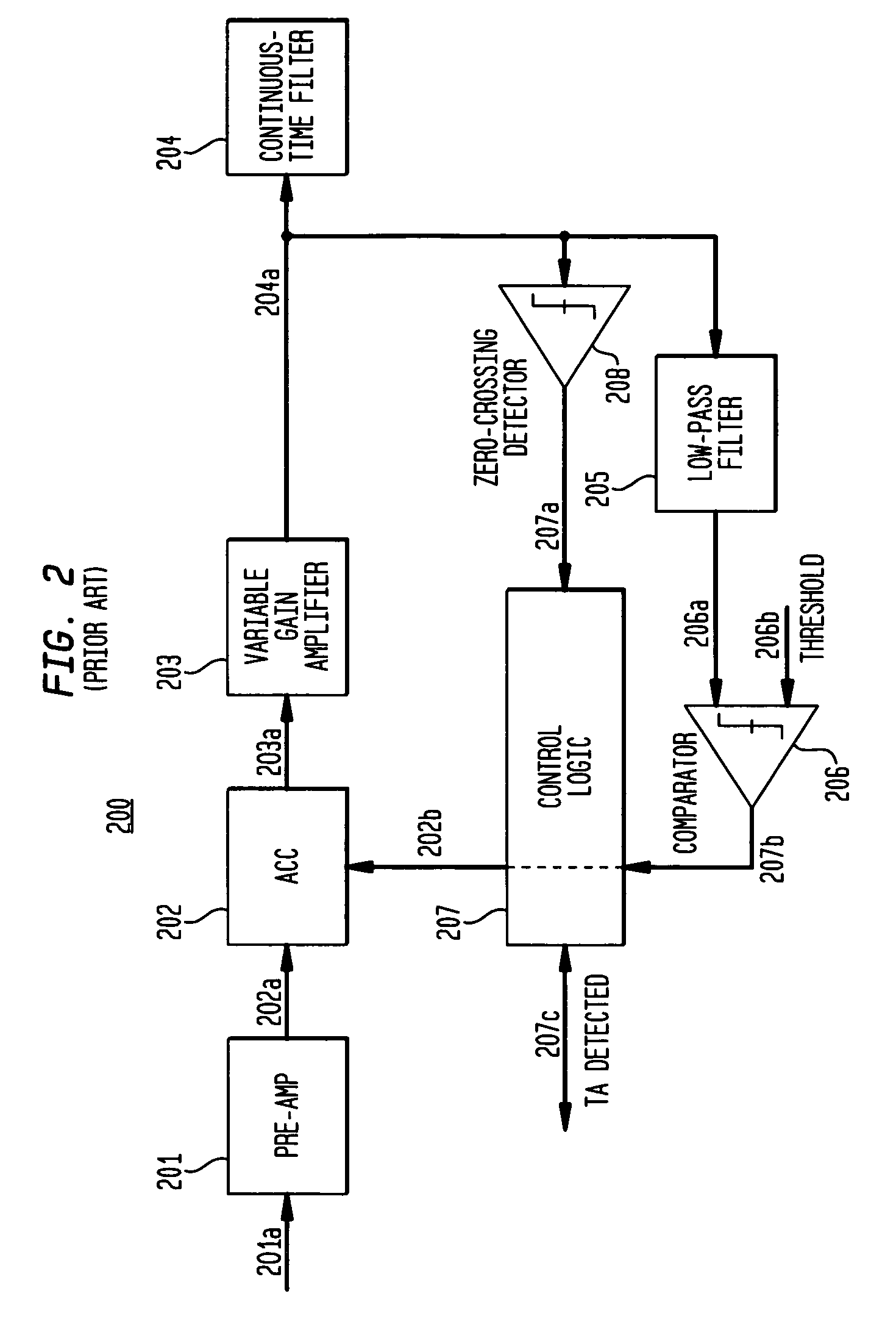

Class of fixed partial response targets in a PRML sampled data detection channel

InactiveUS6249398B1Modification of read/write signalsRecord information storageFrequency spectrumMagnetic media

A new class of fixed partial response targets are disclosed for use in a PRML magnetic medium read channel. The preferred embodiment exhibits an equalization response characterized by the polynomial 7+4*D-4*D2-5*D3-2*D4, where D represents the unit delay operator. This read channel target provides improved matching to the inherent magnetic channel over the known canonical class of targets (1-D)(1+D){circumflex over ( )}N, and thereby reduces equalization losses. The improved spectral matching reduces amplification of noise in the channel, thereby reducing bit-error-rates. The new class of targets also exhibits a spectral null at DC, reducing problems for offset cancellation circuitry and making the disk drive less sensitive to thermal asperities. It also exhibits a spectral depression rather than a spectral null at the Nyquist frequency, making quasi-catastrophic error sequences virtually impossible. The new class of target simplifies coding and allows RLL code ratios that approach unity, improving effective recording densities, while significantly reducing BER.

Owner:LUCENT TECH INC +1

Method of manufacturing substrate for magnetic disk, apparatus for manufacturing substrate for magnetic disk, and method of manufacturing magnetic disk

InactiveUS7175511B2Small sizeStable-quality disk substratesPolishing machinesRevolution surface grinding machinesVolumetric Mass DensityEngineering

Owner:HOYA CORP

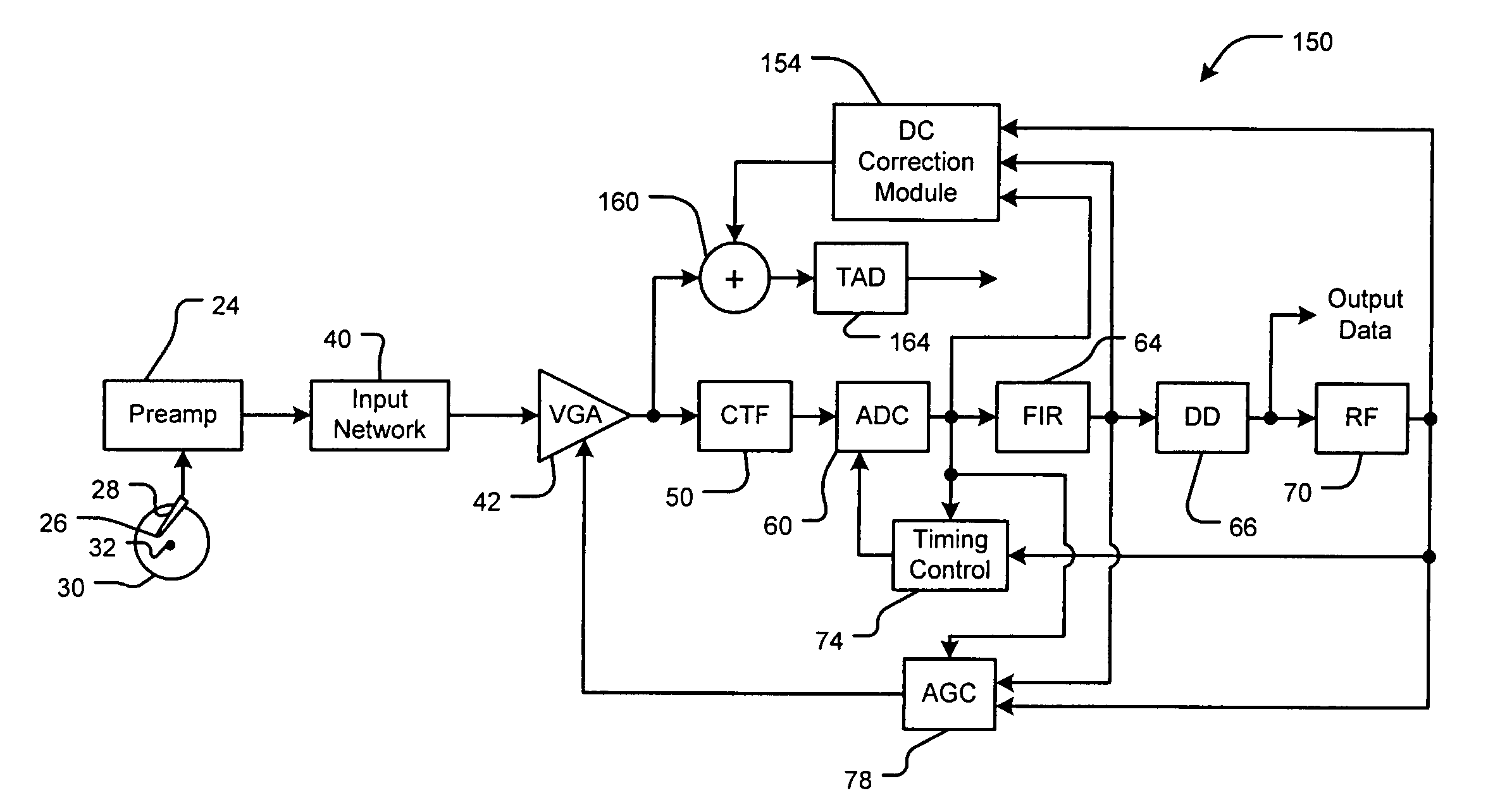

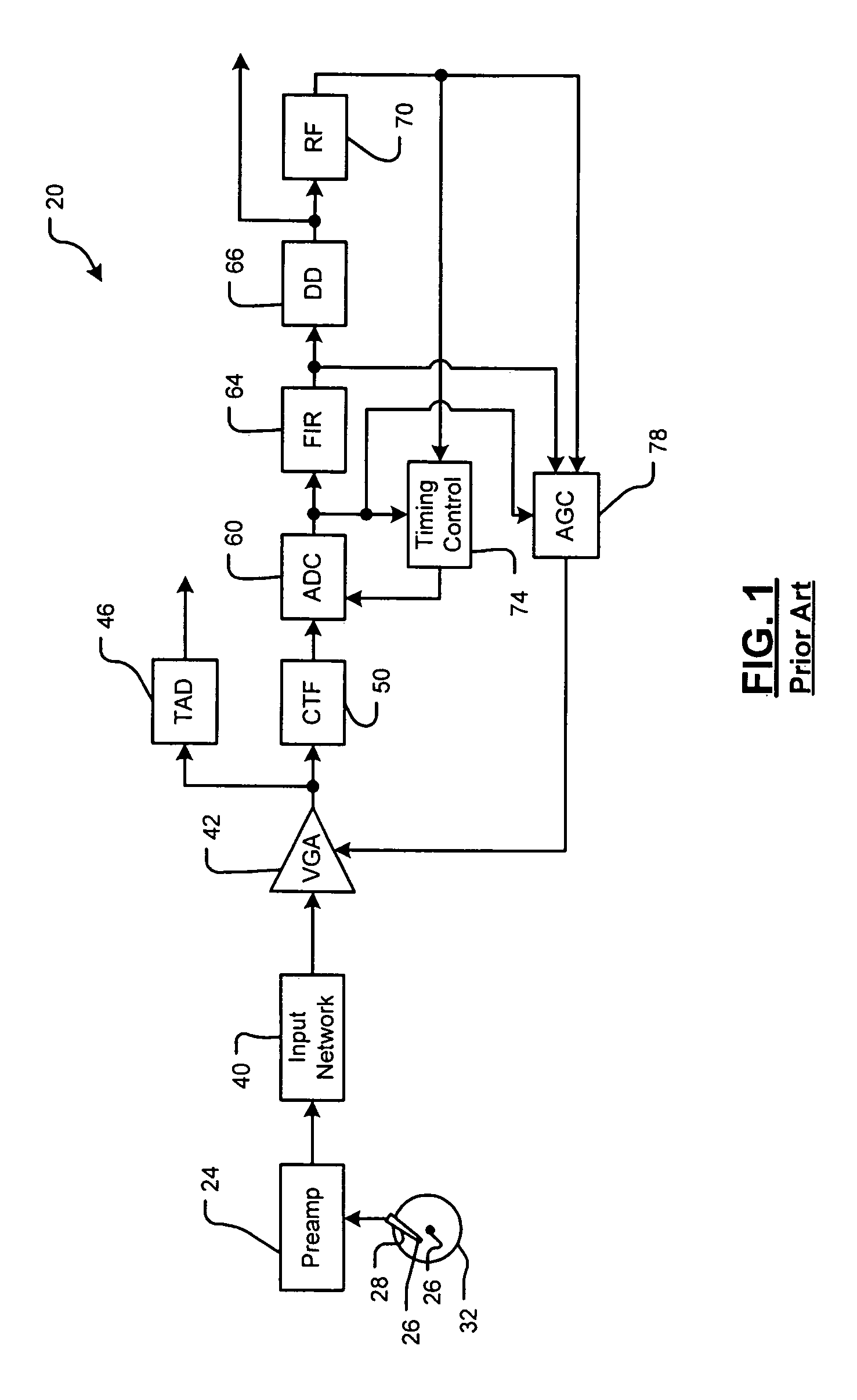

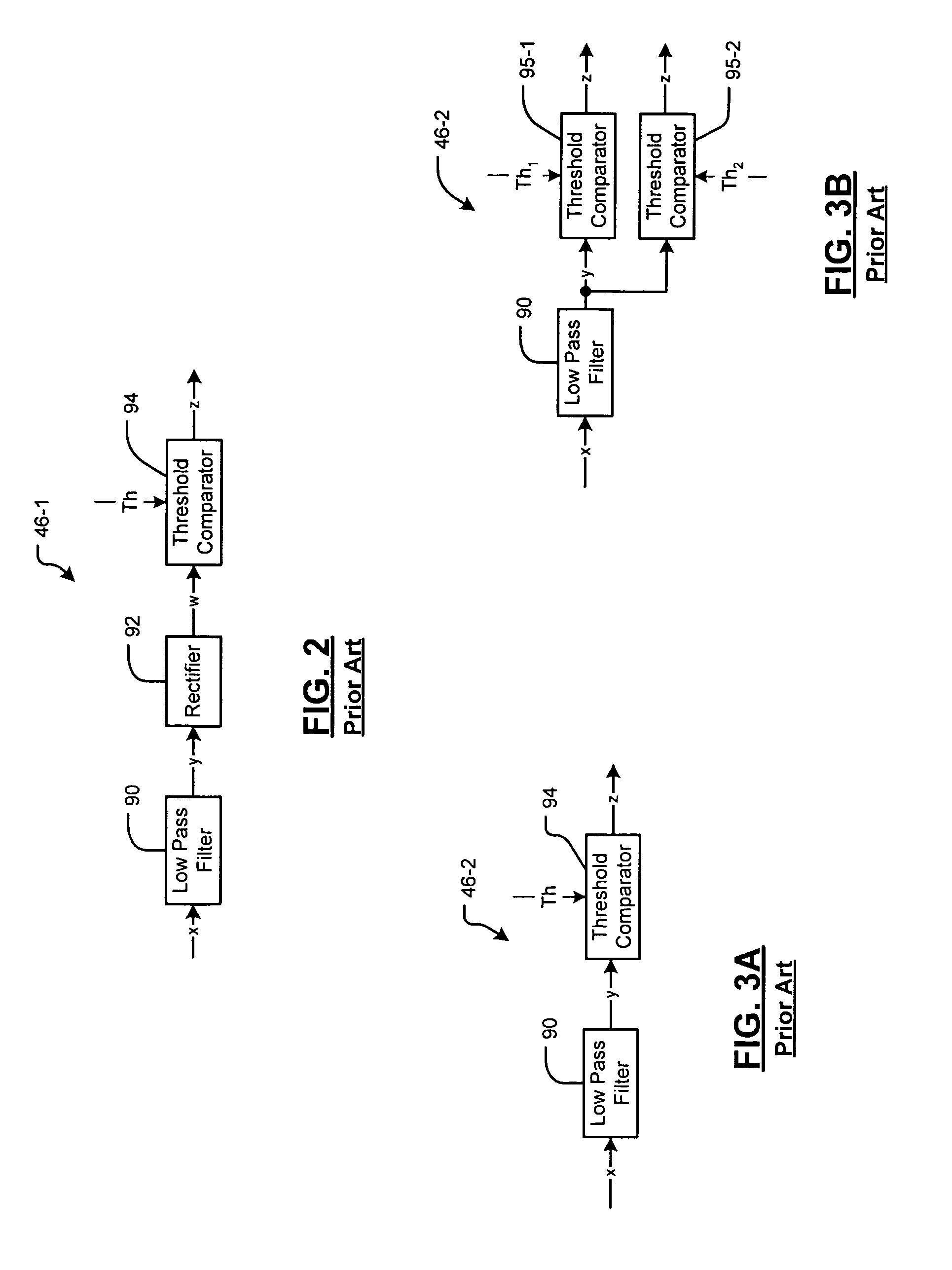

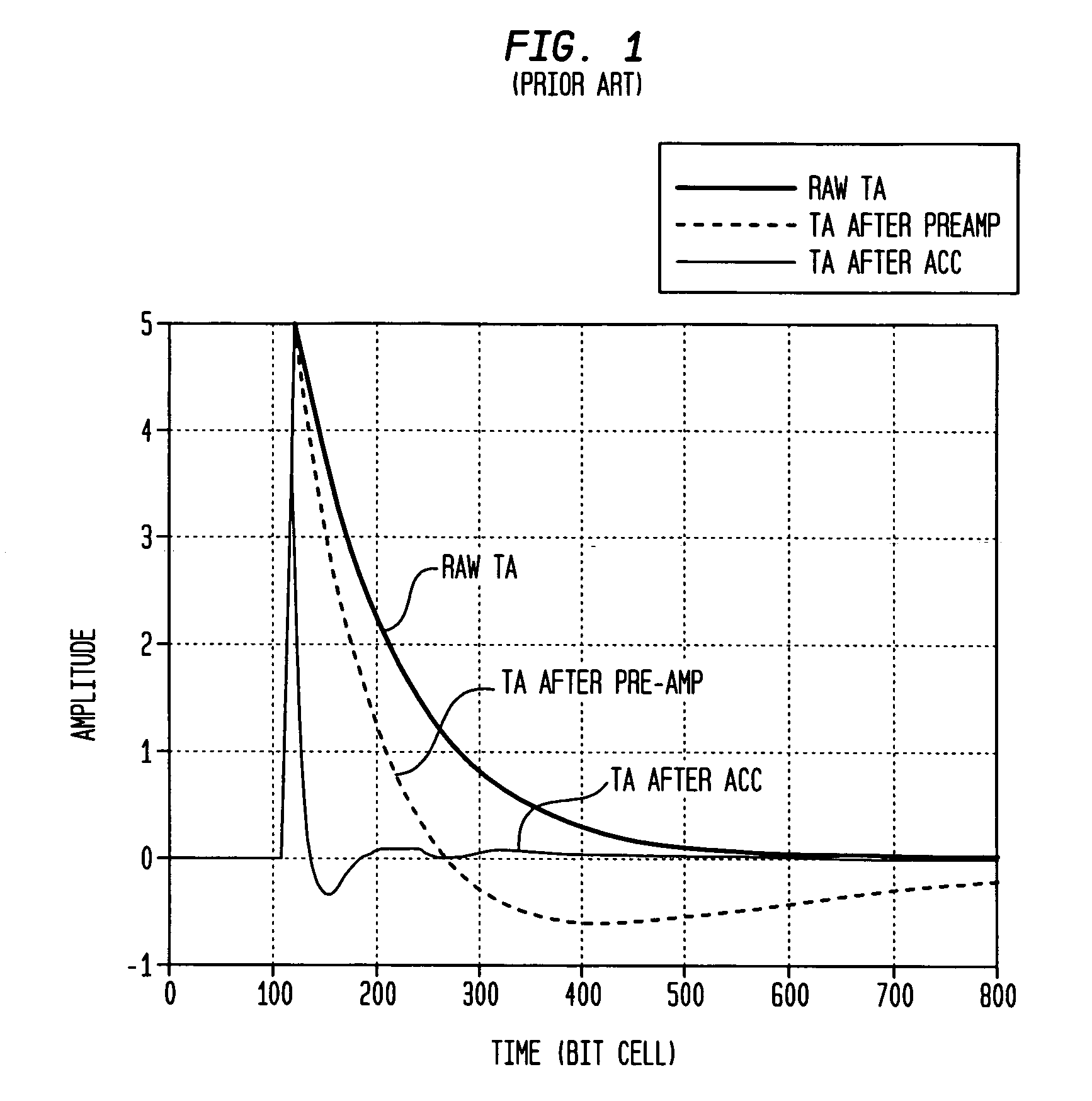

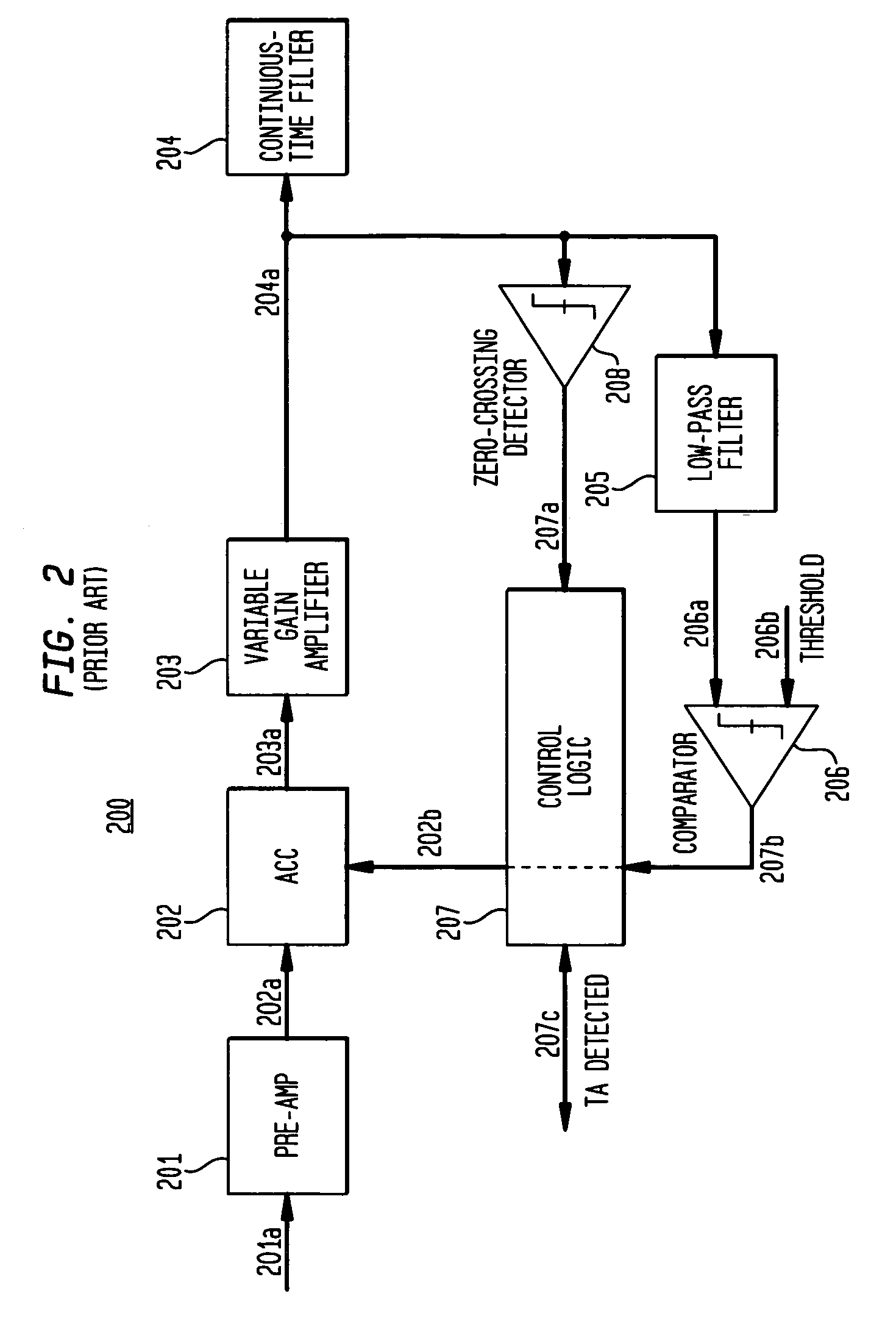

Thermal asperity detection for perpendicular magnetic recording

A perpendicular recording system includes a summing module that has a first input that receives a read signal. A DC correction module selectively generates a DC correction signal to reduce DC offset in the read signal. The DC correction signal is output to a second input of the summing module. A detecting module compares an output of the summing module to a predetermined threshold and selectively detects Thermal Asperity (TA).

Owner:MARVELL ASIA PTE LTD

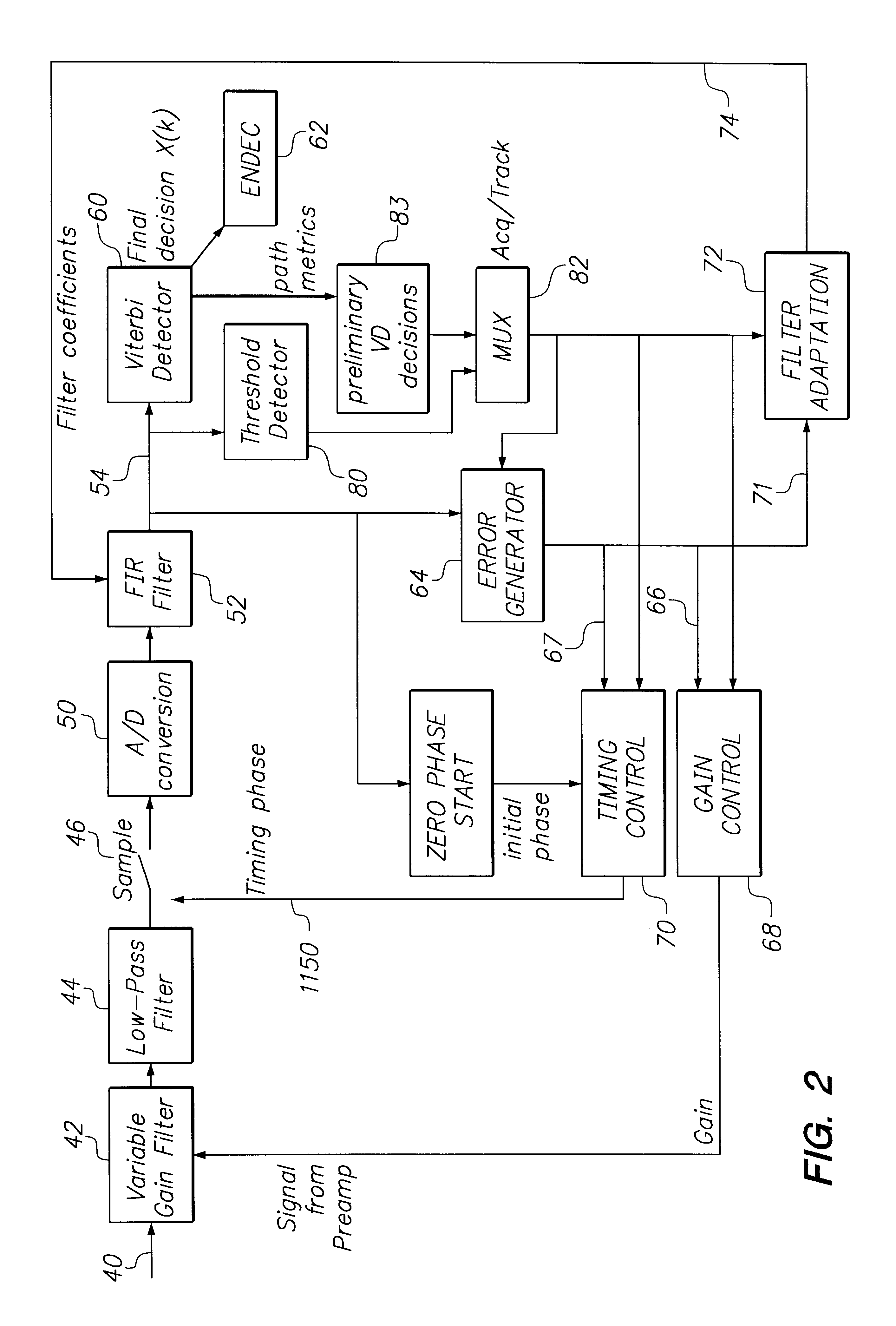

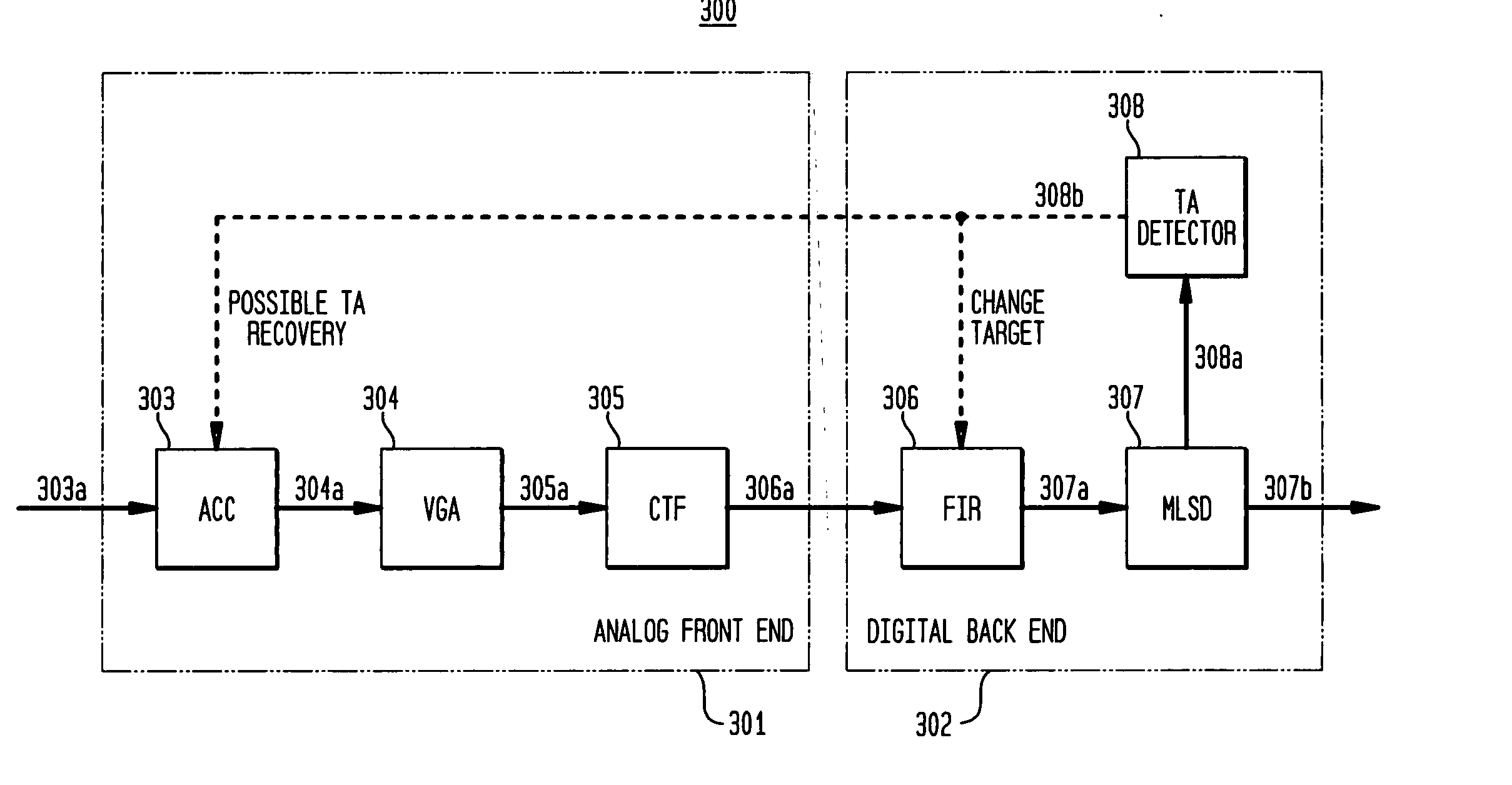

Detection of signal disturbance in a partial response channel

In one embodiment, irregular electronic disturbance signals in a partial-response read channel are detected by a disturbance detector using state metrics generated by maximum-likelihood sequence detector. For example, a thermal asperity (TA) detector detects the occurrence of TAs in the read channel of perpendicularly recorded magnetic media by using the state metrics generated by a Viterbi detector. Changes in state metrics (e.g., magnitudes of the branch metrics of the trellis diagram) used by the Viterbi detector are tracked. If the magnitude of the rise of the path metric increases above a set threshold, then a TA is detected. Alternatively, or additionally, the rate of change of the magnitude of the path metrics is tracked. If the rate of change within a set time window is above a specified threshold, then a TA is detected.

Owner:BROADCOM INT PTE LTD

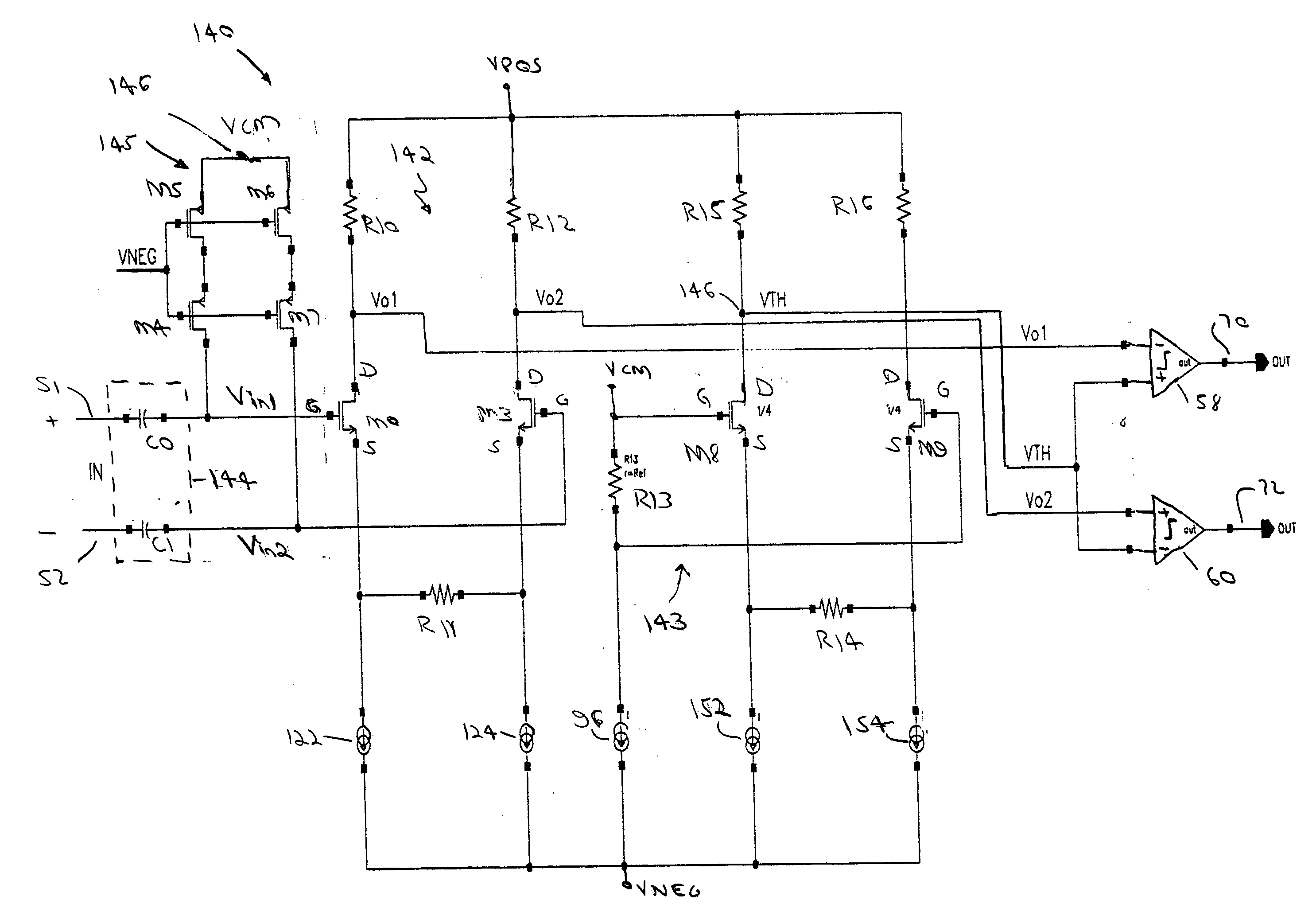

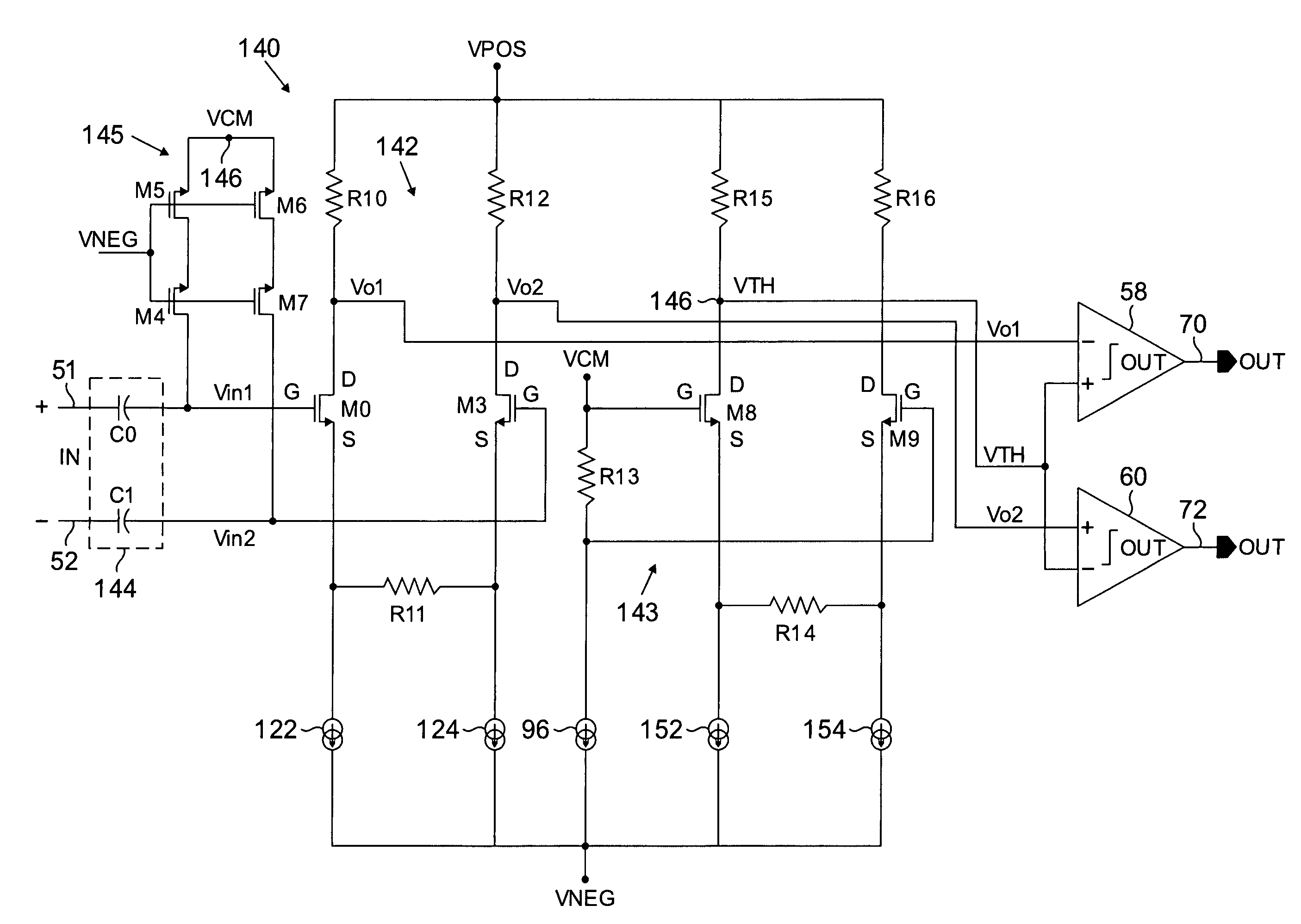

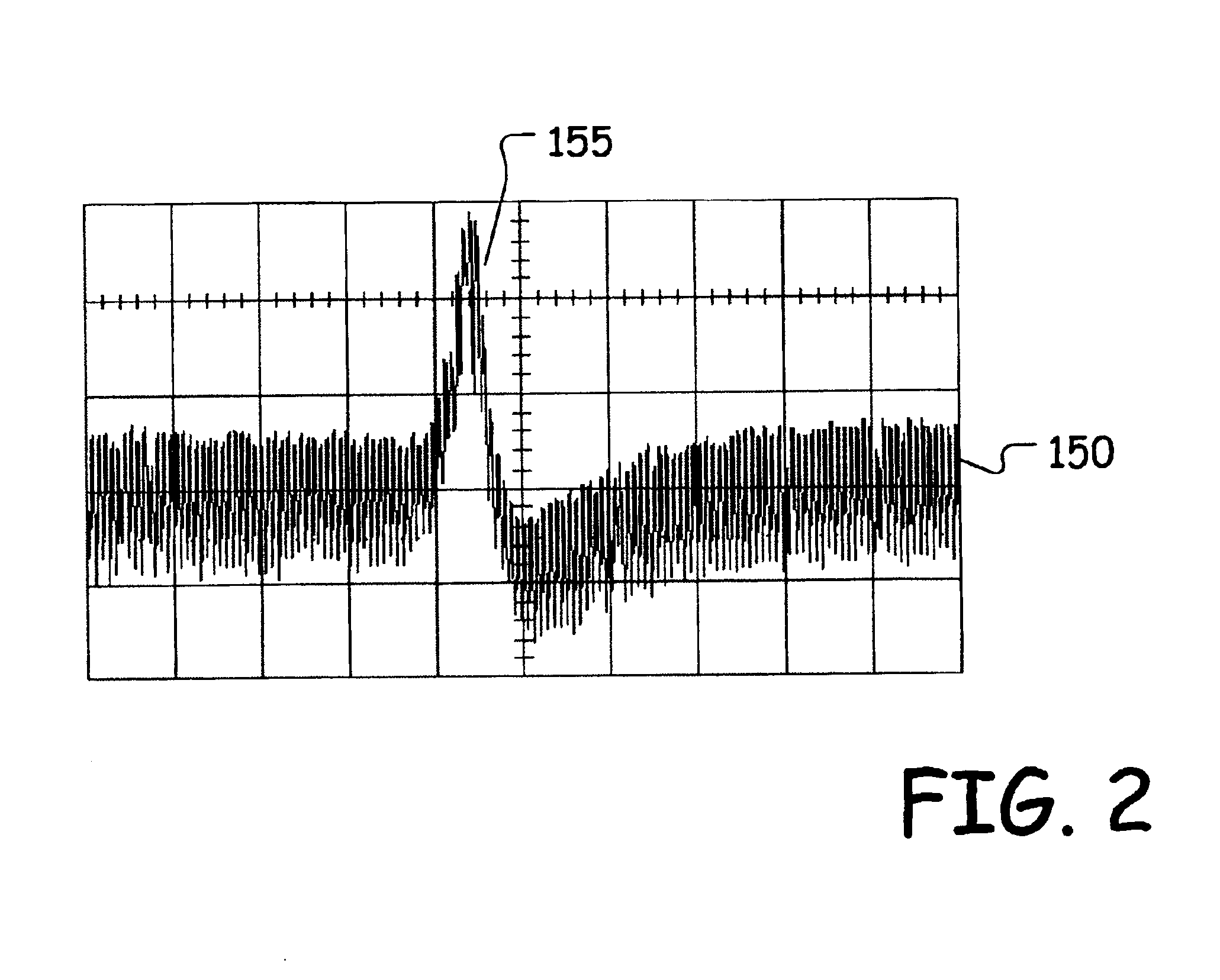

Variable threshold bipolar signal peak detector

InactiveUS20070070534A1Amplifier with semiconductor-devices/discharge-tubesRecord information storageBipolar signalEngineering

A method and apparatus for detecting signal peaks caused by a thermal asperity event in a magnetic recording media to reduce data reading errors introduced by the thermal asperity event. A common mode voltage is determined for differential signals representing data bits read from the magnetic recording media and a threshold voltage produced responsive to the common mode voltage. A comparator determines if either of the differential signals exceeds the threshold voltage, thereby indicating the occurrence of a thermal asperity event.

Owner:AVAGO TECH INT SALES PTE LTD

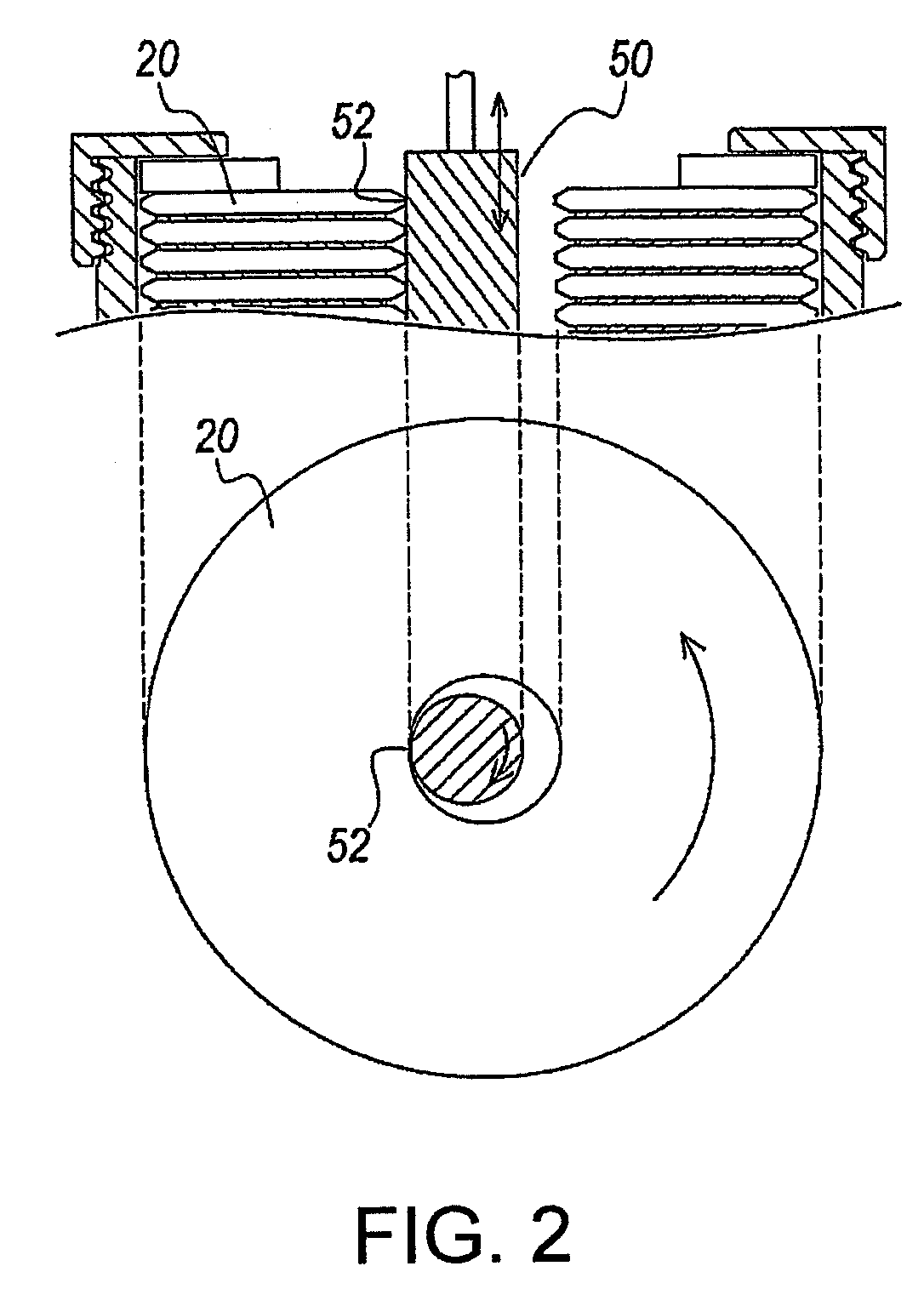

Method of manufacturing glass substrate for magnetic disk, method of manufacturing magnetic disk, and polishing apparatus of glass substrate for magnetic disk

ActiveUS20090233529A1Improve accuracyMade small and stableEdge grinding machinesBase layer manufactureRotational axisEngineering

A method of manufacturing a glass substrate for a magnetic disk is provided, by which polishing accuracy on an inner circumferential end face of a glass substrate is improved, and a thermal asperity trouble can be avoided.In a method of manufacturing a glass substrate for a magnetic disk, by which an inner circumferential end face of a cylindrical polishing object 12 is polished, the polishing object including a plurality of glass substrates 20 stacked on one another, a plurality of polishing cloths disposed around a rotation axis of an inner circumference polishing section having the rotation axis are contacted to the inner circumferential end face 116 of the polishing object at even pressure, then a polishing liquid is supplied between the inner circumferential end face of the polishing object and the inner circumference polishing section, and then the inner circumference polishing section and the polishing object are relatively rotated / moved with the rotation axis as a center, or relatively moved in a direction of the rotation axis, thereby the inner circumferential end face of the polishing object is polished.

Owner:HOYA CORP

Variable threshold bipolar signal peak detector

InactiveUS7626777B2Amplifier with semiconductor-devices/discharge-tubesRecord information storageBipolar signalComputational physics

A method and apparatus for detecting signal peaks caused by a thermal asperity event in a magnetic recording media to reduce data reading errors introduced by the thermal asperity event. A common mode voltage is determined for differential signals representing data bits read from the magnetic recording media and a threshold voltage produced responsive to the common mode voltage. A comparator determines if either of the differential signals exceeds the threshold voltage, thereby indicating the occurrence of a thermal asperity event.

Owner:AVAGO TECH INT SALES PTE LTD

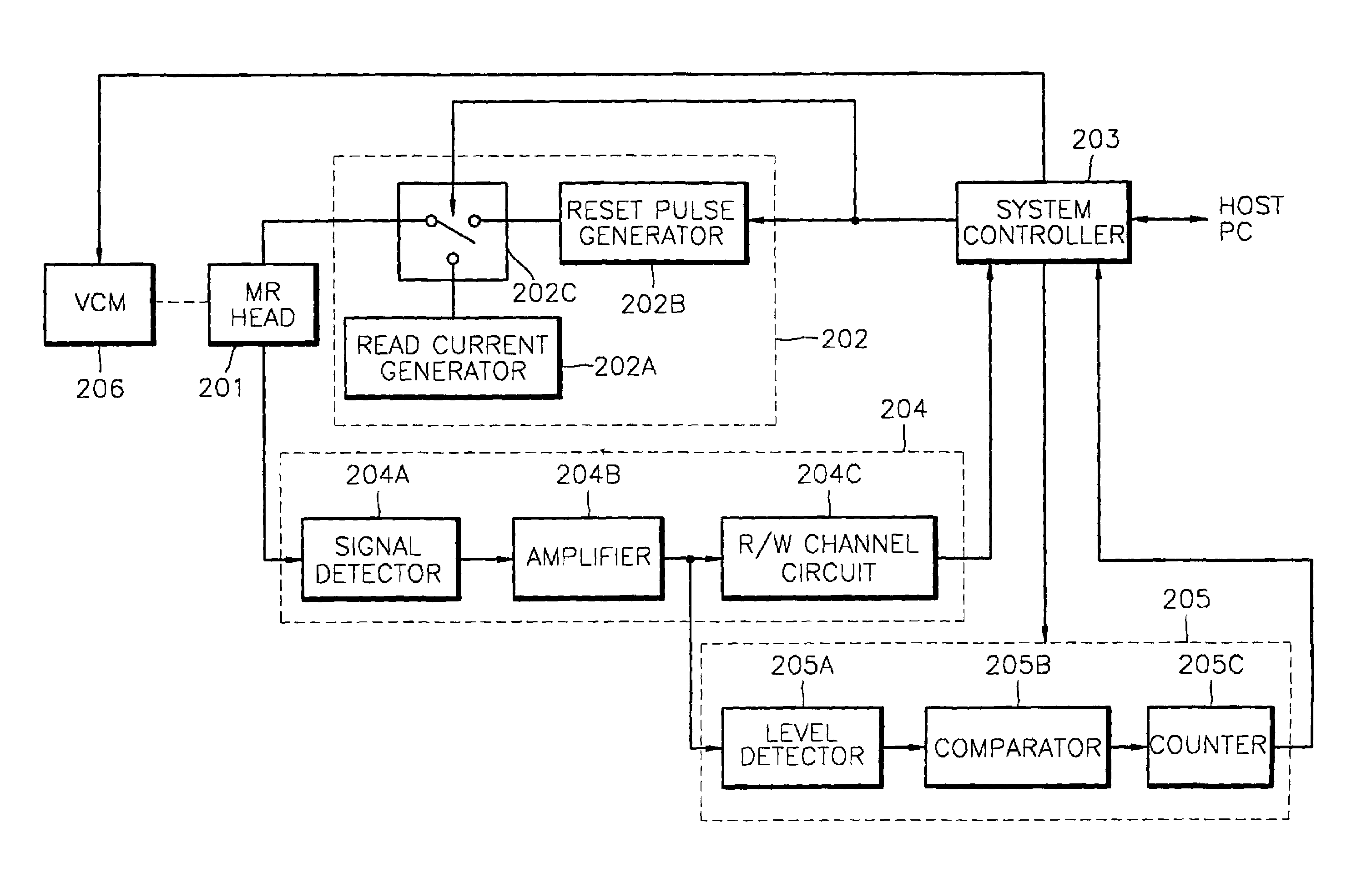

Method and apparatus to control head instability in a data storage system

InactiveUS7062698B2Restore stability of headError detection/correctionCode conversionInstabilityManufacturing data

A method and an apparatus to control a data storage system, and more particularly, a method and an apparatus to restore the stability of a head in a data storage system by automatically applying a bias shock current to the head in accordance with the result of a thermal asperity detection (TAD) method, in case that a quality problem occurs in the manufacturing process and / or under severe user conditions. A thermal asperity detection (TAD) routine operates if BER is large or an ECC error occurs in a process of manufacturing a data storage system or in a user field. Thus, it is determined whether the instability of a head causes a quality problem, and if it is determined that the instability of the head causes the quality problem, a bias shock current is automatically applied to the head to restore the stability of the head. It is accurately determined whether the head is unstable if the data quality problem occurs in the process of manufacturing the data storage system or in the user field to automatically restore the stability of the head. As a result, the quality of the data storage system is improved in the manufacturing process thereof and in the market.

Owner:SAMSUNG ELECTRONICS CO LTD

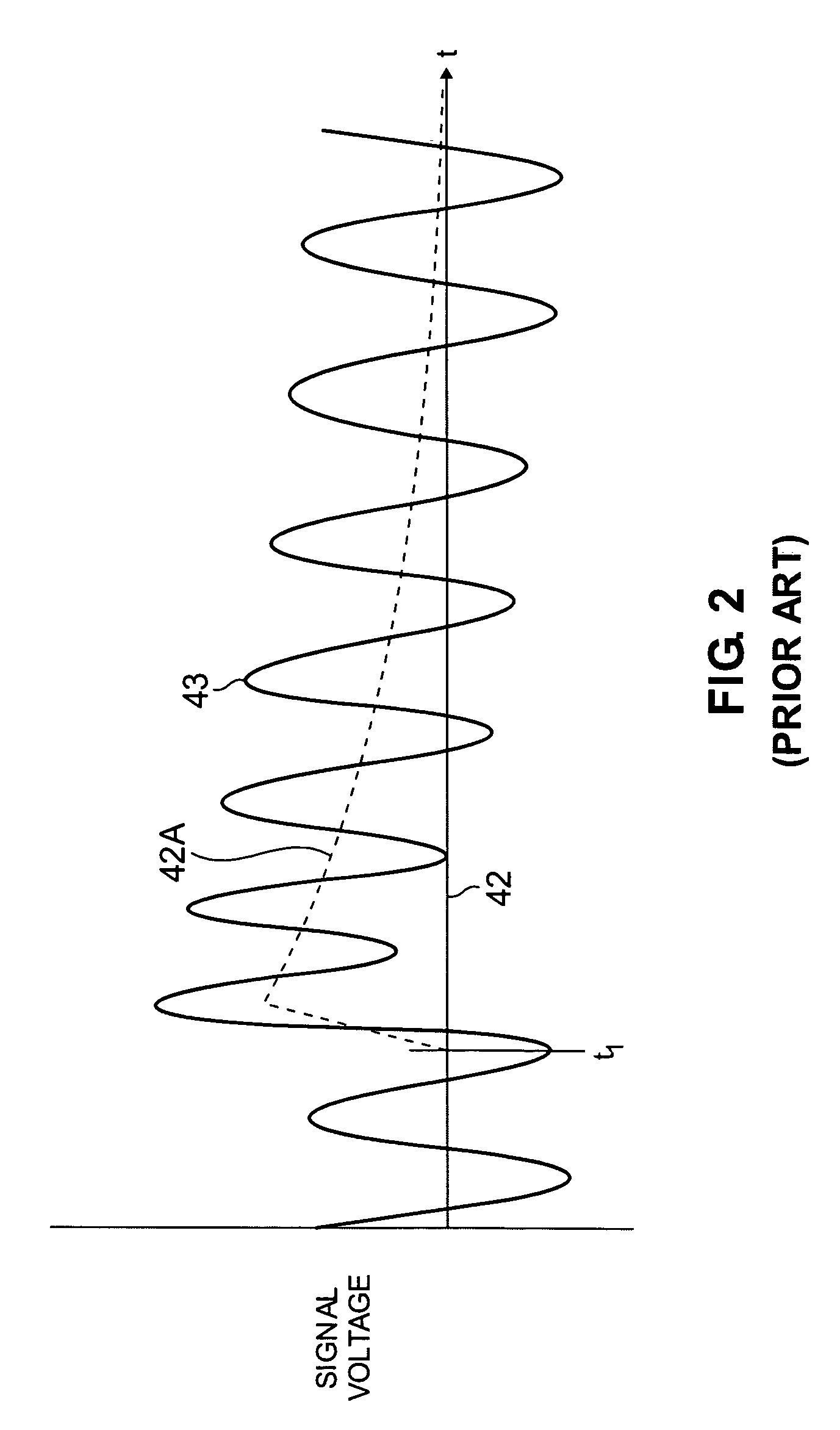

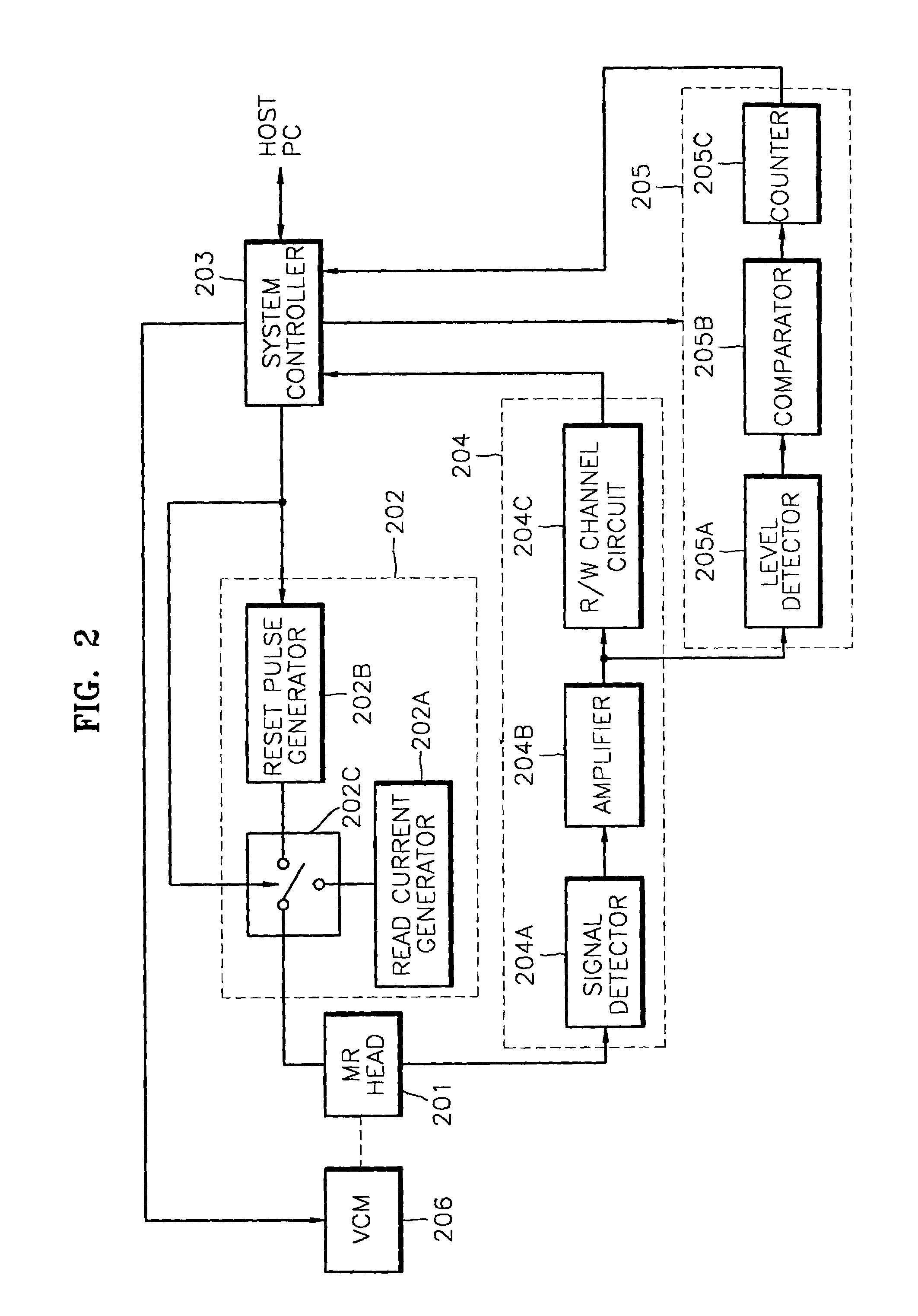

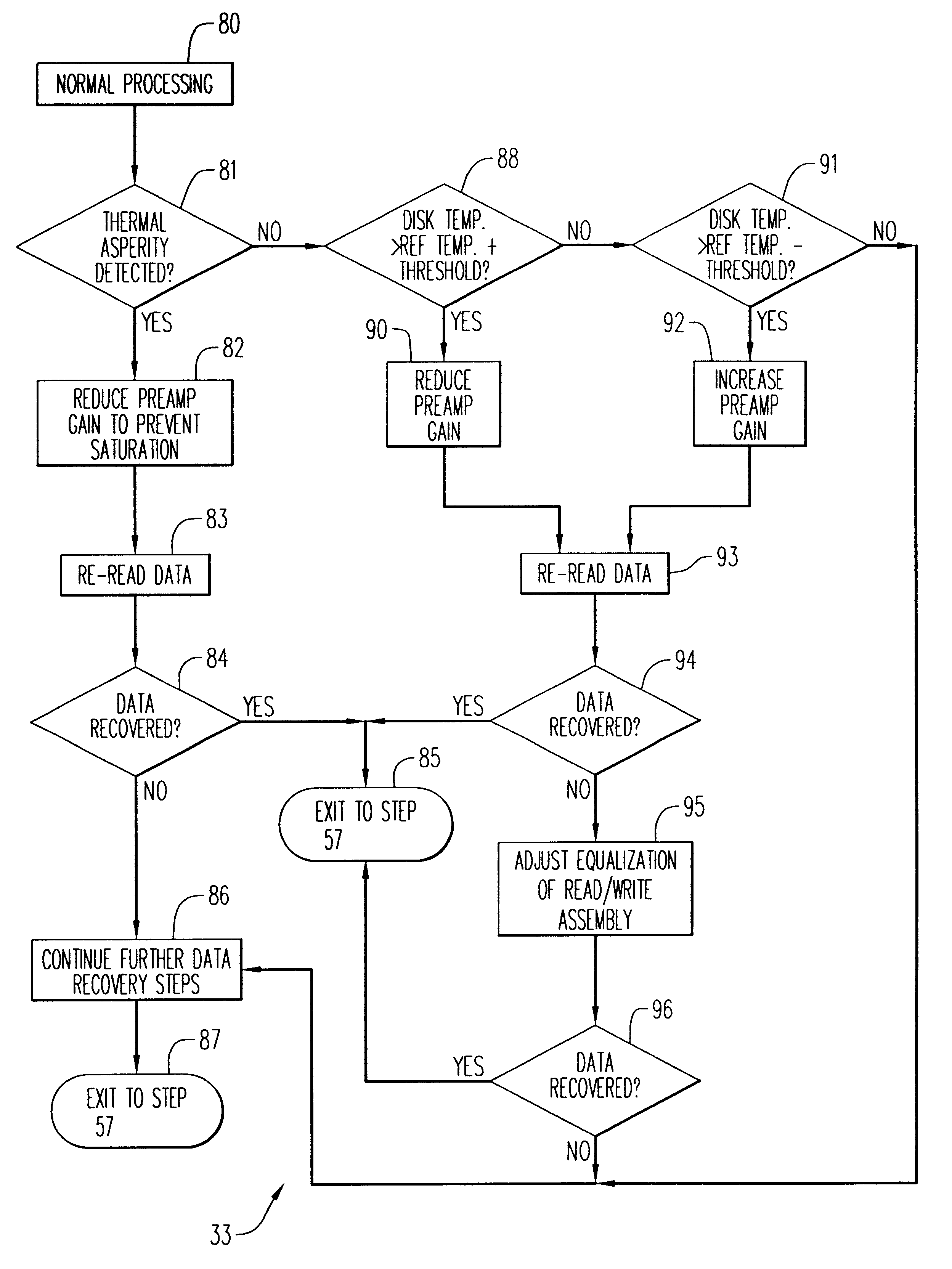

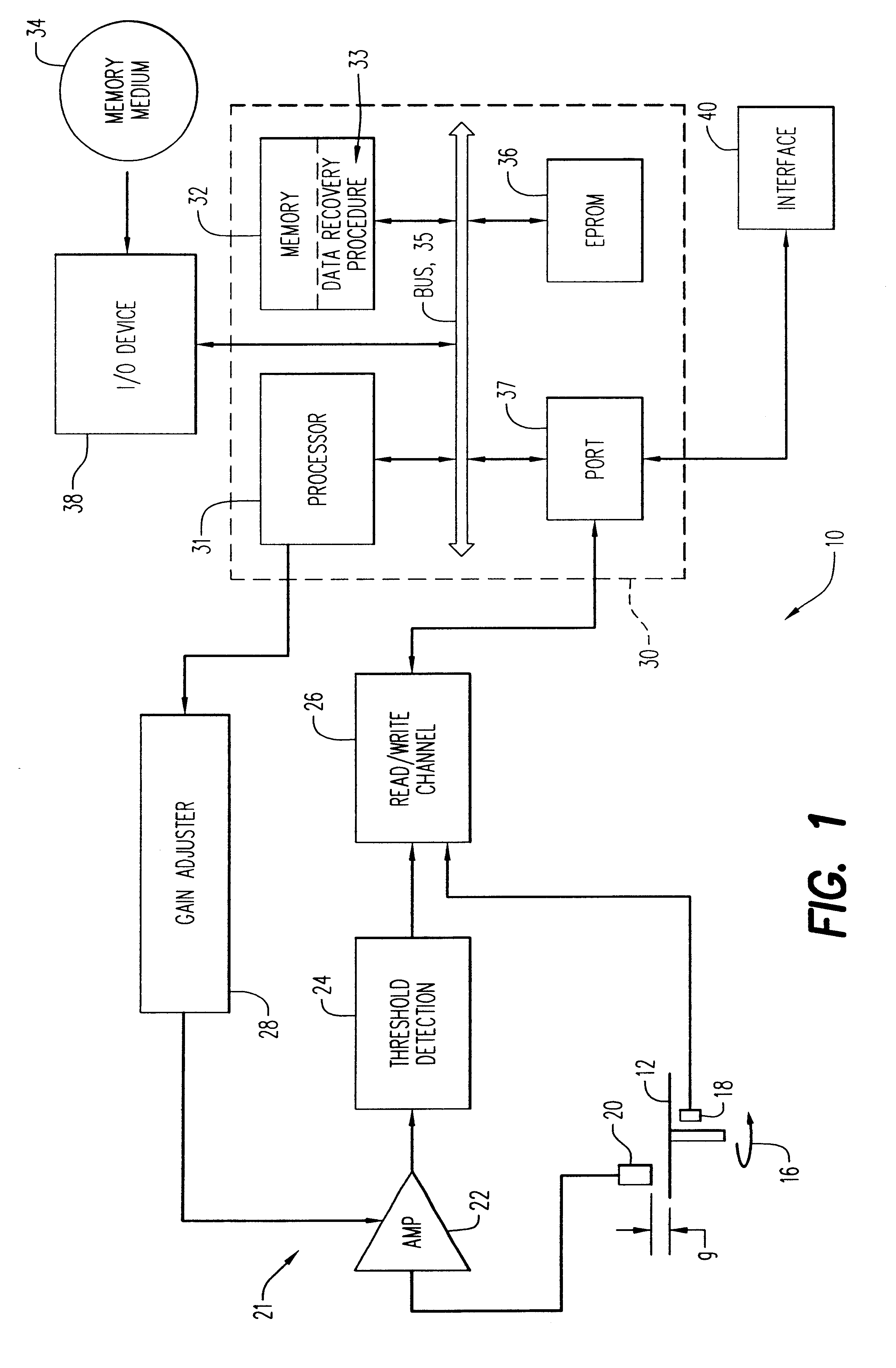

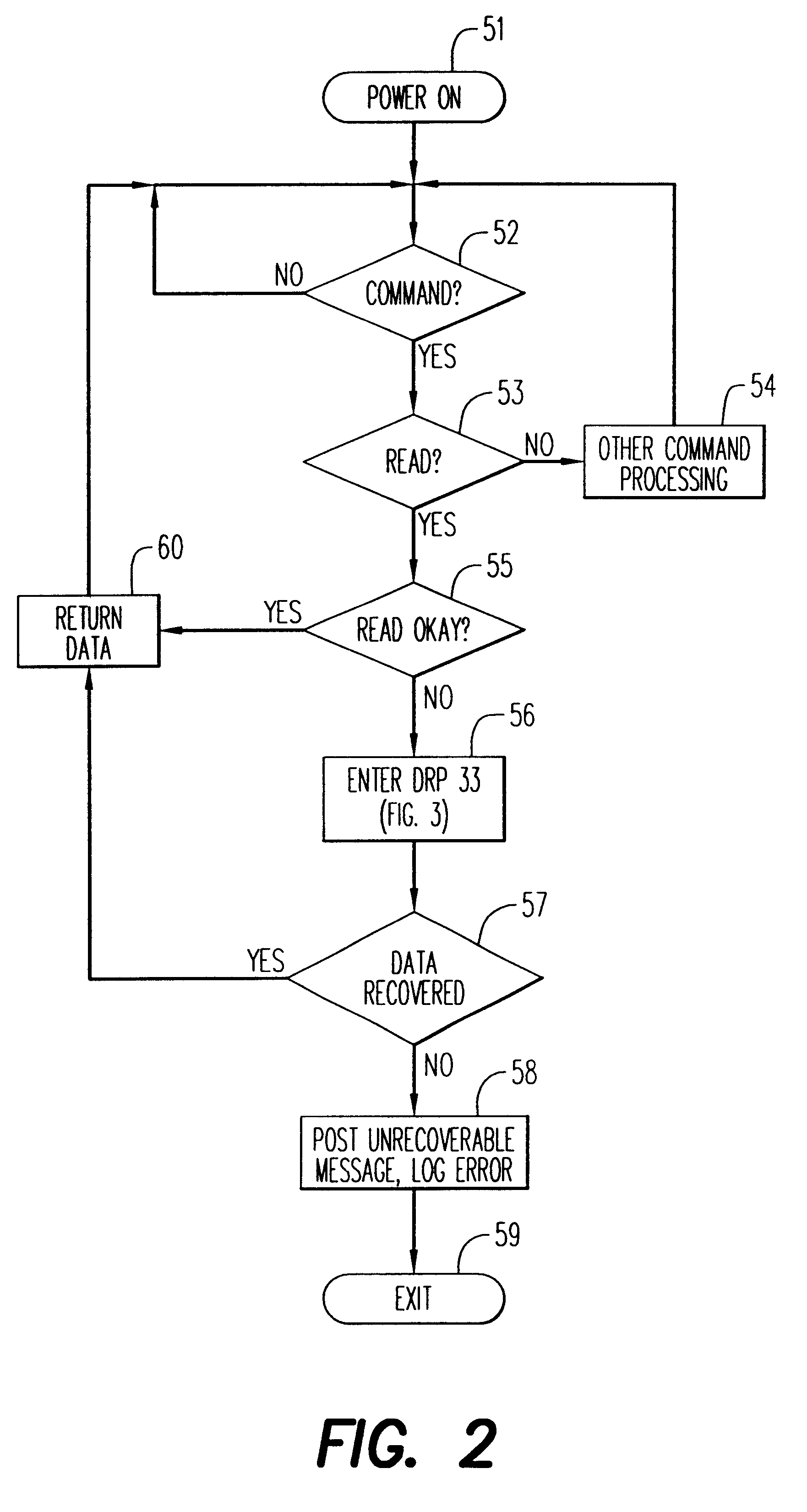

Data recovery apparatus, method and memory medium for a magnetic memory read/write channel

InactiveUS6501611B1High amplitude read signalReduce variationReducing temperature influence on carrierDriving/moving recording headsMethod testAudio power amplifier

A data recovery method for a read assembly of a magnetic memory device. The magnetic memory device has a moving magnetic medium, such as a disk, and a transducer spaced from the disk by a normal gap distance. The read assembly includes a variable gain amplifier and a control computer that controls the read and write operations of the magnetic memory device. The data recovery method uses the control computer to adjust the gain of the amplifier when an error is detected in a read signal. The method tests to see if the error is due to a variance from the normal gap distance by the head that is caused by either an thermal asperity of the disk surface or by a change in temperature of the moving magnetic medium. If a variance is found, the amplifier gain is adjusted and the data is reread. If there is no error the data is provided to an output interface.

Owner:IBM CORP

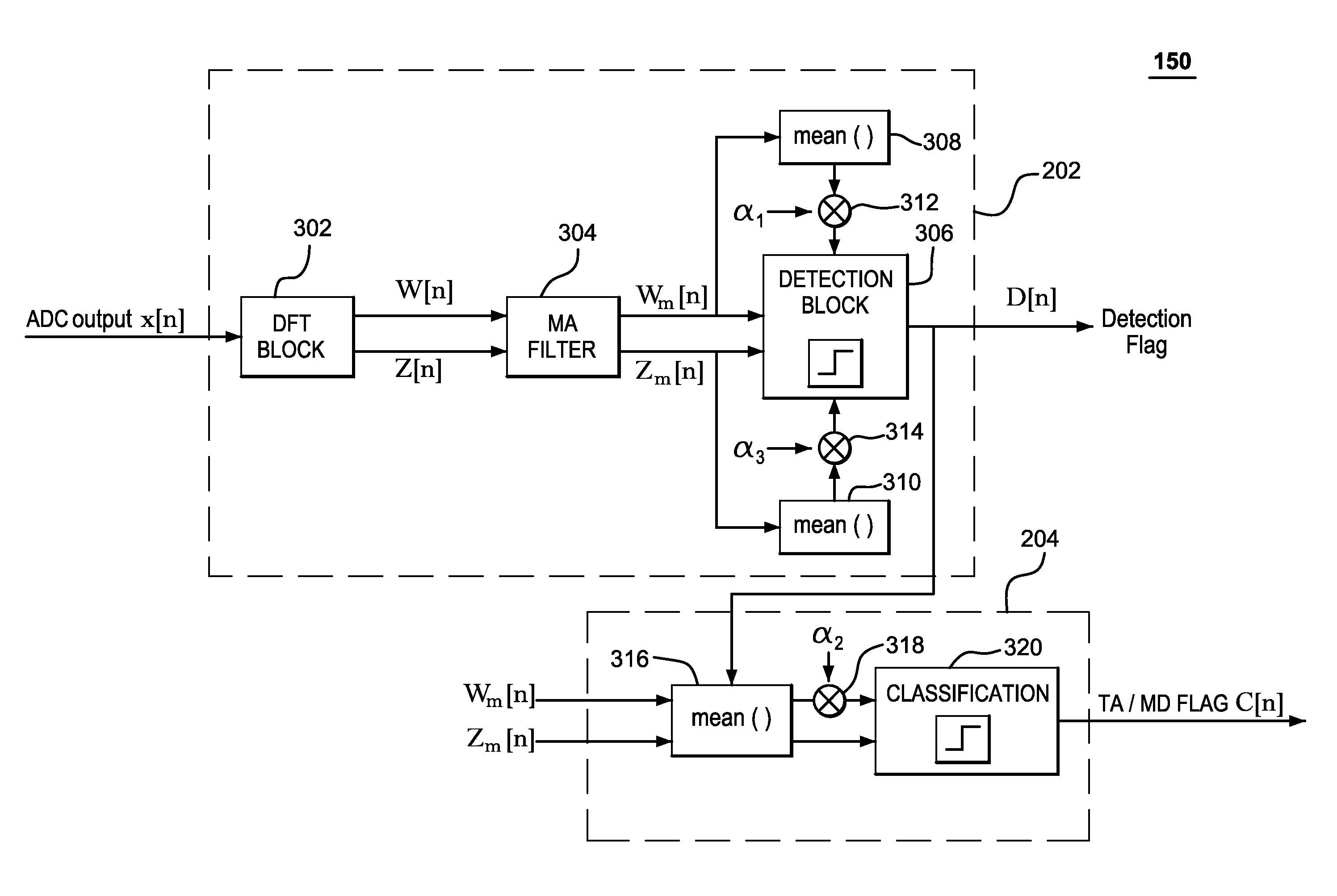

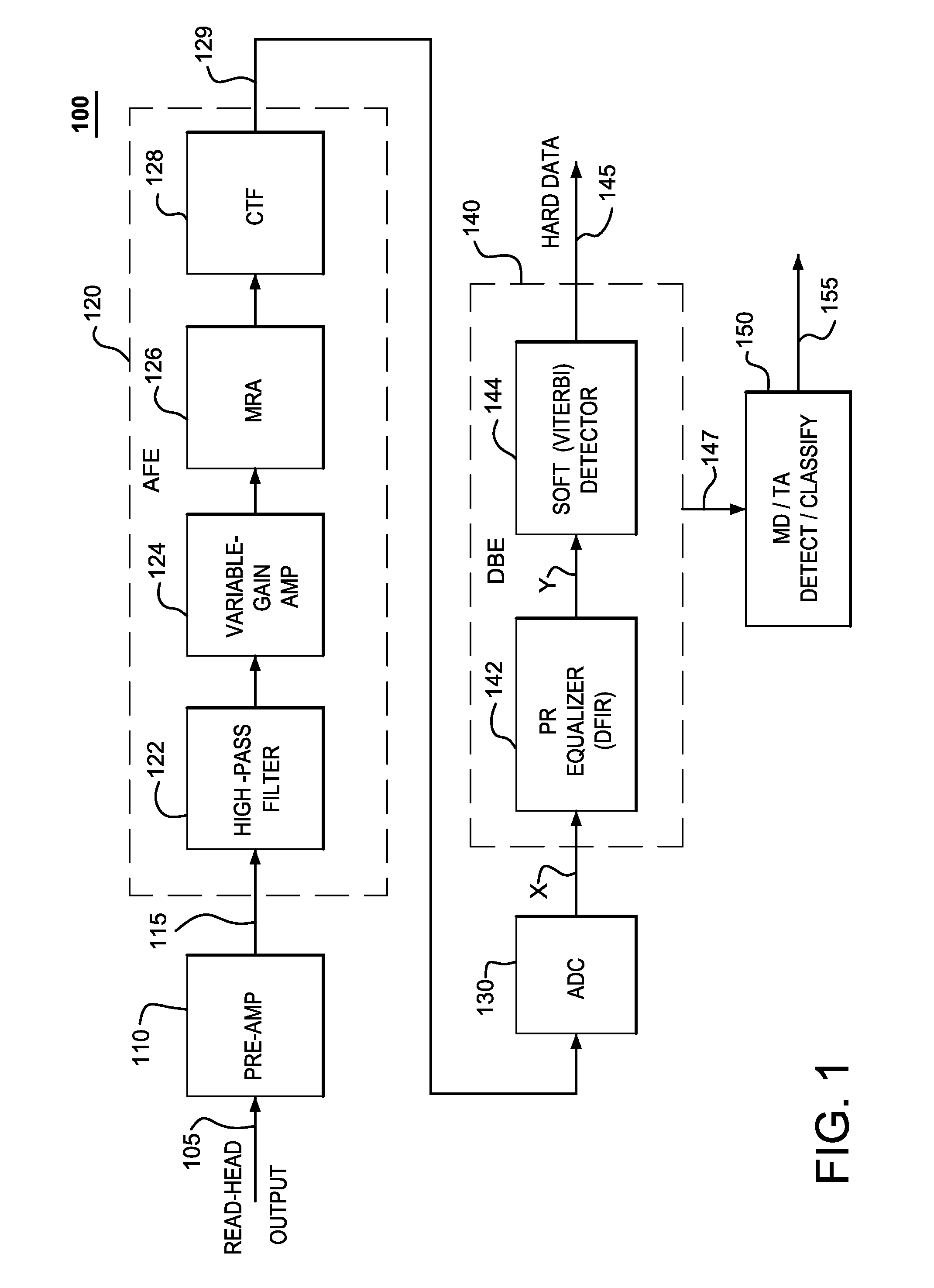

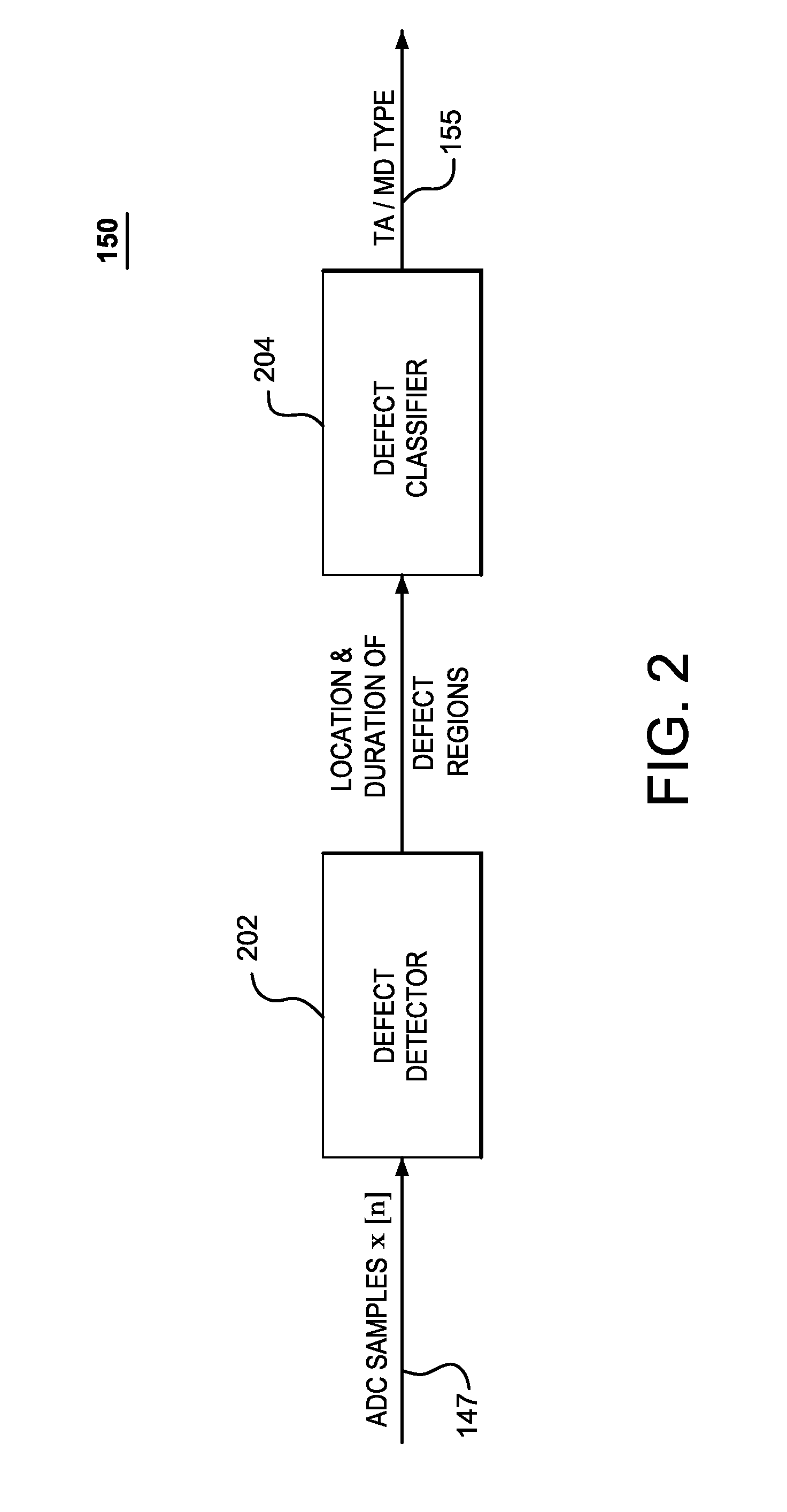

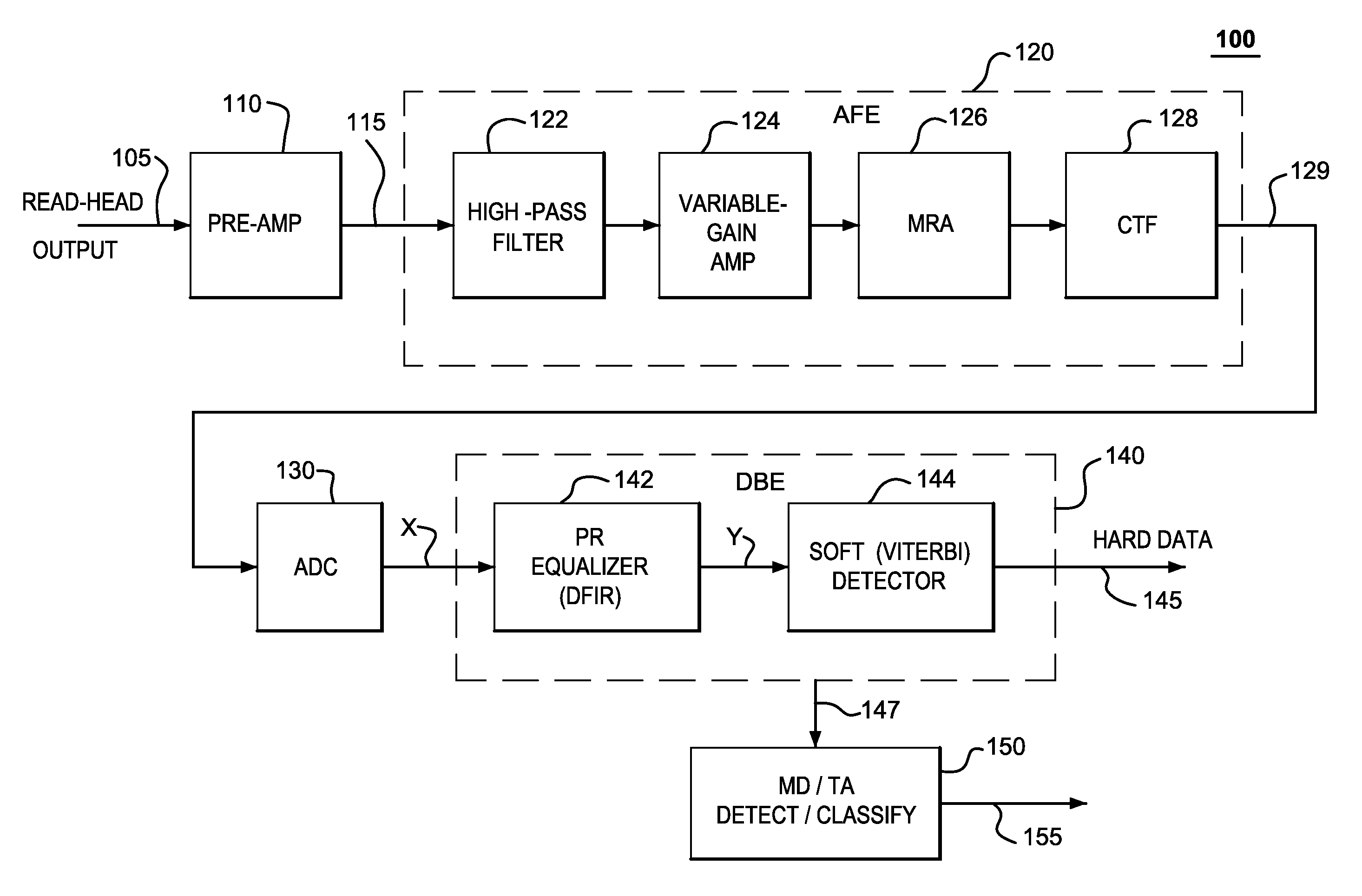

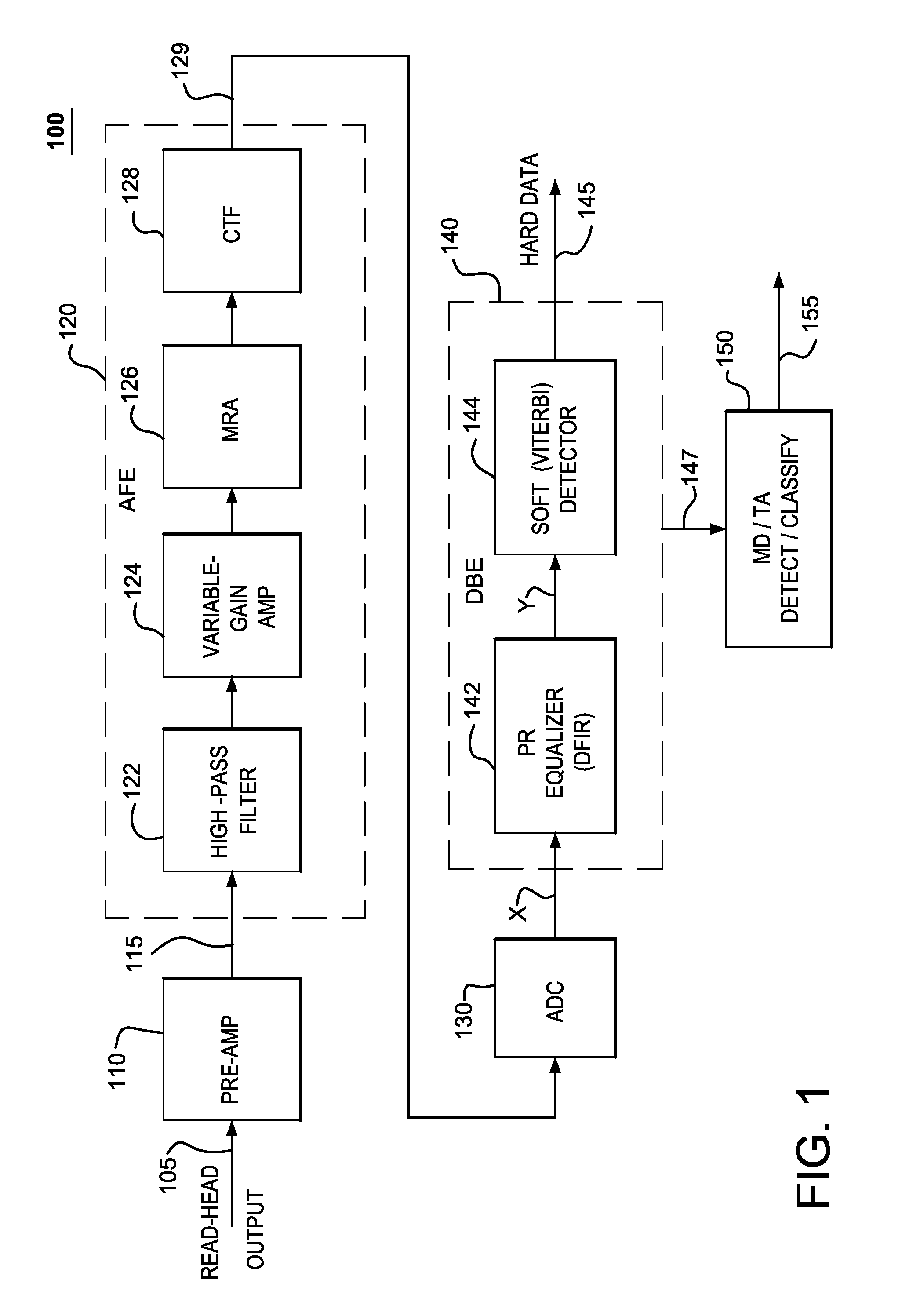

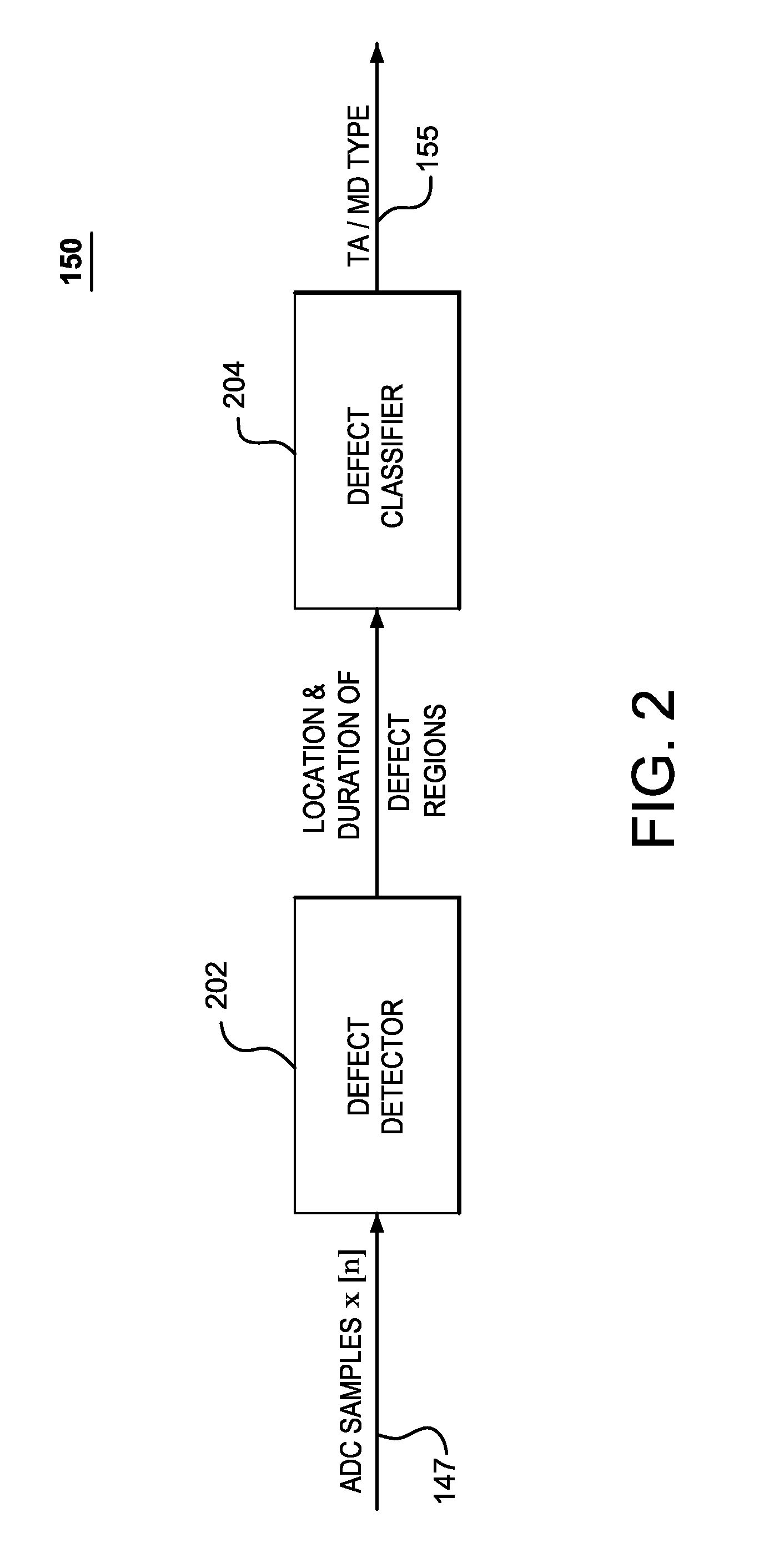

Frequency-based approach for detection and classification of hard-disc defect regions

In a hard-disc drive read channel, frequency-based measures are generated at two different data frequencies (e.g., 2T and DC) by applying a transform, such as a discrete Fourier transform (DFT), to signal values, such as ADC or equalizer output values, corresponding to, e.g., a 2T data pattern stored on the hard disc. The frequency-based measures are used to detect defect regions on the hard disc and / or to classify defect regions as being due to either thermal asperity (TA) or drop-out media defect (MD).

Owner:AVAGO TECH INT SALES PTE LTD

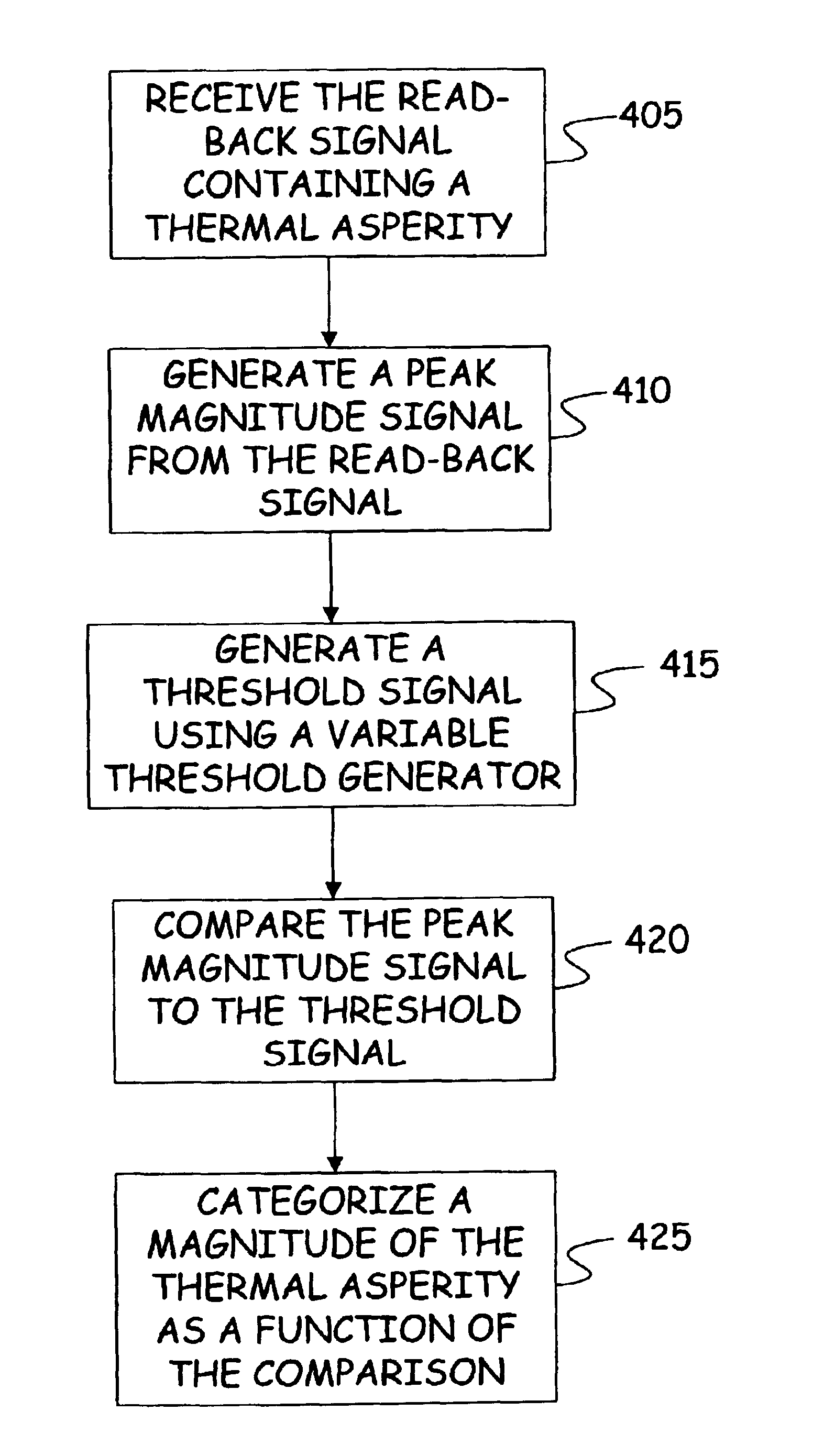

Thermal asperity multi-threshold algorithm using the read/write channel

A method of categorizing magnitudes of thermal asperities in a read-back signal of a data storage system includes receiving the read-back signal from a location containing a thermal asperity. A peak magnitude signal is generated from the read-back signal. A threshold signal is generated using a variable threshold generator. The peak magnitude signal is compared to the threshold signal and a magnitude of the thermal asperity is categorized as a function of the comparison.

Owner:SEAGATE TECH LLC

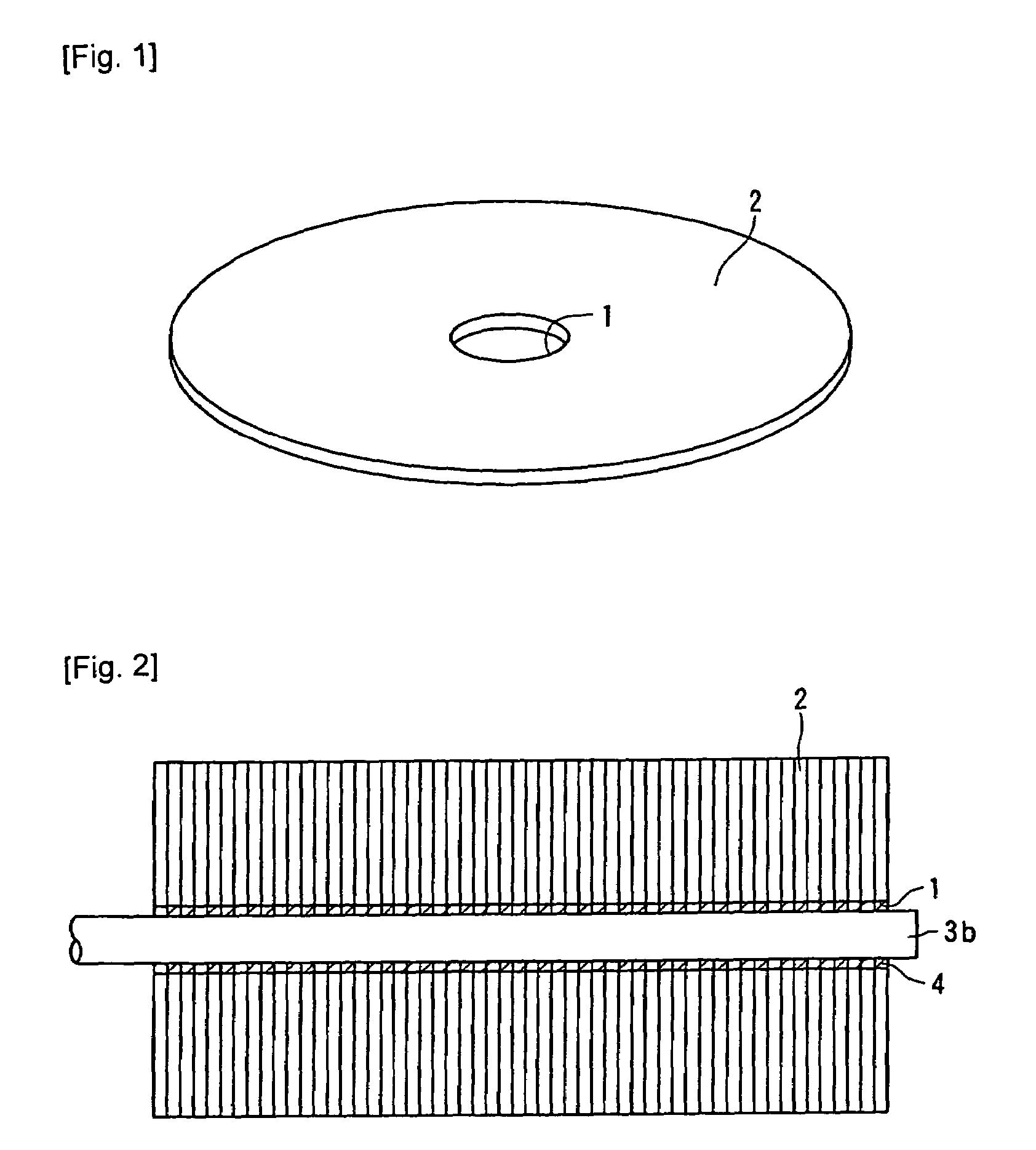

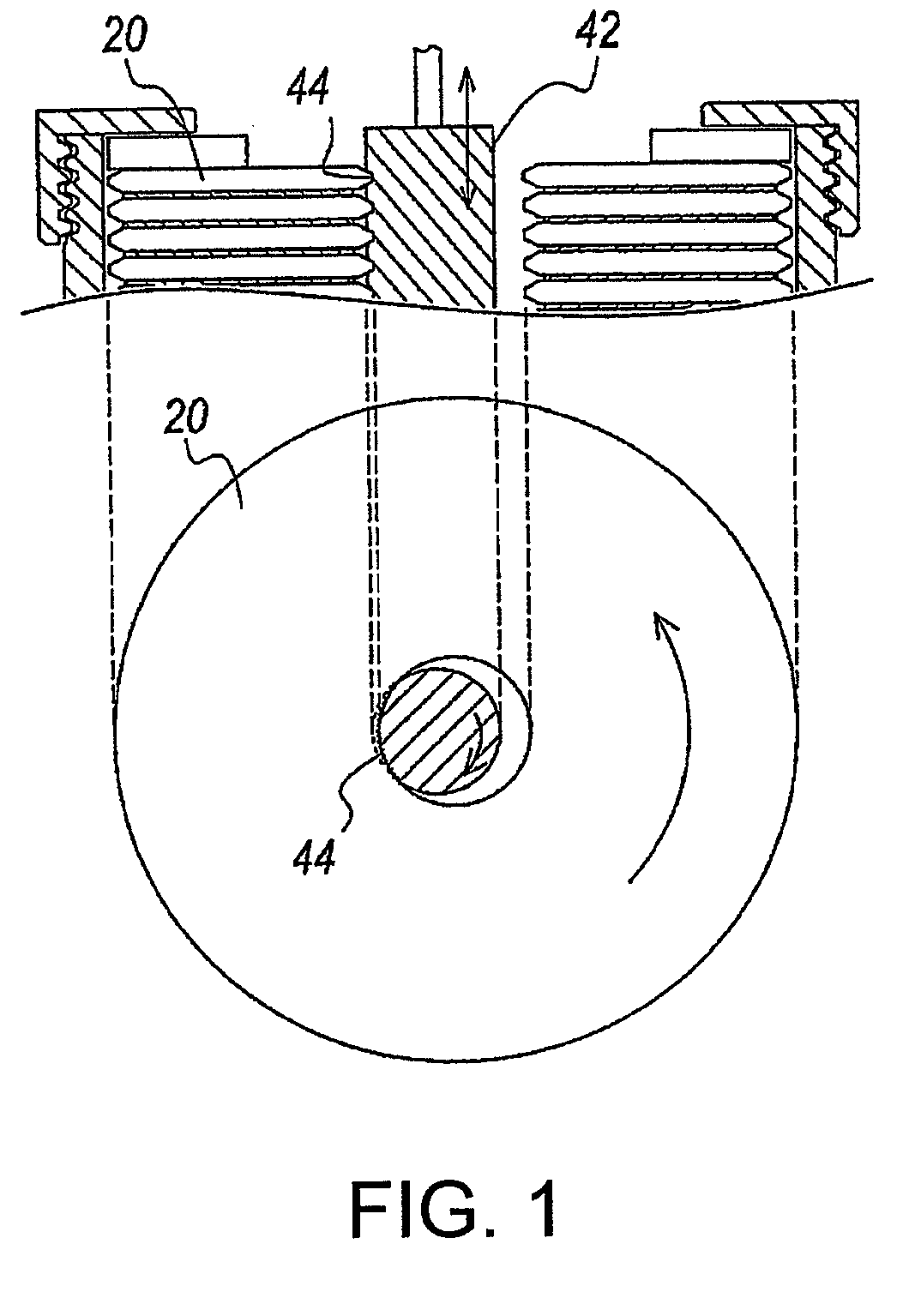

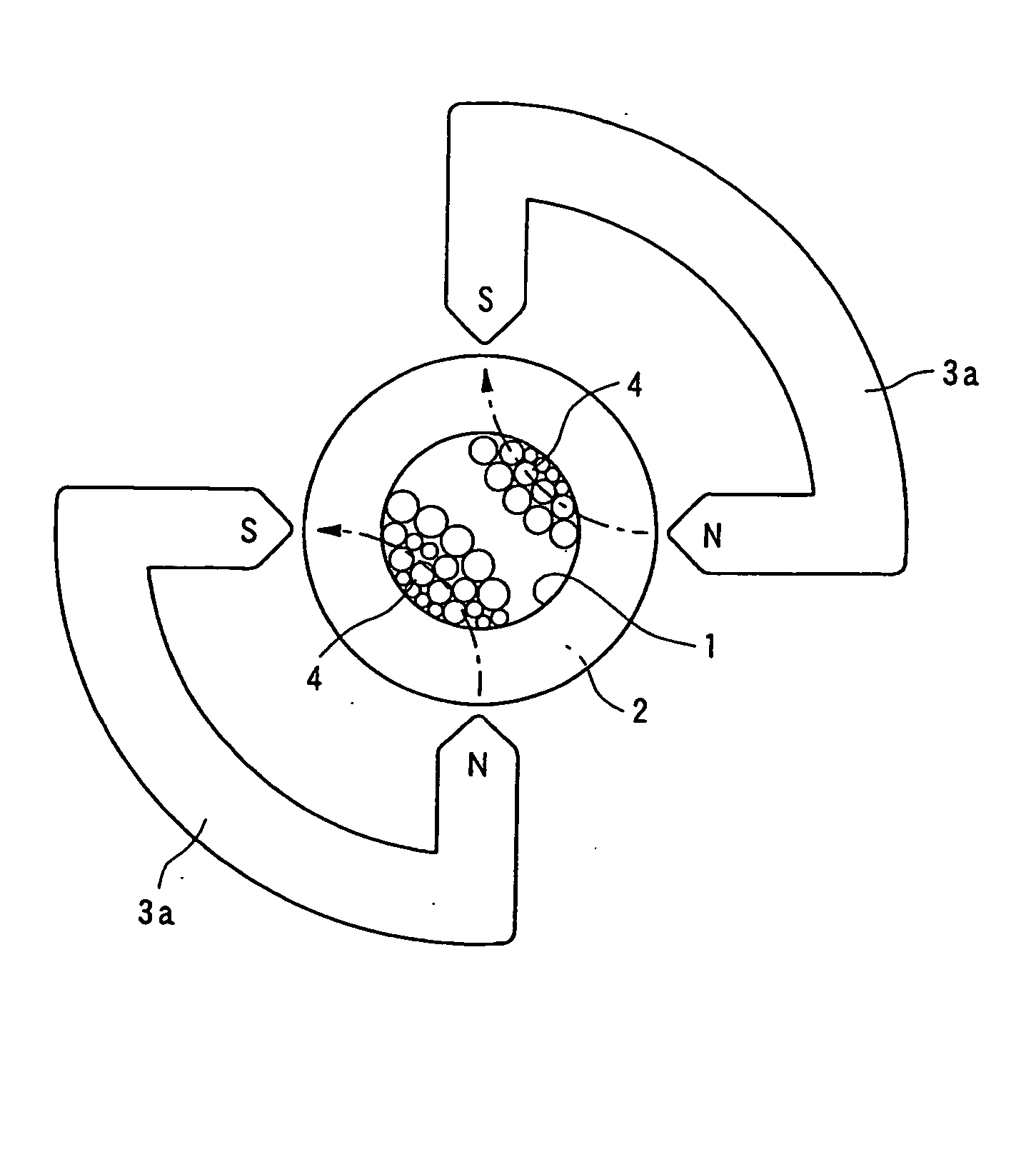

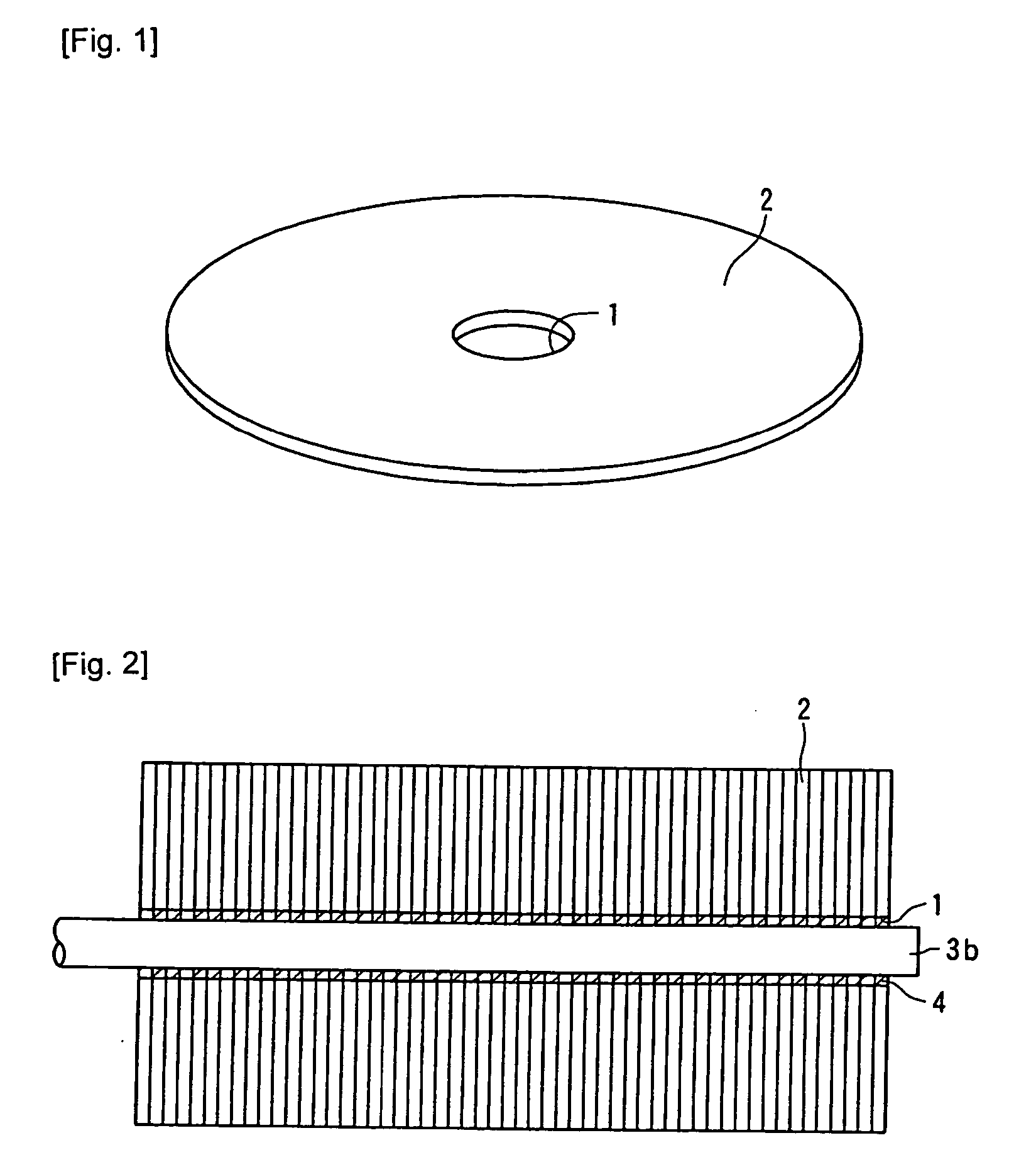

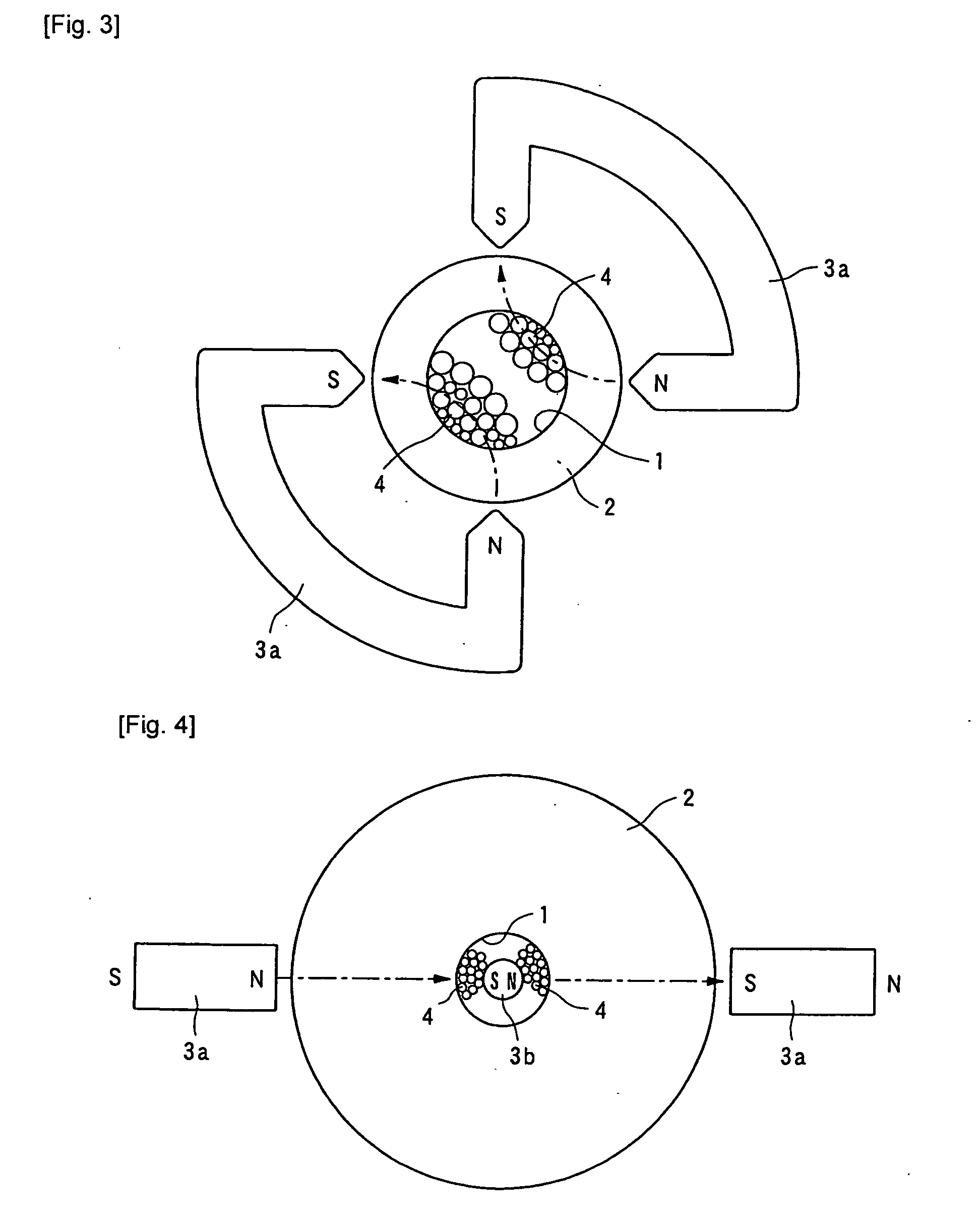

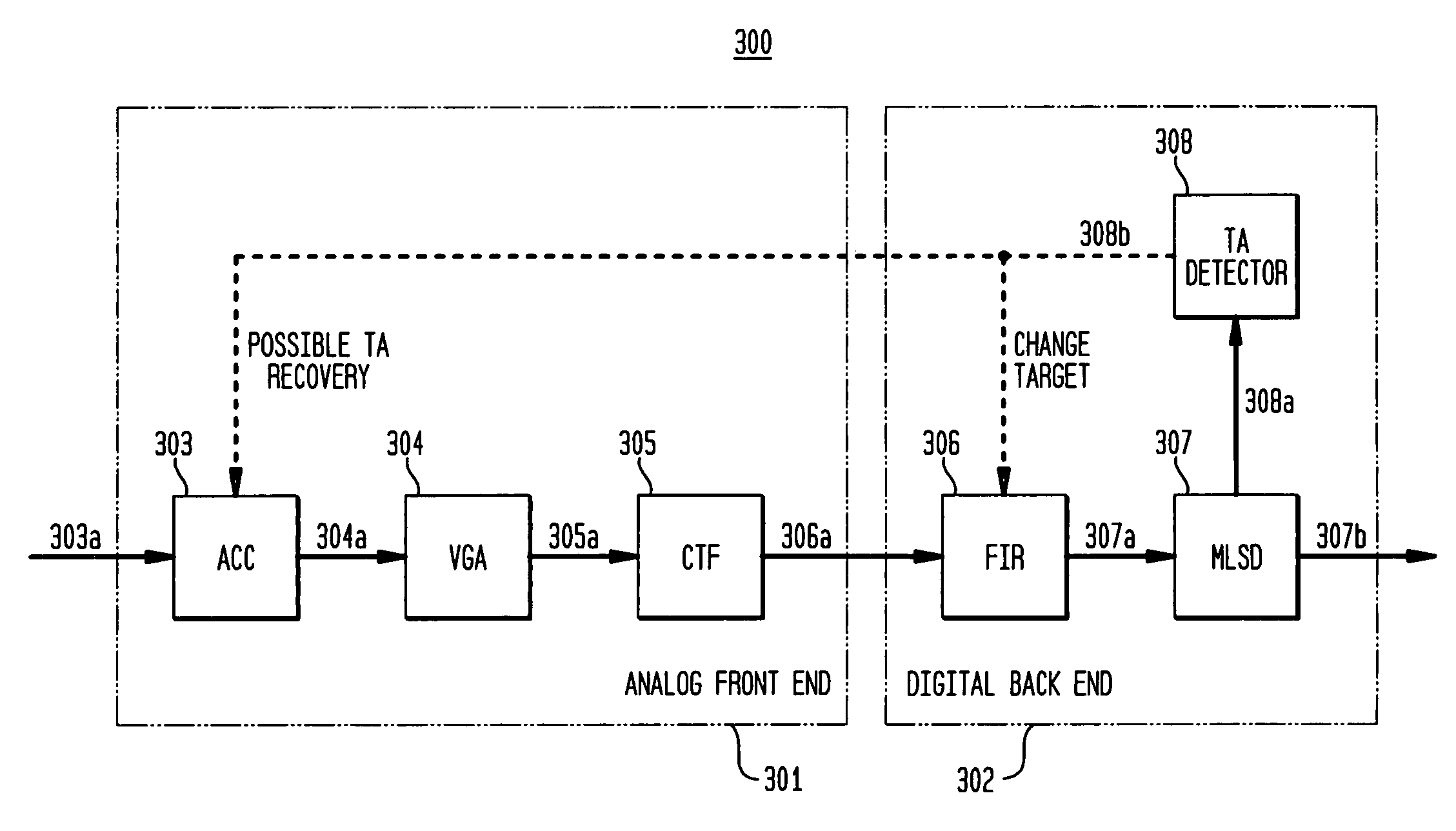

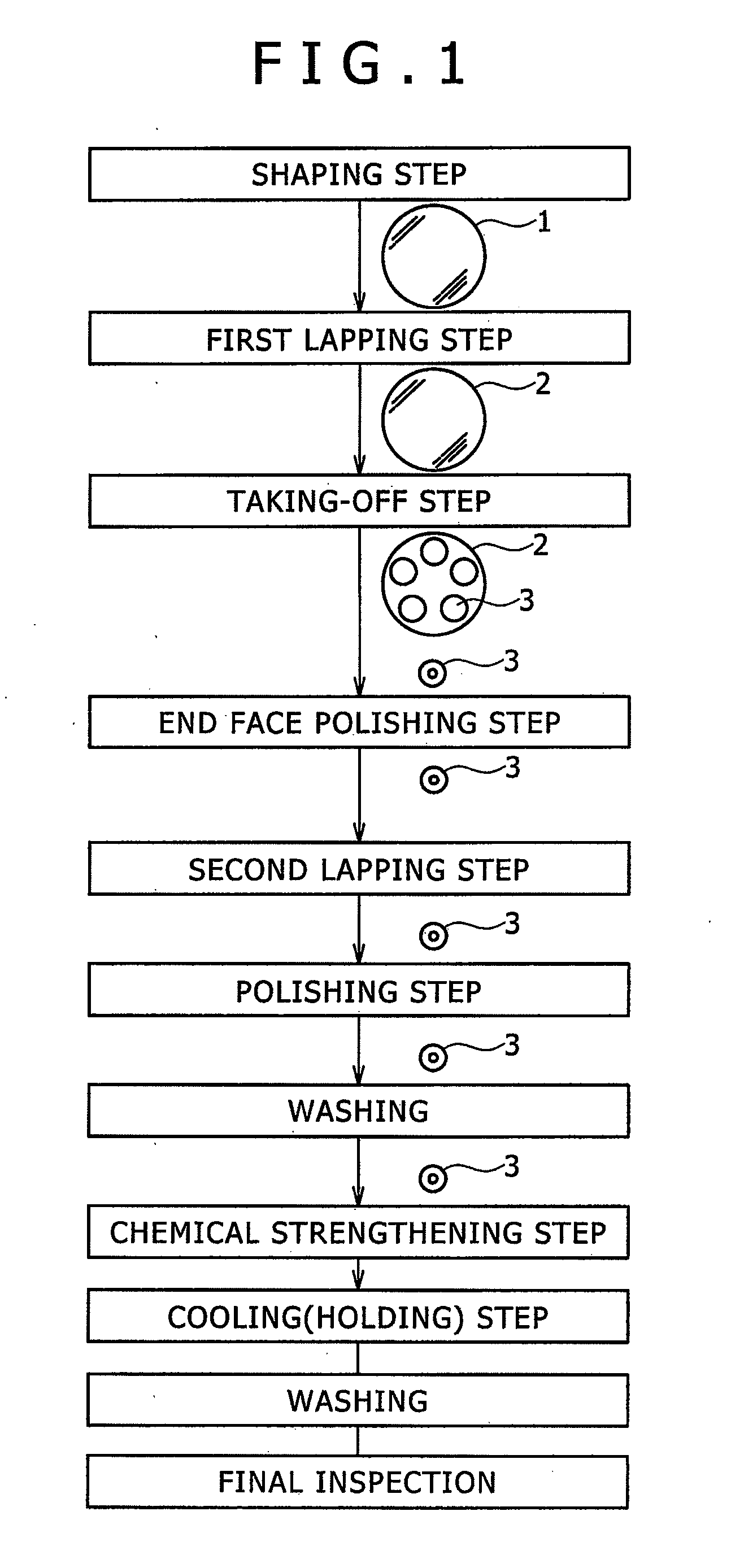

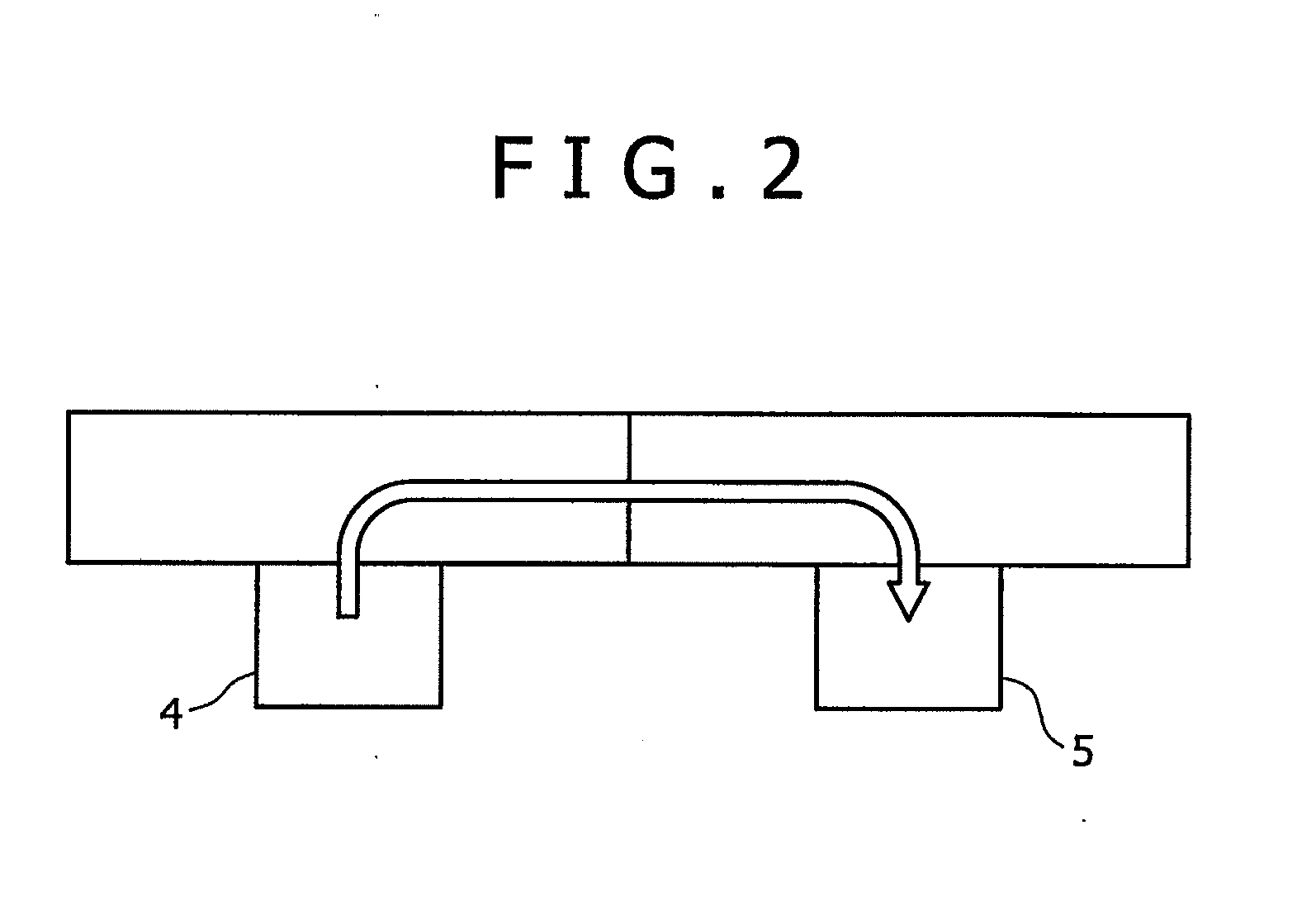

Method and device for manufacturing substrate for magnetic disk, and method of manufacturing magnetic disk

InactiveUS20060148386A1Easily and satisfactorily polishedEfficient polishingPolishing machinesRevolution surface grinding machinesEngineeringVolumetric Mass Density

A magnetic polishing method capable of easily and satisfactorily polishing the inner peripheral end face of a circular hole (1) at the center part of a disk substrate (2) even if the diameter of the circular hole is reduced. By this method, a large quantity of disk substrates with stable quality can be supplied, thermal asperity trouble and head crush can be prevented from occurring on a magnetic disk, and the density of the information recording surface of the magnetic disk can be increased. In the method for polishing the inner peripheral end face of the circular hole (1) at the center part of the disk substrate (2), a magnetic field is formed on the inner peripheral side of the circular hole (1), abrasive materials (4) including magnetic particles and abrasive grains are held by the magnetic field in the circular hole, and the magnetic field is moved to the inner peripheral end face of the circular hole (1) to move the abrasive materials (4) to the inner peripheral end face of the circular hole (1) for polishing the inner peripheral end face of the circular hole (1).

Owner:HOYA CORP

Detection of signal disturbance in a partial response channel

In one embodiment, irregular electronic disturbance signals in a partial-response read channel are detected by a disturbance detector using state metrics generated by maximum-likelihood sequence detector. For example, a thermal asperity (TA) detector detects the occurrence of TAs in the read channel of perpendicularly recorded magnetic media by using the state metrics generated by a Viterbi detector. Changes in state metrics (e.g., magnitudes of the branch metrics of the trellis diagram) used by the Viterbi detector are tracked. If the magnitude of the rise of the path metric increases above a set threshold, then a TA is detected. Alternatively, or additionally, the rate of change of the magnitude of the path metrics is tracked. If the rate of change within a set time window is above a specified threshold, then a TA is detected.

Owner:BROADCOM INT PTE LTD

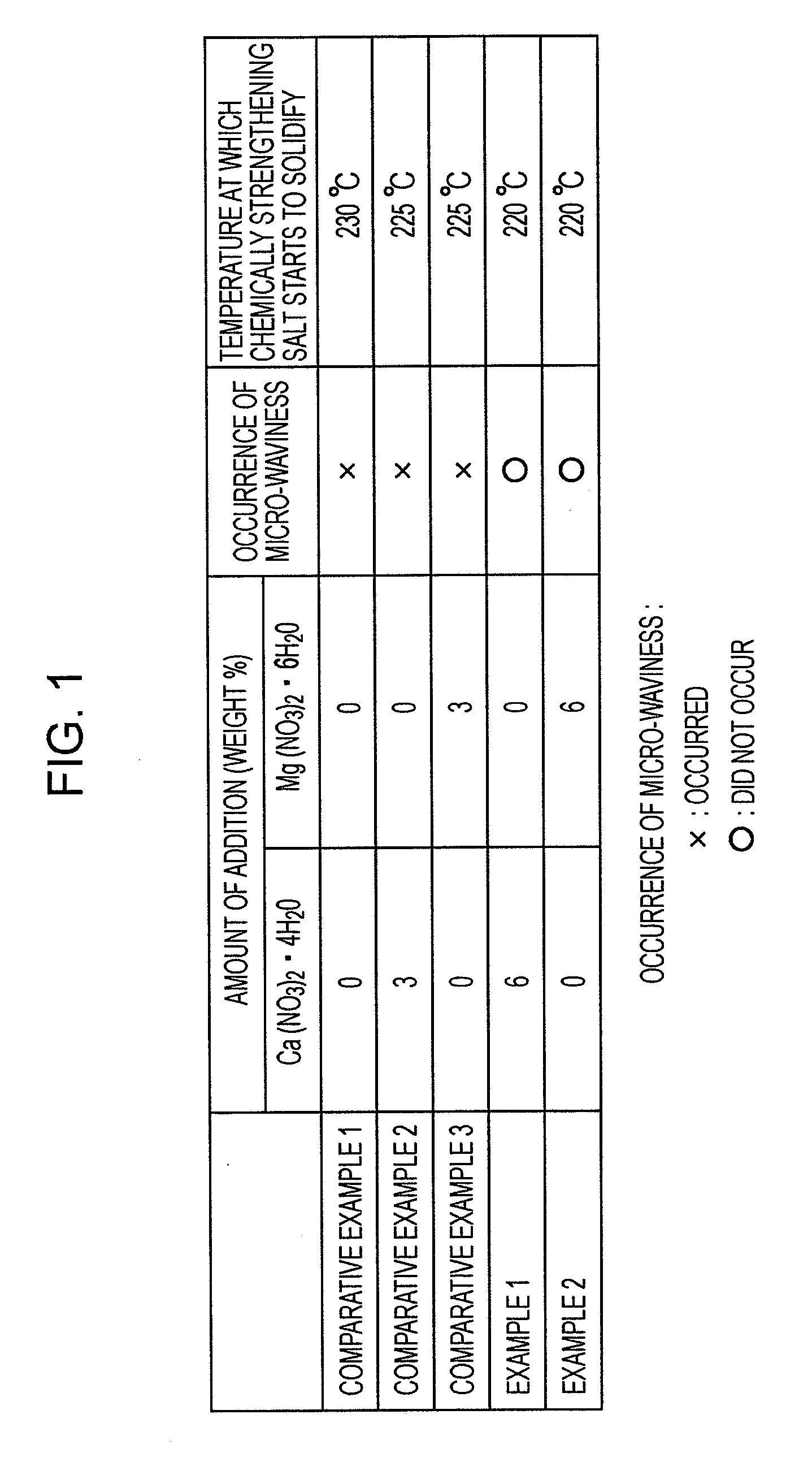

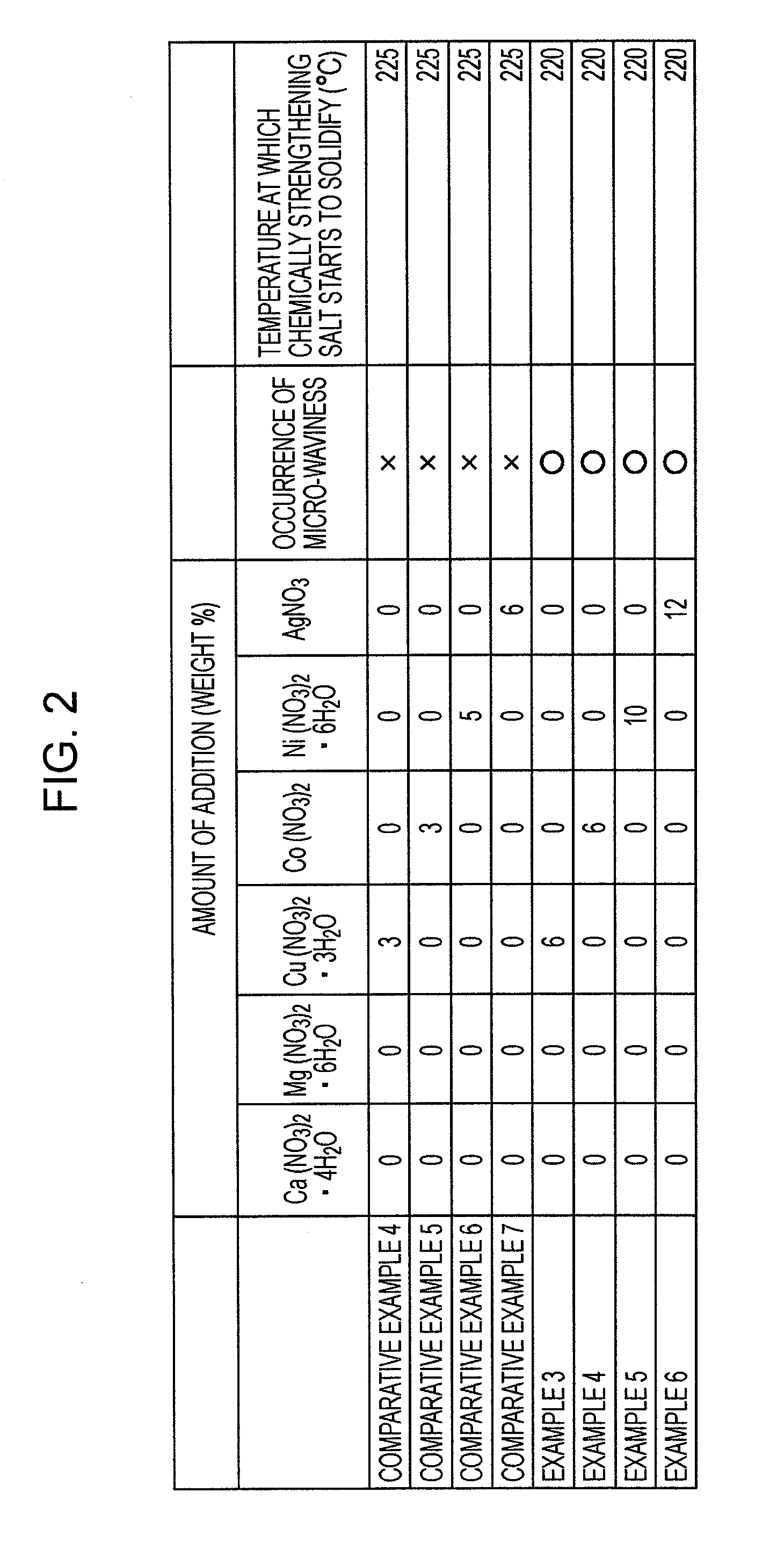

Method for producing glass substrate for magnetic disk and method for producing magnetic disk

ActiveUS20090277222A1Reduce the overall heightHigh-density recordingRecord information storageBase layer manufactureIon exchangeThermal asperity

The present invention provides a method for producing a glass substrate for a magnetic disk in which the occurrence of micro-waviness on the glass substrate is prevented in a cooling step after a chemically strengthening step so that the glass substrate has a significantly smooth principal surface, and provides a method for producing a magnetic disk in which head crash, thermal asperity failures, and the like are prevented, the flying height of a magnetic head can be decreased, and high-density recording is enabled.In a method for producing a glass substrate for a magnetic disk including a chemically strengthening step in which a glass substrate is immersed in a heated chemically strengthening salt solution prepared by dissolving a chemically strengthening salt under heating, and metal ions in the glass substrate are ion-exchanged with metal ions in the chemically strengthening salt, wherein the chemically strengthening step is carried out using a chemically strengthening salt solution in which the dissolved chemically strengthening salt does not solidify until the temperature decreases to a temperature that provides hardness at which the surface shape of the glass substrate is not deformed by a force applied to the glass substrate when the chemically strengthening salt having adhered onto the glass substrate solidifies.

Owner:HOYA CORP

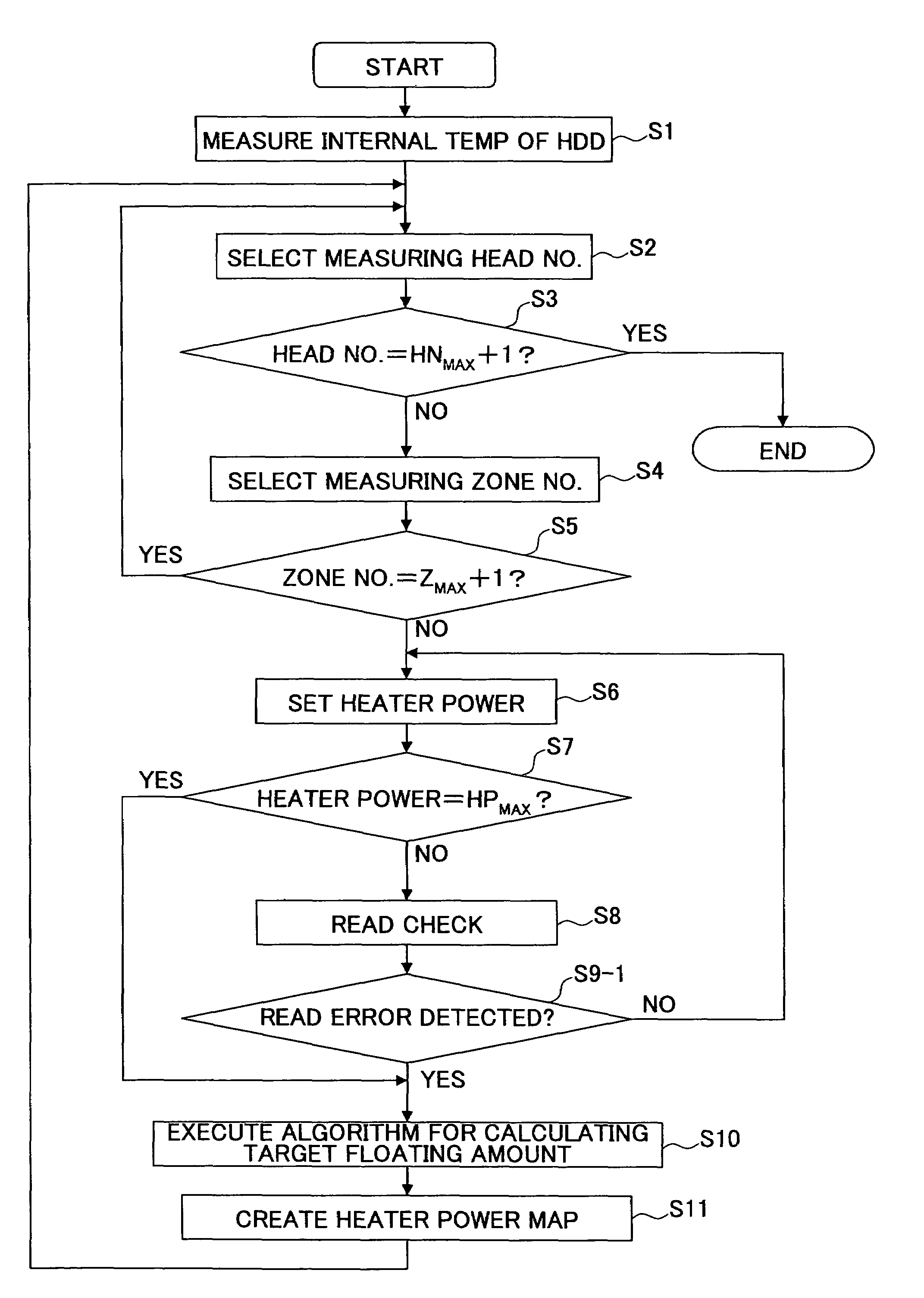

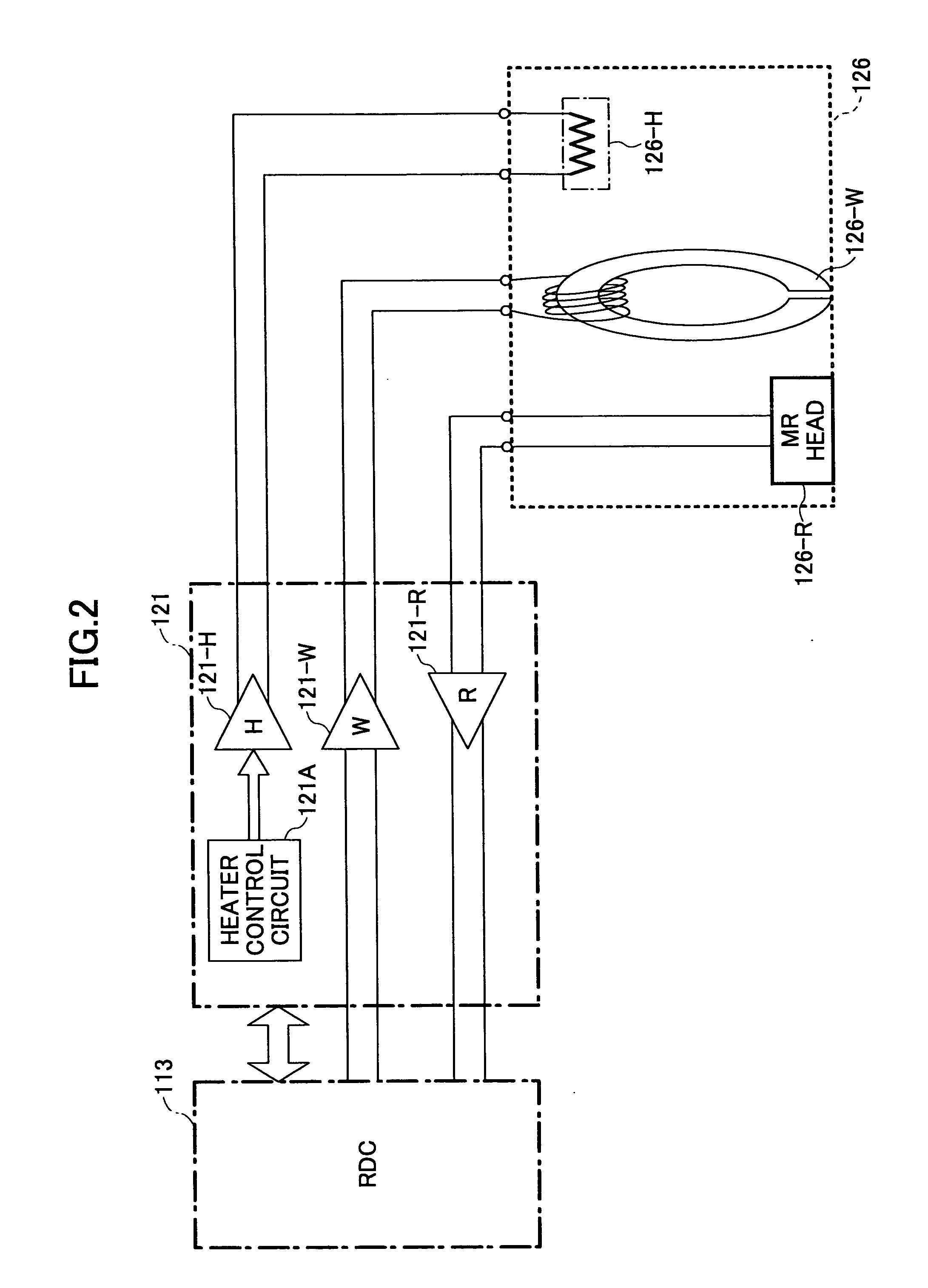

Head floating amount control method and unit, storage apparatus and computer-readable program

ActiveUS7436619B2Driving/moving recording headsRecord information storageThermal expansionThermal asperity

A head floating amount control unit control a head floating amount of each of a plurality of heads respectively having a heater, with respect to a recording medium, by detecting contact between each head and a corresponding recording medium by detecting a thermal asperity or a read error, and judging a heating amount of the heater at a time when the contact is detected as a state where the head floating amount is zero, and controlling the head floating amount of each head to an optimum head floating amount based on a relationship of the heating amount of the heater and an amount of thermal expansion of each head.

Owner:KK TOSHIBA

Head floating amount control method and unit, storage apparatus and computer-readable program

ActiveUS20070268608A1Driving/moving recording headsRecord information storageThermal expansionThermal asperity

A head floating amount control unit control a head floating amount of each of a plurality of heads respectively having a heater, with respect to a recording medium, by detecting contact between each head and a corresponding recording medium by detecting a thermal asperity or a read error, and judging a heating amount of the heater at a time when the contact is detected as a state where the head floating amount is zero, and controlling the head floating amount of each head to an optimum head floating amount based on a relationship of the heating amount of the heater and an amount of thermal expansion of each head.

Owner:KK TOSHIBA

Method for manufacturing glass substrate for magnetic disk and method for manufacturing magnetic disk

InactiveUS20090280241A1Avoid it happening againInhibitionPretreated surfacesBase layer manufactureHigh densityMetallurgy

This invention provides a method for manufacturing a glass substrate for a magnetic disk comprising a chemical strengthening step. The method provides a glass substrate for a magnetic disk that can suppress the occurrence of very small waves in cooling a glass substrate after the chemical strengthening step, and, while preventing troubles such as head crush and thermal asperity, can realize lowered flying height of a magnetic head and high-density information recording, and is particularly suitable for application to small-size magnetic disks for portable information equipment. In the step of cooling after the chemical strengthening step, cooling treatment is carried out in which the glass substrate is brought into contact with a treatment liquid containing a melt of a material having a solidification temperature below that of a chemical strengthening salt. The temperature of the treatment liquid is regulated to be below the temperature of the chemical strengthening salt melted liquid in the chemical strengthening step.

Owner:HOYA CORP

Baseline popping noise detection circuit

A technique to detect head instability by monitoring for a baseline popping (BLP) noise effect on demodulation bursts read from a disk. In one technique, a digital filter is employed as a moving average filter so that the filtering of the bursts has a zero output from the filter if only the bursts are present. However, when a BLP event occurs, the noise effect causes a non-zero output from the filter. A threshold value is set and when the output of the filter exceeds the threshold value, a BLP indication is noted. Although various filters may be used, in one technique, a filter suitable for use in detecting thermal asperity defects is used for the BLP detection filter.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

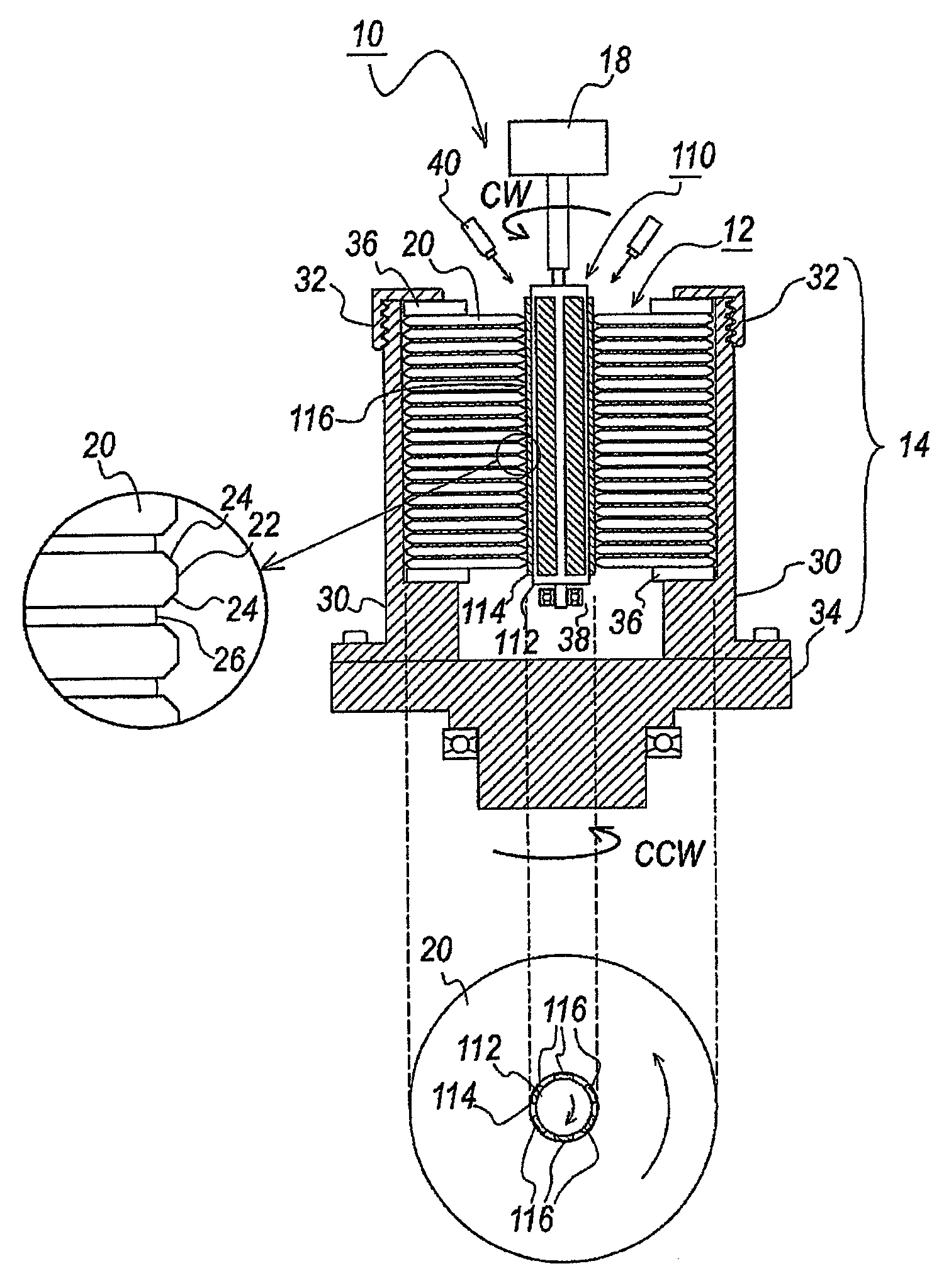

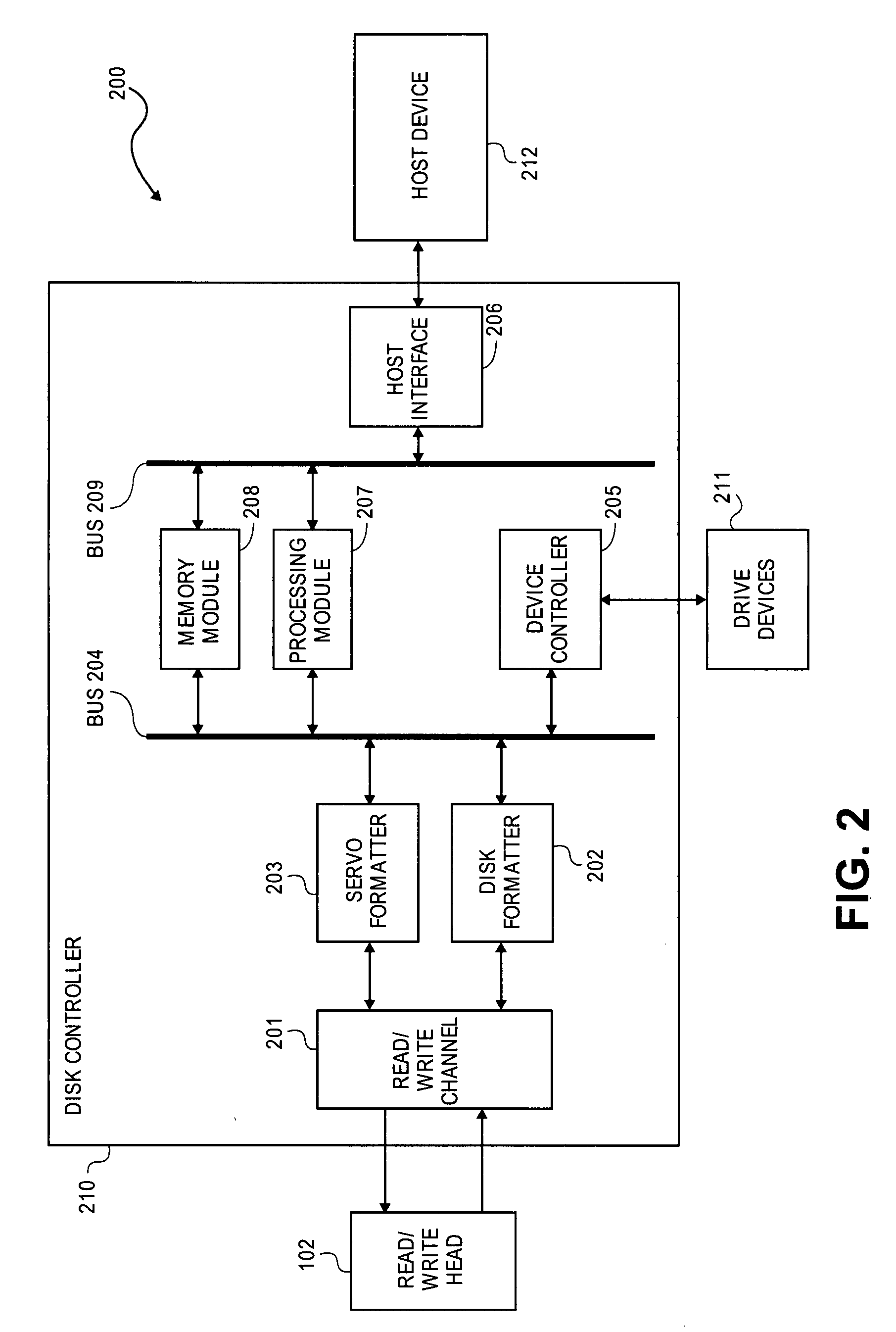

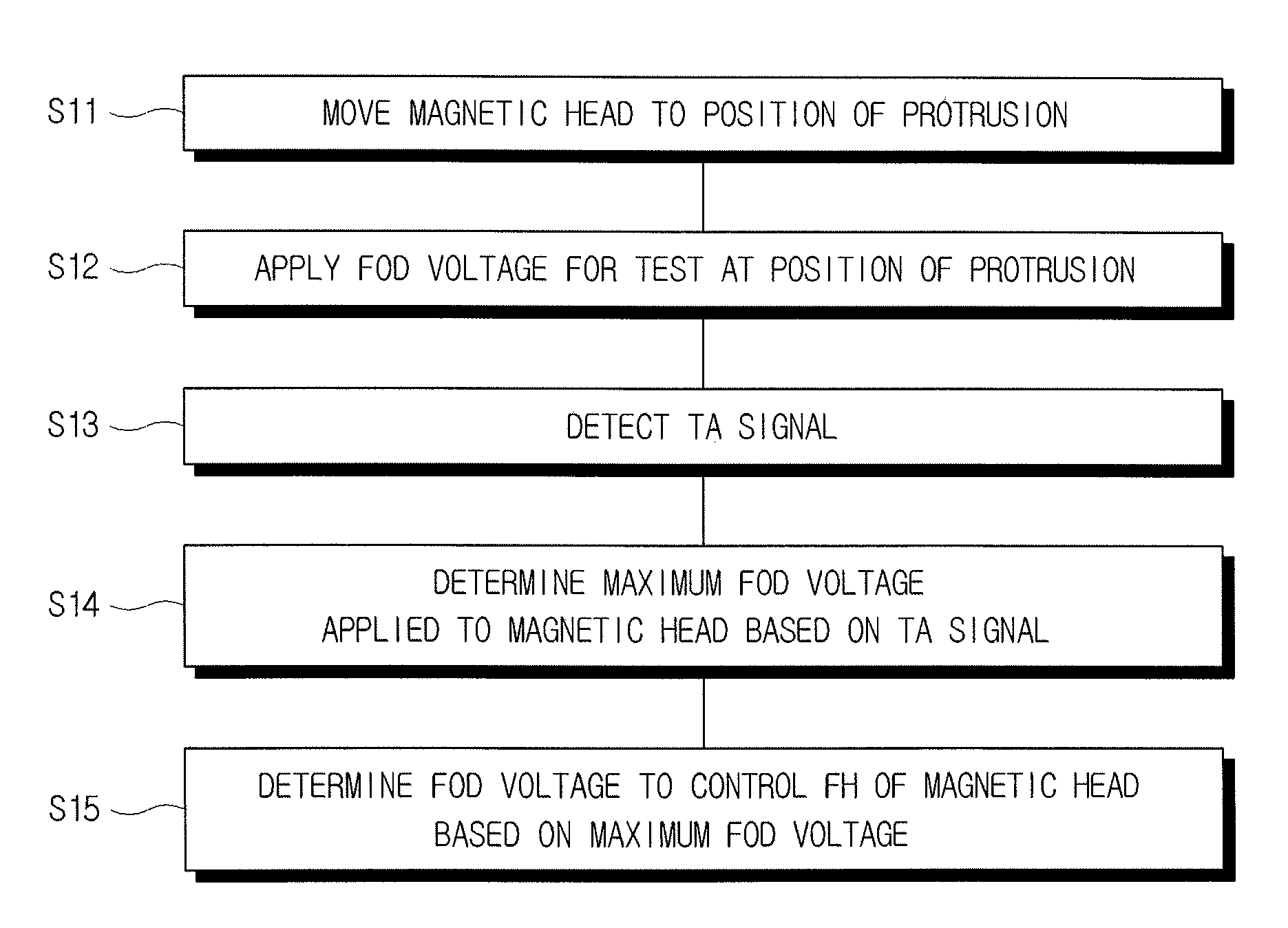

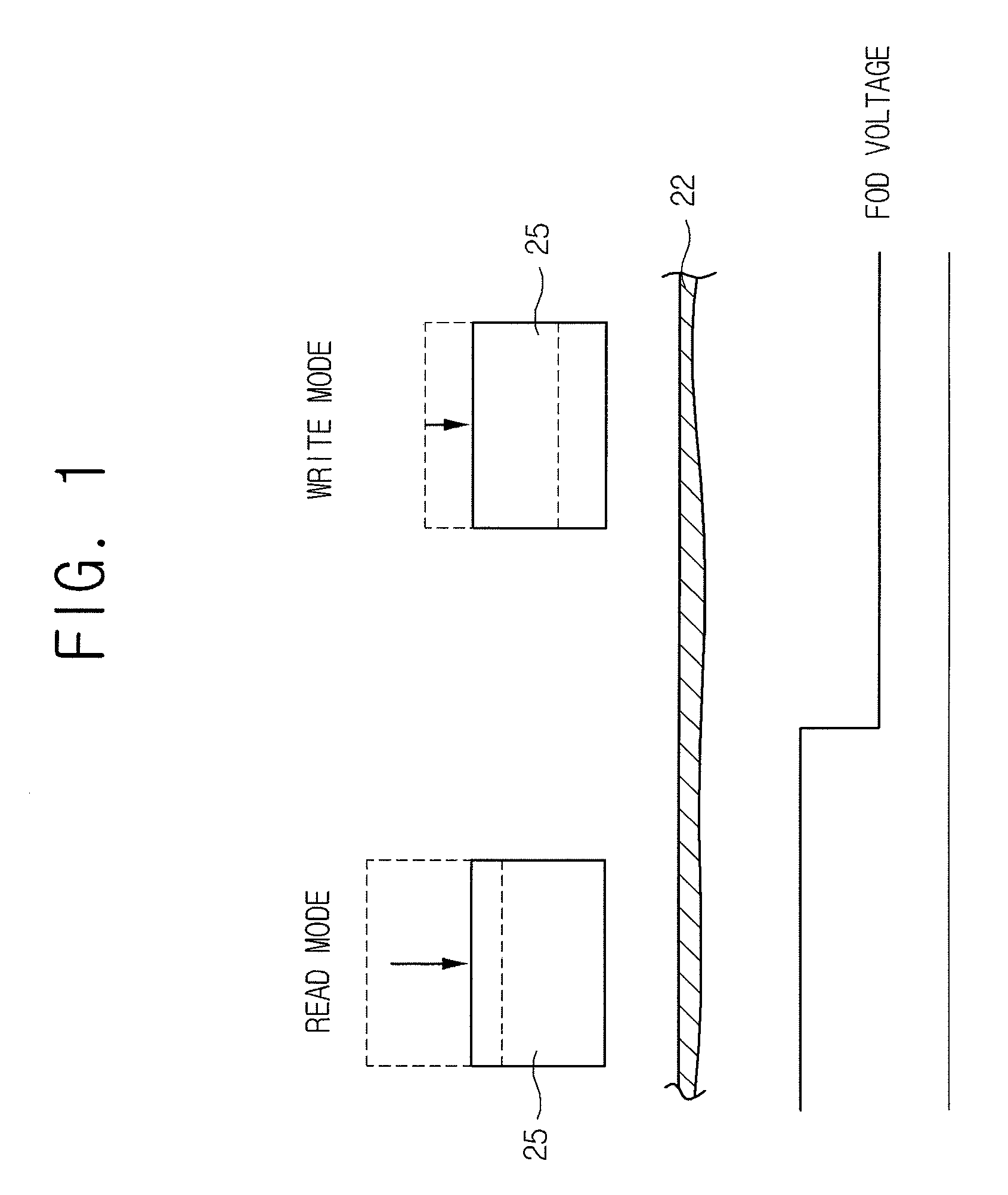

Hard disk drive apparatus, method to control flying on demand of hard disk drive apparatus using thermal asperity signal, and recording media for computer program thereof

InactiveUS7583467B2Improve reliabilityDriving/moving recording headsRecord information storageFlying heightEngineering

A method to control an FOD (flying on demand) voltage of a hard disk drive apparatus using a TA (thermal asperity) signal includes providing at least one protrusion having a predetermined height on a disk, moving a magnetic head to a position of the protrusion, and applying an FOD voltage for a test to the magnetic head, detecting the TA signal generated when the magnetic head touches the protrusion by the applied FOD voltage for a test, and determining the maximum FOD voltage, that is, the maximum FOD voltage applied to the magnetic head, based on the detected TA signal and determining an FOD voltage to control the FH (flying height) of the magnetic head based on the maximum FOD voltage.

Owner:SAMSUNG ELECTRONICS CO LTD

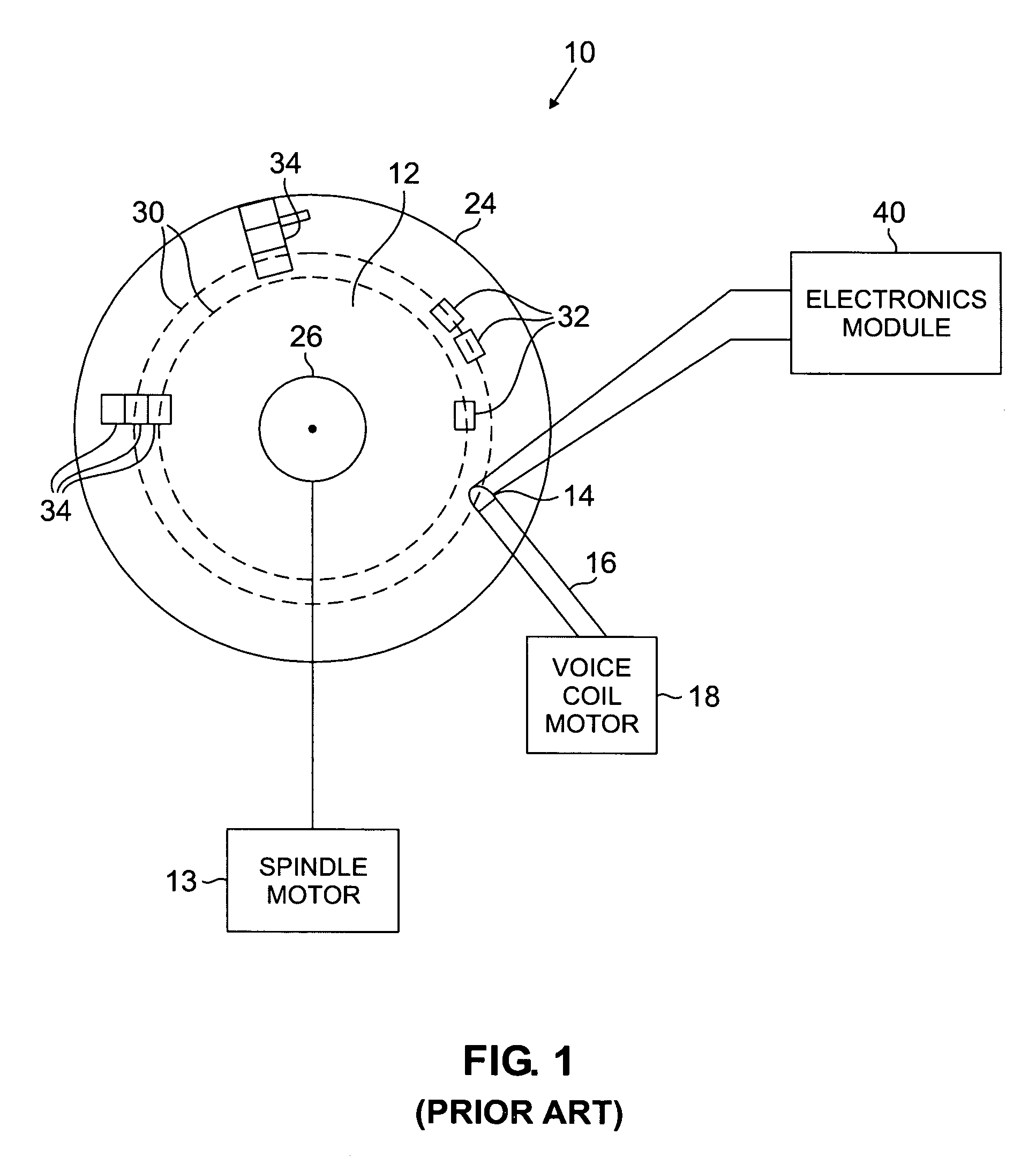

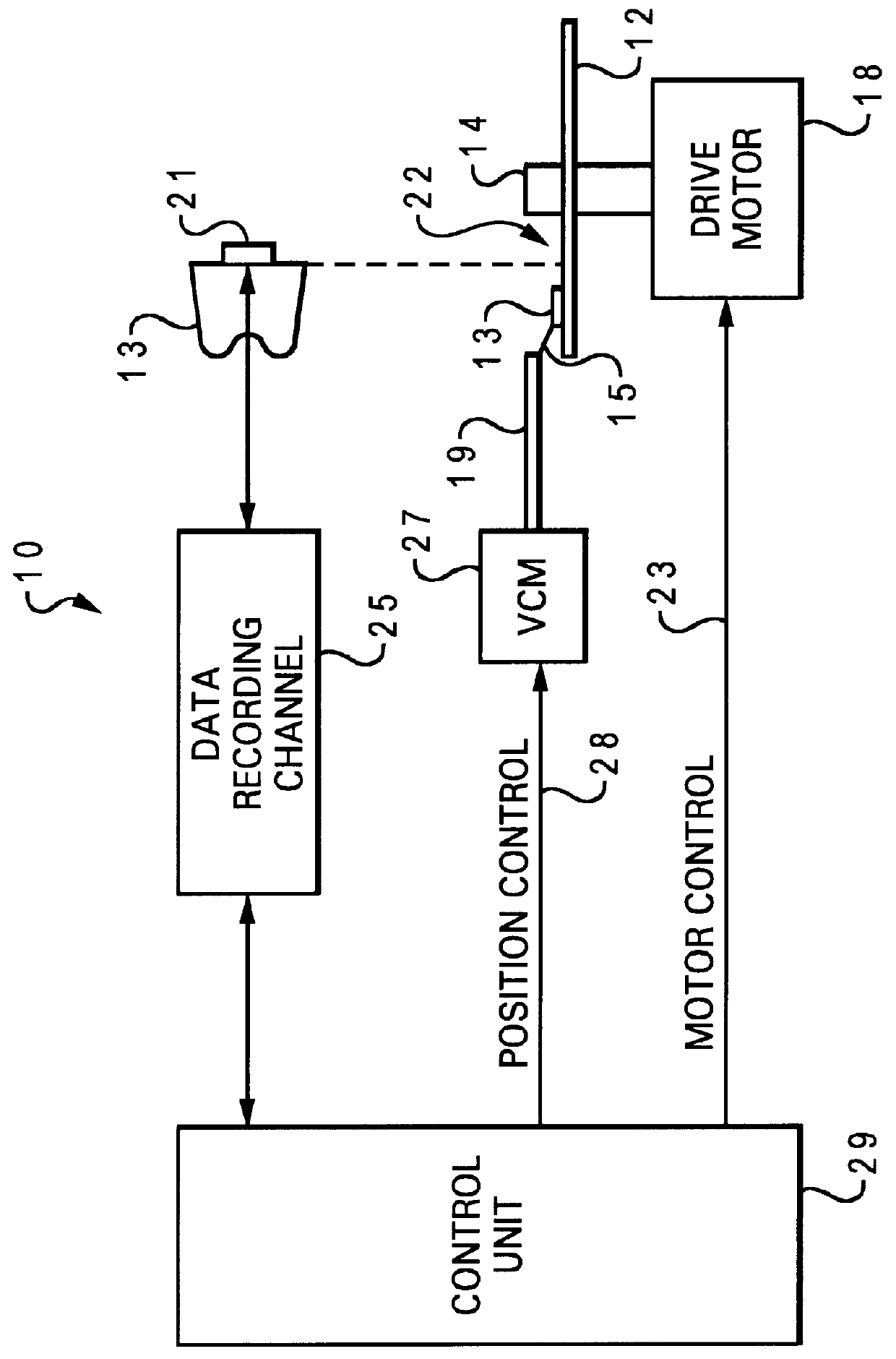

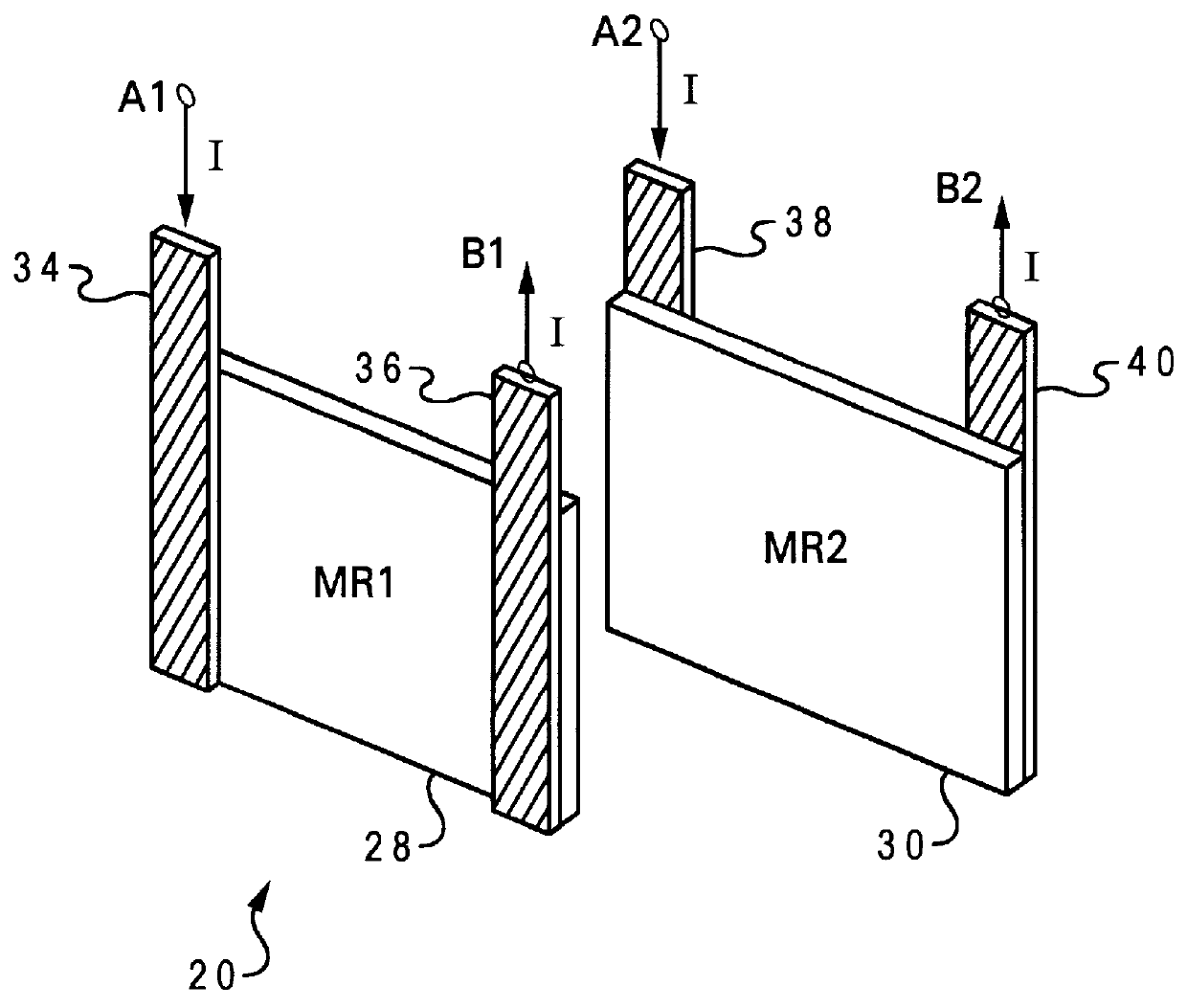

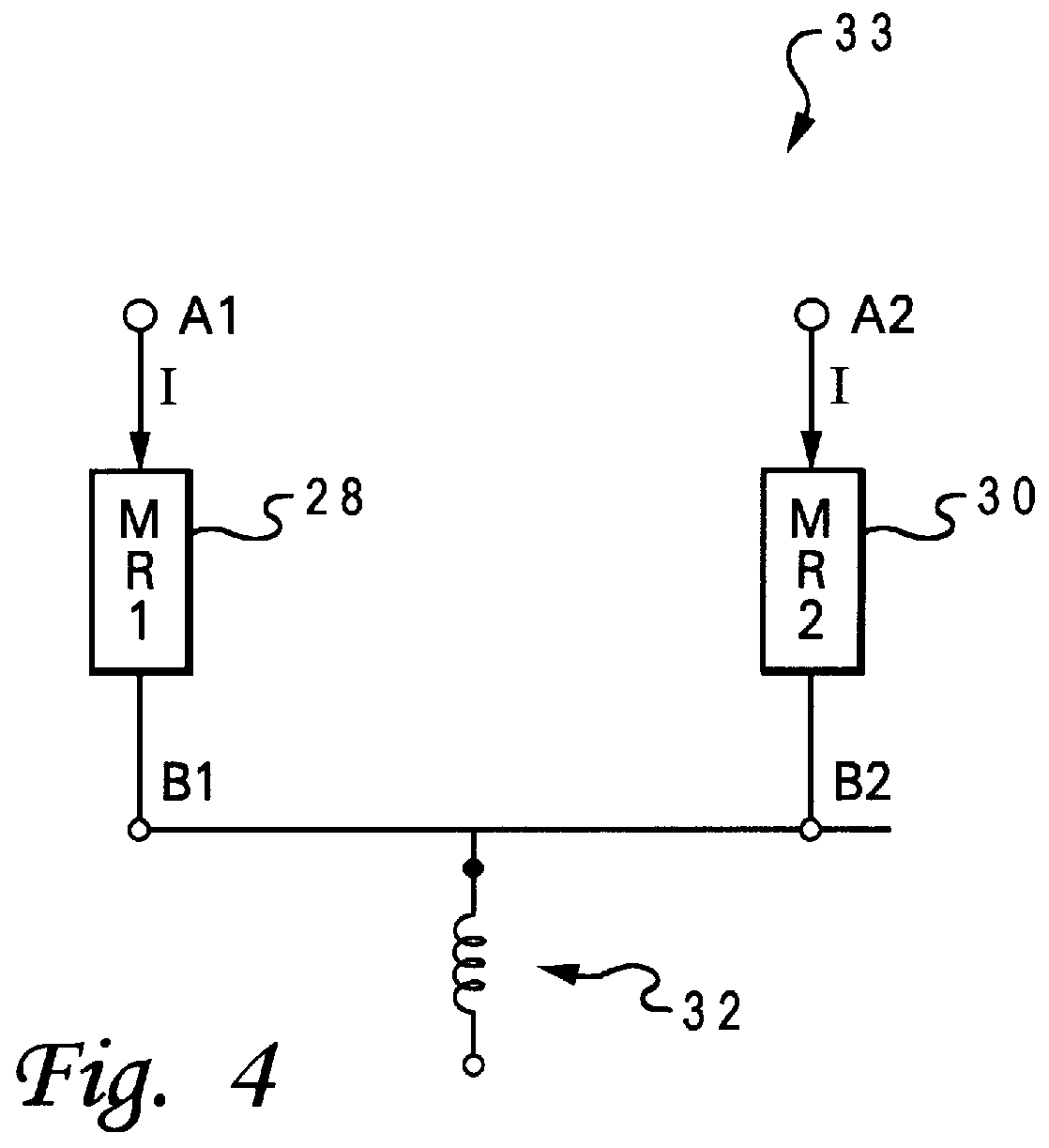

Method and system for detecting common mode disturbances from a dual stripe magnetoresistive head

InactiveUS6128149ACarrier indicating/warning arrangementsFilamentary/web carriers operation controlThermal asperityCommon-mode interference

A method and system for detecting common mode disturbances from a magnetic recording head having dual magnetic recording elements. An electrical current is supplied to both of the dual magnetic recording elements within the magnetic recording head. Thereafter, the electrical current is shunted through only one of the dual magnetic recording elements. A voltage signal is then detected across the dual magnetic recording elements, which occurs in response to the shunting of the electrical current through only one of the dual magnetic recording elements. Finally, the voltage signal is analyzed for indications of common mode disturbances accentuated as a result of the shunting of the electrical current through only one of the dual magnetic recording elements. Common mode disturbances that can be detected include thermal asperities.

Owner:WESTERN DIGITAL TECH INC

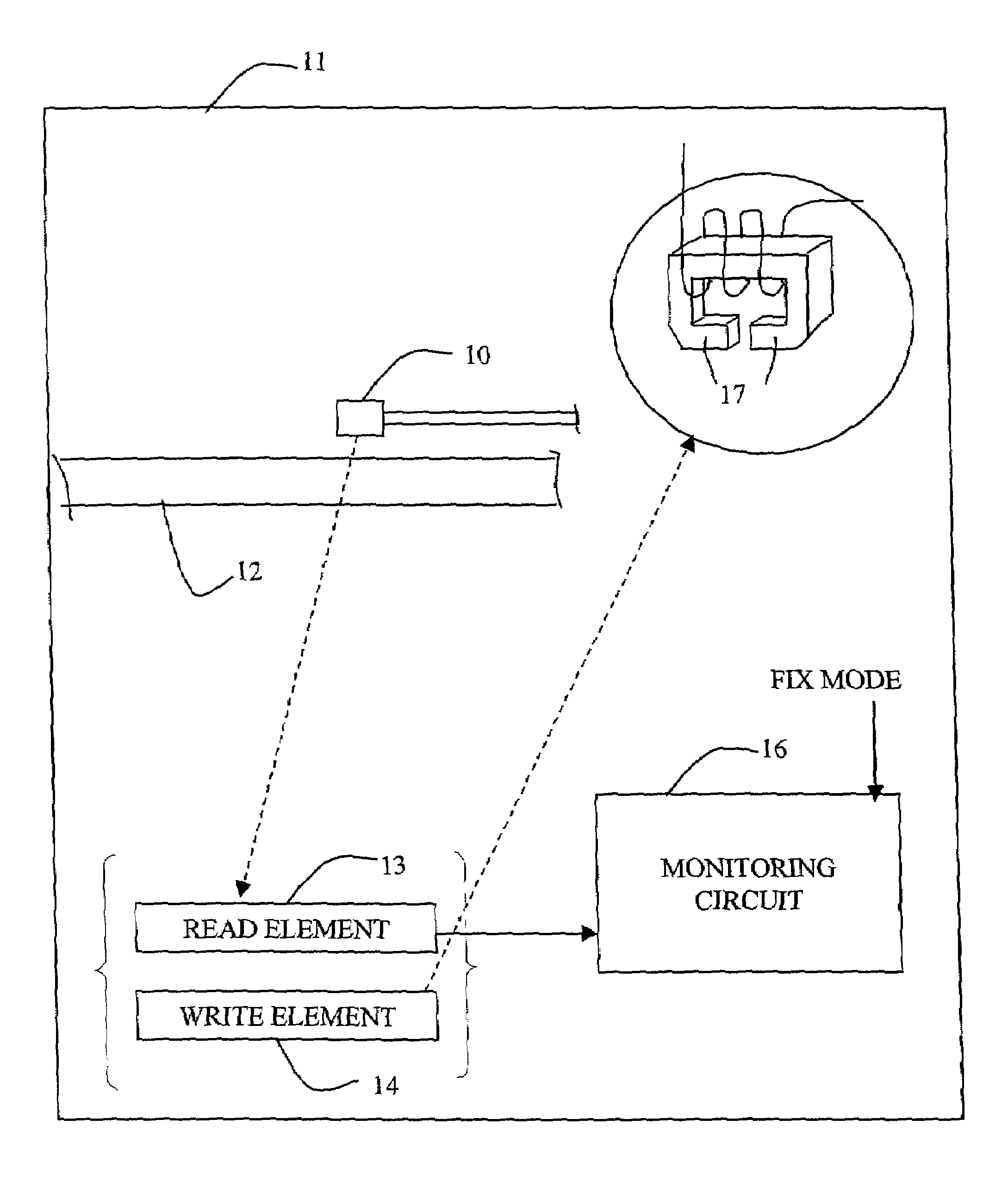

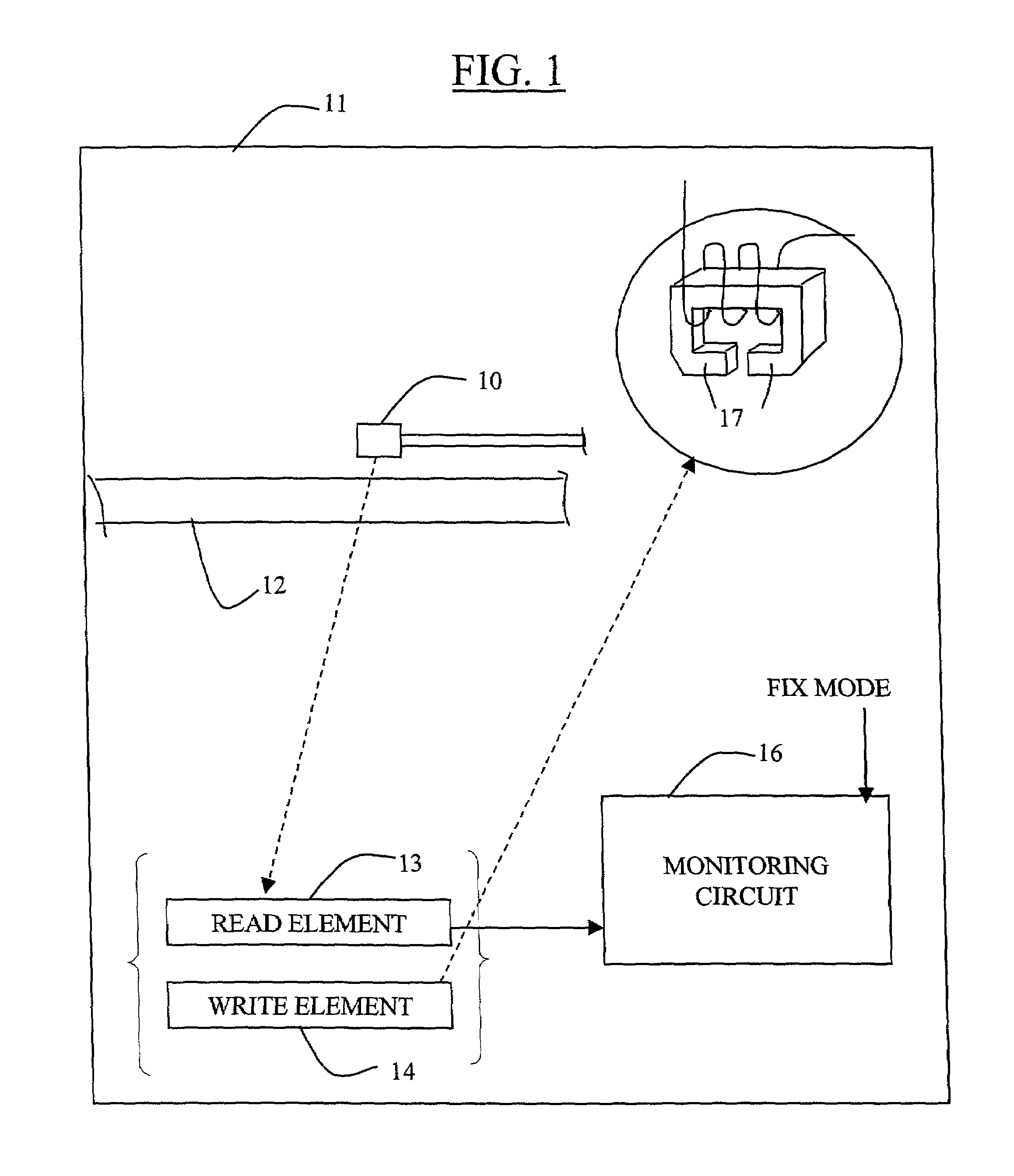

Monitoring of phenomena indicative of PTP in a hard disk and controlling the burnishing of heads

InactiveUS7023632B1Easy to detectRecord information storageCarrier monitoringThermal asperityCondition monitoring

Tools are provided to identify undesired pole tip protrusion (PTP) on a write portion of a read / write head in a hard disk. Such tools may be incorporated in the hard disk. A corrective action arrangement performs a corrective action in response to the identification of an undesired pole tip protrusion. The corrective action may comprise burnishing of pole tips of a write portion of the read / write head. An asperity read signal condition monitoring circuit monitors asperity conditions from the read signal. The asperity condition may be a high fly write condition, or it may be a thermal asperity condition. A PTP determining circuit determines when a monitored condition is indicative of an undesired PTP condition. A PTP test write cycle may be caused, during which the monitoring circuit monitors either during or right after the PTP test write cycle.

Owner:MAXTOR

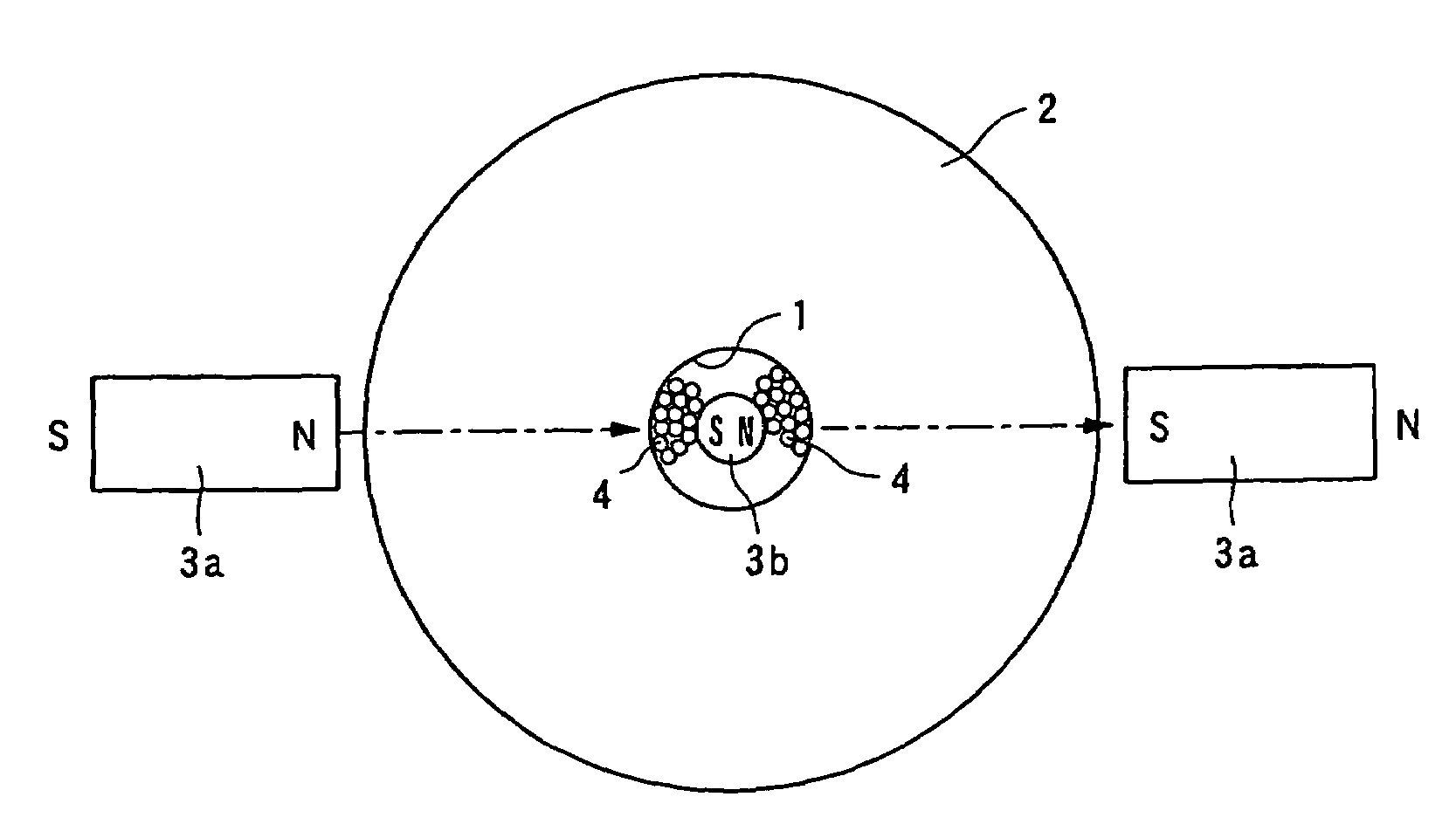

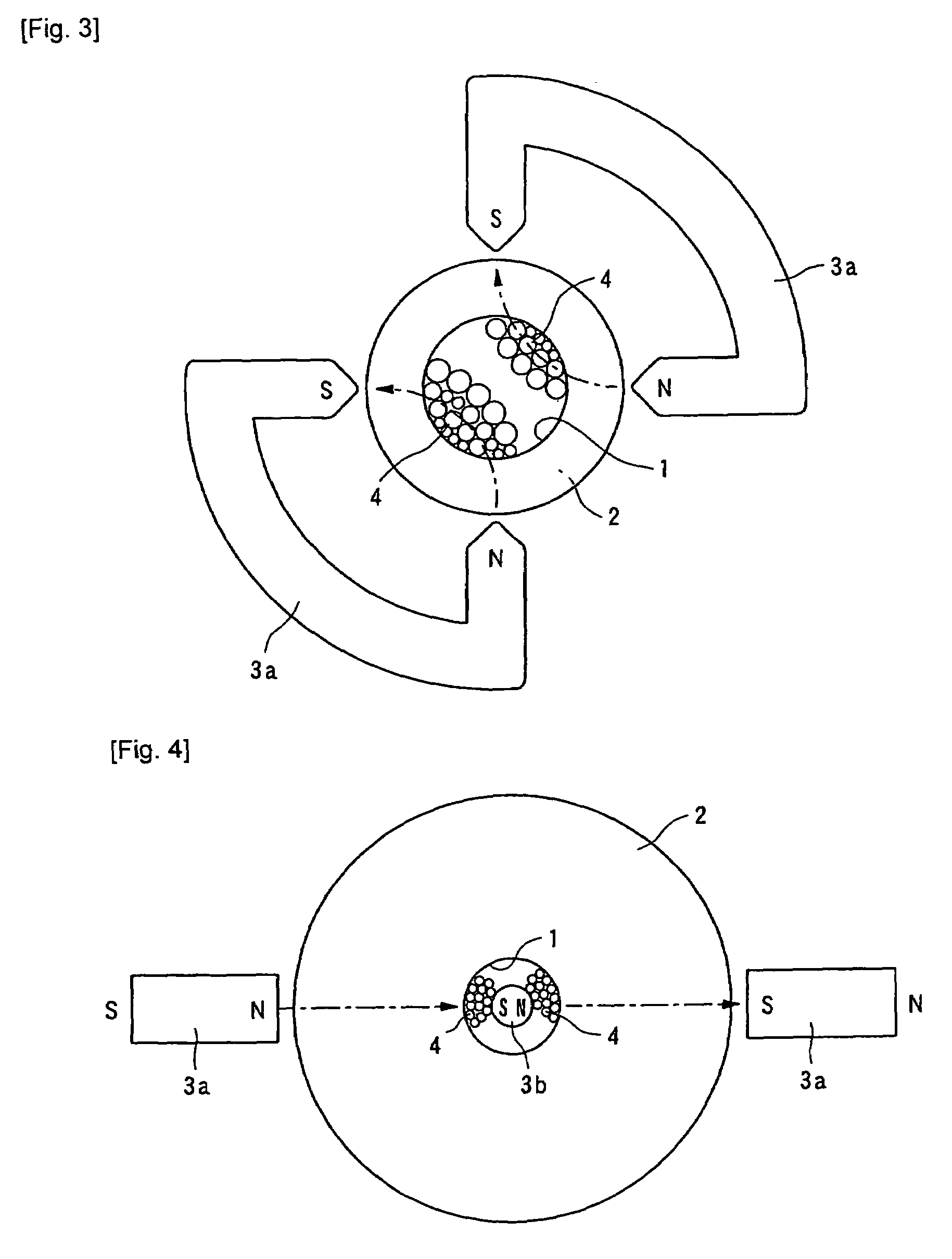

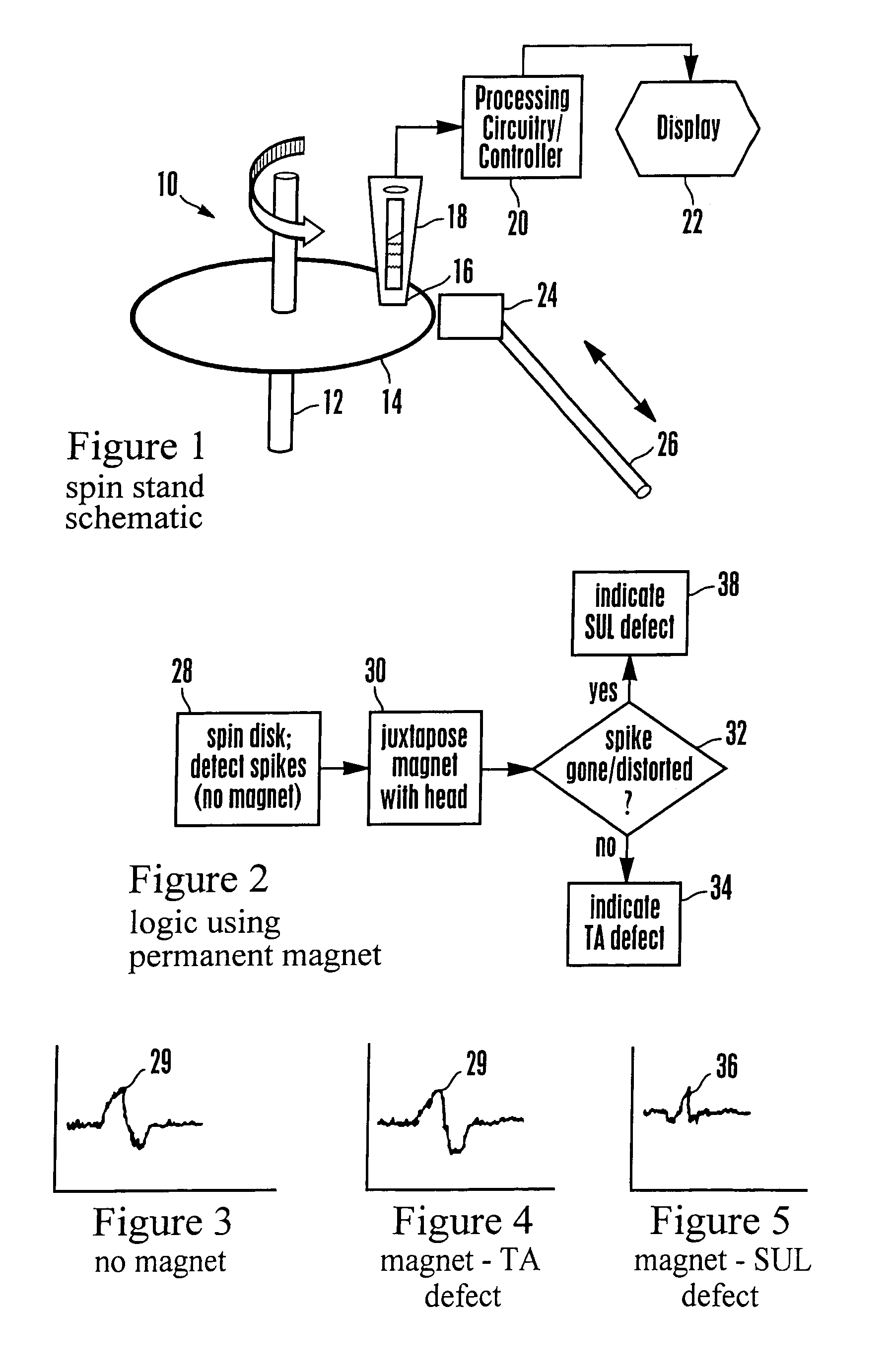

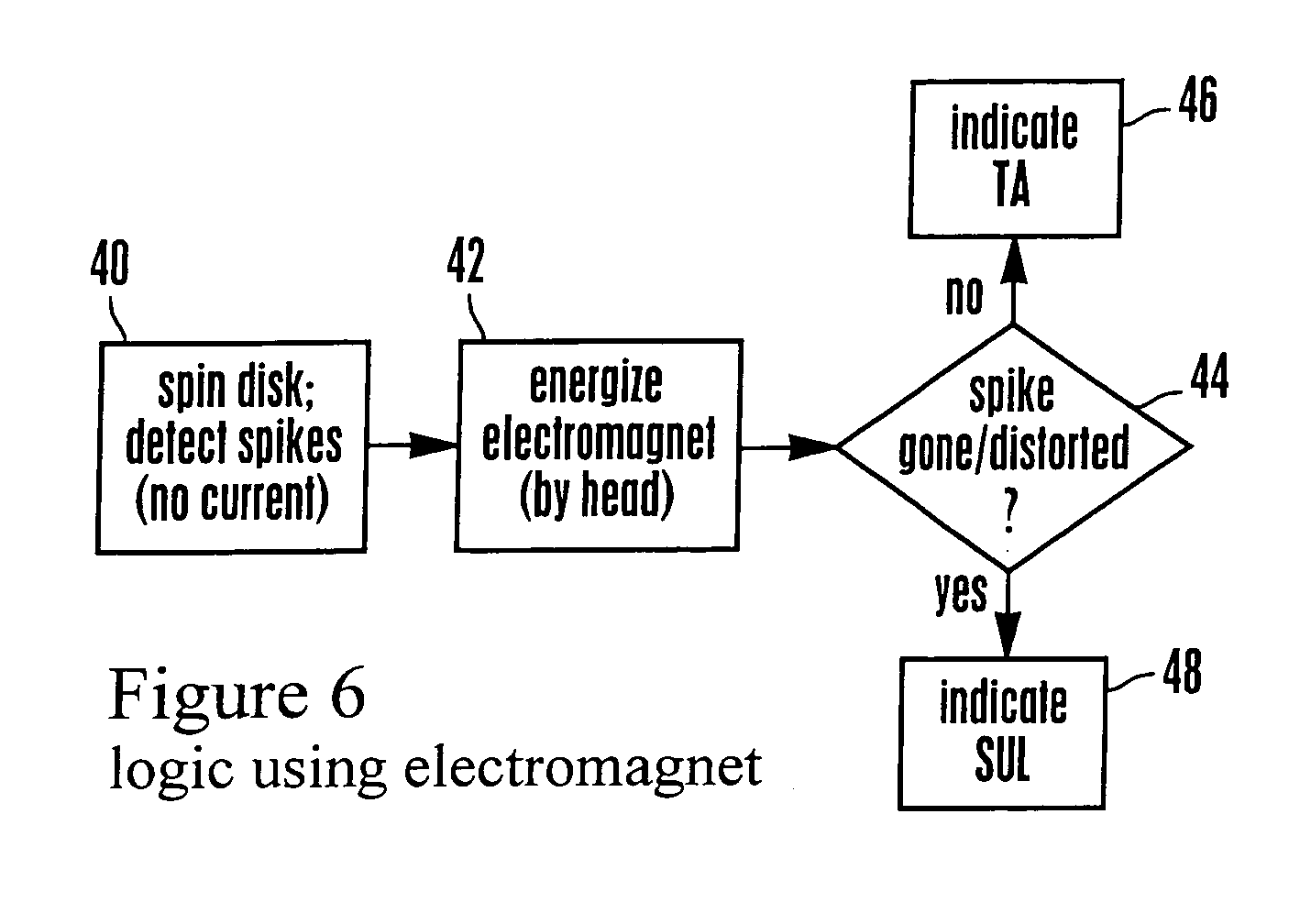

System and method for determining whether defect in perpendicular recording disk drive is from thermal asperity or defect in magnetically soft underlayer

A method for determining whether a spike in a read back signal from a read head positioned over a perpendicular recording disk having a magnetically soft underlayer (SUL) is caused by a defect in the SUL or by a thermal asperity (TA). A first read back signal with the spike is obtained in the absence of a local magnetic field near the read head. Then, a permanent magnet or electromagnet is used to induce a small local magnetic field by the read head, and a second signal is obtained. If the signals are substantially similar, a thermal asperity is indicated. Otherwise a defect in the 13 magnetically soft underlayer of the disk is indicated.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

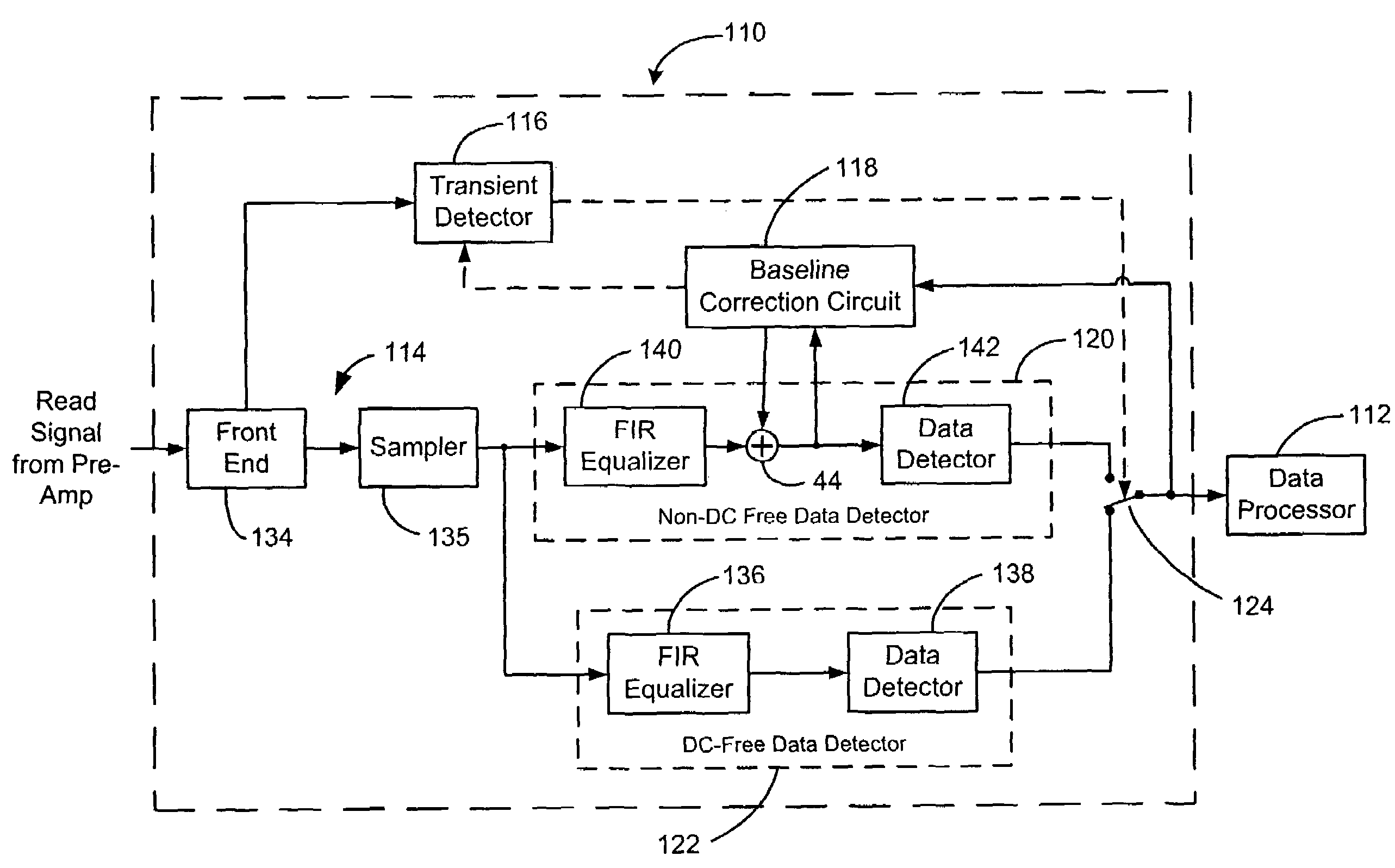

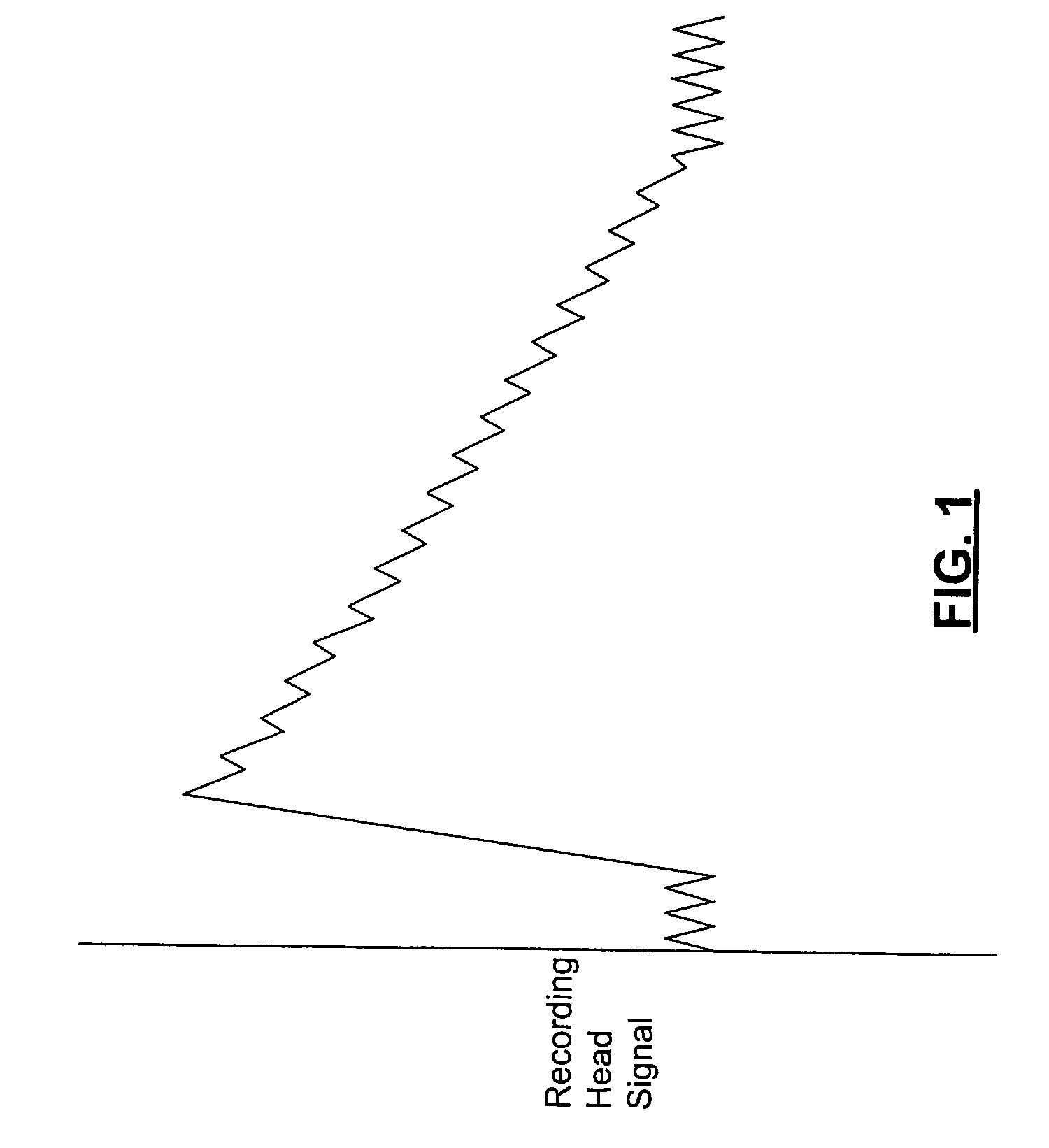

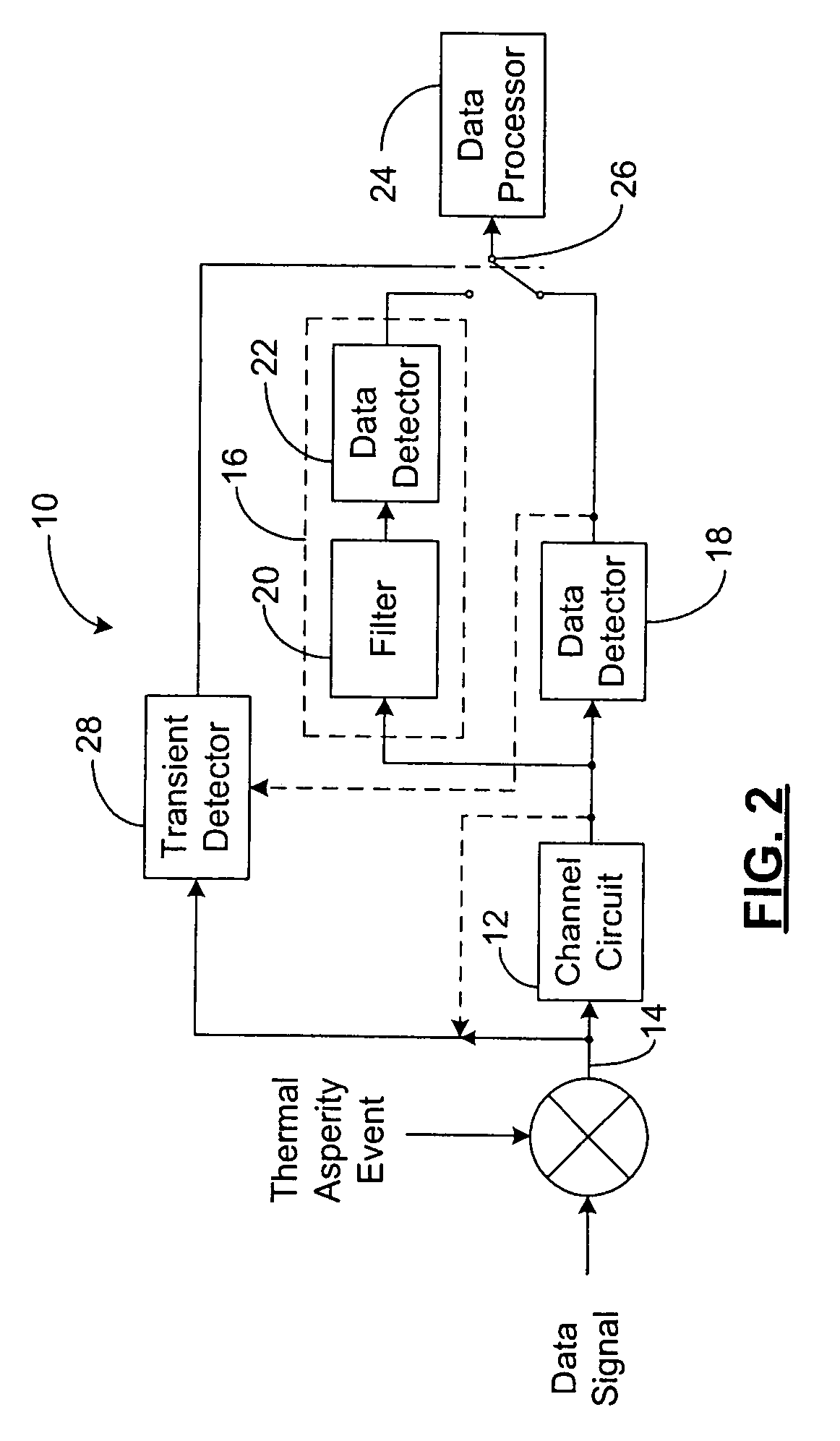

Thermal asperity compensation in perpendicular recording

InactiveUS7286311B1Modification of read/write signalsRecord information storageEqualizationThermal asperity

A data detection circuit includes a transient detector that senses transient events in data. A first data detector path applies a first equalization target to generate a first bit stream from the data. A second data detector path applies a second equalization target to generate a second bit stream from the data. A baseline correction circuit generates a baseline correction signal using the first bit stream when the transient detector does not sense the transient events and the second bit stream when the transient detector senses the transient events. The first equalization target is a non-DC free equalization target and the second equalization target is a DC-free equalization target. When transients are detected during a sector, the detection circuit continues using the DC-free equalization target until the sector ends.

Owner:MARVELL ASIA PTE LTD

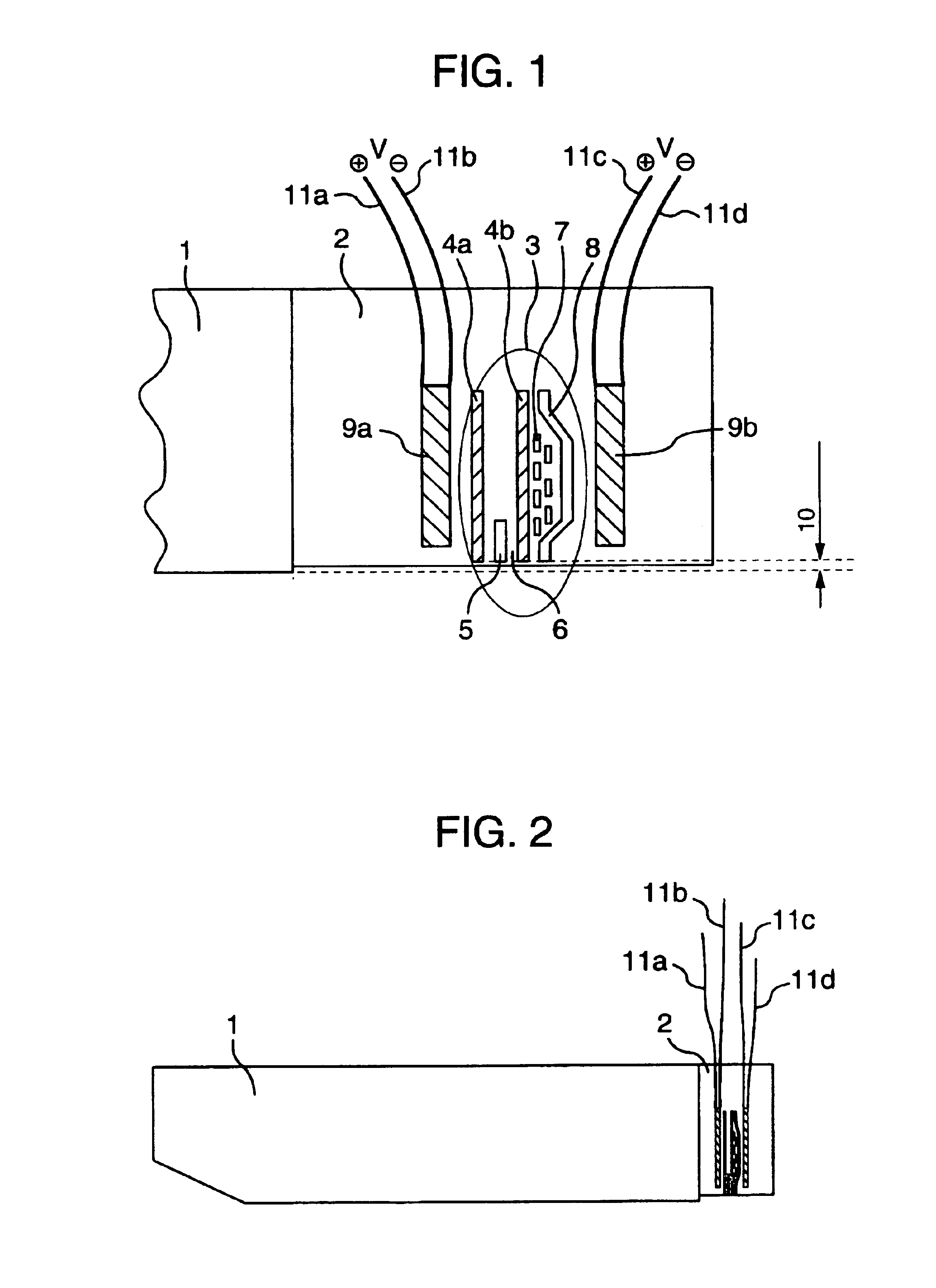

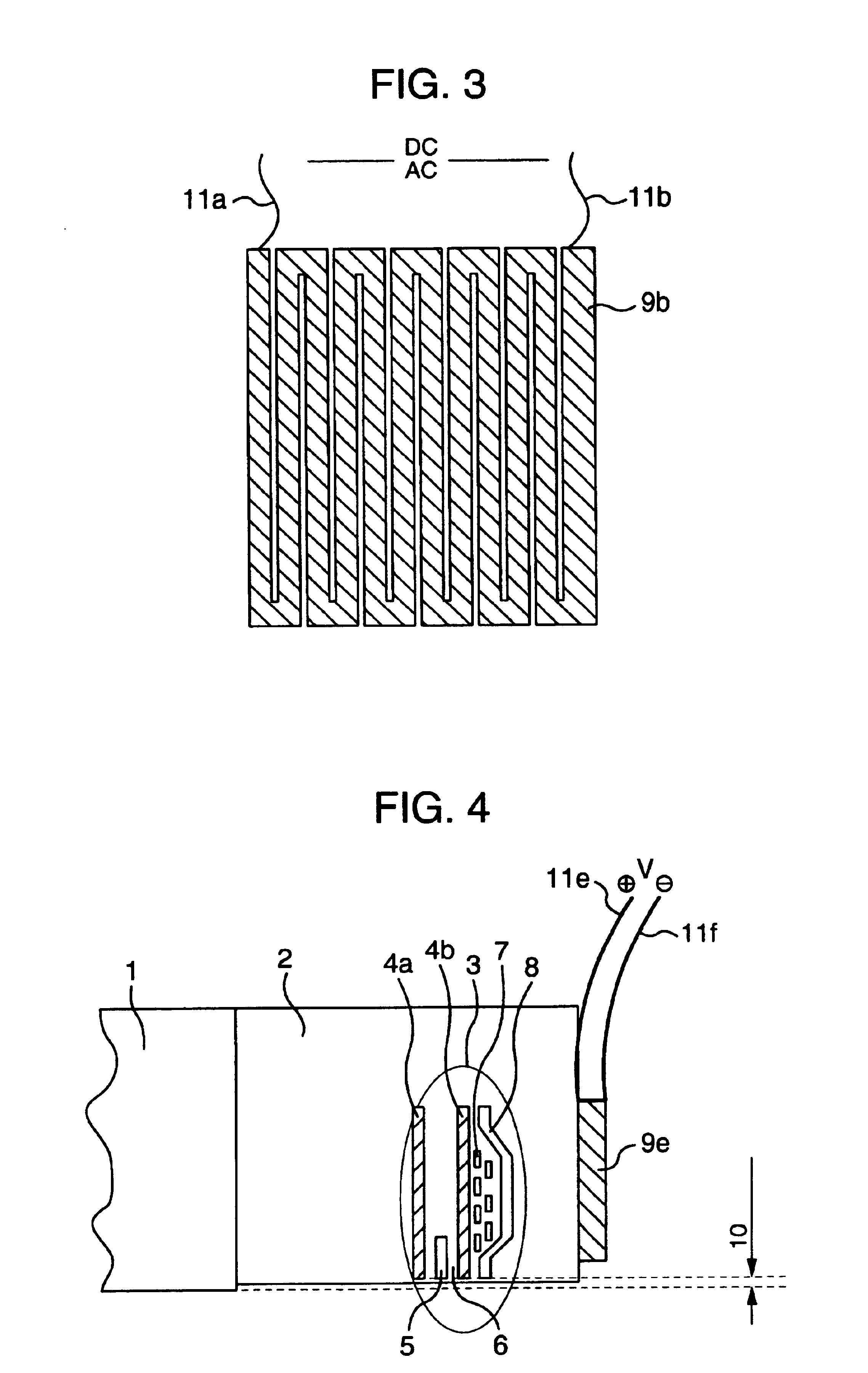

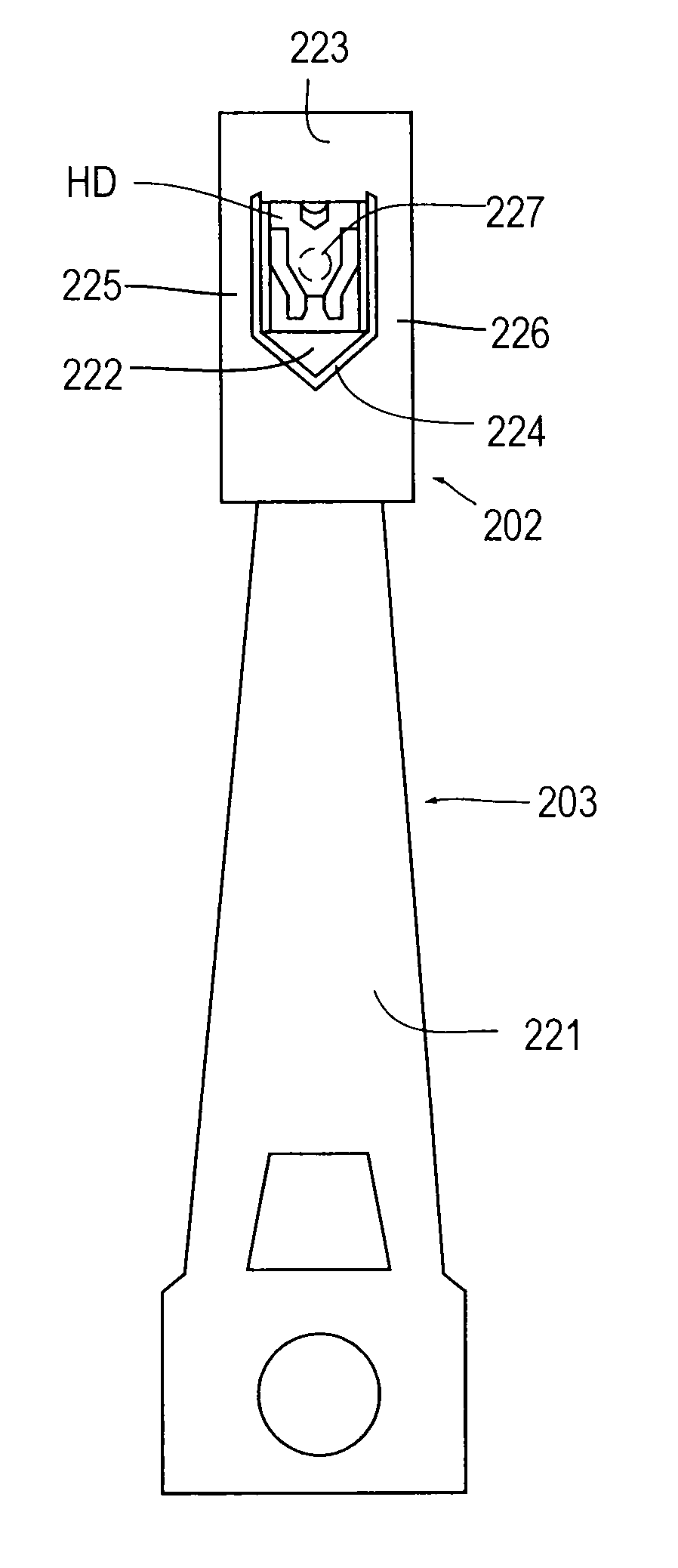

Magnetic head, head assembly and magnetic recording/reproducing apparatus

InactiveUS20100123966A1Efficient detectionAccurate detectionFluid-dynamic spacing of headsRecord information storageElectrical resistance and conductanceElectricity

The present invention relates to a magnetic head, a head assembly, and a magnetic recording / reproducing apparatus which are capable of effectively detecting thermal asperity. The magnetic head according to the present invention includes a heat-generating resistor, a recording coil, and a resistive element. The heat-generating resistor is adapted to generate heat when power is fed thereto so that the heat generation causes at least a part of the air bearing surface to thermally expand and protrude. The recording coil is adapted to generate a recording magnetic field, and the resistive element is disposed closer to the air bearing surface than the recording coil and connected in series or in parallel with the heater. Thus, the resistive element can share a common wiring with the heater for power feeding, which eliminates the waste of wiring and achieves miniaturization.

Owner:TDK CORPARATION

Frequency-based approach for detection and classification of hard-disc defect regions

In a hard-disc drive read channel, frequency-based measures are generated at two different data frequencies (e.g., 2T and DC) by applying a transform, such as a discrete Fourier transform (DFT), to signal values, such as ADC or equalizer output values, corresponding to, e.g., a 2T data pattern stored on the hard disc. The frequency-based measures are used to detect defect regions on the hard disc and / or to classify defect regions as being due to either thermal asperity (TA) or drop-out media defect (MD).

Owner:AVAGO TECH INT SALES PTE LTD

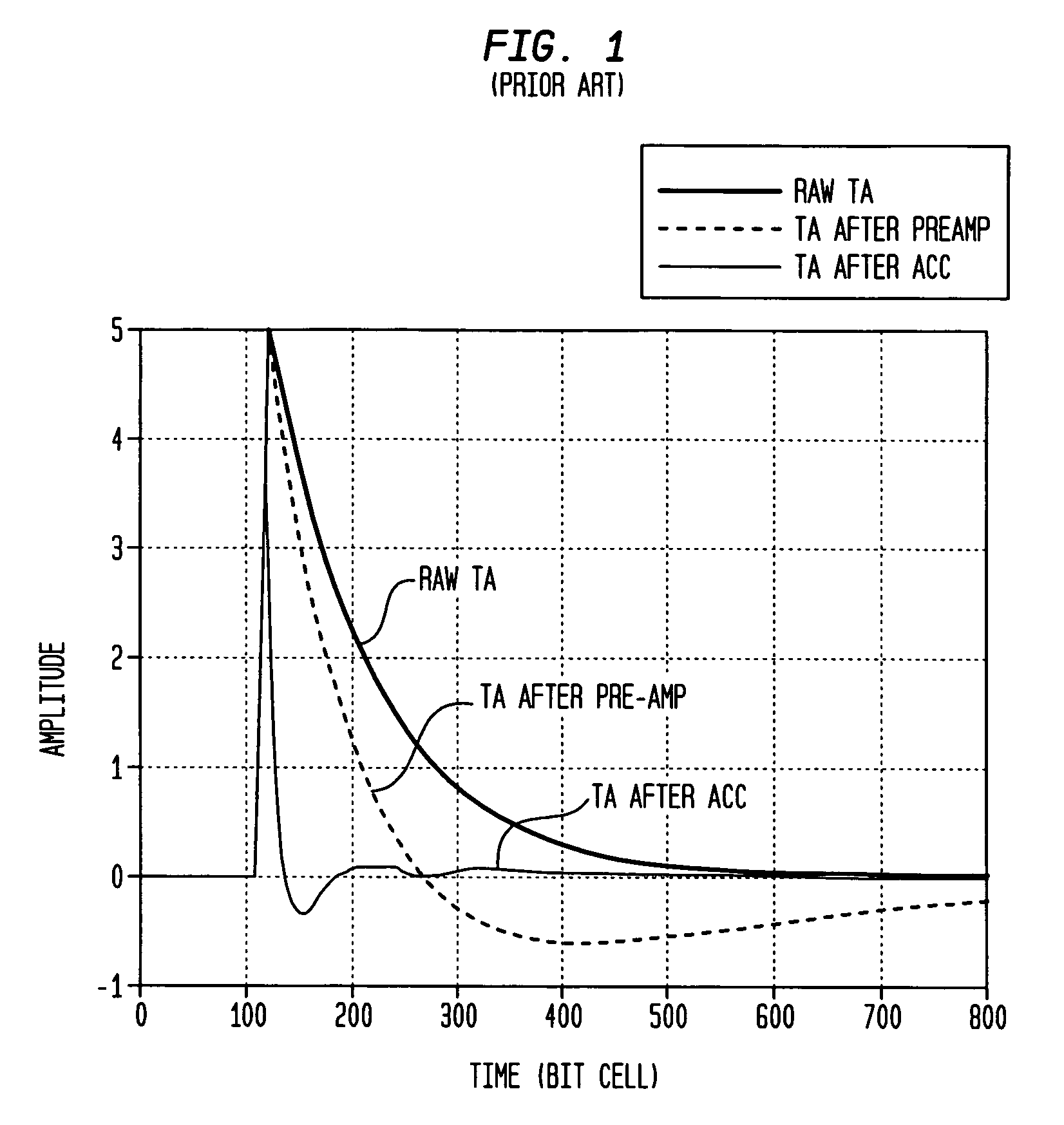

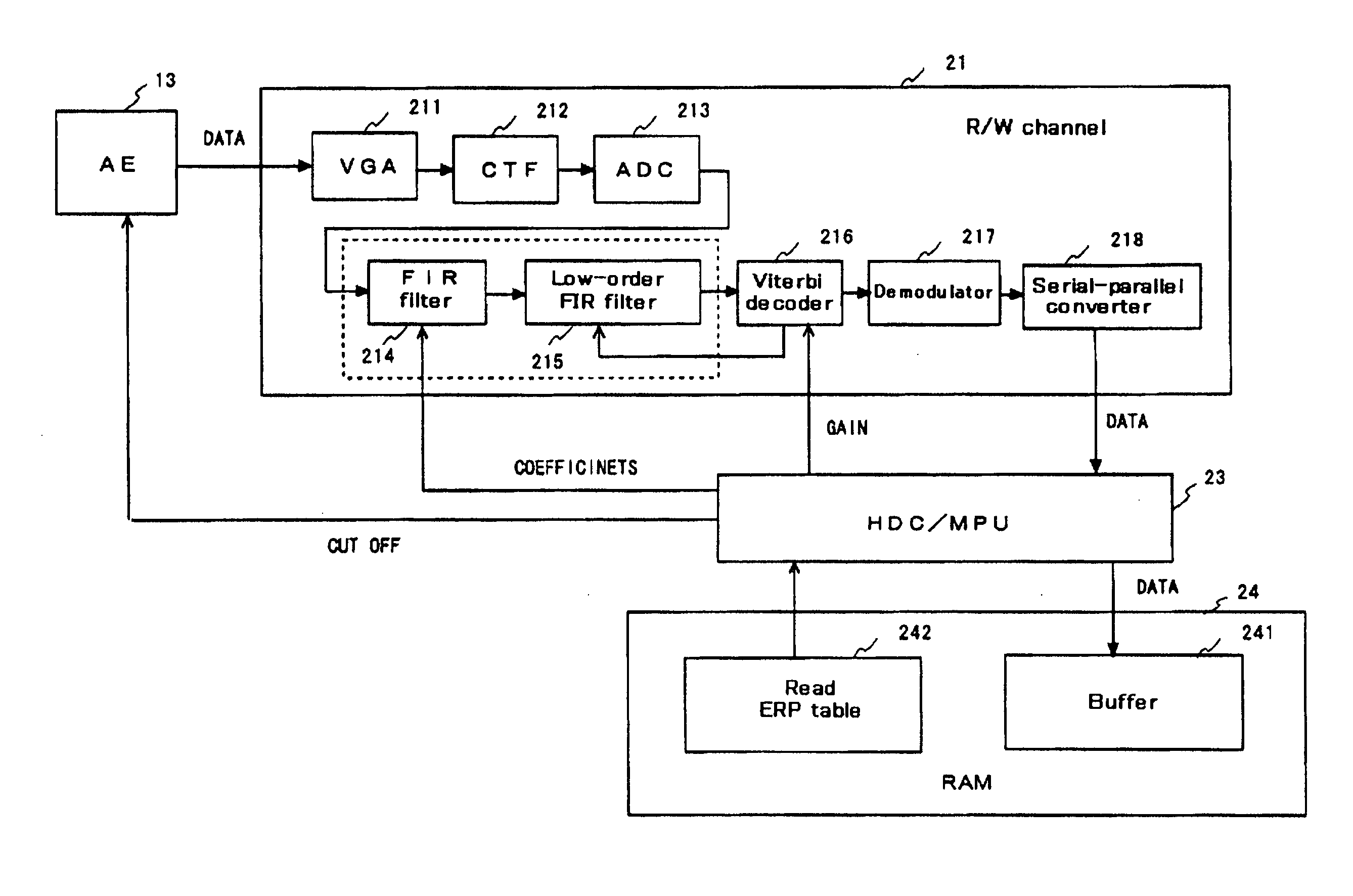

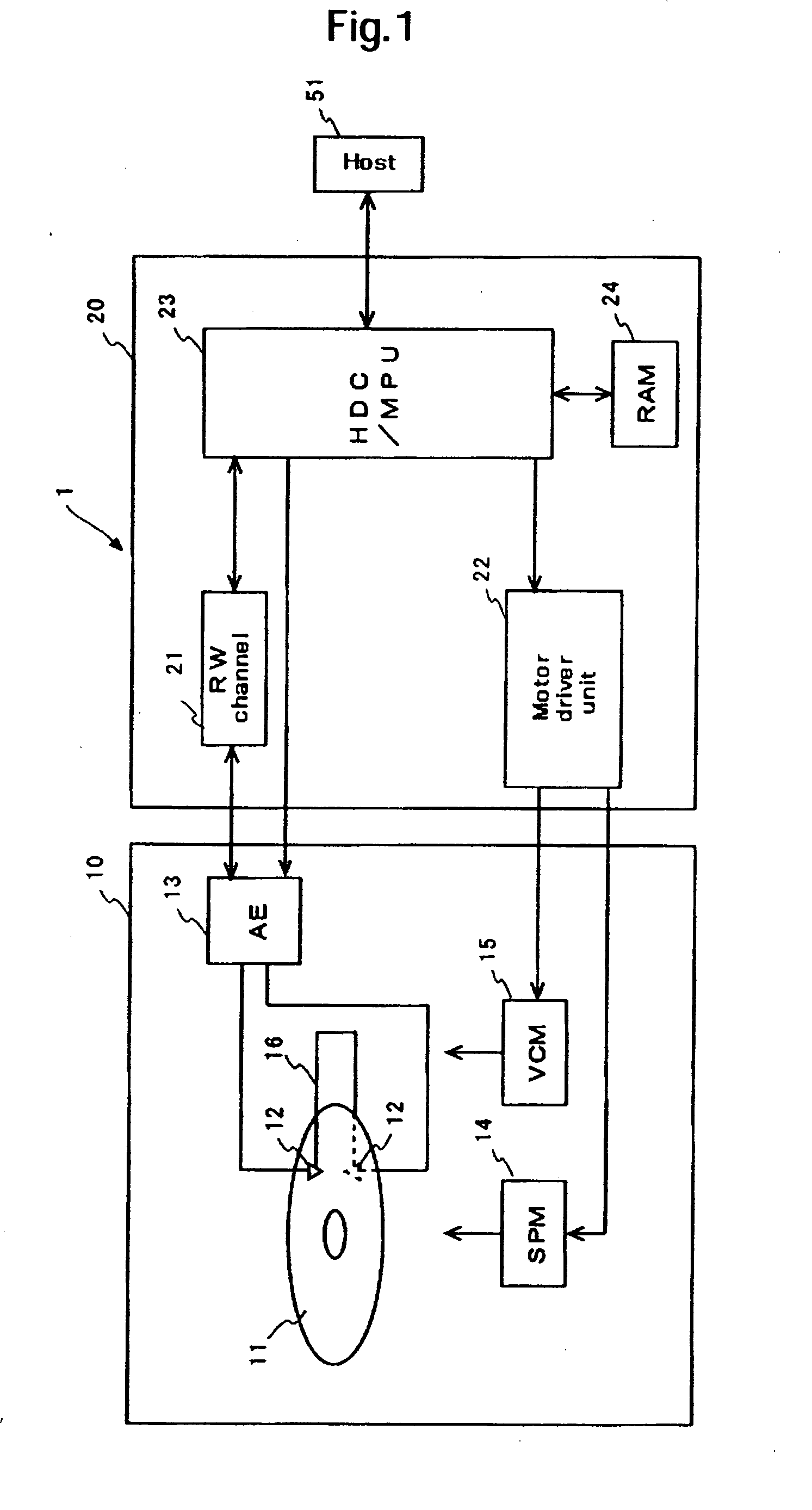

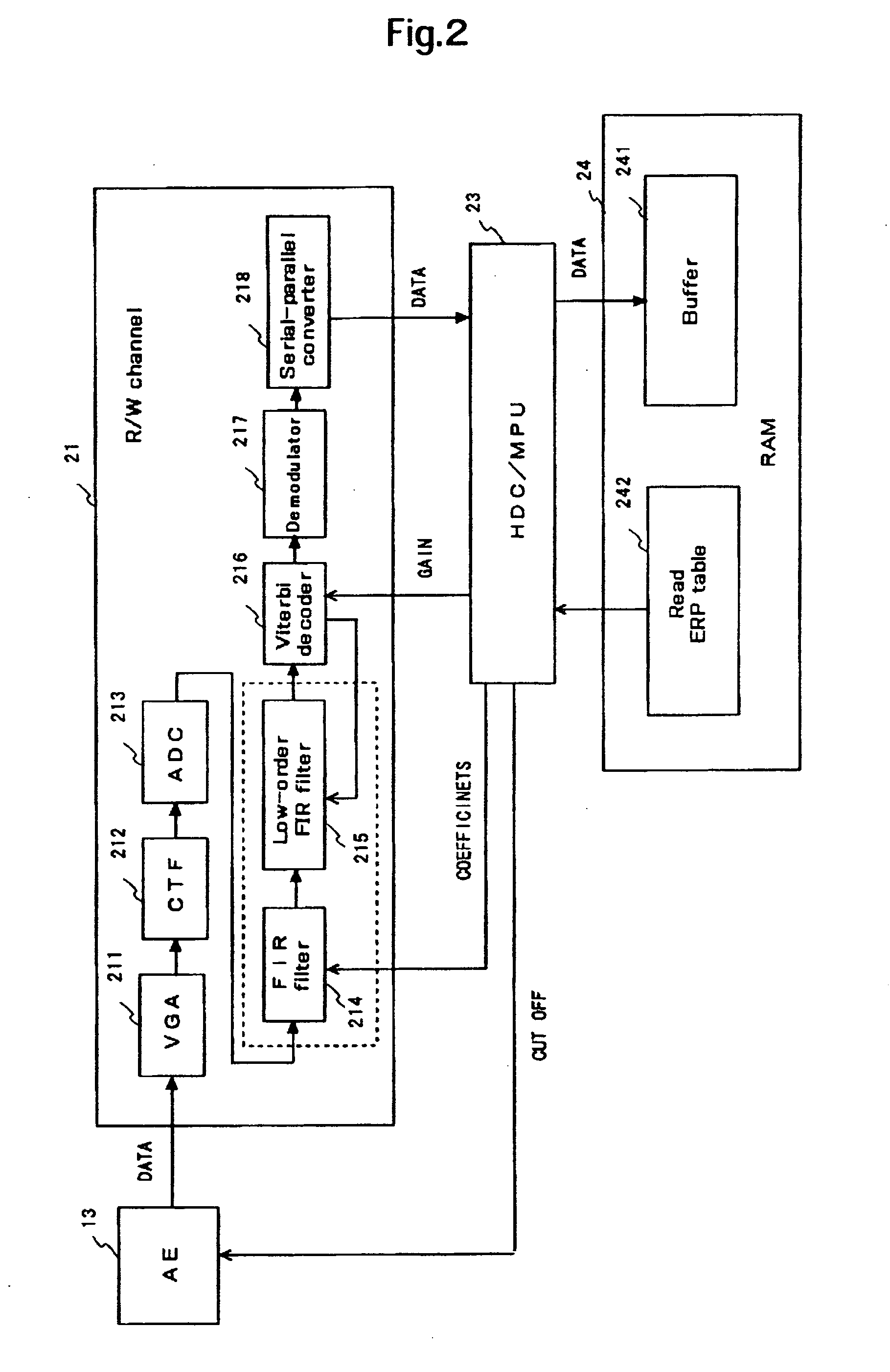

Disk drive

InactiveUS20070263310A1Minimizing error recovery timeError recoveryModification of read/write signalsRecord information storageViterbi decoderBand-pass filter

Embodiments in accordance with the present invention provide a magnetic disk drive capable of achieving error recovery stably in a simple configuration in the event of thermal asperity (TA) and minimizing the error recovery time required, and a method for controlling the disk drive. According to one embodiment, if TA occurs, a cutoff frequency of a high-pass filter to which a data read signal is input is first increased and a loop gain of a low-order finite impulse response (FIR) filter connected in series to an FIR filter is also increased as high as possible. Next, a Viterbi decoder to which a signal is input from the low-order FIR filter provides feedback to the low-order FIR filter so that an input signal error becomes a minimum. Tap coefficients of the low-order FIR filter are thus optimized.

Owner:WESTERN DIGITAL TECH INC

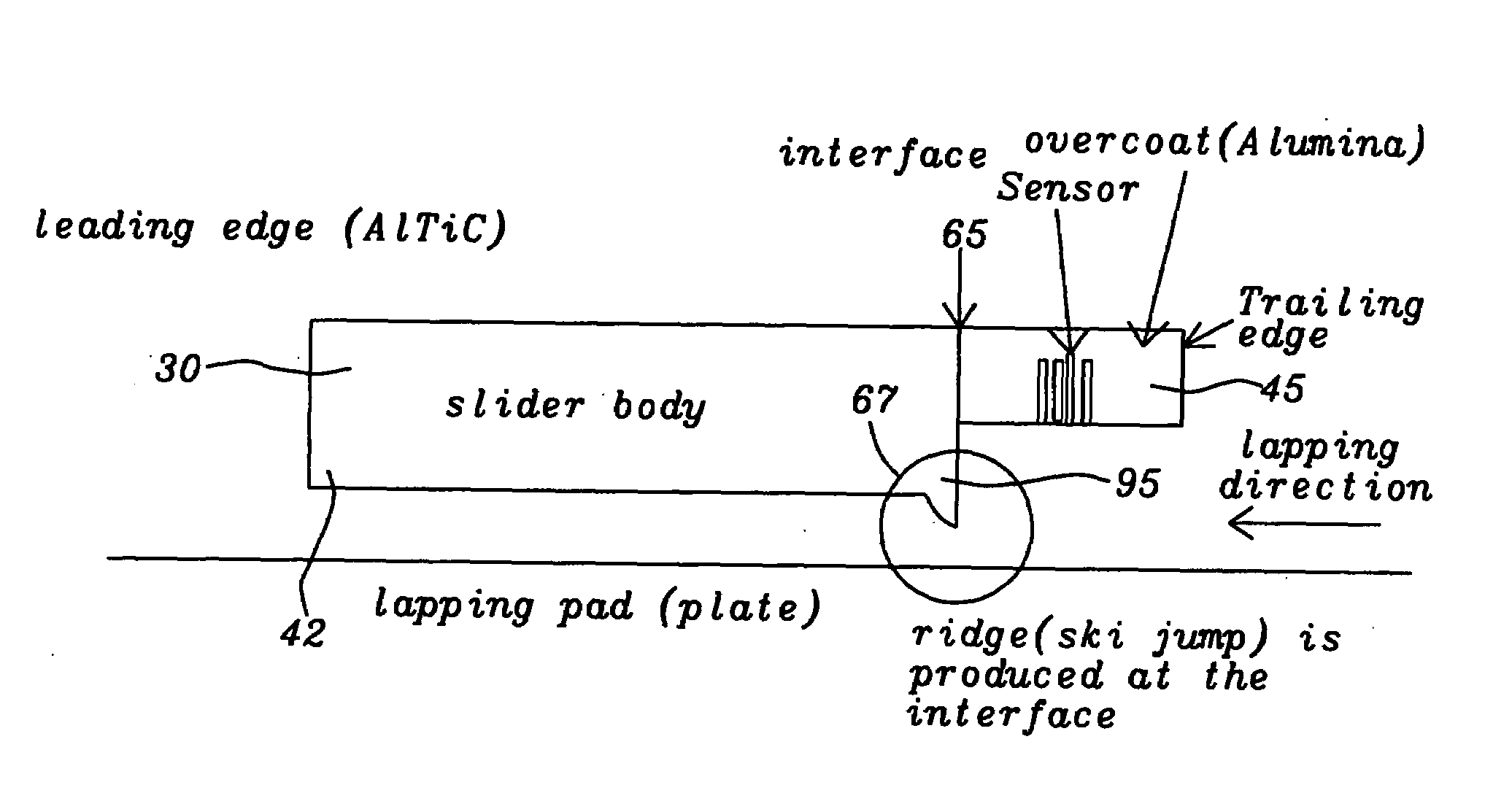

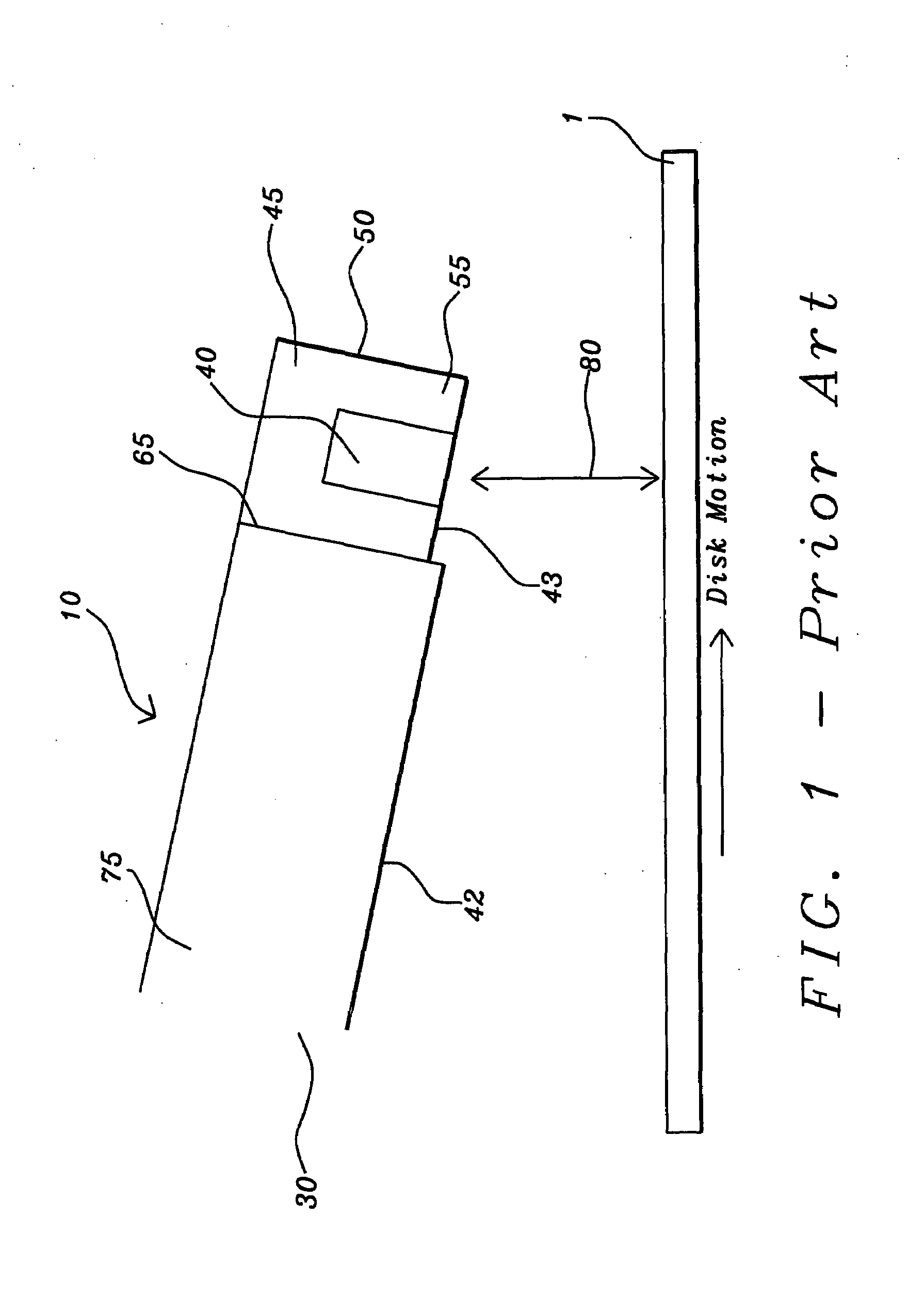

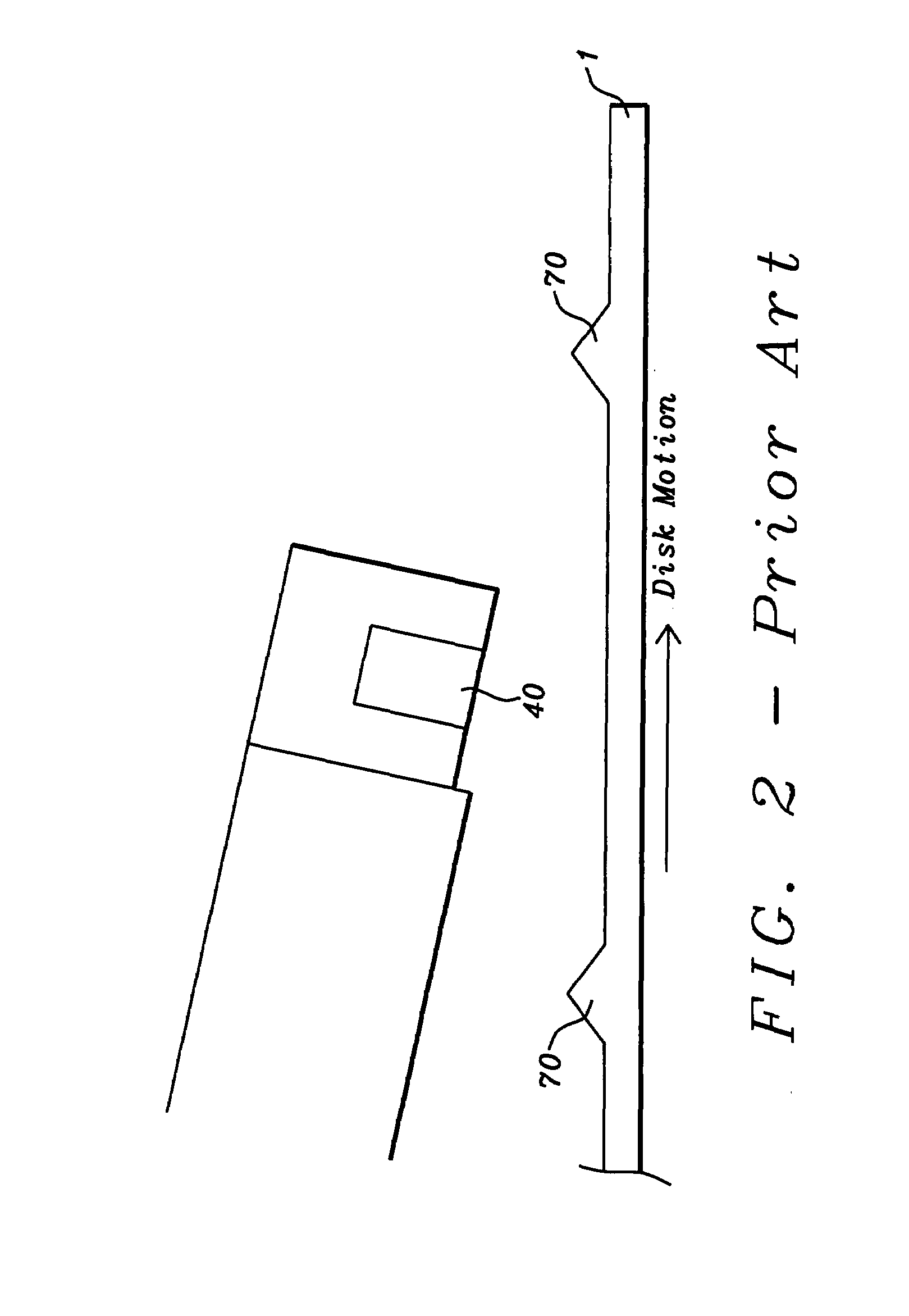

Method to protect the magnetic recording head from thermal asperities during disk drive operation

ActiveUS20080253026A1Easy to implementEasily interfaceElectrical transducersRecord information storageEngineeringSlurry

A slider mounted read / write head is protected from thermal asperities due to head-disk interactions by a ridge formed along an interfacial plane that extends above the ABS plane of the slider. The ridge is formed as part of a lapping process that is directed from the read / write head towards the slider substrate and uses an abrasive slurry to which may be added a strong base such as KOH. The height of the ridge is less than approximately 2 nm.

Owner:SAE MAGNETICS (HK) LTD

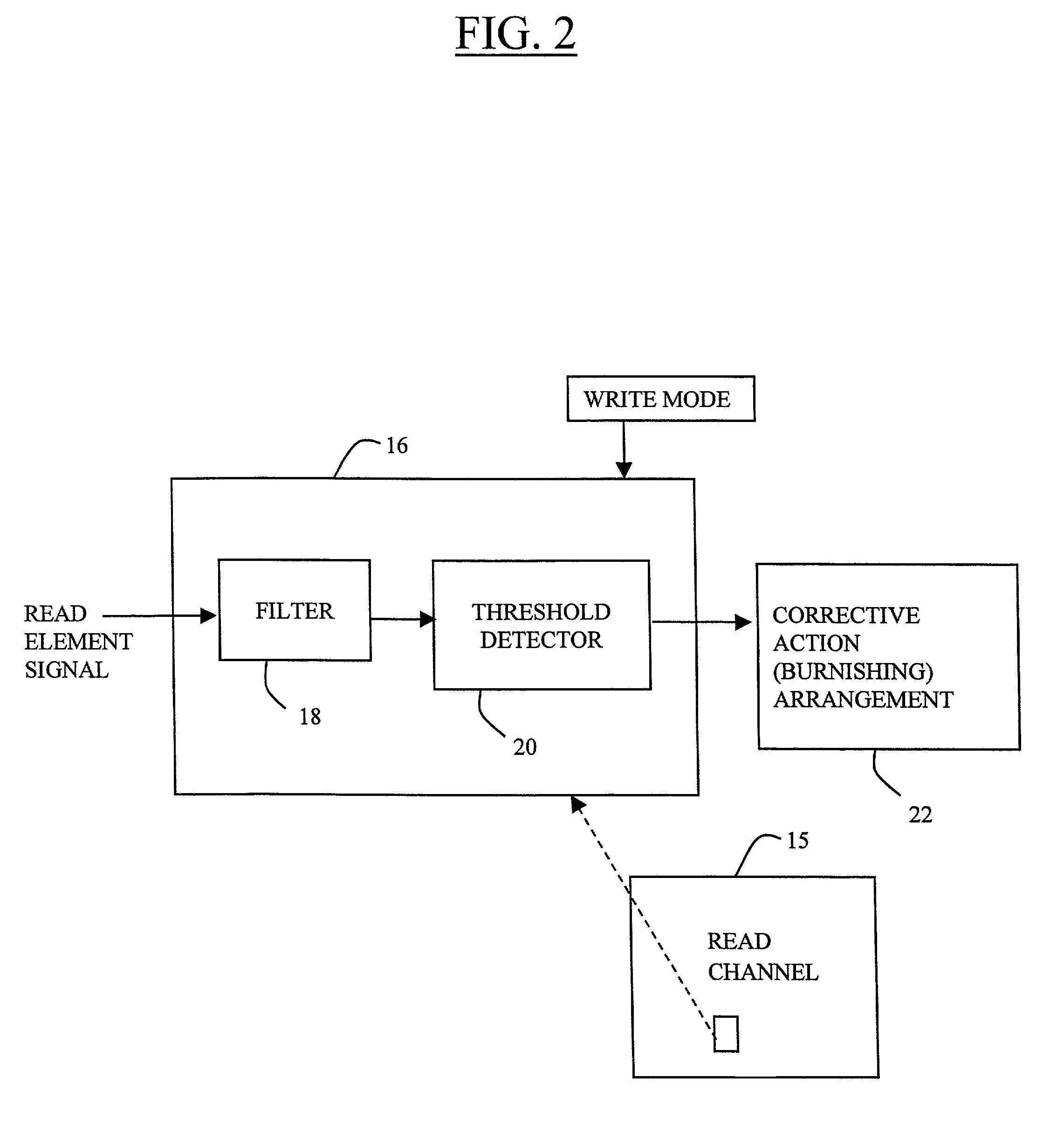

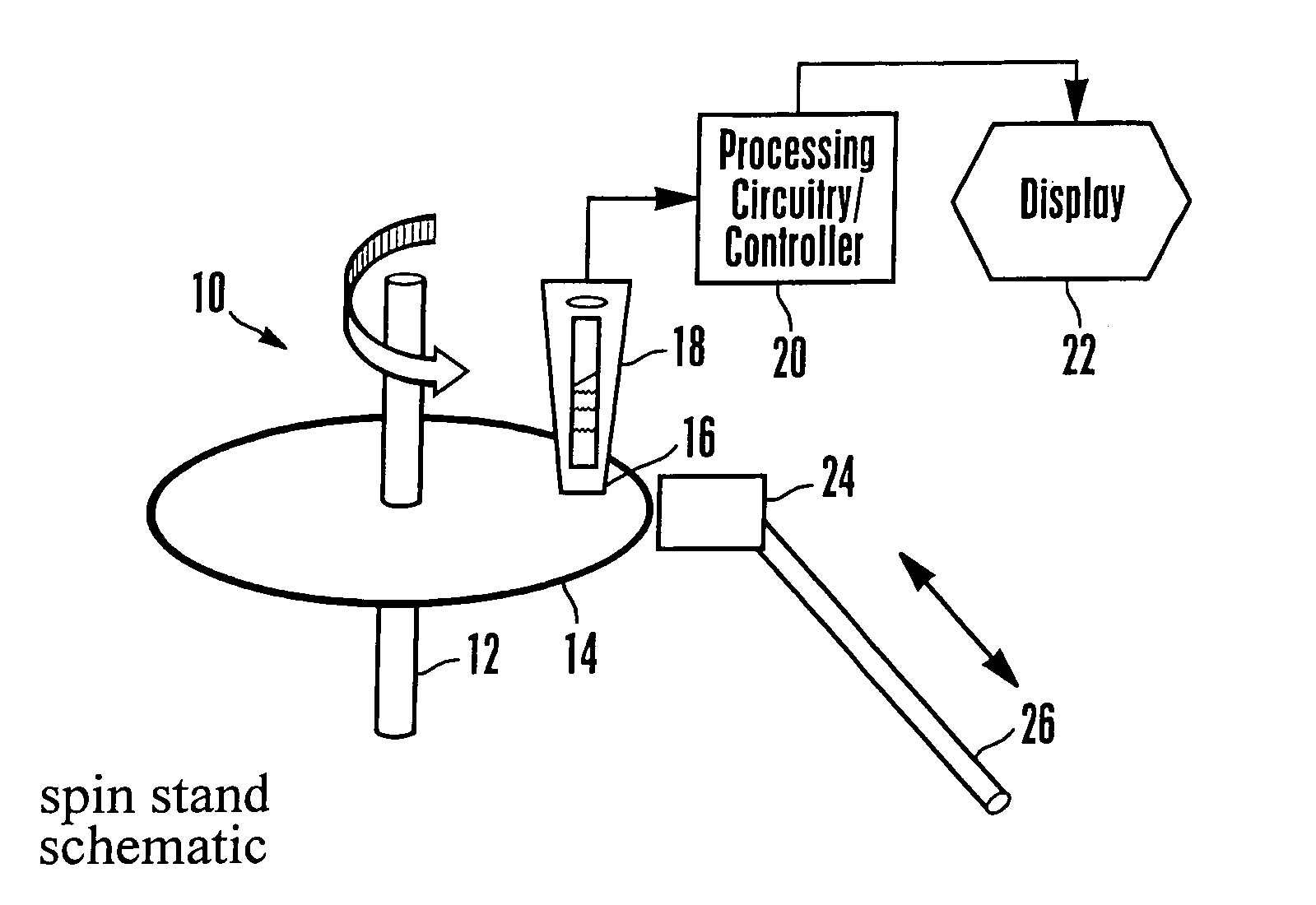

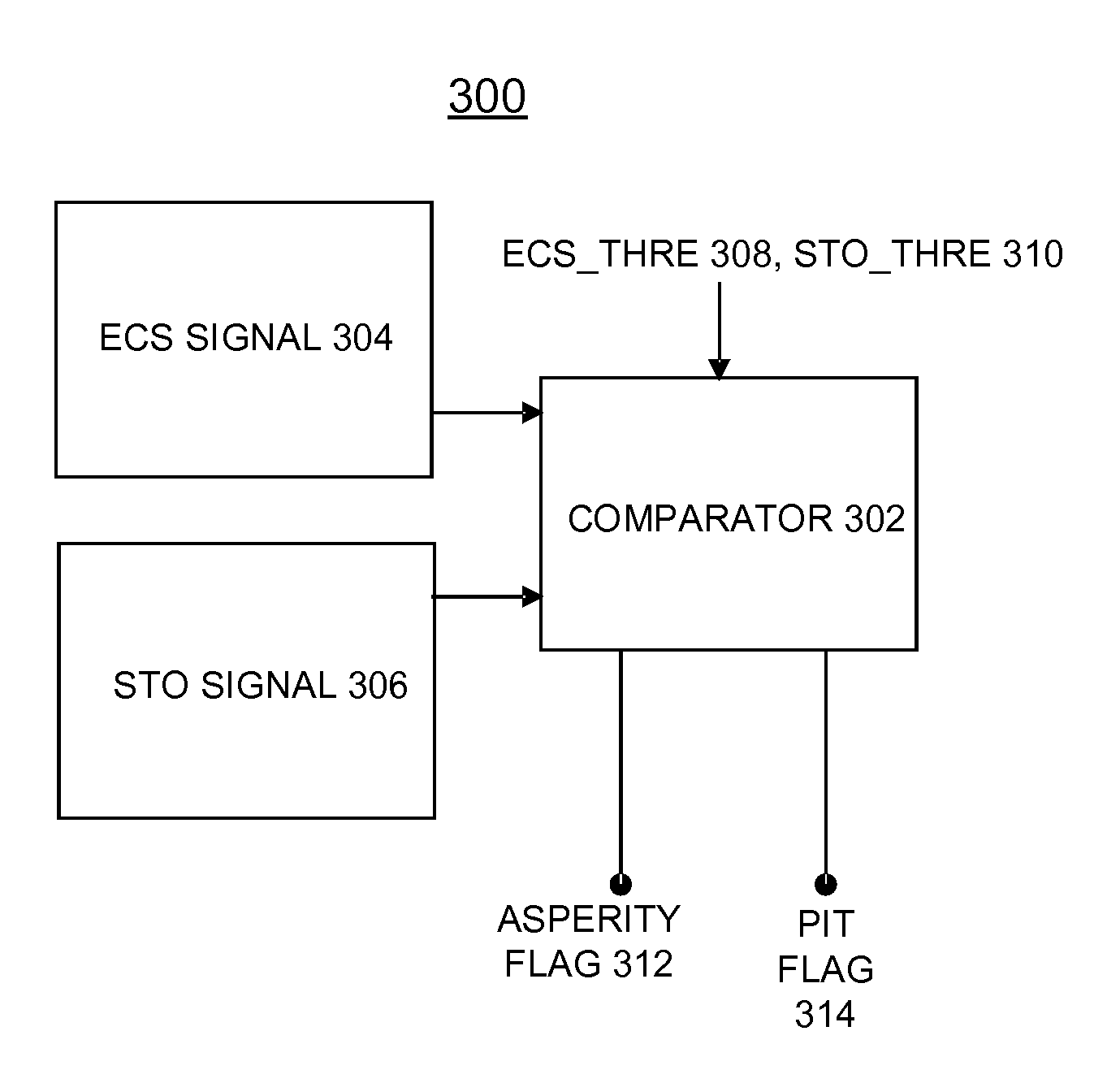

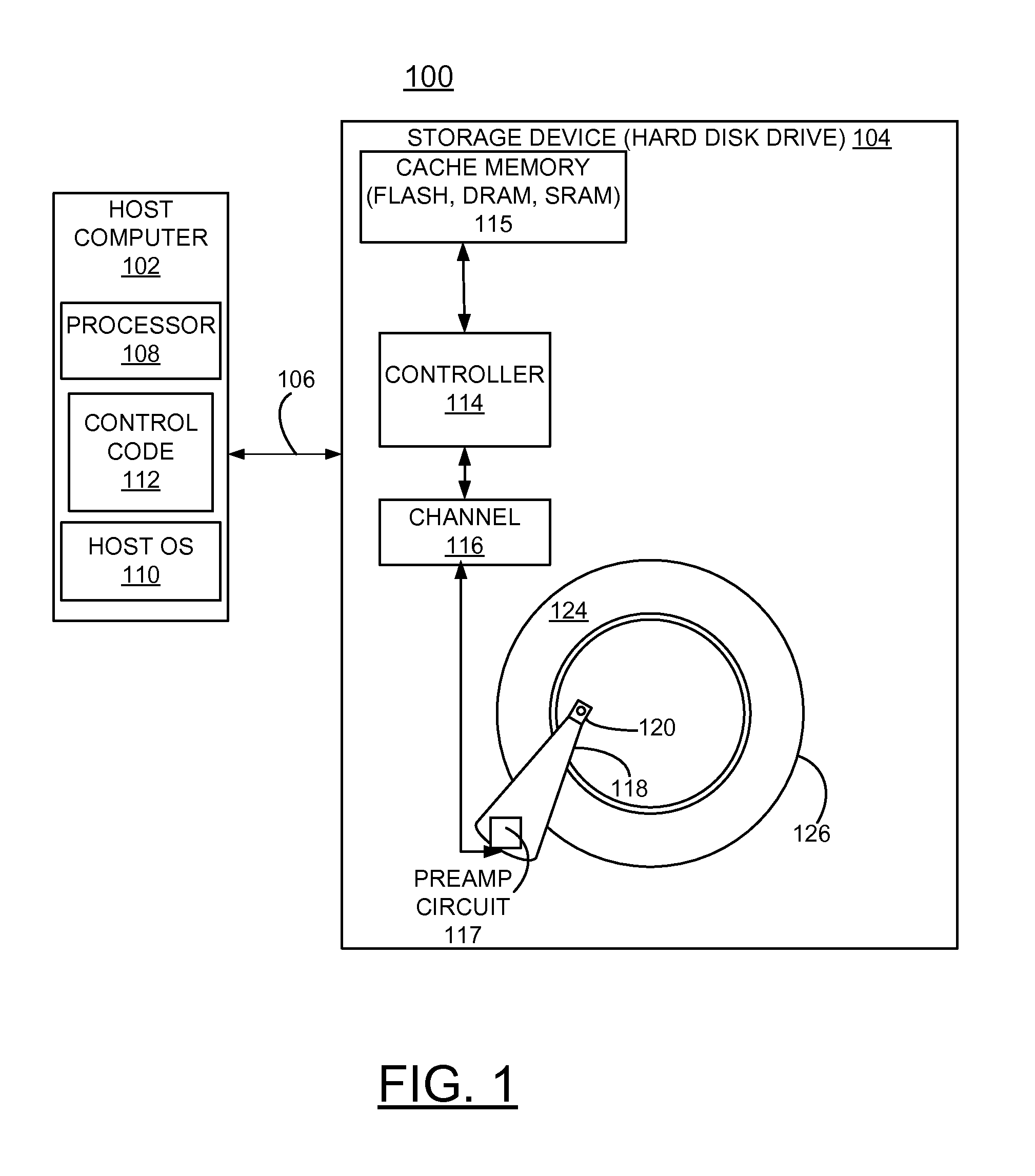

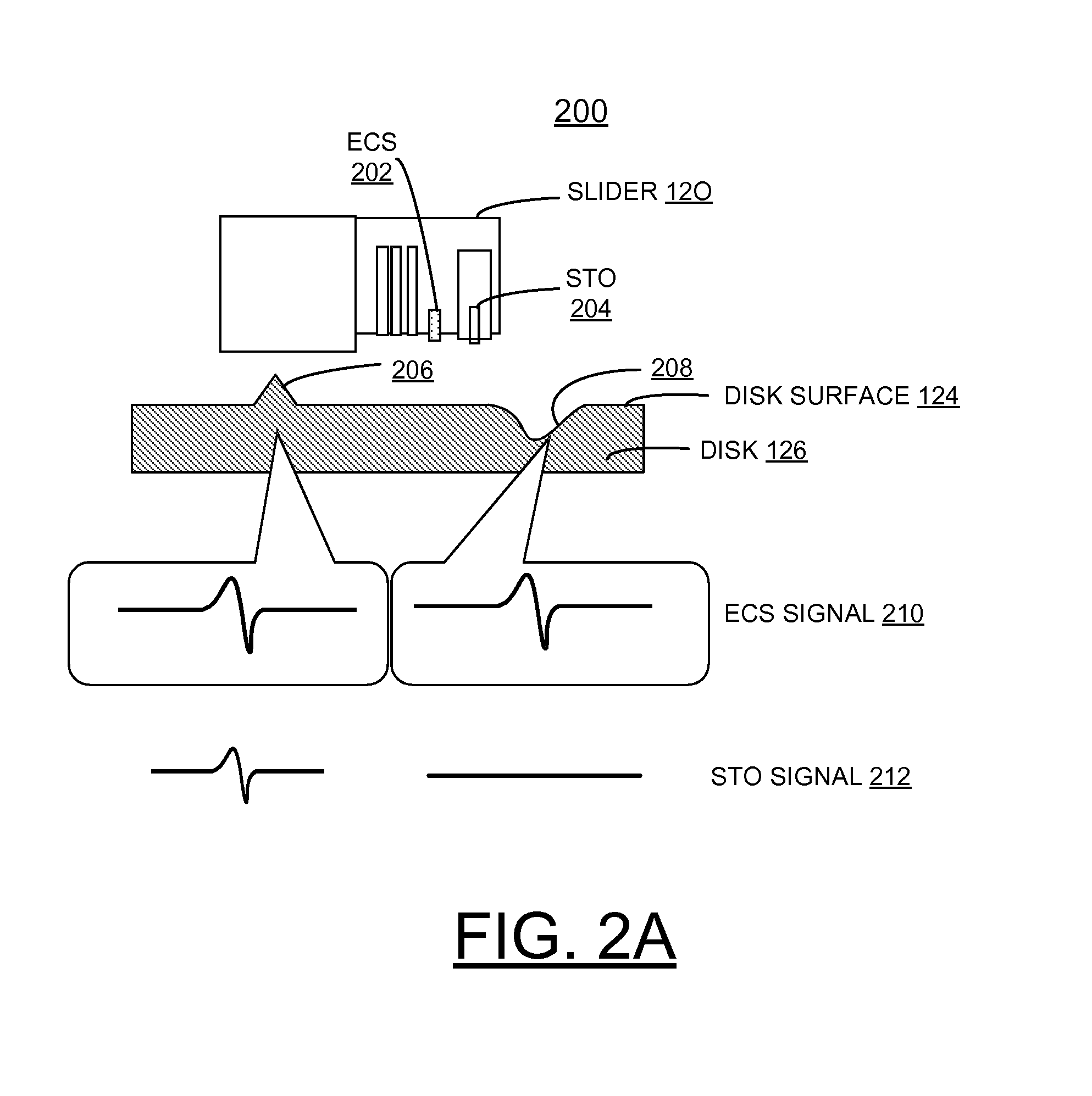

Implementing surface analysis test (SAT) function for microwave-assisted magnetic recording (MAMR) HDD with embedded contact sensor (ECS) and spin torque oscillator (STO) signals

A method, apparatus, and system are provided for implementing enhanced surface analysis test (SAT) function for microwave assisted magnetic recording (MAMR) hard disk drives (HDDs) using embedded contact sensor (ECS) and spin-torque oscillator (STO) signals. A preamplifier circuit receives the embedded contact sensor (ECS) and spin-torque oscillator (STO) signals and compares the received ECS and STO signals to identify magnetic disk media defects including bumps or thermal-asperity (TA) defects and pits or hole defects.

Owner:WESTERN DIGITAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com